Patents

Literature

655 results about "Twist drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

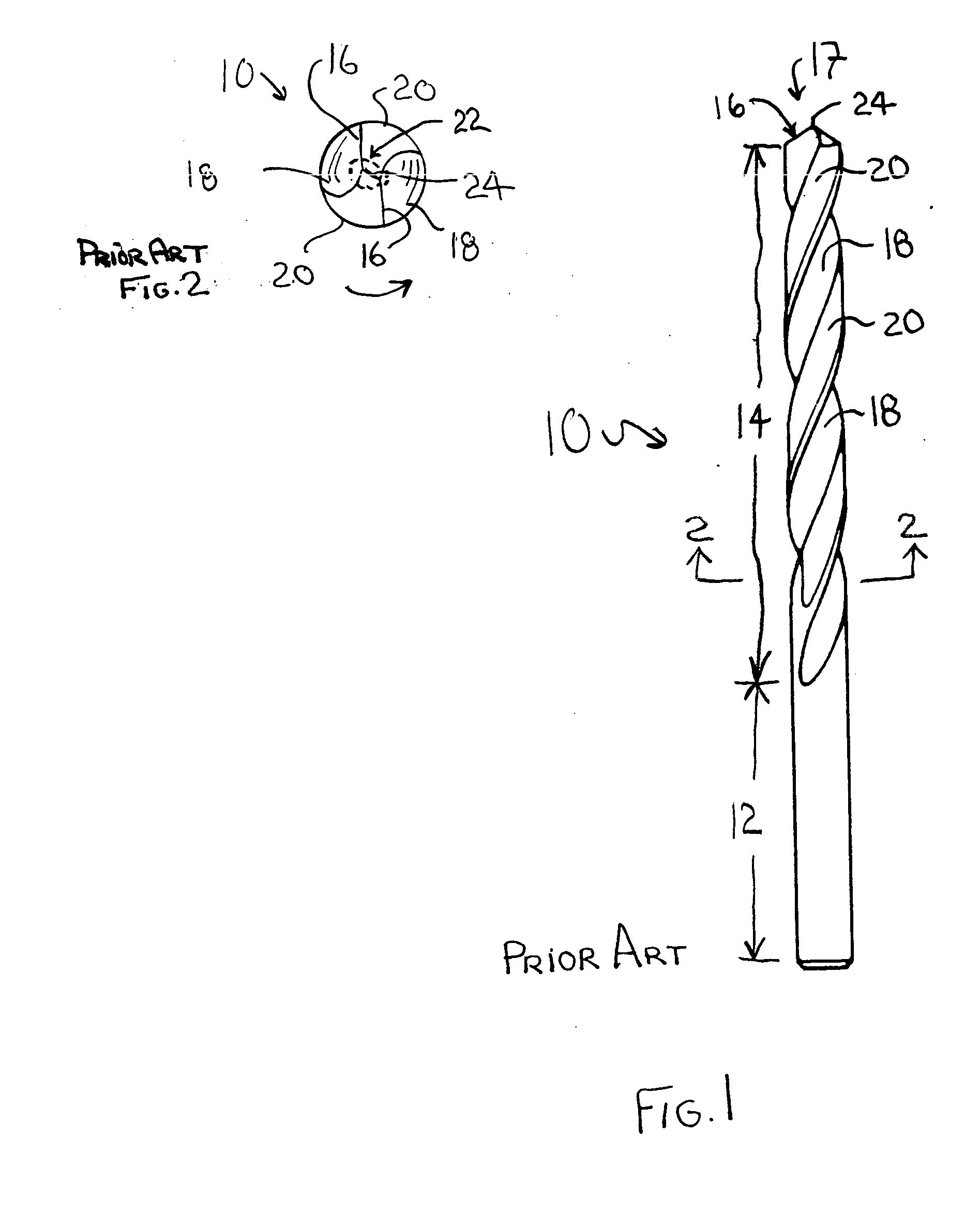

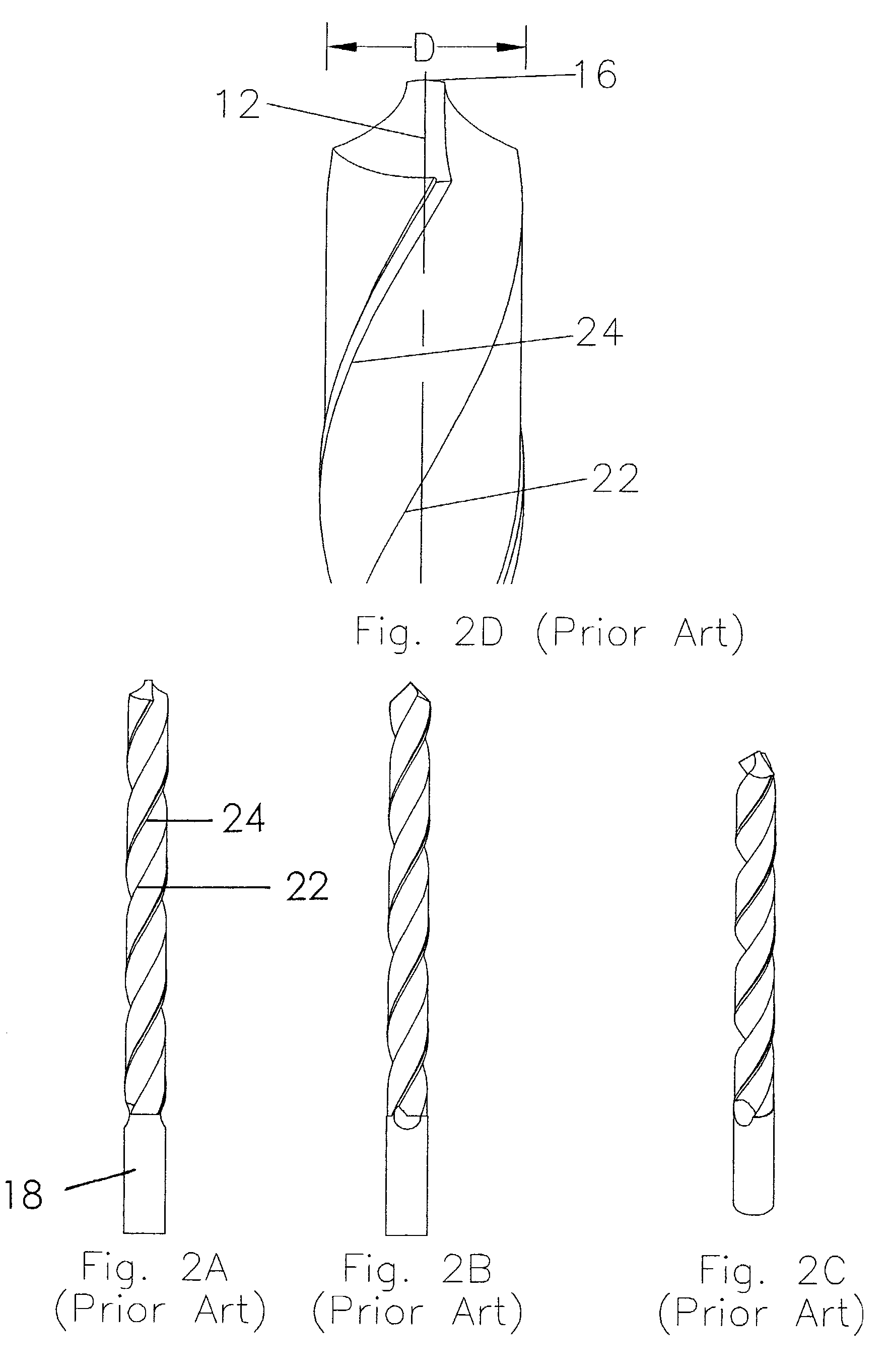

The twist drill is the most widely used and widely produced kind of drill bit. The term twist drill generally refers to the kind of drill bit used, not to the drill itself. A twist drill bit is a metallic cylinder with helical grooves that spiral up the bit.

