Patents

Literature

2866results about "Plate printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

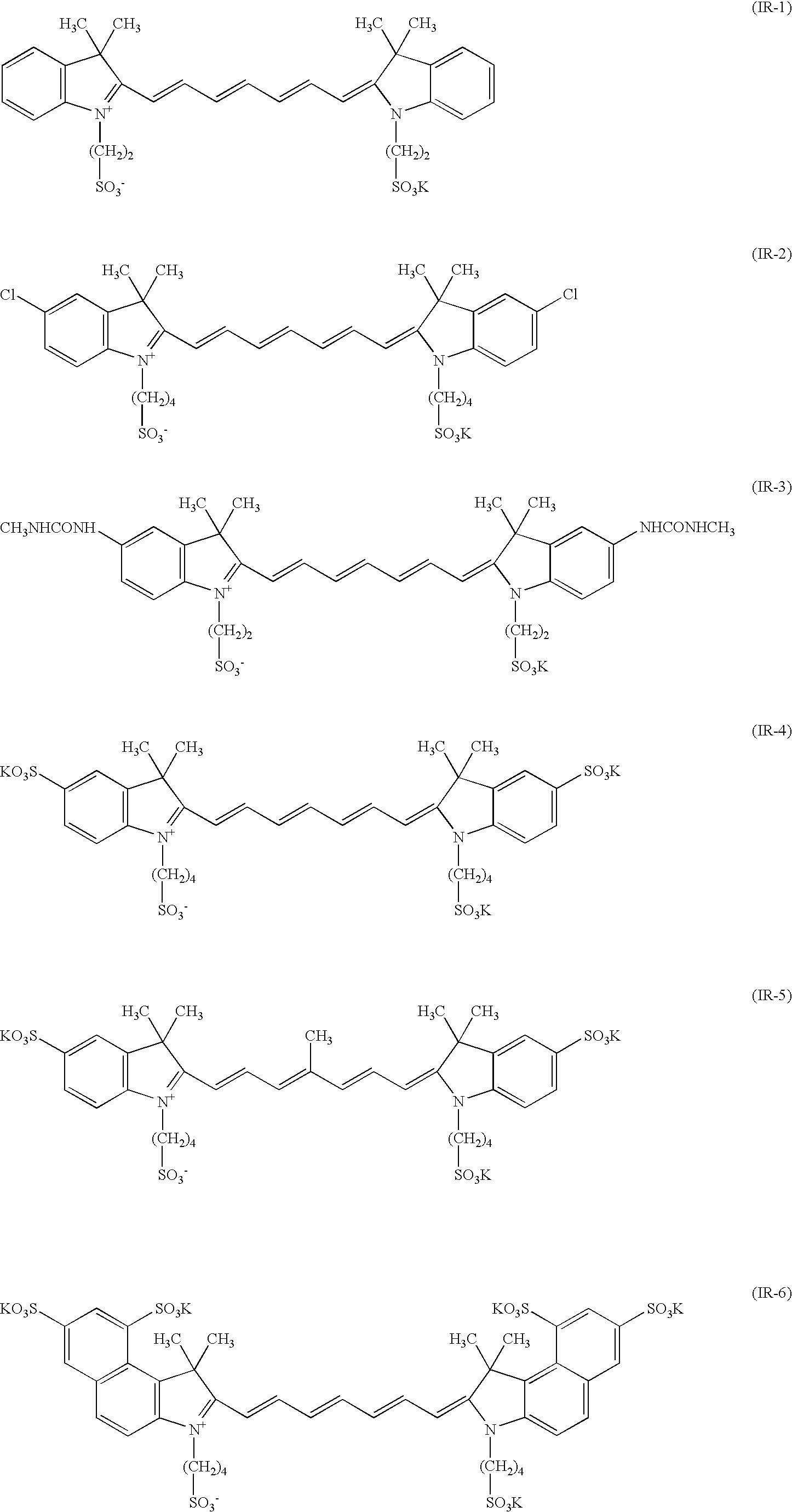

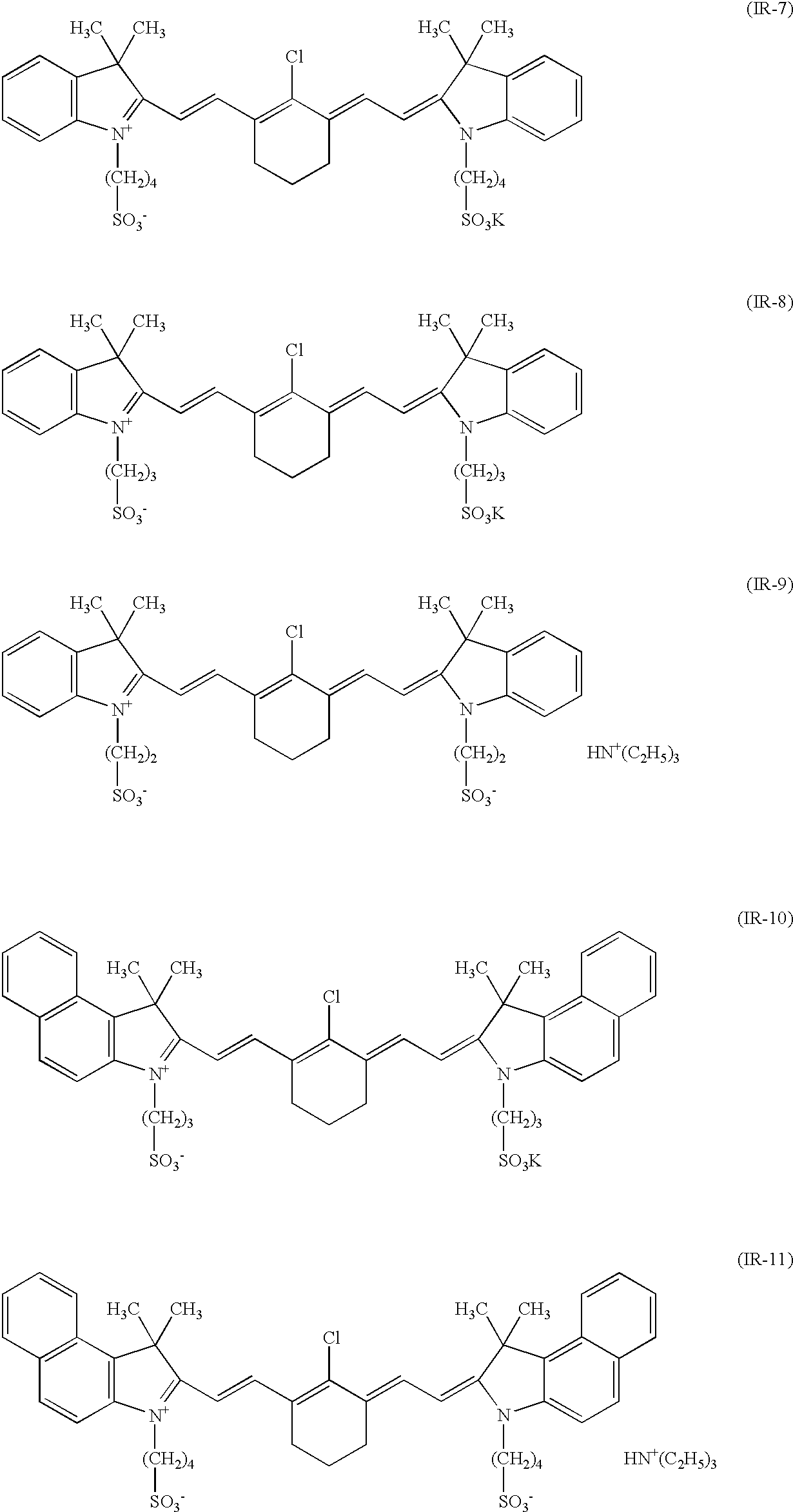

On-press developable IR sensitive printing plates using binder resins having polyethylene oxide segments

InactiveUS6899994B2Prevent steppingRadiation applicationsSemiconductor/solid-state device manufacturingPolymer sciencePolyethylene oxide

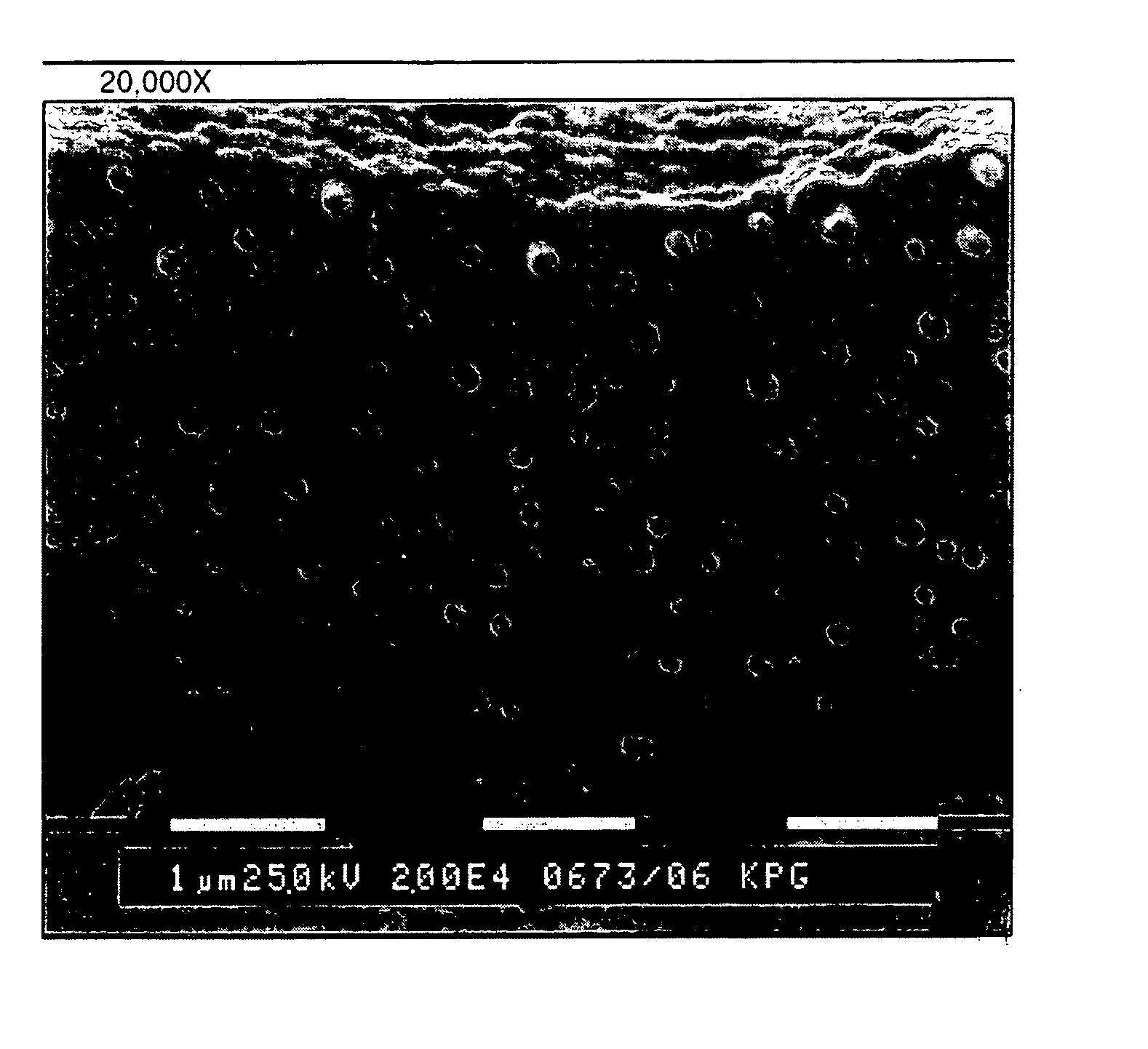

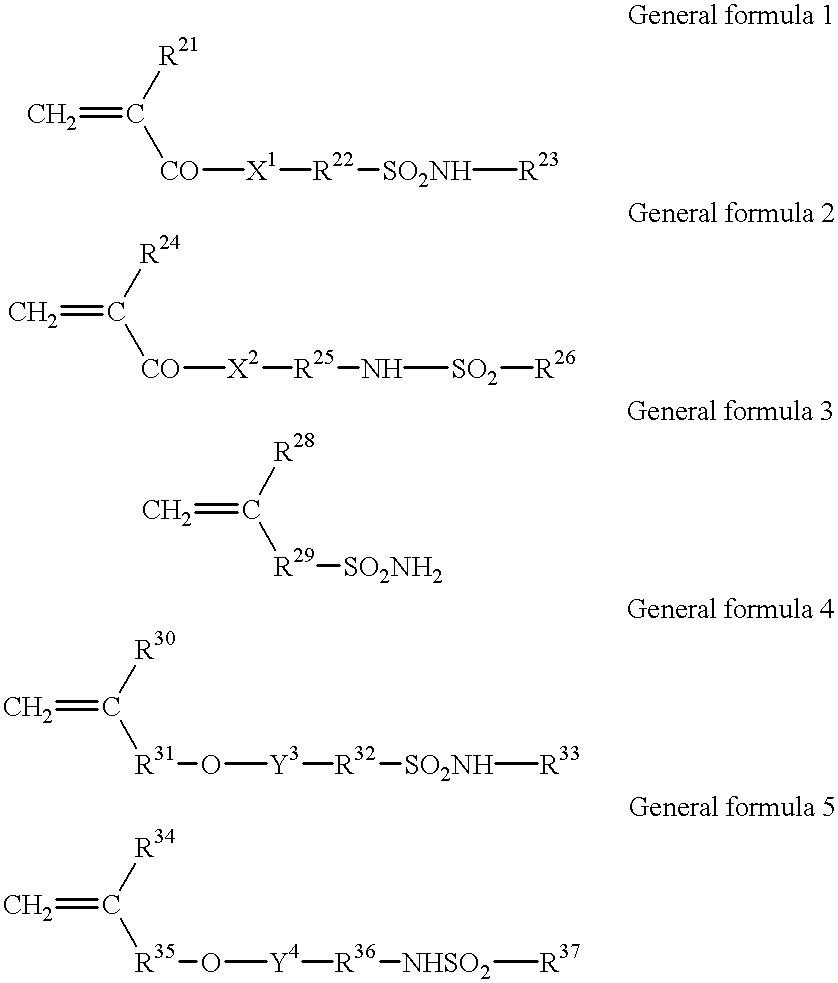

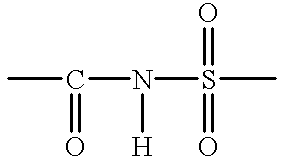

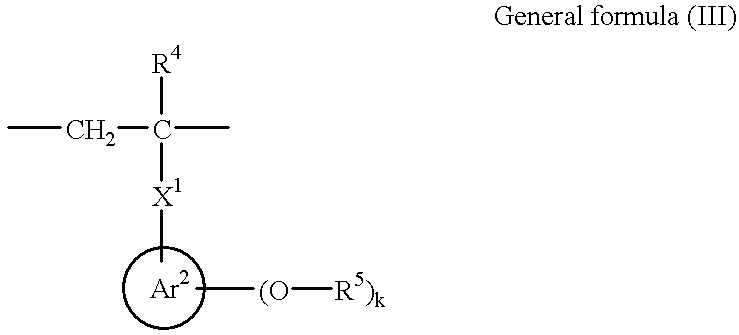

The present invention relates to a polymerizable coating composition suitable for the manufacture of printing plates developable on-press. The coating composition comprises (i) a polymerizable compound and (ii) a polymeric binder comprising polyethylene oxide segments, wherein the polymeric binder is selected from the group consisting of at least one graft copolymer comprising a main chain polymer and polyethylene oxide side chains, a block copolymer having at least one polyethylene oxide block and at least one non-polyethylene oxide block, and a combination thereof. The invention is also directed to an imageable element comprising a substrate and the polymerizable coating composition.

Owner:KODAK POLYCHROME GRAPHICS

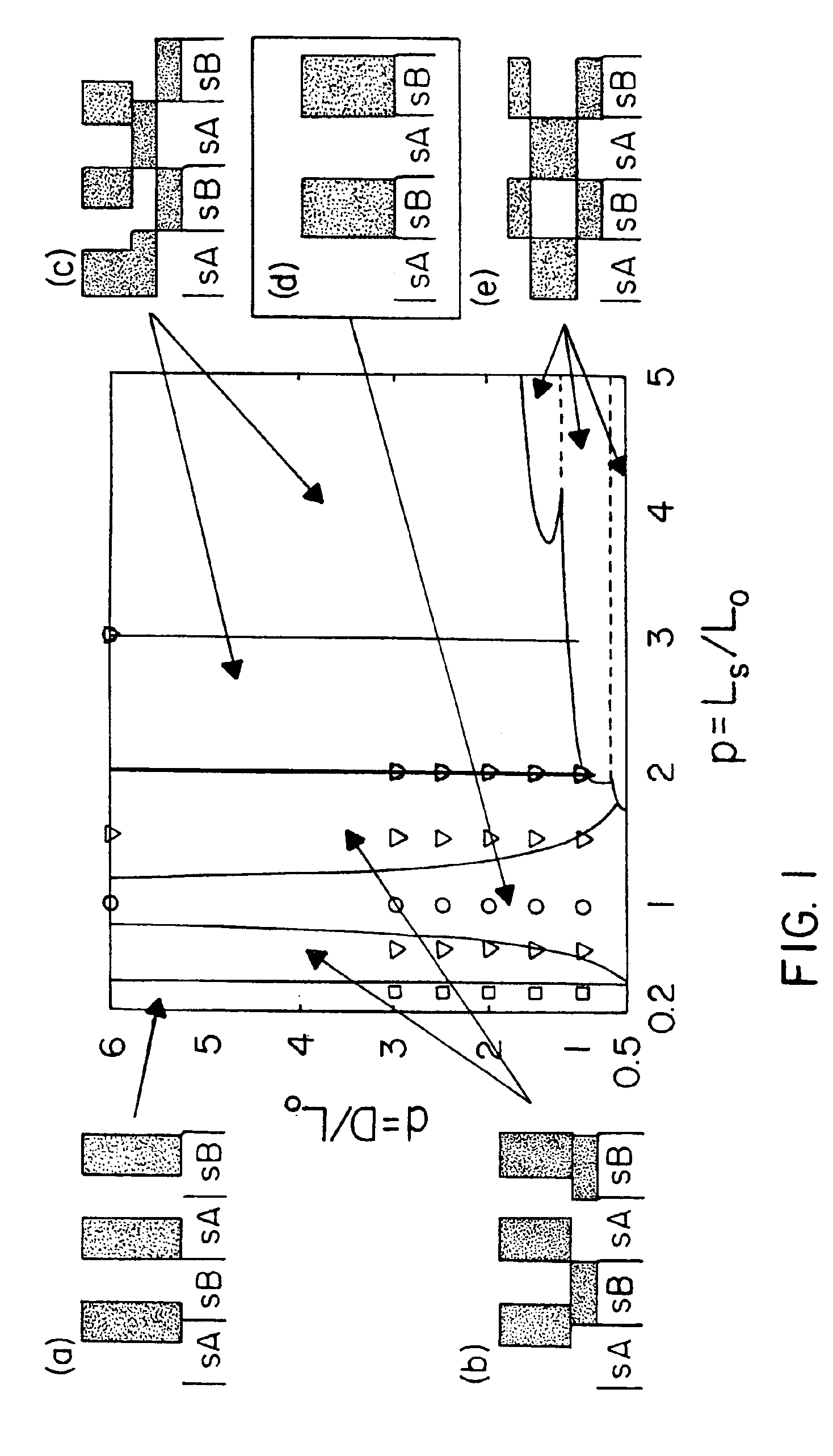

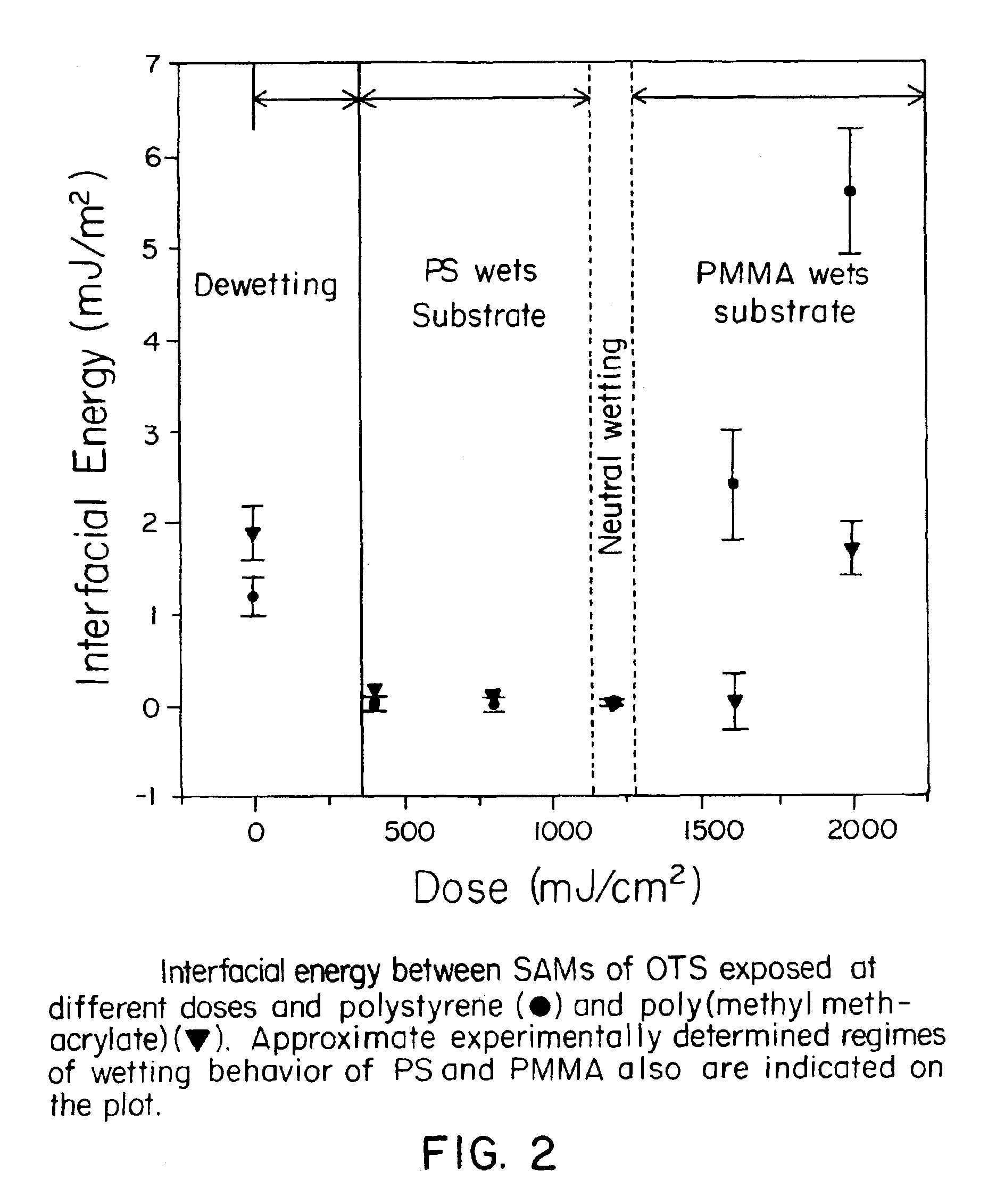

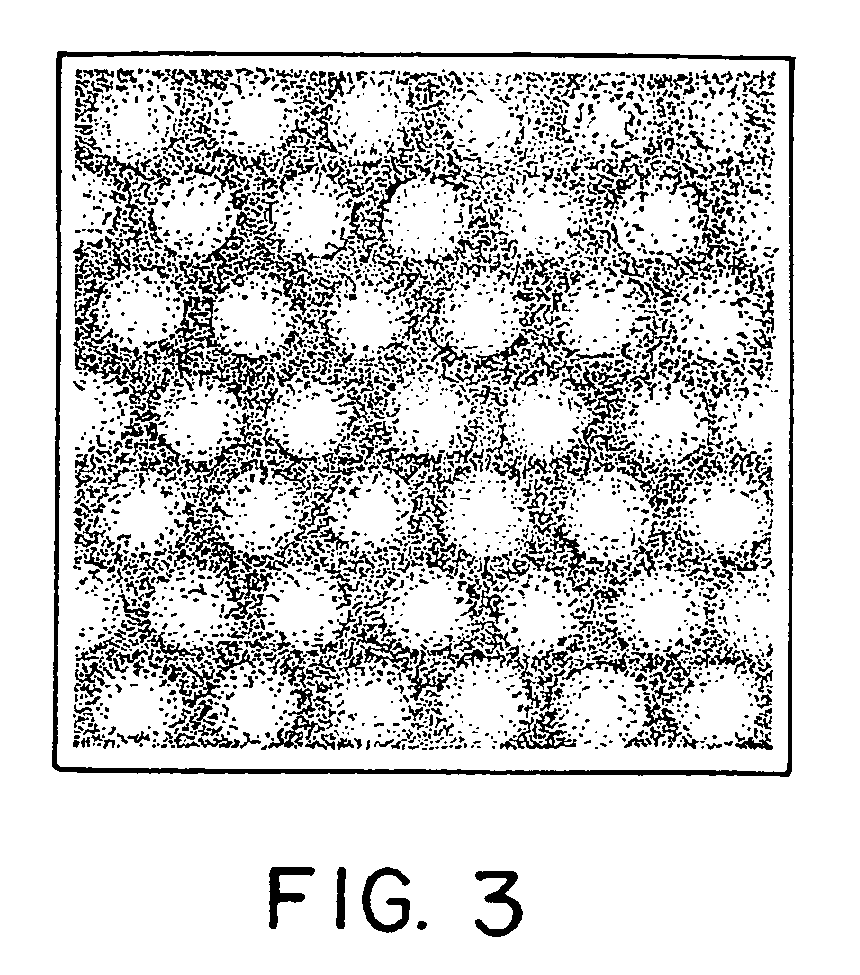

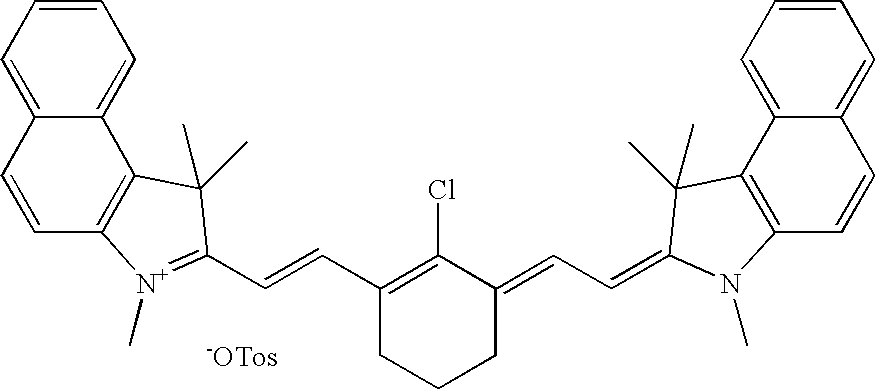

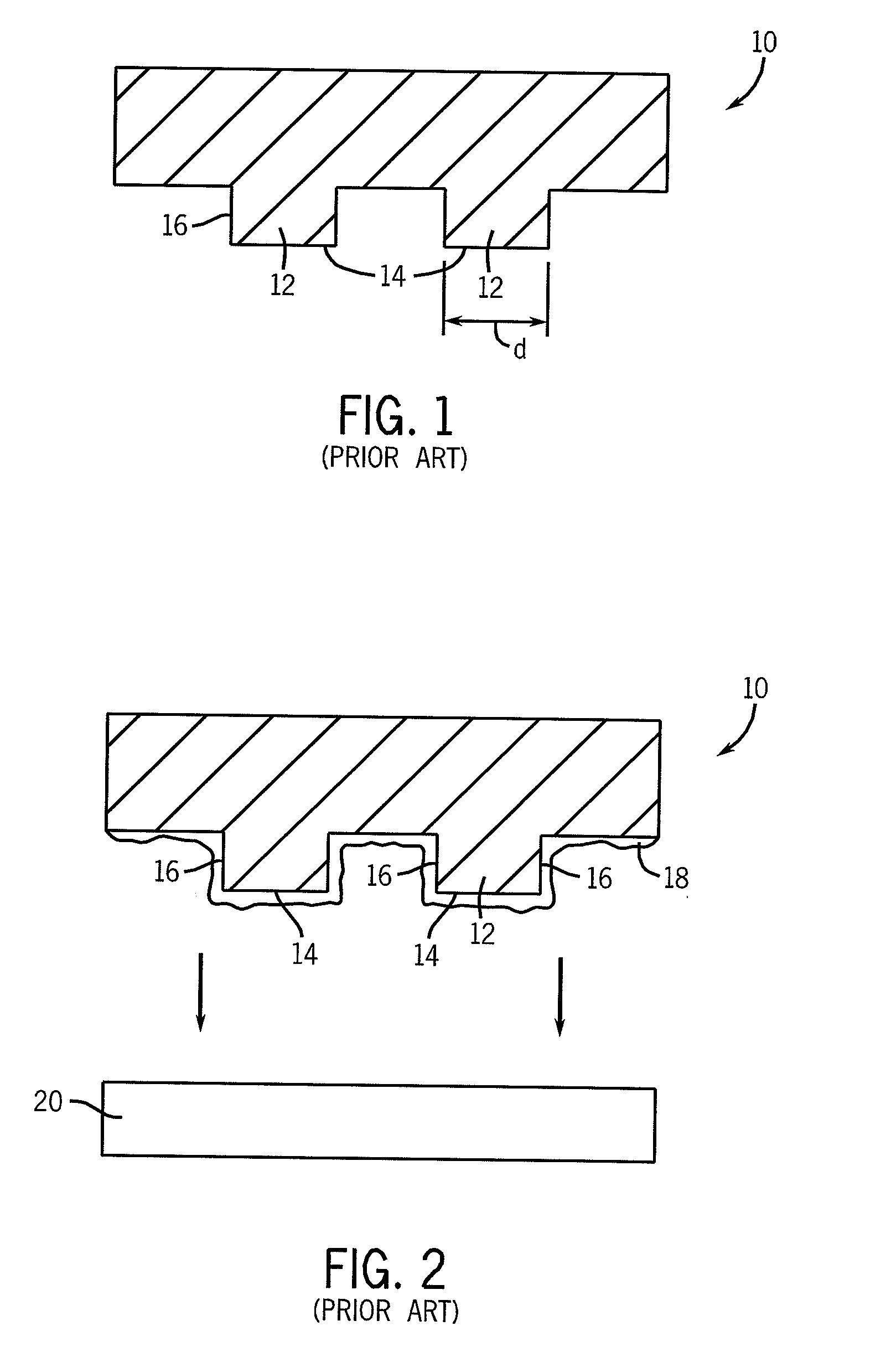

Guided self-assembly of block copolymer films on interferometrically nanopatterned substrates

InactiveUS6926953B2High and low wettabilityMaterial nanotechnologyPhotosensitive materialsLight beamLength wave

Copolymer structures are formed by exposing a substrate with an imaging layer thereon to two or more beams of selected wavelengths to form interference patterns at the imaging layer to change the wettability of the imaging layer in accordance with the interference patterns. A layer of a selected block copolymer is deposited onto the exposed imaging layer and annealed to separate the components of the copolymer in accordance with the pattern of wettability and to replicate the pattern of the imaging layer in the copolymer layer. Stripes or isolated regions of the separated components may be formed with periodic dimensions in the range of 100 nm or less.

