Patents

Literature

131results about How to "Heated with" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photovoltaic power generation and solar heat collector

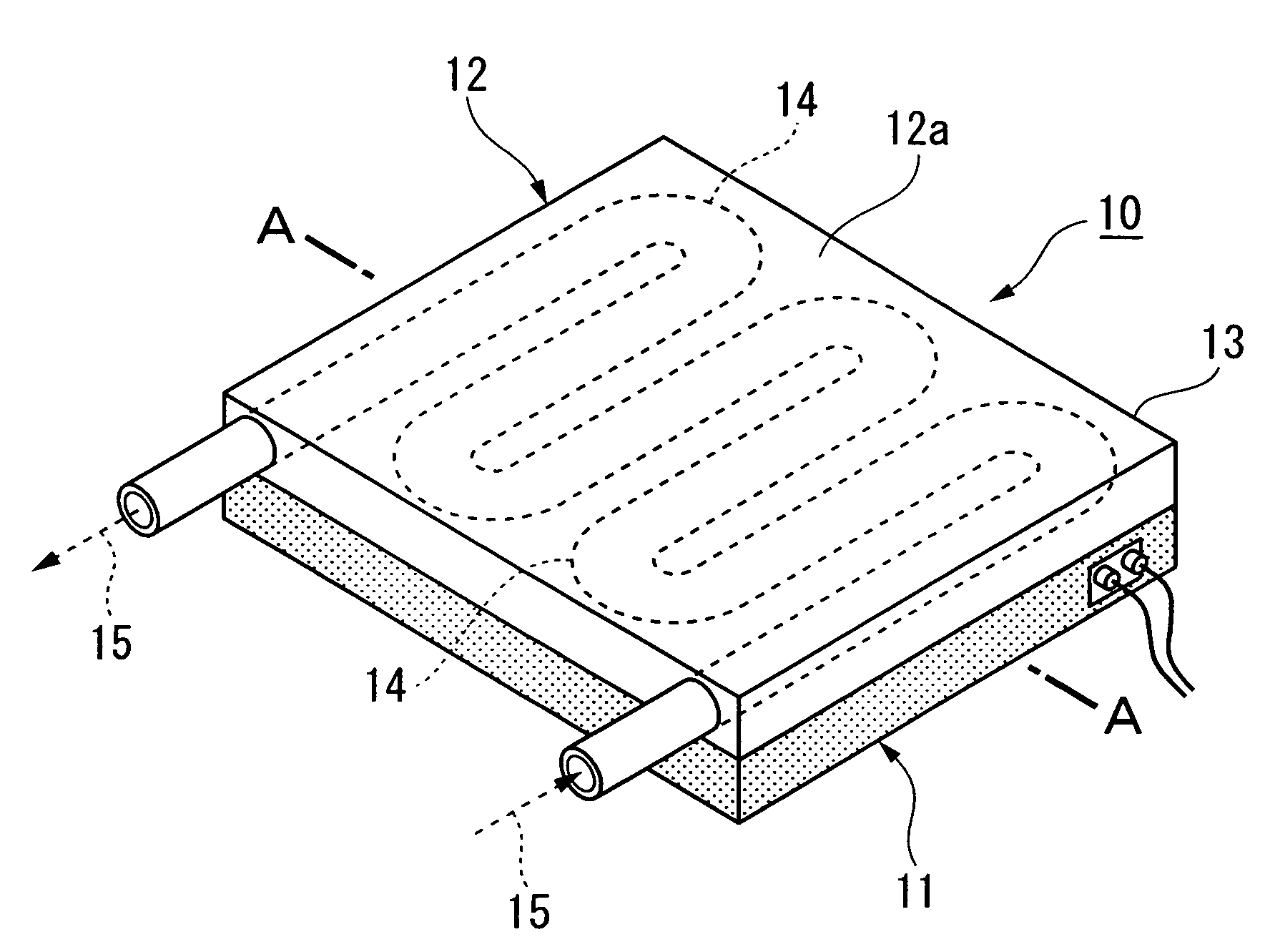

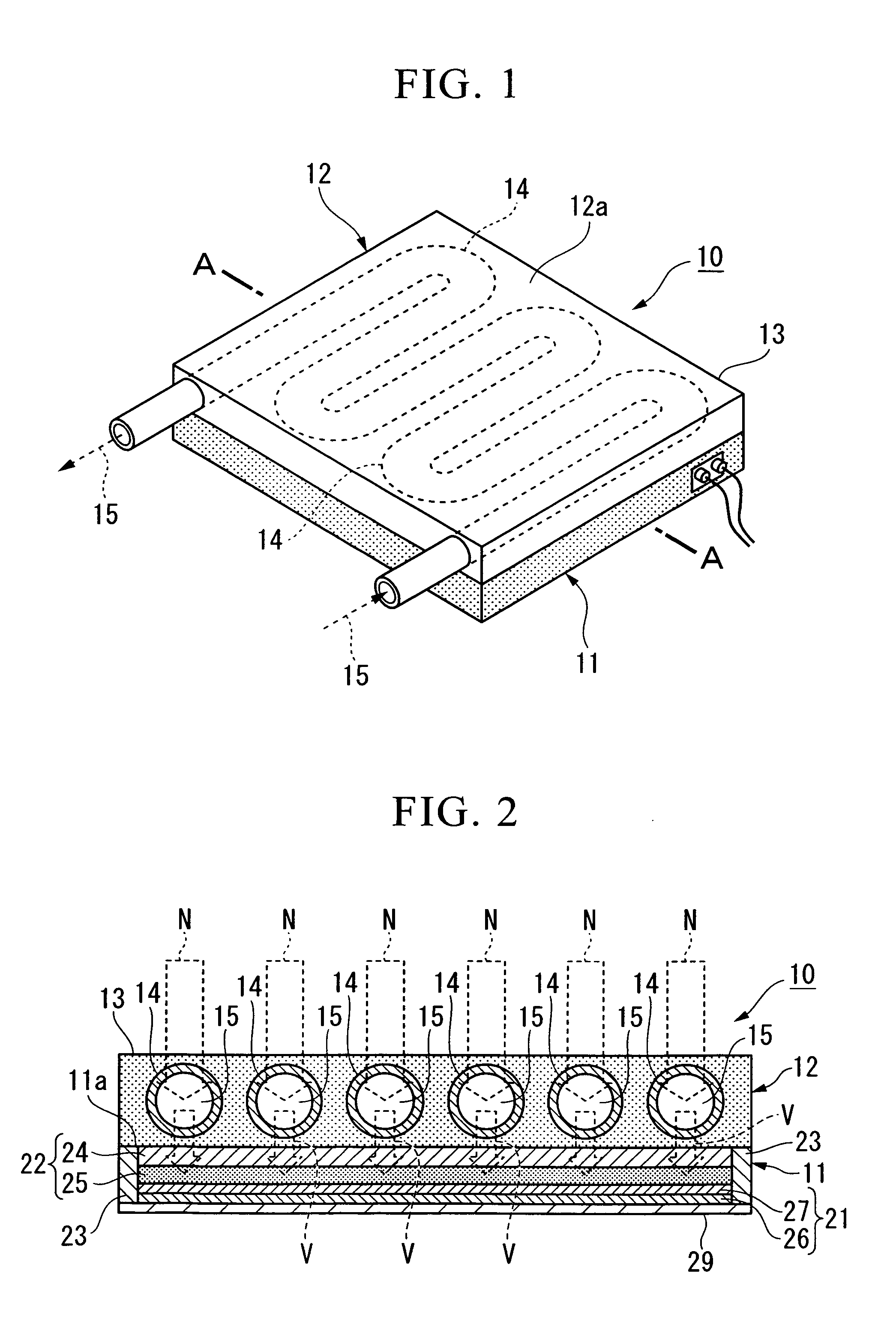

InactiveUS20090288705A1Effectively utilize sunlightRemove electric powerSolar heating energyLight-sensitive devicesEngineeringSolar thermal collector

Provided is a photovoltaic power generation and solar heat collector which can be installed in a small area and can simultaneously maintain a high collection efficiency and a high photoelectric conversion efficiency. The photovoltaic power generation and solar heat collector (10) includes a dye-sensitized photovoltaic cell (11); and a heat collection panel (12) provided on top of the dye-sensitized photovoltaic cell (11). Sunlight is incident on a top surface of the heat collection panel (12).

Owner:ELECTRIC POWER DEVELOPMENT COMPANY

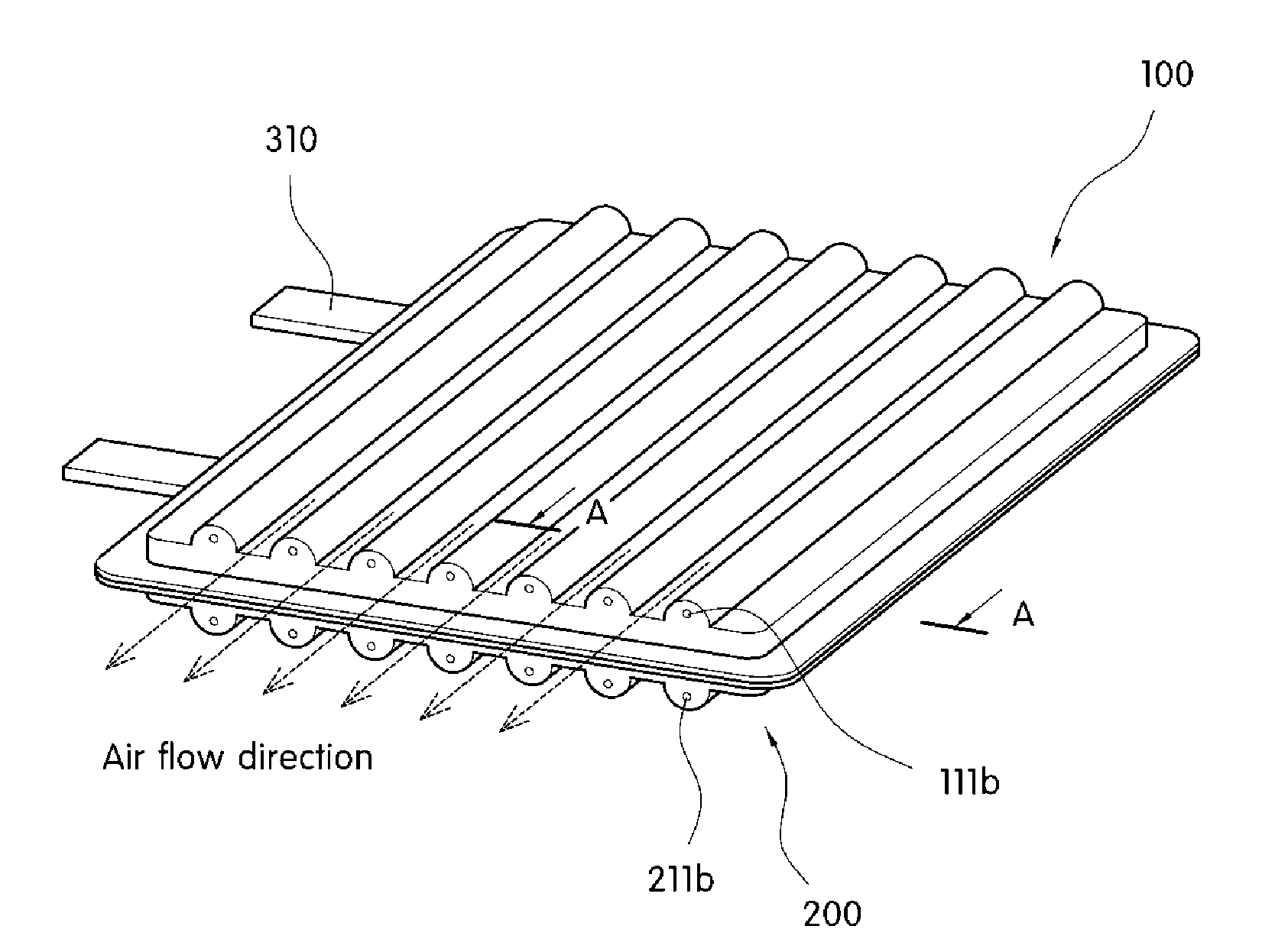

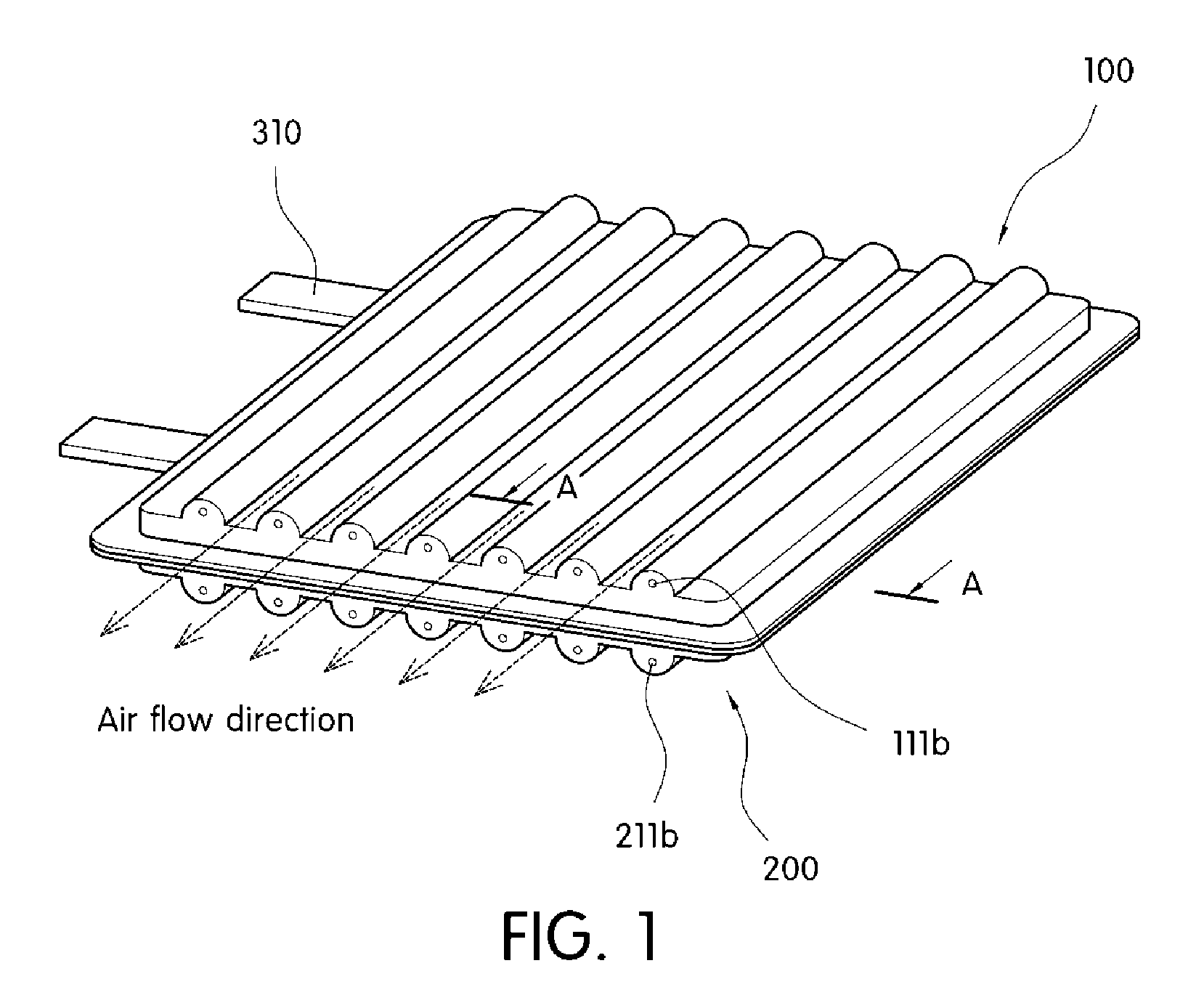

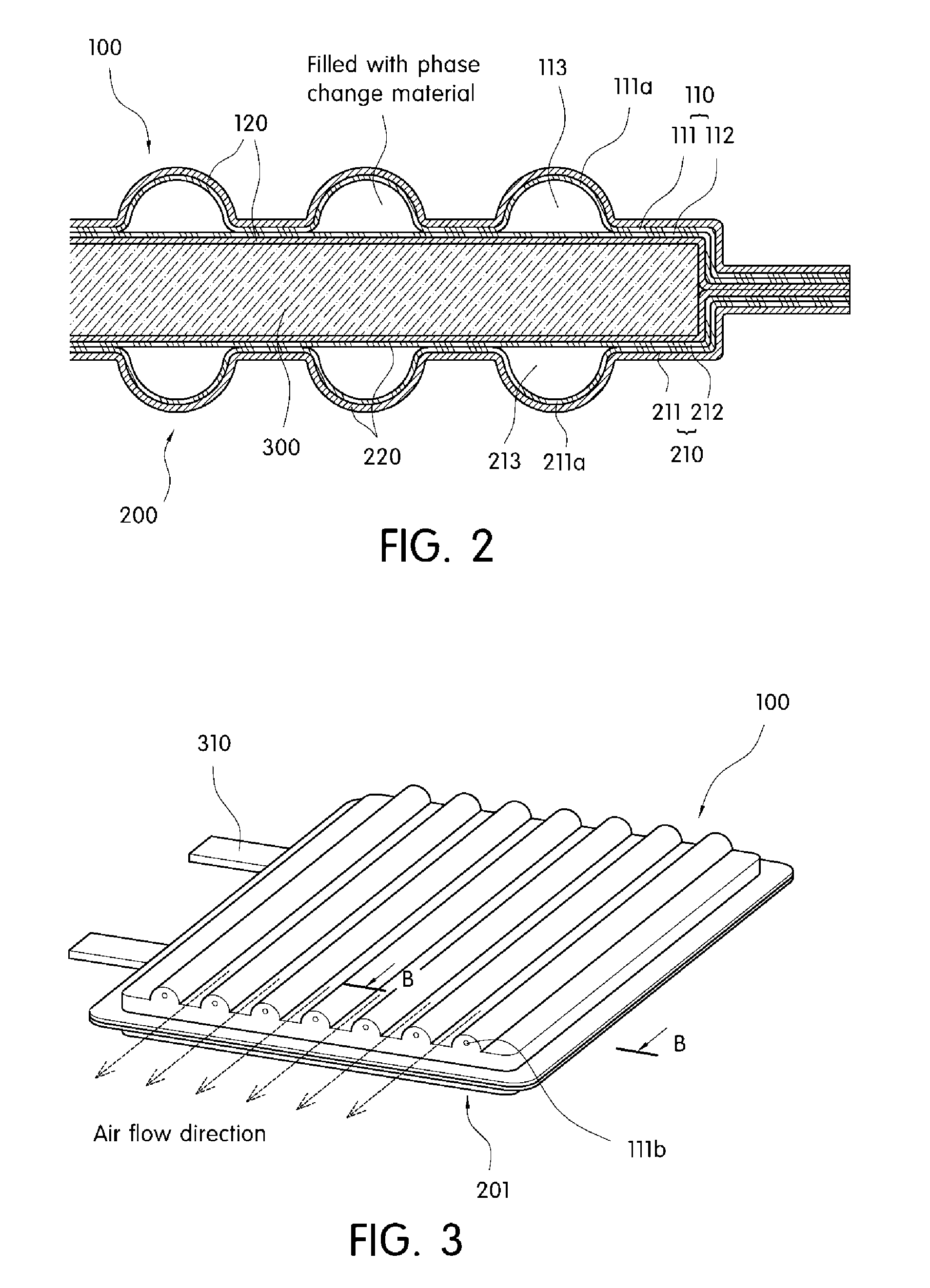

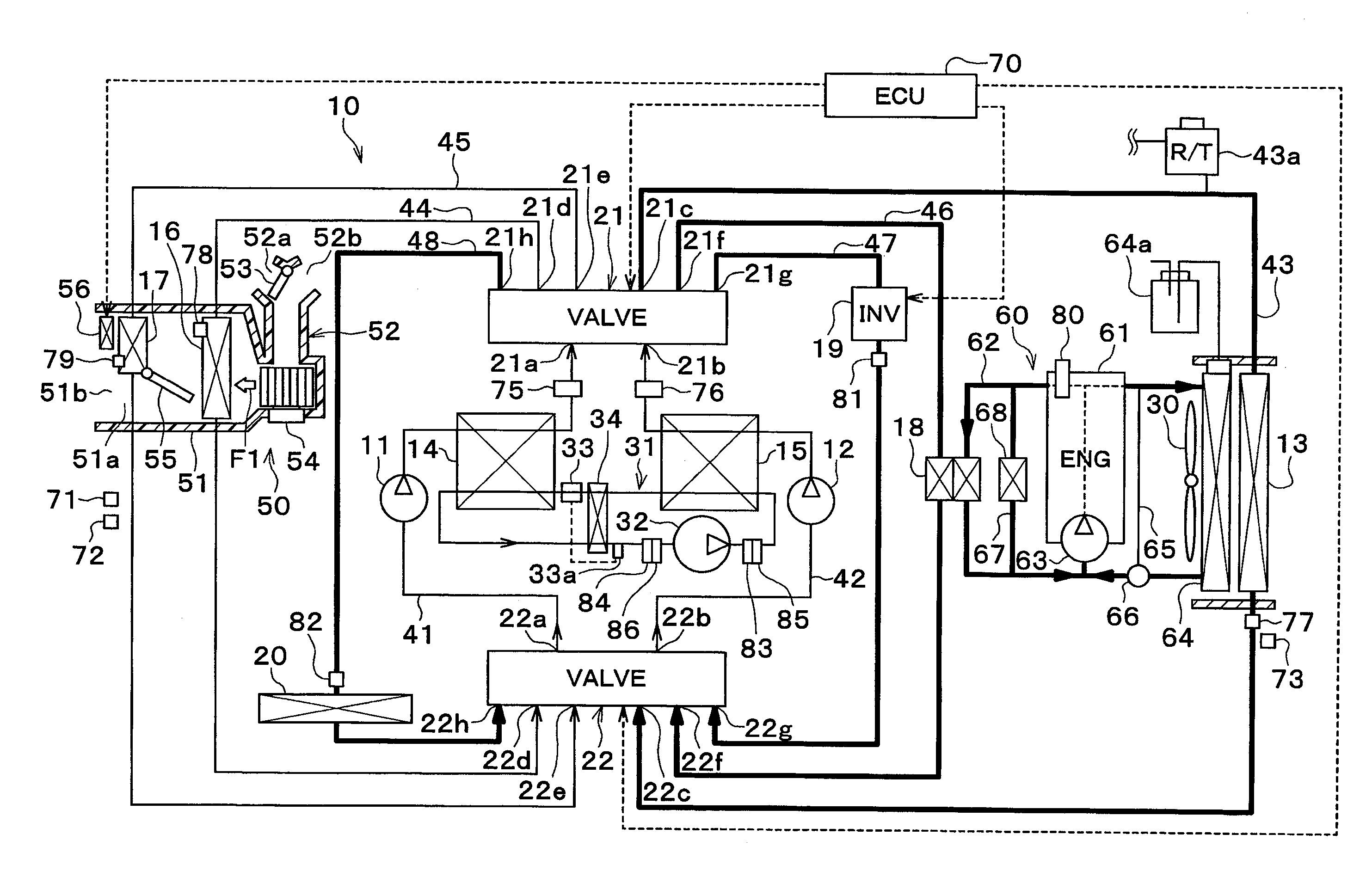

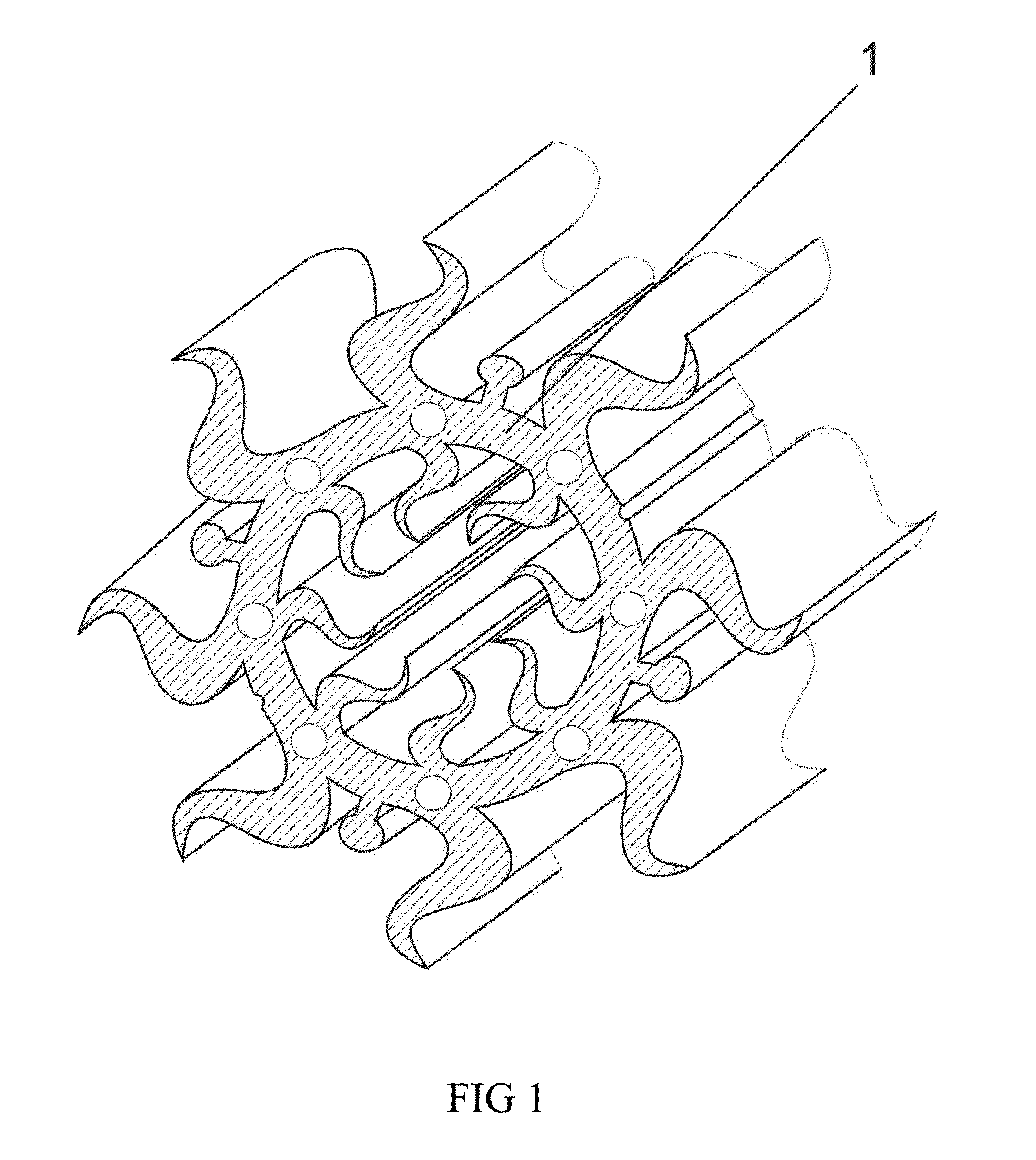

Battery package filled with phase change material and battery using the same

ActiveUS20130084487A1Easy to controlHeated withElectrolyte moving arrangementsSecondary cellsEngineeringPhase change

A battery and battery package is disclosed which improves a battery's heat dissipation capability by using an aluminum material and a phase change material capable of maintaining a suitable temperature through phase change according to a temperature in order to prevent a battery from being deteriorated in terms of performance. More specifically, battery package has a top case and a bottom case as a battery cell case for housing a battery cell. The top and bottom cases are adhered to each other, and either or both the top and bottom cases includes: a top sheet plate repeatedly undulated at predetermined intervals to form a plurality of unidirectionally extended convex parts to be filled with a phase change material; a bottom sheet plate formed in a flat shape and adhered to the top sheet plate; and a phase change material filled in between the convex parts and the bottom sheet plate.

Owner:HYUNDAI MOTOR CO LTD

Air conditioner

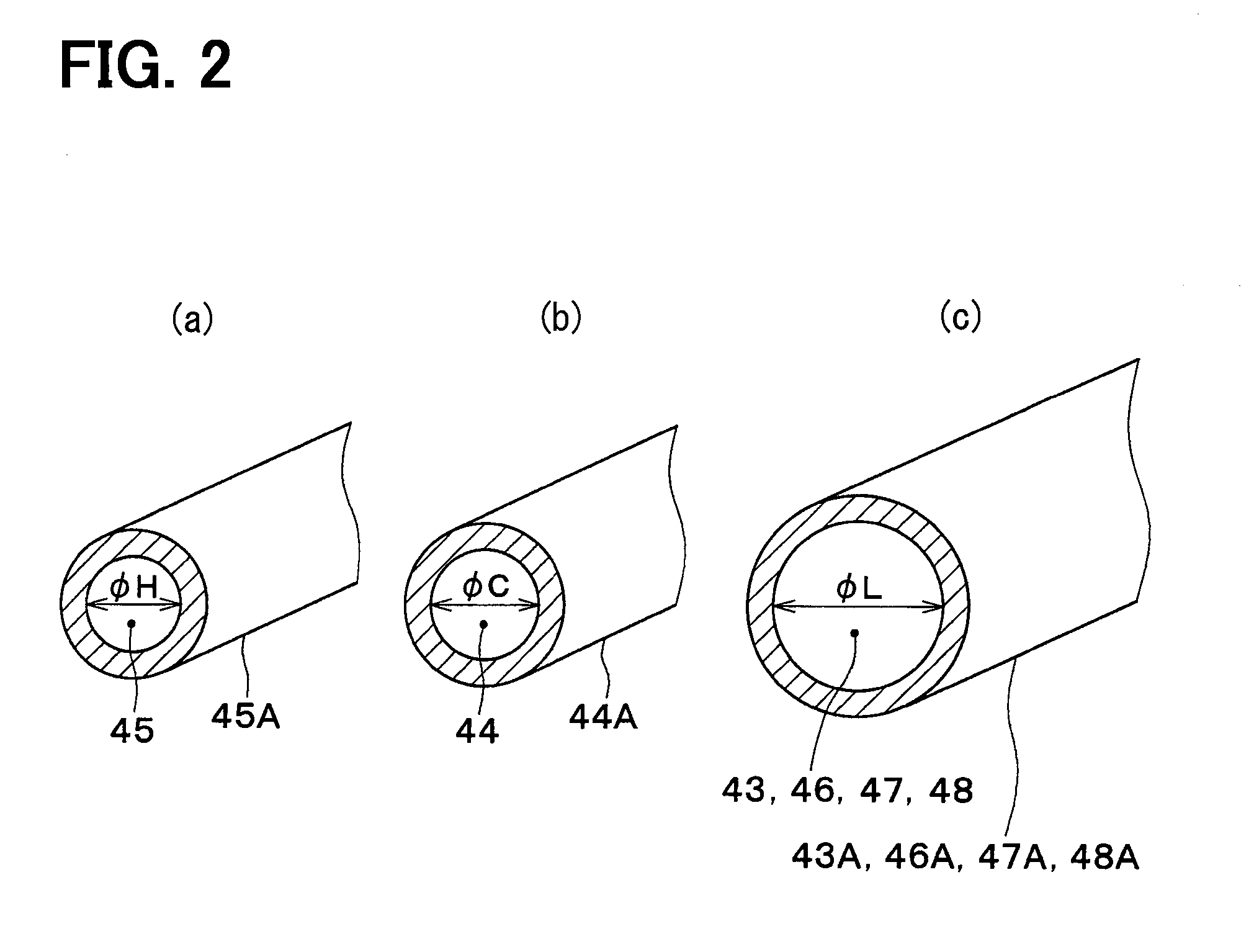

ActiveUS20160339761A1Thermal capacity is reducedImprove responseAir-treating devicesEvaporators/condensersEngineeringMicro heat exchanger

An air conditioner includes: a heat-medium air heat exchanger that exchanges sensible heat between a heat medium having a temperature adjusted by the heat-medium temperature adjuster and ventilation air blowing to a space to be air-conditioned; a heat transfer portion having a flow path through which the heat medium circulates to transfer heat with the heat medium having the temperature adjusted by the heat-medium temperature adjuster; a large-inner-diameter pipe that forms a heat-medium flow path between the heat-medium temperature adjuster and the heat transfer portion; and a small-inner-diameter pipe that forms a heat-medium flow path between the heat-medium temperature adjuster and the heat-medium air heat exchanger. The small-inner-diameter pipe has small inner diameters φH and φC, compared to the large-inner-diameter pipe.