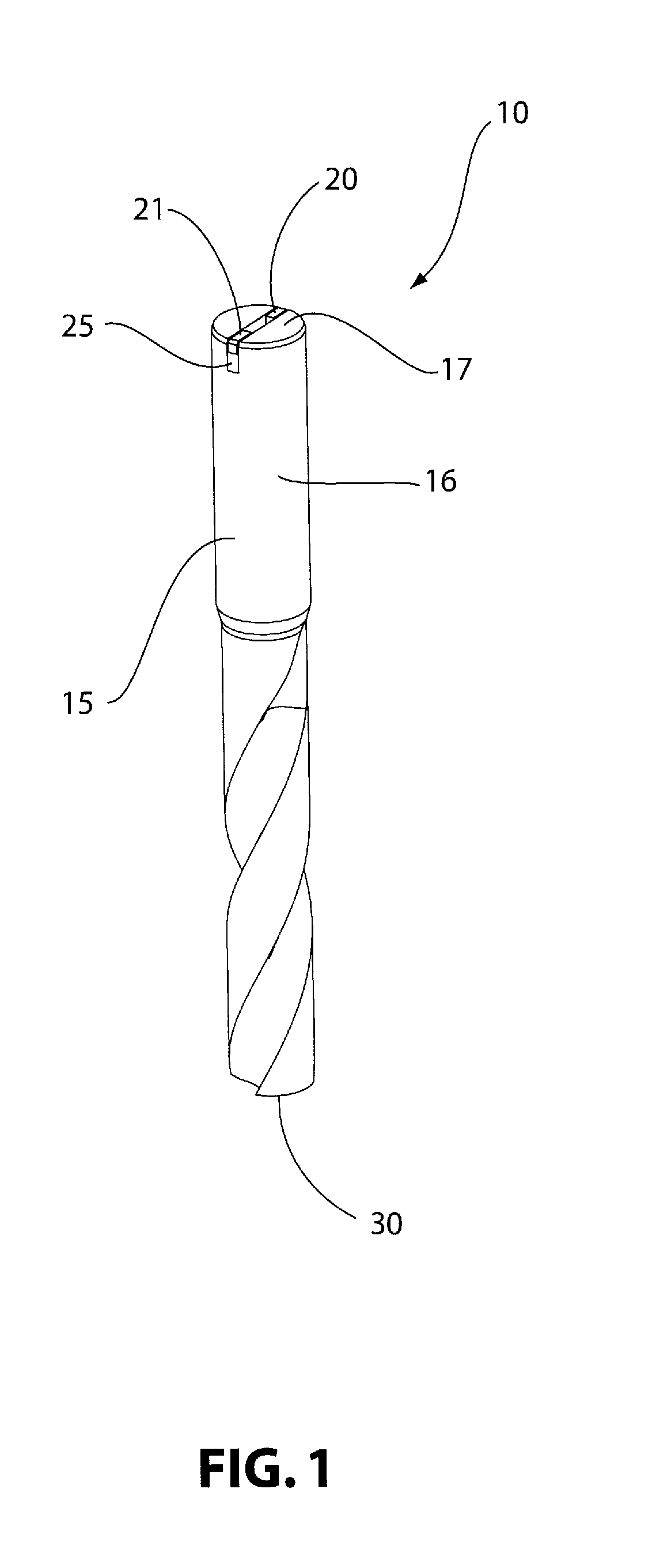

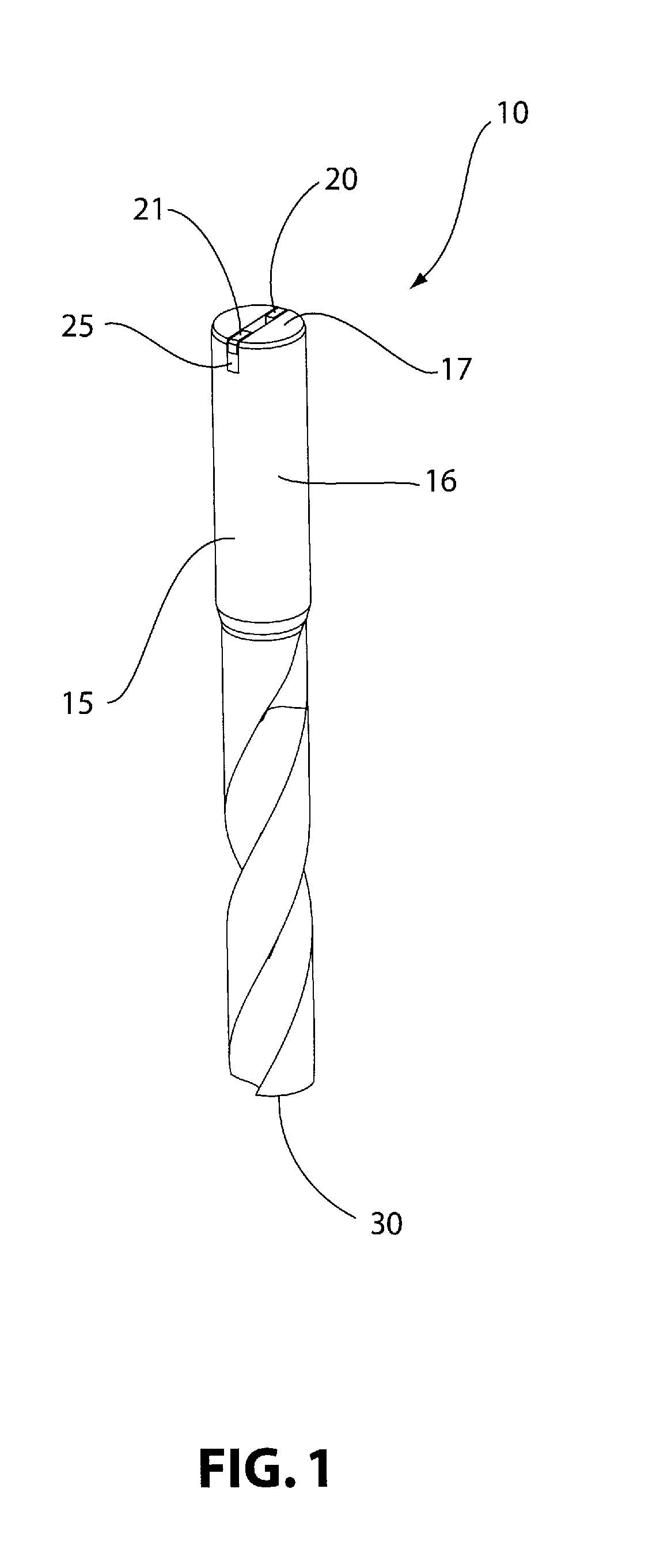

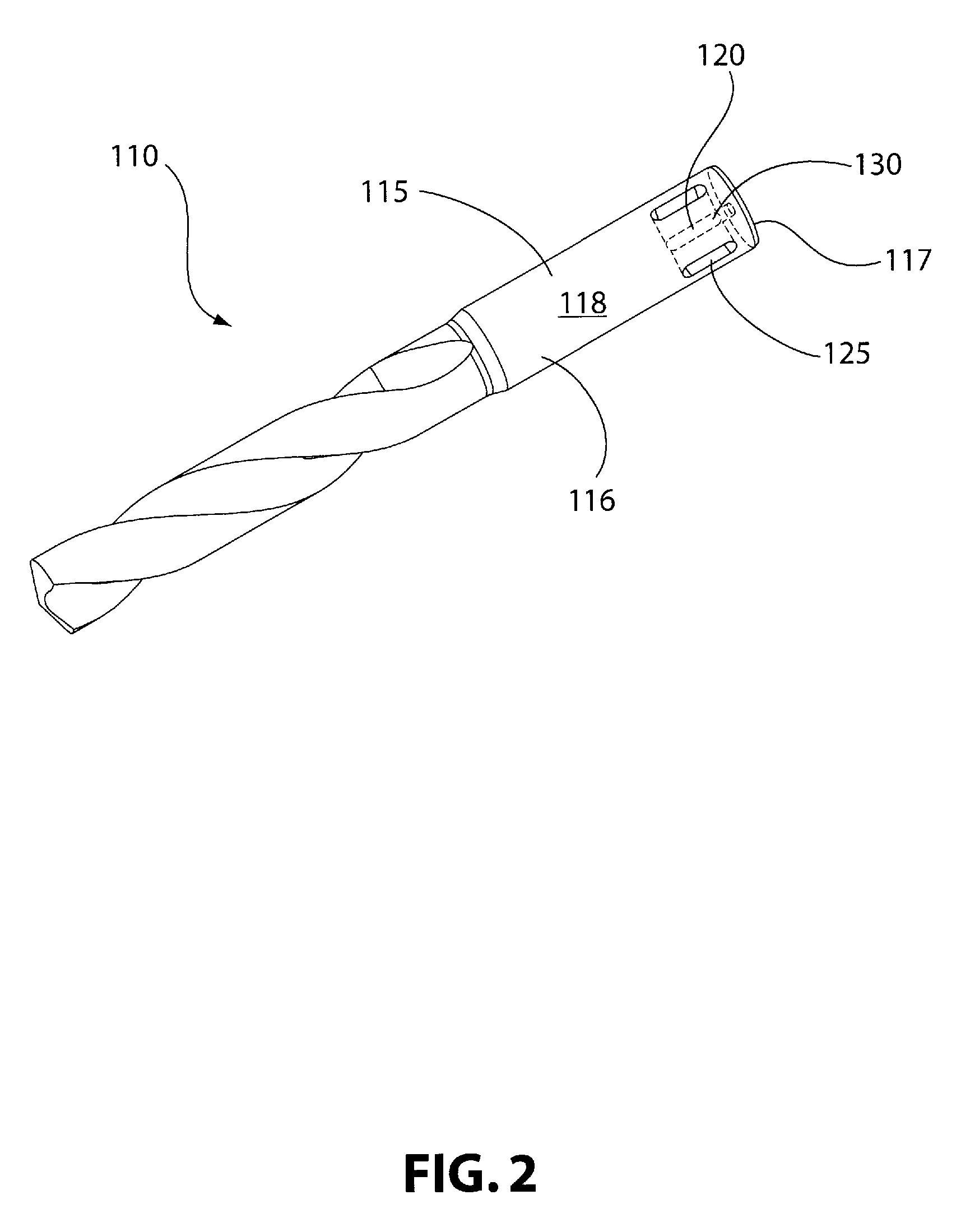

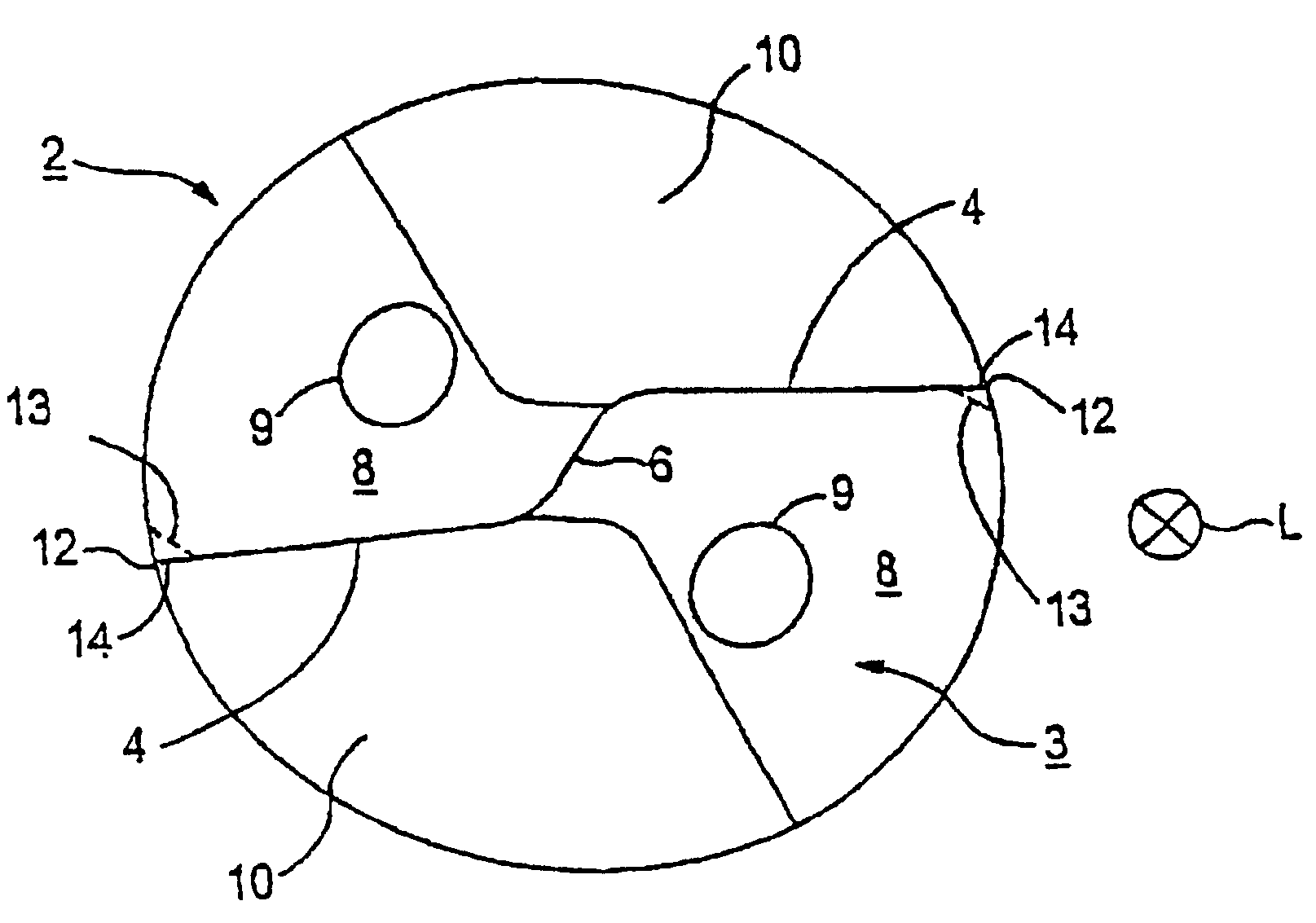

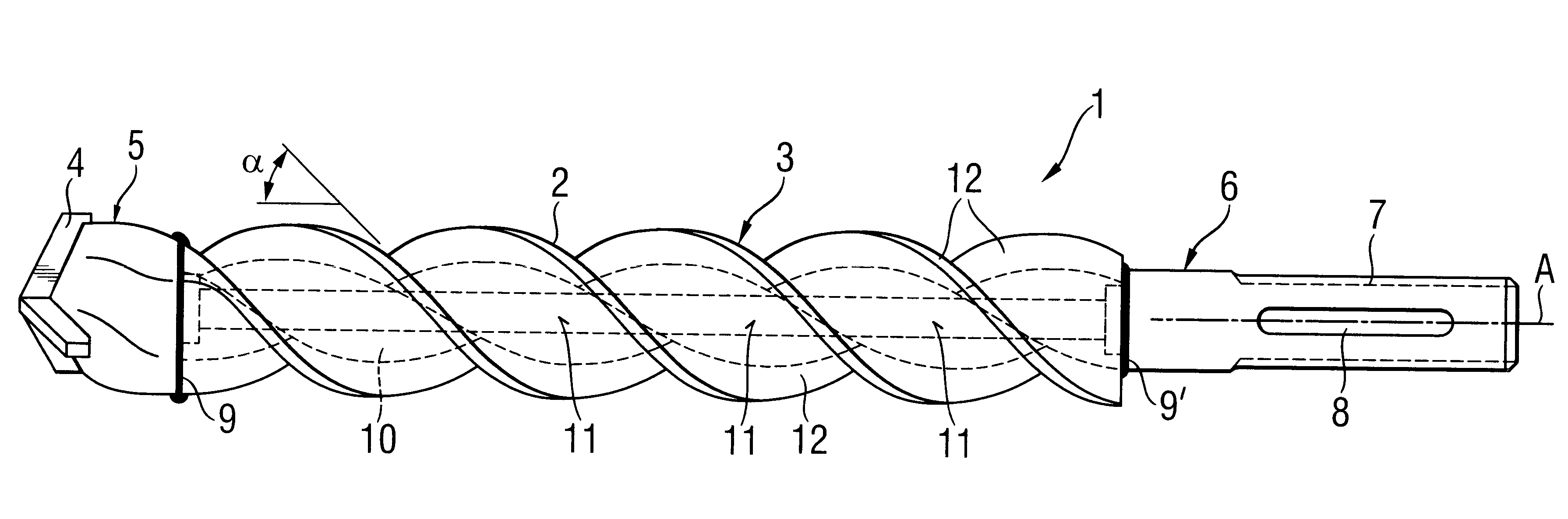

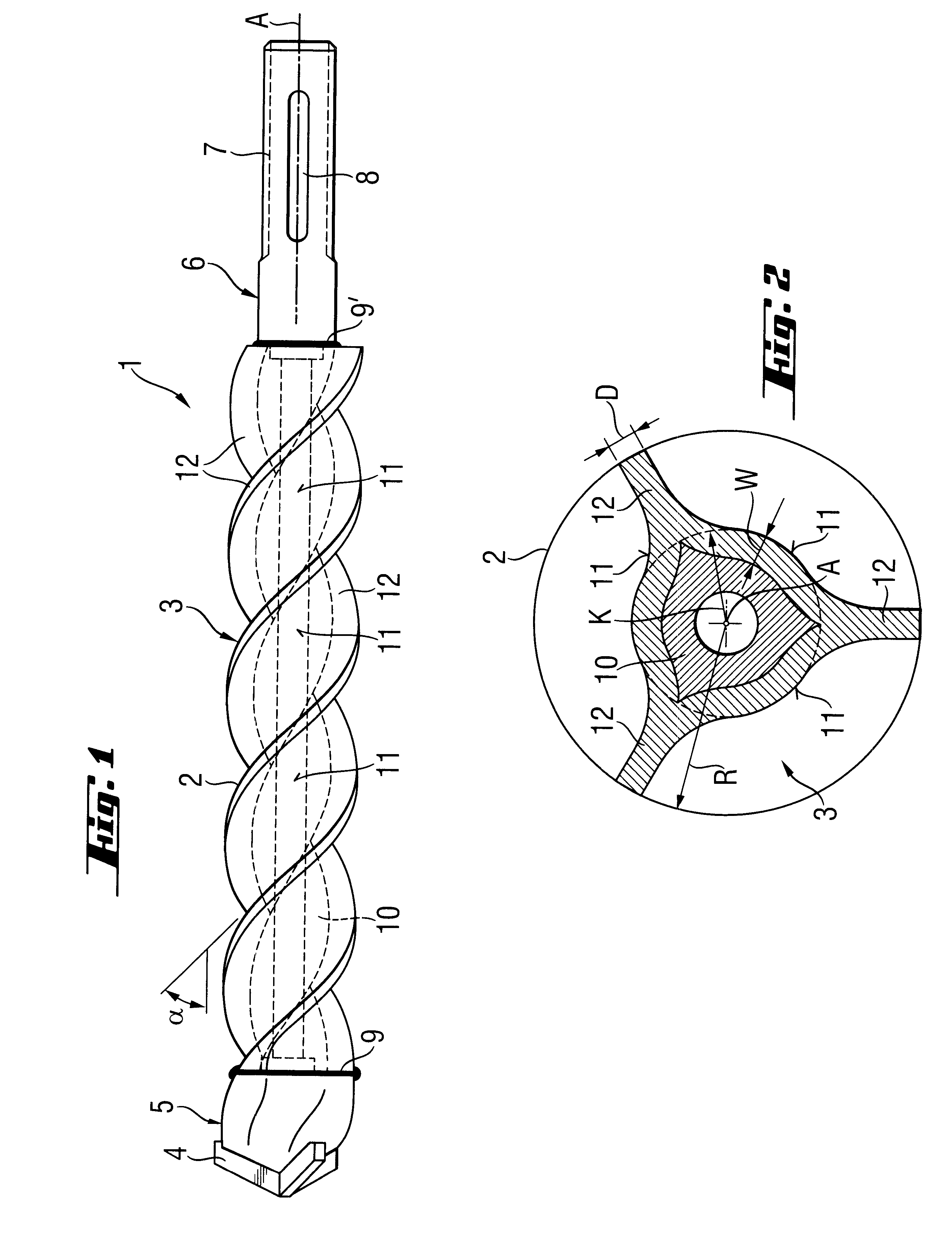

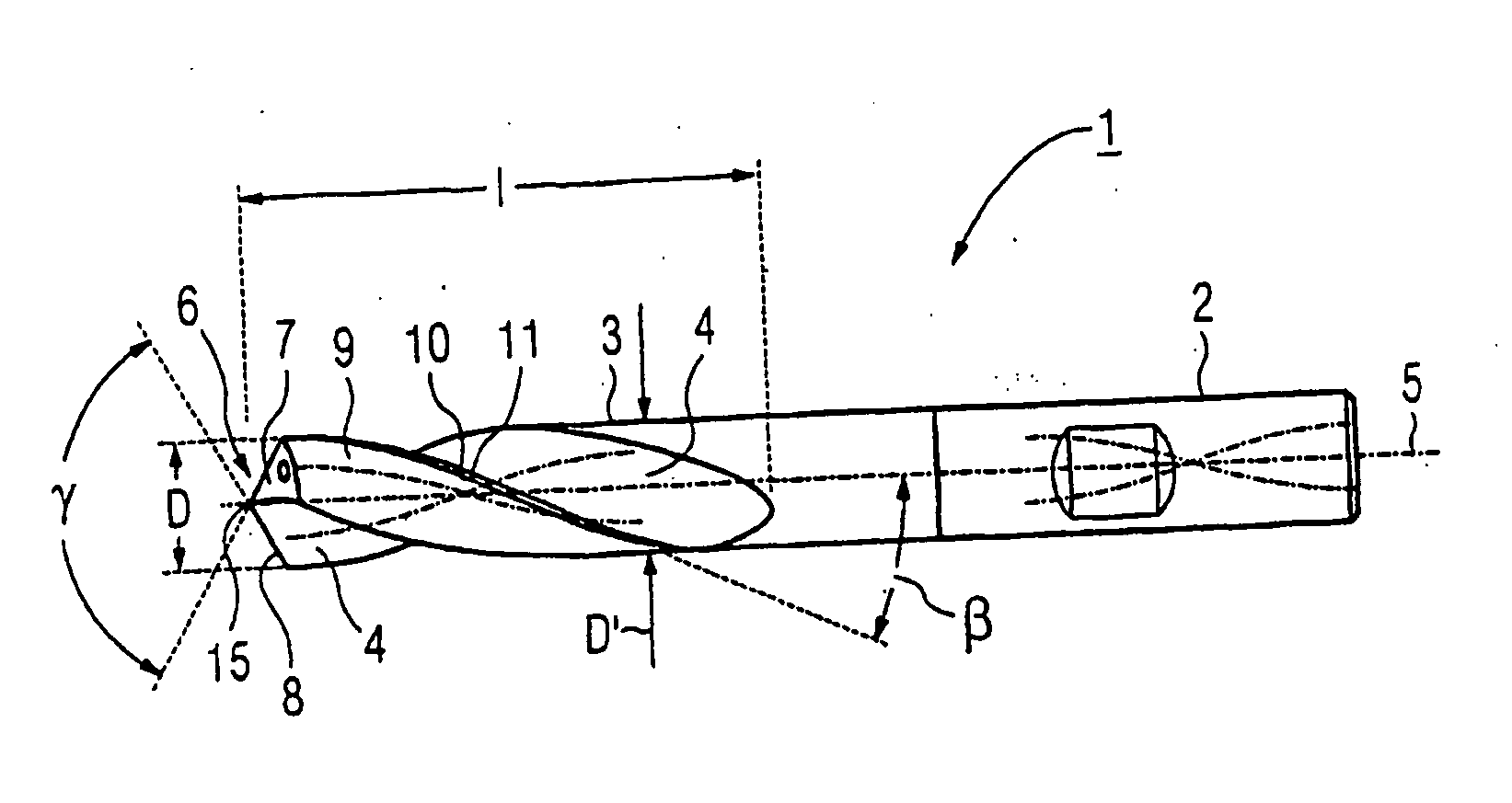

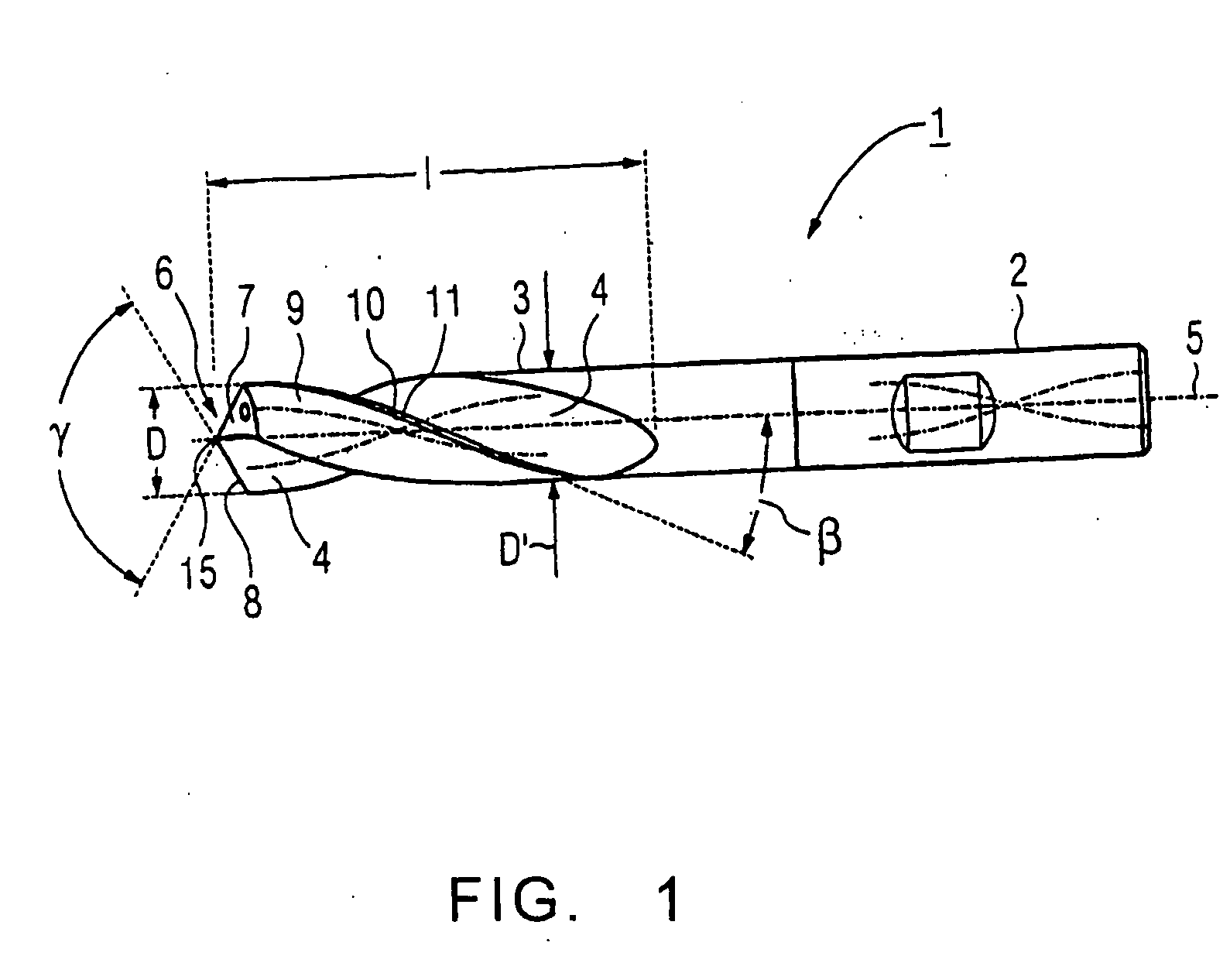

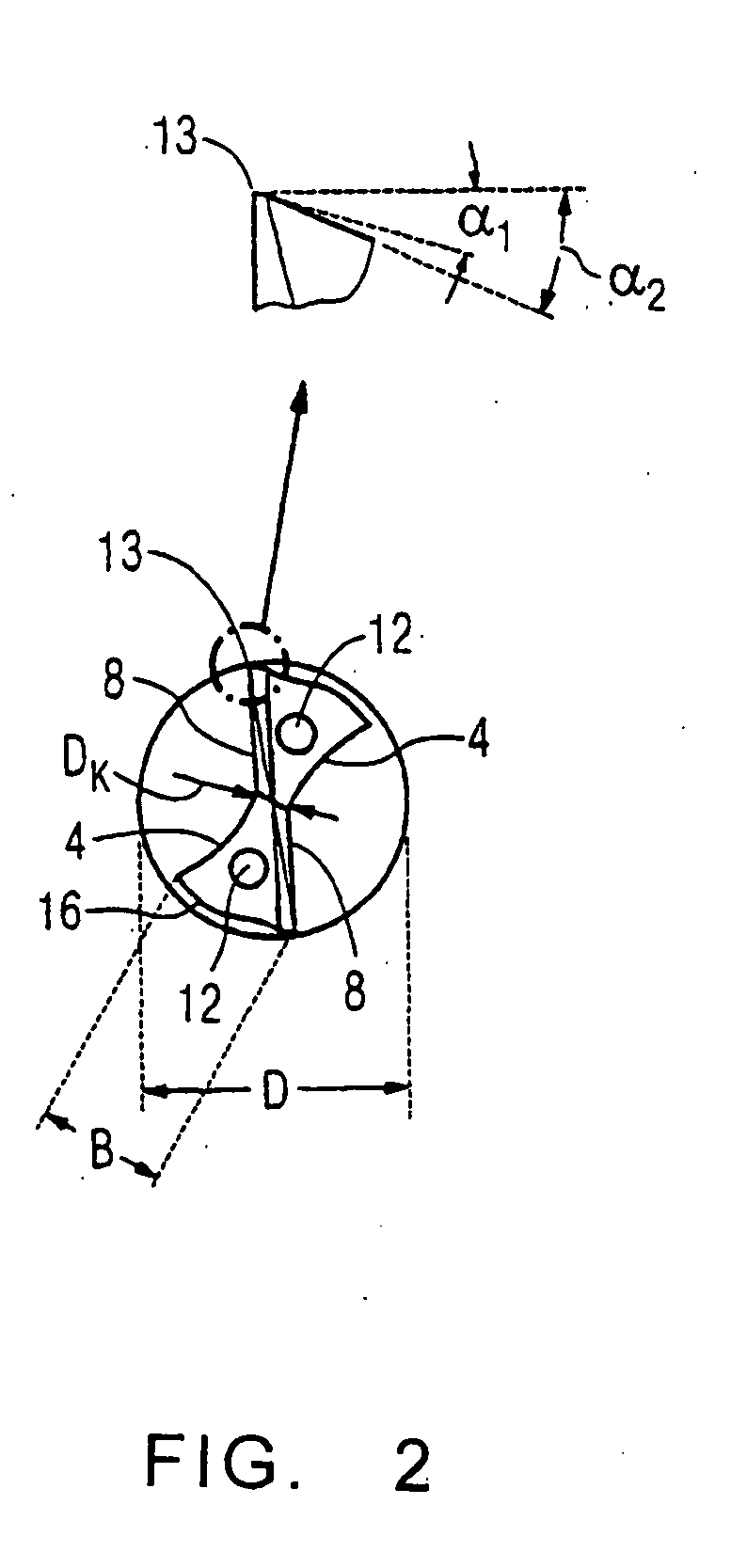

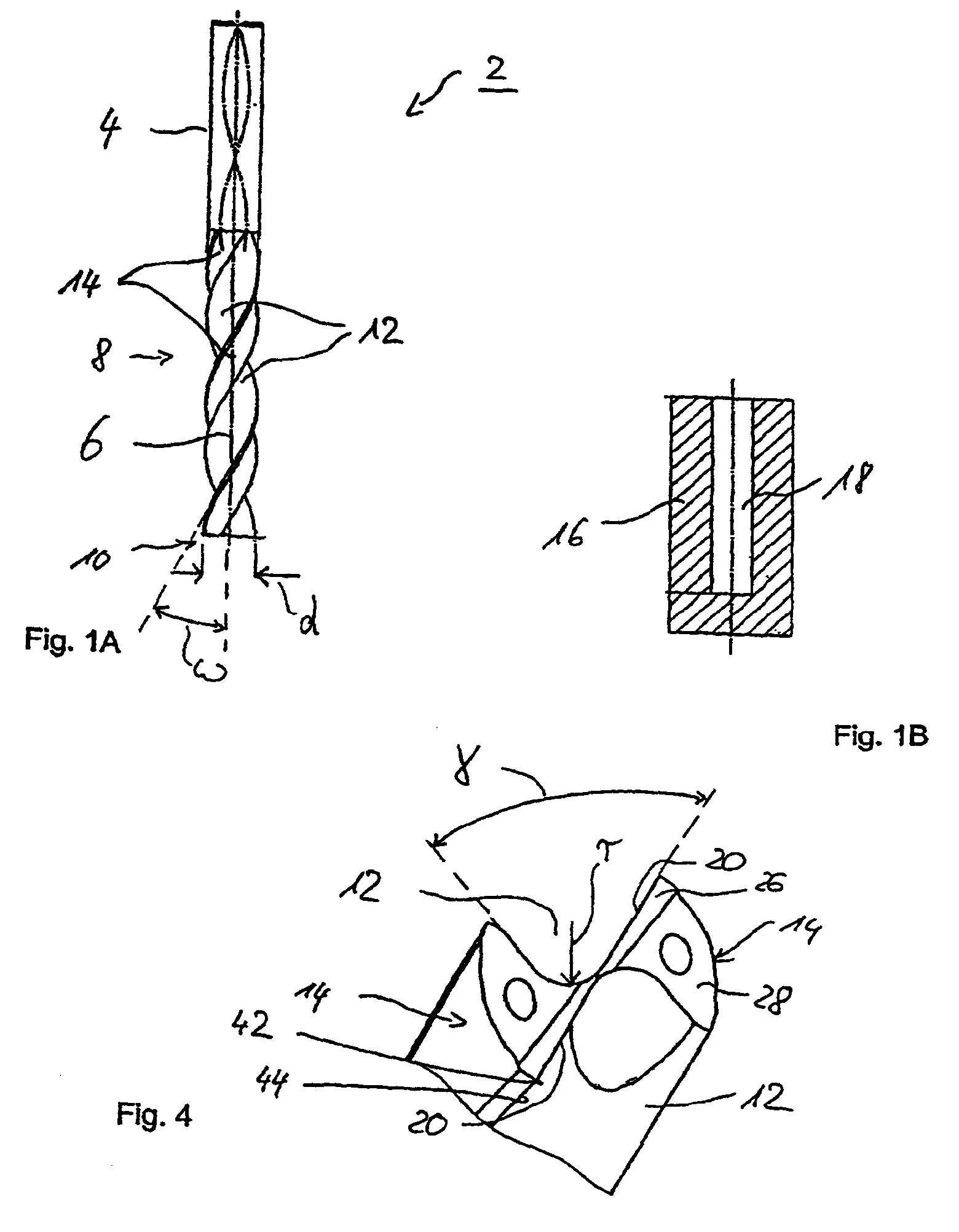

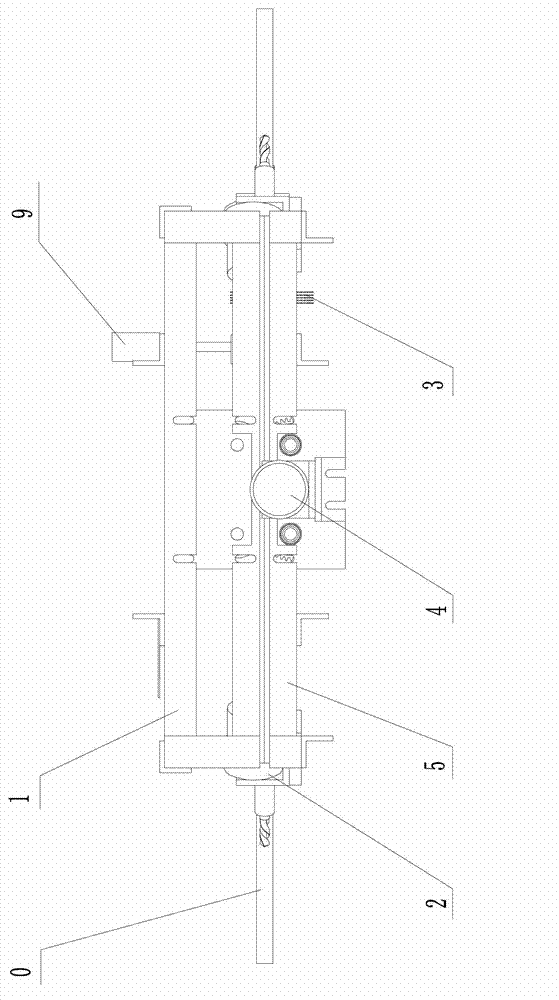

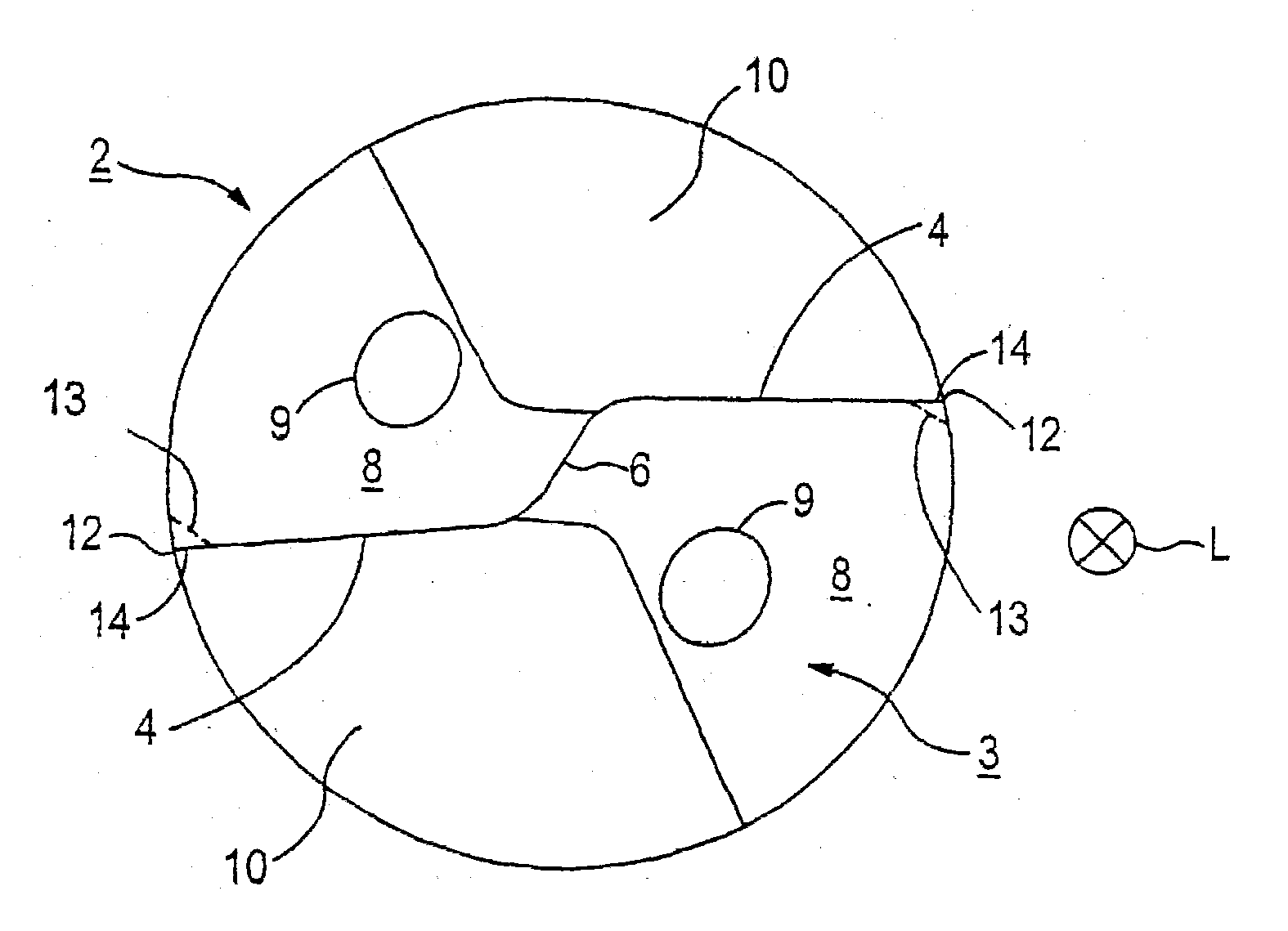

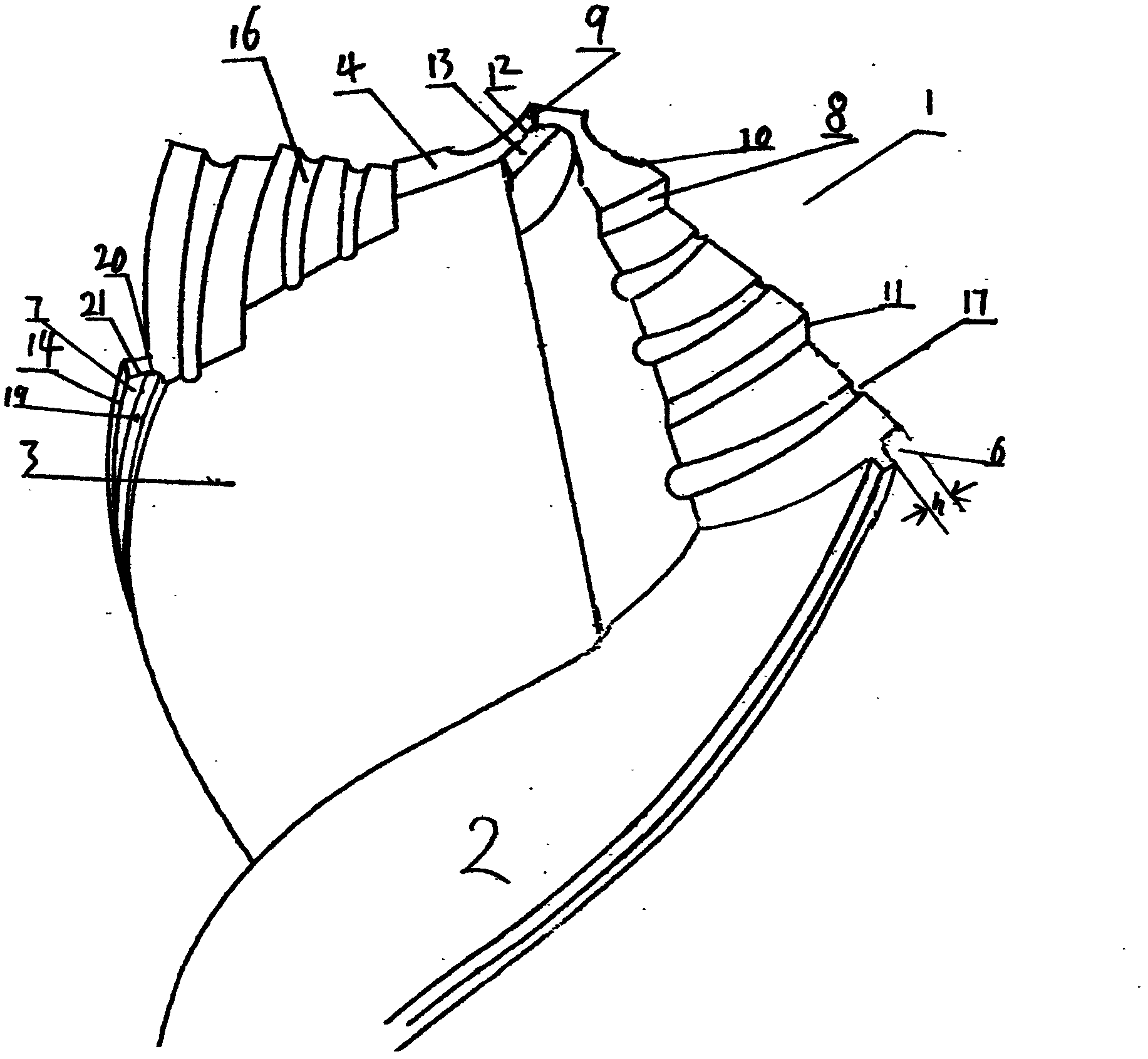

Twist drill for drilling having a replaceable drill tip, and a replaceable drill tip for use in a twist drill

InactiveUS7070367B2Avoid damageAvoid pullingWood turning toolsTransportation and packagingFluteEngineering

