Patents

Literature

12664results about How to "Keep dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

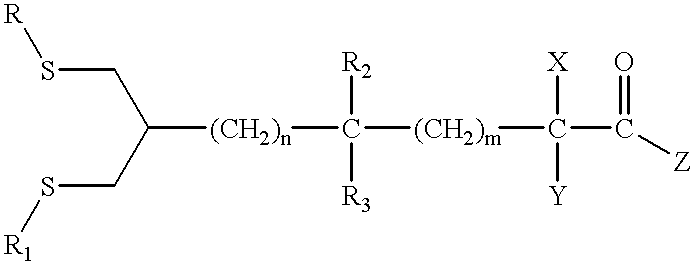

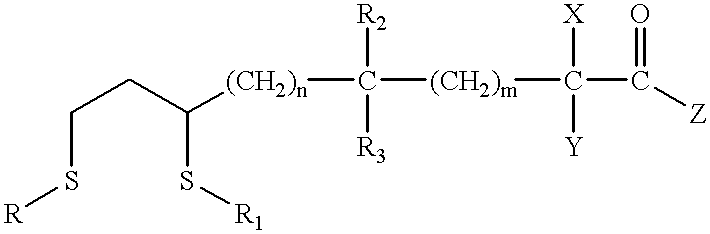

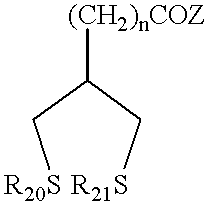

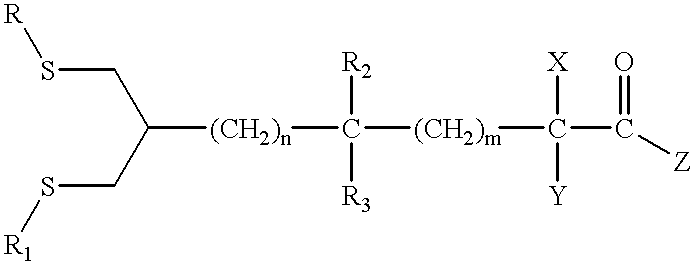

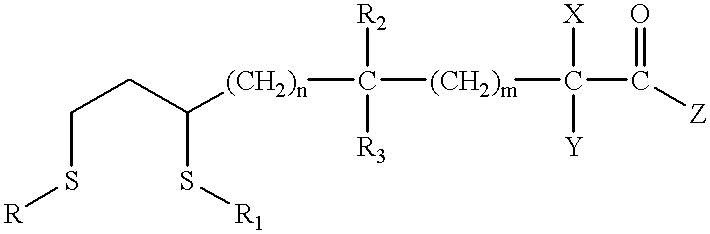

Novel antioxidants

This invention comprises administering to a human or animal in need of treatment an effective amount of an antioxidant lipoic acid derivative and / or pharmaceutically acceptable salts and solvates thereof for the treatment or prevention of pathological (inflammatory, proliferative and degenerative diseases, e.g. diabetes mellitus, atherosclerosis, Alzheimer's disease and chronic viral diseases) and non-pathological (e.g. skin aging and wrinkle formation) conditions caused by oxidative damage. Methods of synthesizing novel antioxidant lipoic acid derivatives and their use in preventing or treating diseases or conditions caused by oxidative stress and other free radical mediated conditions are described. Another aspect of this invention is the use of these antioxidant compositions for the protection of skin from damage caused by ultraviolet radiation and dessication, and to provide improved skin feel by desquamating, cleansing and clarifying the skin. The compositions described in this invention increase cellular viability of epidermal cells, promote cytoprotection, and decrease the production of inflammatory mediators such as inflammatory cytokines in these cells. The antioxidant compositions are incorporated into sunscreen products, soap, moisturizing lotions, skin toners, and other skin care products.

Owner:BETHESDA PHARMA

Antioxidants

This invention comprises administering to a human or animal in need of treatment an effective amount of an antioxidant lipoic acid derivative and / or pharmaceutically acceptable salts and solvates thereof for the treatment or prevention of pathological (inflammatory, proliferative and degenerative diseases, e.g. diabetes mellitus, atherosclerosis, Alzheimer's disease and chronic viral diseases) and non-pathological (e.g. skin aging and wrinkle formation) conditions caused by oxidative damage. Methods of synthesizing novel antioxidant lipoic acid derivatives and their use in preventing or treating diseases or conditions caused by oxidative stress and other free radical mediated conditions are described. Another aspect of this invention is the use of these antioxidant compositions for the protection of skin from damage caused by ultraviolet radiation and dessication, and to provide improved skin feel by desquamating, cleansing and clarifying the skin. The compositions described in this invention increase cellular viability of epidermal cells, promote cytoprotection, and decrease the production of inflammatory mediators such as inflammatory cytokines in these cells. The antioxidant compositions are incorporated into sunscreen products, soap, moisturizing lotions, skin toners, and other skin care products.

Owner:BETHESDA PHARMA

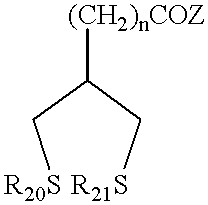

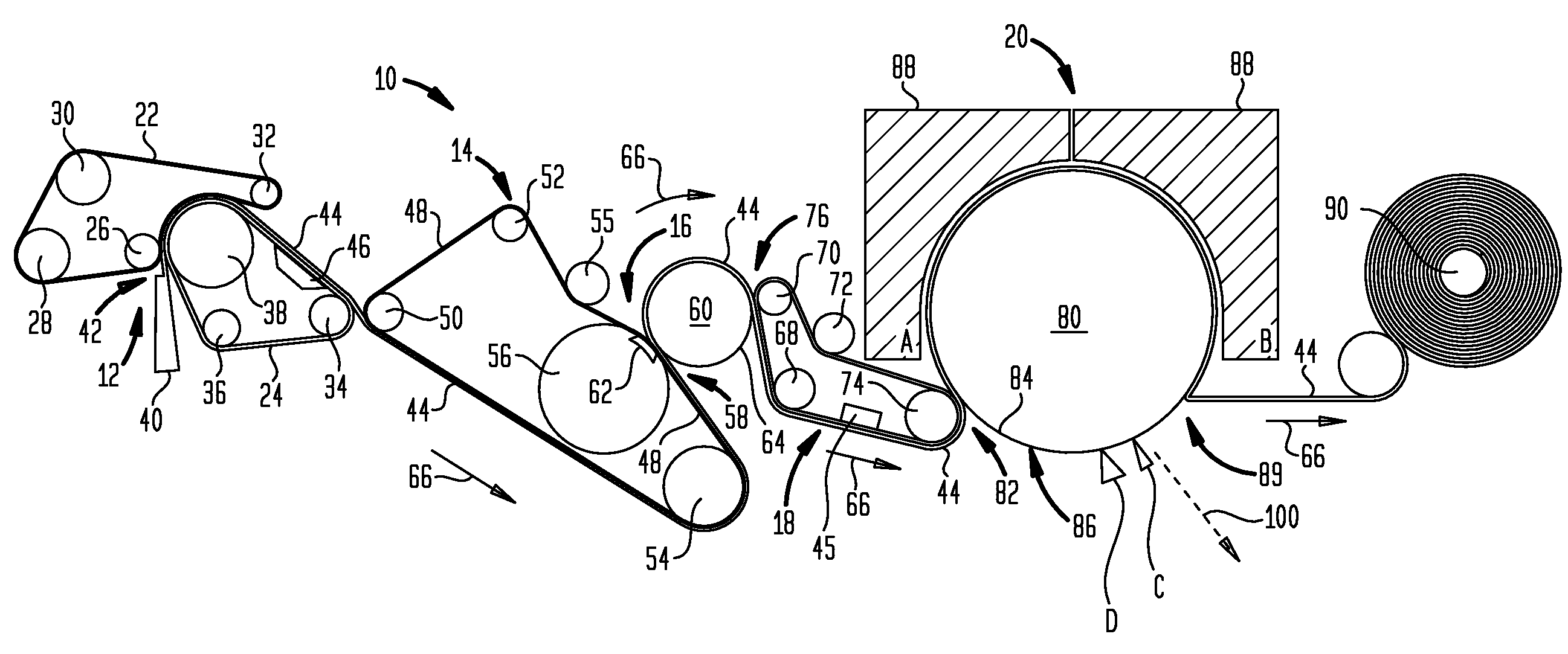

Fabric-crepe process with prolonged production cycle and improved drying

ActiveUS7608164B2Increases the amount of production available from a paper machineKeep dryNon-fibrous pulp additionDrying using combination processesAdhesiveCoating

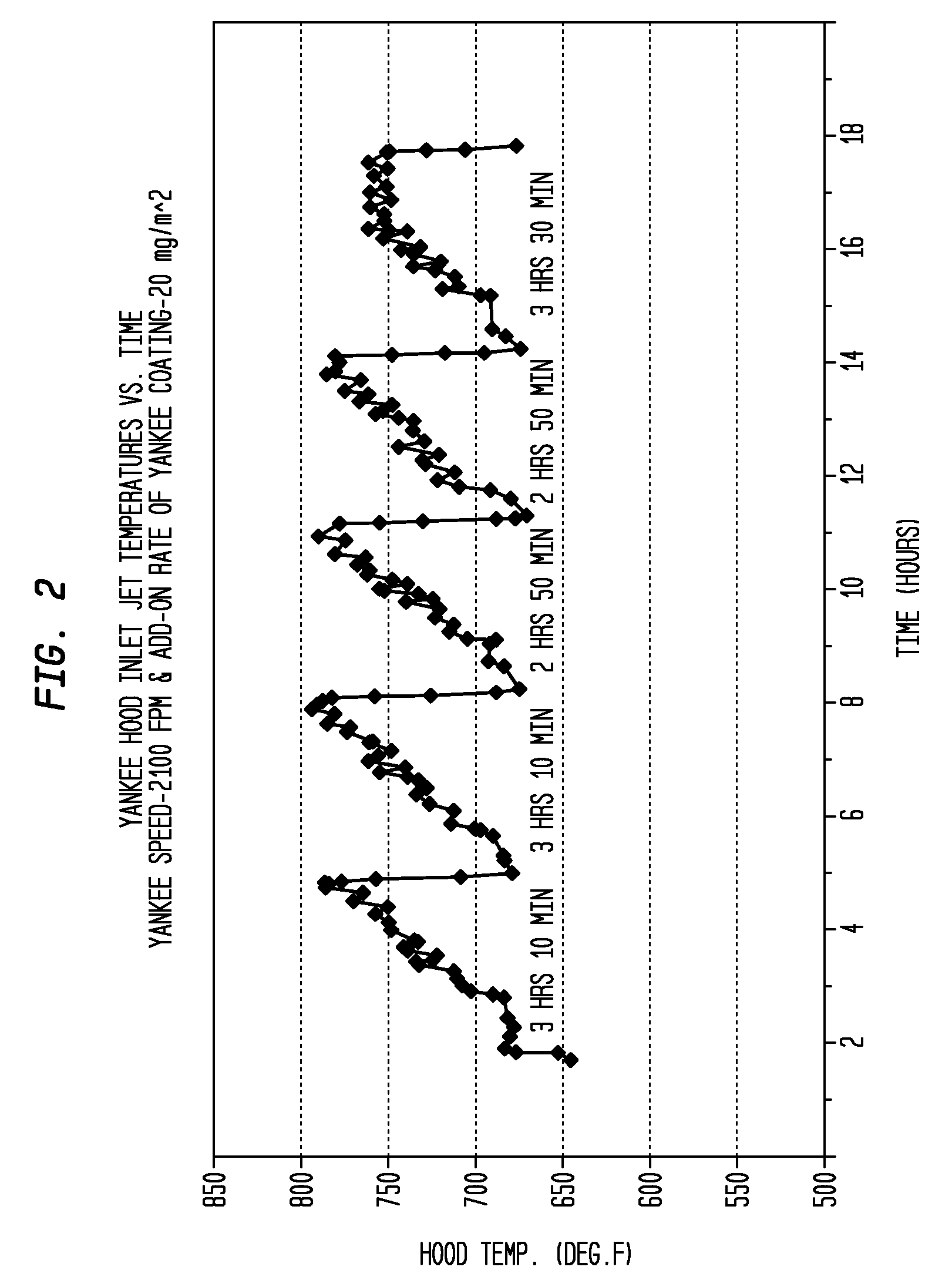

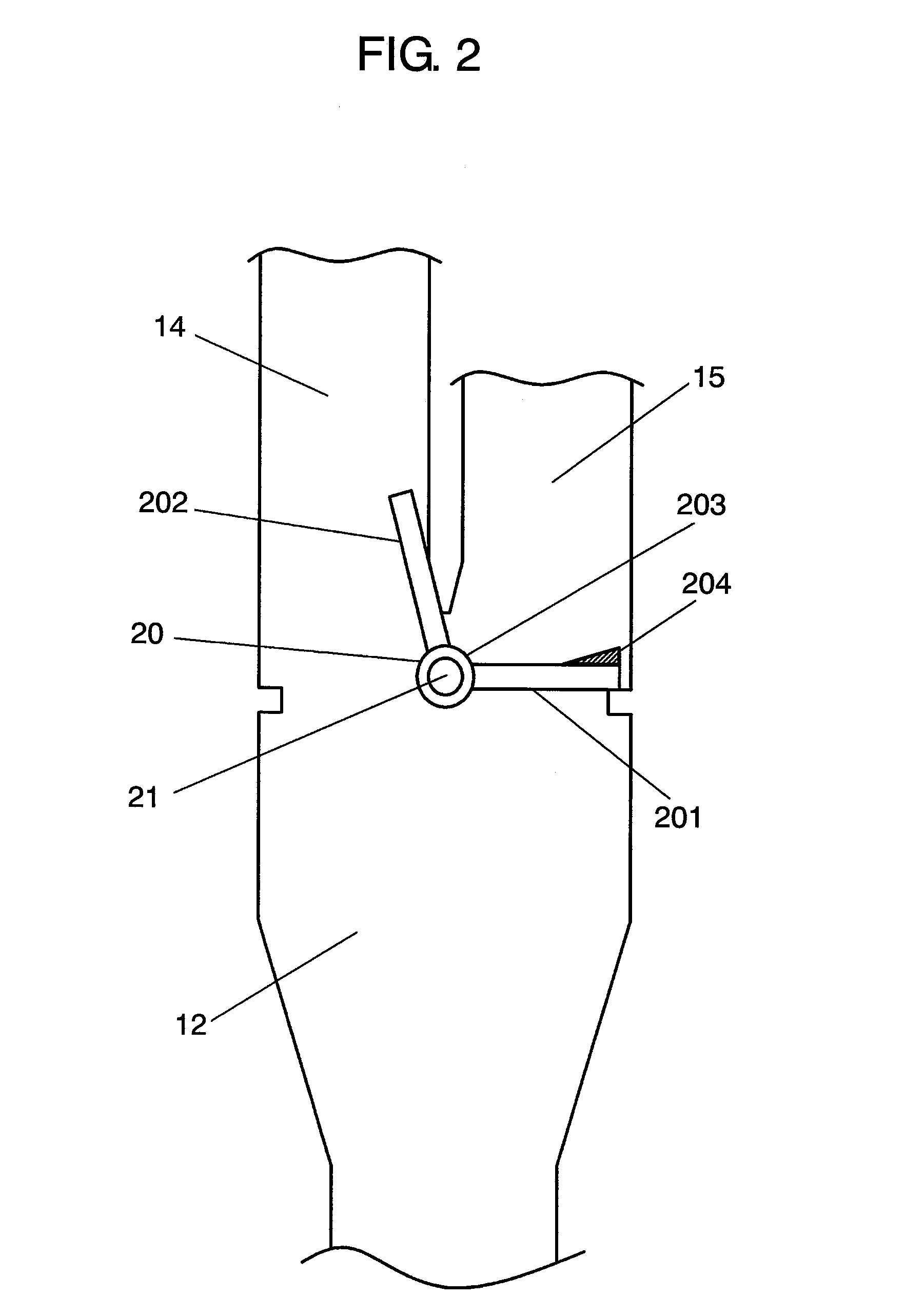

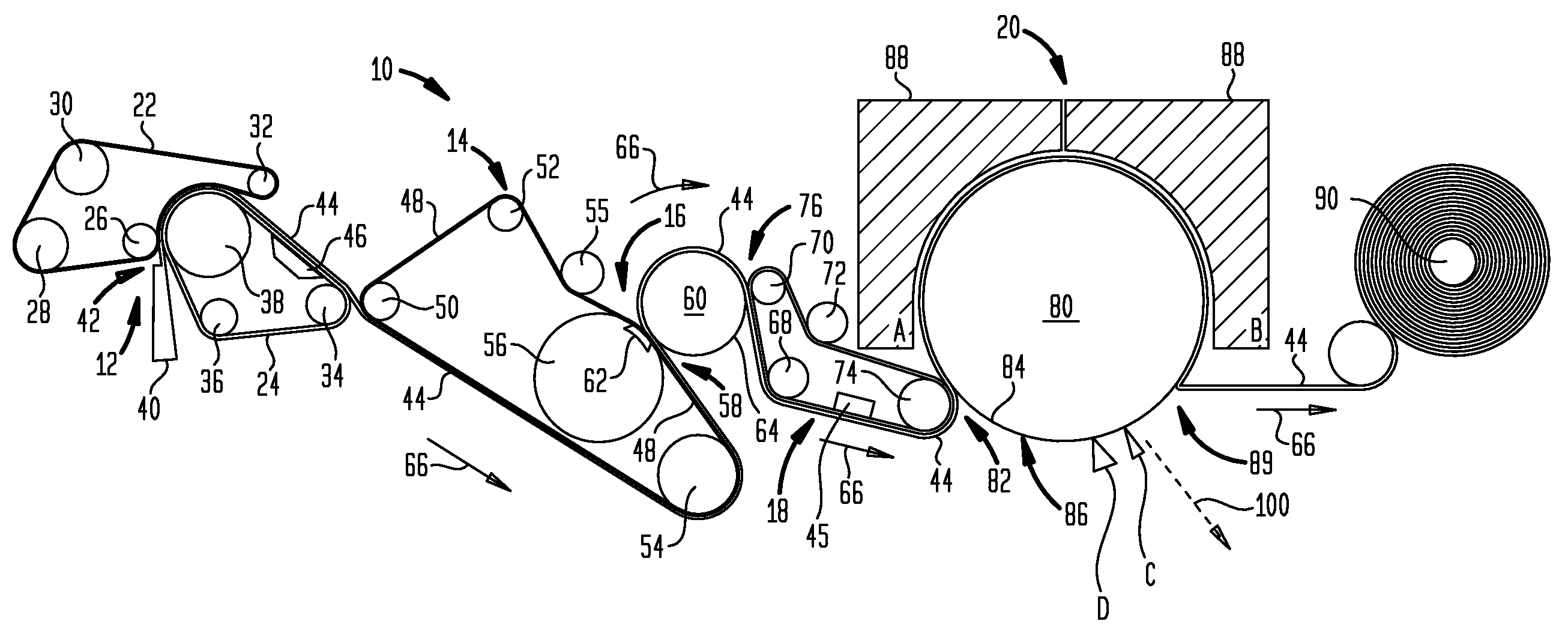

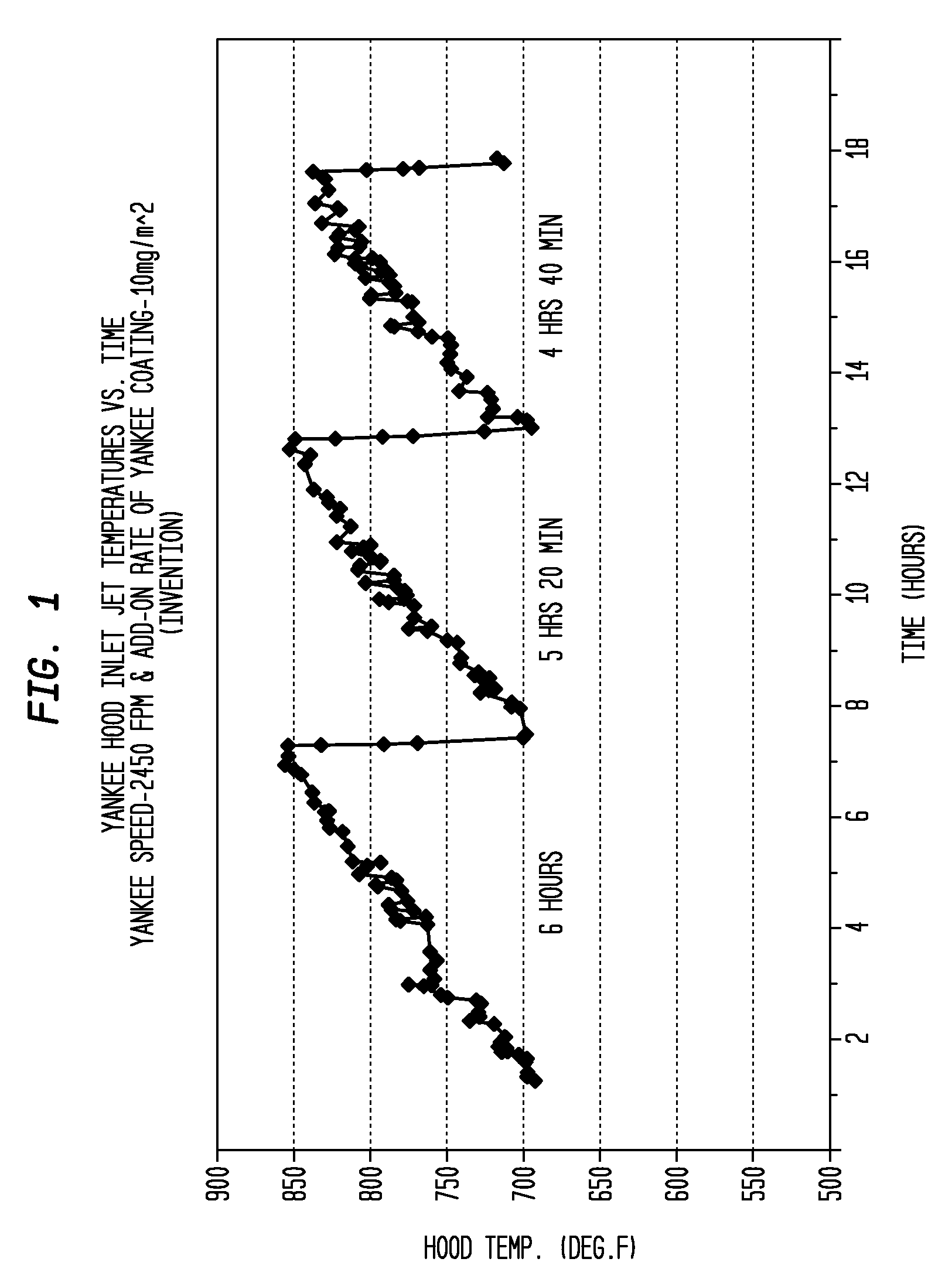

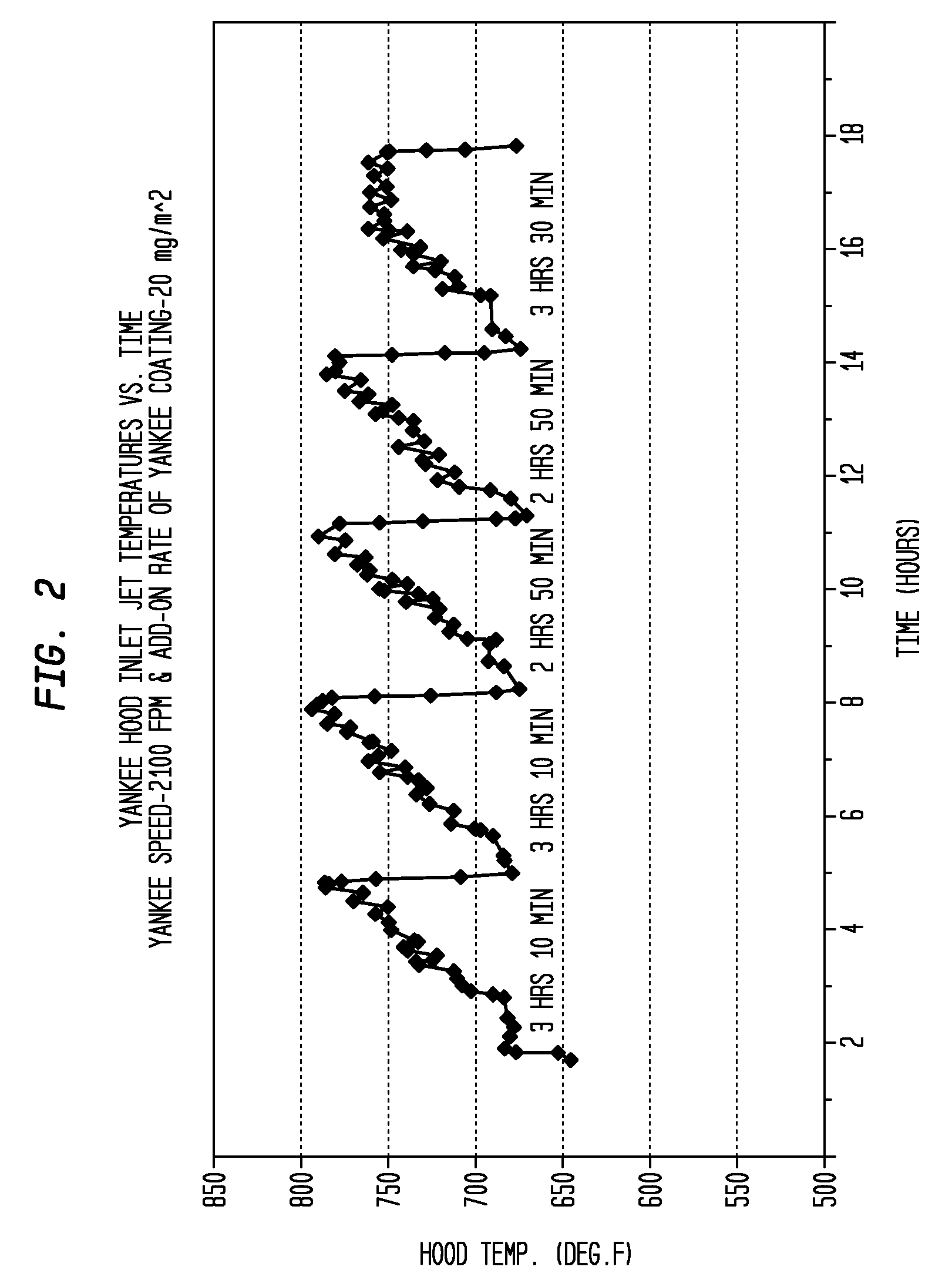

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Absorbent sanitary article with posterior guide ridge member

InactiveUS6652503B1Effective absorptionEffective maintenanceSanitary towelsBaby linensBody fluidBiomedical engineering