Owner:DENSO CORP

Key with built-in transmitting element

InactiveUS6164101AHeated withAverage pressureAnti-theft devicesKeysMechanical engineeringSynthetic resin

A container made from a hard synthetic resin is provided on a key body (12). A container half (26) and the other container half (27) of the container (16) are attached to a key body (12) and a transmitting element (18) is secured to the container halves (26) and (27) in a sealed condition. A soft resin outer skin is molded on the outer surfaces of the key body (12) and the resin container (16). Heat and pressure during the molding of the resin outer skin are received by the resin container (16) so that the transmitting element 18 therein is protected therefrom.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

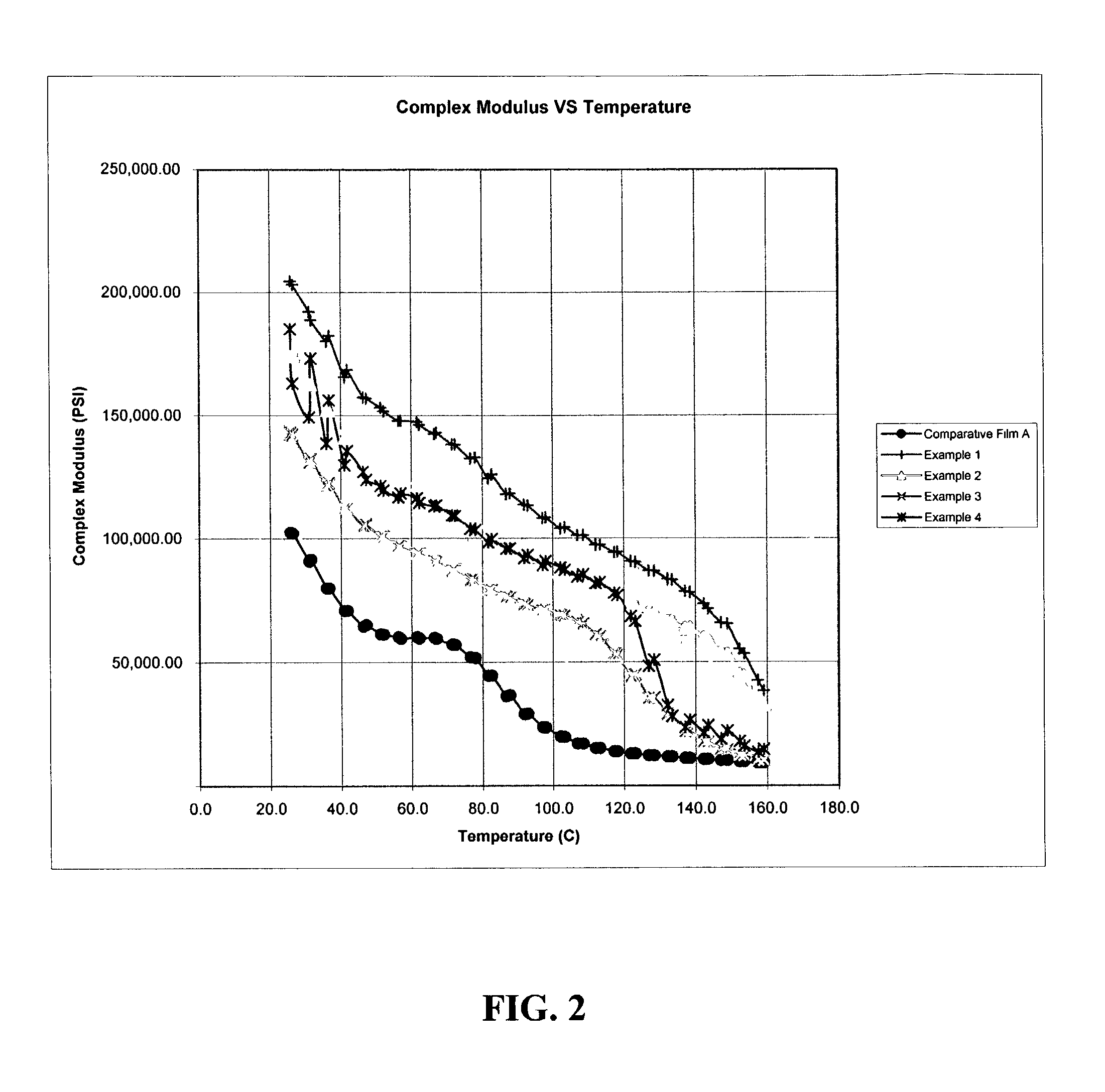

Amorphous polyamide resin composition and molded product

Provided are an amorphous polyamide resin composition having high transparency, and is excellent in heat resistance and stiffness, and a molded product thereof. The glass filler contains, expressed in terms of oxides by mass %, 68 to 74% of silicon dioxide (SiO2), to 5% of aluminum oxide (Al2O3), 2 to 5% of boron oxide (B2O3), 2 to 10% of calcium oxide (CaO), 0 to 5% of zinc oxide (ZnO), 0 to 5% of strontium oxide (SrO), 0 to 1% of barium oxide (BaO), 1 to 5% of magnesium oxide (MgO), 0 to 5% of lithium oxide (Li2O), 5 to 12% of sodium oxide (Na2O), and 0 to 10% of potassium oxide (K2O), where a total amount of lithium oxide (Li2O), sodium oxide (Na2O), and potassium oxide (K2O) is 8 to 12%.

Owner:ASAHI FIBER GLASS CO LTD

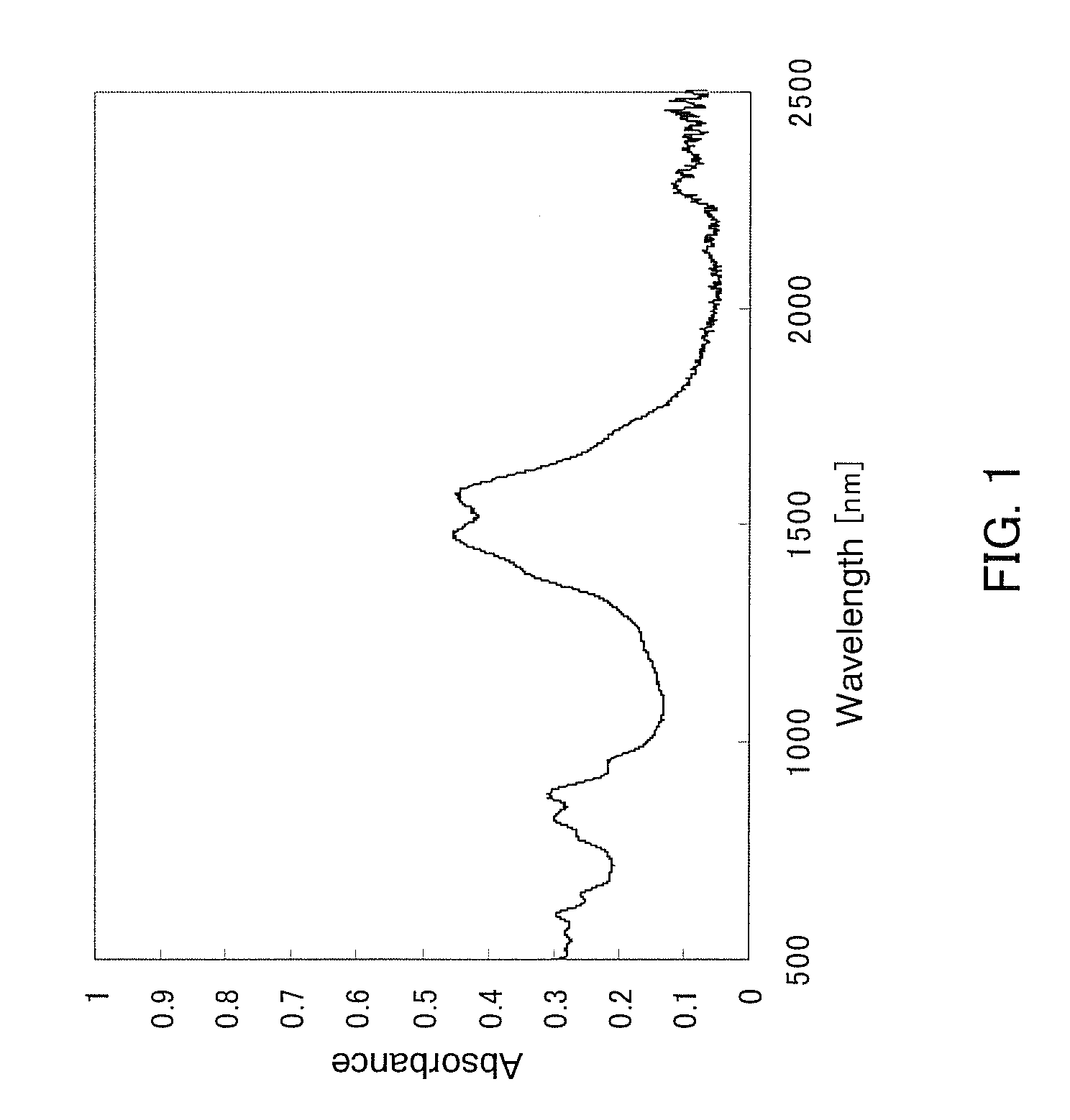

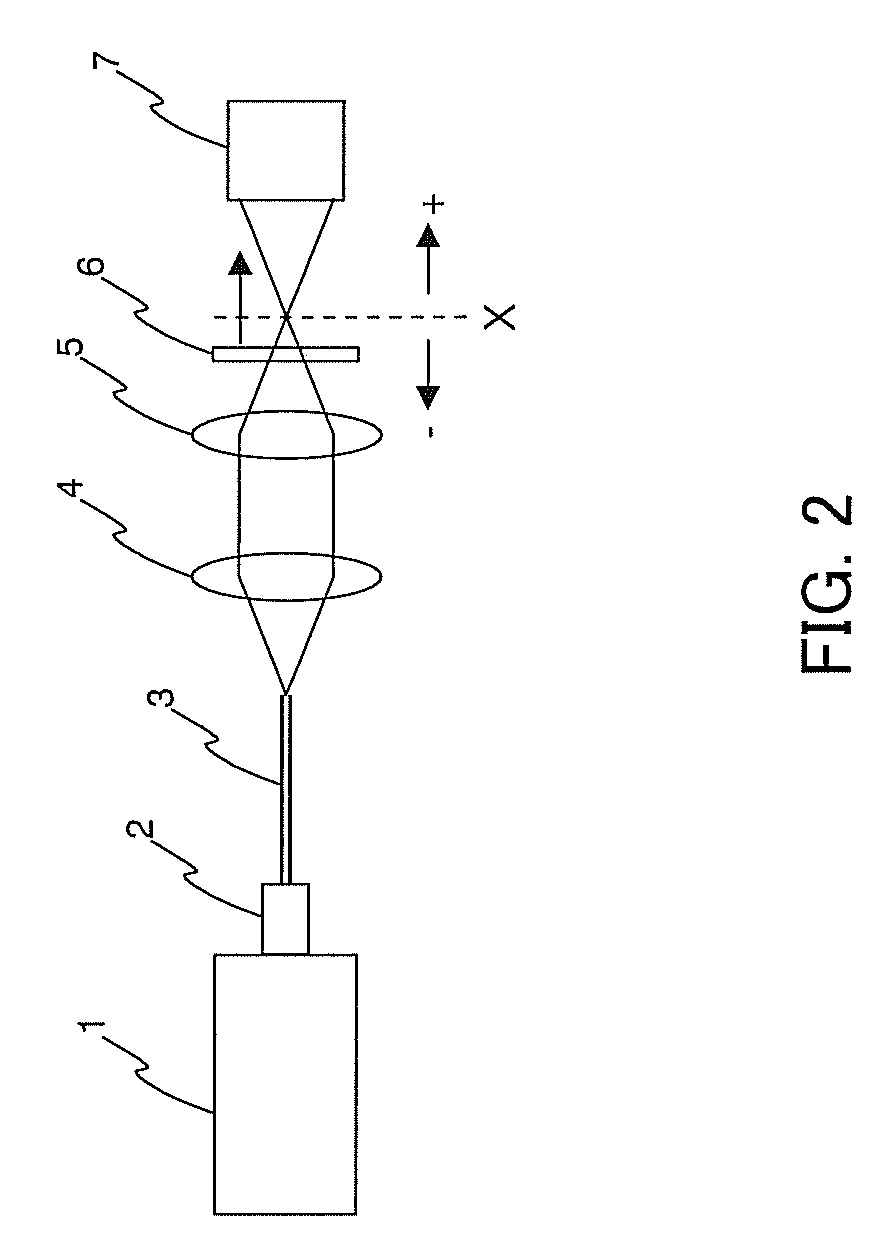

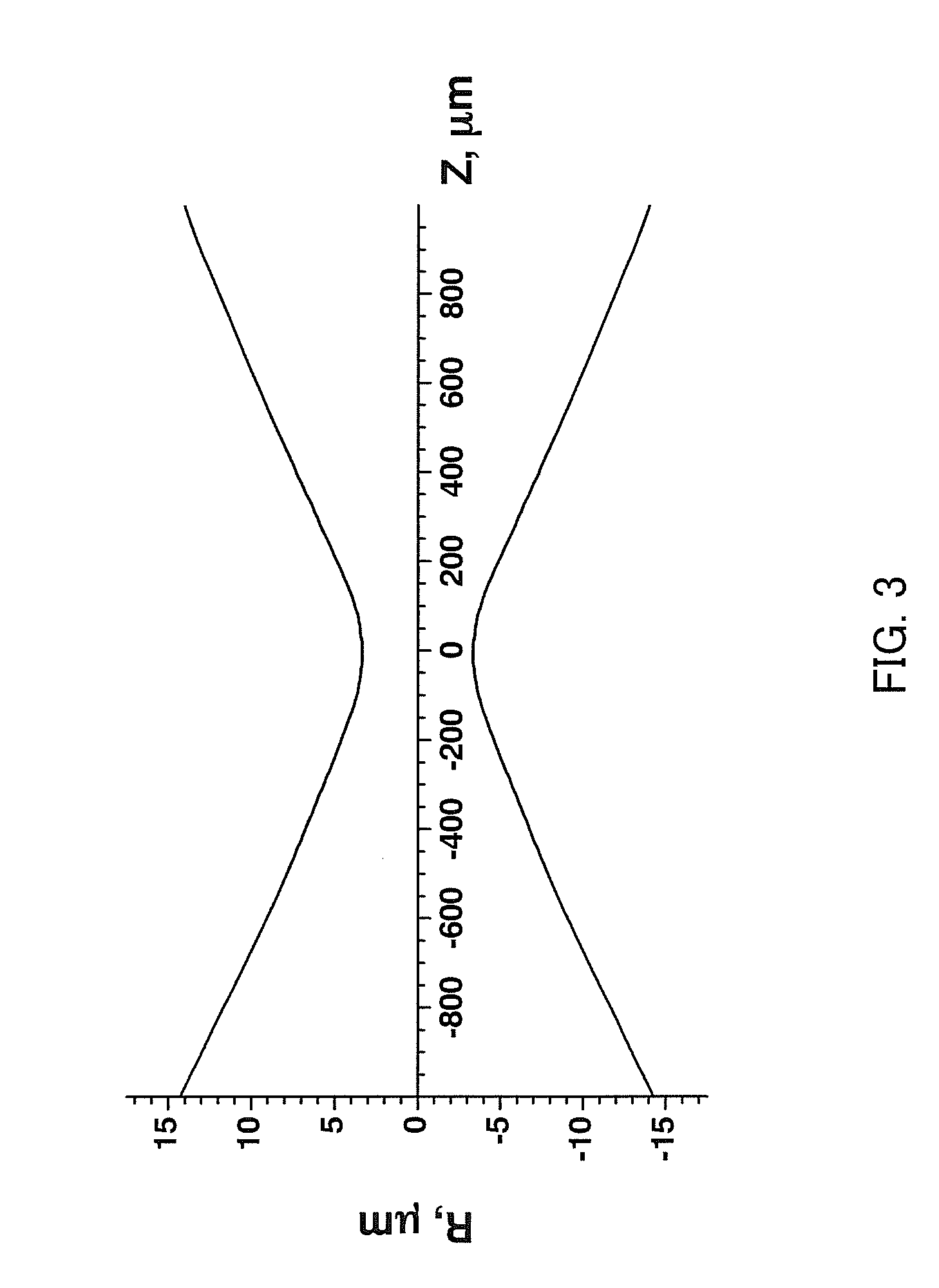

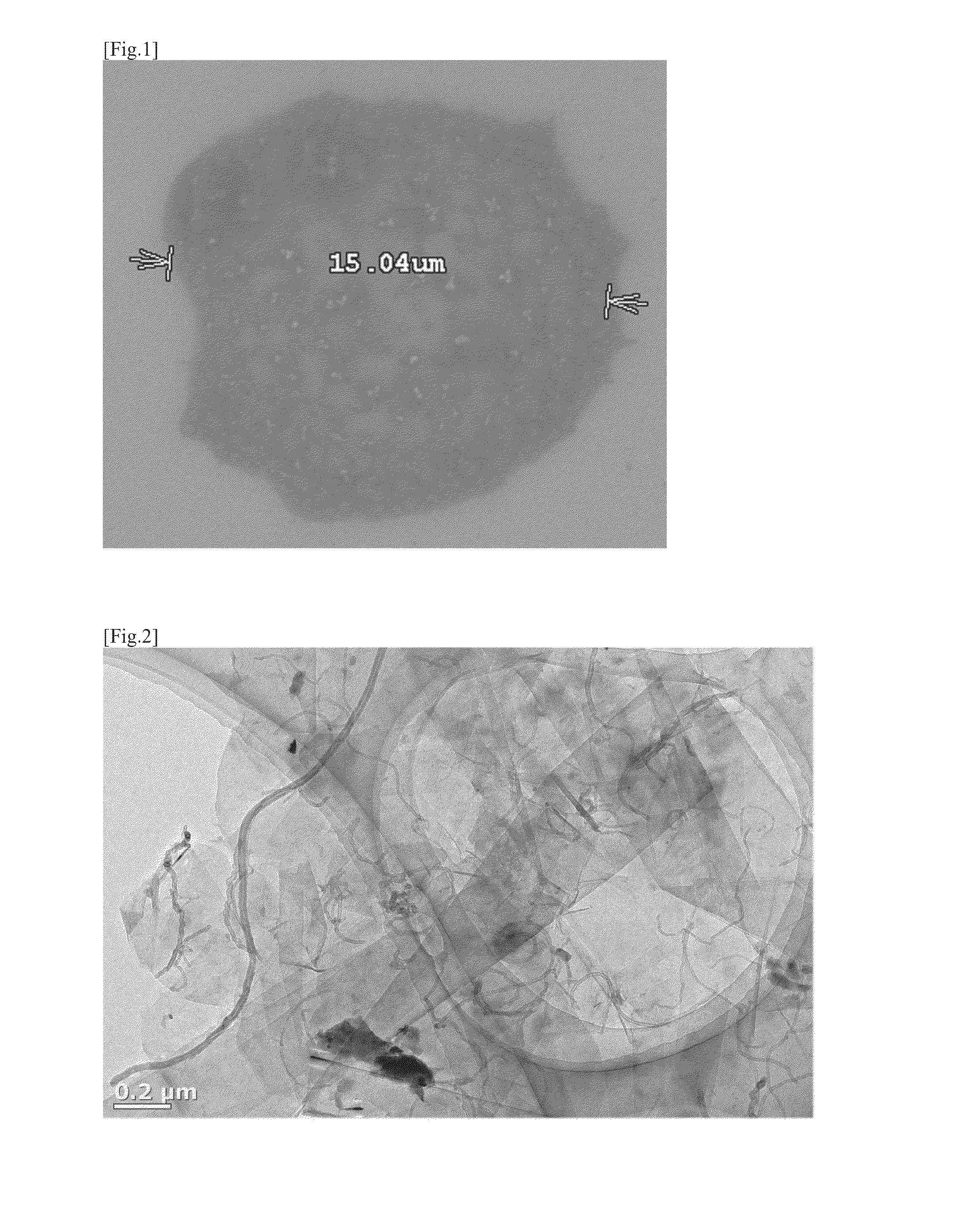

Saturable Absorber of Polyimide Containing Dispersed Carbon Nanotubes

InactiveUS20080258117A1Increase resistanceImprove transmittanceMaterial nanotechnologyDiffusing elementsOrganic solventCarbon nanotube

A carbon nanotube-dispersed polyimide saturable absorber excellent in an optical quality, obtainable by mixing a carbon nanotube dispersion liquid comprising a carbon nanotube, an amide-based polar organic solvent, and a nonionic surfactant and / or a polyvinylpyrrolidone (PVP) with a mixture solution of a solvent soluble polyimide and an organic solvent. A method for producing the same, comprising the steps of dispersing a single-walled carbon nanotube in a mixture solution of an amide-based polar organic solvent and a nonionic surfactant under intensive stirring, mixing the resultant dispersion liquid with a polyimide mixed organic solvent, and removing the solvent.

Owner:NAT INST OF ADVANCED IND SCI & TECH

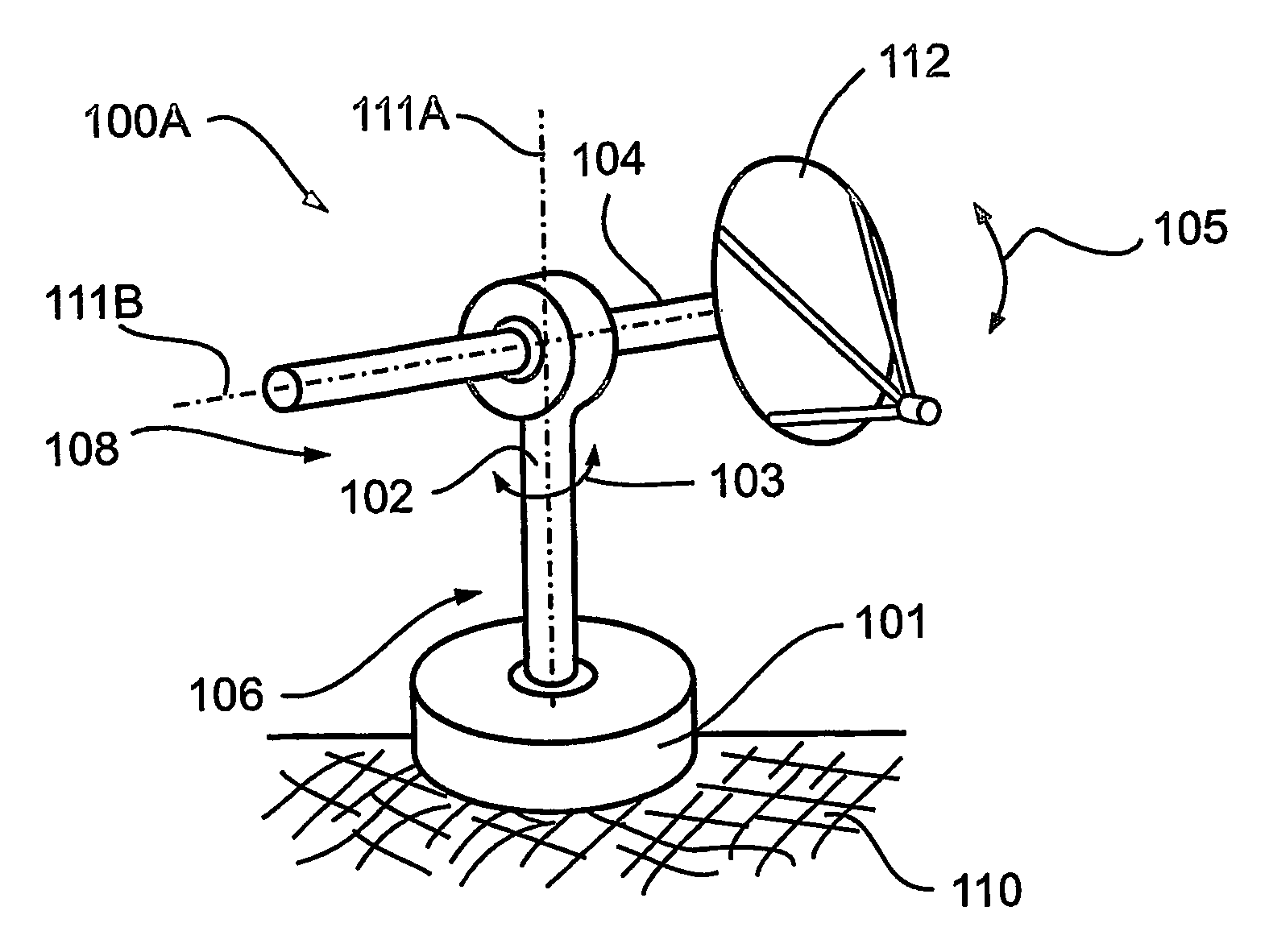

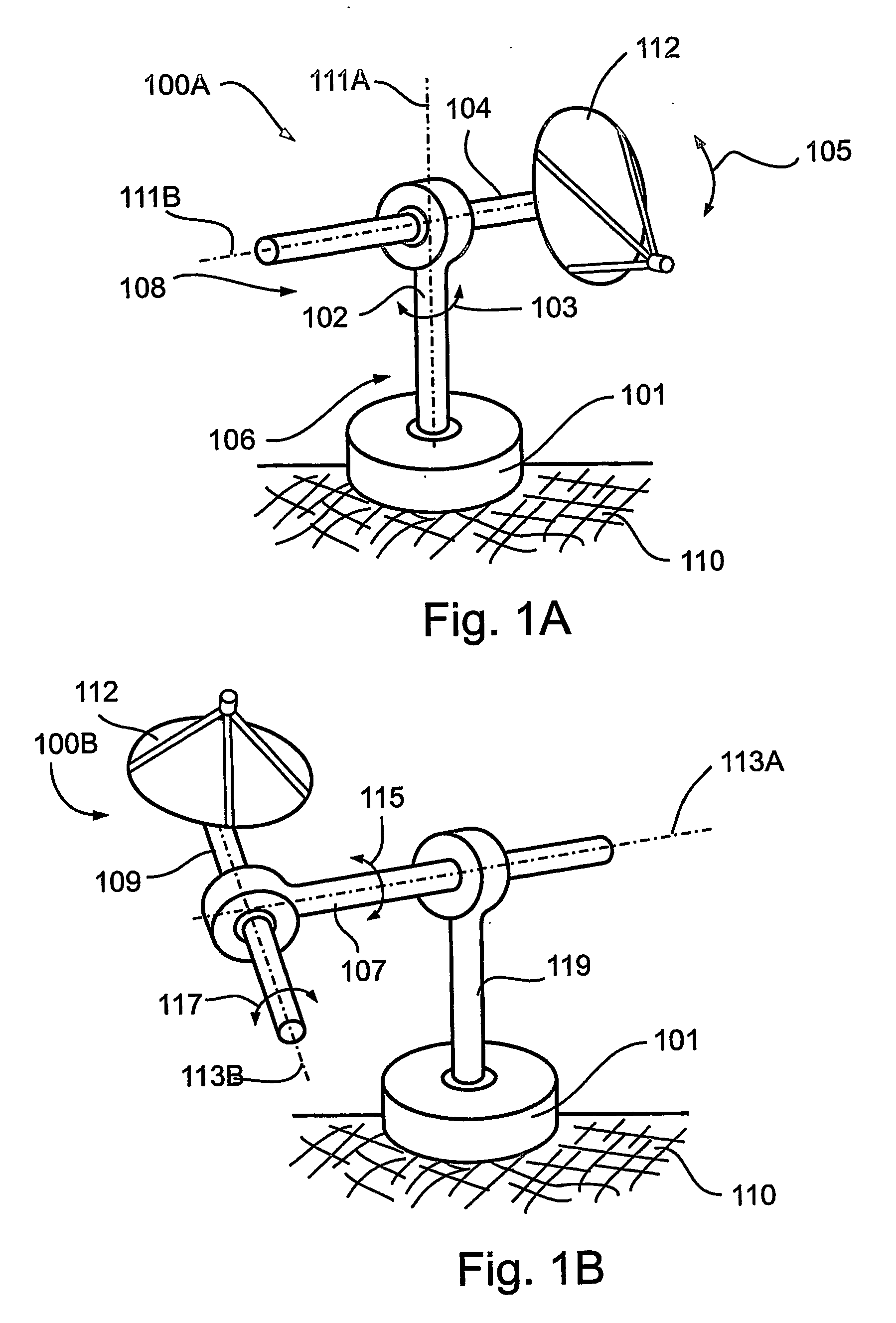

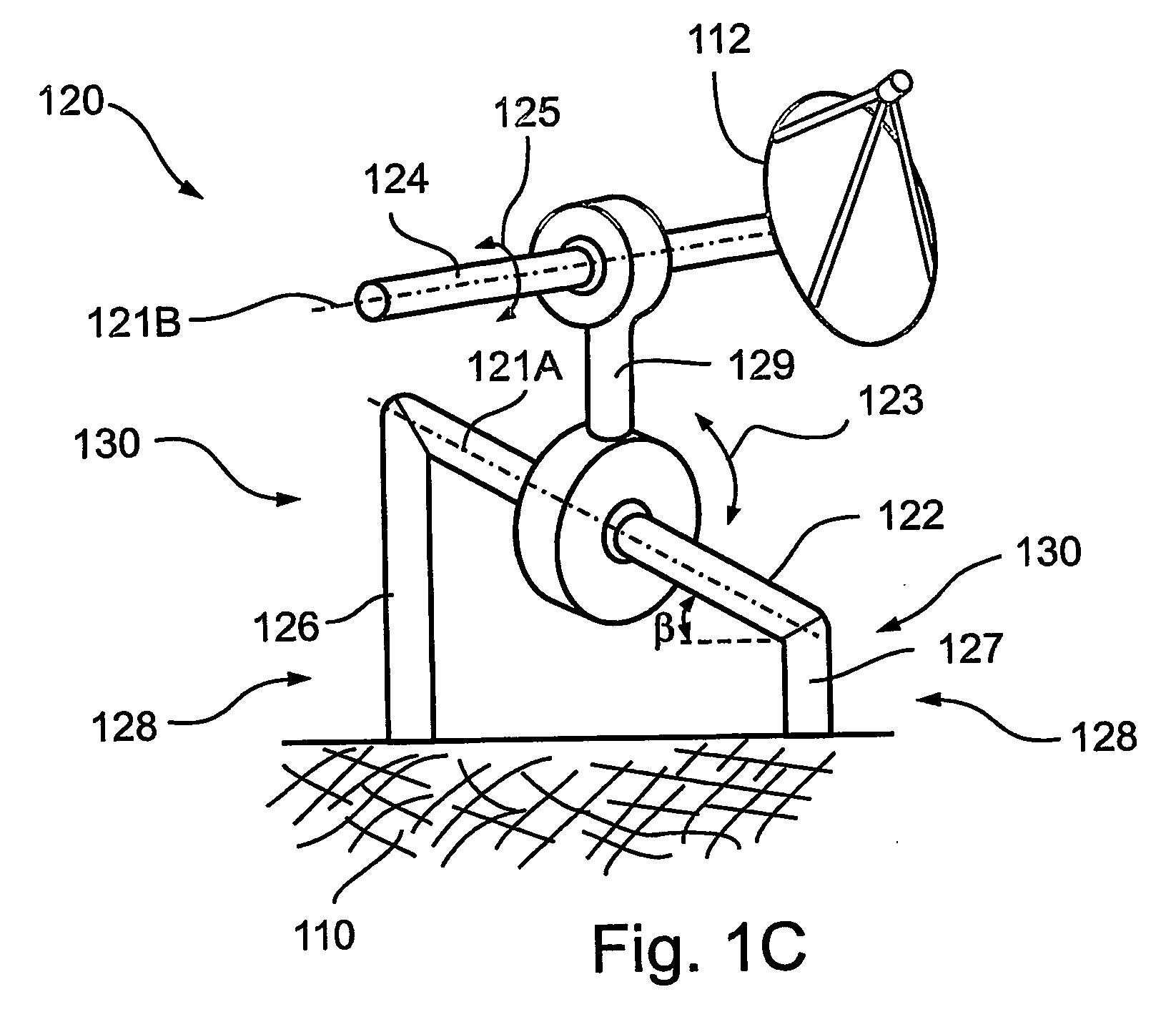

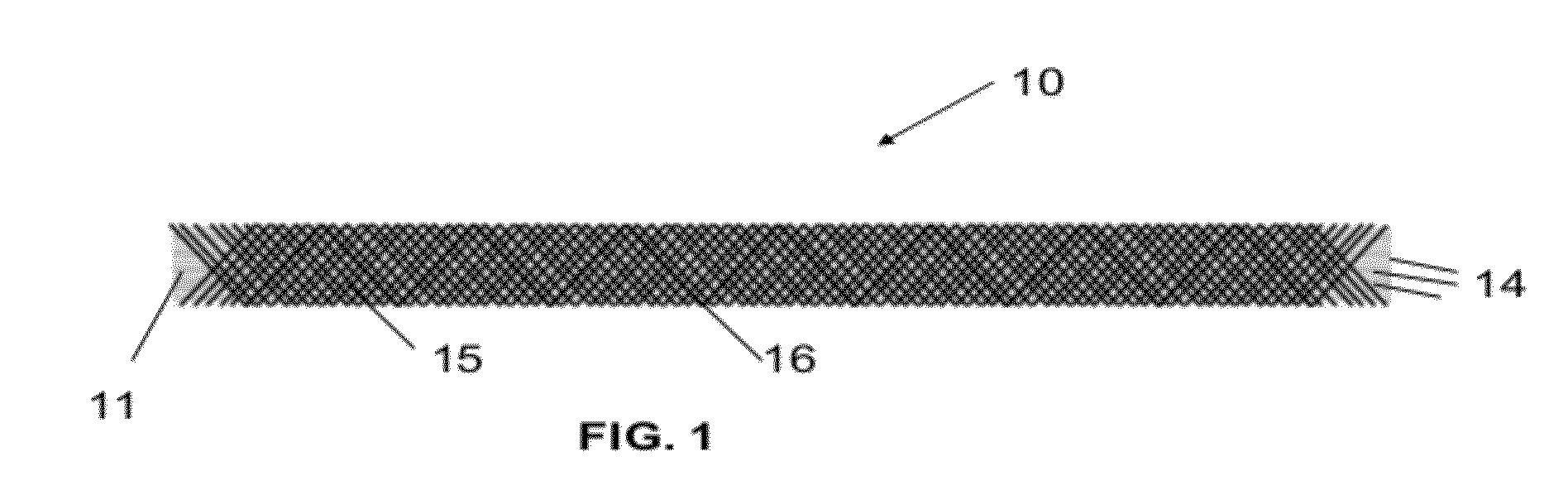

Small-scale, concentrating, solar chp system

InactiveUS20090194145A1Minimal investmentLow production costSolar heating energyPhotometry using reference valueHigh concentrationPower application

A high-efficiency, small-scale, combined heat and power, concentrating solar energy system (200), designed specifically for residential and other relatively low-power applications, rendering it cost-effective and economically viable. Two-axis tracking of a dish-like reflector (10) of between 1 and 2 meters in aperture ensures very high concentrating ratios of between 200 and 8-suns or even higher. In consequence very high coolant outlet temperatures, of 120-180° C. may be reached at the outlet of the collector coolant, which may be oil, gas, or pressurized water. The high coolant temperatures are advantageous because they may be used for air-conditioning. The high concentration is advantageous because the efficiency of the photo_voltaic cells is improved with higher concentration. The overall efficiency is greater than 60%. Additionally, a simple but accurate drive, designed as a radio-dial drive (14), with substantially zero backlash, and substantially zero drive, is provided for driving the concentrating solar energy system. Preferably, two radio-dial drives are employed and tracking is performed along two axes, of an azimuth-elevation mount, a polar mount, or a cross mount.

