Patents

Literature

902 results about "Sodium oleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel lepidolite flotation method

InactiveCN103240185AEfficient separationLarge adsorption capacityFlotationCoconut oilCharge compensation

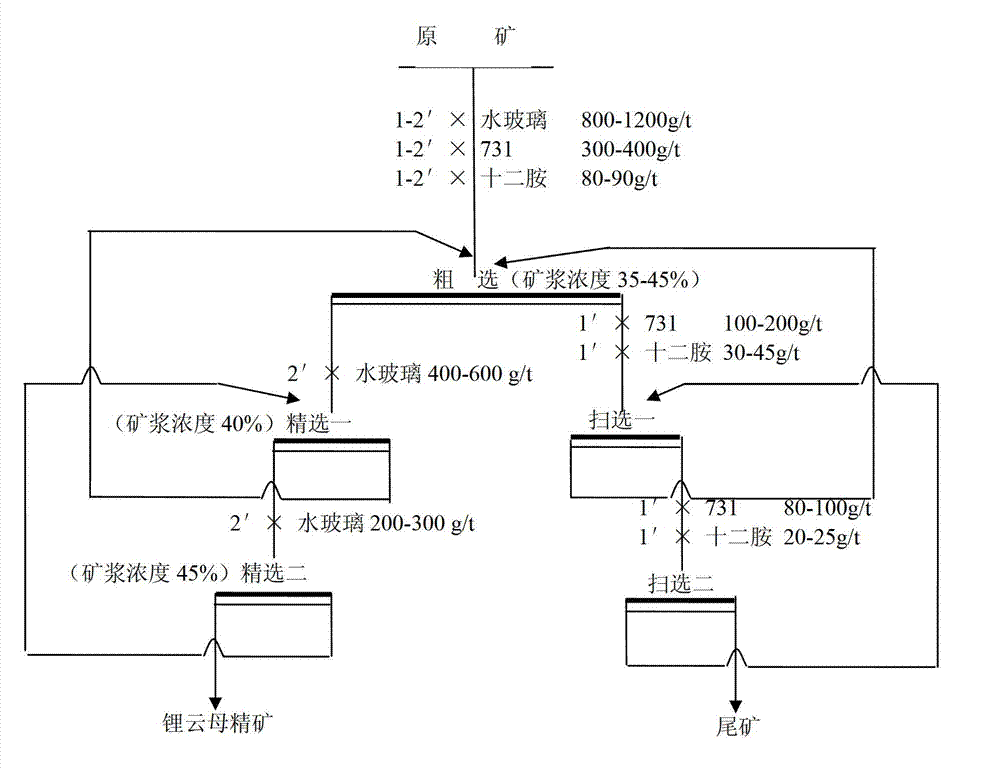

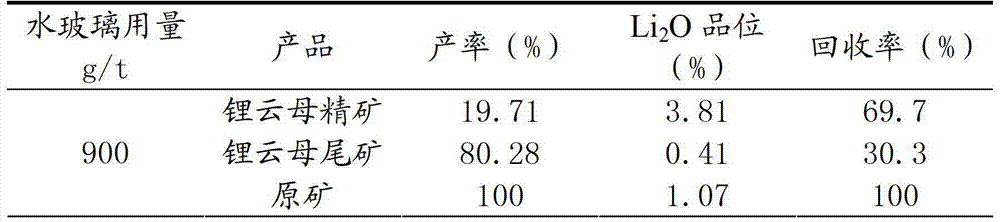

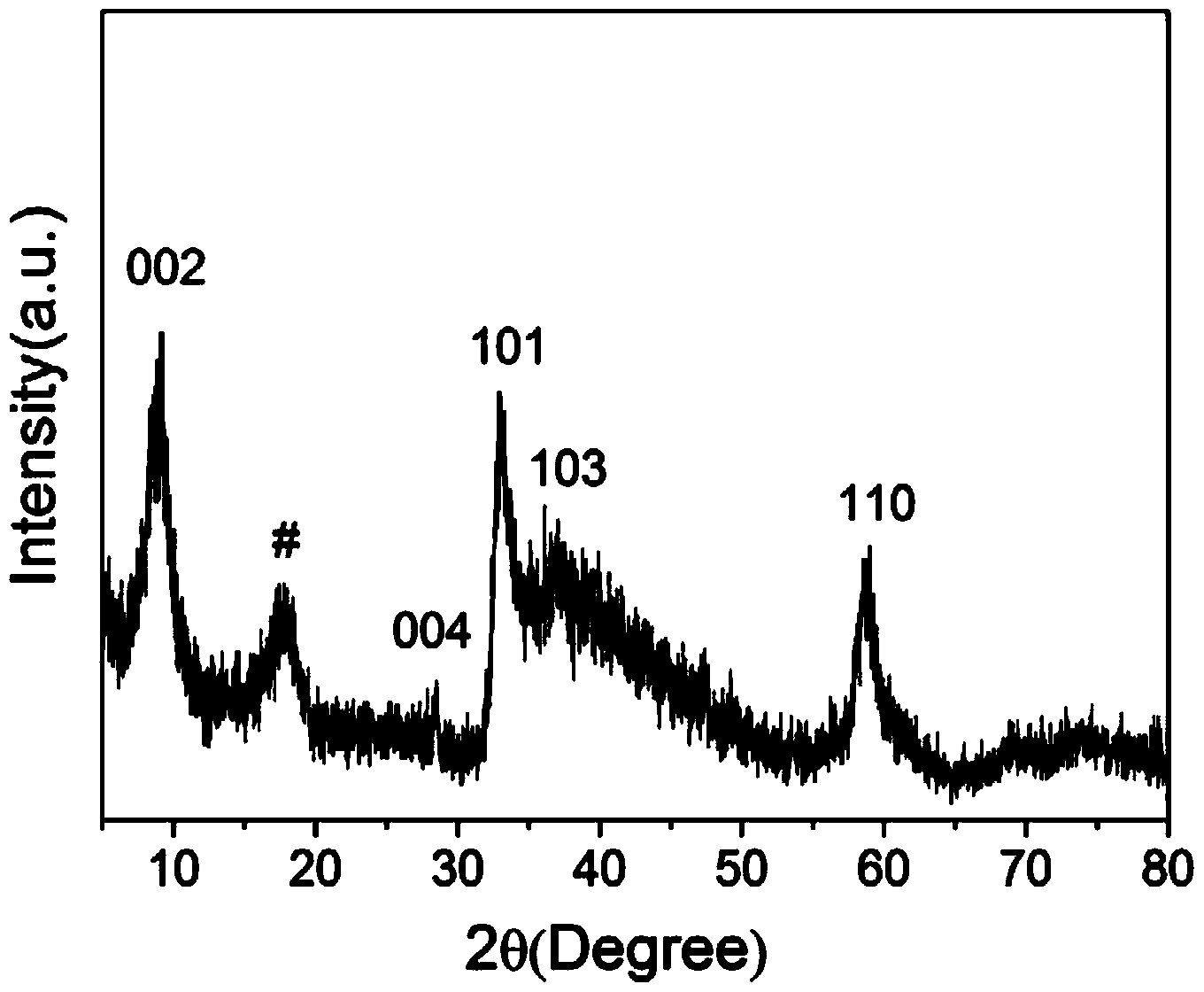

The invention discloses a novel lepidolite flotation method including primary rough selection, secondary fine selection and secondary scavenging. During the flotation, sodium silicate is added as an inhibitor with the amount ranging from 1400g / t to 1900g / t; an anionic collector is sodium oleate or oxyparaffin soap 731 with the amount ranging from 480g / t to 700g / t; and a cationic collector is dodecylamine or coconut oil amine with the amount ranging from 130g / t to 160g / t. The adding sequence of collectors is the anionic collector first and the cationic collector second, or the anionic collector and the cationic collector are added together. By the method, the lepidolite is selected through the combination of the anionic and the cationic, good flotation effect can be realized, flotation efficiency is high, and meanwhile, the synergistic effect is generated between the anionic collector and the cationic collector, and results from joint action of three mechanisms of coadsorption, charge compensation and function complementation.

Owner:JIANGXI UNIV OF SCI & TECH

Low-irritation and high-foaminess fancy soap formula

The invention discloses a low-irritation and high-foaminess fancy soap formula, which is composed of the following components by mass percentage: 2%-10% of alpha-lauryl betaine ampholytic surfactant, 20%-30% of coconut oil sodium salt, 50%-70% of sodium palmitate, 2%-5% of sorbic alcohol, 0.1%-1.5% of antioxidant, 0.05%-0.15% of Kathon, 0.05%-0.2% of chelant, 0.5%-1% of titanium white powder, 0.5%-1.0% of essence and water (the rest). In the fancy soap, the alpha-lauryl betaine ampholytic surfactant is used as additive, which can reduce the irritation of the fancy soap taking the normal sodium soap as the soap base and improve the foaminess of the fancy soap.

Owner:JIANGNAN UNIV +1

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

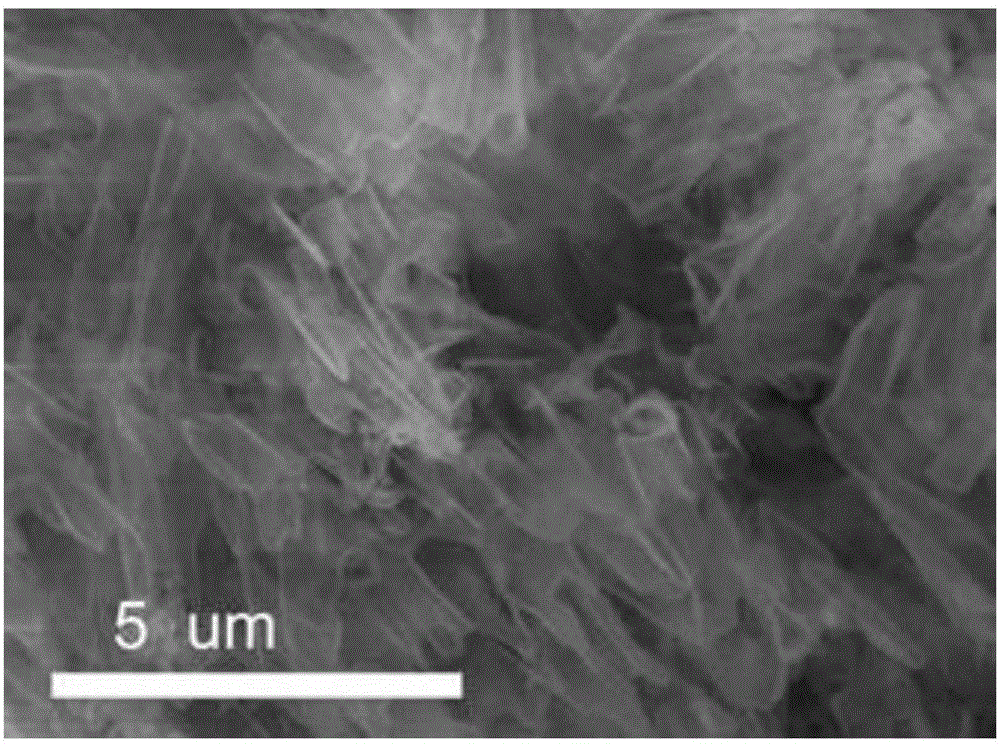

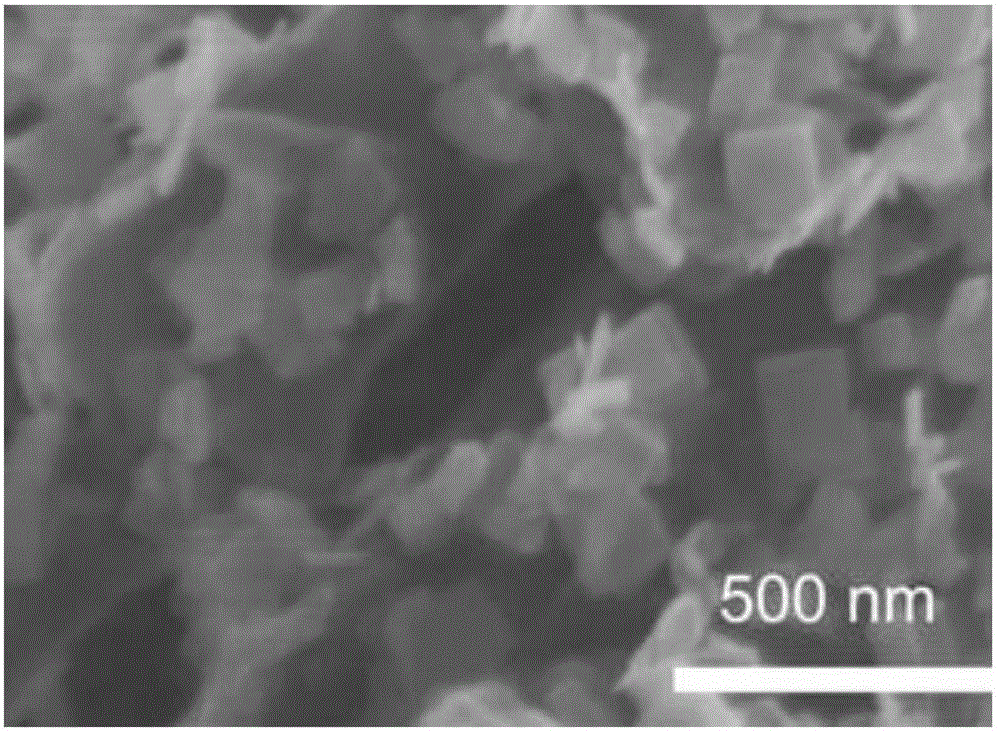

Molybdenum disulfide/mesoporous carbon composite electrode material as well as preparation method and application thereof

