Patents

Literature

352results about How to "Improve denitrification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

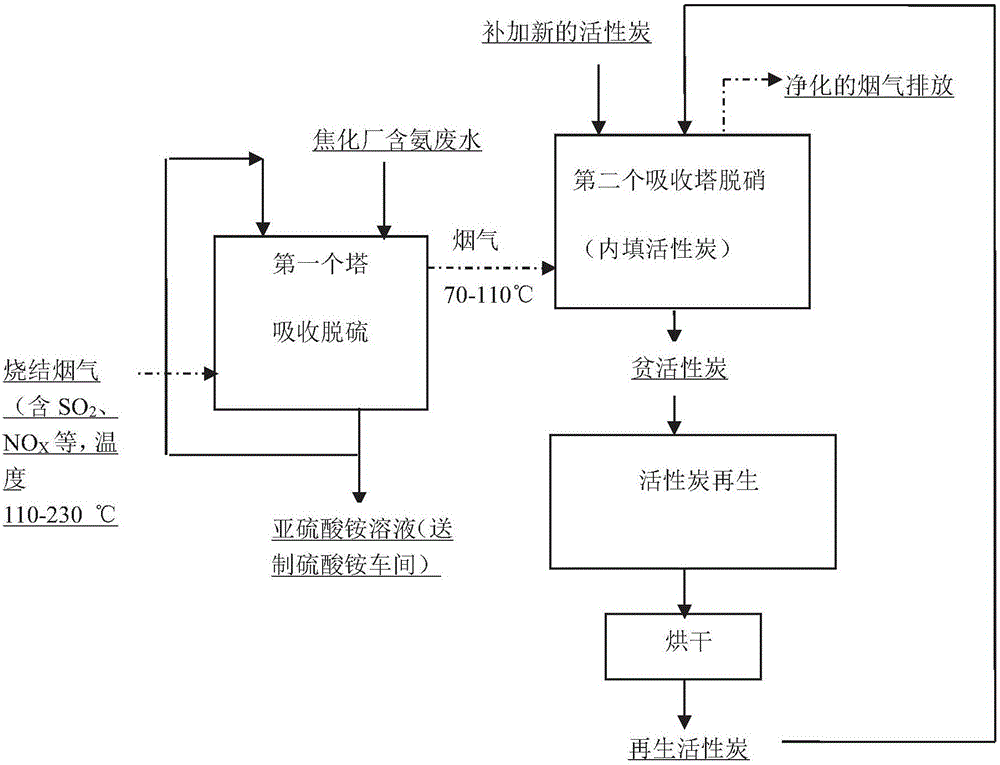

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

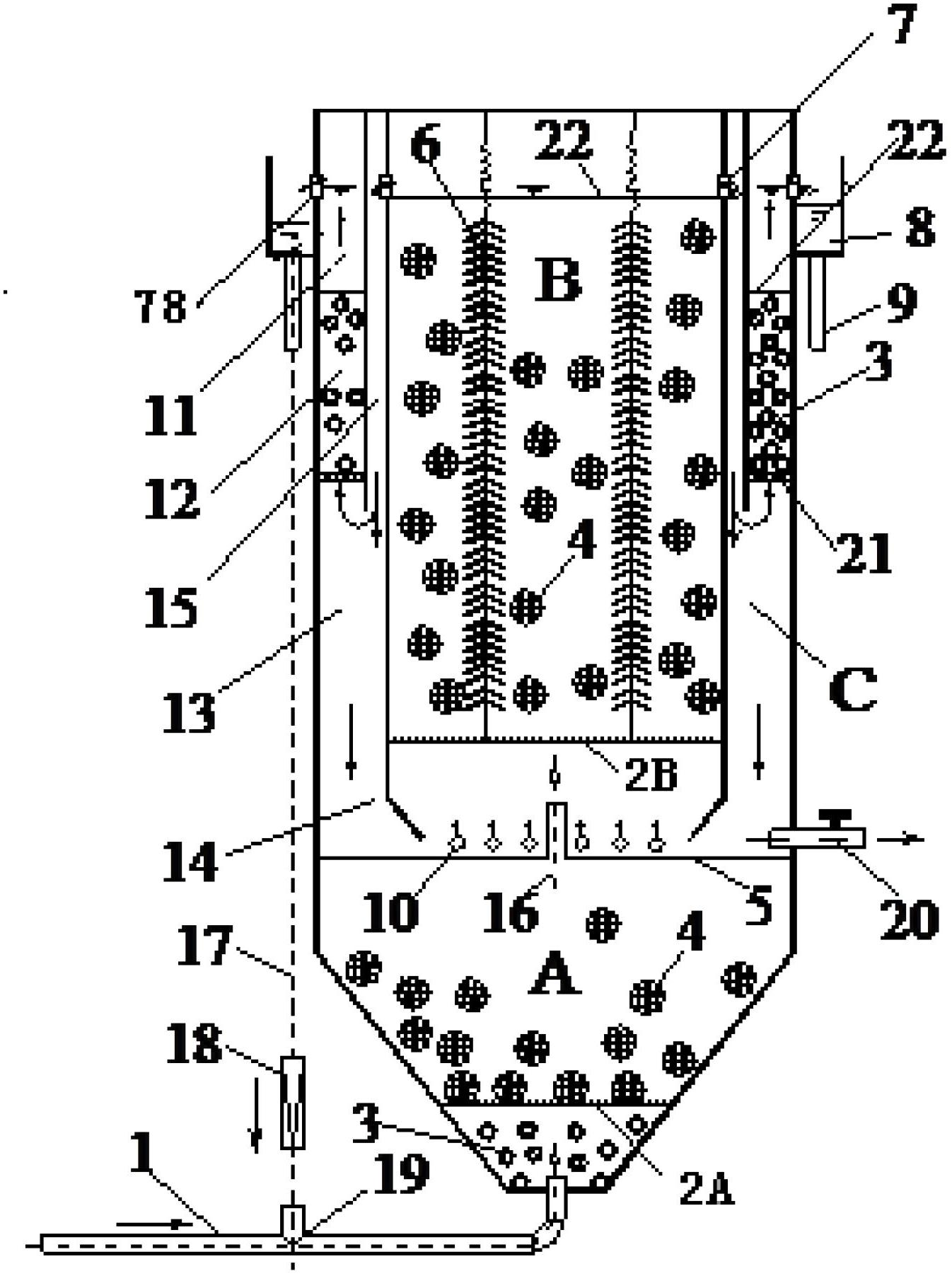

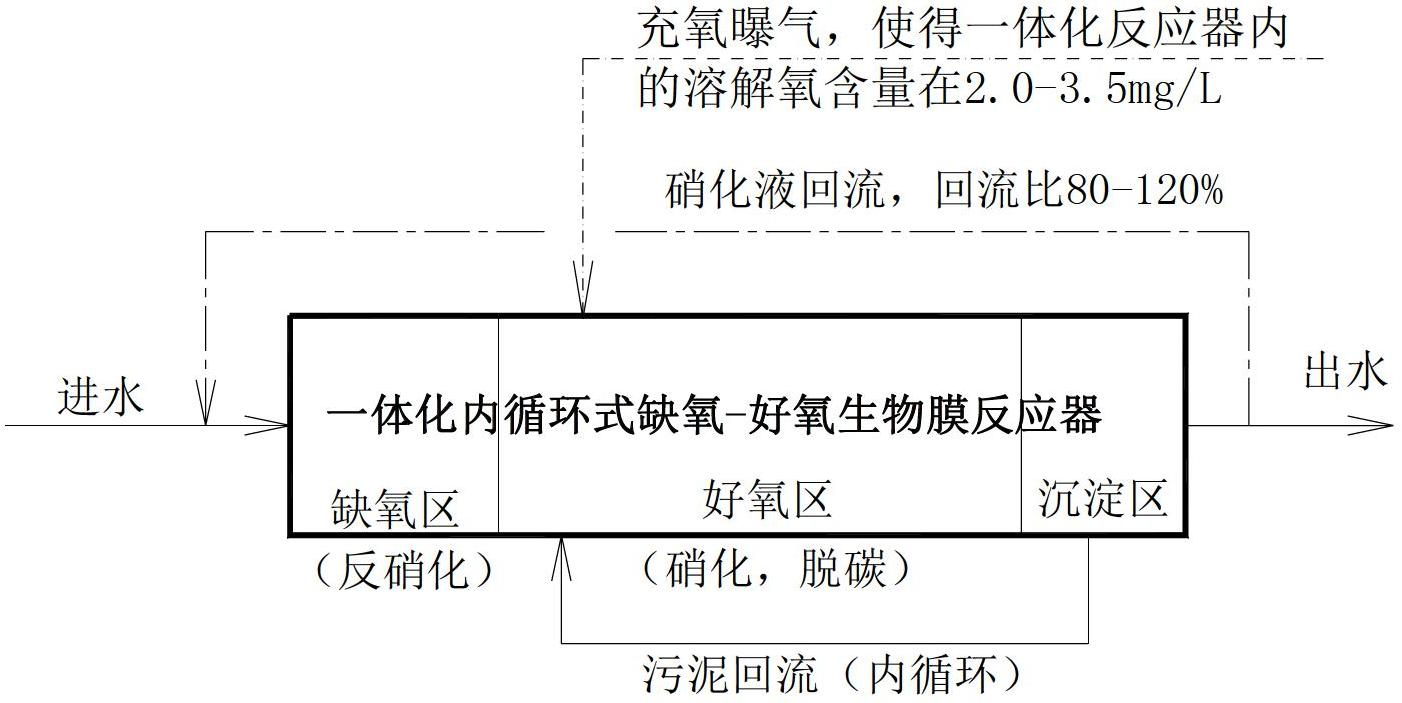

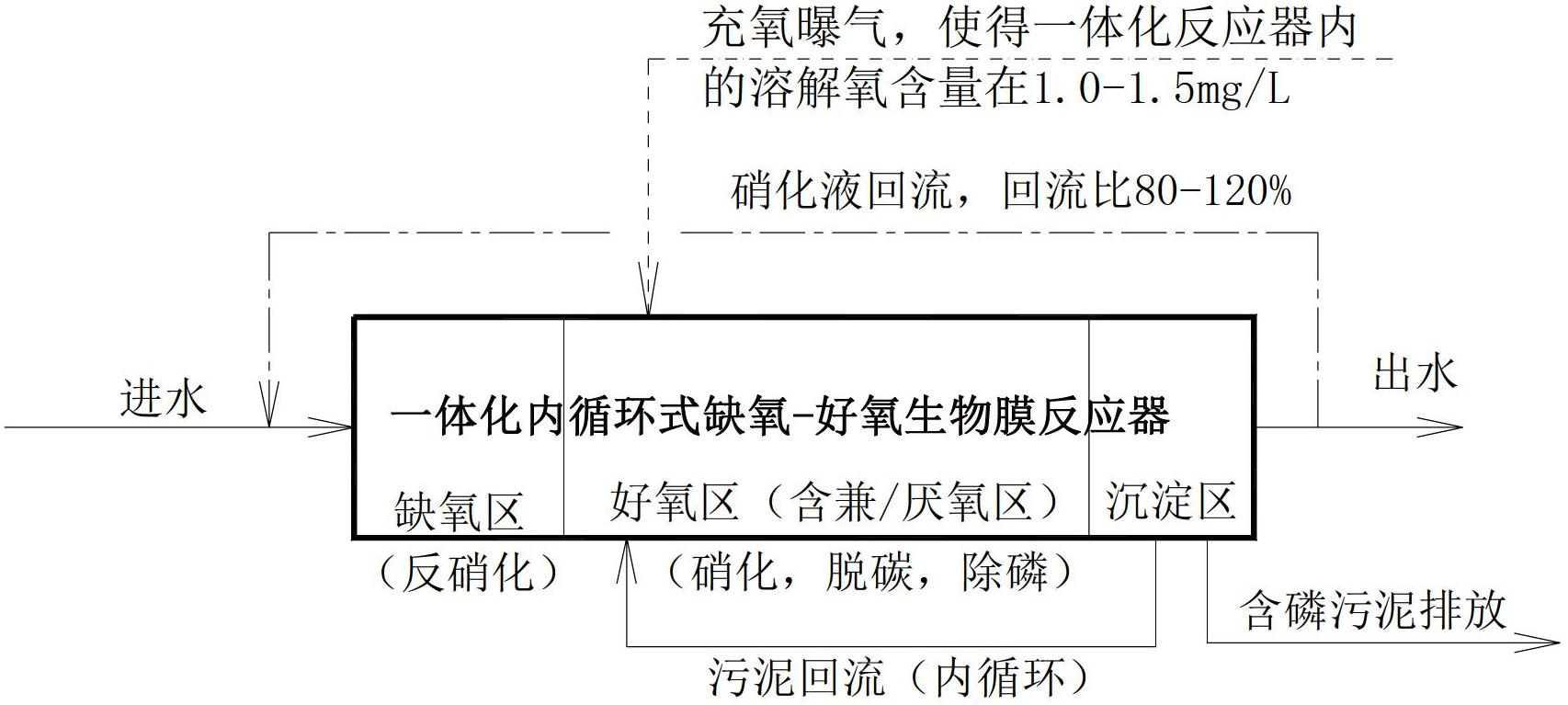

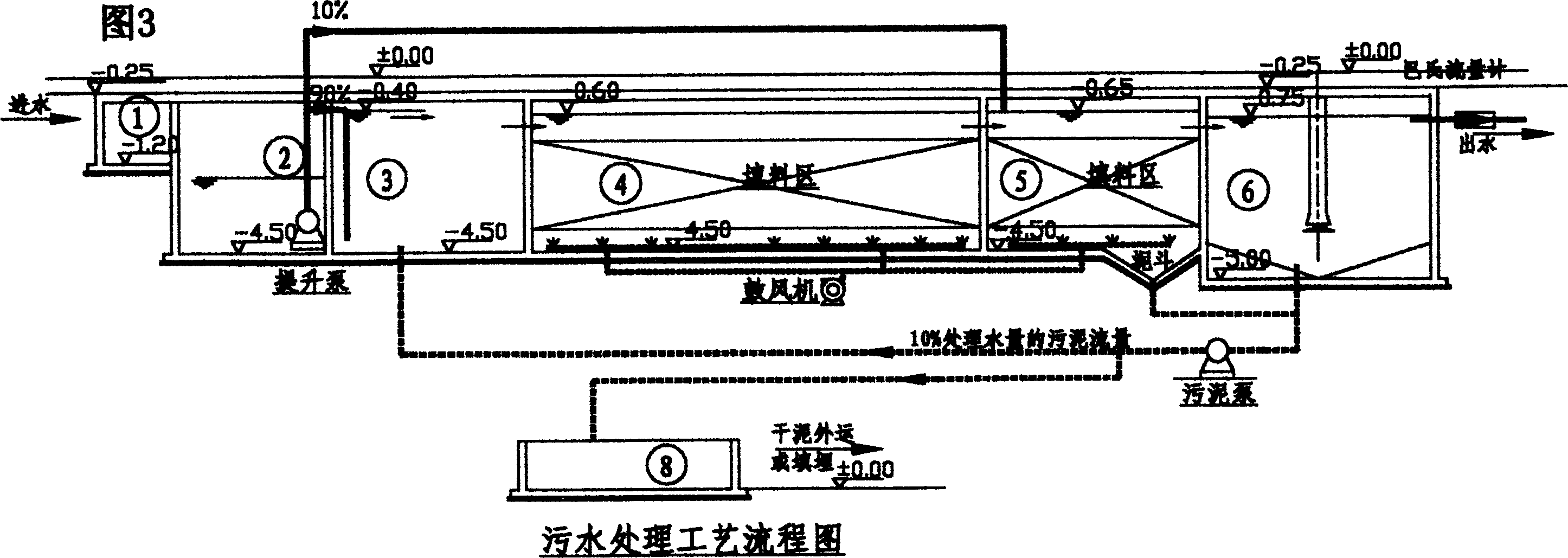

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

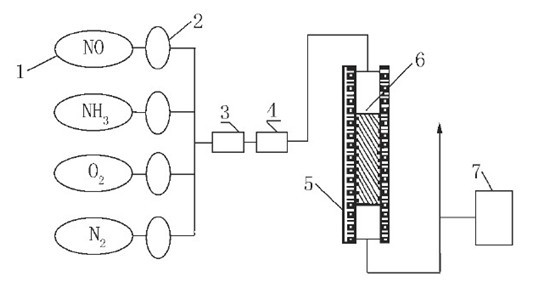

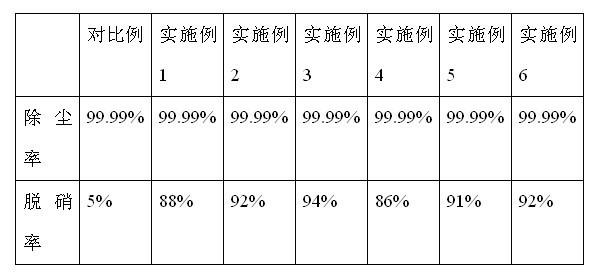

Preparation method of denitration-catalyst-supported polyphenylene sulfide (PPS) filter material

InactiveCN102145241AImprove denitrification rateImprove water resistanceDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsFiberPtru catalyst

The invention provides a supported polyphenylene sulfide (PPS) filter material which belongs to the field of filter materials. The supported PPS filter material is prepared by the following method: making a PPS fiber into a PPS filter material; performing water bath acidification in nitric acid, and washing with deionized water to neutrality; drying to obtain acidified polyphenylene sulfide nitride (PPSN); preparing a catalyst into a solution and stirring; soaking PPSN in the solution; performing water bath baking, and drying in air; and calcining in a nitrogen atmosphere to obtain the supported PPS filter material with denitration function. The denitration-catalyst-supported PPS filter material provided by the invention can be used as a dedusting agent and a denitration agent at the sametime, is prepared by simple steps, realizes dedusting and denitration functions as well, and has the advantages of high denitration rate, high temperature resistance, acid-base resistance, good waterresistance, long service life and the like; and a new application field of the filter-bag catalytic denitration is created.

