Patents

Literature

3606 results about "Dewatering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dewatering /diːˈwɔːtərɪŋ/ is the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes, such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes.

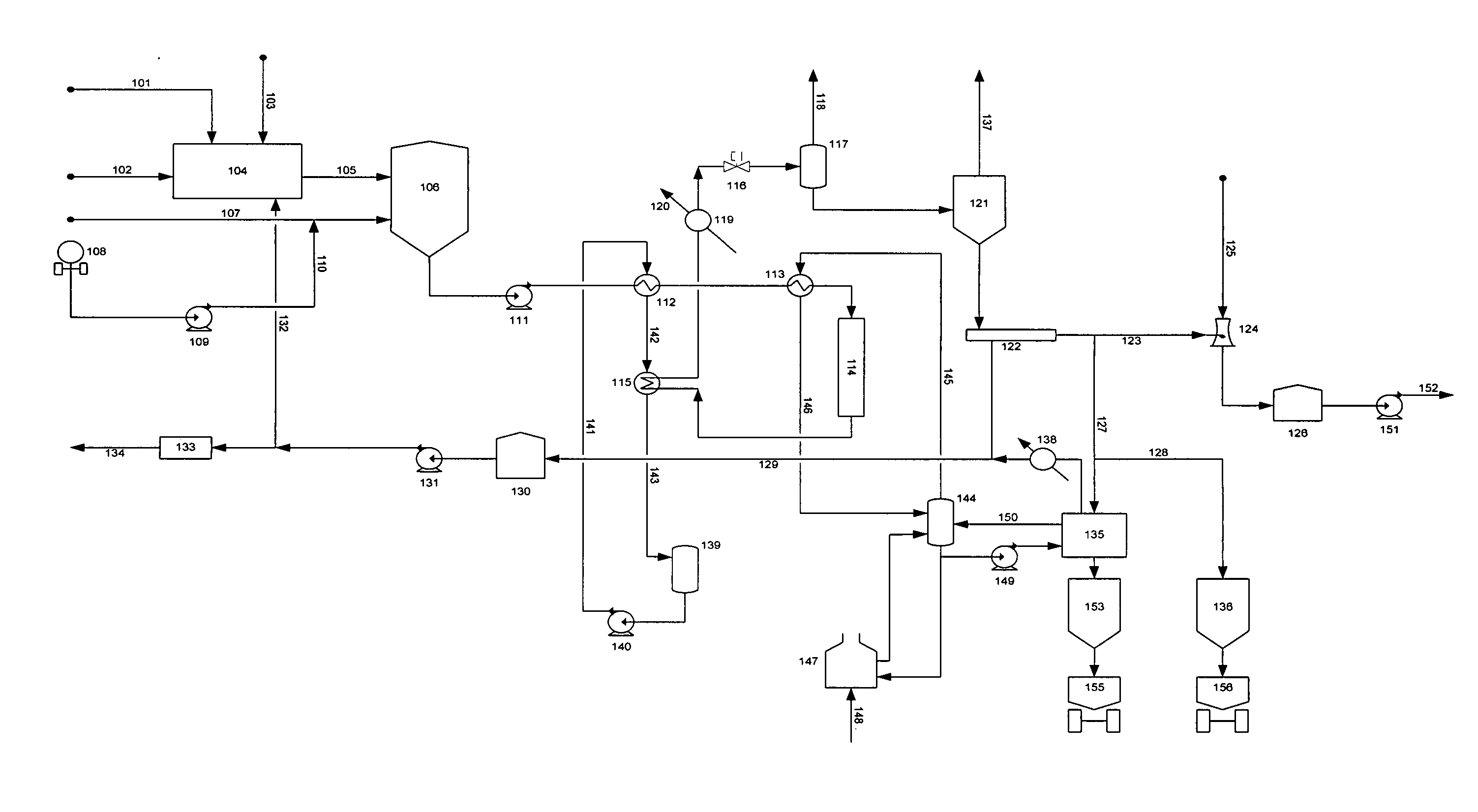

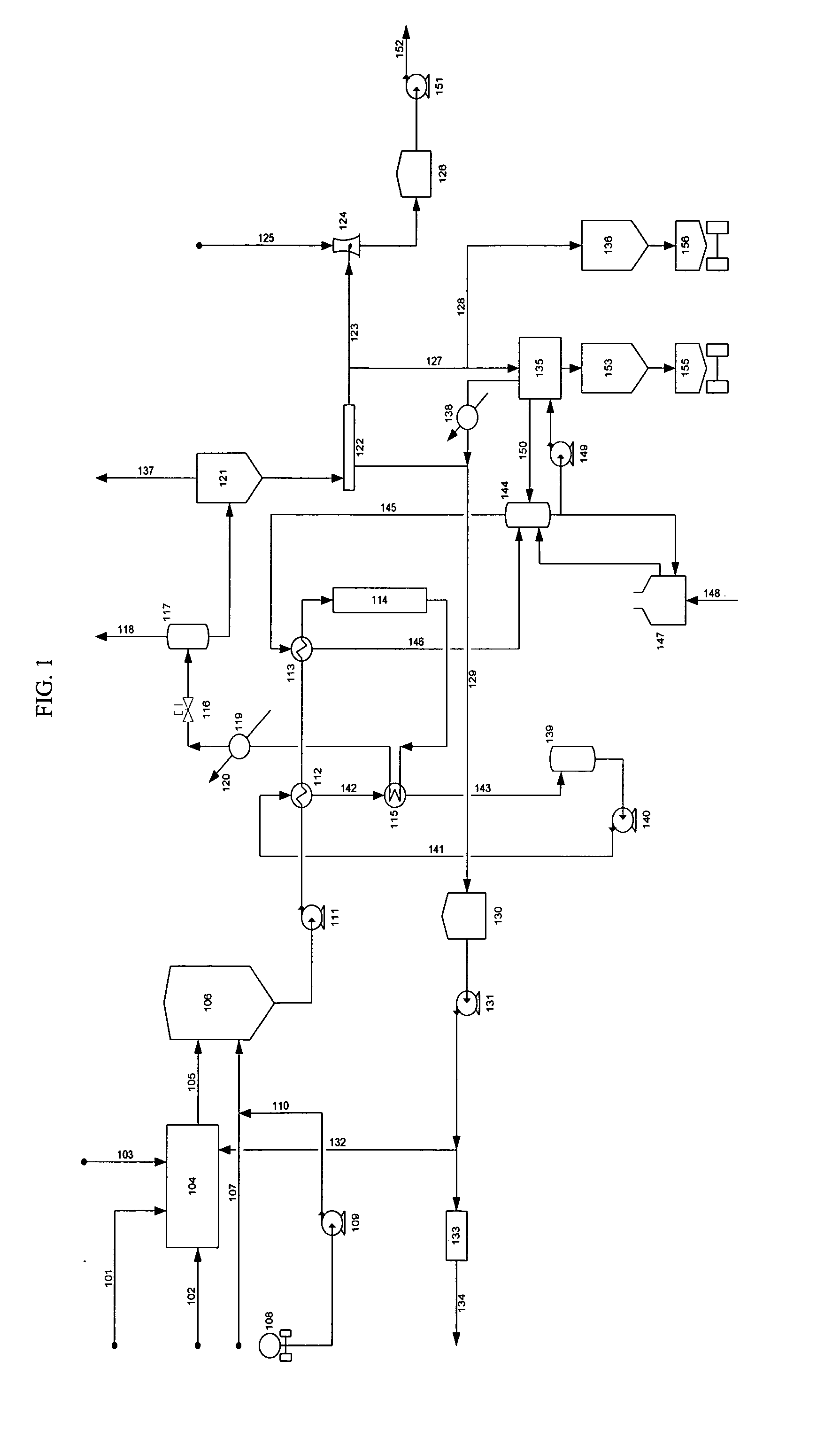

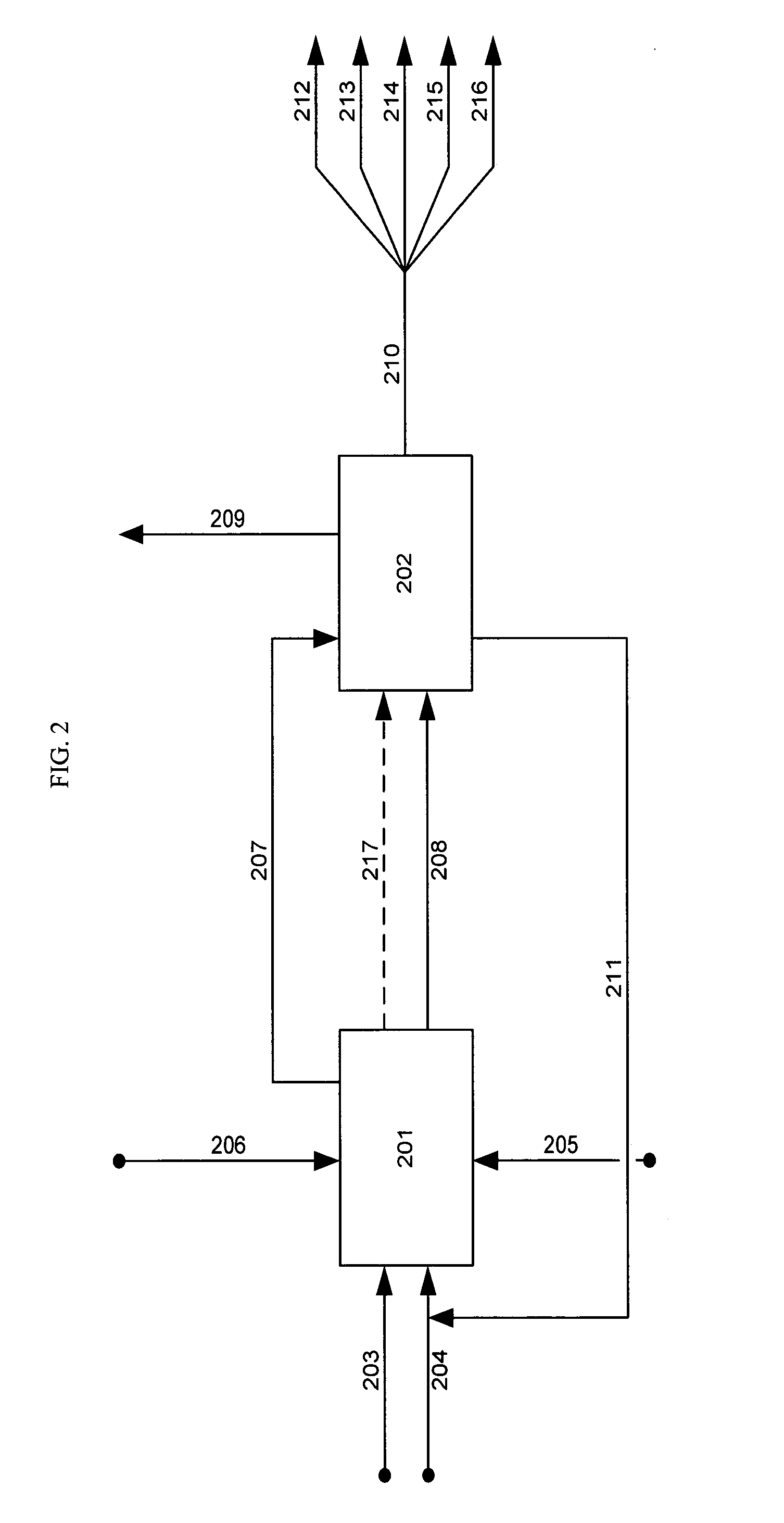

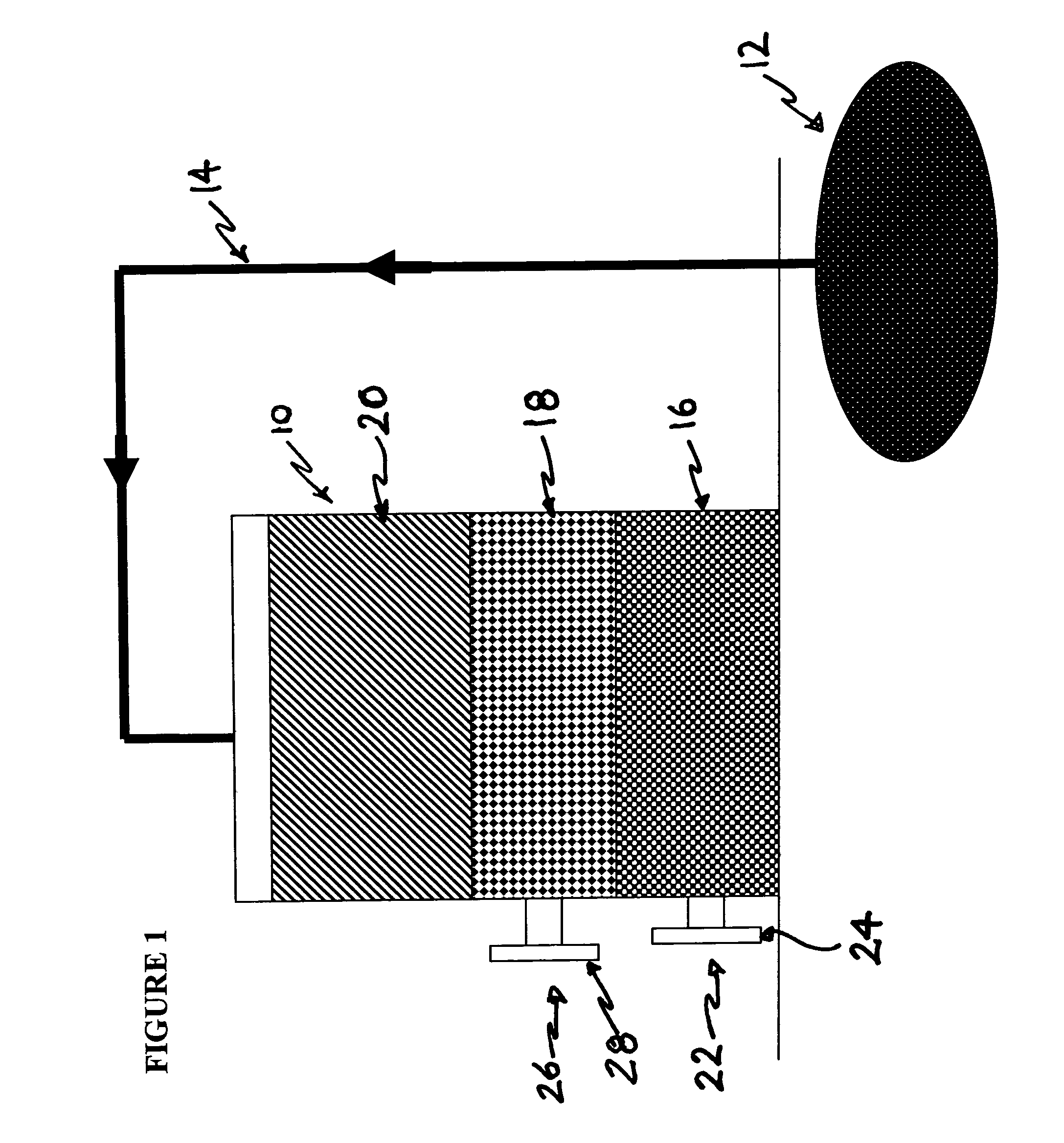

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

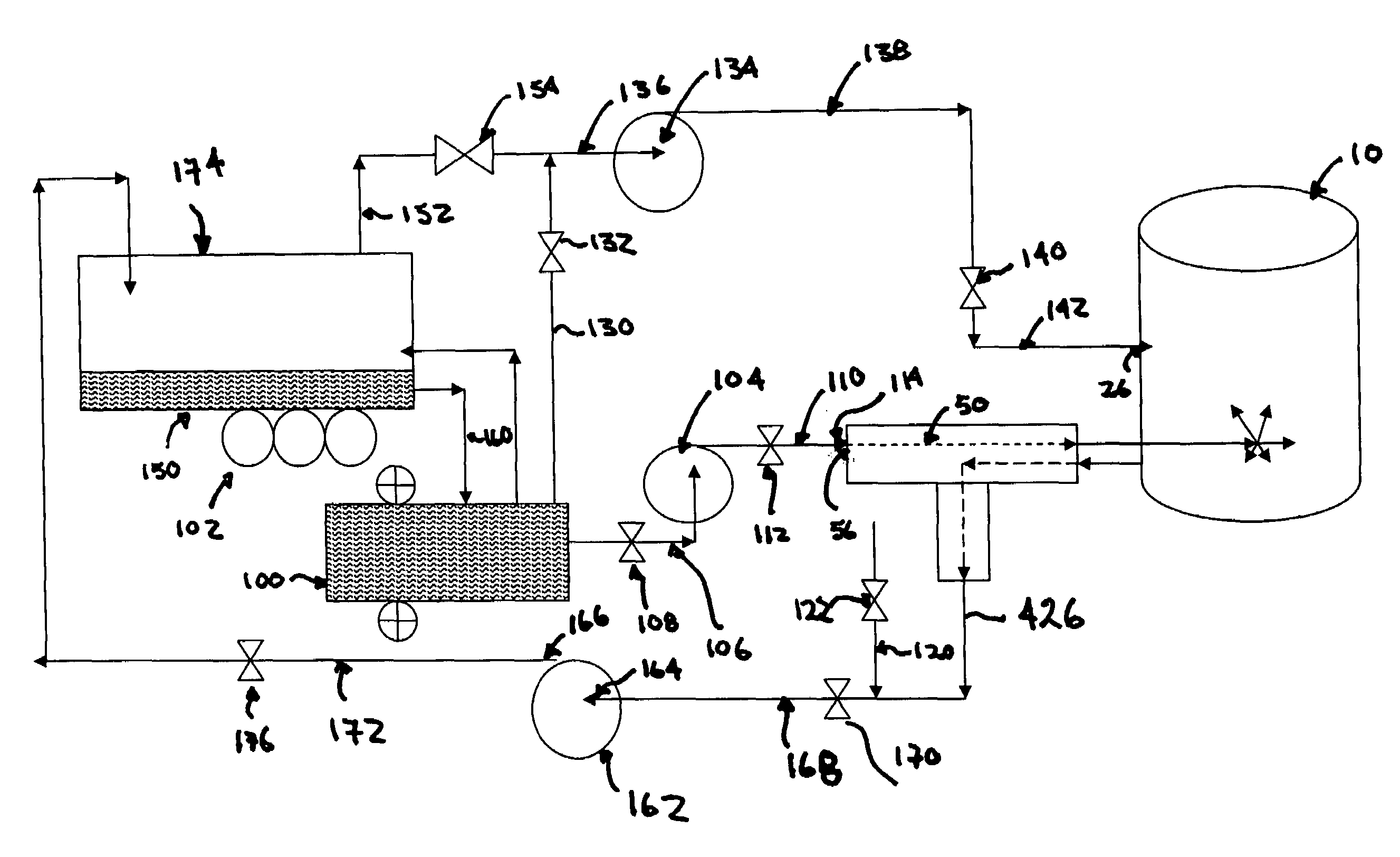

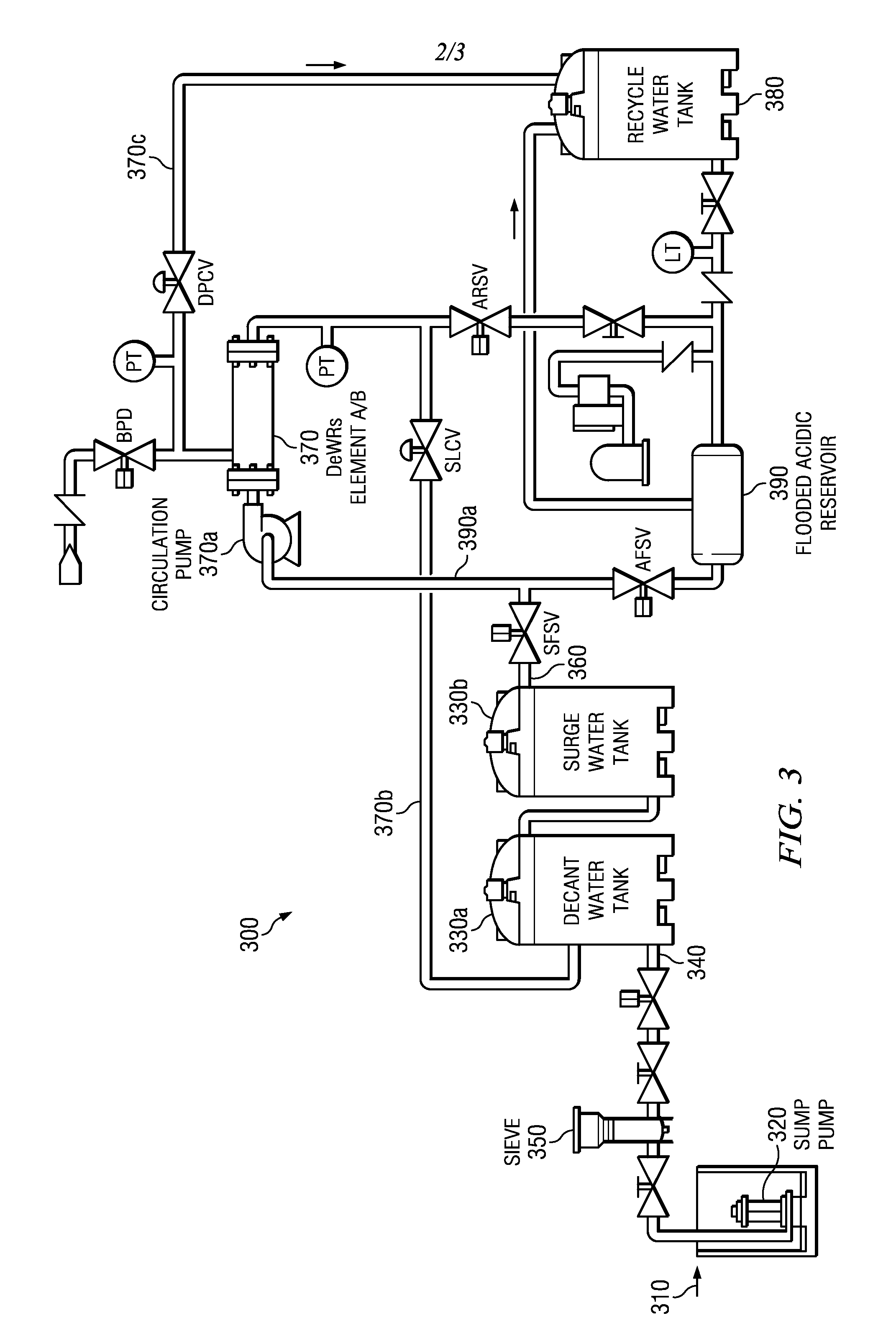

Trailer mounted mobile apparatus for dewatering and recovering formation sand

InactiveUS7240681B2Prevent leakageElectrostatic cleaningMultistage water/sewage treatmentDrive wheelHigh pressure water

An apparatus for removing formation sand from an oil storage tank. The apparatus is mounted to a truck towable trailer so that it may be transported to remote sites. Mounted to the truck towable trailer is a container adapted to accept and dewater a sand-water slurry pumped from the oil storage tank. The slurry is formed by injecting high pressure water from a water reservoir mounted to the truck towable trailer into the approximate centre of mass of the formation sand by way of a pipe having a nozzle generating a spherical spray pattern within the slurry. The pipe is forced into the slurry by way of a two counter-rotating drive wheels in frictional contact with the pipe. Included in the apparatus is a bifurcated conduit adapted for attachment to the storage tank drain port adapted for the injection of high pressure through one branch of the conduit and withdrawal of slurry from the other branch and into the container by way of a slurry pump. The dewatering of the slurry takes place by a plurality of screen filters mounted to the bottom, side and front inside walls of the container. Oil and water extracted from the slurry is recycled back into the storage tank for later removal and treatment. All pumps and conduits are mounted to the truck towable trailer so that the apparatus is self-contained.

Owner:SAIK LARRY

