Patents

Literature

133results about How to "Separate clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

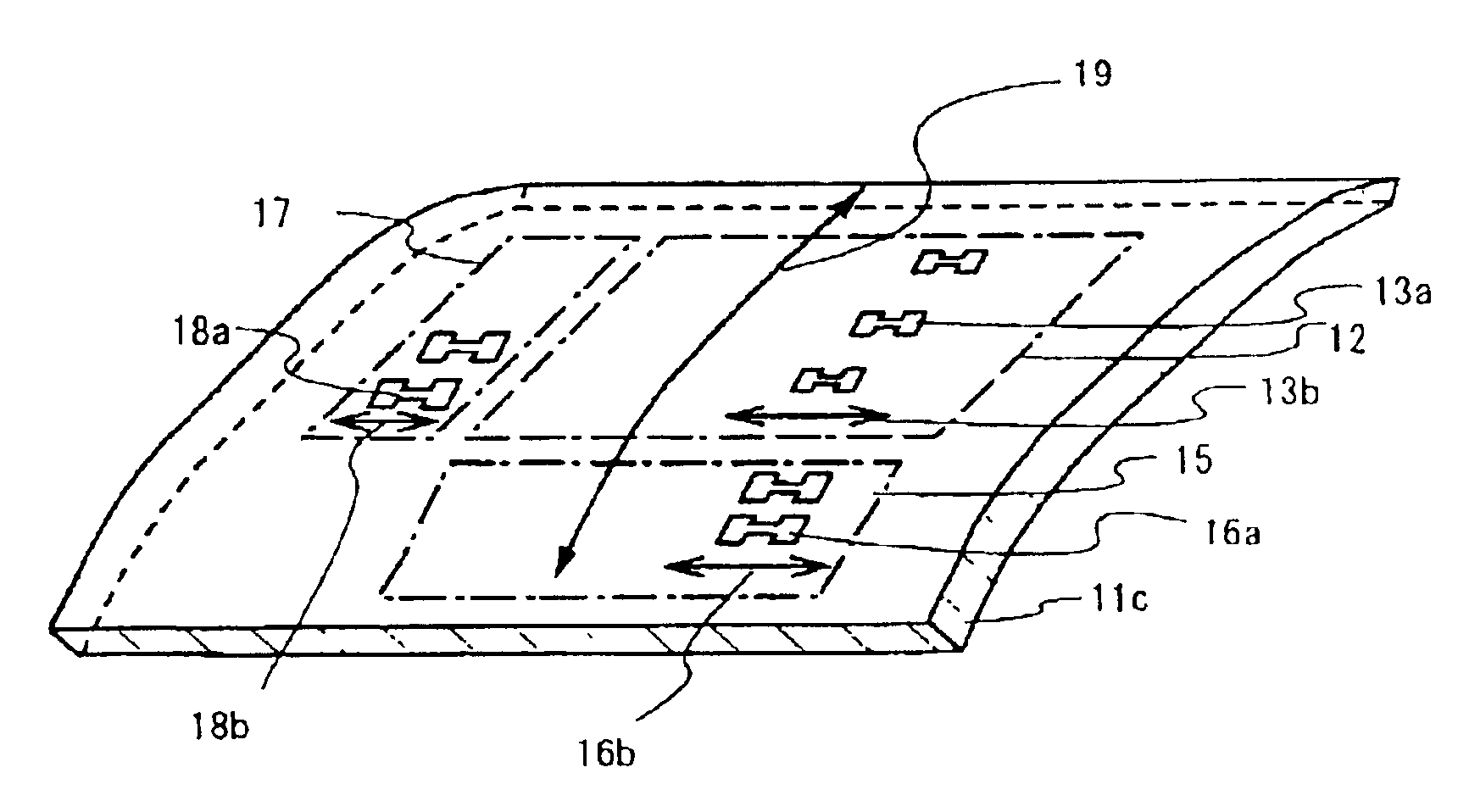

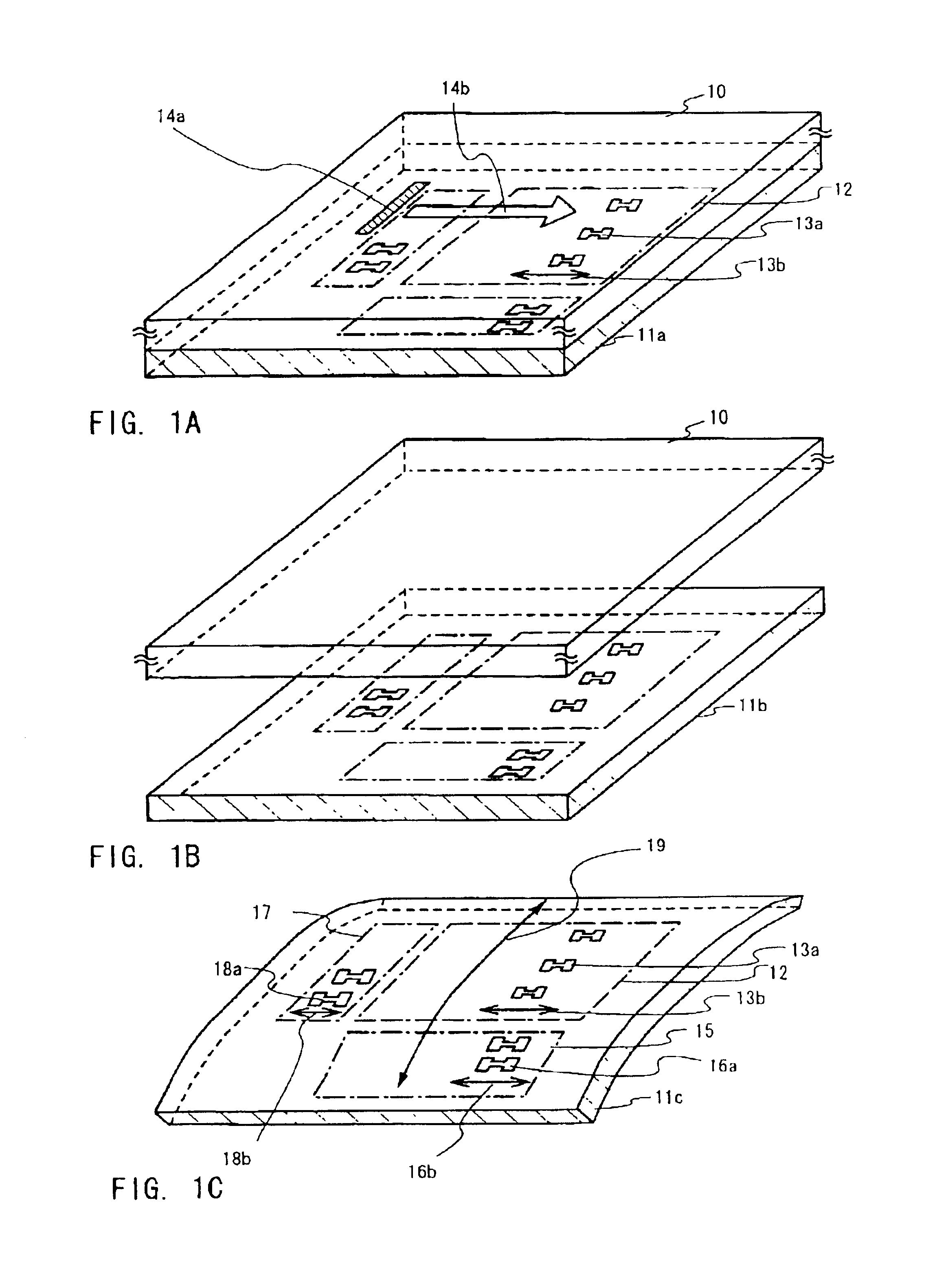

Semiconductor device and manufacturing method thereof

InactiveUS7180091B2Minimize impactSeparate cleanTransistorSolid-state devicesDriver circuitEngineering

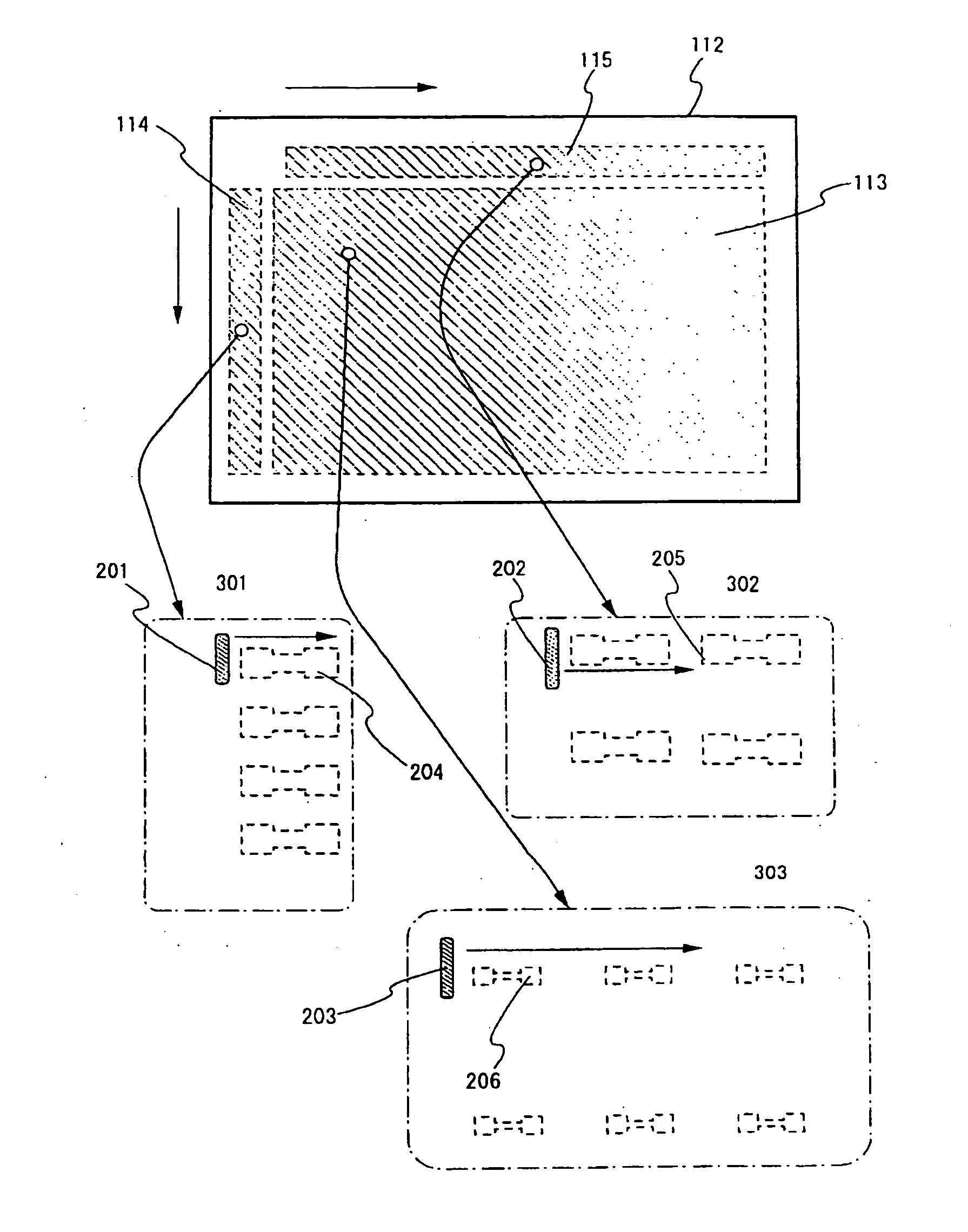

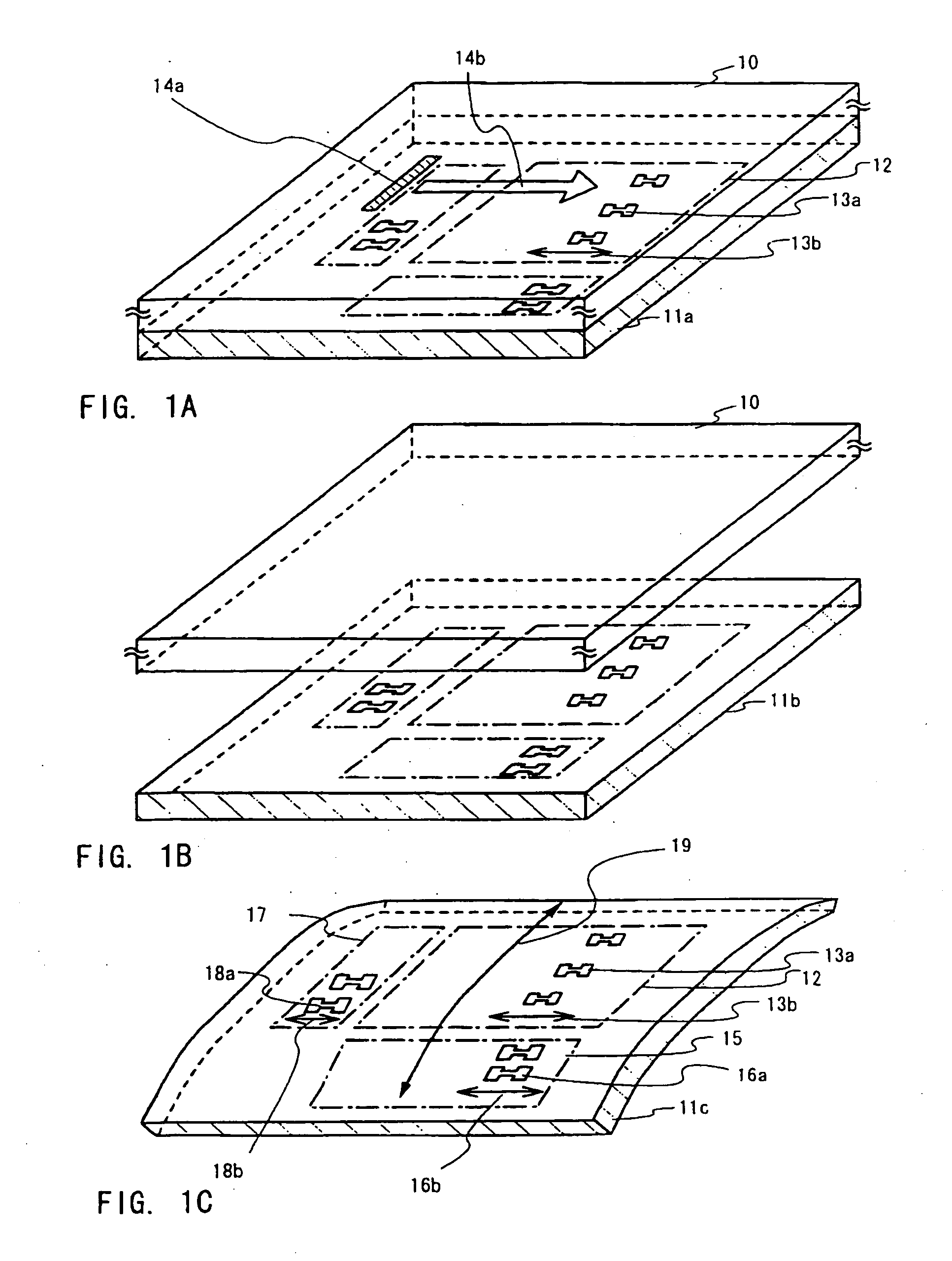

The invention relates to a semiconductor device including a plurality of thin film transistors provided on a base member having a curved surface. The surface may be bent in either a convex shape or a concave shape. All channel length directions of the plurality of thin film transistors may also be aligned in the same direction. Further, the channel length direction may be different from the direction in which the base member is bent. A pixel portion and a driver circuit portion may also be provided on the base member. The invention also includes a method of manufacturing a semiconductor device including forming a layer to be peeled including an element of a substrate, bonding a support member to the layer to be peeled, and bonding a transfer body to the layer to be peeled.