Owner:WISCONSIN ALUMNI RES FOUND

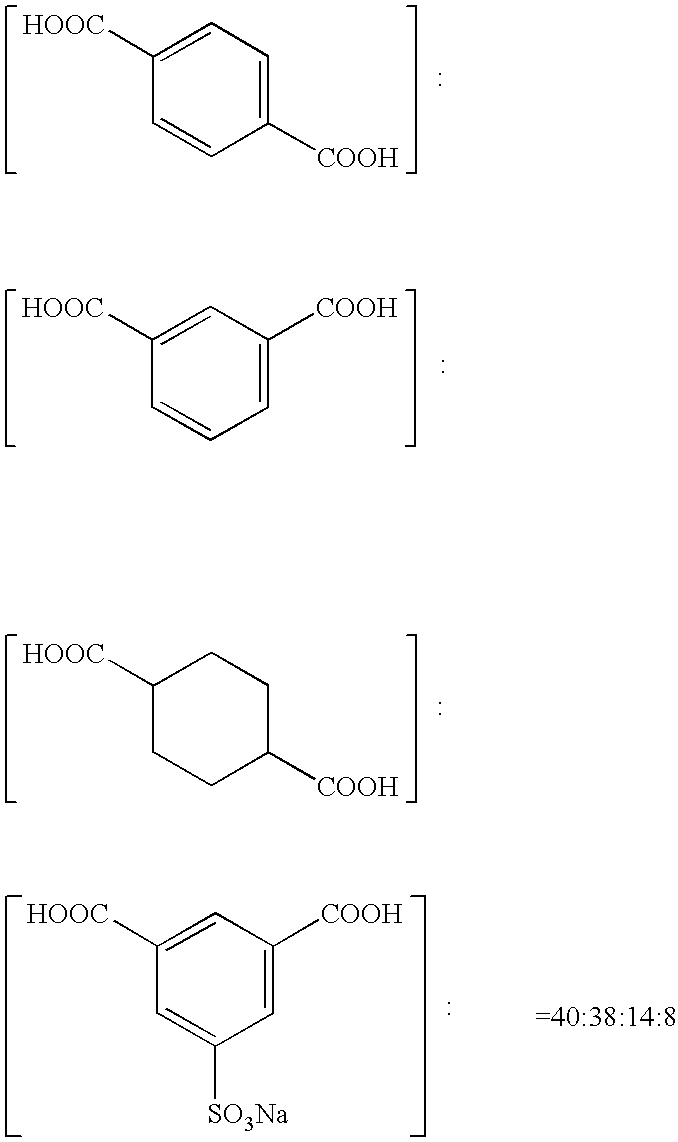

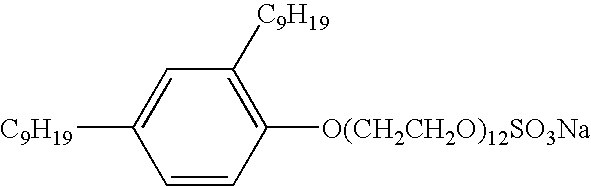

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

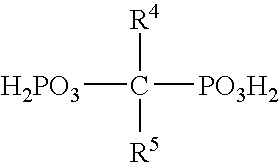

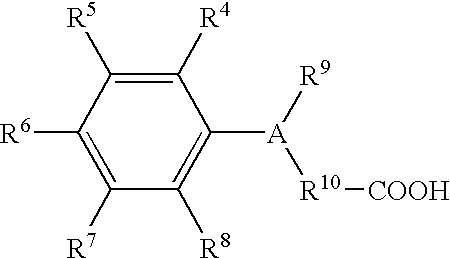

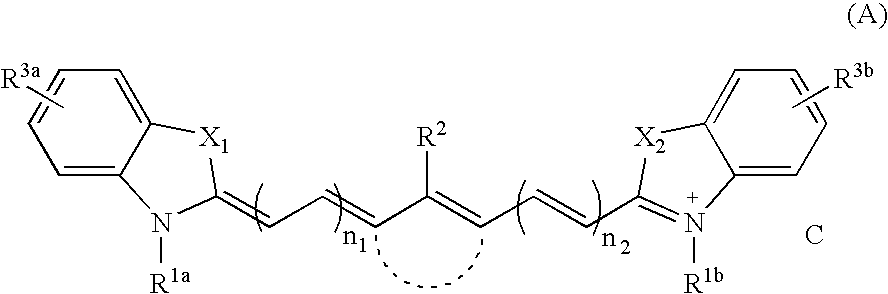

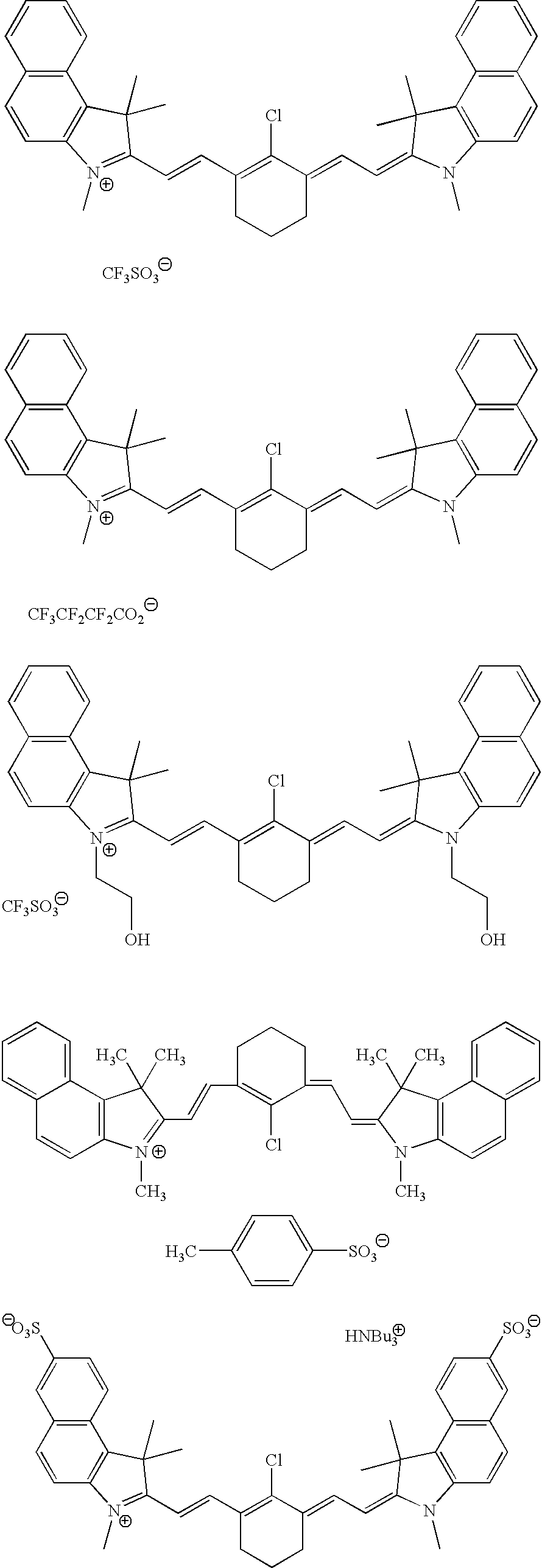

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

High speed negative-working thermal printing plates

Negative working thermally imageable elements useful as lithographic printing plate precursors and methods for their use are disclosed. The elements have a substrate, a layer of imageable composition over the substrate, and, optionally, an overcoat layer over the layer of imageable composition. The imageable composition has an allyl-functional polymeric binder. Optimum resolution and on-press performance can be attained without a post-exposure bake. The elements do not require a post-exposure bake and can be used in on-press development applications.

Owner:KODAK POLYCHROME GRAPHICS

Negative-acting no-process printing plates

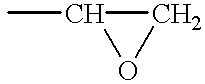

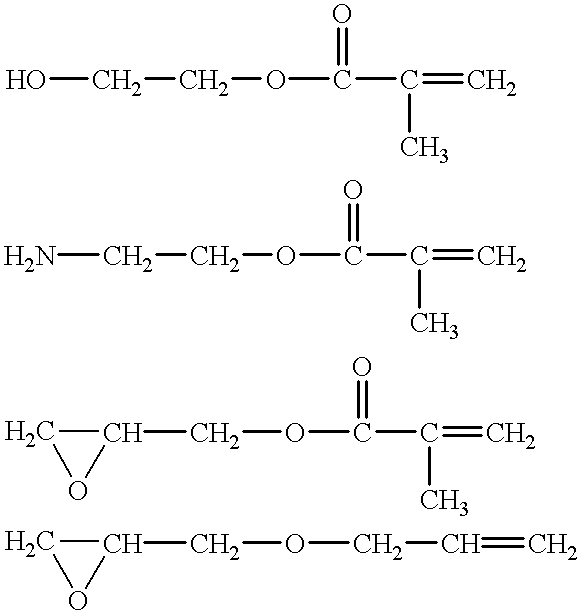

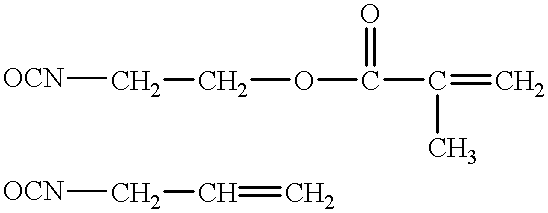

InactiveUS6171735B1Platen pressesSemiconductor/solid-state device manufacturingFunctional monomerOligomer

Owner:3M INNOVATIVE PROPERTIES CO

Printing plates using binder resins having polyethylene oxide segments

InactiveUS20050170286A1Prevent steppingRadiation applicationsSemiconductor/solid-state device manufacturingPolymer sciencePolyethylene oxide

The present invention relates to a polymerizable coating composition suitable for the manufacture of printing plates, which may be developable on-press. The coating composition comprises (i) a polymerizable compound and (ii) a polymeric binder comprising polyethylene oxide segments, wherein the polymeric binder is selected from the group consisting of at least one graft copolymer comprising a main chain polymer and polyethylene oxide side chains, a block copolymer having at least one polyethylene oxide block and at least one non-polyethylene oxide block, and a combination thereof. The invention is also directed to an imageable element comprising a substrate and the polymerizable coating composition.