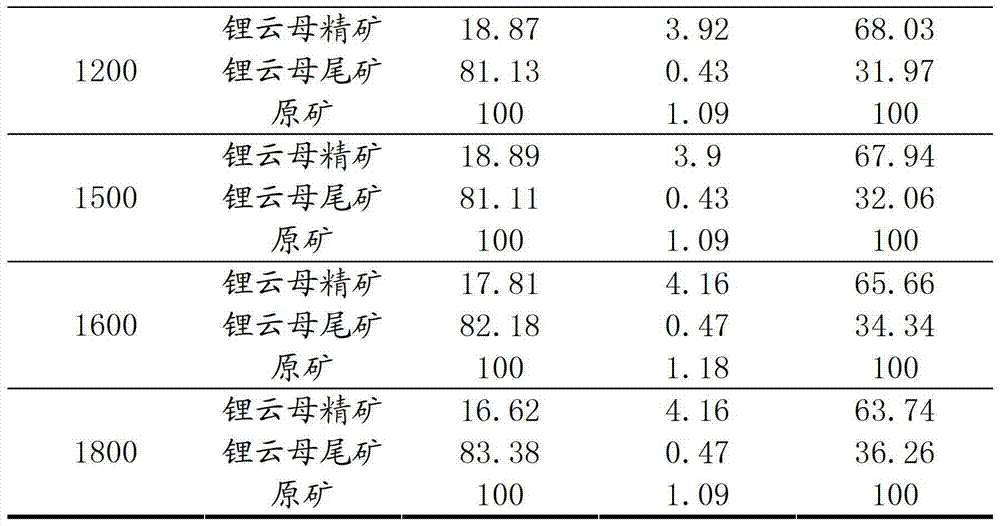

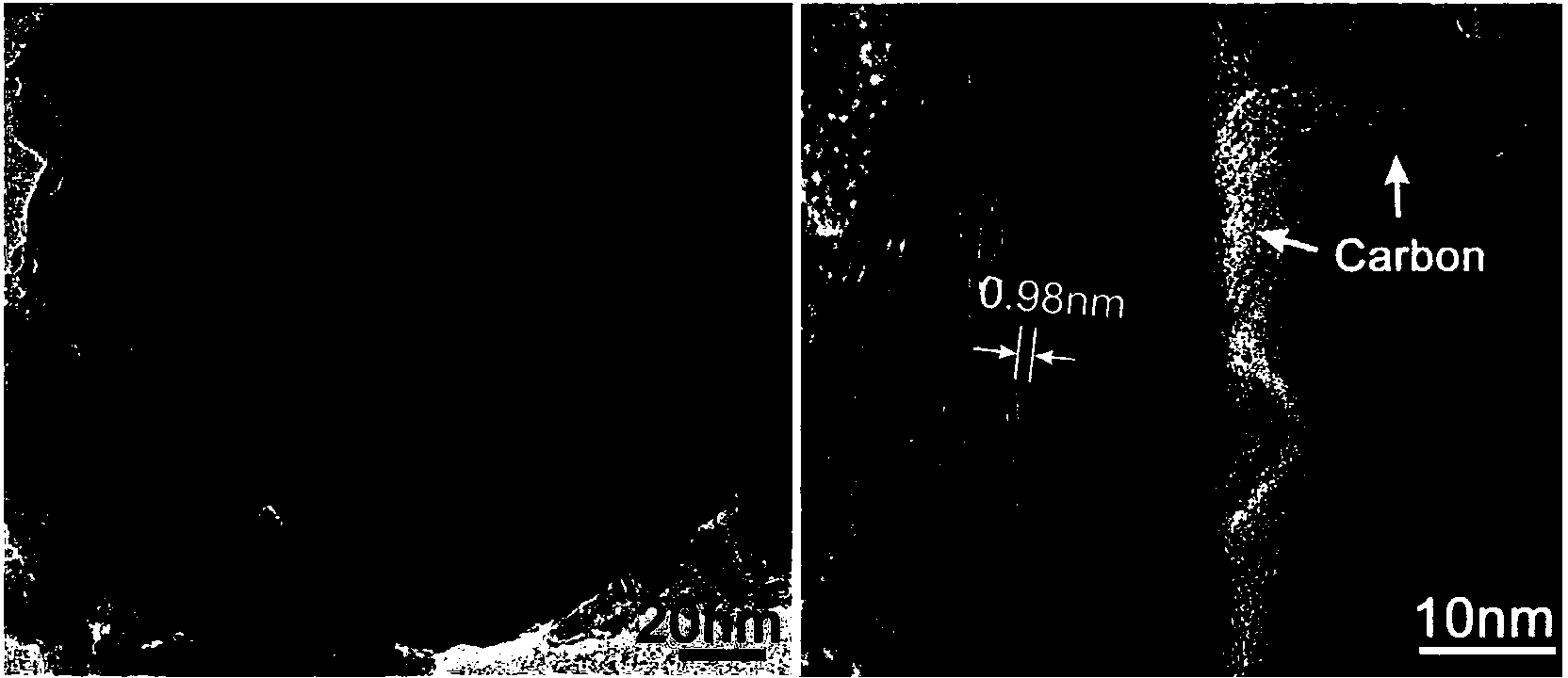

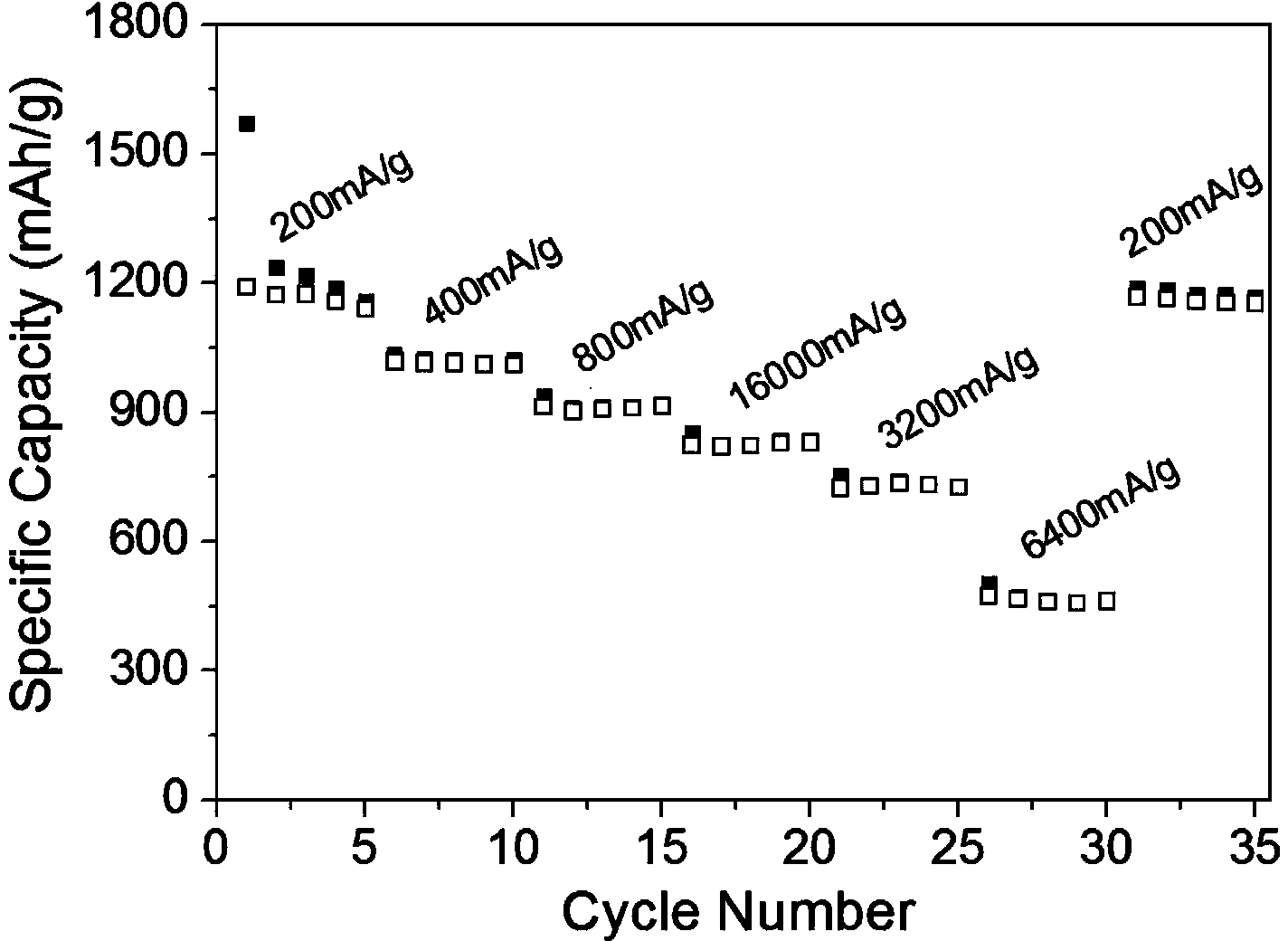

ActiveCN103915630AImprove the utilization rate of electrochemical activityIncrease spacingCell electrodesSecondary cellsChemical reactionThiourea

The invention discloses a molybdenum disulfide / mesoporous carbon composite electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing an oleic acid molecule intercalation molybdenum disulfide precursor through a hydrothermal reaction by adopting oleic acid and sodium oleate as a structure-directing agent and sodium molybdate and thiourea as a molybdenum source and a sulfur source; introducing dopamine into an interlayer by virtue of a chemical reaction of dopamine and oleic acid molecules; self-polymerizing molybdenum disulfide interlayer dopamine to form poly(dopamine) by adopting a tri-block copolymer, polyoxyethylene-polypropylene oxide-polyxyethylene, as a soft template, and then performing a high-temperature carbonization process to prepare the mesoporous carbon-embedded molybdenum disulfide interlayer nano hybrid material. By embedding mesoporous carbon, not only can the interlayer distance of molybdenum disulfide be increased and the re-accumulation of nano-sheets be effectively prevented, but also the electronic conductivity of molybdenum disulfide can be remarkably improved. An electrochemical test result proves that as a lithium ion battery negative material, the molybdenum disulfide / mesoporous carbon composite electrode material has high specific capacity, excellent rate performance and excellent cycling performance, and can be widely applied to the field of lithium ion batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

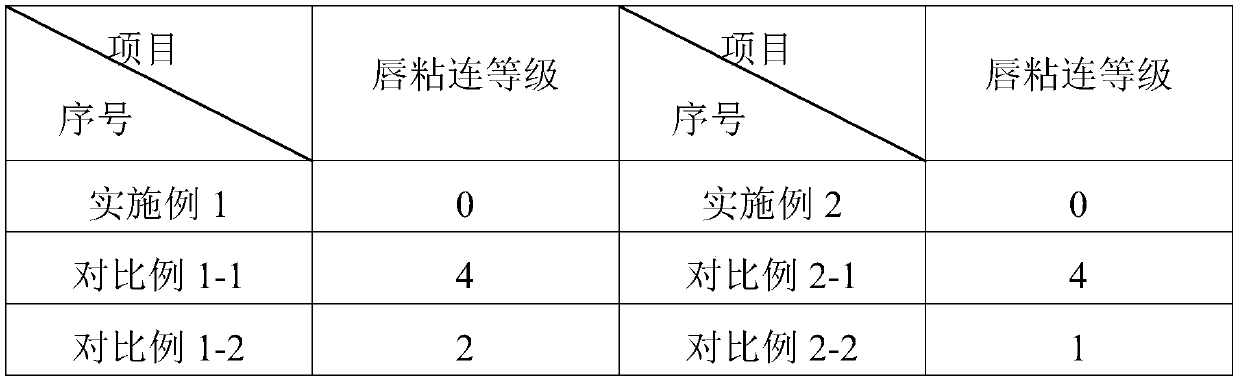

Cigarette tipping paper resistant to lip adhesion

InactiveCN110747691AImprove hydrophobicityImprove water resistanceCoatings with pigmentsSpecial paperPolymer sciencePolymer chemistry

The invention discloses cigarette tipping paper resistant to lip adhesion. The paper comprises a tipping base paper layer, a coloring layer and a varnish layer, the coloring layer is formed by dry coating of lip adhesion resistant alcohol-soluble ink, and the varnish layer is formed by dry coating of water-based lip adhesion resistant varnish; and an anti-sticking auxiliary agent is respectively added into the alcohol-soluble ink and the water-based varnish, and the anti-sticking auxiliary agent is prepared by mixing diatomite, sodium oleate or a hydroxypolysiloxane copolymer. The cigarette tipping paper resistant to lip adhesion provided by the invention has excellent hydrophobic and water-resistant properties, and can effectively prevent an occurrence of lip adhesion of a cigarette filter and improve the quality of cigarette products, and the preparation method is simple and environmentally friendly.

Owner:CHINA TOBACCO YUNNAN IND

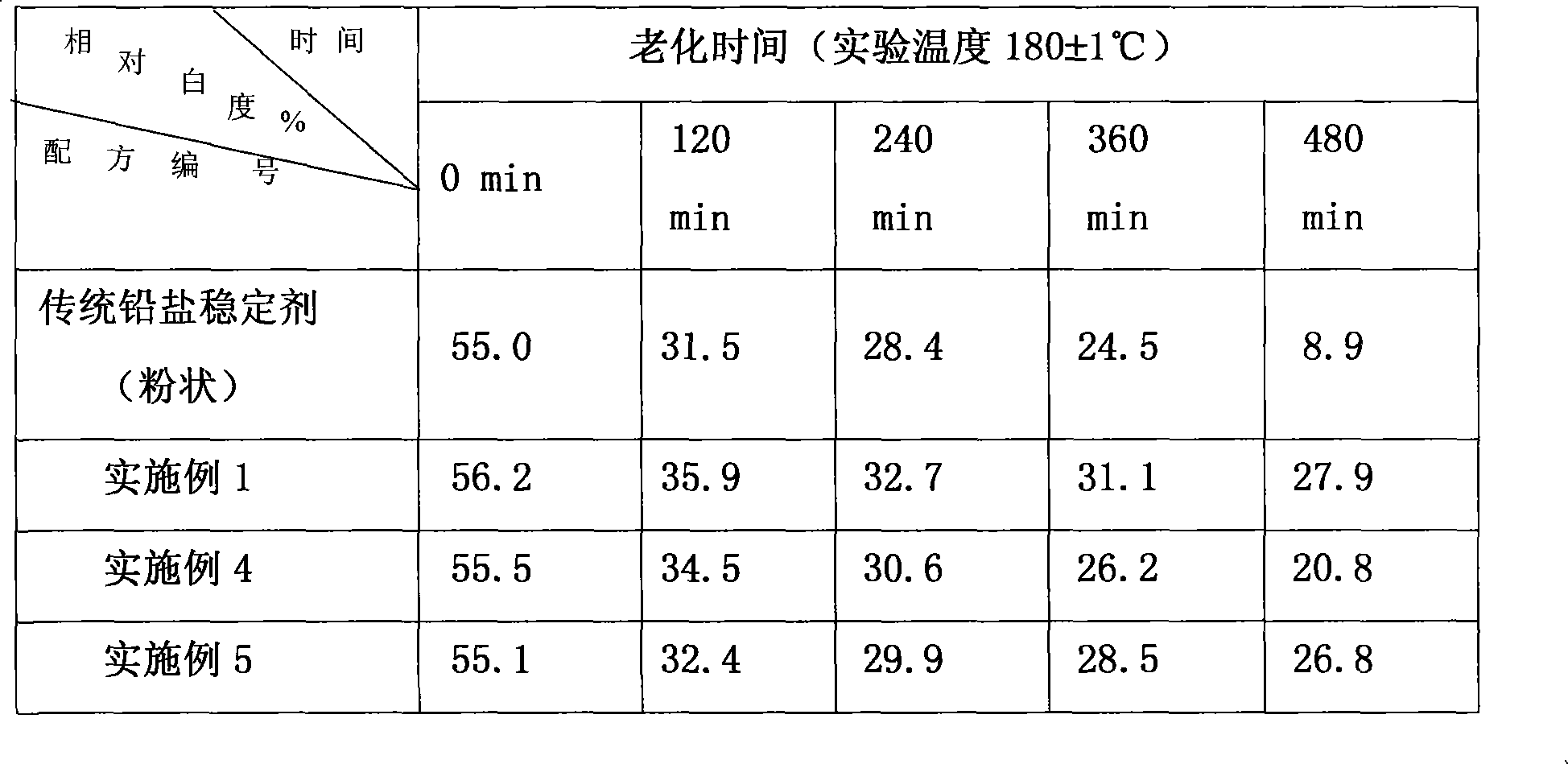

Composite heat stabilizer for hydrophobic nano-hydrotalcite PVC and preparation method thereof

The invention relates to a composite heat stabilizer for hydrophobic nano-hydrotalcite PVC, comprising the following raw materials according to the mass percent: 30-50 of calcium stearate, 10-20 of zinc stearate, 10-30 of hydrophobic nano-hydrotalcite, 5-15 of lubricant, 4-7 of surface modifier and 5-15 of auxiliary heat stabilizer. With the method of coprecipitation, the hydrophobic nano-hydrotalcite is added with eunatrol to prepare hydrophobic nano-hydrotalcite including Mg and Al with the mol ratio of 2-3:1. The nano-hydrotalcite prepared by the invention has good hydrophobic nature. Good compatibility with a PVC basal body can be achieved if the nano-hydrotalcite is used in a composite heat stabilizer for PVC. Advantages of difficult precipitation and good stabilizing effect can be achieved when the nano-hydrotalcite is used as a stabilizer for plastic processing of PVC, and the like. The addition of the hydrophobic nano-hydrotalcite can reduce the balance torque, improve the processing property and reduce the cost. The preparation method causes no pollution and has low energy consumption.

