Patents

Literature

1463 results about "Net shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

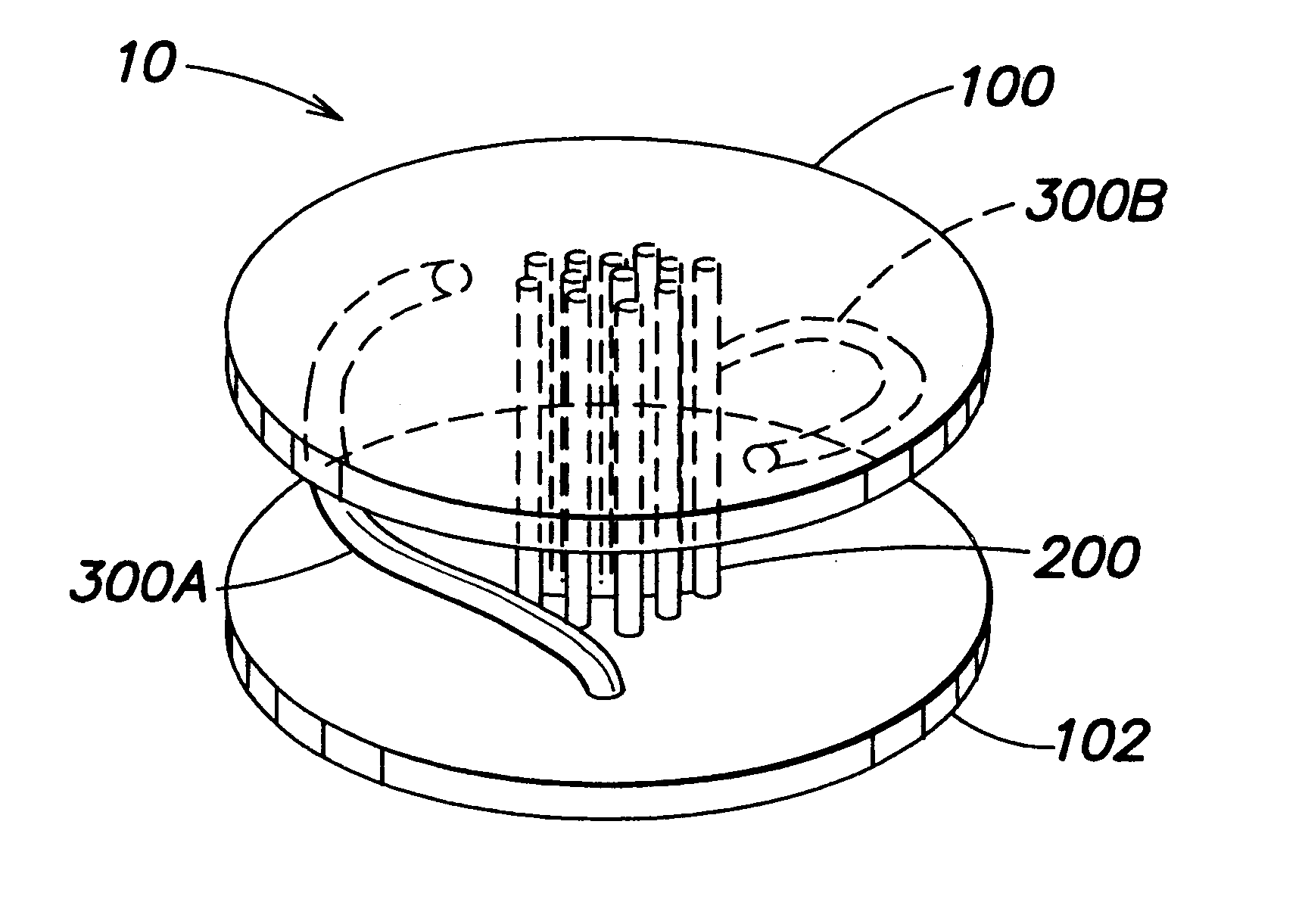

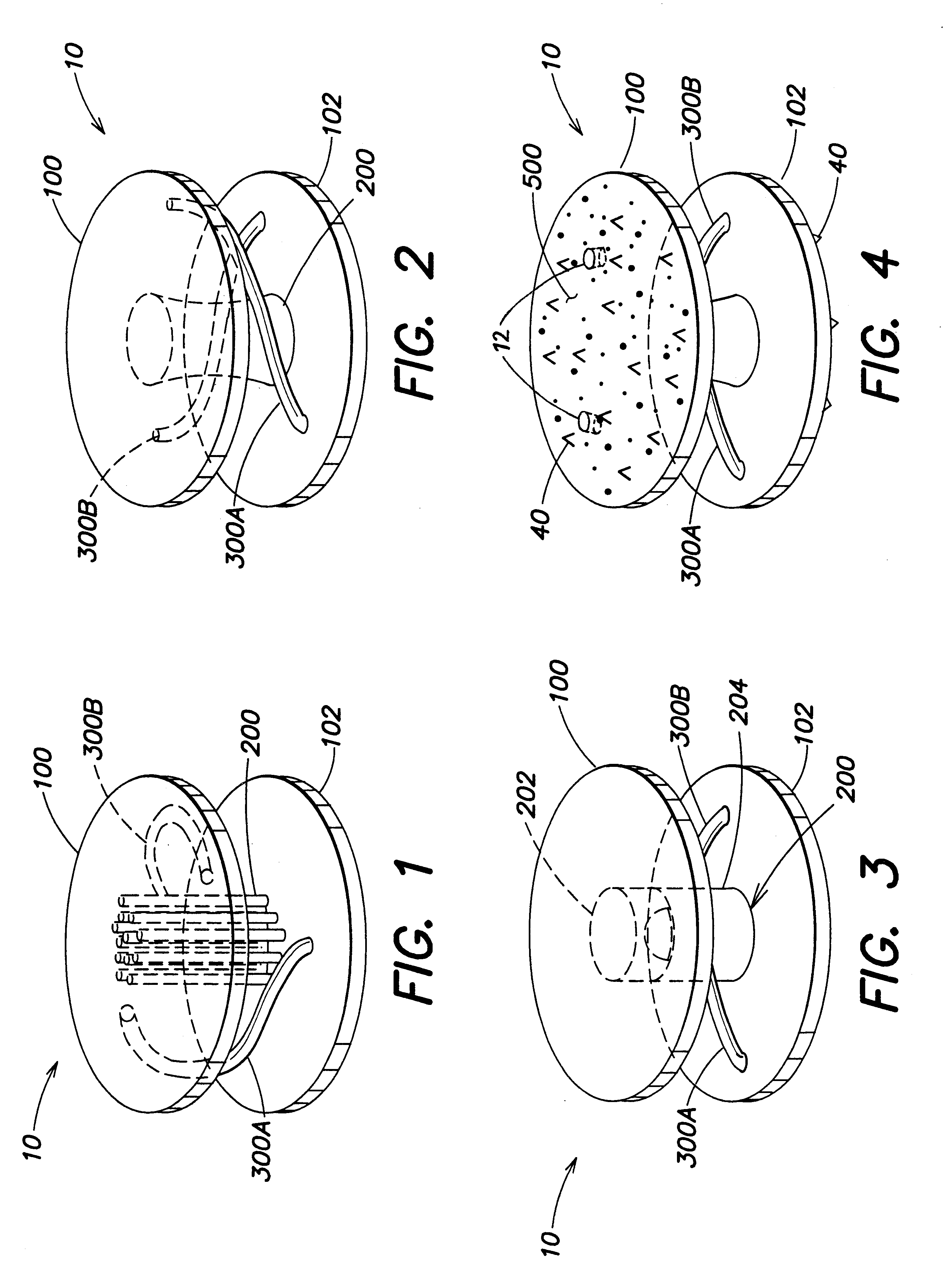

Orthopedic implant

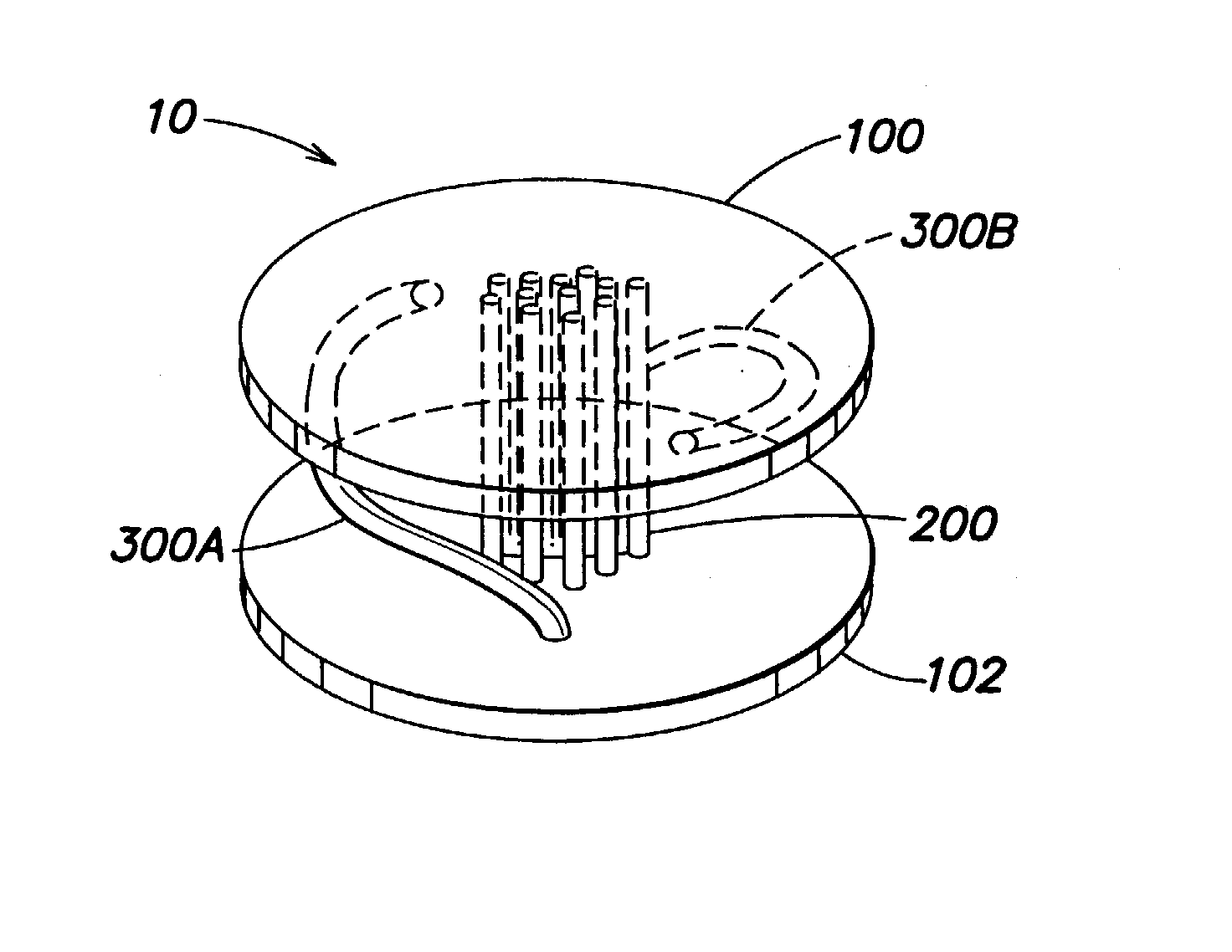

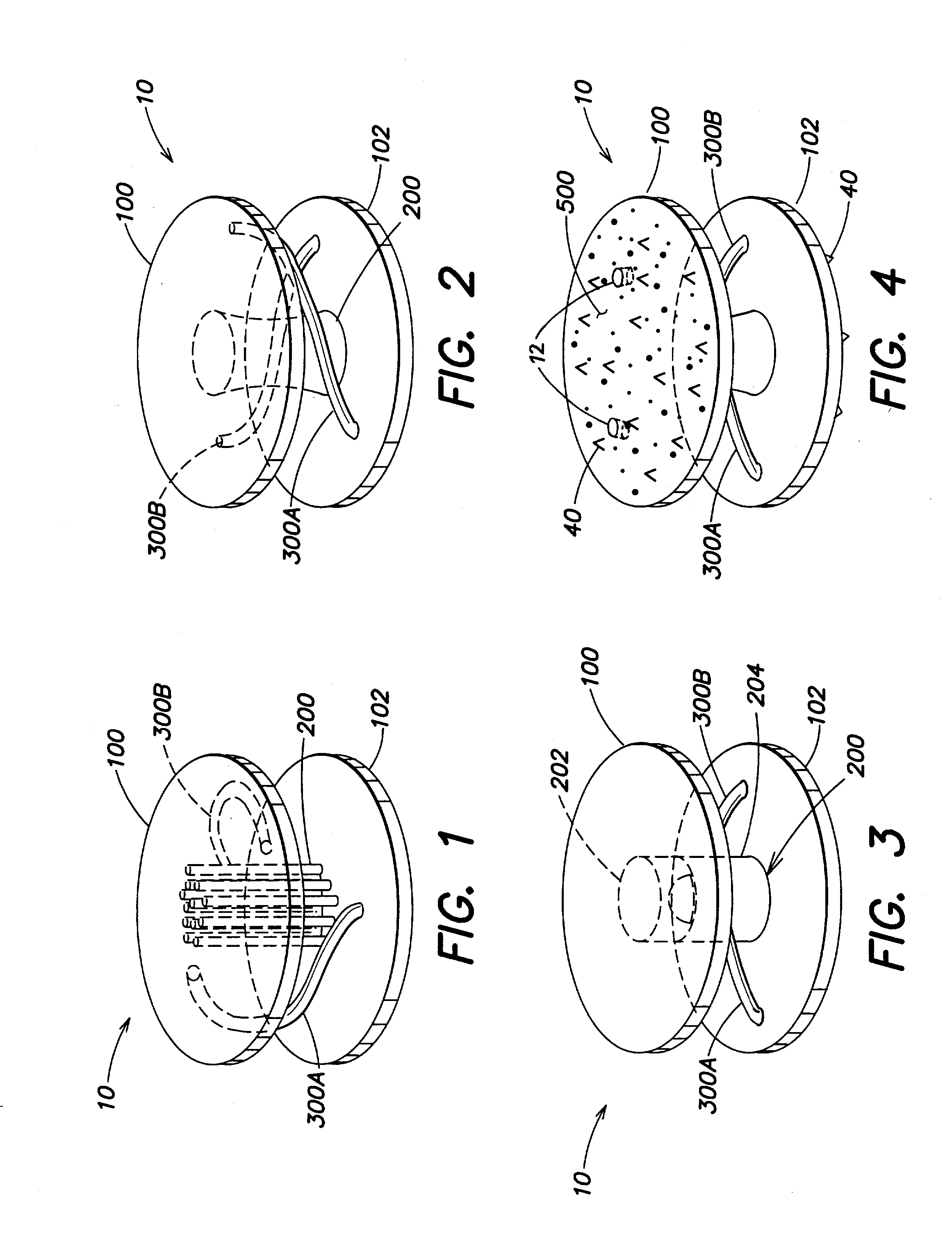

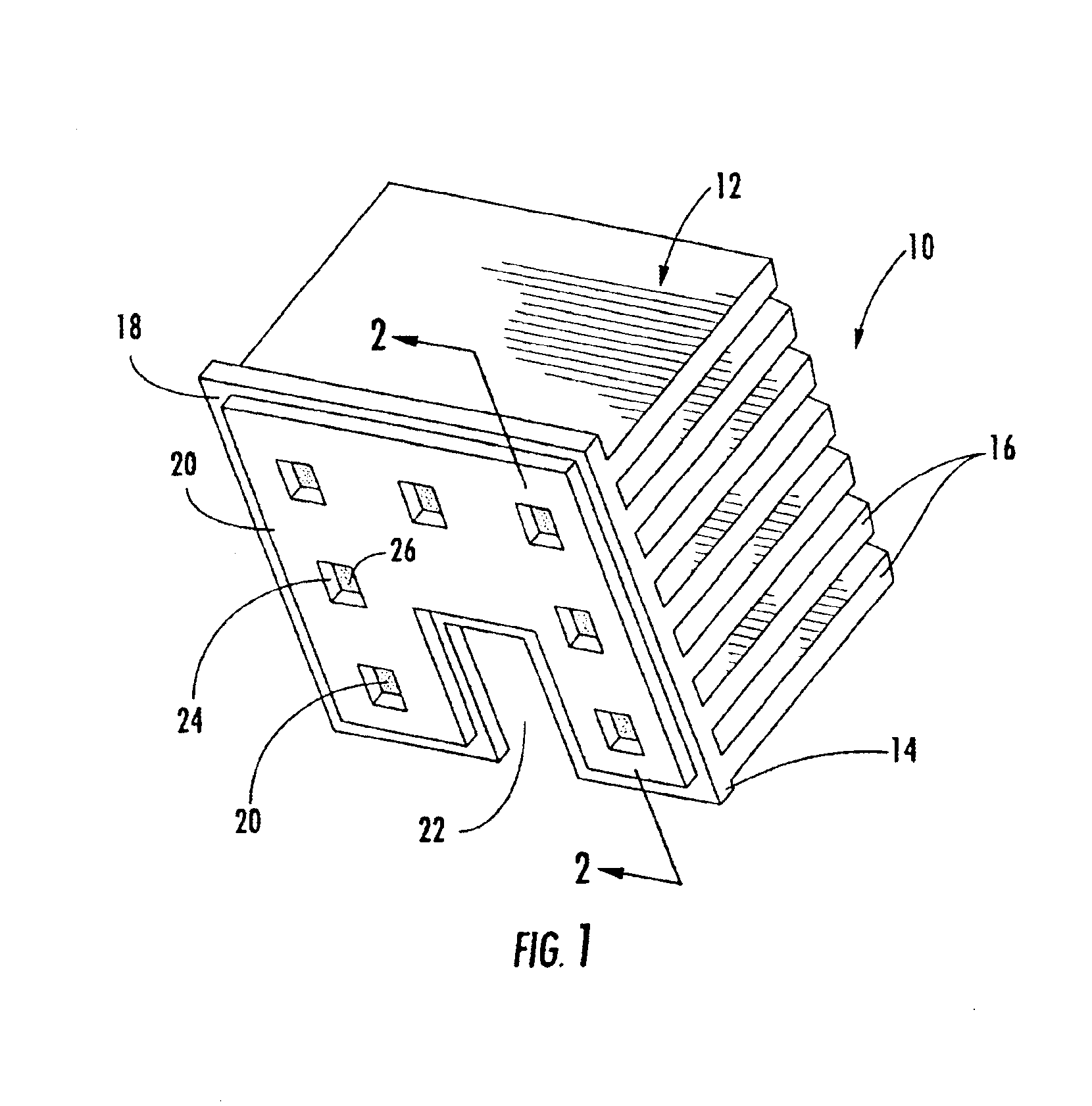

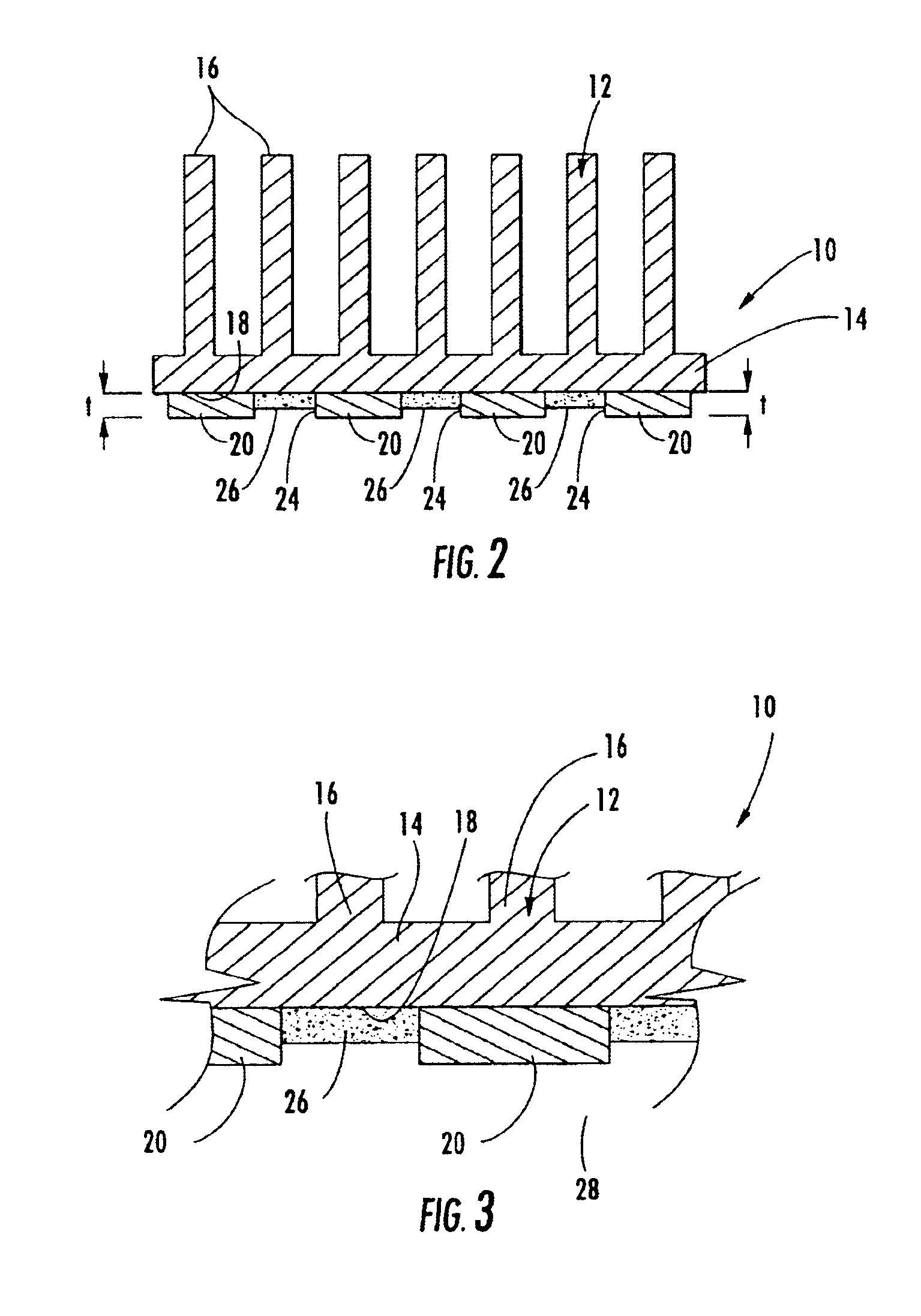

Disclosed is an orthopedic implant suitable for arthroplasty procedures. The orthopedic implant includes a first plate, a second plate, an axial support between the first plate and the second plate and one or more torsional supports connecting the first plate and the second plate. The axial support may be, for example, one or more flexible struts, such as cables, or a ball and socket joint. The torsional supports connect the first and second plates and may be, for example, curved around the axial support. The torsional supports may be integrally formed with the first and second plates as a single unitary device, by, for example, a Laser Engineered Net Shape (LENS) process.