Owner:EASTMAN KODAK CO

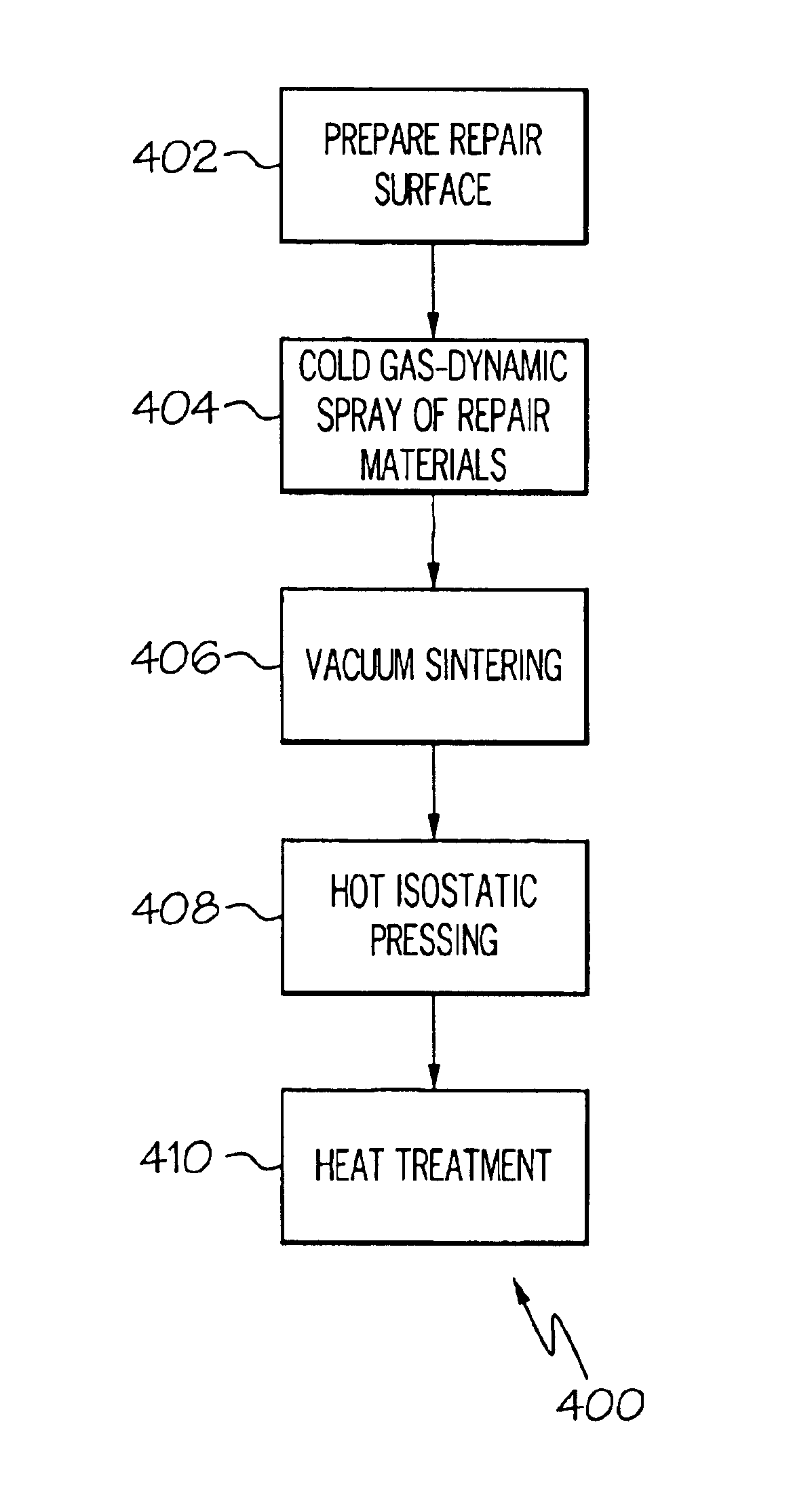

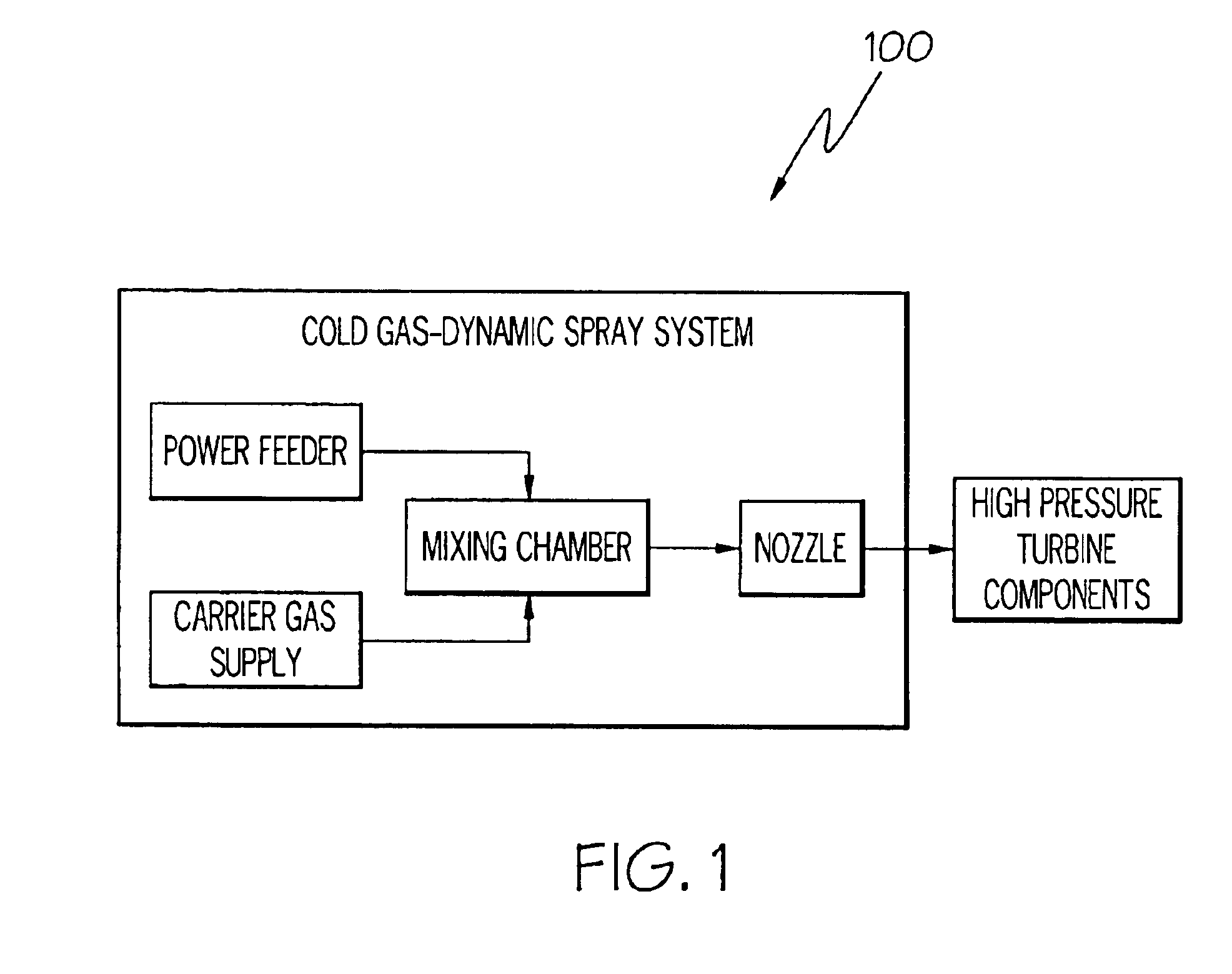

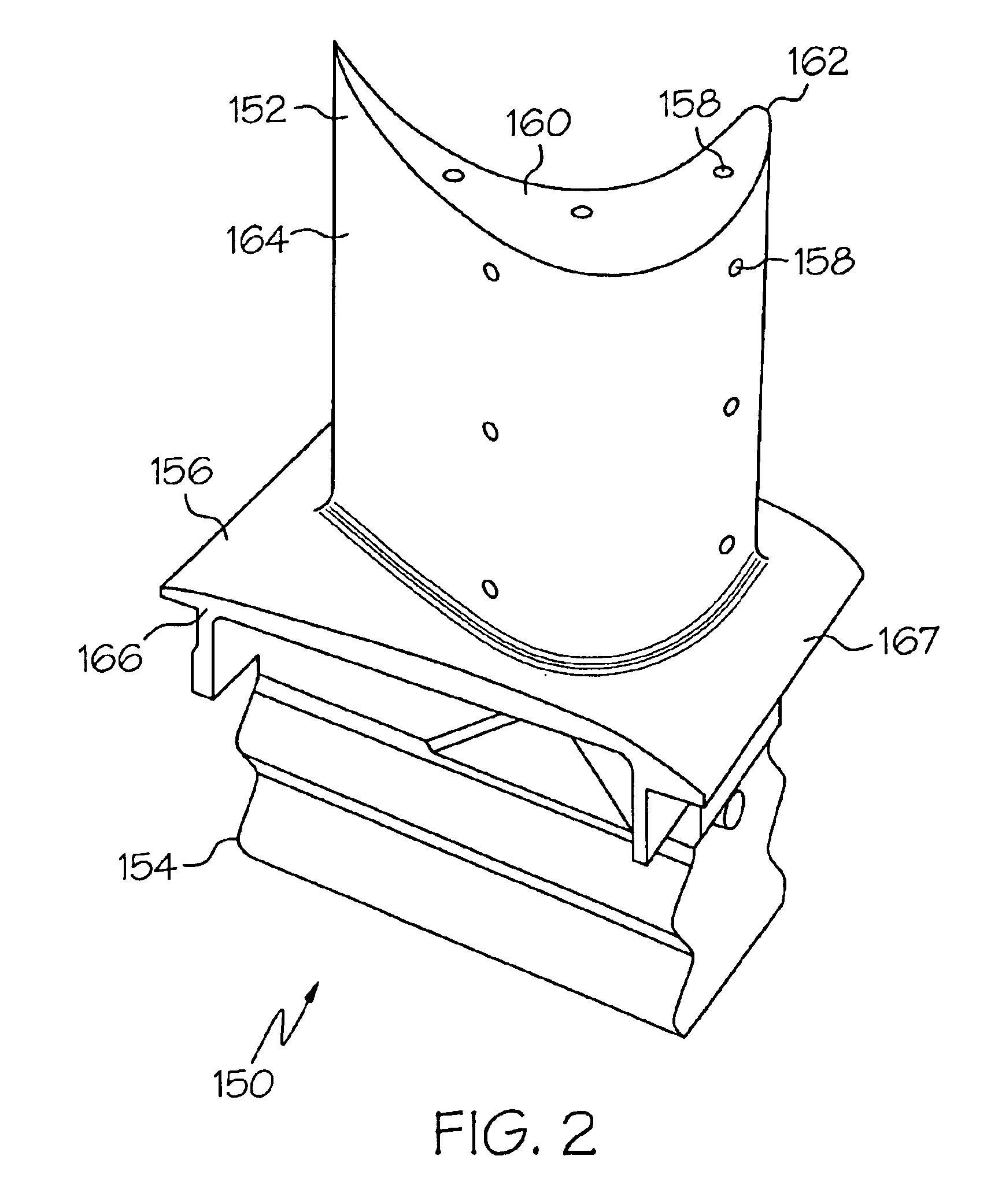

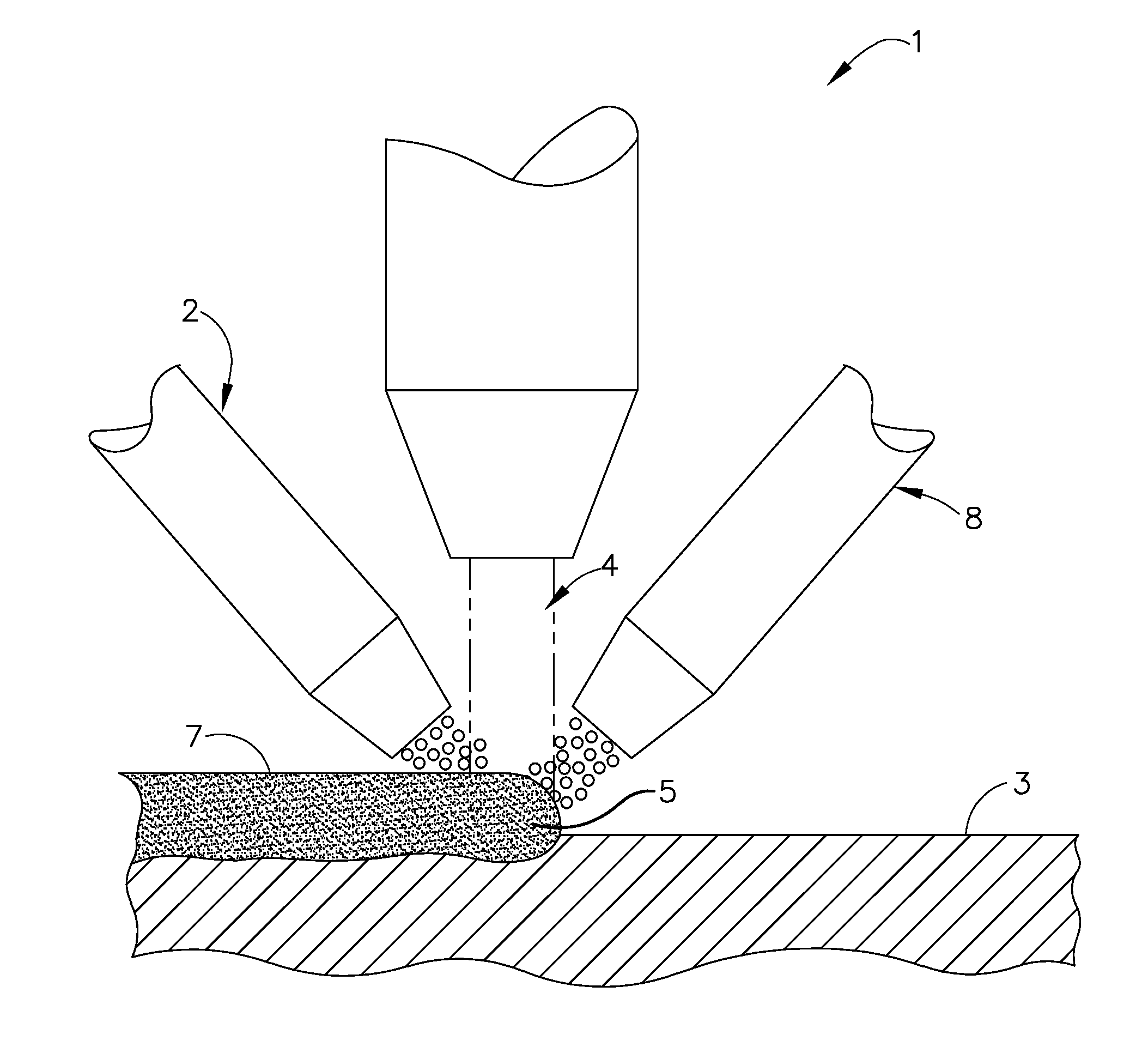

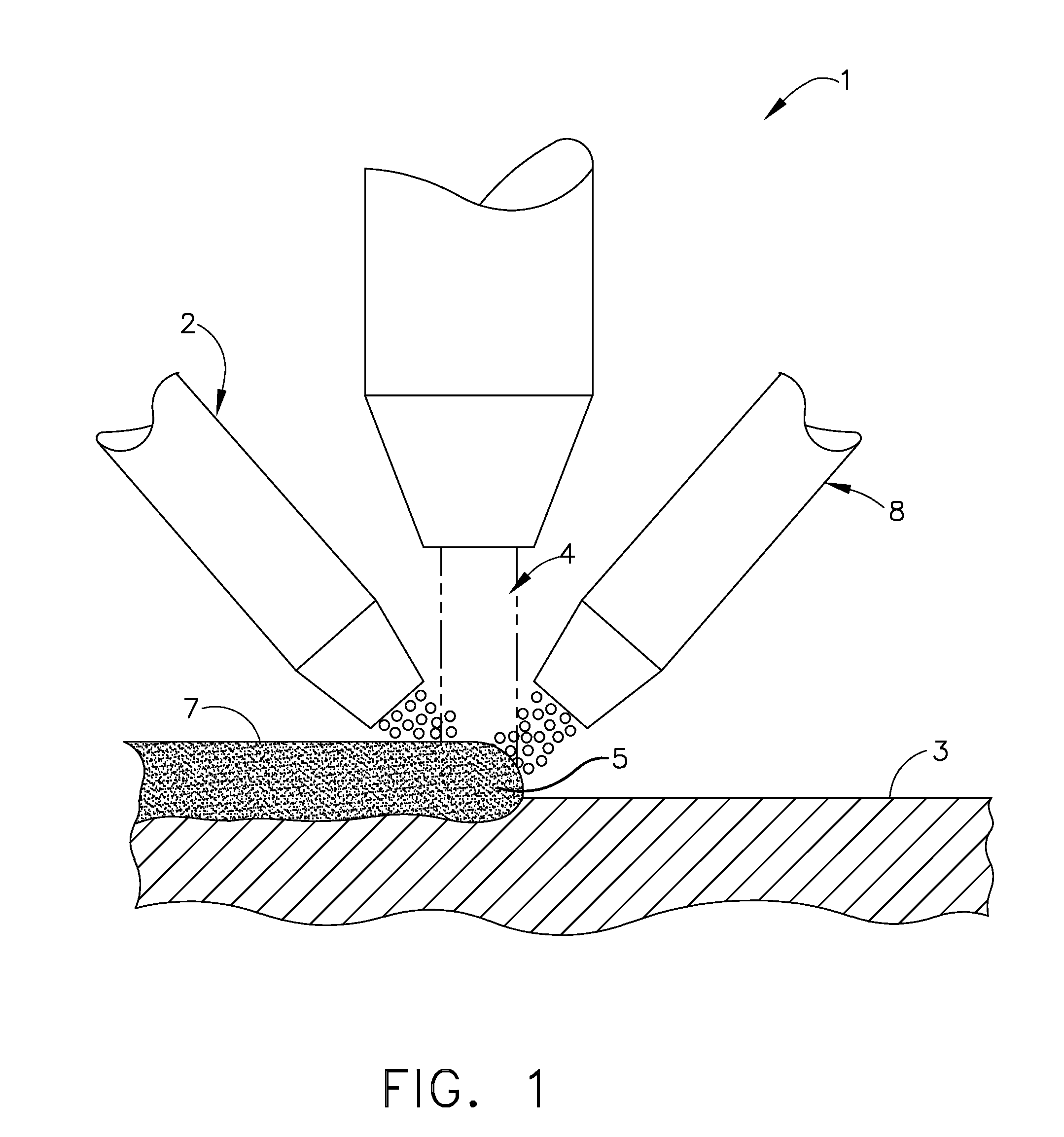

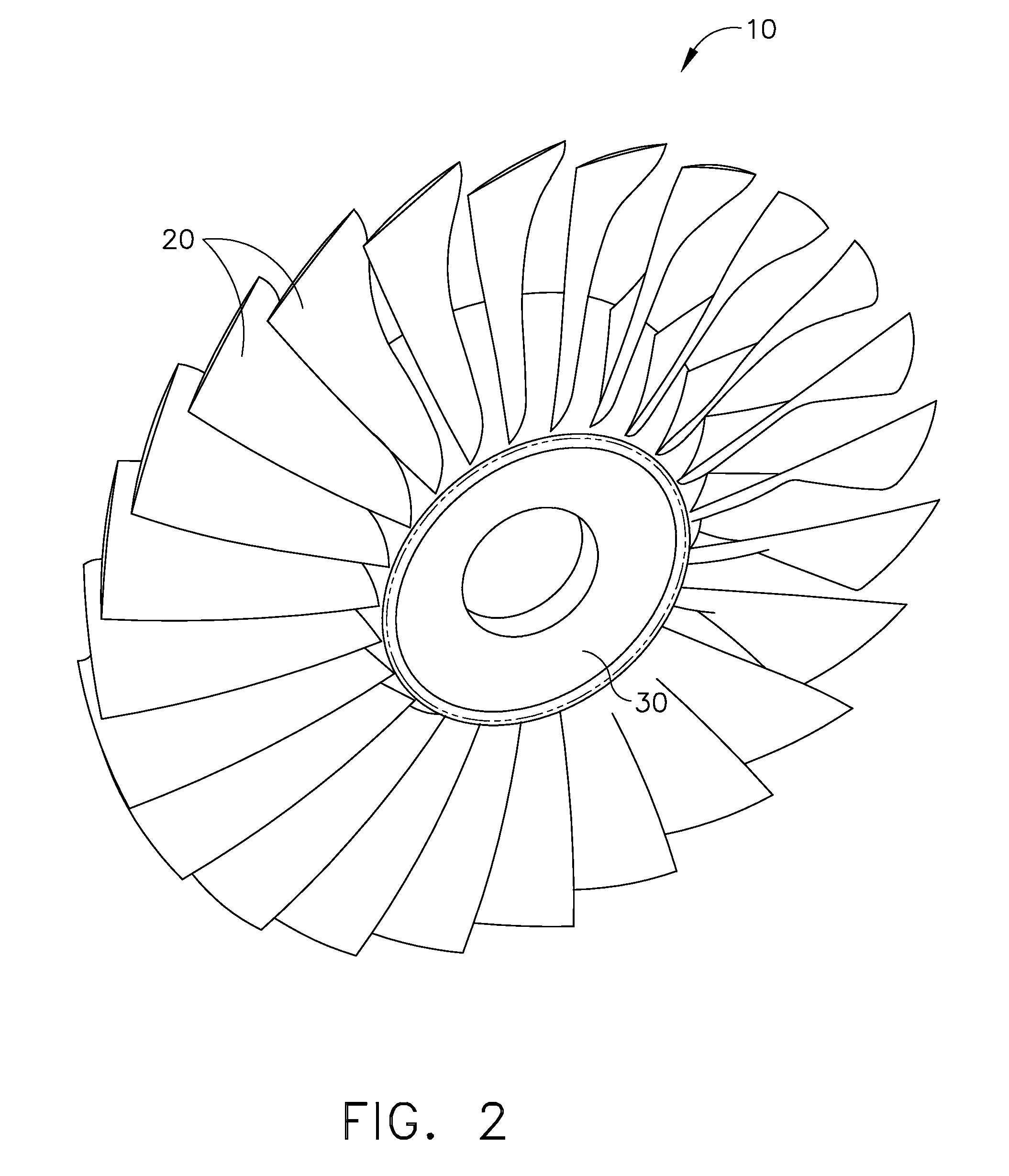

Cold gas-dynamic spray repair on gas turbine engine components

ActiveUS6905728B1Simple methodEasy to weldLayered productsBlade accessoriesTarget surfaceTurbine blade

A new method for repairing turbine engine components is provided. The method utilizes a cold gas-dynamic spray technique to repair degradation on turbine blades, vanes and other components. In the cold gas-dynamic spray process particles at a temperature below their fusing temperature are accelerated and directed to a target surface on the turbine blade. When the particles strike the target surface, the kinetic energy of the particles is converted into plastic deformation of the particle, causing the particle to form a strong bond with the target surface. Post-spray processing is then performed to consolidate and homogenize the applied materials and restore integrity to the material properties in the repaired turbine component. Thus, the cold gas-dynamic spray process and post-spray processing can be employed to effectively repair degraded areas on gas turbine components.

Owner:HONEYWELL INT INC

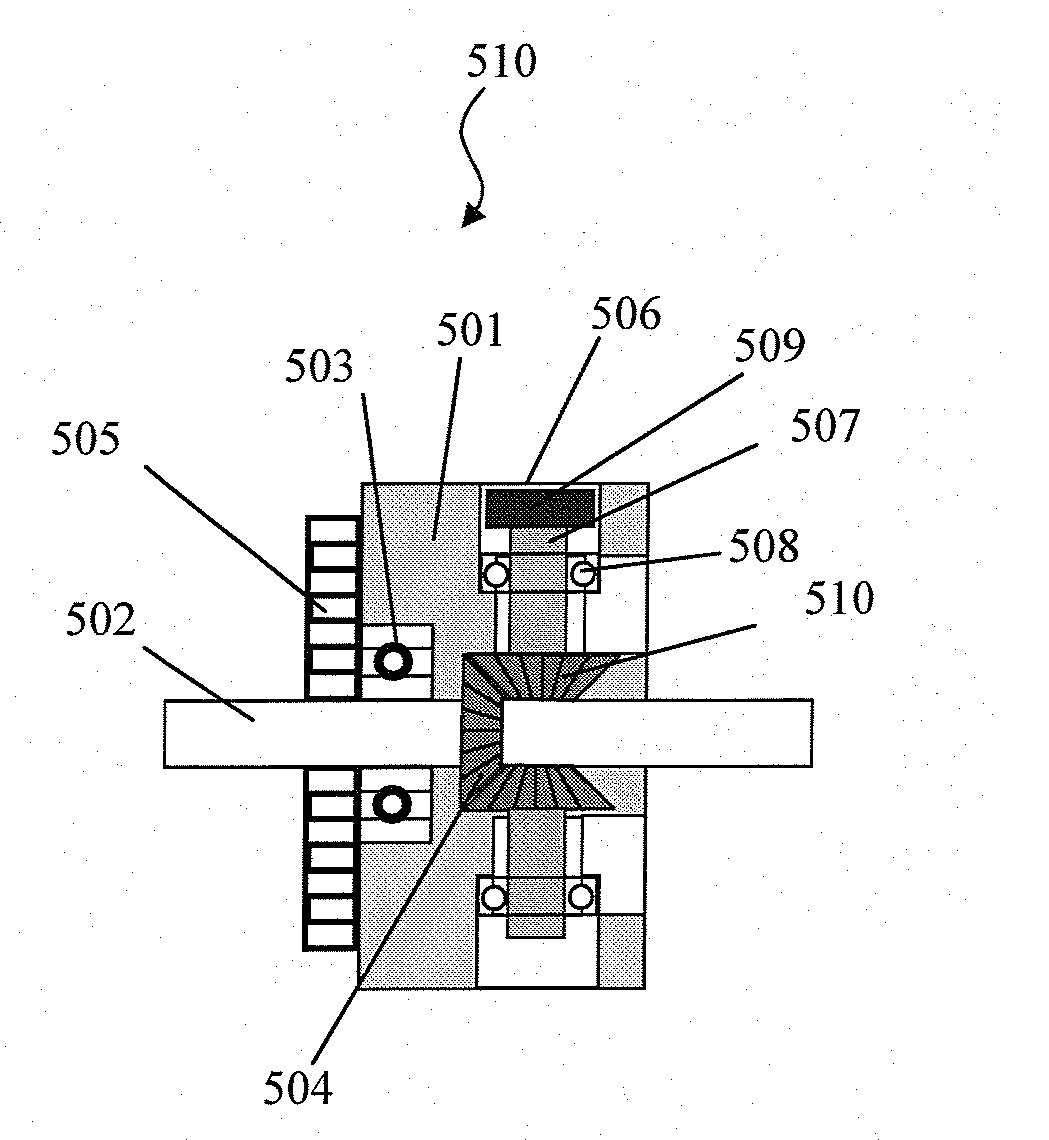

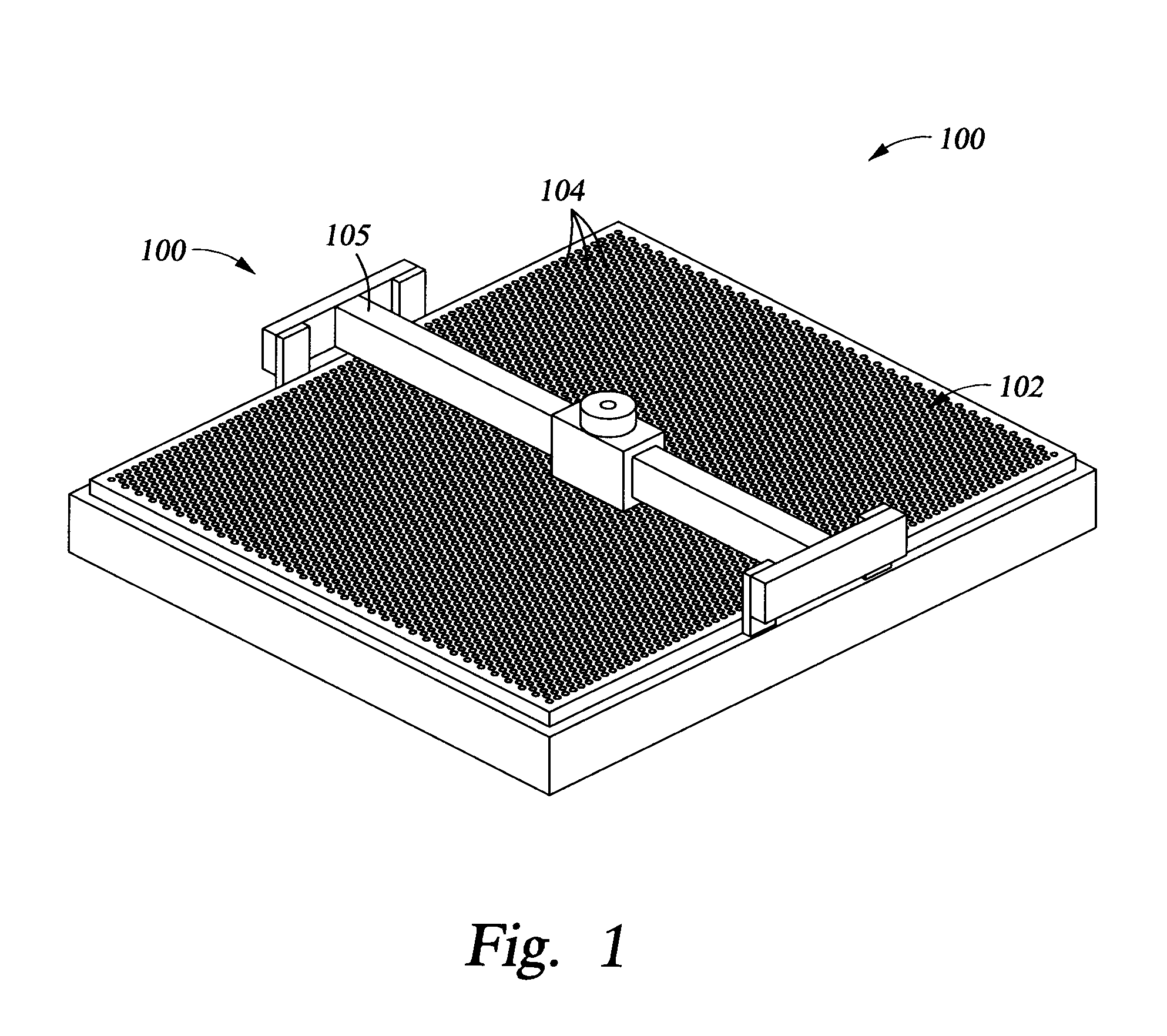

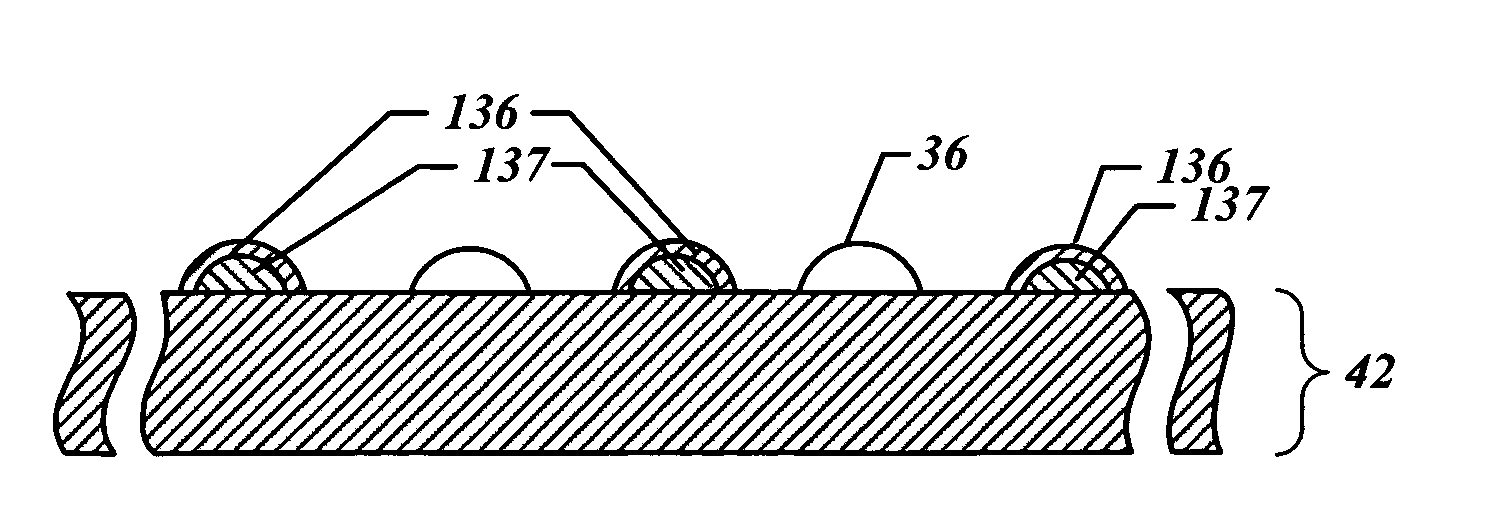

Apparatus For Orienting Magnetic Flakes

A printing apparatus includes a magnetic rotatable roller with a smooth even outer surface for aligning magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnetic portions of the roller, that can be formed by permanent magnets embedded in a non-magnetic roller body, or selectively magnetized portions of a flexible magnetic cover of the roller. In some embodiments, the roller is assembled for a plurality of interchangeable sections, which can include spinning magnets. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

