Patents

Literature

644 results about "Kneader reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kneader reactor (or kneading reactor) is a machine that specializes in mixing and kneading substances, particularly those with high viscosity. Many industries, such as the Food Industry, utilize machines similar to the Kneader reactor to produce goods. For example, polymers, chewing gum can be produced using these machines. Although the machine has existed for decades, kneader reactors are only recently gaining popularity in the processing industry.

High temperature resistant heat-conducting silica gel sheet and preparation method thereof

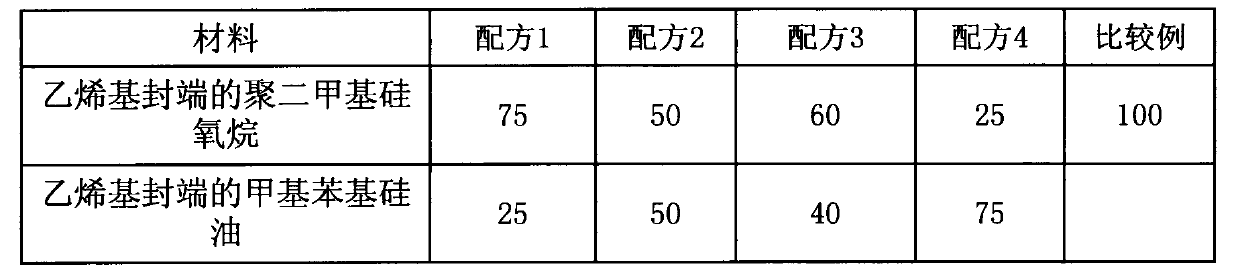

The invention discloses a high temperature resistant heat-conducting silica gel sheet and a preparation method thereof. The high temperature resistant heat-conducting silica gel sheet is characterized by comprising the following components in parts by weight: 50-80 parts of vinyl end capped polydimethylsiloxane (PDMS), 20-50 parts of vinyl end capped methyl phenyl silicone oil, 0.3-10 parts of containing hydrogen silicone oil, 2-6 parts of platinum catalyst, 0.2-0.6 parts of inhibitor, 5-100 parts of heat resistant additive and 400-1200 parts of heat-conducting powder. The preparation method of the high temperature resistant heat-conducting silica gel sheet comprises the following steps: firstly, uniformly mixing the vinyl end capped polydimethylsiloxane and the vinyl end capped methyl phenyl silicone oil in a kneading machine; adding the treated or untreated heat-conducting powder and the heat resistant additive which are added in batches, after mixing uniformly, adding the containing hydrogen silicone oil, the inhibitor and the catalyst; and mixing uniformly, and heating and solidifying in a forming machine to form a sheet. The heat resistant silica gel sheet provided by the invention is aged at 250 DEG C for 1000 hours, but still has good usability, and the changes of the hardness and the heat conductivity coefficient are within acceptable ranges.

Owner:SUZHOU TIANMAI THERMAL TECH

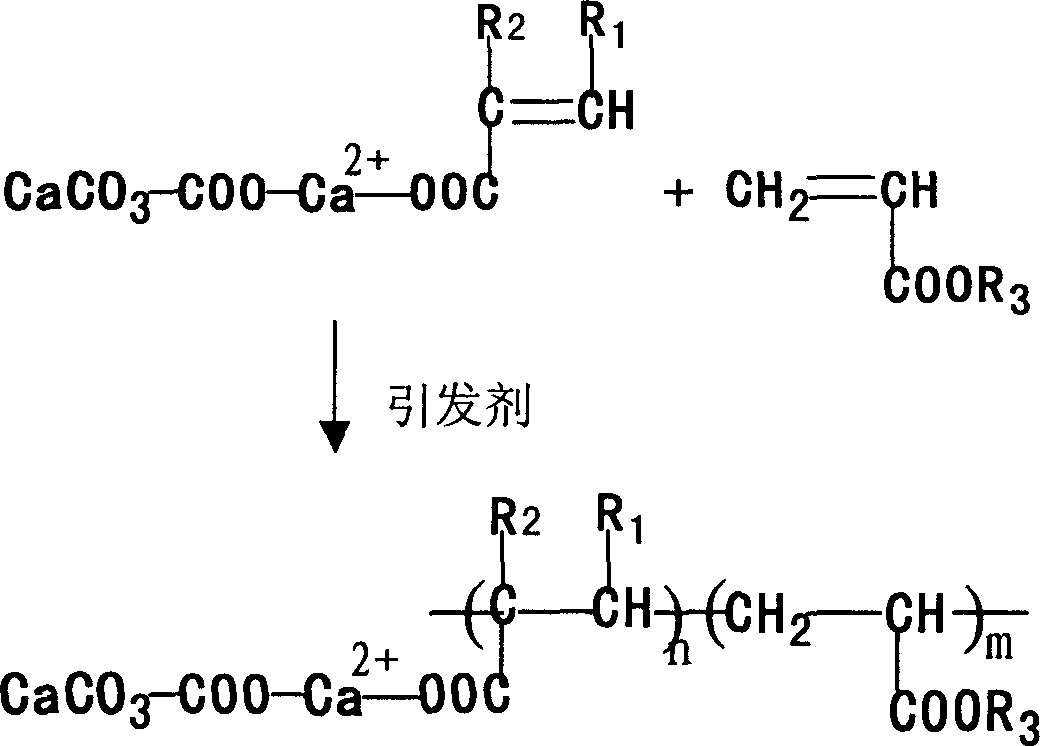

Single-component silicone fluid sealant for solar energy cell assembly and manufacturing method thereof

ActiveCN101353563AImprove adhesionImprove waterproof performanceAdhesivesPhotovoltaic energy generationWater vaporStructural formula

A single component silicone sealant used for a solar module and a manufacturing method thereof are characterized in that the structural formula is as the right formula, n is equal to Alpha between 100 and 2000, according to part by weight, Omega-dihydroxyl dimethicone is 100 parts, petroresins is 1-5 parts, activated chalk is 10-40 parts, and silica micropowder is 30-70 parts, all the materials are added into a vacuum kneader and dehydrated and blended for 30-200 minutes under the conditions of the temperature of 100-150 DEG C and the vacuum degree of 0.06-0.099MPa, and the base stock is obtained after cooling; at room temperature, 1-5 parts of pyrogenic silica, 10-17 parts of crosslinkers, 1-3.5 parts of silane coupling agent, 0.5-1.5 parts of catalysts and 1-10 parts of silicone oil plasticizers, according to parts by weight, are further added into a high-speed dispersator or a planetary stirrer filled with the base stock and stirred for 30-150 minutes under the conditions of the vacuum degree of 0.06-0.099MPa and the rotating speed of 200-600rpm, thus preparing the single component silicone sealant. The single component silicone sealant has excellent weathering resistance and yellowing resistance, low moisture-vapor transmission and good storage stability.

Owner:CHENGDU GUIBAO SCI & TECH

Starch/thermoplastic polyurethane (TPU) composite material with high mechanical property and preparation method thereof

ActiveCN102585485AImprove mechanical propertiesImprove wear resistancePolymer scienceKneader reactor

The invention relates to a starch / thermoplastic polyurethane (TPU) composite material with high mechanical property and a preparation method thereof. The method comprises the following steps of: weighing starch, TPU, a plasticizer, a toughening agent, a reinforcing agent and an interface compatilizer according to a formula, fully mixing the materials, performing mixing molding, extrusion molding and calendering molding by using a double screw extruder, a single screw extruder, a double-step screw extruder, a kneading machine, an open mill and the like with the capacity of applying shearing force, and processing at the temperature of between 100 and 190 DEG C to prepare the starch / TPU composite material. The composite material has the advantages of high mechanical property, low cost, biodegradability, simple preparation process and the like.

Owner:SOUTH CHINA UNIV OF TECH

Crosslinked composition comprising a core/shell copolymer, method of obtaining same and uses thereof

InactiveUS20090306246A1Excellent surface appearanceEasy to processSolesSpecial tyresElastomerPolyolefin

The invention relates to is a crosslinked composition containing in parts by weight: 20 to 100 parts of at least one elastomer (I), 2 to 50 parts of at least one core / shell copolymer (II), and 0 to 100 parts of at least one thermoplastic polymer (III). The invention also relates to a method of producing one such crosslinked composition, which is characterized in that it consists in: mixing an elastomer and a core / shell copolymer optionally in the presence of: a grafted polyolefin, a plasticizer, fillers and / or additives, and a suitably-selected crosslinking system, and subsequently crosslinking said mixture at a suitable temperature. In a preferred embodiment of the invention, the mixture is crosslinked at a temperature of between 150 and 320° C. The invention method be carried out in an internal mixer, or, alternately, in a twin-screw extruder or a Buss®-type co-kneader. Depending on the case, the resulting mass is calendared or extruded, cooled and subsequently granulated. The granules thus obtained are then ready to be transformed, by means of heating, into sheets, plates, extrusions, tubes or other desired products. The invention further relates to the use of one such composition in the production of ducts, pipes, tubing, couplers or similar for conveying fluids, such as the fluid transfer conduits, pipes and other elements which are used in the automobile industry in braking, cooling, steering and air-conditioning systems. The inventive crosslinked composition can also be used in the production of belts, tires, electrical cable sheaths, and shoe soles.”

