Patents

Literature

62results about How to "Improve beneficiation index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

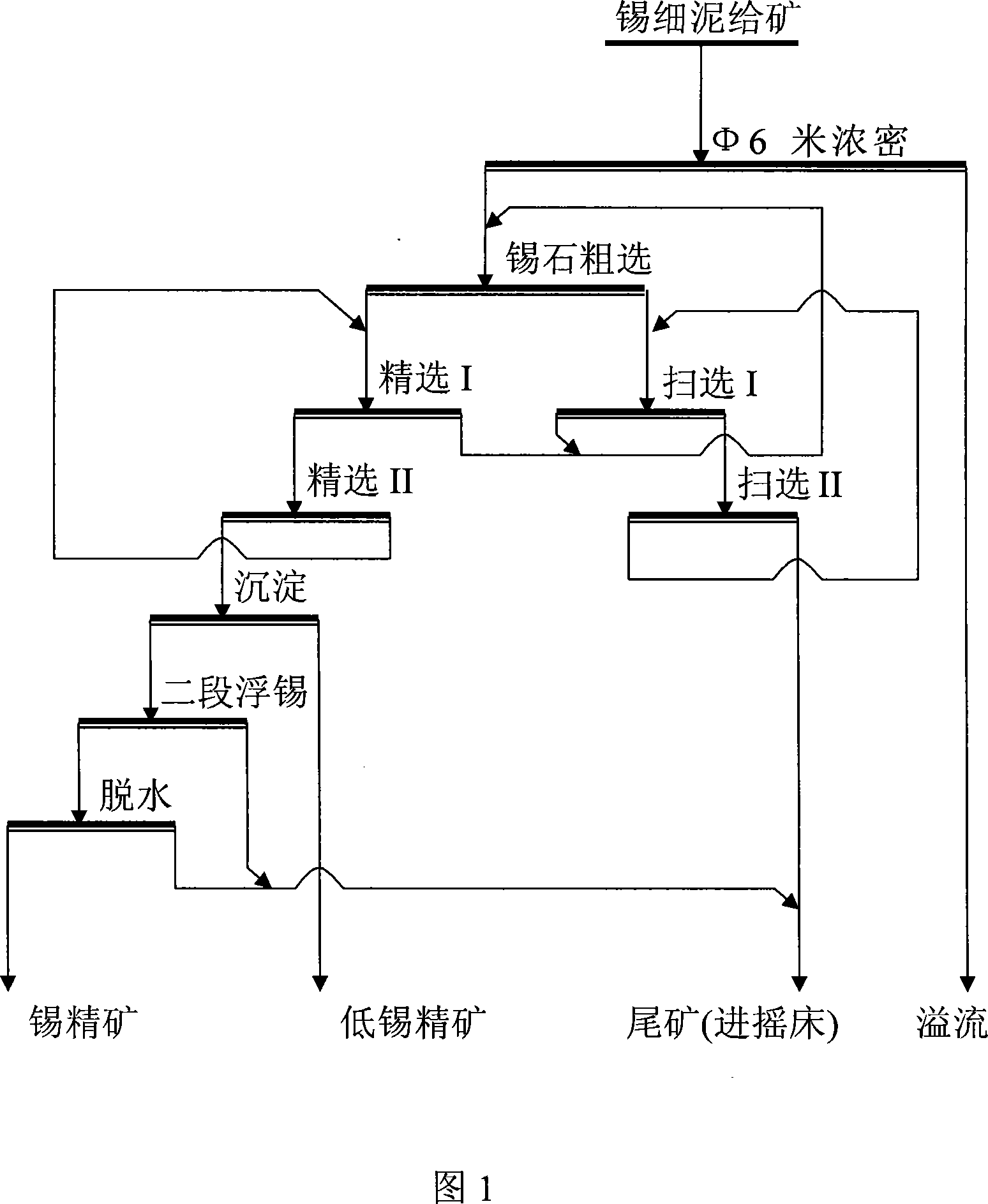

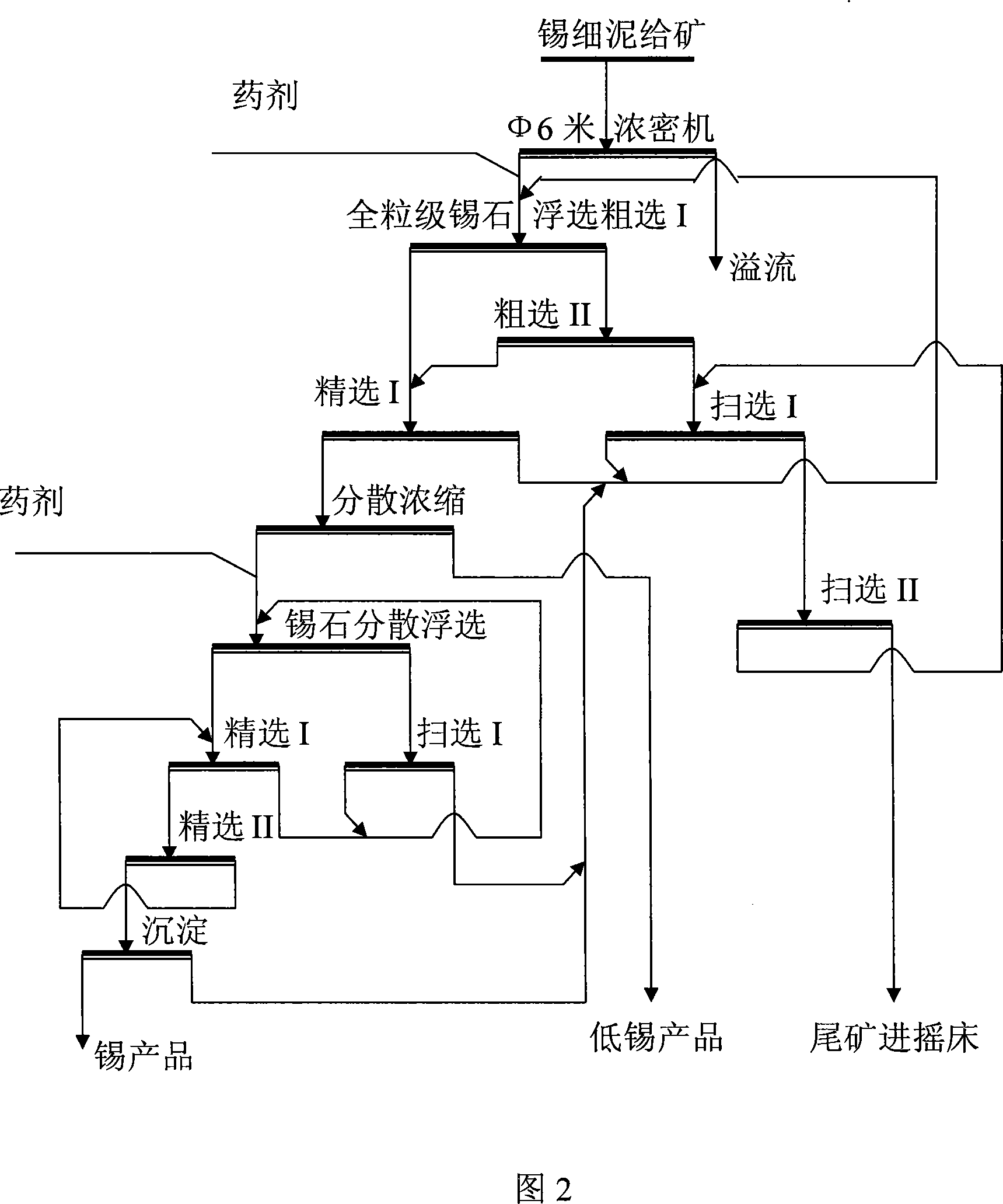

Novel technics of cassiterite clay flotation

ActiveCN101081377AConsistent structure principleImprove beneficiation indexFlotationCassiteriteSlurry

The present invention relates to fine and superfine cassiterite recovering technology. The whole production process of recovering cassiterite includes the following steps: collecting the fine grain ore slurry, dewatering to stabilize, floating all cassiterite of different sizes by means of proper amount of floating agent, dispersion dewatering, shaking table recovering large cassiterite, dispersion floating the desilting from dispersion dewatering, and depositing and dewatering the ultimate tin concentrate.