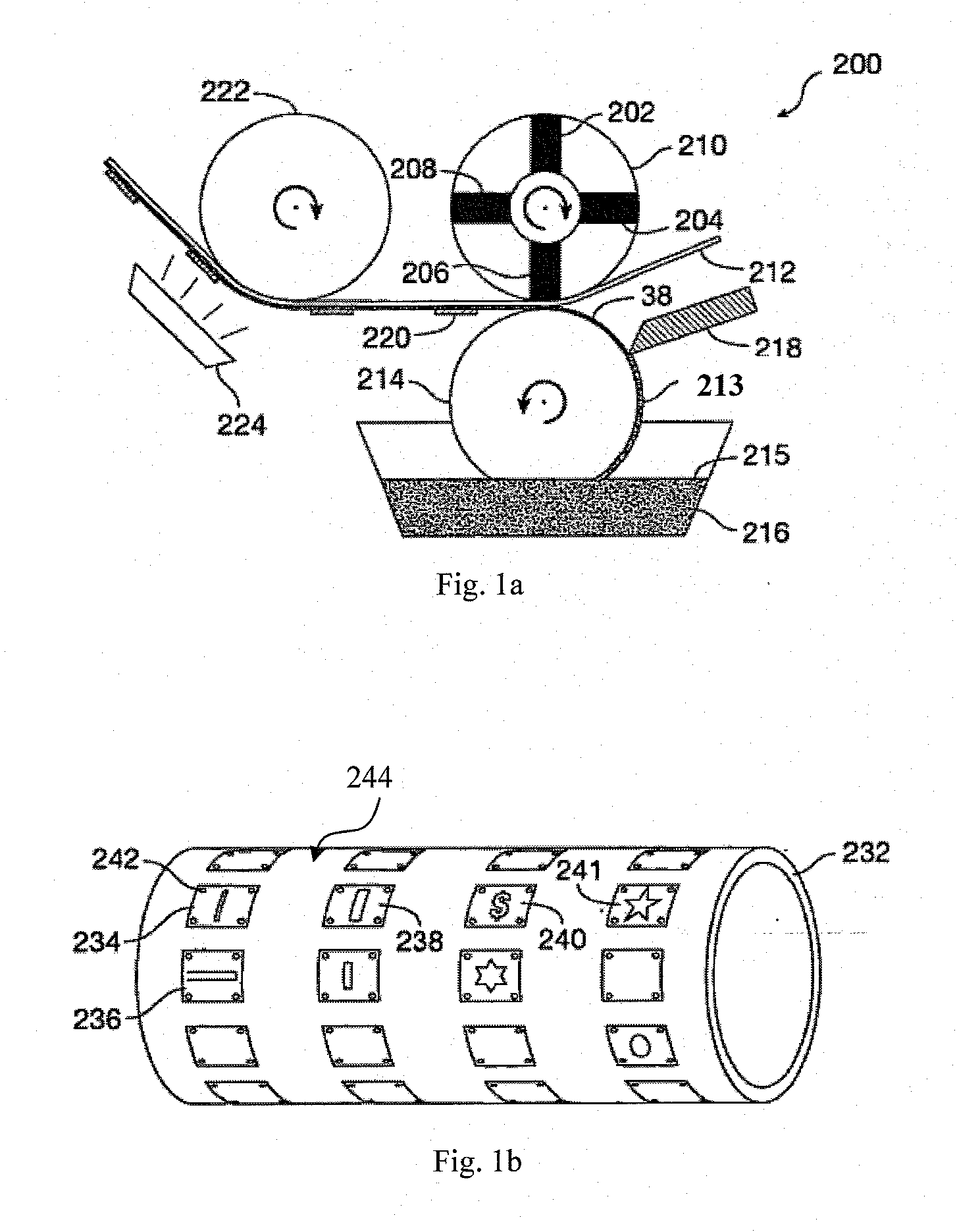

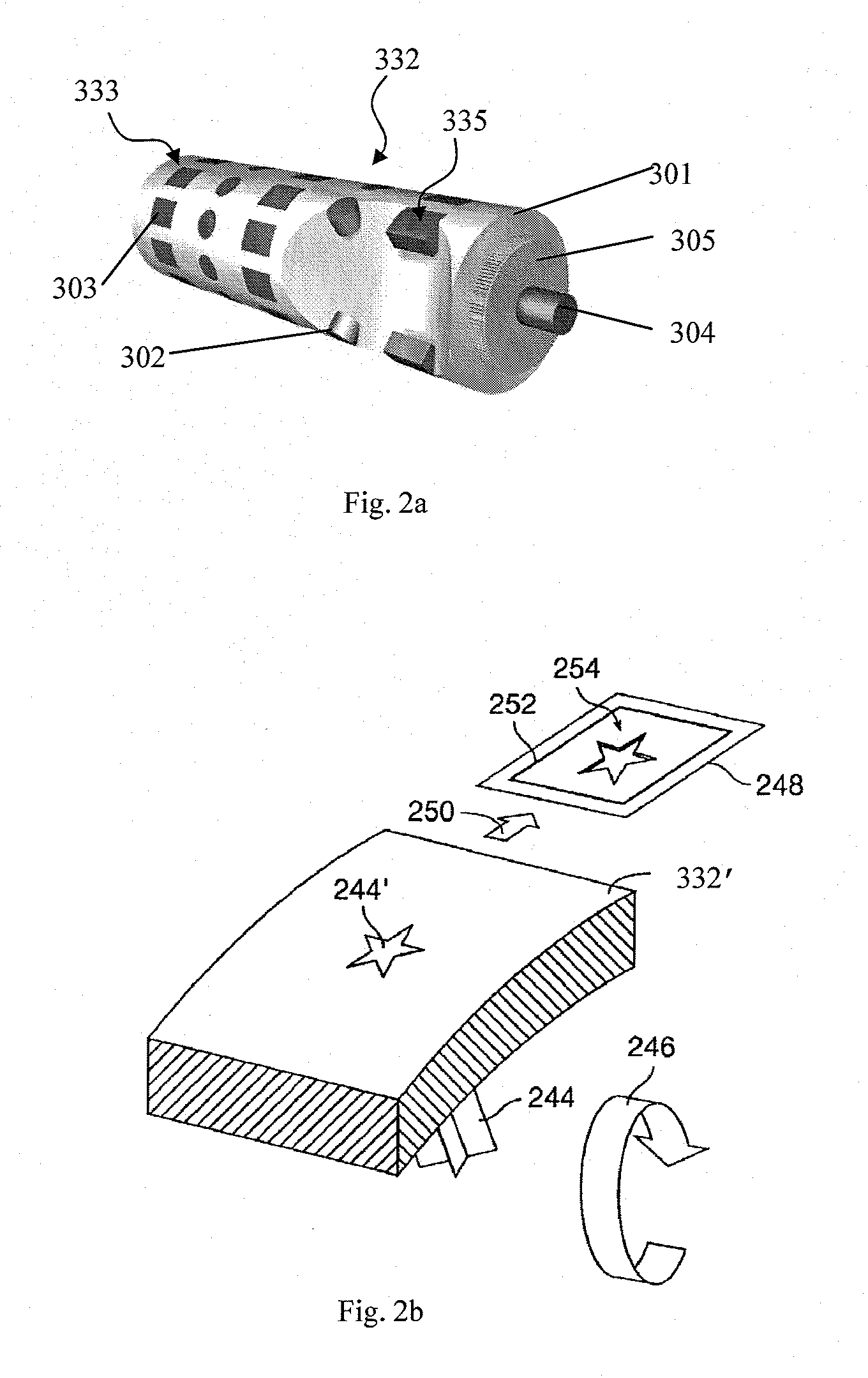

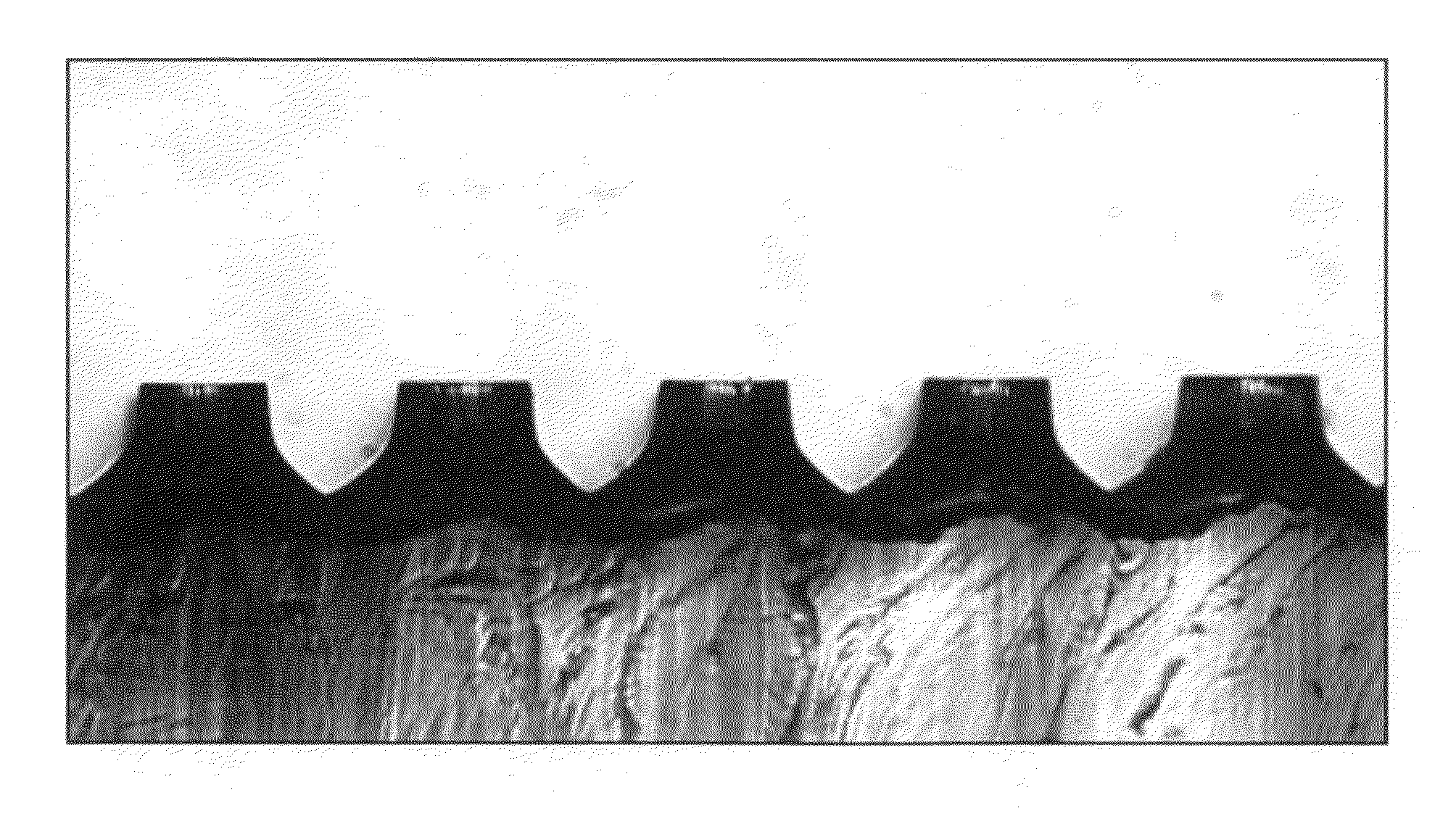

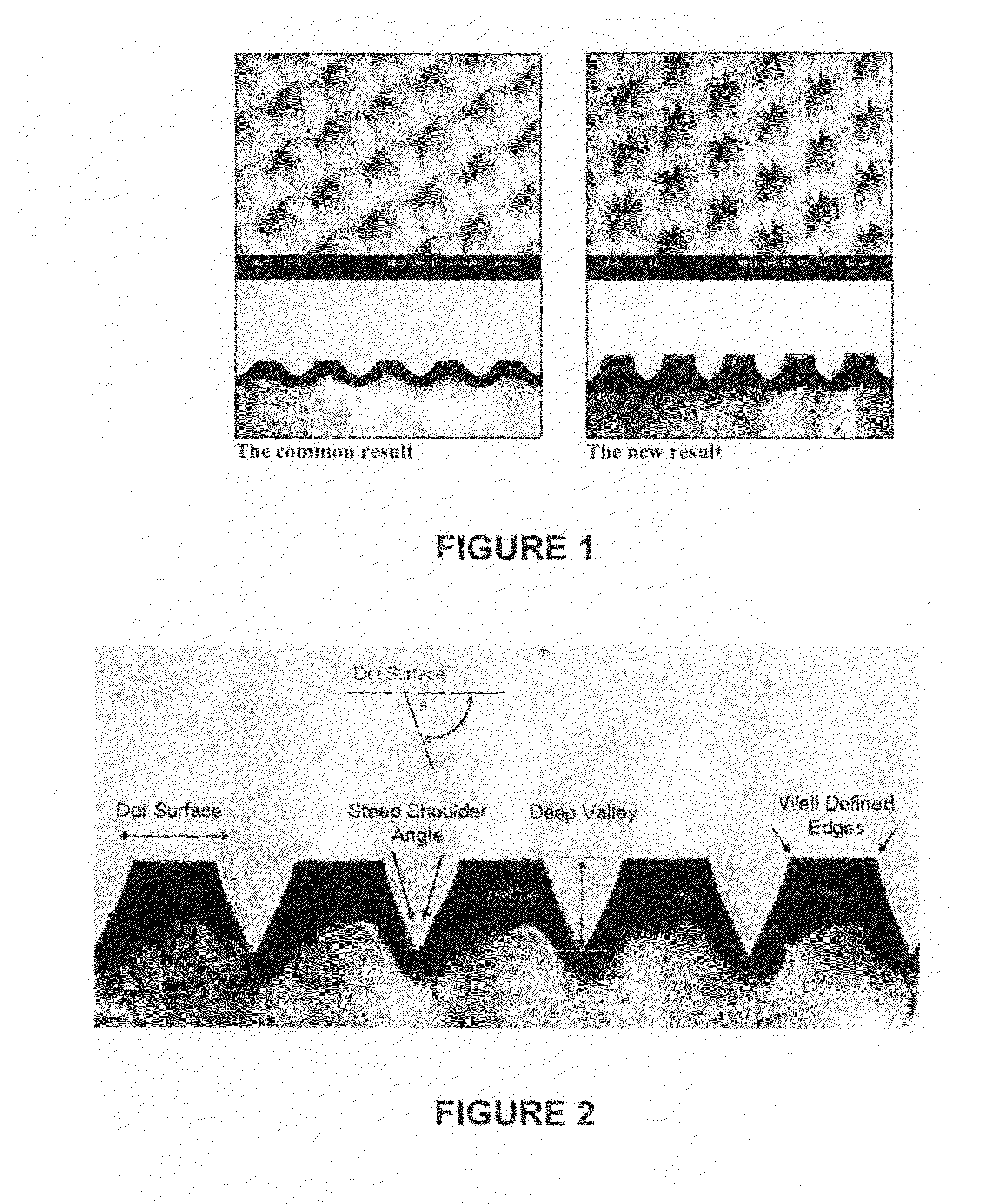

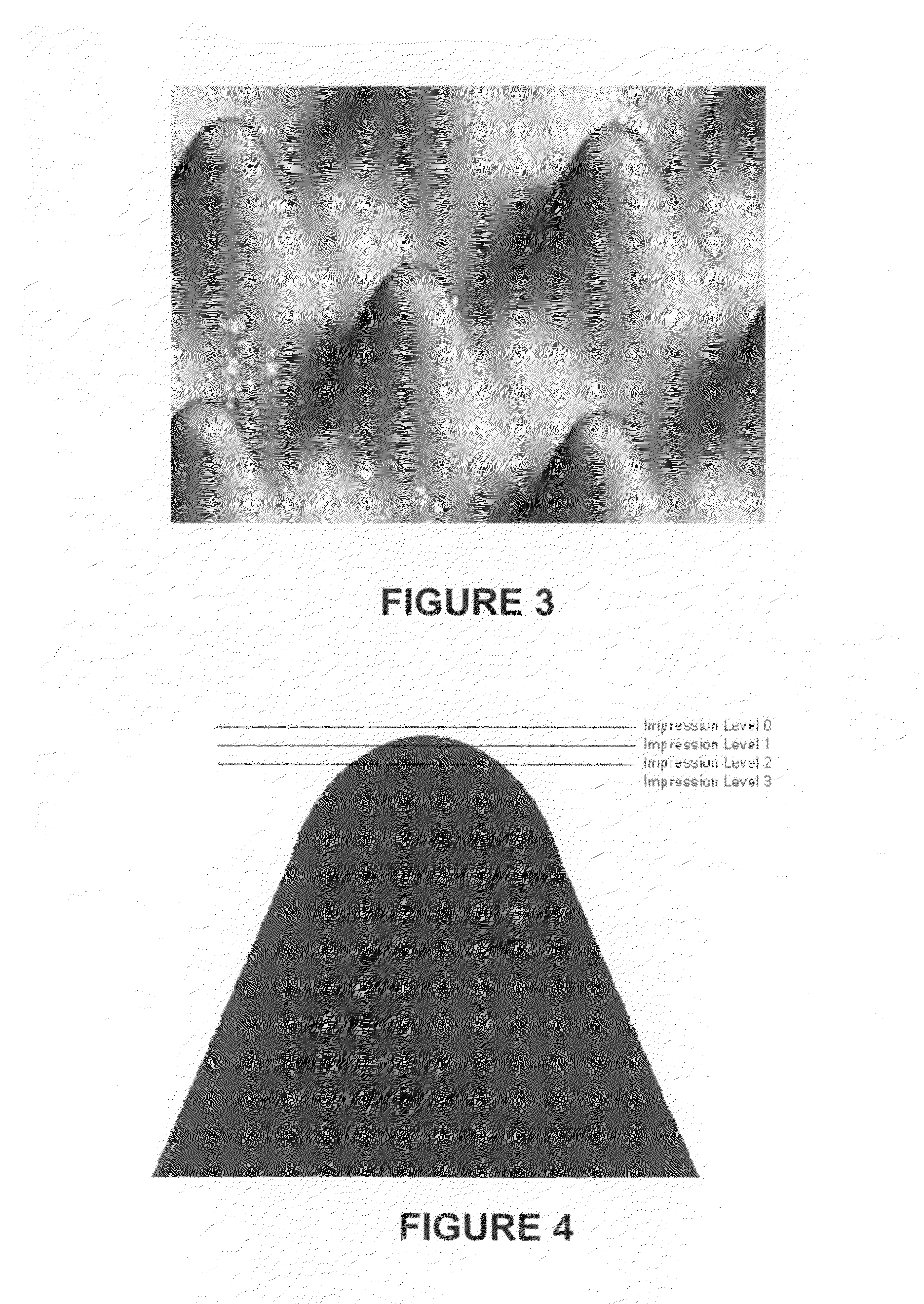

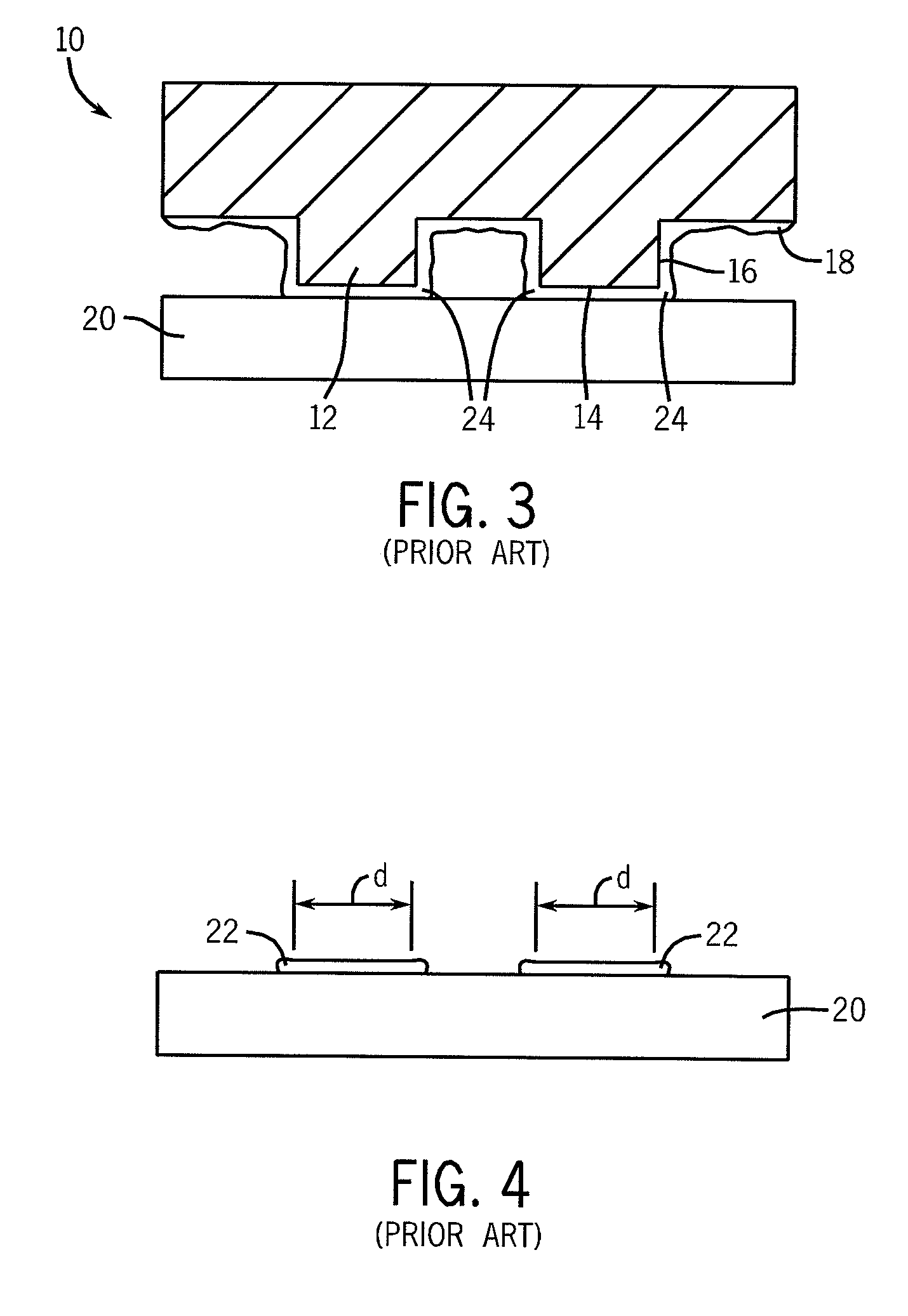

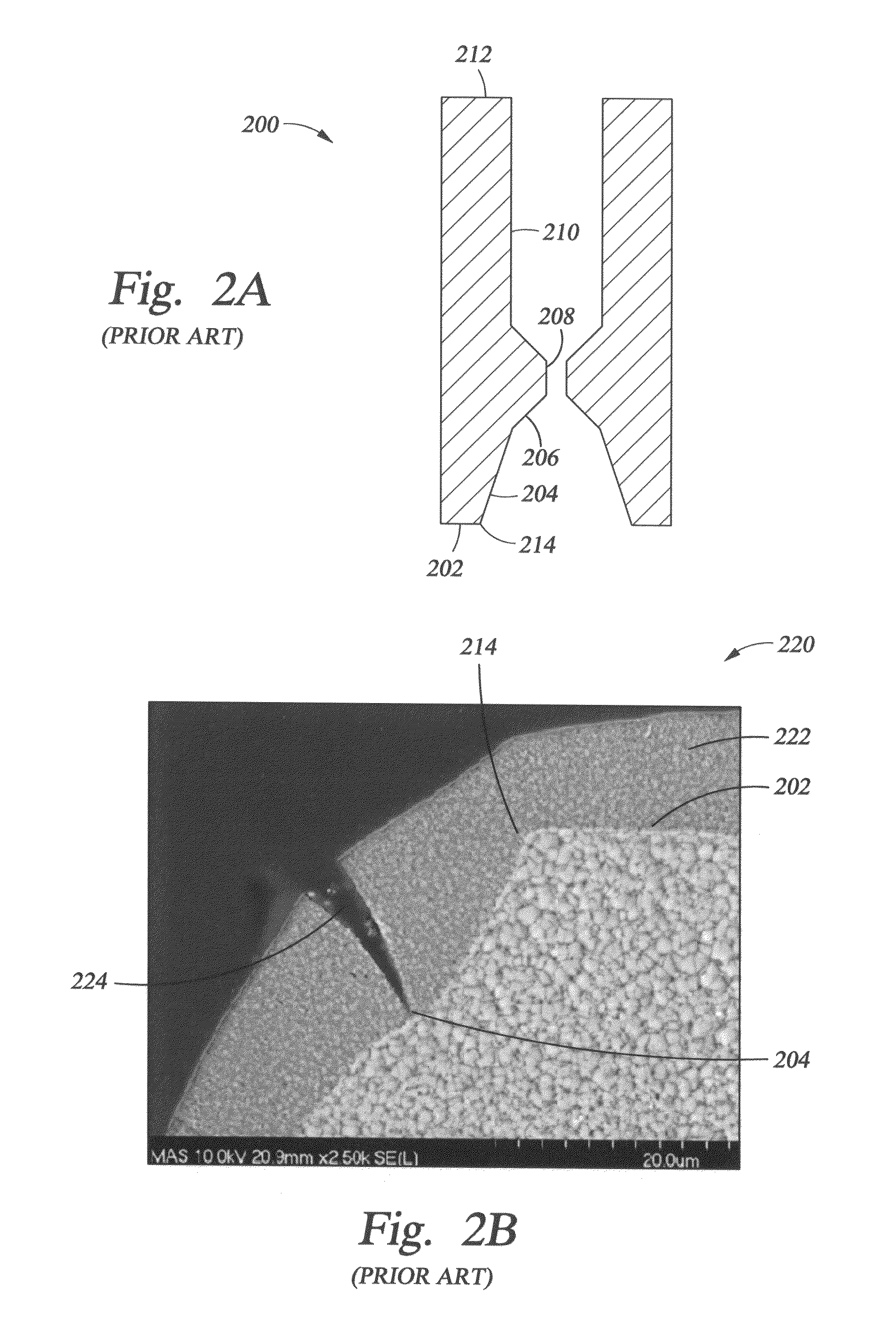

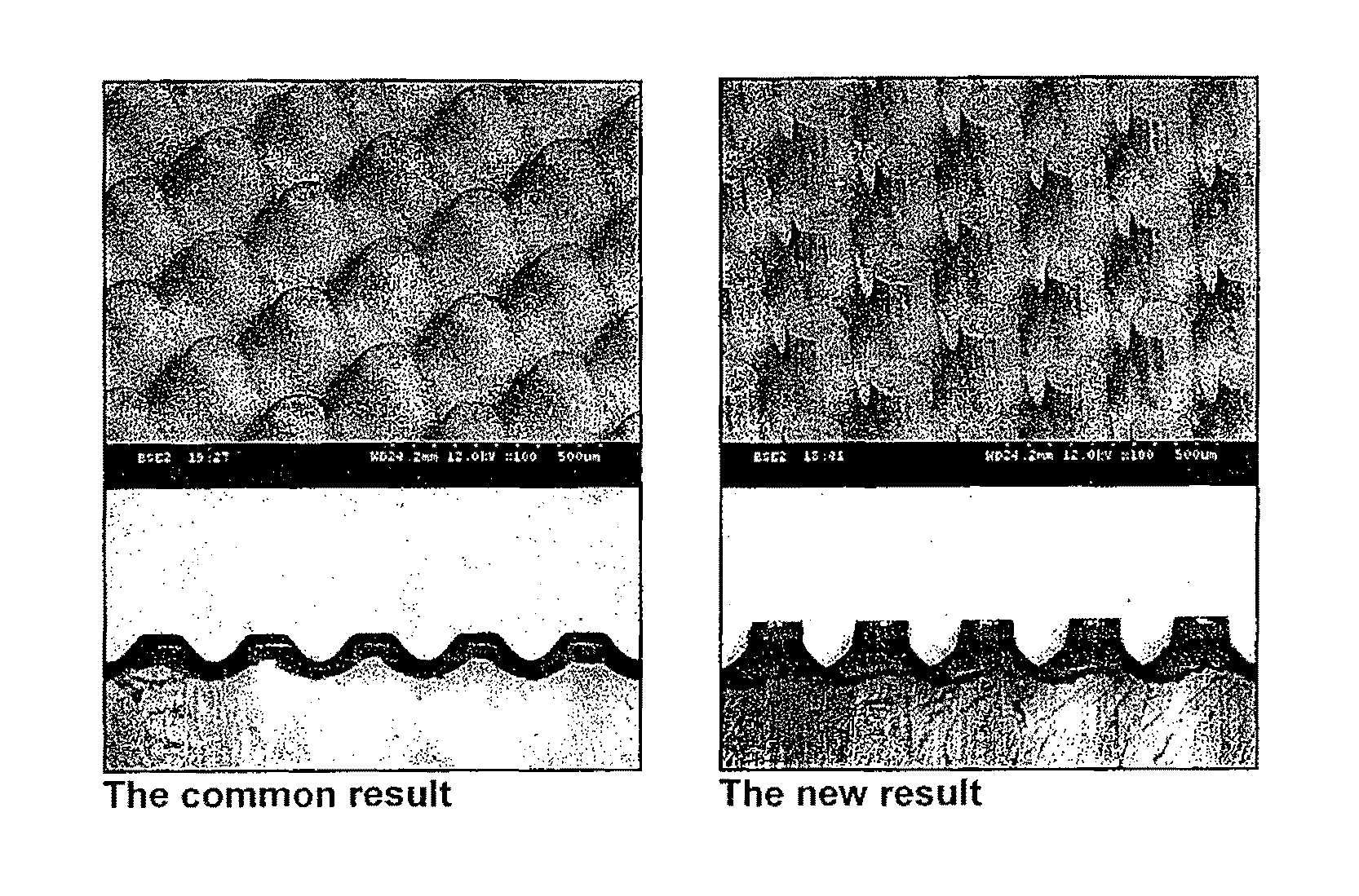

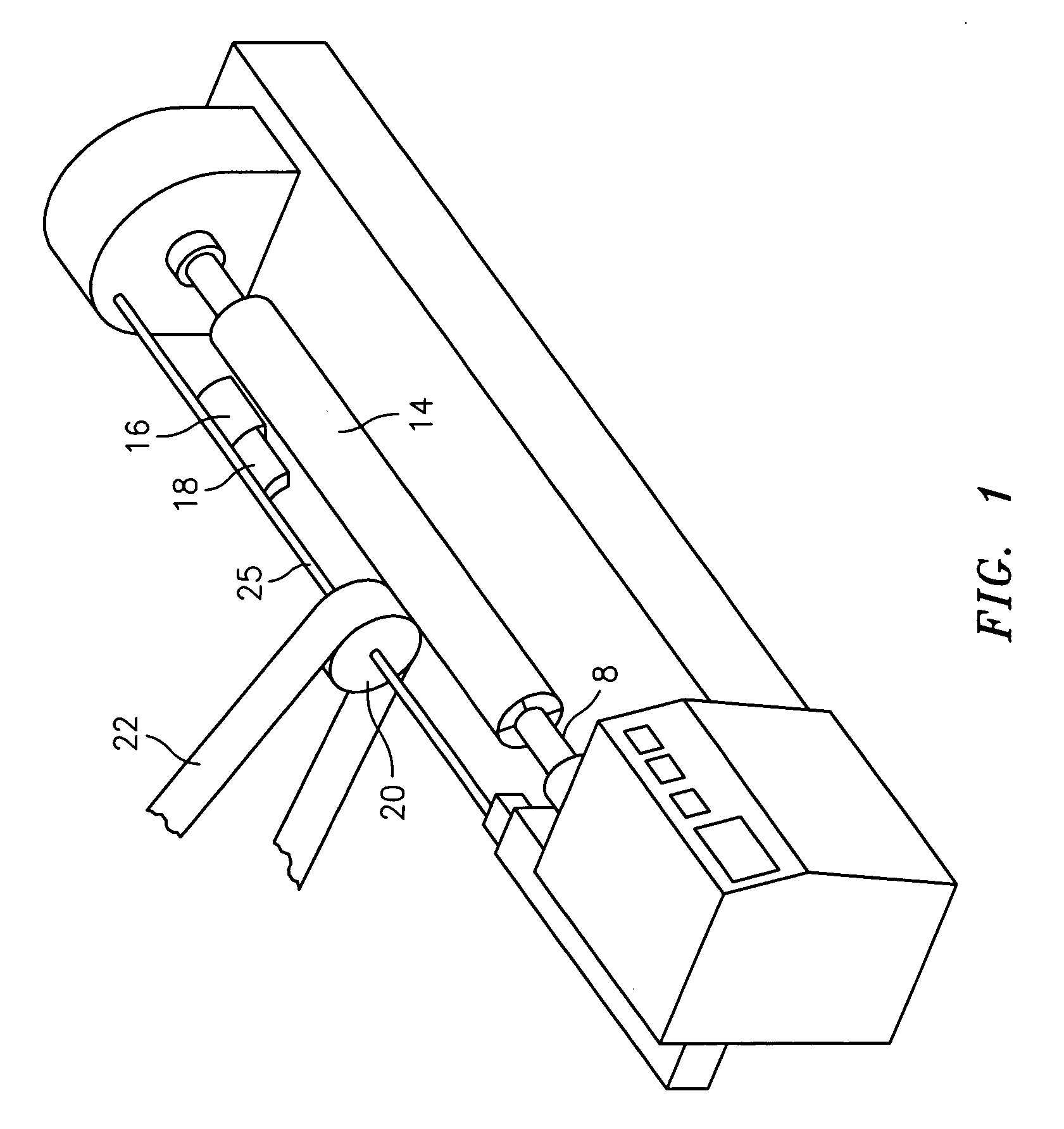

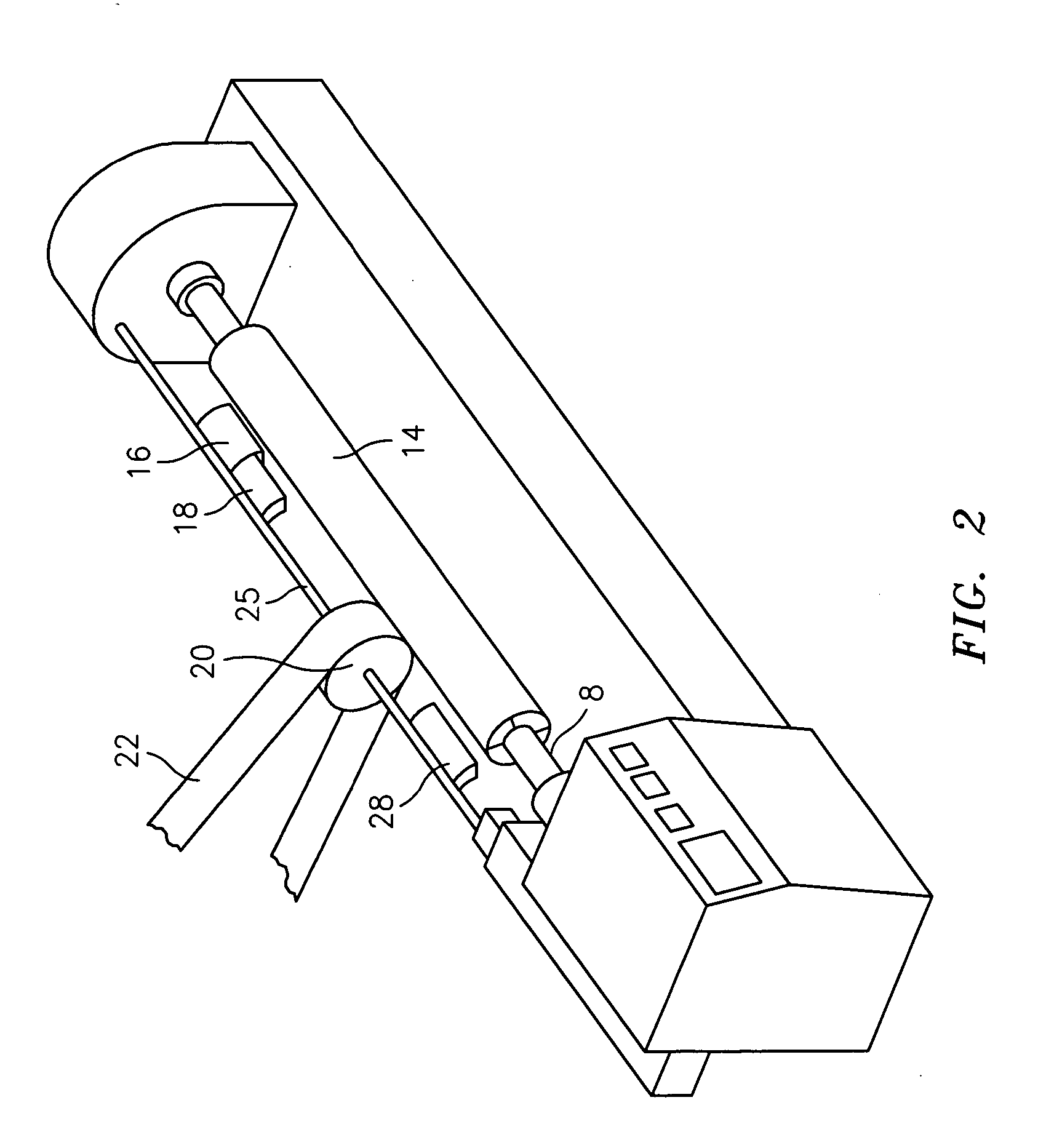

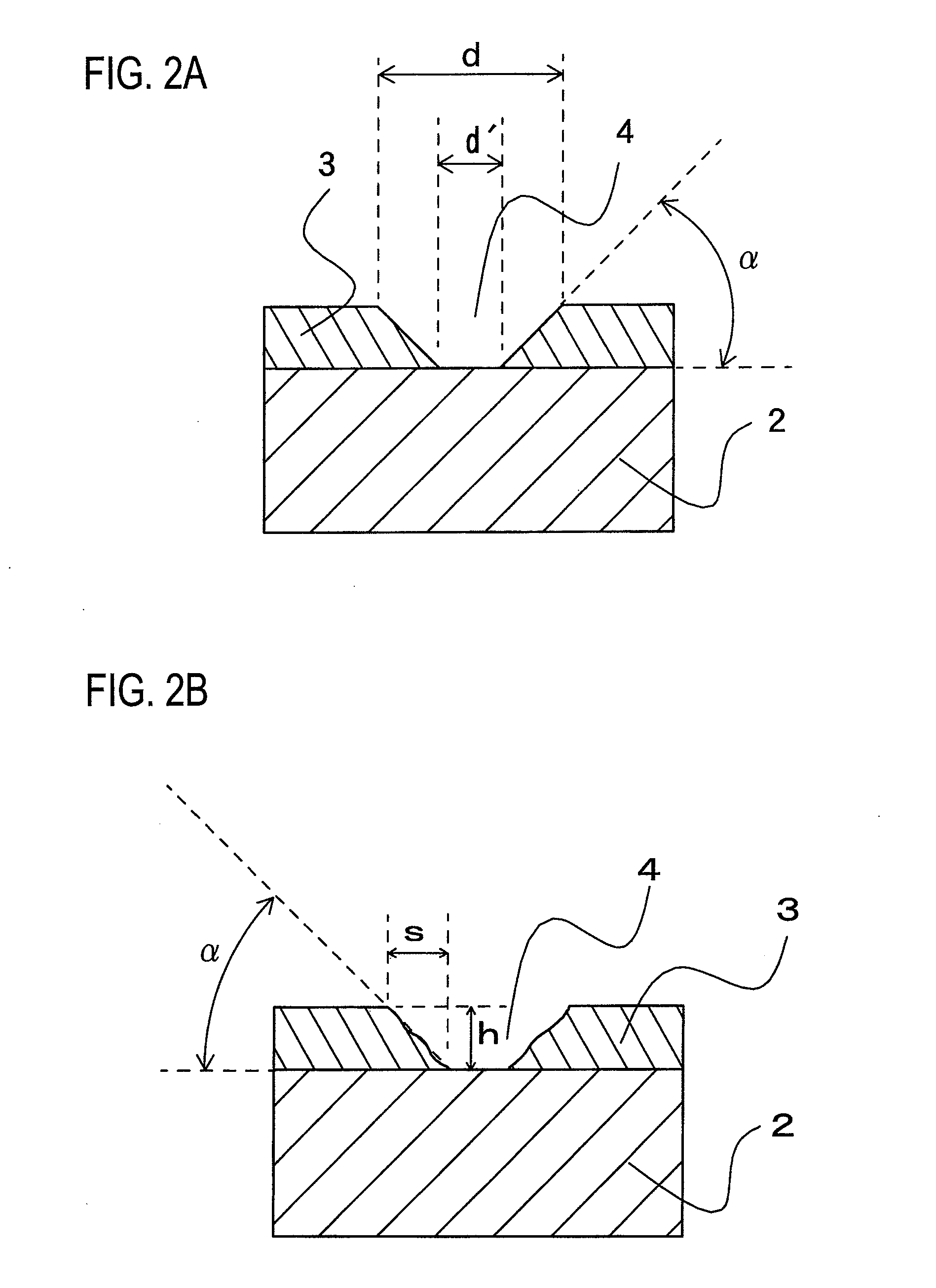

Method of improving print performance in flexographic printing plates

ActiveUS20110079158A1Promote resultsReduces print flutingLayered productsPlate printingCross-linkEngineering

A method of making a relief image printing element from a photosensitive printing blank is provided. A photosensitive printing blank with a laser ablatable layer disposed on at least one photocurable layer is ablated with a laser to create an in situ mask. The printing blank is then exposed to at least one source of actinic radiation through the in situ mask to selectively cross link and cure portions of the photocurable layer. Diffusion of air into the at least one photocurable layer is limited during the exposing step and preferably at least one of the type, power and incident angle of illumination of the at least one source of actinic radiation is altered during the exposure step. The resulting relief image comprises a plurality of dots and a dot shape of the plurality of dots that provide optimal print performance on various substrates, including corrugated board.

Owner:MACDERMID PRINTING SOLUTIONS

Method of making a lithographic printing plate

ActiveUS8232043B2High degree of polymerizationQuality improvementPlaten pressesPhotosensitive materialsInter layerEngineering

A method of making a lithographic printing plate includes the steps of a) providing a lithographic printing plate precursor including (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a coating on the support including a photopolymerizable layer, and, optionally, an intermediate layer between the photopolymerizable layer and the support, b) image-wise exposing the coating in a plate setter, c) optionally, heating the precursor in a preheating unit, and d) developing the precursor off-press in a gumming unit by treating the coating of the precursor with a gum solution, thereby removing the non-exposed areas of the coating from the support, wherein the coating further includes a compound capable of interacting with the support, the compound being present in the photopolymerizable layer and / or in the intermediate layer.