Owner:SEMICON ENERGY LAB CO LTD

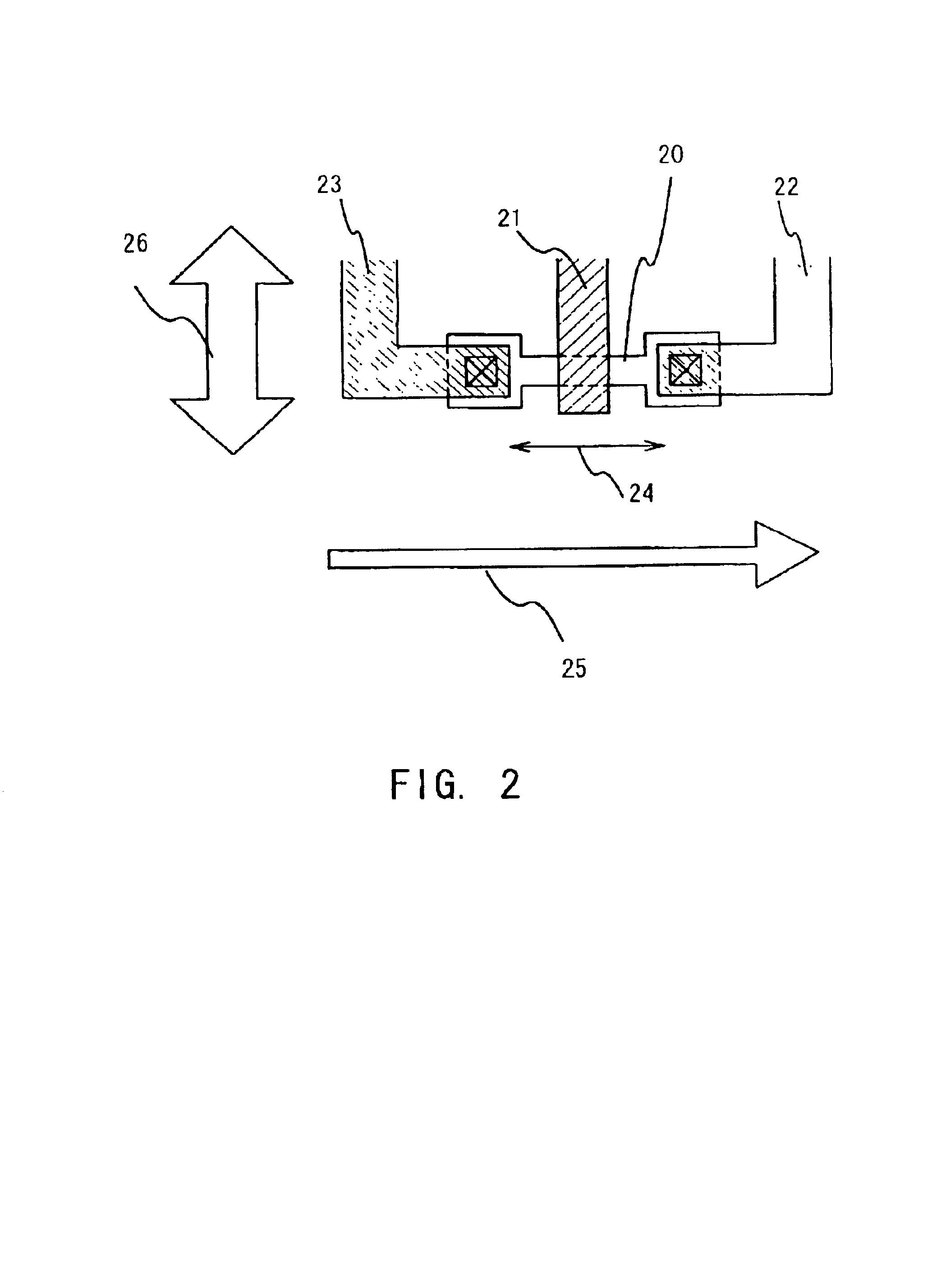

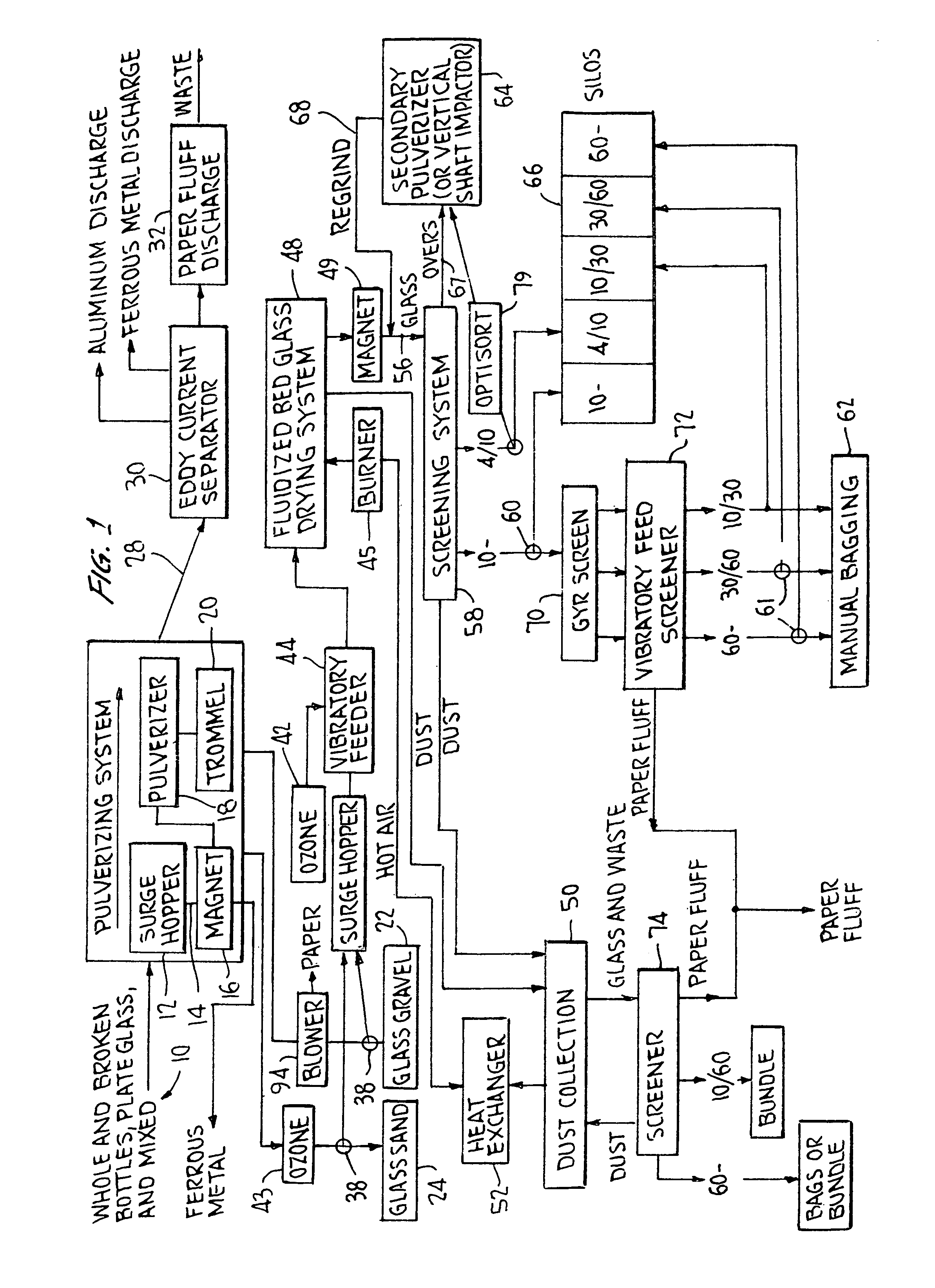

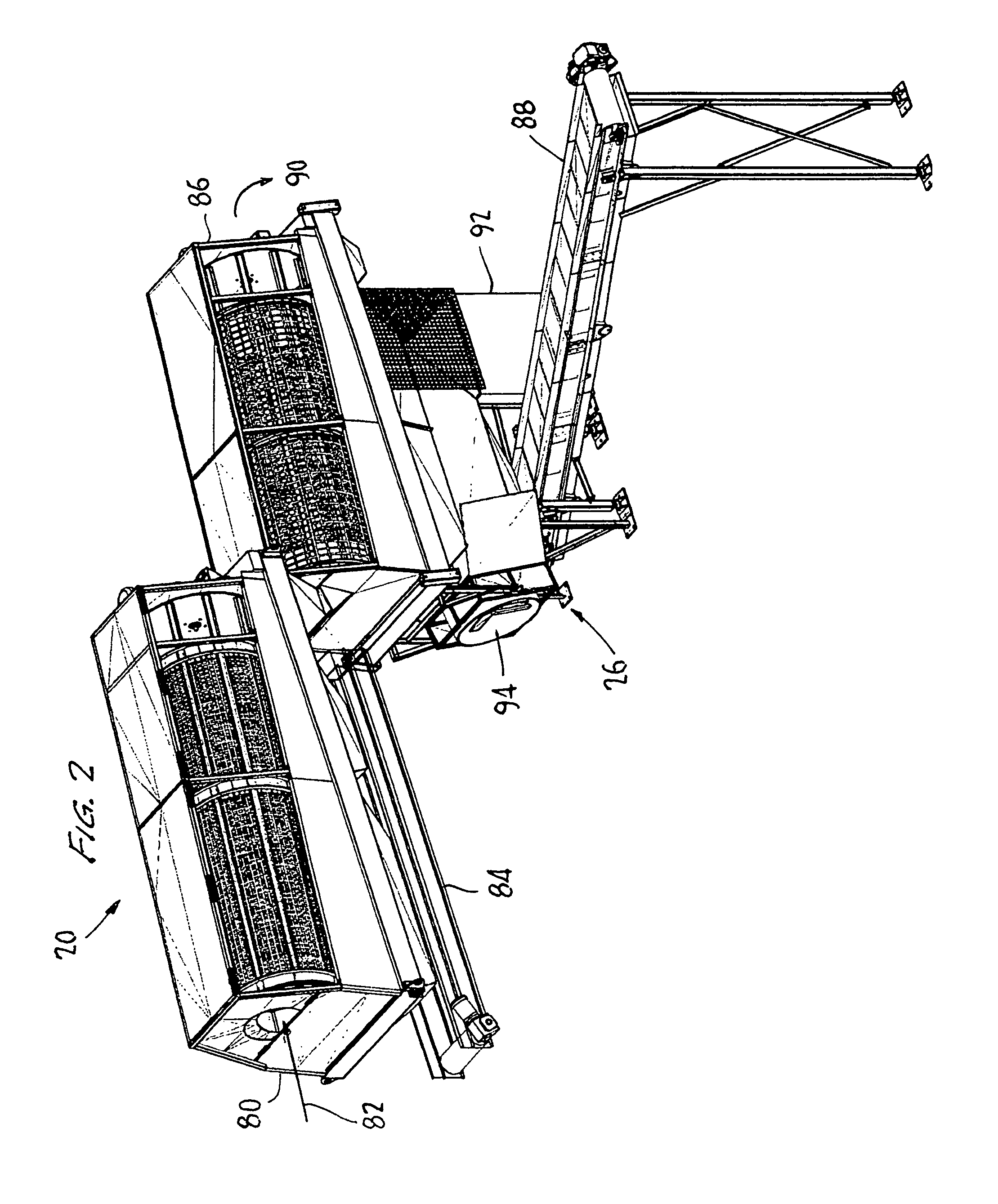

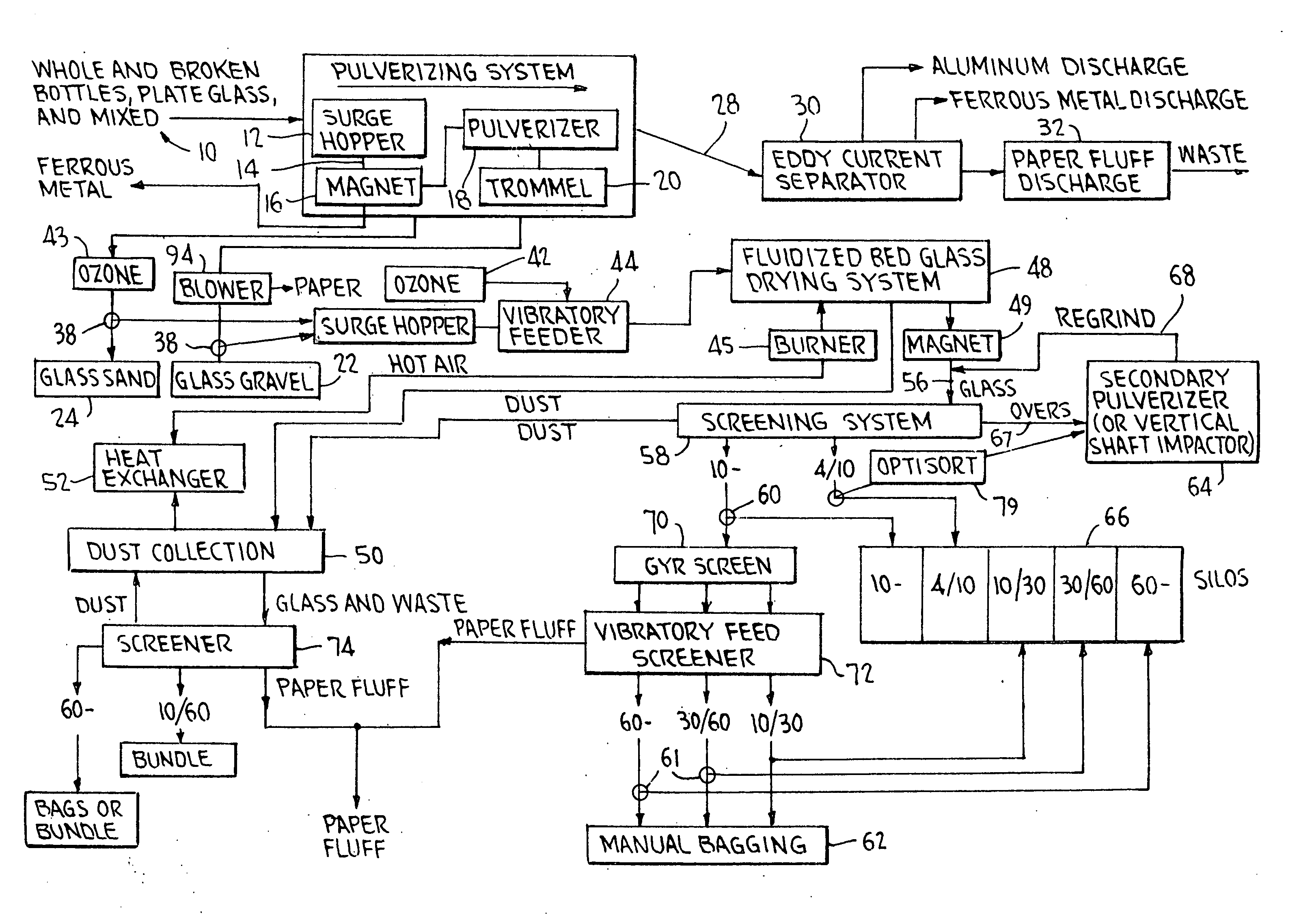

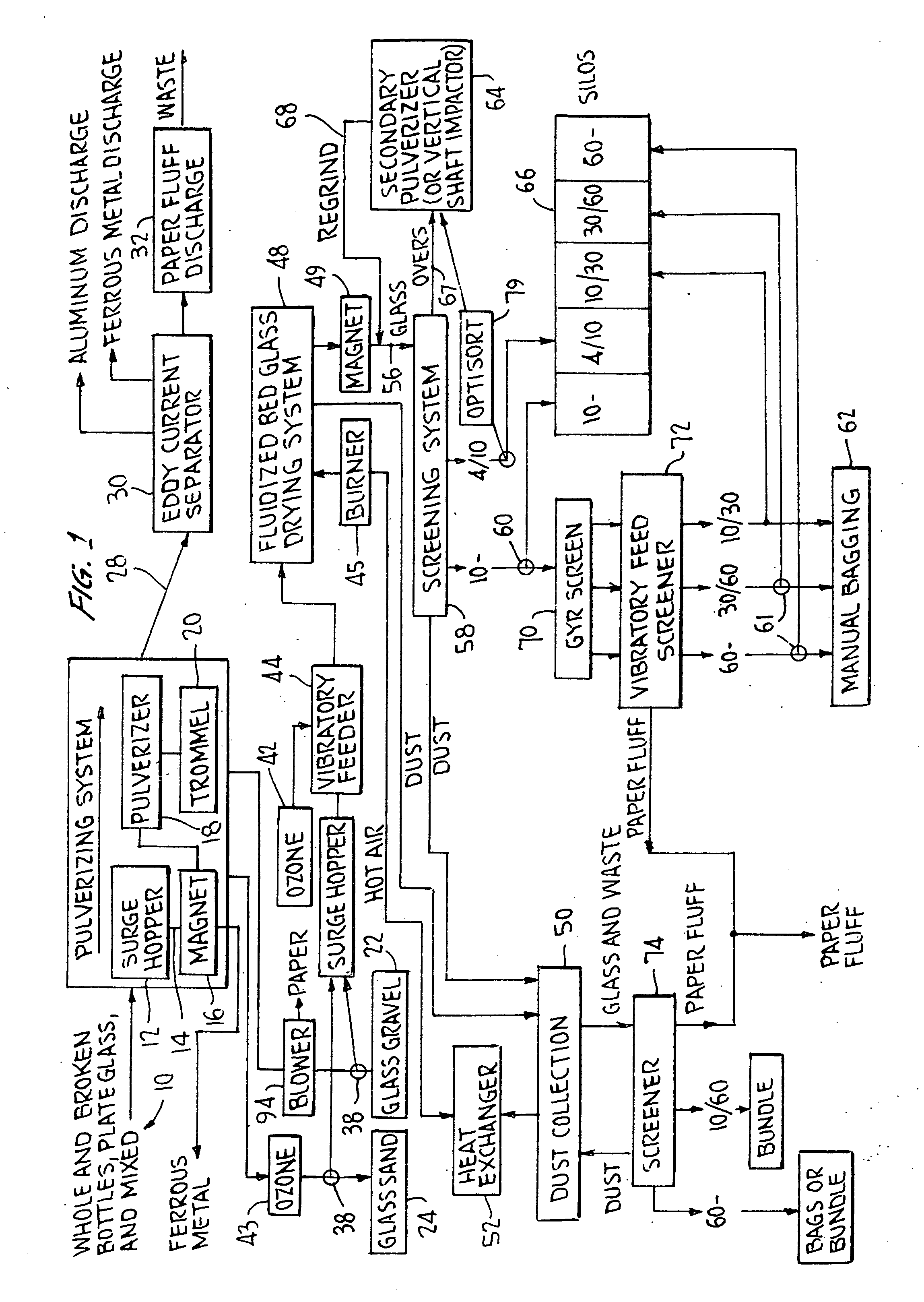

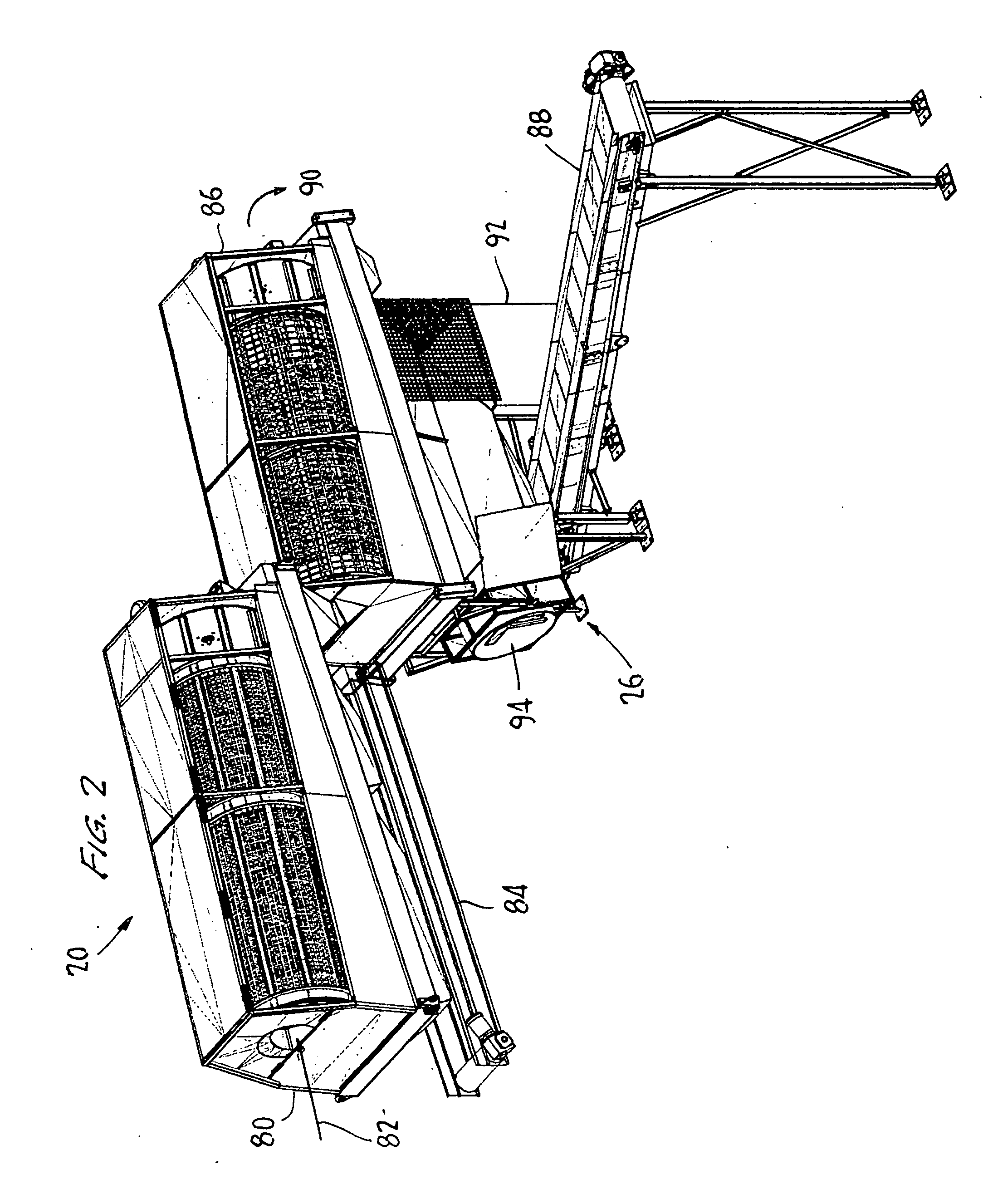

Production of clean glass particles from post-consumer waste

ActiveUS8146841B2Separate cleanInhibit productionMechanical working/deformationGlass recyclingWaste streamPost-consumer waste