Owner:广西华锡矿业有限公司铜坑矿业分公司

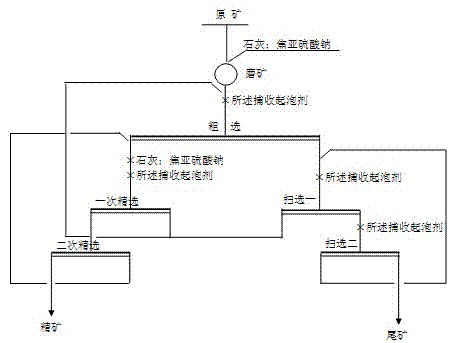

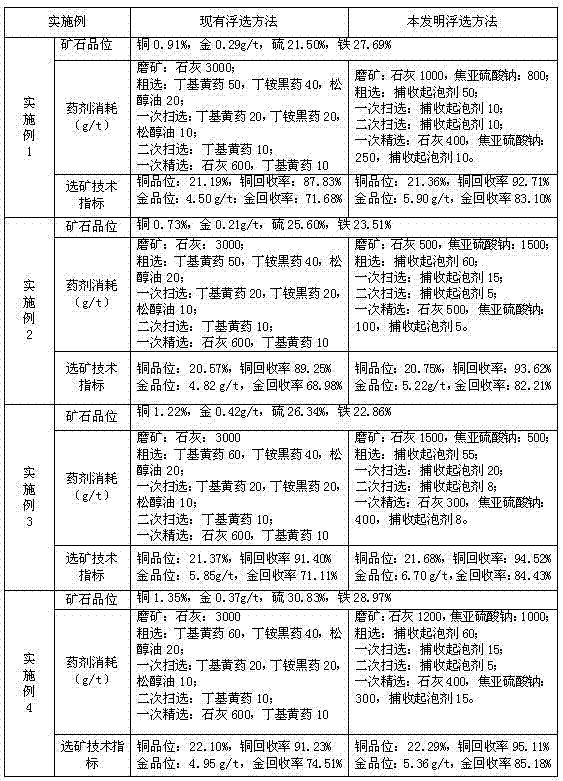

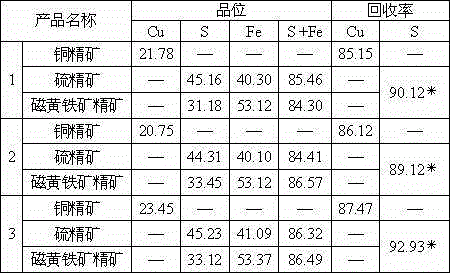

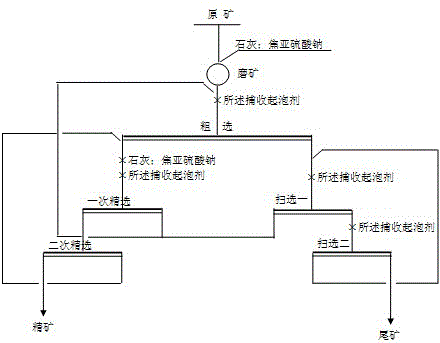

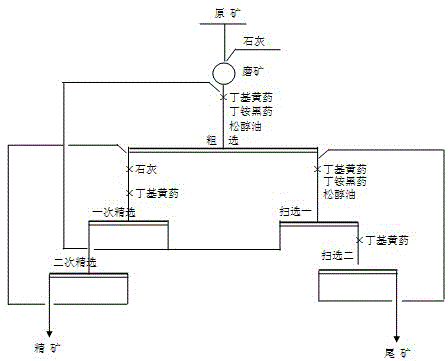

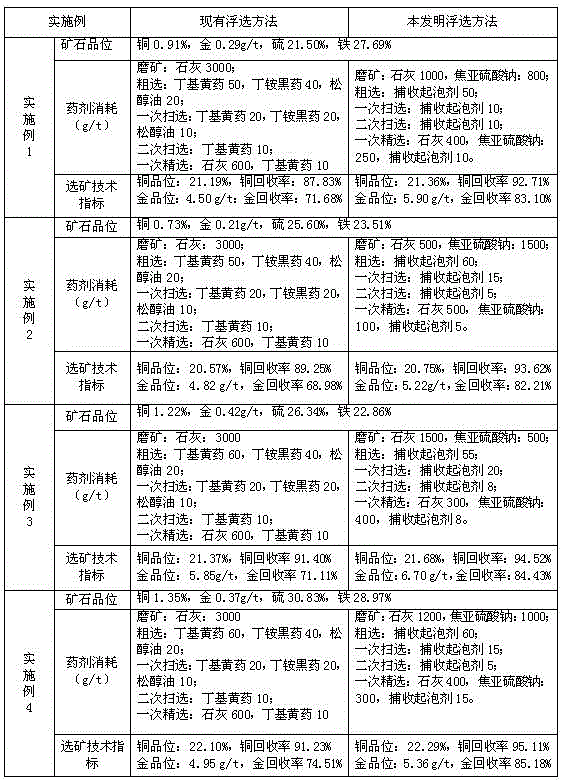

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

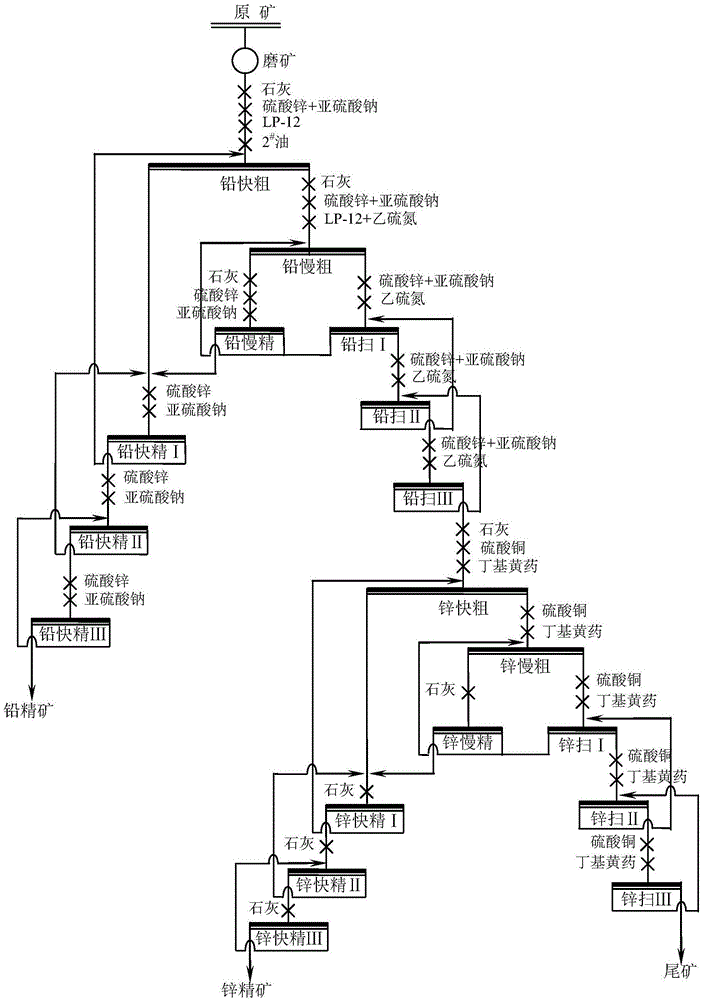

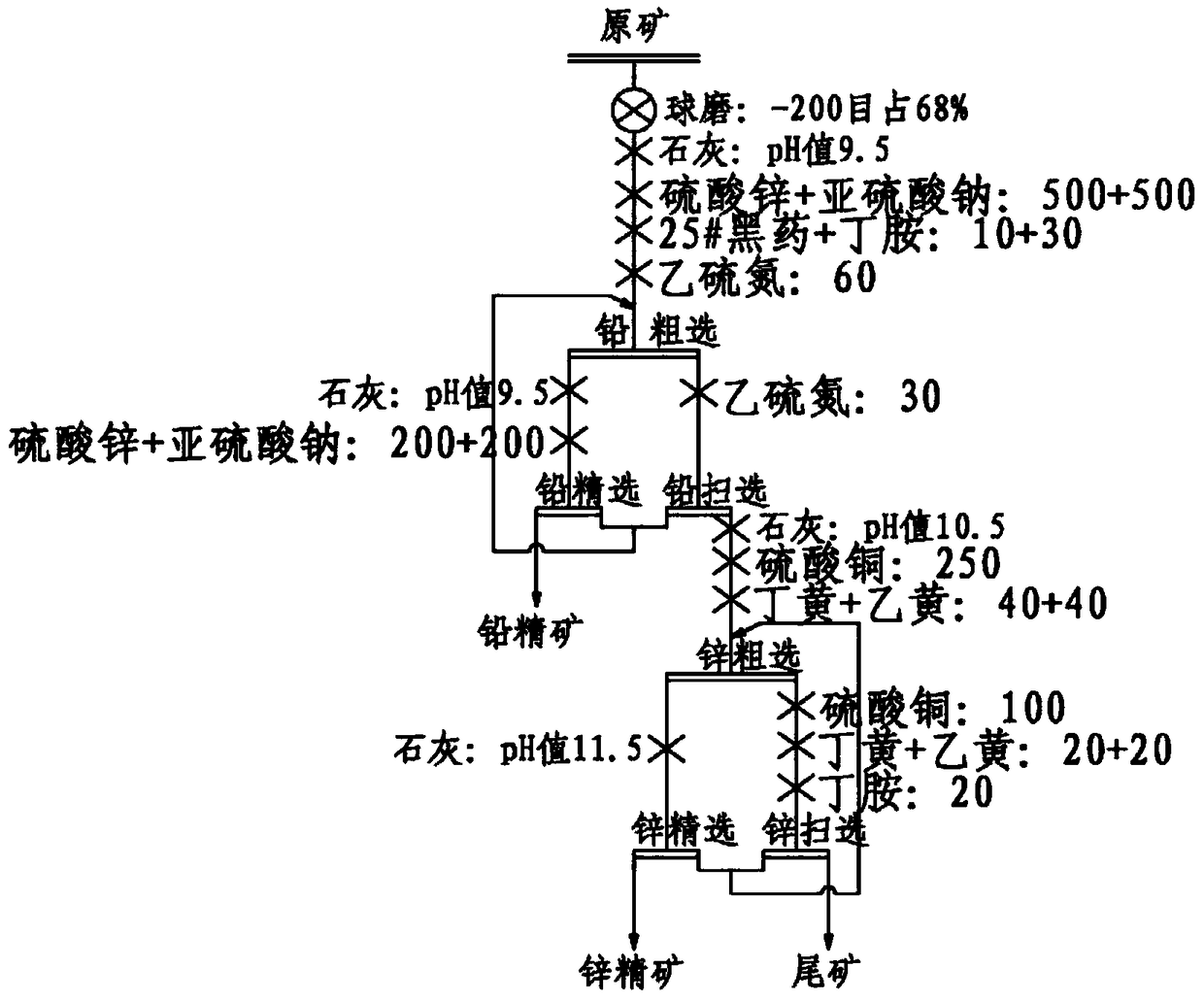

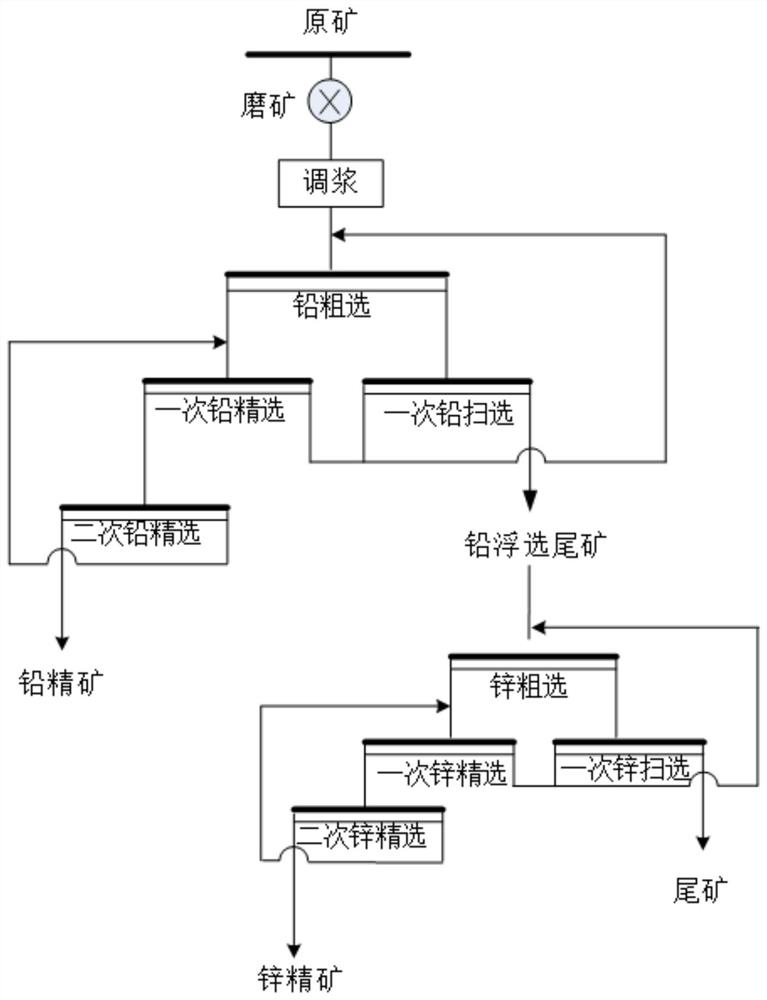

Ore dressing method for lead-zinc-silver poly-metallic ores

The invention provides an ore dressing method for lead-zinc-silver poly-metallic ores. Lead-silver concentrates and zinc concentrates are finally obtained through the steps of raw ore grinding, lead fast roughing, lead slow roughing, lead scavenging, lead fast concentration, lead slow concentration, zinc fast roughing, zinc slow roughing, zinc scavenging, zinc fast concentration and zinc slow concentration. The lead-zinc-silver poly-metallic ores sorted by the ore dressing method provided by the invention are good in sorting index and high in separation efficiency; the ore dressing method is a lead-zinc-silver ore dressing method which is stable, efficient, strong in adaptive capacity, good in sorting effect, high in comprehensive recovery index and low in production cost and is suitable for popularization and application.

Owner:DONGSHENGMIAO MINING LLC +2

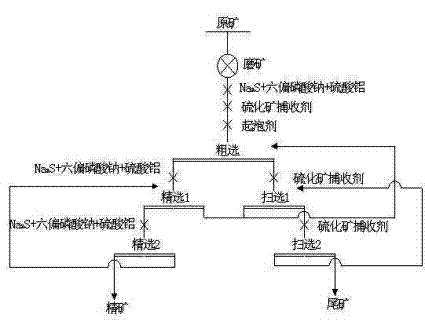

Method for beneficiating high-peat copper sulphide ore

The invention discloses a method for beneficiating high-peat copper sulphide ore and relates to a method for beneficiating nonferrous metals, which specifically relates to a method for beneficiating high-peat copper sulphide ore; regulating agent and composite inhibitor are added before floating ore pulp and after graining raw ore; flotation environment and mineral surface state in ore pulp are improved in the method disclosed by the invention; the inhibition capacity of inhibitor on easily-floated gangue mineral and selective collection of collecting agent on mineral are enhanced; compared with the traditional method for beneficiating pre-deslimed peat, a technical procedure is simplified by the invention; the loss of available mineral caused by pre-deslimed peat is avoided; and the recycle rate of copper is increased by about more than 18%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

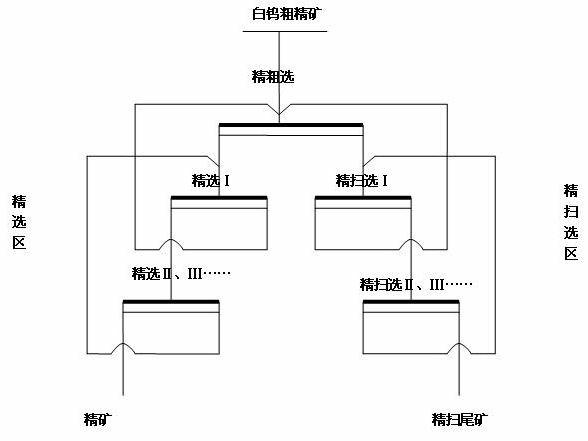

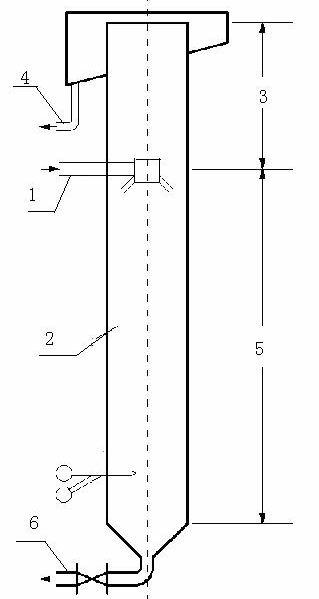

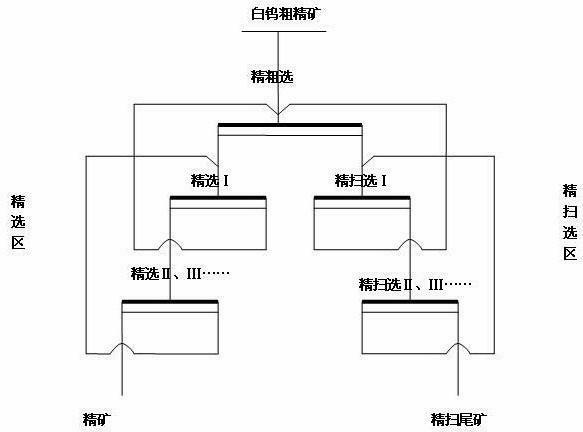

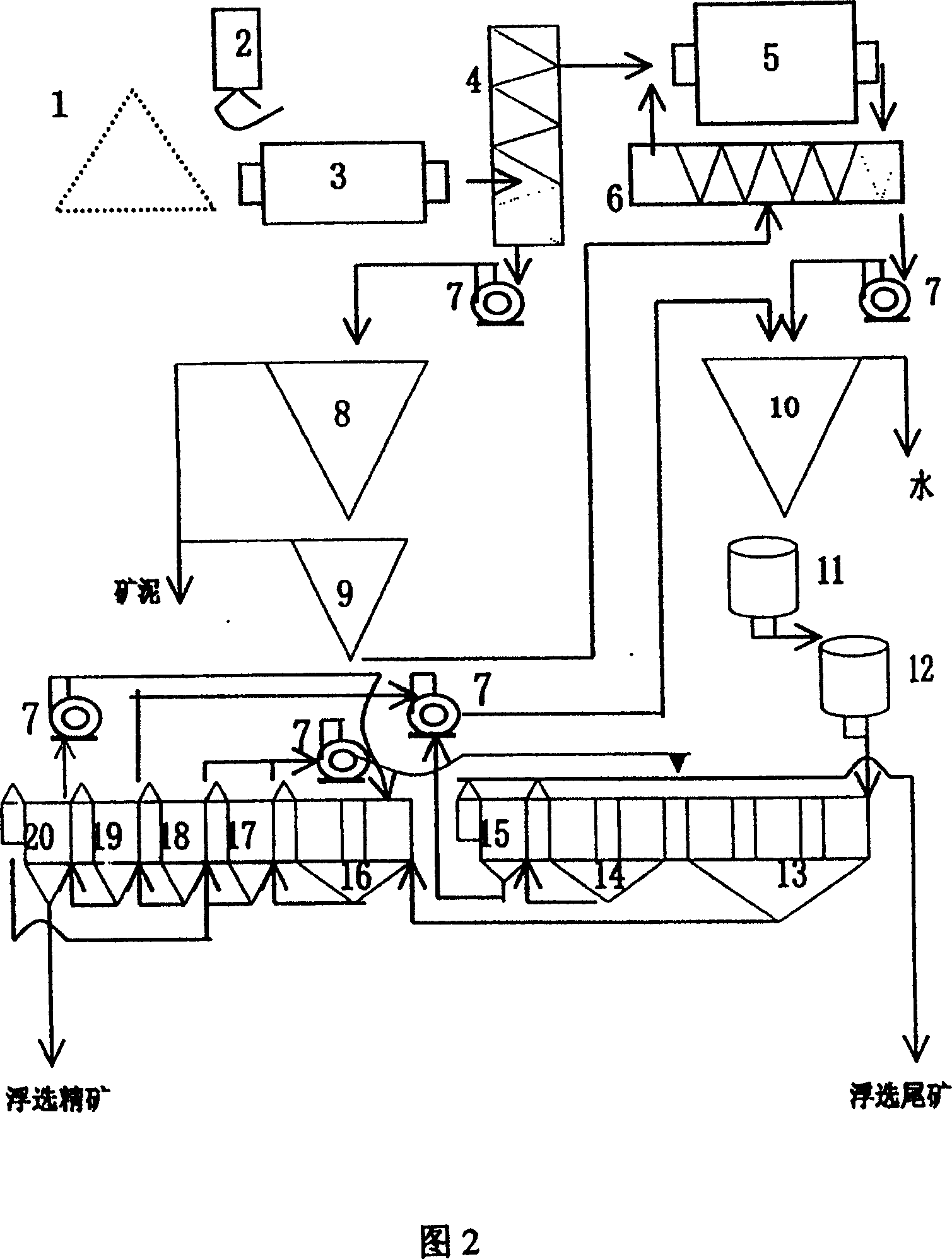

Flotation process adopting flotation column to regrading scheelite instead of flotation machine

InactiveCN102658241AHigh degree of automationSimple structureFlotationTailings damMining engineering

The invention belongs to the technical field of scheelite flotation, and discloses a flotation process adopting a flotation column to regrading scheelite instead of a flotation machine, wherein, the flotation column technology is adopted in scheelite regrading after the scheelite is processed through rough concentration; rough concentrate is regraded repeatedly; well-chosen tailings are also processed through fine scavenging for a plurality of times by adopting the flotation column so as to obtain scheelite concentrate with high grade, that is, the rough concentrate is obtained after rough concentration; ore slurry that is concentrated is then processed through heating, reagent removal and size mixing, so that the ore slurry can enter the flotation column for fine roughing when the contraction of the ore slurry ranges from 20 to 30 percent; foam products obtained in the fine roughing enter a regrading area comprising at least one flotation column and are regraded once or repeatedly, so as to obtain high-grade scheelite concentrate; and the tailings obtained in the fine roughing enter a fine scavenging area, and the tailings that are processed through fine scavenging are conveyed to a tailing dam or return for scheelite roughing. The flotation process can obtain scheelite concentrate with higher grade, the operation energy consumption of the flotation column is low, the mineral dressing index is increased, the labor environment can be improved, the labor intensity is reduced, and smoother production can be ensured.

Owner:CHINA MOLYBDENUM

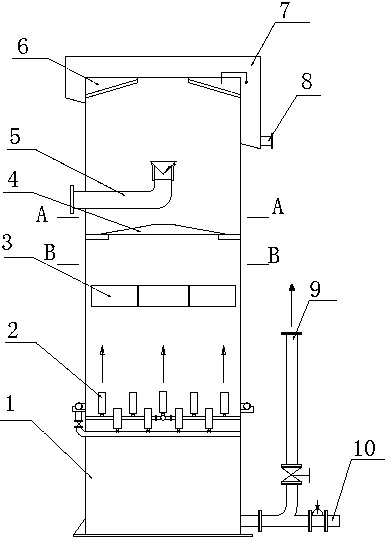

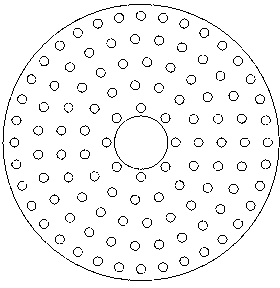

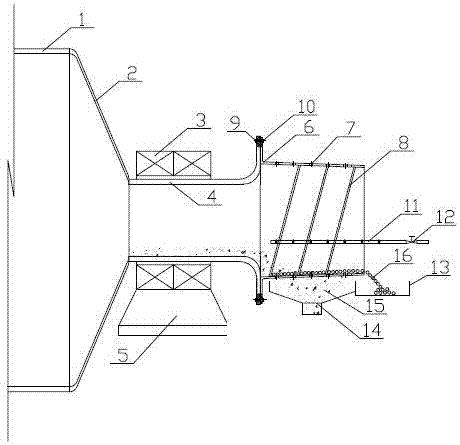

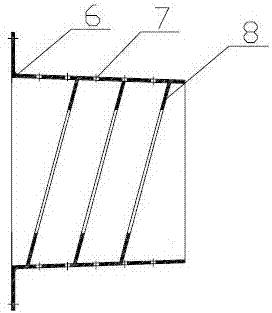

Short flotation column for selecting gold

The invention discloses a short flotation column for selecting gold. The short flotation column comprises a flotation column body (1) with a hollow structure; a foam tank (6), a foam overflow groove (7), an overflow pipe (8) and a feeding device (5) are arranged on the upper part of the flotation column body (1); the lower part of an inner cavity of the flotation column body is provided with a foaming device (2); the bottom of the flotation column body is provided with a blow-down pipe (10) and a tailing discharge device (9); and a steady flow plate (3) and an ore pulp dispersion cover (4) are respectively arranged on the upper part of the inner cavity of the flotation column body. The flotation column is shortened, and the steady flow plate of a well and the ore pulp dispersion cover are added, thereby guaranteeing the stability of a liquid level, and being beneficial to improving the treatment capacity and beneficiation indexes of the flotation column.