Owner:RAMOT AT TEL AVIV UNIV LTD

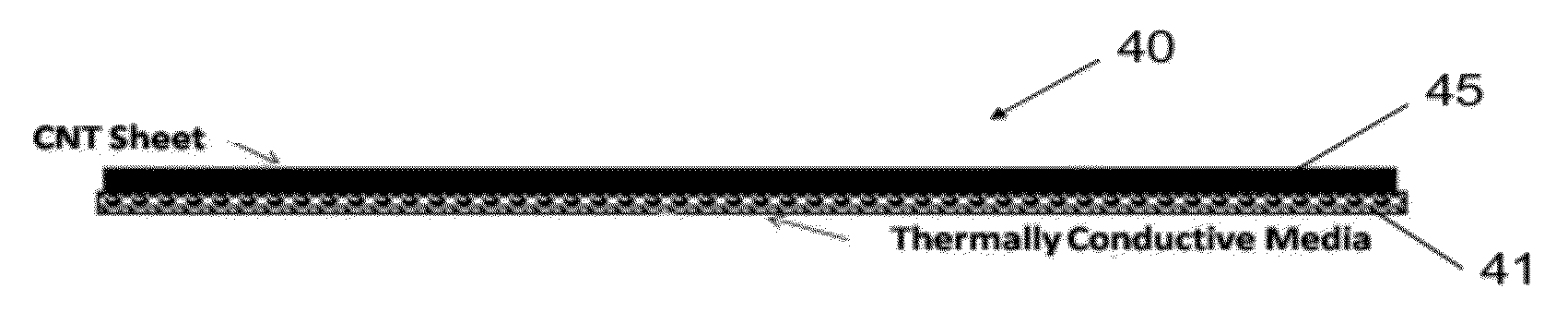

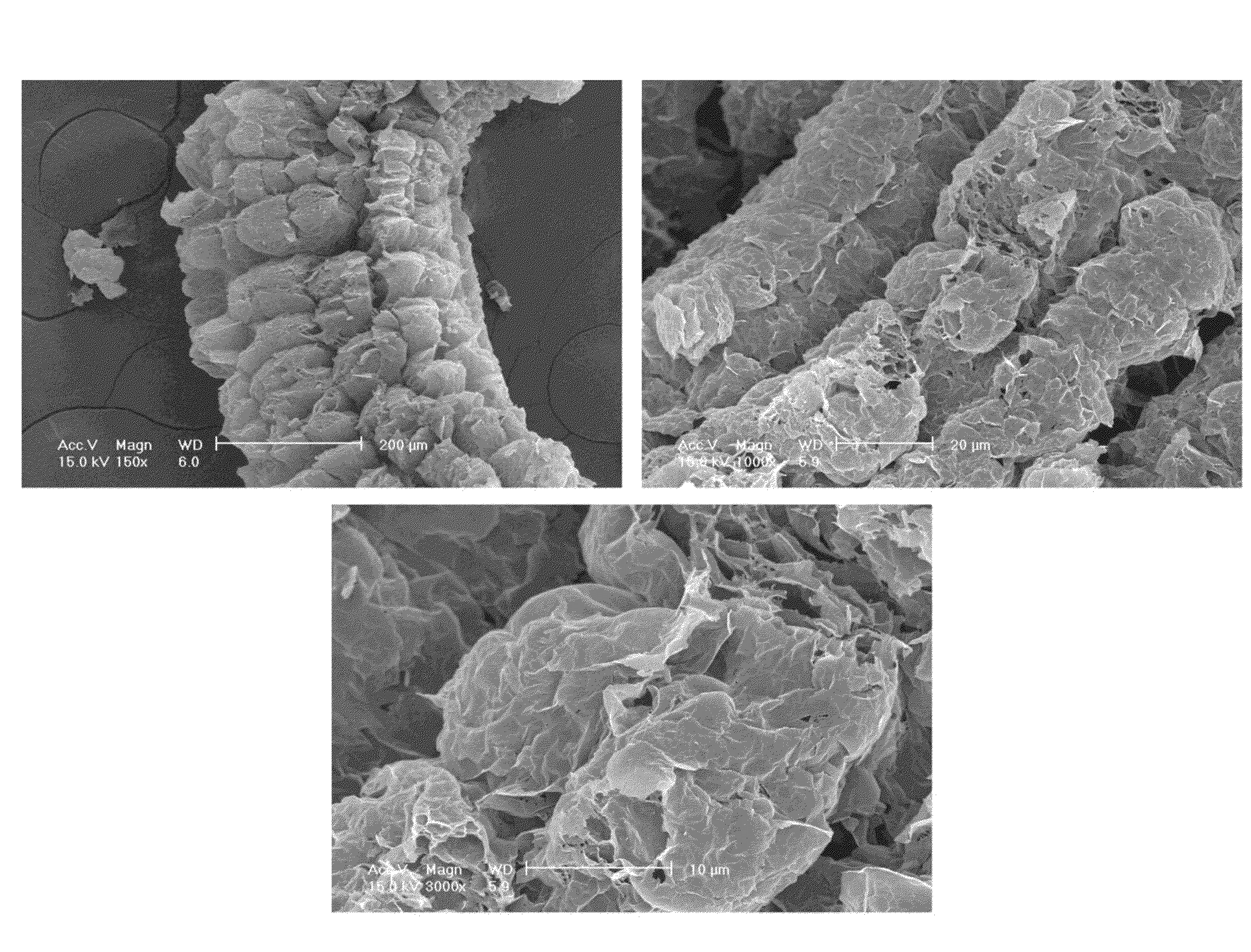

Systems and methods for thermal management of electronic components

InactiveUS20120118552A1Easy transferImprove cooling effectInsulated cablesHeat exchange apparatusElectrical resistance and conductanceCarbon nanotube

The device for extracting heat from carbon nanotubes wires or cables used under high power applications is provided. The device can include a thermally conductive member for placement against a heat source and for directing heat away from the heat source to a heat dissipating medium. The device can further include an electrically conductive member positioned on the thermally conductive member and made from a layer of carbon nanotubes, to reduce electrical resistance along the electrically conductive member. A geometric pattern can be imparted to the electrically conductive member to enhance dissipation of heat away from the thermally conductive member and the heat source.

Owner:NANCOMP TECHNOLOGIES INC

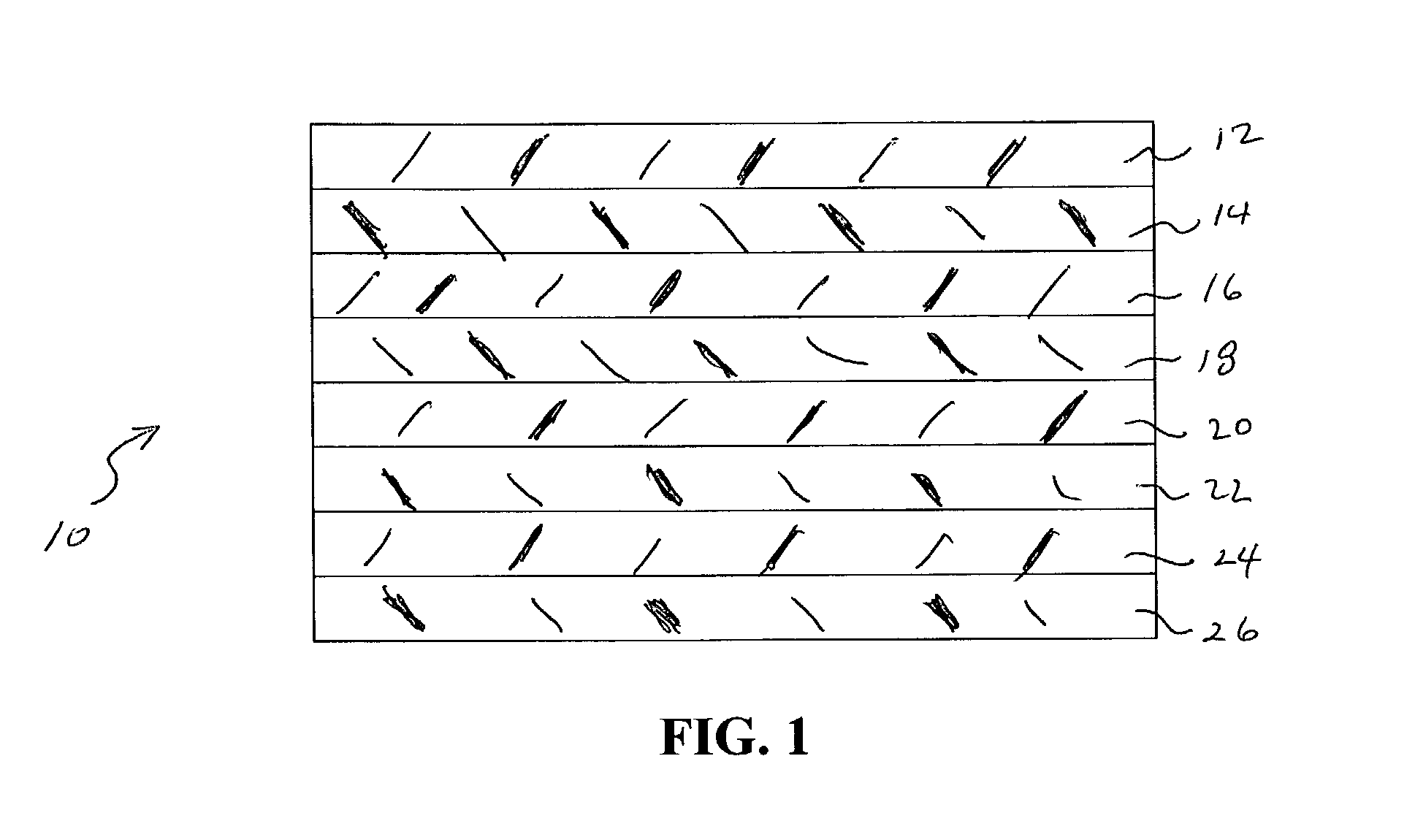

Resin-impregnated base substrate and method for producing the same

InactiveUS20070092709A1Excellent electrical propertiesGood lookingLamination ancillary operationsSynthetic resin layered productsPolyesterGlass fiber

A resin-impregnated base substrate is provided by immersing a sheet in an aromatic liquid crystal polyester solution composition so that the polyester is impregnated into the sheet, and removing the solvent. The composition comprises 20 to 50 parts by weight of an aromatic liquid crystal polyester and 100 parts by weight of an aprotic solvent having no halogen atom, wherein the sheet comprises fiber selected from the group consisting of polyolefin resin fiber, fluorocarbon resin fiber, aramid resin fiber, glass fiber, ceramic fiber and carbon fiber.

Owner:SUMITOMO CHEM CO LTD

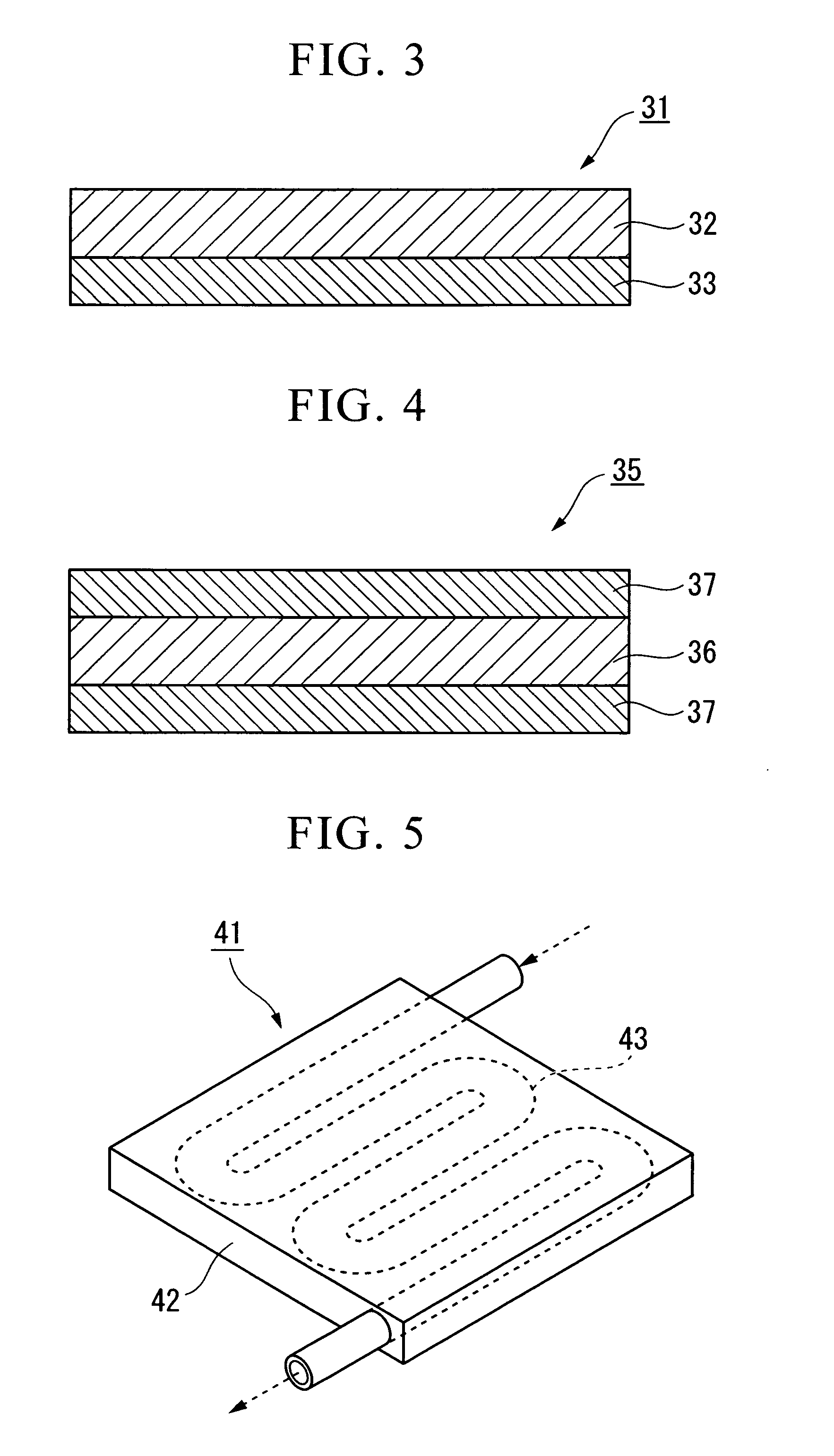

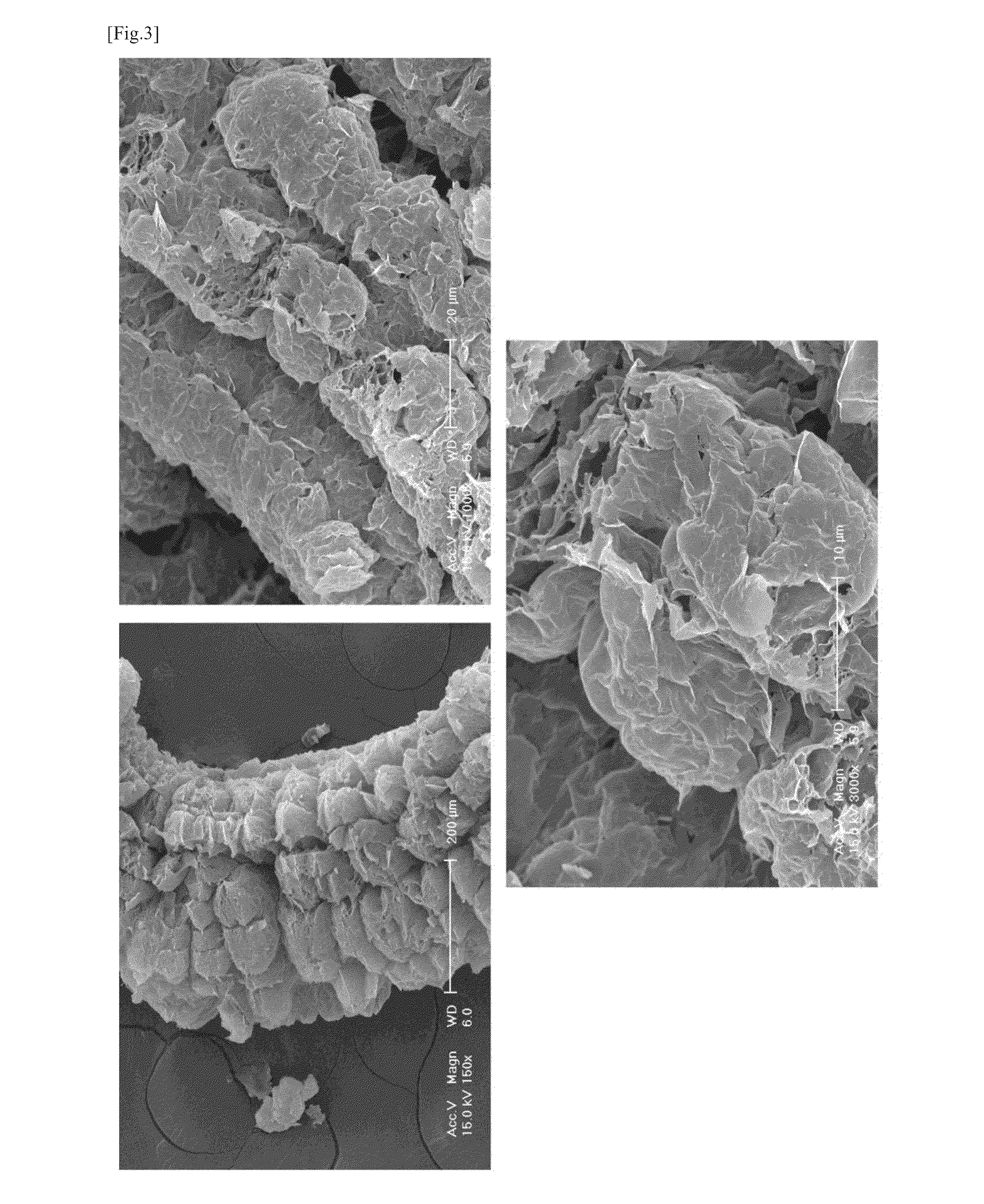

Heat dissipation sheet manufactured using graphene/graphite nanoplate/carbon nanotube/nano-metal complex and method of manufacturing the same

ActiveUS20160153730A1Good heat dissipationReduce metal contentLayered productsSemiconductor/solid-state device detailsMechanical componentsEmissivity

To effectively dissipate heat discharged from various electronic or mechanical components, a high-performance ultra-thin heat dissipation sheet with high thermal conductivity and thermal emissivity by using a graphene / graphite nanoplate / carbon nanotube / nano-metal complex that forms a high-content 3D-structured complex that is stably dispersed, and a method of manufacturing the same, is provided. The method includes preparing a first heat dissipation film by sintering a composition for dissipating heat including a graphene / graphite nanoplate / carbon nanotube / nano-metal complex dispersion solution and a binder, and forming a second heat dissipation film on one surface or two opposite surfaces of the first heat dissipation film by using a graphene adhesive including the graphene / graphite nanoplate / carbon nanotube / nano-metal complex dispersion solution and an adhesive. A heat dissipation sheet according to the present invention may be utilized as a material with heat dissipation properties constituting a heat sink alone or with other materials with heat dissipation properties.

Owner:WORLDTUBE

Heat-generating composition for topical application to skin

ActiveUS7211249B2Protection from damageHeated withCosmetic preparationsPeptide/protein ingredientsSkin surfaceOxygen

The present invention provides a method of sustaining the rate of heat felt on the skin as a result of an exothermic reaction between a combination of an unencapsulated and an encapsulated catalase, and peroxide. The catalase component provides a sustained heat release and in combination with other non-catalase heat-generating agents, the rate of heat released and felt on the skin can be further controlled. The compositions of the present invention also soften the skin and contribute to the health of the skin by reducing the presence of oxygen free radicals on the skin surface.

Owner:COLOR ACCESS

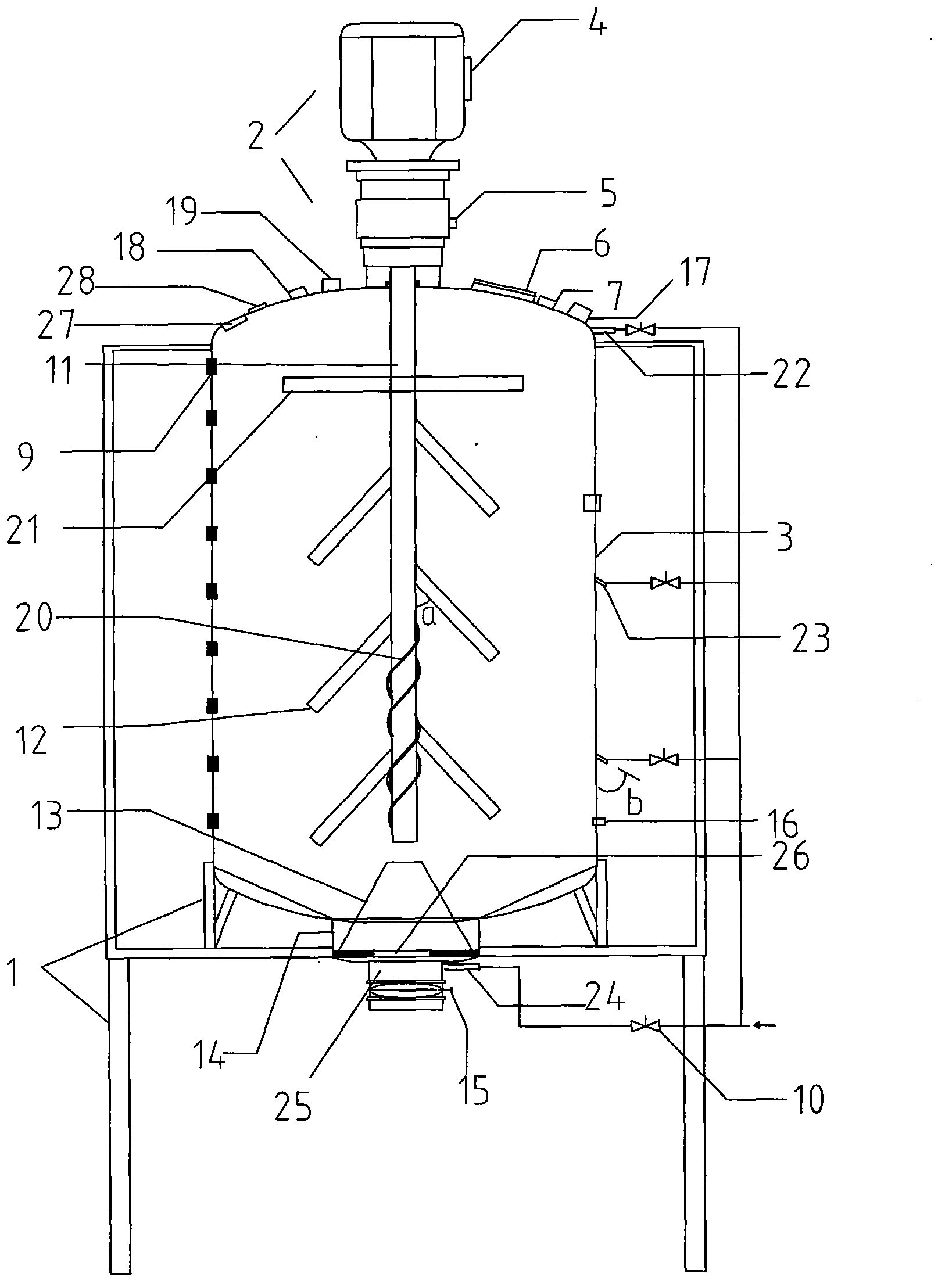

Multiple-magnetron type large-capacity microwave-assisted extraction machine and microwave-assisted extraction method thereof

InactiveCN103505902AHeating evenlyHigh extraction rateEnergy based chemical/physical/physico-chemical processesSolid solvent extractionEngineeringElectromagnetic field

The invention discloses a multiple-magnetron type large-capacity microwave-assisted extraction machine and a microwave-assisted extraction method thereof, belonging to the field of biological raw material extraction equipment and an extraction method. The multiple-magnetron type large-capacity microwave-assisted extraction machine comprises a rack, a transmission device, a microwave tank, a microwave device, an air-entrapping device, a rotor device, a discharging device and a control device, wherein a plurality of magnetron installing holes uniformly and equidistantly distributed are formed in the wall of the microwave tank; the microwave device comprises a plurality of high-frequency magnetrons which are uniformly and equidistantly arranged on the wall of the microwave tank, and the high-frequency magnetrons are connected with an external power source; the air-entrapping device comprises a plurality of compressed air inlets formed in the wall of the microwave tank, a compressed air input pipeline and a plurality of electromagnetic valves; the rotor device comprises a rotating shaft and a plurality of stirring wings which are fixed on the rotating shaft and form certain crossing angles with the rotating shaft. The multiple-magnetron type large-capacity microwave-assisted extraction machine has the advantages that feed liquid in the microwave tank continuously runs and interchanges, an extractive is uniformly subjected to the action of an electromagnetic field to be heated, the extraction rate is increased, and the extraction time is shortened.