Owner:AGFA OFFSET BV

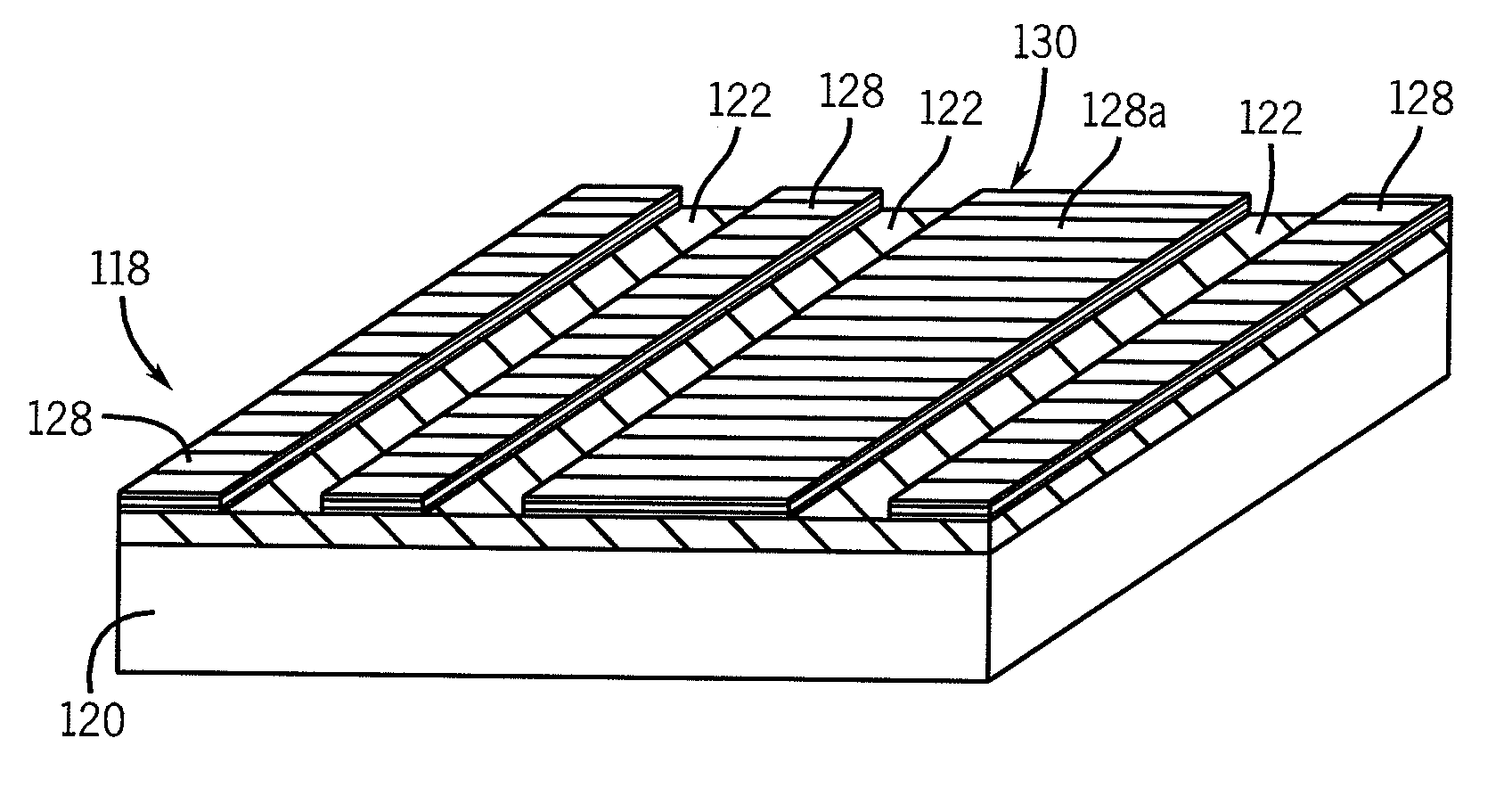

Method to Produce Nanometer-Sized Features with Directed Assembly of Block Copolymers

Owner:MICRON TECH INC

Method for making a lithographic printing plate involving on press development

InactiveUS6030750AImprove printing effectSemiconductor/solid-state device manufacturingPlate printingEngineeringPrinting press

The present invention provides a method for making a lithographic printing plate comprising the steps of: (1) image-wise exposing to light an imaging element comprising (i) on a hydrophilic surface of a lithographic base an image forming layer comprising hydrophobic thermoplastic polymer particles capable of coalescing under the influence of heat and dispersed in a hydrophilic binder and (ii) a compound capable of converting light to heat, said compound being comprised in said image forming layer or a layer adjacent thereto; (2) and developing a thus obtained image-wise exposed imaging element by mounting it on a print cylinder of a printing press and supplying an aqueous dampening liquid and / or ink to said image forming layer while rotating said print cylinder.

Owner:EASTMAN KODAK CO

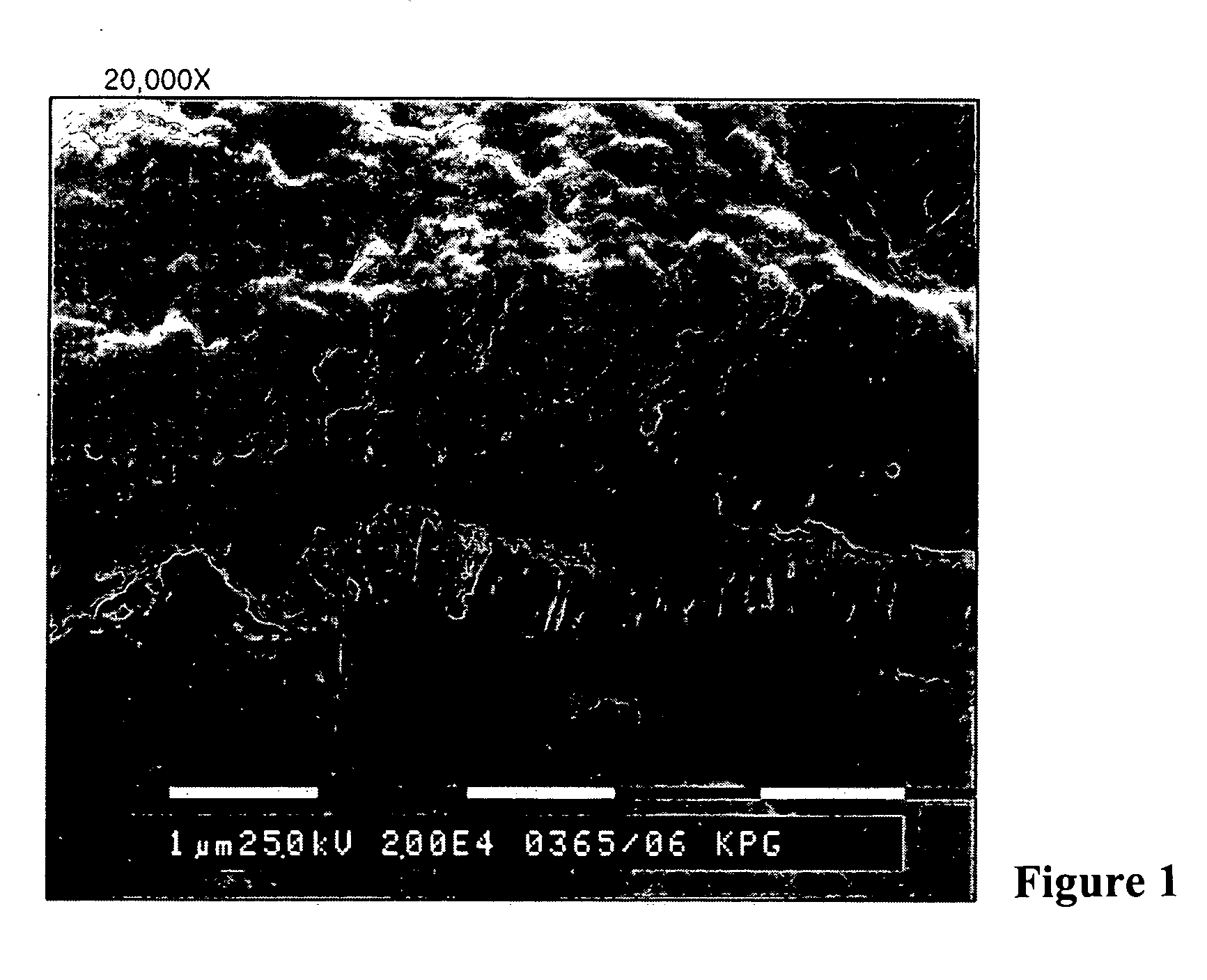

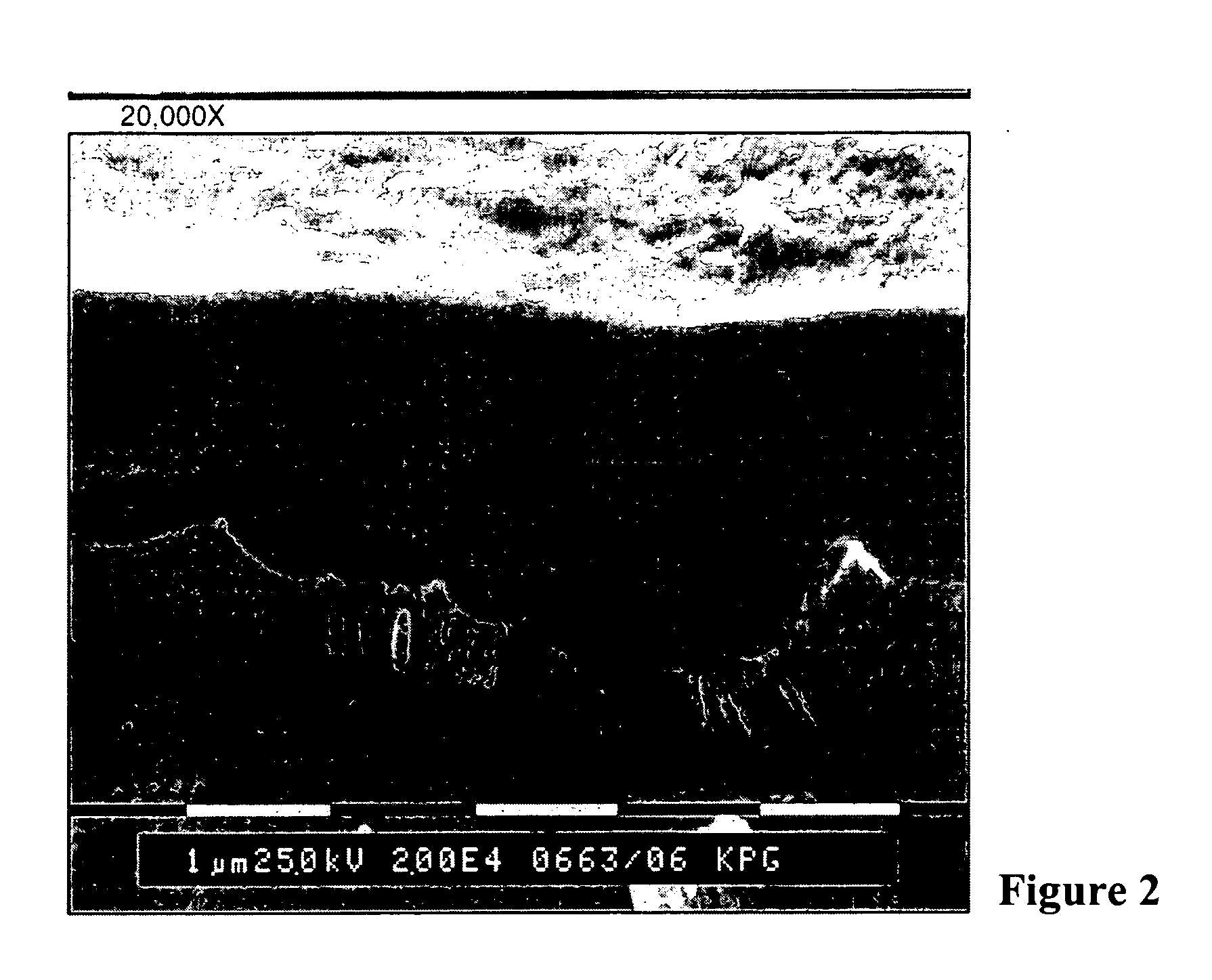

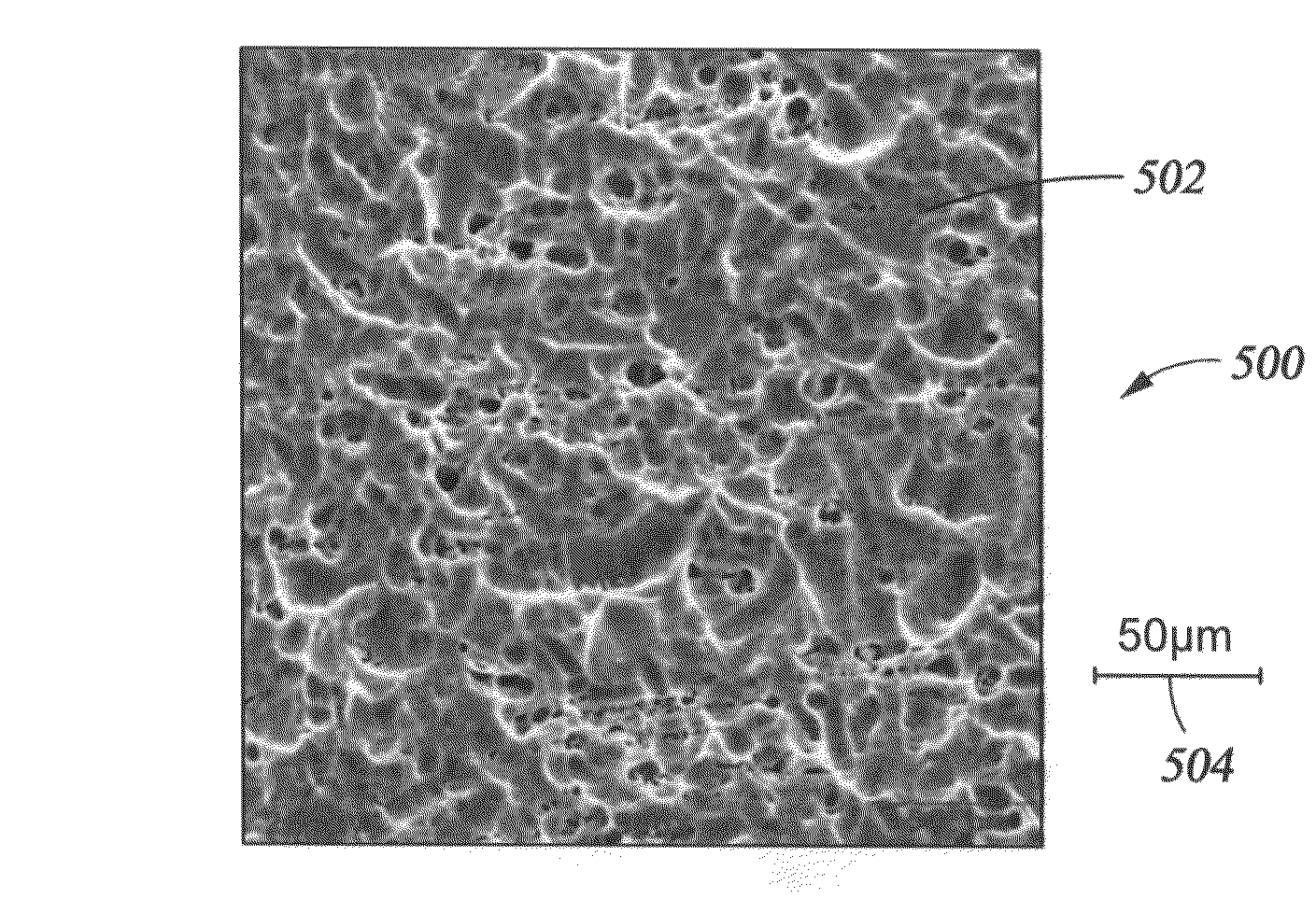

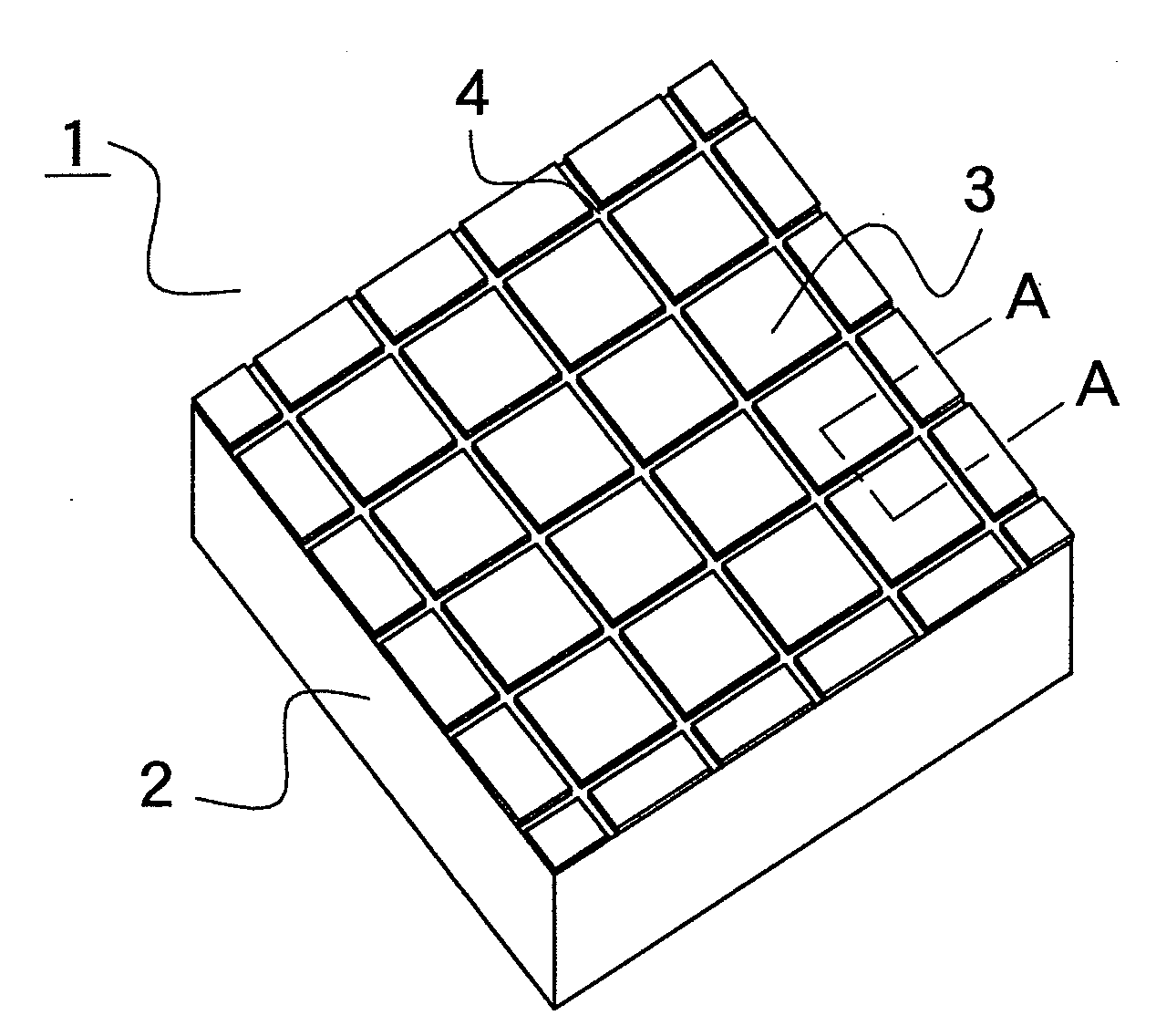

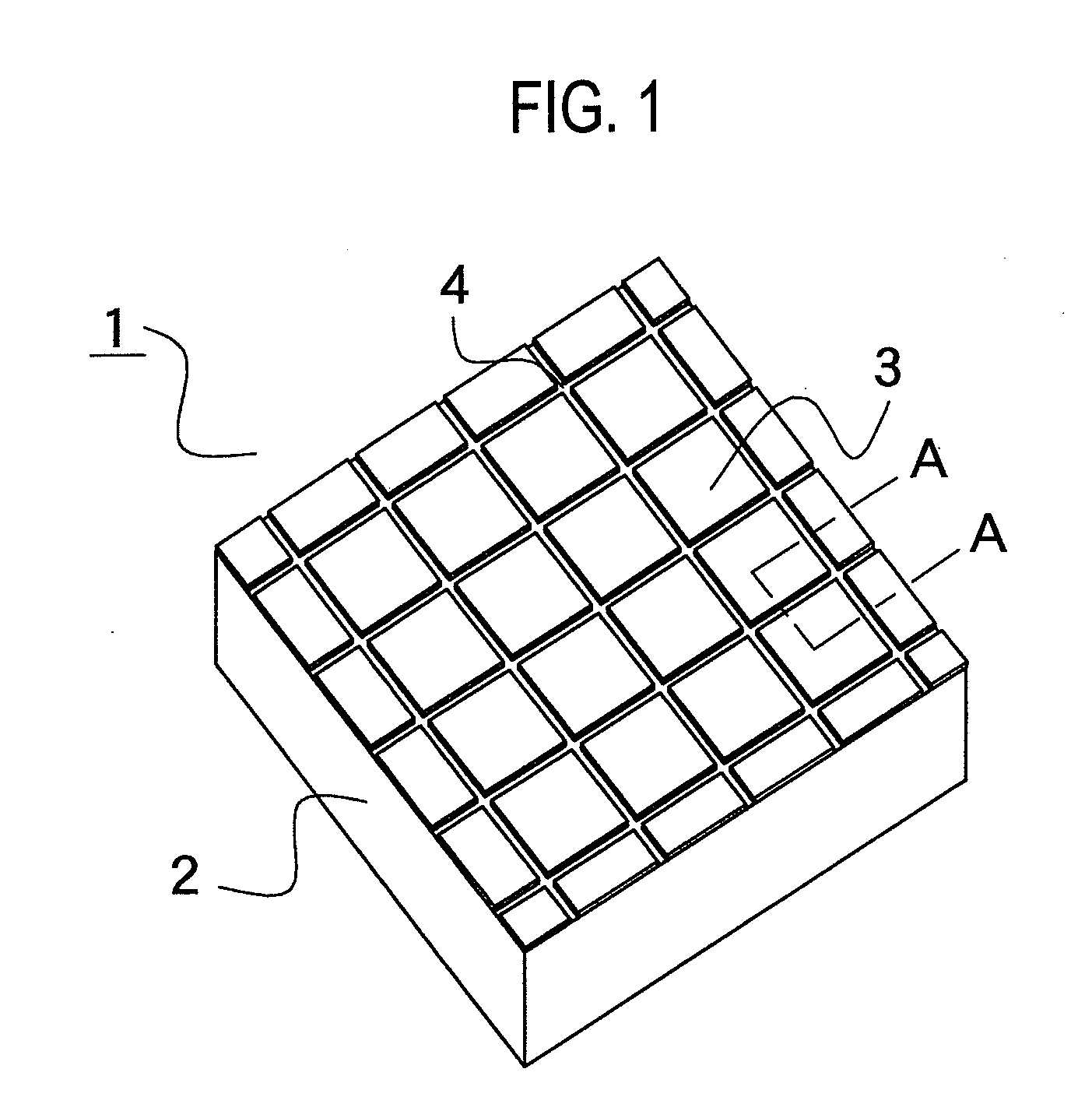

Particle reduction on surfaces of chemical vapor deposition processing apparatus

A method of reducing the amount of particulates generated from the surface of a processing component used during plasma enhanced chemical vapor deposition of thin films. The body of the processing component comprises an aluminum alloy, and an exterior surface of said processing component is texturized to increase the amount of surface area present on the exterior surface. The texturizing process includes at least one step in which the surface to be texturized is bead blasted or chemically grained, so that the surface roughness of the texturized surface ranges from about 50 μ-inch Ra to about 1,000 μ-inch Ra.