Owner:GLASS PROCESSING SOLUTIONS

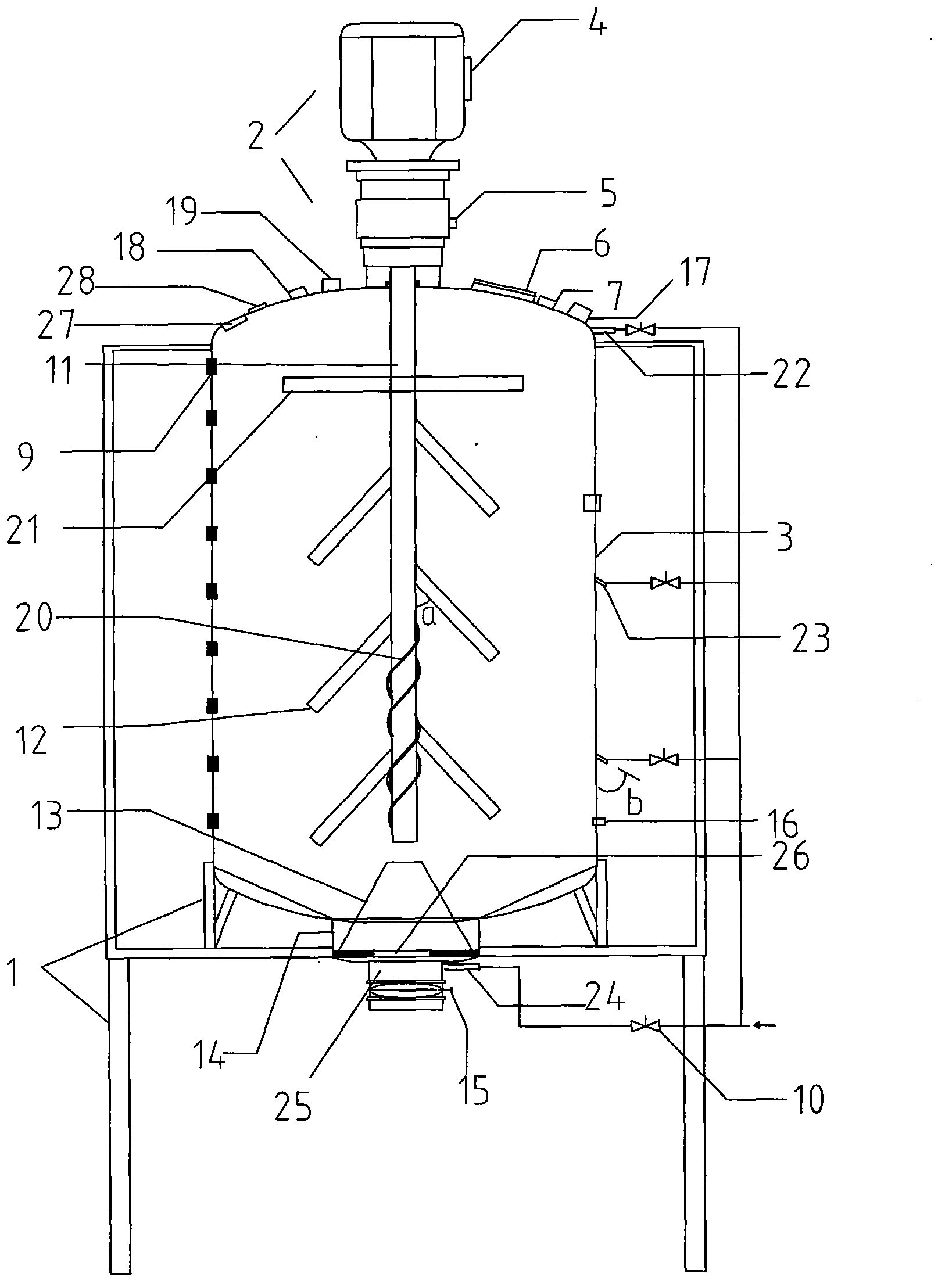

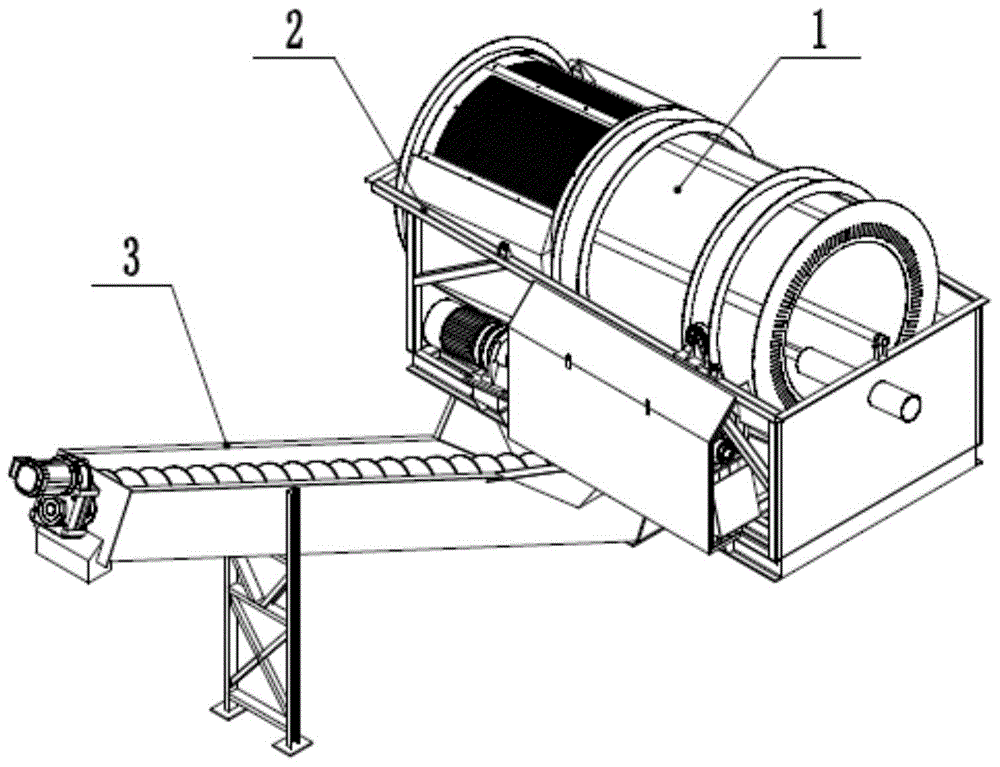

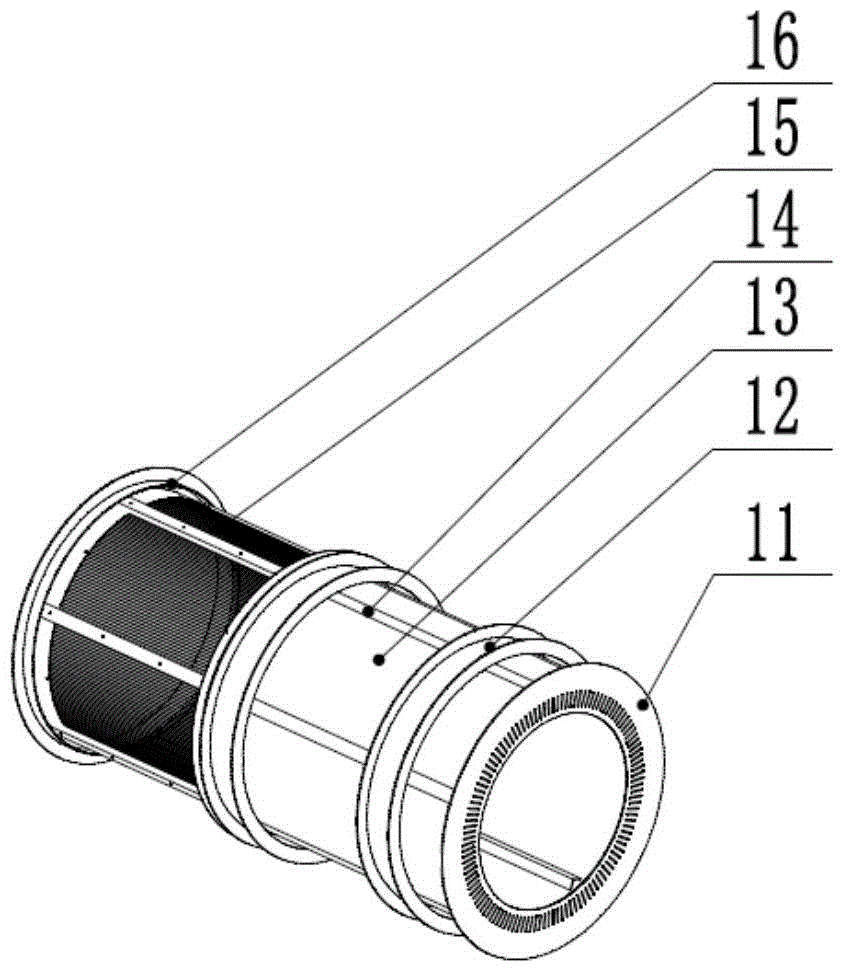

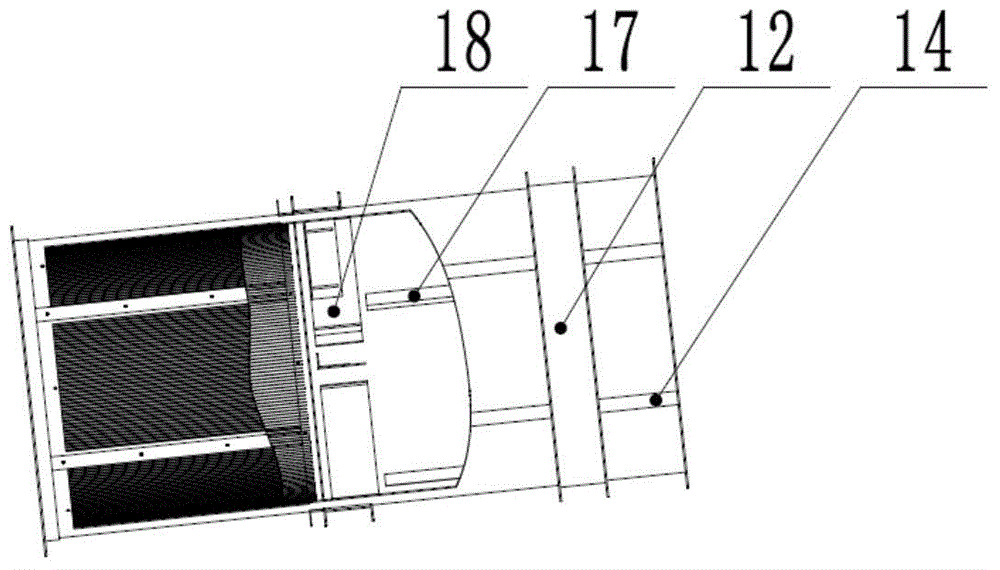

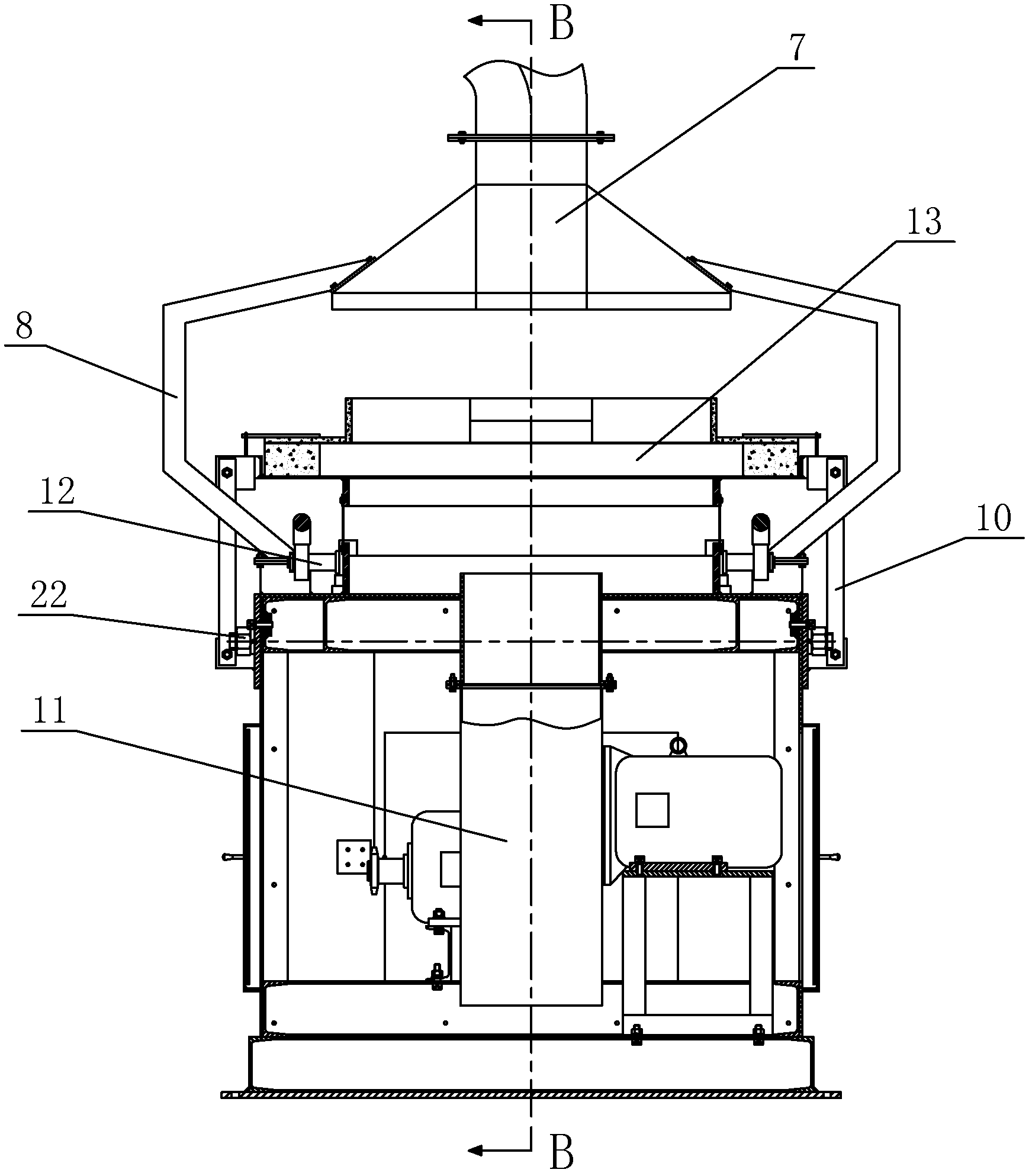

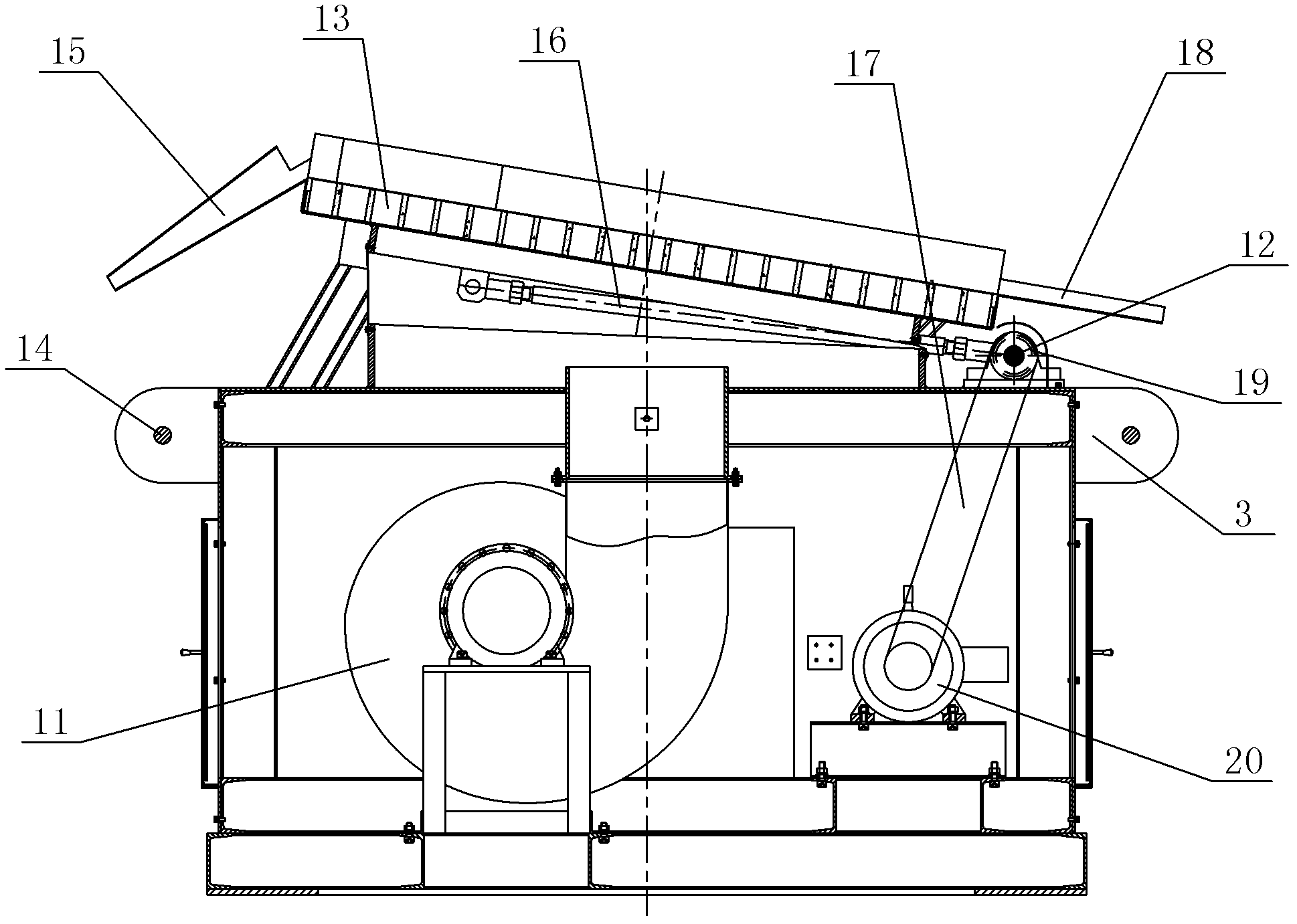

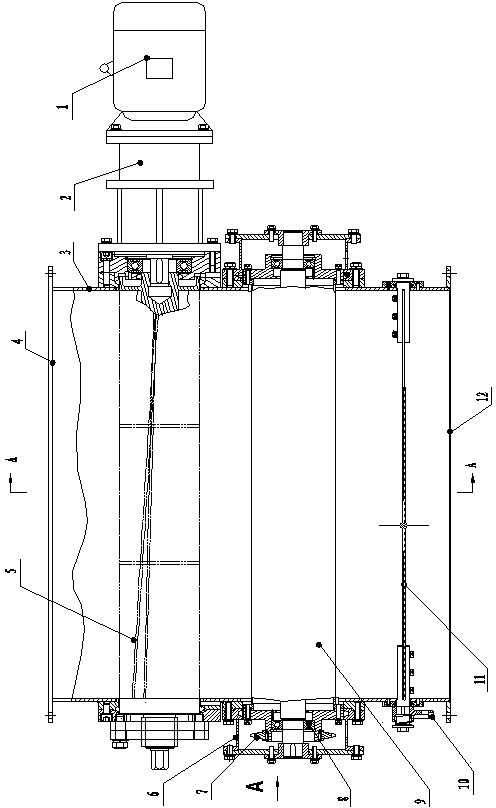

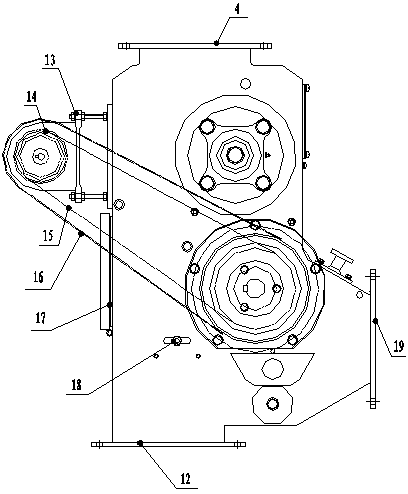

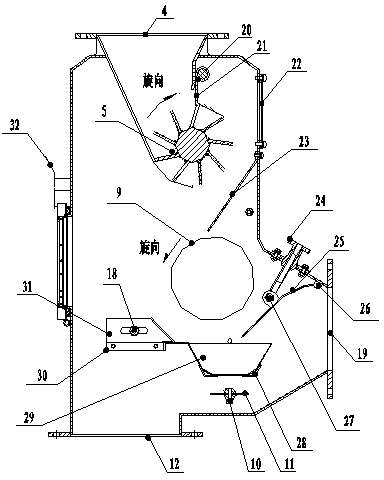

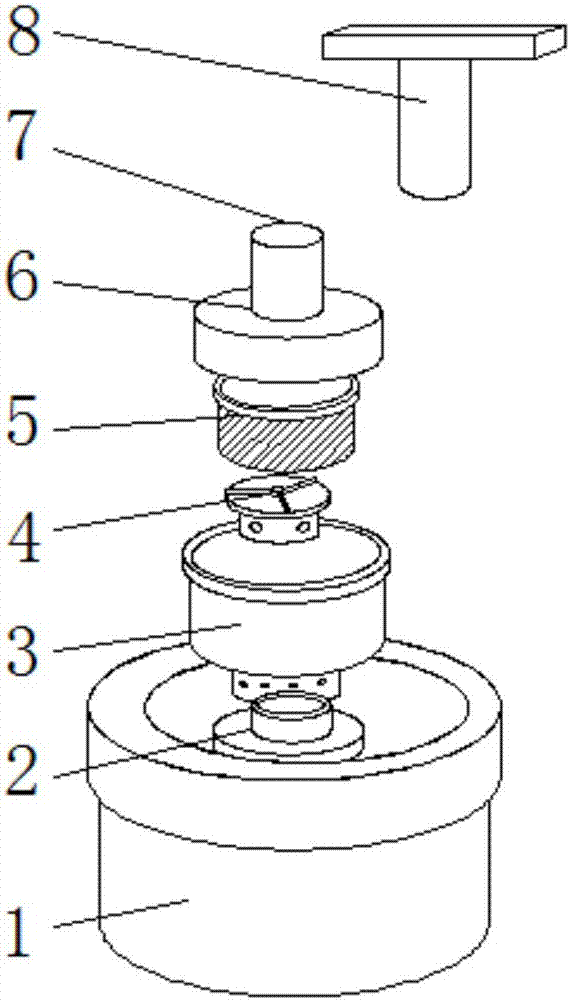

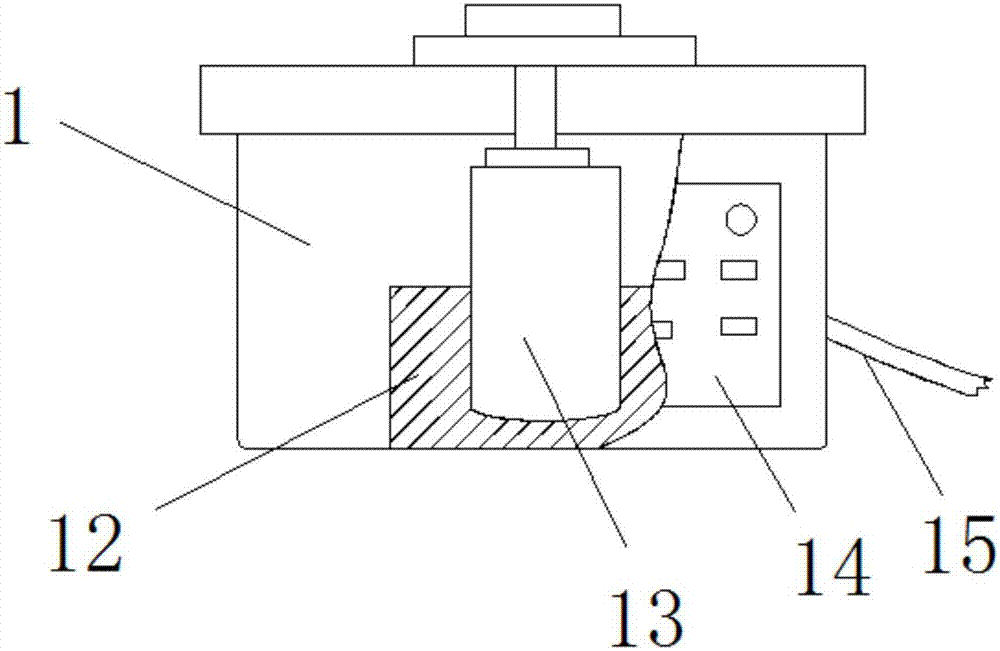

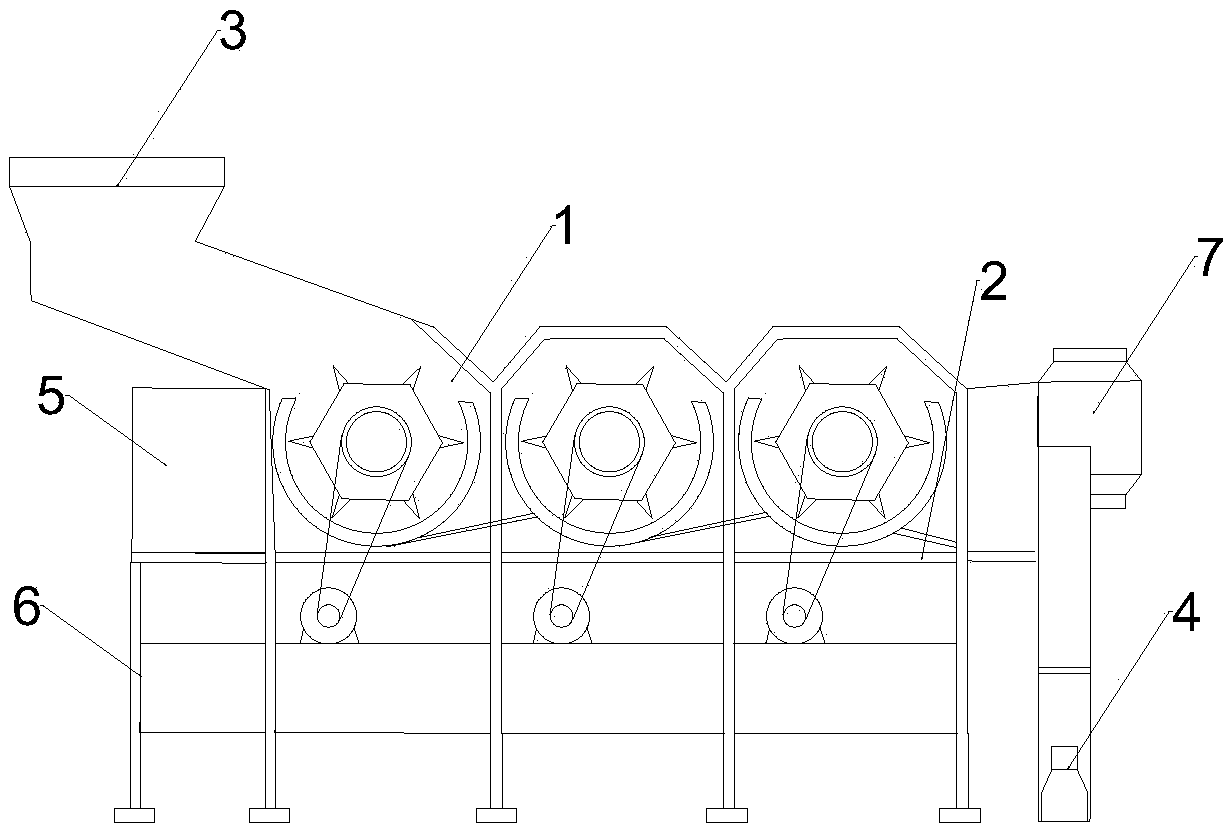

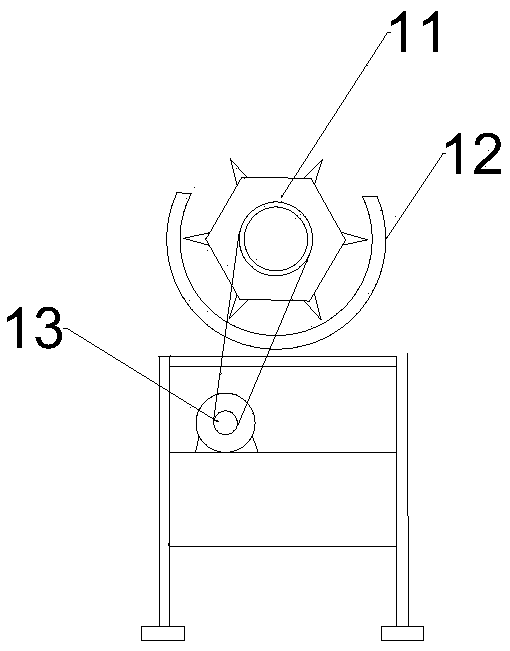

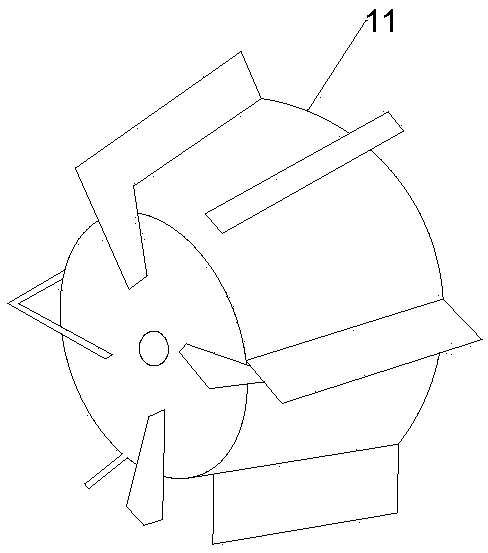

Multiple-magnetron type large-capacity microwave-assisted extraction machine and microwave-assisted extraction method thereof

InactiveCN103505902AHeating evenlyHigh extraction rateEnergy based chemical/physical/physico-chemical processesSolid solvent extractionEngineeringElectromagnetic field

The invention discloses a multiple-magnetron type large-capacity microwave-assisted extraction machine and a microwave-assisted extraction method thereof, belonging to the field of biological raw material extraction equipment and an extraction method. The multiple-magnetron type large-capacity microwave-assisted extraction machine comprises a rack, a transmission device, a microwave tank, a microwave device, an air-entrapping device, a rotor device, a discharging device and a control device, wherein a plurality of magnetron installing holes uniformly and equidistantly distributed are formed in the wall of the microwave tank; the microwave device comprises a plurality of high-frequency magnetrons which are uniformly and equidistantly arranged on the wall of the microwave tank, and the high-frequency magnetrons are connected with an external power source; the air-entrapping device comprises a plurality of compressed air inlets formed in the wall of the microwave tank, a compressed air input pipeline and a plurality of electromagnetic valves; the rotor device comprises a rotating shaft and a plurality of stirring wings which are fixed on the rotating shaft and form certain crossing angles with the rotating shaft. The multiple-magnetron type large-capacity microwave-assisted extraction machine has the advantages that feed liquid in the microwave tank continuously runs and interchanges, an extractive is uniformly subjected to the action of an electromagnetic field to be heated, the extraction rate is increased, and the extraction time is shortened.

Owner:永州中农银杏开发有限责任公司

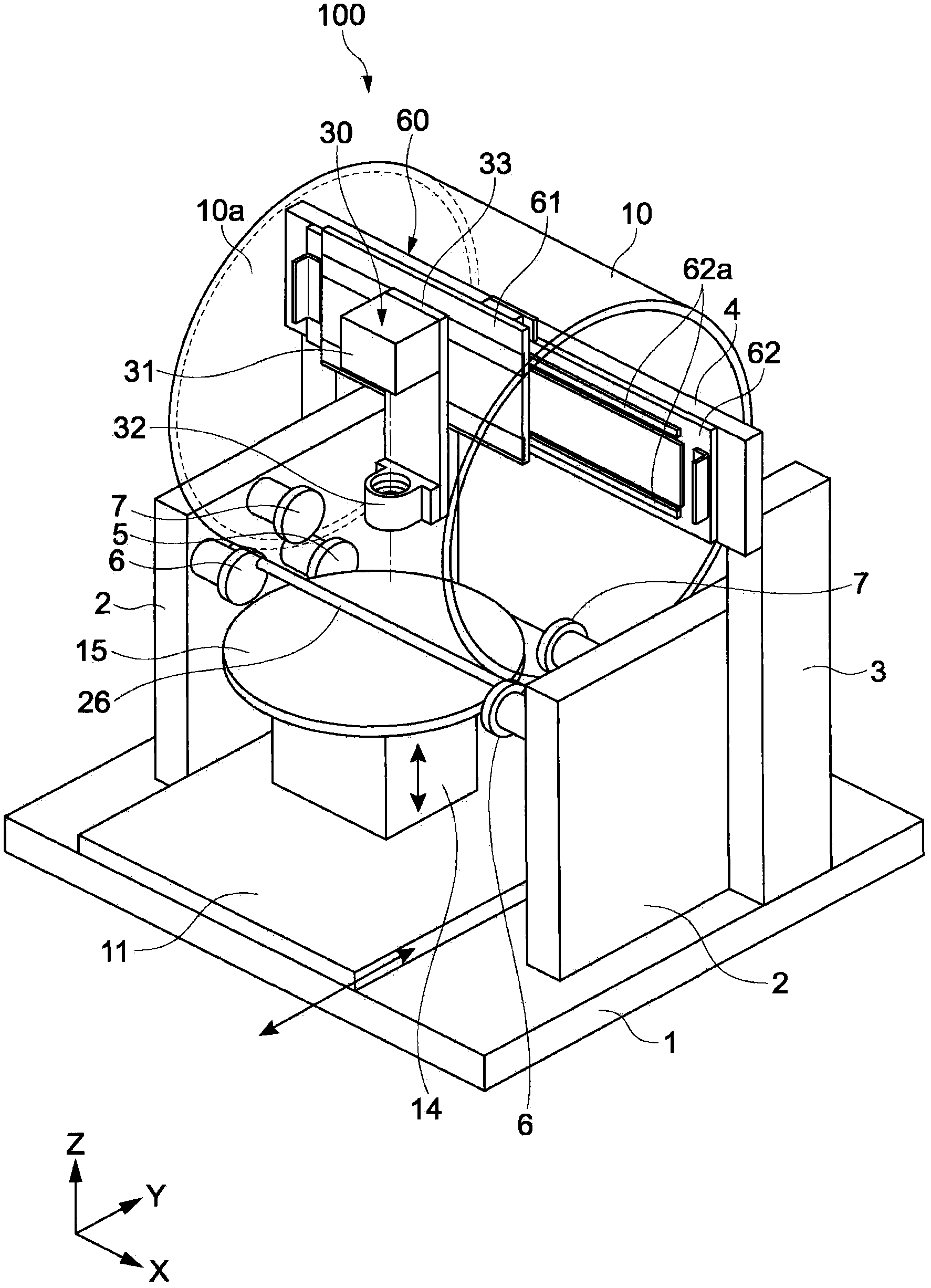

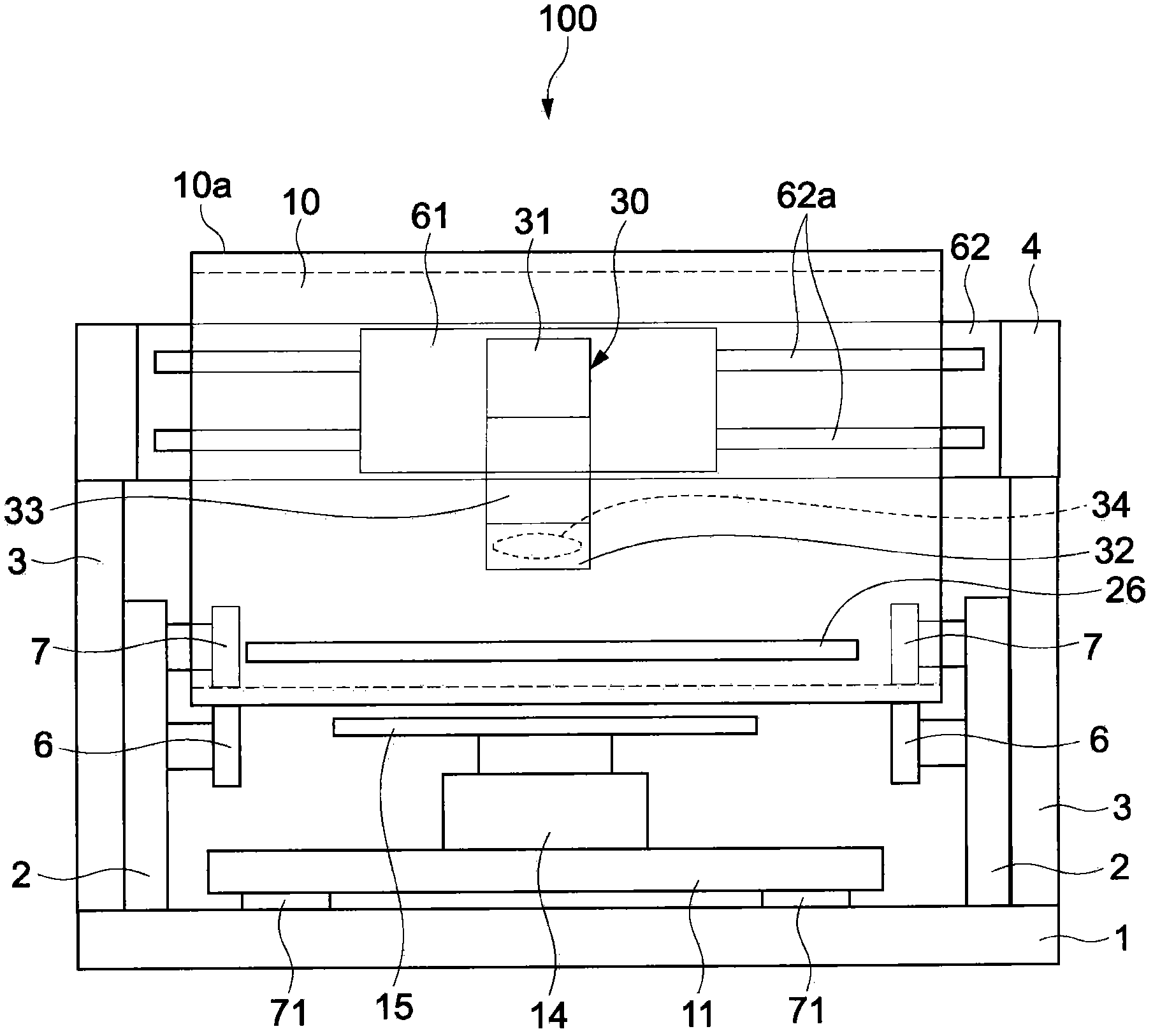

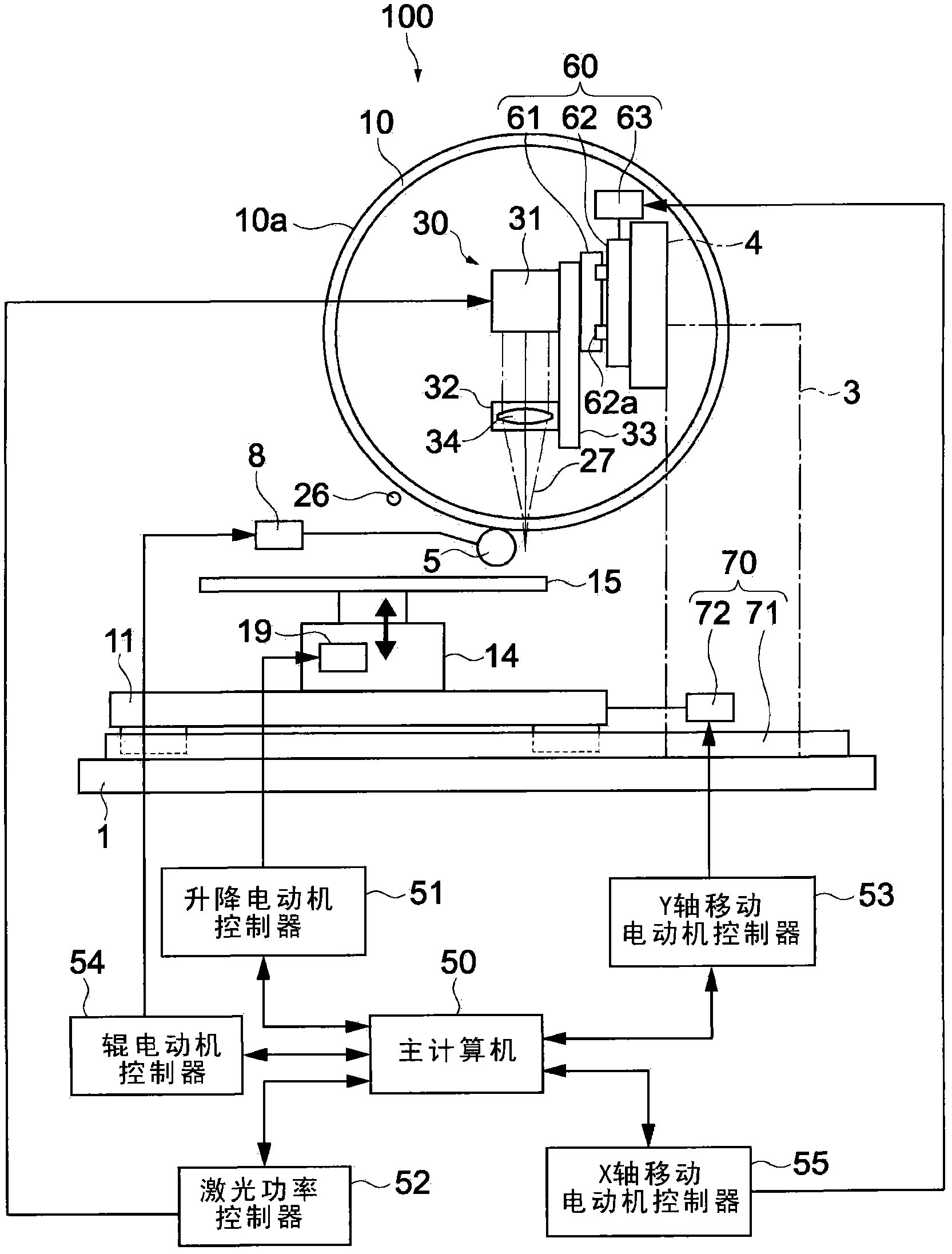

Three-dimensional modeling apparatus, object, and method of manufacturing an object

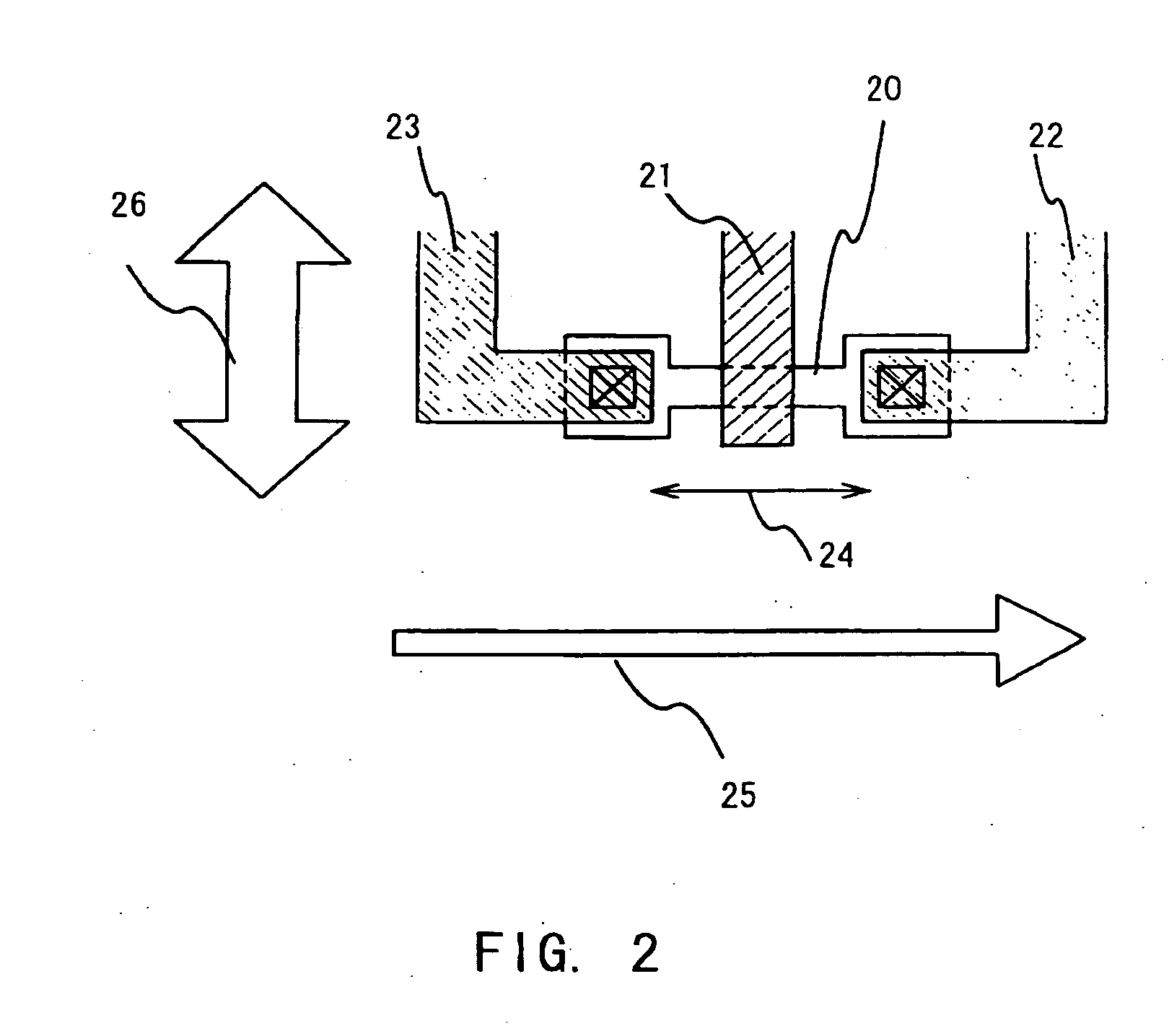

ActiveCN102371680AImprove flatnessSeparate cleanManufacturing driving means3D object support structuresLinear regionMaterial supply

Provided is a three-dimensional modeling apparatus including a stage, a constraining body, a supply nozzle, an irradiation unit, and a movement mechanism. The constraining body includes a surface including a linear region along a first direction, and is opposed to the stage so that the linear region is the closest to the stage. The supply nozzle supplies a material curable by energy of an energy ray into a slit region between the stage and the linear region. The irradiation unit irradiates the supplied material with the energy ray through the constraining body. The movement mechanism moves the stage relative to the constraining body along a second direction for forming a cured layer of the material for one layer, and moves the constraining body and the stage relative to each other along a stacking direction for stacking the cured layers.