Owner:永州中农银杏开发有限责任公司

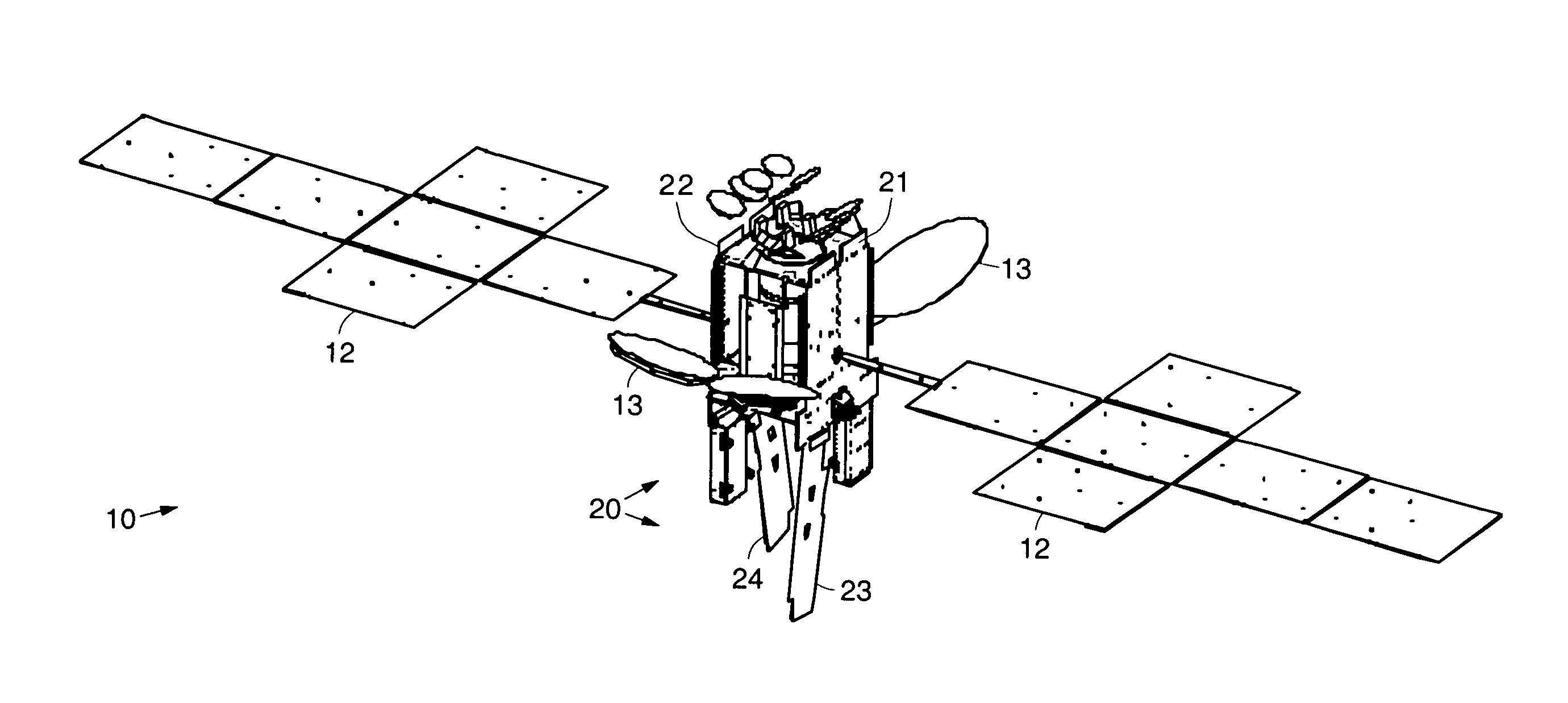

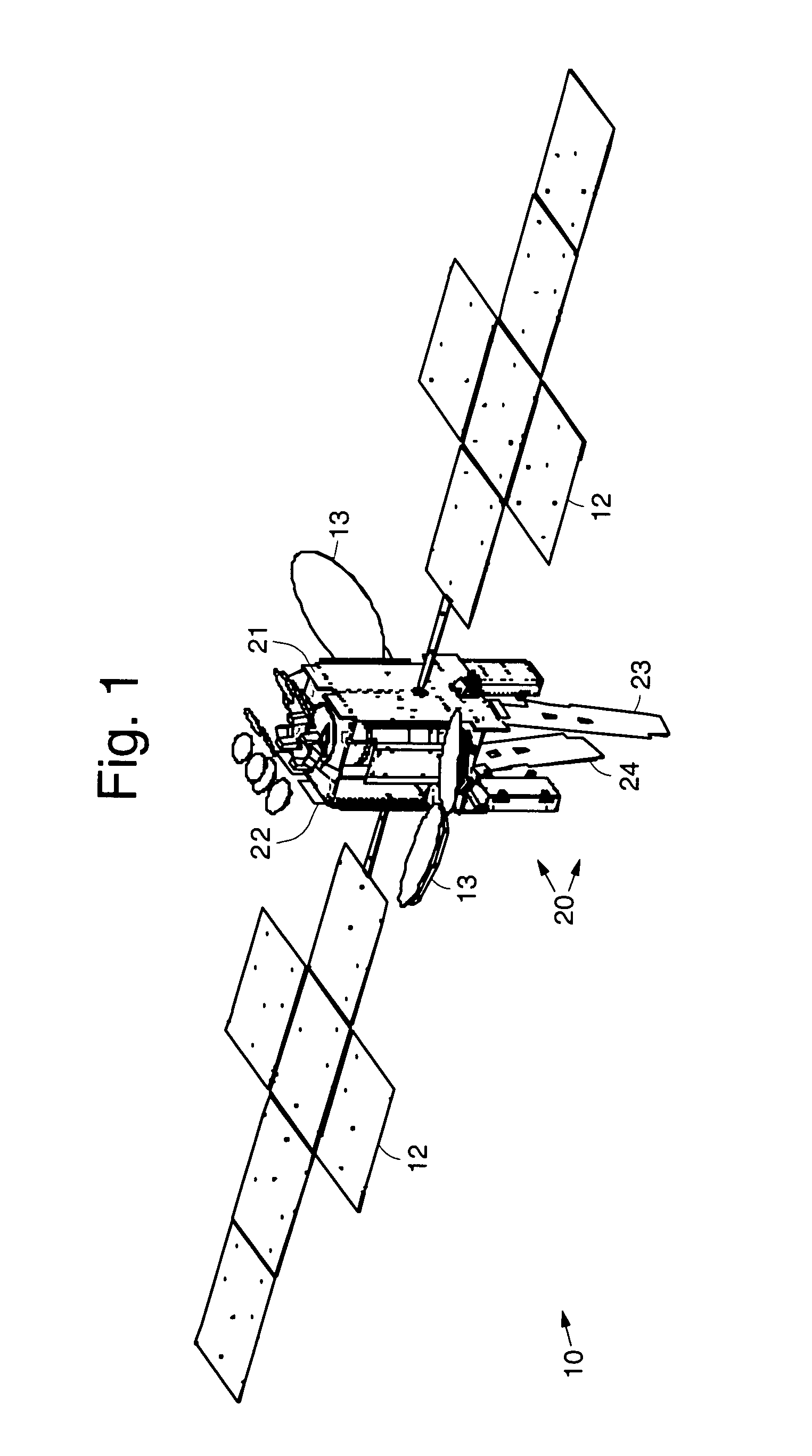

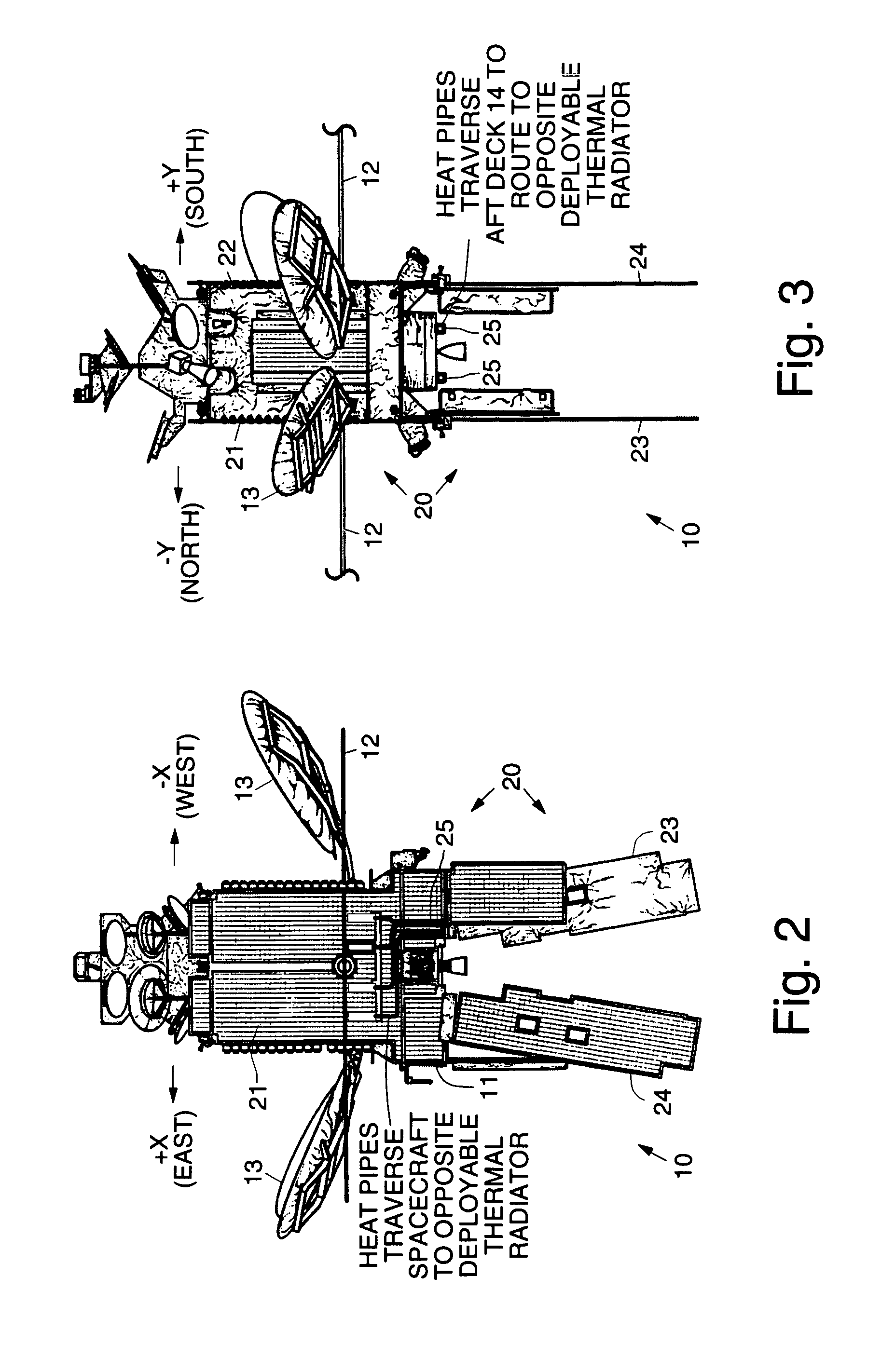

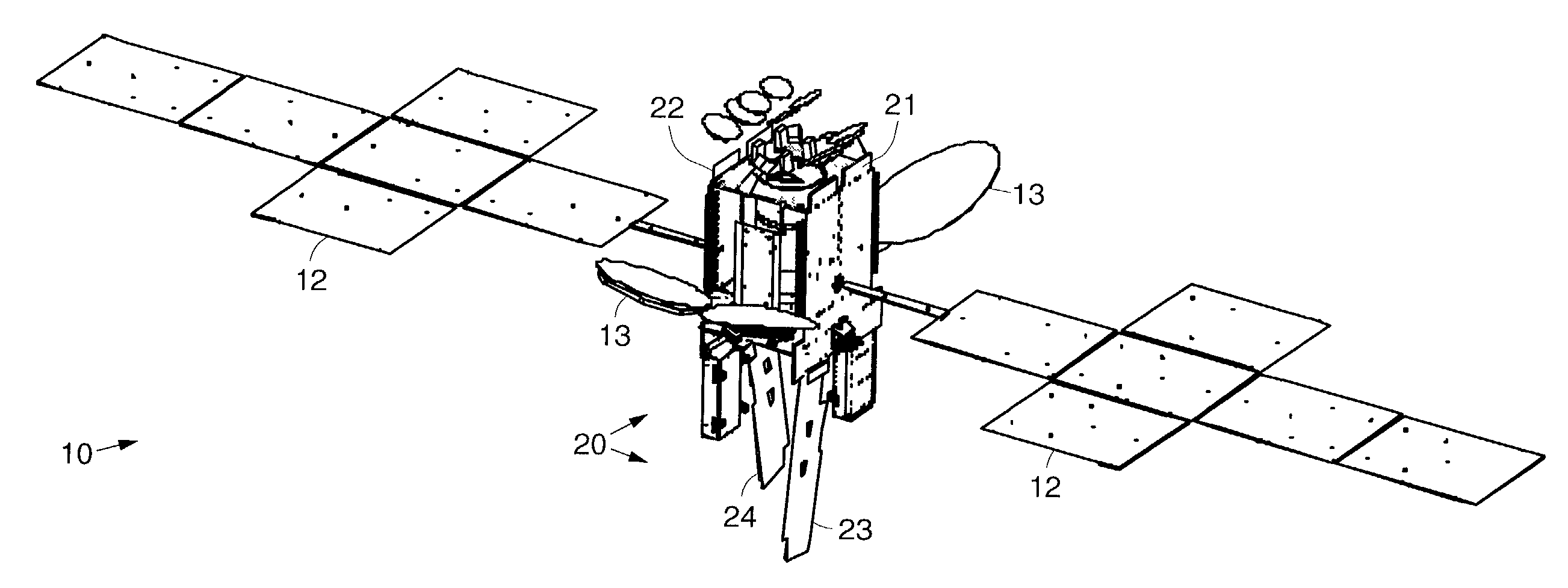

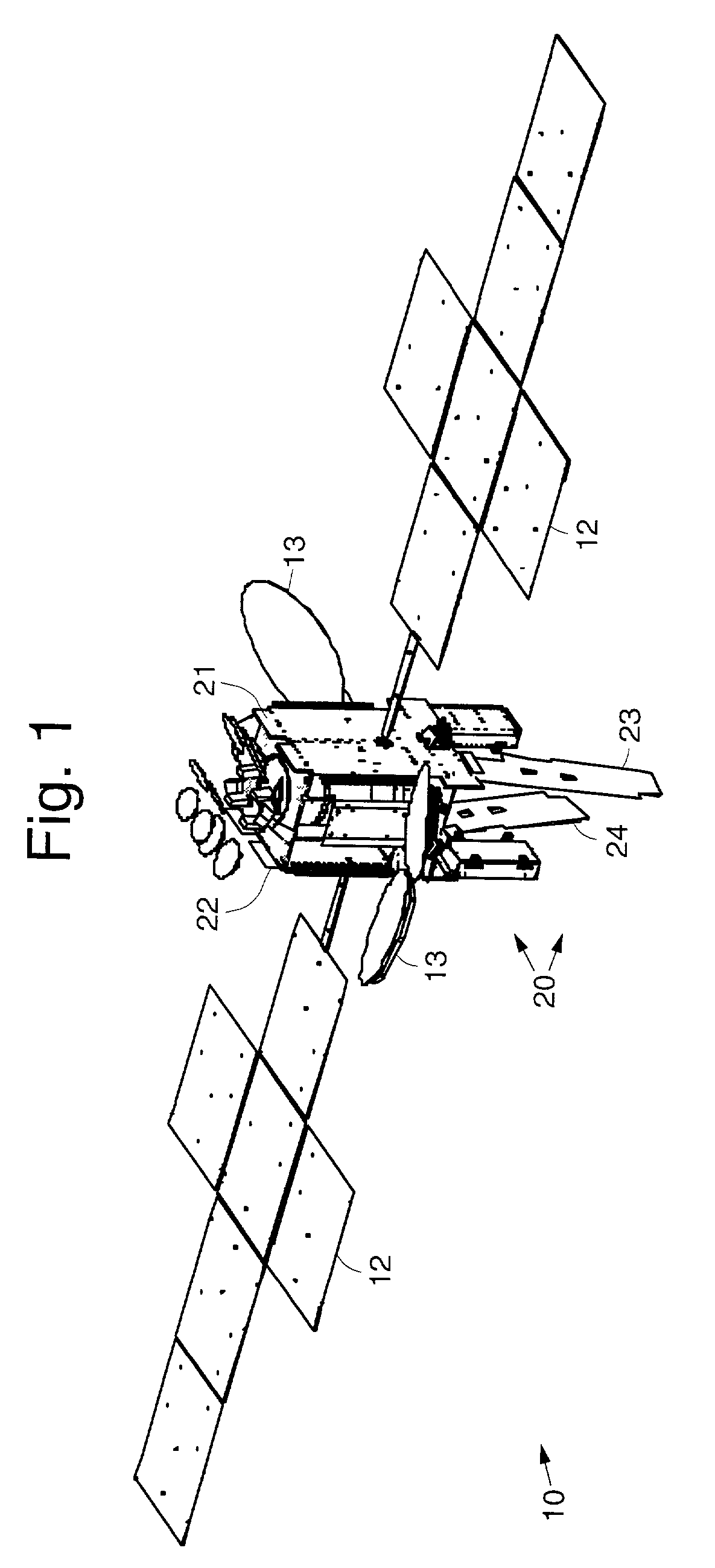

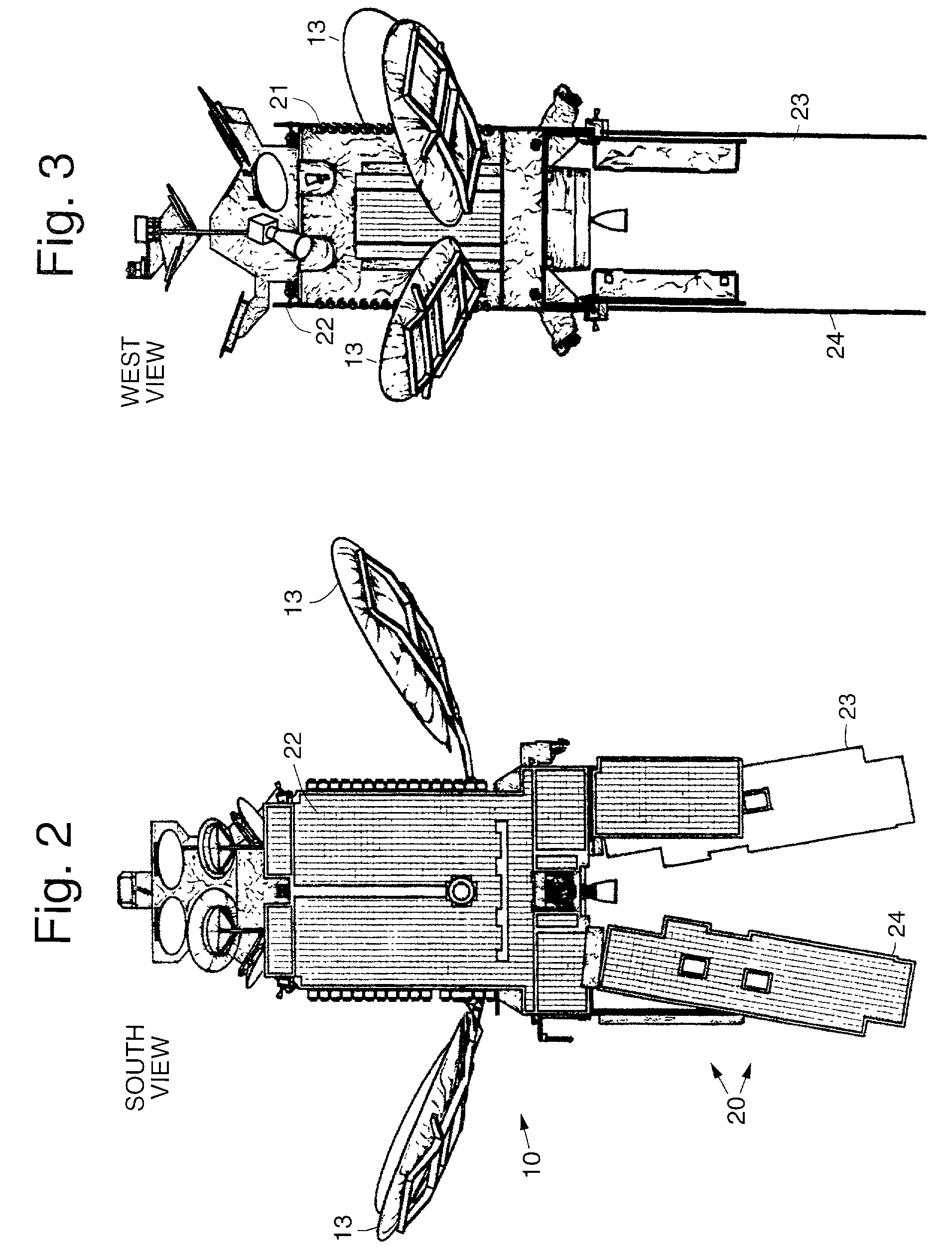

Two-sided deployable thermal radiator system and method

ActiveUS7028953B2Heated withMore capabilityCosmonautic environmental control arrangementCosmonautic vehiclesOrbitHeat pipe

Owner:MAXAR SPACE LLC

Polyester film containing furandicarboxylate unit

ActiveUS20180244878A1Improve heat resistanceImprove mechanical propertiesPolyester resinCarboxylic acid

To provide a furandicarboxylate unit-containing polyester film usable for industrial and packaging purposes. The film of the present invention is a polyester film, which is a biaxially oriented film of a polyester resin including a dicarboxylic acid component containing mainly a furandicarboxylic acid and a glycol component containing mainly ethylene glycol, wherein the film has a plane orientation coefficient AP of not less than 0.005 and not more than 0.200 and a film thickness of not thinner than 1 micro meter and not thicker than 300 micro meters.

Owner:FURANIX TECH BV +1

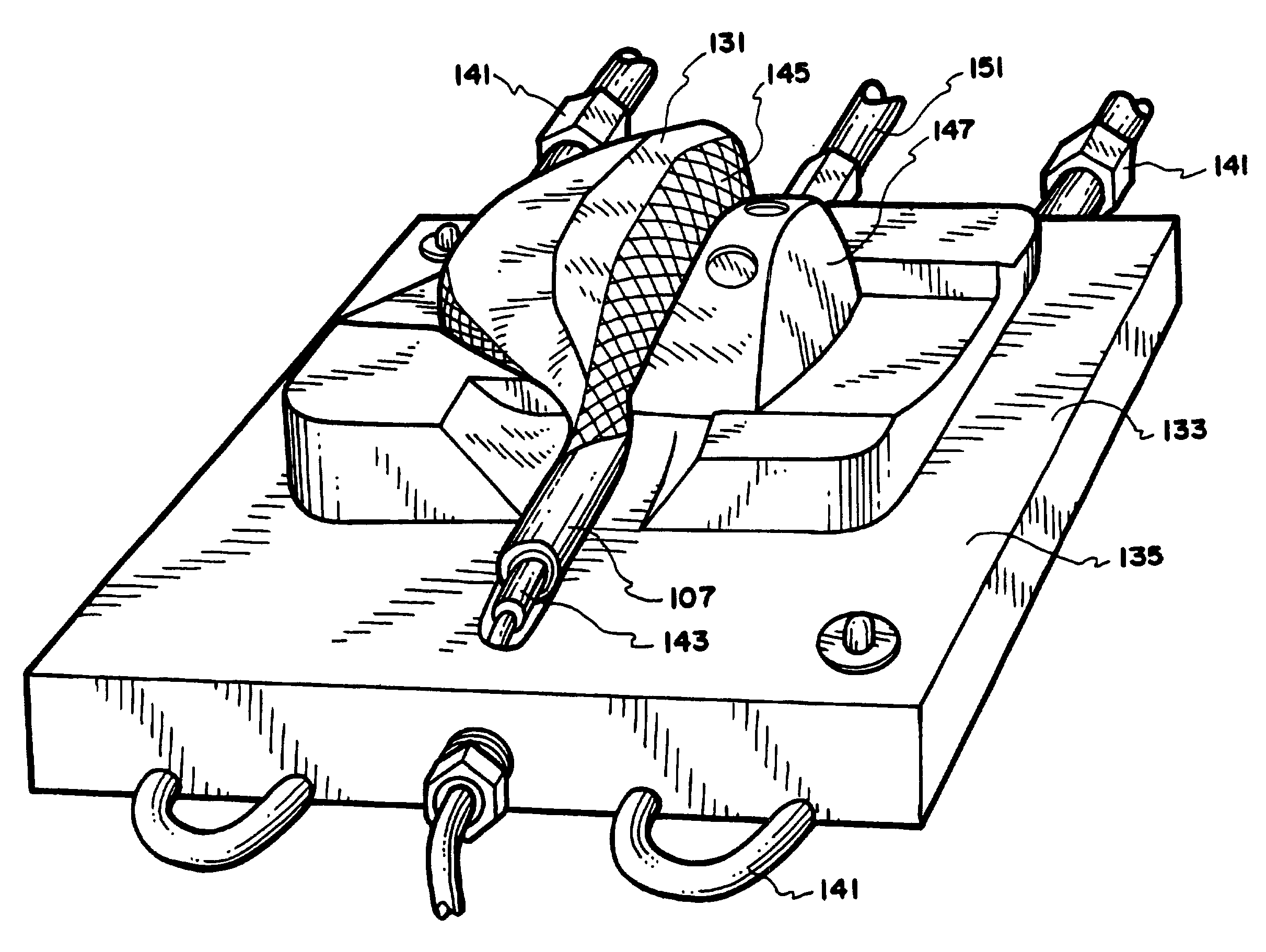

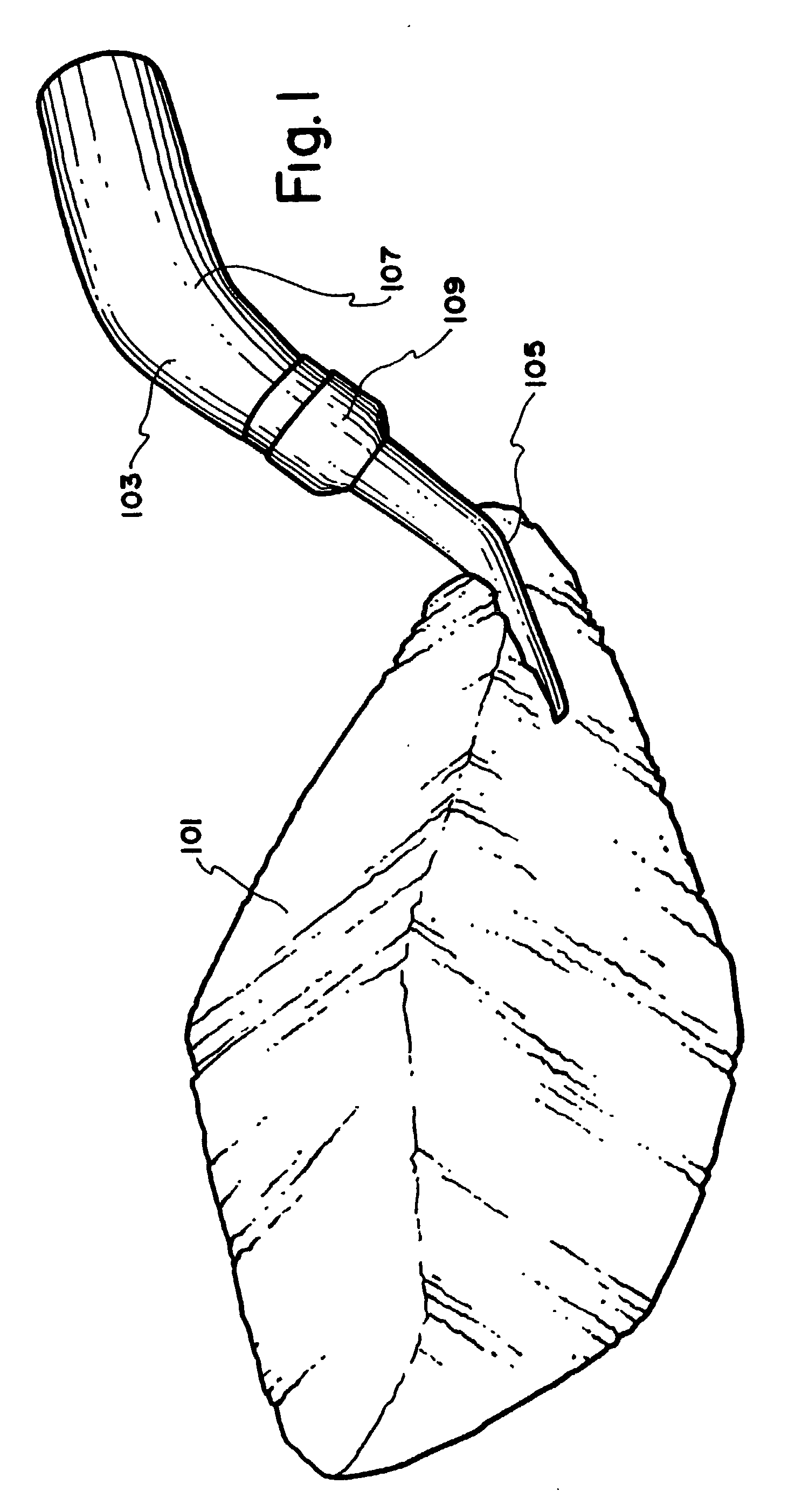

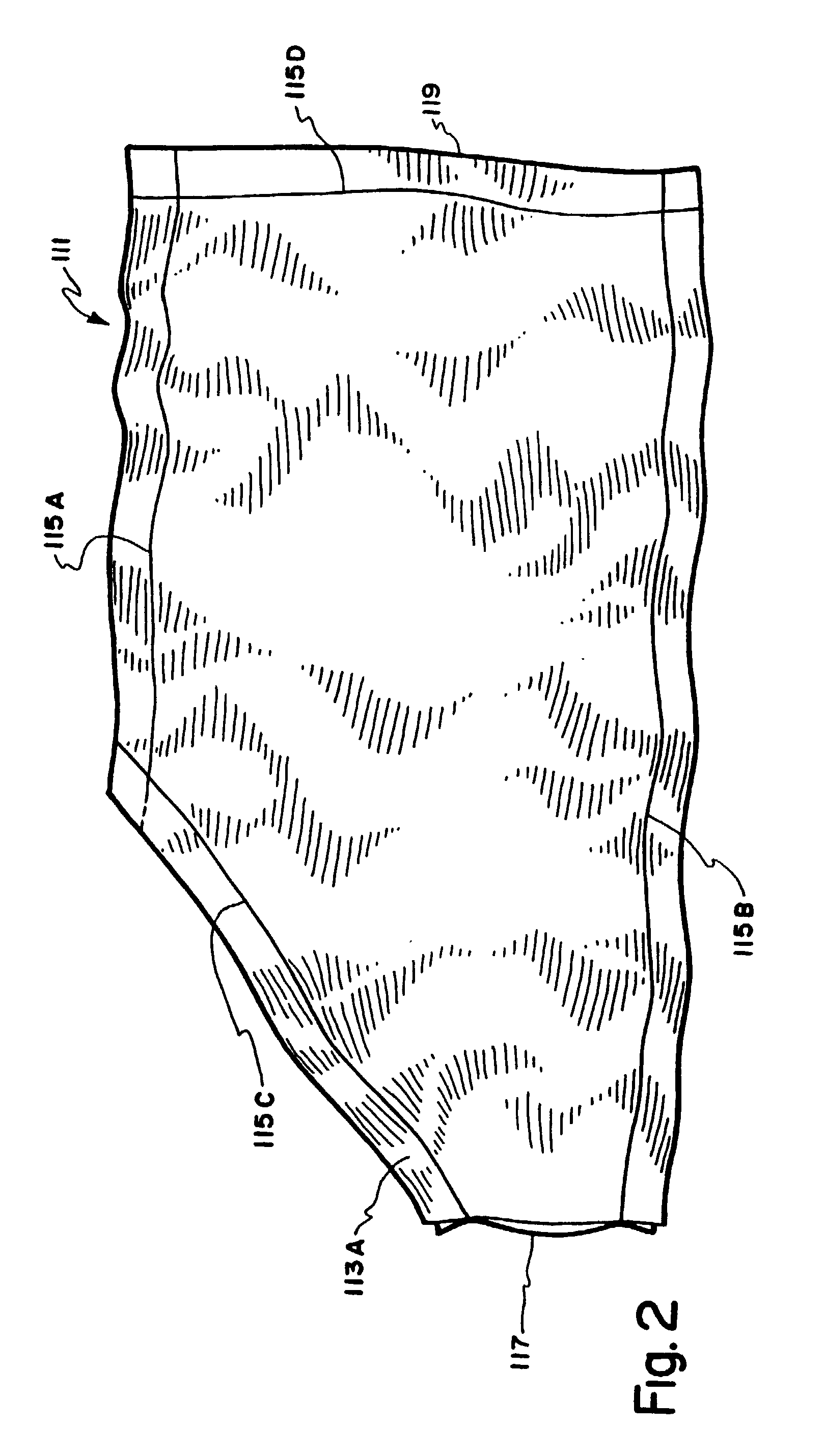

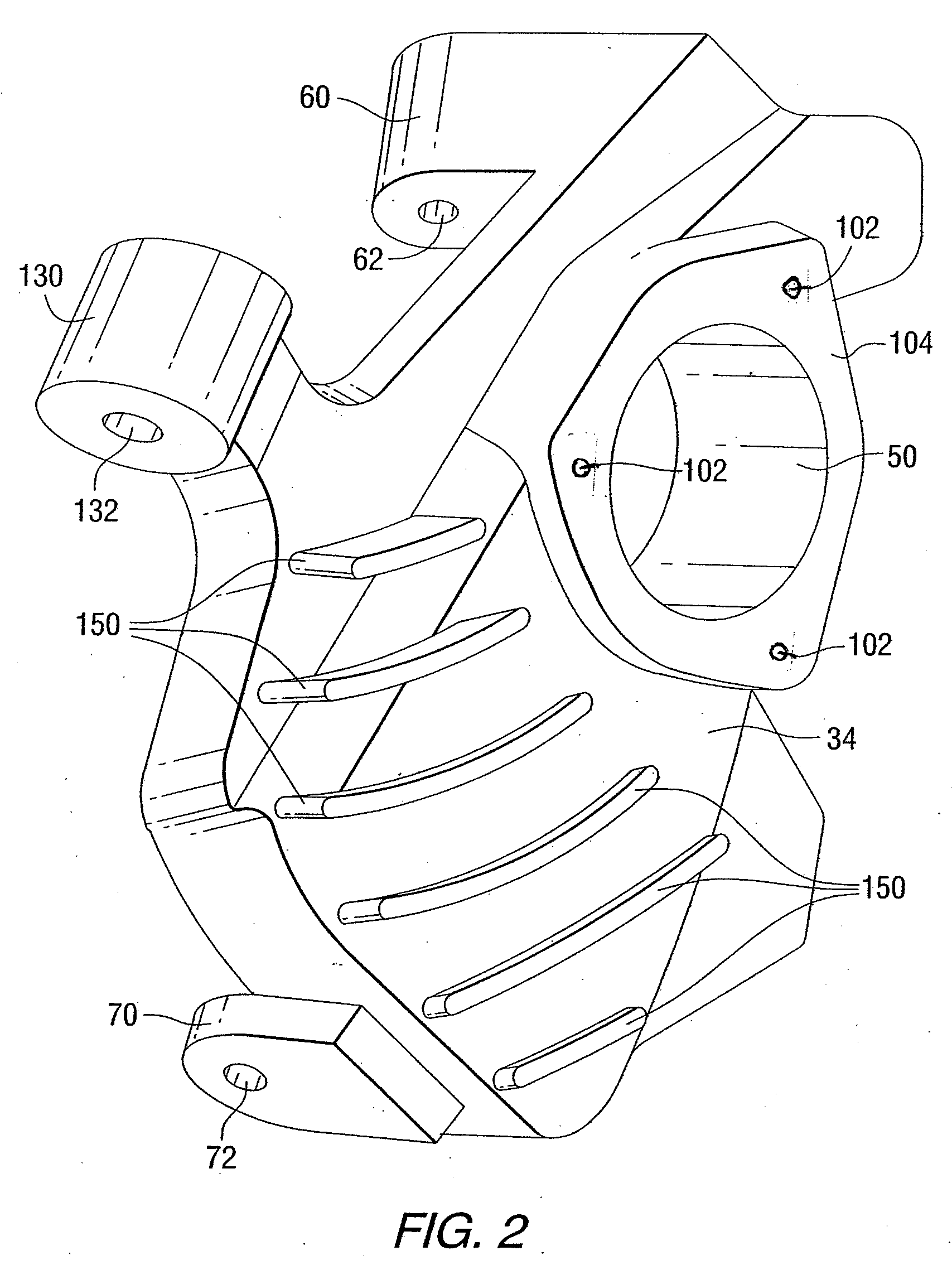

Method of manufacturing a composite golf club head

Disclosed is a method for manufacture of a hollow complex three-dimensional fiber golf club head having at least one hole. The method involves shaping a fluid-removable core in the general form of the golf club head, placing a flexible pressurizable bladder around the core, wrapping over the assembly of core and bladder at least one ply of fiber impregnated with a curable resin, forming a cured part by pressurizing the bladder while the assembly of core, bladder, and impregnated fiber is in a female mold to force the plies against the inner surfaces of the mold, such that compaction of the fiber against the inner surfaces of the mold is from the pressurization of the bladder and not from the core, and heating to cure the resin, removing the bladder and the fluid-removable core from the interior of the cured part by first disintegrating and removing the fluid-removable core with a fluid sufficient to allow removal of the bladder.

