Patents

Literature

59 results about "Mineral collecting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral collecting is the hobby of systematically collecting, identifying and displaying mineral specimens. Mineral collecting can also be a part of the profession of mineralogy and allied geologic specialties. Individual collectors often specialize, for example collecting examples of the various colors and forms taken by the mineral calcite, calcite from widely scattered locations in a region or the world, or minerals found in pegmatites.

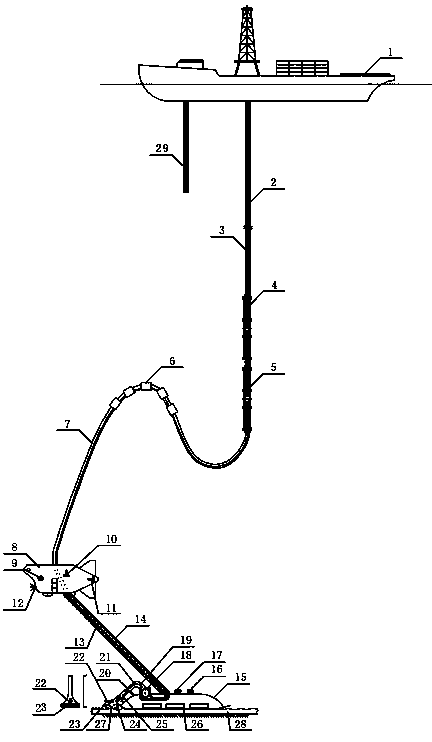

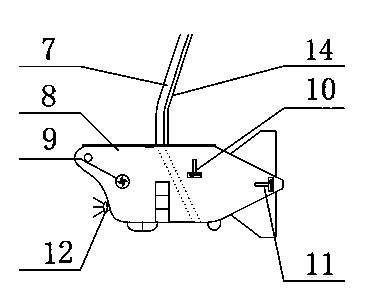

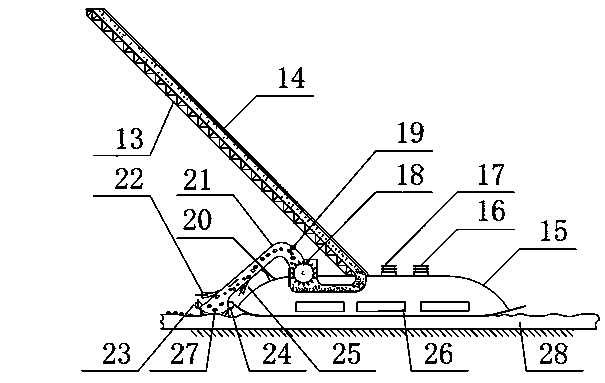

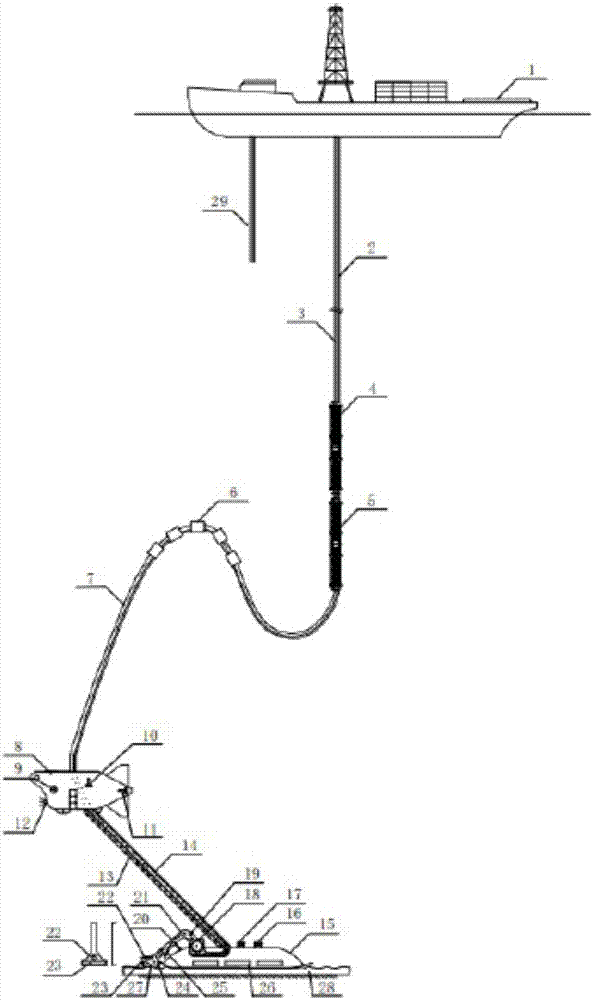

Oceanic mineral resource exploitation device and exploitation method

InactiveCN103628881AReduce disturbanceImprove reliabilityMineral miningFluid removalTerrainElectricity

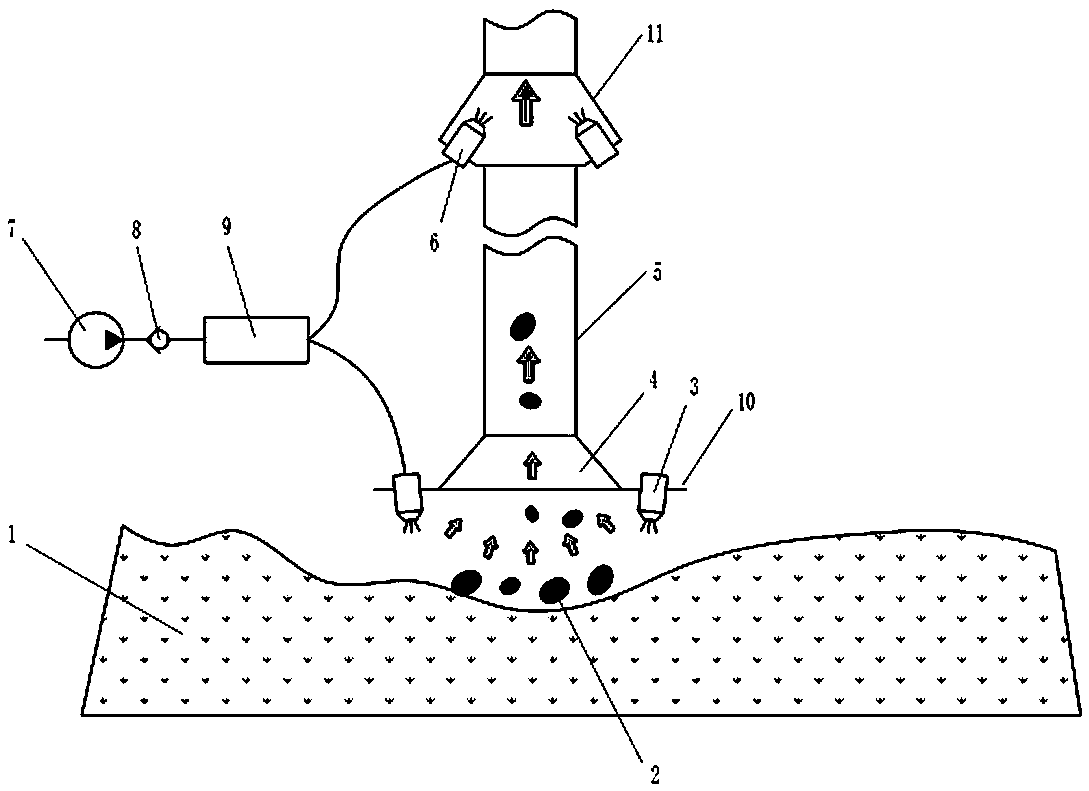

The invention discloses an oceanic mineral resource exploitation device and exploitation method and aims to overcome the technological difficulty of the existing submarine mining vehicle and the pipeline waterpower lifting exploitation system. The exploitation device comprises a water surface mining vessel, a lifting pipe, a lifting electric pump station, a hose, a mineral crushing mechanism and a mining mechanism, wherein a plurality of perturbance jet flow nozzles, a plurality of ascending jet flow nozzles and a flow guide pipe are mounted on the mining mechanism; the flow guide pipe is communicated with the feeding hole of the mineral crushing mechanism; the lifting pipe, the lifting electric pump station, the hose and the mineral crushing mechanism are sequentially connected with the flow guide pipe in series to form an ore pulp lifting passage; the hose is fixed onto an ROV; the ROV is connected with the mining mechanism through a connecting device. The oceanic mineral resource exploitation device is not limited by the complicated terrain and gradient at the bottom of the sea, avoids the slipping and sinking of the underpan of the submarine mining vehicle on a settled layer, greatly reduces the disturbance of mineral mining to bottom sediments, and also solves the problem that the terrain clearance of the mining mechanism is difficult to control.

Owner:HUNAN UNIV

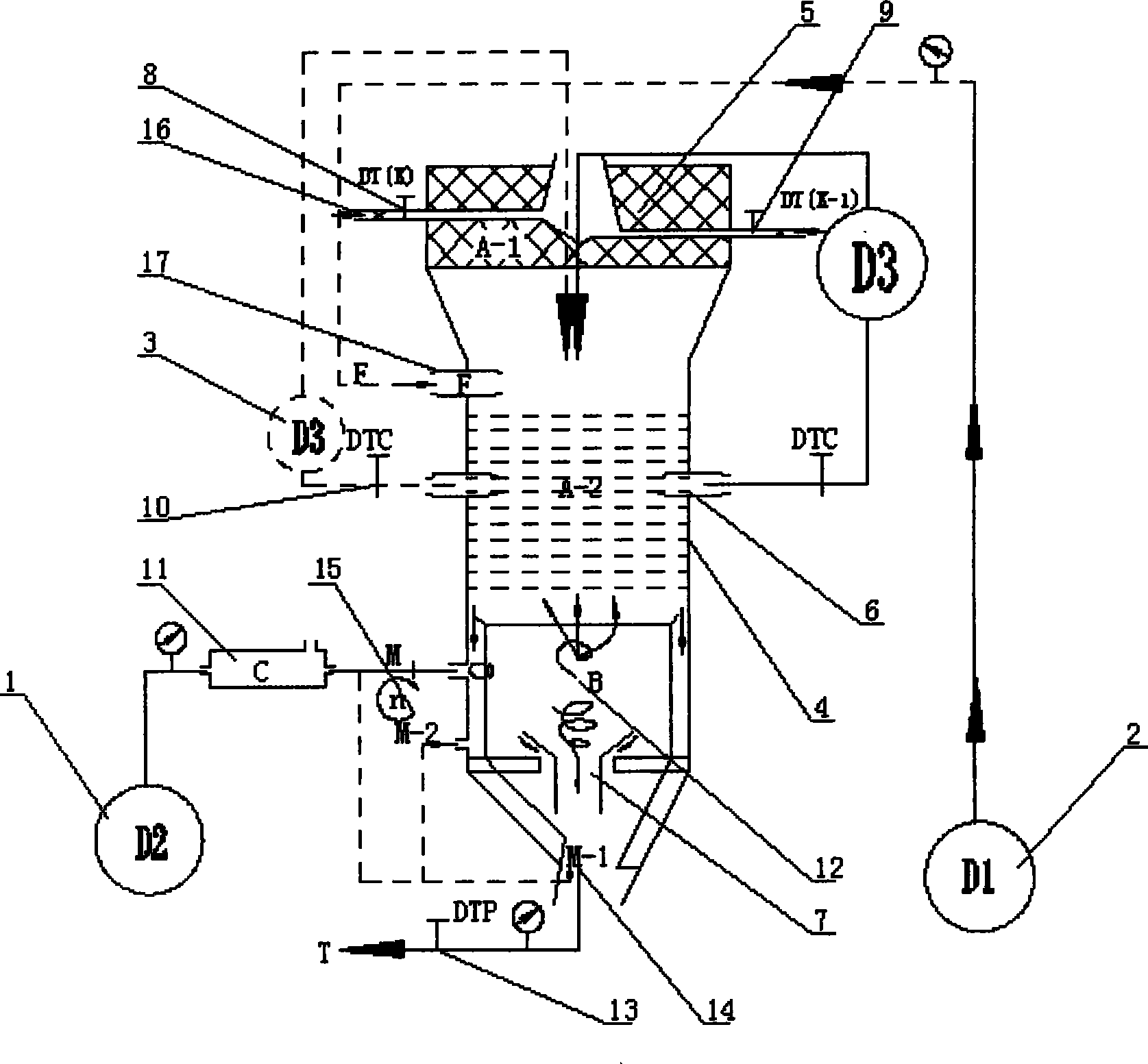

Flotation column for sorting mineral

The invention relates to a floatation column used for mineral separation, which is characterized in that: the floatation column comprises a column body, the interior of the column body is divided into a concentrated mineral collecting tank, a separation bucket and a tail discharge box in sequence from top to down; more than one concentrated mineral discharge ports are opened on the concentrated mineral collecting tank and provided with an electromagnetic valve used for regulating the liquid surface of the discharge of the concentrated mineral; the separation bucket comprises a middle static micro-bubble separation section and a lower cyclonic separation section, and is connected with an external inflator pump and internally provided with a cyclone in the column; the tail discharge port at the bottom of the tail discharge box is provided with an automatic discharge valve linked with the concentrated mineral discharge electromagnetic valve. The invention is a floatation column used for mineral separation which has the advantages of simple and compact structure, low cost, high efficiency and energy conservation, small land occupancy, long service life, rapid floatation speed and large processing capability.