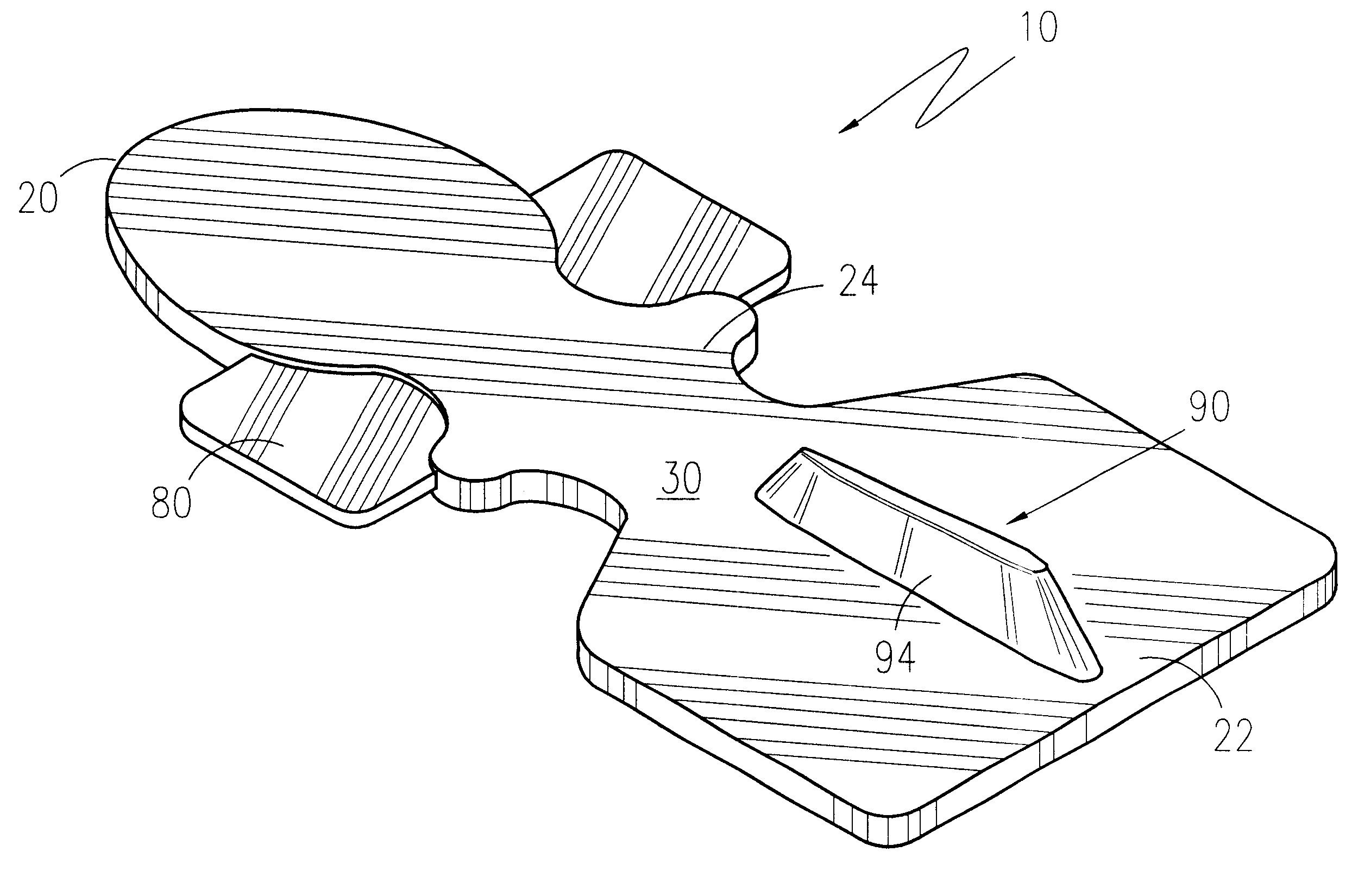

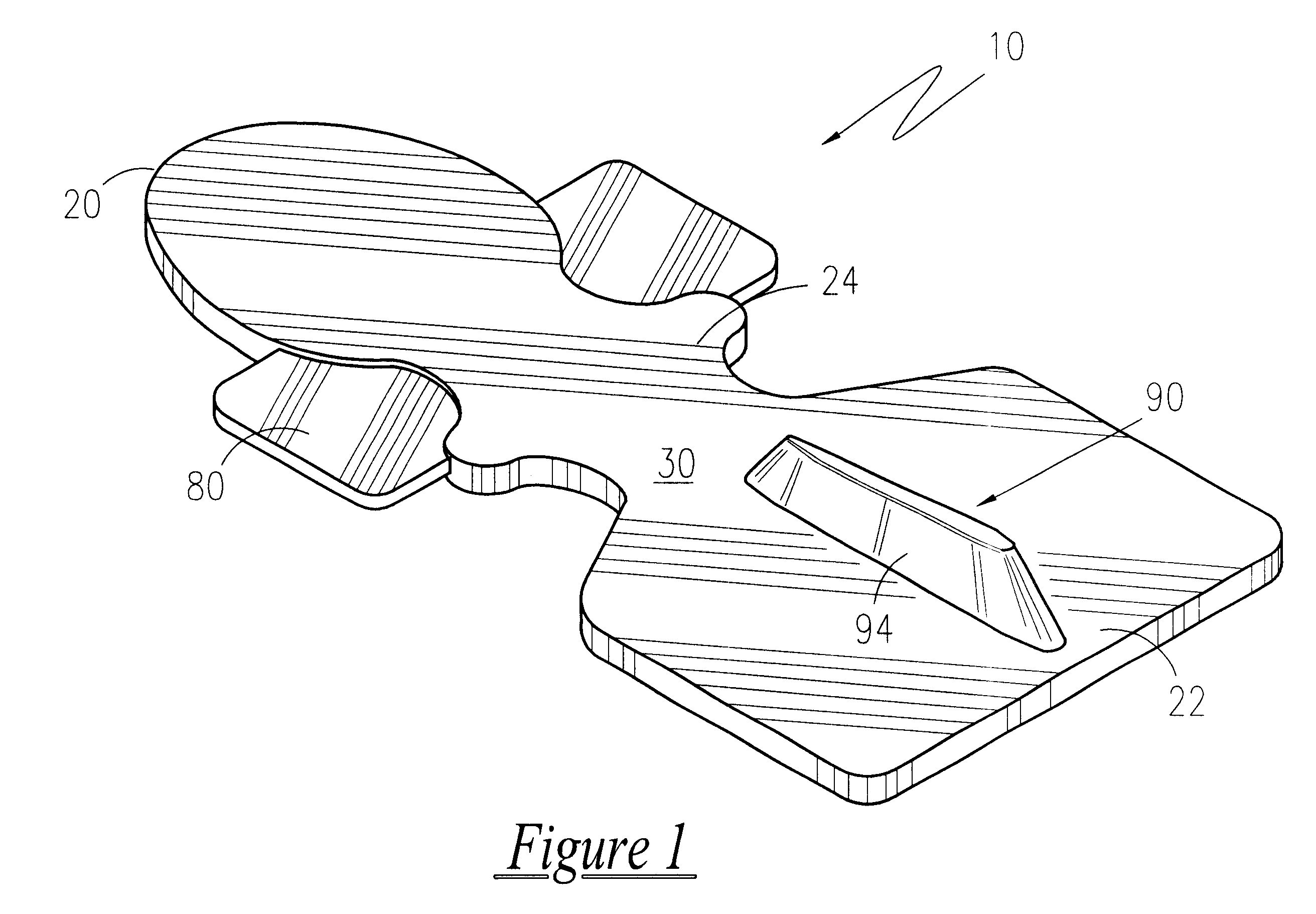

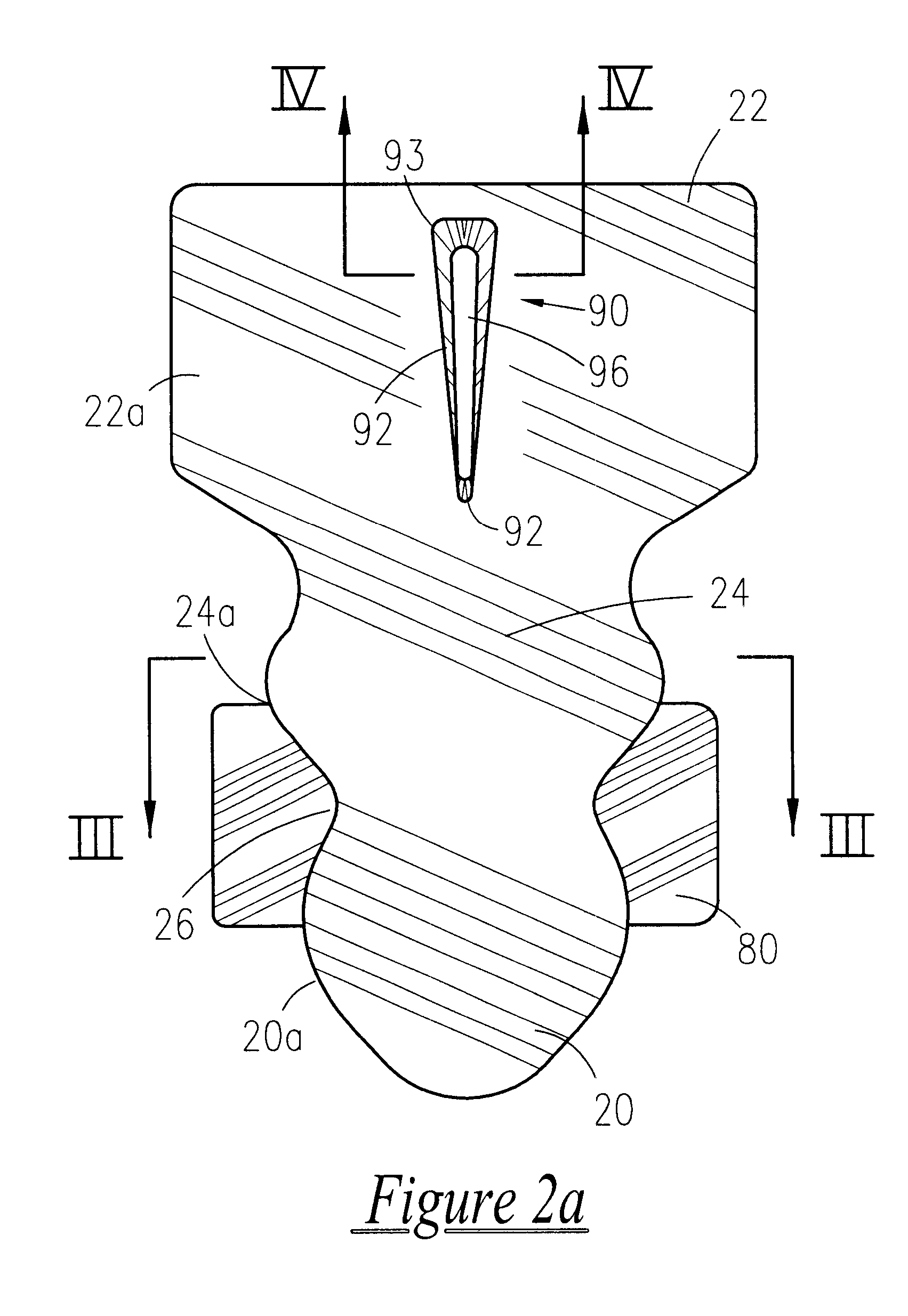

An absorbent sanitary article with posterior guide ridge member is provided for effectively absorbing and retaining bodily fluid in the septum region of a wearer. The absorbent sanitary article with posterior guide ridge member has a bodycontacting surface for providing comfort against body skin and throughwhich bodily fluids will pass. An absorbency core provides some measure of bodily fluid absorbency. A barrier layer is included in order to prevent bodily fluids retained by the absorbency core from penetrating through the present invention and soiling adjacent undergarments. An outer layer imparts a degree of comfort and softness, as well as providing a vapor permeable sheathe. An integrally formed guide ridge is provided in order to be guidably received within a septum region of the wearer to prevent soilage of undergarments and to provide the wearer with a greater sense of dryness.

Owner:BRADLEY ORA

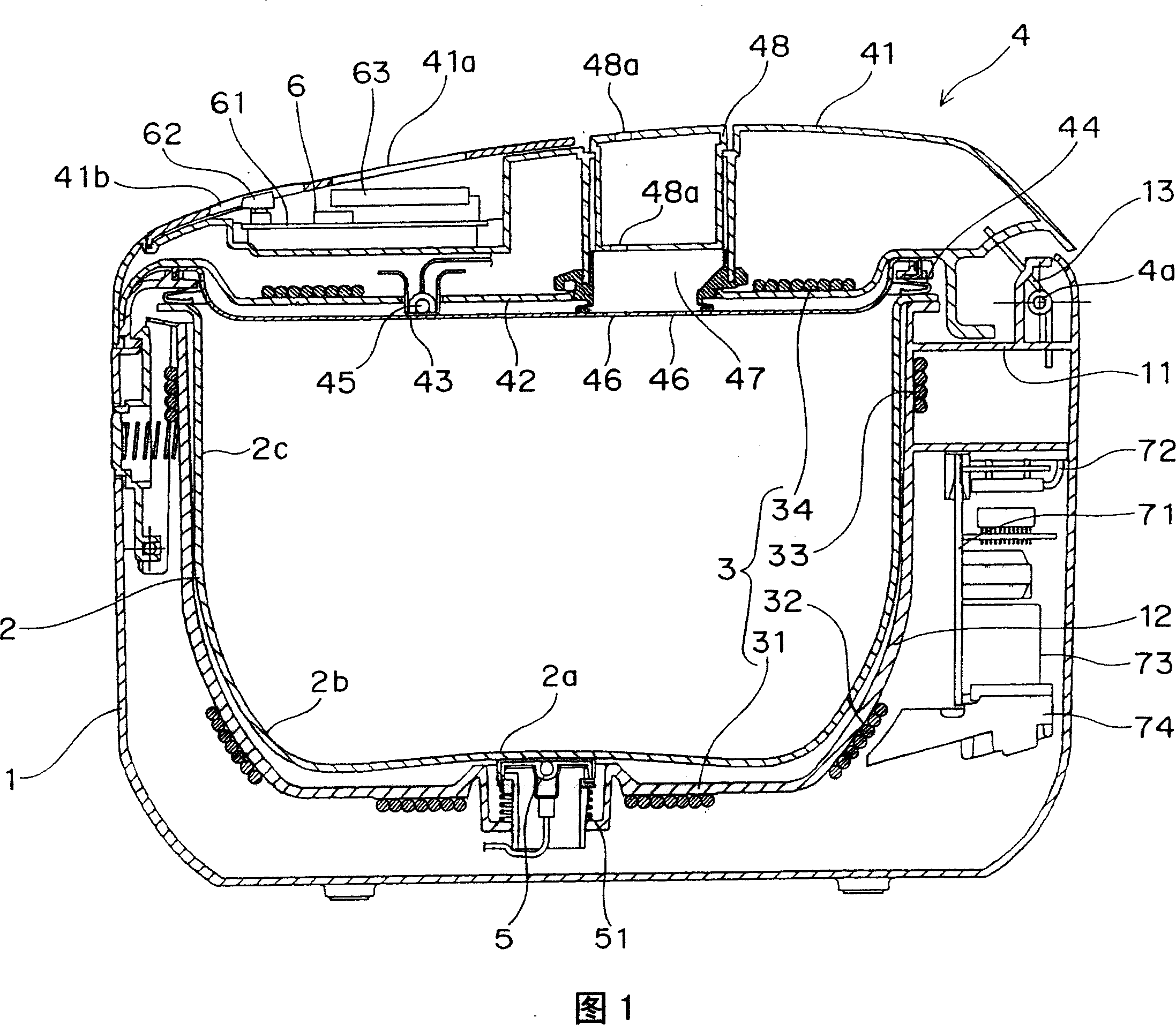

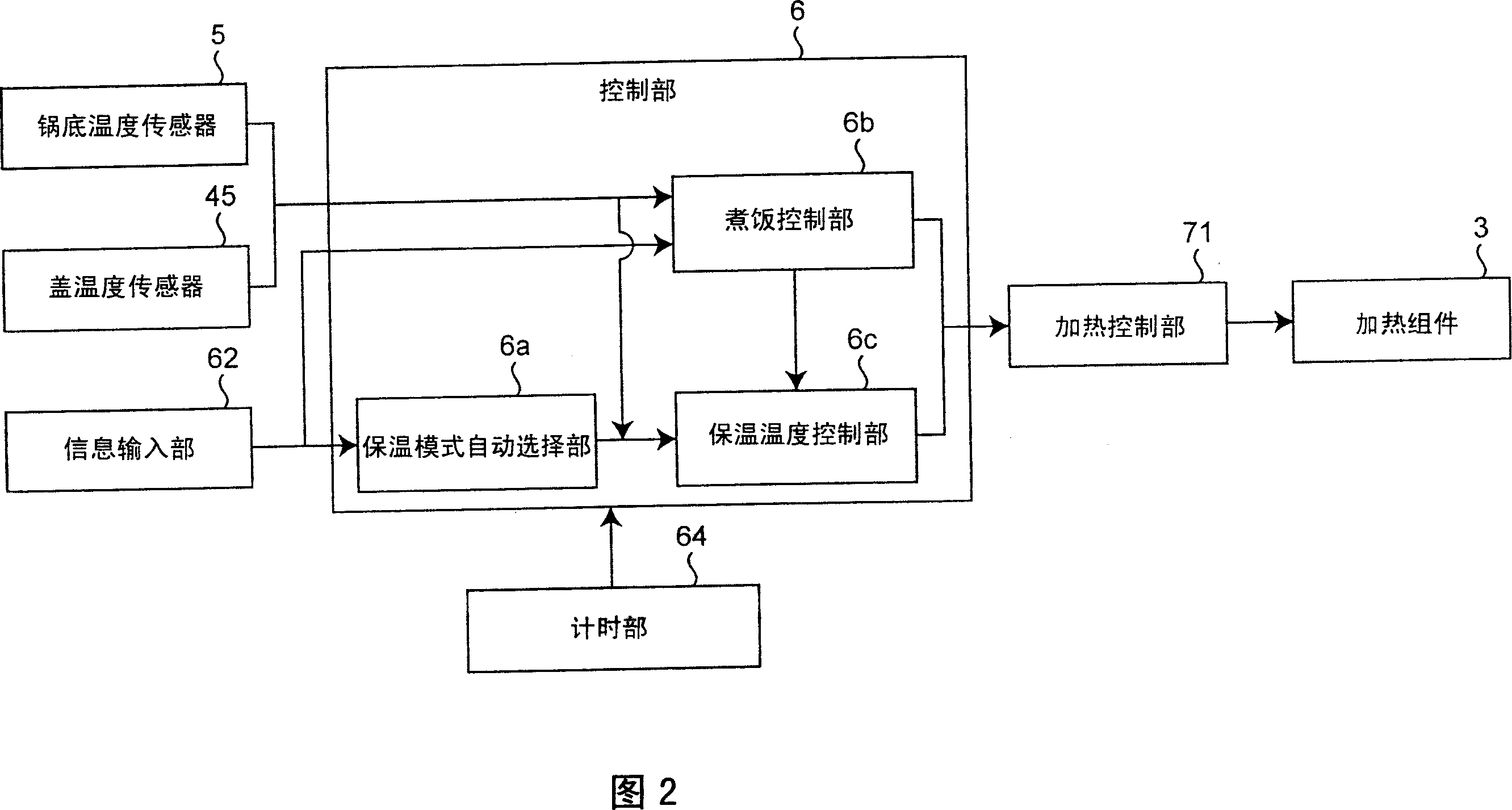

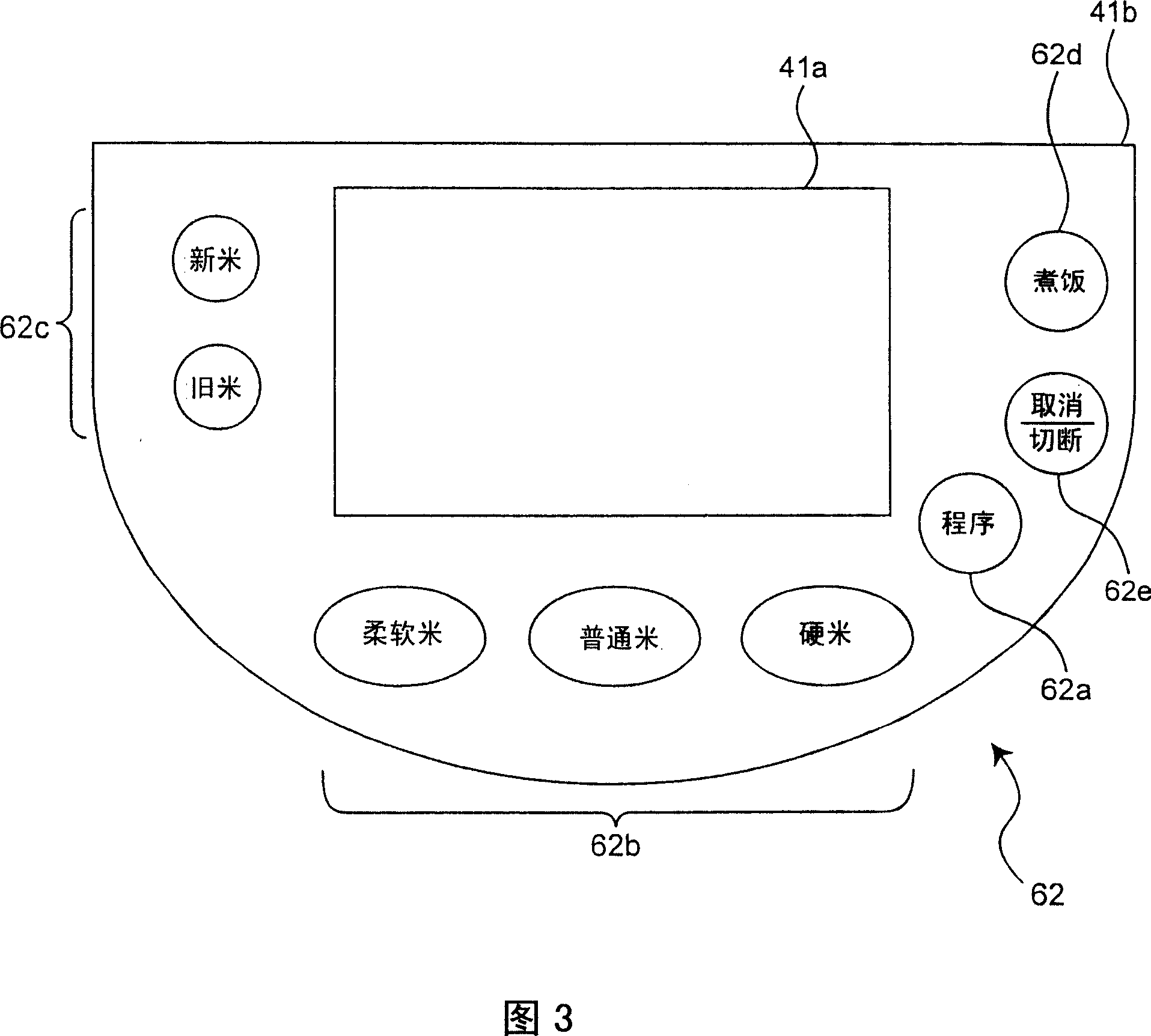

Electric cooker

ActiveCN101023842AReduce the burden onReduce rotBoiling over preventionCooking insertsTemperature controlThermal insulation

The invention provides an electric cooker capable of relieving the burden of user and more effectively depressing the decay of rice and deterioration of edible flavour induced by heat preservation. The electric cooker comprises boiler holding rice inside the electric cooker body; cover easily openned and closed for covering the peristome of upside of the cooker; heating arrangement for heating the pan bottom; cooker temperature test sensor for detecting temperature; heat control section for controlling the heating action of heating arrangement of the pan bottom; cook information input part for inputting the cook information related with cooking rice; automatic selection part of thermal insulation mode for automatically selecting the corresponding thermal insulation mode from many thermal insulation modes based on the cook information input by cook information input part before cooking; holding temperature control section for controlling temperature, based on thermal insulation mode selected by the automatic selection part of thermal insulation mode and controlling the heat control section by temperature detected by cooker temperature test sensor.

Owner:PANASONIC CORP

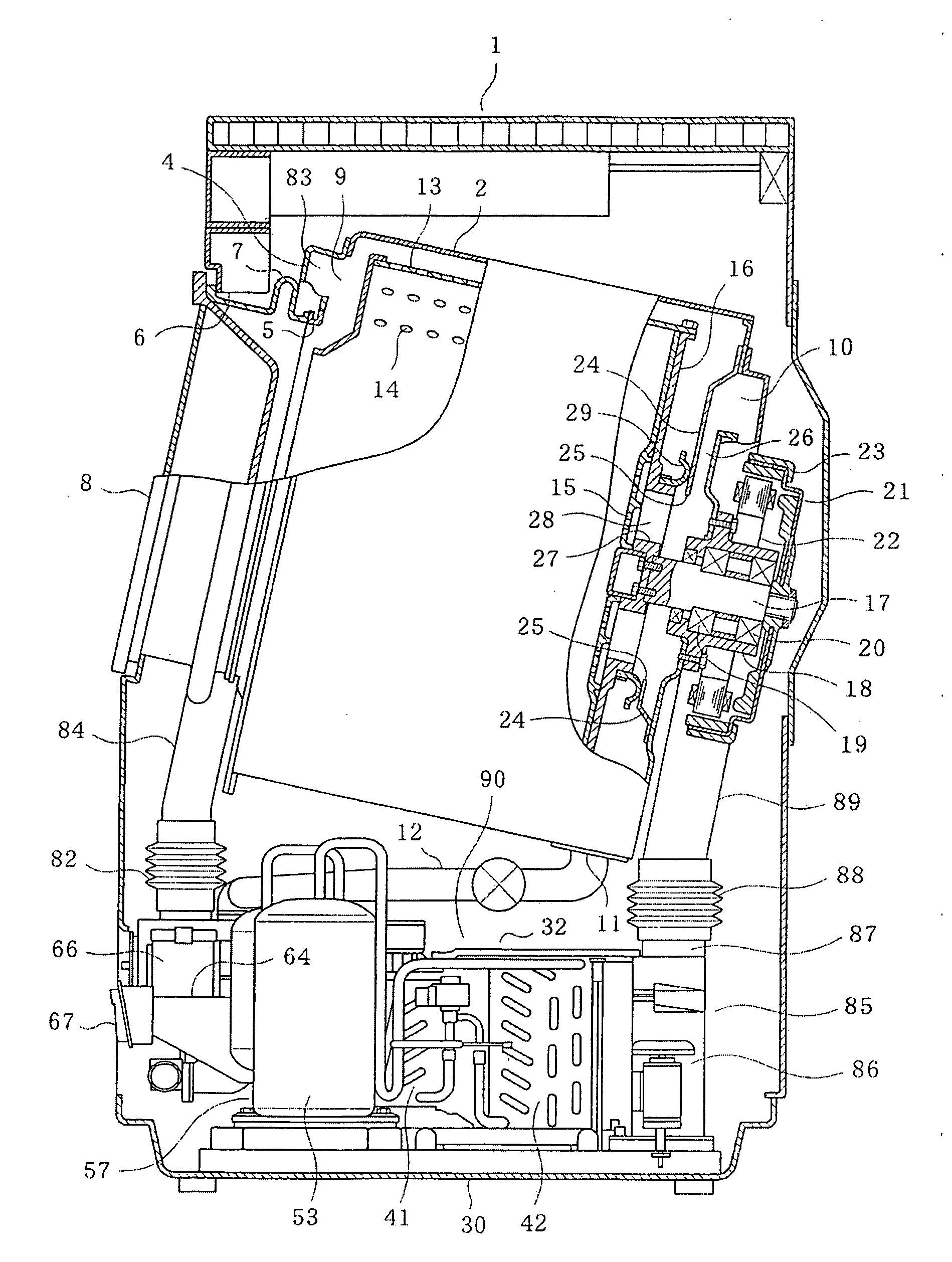

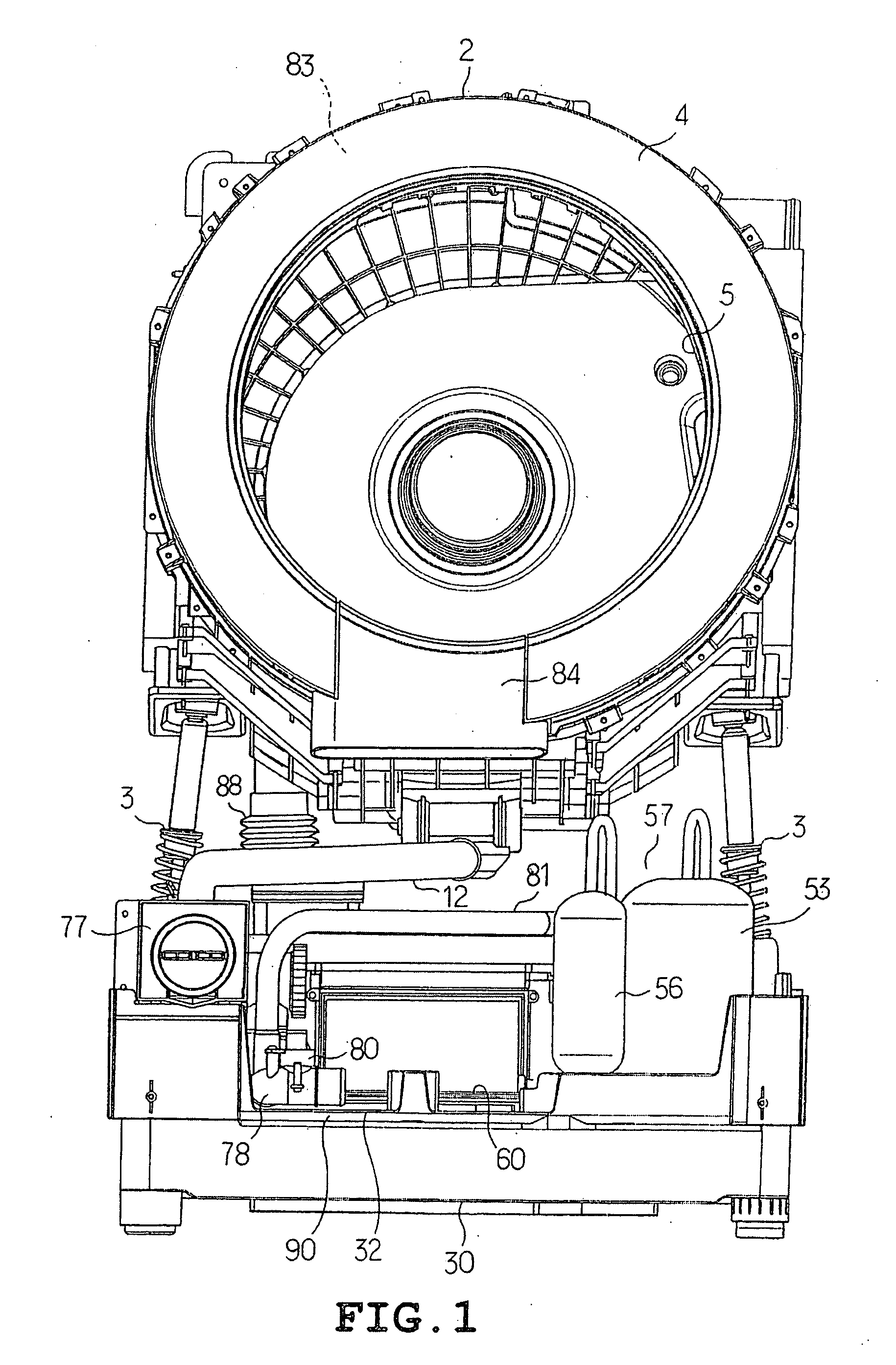

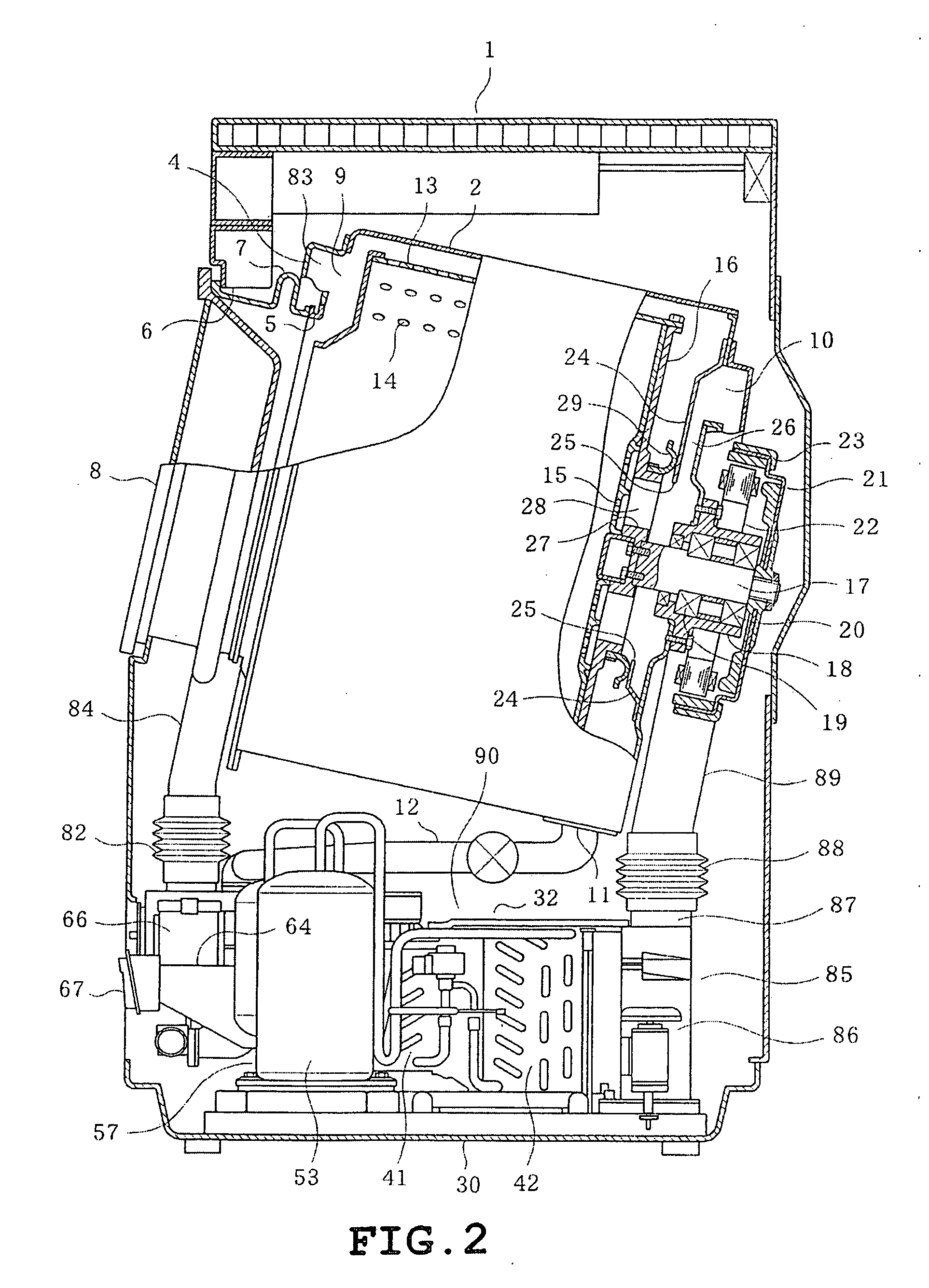

Drum-type washer/dryer

InactiveUS20100107703A1No increase in conduit resistanceIncrease volumeOther washing machinesWashing machine with receptaclesMarine engineeringHeat pump

A warm air inlet (10) and a warm air outlet (9) of a laterally provided cylindrical water tub (2) are separately arranged in the direction of the axis of the water tub (2). An airflow duct (32) connecting the warm air inlet (10) and the warm air outlet (9) is placed in the axis direction of the water tub (2), substantially directly below the water tub (2). A compressor (53) of a heat pump (57) having an evaporator (41) and a condenser (42) that are placed in the airflow duct (32) is placed at a position at a side of the airflow duct (32) so as to be orthogonal to the axis direction of the tub (2).

