Patents

Literature

15176results about "Photosensitive materials for photomechanical apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

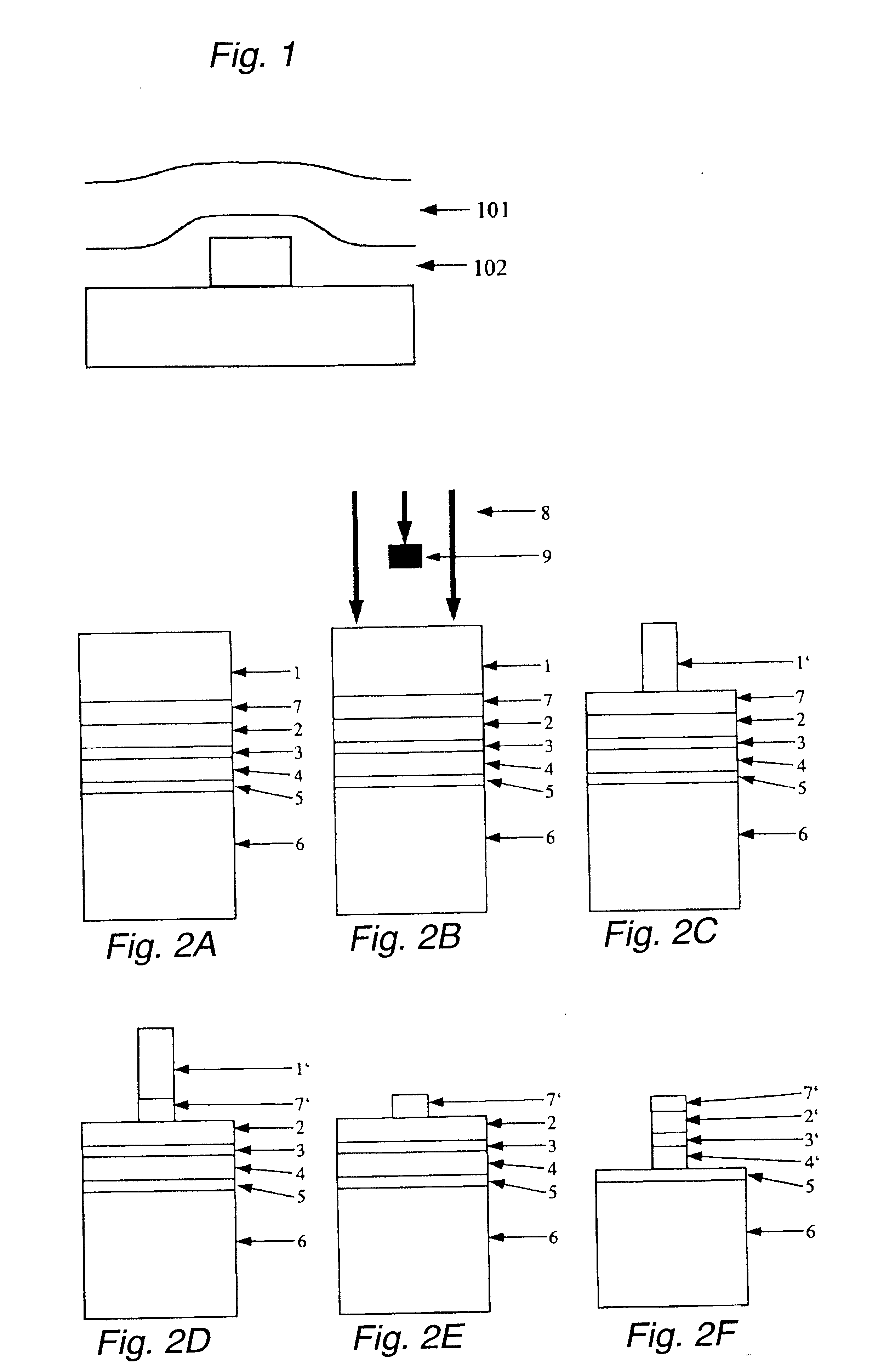

Method and system for immersion lithography

InactiveUS20050147920A1Avoid interactionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImmersion lithographyLight sensitive

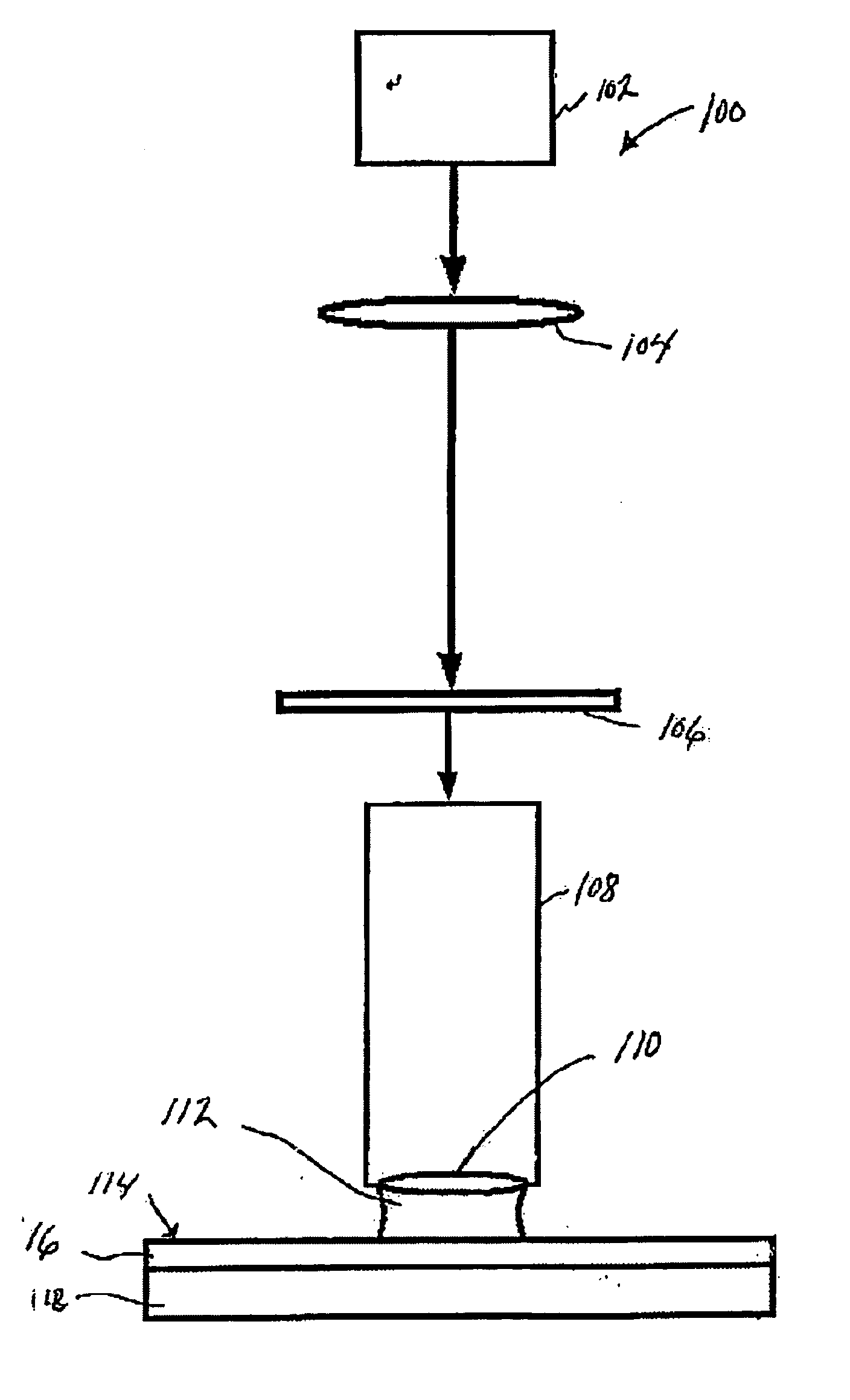

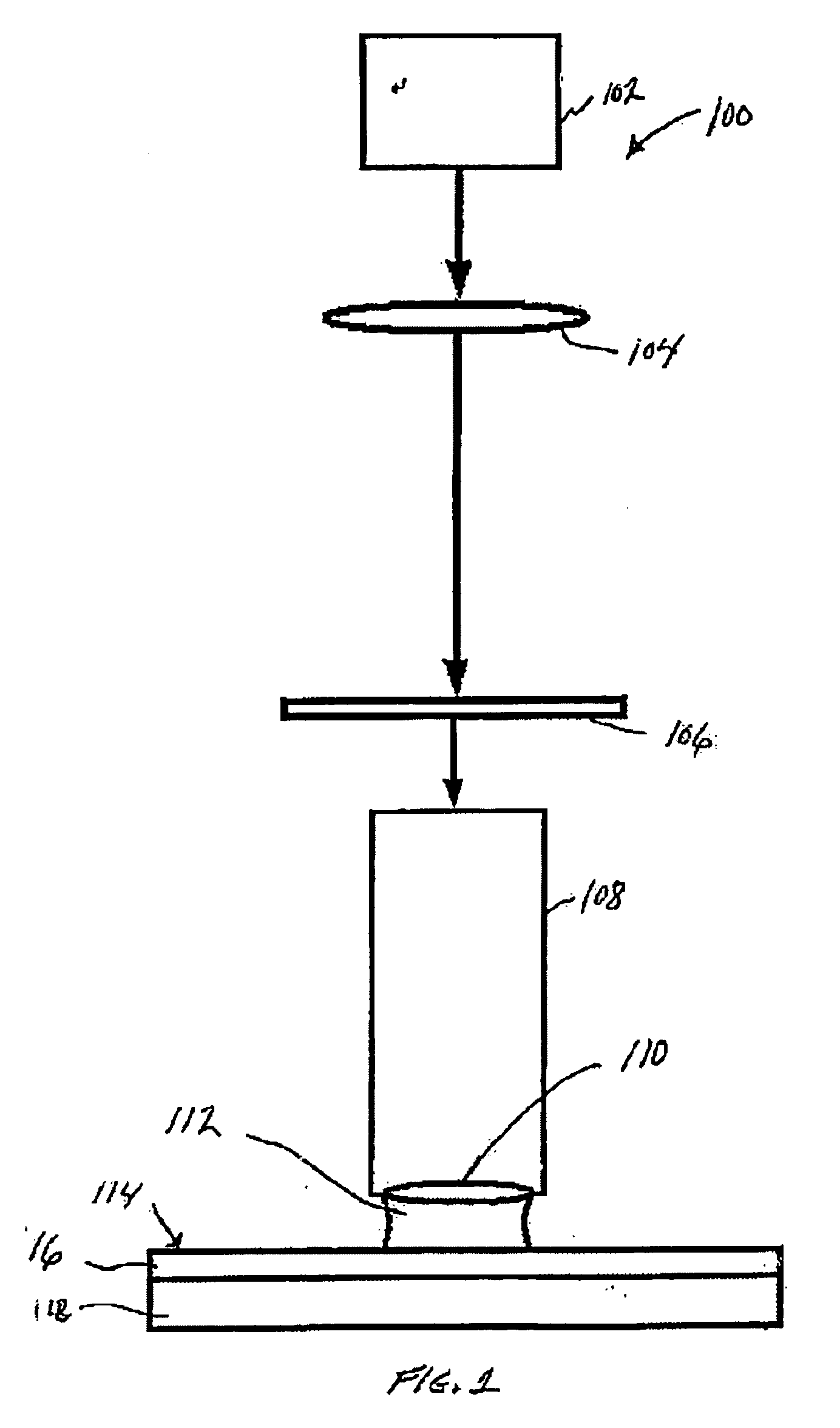

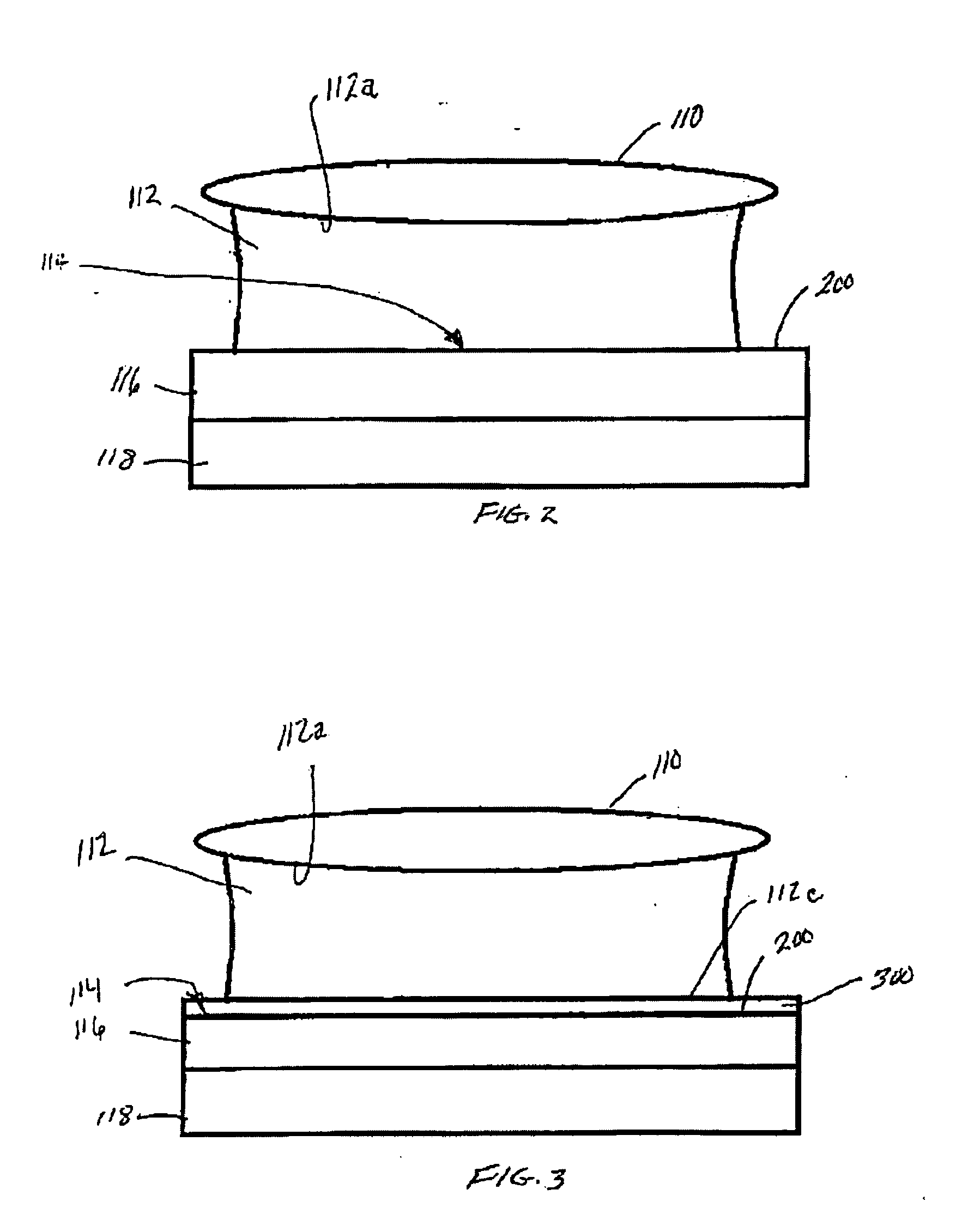

A system (100) and method for immersion lithography is disclosed in which an immersion medium (112) interfaces with a proximal lens (110) that focuses a patterned light beam on a light sensitive material (116), wherein the light sensitive material (116) is covered by a protective film (300) that interfaces with the immersion medium (112).

Owner:TAIWAN SEMICON MFG CO LTD

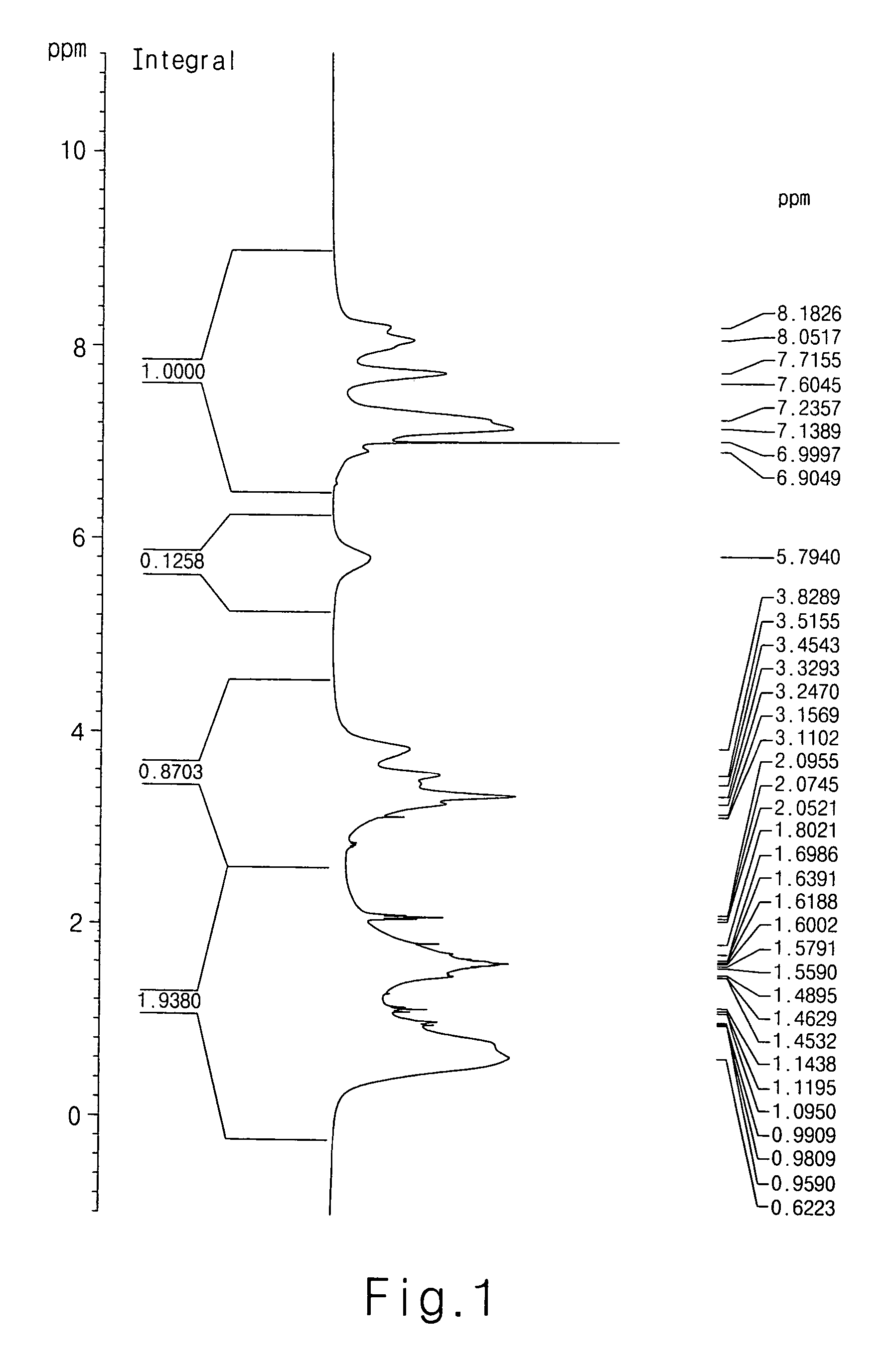

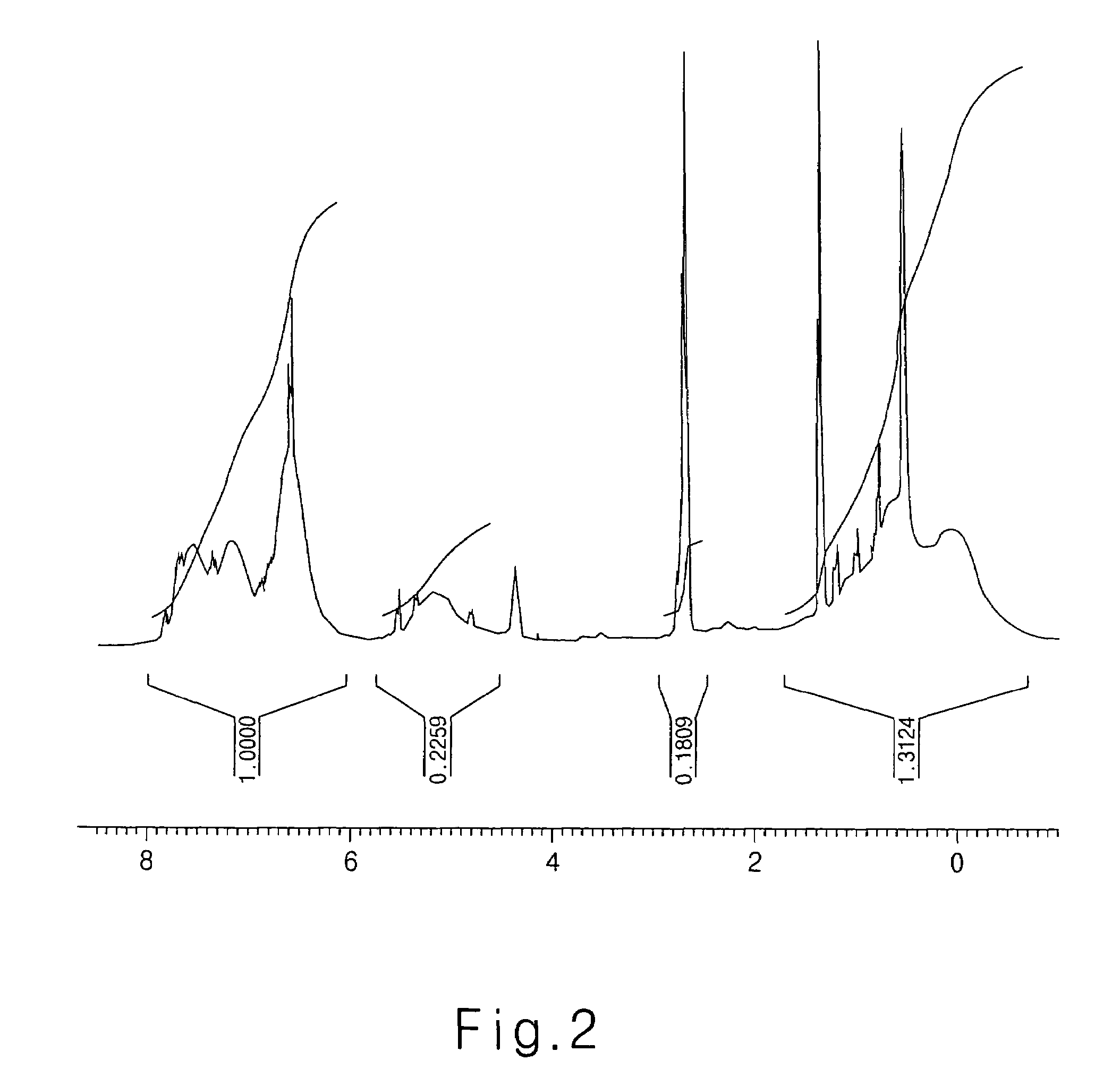

On-press developable IR sensitive printing plates using binder resins having polyethylene oxide segments

InactiveUS6899994B2Prevent steppingRadiation applicationsSemiconductor/solid-state device manufacturingPolymer sciencePolyethylene oxide

The present invention relates to a polymerizable coating composition suitable for the manufacture of printing plates developable on-press. The coating composition comprises (i) a polymerizable compound and (ii) a polymeric binder comprising polyethylene oxide segments, wherein the polymeric binder is selected from the group consisting of at least one graft copolymer comprising a main chain polymer and polyethylene oxide side chains, a block copolymer having at least one polyethylene oxide block and at least one non-polyethylene oxide block, and a combination thereof. The invention is also directed to an imageable element comprising a substrate and the polymerizable coating composition.