Owner:洛阳昶威机械制造安装有限公司

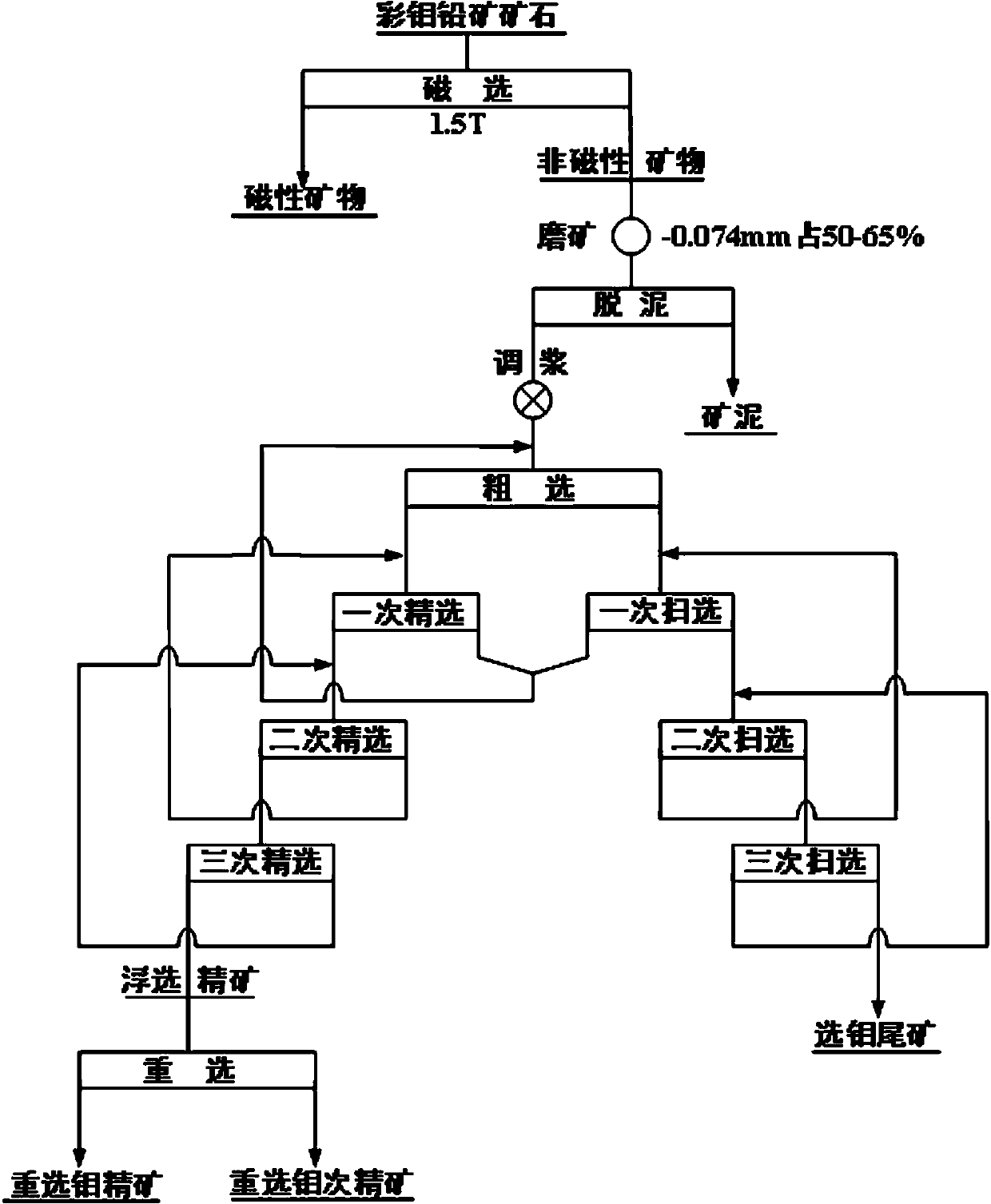

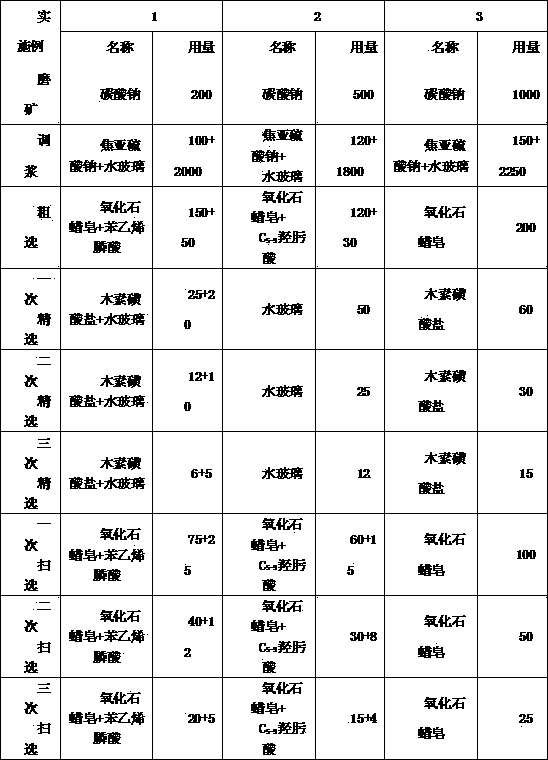

Beneficiation method for color molybdenum lead ores

ActiveCN104209183AEfficient recyclingImprove beneficiation indexFlotationMagnetic separationSodium carbonateGravity separation

The invention discloses a beneficiation method for color molybdenum lead ores. The beneficiation method is characterized by comprising the following steps of performing magnetic separation on the color molybdenum lead ores to obtain nonmagnetic ores; adding sodium carbonate in the nonmagnetic ores and then performing ore grinding and desliming; adding water in the deslimed nonmagnetic ores, mixing to form ore pulp, adding a regulator for adjusting the pH value of the ore pulp, and adding a collecting agent for floating to obtain flotation concentrates; performing gravity separation to separate the flotation concentrate and further obtain gravity separation molybdenum concentrates and gravity separation molybdenum defective concentrates. According to the beneficiation method disclosed by the invention, the high-selectivity collecting agent is adopted for directly floating, so that high-efficiency recovery of molybdenum ores is realized; the process flow is simple, the cost is low and the industrial and large-scale production is easily realized; a multi-product scheme is formed, beneficiation indicators are high, the grade of the gravity separation molybdenum concentrates Mo is greater than 20 percent, the concentration ratio of molybdenum is greater than 150 times, the grade of the gravity separation molybdenum defective concentrates Mo is greater than 7 percent, and the gross recovery is over 85 percent.

Owner:广东省科学院资源利用与稀土开发研究所 +1

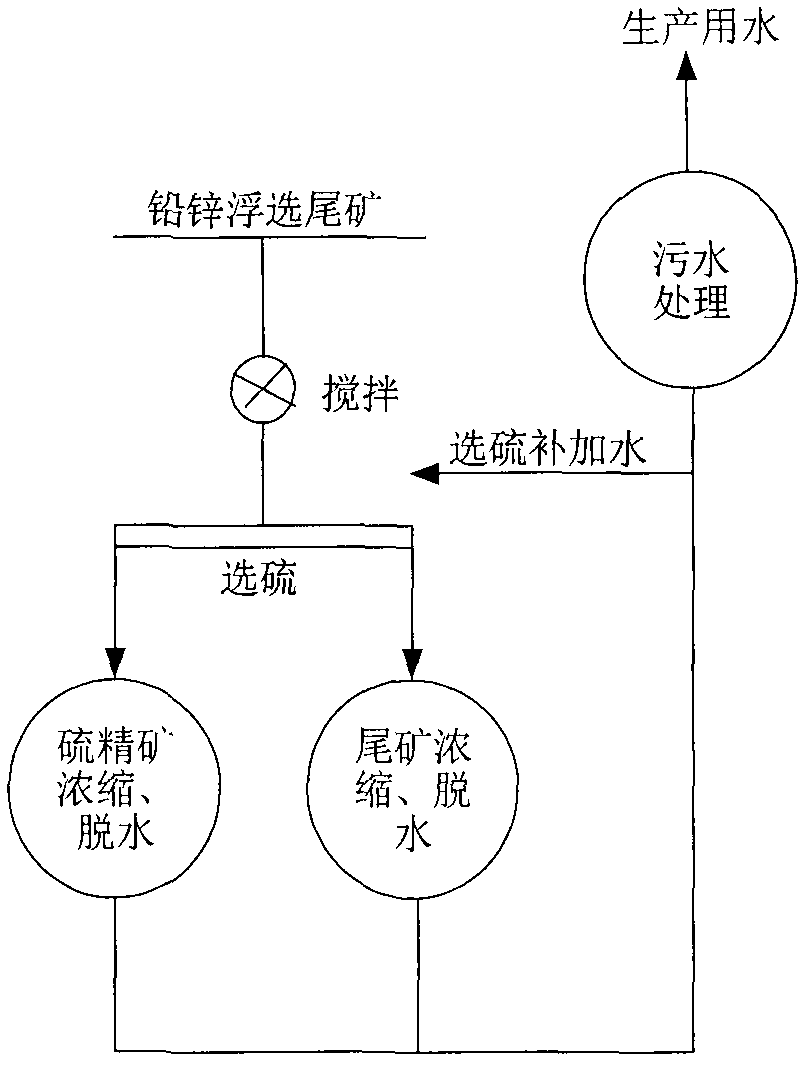

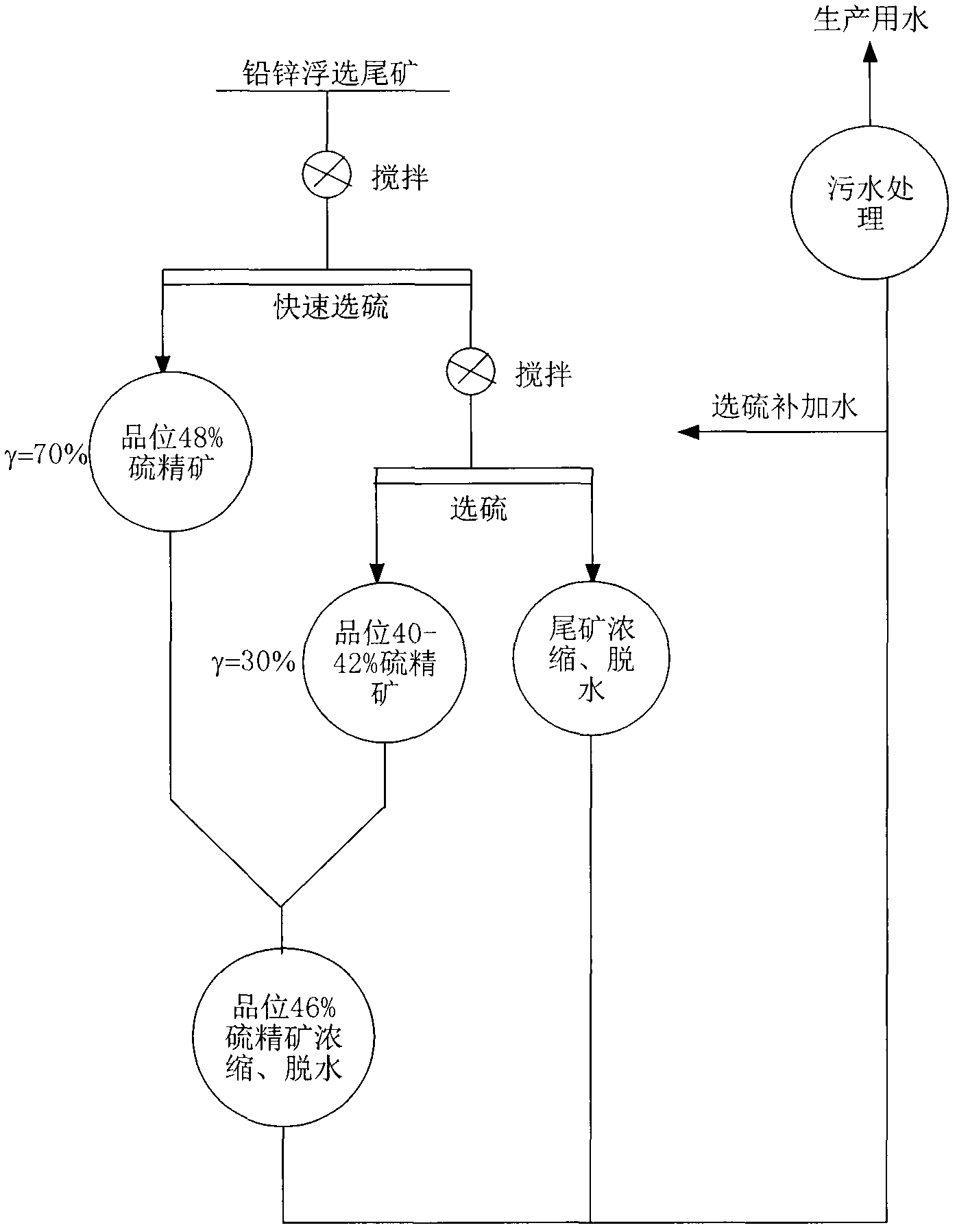

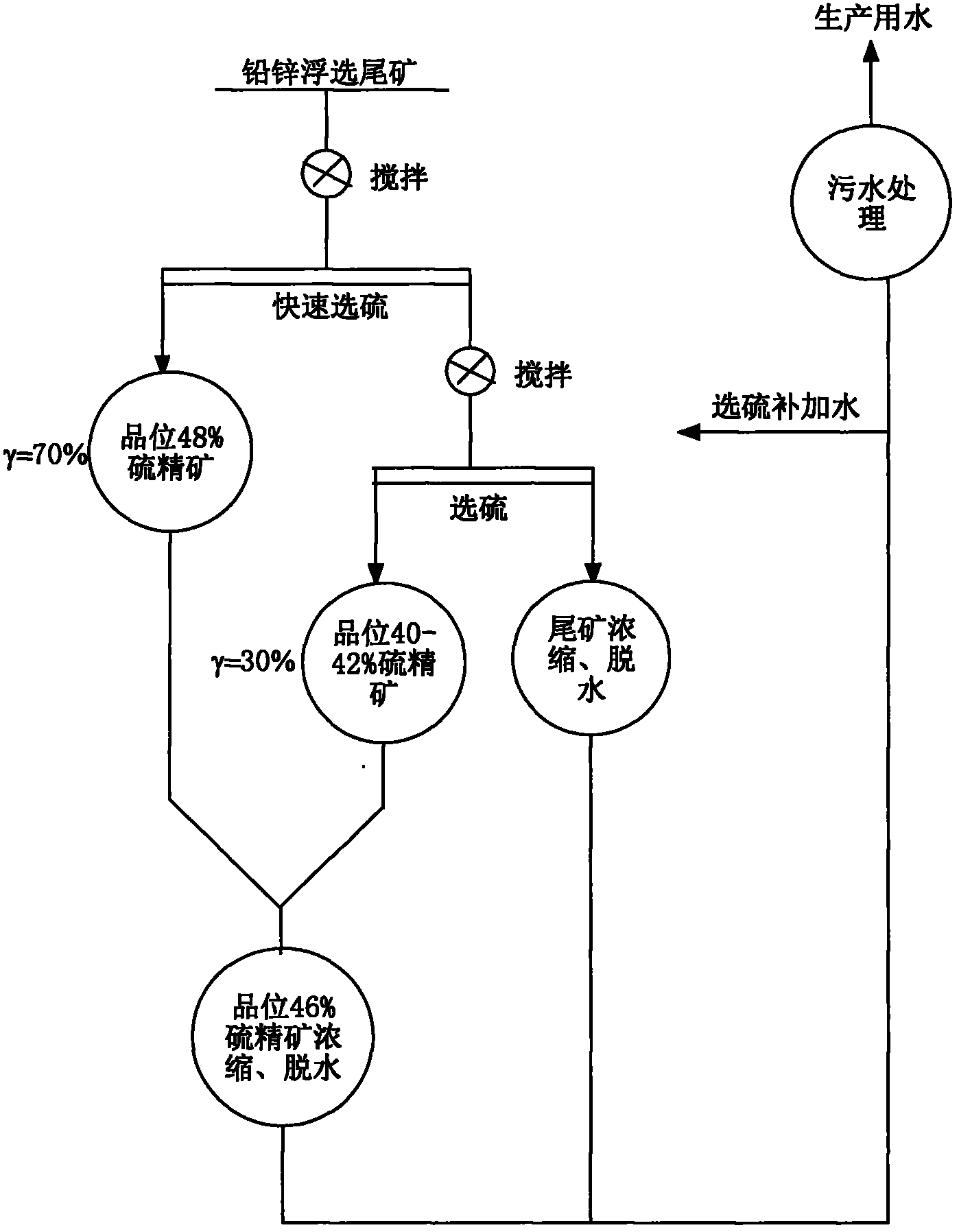

Method for floating high-grade sulfur concentrate from lead-zinc tailings by flow separation and speed division method

InactiveCN102626676AReduce dosageReduce the cost of beneficiationFlotationCell separationFlow diversion

The invention discloses a method for floating high-grade sulfur concentrate from lead-zinc tailings by a flow separation and speed separation method. According to the invention, the flow diversion and speed division method is adopted for carrying out the flotation on iron pyrite according to floatability difference characteristics of the iron pyrite in the lead-zinc tailings so as to obtain high-grade sulfur concentrate; and the problem can be solved that since the concentrate is high in mass, serious sulfur tail deviation is caused, and the recovering rate is low, and the characteristics of saving beneficiation reagent and being low in power consumption for beneficiation are realized. The method comprises the steps of concentrating the lead-zinc flotation tailings, and carrying out the flotation by the flow separation and the speed division method as per the following steps of a, fast flotation: adding sulfuric acid, sodium n-butylxanthate and oil II into the concentrated lead-zinc flotation tailings to float sulfur concentrate, wherein the yield of the sulfur concentrate accounts for more than 70% of the total sulfur concentrate; b. carrying out flotation on tailings after the fast flotation: adding sulfuric acid, sodium n-butylxanthate and oil II into the tailings after the flotation to float sulfur concentrate, wherein the yield of the sulfur concentrate accounts for a range within 30% of the total sulfur concentrate; and finally combing, concentrating and dewatering the sulfur concentrate obtained from step a and the sulfur concentrate obtained from the step b so as to obtain the required mixed sulfur concentrate.

