Patents

Literature

43384results about How to "Easy to produce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multivalent antibodies and uses therefor

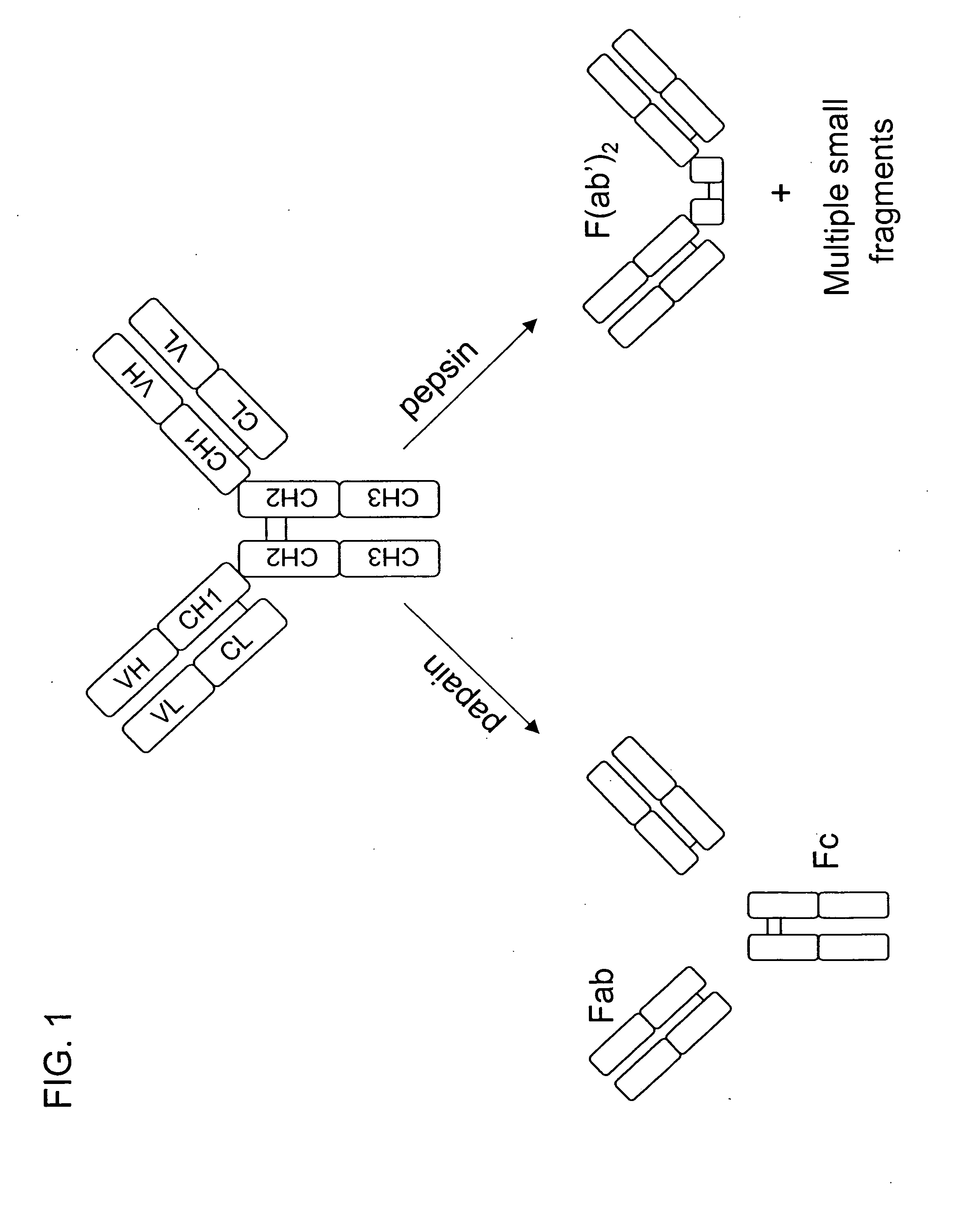

The present application describes engineered antibodies, with three or more functional antigen binding sites, and uses, such as therapeutic applications, for such engineered antibodies.

Owner:GENENTECH INC

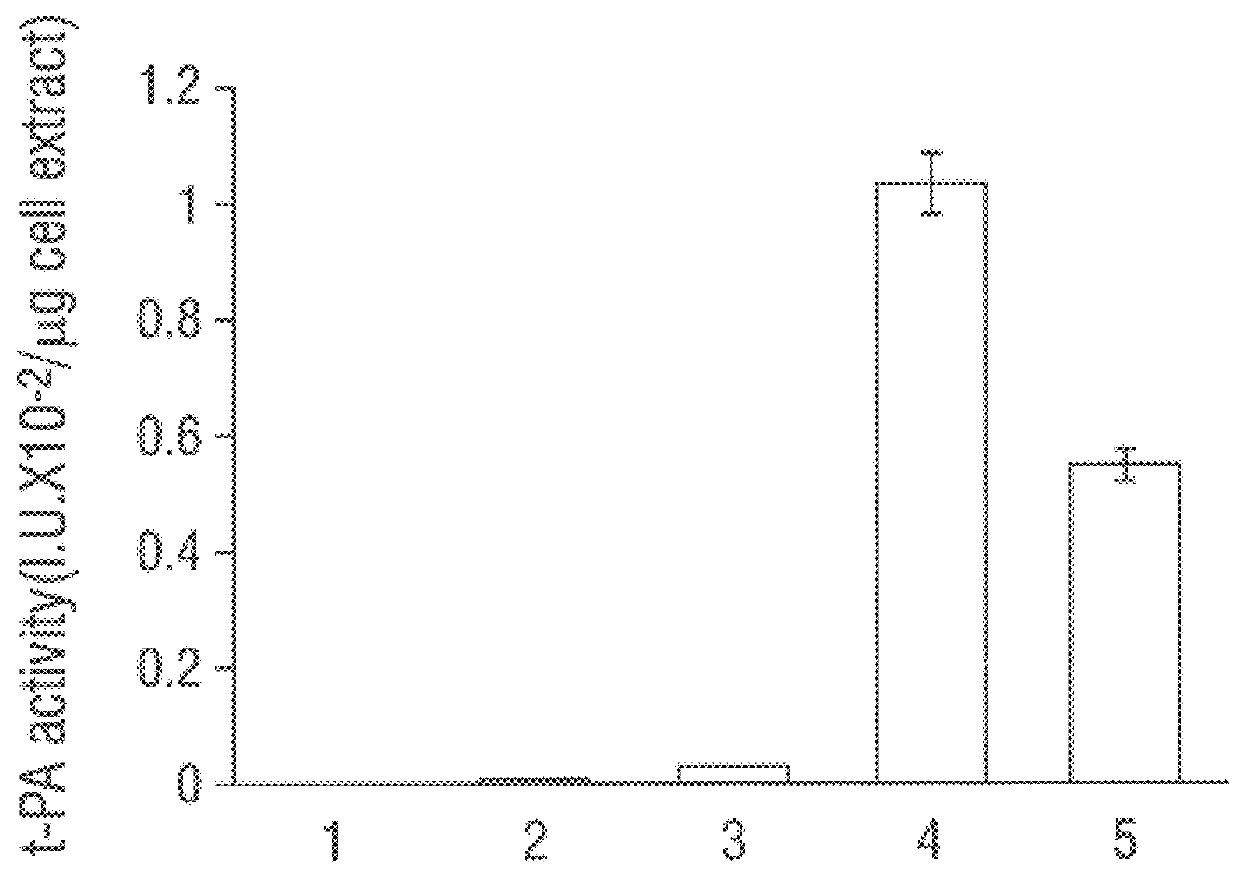

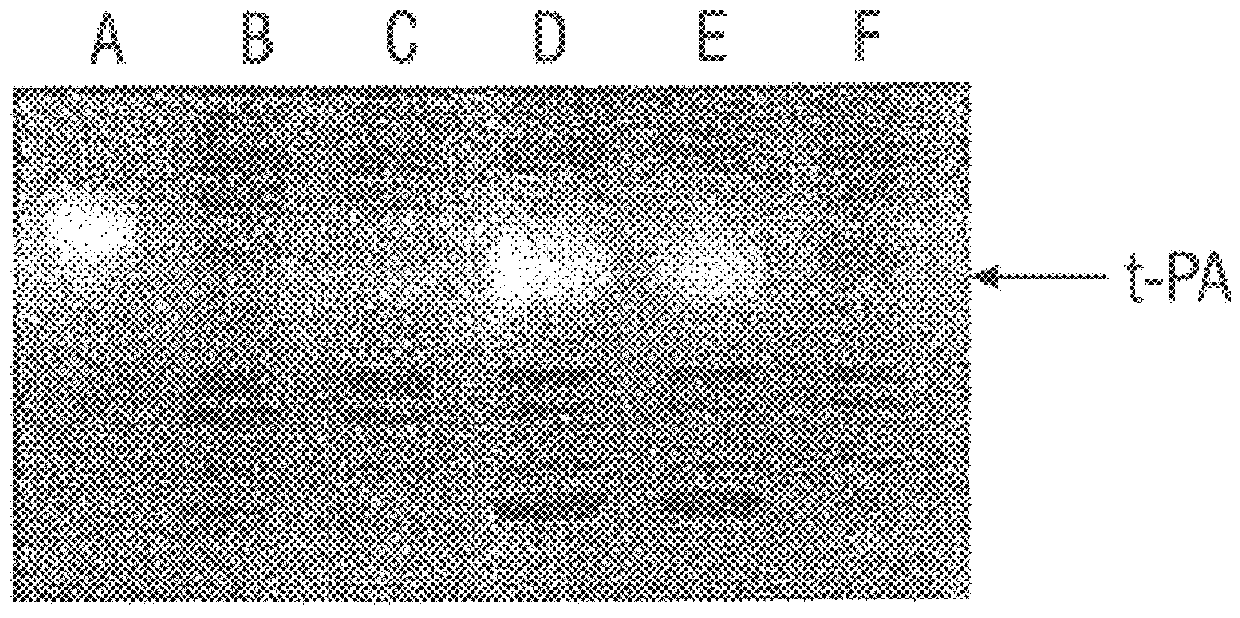

Methods for producing heterologous disulfide bond-containing polypeptides in bacterial cells

InactiveUS6083715AEfficient productionFold preciselyBacteriaUnicellular algaeMolecular biologyDisulfide bond

Disclosed are methods and compositions for producing heterologous disulfide bond containing polypeptides in bacterial cells. In preferred embodiments the methods involve co-expression of a prokaryotic disulfide isomerase, such as DsbC or DsbG and a gene encoding a recombinant eukaryotic polypeptide. Exemplary polypeptides disclosed include tissue plasminogen activator.

Owner:GENENTECH INC +1

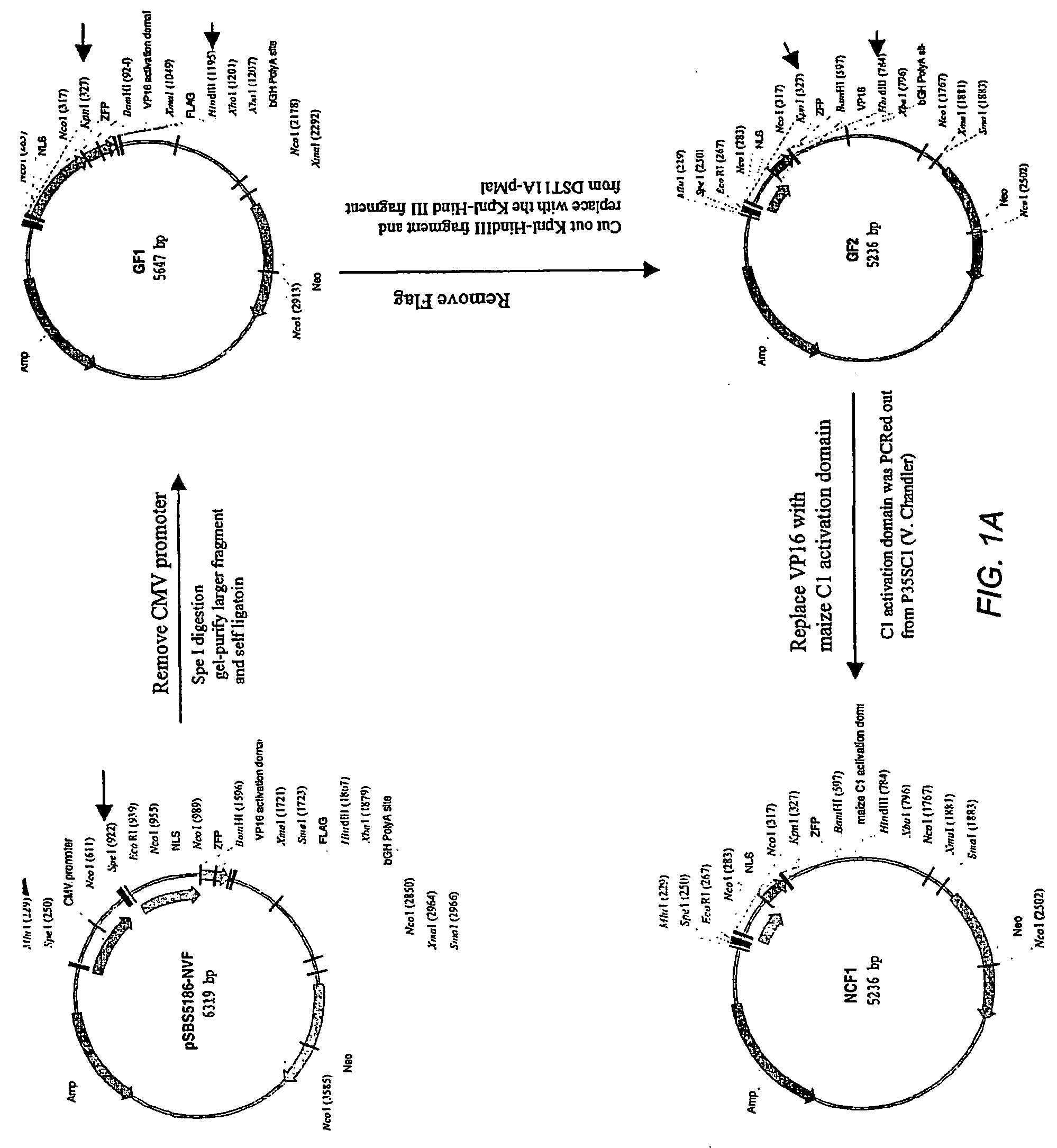

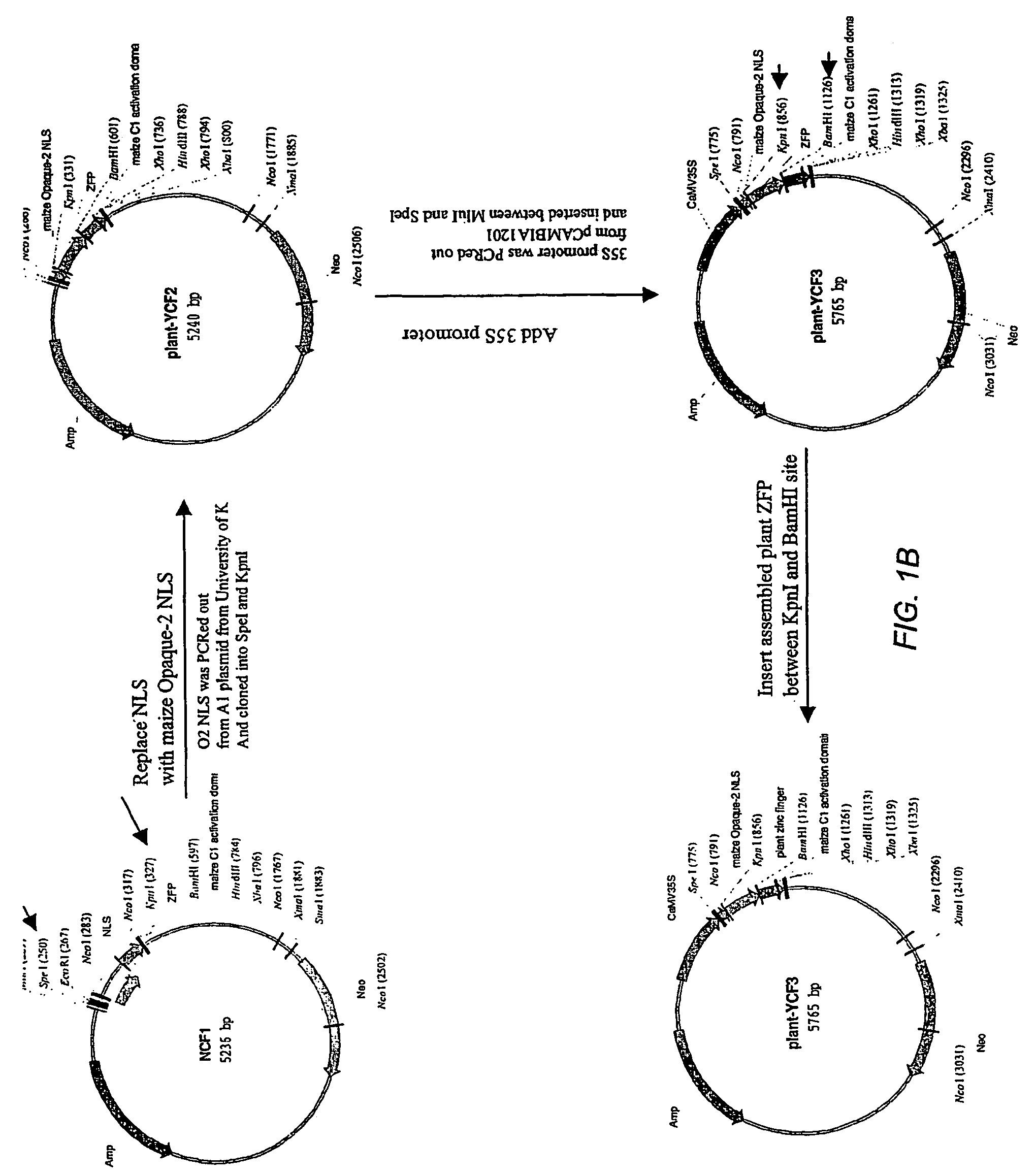

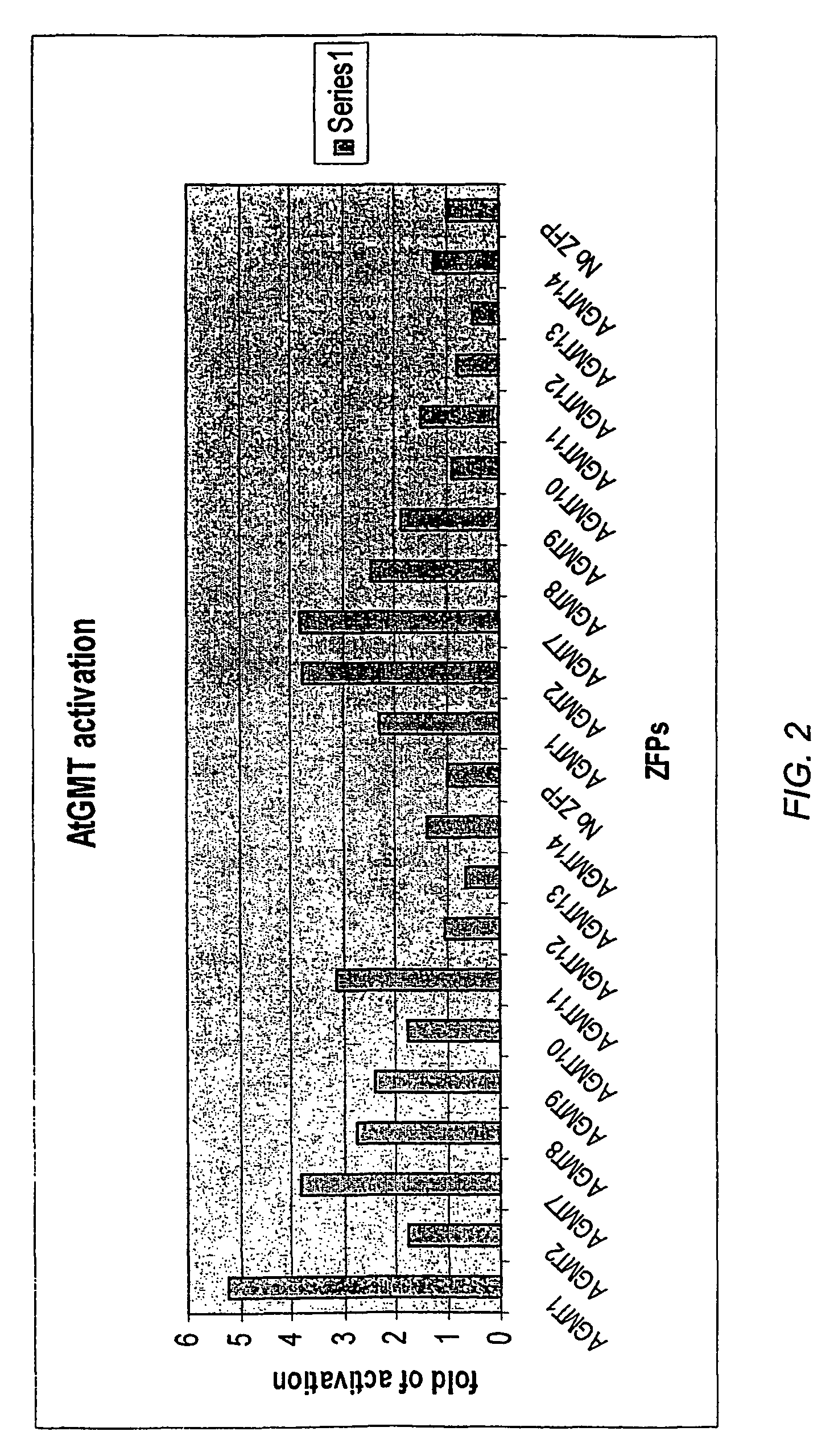

Zinc finger proteins for DNA binding and gene regulation in plants

InactiveUS7262054B2Alters compositionEasy to produceOther foreign material introduction processesFermentationBiotechnologyZinc finger

Disclosed herein are modified plant zinc finger proteins; compositions comprising modified plant zinc finger proteins and methods of making and using modified plant zinc finger proteins. The modified plant zinc finger proteins, in contrast to naturally-occurring plant zinc finger proteins, have a binding specificity that is determined by tandem arrays of modular zinc finger binding units.

Owner:SANGAMO BIOSCIENCES INC

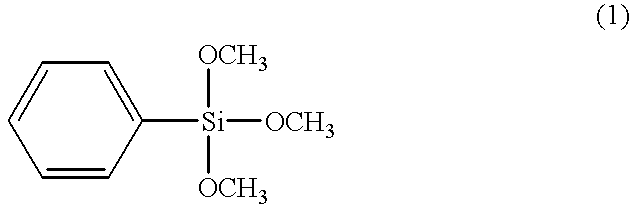

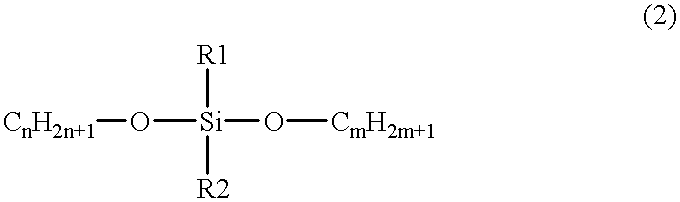

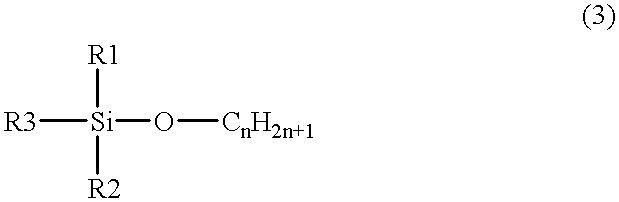

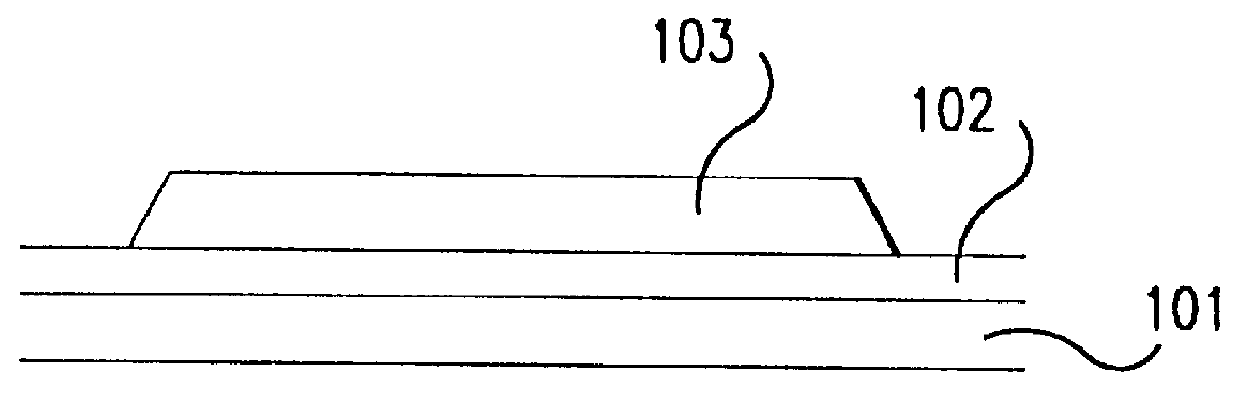

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

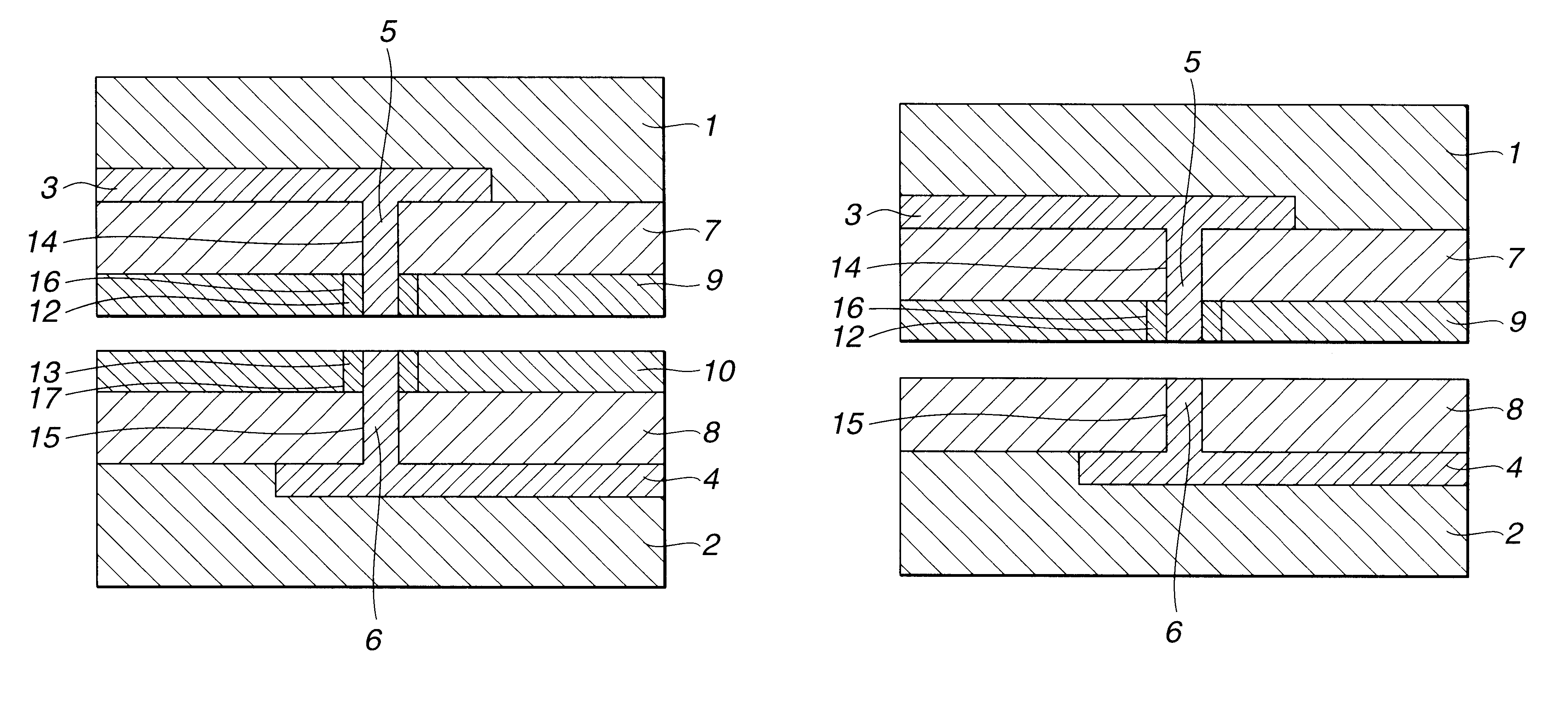

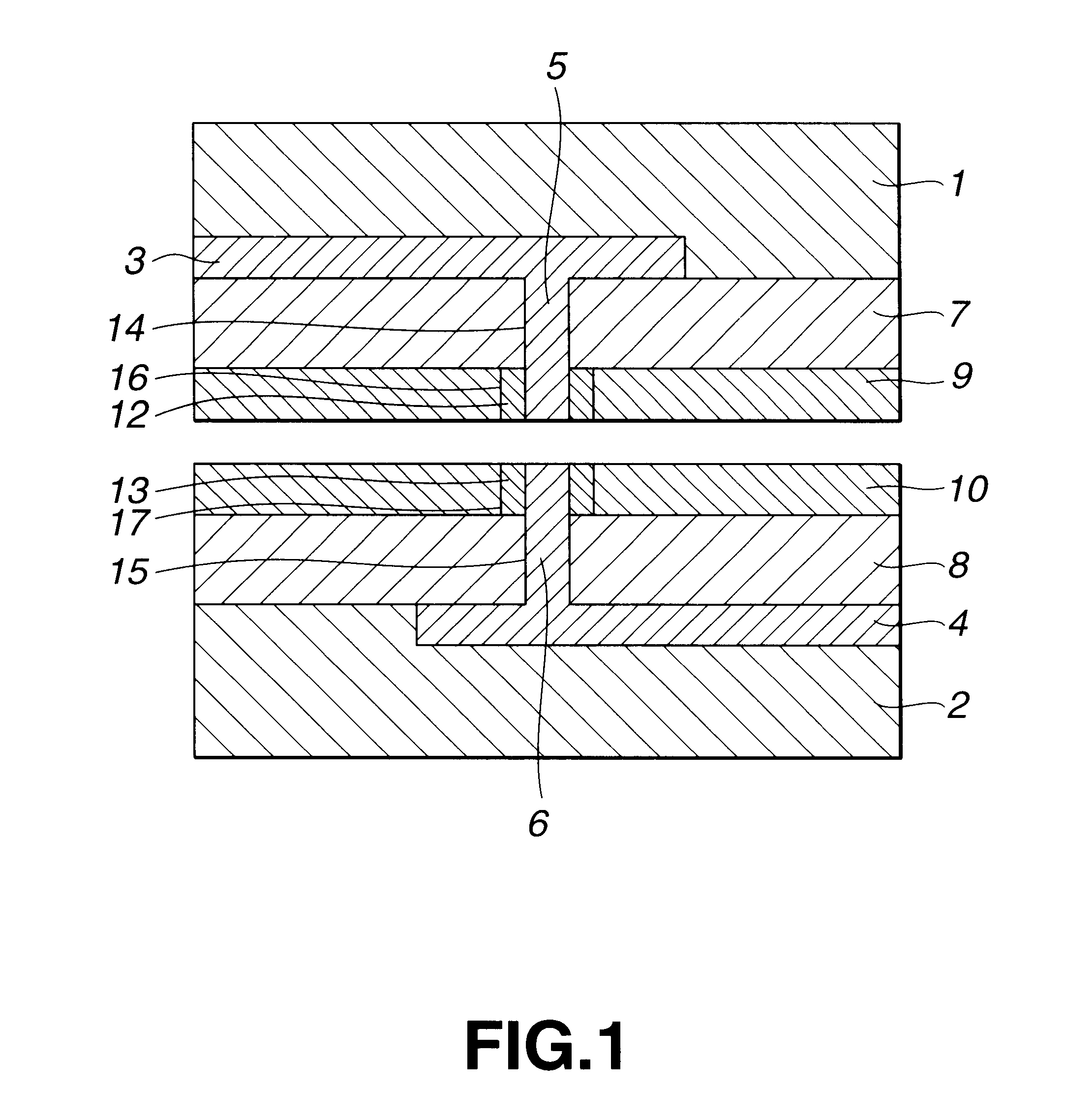

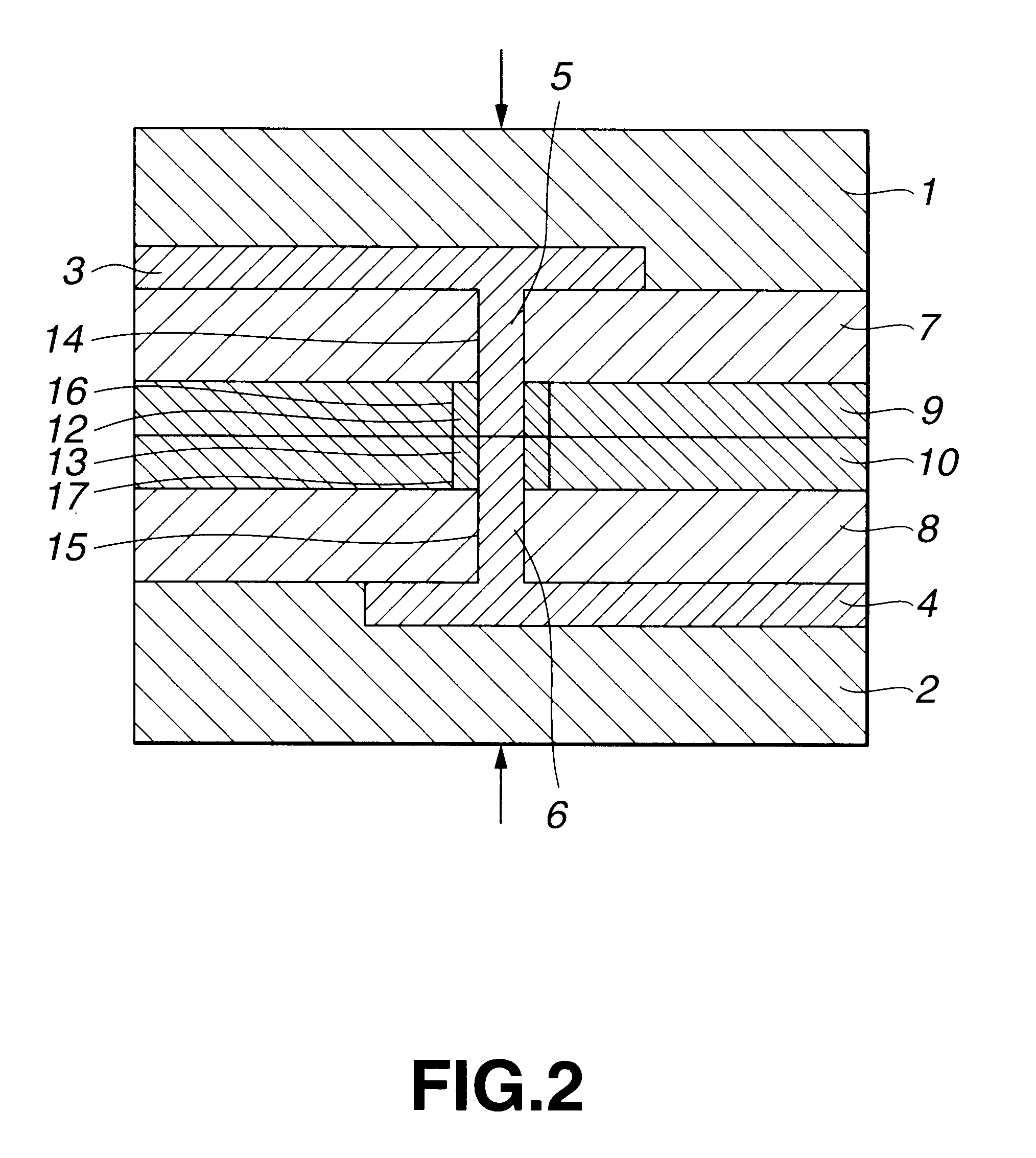

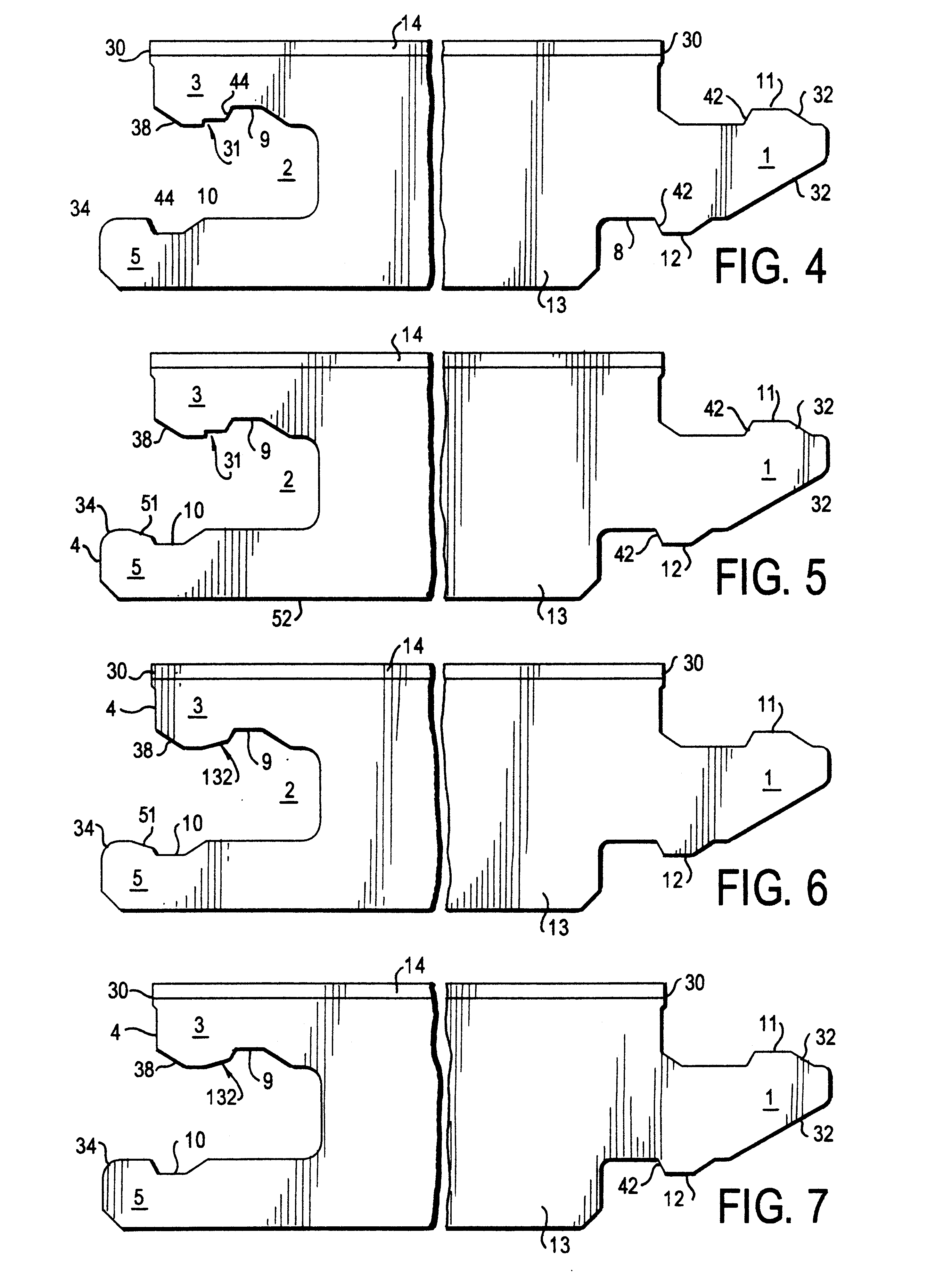

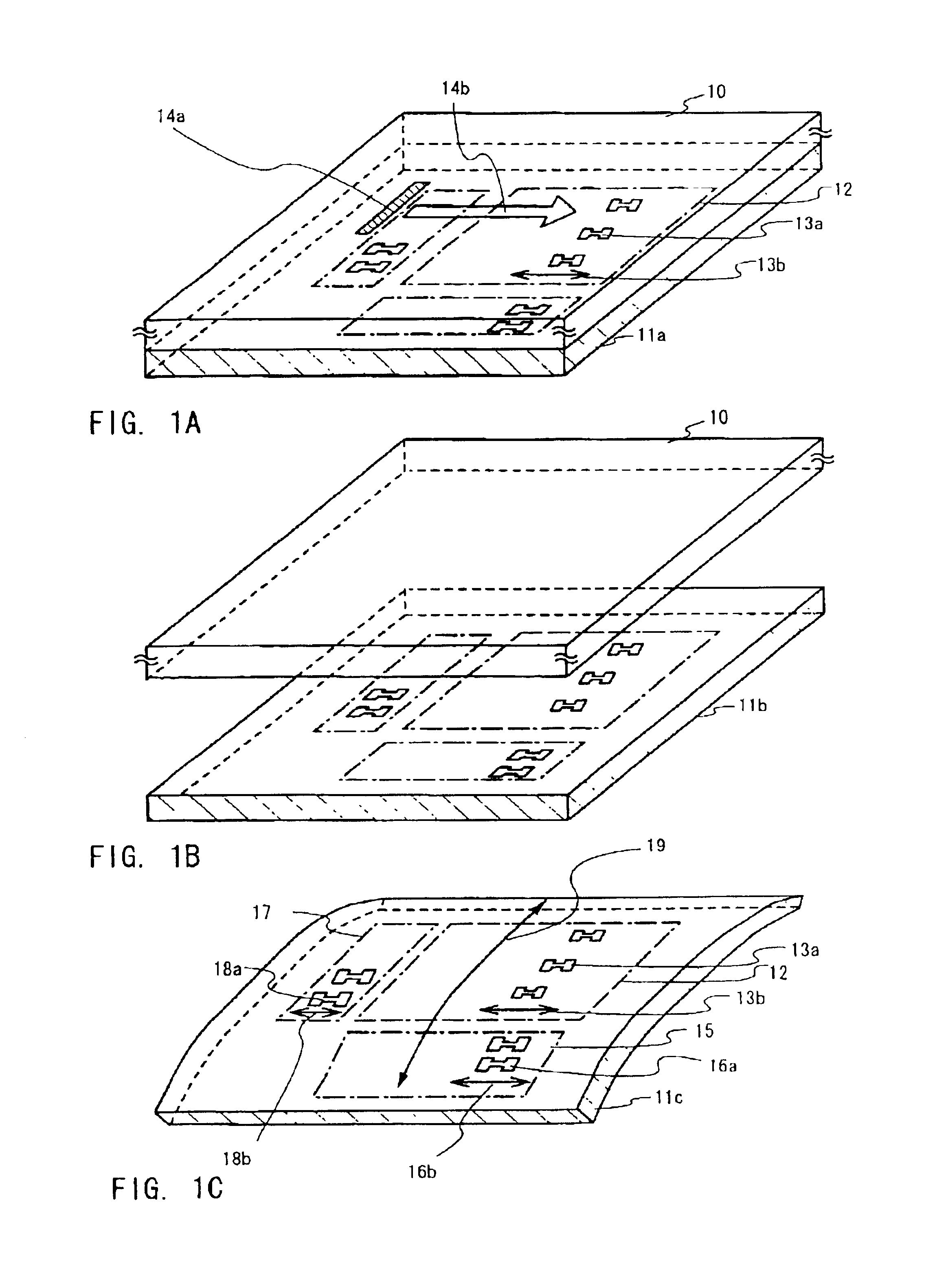

Interconnect structure for stacked semiconductor device

InactiveUS6465892B1Shorten the line lengthEasy to produceSemiconductor/solid-state device detailsSolid-state devicesDevice materialInterconnection

In a multi-layer interconnection structure, the wiring length is to be reduced, and the interconnection is to be straightened, at the same time as measures need to be taken against radiation noise. To this end, there is disclosed a semiconductor device in which plural semiconductor substrates, each carrying semiconductor elements, are bonded together. On each semiconductor substrate is deposited an insulating layer through which is formed a connection wiring passed through the insulating layer so as to be connected to the interconnection layer of the semiconductor element. On a junction surface of at least one of the semiconductor substrates is formed an electrically conductive layer of an electrically conductive material in which an opening is bored in association with the connection wiring. The semiconductor substrates are bonded together by the solid state bonding technique to interconnect the connection wirings formed on each semiconductor substrate.