Owner:KODAK POLYCHROME GRAPHICS

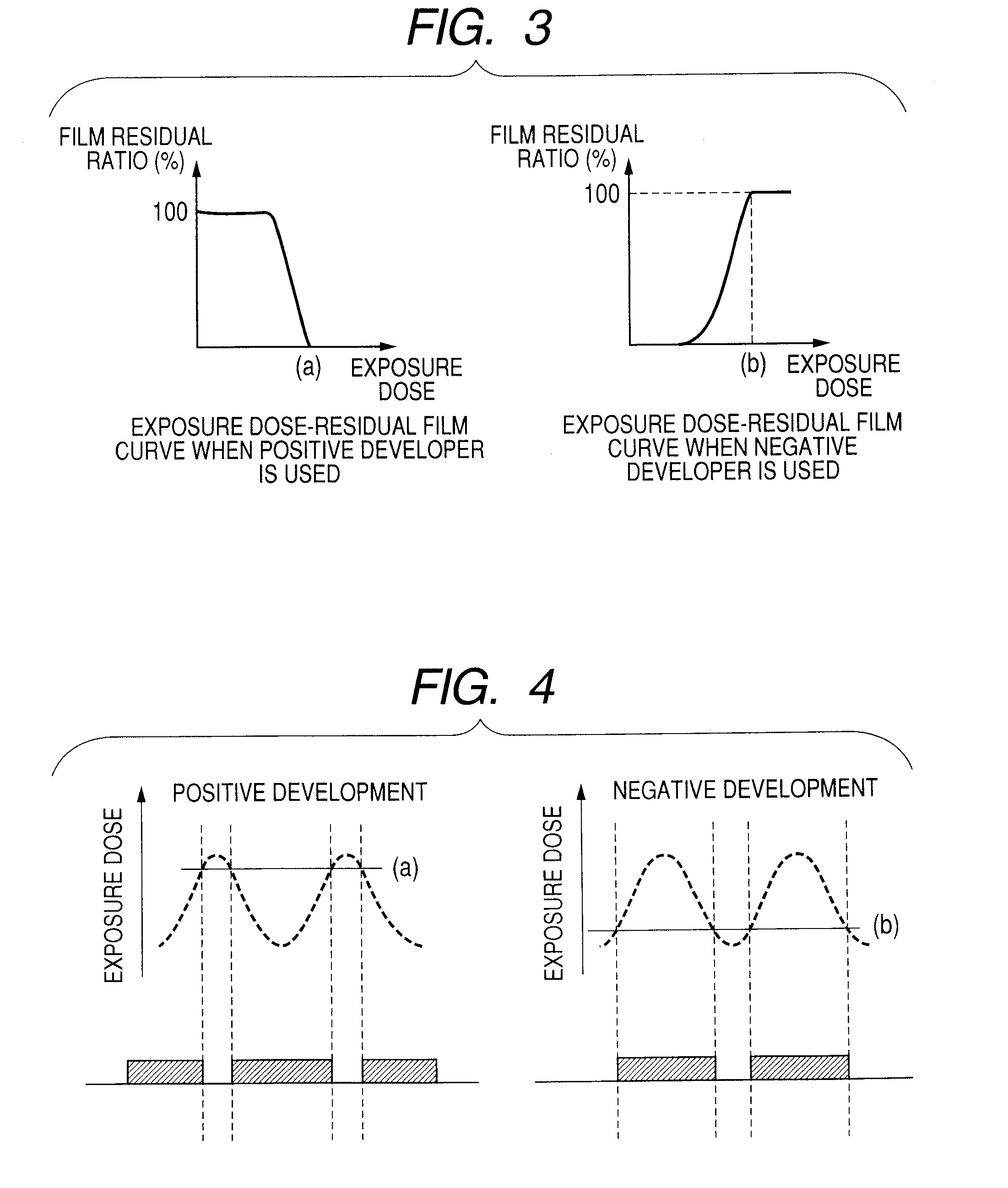

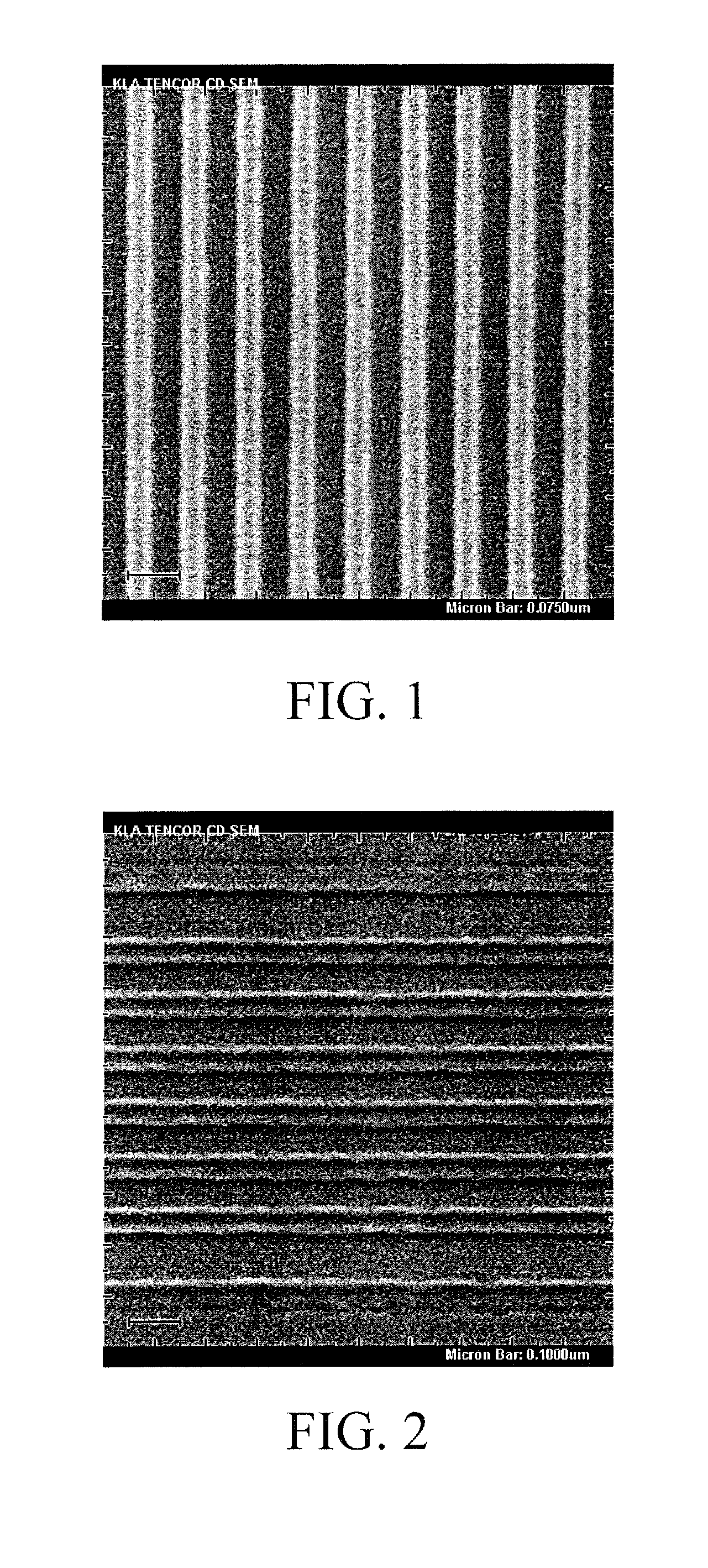

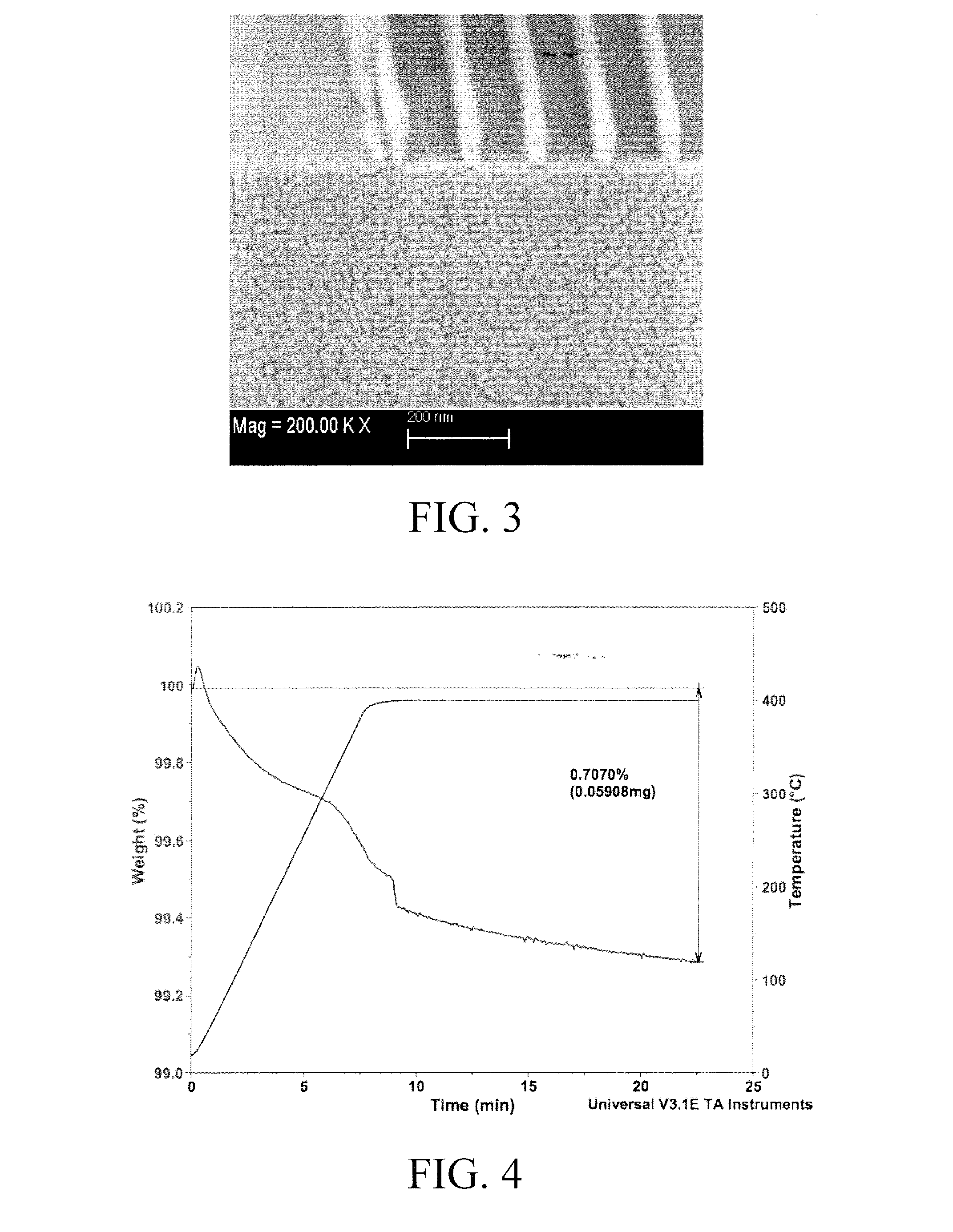

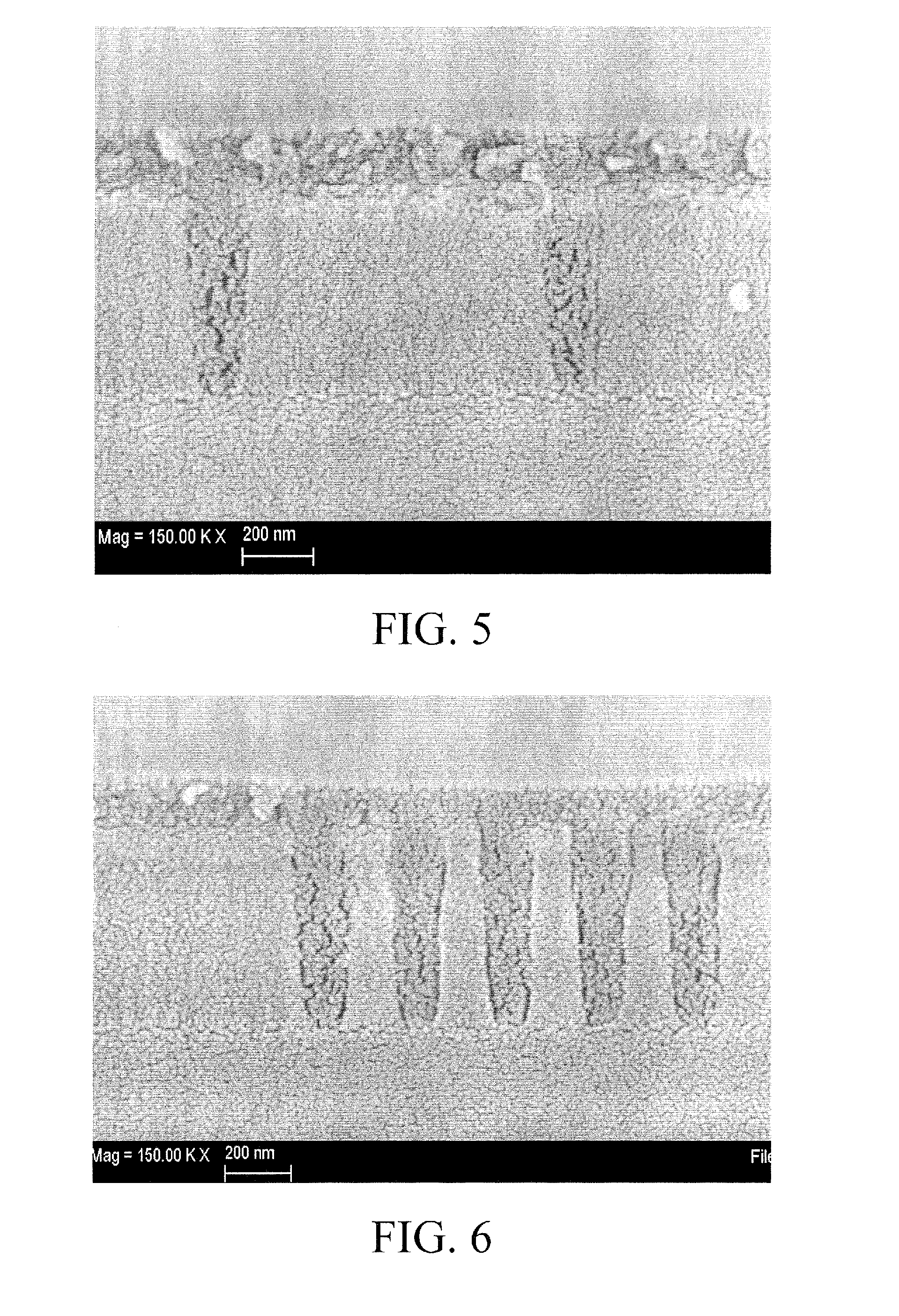

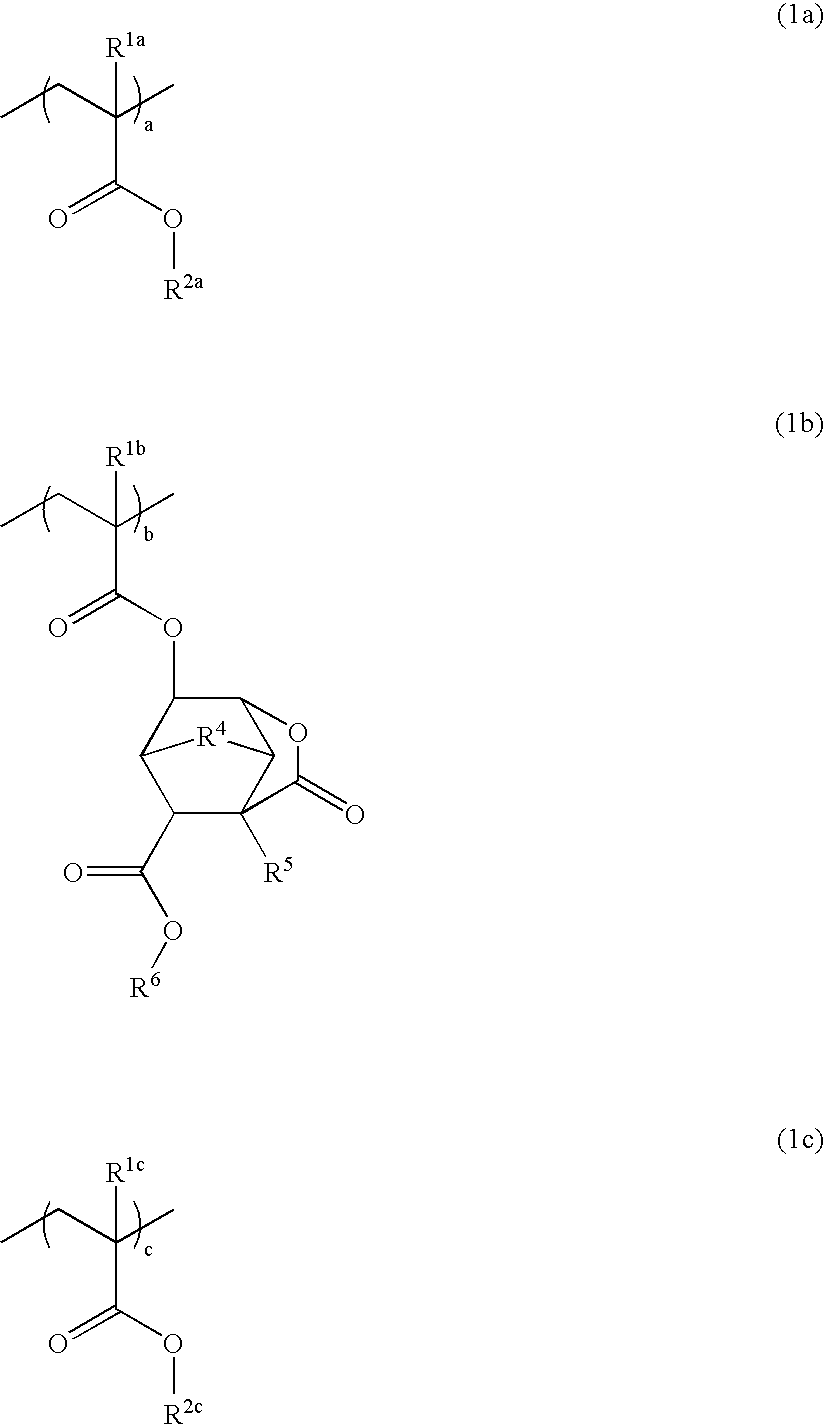

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

ActiveUS20080187860A1Improve accuracyMolding stabilityPhotosensitive materialsLayered productsActinic RaysPhotochemistry