Owner:RADIUS ENG

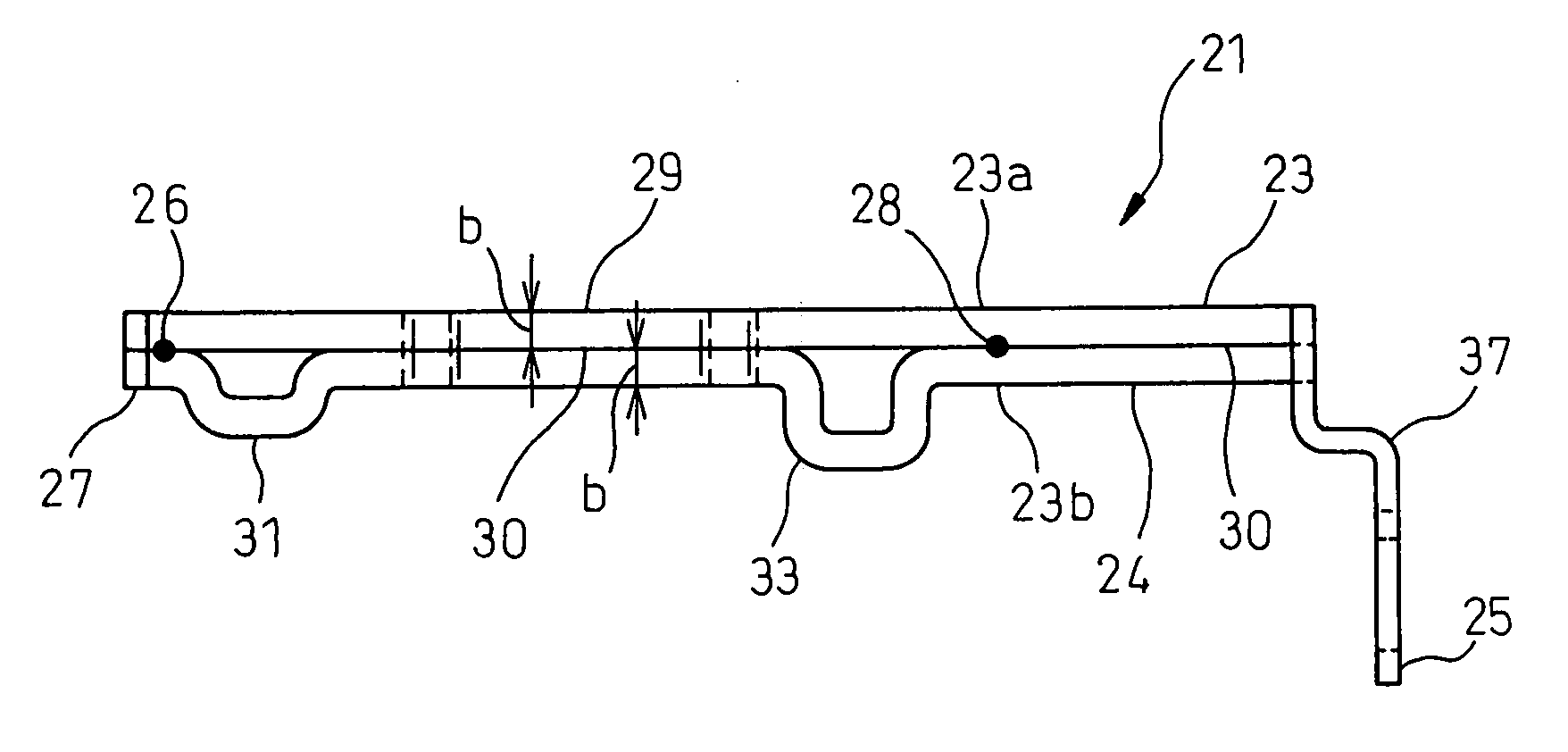

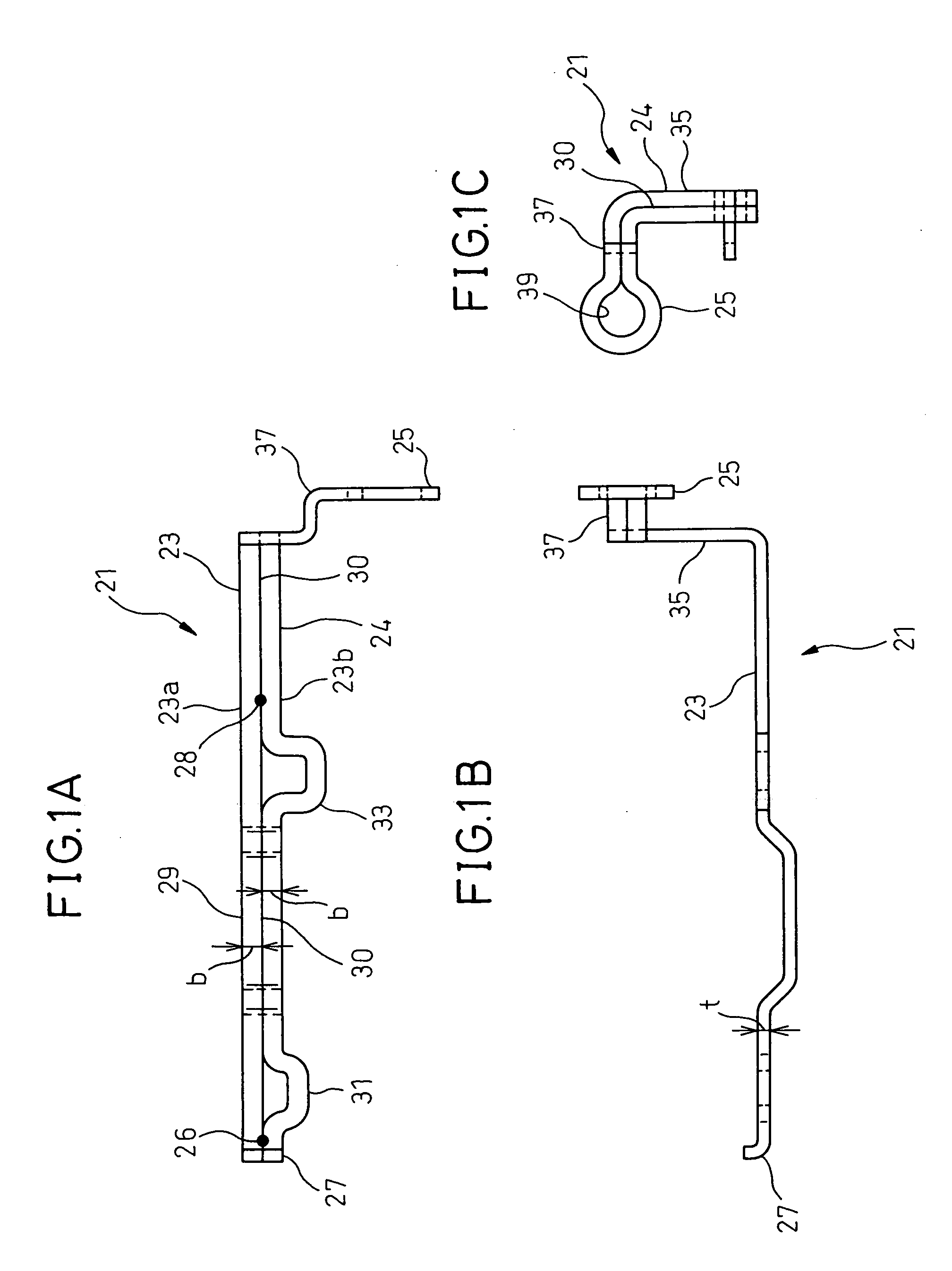

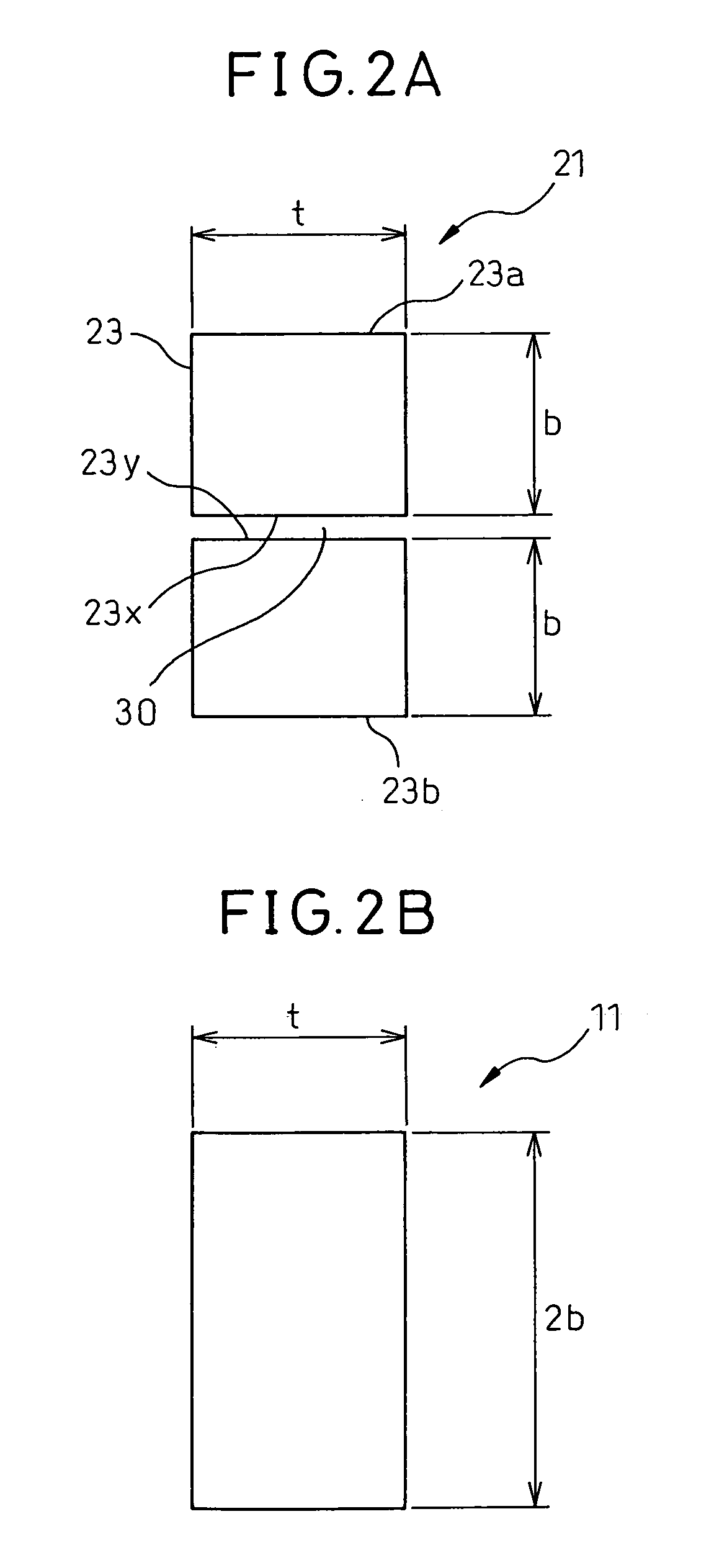

U-turn bus bar

InactiveUS20080308292A1Overcome lack of conductivityEasy to manufactureOpen bus-bar installationsConnection contact member materialEngineeringMechanical engineering

A U-turn bus bar comprises a body portion constituting a linear essential part formed of a conductive plate member, having an overall thickness (t) and an overall width (2b); at least a terminal portion expanded in the direction perpendicular to the longitudinal direction of the body portion; and a connection hole formed at one end of the body portion. The body portion includes a U-turn bend formed by bending the body portion into a U-turn shape.

Owner:DENSO CORP

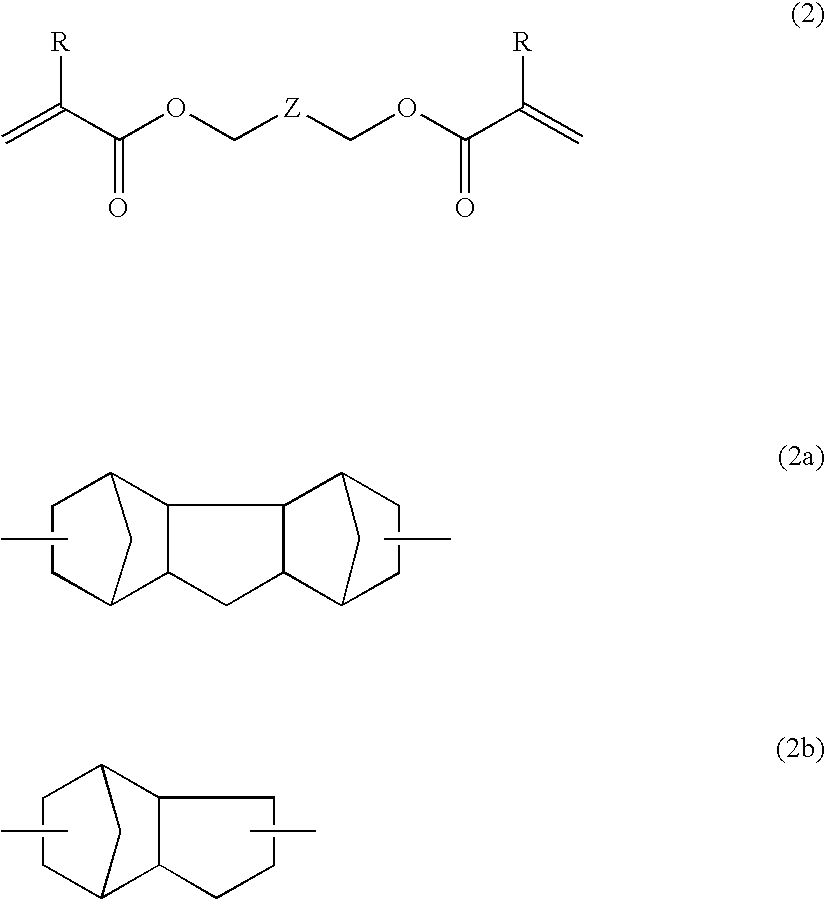

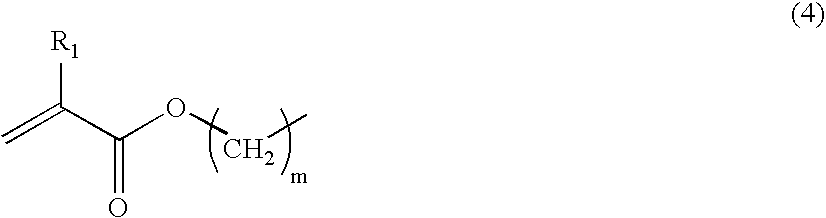

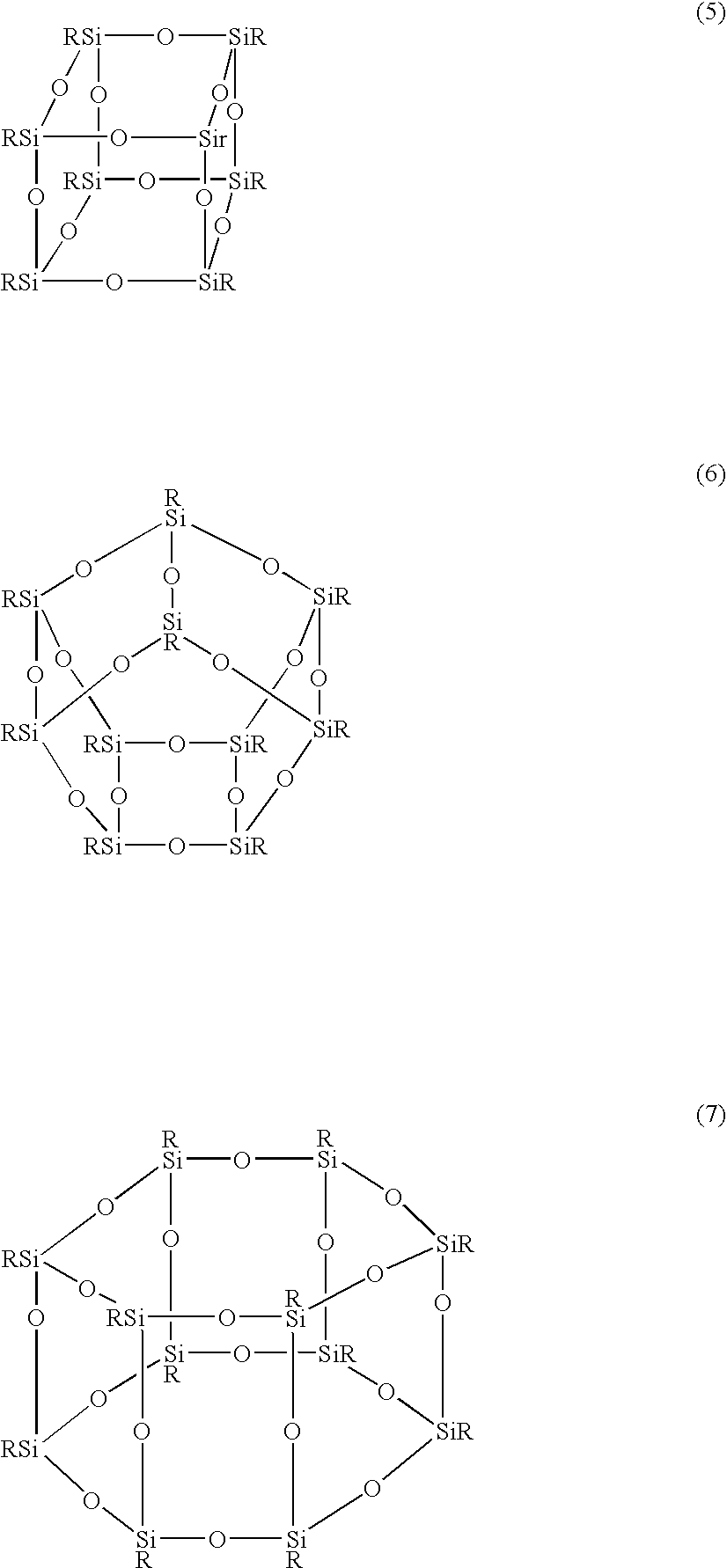

Silicone resin compositions and moldings thereof

InactiveUS20060052567A1Good dimensional stabilityLow water absorptionOptical elementsPolymer scienceMeth-

This invention relates to a silicone resin composition which exhibits high heat resistance, high transparency and high dimensional stability and thus can be suitably used for optical applications such as a lens, an optical disc, an optical fiber, a substrate for a plat panel display, a window material for an automobile, and the like. A silicone resin composition, which comprises a silicone resin comprising, as a primary component, a polyorganosilsesquioxane being represented by the formula: [RSiO3 / 2]n, wherein R represents an organic functional group having a (meth)acryloyl group, and n is 8, 10 or 12, and having a cage type structure in its structural unit, and an unsaturated compound having, in its molecule, at least one unsaturated group represented by —R3—CR4═CH2 or —CR4═CH2, wherein R3 represents an alkylene group, an alkylidene group or a —OCO— group and R4 represents a hydrogen atom or an alkyl group, and being capable of radically copolymerizing with the above silicone resin, in a weight proportion of 1:99 to 99:1.

Owner:NIPPON STEEL CHEMICAL CO LTD

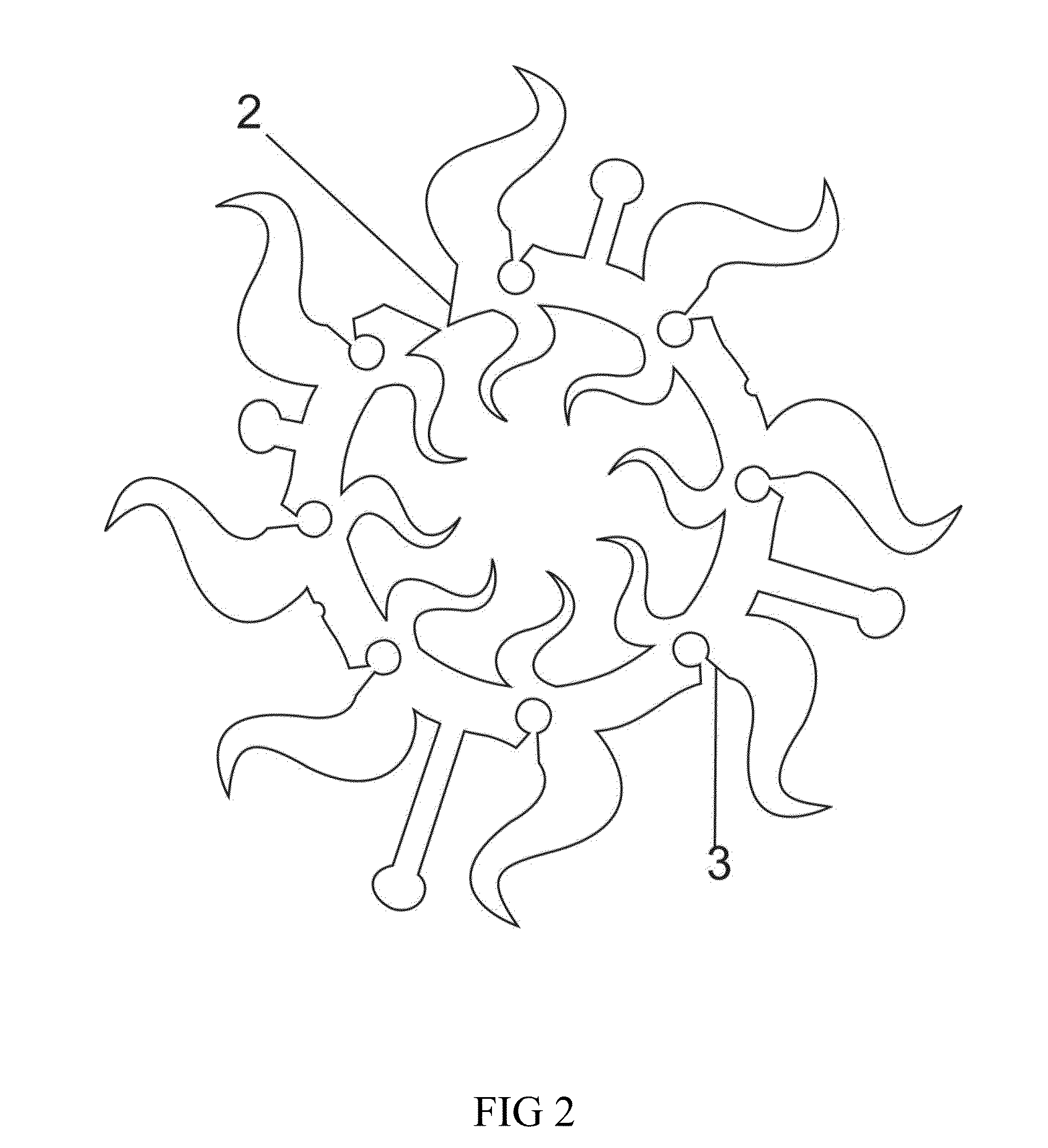

Heat-Exchange Apparatus

InactiveUS20140182828A1Increase contact areaIncrease in amountHeat exhanger finsHeat exchanger casingsEngineeringMechanical engineering

A heat exchanging device has a single extruded part made as a tubular body with external and internal radial branches. The tubular body has longitudinal round holes in a circumferential direction. At least one mount is on the outer surface of the tubular body. Internal and external radial branches taper from the base to the edge of branches and are made sinusoidal with a constant step and amplitude. They can be of the same width from the base to the edge of branches. The sinusoids of external radial branches can be of a variable amplitude and step from the base to the edge. The external radial sinusoidal branches can be of a different length relative and at different distances from each other. The radial branches can be have additional undulating projections. The round holes are made along the entire circumference of the body at equal distances from each other.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETSTVENNOSTJU PRORYVNYE INNOVATSIONNYE TEKHNOLOGII

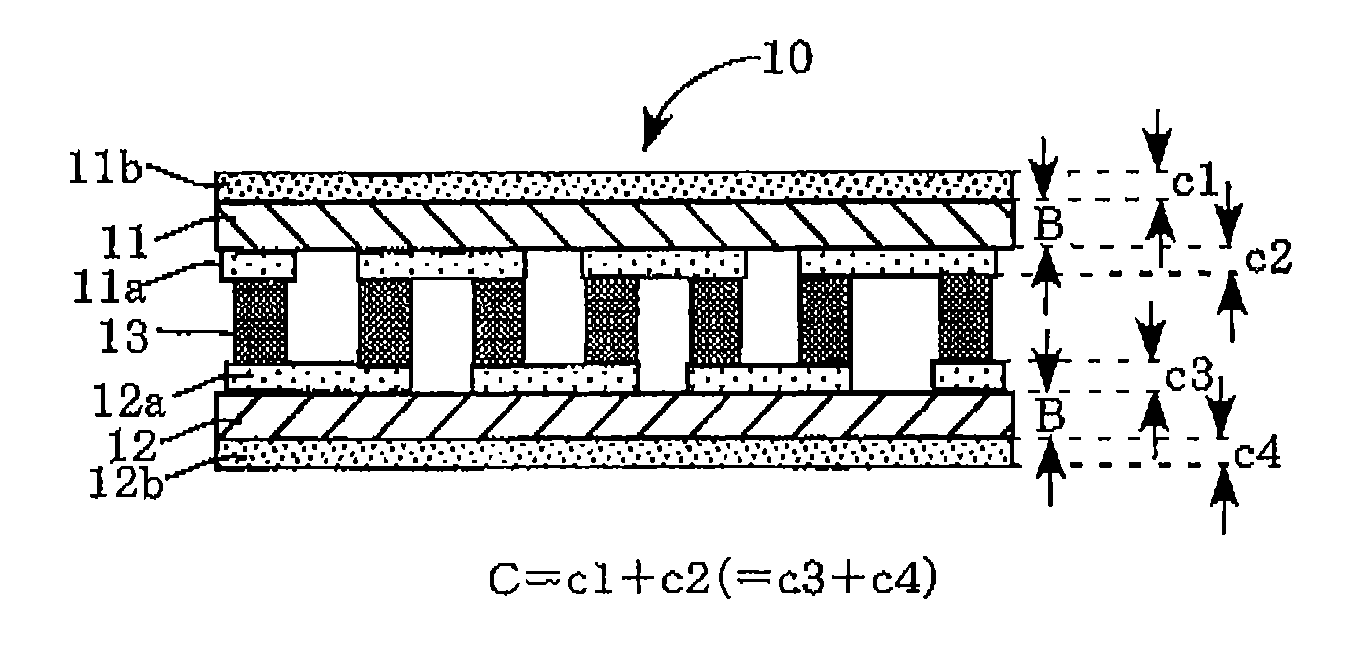

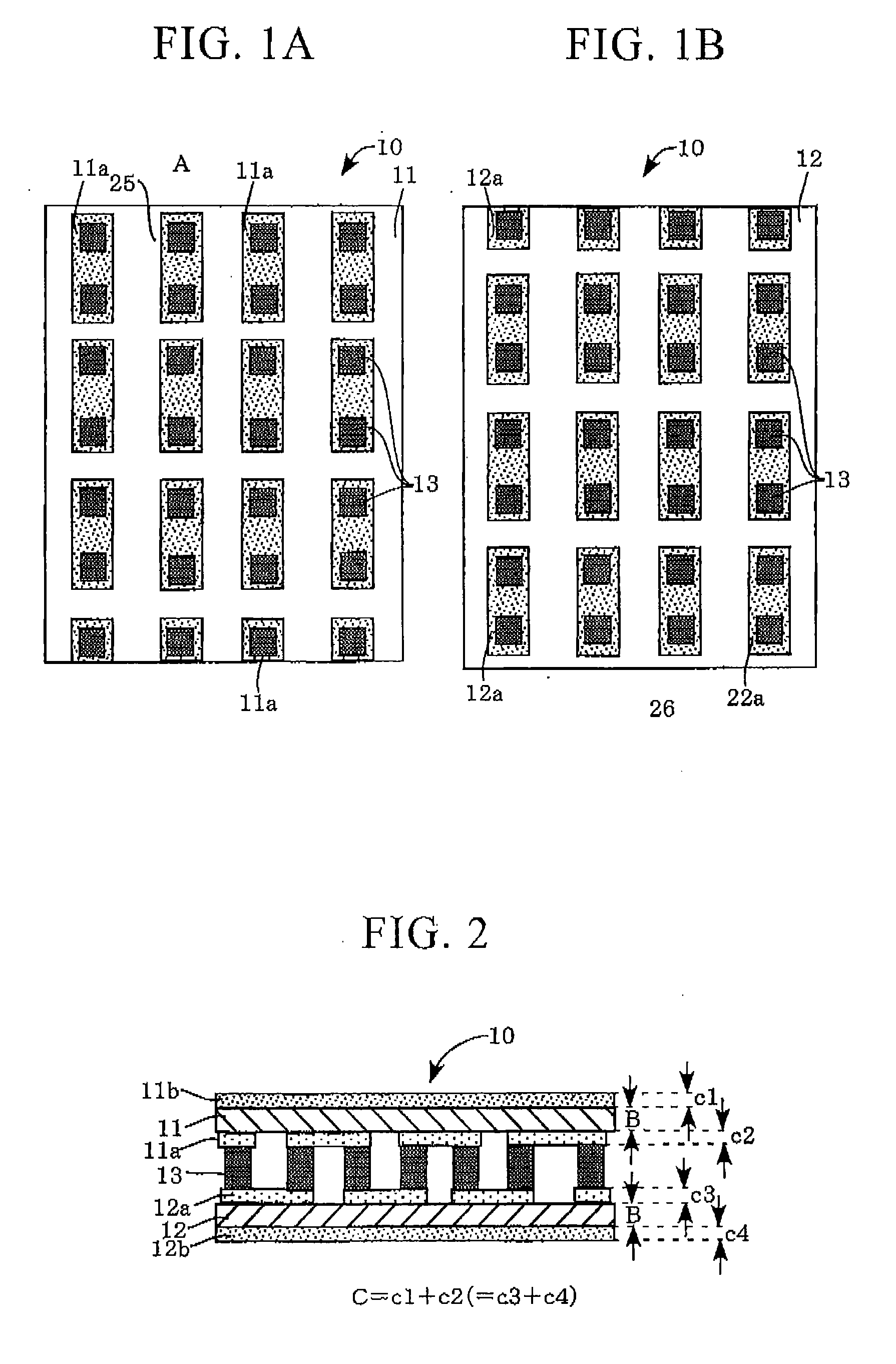

Thermoelectric module substrate and thermoelectric module using such board

InactiveUS20090084423A1Improve heat conductivityReliability be lowerThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsTotal thicknessThermal conductivity

To obtain a thermoelectric module substrate of which reliability such as stress relaxation is improved without damaging the performance as a thermoelectric module such as heat conductivity to provide a thermoelectric module excellent in reliability by using such a substrate. Thermoelectric module substrates of the present invention each comprises a synthetic resin layer including fillers having good thermal conductivity; and a copper-metalized layer or layers, or a copper layer at least including copper plate or copper layers which is or are formed on one face or both faces of the synthetic resin layer. Further, in the case where contents volume percentage of fillers within the synthetic resin layer is expressed as A (%), the thickness of the synthetic resin layer is expressed as B (μm) and the total thickness of the copper layer is expressed as C (μm), the thermoelectric module substrate is formed so as to have the relation expressed as (C / 4)−B≦65, A / B≦3.5, A>0, C>50 and B≧7.