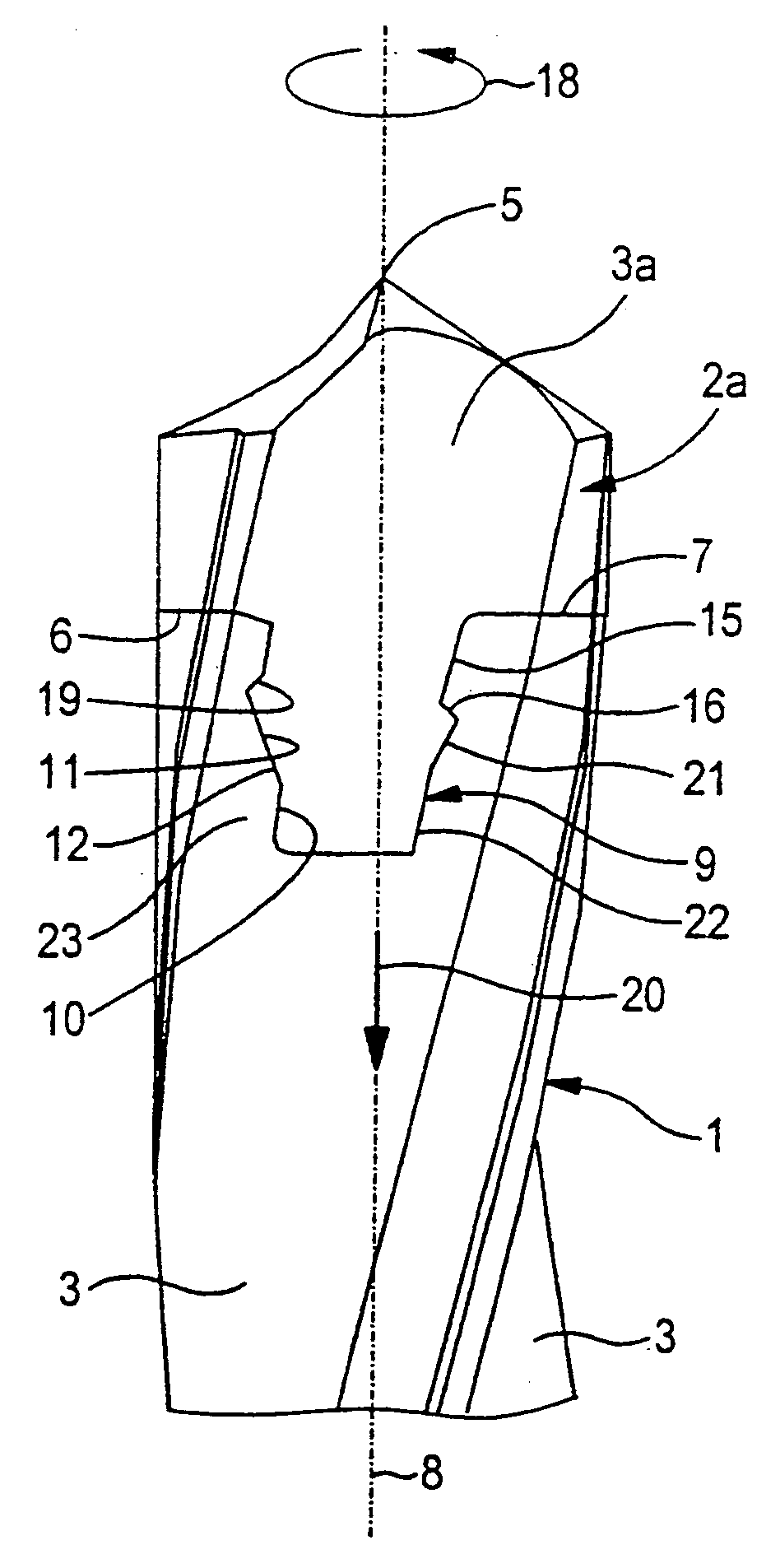

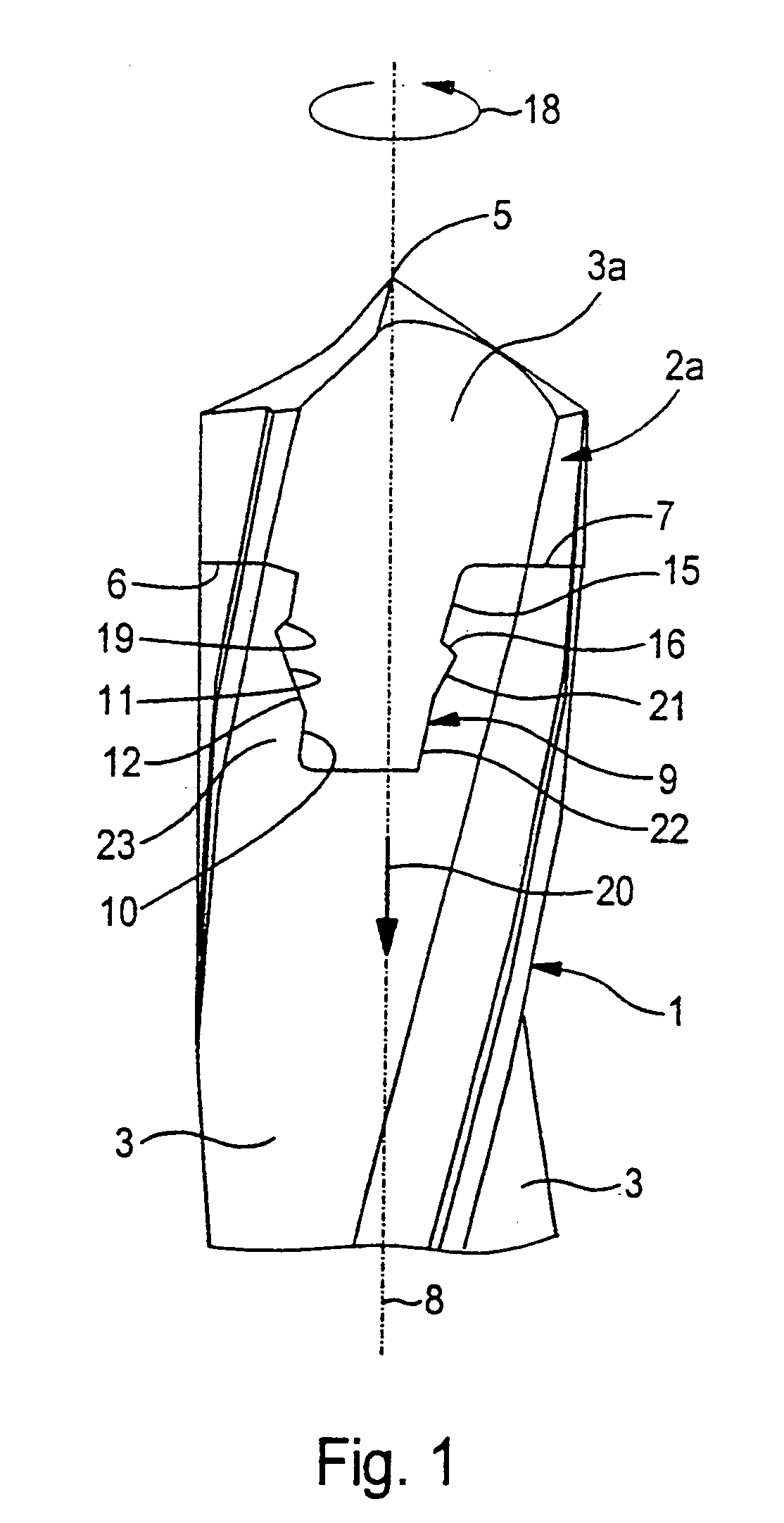

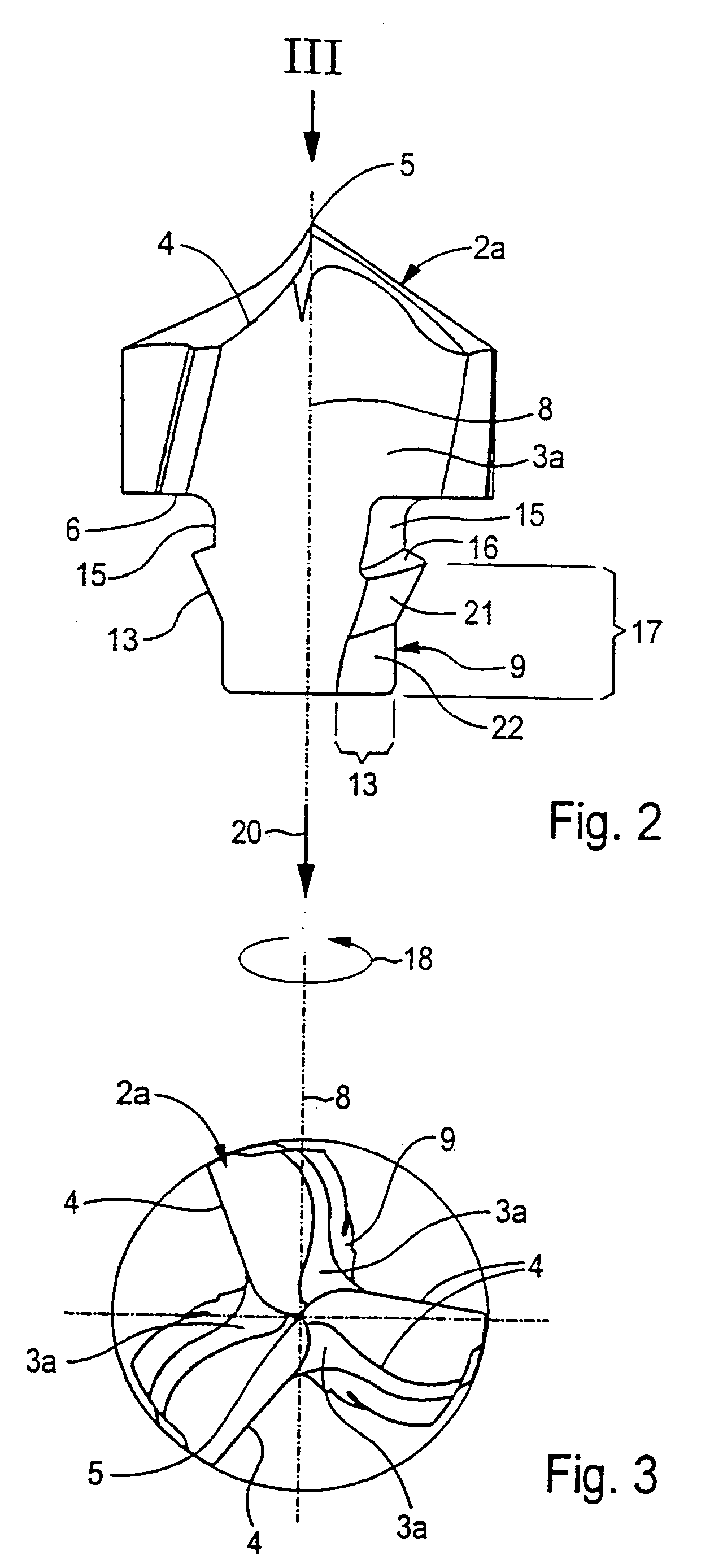

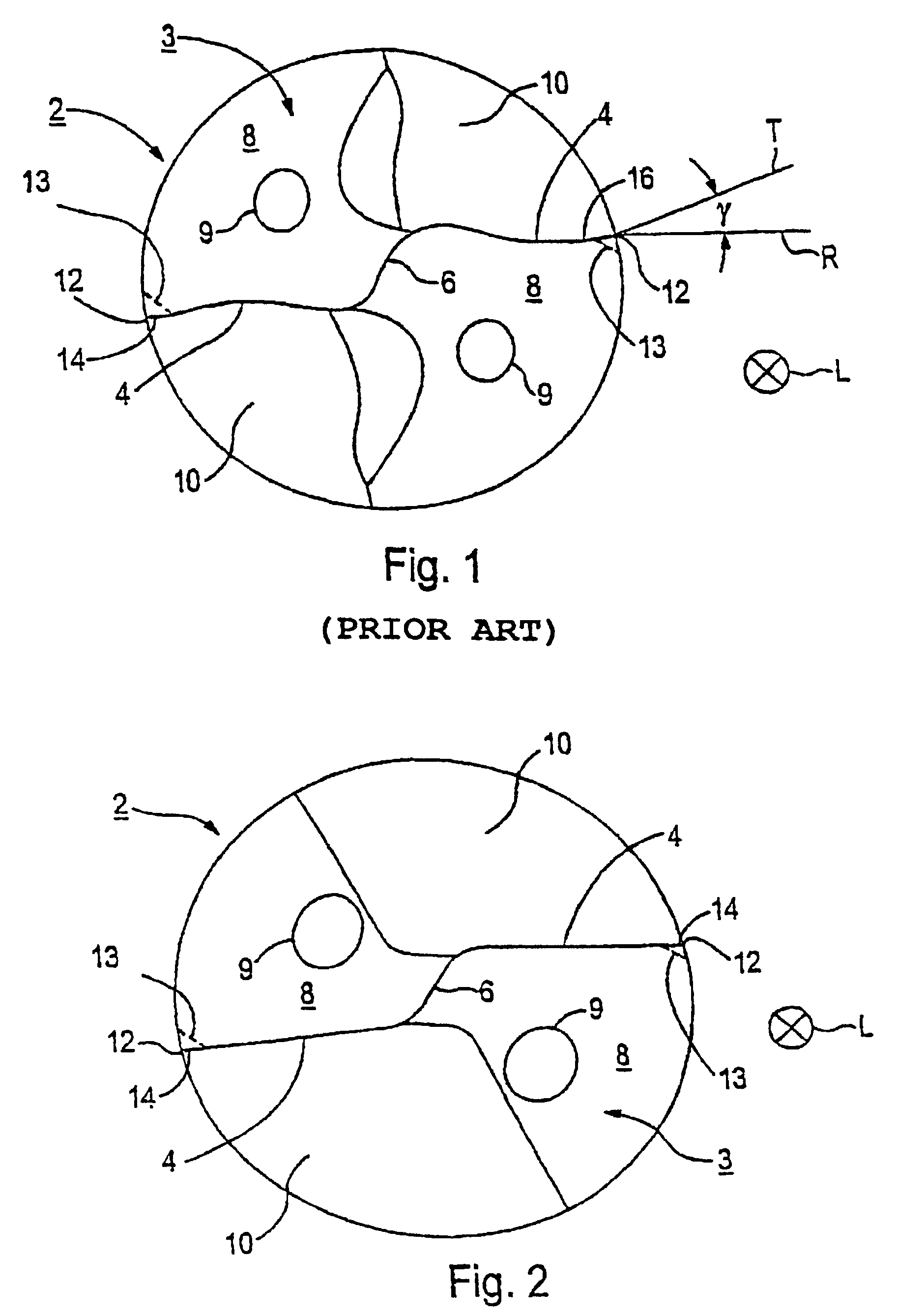

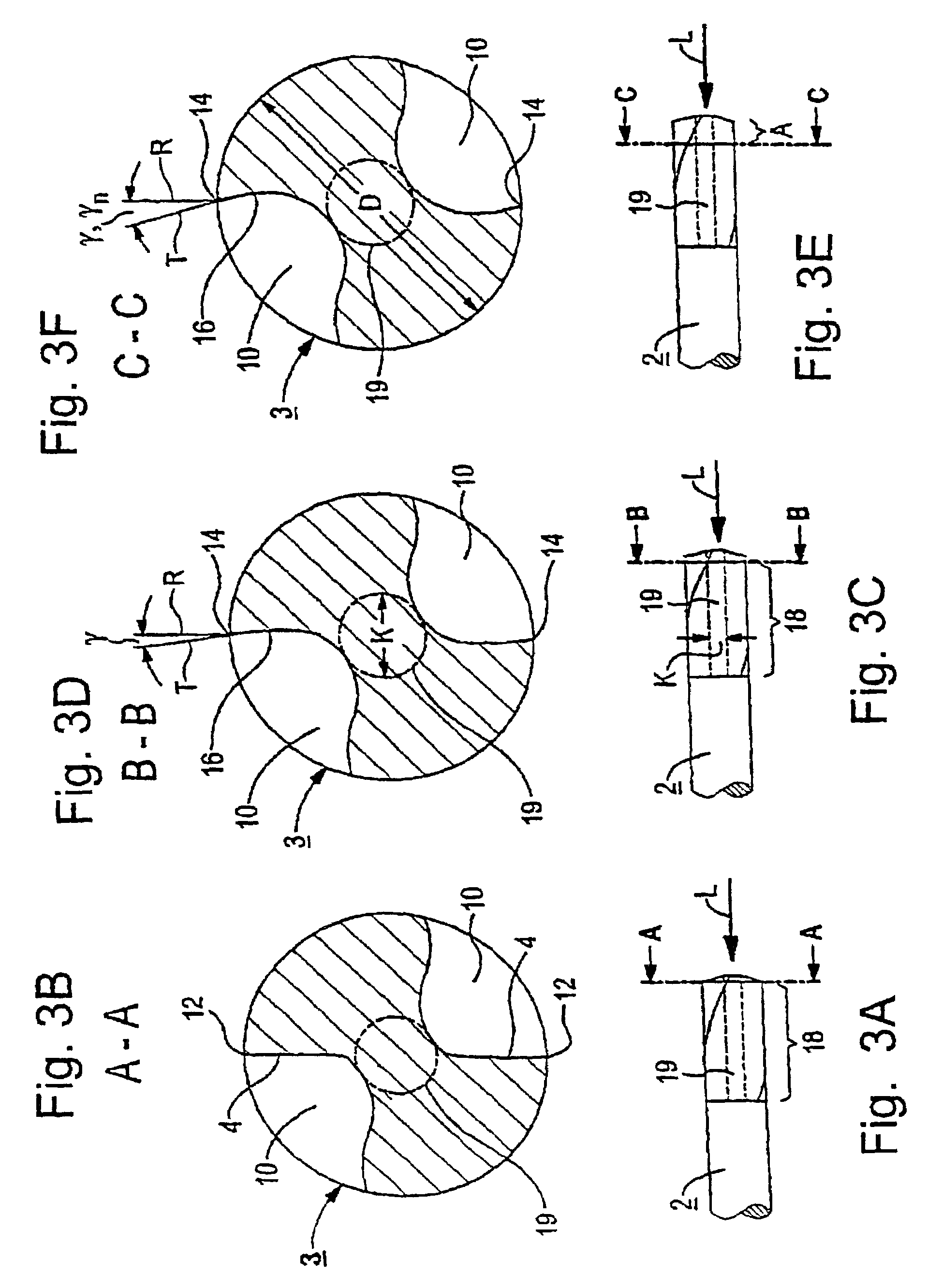

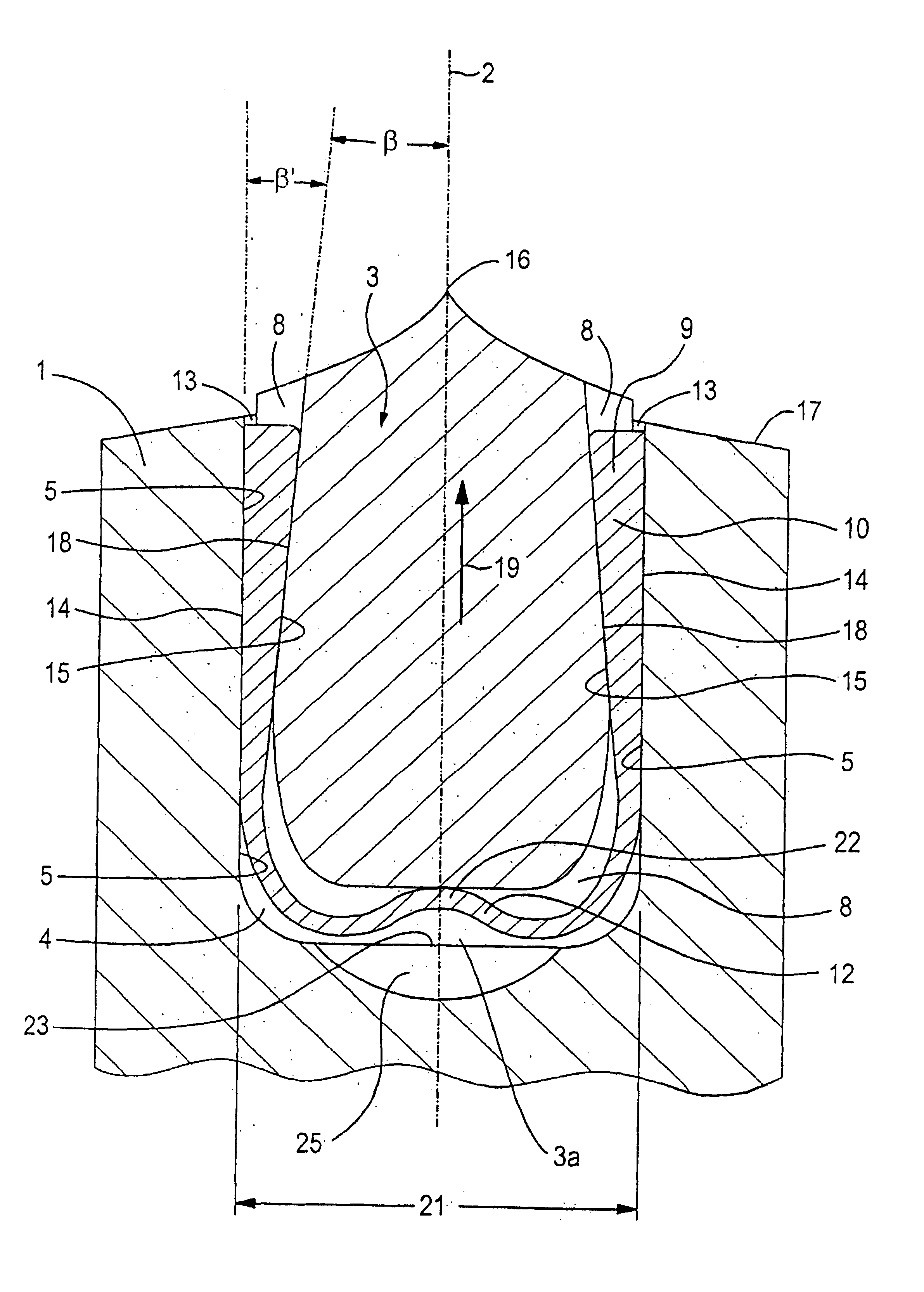

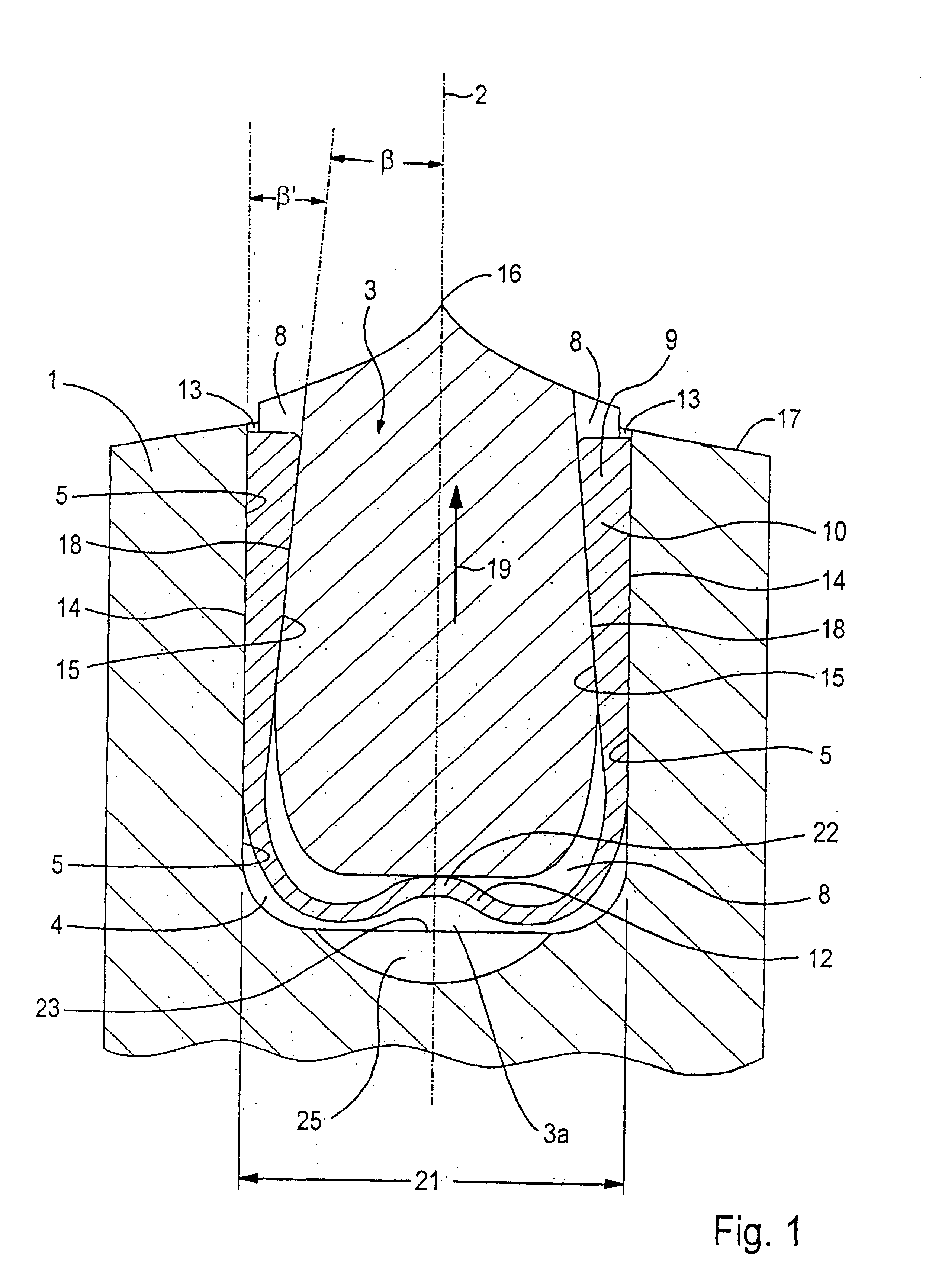

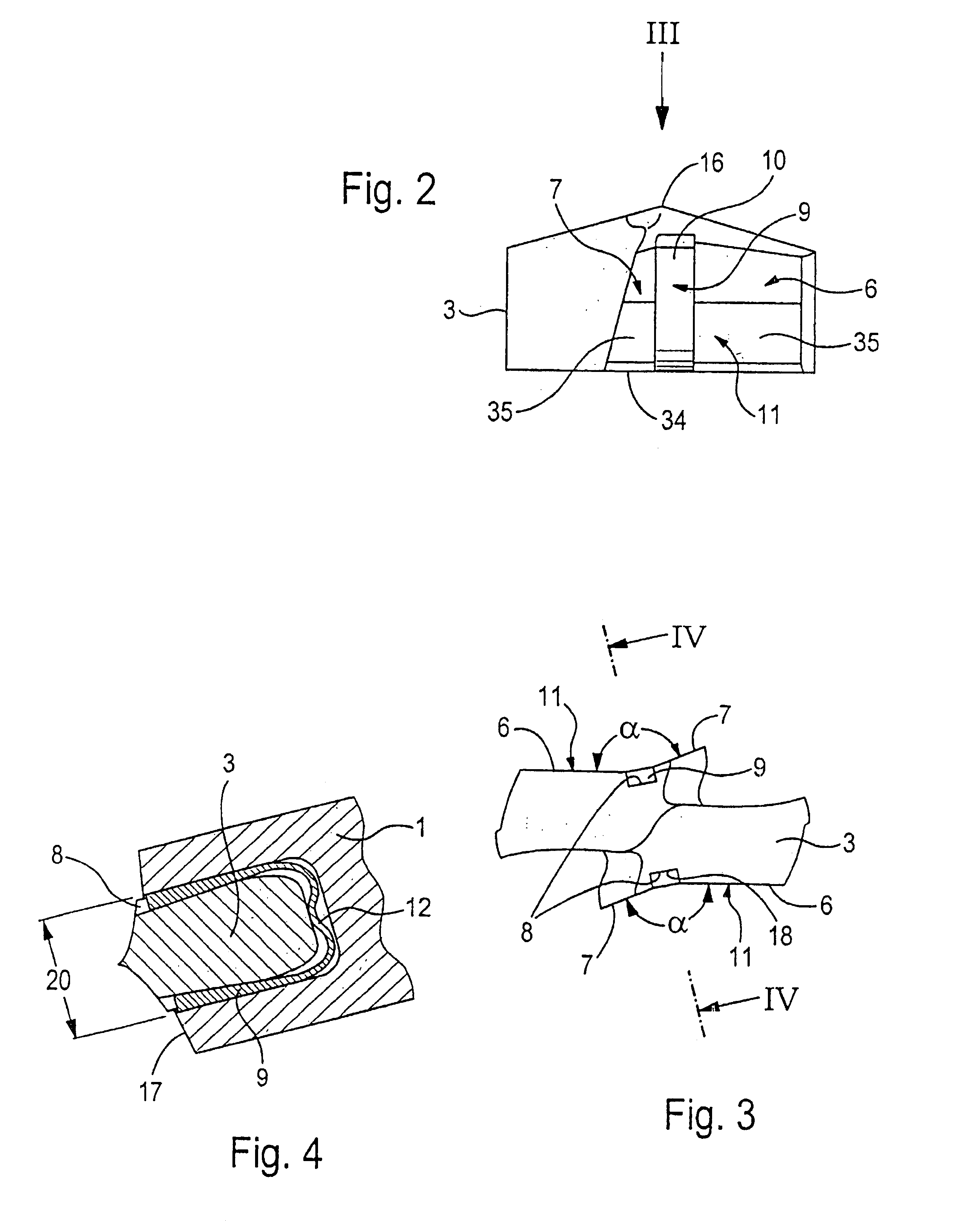

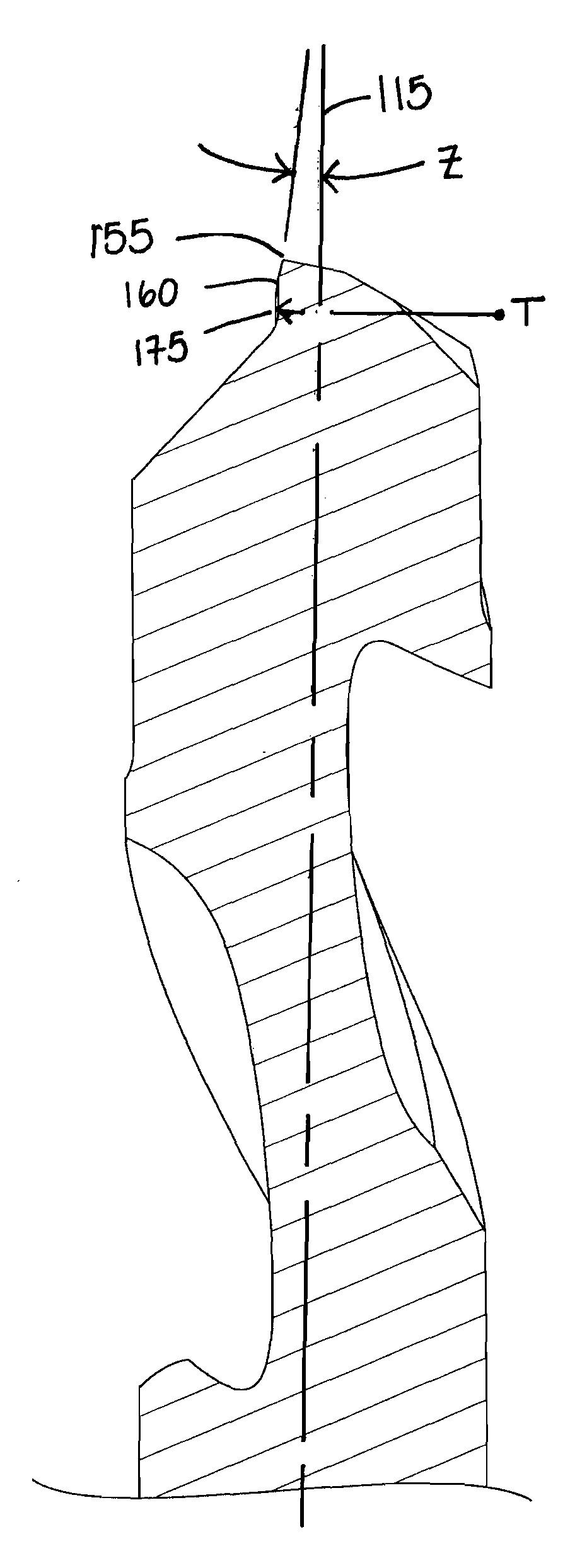

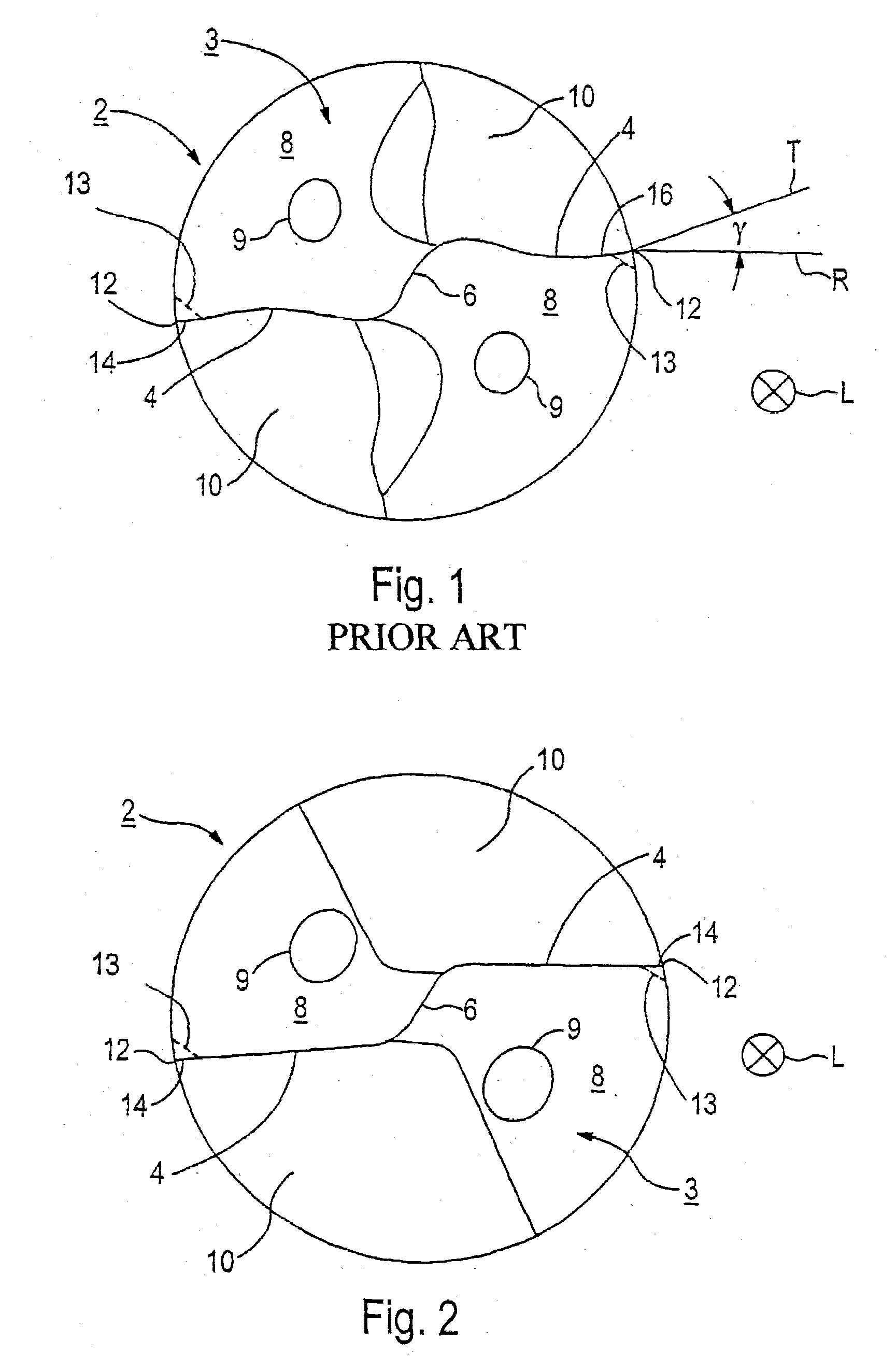

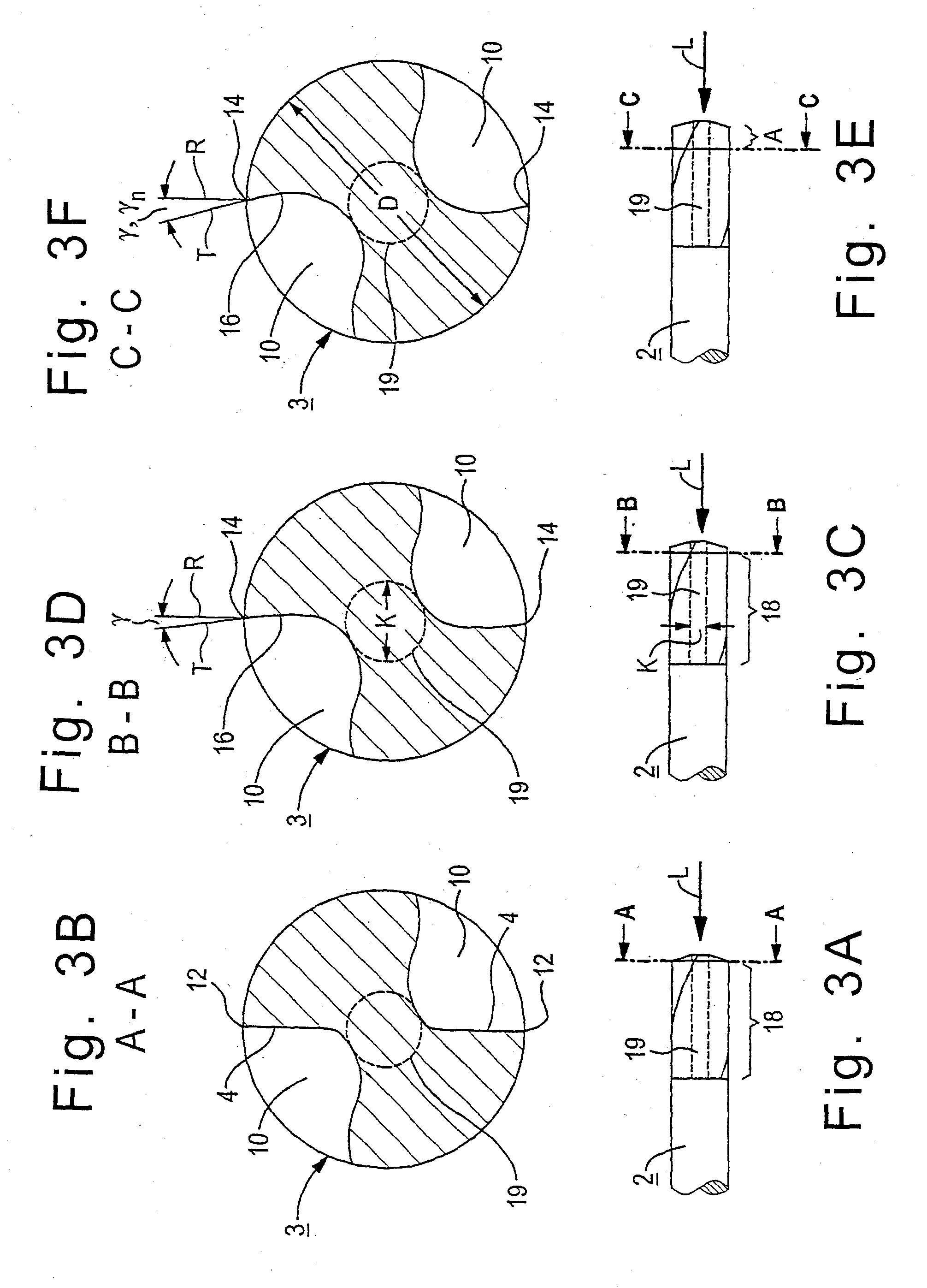

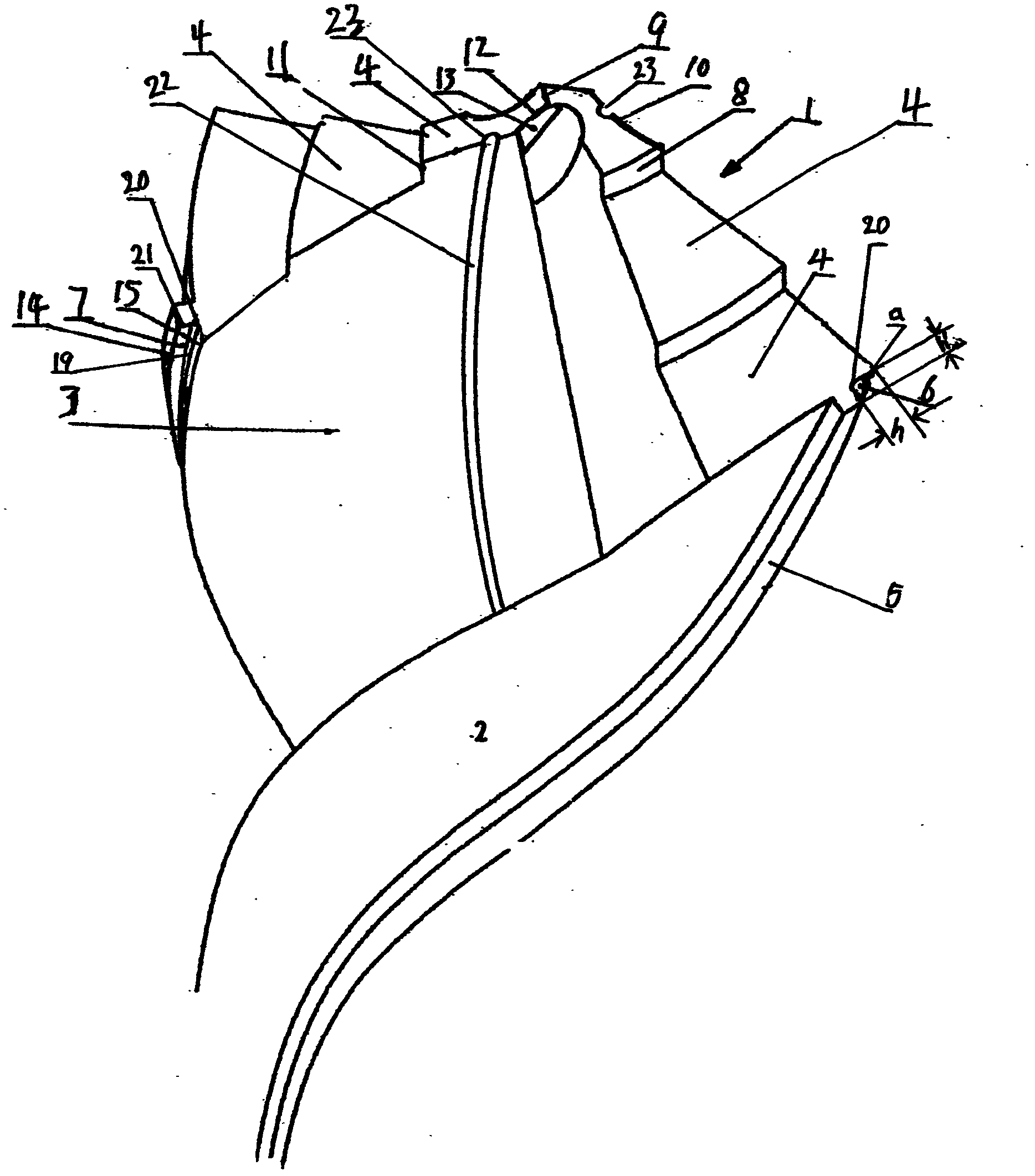

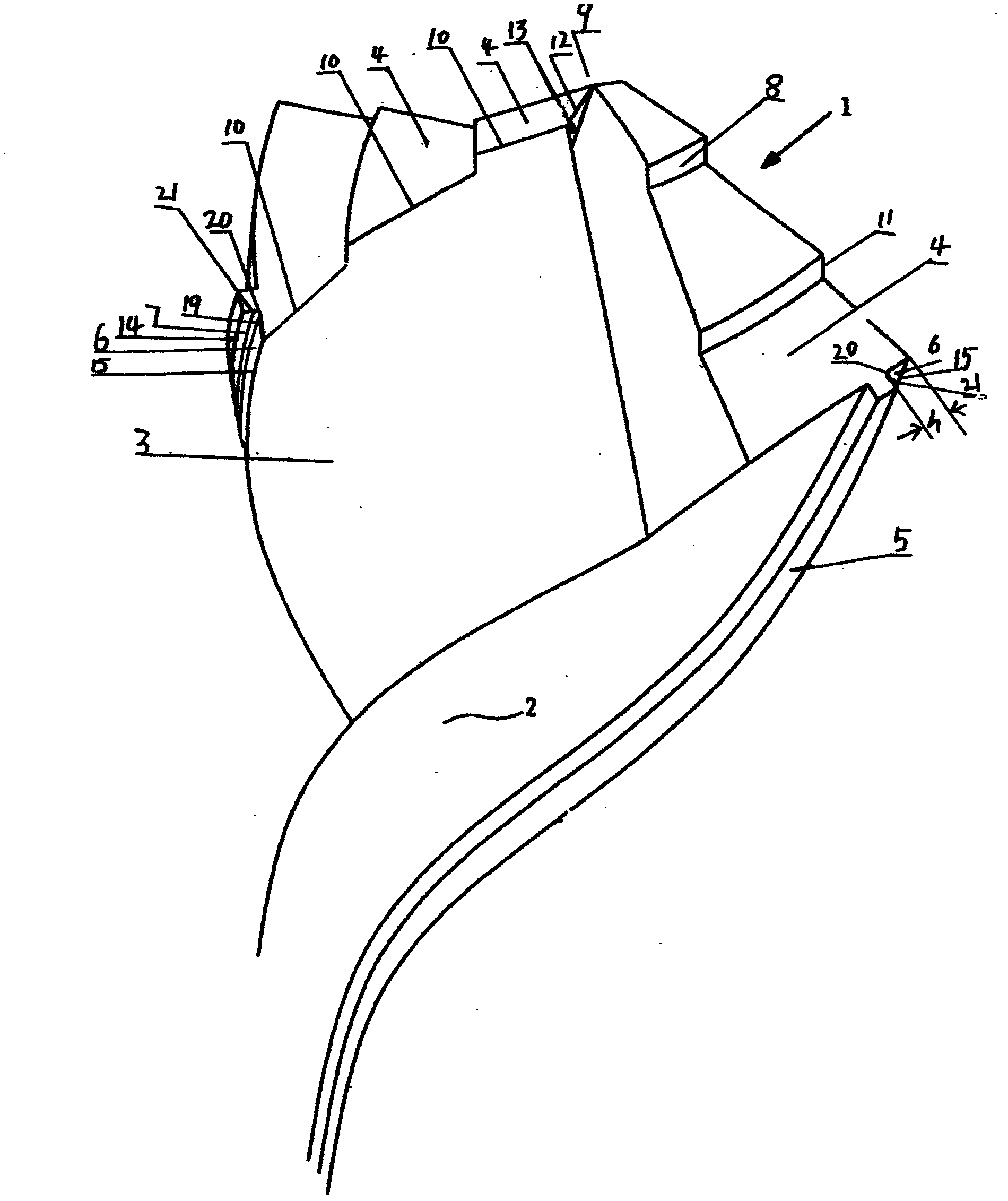

A twist drill, having a replaceable drill tip, comprising a drill bit shaft (1), a cutting insert (2) which is detachably fixed thereto and which forms the tip area of the twist drill, and comprises a flute (3) that continues into the cutting insert (2). The cutting insert rests, with a bearing surface (6) extending orthogonal to the center longitudinal axis (8) of the drill bit, on the face (7) of the drill bit shaft (1) and extends with a fixing stud (9), which centrally protrudes from the bearing surface (6), into a receiving recess (10) which is configured complementary thereto and which is provided in the face (7) of the drill bit shaft (1). At least one peripheral section (13) of the fixing stud (9) comprises a first longitudinal section (15) that, with a screw surface (16) which points away from the drill bit shaft (1), which slopes upward to the drill bit tip (5) in a direction of rotation of the drill bit, and which interacts with an opposite surface (19) on the inner wall (14) of the receiving recess (10), merges into a second longitudinal section (17).

Owner:KENNAMETAL INC

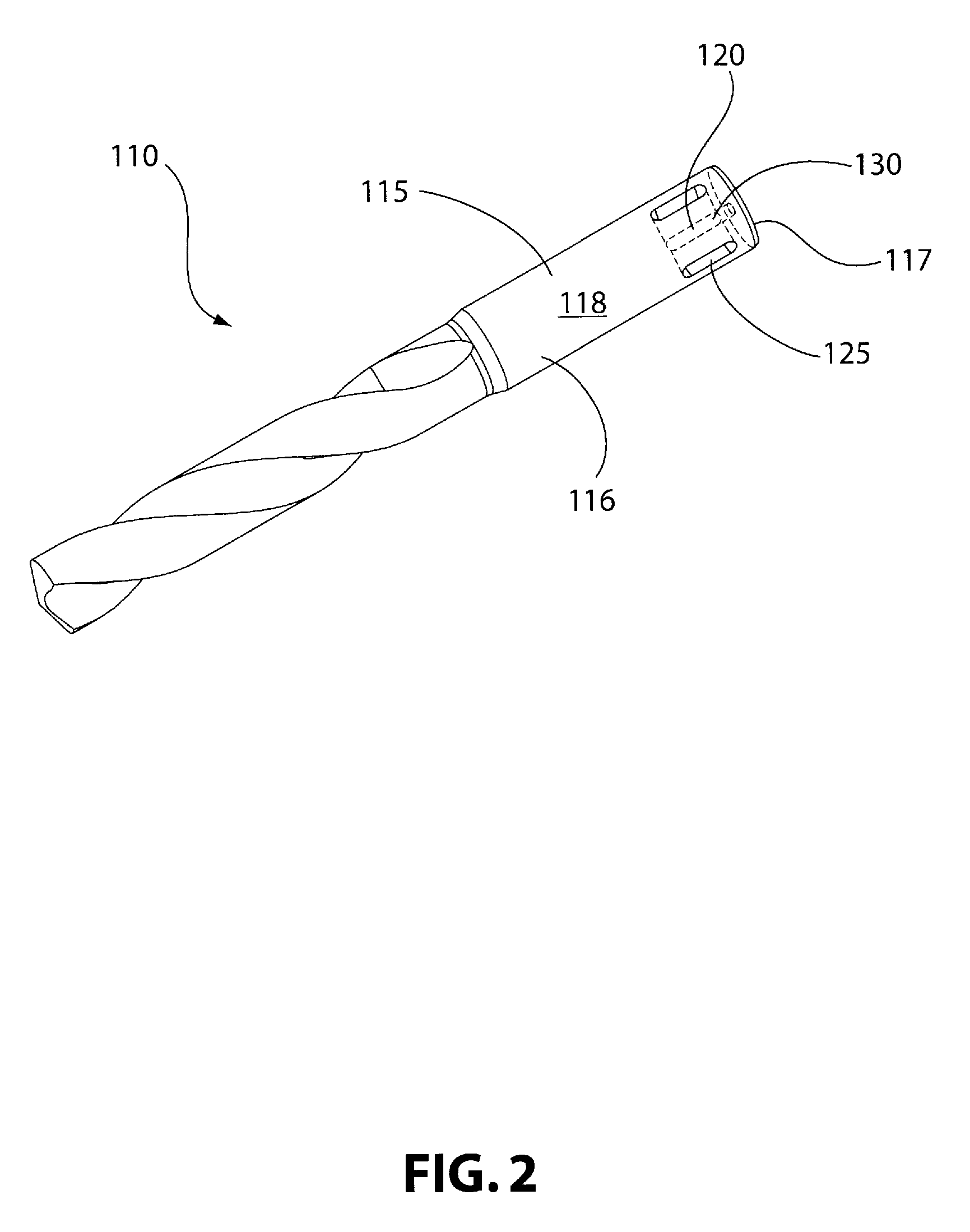

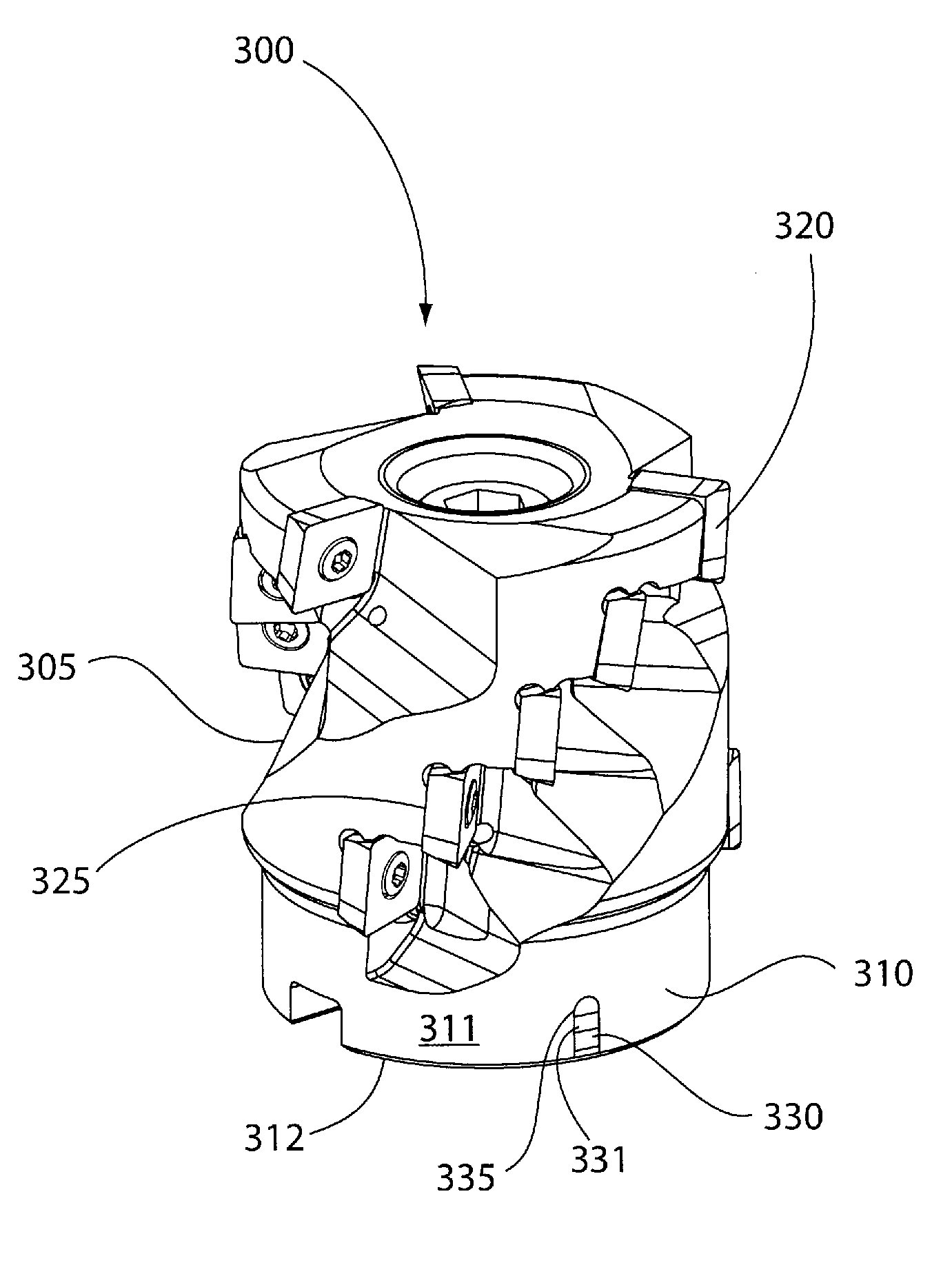

Cutting tool with integrated circuit chip

ActiveUS20090175694A1Programme controlAutomatic/semiautomatic turning machinesMilling cutterMachine tool

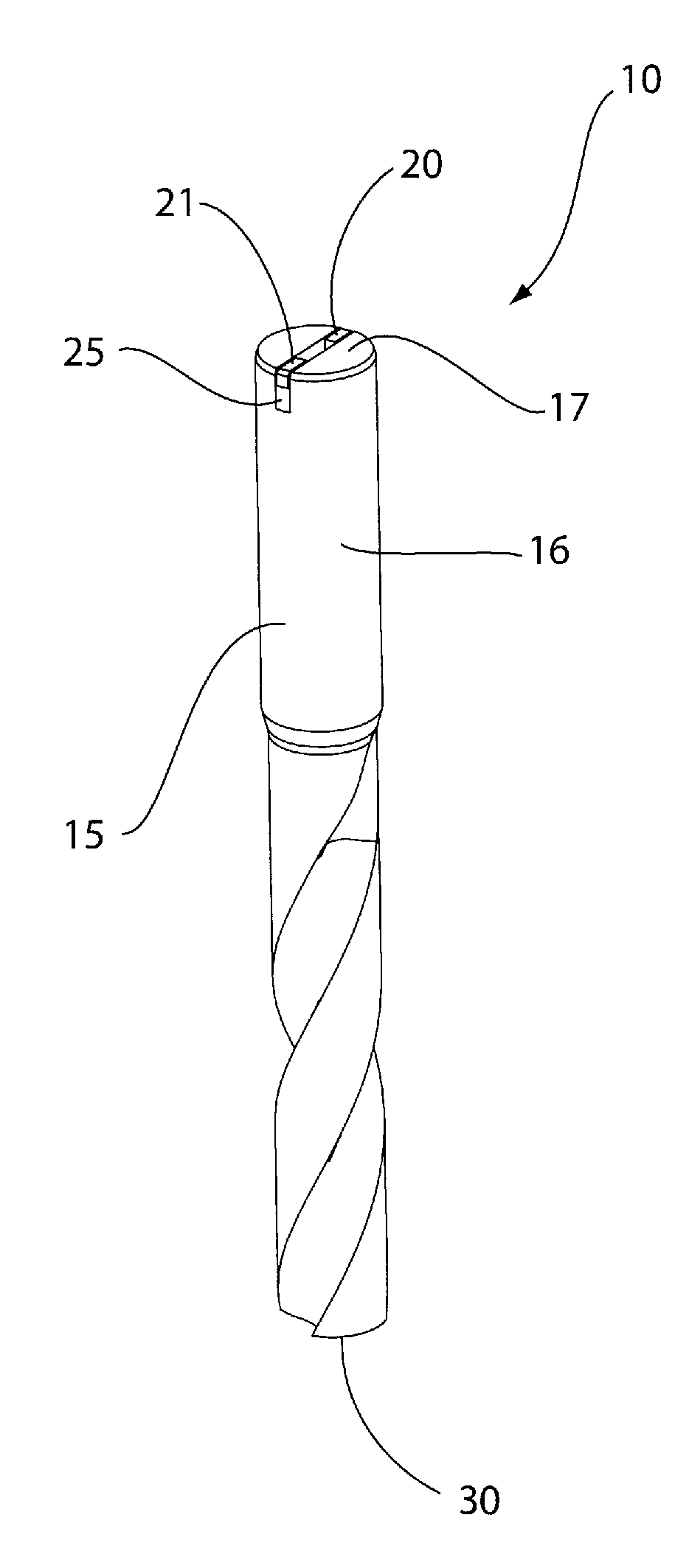

A system manages a machine tool operation. The system includes a cutting tool, which includes a tool body; an integrated circuit chip securely mounted within the tool body and capable of being read and written upon; and a read / write device for communicating with the integrated circuit chip. The integrated circuit chip is an RFID chip. The tool body may be a mounting chuck, adapter, twist drill, thread tap, indexable drill, milling cutter or a square shank lathe tool.