Owner:慧科高新科技股份有限公司

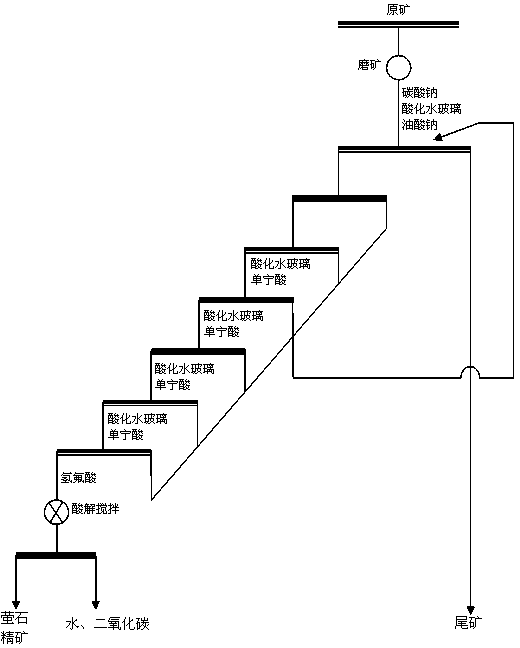

Beneficiation method of high calcium carbonate content type fluorite ore

The invention relates to a beneficiation method of high calcium carbonate content type fluorite ore and belongs to the field of beneficiation. The beneficiation method comprises the steps of conducting flotation, wherein ore grinding is conducted on the high calcium carbonate content type fluorite ore until the fluorite ore with the granularity smaller than 74 microns accounts for 78%-92% firstly, secondly, sodium carbonate serving as a pulp regulator, acidized sodium silicate serving as a gangue inhibitor and sodium oleate serving as a catching agent are added in sequence, and then a fluorite rough concentrate is obtained; conducting concentration six times, wherein concentration is conducted on the fluorite rough concentrate obtained through the last step six times, acidized sodium silicate serving as a gangue inhibitor and tannin are added in sequence every time concentration is conducted from the third time to the sixth time, and a fluorite concentrate pulp is obtained after concentration is conducted six times; conducting acid leaching, wherein the fluorite concentrate pulp obtained from the last step is concentrated, hydrofluoric acid is added, the fluorite concentrate pulp and the hydrofluoric acid are evenly mixed, leaching is conducted, and a high-grade fluorite concentrate can be obtained after liquid-solid separation. By the adoption of the beneficiation method, the beneficiation effect is good and the recovery rate of fluorite is high.

Owner:KUNMING UNIV OF SCI & TECH

Method for recycling carbon and electrolytes from waste cathode carbon block of aluminum electrolytic cell

InactiveCN105821445AReduce dosageReduced dosage of chemicals (reduced amount of collectorElectrolysis componentsCalcium/strontium/barium fluoridesKeroseneFuel oil

The invention discloses a method for recycling carbon and electrolytes from a waste cathode carbon block of an aluminum electrolytic cell. The method comprises the following steps that 1, the cathode carbon block is crushed and grinded; 2, cathode carbon powder obtained from the cathode carbon block subjected to crushing and grinding in the step 1 is stirred and leached in alkali liquor and then filtered, so that a filter cake A1 and filtrate B1 are obtained; and a precipitating agent is added into the filtrate B1, so that a filter cake A2 and filtrate B2 are obtained after filtering is conducted; and 3, the filter cake A1, the filter cake A2, a flotation medium and flotation reagents are subjected to mixing and pulp conditioning, and thus the carbon and electrolytes are obtained through flotation and separation; the flotation reagents comprises the collecting agents, the foaming agents and the conditioning agents; the collecting agents are composed of the collecting agent C1 and the collecting agent C2 at the mass ratio of 0.65-0.75:0.25-0.35; the collecting agent C1 is selected from at least one of coal tar, heavy oil, kerosene and diesel oil; and the collecting agent C2 is selected from at least one of dodecylamine, sodium dodecyl benzene sulfonate, sodium oleate and sodium dodecyl sulfate. According to the method for recycling the carbon and the electrolytes from the waste cathode carbon block of the aluminum electrolytic cell, the carbon powder and the electrolytes are effectively separated and recycled from the waste cathode carbon block.

Owner:CENT SOUTH UNIV

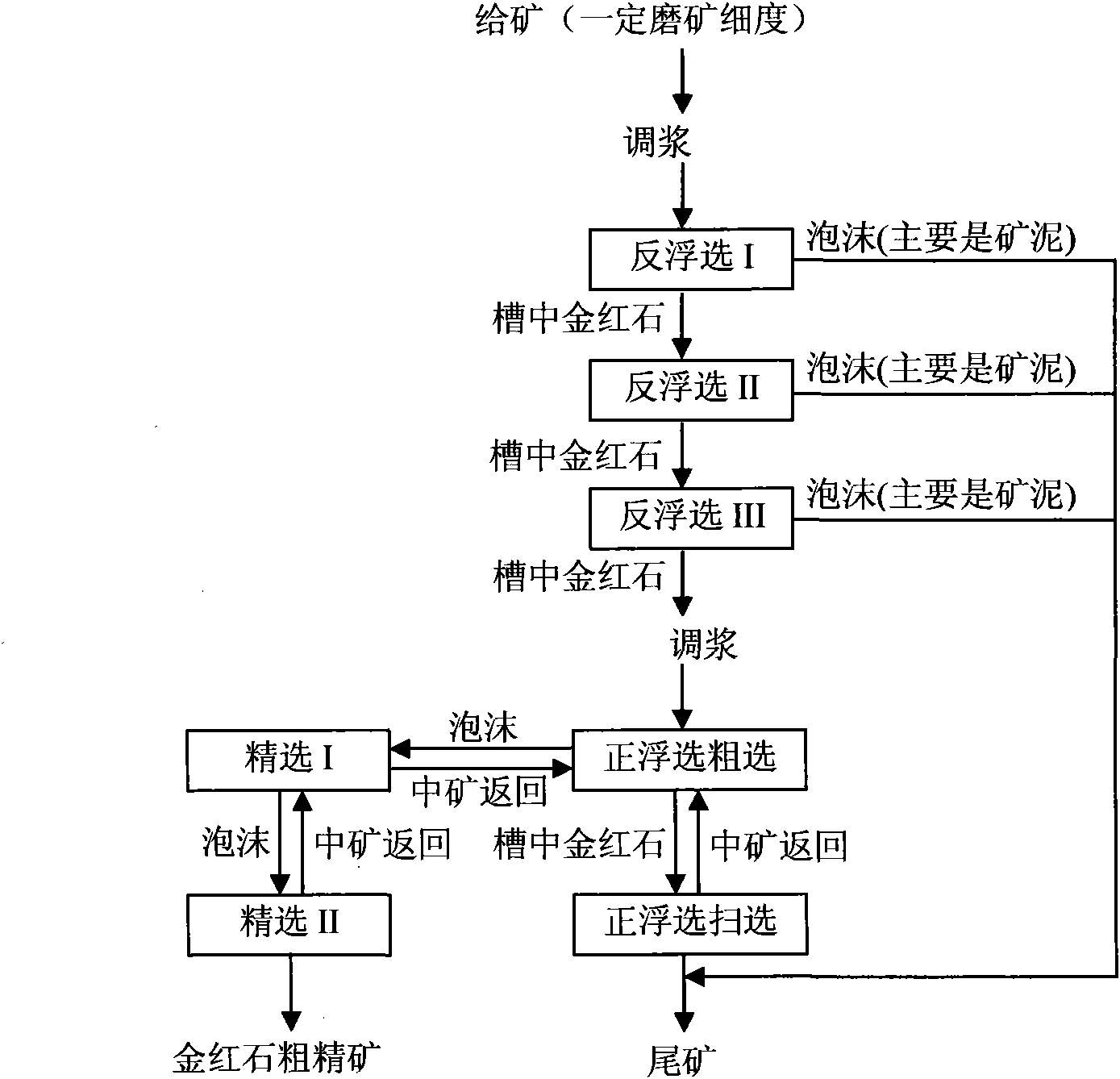

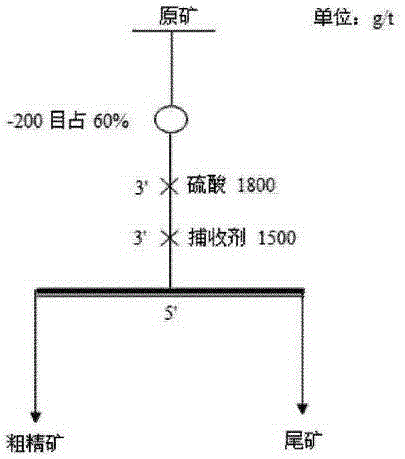

Method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation

The invention provides a method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation, relating to the technique for roughing and tailings-discarding of fine rutile ore by multi-stage floatation and belonging to the technical field of mineral processing engineering. The method of the invention comprises the following steps: firstly, conducting the reverse floatation of rutile by using sodium oleate as a collector according to the characteristics that aluminum sulfate can inhibit the rutile and activate silicate minerals in varying degrees, so as to effectively deslime in the process of reverse floatation; and then, conducting the forward floatation of rutile by using lead nitrate (or lead acetate) as an activator of rutile and using sodium alkyl hydroxamate and benzyl arsonic acid (or styryl phosphonic acid) as a combined collector according to the characteristic that gangue minerals can be inhibited on a combined basis under the synergistic action of sodium fluorosilicate, carboxymethylcellulose and the residual aluminum sulfate in the ore pulp, briefly, the method of the invention can realize the roughing and tailings-discarding of fine rutile by the multi-stage floatation comprising the following steps: firstly, conducting the reverse floatation by inhibiting the rutile; and then, conducting the forward floatation by activating the rutile. The method of the invention has the advantages that the enrichment ratio and recovery rate of rutile are high, the tailings of rutile ore can be discarded thoroughly and the mineral processing cost of rutile can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

