Patents

Literature

6856 results about "Spiral blade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

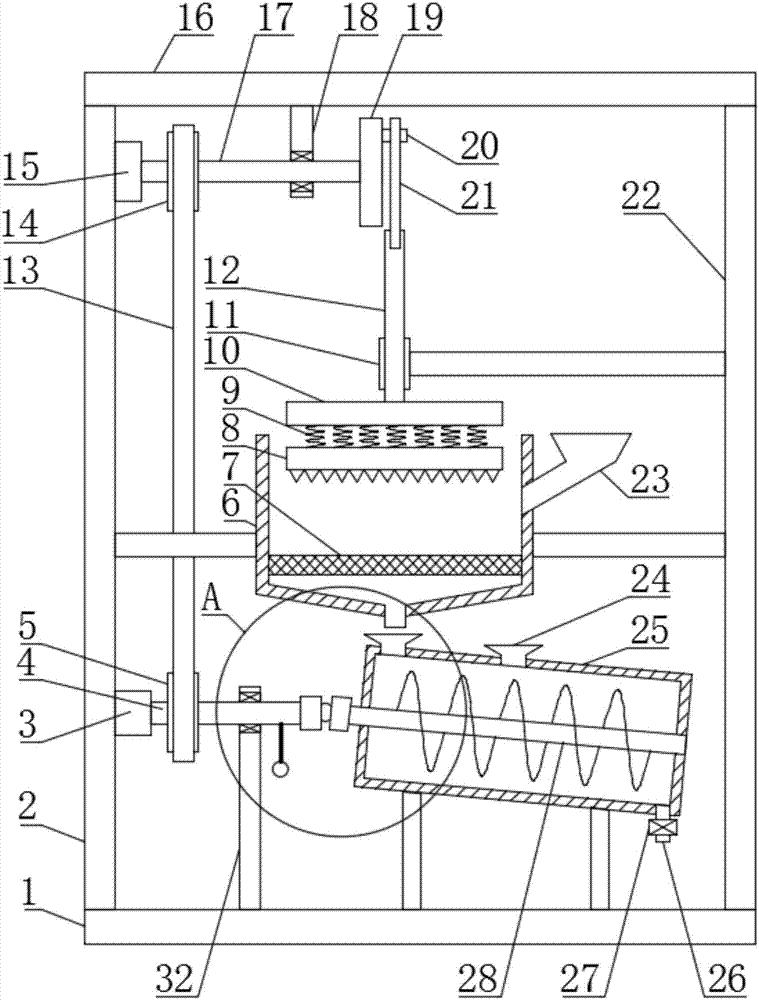

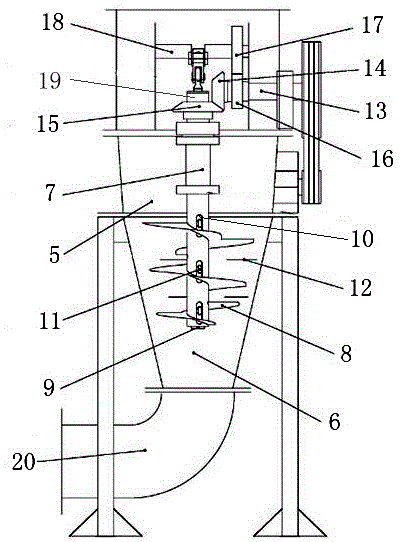

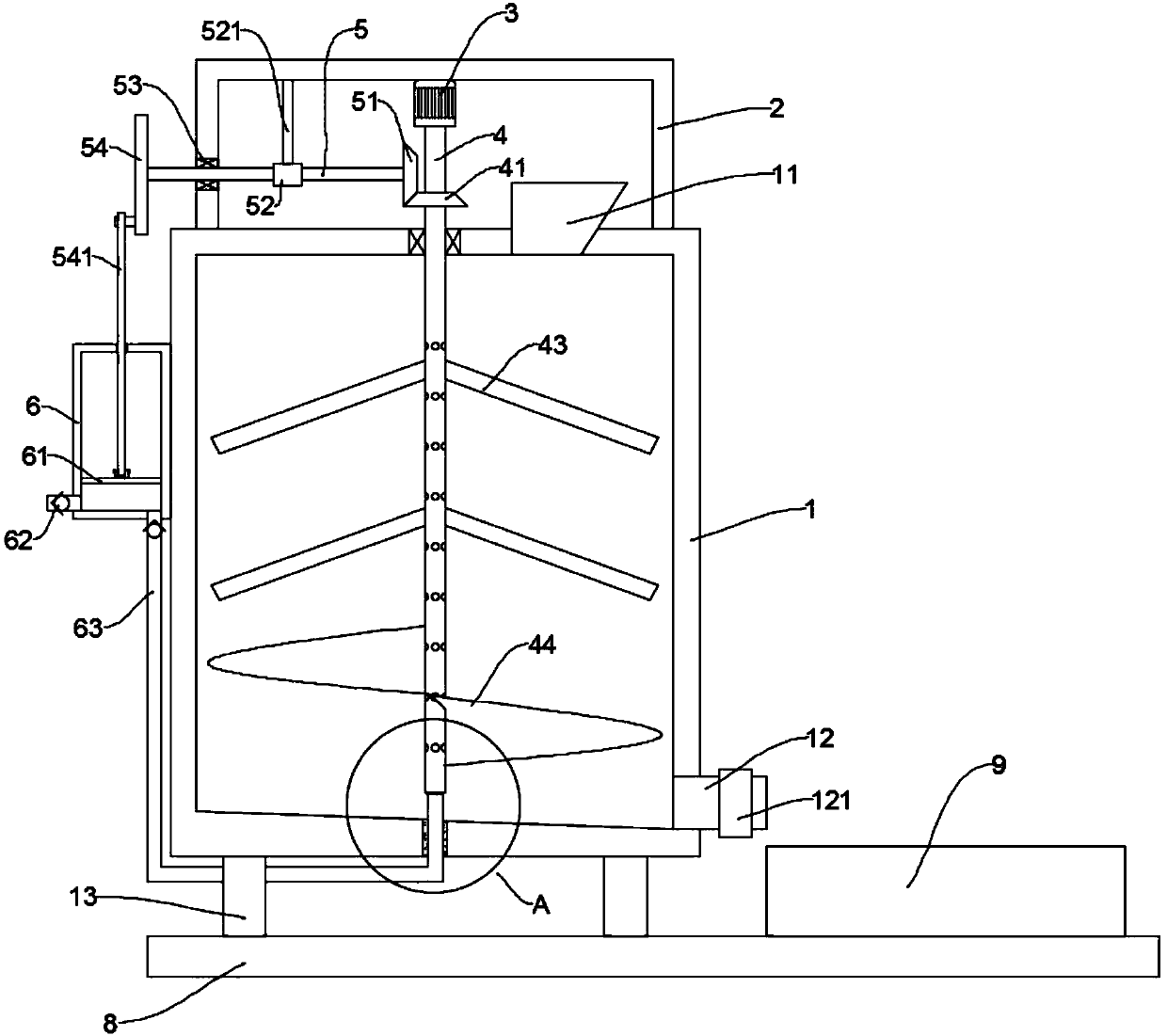

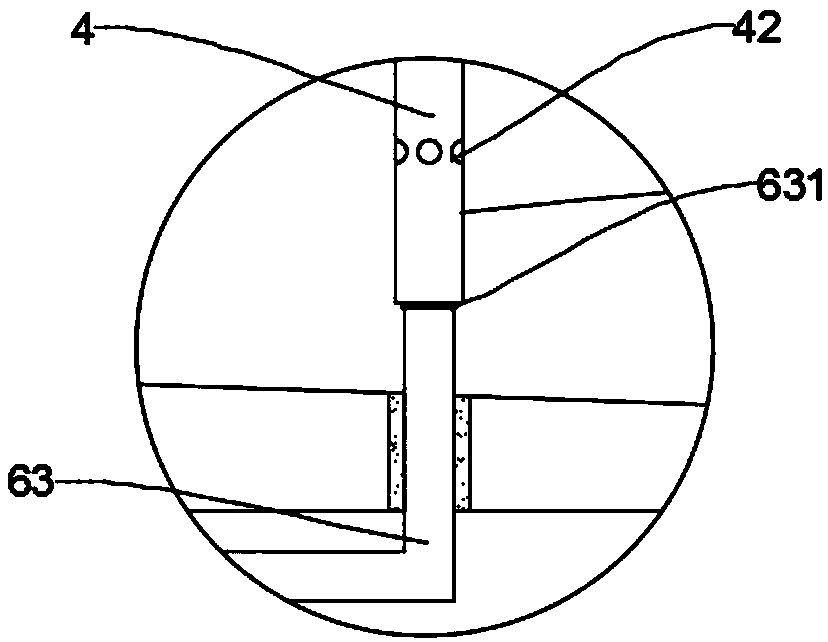

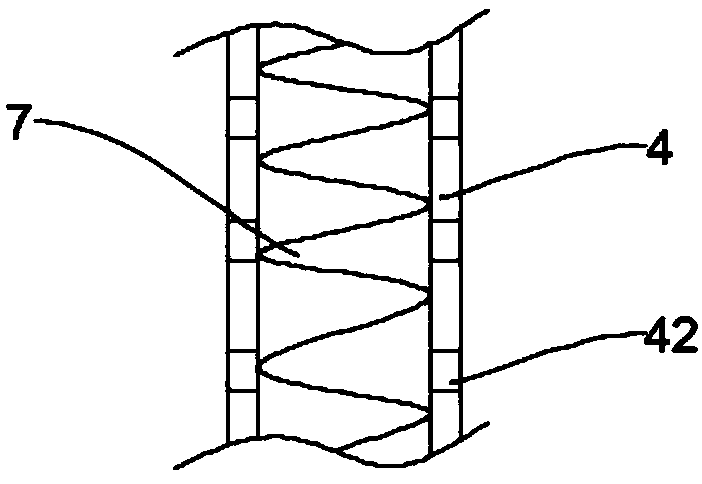

Device for separating water from sludge

InactiveUS10053385B1Convenient guidanceEfficient and cheapSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSpiral bladeSludge