Owner:SONY CORP

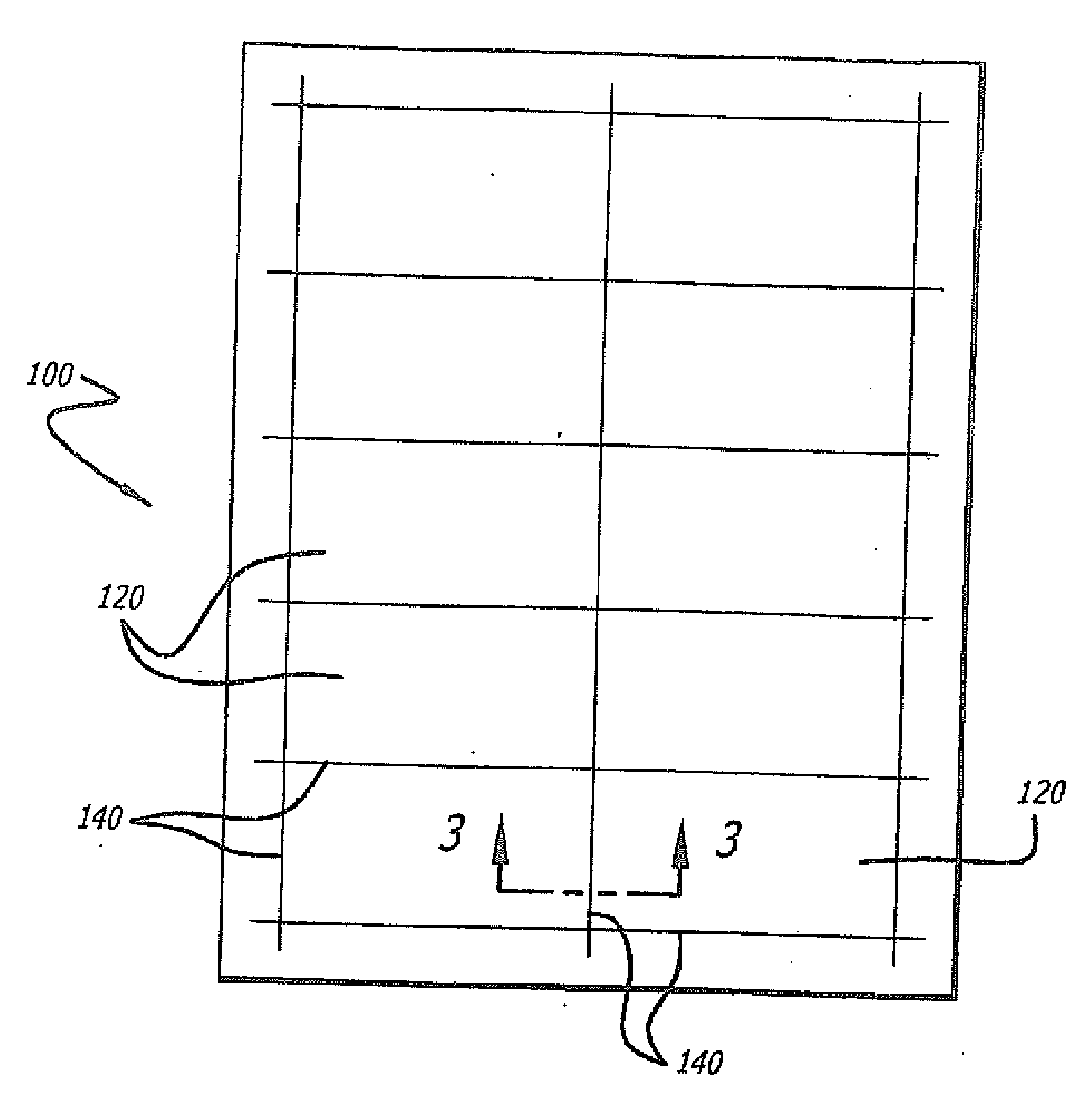

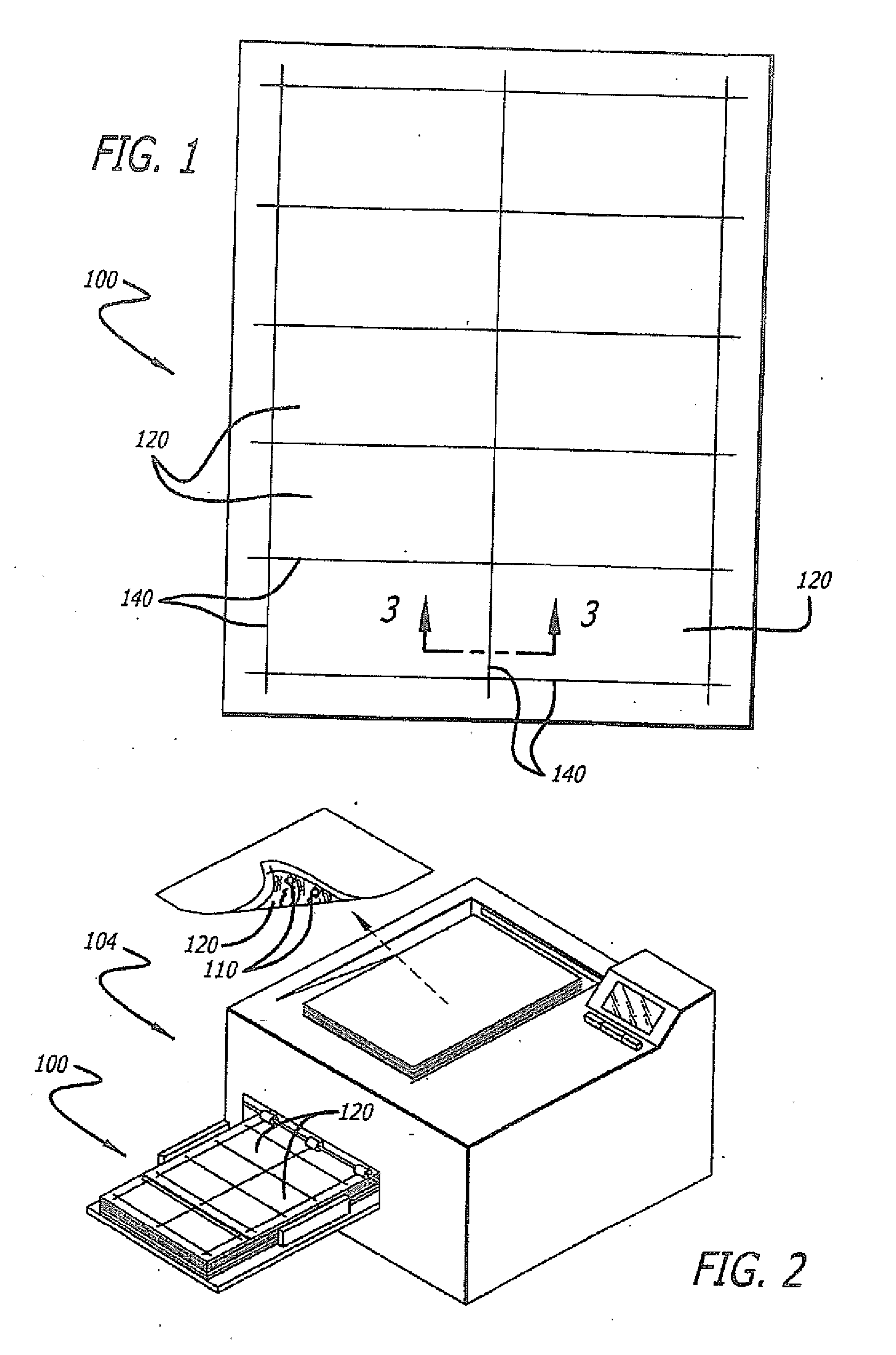

Clean edged cards on plastic carrier

A card sheet includes a top material having weakened separation lines and a carrier material of at least one layer of polymer. The weakened separation lines define the borders of cards. The carrier material is directly applied on an inner surface of the top material. The top material has an outer printable surface. The card sheet is constructed so as to allow the cards to be separated from the carrier material at an interface between the top material and the carrier material to form separate or separable cards after a printing operation on the printable surface.

Owner:CCL LABEL INC

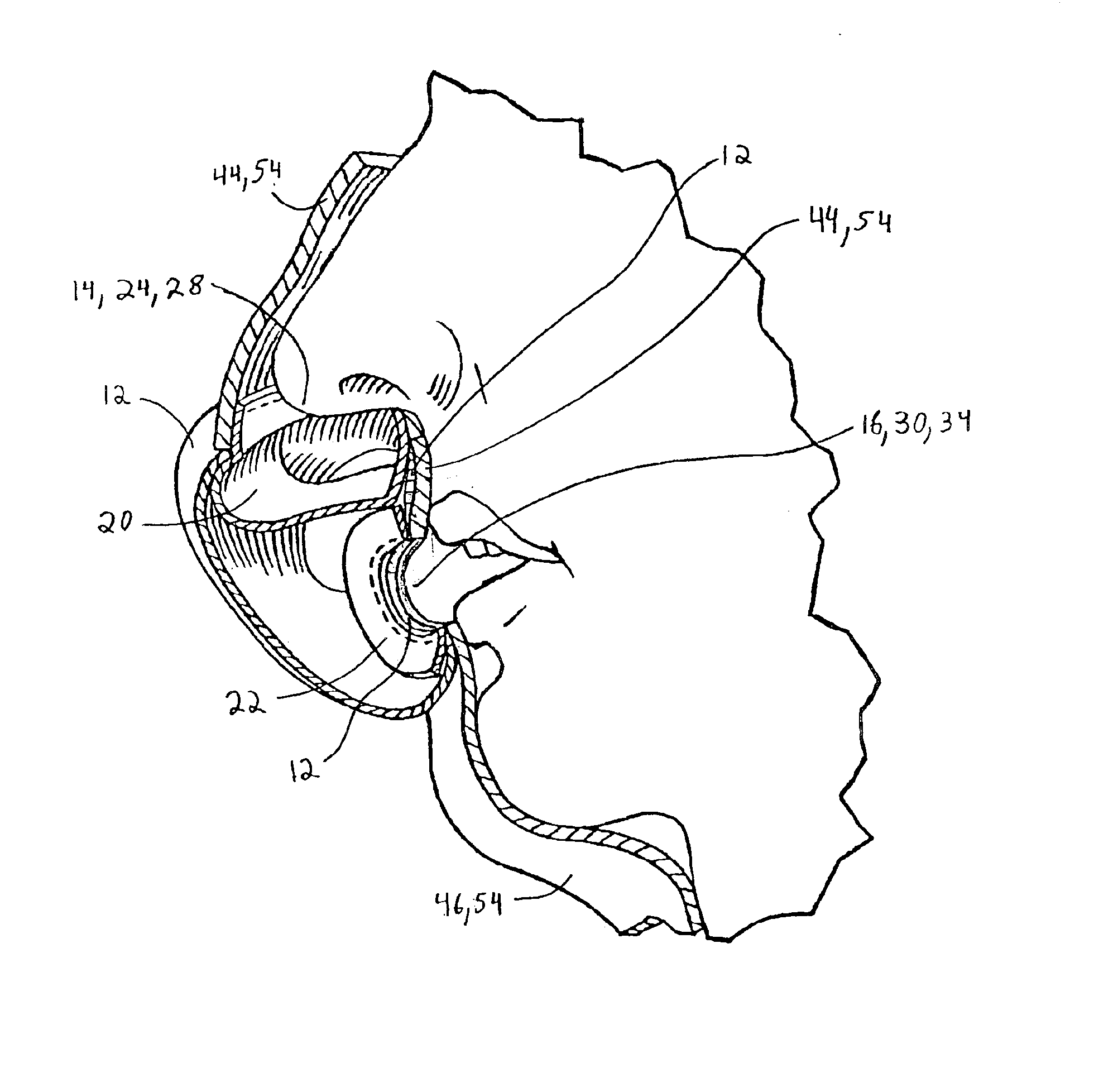

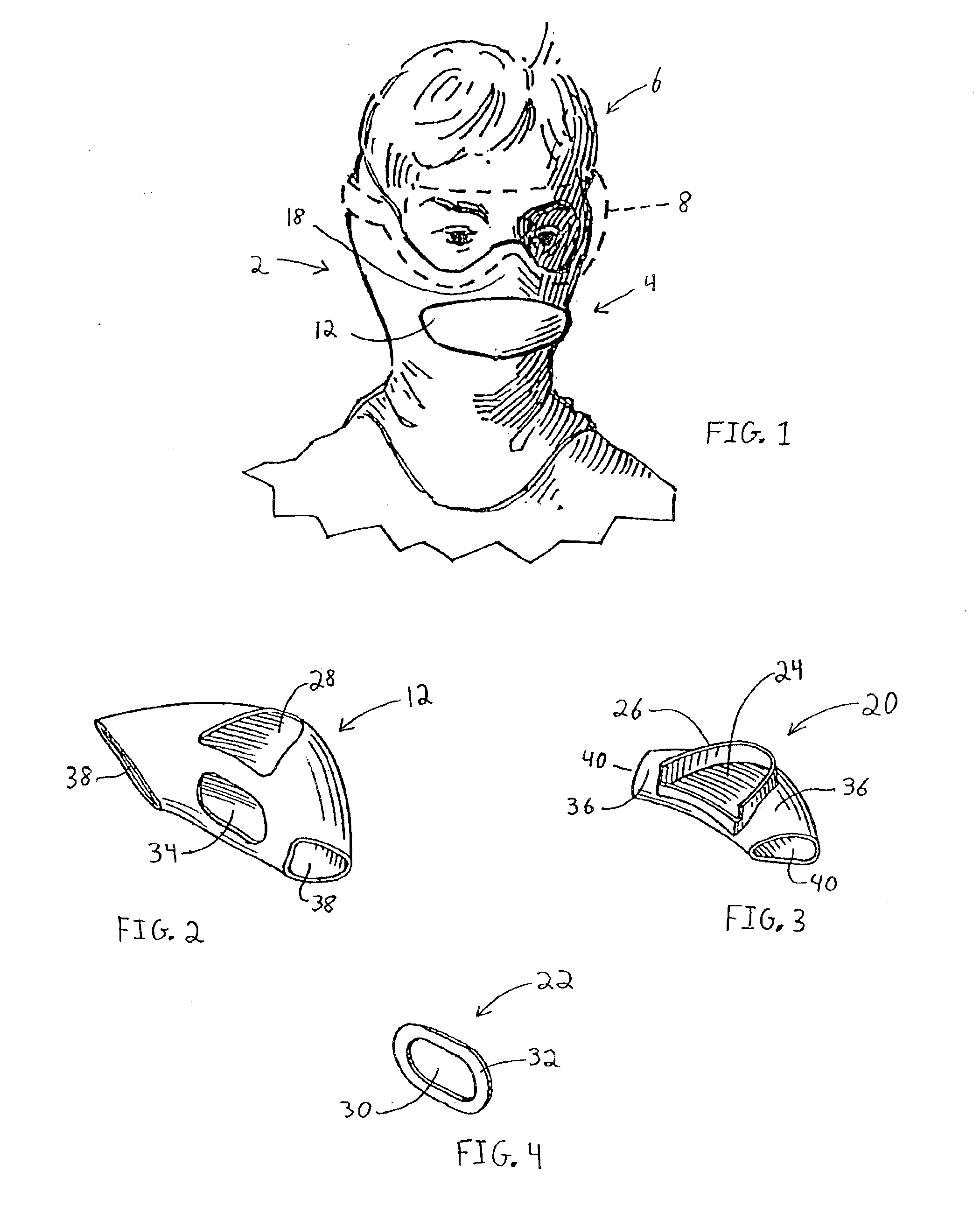

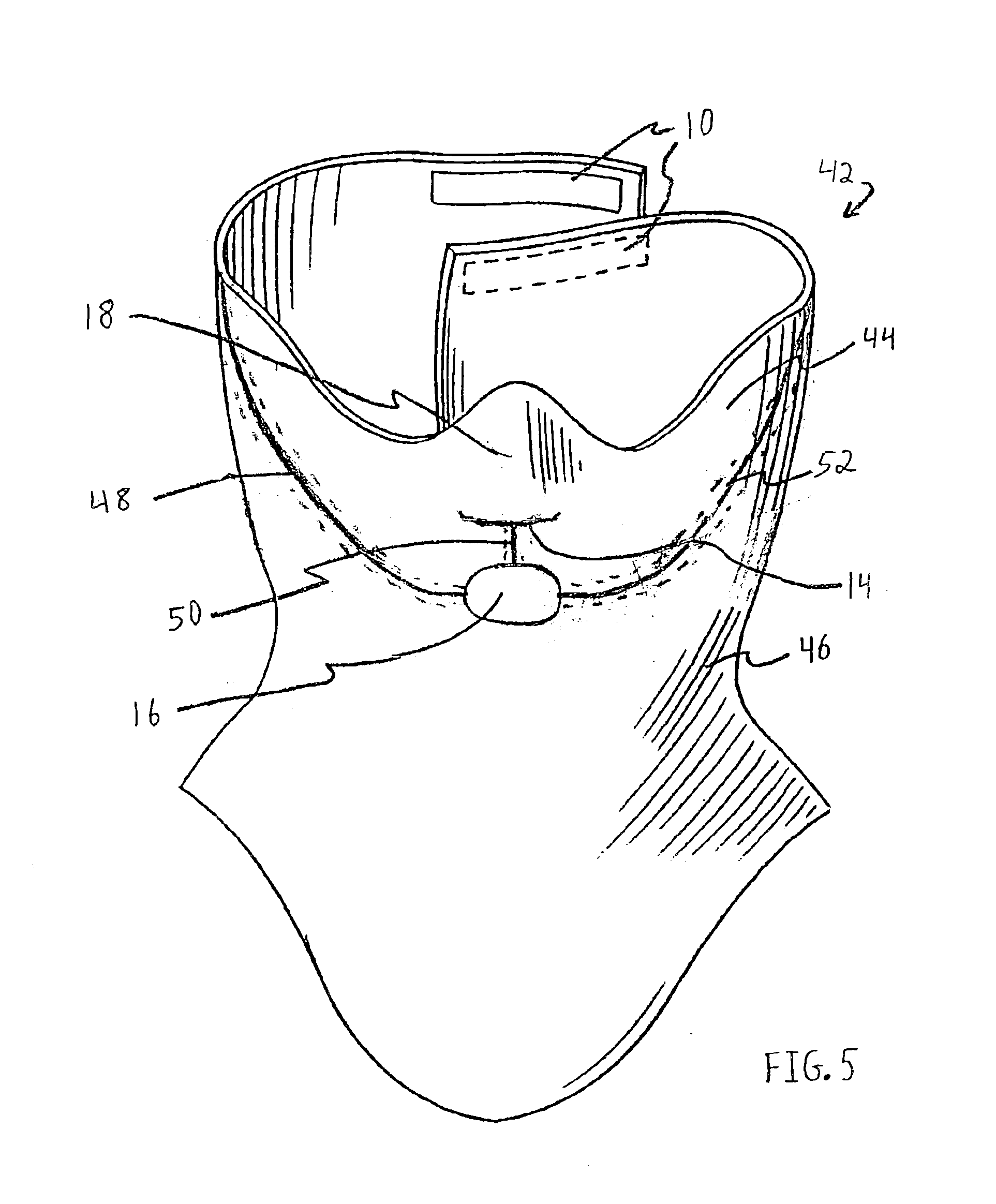

Cold weather breathing apparatus

InactiveUS6868852B2Easy accessPrevents a user's goggles from foggingChemical protectionHeat protectionNostrilCold weather

A cold weather breathing device that protects the face including the mouth and nostril area from direct exposure to the external environment, prevents a user's goggles from fogging in cold environments, and keeps moist exhaled breath away from the user's face. In a preferred embodiment, the device is configured to provide separate breathing channels for exhaled air from the mouth and nose. To promote ease of cleaning, the breathing device can be attached to a head garment with a simple interlocking design that allows its removal and separate cleaning. The breathing device provides a nose-channel-forming member and mouth disc that are mounted on the head garment and inset into a mouth-channel-forming member which is thus attached to the head garment.

Owner:GASCHKE PAUL

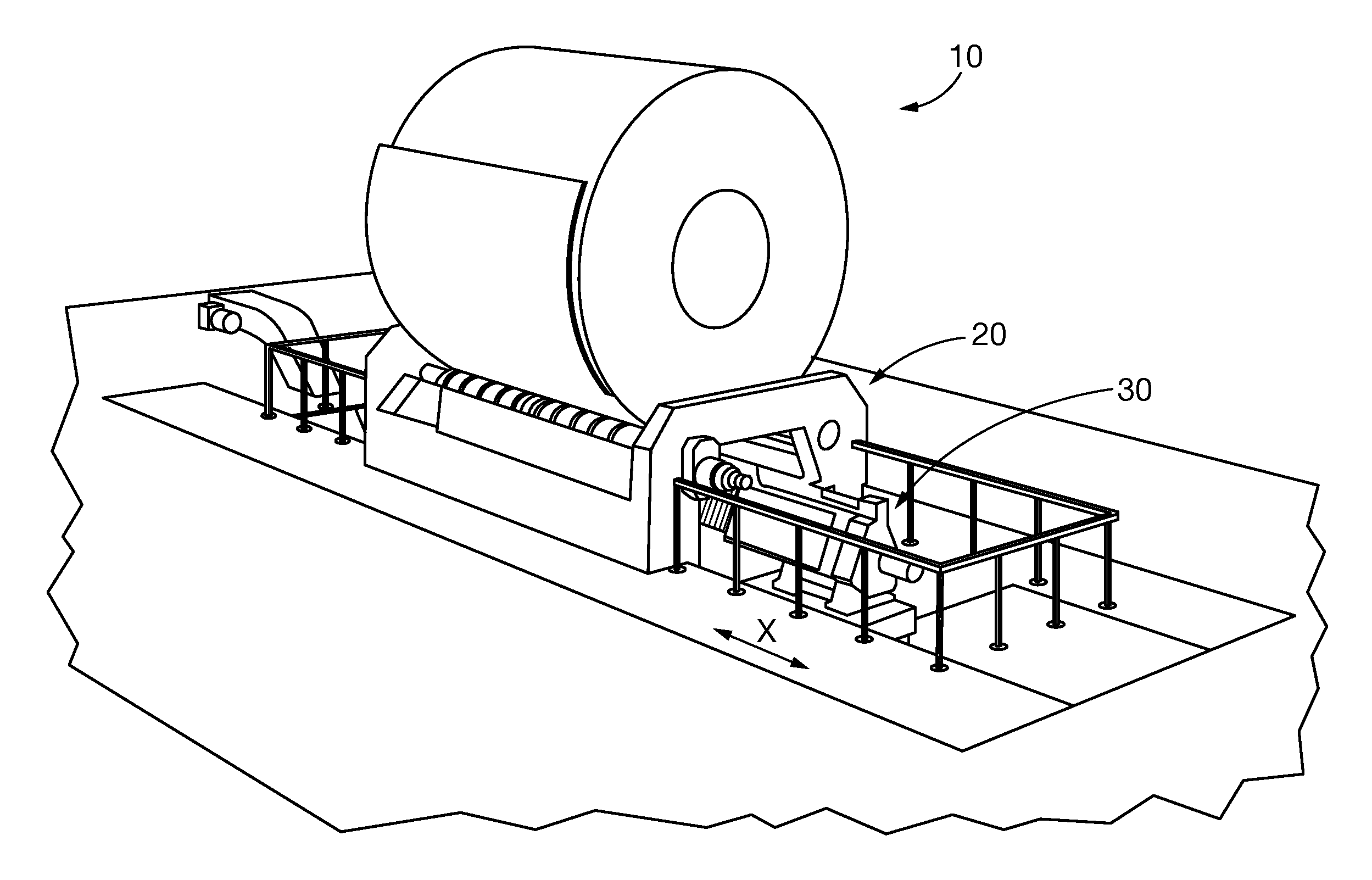

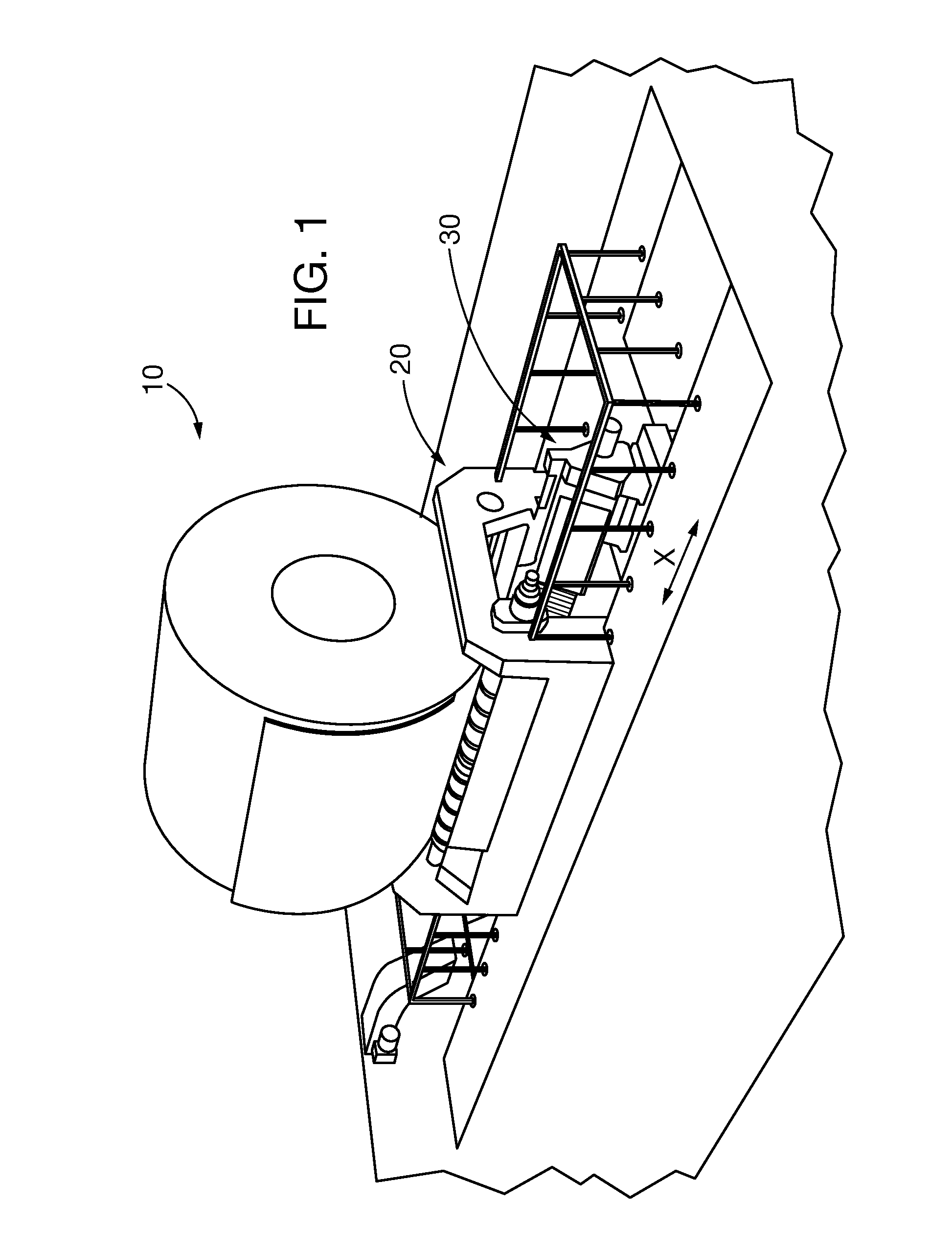

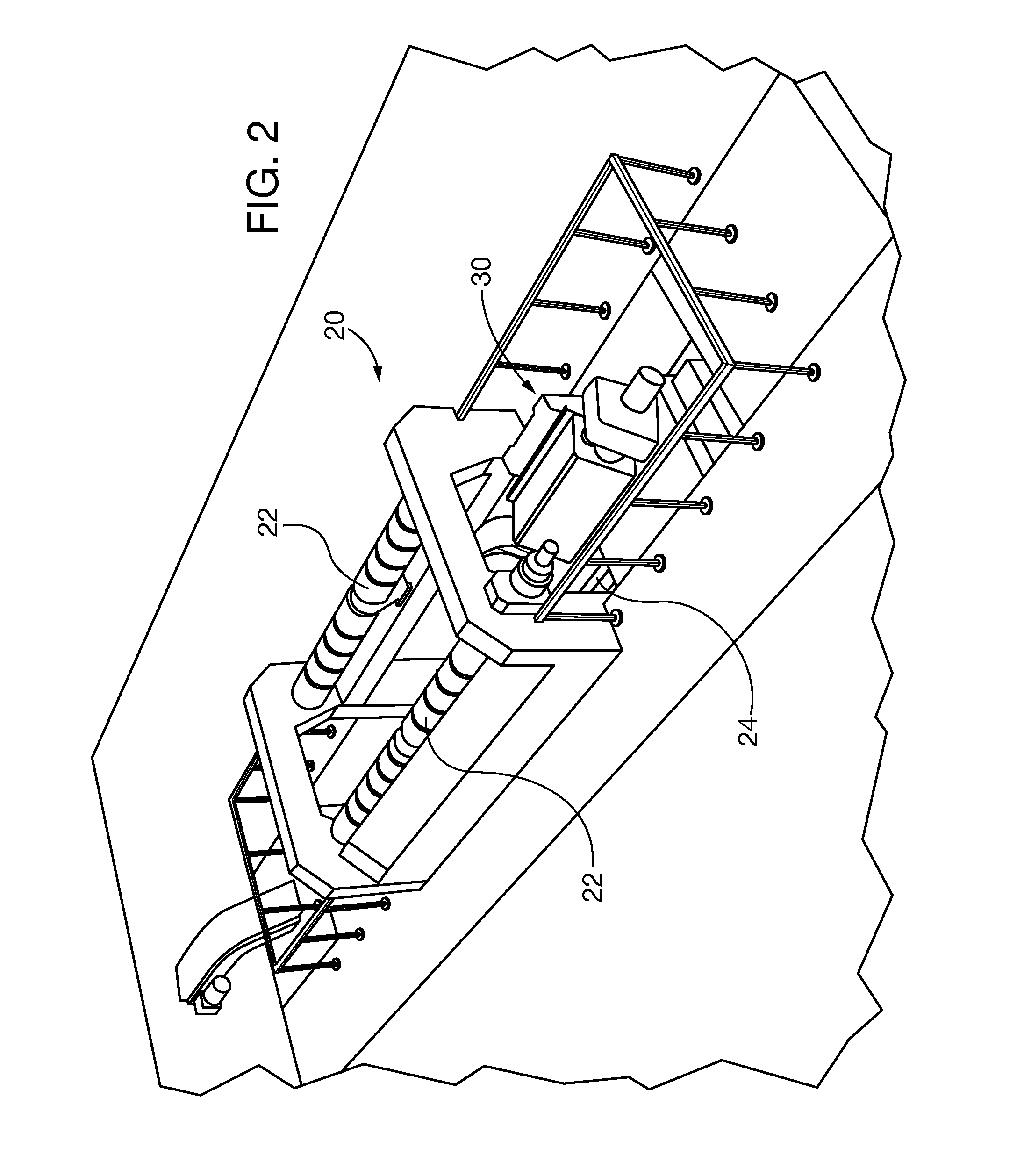

Method and apparatus for trimming a sample from a coiled metal web

ActiveUS20120187091A1Facilitates rebandingPrevent materialWithdrawing sample devicesArc welding apparatusMechanical engineeringMetal

Sample extraction or trimming from an end strip of an elongated formed metal that is coiled in layers within a tensioned metal coil resting on driven rollers. A cut channel is formed across the material width. In some embodiments the cut channel is formed between the rollers and by cutting at an angle relative to the coil outer surface. Coil weight and / or a coil tensioner mechanism inhibits coil relaxation along the cut channel by maintaining tension on wrapped layers against each other when the coil is unbanded for sample extraction. The coil is rotated so that the cut channel clears the rollers laterally. Material downstream the cut is then separated from the coil. After trimming and / or sample extraction the coil maintains rolled tautness for ease of rebanding.