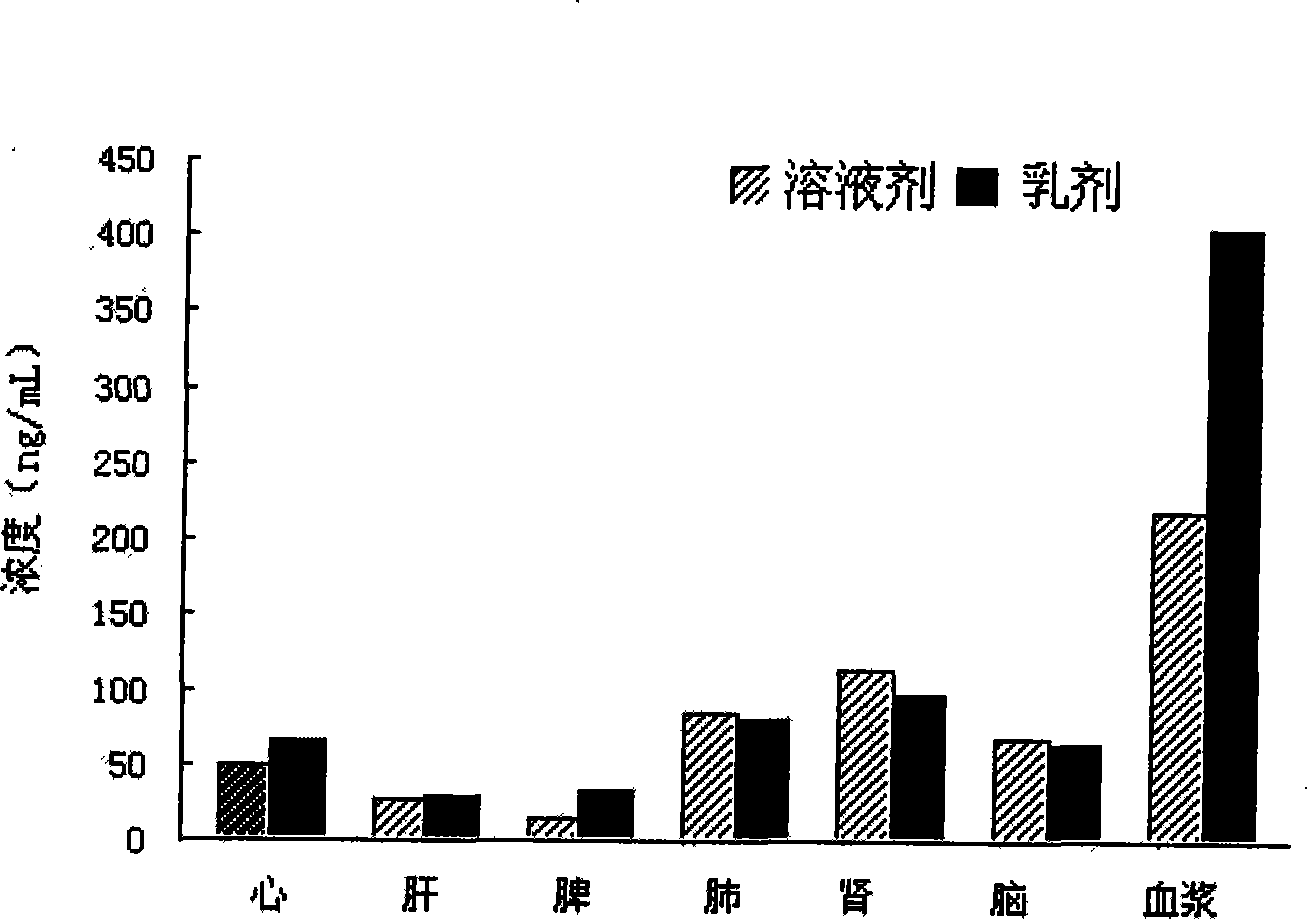

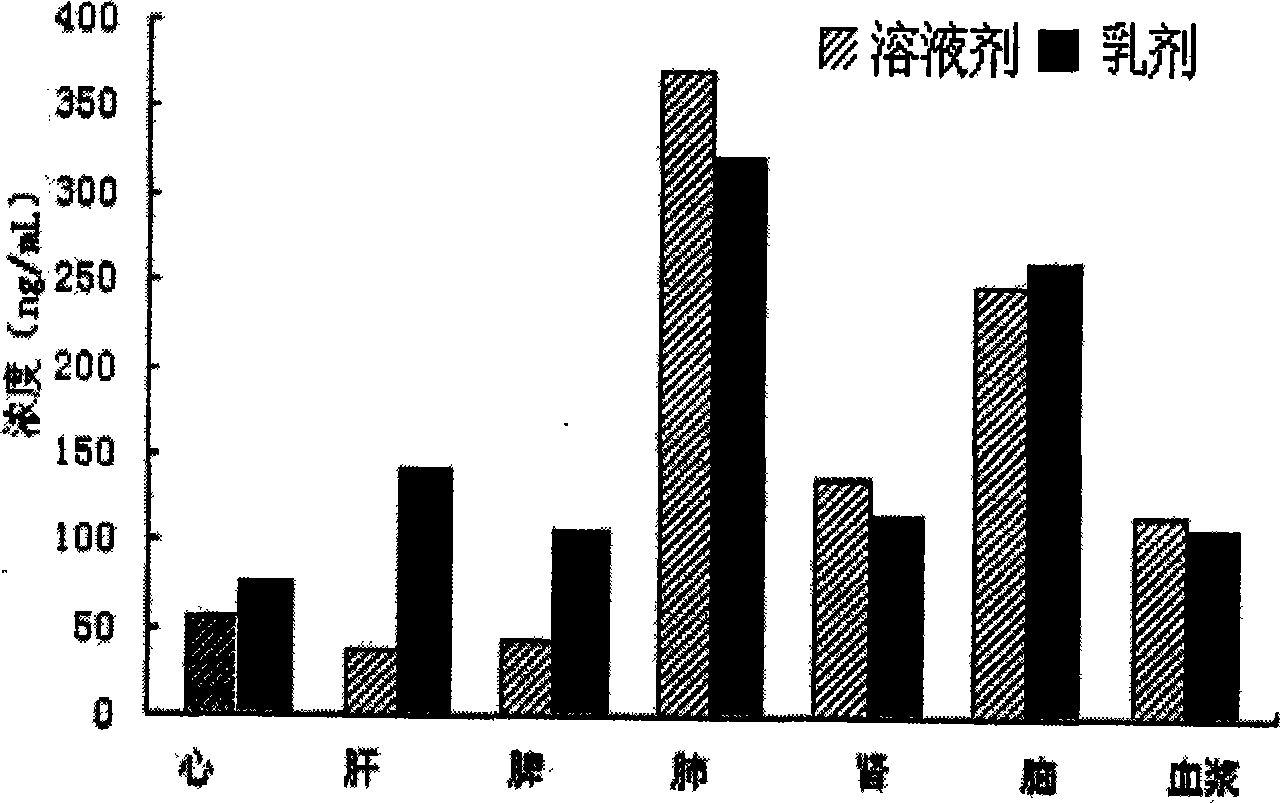

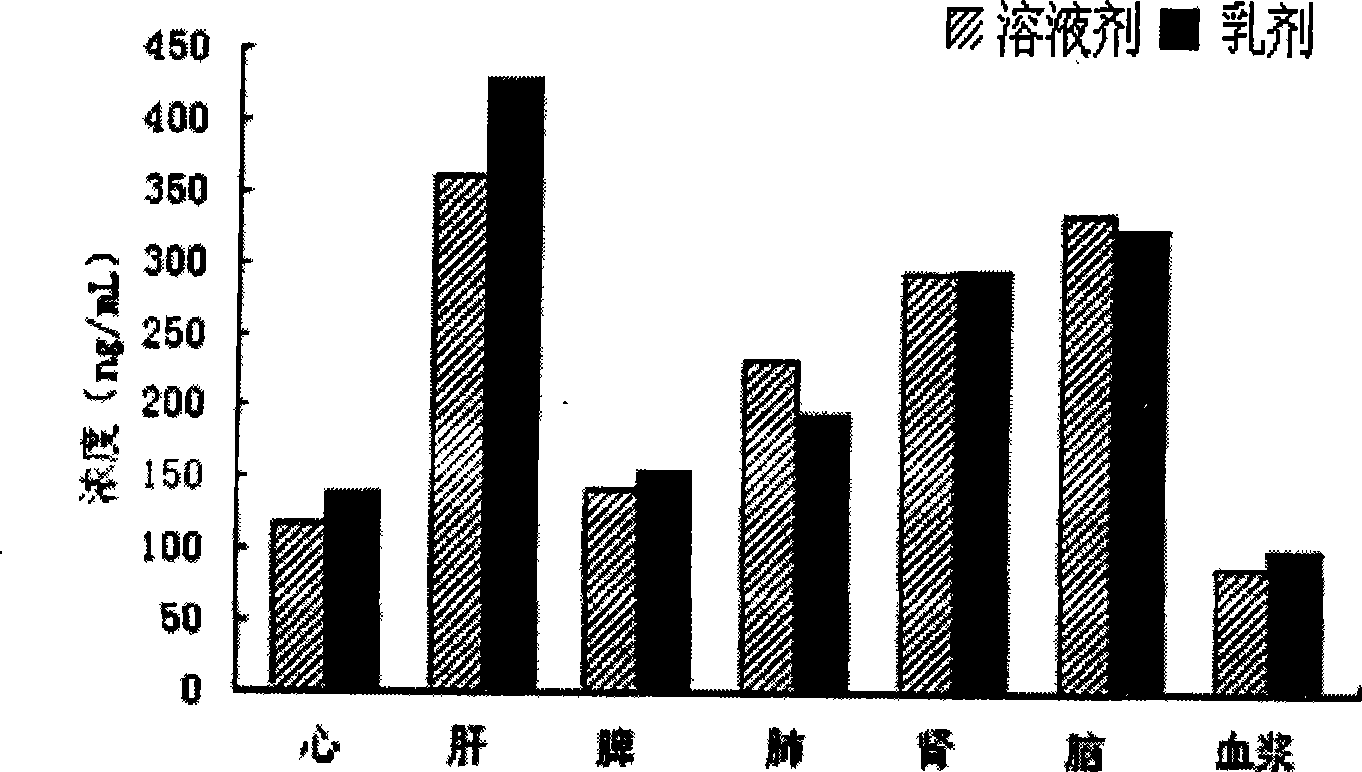

Fat emulsion injection liquid containing soybean oil, medium chain triglyceride, olive oil and fish oil and method for preparing the same

InactiveCN1965806AAvoid exhaustionImprove the outcome of standard clinical treatmentsOrganic active ingredientsMetabolism disorderYolkFish oil

The invention relates to an intralipid injection which contains soya oil, middle chain triglyceride, olive oil, and fish oil, wherein it comprises 48-72g.L soya oil, 48-72g / L middle chain triglyceride, 40-60g / L olive oil, and 24-36g / L fish oil, 108-162 mg / L dl-alpha-tocofecol, 9.6-14.4g / L lipovitellin, 22.5-27.5g / L pure glycerin, 240-360mg / L sodium oleate, 18-22mg / L caustic soda, and 1L injection water. The ratio between w-6 and w-3 aliphatic acid is 3.0-2.2:1. The invention optimizes and balances the aliphatic acid mode.