Owner:湖南君毅科技发展有限公司

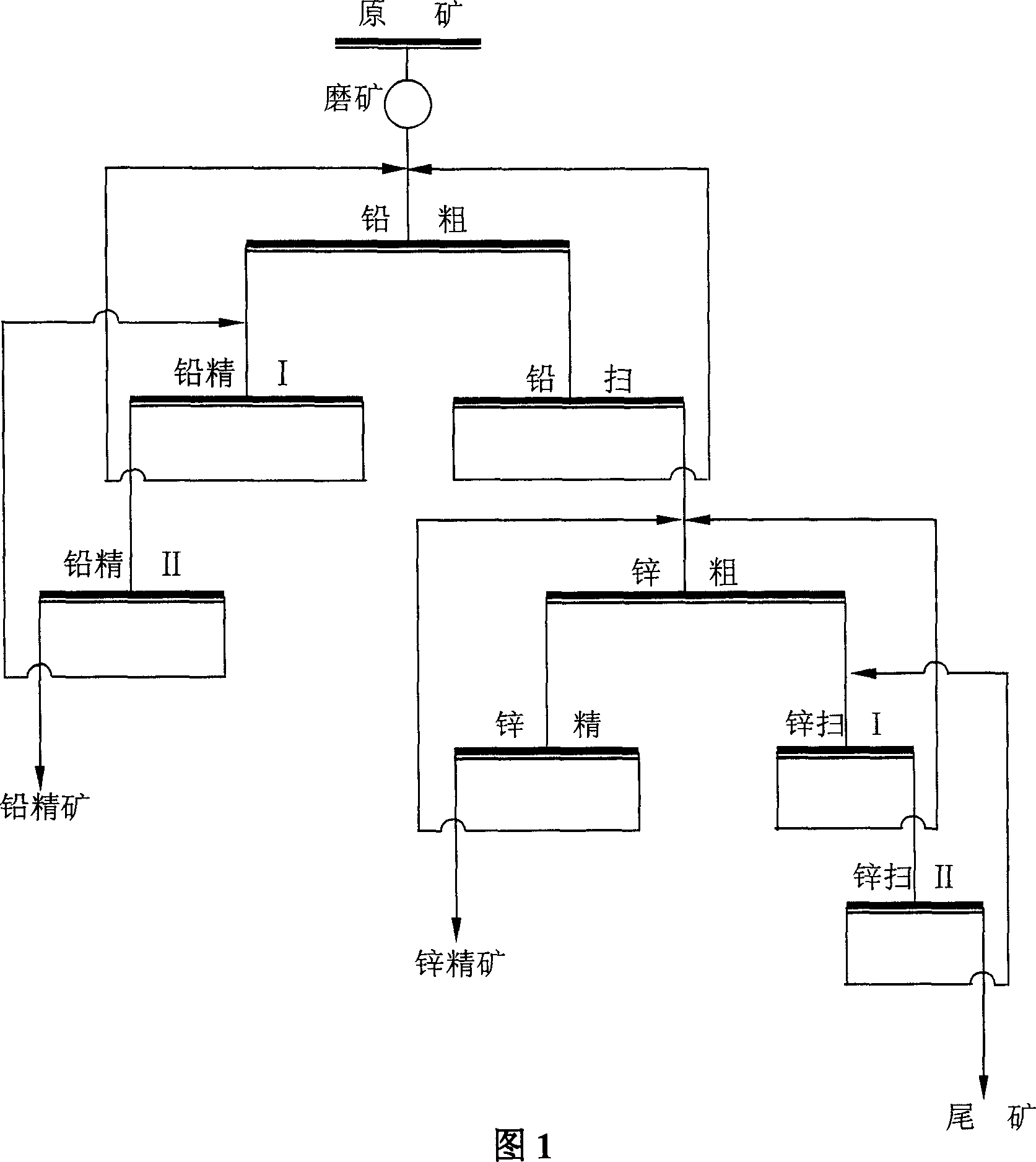

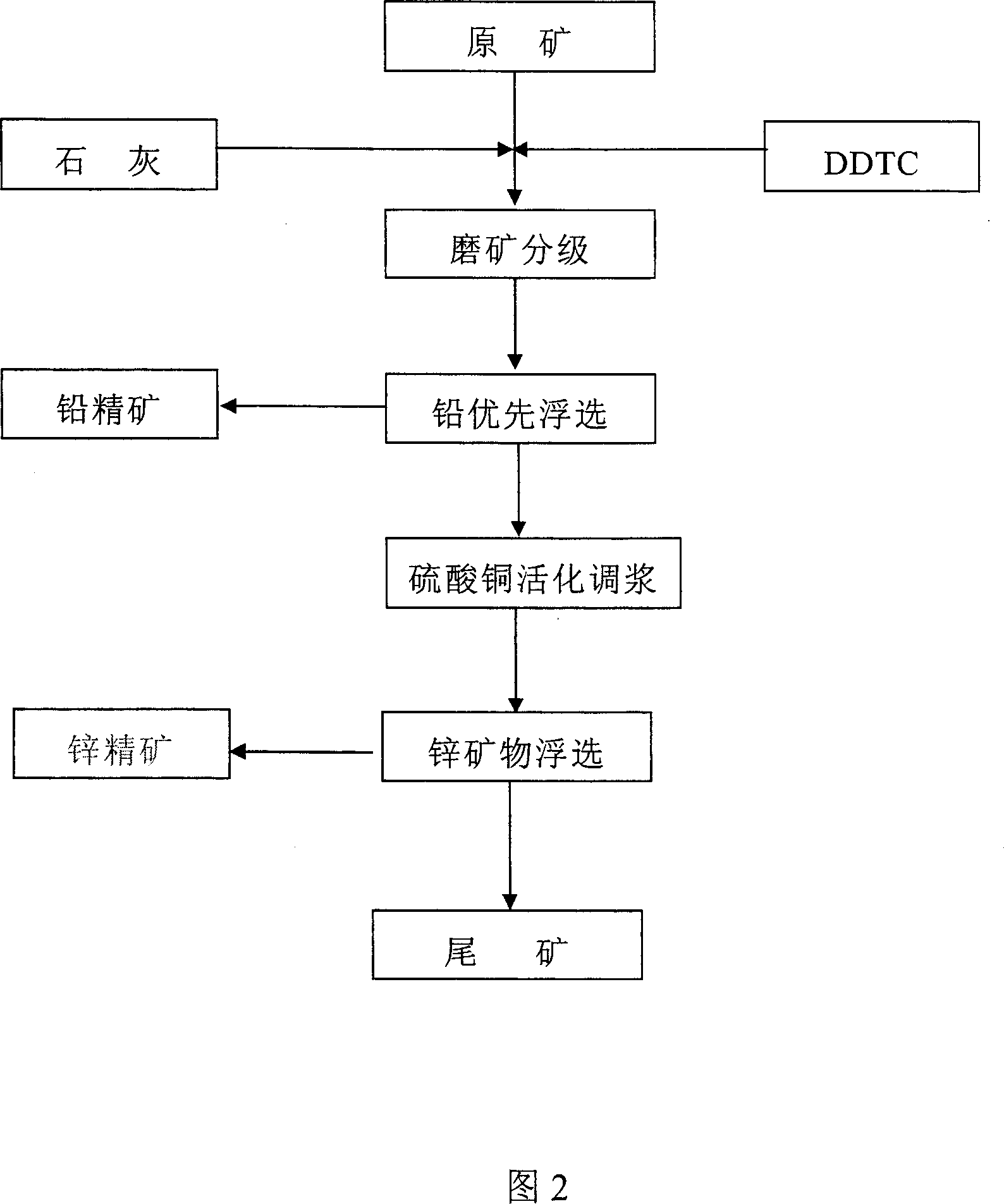

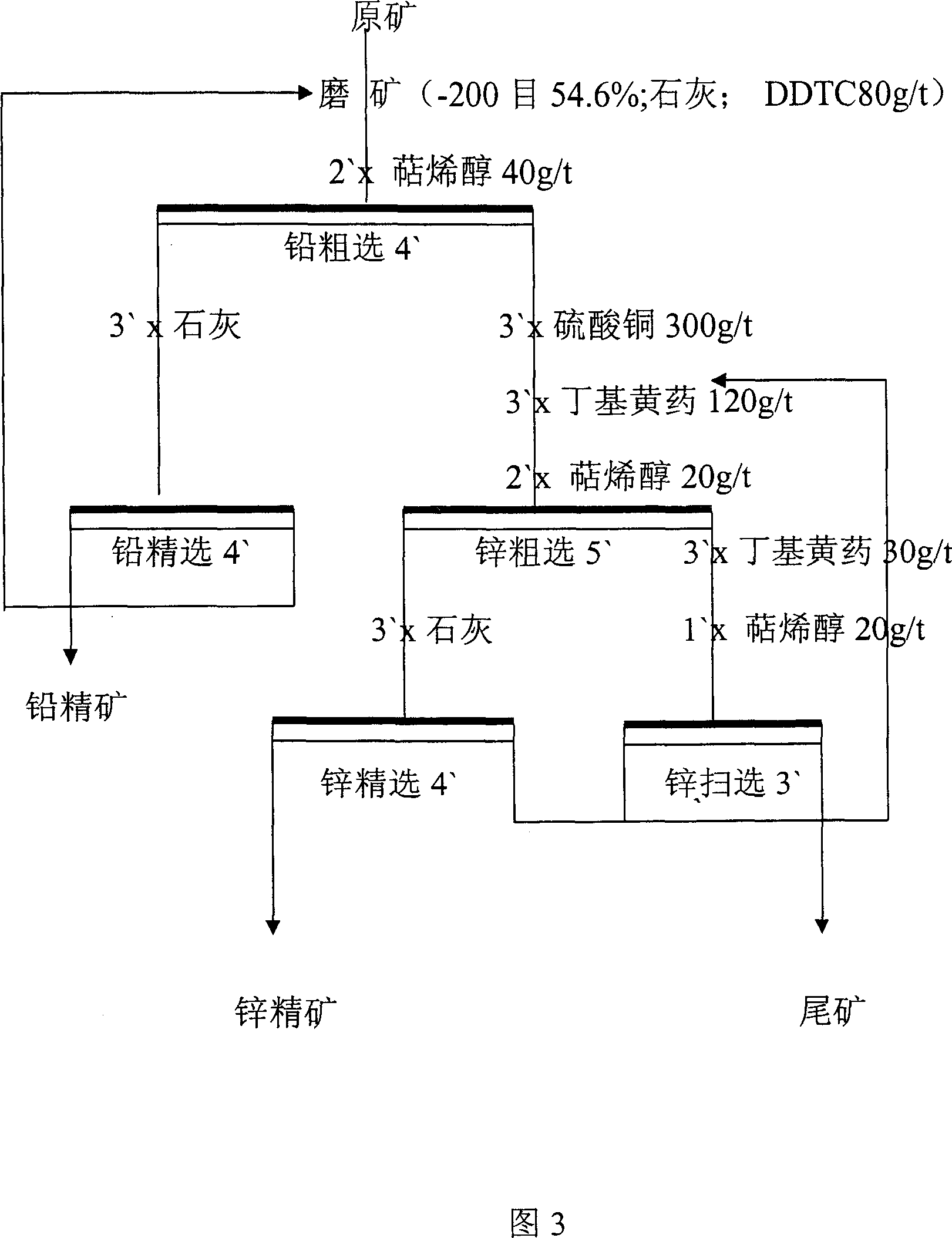

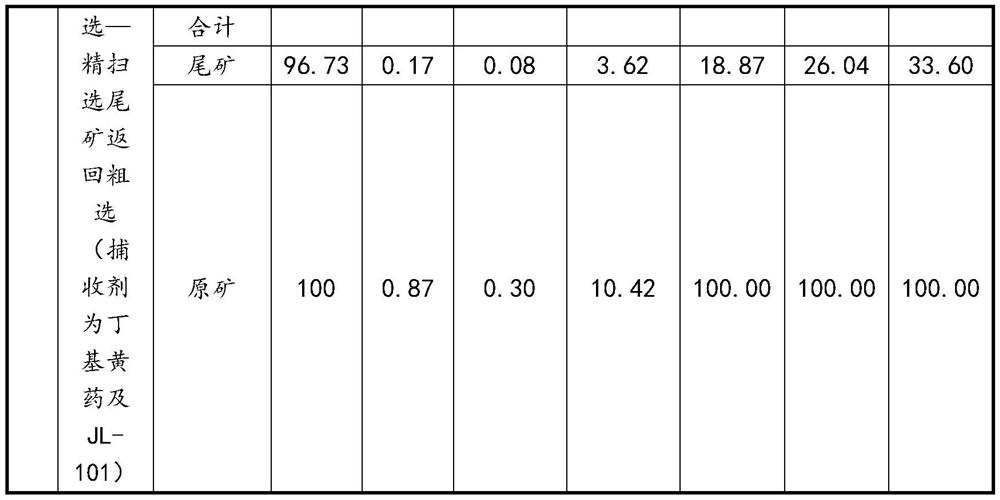

Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

The present invention is green process of recovering complicated lead-zinc sulfide ore in high recovering rate. The technological process adopts lime to form high alkalinity and maintain the original potential of lead-zinc sulfide slurry during ore grinding floatation, sodium diethyl dithioamino formate as the selective lead mineral collecting agent, copper sulfate as the sphalerite activating agent and butyl xanthate as the zinc mineral collecting agent for optimized successive fast floatation. The present invention has raised recovering rate, low chemical consumption, simple technological process and low production cost.

Owner:青海西部矿业科技有限公司

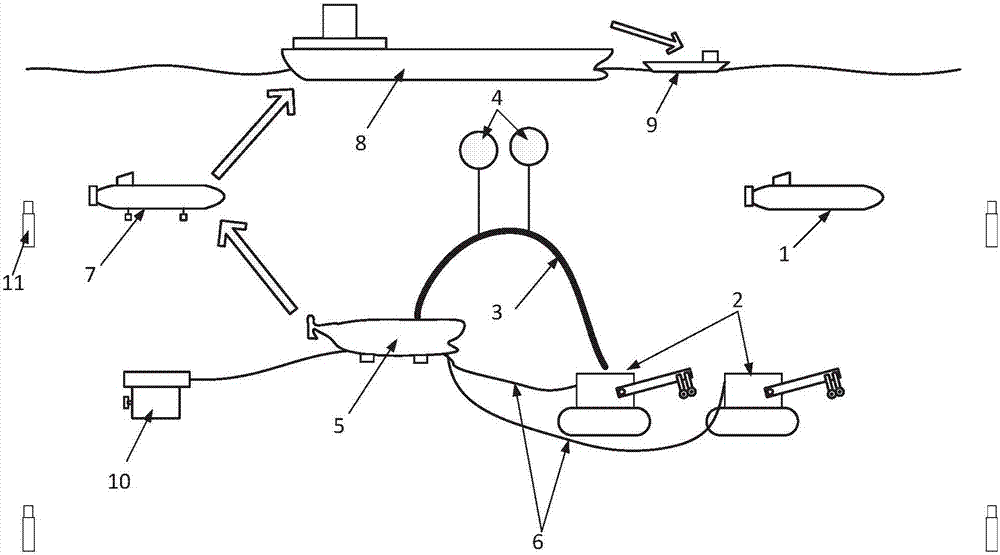

Exploitation system for deep sea mineral resources

PendingCN107120118AReduce job requirementsImprove efficiencyMineral miningUnderwaterResource development

The invention discloses an exploitation system for deep sea mineral resources. The exploitation system comprises an underwater mineral collection subsystem, a mineral transfer subsystem, a water surface support subsystem, an underwater control subsystem and a supporting guarantee subsystem, wherein the underwater mineral collection subsystem comprises mining submersible groups; the mineral transfer subsystem comprises a lifting submersible; the underwater control subsystem comprises a bathyscaph, and a nuclear power station is arranged in the bathyscaph; the supporting guarantee subsystem comprises a maintenance management submersible and a communication and navigation positioning device; the bathyscaph is connected with the mining submersible groups and the maintenance management submersible through umbilical cables and supplies energy and control signals to the mining submersible groups and the maintenance management submersible. According to the exploitation system for the deep sea mineral resources, the underwater subsystems are not required to be powered by the subsystems above water, once meeting severe weather such as heavy storm waves on the sea during working, the subsystems above water can be transferred to other places to avoid stormy waves while the underwater subsystems can continue normal operation, the operation requirements are not high, and the exploitation system is insensitive to the stormy wave weather on the sea.

Owner:CHINA SHIP SCI RES CENT SHANGHAI DIV

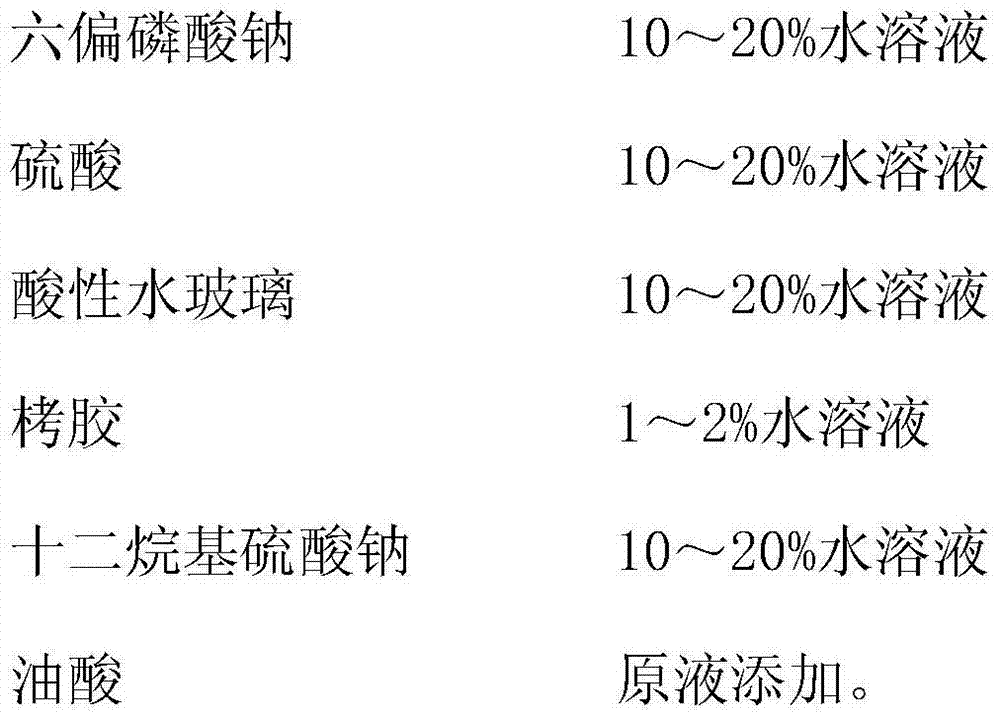

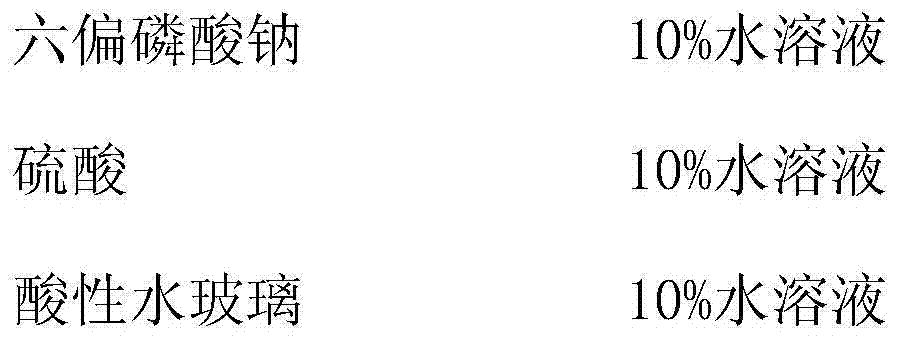

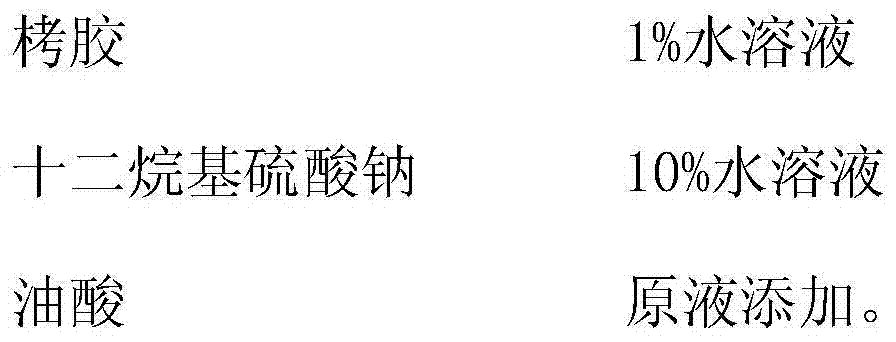

Flotation separation method for aedelforsite and quartz

The invention discloses a flotation separation method for aedelforsite and quartz. According to the method, sodium hexametaphosphate is taken as a mineral dispersing agent, sulfuric acid is taken as a pH value adjusting agent, acid soluble glass and tannin extract are taken as quartz inhibitors, and oleic acid and lauryl sodium sulfate are taken as aedelforsite mineral collecting agents. According to the flotation separation method, flotation separation of aedelforsite minerals from quartz minerals can be realized, the flow structure is simple, the medicament dosage is less, and the aedelforsite minerals can be recovered effectively. After flotation separation is performed under the condition that the content of feeding aedelforsite is 47.85-53.90 percent, aedelforsite concentrate of which the aedelforsite content is 93.83-95.18 percent and the recovery rate is 85.74-89.62 percent is obtained.

Owner:GUANGXI UNIV

Beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof

ActiveCN101632961AEnhanced harvesting capacityGood beneficiation effectFlotationImpurityMineral collecting

The invention relates to a beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof. The beta-hydroxy fatty acid collecting agent is characterized in that the content of the weight percentage of beta-hydroxy fatty acid is over 85 percent of a total collecting agent, and the balance is water and inevitable impurities; the beta-hydroxy fatty acid of the collecting agent mainly comprises thirteen to eighteen carbon atoms; and the weight percent of the beta-hydroxy fatty acid with the thirteen to eighteen carbon atoms is over 95 percent. The beta-hydroxy fatty acid iron mineral collecting agent is a fatty acid class collecting agent capable of forming annular adsorption; and the collecting capacity of the beta-hydroxy fatty acid iron mineral collecting agent is remarkably larger than the adsorption of ore mineral and a common fatty acid class collecting agent carrying out positive anion floatation, thereby obviously increasing the collecting capacity of the collecting agent on the iron mineral.

Owner:ANSTEEL GRP MINING CO LTD

Method for preparing willemite mineral collecting agent

The invention discloses a method for preparing a willemite mineral collecting agent. The method includes the following steps: using two or three of soybeans, castor beans, tea tree seeds and tea tree bark as raw materials, carrying out drying, smashing and screening, fetching fruit tree bark powder, triethanolamine and water with the mass ratio of 5-8 to 2-4 to 5-10, heating the mixture to the temperature ranging from 120 DEG C to 130 DEG C, leading in nitrogen, stirring to enable a reaction to last for 2-3 hours, heating the mixture to the temperature ranging from 150 DEG C to 160 DEG C, leading in nitrogen, stirring to enable a reaction to last for 2-3 hours, cooling the mixture to the temperature lower than 60 DEG C, fetching filter liquor, carrying out centrifugal separation two or three times through a centrifugation machine, carrying out reduced pressure distillation on supermatant liquor, obtaining a deep yellow concentrated solution, heating the deep yellow concentrated solution in a 60-70 DEG C water bath, evaporating a solvent to be dry, and obtaining yellow powder, namely the willemite mineral collecting agent after complete drying is achieved. According to the method, argillization and dolomite-contained willemite minerals can be effectively collected through the collecting agent.

Owner:GUANGXI UNIV

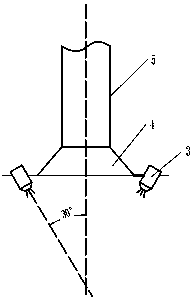

Undersea polymetallic sulfide mining device based on high-pressure water jet

The invention discloses an undersea polymetallic sulfide mining device based on high-pressure water jet. The device comprises cutting nozzles, a lifting pipe, lifting nozzles, a high-pressure water pump and a high-pressure cabin, wherein a mineral collecting cover is arranged at the bottom of the lifting pipe, a cutting nozzle support is arranged at the lower part of the mineral collecting cover,the cutting nozzles are arranged on the cutting nozzle support, outlets of the cutting nozzles directly face a undersea polymetallic sulfide mineral, a lifting nozzle support is arranged in the middleof the lifting pipe, the lifting nozzles are arranged on the lifting nozzle support, and outlets of the lifting nozzles extend into the lifting pipe and face upwards; the high-pressure water pump isconnected with the high-pressure cabin, and the high-pressure cabin is connected with the cutting nozzles and the lifting nozzles. The device integrates a cutting function and a mineral collecting function; during work, the cutting process and the mineral collecting process can be performed simultaneously and are in seamless connection; the probability that polymetallic sulfide particles diffuse toward sea water due to desynchrony of the cutting process and the mineral collecting process is reduced, pollution of the mining process to the undersea environment is reduced to the greatest extent.