Owner:ARKEMA FRANCE SA

Method for preparing silicone sealant

ActiveCN103642452AIncrease the amount addedImprove stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention discloses a method for preparing silicone sealant. The method comprises the following steps: adding alpha,omega-dyhydroxy polydimethylsiloxane, filler and dimethyl silicon oil into a vacuum kneading machine, vacuuming, heating and mixing for 2-5 hours; stopping heating, introducing nitrogen to change the vacuum state, adding a silane coupling agent, mixing for 0.5-1 hour at the vacuum degree of -0.06 to -0.1Mpa, introducing nitrogen to change the vacuum state; sealing and cooling to room temperature, subsequently transferring into a stirring machine, adding a cross-linking agent, a thickening agent and a catalyst, vacuuming, and uniformly stirring and mixing so as to obtain the silicone sealant. According to a product of the silicone sealant, the addition amount of the filler is increased, the product stability and the surface smoothness are improved, the thixotropy and the deep curing are also improved, the curing homogeneity is good, the tensile strength, the elasticity and the cohesiveness are greatly improved, expensive white carbon black can be replaced, the filling amount is large, the curing time is short, the construction efficiency is improved, the process is simple and feasible, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Anticorrosive pressure sensitive adhesive tape and preparation method thereof

InactiveCN102363717AGood self-adhesiveImprove sealingFilm/foil adhesivesCorrosion preventionElastomerPolymer science

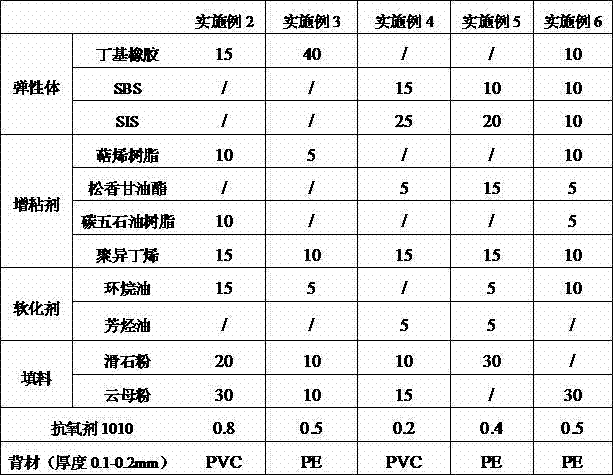

The invention discloses an anticorrosive pressure sensitive adhesive tape and a preparation method thereof. The anticorrosive pressure sensitive adhesive tape consists of a back material and pressure sensitive adhesive coated on the back material, wherein the pressure sensitive adhesive consists of the following components in part by weight: 15 to 40 parts of elastomer, 15 to 35 parts of tackifier, 5 to 15 parts of softening agent, 20 to 50 parts of filler, and 0.2 to 0.8 part of anti-aging agent. The preparation method comprises the following steps of: adding the elastomer, the tackifier, the softening agent, the filler and the anti-aging agent into a kneading machine, kneading for 30 to 70 minutes at the temperature of between 130 and 160 DEG C, and obtaining a self-adhesive material; adding the self-adhesive material into a double-screw extruder, performing melt extrusion, and obtaining the pressure sensitive adhesive; and coating the pressure sensitive adhesive on the back material, and thus obtaining the anticorrosive pressure sensitive adhesive tape. The anticorrosive pressure sensitive adhesive tape has good self-adhesive property, high adhesive strength and good sealing performance and durability.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Method for preparing unsaturated polyester cross-linking waste mold plastic

The invention relates to a method to prepare moulding plastic from unsaturated polyester crosslinked waste, which comprises the steps: (1) the unsaturated polyester crosslinked waste such as glass fiber reinforced plastic, button plastic, etc. are put into a crushing machine to be crushed into 30 to 200 meshes; (2) the powder of unsaturated polyester crosslinked waste, suitable resin and auxilliary materials are mixed in a suitable scattering equipment such as a kneader to equally scatter the unsaturated polyester crosslinked waste powder and resin and assistant materials, wherein, the powder of unsaturated polyester crosslinked waste accounts for 60-95 percent of the total mass; (3) the mixture got form the step (2) is molded in a polymer moulding equipment such as a platens press in order to produce moulding plastic with unsaturated polyester crosslinked waste contents.

Owner:SOUTH CHINA UNIV OF TECH

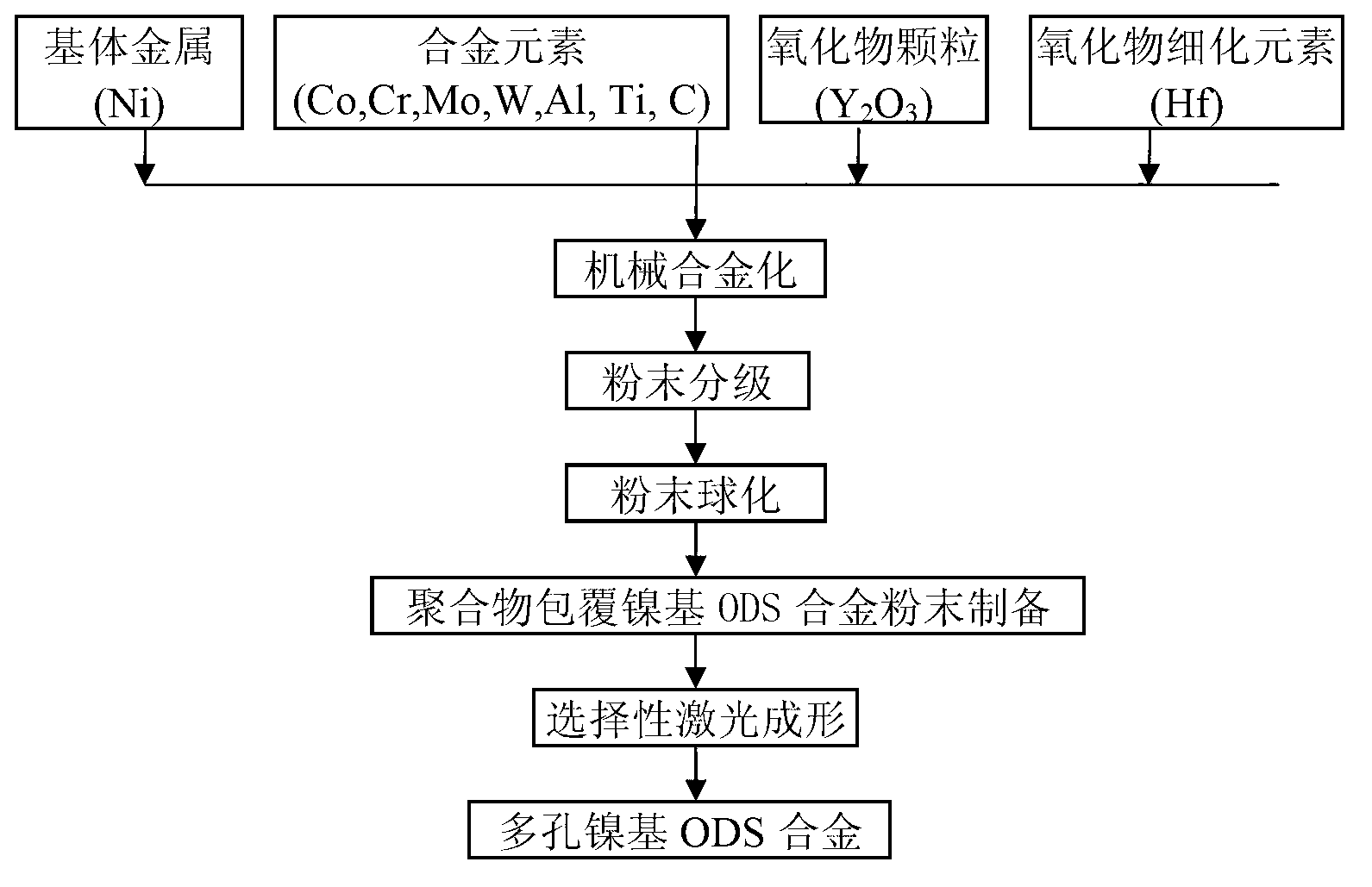

Method for near-net shaping of porous Ni-based ODS (oxide dispersion strengthening) alloy

ActiveCN103060591AIncrease profitNo limit to complexityAdditive manufacturing apparatusIncreasing energy efficiencyKneader reactorOxide dispersion-strengthened alloy

A method for the near-net shaping of a porous Ni-based ODS alloy belongs to the technical field of porous alloy high-temperature preparation. The method comprises the following steps: adopting a mechanical alloyage technology to obtain oxide dispersion reinforced alloy powder, and carrying out grading and plasma spheroidization of Ni-based ODS alloy powder to obtain spherical Ni-based ODS alloy powder having uniform particle sizes; carrying out heating stirring of the Ni-based ODS alloy powder with a thermoplastic polymer in a kneader to obtain polymer coated Ni-based ODS alloy powder; designing a three-dimensional solid model of an Ni-based ODS alloy part through adopting CAD software, carrying out layering slicing treatment of the three-dimensional model to discretize into a series of two-dimensional layers used for the rapid shaping process control; and scanning the Ni-based ODS alloy powder layer by layer according to slice information to obtain a porous Ni-based ODS alloy body. The method is suitable for preparing complex-shape porous metals used under high temperature, corrosion and oxidation resistance conditions, and the porous Ni-based ODS alloy has the characteristics of high high-temeprature strength, and strong porosity and pore size designability.

Owner:UNIV OF SCI & TECH BEIJING

Acrylic artificial stone and method for preparing same

The invention relates to an acrylic artificial stone with natural marble surface patterns and excellent hot water resistance and a method for preparing the same. The acrylic artificial stone comprises the following components by weight portion: 40 to 70 portions of acrylic-based resin monomer, 10 to 25 portions of thickening agent, 200 to 350 portions of inorganic filler, 0.01 to 2 portions of curing agent, and 0 to 30 portions of unsaturated resin, wherein the thickening agent is a hot melt mixture of acrylic polymers and the acrylic-based resin monomer, and the molecular weight of the acrylic polymers is between 100,000 and 400,000. The method for preparing the acrylic artificial stone comprises the following steps of: putting the unsaturated resin, the acrylic-based resin monomer, the thickening agent, the inorganic filler and the curing agent in a kneader according to a formula to obtain an acrylic molding compound; and filling the molding compound in a mold and curing the molding compound at a temperature of between 100 and 145 DEG C and under a pressure of between 10 and 20MPa to prepare the acrylic artificial stone. The prepared acrylic artificial stone has excellent appearance and performance.