Owner:APPLIED MATERIALS INC

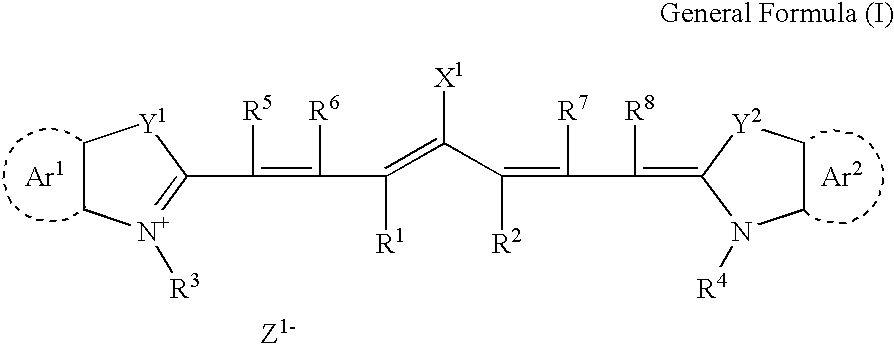

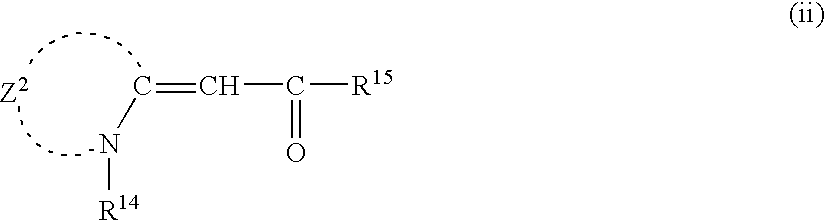

Thermosensitive lithographic printing plate

InactiveUS7108956B2Favorable image formationHigh sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymer scienceWater insoluble

A thermosensitive lithographic printing plate comprising: a hydrophilic support; a lower layer comprising a water-insoluble and alkali-soluble resin; and an upper thermosensitive layer comprising a water-insoluble and alkali-soluble resin and an infrared absorbing dye, whose dissolution in an alkaline aqueous solution increases upon exposure, wherein a surface of the upper thermosensitive layer has protrusions caused by ununiformity of thickness of the upper thermosensitive layer in a proportion of 0.1 or more and not more than 7 per μm2 or the upper thermosensitive layer comprises at least two alkali-soluble resins having a different dissolution speed in an alkaline aqueous solution from each other, and the at least two alkali-soluble resin cause phase separation from each other.

Owner:FUJIFILM HLDG CORP +1

Method of improving print performance in flexographic printing plates

ActiveUS8158331B2Promote resultsReduces print flutingPhotosensitive materialsDuplicating/marking methodsCross-linkEngineering

Owner:MACDERMID PRINTING SOLUTIONS

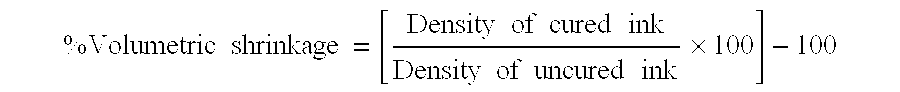

Method for manufacturing a flexographic printing master

InactiveUS20060055761A1Fast and simple and environmentalImprove image qualityPlate printingHand compositionOligomerPolymer science

A method for manufacturing a flexographic printing master comprising the steps of: (a) providing an ink-receiver surface; (b) jetting a curable jettable fluid on the ink-receiver surface characterized in that the curable jettable fluid comprises at least one photo-initiator, at least one monofunctional monomer, at least 5 wt % of a polyfunctional monomer or oligomer and at least 5 wt % of a plasticizer both based on the total weight of the curable jettable liquid capable of realizing a layer after curing having an elongation at break of at least 5%, a storage modulus E′ smaller than 200 MPa at 30 Hz and a volumetric shrinkage smaller than 10%.

Owner:AGFA NV

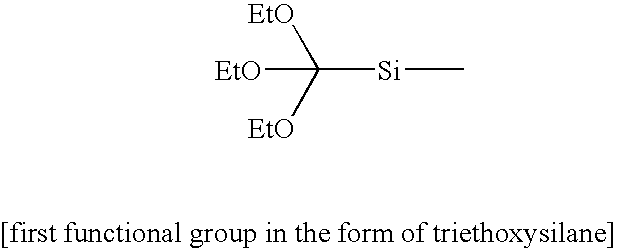

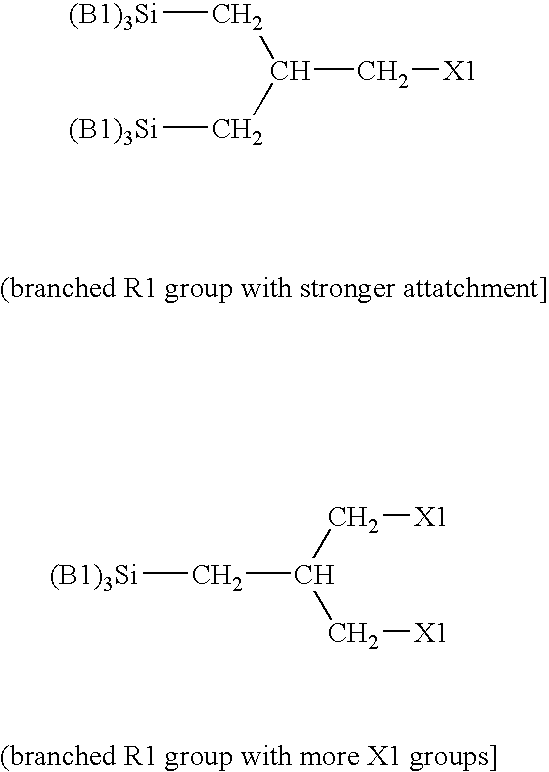

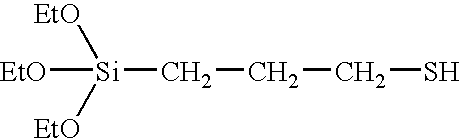

Stamp having an antisticking layer and a method of forming of repairing such a stamp

InactiveUS20050039618A1Good effectStable antisticking layerNanoinformaticsPhotomechanical apparatusCouplingNanoscopic scale

A stamp for use in transferring a pattern in nano-scale has a monomolecular antisticking layer. The anti-sticking layer comprises molecular chains, which are covalently bound to the surface of the stamp and which each comprise at least one fluorine-containing group. Each molecular chain contains a group Q, which comprises a bond which is weaker than the other bonds in the molecular chain as well as the covalent bond that binds the molecular chain to the surface of the stamp. Splitting of said bond in the group Q creates a group Q1, which is attached to the part of the molecular chain being left on the surface of the stamp and which is capable of reacting with a fluorine-containing compound to restore the antisticking layer. In a method of manufacturing a stamp for use in transferring a pattern in nanoscale, the stamp is provided with the above-mentioned molecular chain. In a method of repairing a damaged antisticking layer of the above-mentioned stamp, the stamp is treated with a repairing reagent, which has a coupling end, which is capable of reacting with the group Q1, and a fluorine-containing group located at the other end of the repairing reagent.

Owner:OBDUCAT AB SE

Process for producing thin glass on roll

InactiveUS6092392ALow probability of fractureImprove productivityRibbon machinesDuplicating/marking methodsFiberglass meshFiber

This invention relates to a continuous process for producing a web of thin, chemically hardened glass that can be wound on a roll. The process comprises the steps of (i) drawing glass, containing original alkali ions, to form a web of glass having a thickness equal to or lower than 1.2 mm and having a first and second major surface; (ii) directly after or during said drawing, treating both said surfaces of said web with chemical hardening means during less than two hours, replacing said original alkali ions by alkali ions having a larger radius; and (iii) after treating both said surfaces, winding said web on a core.

Owner:AGFA-GEVAERT NV

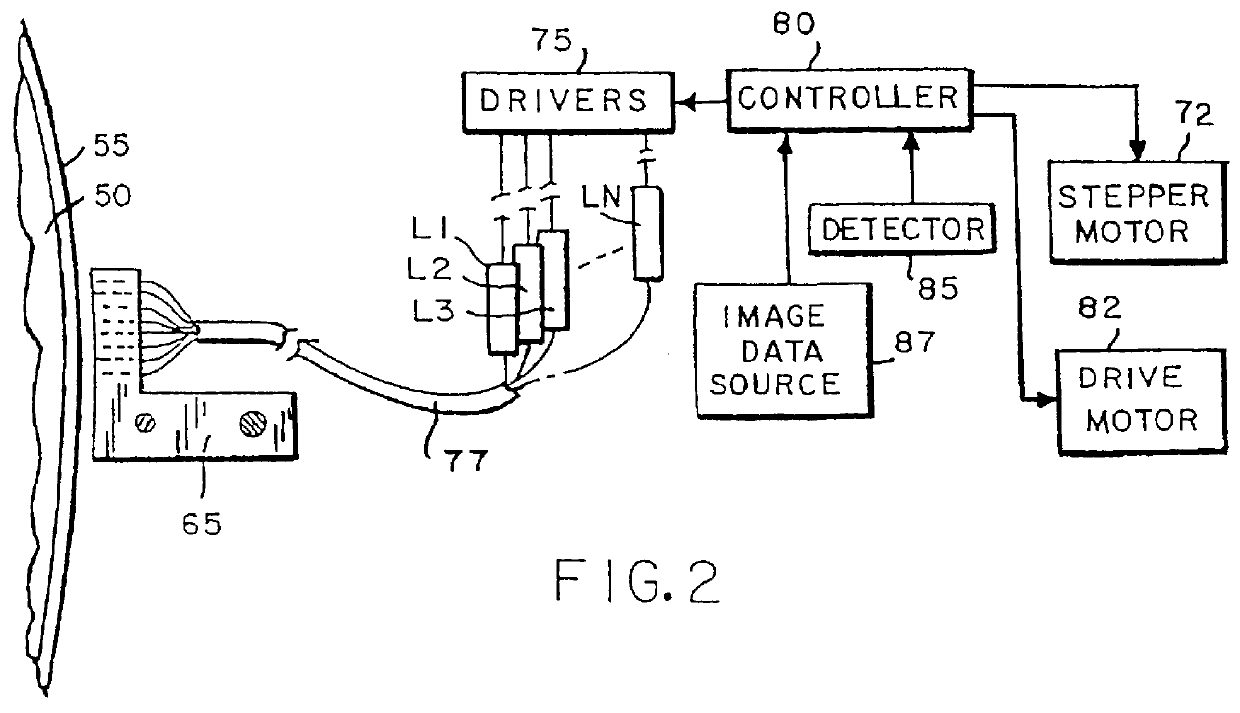

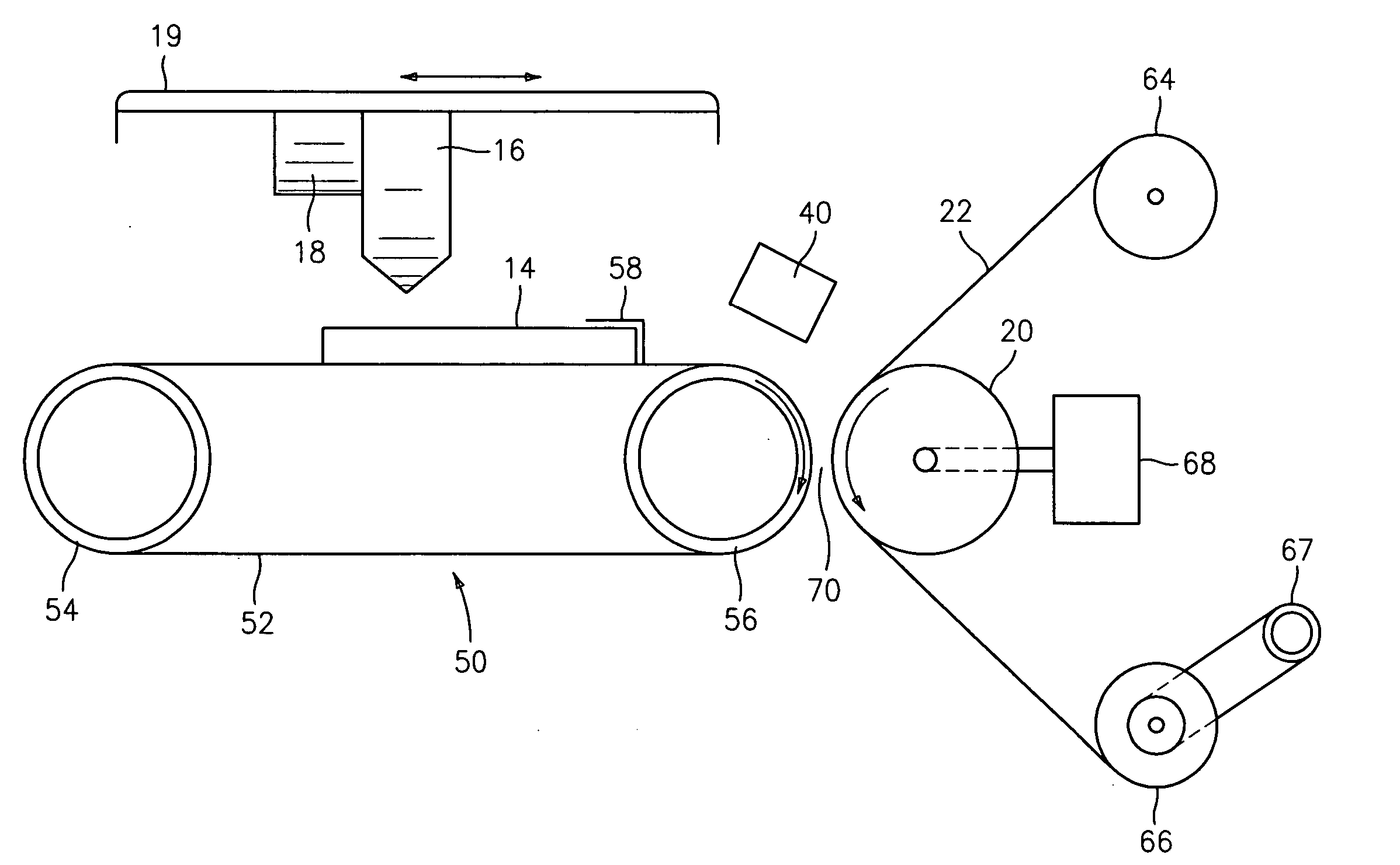

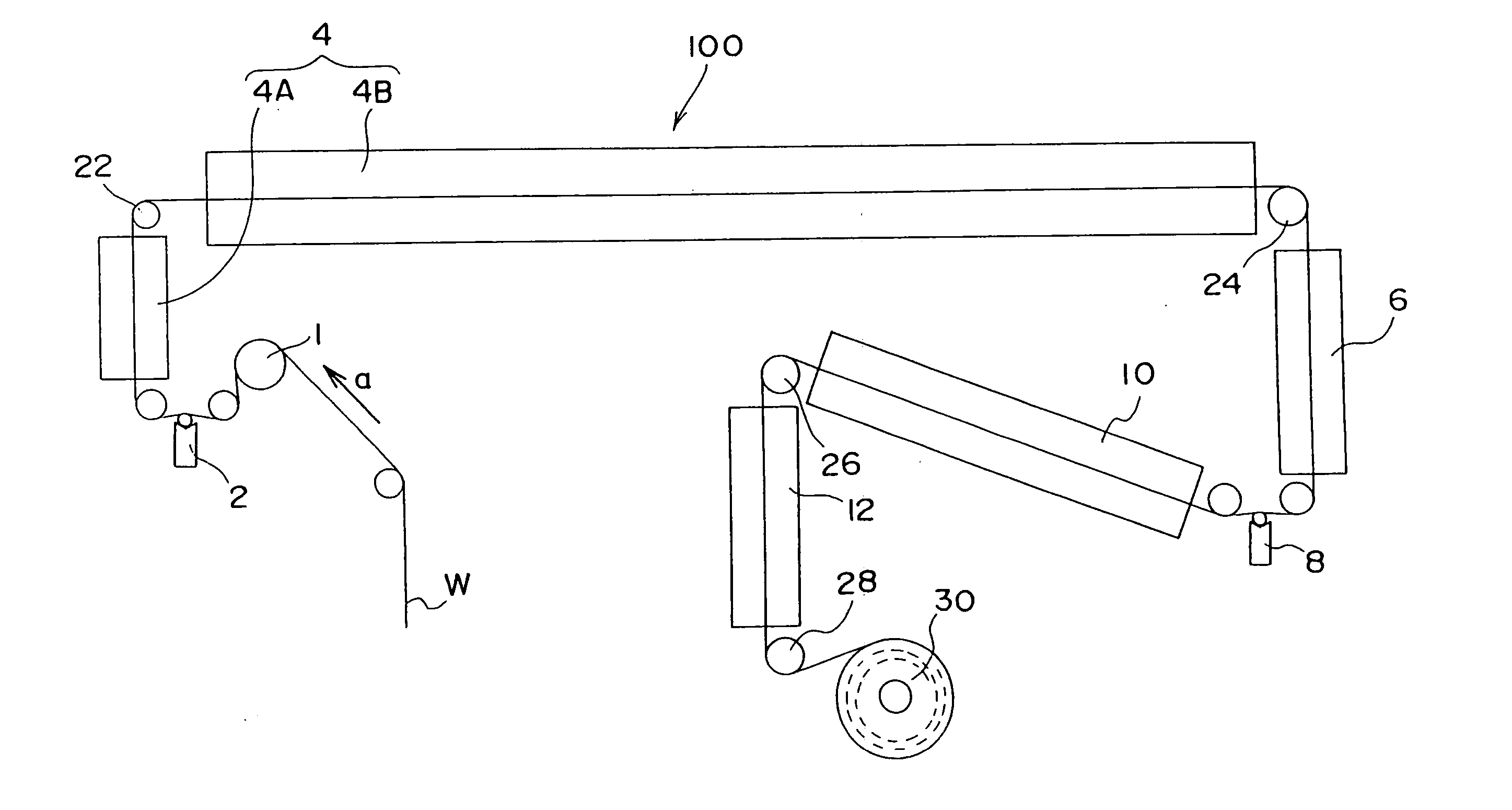

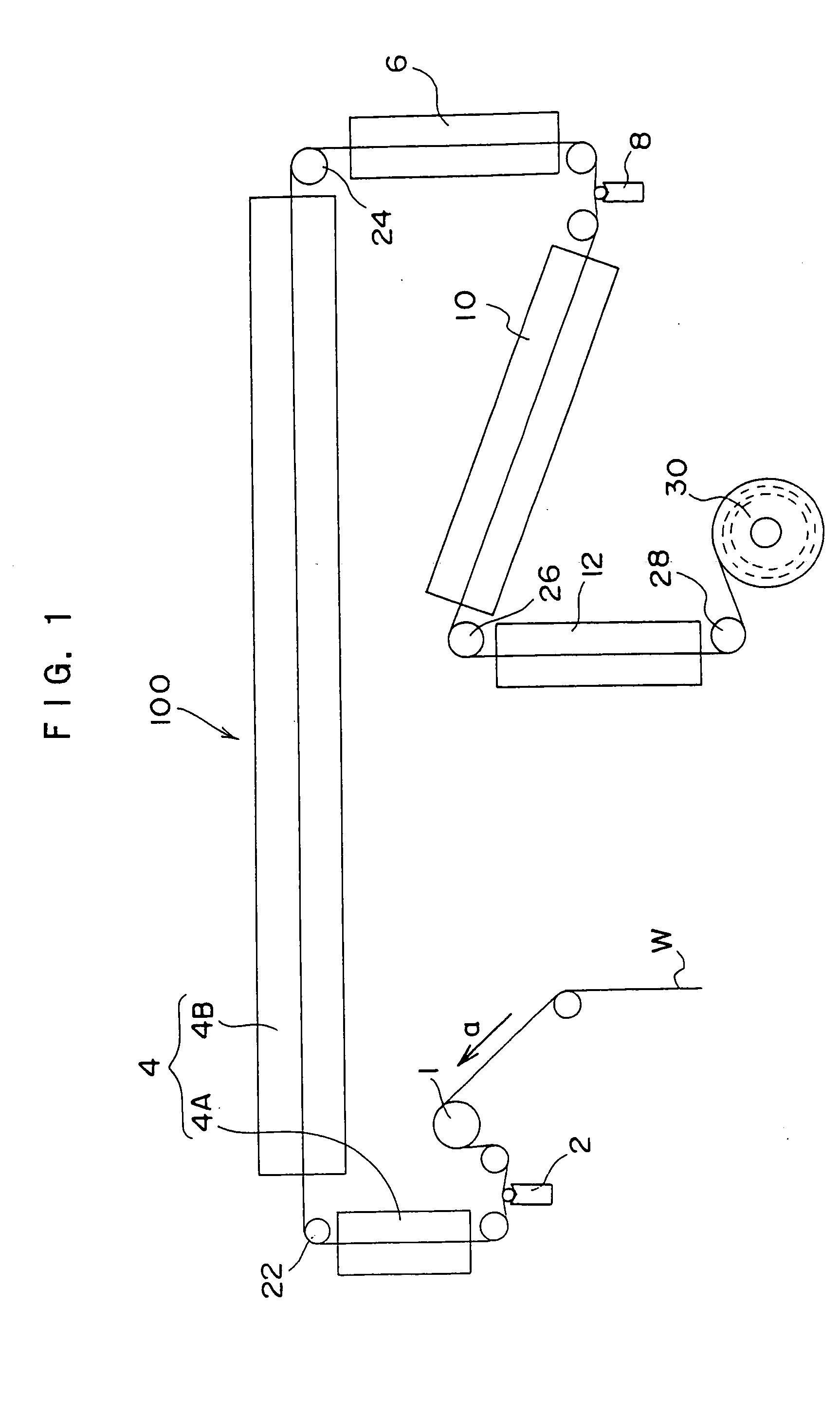

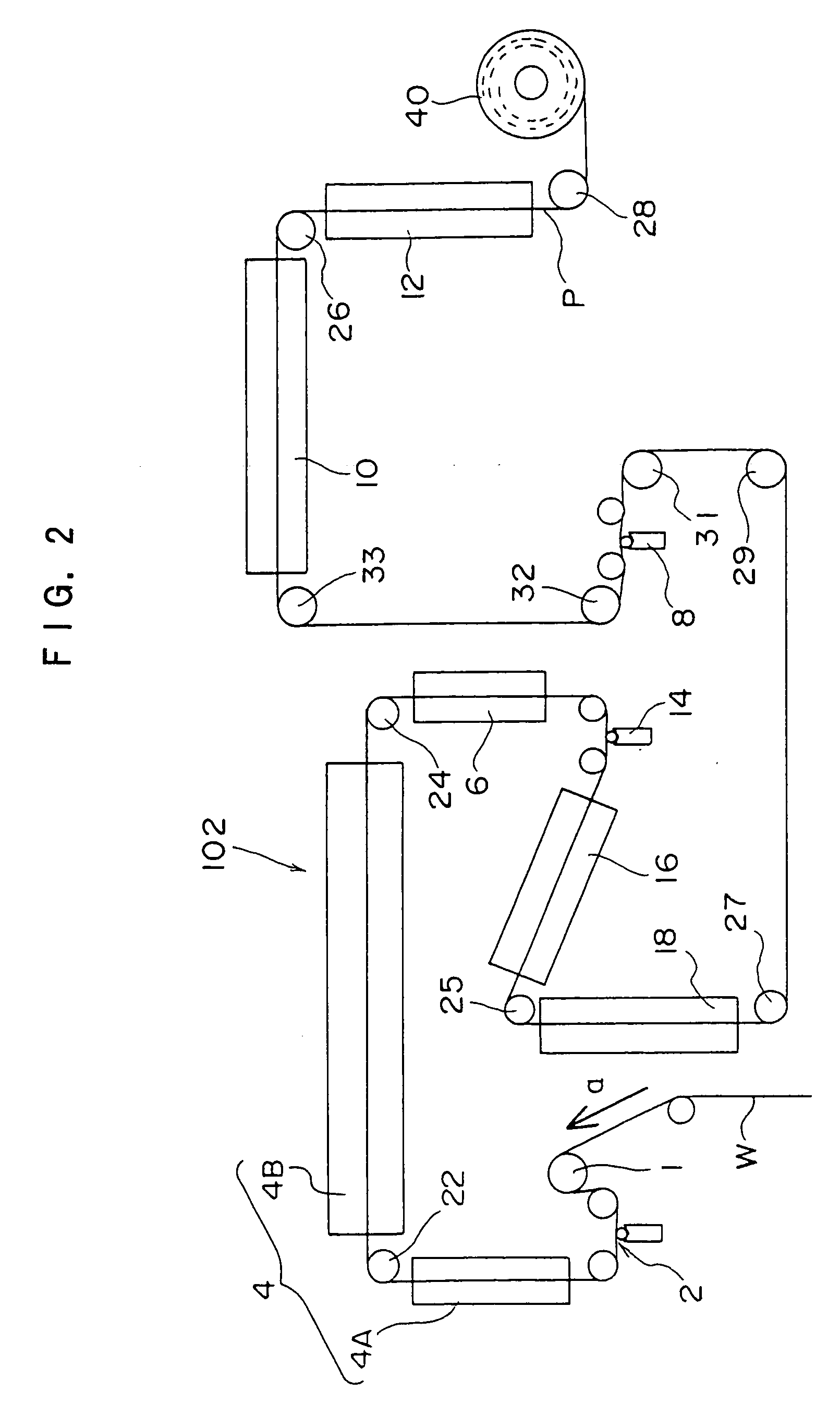

Dynamic UV-exposure and thermal development of relief image printing elements

InactiveUS20070084368A1Simple systemPlate printingPhotosensitive material processingDynamic imagingMask layer

A method and a system for dynamic imaging, UV-exposure and thermal development of relief image printing elements, including printing plates and printing sleeves. The imaging step is accomplished using ink jet printing to create an in situ mask layer on a layer of photocurable material followed by exposing the photocurable layer to actinic radiation through the in situ mask. Thereafter, the printing element is developed in a thermal developing system to create the desired relief image in the surface. If desired, the improved system may also include means for post-exposing / detacking the printing element.

Owner:MACDERMID PRINTING SOLUTIONS

Coating method and planographic printing plate

InactiveUS20050005794A1Low costImprove uniformityPretreated surfacesPhotomechanical coating apparatusPlanographic printingMaterials science

The present invention provides a method of coating a coating solution comprising: providing a web; providing a coating solution; coating the coating solution on at least one surface of the web; and drying the coating solution to form a coated layer, wherein a temperature of the web is maintained at 35° C. or more during coating. According to the coating method, a multi-layered planographic printing plate can be manufactured at low energy cost and running cost.