Owner:DEPUY ACROMED INC

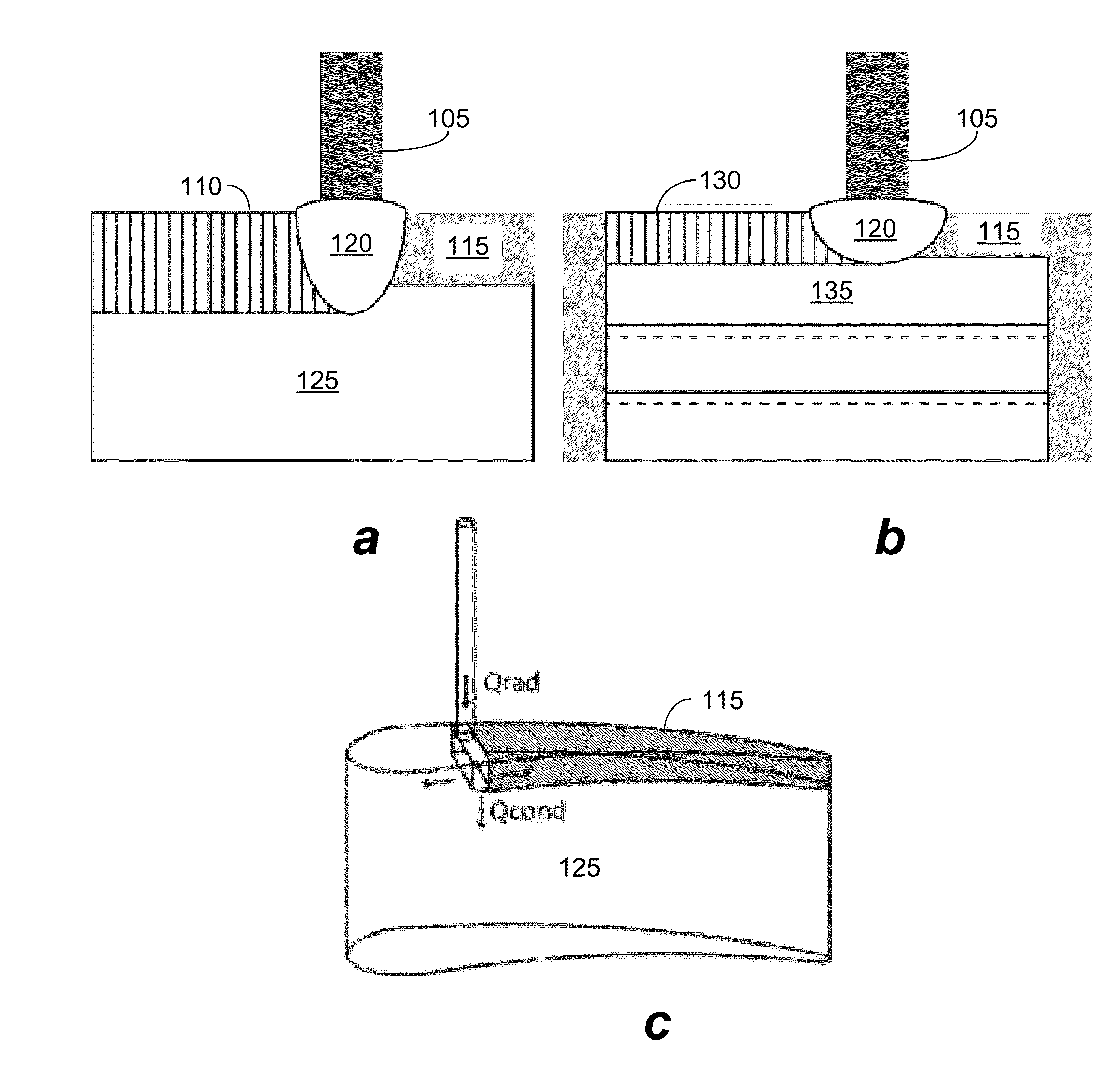

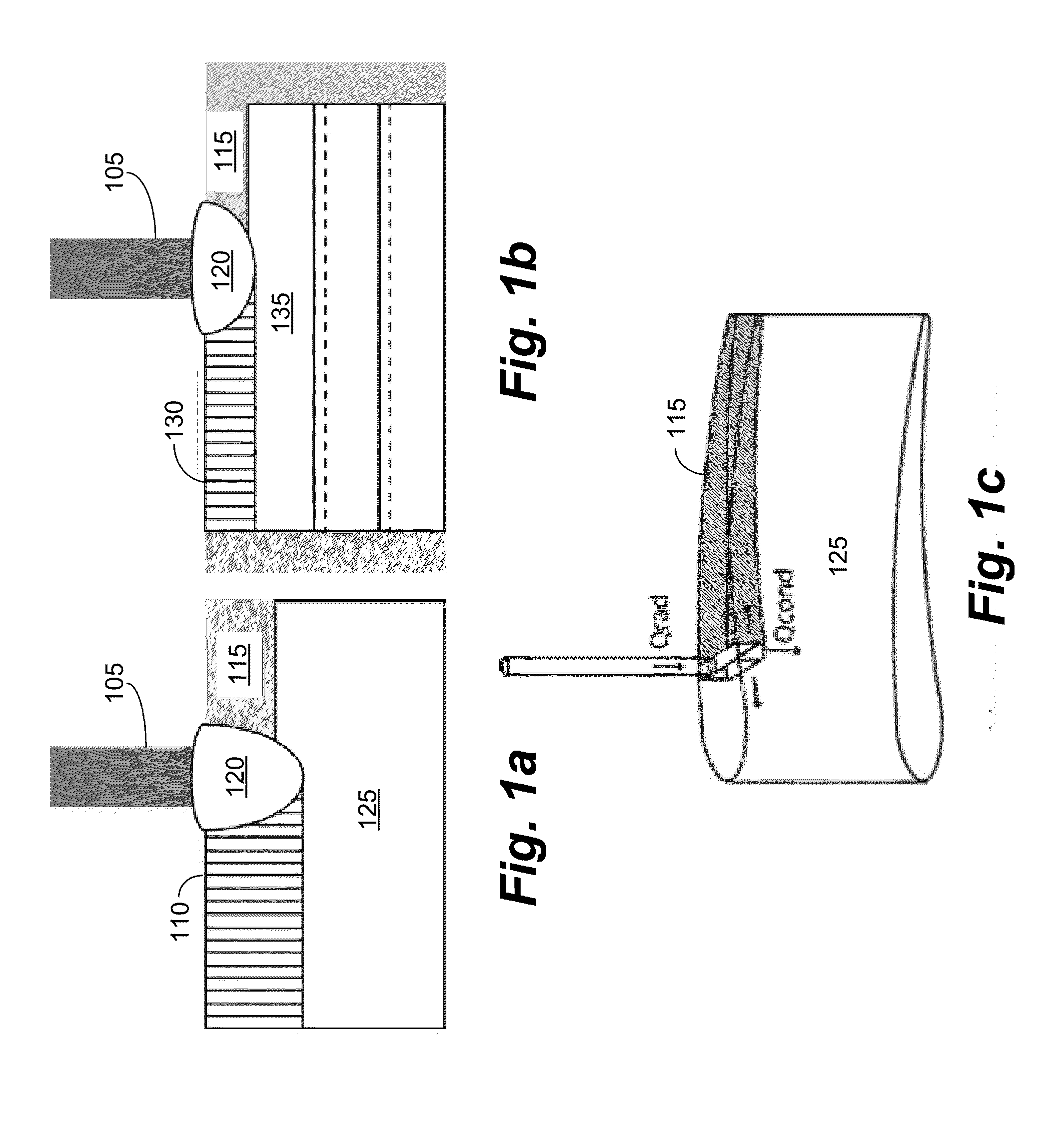

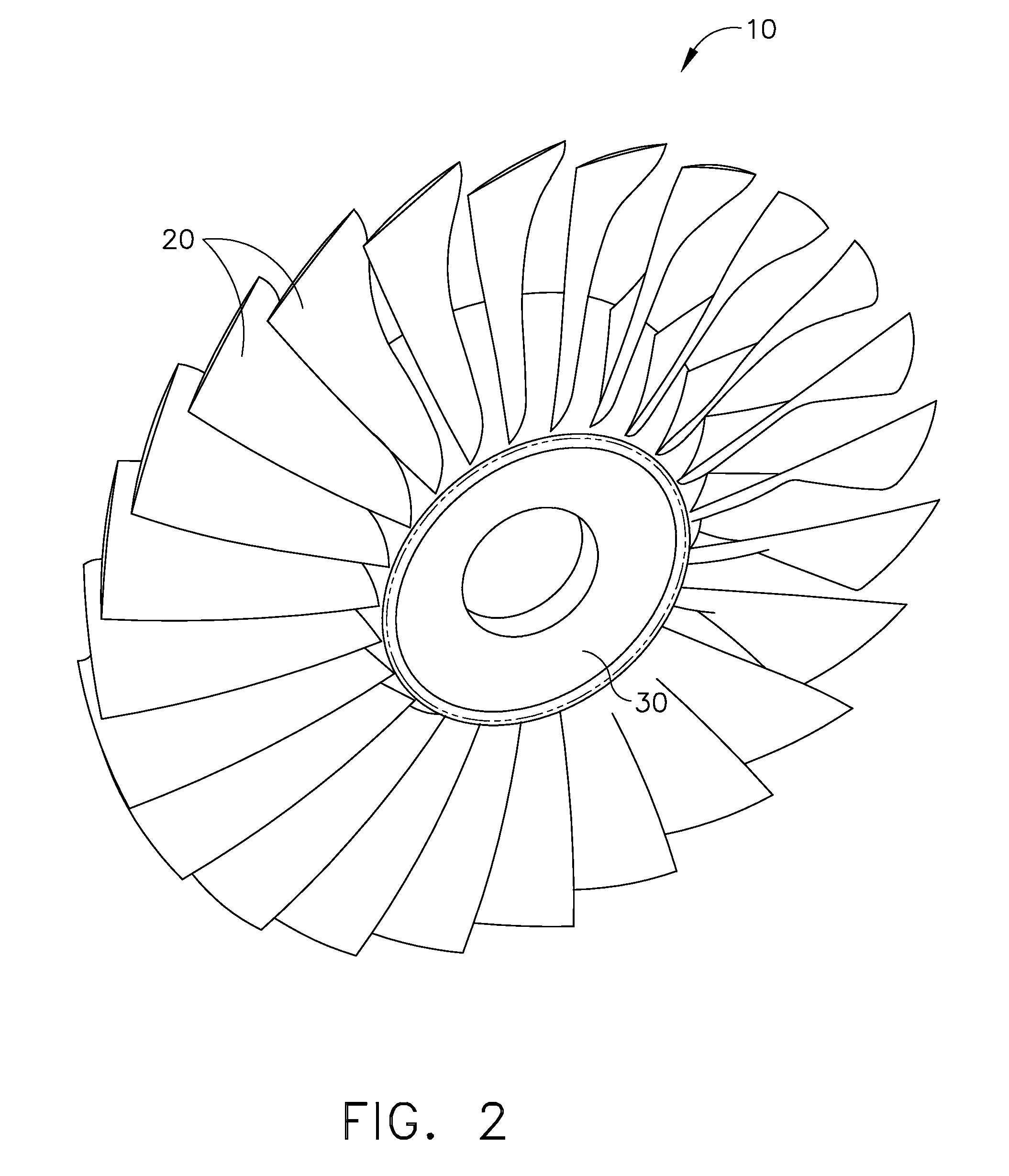

Systems and methods for additive manufacturing and repair of metal components

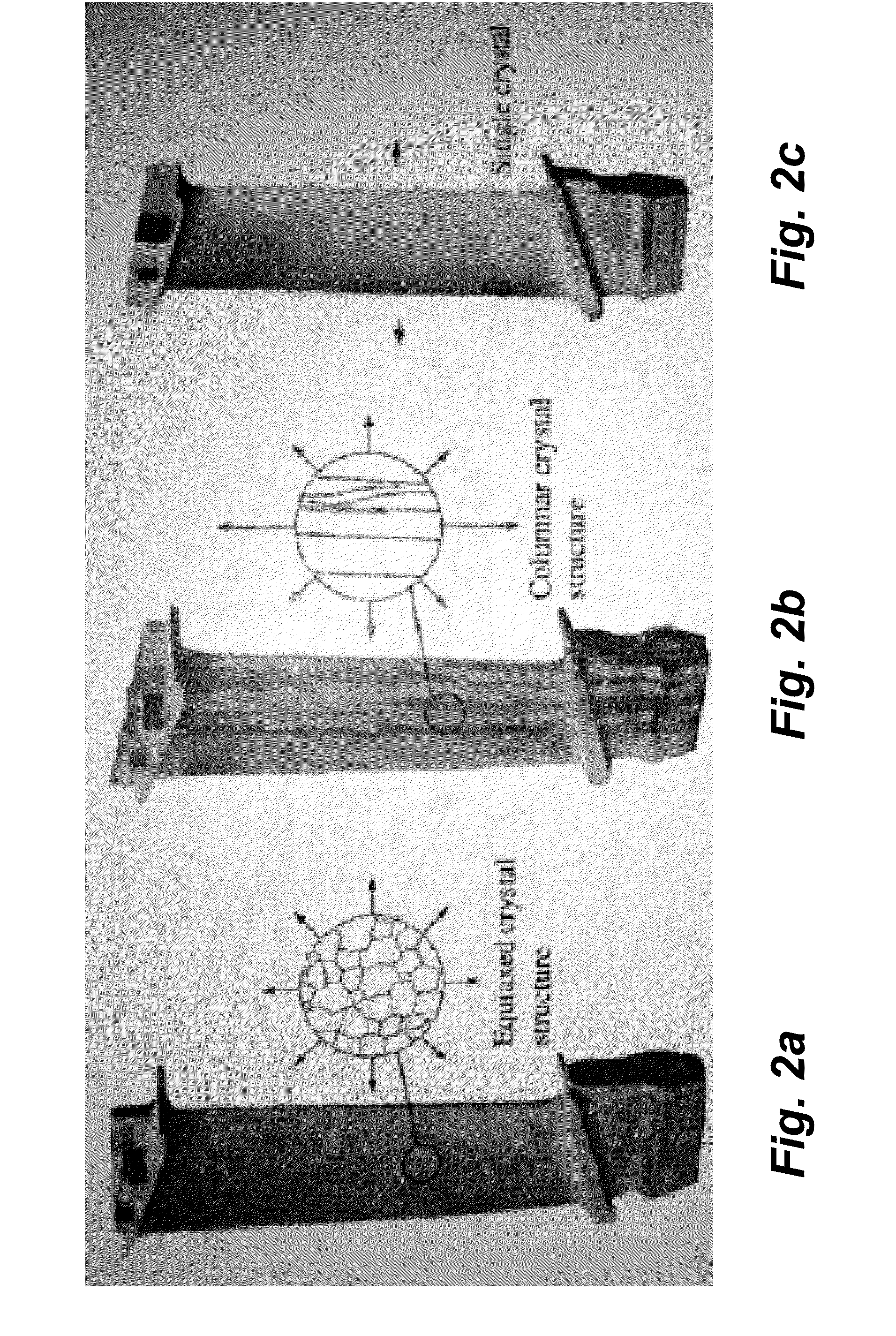

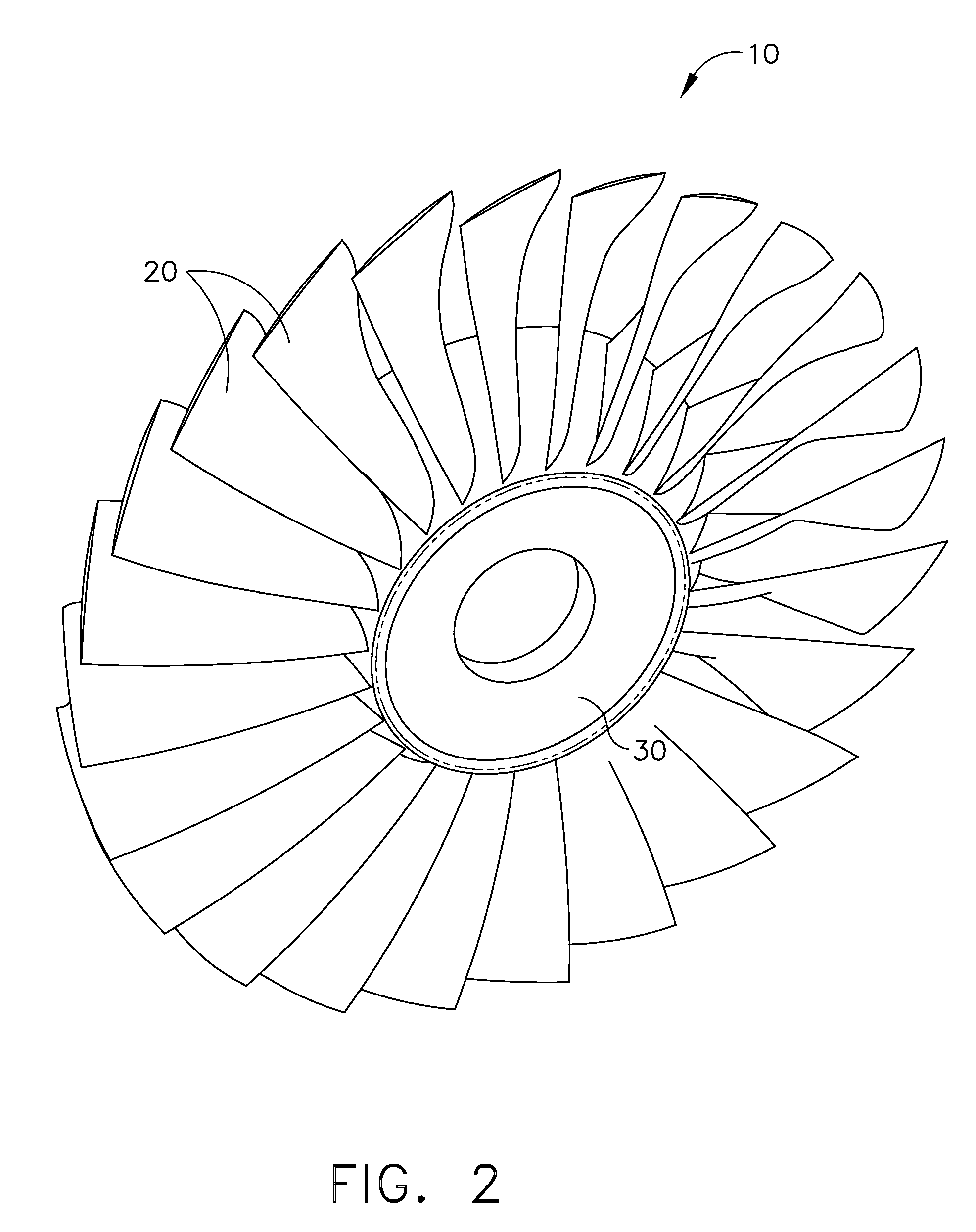

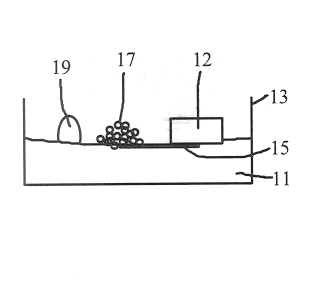

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Orthopedic implant

Disclosed is an orthopedic implant suitable for arthroplasty procedures. The orthopedic implant includes a first plate, a second plate, an axial support between the first plate and the second plate and one or more torsional supports connecting the first plate and the second plate. The axial support may be, for example, one or more flexible struts, such as cables, or a ball and socket joint. The torsional supports connect the first and second plates and may be, for example, curved around the axial support. The torsional supports may be integrally formed with the first and second plates as a single unitary device, by, for example, a Laser Engineered Net Shape (LENS) process.

Owner:DEPUY ACROMED INC

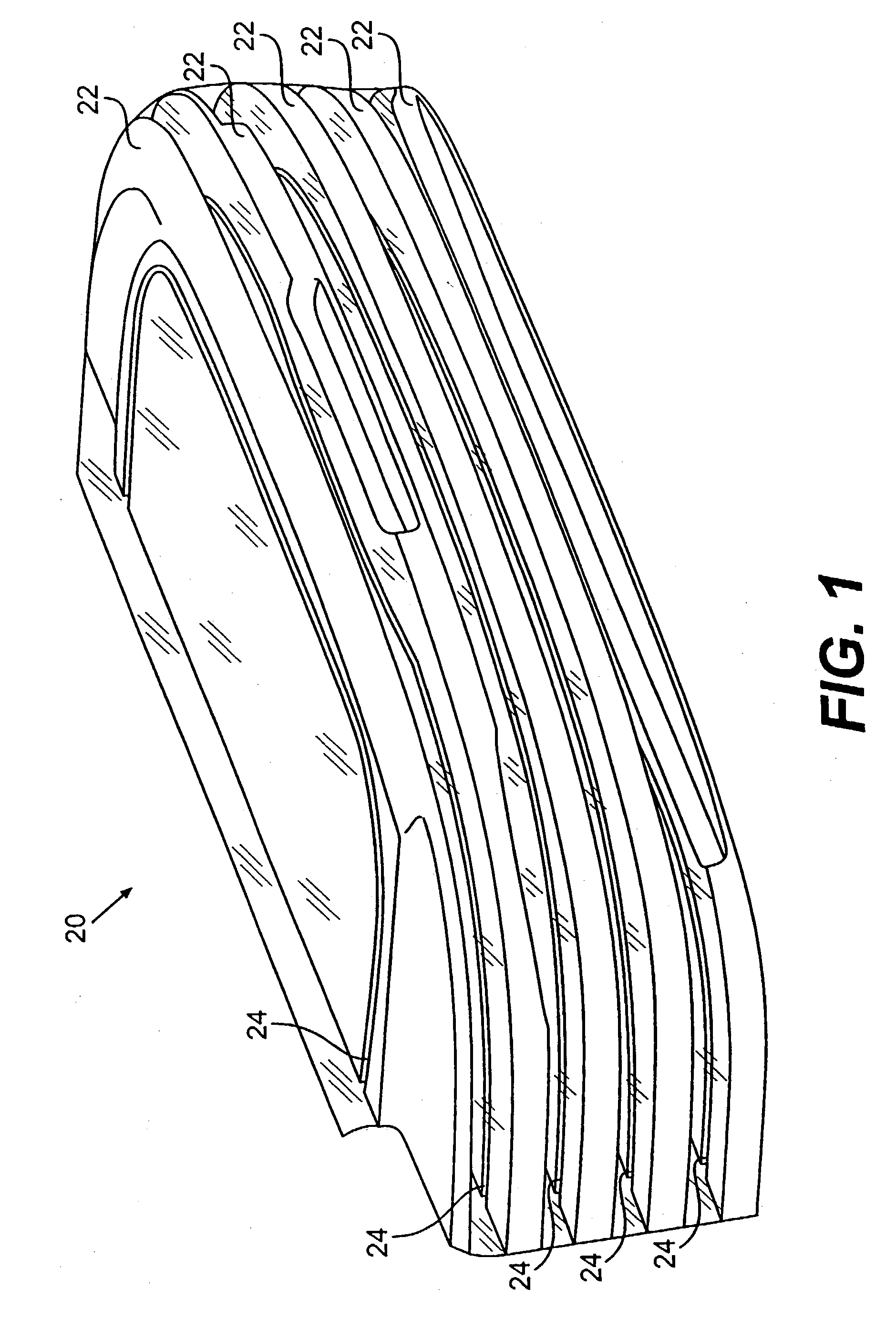

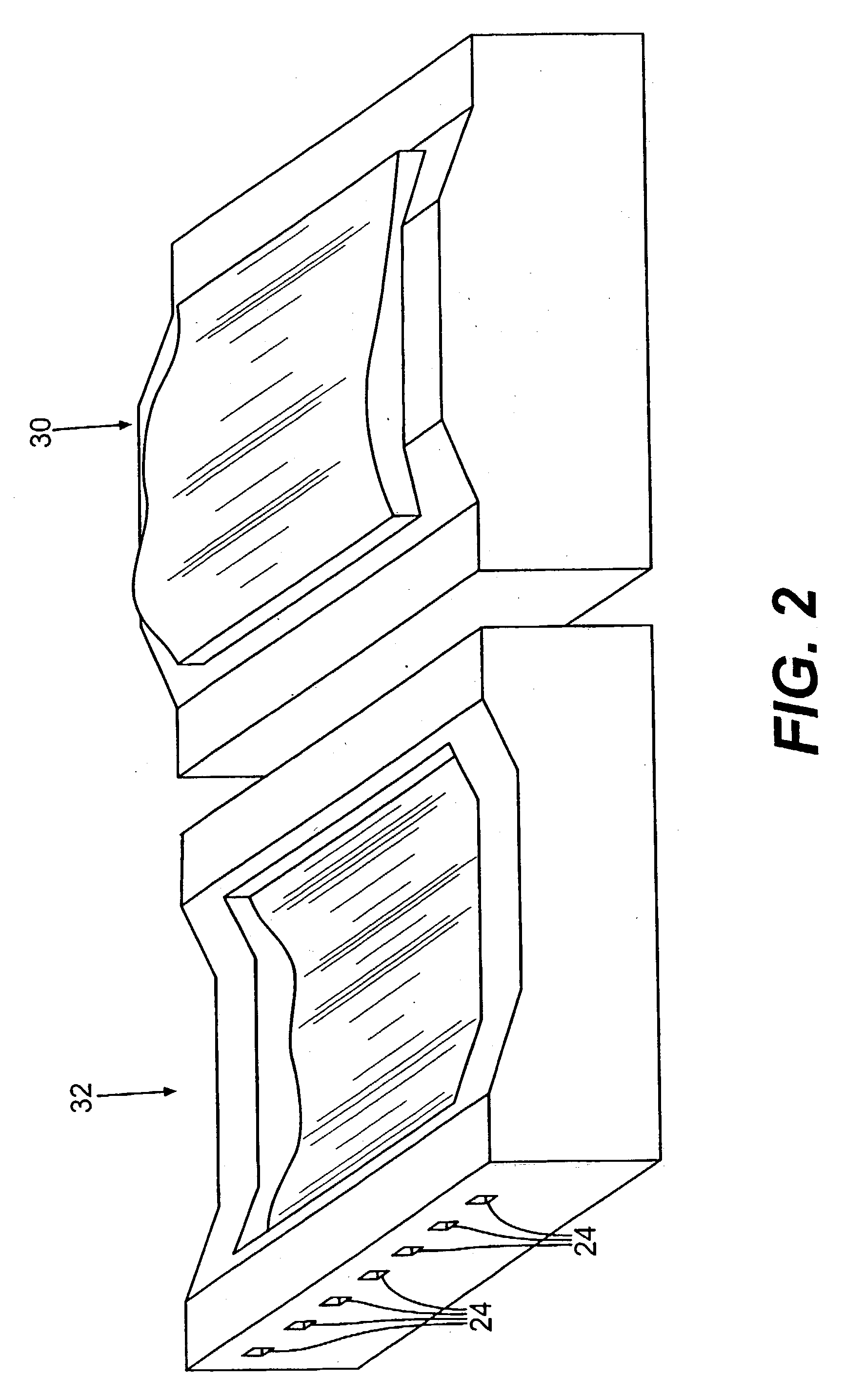

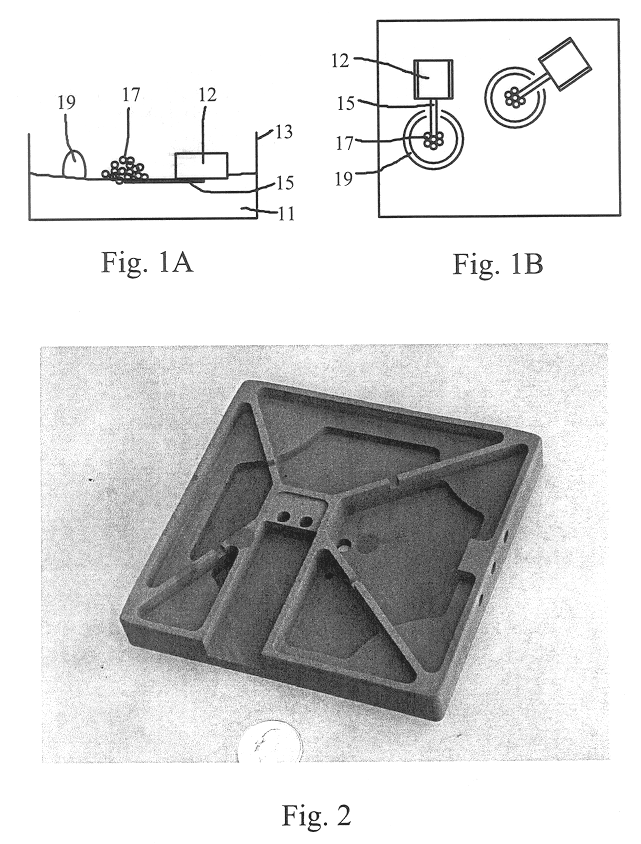

Method for manufacturing a near net-shape mold

A method for manufacturing a near net-shape mold from a weldable material, including creating a computer model of a mold portion (30,32), analytically sectioning the computer model of the mold portion into a plurality of mold zones (22), generating mold zone cutting paths for a cutting machine to follow, cutting the weldable material into plurality of mold zones, generating surface profile cutting paths for a cutting machine to follow, machining surface profiles into the mold zones, assembling the mold zones by placing the mold zones side-by-side, generating welding paths for an electron beam welding a machine to follow, and welding the mold zones together.

Owner:STEWART DAVID H

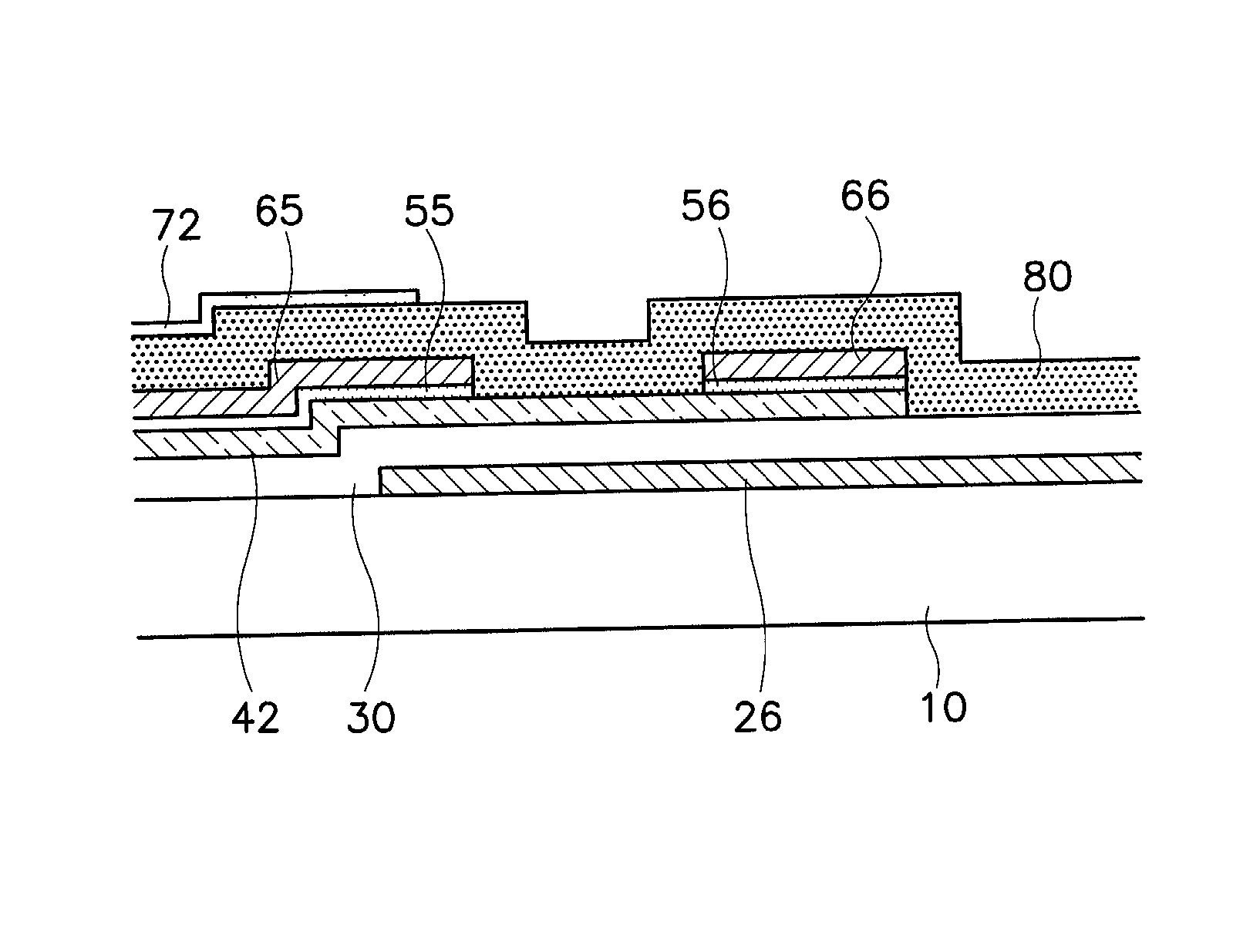

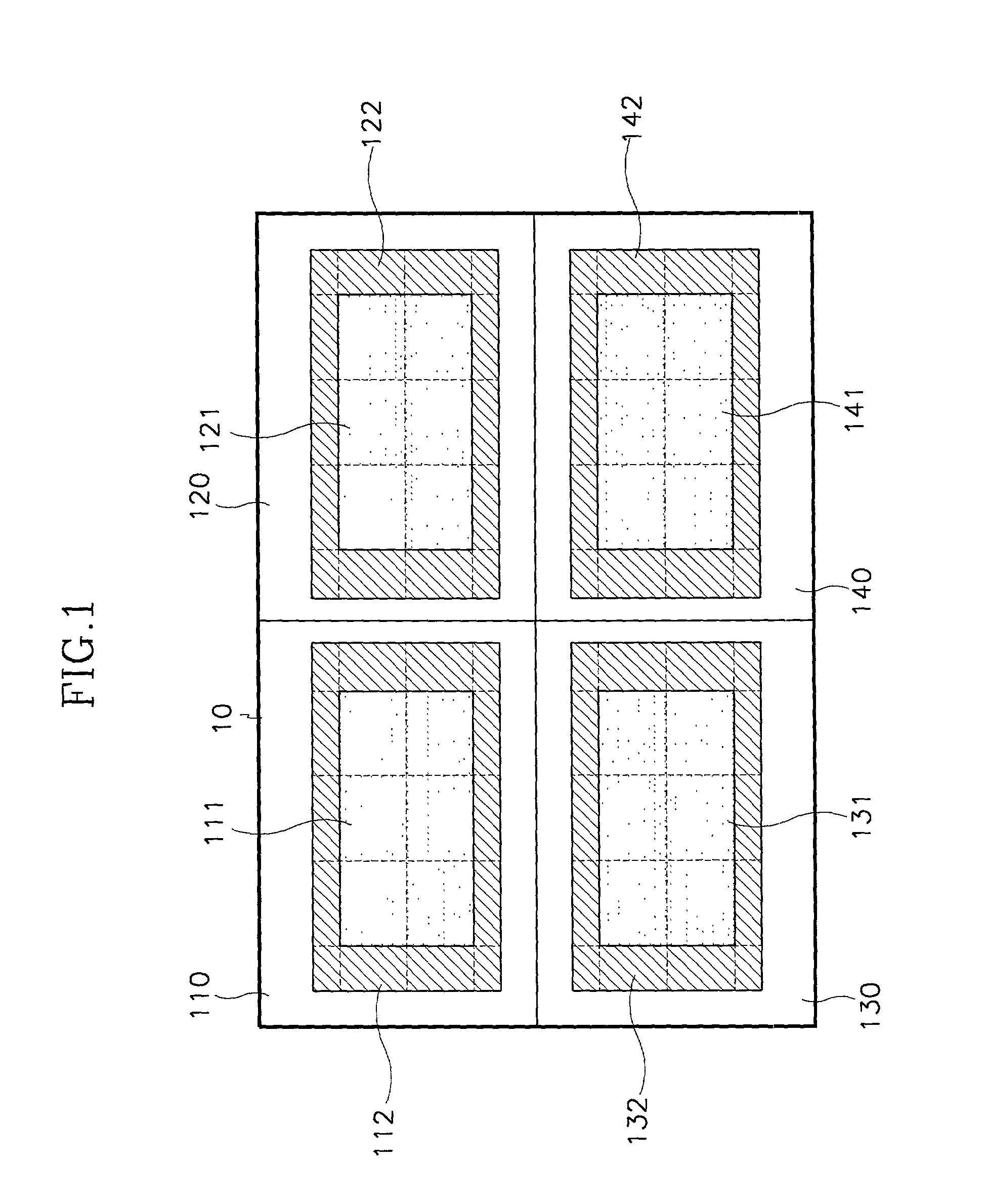

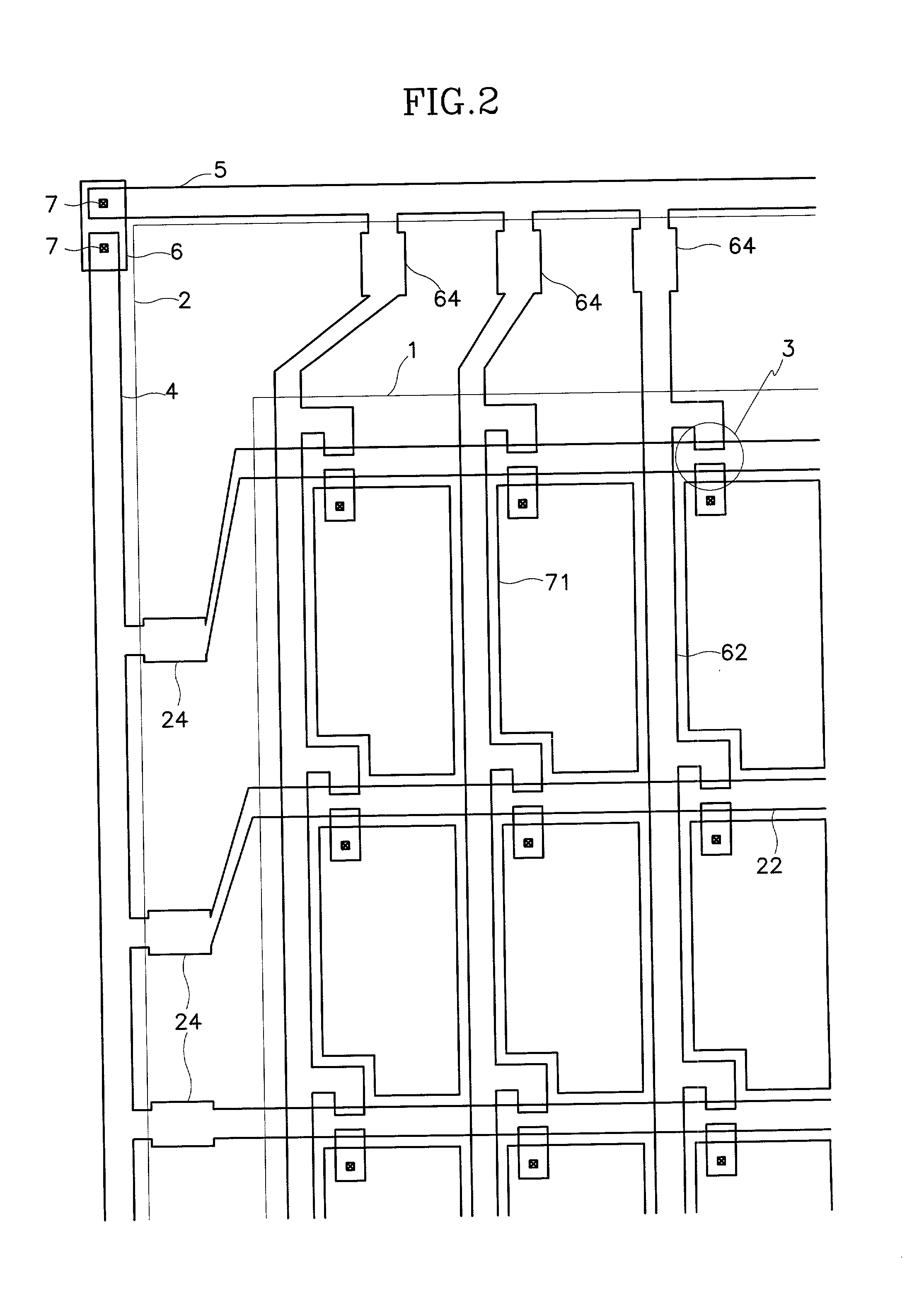

Method for manufacturing thin film transistor array panel for liquid crystal display

Simplified method of manufacturing liquid crystal displays. A gate wire including a gate line, a gate pad and a gate electrode is formed on the substrate by using the first mask. A gate insulating layer, a semiconductor layer, a ohmic contact layer and a metal layer are sequentially deposited to make a quadruple layers, and patterned by a dry etch of using the second mask. At this time, the quadruple layers is patterned to have a matrix of net shape layout and covering the gate wire. An opening exposing the substrate is formed in the display area and a contact hole exposing the gate pad is formed in the peripheral area. Next, ITO is deposited and a photoresist layer coated on the ITO. Then, the ITO layer is patterned by using the third mask and a dry etch, and the data conductor layer and the ohmic contact layer not covered by the ITO layer is dry etched. After depositing a passivation layer, a opening is formed by using the fourth mask and the exposed semiconductor layer through the opening is etched to separate the semiconductor layer under the adjacent data line.