Owner:FUZHOU UNIV

Absorption tower for desulfurization and denitrification combined with oxidant in forward-flow and back-flow spraying and method

InactiveCN102553428AAchieve removalUnique structureDispersed particle separationAir quality improvementOxidation zoneSlurry

The invention discloses an absorption tower for desulfurization and denitrification combined with an oxidant in forward-flow and back-flow spraying mode and a method. The absorption tower includes two washing sections: a first section is a desulfurization loop and arranged on the lower portion of the absorption tower, and sulfur dioxide and hydrogen chloride are removed through slurry forward-flow and back-flow and smoke contact cleaning; a second section cleans oxidized smoke pollutants in slurry back-flow and smoke contact mode mainly for removing oxynitride and heavy metal mercury. A slurry divider is arranged between the two cleaning sections, the bottom of the slurry divider is an oxidization area, and strong oxidant is sprayed in the area. For reducing consumption of the oxidant, a catalyst is added in second-loop slurry for achieving auxiliary oxidization. Sulfur dioxide, oxynitride, heavy metal mercury and the like can be removed simultaneously in a washing tower by the technology, and the absorption tower has the advantages of being high in efficient and simple and suitable for various combustion devices including fuel coal power stations, refuse incineration plants, organic and inorganic production enterprises and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

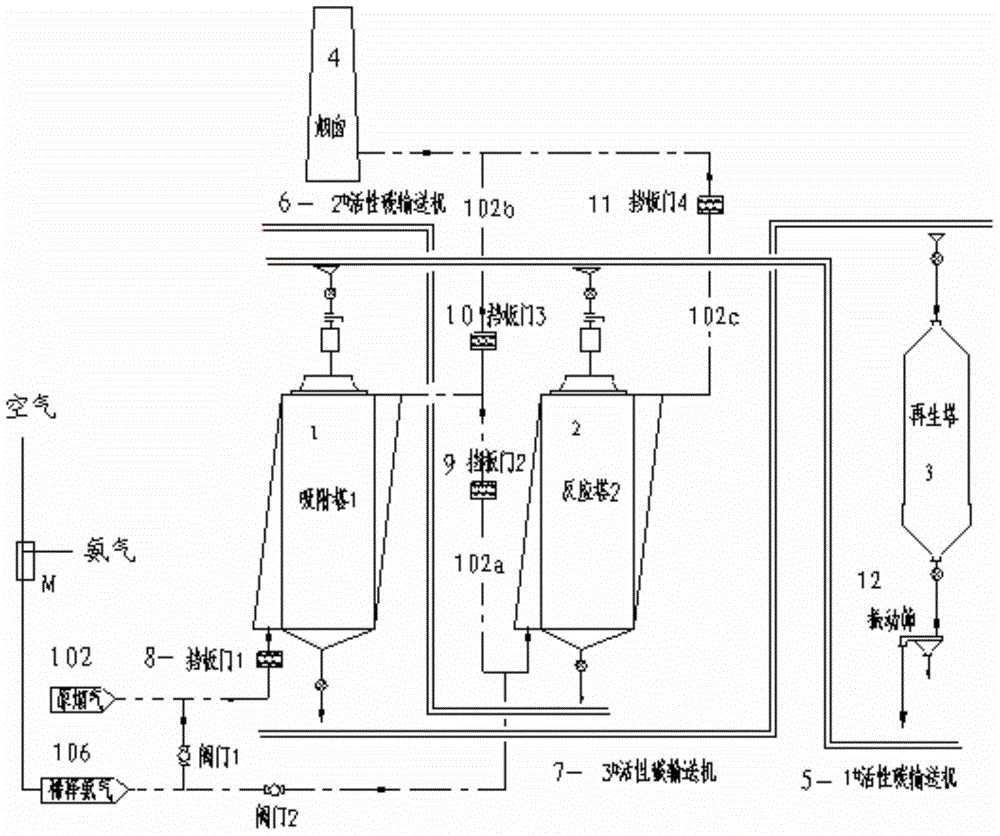

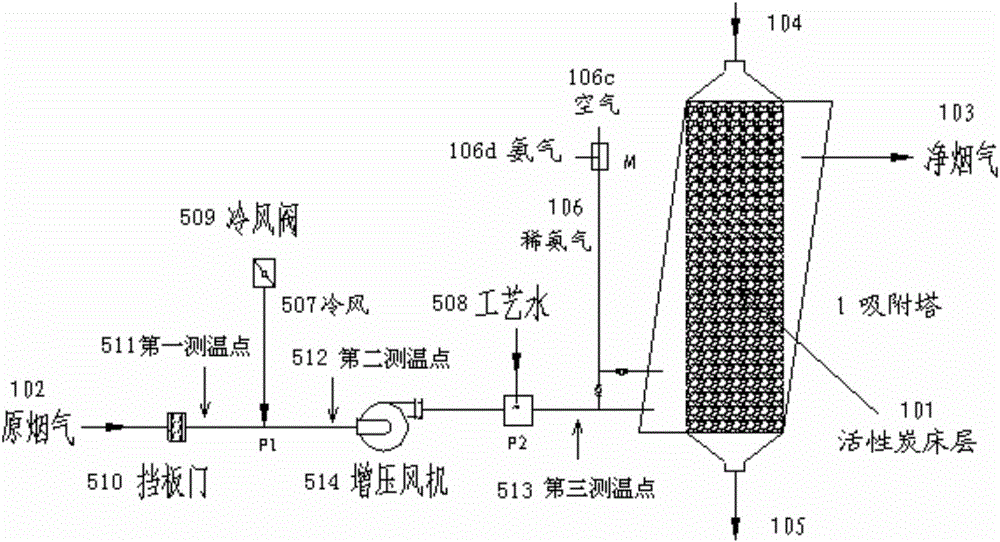

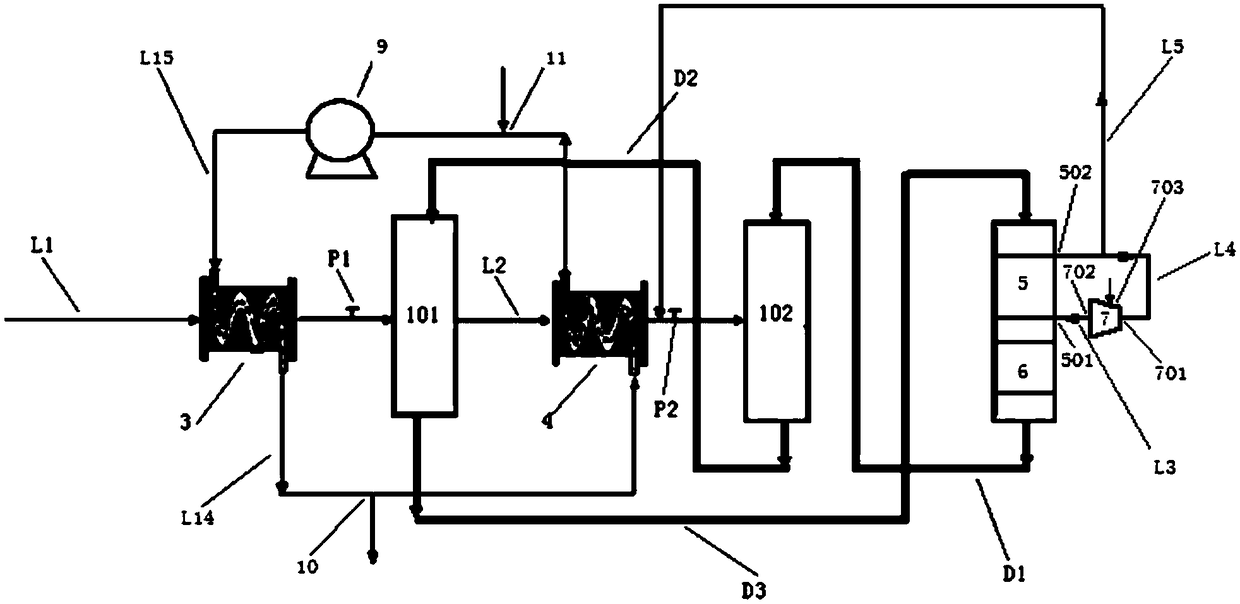

A flue gas desulphurization denitration method adopting two adsorption columns in series connection and a device therefor

ActiveCN105688622AIncrease flexibilityImprove denitrification rateDispersed particle separationSpray coolingEnvironmental geology

A flue gas desulphurization denitration method adopting two activated-carbon adsorption columns (1, 2) in series connection and comprising a flue gas temperature control apparatus and a device therefor are provided. The method includes I) a step of flue gas temperature control and II) a step of desulphurization and denitration, wherein the step of flue gas temperature control comprises (1) a step of subjecting flue gas to first time of cooling by feeding cold air into a flue conveying high-temperature flue gas to activated-carbon adsorption columns from a cold-air inlet at an upstream position (P1) of the flue, (2) spraying cooling water or cold water mist into the flue gas in the flue from a process water spray nozzle at the downstream position (P2) of the position (P1) from which the cold air is fed, and allowing the flue gas to flow along the flue to the adsorption columns, and (3) feeding diluted ammonia gas into the flue gas in the adsorption columns after the flue gas is fed into gas feeding chambers of the adsorption columns. The temperature of the flue gas fed into the adsorption columns is controlled by mixing with the cold air and spraying water. The two activated-carbon adsorption columns (1, 2) in series connection are adopted to significantly increase the denitration efficiency of the device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

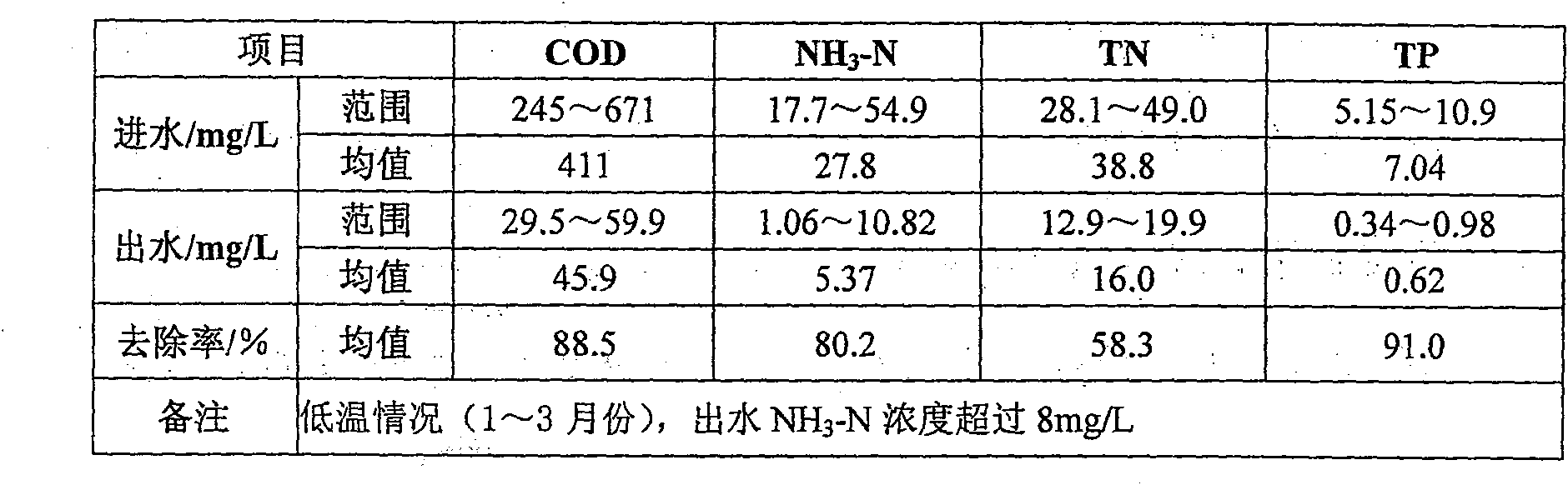

Treatment method for biological nitrogen removal of reinforced sewage

ActiveCN101857337AEnhance nitrification activityIncrease the input rateTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentNitrogen removalSludge

The invention discloses a treatment method for biological nitrogen removal of reinforced sewage, which comprises the following steps of: 1, feeding all or partial treated sewage and sludge refluxed from a secondary sedimentation tank into a reflux sludge denitrification unit together by adopting division point inflow; 2, feeding the outflow of the reflux sludge denitrification unit and the residual sewage to an anaerobic unit or an anoxic unit; 3, feeding the outflow of the anaerobic unit to the anoxic unit, and refluxing the mixed solution of an aerobic unit to the anoxic unit; 4, feeding the outflow of the anoxic unit to a transition unit; 5, feeding the outflow of the transition unit to the aerobic unit, and refluxing the mixed solution of the aerobic unit to the anoxic unit from the outflow end of the aerobic unit; and 6, feeding the outflow of the aerobic unit to the secondary sedimentation tank to perform sludge-water separation. The method can be operated in multiple modes of A-A2O, nitrogen removal AO, inverse AAO and the like and has high controllability, and a system has strong nitrogen removal capability. The method is suitable for upgrade and reform of newly built sewage treatment plants of towns lacking the land and the conventional sewage treatment plants.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Method of desulfurizing and denitrate simultaneously of exhaust gas by micro wave catalysis

The present invention discloses a flue gas purifying method capable of catalyzing flue gas by using microwave and simultaneously making desulfurization and denitration. Said method is characterized by that firstly, the catalyst is placed in a special-designed fixed bed reactor, then the normal-pressure simulated flue gas is introduced to make microwave catalytic desulfurization and denitration reaction. Its desulfurization and denitration efficiency is high, when the space velocity is 8000h-1 and the temperature is 150deg.C, its desulfurization rate can be up to 95% and its denitration rate can be up to 87%, and its catalyst can be regenerated and reused.

Owner:EAST CHINA UNIV OF SCI & TECH

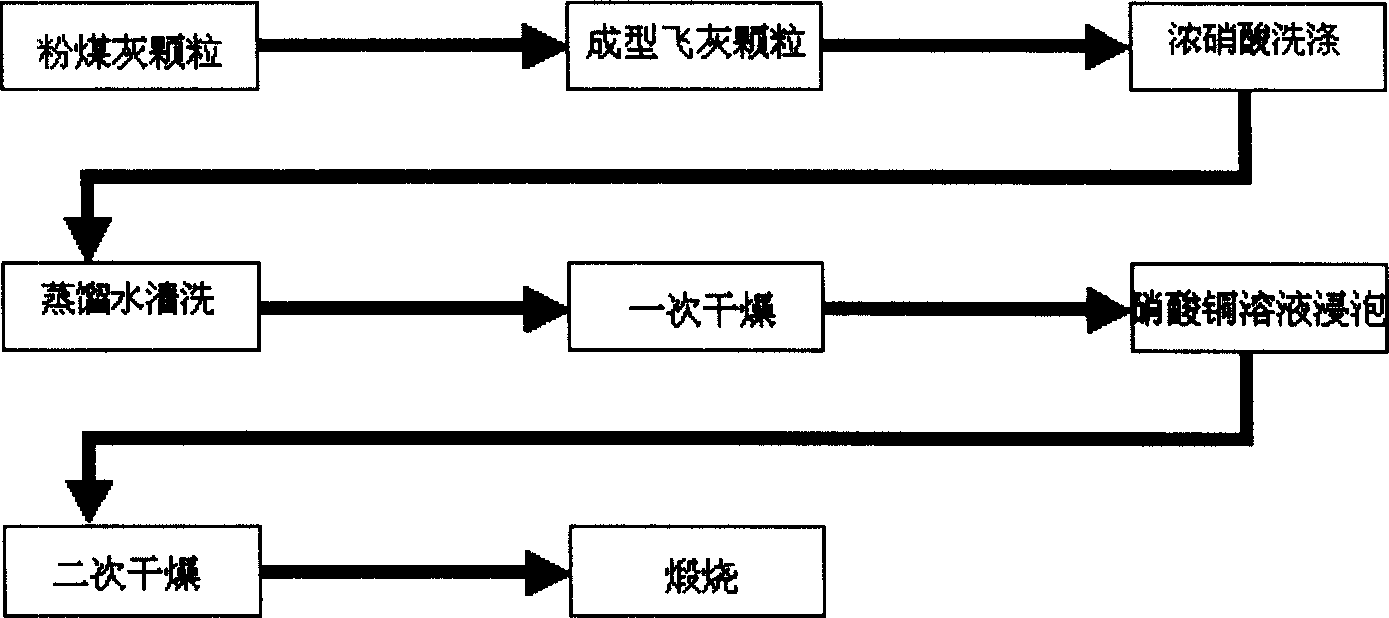

Method for preparing selective catalytic reduction and denitration catalyst by boiler coal ash

ActiveCN1607027AReduce processing costsImprove reliabilityDispersed particle separationHigh concentrationPolymer science

A process for preparing selective catalytic reduction denitration catalyst containes following steps, 1, fly ash and additive are mixed and stirred, active shaping pretreated in reactor, shaped fly ash grain is obtained by pulverizing and sieving fly ash block. 2, soaking shaped fly ash grain by high-concentration strong acid, flushing it to neutrality by distilled water, to form modified SCR denitration catalyst carrier through drying once more. 3, soaking modified SCR denitration catalyst carrier into metal oxide salt solution to obtain the selective catalytic reduction denitration catalyst through two time drying and calcinating.

Owner:TSINGHUA UNIV +1

Energy-saving process for treating high ammonia nitrogen waste water

InactiveCN101195513AHigh removal rateReduce consumptionTreatment using aerobic processesMultistage water/sewage treatmentElectrolysisWater quality

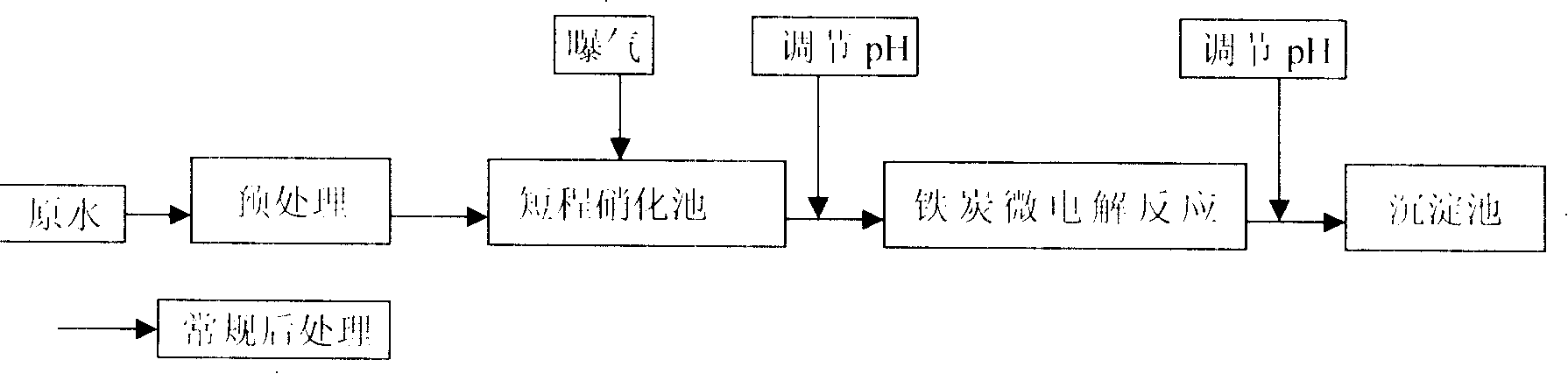

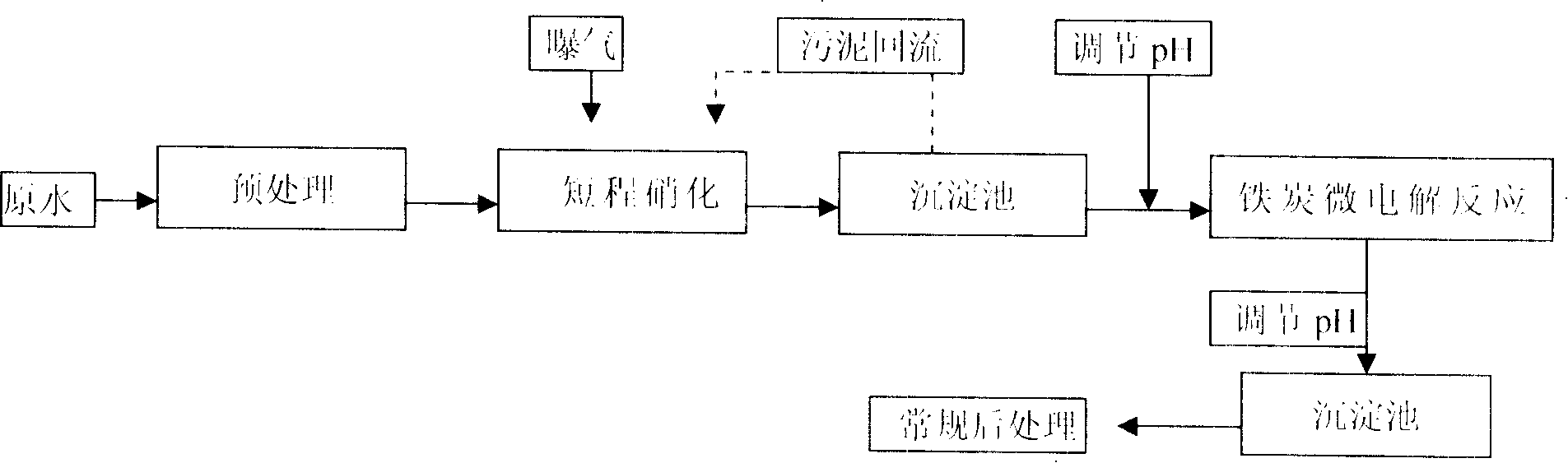

In the invention discloses an energy-saving treatment method of high strength ammonia wastewater, which comprises procedures of pre-processing, short-cut nitrification, micro-electrolysis and after-treatment. The method is characterized in that firstly wastewater is preprocessed to transform Kjeldahl nitrogen into amino nitrogen, then the wastewater enters a main body of the process to be processed. In a short-cut nitrification tank, the amino nitrogen in the wastewater is nitrated and controlled to a nitrite nitrogen stage, then a micro-electrolysis reactor is employed to replace anaerobic denitrification or ammonoxidation process to be denitrified, the nitrite nitrogen and organic pollutants in the wastewater are highly effectively degraded and are further subsequently processed by employing biological method and physicochemical oxidation method, and outlet water of the wastewater reaches standards. The method makes full use of water quality of raw water, the additional medicament consumption is saved, the process flow is shortened, and the process operation is simplified. Compared with the conventional denitrification process, the denitrification rate is increased, the total nitrogen removal rate reaches 60%-75%, and the treatment effect of degrading hardly degradable organics is remarkably increased. The treatment cost of wastewater per ton by employing novel method can be reduced by 30-50%.