Owner:HUNAN INSTITUTE OF ENGINEERING

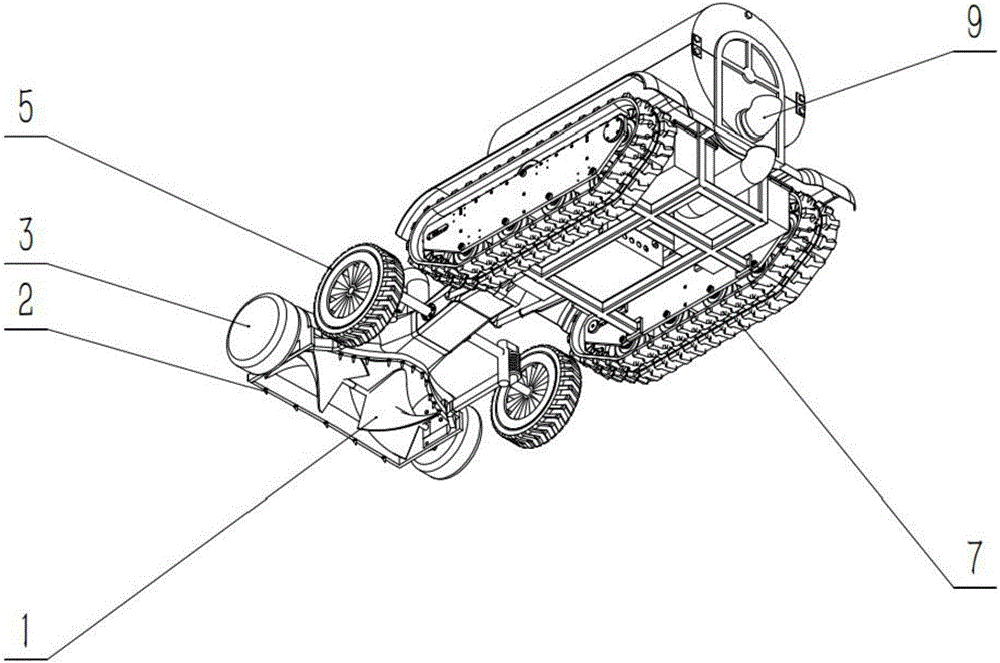

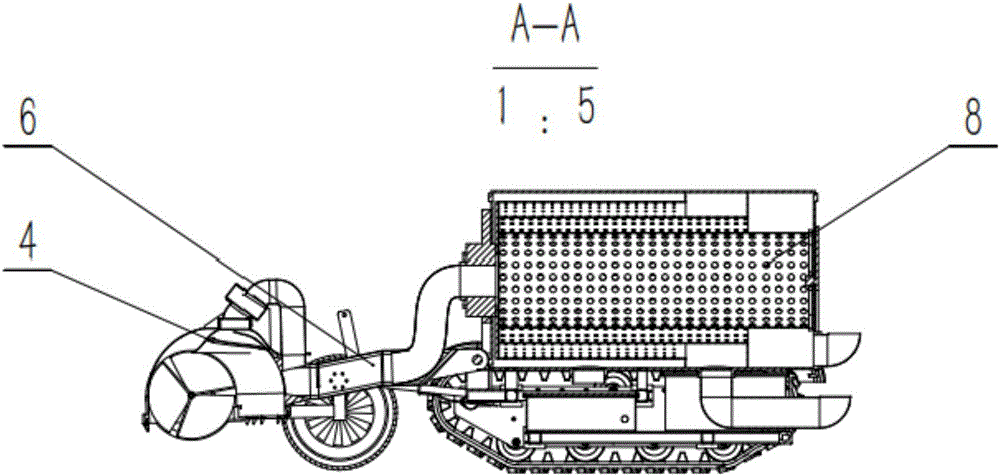

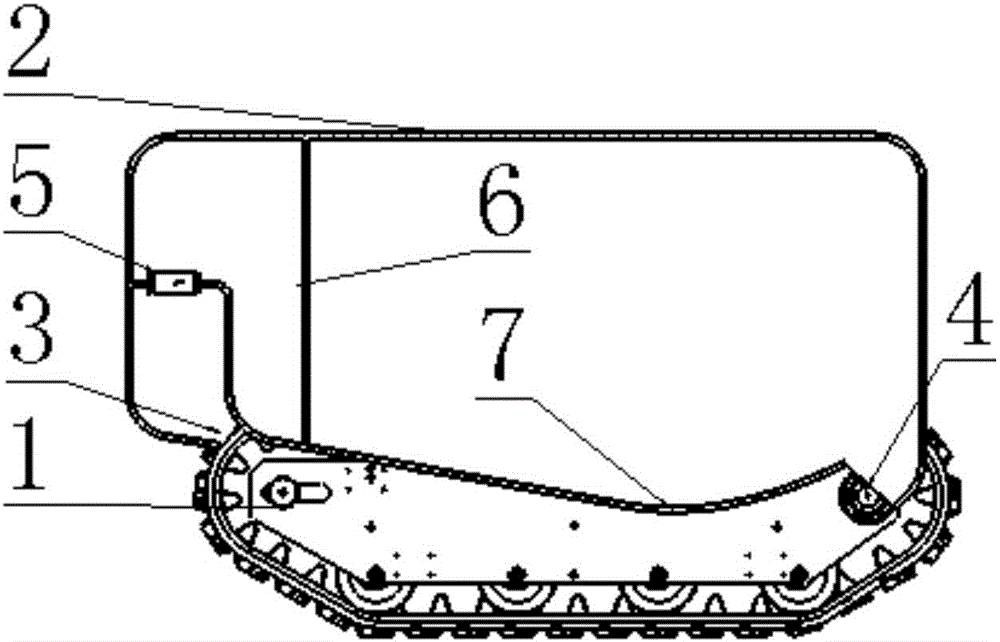

Deep-sea submarine mineral collecting device and mineral collecting method thereof

ActiveCN106121656ALow critical speedAvoid cloggingMineral miningUnderwater equipmentDrive wheelEcological environment

The invention provides a deep-sea submarine mineral collecting device and a mineral collecting method thereof. The device comprises a hydraulic mineral collecting system, a sieving system and a crawler belt walking system, wherein the hydraulic mineral collecting system comprises a hydraulic mineral collecting head, a rotating spiral plate, a water jetting device, a motor, spiral mineral sucking covers, a driven wheel and a mineral collecting head and vehicle body connecting component, the sieving system comprises a rotating screen drum and a mineral outlet, and the crawler belt walking system comprises a crawler belt device. The deep-sea submarine mineral collecting device and the mineral collecting method, provided by the invention, can increase mineral collecting efficiency, efficiently save energy and reduce the damage of a submarine mining process to the surface ecological environment of a sea bed.

Owner:SHANGHAI JIAO TONG UNIV

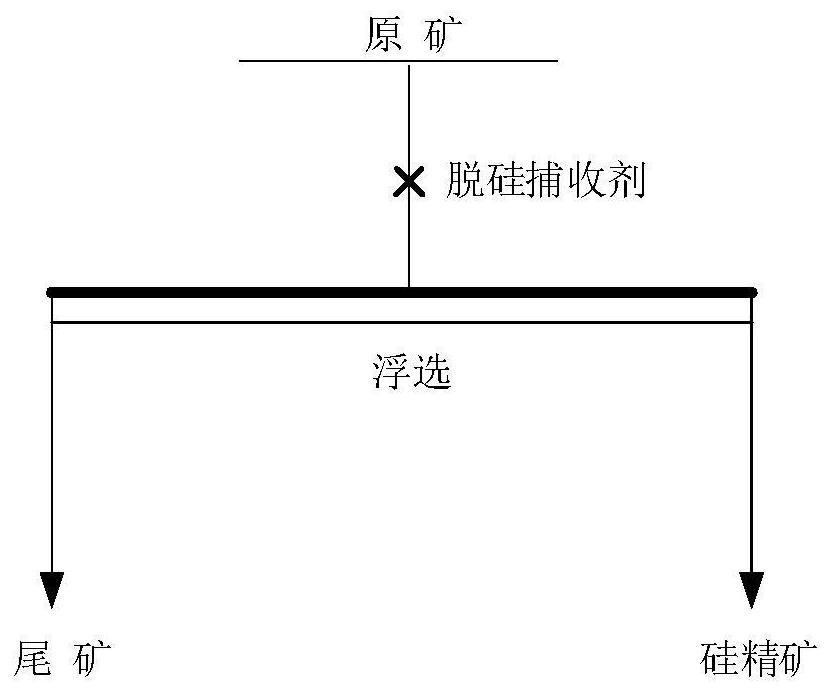

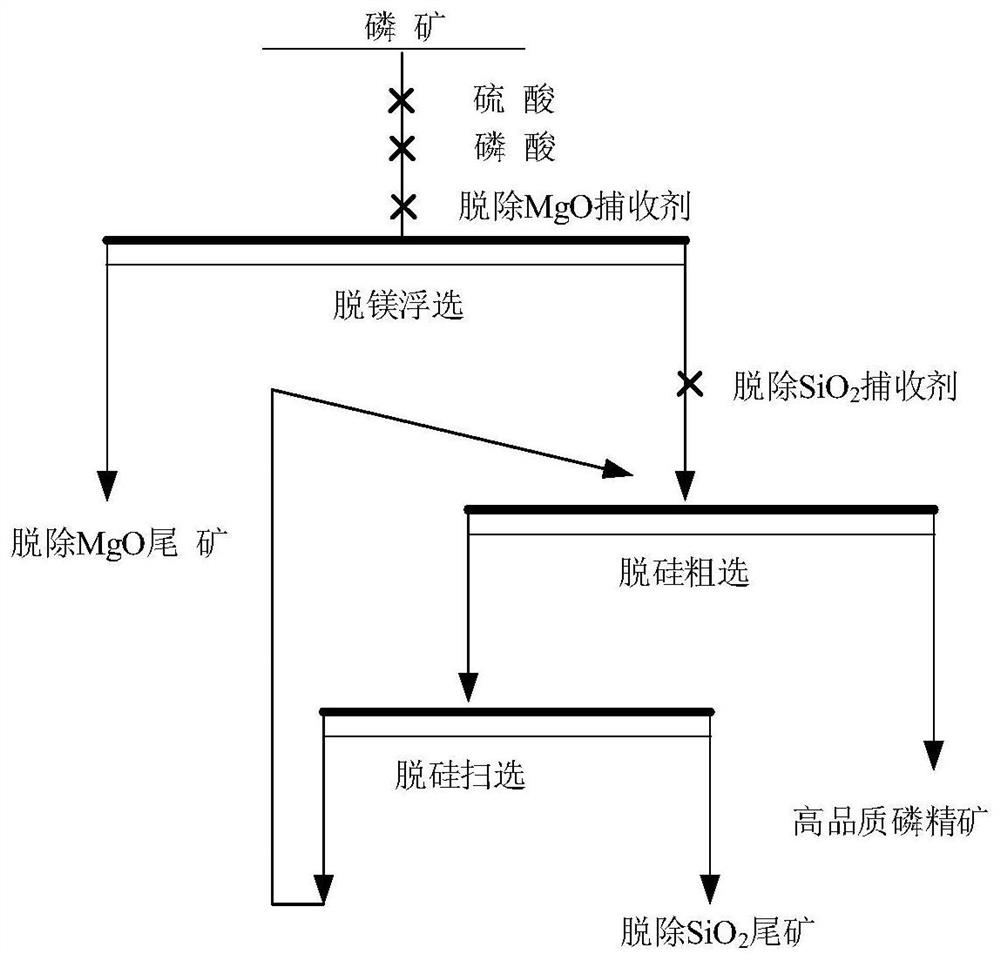

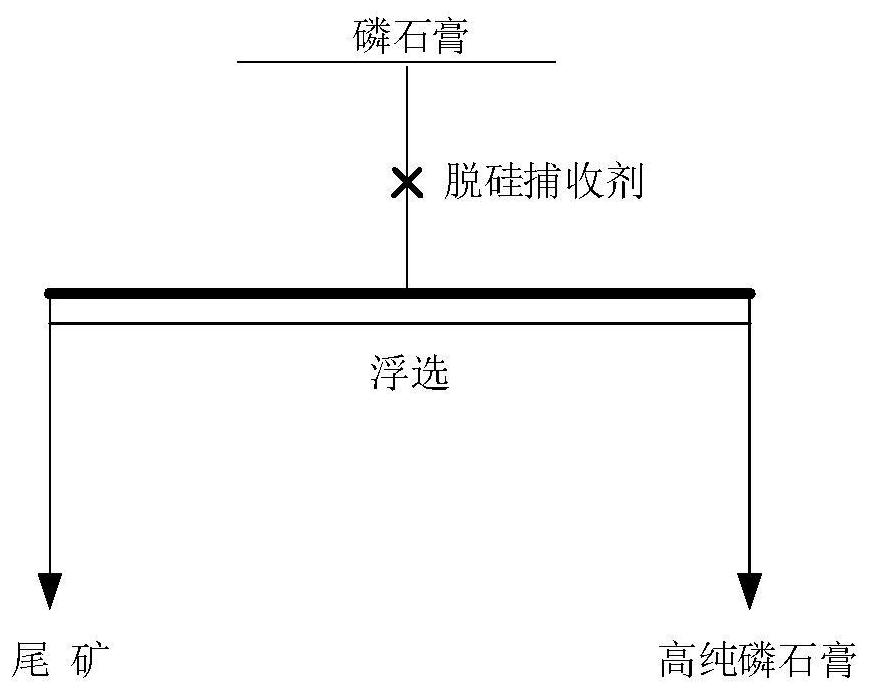

Collecting agent for collecting siliceous minerals and preparation method of collecting agent

The invention discloses an efficient collecting agent for collecting siliceous ores. The main component of the efficient collecting agent is any one or more than two of alkyl halide ion (F, Cl, Br andI) type monoquaternary ammonium salts with the carbon chain length of 8-18; and the auxiliary components comprise sodium oleate, dodecylamine, hydrochloric acid, polyether amine, ether amine, sodiumdodecyl sulfate, lauryl sodium sulfate, diesel oil, tributyl phosphate and water. Main components and auxiliary components of the collecting agent are proportioned according to different treated oresand solid wastes (iron ores, phosphorite, fluorite, barite, phosphogypsum and the like), so that the purpose of floating siliceous minerals in the ores from flotation froth is achieved. The collectingagent is prepared without high temperature and high pressure, the pH application range is wide, the agent process can be greatly simplified, and the agent cost is saved; compared with an existing siliceous mineral collecting agent, the collecting agent is high in pH adaptability, good in siliceous mineral collecting selectivity and free of influences of slime, flotation froth is not sticky, and dissipation and sedimentation are easy.

Owner:福建志远矿业有限公司

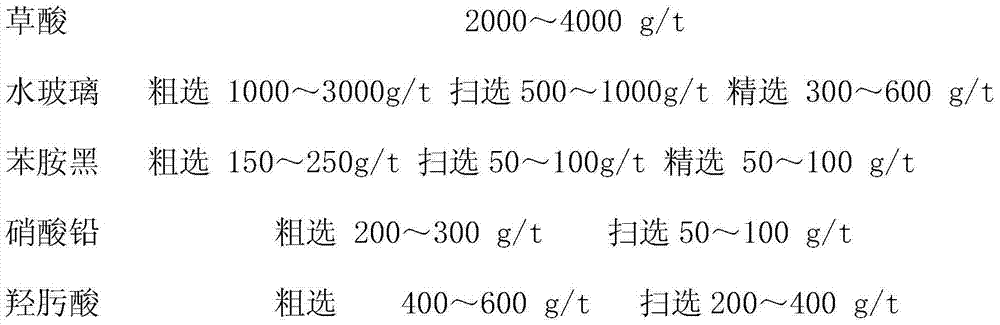

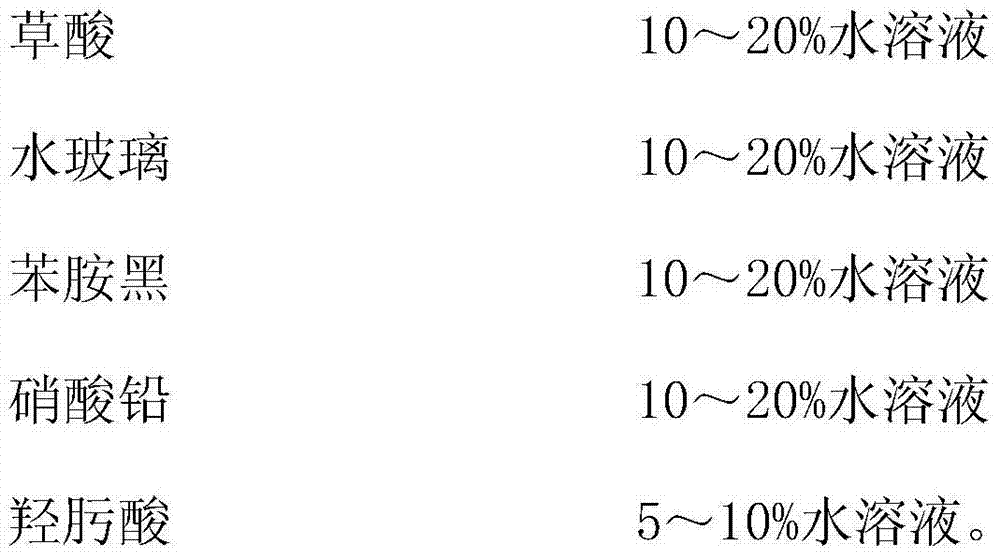

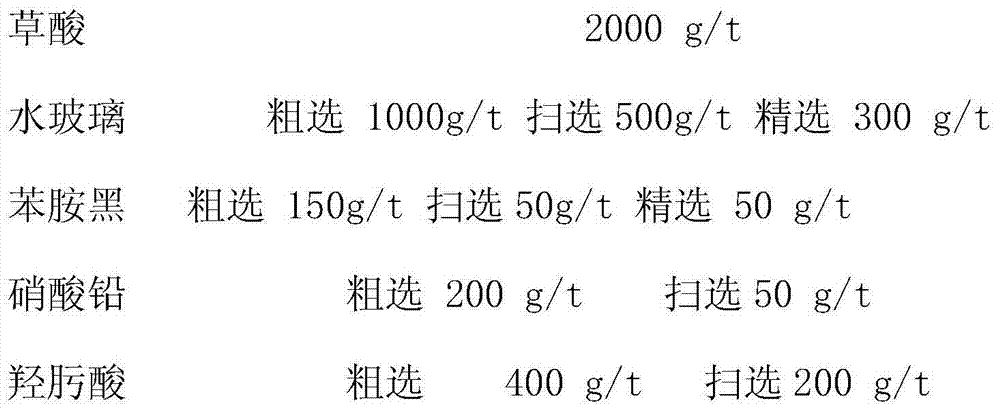

Antimony oxide mineral and quartz flotation separation method

An antimony oxide mineral and quartz flotation separation method comprises that oxalic acids are used as a pH modifier, water glass and nigrosine are used as a quartz inhibitor, lead nitrate is used as an antimony oxide mineral activator, and hydroximic acids are used as an antimony oxide mineral collecting agent. Antimony oxide concentrates with the antimony content between 21.54% and 29.77% and the recovery rate between 74.30% and 80.65% are obtained through flotation separation in the condition of 0.86% to 2.53% of feeding mineral antimony content. By the aid of the method, antimony oxide minerals and quartz can be subjected to flotation separation, the process structure is simple, the chemical use amount is small, and antimony oxide minerals can be recovered effectively.

Owner:GUANGXI UNIV

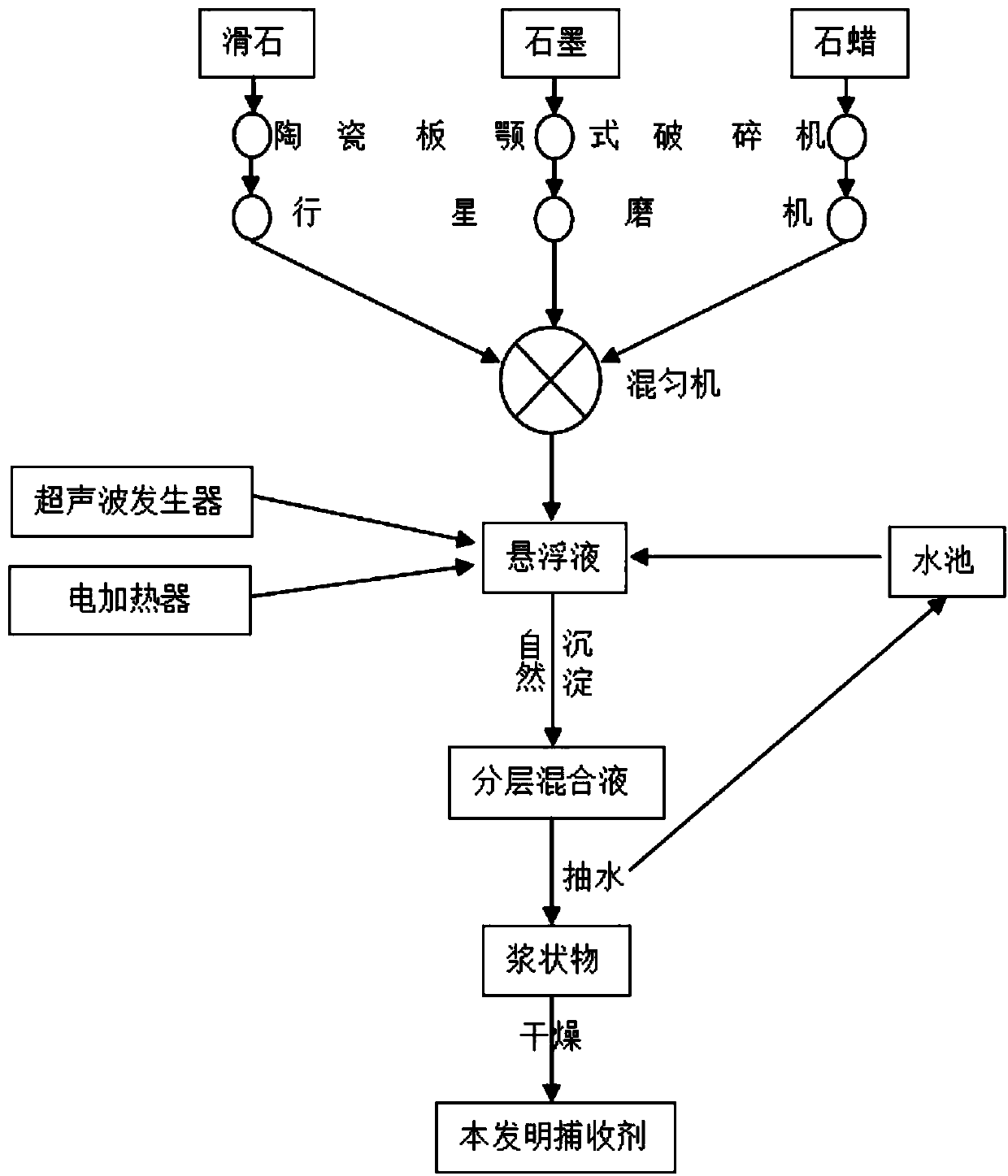

Environmental-friendly glue sulfur and molybdenum mineral collecting agent, preparation method and application