Owner:南京银茂铅锌矿业有限公司

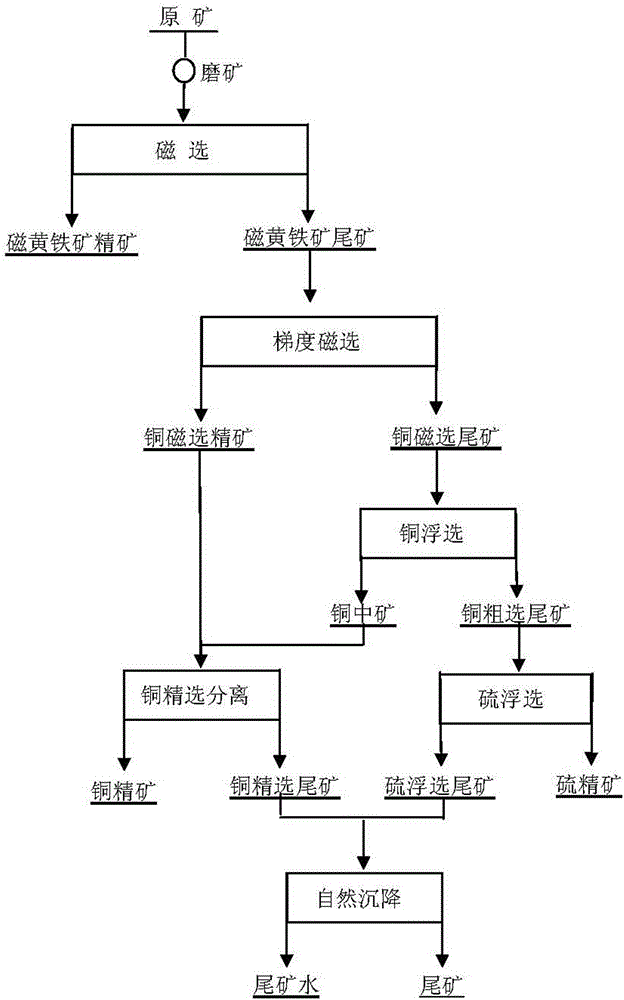

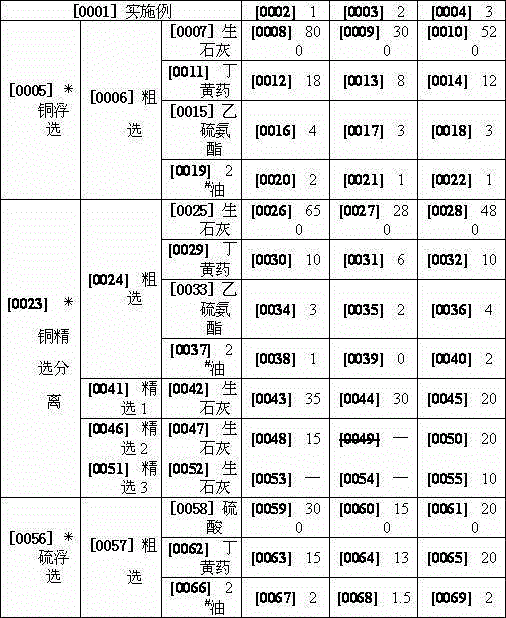

Separation method of copper-sulphur ore rich in pyrrhotite and pyrite

The invention discloses a separation method of copper-sulphur ore rich in pyrrhotite and pyrite. The method is characterized by sequentially comprising the steps of breaking and grinding raw ore; carrying out magnetic separation to obtain pyrrhotite concentrate and pyrrhotite tailings; enabling pyrrhotite tailings to be subjected to gradient magnetic separation so as to obtain copper magnetic separation concentrate and copper magnetic separation tailings; enabling the copper magnetic separation tailings to be subjected to copper floatation to obtain copper middlings and copper roughing tailings; combining the copper magnetic separation concentrate and the copper middlings so as to carry out copper selection separation, and obtaining copper concentrate and copper selection tailings; carrying out sulfur flotation on copper roughing tailings, and obtaining sulfur concentrate and sulfur floatation tailings; and combining the copper selection tailings and the sulfur floatation tailings, then carrying out free settling, obtaining tailing water and tailings, and returning the tailing water to serve as water for raw ore grinding and all steps. The separation method of the copper-sulphur ore is easy to operate, small in medicament use amount, low in cost, beneficial to the improvement of the mineral separation index of the copper-sulphur ore, more beneficial to recycling the tailing water of the copper-sulfur mine and environmental protection building, and suitable for the mineral separation of the copper-sulphur ore rich in the pyrrhotite and the pyrite with Cu larger than or equal to 0.10%.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

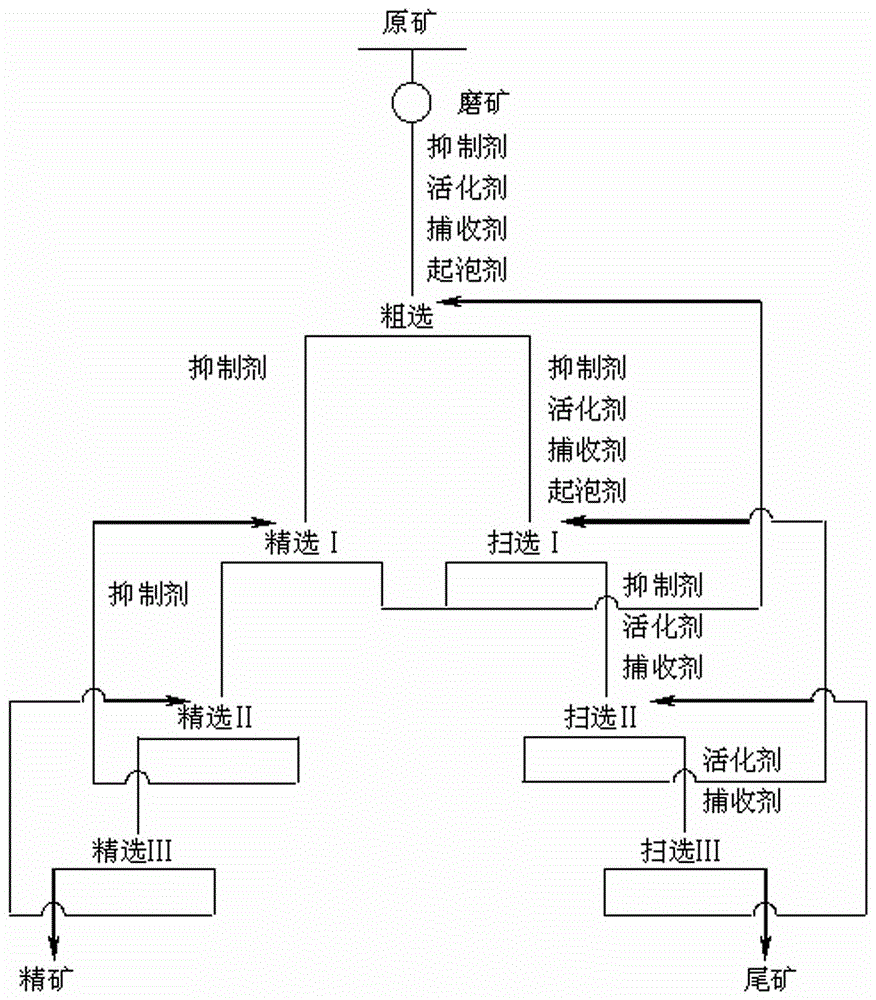

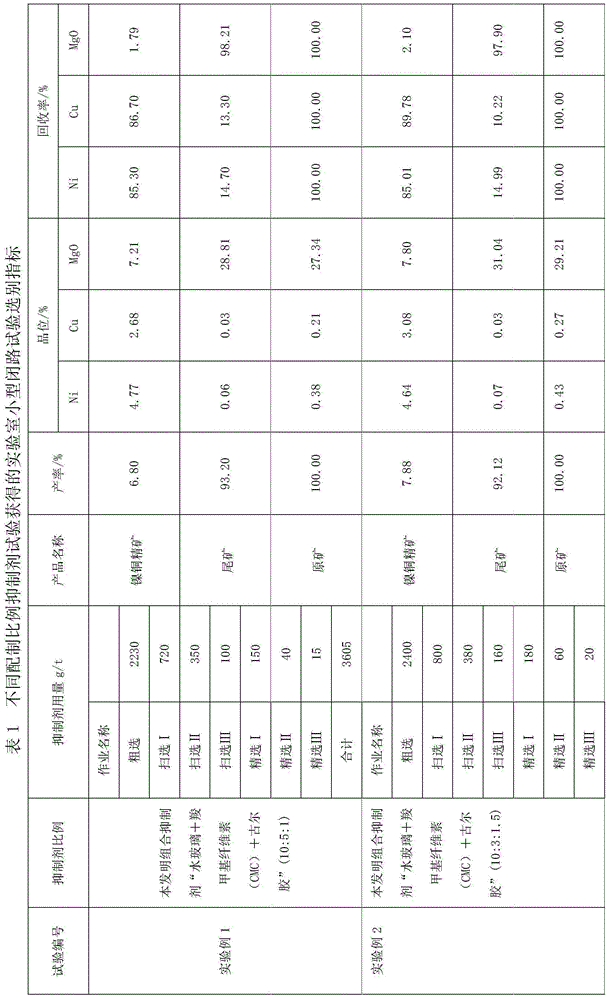

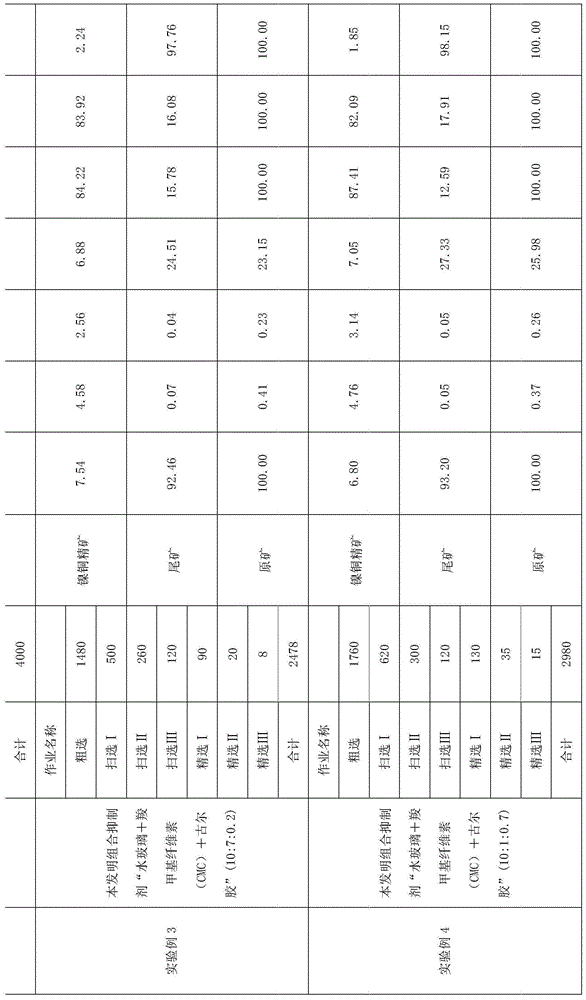

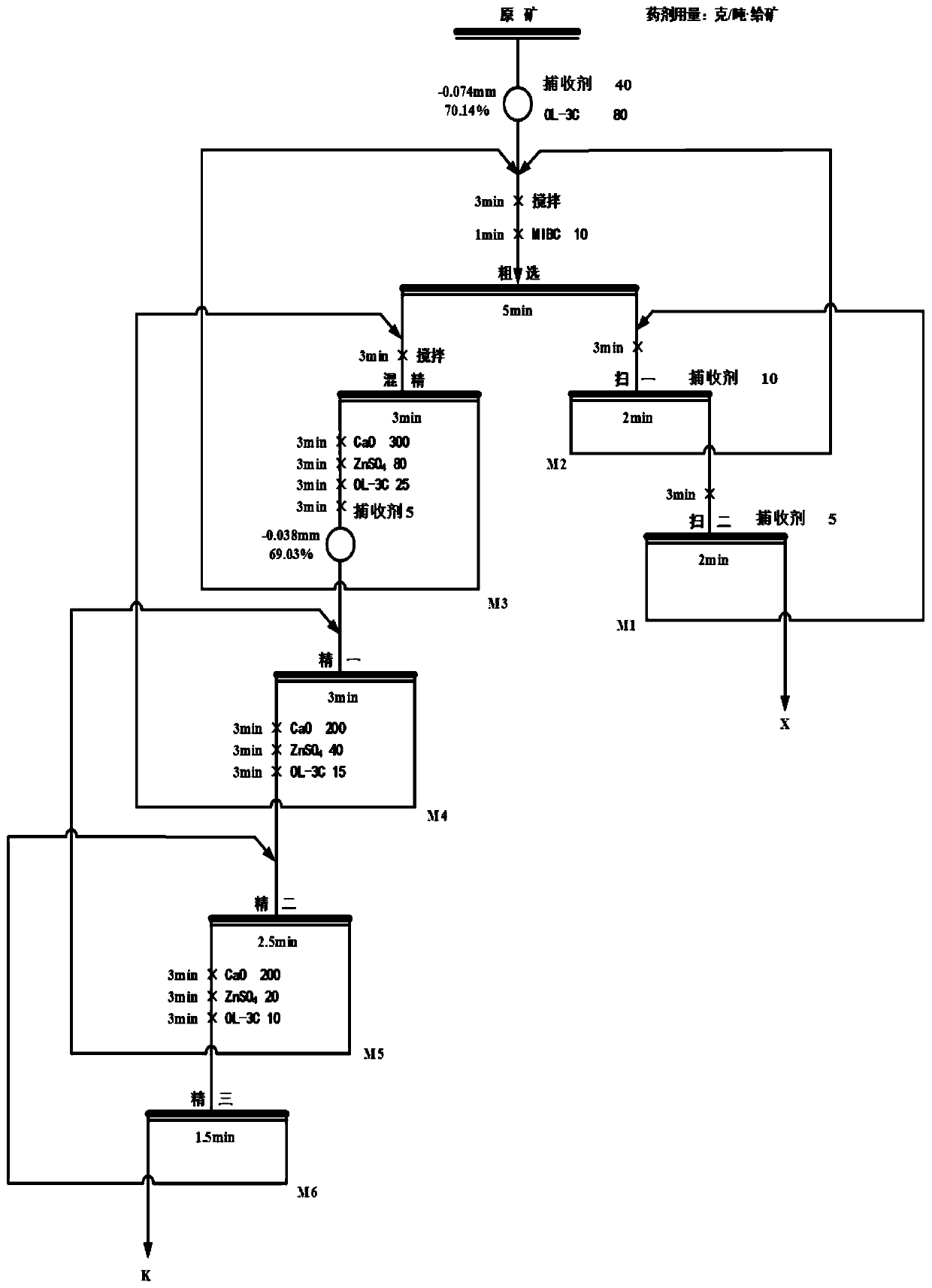

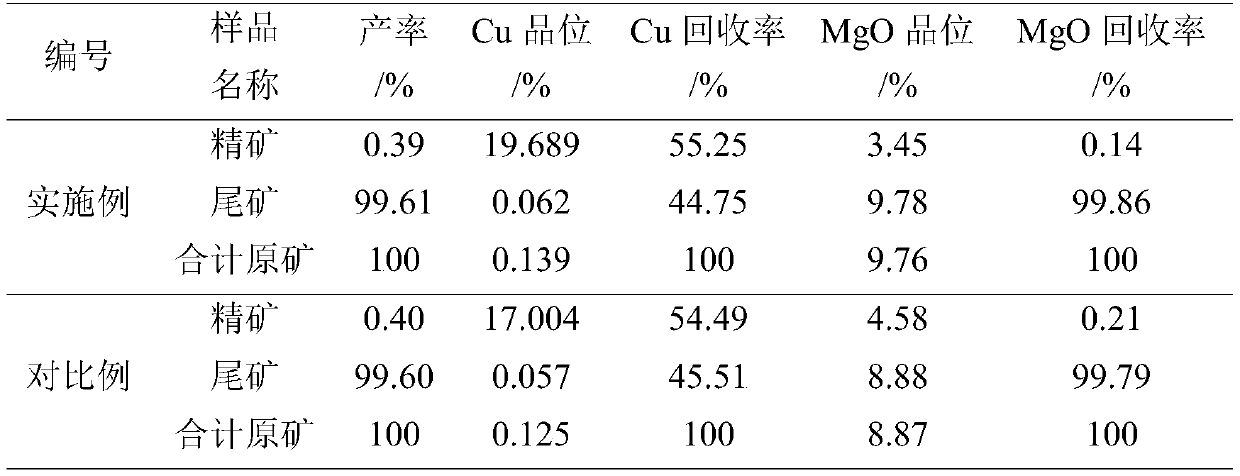

Gangue depressor for flotation of high-magnesium and low-nickel polymetallic ore

ActiveCN104084314ANickel-copper beneficiation index is goodImprove nickel-copper beneficiation indexFlotationSodium silicateSodium carboxymethylcellulose

The invention provides a gangue depressor for flotation of high-magnesium and low-nickel polymetallic ore. The gangue depressor solves the problems that nickel and copper nickel-copper concentrate obtained by means of an existing gangue depressor for flotation of the high-magnesium and low-nickel polymetallic ore are in a low grade, the recovery rate of nickel and copper is low, and the content of a magnesium impurity oxide is high. The gangue depressor comprises, by weight, 10 parts of sodium silicate, 1-7 parts of carboxymethyl cellulose (CMC), 0.2-1.5 parts of guar gum and water, wherein the weight of the water is nine to ninety-nine times that of the total weight of the raw materials.