Owner:LAPIS SEMICON CO LTD +9

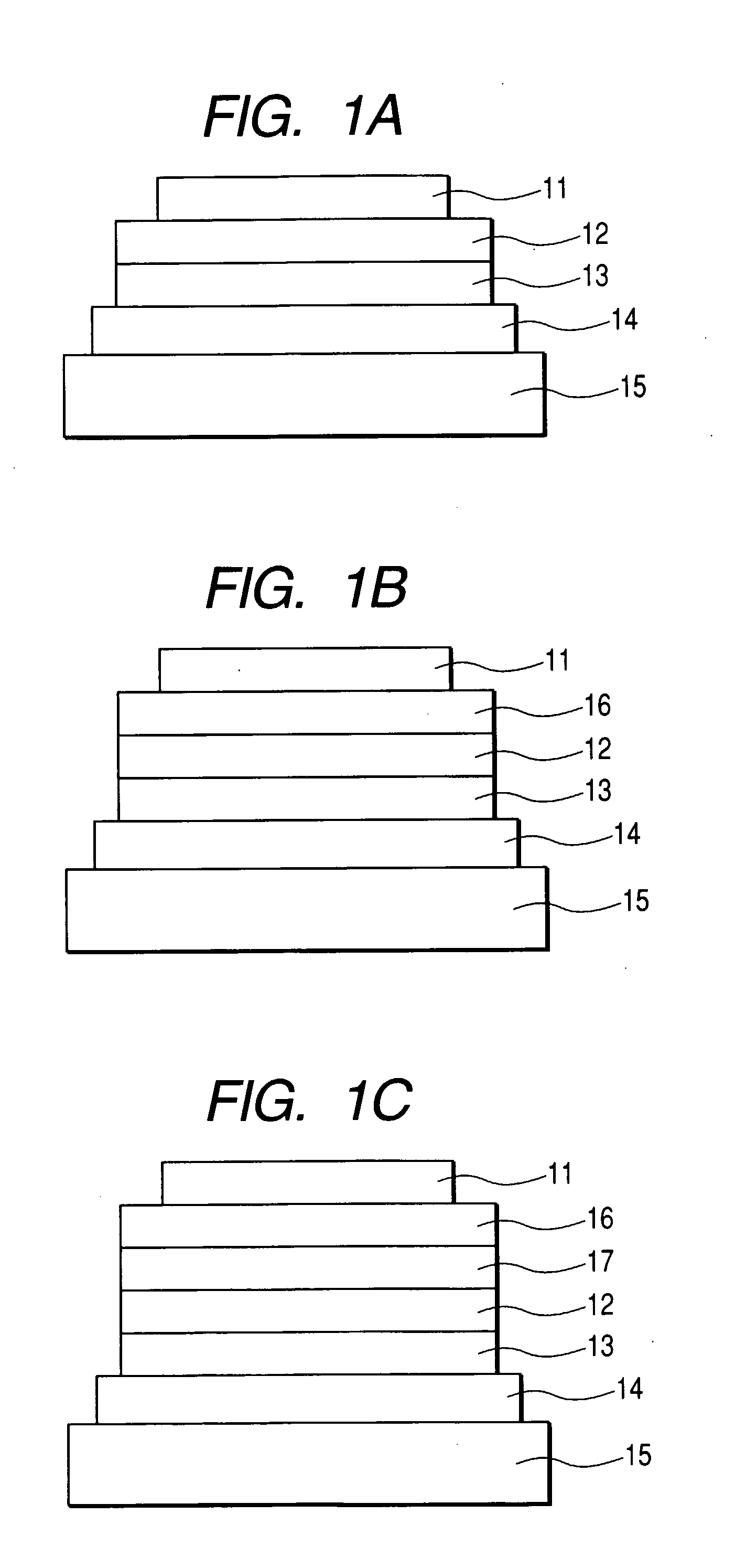

Metal Complex, Light-Emitting Device, and Image Display Apparatus

InactiveUS20080210930A1Improve efficiencyIncrease brightnessIndium organic compoundsSolid-state devicesLight emitting deviceCoordination complex

Owner:CANON KK

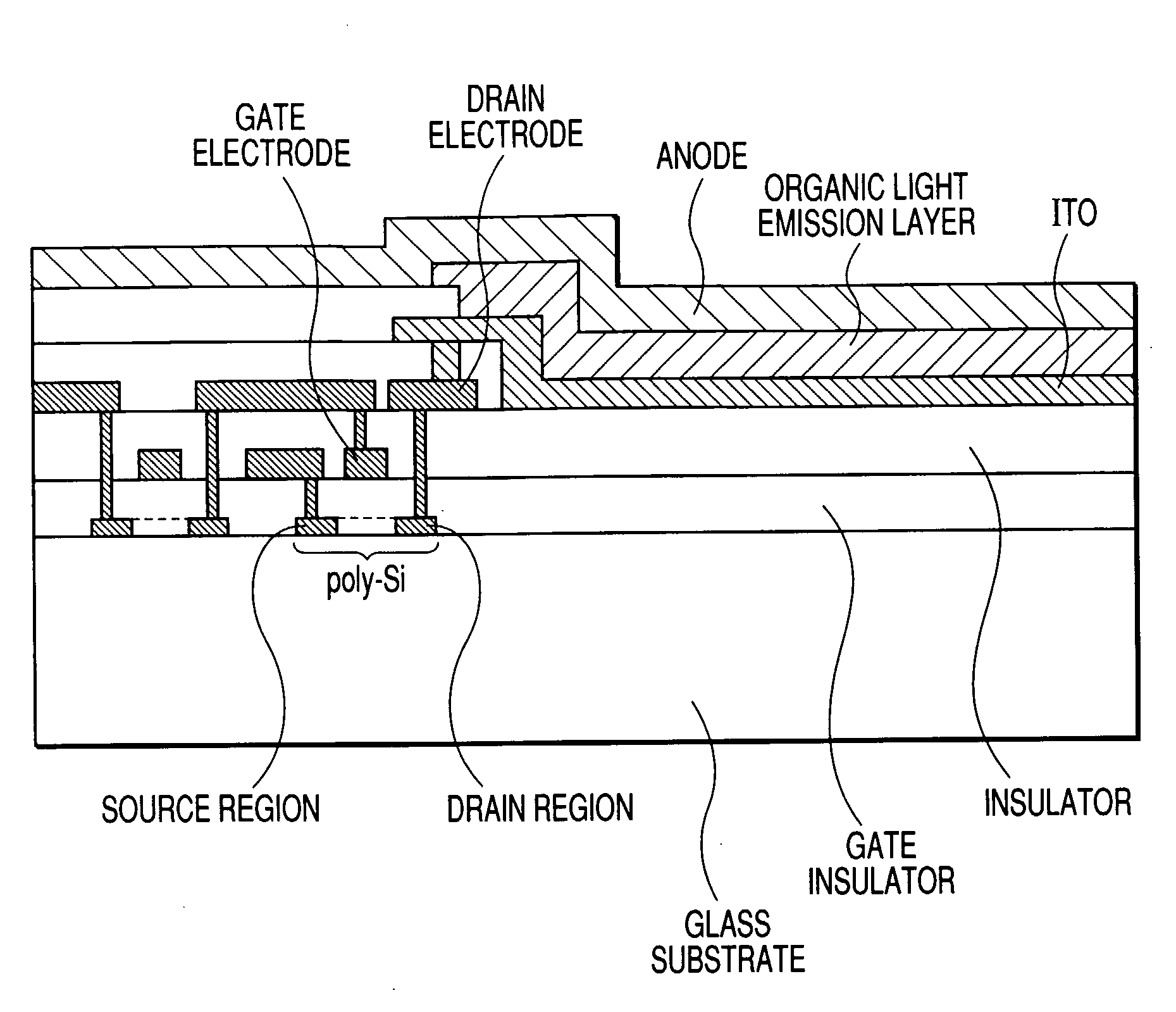

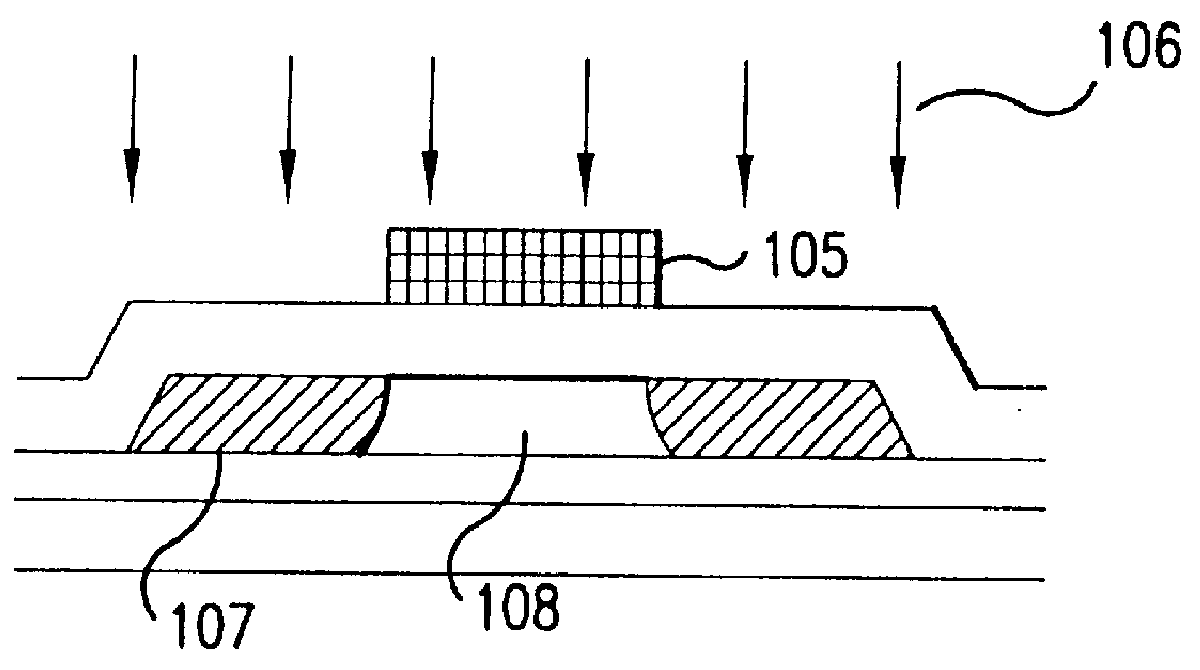

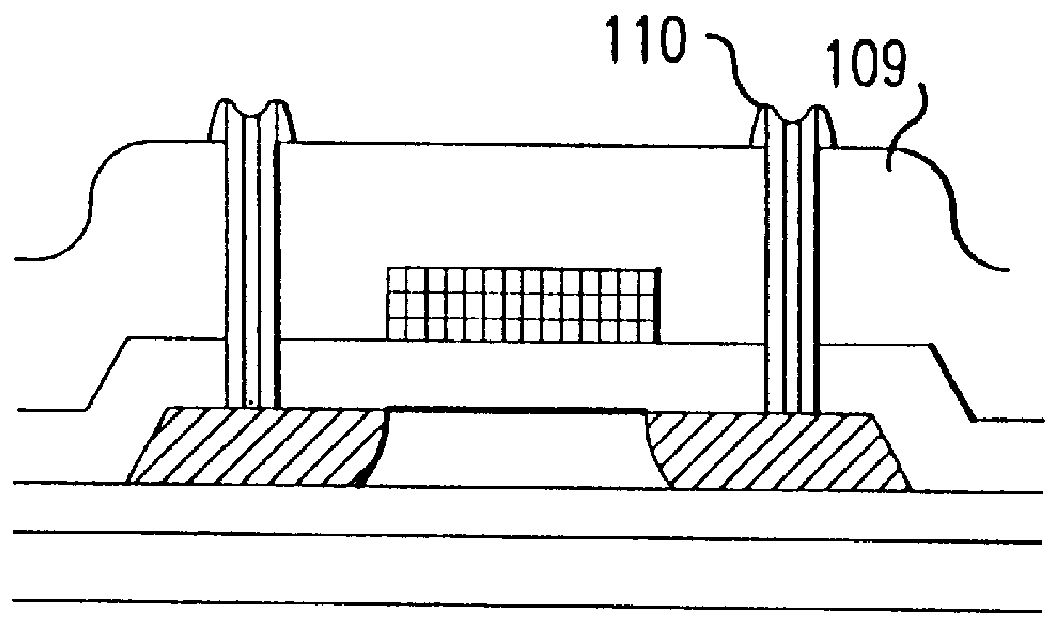

Fabrication method for a thin film semiconductor device, the thin film semiconductor device itself, liquid crystal display, and electronic device

InactiveUS6017779AImprove propertiesWell formedTransistorLinear bearingsElectronic circuitLiquid-crystal display

In order to fabricate a high performance thin film semiconductor device using a low temperature process in which it is possible to use low price glass substrates, a thin film semiconductor device has been fabricated by forming a silicon film at less than 450 DEG C., and, after crystallization, keeping the maximum processing temperature at or below 350 DEG C. In applying the present invention to the fabrication of an active matrix liquid crystal display, it is possible to both easily and reliably fabricate a large, high-quality liquid crystal display. Additionally, in applying the present invention to the fabrication of other electronic circuits as well, it is possible to both easily and reliably fabricate high-quality electronic circuits.

Owner:INTELLECTUAL KEYSTONE TECH

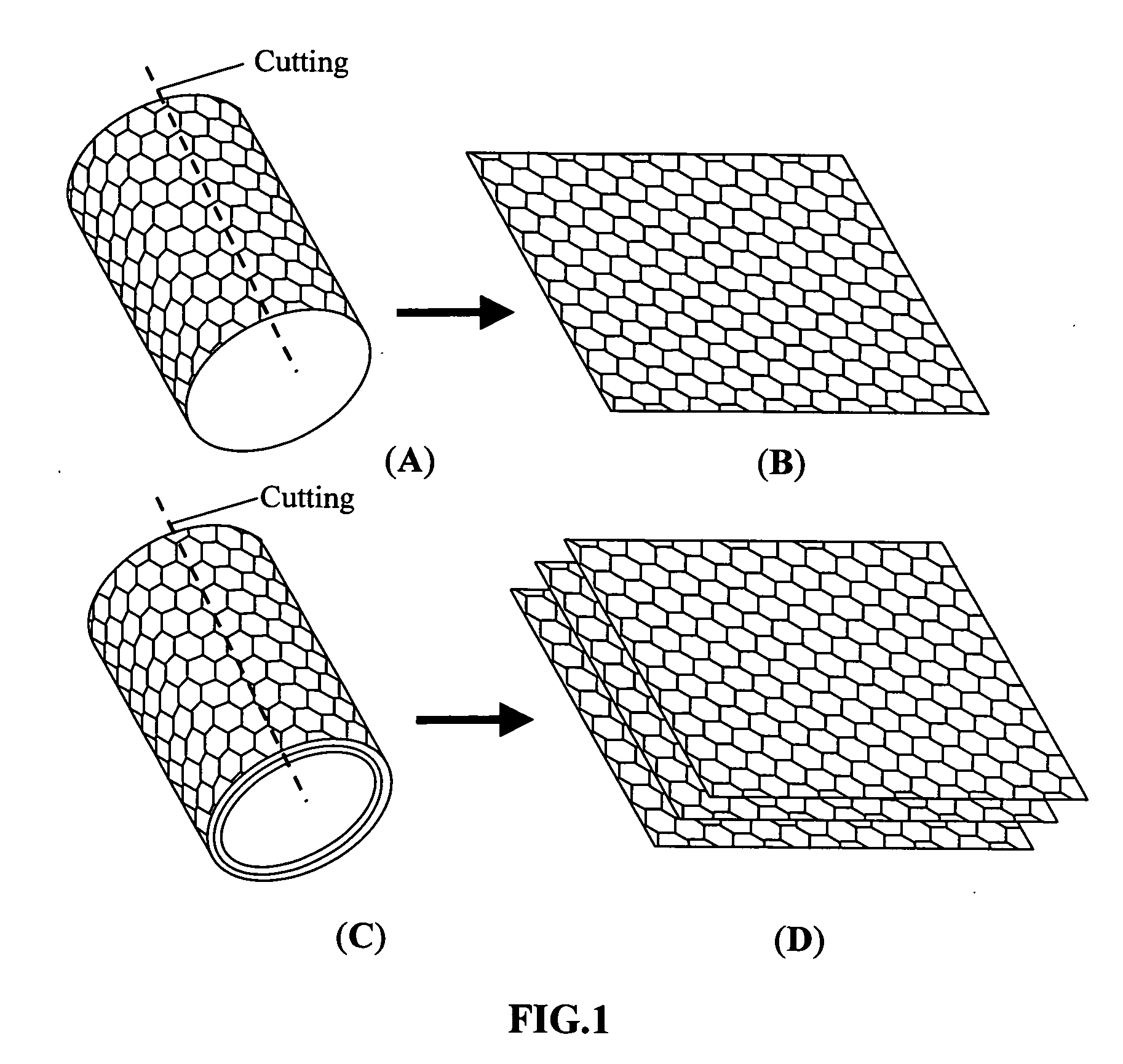

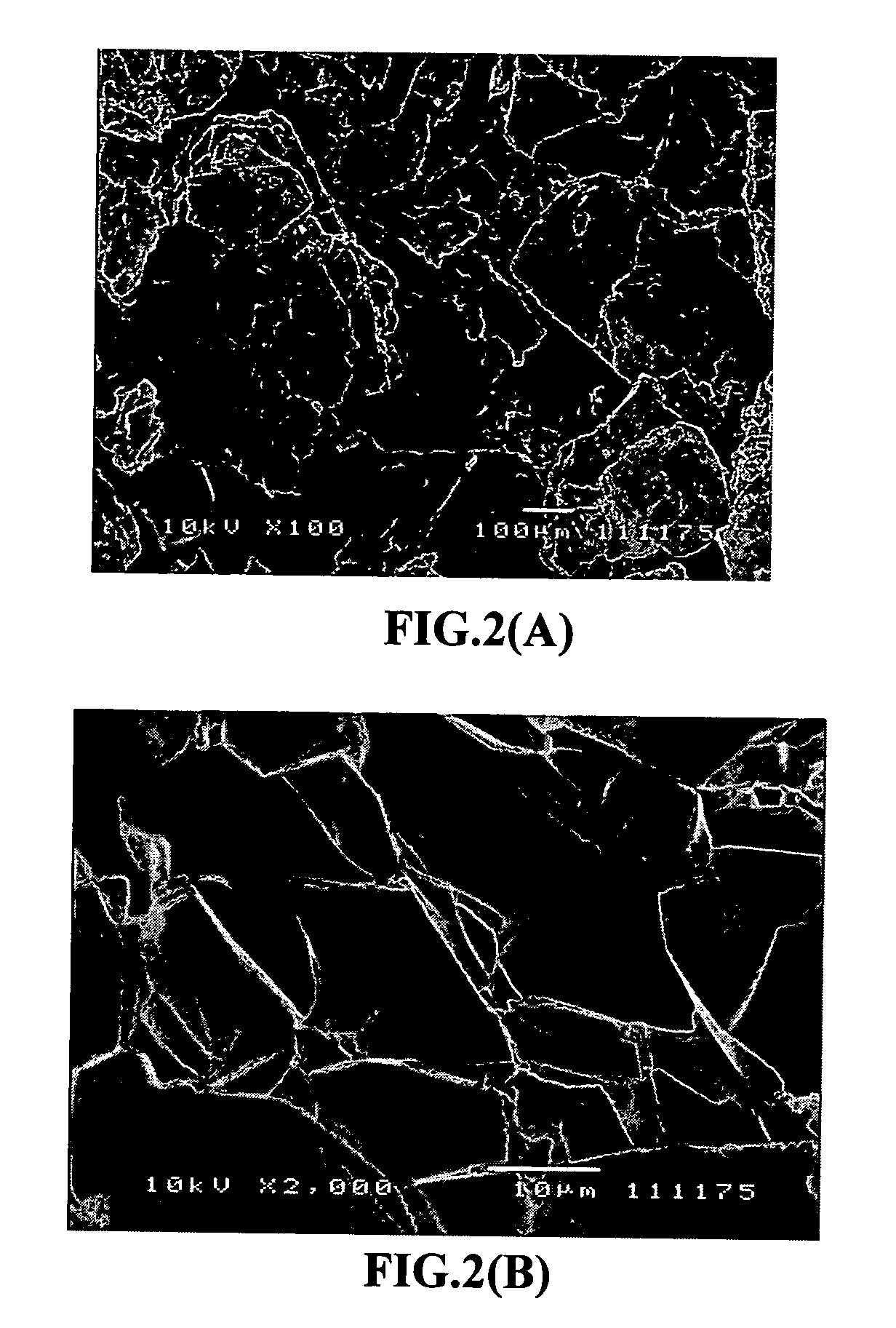

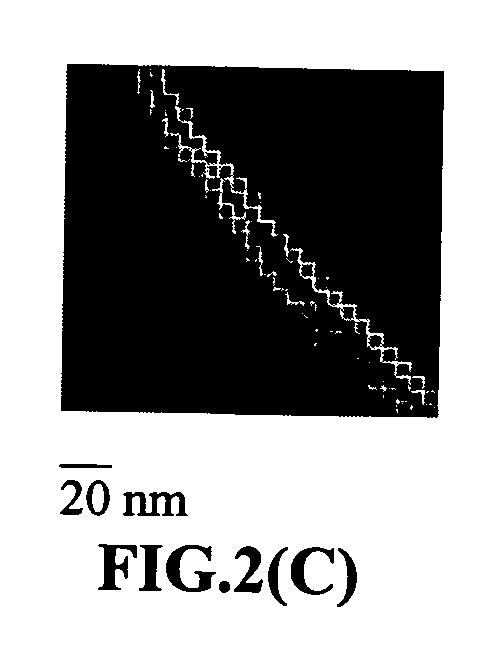

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

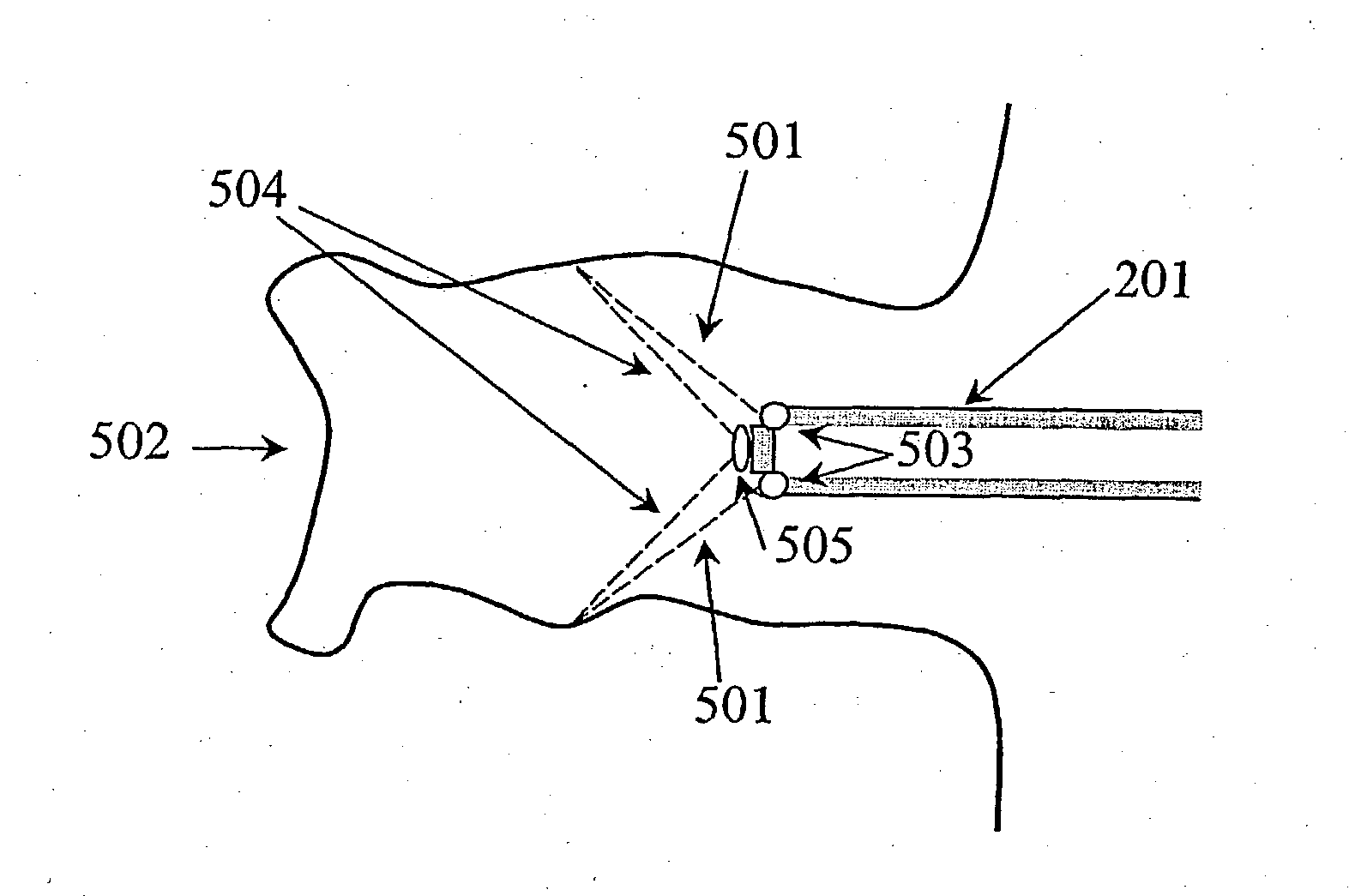

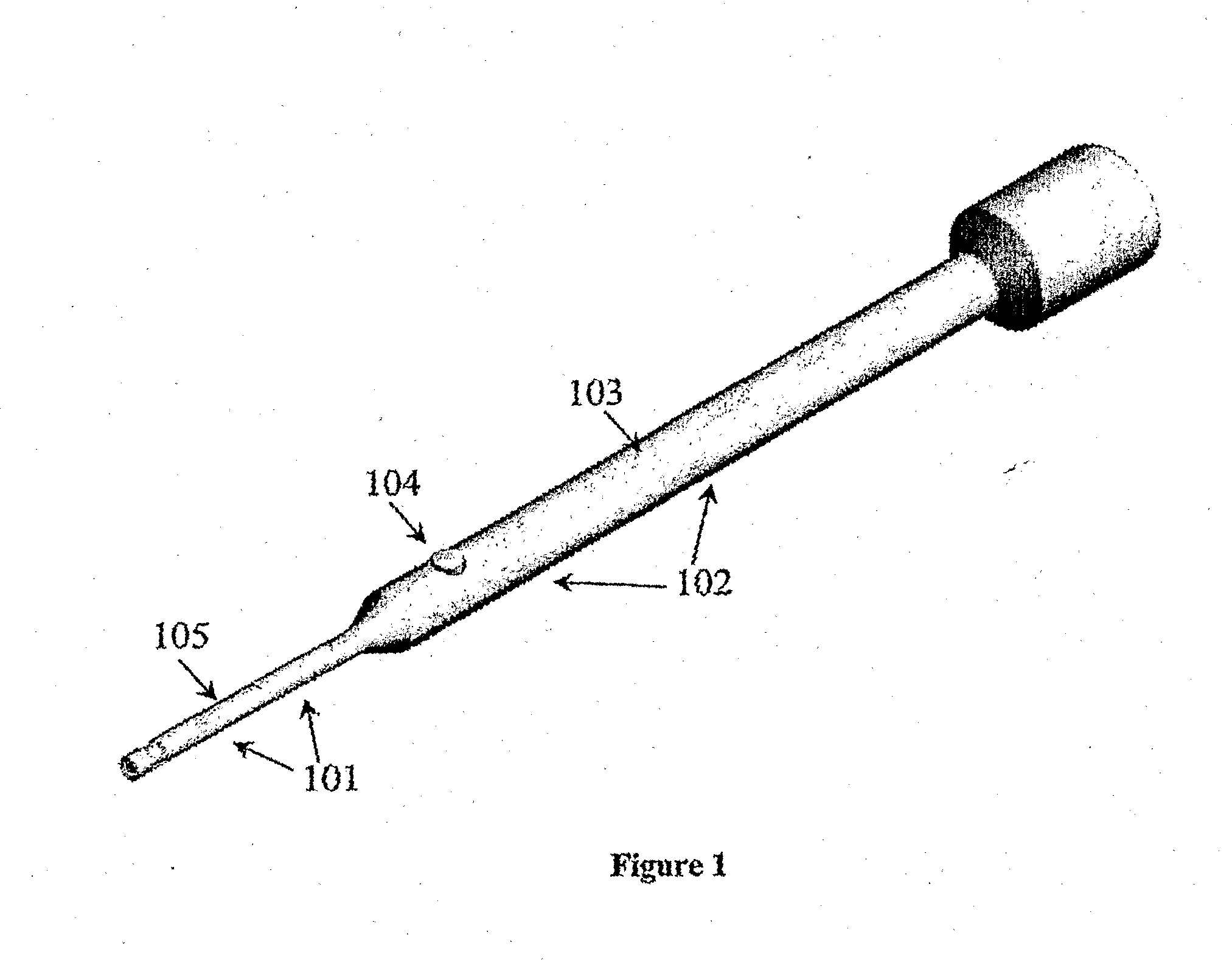

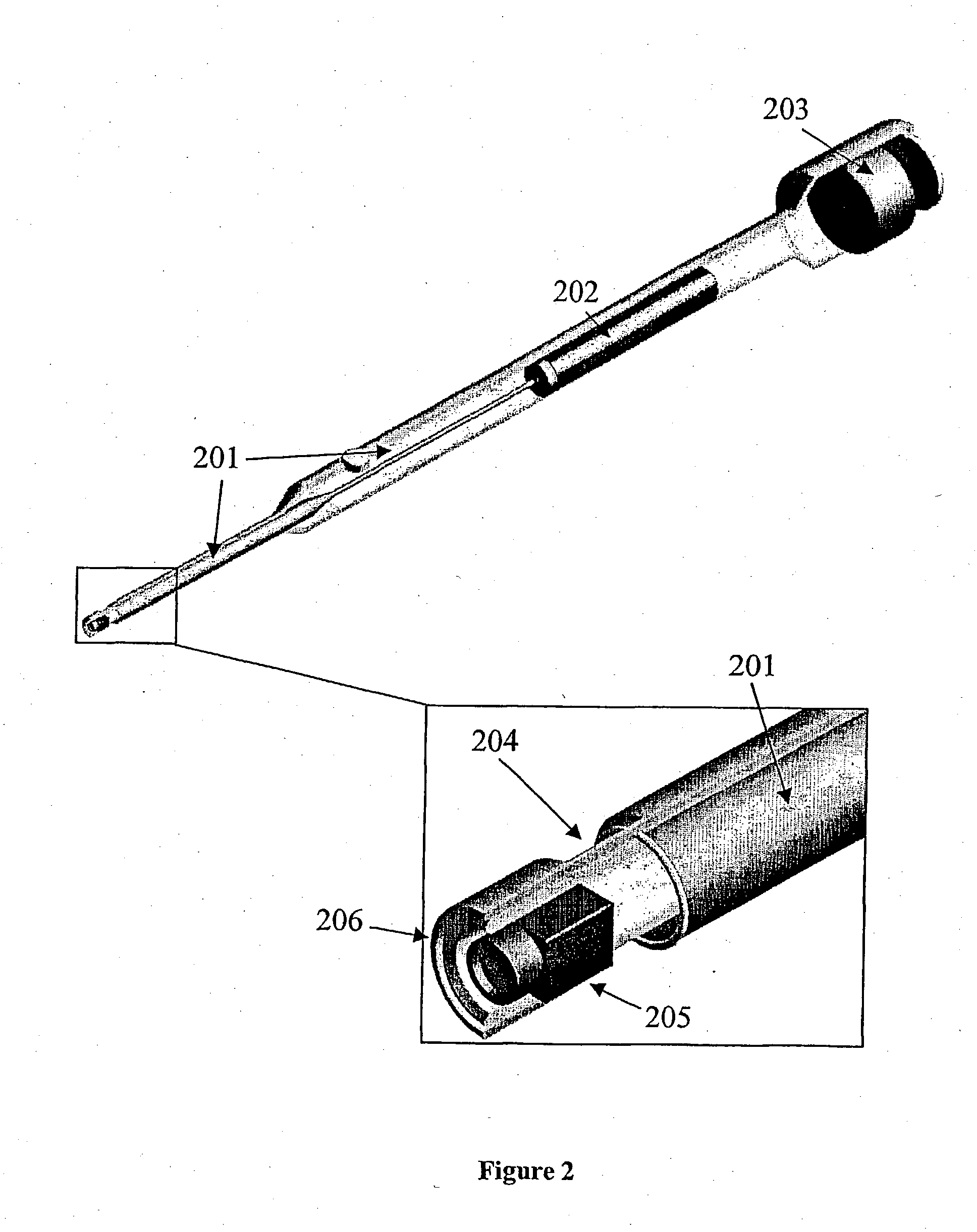

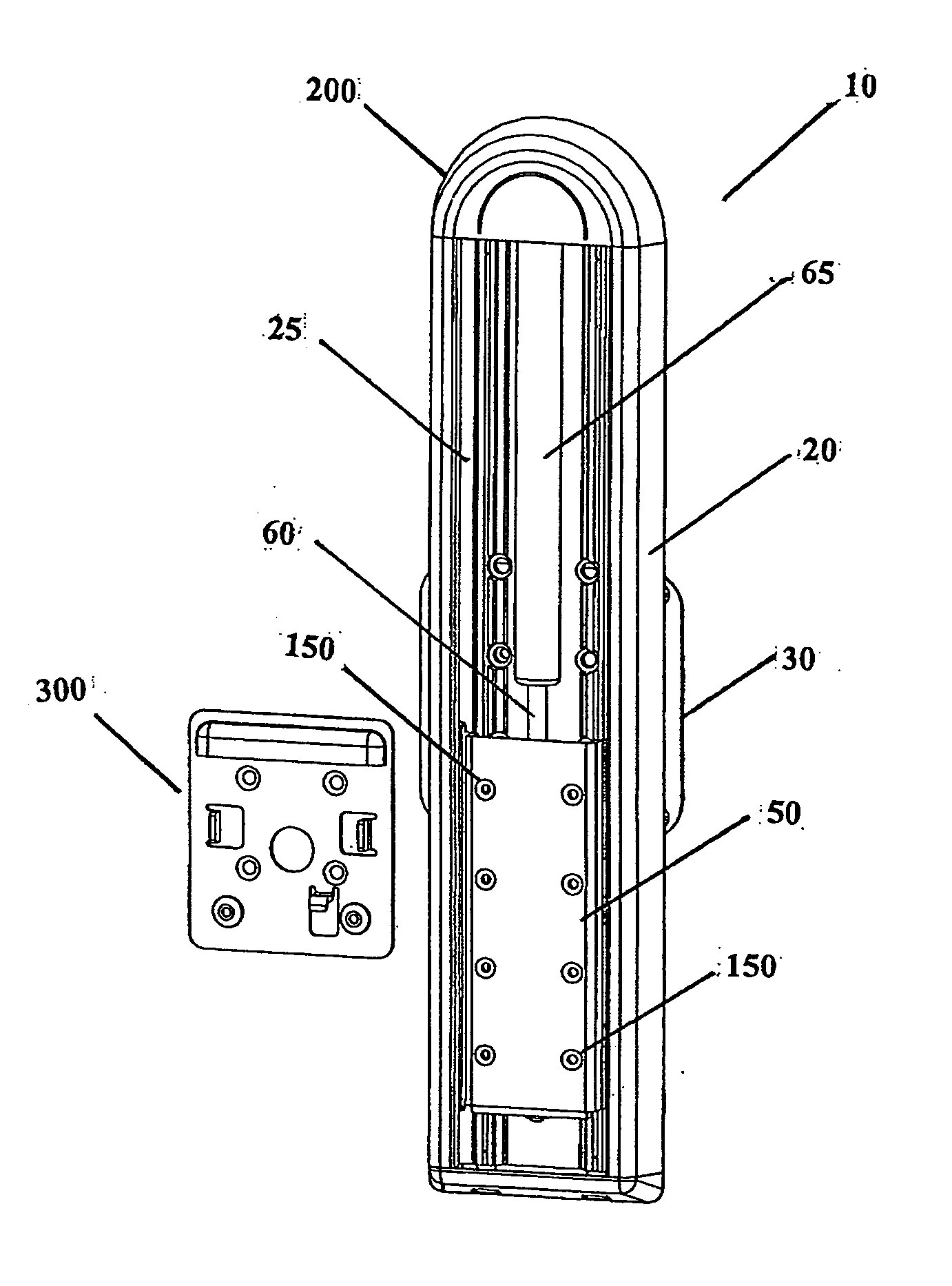

Method and apparatus for three-dimensional optical scanning of interior surfaces

InactiveUS20030164952A1Easy to produceHigh precision scan dataAdditive manufacturing apparatusOtoscopesEar canalOptical scanning

The invention concerns the three-dimensional scanning of interior surfaces or cavities of limited dimensions or with restricted accessibility by providing a probe-shaped non-contact adpated to perform a scan 360° around the axis of the probe and a method for scanning. The invention furthermore relates to the creation of high precision three-dimensional replicas of real objects using 3-D scan data obtainable with the scanner according to the invention. Furthermore, the invention relates to a specific embodiment for scanning the human ear and ear canal.