The invention provides an environmental-friendly glue sulfur and molybdenum mineral collecting agent which is prepared from the following components in parts by weight: 100 parts of nano talc powder,10-60 parts of nano graphite powder and 1-25 parts of nano paraffin powder. The grain sizes of the nano graphite powder and the nano paraffin powder are 240-350nm. The invention also provides a methodof preparing the collecting agent and an application method of the collecting agent.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Mineral collecting agent for collecting oxidized ores such as fluorite and preparation method thereof

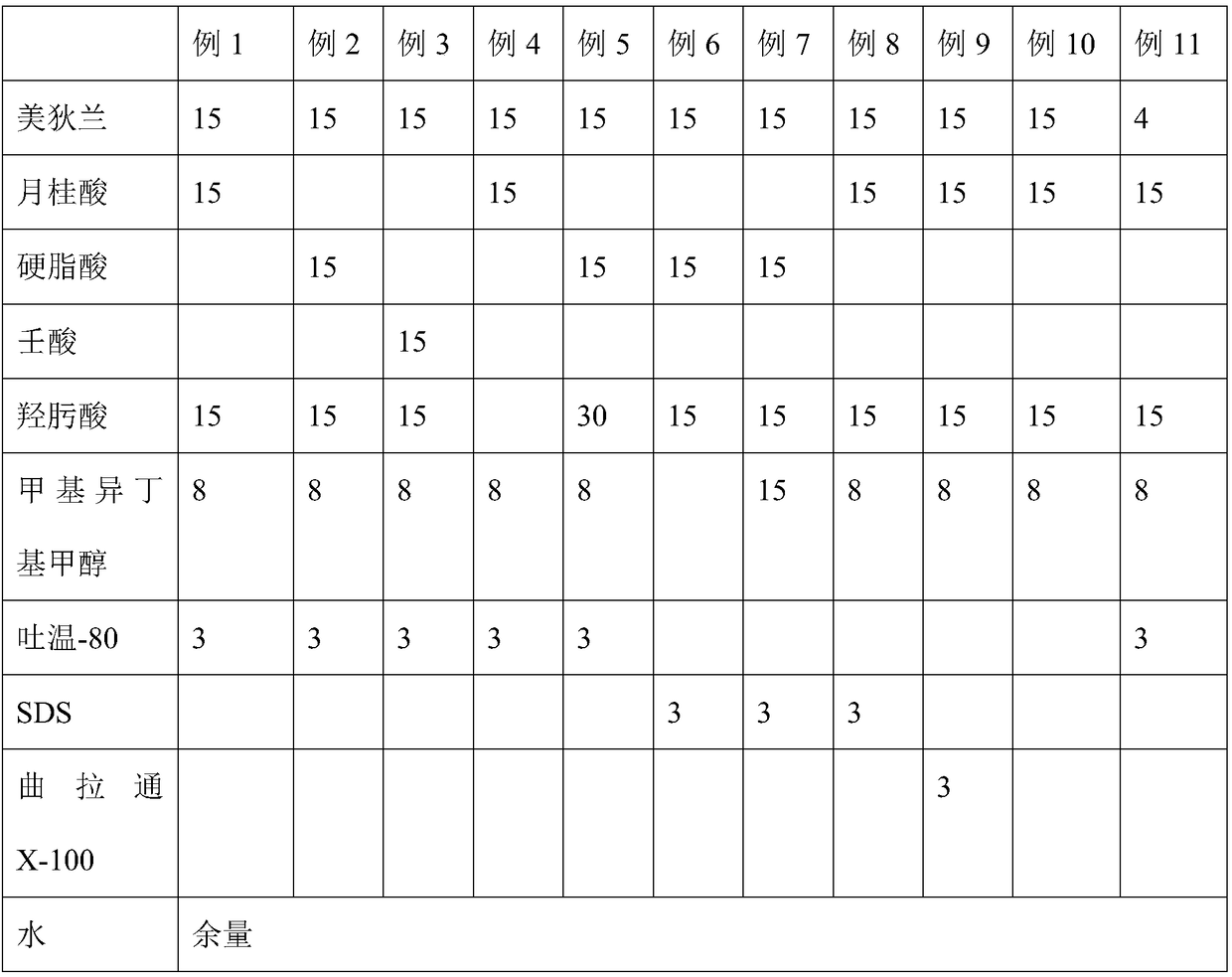

The invention provides a mineral collecting agent for collecting oxidized ores such as fluorite and a preparation method thereof, and belongs to the technical field of a mineral flotation collecting agent. The mineral flotation collecting agent for the oxidized ores such as fluorite is obtained by mixing Medialen, specific carbon atom fatty acid, hydroximic acid, methyl isobutyl carbinol, a surface active agent and the like, and then is used. The mineral flotation collecting agent has the characteristics of good water solubility, good dispersibility and strong preferential adsorption capacityof a target mineral, and is mainly used for flotation separation of useful minerals in the oxidized ores such as the fluorite, calcite, barite and ilmenite. A preparation method of the mineral flotation collecting agent for the oxidized ores has simple process and is easy in control of operation; and the prepared collecting agent has the advantages of strong selectivity, good dispersibility, lessdosage of chemicals, high overall efficiency of beneficiation and the like, and is of great significance for promoting the beneficiation of the minerals such as the oxidized ores.

Owner:河南天鸿选矿科技有限公司

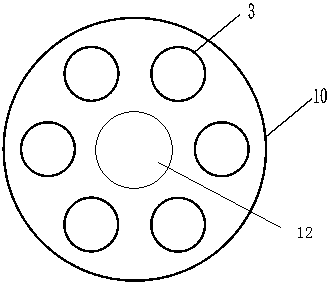

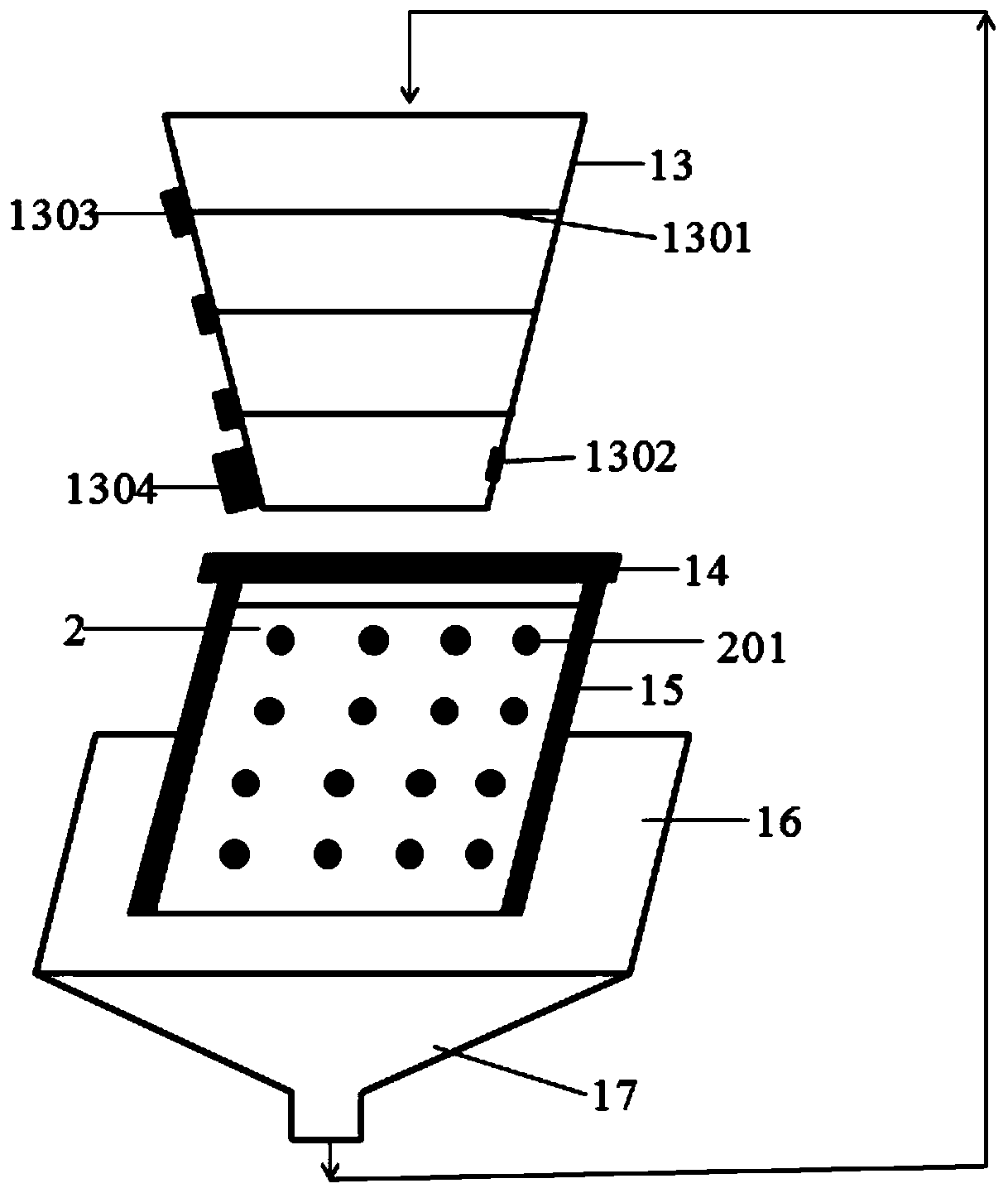

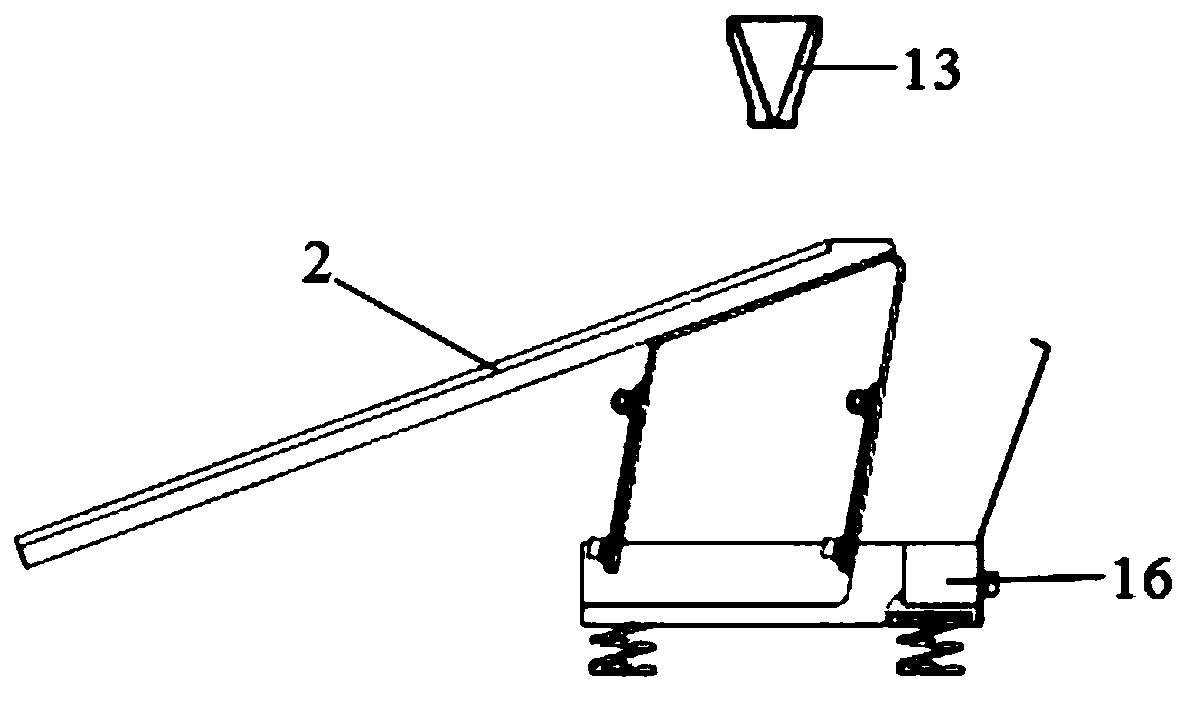

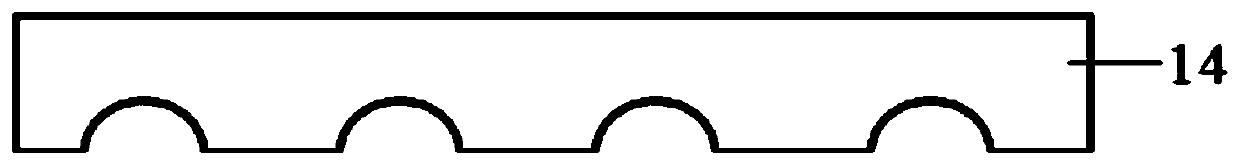

Color separation device for single mineral separation

The invention relates to a color separation device for single mineral separation. The color separation device comprises at least one porous plate, a material distributing device, a mineral collectingdevice, a moving slide rail, a pressure device, a first camera shooting device and a control device, wherein the material distributing device comprises a hopper and a vibrating device; the hopper is arranged above the vibrating device; when the material is distributed, the porous plate is fixed at the top of the vibrating device, and the effect of placing one ore particle in one hole in the porousplate is achieved through the vibrating device; when the material is separated, the porous plate is fixed on a workbench, and the first camera shooting device is arranged above the porous plate; themineral collecting device is fixedly connected to the moving sliding rail and moves in the spatial three-dimensional direction by means of the moving sliding rail, and the moving slide rail is arranged on the workbench; and the pressure device is connected with the top of the mineral collecting device through an air path and provides negative pressure to the mineral collecting device, so that theore particles on the porous plate enter the interior of the mineral collecting device from the bottom end of the mineral collecting device.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

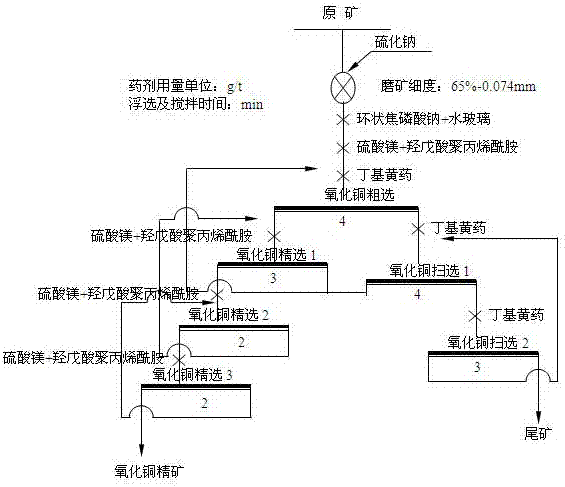

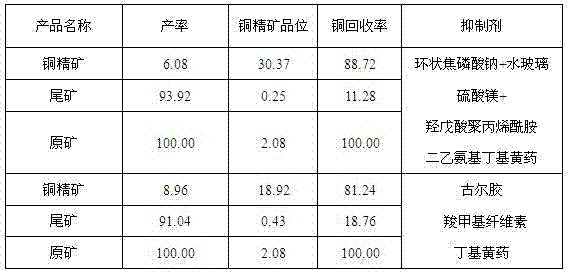

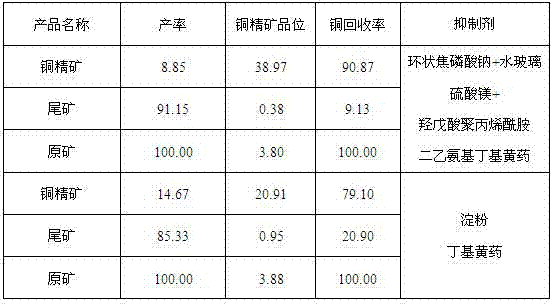

Flotation separating method for separating copper oxide ore and talc

ActiveCN107309091AHigh electronegativityElimination of inevitable ionsFlotationCopper oxidePyrophosphate

The invention discloses a flotation separating method for copper oxide concentrate and talc. Copper oxide minerals are used as raw materials, sodium sulfide is added into raw ore for ore grinding, and the pH value of pulp after ore grinding is 10-10.5; annular sodium pyrophosphate and water glass are added to increase the negative potential on the surfaces of the minerals, the electrostatic repulsion effect among particles is improved, and the pulp is fully dispersed; a combined inhibitor comprising magnesium sulfate and mevolate polyacrylamide is added; and finally diethylamino butyl xanthate is added and used as a copper mineral collecting agent, and efficient separation of the copper oxide mineral and talc is achieved. The flotation agent combination is low-toxic or nontoxic, and has the characteristics of being small in application quantity, good in effect and the like; and the environment-friendly and efficient flotation separating method for the copper oxide mineral and talc is provided.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Mineral collecting agent and flotation process of copper sulphide ore

The invention provides a mineral collecting agent and a flotation process of copper sulfide ore. The mineral collecting agent comprises the following components in parts by weight: 6-8 parts of xanthate, 1-2 parts of black powder and 1-2 parts of thionocarbamate. The xanthate is high in collecting capacity, and black powder and thionocarbamate are good in selectivity to copper sulfide. When the three agents are mixed according to the proportion and used for flotation of copper sulfide ore, the mineral collecting agent can form a stable and uniform adsorption layer on the surface of copper sulfide, and the adsorption capacity of the three agents on the surface of copper sulfide is larger than the sum of the adsorption capacities of the three agents on the surface of copper sulfide after thethree agents are combined. On one hand, the performance complementation among the three parts is facilitated, and on the other hand, the performance of the three parts is better exerted. Based on thesynergistic effect of the two aspects, the copper collecting agent has excellent collecting capacity and selectivity. Based on the factors, the recovery rate of copper sulfide can be improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

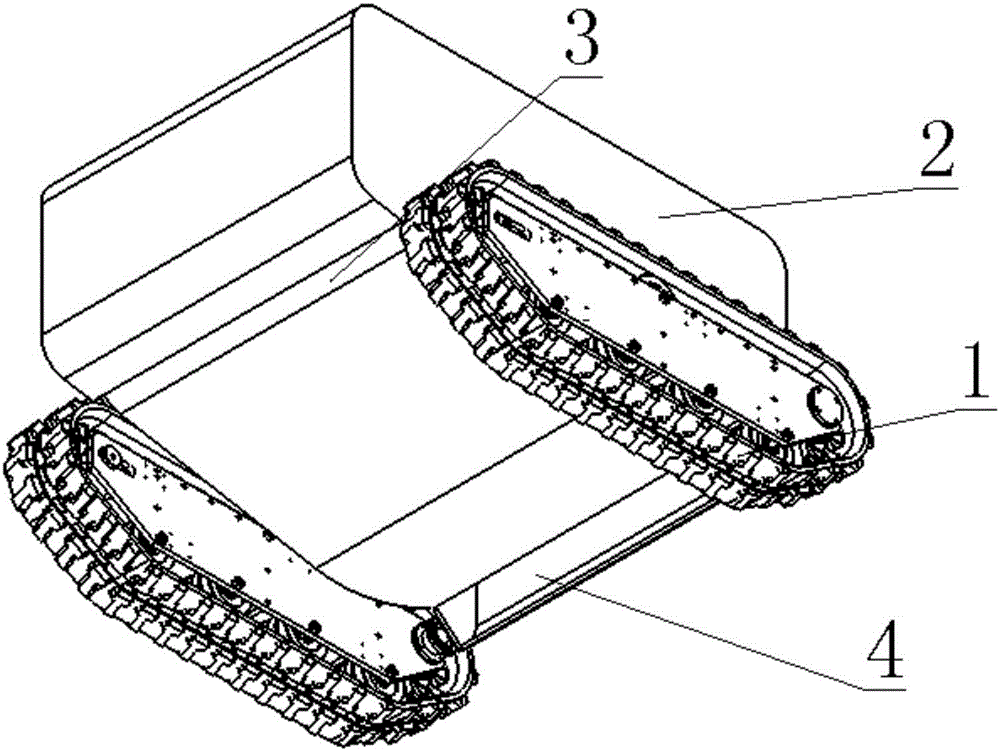

Seabed mineral collecting device based on wall attachment effect and mineral collecting method thereof

ActiveCN106194192ACarry a lotImprove stabilityMineral miningUnderwater equipmentOcean bottomEcological environment

The invention provides a seabed mineral collecting device based on a wall attachment effect and a mineral collecting method thereof. The device comprises a track mechanism, a mineral collecting box, a water jet outlet, a mineral inlet, a propeller, a grille and a small-curvature base plate. The front end of the mineral collecting box is provided with the propeller, and the grille is arranged between the mineral collecting box and the propeller. The mineral collecting box is defined by peripheral and upper closed metal casings and the small-curvature base plate, and the bottoms of the front end and the rear end of the mineral collecting box are provided with the water jet outlet communicated with a propeller area and the mineral inlet communicated with a mineral storage area respectively. The water jet outlet and the mineral inlet are provided with baffles, and the rotating inclination angles of the baffles can be adjusted. According to the seabed mineral collecting device based on the wall attachment effect and the mineral collecting method thereof, in the mineral collecting process, working efficiency and working quality are greatly improved, and the damage to the ecological environment of the surface of a seabed in the seabed mining process is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of barite mineral collecting agent

Provided is a preparation method of a barite mineral collecting agent. The preparation method comprises the following steps that two or three of peanuts, rape seeds, pine seeds and pine bark are adopted as raw materials; the raw materials are dried, smashed and screened with an 80-mesh sieve; the mixture with the mass ratio of powder to diethylamine to water being (2-3):(2-4):(6-10) is fetched and heated to be 150-160 DEG C, nitrogen gas is introduced, stirring is carried out, a reaction is performed for 3.5-4 hours, the mixture is cooled to be below 55 DEG C and filtered, filtrate is obtained and subjected to centrifugal separation with a centrifugal precipitation machine, and supernatant liquid is subjected to reduced pressure distillation so that deep yellow concentrated liquid can be obtained; and the concentrated liquid is heated in a water bath of 75-80 DEG C to make solvent to evaporate, obtained thick liquid is dried in a vacuum drying box with the temperature being 50 DEG C, then yellowish-brown thick solid is obtained, and yellow powder obtained by completely drying the thick solid is just the barite mineral collecting agent. By the adoption of the collecting agent, barite minerals can be effectively collected, the dosage of agents is small, and toxicity and pollution are both avoided.