Owner:TOSHIBA HA PROD +2

Method of improving the aesthetic appearance of epithelia

InactiveUS20050281766A1Reducing number and depthImprove clarityCosmetic preparationsBiocidePresent methodRetinoid

An effective treatment method for improving the appearance of epithelia, such as lip epithelia and vaginal epithelia is provided. According to the present method, an effective amount of a composition containing retinoid, preferably in a cosmetically acceptable carrier, is topically applied to the vaginal or lip epithelia. The present invention also includes compositions for practicing the method.

Owner:AVON PROD INC

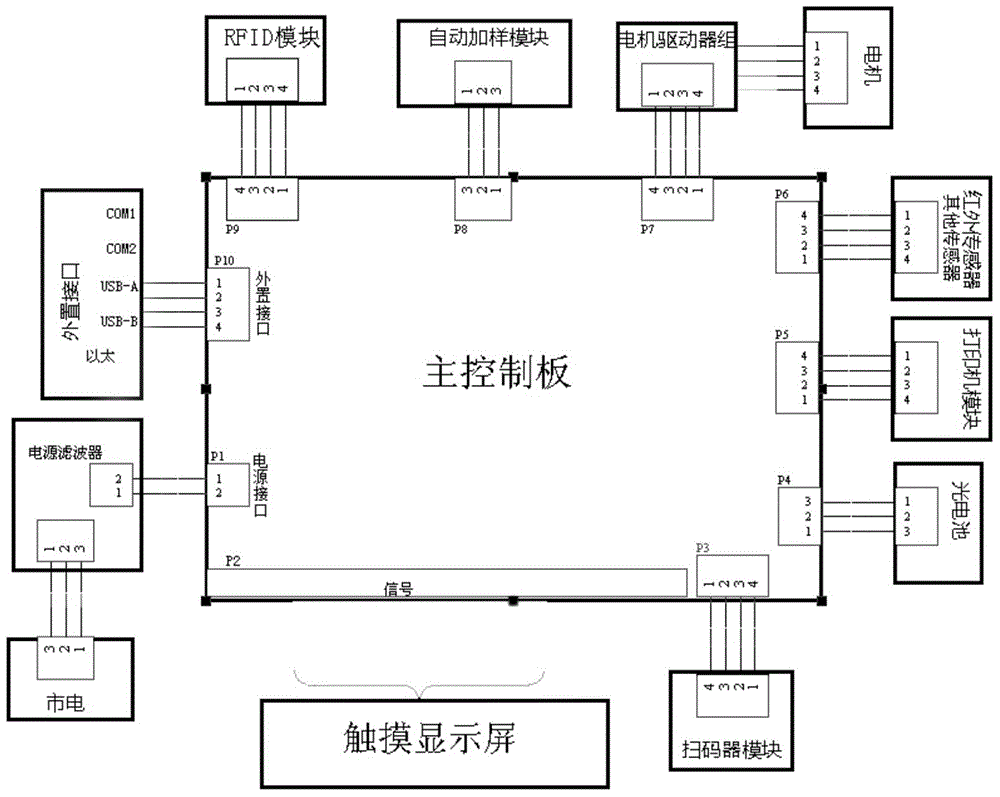

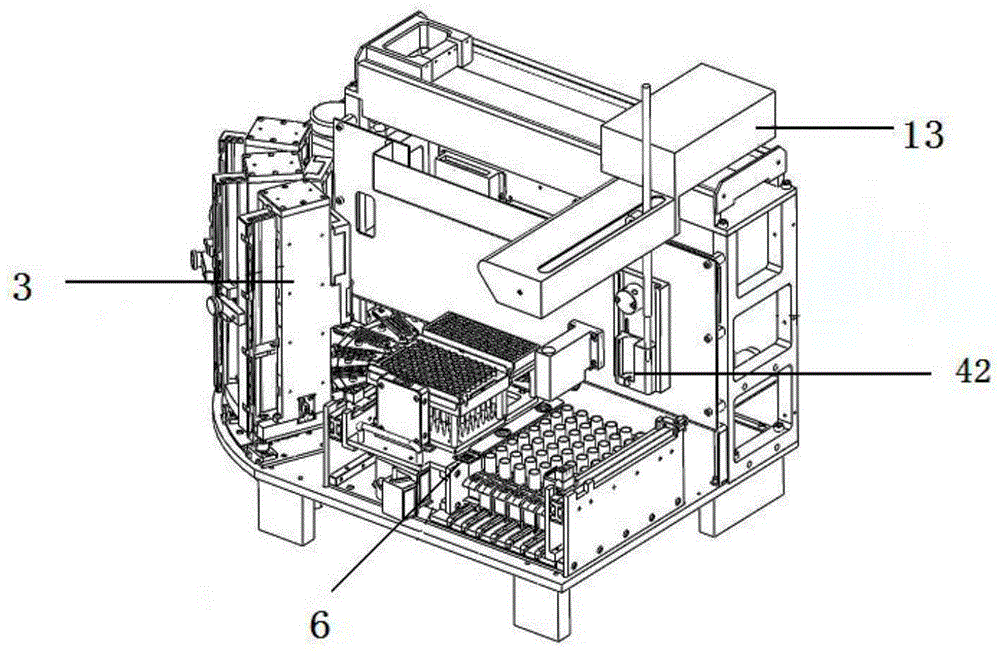

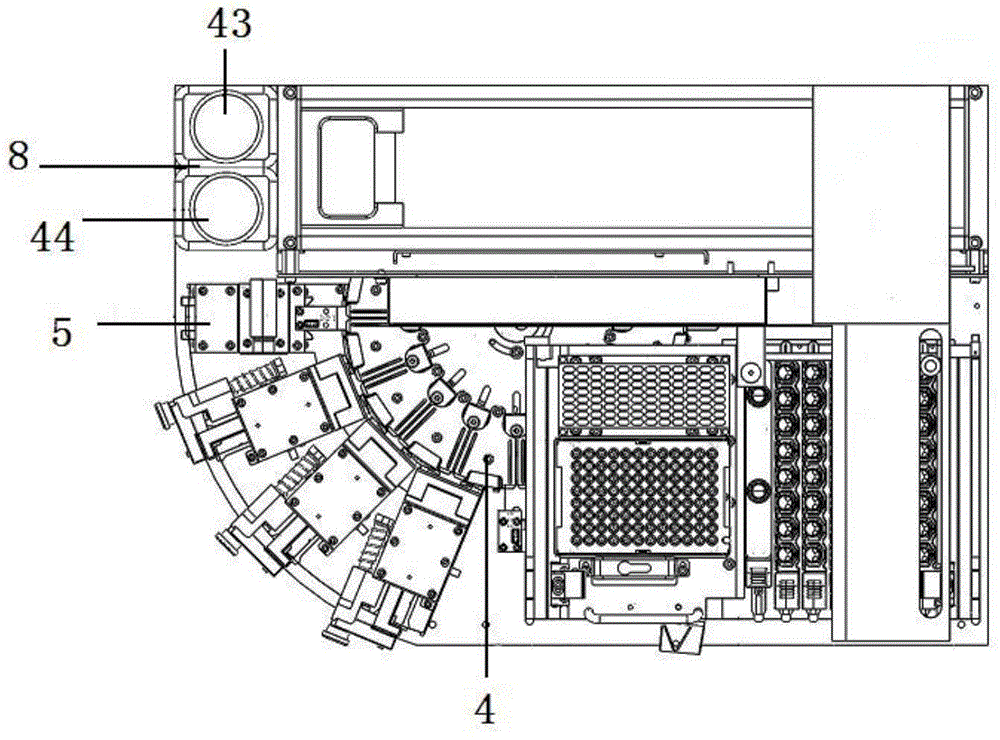

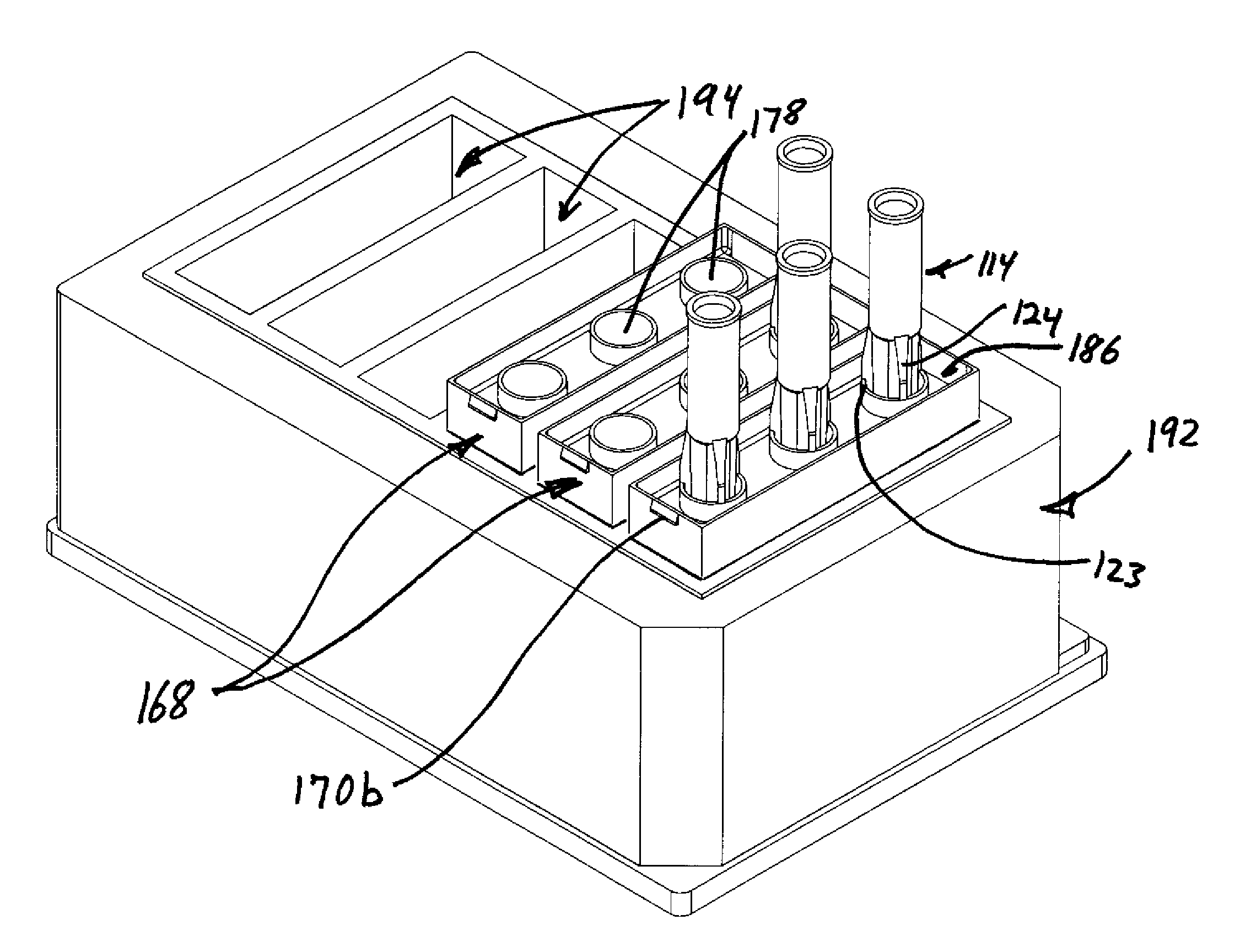

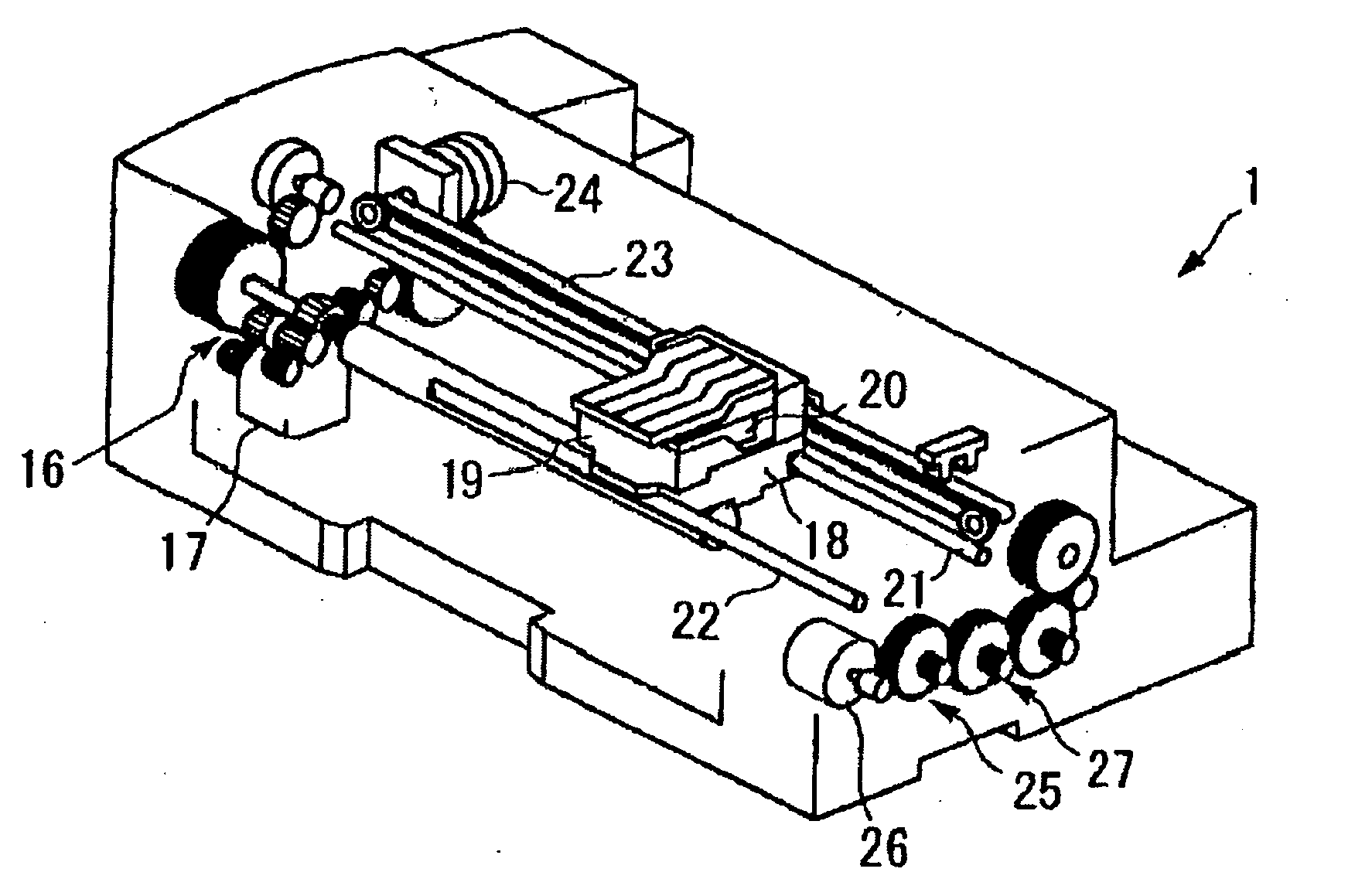

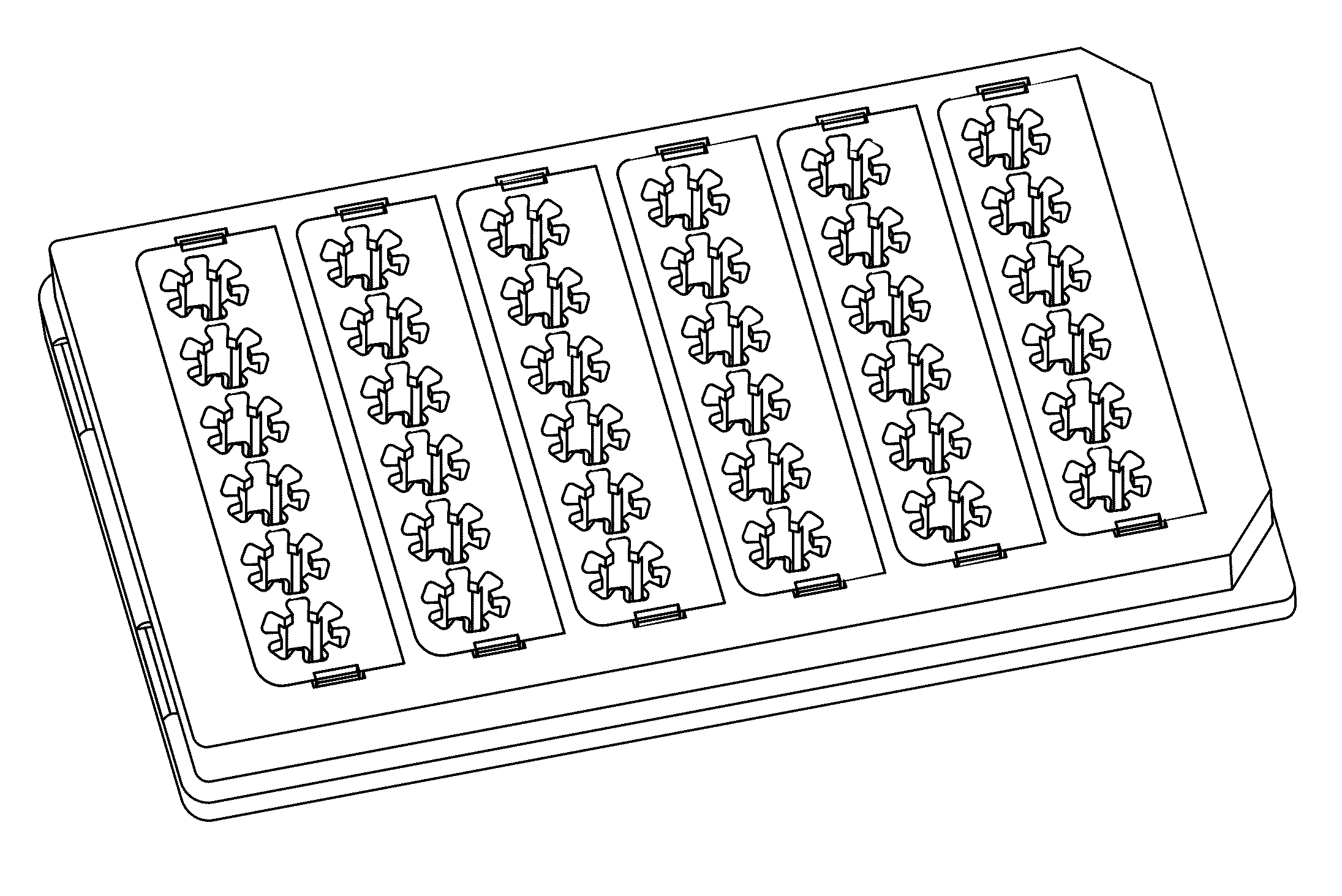

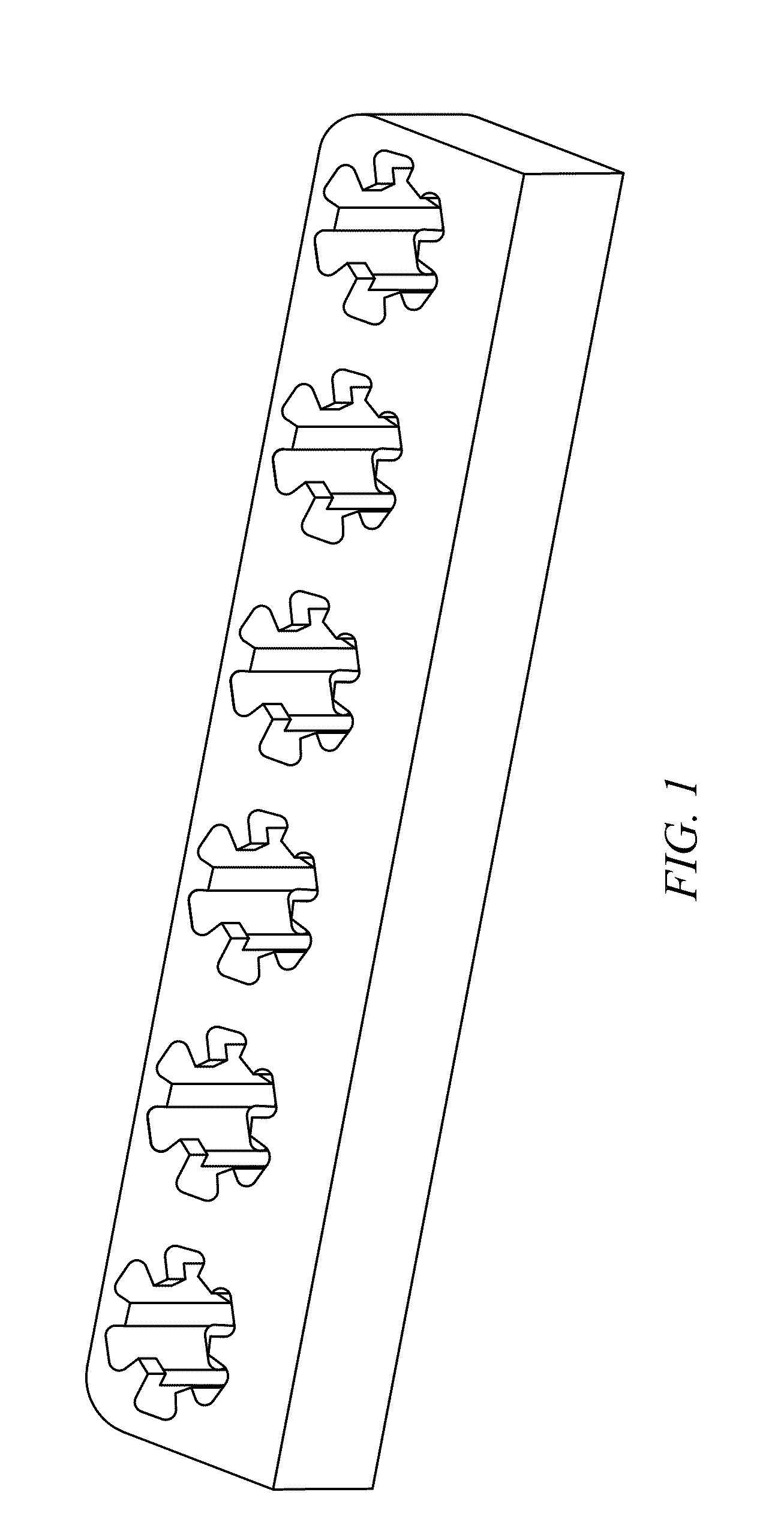

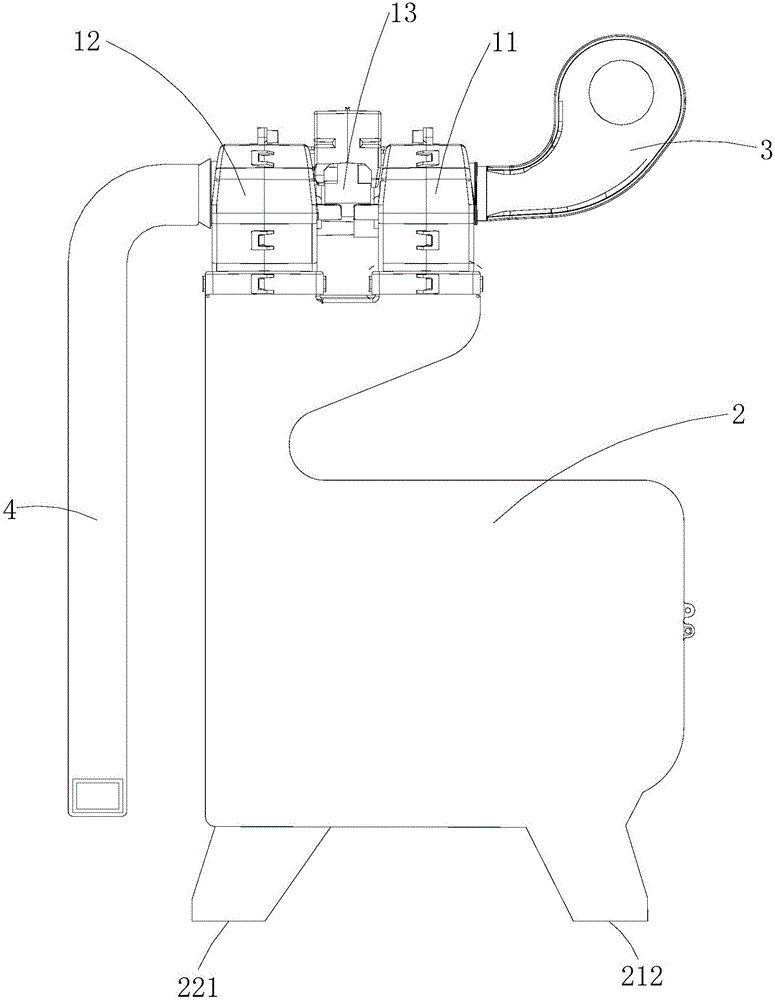

Full-automatic immuno-fluorescence quantitative analysis device and implementation method

ActiveCN104535782ASolving hard-to-automate challengesImprove repeatability and test accuracyMaterial analysisReagent stripControl system

The invention discloses a full-automatic immuno-fluorescence quantitative analysis device and an implementation method, belonging to the field of quantitative immuno-fluorescence analysis and detection. The full-automatic immuno-fluorescence quantitative analysis device comprises a supporting bottom plate, a reagentstrip storage and automatic loading module, a reactiondisc module, a detection module, a sample module, a sample adding module, a washing module and a control system, wherein the reagentstrip storage and automatic loading module, the reactiondisc module, the detection module, the sample module, the sample adding module and the washing module are arranged on the supporting bottom plate in sequence; the reagentstrip storage and automatic loading module provides a reagent strip for the reactiondisc module; the sample adding module is used for adding samples in the sample module into the reactiondisc module to carry out reaction, and after reaction is finished, the samples enter the detection module to be detected. The full-automatic immuno-fluorescence quantitative analysis device and the implementation method disclosed by the invention have the advantages that the difficulty that automation is hard to implement for an in-vitro diagnosis product is solved, the artificial error is reduced, the testing accuracy is improved and the detection efficiency is improved.

