Collecting agent for collecting siliceous minerals and preparation method of collecting agent

A technology of siliceous minerals and collectors, which is applied in the field of collectors, can solve the problems of greater influence of collectors, poor selectivity, weak adaptability, etc., and achieve cost savings, simplification of pharmaceutical systems, and strong pH adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

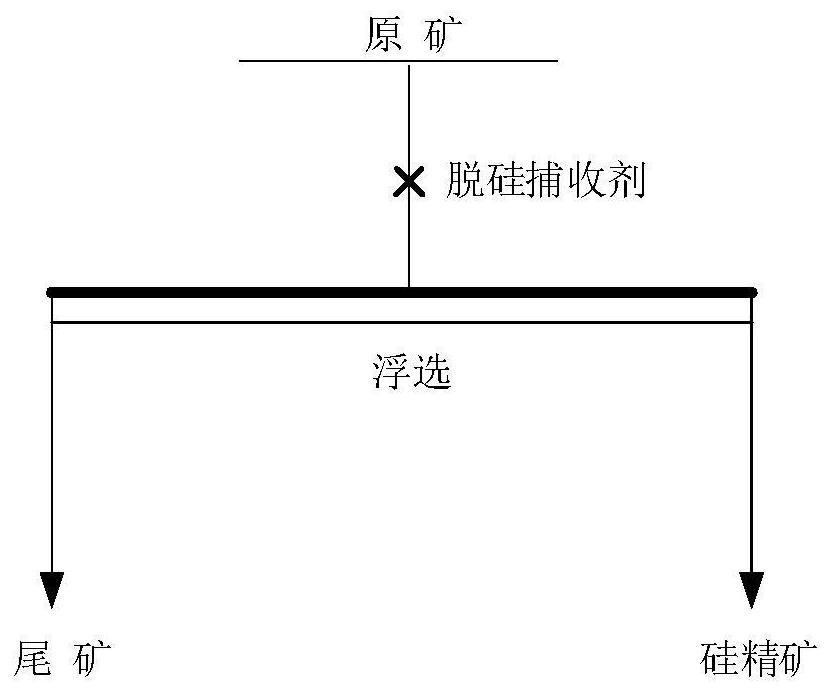

[0028] Example 1: Mix pure quartz minerals and collophanite pure minerals at a ratio of 5:5, the grinding fineness of the two ores is -200 mesh > 70%, and the medicament system is: by weight tetradecyl trimethyl 1 part of ammonium bromide, 0.2 part of sodium dodecylsulfonate, 0.1 part of ether amine, 1 part of water, 0 part of sodium oleate, 0 part of dodecylamine, 0 part of hydrochloric acid, 0 part of polyetheramine, dodecyl 0 parts of sodium alkyl sulfate, 0 parts of diesel oil, 0 parts of tributyl phosphate. The dosage of medicine is 100g / t.

[0029] Get mixed ore 10g and add pure mineral flotation machine, press figure 1 way for flotation, silicon concentrate SiO 2 The content is 96%, and the recovery rate is 99%.