Owner:费森尤斯卡比华瑞制药有限公司

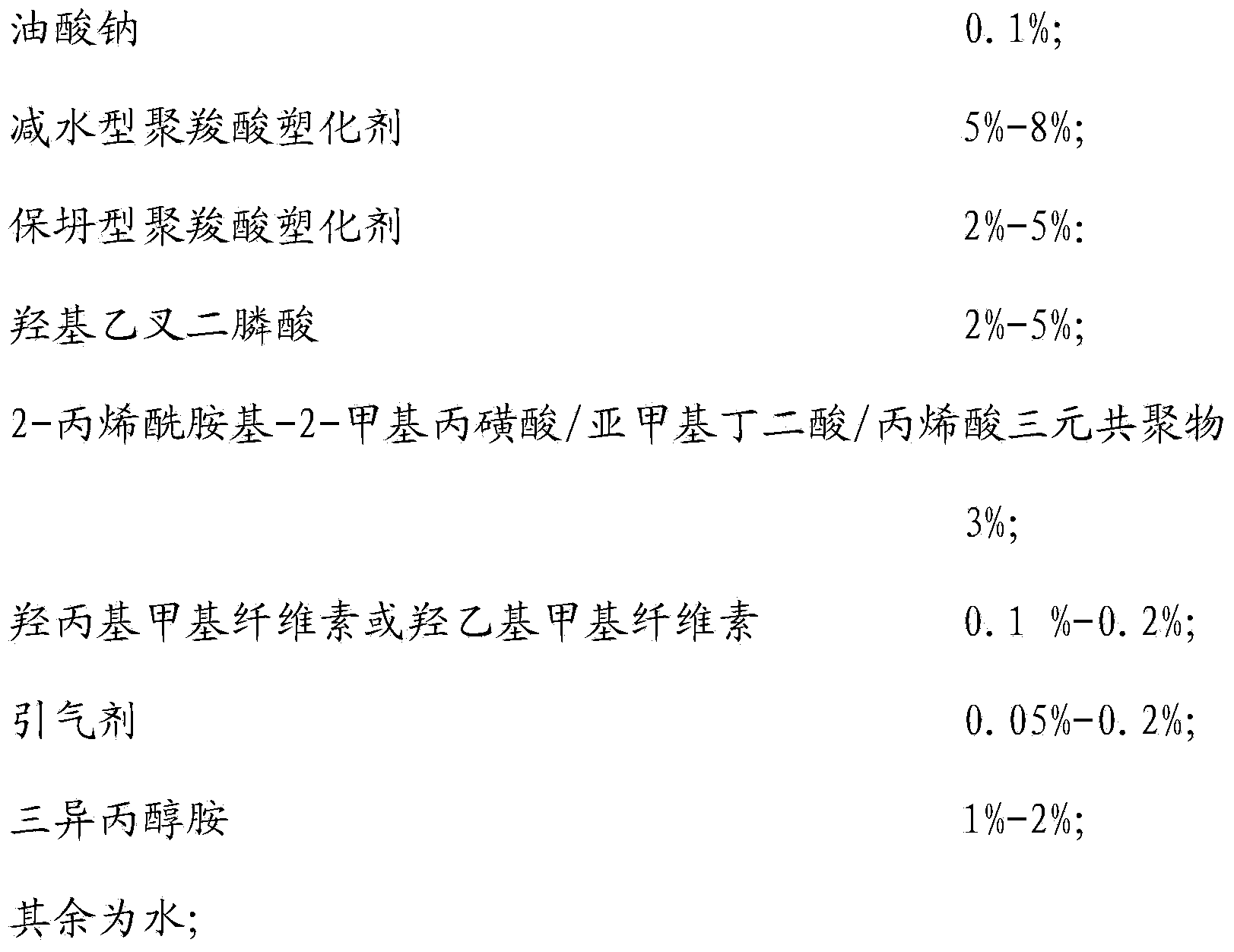

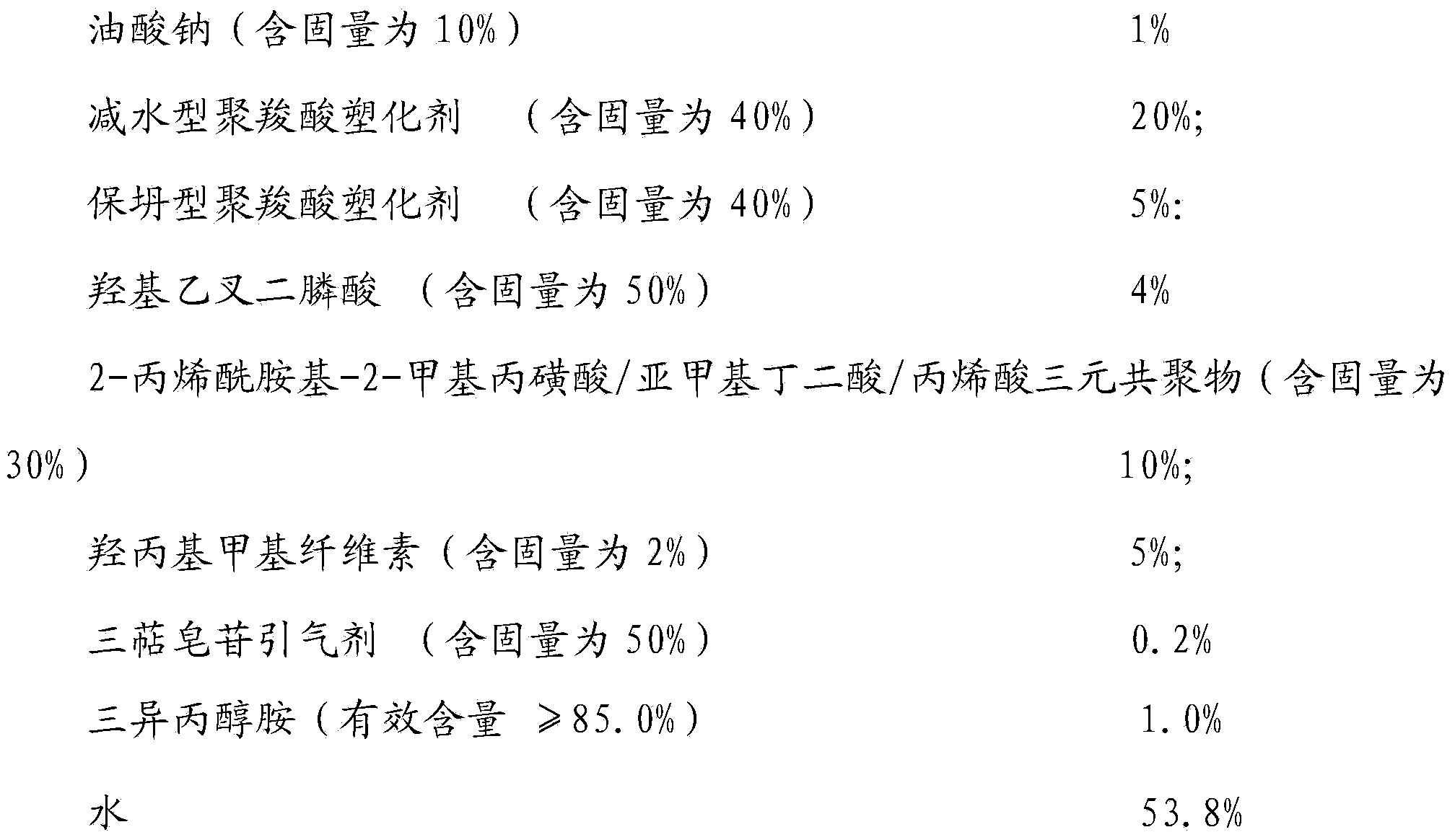

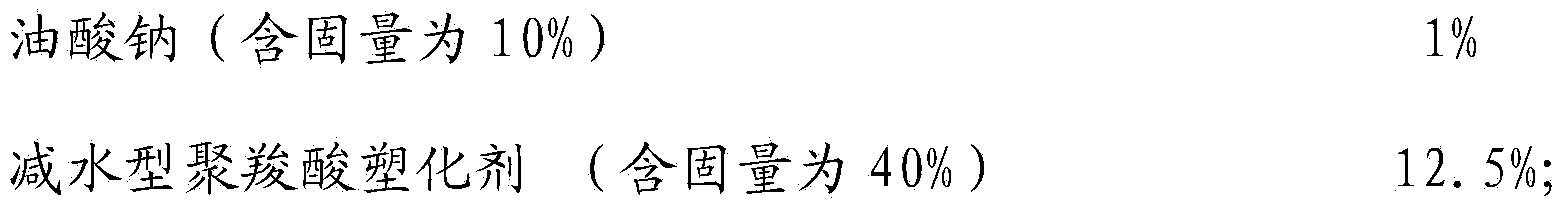

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

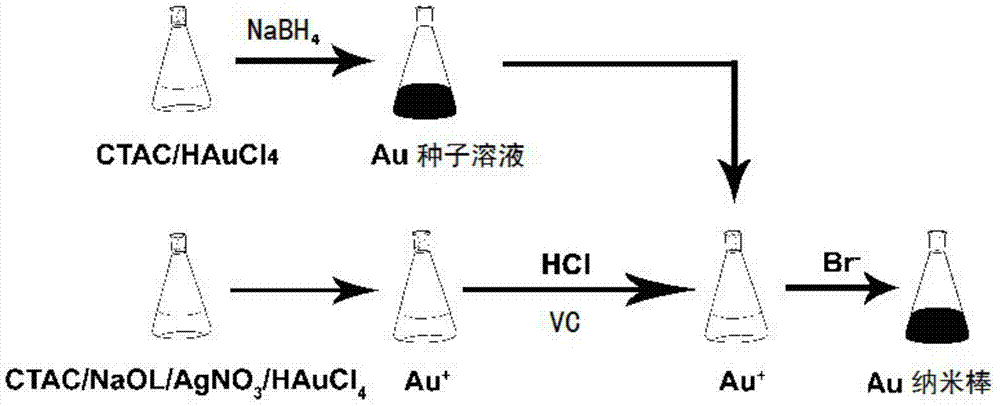

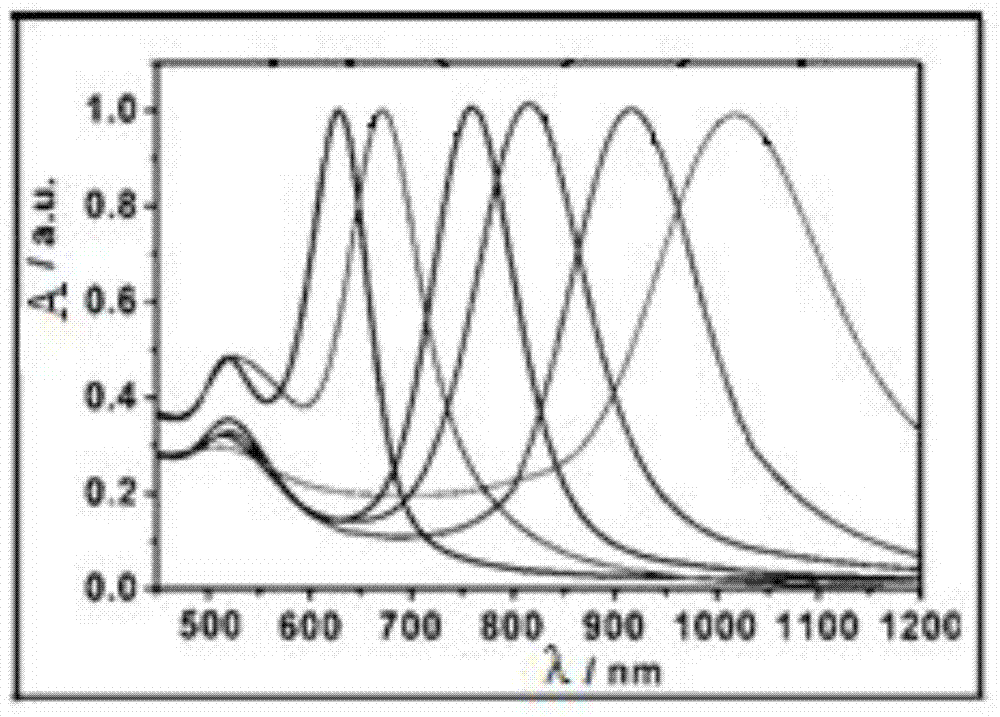

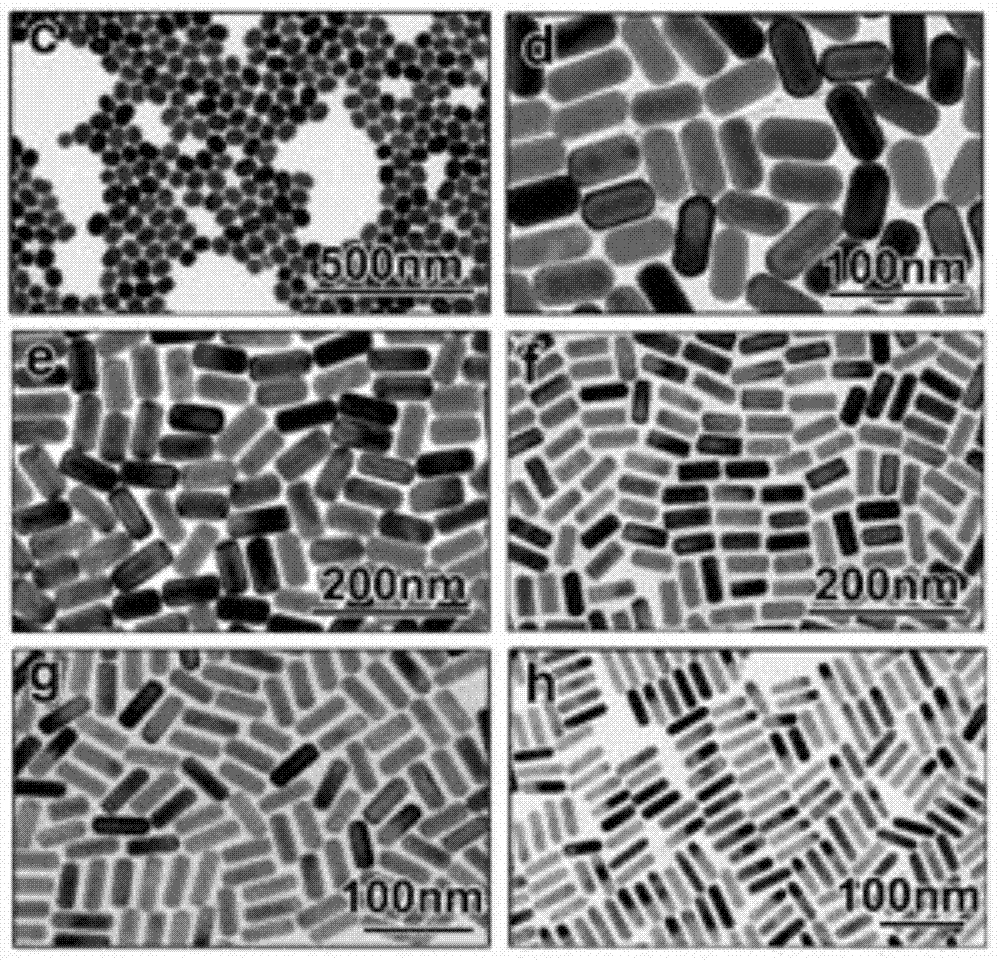

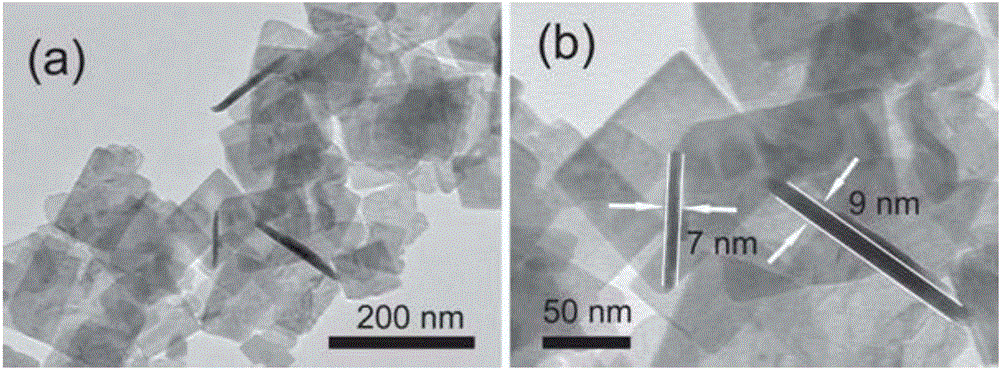

Method for rapidly preparing gold nanorod

The invention discloses a method for rapidly preparing a gold nanorod, which belongs to the technical field of a nano material, and solves the problem that the existing gold nanorod seed induction growth method is long in consumed time. The method is characterized in that cationic surface active agent chloride quaternary ammonium salt is used as a protective agent, gold seeds which are obtained by reducing sodium borohydride through the reducing agent sodium oleate, ascorbic acid are added into a chloroauric acid solution under the assistant effect of ions and silver ions to obtain gold nanorods. According to the method, the synthesis of the gold nanorods can be completed in 15 minutes, so that not only can the synthesis time of the gold nanorods be greatly shortened and a material base be provided for the real application of the gold nanorods, but also the yield of the gold nanorods is high, and fewer spherical particles exist.

Owner:SUZHOU UNIV

Non-sulfide mineral flotation collector, preparation method thereof and application thereof

The invention discloses a non-sulfide mineral flotation collector, a preparation method thereof and an application thereof, and belongs to the technical field of mineral flotation collectors. The non-sulfide mineral flotation collector is obtained by mixing phosphoric acid-2-ethylhexyester or / and 2-ethylhexyl phosphoric acid-2-ethylhexyl ester and sodium oleate or oxidized paraffin soap and the like for use. The non-sulfide mineral flotation collector has the characteristics of good water solubility, good dispersion, strong selective adsorption capacity on target minerals and the like, and is mainly used for floatation separation of useful minerals in ilmenite, scheelite, wolframite, phosphorite, bauxite, rare earth ores, tin ores, fluorite mines or manganese carbonate ores. The preparation method for the non-sulfide mineral flotation collector is simple in process, easy to control in operation, wide in raw material source, low in cost, safe and environmentally-friendly, high in product recovery rate, and easy to realize industrial production.

Owner:河南天鸿新材料科技有限公司

Prepn process of nanometer granular Fe3O4

InactiveCN1421392AReduce dispersionIncrease the areaFerroso-ferric oxidesSal ammoniacOrganic solvent

The preparation process of nano granular Fe3O4 includes the steps of: dropping ammonia water to mixed FeCl3 and FeCl2 solution in protective N2 environment for reaction while high speed stirring; separating Fe3O4 grains and washing with distilled water to eliminate excessive grains, setting the washed Fe3O4 grains into distilled water, adding acid to regulate pH to 1-4, adding anionic surfactant in 0.2-4 % to react under ultrasonic stirring, separating and washing Fe3O4 grains and setting Fe3O4 grains in organic solvent. During the process metal ion may be added in the first step and the anionic surfactant is sodium oleate, sodium dodecyl benzene sulfonate, etc. The prepared Fe3O4 grains have good dispersivity and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

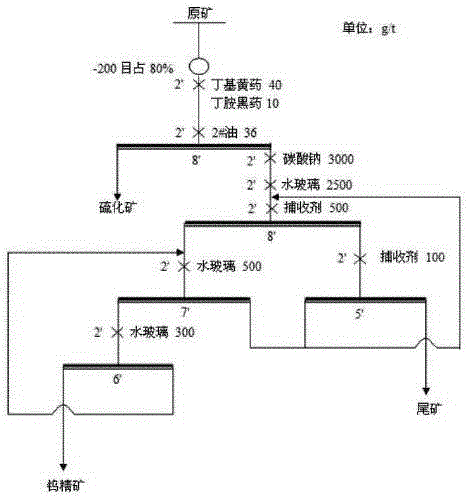

Flotation method of low ore grade manganous carbonate ore

The invention relates to a process that raw mine is ground into powder which is added with water to be prepared into pulp. Under certain pH value, inhibitor of carboxymethylcellulose nano solution, industrial water glass and tannin solution are added proportionally for absorbing calcium, magnesium and silicate. Then, sodium oleate is added as a collector for closed circuit circulation floating. Foam products after the floatation are flushed by water and then enter a sedimentation tank for the sedimentation or the pressure filtration. Thus, manganese concentrate fines above 20 percent are obtained. In the process, floatation is implemented on low grade poor manganese mine containing 10-14 percent of manganese, carbonaceous rock with the manganese content of 4-9 percent and electrolytic manganese leached slags with the manganese content of 1-3 percent to obtain manganese ore fines, the manganese content of which reaches above 20 percent. The recovery of manganese is more than 85 percent. And non-manganese emission for tailings can be realized. The manganese resources are lead to have extremely high utilization rate. Produced products can also lower acid consumption and ammonia consumption for electrolytic manganese production of downstream industry of manganese mines.

Owner:HUAYUAN QIANGHUA MINING

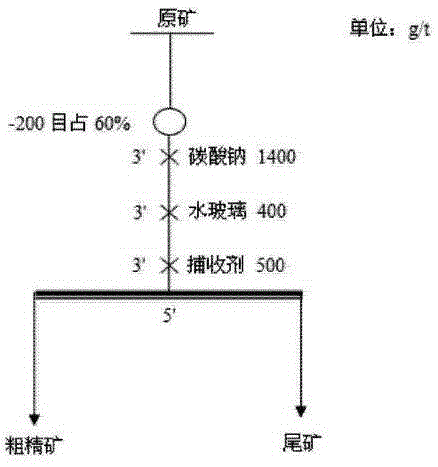

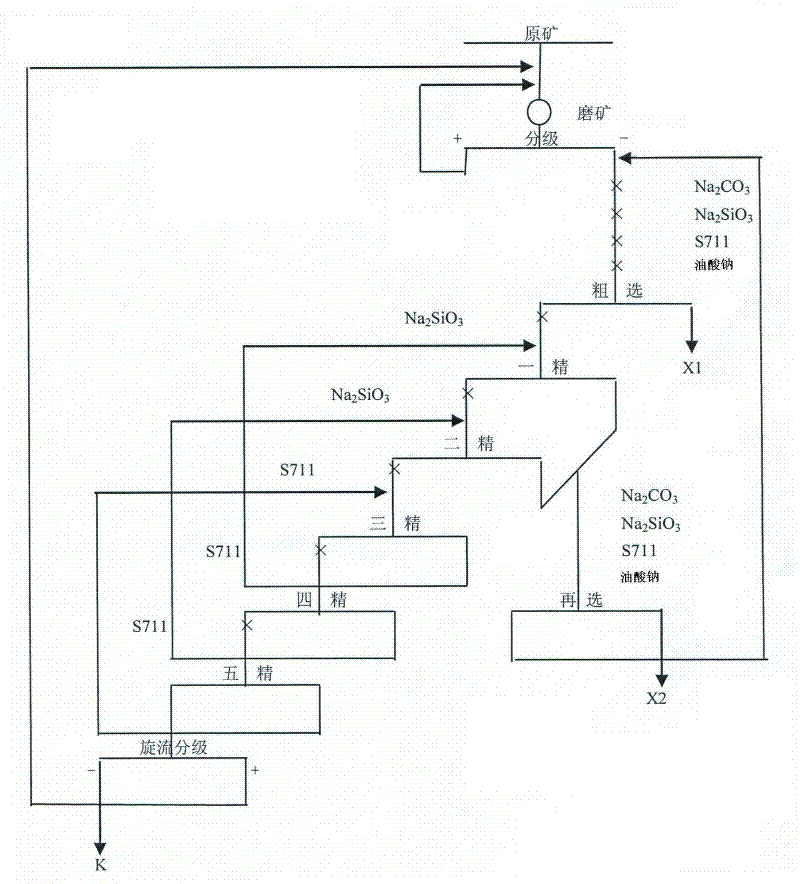

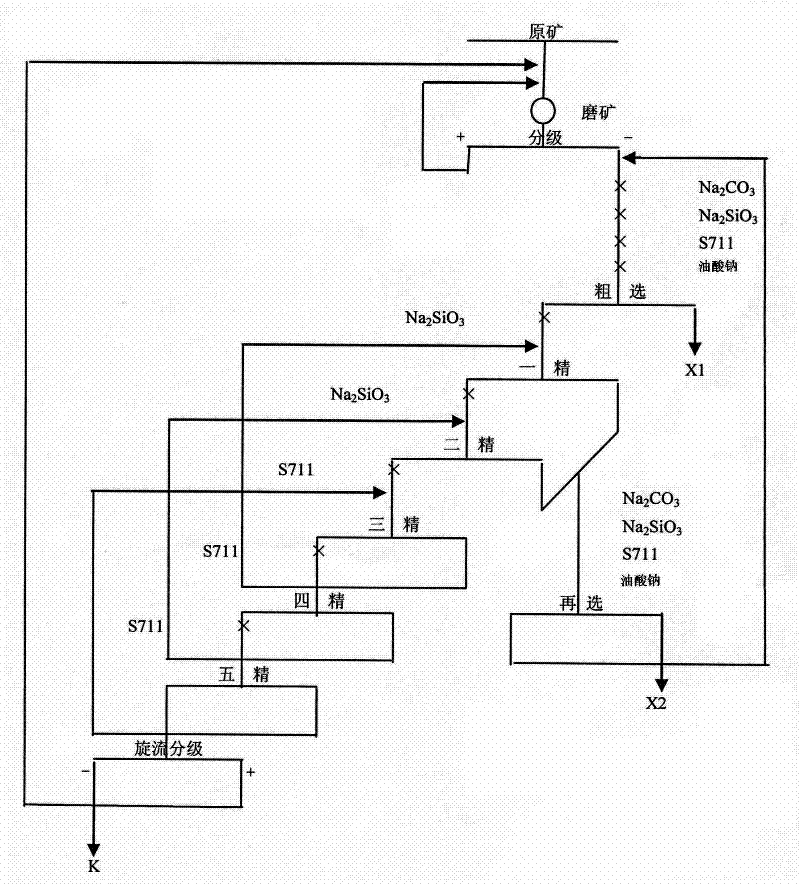

A kind of flotation enrichment process of siliceous-calcium type fluorite ore

The invention relates to a floatation and enrichment process for silicon-calcium mass type fluorite ores, which is characterized by comprising the following steps: dissociating the constituent mineral monomers of the silicon-calcium mass type fluorite ores by crushing and ore grinding, flowing into a stirring tank after adding water and regulating pulp, then adding a regulating agent of sodium carbonate, water glass, S711 and a collecting agent of sodium oleate into the ore pulp for regulating the pulp, roughing the material of which the pulp is regulated, selecting roughed foam for the firsttime, selecting the foam which is selected for the first time for the second time, combining a product in a primary selecting tank, i.e. middlings which are selected for the first time and a product in a secondary selecting tank, i.e. middlings which are selected for the second time, adding the regulating agent and the collecting agent of the sodium oleate, regulating the pulp, selecting the material of which the pulp is regulated again, returning the foam which is selected again for the roughing operation, selecting the foam which is selected for the second time for the third time until selecting for the fifth time, returning the middlings which are selected for the third time, the fourth time and the fifth time by adopting the separating operation, grading the foam which is selected forthe fifth time by a cyclone, overflowing the cyclone, concentrating and filtering to obtain a fluorite concentrate product. The process disclosed by the invention has the advantages of high separation efficiency, excellent process index, high quality of obtained fluorite concentrates and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Nimodipine lipid microsphere injection and preparation method thereof