Owner:KENNAMETAL INC

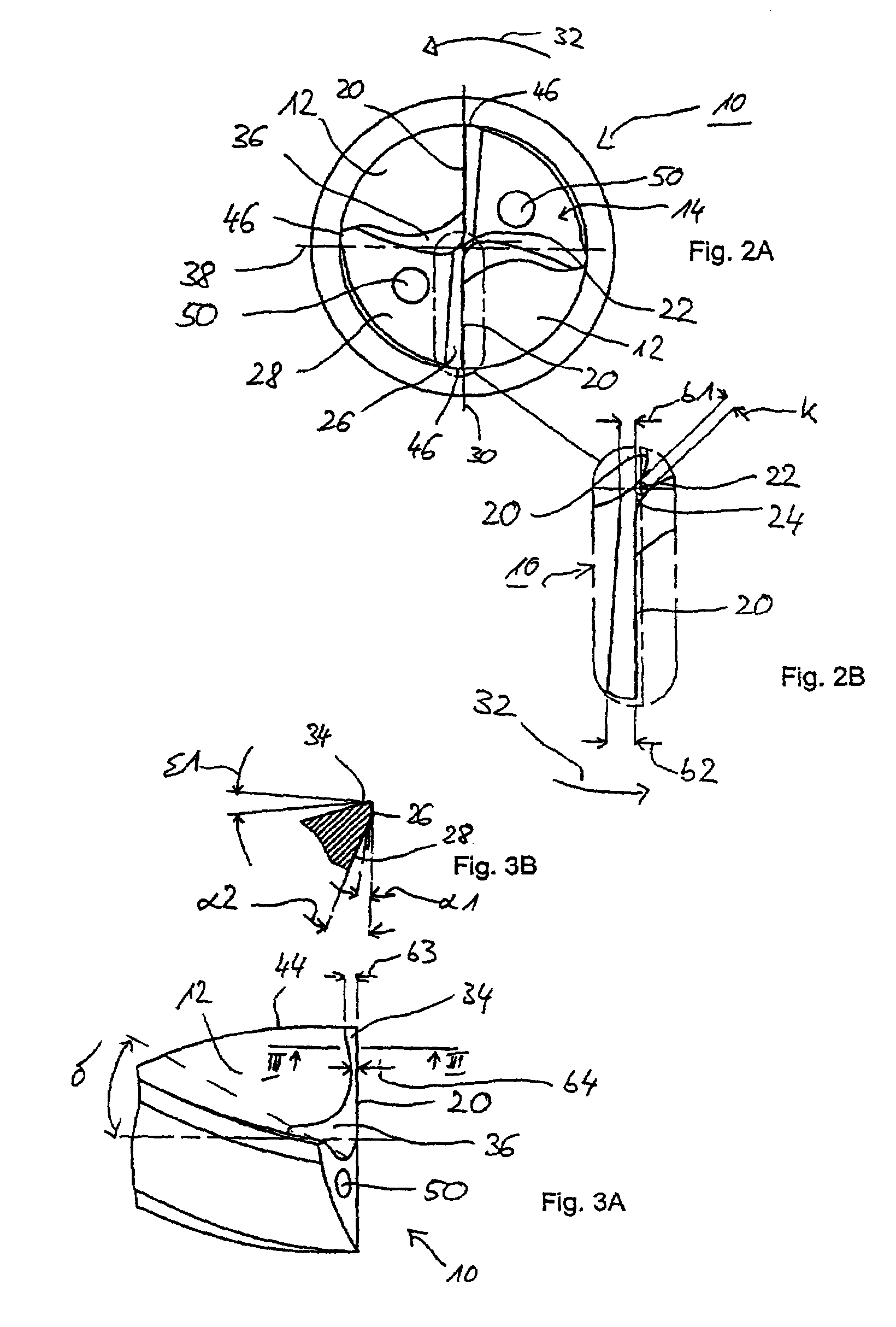

Twist drill with a pilot tip

ActiveUS7520703B2Increase speedSolution to short lifeWood turning toolsTransportation and packagingFluteEngineering

Owner:BLACK & DECKER INC

Cell therapy for chronic stroke

A method of treating stroke in a patient who has undergone a stroke comprising administering at least 2 million suitable neuronal cells to at least one brain area involved in the stroke. The method comprises the step of using a twist drill or a burr to form a hole in the skull through which the cells could be administered. Exemplary cells are hNT neuronal cells, HCN-1 cells, fetal pig cells, neural crest cells, neural stem cells, or a combination thereof. Also disclosed herein is a pharmaceutical composition of 95% pure hNT neuronal cells, which composition further includes a vial containing PBS and human neuronal cells. This vial is provided in a container with liquid nitrogen, whereby the composition is frozen and maintained at -170° C. before use. Also disclosed are methods of improving speech, cognitive, sensory, and motor function in a person who has experienced brain damage which interferes with function by administering a sterile composition of a sufficient number of neuronal cells or neural stem cells to the damaged area. Also disclosed is a method of replacing central nervous cells lost to neurodegenerative disease, trauma, ischemia or poisoning.

Owner:LAYTON BIOSCI +1

Cutting tool with integrated circuit chip

Owner:KENNAMETAL INC

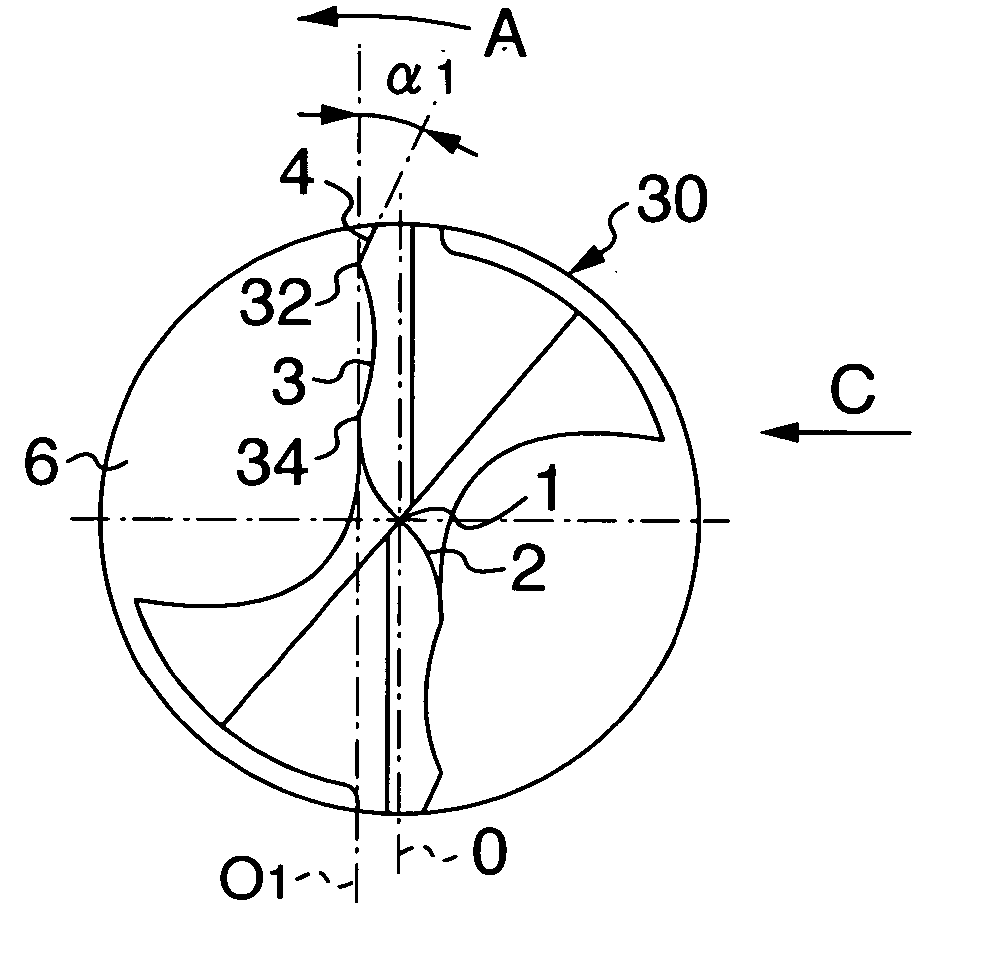

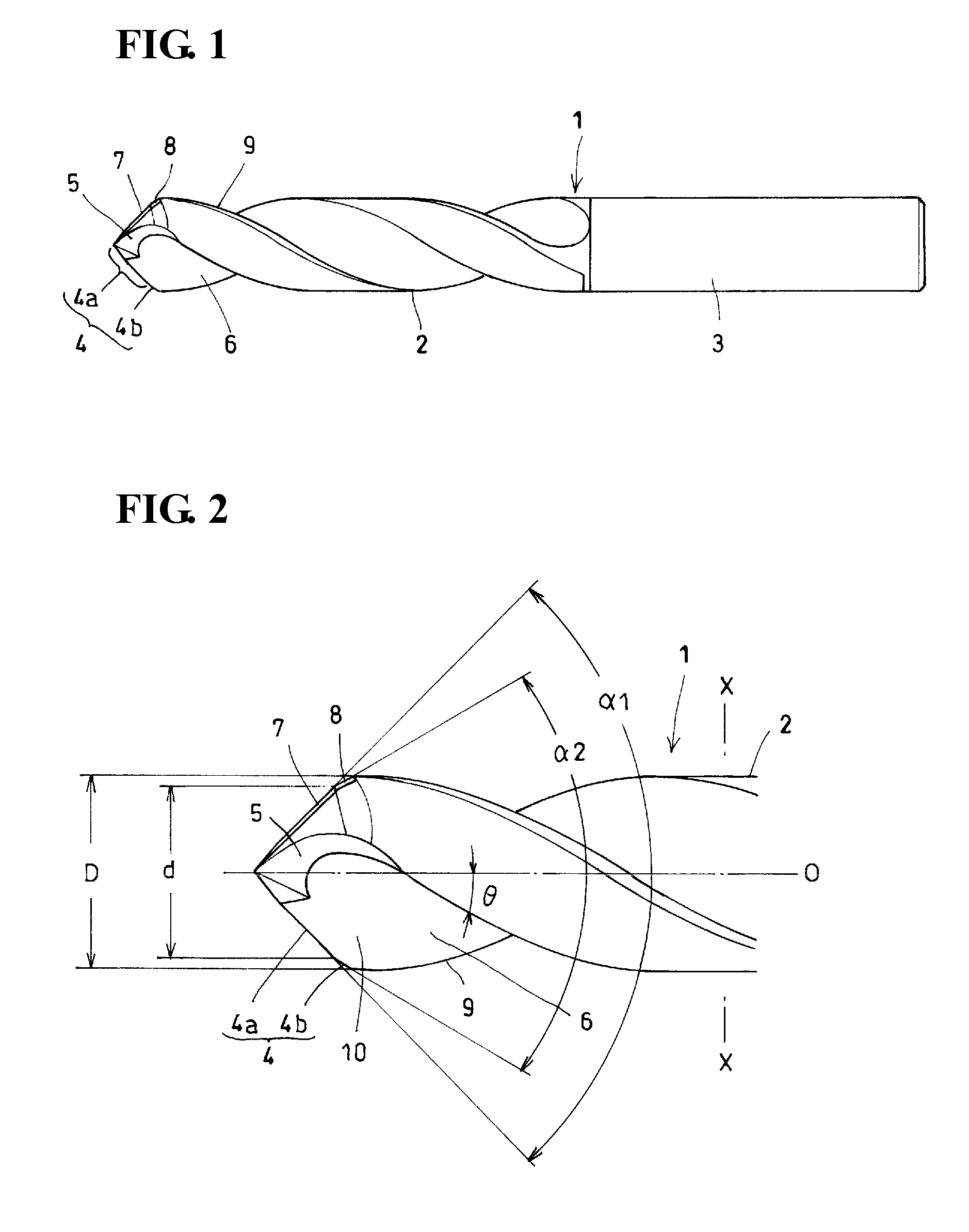

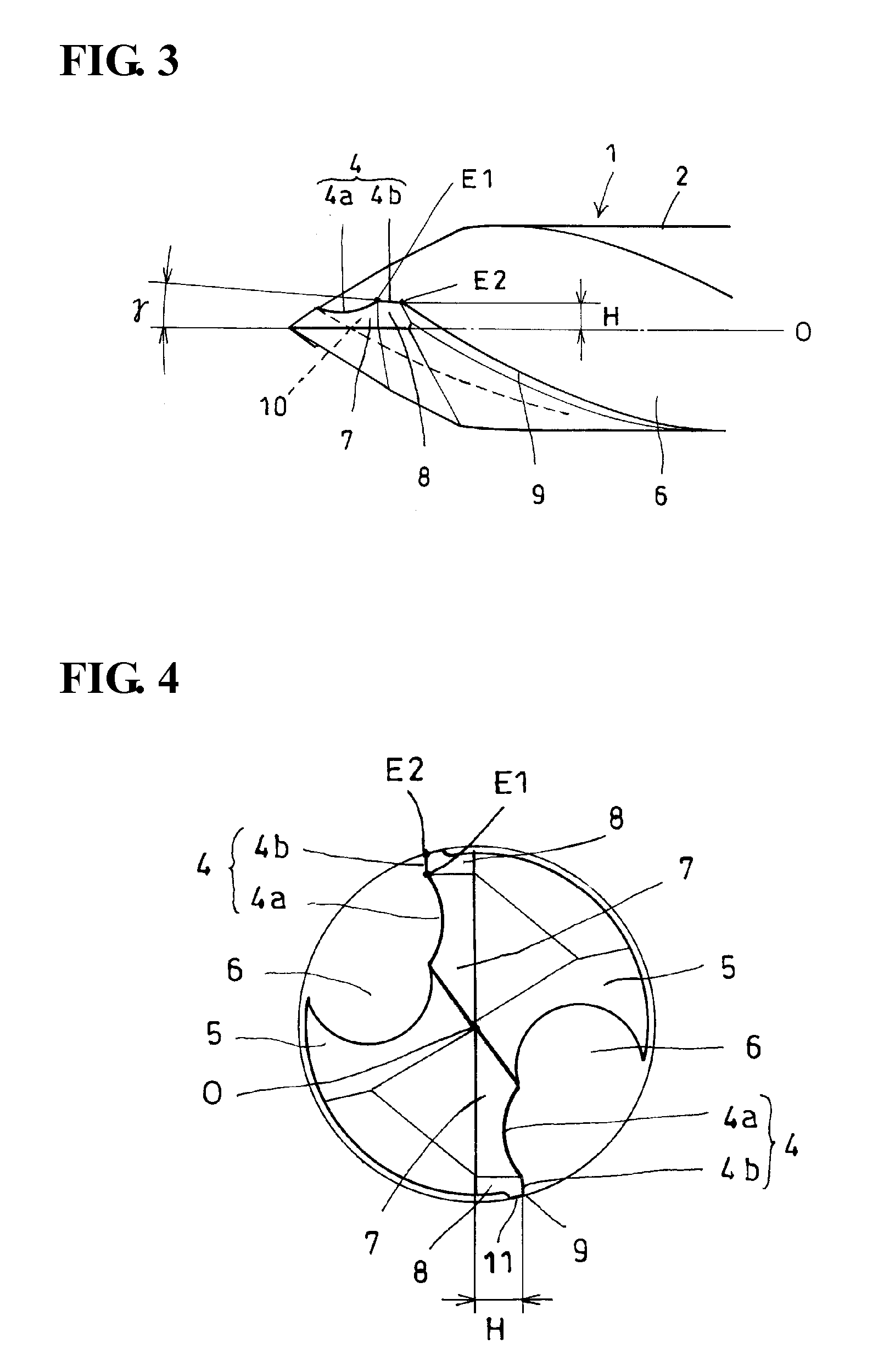

Twist drill

InactiveUS20060269372A1Minimize wearMinimize chippingWood turning toolsTransportation and packagingLeading edgeEngineering

A twist drill has a pair of concave-shaped main cutting edges continuous outwardly to respective center cutting edges, and a pair of corner cutting edges receding at an angle from the outer ends of the respective main cutting edges with respect to a drill rotation direction. Respective ends of the concave-shaped main cutting edges are situated on a straight line almost parallel to a plane passing through a drill axis. These cutting edges have a function of minimizing wear and chipping of corner portions and damage to leading edges in a drilling operation using no cutting oil, or a drilling operation wherein a very small amount of cutting oil is sprayed to the drill, or in a drilling operation on relatively hard steel. They also have a function of facilitating breaking of cut chips into pieces during a drilling operation using cutting oil and during a drilling operation on steel of relatively low hardness such as general structural rolled steels and low carbon steels.

Owner:NACHI-FUJIKOSHI

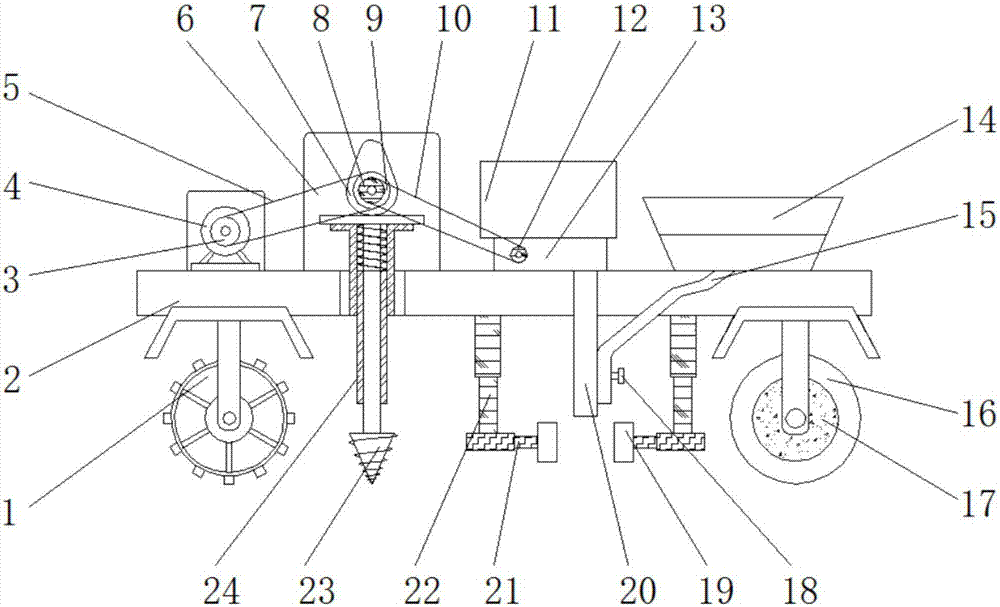

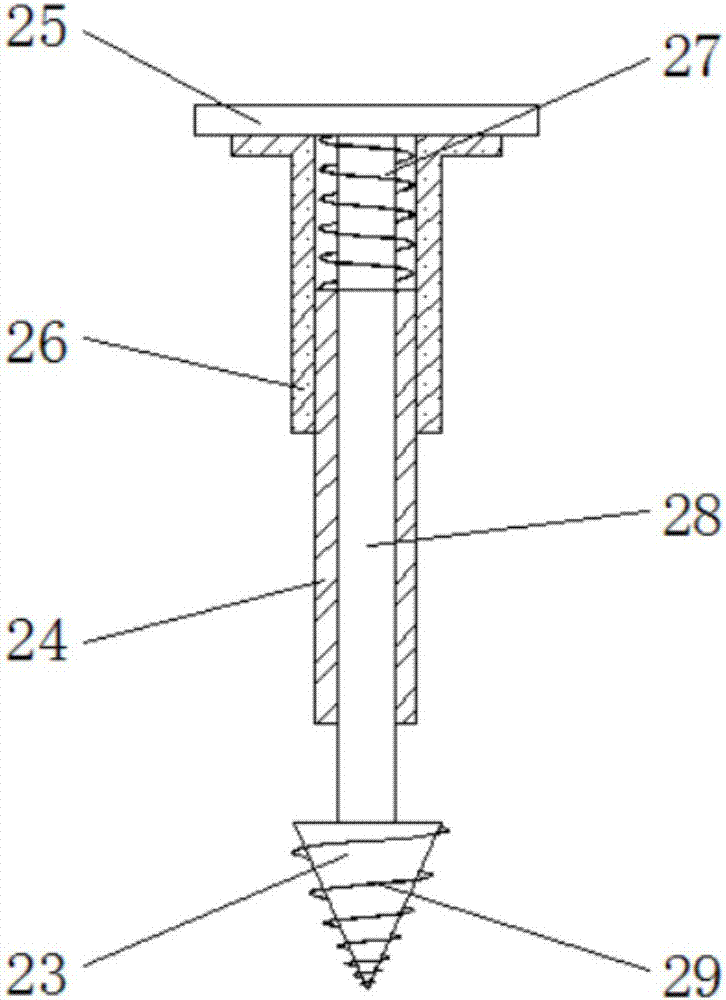

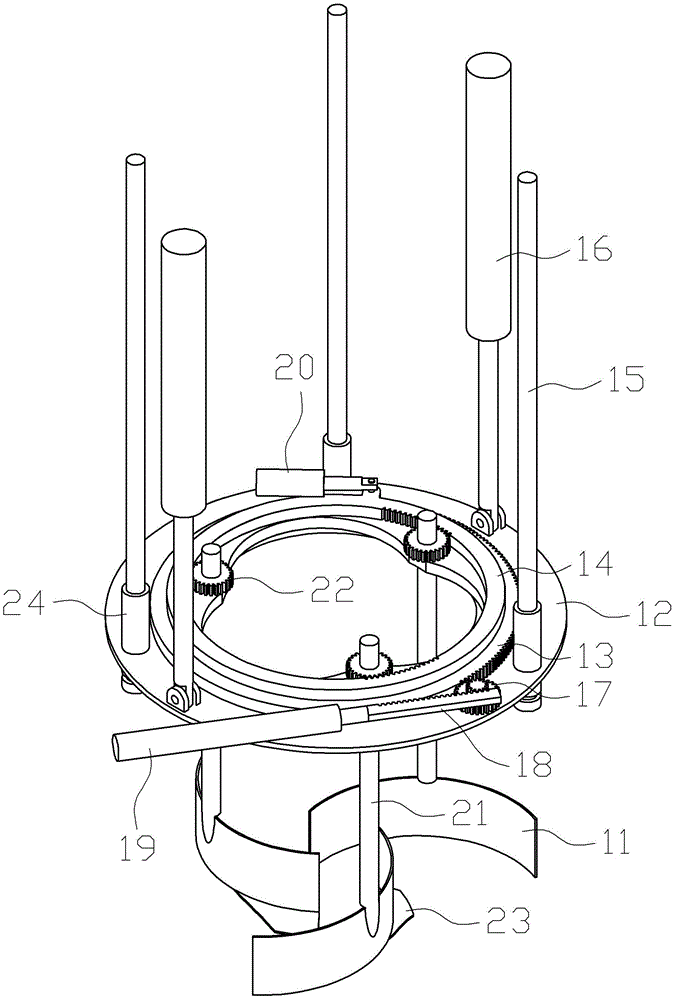

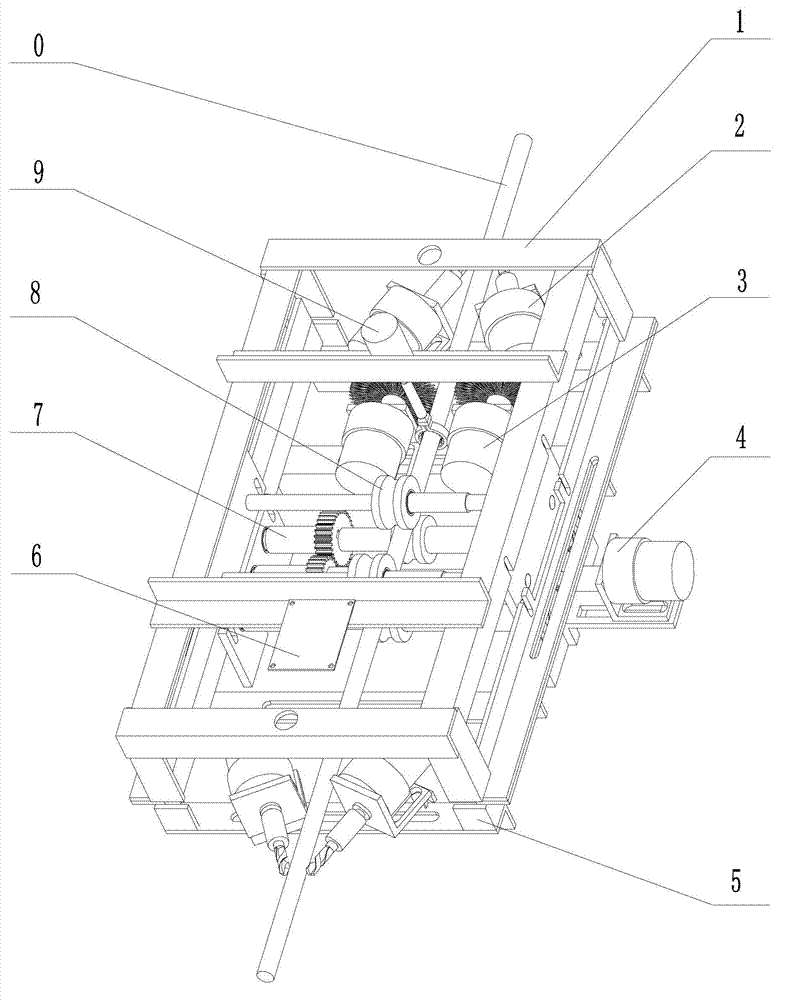

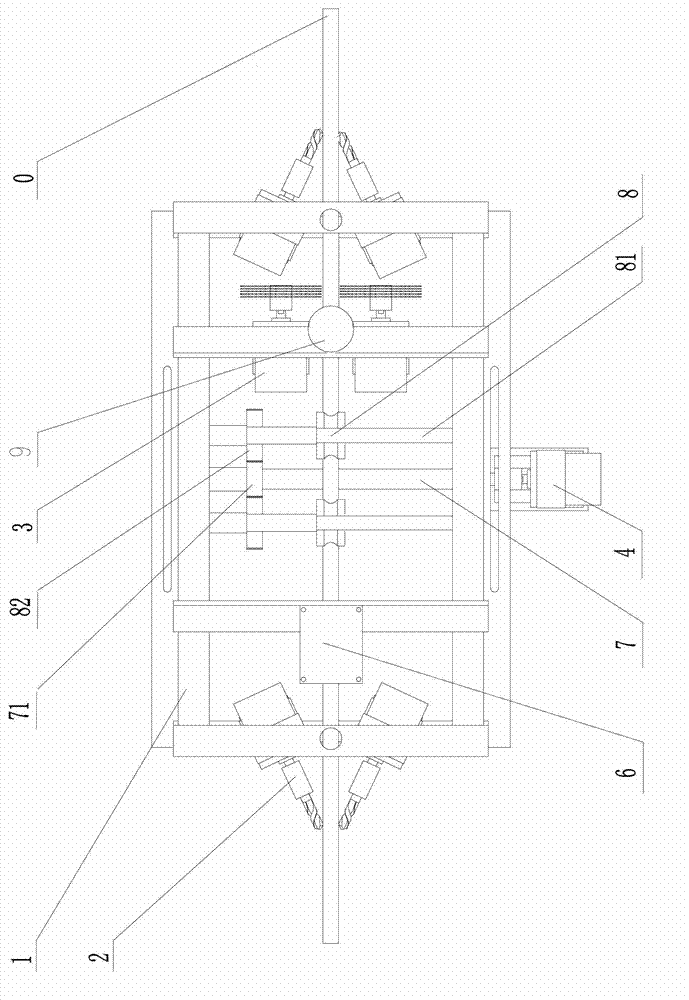

Fruit tree transplanting device

InactiveCN107318588AEasy to transplantGood transplanting effectPlantingFertiliser distributersFruit treeDrive wheel

The invention discloses a fruit tree transplanting device, which comprises a frame, a drilling box, a seedling bucket and a fertilizer box. Both ends of one side of the bottom end of the frame are equipped with walking wheels, and the other end of the bottom end of the frame Both ends of the side are equipped with pressure rollers, the top of the frame is equipped with a drilling box, and the inside of the drilling box is equipped with a cam through a rotating shaft, and a driven wheel is fixed on one side of the cam, and the driven wheel is far away from the cam. One side is fixed with the first sprocket. The invention is equipped with a drilling box, a matching twist rod and a twist pipe sleeve are installed in the drilling box, and a drill bit is installed at the bottom of the twist rod, so that it is convenient to carry out drilling operations in the orchard, and is convenient for transplanting peaches and pears. At the same time, it saves time and labor, and reduces the labor intensity of the staff. The device is equipped with a seedling drop box, and a rack structure is set in the seedling drop box, so that the seedlings can fall into the pre-drilled holes evenly and orderly.

Owner:开州区周传珍种植家庭农场

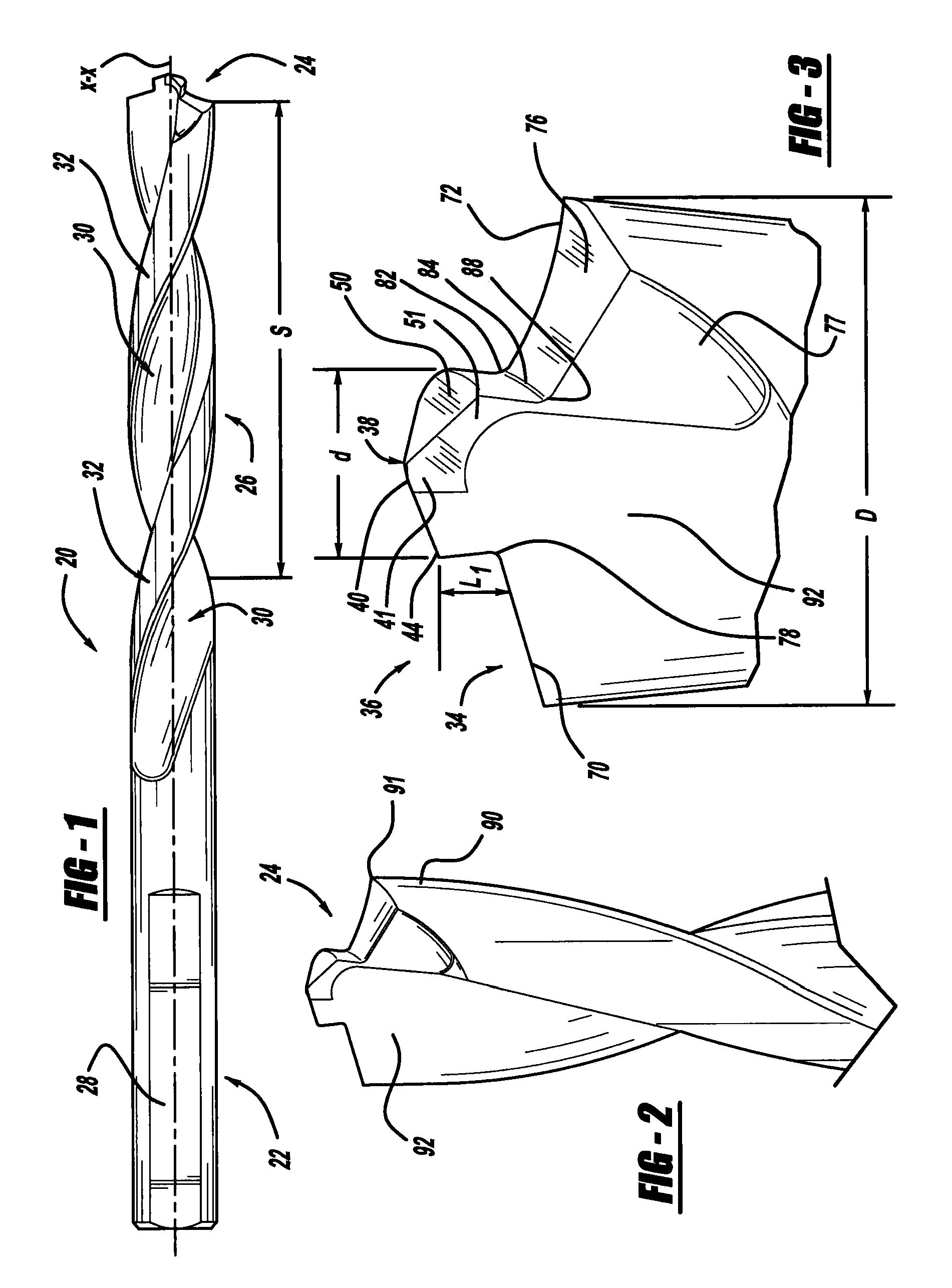

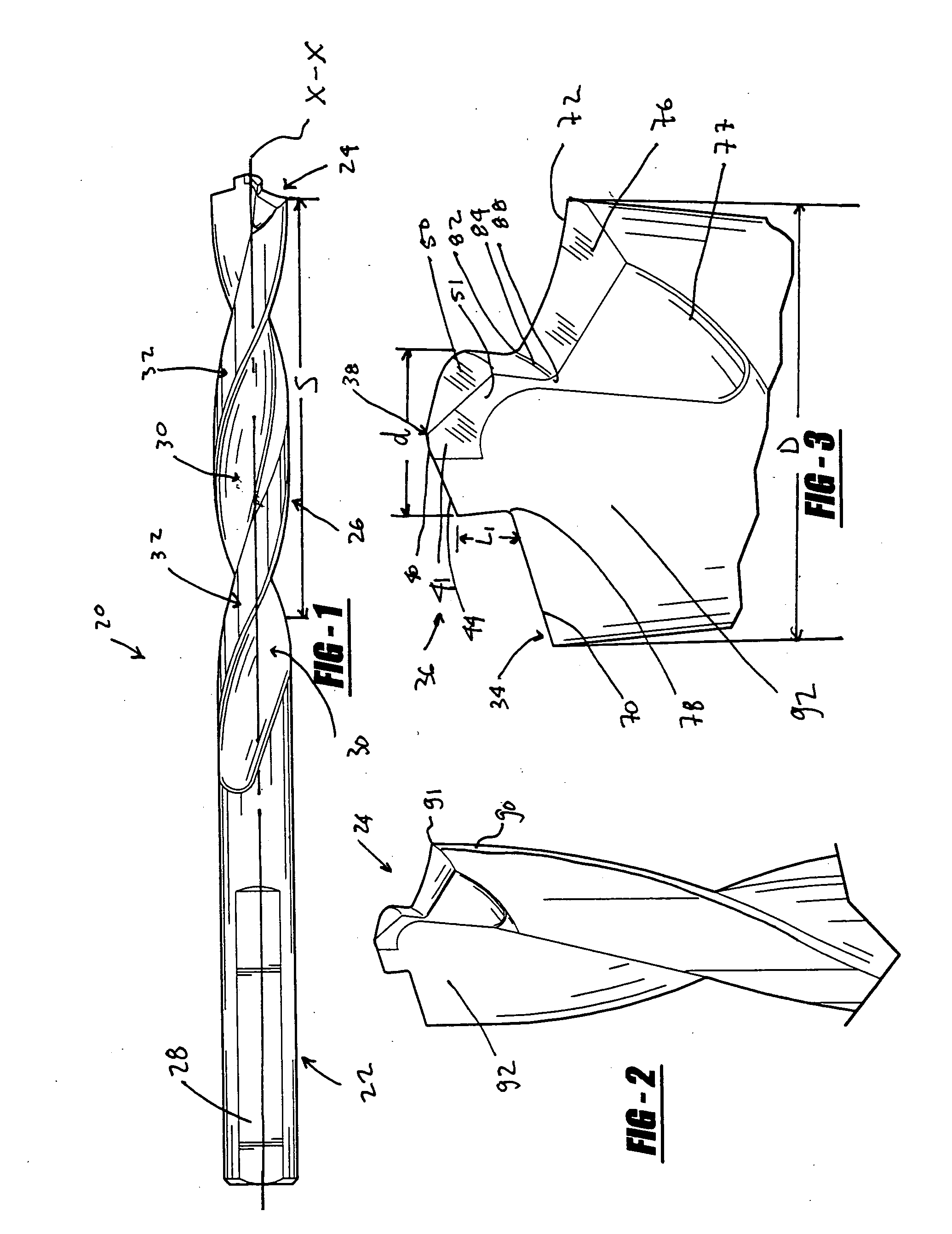

Twist drill and method for producing a twist drill which method includes forming a flute of a twist drill

InactiveUS7201543B2Reduce disadvantagesQuickly and easily groundWood turning toolsTransportation and packagingFluteEdge structure

A twist drill and method for producing is provided. The cutting edge structure has a first portion at the drill tip portion and a second portion disposed away from the drill tip portion. The flute wall extends further into the land structure at the second portion of the cutting edge structure than at the tip portion to provide a greater amount of drill material at the tip portion than at the second portion of the cutting edge structure. The flute wall extends further into the land structure at the second portion of the cutting edge structure than at the tip portion to provide a greater flute volume per length at the second portion of the cutting edge structure than at the drill tip portion.