Owner:GETEIN BIOTECH

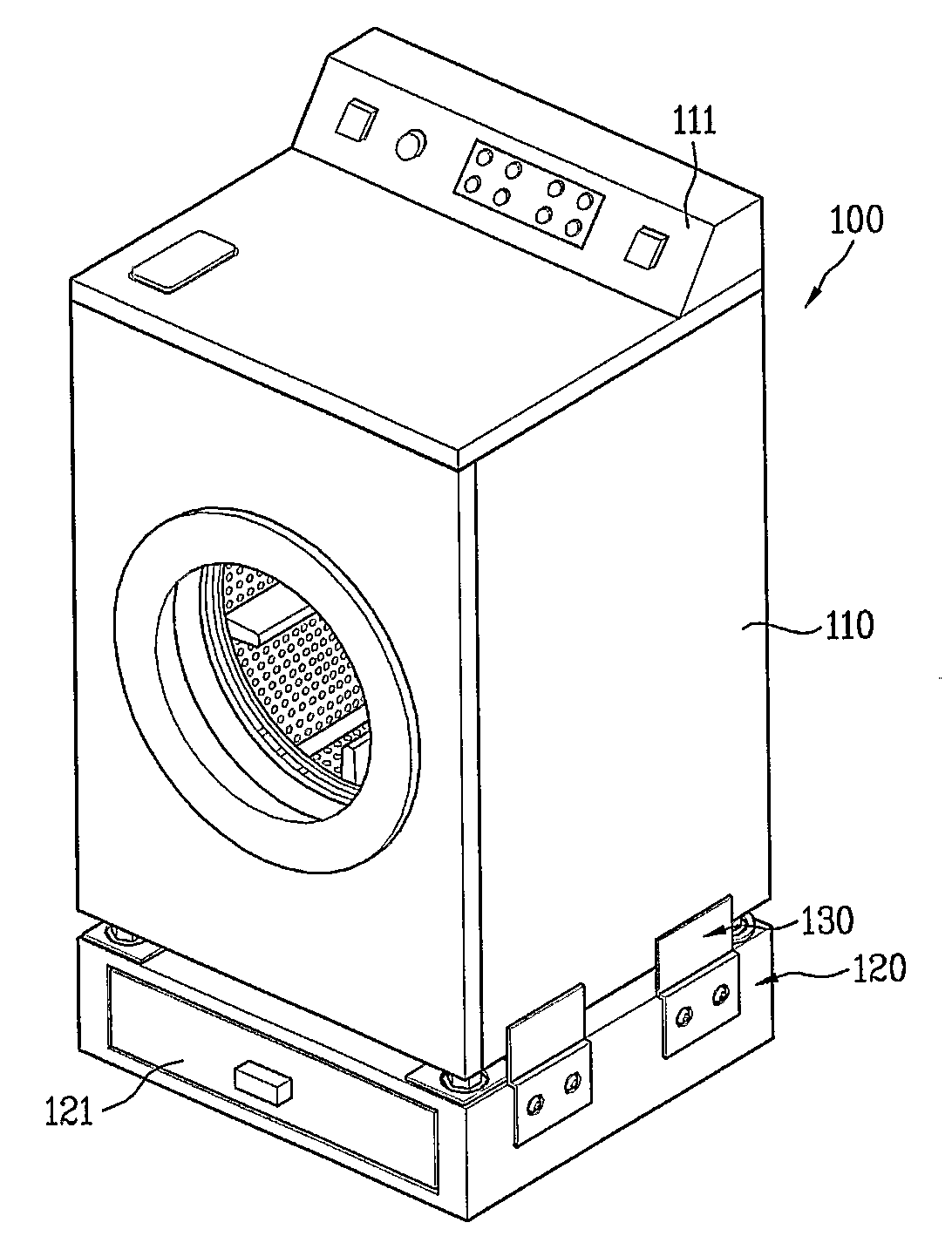

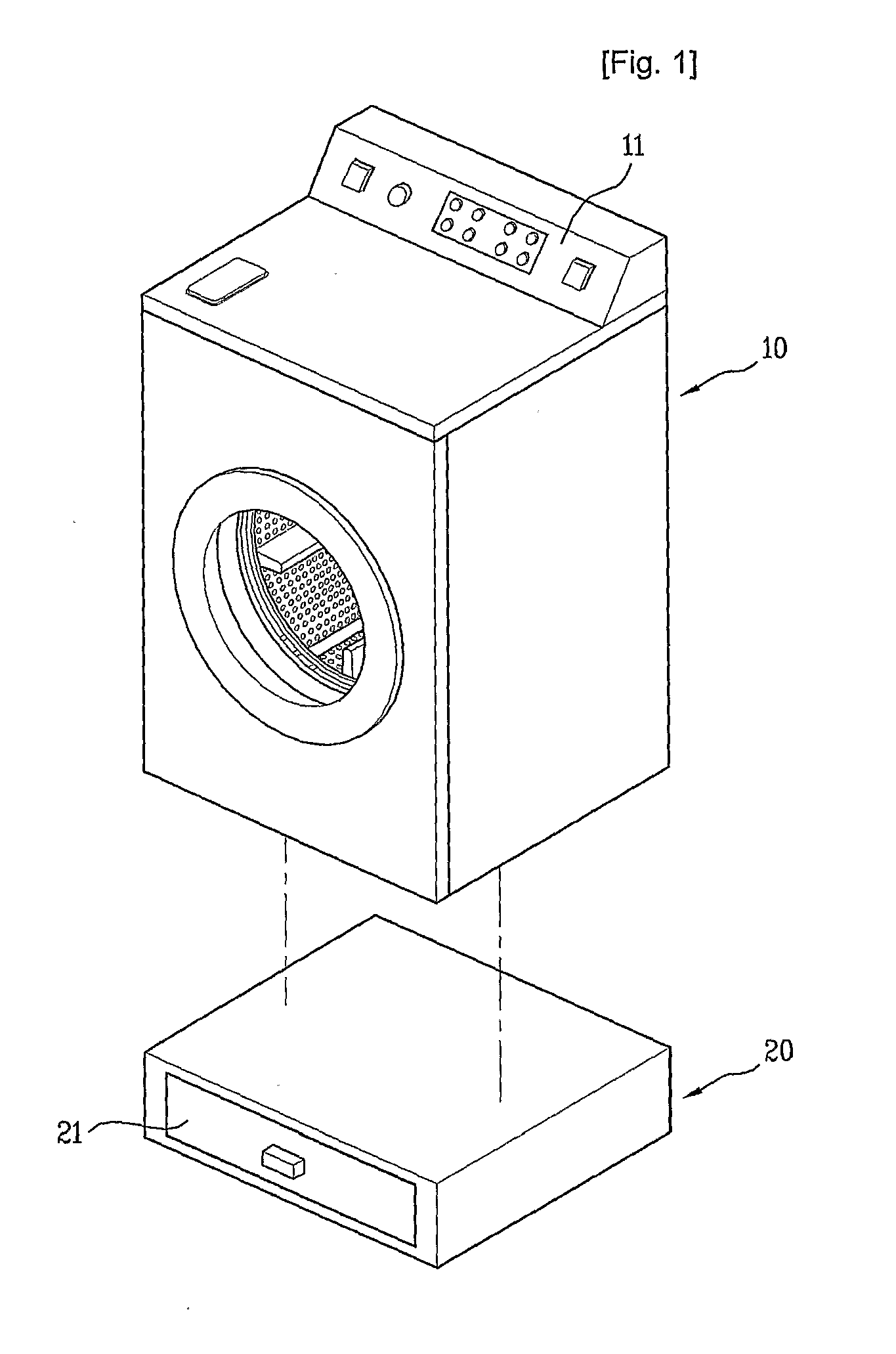

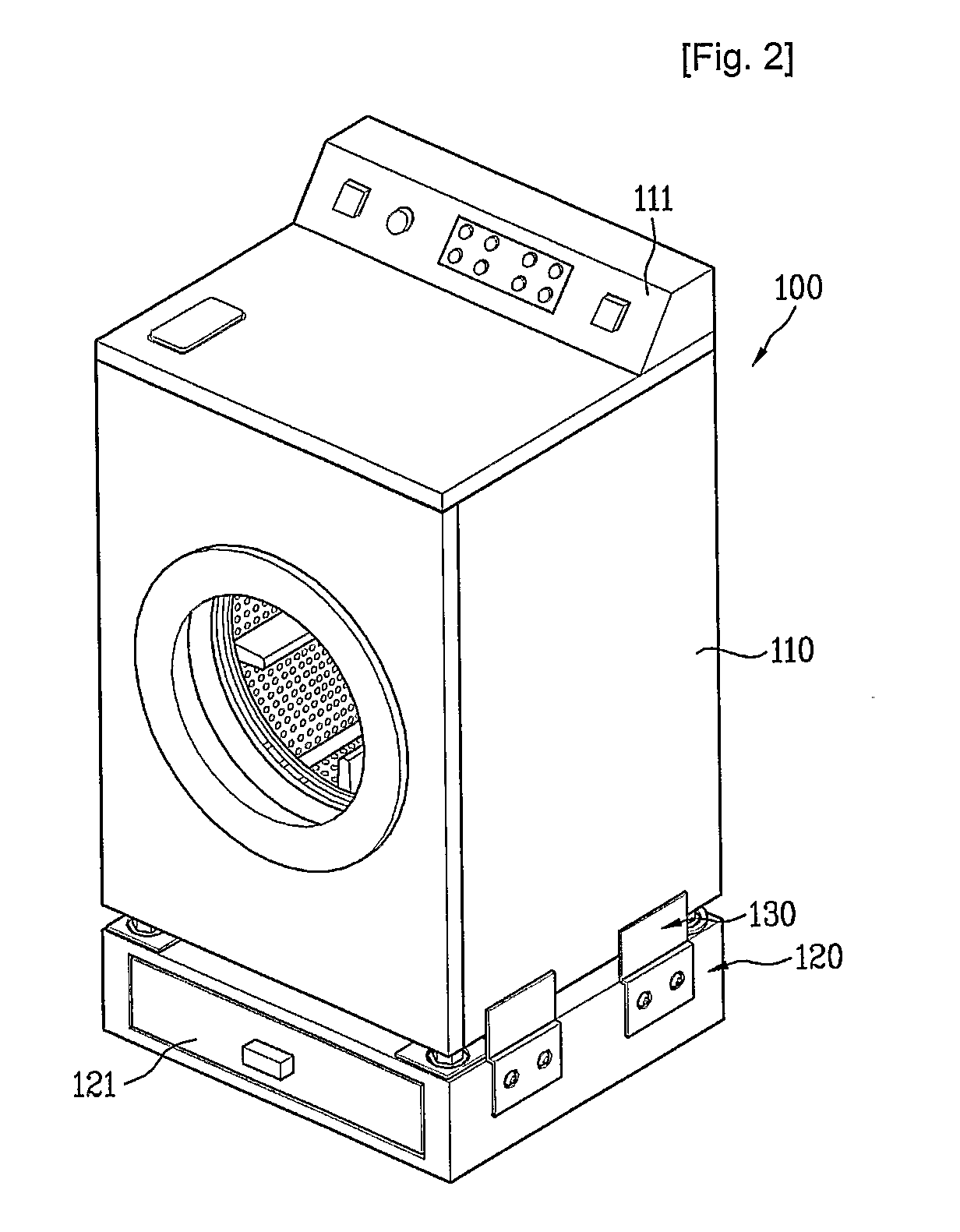

Multiple laundry treating machine

ActiveUS20100011609A1Easy to useSave energyOther washing machinesControl devices for washing apparatusLaundryBiomedical engineering

A multiple laundry treating machine, in which an auxiliary laundry treating device (120) is coupled to a general laundry treating device (110), is disclosed. The multiple laundry treating machine includes a main laundry treating device (110) for washing or drying laundry contained in an interior of the main laundry treating device (110), an auxiliary laundry treating device (120) arranged at one side of the main laundry treating device (110), the auxiliary laundry treating device (120) having a volume and a height respectively smaller than a volume and a height of the main laundry treating device (110), and having a laundry container (121) formed in an interior of the auxiliary laundry treating device (120), and a connecting unit (300) for connecting the main and auxiliary laundry treating devices (110, 120), to enable communication or control operations between the main and auxiliary laundry treating devices (110, 120). In accordance with the multiple laundry treating machine, it is possible to achieve a convenience in use and to save energy because a small amount of clothes or shoes can be dried by the auxiliary laundry treating device (120), without driving a laundry treating device (120) having a relatively-large capacity.

Owner:LG ELECTRONICS INC

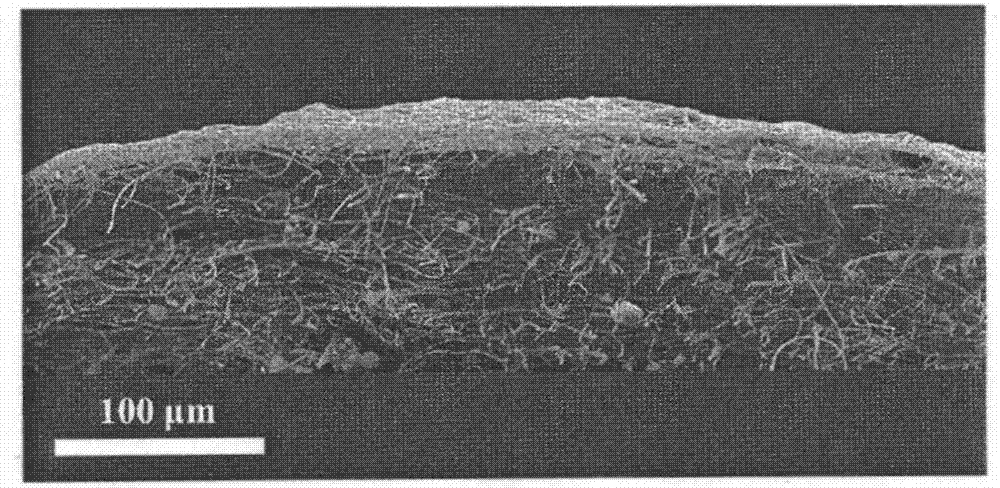

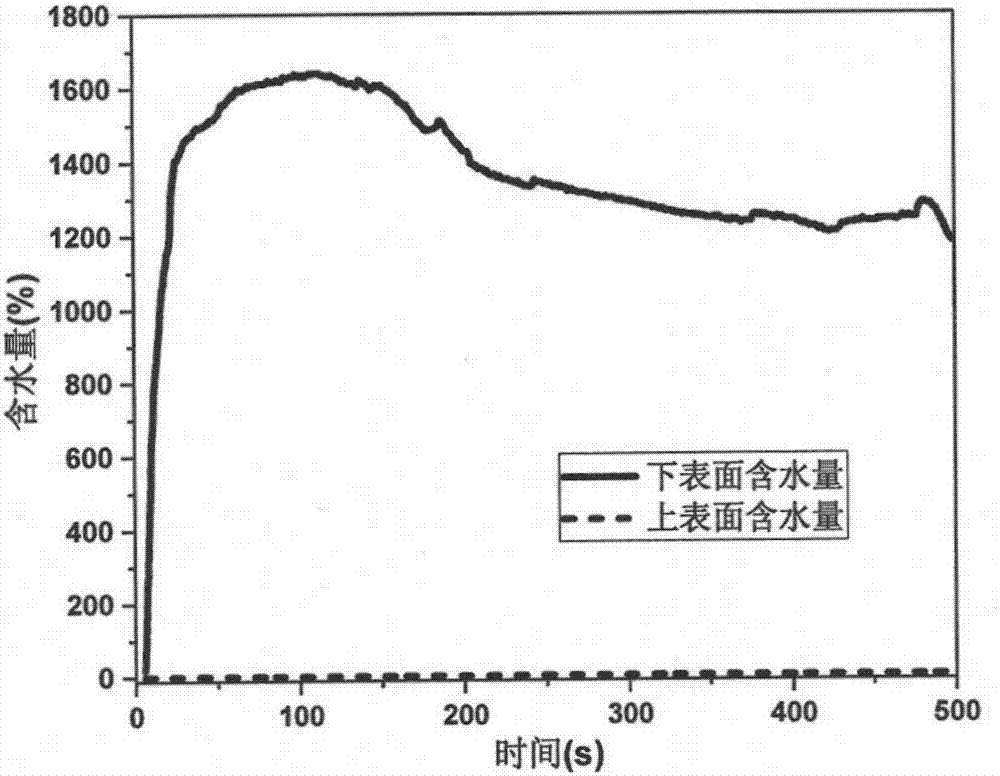

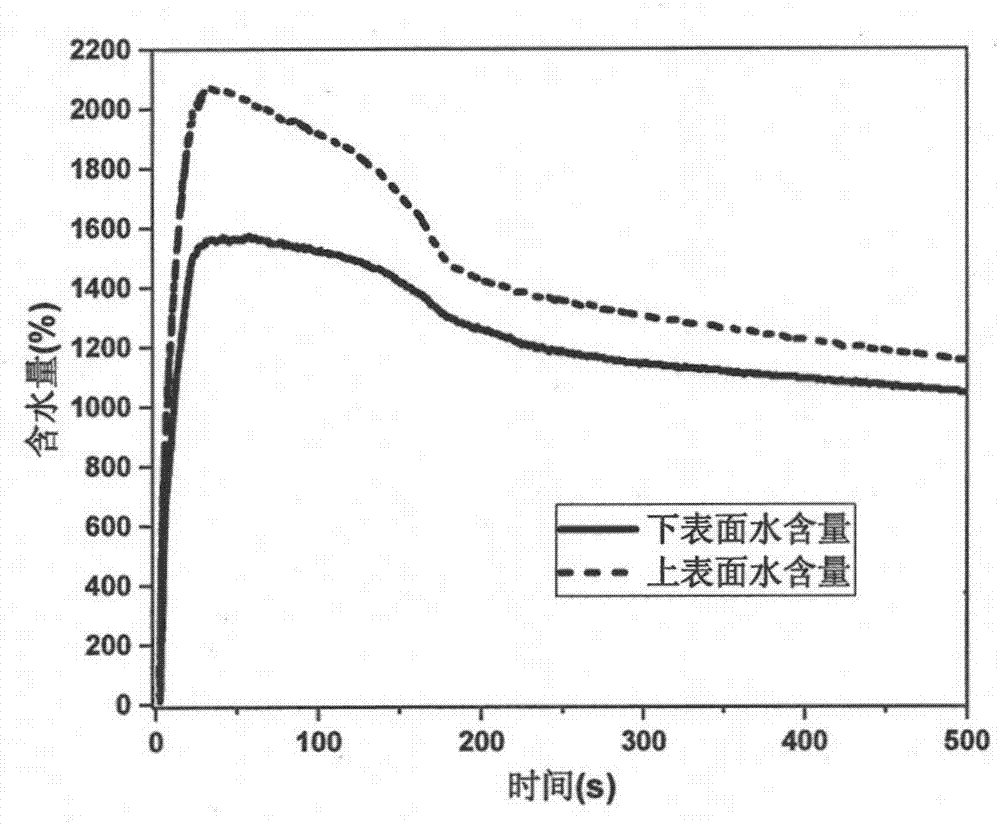

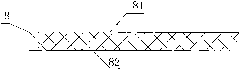

Preparation method of one-way wet conduction nano-fiber multilayer composite membrane with wettability gradient

InactiveCN107059251AExcellent unidirectional moisture transfer performanceWaterproofNon-woven fabricsFiberHydrophobic polymer

The invention discloses a preparation method of a one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient. The method comprises the following steps that hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, a spinning solution A1 is obtained, and a hydrophilic nano-fiber membrane is deposited on a receiving base material through an electrostatic spinning method; hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through the ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, and a spinning solution A2 is obtained; a hydrophobic polymer is dissolved in solvent, and a spinning solution B1 is obtained; the two spinning solutions are deposited on the hydrophilic nano-fiber membrane to form at least one diversion layer through the electrostatic spinning method; a hydrophobic polymer is dissolved in solvent, a spinning solution B2 is obtained, a hydrophobic nano-fiber membrane is deposited on the diversion layers through the electrostatic spinning method, and the one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient is obtained.

Owner:DONGHUA UNIV

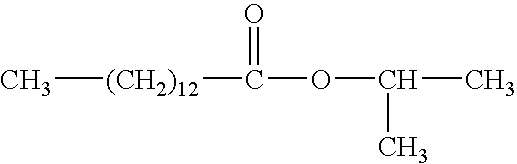

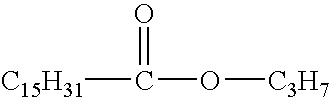

Pesticidal compositions containing isopropyl-containing compounds as pesticidally active ingredients

InactiveUS20070190094A1Raise the ratioReduce greasy feelingBiocideDead animal preservationCompound (substance)Active ingredient

Pesticidal compositions containing a pesticidally acceptable carrier, at least one isopropyl-containing compound as a pesticidally active ingredient, and methods for using same, are disclosed.