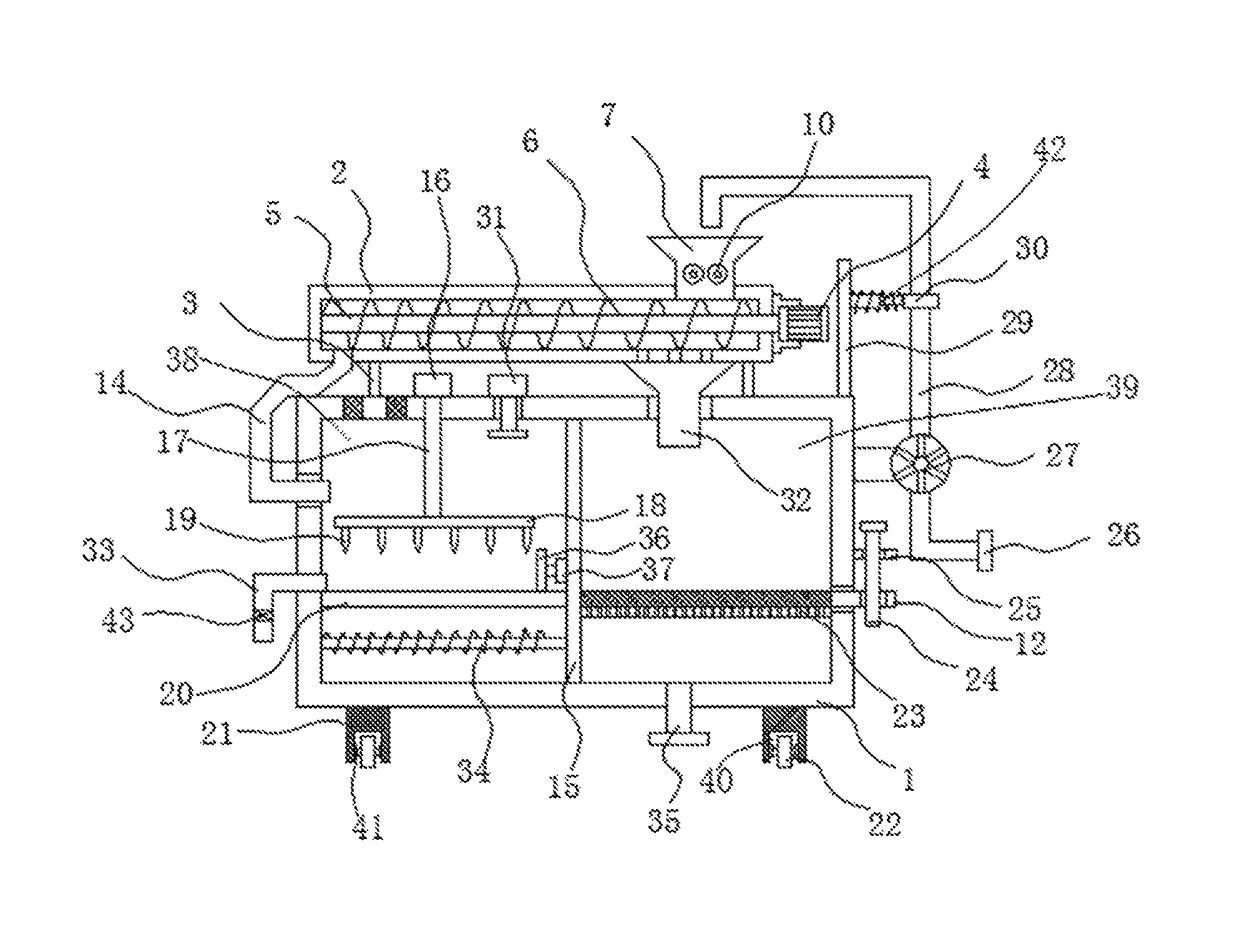

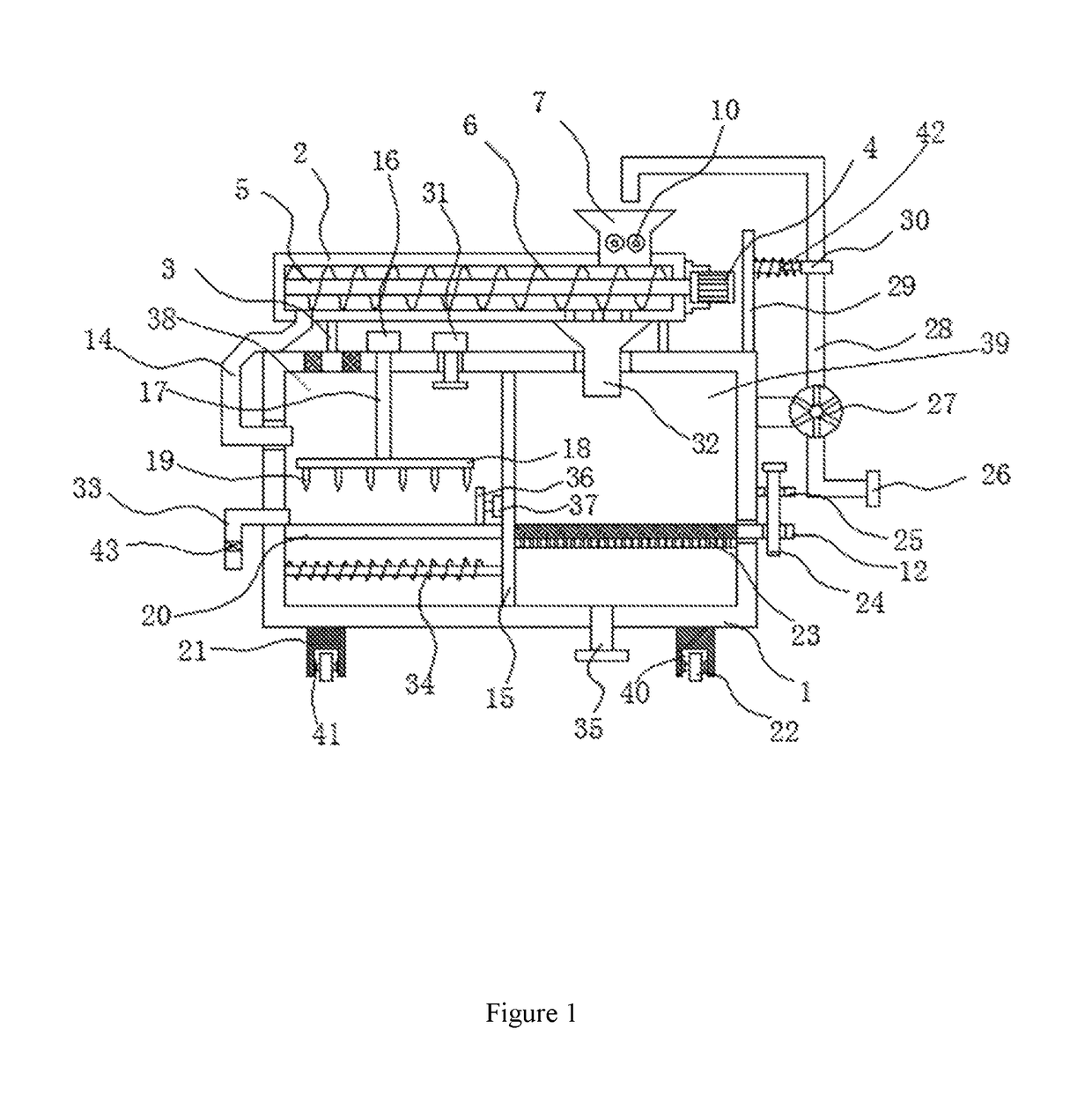

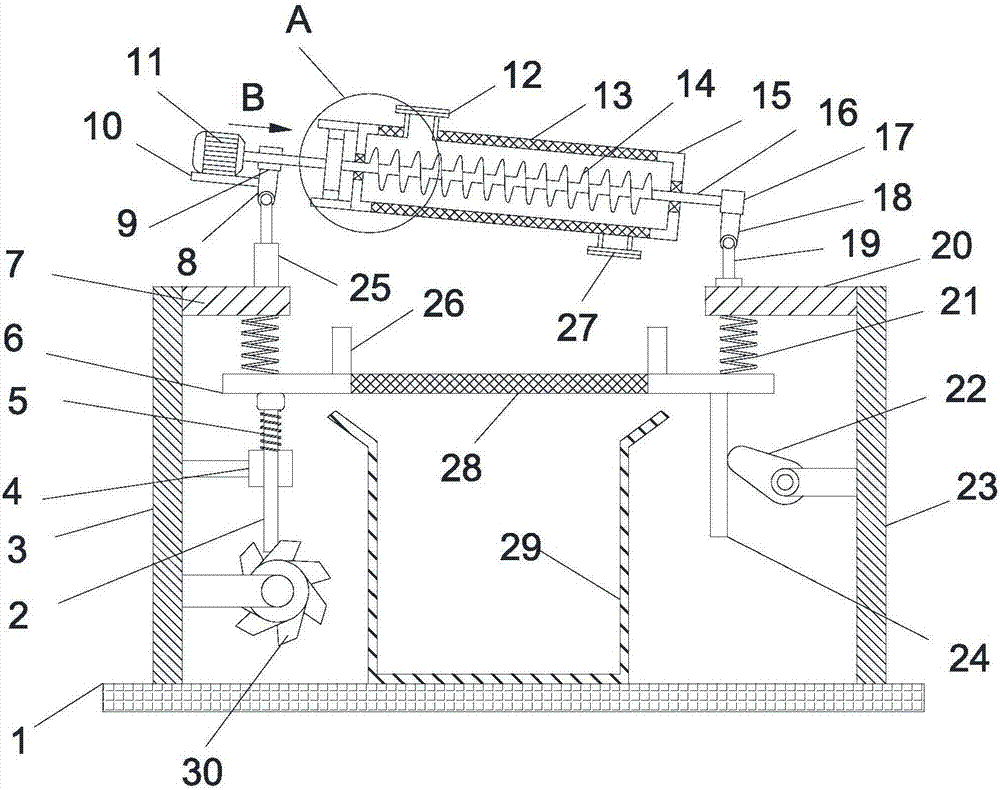

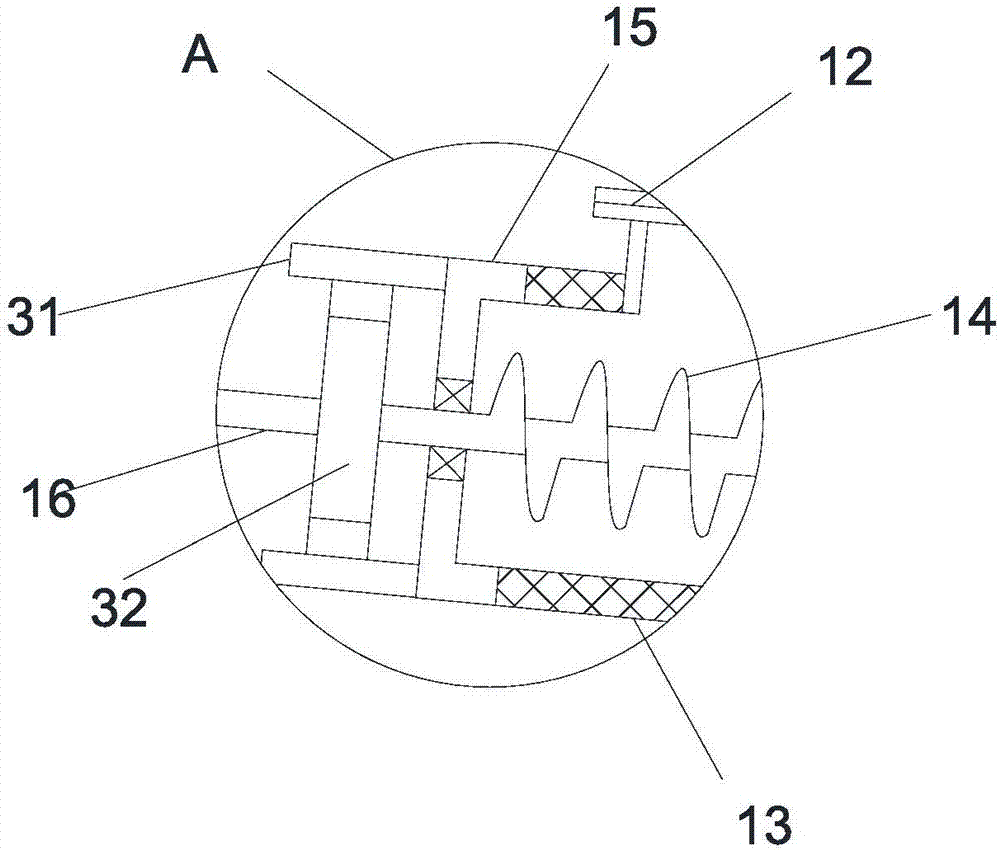

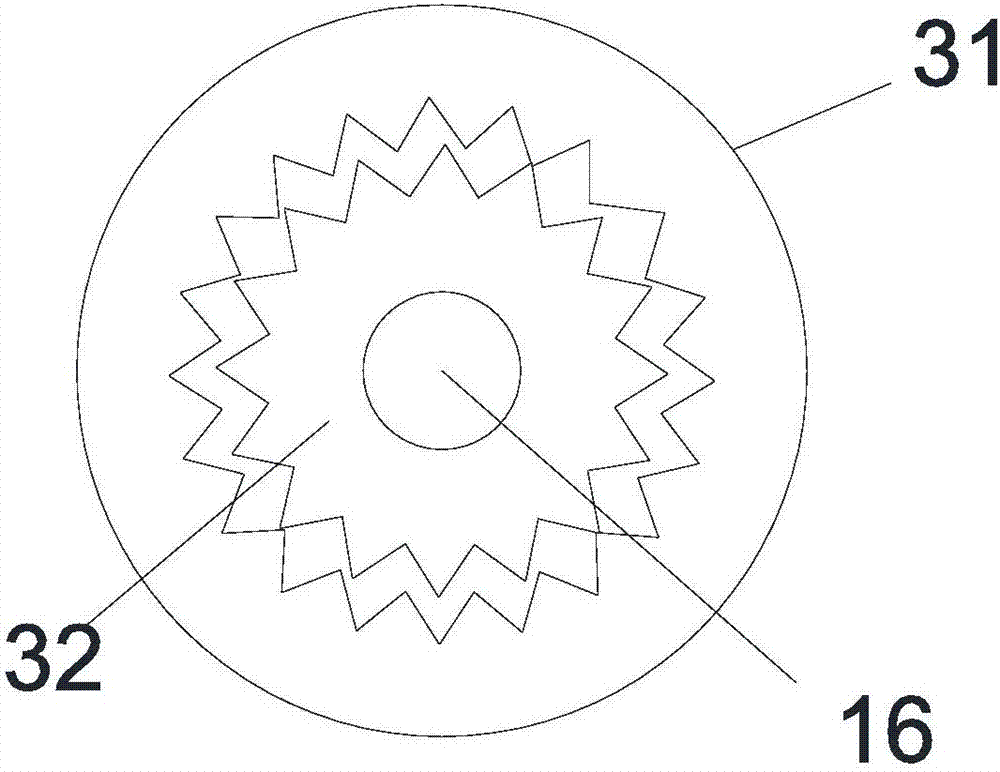

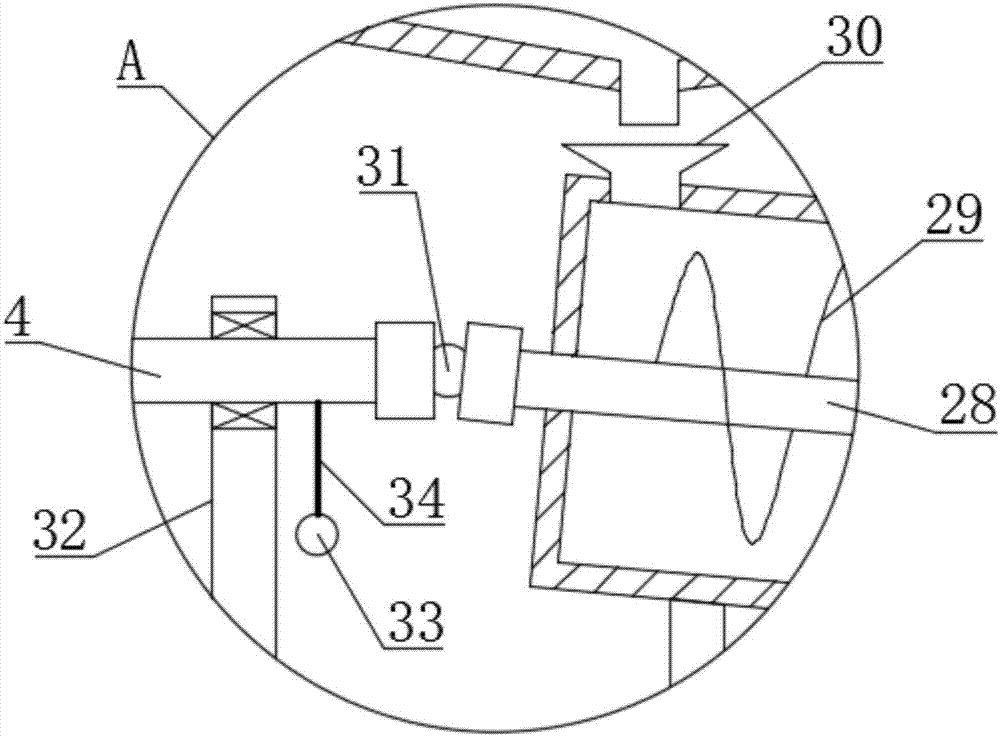

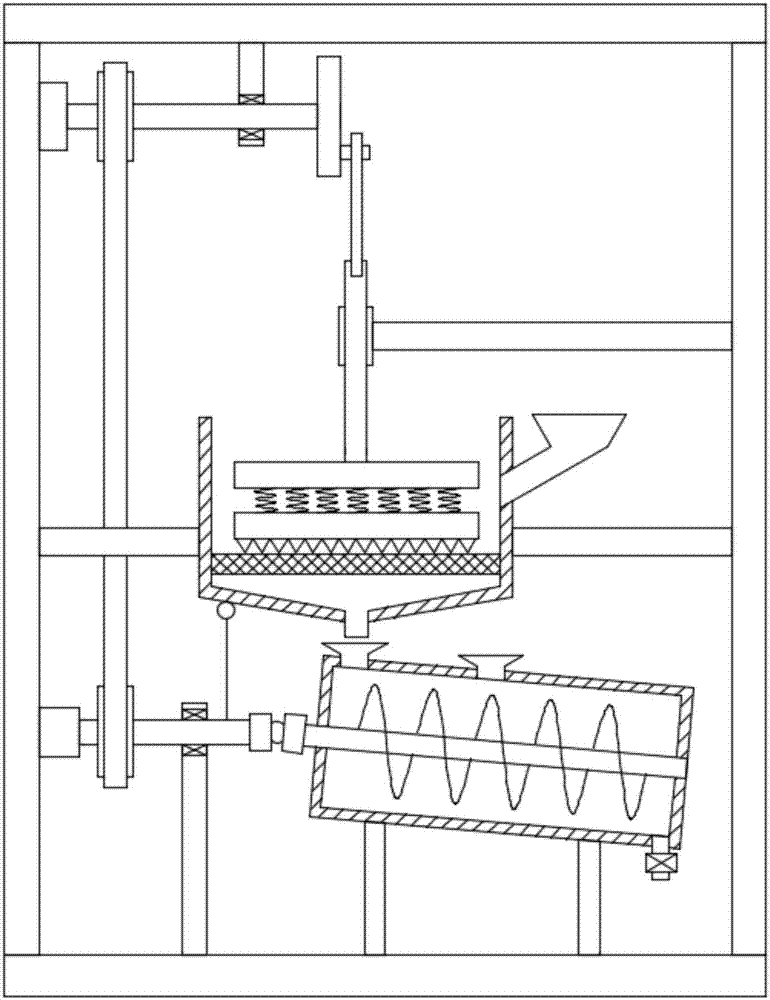

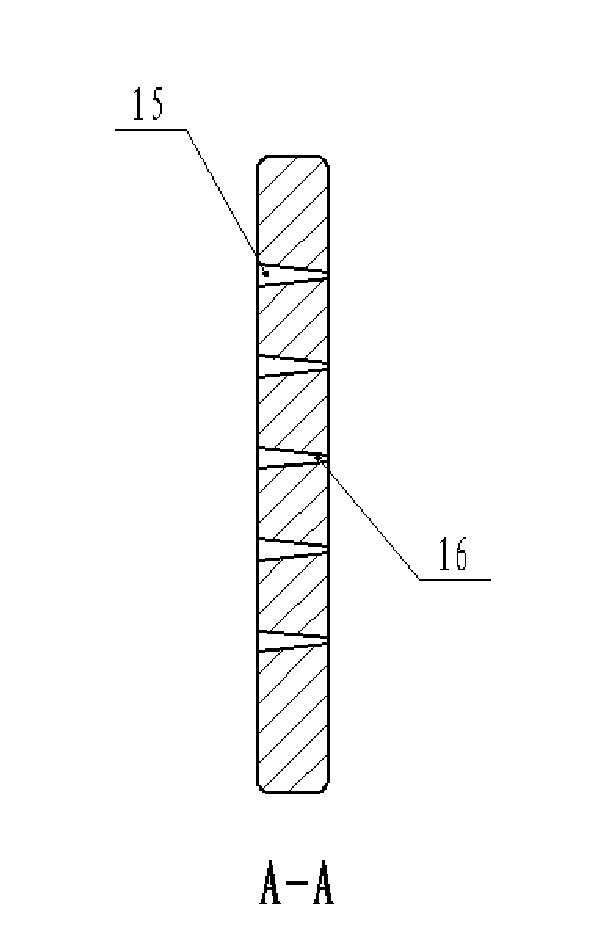

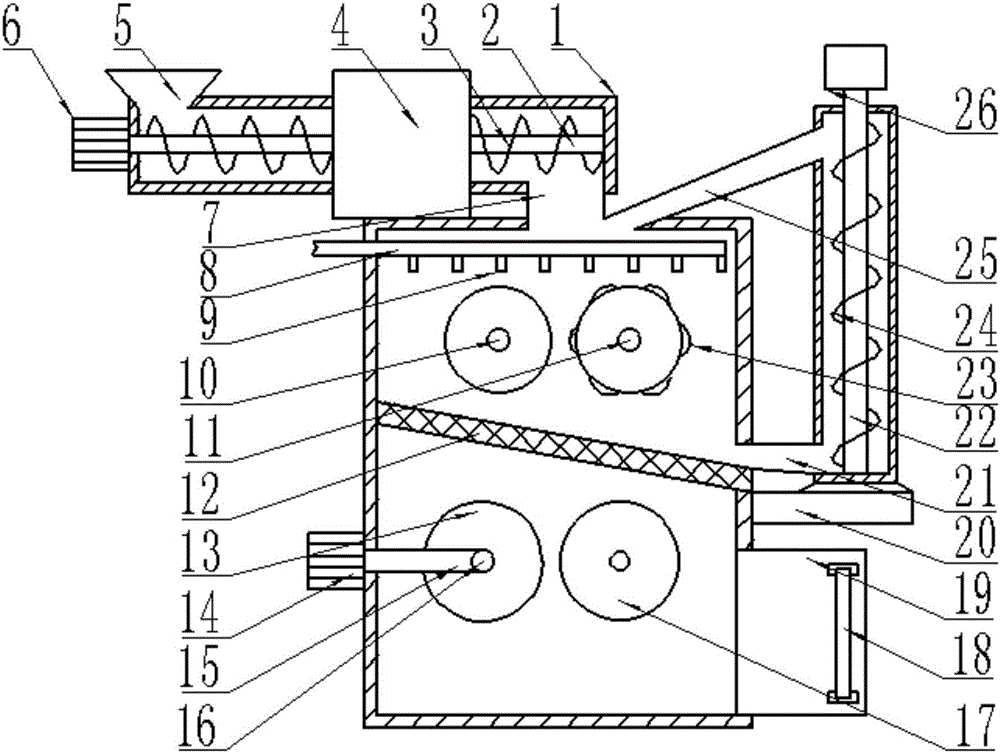

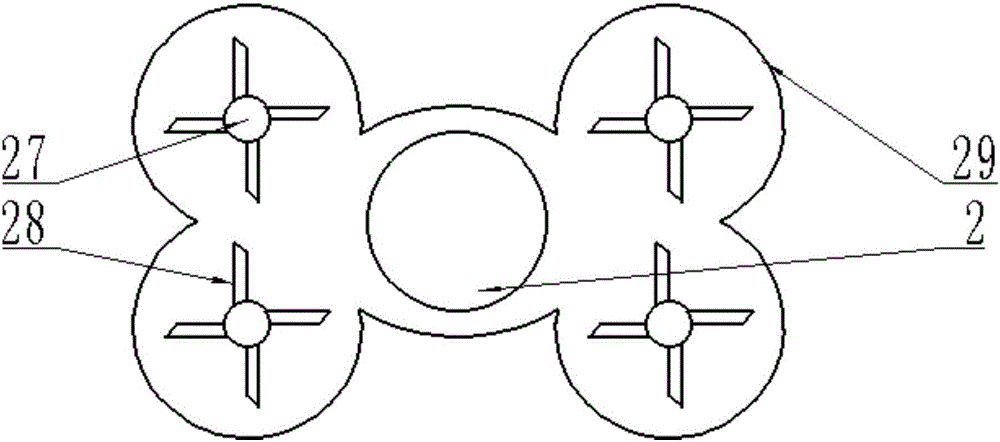

A device for separating water from sludge comprising a processing box, wherein a feeding cylinder is disposed above the processing box, and the feeding cylinder is fixedly connected to the processing box through a plurality of connecting rods; a rotating rod is rotationally connected into the feeding cylinder; a first rotating motor is fixedly connected to one side of the feeding cylinder; the output end of the first rotating motor penetrates through the side wall of the feeding cylinder, and is fixedly connected to the rotating rod; a spiral blade is fixedly sleeved with the rotating rod, and the outer side of the spiral blade is matched with the inner side wall of the feeding cylinder.