Owner:SAMSUNG ELECTRONICS CO LTD

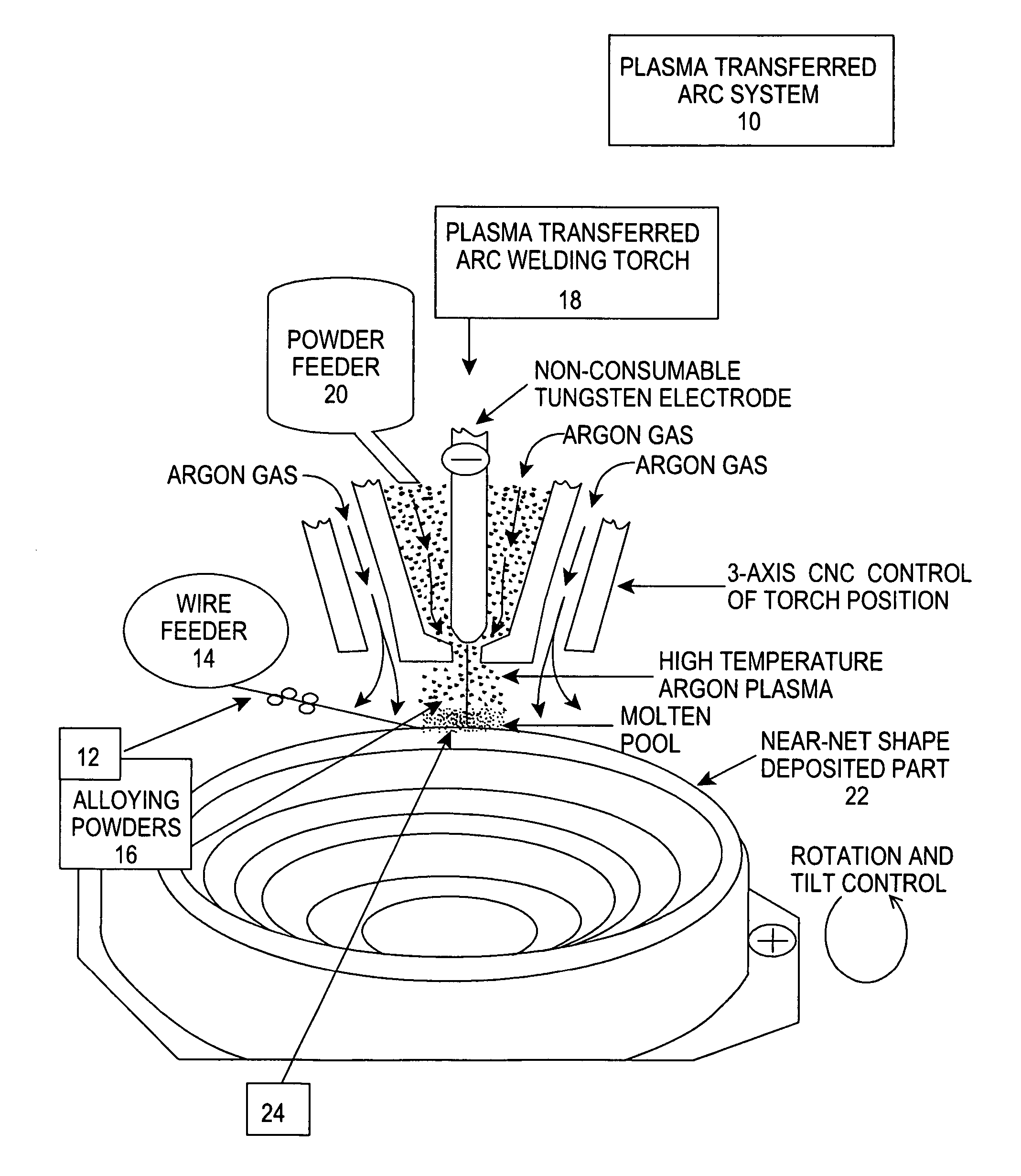

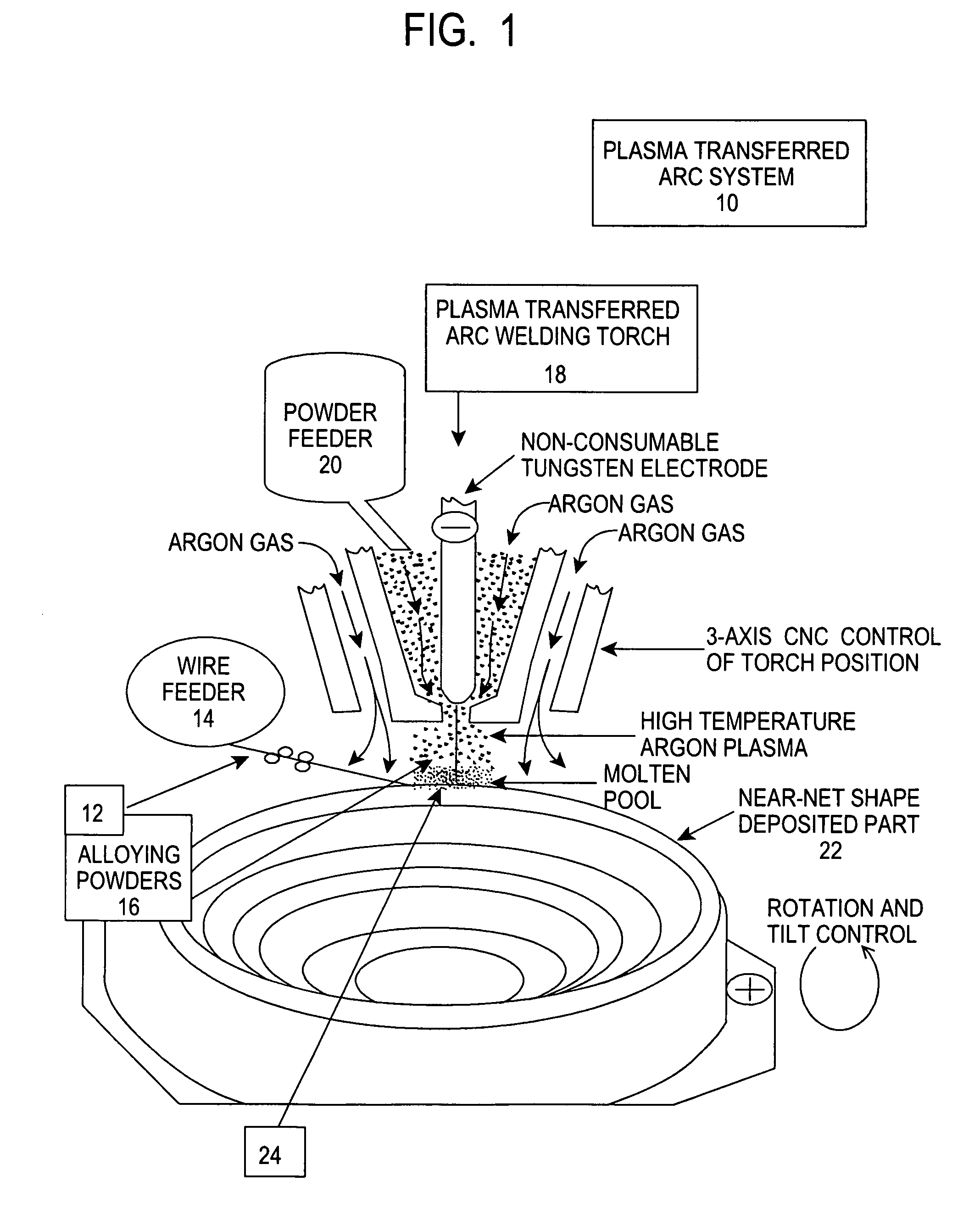

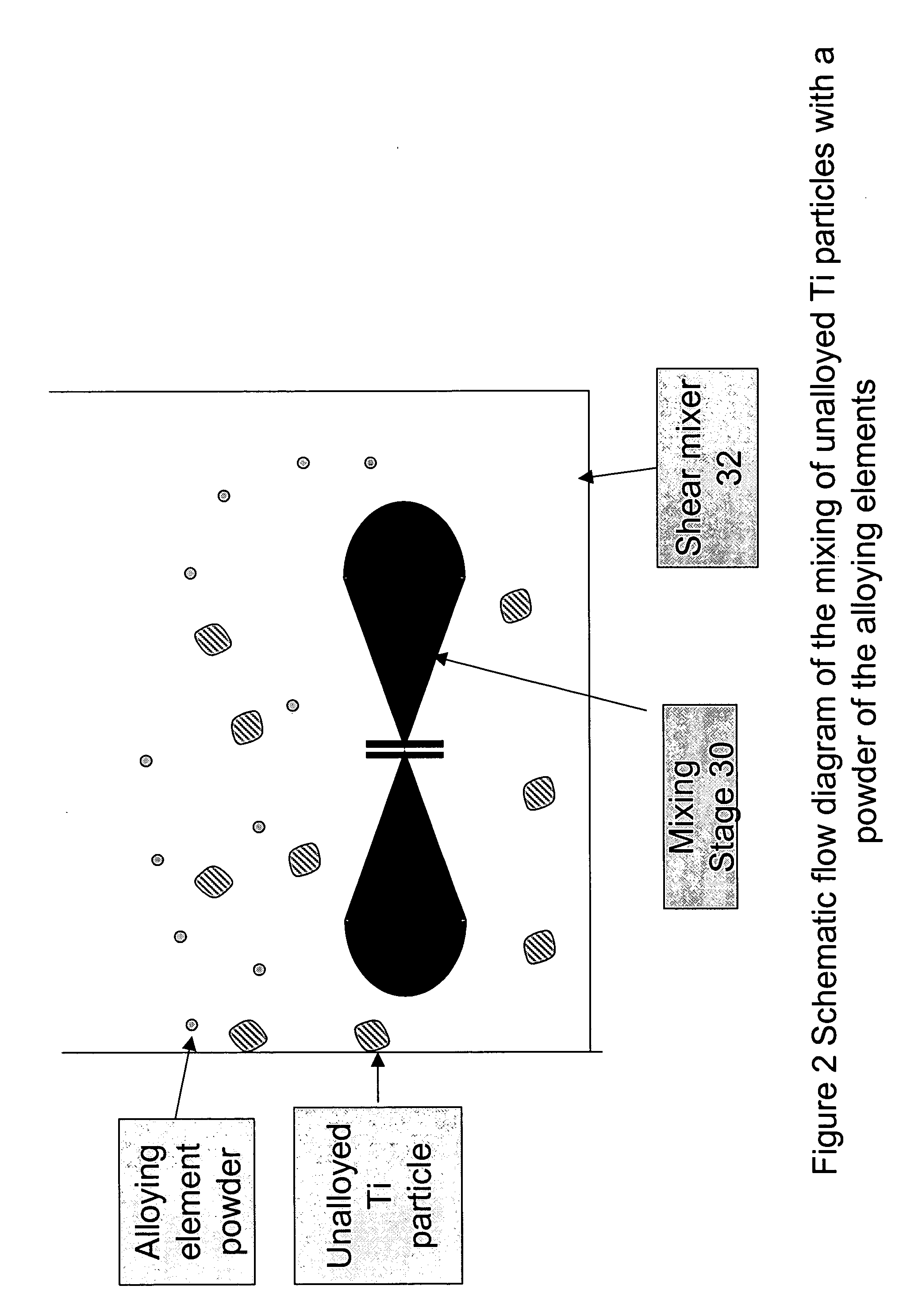

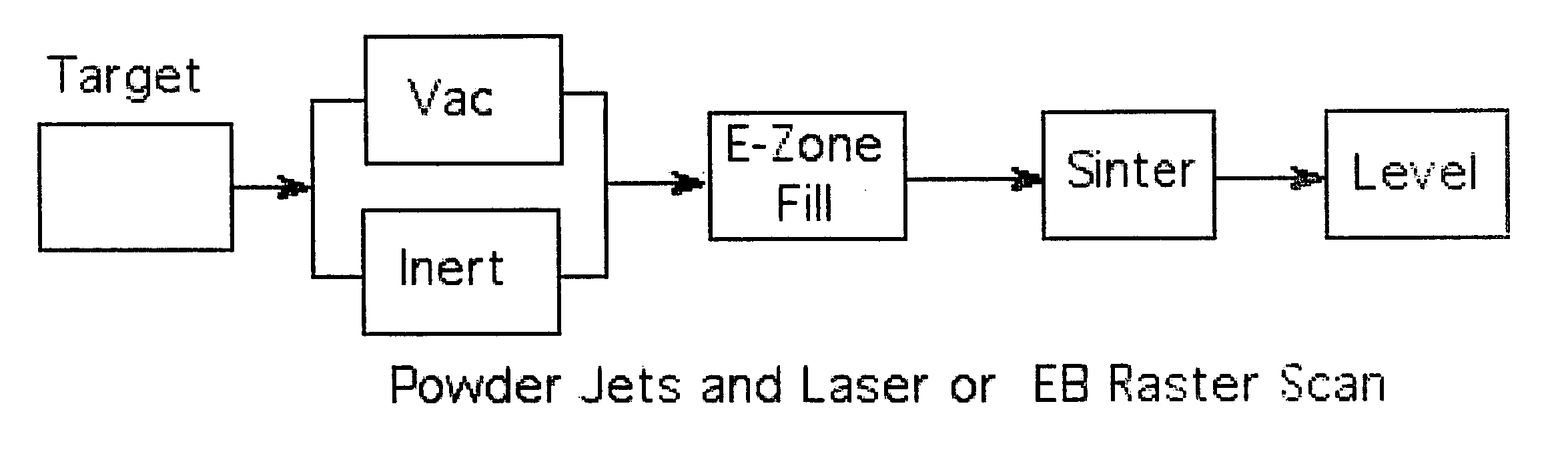

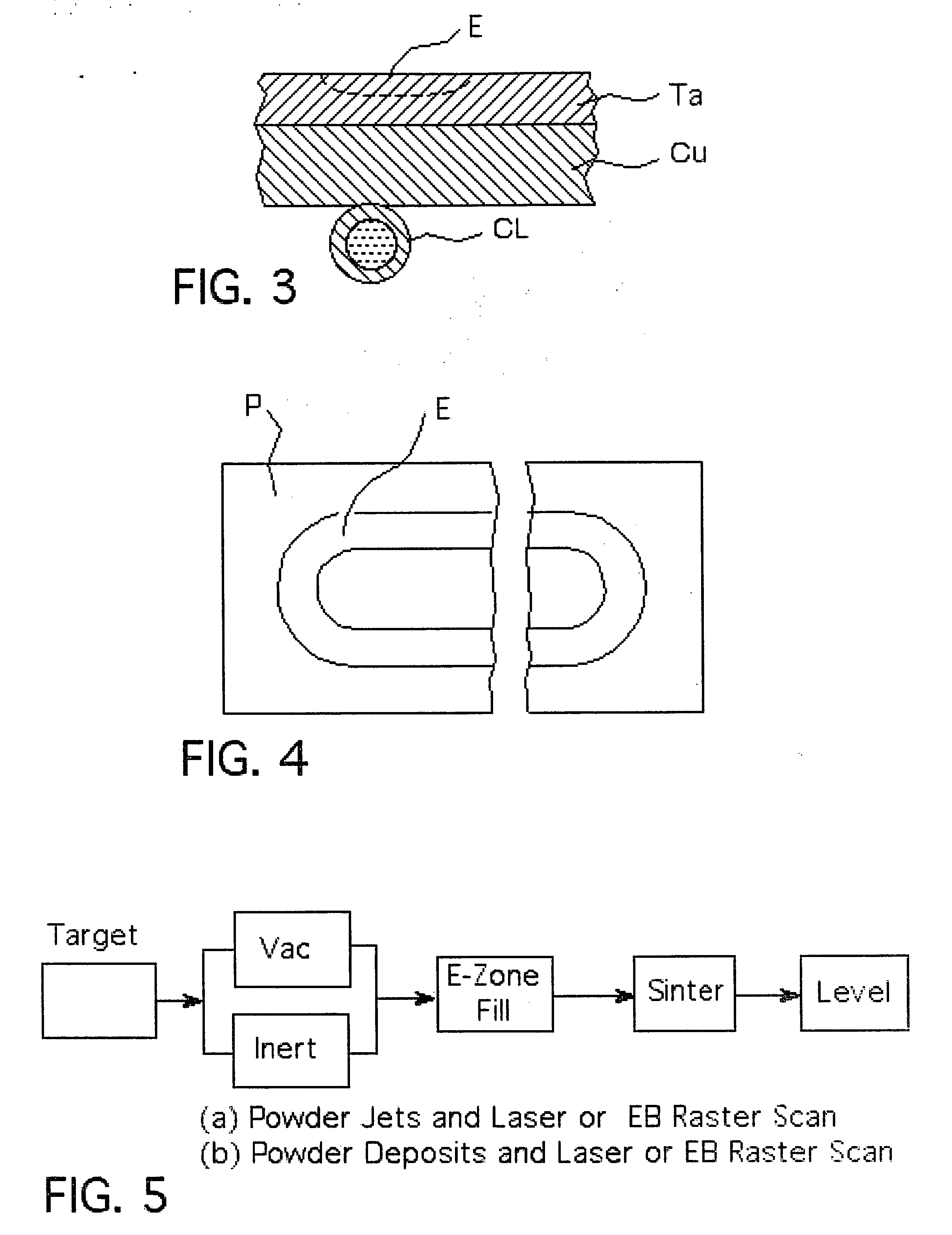

Low cost process for the manufacture of near net shape titanium bodies

InactiveUS20060185473A1Low costAdditive manufacturing apparatusArc welding apparatusHigh energyTitanium

