Novel technics of cassiterite clay flotation

A new process and flotation technology, applied in the field of mineral processing technology, can solve the problems that the mineral processing method cannot meet the requirements and the tin content is reduced, and achieve the effect of improving the effect of the agent, improving the grade and improving the return rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

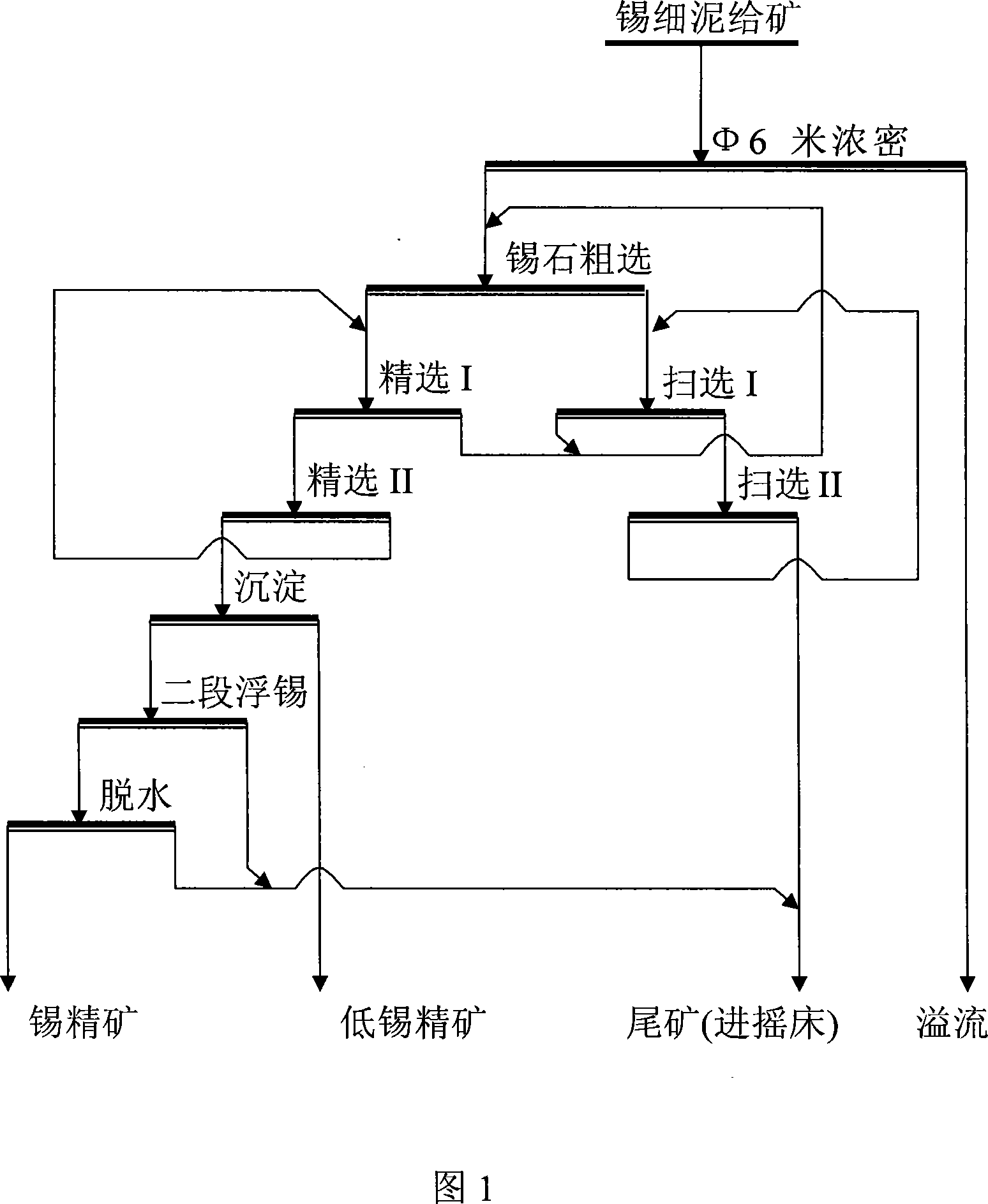

Embodiment 1

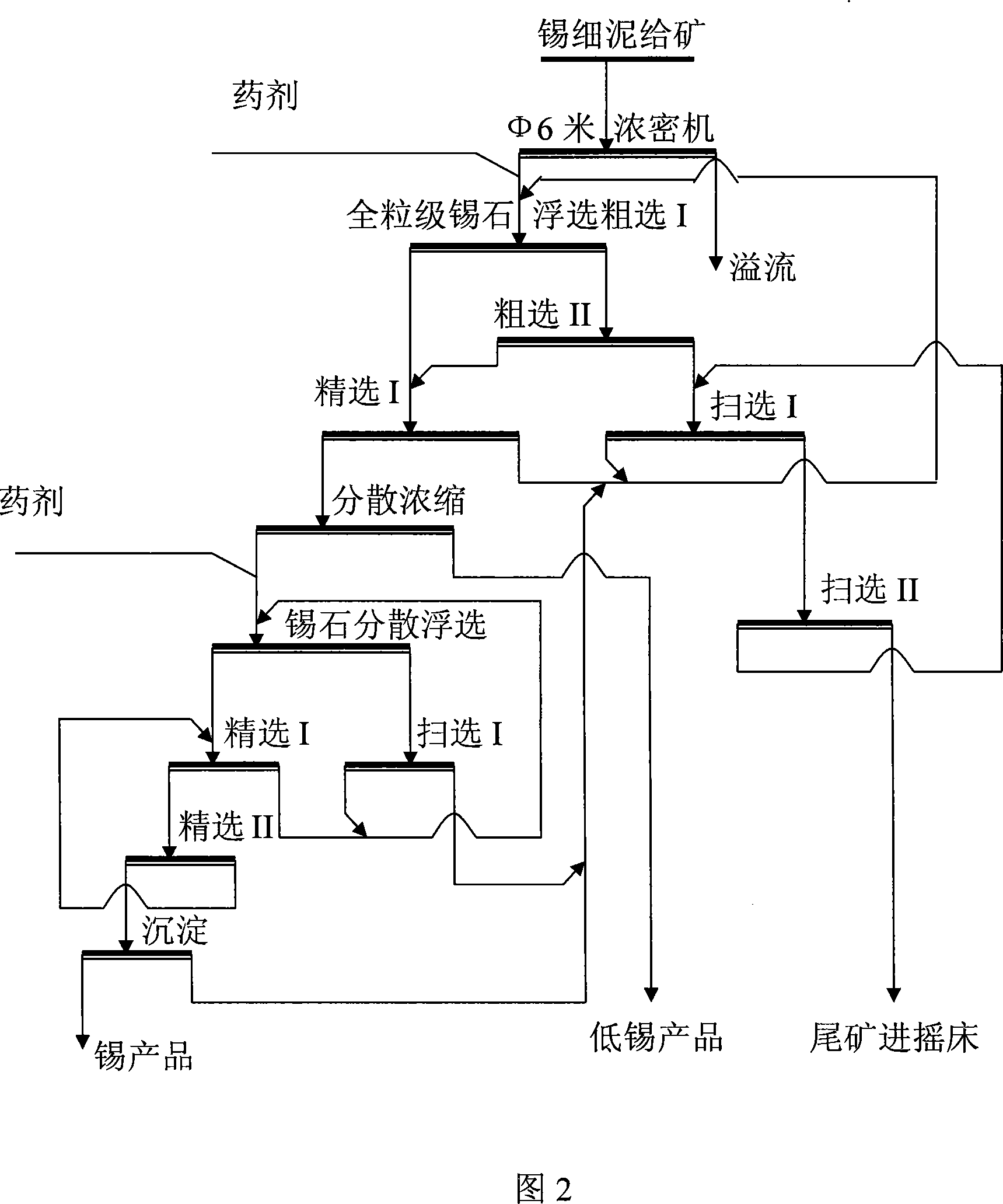

[0047] After the fine-grained tin pulp is classified, it enters the Φ6m thickener after dehydration. The function of the Φ6m thickener is to partially precipitate and dehydrate and buffer and stabilize the ore feeding, creating conditions for uniform ore feeding in subsequent operations. The sand settling of the Φ6m thickener Enter the flotation operation for whole grain flotation. The floating tin process is carried out in two steps. In the first step, the full-grain grade of the Φ6 meter thickener with a tin content of 0.5% enters the flotation. The 0.4% tailings enter the first and second screening, and the final tailings with a tin content of less than 0.2% are produced and enter the shaker system for scanning and recovery; the concentrates of full-size roughing I and roughing II Merge and carry out full-size selection I. In the full-size flotation process, an appropriate amount of regulator sodium carbonate or sodium humate is added, with a weight concentration of 1-2%, a...

Embodiment 2