Owner:UNIV OF SCI & TECH LIAONING

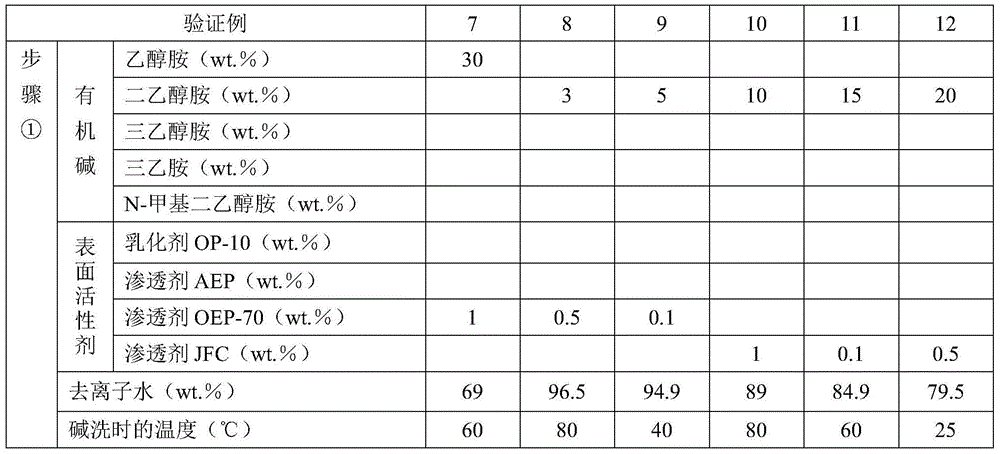

Alkali washing liquid for regenerating SCR denitration catalysts and application thereof

InactiveCN104826669AImprove denitrification rateDispersed particle separationCatalyst regeneration/reactivationBULK ACTIVE INGREDIENTCalcination

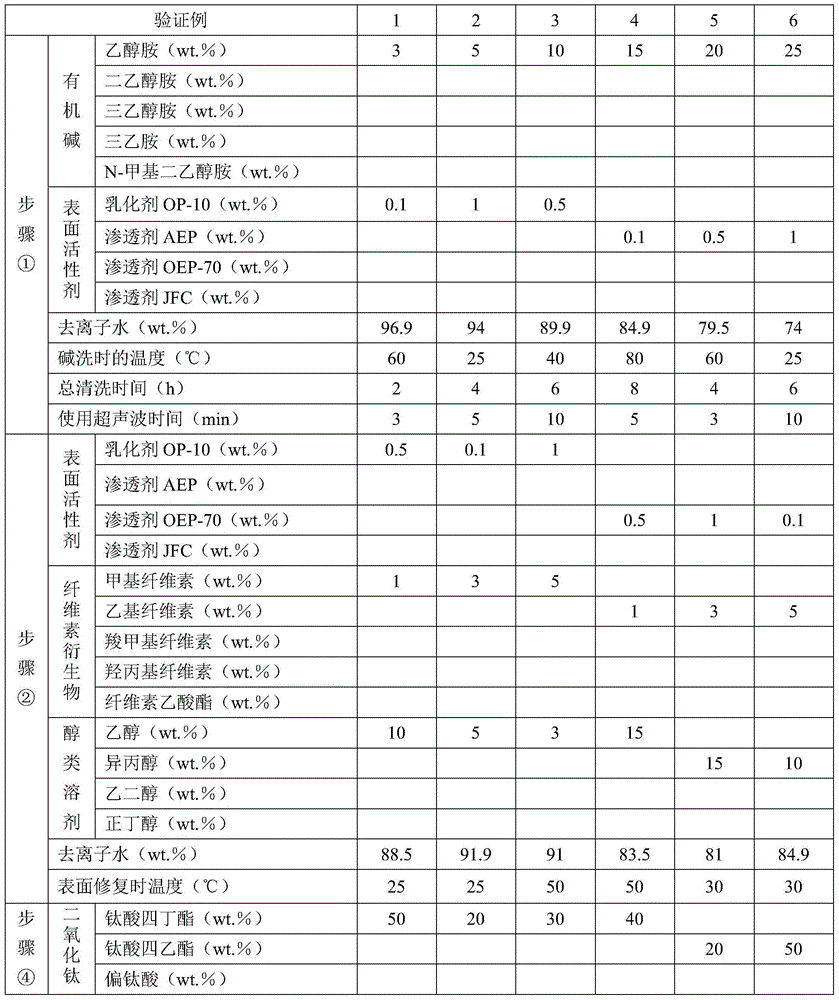

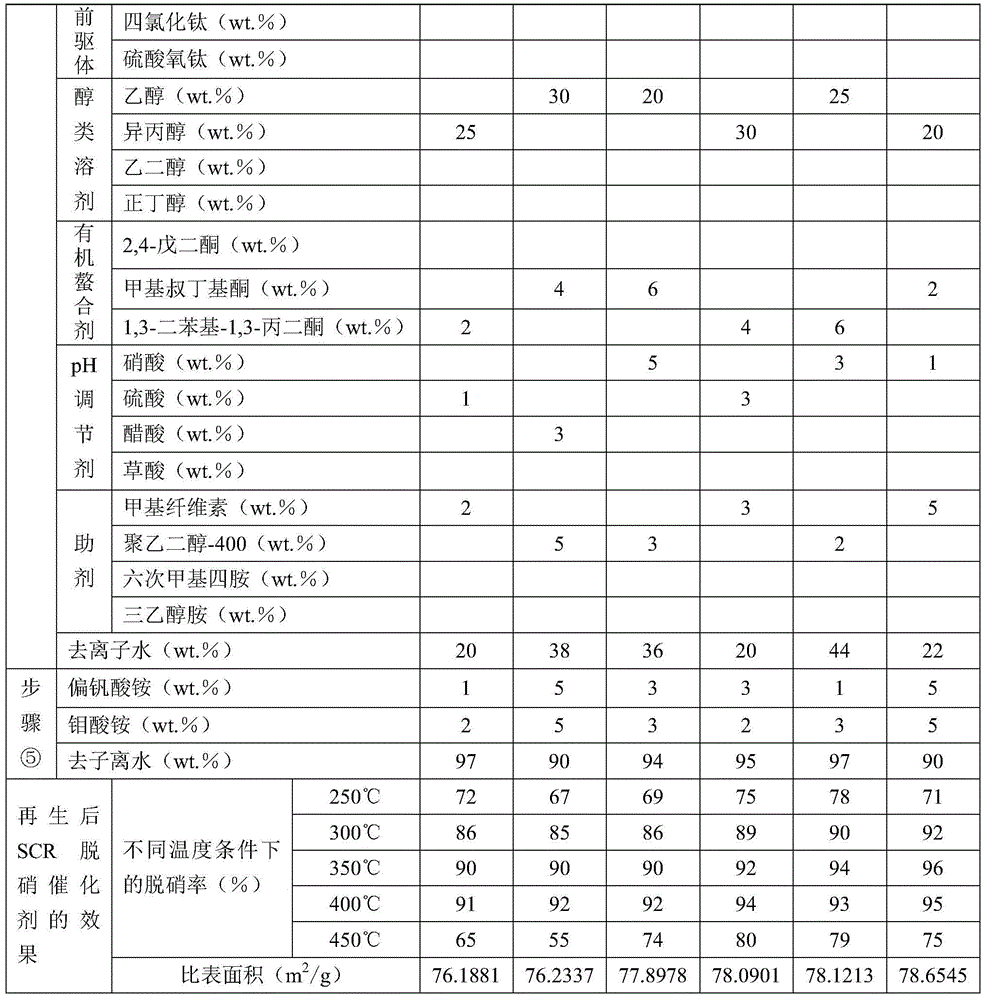

An alkali washing liquid for regenerating SCR denitration catalysts and an application thereof are provided. The alkali washing liquid is composed of an organic alkali, a surfactant and deionized water, wherein the organic alkali is a mixture of one or two of ethanol amine, diethanol amine, triethanolamine, triethylamine and N-methyl diethanol amine. In the method for regenerating the SCR denitration catalysts, firstly, to-be-regenerated SCR denitration catalysts are subjected to air purging and cutting, then immersed in the alkali washing liquid, and subjected to ultrasonic alkali washing. Compared with the prior art, the method has surface repairing and surface reconstruction processes aiming at the to-be-regenerated SCR denitration catalysts increased, and finally, after active ingredient supplementing and calcination processes, the specific surface area and the denitration rate of the obtained regenerated SCR denitration catalysts are both relatively greatly improved compared with those of the conventional washing and regeneration technology. The alkali washing liquid is suitable for regeneration treatment of the honeycomb type, corrugated type and plate type SCR denitration catalysts.

Owner:CHONGQING UNIV

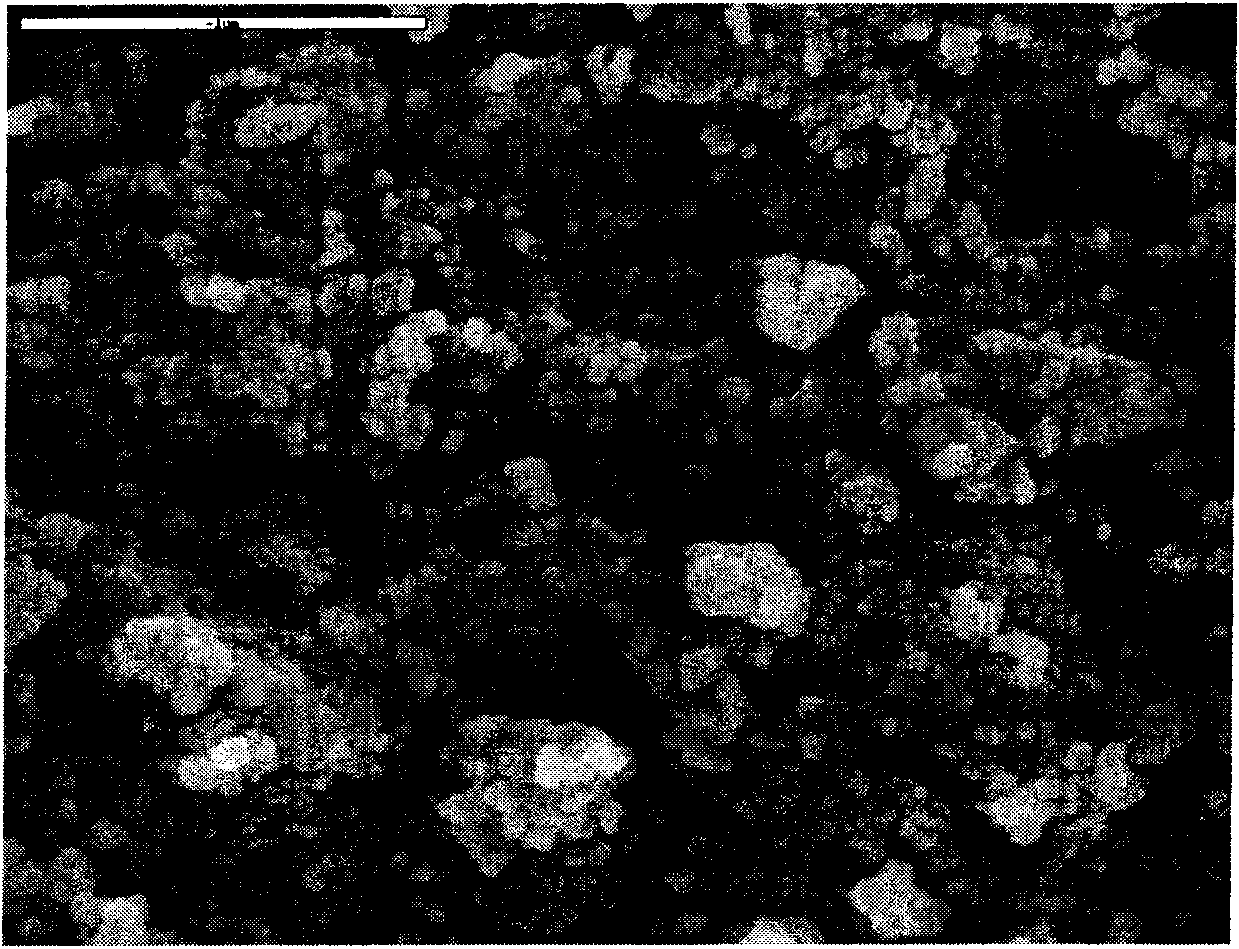

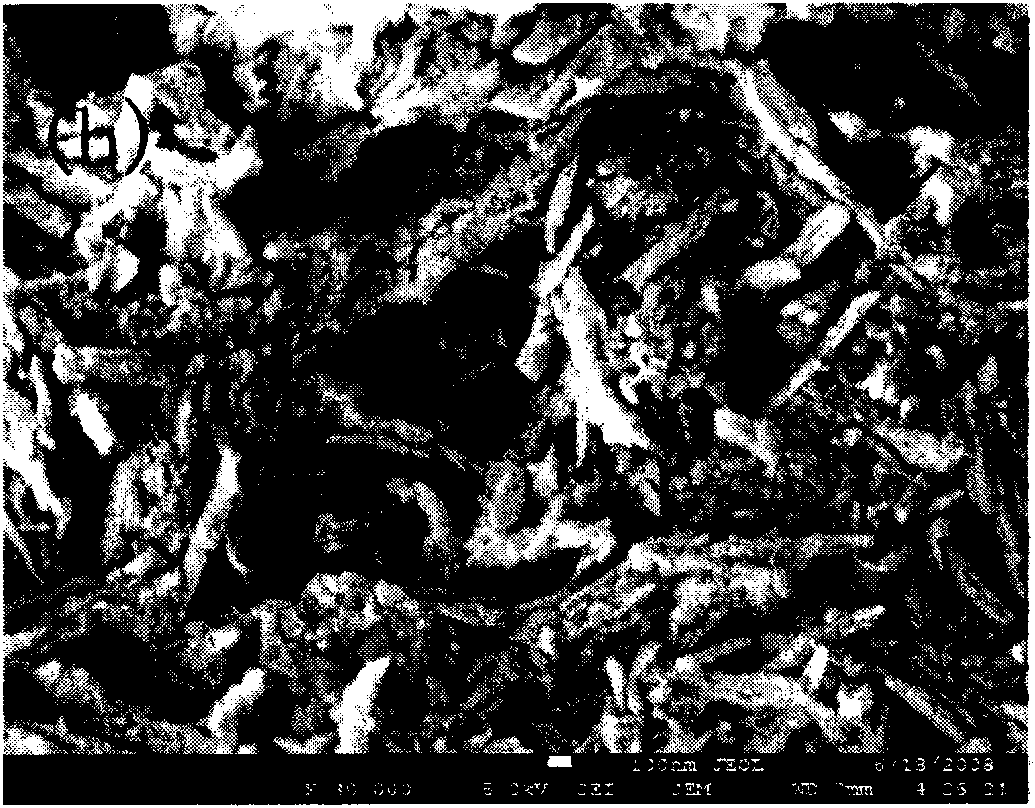

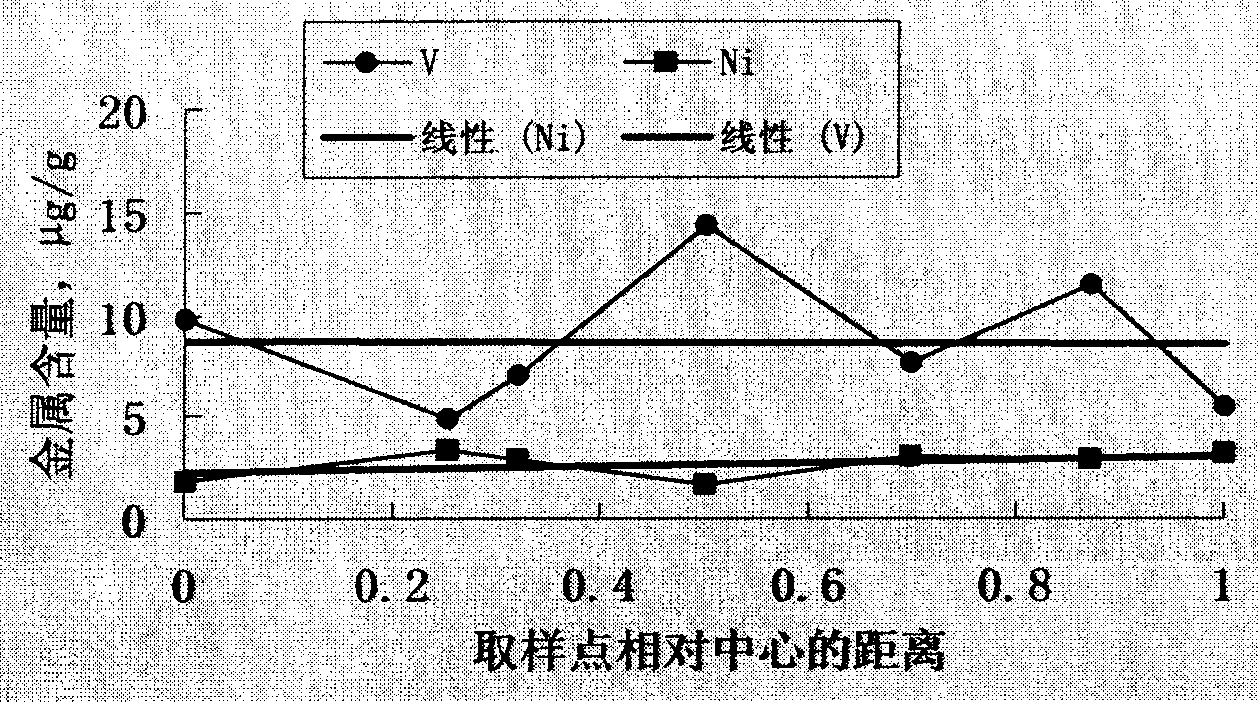

Hydrogenation catalyst and application thereof in residue fixed-bed hydrogenation method

ActiveCN101890378AExtended operating cycleIncrease depositionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPorosityFixed bed

The invention discloses a hydrogenation catalyst and the application thereof in a residue fixed-bed hydrogenation method. The catalyst comprises rod-like nano oxide which is stacked in a framework structure in a disordered way. The catalyst has the advantages of large pore volume, large aperture, high porosity, large outer surface orifice and high duct penetrability. Particularly, when used in the residue fixed-bed hydrogenation method, the catalyst can make reduced metal uniformly deposit on an entire catalyst bed and keep a long-period operation and has a very high desulfurization rate and a very high denitrogenation rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