Owner:3SHAPE AS

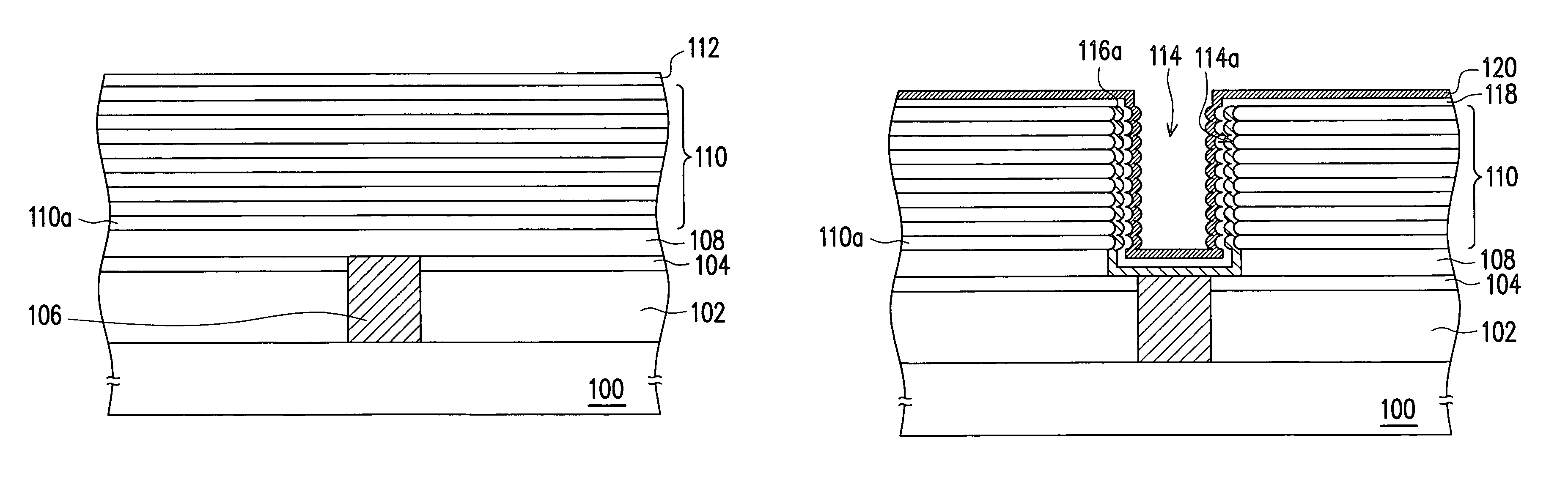

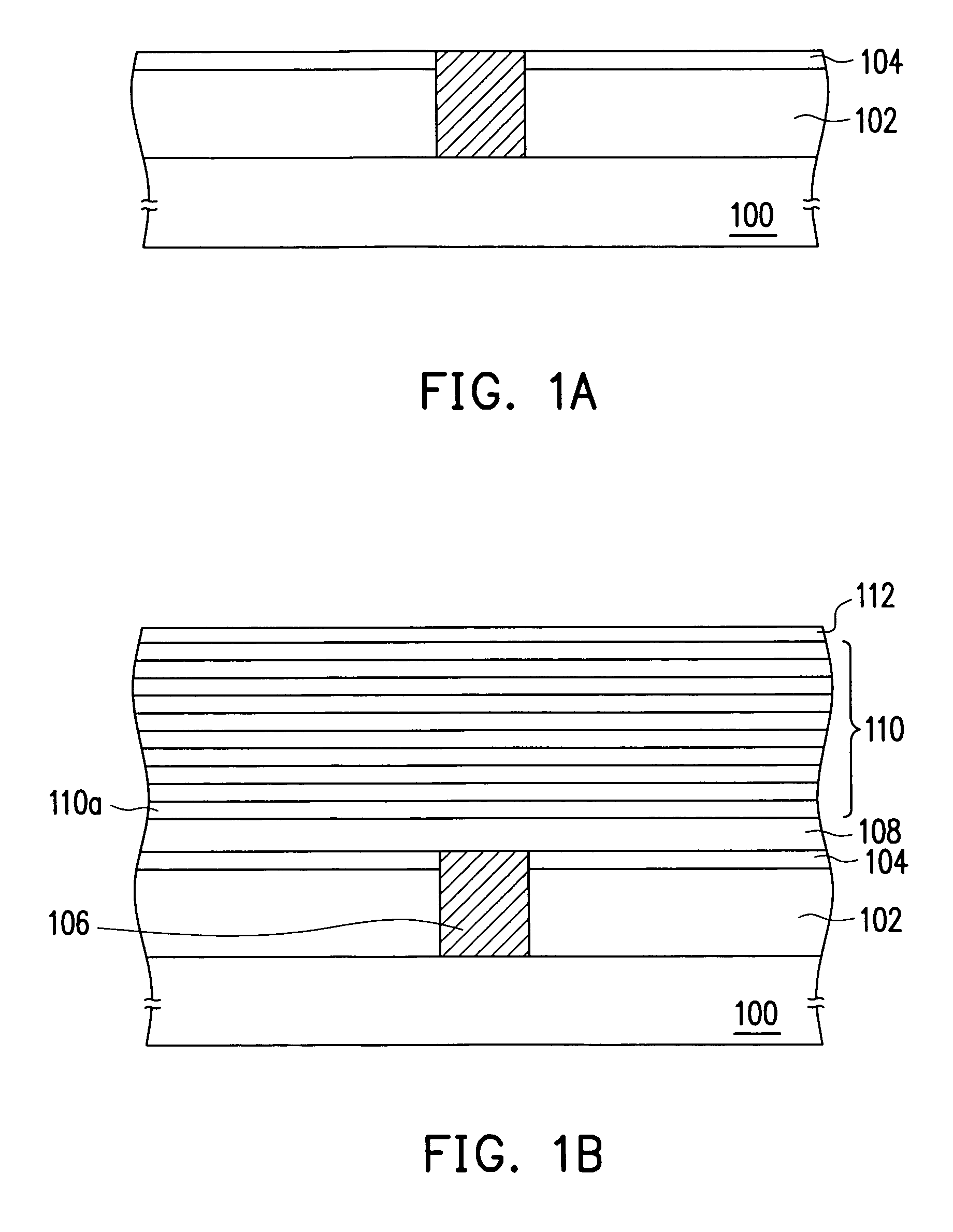

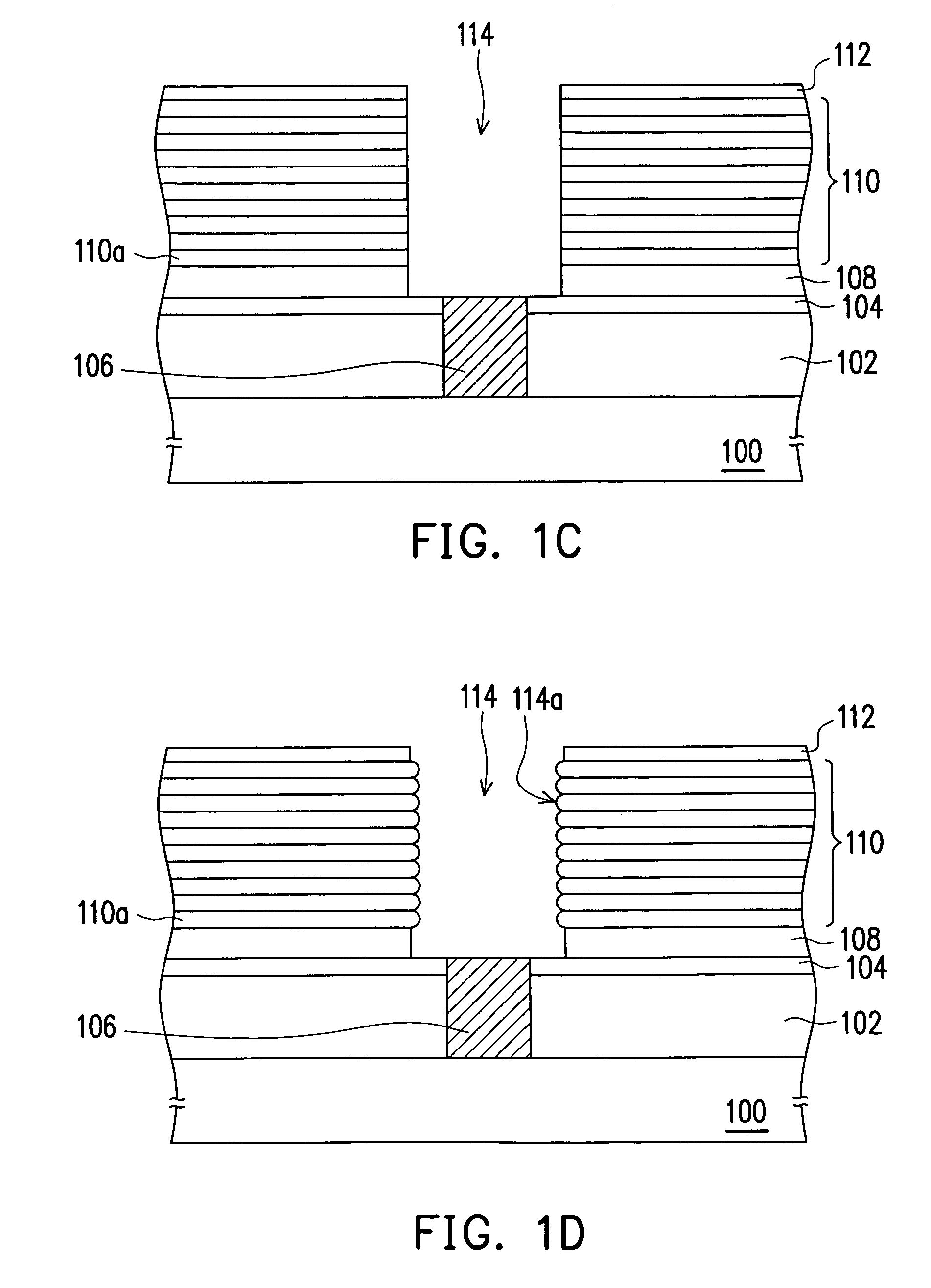

Method of manufacturing charge storage device

InactiveUS7405166B2Increase electrode areaEasy to produceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceHydrogen fluoride

Owner:IND TECH RES INST

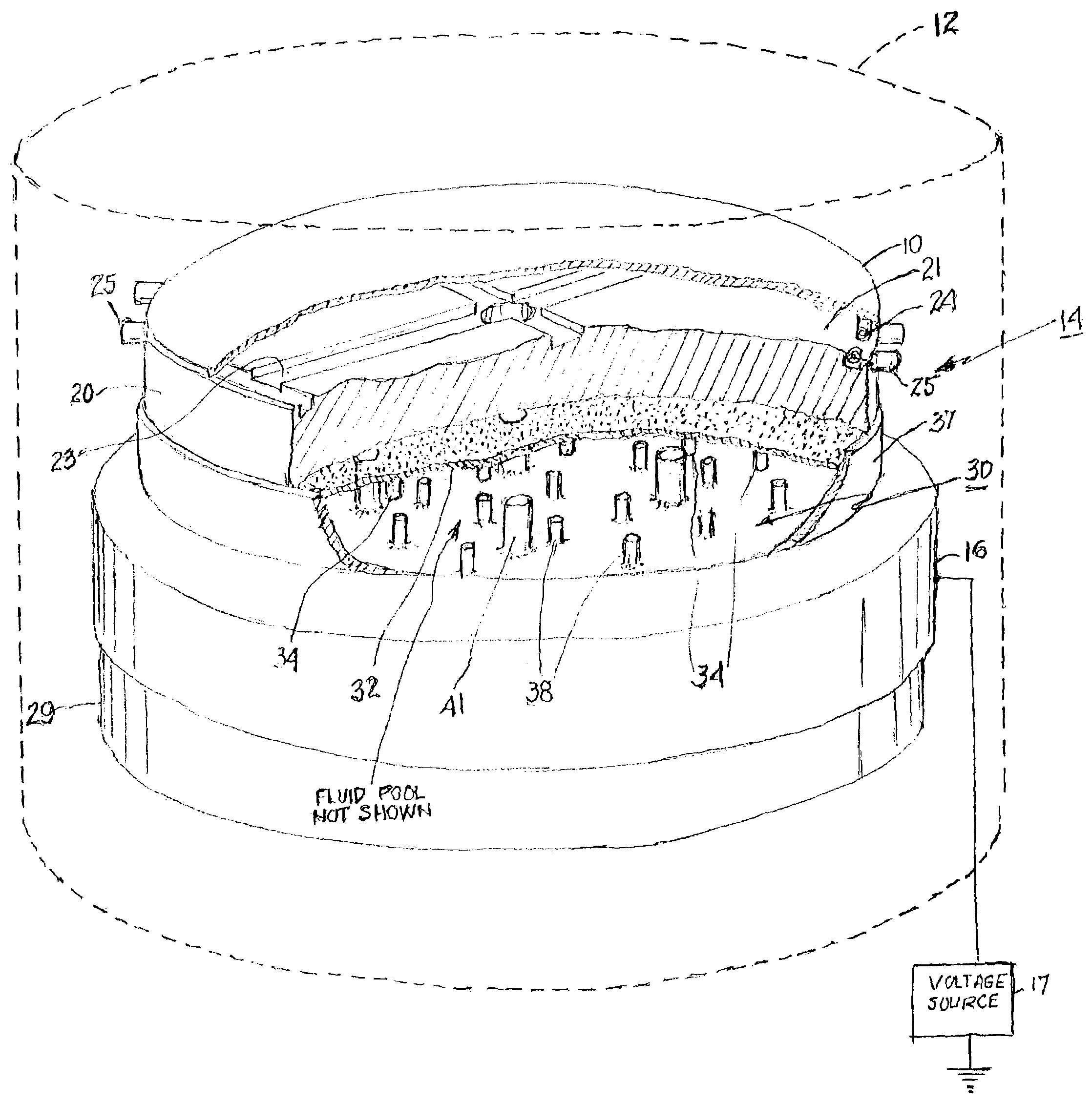

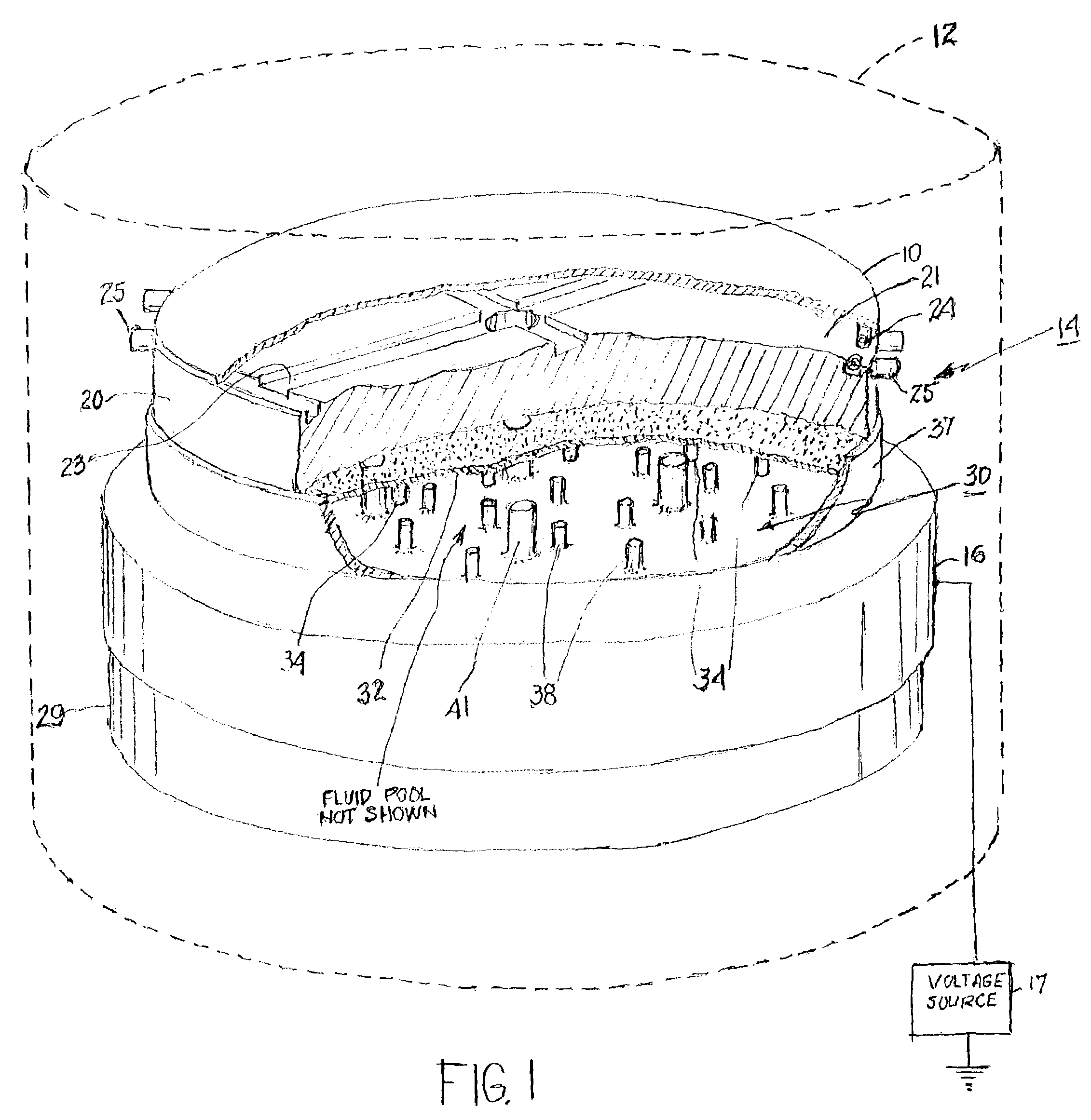

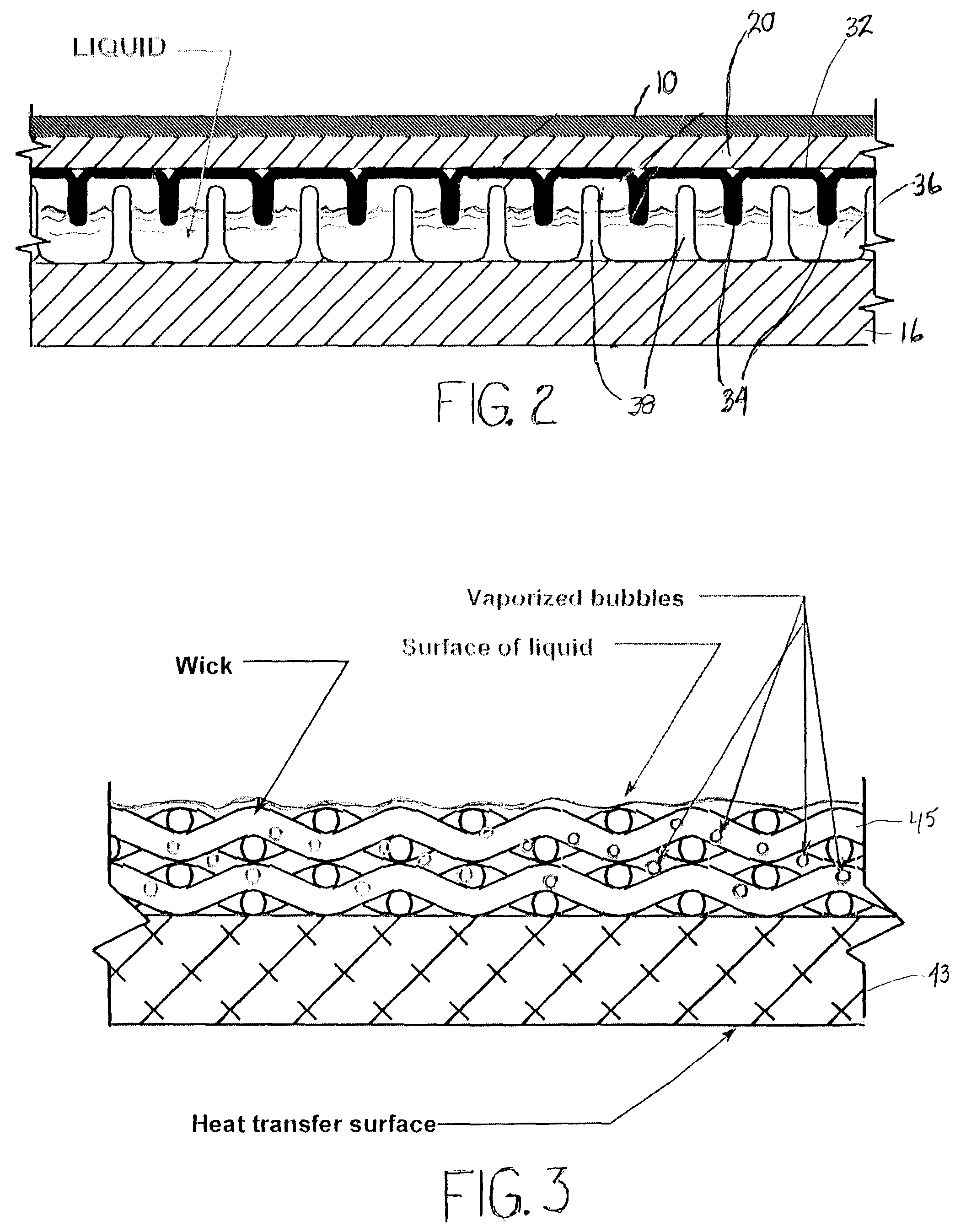

Lateral temperature equalizing system for large area surfaces during processing

ActiveUS7195693B2Rapid temperature stabilizationLittle changeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyShortest distance

In many processes used in fabricating semiconductors the wafer is seated on the top surface of a pedestal and heated in a high energy process step, such as plasma etching. The pedestal, chuck or platen may be cooling but the wafer gradually heats until the process can no longer continue. Where large, e.g. 300 mm diameter, wafers are being processed the temperature level across the wafer is difficult to maintain substantially constant. In this system and method the lateral temperature distribution is equalized by a heat sink structure in a chamber immediately under the wafer support on top of the pedestal. A number of spatially distributed wicking posts extend downwardly from a layer of wicking material across the top of the chamber, into a pool of a vaporizable liquid. At hot spots, vaporized liquid is generated and transported to adjacent condensation posts extending up from the liquid. The system thus passively extracts heat to equalize temperatures while recirculating liquid and assuring adequate supply. The free volume above and within the liquid, and the short distances between posts, assure adequate heat transfer rates.

Owner:BE AEROSPACE INCORPORATED

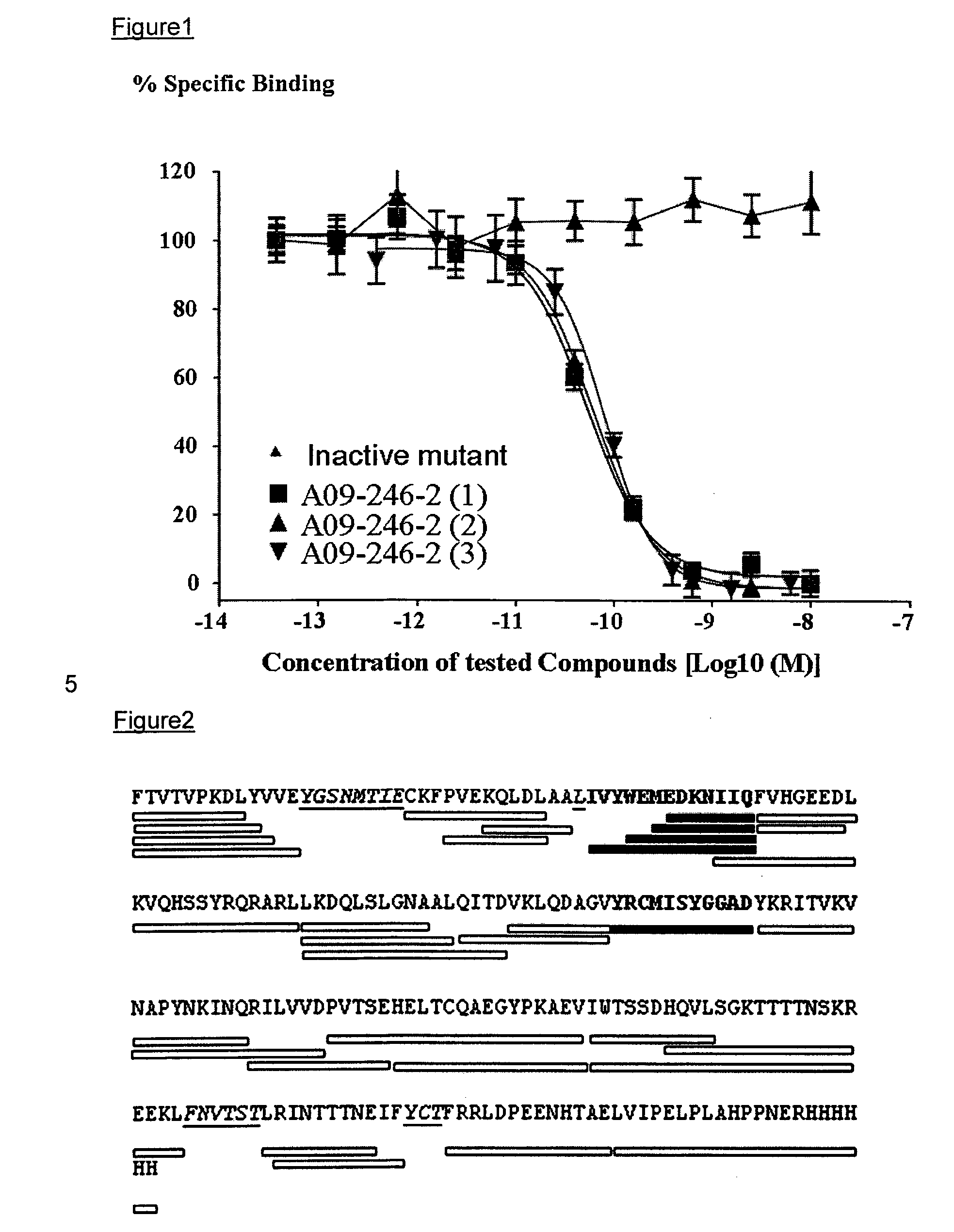

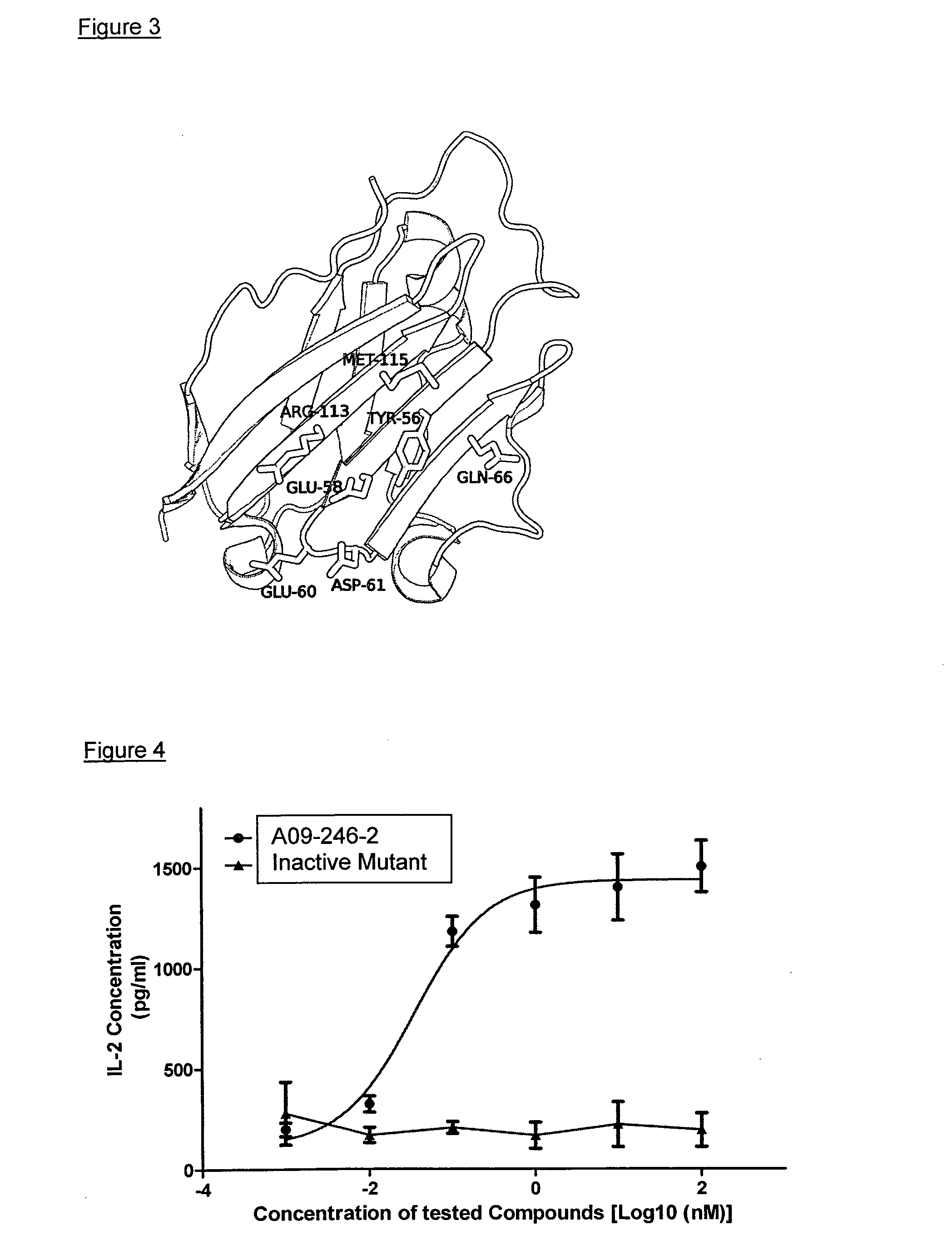

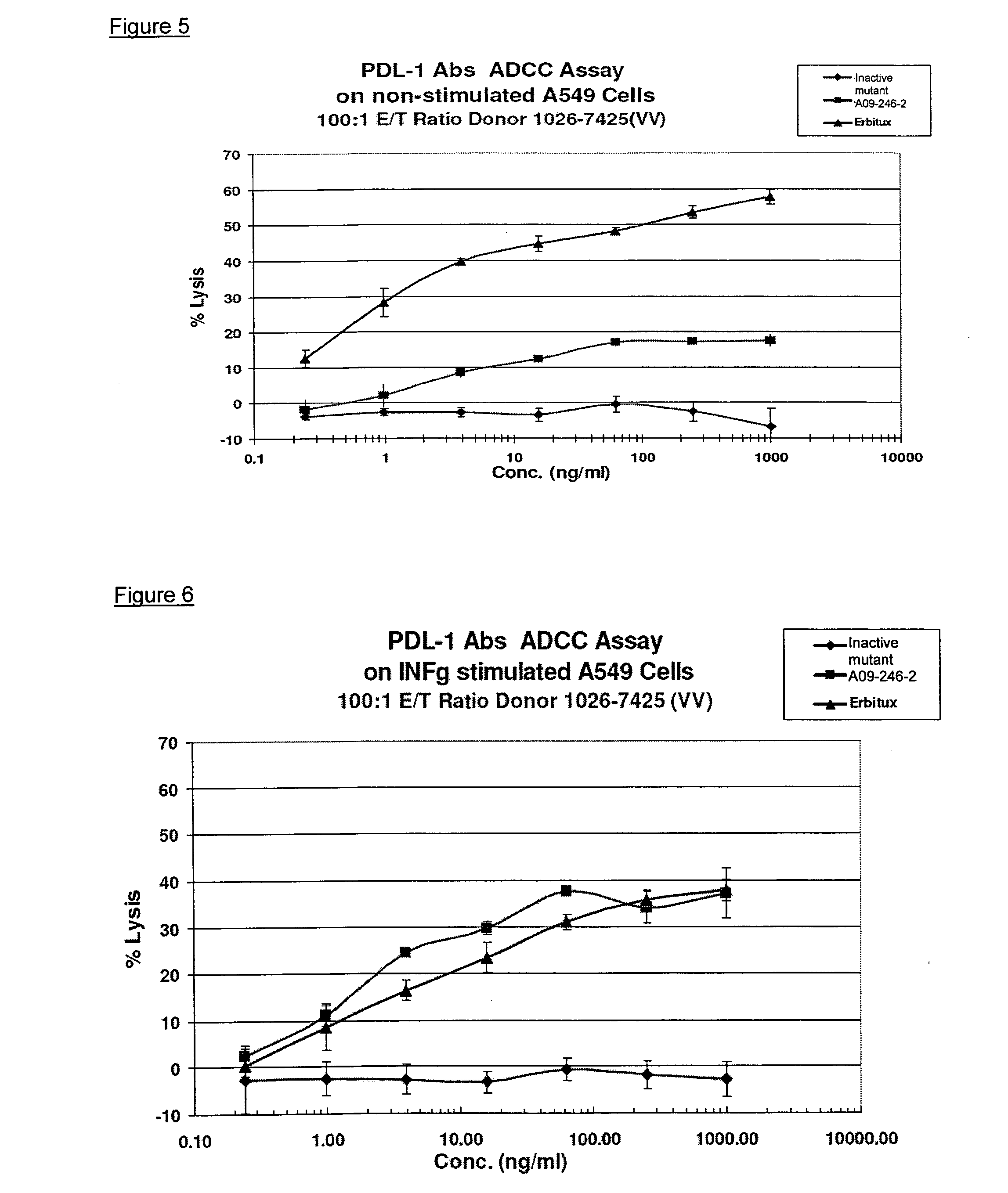

Anti-pd-l1 antibodies and uses thereof

ActiveUS20140341917A1Function increaseUpregulate cell-mediated immune responsesOrganic active ingredientsPeptide/protein ingredientsAntigen Binding FragmentAntigen binding

The present application relates to anti-PD-L1 antibodies or antigen binding fragments thereof, nucleic acid encoding the same, therapeutic compositions thereof, and their use to enhance T-cell function to upregulate cell-mediated immune responses and for the treatment of T cell dysfunctional disorders, such as tumor immunity, for the treatment of and cancer.