Owner:上海新天和树脂有限公司 +1

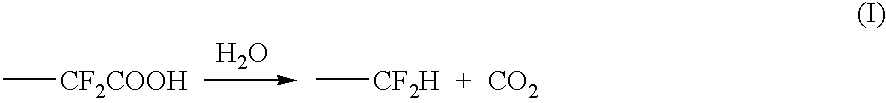

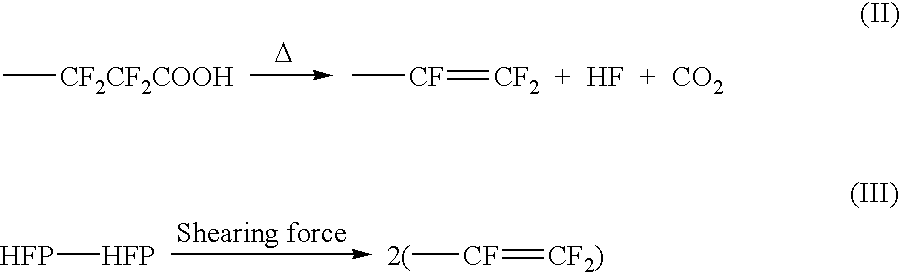

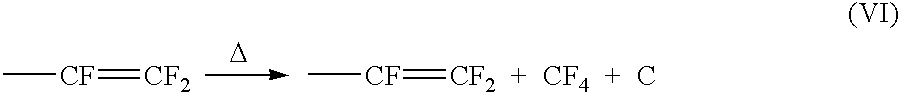

Method of stabilizing fluorine-containing polymer

To provide the stabilization method, in which unstable groups of melt-processable fluorine-containing polymer having unstable groups can be stabilized rapidly and effectively, and even if the obtained stabilized polymer is melt-molded, an obtained molded article is free from bubbles and cavity and no coloration arises. The method of stabilizing a fluorine-containing polymer by melt-kneading a melt-processable fluorine-containing polymer having unstable groups in a kneader having a stabilization treatment zone which satisfies the following conditions:(1) an oxygen-containing gas is present in the stabilization treatment zone,(2) water is present in the stabilization treatment zone, and(3) an absolute pressure in the stabilization treatment zone is adjusted to a pressure of 0.2 MPa or more or (a) an oxygen-containing gas is present in the stabilization treatment zone in a sufficient amount that the fluorine-containing polymer after the stabilization treatment has the number of carbon radical spins measured by an electron spin resonance absorption analysis at a temperature of 77 K of not more than 5x1013 spin / g, and (b) water is present in the stabilization treatment zone.

Owner:DAIKIN IND LTD

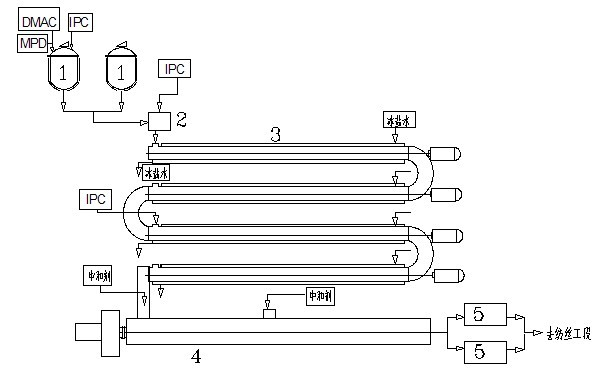

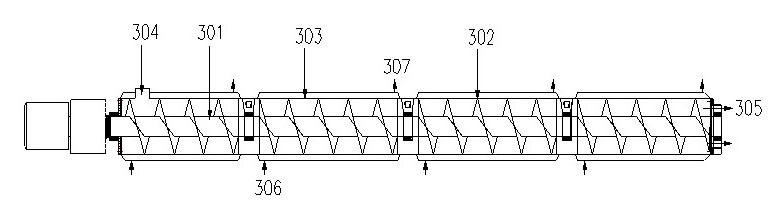

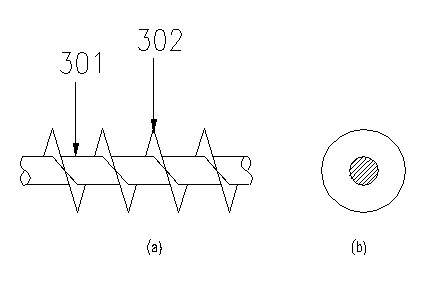

Method for producing polymetaphenylene isophthamide spinning solution

InactiveCN101876092AAvoid lostAvoid the effect of molecular weightSpinning solutions preparationMonocomponent polyamides artificial filamentCalcium hydroxideSpinning

The invention relates to a tube-type continuous method for producing polymetaphenylene isophthamide spinning solution, which is characterized in that a method for serially connecting a self-cleaning tubular reactor serving as a condensation reactor and a twin-screw kneading machine serving as a neutralization reactor is adopted for preparing the polymetaphenylene isophthamide spinning solution. The self-cleaning tubular reactor solves the problems that side reactions are increased due to quick generation of heat in the reaction and the polymer molecular weight cannot be improved; and the twin-screw kneading machine solves the problem of poor dissolution of solid granules in the spinning solution caused by nonuniform liquid / solid kneading in the neutralization process. The preparation method comprises the steps of pre-condensation, condensation, neutralization, and forced extrusion and filtration. The solid content of the final spinning solution is 14 to 20 percent; and calcium hydroxide is adopted for neutralization by one step, and the calcium chloride content is 6.5 to 9.3 percent. If the calcium hydroxide and sodium hydroxide are adopted for neutralization by two steps, the calcium chloride content can be less than 3 percent. Therefore, the method is also suitable for producing spinning solution for a high salt method and a low salt method.

Owner:四川辉腾科技股份有限公司

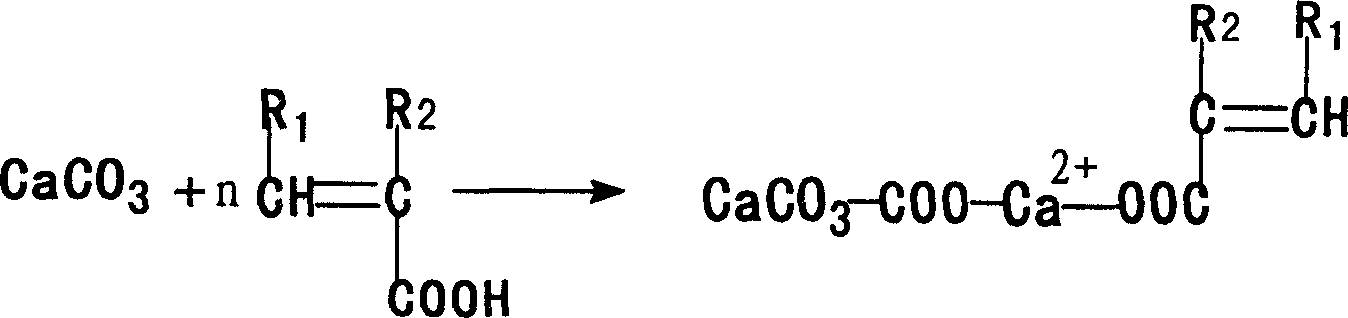

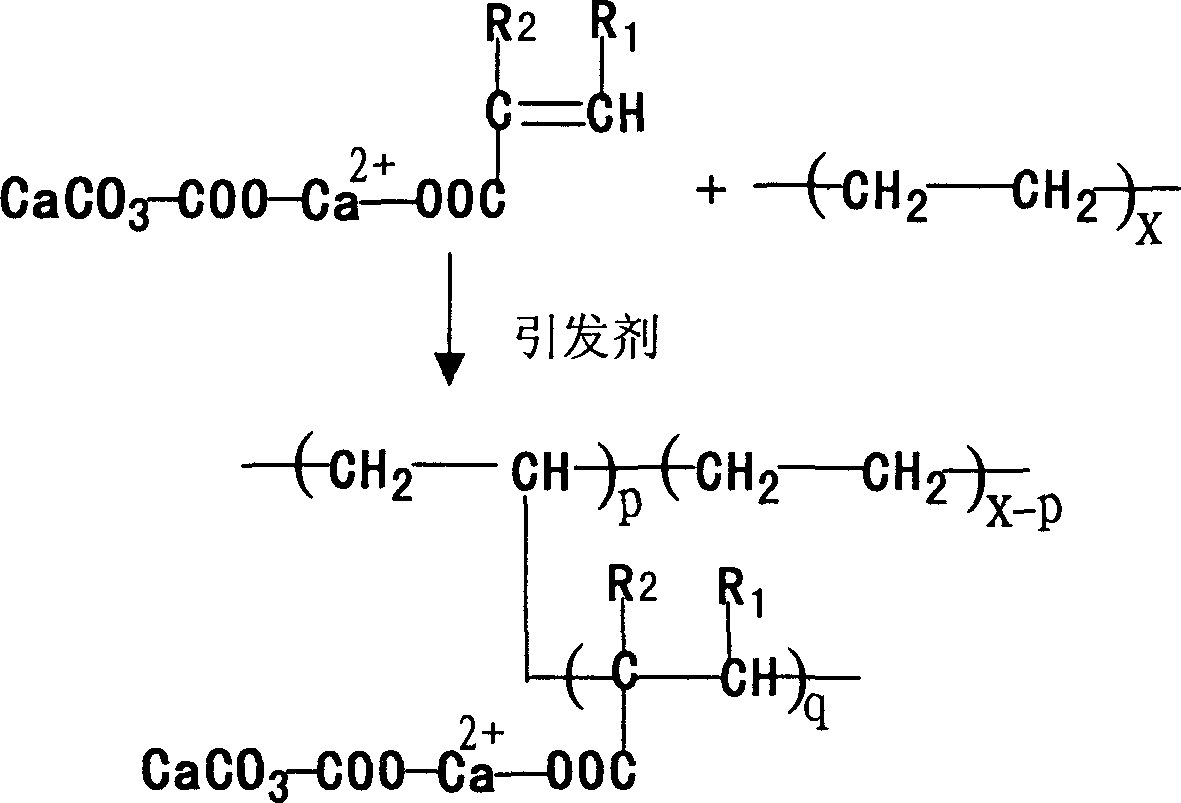

Process for preparing predispersed masterbatch of polyolefin and nano calcium carbonate

The invention relates to a method for preparation of predispersed master batch of polyolefin / nano-alcium carbonate, which includes: (1) adding nano-alcium carbonate into the kneading machine, afterwards, adding unsaturated acid monomer, long fatty chain monomer, initiating agent, polyethersulfonate, macromolecular coupling agent and polyolefin resin in turn, and kneading for 0.5-5 minutes; (2) discharging mixtures into the twin-screw extruder to perform squeezing, granulating and drying, then obtaining the predispersed master batch of polyolefin / nano-alcium carbonate, with a speed of host machine of twin-screw extruder of 50-600 revolutions per minute, a feeding speed of 20-400 revolutions per minute, a heating-up temperature of 80-220 DEG C; the invention is of few job steps, strong interaction between polyolefin and nano-alcium carbonate and is liable to disperse in the polymeric matrix. The said predispersed master batch of polyolefin / nano-alcium carbonate obtained by this invention can be widely used in enhancing, toughening and modifying various plastics, specially adapted for preparation of polyolefin permeability films and so on.