Owner:YAMAHA CORP

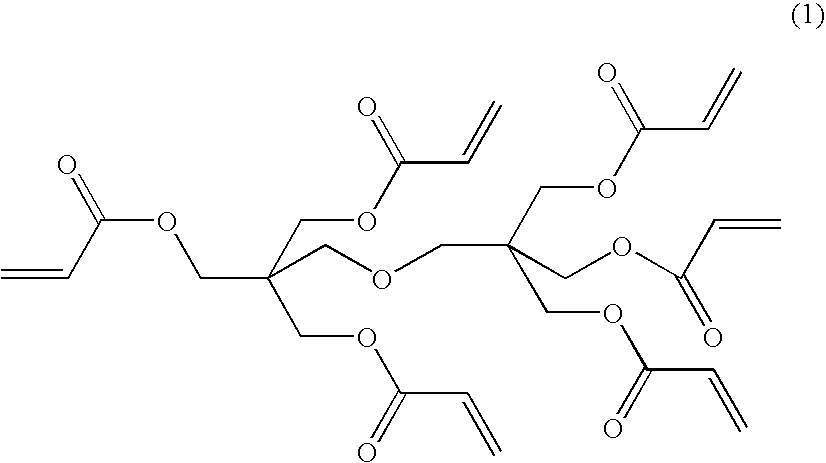

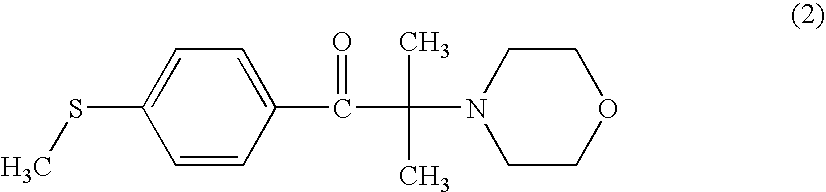

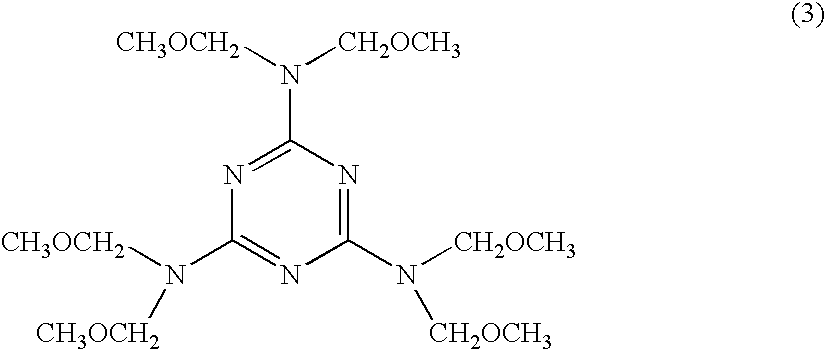

Photoresist composition for LCD light diffuse reflecting film

InactiveUS20050260523A1Increase photosensitivityWell-resolved imageSilver halide emulsionsPhotosensitive materials for photomechanical apparatusResistUltraviolet

A photoresist composition for LCD light diffuse reflecting film is disclosed, which comprises (a) 8 to 90% by weight of base-soluble resin; (b) 1 to 30% by weight of polyfunctional unit; (c) 0.1 to 20% by weight of photopolymerization initiator; (d) 0.1 to 20% by weight of thermosetting cross-linking reagent; (e) 0.01 to 10% by weight of ultraviolet absorber; and (f) 8 to 90% by weight of solvent.

Owner:EVERLIGHT USA INC

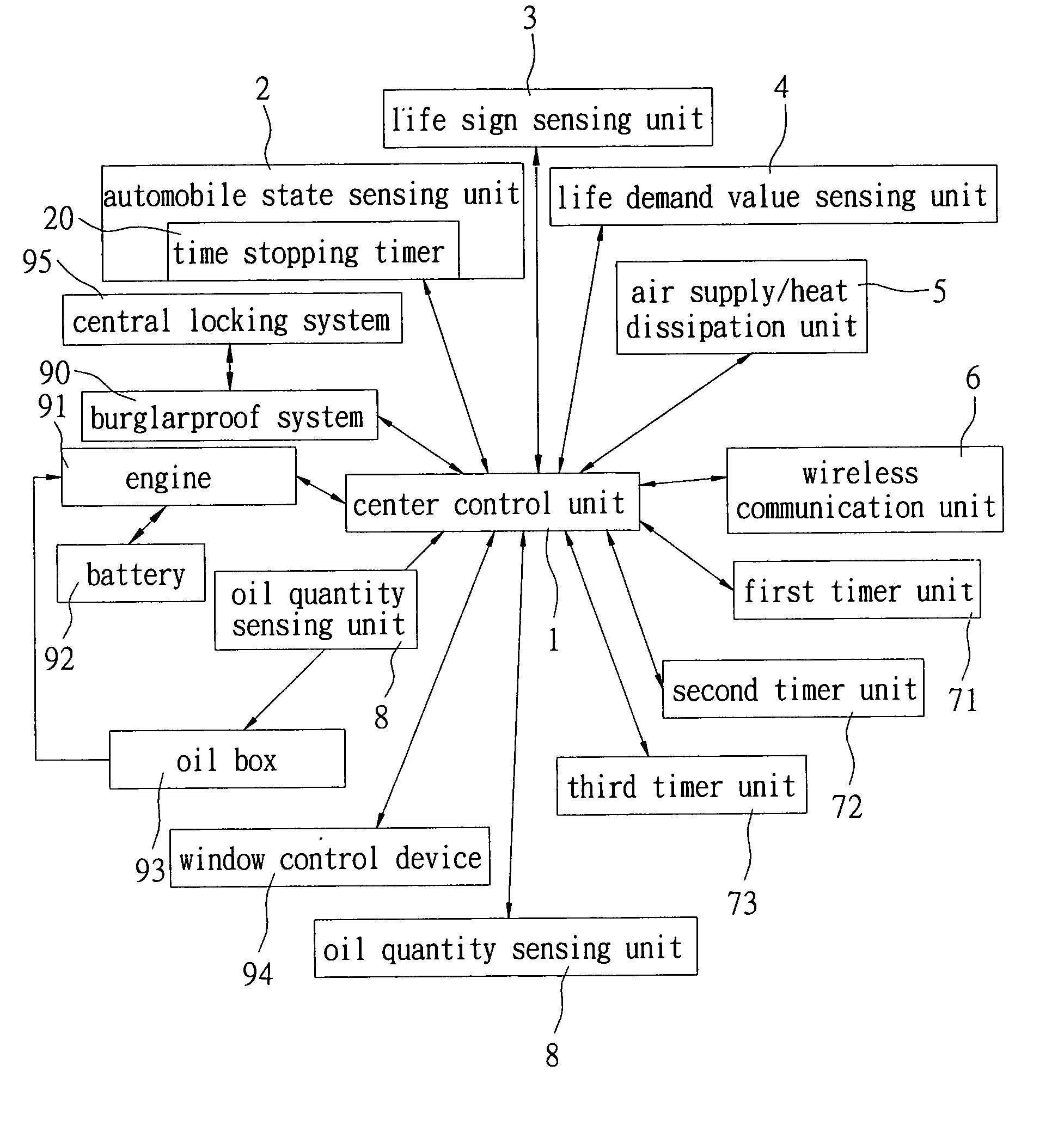

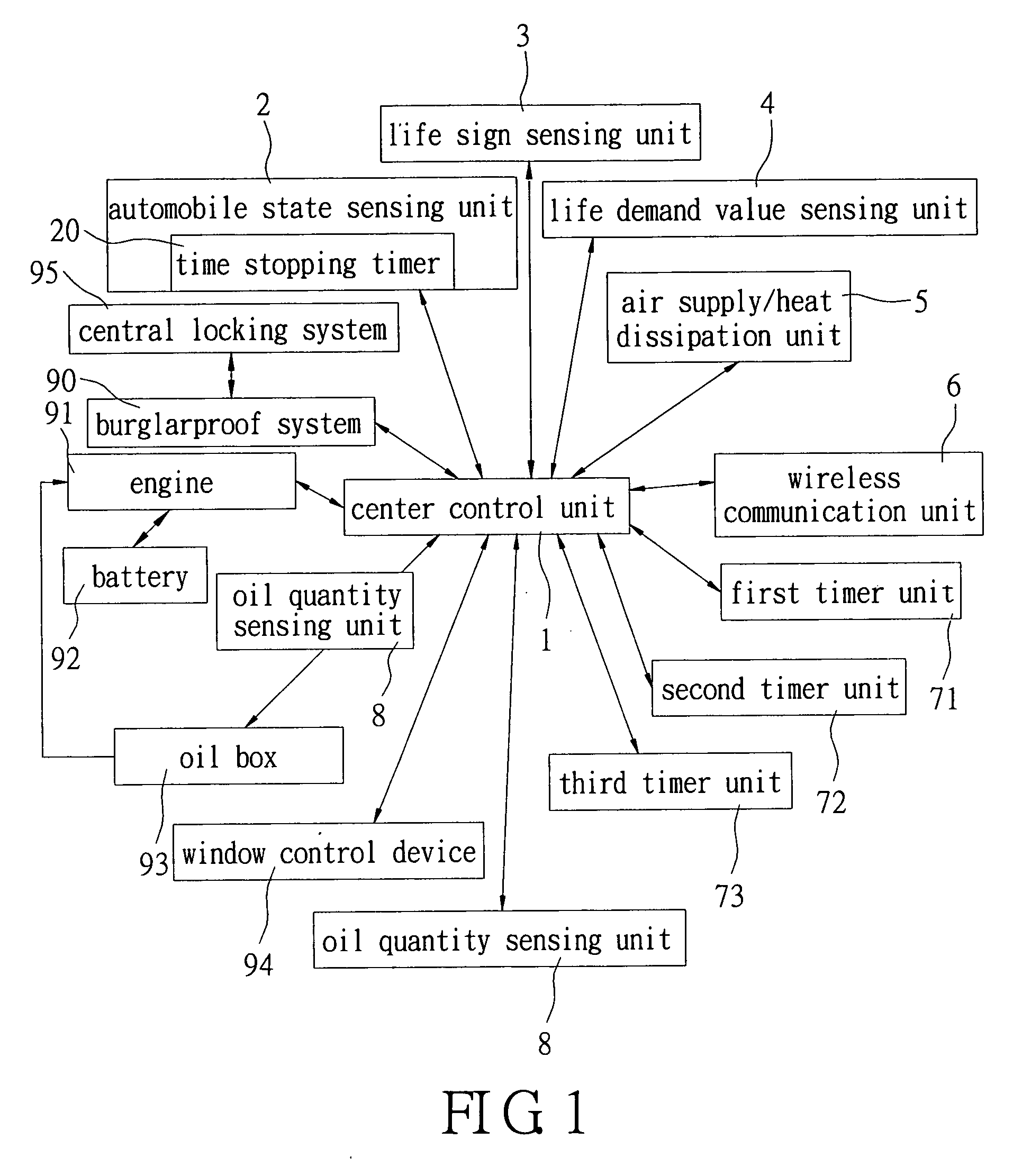

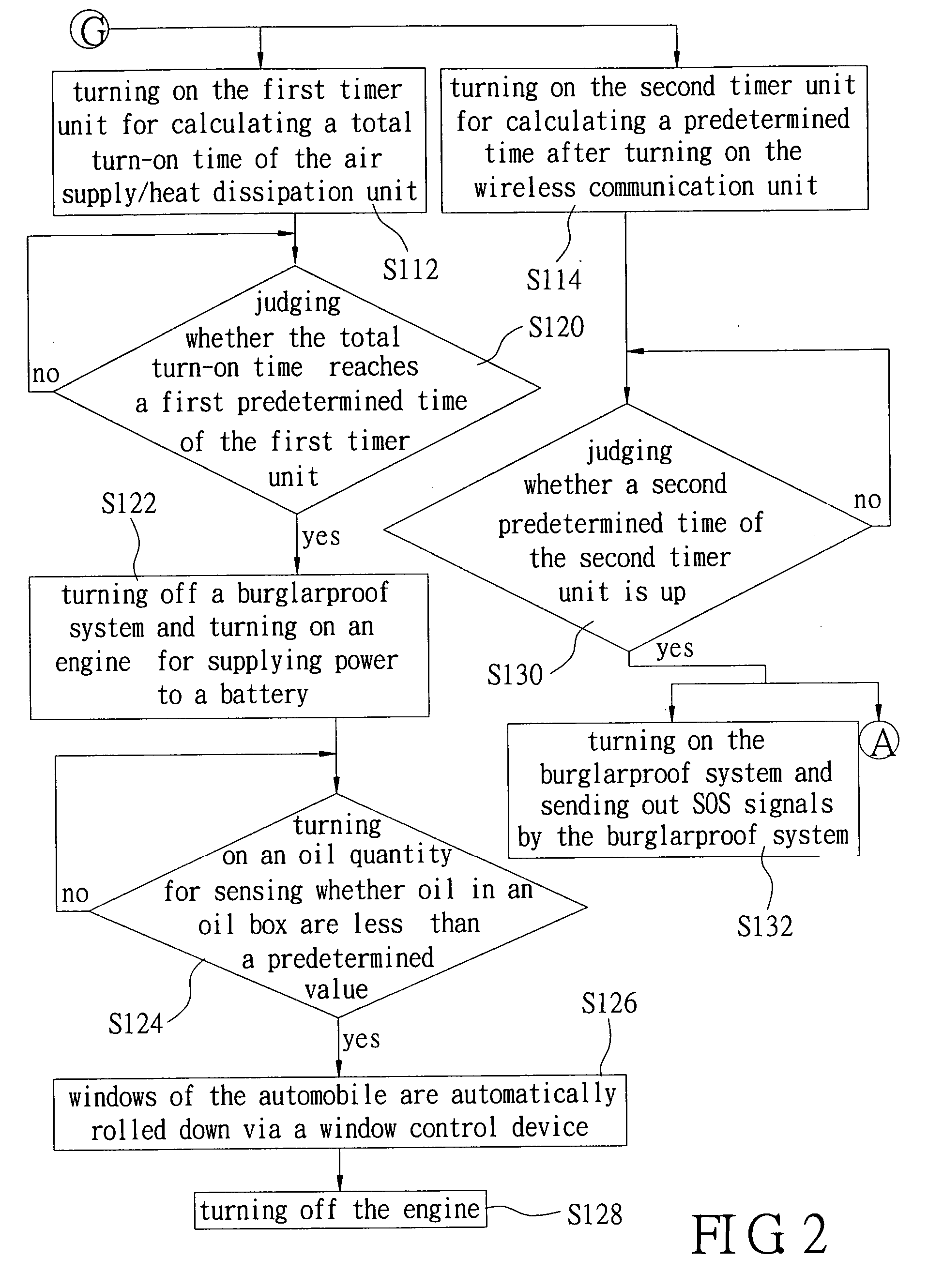

Automobile safety device and method of using the same

InactiveUS20070032918A1Prevent and reduce dangerHeated withAir-treating devicesDigital data processing detailsCommunication unitAutomobile safety

An automobile safety device and a method of using the same are disclosed. The automobile safety device can offer essential urgent treatment automatically (such as utilizing a wireless communication unit in an automobile to notify an automobile owner to come to the location of the automobile, utilizing a burglarproof system of the automobile in order to bring the passerby's attention, turning on an air supply / heat dissipation unit in the automobile or rolling down the windows of the automobile automatically in order to dissipate the heat and supply air) in a situation that people are stranded in the car, by detecting the internal state of the automobile automatically. Hence, the present invention can prevent or reduce the danger that people (especially infant and pre-school children) are stranded in the automobile, such as causing stuffy extremely people's accident due to overheat or lack of oxygen.

Owner:UNIVERSAL SCI IND CO LTD

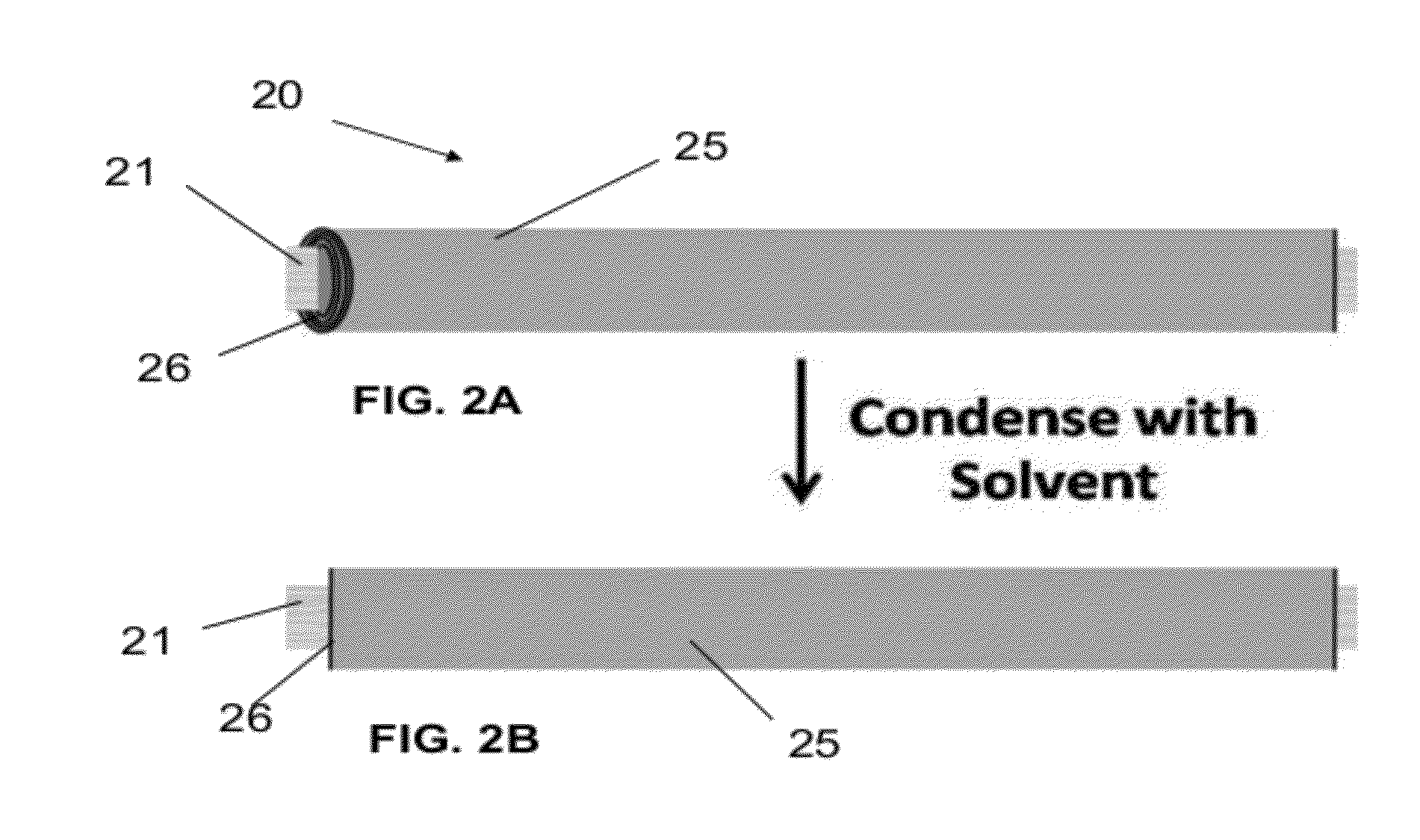

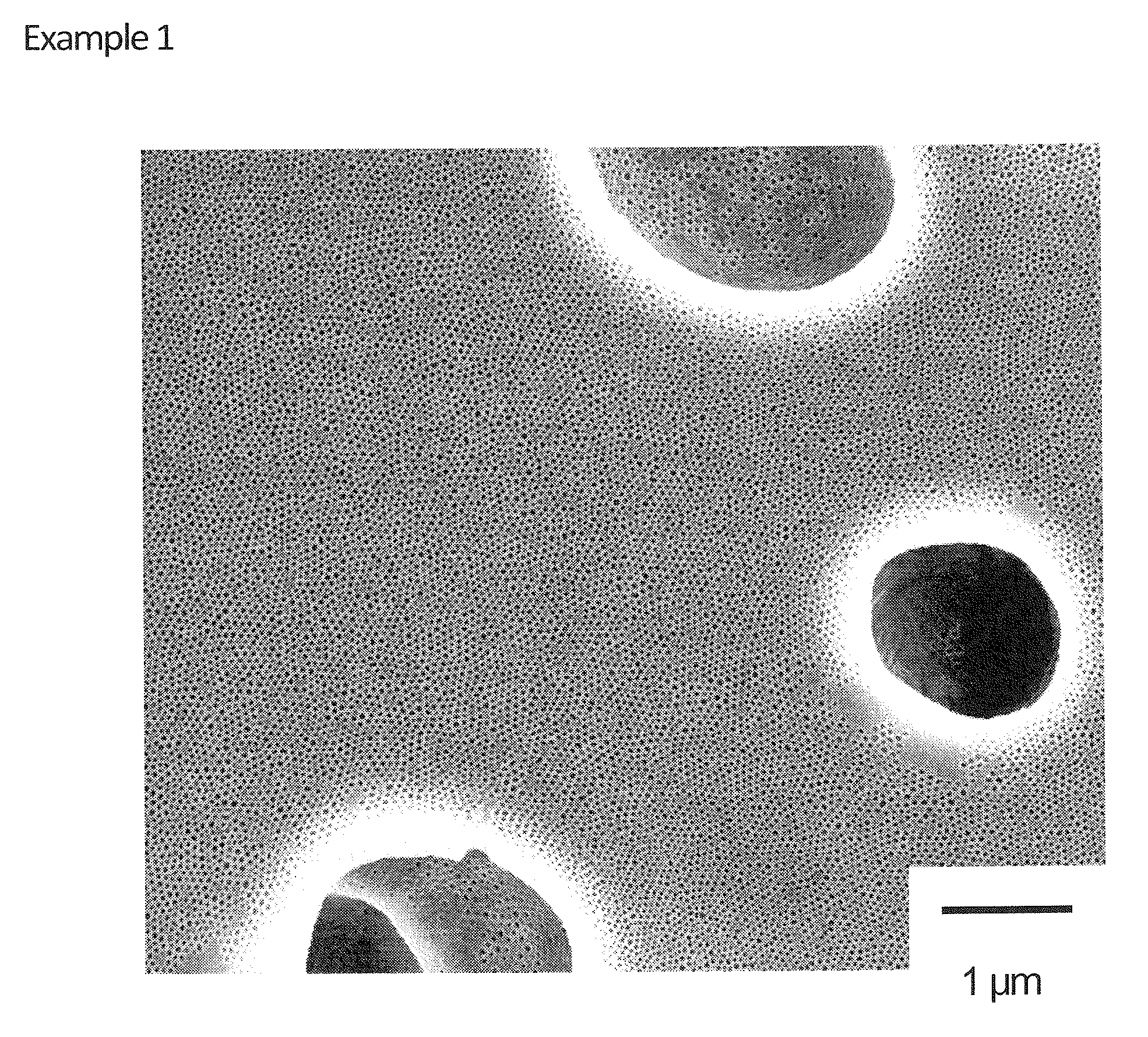

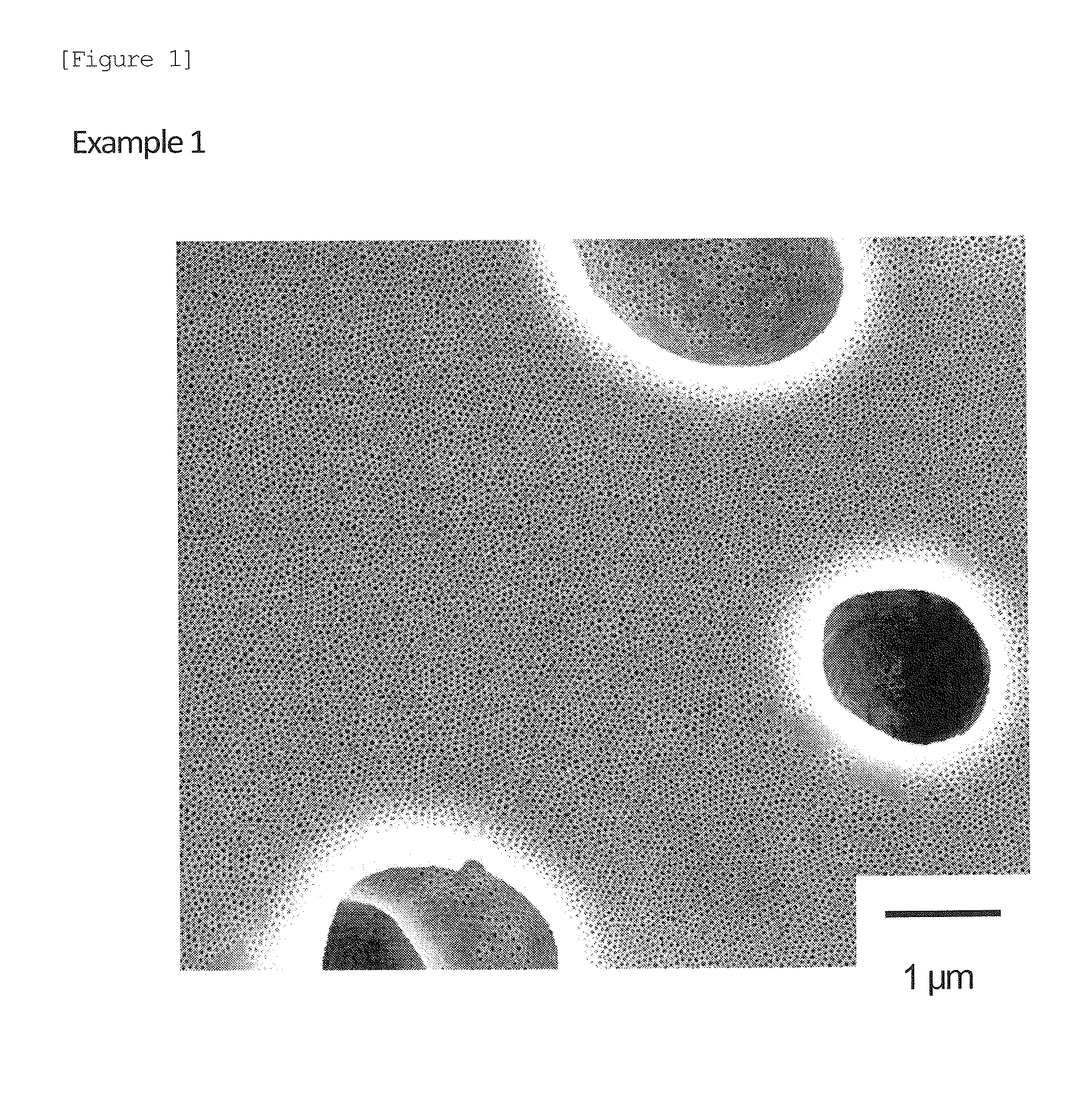

Method for producing a film having a nano-structure on the surface of the film

InactiveUS20140099445A1Conveniently producedHeated withMaterial nanotechnologyMembranesOrganic solventBoiling point

A method is provided for producing easily a membrane (film) having a micro surface structure (porous structure, fibrous structure and the like) in nano-order. The method for producing a film having a nano-structure on the surface of the film, includes the steps of: (1) coating a substrate with a solution containing a copolymer including two or more homopolymer segments and an organic solvent having boiling point of 82° C. or more and a dielectric constant of 30 or less to form a membrane; (2) providing the membrane with a water vapor-containing gas having a relative humidity of 50% or more to age the membrane; and (3) drying the membrane to obtain the film.

Owner:SUMITOMO CHEM CO LTD +1

Two-sided deployable thermal radiator system and method

ActiveUS20050211850A1Heat dissipationMore capabilityCosmonautic environmental control arrangementCosmonautic vehiclesOrbitHeat pipe

A spacecraft heat dissipation method, and a spacecraft having an improved thermal radiator system that uses two-sided deployable thermal radiators that dissipates heat from both front and back surfaces thereof. The use of the two-sided deployable thermal radiators enables the thermal radiator system to have approximately 50% more heat dissipating capability than a system with just one surface exposed to dissipate heat. The spacecraft includes a body, one or more solar arrays, and the present radiator system which comprises opposite facing fixed payload radiators that are thermally coupled to selected ones of the deployable radiators by way of heat pipes. In an exemplary method a spacecraft is configured to have a body, one or more solar arrays opposite facing fixed payload radiators, and one or more two-sided deployable radiators selectively coupled to the fixed payload radiators. The spacecraft is launched into orbit. When in orbit, heat coupled to the opposite facing fixed payload radiators is transferred to the two-sided deployable radiators for radiation into space from both sides thereof.