Owner:四川省地质矿产勘查开发局成都综合岩矿测试中心

Concentration for qualifying headings and increasing recovery rate

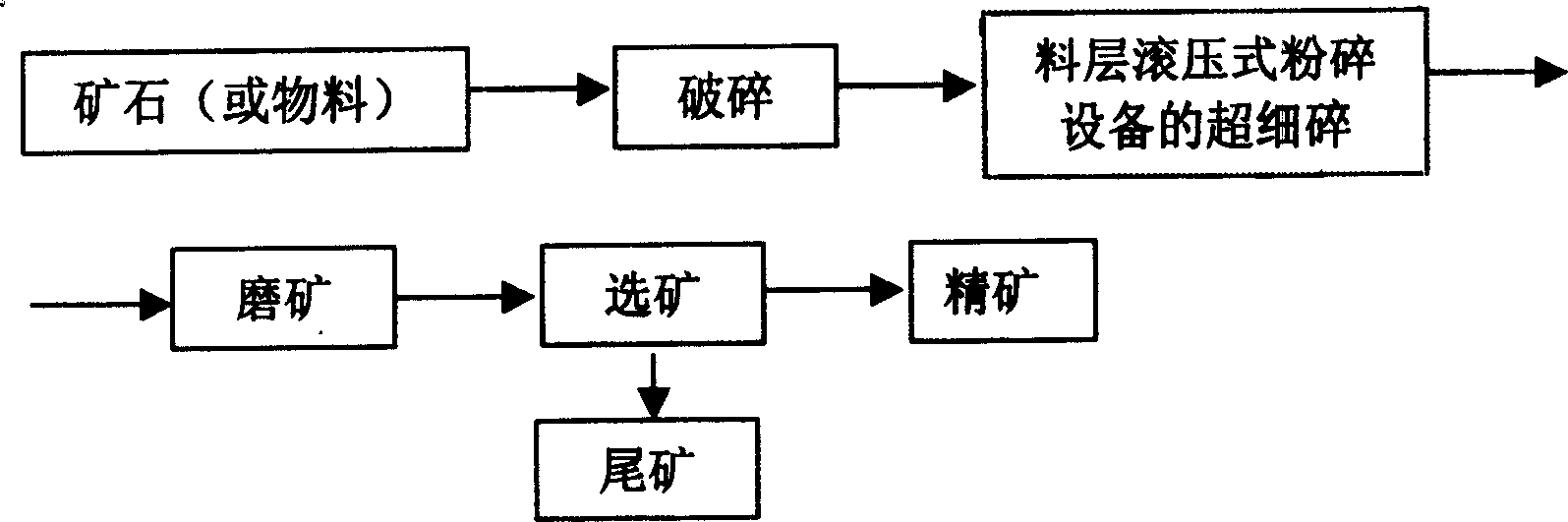

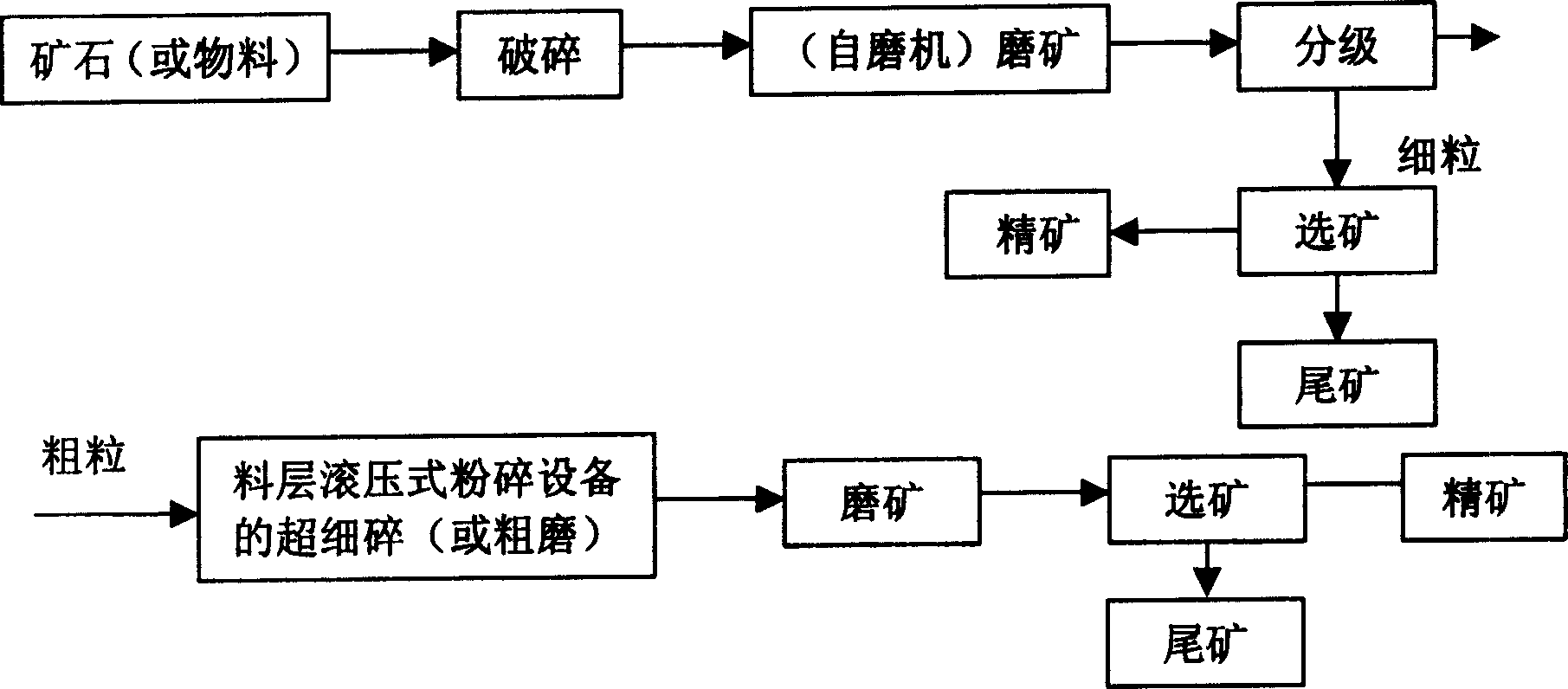

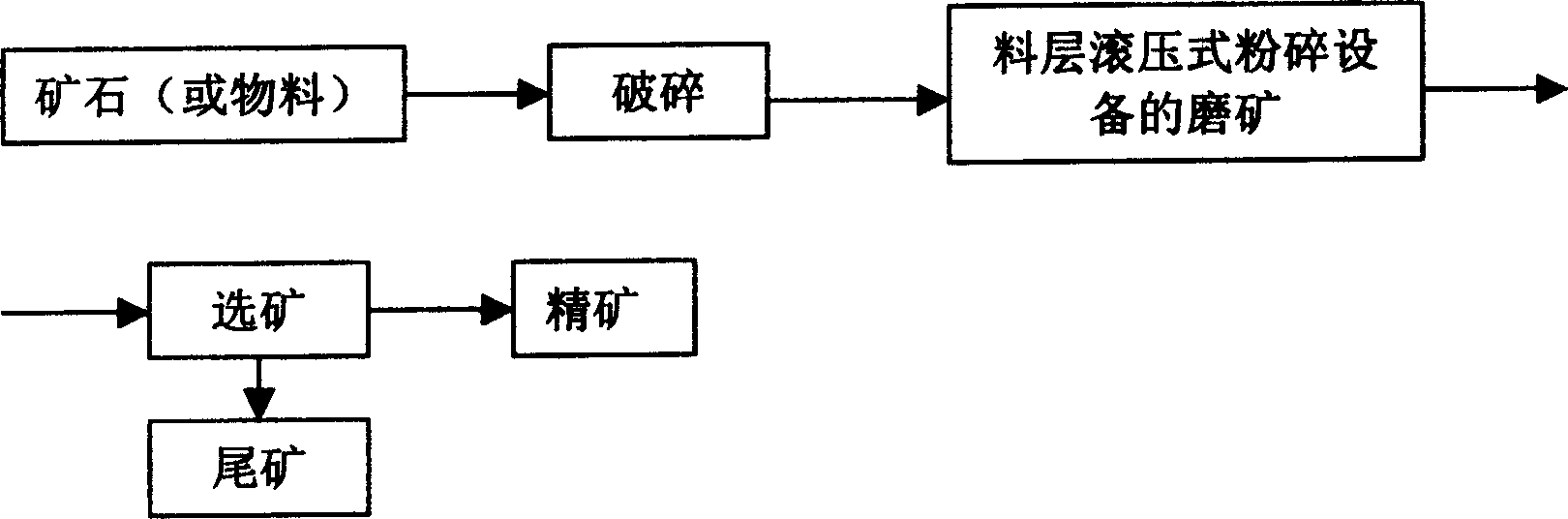

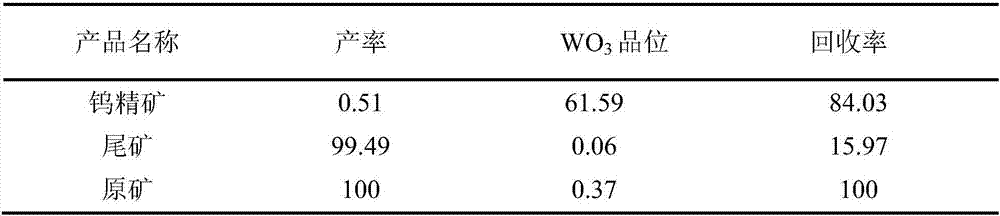

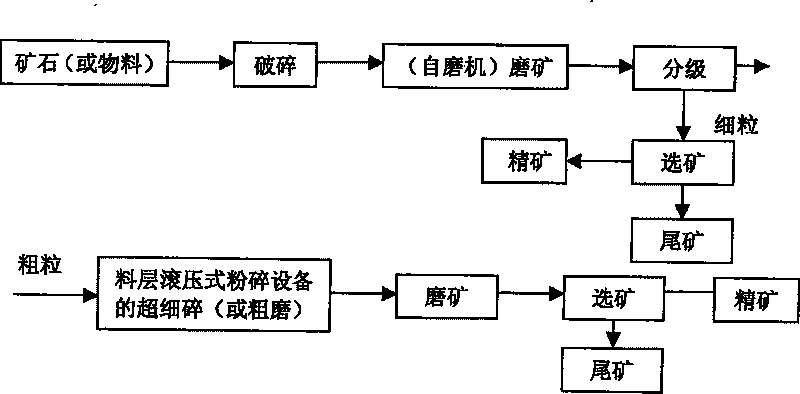

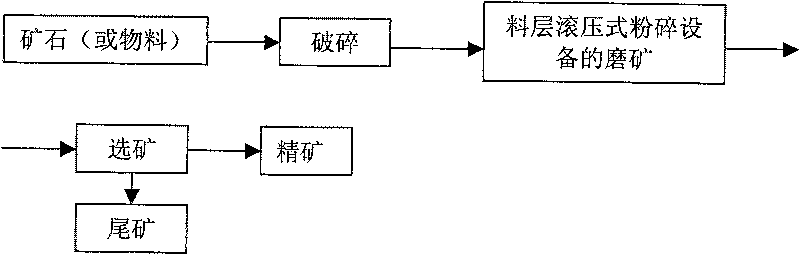

InactiveCN1895788AFacilitate dissociationFast dissociationMagnetic separationGrain treatmentsBall millMaterials science

An ore dressing technology for increasing the quality and recovery rate of ore concentrate includes such steps as crushing, rolling, grinding, and separating. Another two approaches are also disclosed.

Owner:郝志刚

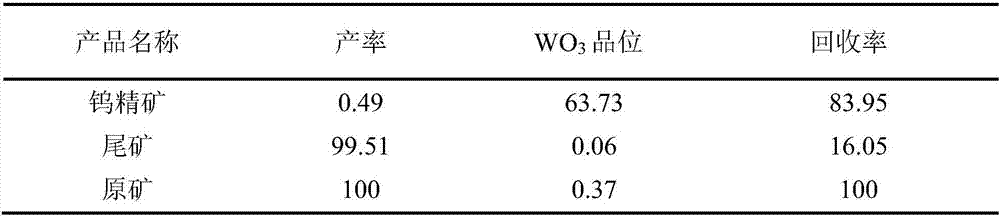

Beneficiation method for improving flotation indexes of microfine-grained scheelite

ActiveCN107138284AImprove beneficiation indexImprove surface hydrophobicityFlotationCritical micelle concentrationLower grade

The invention provides a beneficiation method for improving flotation indexes of microfine-grained scheelite, and belongs to the technical field of beneficiation. According to the beneficiation method, an electriferous surfactant is prepared into solution with certain concentration which is the critical micelle concentration of the electriferous surfactant, the solution is stirred at a high speed in a stirring barrel to generate electriferous micro-bubbles, the micro-bubbles are introduced into a microfine-grained scheelite flotation system, the electriferous micro-bubbles are selectively attached to the surfaces of valuable minerals through the electrostatic interaction by regulating and controlling the property of ore pulp, the surface hydrophobicity of the valuable minerals is enhanced, so that the flotation indexes of the microfine-grained scheelite are improved. The beneficiation method solves the technical problem that microfine-grained scheelite is difficult to recover effectively, and has important significance for realizing efficient utilization of low-grade refractory scheelite.

Owner:CHINA MOLYBDENUM

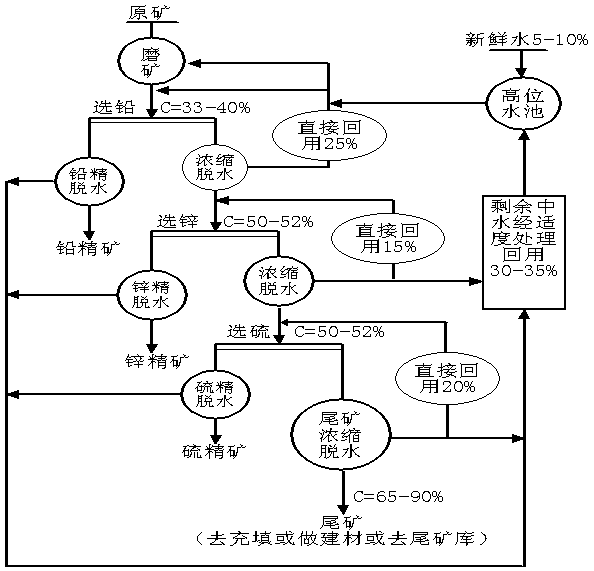

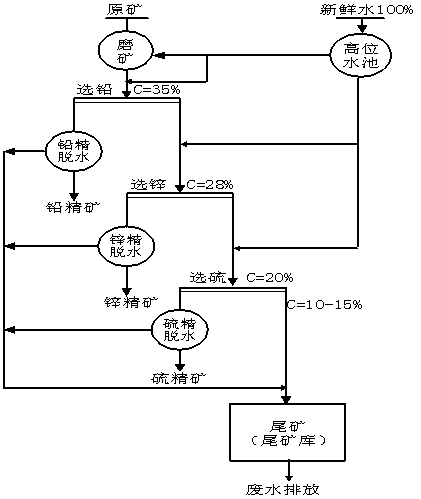

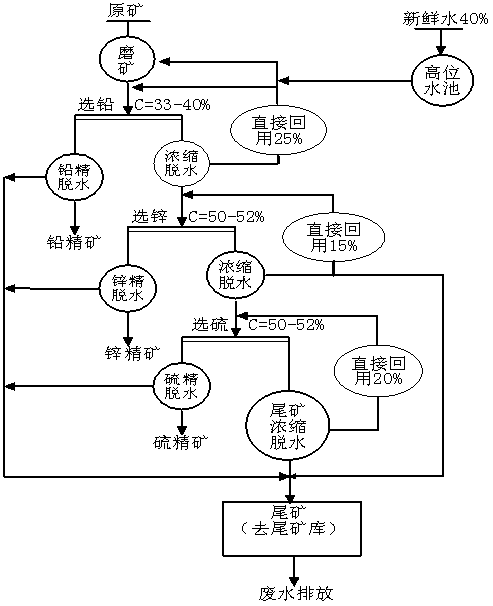

Lead zinc ore beneficiation process capable of saving clean water

The invention provides a lead zinc ore beneficiation process capable of greatly reducing beneficiation clean water consumption, prominently saving clean water resources, stably improving lead zinc ore beneficiation indexes, reducing beneficiation waste water emission and reducing environmental pollution. In the lead zinc ore beneficiation process, lead tail water for lead tailings is directly returned for ball milling and lead separation, zinc tail water for zinc tailings is directly returned for zinc separation, tailing water for sulfur tailings is directly returned for sulfur separation, sothat the use level of the clean water can be prominently saved.

Owner:南京银茂铅锌矿业有限公司

Dressing and smelting method for recovering copper from bonded copper oxide minerals

InactiveCN104988333AImprove beneficiation indexImprove product qualityProcess efficiency improvementCopper oxideOperability

The invention discloses a dressing and smelting method for recovering copper from bonded copper oxide minerals. The method comprises the steps that 1, the bonded copper oxide minerals are smashed and ground and then are mixed with water, and raw ore pulp is obtained; 2, ore dressing is carried out on the raw ore pulp through a low-intensity magnetic separation-gravity separation-high-gradient magnetic separation ore dressing technology; 3, gravity concentrates and high-gradient magnetic concentrates separated out through the ore dressing technology are combined and then filtered to obtain enriched product residues, and primary ore pulp is prepared; 3, sodium hydroxide is added for pretreatment, and pretreatment liquid and pretreatment residues are obtained after filtering; 5, after secondary ore pulp is prepared, acid leaching is carried out on the secondary ore pulp to obtain copper-bearing acid leaching liquid. The recovery rate of copper is not smaller than 80 percent, spongy copper with the mass purity not lower than 90 percent can be obtained through further extraction, and the advantages of being high in ore dressing index, high in product quality, high in operability and simple in technological process are achieved.