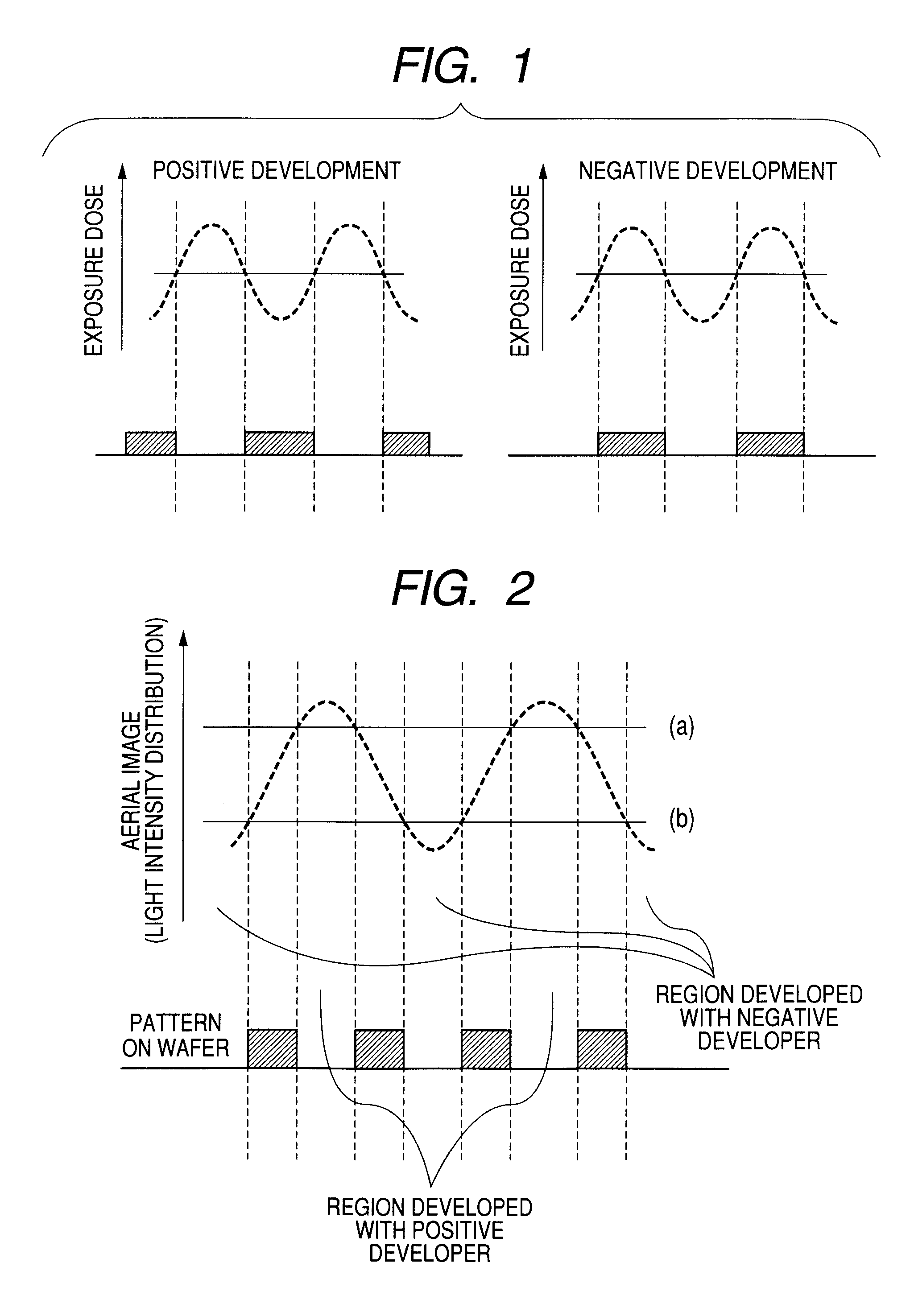

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

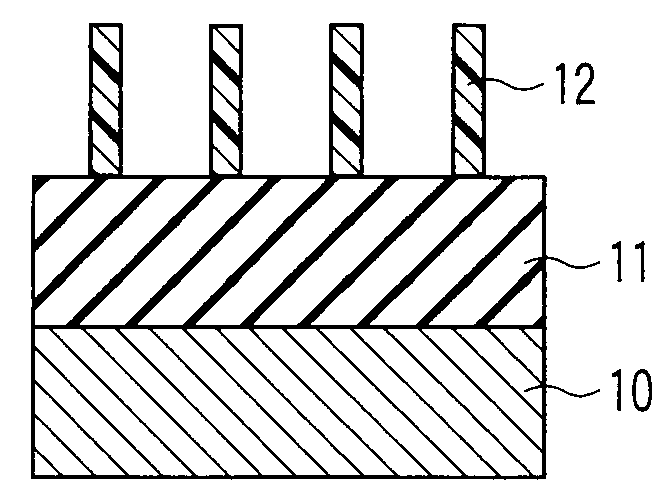

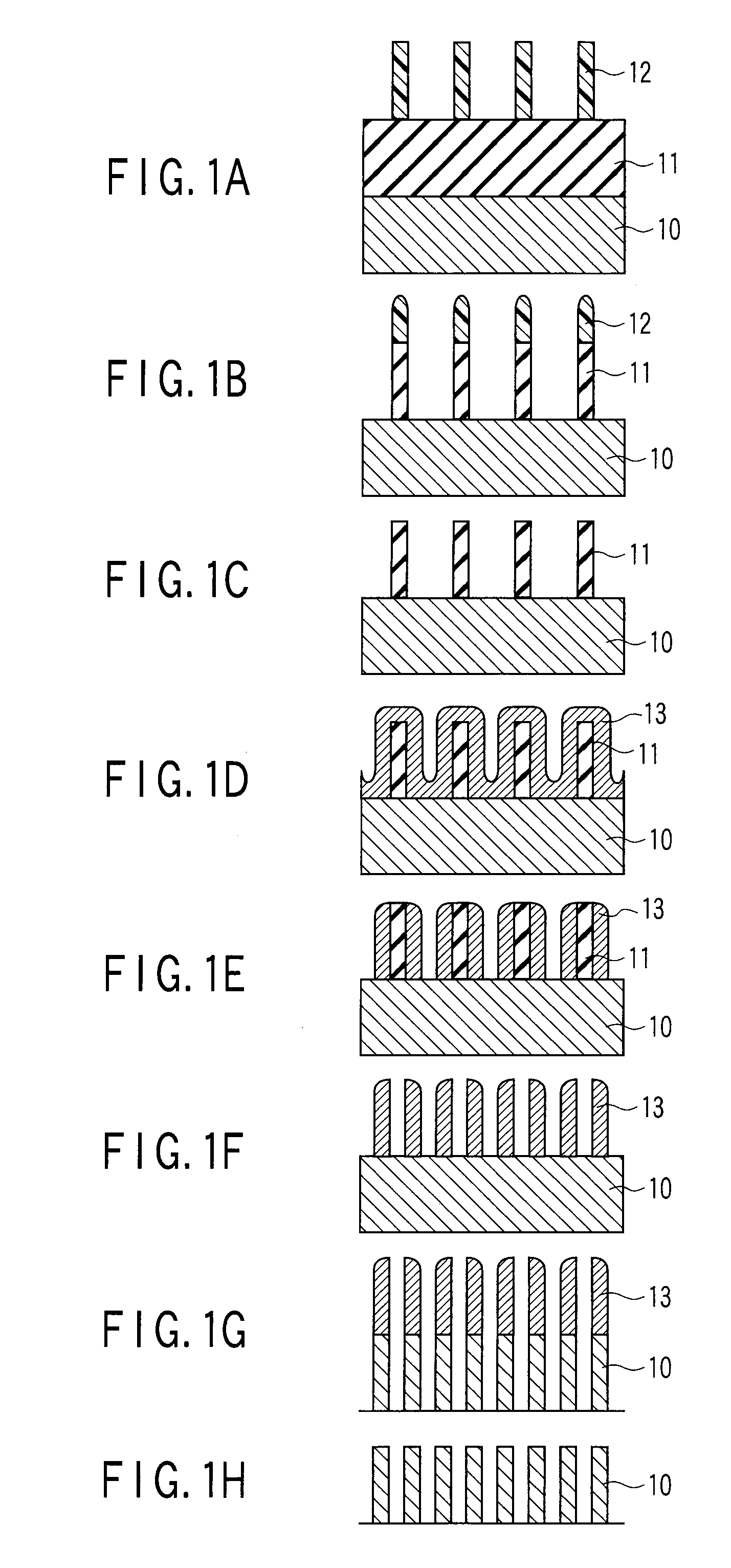

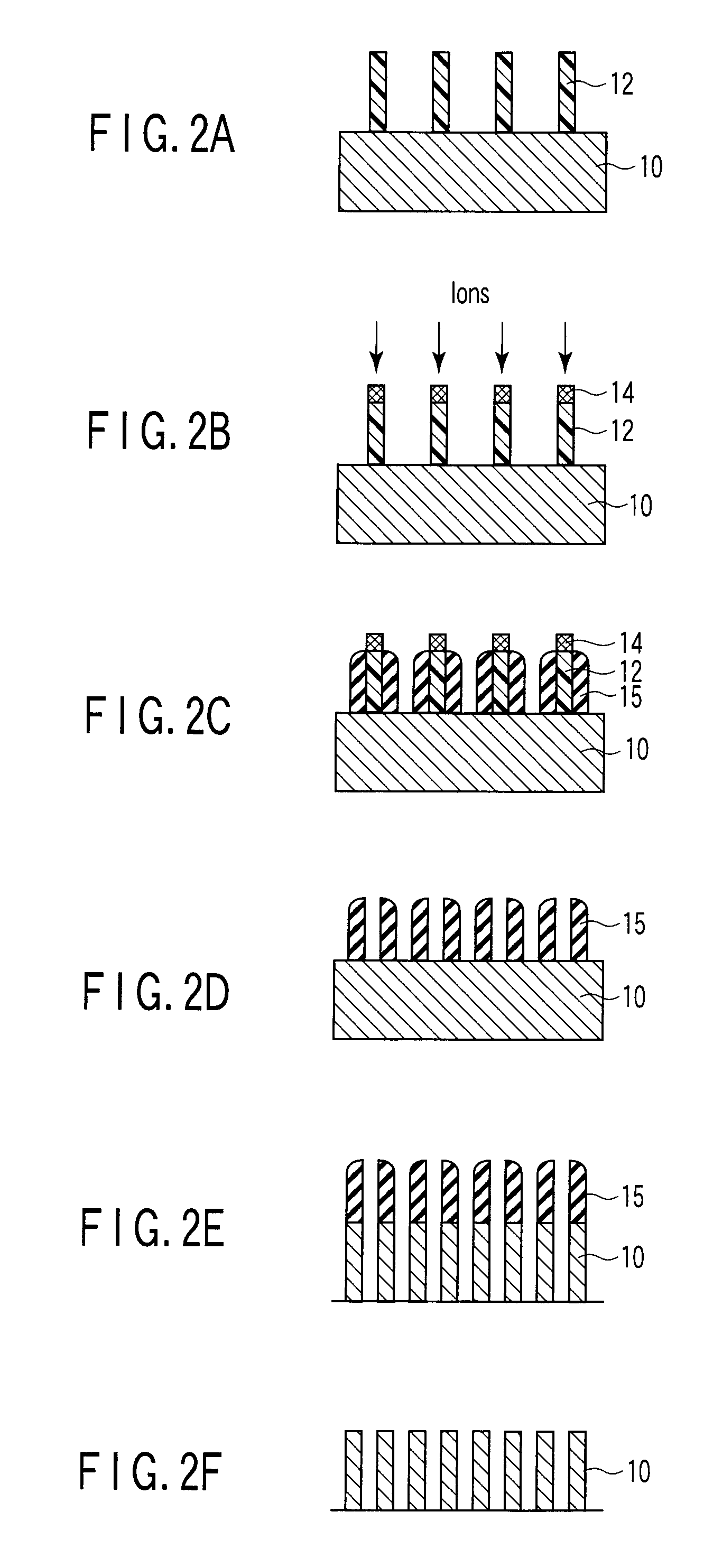

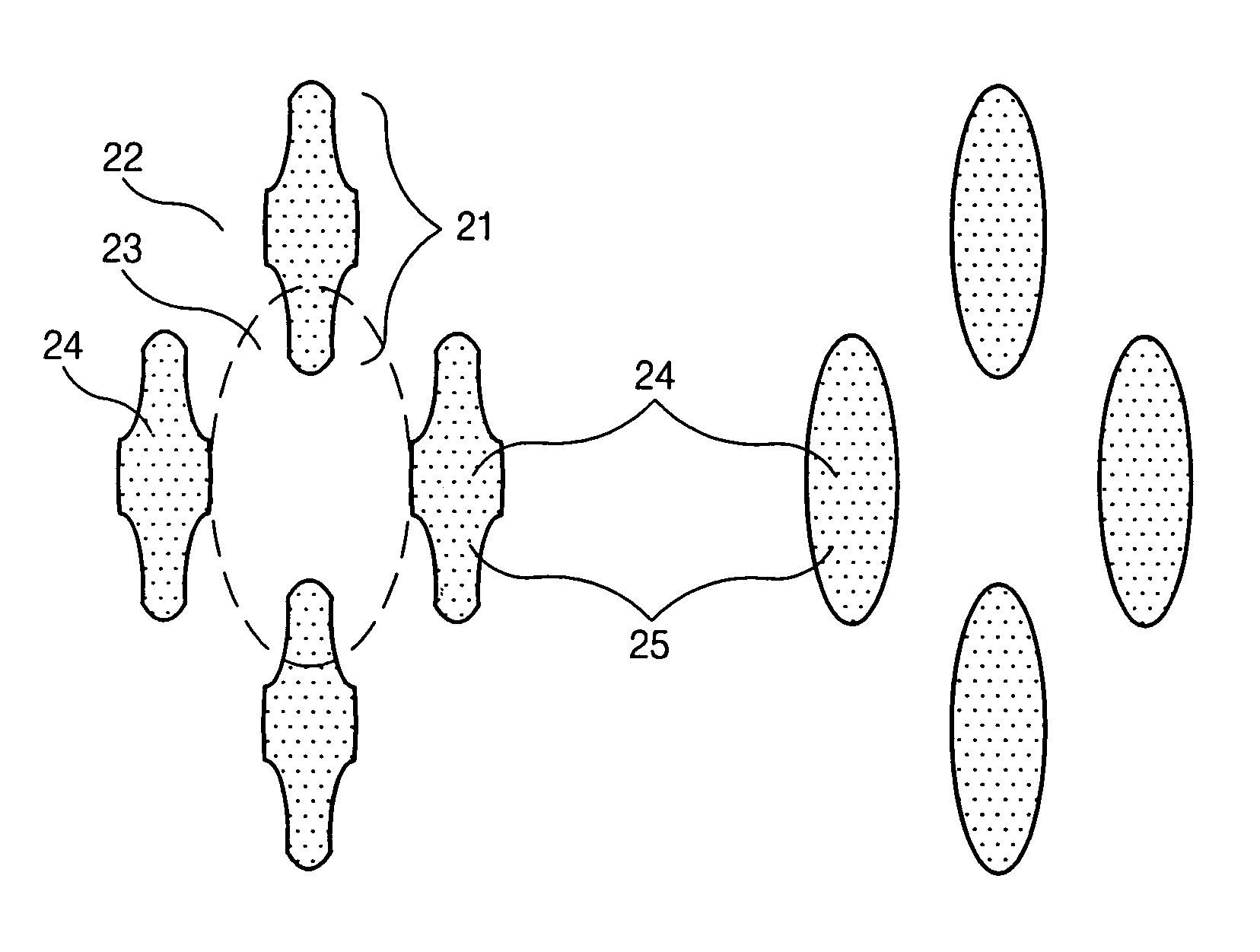

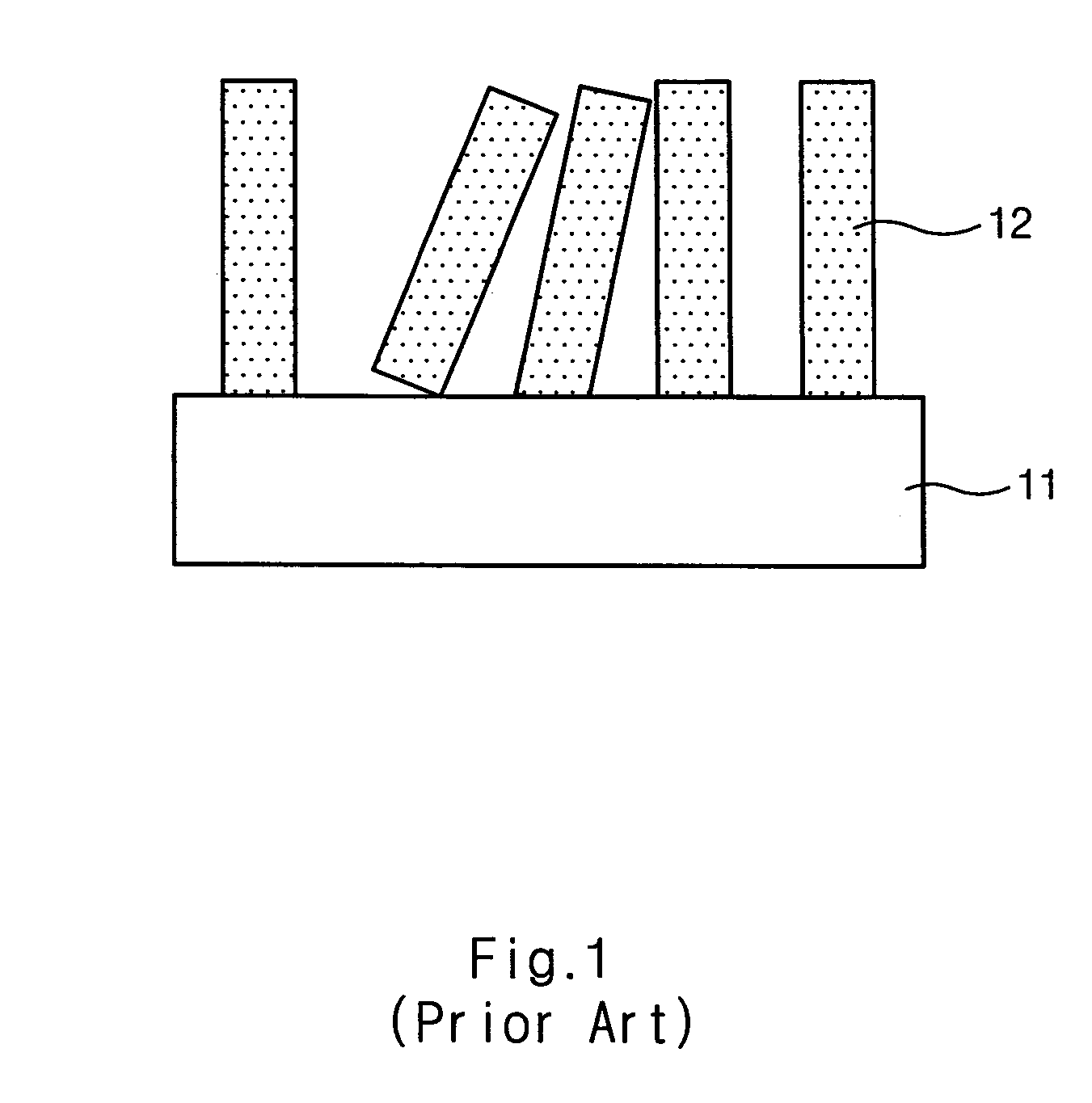

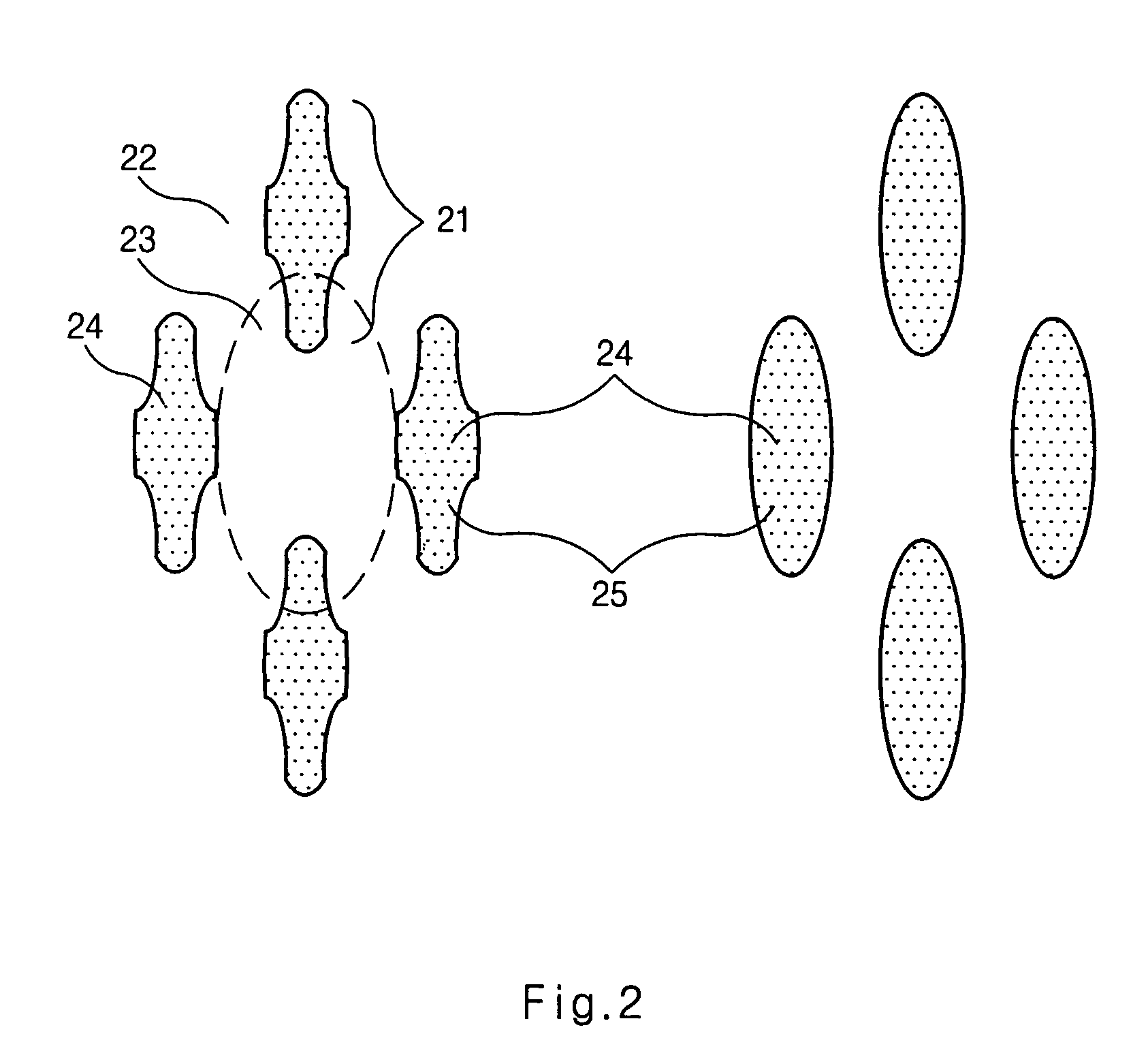

Pattern forming method using relacs process

InactiveUS20080305443A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistOrganic film

A resist pattern is formed on a to-be-processed film. Ions are implanted in the upper surface of the resist pattern. After ion implantation, an organic film is formed to cover the resist pattern and heated. A crosslinked resin film made of the organic film which has crosslinked is formed on the sidewall of the resist pattern by developing the organic film after heating. After formation of the crosslinked resin film, the resist pattern is removed. The to-be-processed film is processed using the crosslinked resin film as a mask.