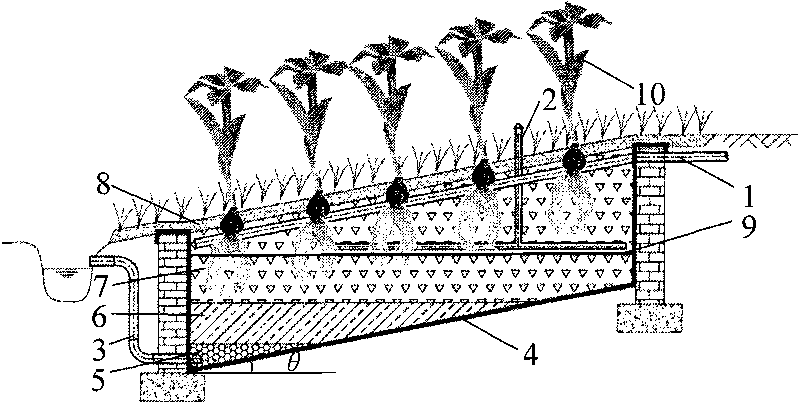

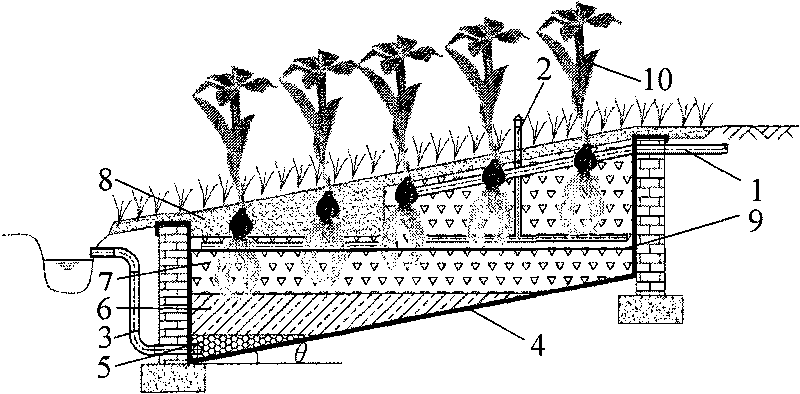

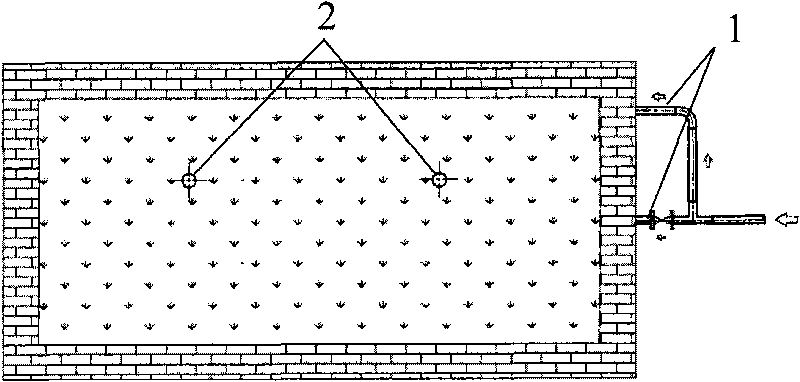

Water treatment technology of inclined plane undercurrent artificial wetland

InactiveCN101708897AConstructed wetlands are simpleRich landscapeTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandSingle stage

The invention belongs to the technical field of environmental protection, in particular to a water treatment technology of inclined plane undercurrent artificial wetland which is composed of water inlet pipe, a vent pipe, a water collecting pipe, an impermeable membrane, a substrate layer and plants; the wetland cross section is a quadrangle which is divided into a nitrification region and a denitrification region; the water to be treated is correspondingly divided into two spouts to enter into the two regions. The flooding water in the nitrification region enters into the denitrification region after nitrification is finished, is mixed with the flooding water in the denitrification region, and utilizes middle carbon source for denitrification, thus realzing the removal of NH4+ / -N and TN. The water treatment technology of the invention is characterized in that nitrification and denitrification reaction are carried out in the same wetland; the nitrogen degassing rate of the single-stage wetland is improved by over 50%; water flows depends on gravity in the purification process; power and operational maintenance are not needed in the treatment process; and the surface of the wetland can be designed into different slopes according to construction of the river channel side slope and mountain land slope and different landscape requirements, thus enriching the landscape of the wetland.

Owner:TONGJI UNIV

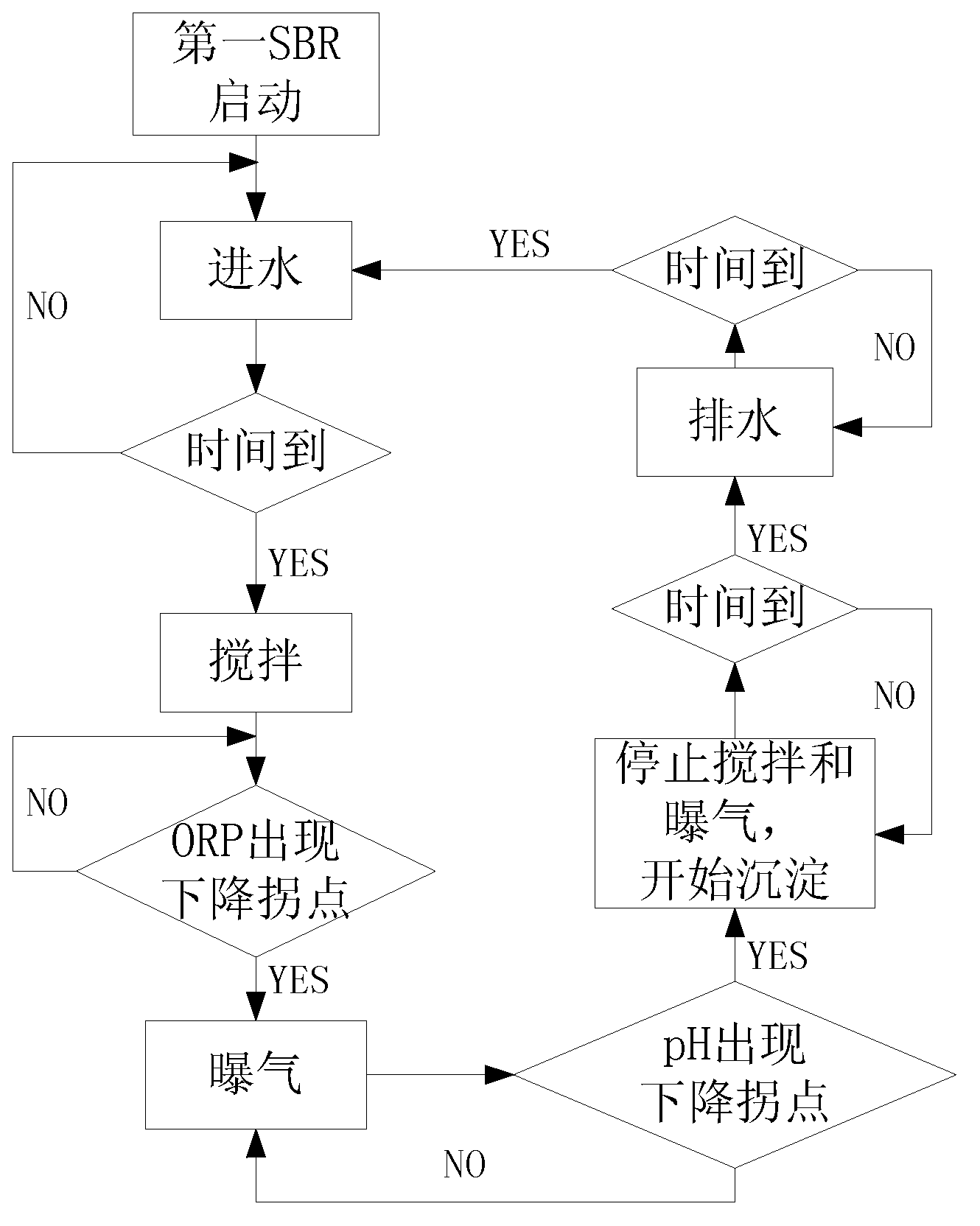

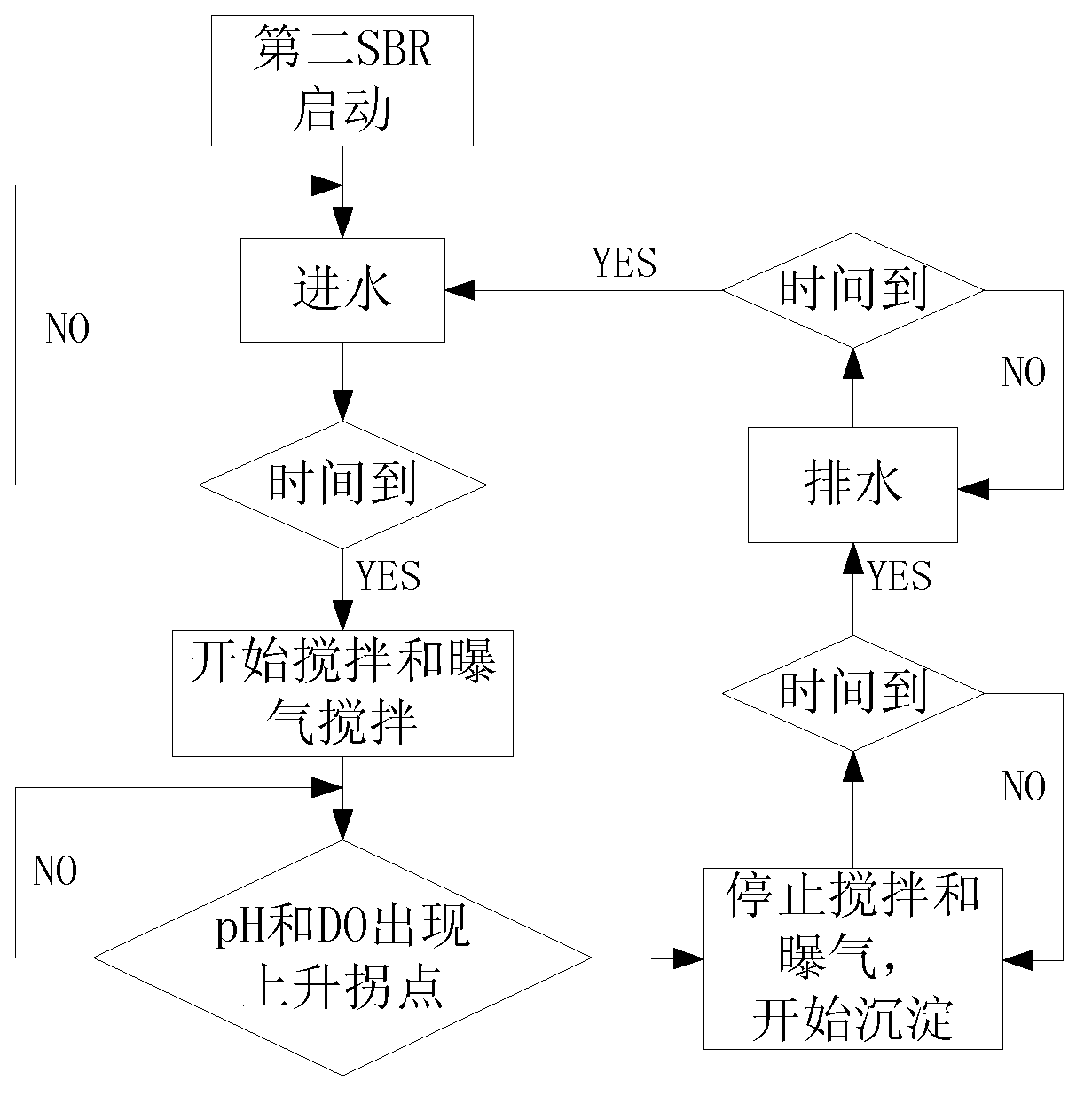

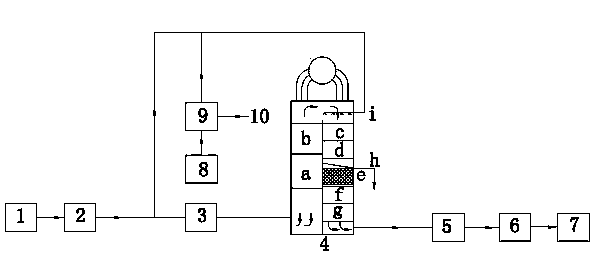

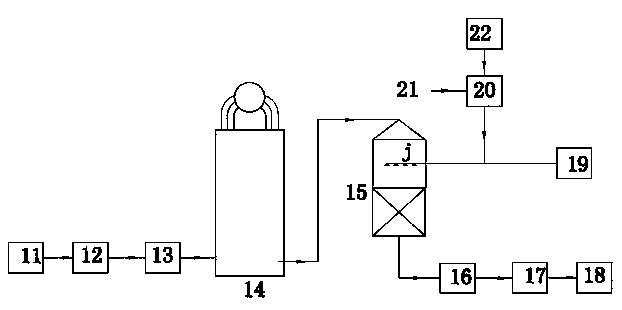

Control method and device for deep denitrification treatment of garbage leachate by combination of short-range nitrification and anaerobic ammoxidation

ActiveCN103011507ARealization of deep denitrificationImprove denitrification rateMultistage water/sewage treatmentProgramme control in sequence/logic controllersSequencing batch reactorDenitrification

The invention discloses a control method and device for deep denitrification treatment of garbage leachate by combination of short-range nitrification and anaerobic ammoxidation, relating to the field of biological sewage treatment. The invention can solve the problem of difficulty in deep denitrification of garbage leachate. Denitrification reaction and organic substance removal are carried out in a first SBR (sequencing batch reactor), and the process is controlled by real-time ORP and pH monitoring. 60% of effluent water of the first SBR directly enters a second SBR to be subjected to short-range nitrification which is controlled by real-time DO and pH monitoring. 40% of effluent water of the first SBR and effluent water of the second SBR are mixed and enter an ASBR (anaerobic sequencing batch reactor) in a continuous water inlet mode to be subjected to anaerobic ammoxidation, and the process is controlled by real-time pH monitoring. After draining, 70% of effluent water flows back to an influent water tank, and the rest of effluent water is discharged for the next cycle. The invention can accurately control the denitrification mixing time as well as organic substance removal and short-range nitrification aeration time, and has the advantages of energy consumption saving, shorter reaction time, no need of external carbon source, high TN removal rate and the like.

Owner:中山公用水务投资有限公司

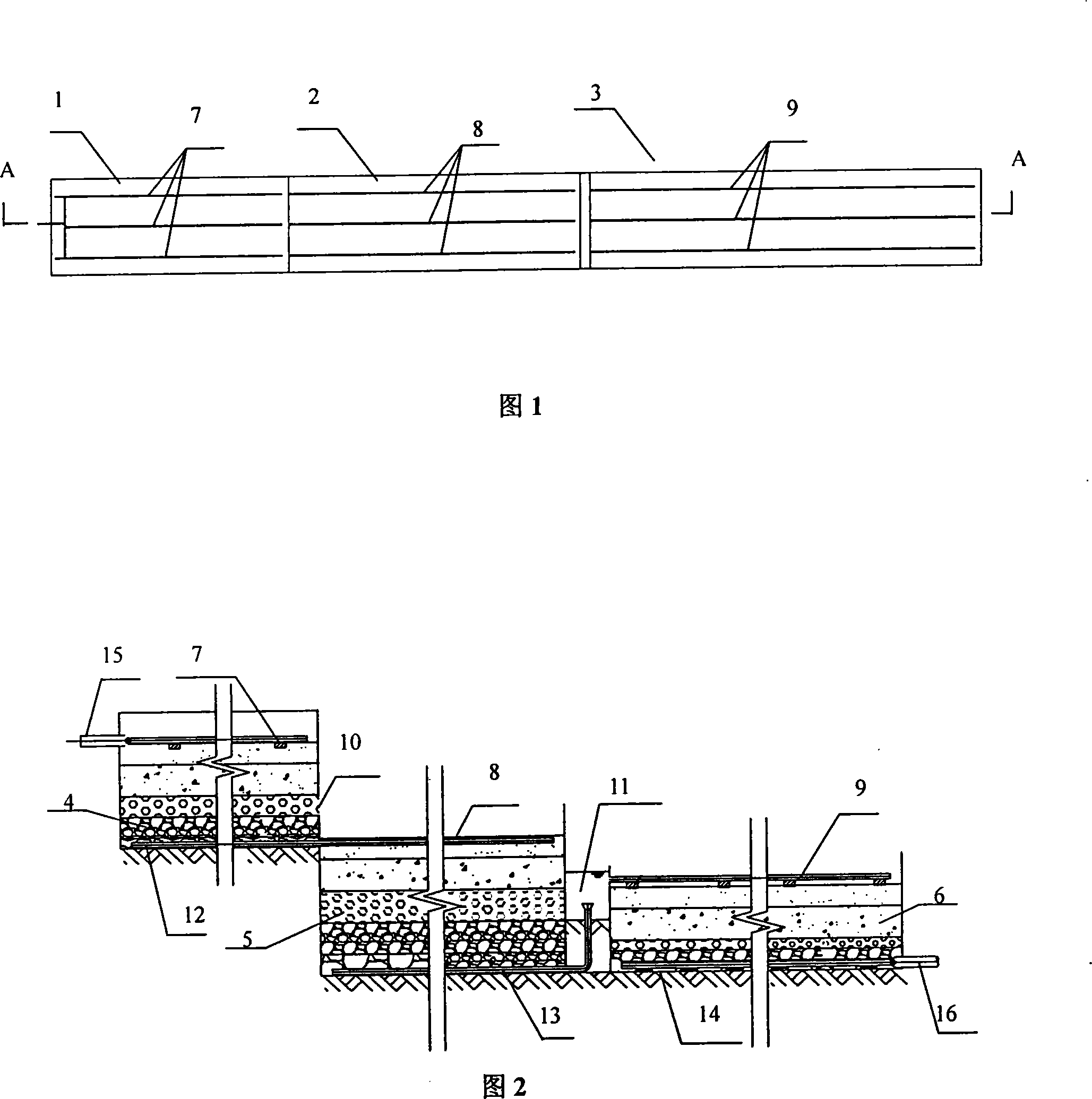

Process method for stairway composite ecological bed clarified sewage and ecological bed thereof

InactiveCN101172712AIncrease dissolved oxygen concentrationImprove denitrification rateTreatment with aerobic and anaerobic processesSewageEngineering

The invention discloses a treatment method for purifying sewage with a ladderlike integral ecological bed. Sewage flows through a three-step integral ecological bed to be treated as nitrification, denitrification, denitrogenation and oxygen enrichment and phosphorus removal, thereby ensuring the stability of the purified outlet water. A water inlet pipe of the ladderlike integral ecological bed is communicated with a perforated water-distributing pipe above the first grade integral ecological bed and a water-gathering weir between the second grade and the third grade of the integral ecological bed, and the sewage is distributed in a free overfall method; the bottom part of the first integral ecological bed is provided with a perforated water-collecting pipe which is communicated with the perforated water-distributing pipe of the second ecological bed; the bottom part of the second integral ecological bed is provided with a water-collecting pipe to guide the outlet water into the water-gathering weir, and the outlet hole of the water-gathering weir is communicated with the perforated water-distributing pipe above a third grade integral ecological bed which is provided with the perforated water-collecting pipe at the bottom part to be communicated with the water outlet pipe. Optimizing the bed structure and the water-distributing system, and adopting the technique of enforcing natural reoxygenation without energy consumption, the invention has the advantages of low cost and steady treatment effect.