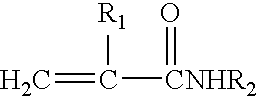

Method of using aldehyde-functionalized polymers to enhance paper machine dewatering

InactiveUS20050161181A1Accelerates the dehydration processNatural cellulose pulp/paperSpecial paperFiberPaper sheet

A method of enhancing the dewatering of a paper sheet on a paper machine comprising adding to the paper sheet about 0.05 lb / ton to about 15 lb / ton, based on dry fiber, of one or more aldehyde functionalized polymers comprising amino or amido groups wherein at least about 15 mole percent of the amino or amido groups are functionalized by reacting with one or more aldehydes and wherein the aldehyde functionalized polymers have a molecular weight of at least about 100,000.

Owner:ECOLAB USA INC

Process for extracting aluminium hydroxide from flyash

InactiveCN1792802AAchieve recyclingEffective leachingAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

A process for extracting aluminum oxide from powdered coal ash includes such steps as grinding, calcining, mixing with H2SO4 solution, heating while reaction for extracting aluminum oxide, boiling in water, concentrating, cooling while educing out aluminum sulfate crystals, heating for dewatering, heating for decomposing to obtain gamma-Al2O3, and further preparing metallurgy-class aluminum oxide.

Owner:朔州市人民政府 +2

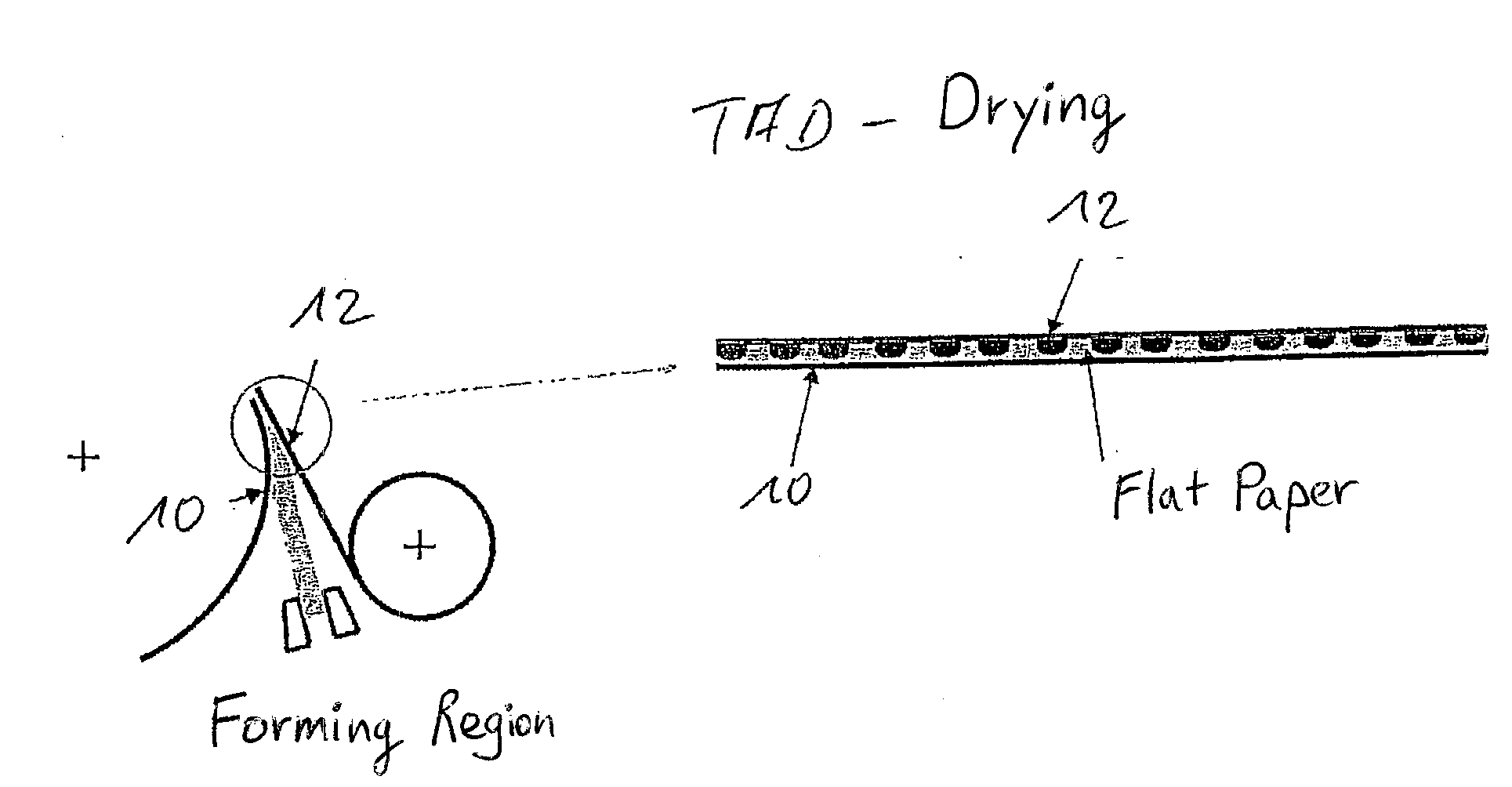

Machine for producing a fibrous web

InactiveUS20080149292A1Reduce absorptionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

A machine for producing a fibrous web, in particular a paper web, paperboard web or tissue web, includes a former on which the fibrous web is formed on a structured belt and is dewatered between said structured belt and a forming belt, and a drying apparatus for the further dewatering of the fibrous web, through which the fibrous web is guided together with the structured belt and in which hot air flows through the permeable structured belt and the fibrous web. The forming fabric is formed by a printed forming fabric or a DSP fabric with zonally different permeability.