Owner:KENNAMETAL INC

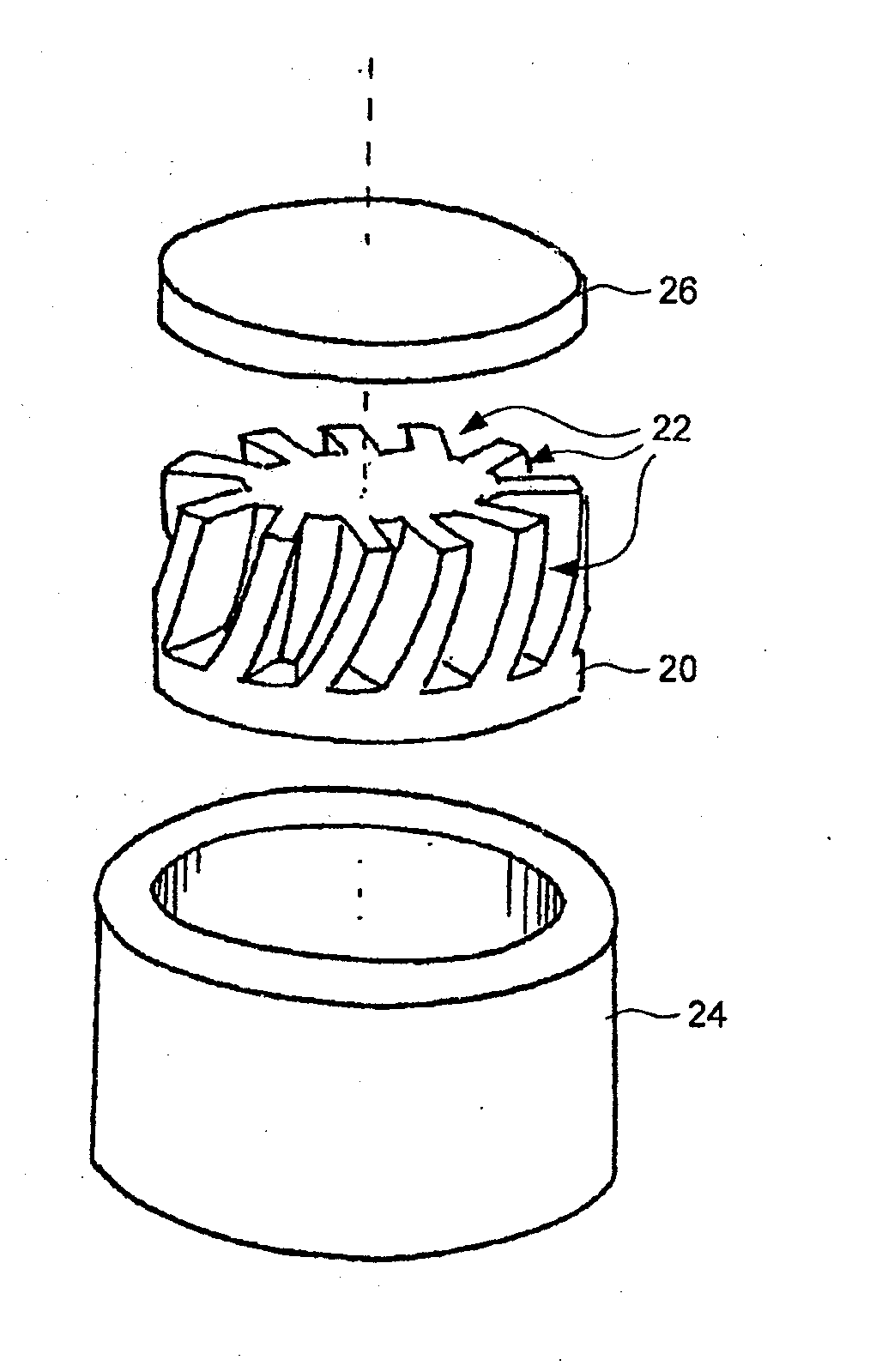

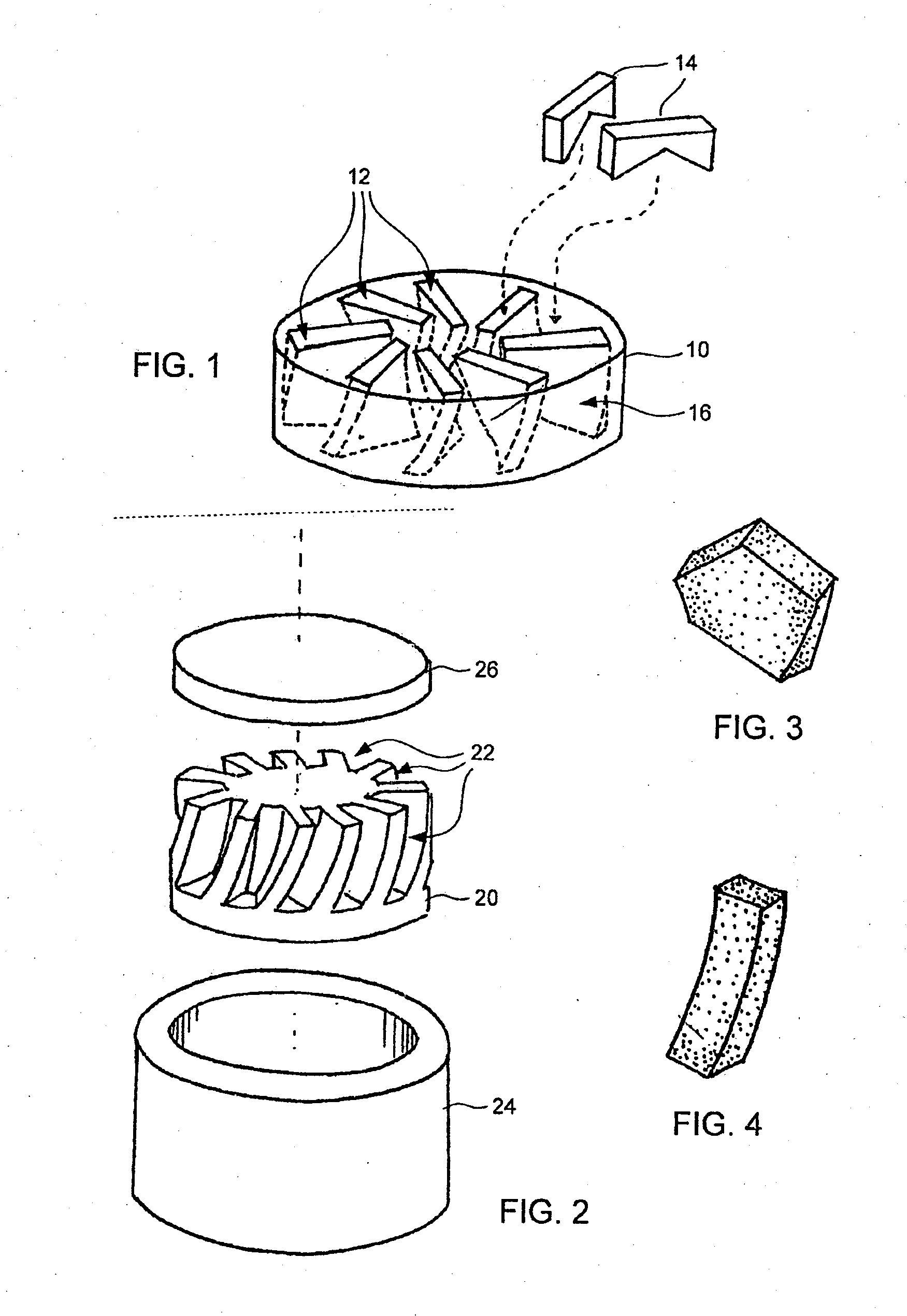

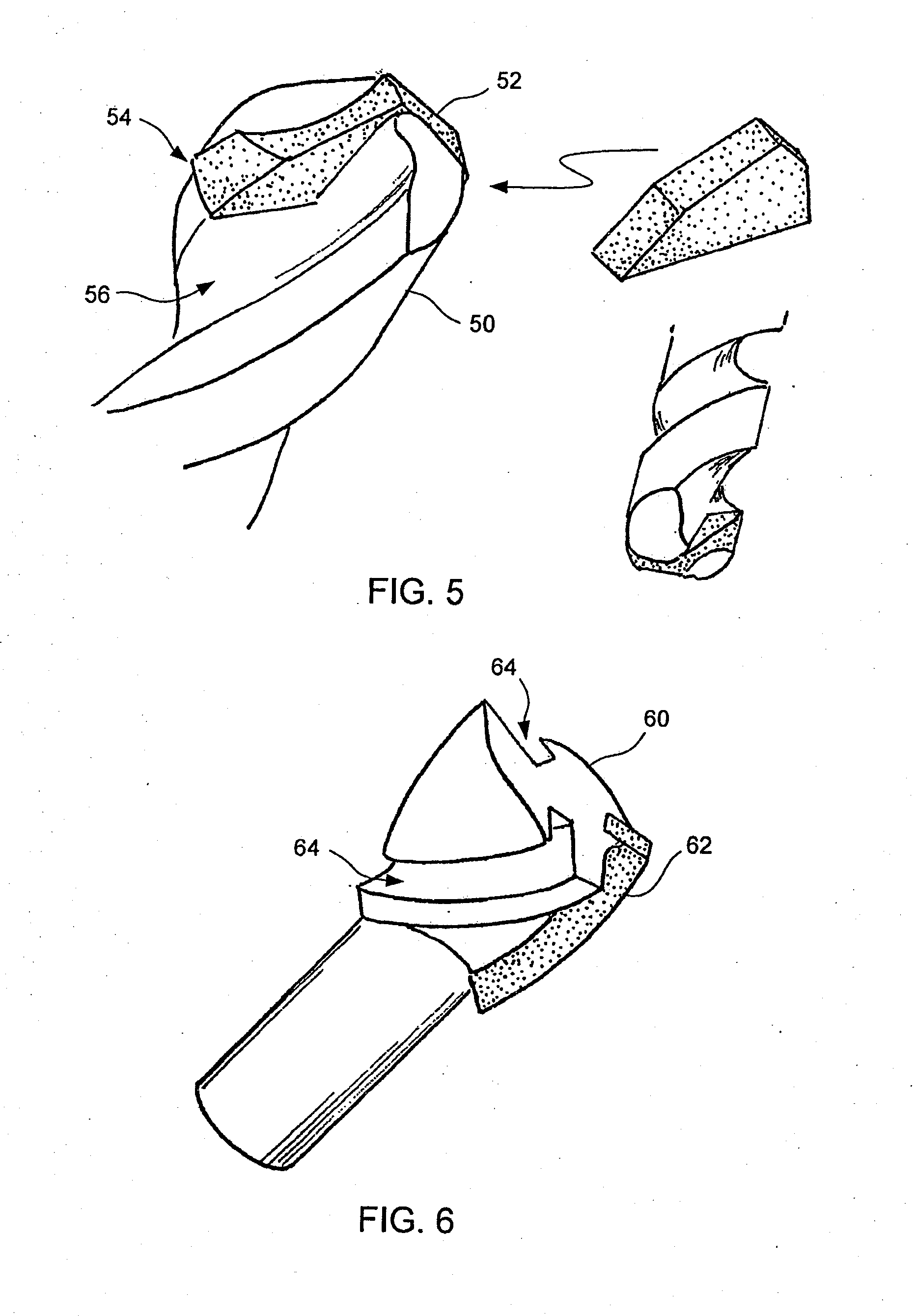

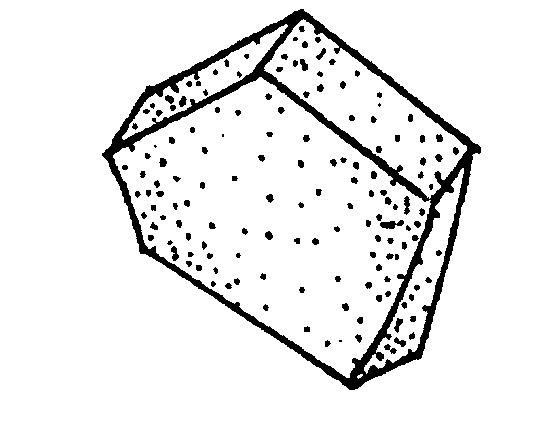

Contoured pcd and pcbn segments for cutting tools containing such segments

Contoured helical solid polycrystalline PCD and PCBN superabrasive segments are provided for attachment to cutting tool substrates such as twist drill tips, reamers, burrs and endmills. Segments are provided in near to net shape for attachment to a tool substrate thereby requiring reduced finishing steps and providing increased tailorability of grade and quality of final polycrystalline segments. Cutting tools comprising cutting tool substrates having attached thereto a contoured helical solid polycrystalline PCD and PCBN superabrasive segments are also disclosed.

