Method for producing polymetaphenylene isophthamide spinning solution

A technology of polym-phenylene isophthalamide spinning and isophthaloyl chloride, which is applied in the direction of spinning solution preparation, one-component polyamide artificial filament, one-component synthetic polymer rayon, etc. It can solve the problems of large heat transfer area, poor heat transfer effect, and short material residence time, so as to achieve good mass transfer effect and avoid material loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

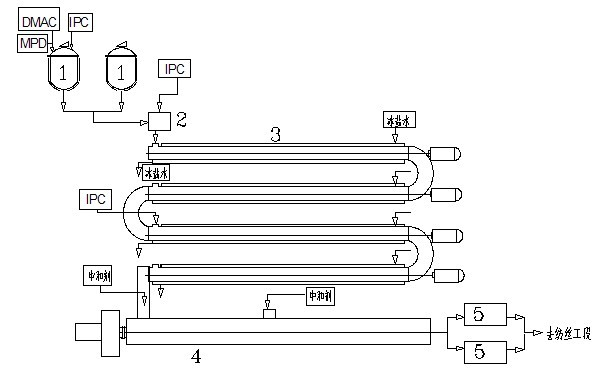

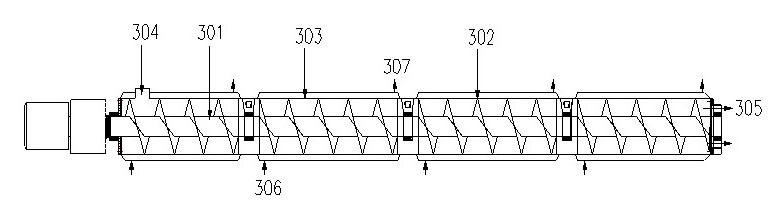

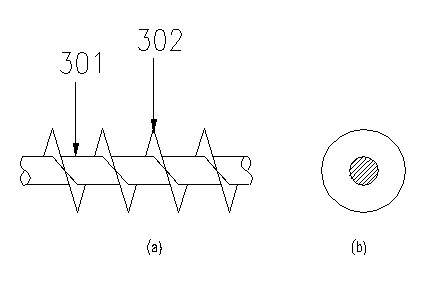

[0041] The production device used in the production of polym-phenylene isophthalamide in this embodiment includes a precondensation reactor 1, a mixer 2, a self-cleaning tubular reactor 3, a twin-screw kneader 4, and a filter 5. The polycondensation reactor 1 is a tank reactor equipped with a cooling coil, and the self-cleaning tubular reactor 3 is formed by sequentially connecting 4 straight pipes with jackets and 3 bent pipes, and the jackets There is a constant temperature liquid inlet 306 and a constant temperature liquid outlet 307 on the top, and the inside of the jacket is ice salt water. The two ends of the reactor are respectively equipped with a feed port 304 and a discharge port 305. The diameter of each straight pipe of the reactor is 0.15m , the length is 5m, the total length of the straight pipe is 20m, the straight pipe is provided with a stirring shaft 301 connected to the motor, the stirring shaft 301 is provided with a continuous spiral blade 302, the edge of ...

Embodiment 2

[0050] The production device of this embodiment is the same as that of Embodiment 1.

[0051] The method for producing the polym-phenylene isophthalamide spinning solution that the present embodiment enumerates may further comprise the steps:

[0052] (1) Preparation of materials: prepare materials according to the equimolar ratio of m-phenylenediamine (MPD) and isophthaloyl chloride (IPC) (the weight ratio of MPD and IPC is MPD:IPC=1:1.88);

[0053] (2) Precondensation: Dissolve m-phenylenediamine in the organic polar solvent DMAC according to the weight ratio of adding 1 kg of m-phenylenediamine per 8.0 kg of solvent, and add the obtained MPD organic solution to a kettle with a cooling coil Type reactor 1, lower the temperature to about -12°C ~ -10°C, add 1.69kg IPC for every 1kg of m-phenylenediamine, add IPC to the MPD organic solution (the amount of IPC added is 90% of the total amount of IPC) for pre-condensation reaction , the precondensation reaction time is about 45m...

Embodiment 3

[0058] The production device of this embodiment is the same as that of Embodiment 1.

[0059] The method for producing the polym-phenylene isophthalamide spinning solution that the present embodiment enumerates may further comprise the steps:

[0060] (1) Preparation of materials: prepare materials according to the equimolar ratio of m-phenylenediamine (MPD) and isophthaloyl chloride (IPC) (the weight ratio of MPD and IPC is MPD:IPC=1:1.88);

[0061] (2) Precondensation: Dissolve m-phenylenediamine in DMAC, an organic polar solvent, according to the weight ratio of adding 1 kg of m-phenylenediamine per 10.7 kg of solvent, and add the obtained MPD organic solution to a kettle with a cooling coil Type reactor 1, lower the temperature to about -15°C, add 1.59kg IPC to MPD organic solution according to every 1kg m-phenylenediamine, add IPC (the amount of IPC added is 85% of the total amount of IPC) to carry out pre-condensation reaction, pre-condensation reaction The time is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com