[0049] After the fine-grained tin pulp is classified, it enters the Φ6m thickener after dehydration. The function of the Φ6m thickener is to partially precipitate and dehydrate and buffer and stabilize the ore feeding, creating conditions for uniform ore feeding in subsequent operations. The sand settling of the Φ6m thickener Enter the flotation operation for whole grain flotation. The floating tin process is carried out in two steps. In the first step, the full-grain grade of the Φ6 meter thickener with a tin content of 0.5% enters the flotation. The 0.4% tailings enter the first and second screening, and the final tailings with a tin content of less than 0.2% are produced and enter the shaker system for scanning and recovery; the concentrates of full-size roughing I and roughing II Merge and carry out full-size selection I. In the full-size flotation process, add an appropriate amount of regulators such as: polymer tanning material or tartaric acid, with a weight concentrati...

Embodiment 3

[0051] After the fine-grained tin pulp is classified, it enters the Φ6m thickener after dehydration. The function of the Φ6m thickener is to partially precipitate and dehydrate and buffer and stabilize the ore feeding, creating conditions for uniform ore feeding in subsequent operations. The sand settling of the Φ6m thickener Enter the flotation operation for whole grain flotation. The floating tin process is carried out in two steps. In the first step, the full-grain grade of the Φ6 meter thickener with a tin content of 0.5% enters the flotation. The 0.4% tailings enter the first and second screening, and the final tailings with a tin content of less than 0.2% are produced and enter the shaker system for scanning and recovery; the concentrates of full-size roughing I and roughing II Merge and carry out whole-grain grade selection I. In the whole-grain grade flotation process, add an appropriate amount of regulators such as: sodium carbonate, polymer tanning material, oxalic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com