Owner:VOITH PATENT GMBH

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

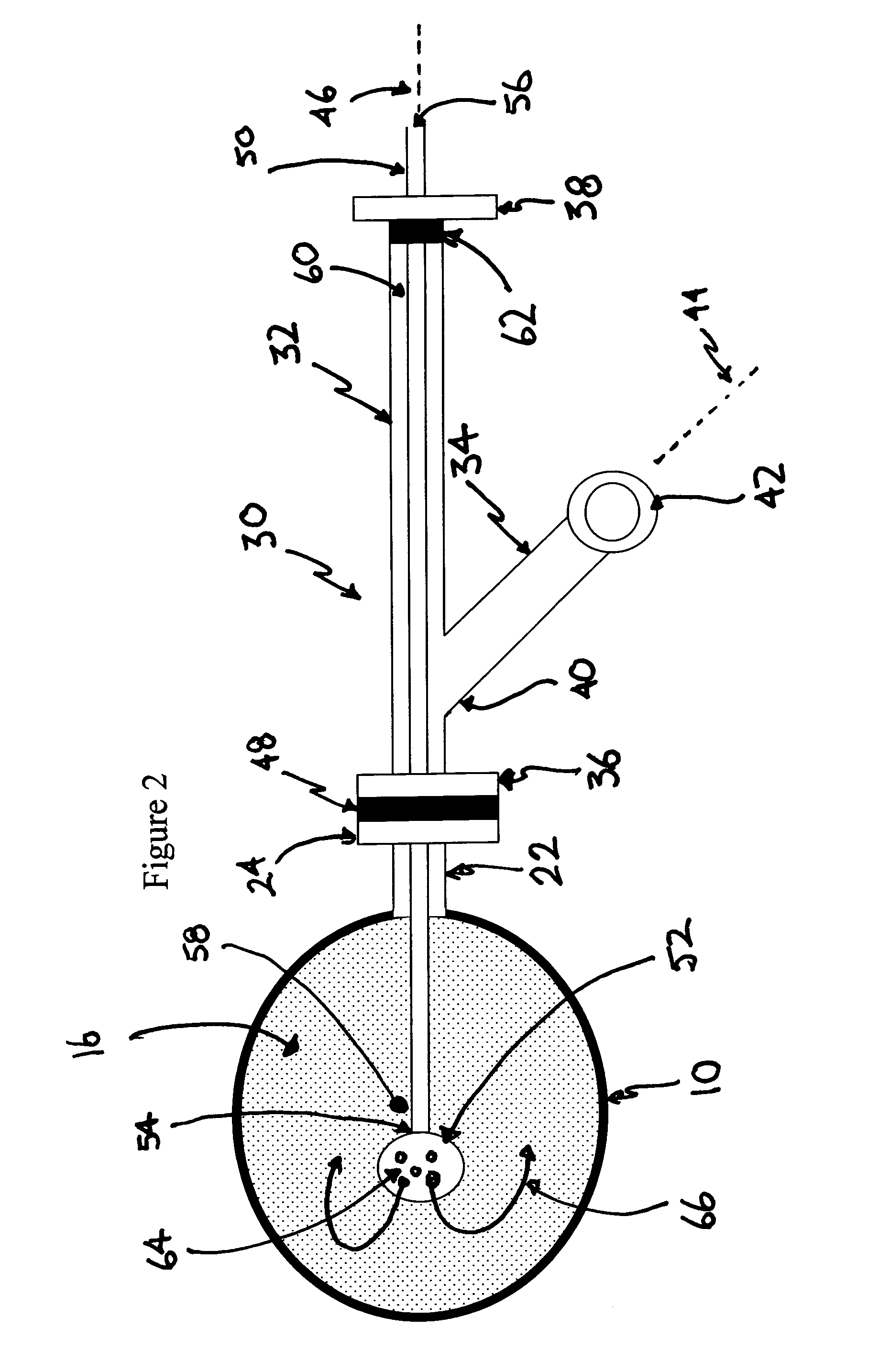

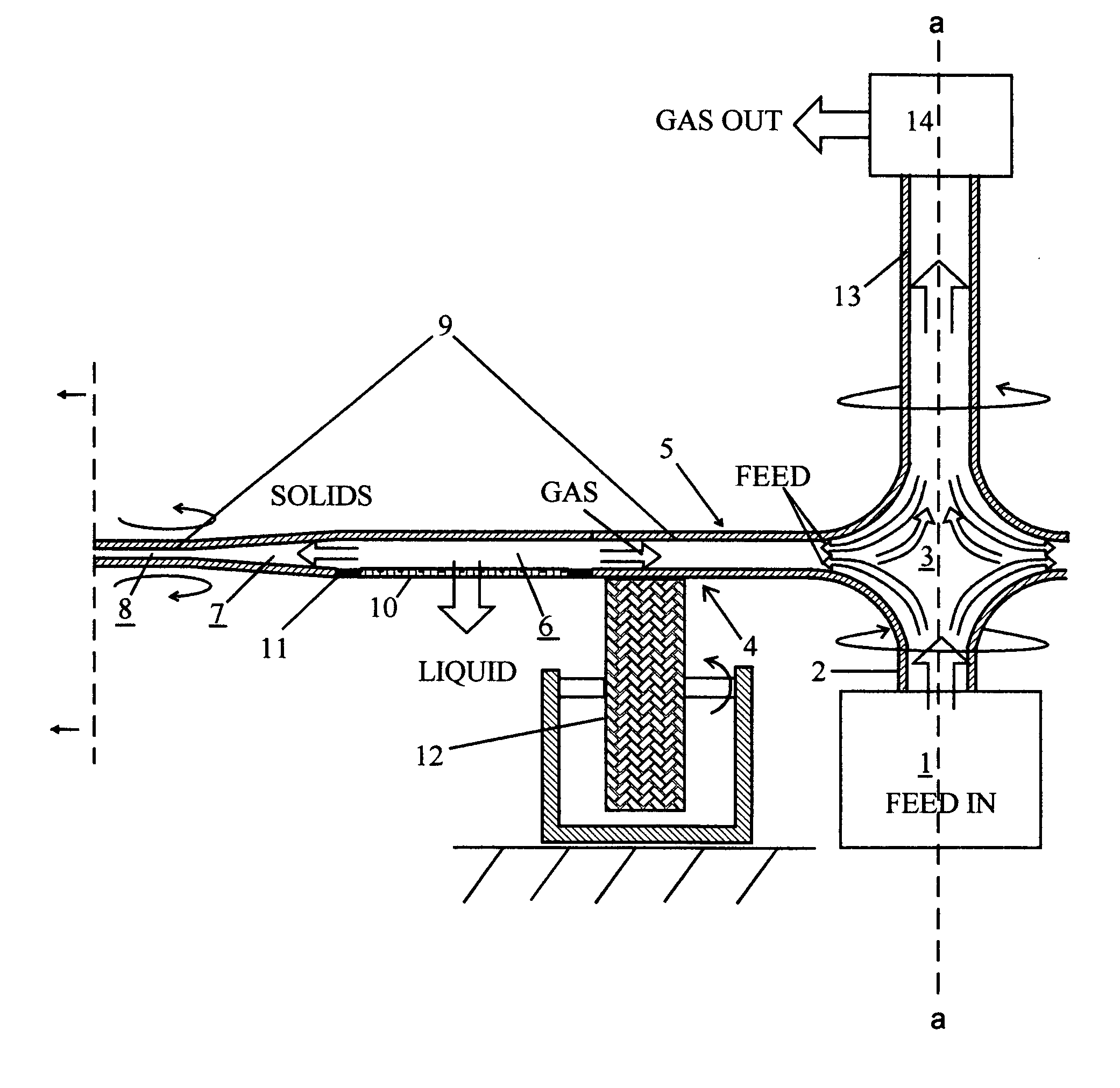

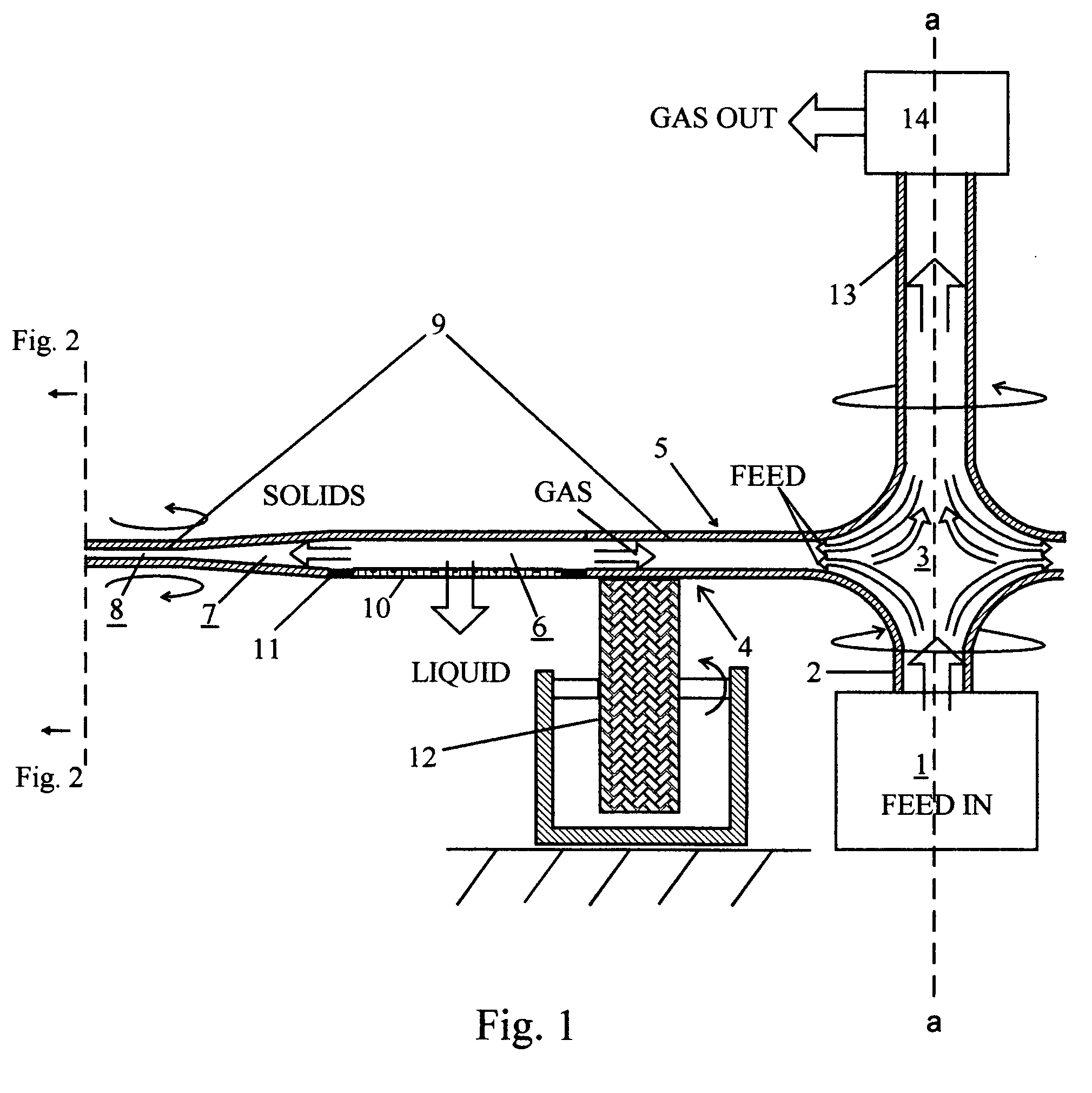

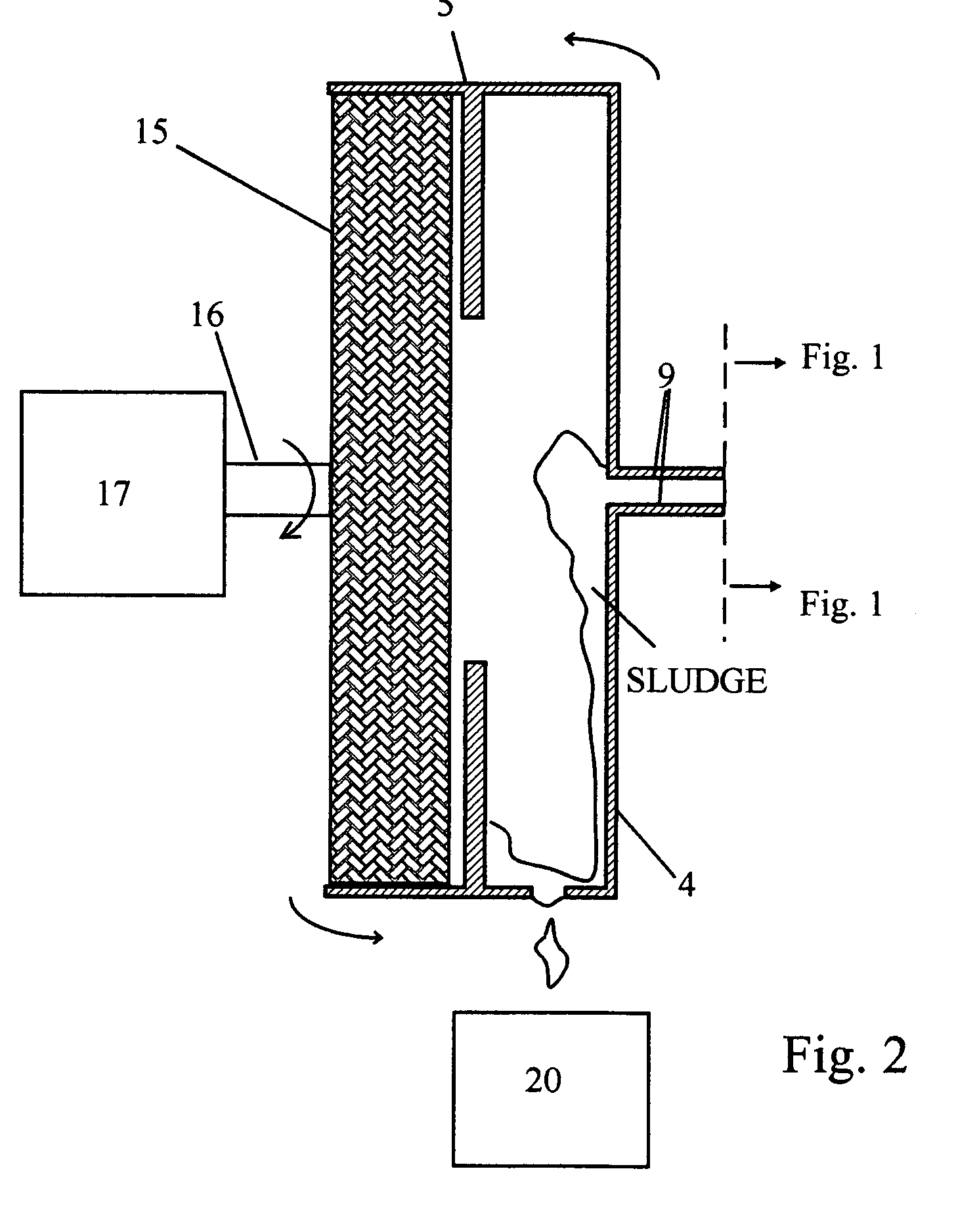

Rotary annular crossflow filter, degasser, and sludge thickener

ActiveUS20090159523A1Accelerate scrubbing reactionAvoid emissionsLiquid degasificationSludge treatmentHigh energySludge

A rotating annular crossflow filter shears radially outward flowing axial feed between counter-rotating coaxial centrifugal impellers. A radial impedance of flow at the impeller periphery slows the radially outward flow and increases residence time of feed between the impellers. Shear lift ejects solids from the boundary layer at the filter surface, and ejected solids collect by centrifugation at the impeller periphery, where they thicken into a sludge and are extruded. Gases, oils, floating solids, and fractions having a specific gravity less than water evolve into radial vortices and are sucked radially inward and out from between the impellers by an axial pump. Three way phase separation proceeds continuously in one pass through a simple mechanical device having a long residence time for feed in the processing zone.Opposing rugose portions of counter-rotating impeller surfaces cause audio frequency pressure pulses. At the impeller periphery, the pressure pulses milk liquid out of sludge. At the portion of the radial passage prior to the filter, pressure pulses evolve gases and degassed cavitation bubbles inactivate microbes. Degassing of the high energy forced periodic cavitation bubbles between the impellers removes the cushion of noncondensibles which would otherwise absorb energy on compression, therefore implosion becomes extremely violent and a barrage of high pressure pulses and ultraviolet light pulses inactivates microbes.Applications include field water purification, municipal and industrial wastewater degassing and sludge thickening, swimming pool filtration, effluent dewatering, wine and beverage degassing and clarification, fruit crushing, olive oil dewatering, produced brine and drilling mud processing, manure slurry dewatering and degassing, and recovery of solvents and fine suspended solids from fluid mixtures such as wastewater from machining operations.

Owner:VORSANA INC

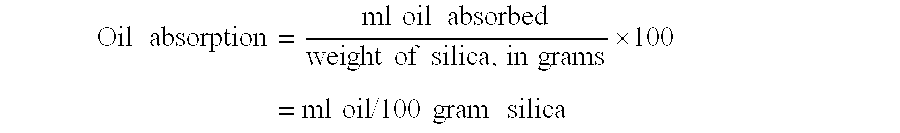

Method for making particulate compositions and products thereof

InactiveUS20070001037A1Easy to produceImprove uniformityCosmetic preparationsOther chemical processesParticulatesSilicon dioxide

A method of making abrasive compositions, and more particularly, it relates to a method of making precipitated silica abrasive compositions having excellent cleaning performance and lower abrasiveness with post-reactor sizing of the abrasive particles being performed directly via wet comminution and centrifugation, optionally followed by hydraulic chamber press filtering combined with vacuum dewatering and de-agglomeration is provided. By targeting a specific particle size range, it has been determined that higher pellicle film cleaning levels may be achieved without also increasing the dentin abrasion properties of the silica products themselves. As a result, dentifrices including such classified abrasive silica products, exhibiting particularly desirable cleaning benefits, can be provided for improved tooth polishing, whitening, and the like, without deleteriously affecting the hard tooth surfaces. Also encompassed within this invention also are products of this selective process scheme and dentifrices containing such particularly manufactured and classified silica products.