Owner:GUANGXI UNIV

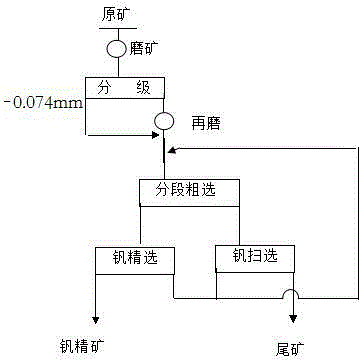

Mineral separation method of finely disseminated vanadium contained carbonaceous shale

InactiveCN104907163AImprove beneficiation indexImprove flotation recoveryFlotationWet separationRoscoeliteMineral collecting

The invention discloses a mineral separation method of finely disseminated vanadium contained carbonaceous shale. The amount of roscoelite with the disseminated grain size less than 0.019mm is larger than 50% of the total amount of roscoelite in the finely disseminated vanadium contained carbonaceous shale. The mineral separation method of the finely disseminated vanadium contained carbonaceous shale includes following steps: (a) performing rough grinding on raw ore after being crushed so as to obtain roughly ground minerals; (b) performing screening classification on the roughly ground minerals, obtaining coarse grain minerals +0.074mm in size and fine grain minerals -0.074mm in size after the screening classification, and combining the coarse grain minerals after being ground twice with the fine grain minerals -0.074mm in size; (c) adding PH (power of hydrogen) regulators into the combined minerals, adjusting PH value to 5-6, adding gangue mineral inhibitor and vanadium mineral collecting agents into ore pulp for 6-12 times, and obtaining concentrated vanadium ore through segmenting rough concentration, vanadium concentration and vanadium scavenging after obtaining flotation pulp by adding flotation reagents once. The mineral separation method of the finely disseminated vanadium contained carbonaceous shale can perform mineral separation on the finely disseminated vanadium contained carbonaceous shale, can effectively improve a mineral separation index, and further can reduce mineral separation cost.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

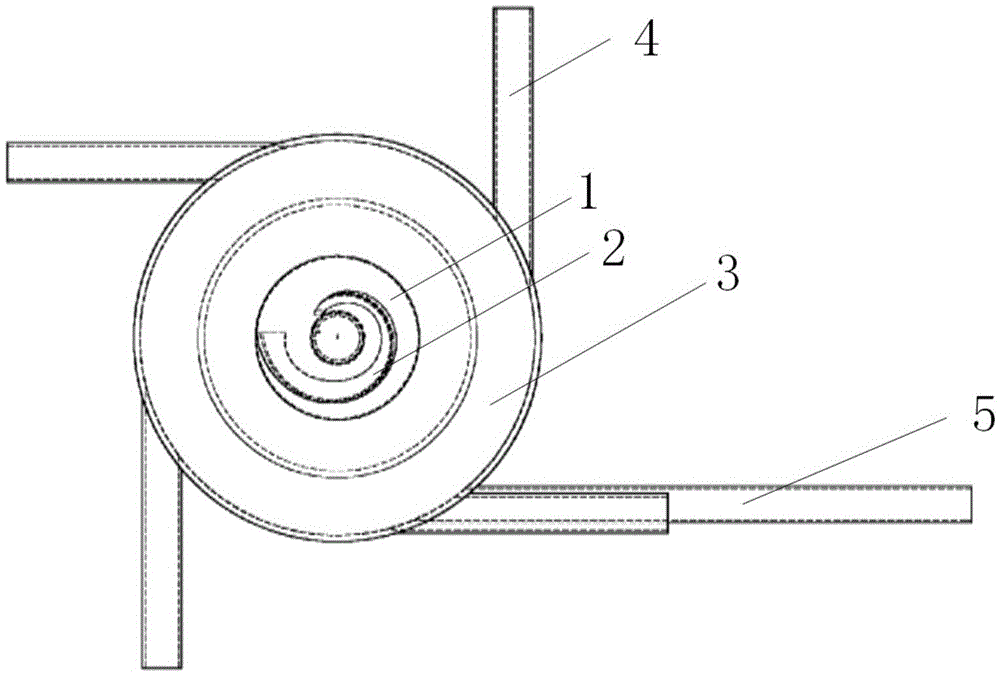

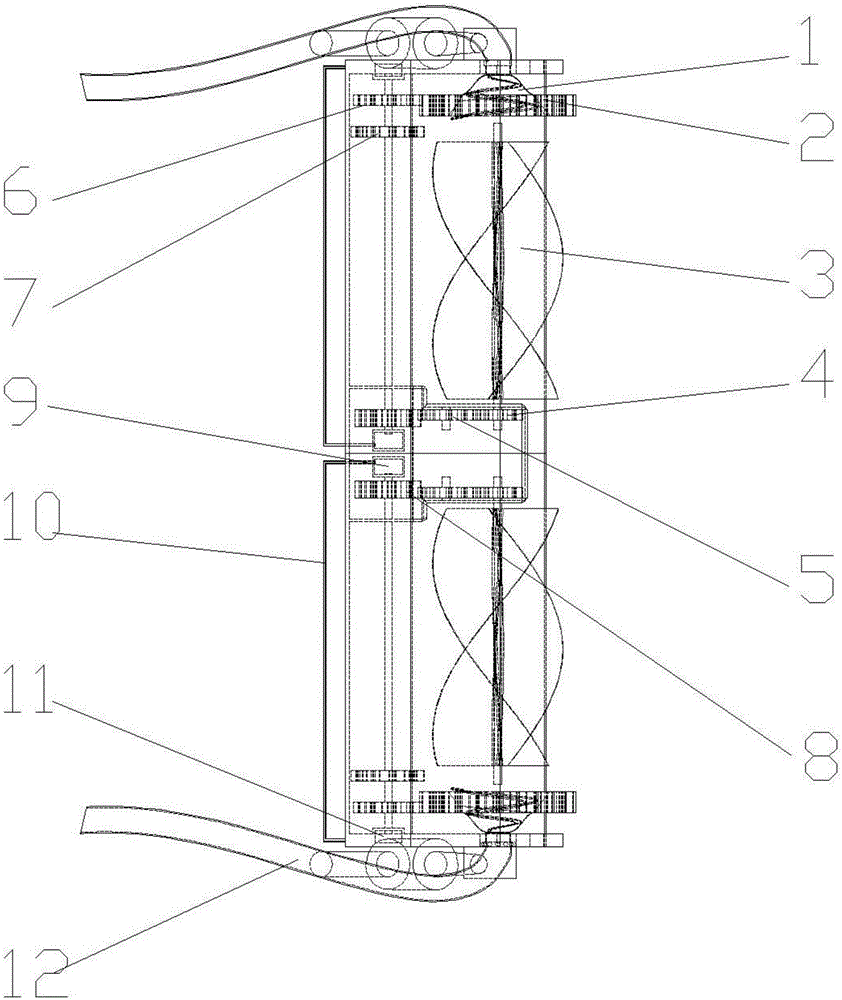

Spiral flow mineral sucking and selecting device and method for separating seawater and minerals through device

The invention discloses a spiral flow mineral sucking and selecting device and a method for separating seawater and minerals through the device.The device comprises a novel spiral mineral sucking device and a cyclone separation device connected with the novel spiral mineral sucking device; vortexes are generated by inducing and sucking water flow through a spiral flow guide plate (2) according to the tornado principle to suck up marine minerals through little energy consumption; solid granular minerals with the large weight generate cyclone centrifugal motion and achieve the downward settlement action by utilizing a cyclone separator through the cyclone and settlement action respectively and are finally discharged into a mineral collecting device through a mineral outlet, and therefore sludge and the seawater are together discharged through a sludge outlet of the cyclone separation device.According to the device, the slurry mixed with the minerals can be directly separated at the seabed, then only the minerals are lifted, not only can energy consumption be significantly reduced, but also the influence of marine benthos on marine upper-layer biotic environment can be reduced to the maximum limitation, and therefore submarine mining achieves sustainable development.