Owner:新兴发展集团有限公司 +1

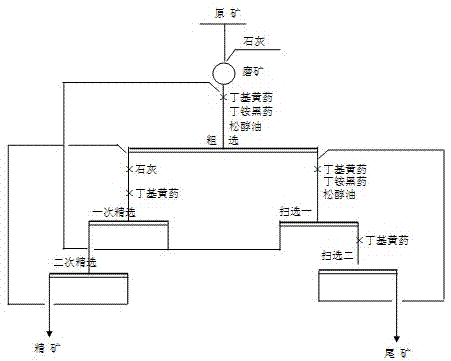

Method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining collecting agent

The invention belongs to the technical field of beneficiation, particularly relates to a method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining a collecting agent. According to the method, ethanethiol is adopted as a main collecting agent in the lead process, a butylamine black medicine, the 25 # black medicine is an auxiliary collecting agent, thezinc flow ethyl xanthate and the butyl xanthate are added according to a ratio of 1:1 to serve as a main collecting agent, and the butyl amine black medicine is used as an auxiliary collecting agent.By utilizing the use of the combined collecting agent, the concentrate grade is stable and even the small amplitude is improved, the recovery rate of the three kinds of metal of the lead and zinc silver is greatly improved, the content of the silver in the lead concentrate is improved, and the economic benefit is obviously improved.

Owner:云南中金共和资源有限公司

Flotation separation method of talcum and copper pyrite

ActiveCN111229451AHighly selective inhibitionIncreased selective inhibitionFlotationCelluloseClay minerals

The invention discloses a flotation separation method of talcum and copper pyrite. The method firstly adopts combination of three drugs carboxymethyl cellucose, CTP and calcium lignosulfonate as an inhibitor to carry out flotation separation on the talcum and the copper pyrite, the efficient selective inhibition effect on the talcum is possessed, meanwhile, clay mineral and copper pyrite particlescan be effectively dispersed, and the foam mixing phenomenon of hydrophilic gangue minerals is obstructed. The inevitable adverse effect of ions in ore pulp is eliminated, the selective inhibition effect of the inhibitor is further reinforced, gangue minerals such as the talcum and chlorite floating easily are selectively inhibited, thus flotation separation of the minerals is benefitted, the grade and the recycling rate of copper concentrate are improved, and the indicators in beneficiation are increased substantially. According to the method, the combined inhibitor is compared with a conventional talcum inhibitor, the three drugs collaborate, and have dual attributes of inhibitive ability and dispersity, the indicators in beneficiation of copper can be increased substantially, and the market application value is possessed.

Owner:CENT SOUTH UNIV

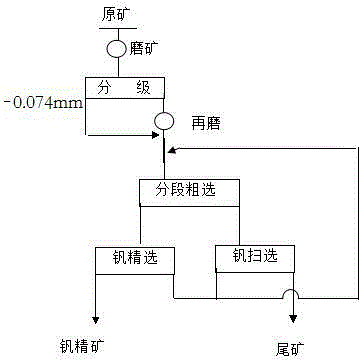

Mineral separation method of finely disseminated vanadium contained carbonaceous shale

InactiveCN104907163AImprove beneficiation indexImprove flotation recoveryFlotationWet separationRoscoeliteMineral collecting

The invention discloses a mineral separation method of finely disseminated vanadium contained carbonaceous shale. The amount of roscoelite with the disseminated grain size less than 0.019mm is larger than 50% of the total amount of roscoelite in the finely disseminated vanadium contained carbonaceous shale. The mineral separation method of the finely disseminated vanadium contained carbonaceous shale includes following steps: (a) performing rough grinding on raw ore after being crushed so as to obtain roughly ground minerals; (b) performing screening classification on the roughly ground minerals, obtaining coarse grain minerals +0.074mm in size and fine grain minerals -0.074mm in size after the screening classification, and combining the coarse grain minerals after being ground twice with the fine grain minerals -0.074mm in size; (c) adding PH (power of hydrogen) regulators into the combined minerals, adjusting PH value to 5-6, adding gangue mineral inhibitor and vanadium mineral collecting agents into ore pulp for 6-12 times, and obtaining concentrated vanadium ore through segmenting rough concentration, vanadium concentration and vanadium scavenging after obtaining flotation pulp by adding flotation reagents once. The mineral separation method of the finely disseminated vanadium contained carbonaceous shale can perform mineral separation on the finely disseminated vanadium contained carbonaceous shale, can effectively improve a mineral separation index, and further can reduce mineral separation cost.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

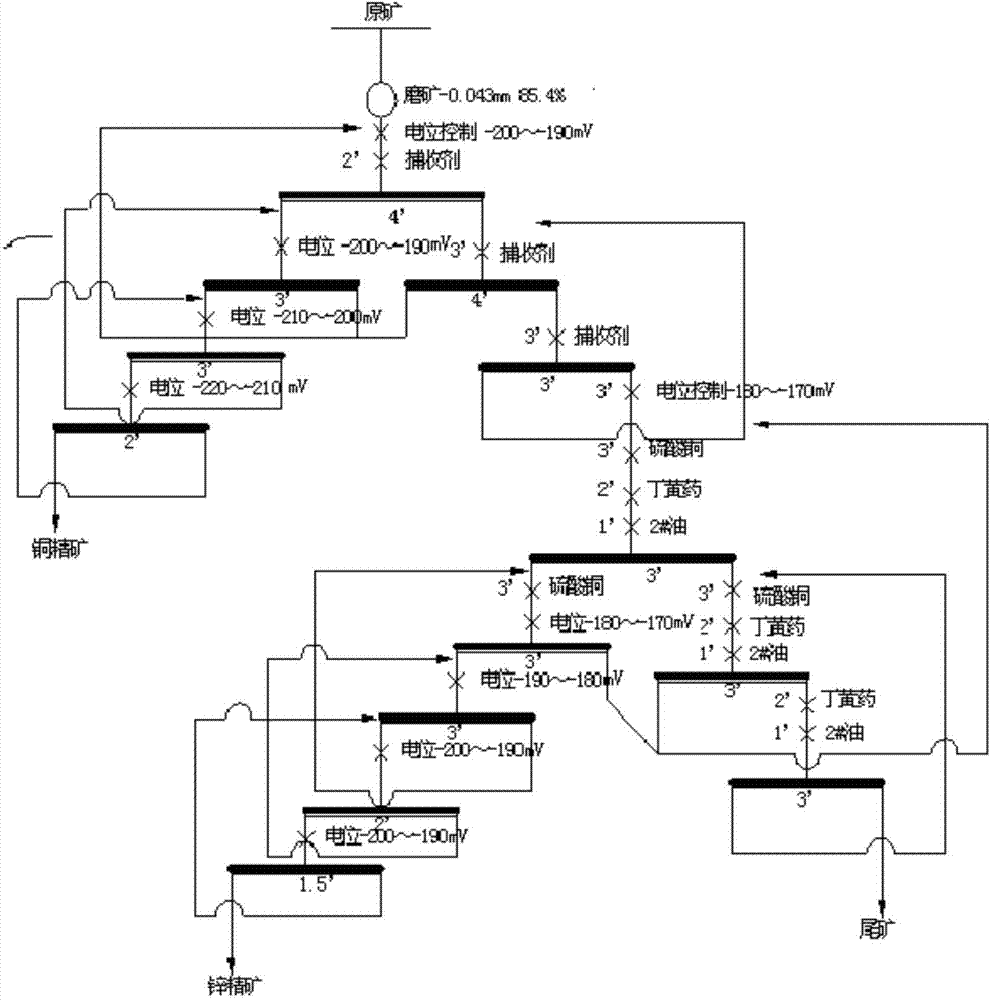

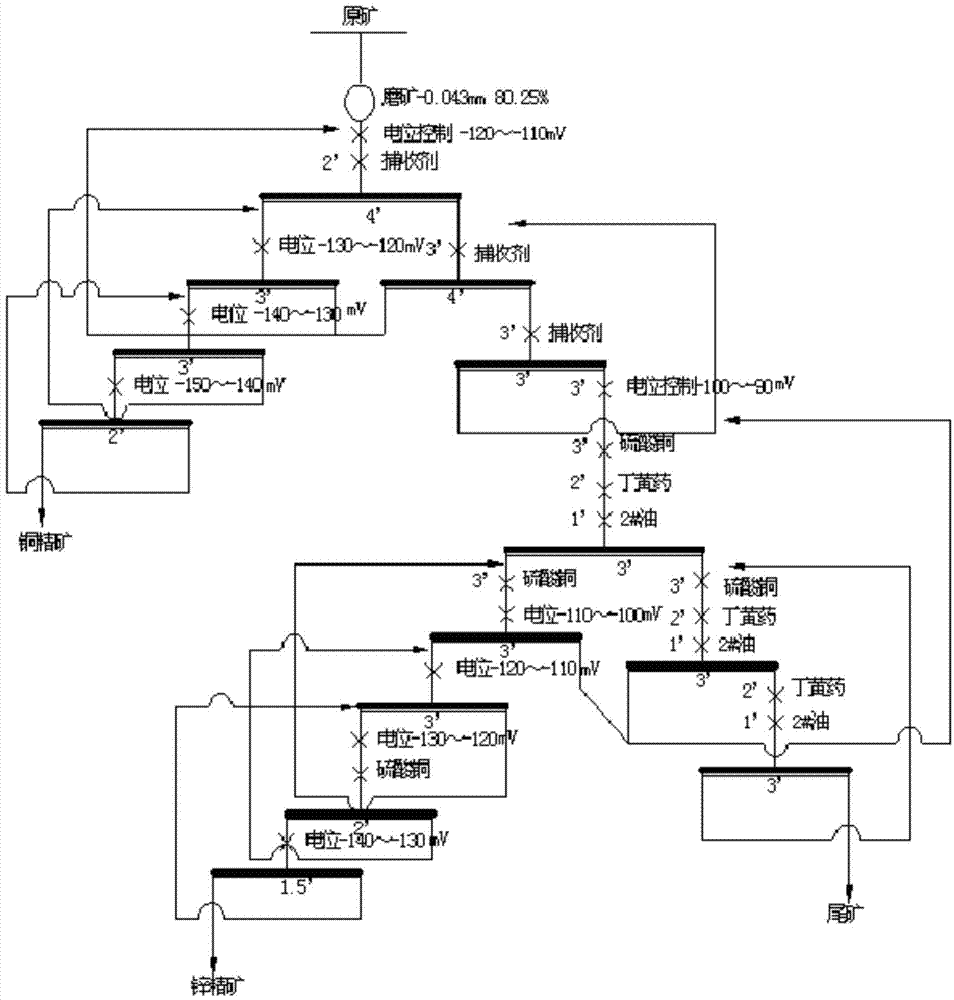

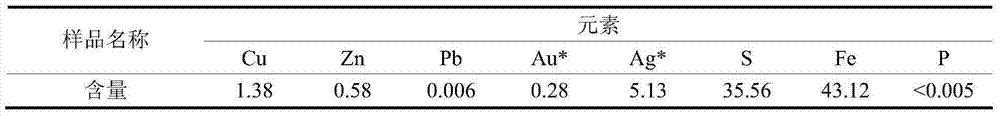

Inhibitor-free floatation separation method for high-sulfur copper and zinc sulphide ore difficult to float

The invention relates to a metal sulphide ore floatation separation technology, in particular to an inhibitor-free floatation separation method for high-sulfur copper and zinc sulphide ore difficult to float. The floatation separation method comprises the following steps that (1) lime is used for adjusting the electric potential of ore pulp under appropriate grinding fineness, the electric potential of the ore pulp is controlled to be -250 mV to -100 mV, copper collectors such as thionocarbamate and xanthate are added, no sphalerite inhibitor is added, and copper is floated preferably; (2) copper tailings are floated to be added with copper sulfate so as to activate sphalerite, the electric potential of the ore pulp is controlled to be -220 mV to -70 mV, xanthate and number two oil are used for floating zinc, and finally a copper concentrate and a zinc concentrate are obtained. Compared with the prior art, by adjusting the electric potential of the ore pulp, the floatability of a copper mineral and the floatability of a zinc mineral are changed, and thus inhibitor-free copper and zinc floatation separation can be realized. The technological process is simple, controlling is easy, meanwhile, drug cost can be saved, and the drug cost can be lowered by 5%-10% compared with a traditional technology.

Owner:厦门紫金矿冶技术有限公司

Method for efficiently recovering iron ore from gold extraction tailings of oxidized ore containing gold and iron

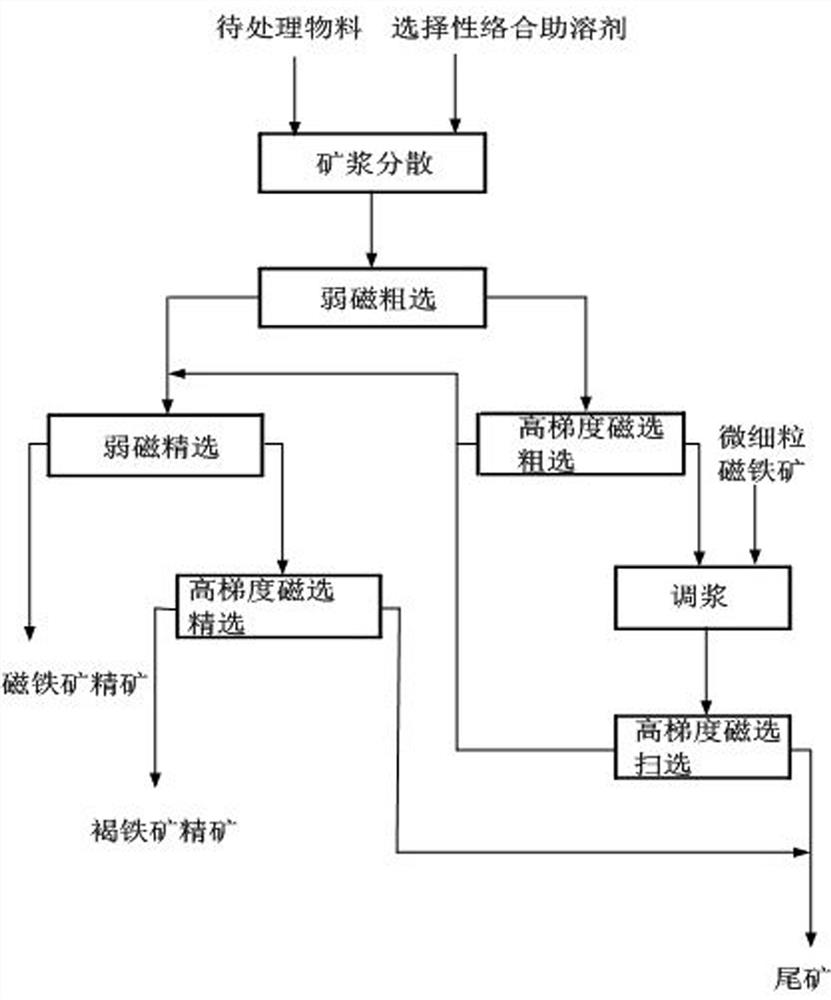

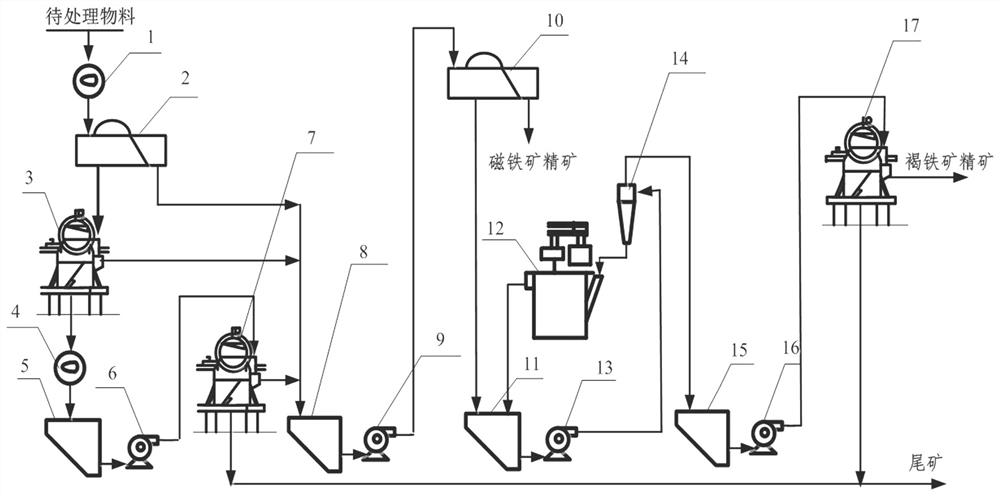

PendingCN112317127AStrong process adaptabilityHigh recovery rateHigh gradient magnetic separationProcess efficiency improvementMining engineeringMagnetite

The invention relates to a method for efficiently recovering iron ore from gold extraction tailings of oxidized ore containing gold and iron, which belongs to the field of ore dressing and comprises the following steps of: (1) dispersing ore pulp, and adding a cosolvent or a dispersing agent for dispersing; (2) performing weak magnetic roughing to obtain magnetite rough concentrate and tailings; (3) performing high-gradient magnetic separation roughing to obtain limonite rough concentrate I and tailings; (4) externally adding micro-fine particle magnetite for size mixing; (5) performing high-gradient magnetic separation scavenging to obtain limonite rough concentrate II and tailings; (6) performing weak magnetic concentration: combining and mixing the magnetite rough concentrate with the limonite rough concentrate I and II to obtain magnetite concentrate and tailings; (7) grinding and dissociating the tailings in the step (6); and (8) performing high-gradient magnetic separation concentration: concentrating the tailings obtained in the step (7) to obtain limonite concentrate and middlings, and combining the middlings with the tailings obtained in the step (5) to serve as total tailings; according to the method, the micro-fine particle magnetite and the limonite can be effectively recycled.