Owner:J M HUBER CORP

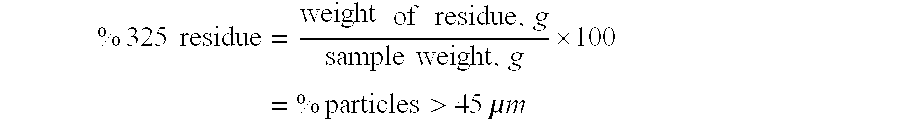

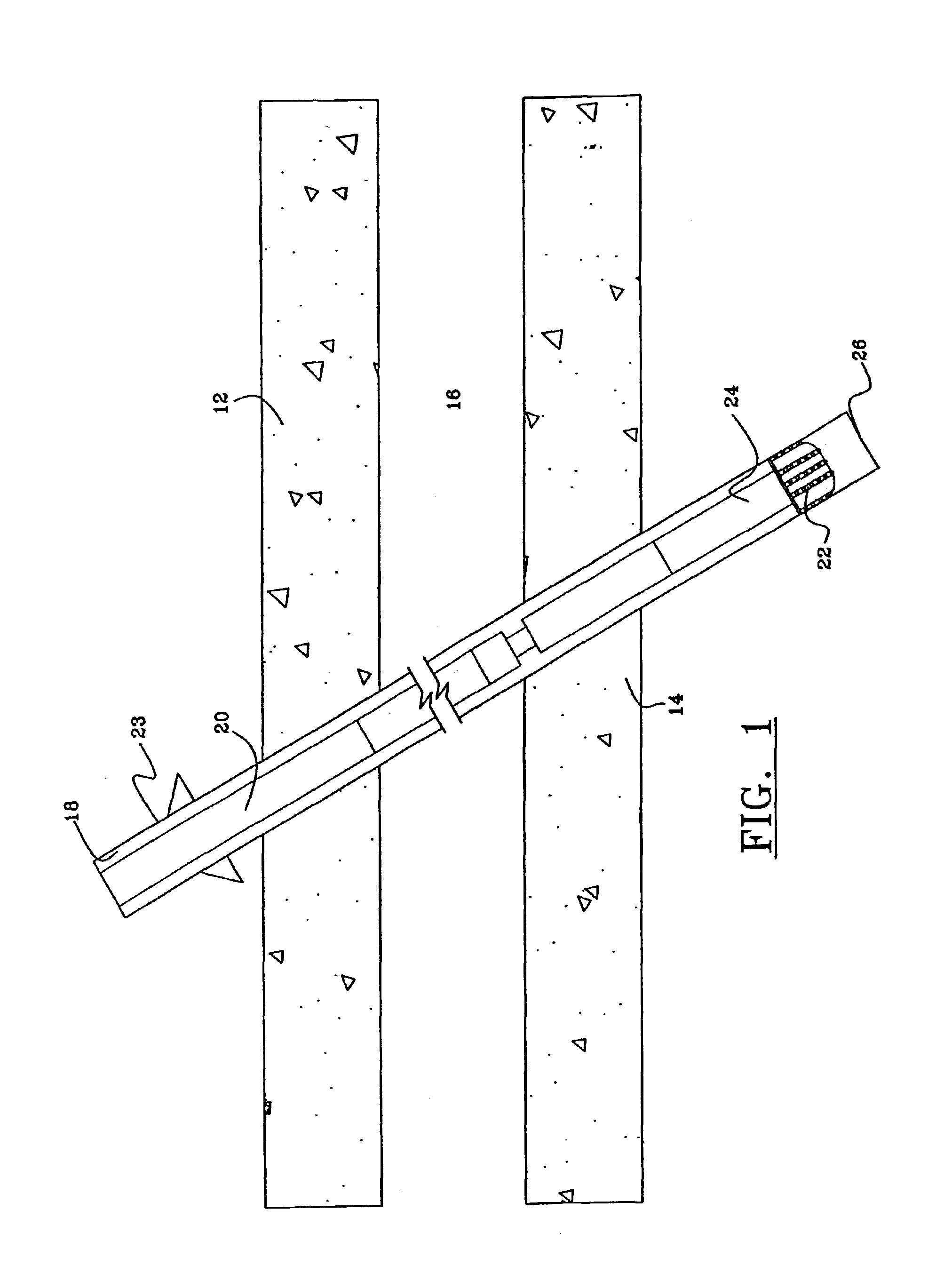

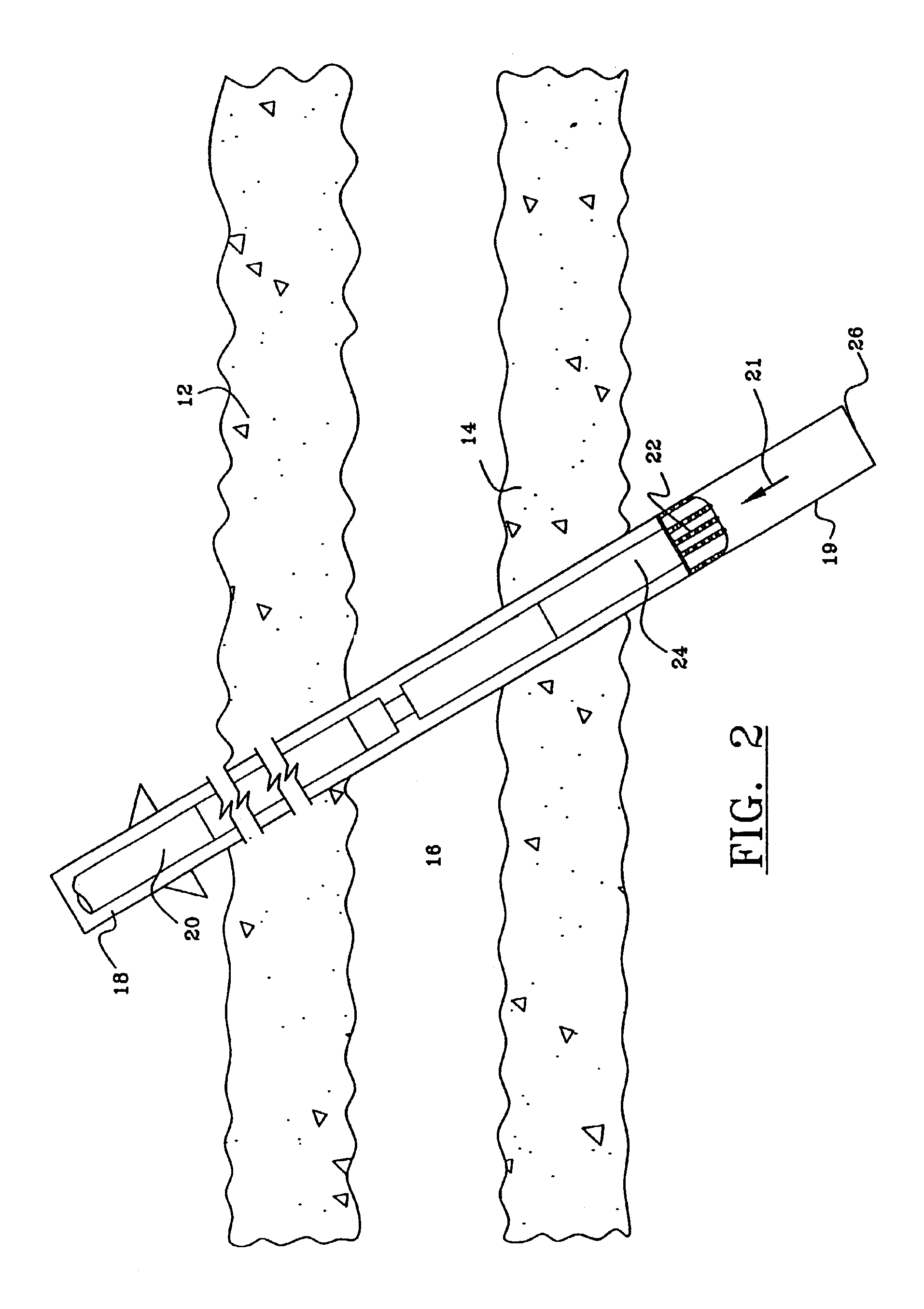

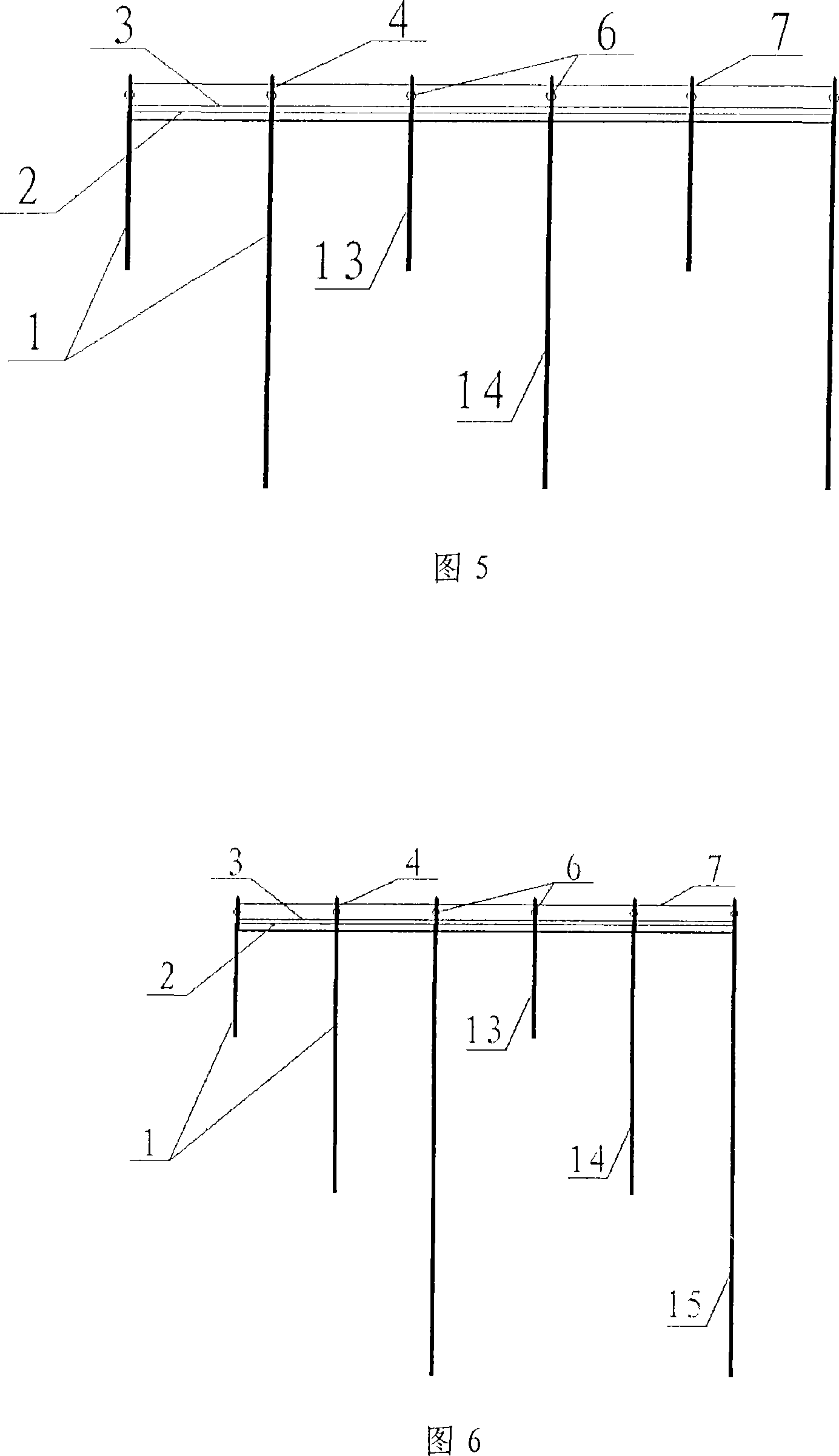

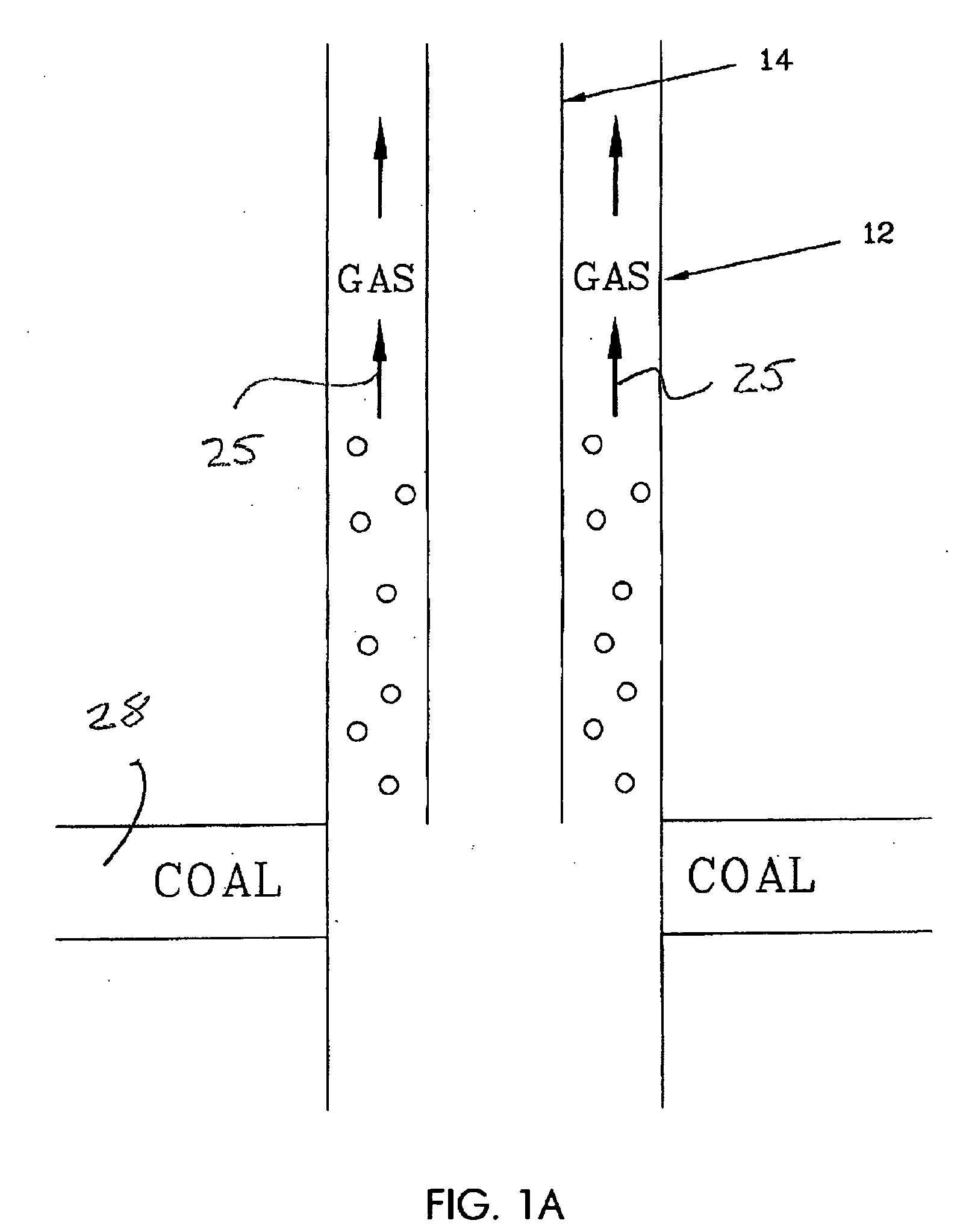

Multi seam coal bed/methane dewatering and depressurizing production system

InactiveUS6923275B2Minimal environmental impactEliminate infrastructure long-term maintenance and environmental impactFluid removalDirectional drillingWell drillingProduct gas

A process for underbalanced drilling into multiple coal and shale formations, and dewatering the drilled formations, which includes drilling a first borehole through several coal seams to a certain depth, defined as a cased borehole; lowering an upstock on the end of a carrier string to the depth of the upper coal seam; lowering a drill string in the carrier string, and angling off of the upstock, to drill a lateral or horizontal borehole within the coal seam; repeating the process for the second coal seam; setting a packer in place above the first coal seam in the annulus between the cased borehole and the carrier string; forming perforations in the wall of the carrier string below the packer; retrieving the upstock from the carrier string; lowering an electrical submersible pump to the bottom of the principal borehole, defined as a sump portion of the borehole; collecting methane gas from the two coal seams through the annulus between the second drill string and the carrier string to the surface; pumping water from the sump portion to the surface within the annulus of the second drill string, while gas within the annulus between the carrier string and the outer casing enters the plurality of perforations in the carrier string to be carried up to the surface.

Owner:GARDES ROBERT

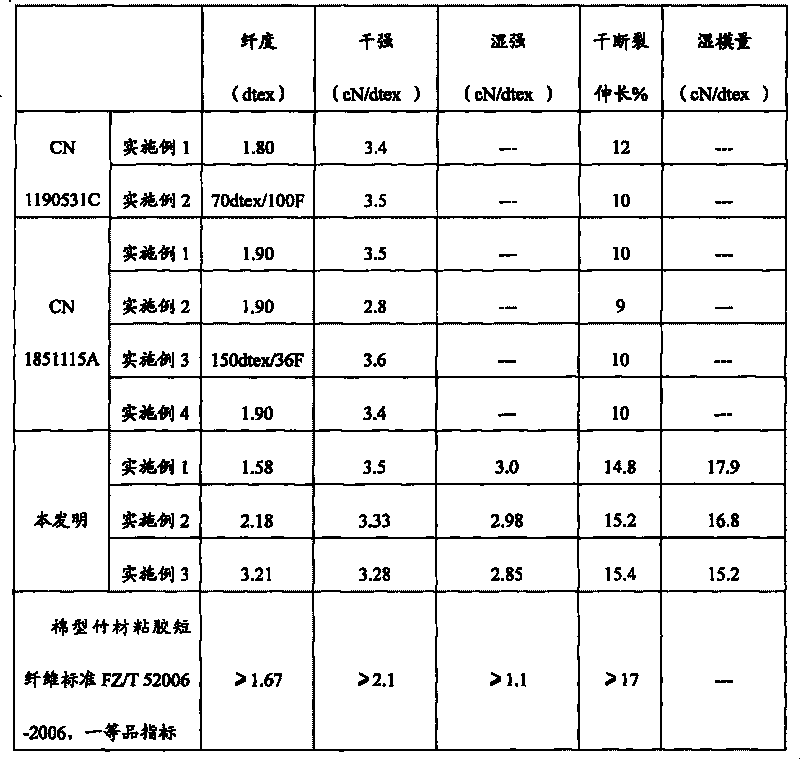

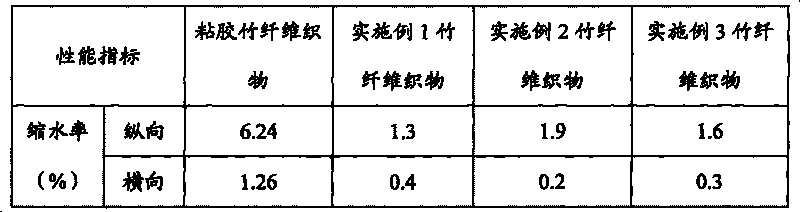

Solvent method high-wet-modulus bamboo fiber and preparation method thereof

ActiveCN101694019AEasy to operateReduce energy consumptionMonocomponent cellulose artificial filamentVegetable materialFiberCellulose

The invention discloses a solvent method high-wet-modulus bamboo fiber and a preparation method thereof. The preparation method of the bamboo fiber comprises the following steps: activation, adding bamboo pulp into deionized water, adjusting the pH value, adding cellulase for activation, and then adding alkali to adjust the pH value; squeezing, vacuum dewatering and squeezing; pre-dissolving, adding water solution containing 50-88% of N-methyl morpholine-N-oxide; dissolving, entering a dissolving machine, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning, spraying through a spinneret plate, and molding by adopting a dry wet spinning; washing; whitening; oiling; and drying. The preparation method has simple operation, no industrial pollution, low energy consumption and high safety performance, and is applicable to manufacturing the solvent method bamboo fiber by large-scale industrialized continuous production; furthermore, the bamboo fiber prepared by the method not only maintains the natural physical and chemical properties of the bamboo fiber, but also generates no harmful chemical residue and has higher wet modulus.

Owner:SHANGHAI LYOCELL FIBER DEV

Methods of using modified natural products as dewatering aids for fine particles

InactiveUS6375853B1Reduce moistureHigh degreeDrying solid materials without heatSolid fuelsNatural productTransesterification

Naturally occurring lipids of vegetable and animal origin are broken into smaller molecules, and used as dewatering aids. The process of breaking the molecules include transesterification, interesterification, and saponification followed by acidulation. The modified lipid molecules can adsorb on the surface of the particles to be dewatered and greatly enhance their hydrophobicity, which will help increase the rate of dewatering and hence reduce cake moisture. The modified lipids are more effective dewatering aids than the naturally occurring unmodified lipids, possibly because they can more readily form close-packed monolayers of hydrophobes on the surface of the particles.