Owner:ATS MER LLC

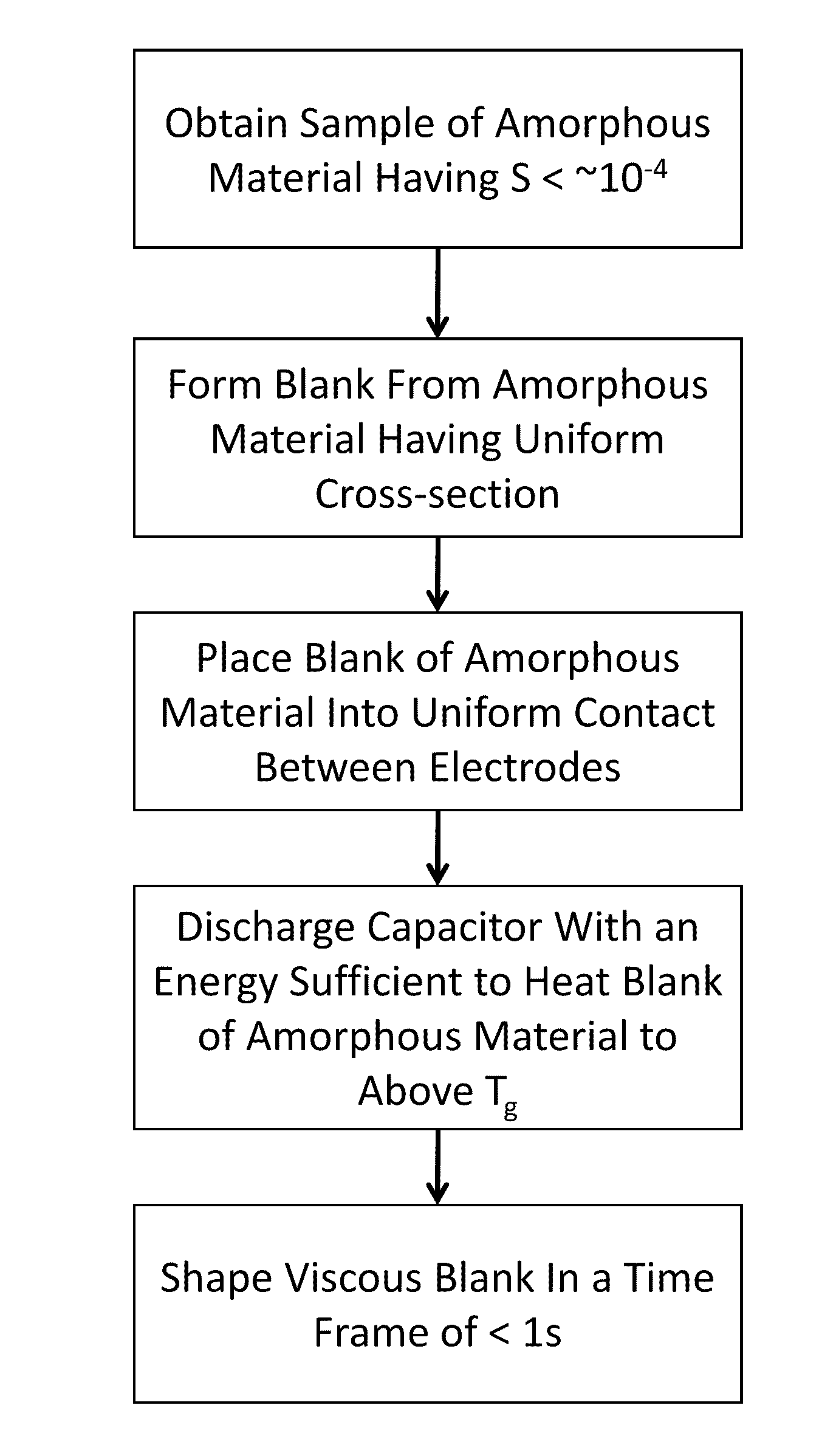

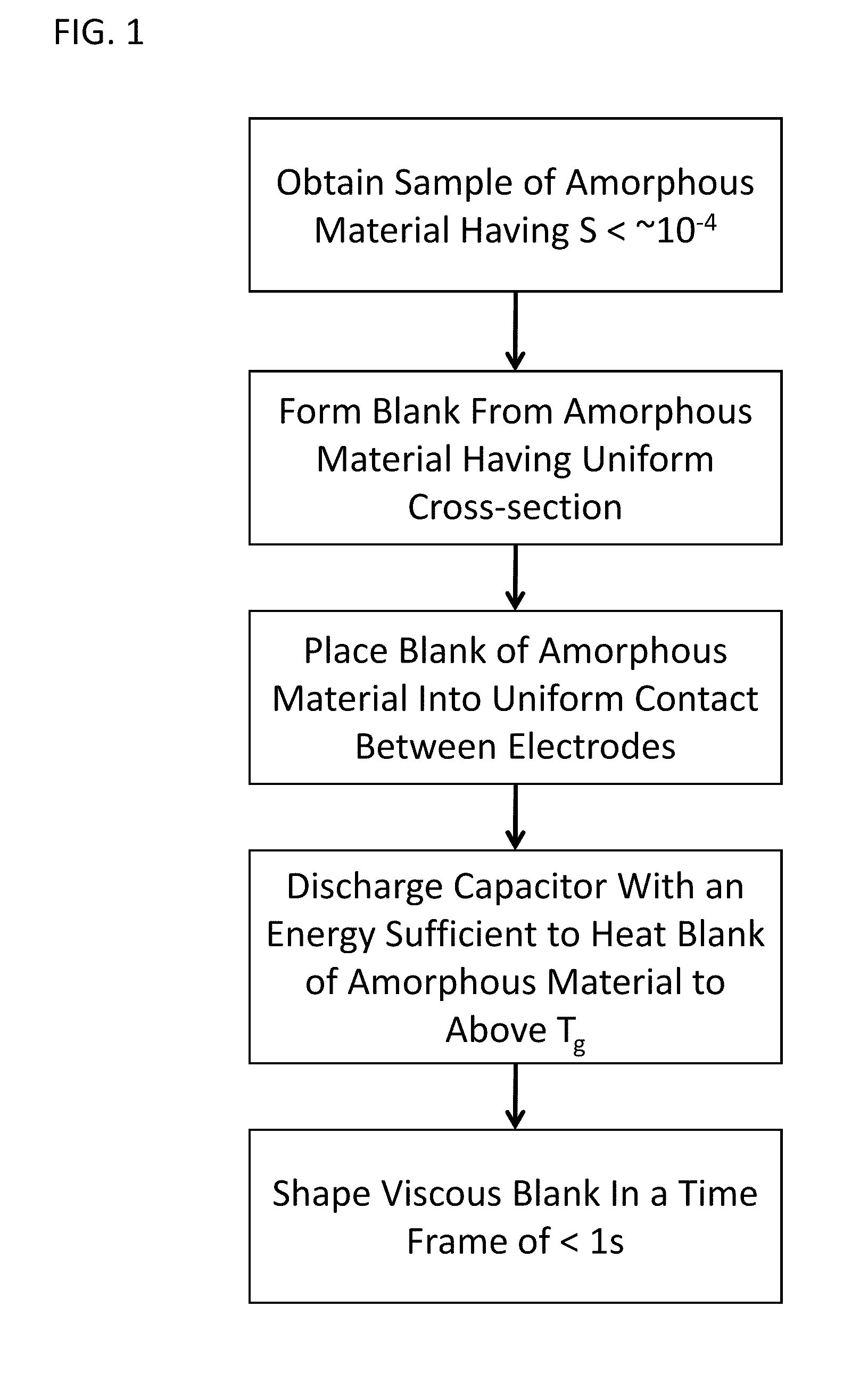

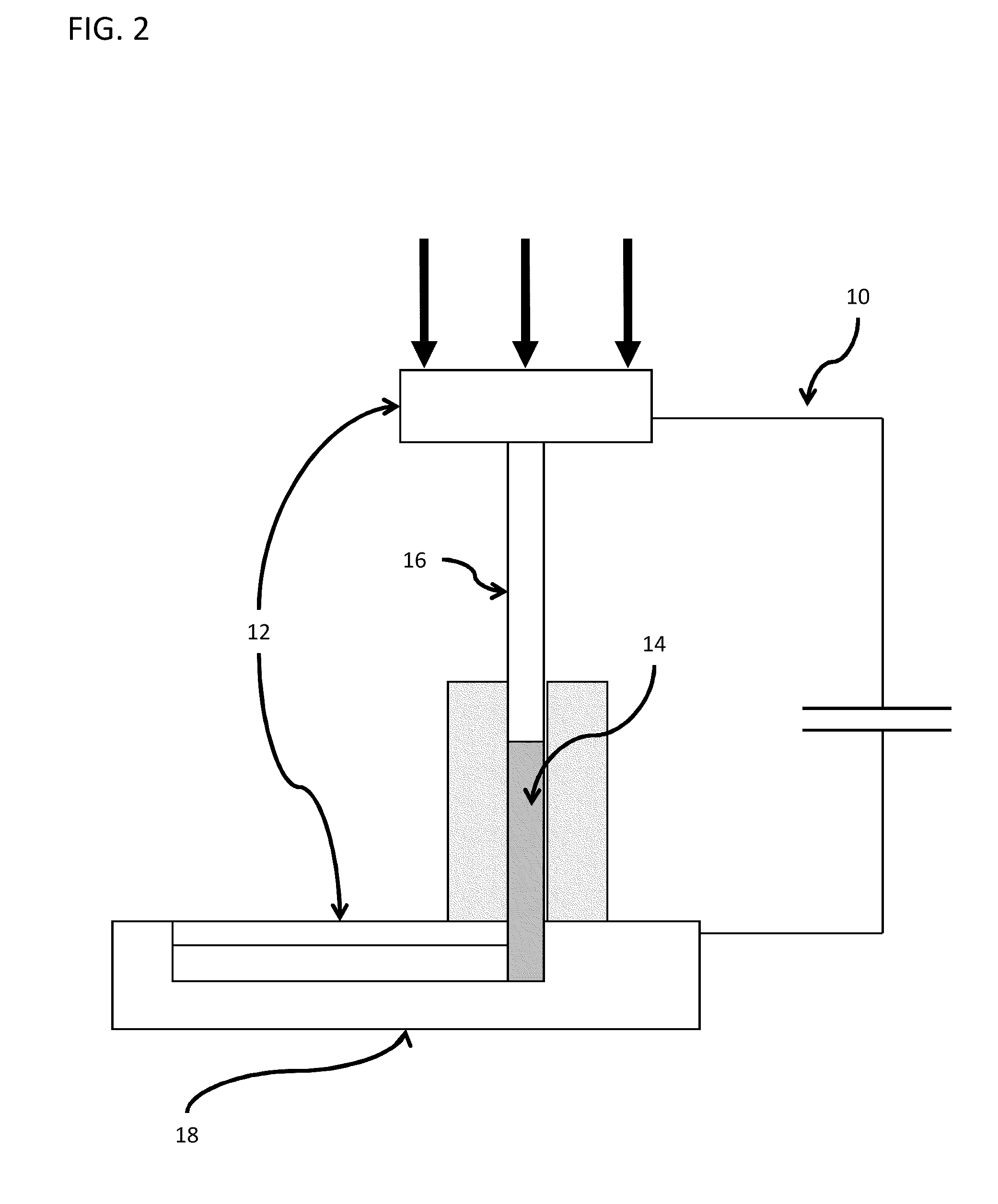

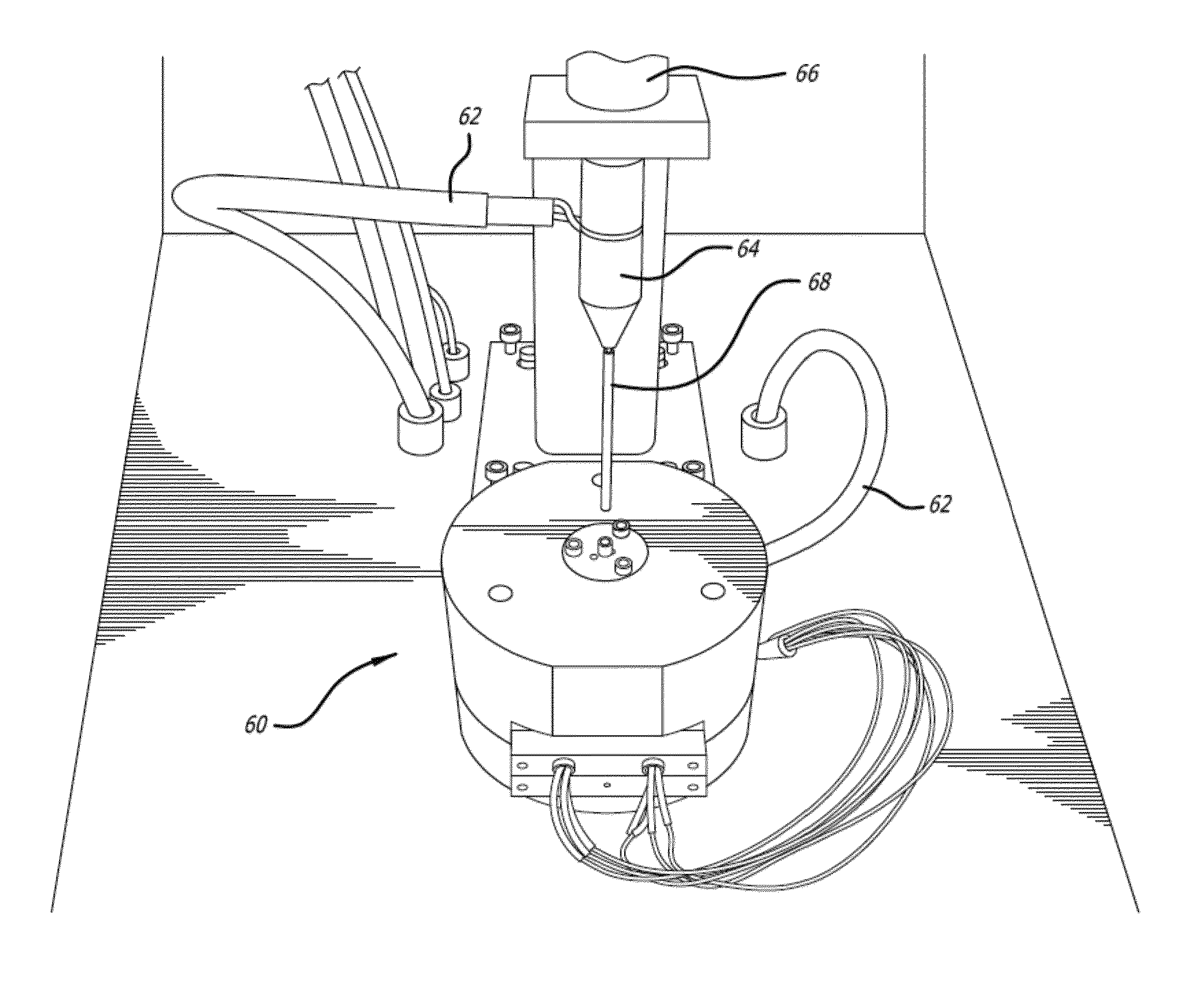

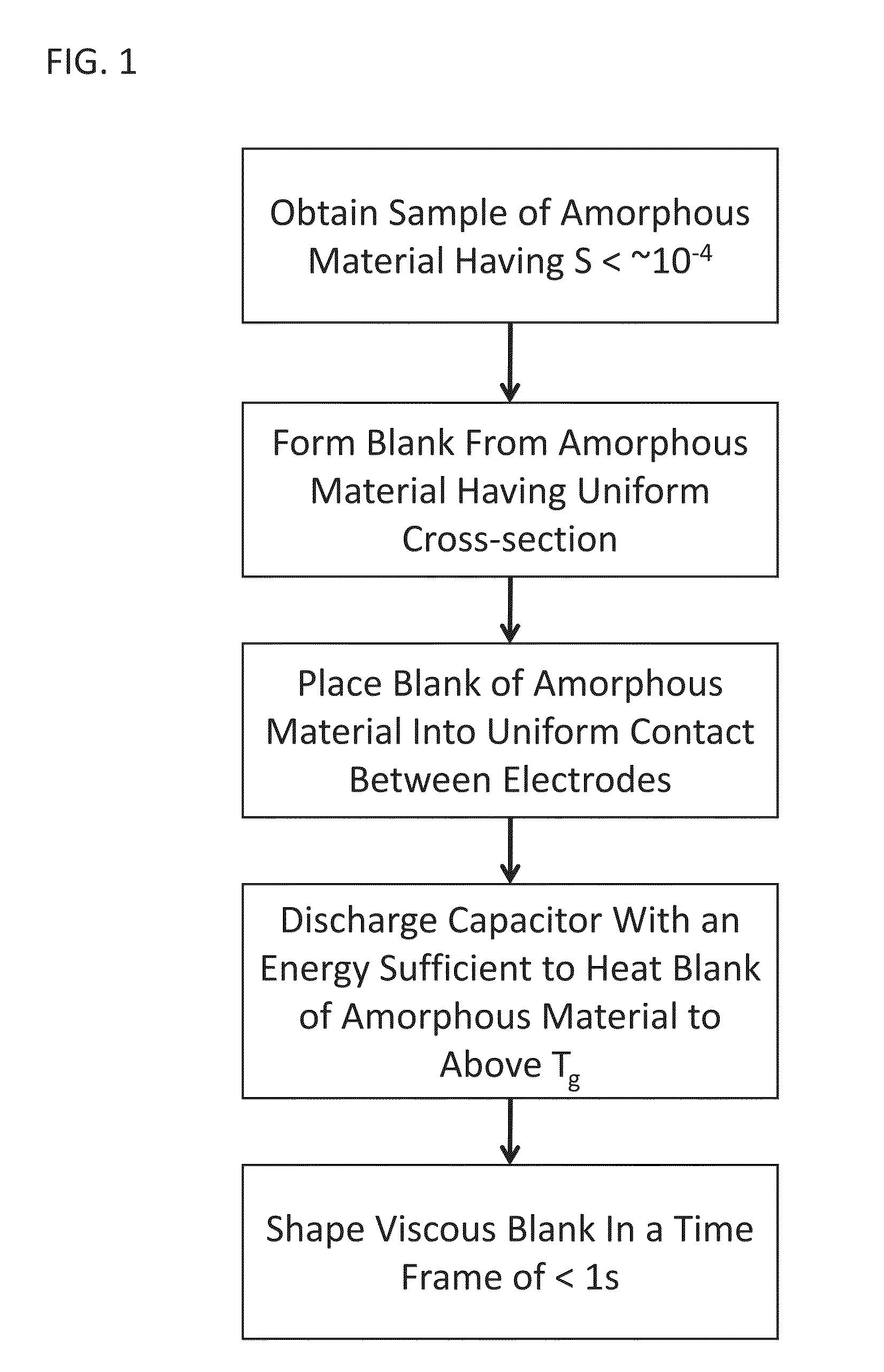

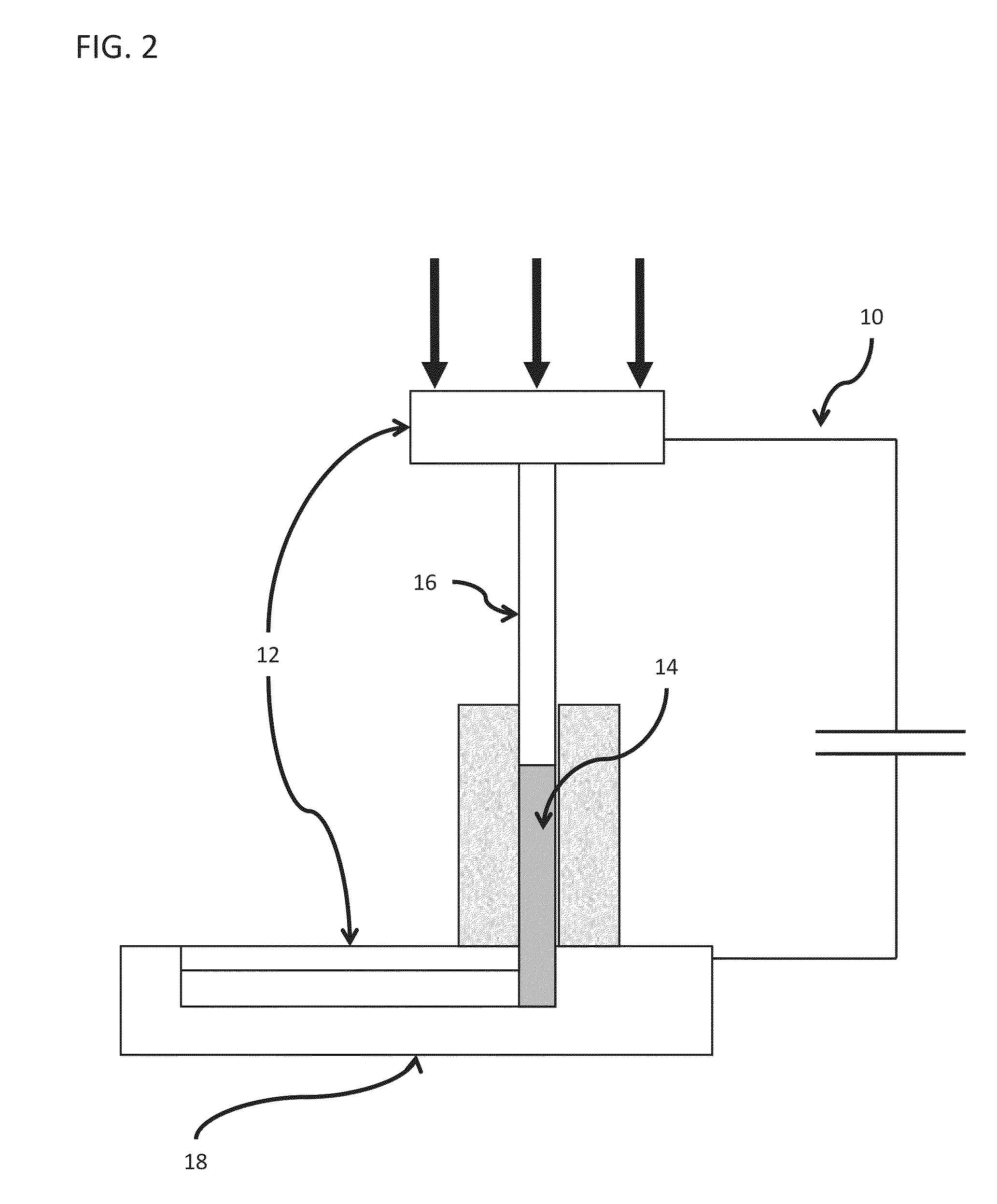

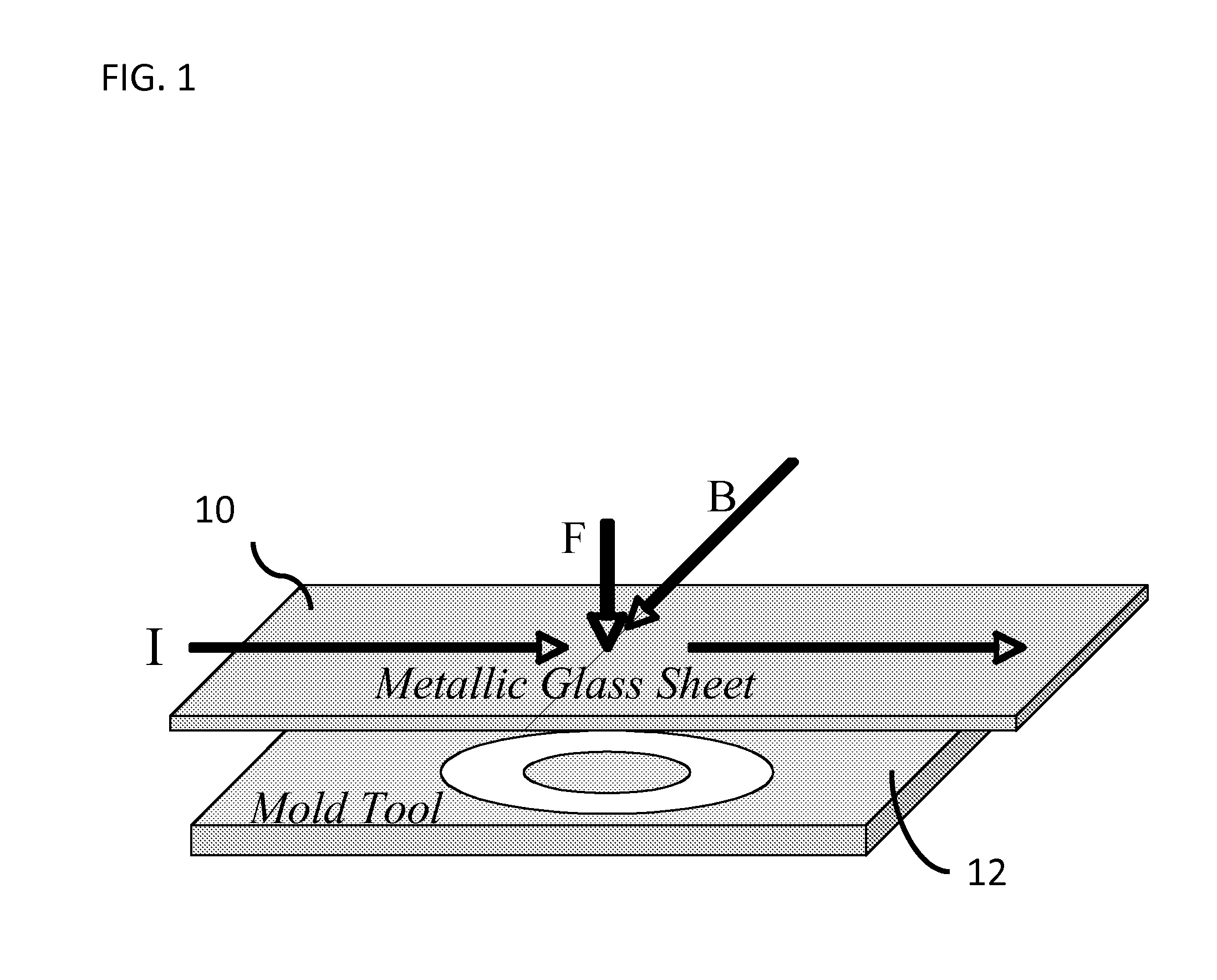

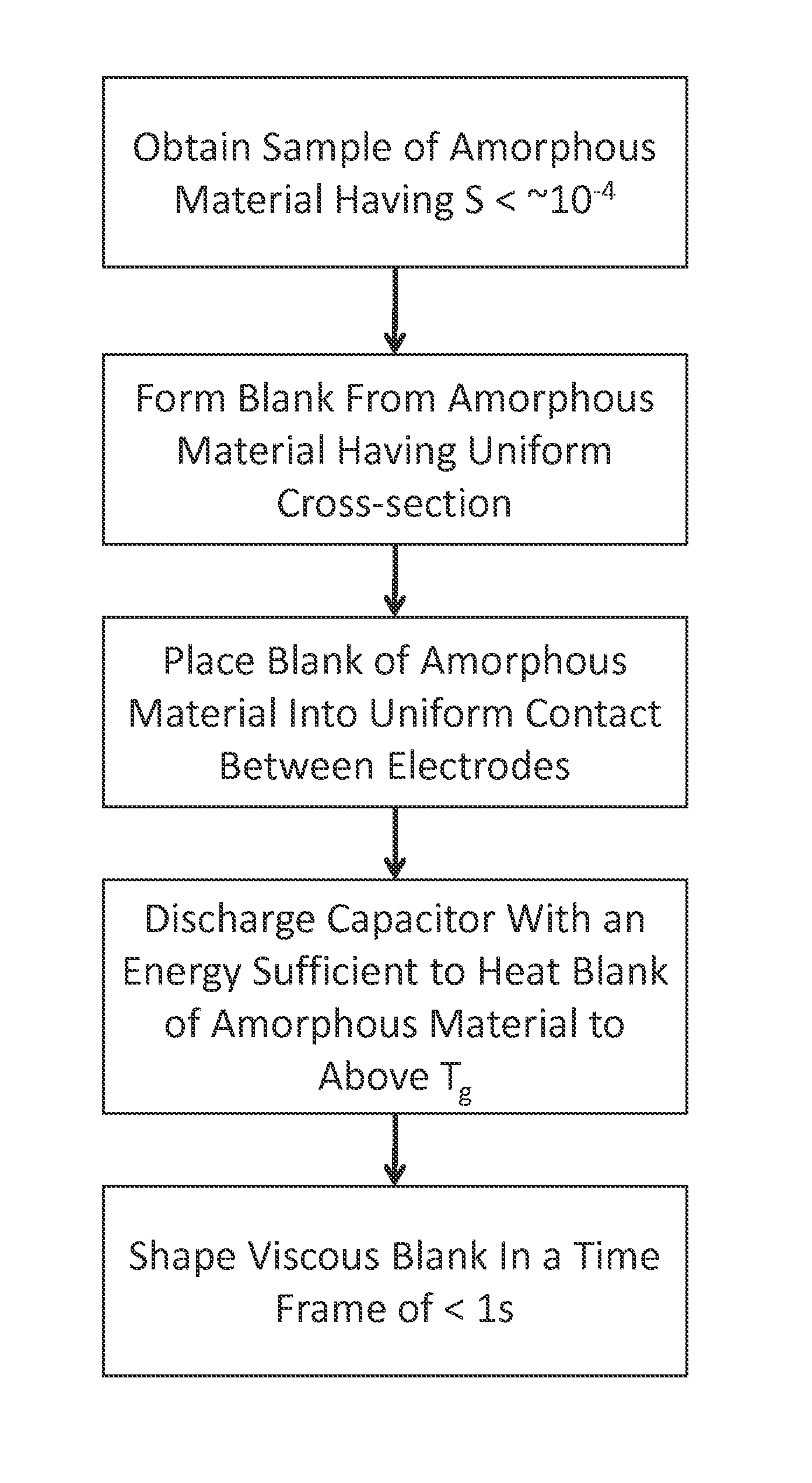

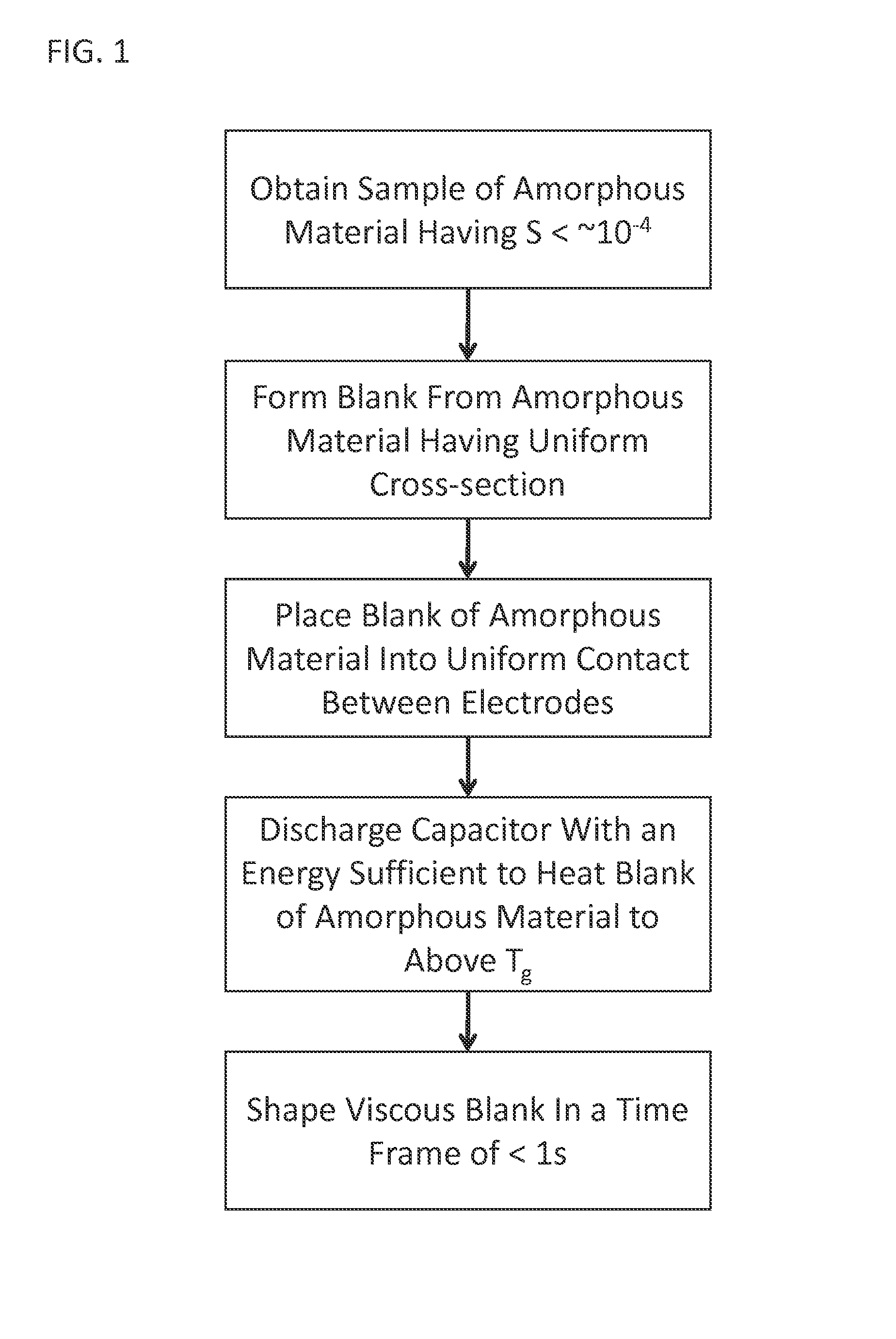

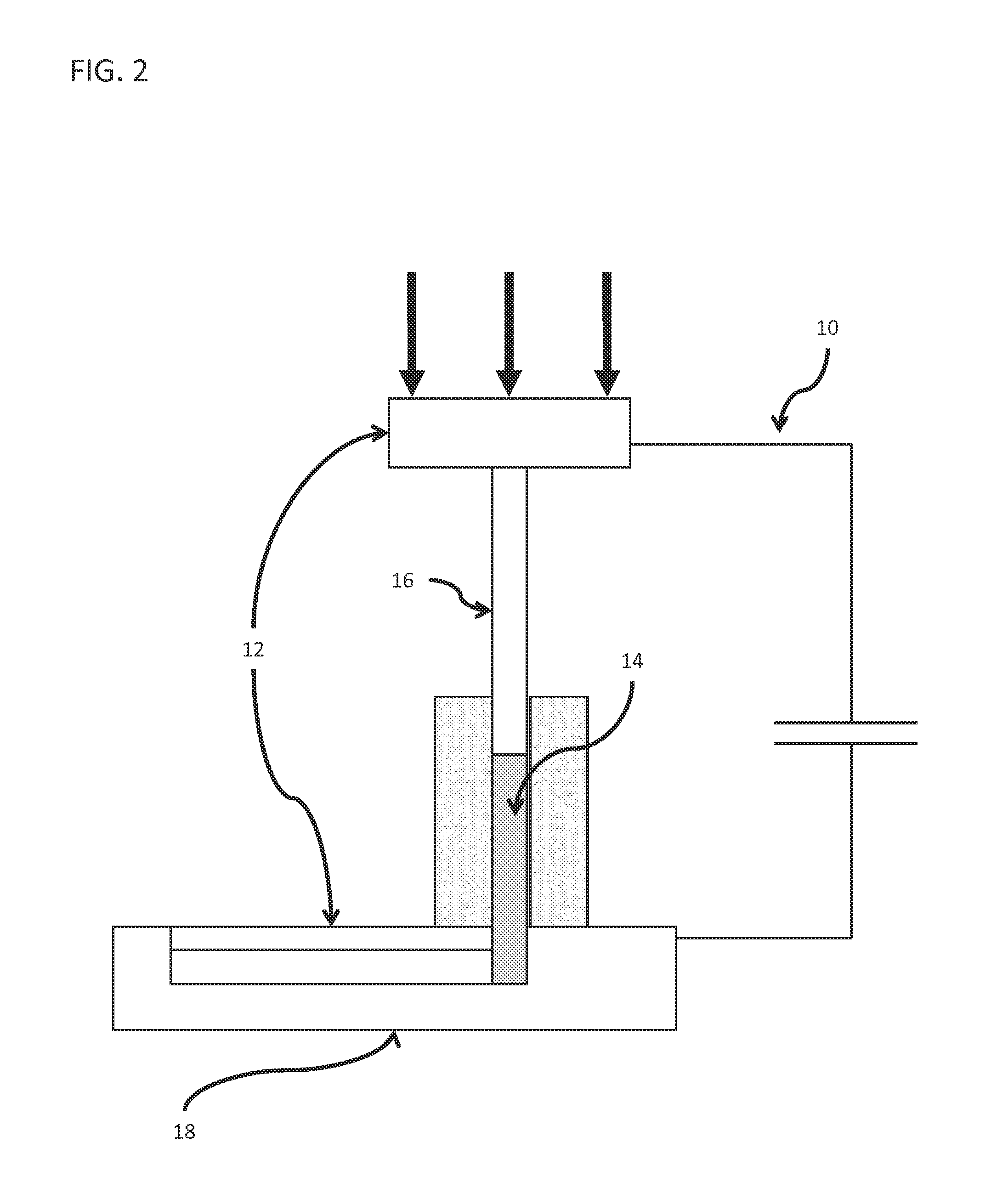

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

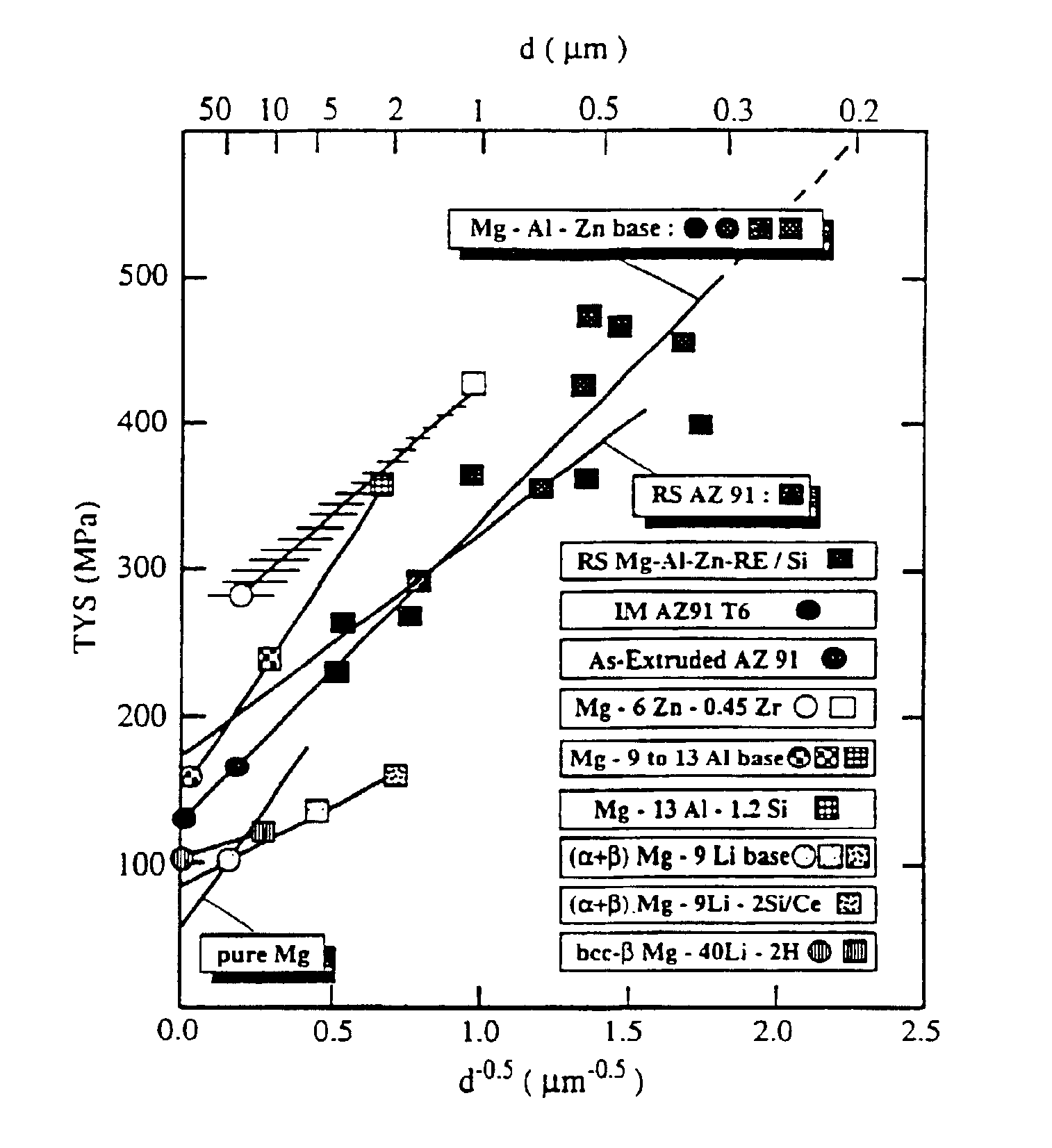

Selected processing for non-equilibrium light alloys and products

InactiveUS6908516B2Reduce resistanceMultiplies numberVacuum evaporation coatingSputtering coatingGas phaseMaterials science

A new class of light or reactive elements and monophase α′-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said α′-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable α′-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting α′-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

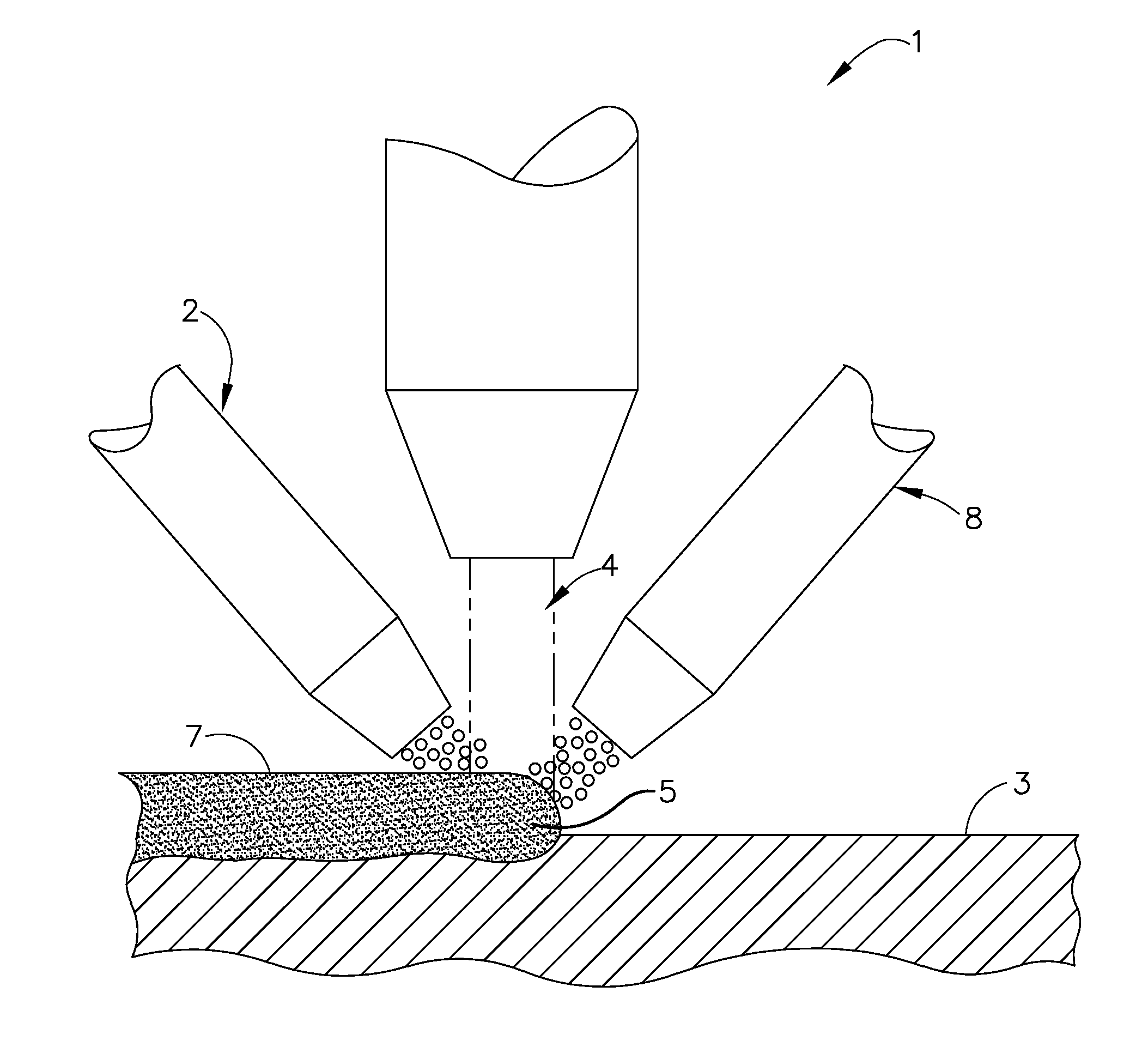

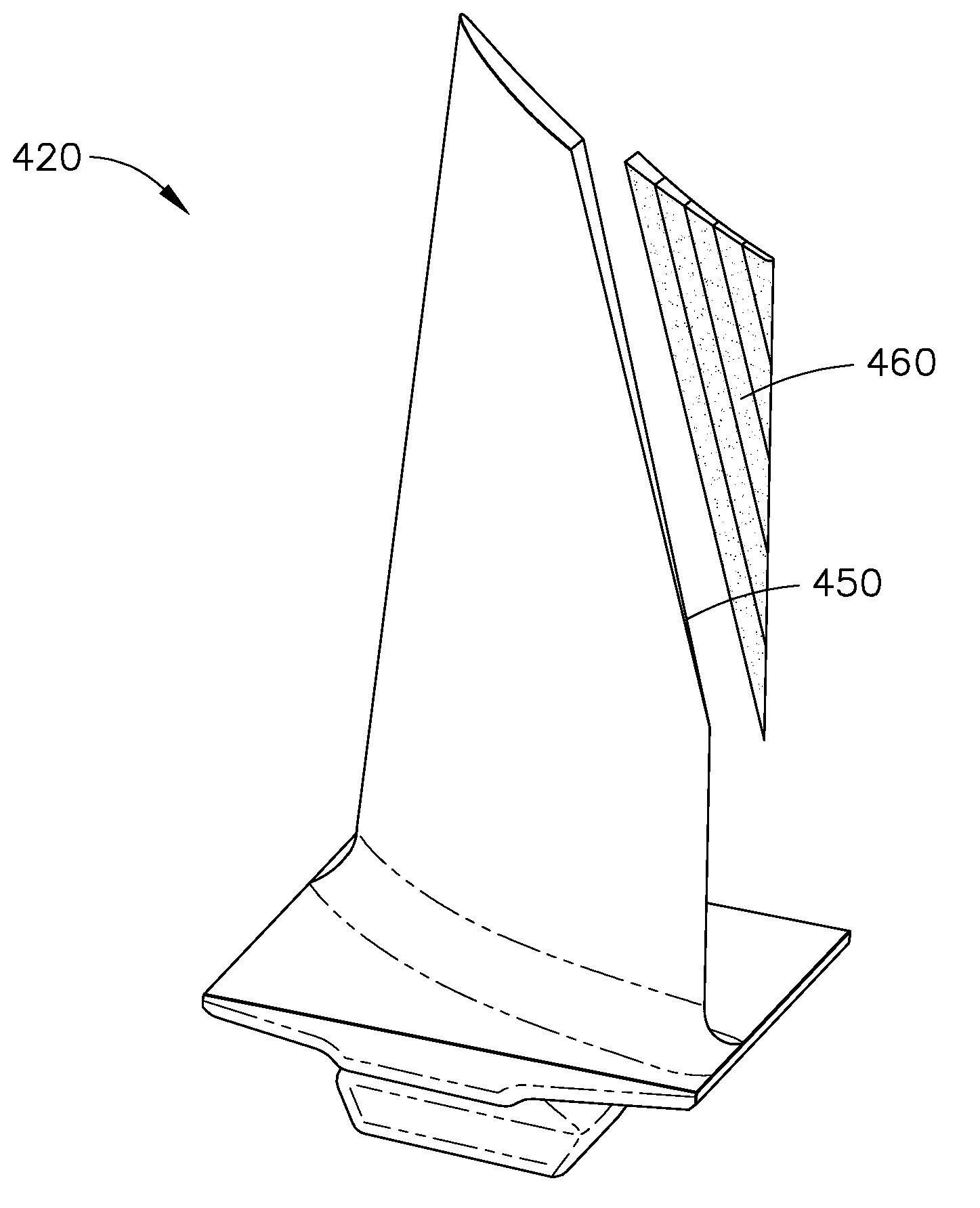

Laser net shape manufacturing and repair using a medial axis toolpath deposition method

InactiveUS20080182017A1Eliminate and reduce numberAdditive manufacturingTurbinesMedial axisNet shape

A method is disclosed for laser net shape manufacturing a part or repairing an area of a part comprising providing a CAD model of the part to be manufactured or repaired, digitally slicing the CAD model into a plurality of deposition layers, determining a medial axis for each of the deposition layers of the part or repair area; and depositing a bead of a material in a pattern centered upon the medial axis of each of the deposition layers so as to build-up the material by each of the deposition layer until the part is manufactured or repaired.