Owner:YUNNAN GOLD MINING GRP

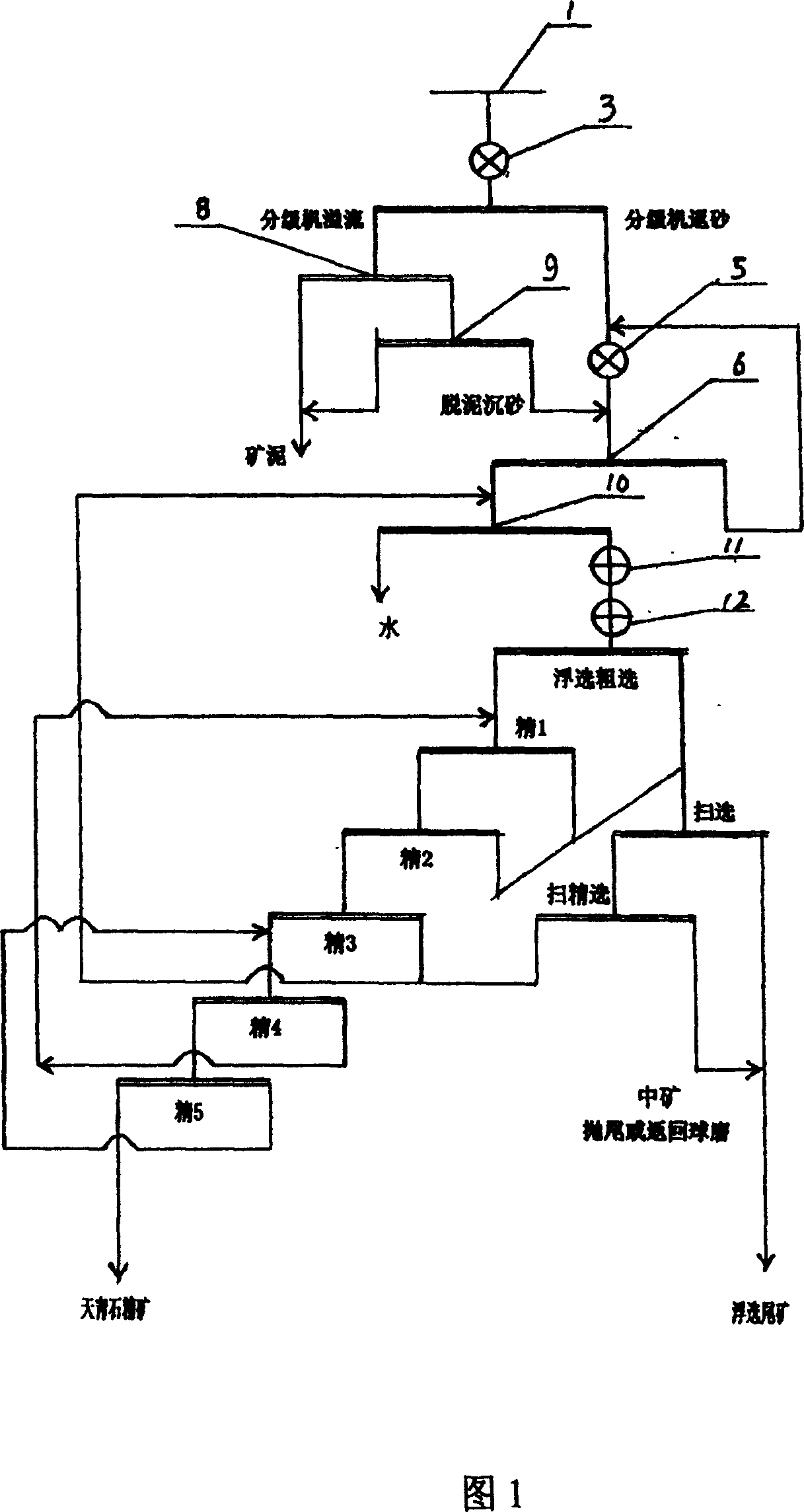

Deslim-floatation celestite inished ore process

InactiveCN1321746CRaise the gradeLarge amount of processingFlotationGrain treatmentsStrontium carbonateScavenger

The invention relates to a process for separating mineral of Celestine, especially relating to a finished ore process of desliming-multiple selection. The inventive method comprises: the ore is processed with rod milling, secondary desmliming, spiral classifying, floatation-roughing separation, secondary scavenger, and fifth classifying. The invention comprises following advantages: the inventive process has better mineral separation index when it is used to classify the Celestine with large content of low-grade mud, while the finished ore productivity is 37.82-42.09%, the content of SrSO4 is 75.75-80.10% and the recovery ratio is 75.17-79.59%; the fifth floatation device has large handling capacity, lower water consumption, lower cost of finishing ore, and lower medicament consumption with simple device. The invention has stable process, simple operation and wide application in the finishing-separation production of Celestine, while it can supply high grade Celestine finished ore for producing strontium carbonate.

Owner:QINGHAI JINRUI MINERAL DEV

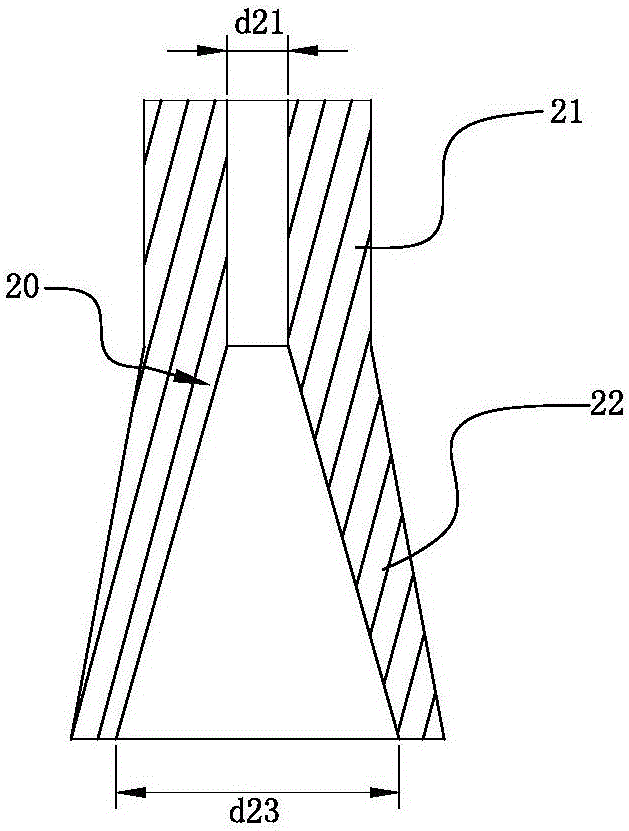

Nozzle used for ore flotation equipment

ActiveCN106238224AImprove operational efficiencyImprove wear resistanceFlotationMineral flotationCeramic

The invention discloses a nozzle used for ore flotation equipment. The nozzle is characterized in that the nozzle is made of a tungsten alloy material, and the tungsten alloy material comprises, by mass, 80.0%-85.0% of tungsten carbide and 11.0%-13.0% of nickel. According to the tungsten alloy nozzle used for the ore flotation equipment, the abrasion resistance is superior to that of a nozzle made of ceramics or manganese steel alloy or tungsten carbide. The average service life of the tungsten alloy nozzle can reach two to three years, and operation efficiency of the flotation equipment is greatly improved; and the workloads of maintenance labor are lowered, cost is reduced, and the indicators in beneficiation are increased.

Owner:洛阳豫鹭矿业有限责任公司

Heating floatation method for middling pulp in zinc oxide ore

InactiveCN105013618AImprove stabilityIncrease vulcanization rateFlotationFoaming agentOpen-circuit test

The invention relates to a heating floatation method for middling pulp in zinc oxide ore and belongs to the technical field of ore processing. After raw ore of the zinc oxide ore is broken and ground, a conventional floatation method is used for conducting an open-circuit test, and therefore concentrates, middlings and tailings are obtained; the obtained middlings are merged; the mass percentage concentration of the pulp is adjusted to be 20%-40%; the pulp is heated to 40-60 DEG C; then, Na2S activating agents are added in sequence so that the pH of the pulp can reach 11-11.5; collecting agents and foaming agents in a conventional floatation process are used for conventional floatation, and therefore concentrates and tailings are obtained; and the obtained concentrates and the concentrates obtained through the open-circuit test are merged, and final zinc concentrates meeting the index requirement are obtained through preparation. According to the heating floatation method, the problems that the middlings in the zinc oxide ore separation process are hard to process, the pH of the middling pulp is low, the use amount of sodium sulfide is too large, closed-circuit work deteriorates due to sludge, and the sludge is hard to scatter are solved.

Owner:KUNMING UNIV OF SCI & TECH

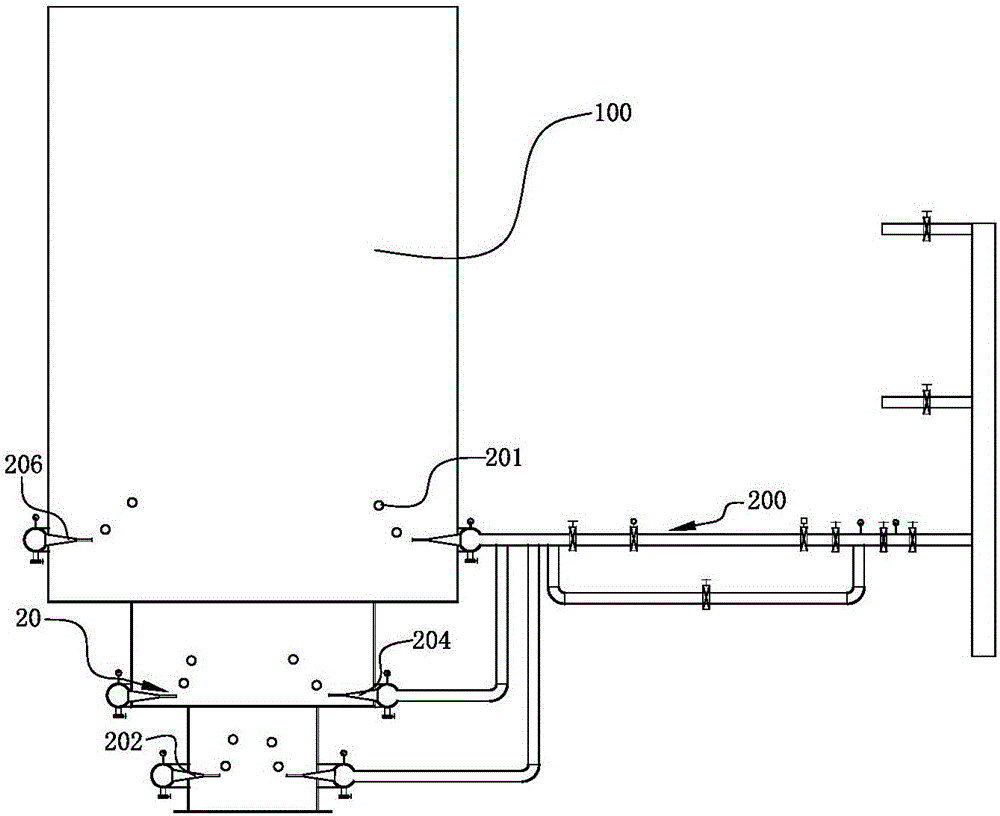

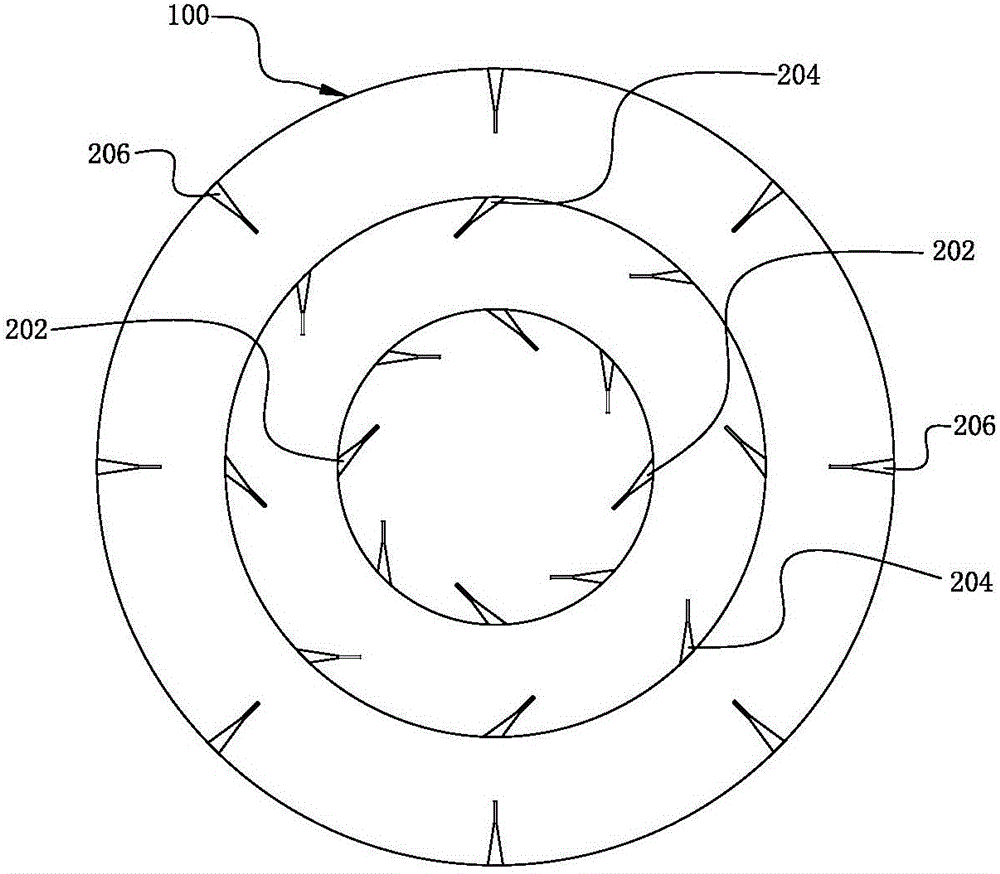

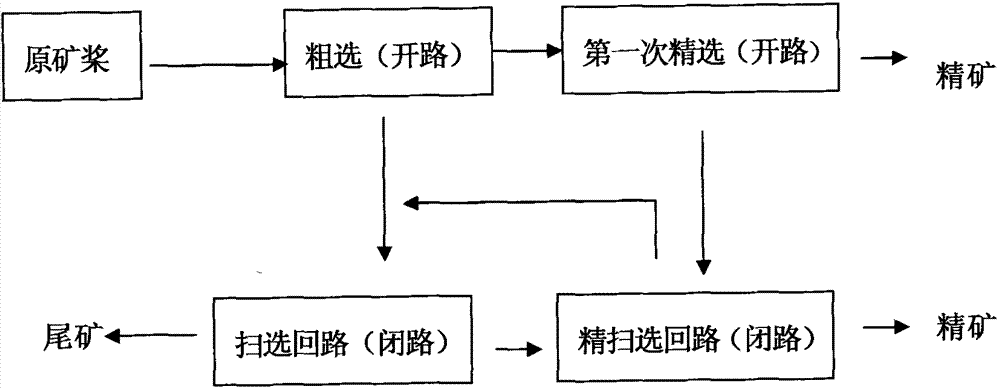

Big-open-loop small-closed-loop mud flotation method of oxidized ore

InactiveCN101695685BReduce step-by-step accumulationGuaranteed RecoveryFlotationClosed loopEngineering

The invention provides a big-open-loop small-closed-loop mud flotation method of an oxidized ore. In the method, during the flotation of the oxidized ore, rough concentration and primary concentration adopt open-circuit flotation and other follow-up flotation operation adopts a normal process. As both the rough concentration and the primary concentration adopt open-circuit flotation without returning middlings, gradual accumulation of slurry in the process is reduced greatly, the interference in the flotation from slurry and the influences of the slurry on the flotation are effectively reduced and the recovery rate of concentrate is guaranteed. A scavenging circuit and a follow-up fine scavenging circuit adopt a normally closed circuit ore dressing flow, the quality of concentrate is guaranteed, and the ore dressing index is improved greatly. In the method, the traditional flotation agent system is not required to be changed, but only the reconnection of ore pulp pipes in the traditional flotation flow is required. And in the method, the operation is convenient, the production cost is low, the quality of the concentrate is high and the recovery rate of the concentrate is high.