Owner:SOUTH CHINA UNIV OF TECH

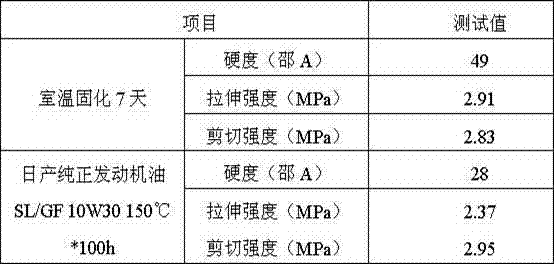

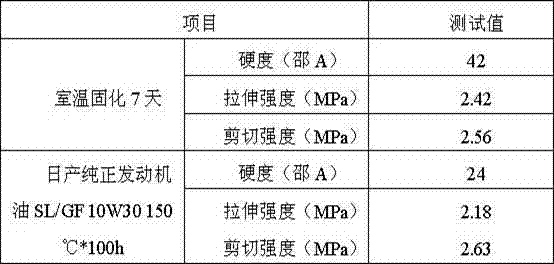

Preparation method of oil-resistant room temperature vulcanization deoximation silicon rubber

The invention discloses a preparation method of an oil-resistant room temperature vulcanization deoximation silicon rubber. According to the invention, a reactant of aminopropyl triacetoximo silane or aminopropyl tributanoximo silane and isocyanate-alkoxy silane is used as a coupling agent, and the preparation method of the oil-resistant room temperature vulcanization deoximation silicon rubber comprises the following steps of: stirring alpha,omega-diyhydroxy polydimethylsiloxane and calcium carbonate in a kneading machine; adding a cross-linking agent and stirring fully; adding white carbon black and stirring fully; and after adding the coupling agent and a catalyst and stirring uniformly, discharging the rubber to obtain a product. According to the invention, the oil resistance of the silicon rubber is improved, and the oil-resistant room temperature vulcanization oxime-silicon removal rubber can be used in a common oil-resistant occasion.

Owner:TONSAN ADHESIVES INC

Compounded rubber racetrack and its processing method

The composite rubber runway is produced with styrene-butadiene rubber, EPDM, natural rubber, silica white, pot clay, stearic acid, spindle oil, naphthenic oil, antioxidant, ultraviolet absorbent, nano particle and promoter, and through weighing materials, cutting rubber materials, mixing, milling, calendering, kneading, sulfurizing in sulfurizing machine, sulfurizing and foaming in tunnel stove, washing, trimming and polishing. The present invention has excellent resilience, toughness and damping effect; is wear resistant, antiaging and ultraviolet resistant, and may be all-weather used.

Owner:绿茵天地体育产业股份有限公司

Solid watercolor and preparation method thereof

InactiveCN101831210ASmall water absorptionReduce viscosityArtist's paintsStarch coatingsDispersed mediaGlycerol

The invention relates to solid watercolor which comprises the following components in parts by weight: 15-20 parts of Arabic gum, 25-30 parts of polyethylene glycol with average molecular weight of 6000-8000, 5-8 parts of dextrin or soluble starch or combination thereof, 3-15 parts of glycerol, 35-43 parts of filler, 5-20 parts of colorant and 0.5-2 parts of dispersant. The preparation method comprises the steps of processing all raw materials in a sealed kneader, extrusion molding through a screw extruder, cooling and hardening. The solid watercolor has low water absorbability, poor viscosity and is convenient to package, store and use. The preparation method has no dust pollution, greater compactness of the obtained product and no need of water as a dispersing medium, and extrusion molding is preformed in one step by the screw extruder without roasting to remove water later, thereby saving energy resources.

Owner:贝碧欧美术颜料(昆山)有限公司

Preparation method of high-tear-resistance silicon compounded rubber

The invention relates to the field of organic silicon, particularly a preparation method of high-tear-resistance silicon compounded rubber, which comprises the following steps: mixing 110-0 methylvinyl silicone rubber and 112 methylvinyl silicone rubber, adding precipitated white carbon black, zinc stearate, hydroxy silicon oil, hydrogen-containing silicon oil and vinyl silicon oil, and mixing in a 50-120-DEG C kneader until the rubber matrix is uniformly distributed; banburying the uniform rubber matrix at 150-190 DEG C under the pressure of -0.065 to -0.1 MPa in a vacuum for 50-70 minutes to obtain a rubber matrix; and carrying out back mixing on the rubber matrix obtained in the step 2) in an open mill until no burr exists, filtering to 250-350 meshes, adding a vulcanizing agent, carrying out vulcanization reaction at 175-180 DEG C for 5-8 minutes, granulating, and cooling for 5-10 hours to obtain the high-tear-resistance silicon compounded rubber. The technical scheme greatly saves the cost, and the performance of the high-tear-resistance silicon compounded rubber can satisfy the market demands.

Owner:YICHANG XINGZHIXIN PLASTIC ELECTRONICS TECH CO LTD

Material special for PVC-M feed pipe member and production method thereof

The invention discloses a special material for a PVC-M water supply pipe and a preparation method thereof. The special material comprises the components by part by weight as follows: 75 parts of PVC resin, 2.7-8.5 parts of toughener, 1.6-2.8 parts of heat stabilizer, 1.2-2.8 parts of lubricant, 3-10 parts of filling agent and 1.2-4.3 parts of processing material. The filling agent is calcium carbonate processed by silica gel coupling agent. The preparation method comprises the steps as follows: (1) all materials are weighed for using according to the prescription; (2) the calcium carbonate which is processed by the silica gel coupling agent is prepared; (3) the PVC resin is poured into a high-speed kneader to be mixed firstly, the heat stabilizer is poured into the high-speed kneader to be mixed continuously, subsequently, other materials are poured into the high-speed kneader to be mixed continuously, and the materials are discharged to be stirred and cooled; and (4) the materials are sent into a double-screw extruder to be melted and extruded to be granulated. The PVC-M water supply pipe made from the special material for the PVC-M water supply pipe has good toughness and high shock strength.

Owner:JIANGSU HUASHENG PLASTIC +1

Method for mfg. moulding plastic and its products by offcut of glassfibre cloth

A process for preparing the raw material for moulding and the moulded product from the glass fiber leftover features that the kneading machine is used as the shearing and dispersing apparatus and the thermosetting liquid resin is used as adhesive and lubricant. Under the squeezing, tearing, shearing and kneading of said kneading machine, the glass fiber leftover can become the adhesive contained bundles of fibers.

Owner:海盐华强树脂有限公司

Method for manufacturing carbon molecular sieve with plant nutshell

InactiveCN102328924ASolve the pollution of the environmentReduce manufacturing costMolecular sieveKneader reactor

The invention discloses a method for manufacturing a carbon molecular sieve with a plant nutshell, which sequentially comprises the following steps: a, crushing the plant nutshell into powdery material; b, drying and grinding the powdery material to obtain micro-powdery material; c, mixing and kneading the micro-powdery material with adhesives in a kneader; d, placing the kneaded material into a bar extruding machine for formation; e, placing the formed material into a converter for carbonization; and f, depositing the carbonized material with carbon to obtain a finished carbon molecular sieve. By adopting the method, the problem of environment pollution caused by the carbon molecular sieve process can be solved effectively, and the environment protection can be facilitated. Meanwhile, the finished carbon molecular sieve is manufactured with the plant nutshell sequentially via crushing, drying, grinding to produce the micro powder, placing of the micro powder along with the adhesives into the kneader, formation, carbonization and surface carbon deposition to obtain the finished carbon molecular sieve. Waste is fully utilized to manufacture high-value products, the manufacturing cost of the carbon molecular sieve is reduced, the process is simple, and industrialization can be realized easily.

Owner:胡耀明

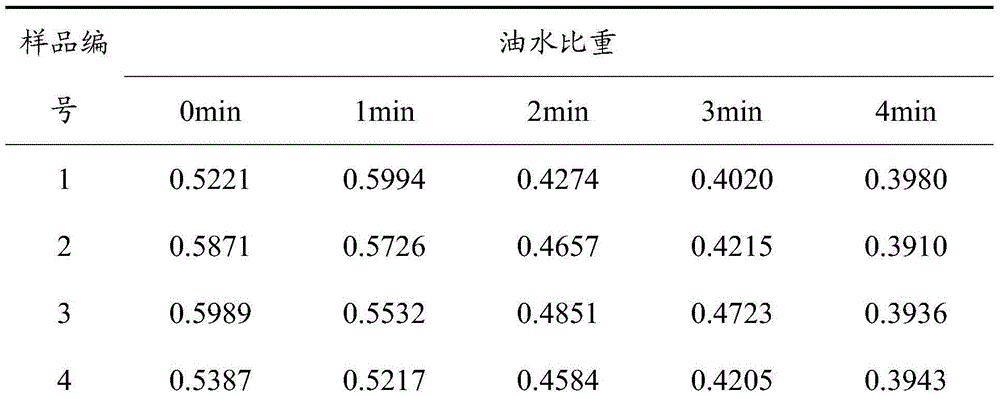

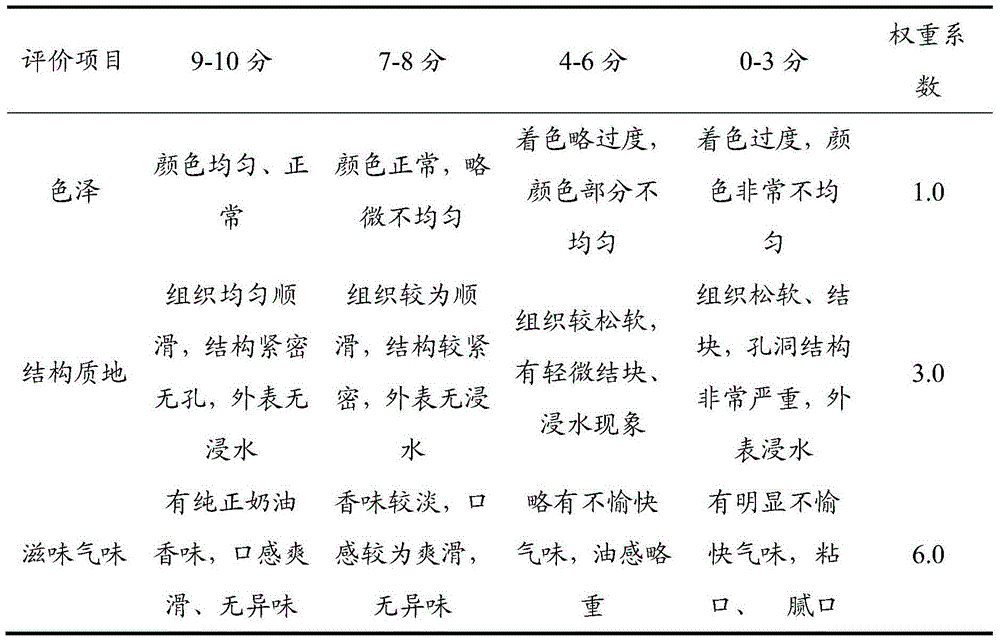

Artificial zero-thans fatty acid cream

InactiveCN104938644AEasy to makeEase of industrial productionEdible oils/fats production/working-upBiotechnologyPOMEGRANATE SEED OIL