Owner:GIBRALTAR BUSINESS CAPITAL LLC

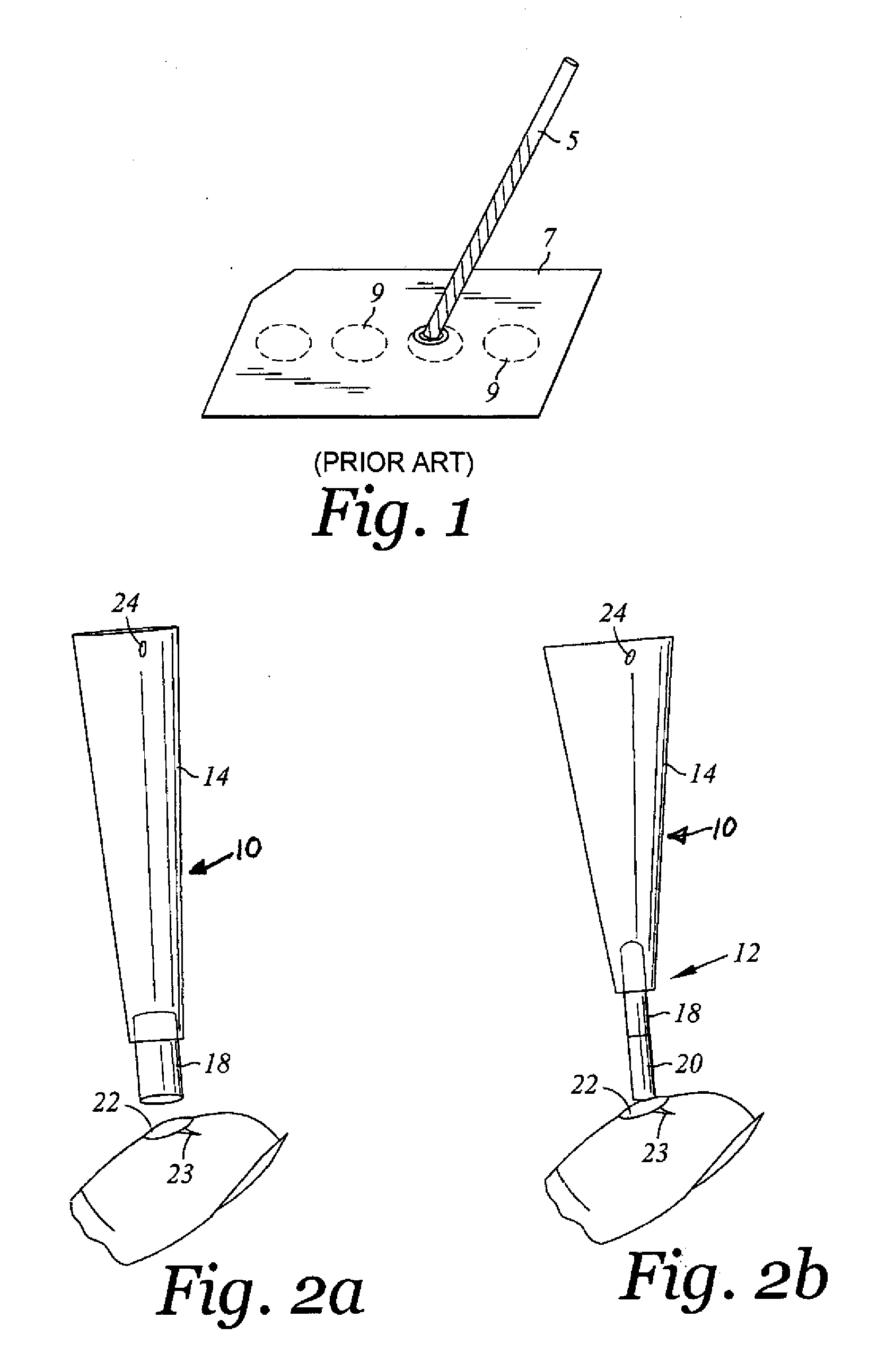

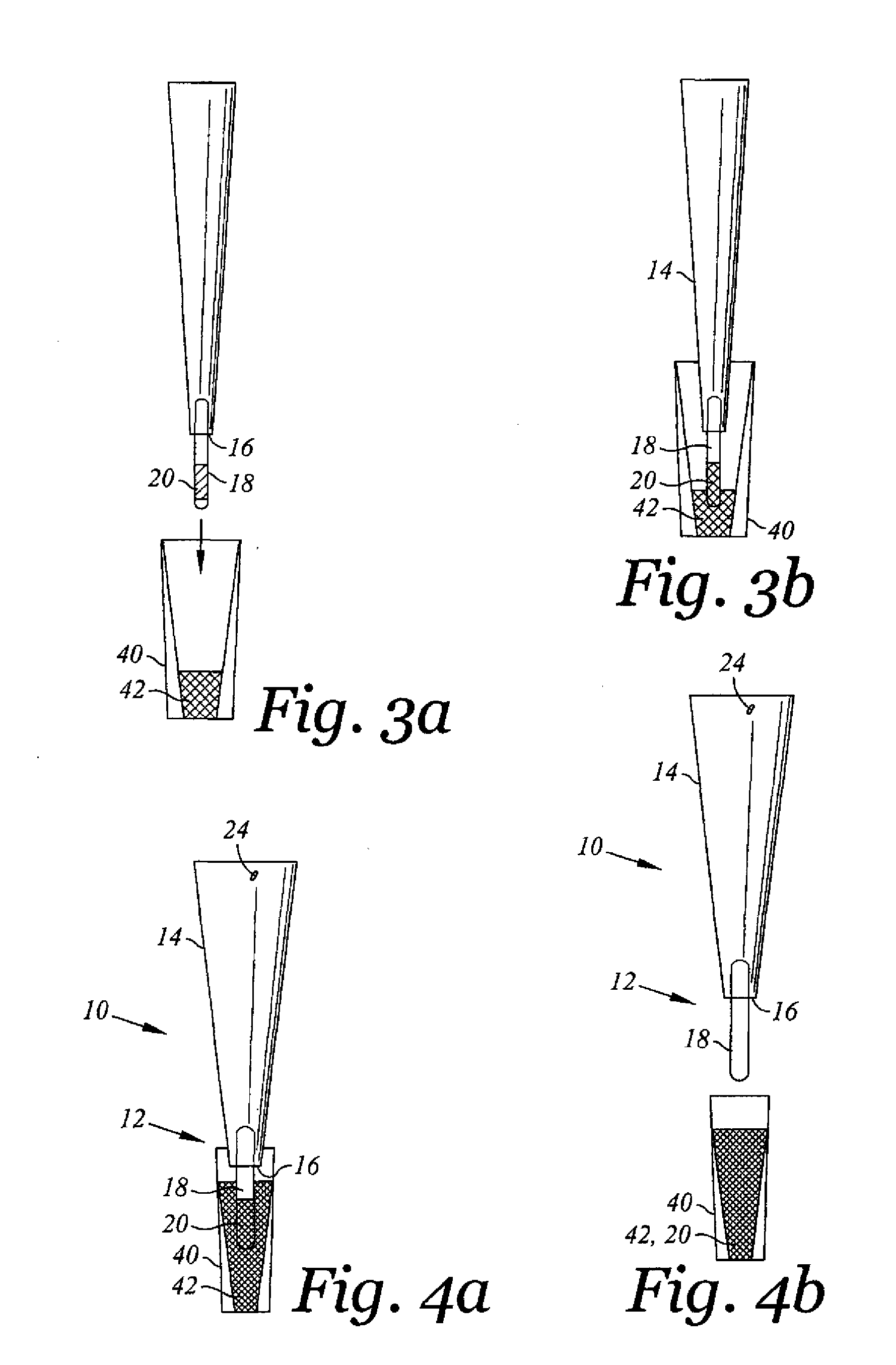

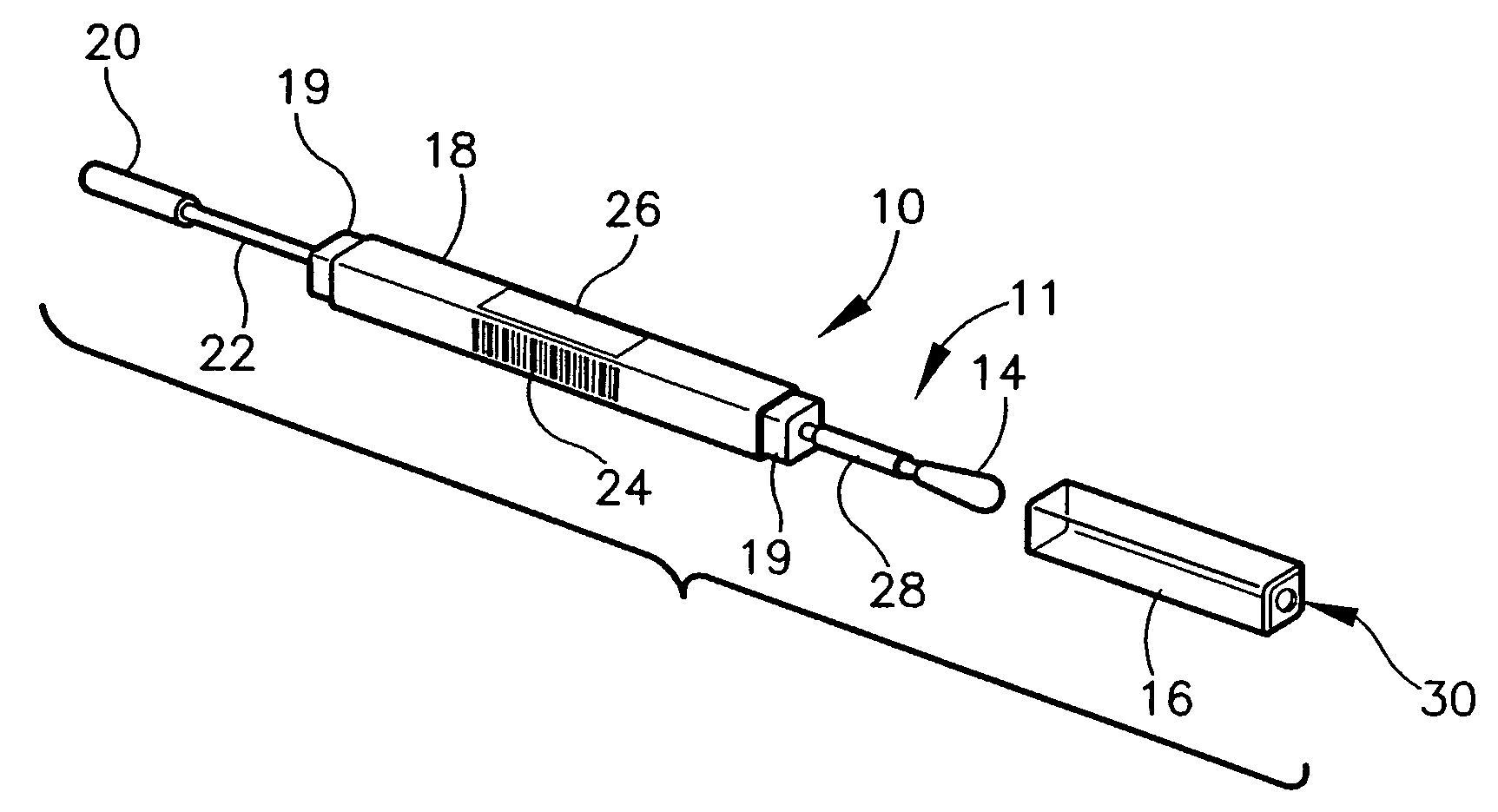

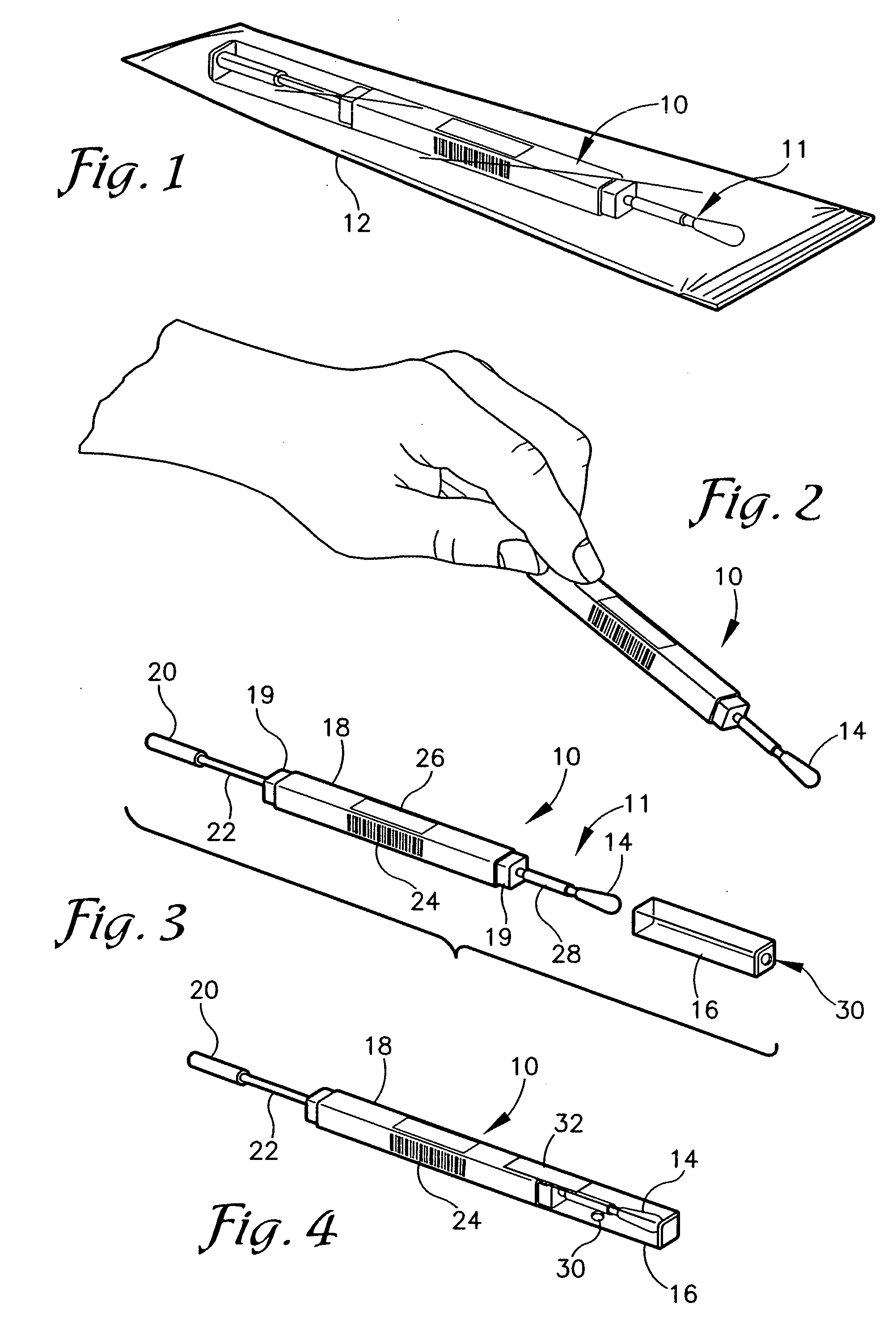

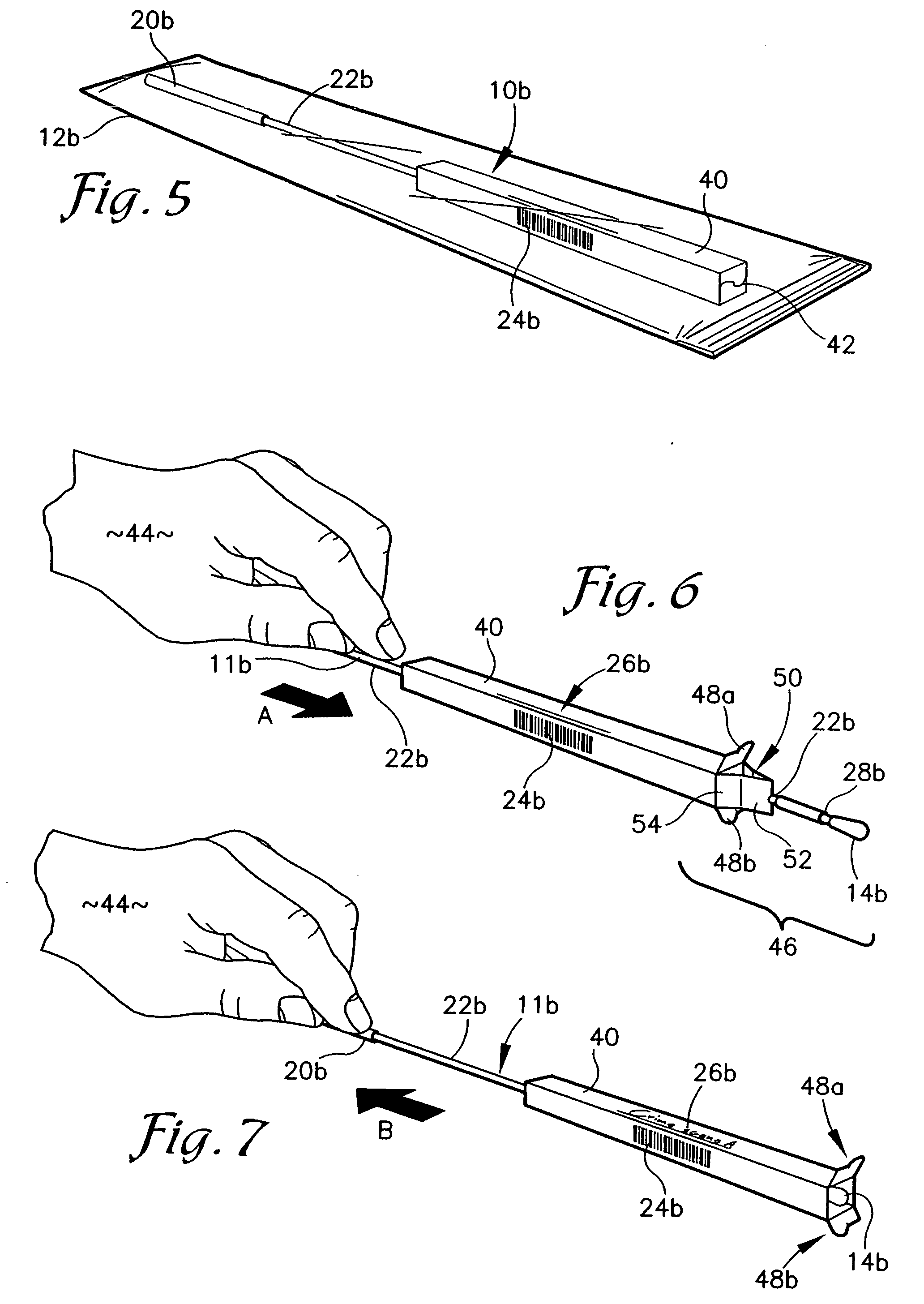

Method and apparatus for acquiring blood for testing

InactiveUS20130116597A1Easily manipulateKeep dryAnalysis material containersSamplingBiomedical engineeringBlood sampling

A blood sampling device is provided having holder with a manipulating end and an absorbent probe on the opposing end. The probe is of hydrophilic polymer sized to directly absorb a predetermined volume of up to about 30 microliters of blood. Ribs on the holder position the probe within a compartment of a container to prevent contact with the container. The ribs also position the probe within extraction wells.

Owner:NEOTERYX

Particulate water absorbing agent with water-absorbing resin as main component

InactiveUS20070066167A1Satisfactory performancePractical to useSynthetic resin layered productsAbsorbent padsParticulatesSaline water

The present invention provides a water absorbing agent which maintains excellent water absorbing properties for a long time, even when urine composition of human urine varies depending. A particulate water absorbing agent comprising a water-absorbing resin obtained by crosslinking polymerization of an unsaturated monomer, which exhibits Centrifuge retention capacity in a physiological saline solution of not lower than 32 g / g, mass median particle size (D50) of 200 to 400 μm, ratio of particles with diameter of smaller than 150 μm of 0 to 2% by weight, and increased extractables by deterioration of 0 to 15% by weight and extractables for one hour in deterioration test liquid of 0.1 to 30% by weight.

Owner:NIPPON SHOKUBAI CO LTD

Silicon dioxide which bears partially or fully silylated polysilicic acid chains on its surface

InactiveUS6183867B1Improve rheologyImprove mechanical propertiesPigmenting treatmentSilicaSilanolSilylation

The invention relates to silicon dioxide which bears partially or fully silylated polysilicic acid chains on its surface, wherein the sum of silanol groups of the silicon dioxide surface (SiOH) and grafted-on silylating agent radicals (SiRa) is greater than the number of silanol groups on the surface of untreated silicon dioxide, where a can be 1, 2 or 3 and R can be identical or different and are each a substituted or unsubstituted hydrocarbon radical.

Owner:WACKER CHEM GMBH

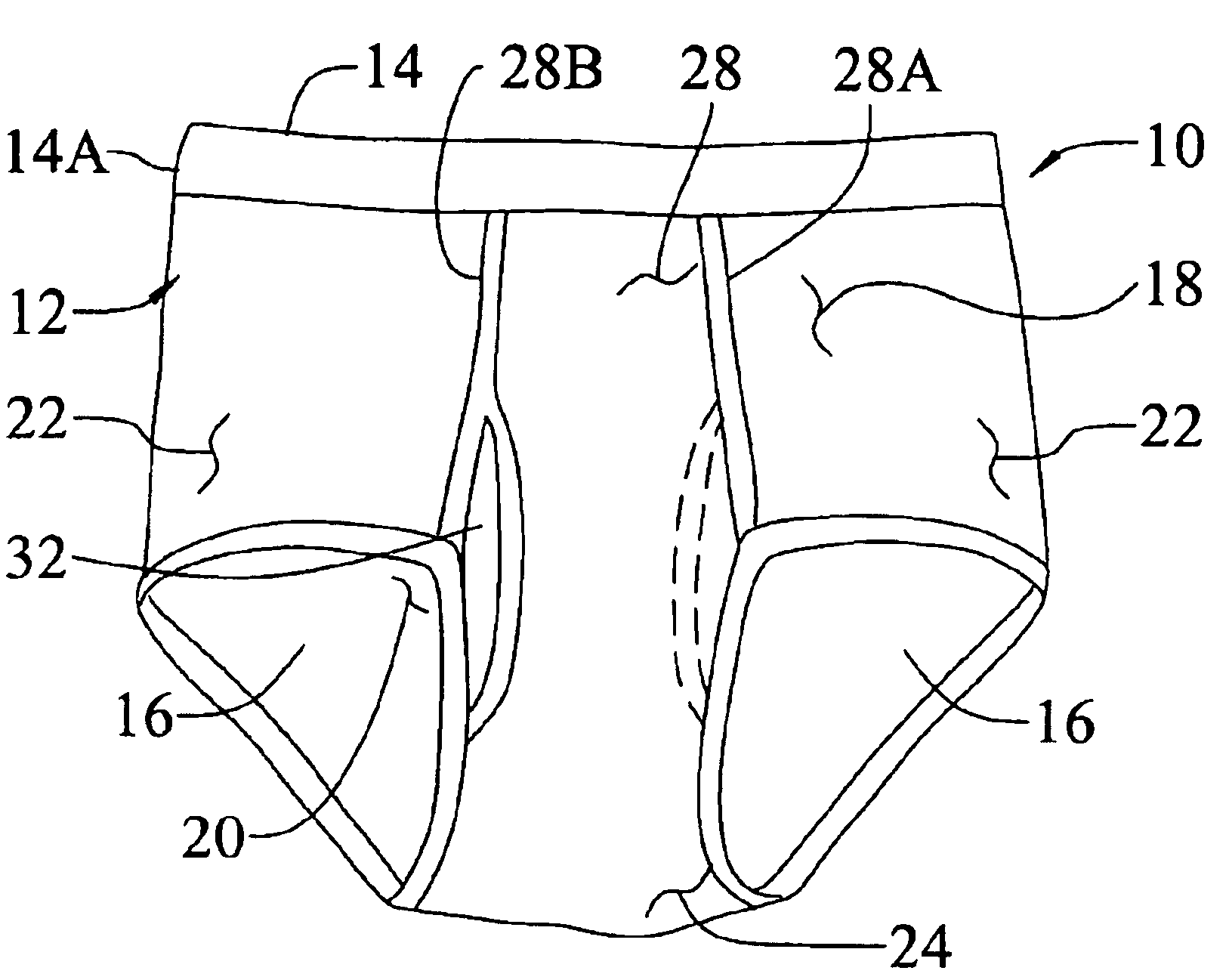

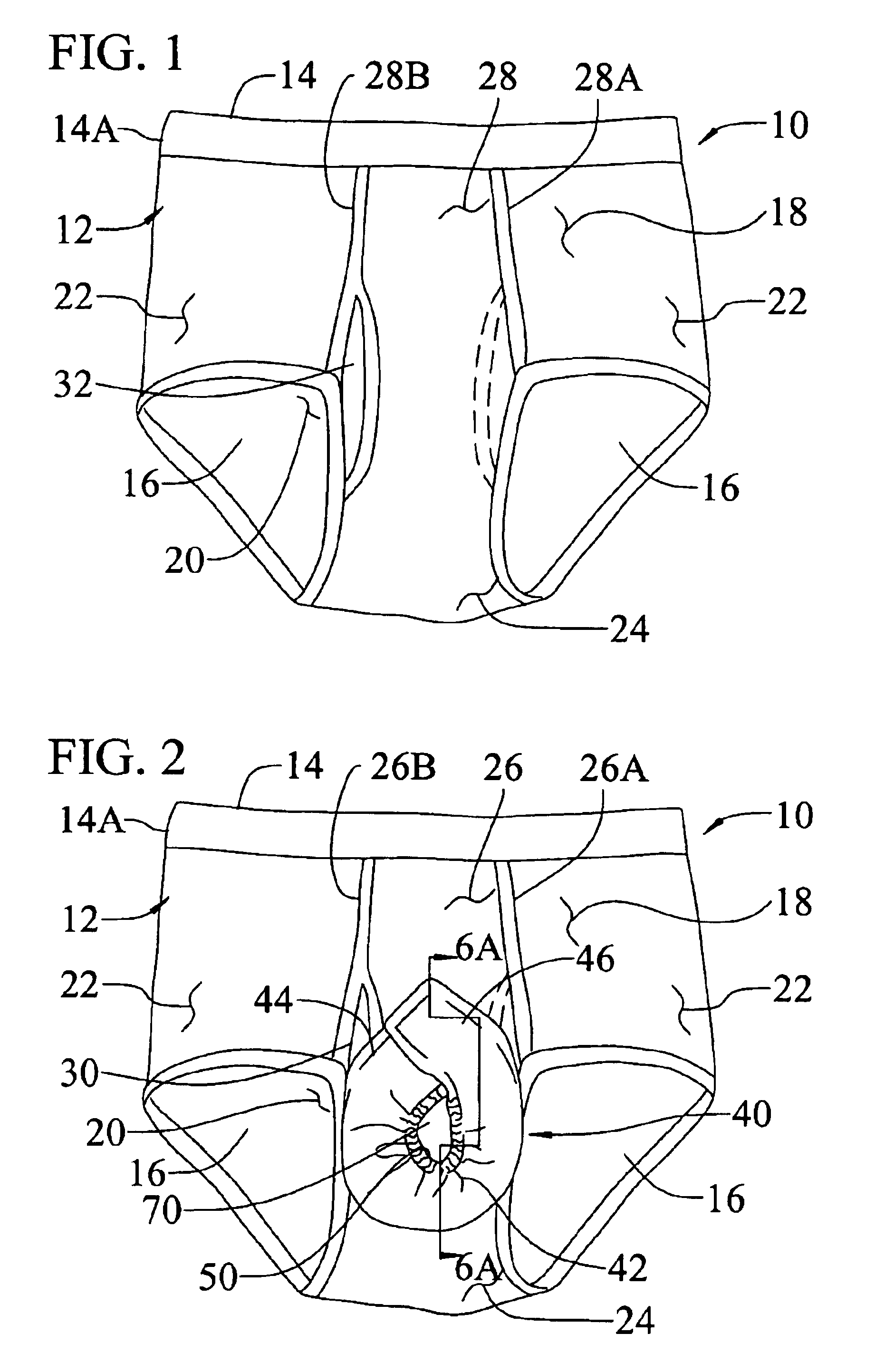

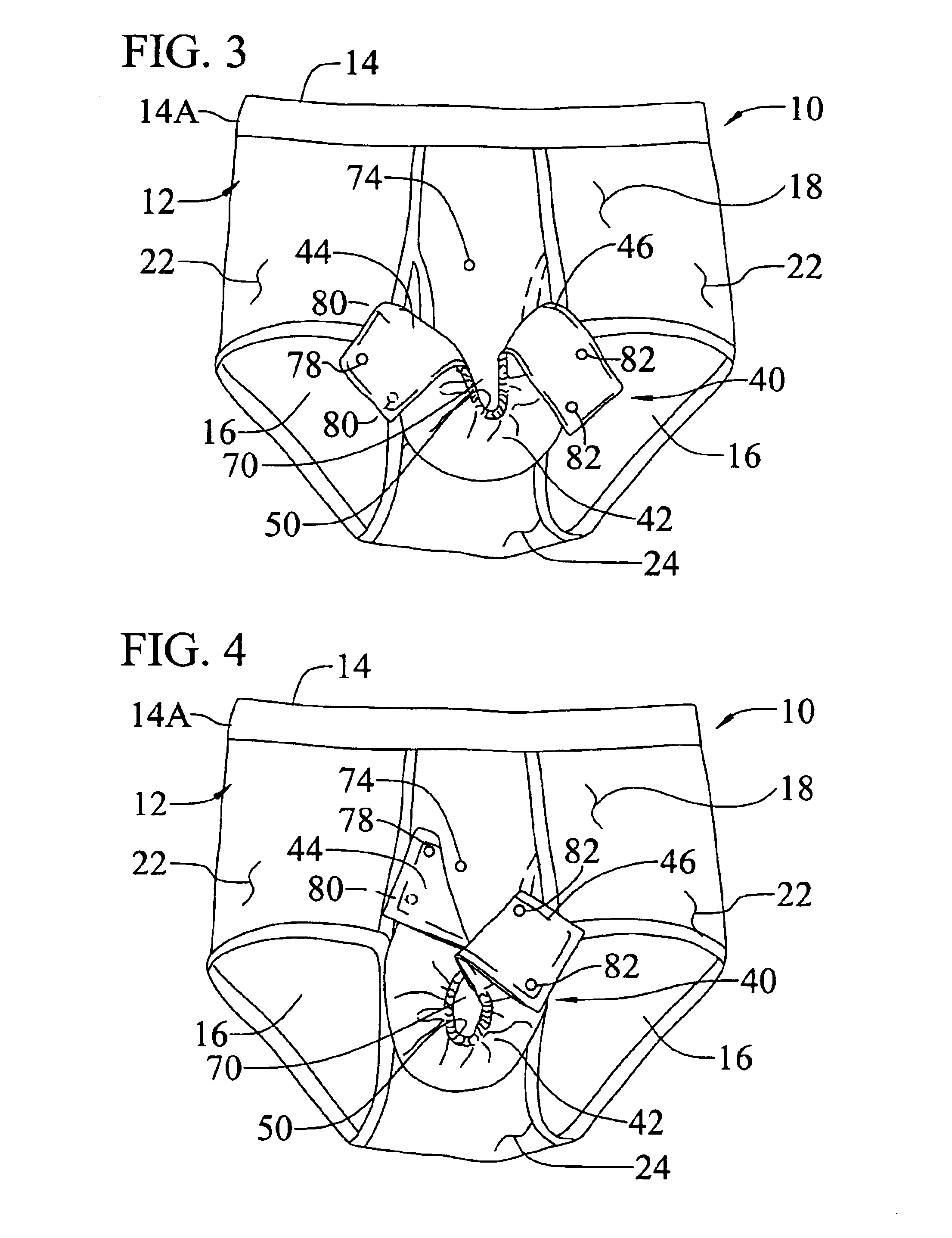

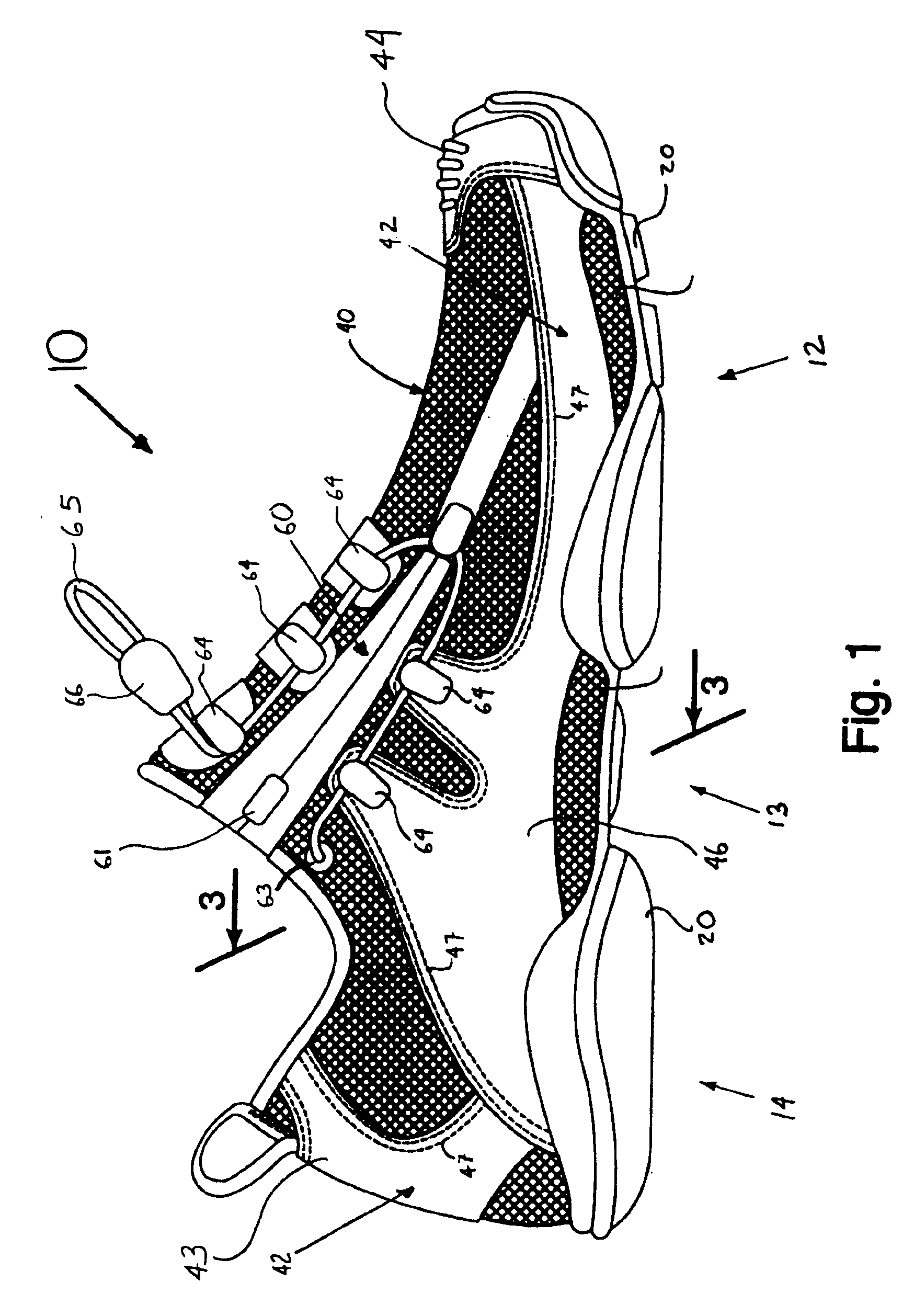

Men's brief with inner support pocket

InactiveUS6901607B1Improve comfortSimple and straightforward in design and implementation and useUndergarmentsBandagesMechanical engineeringEngineering