Owner:YOON ROE HOAN

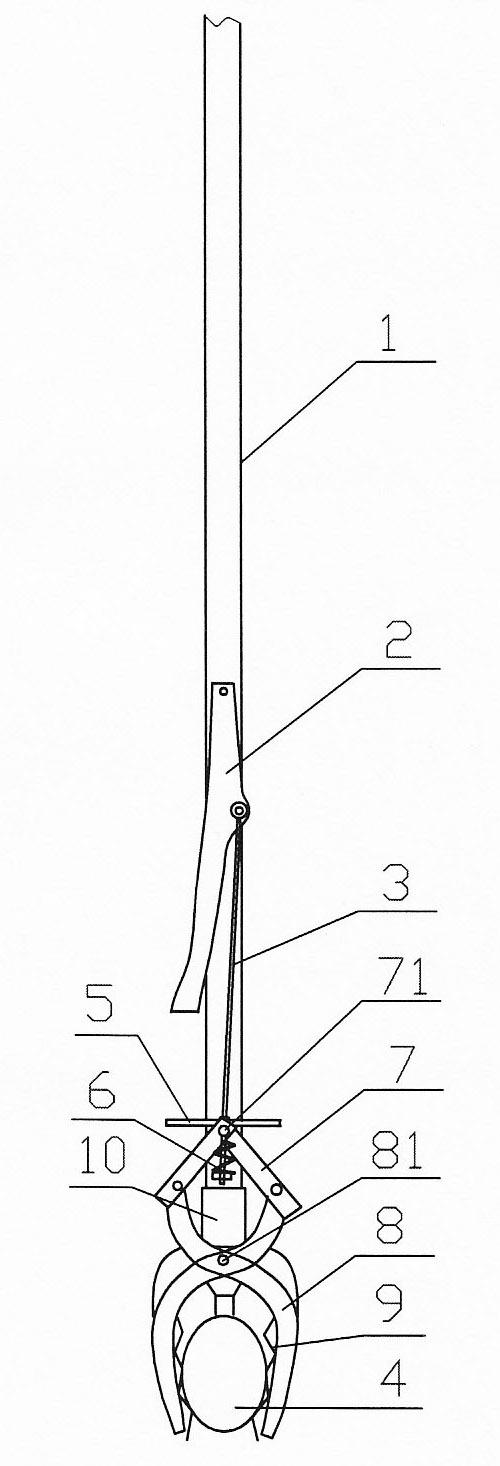

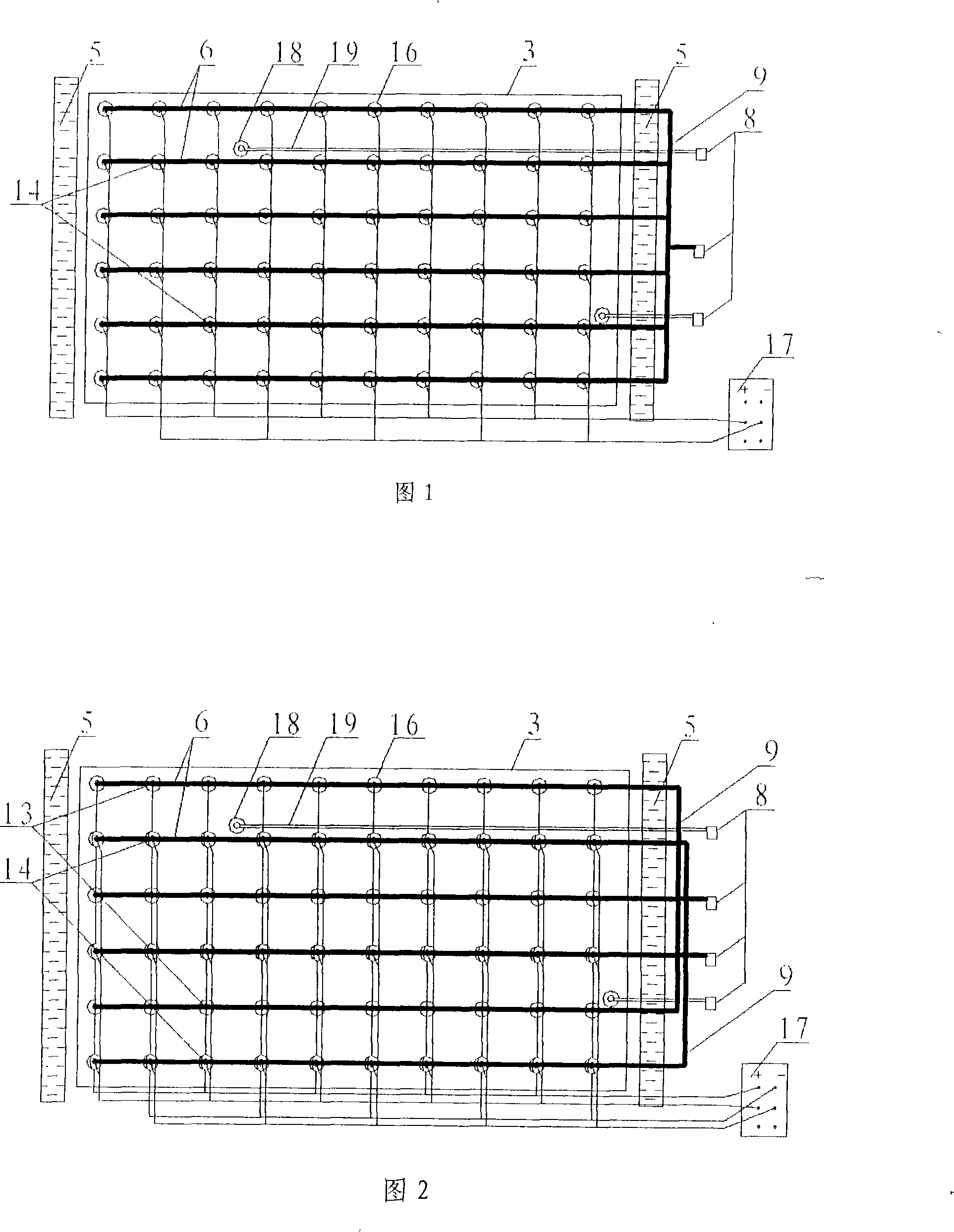

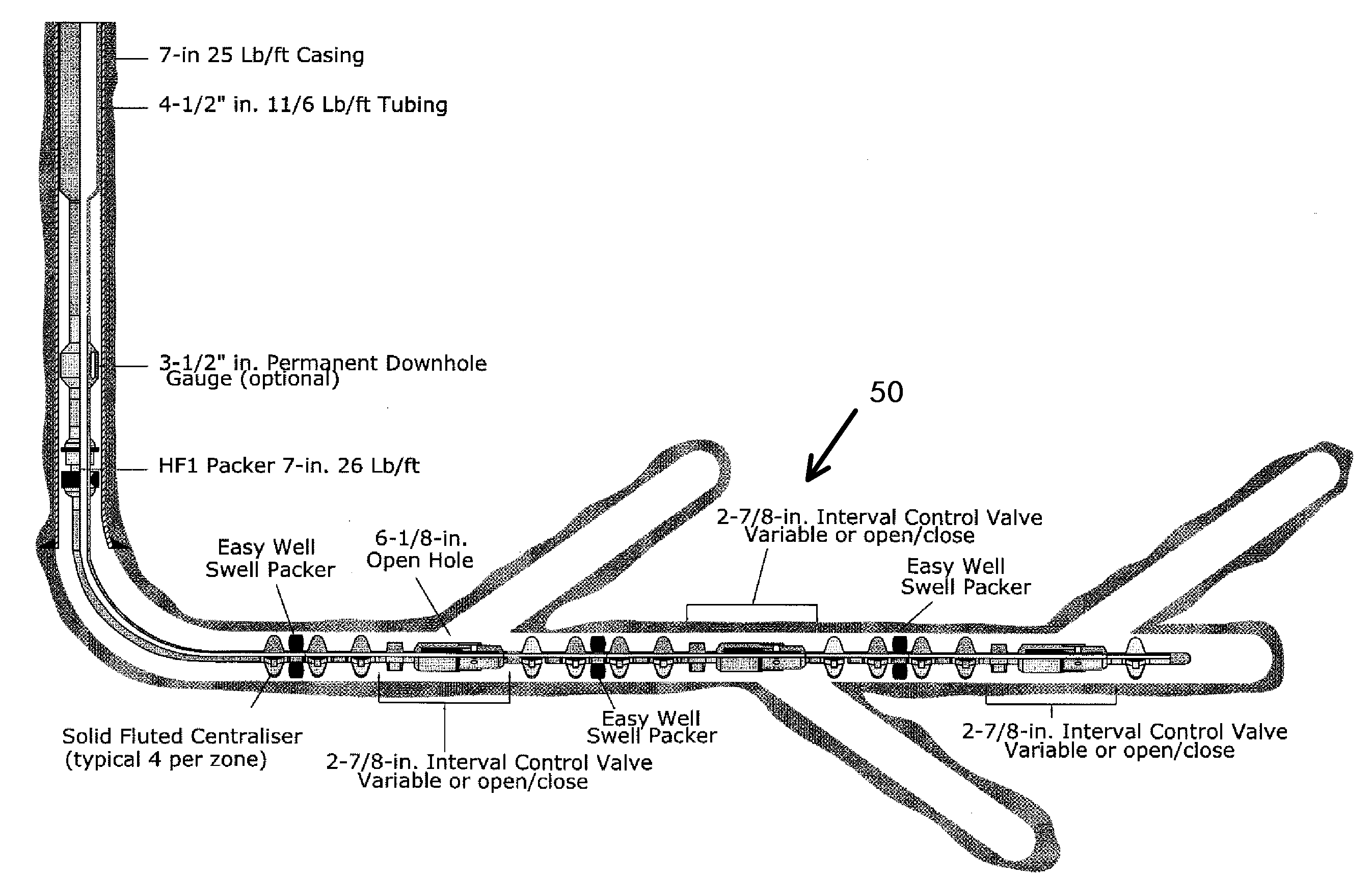

Movable multifunctional collodion cotton mop

InactiveCN102138771AExtended service lifeClean dehydrationCarpet cleanersFloor cleanersPush and pullAgricultural engineering

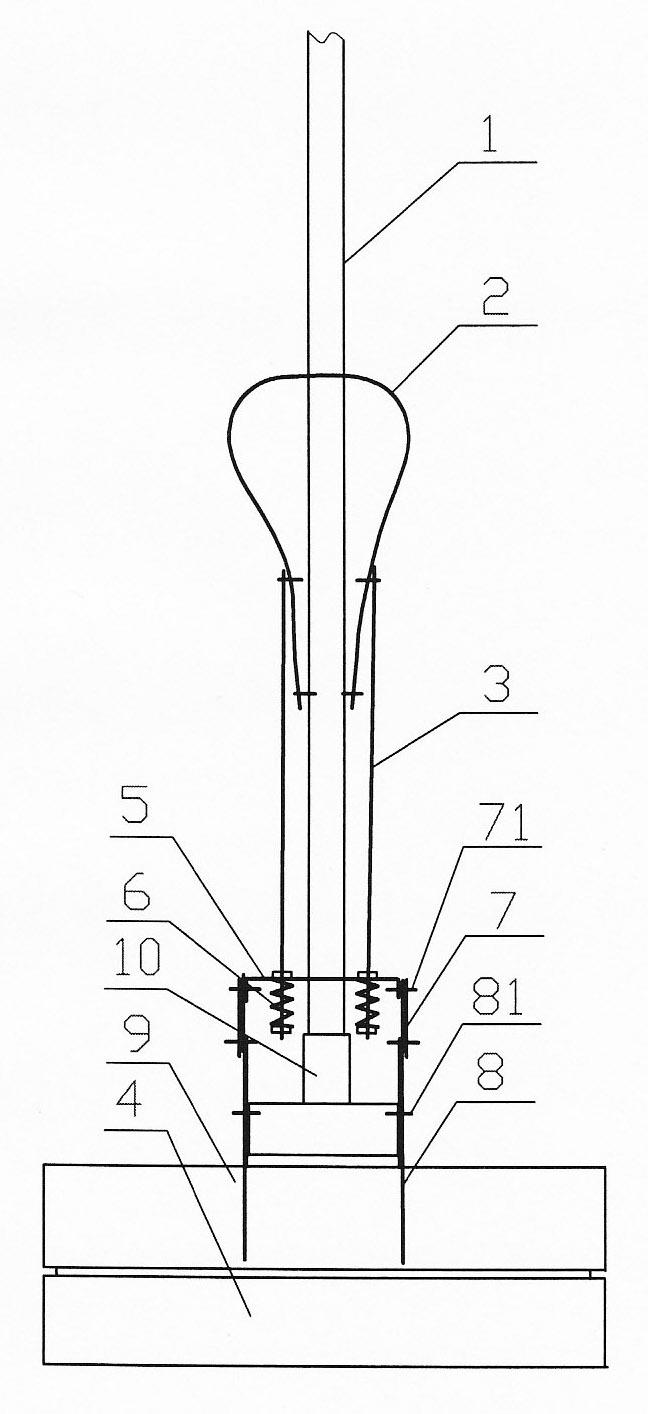

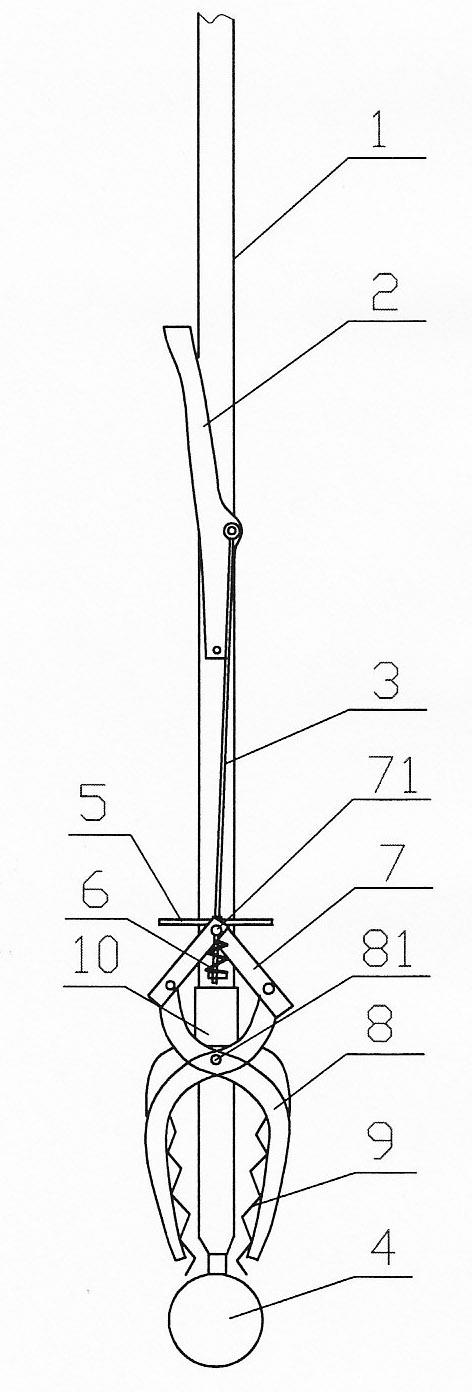

The invention discloses a movable multifunctional collodion cotton mop. The mop comprises a mop rod 1, a handle 2, a push-and-pull rod 3, collodion cotton 4 and a movable dewatering and clamping mechanism, wherein the upper end of the push-and-pull rod 3 is arranged on the handle 2 through a connecting pin, and the lower end of the push-and-pull rod 3 is connected with the movable dewatering and clamping mechanism; the collodion cotton 4 is arranged at the bottom of the mop rod 1; the movable dewatering and clamping mechanism is connected with a connecting plate 5, a spring 6, a connecting rod 7, a dewatering plate frame 8, a dewatering plate 9 and a rod sleeve 10; the connecting plate 5 is sleeved on the mop rod 1; the lower end of the push-and-pull rod 3 is arranged on the connecting plate 5 through the spring 6 and a nut; the upper end of the connecting rod 7 is connected with the connecting plate 5 through a connecting pin 71, and the lower end of the connecting rod 7 is connected with the upper end of the dewatering plate frame 8 through a connecting pin; the dewatering plate frame 8 is X-shaped and is arranged on the rod sleeve 10 through a connecting pin; the dewatering plate 9 is arranged on the X-shaped dewatering plate frame 8; and the rod sleeve 10 is sleeved on the mop rod 1. The mop disclosed by the invention has the advantages of complete dewatering, long service life, easiness of operation and the like.