The invention discloses artificial zero-thans fatty acid cream which is simple in production process, good in taste, good in fermentation and resistant to storage and a preparing method thereof. The preparing method includes the following steps that oil phase is prepared; after natural coconut oil, palm stearin, shea butter and pomegranate seed oil are evenly mixed, double glycerate, lecithin and vitamin E are added to the mixture, the mixture is heated till the grease is totally melt, and the mixture is evenly mixed for use; water phase is prepared, wherein milk powder and salt are added to deionized water to be fully stirred, and the mixture is made to be totally dissolved to be the even water phase for use; the oil phase and the water phase are added to an emulsification tank to be emulsified according to the weight ratio of 8:2, meanwhile ascorbic acid palm ester is added to the mixture, stirring is conducted while the ascorbic acid palm ester is added, the emulsifying temperature ranges from 62 DEG C to 65 DEG C, and the time ranges from 30 min to 33 min; the emulsified lactescence is placed into a shock cooling kneading machine, cooling is conducted while kneading is conducted, the kneaded lactescence is cooled and formed, and artificial cream products are obtained.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

Process for producing large caliber hard polyvinyl chloride double wall corrugated pipe

The production process can produce double wall corrugated pipe of hard polyvinyl chloride and in the caliber up to 800 mm and the corrugated pipe is used for conveying liquid or solid material and protecting under ground wires. The production process includes the following steps: preparing materials including PVC resin, composite stabilizer, stearic acid, PE wax, chlorinated polyethylene and calcium carbonate; kneading the materials in a high speed kneading machine for 12-16 min, stirring in low speed cold mixer at 115-125 deg.c, extruding in a double screw extruder at 90-210 deg.c, setting and drawing in a blowing and sucking molding formation machine, cutting and flaring.

Owner:杭州波达塑料科技股份有限公司

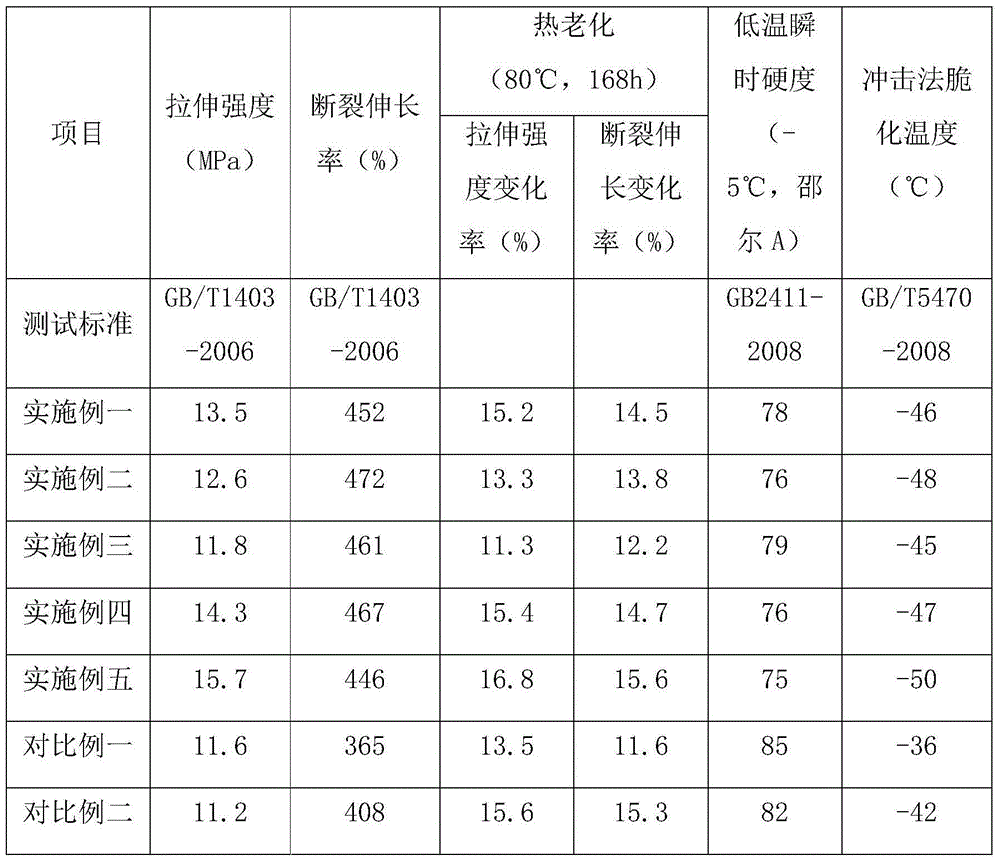

Environment-friendly cold-resistant polyvinyl chloride elastomer composition and preparation method thereof

The invention discloses an environment-friendly cold-resistant polyvinyl chloride elastomer composition and a preparation method thereof. The preparation method comprises the following steps: mixing a polyvinyl chloride resin, dialkyl terephthalate, synthetic vegetable oil, polar rubber, nano activated calcium carbonate, a calcium zinc composite stabilizer, a lubricant, an antioxidant and a pigment in a kneader; after the temperature of the mixture reaches 90-100 DEG C, discharging, cooling, and carrying out extrusion granulation on the cooled mixture in a double screw extruder, wherein the Shore hardness of the elastomer composition at -5 DEG C is lower than 80. The elastomer composition has the advantages of excellent low-temperature toughness, high mechanical strength, high thermal aging resistance, environment friendliness, no toxicity, excellent comprehensive properties and the like, and is especially suitable for preparing escalator balance compensation chain sheaths, door / window and vehicle window seals, insulation sheaths of wires and cables and the like.

Owner:JIANGSU XINGHUA RUBBER BELT

Sealing silicone glue with low moisture permeability for hollow glass and its production process

ActiveCN1810907AImprove adhesionExtended service lifeMineral oil hydrocarbon copolymer adhesivesOther chemical processesMicrosphereRoom temperature

The sealing silicone glue with low moisture permeability for hollow glass contains two components, component A and component B. The component A is prepared with poly(alpha, omega-dihydroxy siloxane 100 weight portions, petroleum resin 5-20 weight portions, active calcium carbonate 80-120 weight portions, quartz powder 20-50 weight portions and hollow glass bead 10-30 weight portions, and through mixing in a kneading machine or high speed planetary stirrer. The component B is prepared with silicate ester 40-60 weight portions, catalyst 0.5-1 weight portions, silane coupler 5-20 weight portions and silicon oil 20-40 weight portions, and through mixing inside a planetary stirrer at vacuum degree 0.06-0.099 MPa and rotation speed 20-600 rpm. When the glue is used, component A and component B are mixed I the ratio of 11-13 at room temperature.

Owner:CHENGDU GUIBAO SCI & TECH

Preparation method of denitration catalyst cellular module

InactiveCN102728343AThe test effect is goodImprove denitrification rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberKneader reactor

The invention relates to a preparation method of a denitration catalyst cellular module. Main powdery materials V2O5-WO3 / TiO2-ZrO2, pottery clay or glass fiber, binder, plasticizer solid-phase powder are well mixed; the mixture is added into a kneading machine; water is added into the kneading machine, and the mixture is kneaded; a lubricating agent with a weight 0.2-0.3 times that of the main powdery materials is added to the mixture, and kneading is continued for 1-3h; a well kneaded pug blank is added into a sealing plastic apparatus, and is subjected to aging in a cool shade; the mixed pug is subjected to 2-3 times of vacuum mixing, such that a cellular ceramic precursor pug is obtained; the cellular ceramic precursor pug is shaped by extrusion by using a cellular ceramic extruding machine; the shaped material is subjected to curve drying in a constant-temperature constant-humidity drying cabinet; the dried cellular ceramic module is baked for 3h under a temperature of 600 DEG C in a high-temperature calcining machine; the modules are cooled and the obtained products are trimmed, such that a cellular ceramic catalyst finished product is obtained. Experimental effects of the cellular ceramic catalyst are better than those of common cellular ceramic catalyst products in the market. The cellular ceramic catalyst provided by the invention has higher denitration rate, larger specific surface area, better sulfur conversion resistance rate, and longer service life.