Owner:ZHU ZIYU

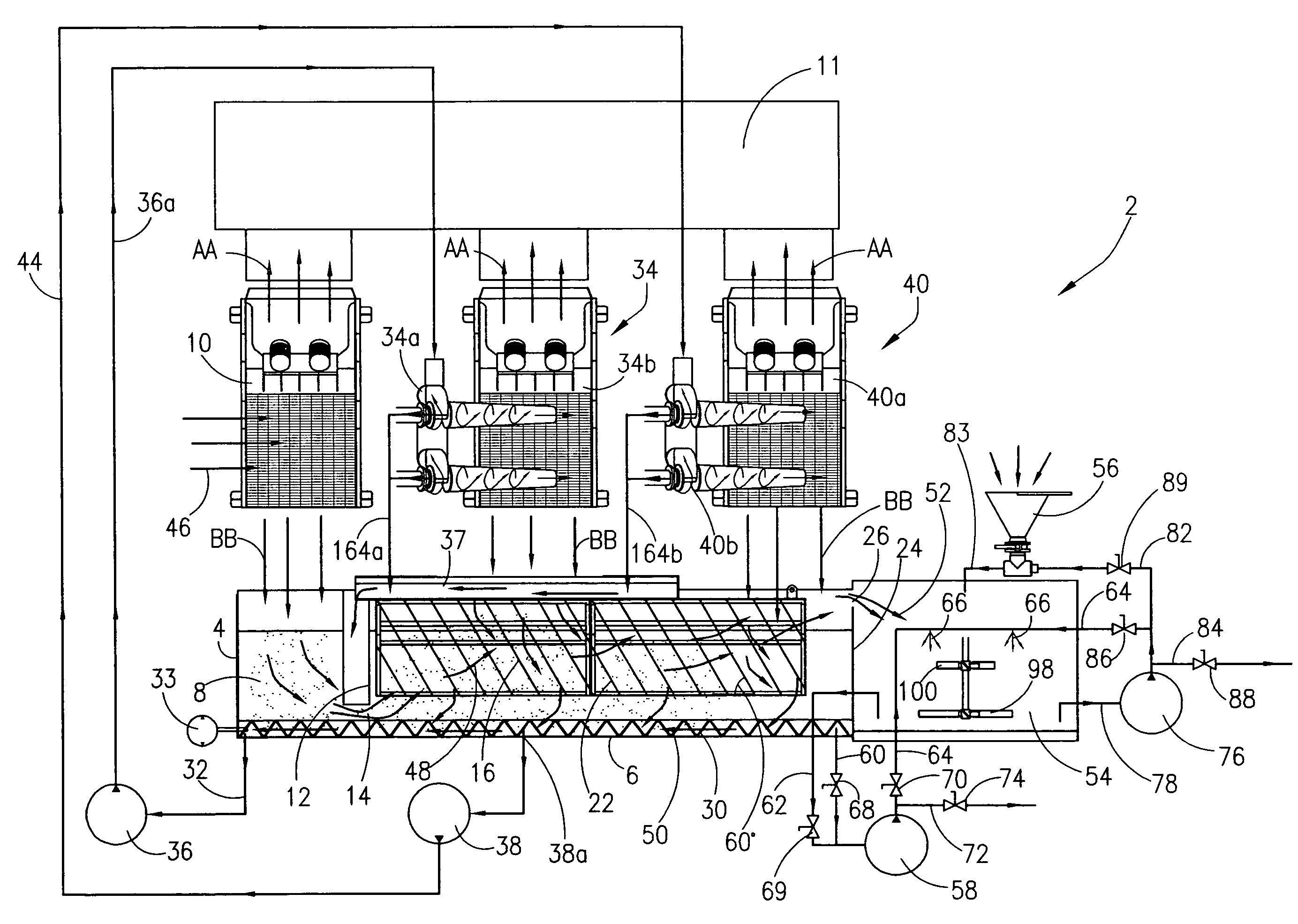

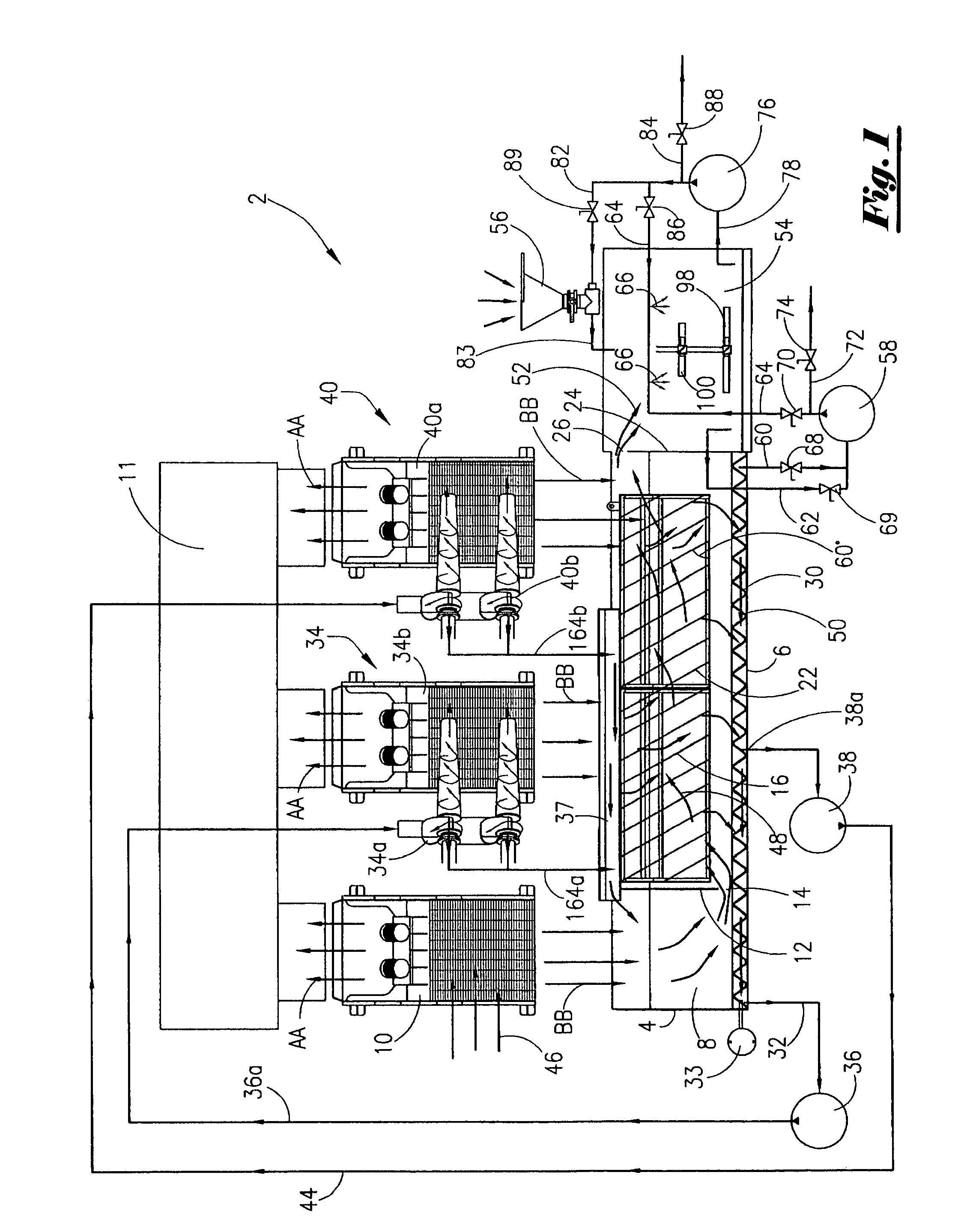

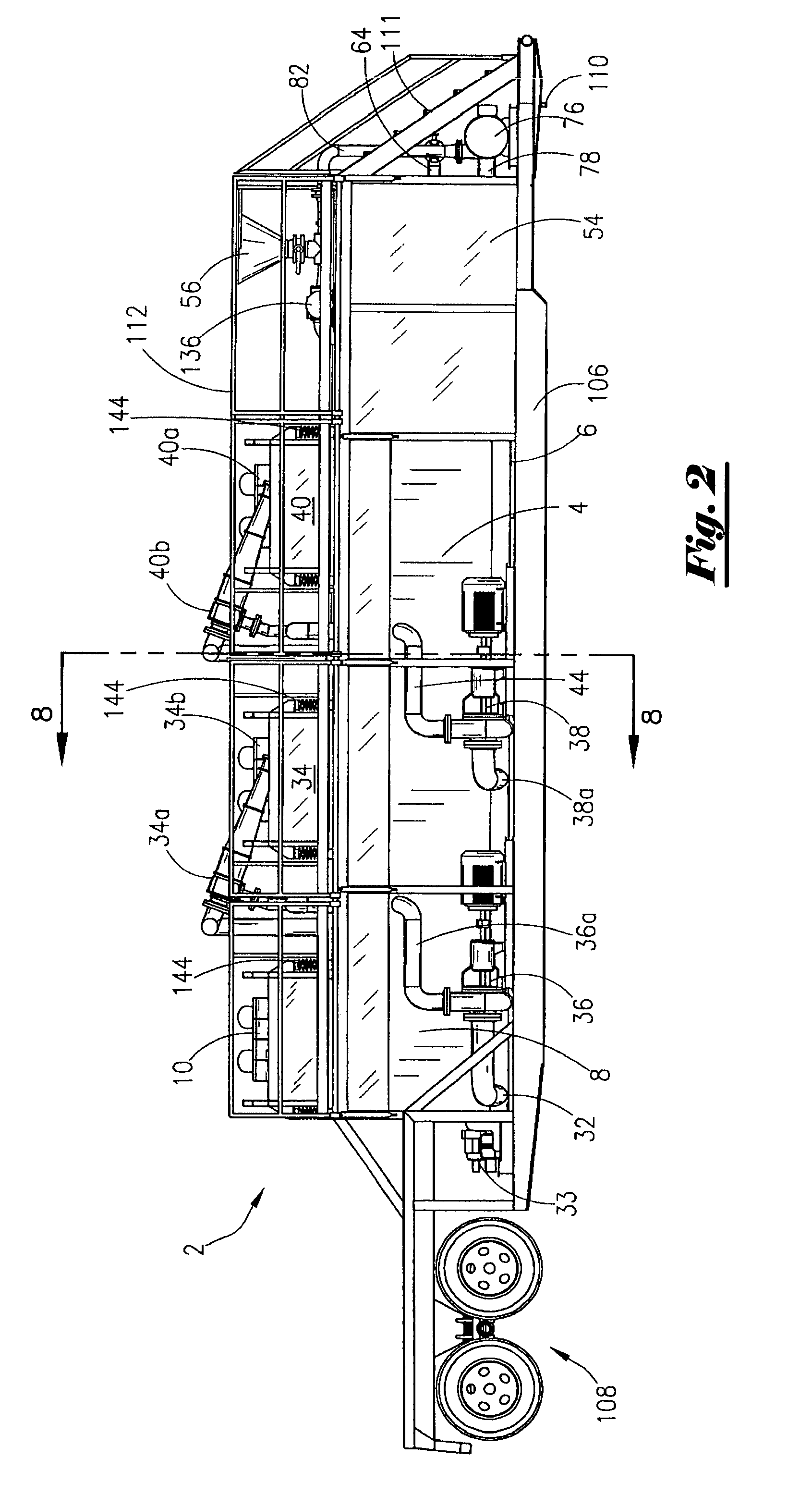

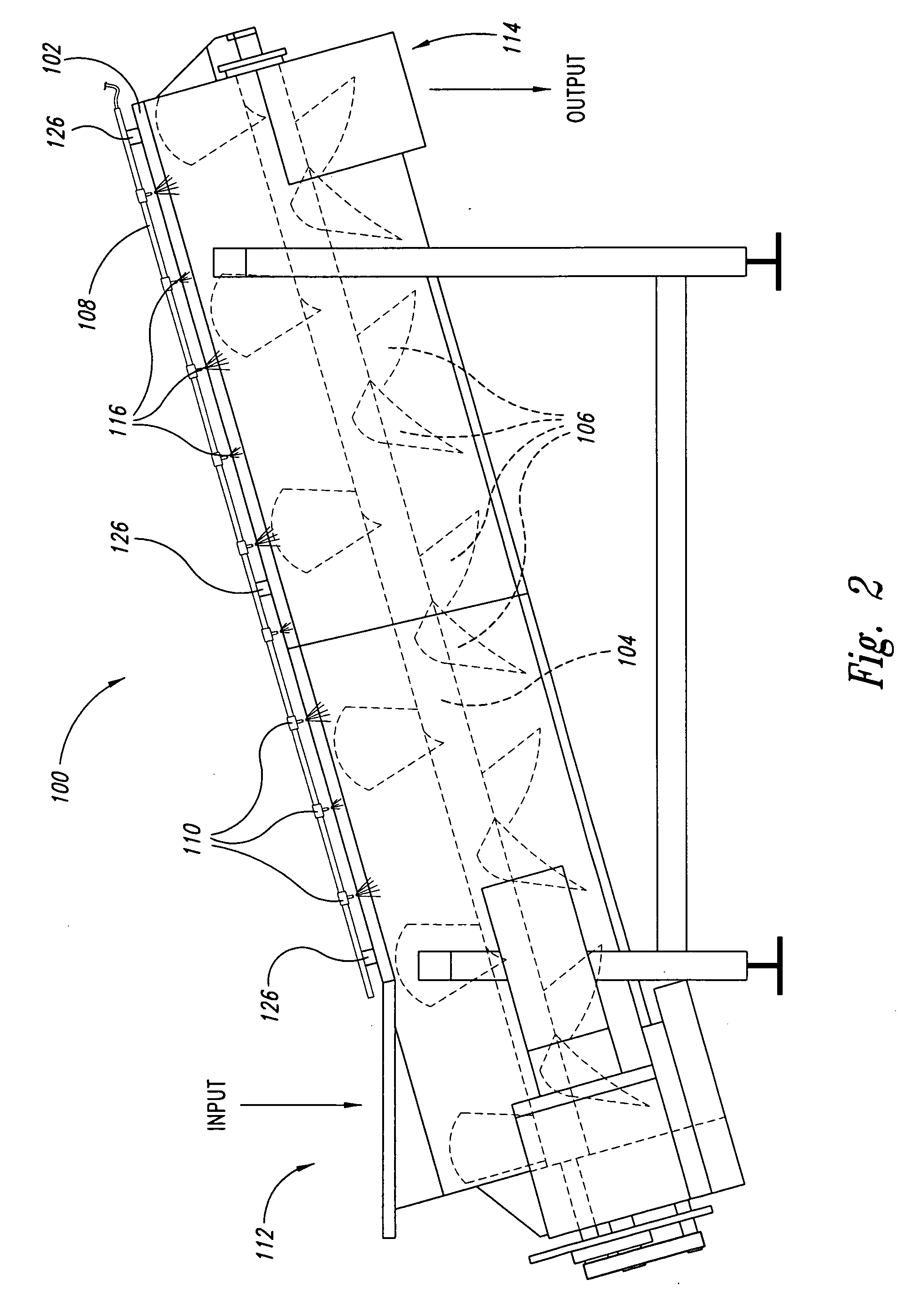

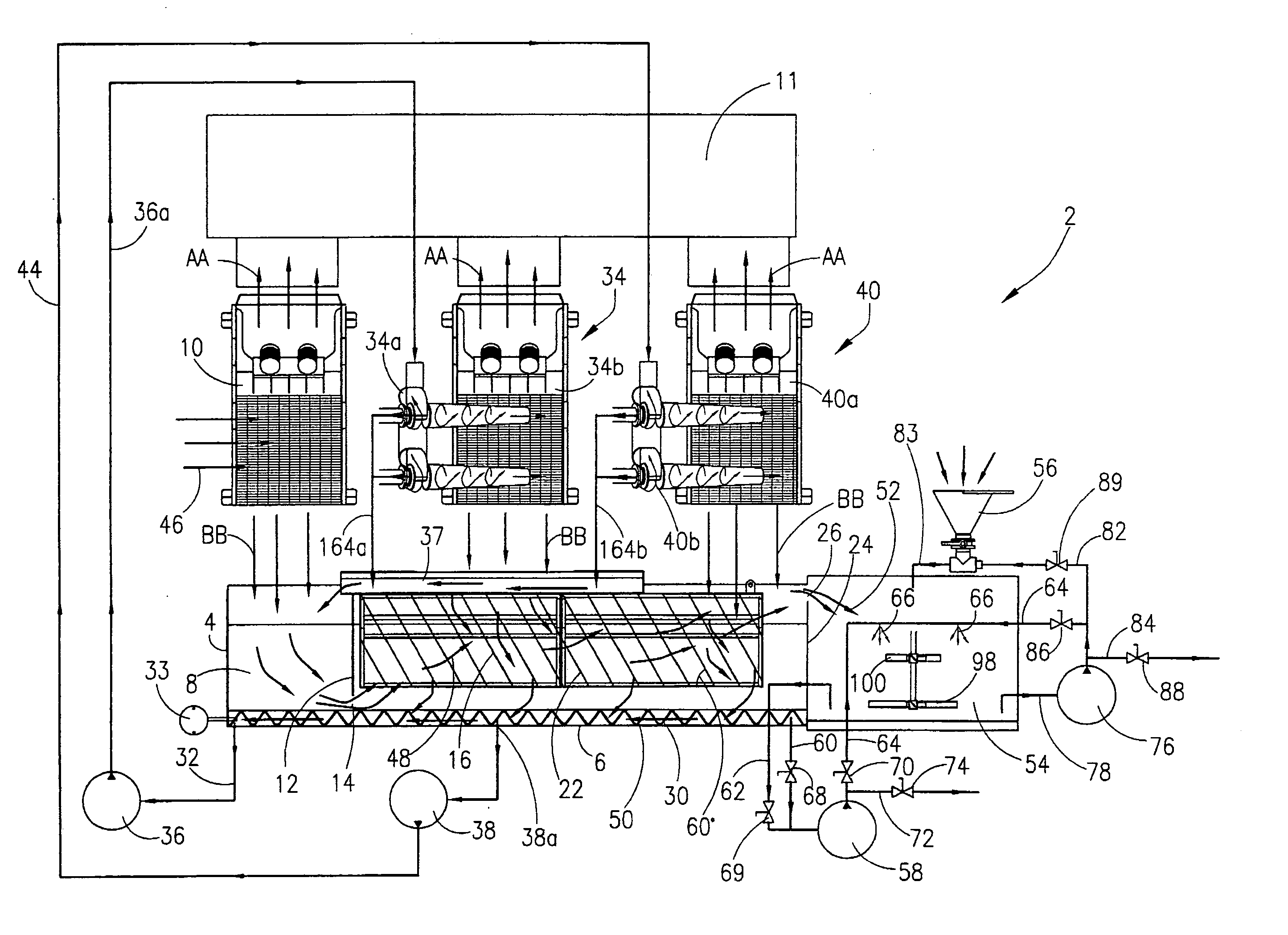

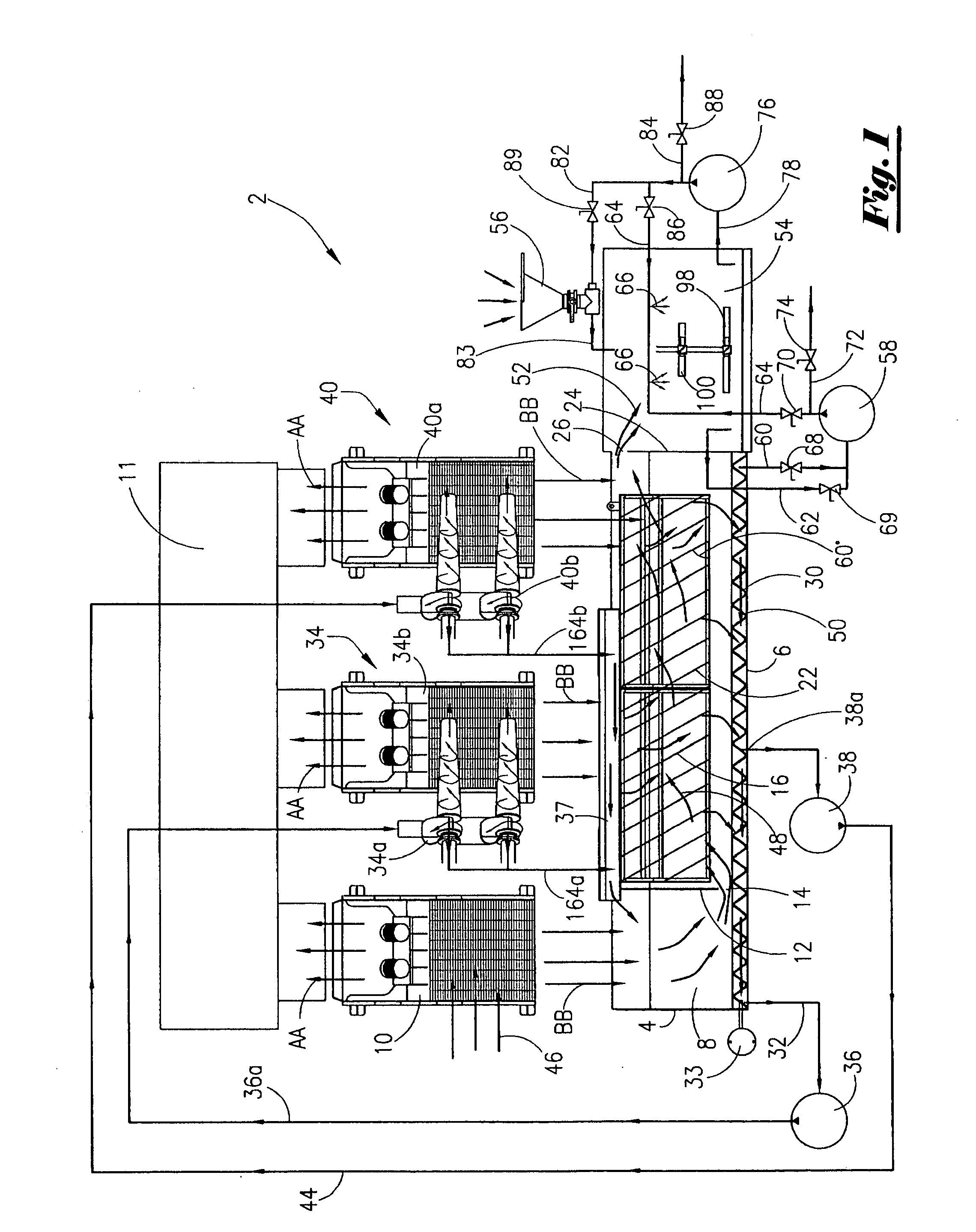

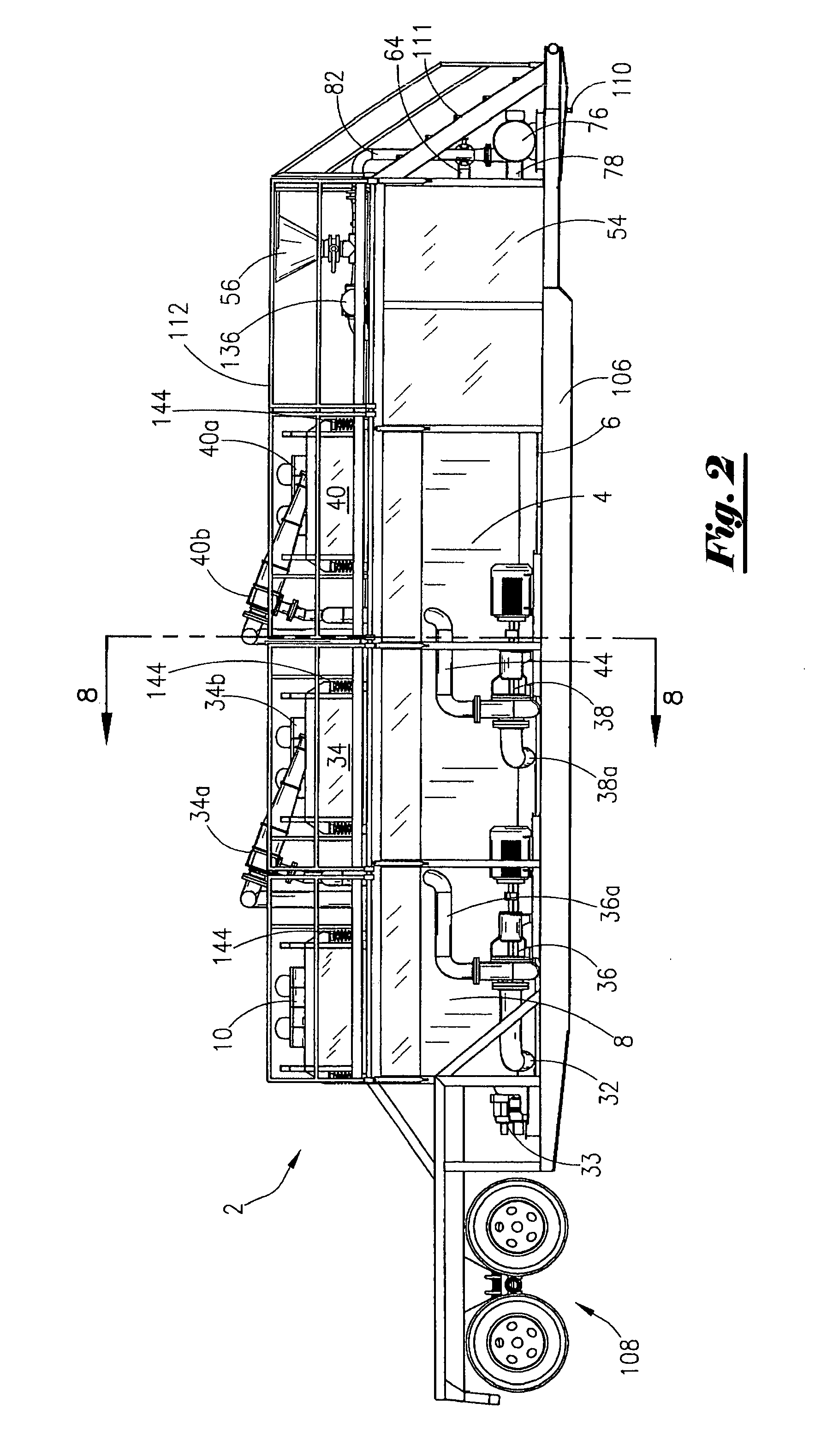

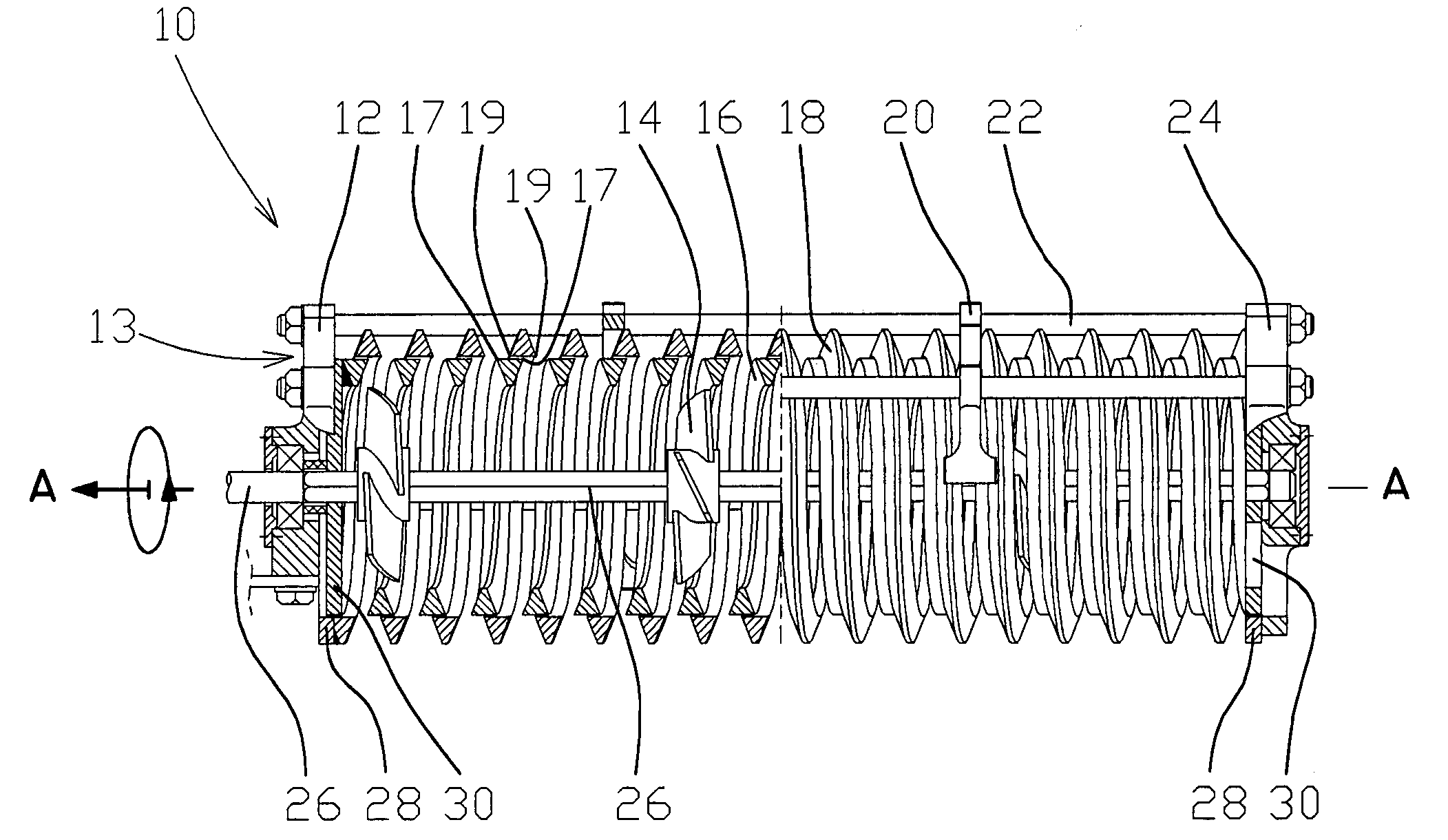

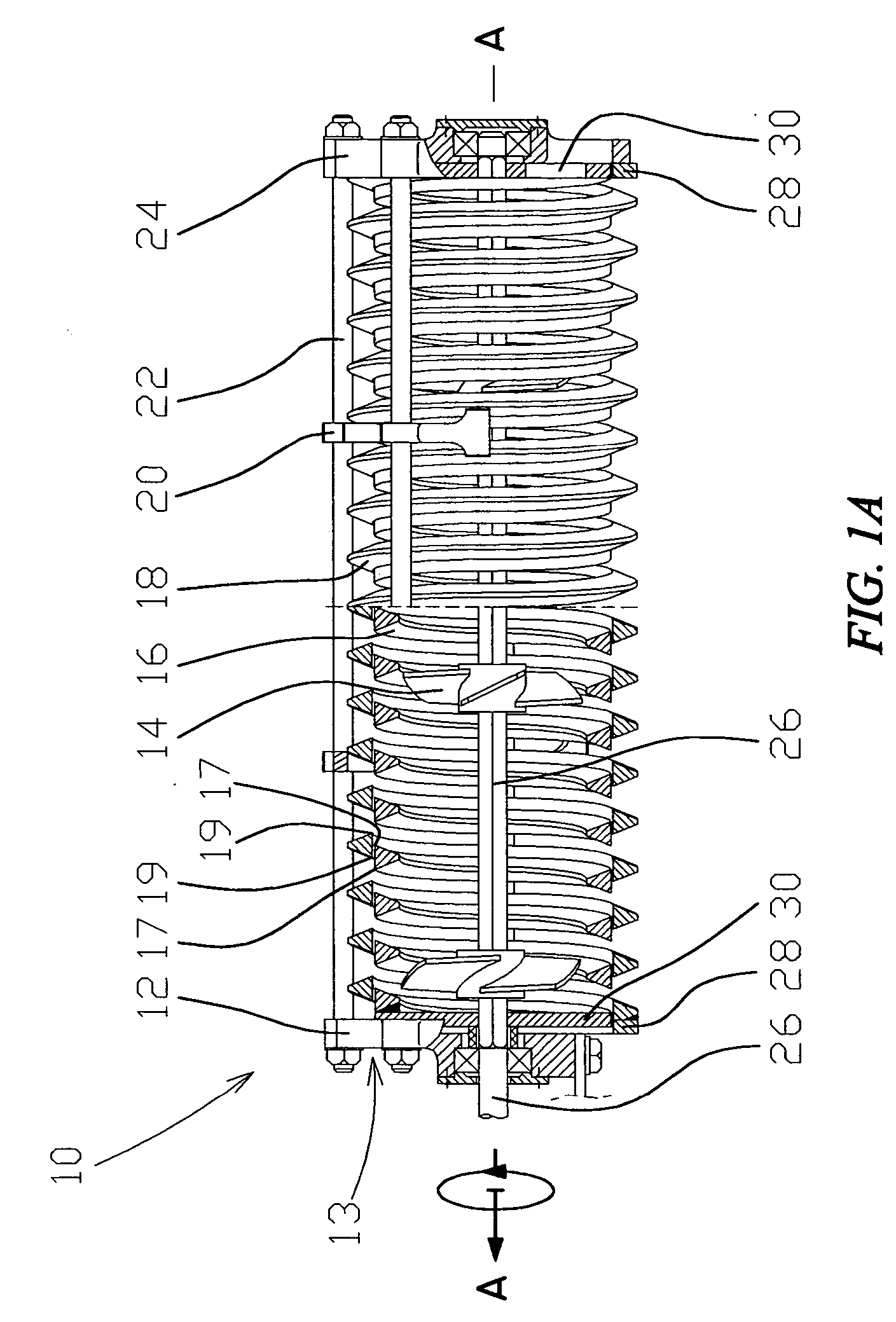

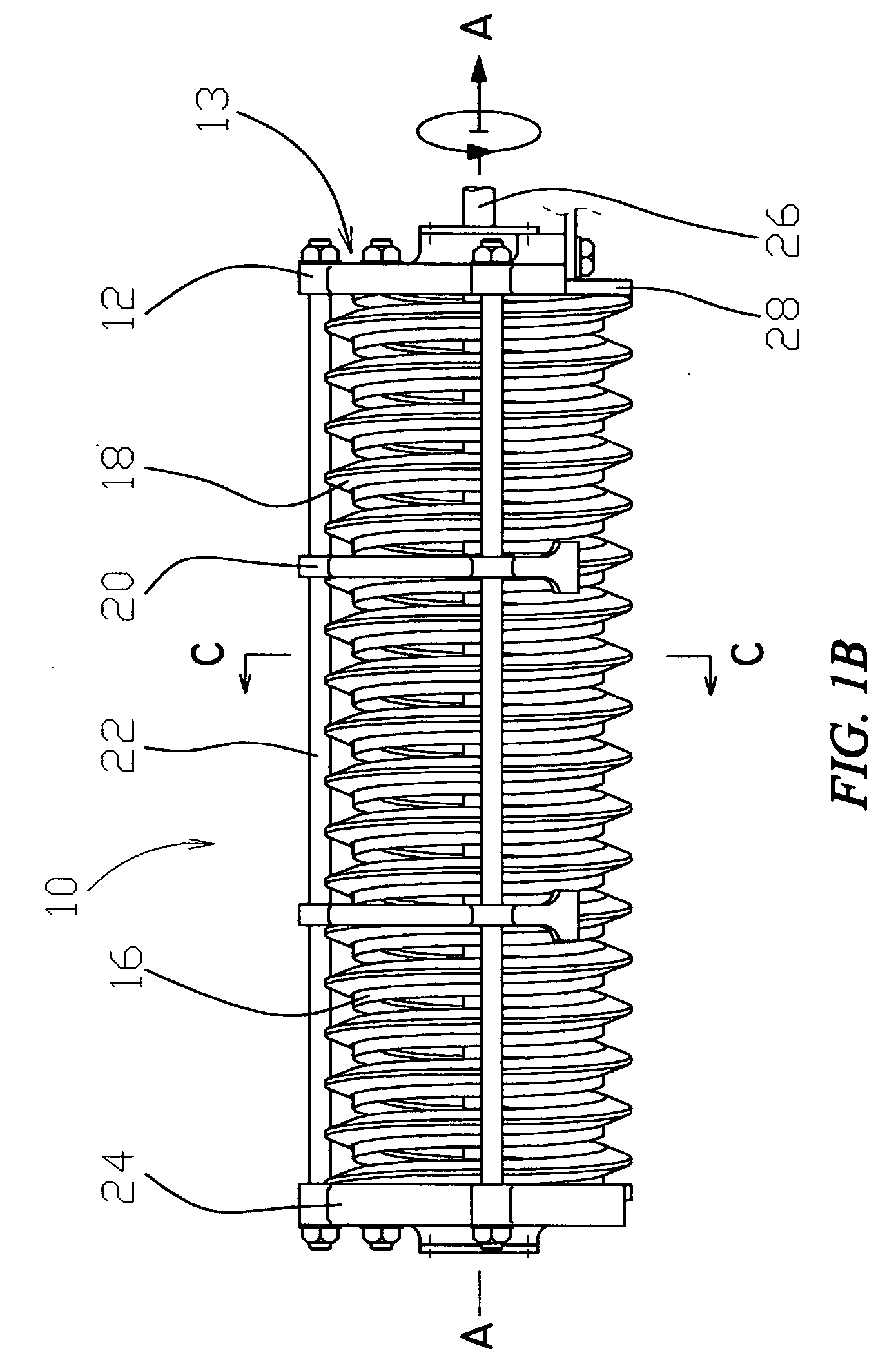

System for separating solids from a fluid stream

InactiveUS7514011B2Easy to transportMaximize impactLiquid separation auxillary apparatusSingle direction vortexSpiral bladeSlurry

Owner:DEL

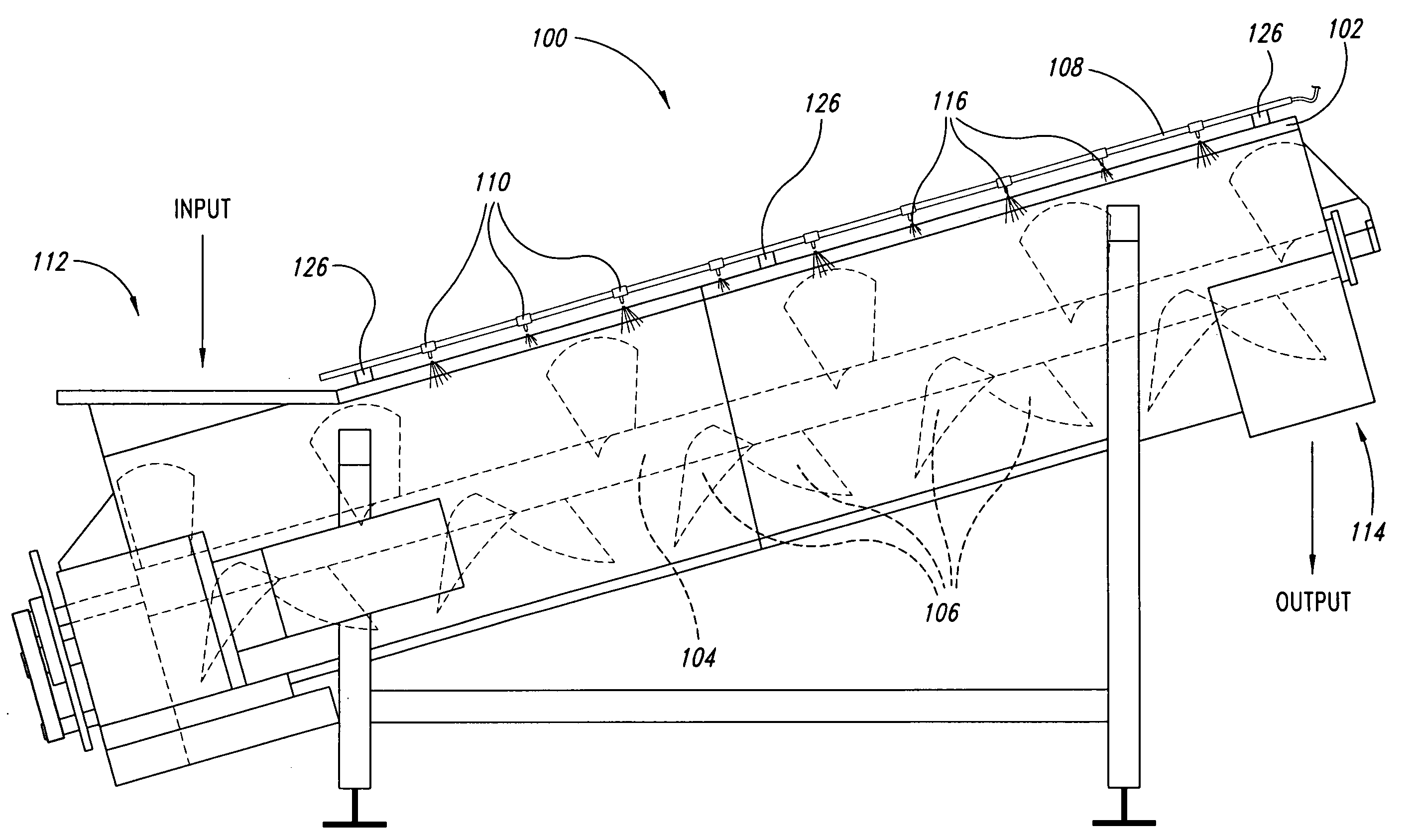

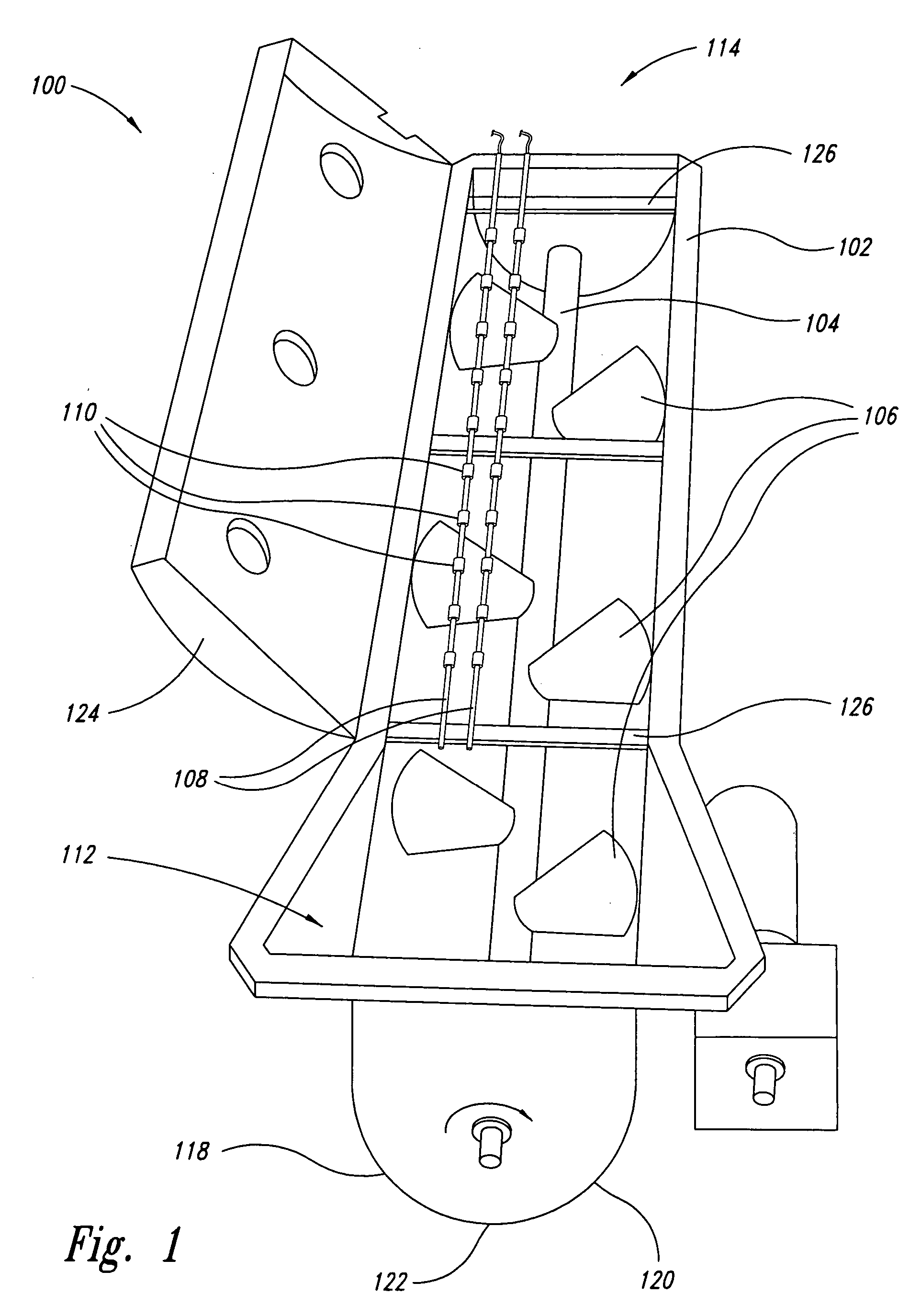

Treatment fluid application apparatus for foodstuffs and methods related thereto

InactiveUS20050058013A1Good lookingImprove EdibilityRotary stirring mixersMeat/fish preservation using liquidsSpiral bladeDisinfectant

Apparatus and methods for applying treatment fluids, such as disinfectants, flavoring agents, and tenderizing agents, to foodstuff surfaces to, for example, reduce populations of microorganisms or fungi, alter taste, or alter texture. In representative embodiments, the apparatus includes a housing, a fluid delivery system, and a shaft with a protruding surface, the latter adapted to rotatably convey, while agitating and tumbling, the foodstuffs from an inlet to an outlet of the housing, as the fluid delivery system applies a treatment fluid to the foodstuffs. In more specific embodiments, the protruding surface may be paddles, or paddles interconnected by a solid web and having angled distal surfaces, or a spiral blade with radial protrusions, or such a spiral blade along a first longitudinal portion of the shaft and paddles along a second longitudinal portion of the shaft.

Owner:ALCIDE CORP

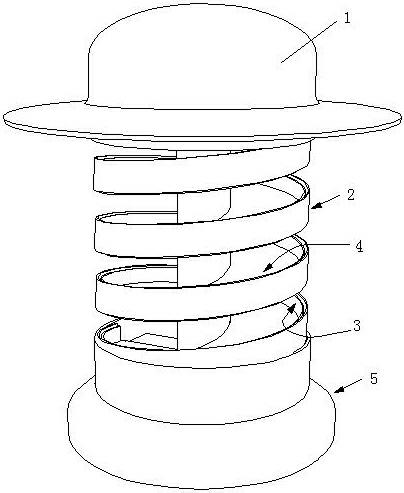

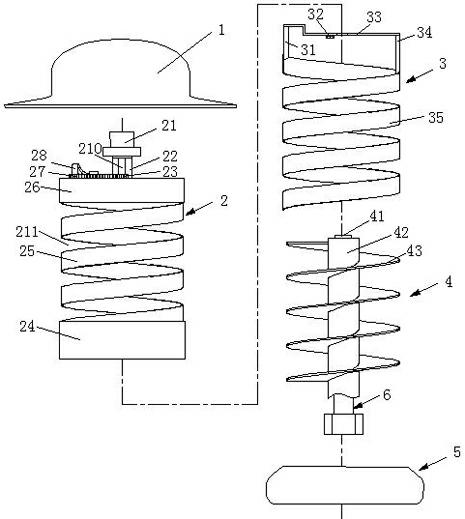

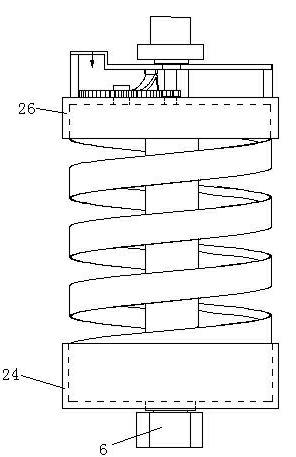

Spiral insect catching machine

InactiveCN102599130AAvoid the disadvantages of unstable deinsectization functionSimple structureInsect catchers and killersEngineeringHigh pressure

The invention relates to a spiral insect catching machine which comprises a spiral cylinder, a spiral door and a spiral wheel, wherein the spiral cylinder is provided with an upper fixed cover, a lower fixed cover, a fixed coil and a lifting transmission component; the fixed coil is in a cylinder spiral shape; the lifting transmission component comprises a motor, a small gear, a big gear, an inclined plane block; the spiral door is arranged in the spiral cylinder, and is composed of a movable coil and a movable connection rod; the spiral wheel is arranged in the spiral door, and is composed of spiral blades and a light tube cylinder; and the lower end of the spiral blade can be provided with an open-close door of the spiral blade. High-voltage electric shock is not used in the spiral insect catching machine provided by the invention, thus obvious sound doesn't exist; and the spiral insect catching machine is especially suitable for quiet environments, and can be used for avoiding the drawback of unstable insect exterminating function caused by the condition that short circuit occurs in the traditional high-voltage power grid. In the invention, as the small motor is started up to operate in a period of time, the electricity can be saved; and the spiral insect catching machine is simple in structure, convenient in injection molding and production, and low in cost.