Owner:MERCK PATENT GMBH

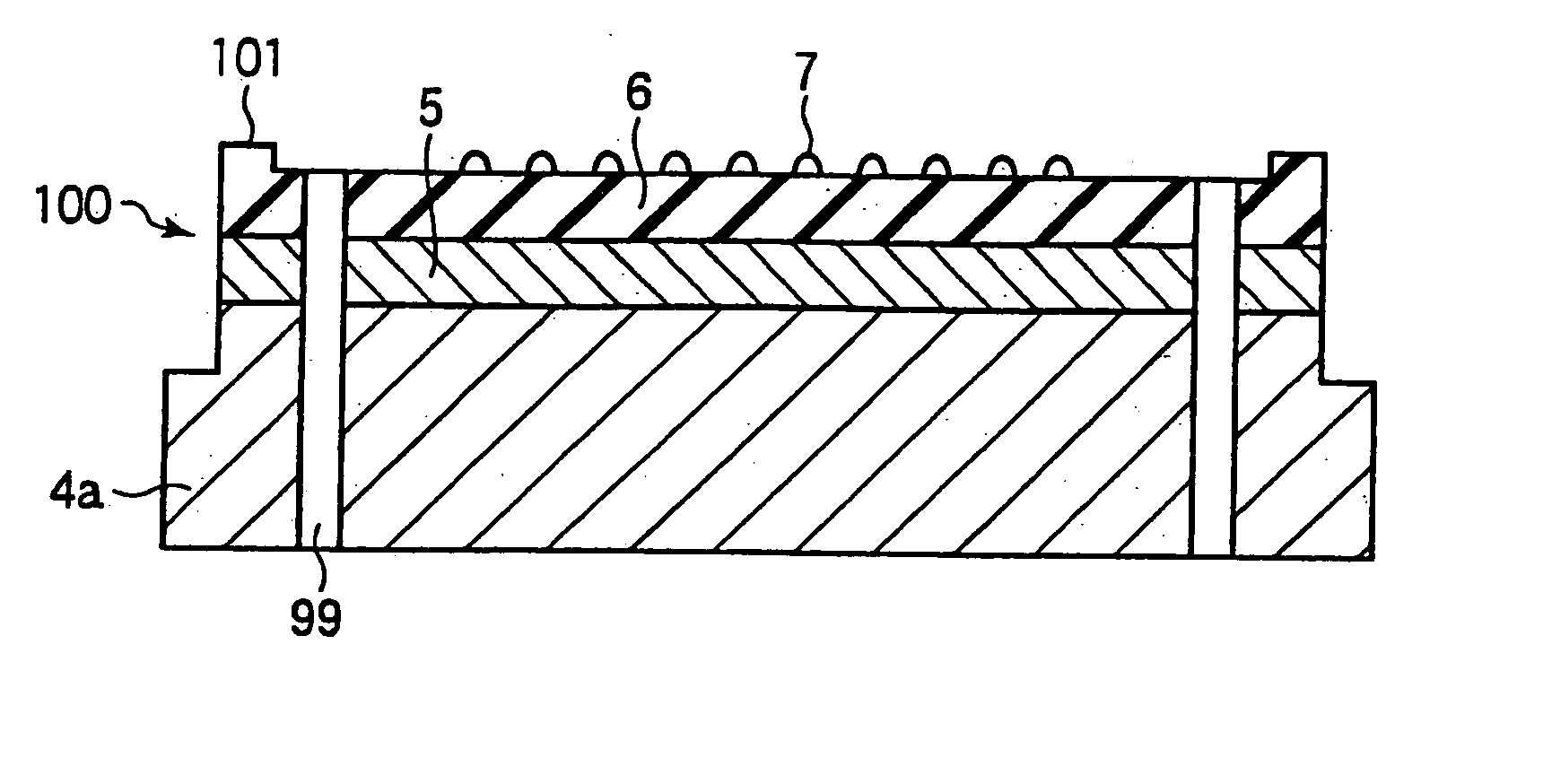

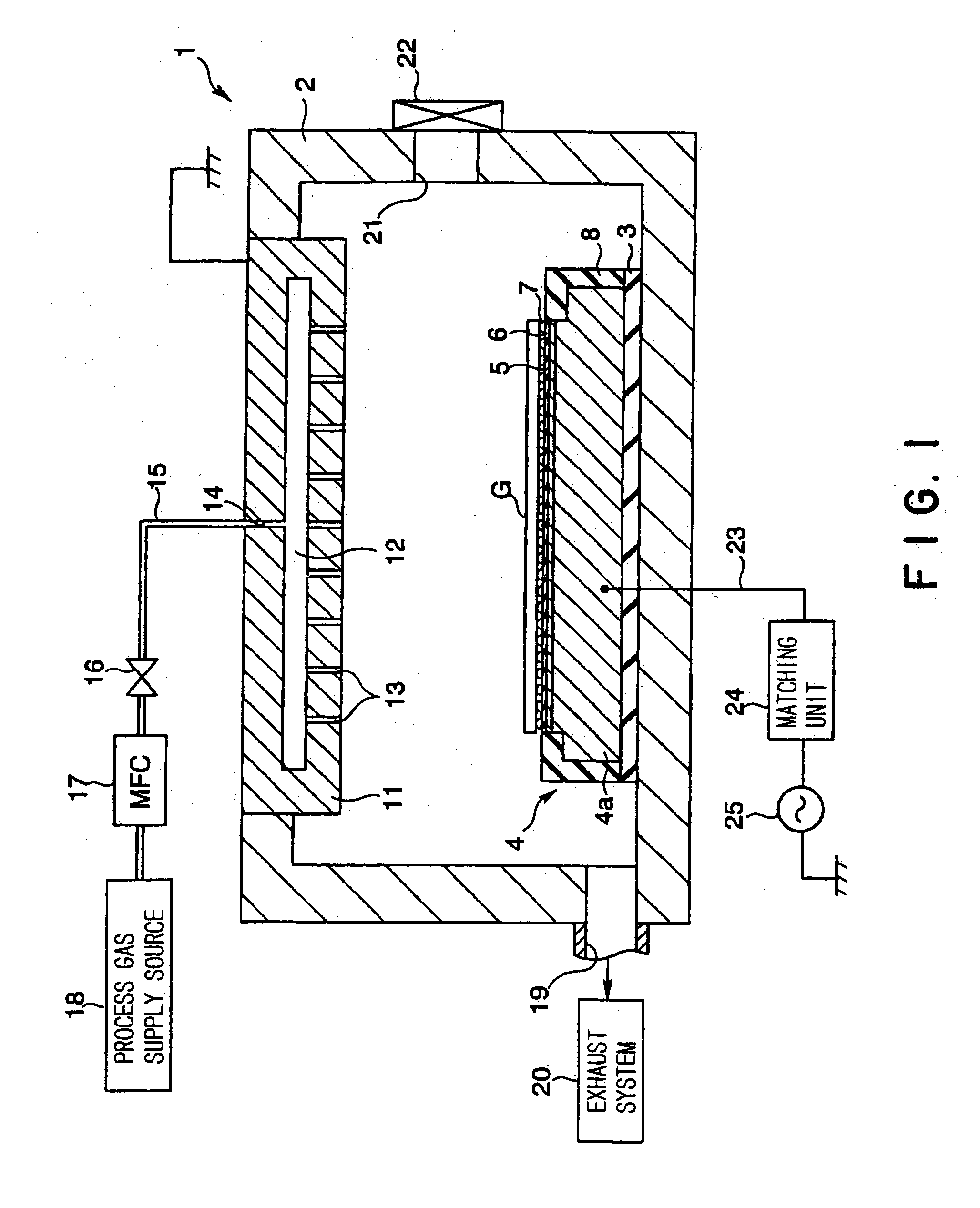

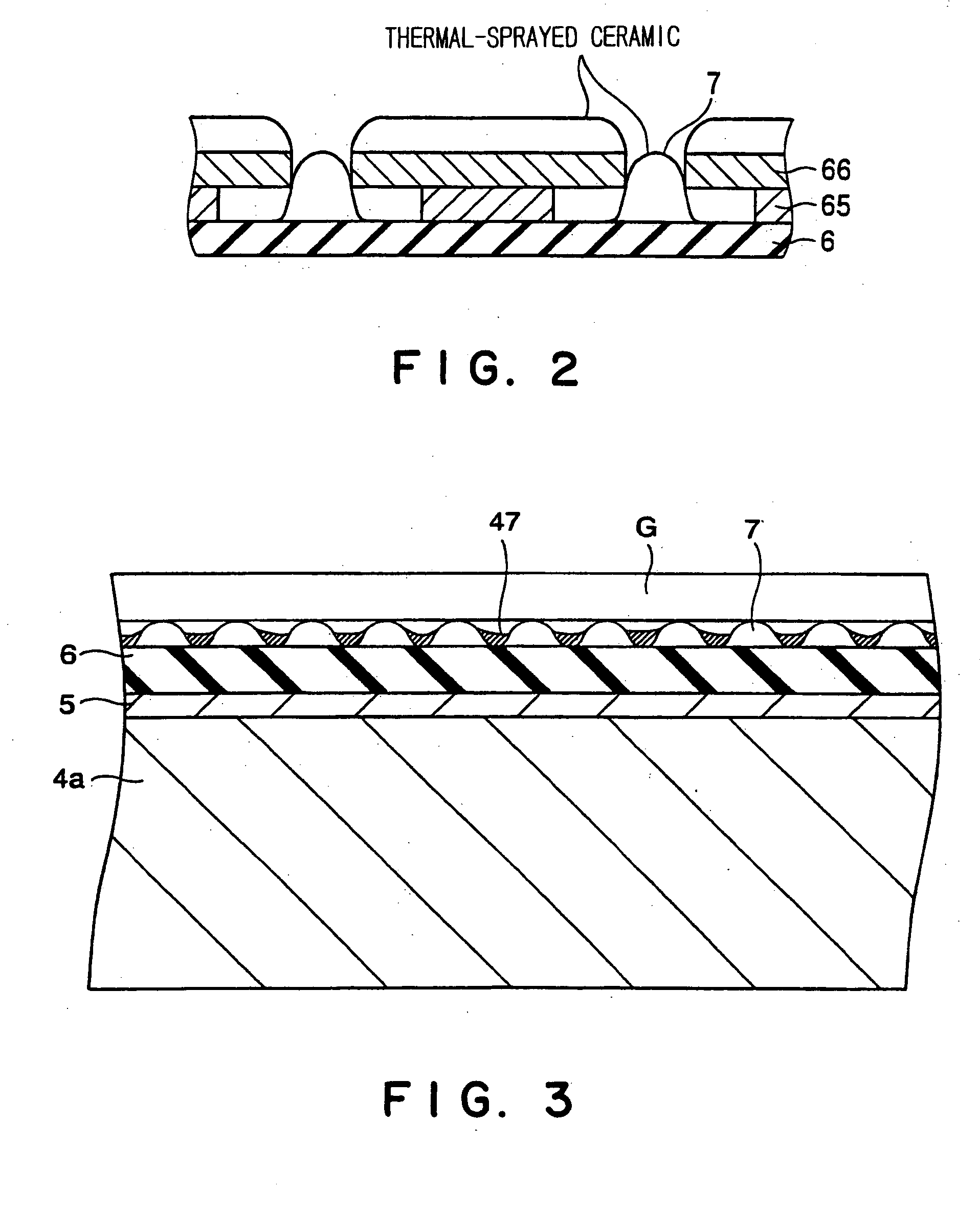

Substrate supporting table, method for producing same, and processing system

InactiveUS20050120962A1Avoid processing irregularityAvoid formingSleeve/socket jointsElectric discharge tubesSusceptorThermal spraying

A plasma processing system has a susceptor, provided in a processing vessel, for supporting thereon a substrate. A process gas is supplied into the processing vessel to produce the plasma of the process gas. The susceptor has a dielectric film formed on a base, and a plurality of protrusions formed on the film. The protrusions of the susceptor are formed by thermal-spraying a ceramic onto the dielectric film via an aperture plate having a plurality of circular apertures.

Owner:USHIODA JOICHI +3

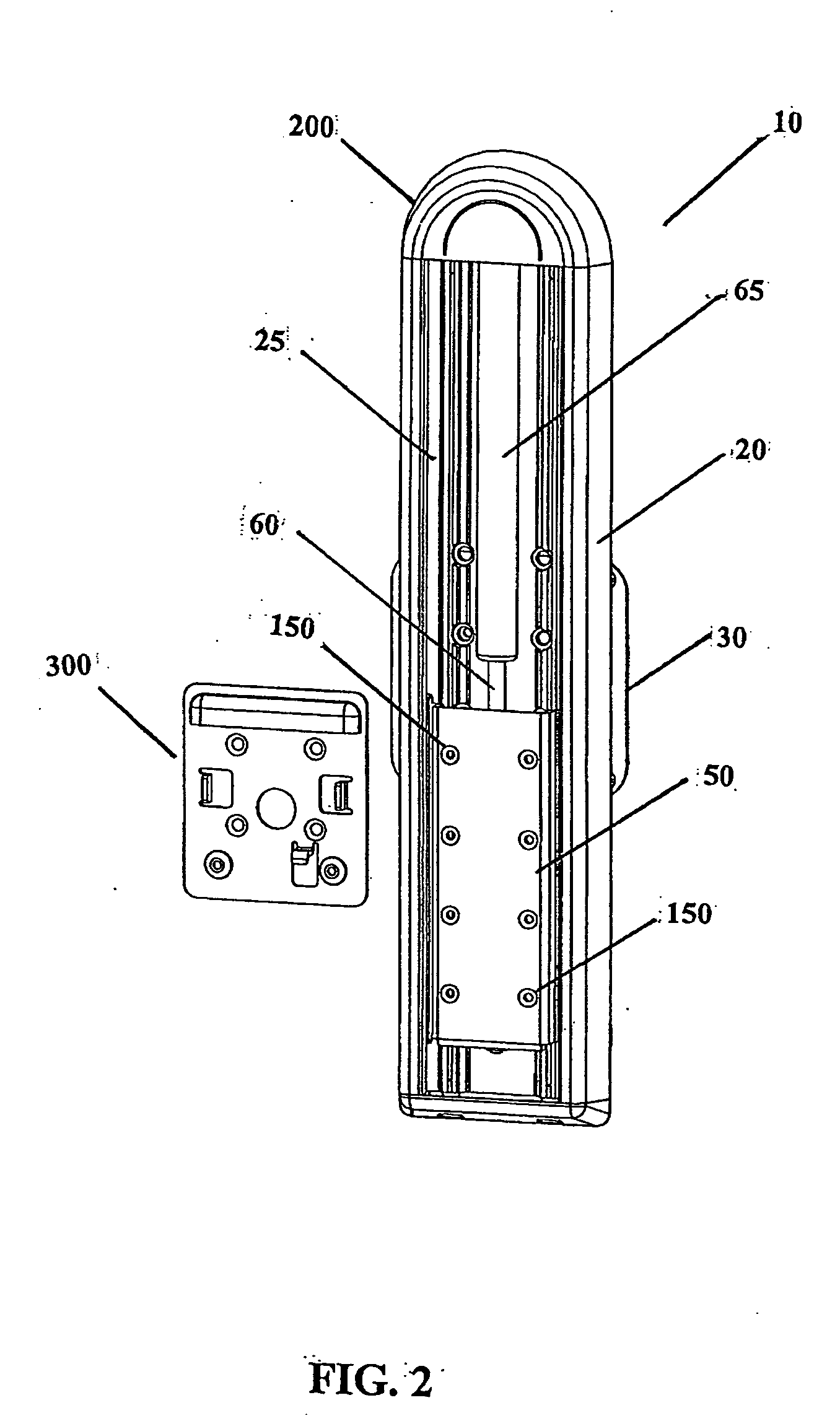

Mechanism for positional adjustment of an attached device

InactiveUS20050284991A1Easy to adjustEasy height adjustmentStands/trestlesKitchen equipmentDisplay deviceEngineering

The invention provides mechanisms useful for adjusting the positioning of an attached device, such as a display or input device. In one embodiment, the mechanism is a front end height adjustment mechanism comprising a track apparatus, a display mounting bracket, a sliding bracket, and a motion regulating device. In another embodiment, the mechanism comprises a device support arm, such as a monitor arm. The invention further provides a method for adjusting the positioning of a display or input device, such as a flat screen monitor, wherein the method comprises providing a mechanism of the invention, attaching the mechanism to a support, attaching a display or input device to the mechanism, and positionally adjusting the display or input device.

Owner:HUMANSCALE CORP

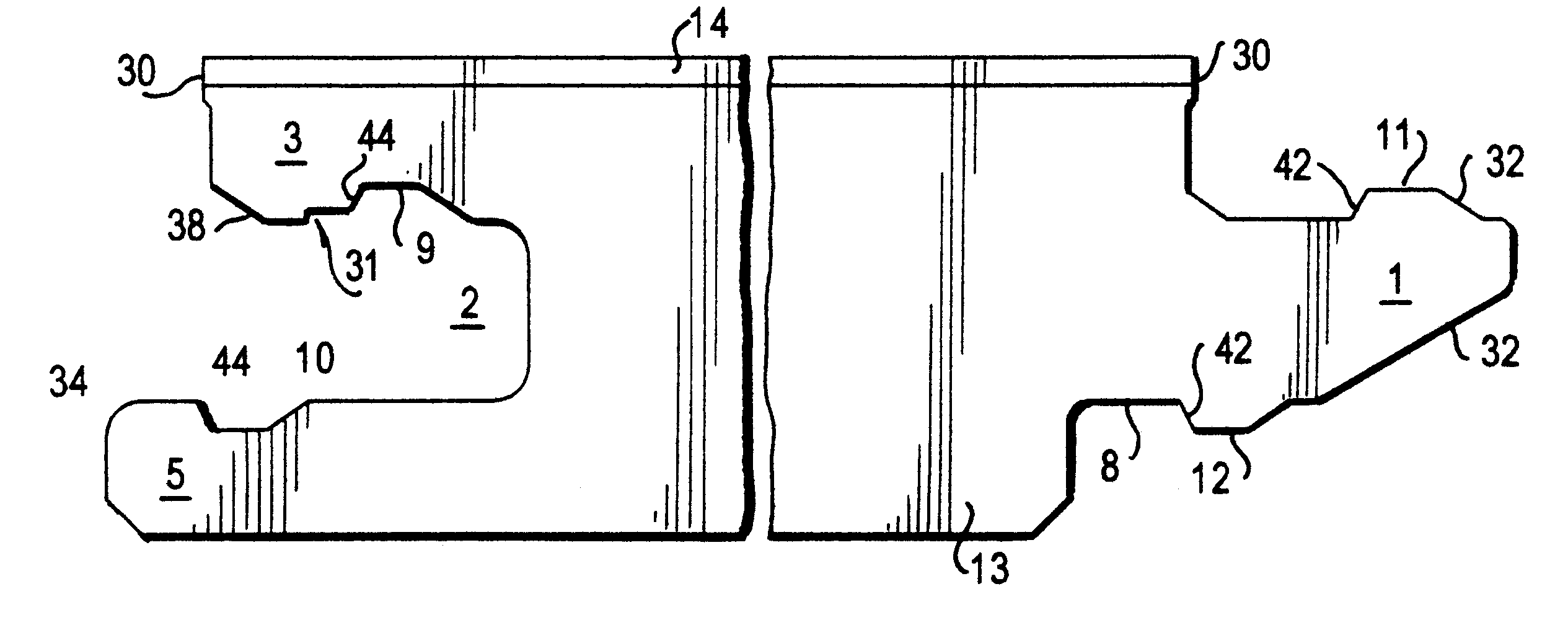

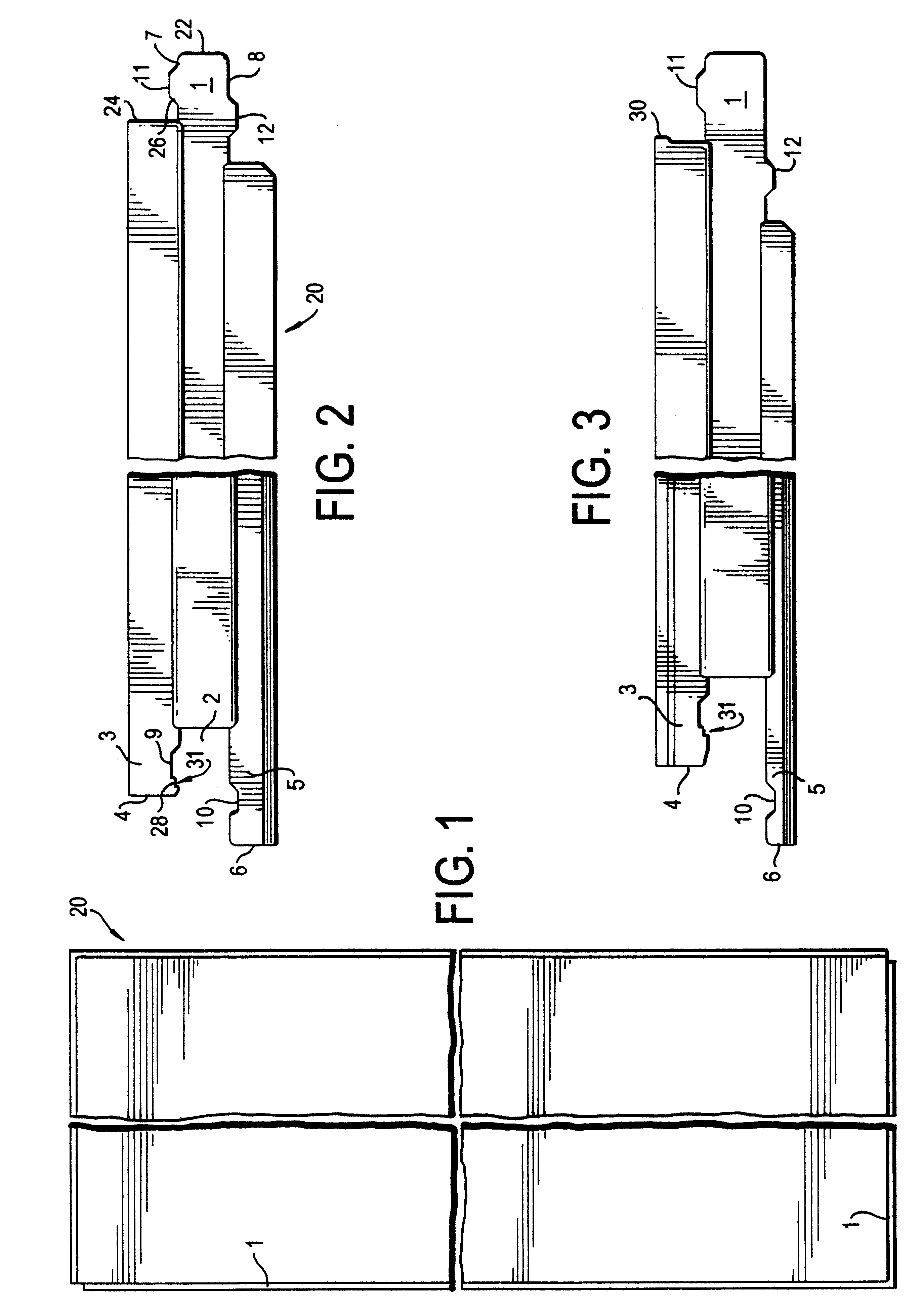

Flooring panel or wall panel

Owner:PERSTORP AB +1

Vapor deposition of silicon dioxide nanolaminates

ActiveUS20050112282A1Easy to produceUniform thicknessMaterial nanotechnologySemiconductor/solid-state device manufacturingPorosityElectrical conductor

This invention relates to materials and processes for thin film deposition on solid substrates. Silica / alumina nanolaminates were deposited on heated substrates by the reaction of an aluminum-containing compound with a silanol. The nanolaminates have very uniform thickness and excellent step coverage in holes with aspect ratios over 40:1. The films are transparent and good electrical insulators. This invention also relates to materials and processes for producing improved porous dielectric materials used in the insulation of electrical conductors in microelectronic devices, particularly through materials and processes for producing semi-porous dielectric materials wherein surface porosity is significantly reduced or removed while internal porosity is preserved to maintain a desired low-k value for the overall dielectric material. The invention can also be used to selectively fill narrow trenches with low-k dielectric material while at the same time avoiding deposition of any dielectric on the surface area outside of the trenches.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