Owner:FUJIFILM HLDG CORP +1

Planographic printing plate precursor and planographic printing method

ActiveUS7005234B2Excellent plate-wear resistanceAvoid small quantitiesPhotosensitive materialsRadiation applicationsPlanographic printingPhotochemistry

The present invention provides a planographic printing plate precursor comprising a photosensitive layer on a support, the photosensitive layer including an infrared absorbent, a radical polymerization initiator and a radical polymerizing compound, the photosensitive layer being recordable with irradiation with an infrared ray, and being at least one of soluble and dispersible in water.

Owner:FUJIFILM CORP

Laser net shape manufacturing and repair using a medial axis toolpath deposition method

InactiveUS20080182017A1Eliminate and reduce numberAdditive manufacturingTurbinesMedial axisNet shape

A method is disclosed for laser net shape manufacturing a part or repairing an area of a part comprising providing a CAD model of the part to be manufactured or repaired, digitally slicing the CAD model into a plurality of deposition layers, determining a medial axis for each of the deposition layers of the part or repair area; and depositing a bead of a material in a pattern centered upon the medial axis of each of the deposition layers so as to build-up the material by each of the deposition layer until the part is manufactured or repaired.

Owner:GENERAL ELECTRIC CO

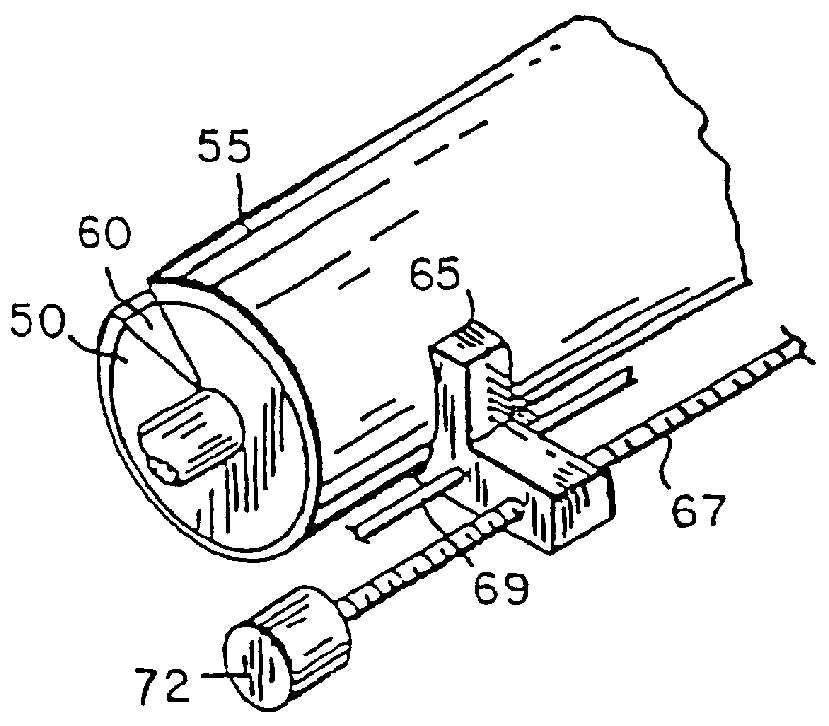

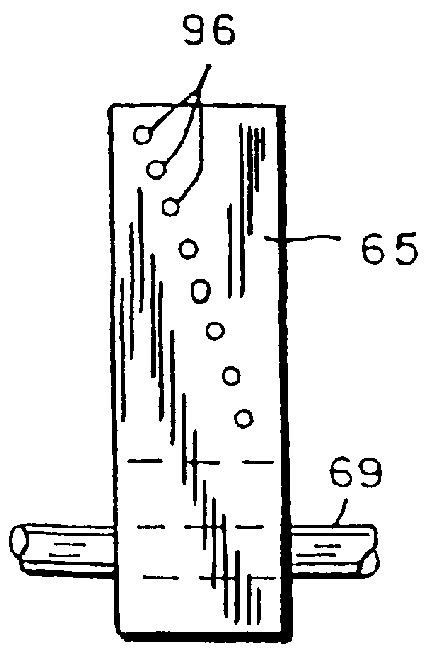

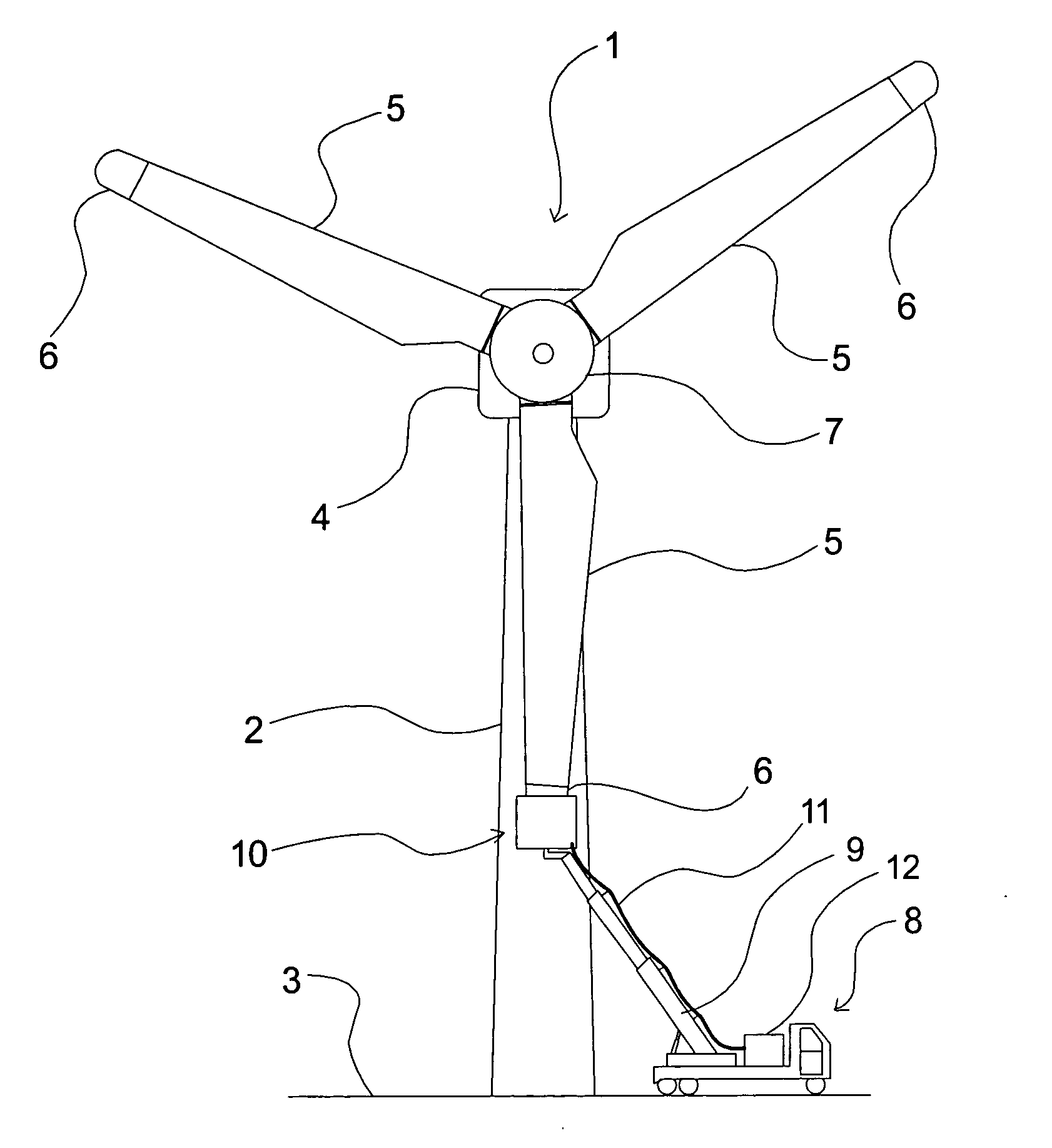

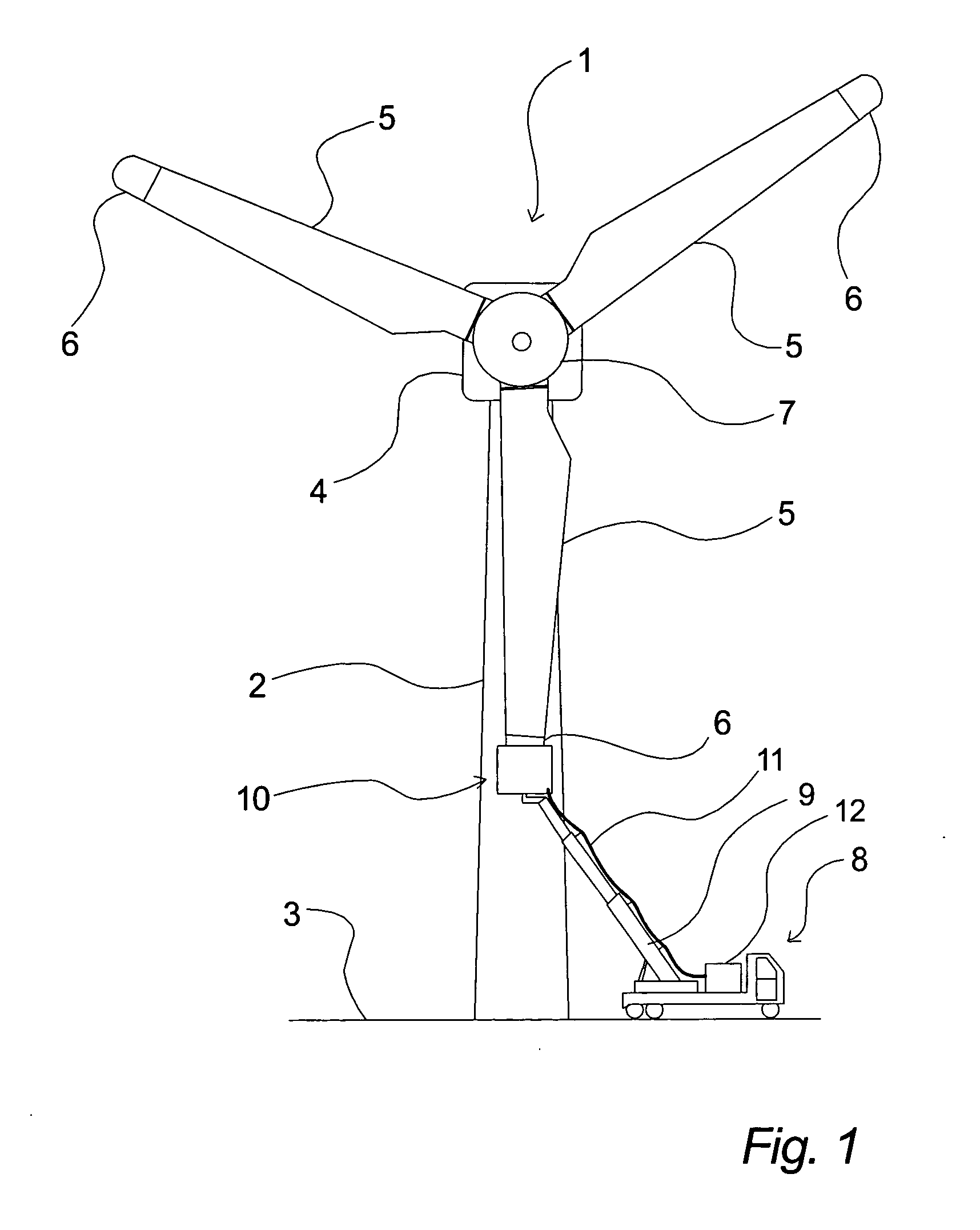

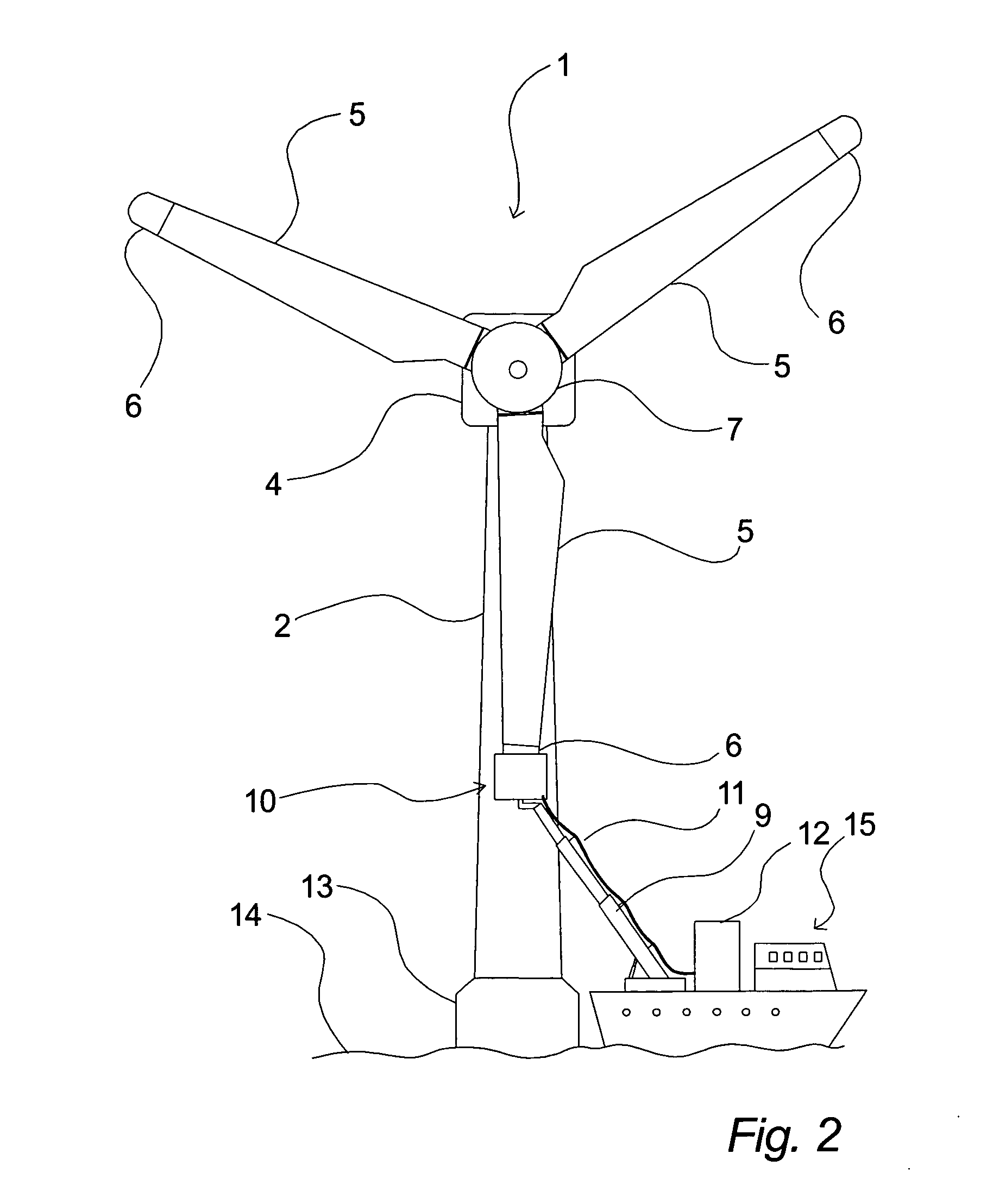

Method and apparatus for treatment of a rotor blade on a windmill

ActiveUS20050042102A1High degree of automationLow costPropellersPretreated surfacesMechanical engineeringWindmill

Method and apparatus for treatment of a surface of a rotor blade of a windmill, the apparatus being placed in such a manner to be moveable in relation to the surface of a rotor blade, and the apparatus being caused to move depending on a form of treatment determined by means for treatment mounted on, in or next to the apparatus. In this manner, various forms of treatment of a rotor blade may be carried out such as for instance washing, finishing, sealing, etc.

Owner:PP ENERGY APS

Planographic printing plate

InactiveUS20010041305A1High purityReduce surface roughnessPhotosensitive materialsRadiation applicationsAnodizingSolubility

A planographic printing plate precursor comprising: an aluminum substrate which has been subjected to a roughening treatment and an anodizing treatment; and a photosensitive layer which provided on a surface of said substrate, and which contains an infrared absorbing agent and a water-insoluble and alkali aqueous solution-soluble polymer compound, and whose solubility in an alkali developing solution varies by infrared laser exposure, wherein said substrate is obtained by electrochemically roughening an aluminum alloy plate which contains a trace amount of certain elements to an aluminum alloy of high purity.

Owner:FUJIFILM CORP

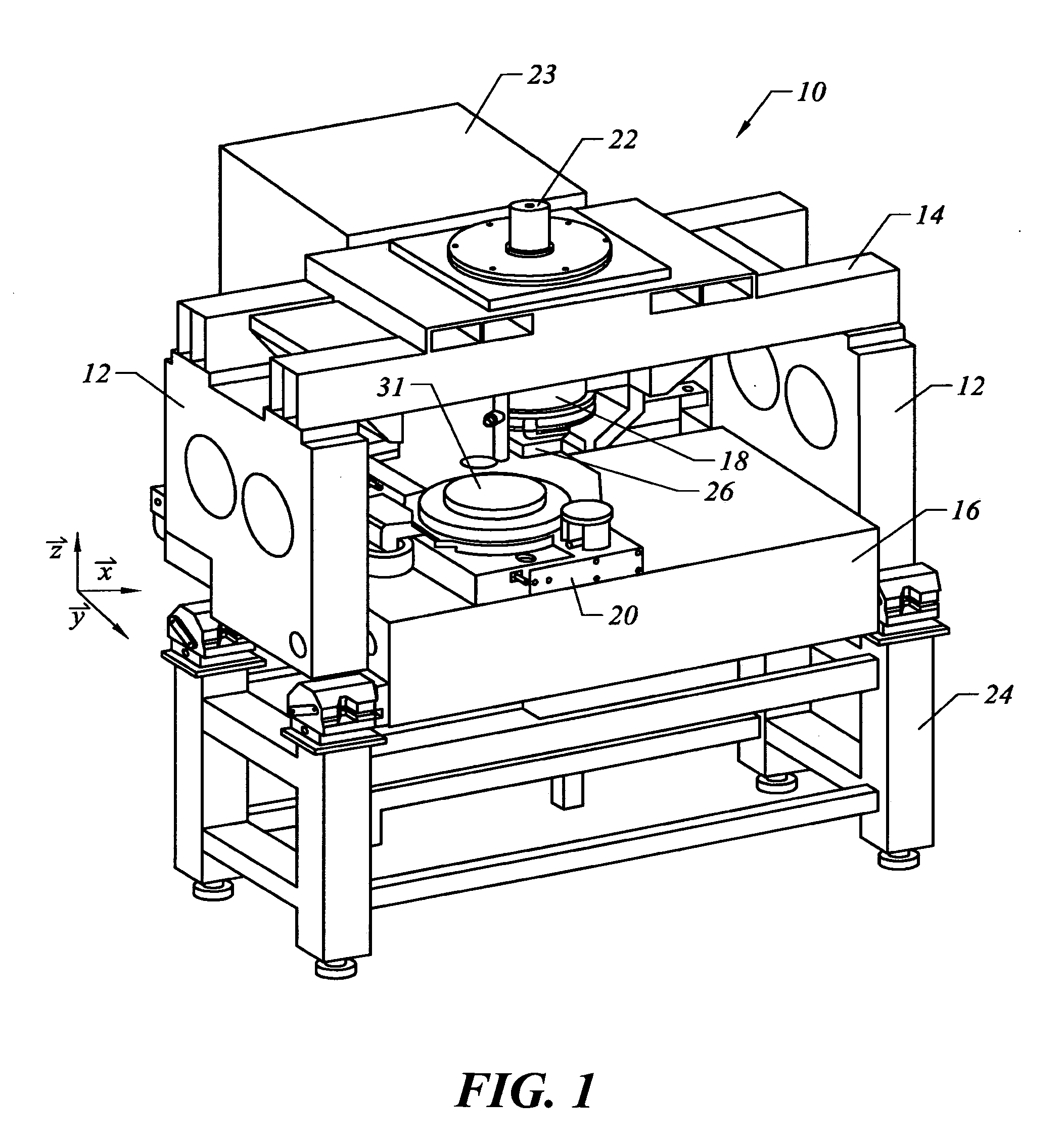

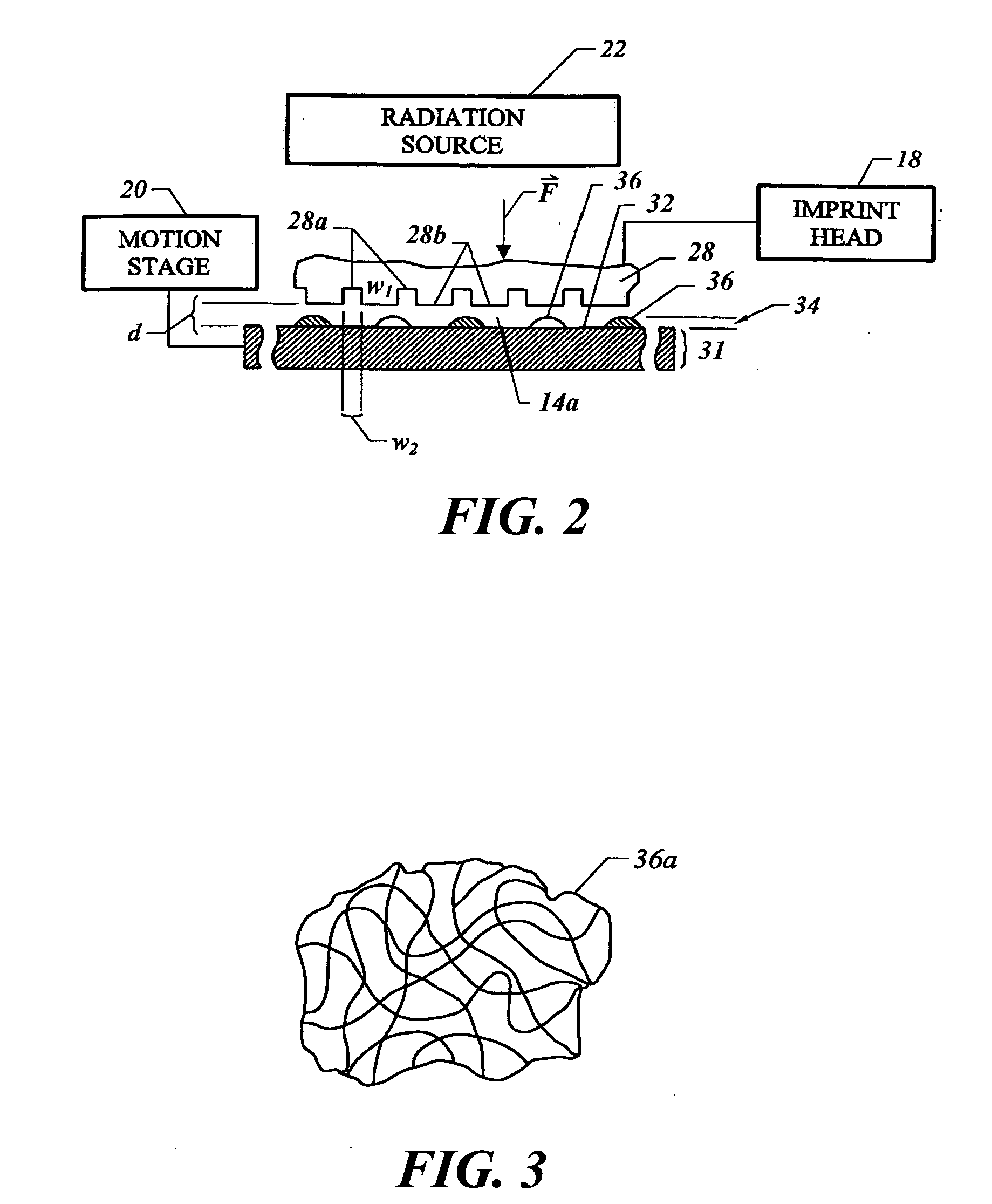

Materials and methods for imprint lithography

One embodiment of the present invention relates to an imprinting material for imprint lithography that includes the surfactant 3M™ Novec™ Fluorosurfactant FC-4432, and another embodiment of the present invention relates to a method for imprint lithography that uses the imprinting material.