Owner:广东雷迅新绿能源科技有限公司

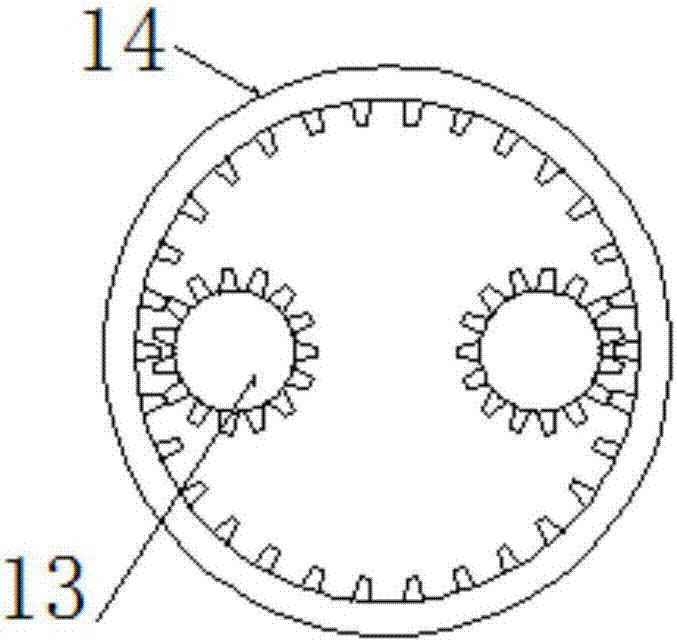

Two-stage sand screening device for building construction

InactiveCN107225080APromote shakingAvoid easy cloggingSievingScreeningSpiral bladeArchitectural engineering

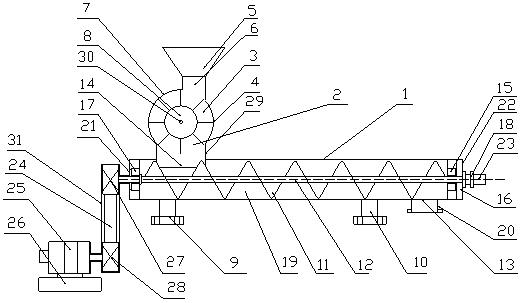

The invention relates to a two-stage sand screening device for building construction. The two-stage sand screening device comprises a base plate, a first stand column and a second stand column are vertically welded and fixedly installed on the base plate, a rotary screening barrel is connected to a rotating shaft, the rotating shaft penetrates the rotary screening barrel, and spiral blades are arranged on the surface of the rotating shaft and are located inside the rotary screening barrel; a plurality of separating through holes are formed in the barrel wall of the rotary screening barrel, a feeding pipe is arranged at the position, close to a connecting ring, of the barrel wall of the rotary screening barrel, and a discharging pipe is arranged at the position, close to a second bearing block, of the barrel wall of the rotary screening barrel; a limiting sliding sleeve is fixedly installed on the right side wall of the first stand column, a ratchet wheel is rotationally arranged on the right side wall of the first stand column, and a cam is connected with the right side wall of a limiting baffle in an abutting-against manner; and a collecting groove is fixedly installed on the base plate and is located under a screening net. The two-stage sand screening device is reasonable in design and ingenious in structure, sand is screened through the separating through holes in the rotary screening barrel and the screening net on a screening plate, and the two-stage screening manner enables the screening process to be better in effect, and the obtained sand is finer and more smooth.

Owner:永春左耳贸易有限公司

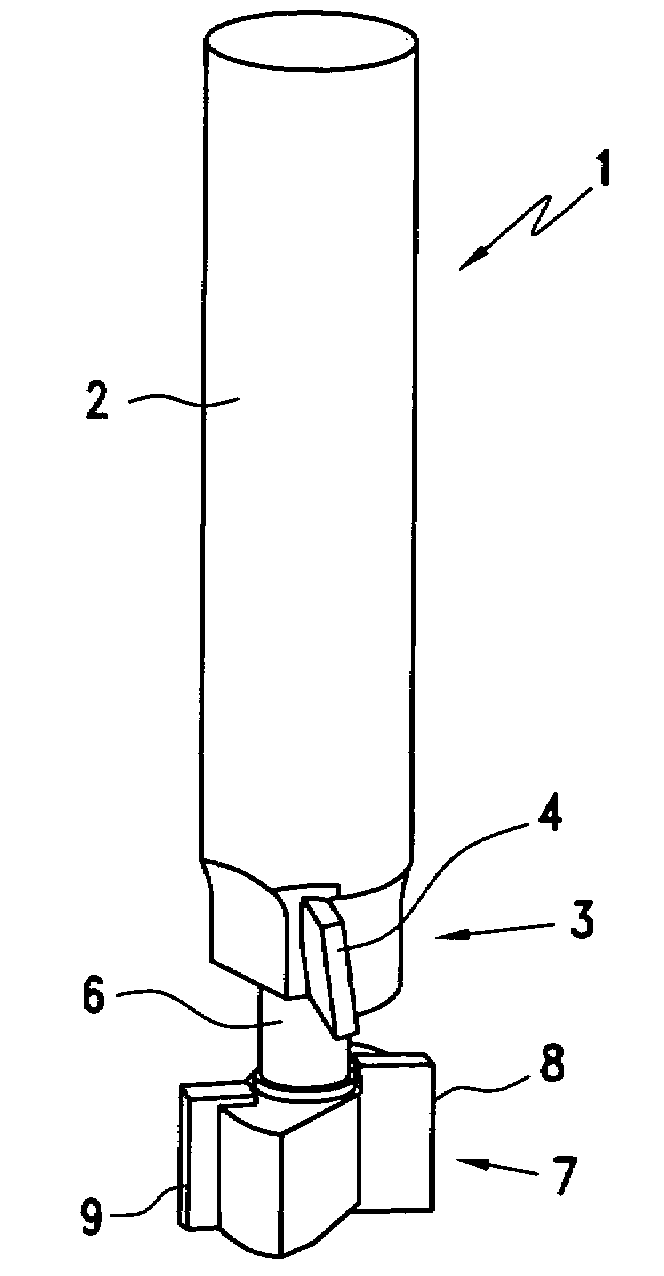

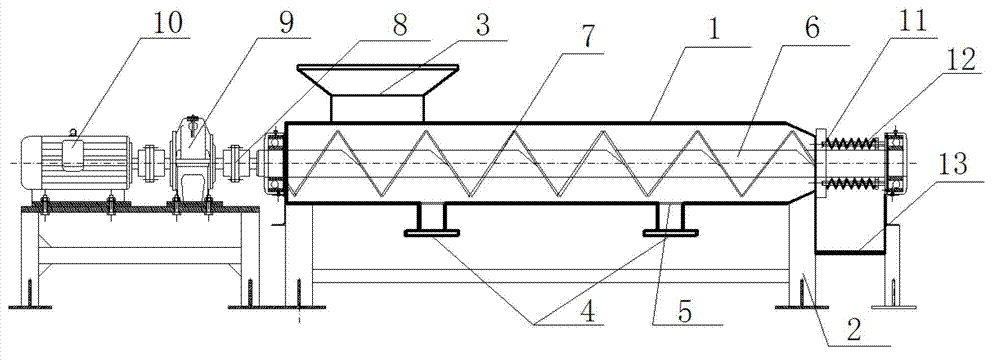

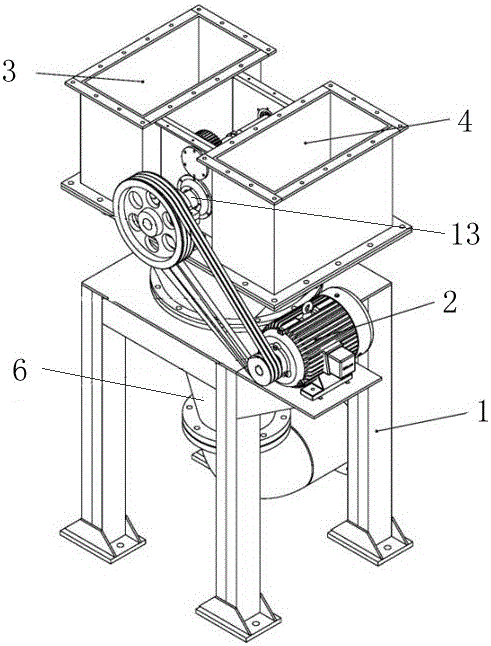

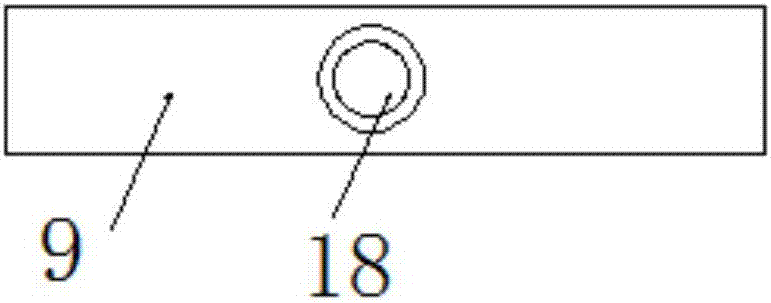

Spiral quantitative feeding device and stable feeding method

InactiveCN101966925AInto the uniformReduced feed stability effectsControl devices for conveyorsPackagingChemical industryMicrocomputer

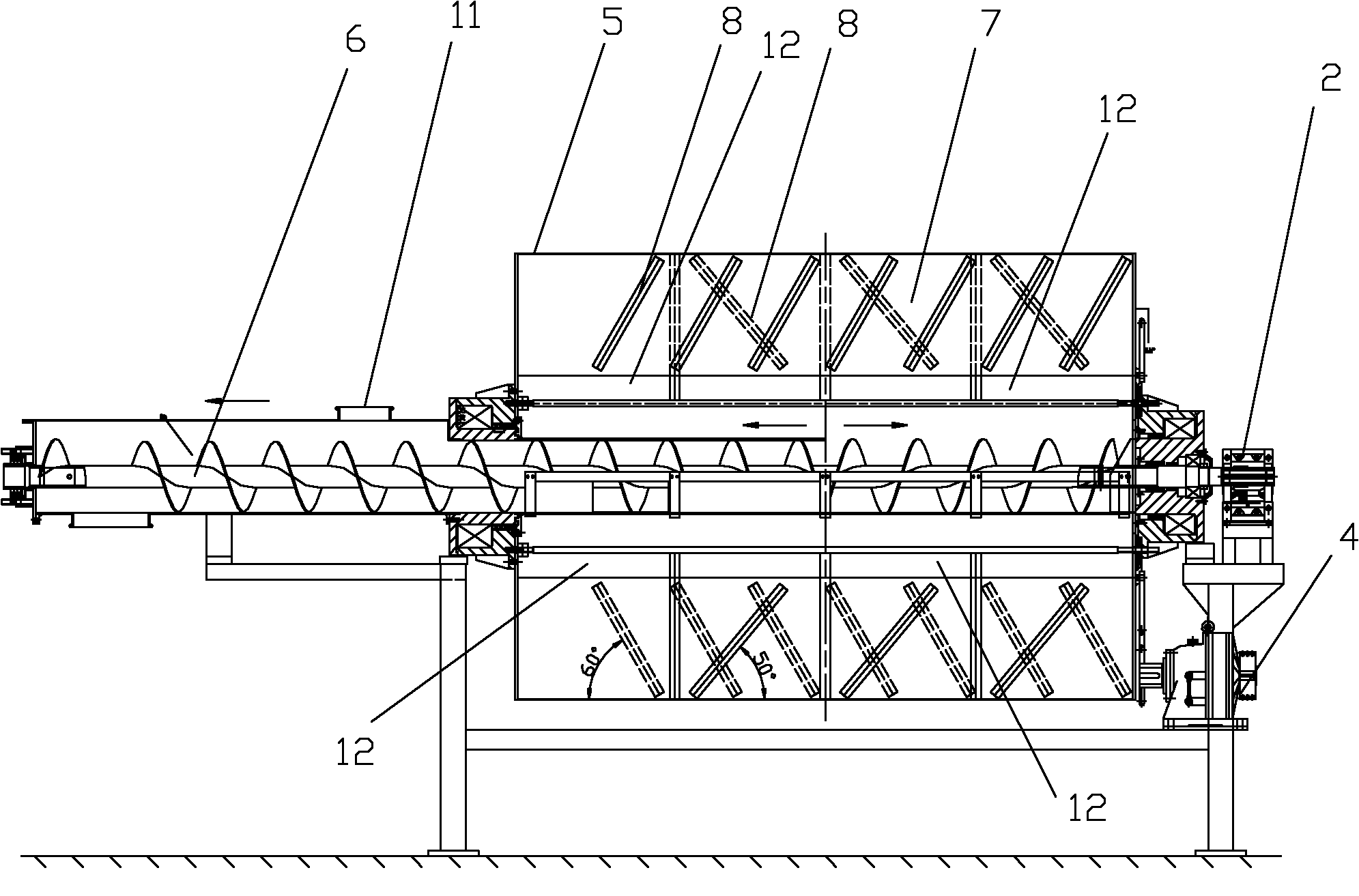

The invention discloses a spiral quantitative feeding device and a stable feeding method. The spiral quantitative feeding device comprises a horizontal spiral conveyor, an automatic feeding adjustment device, a control motor, a drive system, a rotation angle sensor and a single chip microcomputer measurement and control system, wherein the spiral conveyor comprises a spiral shaft, spiral blades, a cylindrical feeding barrel and the like. On one hand, the stable feeding method for the spiral quantitative feeding device reduces the influence on the feeding stability of the spiral feeding device caused by material height change on a storage bin by arranging the automatic feeding adjustment device and eliminates a transient overload phenomenon caused by the extrusion of a material in a spiral material barrel when the device is started next time, on the other hand, the rotating speed and the rotation angle of the motor are controlled by detecting the rotation angle of the spiral shaft by the rotation angle sensor so as to realize accurate quantitative work of the material. The device and the method can be widely used in the transportation, the batching and the packaging production of bulk materials in agriculture, industry, chemical industry and food processing industry.