Owner:KK TOSHIBA

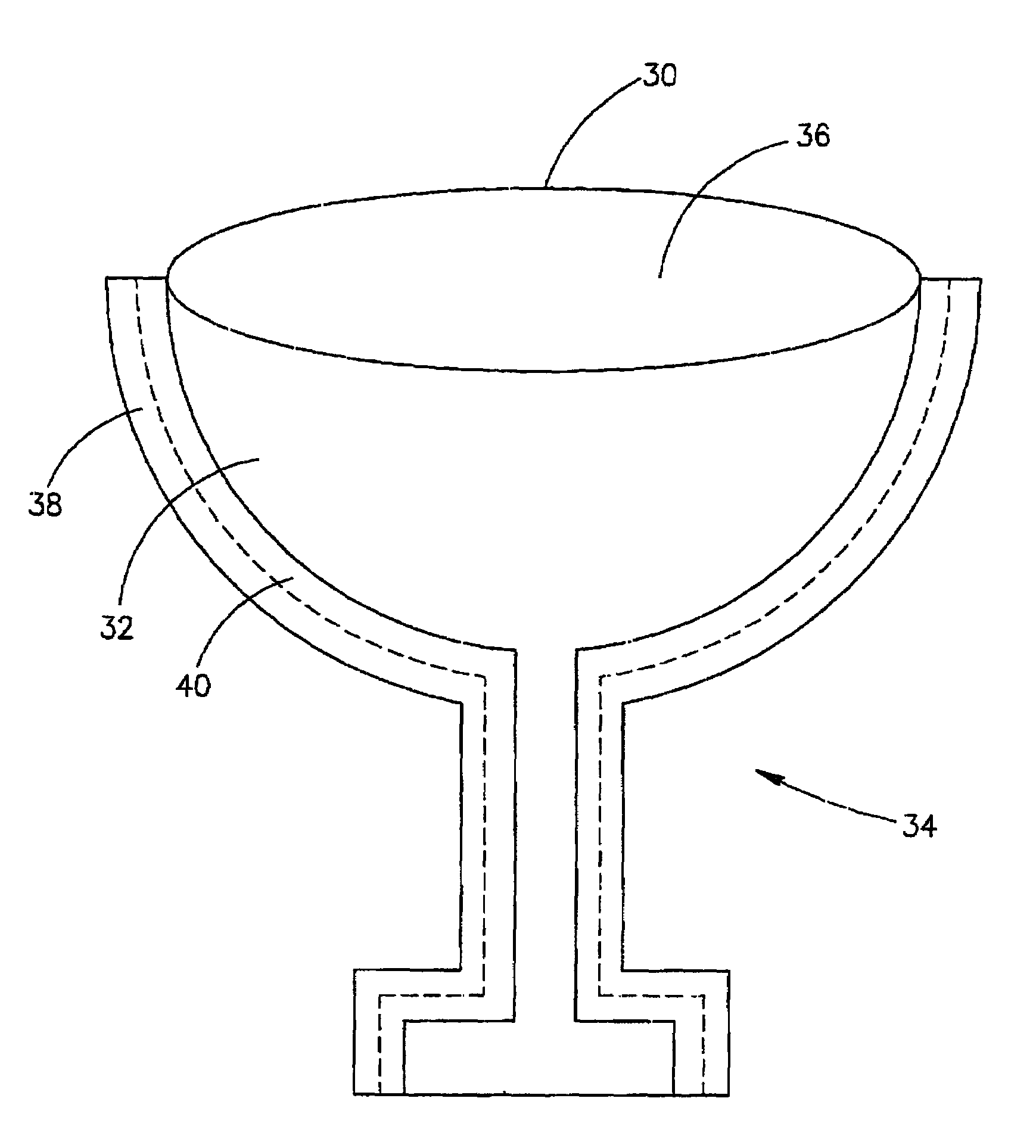

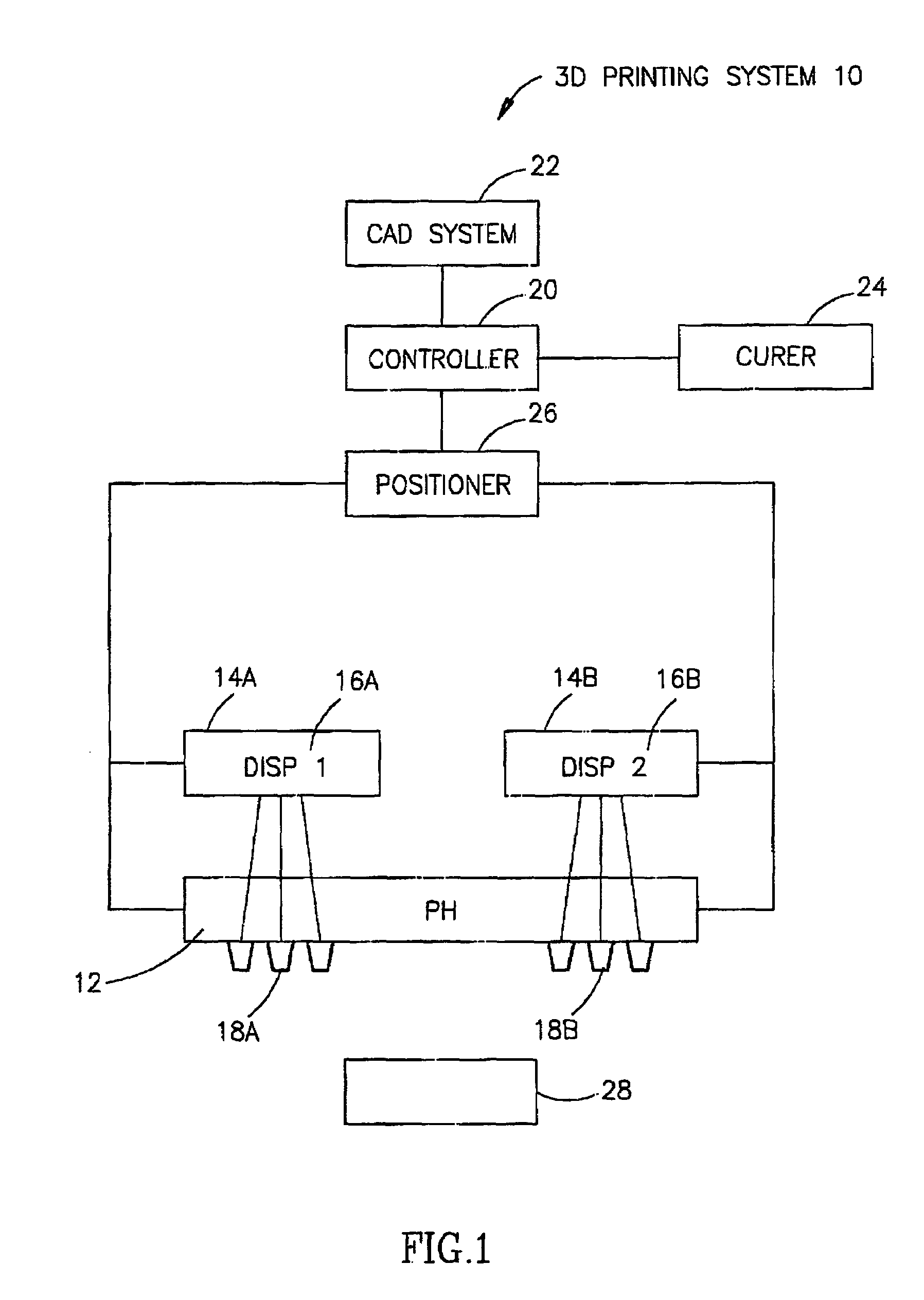

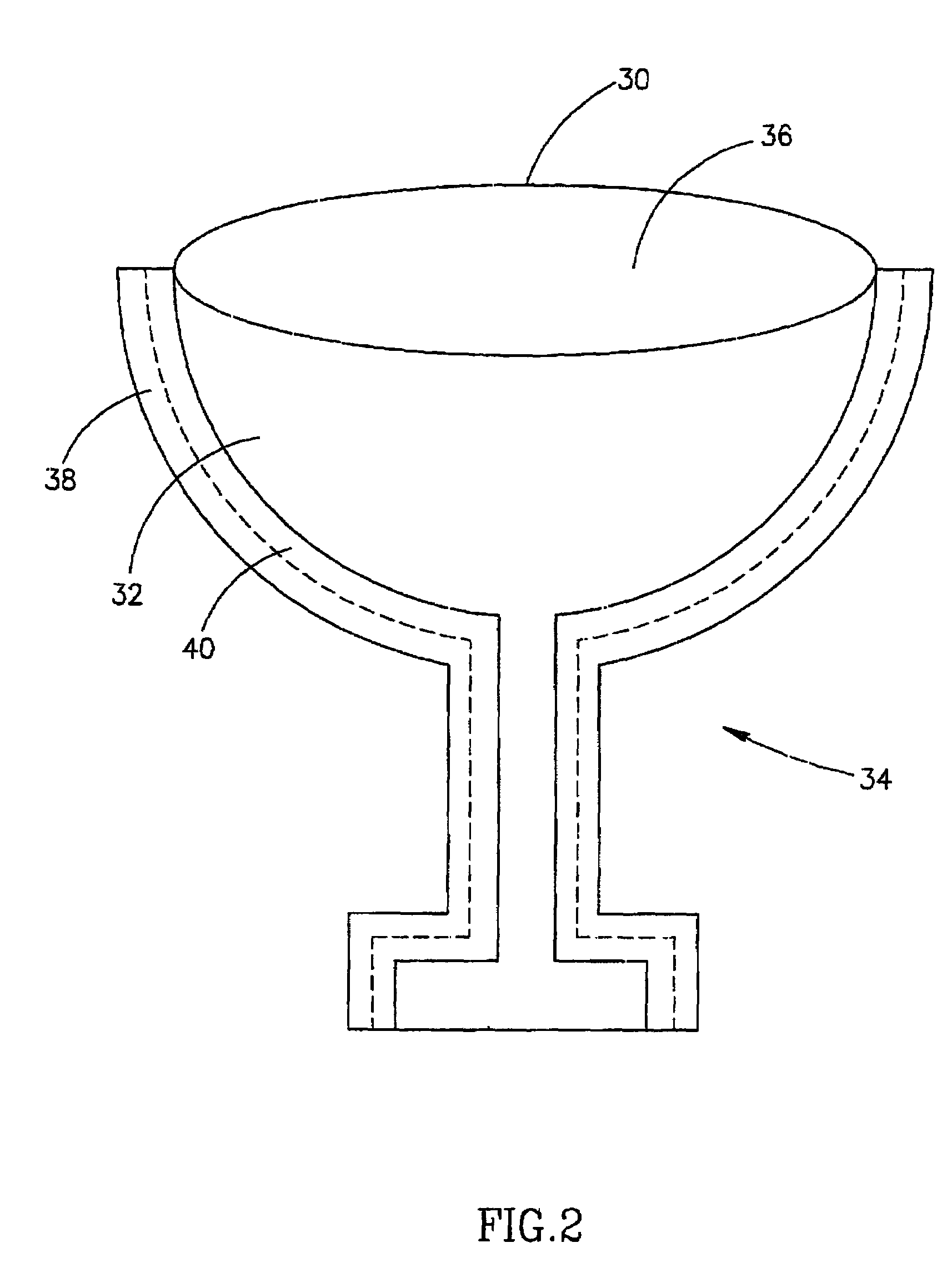

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

Photoresist polymer and photoresist composition containing the same

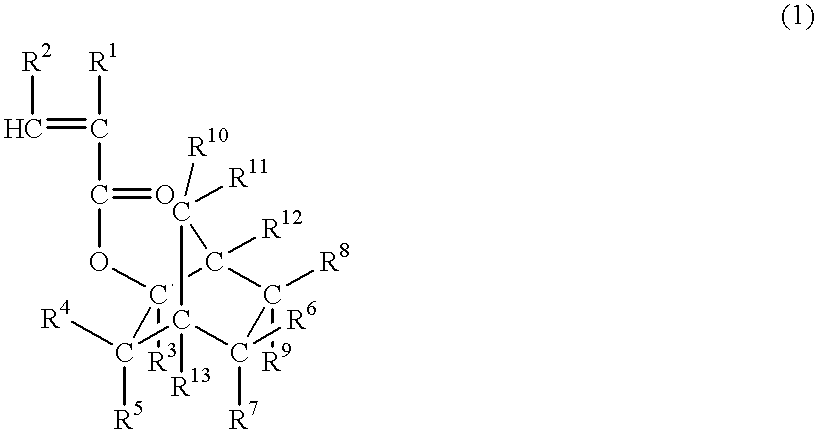

InactiveUS7361447B2Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersResistPolymer science

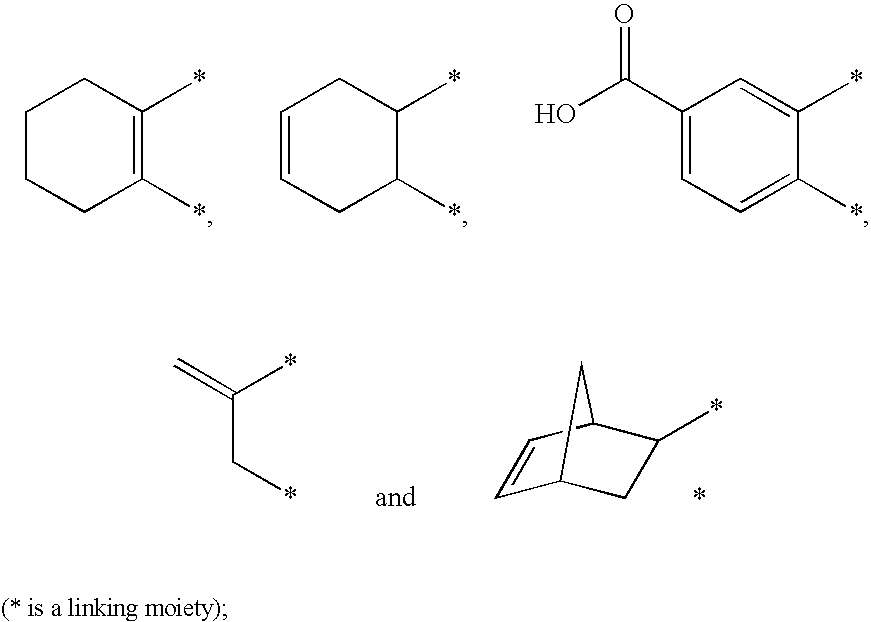

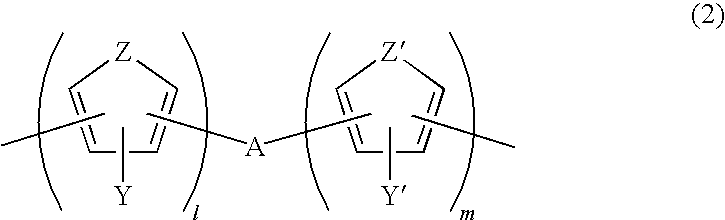

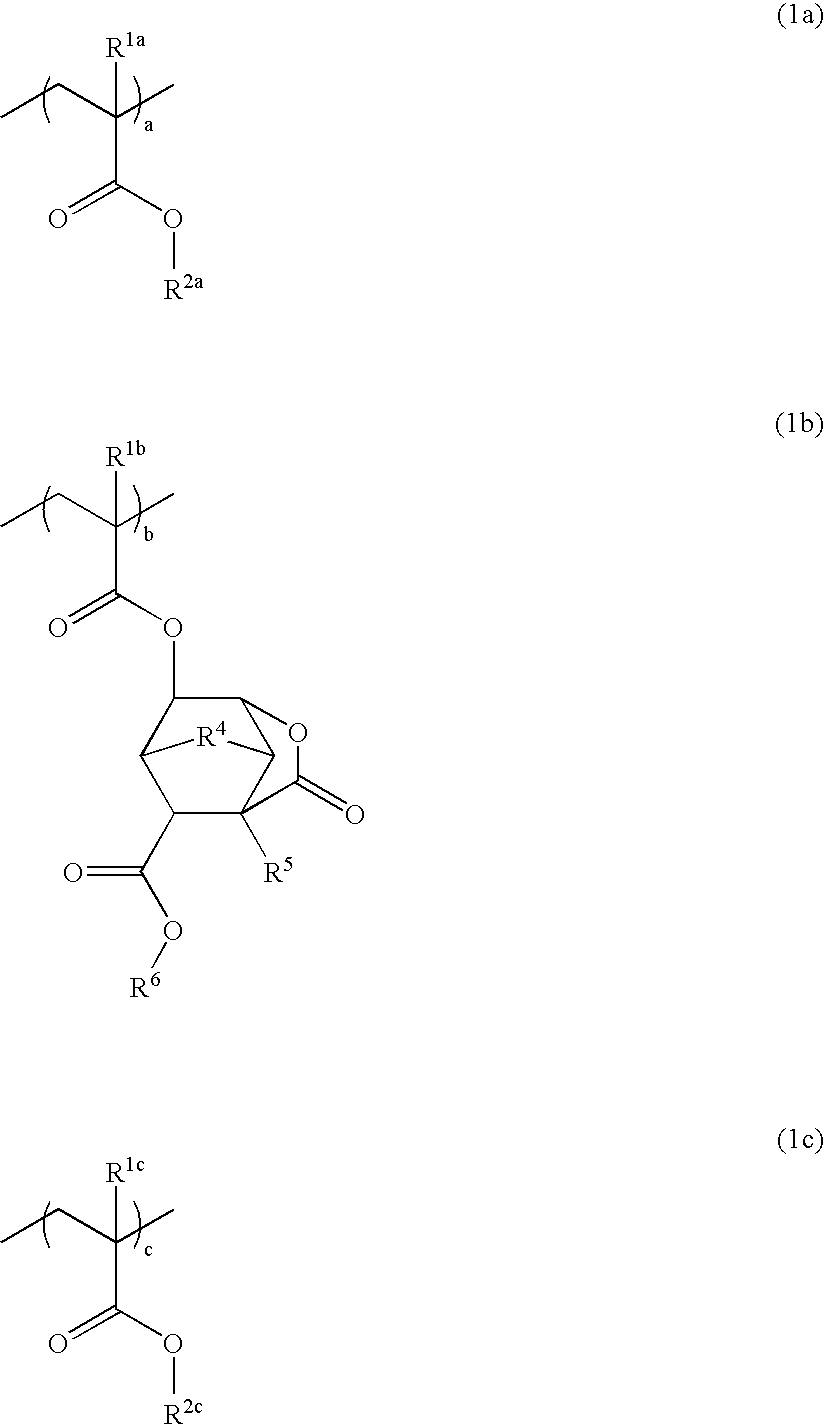

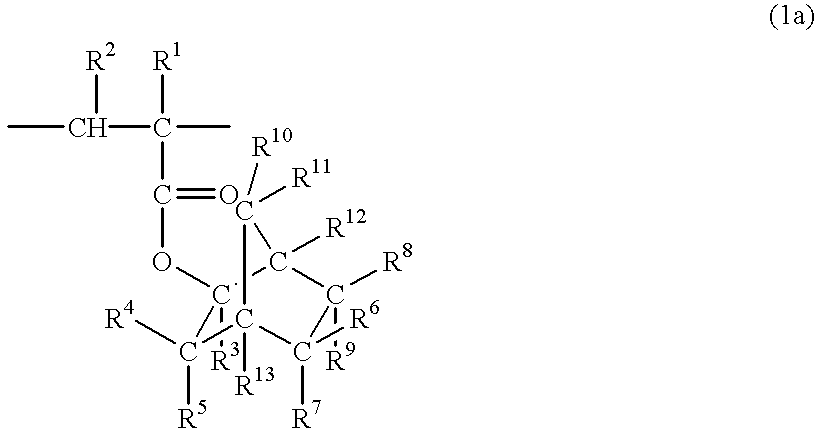

Photoresist polymers and photoresist compositions containing the same. Photoresist patterns of less than 50 nm are achieved with EUV (Extreme Ultraviolet) as an exposure light source with photoresist compositions comprising (i) a photoresist polymer comprising a polymerization repeating unit of Formula 2 or (ii) a photoresist polymer comprising a polymerization repeating unit of Formula 3 with polyvinylphenol. As a result, excellent etching resistance can be secured although the photoresist patterns have a very small thickness.wherein R1, R2, R3, R4, R5, R6, R7, R8, R9, R10, R11, R12, a, b, c, d, e, f and g are as defined in the specification.

Owner:SK HYNIX INC

Photoresist polymer and photoresist composition containing the same

InactiveUS7279256B2Enhance the imageImprove the immunityPhotosensitive materialsRadiation applicationsResistEnergy variation

Photoresist polymers and photoresist compositions are disclosed. A photoresist polymer comprising a polymerization repeating unit represented by Formula I is less sensitive to change in the amount of energy due to its higher active energy than that of a conventional photoresist polymer. As a result, a phenomenon where the portion of the pattern for the storage electrode contact region that receives relatively large amount of light becomes too thin is avoided when the device isolation film pattern is formed, and wherein pattern collapse caused by a high aspect ratio due to high etching resistance is prevented or avoided.whereinR1–R10, a, b, c and d are as defined in the description.

Owner:SK HYNIX INC

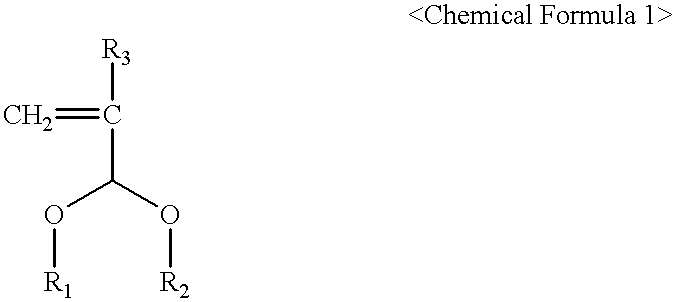

Photoresist cross-linker and photoresist composition comprising the same

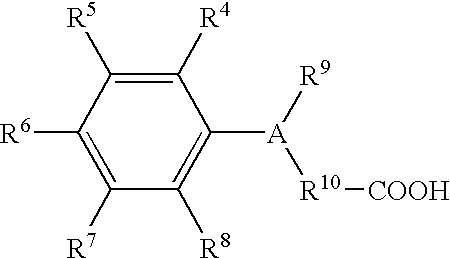

InactiveUS6368773B1Enhance the imageAdequate resultOrganic chemistryPhotosensitive materialsCarboxylic acidKetone

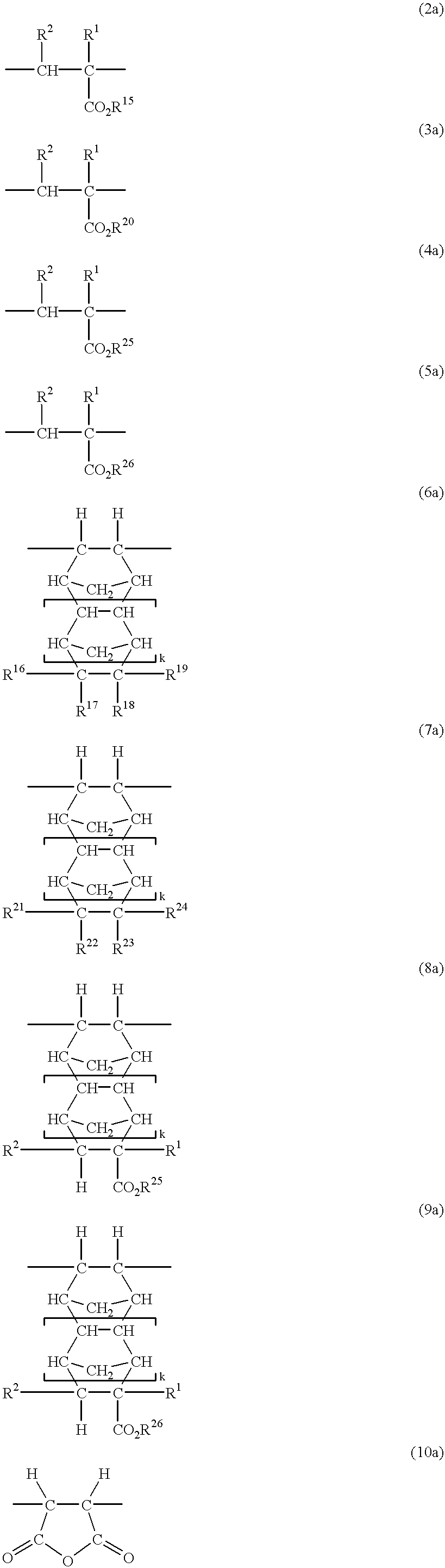

The present invention relates to a cross-linker for photoresist compositions which is suitable for a photolithography process using KrF (248 mn), ArF (193 mn), E-beam, ion beam or EUV light sources. Preferred cross-linkers, according to the present invention, comprise a copolymer of (i) a compound represented by following Chemical Formula 1 and / or (ii) one or more compound(s) selected from the group consisting of acrylic acid, methacrylic acid and maleic anhydride. ##STR1## wherein, R.sub.1 and R.sub.2 individually represent straight or branched C.sub.1-10 alkyl, straight or branched C.sub.1-10 ester, straight or branched C.sub.1-10 ketone, straight or branched C.sub.1-10 carboxylic acid, straight or branched C.sub.1-10 acetal, straight or branched C.sub.1-10 alkyl including at least one hydroxyl group, straight or branched C.sub.1-10 ester including at least one hydroxyl group, straight or branched C.sub.1-10 ketone including at least one hydroxyl group, straight or branched C.sub.1-10 carboxylic acid including at least one hydroxyl group, and straight or branched C.sub.1-10 acetal including at least one hydroxyl group; and R.sub.3 represents hydrogen or methyl.

Owner:HYUNDAI ELECTRONICS IND CO LTD

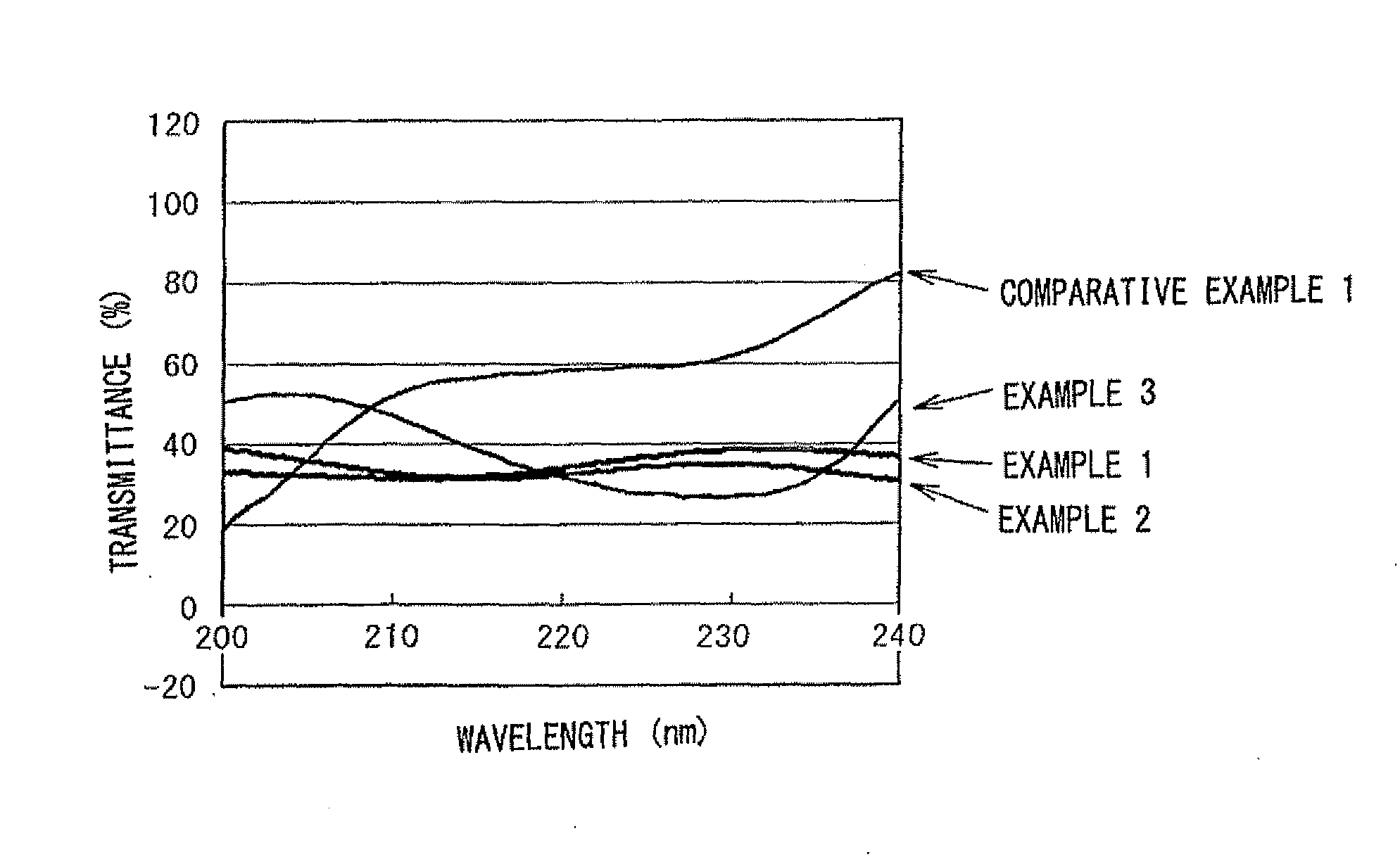

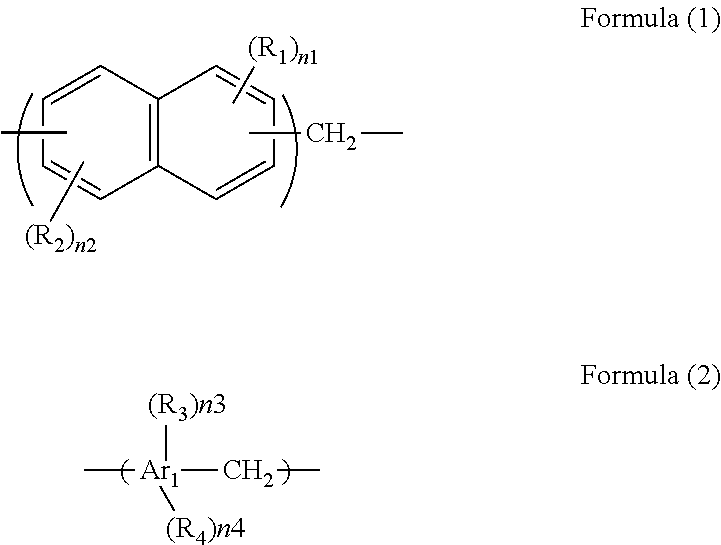

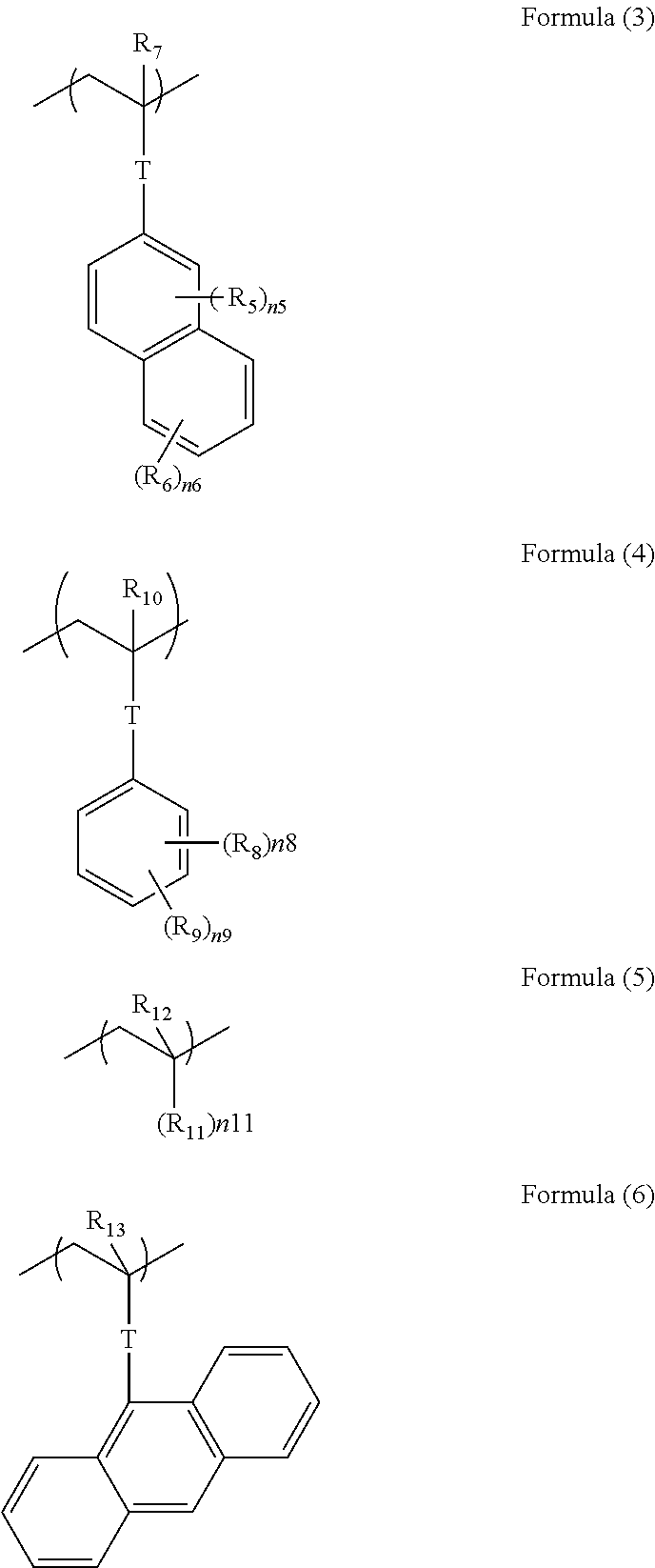

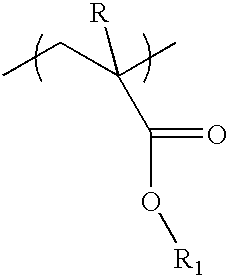

Composition for forming resist overlayer film for EUV lithography

ActiveUS20130209940A1High resolutionSemiconductor/solid-state device manufacturingCoatingsLithographic artistLithography process

