Alkali washing liquid for regenerating SCR denitration catalysts and application thereof

A technology of denitration catalyst and alkaline washing solution, applied in the field of alkaline washing solution, can solve problems such as affecting the denitration rate of SCR denitration catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

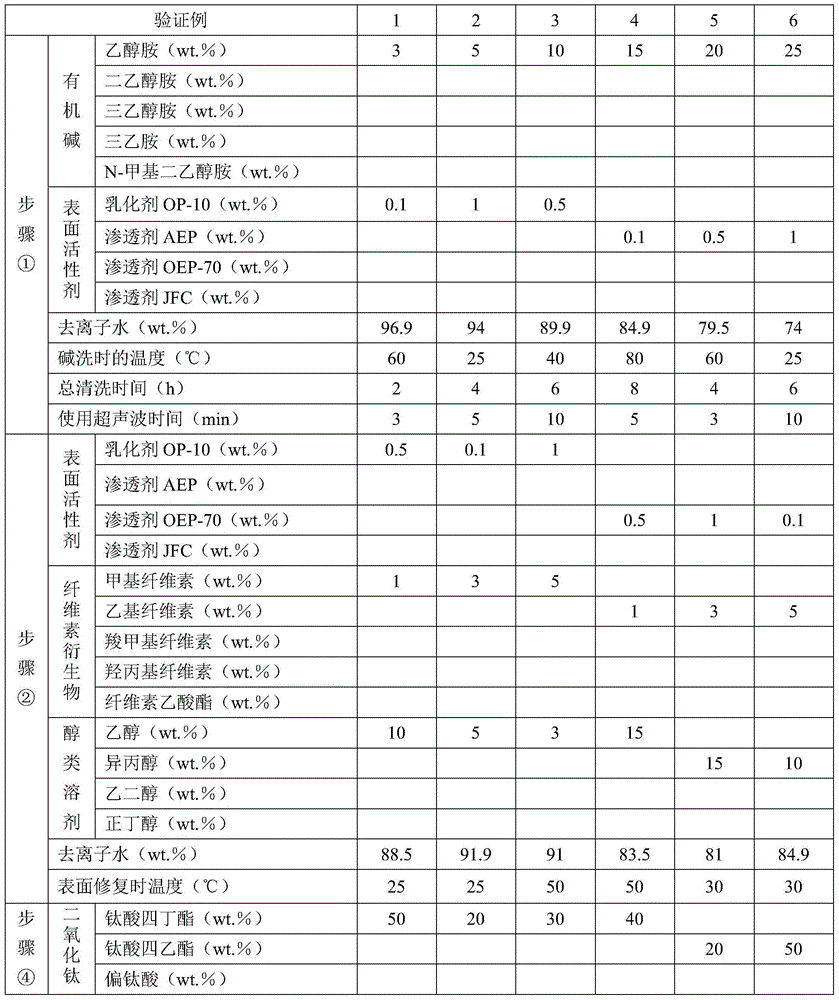

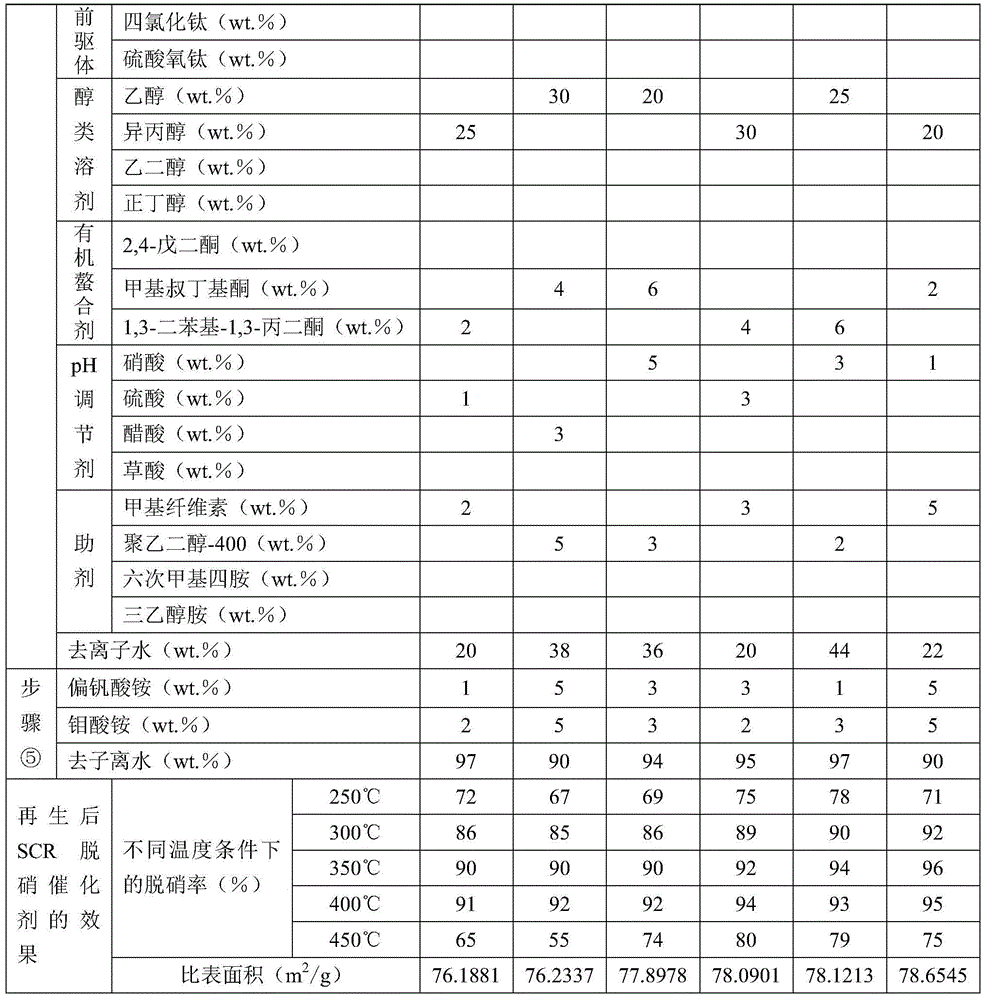

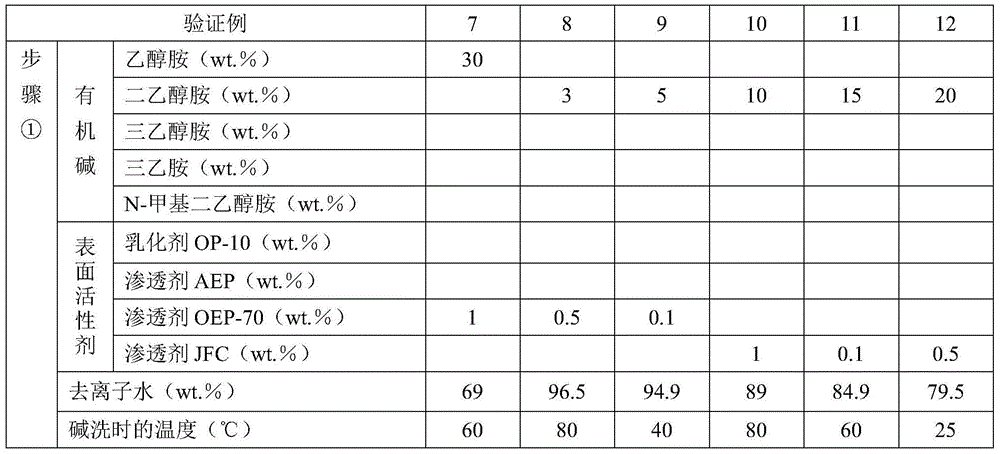

[0020] 1. An alkaline washing liquid used for regenerating the SCR denitration catalyst, the alkaline washing liquid is composed of an organic base, a surfactant and deionized water. In the present invention, the organic base is ethanolamine (C 2 h 7 NO), diethanolamine (C 4 h 11 NO 2 ), triethanolamine (C 6 h 15 NO 3 ), triethylamine [N(CH 2 CH 3 ) 3 ], N-methyldiethanolamine (C 5 h 14 NO 2 ) in one or two mixtures; the surfactant is one or two mixtures of emulsifier OP-10, penetrant AEP, penetrant OEP-70, penetrant JFC; the proportioning of each component is, Organic base 3-30wt.%, surfactant 0.1-1wt.%, deionized water 69-96.9wt.%.

[0021] 2. A method for regenerating an SCR denitrification catalyst, the regeneration method comprising the steps of purging the SCR denitrification catalyst to be regenerated with air, ultrasonic alkaline washing, rinsing with water and then draining, calcining, supplementing active components and secondary calcining. In the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com