Owner:CHO H SAM +4

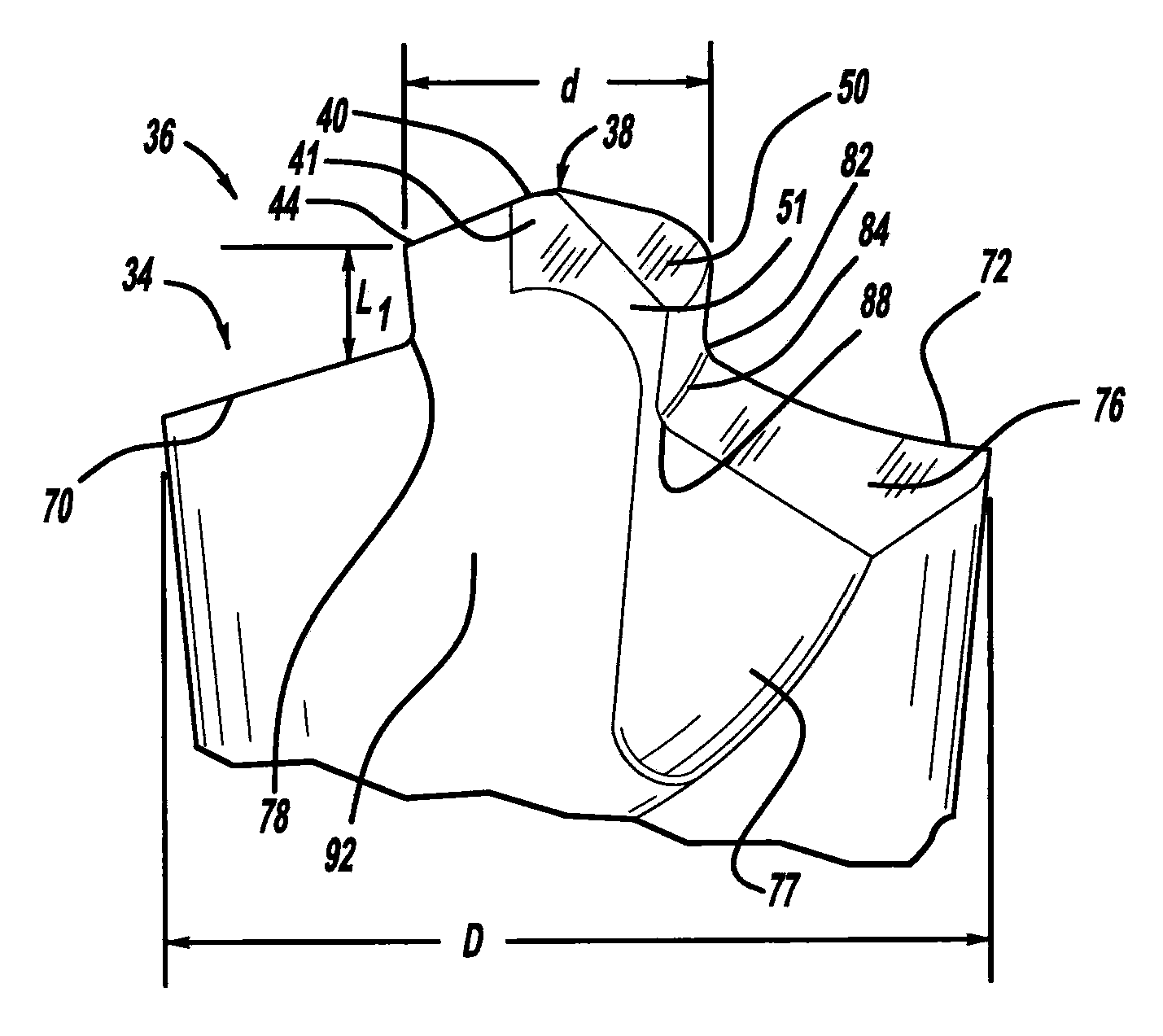

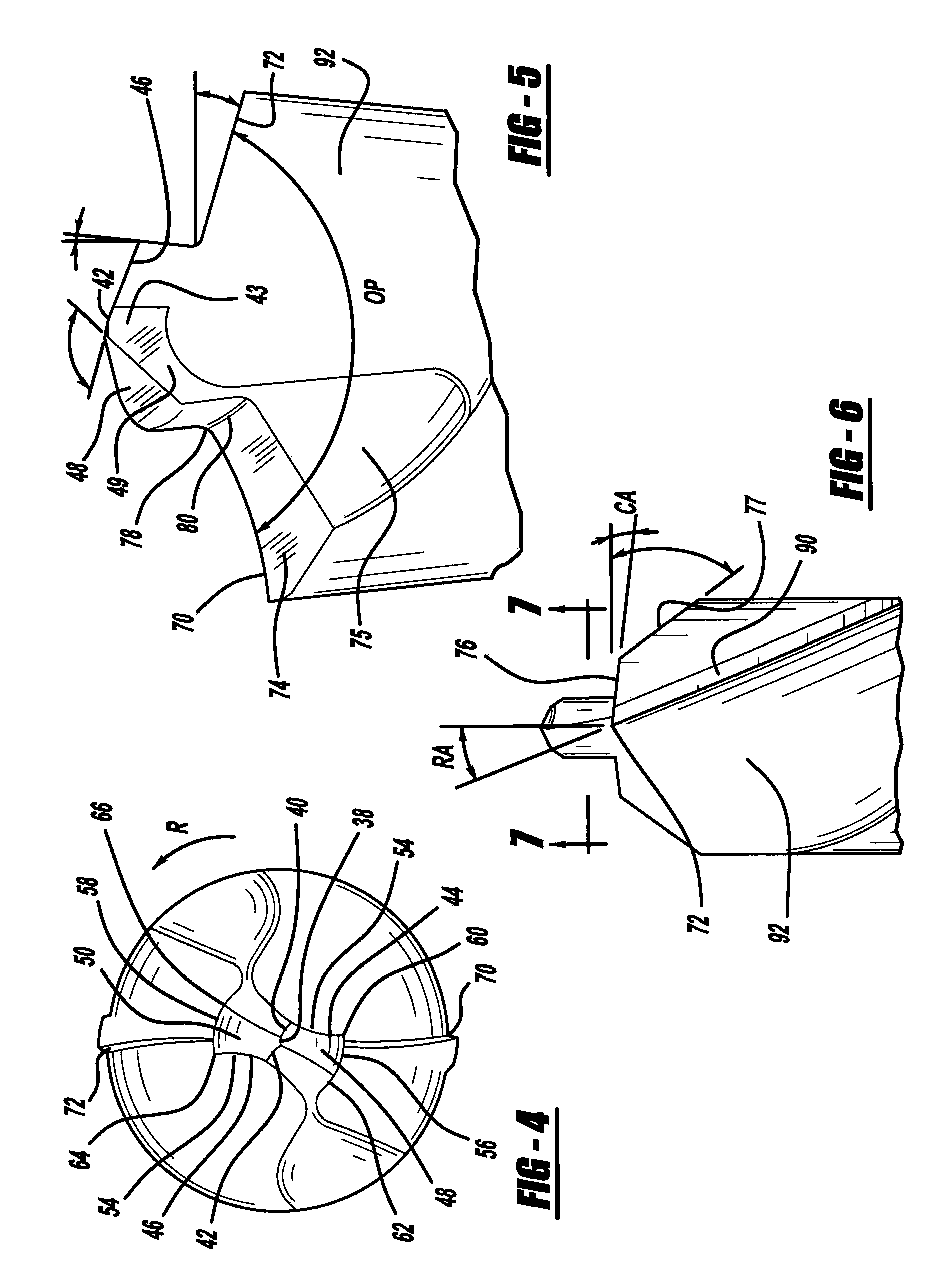

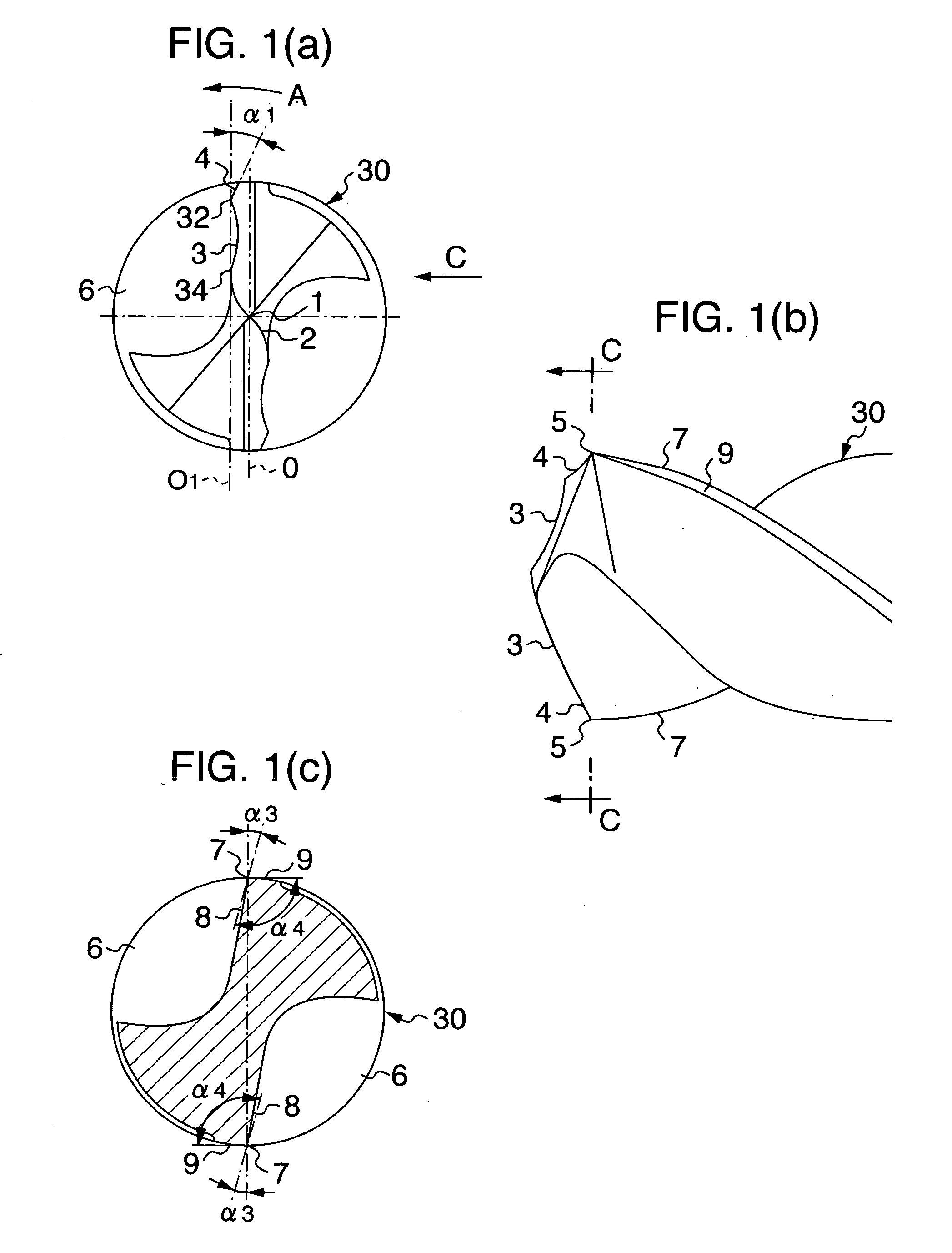

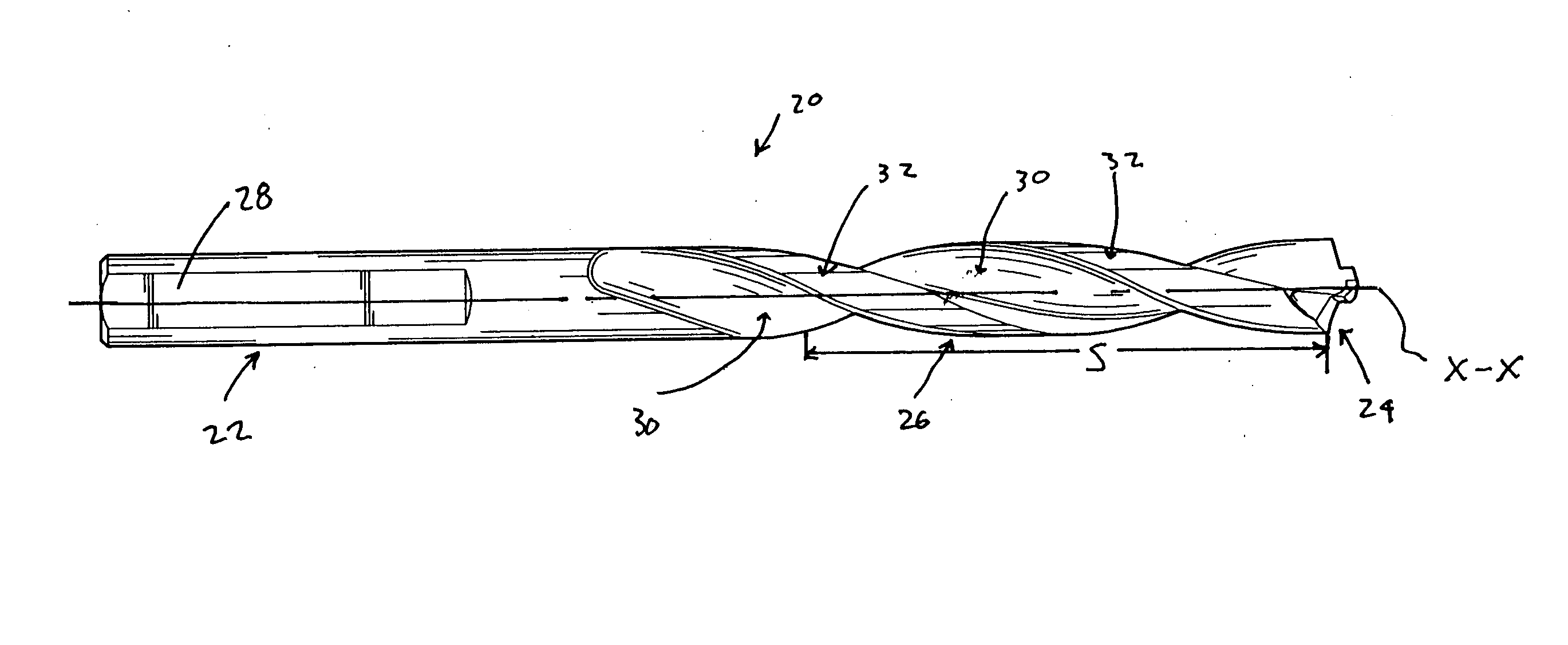

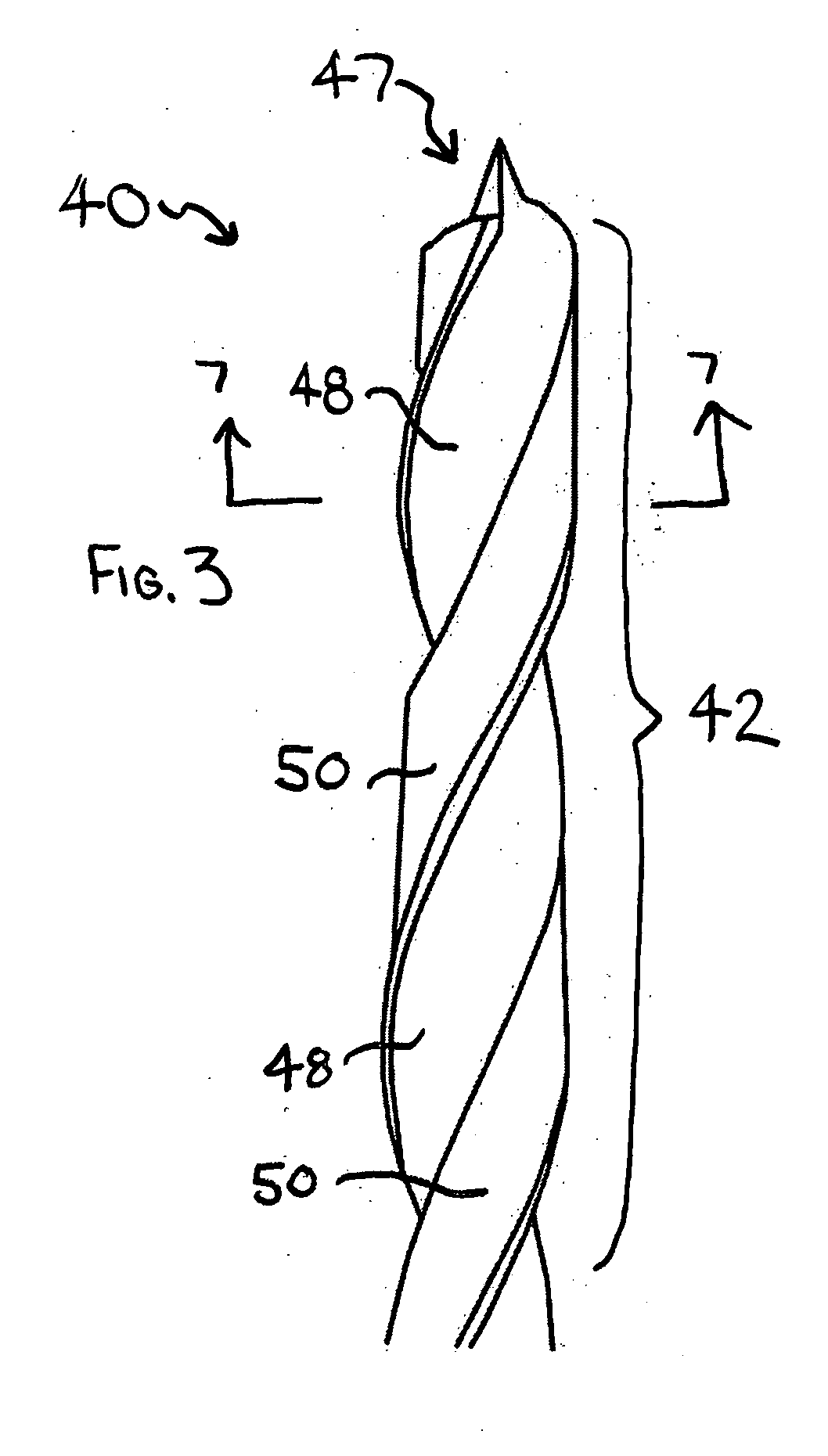

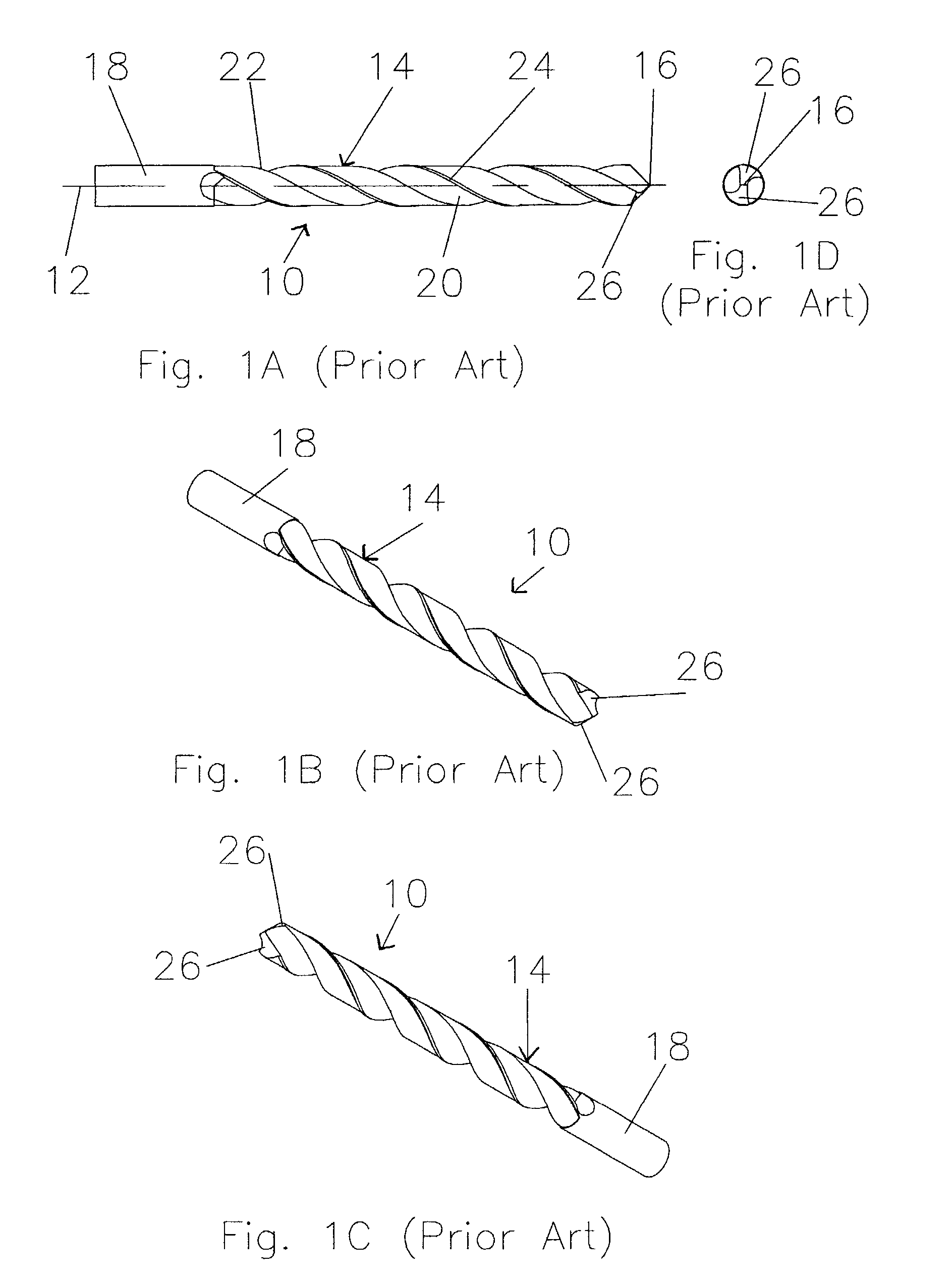

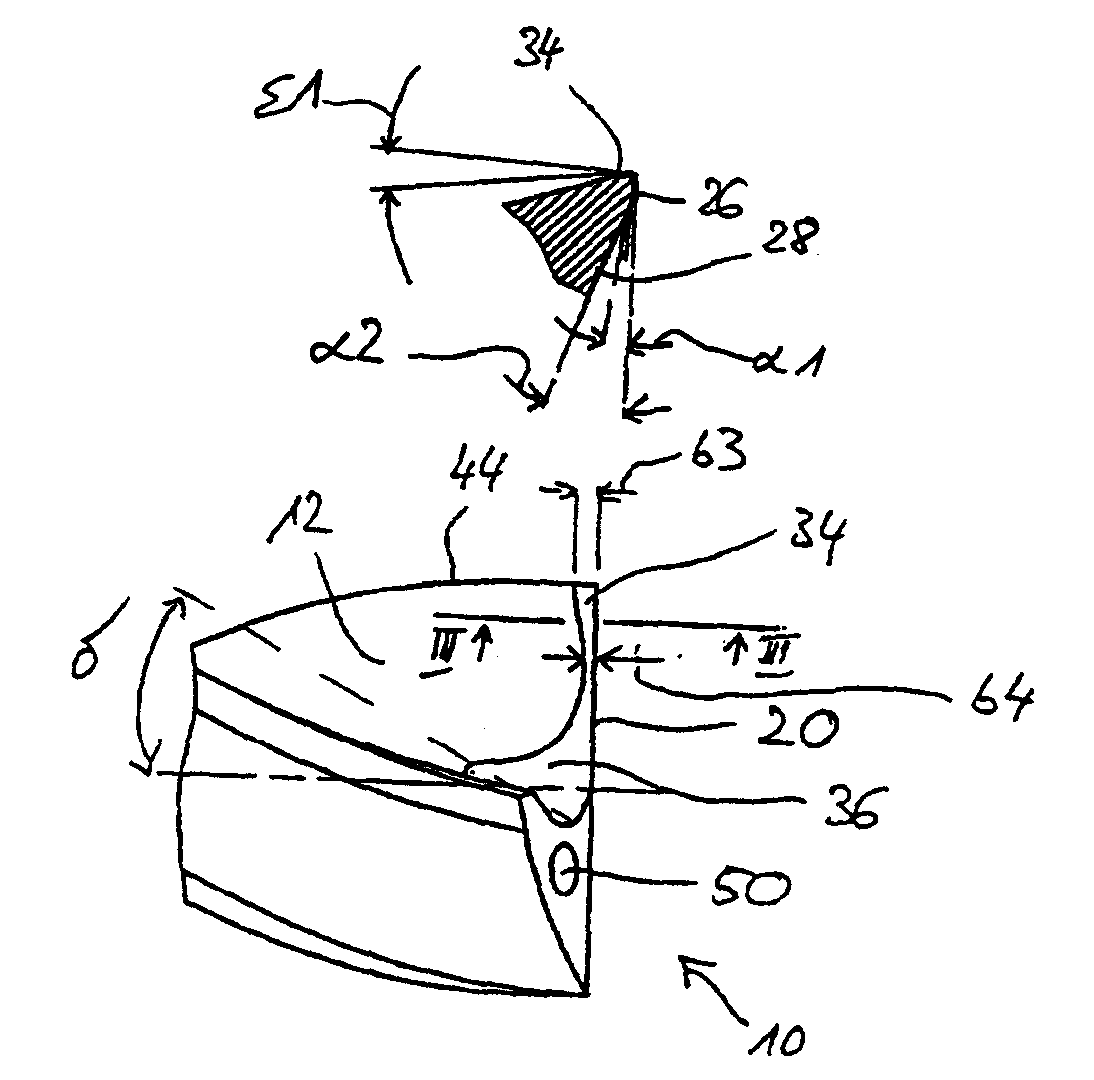

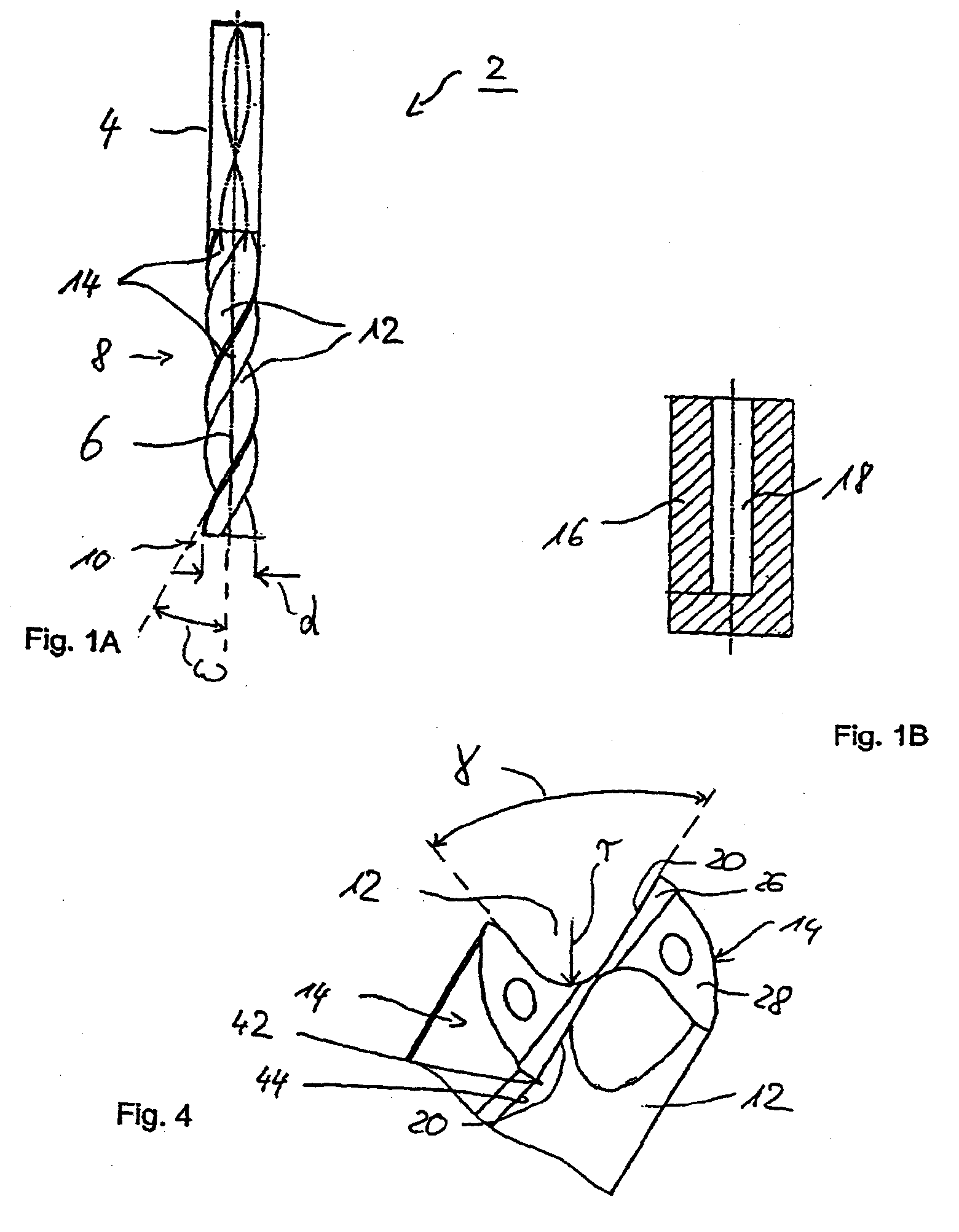

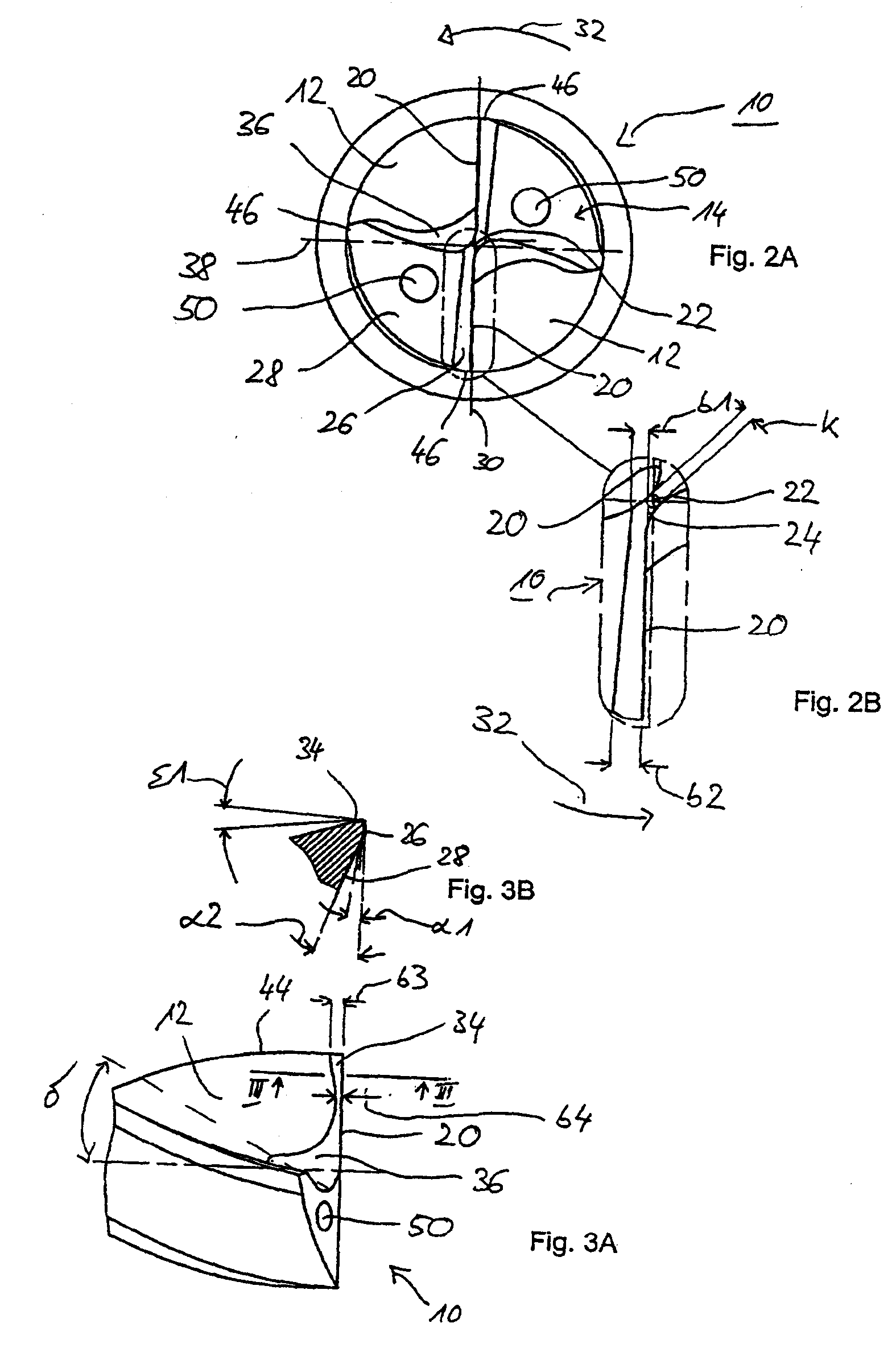

Twist drill with a pilot tip

ActiveUS20060056930A1Increase speedSolution to short lifeWood turning toolsTransportation and packagingFluteEngineering

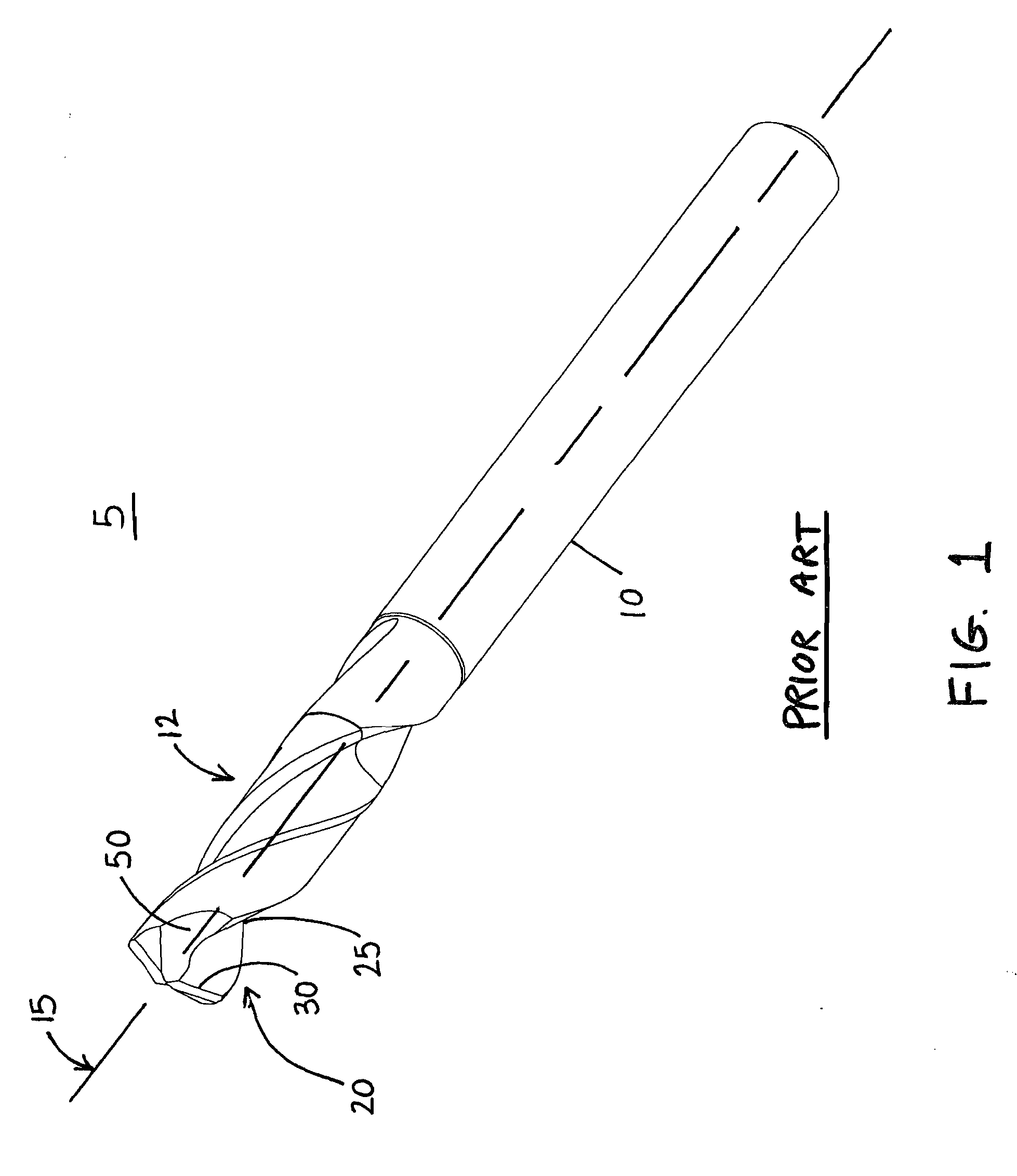

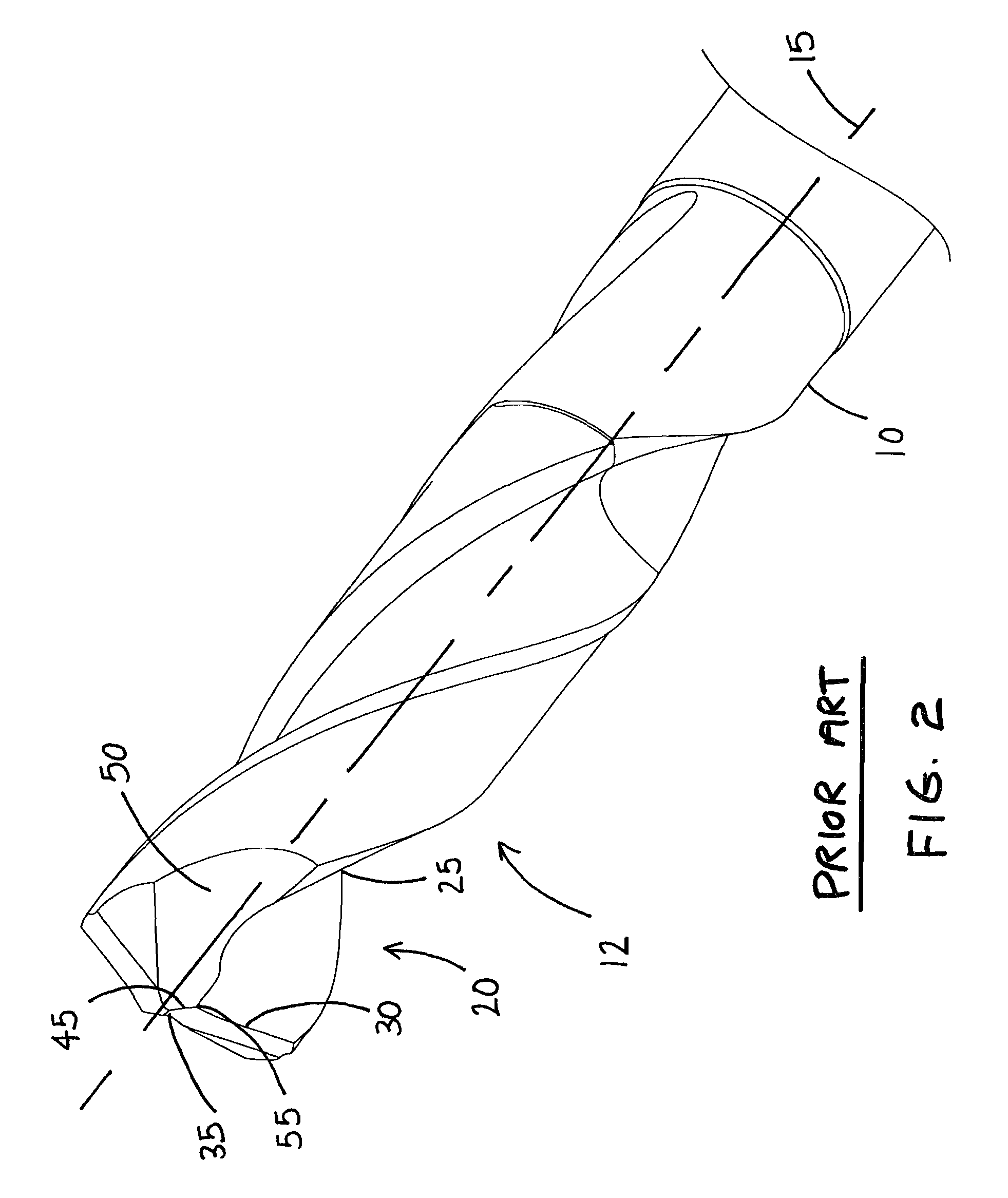

An elongated drill bit has a shank at one end and working end at the other. A flute portion is between the working end and the shank. The flute portion is continuous with the shank and working end and is generally unitarily formed with them. The working end has a pilot tip with a first cutting portion. A second cutting portion is at the terminus of the flute portion and is axially spaced from the pilot tip first cutting portion. The second cutting portion includes a pair of cutting edges on opposing sides of the pilot tip. Each of the second cutting edges is on an angle from about 22° to 27° to a line transverse to the longitudinal axis. The cutting edges are defined by the junction of a rake face, defined by the flute surface, and a primary clearance face. Also, a secondary clearance face may be present which is continuous with the primary face at a different angle. The angle is about 50° to 65° with respect to the longitudinal axis.

Owner:BLACK & DECKER INC

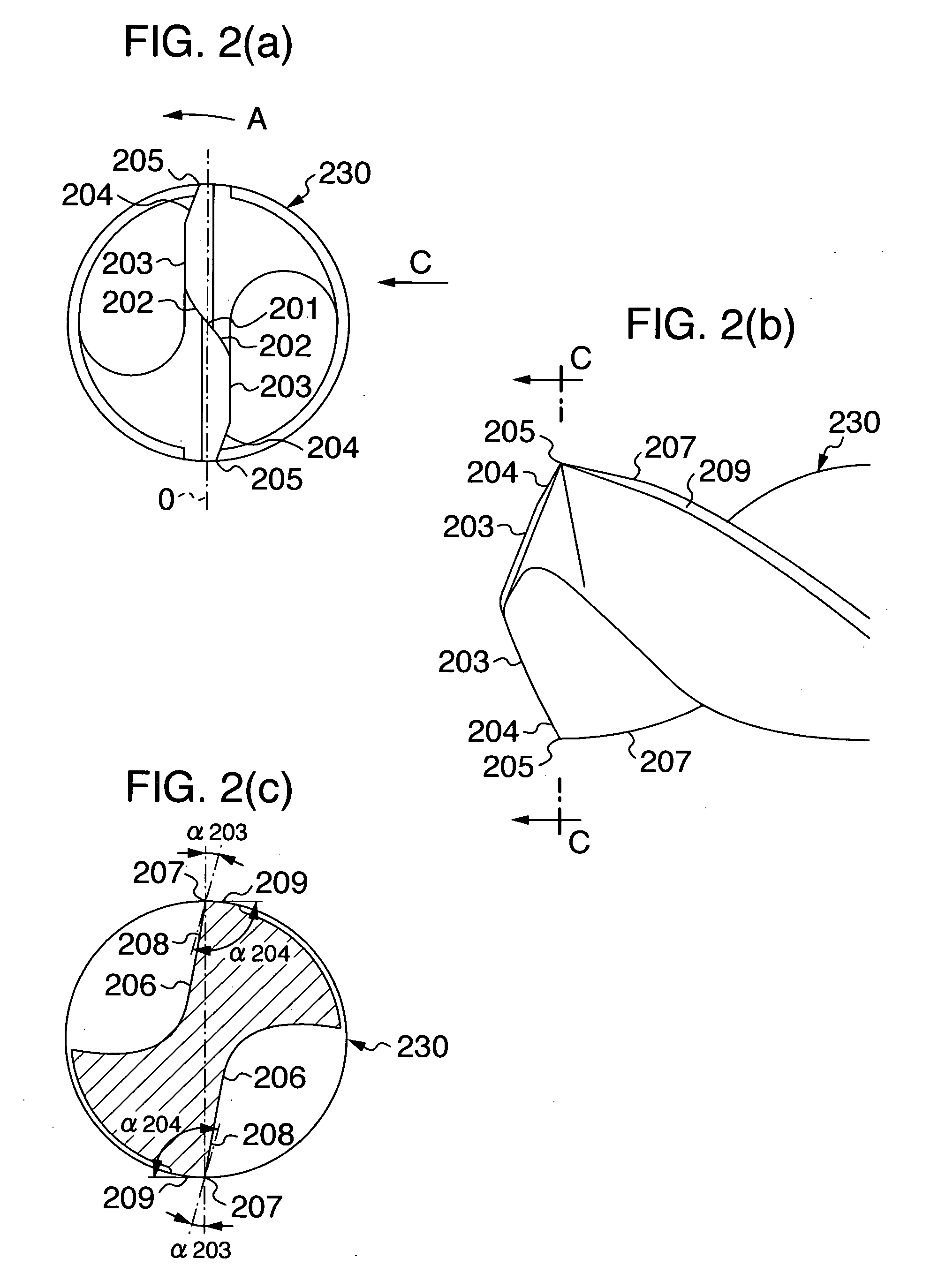

Two-flute twist drill

A twist drill for use, predominantly by non-professional do-it-yourself workers incorporates a flute architecture with an internal ridge for promoting the break up of chips into short length components. The tip of the twist drill includes an axial relief construction for improved performance across a wide variety of materials, and a highly sloped face for prompting transport of chips away from the drill tip.

Owner:TG TOOLS UNITED

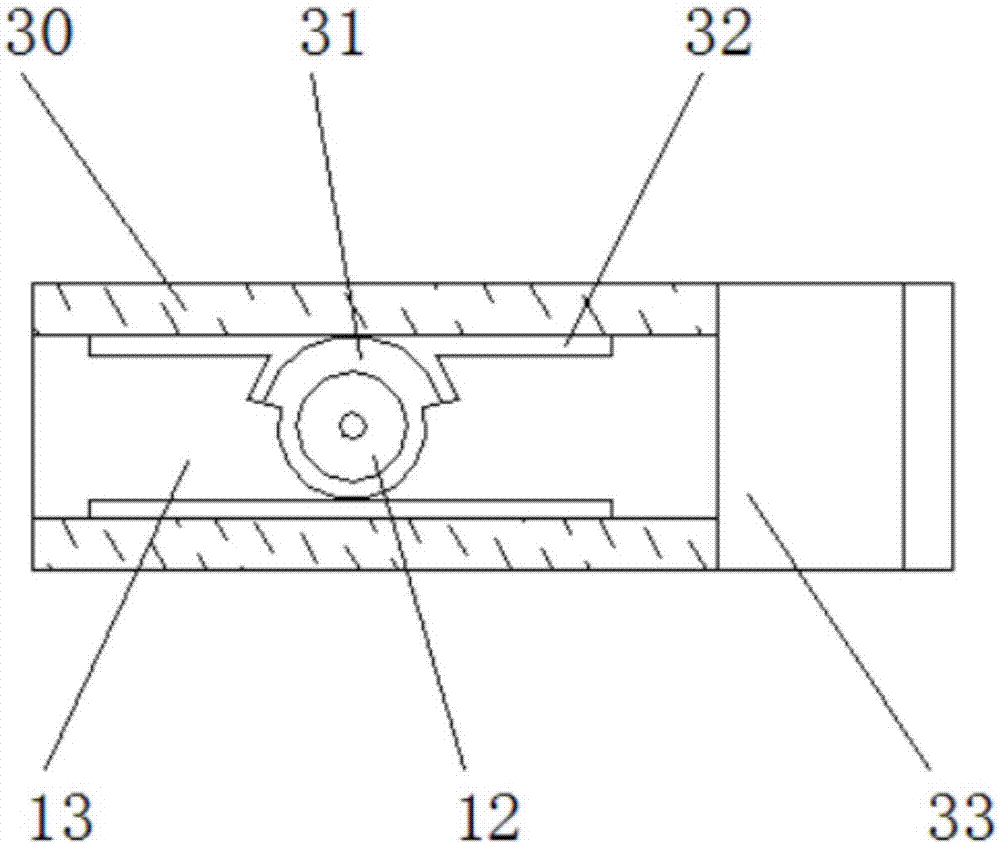

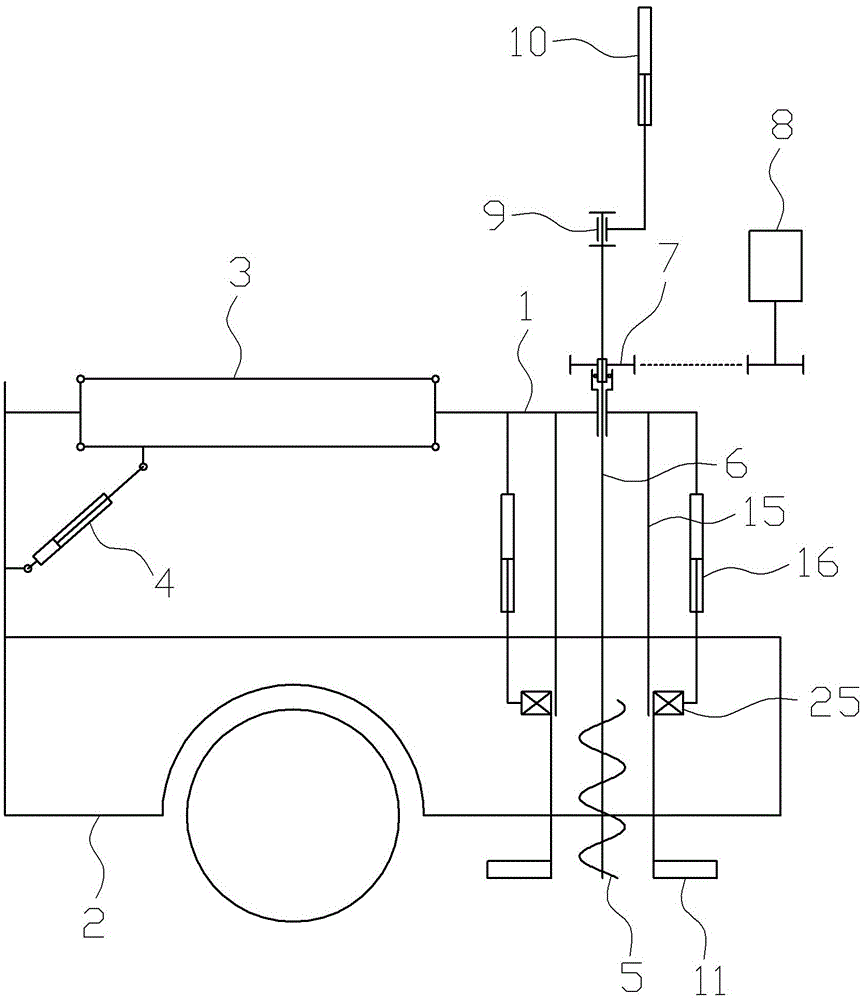

Tree-planting machine

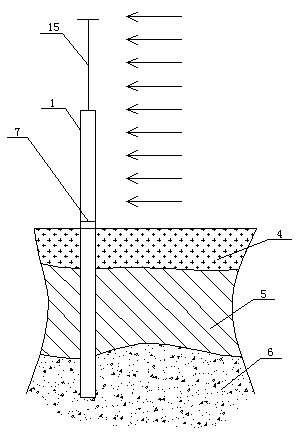

ActiveCN105580529AReasonable designEasy to usePlantingClimate change adaptationHydraulic cylinderEngineering

The invention provides a tree-planting machine which comprises a rack (1), a hole digging device and a trailer box (2) pulled by a maneuvering vehicle head; the rack (1) is connected with the front of the trailer box (2) through a four-connecting-rod mechanism (3) and a lifting hydraulic cylinder (4); the hole digging device comprises a twist drill (5), a drill rod (6) of the twist drill (5) is connected with a power mechanism (8) through a belt wheel (7), the belt wheel (7) is rotatably fixed to the rack (1), the twist drill (5) can be driven by a drill lifting hydraulic cylinder (10) to move vertically while rotating, the twist drill (5) below the rack (1) is provided with a backfilling device, and the backfilling device comprises a soil pushing plate (11) and an annular fixing disc (12), an outer tooth ring (13) and an inner tooth ring (14) which are arranged on the periphery of the twist drill (5) in a sleeving mode respectively. The tree-planting machine has the advantages of being reasonable in design, convenient to use and high in work efficiency, can be mounted on a little four-wheeled vehicle or other agricultural vehicles for use and integrates functions of hole digging, backfilling of soil and compressing.

Owner:黑龙江省牡丹江林业科学研究所 +9

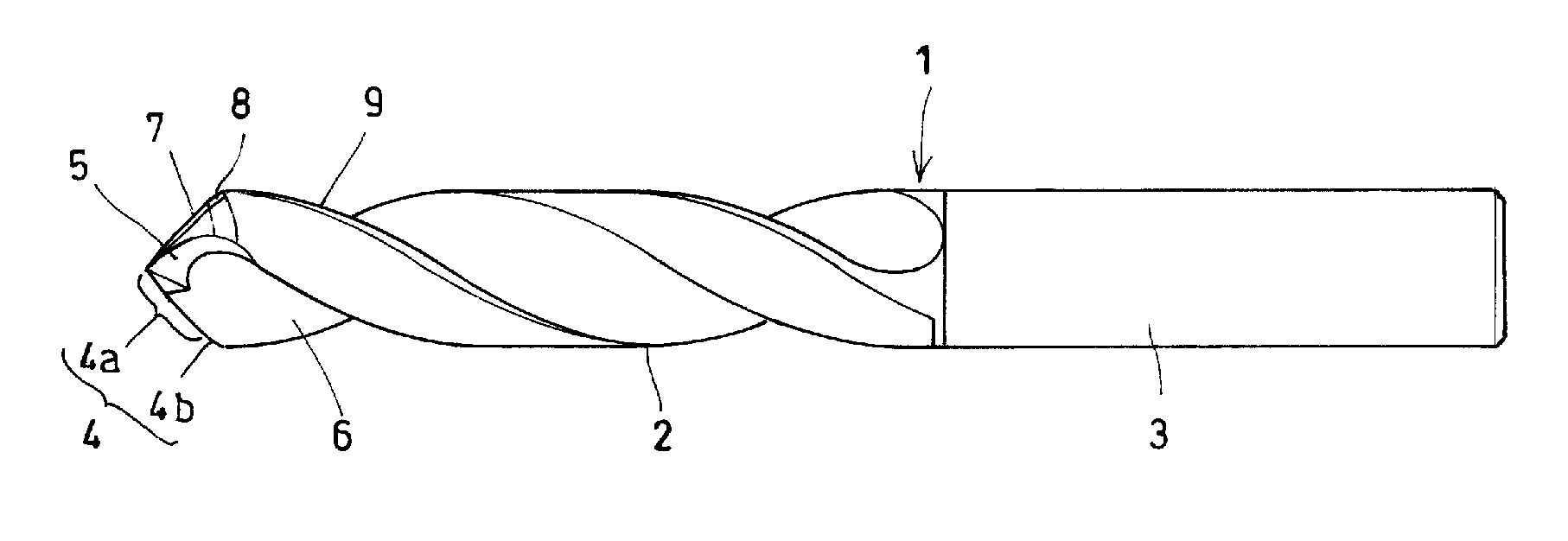

Twist drill

InactiveUS20110081215A1High quality drillingSmall liftWood turning toolsTransportation and packagingFluteLeading edge

Provided is a double-angle twist drill that increases the quality of drilling without increasing the amount of manufacturing work or the like. A secondary cutting edge 4b is substantially parallel to the rotation axis O of the drill, and at least a rake face 10 of the secondary cutting edge is included in the flute face of a helical flute 6. A part of the flute face of the helical flute that is located along a leading edge 9 is convexly curved with respect to the normal direction of rotation of the drill, so that the secondary cutting edge 4b having a small skew angle with respect to the rotation axis can be formed as a ridge at which the flute face intersects a second flank face.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Twist drill

InactiveUS6601659B2Improve efficiencyImprove guidanceDrill bitsDrilling rodsEngineeringMechanical engineering

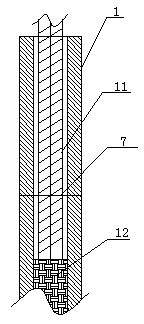

A twist drill including a spiral-forming hollow shaft (3) having a spiral-shaped inner surface, and drilling head(5) and shank (6) connected with the shaft (3) at its opposite ends, respectively; and a method for forming such a twist drill.

Owner:HILTI AG

Reduced energy consuming, lateral cutting twist drill

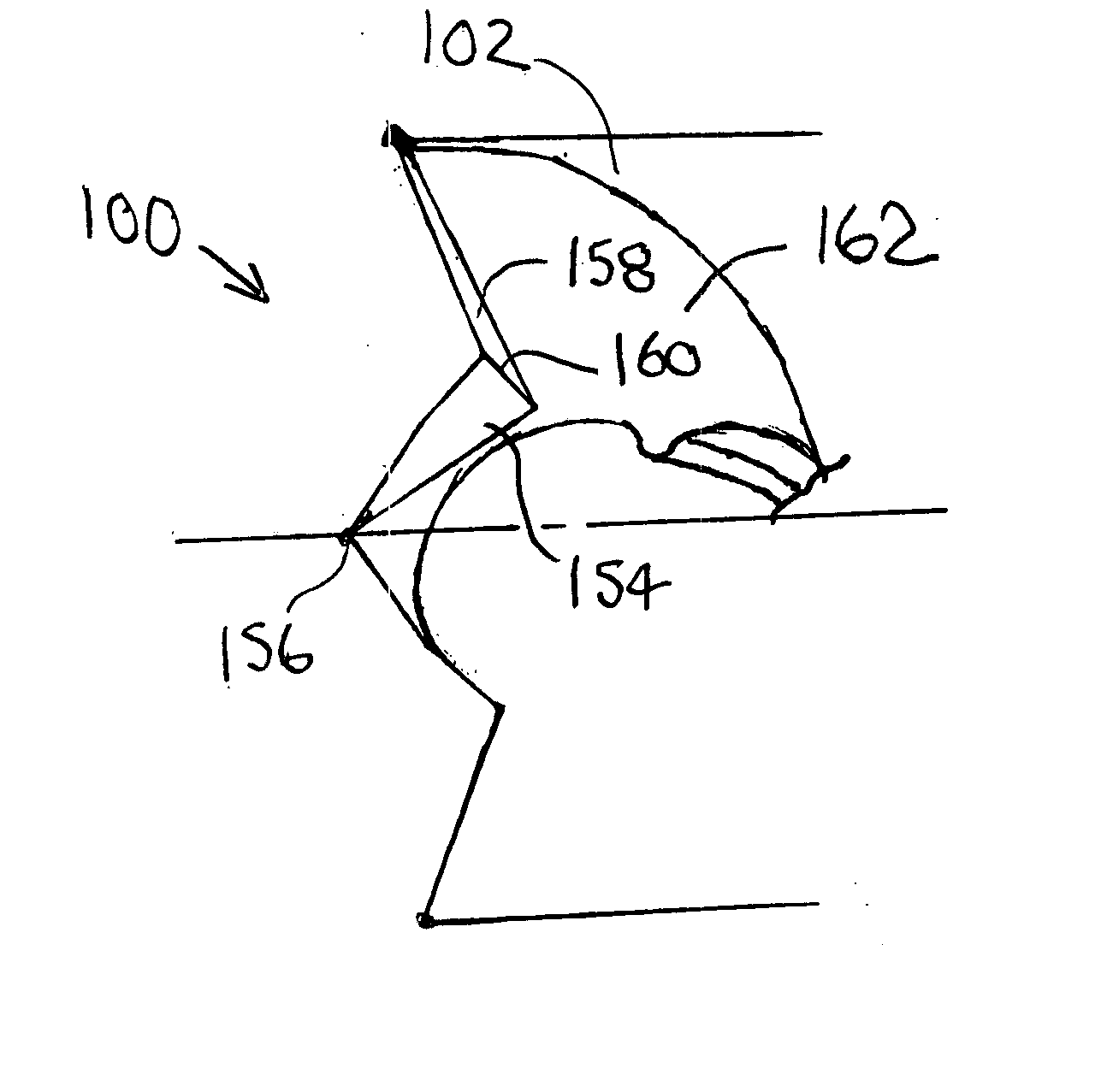

InactiveUS7018143B2Less energyReduce frictionWood turning toolsTransportation and packagingBiomedical engineeringTwist drill

A modified prior art twist drill embodies structural features that require less energy to drill a hole during a normal plunge operation and allow for lateral cutting movement during extraction of the twist drill from a drilled work piece.