Owner:MOLECULAR IMPRINTS

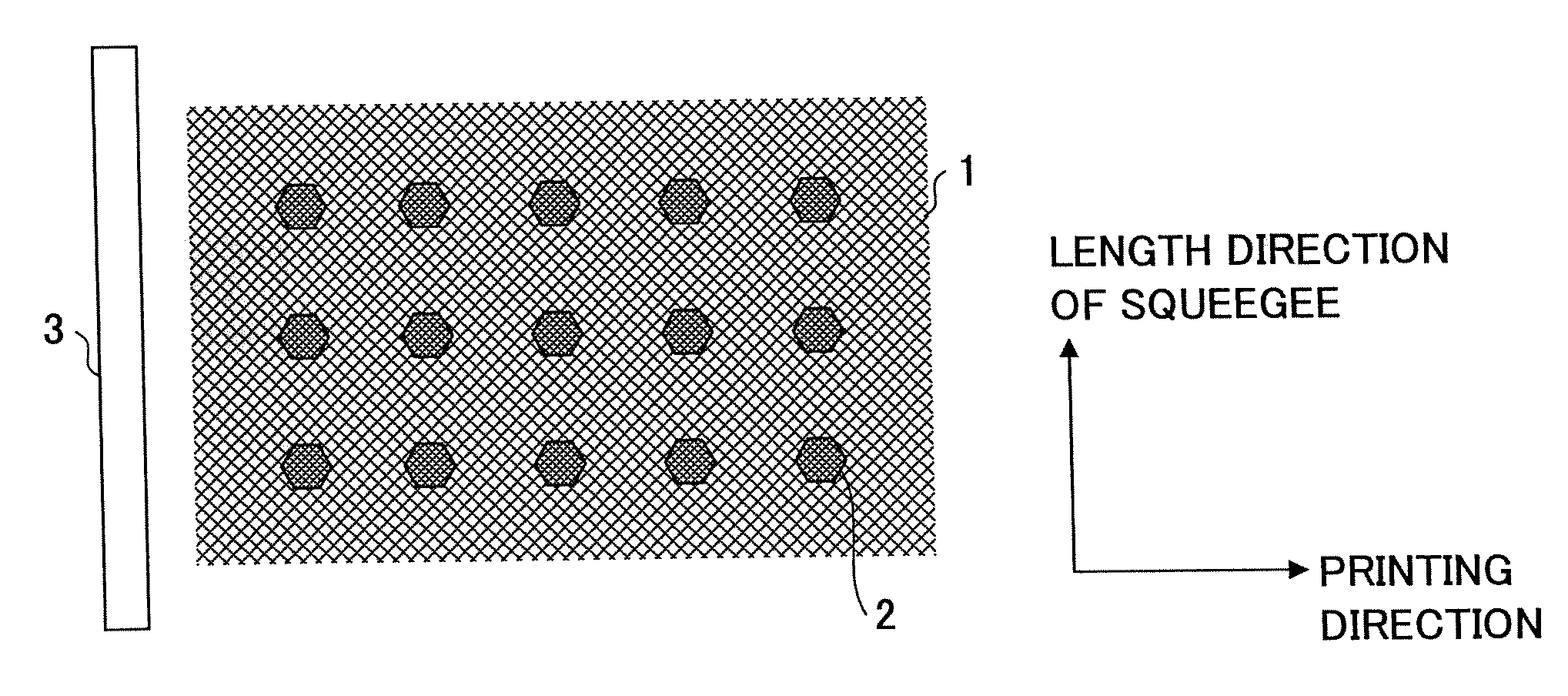

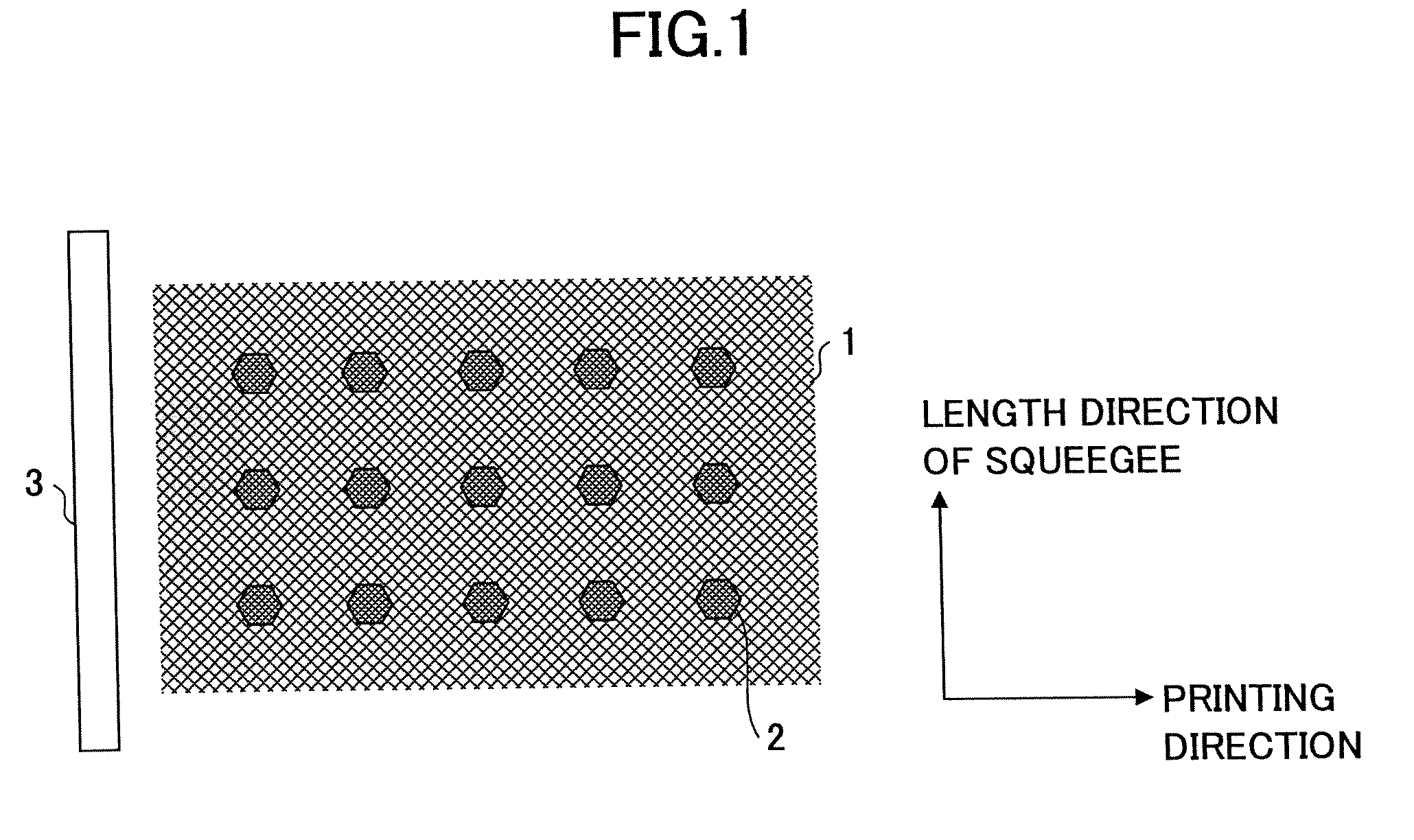

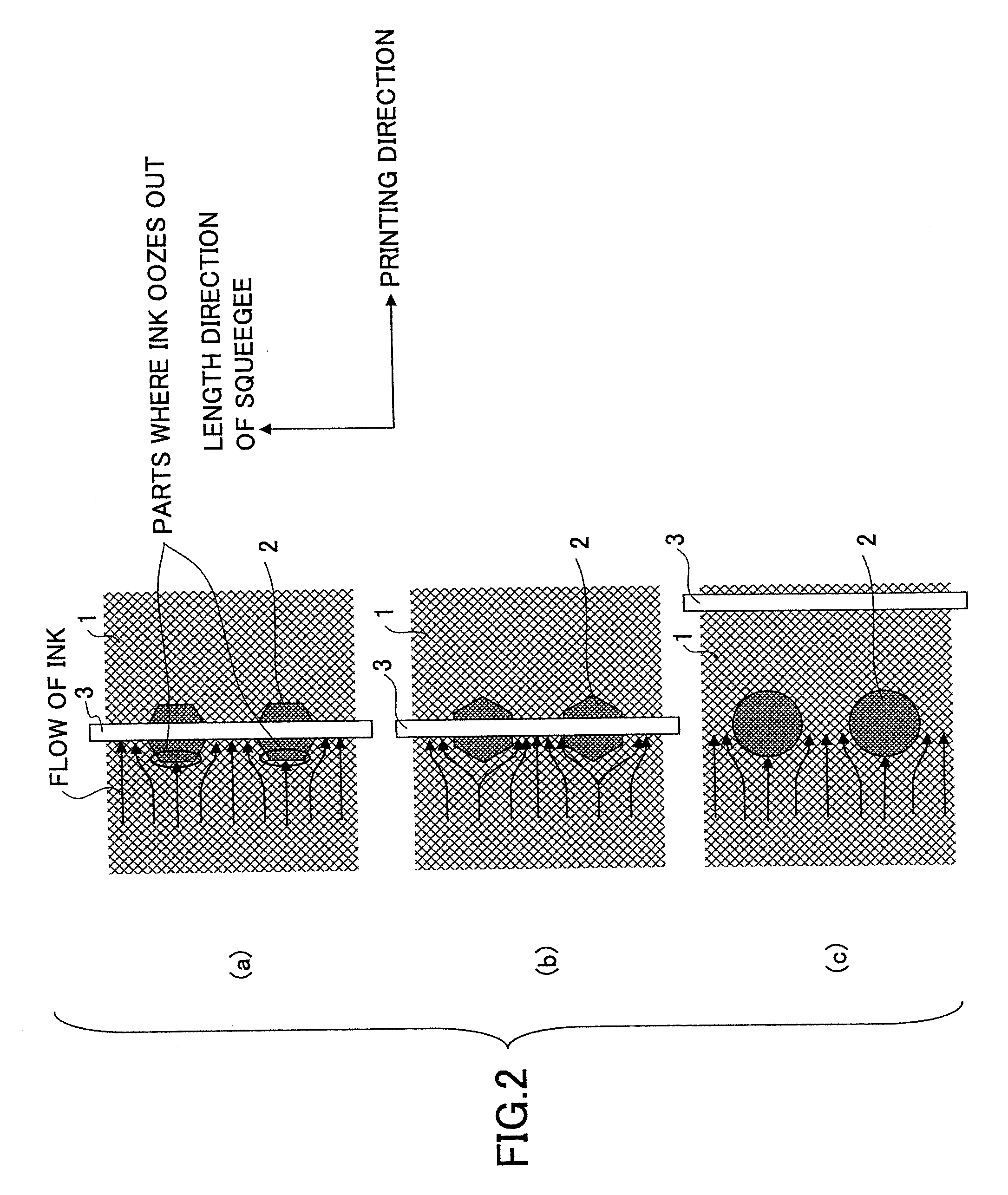

Screen printing plate

InactiveUS20080017053A1Way stableLiquid surface applicatorsPattern printingScreen printingMechanical engineering

A screen printing plate includes a discharging area from which printing liquid is discharged and a non-discharging area from which no printing liquid is discharged. With the screen printing plate, a squeegee is slid to discharge the printing liquid so as to perform printing. The non-discharging area is of a polygonal shape having as an apex the point with which the squeegee first comes in contact when being slid, and a width of the non-discharging area in the length direction of the squeegee increases from the apex to the maximum of the width.

Owner:RICOH KK

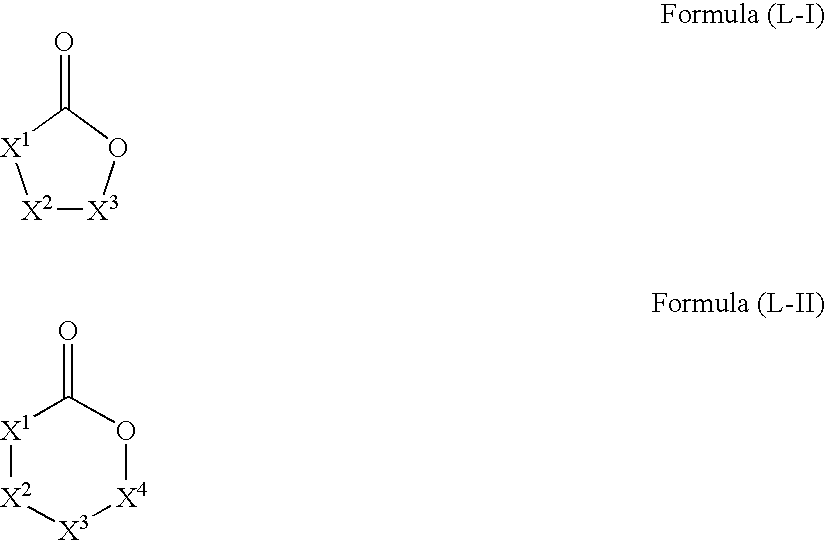

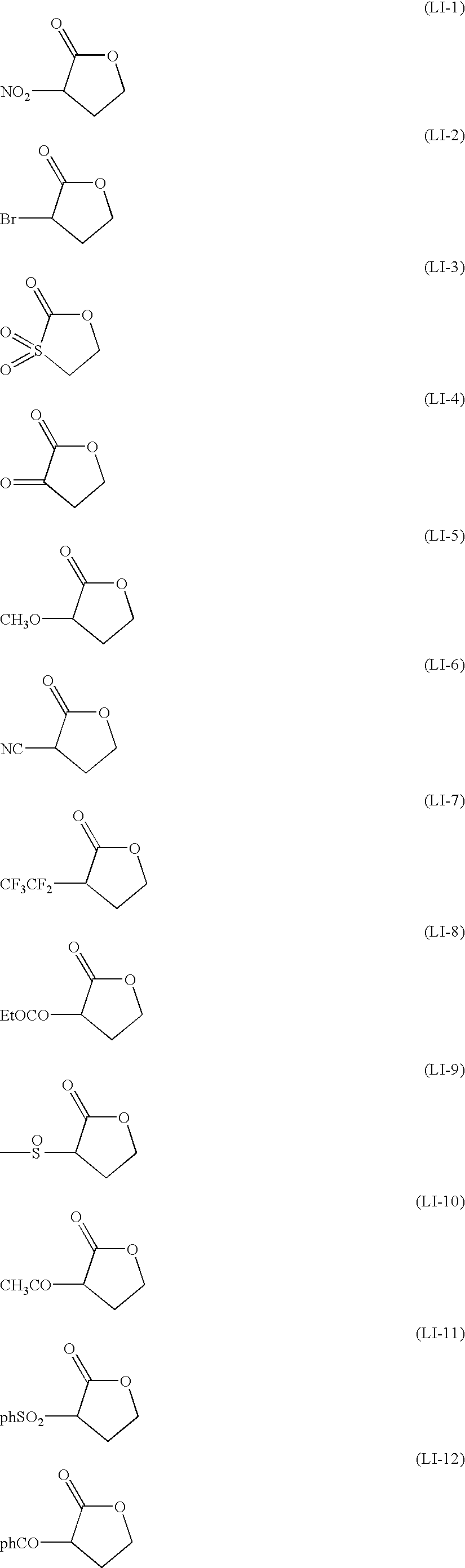

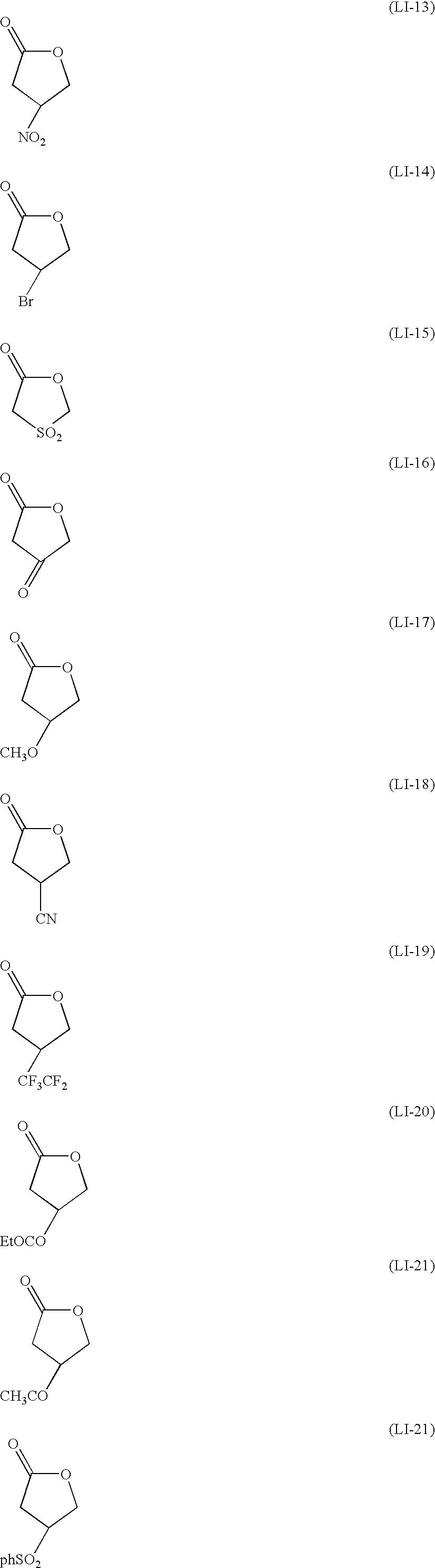

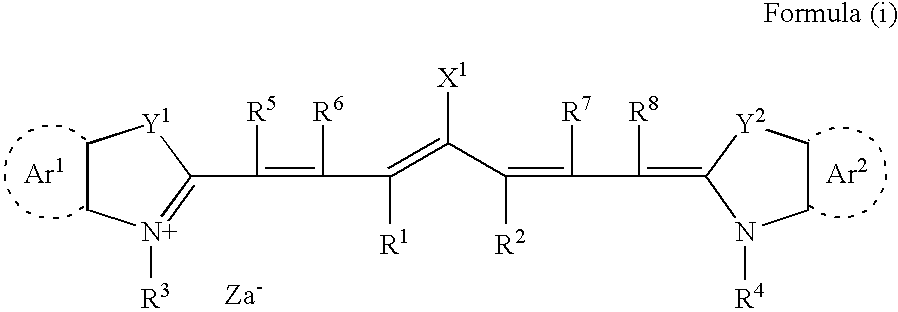

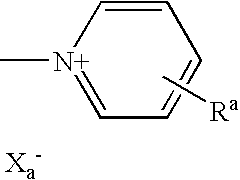

Lithographic printing plate precursor and lithographic printing method

ActiveUS20050069811A1Excellent developabilityProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingActinic RaysImage recording

A lithographic printing plate precursor comprising: a support; an image recording layer comprising (A) an actinic ray absorber, (B) a polymerization initiator, and (C) a polymerizable compound, wherein the image recording layer is capable of being removed with at least one of a printing ink and a fountain solution; and an overcoat layer comprising an inorganic laminar compound. And a lithographic printing method comprising: mounting a lithographic printing plate precursor on a printing press; imagewise exposing the lithographic printing plate precursor with laser beams; and feeding at least one of a printing ink and a fountain solution to the lithographic printing plate precursor to remove a laser beams non-exposed area in an image recording layer; and performing printing.

Owner:FUJIFILM CORP

Planographic printing plate material, planographic printing plate, and printing process employing the same

InactiveUS20060019196A1Excellent printing durabilitySimplify the development processPhotomechanical apparatusPlate printingImage formationWater soluble

Disclosed is a planographic printing plate material comprising a plastic support and provided thereon, a subbing layer containing a water-soluble resin, a hydrophilic layer containing metal oxide particles with an average particle diameter of from 3 to 100 nm, and an image formation layer containing heat melting particles or heat fusible particles in that order, the planographic printing plate material being in the form of roll, wherein a dry coating amount of the water-soluble resin in the subbing layer is in the range of from 0.001 g / m2 to 3.0 g / m2.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

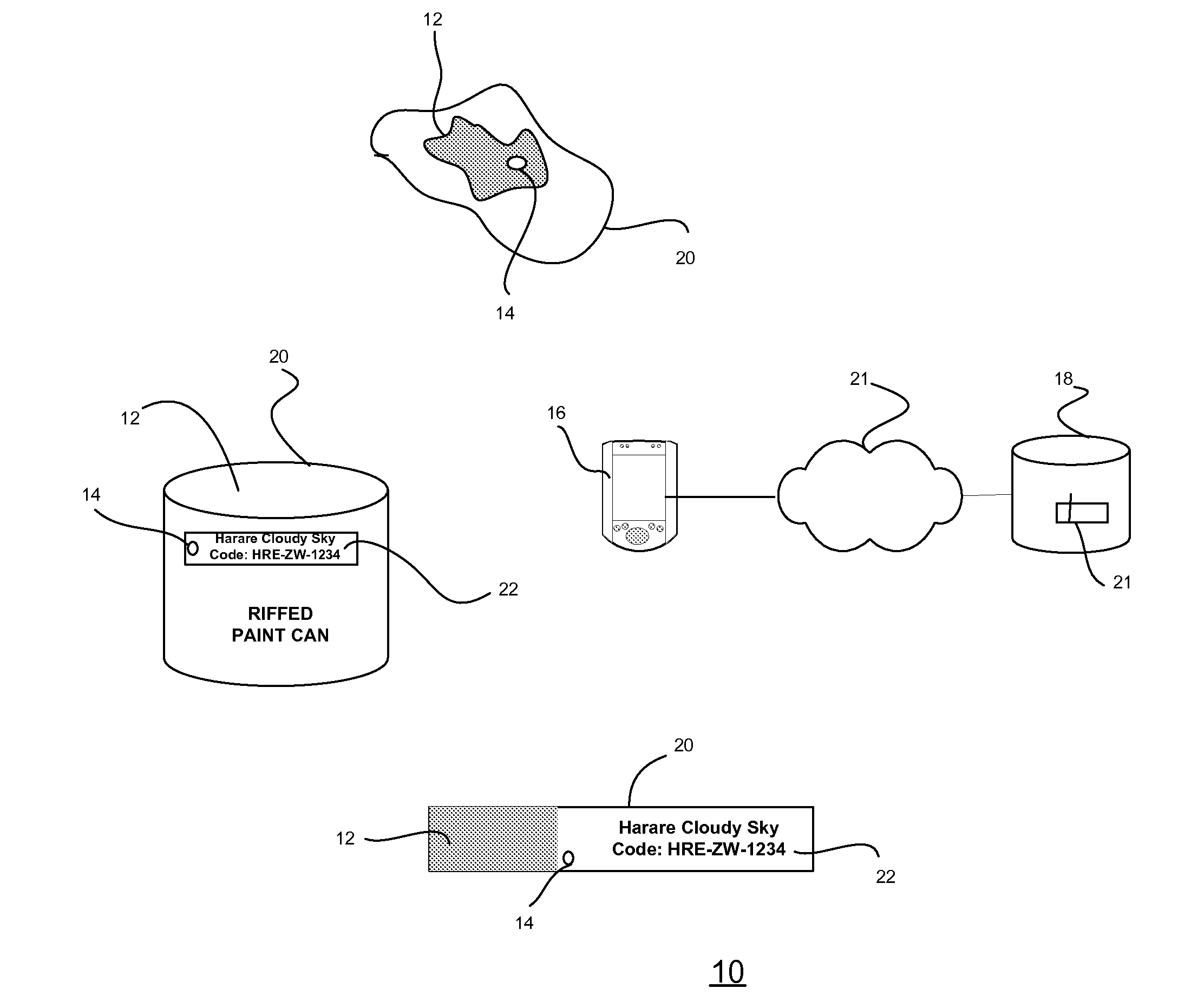

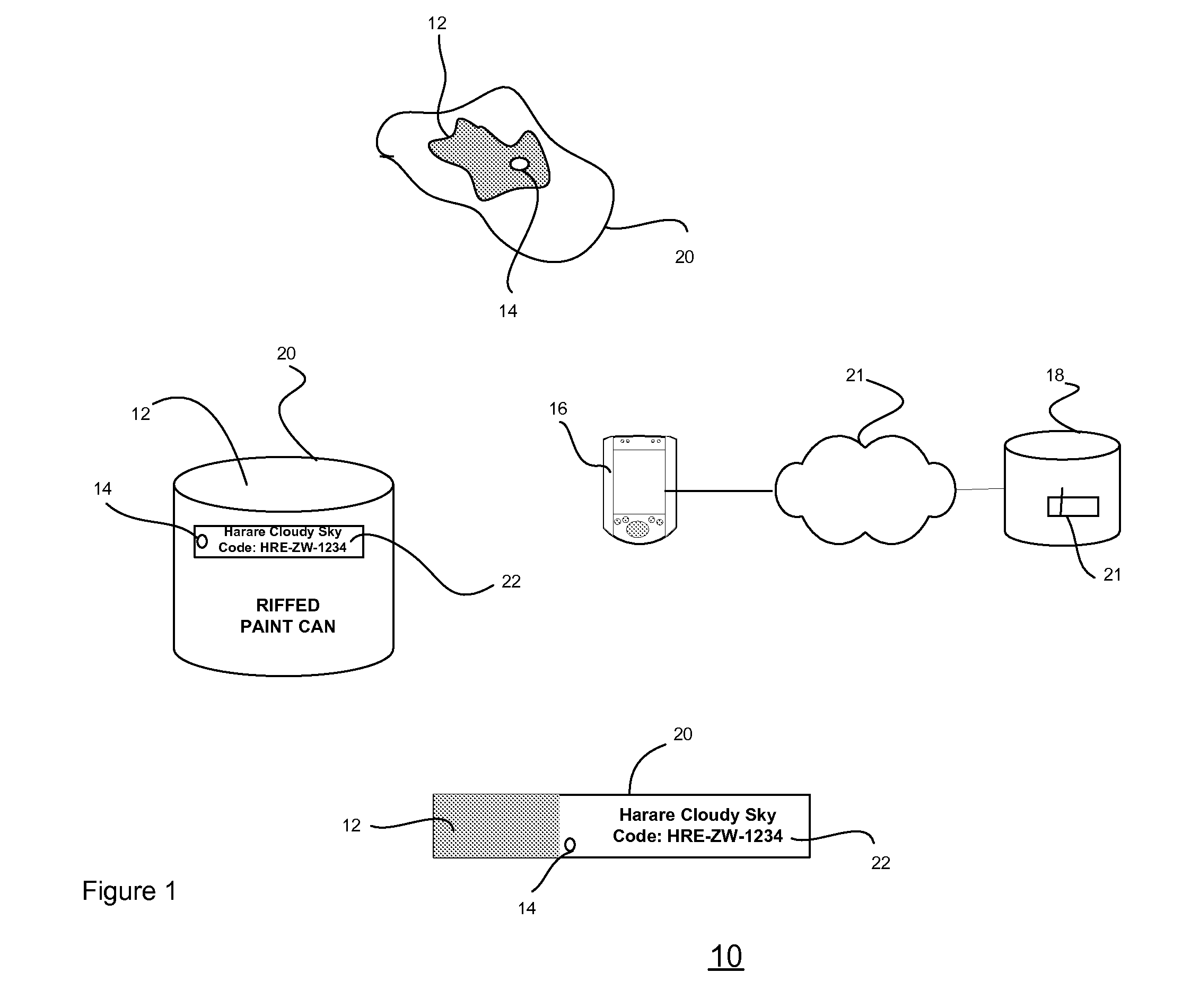

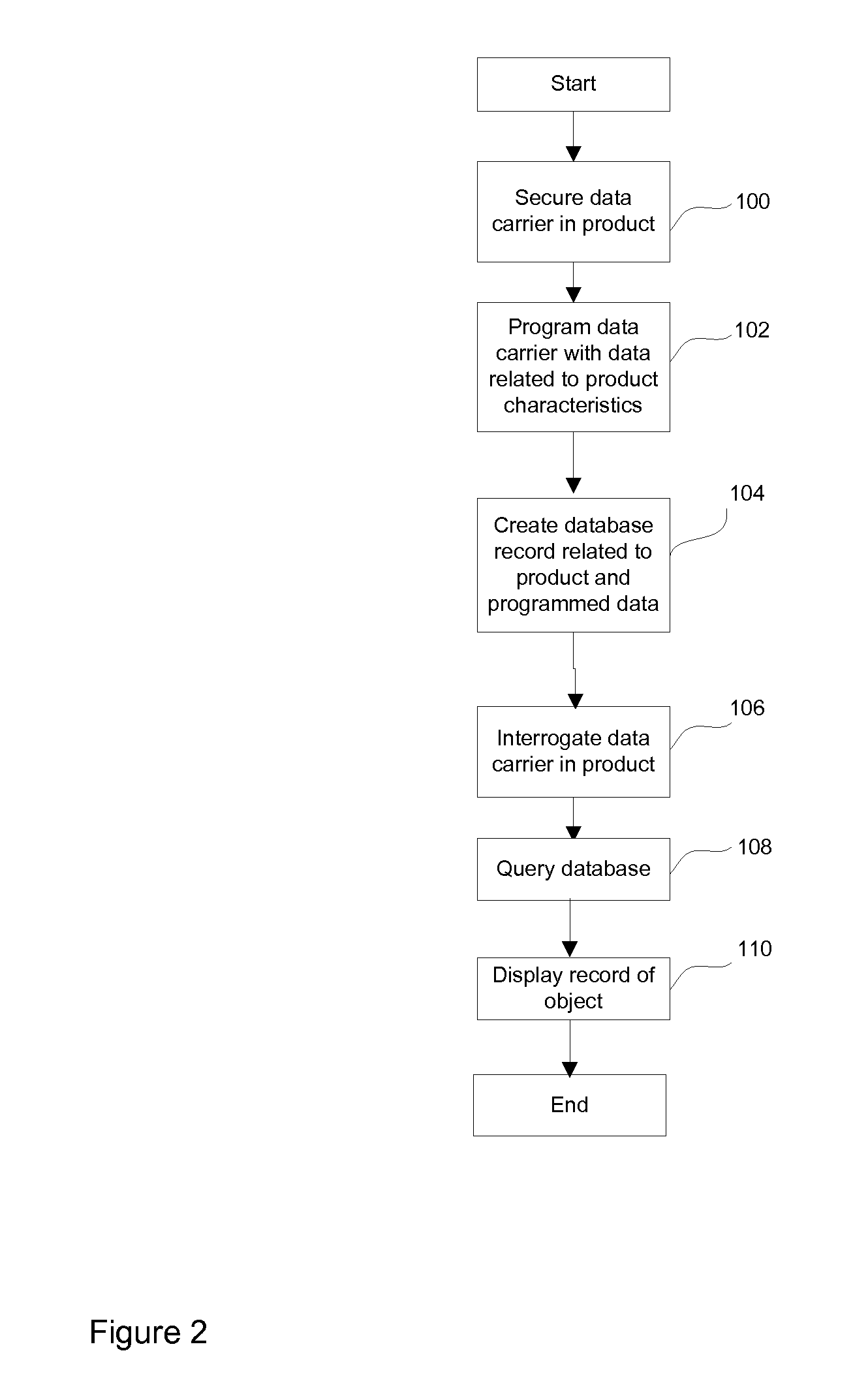

Method & System for Color Matching

A method and system for determining the color characteristics of a paint sample. The paint sample having at least one data carrier having data related to the color characteristics; an interrogator operable in a magnetic and / or electrical mode to emit interrogation signals to the data carrier, the data carrier being operable to emit the data in response to the interrogation signals.

Owner:SABETA ANTON

Engraved plate and substrate with conductor layer pattern using the same

InactiveUS20100021695A1High precision and miniaturization of patterningFlat surfaceMagnetic/electric field screeningLayered productsElectrical conductorEngineering

Owner:HITACHI CHEM CO LTD

Popular searches

Photosensitive material auxillary/base layers Photothermographic systems Photomechanical exposure apparatus Microlithography exposure apparatus Originals for photomechanical treatment Silver halide emulsions Thermography Foil printing Lithography Photosensitive materials for photomechanical apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com