Owner:PRIMETALS TECH USA

Production of clean glass particles from post-consumer waste

ActiveUS20120018548A1Separate cleanInhibit productionGlass recyclingGrain treatmentsWaste streamPost-consumer waste

Owner:GLASS PROCESSING SOLUTIONS

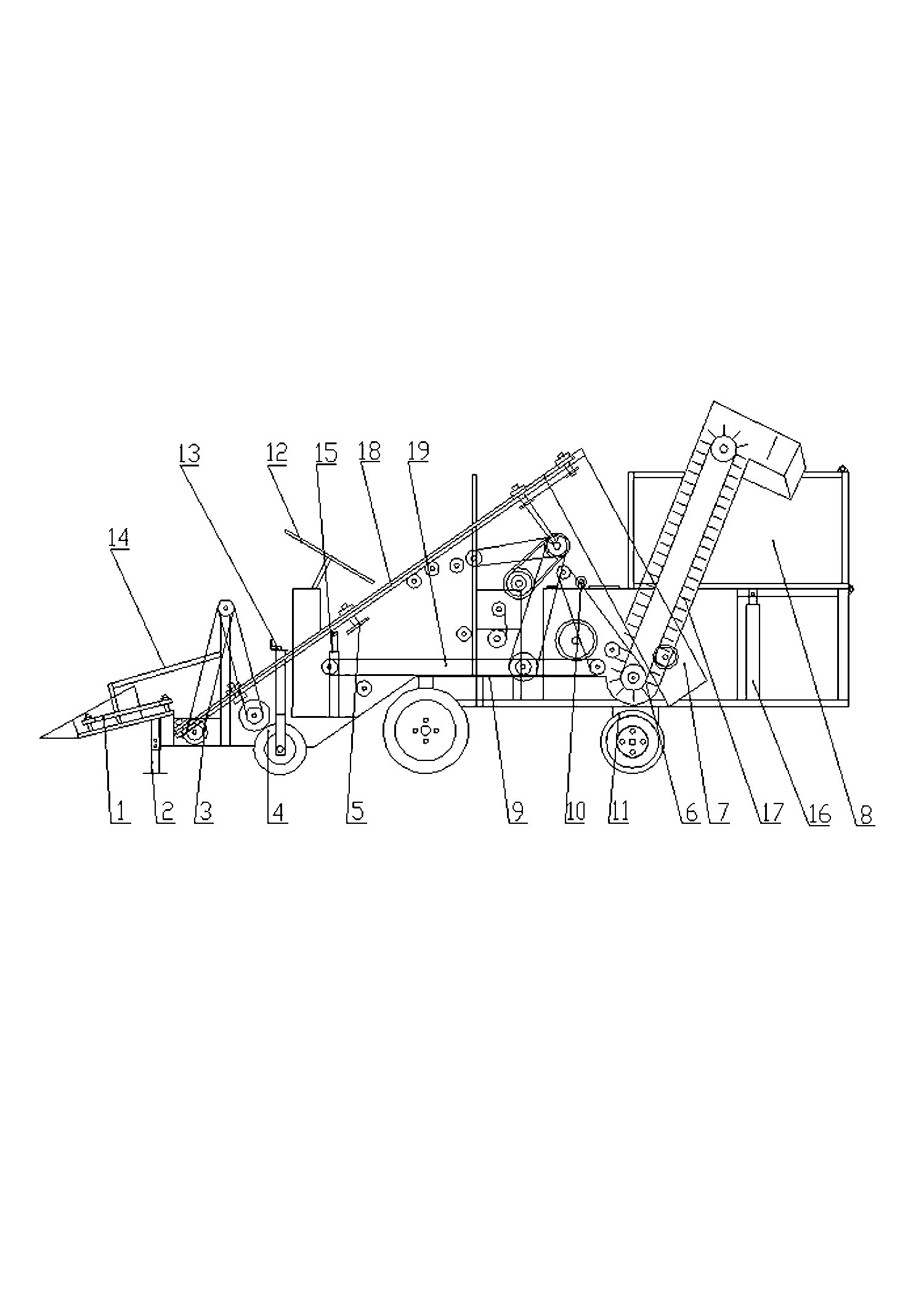

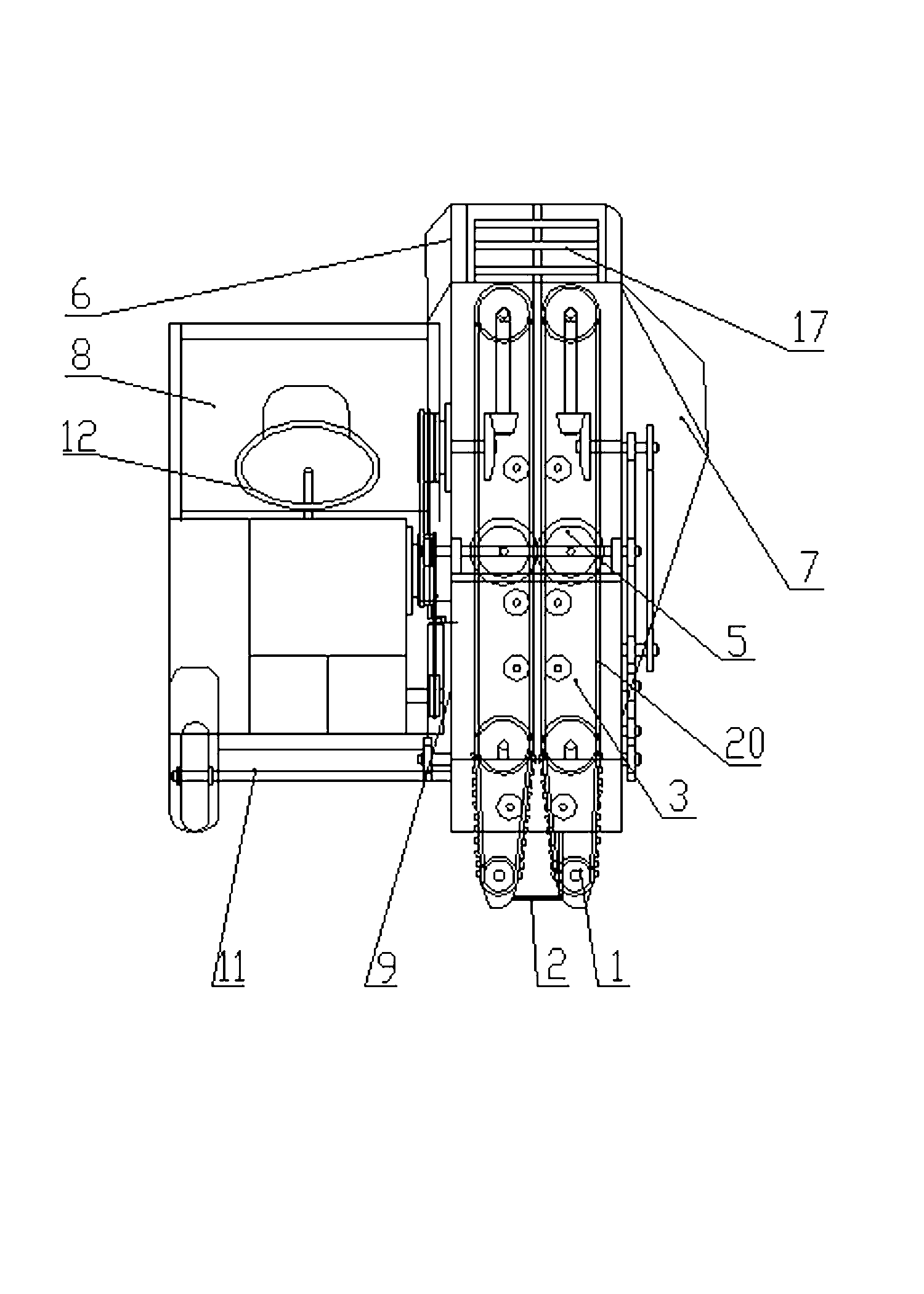

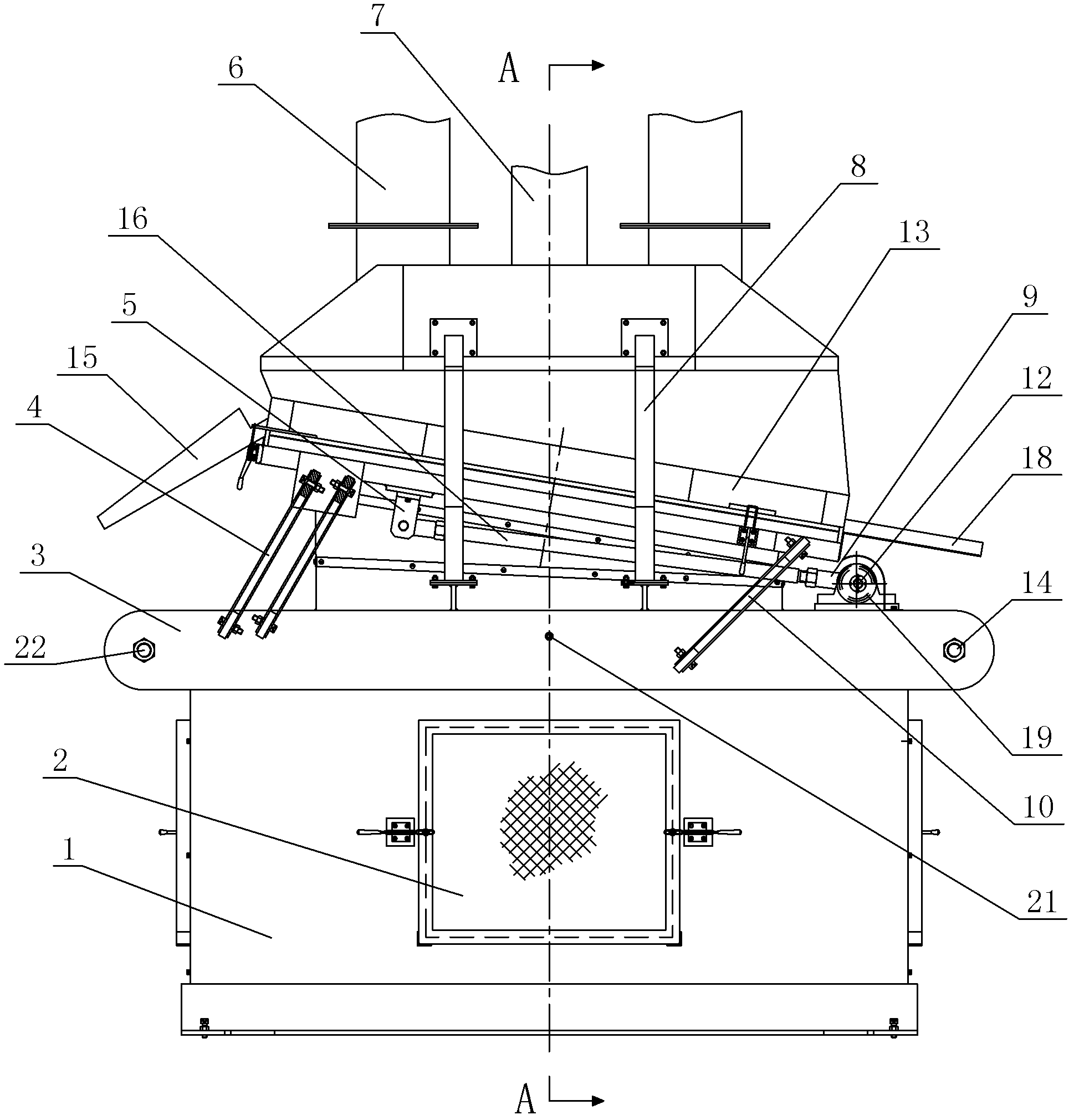

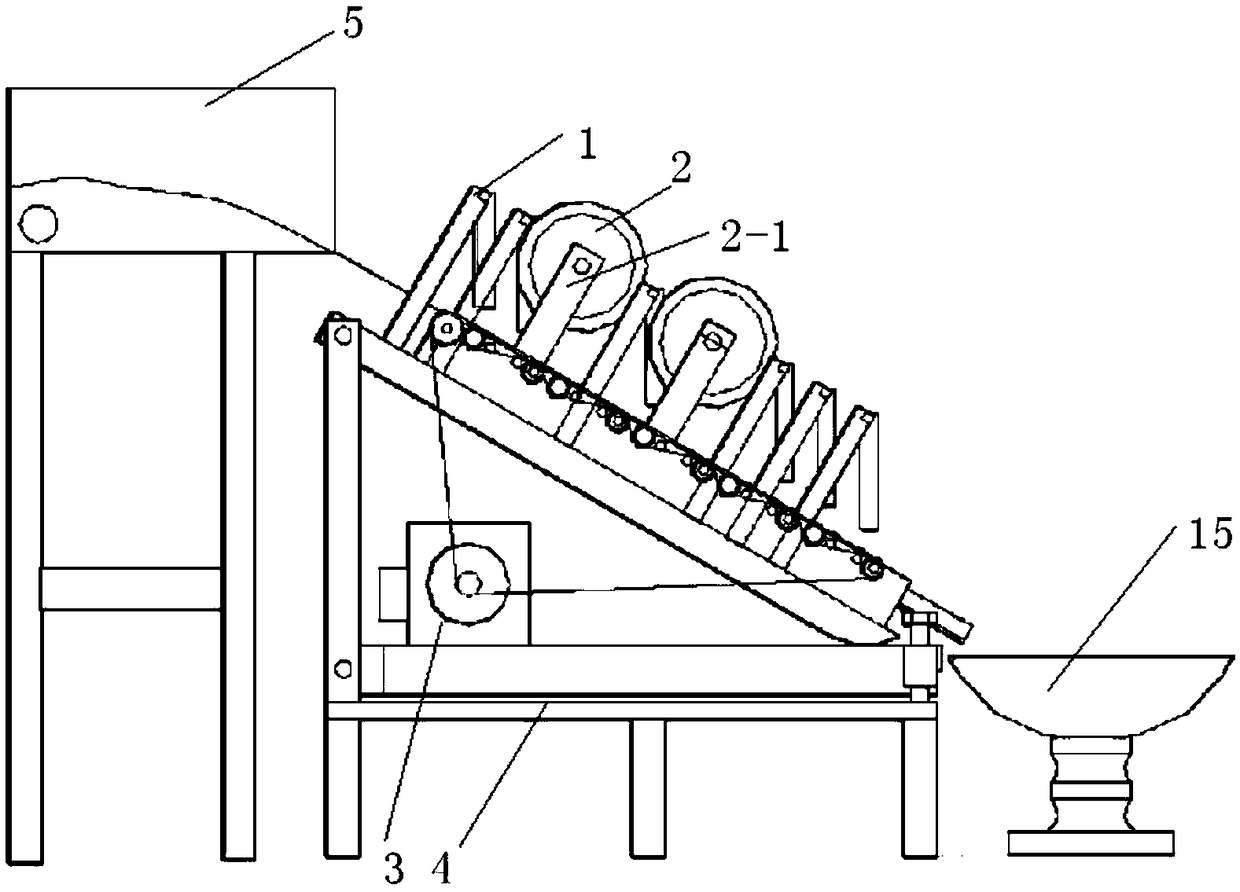

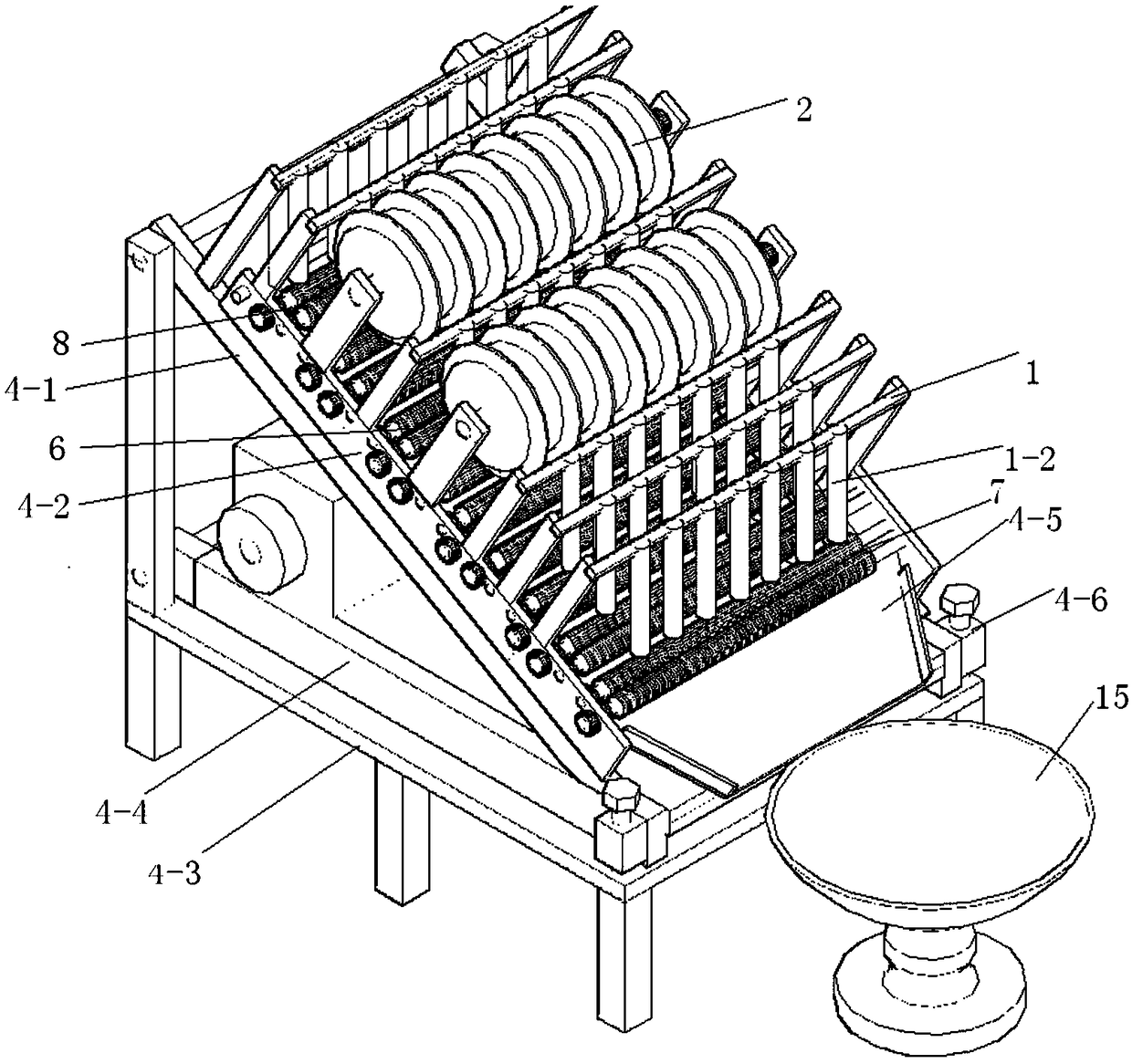

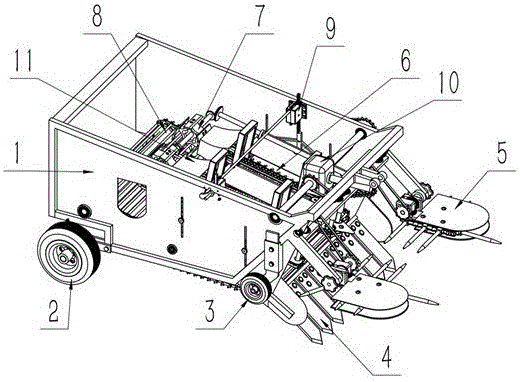

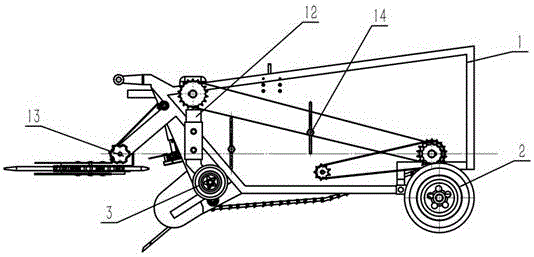

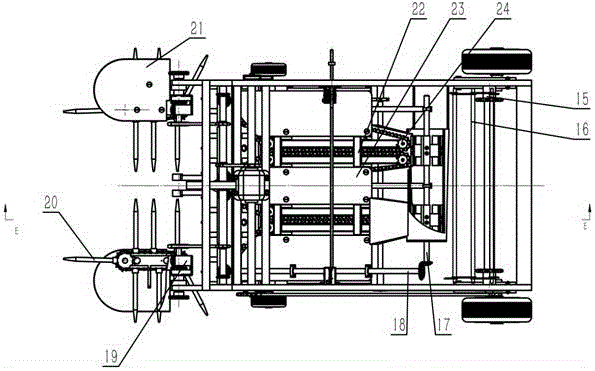

Combine-harvester for garlic and carrot

InactiveCN103222368ACompact structureReduce volumeLiftersTopping machinesControl systemProcess engineering

The invention relates to a combine-harvester for garlic and carrot. The combine-harvester for garlic and carrot comprises a working part, a walking part, a driving part and a control system, wherein the working part adopts a machine frame as a mounting supporter; a clamping device, a digging shovel, and an adjusting and limiting wheel are arranged at the front end of the machine frame; a vibration mud cleaning, conveying and cutting device is arranged in the middle of the machine frame; and a lifting mechanism, an output device and a container are arranged at the rear end of the machine frame. The combine-harvester for the garlic and the carrot combines the functions such as digging, harvesting, cutting and containing into a single machine, has the advantages of simple and compact structure, small size, light weight, strong adaptation, high operating efficiency, convenience in use, assembly and disassembly, easiness in maintenance, low power consumption, cleanliness in separation, less impurity, wide application range and remarkable benefits, and can meet various field operation requirements.

Owner:GUANGDONG DANXIA AGRI MACHINERY

Semiconductor device and manufacturing method thereof

InactiveUS20070085138A1Minimize impactSeparate cleanTransistorSolid-state devicesDriver circuitDevice material

The invention relates to a semiconductor device including a plurality of thin film transistors provided on a base member having a curved surface. The surface may be bent in either a convex shape or a concave shape. All channel length directions of the plurality of thin film transistors may also be aligned in the same direction. Further, the channel length direction may be different from the direction in which the base member is bent. A pixel portion and a driver circuit portion may also be provided on the base member. The invention also includes a method of manufacturing a semiconductor device including forming a layer to be peeled including an element of a substrate, bonding a support member to the layer to be peeled, and bonding a transfer body to the layer to be peeled.

Owner:SEMICON ENERGY LAB CO LTD

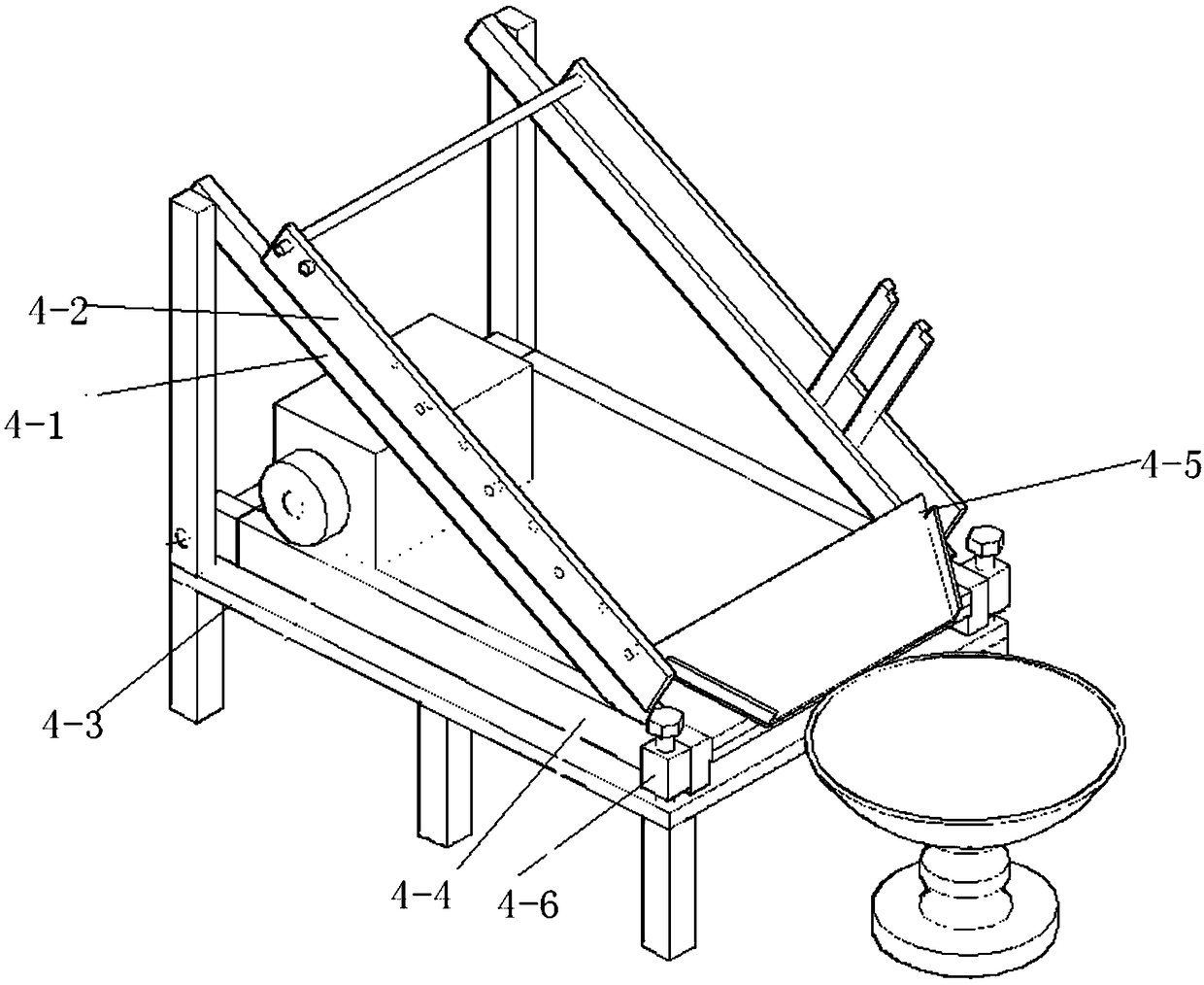

Sand and stone separator

ActiveCN105618417ASimple structureFew wearing partsCleaning using liquidsDrying machinesStarch solutionCorrosion

The invention discloses a sand and stone separator. The sand and stone separator comprises a roller washing and screening machine cylinder, a roller washing and screening machine frame and a sand spiral dehydrator; the roller washing and screening machine cylinder is placed on the roller washing and screening machine frame; and the sand spiral dehydrator is placed below the roller washing and screening machine frame. The sand and stone separator adopts a separate design of sand and stone screening and sand dehydration; the sand and stone screening adopts a two-stage mechanism; firstly, concrete is screened after rolling and cleaning; and a high-pressure cleaning device is arranged on a screen, so that the sand and stone separation is more thorough and cleaner. The cleaning part volume of the roller washing and screening machine cylinder is high, so that the instant high-flow impact of sand and stone starch solution can be stopped; and after the separation work is finished, the starch solution in the sand and stone separator is totally rotated out without residues, so that such problems as internal caking, blockage and corrosion are preferably solved. The sand and stone separator is simple in structure, fewer in wear parts, free of maintenance at ordinary times, long in equipment service life and simple in maintenance.