Owner:CHANGCHUN XINRUI TECH & TRADE

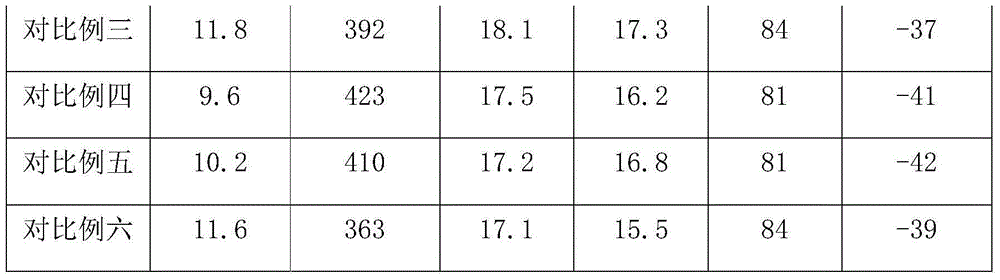

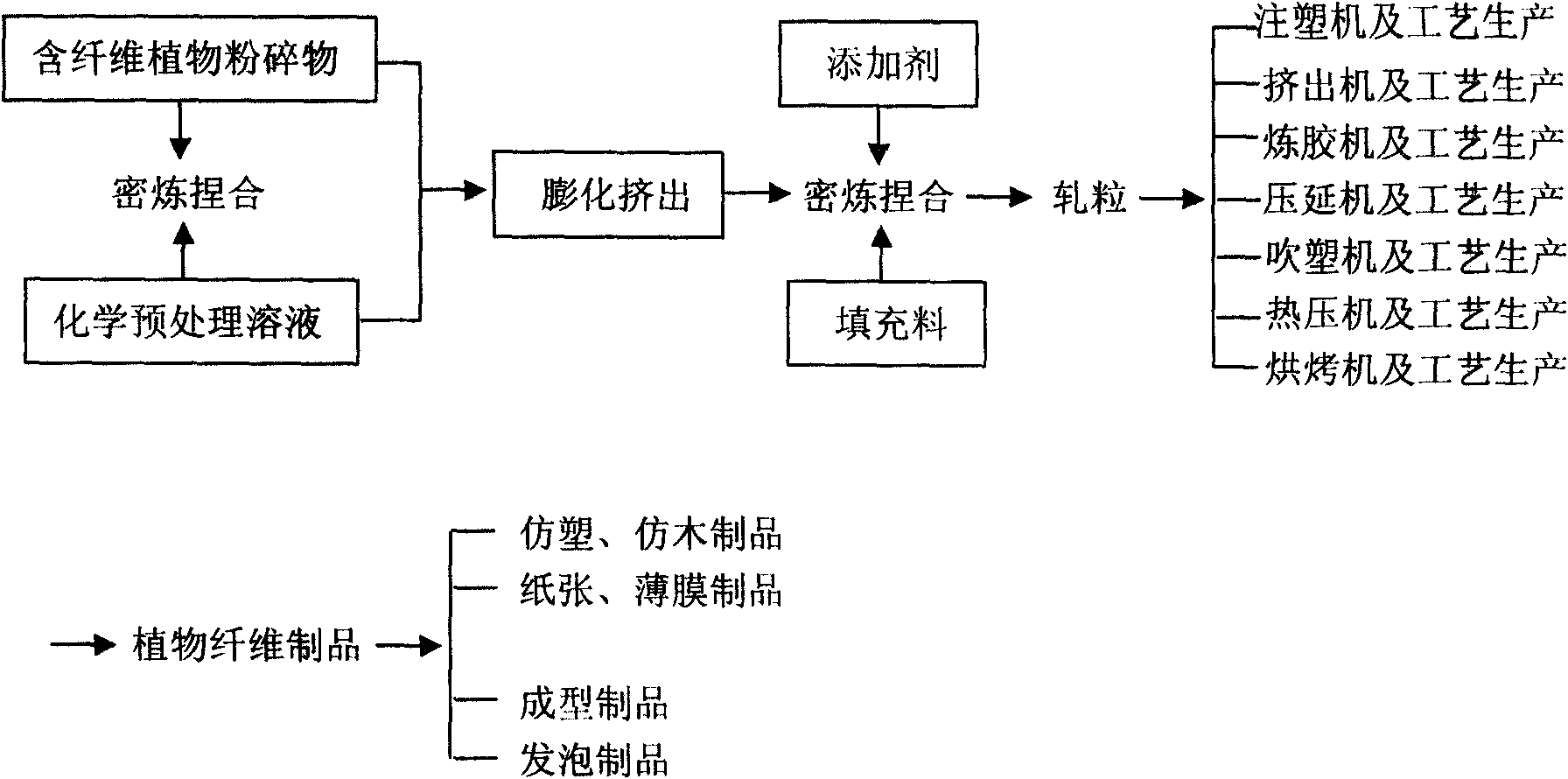

Manufacturing method of plant fibre products

The invention relates to a manufacturing method of plant fibre products, which comprises the steps: pulverized substances containing textile plants are poured into a banburying kneader and chemical pretreatment solution is added, so the fibre pretreatment chemical modification is realized simultaneously when mechanical physics modifying is realized; after entering into an expansion extruder for expansion modification, the pulverized substances are added with various additives and fillings, which are banburied and kneaded together, and the banburying kneading substance is rolled into particles by a particle rolling machine; or plant fibre subjected to banburying kneading chemical modification and various additives and fillings are directly and together banburied and kneaded and then are extruded and produced to form particles or extrusion sectional materials by the expansion extruder; the produced particles or sectional materials can be used for producing plant fibre products of various types and performances and plant fibre products of sheets, sectional materials, paper, membranes, and the like by utilizing the prior plastic injection machine, extruder, blow moulding machine, rubber refining machine, calander, hot press, and equipment and technology principles of microwave and infrared, steam drying, and the like so as to replace plastic, plastic foam, woodworks, paper and membranes.