Owner:ELWELL JEAN D

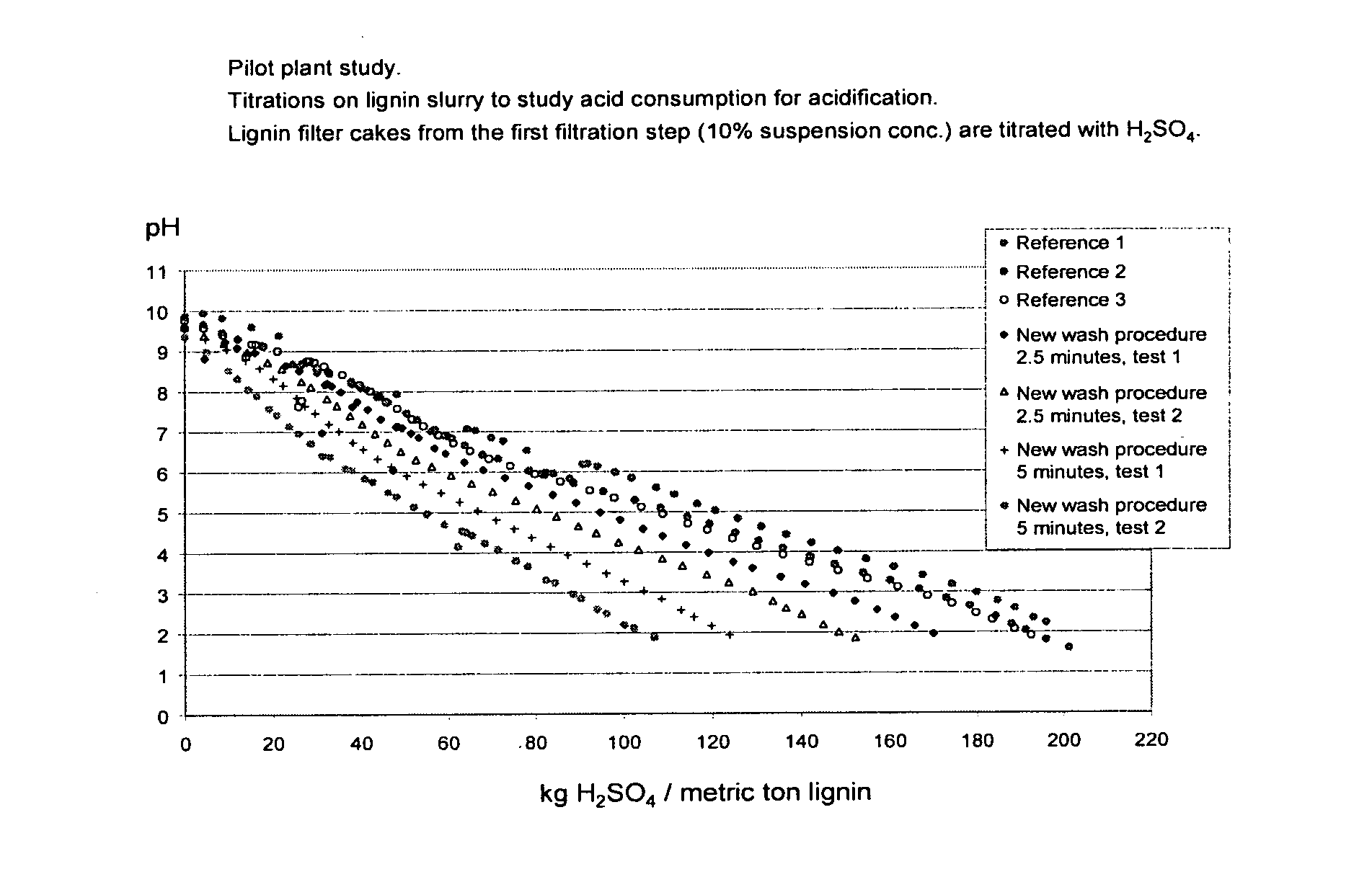

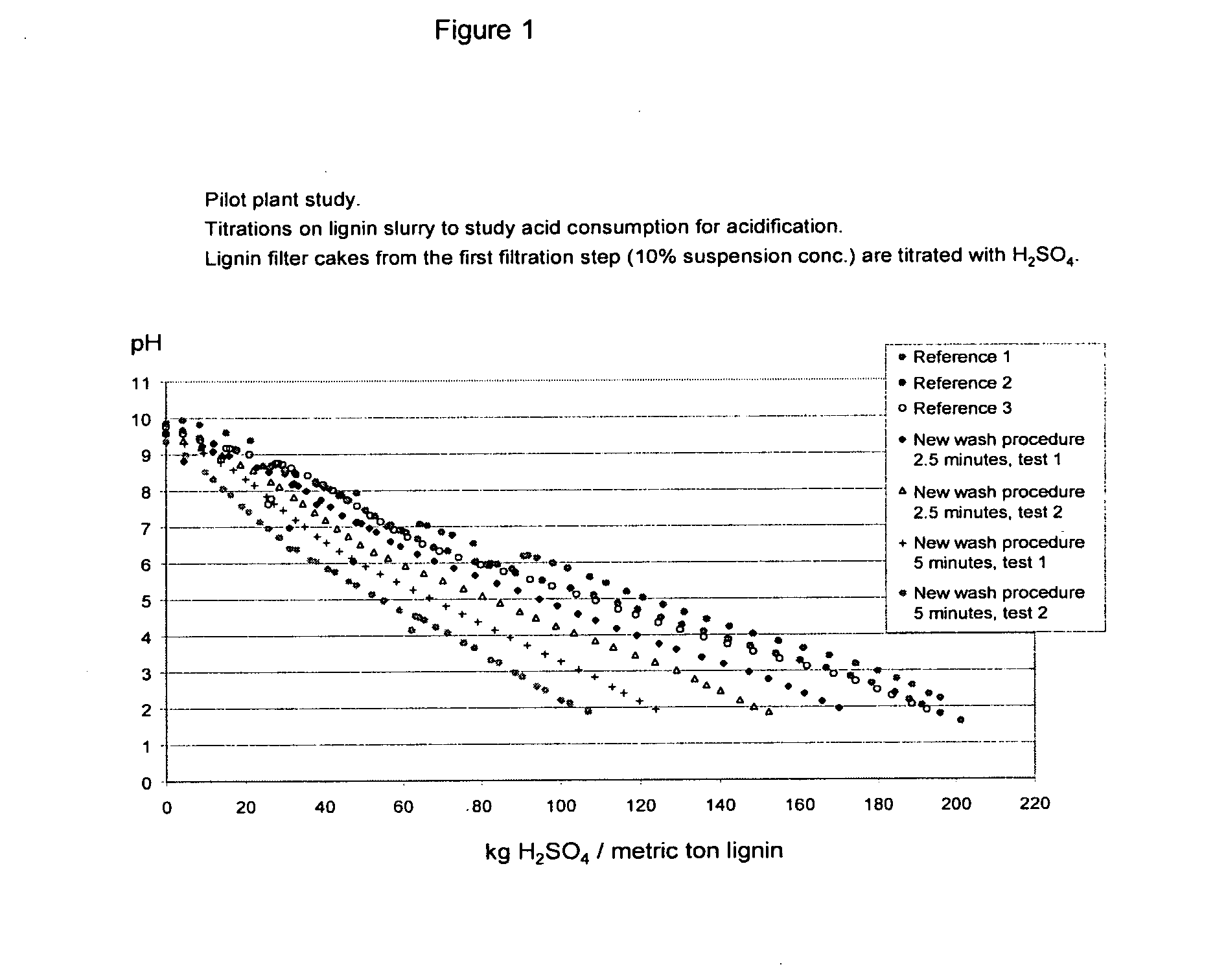

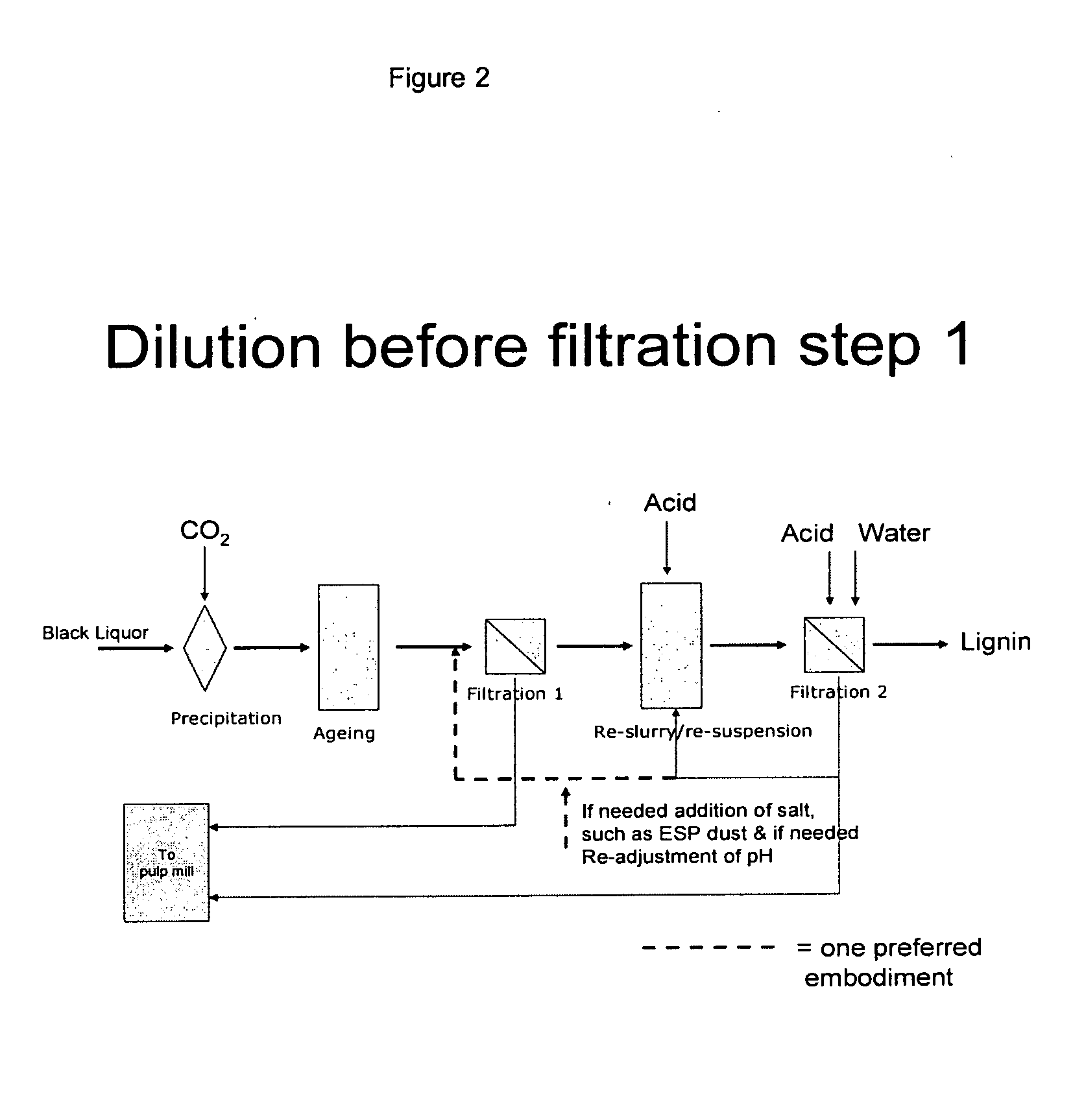

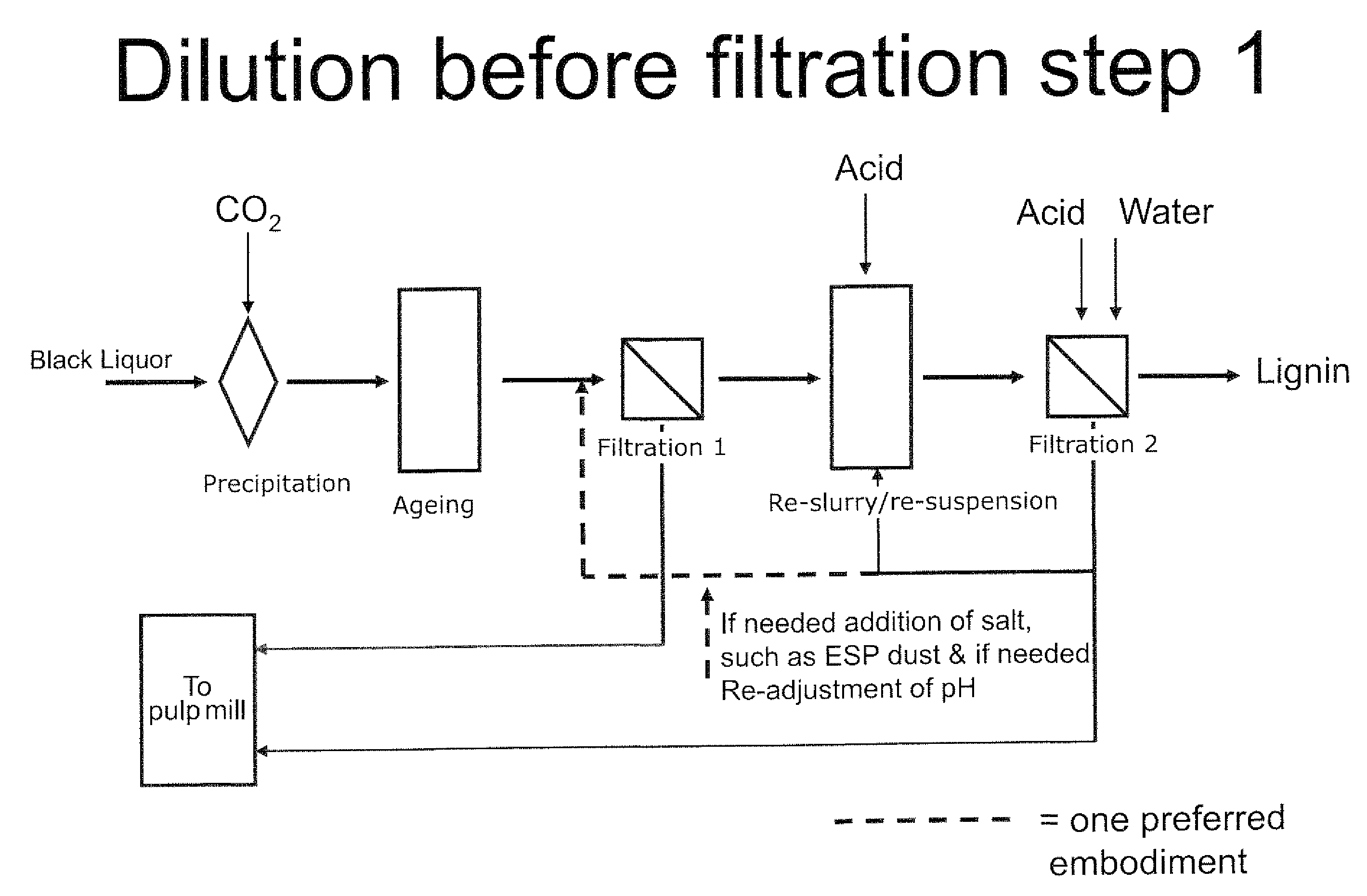

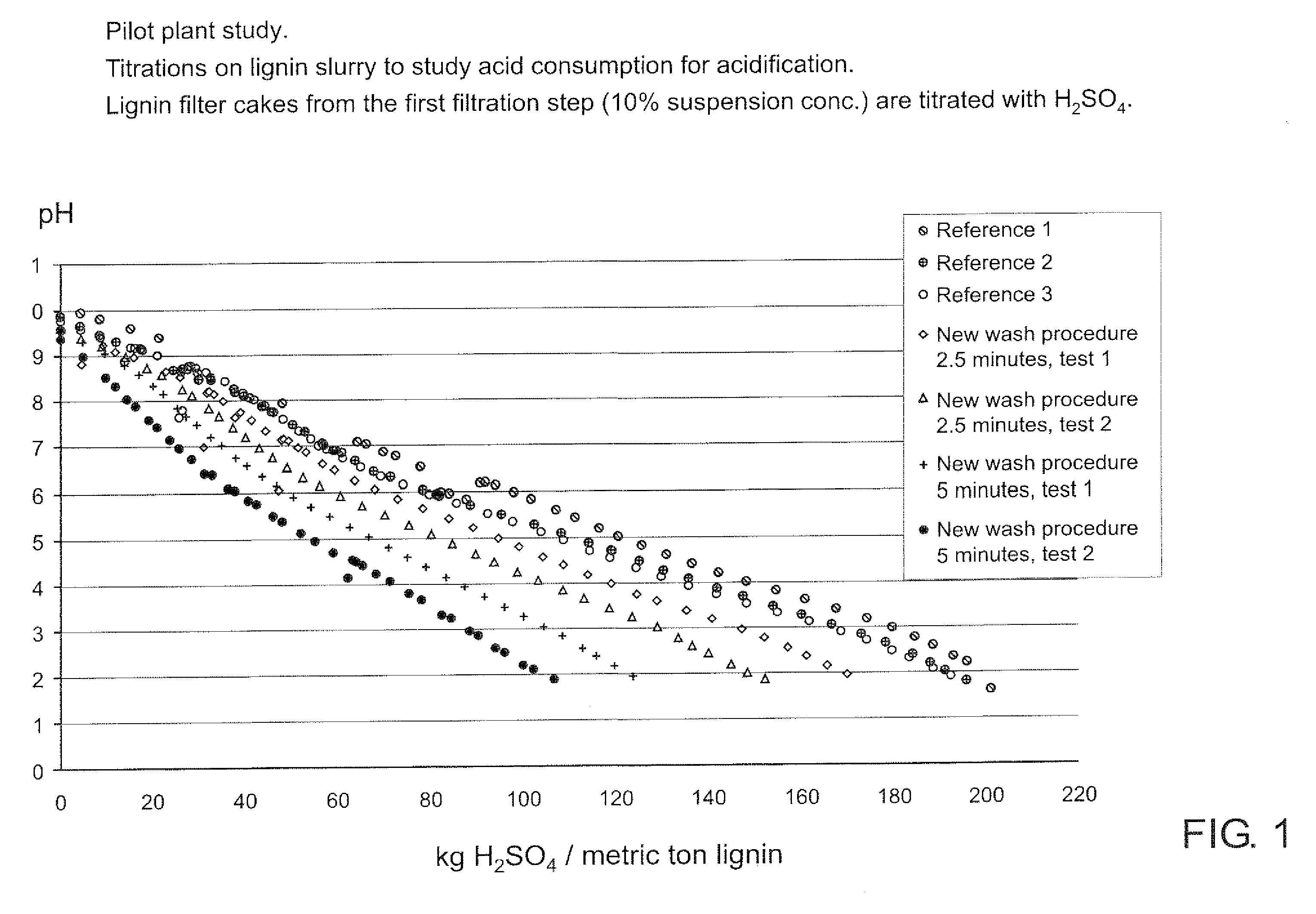

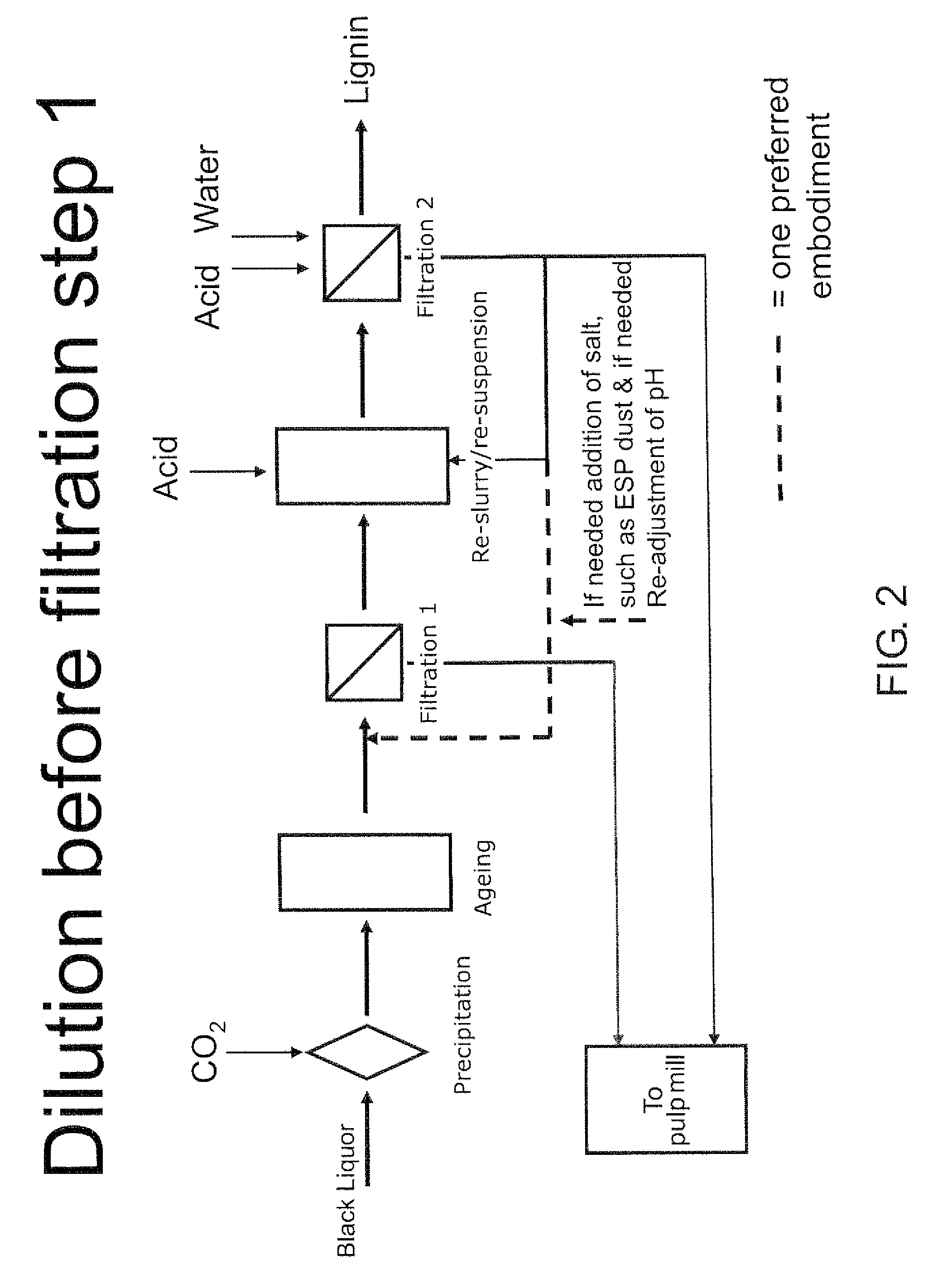

Method for separating lignin from black liquor, a lignin product, and use of a lignin product for the production of fuels or materials

ActiveUS20100325947A1Control balanceLower requirementSolid fuelsPulp by-products recoveryChemistryRecovery boiler

The method is for controlling a sodium and sulphur balance of a pulp mill while separating lignin from black liquor. Lignin is precipitated by using an acid followed by filtration. The lignin filter cake thus obtained is re-suspended in acidic liquid and dewatered to form a second cake. The filtrate obtained after dewatering of the second cake is returned for washing and suspension of the first cake. Sodium sulphate-rich ESP (electrostatic precipitator) dust produced in the recovery boiler is used in the washing of the precipitated lignin cake.

Owner:VALMET AB

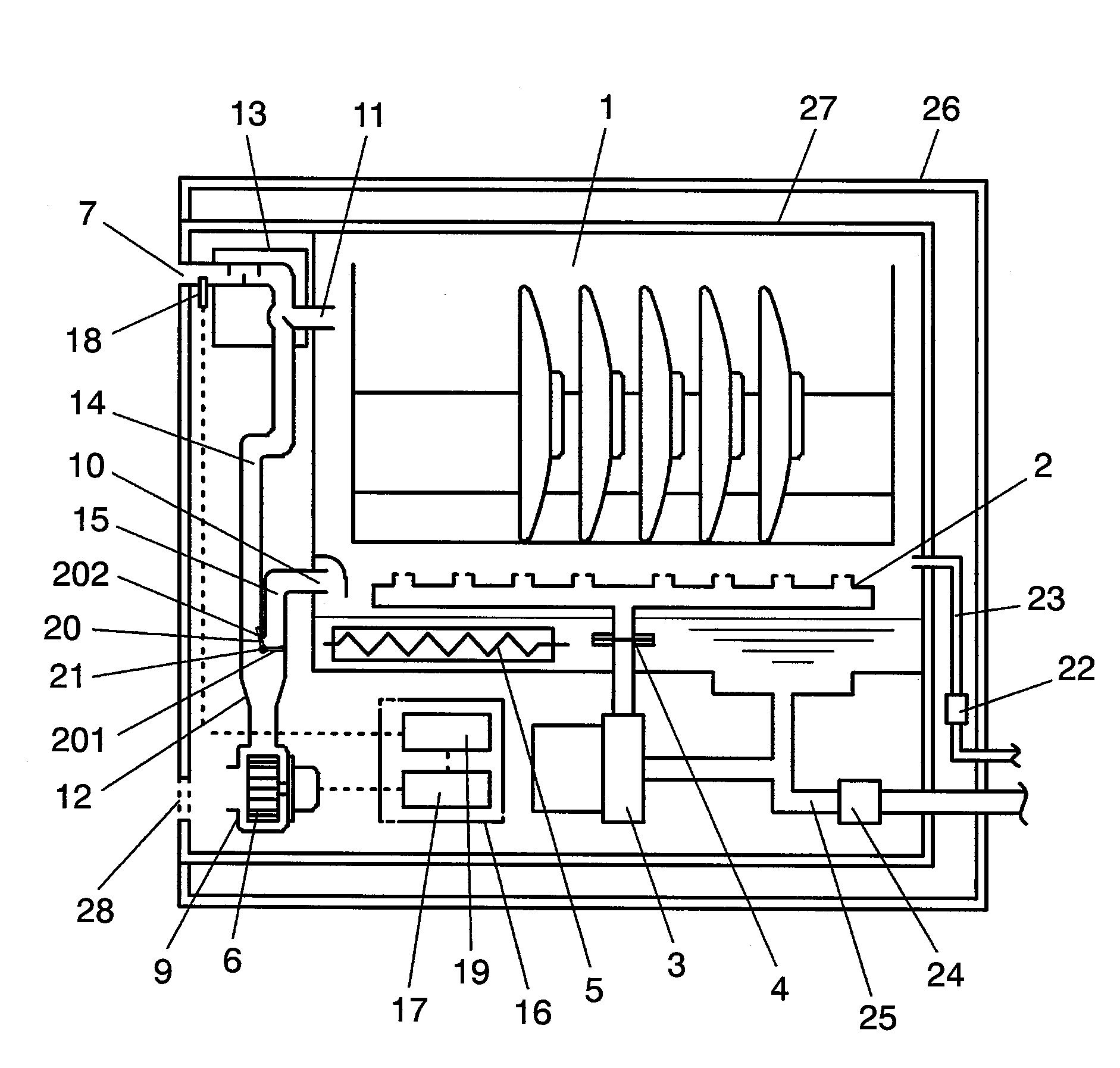

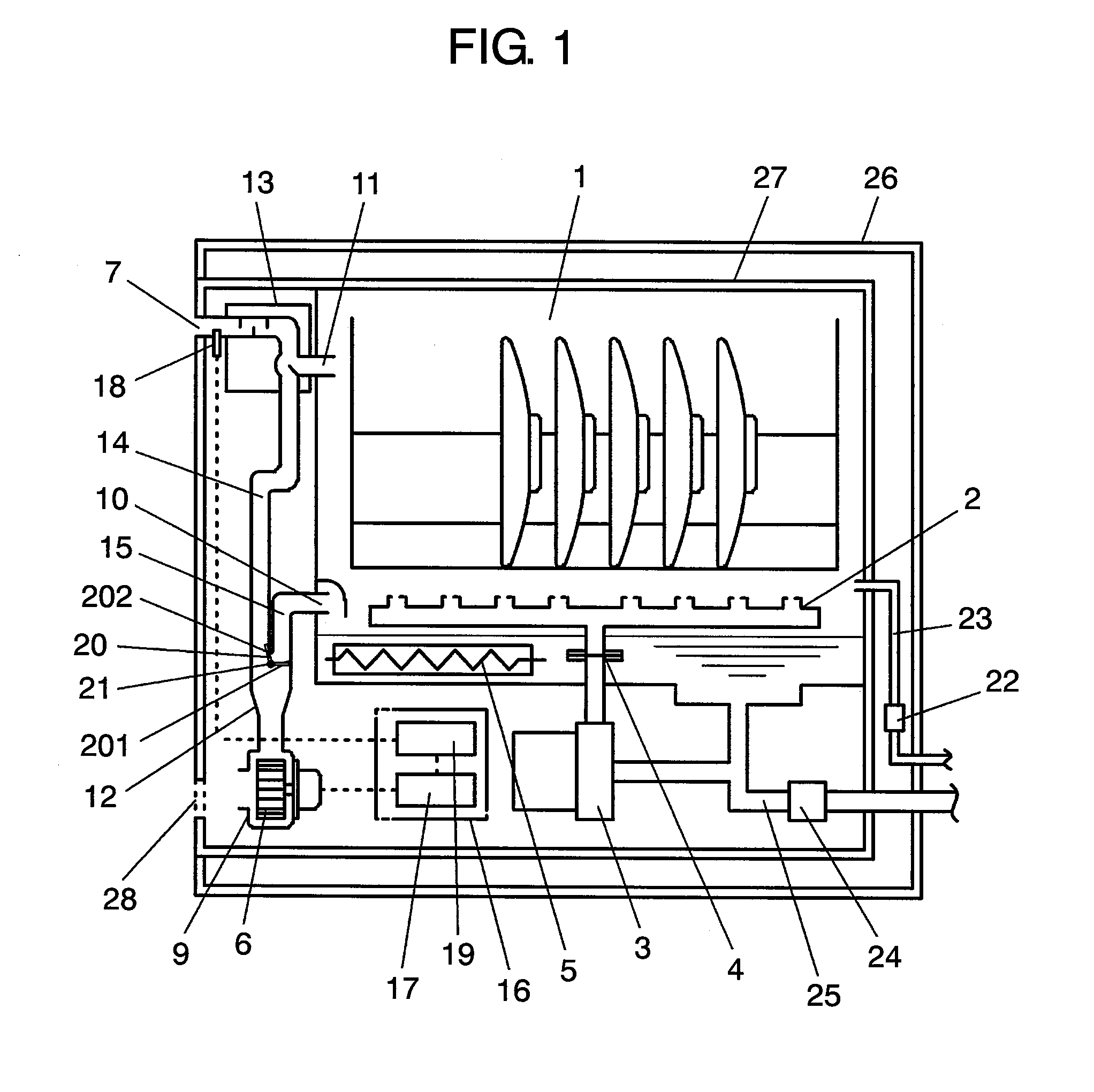

Dish washer/dryer

ActiveUS20090095330A1Reliable preventionReduce humidityTableware washing/rinsing machine detailsMultiple way valvesAir volumeAir blower

A dish washer / dryer includes a washing tub for accommodating an object to be washed, a washing section for washing the object to be washed, a heater for heating washing water, an exhaust port for discharging moisture inside the washing tub, an air blower for blowing outside-air, a mixing section disposed at an upstream side of the exhaust port and mixing the outside-air with washing-tub-inside-air, and an air volume distribution section for changing the feeding ratio of outside-air into the washing tub and the mixing section. This configuration provides a dish washer / dryer, in which a sufficient amount of outside-air is mixed with exhaust air in the washing tub so as to promote the temperature reduction of the exhaust air and the reduction of the moisture content in the exhaust air during drying operation, thereby enhancing the comfort of the exhaust air.

Owner:PANASONIC CORP

Fabric-Crepe Process With Prolonged Production Cycle and Improved Drying

ActiveUS20080264589A1Improve productivityLower levelDrying using combination processesNon-fibrous pulp additionAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Method

ActiveUS20080214796A1Lower requirementInhibition of dissolutionLignin derivativesPulp by-products recoveryBlack liquorPulp mill

A method for controlling the sodium and sulphur balance of a pulp mill while separating lignin from black liquor, and also a lignin product or an intermediate lignin product obtainable by the method. The present invention also provides use of a lignin product or an intermediate lignin product for the production of fuel (solid, gaseous or liquid) or materials.