Owner:CHONGQING UNIV

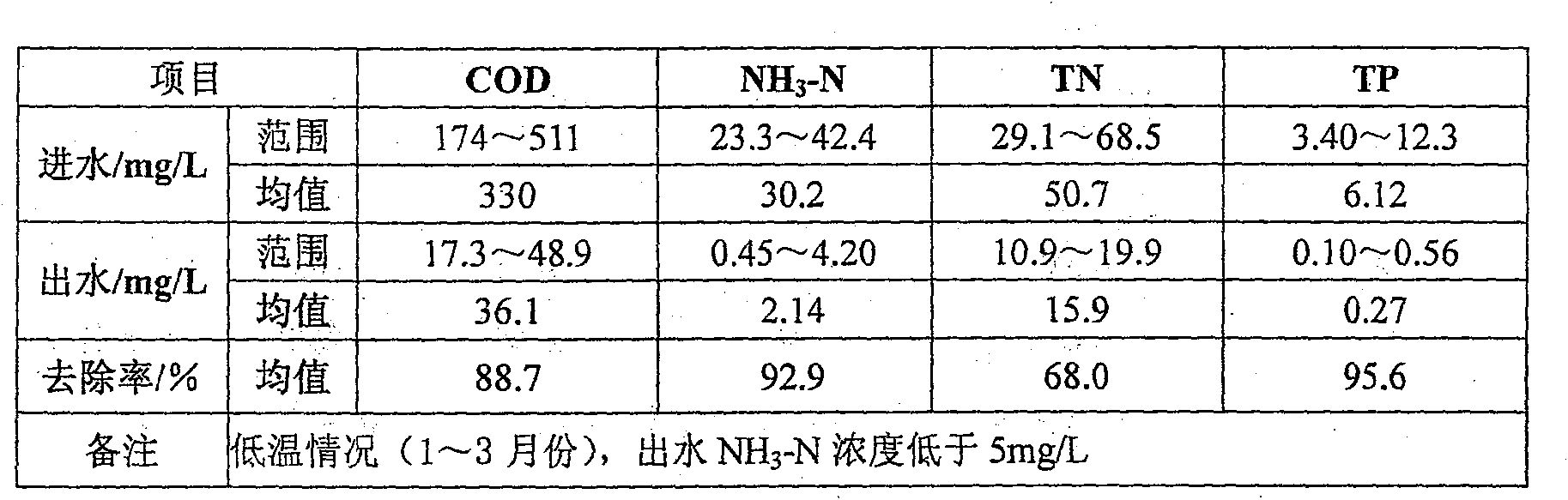

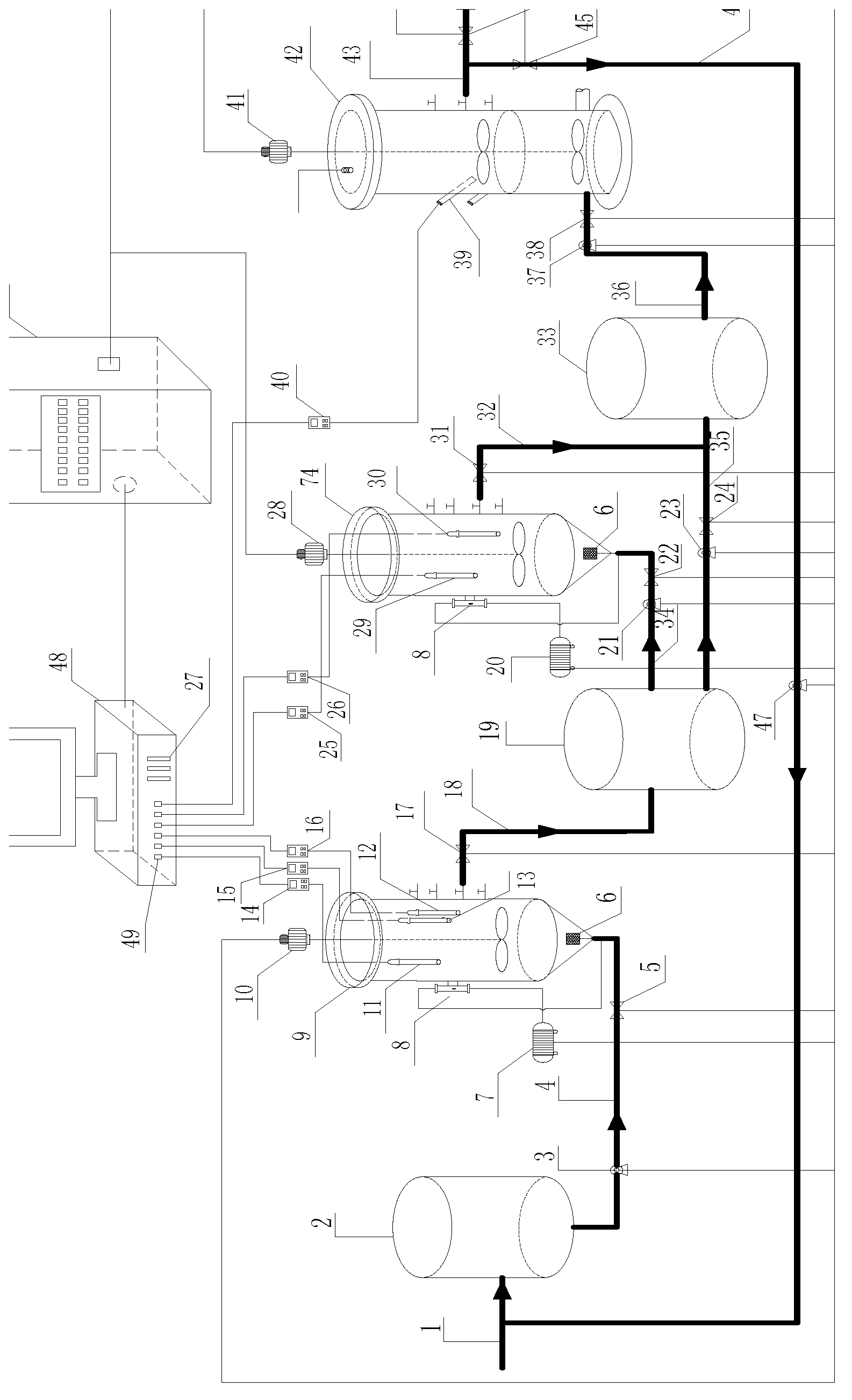

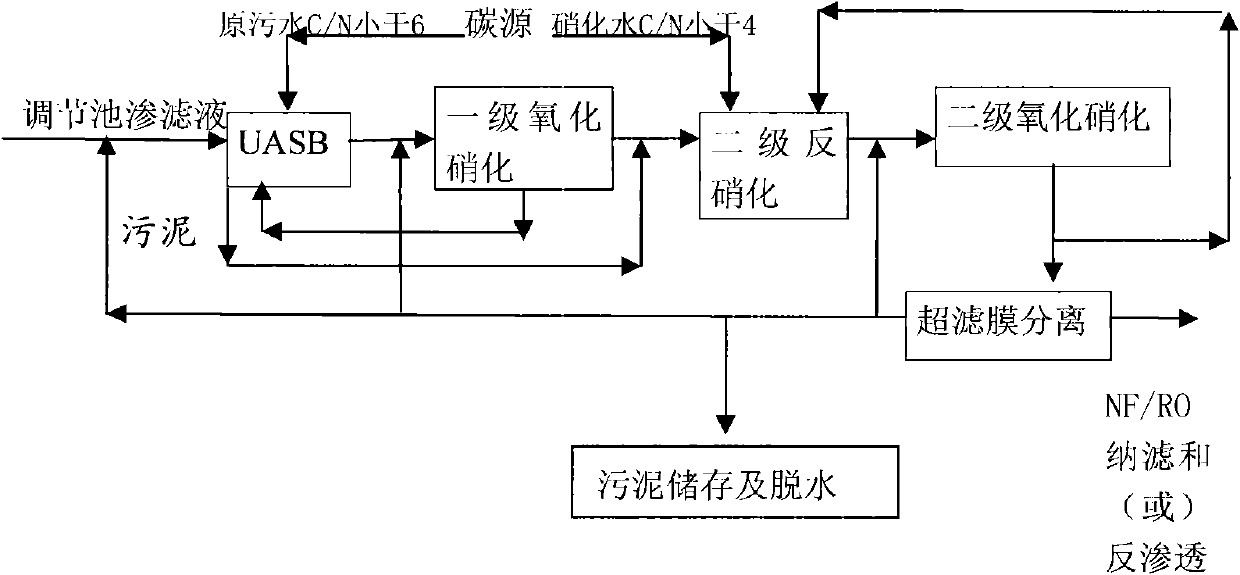

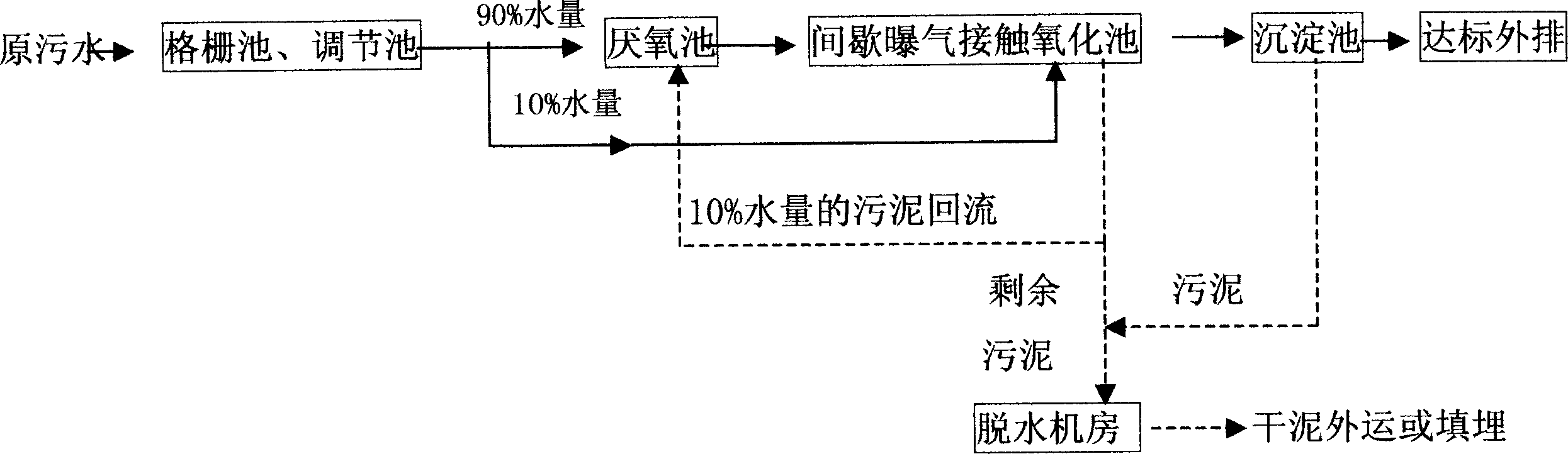

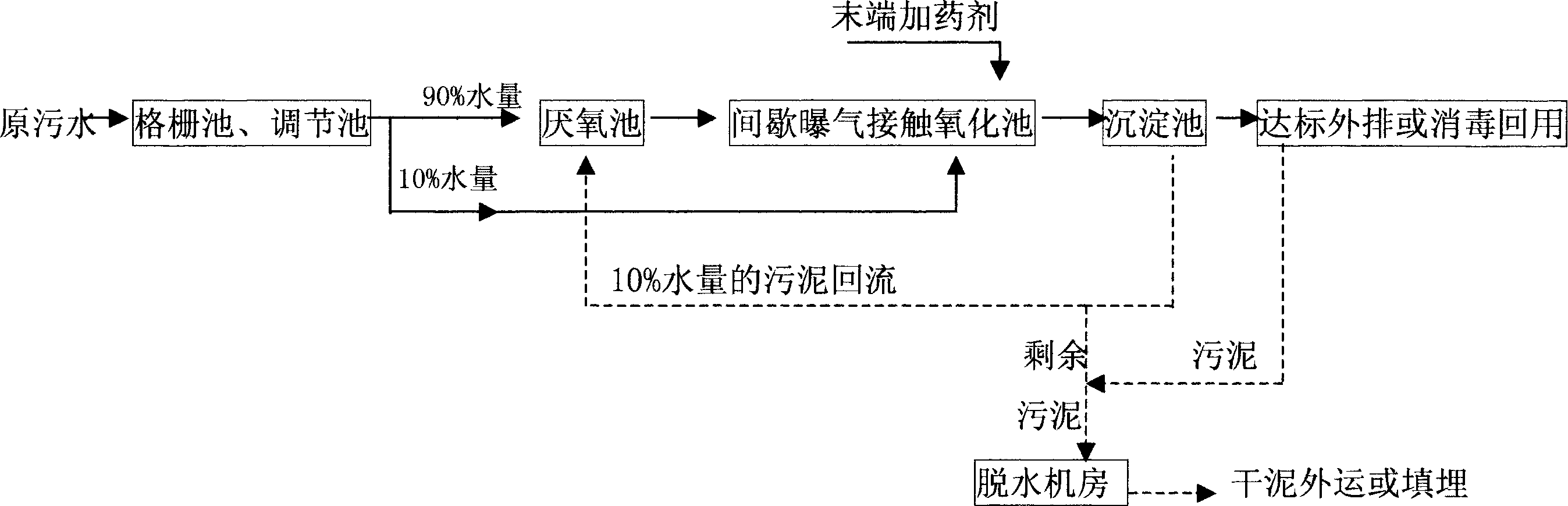

New high-nitrogen organic sewage treatment biochemical denitrification process

ActiveCN102001786ASolve the problem of no refluxReduce denitrificationMultistage water/sewage treatmentFiltration membraneNitration

The invention relates to a new high-nitrogen organic sewage treatment biochemical denitrification process. The process mainly comprises the following technical steps of: 1, feeding raw sewage which accords with conditions into an upflow anaerobic sludge blanket (UASB); and simultaneously feeding reflow mixed solution of a subsequent oxidation nitration tank (O1) and a part of thick solution of a membrane bioreactor (MBR) ultra-filtration membrane separation device into the UASB; 2, simultaneously feeding effluent of the UASB, a part of thick solution of the MBR ultra-filtration membrane separation device and air into the oxidation nitration tank (O1); 3, feeding the effluent of the O1 tank into a denitrification tank (a tank A) of anoxic zone / aerobic zone A / O(2), simultaneously feeding the remaining sludge of the UASB and replenishing carbon, forming an anoxic condition at the tank A to perform denitrification, replenishing the part of thick solution of the MBR ultra-filtration membrane separation device and supplying air (oxygen) into the O(2) tank to further perform oxidation nitration reaction respectively, and removing chemical oxygen demand (COD), biochemical oxygen demand after 5 days (BOD5), total nitrogen (TN) and NH3-N; and 4, feeding the effluent of the A / O (2) into the MBR ultra-filtration membrane separation device, intercepting the active sludge and macromolecularCOD and enriching in the thick solution; feeding the thick solution into the UASB, the O1 tank and the A / O (2) tank respectively; performing sludge dehydration treatment on the remaining thick solution; and removing the COD and the BOD5. The total nitrogen removal rate of the technology is improved by over 50 percent.

Owner:CHINA NERIN ENG

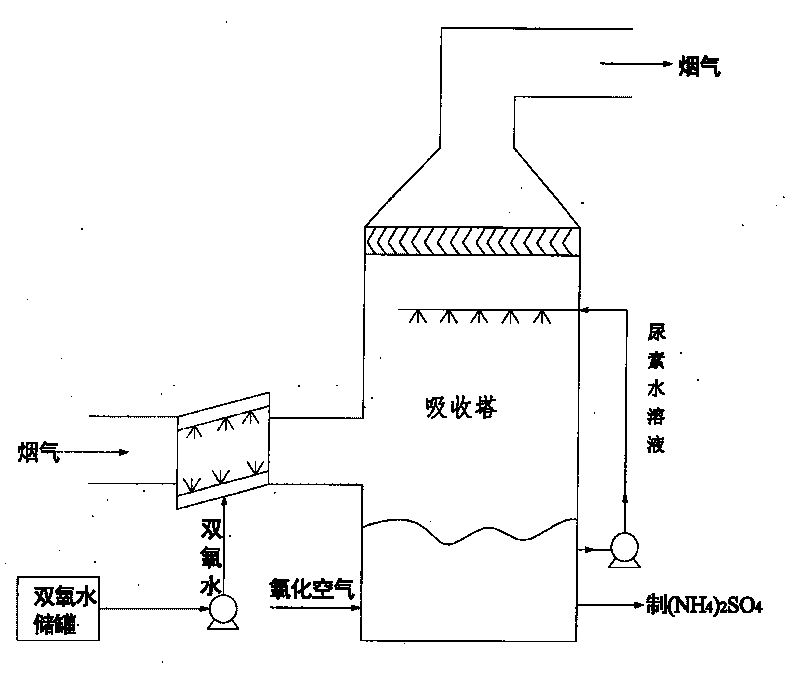

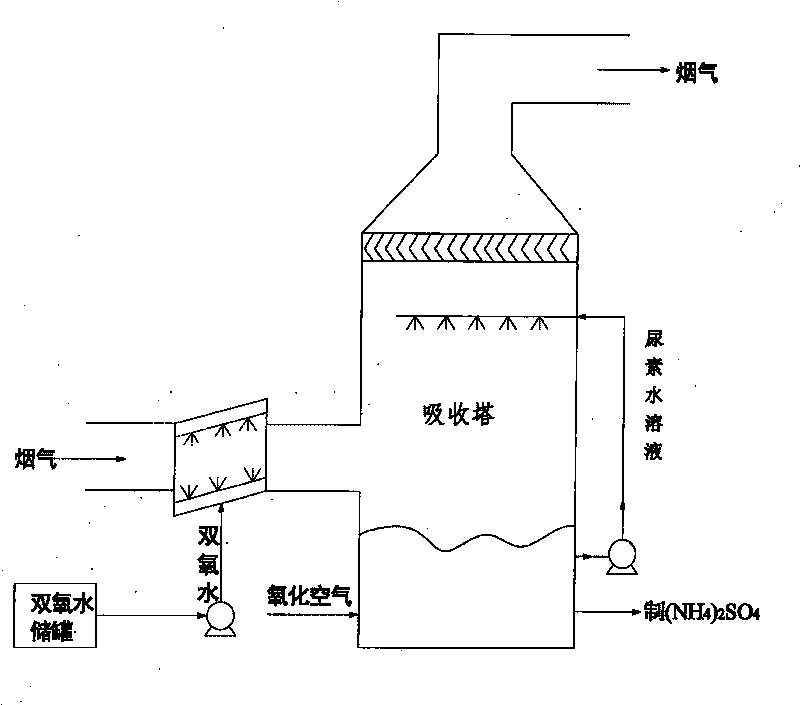

Coal-fired flue gas denitration and desulfurization method combined with urea wet method

ActiveCN101708419AImprove denitrification rateGood chemical stabilityLighting and heating apparatusDispersed particle separationUreaAqueous solution

The invention discloses a coal-fired flue gas denitration and desulfurization method combined with the urea wet method. The method comprises the following steps: spraying 50wt% of hydrogen peroxide at the coal-fired flue gas inlet of a absorption tower while keeping the molar ratio of H2O2 to NO to be 2-3, so as to oxidize NO in the coal-fired flue gas to NO2 and increase the oxidization degree of NOX; and perform denitration and desulfurization simultaneously by using the urea aqueous solution in the absorption tower. The method of the invention increases the denitration rate of the coal-fired flue gas denitration and desulfurization combination technology by increasing the oxidization degree of NOX and the temperature of the absorption solution. The method has simple technology, convenient operation and management, no secondary pollution and good environmental and economic benefits.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