Owner:KUNMING UNIV OF SCI & TECH

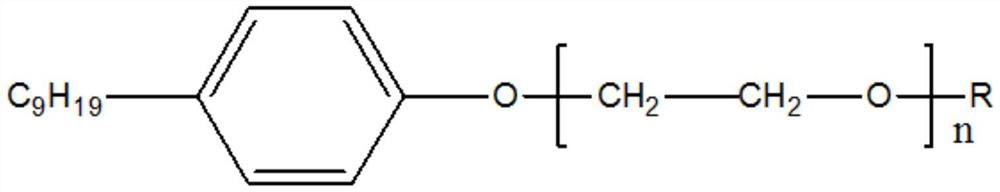

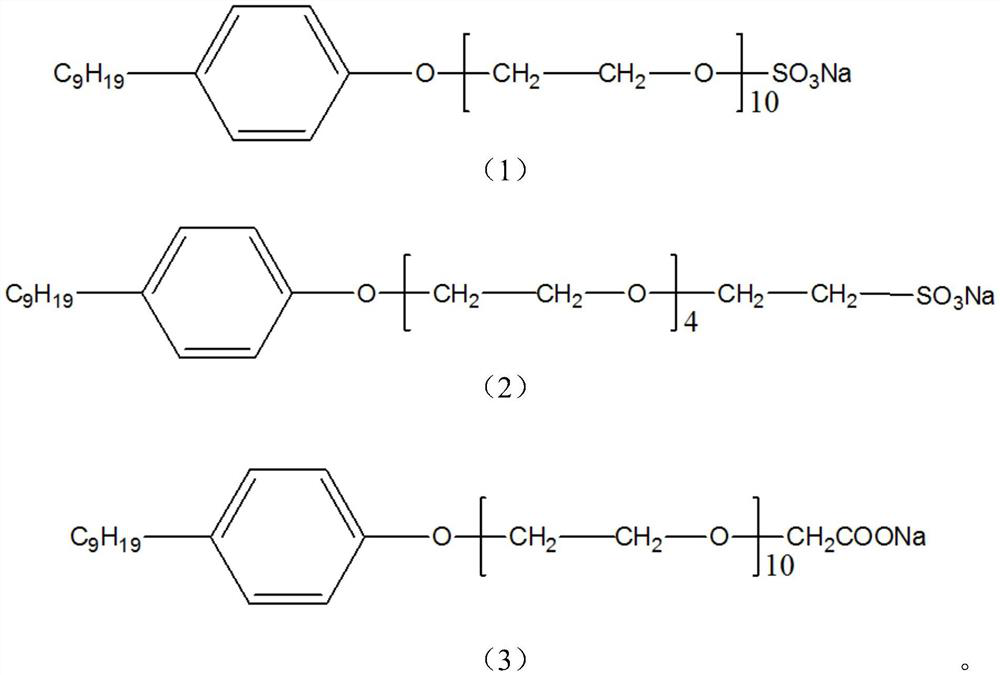

Carbon inhibitor in lead-zinc sulfide ore flotation process and application thereof

The invention discloses a carbon inhibitor in a lead-zinc sulfide ore flotation process and application thereof, and belongs to the field of sulfide ore flotation reagents. The structural formula of the carbon inhibitor is shown as the specification, wherein R is an oxygen-containing hydrophilic group, and n is 4-10. The carbon inhibitor provided by the invention takes nonylphenol as a carbon-philic group and uses polyoxyethylene ether and sulfo / carboxymethyl as hydrophilic groups, can effectively inhibit flotation of carbon when used for flotation of carbonaceous lead-zinc sulfide ore, the consumption of a collecting agent by carbon impurities is reduced, the carbon content in concentrate products is reduced, and the beneficiation index of lead-zinc concentrate is favorably improved.

Owner:CENT SOUTH UNIV

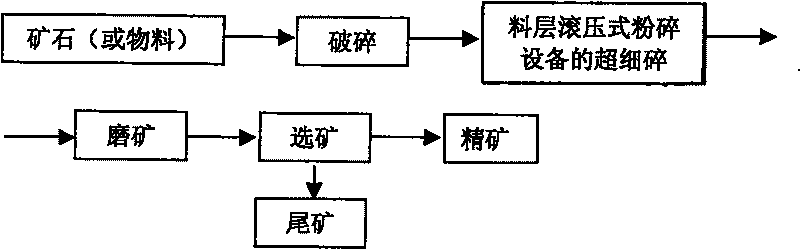

Concentration method for qualifying headings and increasing recovery rate

InactiveCN1895788BFacilitate dissociationFast dissociationMagnetic separationGrain treatmentsBall millMaterials science

Owner:郝志刚

Automatic collection device and method for waste steel balls and sundries in discharged materials of ball mill

PendingCN107051660ARealize automatic collectionAddressing the impact of beneficiation operationsSievingScreeningProcess engineeringSteel ball

The invention relates to an automatic collection device and method for waste steel balls and sundries in discharged materials of a ball mill. The collection device comprises a ball mill barrel, a ball mill end cap and a ball mill discharging barrel; and the collecting device is characterized in that a taper drum sieve is fixedly connected to a discharging opening of the ball mill discharging barrel, an ore slurry receiving box is installed under the taper drum sieve, and a waste steel ball and sundry collecting box is installed at an outlet of the taper drum sieve, a plurality of screen holes are evenly distributed on the taper drum sieve, a spiral plate is welded to the inner side wall of the taper drum sieve, and the rotating direction of the spiral plate is opposite to the rotating direction of the ball mill; and a washing water pipe is installed at the middle axis of the taper drum sieve, and a row of thin holes are drilled in the washing water pipe. By means of the automatic collection device and method for the waste steel balls and the sundries in the discharged materials of the ball mill, dressing materials are purified, and the indicators in beneficiation can be effectively improved; and meanwhile, the collected waste steel balls can be recycled for machining and using, and the level of resources utilization is improved.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

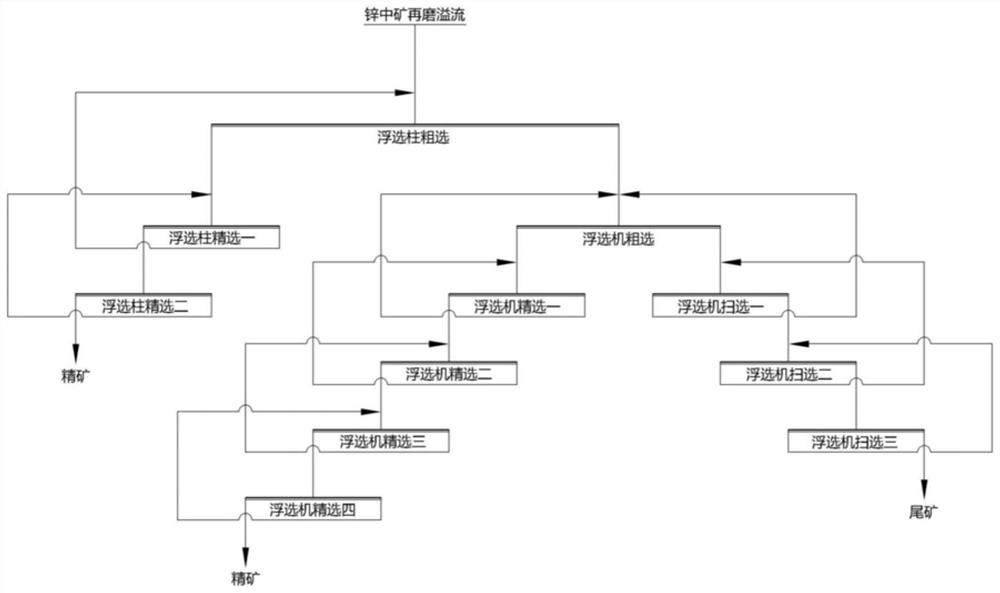

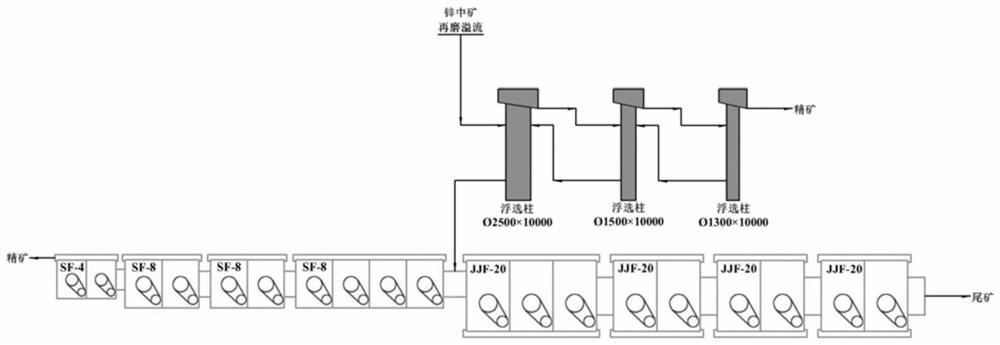

Method and system for treating refractory zinc middlings through machine column combined configuration

PendingCN114308374AImprove beneficiation indexThe recovery rate is double up to the standardSolid separationZinc metalEngineering

The invention discloses a method and system for treating refractory zinc middlings through machine-column combined configuration. The method comprises the following steps: regrinding and overflowing the refractory zinc middlings, and carrying out flotation column roughing to obtain flotation column roughing ores and flotation column roughing tailings; flotation column fine separation is conducted on the flotation column rough separation ore twice, and zinc concentrate is obtained; the flotation column roughing tailings are subjected to flotation machine roughing, and flotation machine roughing tailings and flotation machine roughing tailings are obtained; performing flotation machine fine separation on the flotation machine coarse separation ore for four times to obtain zinc concentrate; and the flotation machine roughing tailings are subjected to flotation machine scavenging for three times, and flotation machine scavenging tailings are obtained. According to the method, a machine-column combined flotation method is adopted for roughing and selecting refractory zinc middling ore through a flotation column to obtain high-grade zinc concentrate, then a flotation machine is used for conducting roughing once, scavenging three times and concentration four times, micro-fine particle refractory zinc metal minerals are subjected to flotation enrichment, and refractory fine-particle-size zinc metal is recycled as much as possible; and the zinc concentrate grade and the zinc recovery rate both reach the standard and are stably improved.

Owner:CHINA HUAYE GROUP

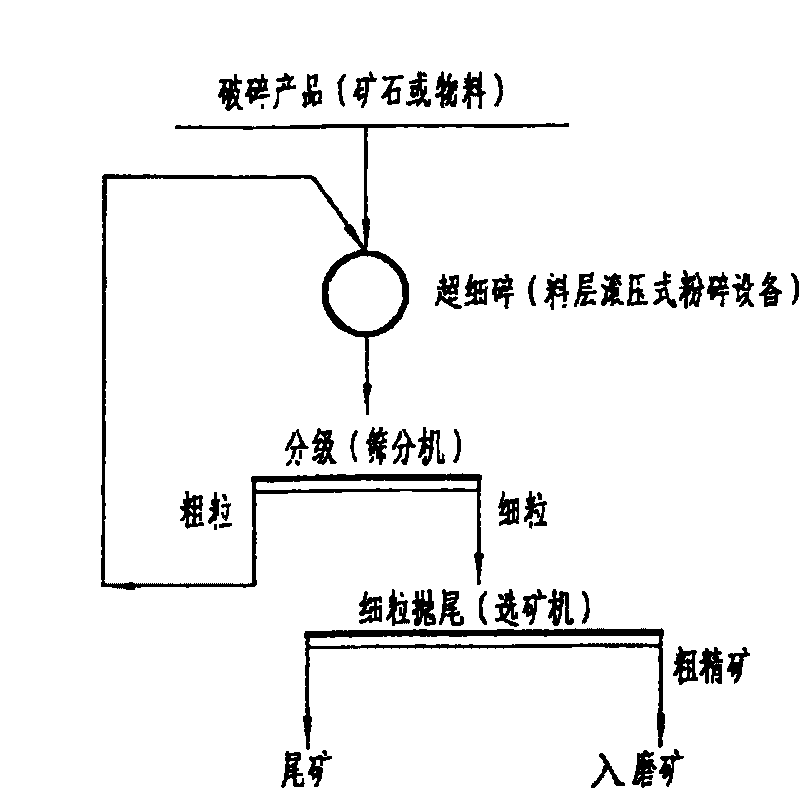

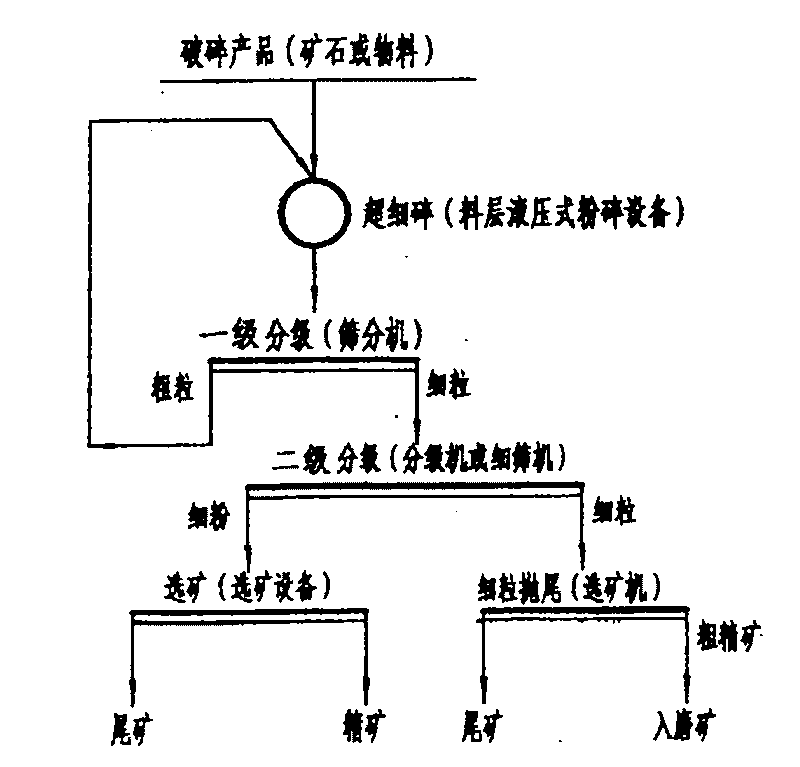

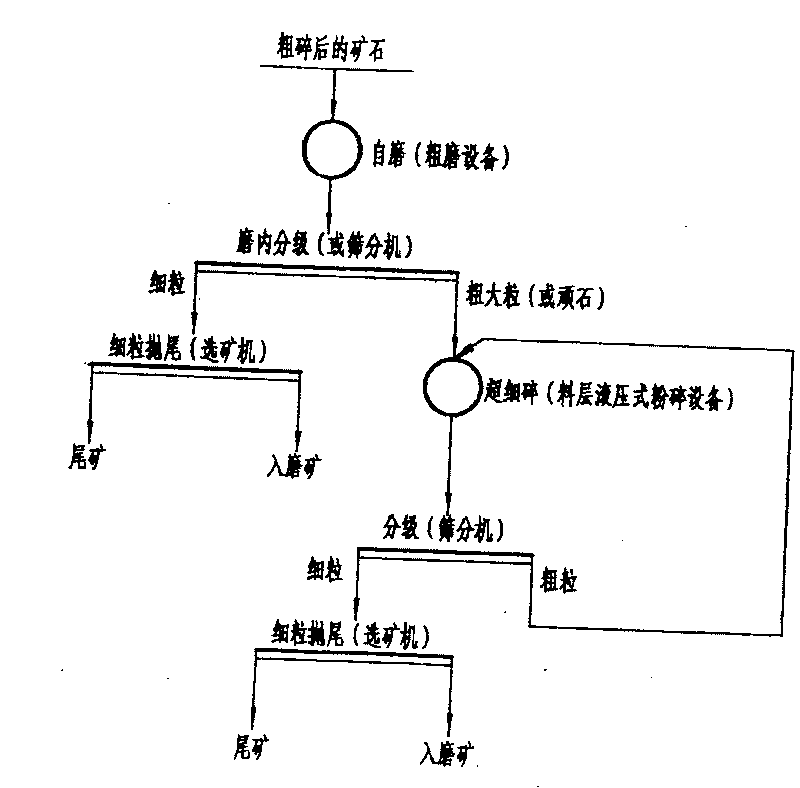

Technological method capable of enhancing ore dressing efficiency and ore dressing index

InactiveCN1911523BImprove beneficiation efficiencyImprove beneficiation indexGas current separationGrain treatmentsCrusherMaterials science

The present invention is technological process with high ore dressing efficiency and goal. One of the technological process includes the steps of crushing, grinding and ore separating, and the crushing step has rolling crusher adopted and the fine grain tail eliminated. One other technological process includes the steps of crushing, grinding in a autogenous mill, grinding and ore separating. One third technological process includes the steps of crushing and ore separating. The present invention has raised ore grinding and ore separating efficiency, raised production capacity, and raised concentrate grade and recovering rate.

Owner:郝志刚

A kind of flotation method of high-sulfur gold-containing copper ore

ActiveCN103691569BEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

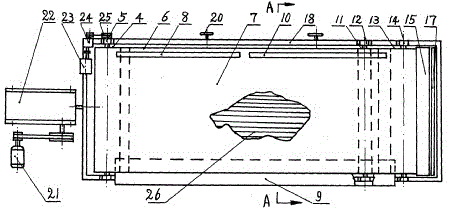

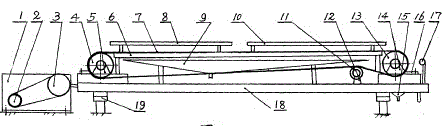

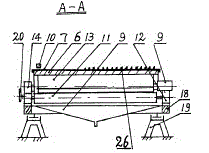

Shaking-table cross flow belt concentrator

The invention discloses a shaking-table cross flow belt concentrator, which is provided with a frame, a head wheel, a tail wheel and conveyer belts, wherein the head wheel, the tail wheel and the conveyer belts are arranged on the frame; a tail wheel end is provided with an ore concentrate flushing drain pipe and an ore concentrate receiving groove; the low side of each conveyer belt is provided with a tailing groove; the high side of each conveyer belt is provided with an ore feeder and a flushing water pipe; the frame is supported on a sliding mechanism and moves in a reciprocating way; thehead wheel end, the tail wheel end or the lower part of the frame is provided with a push-pull rod connected with a machine head; the machine head is a mechanism with reciprocating push-pull effort; each conveyer belt is provided with a reciprocating bar; the frame is provided with a lifting plate inserted into a space between adjacent conveyer belts; multiple rows of multi-layer conveyer belts can be arranged on the same frame; and the machine head is driven by a speed regulating motor. In the invention, the motion characteristic of a shaking table is organically combined with a cross flow belt concentrator, and a revolving gear at the bottom of the frame is eliminated, so that a combination effect is achieved by using two motion characteristics. By adopting the concentrator, the concentrating indexes of heavy metal ores such as tin, tungsten, lead and the like of over 10 microns can be greatly increased, the concentration belt separation is very remarkable, the recovery ratio is up to 85 percent in maximum, the concentration ratio is as high as 10-40 times, and the handling capacity is 10-25 tons / set.

Owner:李钱江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com