Owner:LIGNOBOOST

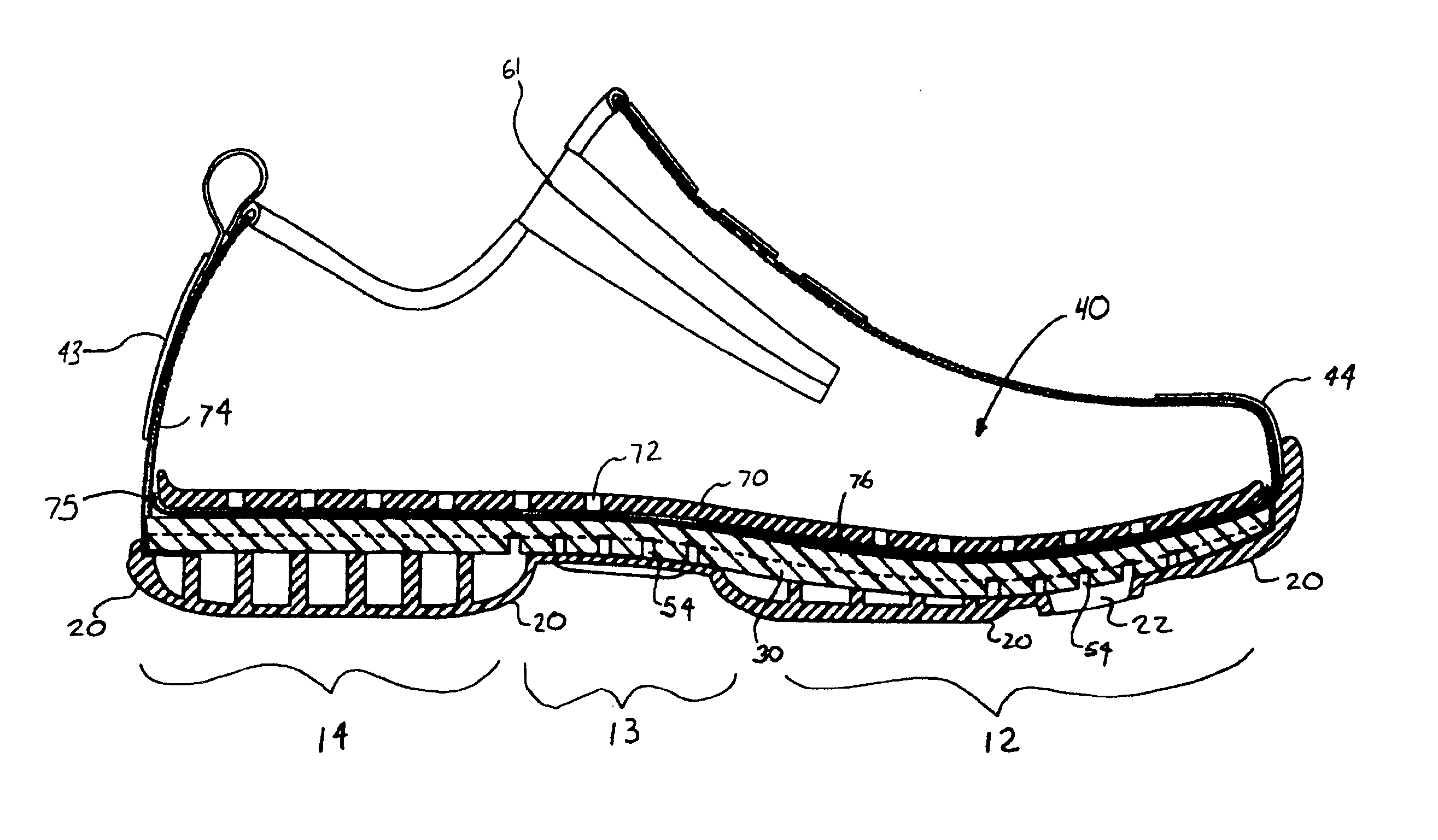

Self draining shoe

InactiveUS6874252B2Flat surfaceEliminating pressure pointInsolesFasteningsBuilding constructionCivil engineering

Owner:WOLVERINE WORLD WIDE

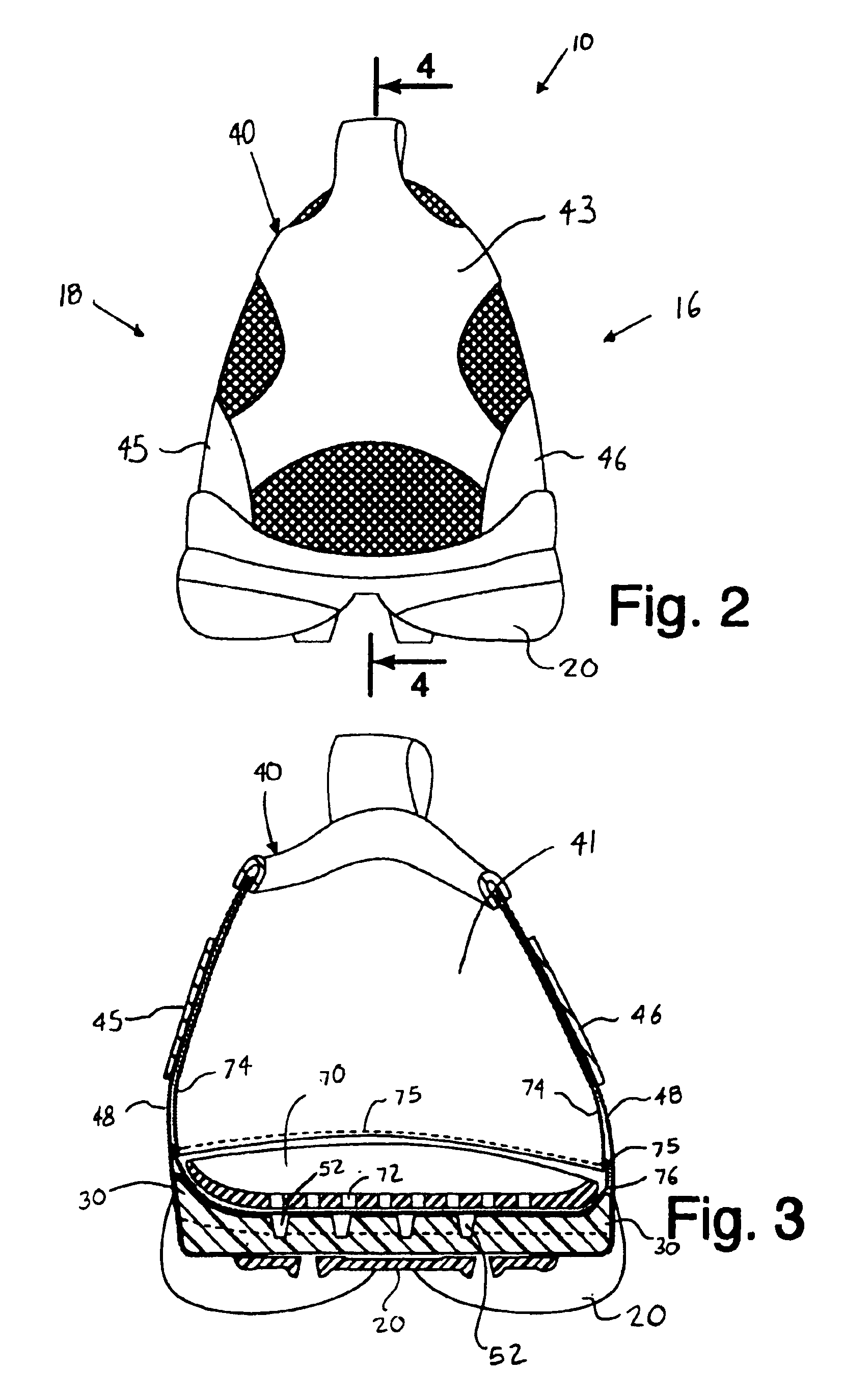

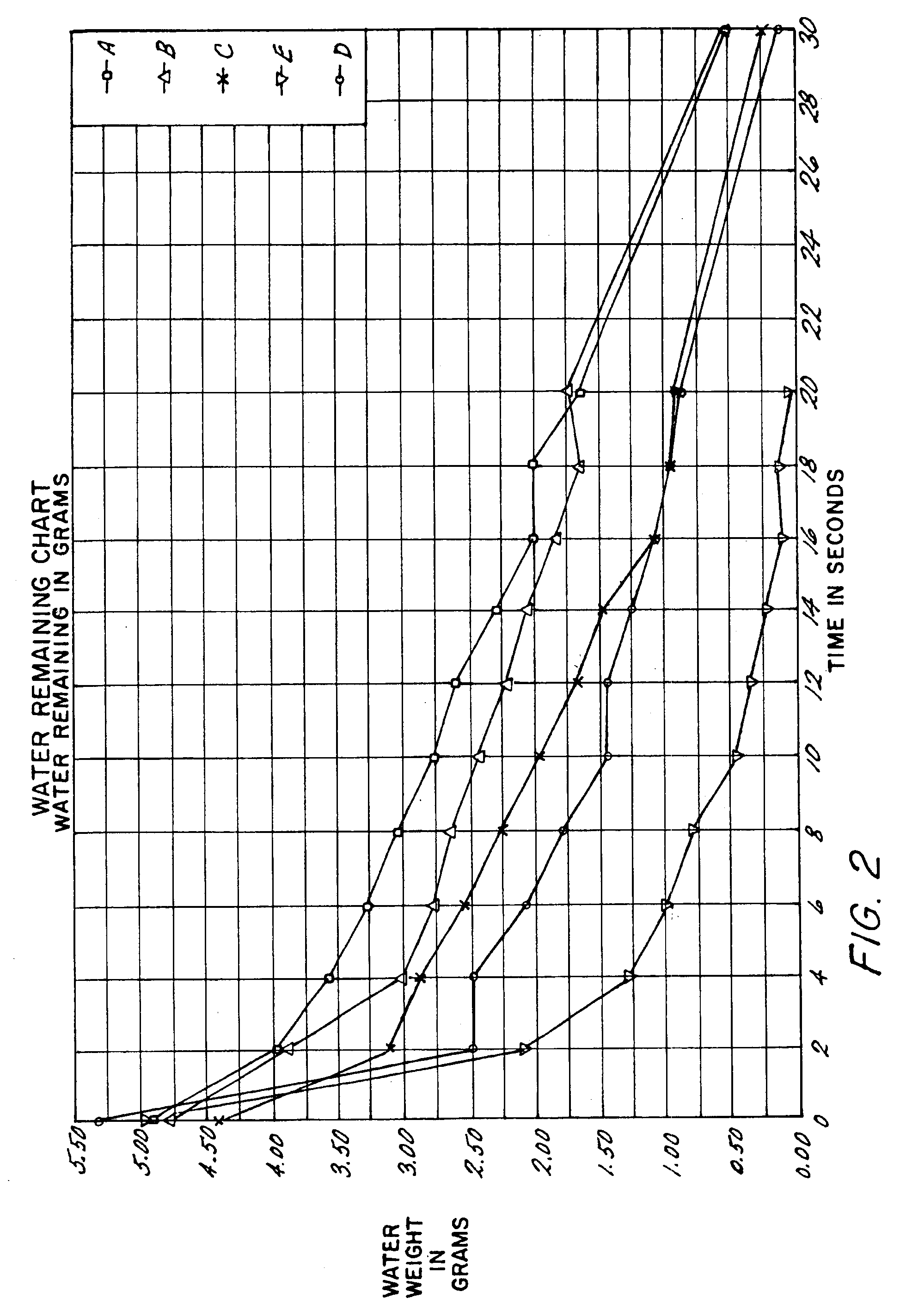

Method and apparatus for hand drying

InactiveUS7039301B1Improve the forceIncrease temperatureDrying solid materials with heatDrying gas arrangementsAir entrainmentEvaporation

After washing, the hands are dried rapidly and comfortably by using a shaped high speed flow of heated air. The air flows in a direction controlled by an air outlet shaped to retain much of the exiting forceful air flow and temperature at a distance where the hands are dried. The air entrainment is controlled so that the properties of the air flow are not diluted by the air entrainment to a point where the drying performance is degraded. The forceful air flow blows off most of the loose water on the hands. The forceful air flow also reduces the stagnation boundary layers in the hands so that the evaporation removal of the remaining film of water is improved. These result in reduced drying time and comfort during and after drying.

Owner:EXCEL DRYER

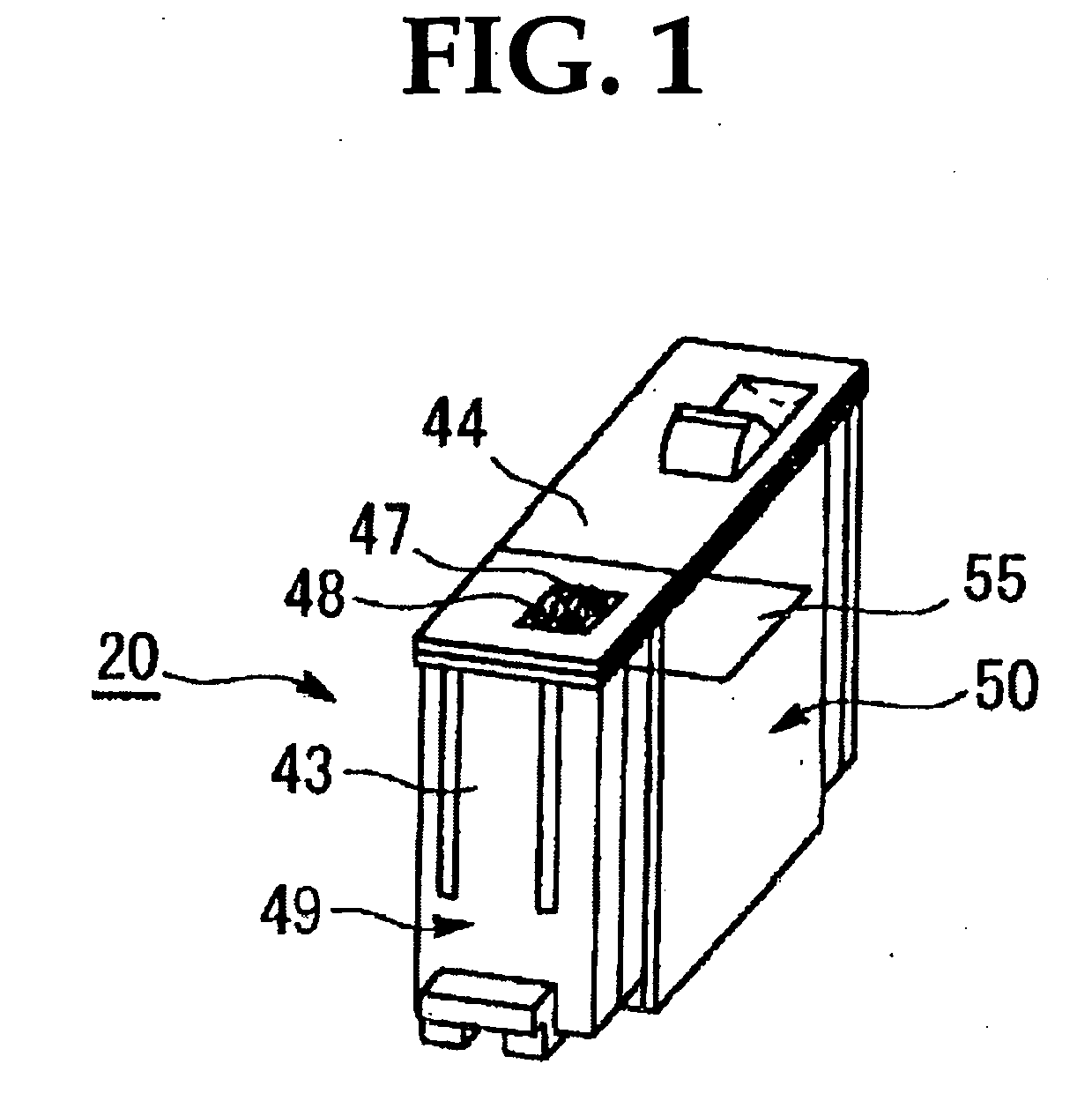

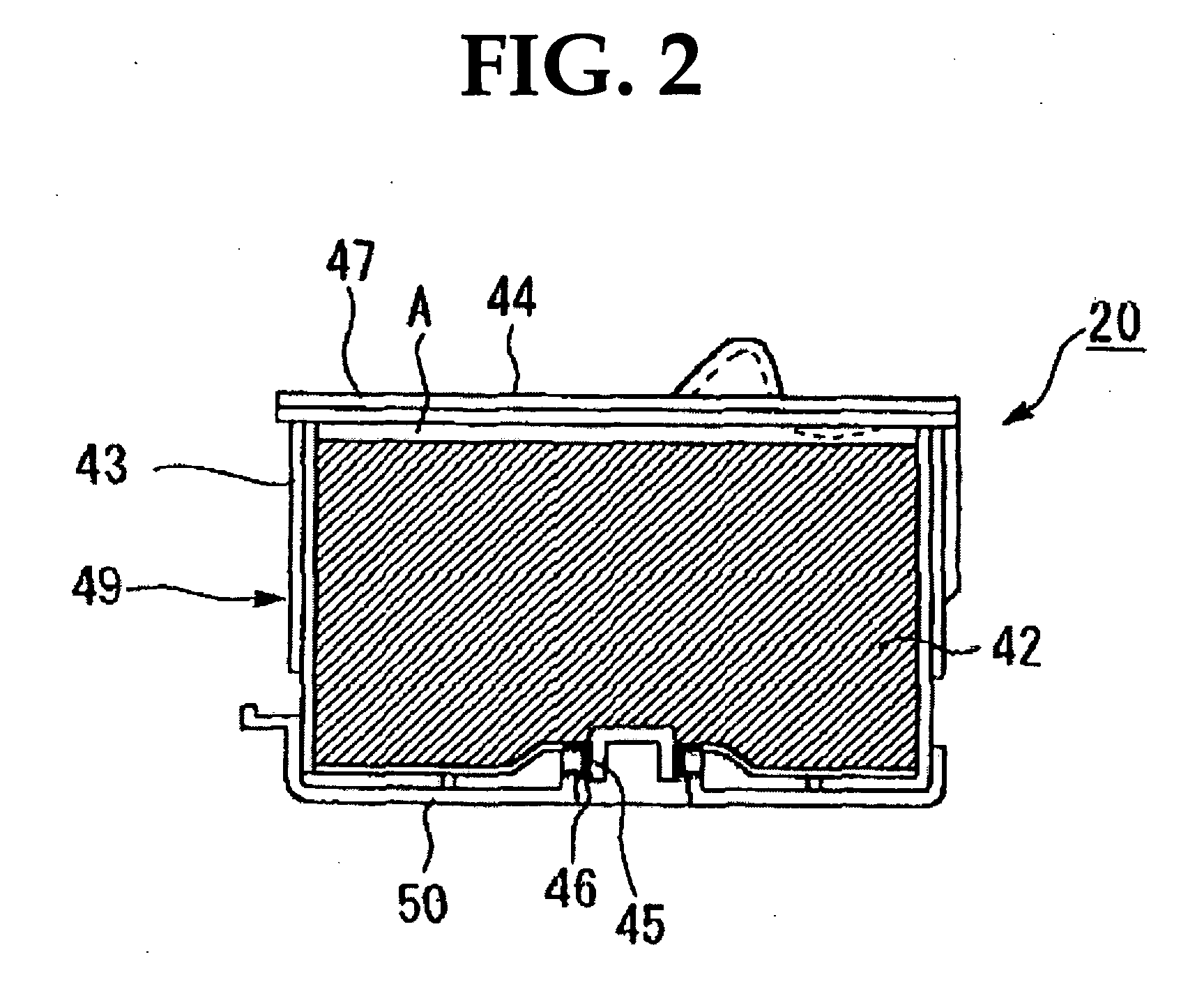

Ink set, ink-jet printing method, and ink-jet printer

InactiveUS20050012798A1Improve wear resistanceSuppress featheringMeasurement apparatus componentsInksComputer printingInk printer

The present invention provides an ink set which includes a combination of a recording liquid including a resin-coated colorant, and a treatment liquid including a particle which has a reactivity with the resin-coated colorant. The ink set can obtain a high quality image free from feathering and color bleeding, can obtain a high quality image even when used for printing on a plain paper sheet, can obtain a print excellent in wear resistance, can obtain a high image density without causing a deep permeation of a recording liquid in the paper sheet, can perform a favorable double-sided printing with a low image density when the image is viewed from an opposite face of an image print face, can be free from an image stain attributable to drying failure of the recording liquid, and can provide the print with a proper glossiness.

Owner:RICOH KK

Containerized sample collection apparatus and method

InactiveUS20070299364A1Keep dryReduce stressSurgeryVaccination/ovulation diagnosticsEngineeringSample collection

A containerized low pressure sample collection apparatus includes an elongated tubular shaft with a vacuum connection at one end and a swab at an opposite end. The shaft extends through a housing which can be used as a handle. The housing is adapted to receive a cap at either end, at one end for storage and at the other to cover and protect the swab with a collected sample. A second slide-out of the apparatus embodiment includes a swab structure including a tubular shaft, a swab, and a centering structure which can be slid out of and back into a housing which can also be used as a handle to manipulate the apparatus to collect a sample. Both embodiments can be connected to a vacuum unit to draw air through the swab to collect certain kinds of samples.

Owner:BODE TECH GROUP

Processing process of woven fabric with one-way quick moisture conducting composite structure

The invention discloses a processing process of a woven fabric with a one-way quick moisture conducting composite structure. The process comprises a design process and a weaving process, wherein the design process comprises the steps of: establishing a one-way quick moisture conducting model and designing an organization structure; and the weaving process comprises the steps of: selecting and weaving warp and yarn raw materials by the moisture conducting principle of the established fabric moisture conducting model. The invention can be used for designing and weaving the woven fabric with a one-way quick moisture conducting composite structure, and moisture conducting and quick drying series functional fabrics are a great trend of the future consumer market and have wide development prospect.

Owner:杭州新天元织造有限公司

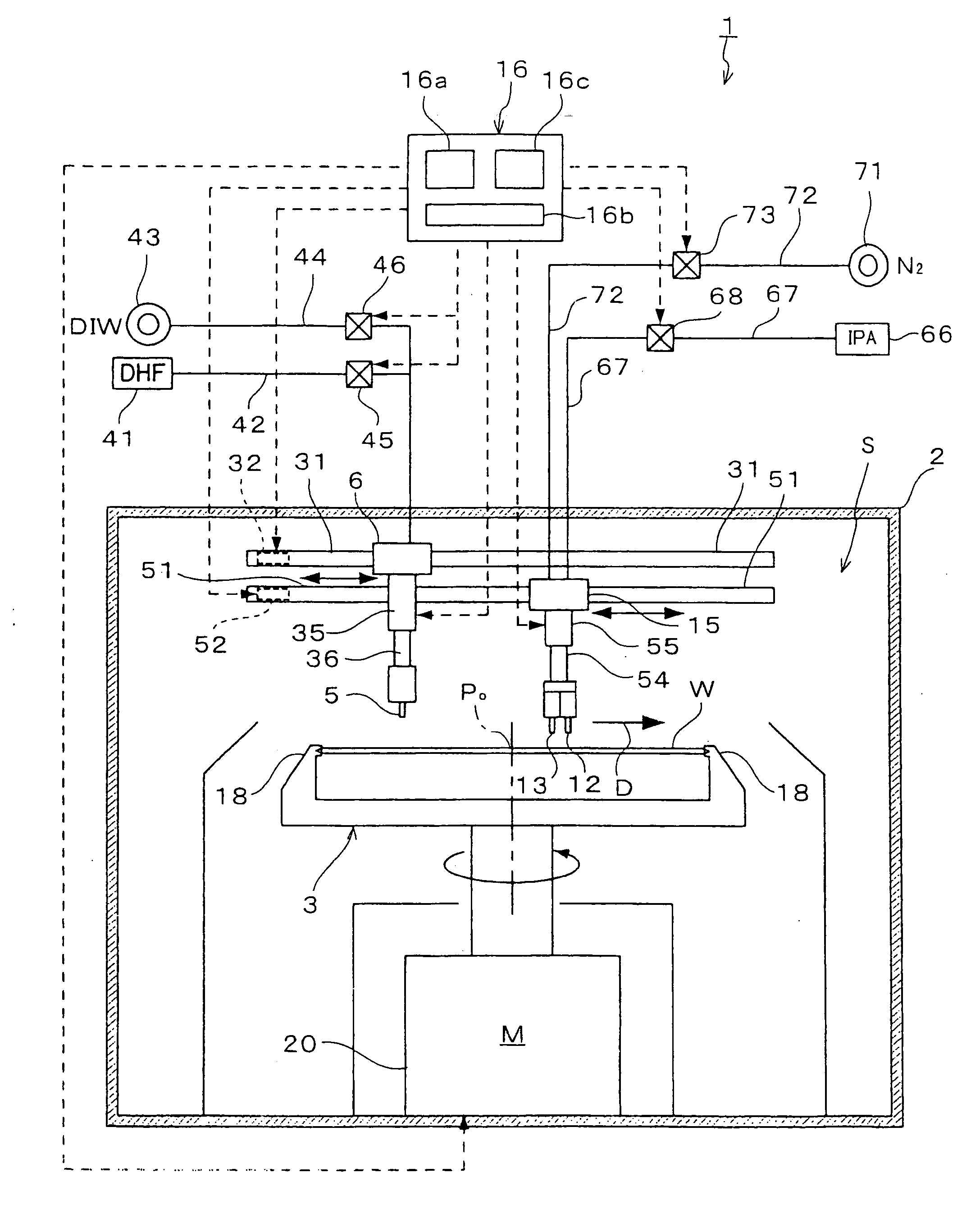

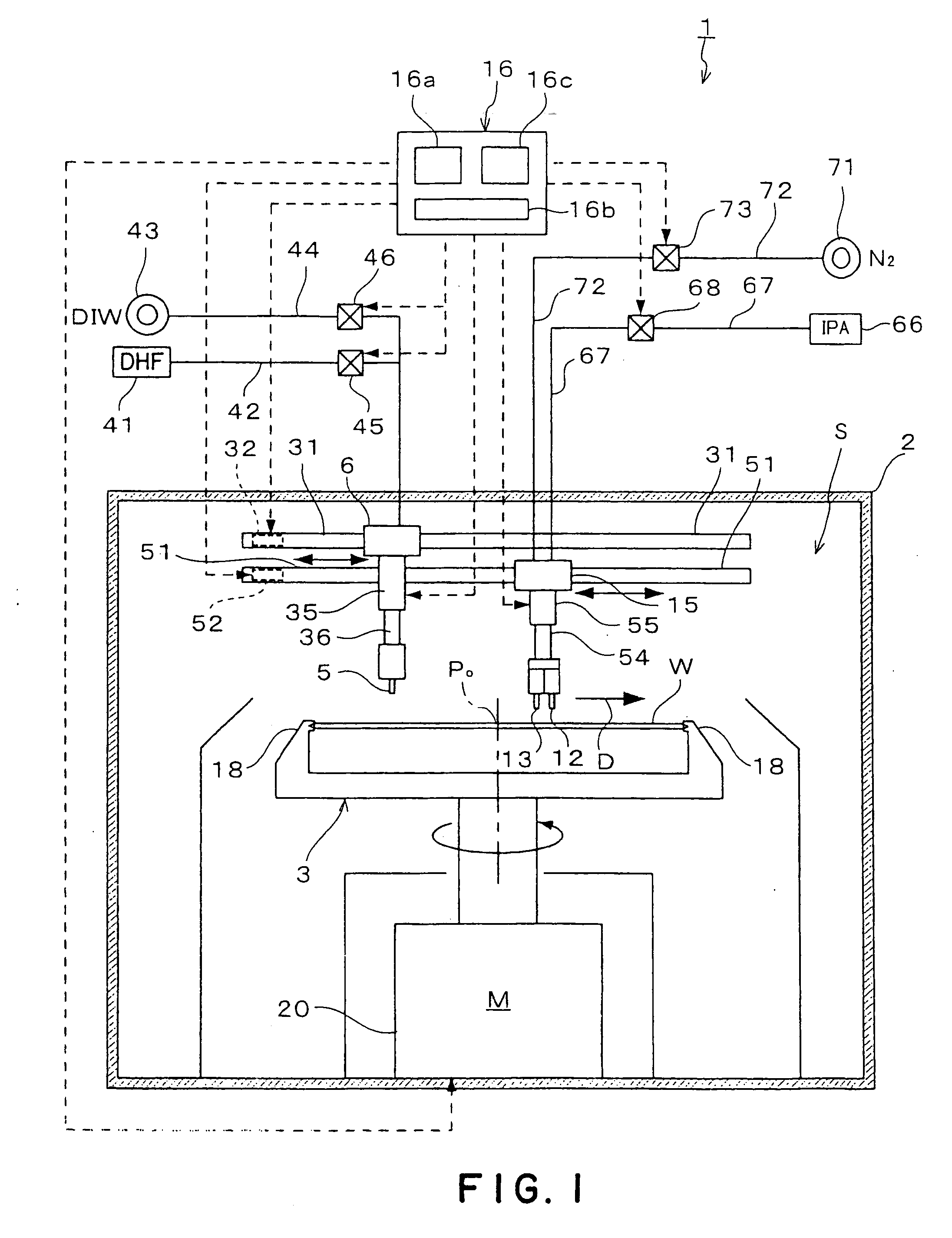

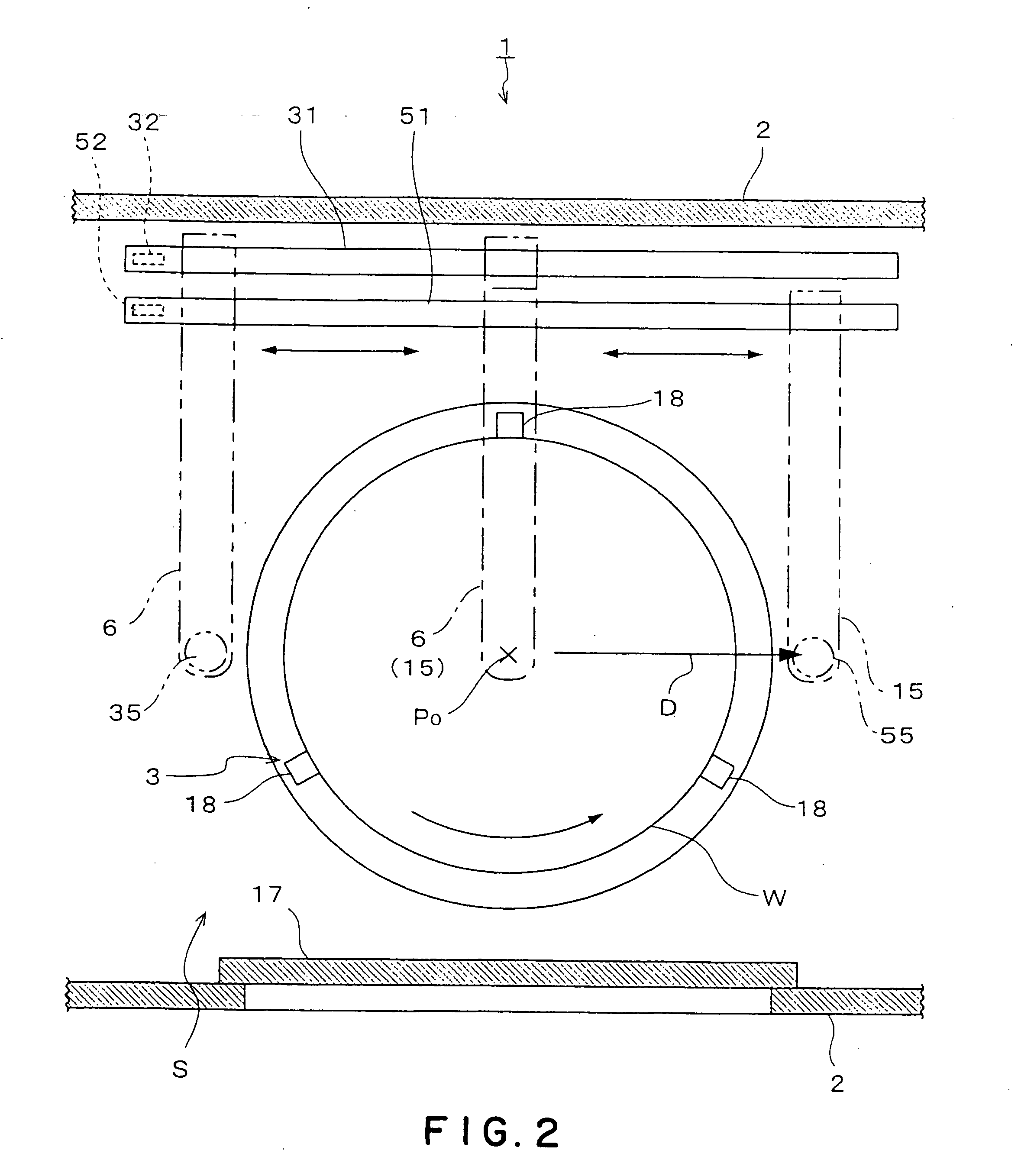

Substrate Processing method and substrate processing apparatus

ActiveUS20070017555A1Decreasing amount of usedAvoid it happening againSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringIon

A substrate (W) is processed with the use of a process liquid such as a deionized water. Then, a first fluid which is more volatile than the process liquid is supplied to an upper surface of the substrate (W) from a fluid nozzle (12) to form a liquid film. Next, a second fluid which is more volatile than the process liquid is supplied to the upper surface of the substrate (W) from the fluid nozzle (12), while the wafer (W) is being rotated. During this supply operation, a supply position (Sf) of the second fluid to the substrate (W) is moved radially outward from a rotational center (Po) of the substrate (W). As a result, it is possible to prevent the generation of particles on the substrate (W) after it is dried by using the first and second fluids.