Owner:BITMOORE AN OREGON GEN PARTNERSHIP

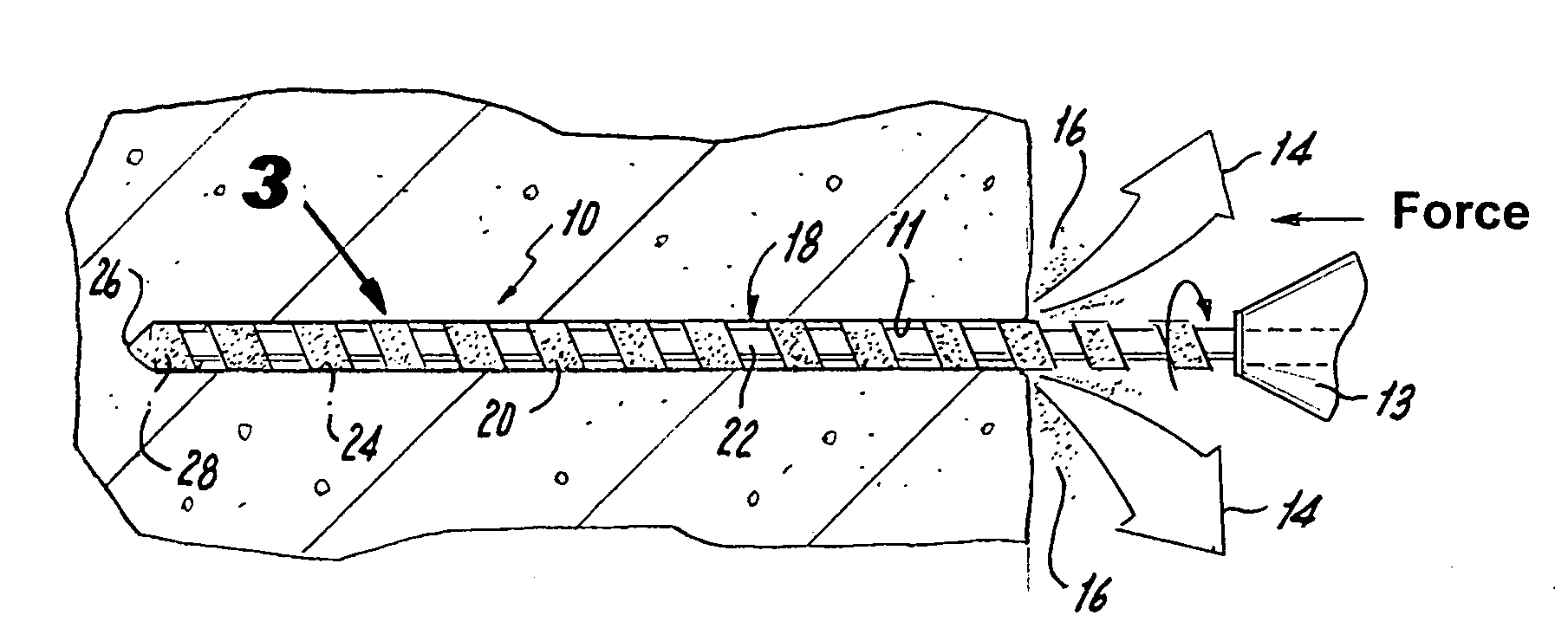

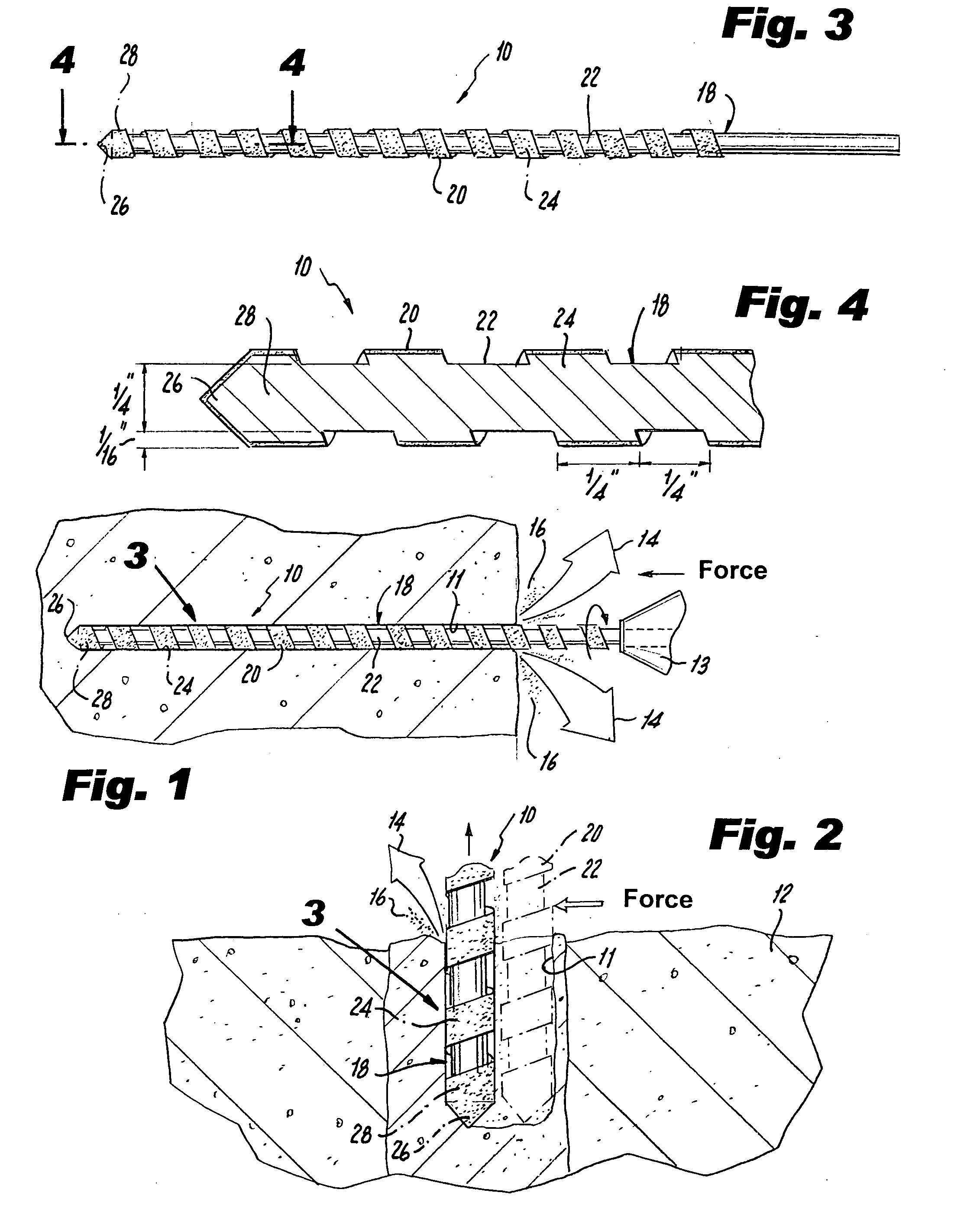

Twist bit for drilling mortar and for optimizing dissipation of heat and dust created by the drilling

InactiveUS20070000700A1Accelerated dissipationAvoid disadvantagesDrill bitsWorkpiecesFluteEngineering

A twist bit for drilling mortar and for optimizing dissipation of heat and dust created by the drilling. A shaft has a flute therein configured in a spiral configuration therealong leaving a flute land thereon also configured in a spiral configuration therealong, a tip, and a head including the tip and a portion of the flute land coextensive with the tip. Diamond dust is disposed only on the flute land and the head. To optimize the dissipation of the heat and the dust created by the drilling, the twist drill operates via a drill motor in a range of approximately 25,000 RPMs to approximately 26,000 RPMs. The flute has a width of approximately ¼″ and the flute land has a width of approximately ¼″ and a height of approximately 1 / 16″.

Owner:SWITZER BRUCE D

Twist drill

ActiveUS20070237594A1Long useful lifeShort processing timeWood turning toolsTransportation and packagingFluteTrademark

Twist drill with a drill shaft and a cutting part that extends to a drill tip, with spiral chip flutes along the cutting part that form a drill core, wherein the drill diameter and / or core thickness diminish or taper from the drill tip toward the shaft. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

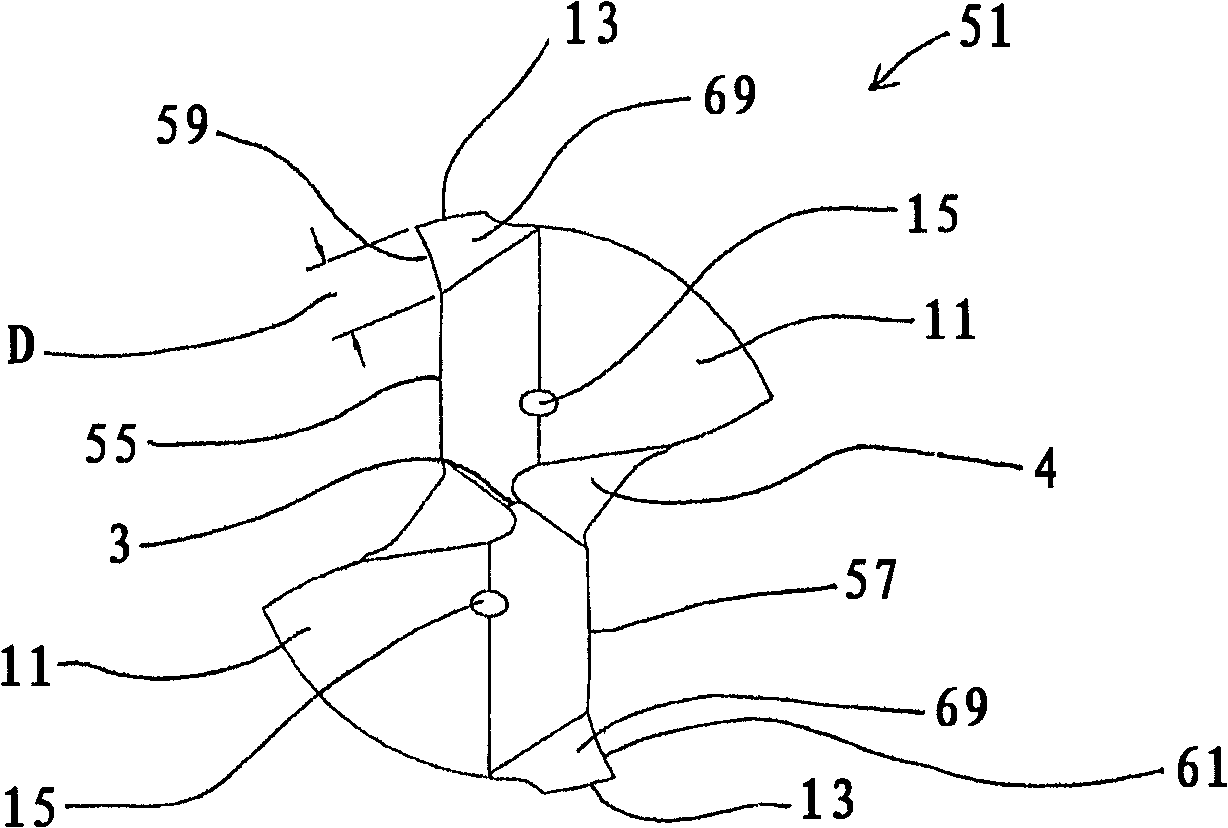

Twist drill

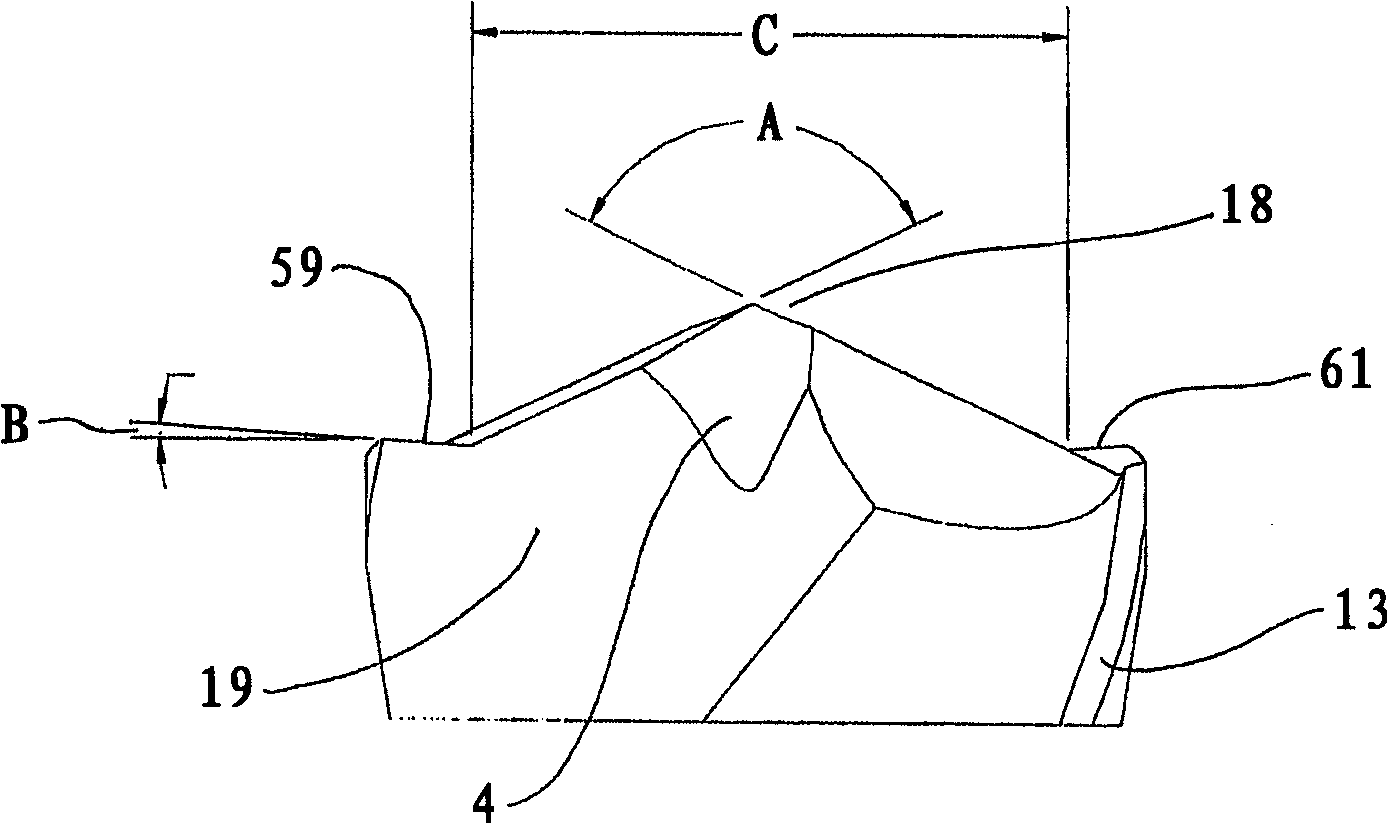

ActiveCN101282806ARelieve pressureReduce the temperatureWorkpiecesTurning toolsBurr heightMetalworking

A metal-working twist drill is provided with inner cutting edges that form a point (18) having an angle, A, of 130 degrees . An outer, peripheral, part of each cutting edge (55, 57) forms an outer cutting portion (59, 61). The outer cutting portions slope in the opposite direction to the corresponding inner cutting edges and form an angle B, of 3 degrees with respect to a plane normal to the axis of rotation of the twist drill. The width of the outer cutting portion, D as measured at the cutting edge, is 10.5% of the diameter of the twist drill. The metal-working twist drill produces bores having a reduced exit burr height.

Owner:天窗工具有限公司

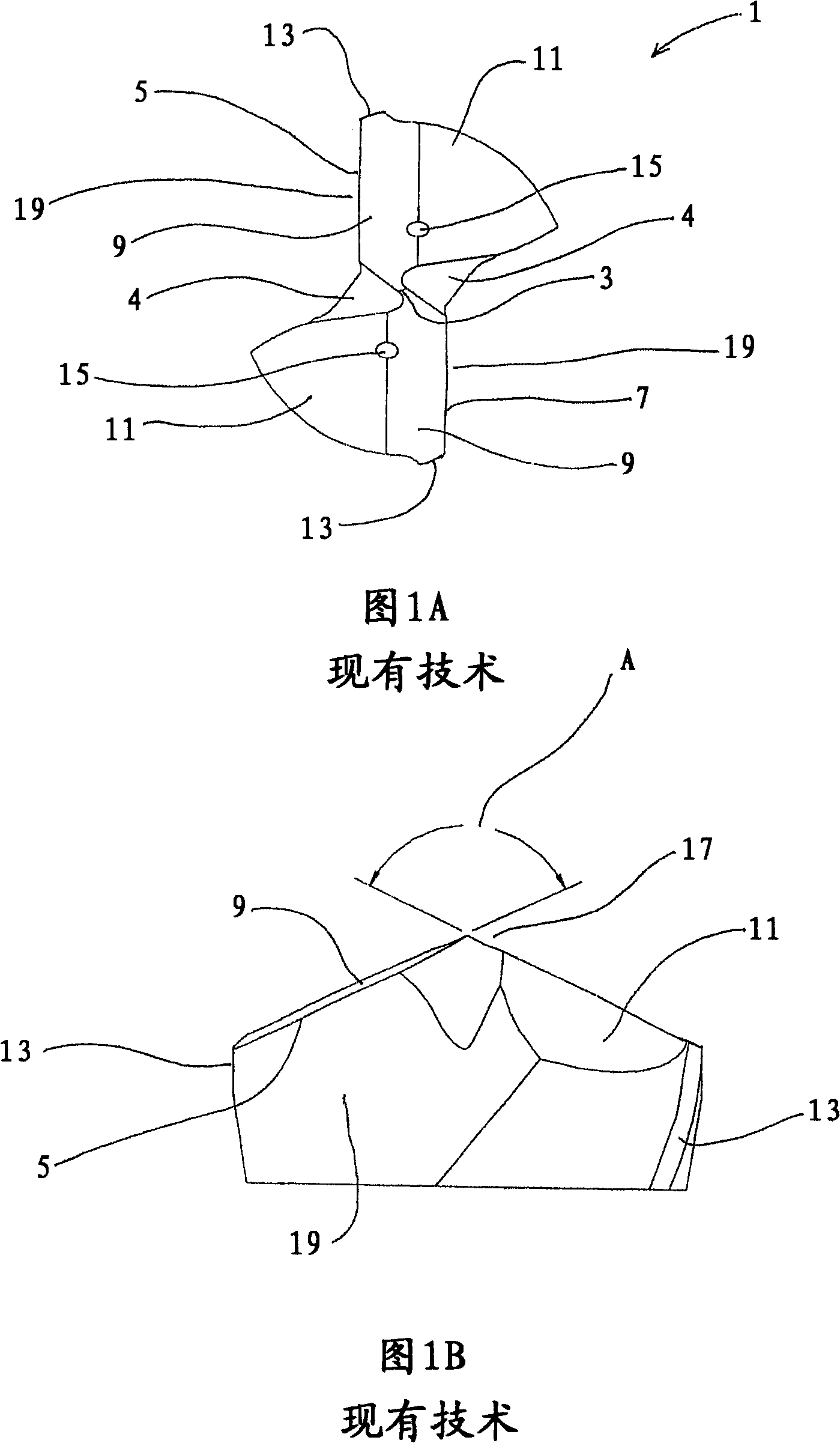

Twist drill for drilling, a drill with a cutting insert, and a replaceable cutting insert for a twist drill

InactiveUS7008150B2Easy to manufactureSecurely holdWood turning toolsTransportation and packagingEngineeringSelf locking

On a drill with a base body and a replaceable cutting insert, the cutting insert lies in a receptacle that runs through the base body at a right angle to the latter's longitudinal axis and is open toward the drill tip, whereby the cutting insert is in contact by means of two diametrically opposite contact surfaces against the side walls of the receptacle. Between each contact surface of the cutting insert and a side wall of the receptacle, there is a groove that extends in the direction of the longitudinal axis, in which groove a clamping wedge sits with a form-fit and a friction-fit, and interacts with the base body and the cutting insert in the manner of a self-locking device that acts toward the drill tip.

Owner:KENNAMETAL INC

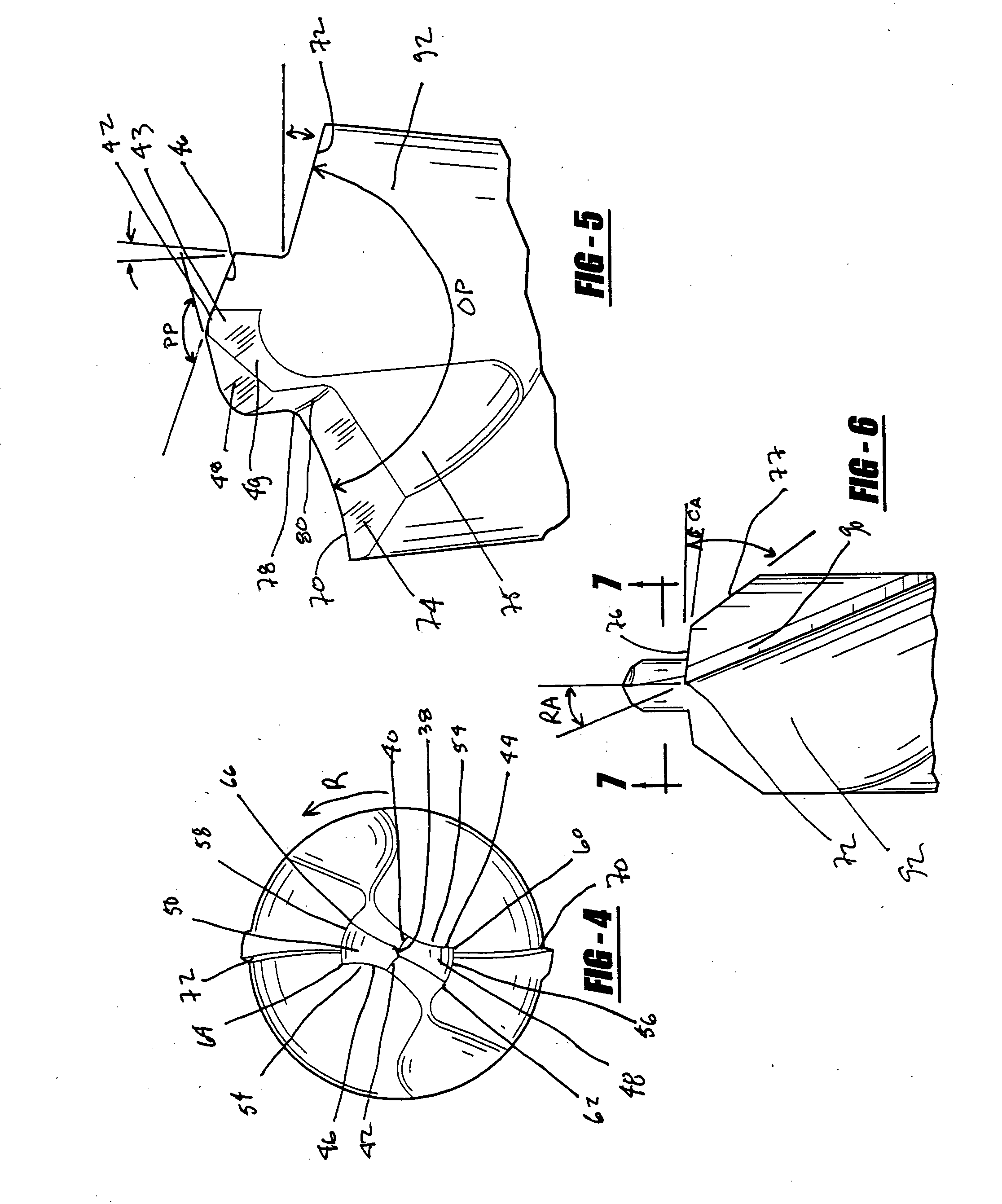

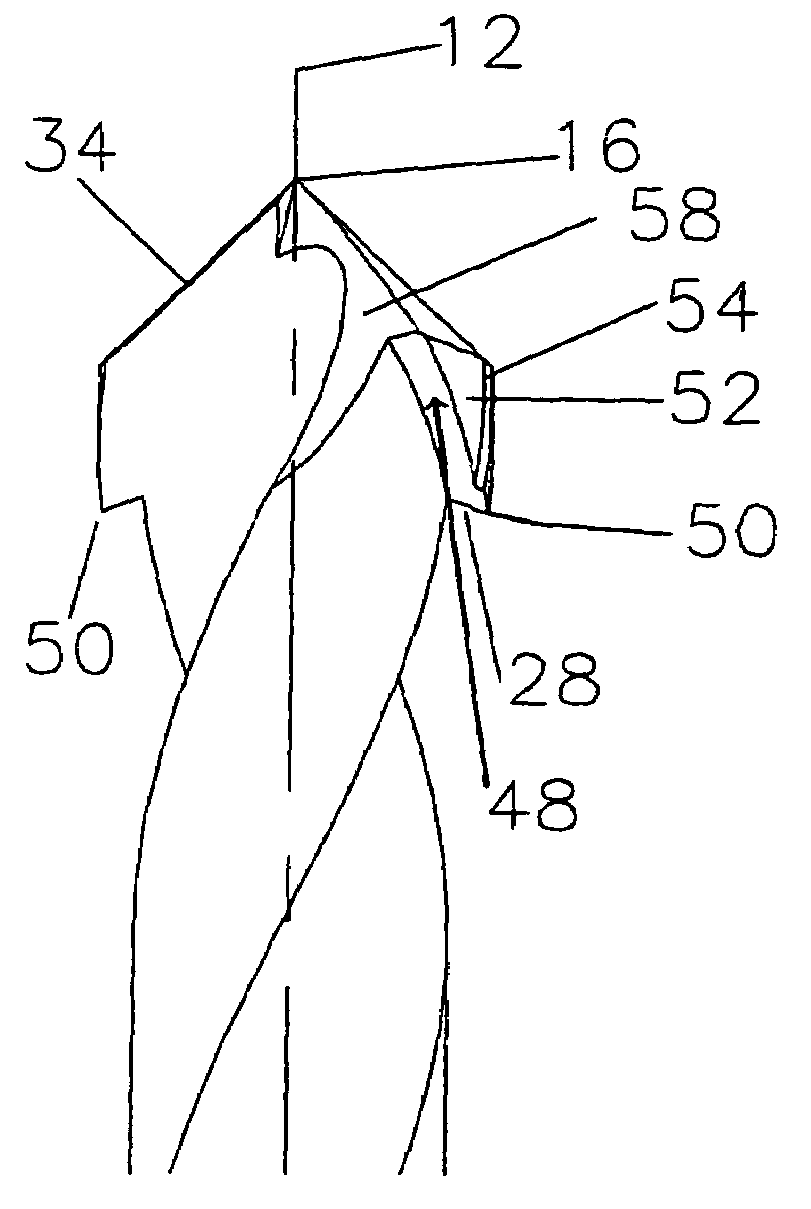

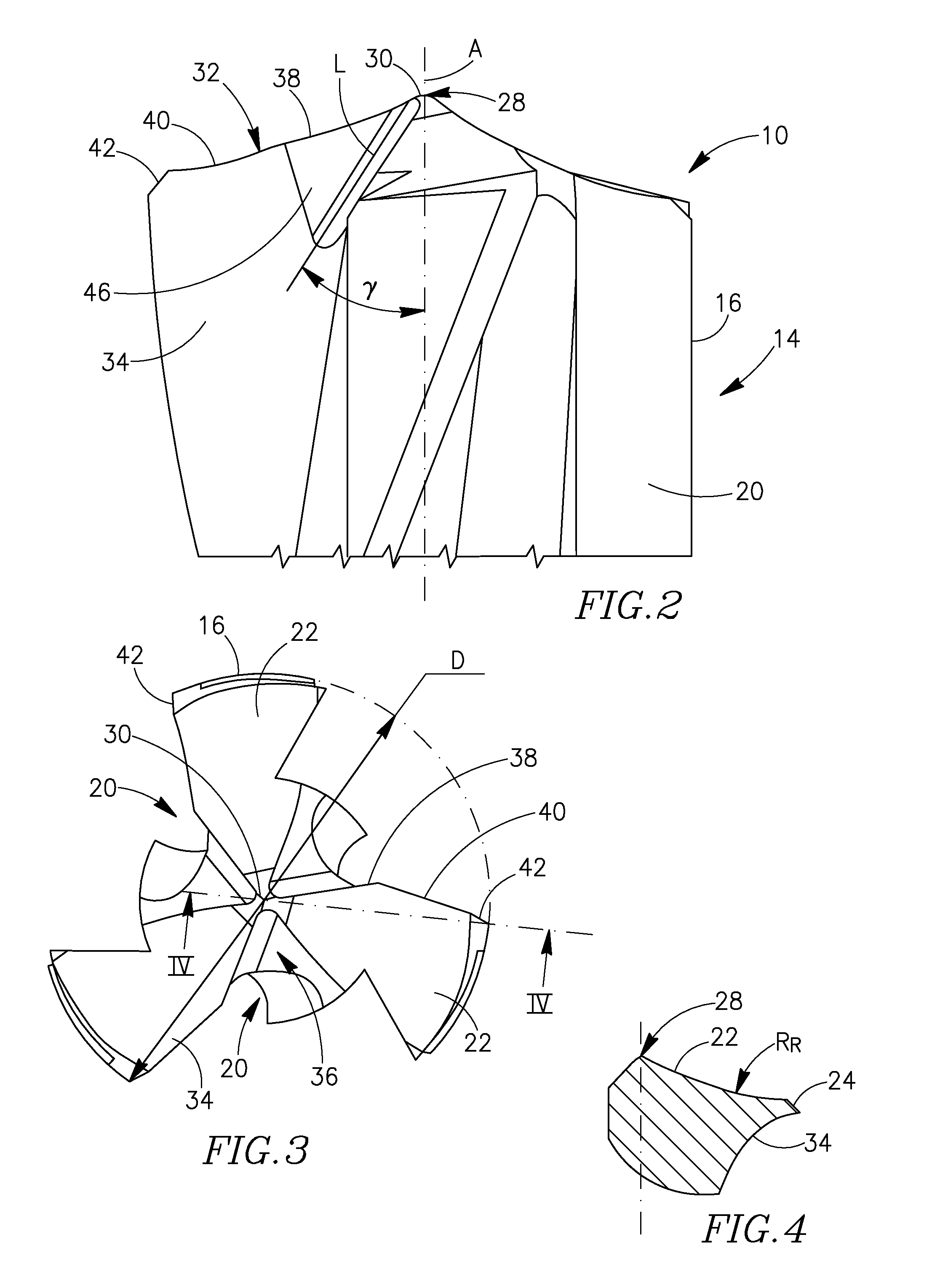

Twist Drill With Negative Axial Rake Transition Between The Lip And The Secondary Cutting Edge

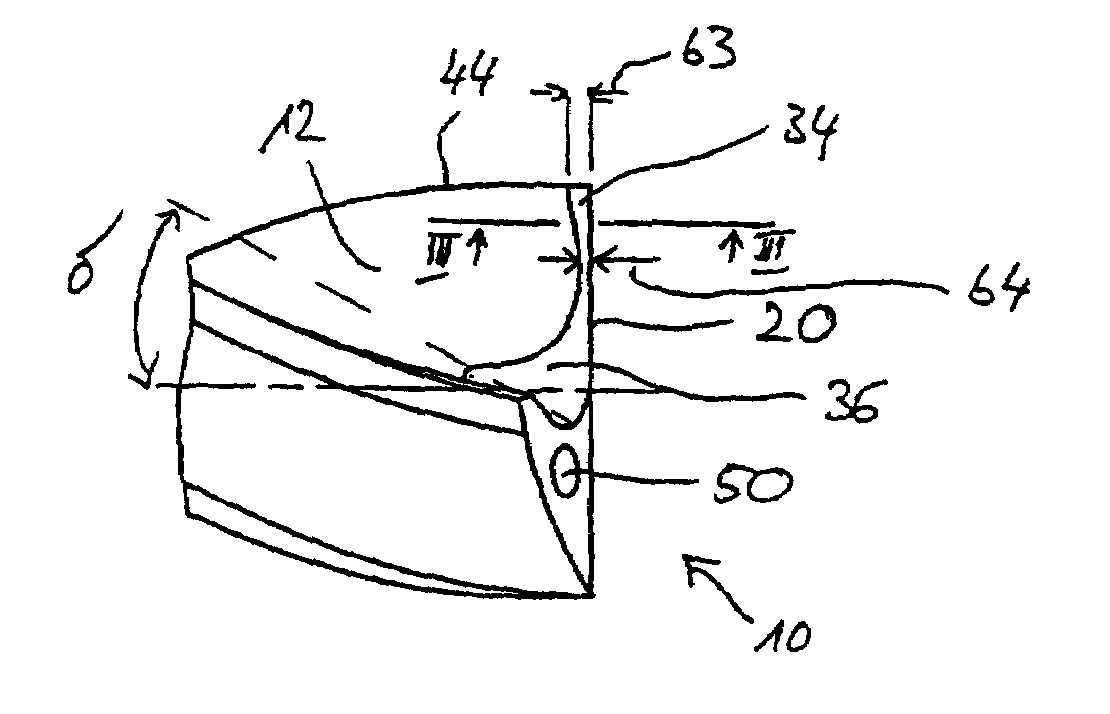

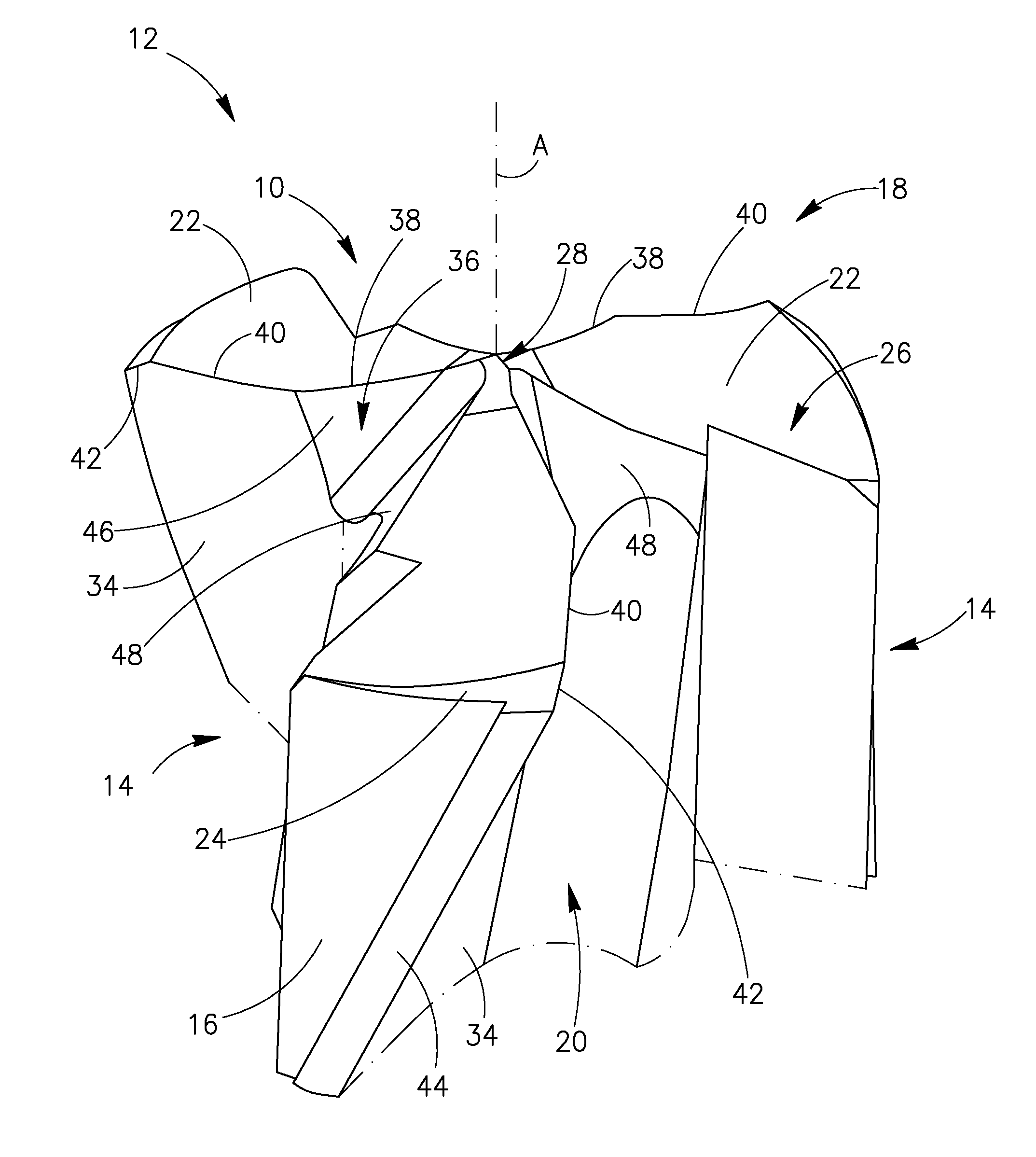

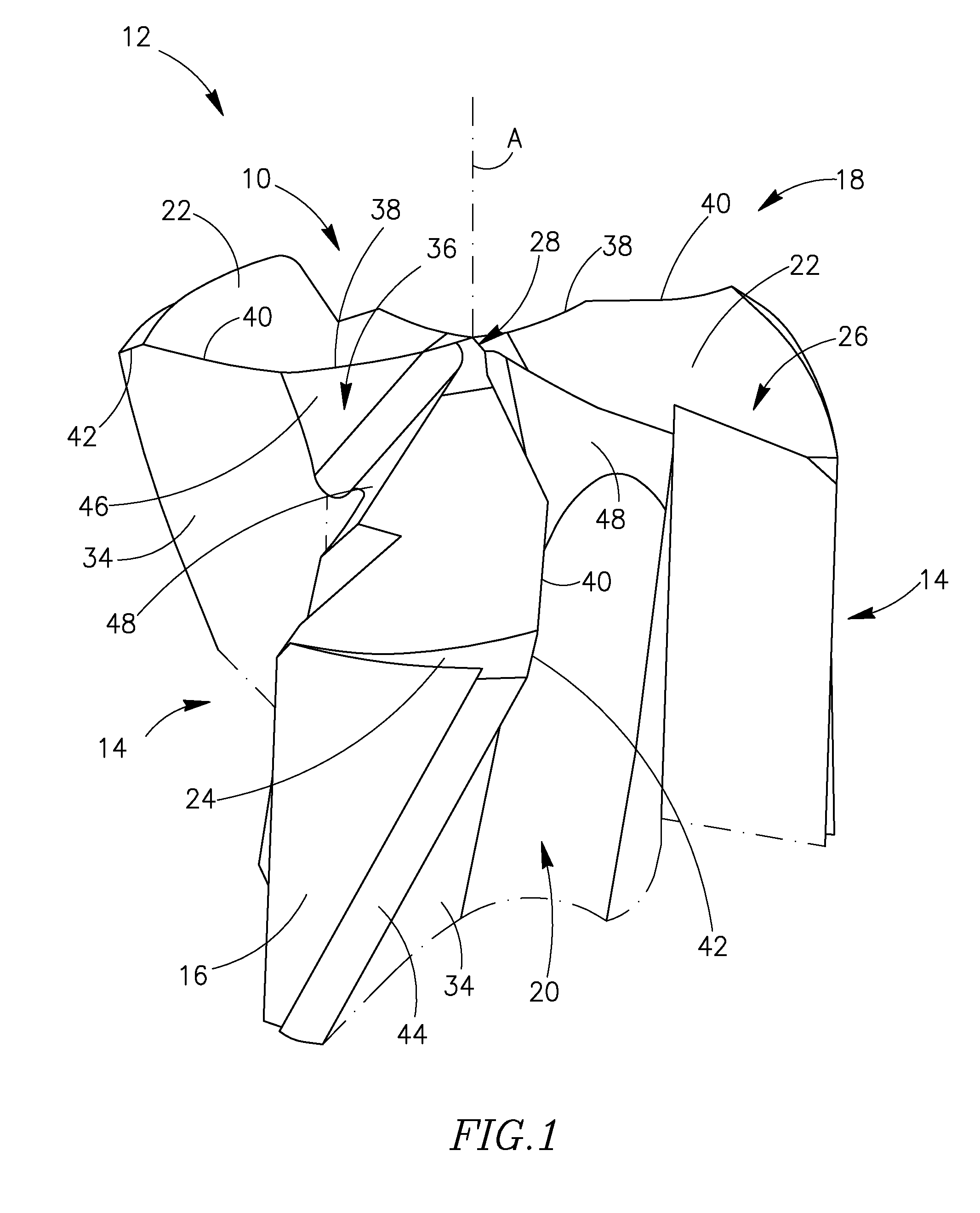

A drill for making a hole within a workpiece has a body extending along a longitudinal axis, at least one flute extending along the body, and a drill point extending from the end of the body. The drill point has a periphery and is comprised of a chisel edge, a primary cutting edge extending inwardly from the periphery, a secondary cutting edge extending outwardly from the chisel edge, and a tertiary cutting edge connecting the primary cutting edge with the secondary cutting edge, wherein the tertiary cutting edge has a negative axial rake angle. A method for producing such a drill point is also disclosed wherein in one grinding pass a gash forms the axial rake angle of the secondary cutting edge, and in a separate grinding pass a portion of the secondary cutting edge is removed to produce a tertiary cutting edge having an axial rake angle that is negative.