Owner:SHANGHAI JIAO TONG UNIV

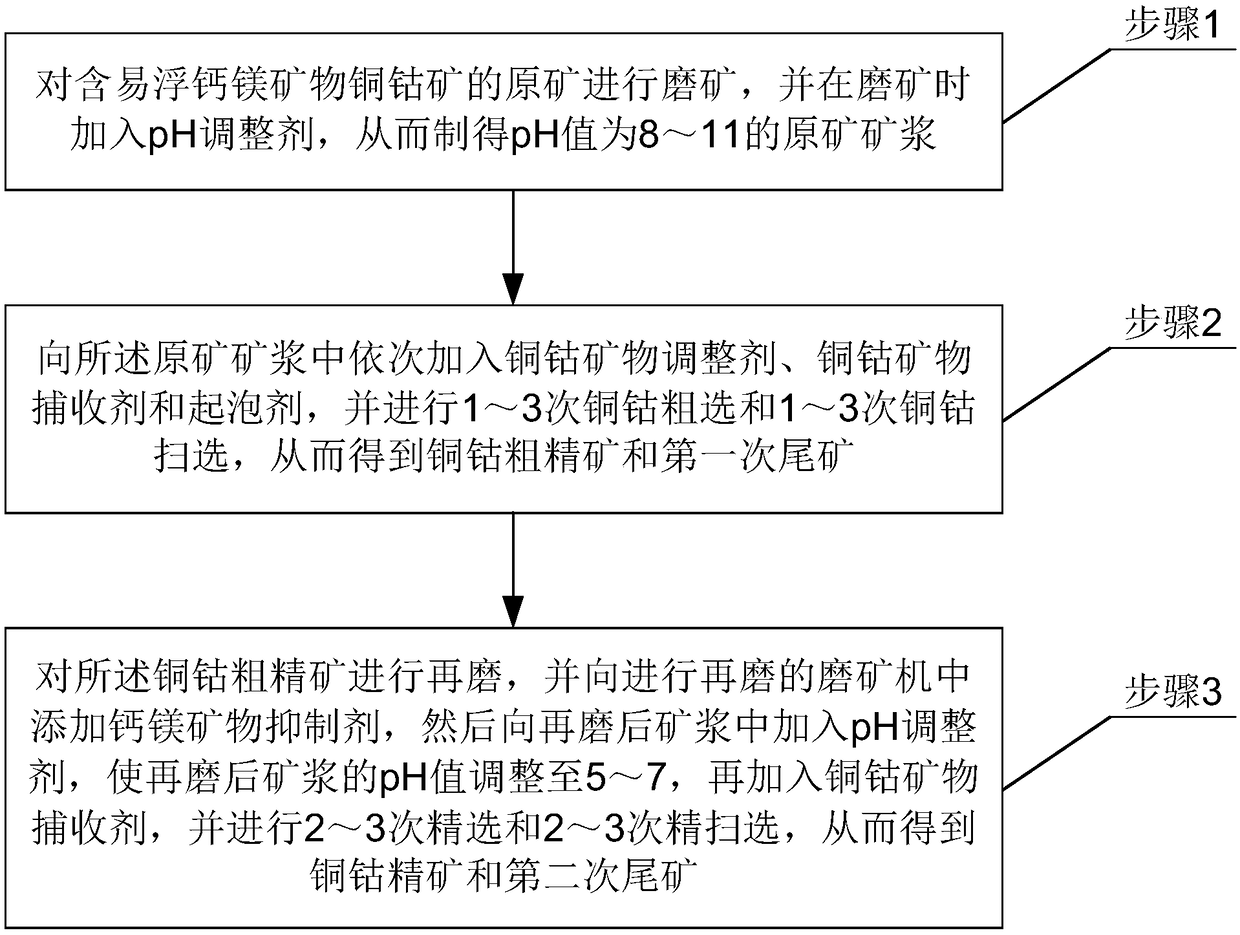

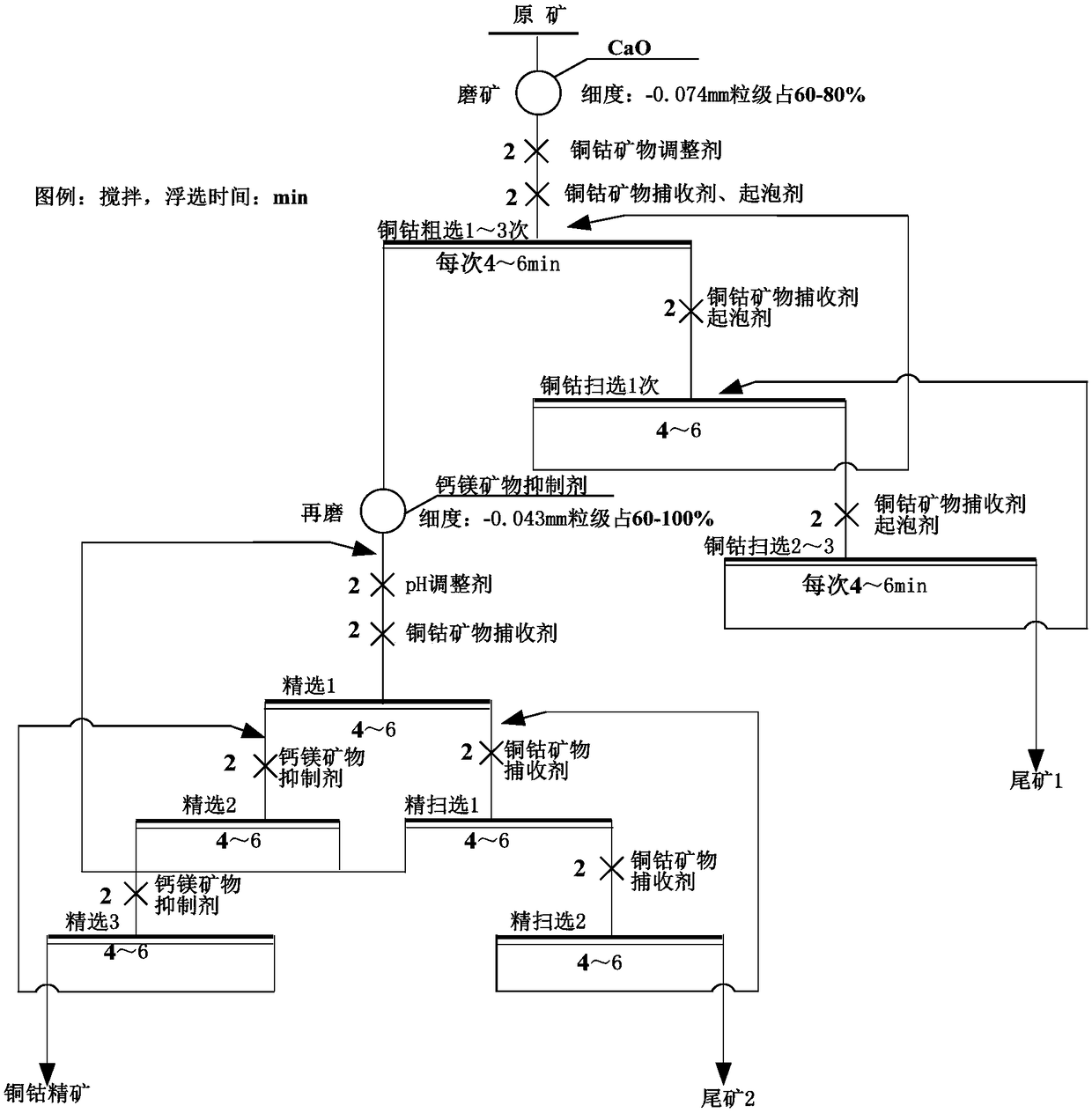

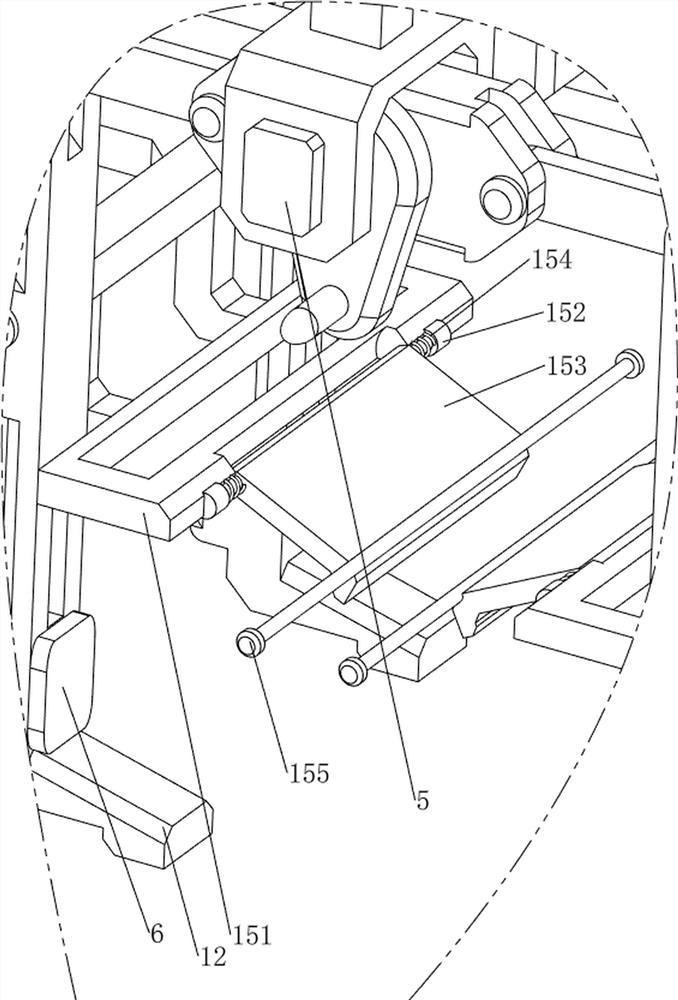

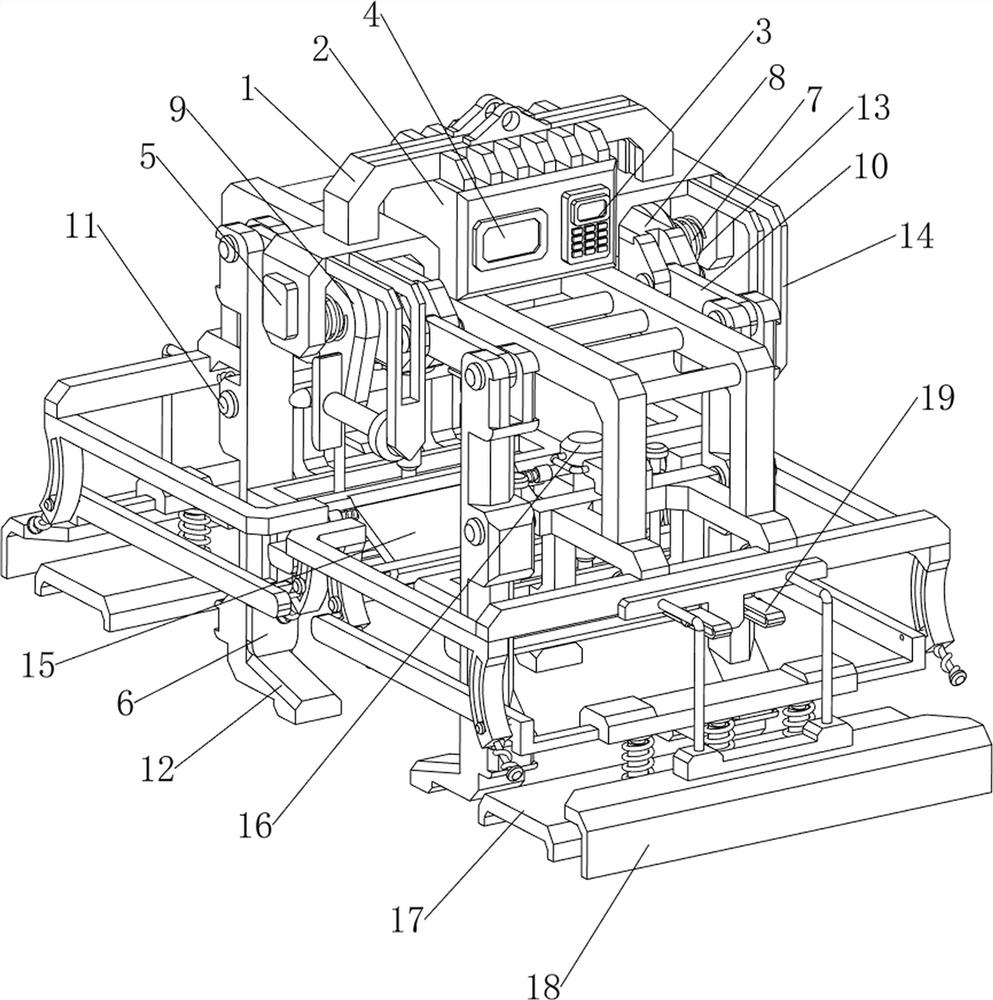

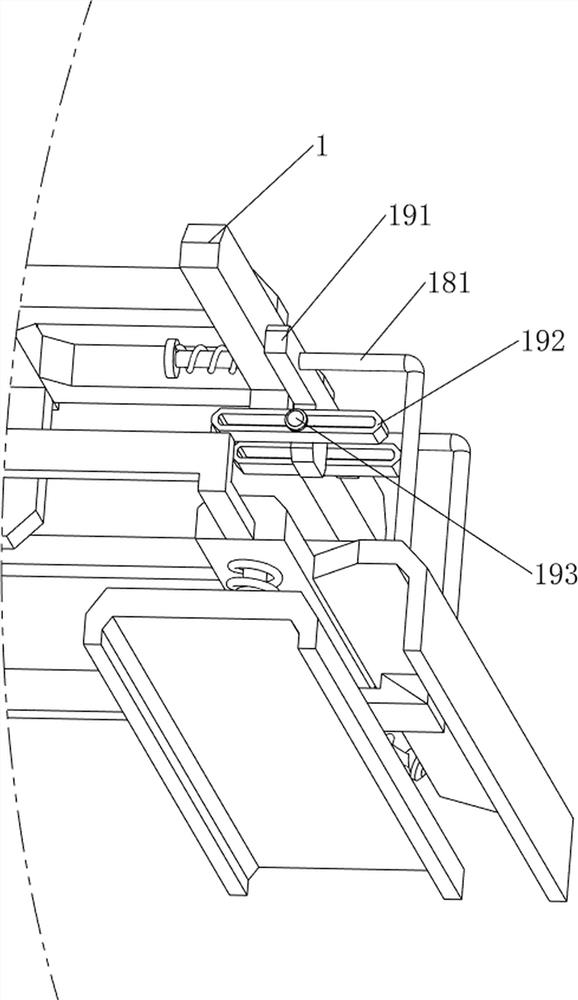

Mineral separation method for copper-cobalt ore containing easy-to-float calcium magnesium minerals

The invention discloses a mineral separation method for copper-cobalt ore containing easy-to-float calcium magnesium minerals. Raw ore of copper-cobalt ore containing easy-to-float calcium magnesium minerals is ground, during ore grinding, a pH regulator is added, and therefore raw ore pulp with the pH value being 8-11 is manufactured; a copper-cobalt mineral regulator, a copper-cobalt mineral collecting agent and a foaming agent are sequentially added into the raw ore pulp, copper-cobalt roughing is performed one to three times, and copper-cobalt scavenging is performed one to three times, sothat copper-cobalt rough concentrate is obtained; the copper-cobalt rough concentrate is ground again, a calcium magnesium mineral inhibitor is added into a grinder for performing regrinding, then, the pH regulator is added into reground ore pulp, the pH value of the reground ore pulp is adjusted to 5-7, the copper-cobalt mineral collecting agent is added, selection is performed two to three times, and fine scavenging is performed for two to three times, so that copper-cobalt concentrate is obtained. Easy-to-float calcium magnesium minerals in copper-cobalt ore can be effectively restrained,the gangue content in the copper-cobalt concentrate is lowered, and the copper-cobalt recycling rate can be increased while the copper-cobalt concentrate grade is ensured.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Environment-friendly seabed mineral collecting device capable of achieving accurate positioning

The invention relates to a seabed mineral collecting device, and particularly relates to an environment-friendly seabed mineral collecting device capable of achieving accurate positioning. The environment-friendly seabed mineral collecting device capable of achieving accurate positioning can prevent minerals from falling off and cannot damage seabed ecology. According to the technical scheme, the environment-friendly seabed mineral collecting device capable of achieving accurate positioning comprises a first fixing frame, a fixing box and a distance sensor, wherein the upper portion of the first fixing frame is connected with the fixing box, and the distance sensor is installed on one side of the first fixing frame. According to the environment-friendly seabed mineral collecting device capable of achieving accurate positioning, the minerals can be clamped by rotating clamping plates and prevented from falling off, the minerals can be pressed by a pressing mechanism and further prevented from falling off, a seabed can be pressed by a compacting mechanism, eddy currents are prevented from being generated, and the seabed ecology is prevented from being damaged.

Owner:JIANGXI UNIV OF SCI & TECH

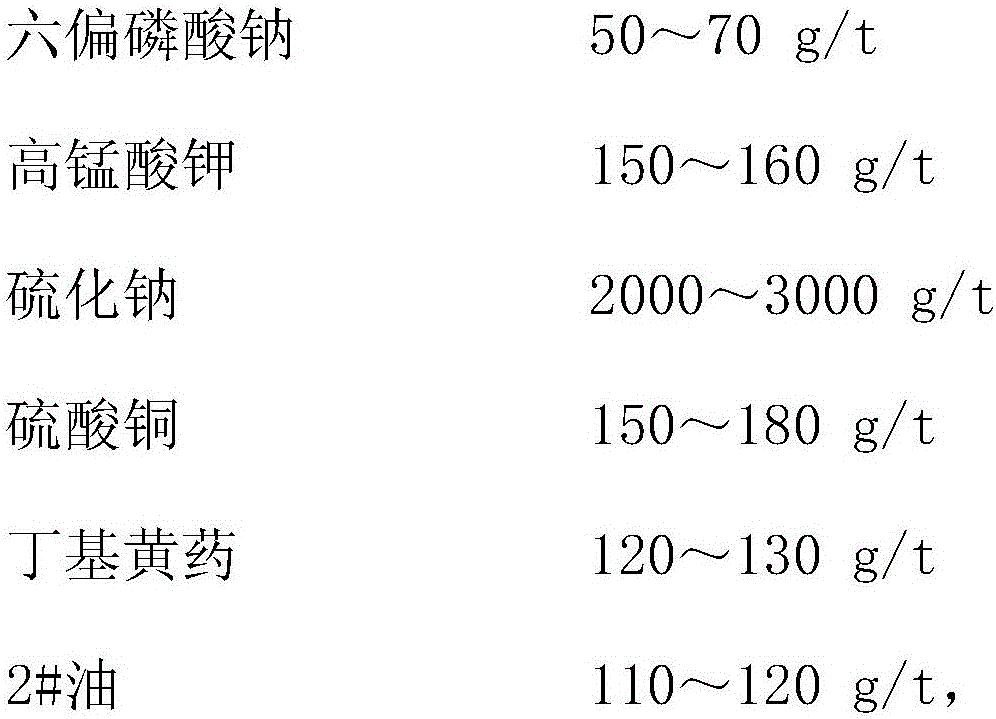

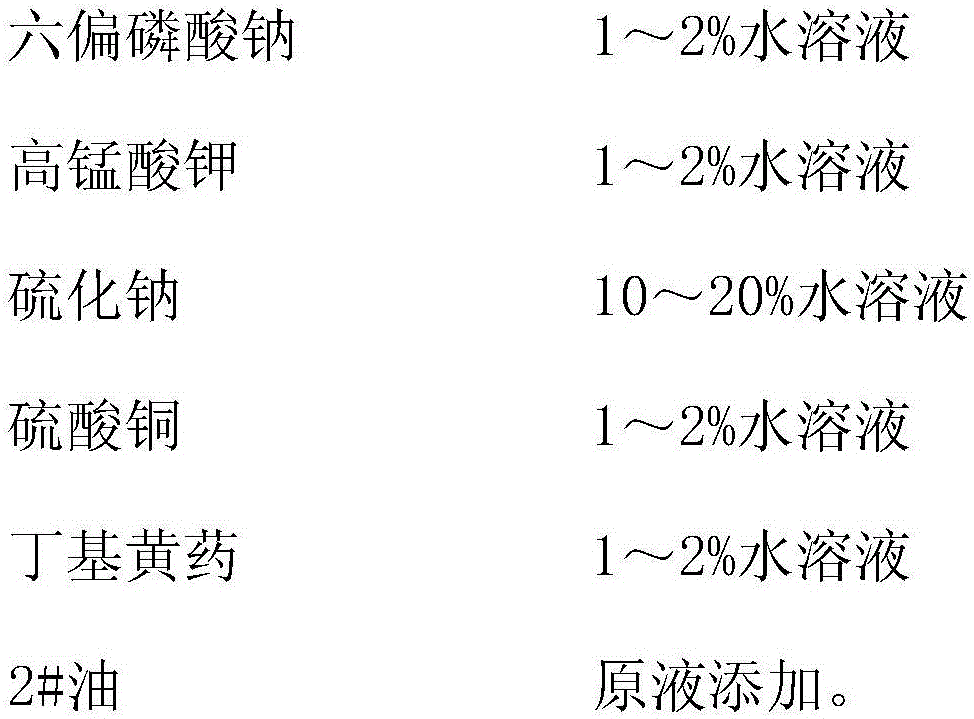

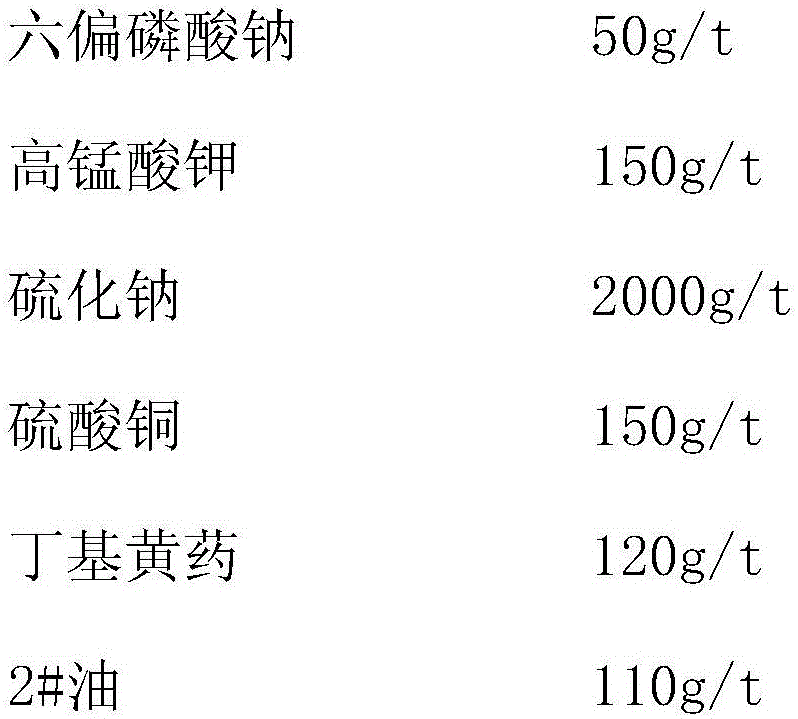

Sulfur-oxygen symbiotic mixed antimony ore flotation recovery method

The invention discloses a sulfur-oxygen symbiotic mixed antimony ore flotation recovery method which includes the steps and reagent systems: taking sodium hexametaphosphate as a mineral dispersing agent; taking potassium permanganate as a mineral oxidant; taking sodium sulfide as a mineral vulcanizing agent; taking copper sulfate as a mineral activating agent; taking butyl xanthate as a mineral collecting agent; taking 2# oil as a foaming agent; collecting sulfur-oxygen symbiotic mixed antimony to obtain antimony concentrate. Sulfur-oxygen symbiotic mixed antimony ores can be effectively recovered, and the antimony concentrate with 48.72%-51.30% antimony grade and 87.21%-90.53% recovery rate can be obtained under the condition of 1.59%-2.56% antimony grade and 21.34%-25.76% antimony oxidation rate of feed ore.

Owner:广西南丹县三鑫环境治理有限公司

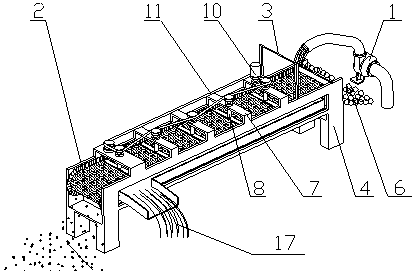

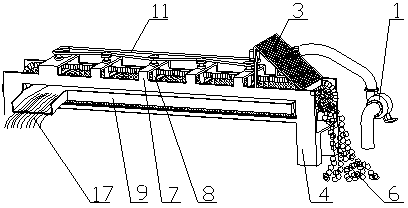

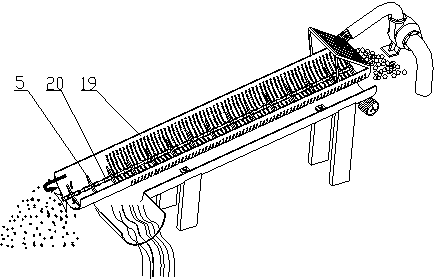

Micro-power mining machine capable of obtaining both high-quality river sand and multiple metal mineral powder

The invention discloses a micro-power mining machine capable of obtaining both high-quality river sand and multiple metal mineral powder. The whole machine is formed by double layers of frames (4), wherein the upper-layer frame comprises a conveyor belt (2) covered with small draining holes or a sand passing tank formed by semi-circular solid grooves (19) as well as a stirring mechanism suspended above the sand passing tank; a mineral collecting tank (9) is fixed on the lower-layer frame; river sand particles smaller than the small draining holes and mineral powder included in the river sand drip with water drops into the mineral collecting tank (9) arranged below the conveyor belt, and then enter a sedimentation tank 16 from a mineral collecting tank gap 17 for treatment, medium sand (18) which is the larger-particle high-quality river sand reaches the tail end of the conveyor belt, so that the technical purpose of integrated mining including double obtaining by one-time power, national resources are saved, the production cost of a mining enterprise is reduced, and the economic value and social value are huge.