Owner:MAXAR SPACE LLC

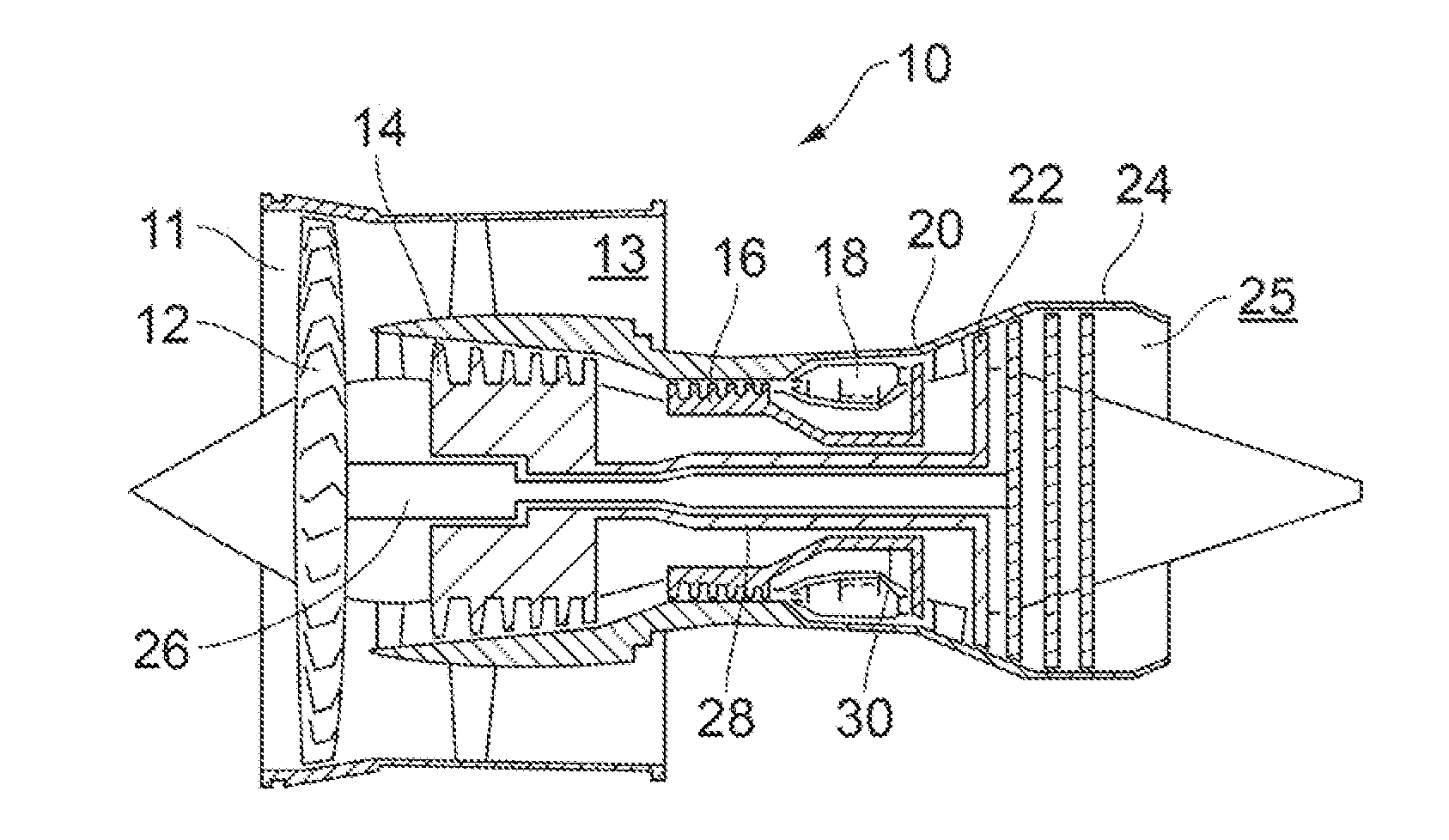

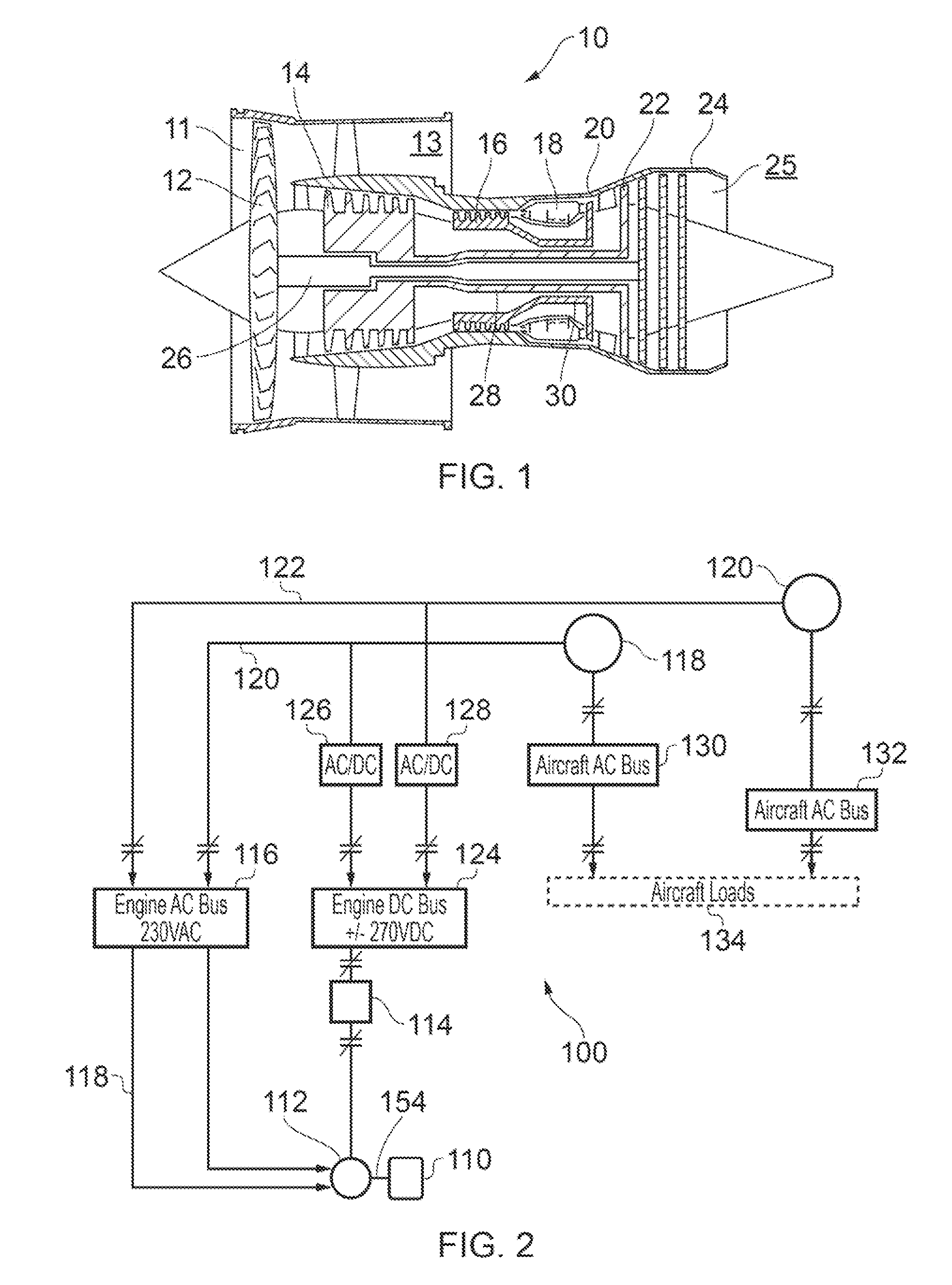

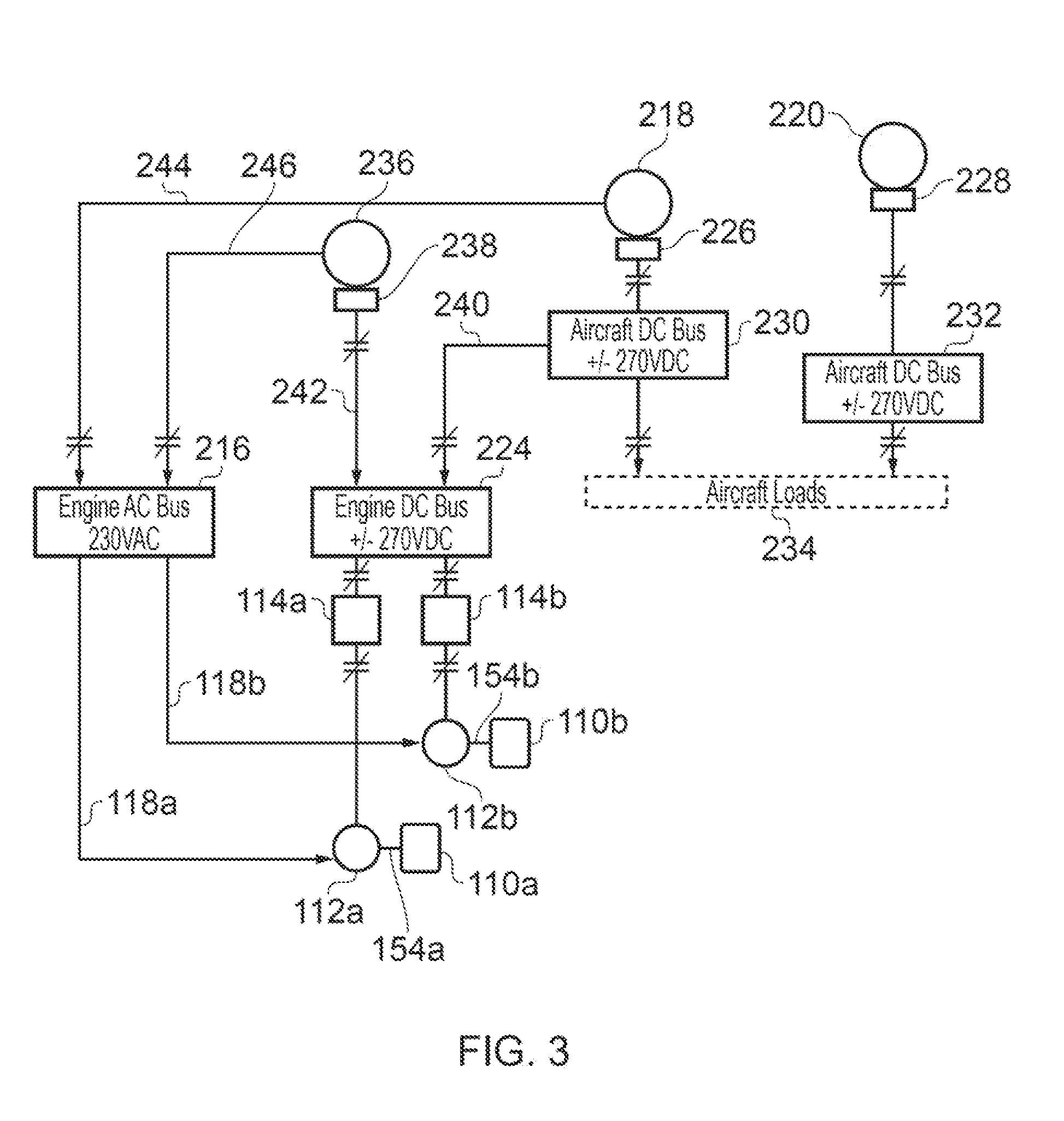

Gas turbine engine fuel system

ActiveUS20150315980A1Further flexibilityIncreasing and reducing torqueEngine fuctionsGas turbine plantsEngineeringPiezoelectric generator

The present application discloses a fuel system for a gas turbine engine. The engine includes a main alternating current electrical generator driven by an engine shaft such that the electrical output frequency of the electrical generator varies in dependence on shaft rotational speed. The fuel system includes a variable flow fuel pump for providing a fuel flow to the engine, a frequency and / or voltage controller configured to provide electrical power having at least one of a predetermined output frequency and a predetermined voltage, and a variable speed electric motor configured to drive the fuel pump. The electric motor includes an induction motor having a stator and at least a first rotor, the stator having first and second sets of stator windings. Each set of stator windings is configured to impart a torque on the rotor in use.

Owner:ROLLS ROYCE PLC

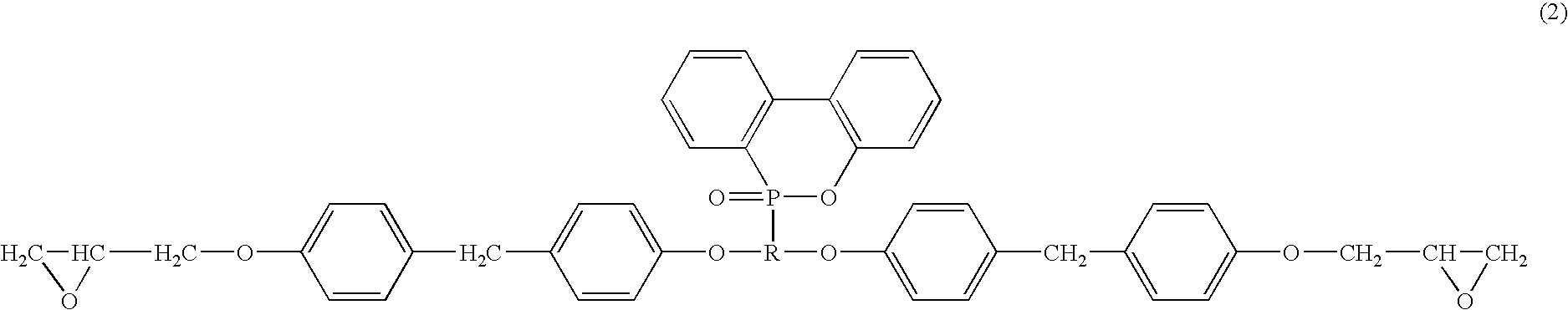

Adhesive Composition for Semiconductor Device and Cover Lay Film, Adhesive Sheet, and Copper-Clad Polymide Film Made With the Same

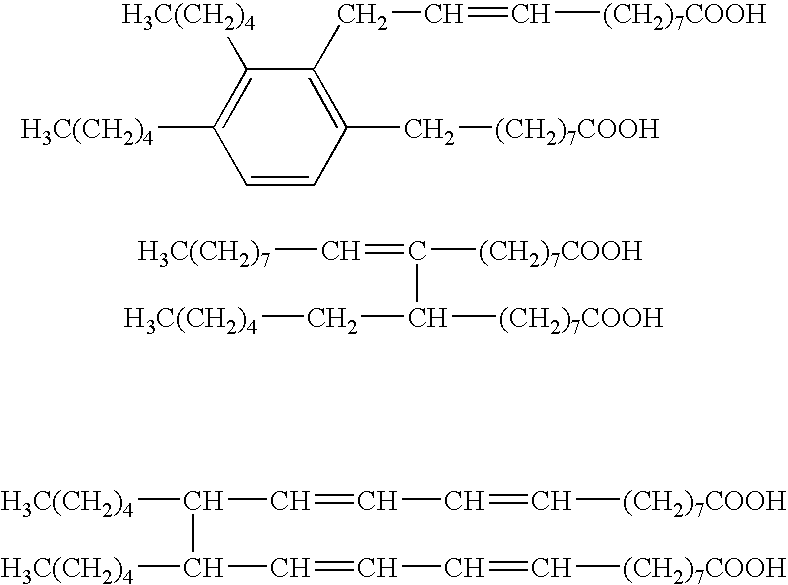

InactiveUS20080131639A1Excellent in flexural propertyExcellent propertyInsulating substrate metal adhesion improvementNon-macromolecular adhesive additivesPolyimide membraneChemistry

An adhesive composition for semiconductor devices which comprises an epoxy resin, a phenoxy resin, and a hardener, wherein part or all of the epoxy resin comprises at least one type of epoxy resin selected from the followings:(a) a dimer acid modified epoxy resin(b) a phosphorus containing epoxy resin having an epoxy equivalent of 2000 to 6000.Said adhesive composition has satisfactory flexural properties even in a high-temperature environment while retaining an excellent toughness of the adhesive and is excellent in soldering heat resistance, adhesive property, flame retardancy and electrical properties. The adhesive composition can suitable be used for cover lay films, adhesive sheets and copper-clad polyimide films.

Owner:TORAY IND INC

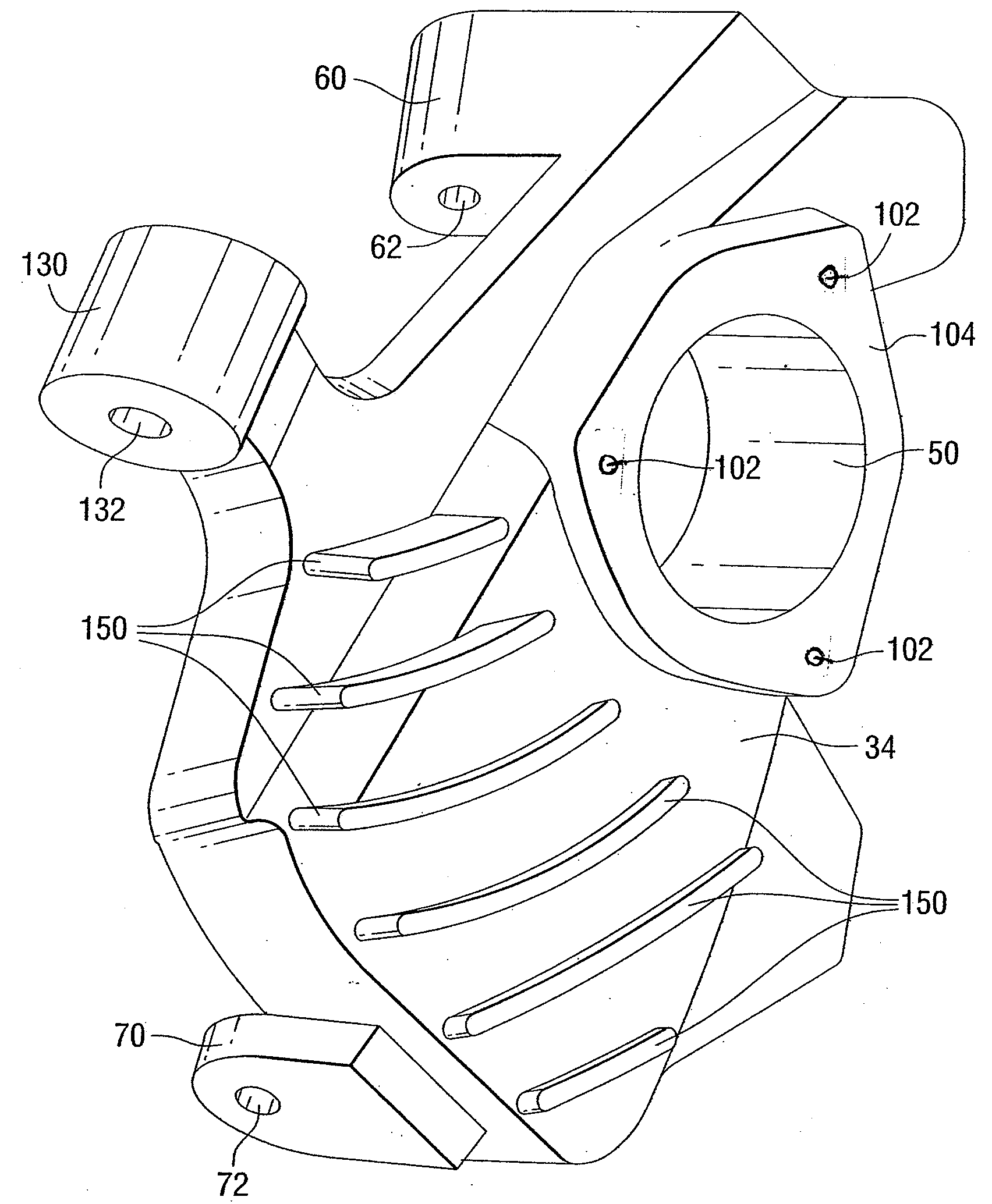

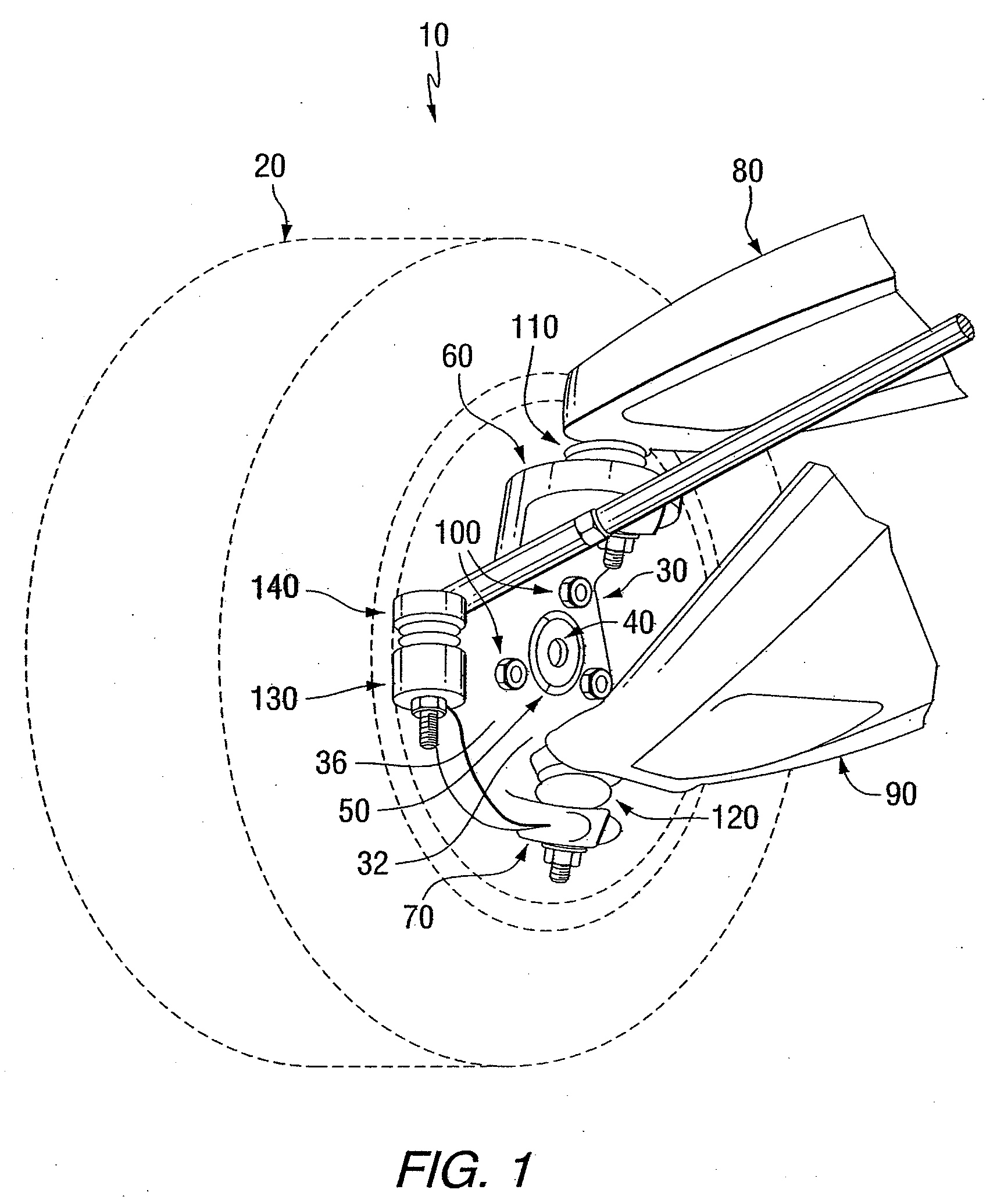

Spindle cooling device

InactiveUS20090001678A1Prevent overheating and premature failure of partEasy to assembleSteering linkagesBrake coolingEngineeringHeat sink

A spindle with cooling fins is disclosed. The spindle has raised cooling fins on an outside exterior surface. The fins create cooling channels which direct air upward when the vehicle is in motion. The redirected air passes over and around the brake and hub assemblies. This effectively dissipates heat from the brake and hub assemblies and will help to prevent overheating and premature failure of the parts.