There is provided a composition for forming an EUV resist overlayer film that is used in an EUV lithography process, that does not intermix with the EUV resist, that blocks unfavorable exposure light for EUV exposure, for example, UV light and DUV light and selectively transmits EUV light alone, and that can be developed with a developer after exposure. A composition for forming an EUV resist overlayer film used in an EUV lithography process including a resin containing a naphthalene ring in a main chain or in a side chain and a solvent, in which the resin may include a hydroxy group, a carboxy group, a sulfo group, or a monovalent organic group having at least one of these groups as a hydrophilic group.

Owner:NISSAN CHEM IND LTD

Photoresist composition for deep UV and process thereof

InactiveUS6447980B1Radiation applicationsSemiconductor/solid-state device manufacturingResistSide chain

The present invention relates to a chemically amplified system, which is, sensitive to wavelengths between 300 nm and 100 nm, and comprises a) a polymer that is insoluble an aqueous alkaline solution and comprises at least one acid labile group, b) a compound capable of producing an acid upon radiation. The present invention comprises a polymer that is made from a alicyclic hydrocarbon olefin, an acrylate with a pendant cyclic moeity, and a cyclic anhydride. The present invention also relates to a process for imaging such a photoresist.

Owner:AZ ELECTRONICS MATERIALS USA CORP

Anti-reflection film and display device using the same

An anti-reflection film comprises a high refractive index layer having a refractive index of 1.65-2.40, and a low refractive index layer having a refractive index of 1.20-1.55. Another anti-reflection film comprises only a low refractive index layer having a refractive index of 1.20-1.55. In the invention, the first improvement resides in a high refractive index layer composed of inorganic fine particles having a mean particle size of 1-200 nm in an amount of 5-65 vol. % and a crosslinked anionic polymer in an amount of 35 to 95 vol. %. The second improvement resides in a low refractive index layer composed of inorganic fine particles having a mean particle size of 0.5-200 nm in an amount of 50-95 wt. % and a polymer in an amount of 5-50 wt. %, and two or more of those particles are piled up to form micro voidsby the adjacent particles.

Owner:FUJIFILM CORP

Spin-on carbon compositions for lithographic processing

The invention described herein is directed towards spin-on carbon materials comprising polyamic acid compositions and a crosslinker in a solvent system. The materials are useful in trilayer photolithography processes. Films made with the inventive compositions are not soluble in solvents commonly used in lithographic materials, such as, but not limited to PGME, PGMEA, and cyclohexanone. However, the films can be dissolved in developers commonly used in photolithography. In one embodiment, the films can be heated at high temperatures to improve the thermal stability for high temperature processing. Regardless of the embodiment, the material can be applied to a flat / planar or patterned surface. Advantageously, the material exhibits a wiggling resistance during pattern transfer to silicon substrate using fluorocarbon etch.

Owner:BREWER SCI

Replication and transfer of microstructures and nanostructures

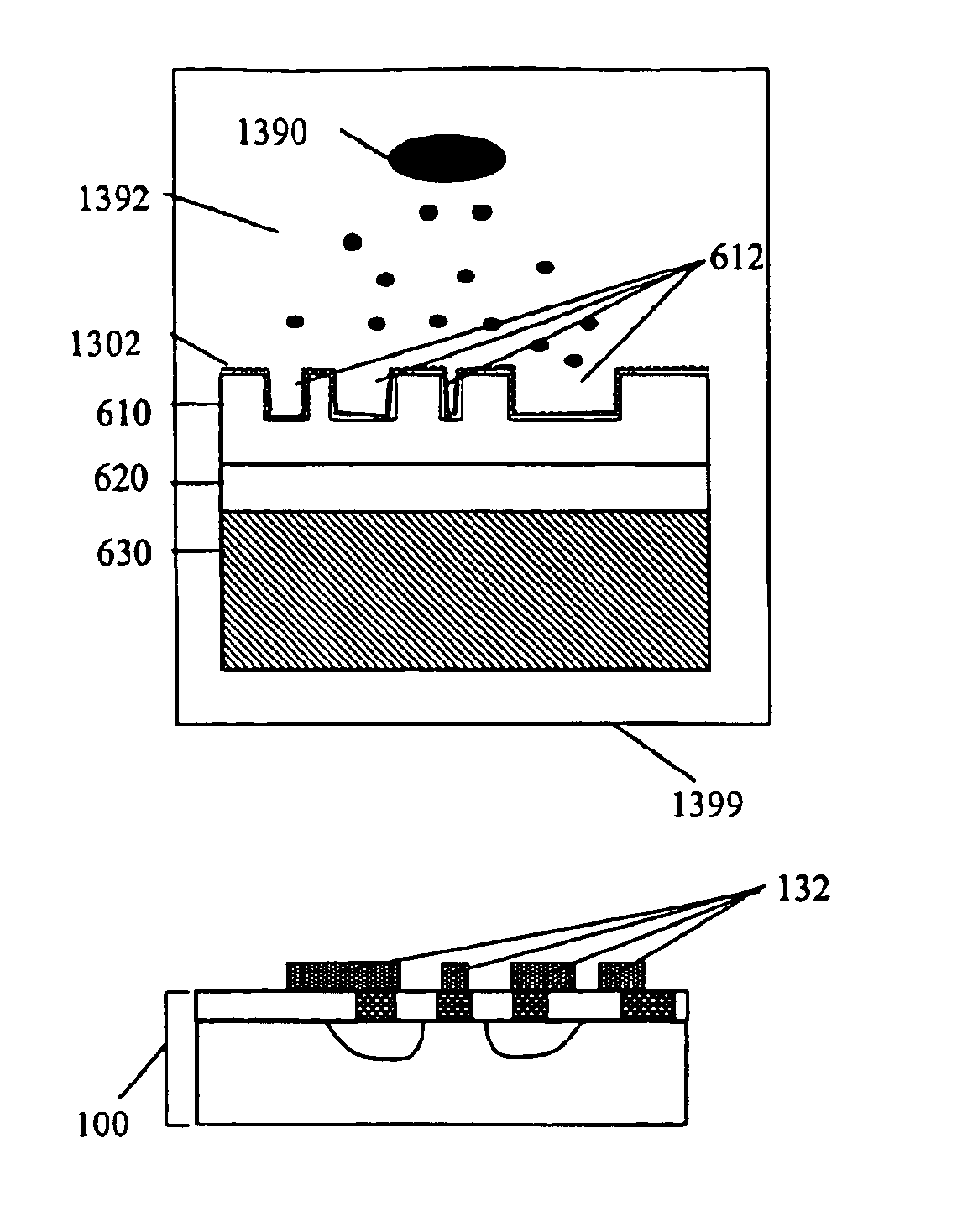

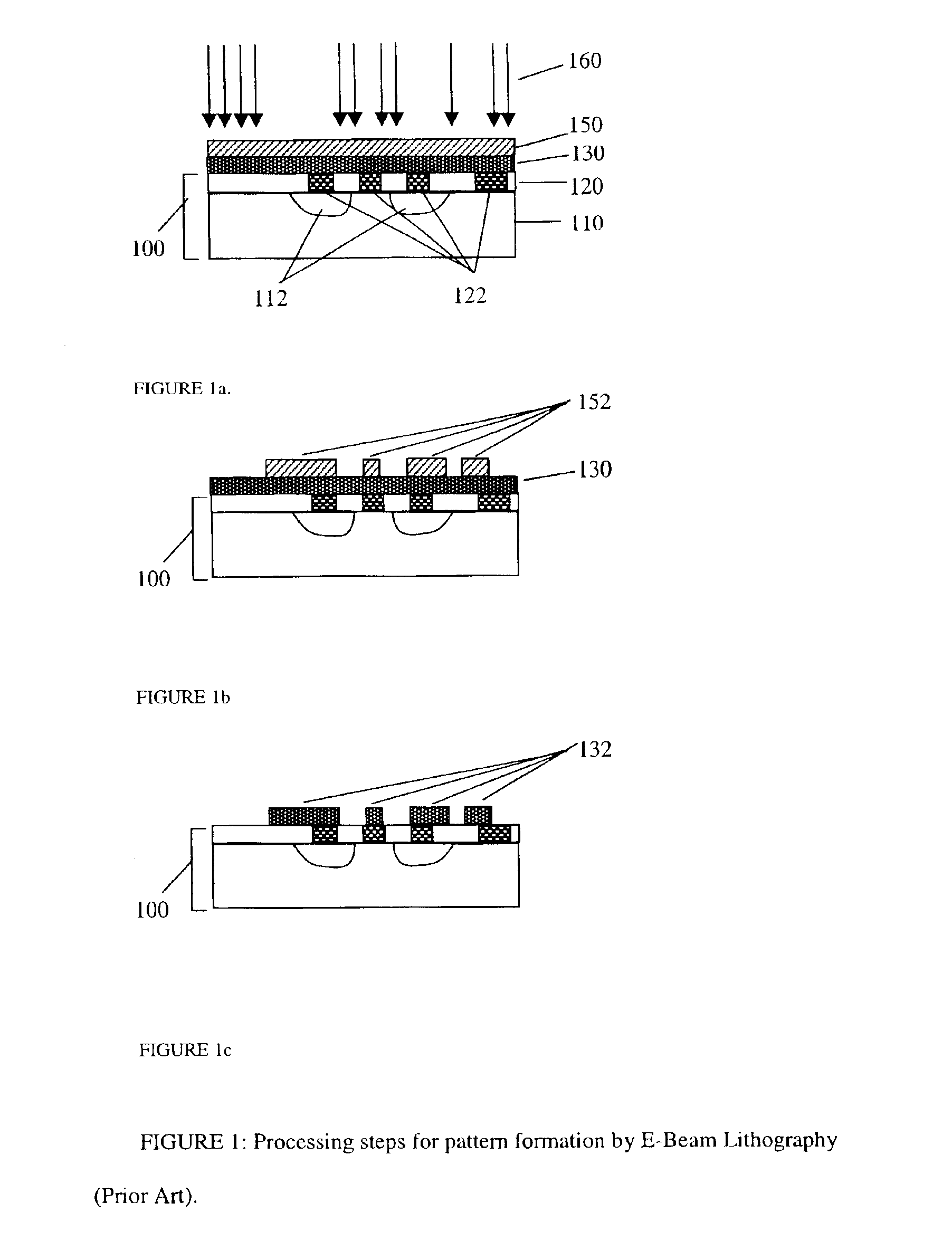

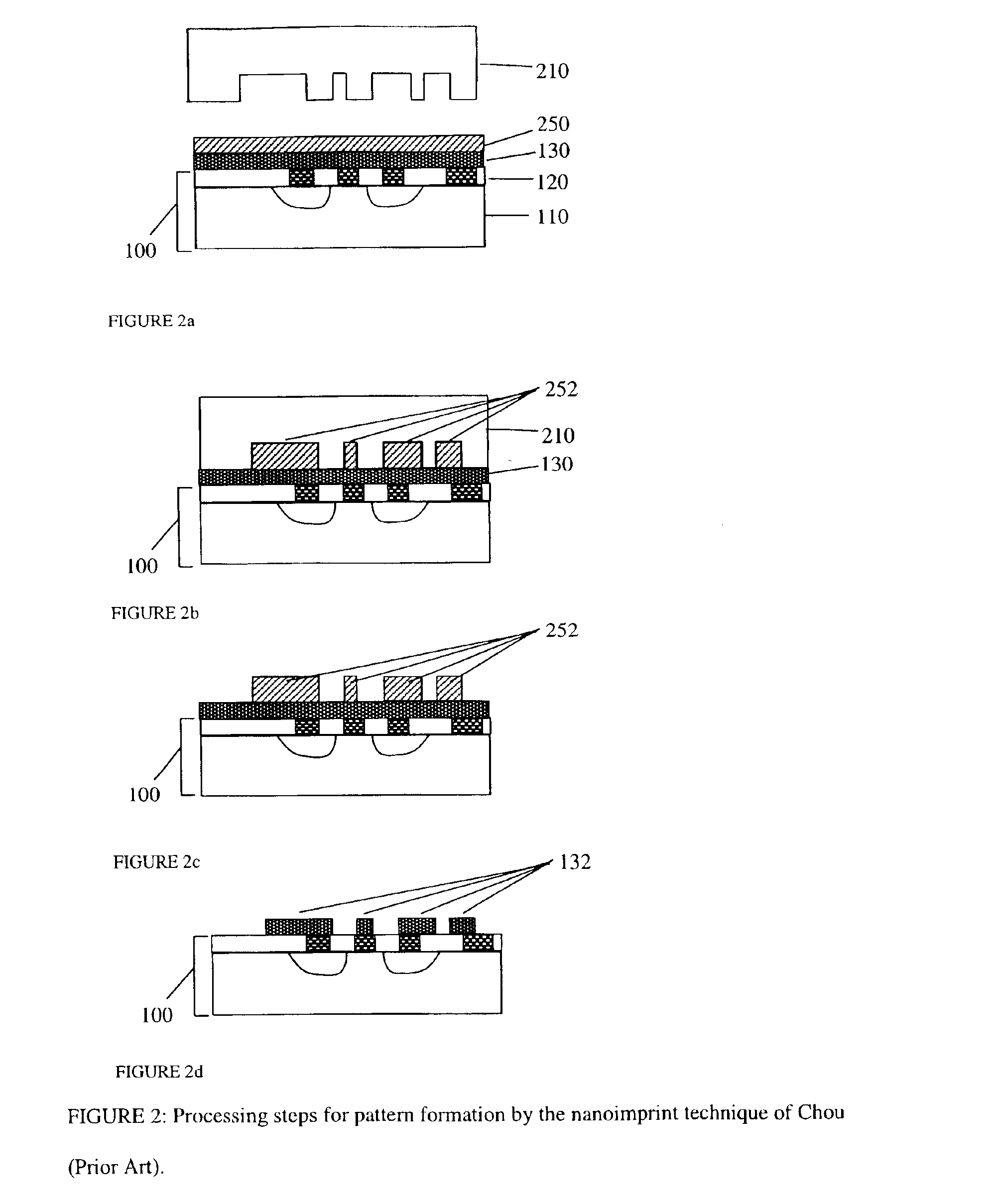

InactiveUS6849558B2Facilitates pattern transferCheap to makeNanostructure manufactureDecorative surface effectsEngineeringMicroscopic scale

A method for the duplication of microscopic patterns from a master to a substrate is disclosed, in which a replica of a topographic structure on a master is formed and transferred when needed onto a receiving substrate using one of a variety of printing or imprint techniques, and then dissolved. Additional processing steps can also be carried out using the replica before transfer, including the formation of nanostructures, microdevices, or portions thereof. These structures are then also transferred onto the substrate when the replica is transferred, and remain on the substrate when the replica is dissolved. This is a technique that can be applied as a complementary process or a replacement for various lithographic processing steps in the fabrication of integrated circuits and other microdevices.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

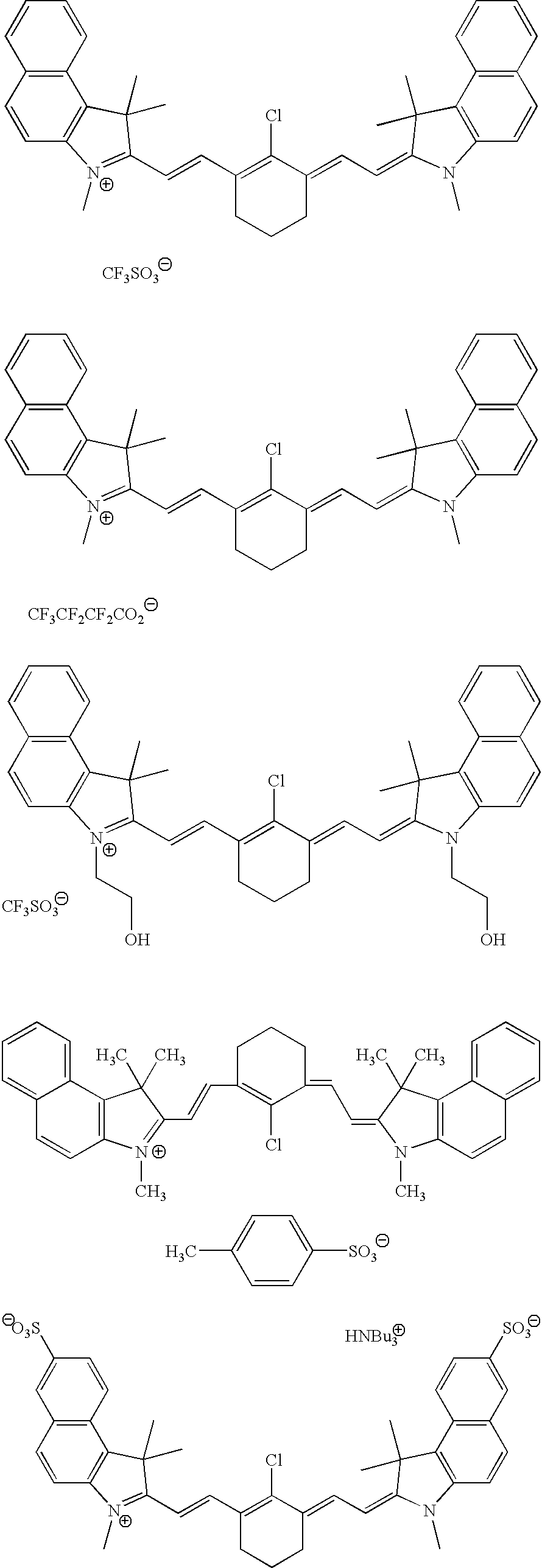

Antireflective coatings comprising poly(oxyalkylene) colorants

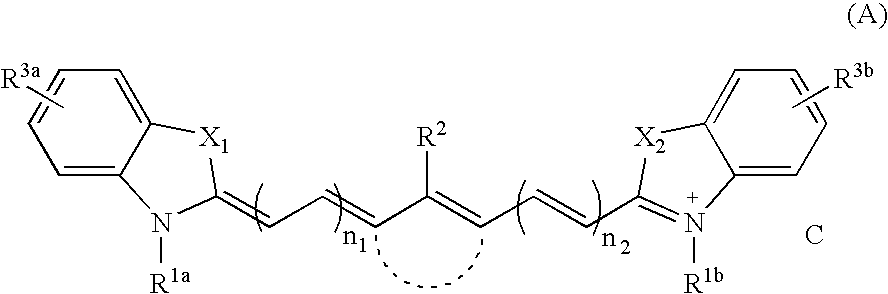

InactiveUS6048662AReduce the amplitudeImprove anti-reflectionPhotosensitive materialsRadiation applicationsCounterionThin layer

This invention relates to antireflective coatings comprising polymeric polyoxyalkylenated colorants. More particularly, the present invention relates to antireflective coatings for utilization in forming thin layers between reflective substrates and photoresist coatings. Such antireflective coatings are very useful and beneficial within the production and fabrication of semiconductors through photolithographic procedures due to the liquid, non-crystallizing nature of polyoxyalkylenated colorants, and the lack of potentially damaging counterions, metals, and / or electrolytes within the inventive antireflective colored coatings. The inventive coatings may also be applied on lenses, mirrors, and other optical components. Methods of forming such antireflective coatings are also contemplated within this invention.

Owner:MILLIKEN & CO

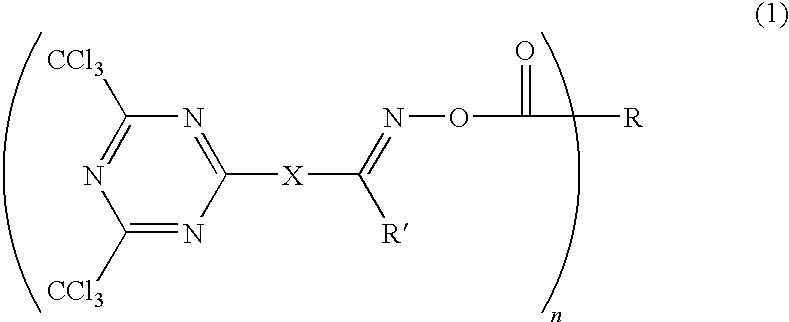

Photosensitive composition comprising triazine-based photoactive compound containing oxime ester

ActiveUS7556910B2Effective absorptionDevelopment durabilityOrganic chemistryPhotosensitive materialsOximePhotochemistry

The present invention relates to a photosensitive composition comprising a triazine-based photoactive compound containing oxime ester. The photosensitive composition according to the present invention has good sensitivity, retention rate, mechanical strength, heat resistance, chemical resistance and developing durability since it contains, as photopolymerization initiator, a compound having an oxime ester group and a triazine group in one molecule and thus effectively absorbs UV radiation. Therefore, the photosensitive composition according to the present invention is advantageous not only in curing of materials for color filters, resin black matrixes, column spacers, overcoats and passivation films of liquid crystal displays, but also in high temperature process characteristics.