Owner:六安金龙矿山机械科技有限公司

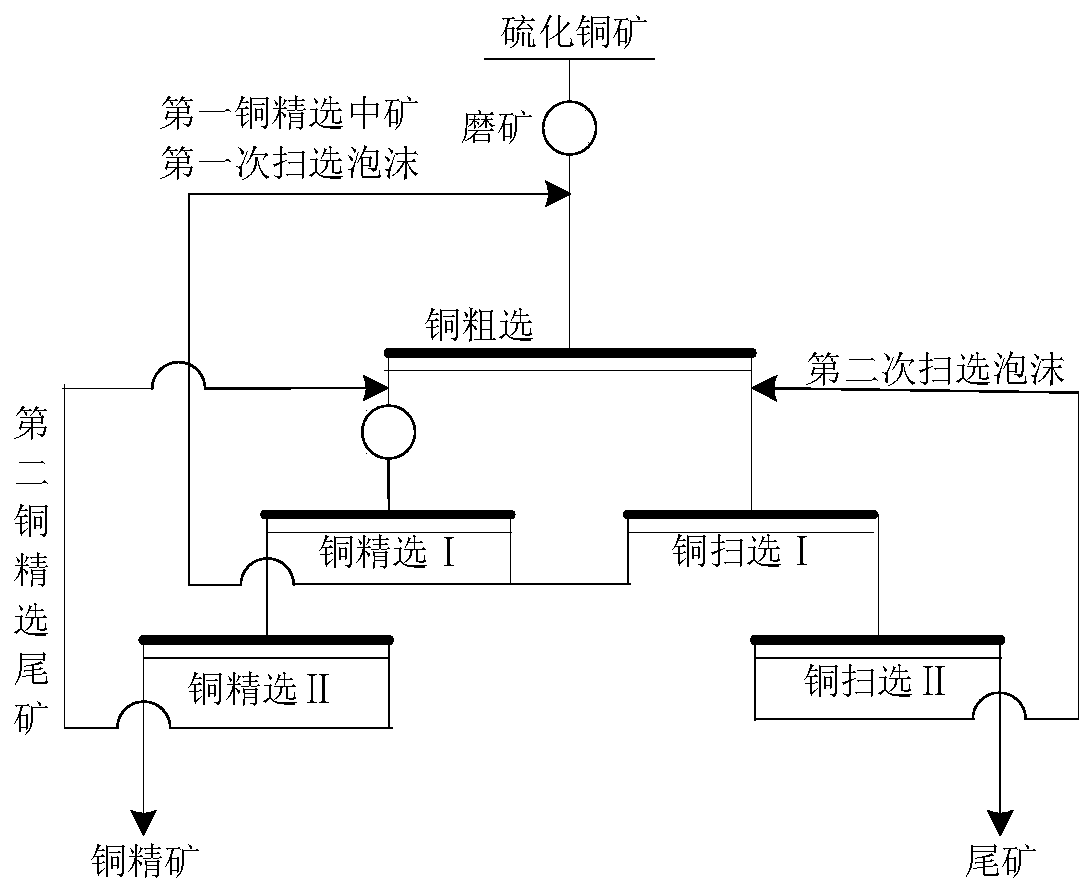

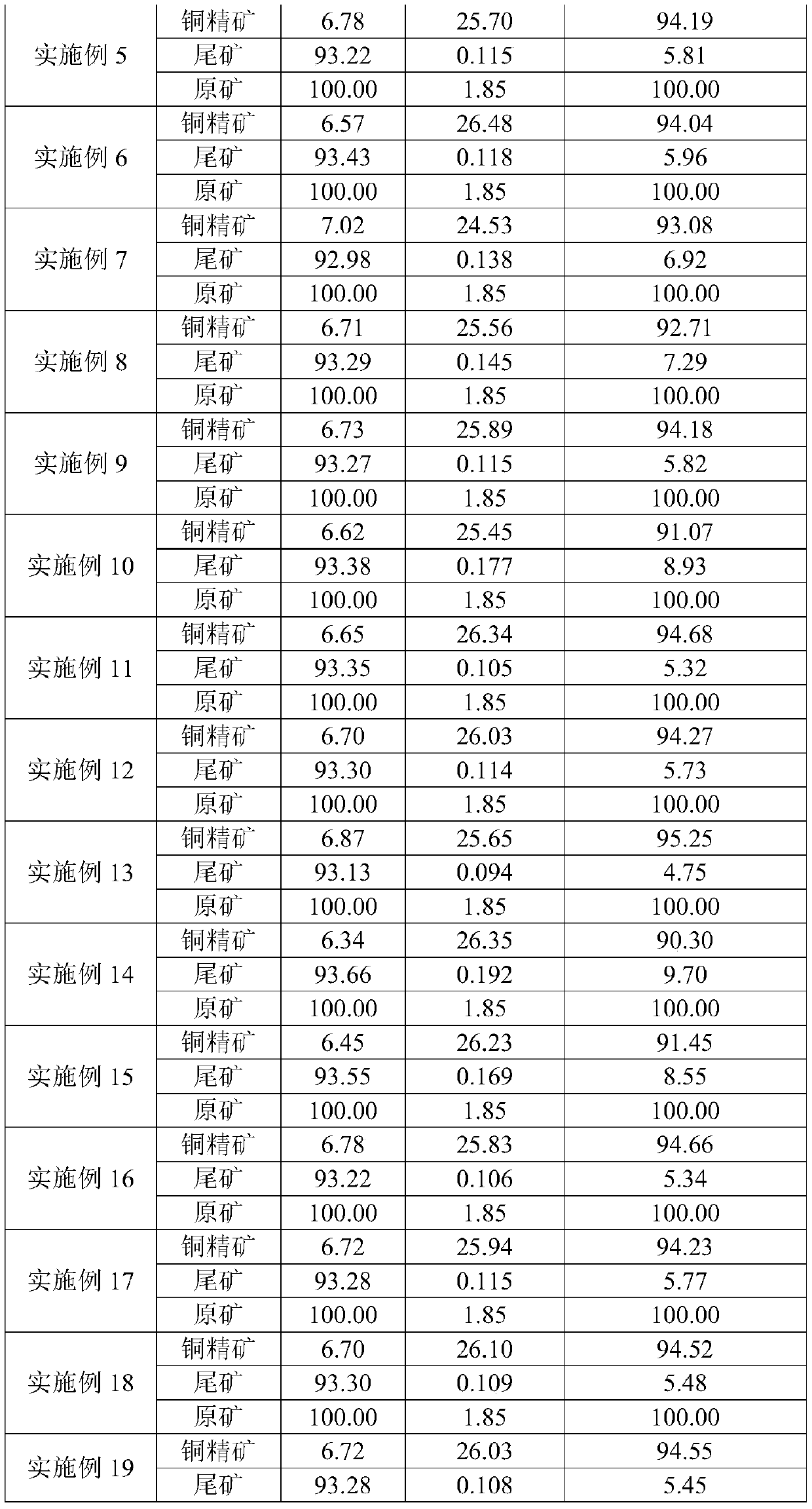

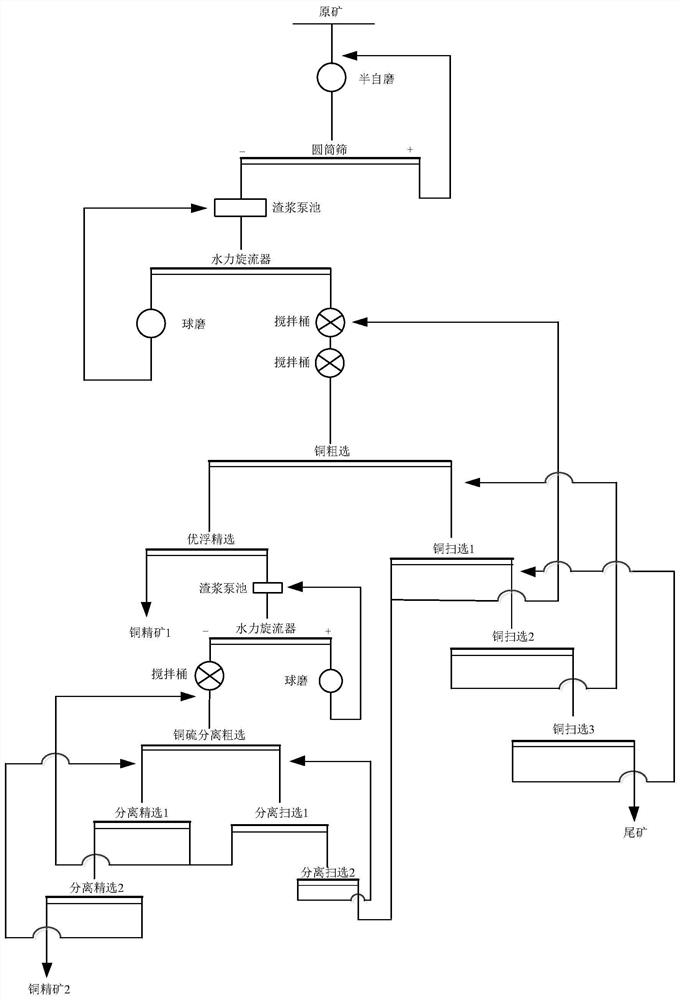

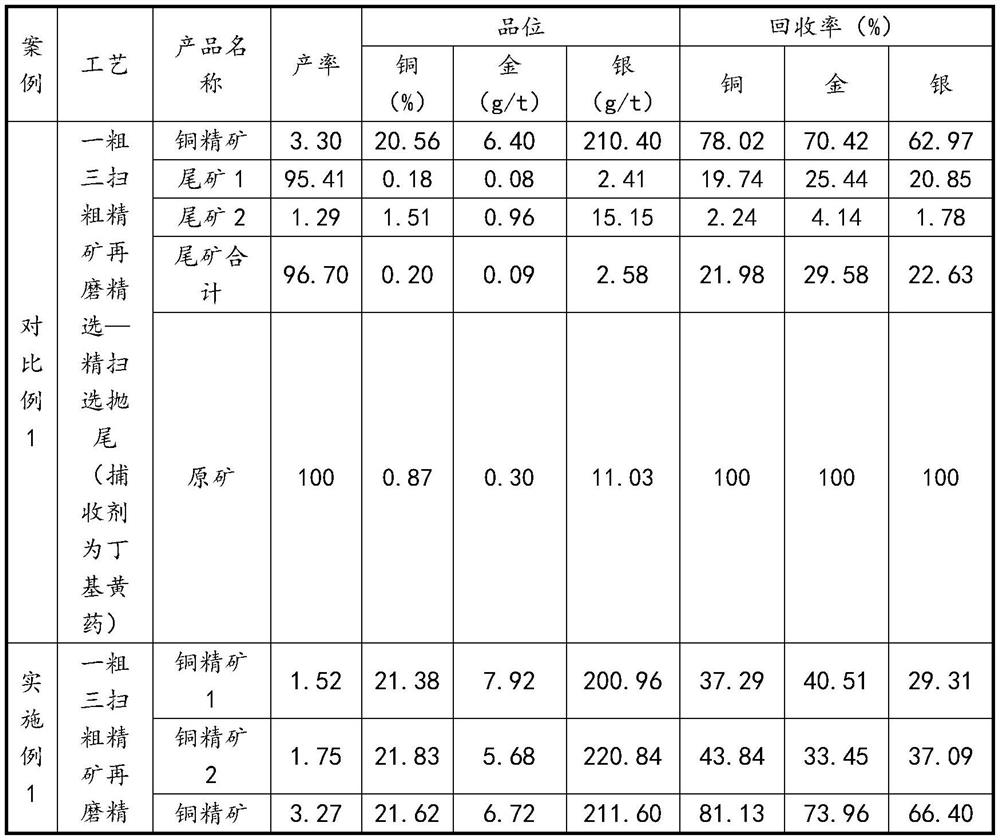

Beneficiation method for fine-grained disseminated copper ore in plateau area

ActiveCN113333153AWiden the difference in hydrophobicityEasy to recycleMechanical material recoveryWet separationEngineeringMetal recycling

The invention relates to a beneficiation method for fine-grained disseminated copper ore in a plateau area. The method comprises the following steps: performing semi-autogenous grinding chemical adding and ore grinding, chemical adding and pulp mixing in a slurry pump pool, ore pulp grading and an ore grinding grading system for grinding ore in a ball mill, and obtaining copper concentrate I through one-time roughing, three-time scavenging and one-time optimal flotation concentration, and enabling optimal flotation tailings to be subjected to regrinding grading, copper-sulfur separation and separation and concentration to obtain second copper concentrate, conducting separation and scavenging, and returning separation and scavenging tailings for roughing. According to the method, a flotation reagent adding point is optimized, a novel copper mineral collecting agent is developed, the flotation technological process is optimized, operability is good, the grade of the copper concentrate can be improved, the metal recovery rate of copper and associated element gold and silver in the copper concentrate is increased, the copper concentration operation capacity is greatly released, the mine production and operation benefits are increased, reference is provided for development of mines of the same type, and the beneficiation method is particularly suitable for processing skarn type copper ore with embedded fine particles in the plateau area.

Owner:ZIJIN MINING GROUP +1

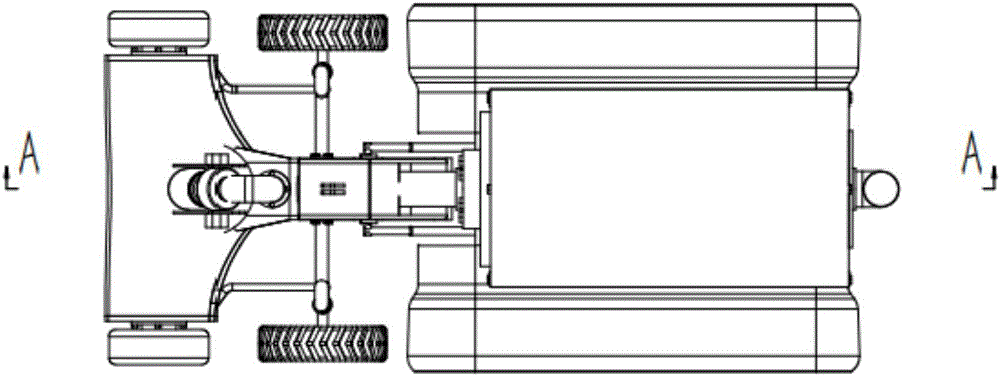

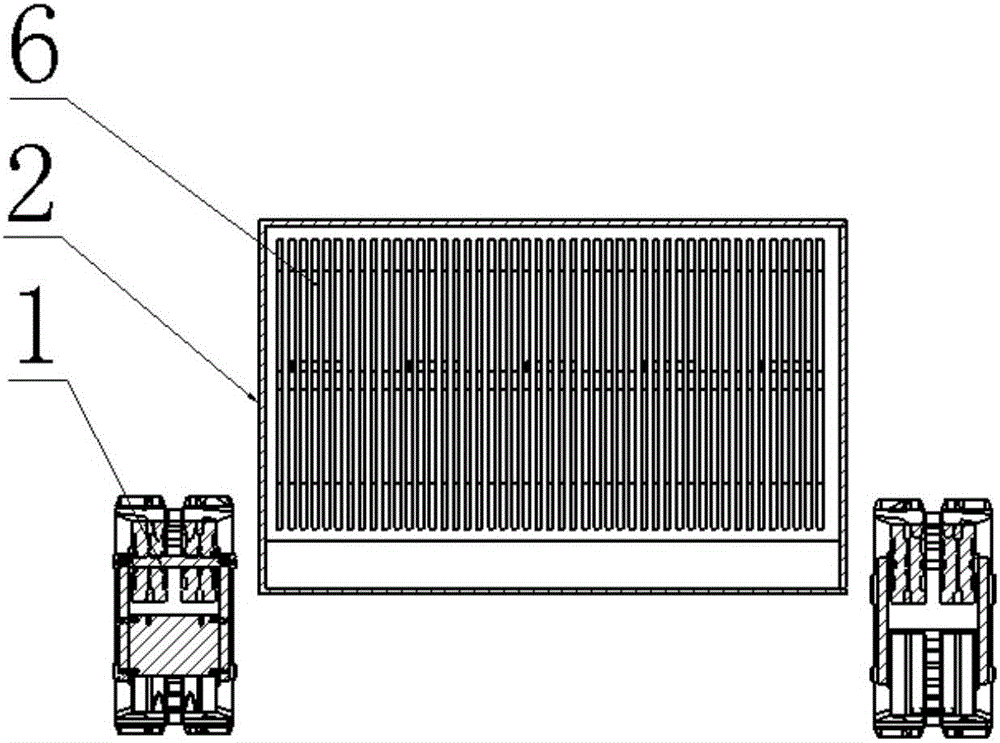

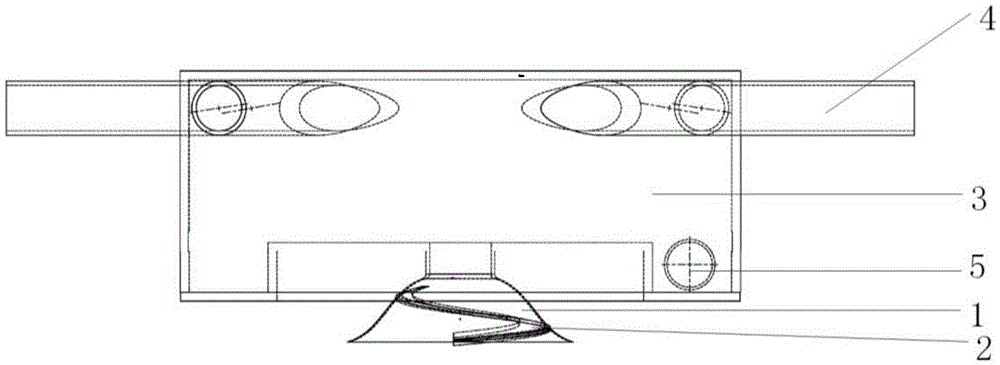

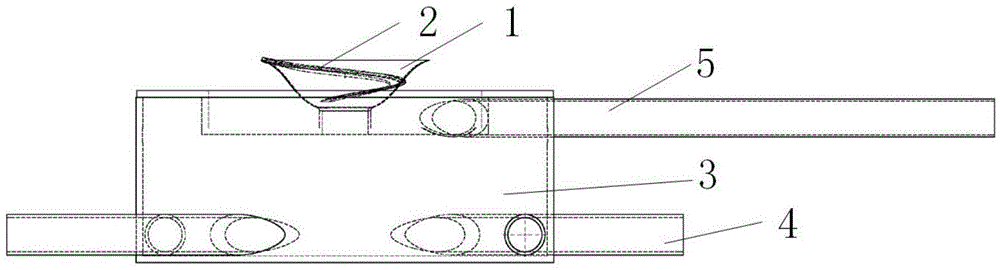

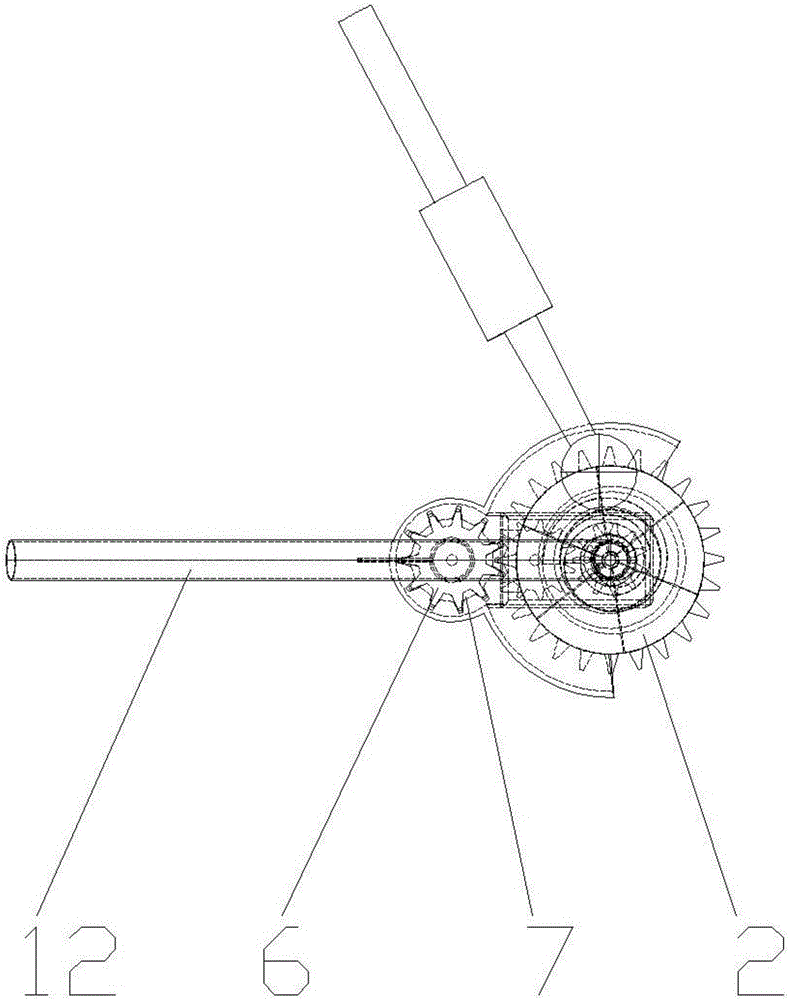

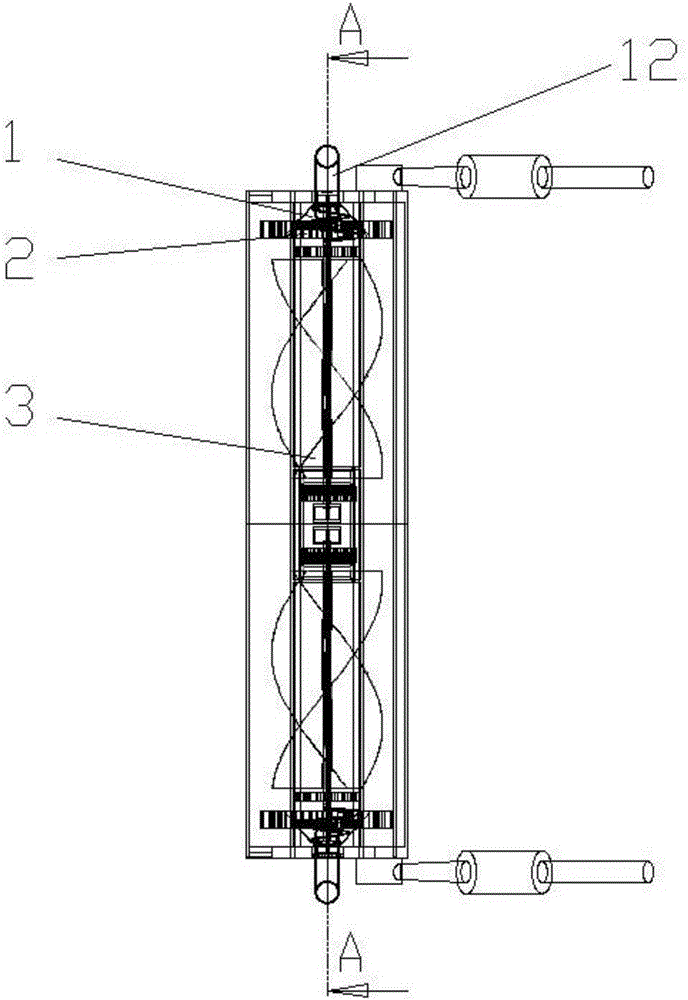

Hydraulic mineral collecting head of submarine mining vehicle and mineral collecting method

The invention provides a hydraulic mineral collecting head of a submarine mining vehicle and a mineral collecting method. The hydraulic mineral collecting head comprises a shell with an opening, mineral conveying pipes, support connectors and spiral rotating plates, wherein the support connectors and the mineral conveying pipes are connected to the outer side of the shell, and the spiral rotating plates are arranged in the shell. Spiral mineral sucking covers are arranged at the two sides in the shell, cylindrical parts at the bottom ends of the spiral mineral sucking covers are connected with the mineral conveying pipes by bearings, the front ends of the spiral mineral sucking covers are fixedly connected with driving plate type height limiting wheels, the driving plate type height limiting wheels and a driving gear group are matched with each other and are all arranged on the side, far from the opening, of the shell, the two ends of a shaft of the driving gear group separately extend into a first hydraulic cabin and a second hydraulic cabin, and the two hydraulic cabins communicate via a conveying pipe. The collection of submarine minerals is realized by adopting spiral water flow, and external gear shifting can be realized when running speed does not meet requirements. Compared with original submarine mineral collecting equipment, the hydraulic mineral collecting head is more environment-friendly, efficient, energy-saving and reliable.

Owner:SHANGHAI JIAO TONG UNIV

Flotation separation method of antimony sulfide gold minerals

A flotation separation method of antimony sulfide gold minerals comprises the steps of performing bulk flotation to obtain antimony-gold mixed concentrate firstly and then separating the antimony-gold mixed concentrate to obtain antimony concentrate and gold concentrate, wherein in the bulk flotation, lead nitrate is taken as an activator for the antimony gold minerals, while sodium n-butylxanthate is used as a collecting agent and 2# oil is taken as a foaming agent; and in the flotation separation process, active carbon is used for reagent removal, while sodium hydroxide is used for adjusting the pH value to be 8.5-9.5, sodium humate and starch are used as a gold-containing mineral inhibitor and N, N-sodium diethyldithiocarbamate is used as the antimony mineral collecting agent. According to the flotation separation method, the antimony sulfide minerals can be effectively separated from the gold-carrying minerals through flotation, so that the antimony concentrate having the antimony grade of 33.82%-37.28% and the recovery rate of 87.21%-91.62% is obtained, and simultaneously, the gold concentrate having the grade of 40.27-45.81g / ton and the recovery rate of 85.64%-92.16% is obtained, through bulk flotation and further separation under the conditions that the feeding antimony grade is 0.37%-0.87% and the gold grade is 1.86-3.26 g / ton.