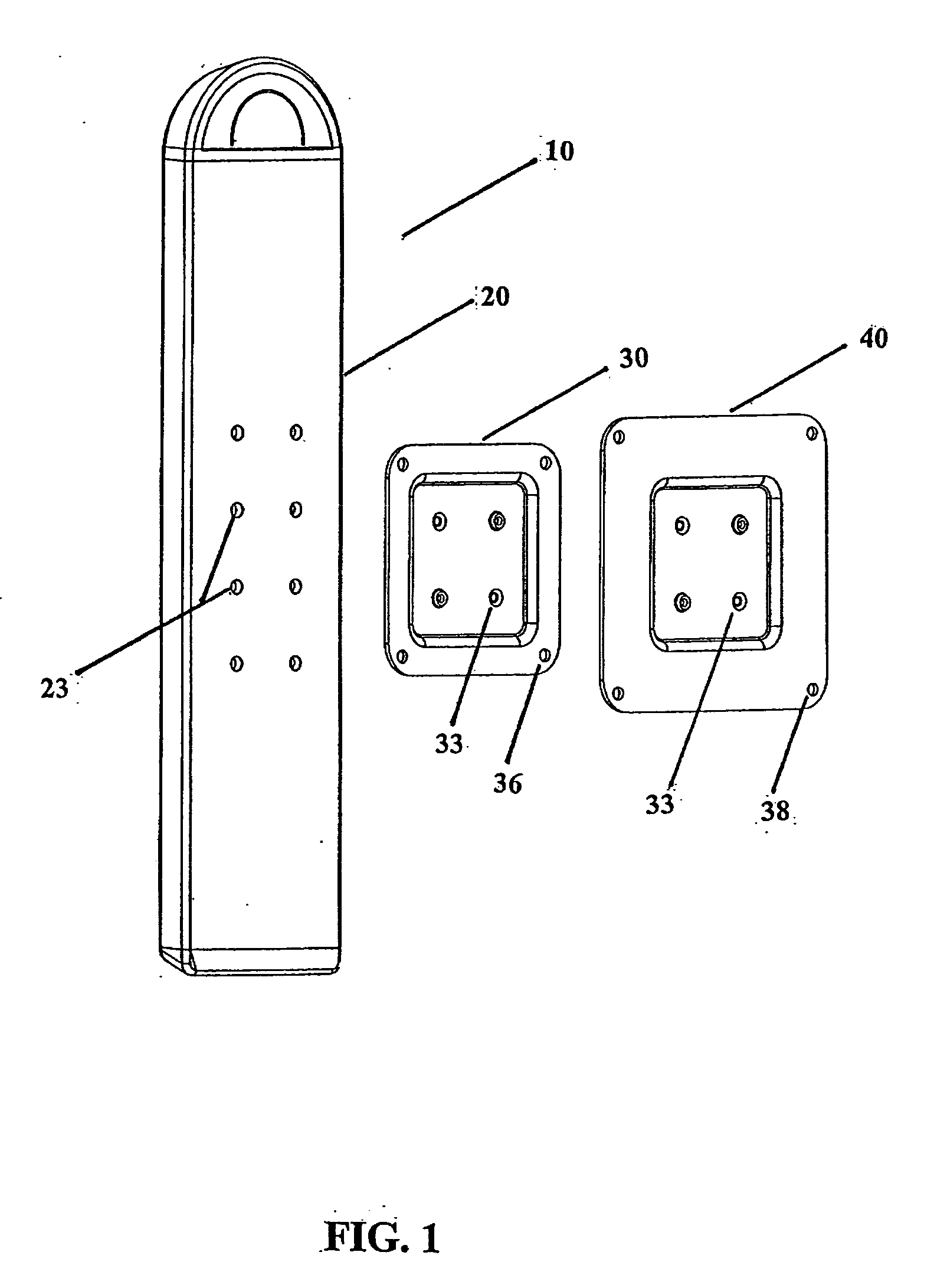

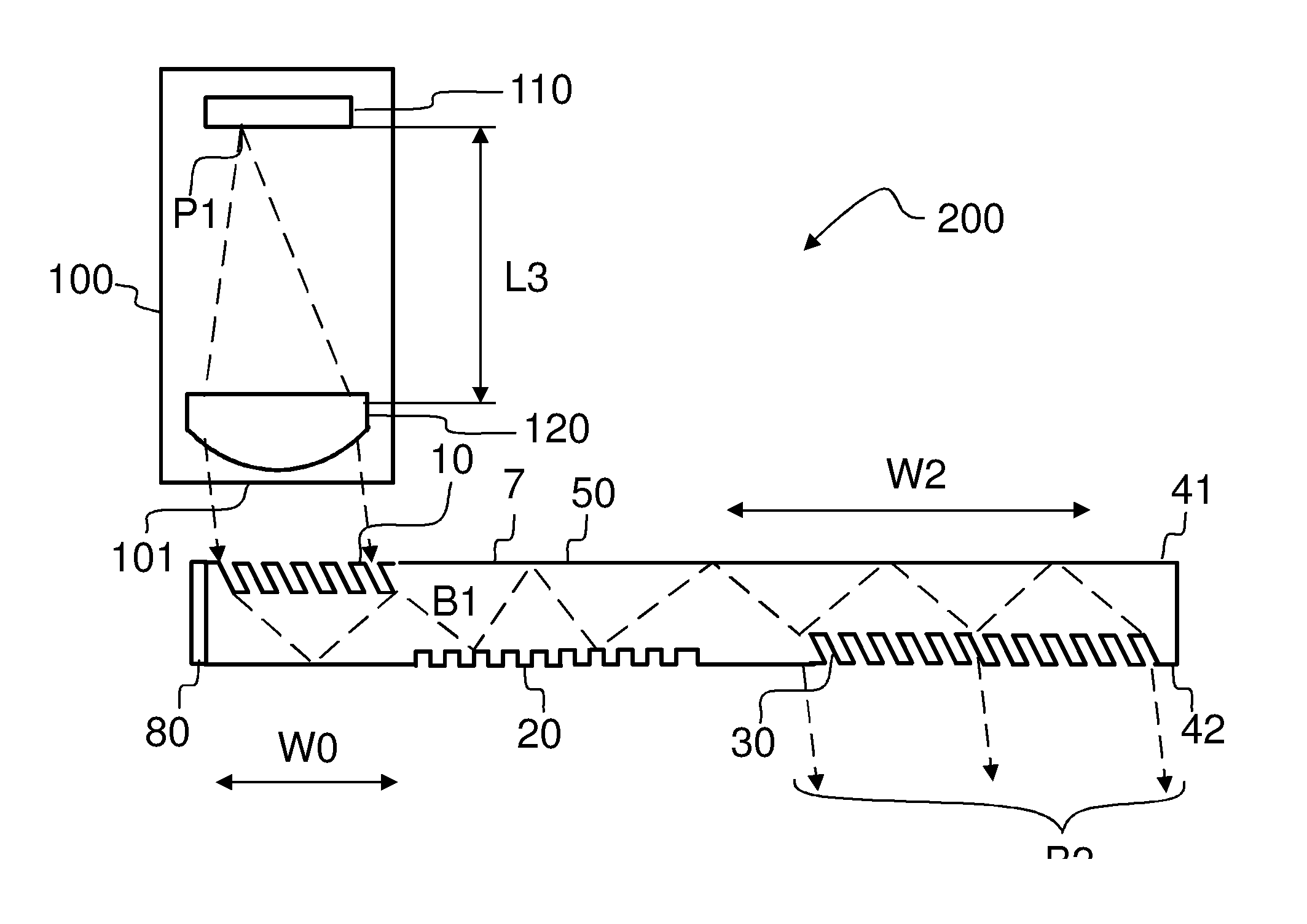

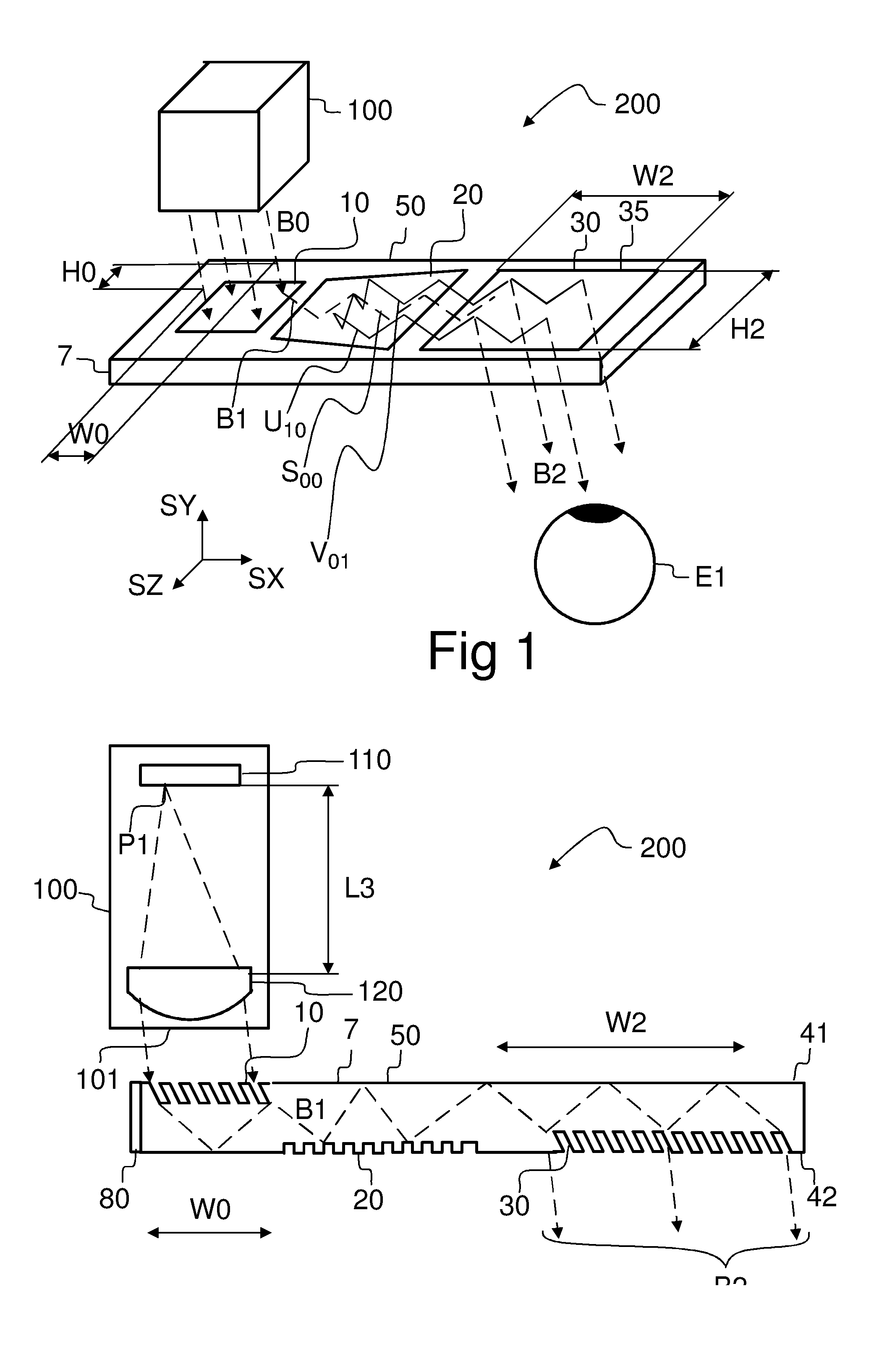

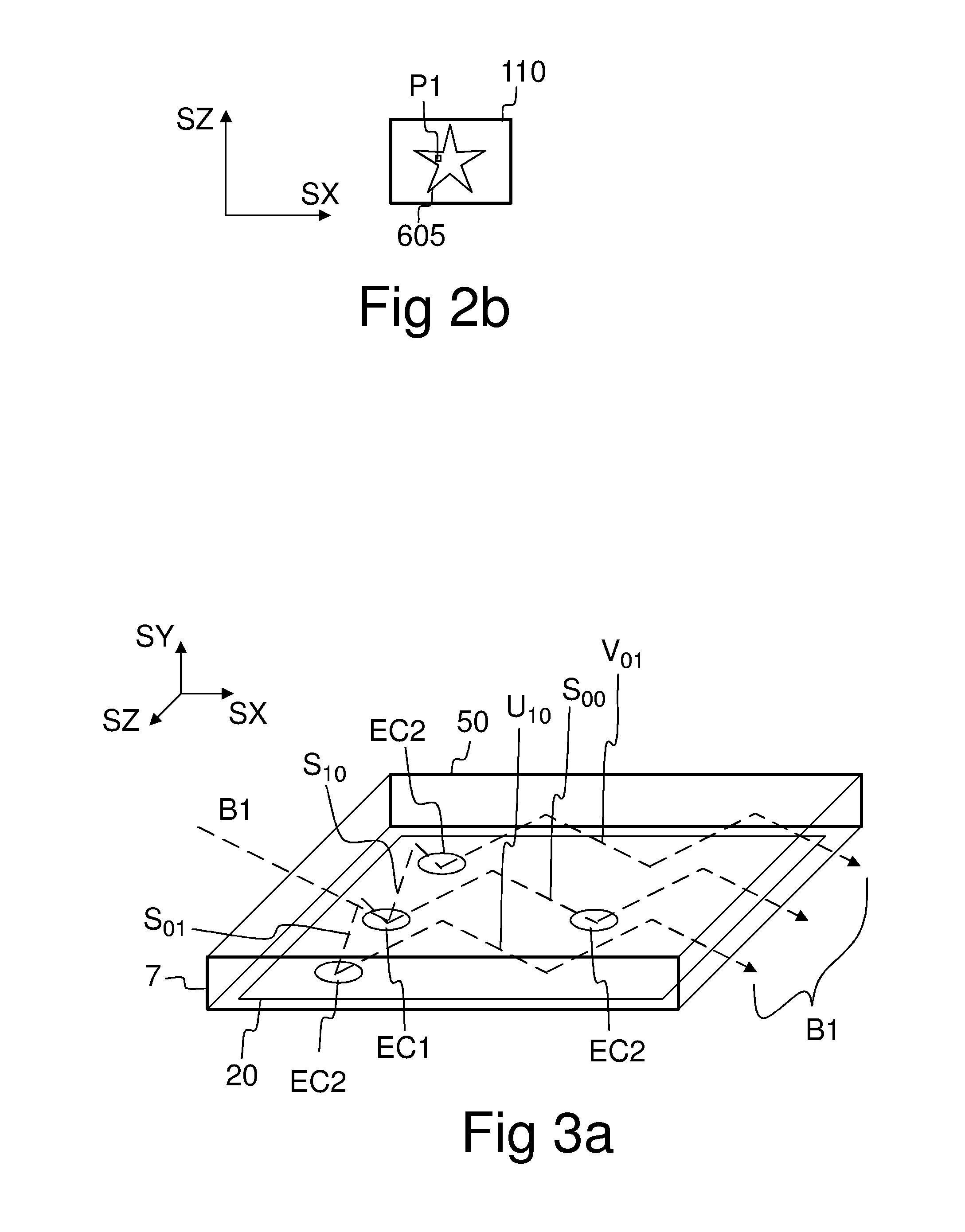

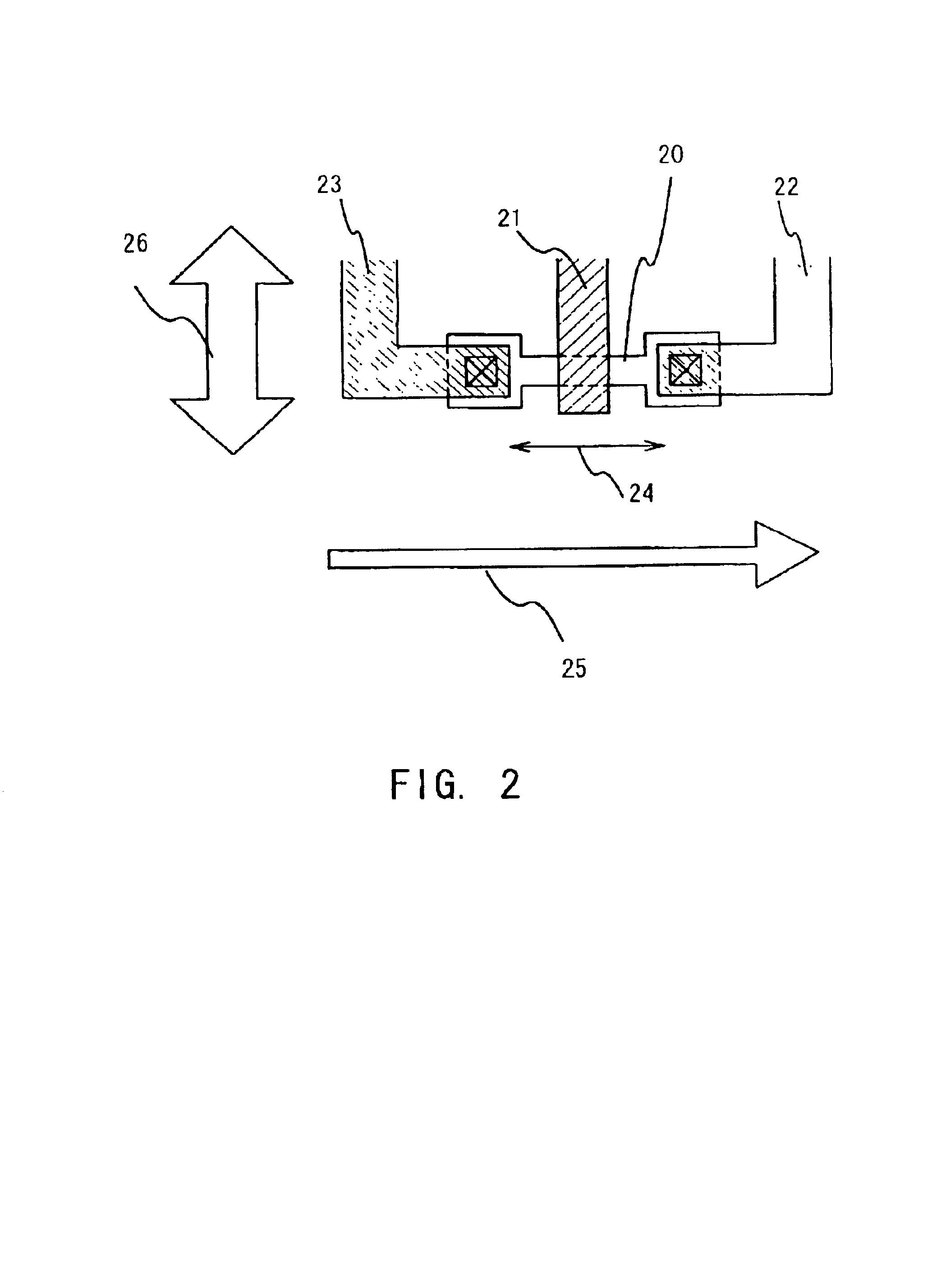

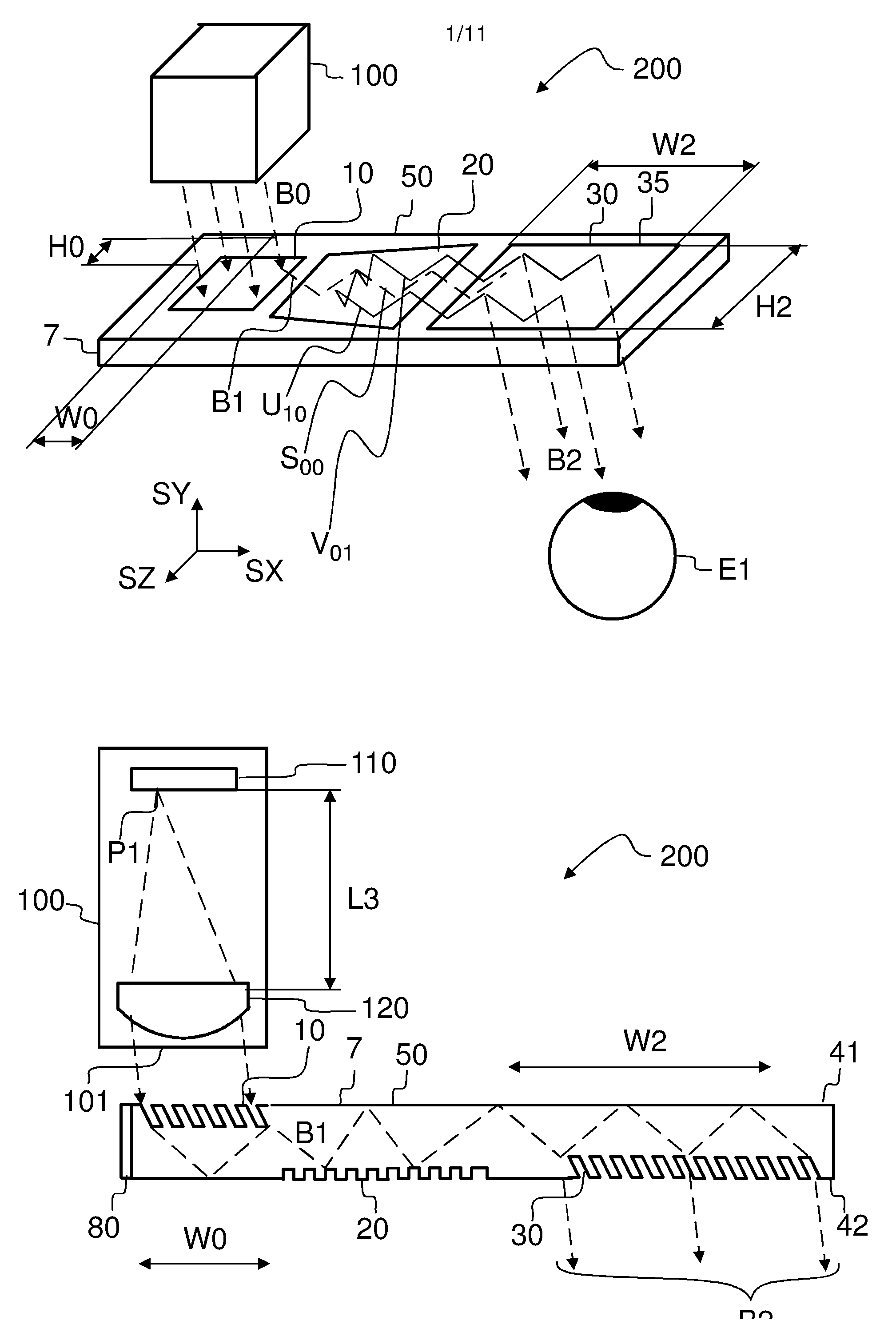

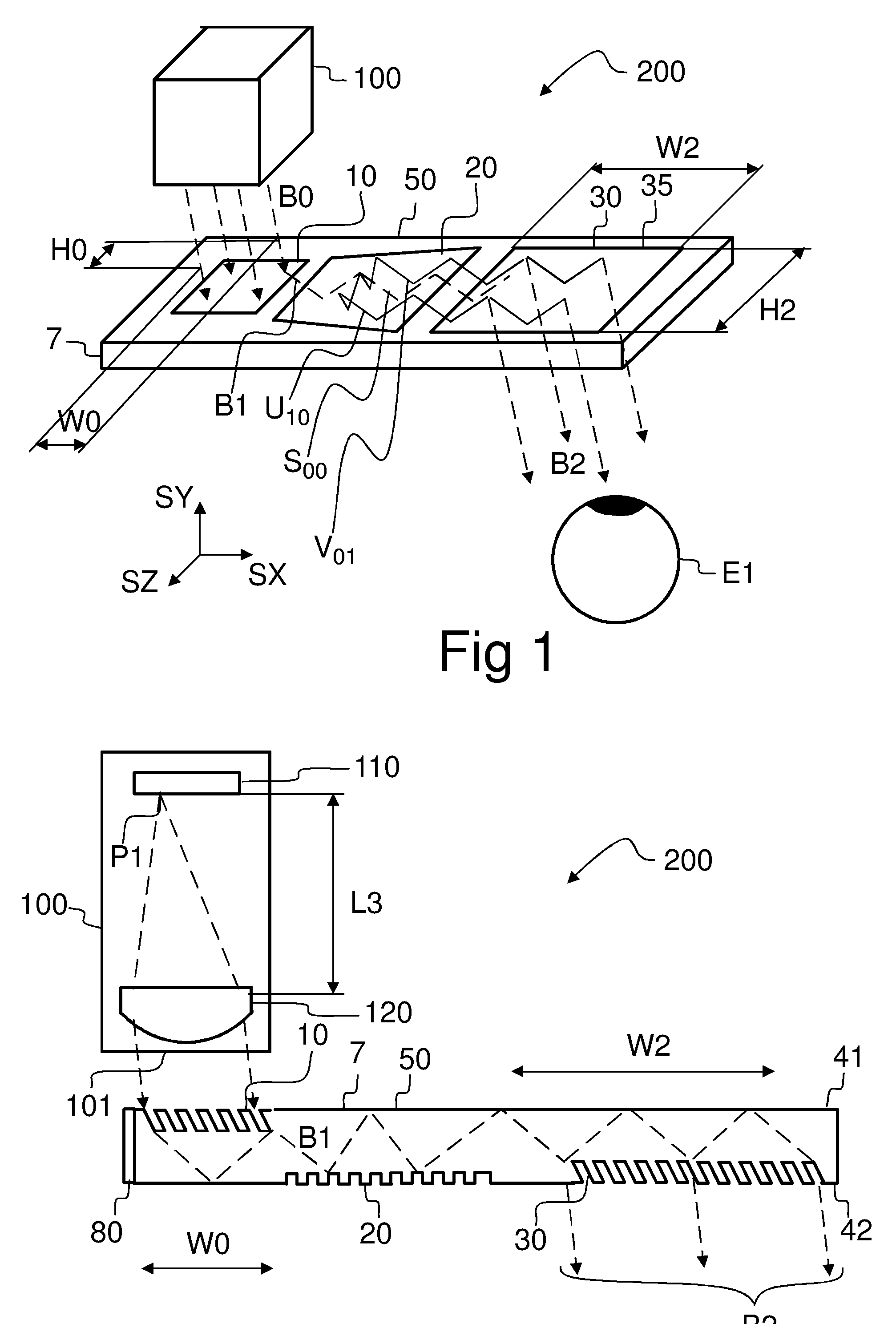

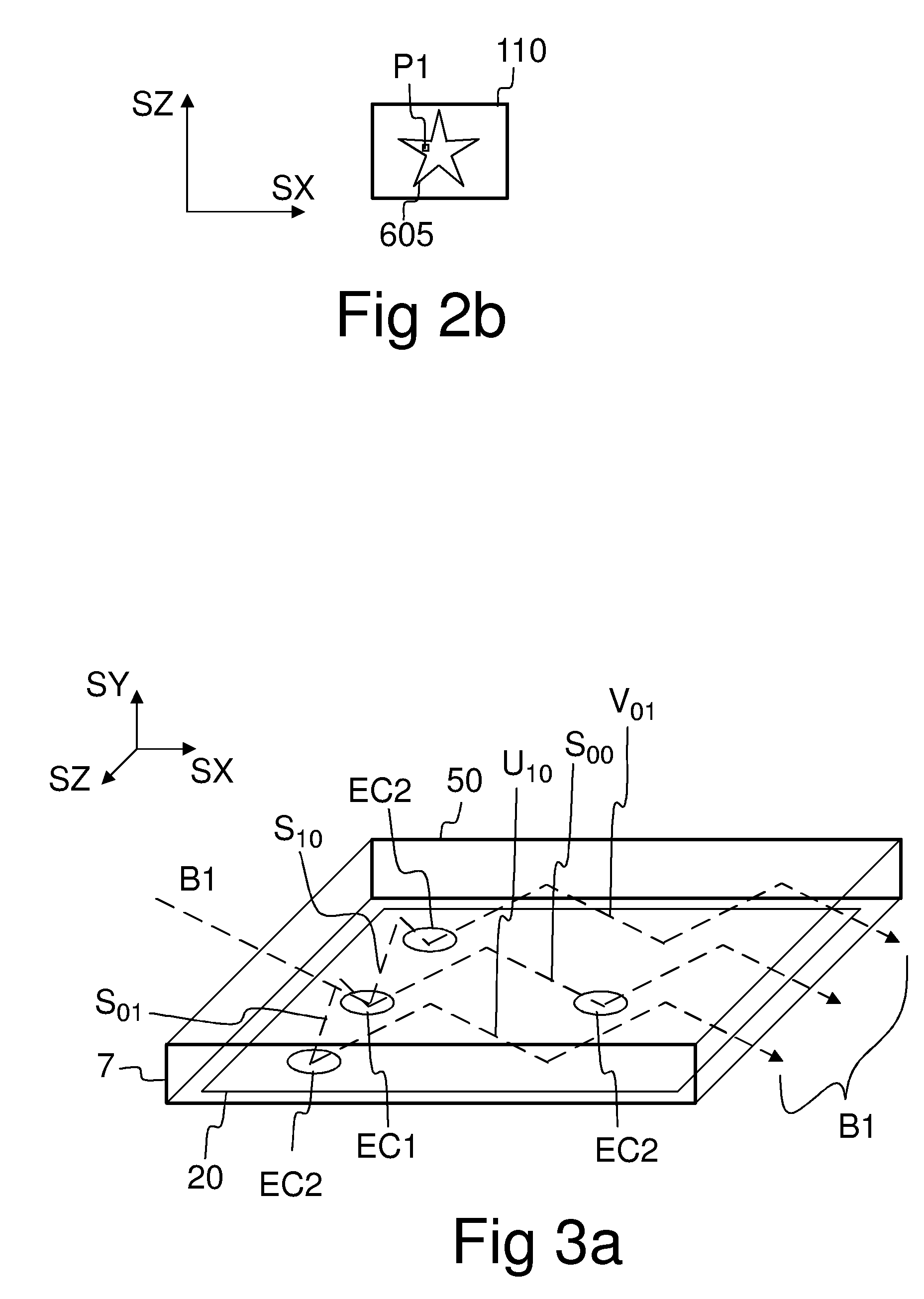

Device for expanding an exit pupil in two dimensions

ActiveUS20100321781A1High image qualityEfficient couplingDiffraction gratingsCoupling light guidesPhysicsExit pupil

A diffractive beam expander (50) comprises an input grating (10), a crossed grating (20), and an output grating (30) implemented on a planar transparent substrate (7). The crossed grating (20) comprises a plurality of diffractive features (23) arranged along the lines of a first set of parallel lines (25) and along the lines of a second set of parallel lines (26) such that the lines (25) of the first set are parallel to the lines (26) of the second set. The lines of the first set have a first grating period and the lines of the second set have a second grating period. A light beam (B1) coupled into the substrate (7) by the input grating (10) impinges on the crossed grating (20) at a first location (EC1) and further locations (EC2). Interaction at the first location (EC1) provides several sub-beams (S00, S01, S10) which propagate in different directions. Further interactions at second locations (EC2) provide further sub-beams (V01, U10) which propagate in the same direction as the original in-coupled light (B1). Light is subsequently coupled out of the substrate (7) by the output grating (30) to provide a light beam (B2) which is expanded in two directions (SX, SZ) with respect to the beam (B0) impinging on the input grating. A virtual display device (200) may comprise said diffractive beam expander (50).

Owner:MAGIC LEAP

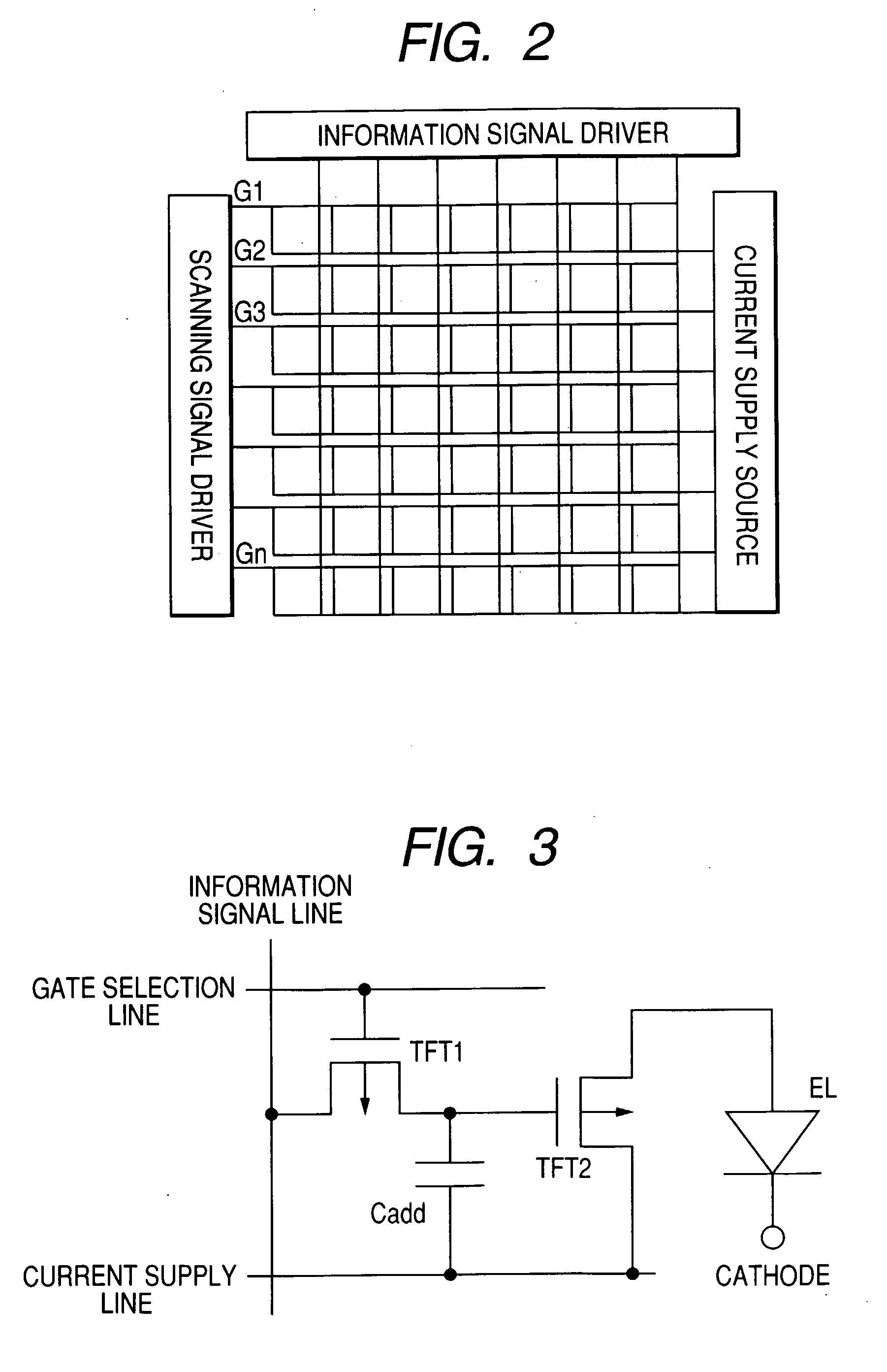

Semiconductor device and manufacturing method thereof

InactiveUS7180091B2Minimize impactSeparate cleanTransistorSolid-state devicesDriver circuitEngineering

The invention relates to a semiconductor device including a plurality of thin film transistors provided on a base member having a curved surface. The surface may be bent in either a convex shape or a concave shape. All channel length directions of the plurality of thin film transistors may also be aligned in the same direction. Further, the channel length direction may be different from the direction in which the base member is bent. A pixel portion and a driver circuit portion may also be provided on the base member. The invention also includes a method of manufacturing a semiconductor device including forming a layer to be peeled including an element of a substrate, bonding a support member to the layer to be peeled, and bonding a transfer body to the layer to be peeled.

Owner:SEMICON ENERGY LAB CO LTD

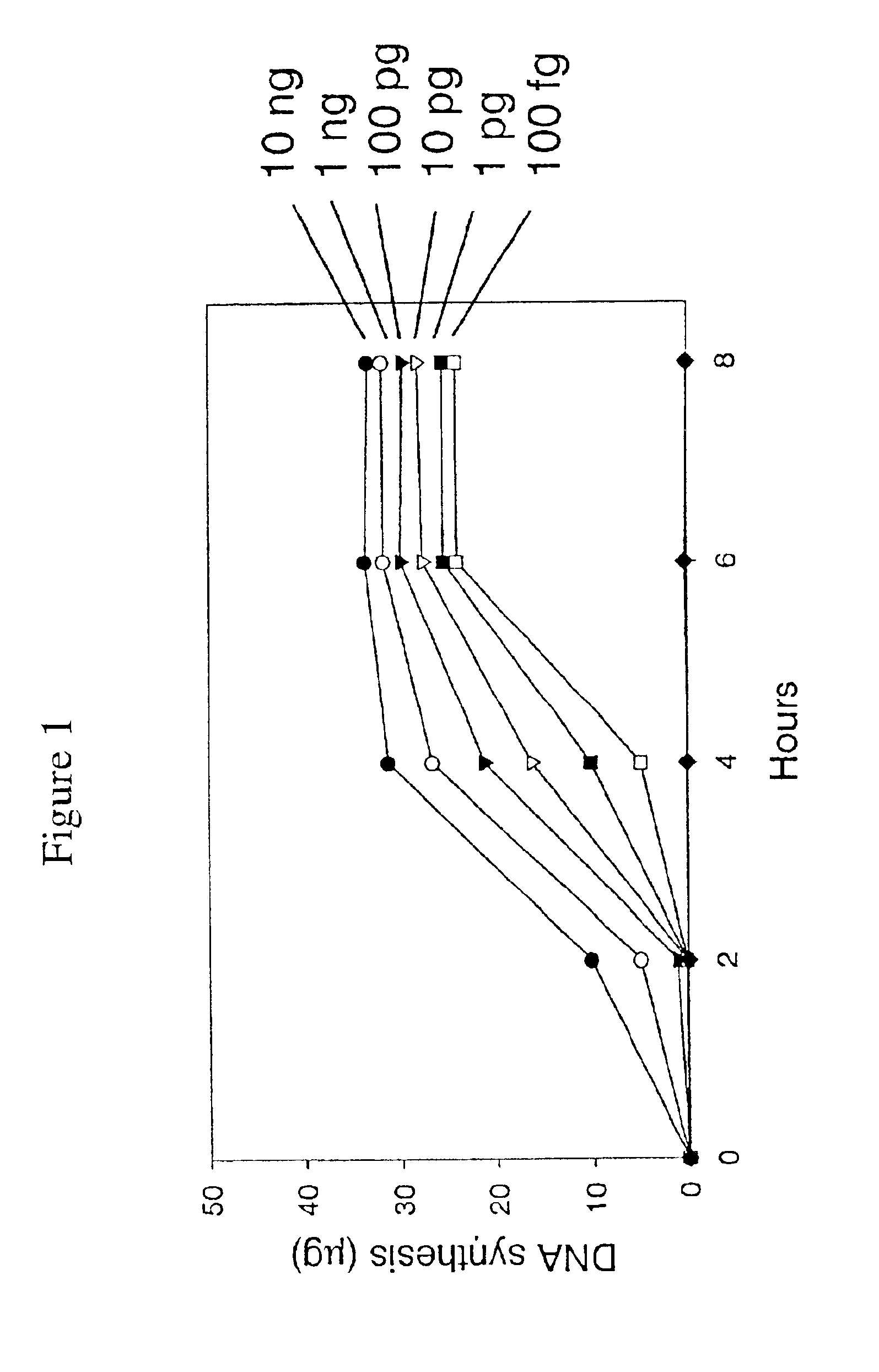

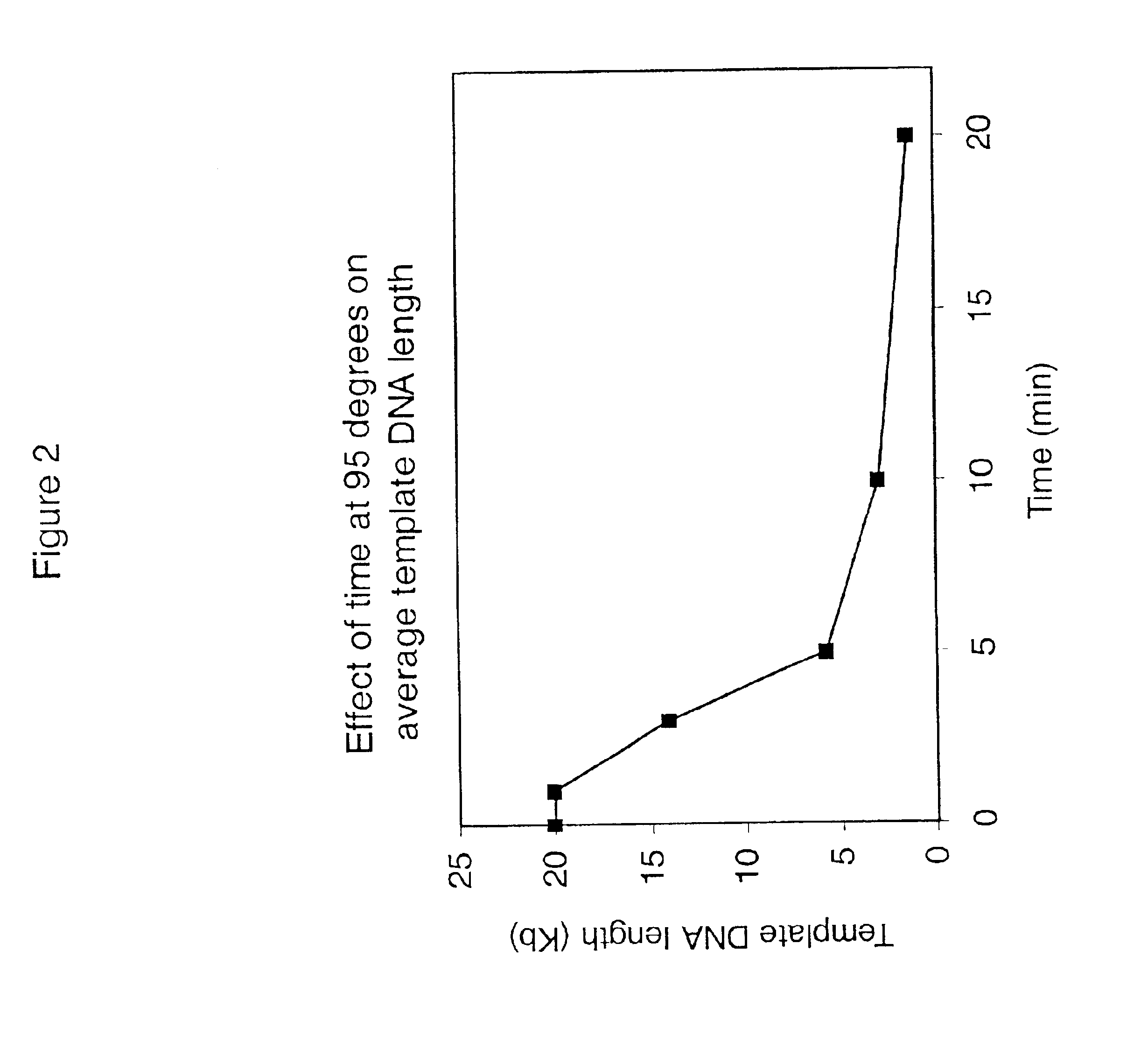

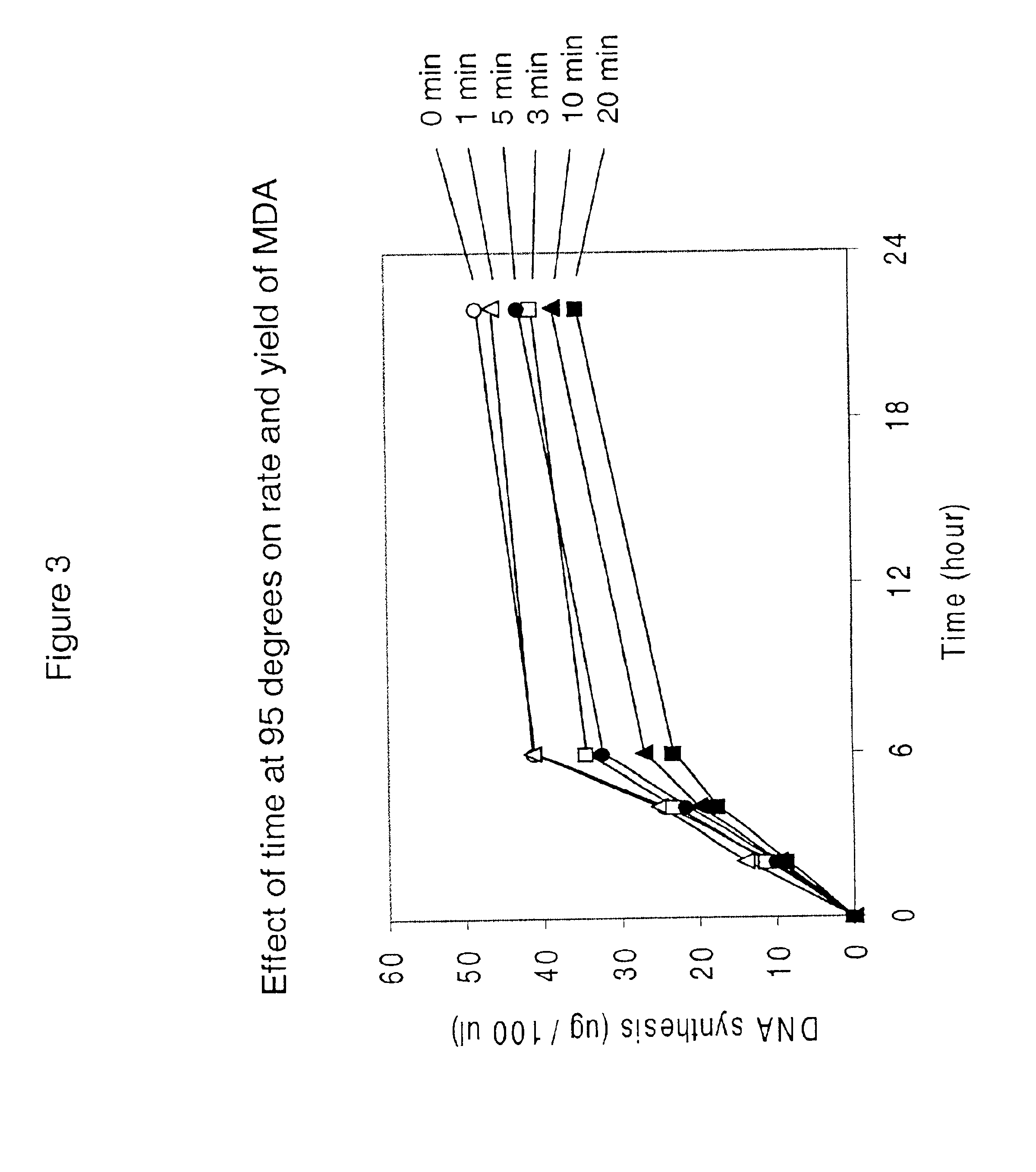

Multiple displacement amplification

InactiveUS6977148B2Consistent outputQuick buildMicrobiological testing/measurementFermentationNucleotideGenomic DNA

Disclosed are compositions and a method for amplification of nucleic acid sequences of interest. The disclosed method generally involves replication of a target sequence such that, during replication, the replicated strands are displaced from the target sequence by strand displacement replication of another replicated strand. In one form of the disclosed method, the target sample is not subjected to denaturing conditions. It was discovered that the target nucleic acids, genomic DNA, for example, need not be denatured for efficient multiple displacement amplification. The primers used can be hexamer primers. The primers can also each contain at least one modified nucleotide such that the primers are nuclease resistant. The primers can also each contain at least one modified nucleotide such that the melting temperature of the primer is altered relative to a primer of the same sequence without the modified nucleotide(s). The DNA polymerase can be φ29 DNA polymerase.