Owner:LG CHEM LTD

Silsesquioxane polymers, method of synthesis, photoresist composition, and multilayer lithographic method

InactiveUS6087064AReduce usageAvoid pollutionPhotosensitive materialsRadiation applicationsResistPolymer science

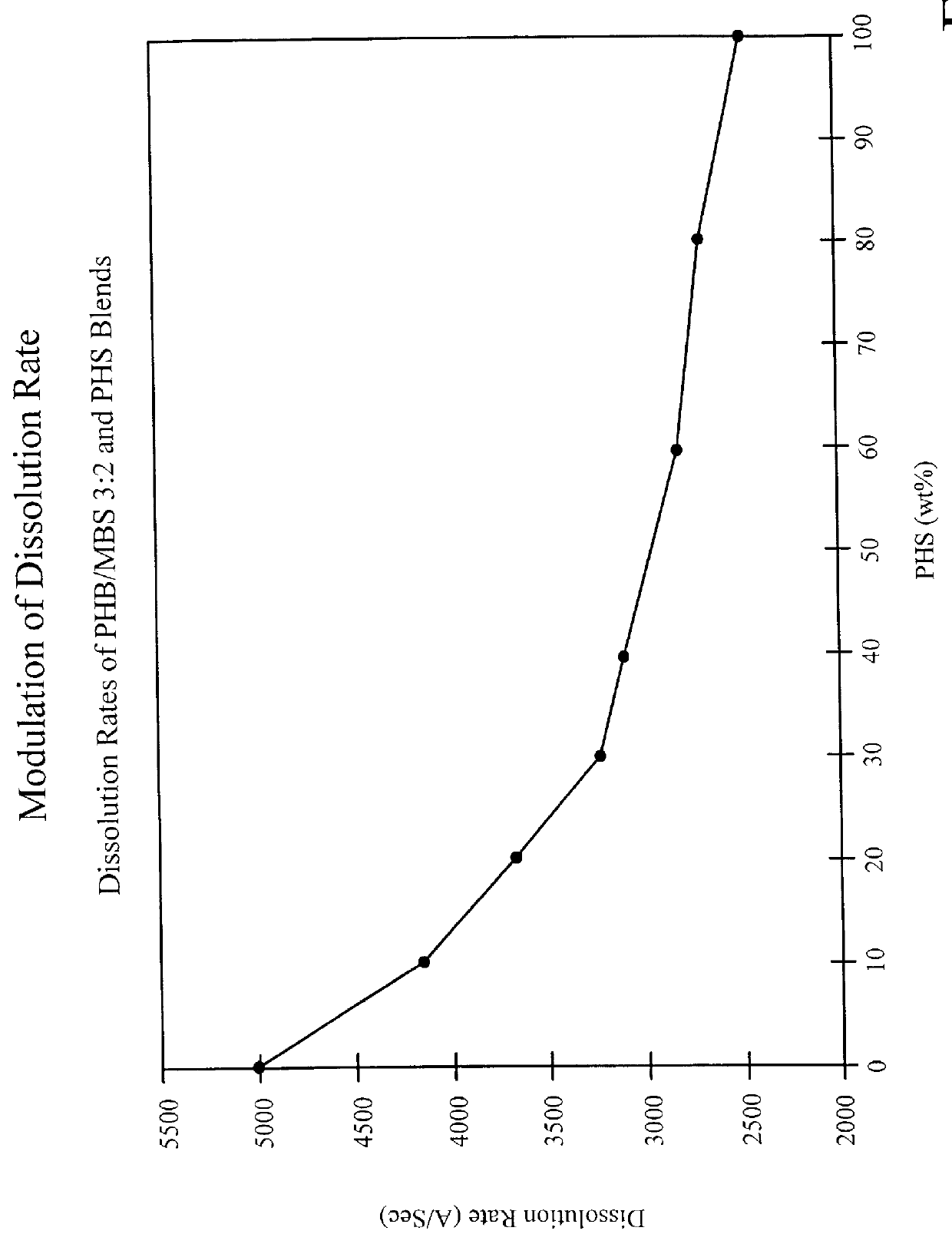

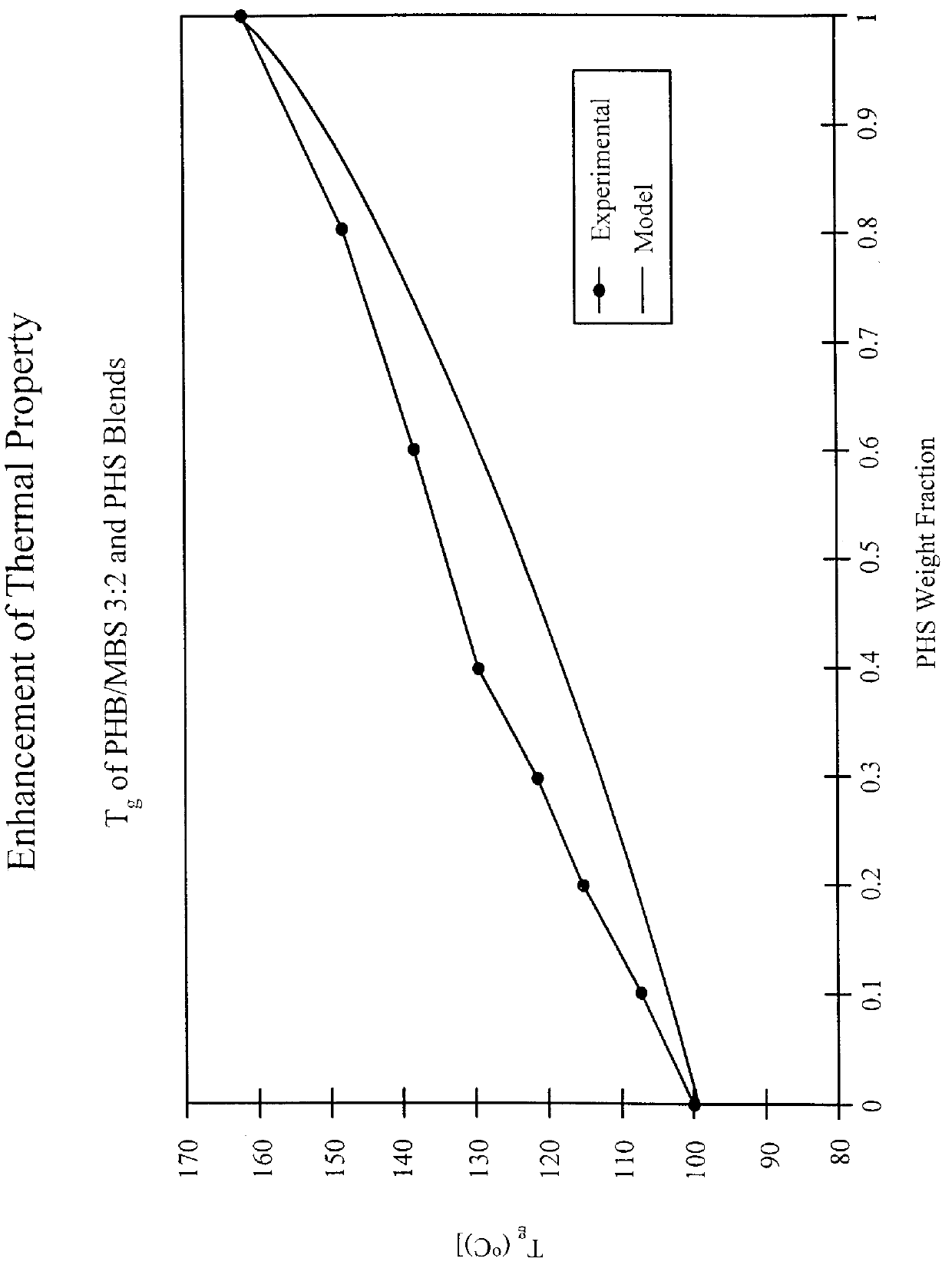

Novel silsesquioxane polymers are formed by methods which avoid the use of BBr3. The novel silsesquioxane polymers are especially useful in negative photoresist compositions and photolithographic processes. Alternatively, improved silsesquioxane polymer-containing negative photoresist compositions are obtained by using a polymer component containing a blend of silsesquioxane polymer and non-silsesquioxane polymer. The photoresist compositions provide improved dissolution characteristics enabling the use of 0.26 N TMAH developer. The photoresist compositions also provide improved thermal characteristics enabling use of higher processing temperatures. The photoresist compositions are especially useful in a multilayer photolithographic processes and are capable of producing high resolution.

Owner:GLOBALFOUNDRIES INC

Acid generator, sulfonic acid, sulfonic acid derivatives and radiation-sensitive resin composition

A novel photoacid generator containing a structure of the following formula (I), wherein R is a monovalent organic group with a fluorine content of 50 wt % or less, a nitro group, a cyano group, or a hydrogen atom, and Z1 and Z2 are individually a fluorine atom or a linear or branched perfluoroalkyl group having 1-10 carbon atoms, is provided. When used in a chemically amplified radiation-sensitive resin composition, the photoacid generator exhibits high transparency, comparatively high combustibility, and no bioaccumulation, and produces an acid exhibiting high acidity, high boiling point, moderately short diffusion length in the resist coating, and low dependency to mask pattern density.

Owner:JSR CORPORATIOON

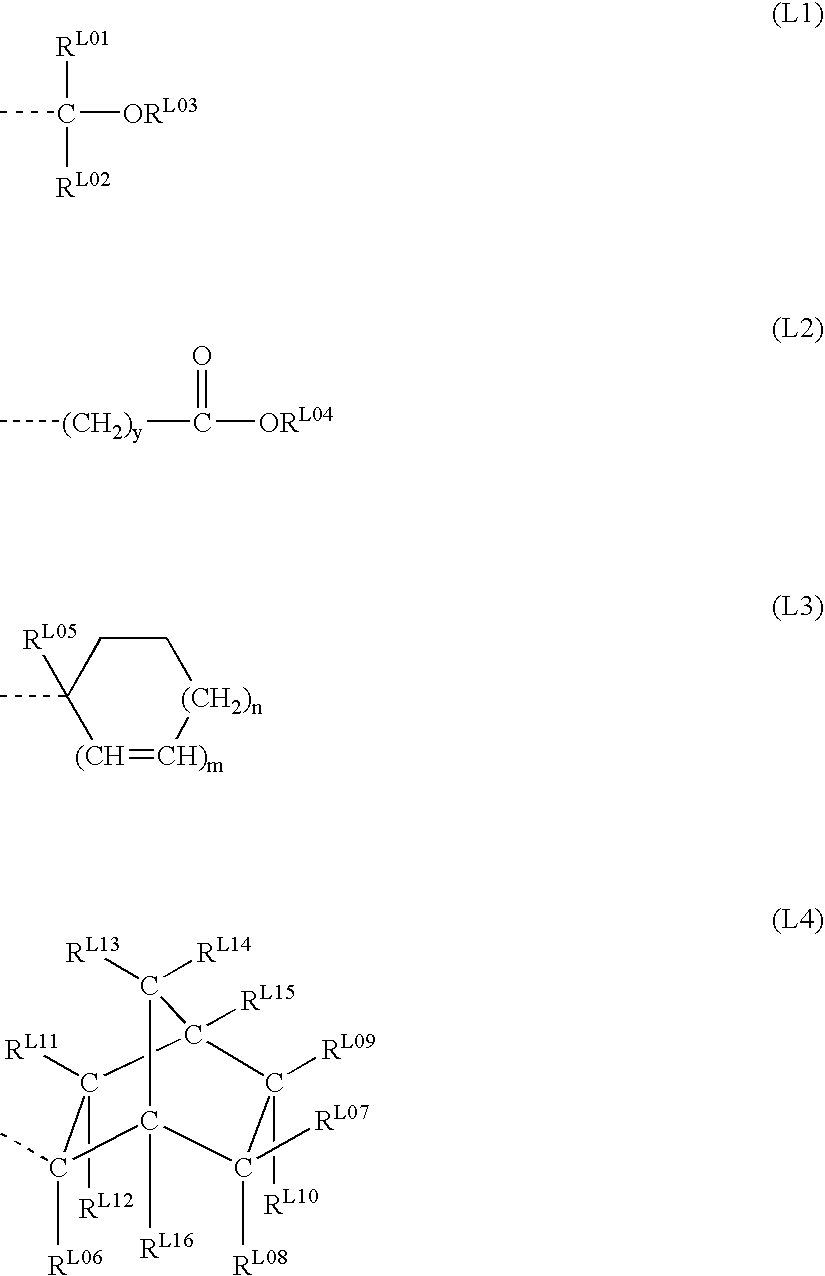

Polymer, resist composition, and patterning process

To a resist composition, an alkali-soluble polymer having fluorinated ester-containing lactone units incorporated therein is included as an additive. The resist composition forms a resist film having a reduced contact angle after development. The resist film prevents water penetration during immersion lithography.

Owner:SHIN ETSU CHEM IND CO LTD

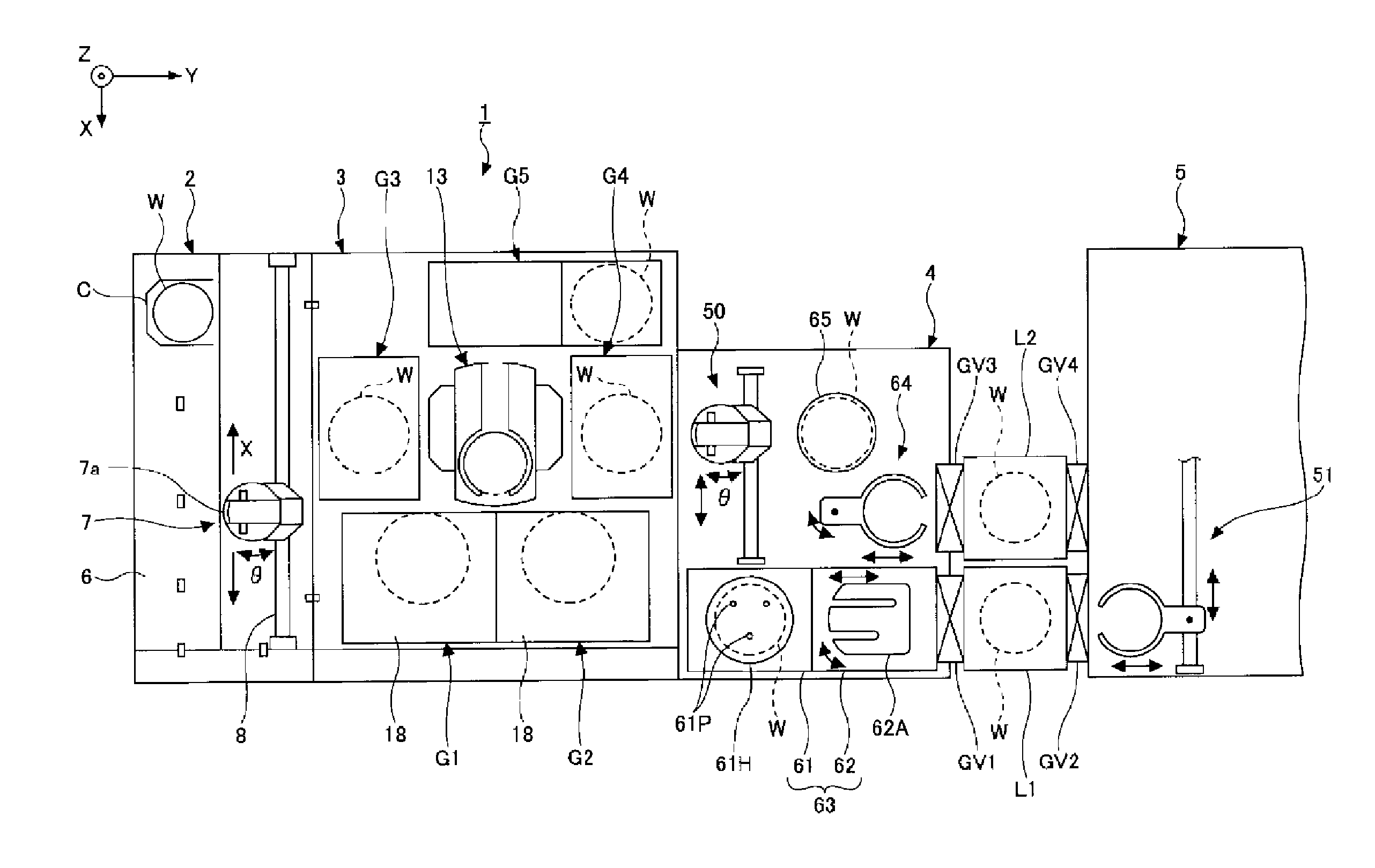

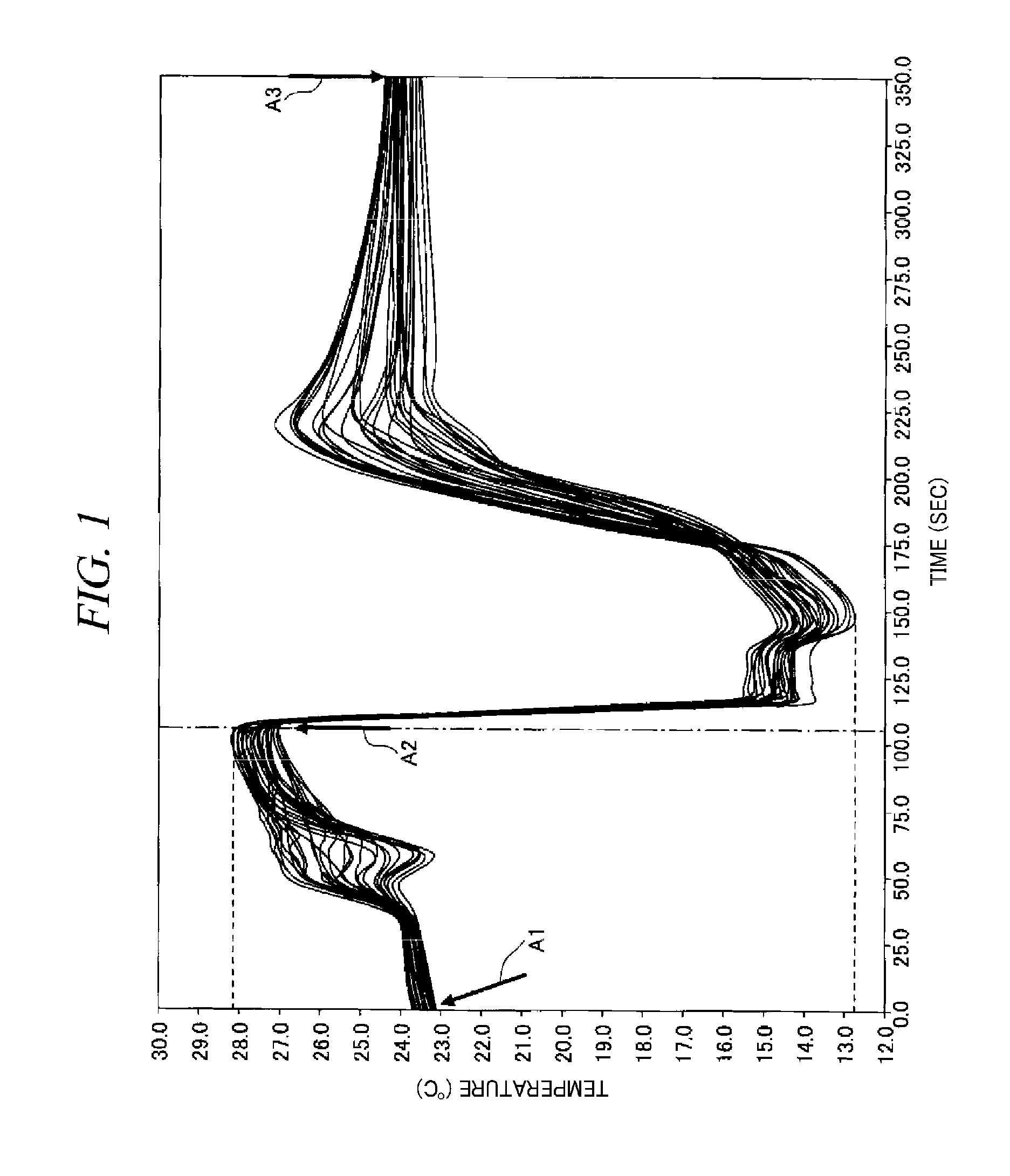

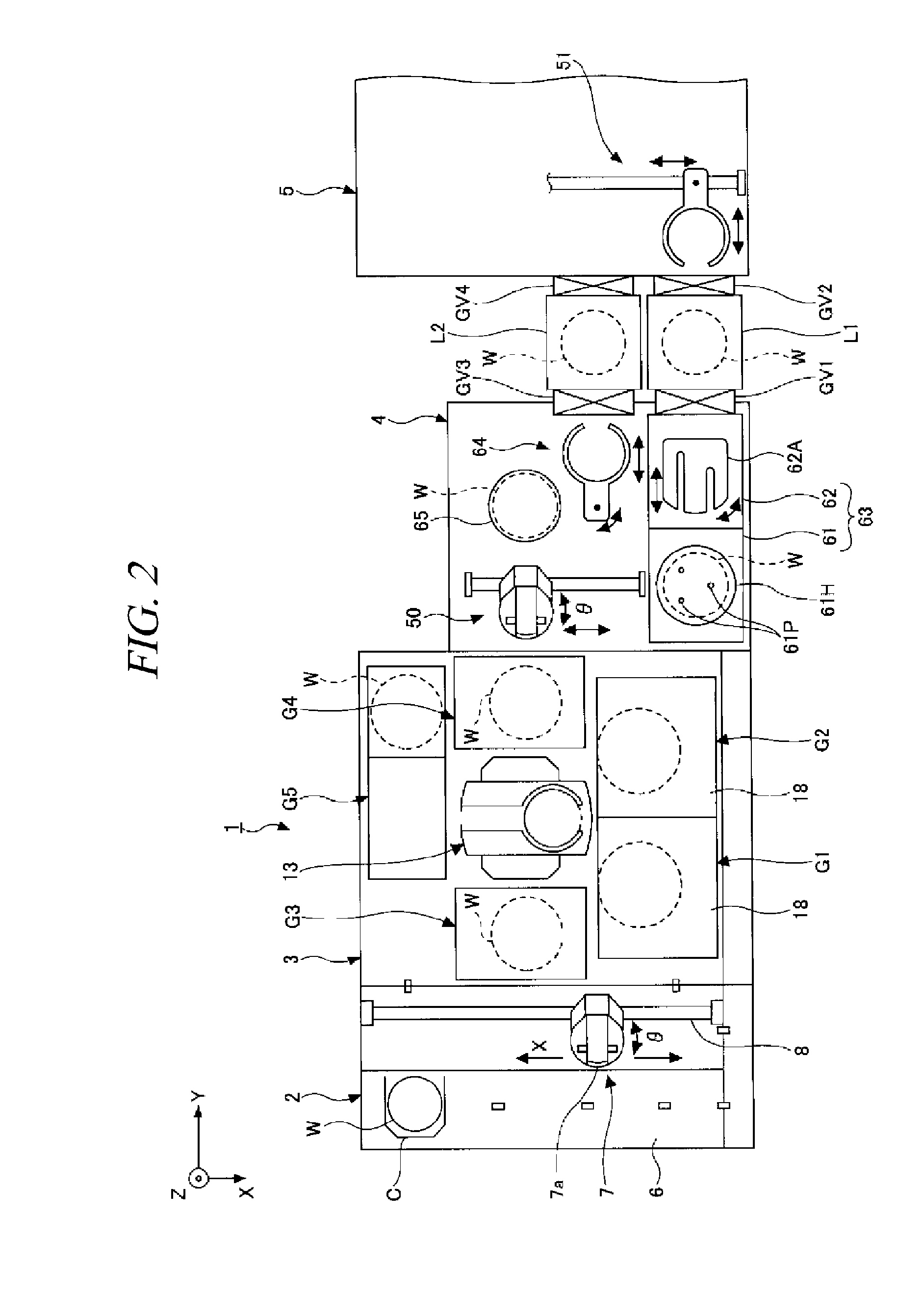

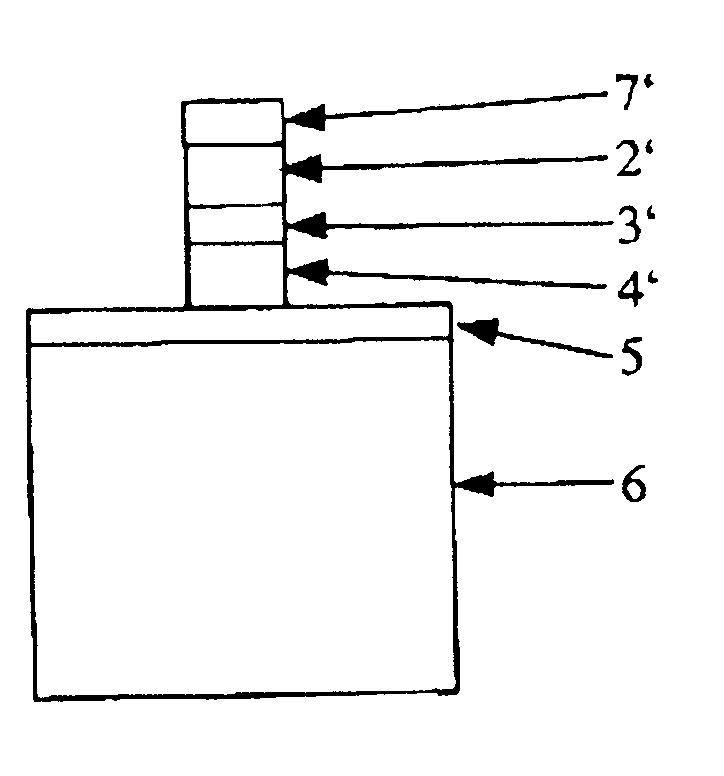

Photoresist coating and developing apparatus, substrate transfer method and interface apparatus

A photoresist coating and developing apparatus 1 includes a photoresist film forming unit that forms a photoresist film on a substrate; a heat treatment unit that heats the substrate on which the photoresist film is formed by the photoresist film forming unit; a cooling unit that cools the substrate, on which the photoresist film is formed and which is heated by the heat treatment unit, to normal temperature; a heating unit 61 that heats the substrate, which is cooled to normal temperature by the cooling unit, to a predetermined temperature; a load-lock chamber L1 that unloads the substrate under depressurized atmosphere to expose the photoresist film; and a transfer device 62 that transfers the substrate from the heating unit 61 to the load-lock chamber L1.