Owner:GENERAL ELECTRIC CO

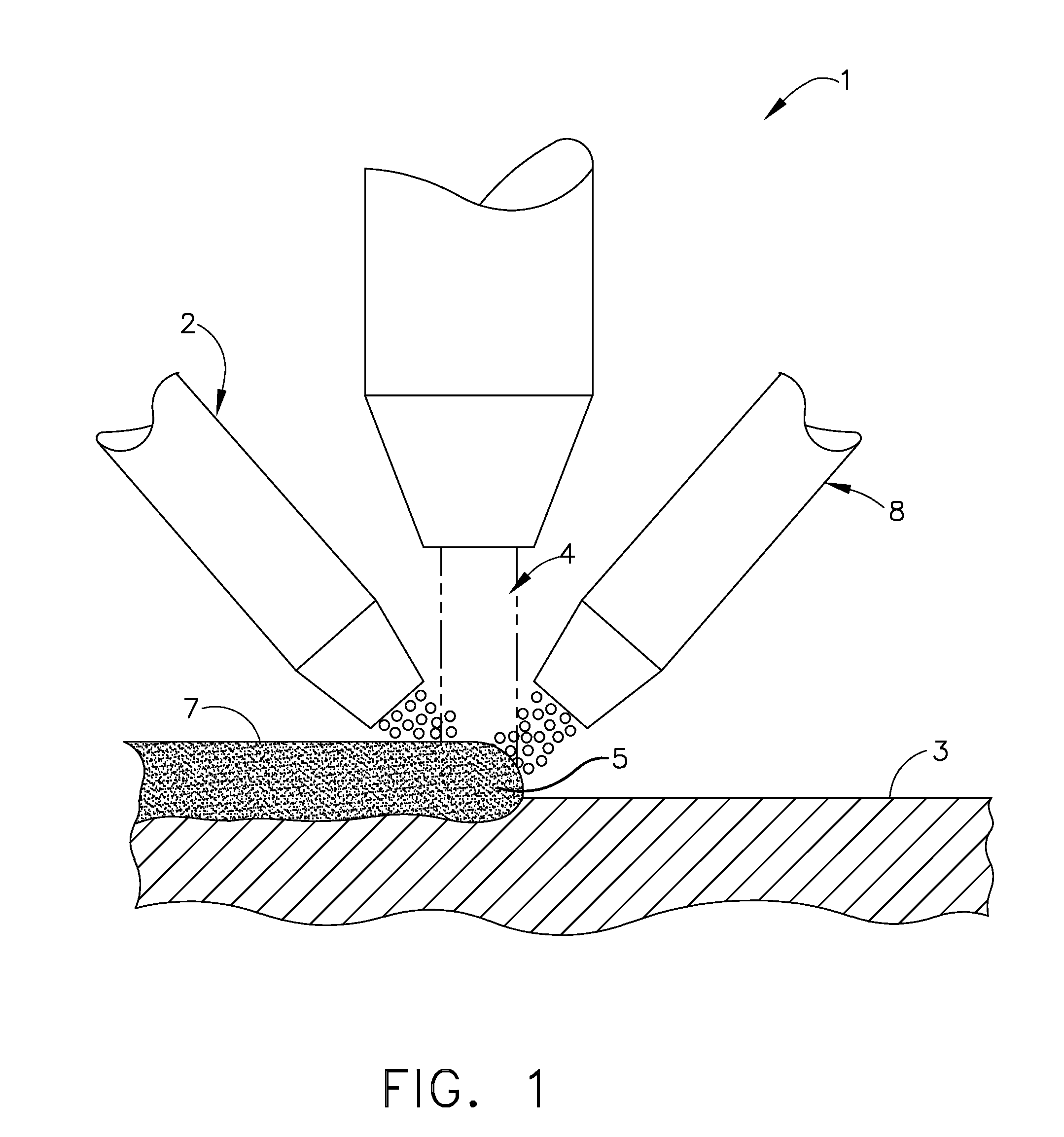

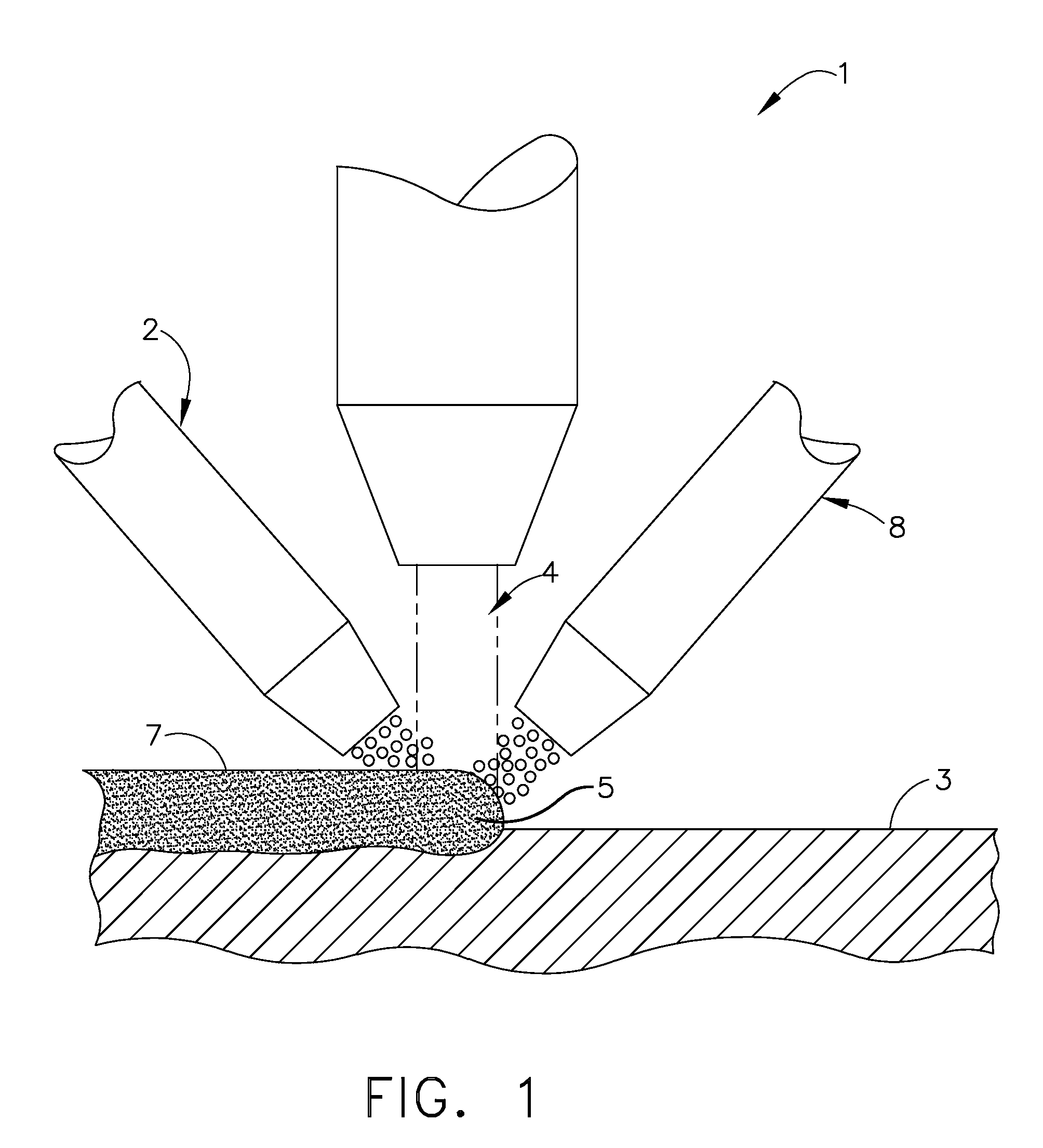

Laser net shape manufacturing using an adaptive toolpath deposition method

A method is disclosed for laser cladding a substrate, comprising providing the substrate; depositing a first determined variable bead width of a material along a toolpath upon the substrate; depositing a second adjacent determined variable bead width of a material along the toolpath which overlaps the first determined variable bead width of deposited material; continuing to deposit a plurality of overlapping predetermined adjacent variable bead widths of a material until a first material layer is complete; forming a second material layer by depositing a plurality of overlapping predetermined variable bead widths of a material on top of the first material layer; and continuing to deposit material layers on top of deposited material layers until the cladding is complete; wherein the variable bead width of the deposited material is controlled by a computer having a plurality of input parameters to maintain an approximately constant percent of bead width overlap.

Owner:GENERAL ELECTRIC CO

Method for manufacturing thin film transistor array panel for liquid crystal display

InactiveUS20020063253A1Inhibit currentTransistorSolid-state devicesElectrical conductorLiquid-crystal display

Simplified method of manufacturing liquid crystal displays. A gate wire including a gate line, a gate pad and a gate electrode is formed on the substrate by using the first mask. A gate insulating layer, a semiconductor layer, a ohmic contact layer and a metal layer are sequentially deposited to make a quadruple layers, and patterned by a dry etch of using the second mask. At this time, the quadruple layers is patterned to have a matrix of net shape layout and covering the gate wire. An opening exposing the substrate is formed in the display area and a contact hole exposing the gate pad is formed in the peripheral area. Next, ITO is deposited and a photoresist layer coated on the ITO. Then, the ITO layer is patterned by using the third mask and a dry etch, and the data conductor layer and the ohmic contact layer not covered by the ITO layer is dry etched. After depositing a passivation layer, a opening is formed by using the fourth mask and the exposed semiconductor layer through the opening is etched to separate the semiconductor layer under the adjacent data line.

Owner:SAMSUNG ELECTRONICS CO LTD

Refractory metal and alloy refining by laser forming and melting

ActiveUS20050142021A1Shorten cycle timeRadiation applicationsVacuum evaporation coatingNiobiumLinearity

Owner:MATERION NEWTON INC

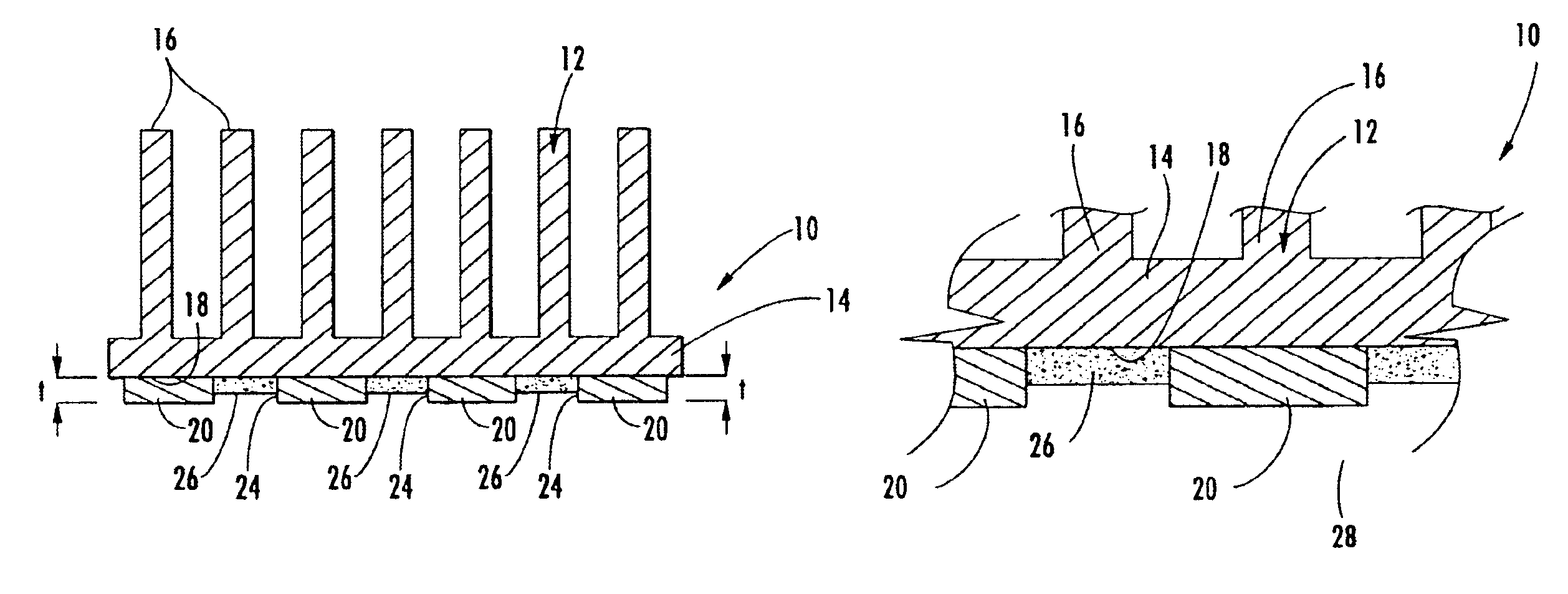

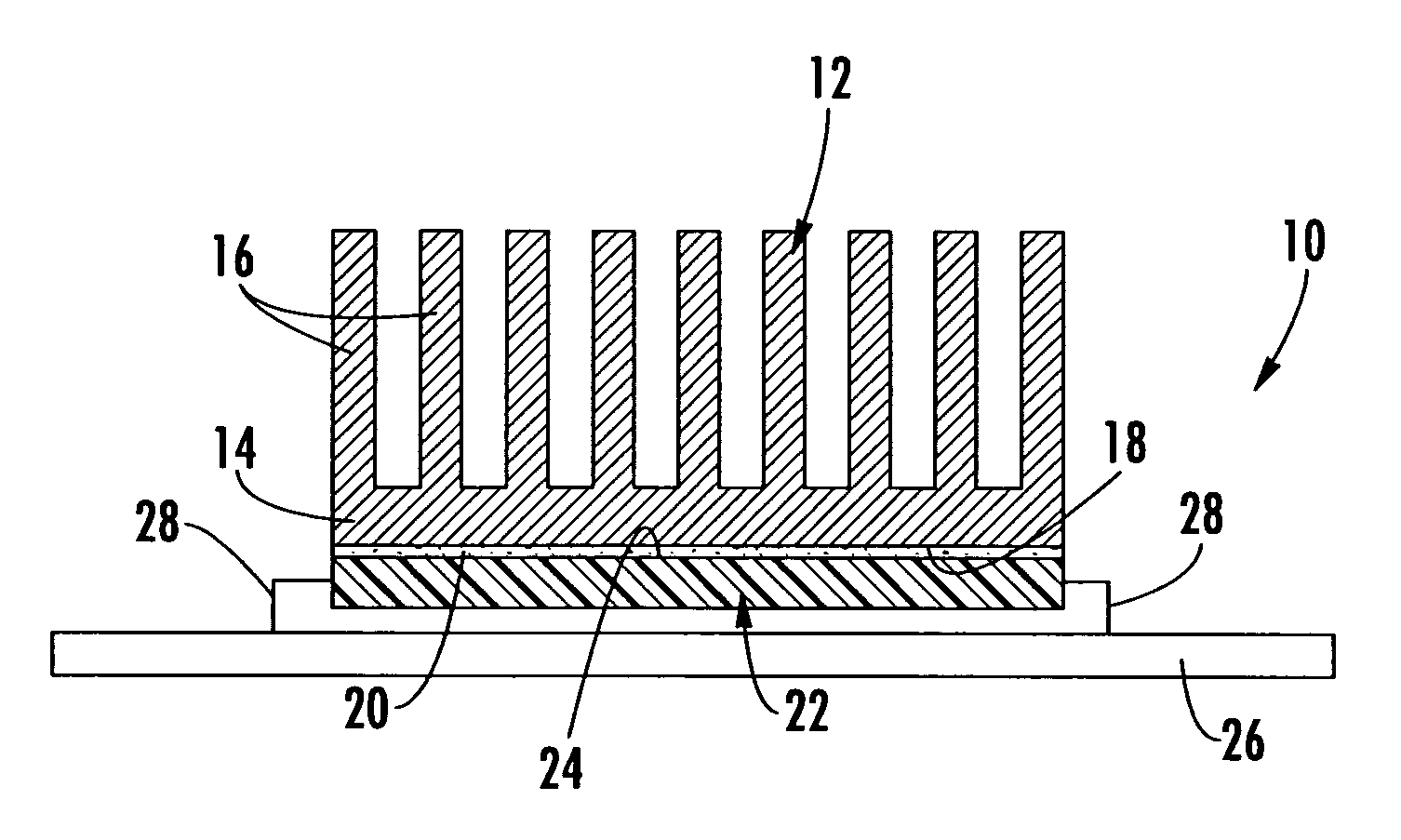

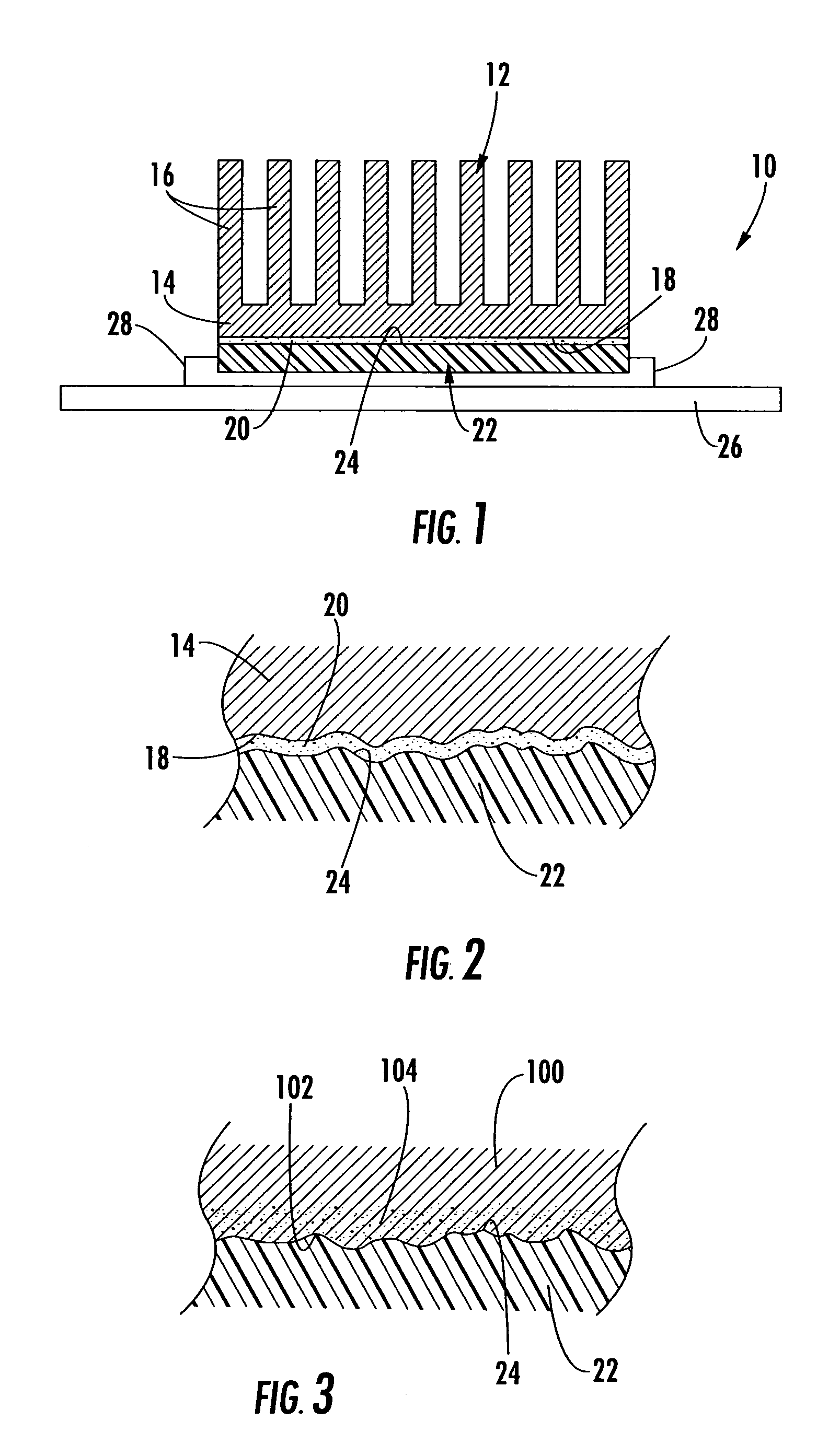

Structure and method of attaching a heat transfer part having a compressible interface

InactiveUS6896045B2Increase contact pressureImprove thermal conductivityMetal-working apparatusHeat transfer modificationCompressible materialElastomer

The present invention discloses a thermal transfer interface having an integrally formed means for fastening and maintaining intimate thermal contact between a heat generating device and a heat-dissipating device. The interface of the present invention includes two components, a compressible thermal transfer component having a first thickness and an adhesive fastening component having a second thickness that is less than the first. The first component, the thermal transfer element, includes a base polymer matrix compound that is loaded with a thermally conducting filler that imparts thermally conductive properties to the net shape moldable material. The polymer base matrix is preferably a highly compressible material such as an elastomer. The second component of the present invention is a pressure sensitive adhesive component. The adhesive is applied adjacent to the thermal transfer element or in an alternating pattern throughout a base field of thermal transfer material. The adhesive component has a thickness that is less than the overall thickness of the thermal transfer material. When, the heat dissipating device with the present invention applied is pressed into contact with a heat generating surface the elastomer is compressed and maintained in the compressed state by the pressure sensitive adhesive material.

Owner:TICONA POLYMERS INC

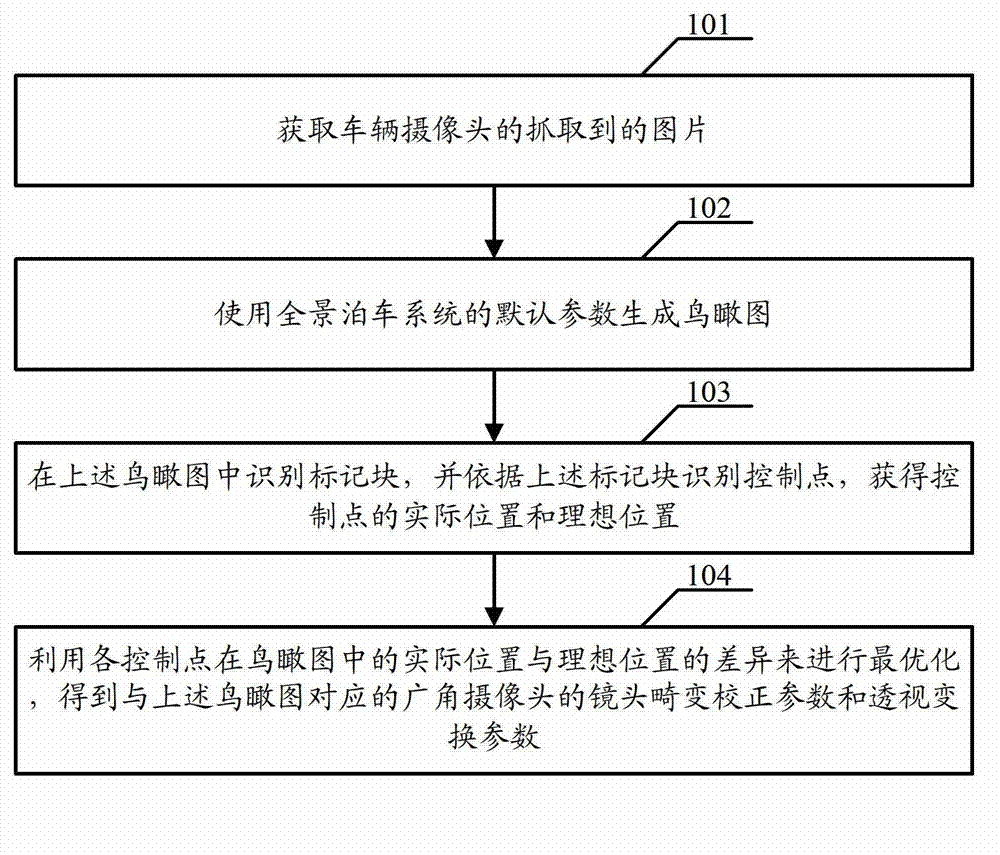

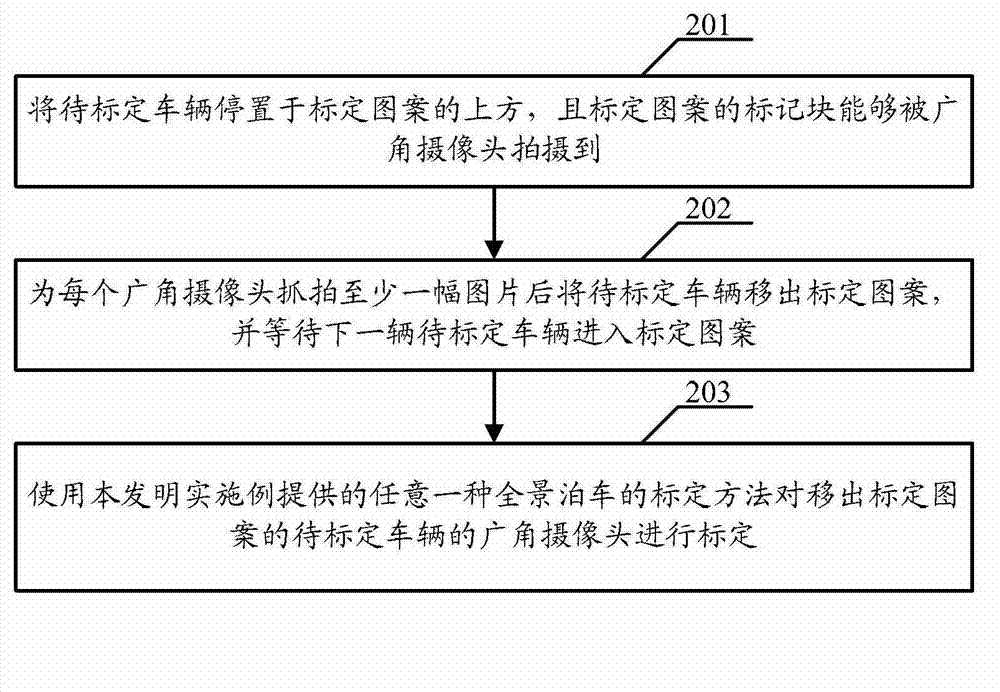

Panorama parking calibration method and device, and automatic calibration method

ActiveCN103035005AGood stitchingPrecise positioningImage enhancementImage analysisCamera lensPerspective transformation

The invention discloses a panorama parking calibration method and a device, and an automatic calibration method, wherein the panorama parking calibration method comprises the steps of obtaining pictures which is captured by an automobile camera; using default parameters of a panorama parking system to generate an aerial view; distinguishing tag blocks on the aerial view; distinguishing controlling points according to the tag blocks; obtaining actual positions and ideal positions of the controlling points, wherein the controlling points are intersection points of lines and distributed in a net shape, and the ideal positions are appointed positions in the aerial view; and optimizing by utilizing difference between the actual positions and the ideal positions of each controlling point in the aerial view and obtaining lens distortion correction parameters and perspective transformation parameters of a wind-angle camera which corresponds to the aerial view. The area of the tag blocks is greater than that of the intersection points and is easy to distinguish. A light color is adopted on distinguish strips and a deep color is adopted on a carrier so as to reduce effects which are caused by reflect light, an absolute coordinate of a calibration pattern on a coordinate system is positioned and calibrated accurately, and a success rate of calibration is improved.

Owner:GUANGZHOU ZHIYUAN ELECTRONICS CO LTD

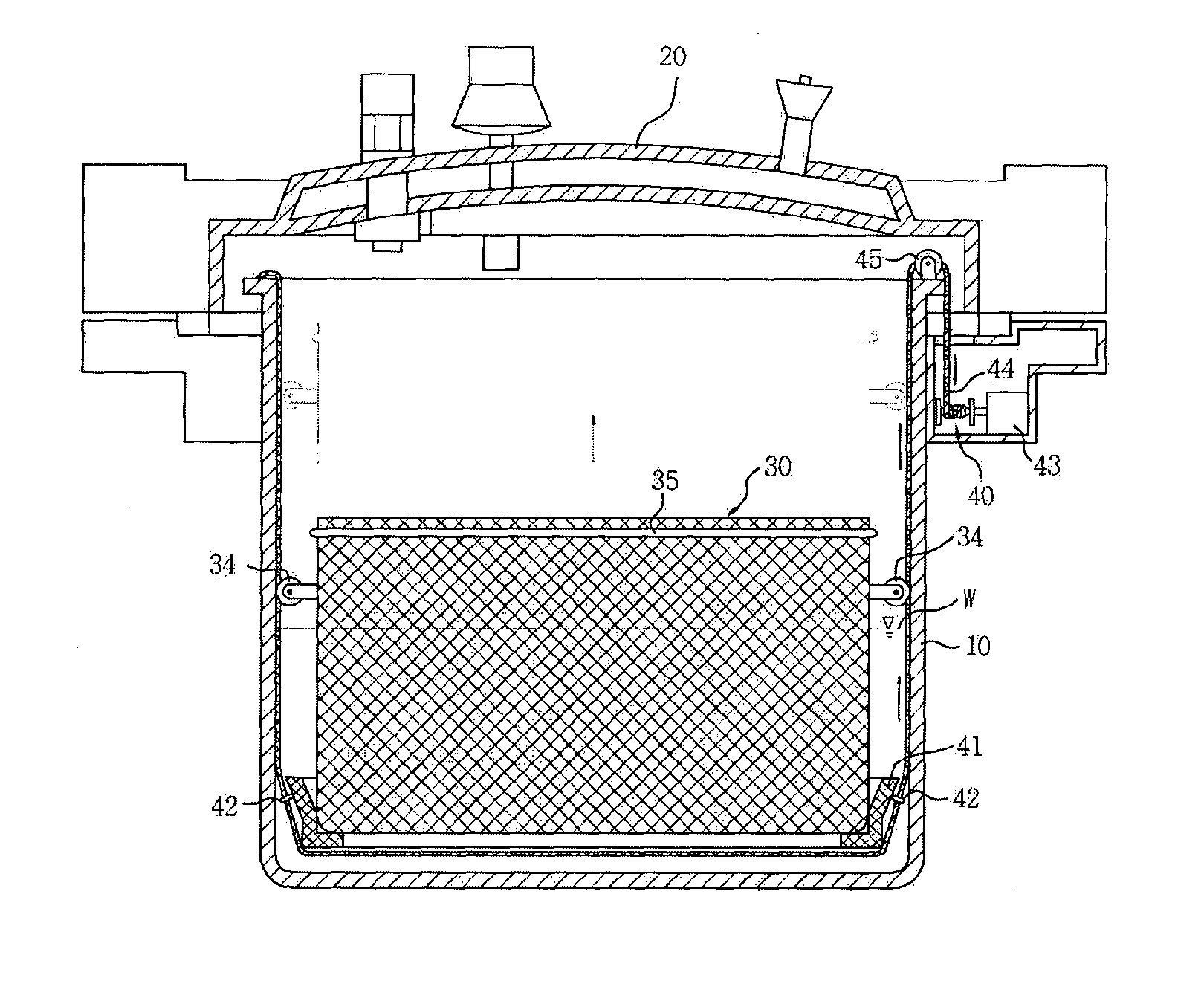

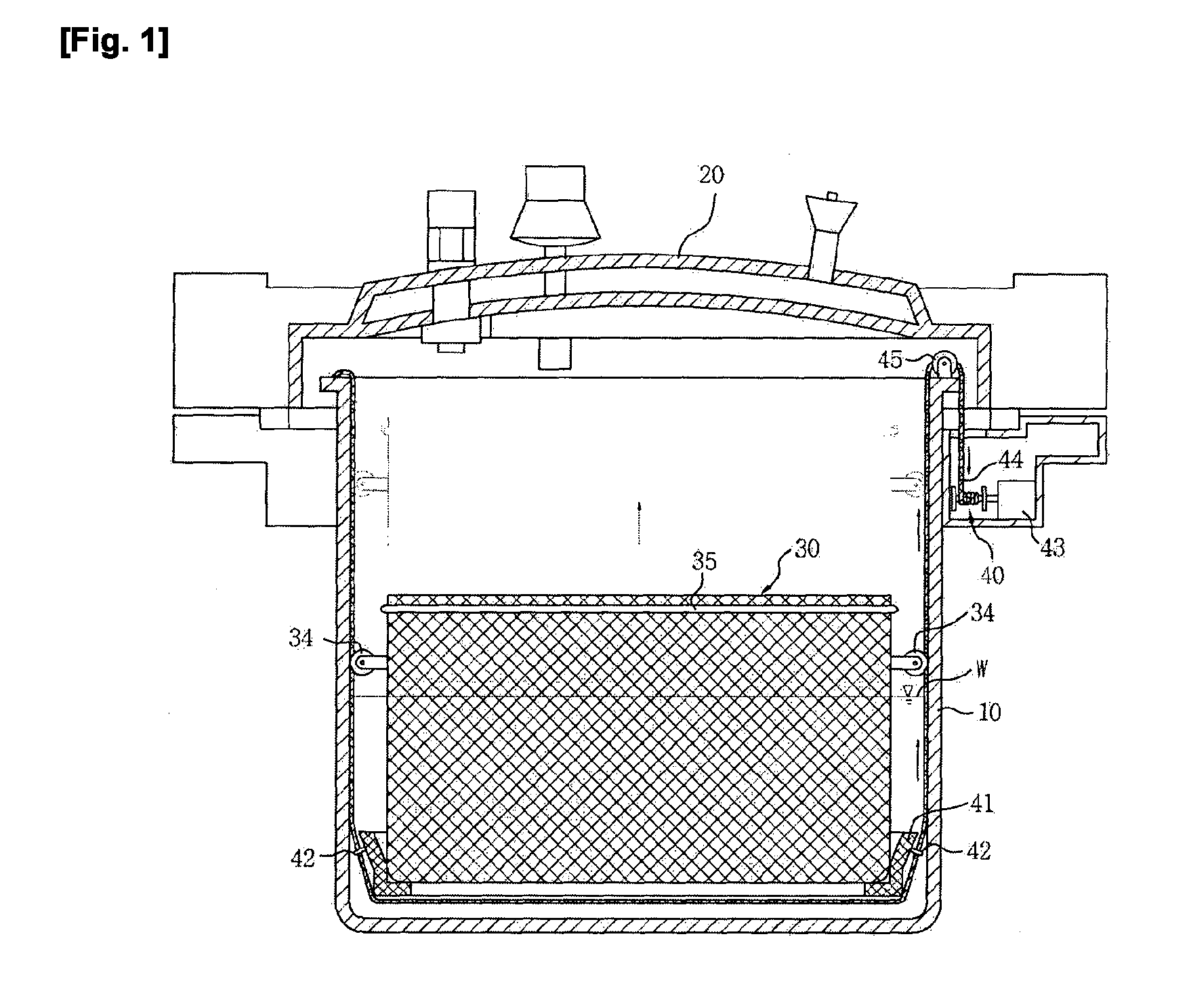

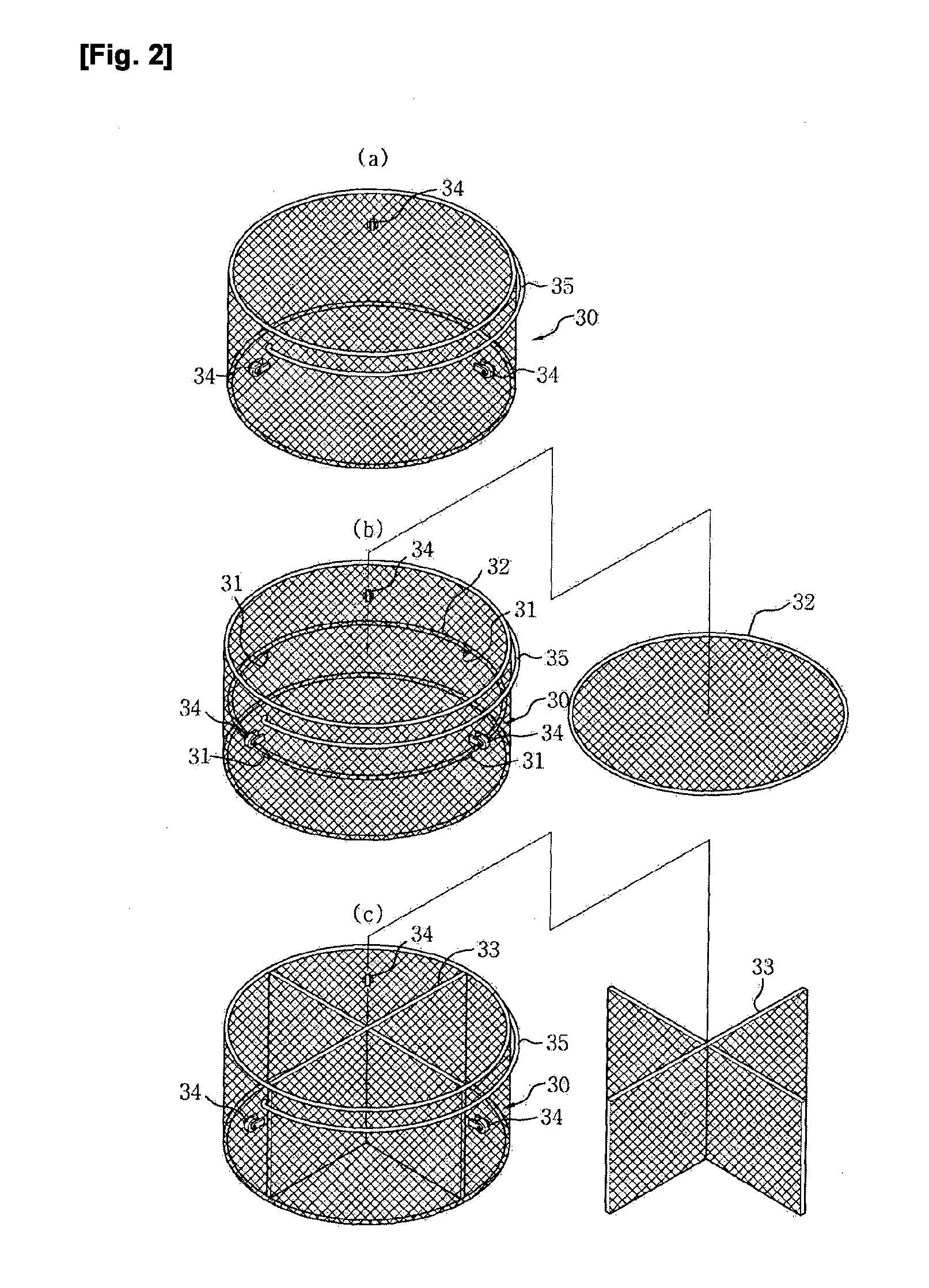

Pressure cooker for cooking noodles

The present invention relates to a pressure cooker for cooking noodles, wherein a cooking container capable of cooking noodles is formed into a net shape inside a main body of the pressure cooker and a lifting means capable of lifting the cooking container is provided, thereby allowing noodles to be evenly cooked through and enabling cooking of high quality noodles with taut and excellent texture through a dual cooking process comprising the following steps: putting noodles in the cooking container, boiling the noodles, and then lifting the cooking container to the surface of the water using the lifting means to steam the noodles at a high temperature and at a high pressure.