ActiveCN101485632AImprove solubilityImprove stabilityOrganic active ingredientsNervous disorderSolubilityLipid formation

The invention provides a nimodipine lipid microsphere injection, which is prepared from the following components in percentage by weight: 0.08 percent of nimodipine, 0.5 to 2.3 percent of lecithin for injection, 2 to 8 percent of soybean oil for injection, 2 to 8 percent of medium chain fatty acid for injection, 1 to 3 percent of glycerin, 0.1 to 0.2 percent of tween-80, 0.03 to 0.05 percent of sodium oleic acid, and the balance being water for injection. The preparation method comprises steps of preparation of an oil phase, preparation of water phase, preparation of colostrum, homogenization and canning. In the nimodipine lipid microsphere injection, the soybean oil for injection and the medium chain fatty acid for injection are used to prepare the oil phase, the nimodipine is a fat soluble drug and can be better dissolved in the oil phase, the lipid microsphere in which the soybean oil for injection is the main component has solvent characteristics, is non-toxic, and can guide the fat soluble drugs to be dissolved in emulsion particles and perform the metabolism along with lipid oil drops and slowly release, thereby maintaining the effective blood concentration, lowering toxic and side effects of the drugs, increasing the solubility and stability of the nimodipine drug, improving the drug-loading rate and reducing the hydrolysis of the drugs.

Owner:沈阳信康药物研究有限公司

Process for metalworking fluid from heavy alkylate

InactiveUS20050215440A1Component is toxicHigh specific and latent heatWork treatment devicesLiquid carbonaceous fuelsMetalworking fluidVegetable oil

The process relates to composition of metalworking fluid and for its preparation based on heavy alkyl benzenes having 22 to 26 carbon atoms to replace mineral oil and process for the same. A process for heavy alkylate based less toxic metalworking fluid composition comprising of heavy alkyl benzene, one emulsifier which is a sodium oleate, sulfonate or mixtures thereof, a vegetable oil as lubricity booster, an antioxidant, a fungicide, an extreme pressure additive, an antirust, a co-surfactant, a coupling agent and alkali component. The process comprising of removing of insoluble matter from the heavy alkylate, addition of emulsifier, additives, coupling agent and co-surfactant, homogenizing the mixture at 20-120° C., followed by conditioning of the metal working fluid concentrate which can be used as emulsion in water.

Owner:COUNCIL OF SCI & IND RES

Method for preparing morphology and constitution controllable WO3 nano sheet/g-C3N4 nano composite material

InactiveCN106824248AImprove stabilityGood catalyticPhysical/chemical process catalystsWater/sewage treatment by irradiationNano compositesSodium tungstate

The invention discloses a method for preparing a morphology and constitution controllable WO3 nano sheet / g-C3N4 nano composite material, and belongs to the field of photocatalysts. The nano composite material is of a structure that WO3 nano sheets are uniformly distributed on layered g-C3N4 nano sheets. The nano composite material is simple in preparation process and is prepared by using a one-step method. The method comprises the following steps: by taking sodium oleate as a surfactant, firstly, dissolving the surfactant into a dilute nitric acid solution at certain temperature, adding g-C3N4, sufficiently dispersing the g-C3N4, slowly adding a sodium tungstate solution, and performing reaction for 120 minutes at 60 DEG C, thereby obtaining the WO3 nano sheet / g-C3N4 nano composite material. The nano composite material can be used as a photocatalyst for degrading MO, and has good catalysis effects and stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method and application of magnetic chitosan nanometer material

InactiveCN103861568AImprove adsorption capacityLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesWater bathsFerrous salts

The invention relates to a preparation method and application of a magnetic chitosan nanometer material which is used for removing phosphorus from treated phosphorus wastewater. The magnetic chitosan nanometer material can be used for removing phosphorus in industrial wastewater and domestic wastewater, thus facilitating purification of the environment. According to the technical scheme, the preparation method comprises the following steps: firstly soaking chitosan powder in a sulfuric acid solution, separating, washing, drying, and pounding into powder to obtain modified chitosan; subsequently preparing a mixed solution from ferrous salt and ferric salt, adding ammonia water under water bath till the pH is 11, stirring and reacting for 1 hour, adding a sodium oleate solution and reacting for 3 hours, separating and then washing, drying and grinding solid into fine powder so as to obtain nano ferroferric oxide; and finally preparing a chitosan acetate solution form the modified chitosan, then adding the nano ferroferric oxide, Span-80, liquid paraffin and a glutaraldehyde solution and reacting four 3-4 hours in the water bath, and then separating, washing and drying to prepare the magnetic chitosan nanometer material. By modifying the modified chitosan and the sodium oleate, the adsorption effect is improved by the method; the magnetic chitosan nanometer material is applicable to treatment of the industrial wastewater and the domestic wastewater.

Owner:SOUTHWEST PETROLEUM UNIV

Uniformly-coated non-lip-sticking base paper of tipping paper and preparation method thereof

ActiveCN104213461AUniform coatingGood flexibilityInorganic compound additionPhosphoric acidSoybean Phospholipids

The invention discloses a uniformly-coated non-lip-sticking base paper of tipping paper. The base paper is prepared from following raw materials, by weight, 110-125 parts of Korean pine pulp, 35-50 parts of juncus effusus pulp, 45-60 parts of wheat straw pulp, 0.6-0.8 parts of rosin, 0.8-1.2 parts of sodium oleate, 1-2 parts of cloves, 2-3 parts of peels of shaddocks, 0.7-1 part of sodium chloride, 1.5-2.5 parts of porous calcium phosphate, 2-3 parts of soybean phospholipids, 1-2 parts of isomaltulose, 1-2 parts of cassava starch and 3-4 parts of a mixed spice. The base paper is reasonable in formula, is healthy and toxic-free and is special in technology. The base paper is uniform in coating, is good in flexibility, is excellent in tensile strength and can increase an adsorption amount of tar. By means of the added sodium oleate, the base paper has a waterproof effect and is free from being stuck on lips. By means of the addition of the clove, the peels of the shaddocks and the mixed spice, the base paper is refreshing, pungent smoke and odor of a cigarette is improved, and mouth is maintained to be refreshing.

Owner:浙江恒成高分子材料股份有限公司

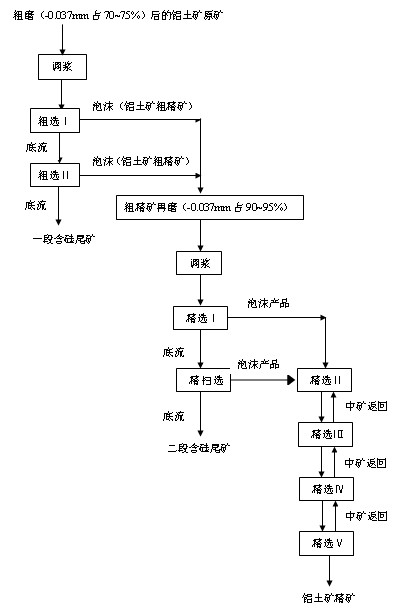

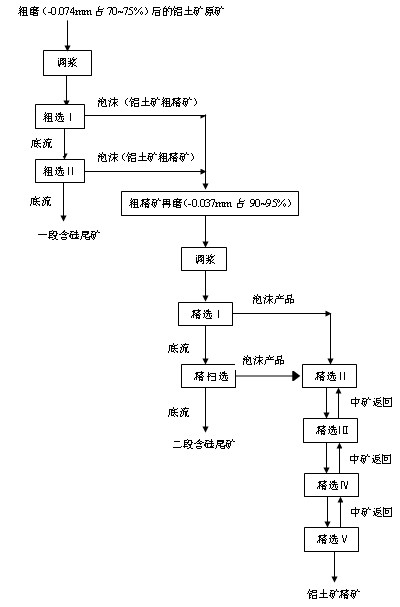

Flotation two-stage desiliconization method for high-silicon bauxite

ActiveCN102489411AReduce distractionsEfficient enrichment and recoveryFlotationSodium phosphatesEngineering

The invention relates to a flotation two-stage desiliconization method for high-silicon bauxite, which is a flotation desiliconization technology for bauxite and belongs to the technical field of mineral processing engineering. The method comprises the following steps of: coarsely grinding the bauxite into particles with certain fine granularity; under the condition of a certain ore pulp concentration, performing flotation first-stage desiliconization by using sodium carbonate as a pH regulator and a dispersing agent of the ore pulp, water glass and sodium hexametaphosphate as a combined inhibitor of gangue mineral, lead acetate as an activating agent of the bauxite, sodium oleate as a collector of the bauxite and pine oil as a foaming agent, wherein the base flow in a flotation groove is a section of silicon-containing tailings; allowing foam products to enter a grinding machine and grinding the foam products into particles with fine granularity; adding the medicaments sequentially and mixing pulp; performing flotation second-stage desiliconization, wherein the base flow in the flotation groove is a section of silicon-containing tailings; and selecting the foaming products for multiple times to form bauxite concentrate. The sectional desiliconization method for 'flotation first-stage desiliconization after coarse grinding and flotation second-stage desiliconization after regrinding rough concentrate' is utilized, so the influence of ore argillization phenomenon on desiliconization is greatly reduced, the flotation desiliconization effect on the high-silicon bauxite is obvious, the silicon dioxide content of the bauxite concentrate can be reduced greatly, the ratio of aluminum to silicon of the bauxite concentrate is increased, and the recovery rate is high.

Owner:山西道尔铝业有限公司

Carbon nano-sphere/NiCo2O4 composite material as well as preparation method and application thereof

ActiveCN104979551AIncrease capacityGood charge and discharge performanceHybrid capacitor electrodesCell electrodesCapacitanceHigh energy

The invention relates to a high-energy-density carbon nano-sphere / NiCo2O4 composite material of a lithium ion battery and a super-capacitor as well as a preparation method and application of the composite material. The nano-sphere / NiCo2O4 composite material is a core-shell structure nano sphere with the grain diameter of 100-300nm; and the inner layer of the nano-sphere / NiCo2O4 composite material is a carbon nano sphere with the grain diameter of 50-200nm and the outer layer of the nano-sphere / NiCo2O4 composite material is a NiCo2O4 coating layer with the thickness of 20-100nm. The preparation method comprises the following steps: mixing the carbon nano sphere with the grain diameter of 50-200nm with sodium oleate and uniformly dispersing by ultrasounds; then adding weak alkali, Co<2+> and Ni<2+>; and uniformly mixing, then carrying out hydrothermal treatment to obtain the carbon nano-sphere / NiCo2O4 composite material with the core-shell structure. The method has the advantages of simplicity in operation, environment friendliness, wide raw material resource, low production cost and the like, and is suitable for large-scale production and preparation. The first-time discharge capacity of a lithium ion battery negative electrode material prepared from the material can reach 1600mAh / g. The material is used as a super-capacitor electrode material and has the specific capacitance being up to 1420F / g (1A / g).