Owner:广州市盛恒工程机械有限公司

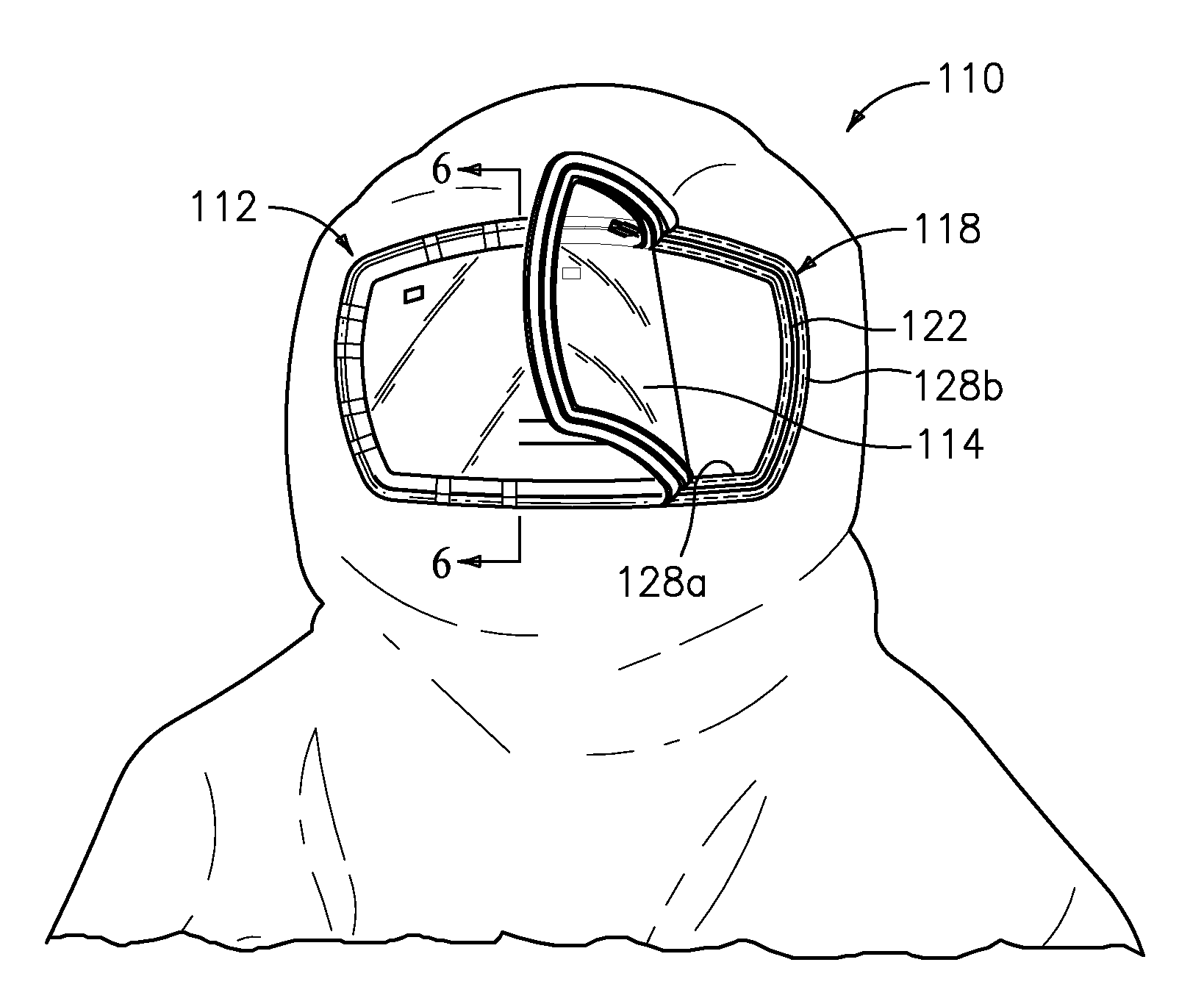

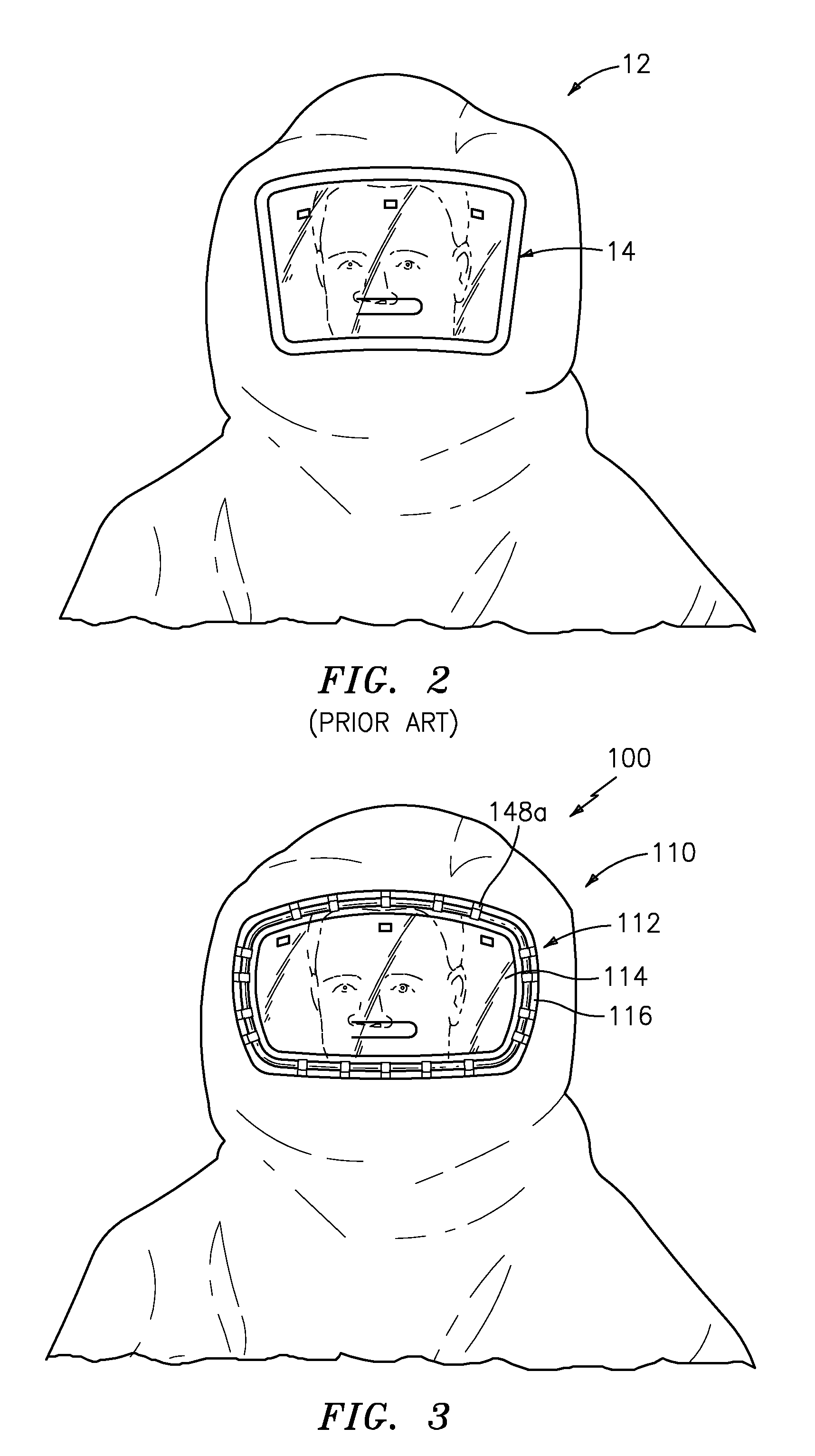

Launderable tritium hood

InactiveUS20090100560A1Easy to removeEasy to replaceChemical protectionHeat protectionEngineeringMechanical engineering

Applicant has disclosed a “Launderable Tritium Hood” with a removable visor assembly that allows the visor (i.e., view plate) and the remainder of the hood to be cleaned separately, and by different methods, for their reuse. In the preferred embodiment, Applicant's invention comprises: a launderable tritium suit hood; a removable visor assembly with a visor removably attached to a channel assembly; and, a bead assembly attached to the hood's fabric by stitching, wherein the channel assembly, with its attached visor, can be press-fit onto the bead assembly and subsequently peeled off when desired. Applicant's invention can also be thought of as a method comprising: press fitting a removable visor assembly onto a bead affixed to a tritium suit hood to create a gas-tight seal between the visor assembly and hood; and lifting and peeling the visor assembly off the bead to remove the visor assembly from the hood.

Owner:UNITECH SERVICES GROUP

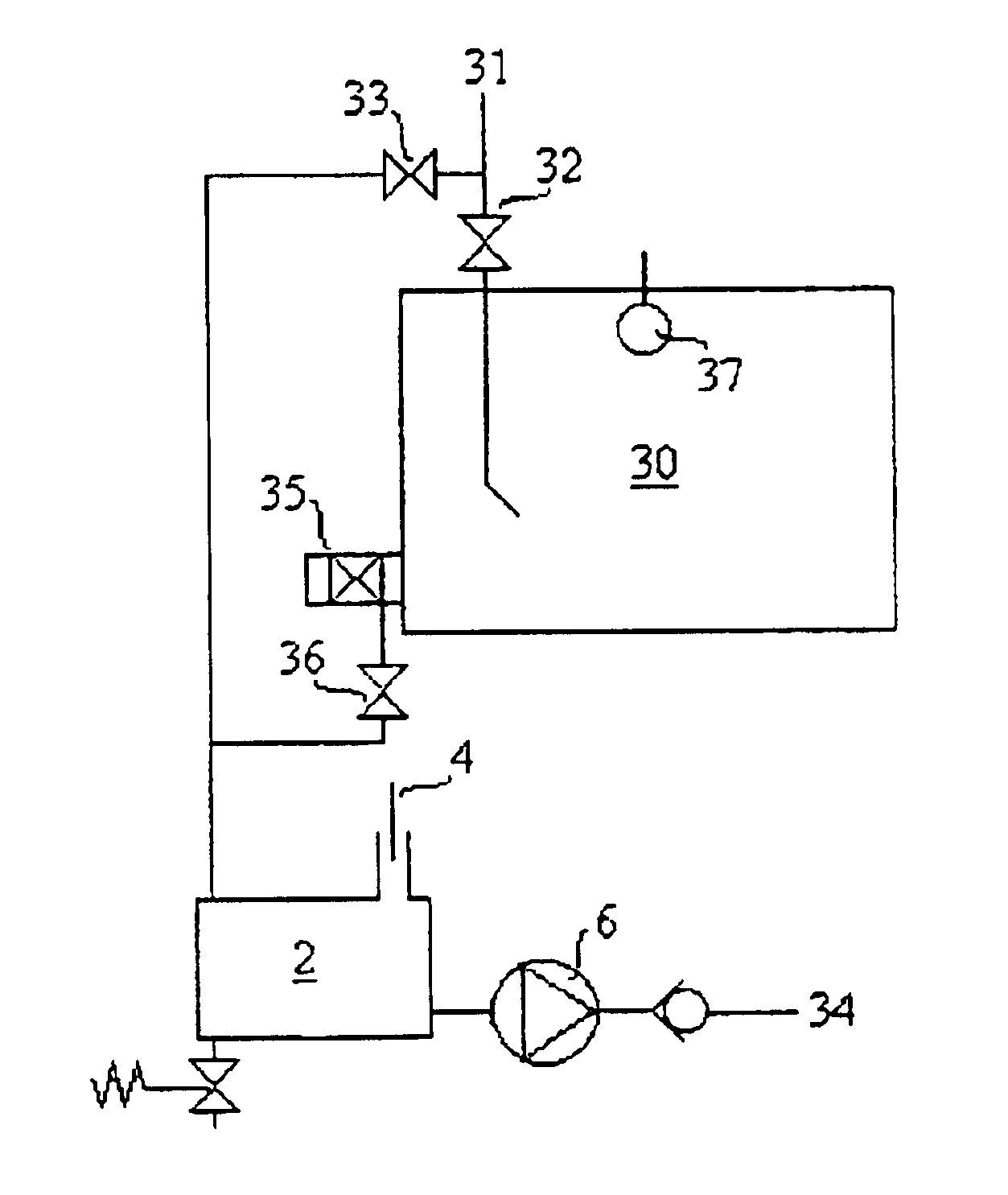

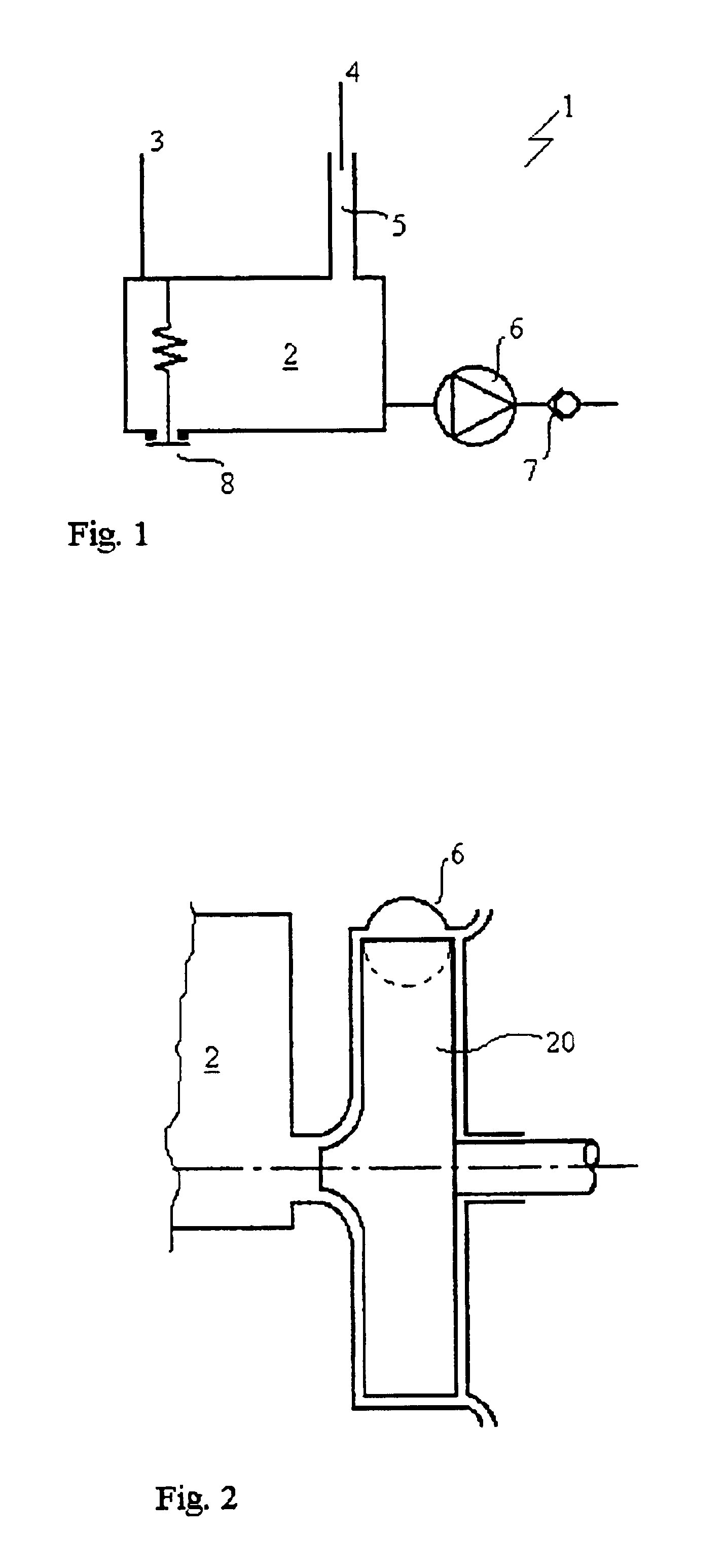

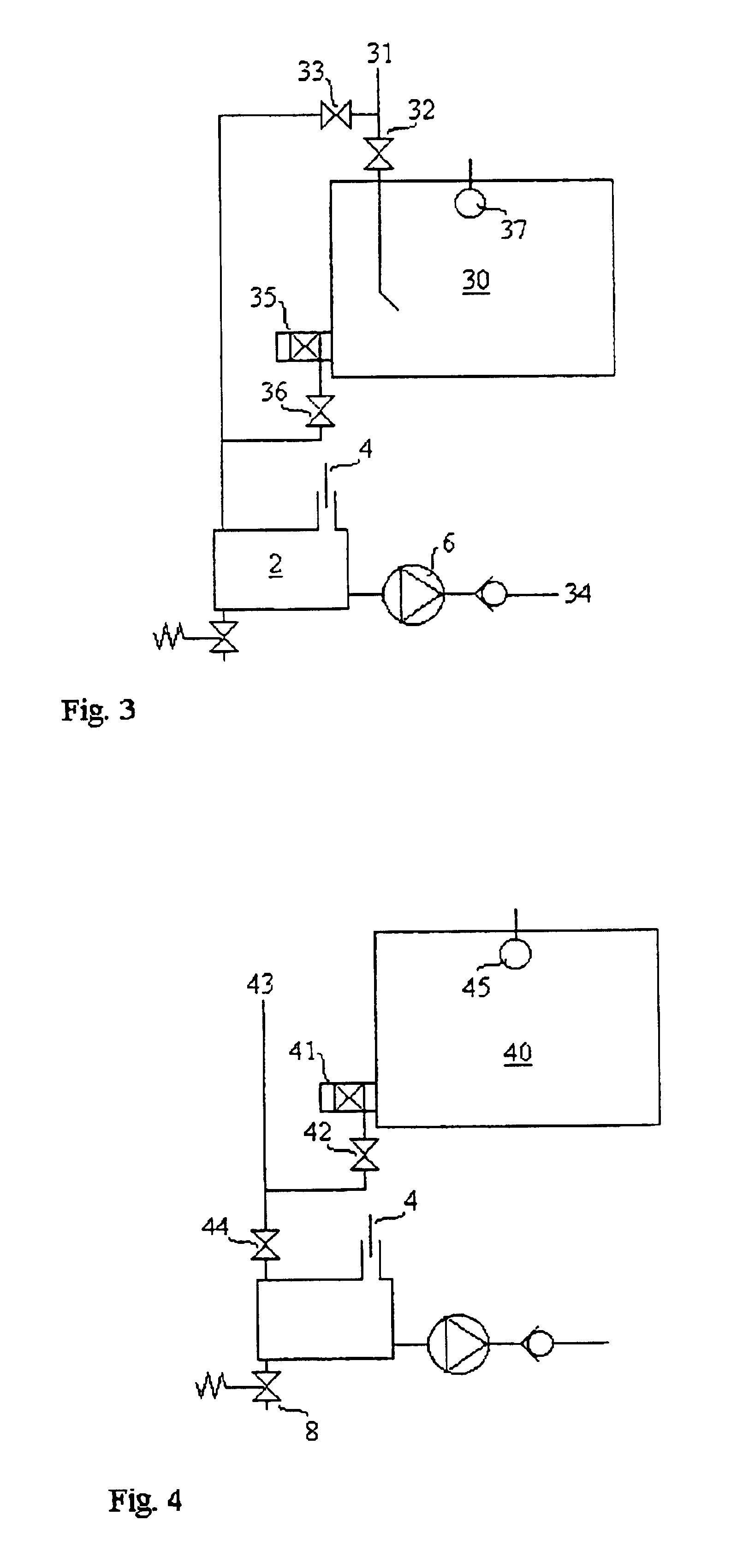

Method and apparatus for cleaning of a milking plant

InactiveUS6852172B1Prevent leakageSeparate cleanHollow article cleaningCleaning using gasesEngineeringTwo fluid

A milking plant for milking animals, such as cows, wherein milk collecting means, prefeably in the form of teat cups, are attached to the teat of the animal whereafter milk is taken from the animal by use of vacuum. The milk is transported by a milk line system (31) to milks storage means comprising a cooling tank (30). For cleaning purposes the milk line system from each milk collecting means can be shut off from the milk tank by valve means (32) in order for separate cleaning of the milk line system. The invention is characterized by preventing any possible leakage of detergent from a cleaning fluid to the milk that has been collected in the milk tank, by providing a pressure difference between the two fluids. The pressure difference between the fluids is preferably achieved by connecting the cleaning fluid to the vacuum supply (4) of the milking plant.