Owner:KENNAMETAL INC

Drill, such as a twist drill

ActiveUS7530772B2Short processing timeWood turning toolsTransportation and packagingFluteStructural engineering

A drill bit, such as a twist drill, having a body equipped with flutes, as well as a drill bit face that includes two main cutting edges that merge together. In order to drill a blind hole, such as with a level drilled bottom, the main cutting edge forms a continuous cutting edge that runs in a plane perpendicular to the drill bit's longitudinal axis. The main cutting edges, with respect to a cutting direction, are arranged behind a center line lying in the plane which is perpendicular to the longitudinal axis of the drill and extending through the center of the drill as well as in the direction of the main cutting edges.

Owner:KENNAMETAL INC

Anticing device of power transmission line and application method

The invention provides an anticing device of the power transmission line and application method. The anticing device of the power transmission line is provided with a drive motor, a road wheel, a coating mechanism and a dehydration mechanism. A coating pipe, a coating brush and a power transmission which is surrounded by a semi-circle coating brush body are connected with the bottom of the coating bottle. Two dehydration motors which are fixed on the frame are connected respectively with the dehydration brush. The front end and the back end of the anticing device of the transmission line are provided with a deicing motor and a deicing mechanism of deicing twist drill. Microprocessors of a temperature and humidity sensor and an infrared reflection sensor of a control system are connected with each motor through the pulse-width modulation (PWM). A flow control valve is connected with the microprocessor. The anticing is installed on the power transmission line. According to different humilities and temperatures, the control system starts the drive motor and opens the flow control valve to coat the power transmission line with hydrophobic coatings or open the drive motor and the dehydration mechamism. Dehydration and deicing back and forth can be achieved on the power transmission line preventing the power transmission line from freezing, and the drive motor, the waterproof device and deicing device is launched when ice coating exists used for deicing and dewatering back and forth on power transmission line The anticing device has the advantages of operating automatically and being practical and effective.

Owner:GUILIN UNIV OF ELECTRONIC TECH

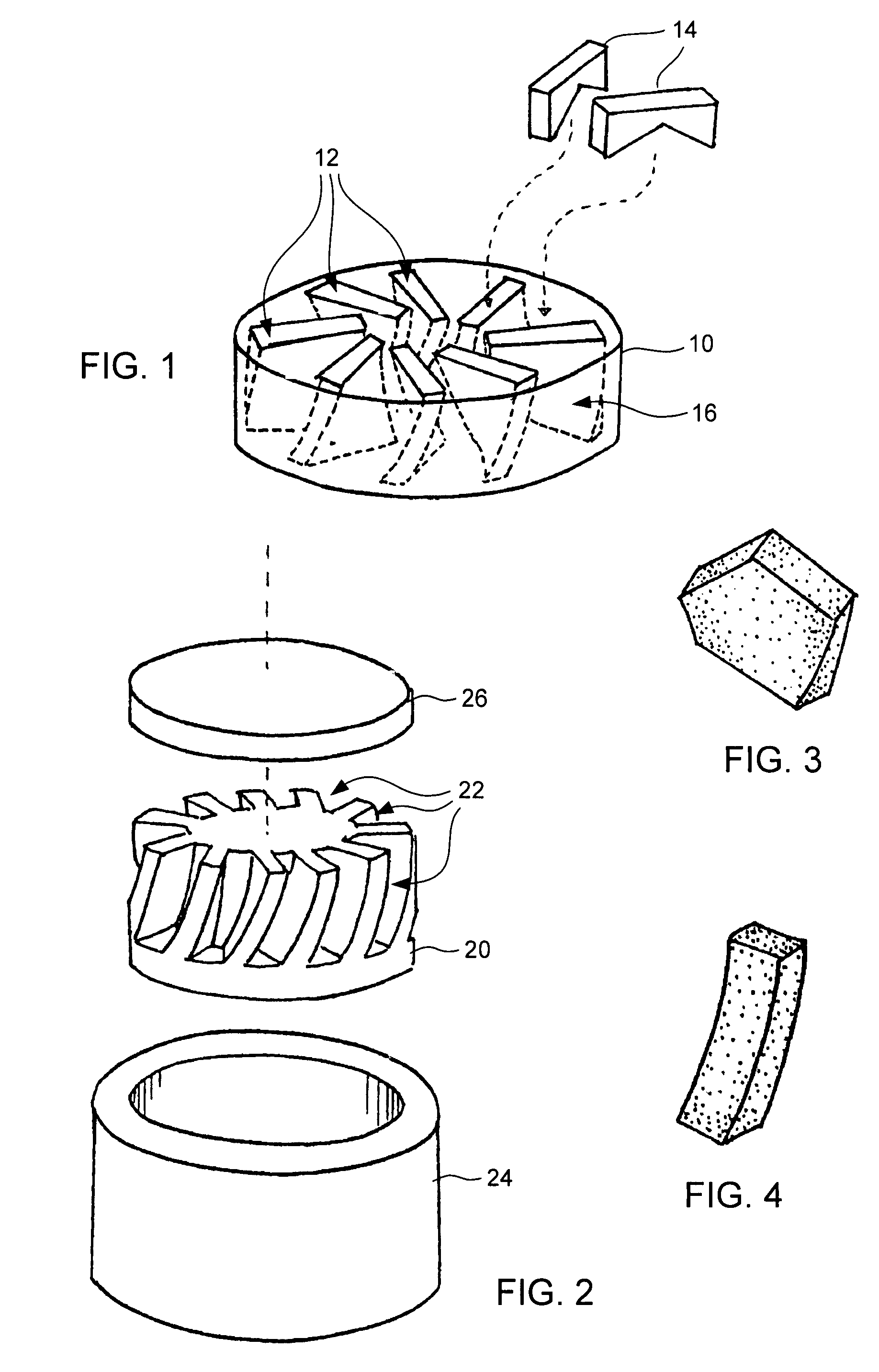

Contoured PCD and PCBN for twist drill tips and end mills and methods of forming the same

ActiveUS8052765B2Reduce manufacturing costEasy to makePigmenting treatmentAdditive manufacturing apparatusParticulatesMaterials science

Contoured solid polycrystalline superabrasive material such as twist drill tips and endmill flank segments can be formed by preparing a precursor mold having a plurality of shaped openings each corresponding to a predetermined shape. A specially prepared charge feed can be placed into the shaped openings to form a charged precursor. The charge feed can include a substantially homogeneous mixture of superabrasive source particulates, sintering binder, and optional inorganic bonding medium. A loaded reaction cup-assembly including the charged precursor can be subjected to a pressure, temperature and time sufficient for sintering and formation of the contoured polycrystalline superabrasive material. Reduced finishing steps and increased tailorability of grade and quality of final polycrystalline products can be readily achieved.

Owner:CHO H SAM +4

Drill, such as a twist drill

ActiveUS20070134071A1Short processing timeWood turning toolsTransportation and packagingTrademarkClassical mechanics

A drill, such as a twist drill. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

Twist drill and method for producing a twist drill which method includes forming a flute of a twist drill

InactiveUS20070081870A1Stress minimizationQuickly and easily groundWood turning toolsTransportation and packagingFluteEdge structure

There is now provided a twist drill and a method for producing a twist drill which method includes forming a flute of a twist drill. The drill has drill material and a tip portion with a cutting lip. The drill has a land structure and a flute to remove chip residue. The land structure has a flute wall and a cutting edge structure that is disposed longitudinally along the flute wall. The cutting edge structure has a first portion at the drill tip portion and a second portion disposed away from the drill tip portion. The flute wall extends further into the land structure at the second portion of the cutting edge structure than at the tip portion to provide a greater amount of drill material at the tip portion than at the second portion of the cutting edge structure. The flute wall extends further into the land structure at the second portion of the cutting edge structure than at the tip portion to provide a greater flute volume per length at the second portion of the cutting edge structure than at the drill tip portion. The method provides for forming a drill with a grinding tool to form different angular transitions of the cutting edge structure.

Owner:KENNAMETAL INC

Twist Drill

A twist drill includes a cutting portion and a drill body. The cutting portion has a chisel edge, a segment relief surface, a chamfer relief surface and at least two flutes extending longitudinally to the drill body. Each flute has a rake surface and a gash extending away from the chisel edge. The cutting portion further has at least two cutting segments, each cutting segment having a first curved cutting edge, a second curved cutting edge and a chamfer cutting edge.

Owner:ISCAR LTD

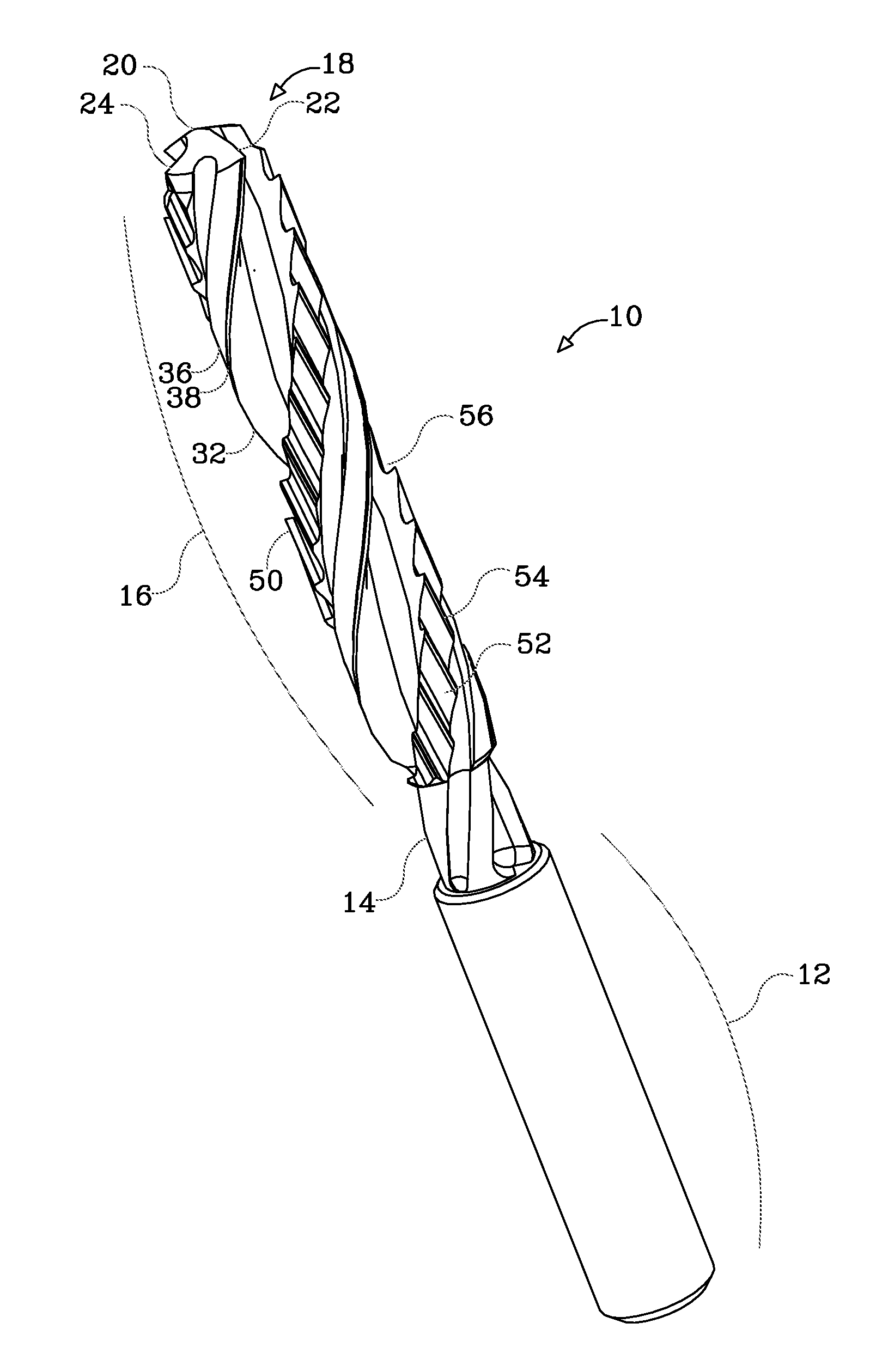

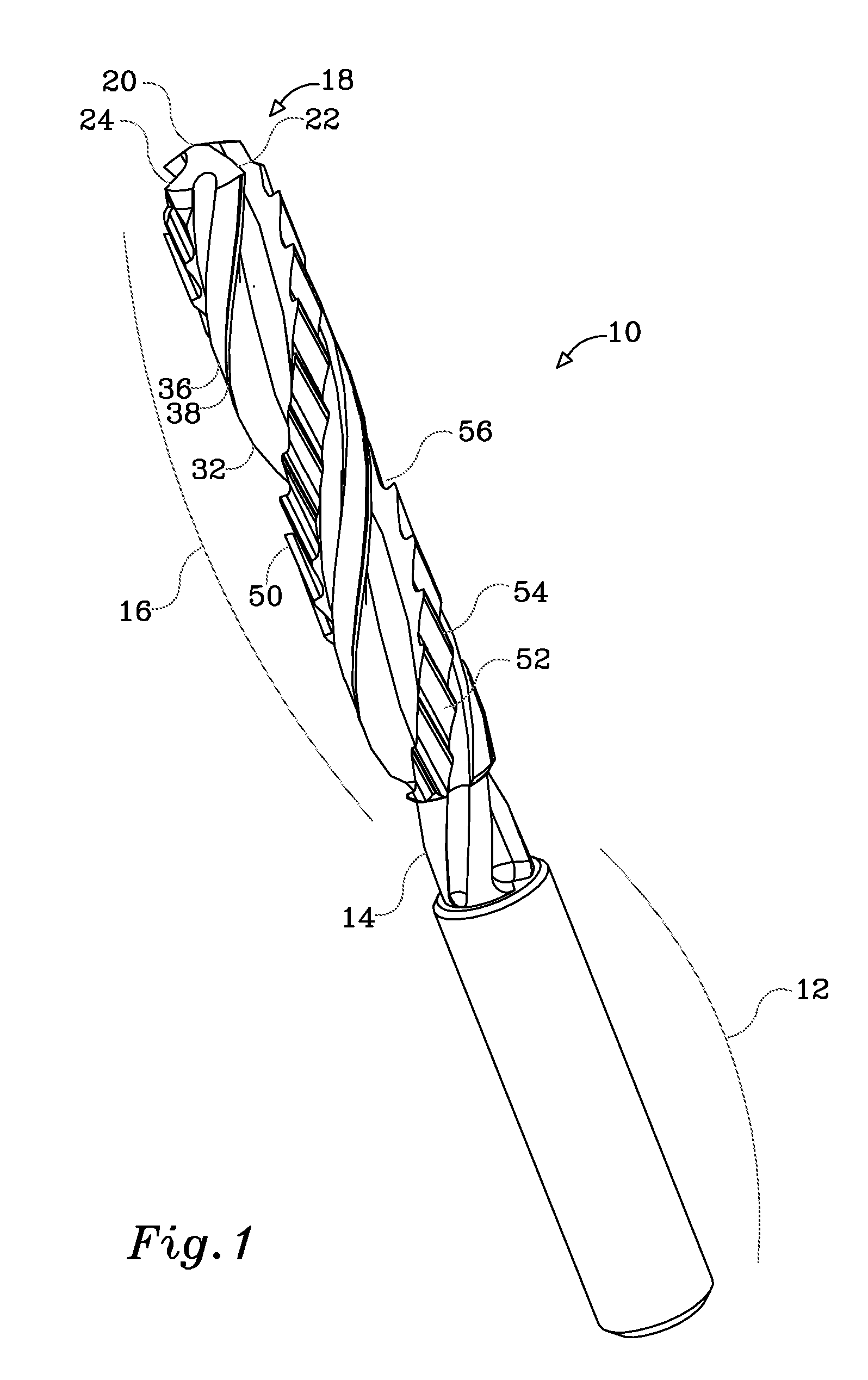

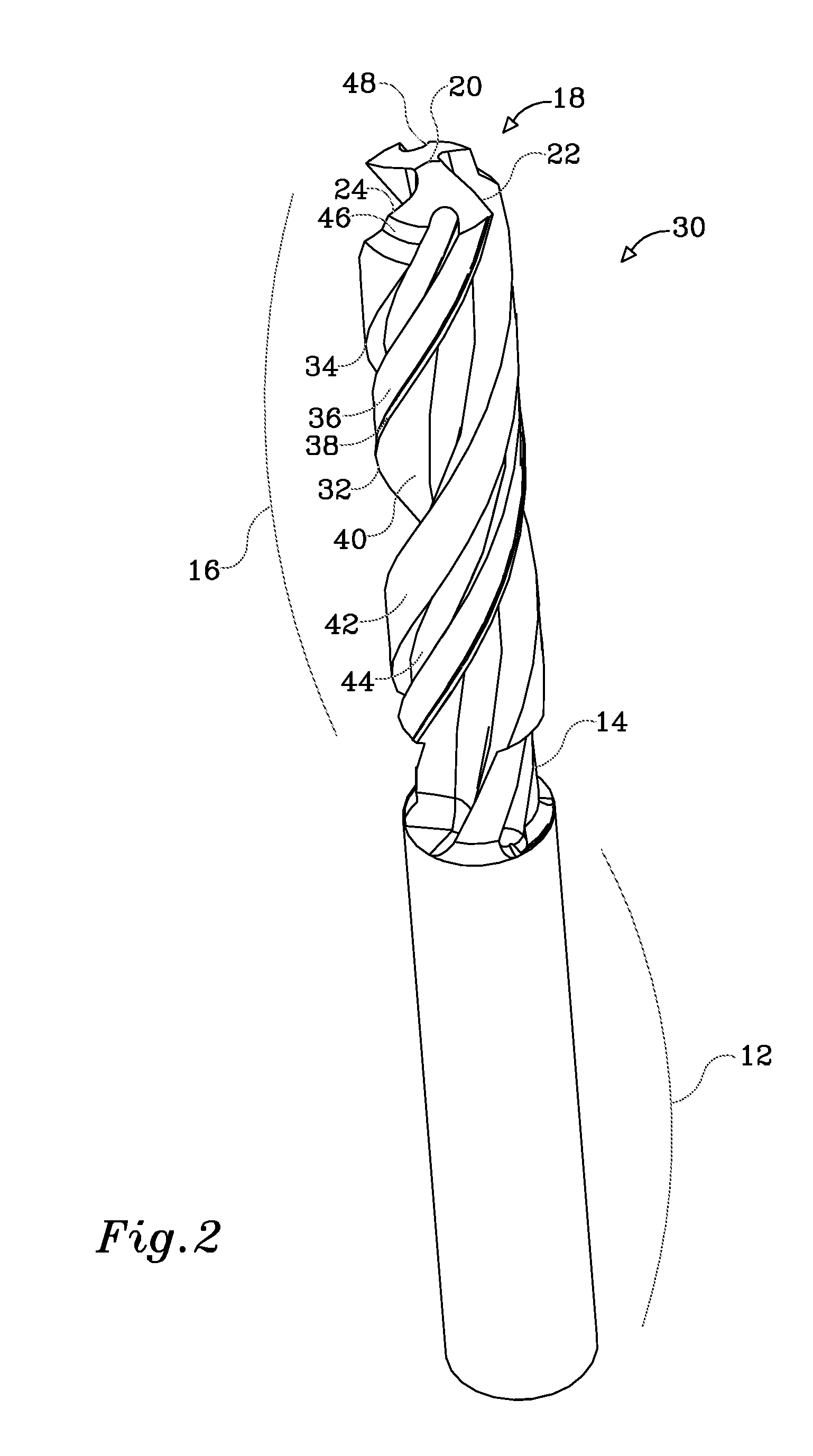

Combined drill and reamer tool

A drill-reamer tool comprises a shank portion and a cutting portion coaxial with the shank portion, the cutting portion having an operational portion comprising at least one twist drill spiral roughing cutting edge associated with a land margin, a land clearance and a flute. The cutting portion further comprises at least one spiral finishing edge interlaced with the spiral roughing cutting edge and having associated therewith only a land margin and a flute. The land margin of said finishing edge being provided with a plurality of reamer cutting edges spiraling in an opposite direction to that of the roughing cutting edge. The reamer cutting edges being configured to cut a larger hole than said roughing edge. The operational portion being dimensioned such that during operation, both the roughing cutting edge and the reamer cutting edge are simultaneously operative.

Owner:HANITA METAL FACTORY LTD SUBSIDIARY OF KENNAMETAL

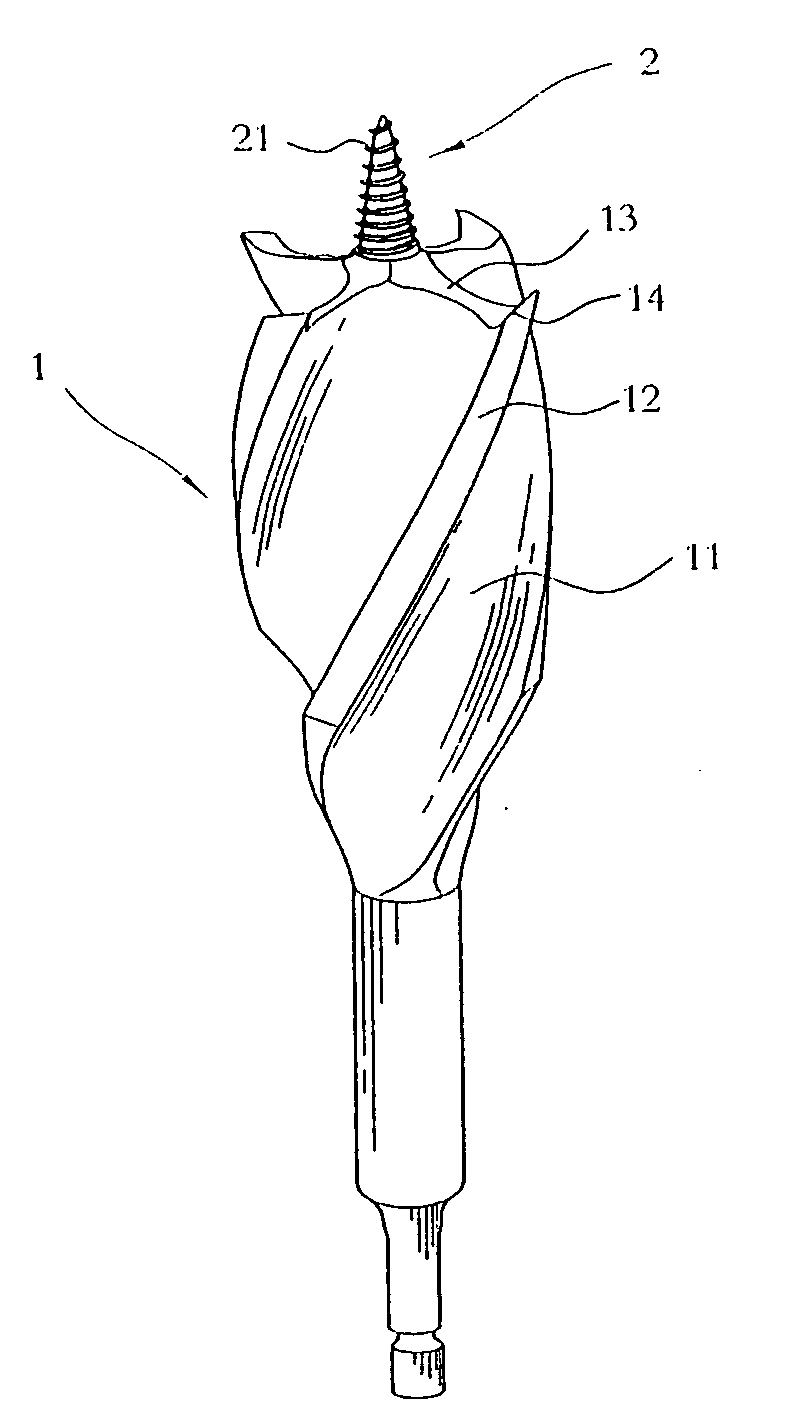

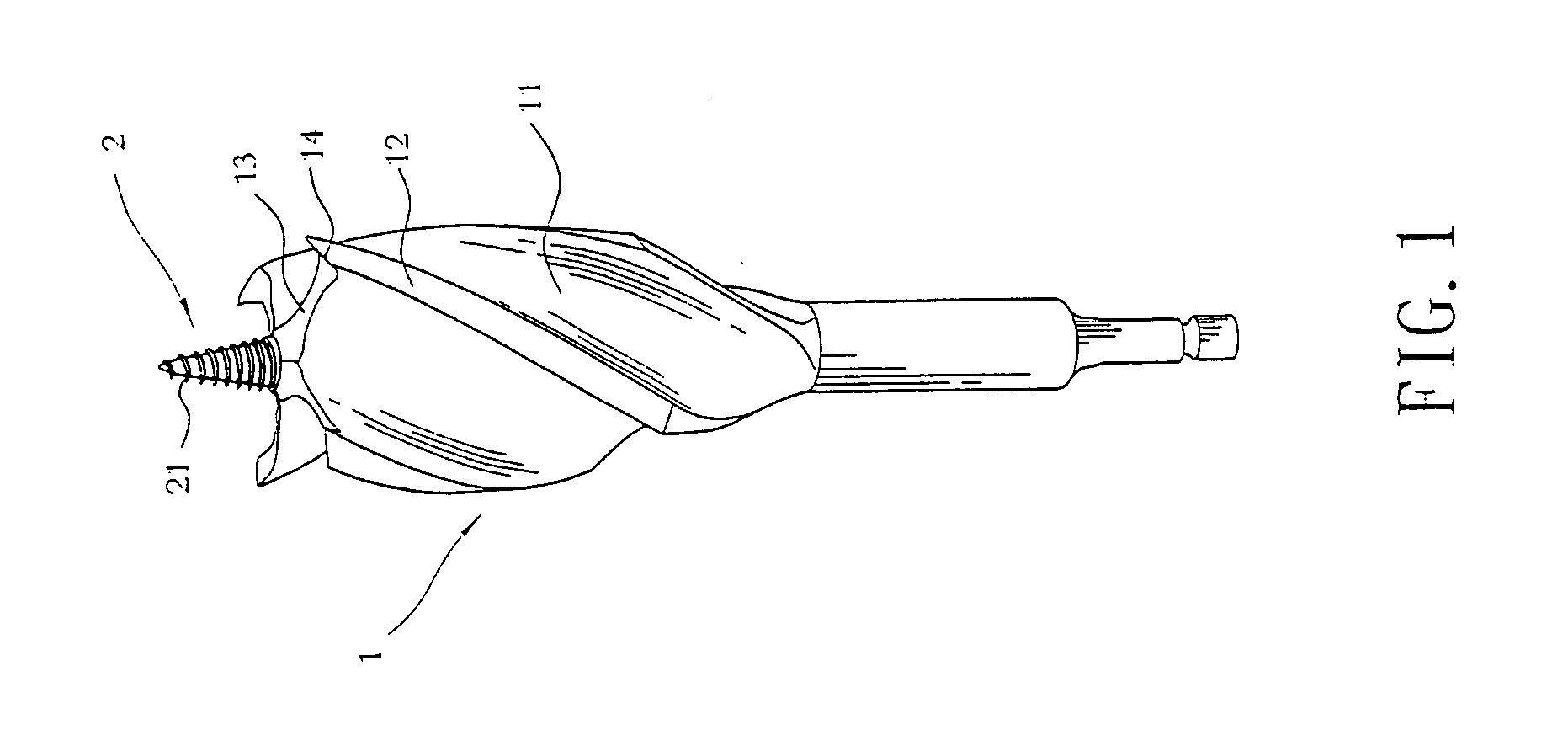

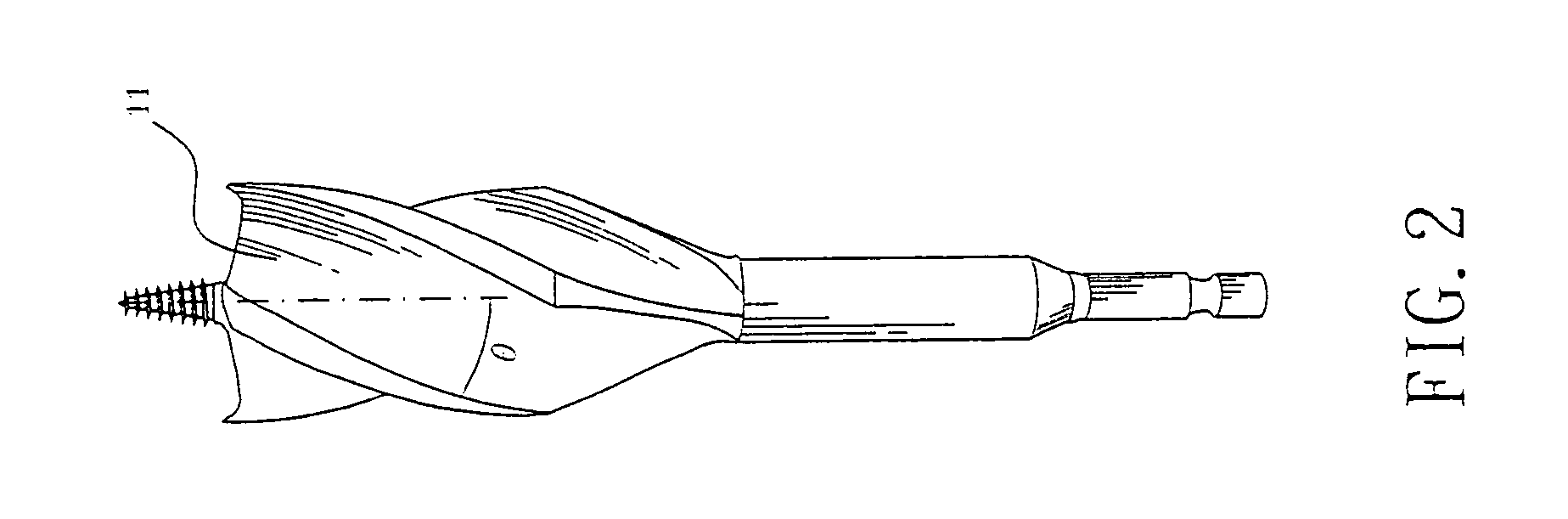

Multiple spur multiple spiral groove twist drill

InactiveUS20090047085A1Improve structural strengthHigh strengthWood turning toolsTransportation and packagingFluteCost effectiveness

A MULTIPLE SPUR MULTIPLE SPIRAL GROOVE TWIST DRILL includes a flute, whose shank is clamped and secured to a tooling holder of a drilling machine and contains multiple spiral flute grooves; each flute groove is disposed on its peripheral a flute land, a cutting section is formed on a front tip of the flute land; a spur formed at where the cutting section and the flute land crossing each other; and a lead screw point with tapered thread being disposed at a center on the front of the flute to increase strength of the cutting section; and the flute groove in conjunction with the flute to fortify the overall structural strength to provide longer service life and cost benefits of the drill.

Owner:LIAO CHUNG LIANG +1

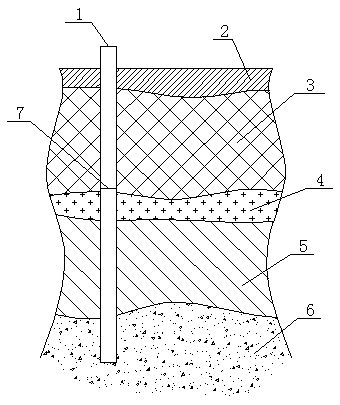

High-intensity prestressed concrete tubular pile lead hole hammering construction method for soft soil layer

ActiveCN102011401ASolve the carrying capacityAddress mechanical propertiesFoundation testingBulkheads/pilesMaterials processingEarth surface

The invention discloses a high-intensity prestressed concrete tubular pile lead hole hammering construction method for a soft soil layer. The method comprises the following construction steps of: measuring and positioning; performing lead hole construction by using a long twist drill; and constructing by using a guide-rod diesel hammer pile driver. The construction method solves the problems of low earth surface bearing capacity, inconvenient construction machinery, material processing and transportation, serious influence of weather and the like existing on a construction site. A pile foundation is manufactured without cast-in-place concrete, so that the defect of reaching design required intensity of a concrete pile foundation by waiting for about a month is overcome; and gas shielded welding is performed between pile sections, so that the shearing resistance of a weld position is enhanced. After all, the construction method fulfills the aims of shortening construction period, saving money and ensuring engineering quality and is particularly suitable for construction of soft soil layers with poor bearing force and prestressed tubular piles with earthquake-proof intensity of lower than grade 7. Of course, the construction method is widely applicable to construction of other floor civil buildings.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

Compound positioning and cutting spiral cutter

The invention provides a compound positioning and cutting spiral cutter, and mainly relates to a machine twist drill for machining. The spiral cutter is high in stability and heat radiating efficiency and long in service life and can be easily positioned when used for drilling and processing. The spiral cutter comprises a cutter head and is characterized in that the height relationship between an anti-crack slitting table or an efficient slitting table and an adjacent efficient slitting table on the inner side is defined, the included angle between a compound spiral cutting face and an adjacent compound positioning resolving table is greater than or equal to 90 degrees, a centering chamber and a rear cutting face of a drill tip are intersected to form an included angle of less than or equal to 120 degrees, or the height of the adjacent compound spiral cutting face is greater than or equal to 0.01 mm or smaller than four fifths of the thickness of discharged chips, or less than or equal to the height of the product of 9 times of the cutting feed amount, or the width of the anti-crack slitting table is greater than 0.6 mm or less than or equal to one third of the diameter of the cutter, or a spiral groove is formed in the compound spiral cutting face.

Owner:李仕清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com