Owner:张承志

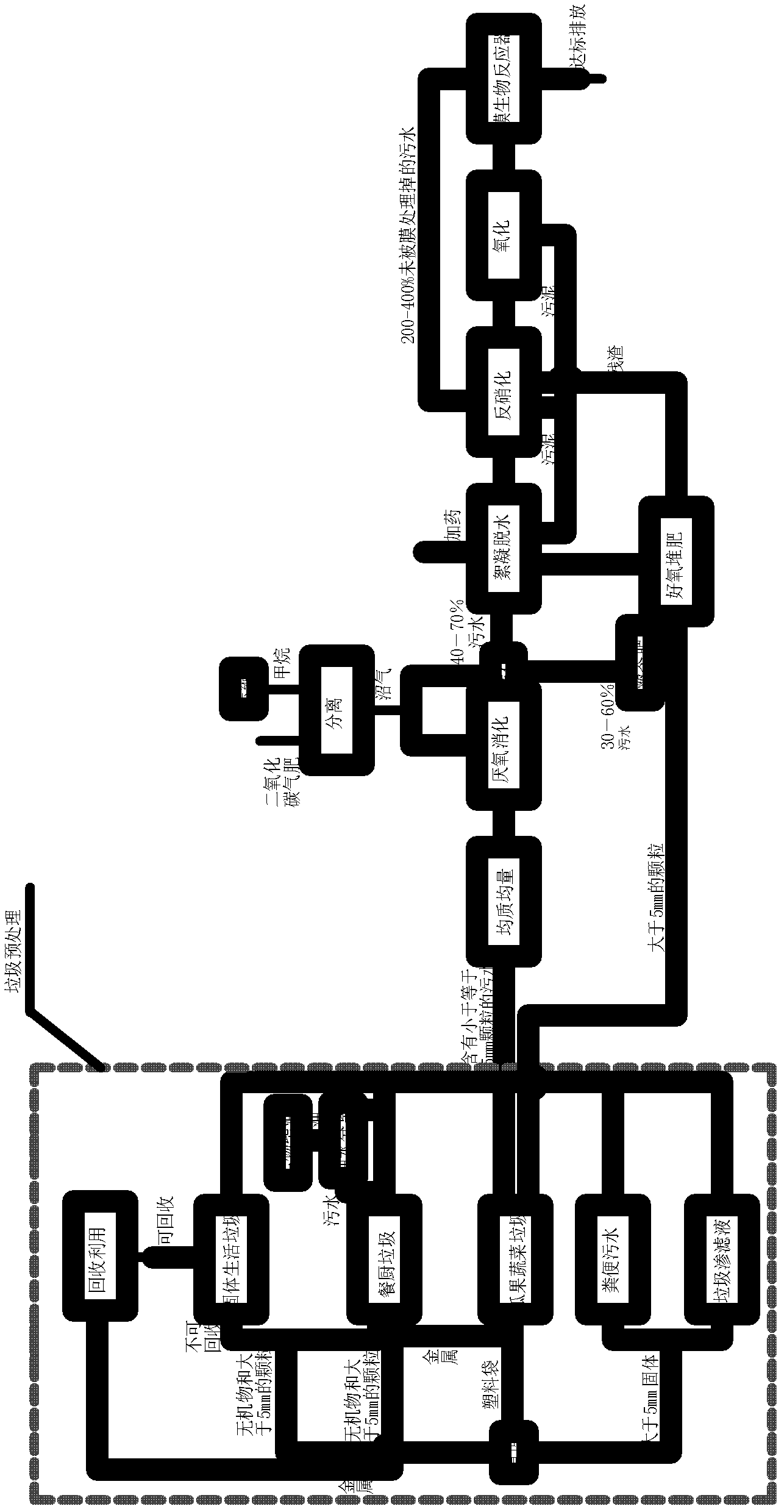

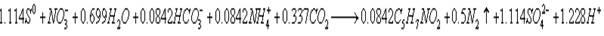

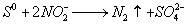

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

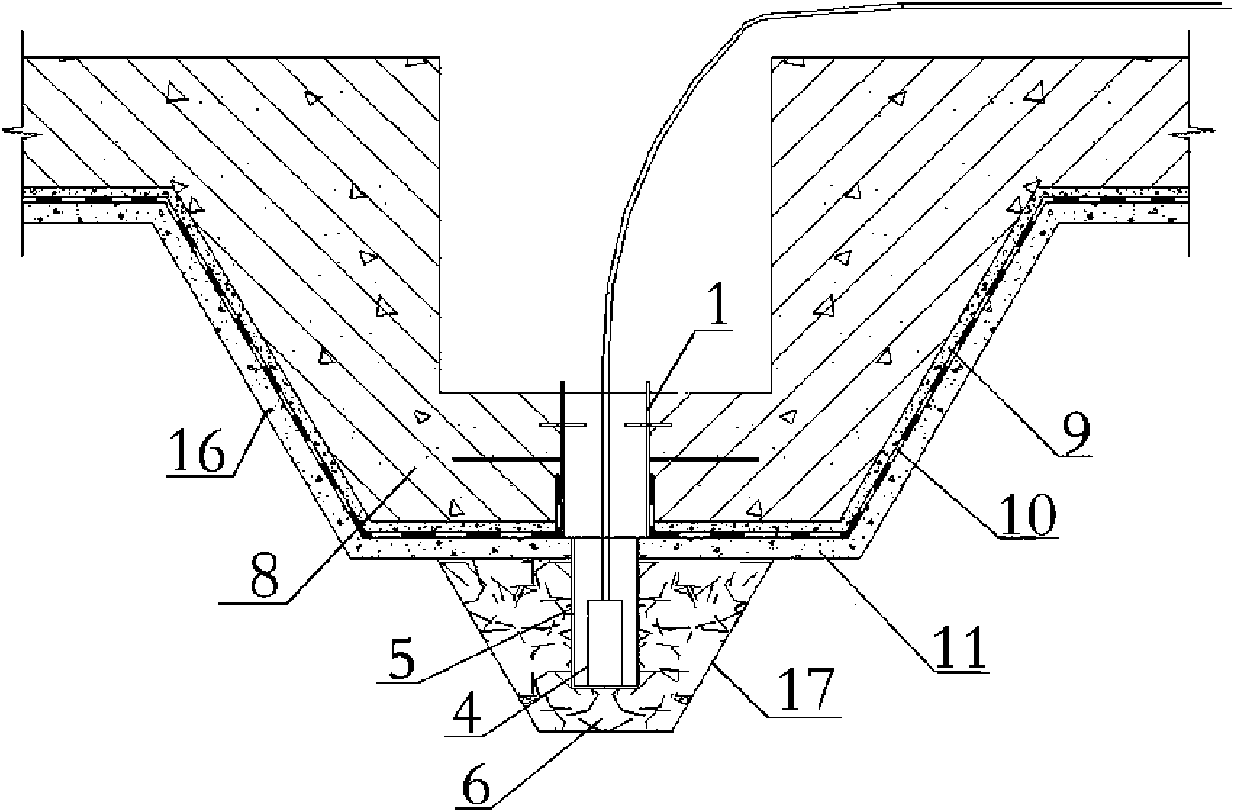

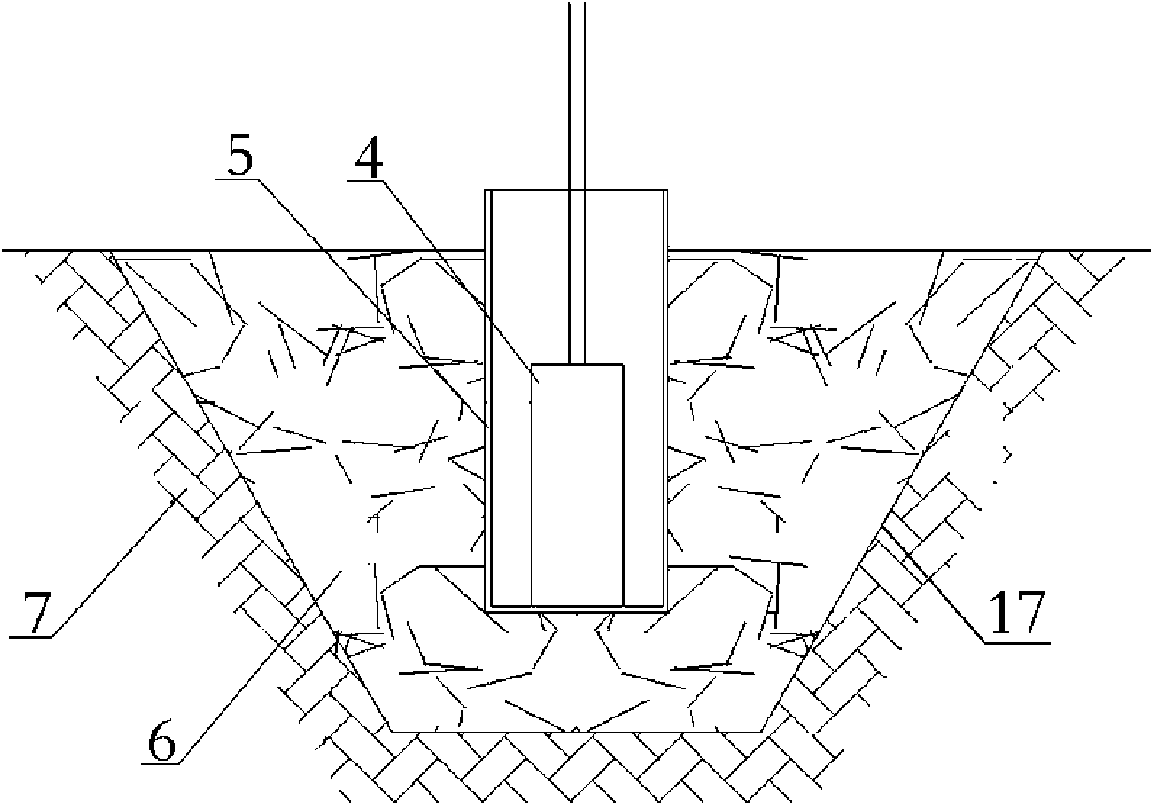

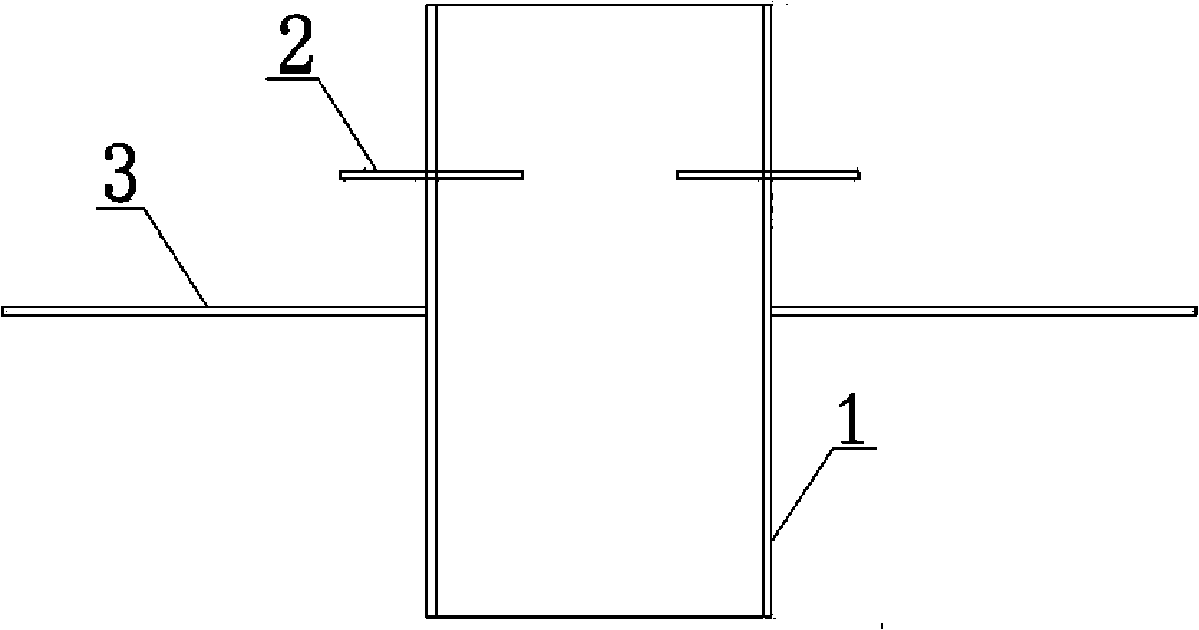

Base pit dewatering and water saving device and construction method thereof

InactiveCN101768976ASolve the precipitation problemEfficient use ofProtective foundationExcavationsWater savingBaseboard

The invention relates to a base pit dewatering and water saving device and a construction method thereof. The middle part of the base pit of a baseboard structure is provided with a well pit; the well pit is internally and vertically provided with a no-sand tube; pebbly sand is filled between the bottom and periphery of the no-sand tube; the top of the no-sand tube is higher than the top surface of the well pit; a water pump is arranged in the no-sand tube; blinding layer concrete is poured at the top surface of the well pit which is at the periphery of the no-sand tube and the side wall of the base pit of the baseboard structure; and the top elevation of the no-sand tube is flush with the elevation of a blinding layer; a dewatering conduit is pre-buried in a base pit baseboard right above the no-sand tube, a waterproof layer is paved on the blinding layer concrete, a layer of waterproof and protective concrete is poured on the waterproof layer, and the base pit baseboards are poured above the waterproof and protective concrete and at the periphery of the dewatering conduit. The method of the invention has lower investment, saved cost and less amount of dewatering amount, thereby reducing the loss of underground water and protecting water resource; and the method can be adopted for a project in which the well point dewatering method is not ideal for dewatering or a project in which the underground water is near the base pit elevation.

Owner:CSCEC CITY CONSTR DEV +1

Foundation treatment method for controlling post-construction settlement and deformation of soft soil

InactiveCN102226335AIncrease effective preloadEffective reinforcementSoil preservationEngineeringCut and fill

The invention discloses a foundation treatment method for controlling the post-construction settlement and deformation of soft soil. the method sequentially comprises the following steps: setting a vertical envelope wall around an area to be reinforced; inserting vertical drainage systems and laying horizontal drainage systems in the area to be reinforced; paving sealing materials on the surface of a foundation; backfilling settlement refills or exerting pre-loads on the foundation; carrying out vacuumizing, well-point dewatering or vacuum well-point dewatering on the drainage systems so as to reinforce the foundation; and after the consolidation degree of the foundation reaches 60-90%, carrying out sealing on all the vertical and horizontal drainage systems. The method disclosed by the invention is used for simultaneously carrying out reinforcement and plugging on an untreated soft soil foundation, so that the post-construction settlement can be controlled while the foundation is treated. Duo to the one-time treatment, the treatment time can be saved, and the treatment cost can be reduced, thereby achieving the purpose of effectively reinforcing the foundation and controlling the post-construction settlement.

Owner:CCCC FOURTH HARBOR ENG INST +4

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Methods of using natural products as dewatering aids for fine particles

InactiveUS6526675B1Reduce moistureImprove hydrophobicityPigmenting treatmentDrying using combination processesLipid formationSlurry

A method of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic. A lipid of vegetable or animal origin is then added to the slurry in solutions of light hydrocarbon oils and short-chain alcohols, so that the hydrophobic lipid molecules adsorb on the moderately hydrophobic surface and, thereby, greatly enhance its hydrophobicity. By virtue of the enhanced hydrophobicty, the water molecules adhering to the surface are destabilized and more readily removed during the process of mechanical dewatering. The moisture reduction can be further improved using appropriate electrolytes in conjunction with the lipids, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and using combinations thereof.

Owner:YOON ROE HOAN

Polyurethane water dispersion and its preparing method

InactiveCN1425726APrevent flocculationAvoid layeringPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to paint and is especially aqueous polyurethane dispersion and its preparation process. The preparation process includes: vacuum dewatering of polyol at 90-120 deg.c vacuum degree 0.05-0.1 MPa for 1.0-2.0 hr before cooling; adding polyol and diisocyanate monomer, heating to 60-100 deg.c for 1.0-2.0 hr, adding small molecular dibasic alcohol as chain expander, reaction at 60-80 deg.c until reaching required NCO group content, adding hydrophilic chain expander and reaction at 50-70 deg.c to unchanged NCO group content to obtain polyurethane prepolymer; cooling the prepolymer, neutralizing with neutralizing agent, transferring the product to emulsifying reactor, high speed emulsifying while adding deionized water, adding amine to expand chain, adding NCO group collecting agent and defoaming agent for stabilizing treatment, and eliminating acetone.

Owner:SOUTH CHINA UNIV OF TECH

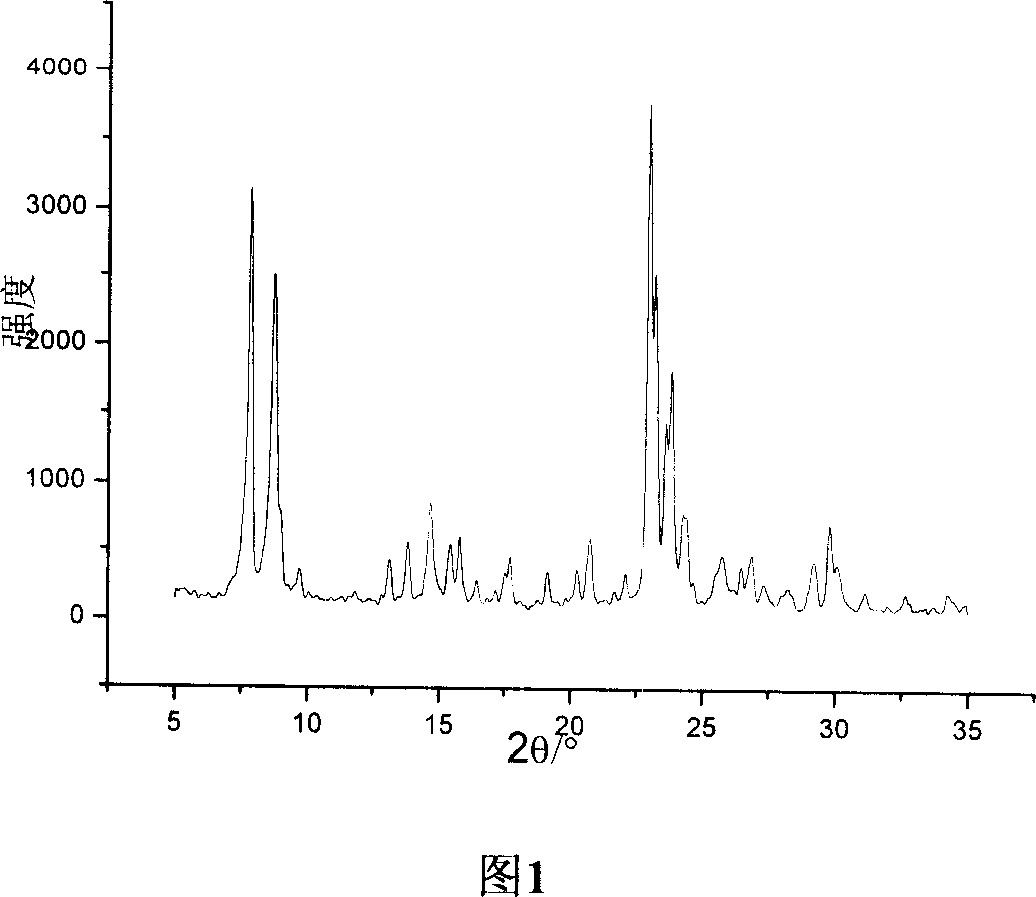

Modified no-adhesive ZSM-5 zeolite catalyst and its prepn process

InactiveCN1974007ASimple preparation processLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlcoholWater vapor

The present invention belongs to the field of material synthesis technology, and is especially modified no-adhesive ZSM-5 zeolite catalyst and its preparation process and application in catalyzing the dewatering of dilute alcohol solution to prepare ethylene. The catalyst is prepared with no-adhesive ZSM-5 zeolite as basic material and through one modification process combining high temperature water vapor and acid treatment. The catalyst has high content of effective component ZSM-5 zeolite, high molecule diffusion, high crystallization degree, opened channels and great specific surface area. In catalyzing the dewatering of dilute alcohol solution to prepare ethylene, the catalyst has high catalytic activity, low reaction solution ethanol concentration, low reaction temperature, high ethanol converting rate, high ethylene selectivity and high space velocity.

Owner:FUDAN UNIV

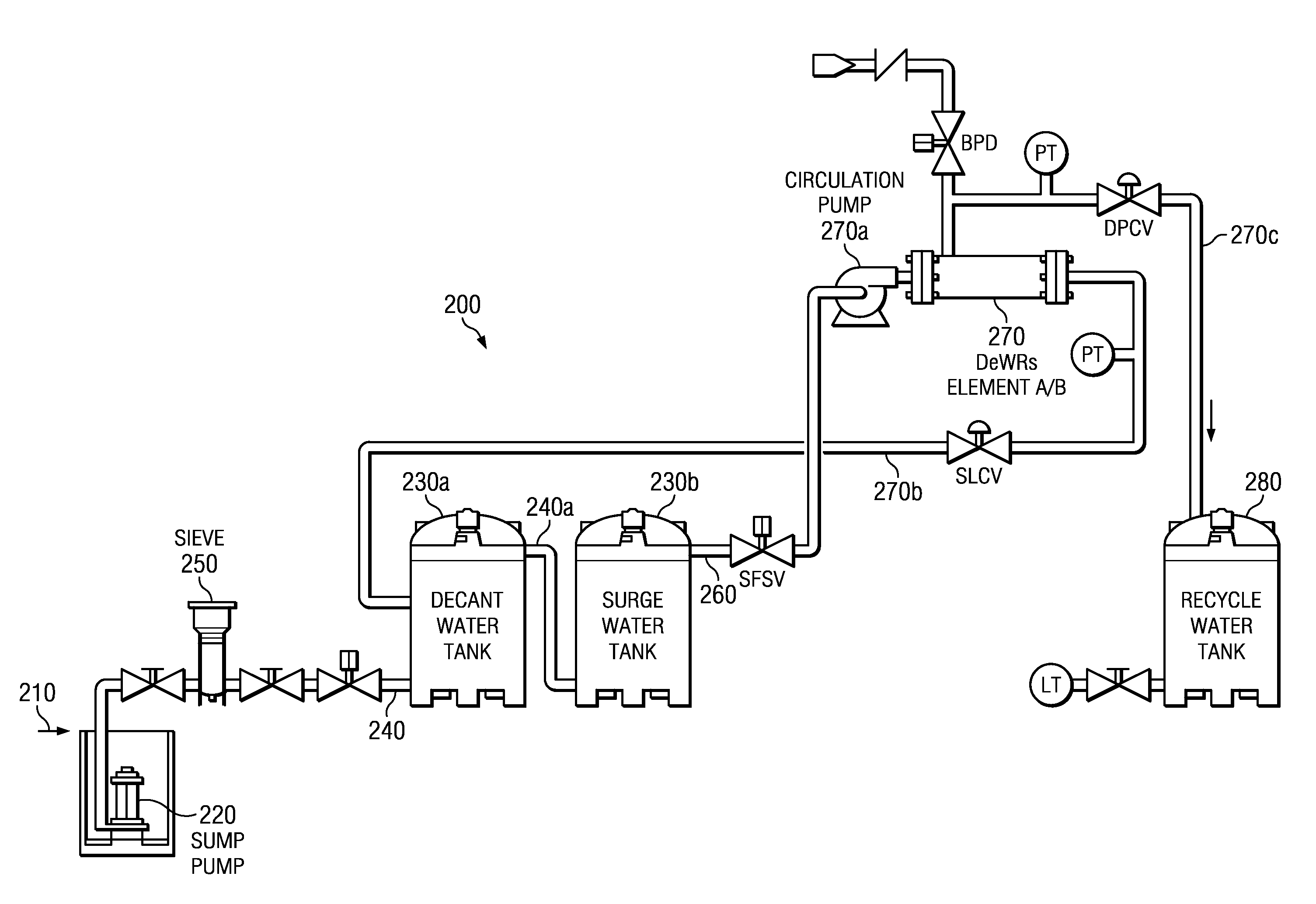

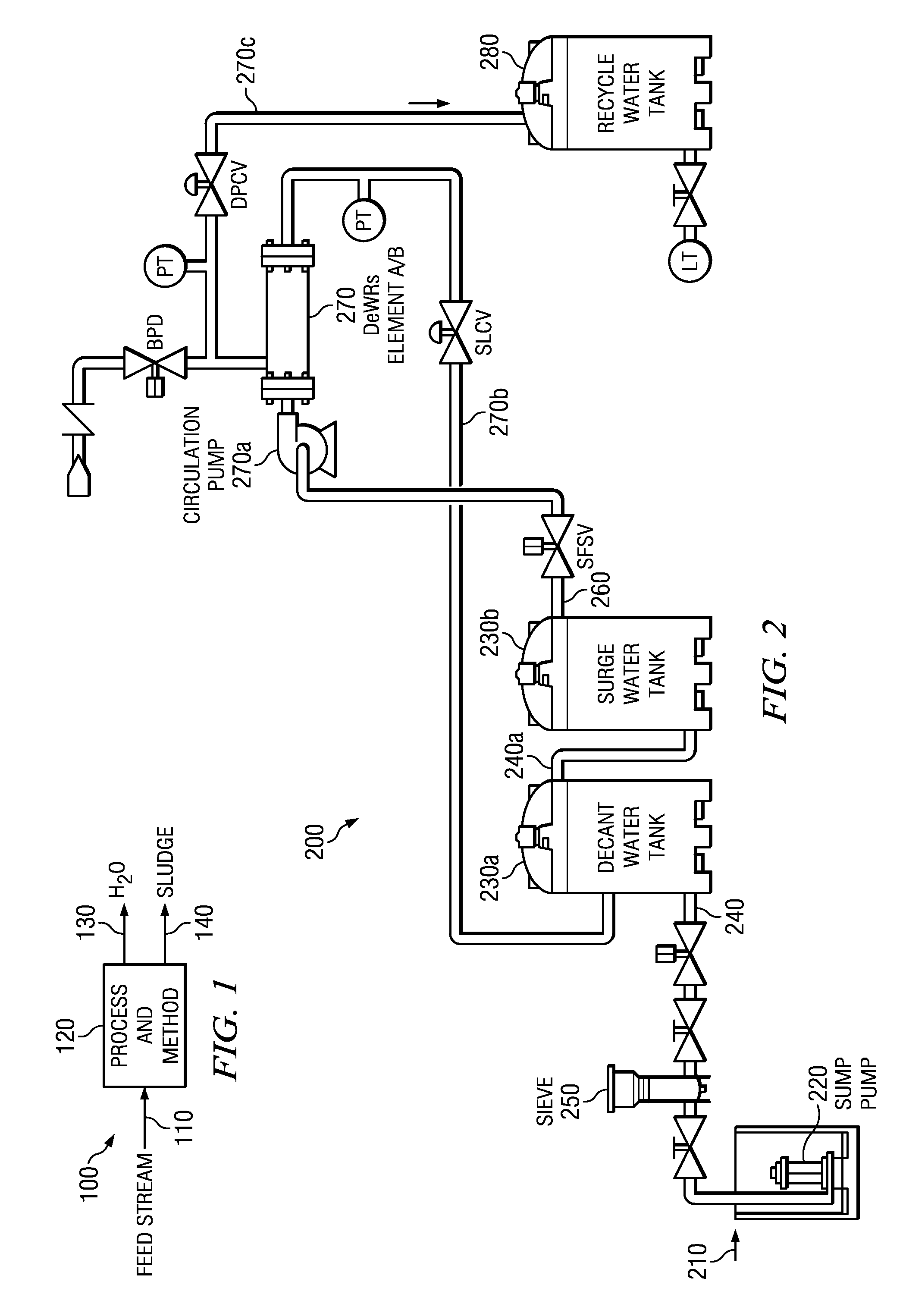

Integrated particulate filtration and dewatering system

The disclosed principles for providing a chemical-free filtering of particulate down below sub-micron levels, while concentrating the particulate into a sludge. The disclosed principles integrate cross-flow filtration (i.e., micro-filtration or ultra-filtration) with a settling tank (or “weir”) to provide sequential filtration and dewatering of an aqueous media. The disclosed technique operates chemical-free and is continuous. Applications for systems and processes in accordance with the disclosed technique are wide, and include aggregate fines removal, sediment removal, replacement for clarifiers, etc.