Owner:LEE KEUN YOUNG

Silicon carbide composites and methods for making same

InactiveUS6503572B1Improve permeabilityReduce the amount requiredPretreated surfacesCoatingsNet shapeToughness

Improved silicon carbide composites made by an infiltration process feature a metal phase in addition to any residual silicon phase. Not only are properties such as mechanical toughness improved, but the infiltrant can be so engineered as to have much diminished amounts of expansion upon solidification, thereby enhancing net-shape-making capabilities. Further, multi-component infiltrant materials may have a lower liquidus temperature than pure silicon, thereby providing the practitioner greater control over the infiltration process. In particular, the infiltration may be conducted at the lower temperatures, where low-cost but effective bedding or barrier materials can terminate the infiltration process once the infiltrant has migrated through the permeable mass up to the boundary between the mass and the bedding material.

Owner:BUSINESS ALLIANCE CAPITAL +1

High-strength discontinuously-reinforced titanium matrix composites and method for manufacturing the same

The invention relates to manufacturing the flat or shaped titanium matrix composite articles having improved mechanical properties such as lightweight plates, sheets for aircraft and automotive applications, heat-sinking lightweight electronic substrates, armor plates, etc. High-strength discontinuously-reinforced titanium metal matrix composite (TMMC) comprises (a) titanium matrix or titanium alloy as a major component, (b) ceramic and / or ≦50 vol. % intermetallic hard particles dispersed in matrix, (c) complex carbide- and / or boride particles at least partially soluble in matrix at sintering or forging temperatures such as ≦50 vol. % AlV2C, AlTi2Si3, AlTi6Si3, VB2, TiVSi2, TiVB4, Ti2AlC, AlCr2C, TiAlV2, V2C, VSi2, Ta3B4, NbTiB4, Al3U2C3 dispersed in matrix. Method for manufacturing these TMMC materials is disclosed. Sintered TMMC density exceeds 98% and closed discontinuous porosity allows performing hot deformation in air without encapsulating. Near-full density near-net shape TMMC parts with acceptable mechanical properties were manufactured without hot deformation.

Owner:ADVANCED MATERIALS PRODS

Elastomeric heat sink with a pressure sensitive adhesive backing

InactiveUS6886625B1Improved thermal interfaceLower thermal resistivityCooling/ventilation/heating modificationsLaminated elementsElastomerEngineering

The present invention discloses a net-shape molded elastomeric heat-dissipating device that includes an integrally formed conformable interface surface. A base elastomeric matrix material is loaded with thermally conductive filler and injected into a mold cavity to form the completed device. Further, a layer of thermally conductive pressure sensitive adhesive material is applied to the conformable interface surface to allow the device to be securely fastened to a heat-generating surface. The present invention provides superior sealing and elimination of voids and air gaps that are typically found between the thermal transfer surfaces thereby facilitating enhanced thermal transfer properties. In addition, the present invention provides a method of manufacturing an elastomeric heat sink device as described above.

Owner:TICONA POLYMERS INC

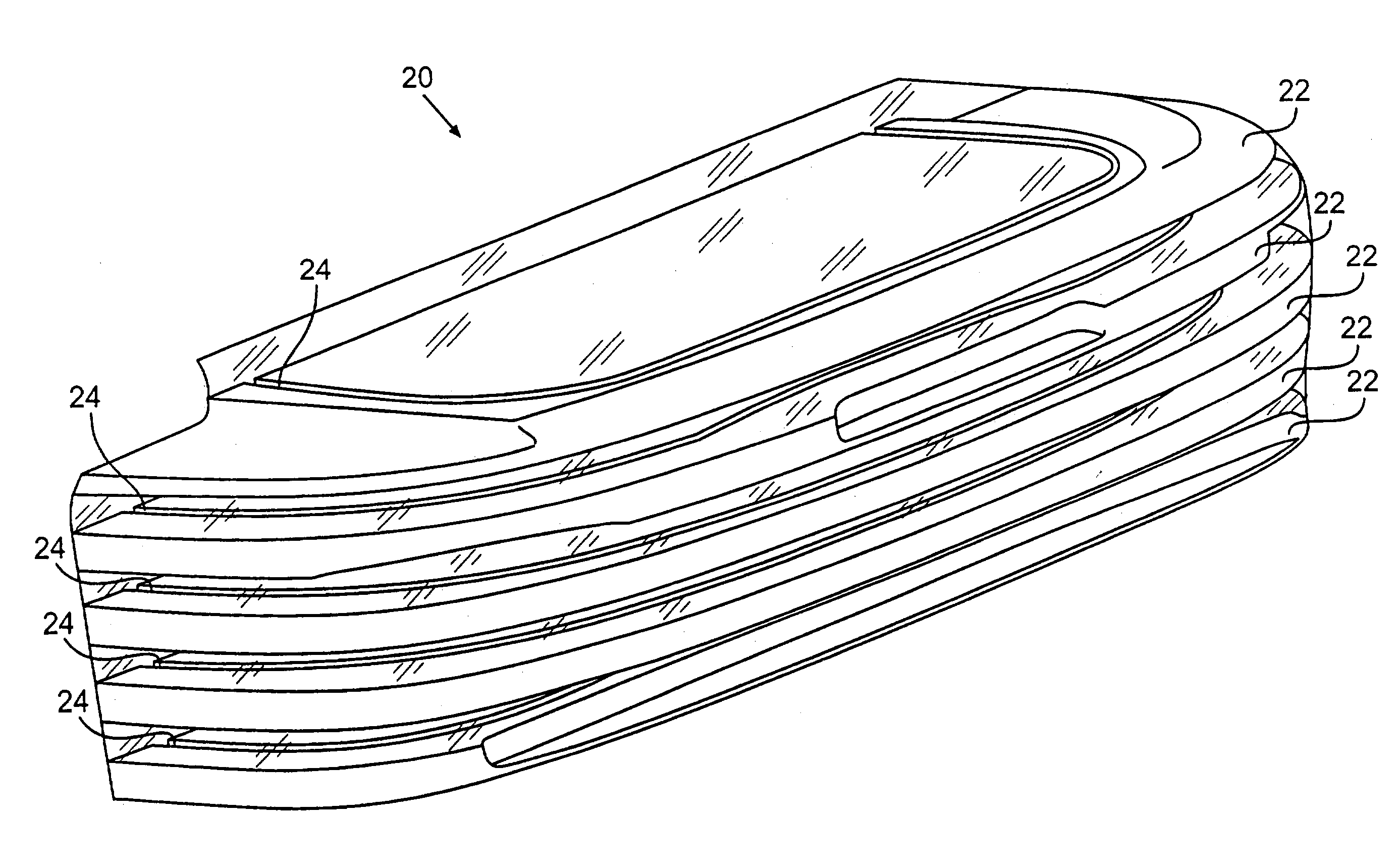

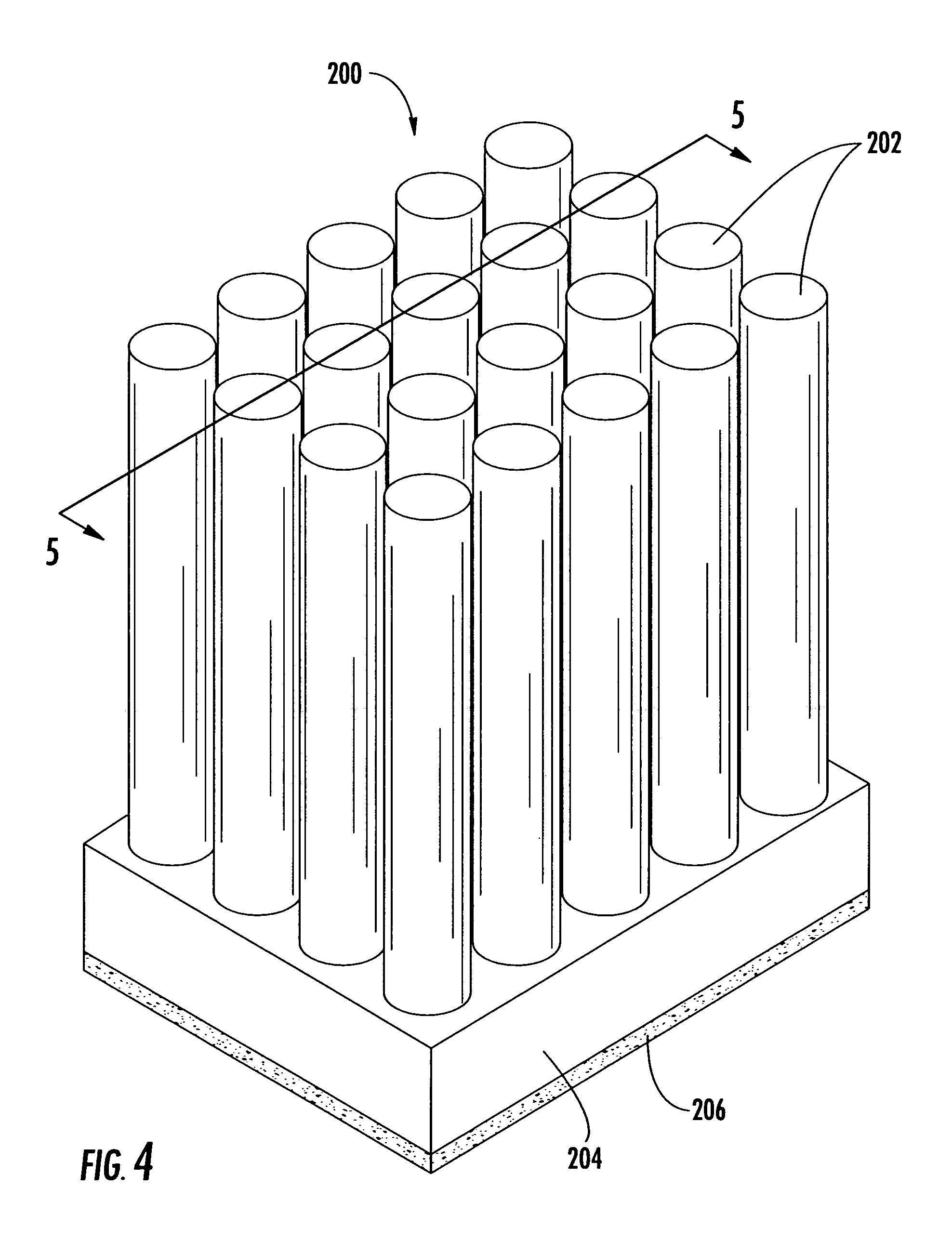

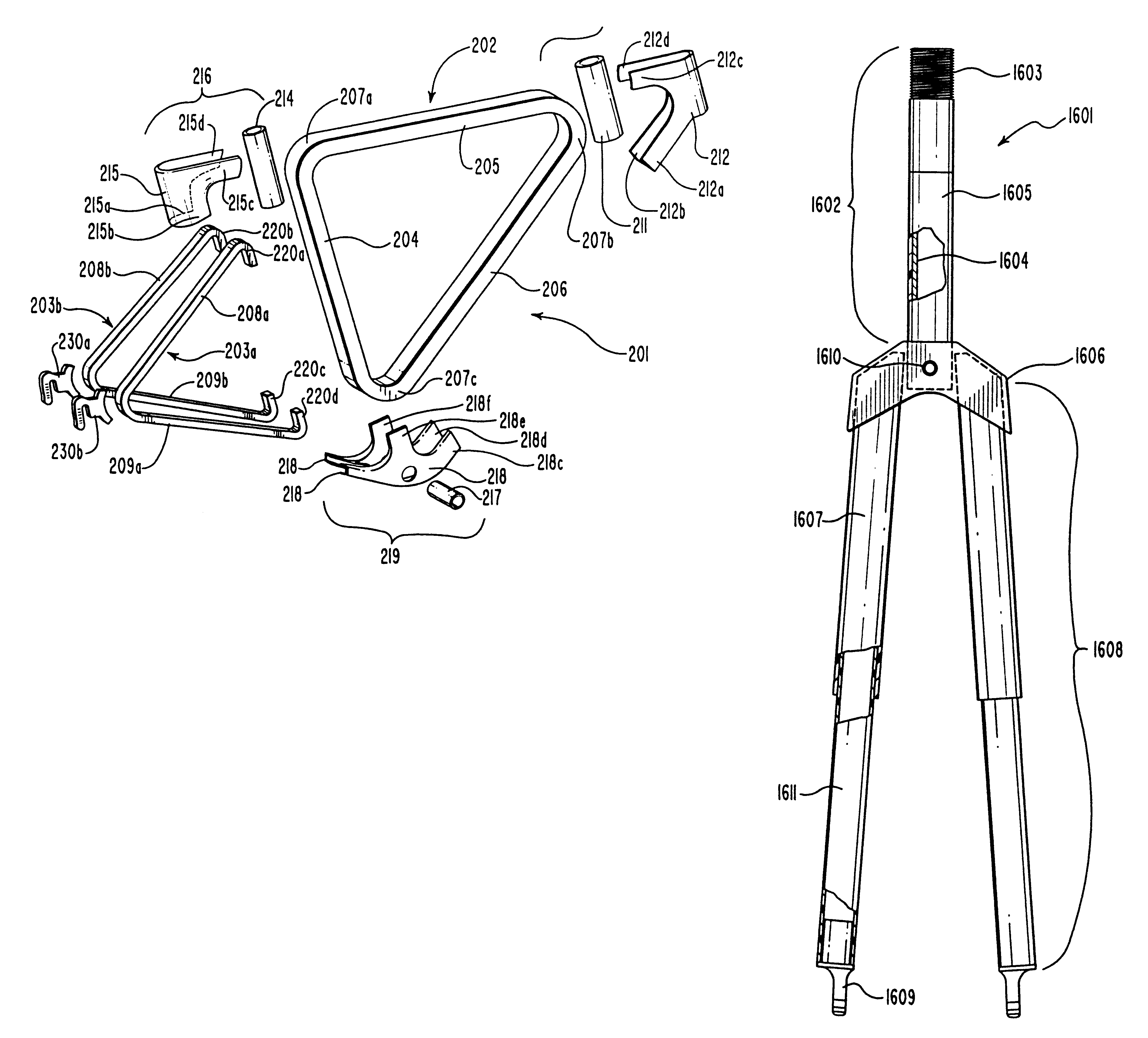

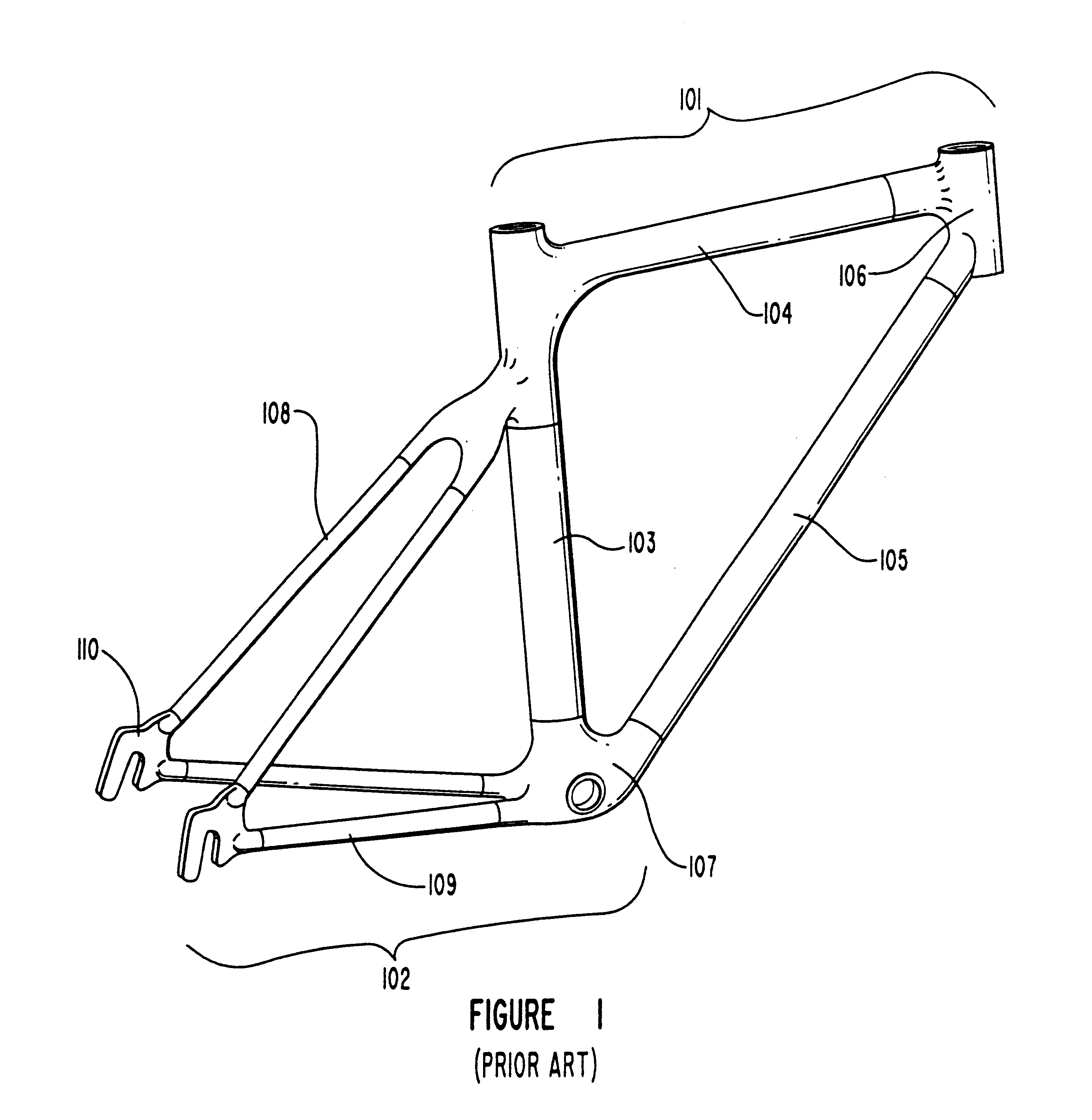

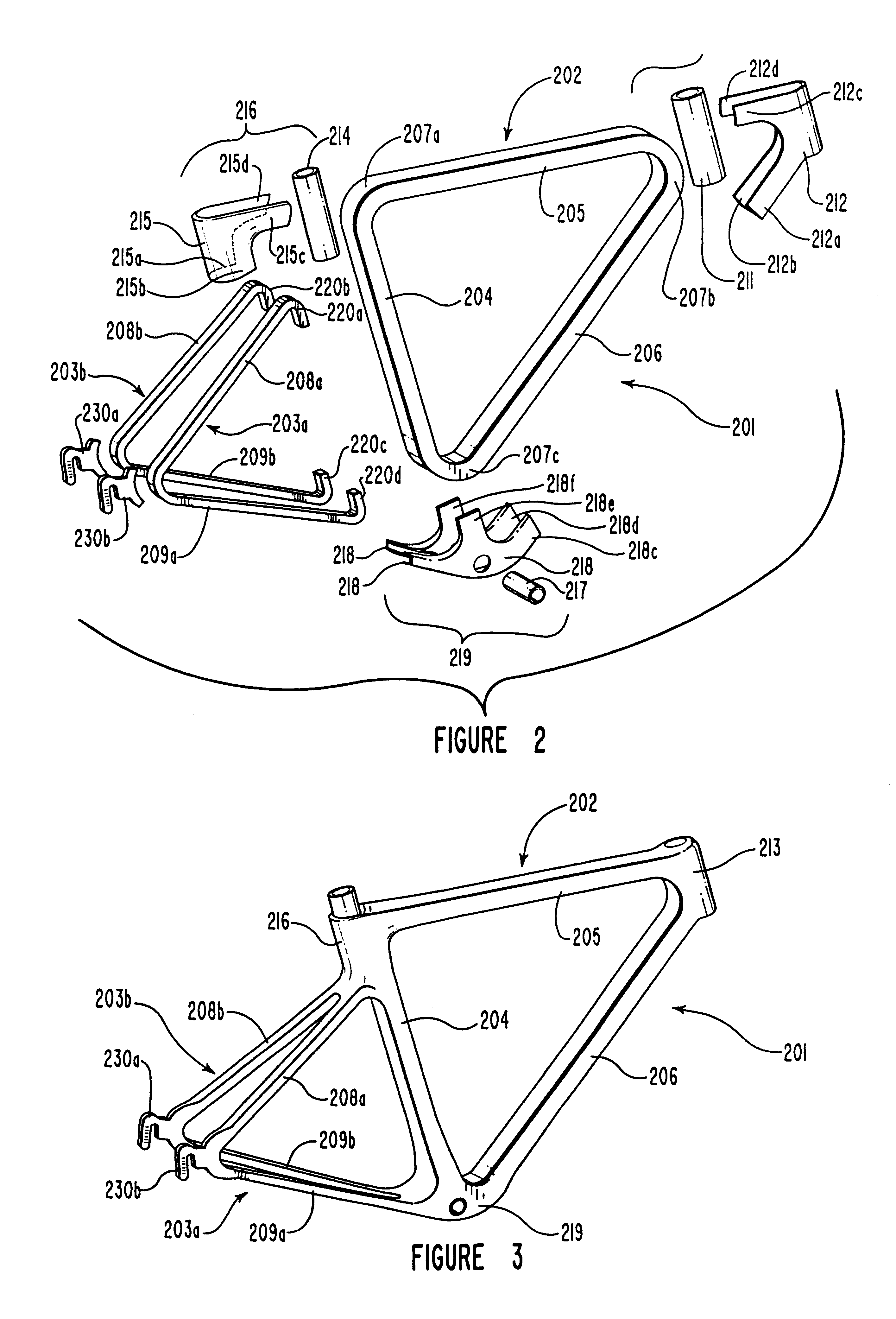

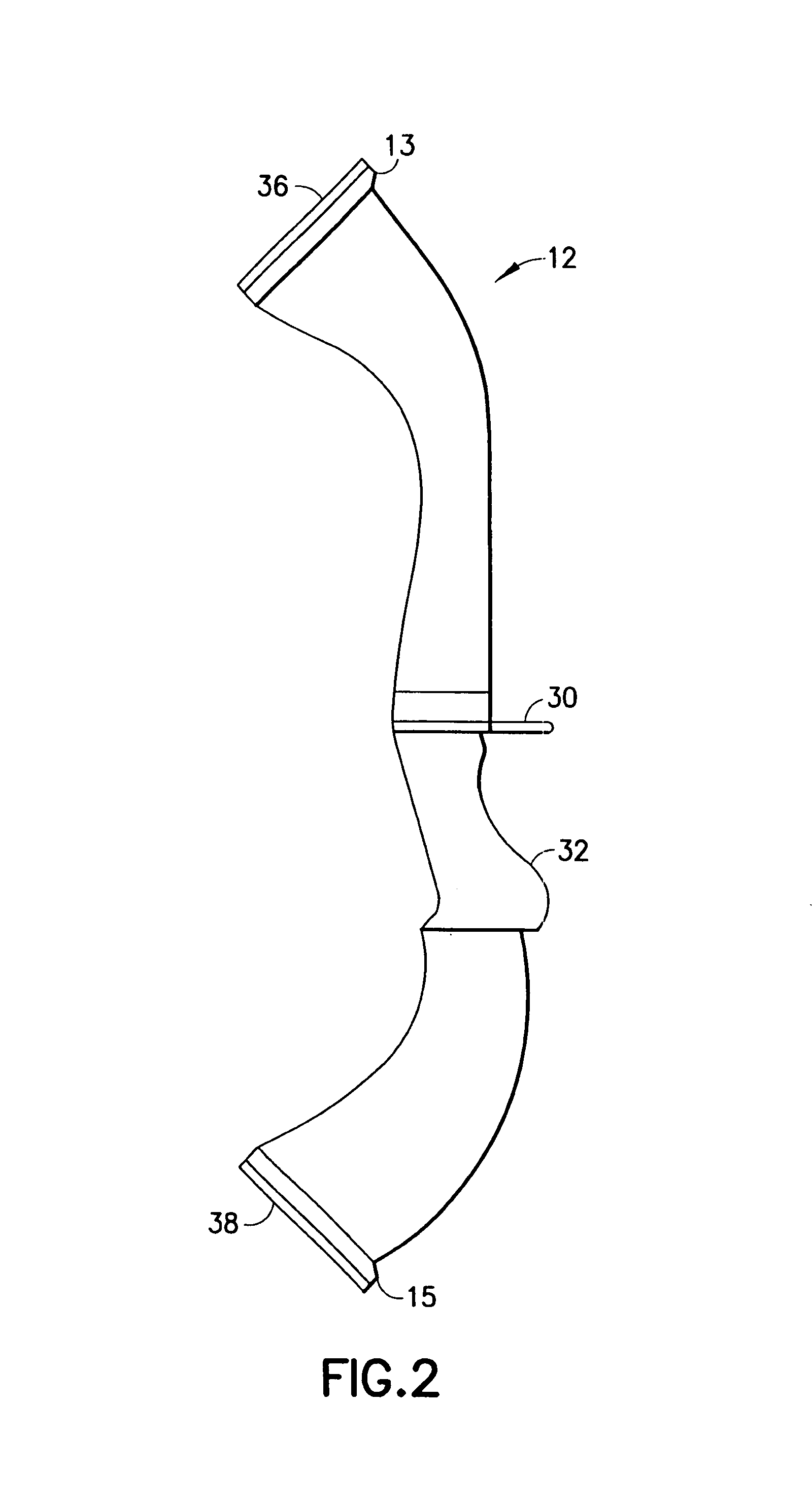

Net shape filament winding manufacturing process, articles made therefrom and composite bicycle fork and other components

InactiveUS6267399B1Manufactured quickly and inexpensivelyHigh strengthPassenger cyclesWheel based transmissionNet shapeFilament winding

A high production net shape filament winding manufacturing process and resulting products are disclosed. The manufacture of bicycle frame and their components from filament wound components which have been cut from a section of filament wound stock is disclosed. Also disclosed is a bicycle frame and its manufacturing process and a composite bicycle fork and components thereof.

Owner:ADVANCED COMPOSITES

Injection molding of metallic glass by rapid capacitor discharge

ActiveUS20130025814A1Avoid failureAvoid thermal transport and development of thermalFoundry mouldsHeat treatment process controlAlloyInjection molding machine

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming magnetic metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, sheet forming, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

Electromagnetic forming of metallic glasses using a capacitive discharge and magnetic field

ActiveUS20120006085A1Welding/cutting media/materialsSoldering mediaCapacitanceTransverse magnetic field

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool in combination with an electromagnetic force generated by the interaction of the applied current with a transverse magnetic field. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous metal and the equilibrium melting point of the alloy in a time scale of several milliseconds or less, at which point the interaction between the electric field and the magnetic field generates a force capable of shaping the heated sample into a high quality amorphous bulk article via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time scale of less than one second.