Owner:JIANGSU UNIV

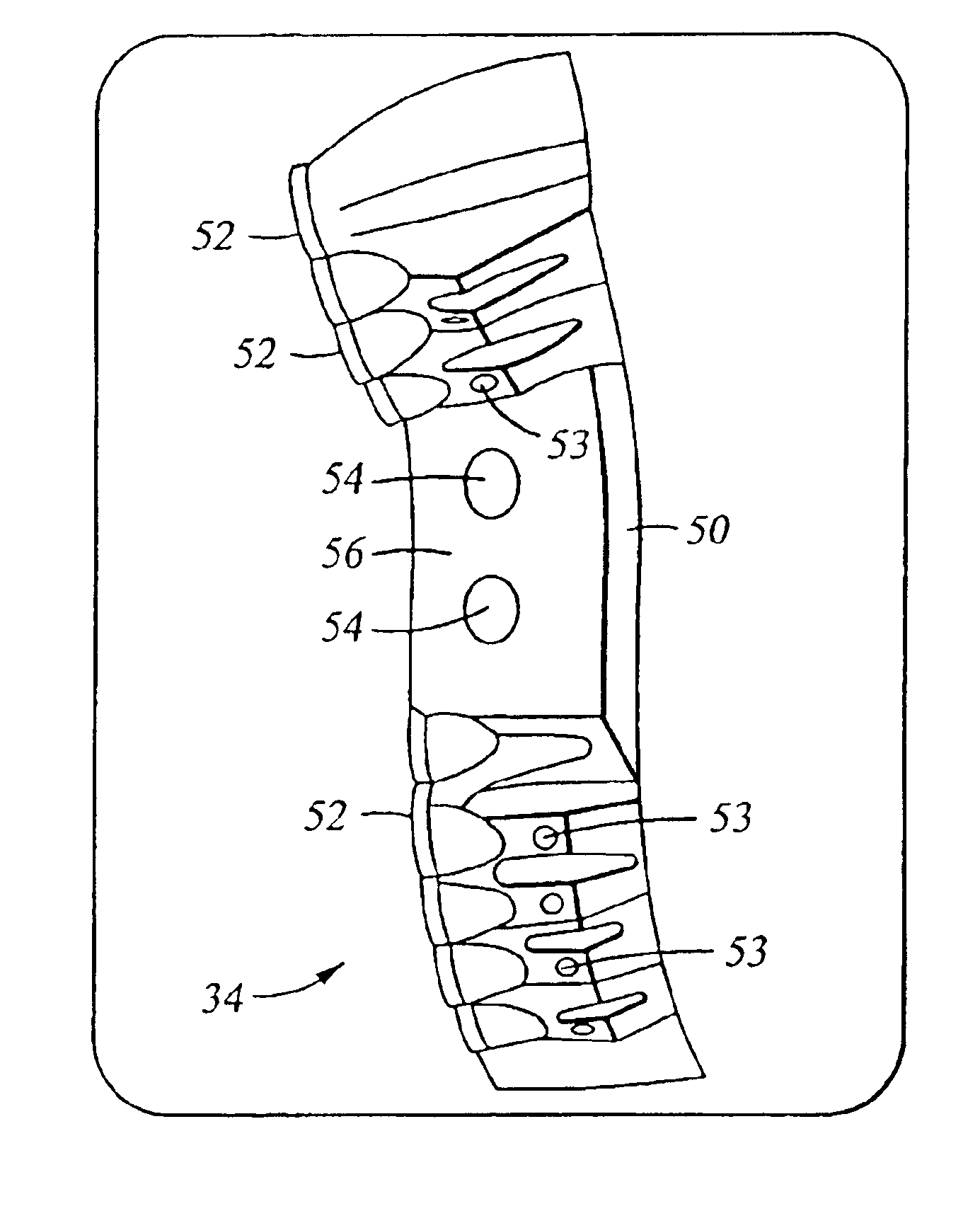

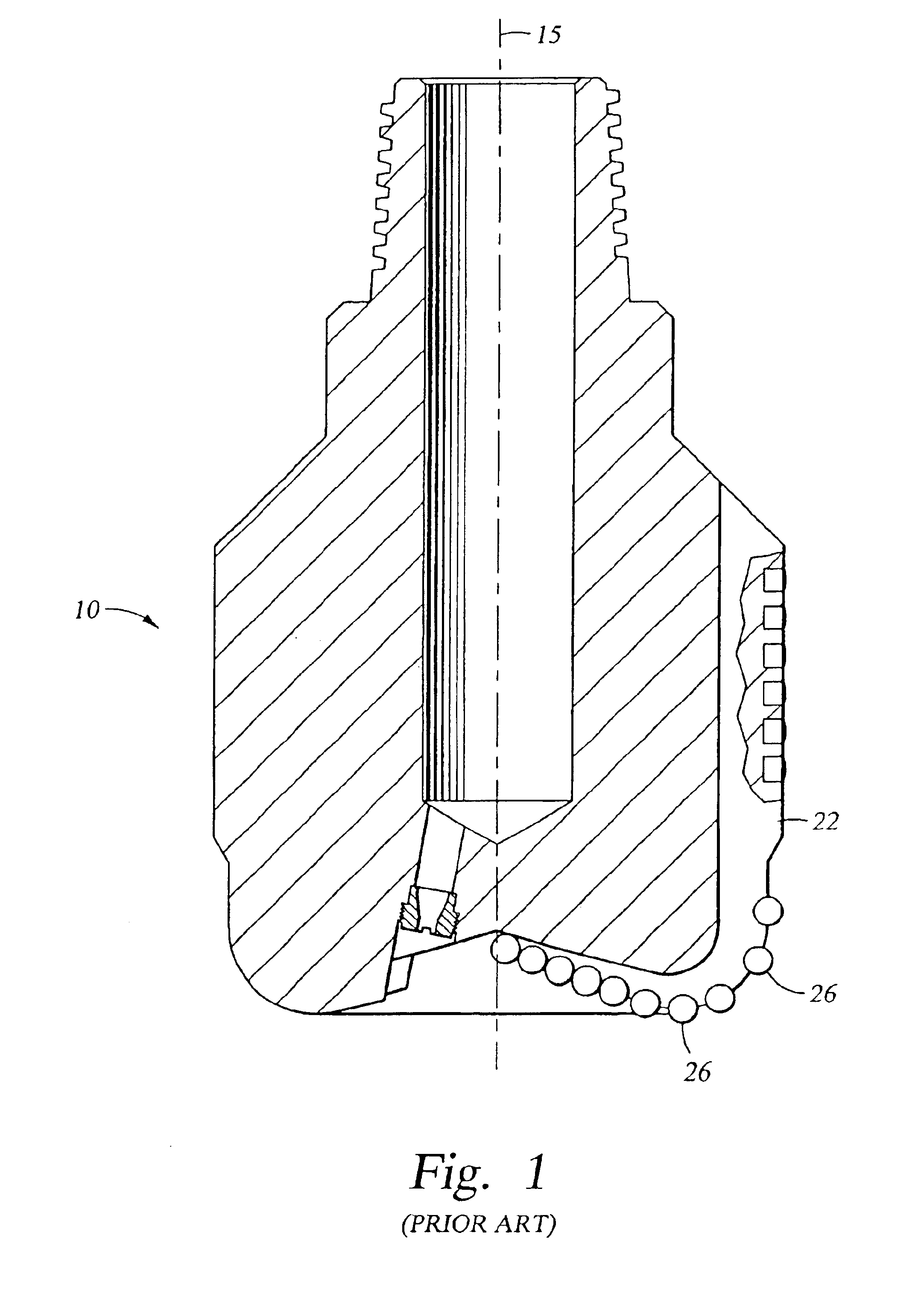

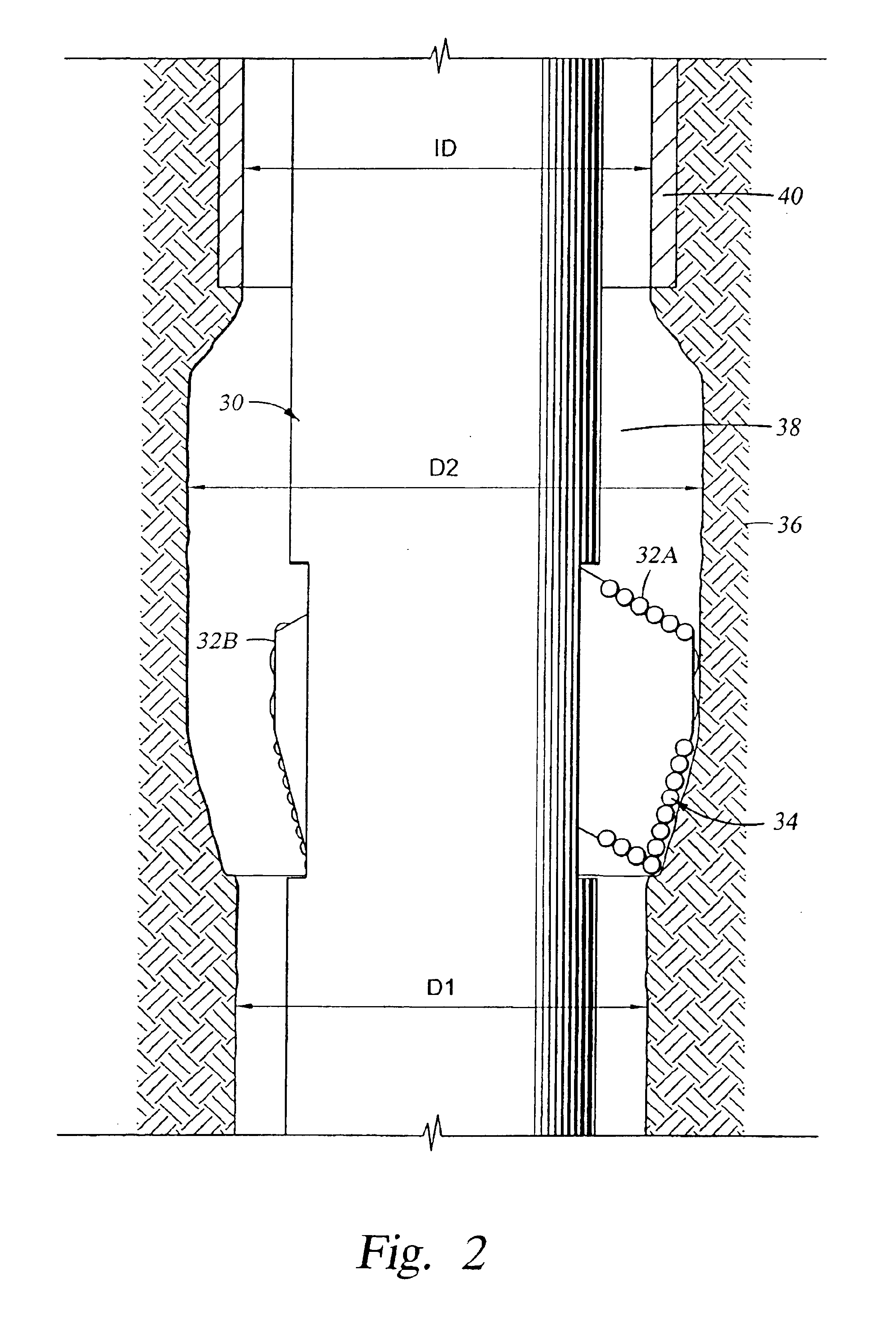

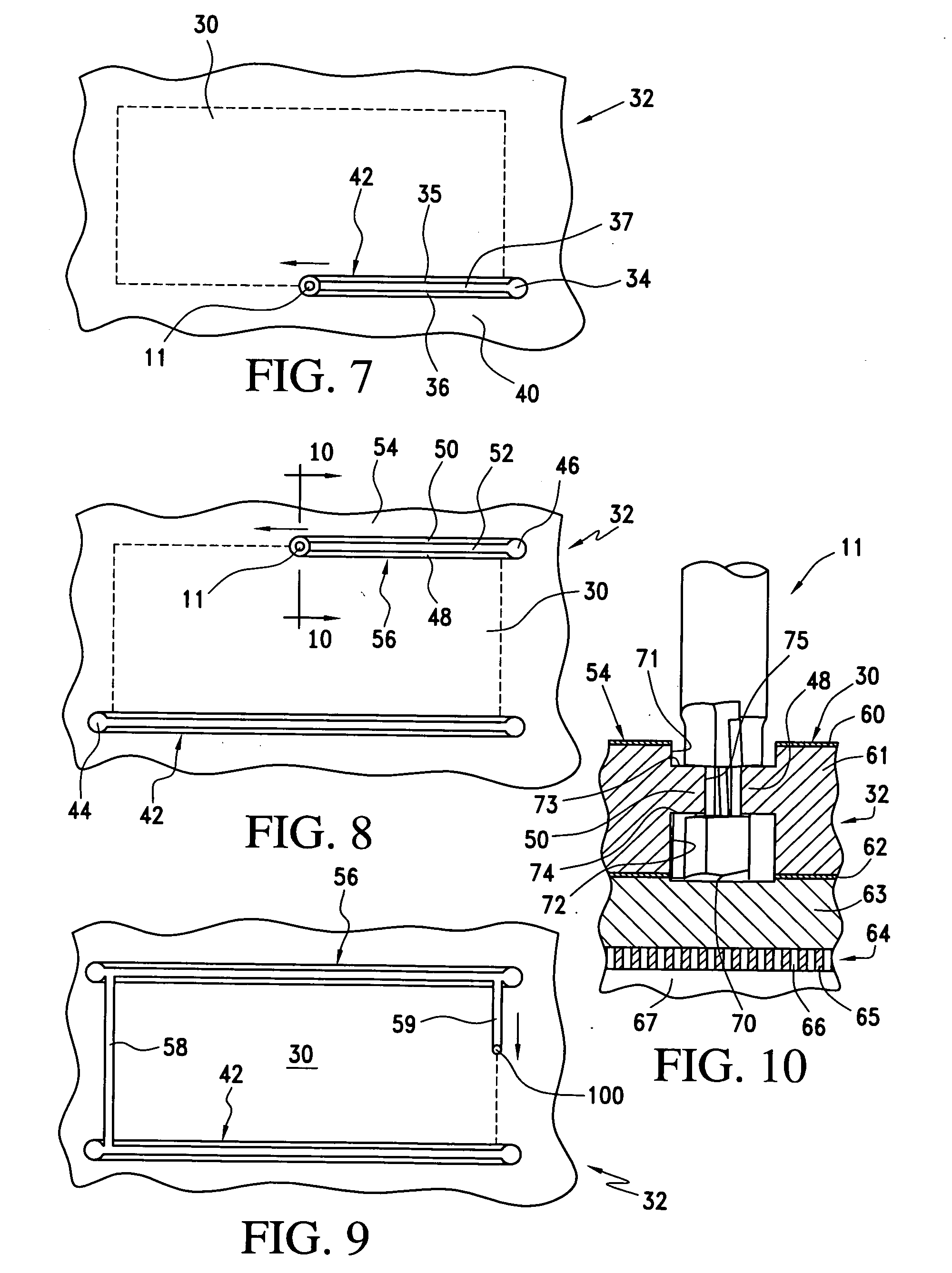

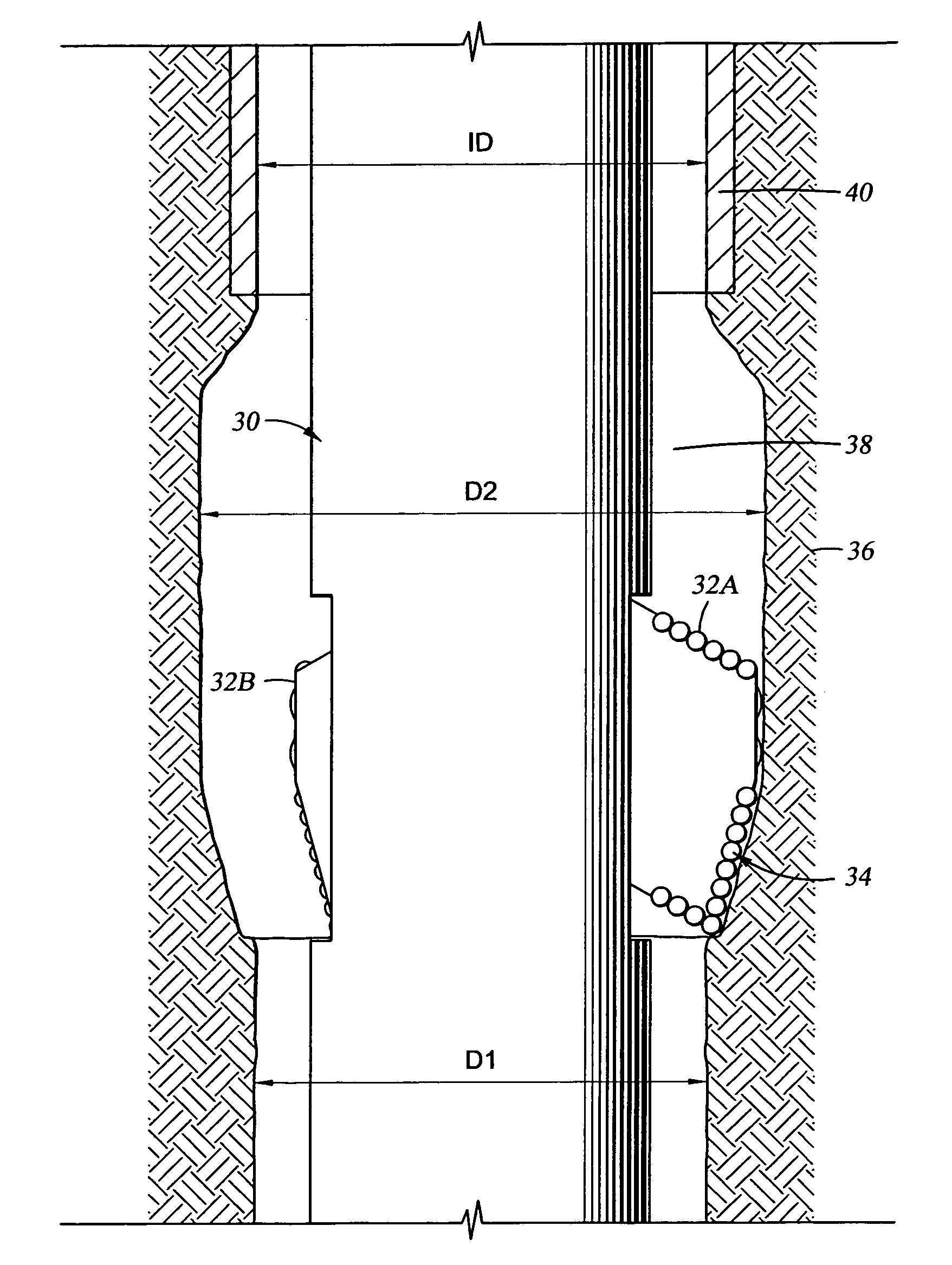

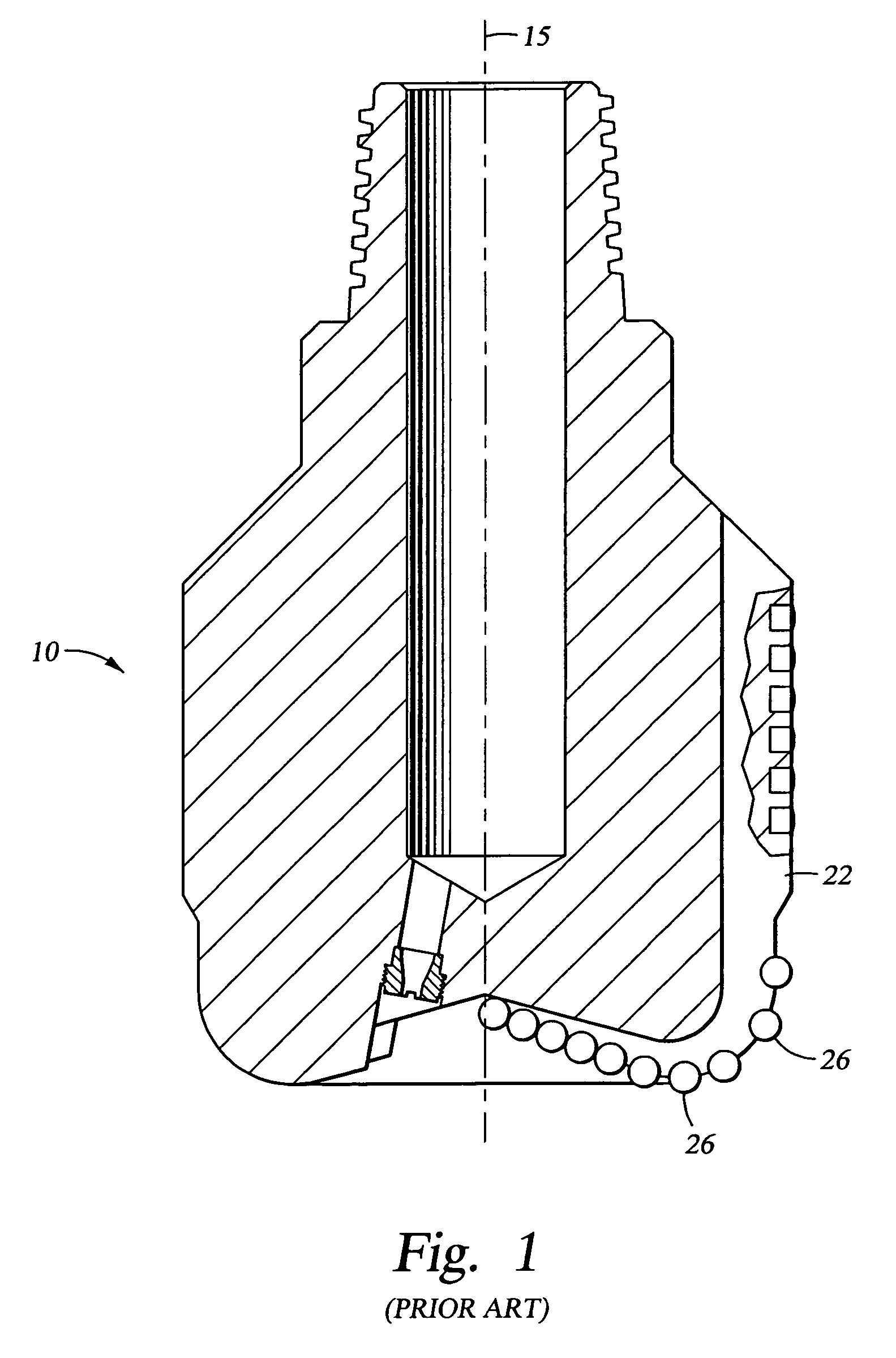

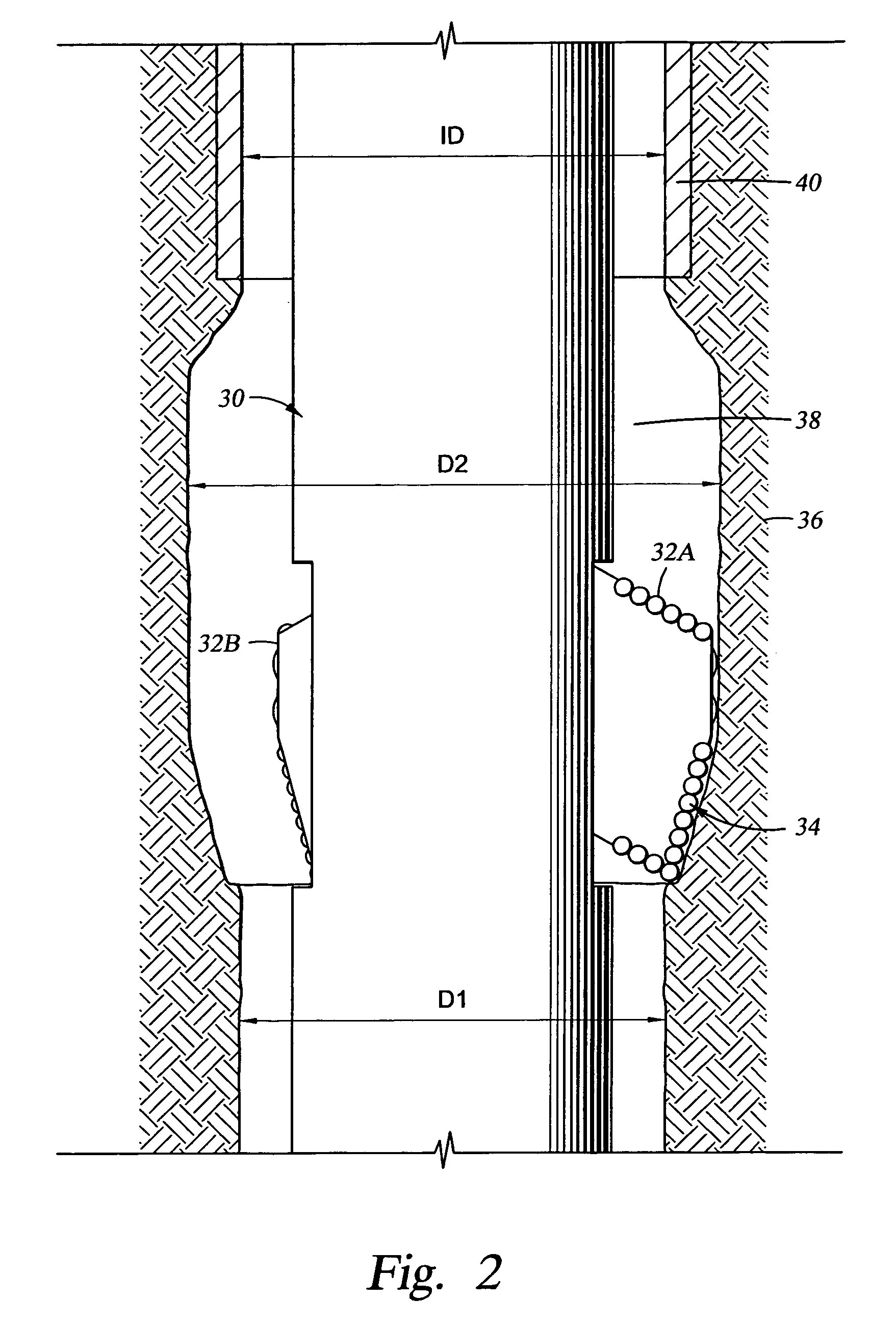

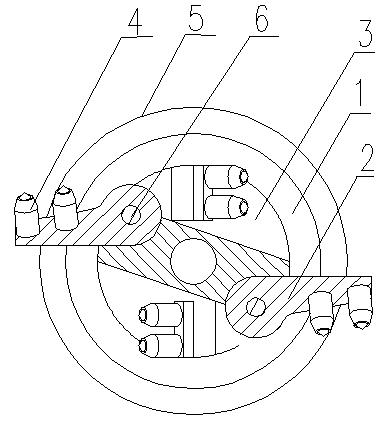

Advanced expandable reaming tool

An expandable reaming tool including at least two reamer pads connected to a tool body. The reamer pads are adapted to be displaced between a retracted position and an expanded position. At least one spiral blade is formed on at least one reamer pad. A plurality of cutting elements are disposed on the at least one spiral blade.An expandable reaming tool including at least two reamer pads connected to a tool body. The reamer pads are adapted to be displaced between a retracted position and an expanded position. At least one blade is formed on the at least two reamer pads. A plurality of cutting elements are disposed on the at least one blade and at least one gage protection element is disposed on a gage surface of the at least one blade. The plurality of cutting elements are arranged so as to enable the expandable reaming tool to backream a formation in a wellbore.

Owner:SMITH INT INC

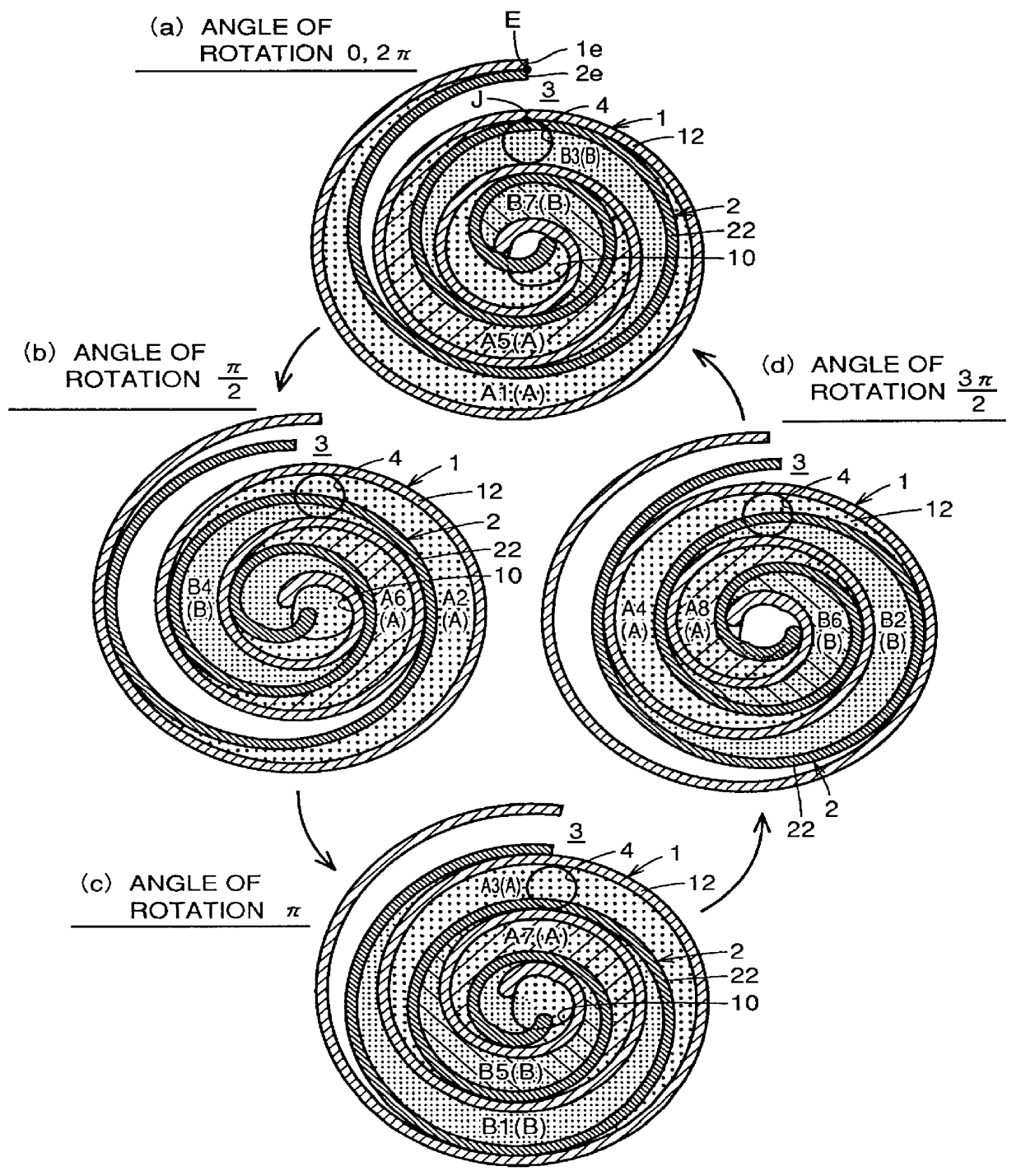

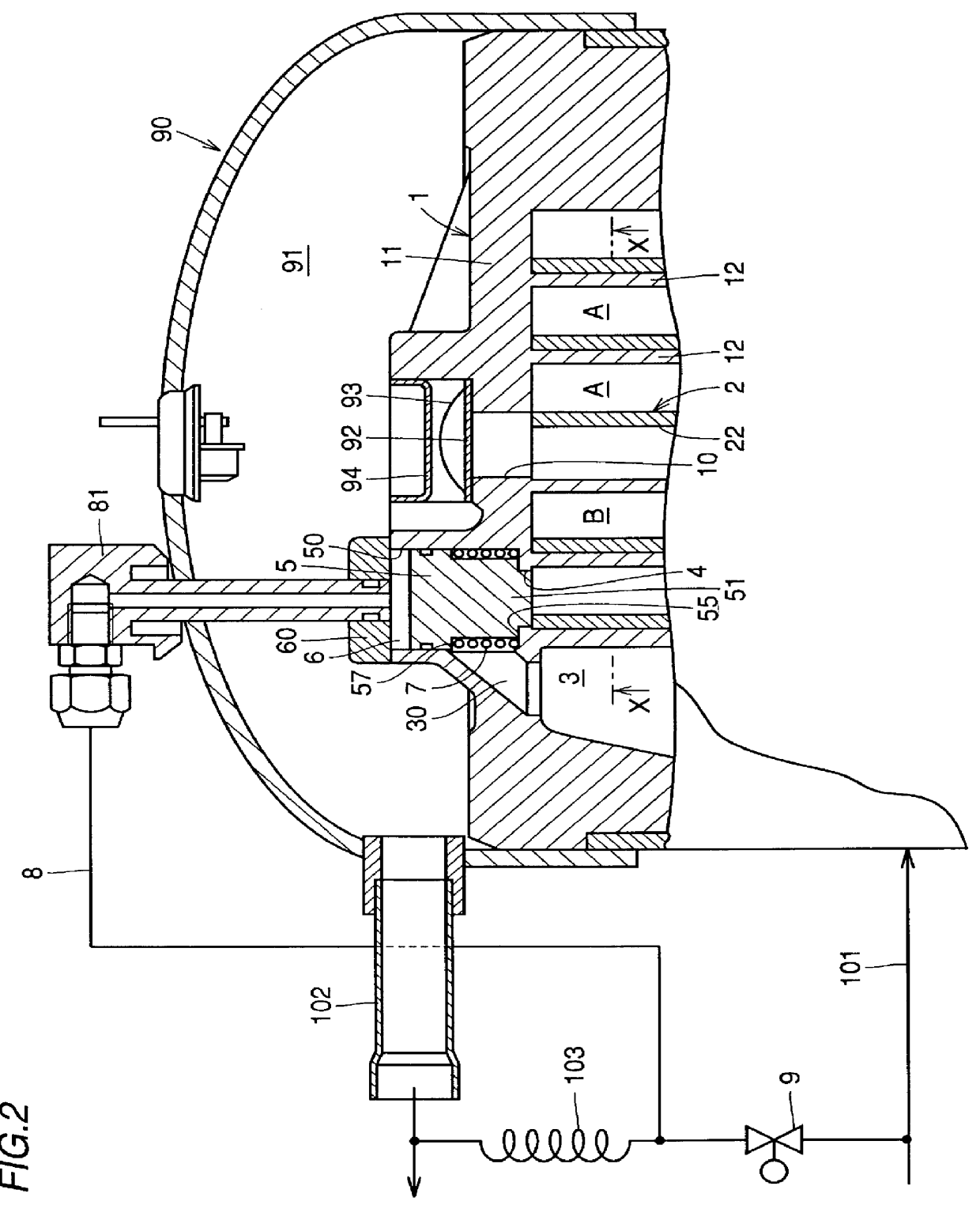

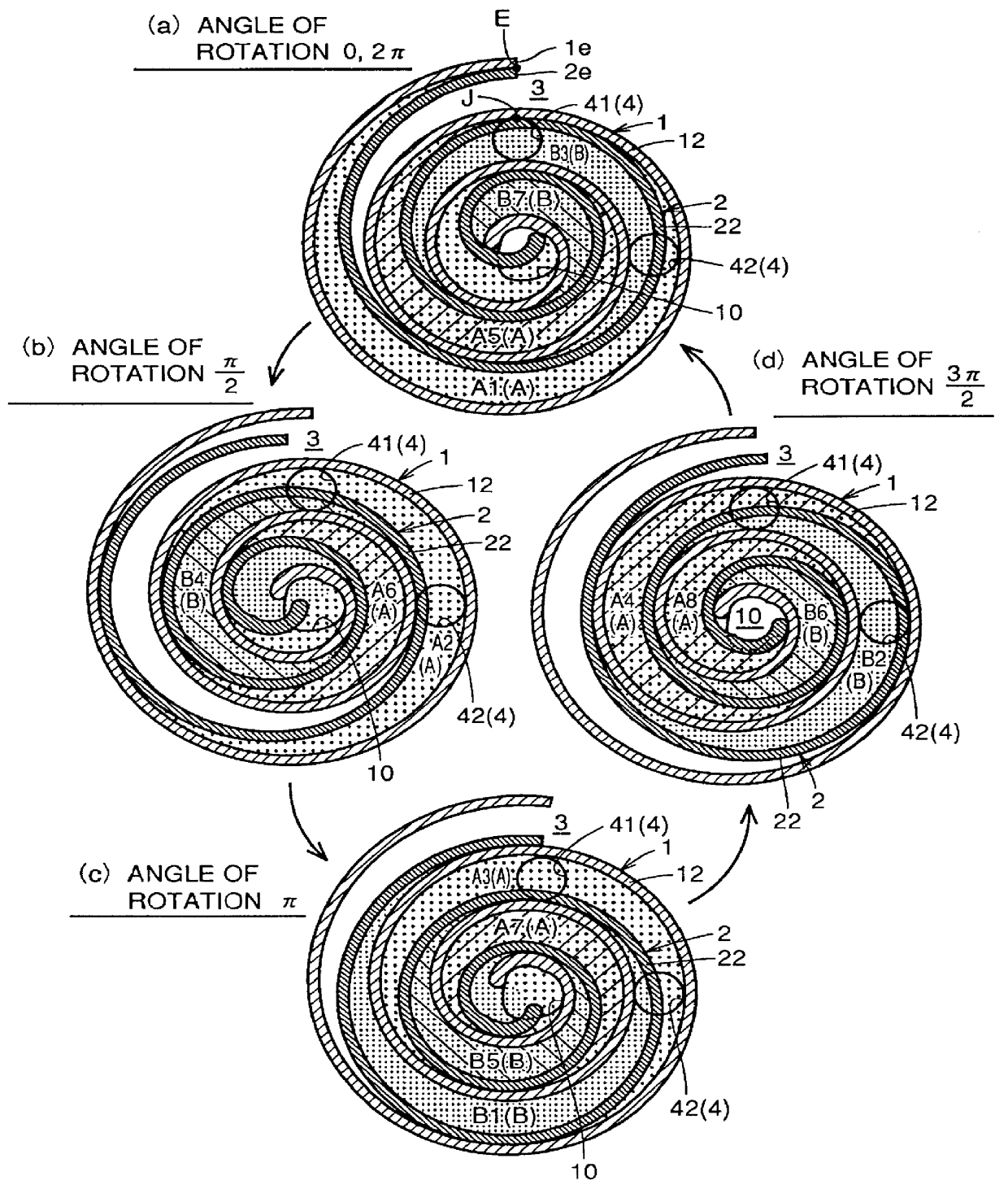

Scroll type fluid machine

InactiveUS6139287AOperating means/releasing devices for valvesEngine of arcuate-engagement typeSpiral bladeEngineering

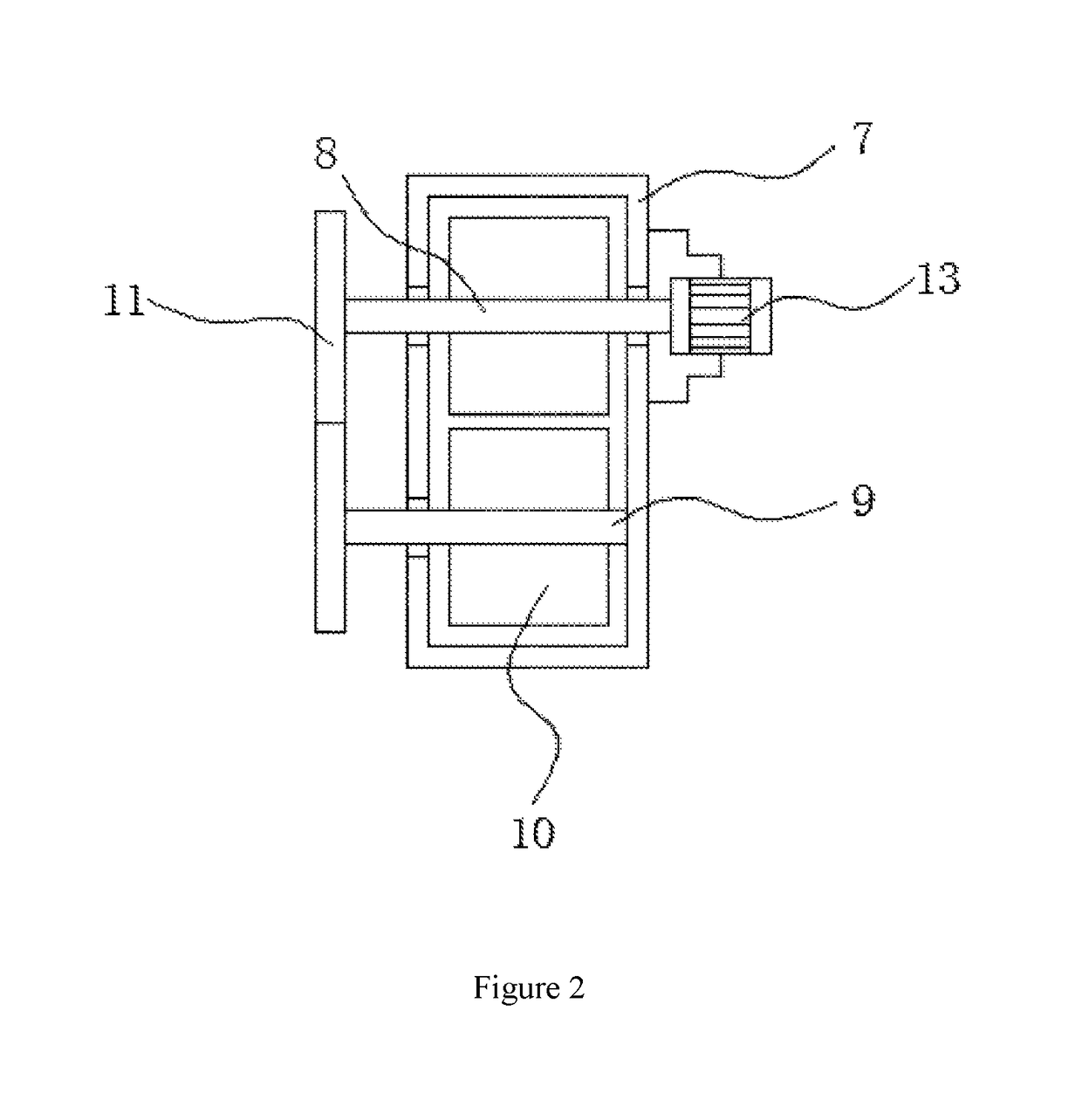

PCT No. PCT / JP97 / 02013 Sec. 371 Date Nov. 3, 1998 Sec. 102(e) Date Nov. 3, 1998 PCT Filed Jun. 11, 1997 PCT Pub. No. WO98 / 57066 PCT Pub. Date Dec. 17, 1998A scroll type fluid machine having a bypass hole structure for capacity control is disclosed. The scroll type fluid machine comprises a first scroll having a first spiral blade, and a second scroll having a second spiral blade. A first fluid working chamber is formed between an inner surface of the first spiral blade, and a second scroll having a second spiral blade. A first fluid working chamber is formed between an inner surface of the first spiral blade and an outer surface of the second spiral blade, and a second fluid working chamber is formed between an outer surface of the first spiral blade and an inner surface of the second spiral blade. A winding end of the first spiral blade is extended so that the first fluid working chamber and the second fluid working chamber open and close with respect to a single low-pressure port. A common bypass hole making the first and second fluid working chambers communicate with the low-pressure port in common is provided.