Owner:PURIFICS ENVIRONMENTAL TECH

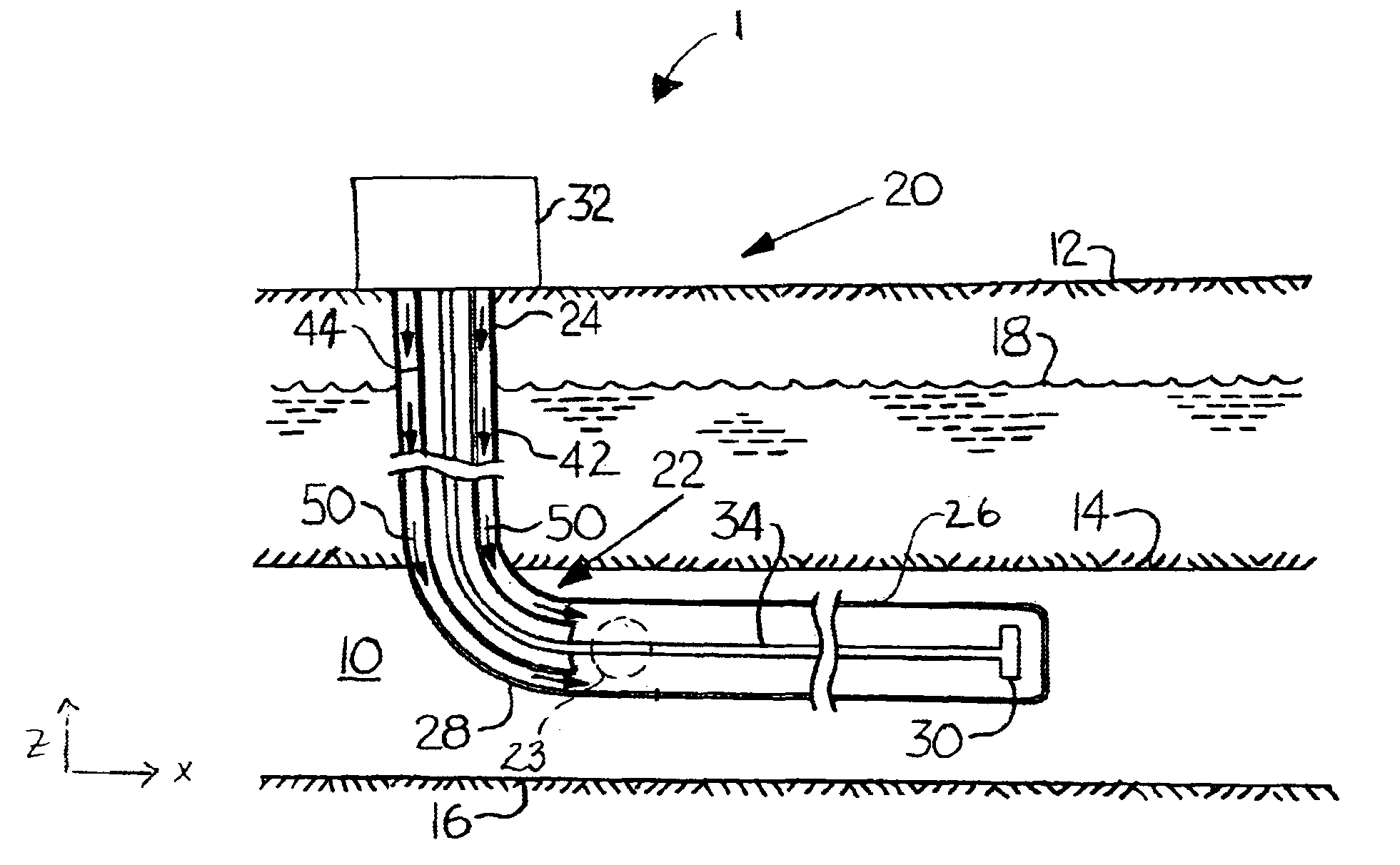

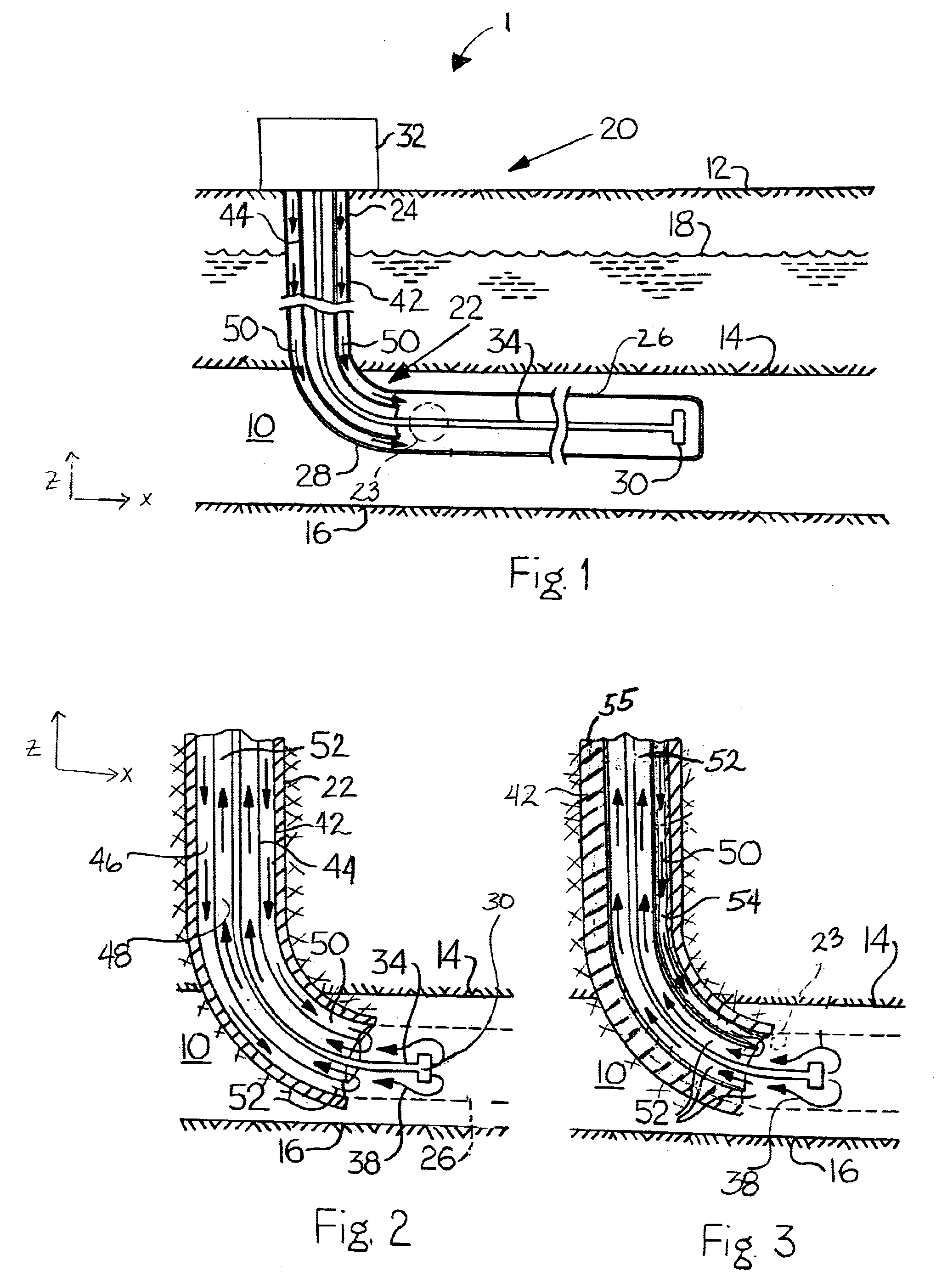

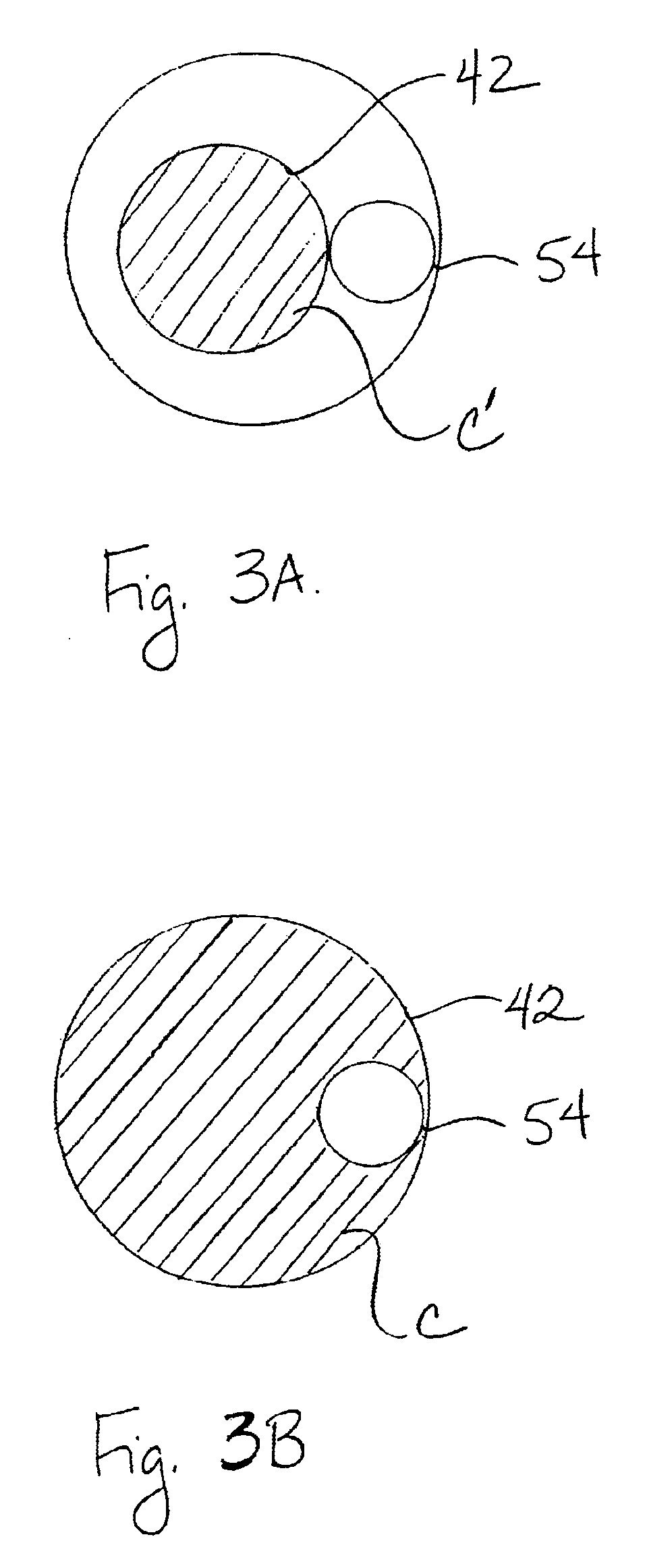

Method and system for production of gas and water from a gas bearing strata during drilling and after drilling completion

A method for producing gas and water during and after drilling from a subterranean coal seam, including the steps of: (a) drilling a main bore intersecting the coal seam, the main bore having an upper substantially vertical portion, a lower substantially horizontal portion or portions, and a curved portion connecting the vertical and horizontal portions; (b) drilling one sumphole drainage bore exiting the curve or horizontal portion of the main bore and extending in the direction at least partially vertically and downwardly with respect to the horizontal portion of the main bore; (c) collecting gas produced from the coal seam through the main bore and branched bores; (d) removing water and effluent from the main bore both during drilling operations and afterwards through the use of parallel casing, whereby a first casing introduces compressed air or gas to the main bore and the annular space between the first and second casing is used for return of the mixture of water, effluent and air or gas to the surface; and (e) enhancing gas production by simultaneously removing effluent and water from the main bore by utilizing gas lifting or dewatering pumps in the drainage bore after drilling completion. The system includes a directional drilling system having a drill mechanism for cutting an object area of the coal seam, and a drill string connected to the drill mechanism to power and control. The system also includes using two casings or one casing and a compressed air tubing to air lift waste material during drilling and a dewatering device(s) installed in the sumphole drainage bore used to dewater the main bore after drilling completion.

Owner:TARGET DRILLING LLC

Biogas residue organic fertilizer and preparation method thereof

ActiveCN101774848AIncrease profitEasy accessBio-organic fraction processingClimate change adaptationHigh energyFermentation

The invention relates to a biogas residue organic fertilizer and a preparation method thereof. The biogas residue organic fertilizer uses biogas residue as major raw materials (the consumption is higher than 80 percent) to be mixed with humic acid, nitrogenous fertilizers, phosphate fertilizers, potash fertilizers and trace elements. By aiming at two problems that the biogas residue can not be dewatered and solidified easily and the mechanical dewatering has high energy consumption, the invention utilizes a shallow tank natural solidifying and air drying process, and the biogas residue carries out aerobic secondary fermentation, air drying and solidification in a shallow tank to meet the pelletization moisture and physical property requirements. The biogas residue organic fertilizer of the invention can meet the requirement of nutrient required by crop growth, and can also fertilize the soil and improve the yield.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

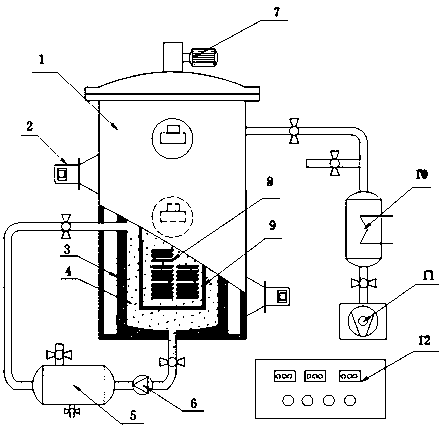

Microwave and vacuum frying integrating device for food processing, and efficient frying method

The invention relates to a microwave and vacuum frying integrating device for food processing and an efficient frying method, and belongs to the field of rapid frying, dewatering and drying devices for foods. The integrating device comprises a microwave heating cavity, a microwave generator, a microwave vacuum frying vessel, an oil storage tank, an oil pump, a hanging basket, a hanging basket rotating device, a condenser and a control panel, wherein the hanging basket is used for placing materials; the microwave generator is a variable-frequency microwave generator with high precision; the circumferences of the microwave generator are distributed evenly, vertically and spirally; the microwave generator adopts a waveguide feeding operation in a side part extending manner; the microwave vacuum frying vessel is used for frying the materials; and the oil pump is connected with the vacuum frying vessel, so that the materials are heated evenly in a pulse spouting manner. After the frying operation is finished, the frying oil is pumped back to the oil storage tank, and a vacuum de-oiling operation is carried out through the hanging basket rotating device. The integrating device has the advantages of high efficiency, rapidness, energy conservation and reduction in production cost. In order to realize an effect similar to a stirring effect, the pulse spouting manner is adopted, so that the frying effect is more uniform and the frying quality is very good. In addition, the flavor, the color and the nutritional ingredients of an original product are maintained when the materials are processed in the vacuum frying manner.