Owner:CALIFORNIA INST OF TECH

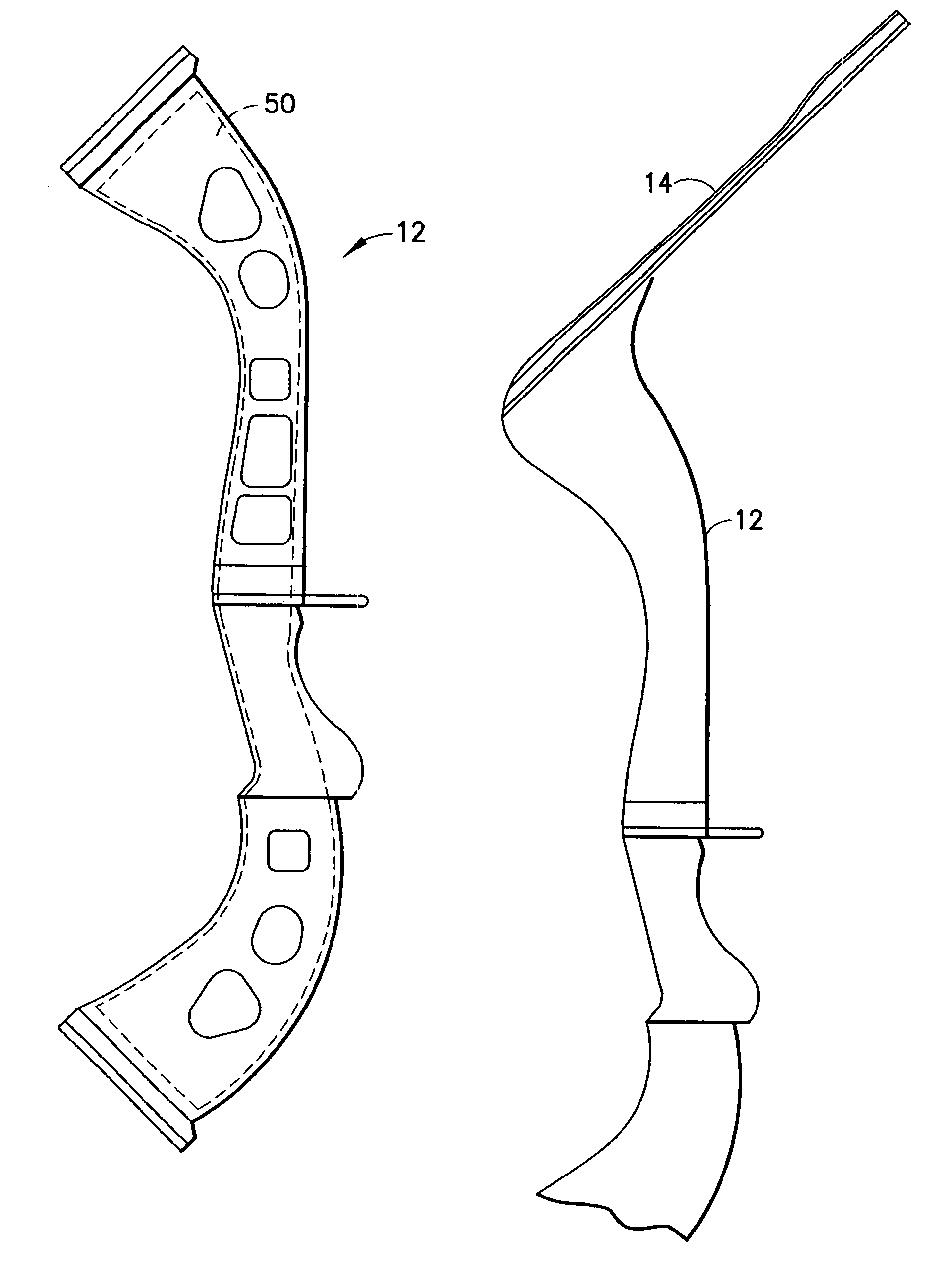

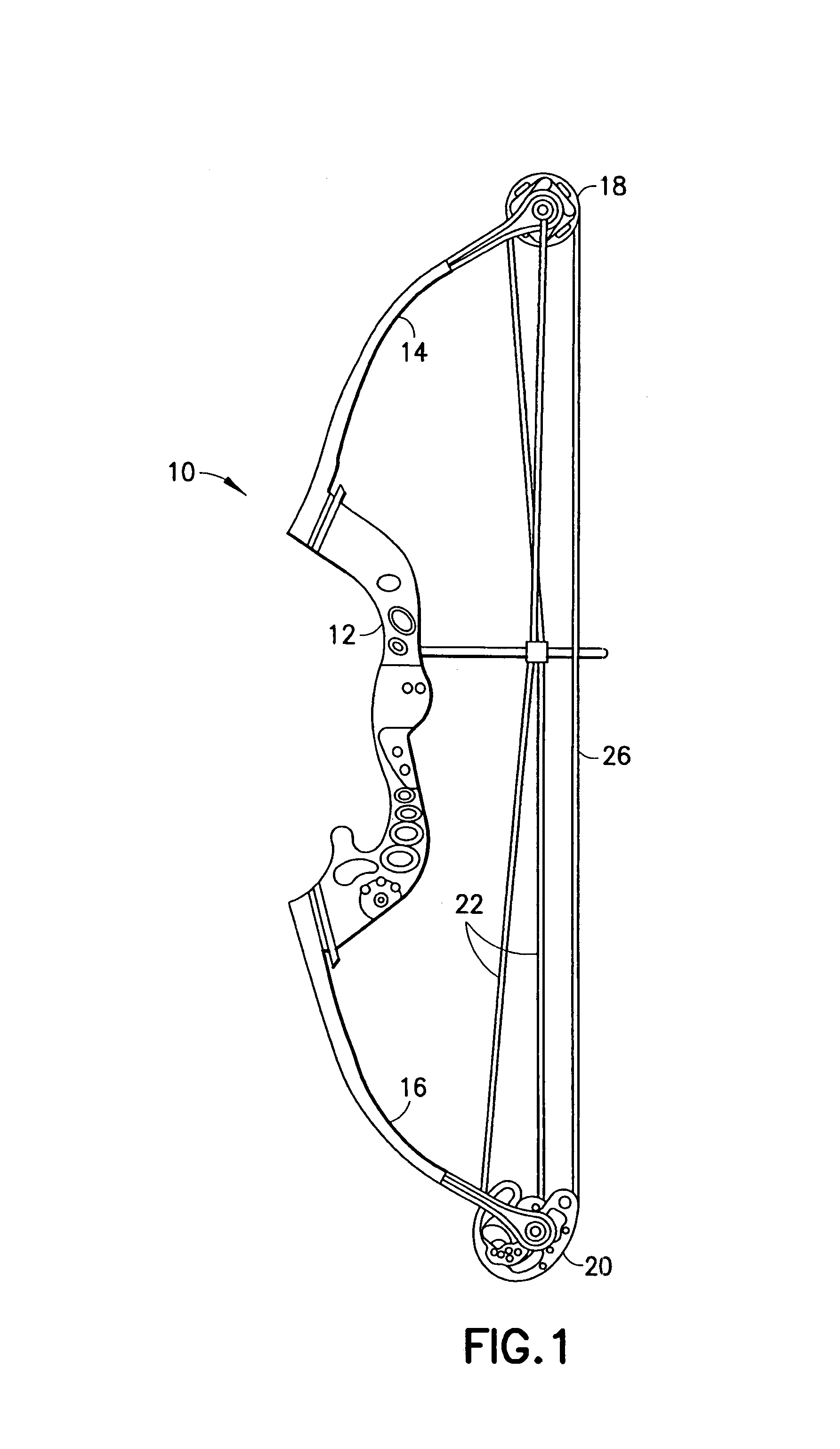

Thermoplastic composite bow riser, limb, and cam

Owner:AVIENT CORP

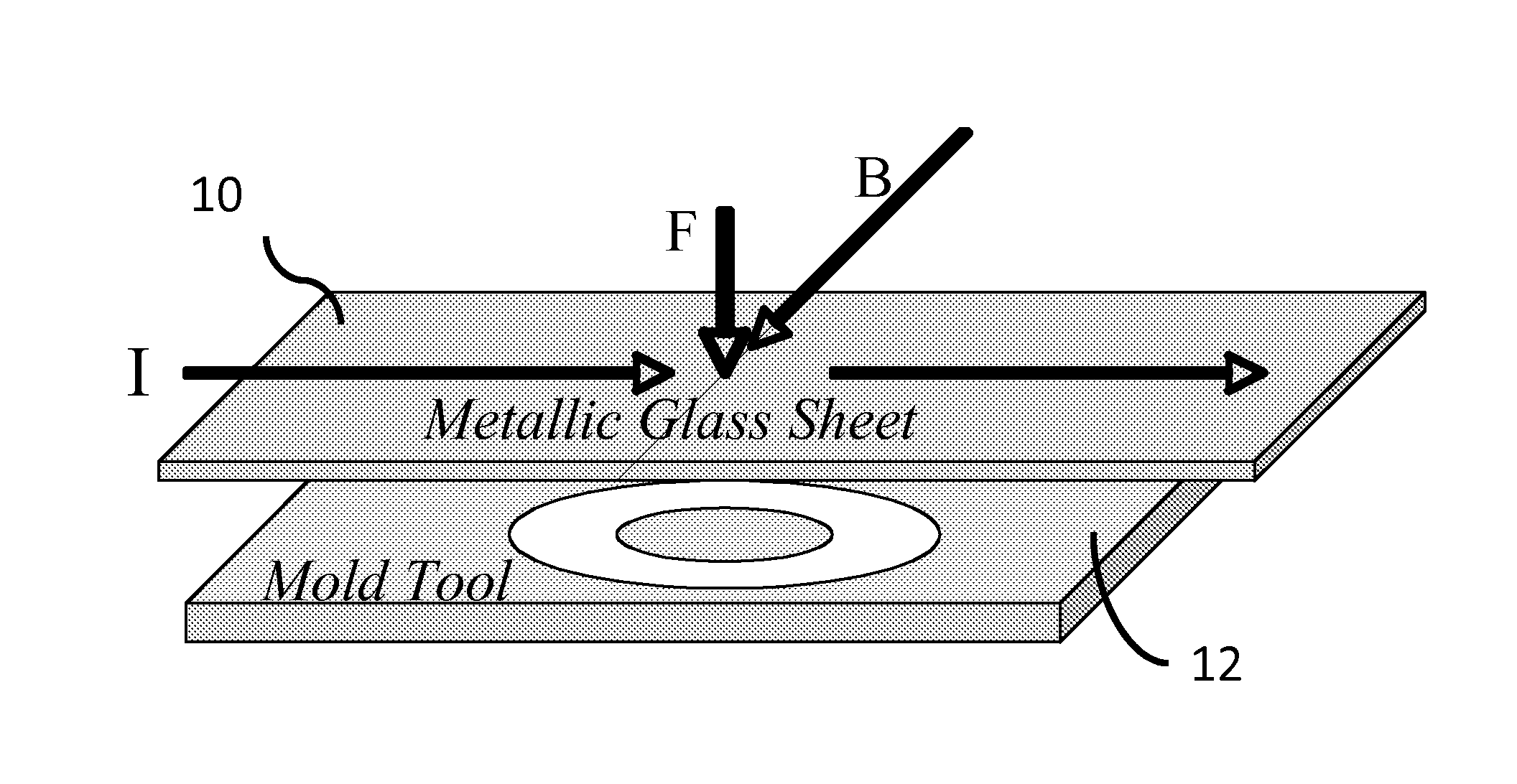

Sheet forming of metallic glass by rapid capacitor discharge

ActiveUS8613815B2Avoid thermal transport and development of thermalHeating evenlyDielectric heatingShaping toolsAlloyGlass transition

Owner:CALIFORNIA INST OF TECH

Petroleum pitch-based carbon foam

InactiveUS6833012B2Useful and reliableImprove efficiencyPigmenting treatmentHarvestersLow densityNet shape

Petroleum or coal tar pitch-based cellular or porous products having a density of preferably between about 0.1 g / cm<3 >and about 0.8 g / cm<3 >are produced by the controlled heating of mesophase carbon materials derived from coal tar or petroleum pitch having a softening point in excess of about 300° C. and preferably between about 300 and about 400° C. in a "mold" and under a non-oxidizing atmosphere. The porous product thereby produced, preferably as a net shape or near net shape, can be machined, adhered and otherwise fabricated to produce a wide variety of low cost, low density products.

Owner:TOUCHSTONE RES LAB

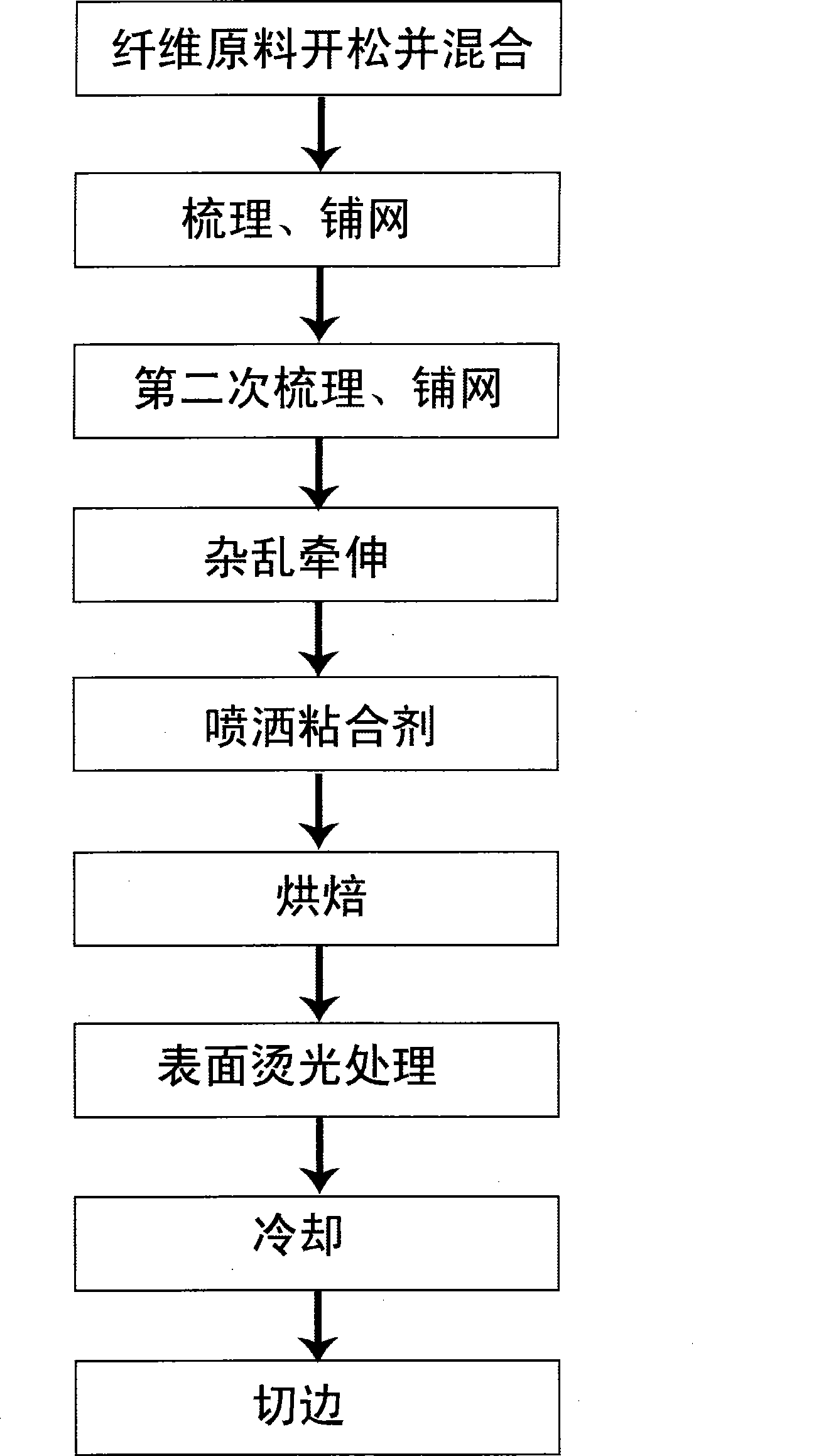

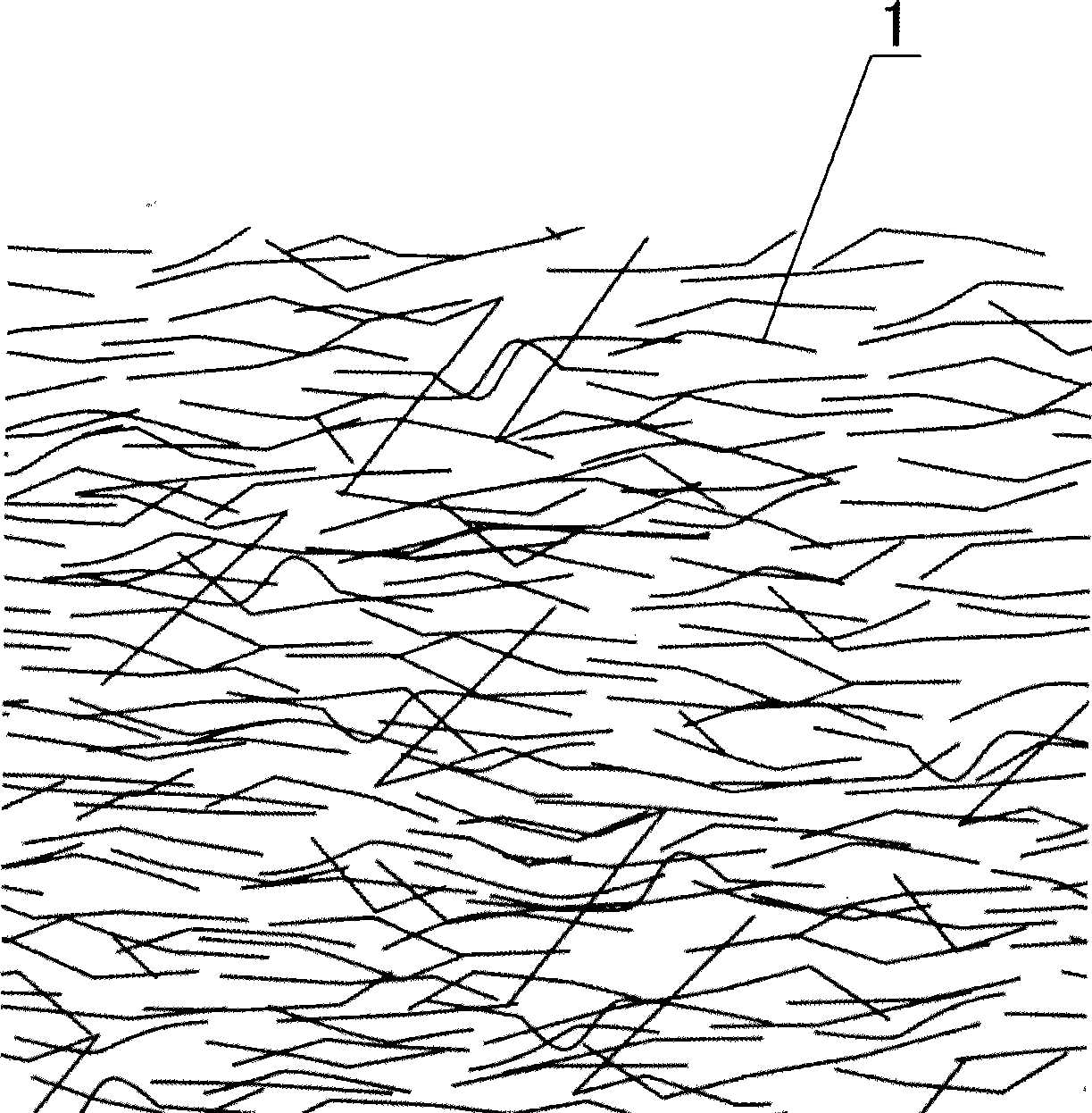

Thermal protection flocculus and manufacturing method thereof

InactiveCN101476212AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberNet shape

The invention provides a keeping warm flocculus which is prepared from raw material by weight including 56%-85% fine denier fibre and / or super fine denier fibre, 0-30% hollow fibre, 5-30% felt fibre. The preparing method includes steps as follows: loosing and mixing various fibre raw material; then combing, lapping for forming fibre net; then processing disorder drafting to the felt net for forming solid net shape crossing struture; then heating and baking the felt net, at least melting surface of the felt fibre for felting surrounding fibre. The fine denier fibre can increase content of still air in the keeping warm flocculus, reduce heat quantity conduction, and can divide space in the keeping warm flocculus into smaller space for avoiding or reducing air convection, accordingly increase warm keeping property of the keeping warm flocculus; the hollow fibre can increase filling power and compress rebound property of the warm keeping flocculus; filling power and compress rebound property of the warm keeping flocculus are increased after being disorder draft.

Owner:汕头市奥山服饰有限公司

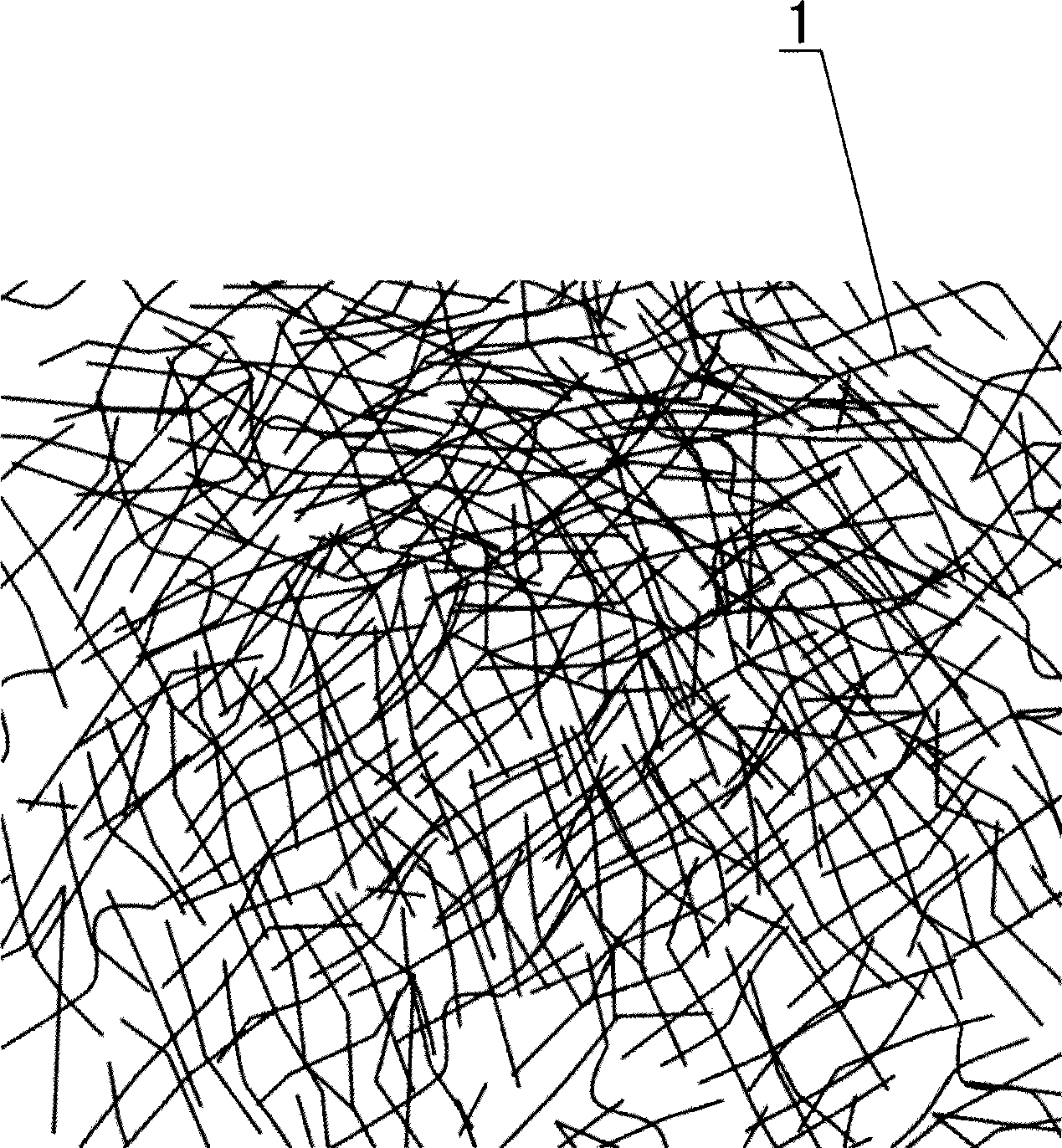

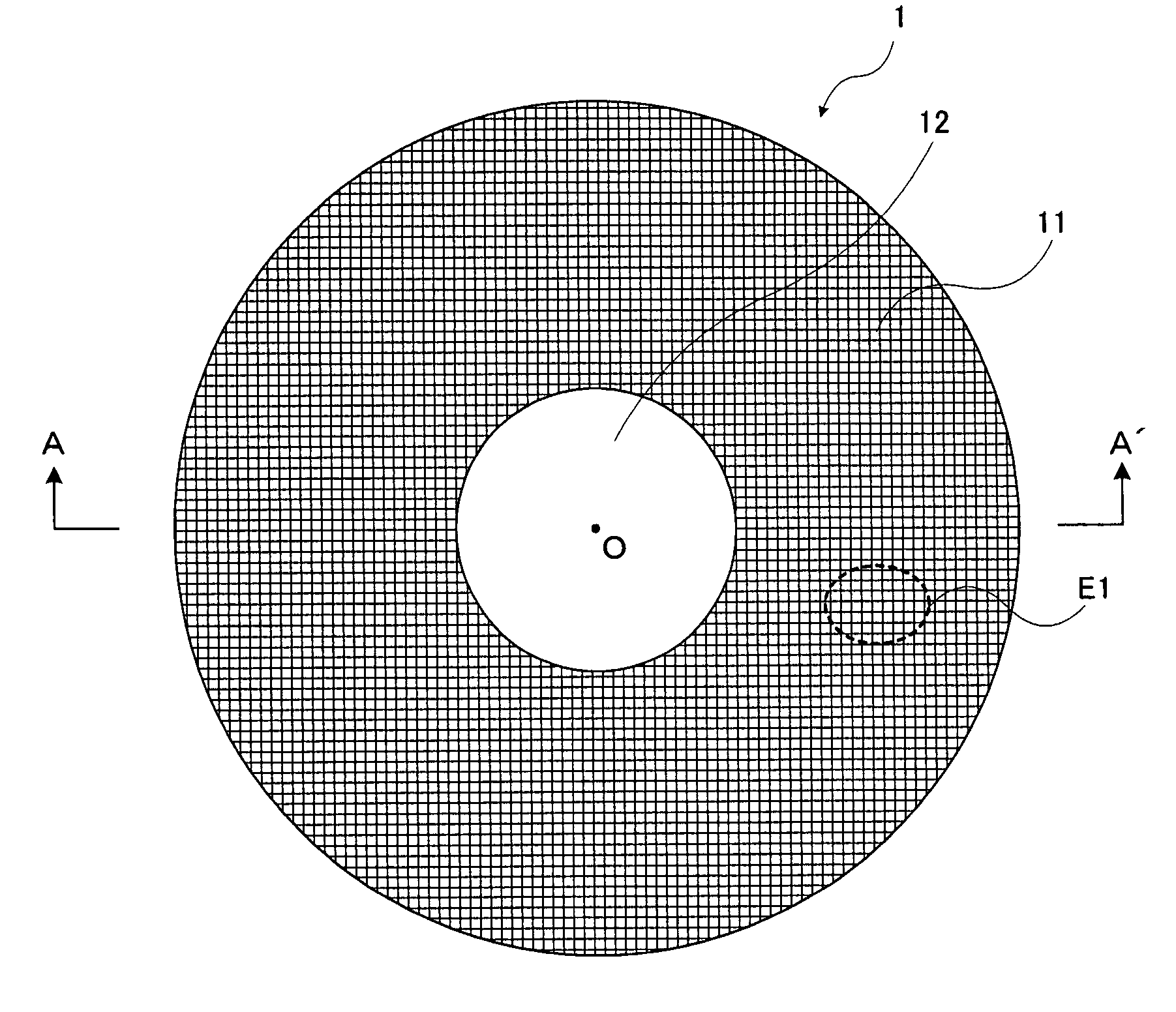

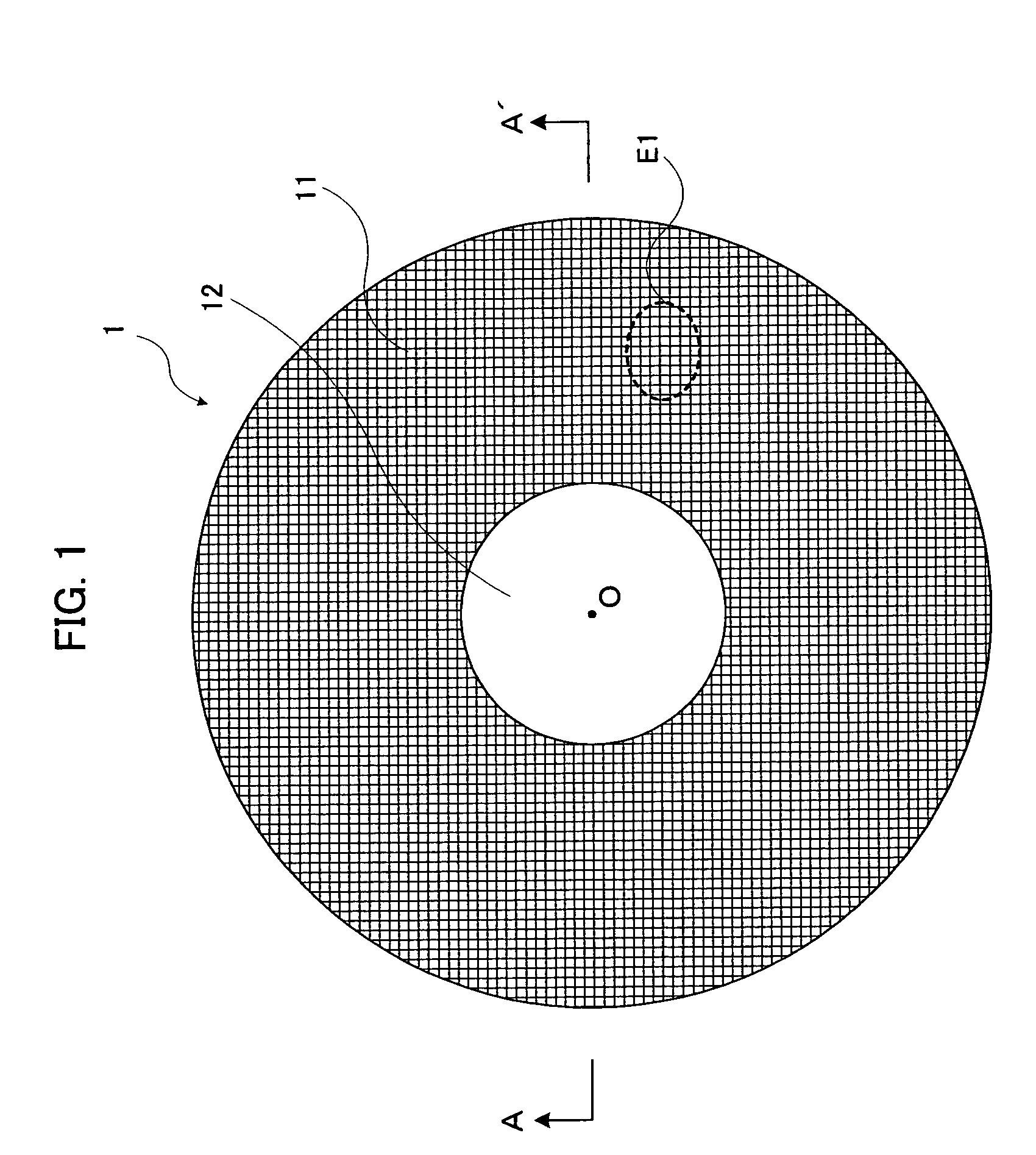

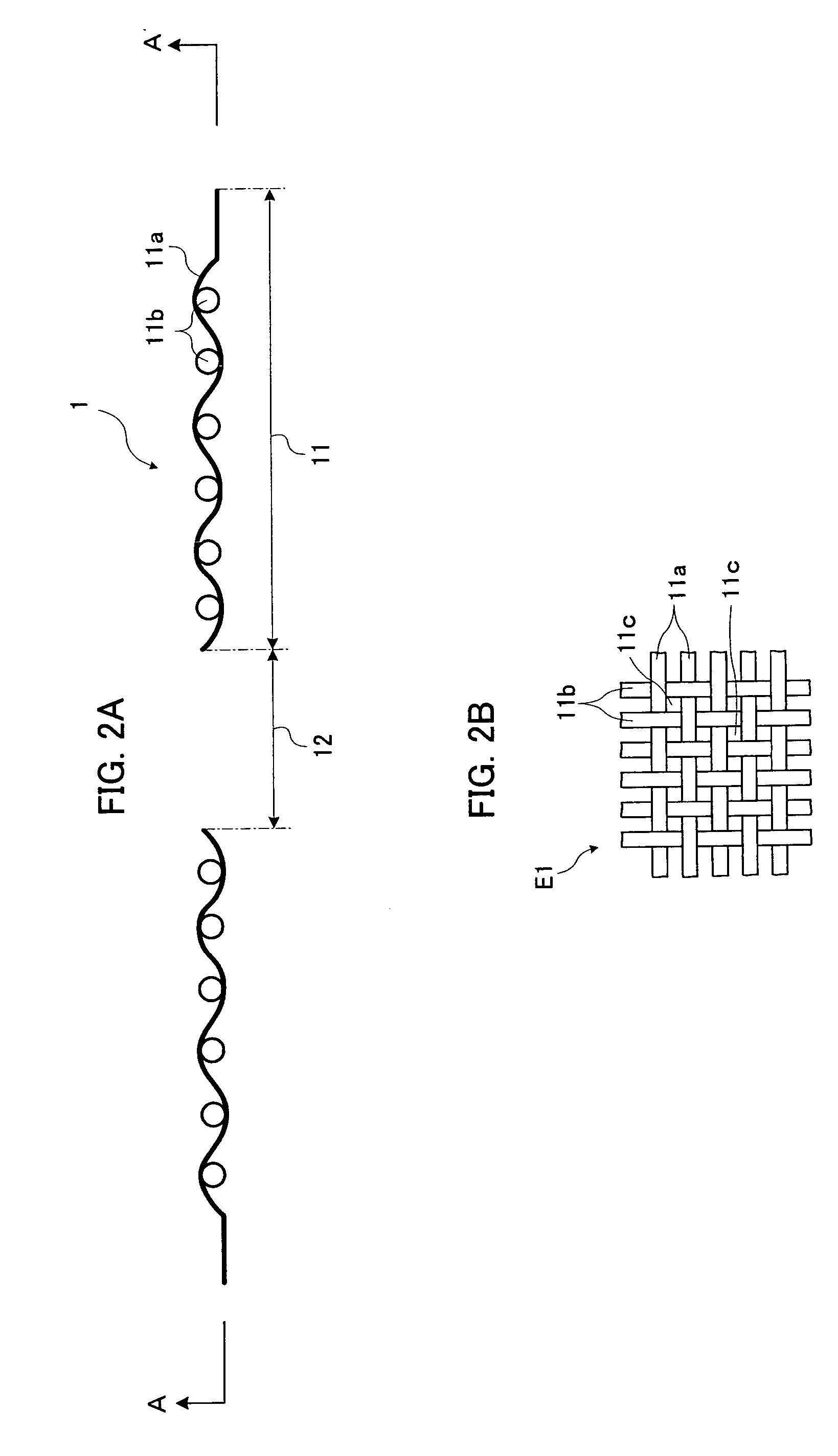

Damper for speaker device, speaker device using the damper and manufacturing method therefor

InactiveUS20050254682A1Resistant effectReliable supportTransducer detailsDeaf-aid setsBobbinEngineering

A damper having an annular elastic part is manufactured by stamping out a wire mesh material formed by weaving a plurality of metal wires into a net shape with a press device. The elastic part of the damper thus manufactured has a wire mesh structure. Thereby, a damper with high durability is obtained. Consequently, by applying this damper to the speaker device, the voice coil bobbin, a diaphragm and the like can be restrained / prevented from vibrating more than necessary even when an abnormal large signal is inputted into the speaker device.