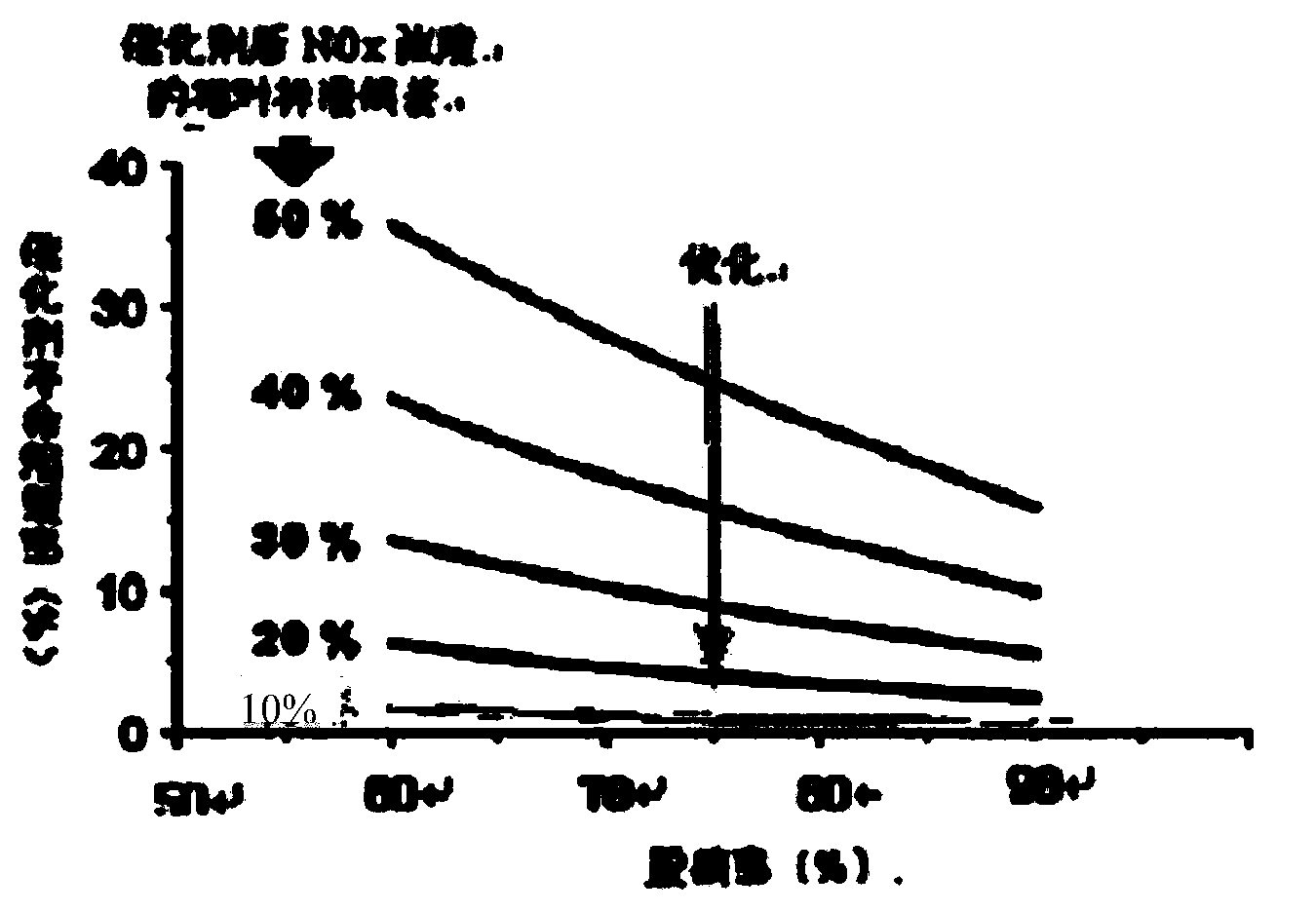

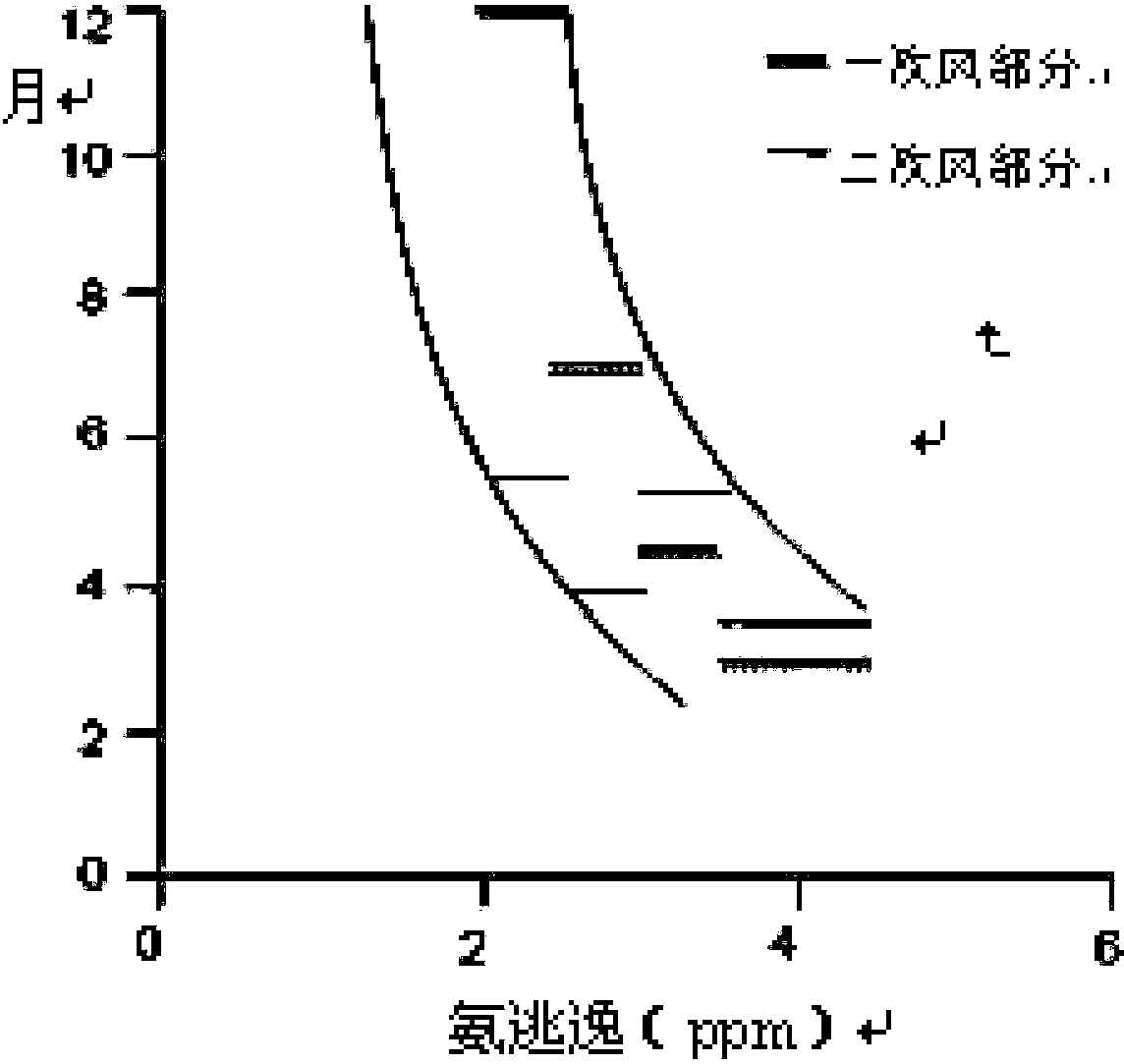

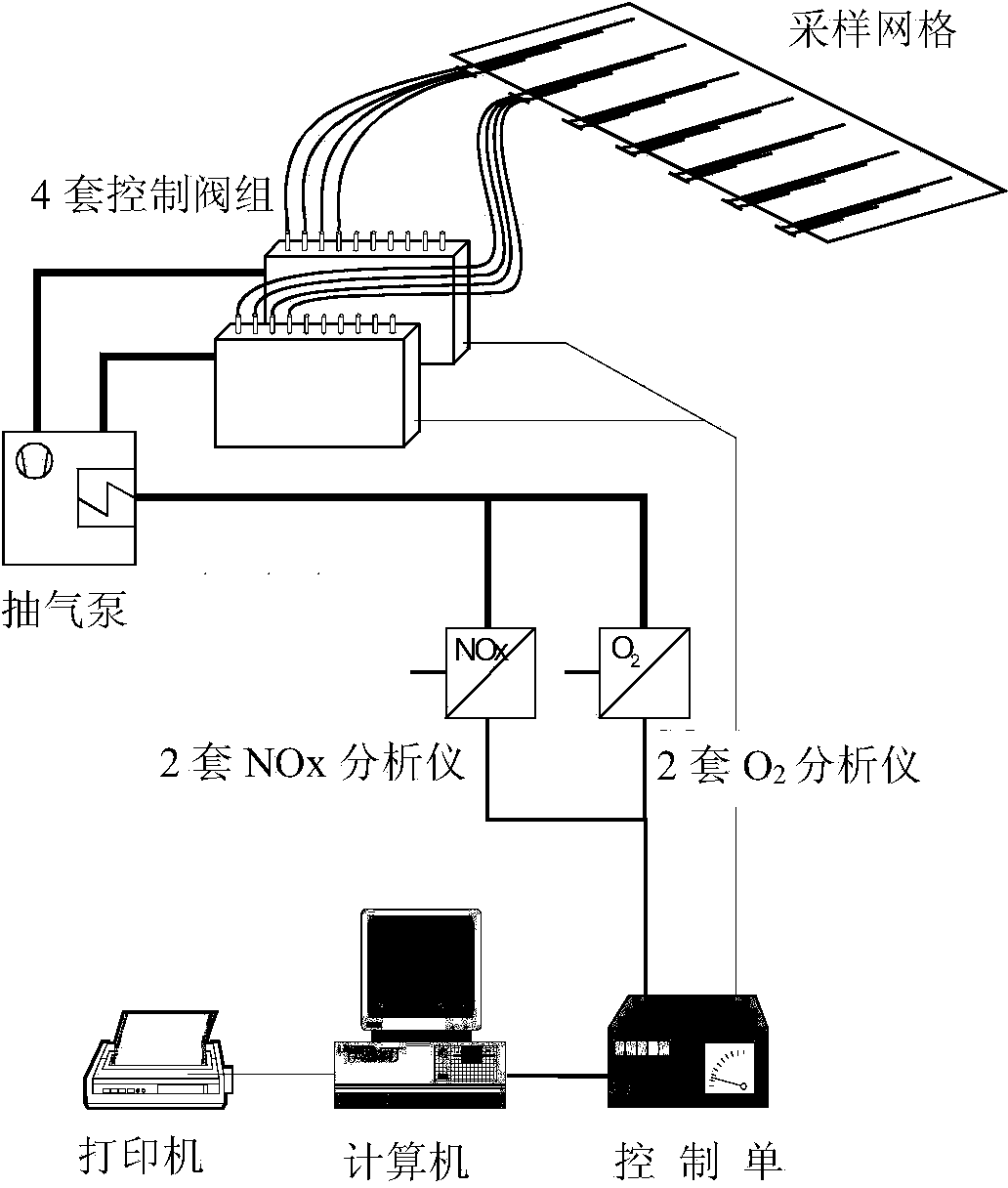

Method for improving denitration rate of SCR (Selective Catalytic Reduction) denitration system of power station boiler

InactiveCN103521073AReduced service lifeReduce availabilityDispersed particle separationSystem safetyValve opening

The invention discloses a method for improving the denitration rate of an SCR (Selective Catalytic Reduction) denitration system of a power station boiler. The method comprises the following steps: (1) measuring concentration distribution of NOx at the outlet of an SCR denitration reactor; (2) calculating the unevenness Cv of concentration distribution of NOx according to the measuring result in the step (1); (3) when Cv is greater than 20%, adjusting the valve opening in an area corresponding to an ammonia injection grid according to the concentration distribution of NOx at the outlet of the SCR denitration reactor; (4) repeating the steps (1) to (3) until Cv is less than or equal to 20%. Through optimization and adjustment by the invention, the evenness of distribution of NOx at the outlet of the SCR denitration reactor is remarkably improved, and the relative standard deviation of NOx is reduced from 46.4% to 14.8%. On the premise of ensuring that ammonia escape does not exceed standard, the denitration rate is improved from 77% to 83%. The method disclosed by the invention has important guiding meaning and engineering application value to safe, efficient and stable operation of the SCR denitration system of the power station boiler.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

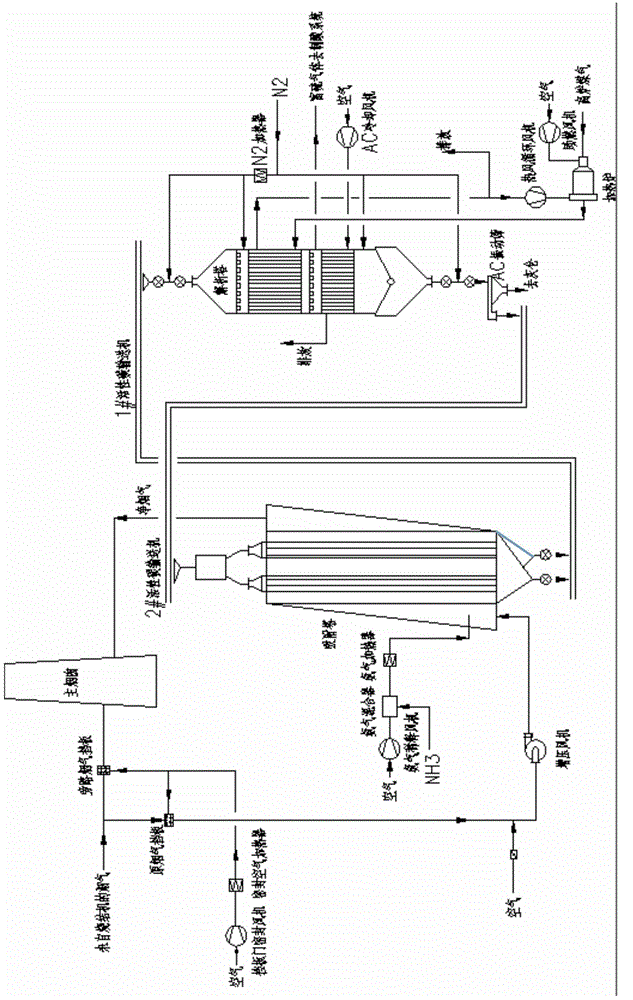

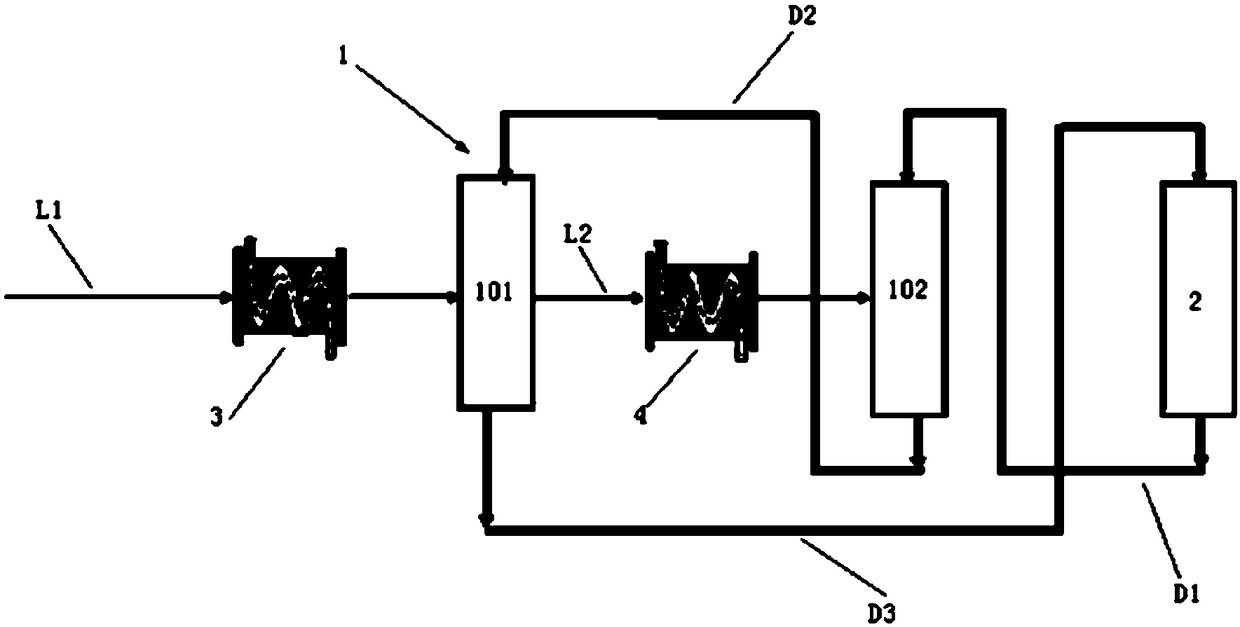

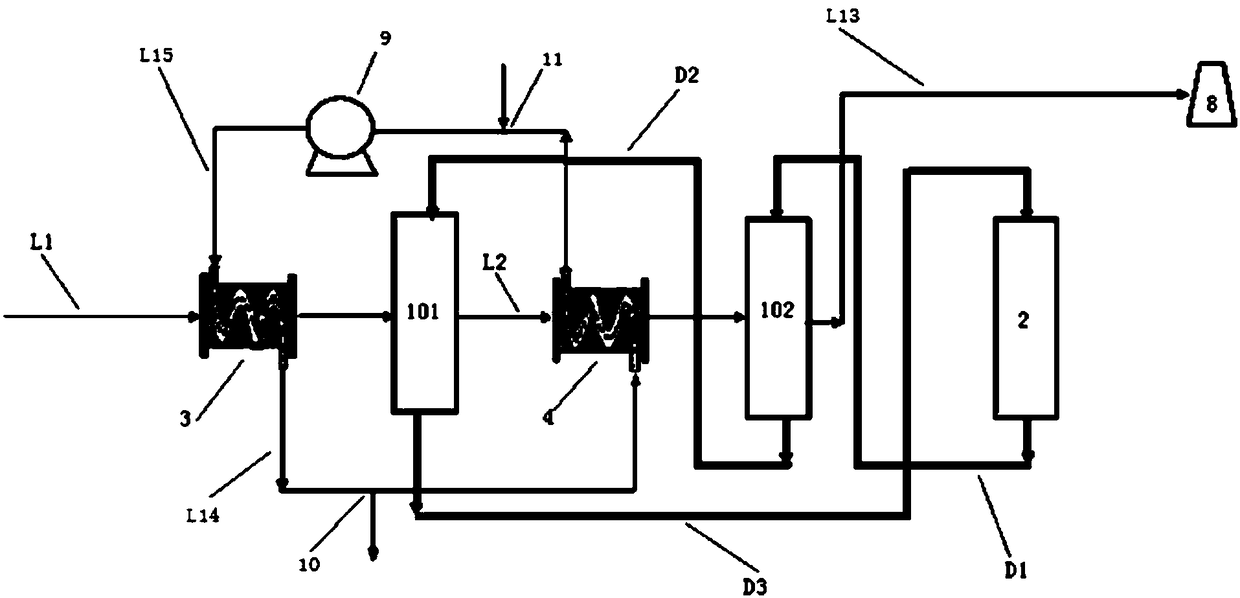

Activated carbon treatment system for improving waste heat utilization rate and denitration rate and using method thereof

ActiveCN108939808AGuaranteed temperatureImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationActivated carbonFlue gas

