Printing ink cleaning agent and preparation process thereof

A technology for printing inks and cleaning agents, applied in the field of cleaning agents, can solve the problems of flammability, harm to human health, and explosive pollution of the environment, and achieves the effects of simple preparation process, no skin damage, and good cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

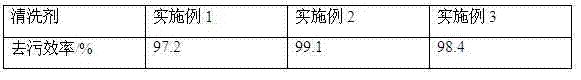

Examples

preparation example Construction

[0016] The preparation technology of described printing ink cleaning agent, comprises the following steps:

[0017] (1) Add demineralized water into the mixing tank, heat it to 46-55°C, and keep it warm;

[0018] (2) Octylphenol polyoxyethylene ether (TritonX-100), oleic acid, sodium oleate, oil-soluble flavor (oil-soluble food flavor, contains hydrophobic groups, dissolves ink, and produces fragrance) by weight ratio After weighing, add to the mixing tank and stir for 15-25min;

[0019] (3) Add sodium alkylbenzene sulfonate (LAS) into the mixed solution prepared in step (2), and stir for 15-25 minutes to obtain a cleaning agent for printing ink.

[0020] The following are several specific examples of the present invention to further describe the present invention, but the present invention is not limited thereto.

Embodiment 1

[0022] This embodiment is made from the following mass fraction raw materials:

[0023] 15 parts of octylphenol polyoxyethylene ether;

[0024] 15 parts of oleic acid

[0025] 5 parts sodium oleate

[0026] 5 parts oil-soluble essence

[0027] Sodium alkylbenzene sulfonate 10 parts

[0028] 50 parts of demineralized water,

[0029] Preparation:

[0030] (1) Weigh the demineralized water into the mixing tank to 46°C and keep it warm;

[0031] (2) Weigh octylphenol polyoxyethylene ether, oleic acid, sodium oleate, and oil-soluble essence, and stir for 25 minutes;

[0032] (3) Weigh the sodium alkylbenzene sulfonate, add the mixture, and stir for 25 minutes to make a milky white liquid.

Embodiment 2

[0033] Example 2: Best Practice

[0034] This embodiment is made from the following mass fraction raw materials:

[0035] 20 parts of octylphenol polyoxyethylene ether;

[0036] 10 parts of oleic acid

[0037] 5 parts sodium oleate

[0038] 5 parts oil-soluble essence

[0039] Sodium alkylbenzene sulfonate 10 parts

[0040] 50 parts of demineralized water,

[0041] Preparation:

[0042] (1) Weigh the demineralized water into the mixing tank to 50°C and keep it warm;

[0043] (2) Weigh octylphenol polyoxyethylene ether, oleic acid, sodium oleate, and oil-soluble essence, and stir for 20 minutes;

[0044] (3) Weigh the sodium alkylbenzene sulfonate, add the mixture, stir for 20 minutes, and make a milky white liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com