Owner:PIONEER CORP +1

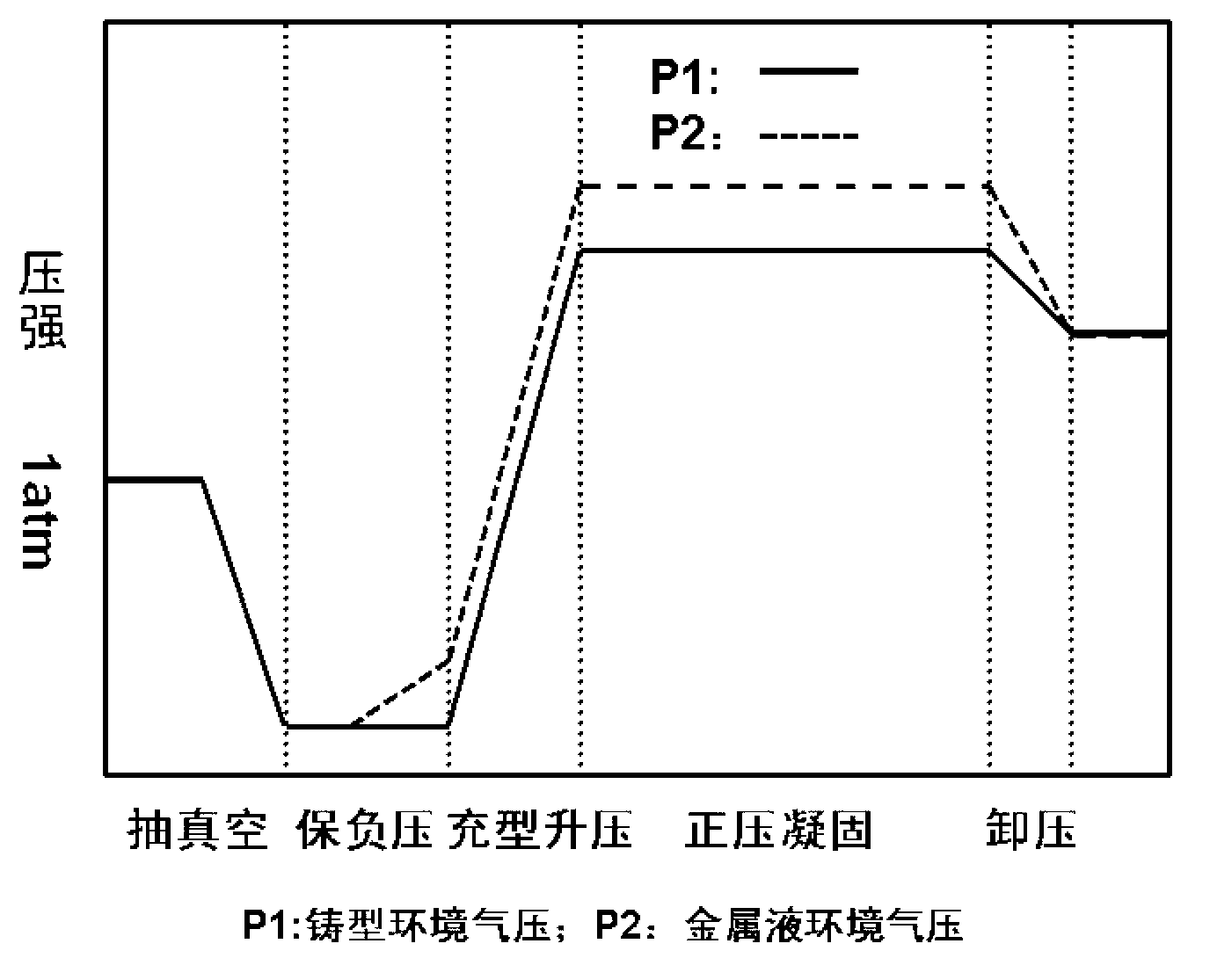

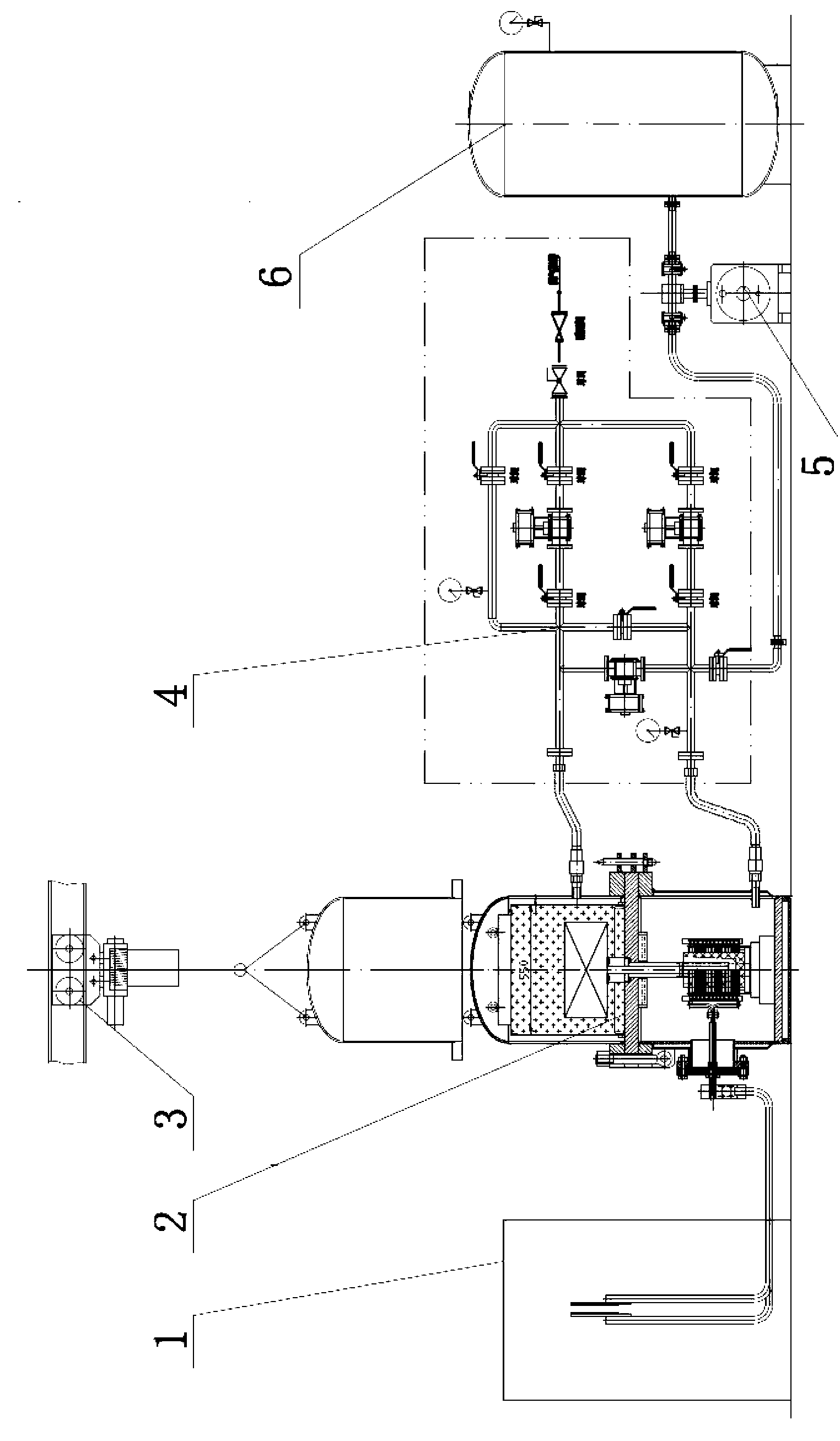

Precesion casting method for high temperature alloy complex thin-walled castings

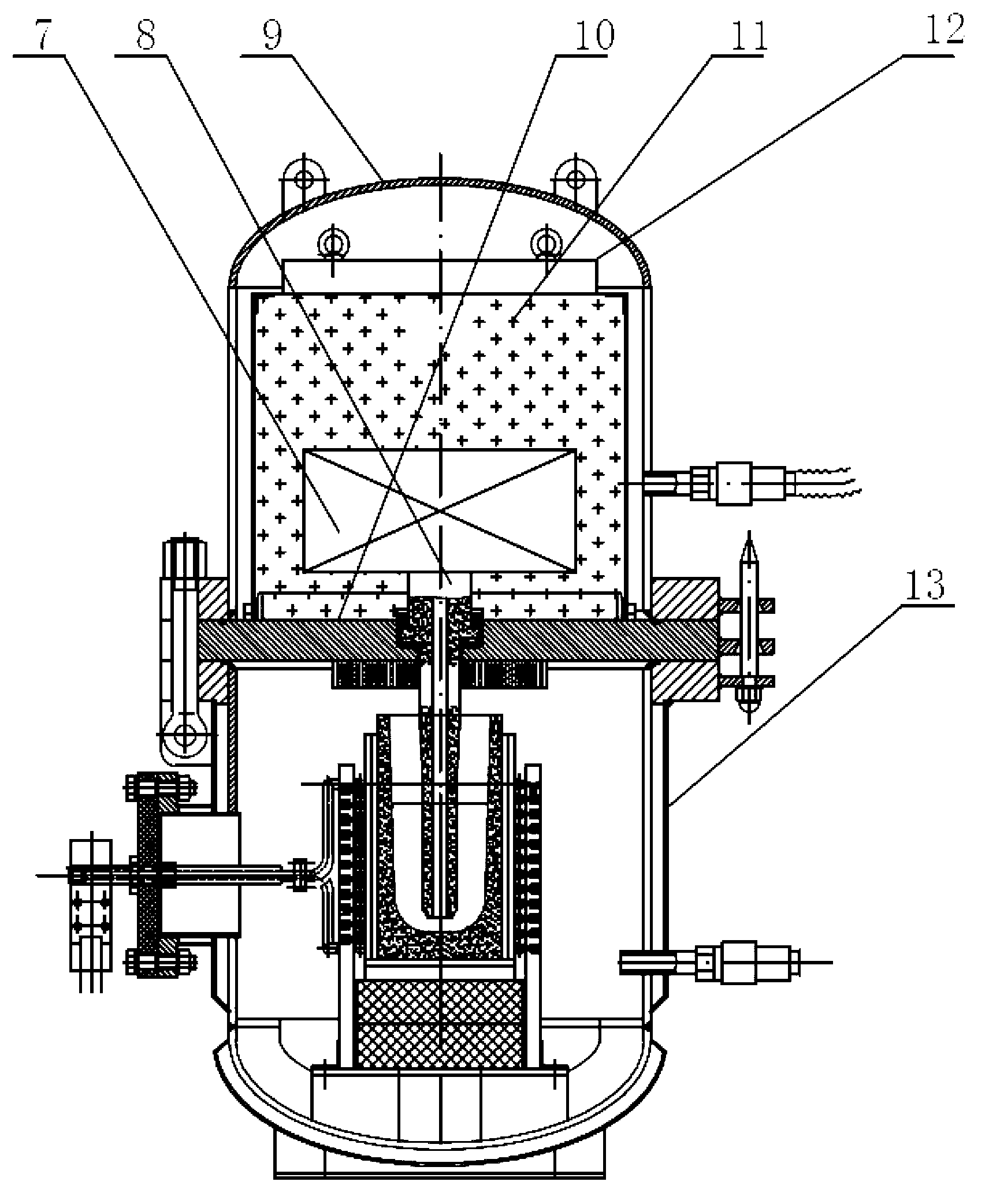

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

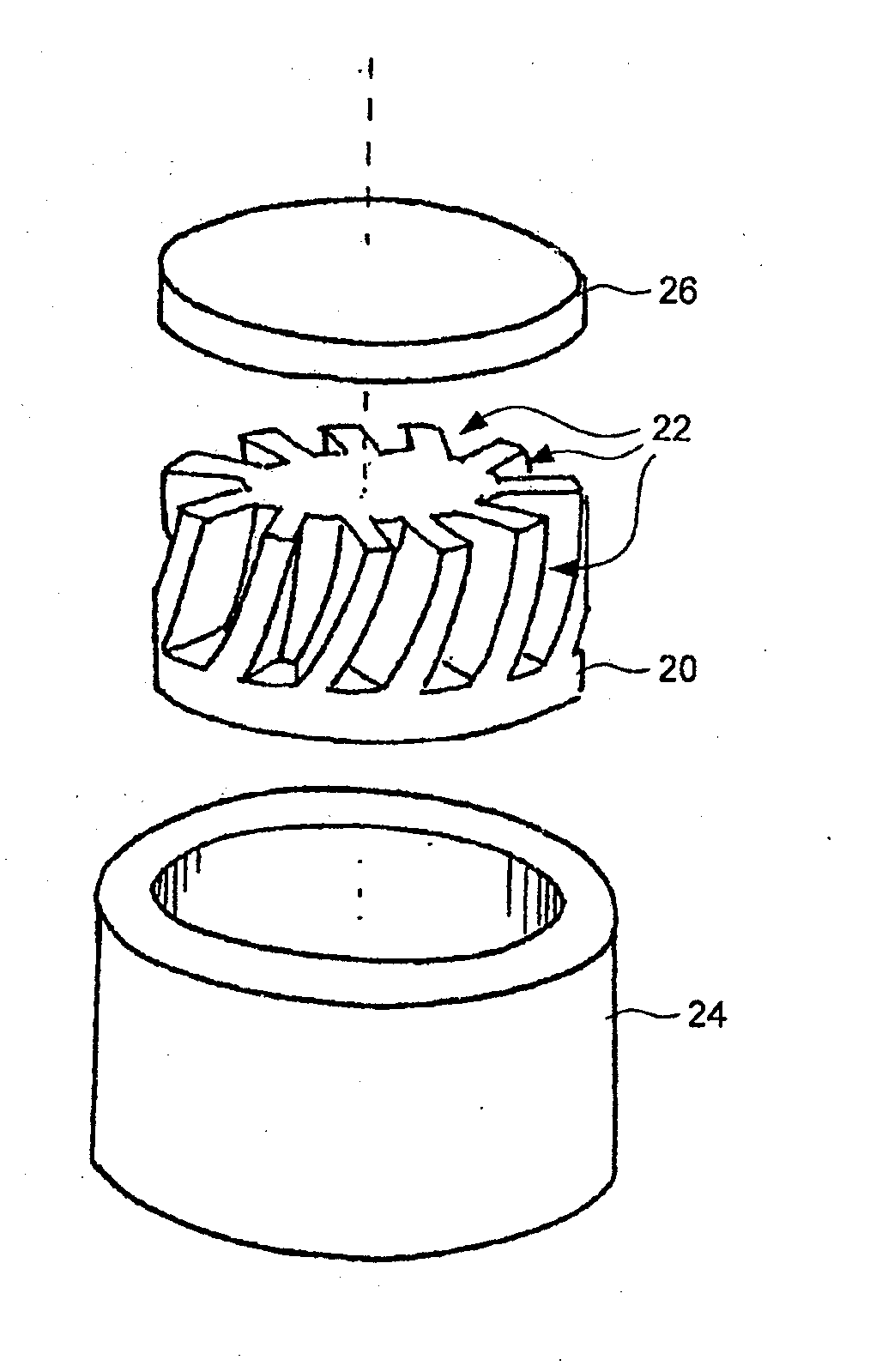

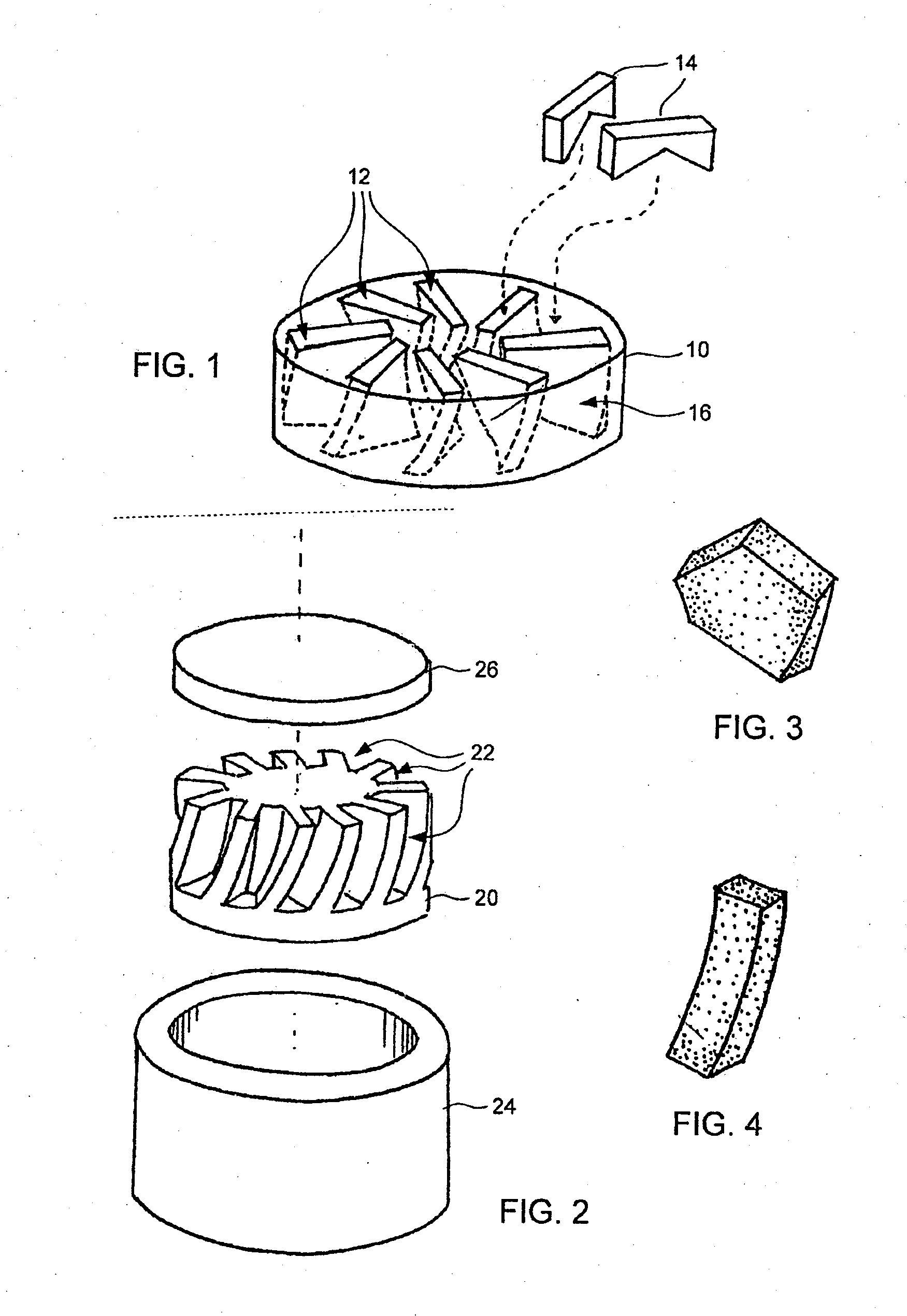

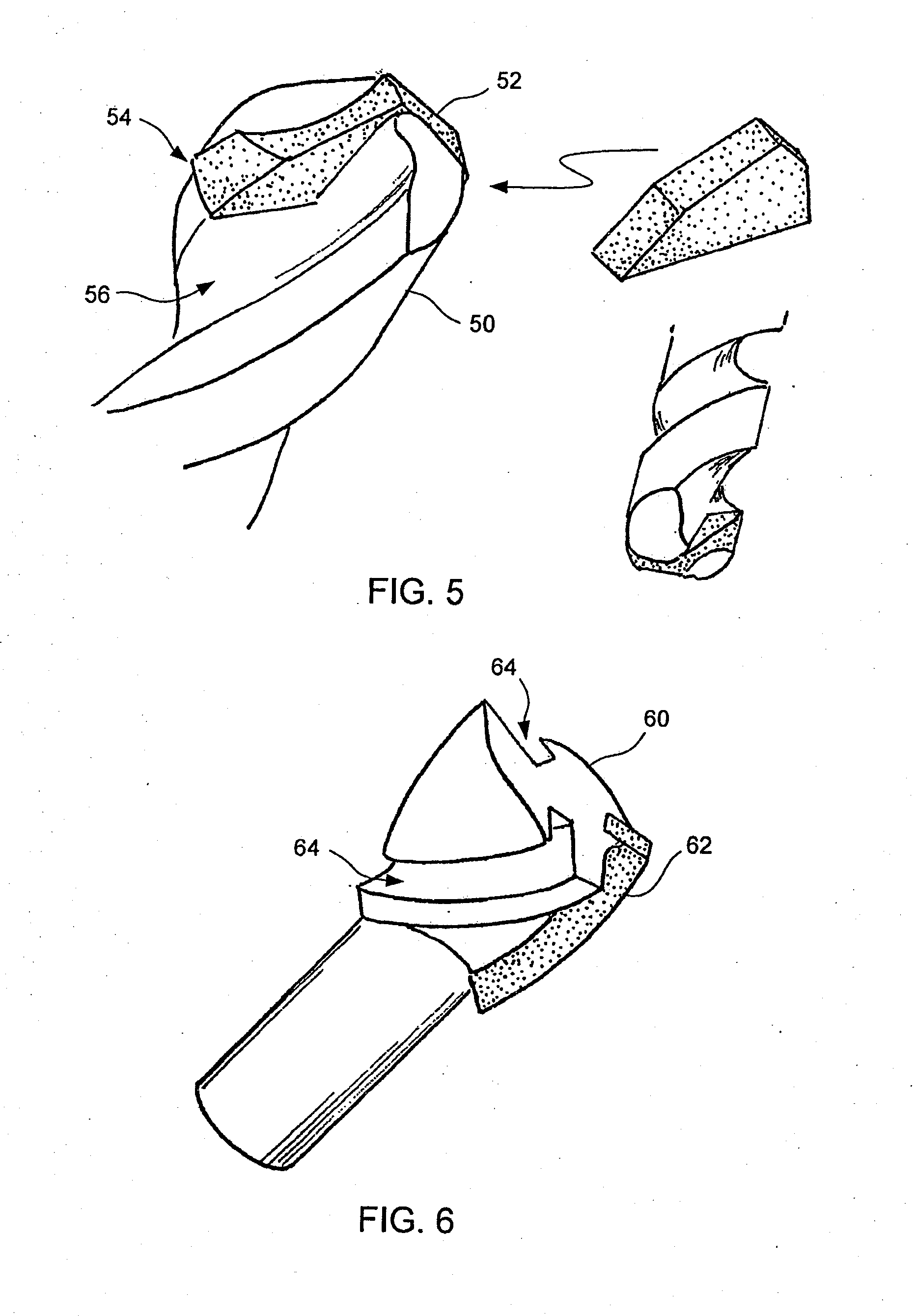

Contoured pcd and pcbn segments for cutting tools containing such segments

Contoured helical solid polycrystalline PCD and PCBN superabrasive segments are provided for attachment to cutting tool substrates such as twist drill tips, reamers, burrs and endmills. Segments are provided in near to net shape for attachment to a tool substrate thereby requiring reduced finishing steps and providing increased tailorability of grade and quality of final polycrystalline segments. Cutting tools comprising cutting tool substrates having attached thereto a contoured helical solid polycrystalline PCD and PCBN superabrasive segments are also disclosed.

Owner:CHO H SAM +4

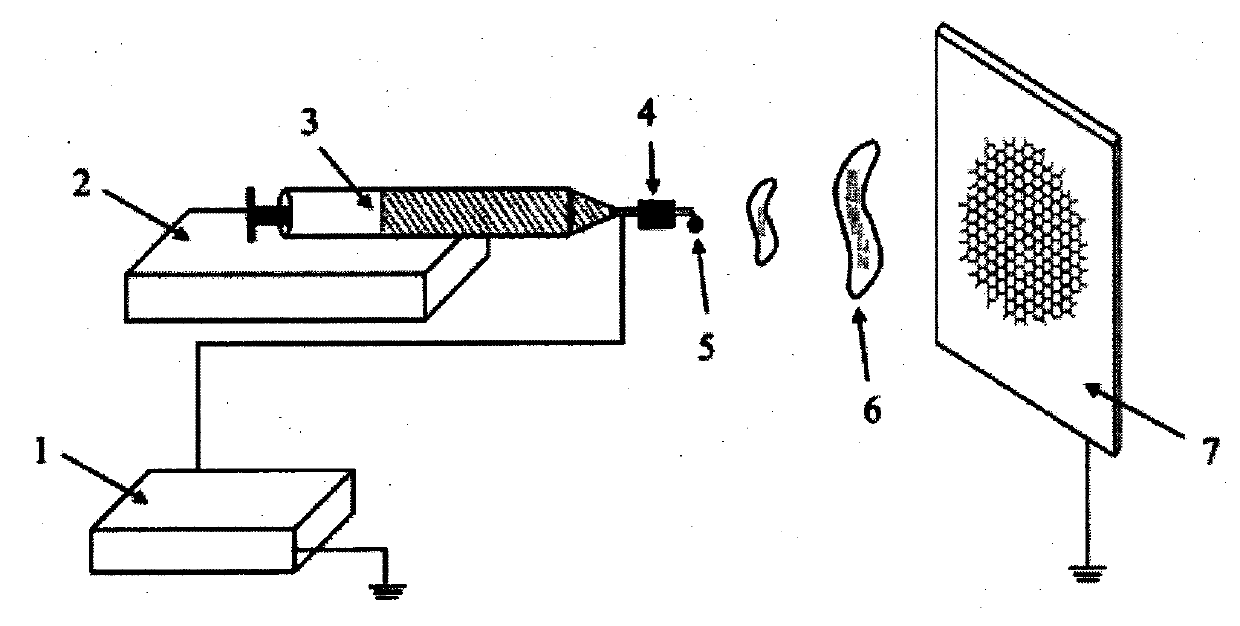

High-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and preparation method thereof

InactiveCN107557894AImprove throughputHigh porosityFatty/oily/floating substances removal devicesUltrasonic/sonic fibre treatmentFiberNanofiber

The invention discloses a high-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and a preparation method thereof. The preparation method comprises the following steps: a polymer solution is prepared from a selected polymer, a net is formed through electrostatic direct injection of the polymer solution, a spinneret vibrates in situ by the aid of external force inan electrostatic direct injection process to promote generation of charged droplets, the droplets are subjected to phase separation, and a uniform 2D net-shaped ultrafine nanofiber material is formedon the surface of a receiving substrate and is in a continuous and seamlessly stacked shape; then the obtained material is subjected to surface modification, and the 2D net-shaped ultrafine nanofiberoil-water separation material with selective surface and interface wetting property is obtained. The preparation process is simple, raw material limitations are few, and the net-shaped ultrafine nanofiber oil-water separation material has tiny meshes and good pore channel connectivity and has great application prospect in the fields of oil purification, oil-containing wastewater treatment and thelike.

Owner:DONGHUA UNIV

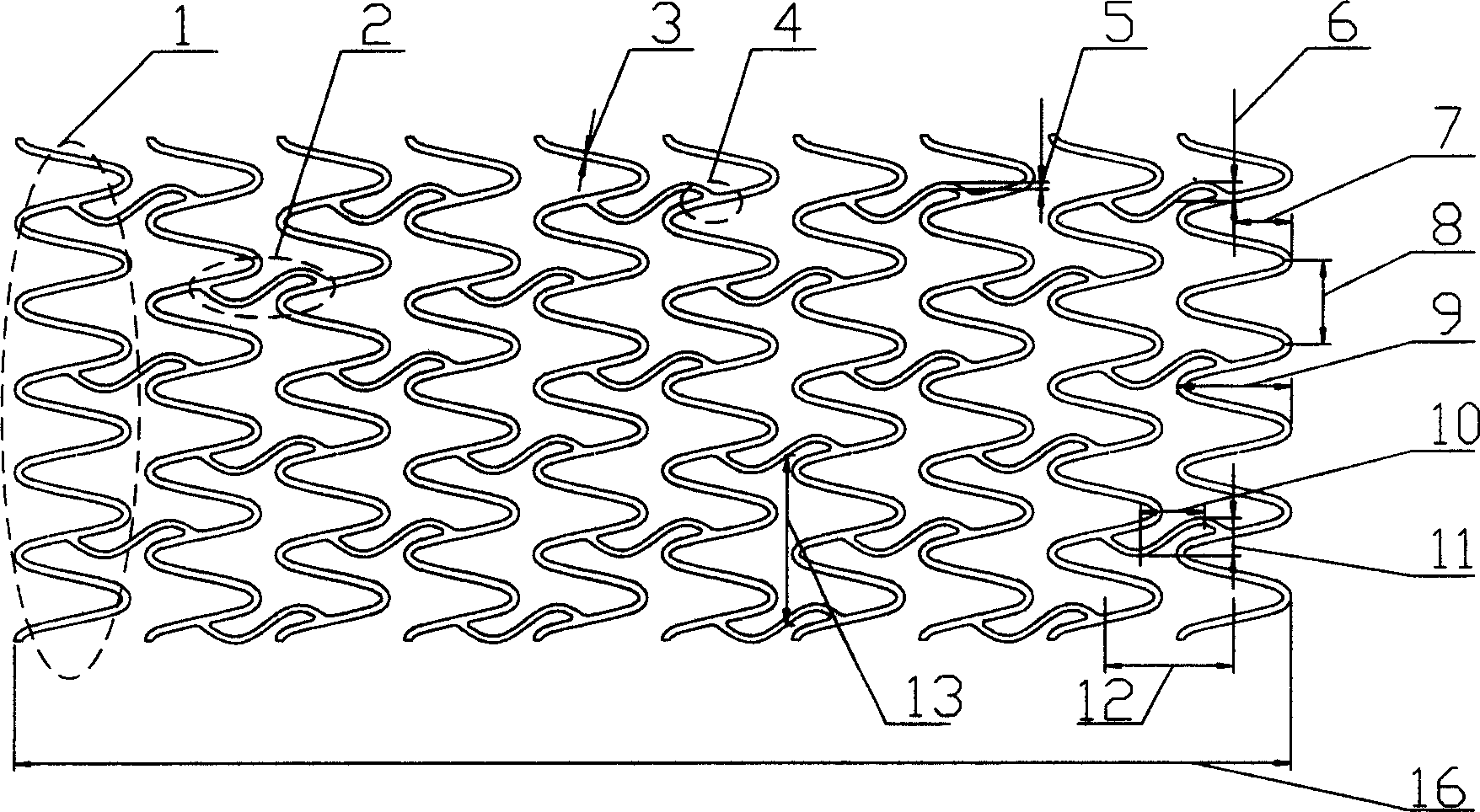

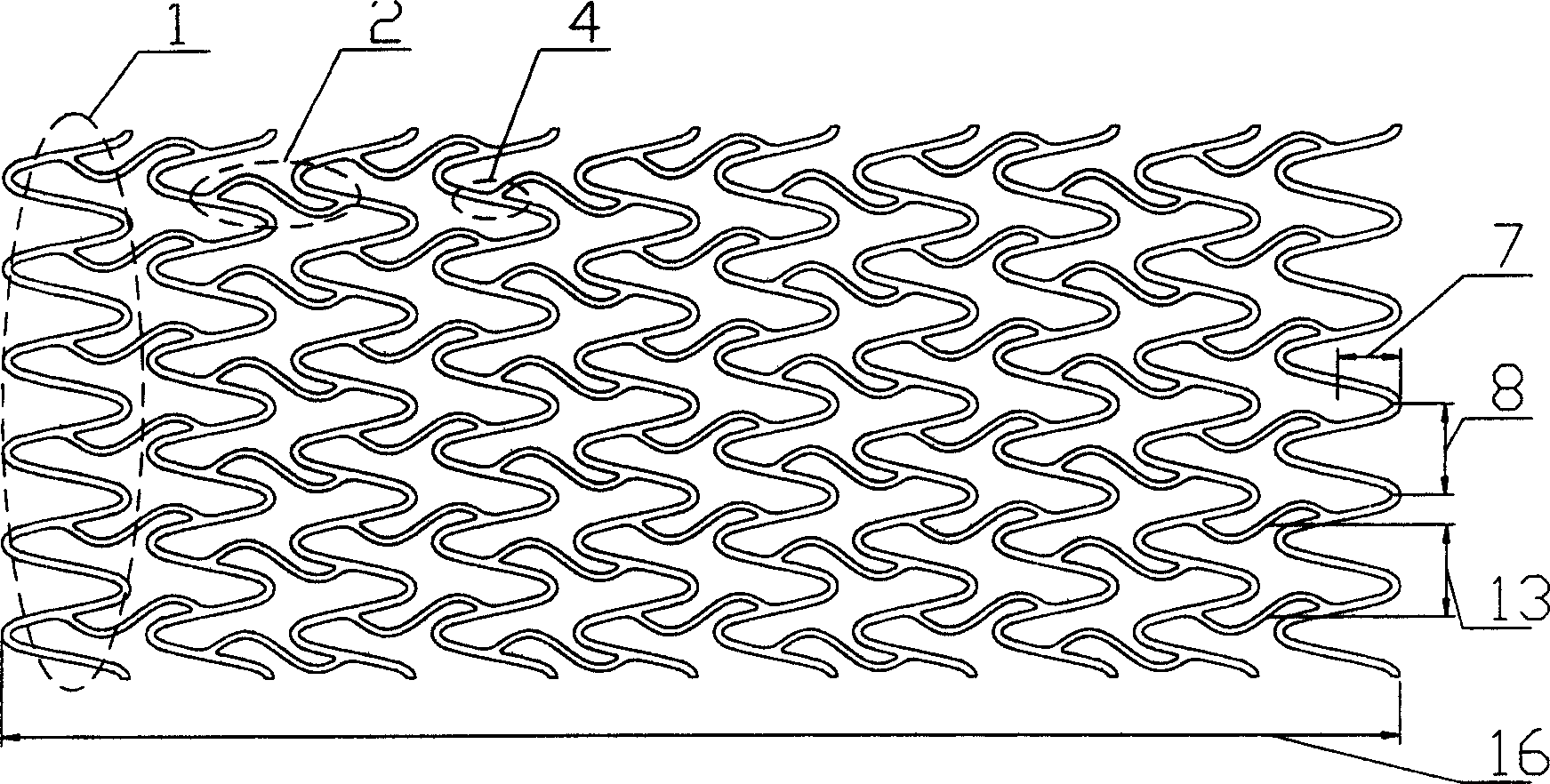

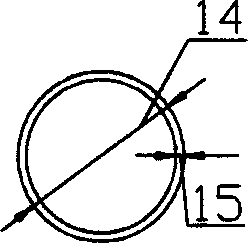

Sine-wave tubular medical interventional stent

The present invention relates to a sine wave shaped tubular medical intervertional supporting frame for dilating and supporting the narrow blood vessel, esophagus, bill duct, intestinal track and urethra, etc. of human interior. It is made up by etching metal tube, and has a tubular net-shaped structure formed from several sine wave shaped circular ring-like basic structures uniformly distributed along its axial direction. Said invention also provides its concrete structure and its advantages of adjustable radial supporting force and good axial flexibility, etc.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com