Owner:白银金锑矿业科技有限公司

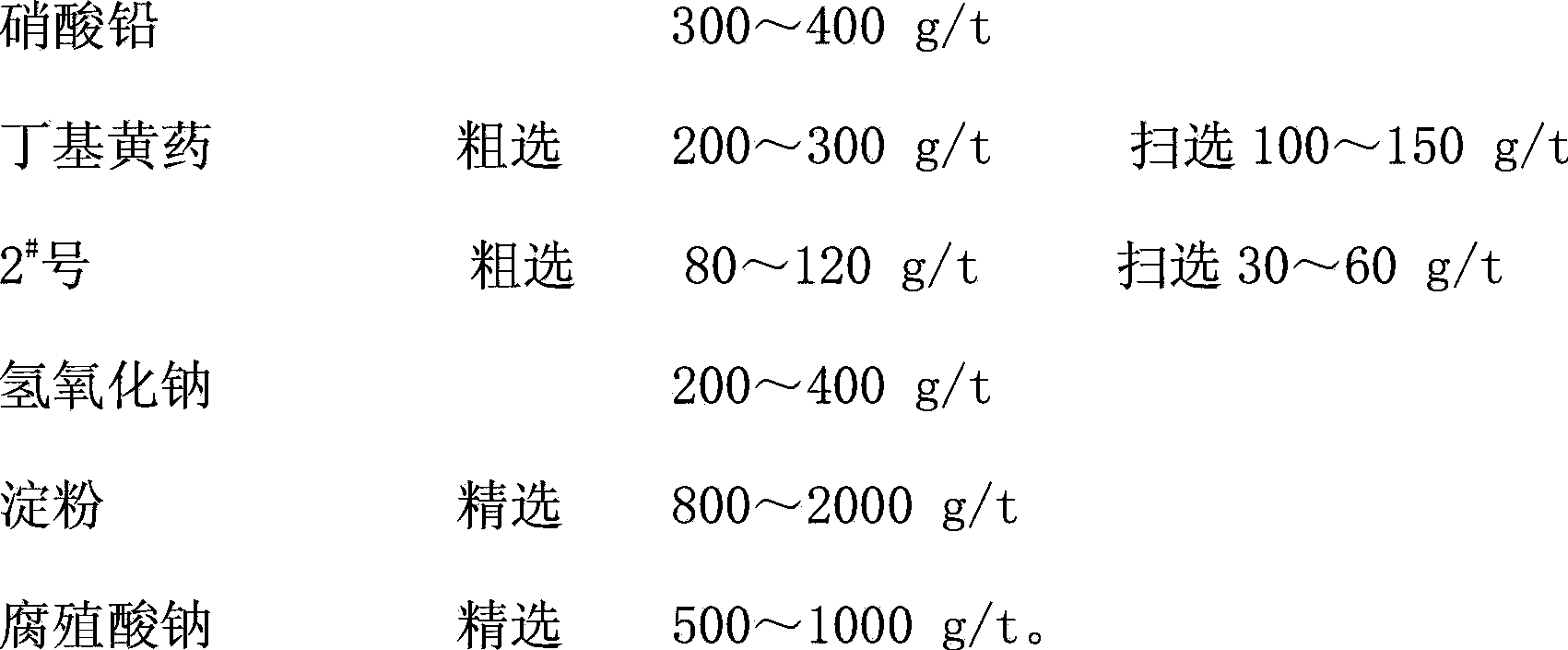

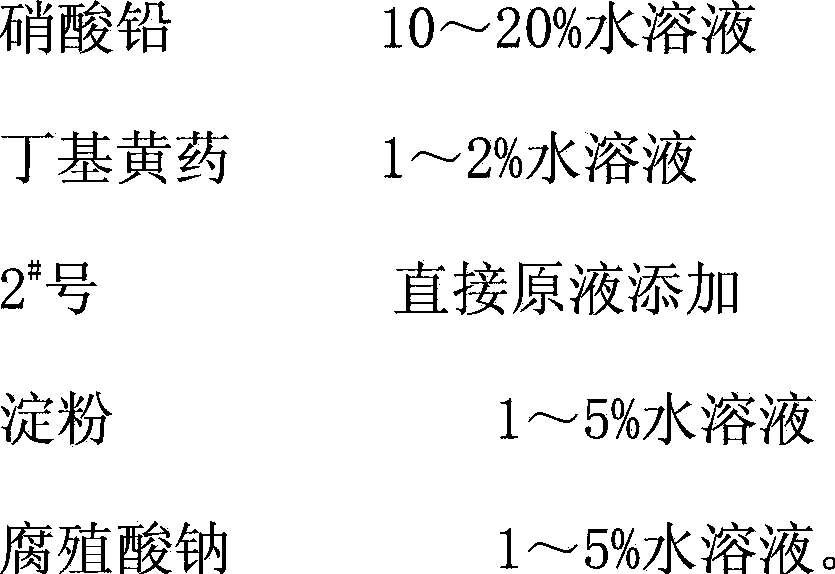

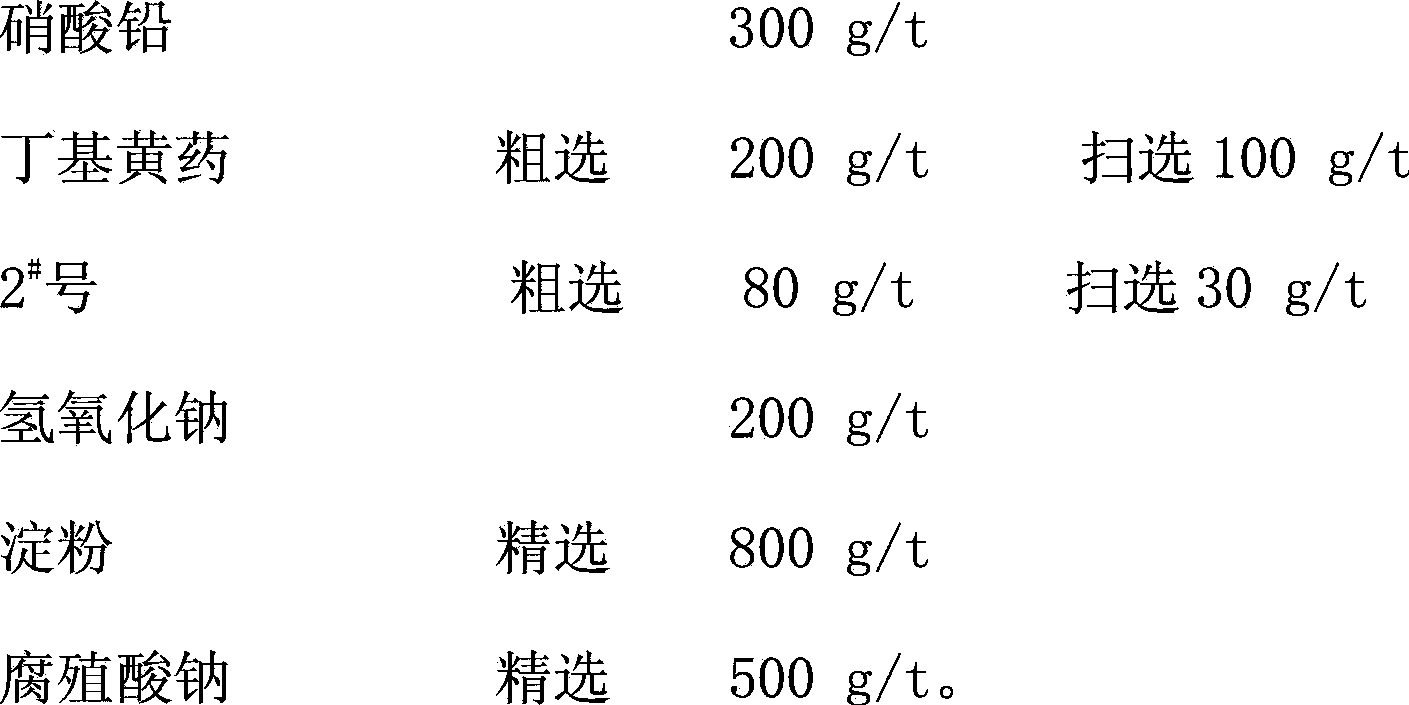

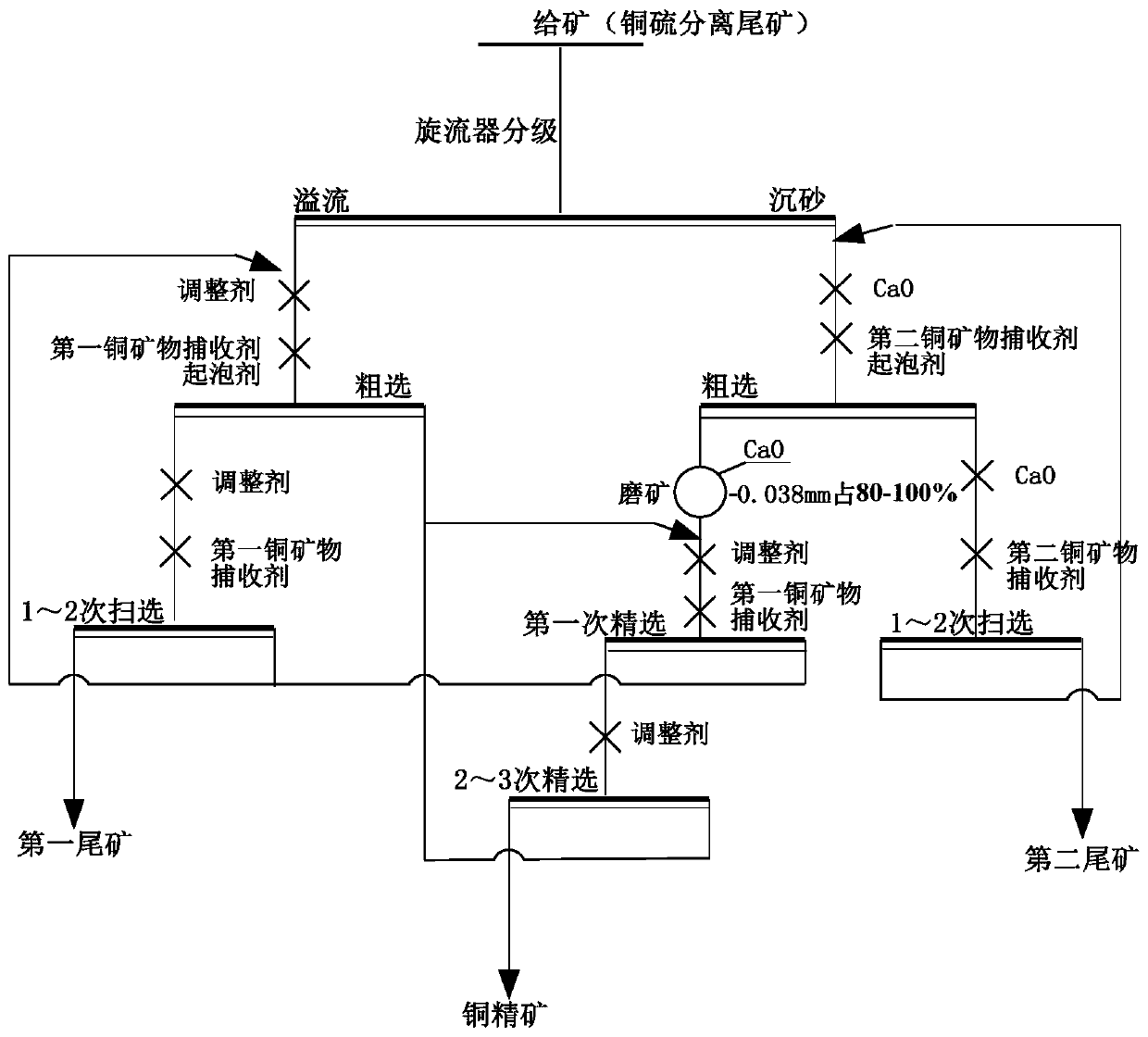

Method for recycling copper minerals from copper and sulfur separating tailings

ActiveCN111036391ASolve the problem of low flotation recovery rateImprove floatabilityVortex flow apparatusSolid separationFoaming agentMaceral

The invention discloses a method for recycling copper minerals from copper and sulfur separating tailings. The method comprises the following steps: performing size grading on the copper and sulfur separating tailings through a whirlcone, thereby obtaining overflow and sand settling; adding a regulator, a foaming agent and a first copper mineral collecting agent into the overflow under a natural pH value condition to perform roughing, thereby obtaining first rough concentrate; regulating the pH value of pulp to be 10-12 with lime for the sand setting, adding the foaming agent and the second copper mineral collecting agent, and performing roughening, thereby obtaining second rough concentrate; performing mineral grinding on the second rough concentrate to obtain mineral-grinded second roughconcentrate; combining the first rough concentrate with the mineral-grinded second rough concentrate, and adding the regulator and the first copper mineral collecting agent to perform concentration,thereby obtaining copper concentrate. The method can increase a recovery rate of the copper minerals, obtains copper concentrate with qualified grade, is moderate in middling circulating amount, is simple to operate, is stable in process, is convenient for field management, and is high in adaptation.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Rare-earth mineral collecting agent

The invention provides a rare-earth mineral collecting agent. The rare-earth mineral collecting agent comprises, by weight, 70-90 parts of C5-9 hydroximic acid, 5-15 parts of Medialan and 5-15 parts of C11-16 alkane kerosene. The rare-earth mineral collecting agent is good in selectivity, wide in pH applied range and high in collecting capacity.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

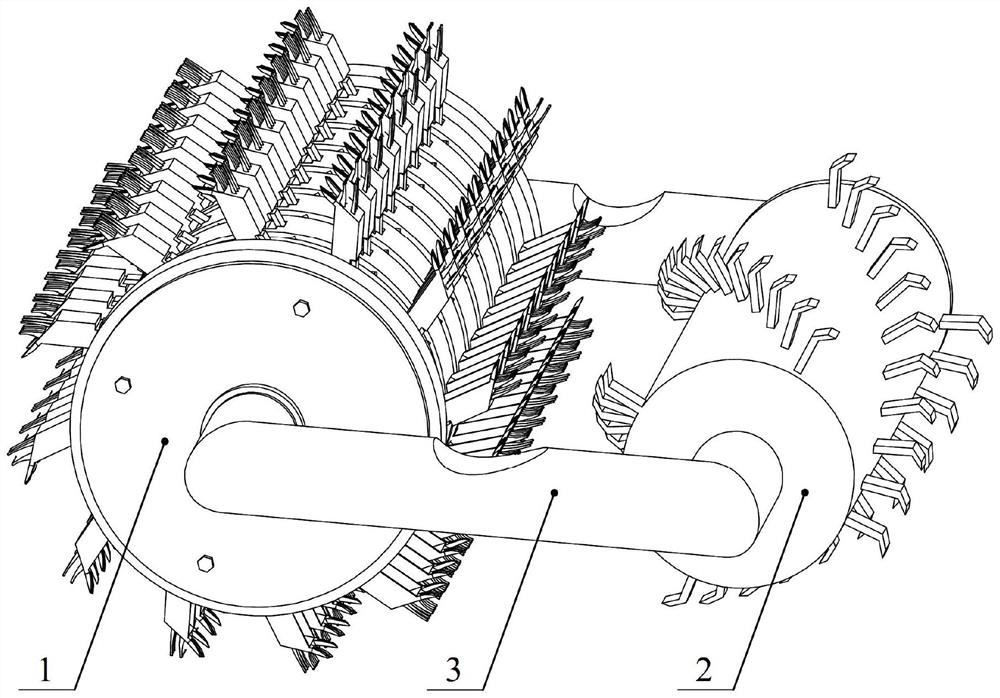

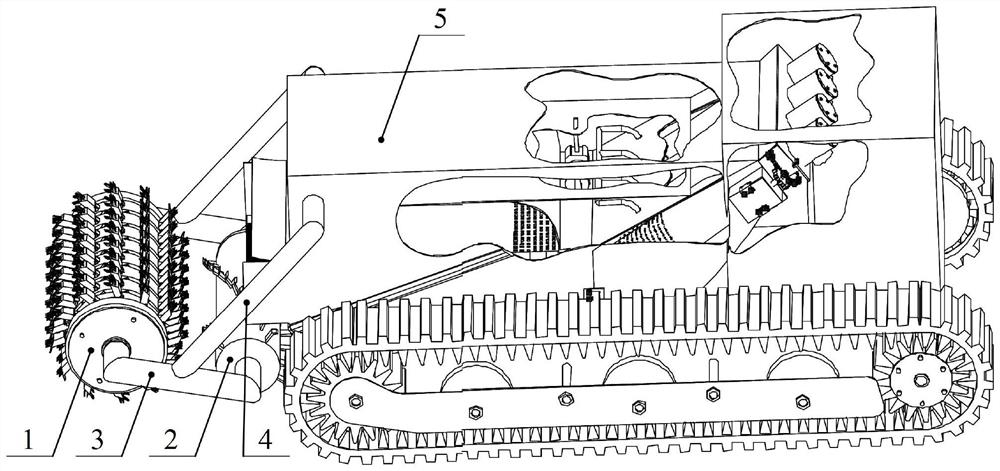

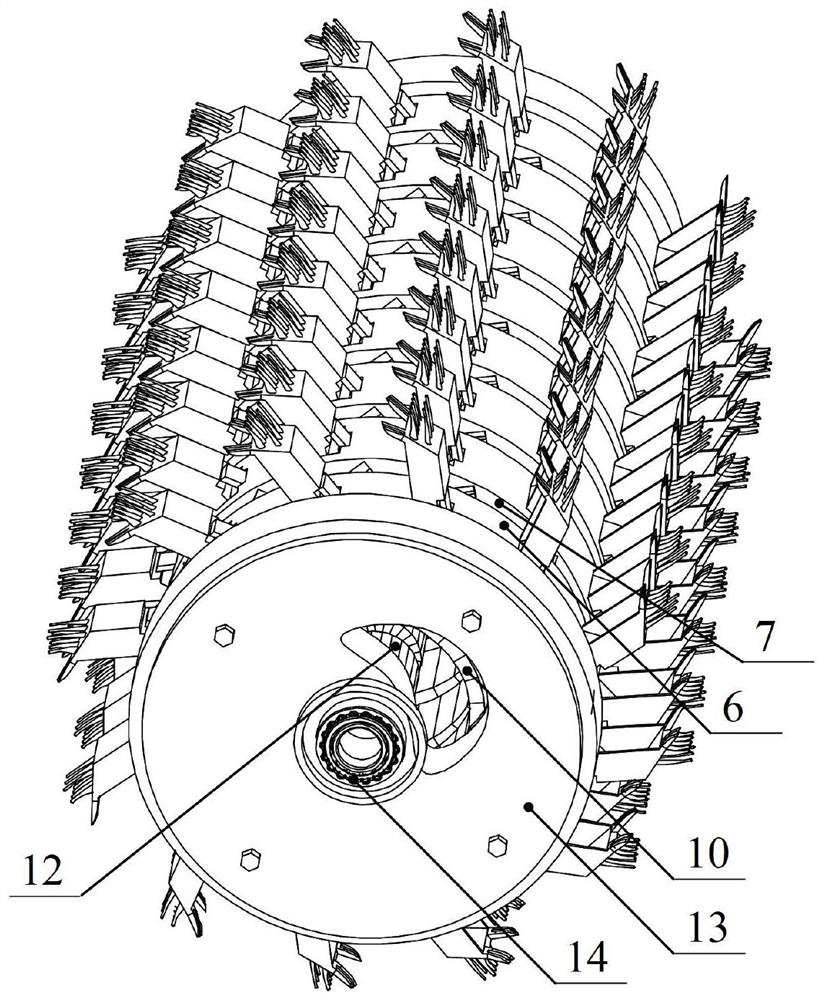

Composite collecting mechanism of seabed mining vehicle and using method of composite collecting mechanism

PendingCN114109390AFit tightlyEfficient collectionMineral miningMining engineeringMineral collecting

The composite collecting mechanism comprises a collecting roller, a missing collecting roller, a supporting frame and a connecting rod, the collecting roller and the missing collecting roller are rotationally arranged on the supporting frame side by side, the connecting rod is installed on the supporting frame, and the collecting roller comprises a plurality of collecting sheet bodies arranged alternately and a first sealing ring; a plurality of collecting claws are arranged on the outer circumference of the collecting sheet body, and the leakage collecting roller comprises a roller body and a plurality of rows of bent row teeth spirally arranged on the roller body. According to the composite collecting mechanism of the seabed mining vehicle, through the gap between the outer magnetic ring and the inner magnetic ring and under the magnetic constraint effect, all the collecting piece bodies in the collecting roller can be subjected to height self-adaptive adjustment along with the uneven seabed ground, the collecting claw is tightly attached to the uneven seabed ground, and efficient seabed mineral collection is completed. And through matched movement of the T-shaped push rod and the guide gravity sliding block, rotation constraint of the collecting claw can be achieved, and the efficiency of the mineral collecting process of the mining vehicle is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com