Owner:TOKYO ELECTRON LTD

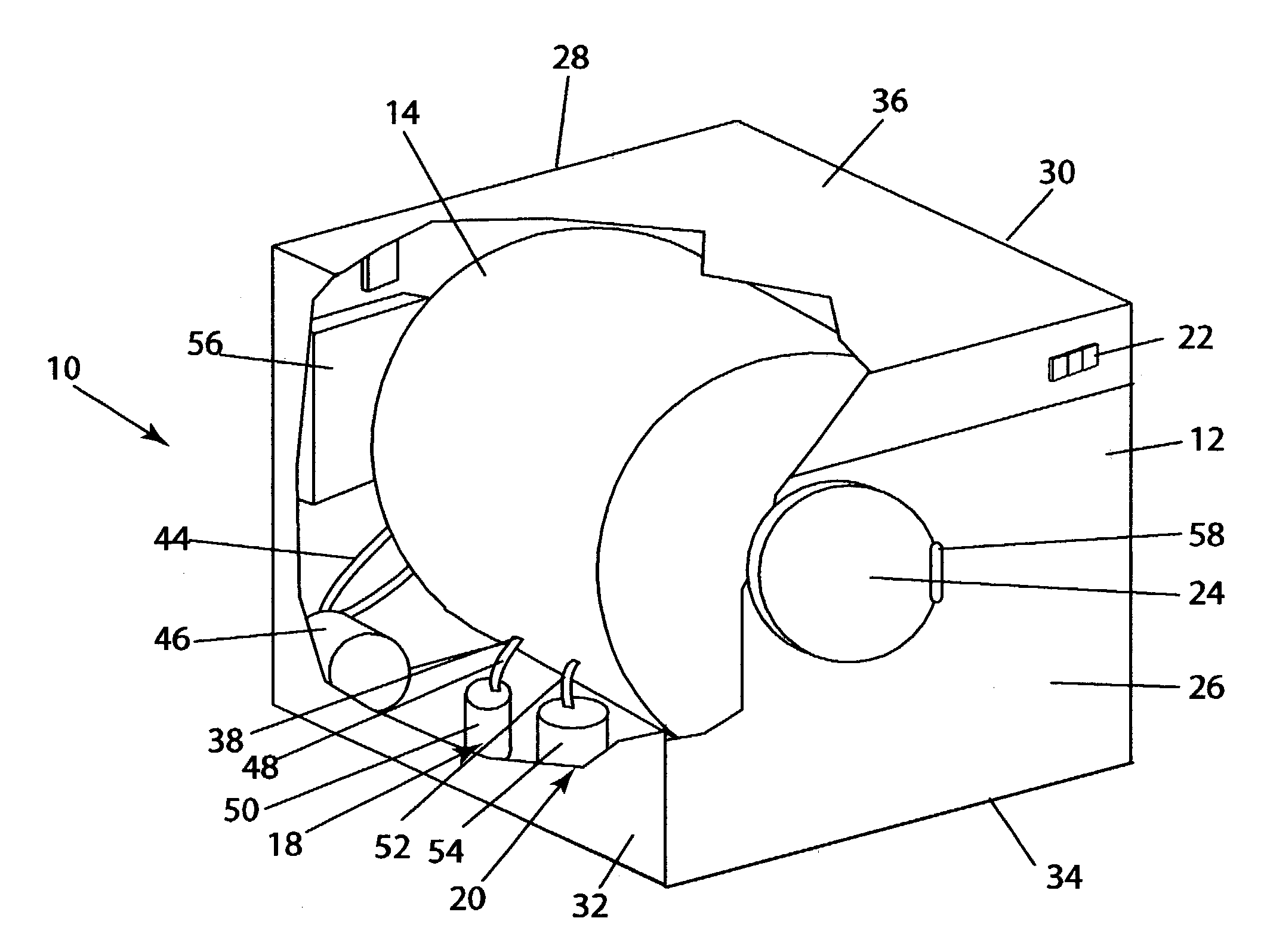

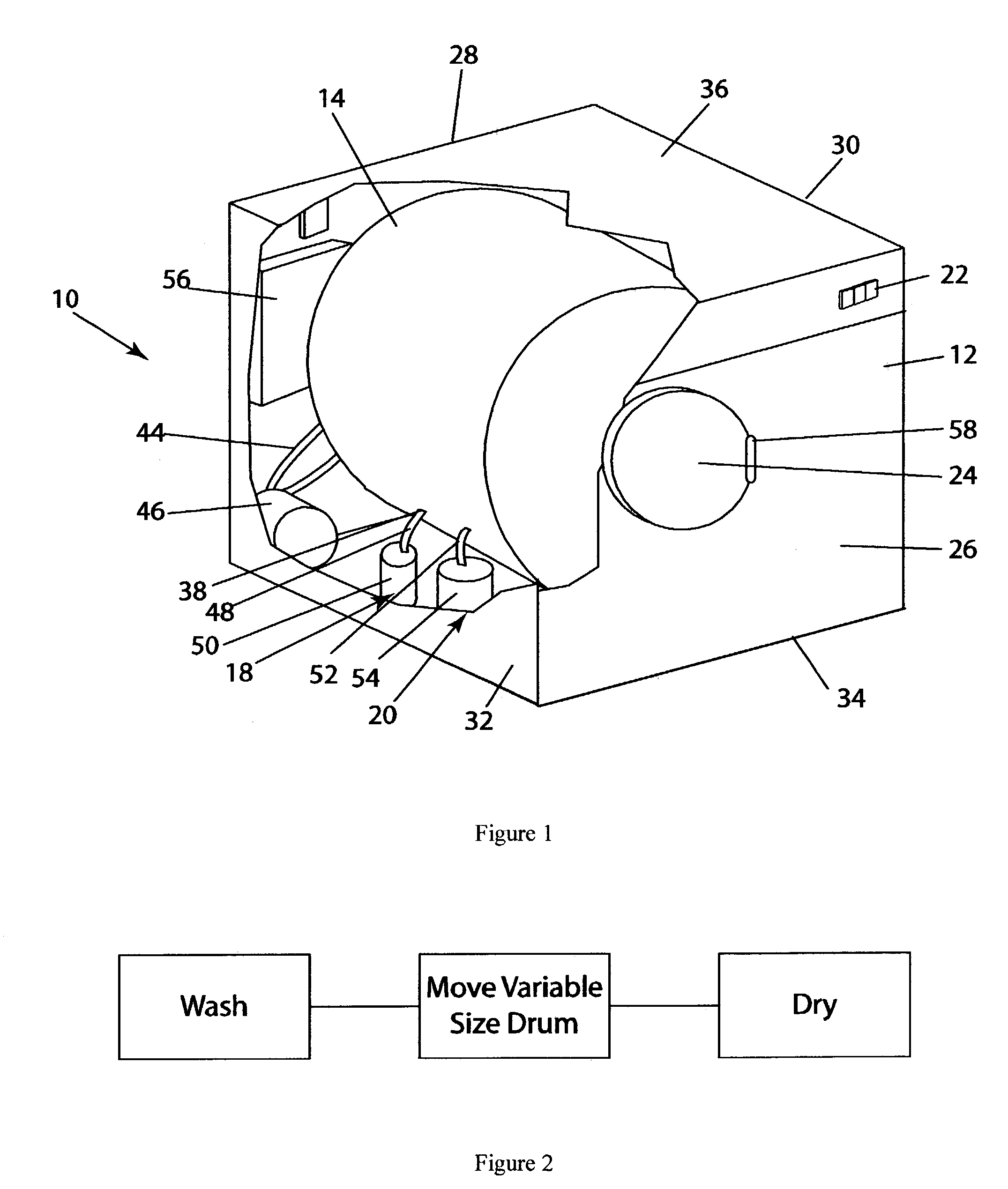

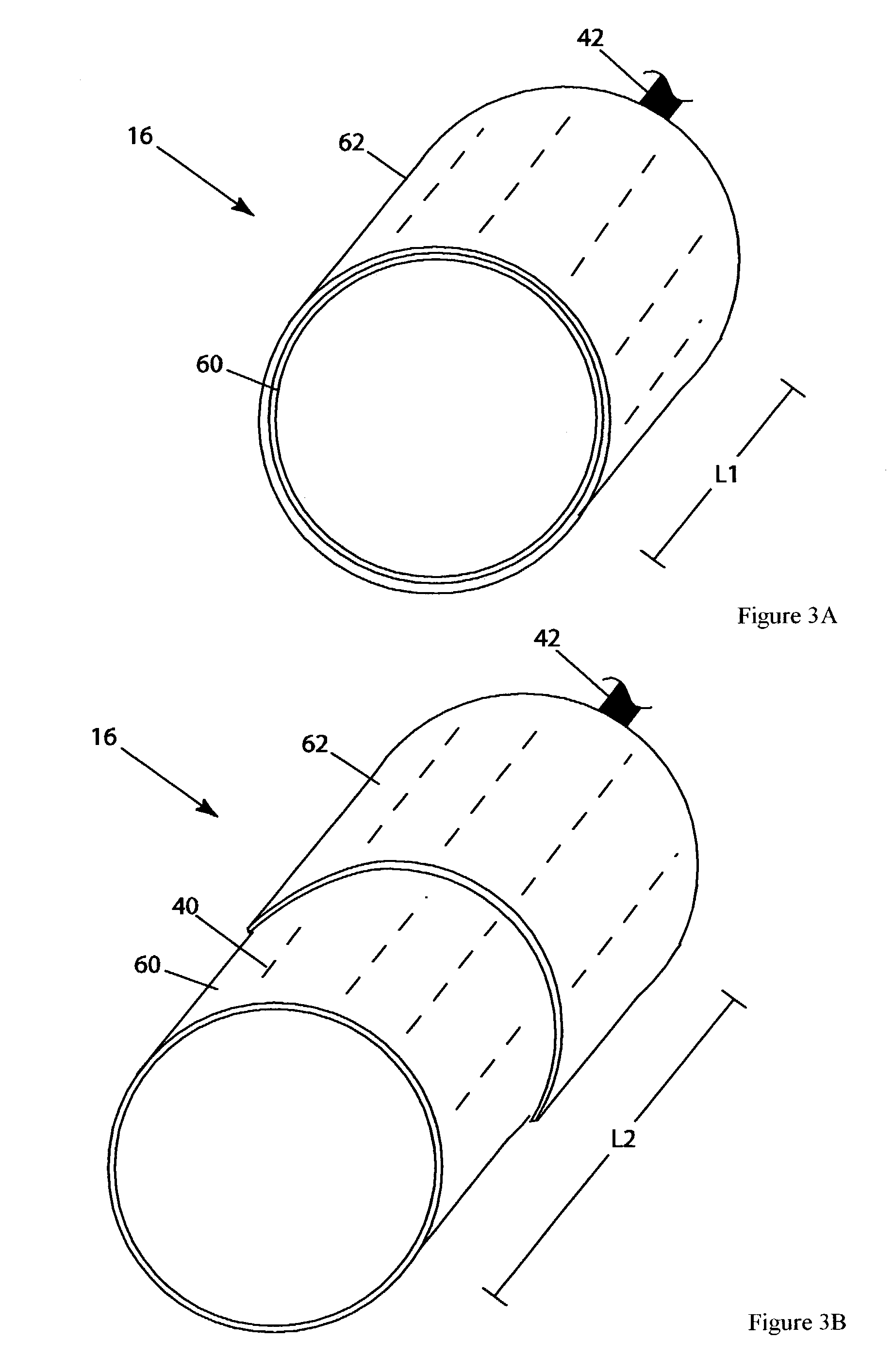

Combined washer dryer

InactiveUS7380423B1Large load capacityDry ability be improveOther washing machinesControl devices for washing apparatusAerospace engineeringWater treatment system

A combined washer dryer is provided. The combined washer dryer comprises an outer drum; a rotatable cylindrical variable size inner drum arranged coaxially within the outer drum and movable from a first position to a second position; a water handling system adapted to intake water into the inner drum and to remove water from the outer drum; an air handling system adapted to intake air into the inner drum and to remove air from the outer drum; and a control system adapted to control the movement of the variable size inner drum.

Owner:MUSONE JOHN P

Biosample storage devices and methods of use thereof

InactiveUS20100209957A1Easy to evaporateFacilitate air flowBioreactor/fermenter combinationsBiological substance pretreatmentsCell lysatesTissue homogenate

The present invention provides sample collection, shipping, and storage devices and methods of using the same. These devices and methods are useful, for example, for collecting, shipping, and storing biological samples, such as blood, serum, buccal samples, tissue homogenates, or cell lysates in a dry state. The devices and methods facilitate the rapid drying of biological samples collected on the devices, thereby improving the quality of the stored sample, particularly the protein and small molecule components of the stored sample. The present invention further provides methods of recovering biological samples from such devices.

Owner:GENTEGRA

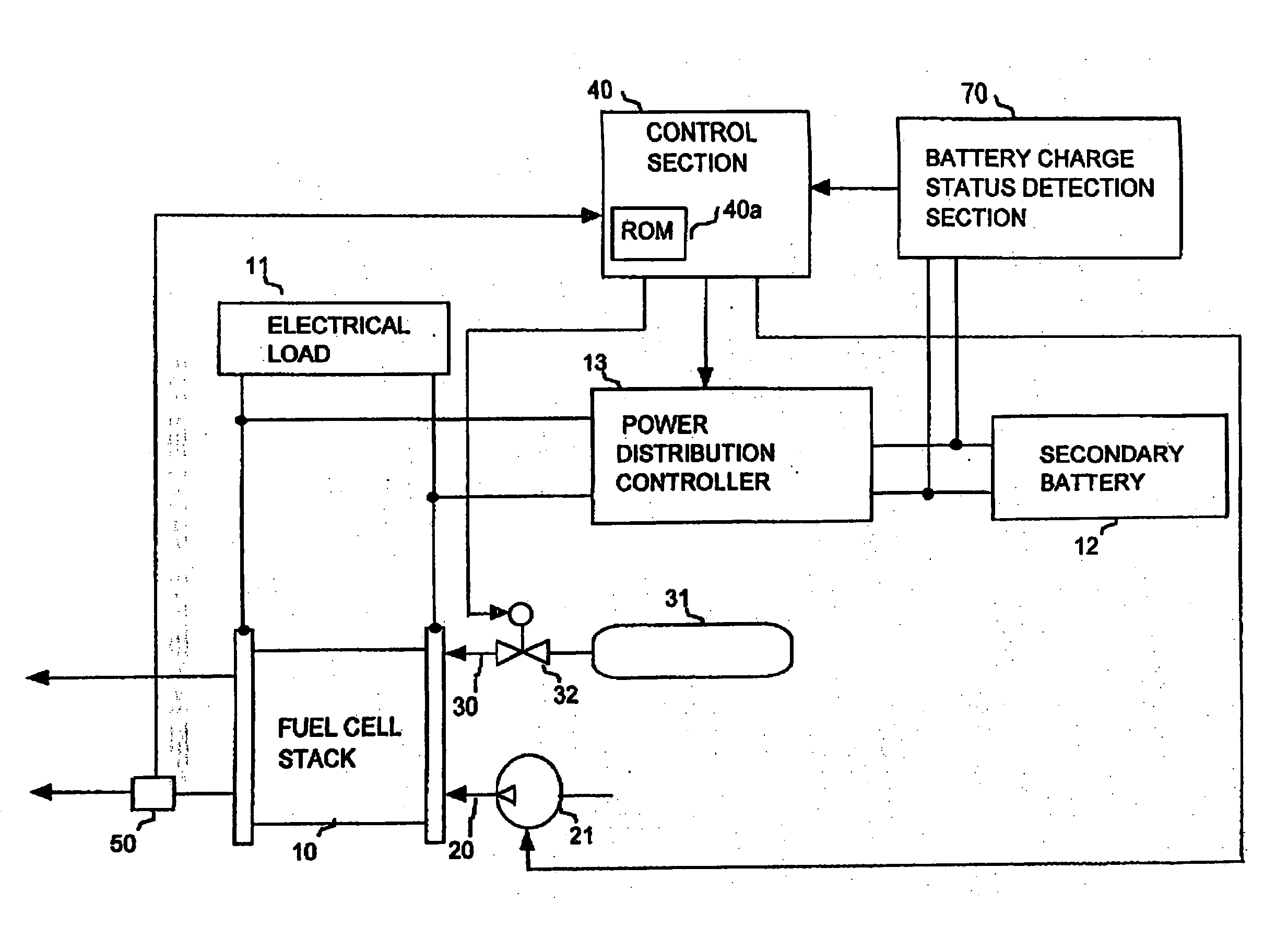

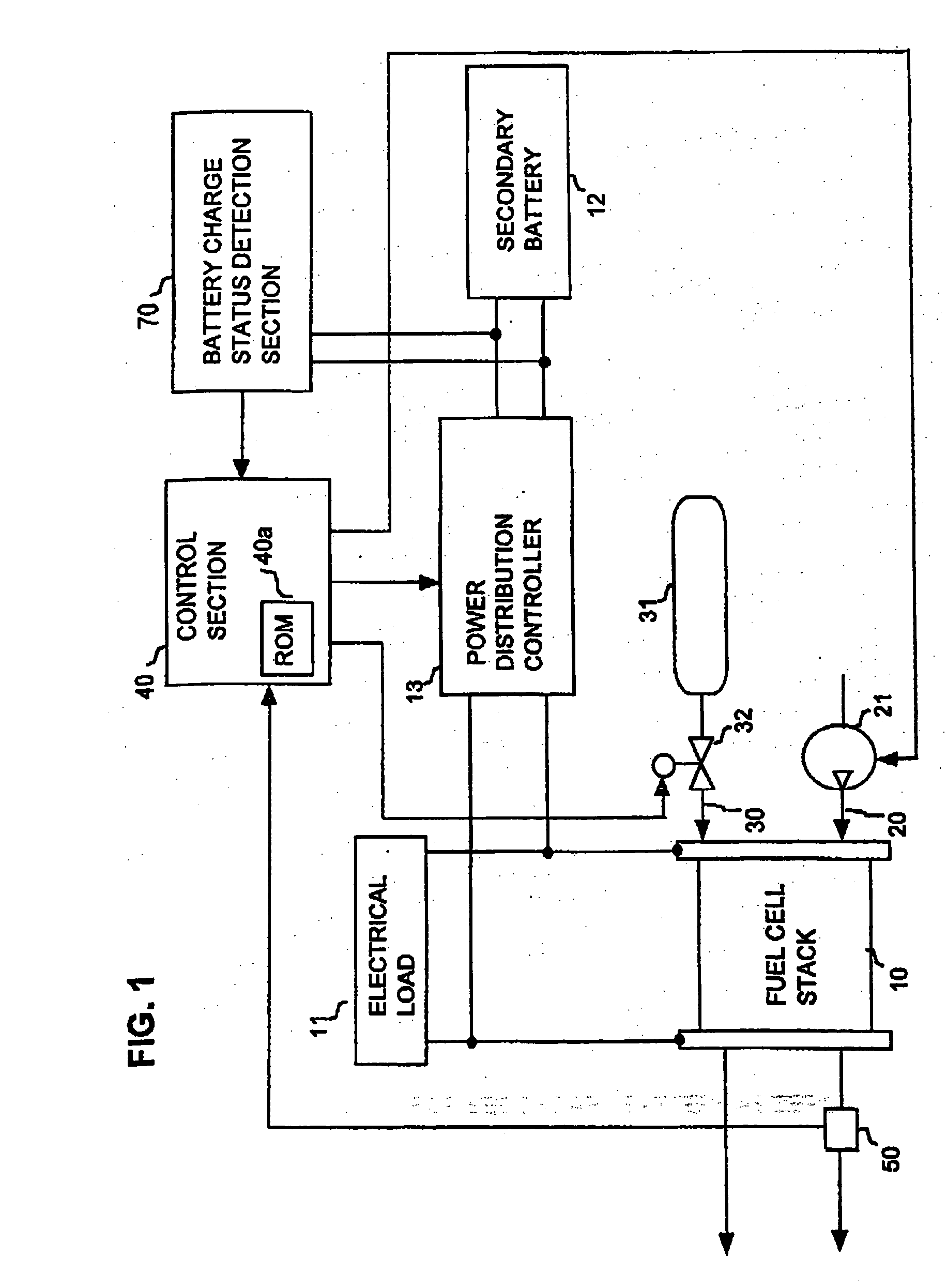

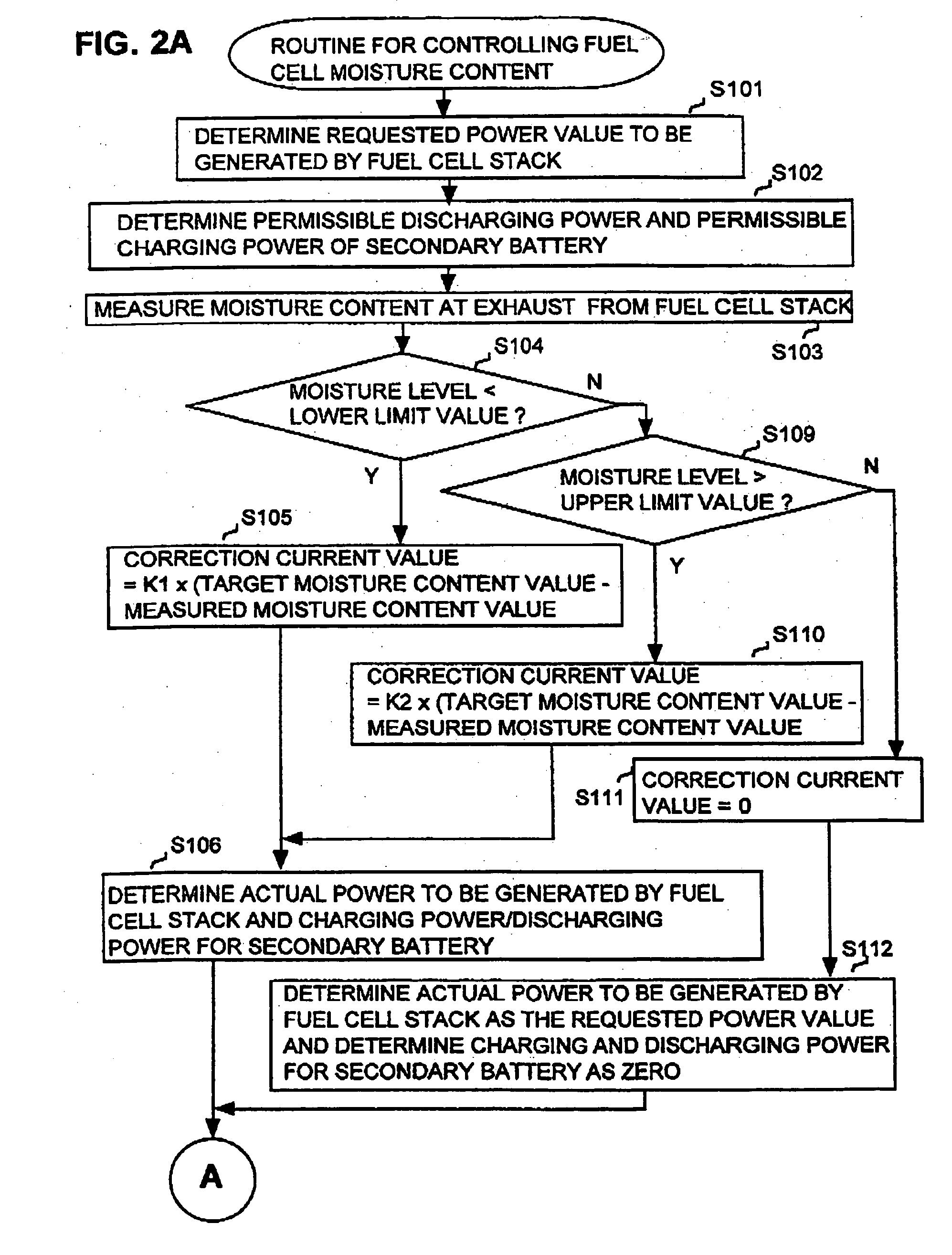

Fuel cell system utilizing control of operating current to adjust moisture content within fuel cell

InactiveUS20040166387A1Keep dryIncrease spawn rateDc network circuit arrangementsBatteries circuit arrangementsFuel cellsHydrogen

In a fuel cell system utilizing fuel cells which generate electric power by a reaction between oxygen and hydrogen, the moisture content within a fuel cell is adjusted to be brought within an appropriate range by adjusting the operating current of the fuel cell. The total amount of electric power generated by the system is maintained at a required value by supplying / obtaining electric power to / from a secondary battery as required, or by utilizing a plurality of separately controlled fuel cells (or fuel cell stacks) and increasing or decreasing the electric power generated by another fuel cell or stack that is currently operating with an appropriate moisture content.

Owner:DENSO CORP

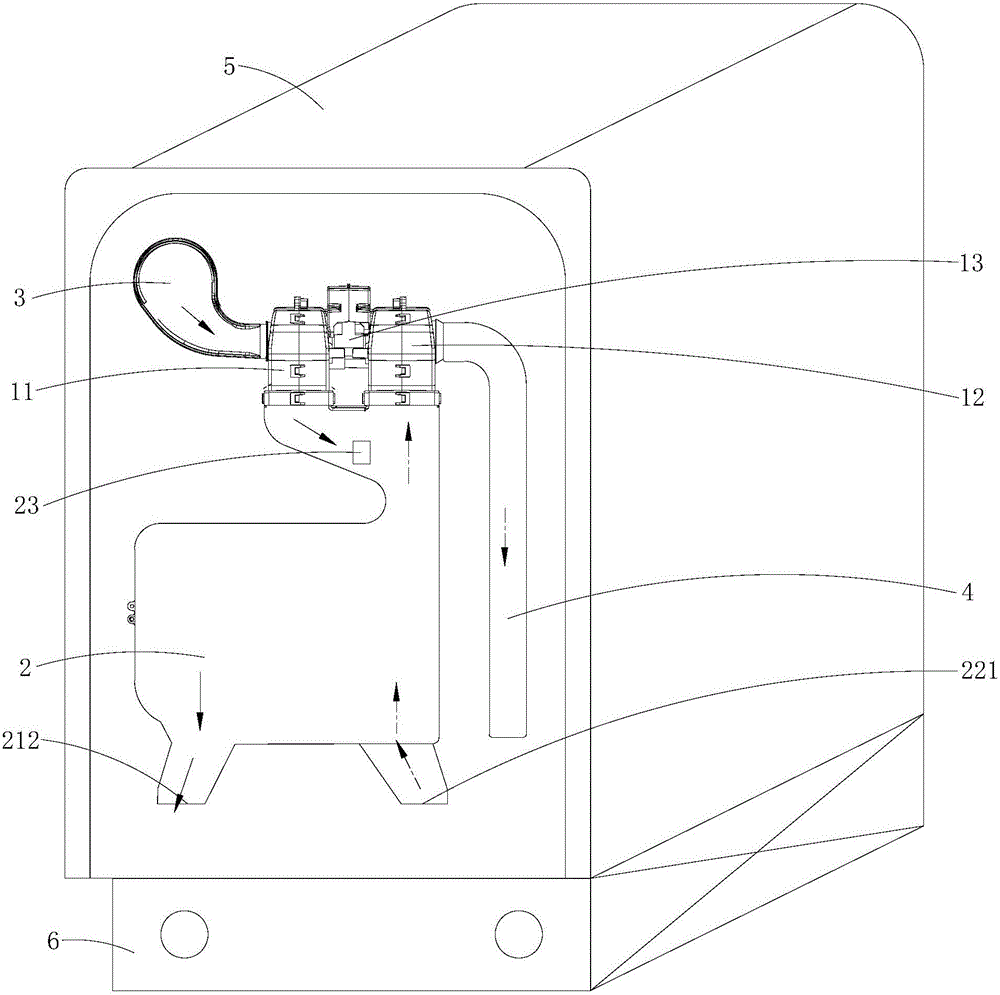

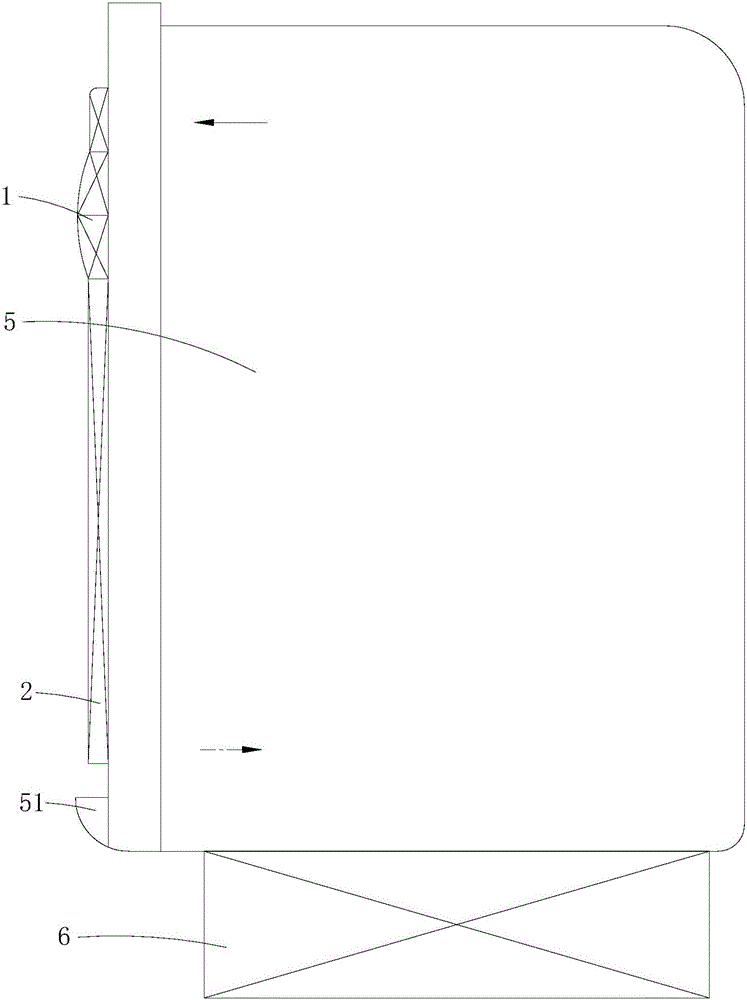

Condensing and drying device of dish-washing machine and dish-washing machine

InactiveCN105796033AKeep dryImprove drying efficiencyTableware washing/rinsing machine detailsHome appliance efficiency improvementWater flowEngineering

The invention is applicable to the field of dish-washing machines, and discloses a condensing and drying device of a dish-washing machine and the dish-washing machine. The condensing and drying device of the dish-washing machine is installed between an inner door and an outer door of the dish-washing machine and comprises an air-blasting assembly and a heat exchange component; a condensing cavity and a heating cavity are formed in the heat exchange component side by side, the air-blasting assembly comprises a first air-blasting component, a second air-blasting component and a power component, wherein the first air-blasting component can suck humid and hot air in an inner container of the dish-washing machine into the condensing cavity and outwards exhaust the air subjected to condensation of the condensing cavity, the second air-blasting component can suck external air located in front of the outer door into the heating cavity and exhaust the external air heated by the heating cavity into the inner container, and the power component is used for driving the first air-blasting component and the second air-blasting component to operate. According to the condensing and drying device of the dish-washing machine and the dish-washing machine, the situation that due to the fact that air exhausted from the dish-washing machine forms condensed water on the outer surface of the dish-washing machine, the condensed water sags on the outer surface of the dish-washing machine or drips onto the ground is prevented, necessary energy consumption in the drying process of the dish-washing machine is reduced, and meanwhile the internal hygiene condition of the dish-washing machine is effectively improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com