Owner:DELAVAL HLDG AB

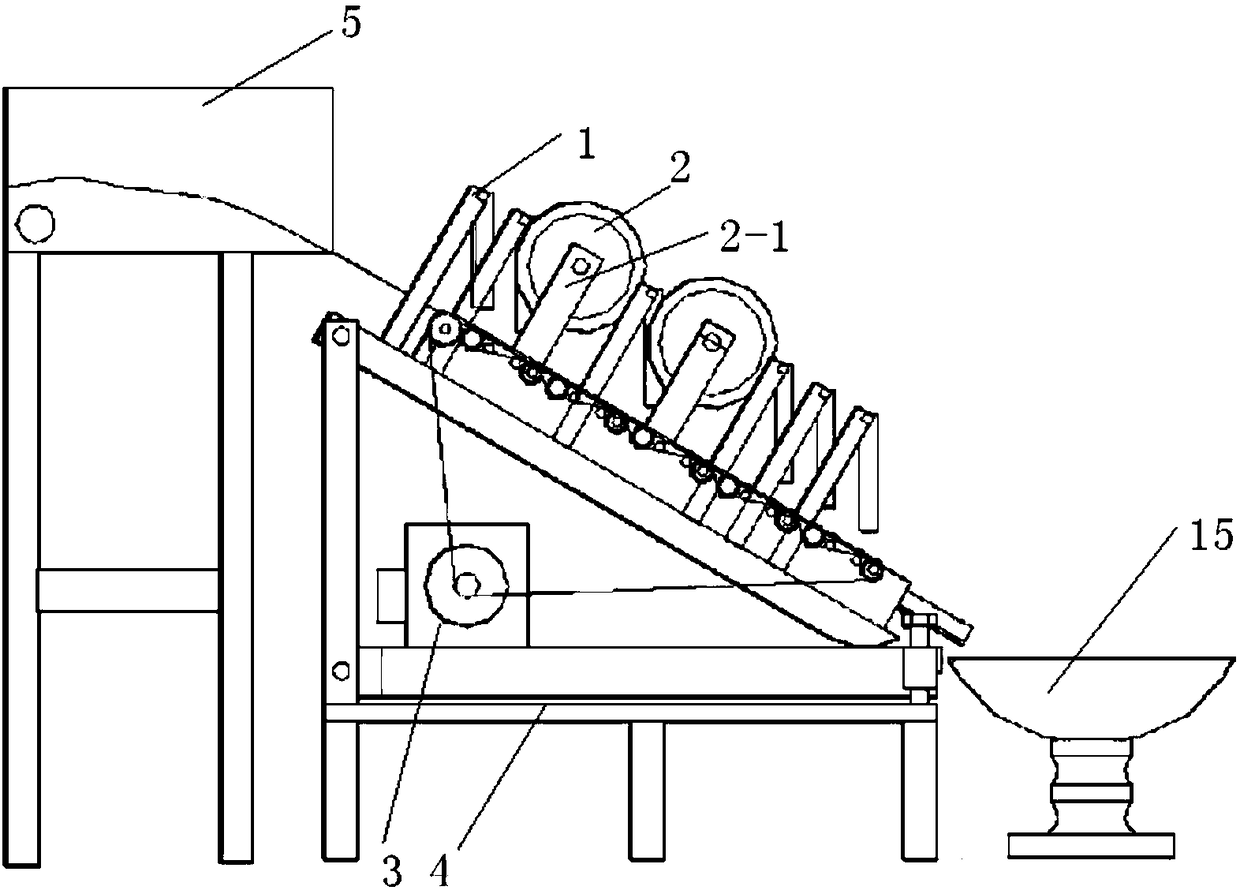

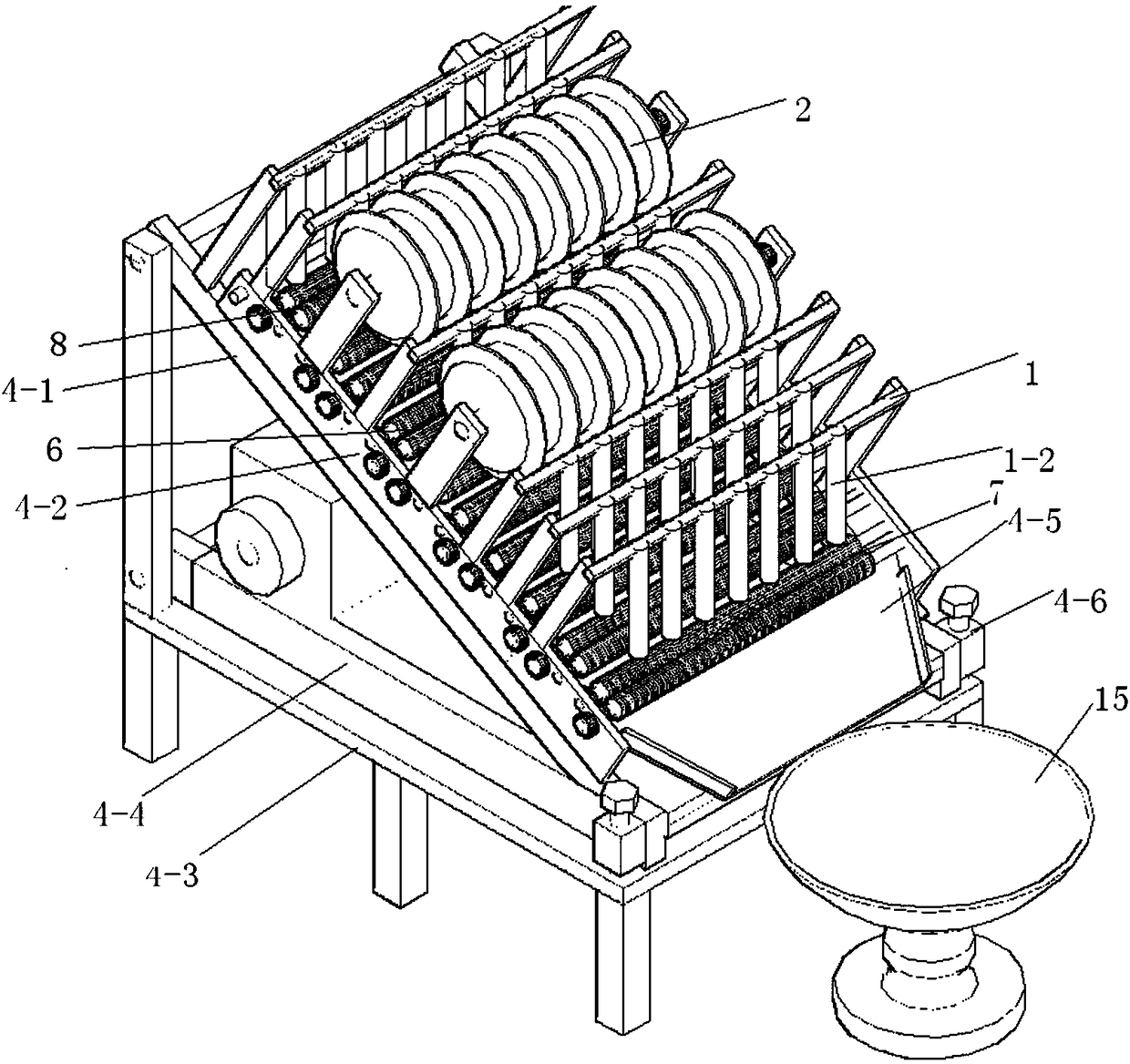

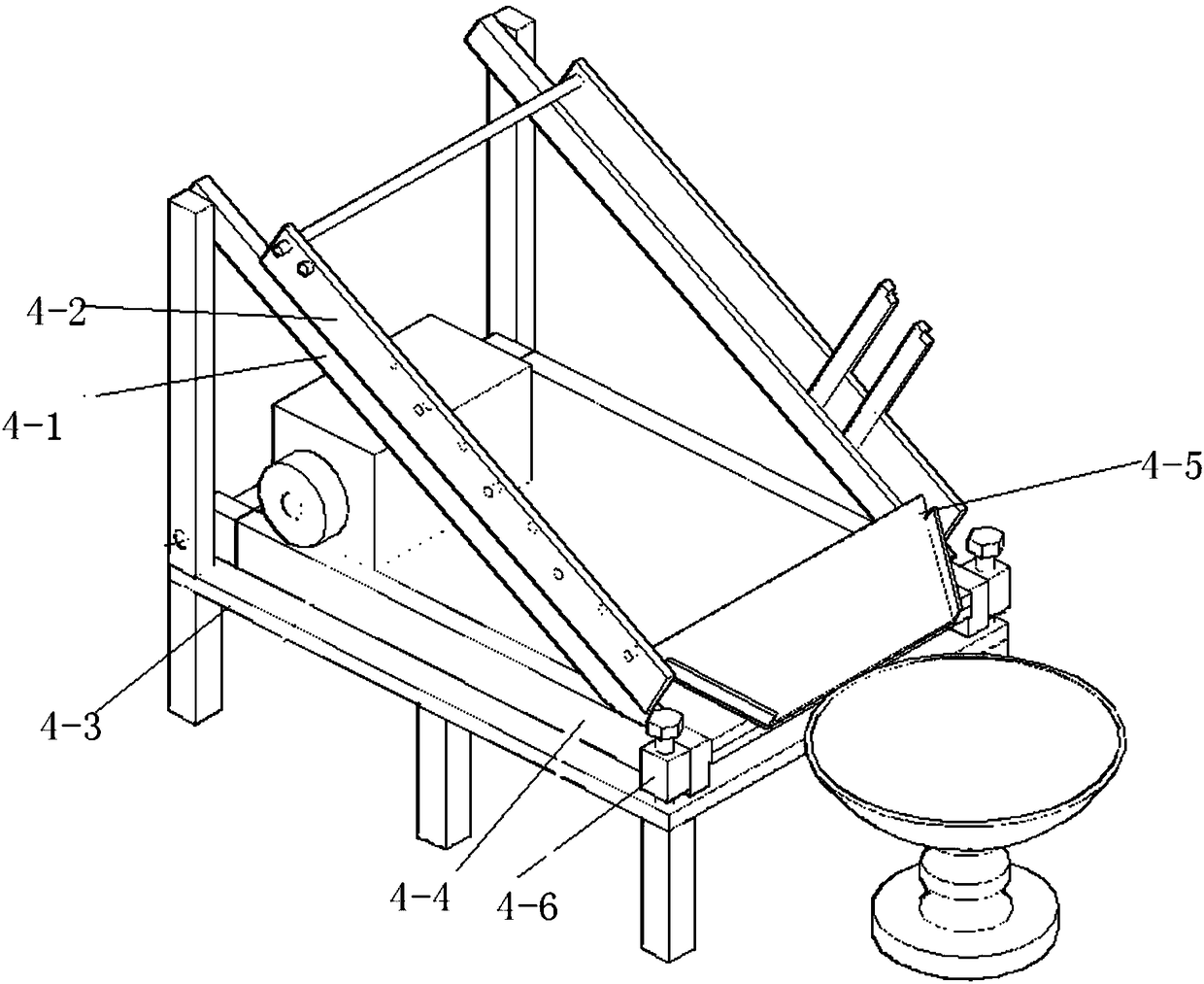

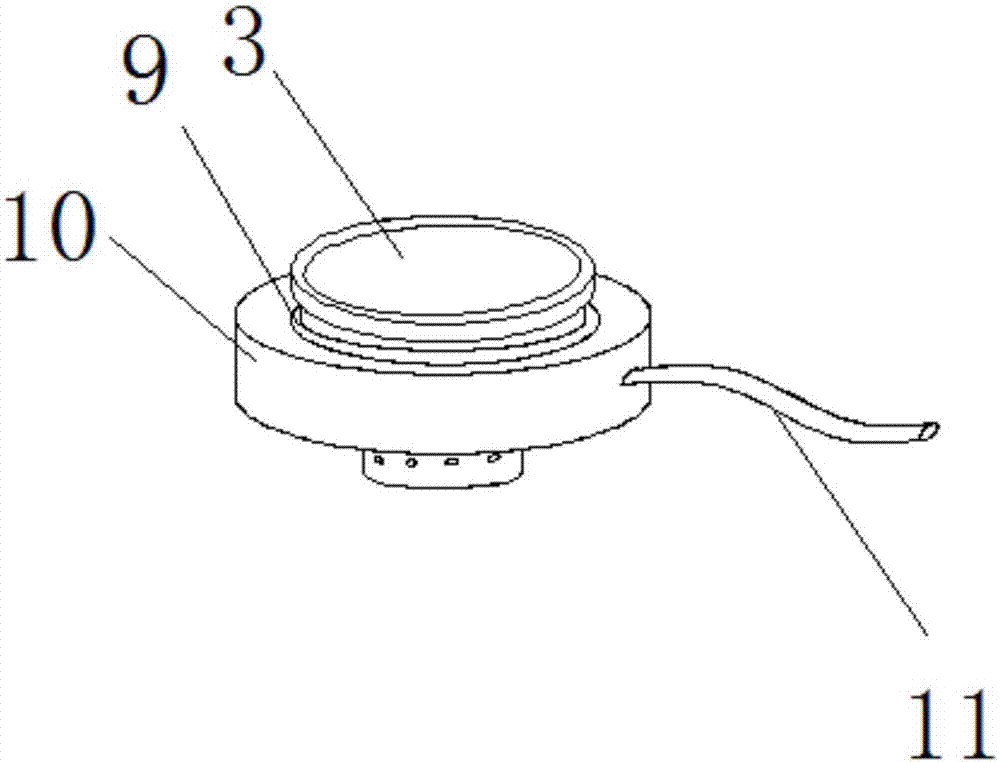

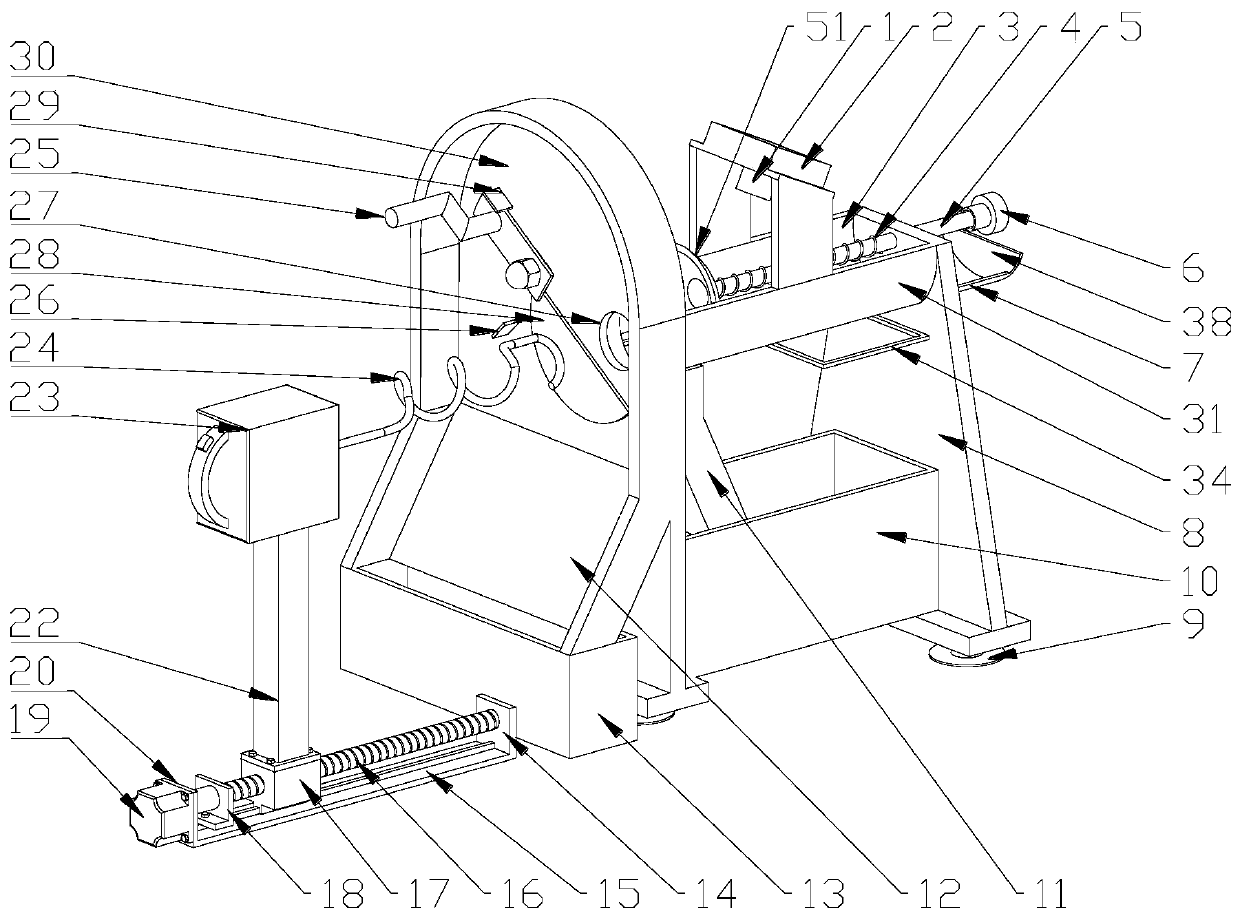

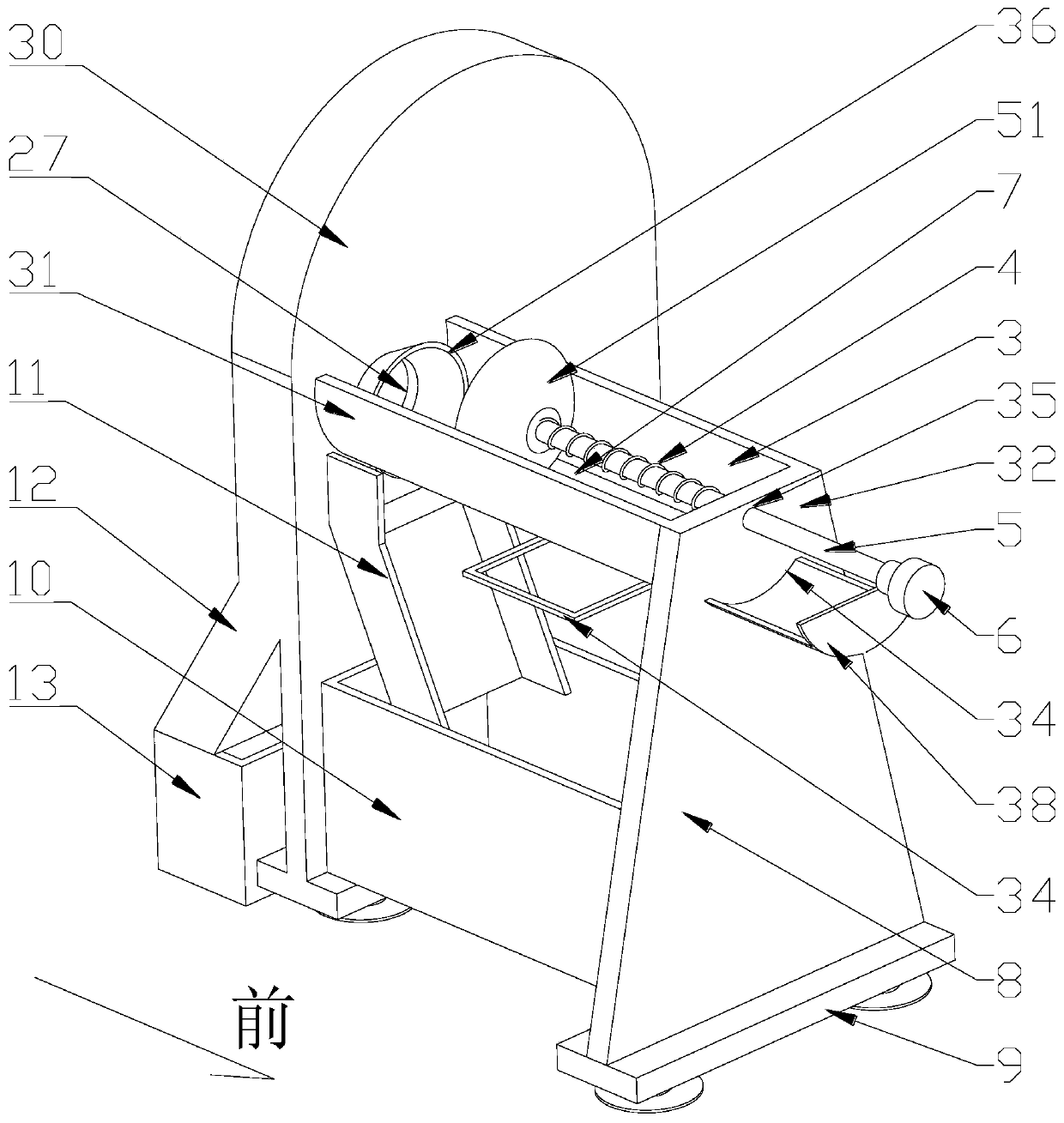

Roller-type mandarin orange peeling system and control method thereof

ActiveCN108464515AImprove peeling efficiencyKeep it originalVegetable peelingEngineeringCitrus nobilis

The invention discloses a roller-type mandarin orange peeling system and a control method thereof. The roller-type mandarin orange peeling system comprises a material feeding and receiving apparatus,and a peeling apparatus; the material feeding and receiving apparatus comprises a material box, a material receiving disc, and a second motor; the peeling apparatus comprises a first motor, a machineframe, and a peel cutting mechanism used for cutting open mandarin orange peel and a peeling mechanism used for separating the mandarin orange peel which are orderly arranged on the machine frame; thematerial box is connected with the peel cutting mechanism; the material receiving disc is connected with the peeling mechanism; and the second motor is respectively connected with the peel cutting mechanism and the peeling mechanism. A single-chip is used as a control device of the roller-type mandarin orange peeling system; and thus, fully automated manual-operation-free processing way is realized. Peeling is achieved by the peel cutting mechanism, the peeling mechanism and a tangerine pith separating mechanism instead of the processes of performing heating, steaming and peeling of the priorart; and thus, the effects of high degree of integrity is achieved without causing damage on mandarin orange flesh. The roller-type mandarin orange peeling system effectively solves the problems of the prior art, namely oversize equipment, excessive low efficiency, excessive low final-product utilization rate, unavailable direct eating and requirement for re-processing treatment.

Owner:YULIN UNIV

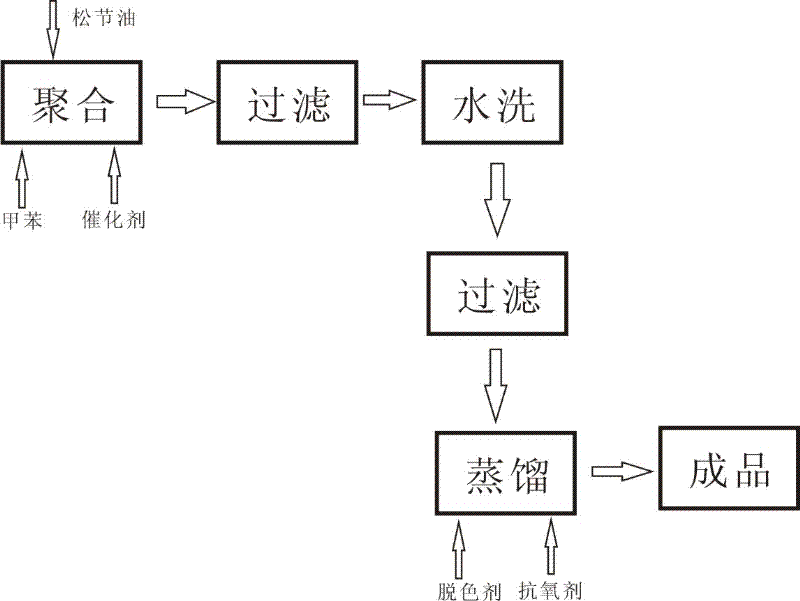

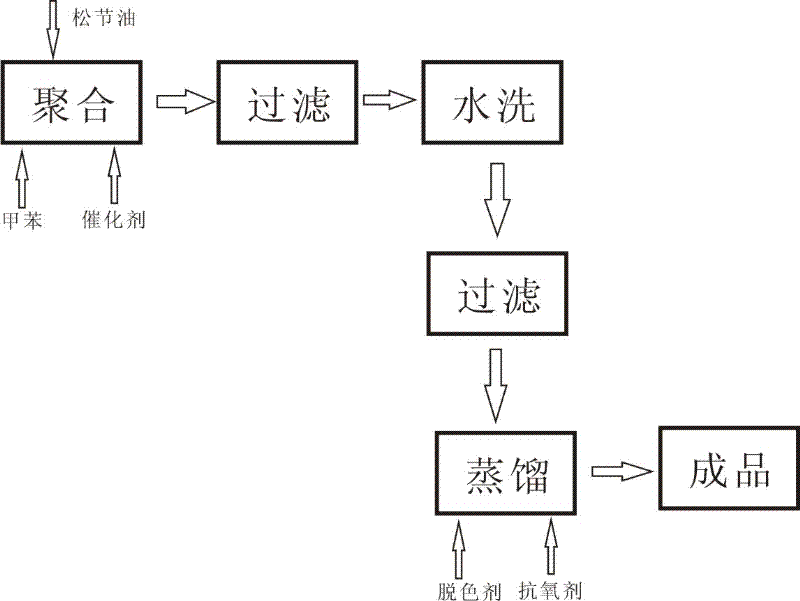

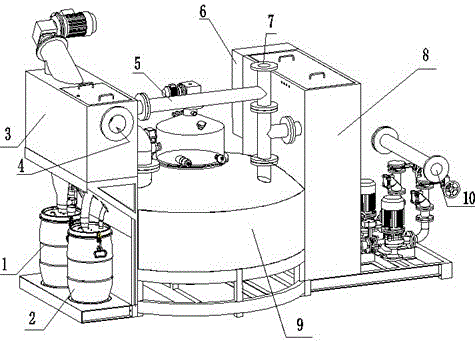

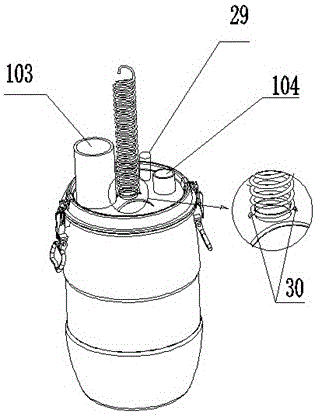

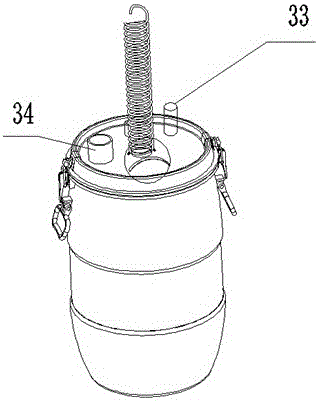

Ultralight-colored polyterprene resin production process

The invention discloses an ultralight-colored polyterprene resin production process. The ultralight-colored polyterprene resin production process includes polymerizing, washing and distilling, and turpentine oil and catalyst of alchlor are polymerized in a reactor during the polymerizing procedure. The ultralight-colored polyterprene resin production process is characterized in that 0.2% by weight of hindered phenol oxidation inhibitor and 0.1 % by weight of decolorizer are added into a polymerized mixed product which is washed during the distilling procedure. Since the core technology at international advanced level is combined with the antioxidant decolorizer and the hindered phenol oxidation inhibitor, the product can be decolored effectively, and mother liquid in color luster ranging from 7# to 8# can be decolored into the product in color luster of 1#. Besides, the filtering procedures are added before and after the washing procedure respectively, so that aluminum dross and impurities can be separated more thoroughly, separation rate can be up to 98% or above. Further, ions, low-boiling-point components and by-products can be separated completely by the aid of precise distilling equipment integrating with the optimum process, odor of products is lightened, and pollution to the environment is reduced.

Owner:GUANGDONG HUALIN CHEM

Fully-automatic kitchen garbage separation equipment

InactiveCN106731200AIncrease in sizeIn line with the law of fluid operationFiltration circuitsNon-miscible liquid separationFully automaticGarbage disposal

The invention discloses fully-automatic kitchen garbage separation equipment, and belongs to the technical field of garbage disposal. The equipment is provided with a primary separation module, wherein the primary separation module is arranged on a support frame, and comprises a primary settling banker and a solid-liquid separation mechanism, the solid-liquid separation mechanism is arranged in the primary settling banker, an inlet, a primarily separated liquid outlet and an overflow port are formed in the primary settling banker, the overflow port is connected with an overflow pipeline, the primary settling banker is provided with a primary settling banker outlet, an exhaust port I and an exhaust port II, and the exhaust ports I and the exhasut port II are connected with the primary settling banker through a pipeline. The equipment is mainly applied to restaurant garbage disposal.

Owner:徐海

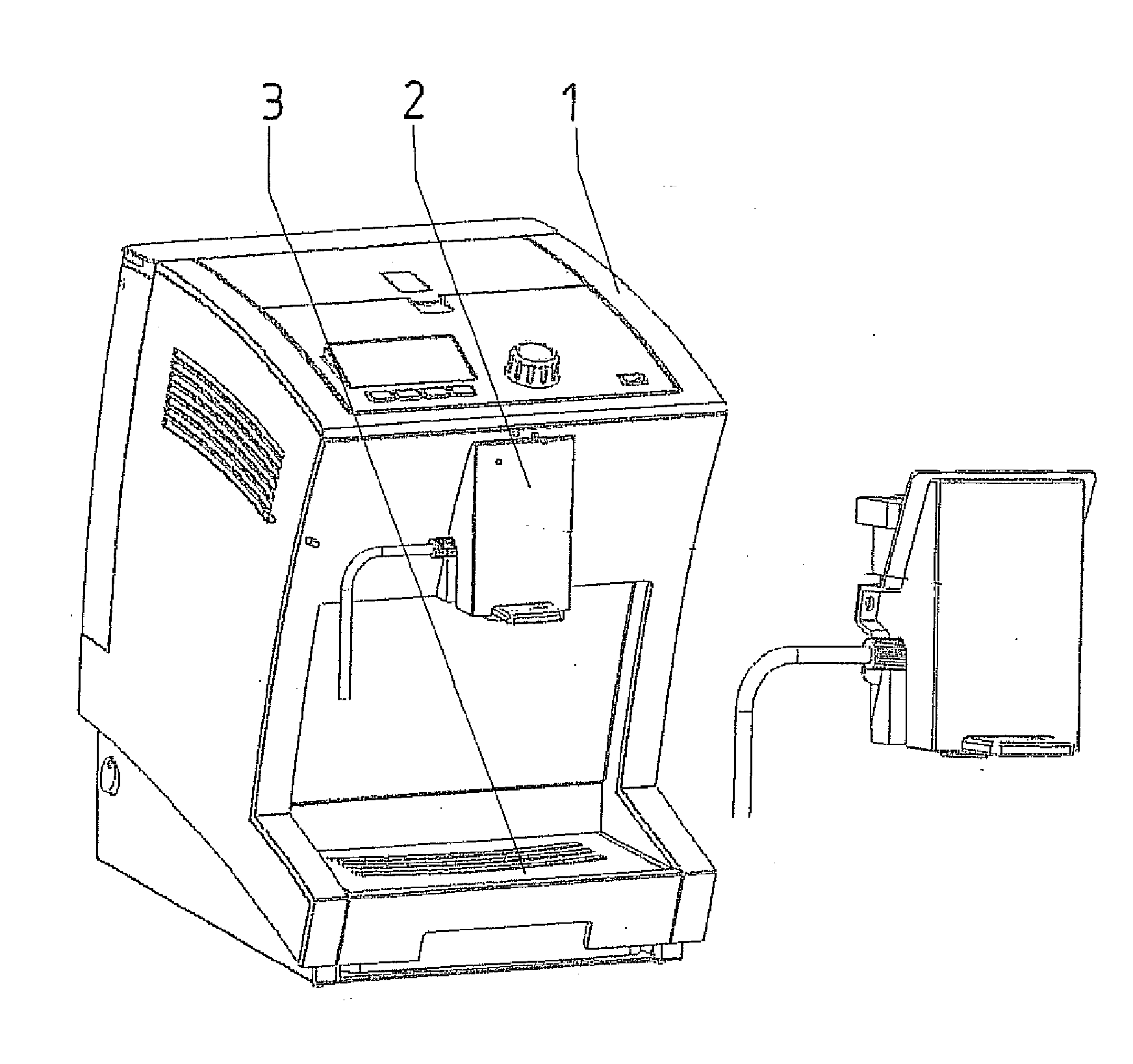

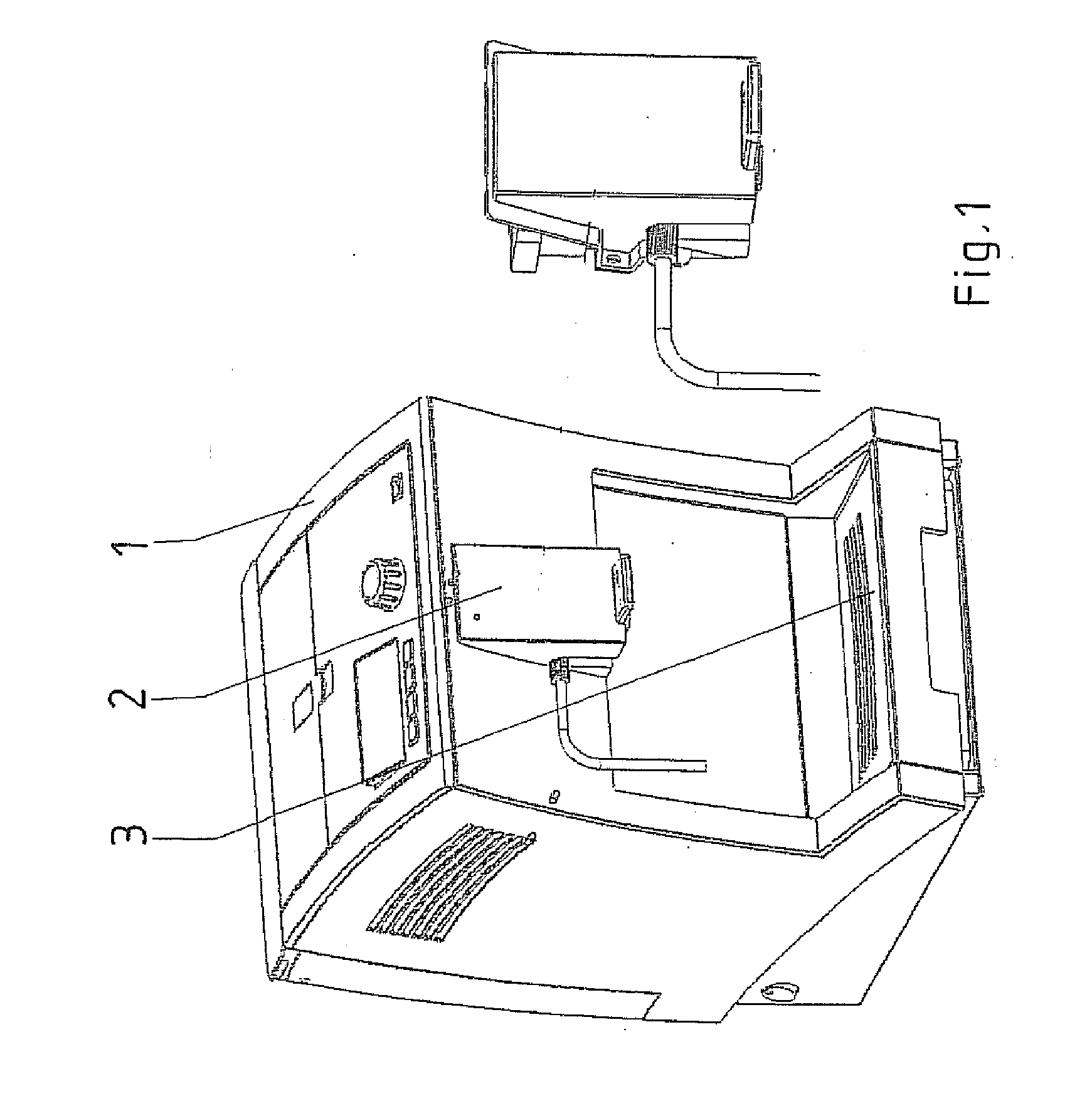

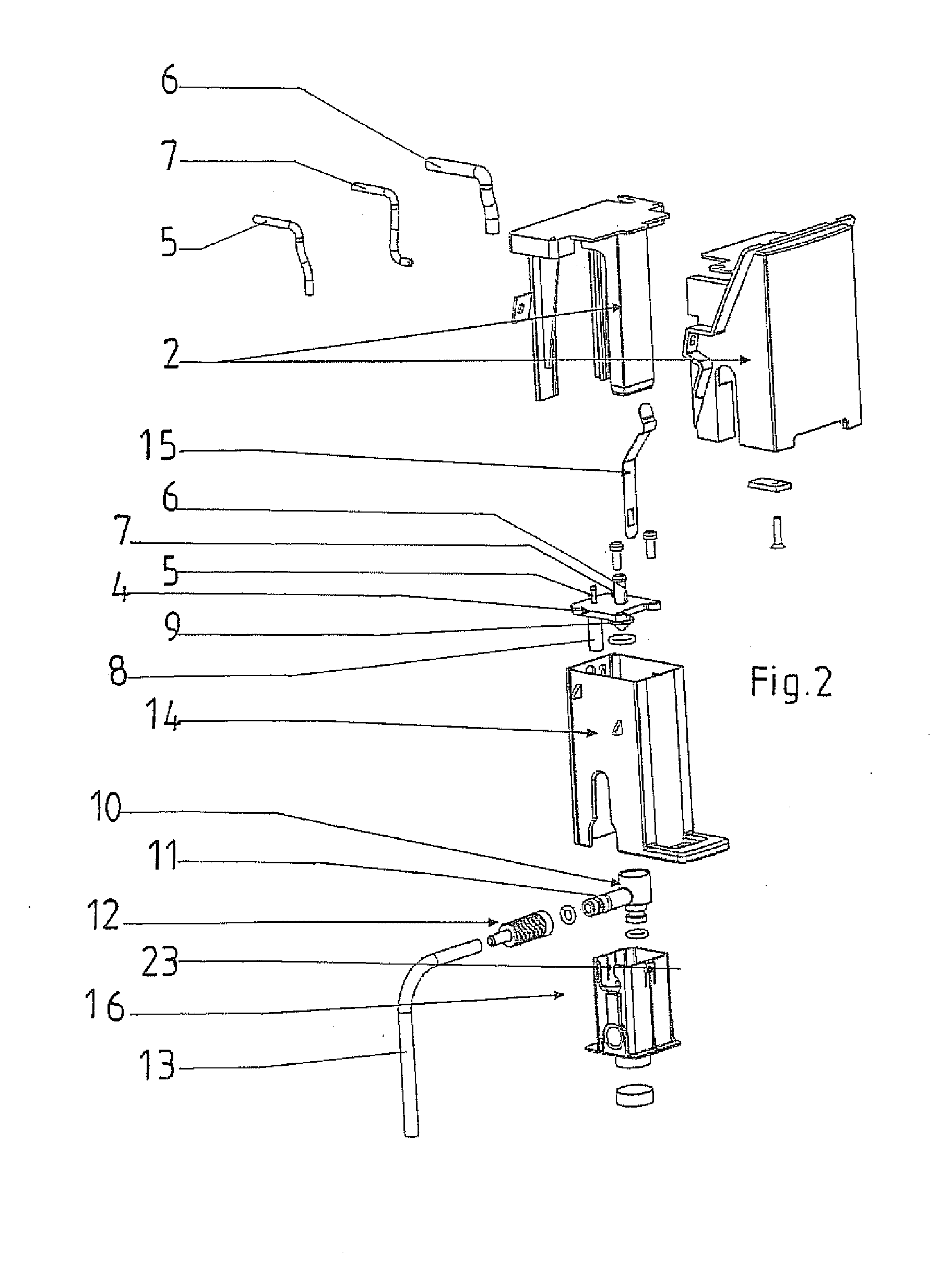

Electrical beverage preparation machine

In order to provide an electrical beverage preparation machine, in particular for preparing coffee, espresso, mixed milk drinks or the like, the machine comprising an outlet housing part that has an inlet for coffee, fresh air and hot steam as well as milk and outlets for on the one hand coffee and on the other hand milk and milk foam, wherein the coffee outlet as well as the milk frothing system can easily be cleaned, it is proposed that a connector plate is fixed in the outlet housing part, said connector plate comprising connections for the coffee inlet, the steam inlet and the air inlet, and the coffee outlet branching off therefrom, as well as a connection port or similar coupling part, which comprises the steam and air outlets, and at which a mixing chamber with a milk connection is attached in a tightly mountable or detachable manner.