Owner:TOKYO ELECTRON LTD

Photoresist composition for deep UV radiation containing an additive

InactiveUS6723488B2Reduce impactPrevent degradationPhotosensitive materialsElectric discharge tubesUltravioletAqueous solution

Owner:AZ ELECTRONICS MATERIALS USA CORP

Radiation-sensitive colored composition, colored cured film, color filter and method of producing the same, solid-state imaging device, liquid crystal display apparatus, and method of producing dye

ActiveUS20120235099A1Reduce pollutionSuppress generationMonoazo dyesDisazo dyesLiquid-crystal displayHalogen

The object of the present invention is to provide a radiation-sensitive colored composition which can supress the generation of the contamination of the device.A radiation-sensitive colored composition including: (A) a dye containing of from 10 ppm to 1000 ppm of a halogen ion; (B) a polymerizable compound; and (C) a solvent.

Owner:FUJIFILM CORP

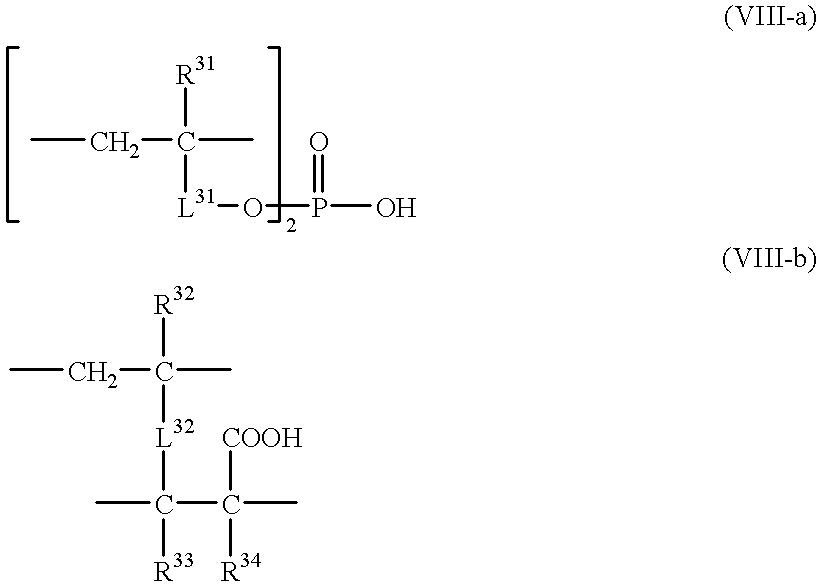

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

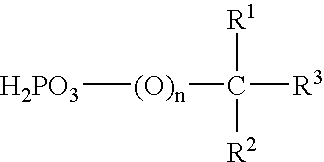

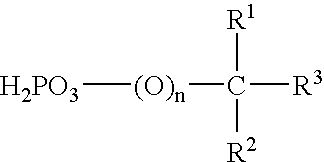

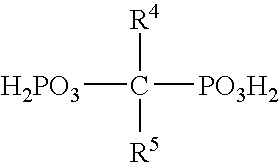

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

Negative-acting no-process printing plates

InactiveUS6027857APhotosensitive materialsPhotosensitive material processingFunctional monomerOligomer

A photosensitive composition is prepared containing a polymer of the formula B(X)(Y) wherein B represents an organic backbone, each X independently is an acidic group or salt thereof and each Y independently is a photocurable group and a photoinitiating compound or compounds. Preferably, free-radically polymerizable multi-functional monomer and / or oligomer is added to the photosensitive composition. The photosensitive composition can be coated on a suitable substrate for planographic printing plate applications. Imagewise irradiation causes the light struck regions to photocure, becoming insoluble in aqueous and organic mediums, while the non-light struck regions remain highly soluble / dispersable. Printing plates of this construction do not require processing prior to being run on a press.

Owner:3M CO

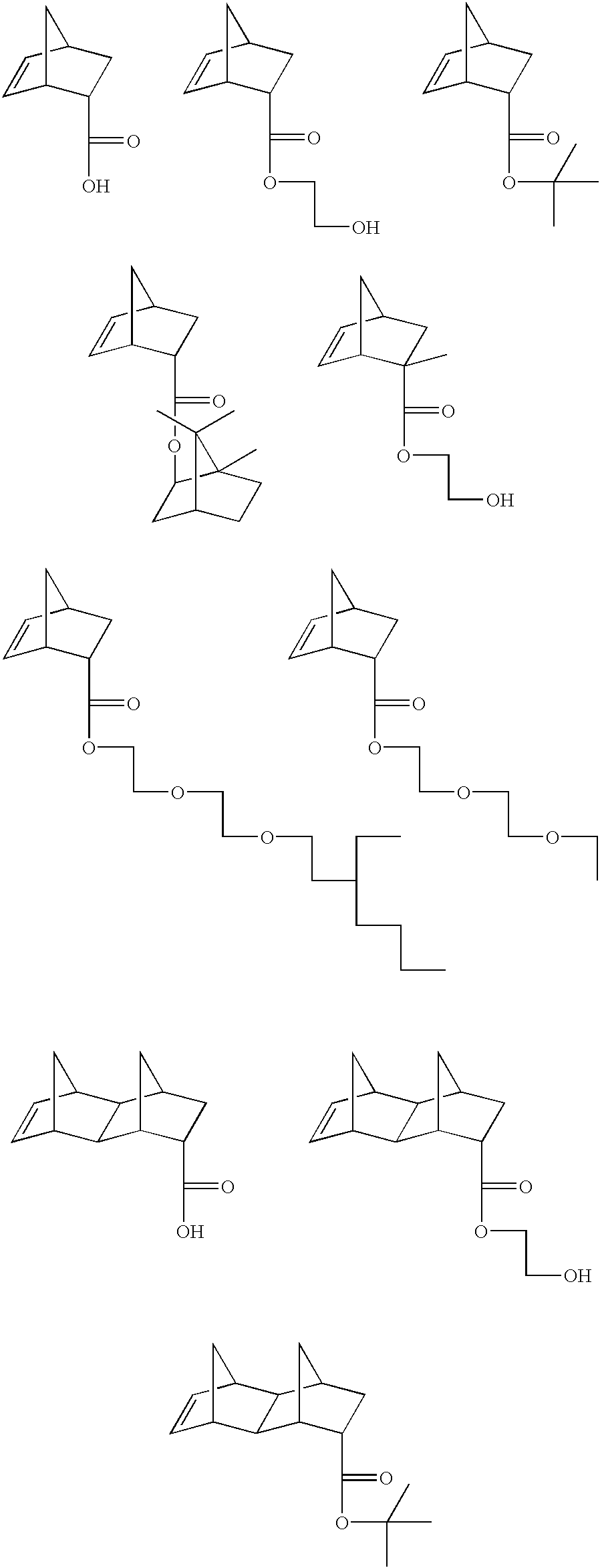

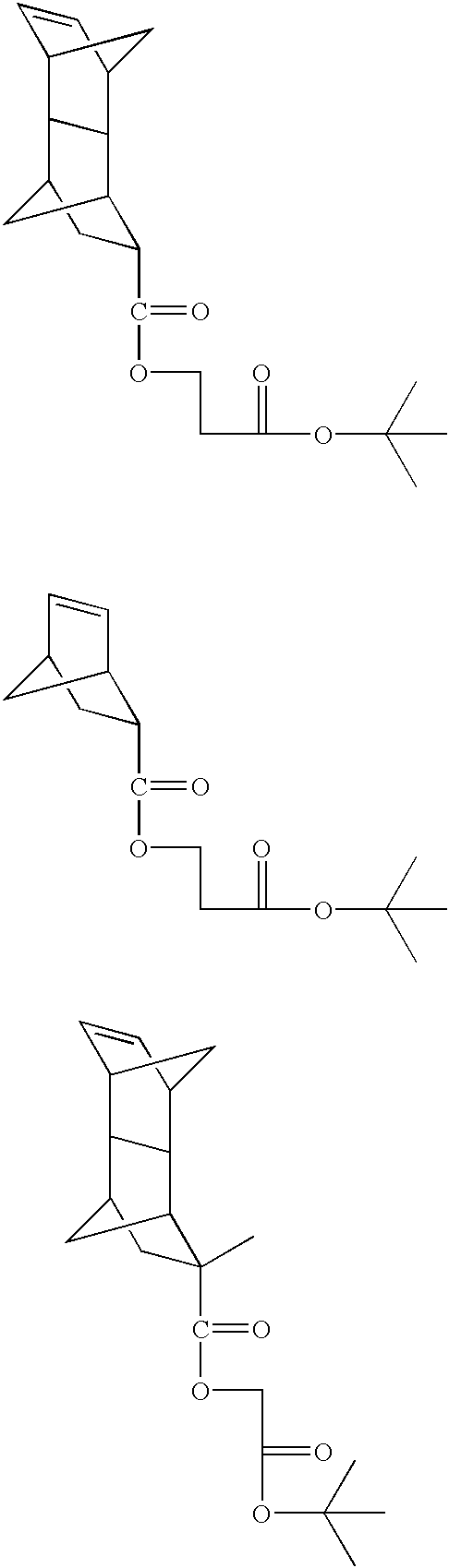

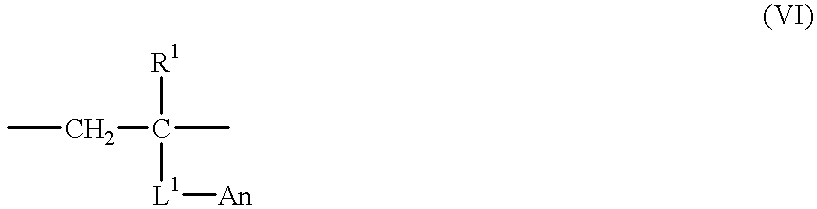

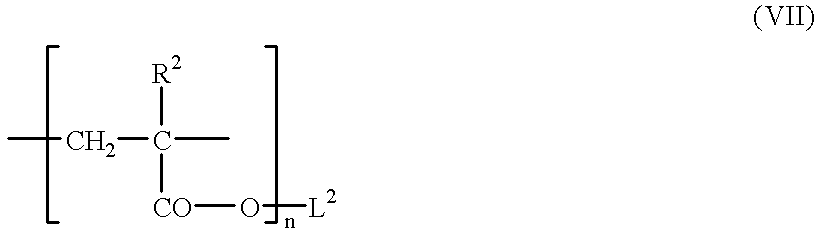

Ester compounds, polymers, resist compositions and patterning process

A novel ester compound having an exo-form 2-alkylbicyclo[2.2.1]heptan-2-yl group as the protective group is provided as well as a polymer comprising units of the ester compound. The polymer is used as a base resin to formulate a resist composition having a higher sensitivity, resolution and etching resistance than conventional resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

High speed negative-working thermal printing plates

Negative working thermally imageable elements useful as lithographic printing plate precursors and methods for their use are disclosed. The elements have a substrate, a layer of imageable composition over the substrate, and, optionally, an overcoat layer over the layer of imageable composition. The imageable composition has an allyl-functional polymeric binder. Optimum resolution and on-press performance can be attained without a post-exposure bake. The elements do not require a post-exposure bake and can be used in on-press development applications.

Owner:KODAK POLYCHROME GRAPHICS

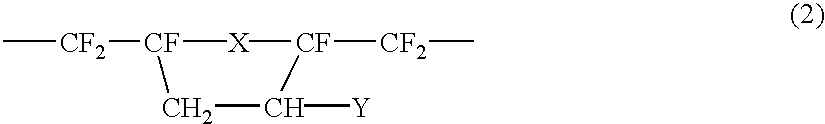

Resist composition

The following resist composition which is excellent particularly in transparency to light beams and dry etching properties and gives a resist pattern excellent in sensitivity, resolution, evenness, heat resistance, etc., as a chemical amplification type resist, is presented. A resist composition which comprises a fluoropolymer (A) having repeating units represented by a structure formed by the cyclopolymerization of one molecule of a fluorinated diene and one molecule of a monoene, in which the monoene unit in each repeating unit has a blocked acid group capable of regenerating the acid group by the action of an acid, an acid-generating compound (B) which generates an acid upon irradiation with light, and an organic solvent (C).

Owner:ASAHI GLASS CO LTD

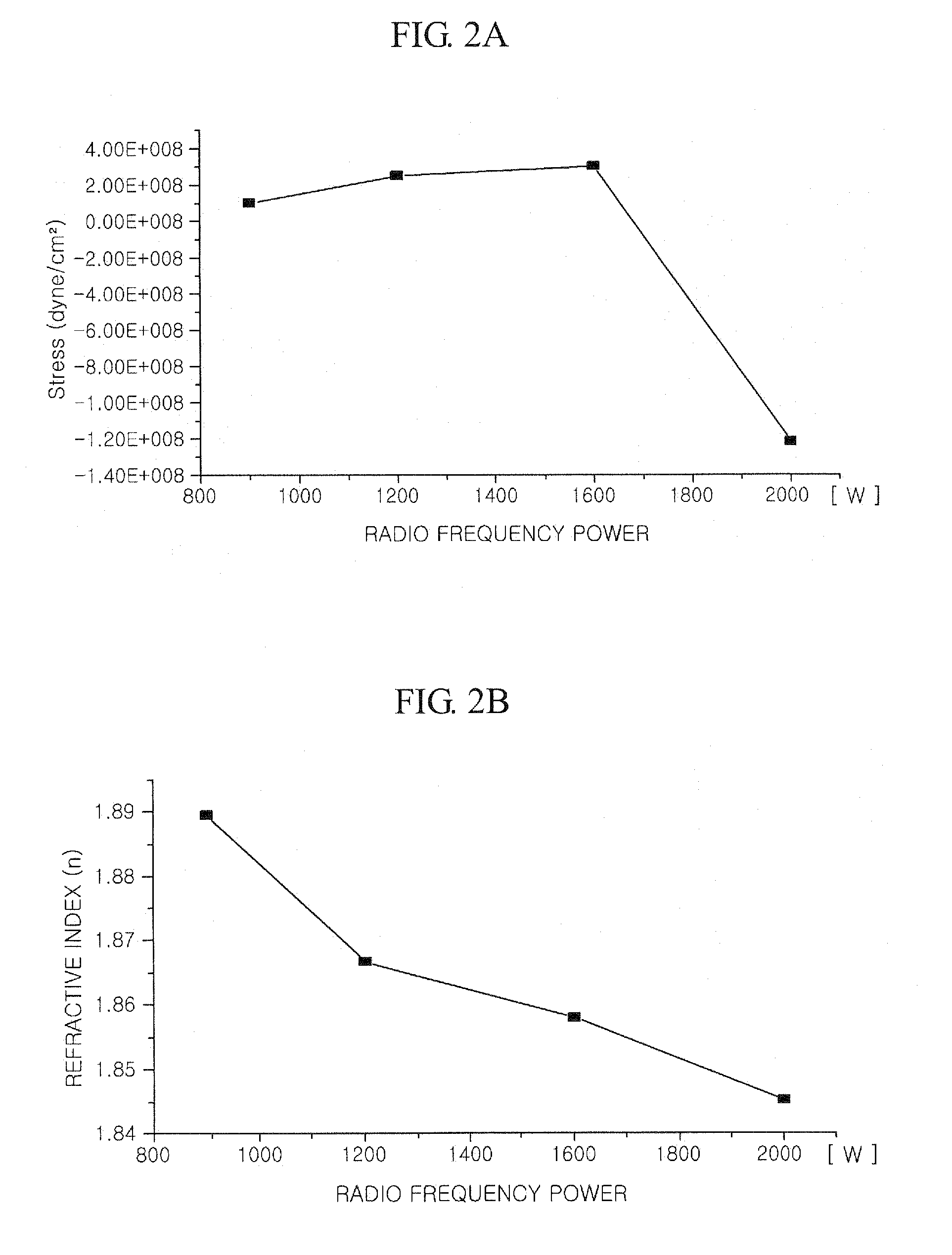

Method of forming fine pattern

InactiveUS6586163B1Decorative surface effectsSemiconductor/solid-state device manufacturingResistSilicon oxide

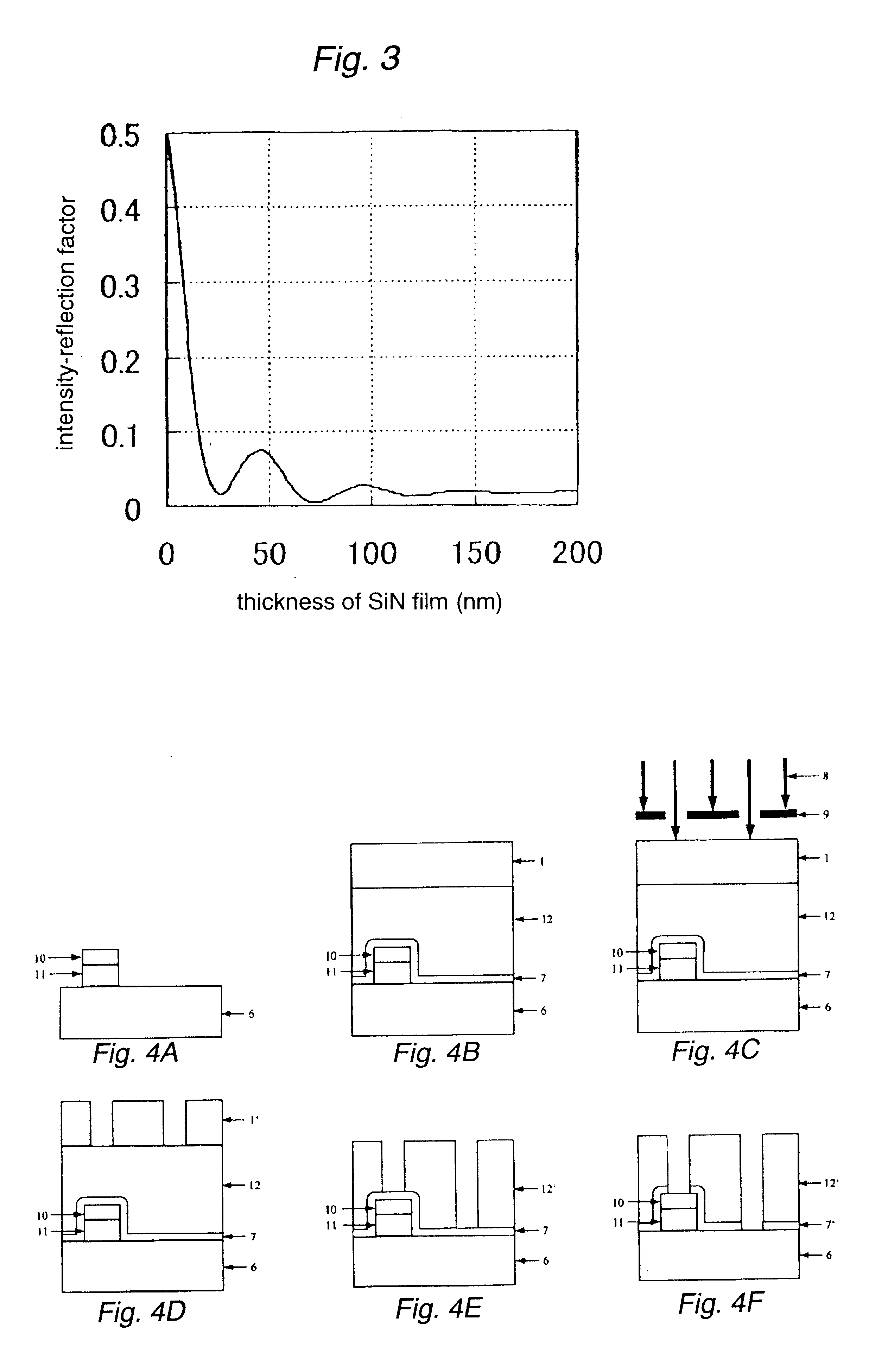

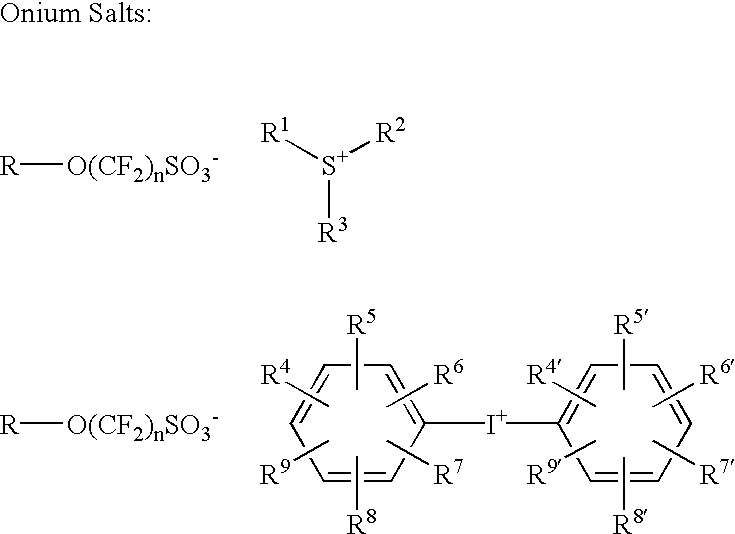

There is described a method of forming a fine pattern aimed at depositing a silicon-nitride-based anti-reflection film which is stable even at high temperature and involves small internal stress. The method is also intended to preventing occurrence of a footing pattern (a rounded corner) in a boundary surface between a photoresist and a substrate at the time of formation of a chemically-amplified positive resist pattern on the anti-reflection film. The method includes the steps of forming a silicon-nitride-based film directly on a substrate or on a substrate by way of another layer; and forming a photoresist directly on the silicon-nitride-based film or on the silicon-nitride-based film by way of another layer. The silicon-nitride-based film is deposited while the temperature at which the substrate is to be situated is set so as to fall within the range of 400 to 700° C., through use of a plasma CVD system. The method further includes a step of depositing a silicon-oxide-based film immediately below the photoresist. The silicon-oxide-based film is deposited while the temperature at which the substrate is to be situated is set so as to fall within the range of 400 to 700° C., through use of a plasma CVD system.