Owner:朱秀刚

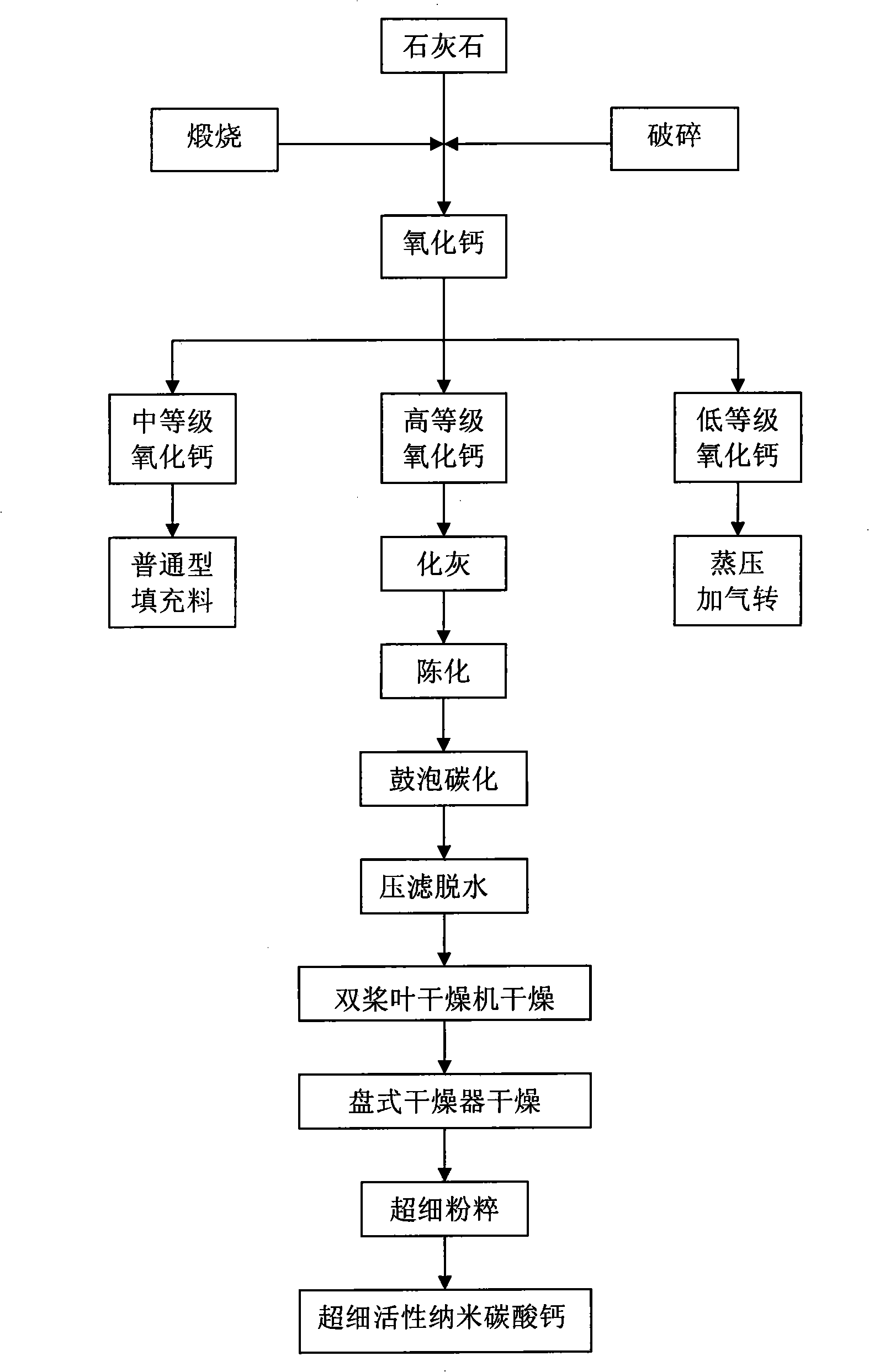

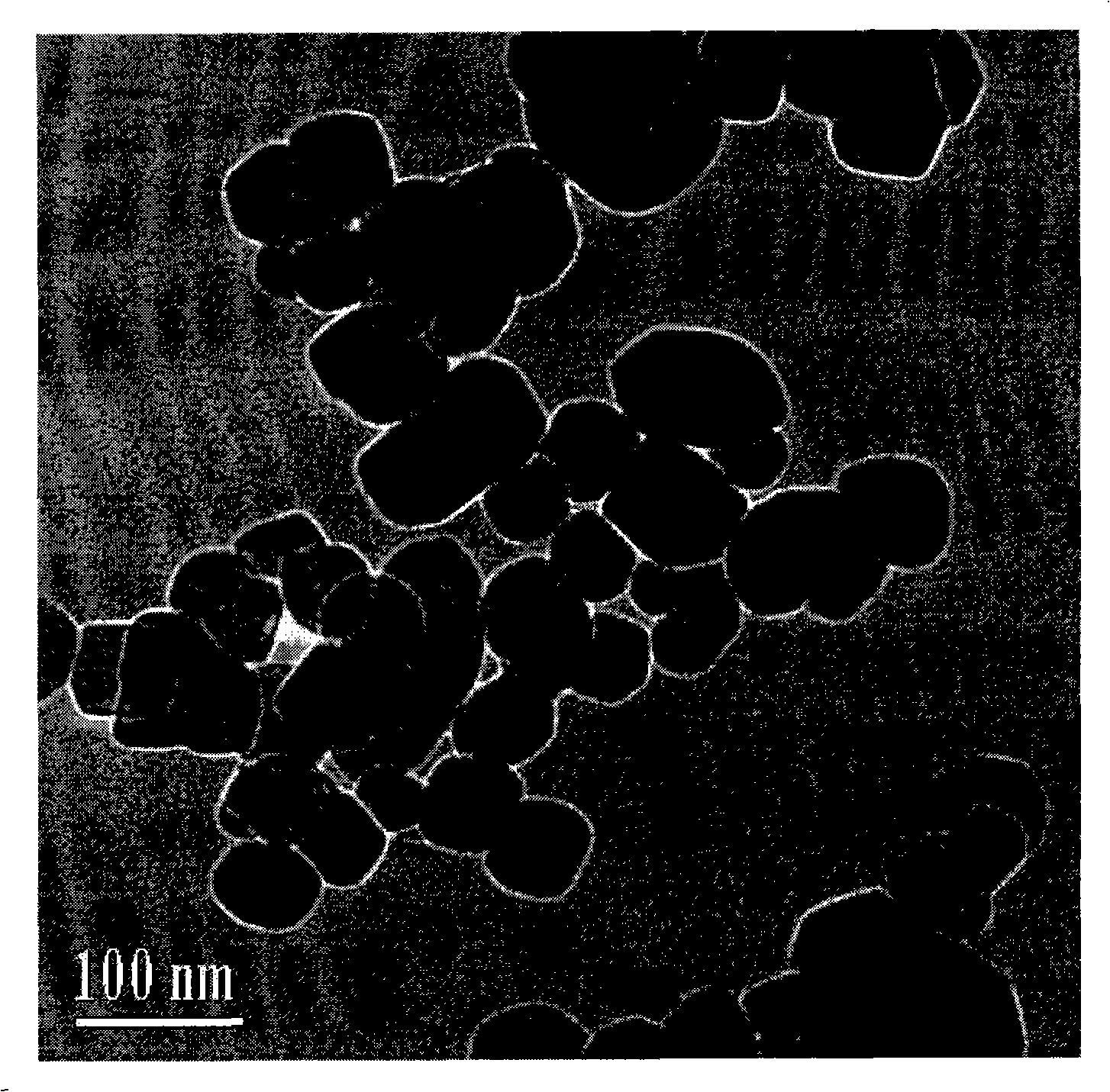

Method for preparing ultra-fine active nano-calcium carbonate with low-ore grade limestone activation of activation tank

InactiveCN101318685AIncrease productivitySolving Lime Burning and OverburningCalcium/strontium/barium carbonatesPoor qualityCalcium hydroxide

The invention provides a method for preparing superfine activated nano calcium carbonate by utilization of low-grade lime. The method adopts the technical proposal that: firstly, the low-grade lime is calcined and crushed so as to prepare calcium oxide; secondly, staged sieving is performed, namely a part of low-quality calcium oxide is grinded into intermediate-grade calcium oxide products through a high-speed kneader or a ring roll, another part of high-quality calcium oxide enters into the next procedure for producing calcium hydroxide and calcium carbonate, and finally calcium oxide with poor quality is used for producing green building materials - aerated concrete blocks; and thirdly, the superfine activated nano calcium carbonate product is prepared after incineration through an incinerator, heat-insulated aging, bubbling carbonization, secondary aging, wet-way secondary activation, recarbonization, centrifugal dewatering, drying and superfine crushing of the high-quality calcium oxide. The method utilizes the low-grade lime to the utmost extent to prepare superfine functional calcium inorganic powder materials.

Owner:福建省万旗非金属材料有限公司

Low-temperature hot melt adhesive and preparation method thereof

ActiveCN102321442AHigh peel strengthGood construction performanceMineral oil hydrocarbon copolymer adhesivesCorrosion preventionElastomerPolymer science

The invention discloses a low-temperature hot melt adhesive and a preparation method thereof, and the low-temperature hot melt adhesive comprises the following components by weight: 28-70 parts of matrix resins, 20-46 parts of tackifying resins, 10-25 parts of maleic anhydride graft copolymers, 0.5-2 parts of anti-oxidants; the matrix resin comprises 20-50 parts by weight of ethylene-octene copolymer elastomers, and 50-80 parts by weight of ethylene-butyl acrylate copolymers. By using a mixing method, the raw materials are mixed in a kneader. The low-temperature hot melt adhesive obtained by the formula and the method of the invention has a low brittle temperature, good bonding performance, good sealing performance, stable performance, a simple process, and low cost, is applicable to the field of metal pipeline repaired mouth anticorrosion, and has very good economic benefit and industrial production prospects.