Owner:WUHAN UNIV

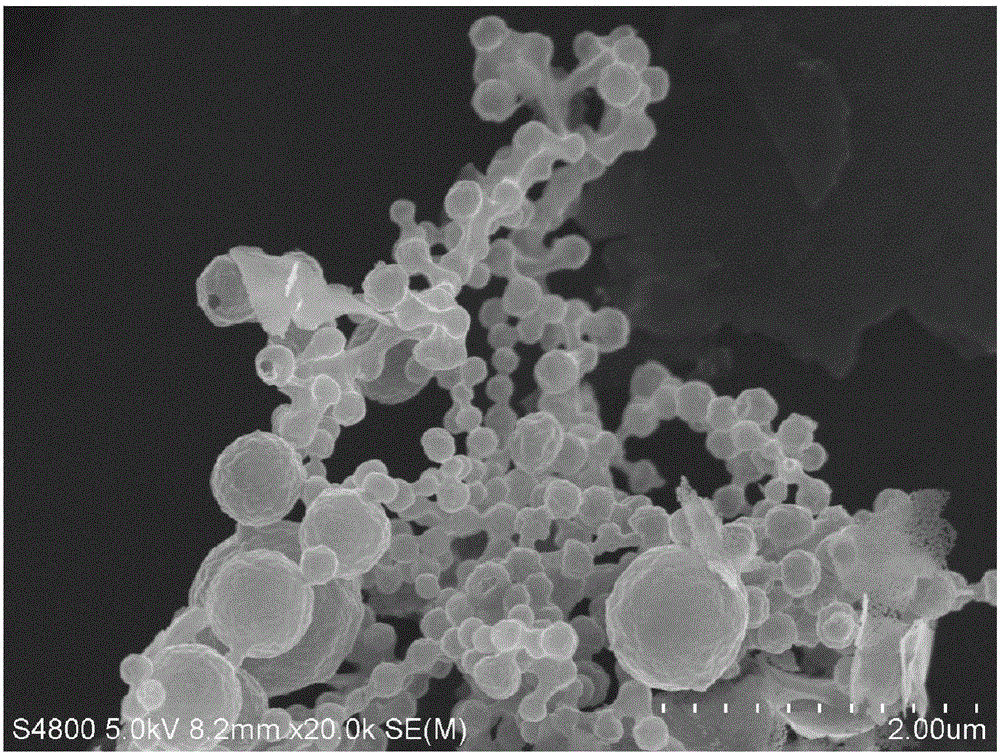

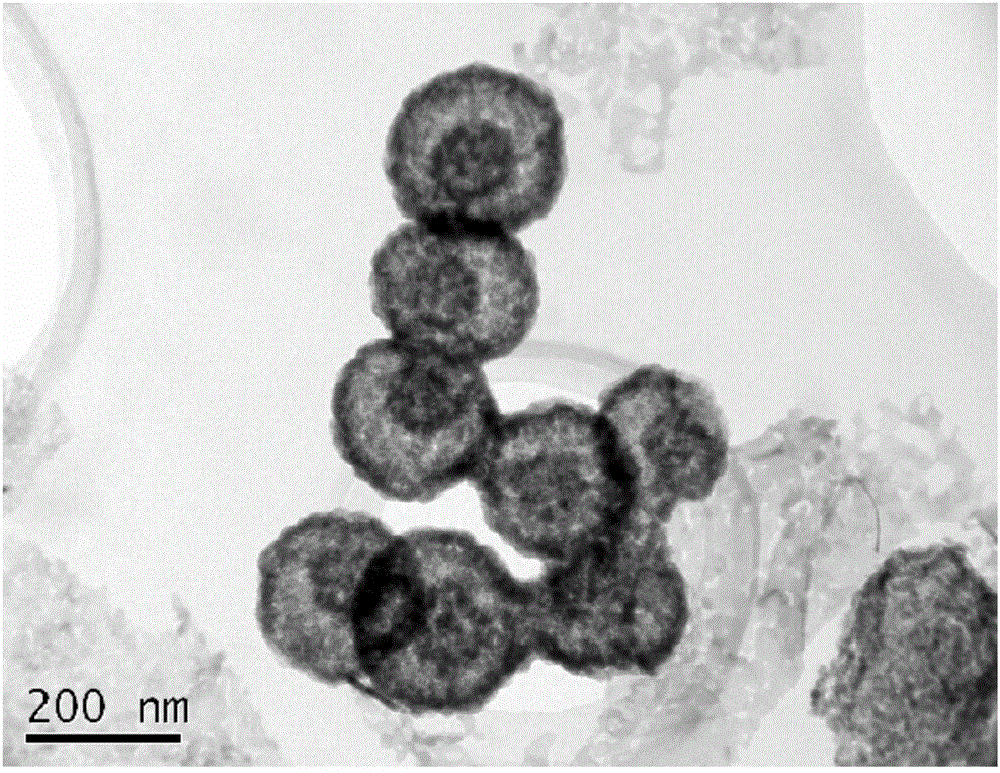

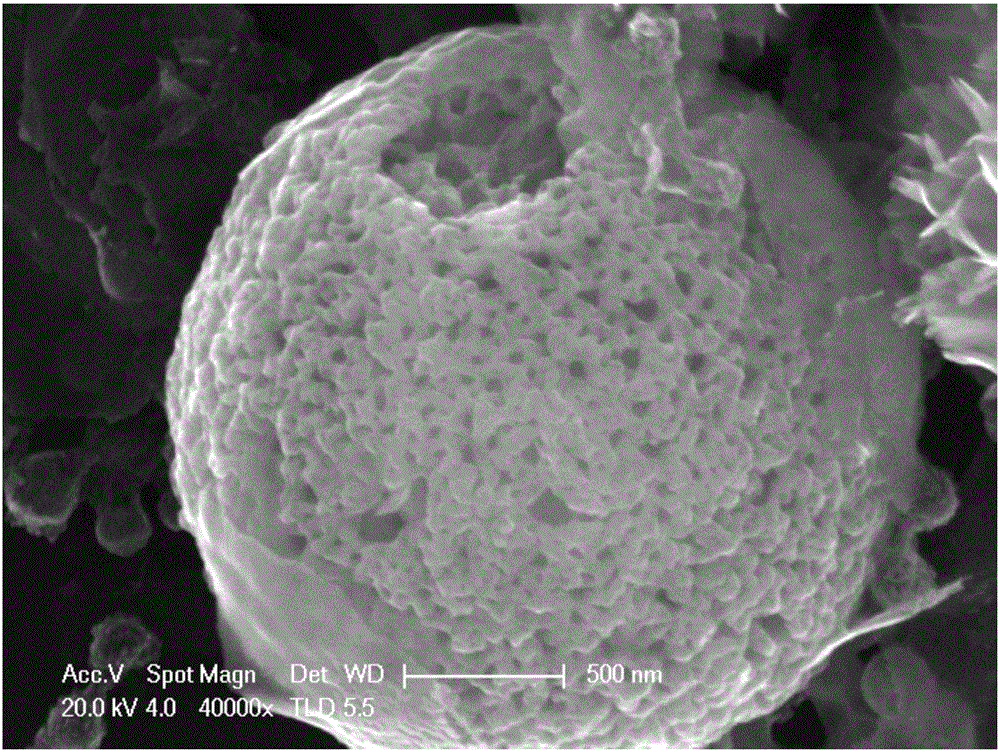

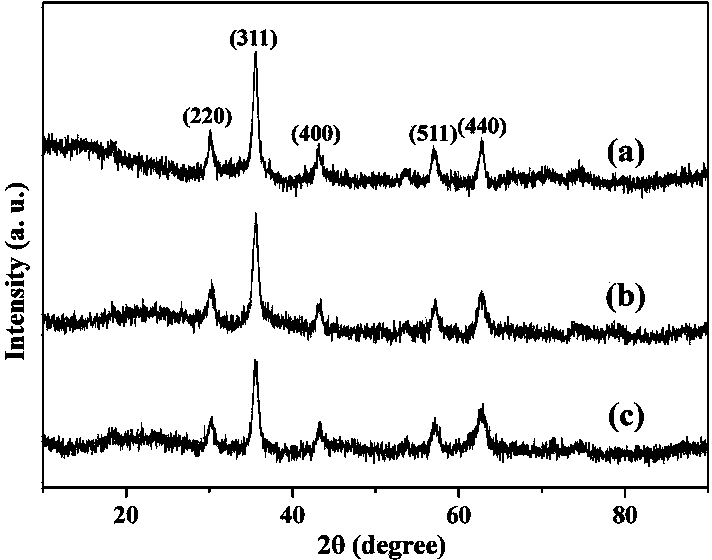

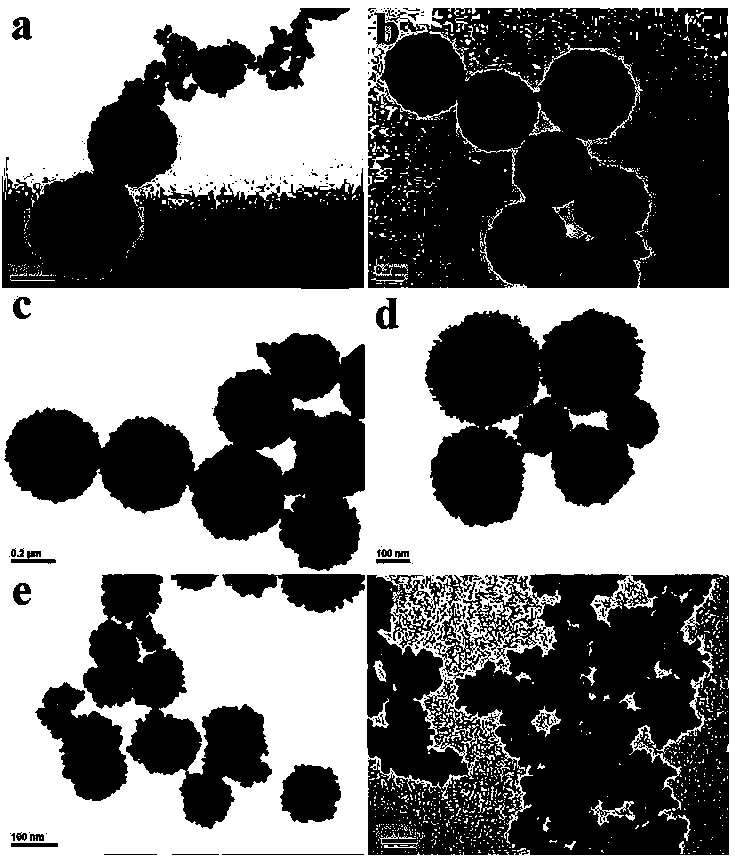

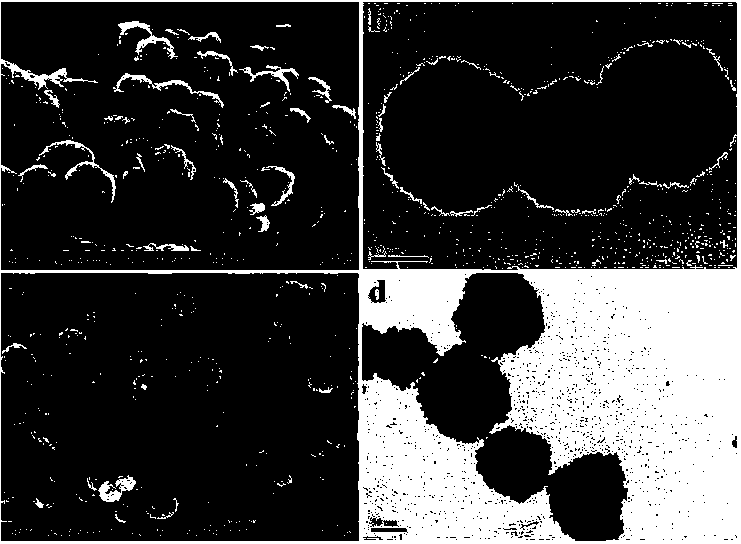

Preparation method and purpose thereof of spherical ferriferrous oxide nano particles with controllable size

InactiveCN104167536AUniform shapeThe particle size can be adjustedCell electrodesSecondary cellsActive agentEngineering

Owner:ZHEJIANG UNIV

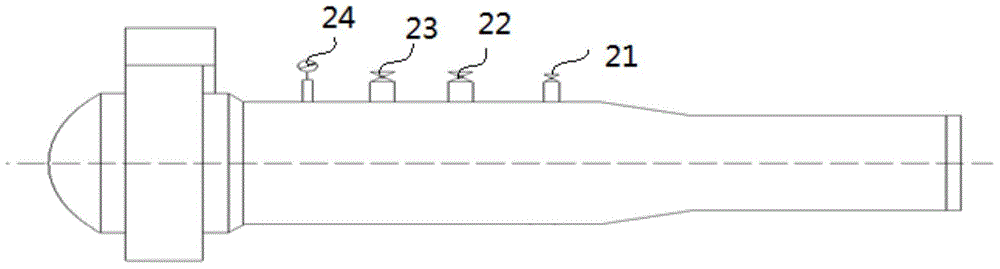

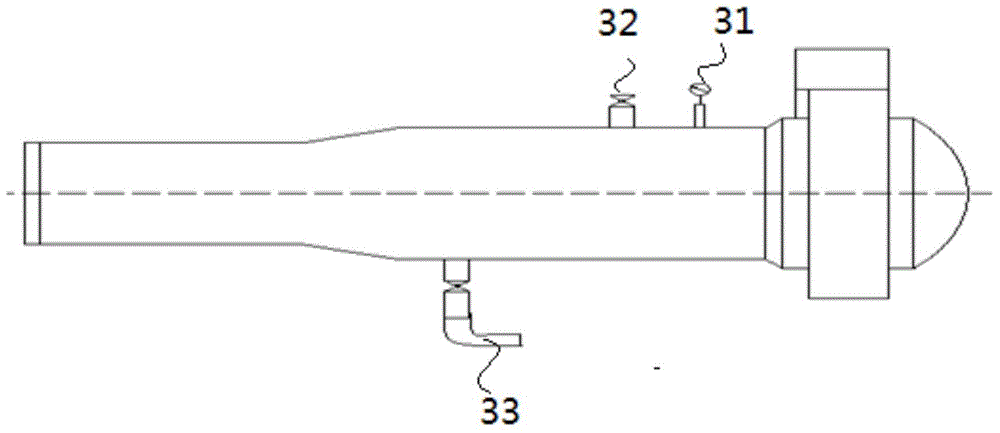

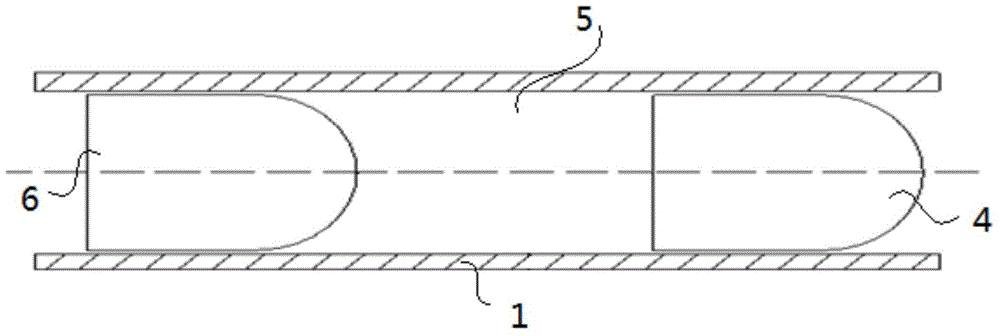

Pollution-free, high-efficiency and long-distance pipe installing and cleaning system

ActiveCN104307821AGood degreasing effectShort construction periodInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkylphenolEngineering

The invention discloses a pollution-free, high-efficiency and long-distance pipe installing and cleaning system, and belongs to the field of pipe cleaning. The pollution-free, high-efficiency and long-distance pipe installing and cleaning system comprises a ball sending device, a ball receiving device, pipe cleaners and a chemical agent, wherein the ball sending device and the ball receiving device are installed at the two ends of a pipe to be cleaned; the pipe cleaners and the chemical agent form a pipe-cleaning train of the pipe cleaner-the chemical agent-the pipe cleaner; the pipe cleaners comprise a first pipe cleaner and a second pipe cleaner; the first pipe cleaner is sent into a pipe to be cleaned and at a 10cm position from an inlet; the second pipe cleaner is put into the ball sending device; the chemical agent is positioned between the two pipe cleaners; the chemical agent comprises a passivating agent or a degreasing agent; the passivating agent comprises 2-3% of sodium nitrite, 0.5-1% of trisodium phosphate and 96-97.5% of water; the degreasing agent comprises 2-3.5% of sodium tripolyphosphate, 1-2% of sodium carbonate, 0.5-1.5% of sodium hydroxide, 0.2-0.4% of sodium borate, 0.1-0.2% of disodium ethylenediamine tetraacetate, 0.05-0.1% of sodium oleate, 0.05-0.1% of sodium dodecyl sulfate, 0.05-0.1% of alkylphenol ethoxylate and 92.1-96.05% of water. The pollution-free, high-efficiency and long-distance pipe installing and cleaning system can achieve synchronous and high-efficiency operation of physical cleaning and chemical cleaning of a long-distance pipe.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Nano silver facial perfuming soap

PendingCN101130719AGuaranteed healthy skinGood effectInorganic/elemental detergent compounding agentsSodium laurateSodium stearate

The invention discloses a beauty soap of nanometer silver, which comprises the following steps: 1. 5-2. 5% nanometer colloid silver, 2. 0-3. 0% pure embryo element, 0. 05-0. 15% collagen, 0. 05-0. 15% ursin, 6. 0-8. 0% deep sea, 7. 0wt% coagulant, 12. 0-14. 0% water, 21. 5-22. 5% glycerin, 8. 0-9. 0% sodium oleate, 21. 0-23. 0% sodium stearate, 11. 0-13. 0% sodium laurate and 3. 0-4. 0 essence. The invention not only has strong detergency, but also possesses the function of antibiotic and disinfection to maintain the oil-water balance of skin, prevent skin from aging with skin beauty.