Owner:ASM JAPAN +1

Photoacid generators for use in photoresist compositions

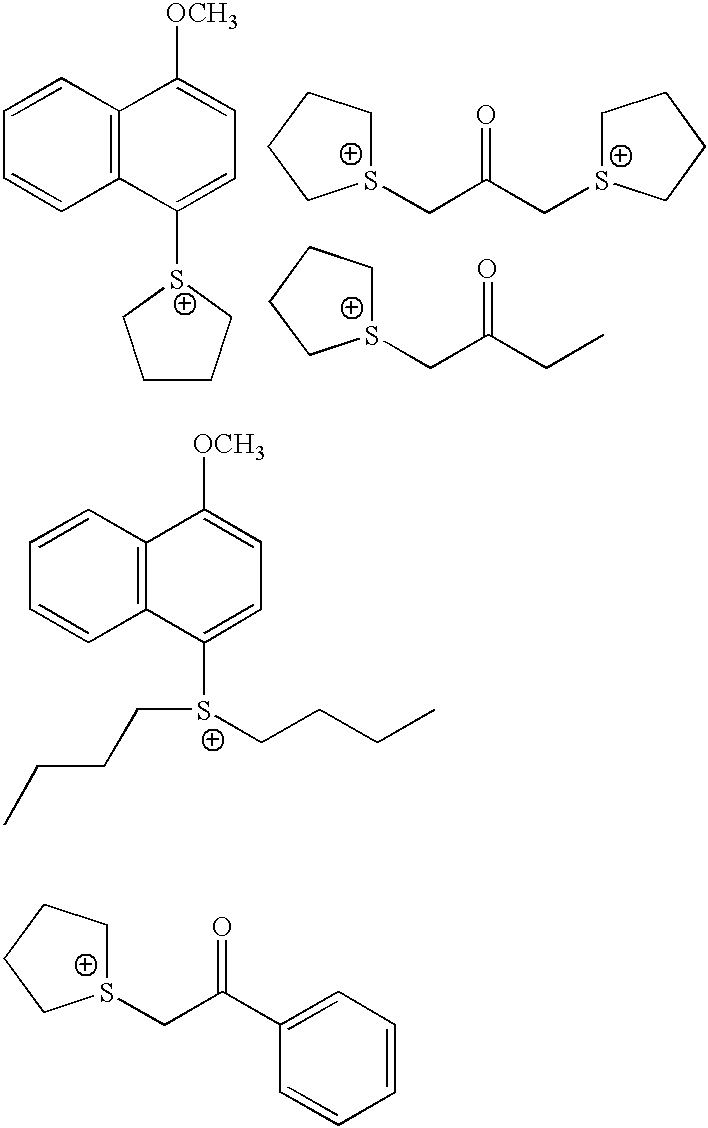

A photoacid compound having the following general structure:<paragraph lvl="0"><in-line-formula>R-O(CF2)nSO3X< / in-line-formula>wherein n is an integer between about 1 to 4; R is selected from the group consisting of: substituted or unsubstituted C1-C12 linear or branched alkyl or alkenyl, substituted or unsubstituted araalkyl, substituted or unsubstituted aryl, substituted or unsubstituted bicycloalkyl, substituted or unsubstituted tricycloalkyl, hydrogen, alkyl sulfonic acid, substituted or unsubstituted perfluoroalkyl, the general structure F((CF2)pO)m(CF2)q- wherein p is between about 1 to 4, m is between about 0 to 3 and q is between about 1 to 4, and substituted or unsubstituted partially fluorinated alkyl, halofluoroalkyl, perfluoroalkylsulfonic, or glycidyl; and X is selected from the group consisting of: organic cations and covalently bonded organic radicals.

Owner:FUJIFILM ELECTRONICS MATERIALS US

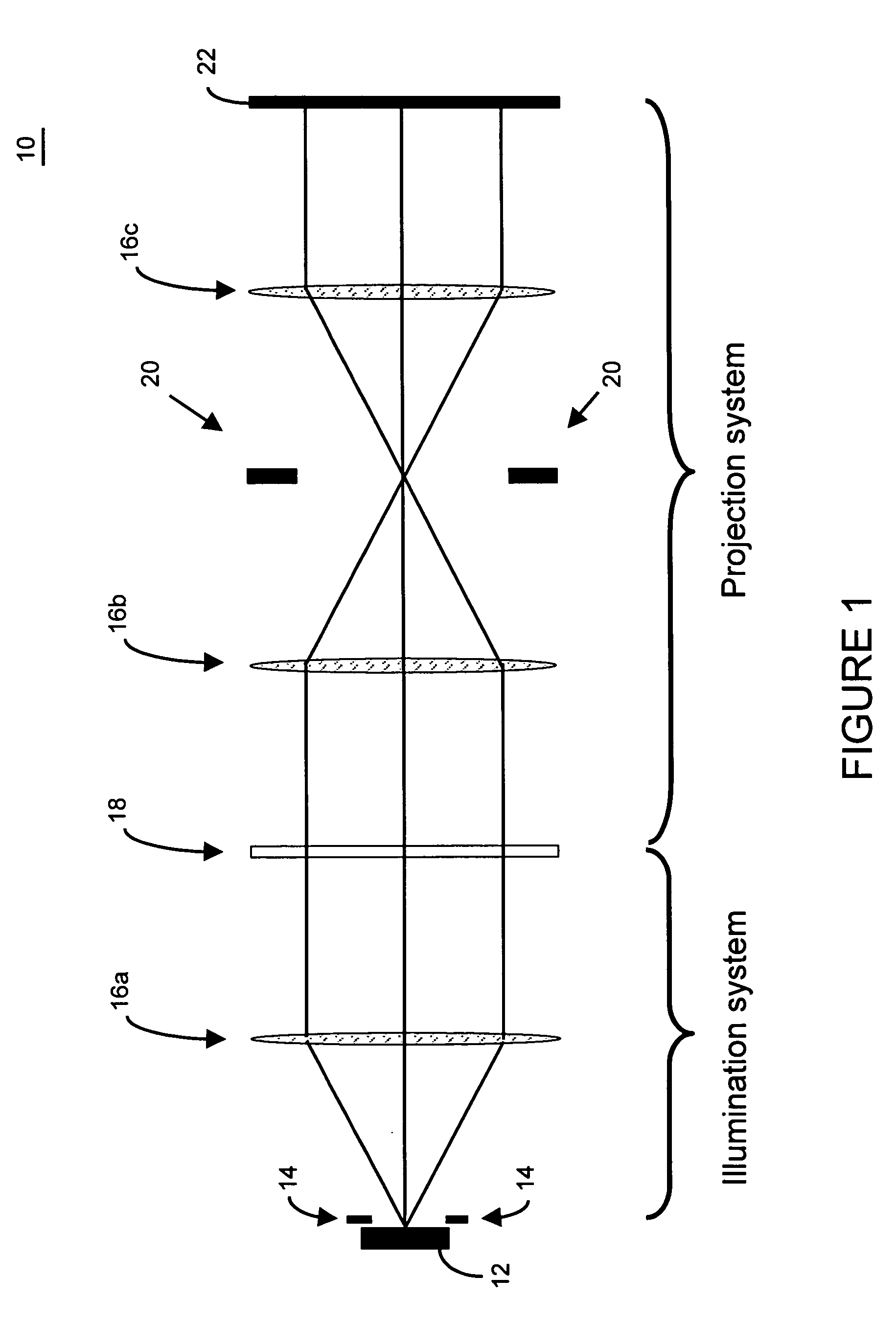

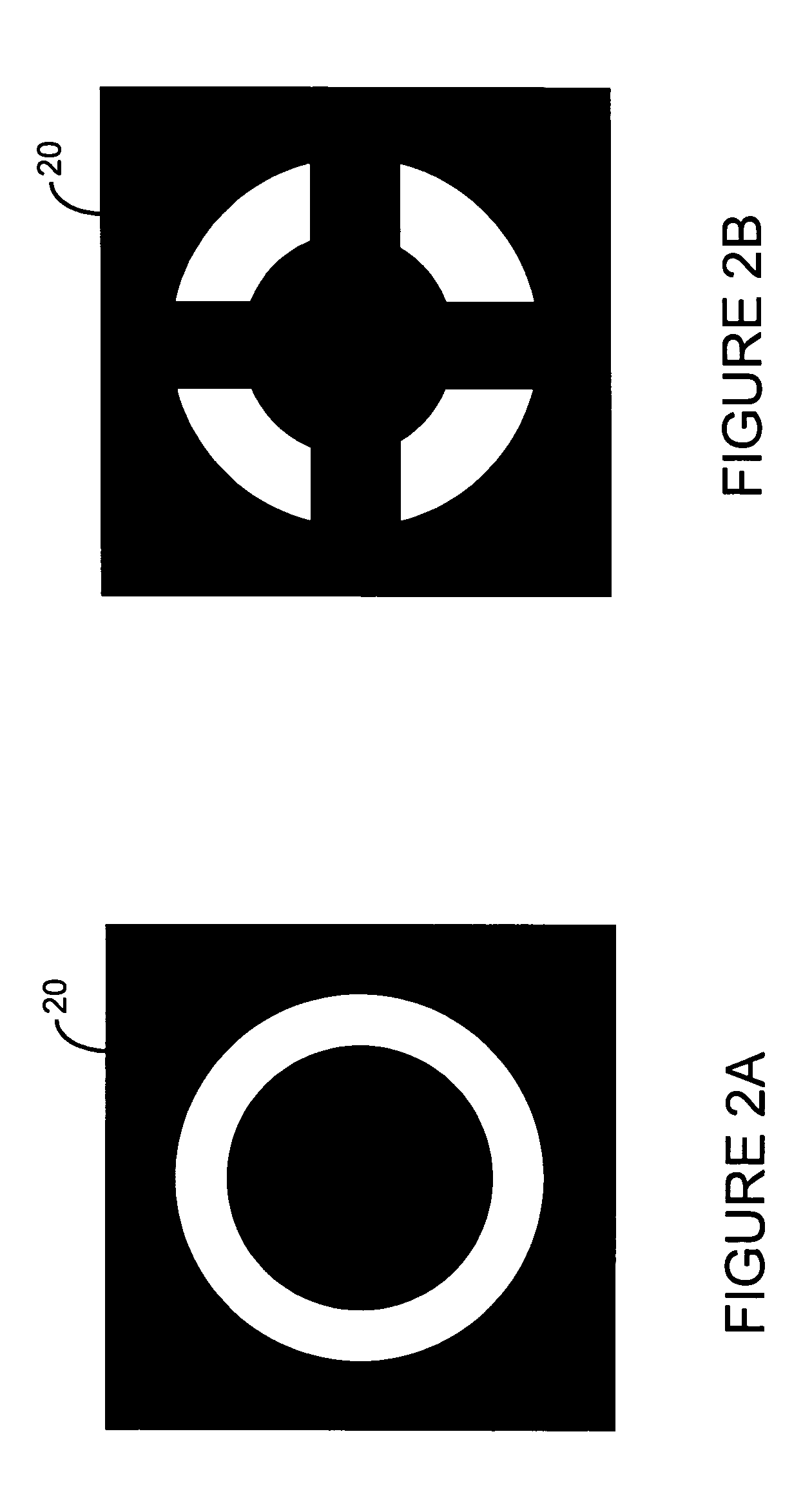

System and method for lithography simulation

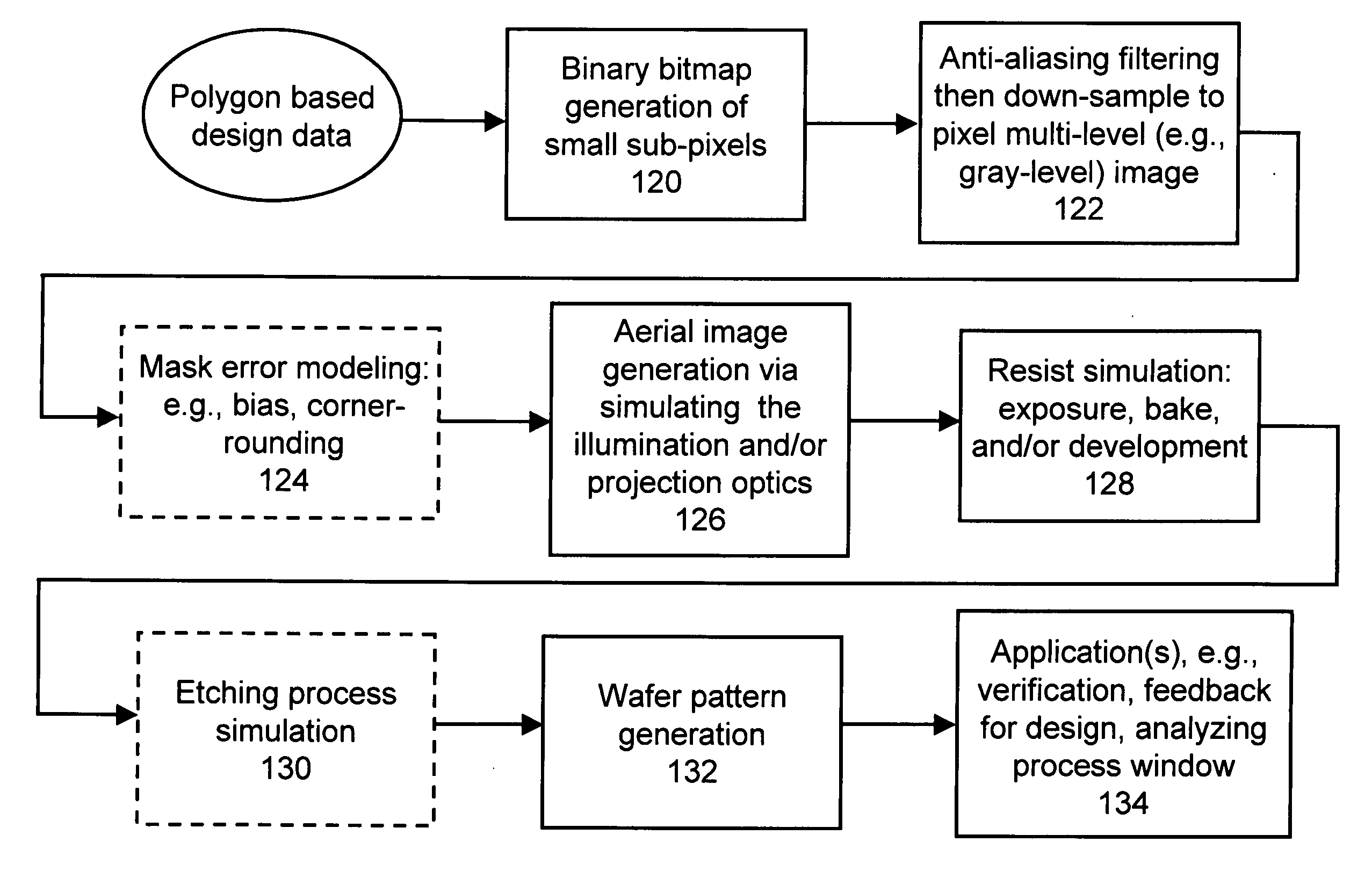

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a technique of, and system for simulating, verifying, inspecting, characterizing, determining and / or evaluating the lithographic designs, techniques and / or systems, and / or individual functions performed thereby or components used therein. In one embodiment, the present invention is a system and method that accelerates lithography simulation, inspection, characterization and / or evaluation of the optical characteristics and / or properties, as well as the effects and / or interactions of lithographic systems and processing techniques. In this regard, in one embodiment, the present invention employs a lithography simulation system architecture, including application-specific hardware accelerators, and a processing technique to accelerate and facilitate verification, characterization and / or inspection of a mask design, for example, RET design, including detailed simulation and characterization of the entire lithography process to verify that the design achieves and / or provides the desired results on final wafer pattern. The system includes: (1) general purpose-type computing device(s) to perform the case-based logic having branches and inter-dependency in the data handling and (2) accelerator subsystems to perform a majority of the computation intensive tasks.

Owner:ASML NETHERLANDS BV

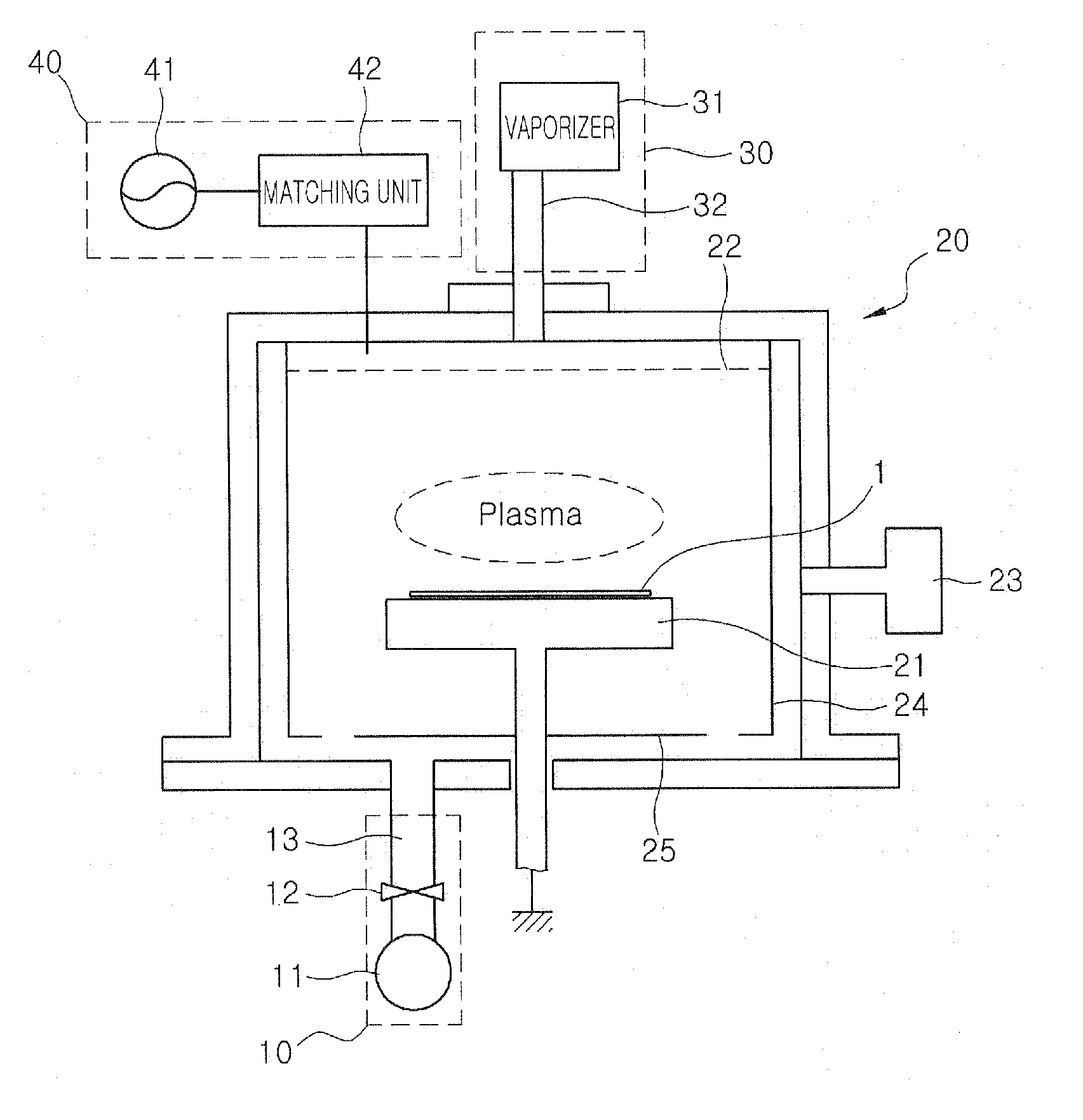

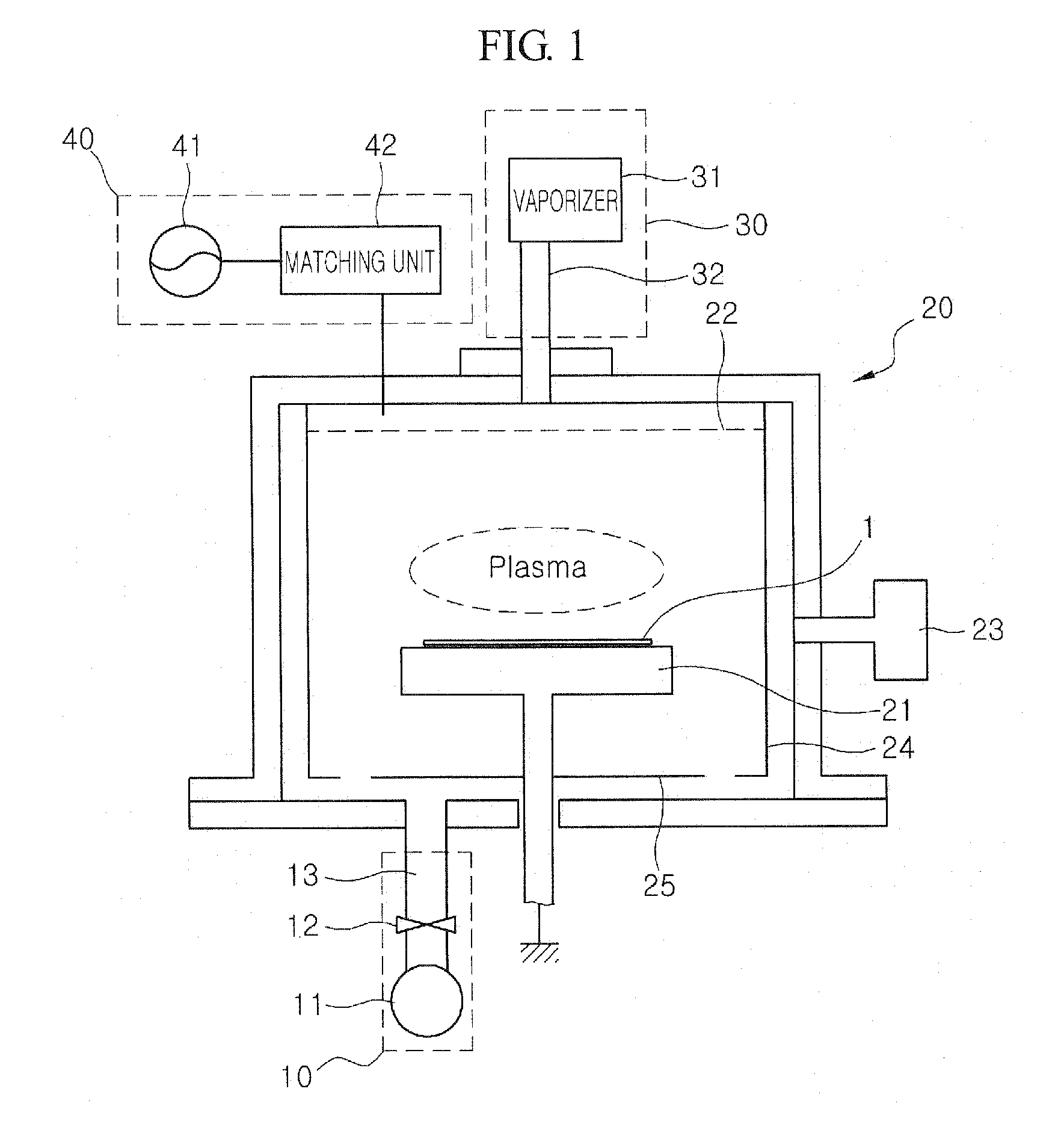

Method of forming amorphous carbon film and method of manufacturing semiconductor device using the same

InactiveUS20080293248A1Better controllableLight absorption coefficient is lowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRefractive indexDiffuse reflection

The present invention relates to a method of forming an amorphous carbon film and a method of manufacturing a semiconductor device using the method. An amorphous carbon film is formed on a substrate by vaporizing a liquid hydrocarbon compound, which has chain structure and one double bond, and supplying the compound to a chamber, and ionizing the compound. The amorphous carbon film is used as a hard mask film.It is possible to easily control characteristics of the amorphous carbon film, such as a deposition rate, an etching selectivity, a refractive index (n), a light absorption coefficient (k) and stress, so as to satisfy user's requirements. In particular, it is possible to lower the refractive index (n) and the light absorption coefficient (k). As a result, it is possible to perform a photolithography process without an antireflection film that prevents the diffuse reflection of a lower material layer.Further, a small amount of reaction by-product is generated during a deposition process, and it is possible to easily remove reaction by-products that are attached on the inner wall of a chamber. For this reason, it is possible to increase a cycle of a process for cleaning a chamber, and to increase parts changing cycles of a chamber. As a result, it is possible to save time and cost.

Owner:TES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com