Embodiment 2

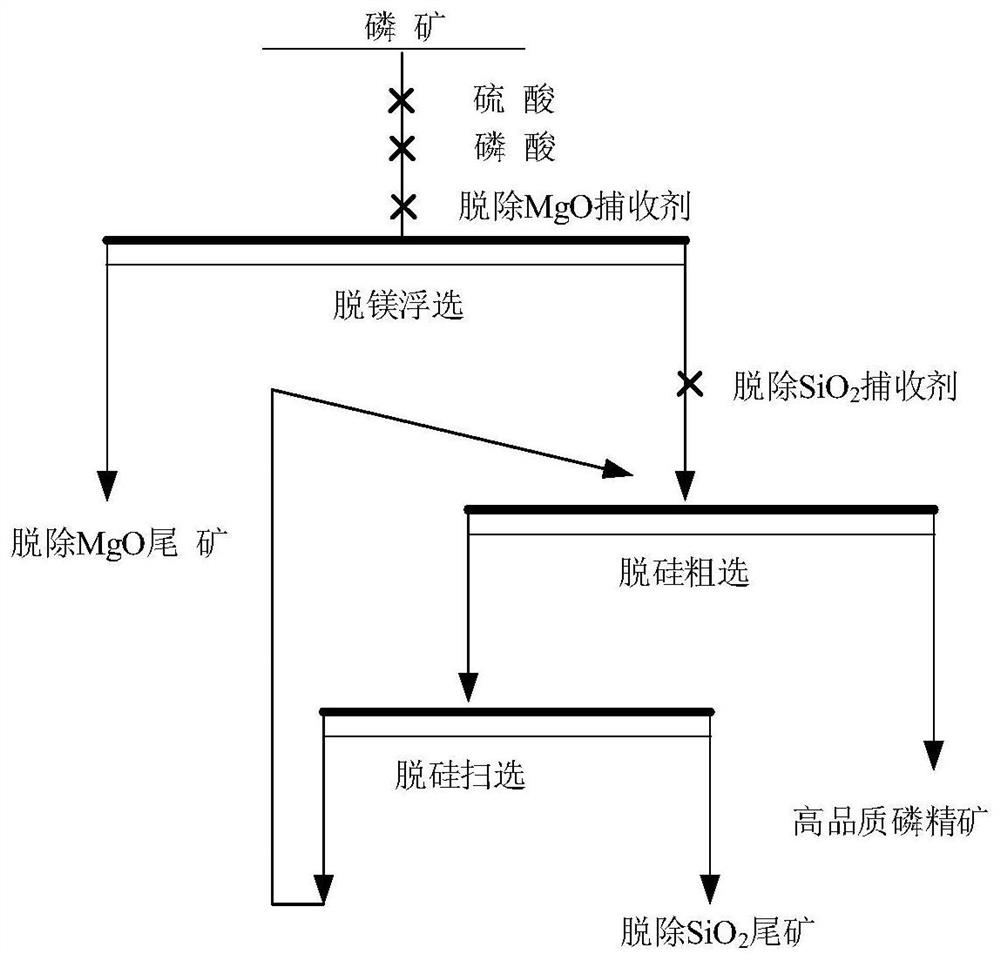

[0030] Embodiment 2: get the demagnesium-phosphorus concentrate after reverse flotation demagnesification of a phosphate ore flotation plant in Yunnan, press figure 2 Carry out desiliconization reverse flotation, use medicament system as: by weight 7 parts of cetyltrimethylammonium bromide, 1 part of sodium lauryl sulfate, 0.1 part of diesel oil, 1 part of tributyl phosphate, 1 part of water 0 parts, 0 parts of sodium oleate, 0 parts of dodecylamine, 0 parts of hydrochloric acid, 0 parts of polyetheramine, 0 parts of etheramine, 0 parts of sodium dodecylsulfonate. The dosage of the agent is 200g / t, and the indicators shown in the following table can be obtained by adopting the process of one roughing and one sweeping:

[0031]

Embodiment 3

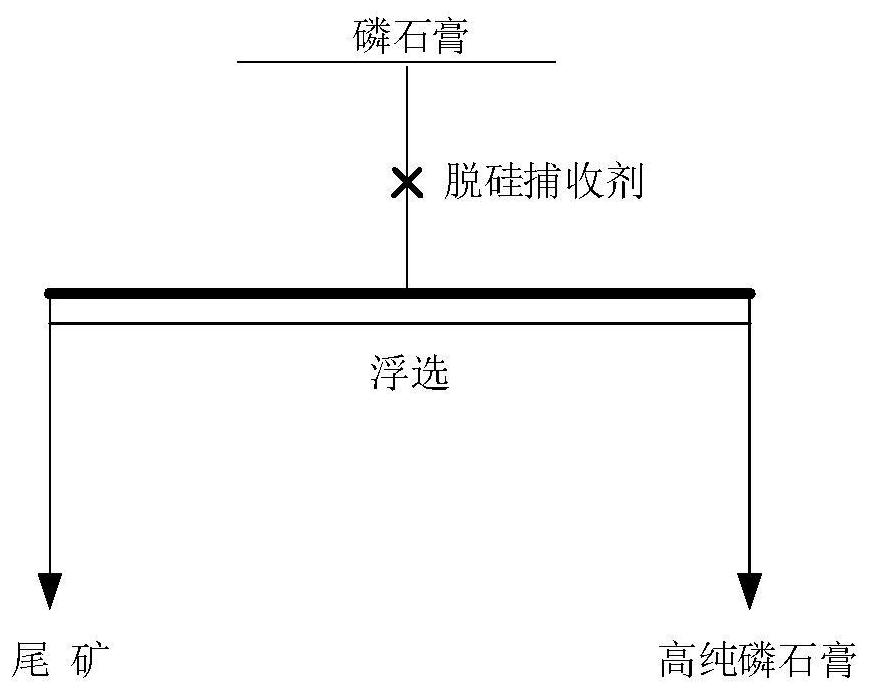

[0032] Embodiment 3: get the phosphogypsum 200g that some wet-process phosphoric acid factory discharges in Yunnan and add flotation machine, press image 3 Carry out flotation to remove SiO contained in phosphogypsum 2 , to increase CaSO in phosphogypsum 4 2H 2 O purity. The pharmaceutical system is: by weight 1 part of cetyltrimethylammonium chloride, 0.5 part of polyetheramine, 1 part of sodium dodecylsulfonate, 1 part of water, 0 part of sodium oleate, 0 part of dodecylamine 0 parts, hydrochloric acid 0 parts, etheramine 0 parts, sodium lauryl sulfate 0 parts, diesel oil 0 parts, tributyl phosphate 0 parts. The dosage of the agent is 300g / t, and the SiO in the phosphogypsum can be removed by one rough selection. 2 The content was reduced from 15.7% to 1.4%. The specific indicators are shown in the table below:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com