Owner:DAIKIN IND LTD

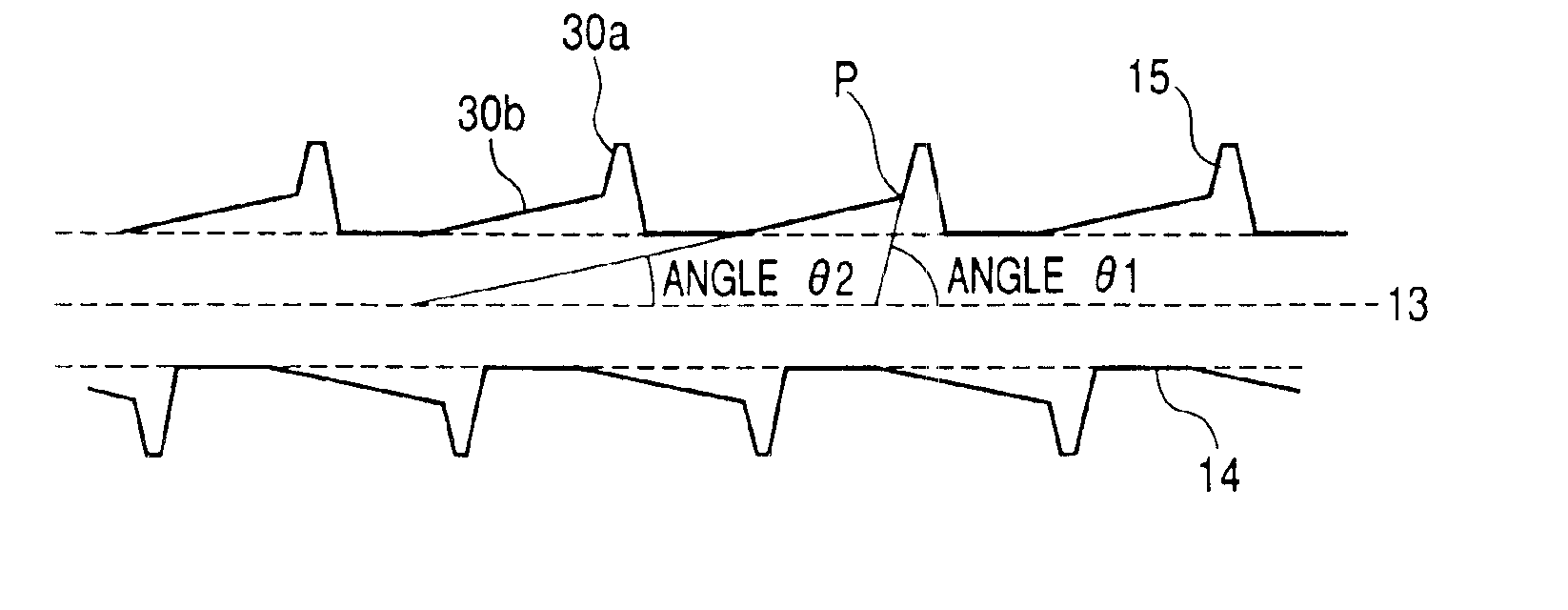

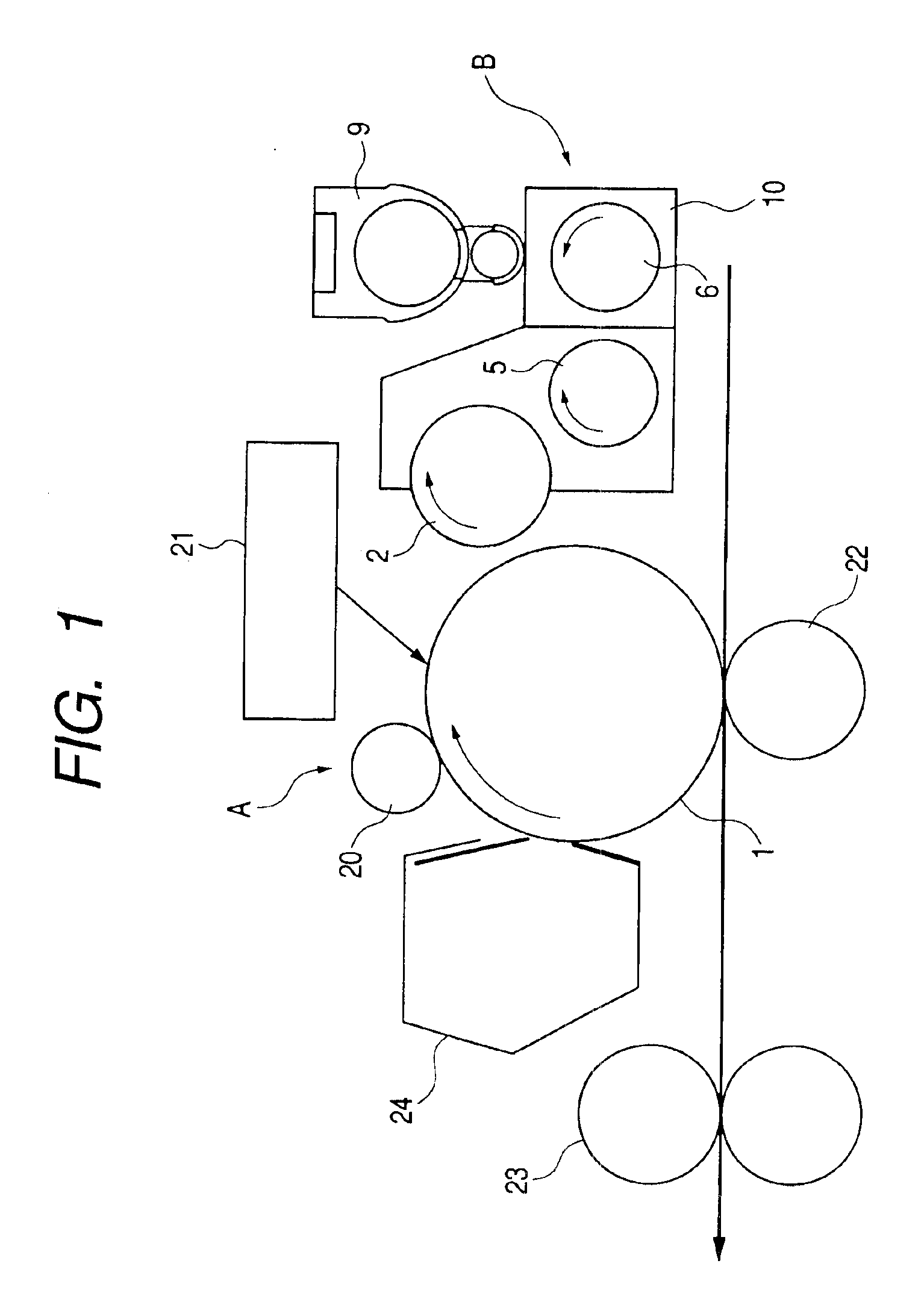

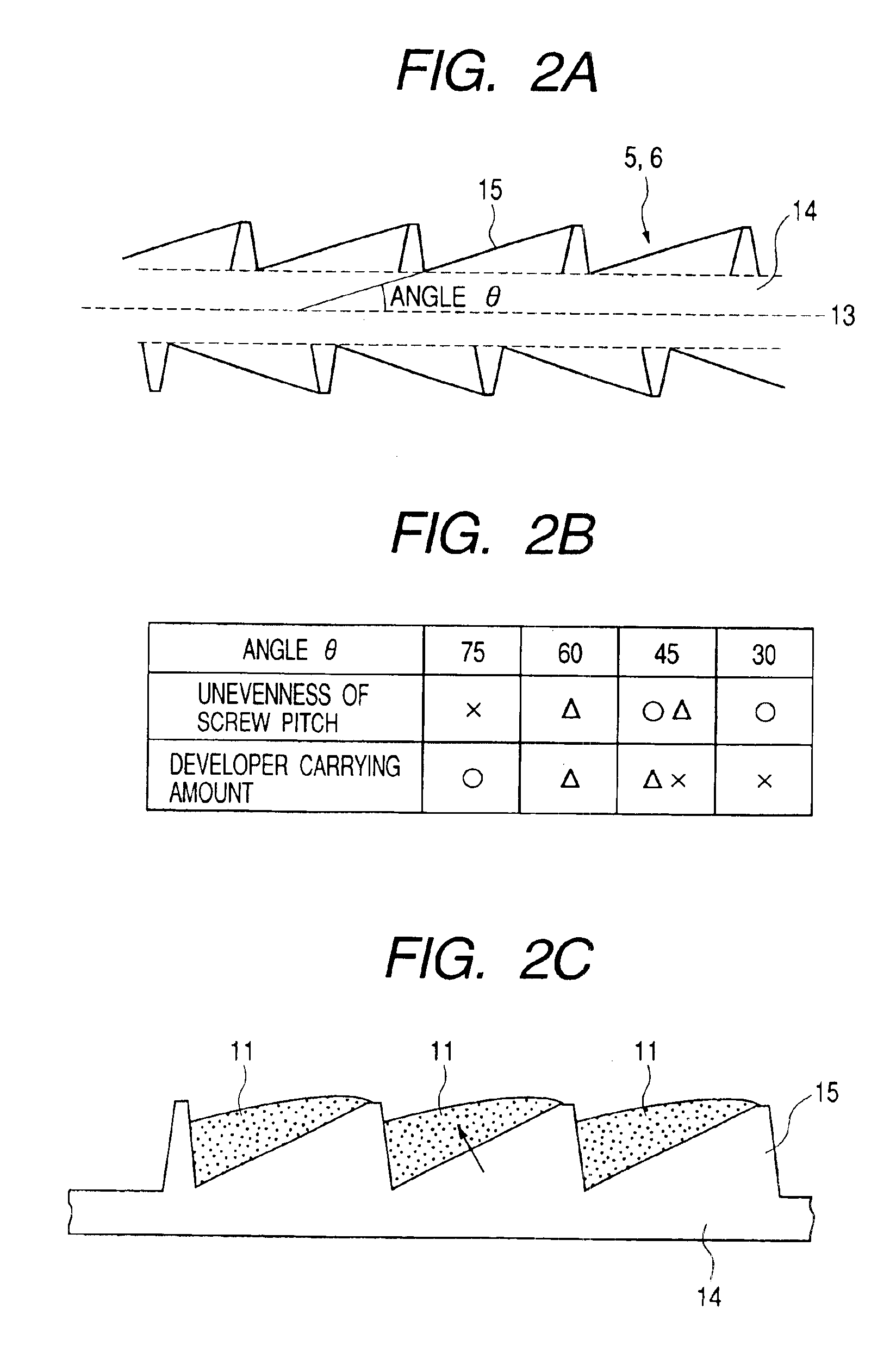

Developing apparatus having developer carrying screw with a plurality of inclination angles

ActiveUS7035573B2Reduce inconsistencyReduce unevennessElectrographic process apparatusSpiral bladeEngineering

An object of the present invention is to provide a developing apparatus capable of reducing unevenness of density of an image in a longitudinal direction of a photosensitive member. For this purpose, in the present invention, a developing apparatus includes a developer bearing member, and a developer carrying screw placed adjacently to the developer bearing member in parallel with the developer bearing member, and an inclination angle of “a carrying surface facing in a developer carrying direction of a spiral blade of the developer carrying screw” to a shaft of the developer carrying screw is equal to or less than 60 degrees.

Owner:CANON KK

Stone-crushing concrete preparation device for buildings

InactiveCN107415049APlay a buffer roleAvoid cloggingMixing operation control apparatusPretreatment controlStone particleSpiral blade

The invention discloses a stone-crushing concrete preparation device for buildings. The stone-crushing concrete preparation device comprises a base, wherein a left supporting plate and a right supporting plate are correspondingly arranged on the left side and the right side of the base; a crushing box is fixedly arranged between the left supporting plate and the right supporting plate through a support; an extruding plate is fixedly arranged at the inner bottom of the crushing box; a marble is connected to a first rotating shaft through a snapline and positioned below the crushing box; an agitator is obliquely arranged on the base through a support, and a receiving hopper is arranged on the left side of the top of the agitator; a third rotating shaft is rotationally connected to the interior of the agitator; a spiral blade is mounted on the third rotating shaft; and the left end of the third rotating shaft penetrates the left side wall of the agitator and is connected with the right end of the first rotating shaft through a universal coupler. According to the stone-crushing concrete preparation device, the bottom of the crushing box is knocked by the marble, so that adhesion blockage is prevented; and screened stone particles directly enter the agitator to prepare concrete without manual control, so that the processing efficiency is effectively improved.

Owner:李小强

System for separating solids from a fluid stream

InactiveUS20050040119A1Easy to transportDecreasing and increasing rotation rateLiquid separation auxillary apparatusSingle direction vortexSpiral bladeSlurry

Owner:DEL

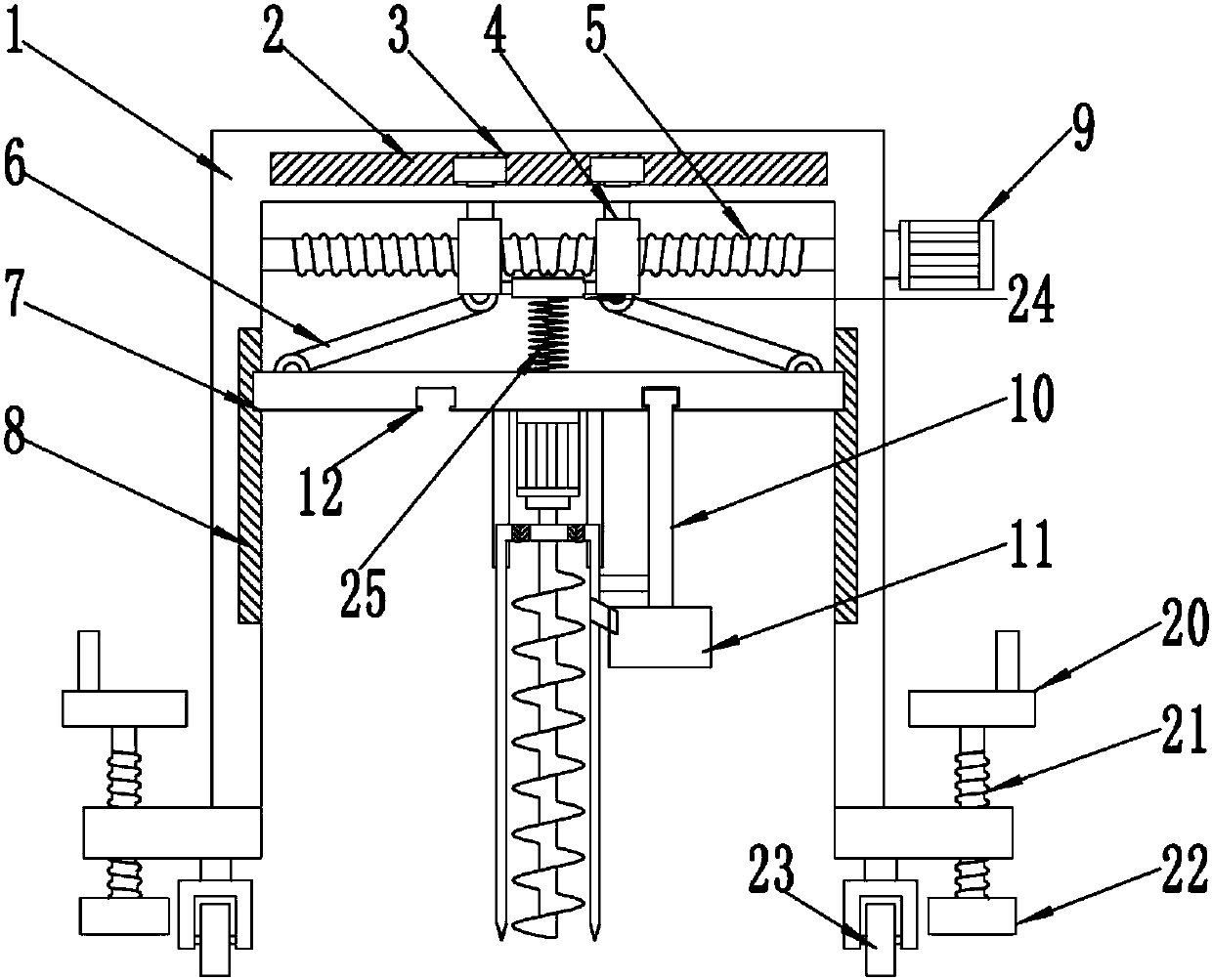

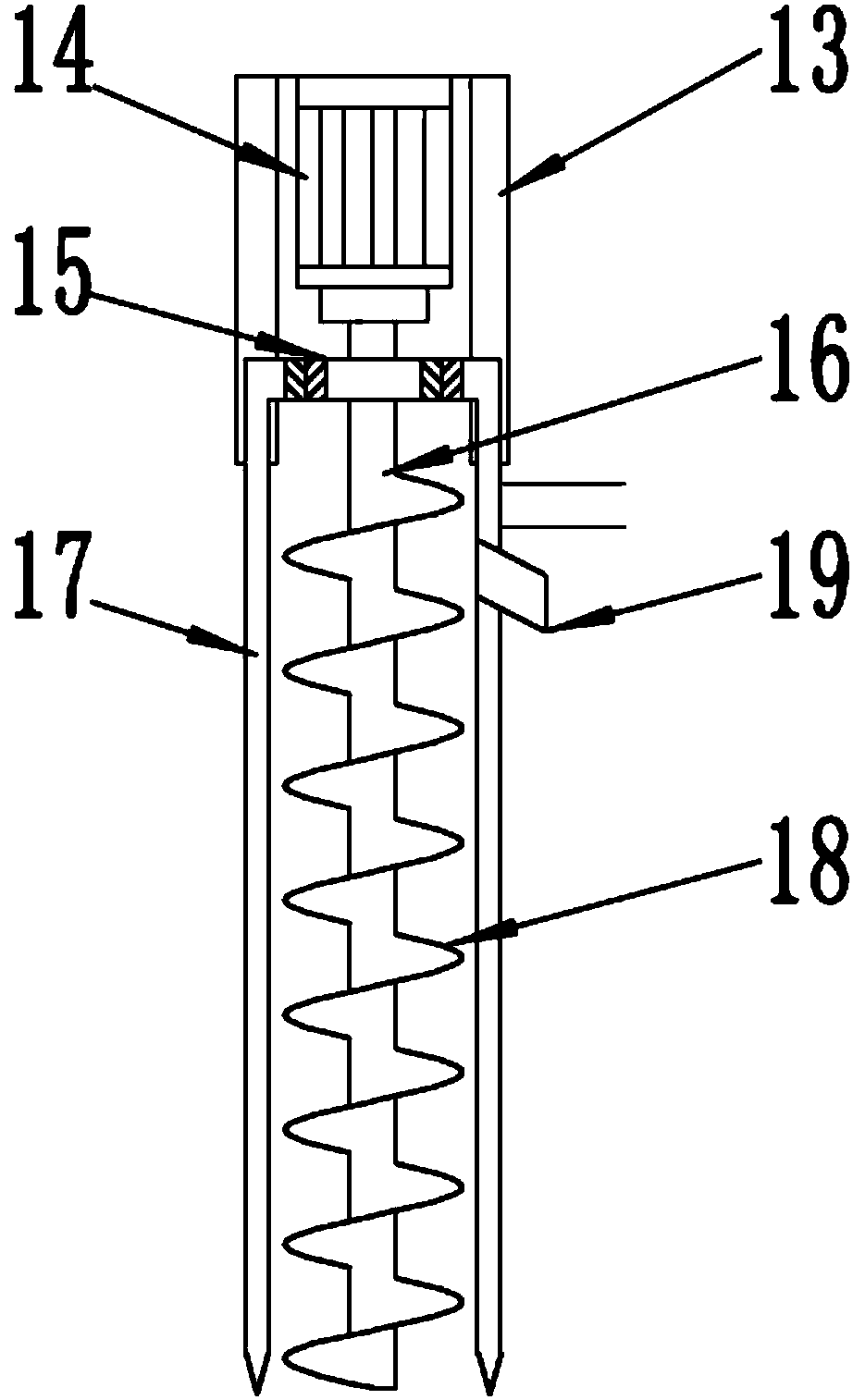

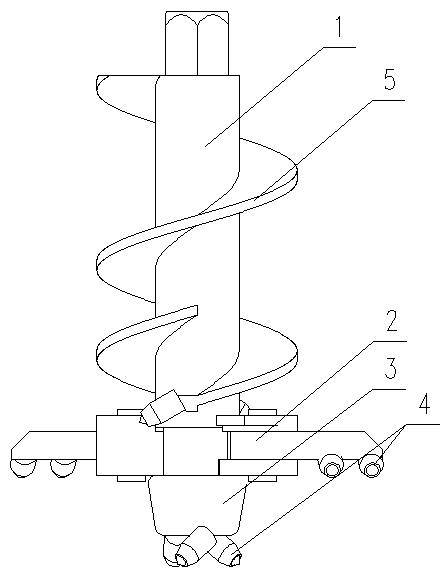

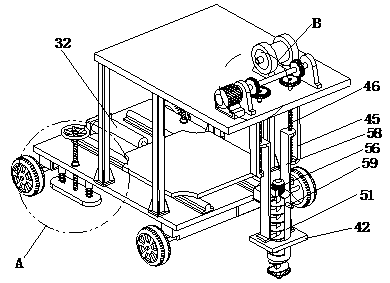

Digging device for municipal garden planting

InactiveCN107593038AFacilitate subsequent landfillEasy to operatePlantingFurrow making/coveringSpiral bladeEngineering

The invention discloses a digging device for municipal garden planting. The device comprises a rack, a reversible motor, a two-way thread rod, a push plate, a digging mechanism, a fixing mechanism andwheels, wherein the reversible motor is arranged on the right of the rack, and the two-way thread rod is fixedly connected with the output end of the reversible motor; moving blocks are connected onthe two-way thread rod in a symmetric threaded manner; a connecting rod is hinged at lower ends of the moving blocks, and the other end of the connecting rod is hinged with the upper end of the push plate; the digging mechanism is fixedly arranged at the lower end of the push plate, and comprises a fixed cylinder, a rotary motor, a gear, a rotating shaft, a rotating sleeve, a spiral blade and a soil output pipe; a collection hopper is arranged on the right of the rotating sleeve; the wheels are arranged at the lower end of the rack; and the fixing mechanism is arranged outside the wheels. Thedigging device is simple in structure and convenient to operate, can be used for collecting soil, is convenient for subsequent refilling, has high digging efficiency, good digging effect and long service life, and is worthy of popularization.