Owner:QIAGEN GMBH

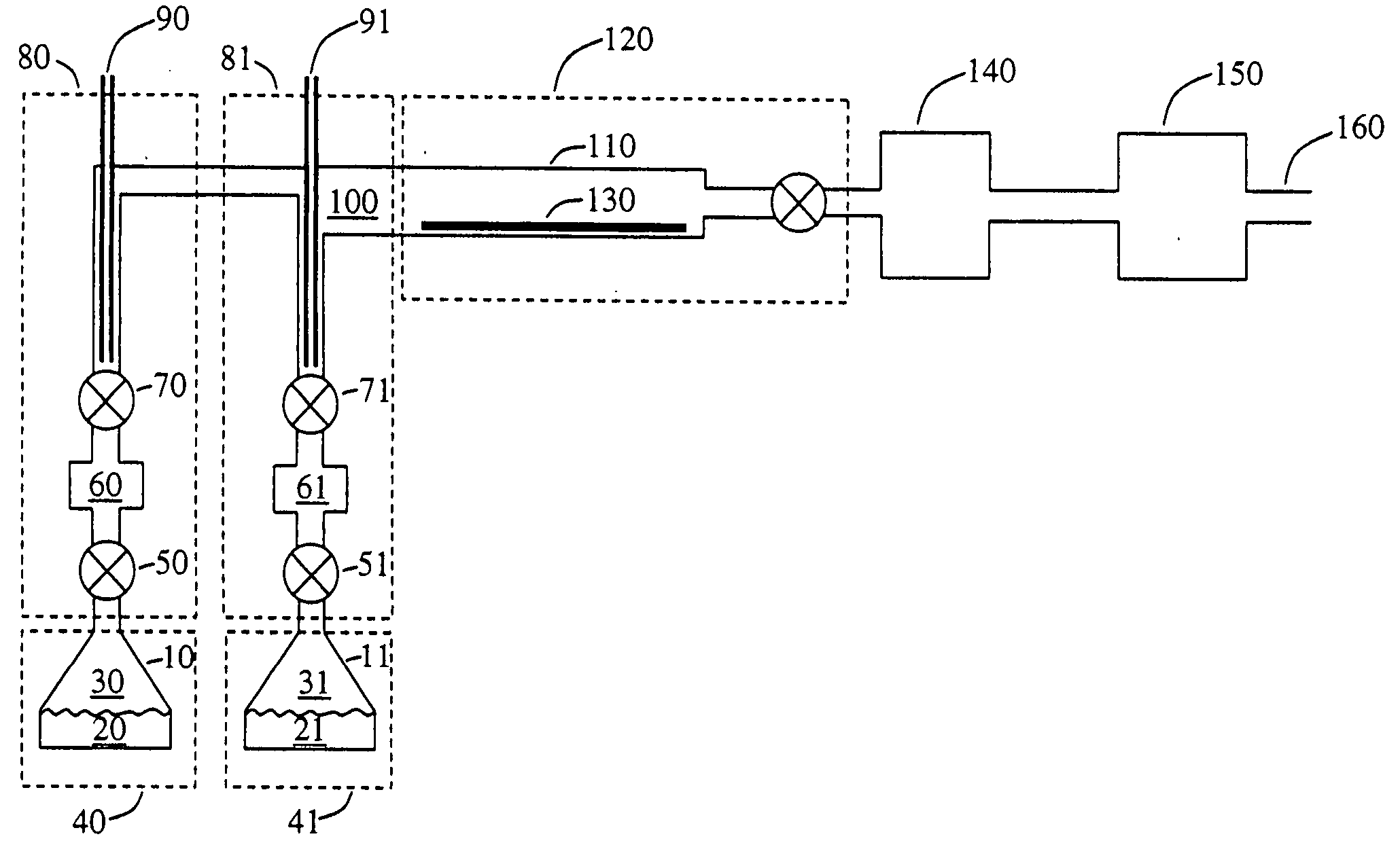

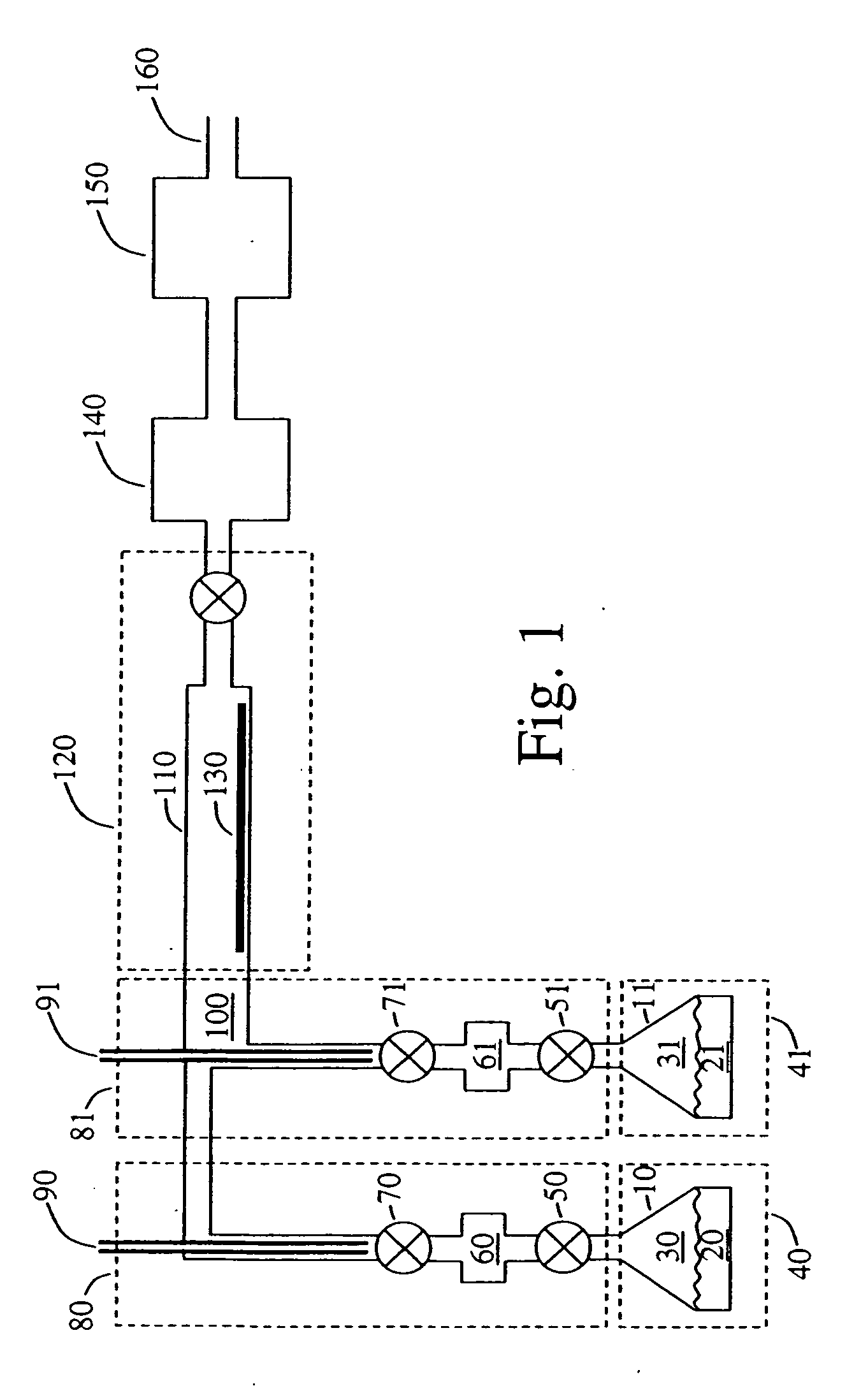

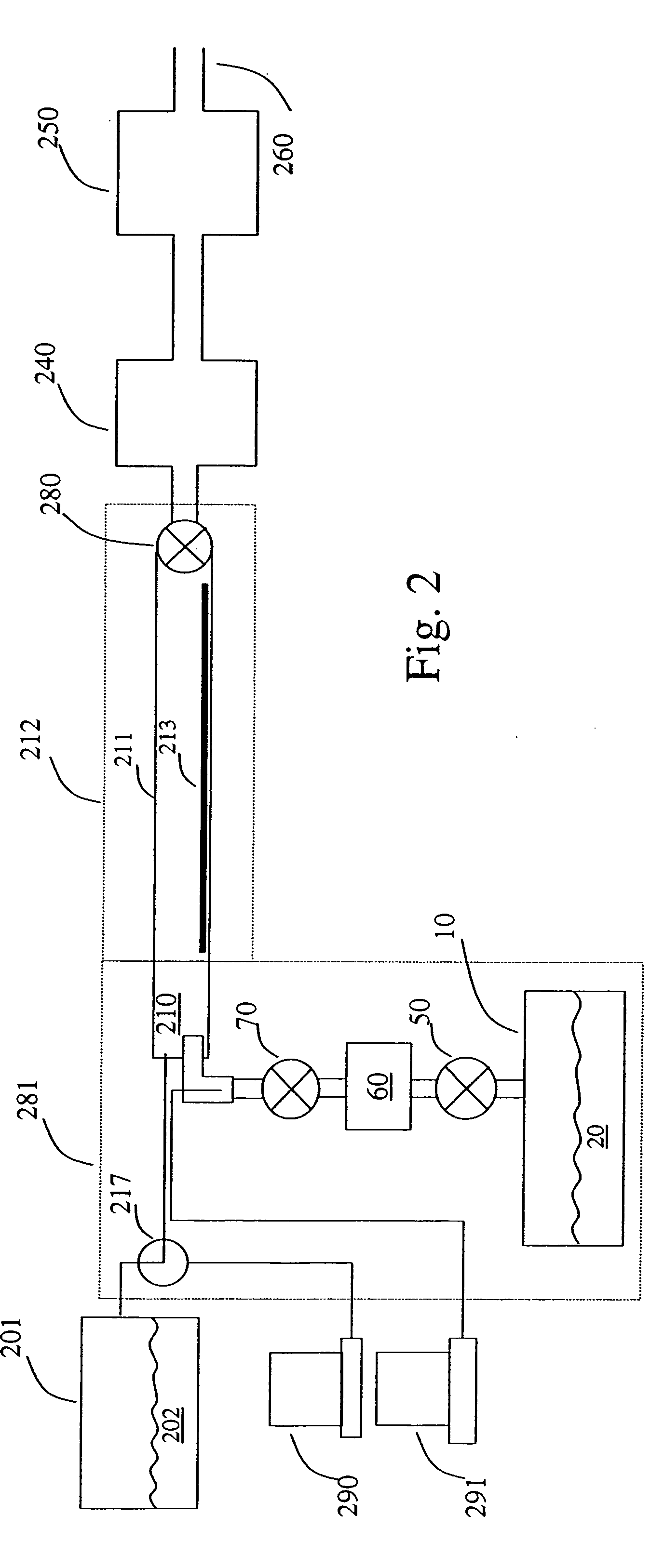

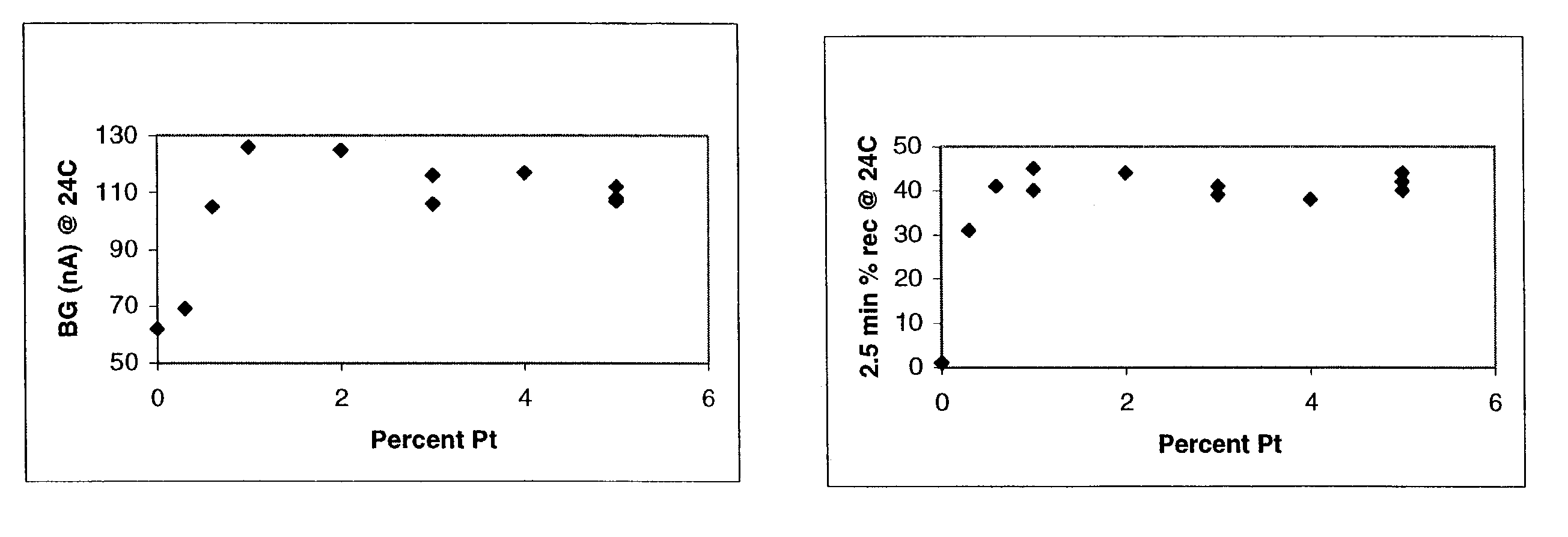

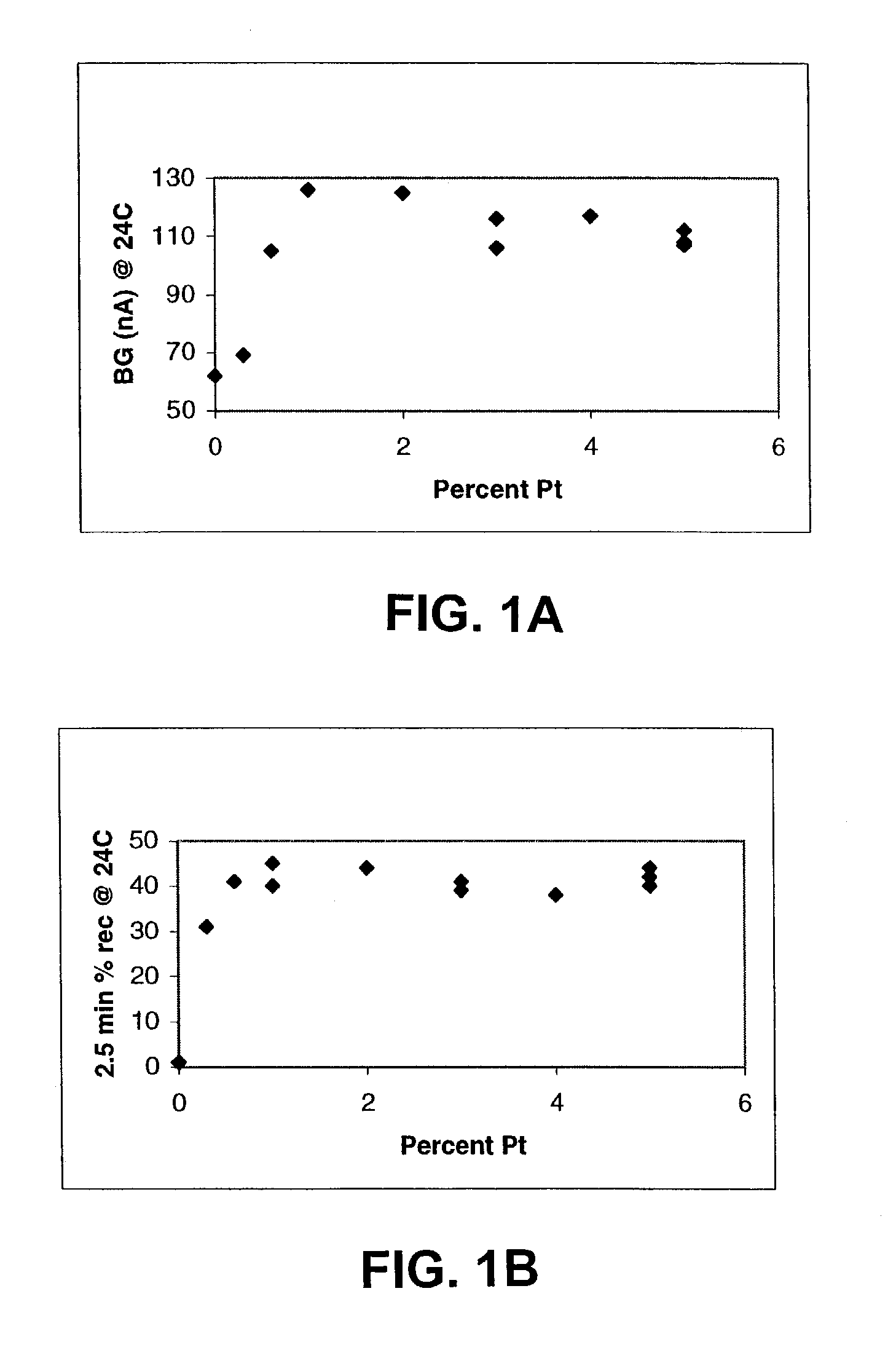

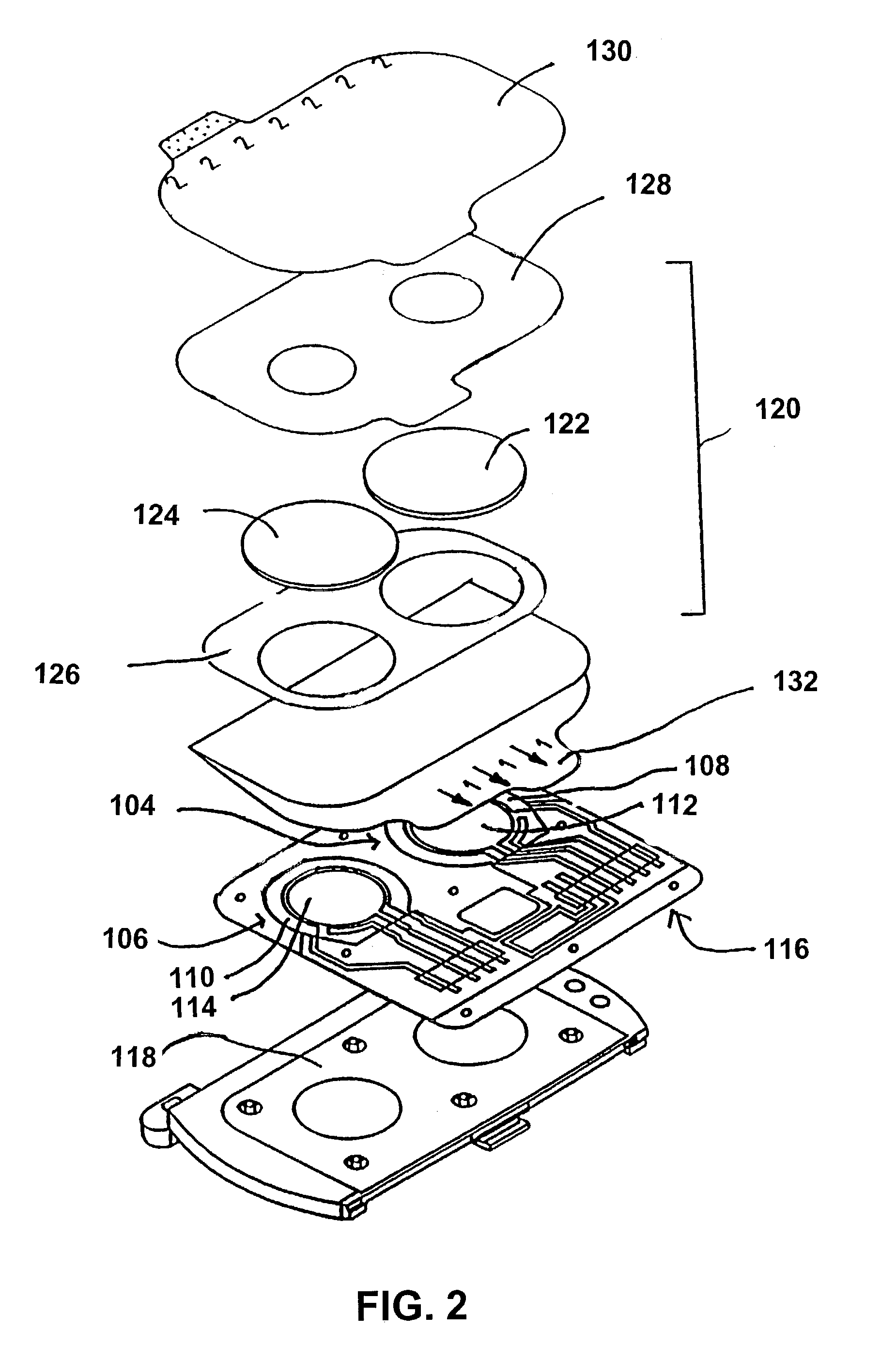

Highly catalytic screen-printing ink

ActiveUS7018568B2Easy to produceConductive layers on insulating-supportsConductive materialConductive polymerPrinting ink

The invention is directed to conductive polymer compositions, catalytic ink compositions (e.g., for use in screen-printing), electrodes produced by deposition of an ink composition, methods of making, and methods of using thereof. An exemplary ink material comprises platinum black and / or platinum-on-carbon as the catalyst, graphite as a conducting material, a polymer binding material, and an organic solvent. The polymer binding material is typically a copolymer of hydrophilic and hydrophobic monomers. The conductive polymer compositions of the present invention can be used, for example, to make electrochemical sensors. Such sensors can be used in a variety of analyte monitoring devices to monitor analyte amount or concentrations in subjects, for example, glucose monitoring devices to monitor glucose levels in subjects with diabetes.

Owner:LIFESCAN IP HLDG LLC +1

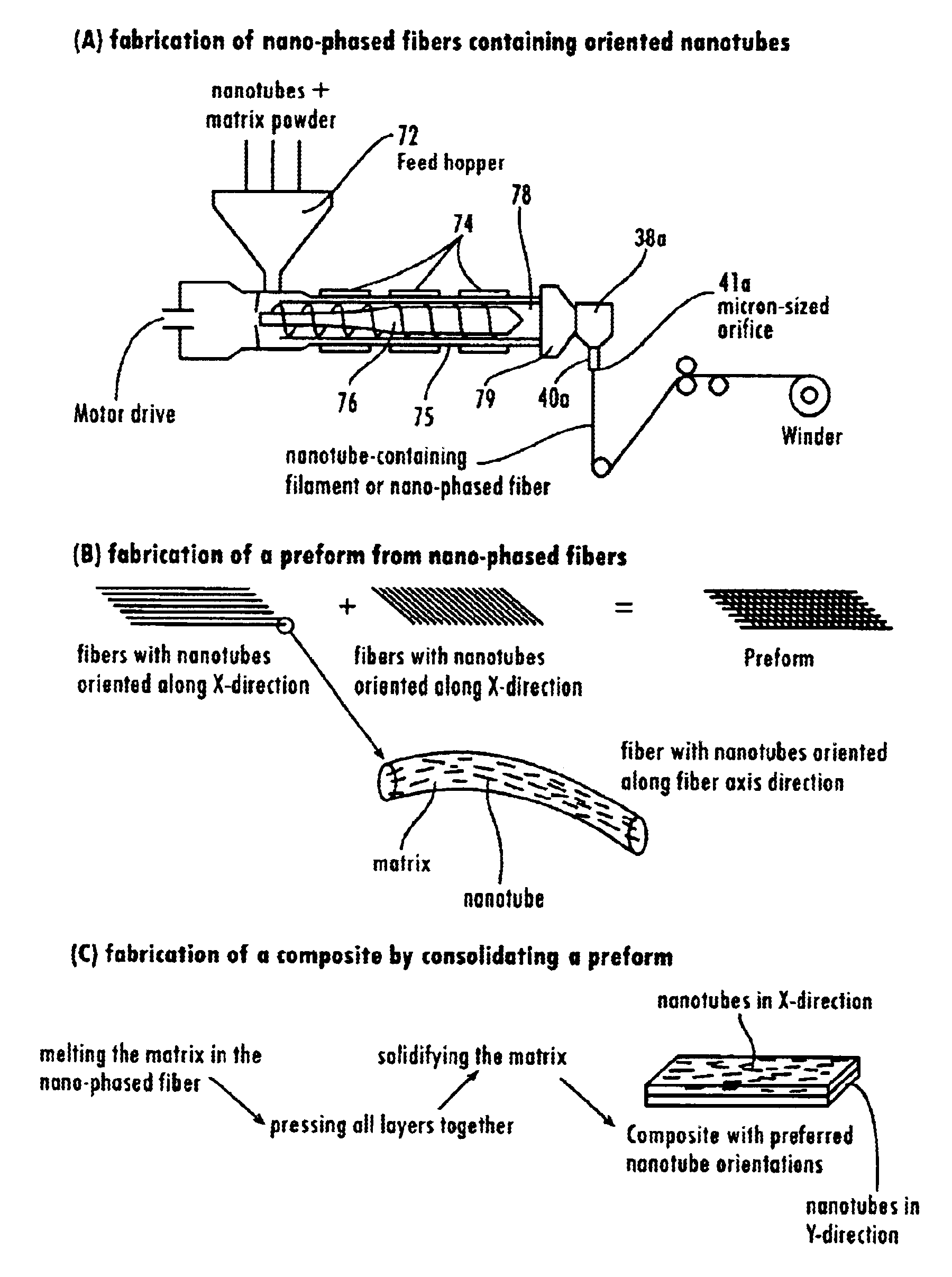

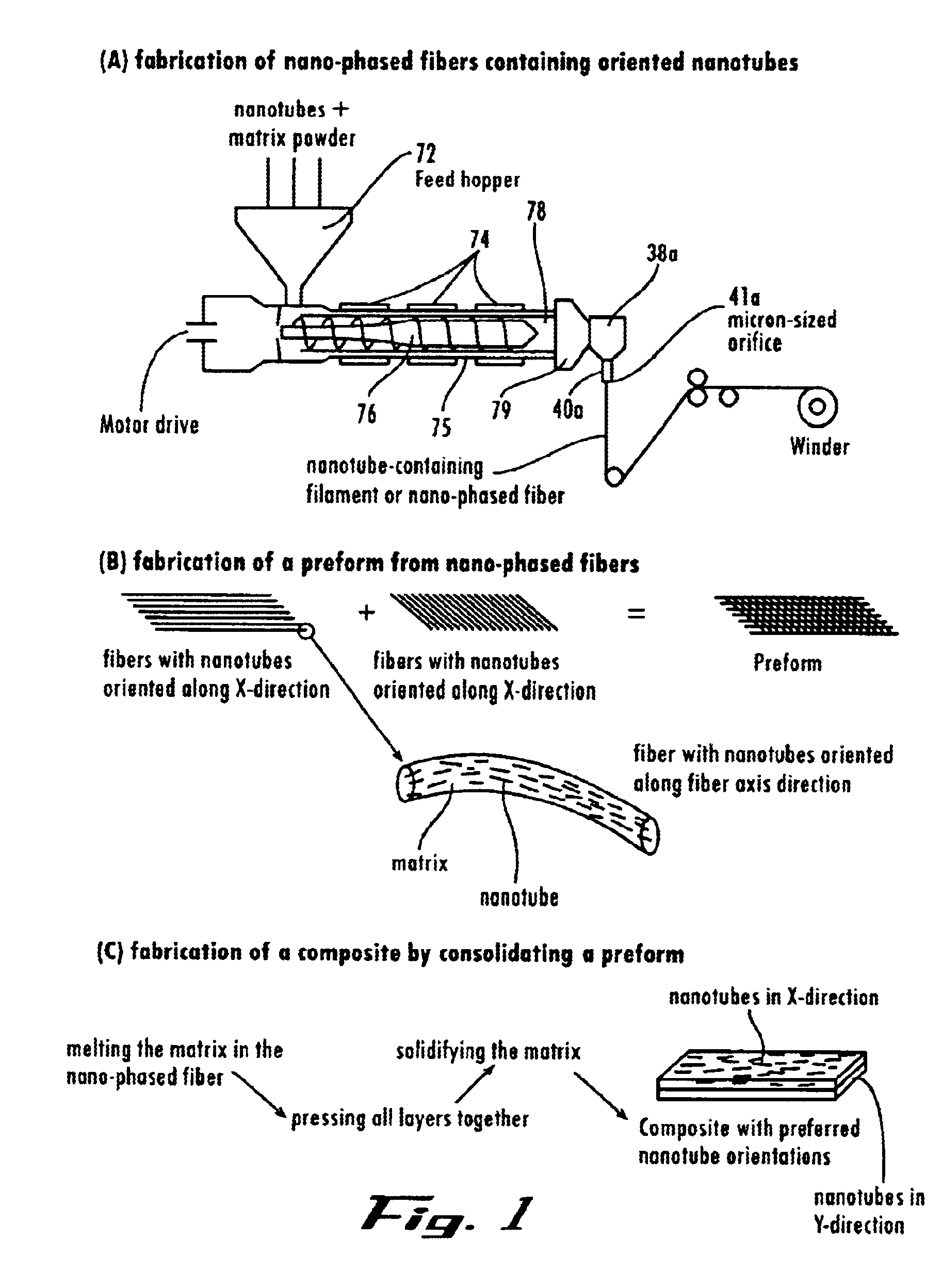

Nanotube fiber reinforced composite materials and method of producing fiber reinforced composites

InactiveUS6934600B2Requires minimizationGenerate efficientlyMaterial nanotechnologyAdditive manufacturing apparatusFiber-reinforced compositeMotion controller

Owner:AUBURN UNIV

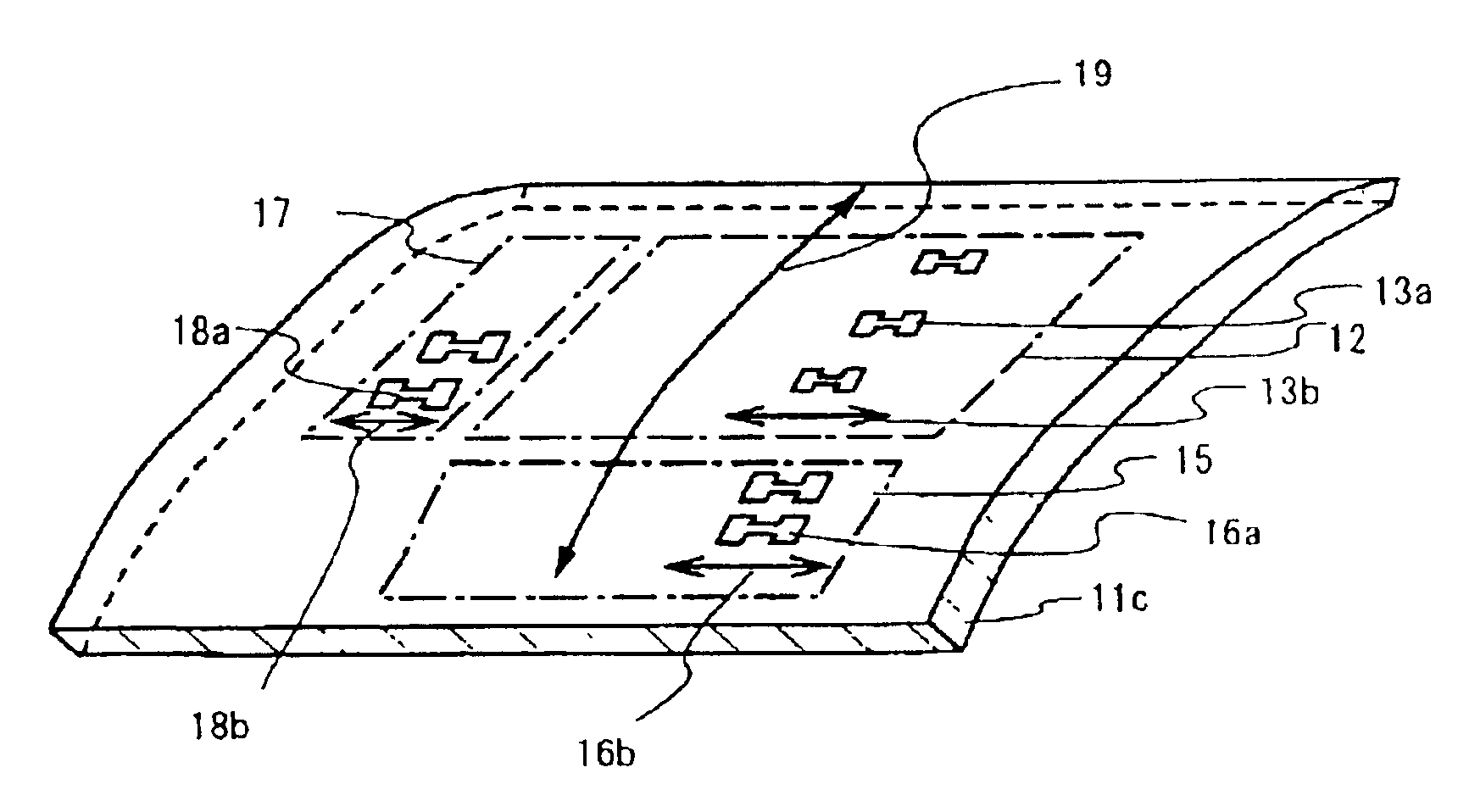

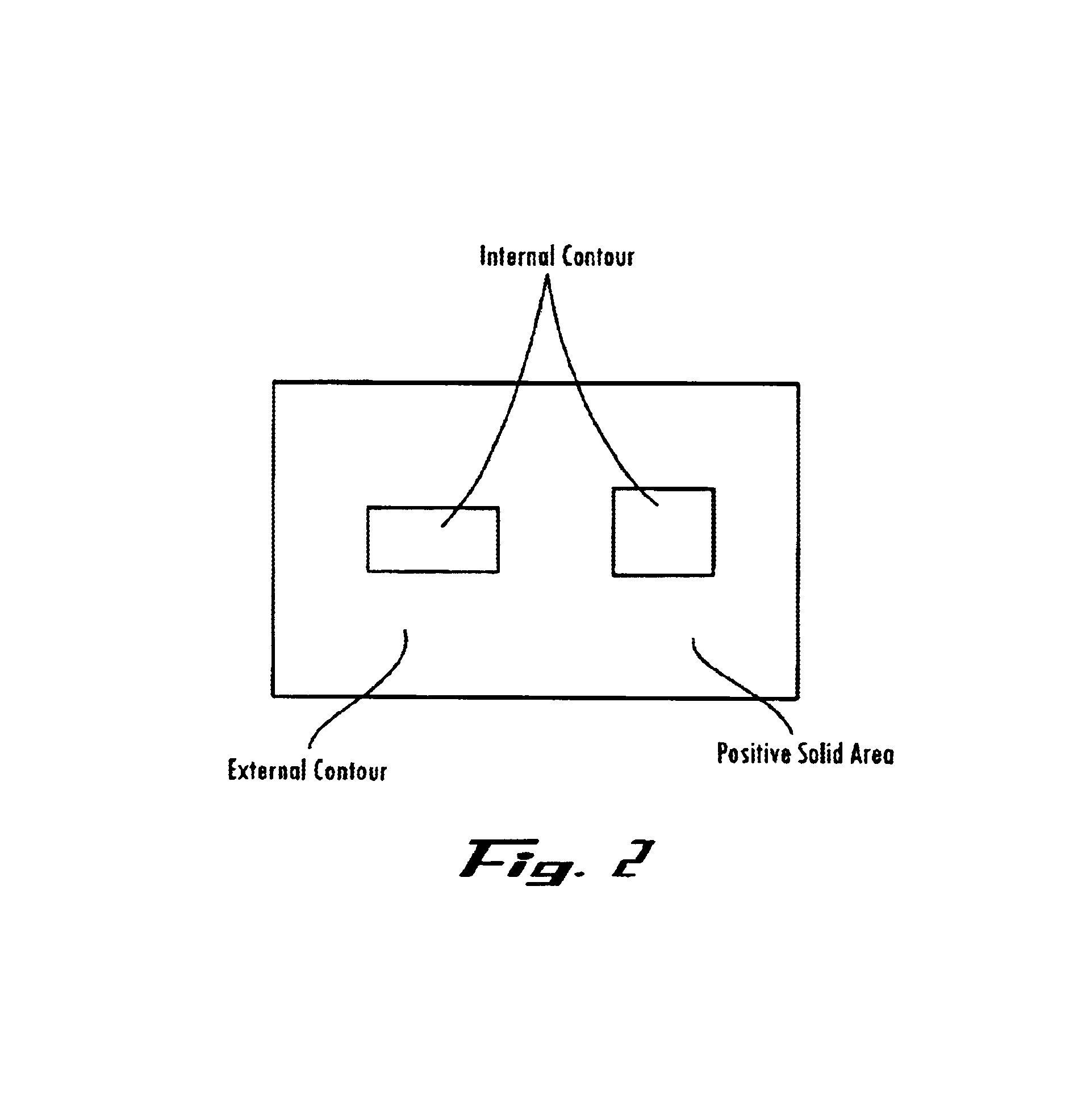

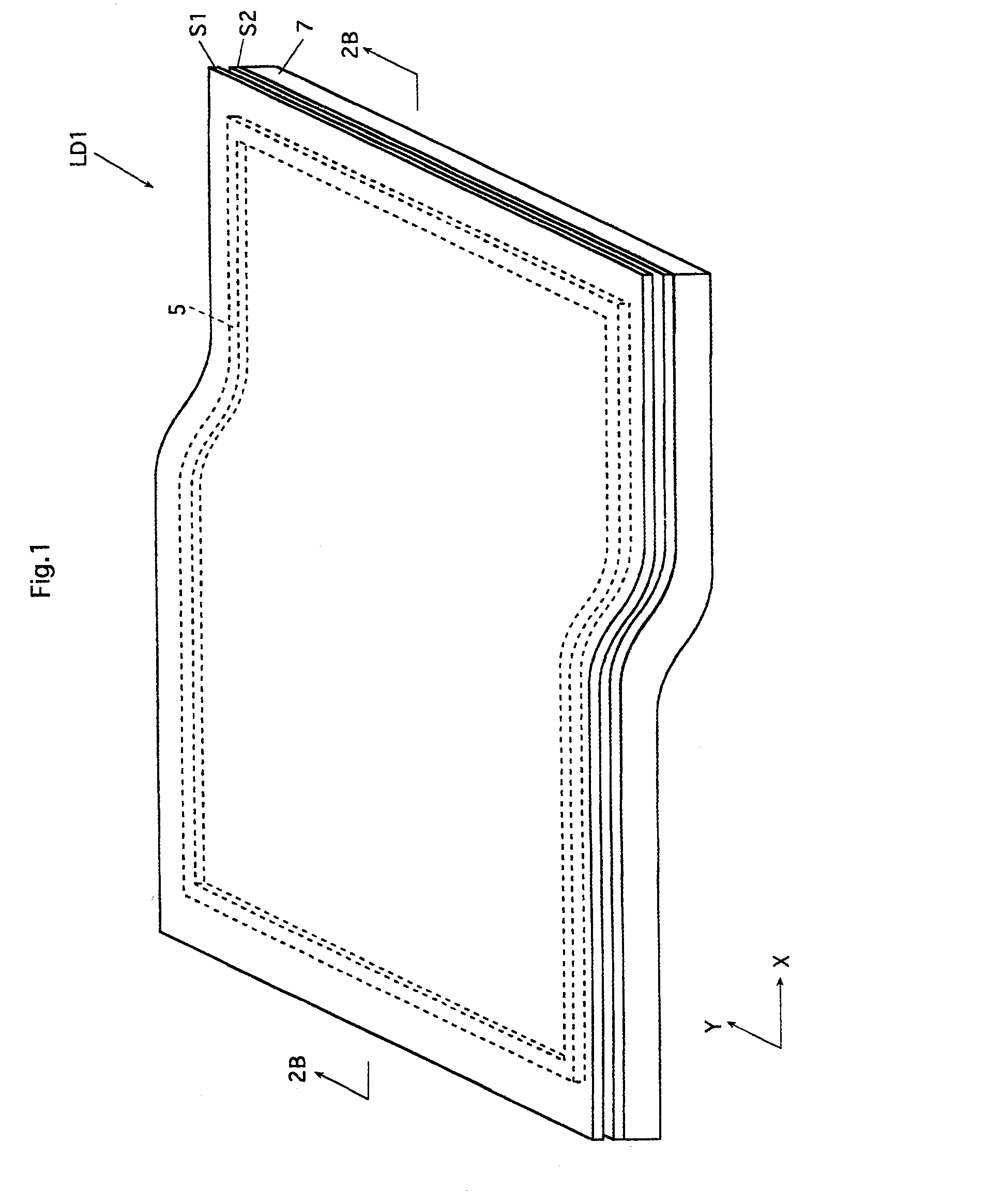

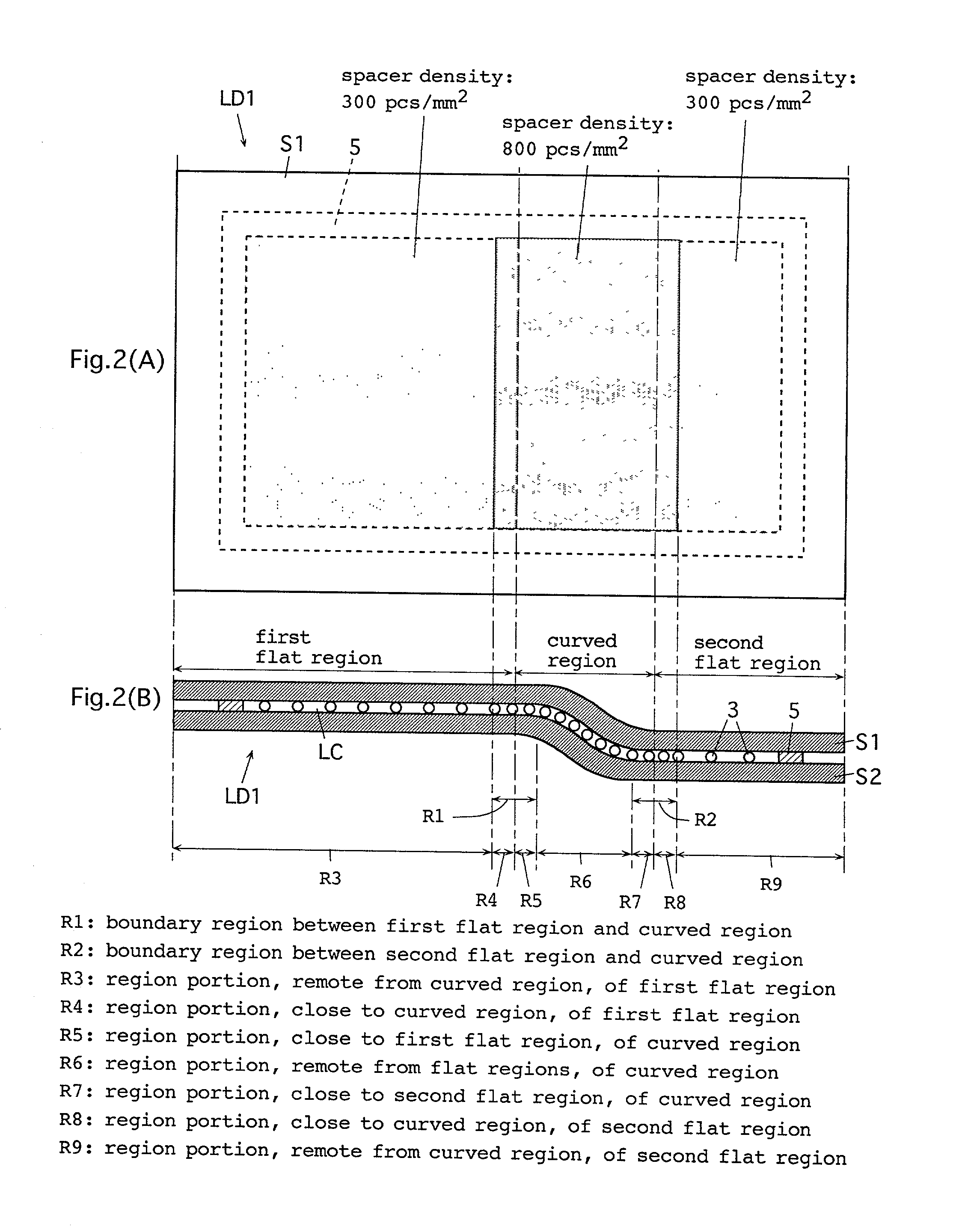

Non-flat liquid crystal display element and method of producing the same

InactiveUS20020027636A1High uniformity in gapEasy to displayVisible signalling systemsNon-linear opticsLiquid-crystal displayEngineering

Disclosed is a non-flat liquid crystal display (LCD) element having a liquid crystal, a sealing wall and paired substrates opposed to each other such that a major surface of the LCD element has a non-flat form. In an aspect, spacers are disposed between the substrates, and a spacer density in a predetermined region is different from that in at least a portion of the other region. In another aspect, resin structures are disposed between the substrates and are adhered to the substrates, and a resin structure adhesion area, per unit area of the substrate, with respect to the substrate in a predetermined region is different from that in at least a portion of the other region. In further another aspect, at least one of pixel form, size and arrangement pitch in a predetermined region is different from that in at least a portion of the other region. In further another aspect, the resin structures are disposed between the substrates, and at least one of resin structure form, size and arrangement pitch in a predetermined region is different from that in at least a portion of the other region. Also disclosed is a method of producing a non-flat LCD element. The method includes the steps of: holding a liquid crystal between paired flat substrates to produce a flat LCD element having an entirely flat form; and deforming the flat LCD element into a predetermined non-flat form.