Owner:GROUND FORCE MARKETING

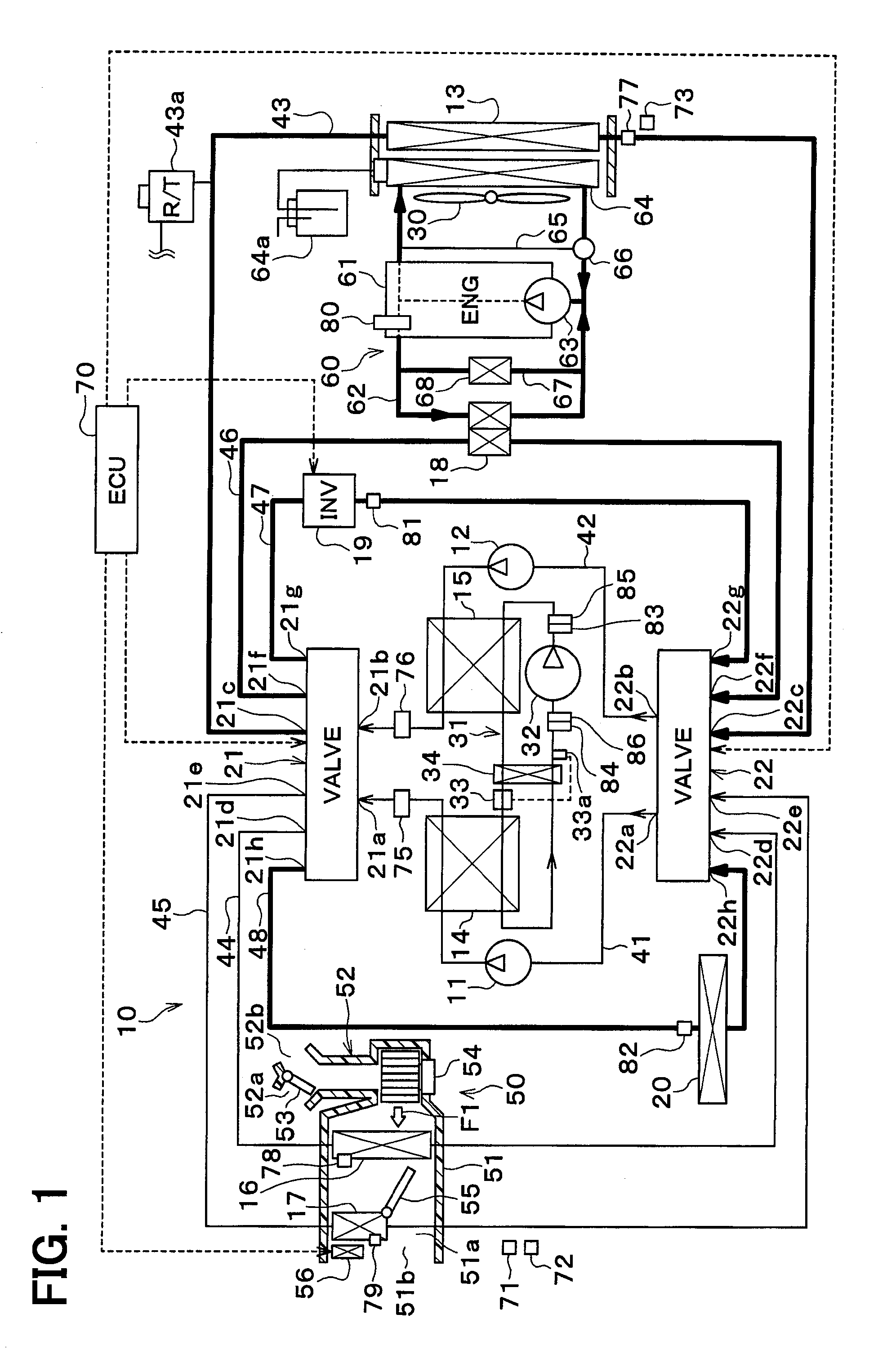

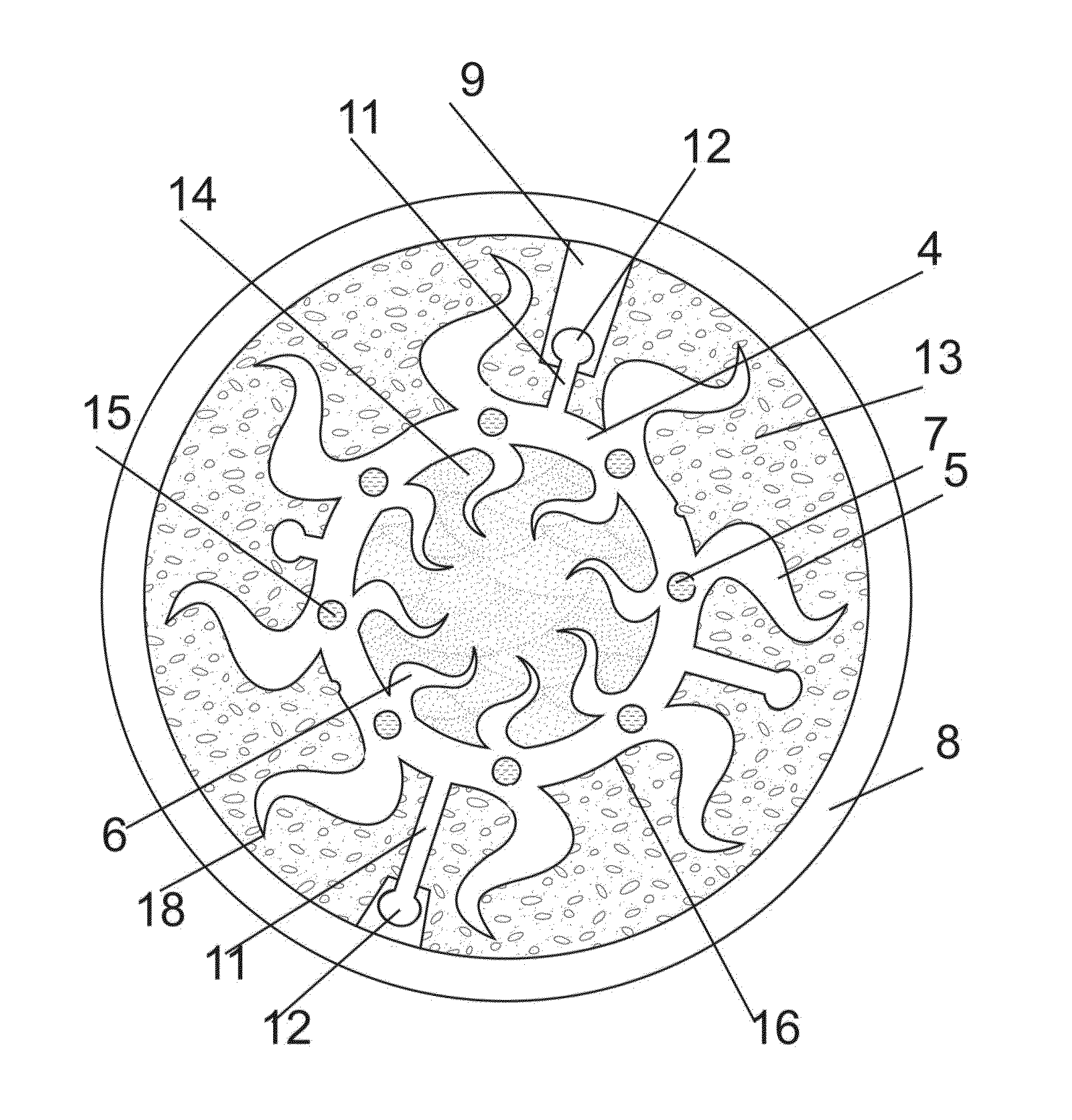

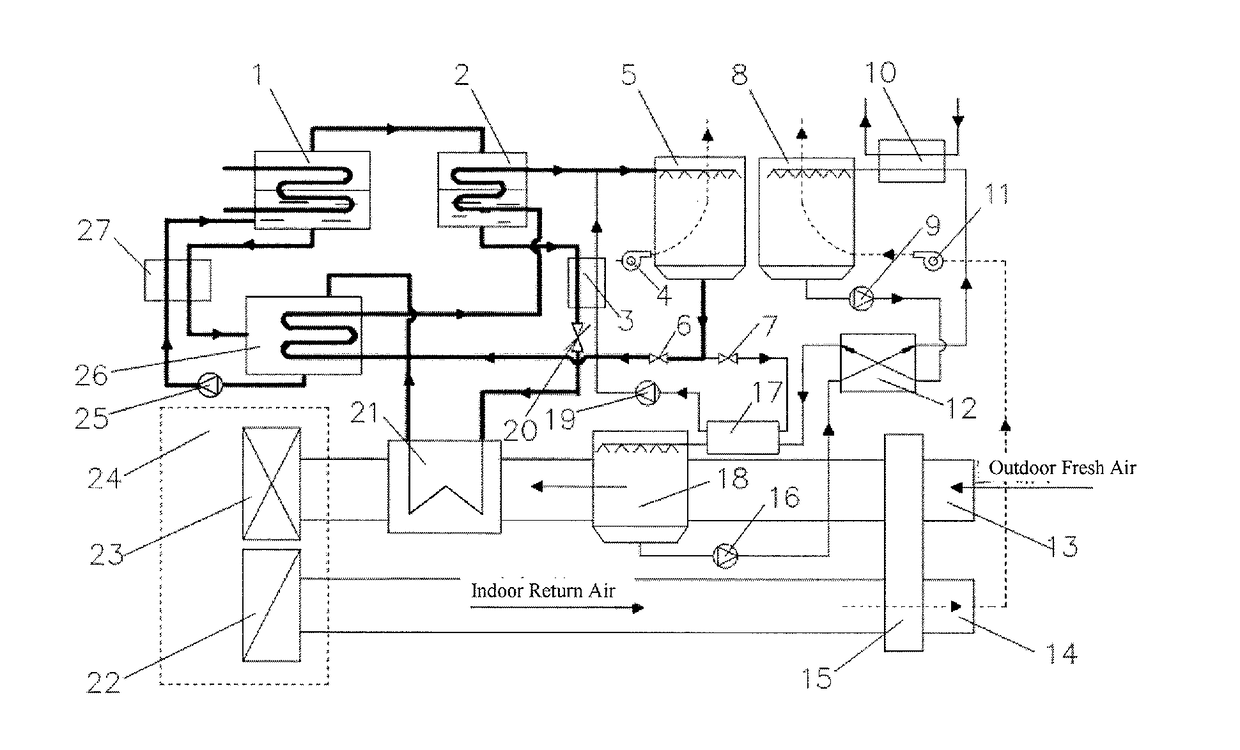

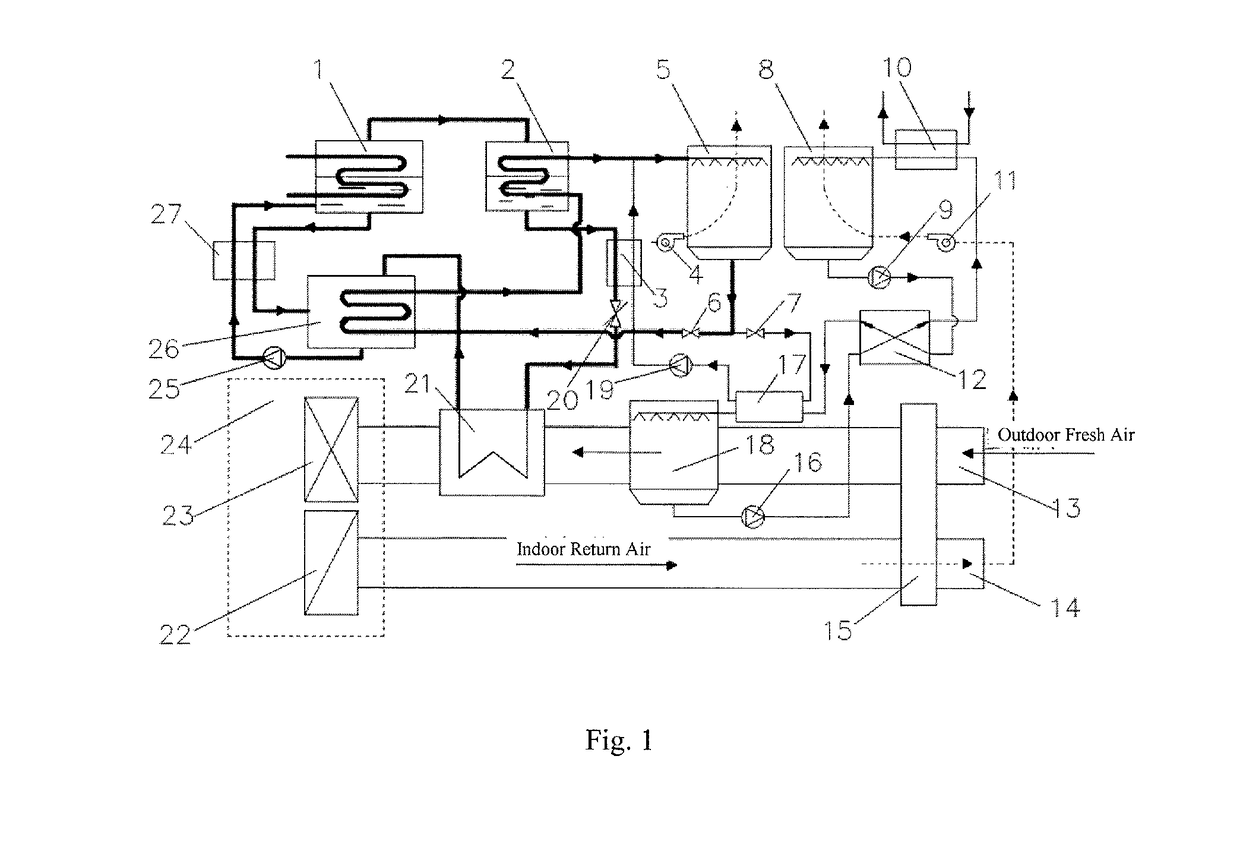

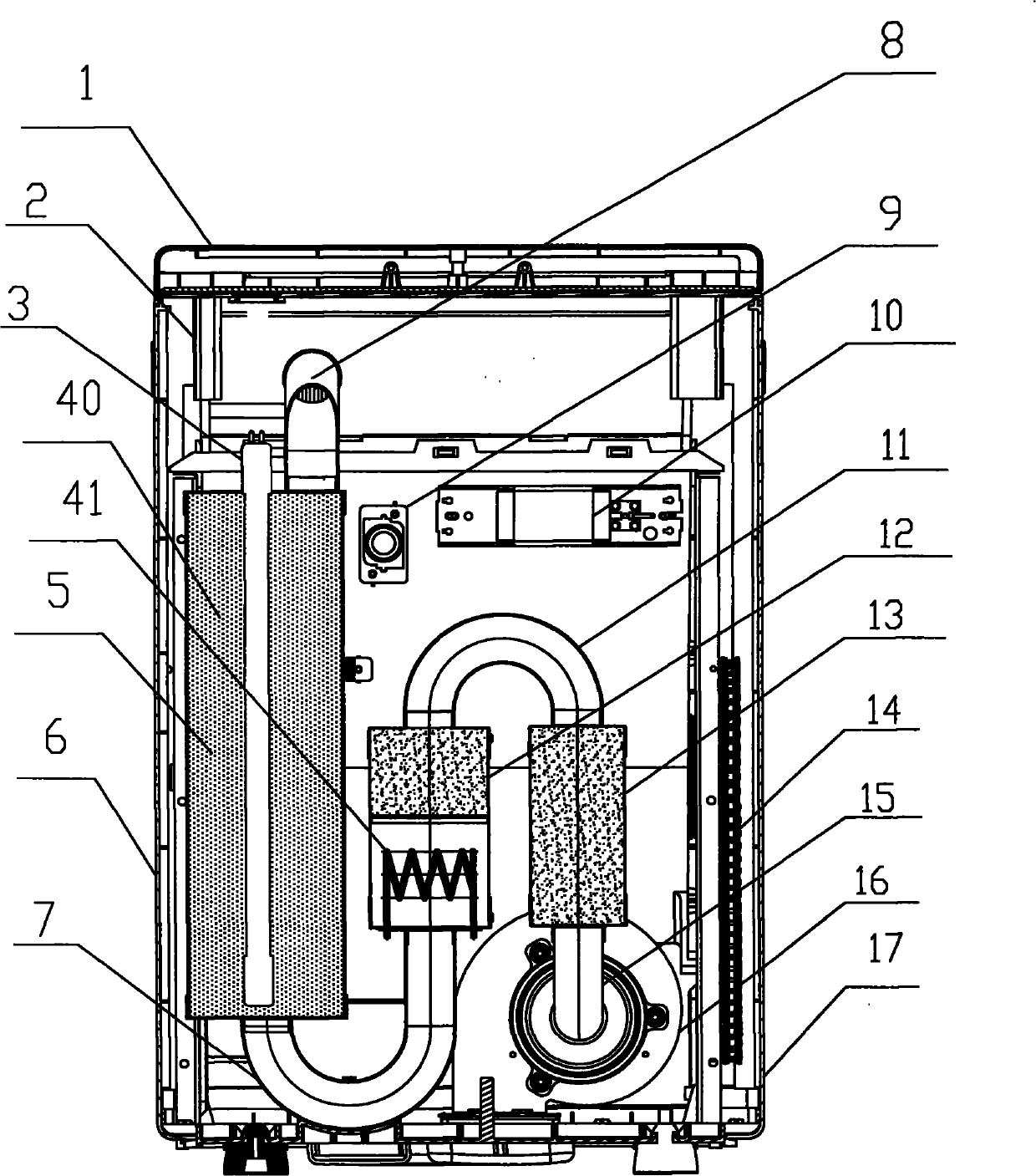

Independent temperature and humidity processing air conditioning system driven by low-level thermal energy

ActiveUS20180259203A1Improve energy efficiencyHeated withHeat pumpsEnergy efficient heating/coolingThermal energyEngineering

An independent temperature and humidity processing air conditioning system driven by low-level thermal energy, comprising an absorption-type refrigeration circulation loop, a solution dehumidification and regeneration circulation loop, a water cooling circulation loop, and a central air conditioning air supply and air return pipeline; the absorption-type refrigeration circulation loop comprises an evaporator (21), an absorber (26), a generator pump (25), a second solution heat exchanger (27), a generator (1), a condenser (2), a water-water heat exchanger (3), and a throttle valve (20); the solution dehumidification and regeneration circulation loop comprises a regenerator (8), a first solution pump (9), a solution heater (10), a first solution heat exchanger (12), a second solution pump (16), a solution cooler (17), and a dehumidifier (18); the water cooling circulation loop comprises two branches; and the central air conditioning air supply and a return pipeline comprises an air supply pipeline (13), an air return pipeline (14), an air conditioning heat exchanger (15), a dehumidifier (18), an evaporator (21), an air supply induction opening (23), an air return induction opening (22), a second flow guide fan (11), and a regenerator (8). The present air-conditioning system can resolve the problem of efficiently driving absorption-type cooling for air conditioning adjustment under 80° C.

Owner:SOUTHEAST UNIV

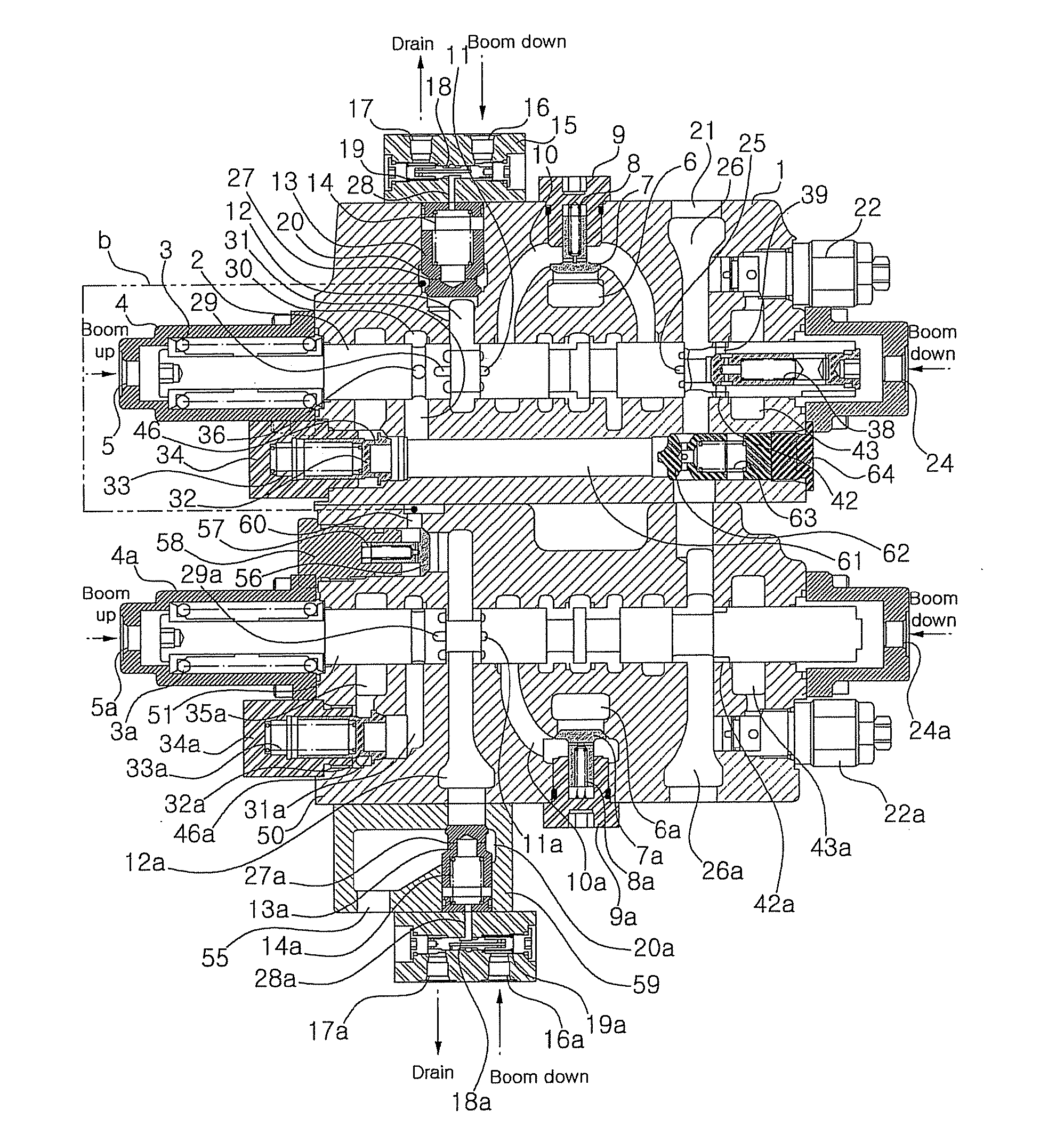

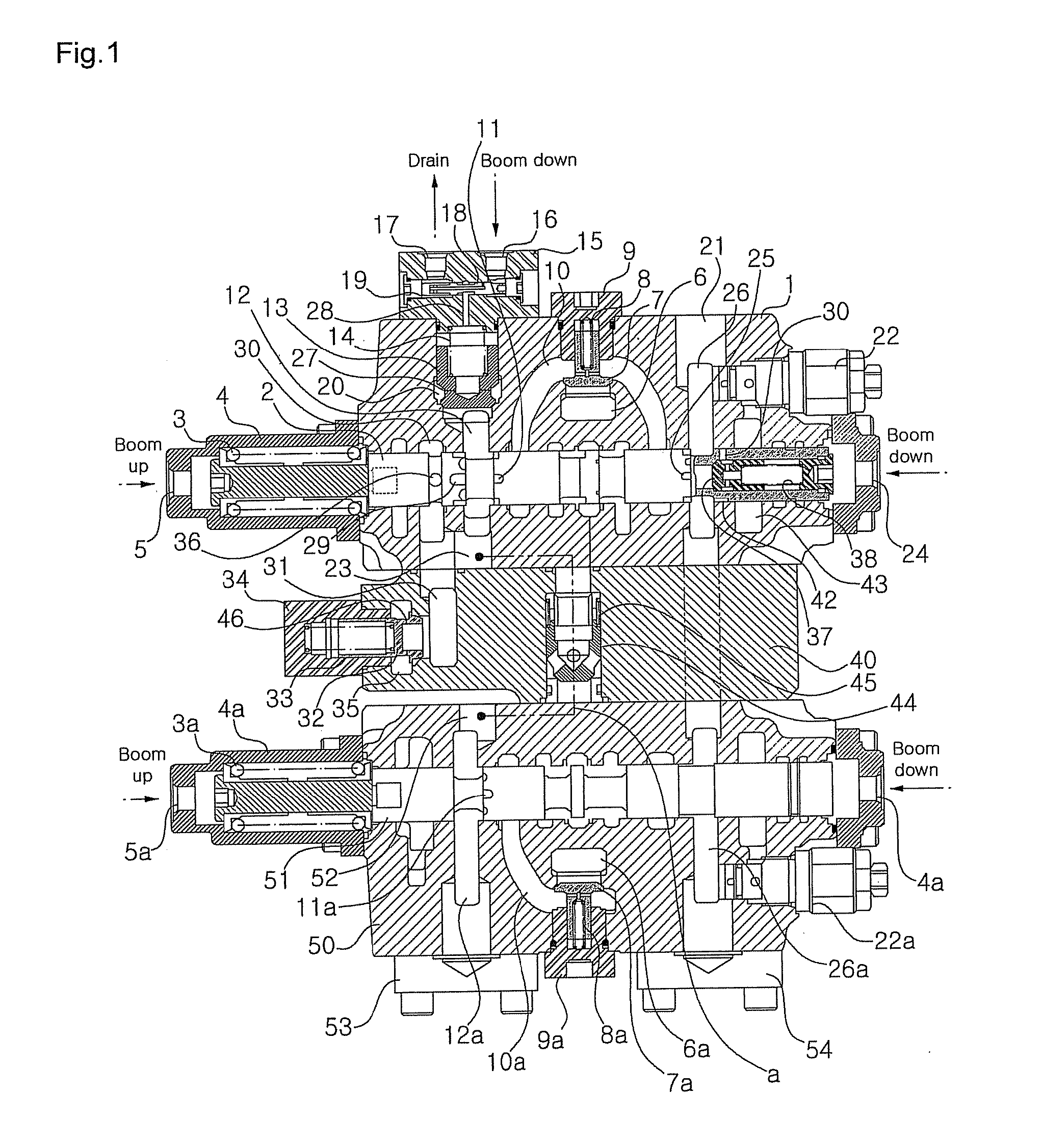

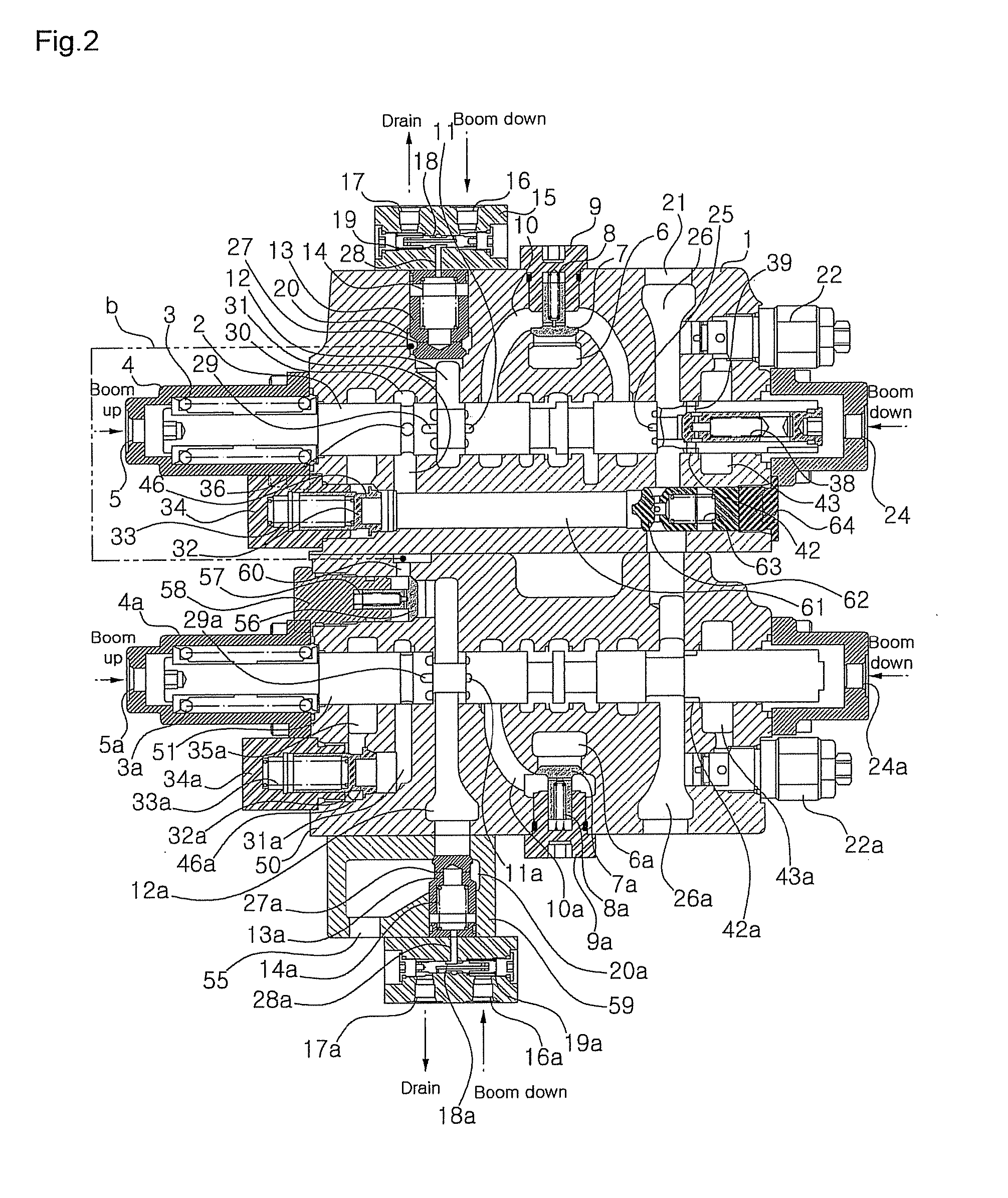

Flow control valve for construction machinery

Disclosed is a flow control valve for construction machinery, the flow control valve being adapted to reduce pressure loss due to flow on return to a hydraulic tank during the boom-down operation of a large-scale excavator. The flow control valve for construction machinery according to the present invention comprises: first and second boom spools which are respectively coupled to first and second boom valve blocks, and which regulate working fluid that is respectively supplied from first and second hydraulic pumps to a boom cylinder during direction reversal; a boom-up flow-adjusting means which, in direction reversal of the first and second boom spools for boom-up drive, supplies working fluid from the first and second hydraulic pumps into a large chamber of the boom cylinder via the first and second boom spools respectively, and causes part of the flow of working fluid from the second hydraulic pump to pass via the second boom spool so as to be combined with working fluid being supplied from the first hydraulic pump to the large chamber of the boom cylinder due to direction reversal of the first boom spool; and a boom-down flow-adjusting means which, in direction reversal of the first and second boom spools for boom-down drive, causes part of the flow of working fluid coming back from the large chamber of the boom cylinder to return to the hydraulic tank via the first and second boom spools respectively, and causes part of the flow of working fluid coming back from the large chamber of the boom cylinder to combine as respective regenerative flows for working fluid on the small chamber side of the boom cylinder.

Owner:VOLVO CONSTR EQUIP AB

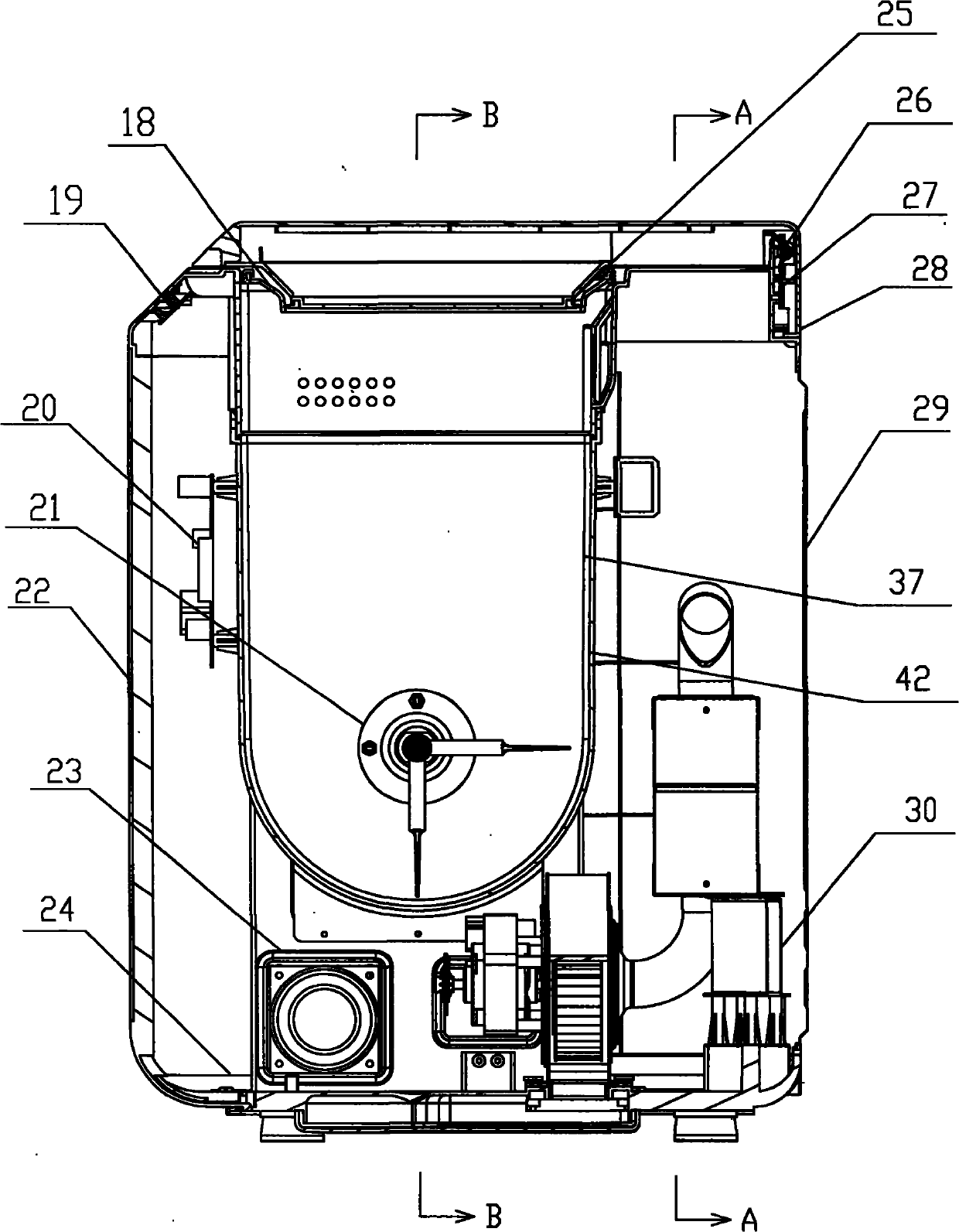

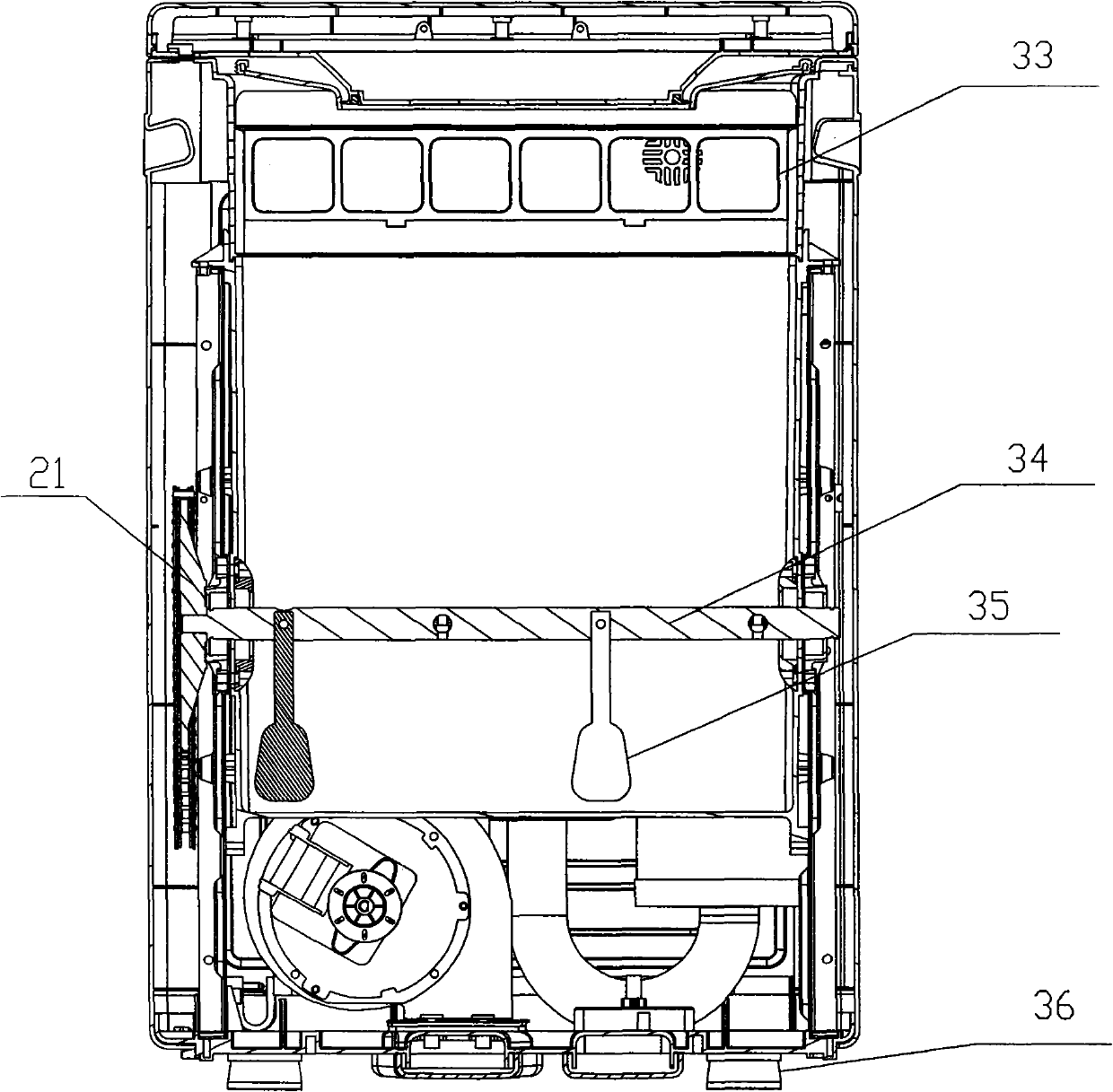

Method for processing kitchen waste and equipment thereof

ActiveCN101791531AMeet the needs of combined useMeet UV/O

<sub>3</sub>

Combined use needsDispersed particle separationChemical/physical/physico-chemical stationary reactorsEngineeringAir blower

The invention discloses equipment for processing kitchen waste. In the equipment, a shell consists of a cover assembly, a front casing, a left side plate, a right side plate, a rear cover plate, a feeding cover and a base; a stirring vessel and a stirring motor are arranged in the shell; a stirring shaft driven by the motor is inserted into the center of the stirring vessel; a stirring rod is fixedly arranged on the stirring shaft; a sealing strip is arranged between the stirring vessel and the feeding cover for sealing; a photocatalyst assembly which is communicated with a gas outlet in the middle-upper part of the inner chamber of the stirring vessel by a first elbow pipe is arranged in the shell; the other end of the photocatalyst assembly is sequentially connected in series with a second elbow pipe, a first catalyst tank, a third elbow pipe and a second catalyst tank which are arranged in the shell in a communication way; and the other end of the second catalyst tank is provided with a fourth elbow pipe which is connected with a second air blower. The invention also discloses a method for processing the kitchen waste. The method comprises the steps of placing the kitchen waste and digestive bacteria into the stirring vessel; starting the stirring motor and heating the stirred materials to the temperature of about 50 DEG C; and allowing gases to enter a gas processing system through negative pressure of the first air blower, and then exhausting the gases.

Owner:HANYU GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com