Owner:SEVERIN ELEKTROGERATE

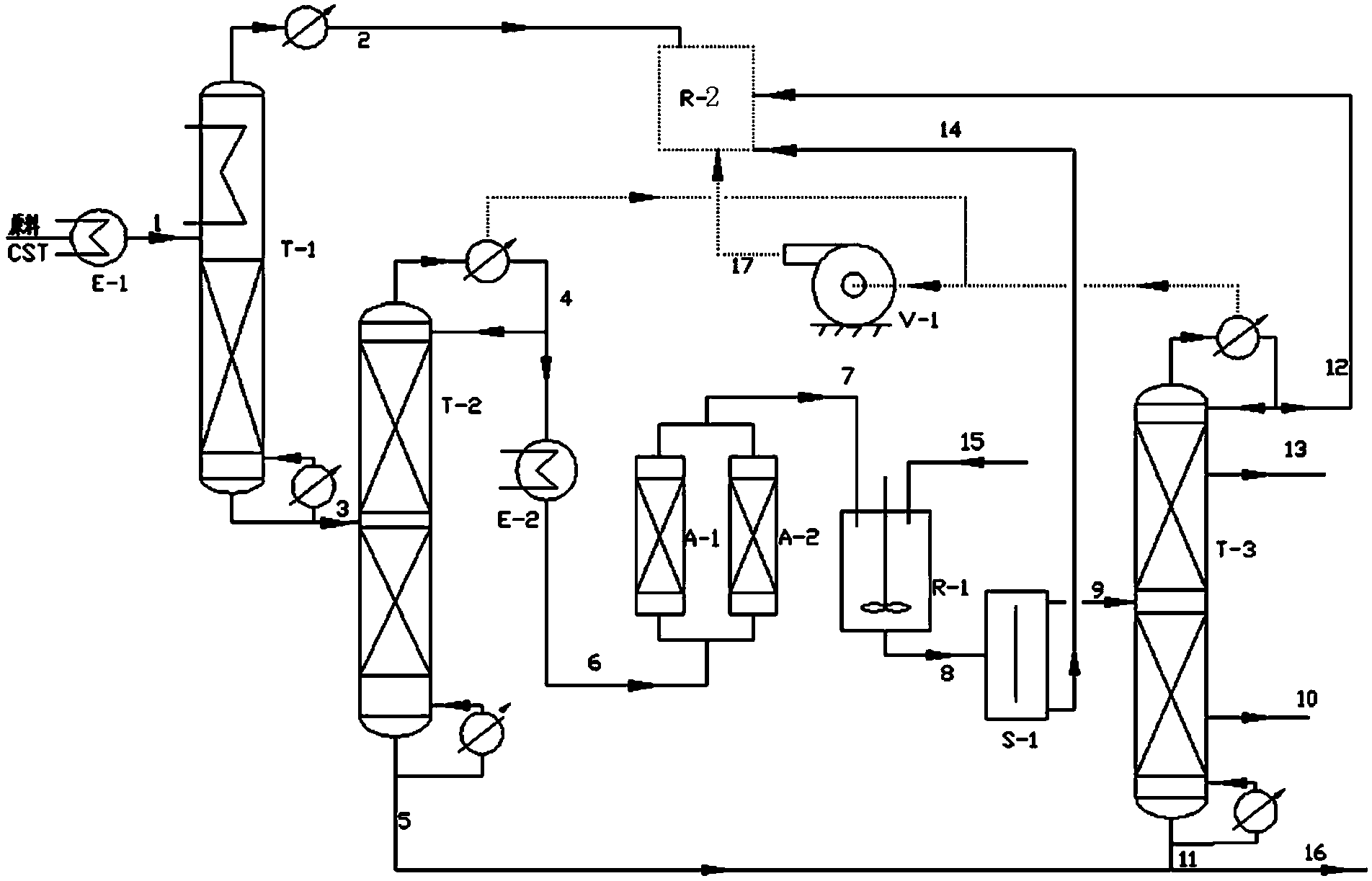

Vibrating screening and separation mechanism of copper crushing machine

InactiveCN103128048ACompact structureReasonable designSievingScreeningAgricultural engineeringSprocket

The invention discloses a vibrating screening and separation mechanism of a copper crushing machine. The vibrating screening and separating mechanism of the copper crushing machine comprises a rack, an air rack, an adjusting plate, a first spring plate, an air suction port, a feeding port, a support frame, a second spring plate, a fan, an eccentric shaft, a screen, a pull rod, a first discharge port, a connecting rod, a chain, a second discharge port and a motor. The air inlet is arranged on the lower portion of the rack, the fan is arranged at the air inlet, the adjusting plate and the pull rod are both arranged on the middle portion of the rack, the first spring plate and the second spring plate are both arranged between the adjusting plate and the screen, and the first discharge port and the second discharge port are both arranged on the screen. The eccentric shaft is arranged on the adjusting plate, and the motor and the eccentric shaft form chain transmission through the chain and a chain wheel. One end of the connecting rod is connected with the eccentric shaft, and the other end of the connecting rod is connected with the screen. The feeding port is arranged on the eccentric shaft through the support frame, and the air suction port is arranged at the feeding port. The vibrating screening and separation mechanism of the copper crushing machine is compact in structure, reasonable in design, safe and reliable to use, high in screening and separation efficiency, small in labor intensity, thorough in separation and free of pollution.

Owner:THE NORTHWEST MACHINE

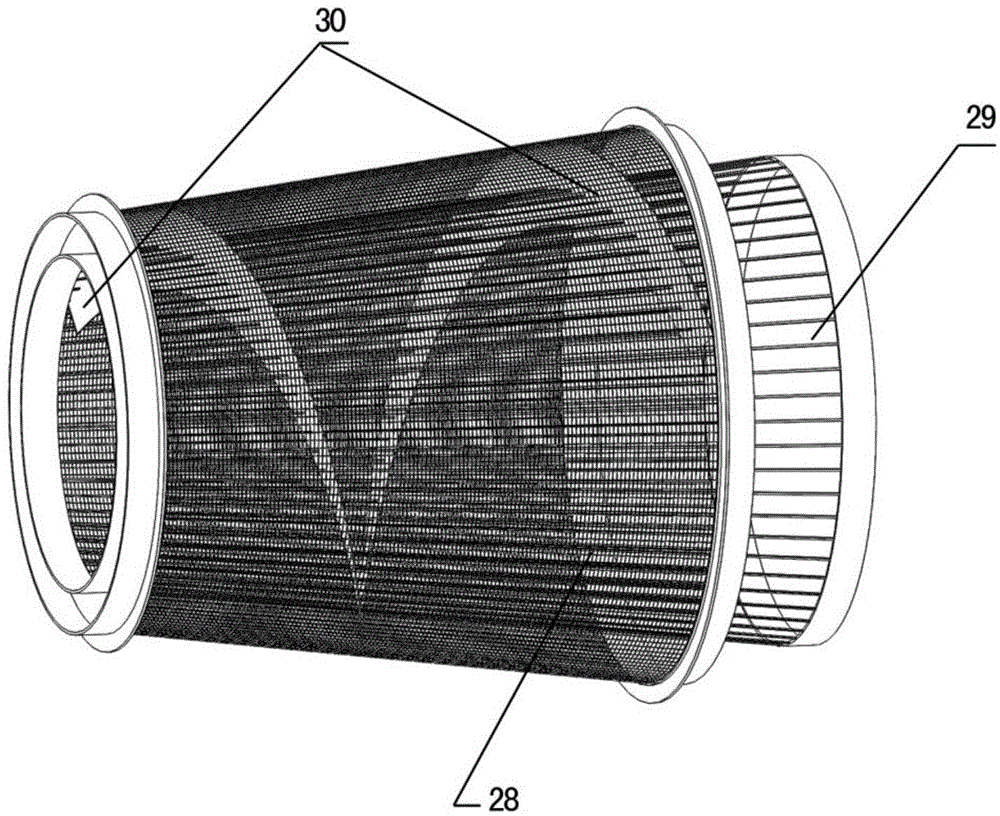

Chinese artichoke harvester

The invention belongs to an agricultural machine, and particularly relates to a Chinese artichoke harvester. The Chinese artichoke harvester comprises a rack. The rack is provided with a traction frame. An excavation shovel is arranged below the rack. The Chinese artichoke harvester is characterized in that a main speed reduction box is arranged between the upper portion of the rack and the traction frame, a first transmission shaft, a first conveying chain shaft, a second conveying chain shaft and a second transmission shaft are fixedly installed on the rack, and the first conveying chain shaft and the second conveying chain shaft are connected through a conveying chain; a transition feeder is arranged above the rack, one end of the transition feeder is arranged at the feeding port of the conveying chain in parallel, and the other end of the transition feeder stretches into a rotary screen; the rotary screen is installed on a rotary screen frame, and a material collecting box is arranged at the position, located at the outlet of the rotary screen, at the rear end of the rotary screen frame. The Chinese artichoke harvester is compact in structure, thorough in separation and low in damage rate, excavating, screening and collecting can be finished at a time, time and labor are saved, convenience and reliability are achieved, the production efficiency is high, labor force is greatly reduced, the planting cost of Chinese artichoke is reduced, the planting benefits of farmers are increased, and the confidence of the farmers for planting the Chinese artichoke is improved.

Owner:青铜峡市民乐农业机械有限公司

Integrated feeder

ActiveCN103861715AEfficient removalAxially distributed evenlyGas current separationMagnetic separationAir volumeEngineering

The invention relates to a feeding device used for screening and conveying a material by utilizing gravity flow, and in particular relates to an integrated feeder. The integrated feeder comprises a shell, and a feeding hole and a discharge hole which are arranged on the shell, wherein the shell is internally provided with a feed roller, a magnetic separation roller and a stone remover; the magnetic separation roller is arranged under the feed roller; a slide carriage is arranged between the magnetic separation roller and the feed roller; the stone remover is arranged under the magnetic separation roller; an air inlet is arranged on the side wall of the shell corresponding to the stone remover; the side wall of the shell is provided with an upper air volume adjustment plate at the inner side of the air inlet; a junk drawer is arranged between the stone remover and the air inlet; and the lower part of the junk drawer is provided with a lower air volume adjustment plate. After the integrated feeder is adopted, iron and steel impurities can be effectively removed; the stone remover is matched with the function of the airflow of the air inlet, so that the impurities with the specific gravity heavier than that of material can be separated from the material; the air speed for separating the material and the impurities can be obtained by the adjustment of air volume adjustment plates, so that the different impurities can be conveniently removed.

Owner:TANGSHAN CITY FENGNAN DISTRICT SHUANGYI FEED MACHINERY CO LTD

Juice squeezing device

InactiveCN107213962AIncrease collection volumeSpeed up extractionJuice extractionRotary centrifugesSlagFlesh

The invention discloses a fruit juice extracting device, which comprises a extracting device body, a connector assembly is arranged at the center of the bottom of the top groove of the extracting device body, and the connector assembly is rotatably connected to the bottom of an extraction cylinder, and the extraction cylinder is provided with a A slag collecting basket, and a crushing cutterhead is arranged on the inner bottom plate of the slag collecting basket, a sealing cover is arranged at the top opening of the extraction cylinder, and a feeding port is arranged at the center of the upper surface of the sealing cover, and the juice extracting device also includes A push rod used in conjunction with the juice extraction device. In the present invention, the slag collection basket is driven by the motor to rotate, and centrifugal force is used to separate the pulp and juice, the separation is cleaner, and the efficiency of extracting juice and the amount of juice collected are improved. Secondly, a push rod is provided to extract the pulp inside the extraction cylinder. Squeeze onto the crushing cutterhead, which improves the efficiency of the crushing cutterhead to crush the pulp.

Owner:CHENGDU YANXINGGUO TECH CO LTD

Peel removing device for citrus-type fruits

ActiveCN108851104AImprove peeling efficiencyKeep it originalVegetable peelingMechanical engineeringCitrus fruit

The invention discloses a peel removing device for citrus-type fruits. The device comprises a motor, a rack, a peel cutting mechanism and a peel stripping mechanism, wherein the peel cutting mechanismand the peel stripping mechanism are arranged on the rack in sequence and connected with the motor separately; the peel cutting mechanism comprises multiple peel cutting roll sets which are arrangedat intervals and comprise driving peel cutting rolls and driven peel cutting rolls, peel cutting knifes are arranged on the driving peel cutting rolls and the driven peel cutting rolls, the driving peel cutting rolls and the driven peel cutting rolls rotate oppositely, during peel stripping, an existing mode of heating, citrus steaming and peel stripping is not used any more, and peel stripping iscompleted through the peel cutting mechanism, the peel stripping mechanism and a citrus fiber separating mechanism, so that the completeness of peel stripping is high without damage to citrus flesh.The problems are effectively solved that existing equipment is too large and low in efficiency, the utilization rate of finished products is low, and the finished products can not be eaten directly orsubjected to technology treatment.

Owner:YULIN UNIV

Method for preparing chicken essence by using bone residue enzymolysis concentrate

The invention discloses a method for preparing chicken essence by using bone residue enzymolysis concentrate. The method for preparing the chicken essence by using the bone residue enzymolysis concentrate comprises the following steps of: (1) performing enzymolysis on bone residues, and performing rotary evaporation and concentration on the enzymolysis solution to prepare the bone residue enzymolysis concentrate, wherein the soluble solid content of the enzymolysis concentrate is 30 to 42-degree brix; and (2) proportioning the following raw materials in part by weight: 60 to 90 parts of enzymolysis concentrate, 20 to 40 parts of water and 20 to 42 parts of auxiliary material, and performing reaction for 1 to 3 hours at the temperature of between 100 and 120 DEG C to obtain the chicken essence. The chicken essence is mainly prepared from the bone residues, so byproducts are effectively utilized. The chicken essence prepared from the concentrate obtained by enzymolysis of the bone residues under the optimal enzymolysis process conditions according to a formula is assessed according to the intensities of sweet fragrance, meat fragrance, fat fragrance, burnt smell, fishy smell and sulfur smell. The product has integrally soft and mellow fragrance, predominant meat fragrance and good chicken fat flavor.

Owner:HENAN AGRICULTURAL UNIVERSITY

Enzymolysis method for bone dregs

InactiveCN102150875AIncrease added valueGood deboning effectFood preparationEssential amino acidAmino acid content

The invention discloses an enzymolysis method for bone dregs, which comprises the following steps of: adding water into the bone dregs, wherein the adding amount of the water is 1 to 2 times mass of the bone dregs; adding enzyme in a mass which is 0.1 to 0.2 percent of the mass of the bone dregs, performing enzymolysis at the temperature of between 55 and 65DEG C for 1.5 to 3 hours; and killing enzyme at the temperature of between 80 and 95DEG C for 10 to 20 minutes. The added value of the bone dregs is improved. By the enzymolysis method, the effect of separating meat from the bone dregs is better, the bones and the meat are separately thoroughly, the hydrolysis effect is good, and the residue amount is 26 to 43 percent. The enzymolysis solution has rich main free amino acids, the total content of amino acids and the content of essential amino acids in protease enzymolysis solution are respectively 14.97mg.g<-1> and 8.92mg.g<-1>, and the content of glutamic acid and the content of aspartic acid are respectively 1.951mg.g<-1> and 1.257mg.g<-1>.

Owner:HENAN AGRICULTURAL UNIVERSITY

Separator for part surface treatment sand

The invention provides a separator for part surface treatment sand, and relates to the technical field of part surface treatment. The separator comprises a transporting device and a separating device disposed at the rear end of the transporting device, wherein the transporting device comprises a funnel, a funnel support fixed under the funnel and a transporting pipe disposed below the funnel; and the separating device comprises a separating support, a box body disposed above the separating support and a separating drum disposed in the box body, wherein the tail end of the separating drum is provided with a belt wheel which is connected with a driving motor disposed below the separating support through a belt; and sand discharging port and a part discharging port are disposed below the box body. The separator can save physical power and labor force, is labor-saving and time-saving, and can separate the part surface treatment sand clean and thoroughly at a fast speed and with high efficiency.

Owner:安徽朝阳车链有限公司

Photovoltaic module separation and recovery method

PendingCN113385521ASolve pollutionReduce consumptionWaste processingSolid waste disposalThermodynamicsEngineering

The invention discloses a photovoltaic module separation and recovery method. The photovoltaic module separation and recovery method comprises the following steps that A1, an aluminum frame and a junction box of a photovoltaic module are removed; A2, a back plate is subjected to friction, and obtained back plate particles are collected and recovered; A3, the photovoltaic module of which the back plate is removed after friction is placed on an operation platform, heating is carried out to soften EVA, and then a battery piece layer is separated from glass; A4, high-temperature calcination is carried out on the separated battery piece layer, and a silicon battery piece is recovered after calcination; and A5, the EVA remained on the surface of the separated glass is removed, and fallen EVA particles are collected, wherein in the step A3, the heating temperature ranges from 80 DEG C to 200 DEG C. According to the photovoltaic module separation and recovery method, a method of softening the EVA and then removing the EVA by a scraper knife is adopted to separate the battery piece layer from the glass, and the subsequent high-temperature heat treatment only aims at the battery piece layer, so that the energy consumption in the whole photovoltaic module recovery process is obviously reduced, the EVA remained on the module is obviously reduced, and the separation degree is greatly improved.

Owner:铉锦(上海)环保科技有限公司

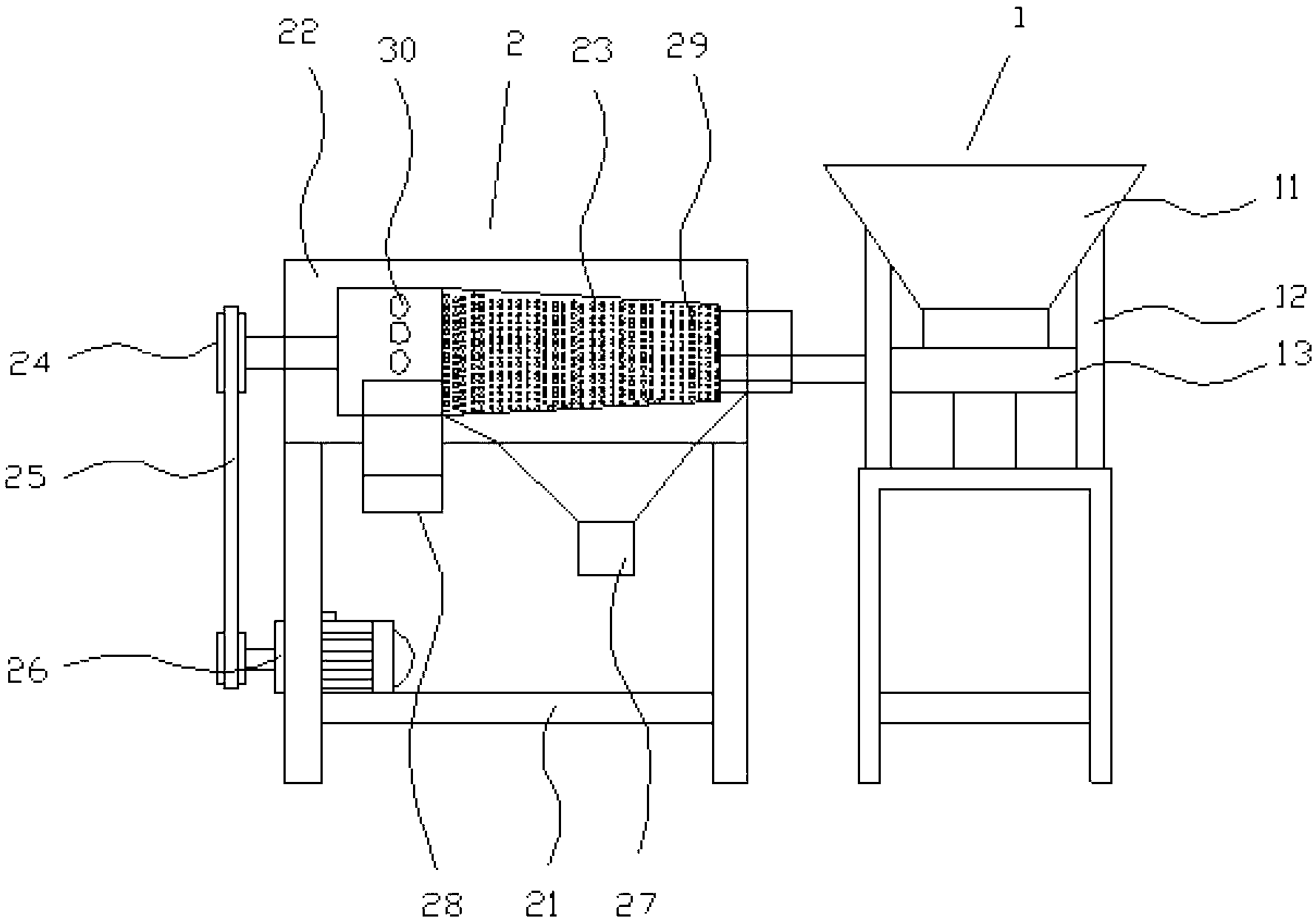

Refined method for crude sulfate turpentine

ActiveCN103787818ASeparate cleanLess quantityHydrocarbon purification/separationHydrocarbonsTurpentine OilPhysical chemistry

The invention relates to a refined method for crude sulfate turpentine. The method for the crude sulfate turpentine comprises the following steps that (1),CST conducted heat transfer enters a flashing tower to conduct flash separation, materials flowing from the bottom of the flashing tower are collected and sent to the middle portion of a vacuum rectifying column to be rectified and separated; (2), after materials flowing from the tower roof of the vacuum rectifying column are heat transferred, the materials enter an oxidation absorption tower to be oxidized and adsorbed; (3), materials after being oxidized and adsorbed enter an alkali wash reaction still and are alkali washed by alkaline solutions; (4), materials after being alkali washed enter a phase splitter, an upper layer oil phase acquired from layers being separated enters ithe vacuum rectifying column with a side line discharging to be separated, a Alpha-pinene product is acquired from an upper side line and a Beta -pinene product is acquired from a lower side line. The refined method for the crude sulfate turpentine applies a method which combines the processes of rectification, adsorption and chemical oxidation to acquire a pinene product with super low sulfur. The refined method for the crude sulfate turpentine is simple, low in energy consumption and production cost, and high in industrial reliability.

Owner:NANJING ENETEKS

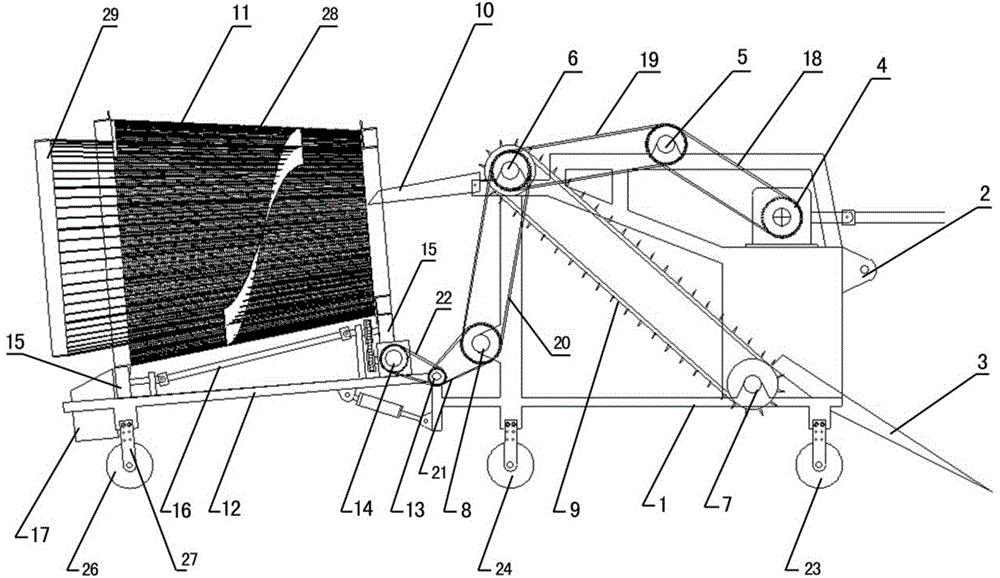

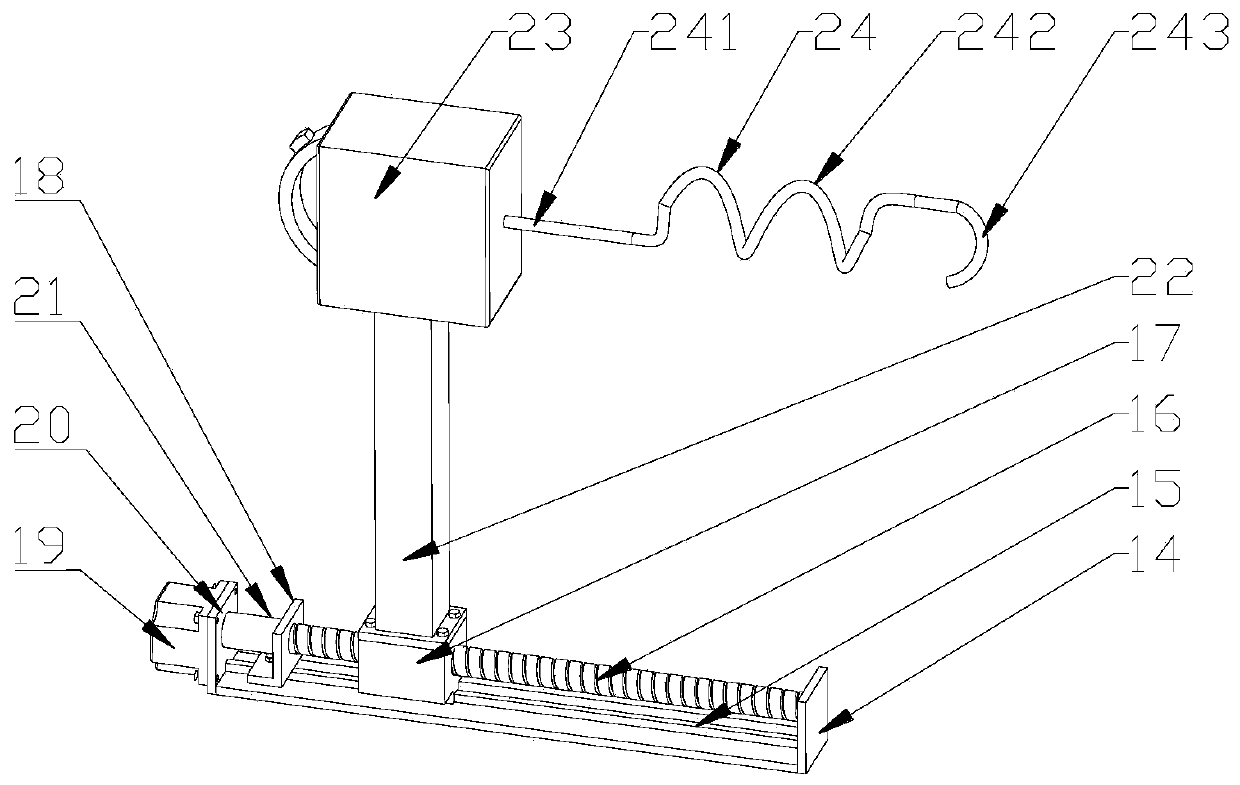

Mountain land small-size potato harvesting and seedling vine separation combination machine

ActiveCN106612876AReduce omissionsAdaptive harvestLiftersTopping machinesAgricultural engineeringDepth limit

The invention relates to a mountain land small-size potato harvesting and seedling vine separation combination machine, belonging to the technical field of agricultural machinery equipment. The combination machine mainly comprises a rack, supporting wheels, a depth limiting wheel device and the like, wherein the depth limiting wheel device is used for ensuring that a digging blade device reaches a suitable digging depth and reaches a suitable height during traveling on the ground; the digging blade device is used for digging soil and turning potatoes out of the ground; a conveying and vibrating device is used for separating potatoes from soil; a vine lifting device is used for accurately lifting seedling vines on two sides of the machine and lodging vines into a vine clamping device; the vine clamping device is used for conveying received seedling vines to a cutting device; a worm and gear adjusting device is used for driving the vine clamping device to adjust the height up and down; the cutting device is used for accurately cutting the seedling vines delivered by the vine clamping device; and a transmission system is used for providing transmission power for the vine lifting device, the vine clamping device, the cutting device and the conveying and vibrating device. The combination machine provided by the invention can adapt to complex mountain land potato harvesting, better solves the problem that the seedling vines intertwine the machine, and enables harvested potatoes to be cleaner.

Owner:KUNMING UNIV OF SCI & TECH

Automatic holboellia latifolia skin-and-flesh separation device

ActiveCN110710695AHigh speedImprove efficiencyFruit stoningVegetable peelingControl systemHolboellia latifolia

The invention discloses an automatic holboellia latifolia skin-and-flesh separation device, and belongs to the field of agricultural machinery. A flesh advancement device, a shielding disc, an end-cutting device and a flesh scraping device are sequentially installed on the ground from front to back, a fixing device for fixing holboellia latifolia to be processed is arranged on the upper part of the flesh advancement device, an information acquisition module in a control system is installed on the upper part of the fixing device, a driver in the control system is connected with a stepping motorin the flesh scraping device, the flesh advancement device and the end-cutting device are separately arranged outside the front end face and the rear end face of the shielding disc which is vertically arranged, and a suction cup for fastening is arranged at the lower end of the shielding disc. The one-time skin-and-flesh separation of holboellia latifolia is achieved, high speed and high efficiency are achieved, fruit seeds and fruits are separated in a rotating mode together to make up for the lack of mechanical peeling of the whole holboellia latifolia, time is greatly saved, and clean separation, high speed, high efficiency and simple and convenient operation are achieved.

Owner:CHINA AGRI UNIV

Paddy rice threshing apparatus

The invention belongs to the technical field of agricultural machines, concretely relating to a paddy rice threshing apparatus. The problem that uniaxial and biaxial threshing cylinder structures failto meet the requirement of agricultural production is resolved. In order to resolve the technical problem, the invention puts forward the paddy rice threshing apparatus comprising crushing devices, acleaning sieve board, a feeding hopper, a winnower, a fan, a frame and a whirlwind separating cylinder. The paddy rice threshing apparatus has high threshing efficiency.

Owner:JIXI YUANDAO AGRI IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com