Owner:MINOLTA CO LTD

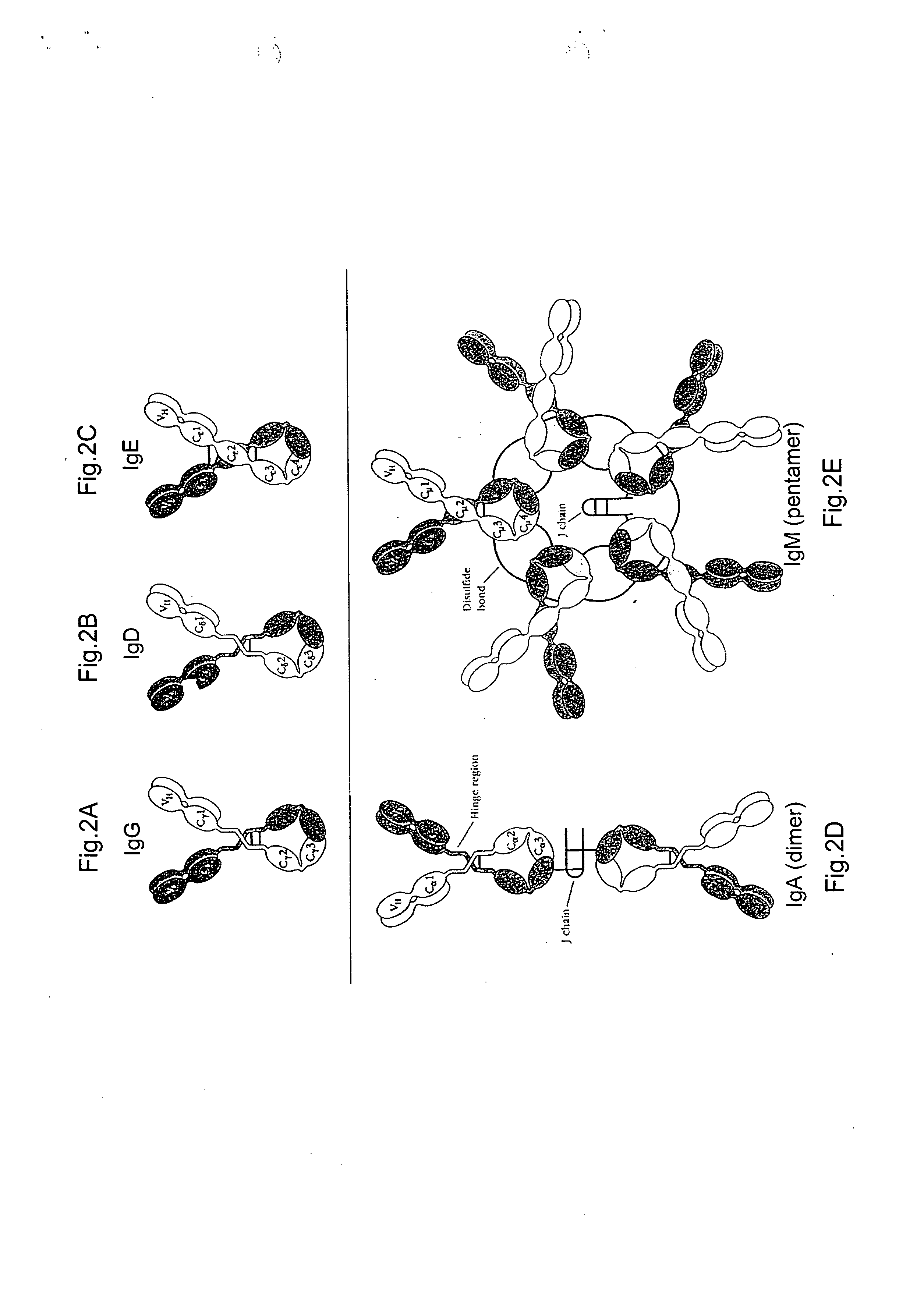

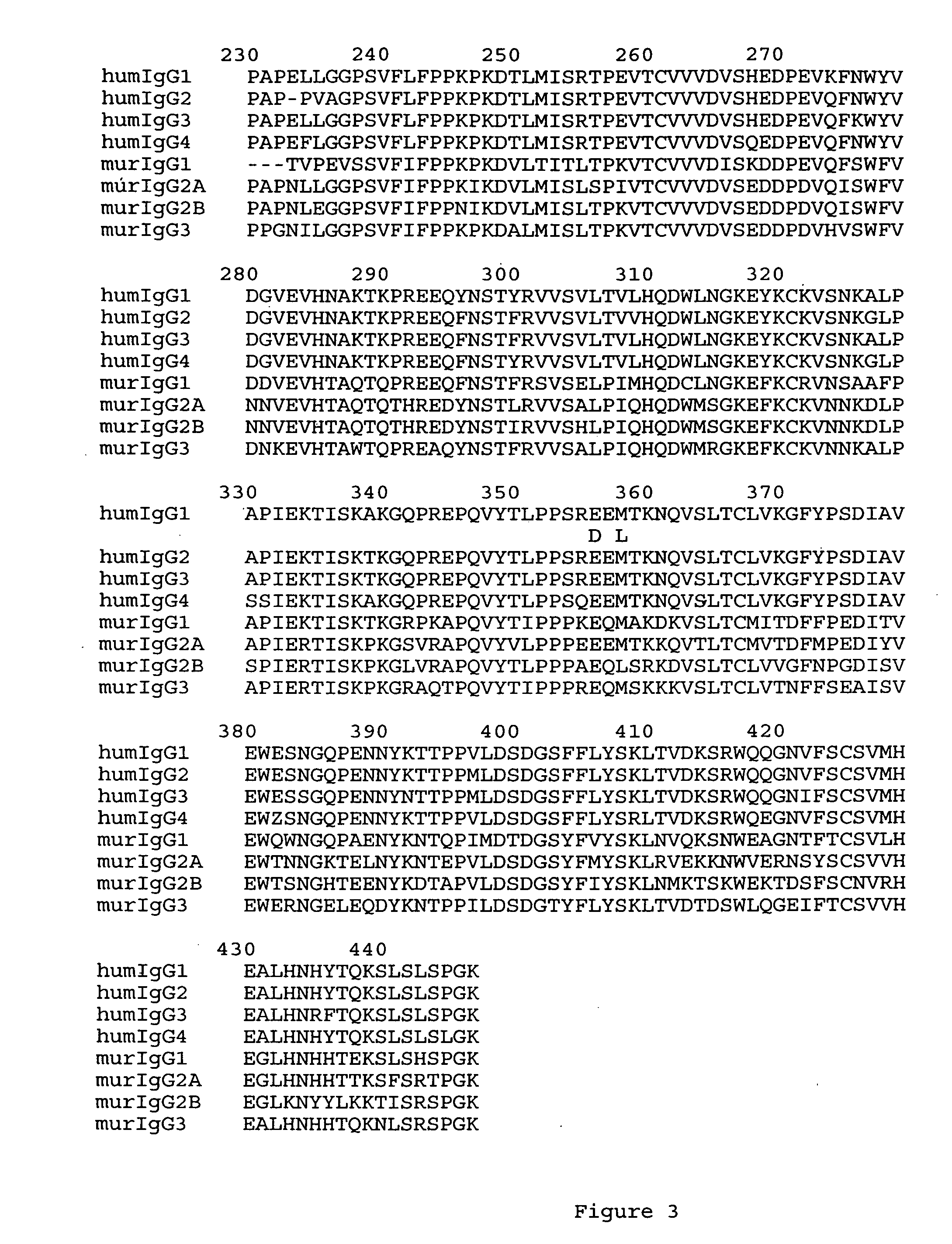

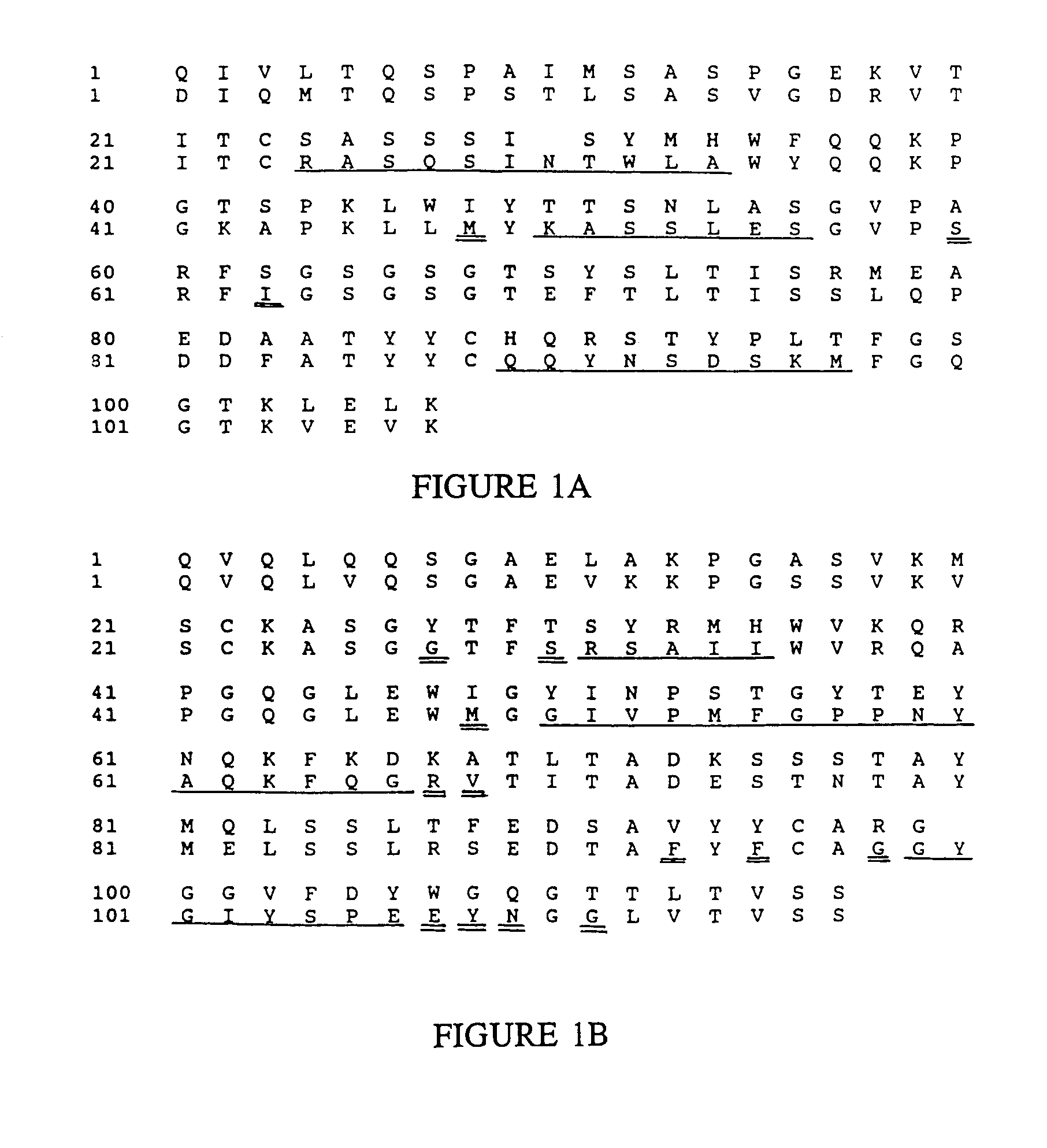

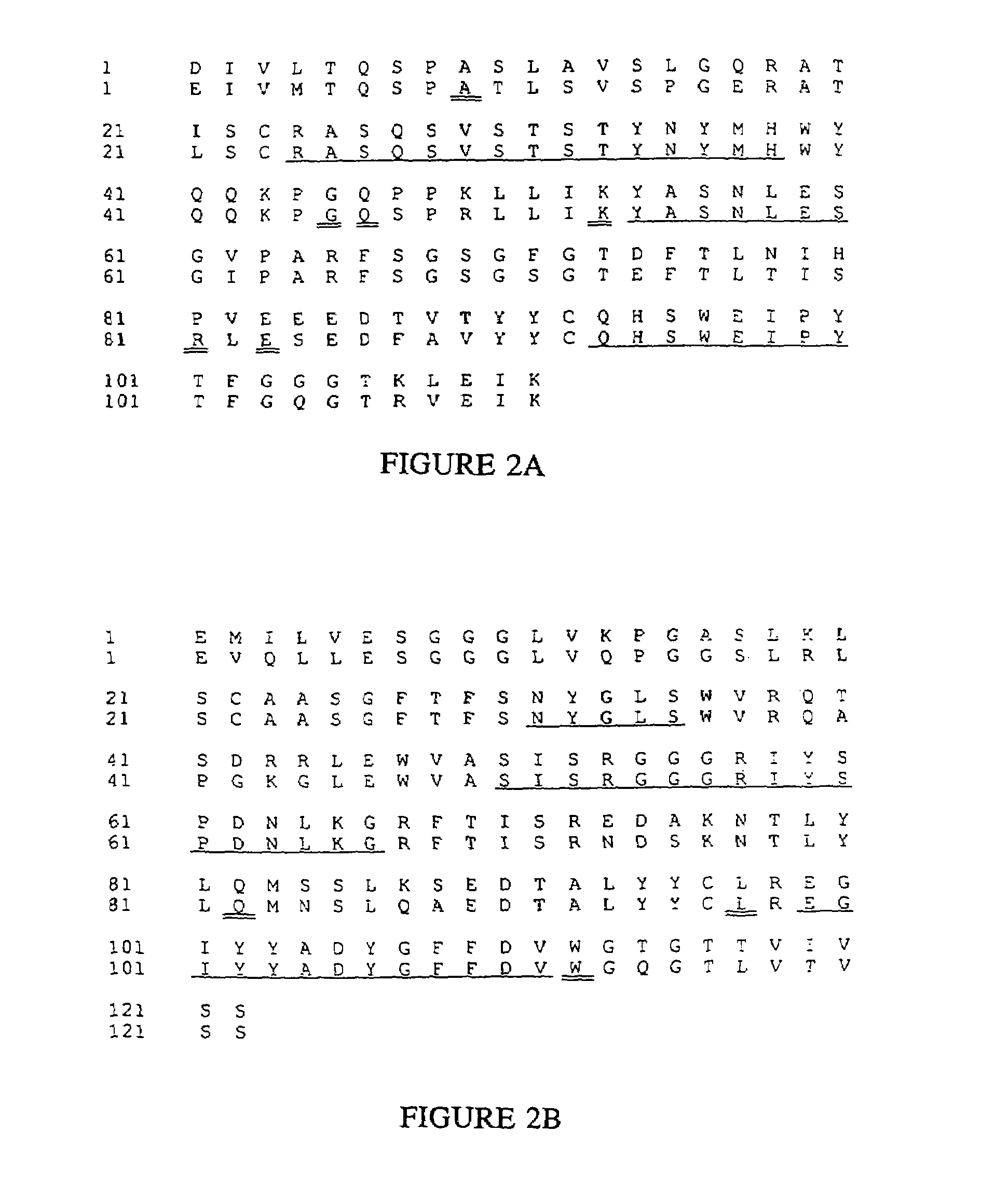

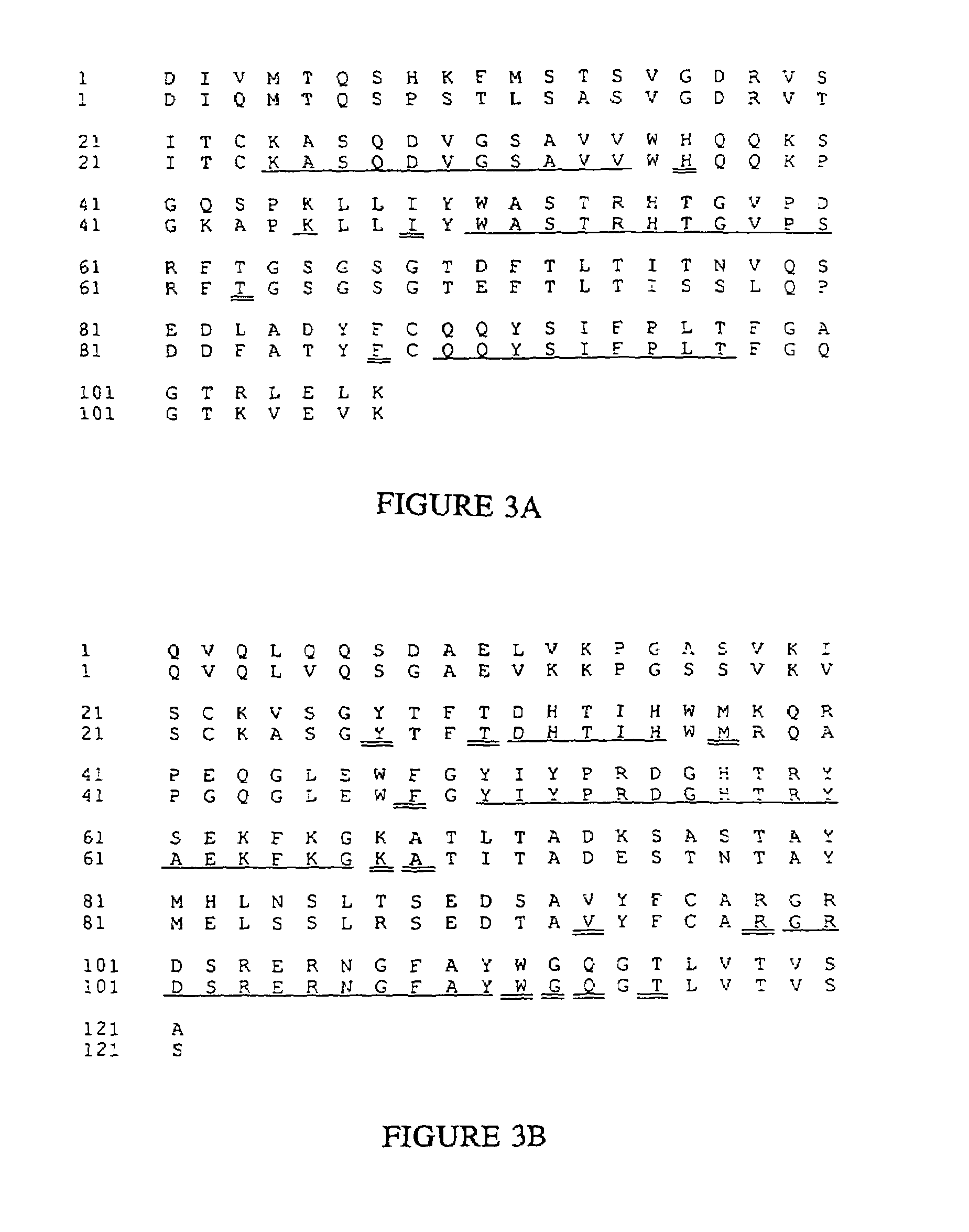

Humanized immunoglobulins

Novel methods for producing, and compositions of, humanized immunoglobulins having one or more complementarity determining regions (CDR's) and possible additional amino acids from a donor immunoglobulin and a framework region from an accepting human immunoglobulin are provided. Each humanized immunoglobulin chain will usually comprise, in addition to the CDR's, amino acids from the donor immunoglobulin framework that are, e.g., capable of interacting with the CDR's to effect binding affinity, such as one or more amino acids which are immediately adjacent to a CDR in the donor immunoglobulin or those within about about 3Å as predicted by molecular modeling. The heavy and light chains may each be designed by using any one or all of various position criteria. When combined into an intact antibody, the humanized immunoglobulins of the present invention will be substantially non-immunogenic in humans and retain substantially the same affinity as the donor immunoglobulin to the antigen, such as a protein or other compound containing an epitope.

Owner:PDL BIOPHARMA INCORPORATED

Device for expanding an exit pupil in two dimensions

ActiveUS8160411B2Improve image qualityEfficient couplingDiffraction gratingsCoupling light guidesBeam expanderGrating

A diffractive beam expander (50) comprises an input grating (10), a crossed grating (20), and an output grating (30) implemented on a planar transparent substrate (7). The crossed grating (20) comprises a plurality of diffractive features (23) arranged along the lines of a first set of parallel lines (25) and along the lines of a second set of parallel lines (26) such that the lines (25) of the first set are parallel to the lines (26) of the second set. The lines of the first set have a first grating period and the lines of the second set have a second grating period. A light beam (B1) coupled into the substrate (7) by the input grating (10) impinges on the crossed grating (20) at a first location (EC1) and further locations (EC2). Interaction at the first location (EC1) provides several sub-beams (S00, S01, S10) which propagate in different directions. Further interactions at second locations (EC2) provide further sub-beams (V01, U10) which propagate in the same direction as the original in-coupled light (B1). Light is subsequently coupled out of the substrate (7) by the output grating (30) to provide a light beam (B2) which is expanded in two directions (SX, SZ) with respect to the beam (B0) impinging on the input grating. A virtual display device (200) may comprise said diffractive beam expander (50).

Owner:MAGIC LEAP INC

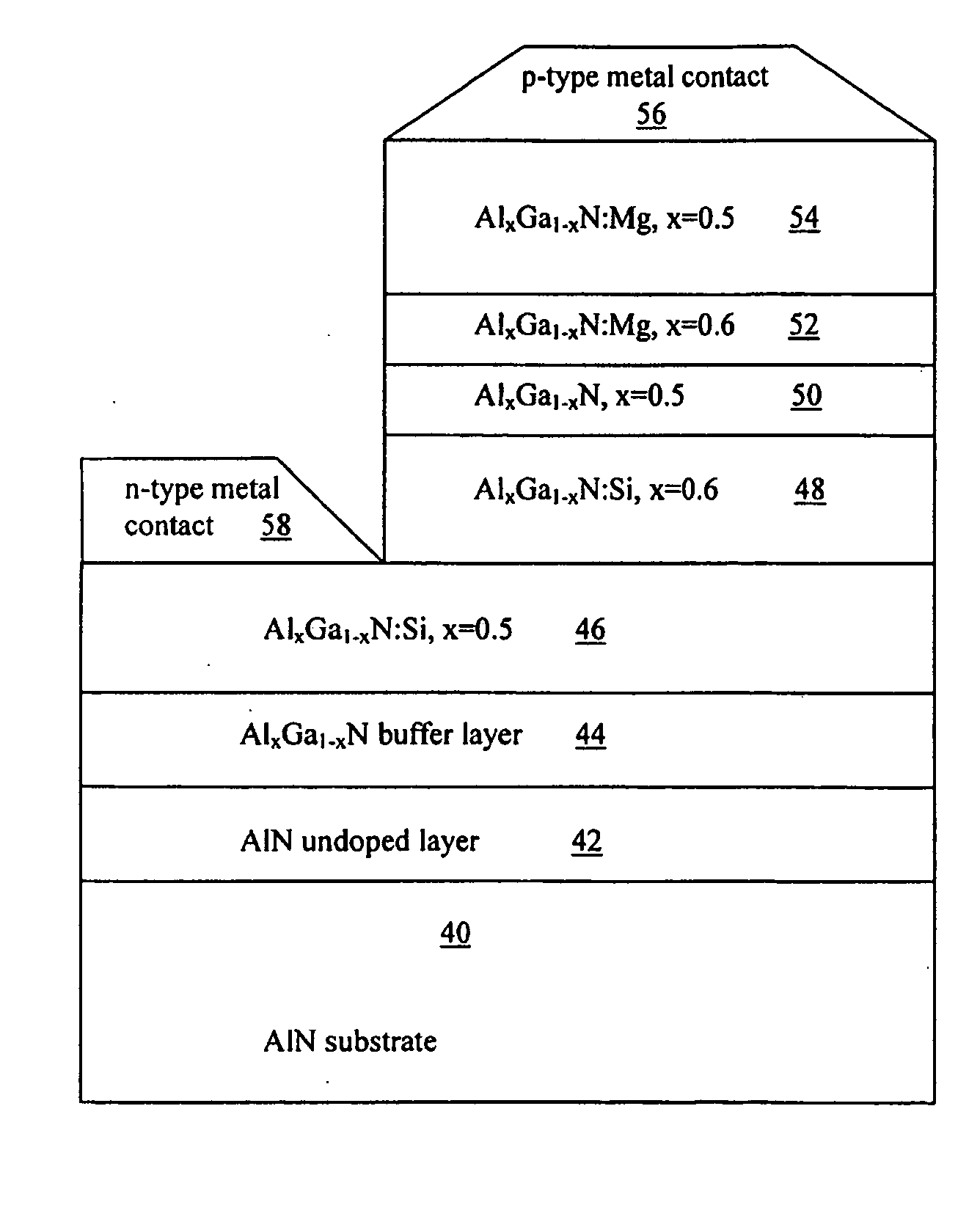

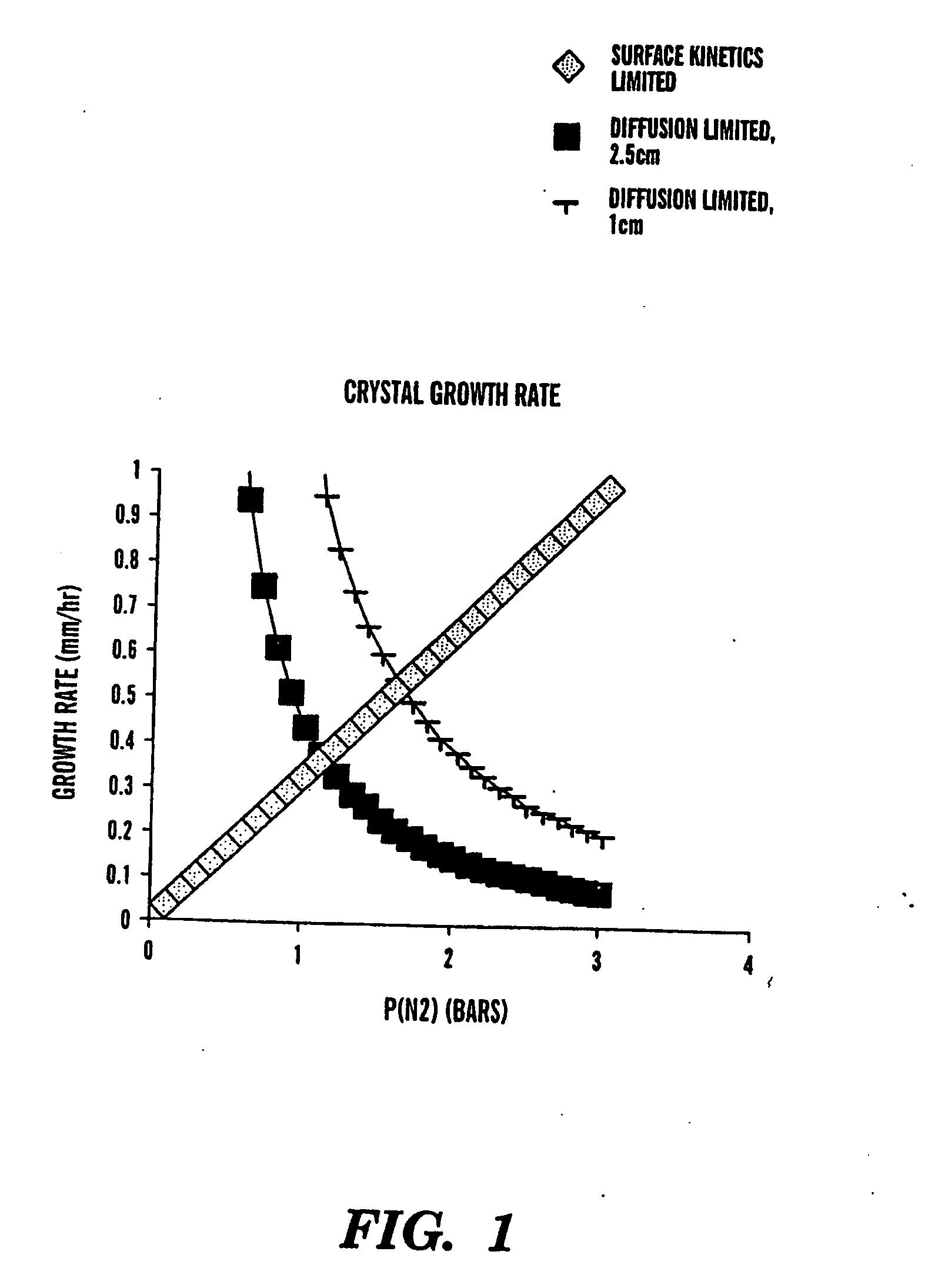

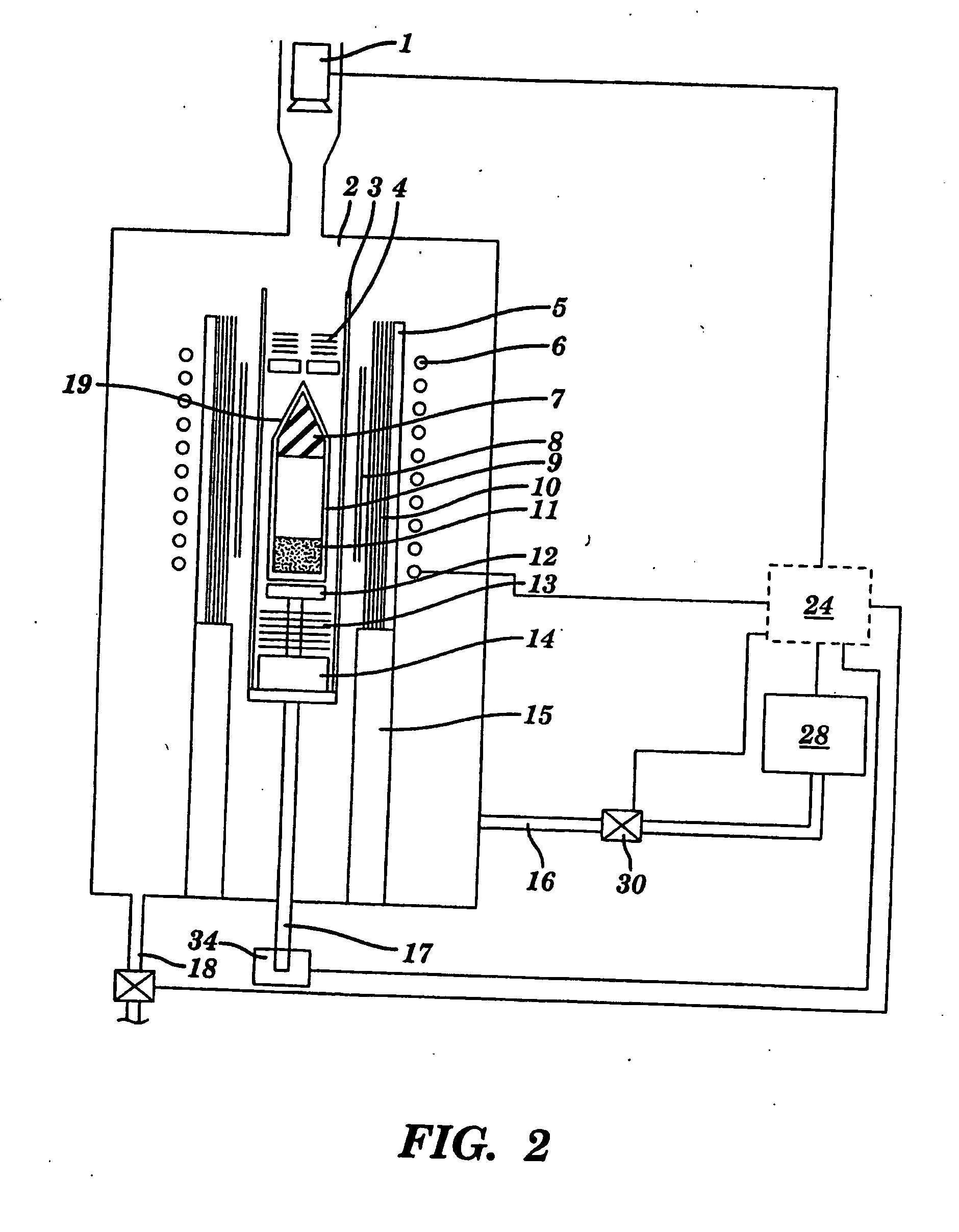

Method and apparatus for producing large, single-crystals of aluminum nitride

ActiveUS20070101932A1Facilitate productionEasy to manufacturePolycrystalline material growthSolid-state devicesDislocationBulk crystal

Bulk single crystals of AlN having a diameter greater than about 25 mm and dislocation densities of about 10,000 cm−2 or less and high-quality AlN substrates having surfaces of any desired crystallographic orientation fabricated from these bulk crystals.

Owner:CRYSTAL

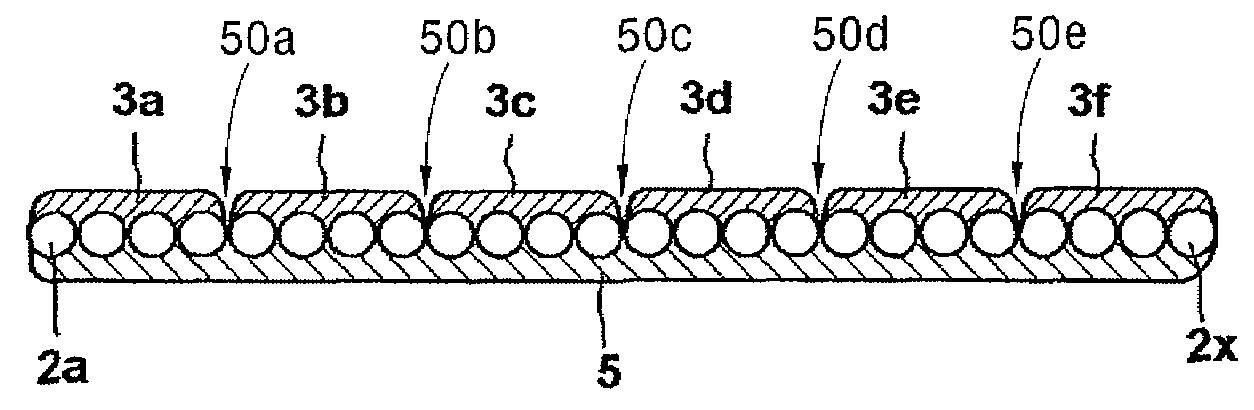

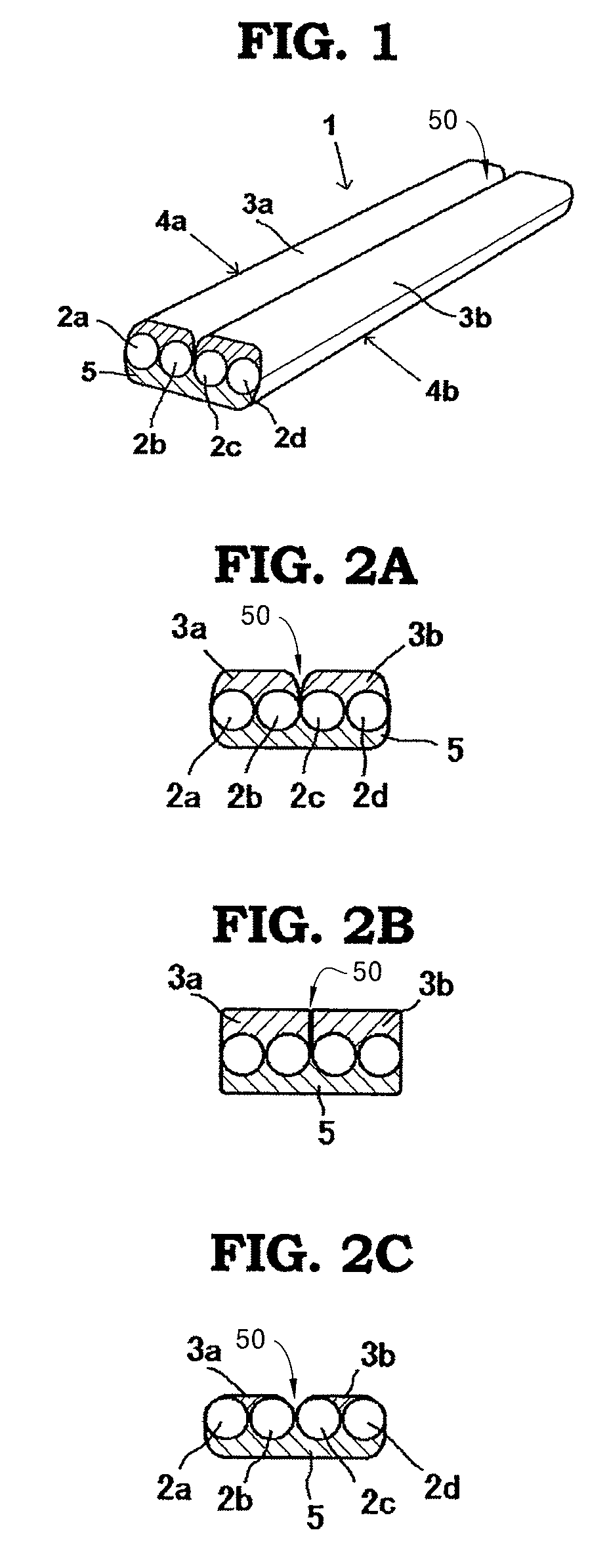

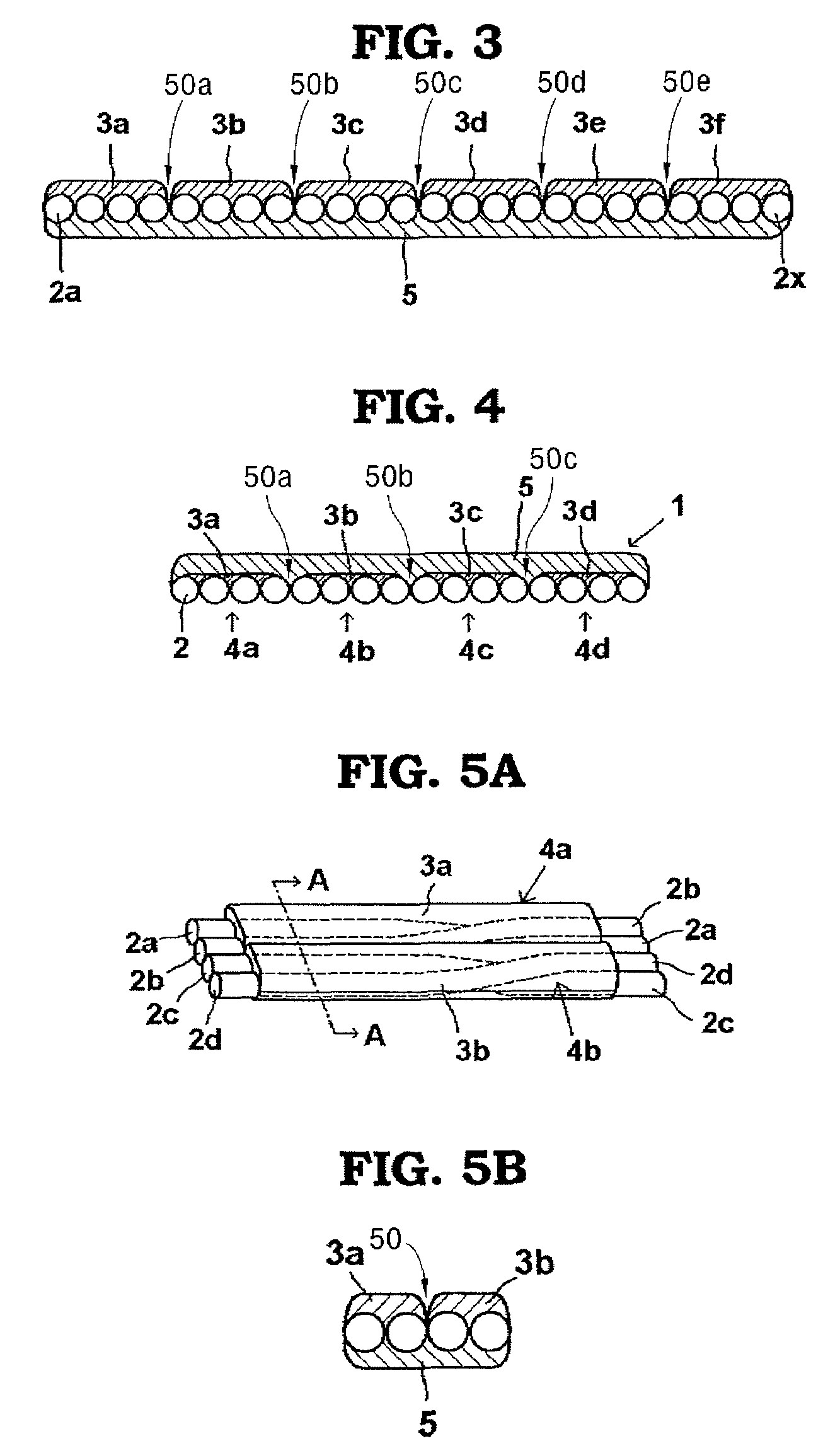

Optical fiber structure and method of manufacturing same

InactiveUS7509009B2Easily branchedPromote divisionGlass optical fibreFibre mechanical structuresEngineeringUltimate tensile strength

The present invention provides an optical fiber structure that allows for reliable and easy branching of optical fibers, as well as a method of manufacturing such optical fiber structure. The optical fiber structure proposed by the present invention is characterized by a structure wherein multiple optical fiber units, each comprising multiple optical fibers that are aligned two-dimensionally in such a way that one side is covered by a first covering body, are aligned so that the covered surfaces face the same direction, and the covered or uncovered surfaces of the multiple optical fiber units are integrally covered by a second covering body. The second covering body should preferably be made of silicone rubber having a tearing strength of 29 kgf / cm or below.