The invention provides an activated carbon treatment system for improving waste heat utilization rate and denitration rate and a using method thereof. Heat exchangers are separately disposed before flue gas is input into a first-stage adsorption column and a second-stage adsorption column, the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column is controlled, thereby ensuring the temperature of desulfurization and denitration. The activated carbon treatment system utilizes high-temperature flue gas (about 150-170 DEG C) after a main exhaust blower, adopts a mode of heat exchange, artificially controls the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column, and enables the efficiency of removal of SO<2> and NO<x>; and the utilization rate of the high-temperature flue gas after the main exhaust blower is increased, and the temperature of the flue gas entering a desulfurization tower and a denitration tower is controlled to improve the efficiency of desulfurization and denitration.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

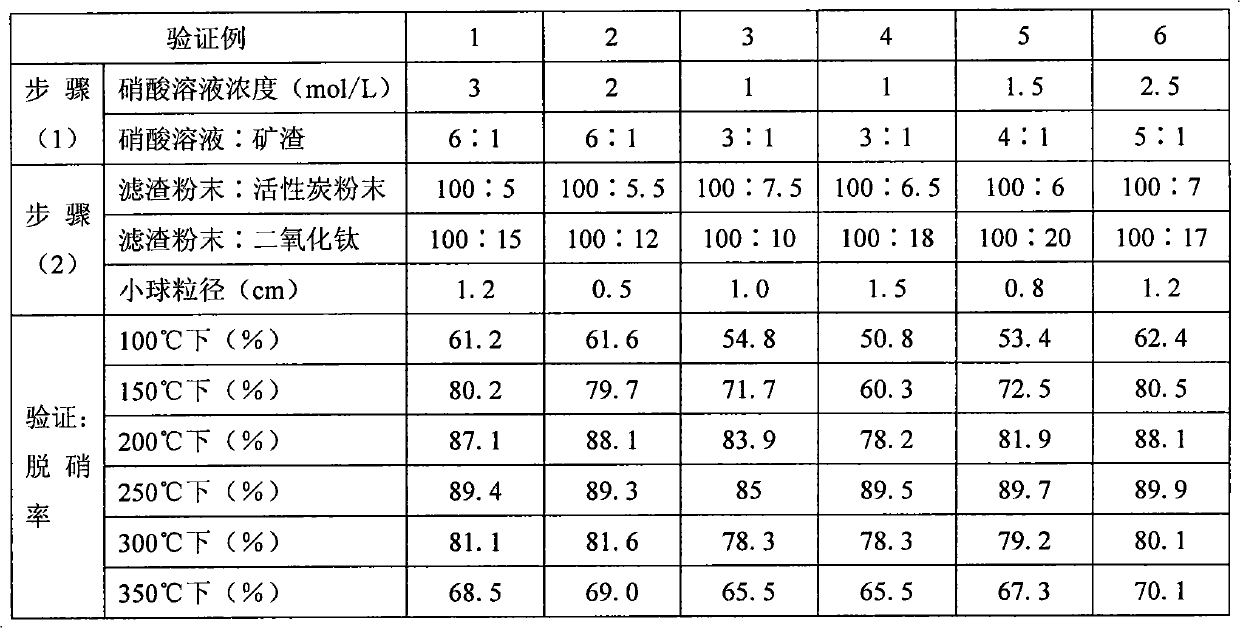

Method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and catalyst thereof

InactiveCN102000563ALow raw material costHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated charcoal powderPtru catalyst

The invention relates to a method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and a catalyst thereof. The catalyst uses slag remained after potassium manganate is extracted as a main raw material. The preparation method comprises the following steps of: washing slag by a nitric acid solution, filtering the slag, drying and pulverizing; fully mixing filter slag powder with active carbon powder; then after adding titanium dioxide sol and deionized water for being adjusted into proper slurry, rubbing into strips and preparing small balls; and drying and roasting in sequence for activating. Compared with the prior art, the SCR denitration catalyst has catalytic activity in the range of smoke temperature of 150-350 DEG C and higher catalytic activity compared with the prior art within 200 DEG C and 300 DEG C (particularly 250 DEG C or so); and by applying the catalyst of the invention for carrying out SCR denitration, the denitration rate is high. The invention also has the advantages of raw material cost saving, elimination of pollution of high-valence manganese-contained wastes on environment and simple preparation process.

Owner:CHONGQING UNIV

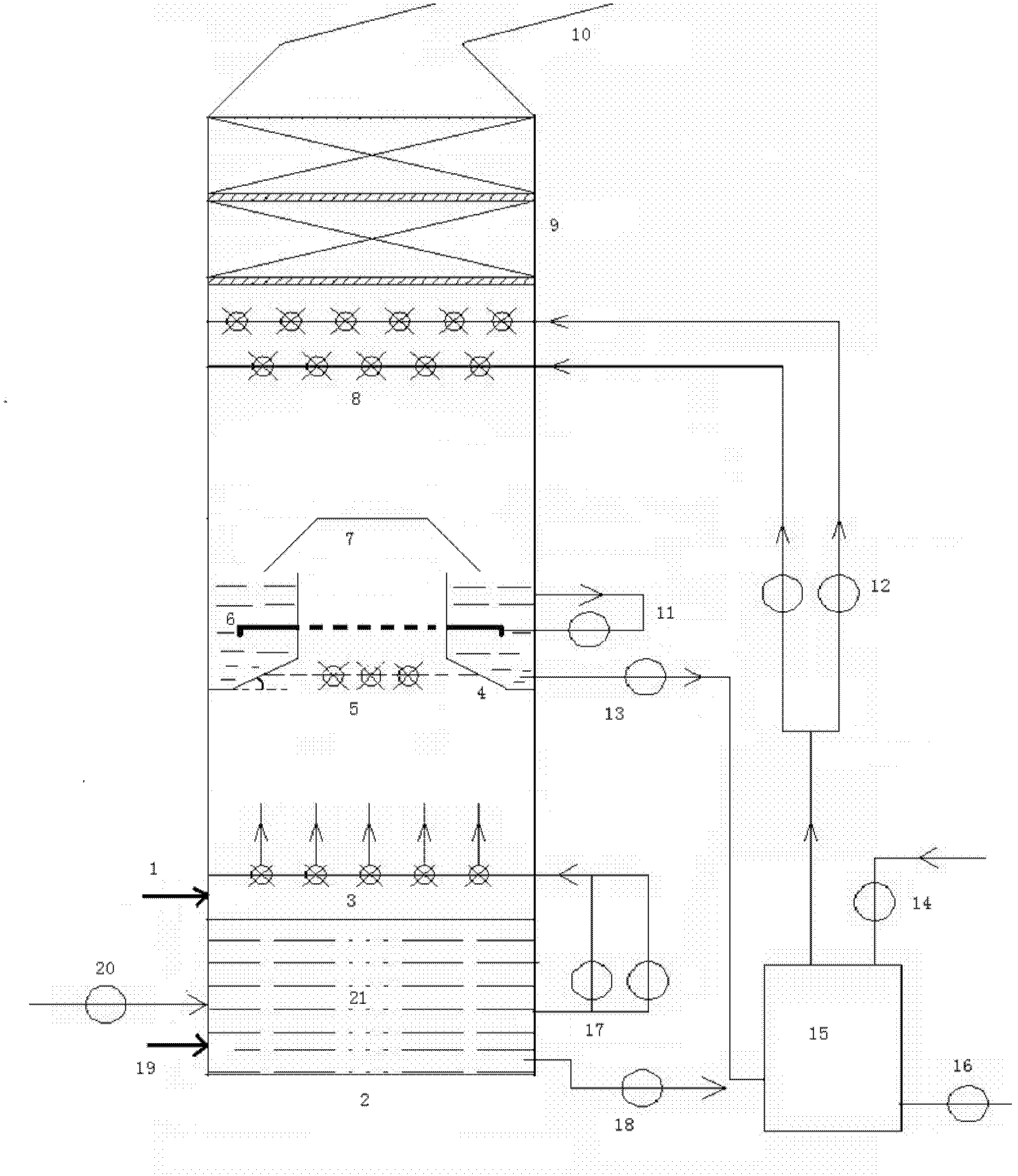

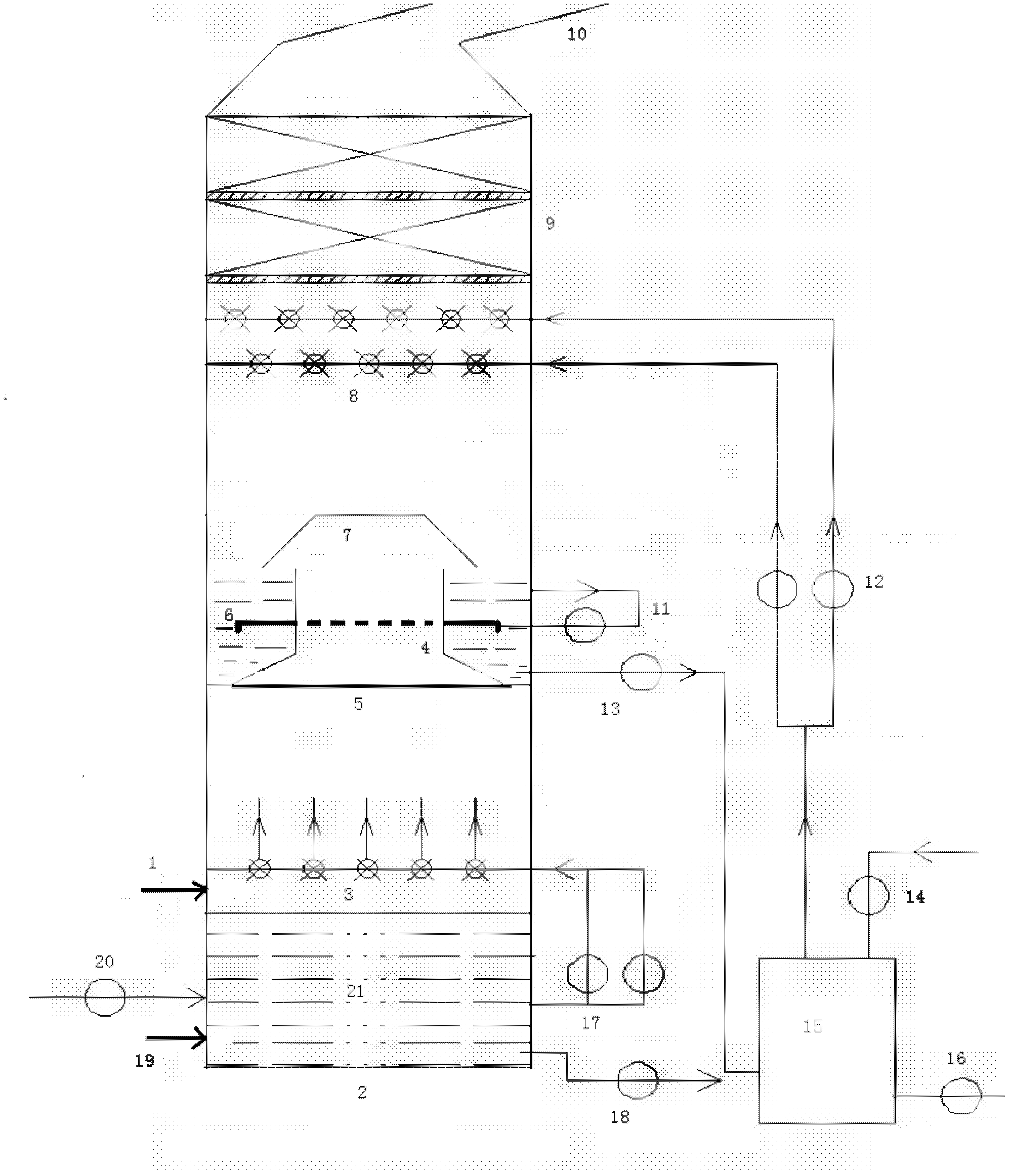

Novel ceramic membrane tube with catalytic function and preparation method of novel ceramic membrane tube

ActiveCN106732641ALow running costThe preparation method is simple and controllableSemi-permeable membranesDispersed particle filtrationActive componentCatalytic function

The invention provides a novel ceramic membrane tube with a catalytic function and a preparation method of the novel ceramic membrane tube. The novel ceramic membrane tube comprises a support with one end open, a separation membrane coating the surface of the support, catalytic cotton filled in an inner cavity of the support and a honeycomb ceramic baffle which seals an opening of the support to be used for blocking and pressing the catalytic cotton. The novel ceramic membrane tube and the preparation method have the advantages that the method is novel and simple to implement, the original structure and the filtering function of the membrane tube are maintained, the catalyst function of the membrane tube is realized, the contact area of the catalytic active component and to-be-filtered gas is increased, the catalytic purification effect is improved, the catalytic component can be replaced or retreated after the ceramic membrane tube is used for a period of time due to the fact that the catalyst and the membrane tube can be separated, the service life of the membrane tube is prolonged, and the use cost is reduced.

Owner:江苏省陶瓷研究所有限公司 +1

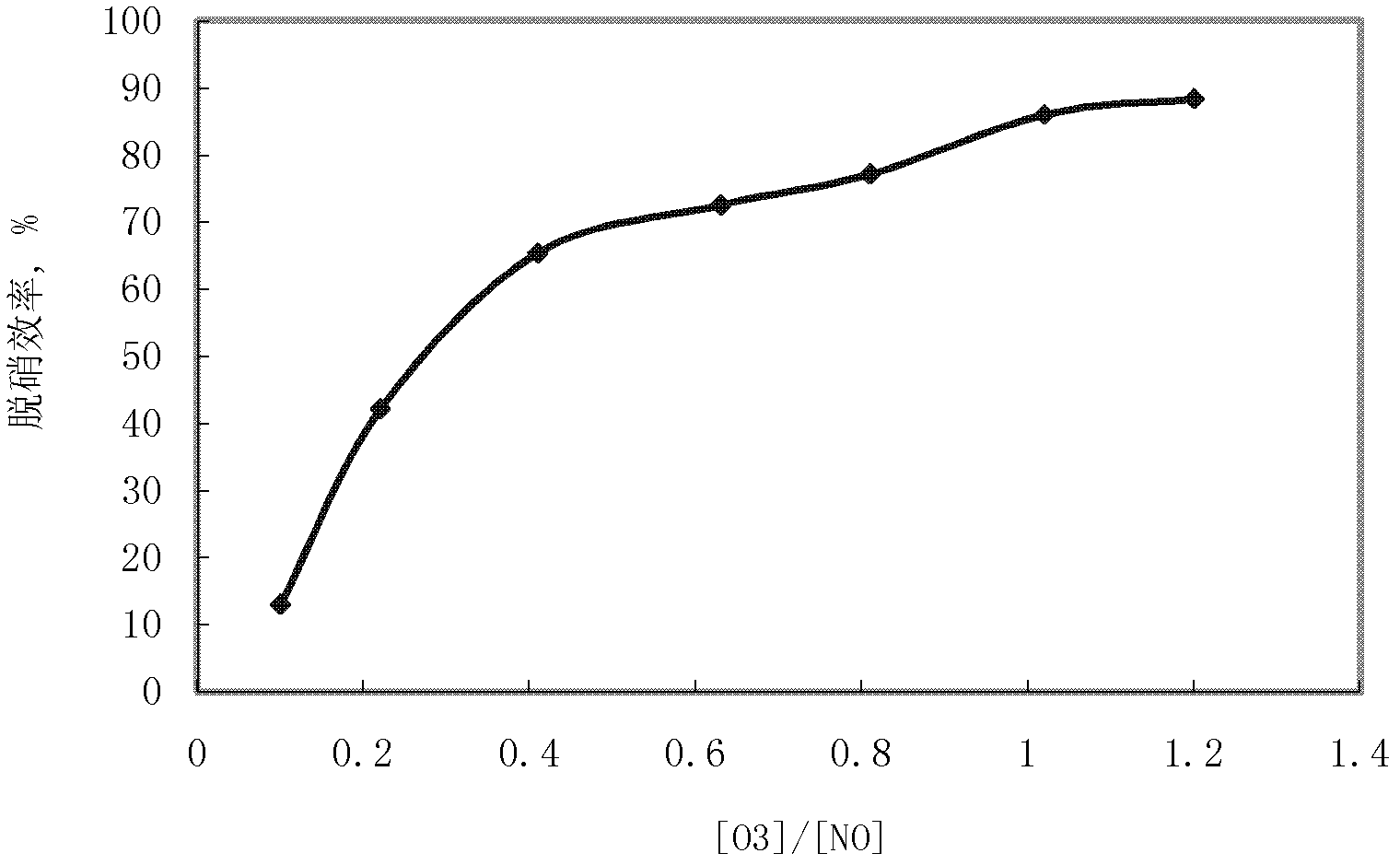

Boiler flue gas ozonation and denitration method

InactiveCN109224820AImprove absorption efficiencyEfficient oxidationDispersed particle separationNitrogen monooxideFlue gas

The invention belongs to the technical field of environmental protection, and particularly relates to a boiler flue gas ozonation and denitration method which comprises the following steps: spraying oxygen into a boiler flue; when the temperature of the boiler flue is reduced to 200-250 DEG C, spraying ozone into the boiler flue, wherein the ozone experiences an oxidation reaction with nitrogen monoxide in the flue to generate a mixed gas of NO2, NO3 and N2O5; feeding the mixed gas into a denitration absorption tower from the bottom of the denitration absorption tower; adding absorption liquidinto a tower kettle of the denitration absorption tower; pumping the absorption liquid to the upper part of the denitration absorption tower by a circulating pump; performing spray circulation absorption to realize denitration of the mixed gas; discharging the denitrated flue gas through a chimney. With a high denitration rate, the method provided by the invention greatly reduces air pollution and realizes harmless treatment of the flue gas and thus completely satisfies current discharge standard.

Owner:实友化工(扬州)有限公司

Regenerated liquid of vanadium and titanium-based selective catalytic reduction (SCR) denitration catalyst

InactiveCN103878035AEasy to handleMaintain strengthDispersed particle separationCatalyst regeneration/reactivationHazardous substanceTungstate

The invention discloses a regenerated liquid of a vanadium and titanium-based selective catalytic reduction (SCR) denitration catalyst. The regenerated liquid comprises a cleaning liquid and an active replenishing liquid, wherein the cleaning liquid consists of alkaline organic salt, a surfactant and deionized water; the active replenishing liquid consists of weak acid, ammonium metavanadate, ammonium tungstate, cerous nitrate and deionized water. The cleaning liquid ingredient in the denitration catalyst regenerated liquid provided by the invention can eliminate adverse effects of harmful substances to the SCR denitration catalyst, and recover the pore pathway structure; the active replenishing liquid ingredient can improve the activity of the denitration catalyst, increase the thermal stability of the catalyst, and prolong the service life of the catalyst; the denitration ratio of the regenerated catalyst can reach 82%-90%; the SO2 / SO3 conversion rate is less than 1%; the service life of the regenerated liquid is mo than 85% of that of a fresh catalyst.

Owner:北京宏庚环保科技有限公司

Flue gas simultaneous desulfurization and denitrogenation by utilizing triethylenediamine cobalt (III) and carbamide

InactiveCN1768903AReduce dosageLow costDispersed particle separationAir quality improvementEthylenediamineCatalytic oxidation

The invention relates to a method for synchronously de-sulfuration and de-nitrification with ethanediamine cobalt and carbamide wet method from smoke. The invention uses absorption solution to absorb the SO2 and NO of smoke, while the absorption solution is prepared by water-soluble inorganic cobalt salt, ethanediamine, carbamide, and sodium-hydroxide water solution, while the water-soluble inorganic cobalt salt can react with ethanediamine to generate ethanediamine cobalt. The invention uses ethanediamine cobalt as absorbent and catalysis oxidant of NO, while in the purpose for avoiding the Co2(SO3)3 reducing NO removing ratio, it adds carbamide and uses O2 as oxidant to transform the SO32- completely into SO42, to realize de-sulfuration and de-nitrification synchronously. The invention can make lowest concentration of SO3 and NO at outlet reach 0%, the oxidization ratio of SO32- reach 100%, and the ethanediamine cobalt can be regenerated easily, therefore, it only needs material one time. Since the cost of carbamide is lower, the total cost of chemical agents is lower without secondary pollution, which can apply the industry.