Owner:浙江辰基建设有限公司

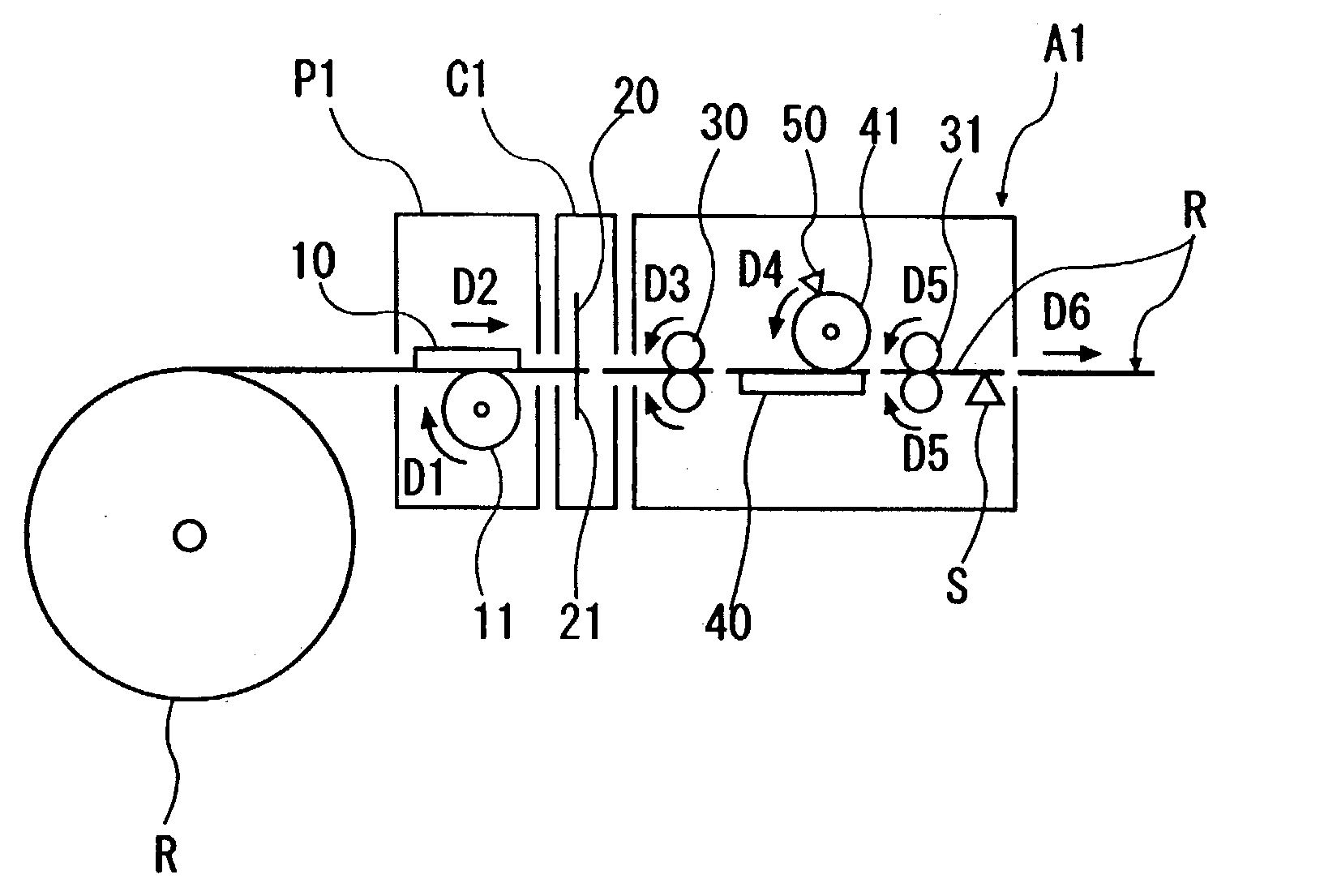

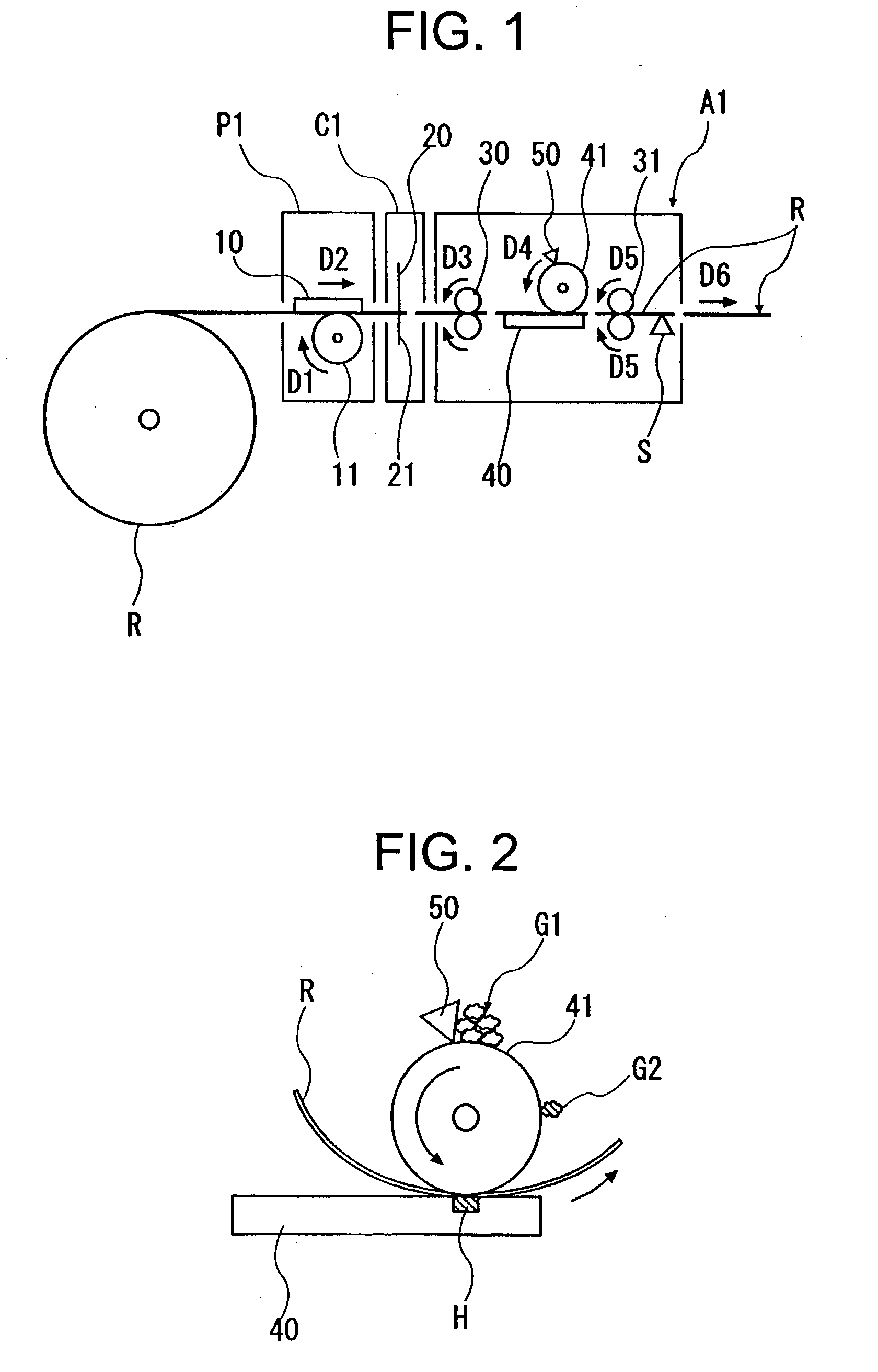

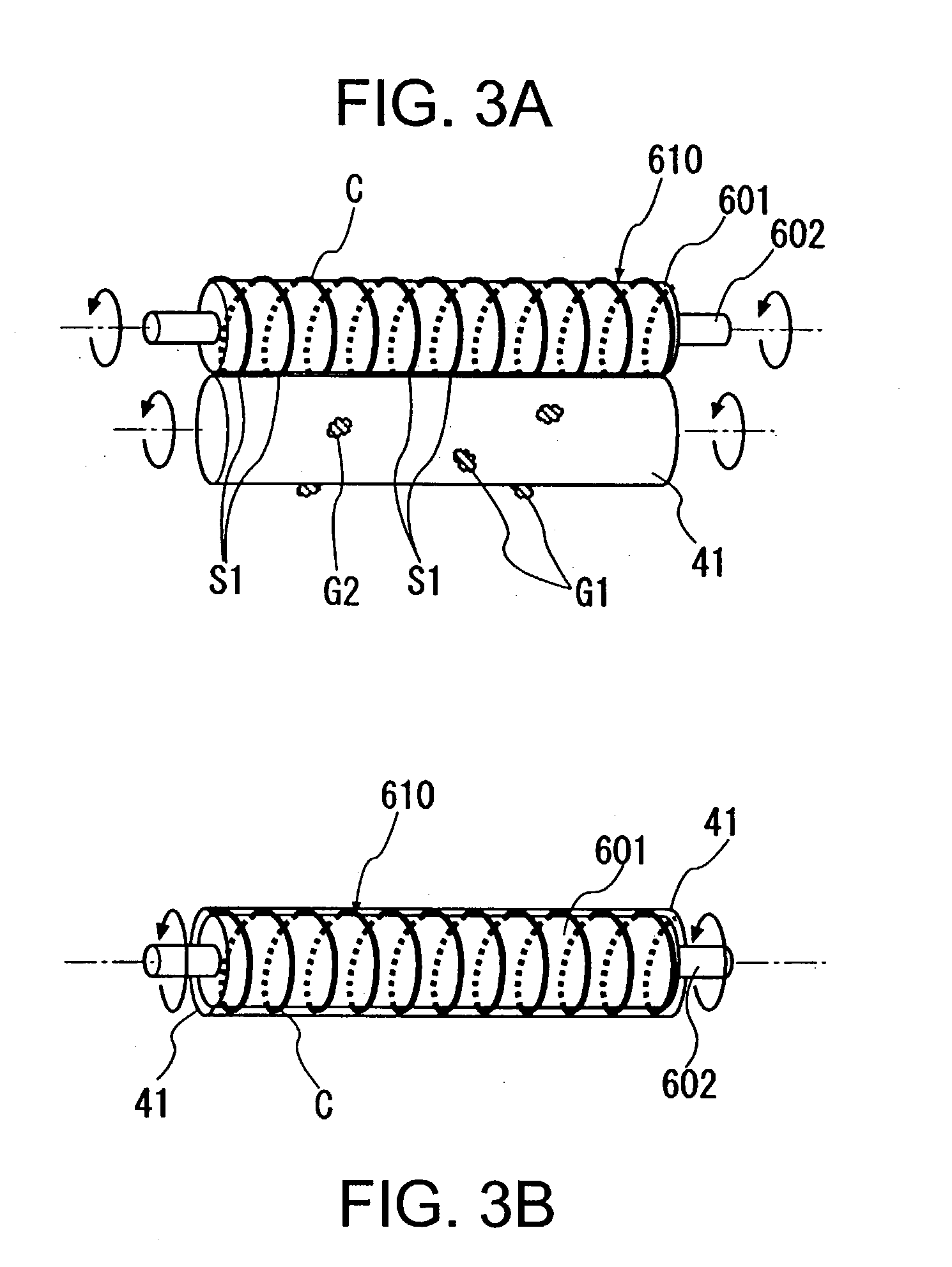

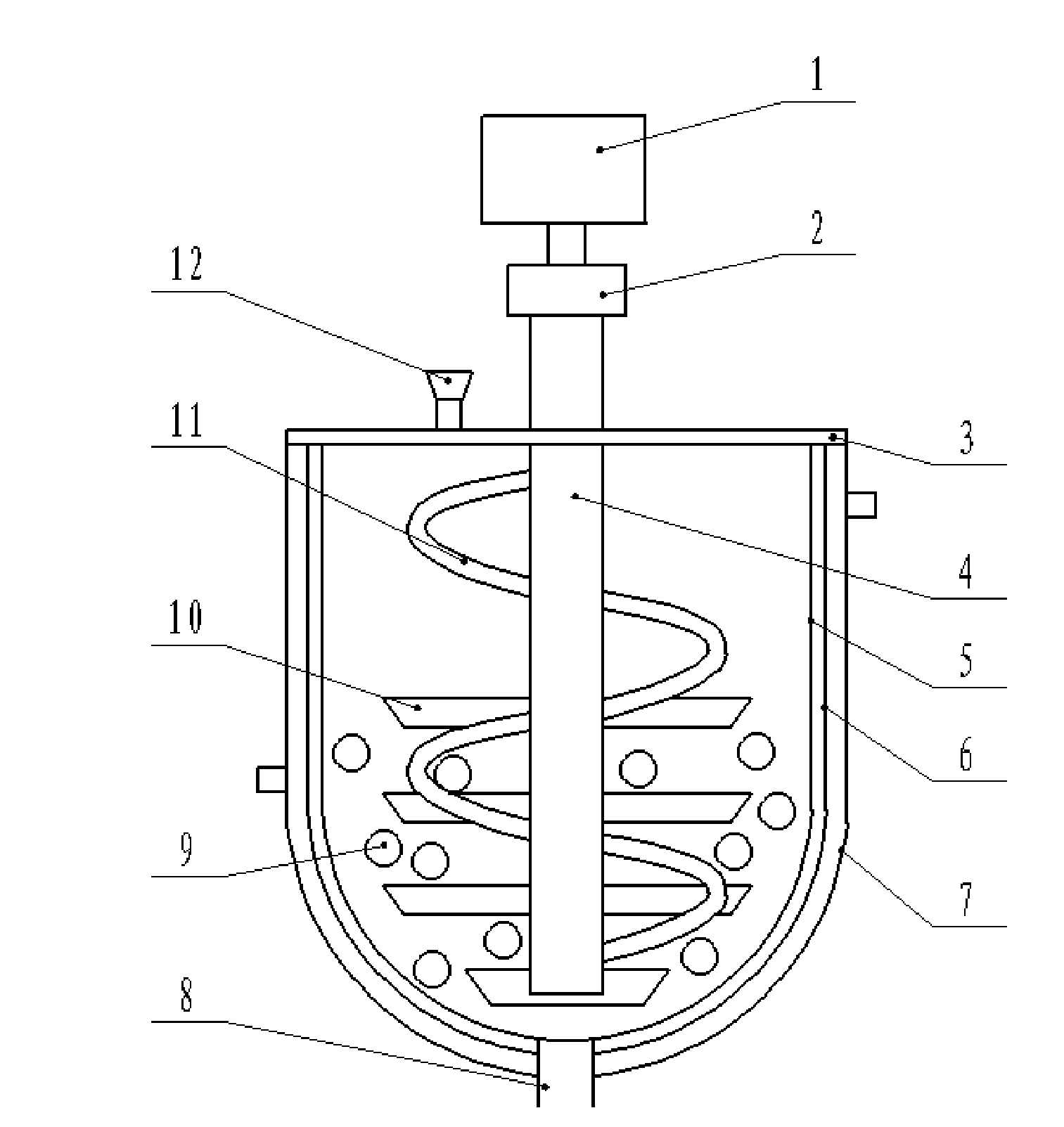

Thermal activator for heat sensitive adhesive sheet and printer apparatus utilizing the thermal activator

There is provided a thermal activator for a heat sensitive adhesive sheet capable of preventing or removing the heat sensitive adhesive and a product of denaturation of the heat sensitive adhesive from adhering to means for transporting the heat sensitive adhesive sheet and a printer apparatus utilizing the thermal activator. In a thermal activator for a heat sensitive adhesive sheet having at least heating means for activation (a thermal head 40 for thermal activation and a heating element H) for heating and activating a heat sensitive adhesive layer of a heat sensitive adhesive sheet (a heat sensitive adhesive label R) constituted of a printable surface (a thermal coat layer 501 and a color printing layer 502) and the heat sensitive adhesive layer (K) formed on one and another side of a base material (base paper 500) respectively and transport means (a platen roller 41 for thermal activation and the like) for transporting the heat sensitive adhesive sheet in a predetermined direction, there is provided anti-adhesion means (sheet materials 81 and 600 for cleaning) for preventing the heat sensitive adhesive or a product of denaturation of the heat sensitive adhesive from adhering to the transport means or removal means (a scraper 50, a rotary body 610 having a spiral groove or protrusion, a cylindrical rotary body 700 having a spiral blade, wires W, scraping tools 900 and 1100 in the form of a cutter blade, a transfer material 60, a cleaning roller 70, or the like) for removing the heat sensitive adhesive and the product of denaturation of the heat sensitive adhesive that have adhered to the transport means.

Owner:SAMBONGI NORIMITSU +5

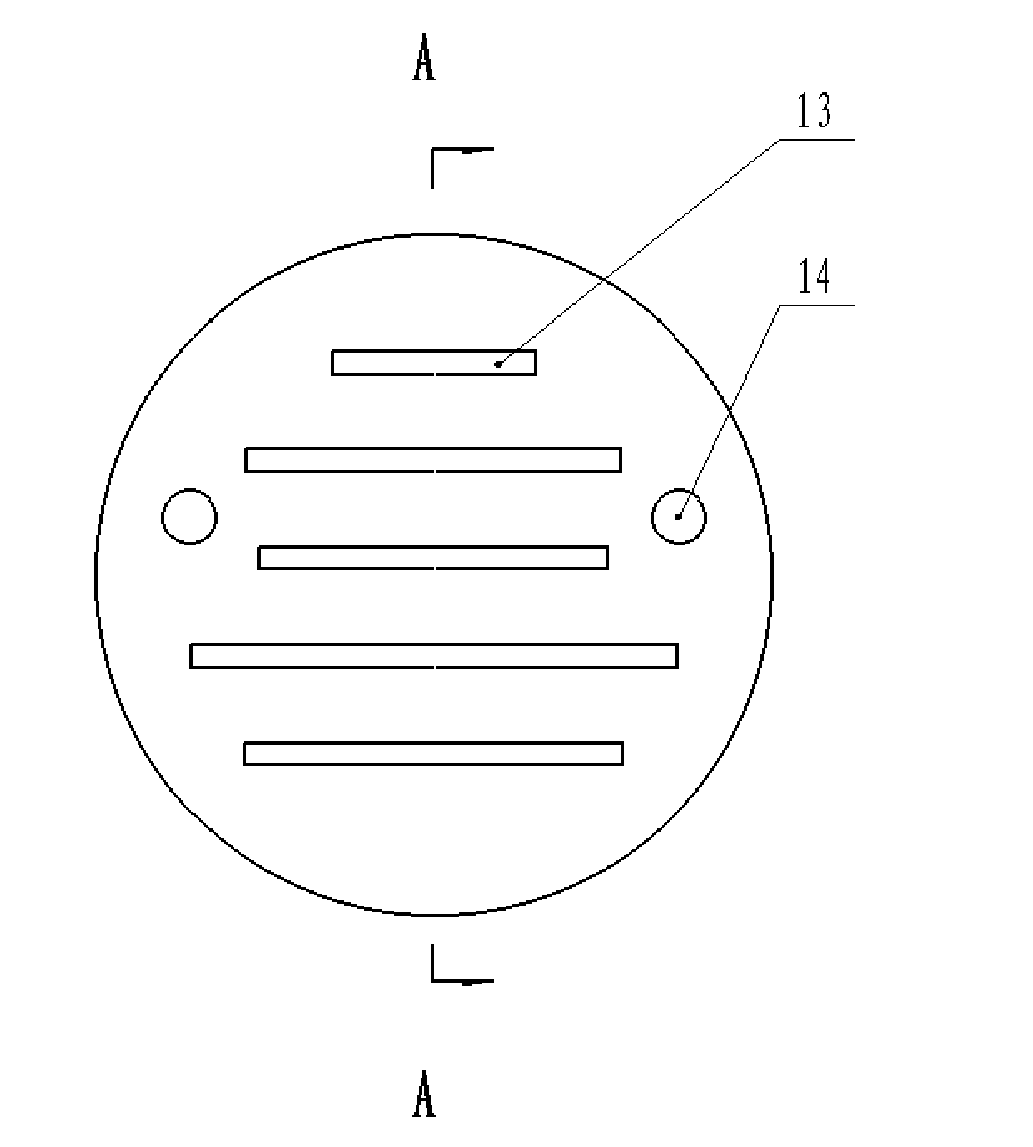

Vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers

ActiveCN102935350AImprove the perturbation effectHigh activityChemical/physical/physico-chemical stationary reactorsGrain treatmentsReaction fieldSpiral blade

The invention relates to a vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers, and a stirring shaft is driven by a drive unit through a coupling. The reactor further comprises a cylinder cover plate, a grinding inner cylinder, a lining plate, a funnel type material feeding port, a material discharging port and grinding balls. A stirring blade set composed of inclined plate blades and an S-shaped spiral blade is mounted on the stirring shaft, the inclined plate blades are mounted on the stirring shaft in parallel, and the S-shaped spiral blade is vertically mounted on the stirring shaft; and a plurality of through holes for grinding balls in the grinding inner cylinder to pass through are arranged on the inclined plate blades. According to the reactor, the stirring blade set is added, so that materials can be mixed evenly, and accordingly, the production efficiency is improved. Simultaneously, the stirring shaft and the S-shaped spiral blade are manufactured into hollow structures, and fed cooling substances are helpful for keeping the temperature to be uniform and the constant-temperature reaction field; and the bottom of grinding inner cylinder is hemispherical, so that grinding dead angles are avoided.

Owner:广西防城港五星环保科技股份有限公司

Construction waste smashing and recycling device

The invention provides a construction waste smashing and recycling device which comprises a discharging device, a smashing device, a cleaning device, a cycle delivery device and a bin door. The discharging device comprises a first motor, a feeding hopper and a pre-smashing mechanism. The pre-smashing mechanism is arranged in the middle of the discharging device, and comprises a hobbing rotary shaft and a groove. The smashing device comprises a left breaking roller, a right breaking roller and a second motor. The cleaning device comprises a water inlet pipe and a sprayer. The cycle delivery device comprises a feed pipe, a discharge pipe and a third motor, and a storage plate is arranged at the lower end of the cycle delivery device. A third rotary shaft is arranged at the lower end of the third motor, and the third rotary shaft is provided with a second spiral blade. The storage plate is fixed to the right end of a bin body in a welded manner. The bin door is arranged at the right end of the bin body and provided with a handle. The construction waste smashing and recycling device can carry out smashing to avoid blocking, can carry out cycle smashing to achieve thorough smashing and can also carry out fine smashing to achieve complete smashing.

Owner:郑州吉音动漫科技有限公司

Material mixer

ActiveCN101829518AMix well and evenlyReduce speedRotating receptacle mixersTransportation and packagingSpiral bladeReduction drive

The invention relates to a material mixer for mixing materials. The material mixer comprises a primary motor, a secondary motor, a primary reducer, a secondary reducer and a cylindrical barrel, and is characterized in that: a rotary shaft is arranged in the barrel, the rotary shaft is a spiral shaft provided with spiral blades and comprises a left part and a right part, and the spiral directions of the spiral blades on the left part and the right part of the rotary shaft are opposite; the inner wall of the barrel is provided with a group of bearing plates, one end of each of the bearing plates is welded on the inner wall of the barrel, and the other end of each of the bearing plates points to the rotary shaft and deviates from the center of the rotary shaft at a certain distance; and the bearing plates are also provided with guided material-scraping plates. Because the rotary shaft is the two-segment type bidirectional spiral shaft in the barrel, the materials in the barrel do not deviate toward one end of the barrel in the stirring process, so that the materials can be evenly mixed.

Owner:格林凯尔(应城)肥料有限公司

Dual cutter router bit

The router bit includes an upper and a lower cutter, axially aligned and separated by a fixed longitudinal displacement. No substantial portion of the bit extends beyond the lower end of the lower cutter. In some embodiments, the lower cutter may be configured with bottom face blades to allow the router to be used as a plunging bit. The cutters may use wing blades or spiral blades. The portion of the bit intervening between the upper and lower cutters may also be configured as a cutter. In some embodiments, the router bit is integral. In other embodiments, it comprises separate elements that may be axially secured.

Owner:HILKER DAVID

Advanced expandable reaming tool

An expandable reaming tool including at least two reamer pads connected to a tool body. The reamer pads are adapted to be displaced between a retracted position and an expanded position. At least one spiral blade is formed on at least one reamer pad. A plurality of cutting elements are disposed on the at least one spiral blade.An expandable reaming tool including at least two reamer pads connected to a tool body. The reamer pads are adapted to be displaced between a retracted position and an expanded position. At least one blade is formed on the at least two reamer pads. A plurality of cutting elements are disposed on the at least one blade and at least one gage protection element is disposed on a gage surface of the at least one blade. The plurality of cutting elements are arranged so as to enable the expandable reaming tool to backream a formation in a wellbore.

Owner:SMITH INT INC

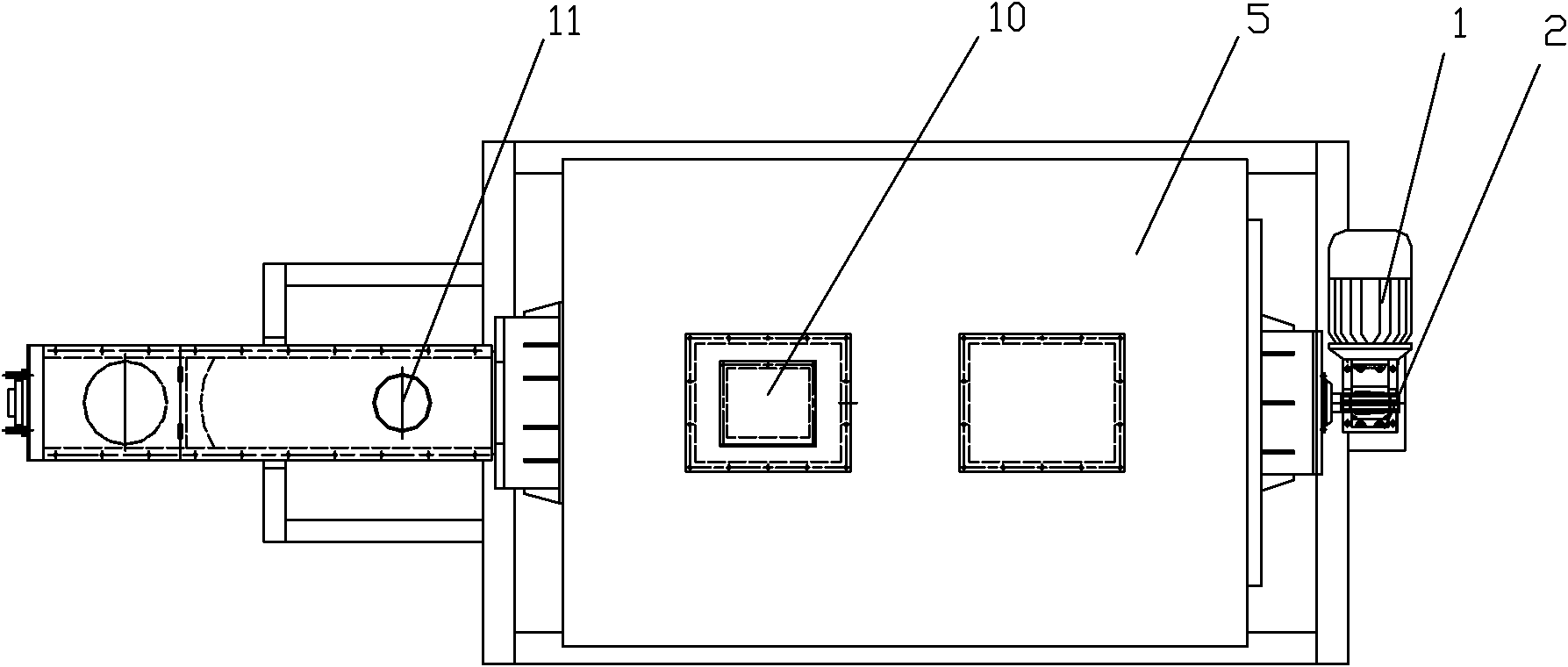

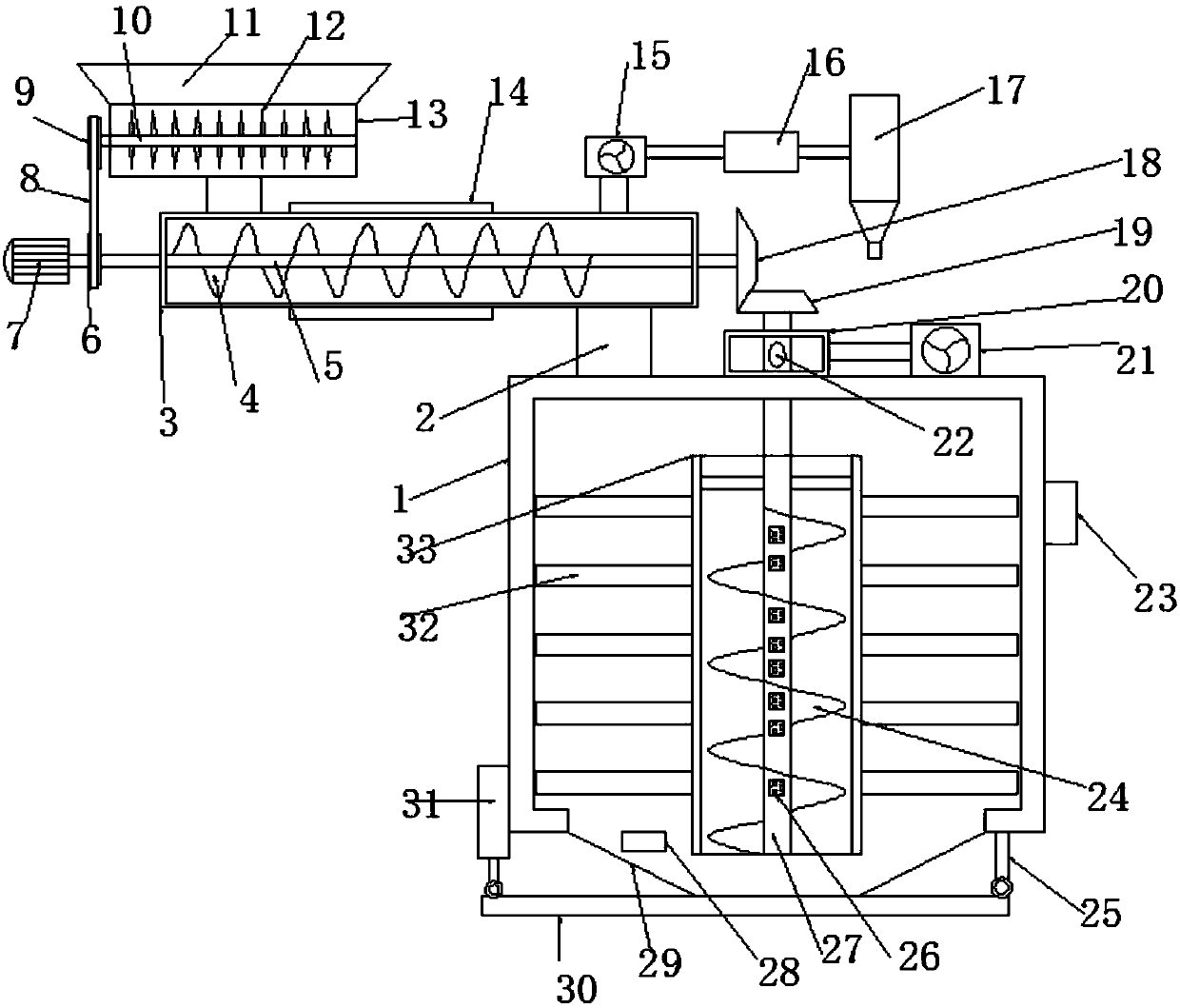

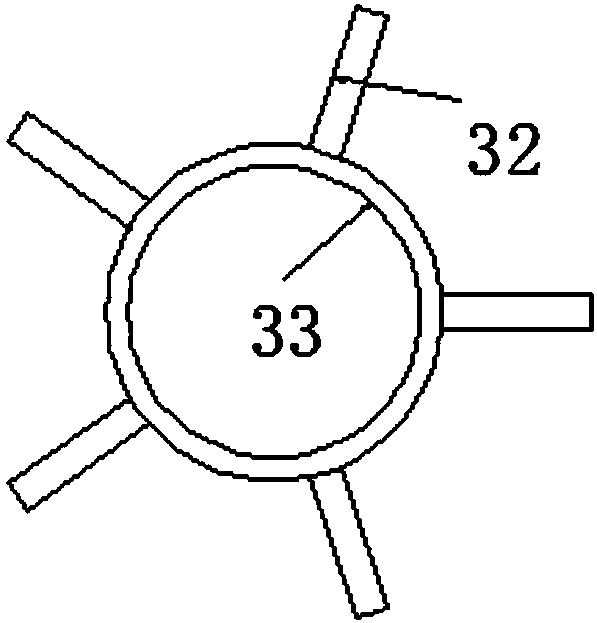

Internal circulation type traditional Chinese medicine drying equipment

InactiveCN107940974AReduce volumeFully dryDrying machine combinationsDrying gas arrangementsSpiral bladeBiochemical engineering

The invention discloses internal circulation type traditional Chinese medicine drying equipment. The equipment comprises a processing box, a connecting channel and a feeding cylinder; the connecting channel is formed in the left upper end of the processing box, and the upper end of the connecting channel is connected with and fixed to the feeding cylinder, a pushing shaft is arranged in the feeding cylinder in a penetrating mode, and a spiral blade is arranged on the pushing shaft; a heating block sleeves the outer side of the feeding cylinder and is used for heating materials in the feeding cylinder, the two ends of the pushing shaft penetrate through the feeding cylinder, the left end of the pushing shaft is fixedly connected with the output end of a driving motor, and a driving gear isarranged at the right end of the pushing shaft; and a driving belt wheel is arranged on the part, close to the driving motor, of the pushing shaft, a feeding pipe is arranged on the upper left side ofthe feeding cylinder, and a crushing box is arranged at the upper end of the feeding pipe. According to the equipment, the structure is simple and reasonable; the materials are crushed in advance sothat the size of the materials can be reduced, and later drying can be facilitated; and meanwhile, circulation drying of the materials in the processing box can be realized through the equipment so that the materials can be fully dried, and the equipment is high in practicability.