Owner:TOMOEGAWA PAPER CO LTD

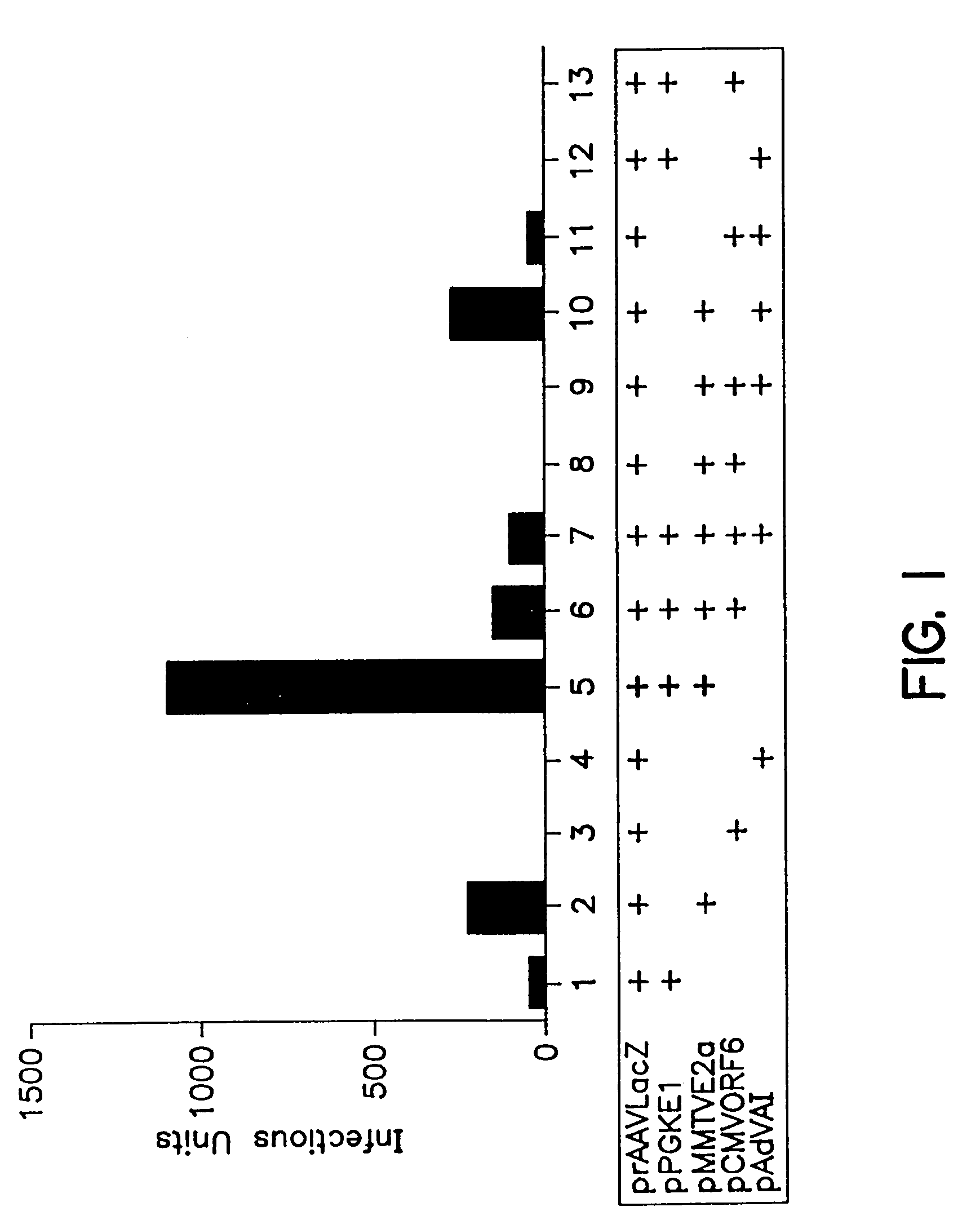

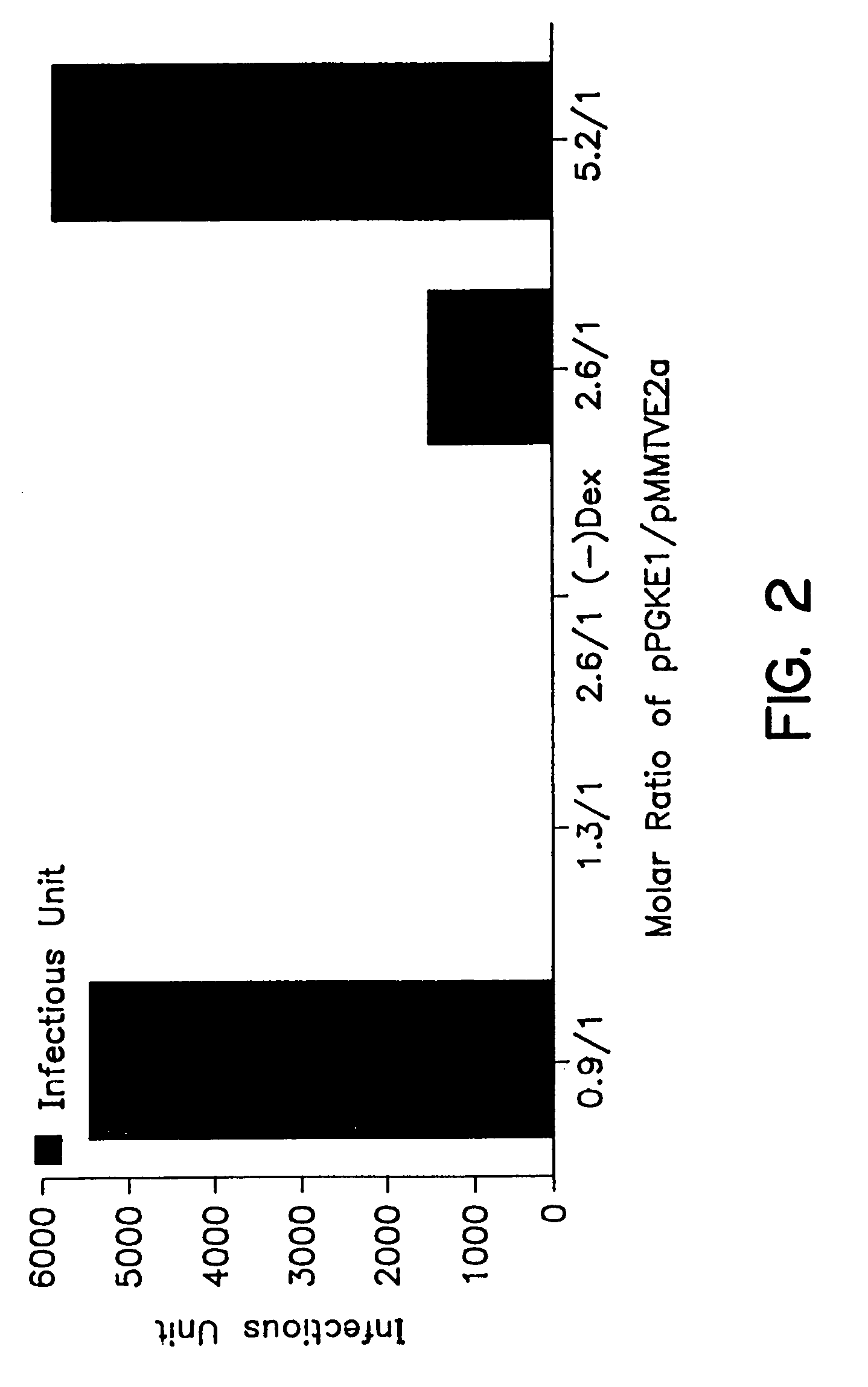

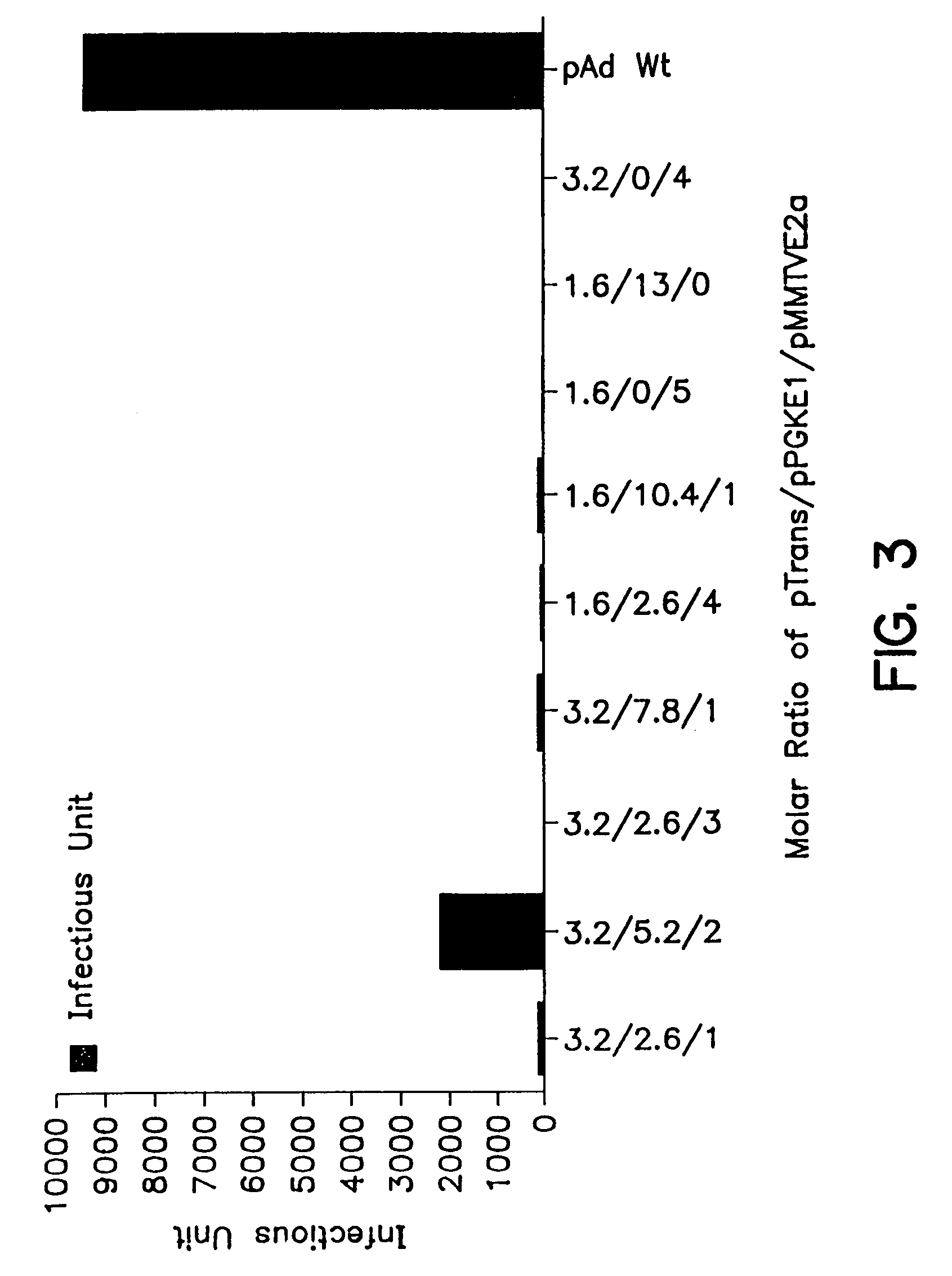

Compositions and methods for helper-free production of recombinant adeno-associated viruses

InactiveUS6953690B1Efficient productionIncrease the number ofBiocideGenetic therapy composition manufactureMammalWild type

A method for producing recombinant adeno-associated virus in the absence of contaminating helper virus or wild-type virus involves culturing a mammalian host cell containing a transgene flanked by adeno-associated virus (AAV) inverse terminal repeats and under the control of regulatory sequences directing expression thereof, an AAV rep sequence and an AAV cap sequence under the control of regulatory sequences directing expression thereof, and the minimum adenovirus DNA required to express an E1a gene product, an E1b gene product and an E2a gene product, and isolating therefrom a recombinant AAV which expresses the transgene in the absence of contaminating helper virus or wildtype AAV. This method obviates a subsequent purification step to purify rAAV from contaminating virus. Also provided are various embodiments of the host cell.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

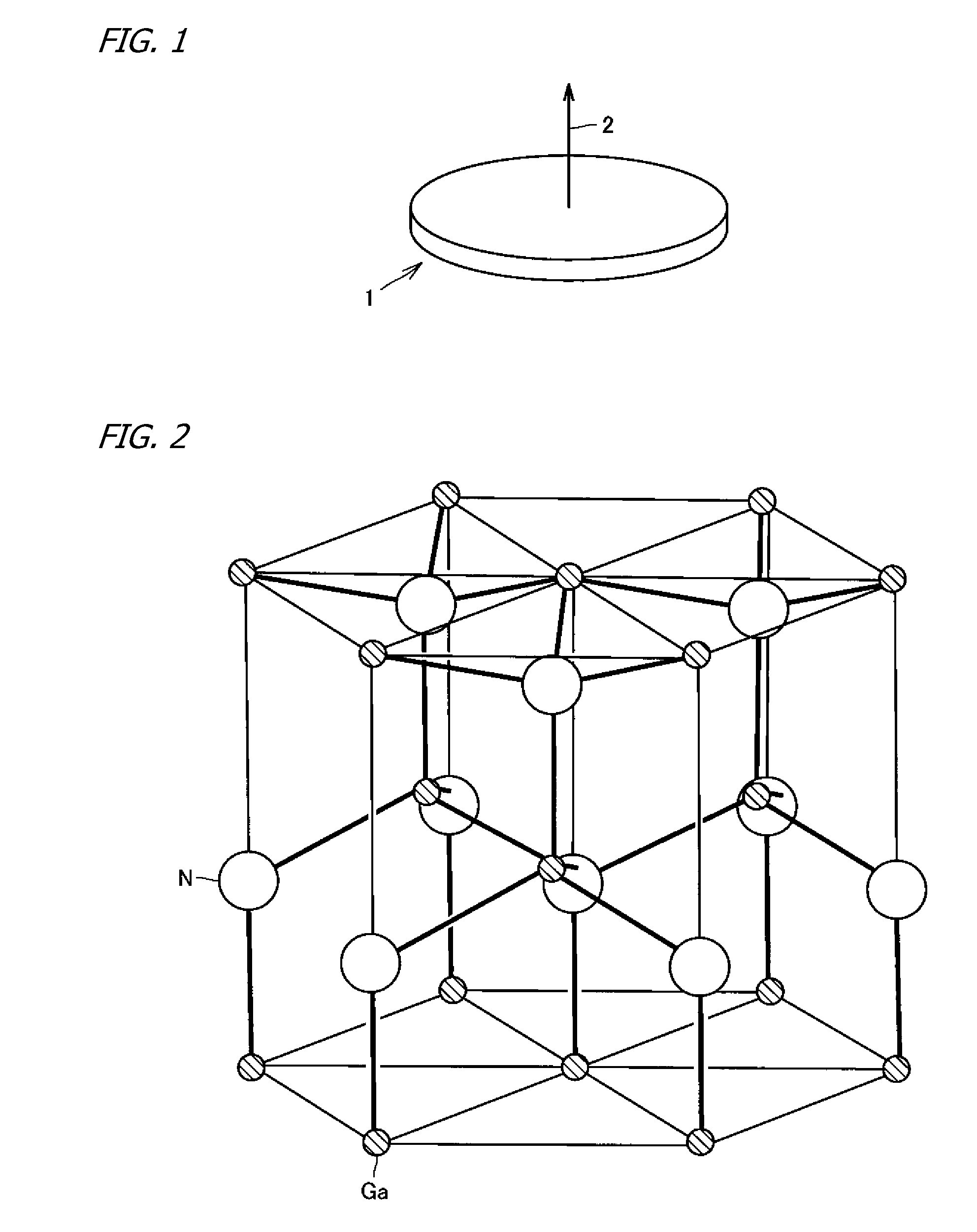

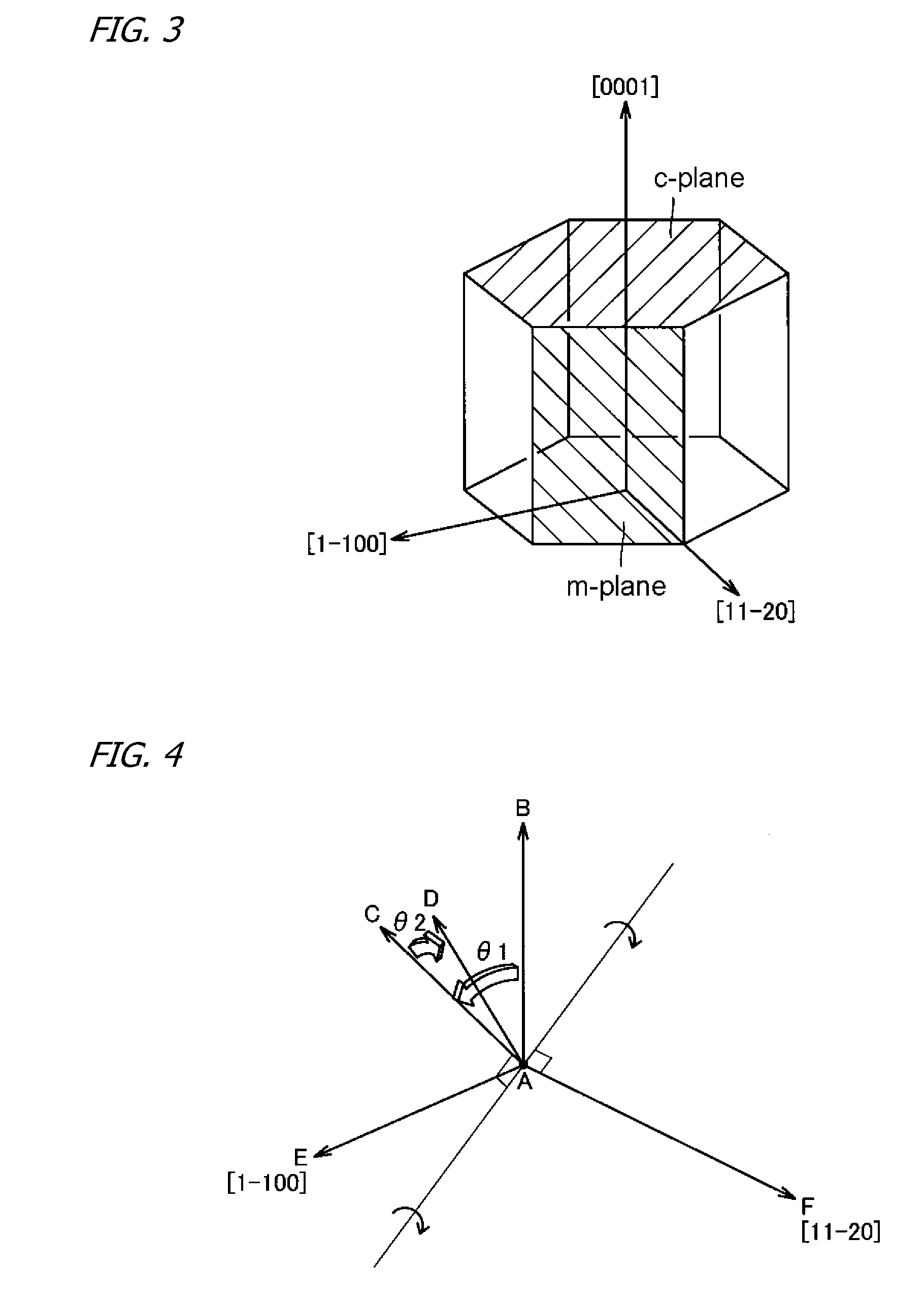

GaN Substrate, Substrate with an Epitaxial Layer, Semiconductor Device, and GaN Substrate Manufacturing Method

InactiveUS20080308815A1Control fluctuationsImprove emission efficiencyAutomatic/semiautomatic turning machinesPolycrystalline material growthDevice materialPlane orientation

Affords a GaN substrate from which enhanced-emission-efficiency light-emitting and like semiconductor devices can be produced, an epi-substrate in which an epitaxial layer has been formed on the GaN substrate principal surface, a semiconductor device, and a method of manufacturing the GaN substrate. The GaN substrate is a substrate having a principal surface with respect to whose normal vector the [0001] plane orientation is inclined in two different off-axis directions.

Owner:SUMITOMO ELECTRIC IND LTD

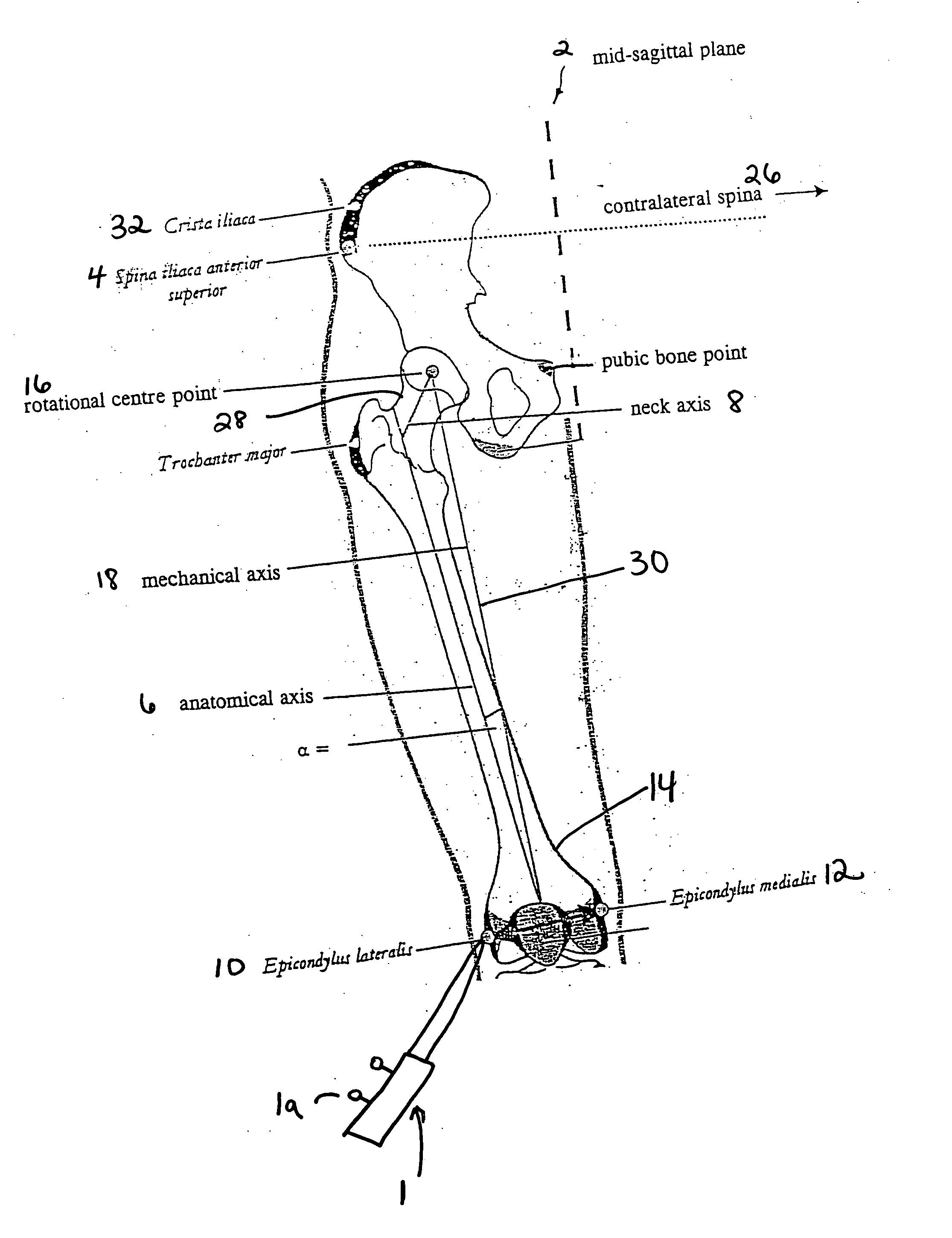

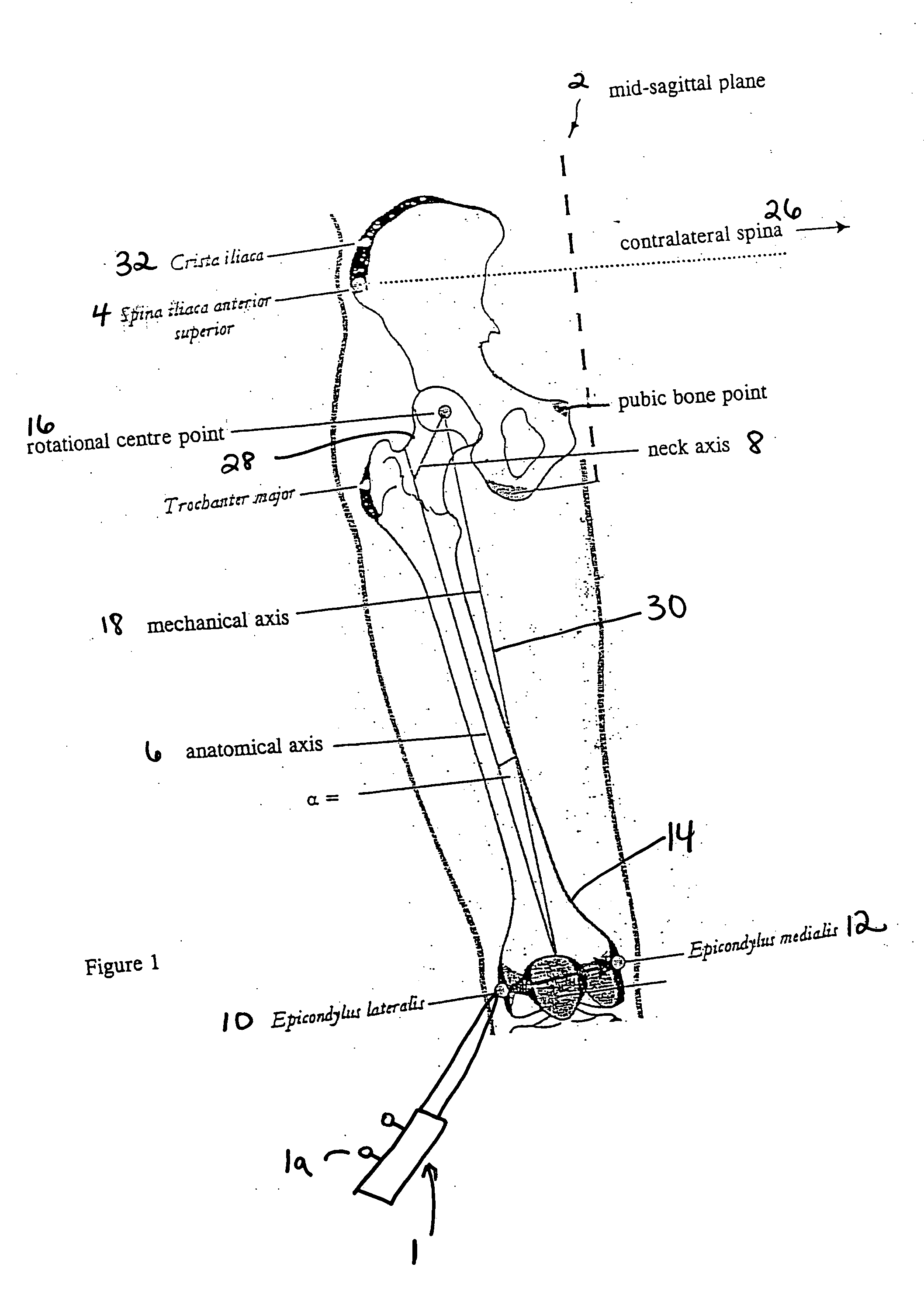

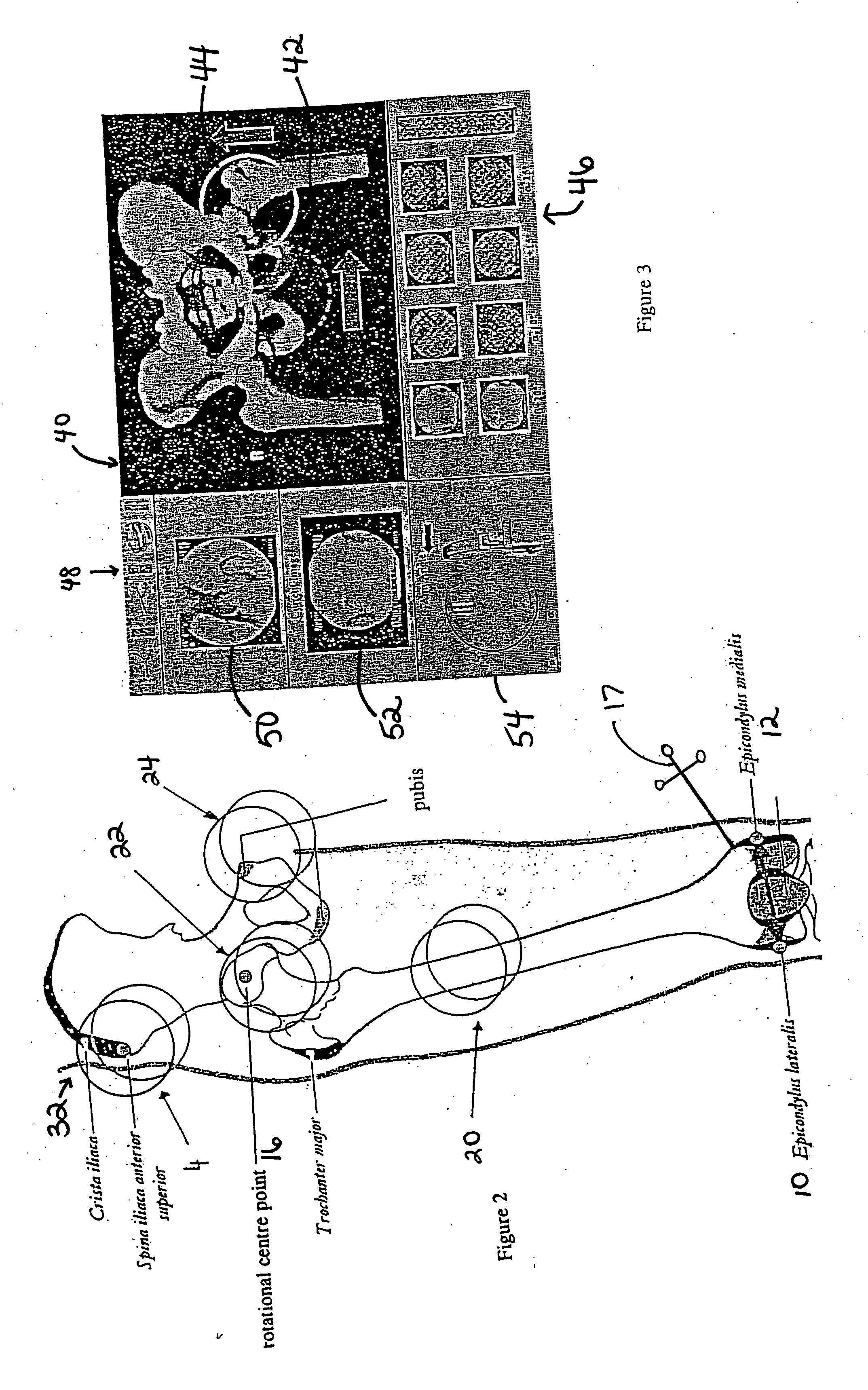

Method and system for generating three-dimensional model of part of a body from fluoroscopy image data and specific landmarks

InactiveUS20060004284A1Overcome disadvantagesSimpler and less-elaborate calculationSurgical navigation systemsJoint implantsData setNavigation system

A method for generating a three-dimensional model of a part of the body with the aid of a medical and / or surgical navigation system, comprising the steps of identifying to the navigation system landmarks on the part of the body that are characteristic of the model of the part of the body; obtaining at least two fluoroscopy image data sets for each of one or more predetermined, individual and delimited regions of the part of the body; ascertaining characteristic body part data by processing and combining the landmark positions and parameters of the fluoroscopy data sets; and generating a three-dimensional and positionally determined model of the part of the body from the characteristic body part data.

Owner:BRAINLAB

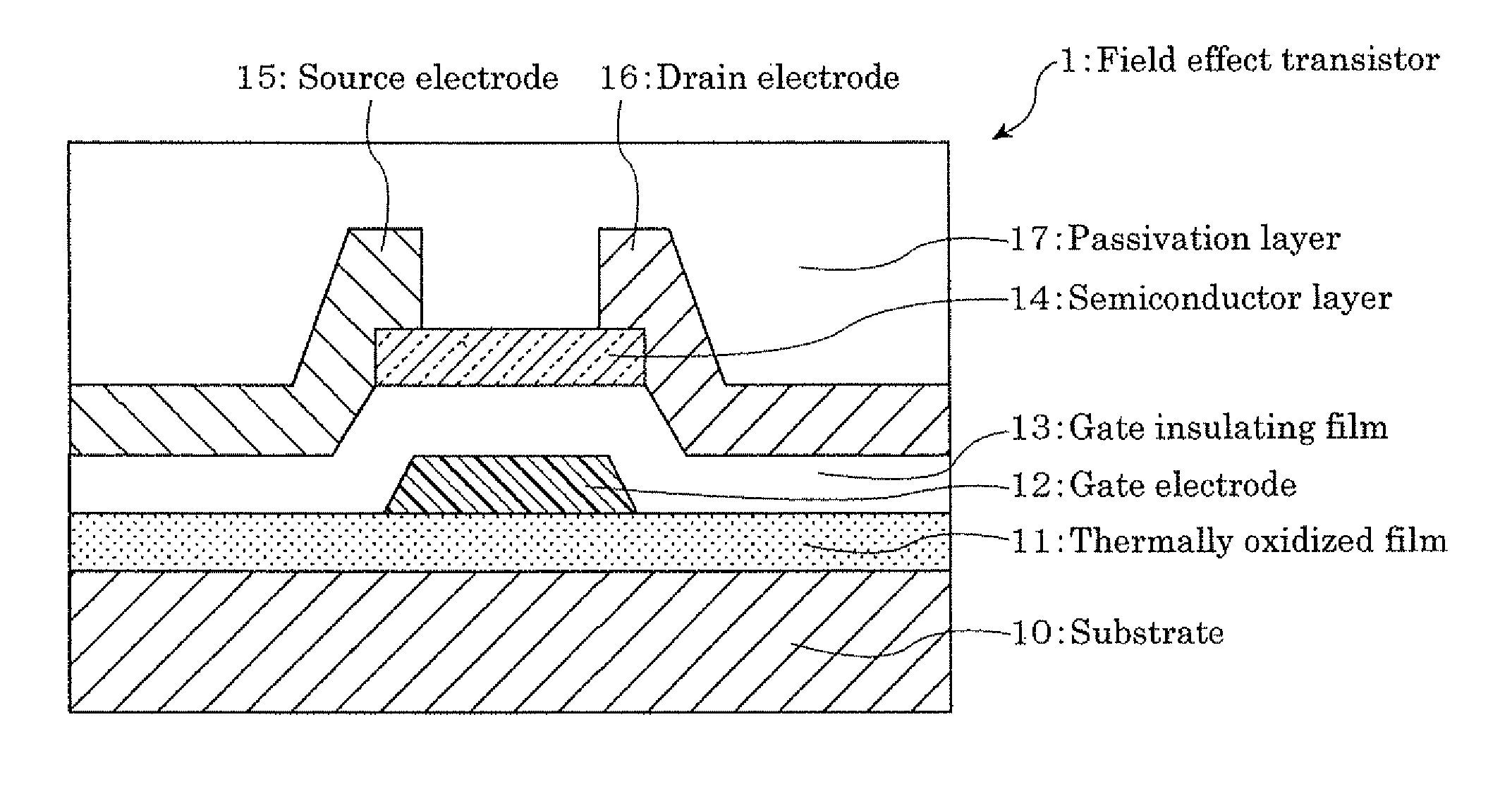

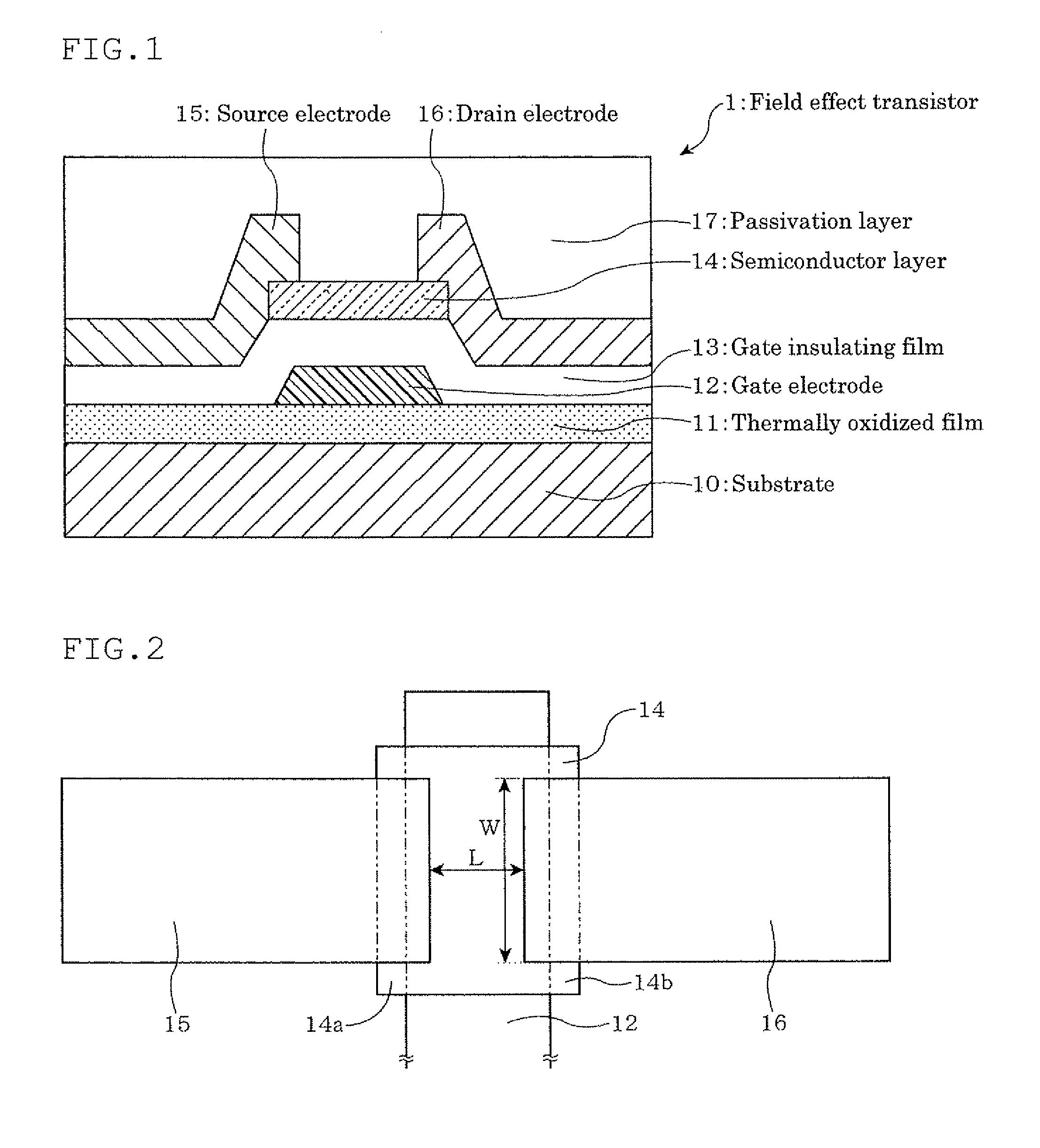

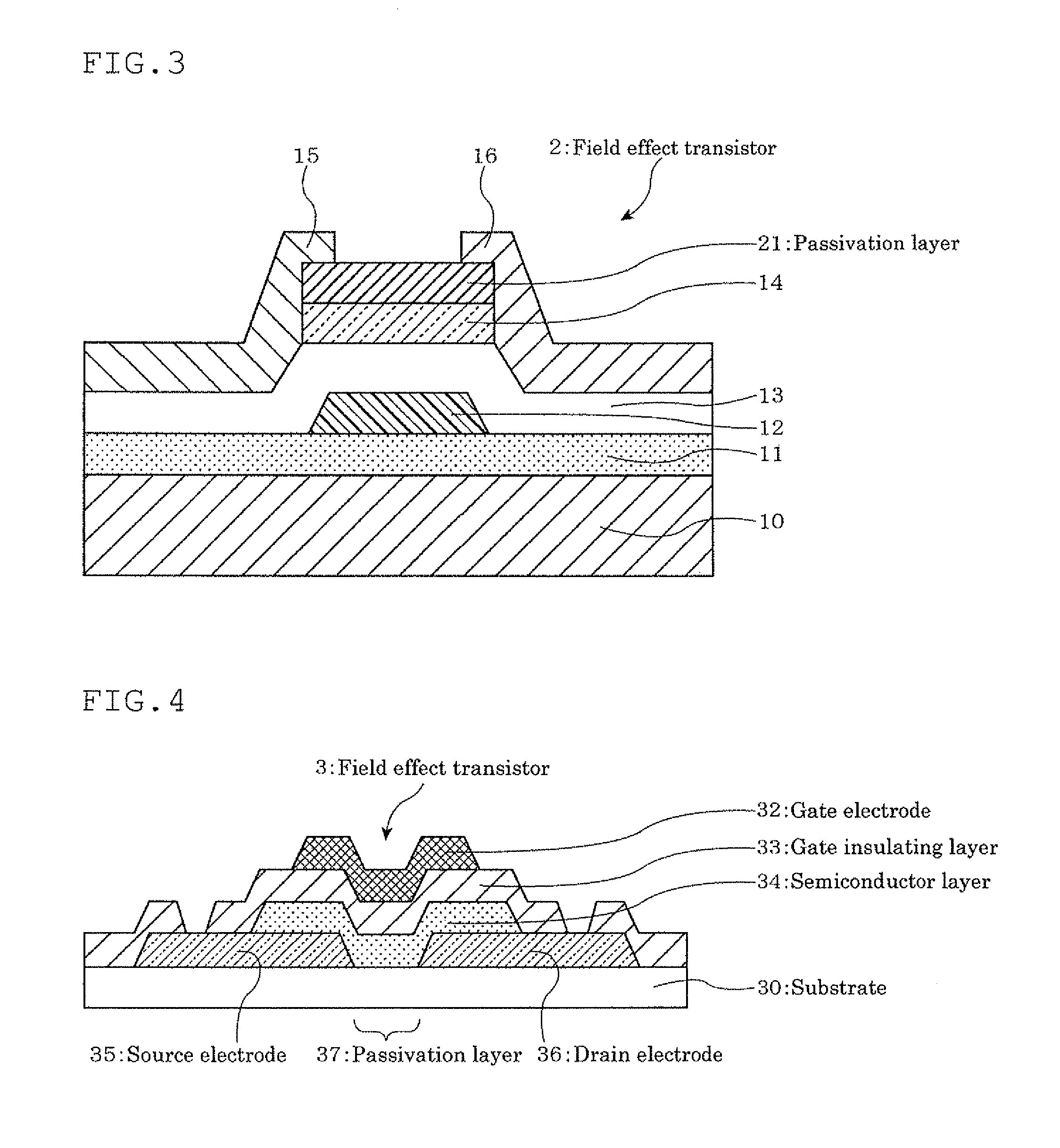

Field effect transistor using oxide semicondutor and method for manufacturing the same

ActiveUS8384077B2Easy to produceLower resistanceSemiconductor/solid-state device manufacturingDiodeIndiumField-effect transistor

A field effect transistor which includes, on a substrate, at least a semiconductor layer, a passivation layer for the semiconductor layer, a source electrode, a drain electrode, a gate insulating film and a gate electrode, the source electrode and the drain electrode being connected through the semiconductor layer, the gate insulating film being present between the gate electrode and the semiconductor layer, the passivation layer being at least on one surface side of the semiconductor layer, and the semiconductor layer including a composite oxide which comprises In (indium), Zn (zinc) and Ga (gallium) in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+Ga)=0.59 to 0.99 (2)Zn / (Ga+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com