Owner:JIANGNAN UNIV

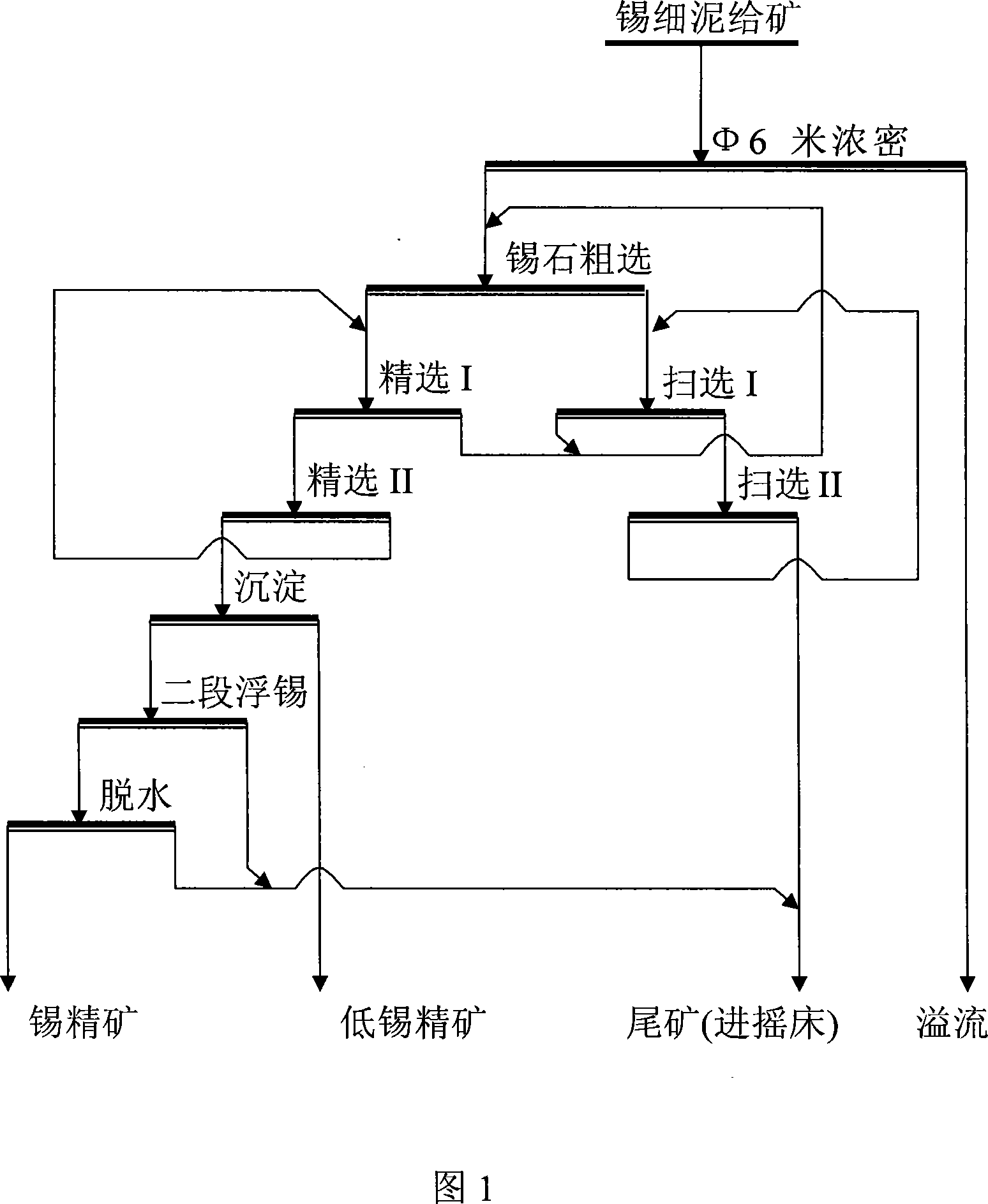

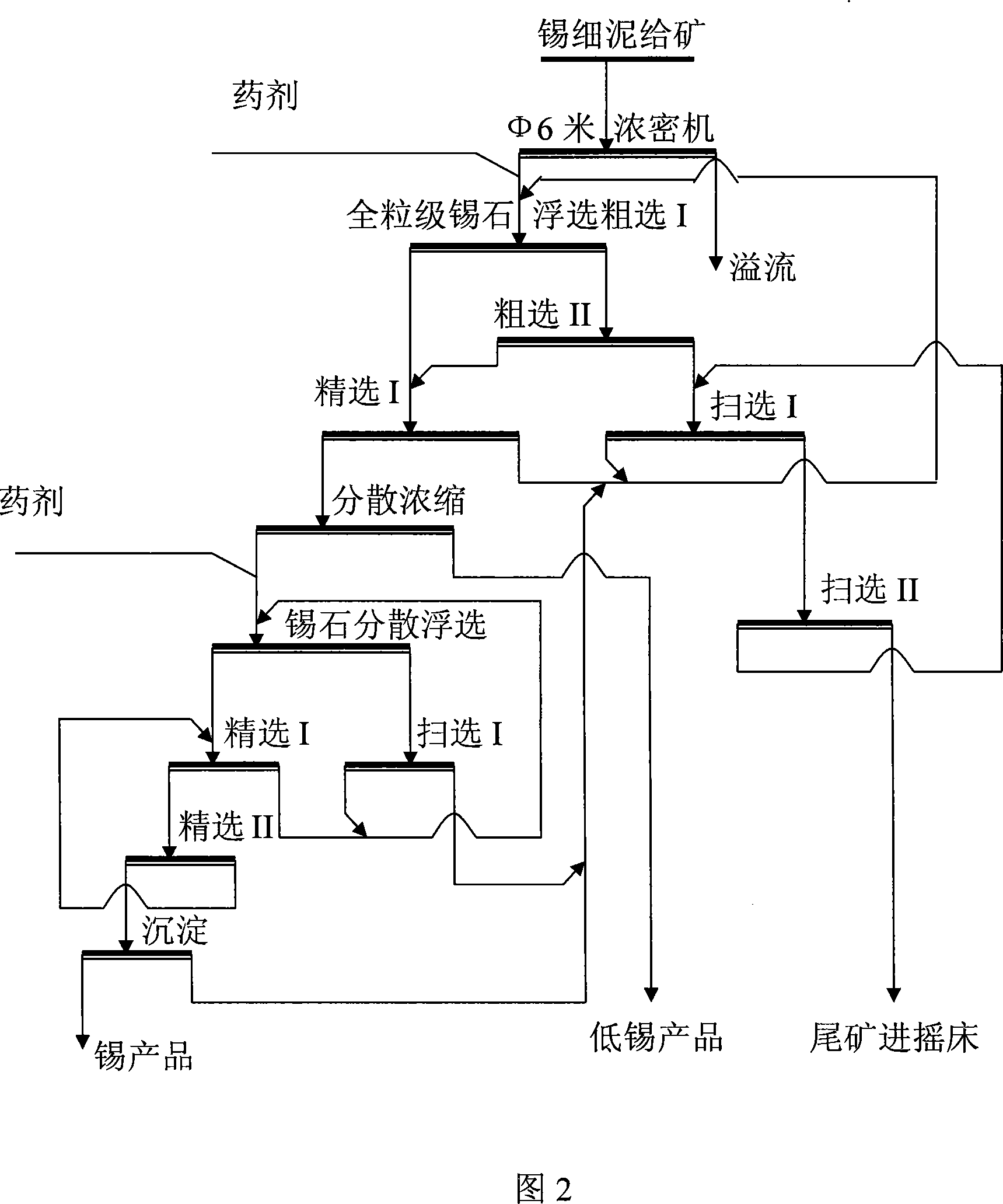

Novel technics of cassiterite clay flotation

ActiveCN101081377AConsistent structure principleImprove beneficiation indexFlotationCassiteriteSlurry

The present invention relates to fine and superfine cassiterite recovering technology. The whole production process of recovering cassiterite includes the following steps: collecting the fine grain ore slurry, dewatering to stabilize, floating all cassiterite of different sizes by means of proper amount of floating agent, dispersion dewatering, shaking table recovering large cassiterite, dispersion floating the desilting from dispersion dewatering, and depositing and dewatering the ultimate tin concentrate.

Owner:广西华锡矿业有限公司铜坑矿业分公司

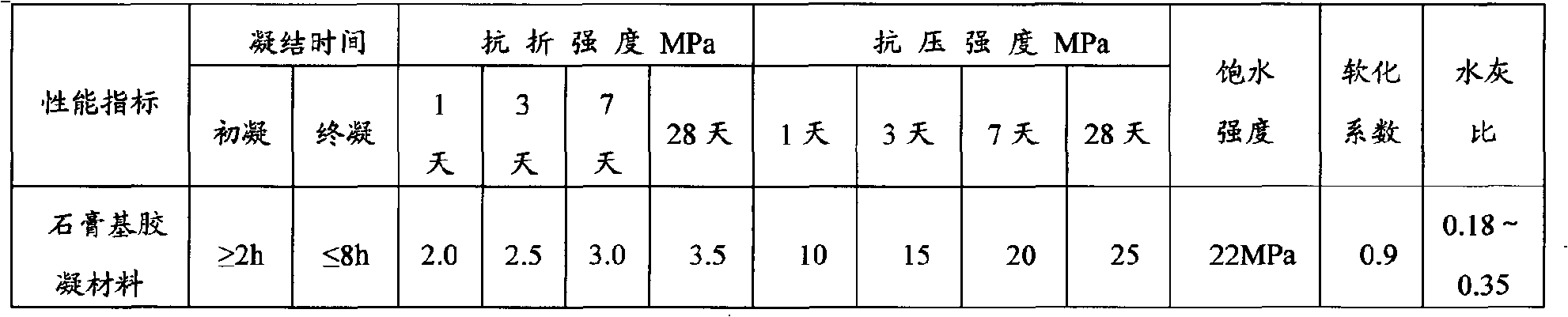

Gypsum based gel material prepared from undisturbed industry by-product gypsum and preparation thereof

InactiveCN101348340AHigh strengthImprove water resistanceSolid waste managementAlkali activatedUltimate tensile strength

The invention provides a gypsum based gelled material prepared from original state industrial by-product gypsum. The gelled material comprises the following components in mass percentage: 36 to 65 percent of original state dihydrate gypsum phase industrial by-product gypsum, 30 to 60 percent of silicon-aluminum active mineral material and 2 to 10 percent of alkali-activated material; the original state dihydrate gypsum phase industrial by-product gypsum which does not need to have impurities and adsorption water removed and be finely ground is directly mixed with the alkali-activated material and the active mineral material according a ratio, and the gypsum based gelled material with high strength, good water resistance and perfect comprehensive performance can be prepared by the extremely simple mixing-stirring step, and by taking the gypsum based gelled material as the base material, various gypsum building material products with high strength, water resistance and perfect comprehensive performance can be produced; therefore, the conventional mode of producing the gypsum building material product that the semi-hydrated building gypsum powder must be firstly prepared by calcining and dewatering, and the semi-hydrated building gypsum powder is used as the base material to produce the gypsum building material product is changed.

Owner:镇江沃地新材料投资有限公司

Method for preparing porous starch through enzyme method in high temperature

A process for preparing the porous starch by high-temp enzyme method includes such steps as proportionally mixing starch with water, regulating pH=1.5-12.5, adding the cross-linking agent with multiple function groups, stirring while reacting to obtain cross-linked starch, regulating pH=6-7, dewatering, washing, drying to obtain powdered cross-linked starch, regulating concentration of emulsion, adding amylase, enzymolyzing, regulating pH=6-7, filtering, washing, centrifugal dewatering, pulverizing filtered cake, and drying to obtain porous starch.

Owner:SOUTH CHINA UNIV OF TECH

Process for preparing acrolein by glycerin dewatering

ActiveCN101070276AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationAlcoholGlycerol

This invention relates to acidity zeolite catalyst used for glycerol dehydration to perpare acrolein and the reaction craft. Glycerine directly dehydrate to generate acrolein under the condition of acidity zeolite catalyst, 200 to 500deg temperature, 0.001 to 3.0MPa pressure and 0.1 to 100.0h - 1 liquid airspeed, at the same time produce byproduct pyruvic alcohol. The raw material raw glycerine could be mixed liquor of water solution, alcosol, fatty acid ester solution at any ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

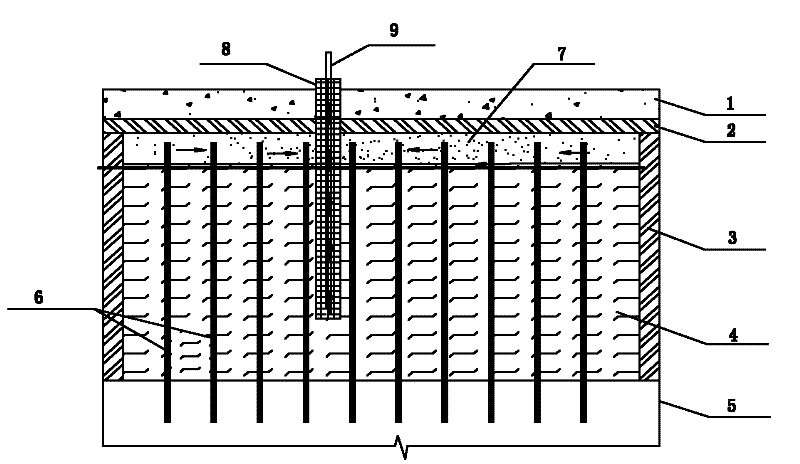

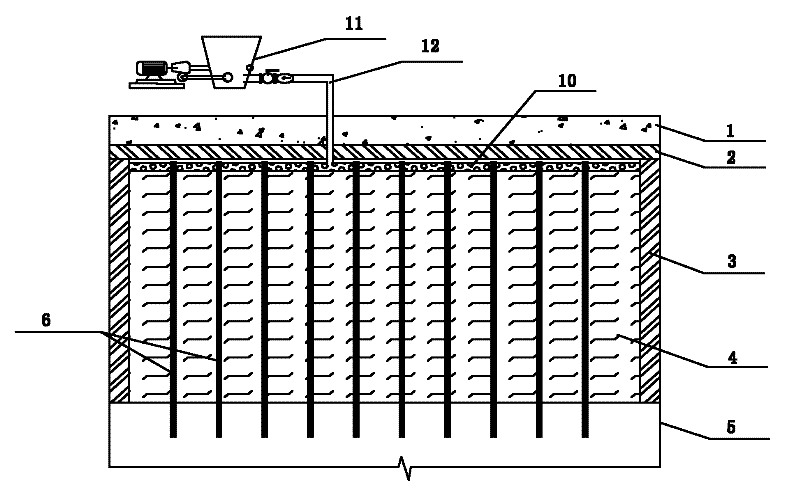

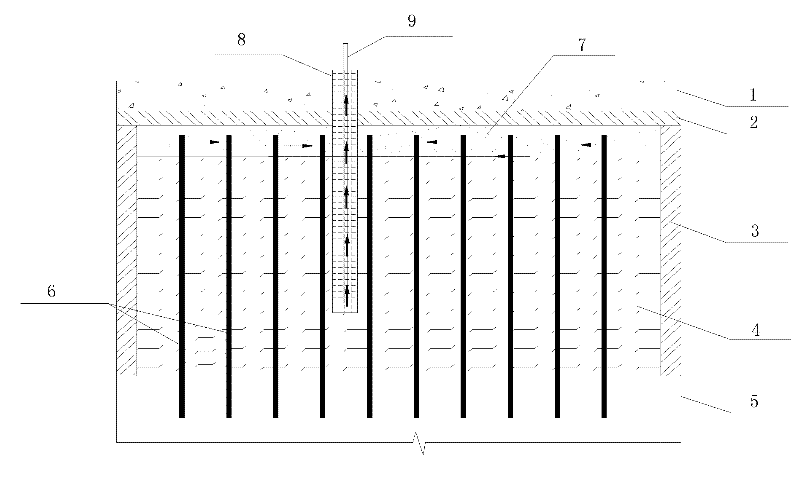

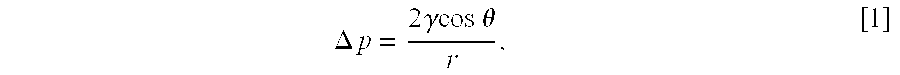

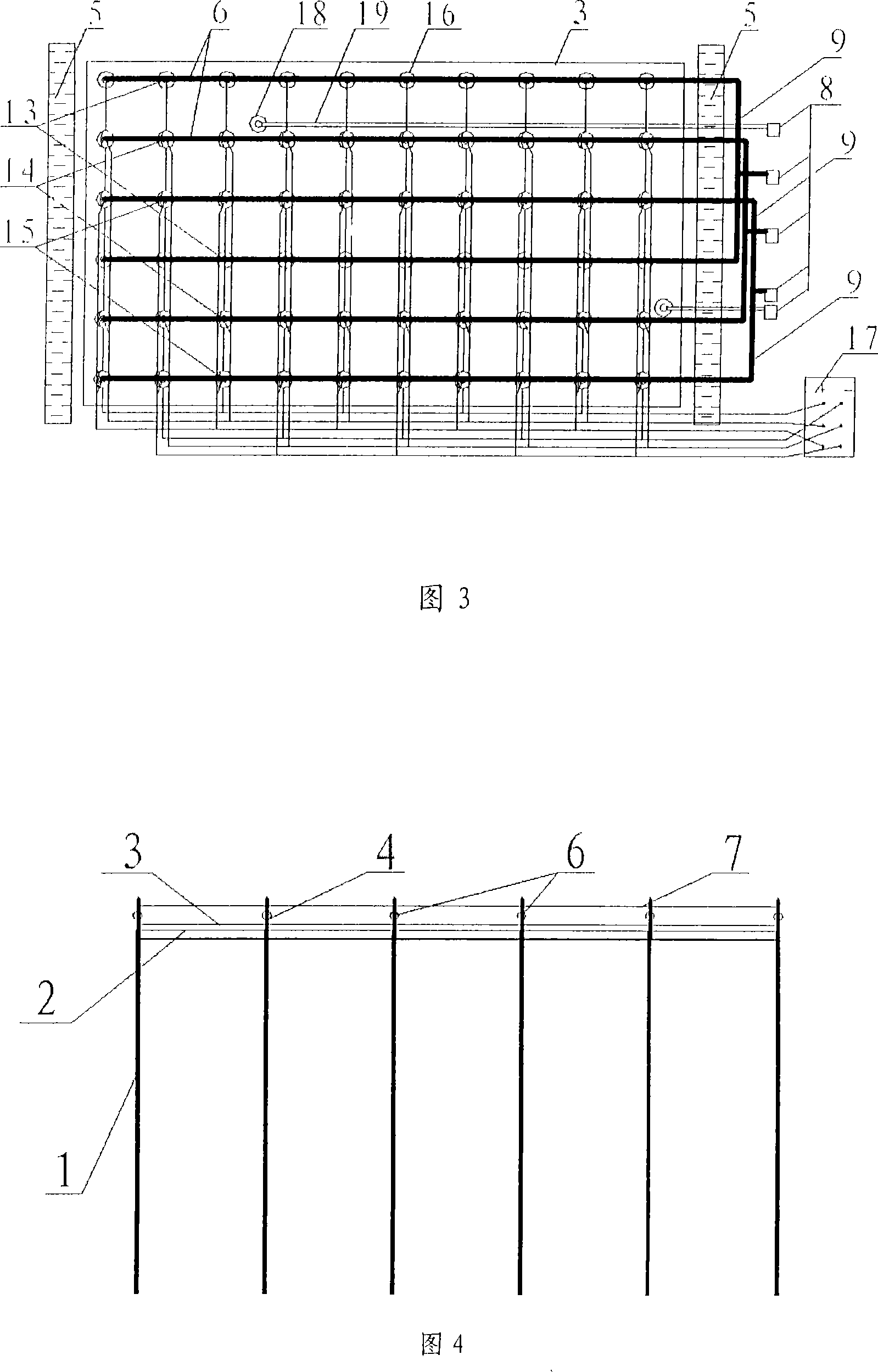

Method of composite electroosmosis, vacuum precipitation and vacuum preload reinforcement foundation and device thereof

ActiveCN101182709AGuaranteed closureExpand the scope of reinforcementSoil preservationEngineeringPermeability coefficient

The invention discloses a method for strengthening the foundation with composite electroosmosis, vacuum dewatering and vacuum preloading, and aims to provide a method for foundation treatment, especially for various types of soil with a permeability coefficient of <10-5cm / s in a large area. Methods of strengthening soft soil foundations. The device used in the method of the present invention adopts a composite pipe and a redundant film with openings or a mesh cap eye film or a mesh cap eye vacuum film with a connector. The method of the invention is a method for reinforcing the foundation that combines electroosmosis, vacuum dewatering and vacuum preloading, and can be implemented in parallel. It has the advantages of balanced treatment, simple and convenient construction, short project time, and high cost performance.

Owner:广西华业建筑工程有限公司

Process to Increase the Area of Microbial Stimulation in Methane Gas Recovery in a Multi Seam Coal Bed/methane Dewatering and Depressurizing Production System Through the Use of Horizontal or Multilateral Wells

InactiveUS20090308598A1Great area of stimulationIncrease and maximize areaArtificial islandsFluid removalWell drillingProduct gas

A process to increase the area of microbial stimulation in a process of methane gas recovery in a multi seamed coal bed / methane dewatering and depressurizing production system by first utilizing an underbalanced multilateral drilling technique. At this point in the process one could introduce the microorganisms into the horizontal well bore to achieve a greater area of stimulation of the coal bed than would a vertical well. An even more preferred method would to first drill a series of lateral wells off of the horizontally drilled well bore, so as to increase or maximize the area of coal bed which is being covered. At that point, one would take the steps of what is known in the art of introducing a particular type of microorganism, which would then be injected via the plurality of lateral bores into the coal bed formation, to maximize the area of penetration, which would include, most, if not all, of the area of the coal bed through the series of lateral wells.

Owner:INNOVATIVE DRILLING TECH

Method for preparing gardenia yellow pigment

The invention discloses a process for preparing gardenin comprising the steps of, A. airing cape jasmine dried fruits, disintegrating and sieving, B. charging petroleum benzene, supersonic extracting, and combining the filter liquor, reclaiming petroleum benzene to obtain vegetable oil, C. ethanol supersonic extracting, filtering, reclaiming ethanol, obtaining ethanol extract, D. eluting the ethanol extract with deionized water, E. depigmenting with ethanol, reclaiming the ethanol to obtain crude gardenin, F. removing impurities with 5% ethanol elution, E. depigmenting with 10% ethanol, concentrating the ethanol, drying and dewatering, thus obtaining gardenin.

Owner:中国科学院武汉植物研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com