Owner:成都长江热缩材料有限公司

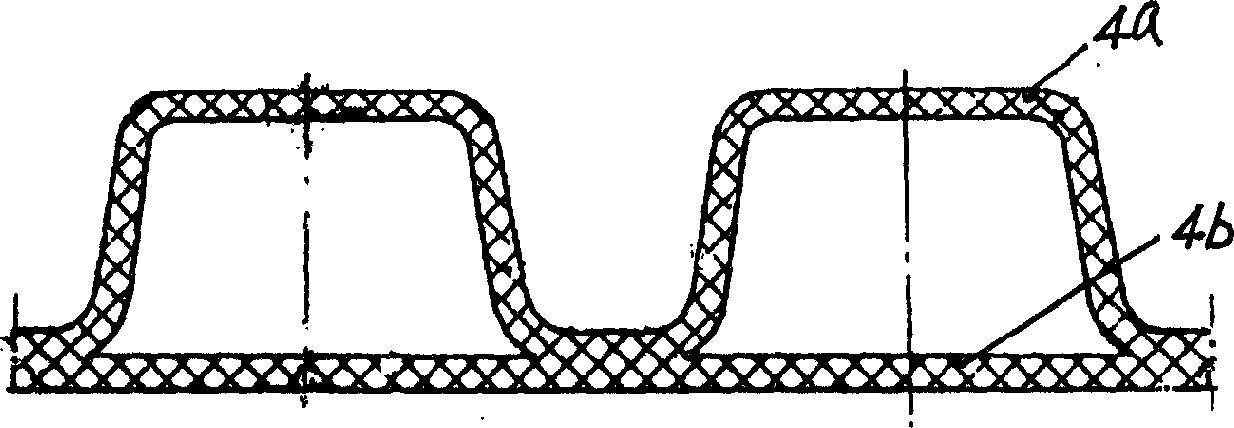

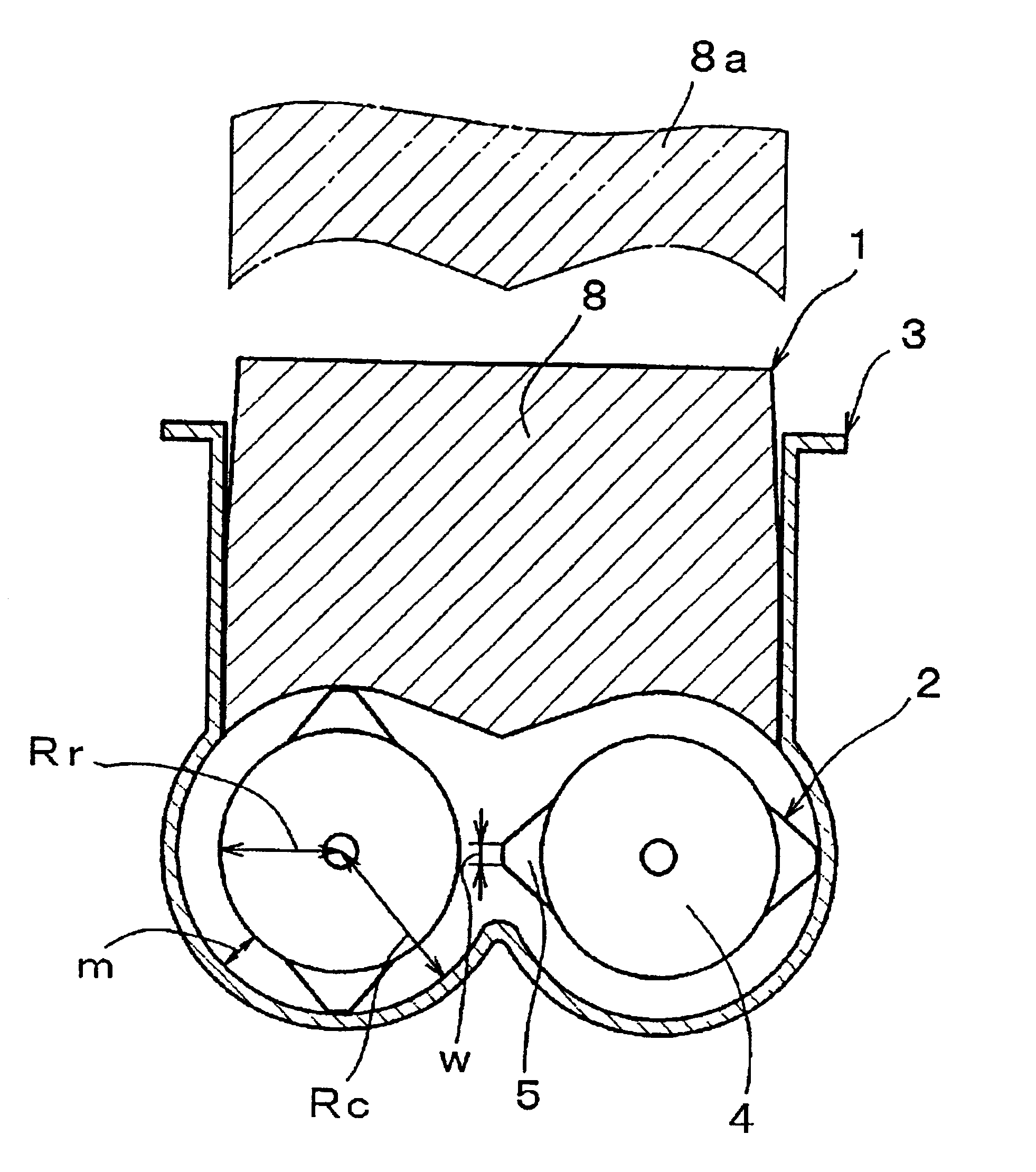

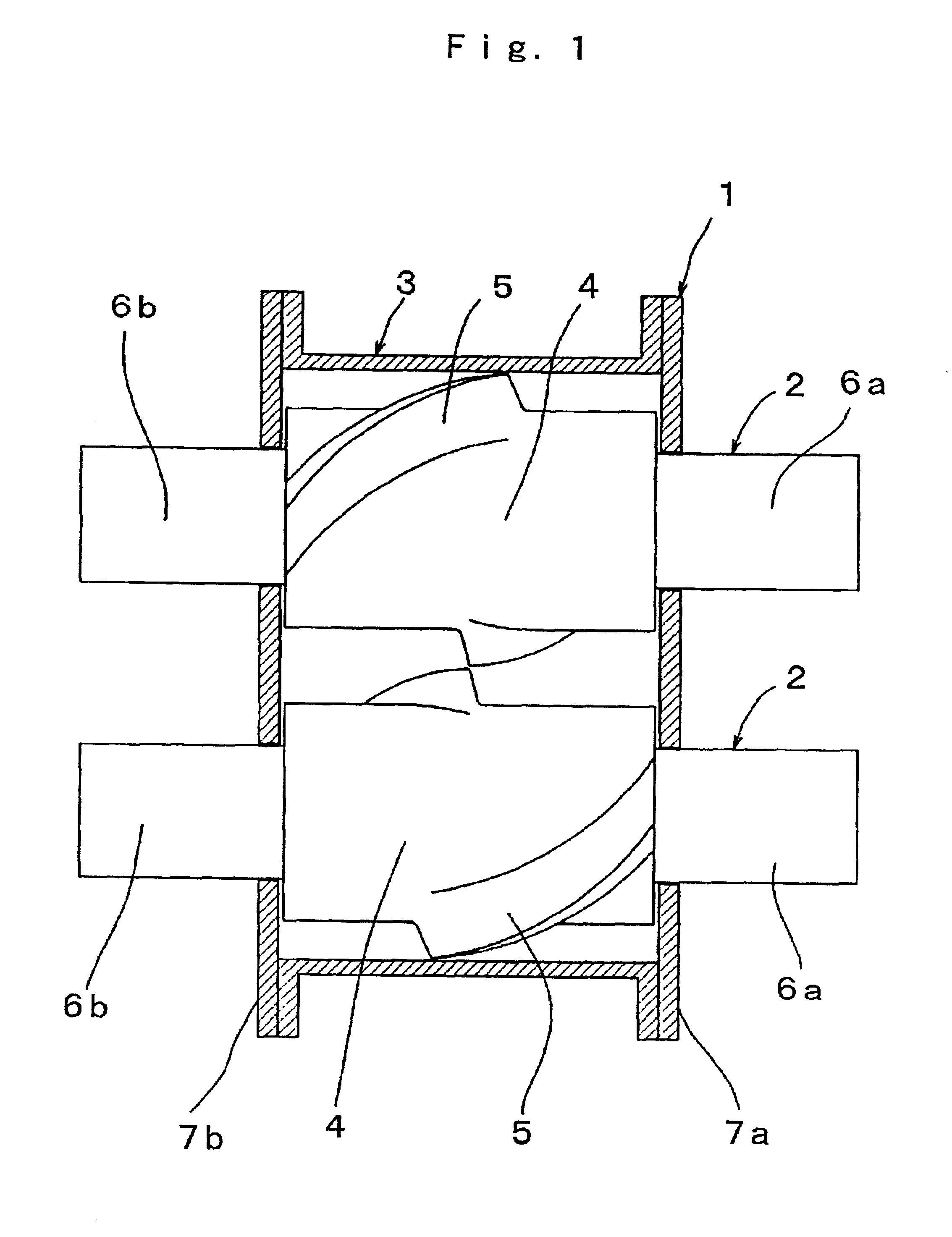

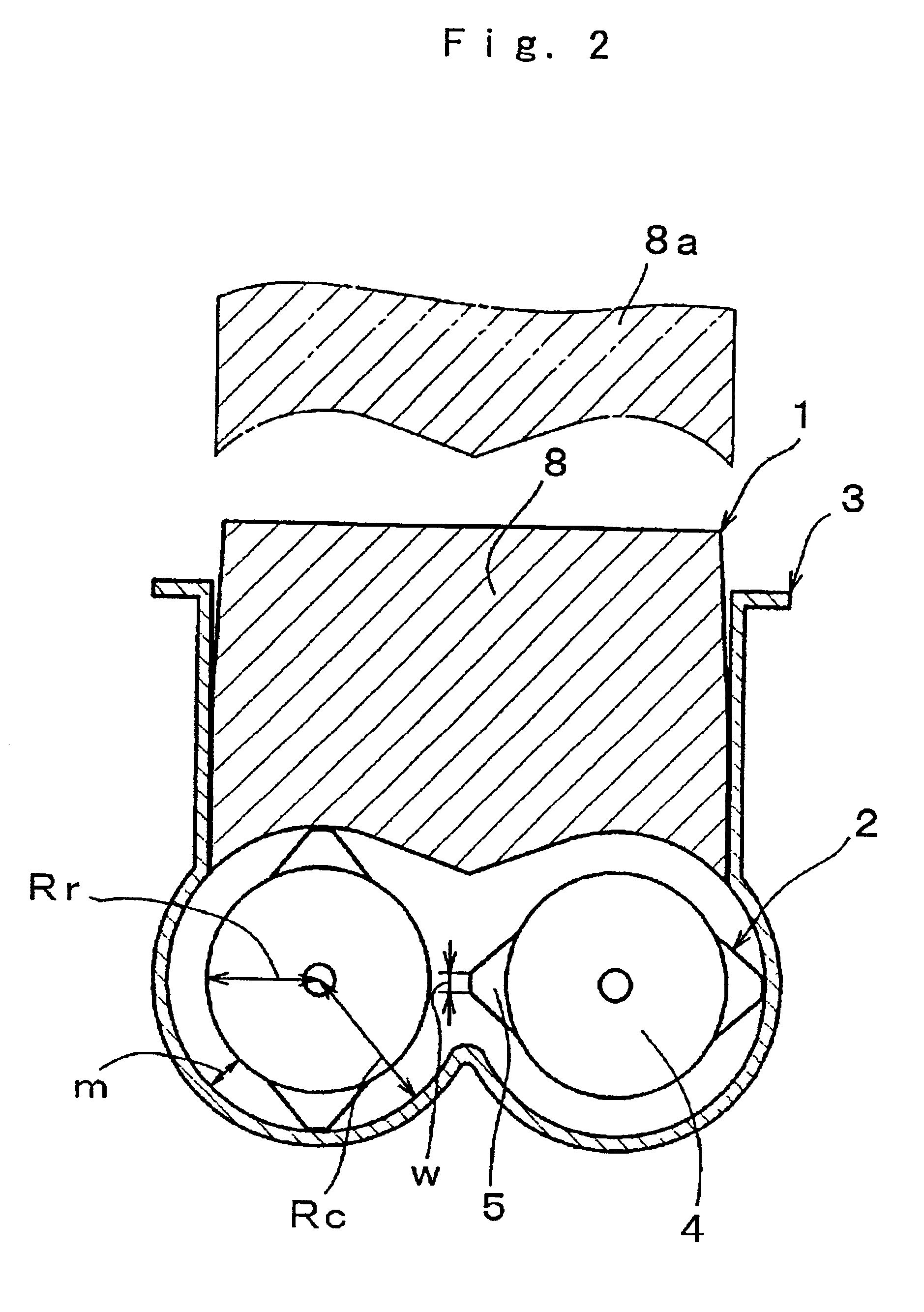

Closed kneader

InactiveUS6913379B2Reduce thicknessImprove cooling effectRotary stirring mixersTransportation and packagingKneader reactorLine tubing

With conventional closed kneaders, the temperature of the kneaded material remains high at the end of primary kneading because insufficient cooling is made in the interior part of the kneaded material, making it necessary to either provide cooling time between the primary and secondary kneading or to transfer materials to another kneader after the end of primary kneading for the secondary kneading. This has constituted an obstruction to productivity. In view of such problems, a closed kneader is capable of controlling the kneaded material temperature at the end of primary kneading at a level no higher than the temperature that allows addition of a vulcanizing agent line, and can perform secondary kneading immediately after the end of primary kneading. In a closed kneader provided with a chamber for storing kneaded material and a pair of rotors installed in the chamber, the proportion of the radius of the rotor shaft to the radius on the inner face of the chamber is kept at no less than 0.65.

Owner:MORIYAMA +1

A liquid state mulching film forming material and method for preparing same

InactiveCN1464028AHigh organic contentImprove aggregate structureOrganic fertilisersSoil conditioning compositionsLiquid statePhosphate

The biological liquid mulching filming material includes four kinds of components including kelp powder, starch phosphate, alpha-starch and ammonium carbonate. The preparation process includes soaking, decoloring and crushing kelp; adding starch phosphate, alpha-starch and ammonium carbonate; mixing in a kneading machine or screw extruder; pelletizing and drying. The biological liquid mulching filming material contains no polymer and chemical fertilizer, and has no negative effect on soil, underground water and other crop growth environment. Used mulching residue can raise organic matter content in soil to improve the aggregate structure and fix surface soil.

Owner:CHINA AGRI UNIV

Foam discharging balls for gas well and preparation method thereof

ActiveCN103468234AImprove temperature resistanceImprove salt resistanceDrilling compositionKneader reactorActive agent

The invention relates to the technical field of water drainage for a gas well to increase production in an oil and gas field and provides a foam discharging ball for a gas well and a preparation method thereof. The foam discharging ball for the gas well is prepared from the following raw materials in parts by weight: 50-70 parts of surfactant, 15-25 parts of antiscaling stabilizer and 15-25 parts of foam stabilizer. The foam discharging ball for the gas well is prepared through the following steps of: the first step, heating the desired surfactant so that the surfactant is melton and evaporated until the mass percent moisture content of the surfactant is less than or equal to 5%, and then adding the desired antiscaling stabilizer and the desired foam stabilizer, and then stirring evenly to obtain a mixture. The foam discharging balls provided by the invention are obtained by heating the surfactant so that the surfactant is melton and evaporated, and then adding the antiscaling stabilizer and the foam stabilizer for mixing, kneading through a kneading machine, squeezing into a mold and then demolding. The foam discharging balls obtained are applicable to natural gas wells in different regions at present in China, and are excellent in temperature resistant, salt resistance, anti-freezing and oil separation properties, and bubbling water carrying performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com