Owner:全昌均 +1

Metal polishing solution

The invention discloses metal polishing solution, which comprises the following components in percentage by weight: 15-20% of sodium oleate, 2-5% of citric acid, 5-7% of sodium tripolyphosphate, 3-4% of sodium dodecyl benzene sulfonate, 1-2% of 2-(heptadecene)-4,5-dihydro-1H-imidazole-1-ethanol, 8-10% of quartz sand and the balance of water. According to the metal polishing solution disclosed by the invention, greasy dirt and rust spots on the surface of a metal appliance, such as steel, iron, copper and aluminum can be effectively removed, and metallic luster of the appliance is kept and the appliance is bright as new, and the appliance is prevented from being rusted again for more than one year after cleaning one time.

Owner:深圳市永霖科技有限公司

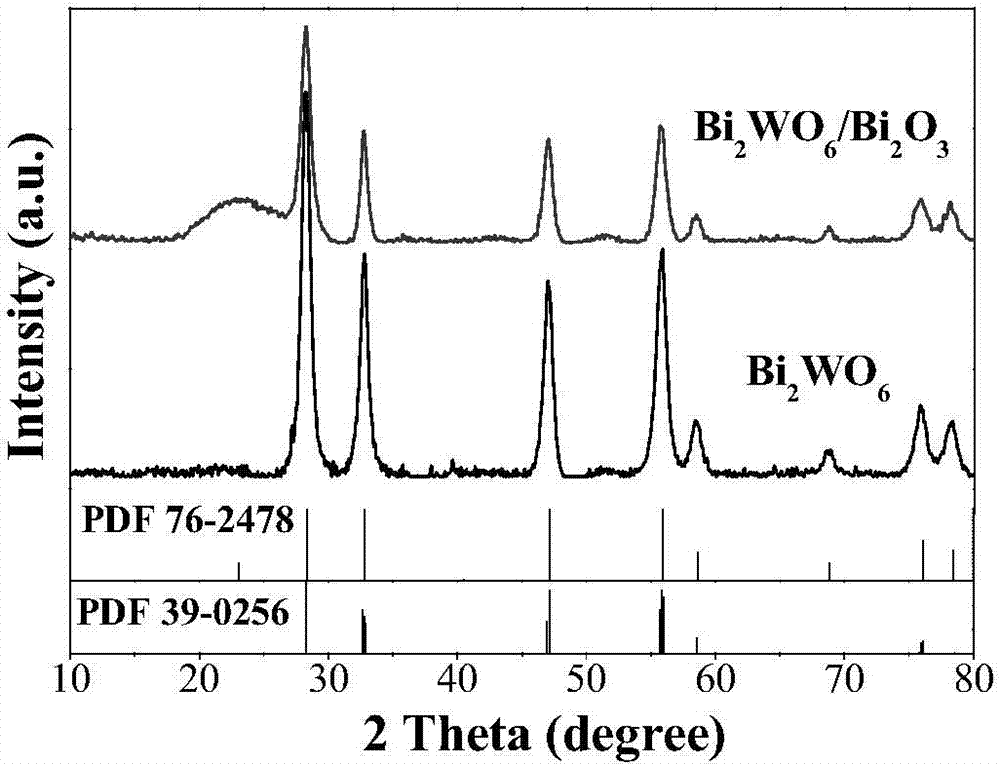

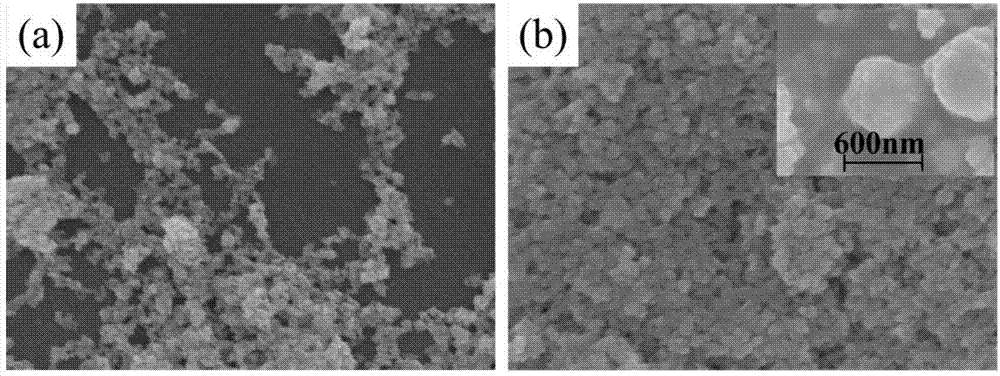

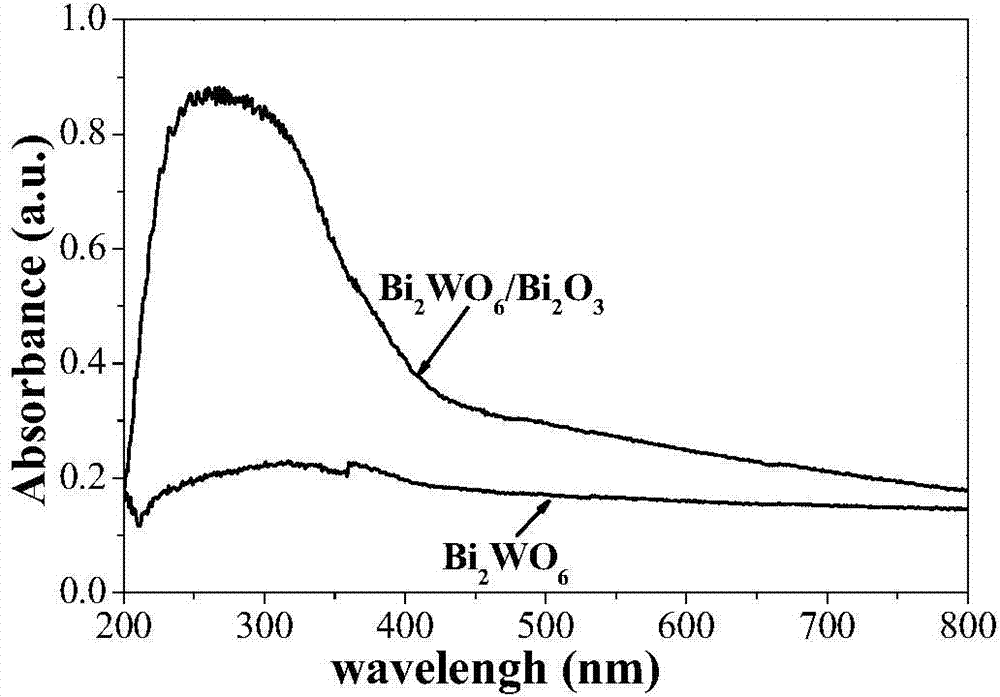

Visible light responded load type Bi2WO6/Bi2O3 heterojunction photocatalyst and preparation method thereof

InactiveCN104722293AImprove visible light absorptionEasy to recycleWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionEngineering

The invention relates to a visible light responded load type Bi2WO6 / Bi2O3 heterojunction photocatalyst and a preparation method thereof. The visible light responded load type Bi2WO6 / Bi2O3 heterojunction photocatalyst is prepared from the following components in parts by weight: sodium oleate, an ethanediol solution, bismuth nitrate, sodium tungstate and a carrier. The preparation method is simple and the operation is simple and convenient; preparation conditions are moderate and are free from toxin and secondary pollution is not caused in a preparation process; the batch production can be realized; the prepared visible light responded load type Bi2WO6 / Bi2O3 heterojunction photocatalyst has a high visible light absorption capability, has strong light absorption property and strong organic matter light degradation capability in a visible light region, and has a good application prospect of degrading RhB under the visible light; and particularly, the degradation rate of rhodamine B can be up to 99.5% under the condition of illuminating for 90 minutes under visible light with the wavelength more than nm. The prepared composite photocatalyst is convenient to recycle and reuse, and the difficulty that the recycling is difficult when a photocatalysis technology is actually applied in environment purification can be solved.

Owner:JILIN UNIV

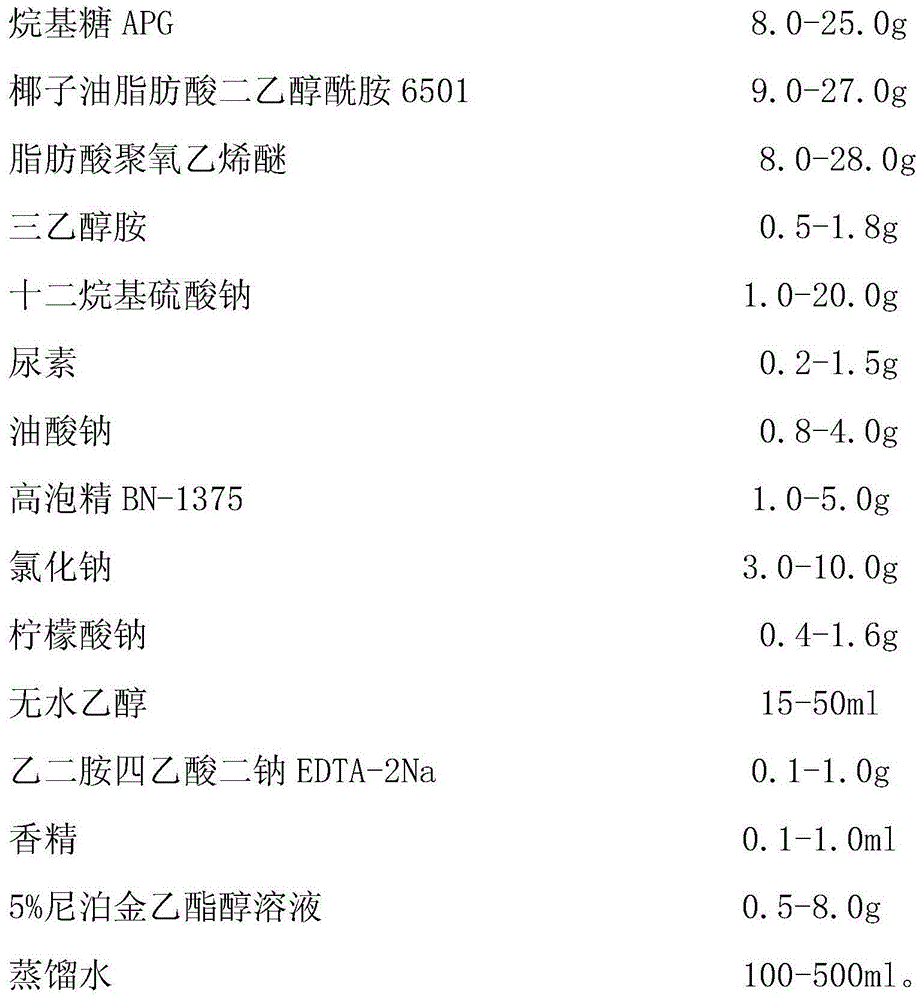

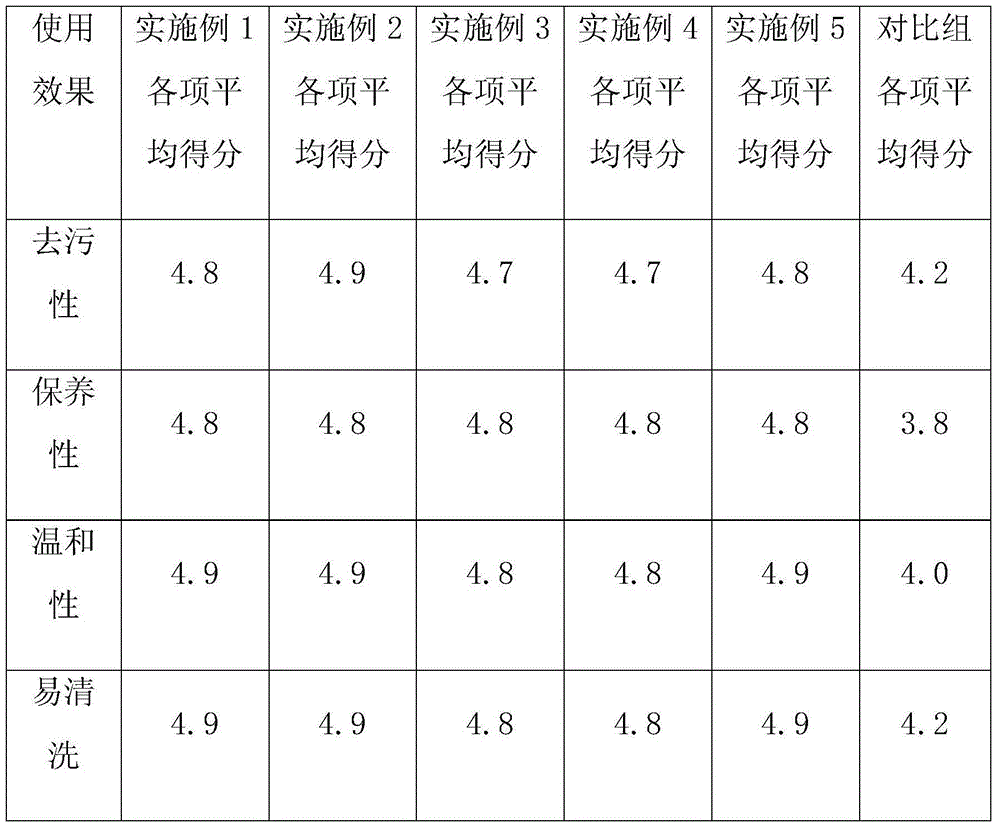

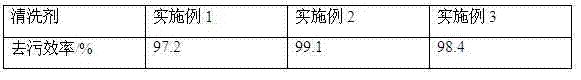

Range hood cleaning agent and preparation method thereof

ActiveCN104611146AModerate viscosityModerate consistencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsFatty alcohol

The invention relates to a range hood cleaning agent and a preparation method thereof. The cleaning agent comprises the following matters: polyoxyethylene fatty alcohol sodium sulfate AESA, APG (Alkyl Polyglucoside), coconut fatty acid diethanolamide 6501, fatty acid polyoxyethylene ether, triethavolamine, sodium dodecyl sulfate, urea, sodium oleate, high-foaming essence BN-1375, sodium chloride, sodium citrate, anhydrous ethanol, disodium edetate dehydrate EDTA-2Na, essence, and a 5-percent ethylparaben alcoholic solution. The cleaning agent provided by the invention has the characteristics of greenness, high efficiency, sterilization, rust prevention and corrosion inhibition and the like, and is environment-friendly, nontoxic and harmless to environment, high in cost performance and easy to clean, and the range hood cleaning agent can remove stubborn stains on a range hood, and also can effectively remove yellow rust on the surface of the range hood.

Owner:贵州宏吉伟业实业有限公司

Printing ink cleaning agent and preparation process thereof

InactiveCN102775840AImprove cleanlinessSimple preparation processChemical paints/ink removersPolyethylene glycolPrinting ink

The invention relates to a printing ink cleaning agent for washing printing ink of printing machines, printing plates, rubber covered rollers, rubber cloth and the like and a preparation process of the printing ink cleaning agent. The printing ink cleaning agent is composed of the following raw materials by weight 15-25% of symplectic alkyl phenol polyethylene glycol ether, 5-15% of oleic acid, 3-7% of sodium oleate, 2-8% of oil soluble essence, 5-15% of sodium alkyl benzene sulfonate and the balance of softened water. According to the printing ink cleaning agent and the preparation process provided by the invention, an organic solvent such as gasoline and kerosene can be replaced and the safety, high efficiency and environmental protection can be realized, and hydrophobic groups in emulsion can well dissolve oiliness content in the ink to achieve washing effects. The printing ink cleaning agent is simple in preparation process, and has the advantages of being low in cost, simple in preparation process, free of damage to the rubber covered rollers, non-ignitable, good in clearing performance, free of damage to skin and the like compared with the existing cleaning agent.

Owner:HONGBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com