Owner:SOUTH CHINA UNIV OF TECH

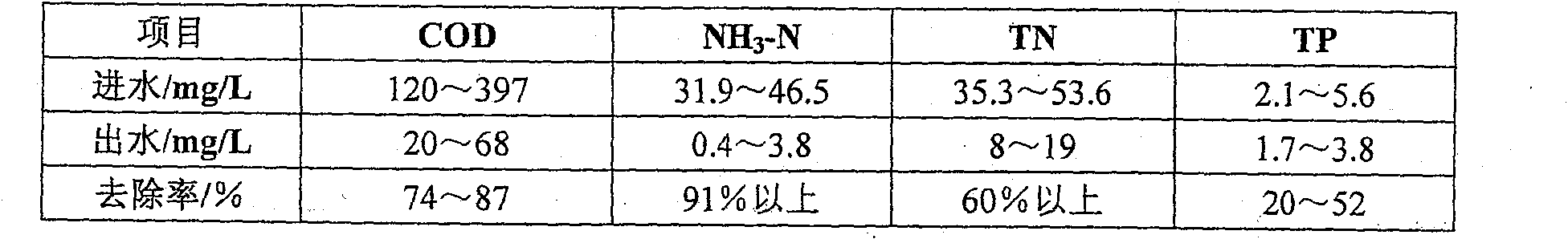

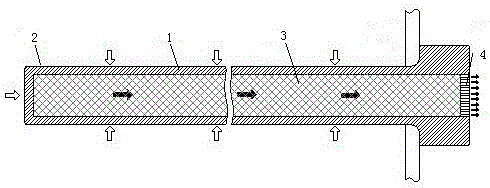

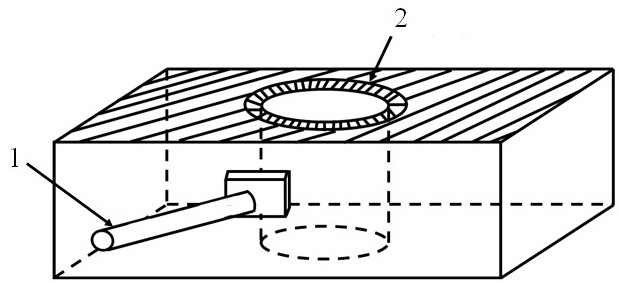

Domestic sewage treatment method by intermittent aeration contact oxidation process

InactiveCN1594140AIntermittent time flexible regulationImprove denitrification rateWater/sewage treatmentTreatment with aerobic and anaerobic processesSludgeWater quality

The invention provides a domestic sewage treatment device and method by intermittent aeration contact oxidation process, wherein the device comprises a regulating reservoir (or water collecting tank), an naerobic pool, an intermittent aeration contact oxidation pool, a deposition pool and pipe-lines, water pumps for connecting these pools, a bagger is arranged on the extremity end of the intermittent aeration contact oxidation pool. The intermittent aeration contact oxidation pool can be charged with agents on the tail end as required, the sludge in the bagger returns to the anaerobic pool for treatment.

Owner:戴双建

Preparation method of Cu-Fe-ZSM-5-attapulgite compound flue gas denitrification catalyst

ActiveCN103447079AImprove use valueLarge specific surface areaNitrous oxide captureMolecular sieve catalystsFiltrationCopper salt

The invention discloses a preparation method of a Cu-Fe-ZSM-5-attapulgite compound flue gas denitrification catalyst. The preparation method comprises the following steps: firstly, preparing acidified attapulgite from attapulgite through burning, hot acidic liquor treatment, suction filtration and water washing; secondly, adding an alkali liquor and an organic template agent, and carrying out aging, hydrothermal crystallization, suction filtration, water washing, drying and calcining to prepare ZSM-5 zeolite; next, mixing the ZSM-5 zeolite with the attapulgite and a mixed solution of a copper salt and an iron salt and stirring, carrying out heating reflux treatment, and finally, carrying out drying, strip extrusion and calcining moulding to prepare the Cu-Fe-ZSM-5-attapulgite compound flue gas denitrification catalyst. The preparation method is characterized in that the attapulgite carrier and a viscosity characteristic are utilized, low-cost ZSM-5 zeolite is added, the adsorption characteristic of the ZSM-5 to NO is utilized and a cheap iron salt is introduced so that the cost is reduced, and consequently, the obtained catalyst shows excellent denitrification activity at 250-330 DEG C.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

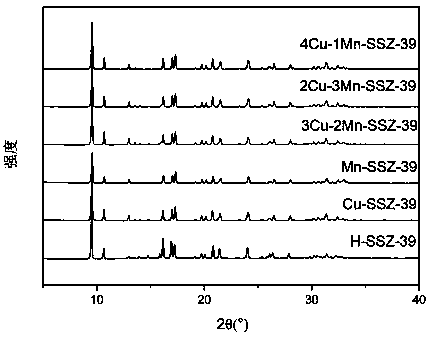

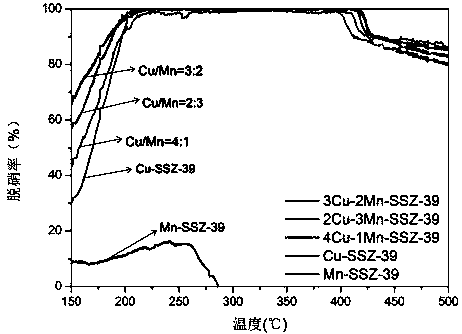

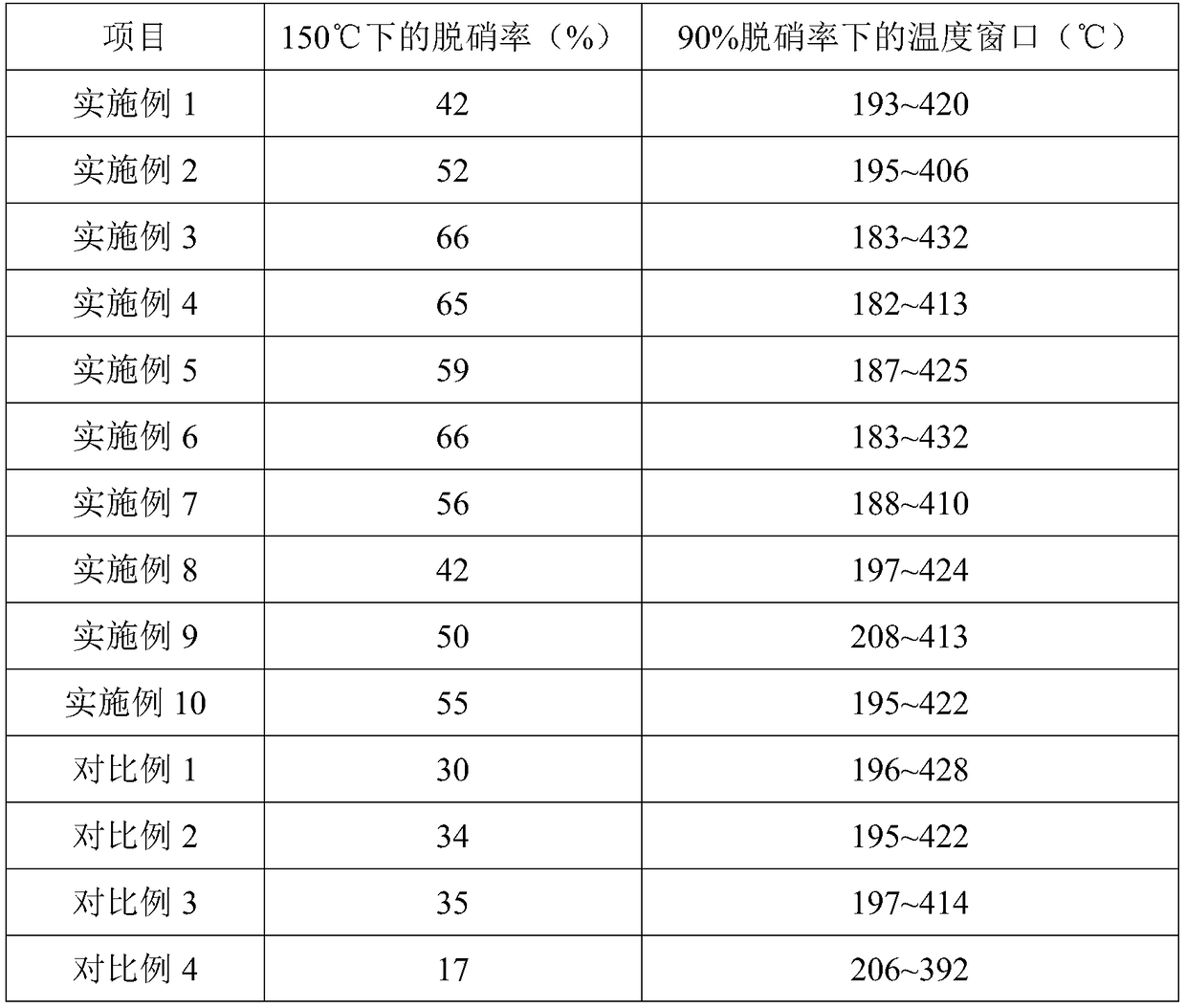

Cu/Mn-SSZ-39 catalyst, preparation method and application thereof

InactiveCN109433256AImprove denitrification rateLow temperature activeMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention discloses a Cu / Mn-SSZ-39 catalyst, a preparation method and the application thereof. The catalyst is characterized by the catalyst taking H-SSZ-39 molecular sieve as a carrier, and active components comprise copper and manganese. Through the synergistic effect between copper and manganese, the catalyst ensures that the denitration ratio is 42 to 66 percent at 150 DEG C, and reaches 100 percent at 200 to 420 DEG C, and shows excellent SCR activity at 150 to 500 DEG C. The Cu / Mn-SSZ-39 catalyst formed through an ion exchange method not only has low-temperature activity and high denitration ratio, but also has a wide activity temperature window, and the preparation method is simple, can be completely used for catalytic reduction of oxynitride, can eliminate oxynitride in dieselvehicle tail gas, and is applicable to diesel vehicle tail gas purification systems.

Owner:GUANGDONG UNIV OF TECH

Preparation method of denitration catalyst cellular module

InactiveCN102728343AThe test effect is goodImprove denitrification rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberKneader reactor

The invention relates to a preparation method of a denitration catalyst cellular module. Main powdery materials V2O5-WO3 / TiO2-ZrO2, pottery clay or glass fiber, binder, plasticizer solid-phase powder are well mixed; the mixture is added into a kneading machine; water is added into the kneading machine, and the mixture is kneaded; a lubricating agent with a weight 0.2-0.3 times that of the main powdery materials is added to the mixture, and kneading is continued for 1-3h; a well kneaded pug blank is added into a sealing plastic apparatus, and is subjected to aging in a cool shade; the mixed pug is subjected to 2-3 times of vacuum mixing, such that a cellular ceramic precursor pug is obtained; the cellular ceramic precursor pug is shaped by extrusion by using a cellular ceramic extruding machine; the shaped material is subjected to curve drying in a constant-temperature constant-humidity drying cabinet; the dried cellular ceramic module is baked for 3h under a temperature of 600 DEG C in a high-temperature calcining machine; the modules are cooled and the obtained products are trimmed, such that a cellular ceramic catalyst finished product is obtained. Experimental effects of the cellular ceramic catalyst are better than those of common cellular ceramic catalyst products in the market. The cellular ceramic catalyst provided by the invention has higher denitration rate, larger specific surface area, better sulfur conversion resistance rate, and longer service life.

Owner:CHANGCHUN XINRUI TECH & TRADE

Flue gas denitration process for CO exhaust-heat boiler of FCC apparatus

ActiveCN103768932AImprove the mixing effectWell mixedDispersed particle separationEvaporationStreamflow

The invention discloses a flue gas denitration process for a CO exhaust-heat boiler of an FCC apparatus. Flue gas produced by an FCC regenerator is dedusted by a deduster, and before entering the CO exhaust-heat boiler, a cloud of flue gas is led out and used as a diluent gas for ammonia gas; and the flow of the diluent gas is 0.1 v%-5.0 v% of that of the original regeneration flue gas. The rest of the flue gas has energy recovered by a flue gas turbine, and is sent into the CO exhaust-heat boiler. The upper part of a high temperature evaporation section of the CO exhaust-heat boiler is provided with an ammonia injection grid, and an SCR denitration catalyst module is arranged between a low temperature evaporation segment and a high temperature economizer. The process provided by the invention uses FCC regeneration flue gas as the diluent gas for ammonia gas to dilute and carry the ammonia at the same time, so as to improve the mixing effect of ammonia gas and flue gas, not increase the rate of oxygen content rate of the CO exhaust-heat boiler, and avoid security risks; at the same time CO removal, waste heat recovery and denitrification of flue gas are accomplished in the CO exhaust-heat boiler, thereby omitting a separate SCR denitration reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

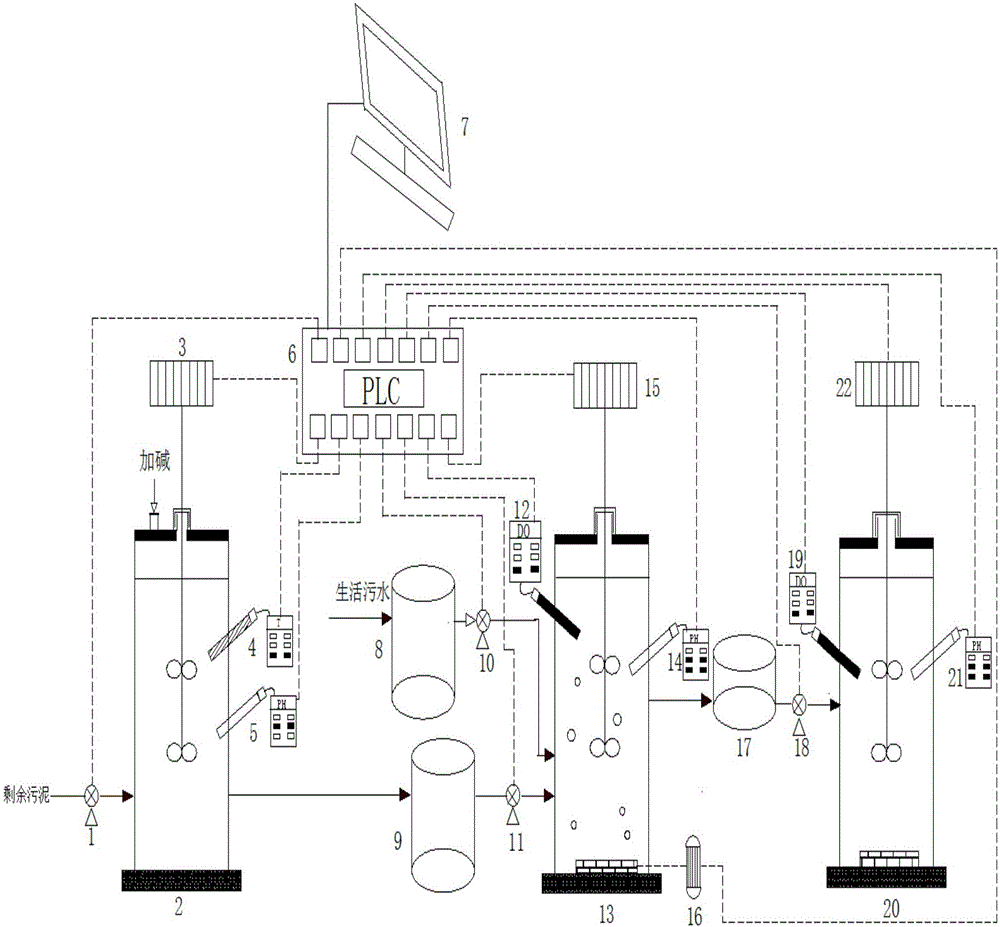

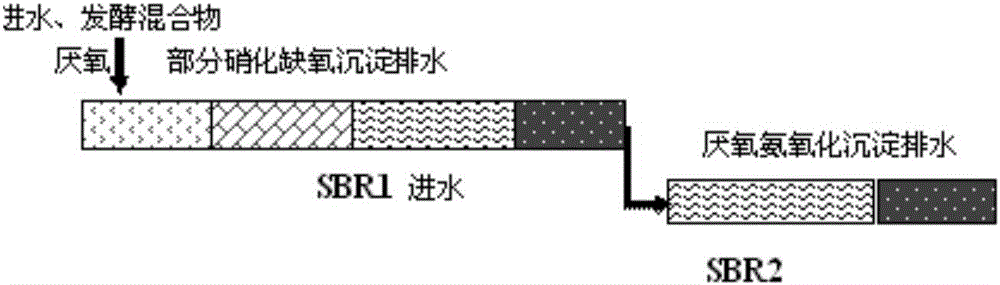

Method and device for realizing partial shortcut nitrification and anaerobic ammonia oxidation of municipal sewage by sludge fermentation

ActiveCN106115920ARealize reduction processingLow costWater contaminantsBiological treatment apparatusReduction treatmentPh control

A method and a device for realizing partial shortcut nitrification and anaerobic ammonia oxidation of municipal sewage by sludge fermentation belong to the field of municipal sewage treatment and sewage biological treatment. In a first SBR of a reactor, organics and phosphorus are removed, partial shortcut nitrification and denitrification actions are taken, and phosphorus is removed through real-time DO and pH control and sludge discharge. Effluent of the first SBR of the reactor enters a second SBR of the reactor for anaerobic ammonia oxidation reaction, so that the purpose of deep nitrogen and phosphorus removal is achieved. As residual sludge and domestic wastewater are mixed for treatment, the problem that shortcut nitrification of domestic wastewater cannot be stably realized due to low ammonia concentration can be solved, carbon sources are saved, the nitrogen and phosphorus removal efficiency is improved, and meanwhile, the sludge reduction treatment is realized.

Owner:BEIJING UNIV OF TECH

Method for obtaining low-nitrogen steel by reducing nitrogen content in steel in electric furnace steelmaking process

ActiveCN112981038AReduce nitrogen uptakeGood emulsificationElectric furnaceSteelmakingElectric arc furnace

The invention relates to a method for obtaining low-nitrogen steel by reducing nitrogen content in steel in an electric furnace steelmaking process. The method comprises the following steps that in the smelting process of an electric arc furnace, a mode of mixed smelting of waste steel and molten iron is adopted, a rapid slagging technology is assisted, and silicon iron is added in the tapping process to carry out weak deoxidation on molten steel; in the LF refining procedure, a high-temperature-resistant material sealing sleeve is installed at an electrode opening, refining synthetic slag is added in the smelting process for slagging, and the appropriate bottom blowing argon flow is adjusted; in the VD vacuum treatment process, a high vacuum degree, treatment time prolonging and bottom blowing argon flow increasing strong stirring mode is adopted; and in the continuous casting process, protective pouring and immersion type sleeve sealing measures are adopted. According to the method, the nitrogen content in the steel is obviously reduced on the basis of molten steel nitrogen absorption and denitrification mechanisms and in combination with the operation characteristics of all the procedures, the method is easy to operate, nitrogen control of the whole process in the electric furnace steelmaking process is stable, and it can be effectively guaranteed that the nitrogen content in a finally obtained product is smaller than 30ppm.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com