Owner:马良彬

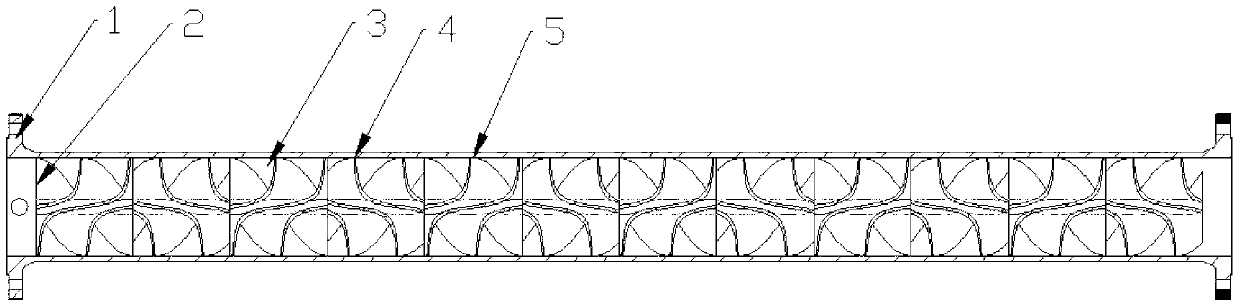

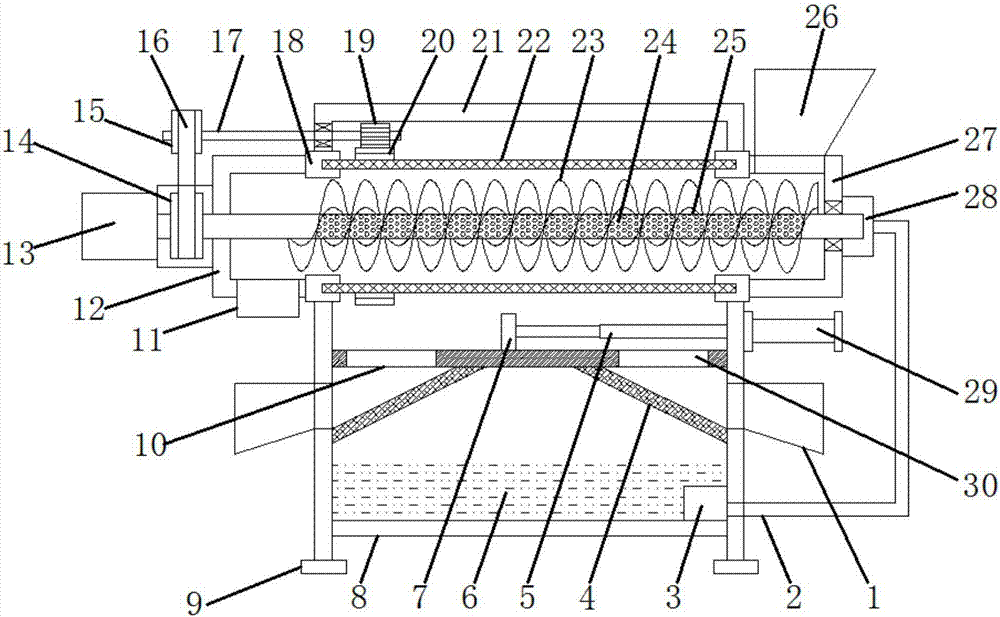

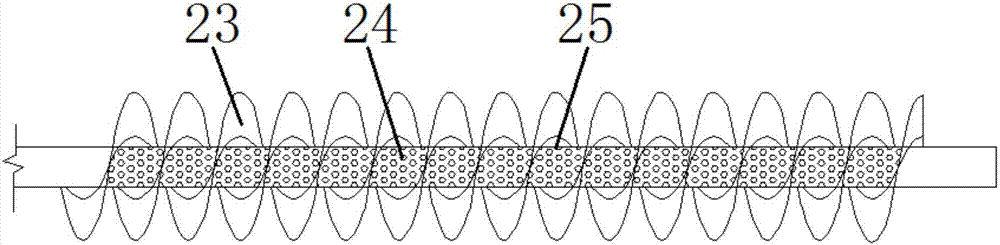

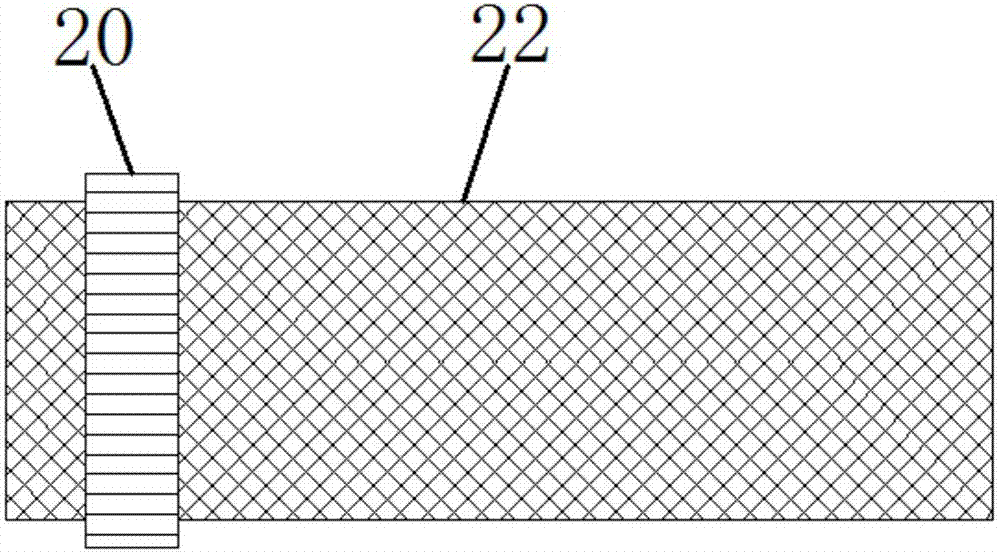

Kitchen waste drying squeezer

The invention relates to a kitchen waste drying squeezer. The kitchen waste drying squeezer is characterized by comprising a squeezing barrel which is transversely arranged on a frame, wherein the squeezing barrel comprises a head end and a tail end; a feeding hole is formed in the top close to the head end; the tail end is in a cone shape which is gradually shrunk; a plurality of water outlets are formed in the bottom of the squeezing barrel at intervals; a solid-liquid separation fence is arranged on each water outlet; a spiral shaft is axially arranged in the squeezing barrel; spiral blades are arranged on the spiral shaft; the screw pitch of the spiral blades is continuously reduced from the head end to the tail end of the squeezing barrel; one end, which is close to the feeding hole, of the spiral shaft penetrates out of the head end of the squeezing barrel and is connected with a motor through a coupler; the other end of the spiral shaft penetrates out of the tail end of the squeezing barrel and is arranged on the frame; the outer side of the tail end of the squeezing barrel is provided with a baffle; a squeezing spring is arranged on the spiral shaft on the outer side of the baffle; the other end of the squeezing spring is fixed on the frame; and a discharge opening is formed below the squeezing spring. The kitchen waste drying squeezer is simple in structure and low in processing cost and can be widely applied to the kitchen waste treatment process, and moisture in the kitchen waste can be effectively reduced.

Owner:北京洁绿环境科技股份有限公司

Pipeline transporting spiral crushing device for solid waste and household garbage

The invention belongs to the technical field of garbage disposal equipment and discloses a pipeline transporting spiral crushing device for solid waste and household garbage. The pipeline transporting spiral crushing device for the solid waste and the household garbage is used for solving the problems that because a direct recycling manner is adopted for scenic spots, stations, airports and other sites which are huge in waste amount and require instantaneous recycling in the prior art, a conveying pipeline can be blocked easily, and the gas explosion noise can be caused easily. The pipeline transporting spiral crushing device for the solid waste and the household garbage comprises a machine body which is provided with a feeding bin; the lower end of the feeding bin is communicated with a feeding channel; the lower end of the feeding channel is communicated with a spiral crushing barrel; the lower end of the spiral crushing barrel is communicated with a conveying pipeline of a matched pneumatic waste recycling system; a hollow rotating shaft is arranged in the spiral crushing barrel; spiral blades are arranged on the periphery of the hollow rotating shaft; a plurality of through grooves formed in the axial direction of the hollow rotating shaft are formed in the circumferential wall of the hollow rotating shaft; a core shaft capable of rotating along with the hollow rotating shaft and capable of moving up and down along the hollow rotating shaft is arranged in the hollow rotating shaft in a sleeved manner; and the core shaft is connected with a plurality of longitudinal cutters capable of sliding up and down in the through grooves.

Owner:浙江易顺通科技有限公司

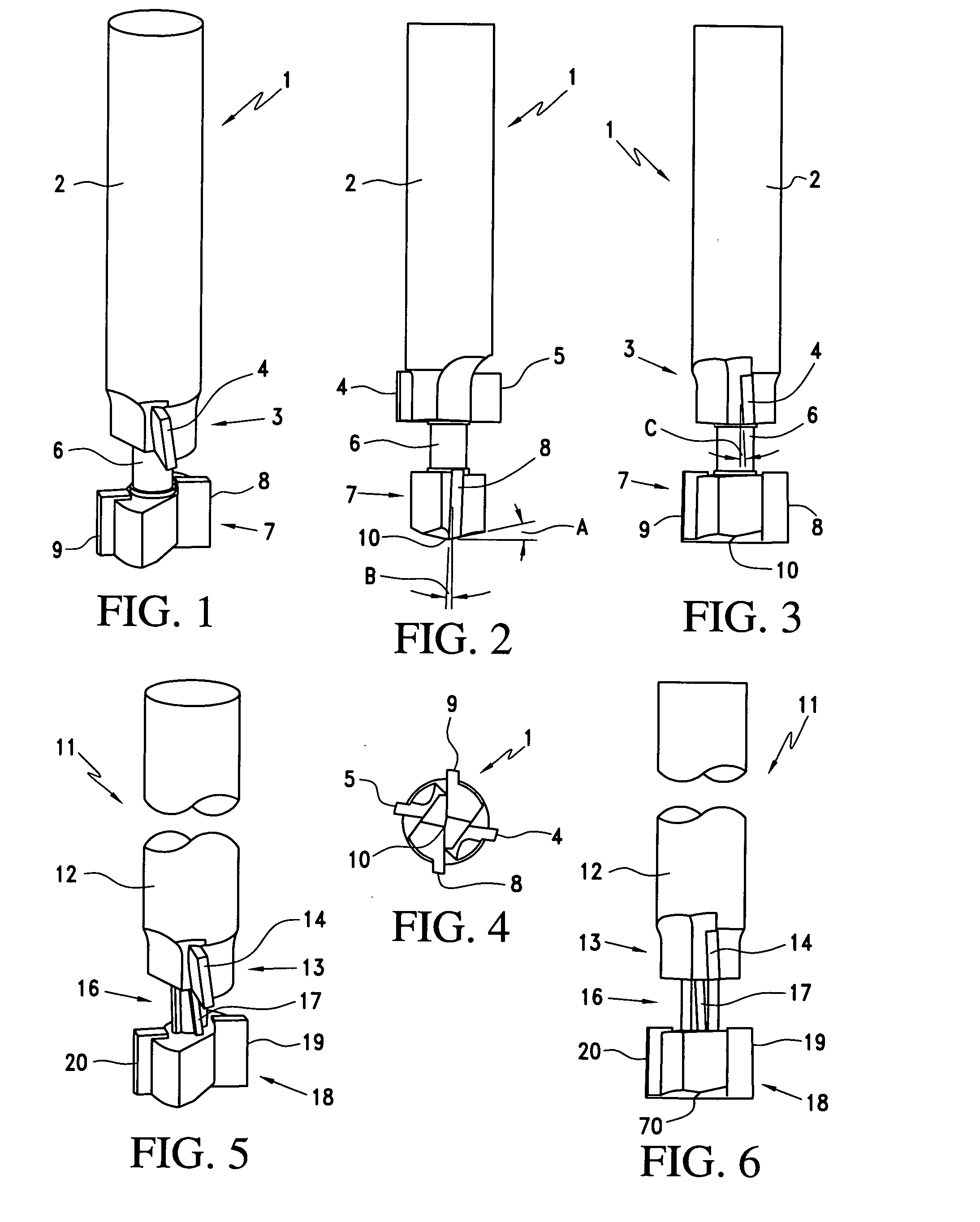

Cutting device with spiral blades

Cutting device for cutting objects, such as leaves, twigs, grass-like plants, fibers, hairs, and the like, having two sets of internally coupled blades, with at least one set of blades being static or dynamically formed whole spiral shape, and the blades having relative rotation therebetween for rotation, oscillation along the axes, rotational oscillation around the axes, or combinations of these motions, to create cutting actions such as shearing, sawing, or a combination of shearing and sawing, with an integrated function of mulching the cuttings generated by the cutting actions.

Owner:JIANG YUNING

Linkage type pig feed drying and stirring device

InactiveCN107913628AAvoid depositionWell mixedFeeding-stuffTransportation and packagingSpiral bladeEngineering

The invention discloses a linkage type pig feed drying and stirring device which comprises a stirring box, a door-shaped frame, a transverse shaft, a cylinder and a base; the stirring box is fixed tothe top of the base through a supporting leg; the door-shaped frame is fixed to the top of the stirring box; the cylinder is fixed to the outer wall of the left side of the stirring box; a short shaftpenetrates through a left side frame body of the door-shaped frame and is rotationally connected with the door-shaped frame through a bearing. During working, a spiral blade continuously drives feedat the bottom of the stirring box to swarm upwards, the feed is prevented from being deposited, and therefore the feed is mixed to be more uniform; rotary air injection is performed through a hollow rotary shaft, so that hot air is distributed more uniformly in the stirring box, and the drying efficiency is improved; meanwhile, due to the linkage design, air blowing and stirring can be performed synchronously, and therefore the whole device is easier to control.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

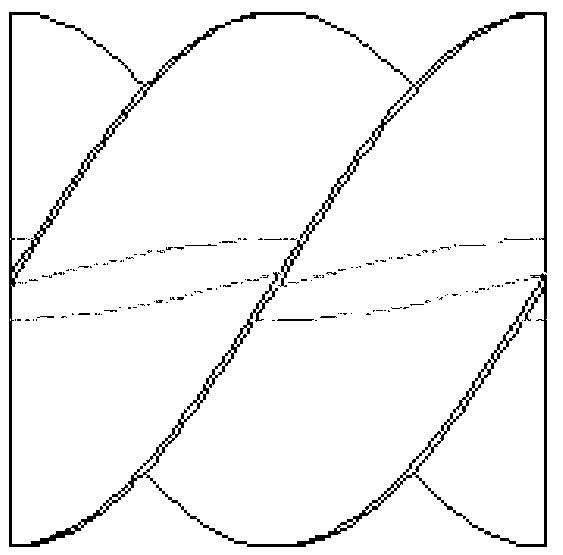

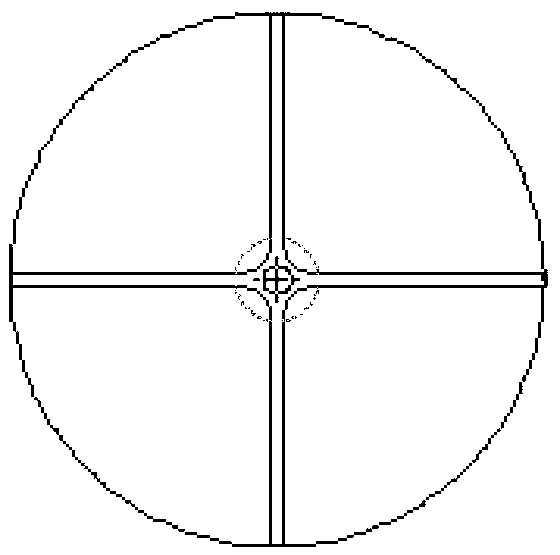

Spiral static mixer

The invention discloses a spiral static mixer which is applied to mixing of multiple materials and particularly mixing of high-viscosity materials. The spiral static mixer comprises a shell, mounting flanges, left rotating blades and right rotating blades and is characterized in that the mounting flanges are respectively arranged at the two ends of the shell, the left rotating blades and the right rotating blades are in multiple-spiral blade structures and sequentially and alternately arranged from an inlet of the shell to an outlet of the shell, the adjacent left rotating blades and right rotating blades are fixedly connected at the periphery in a staggering manner, and a washing lifting ring is connected at one end of a blade group formed by the left rotating blades and the right rotating blades. The spiral static mixer provided by the invention has the advantages of simple structure, high mixing efficiency, convenience and fastness in installation, low cost, convenience in washing and suitability for long-time working; a mixed blade unit can be replaced; and the spiral static mixer is more widely applied to mixing of the high-viscosity materials in the chemical engineering industry.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

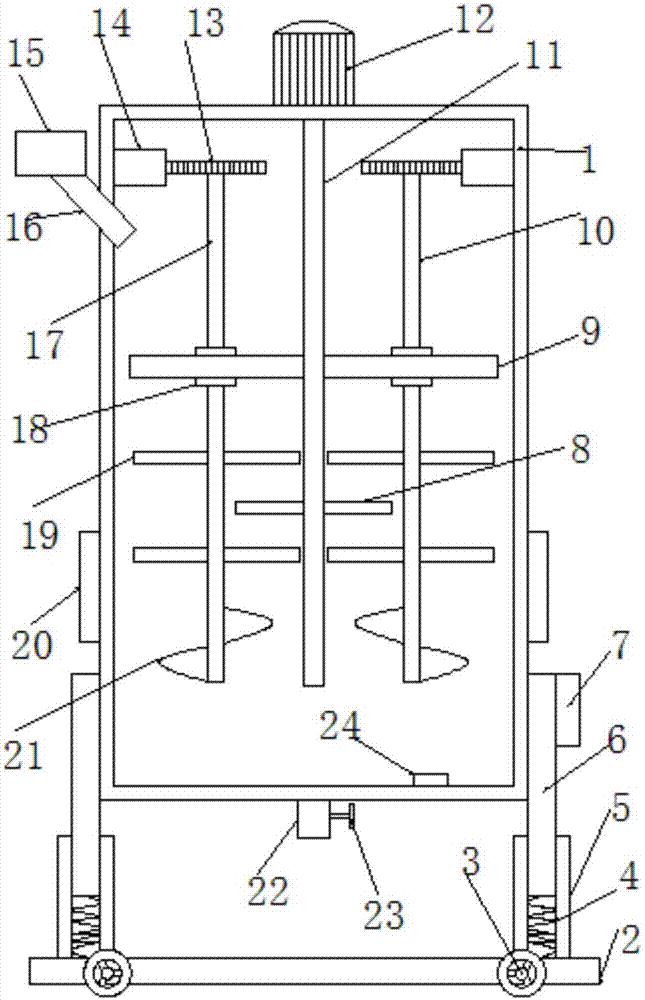

Efficient three-shaft reaction kettle

InactiveCN107096487AImprove the mixing effectSimple structureRotary stirring mixersTransportation and packagingSpiral bladeBiochemical engineering

The invention discloses an efficient three-shaft reaction kettle which comprises a processing box. A driving motor is fixed in the middle of the upper end of the processing box, a stirring spindle is fixed at the output end of the driving motor, a second stirring rod and a first stirring rod are symmetrically arranged on the stirring shaft, length of the second stirring rod is twice that of the first stirring rod, the second stirring rod is positioned above the first stirring rod, mounting holes penetrate the left side and the right side of the second stirring rod, a first stirring shaft and a second stirring shaft are penetratingly arranged in the left mounting hole and the right mounting hole respectively, a rotating bearing matched with the first stirring shaft and the second stirring shaft is arranged in the mounting holes, auxiliary stirring rods are symmetrically arranged on the left and right sides of each of the first stirring shaft and the second stirring shaft, the auxiliary stirring rods and the first stirring rod are in spaced distribution, and a spiral blade is arranged at the lower end of each of the first stirring shaft and the second stirring shaft. The efficient three-shaft reaction kettle is simple in structure, convenient to carry and good in anti-seismic performance, the defect that conventional stirring is unitary is eliminated, and improving of production efficiency is facilitated.

Owner:沈美珍

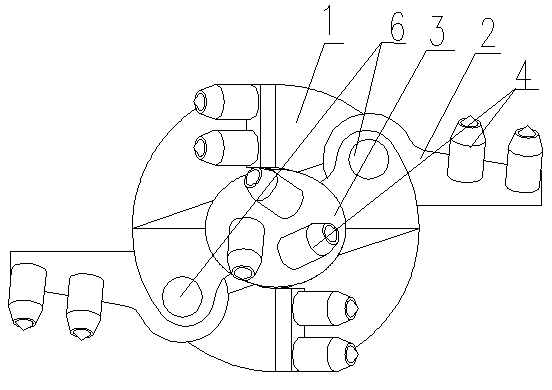

Bearizing drilling bit

The invention discloses a bearizing drilling bit, which is provided with a drilling bit main body and at least one bearizing wing, wherein a spiral blade is arranged on the side wall of the drilling bit main body; grooves, of which the number is the same as that of the bearizing wings, are formed in the drilling bit main body on the upper part of a drilling bit guide head; one end of each bearizing wing is hinged in the corresponding groove through a pin shaft; the bearizing wings can rotate around the pin shafts to open and close; cylindrical concentric matched structures are adopted at the connection ends and on the connection parts of the bearizing wings and the drilling bit main body; and drilling teeth are formed on the guide head, the drilling bit main body and the bearizing wings. The connection parts of the bearizing wings and the drilling bit main body have the cylindrical concentric matched structures, so that a hollow cavity is not formed at a joint between each bearizing wing and the drilling bit main body; therefore, interference of drilling slag on the folding of the bearizing wings is avoided; and the work reliability is improved.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +2

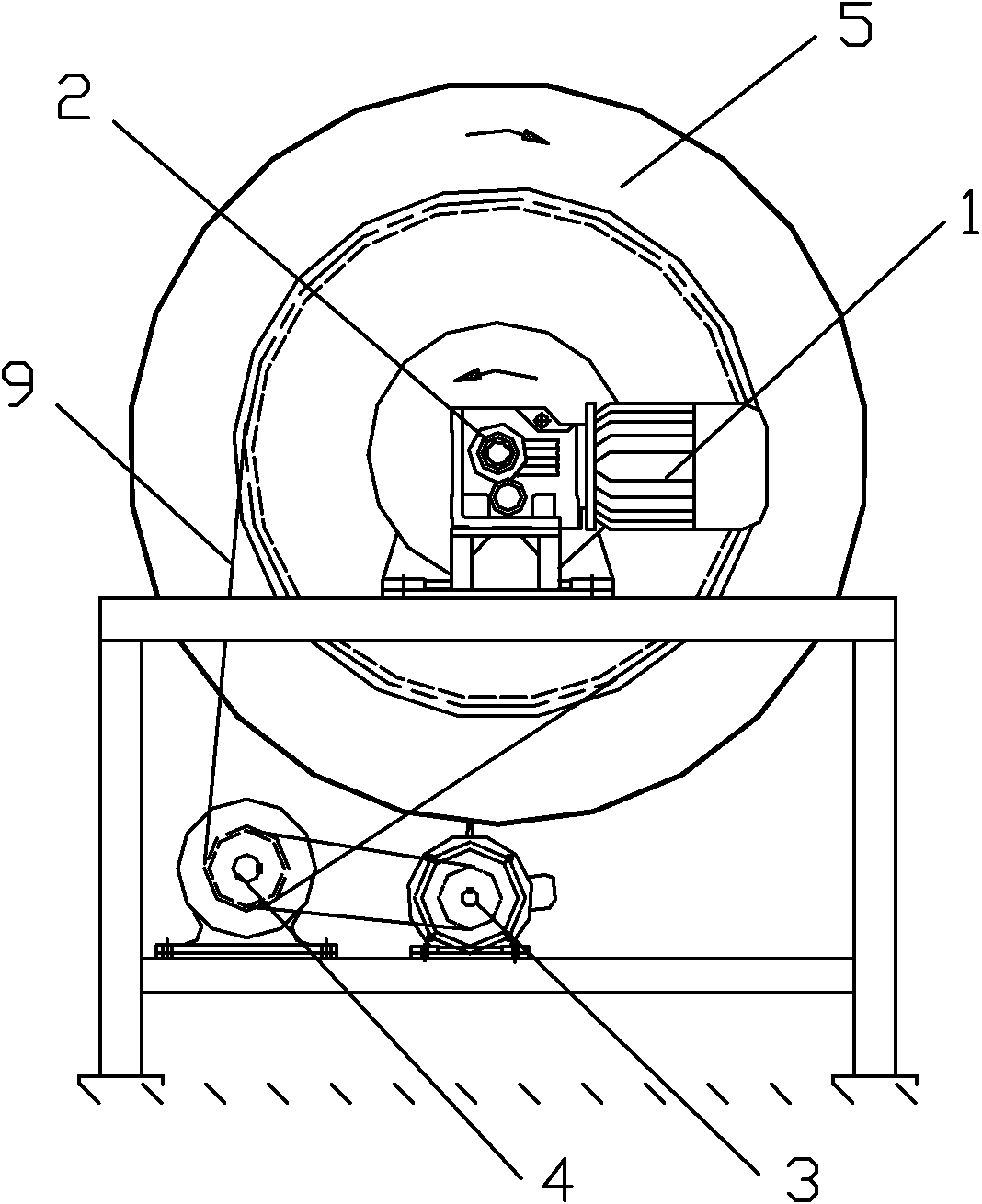

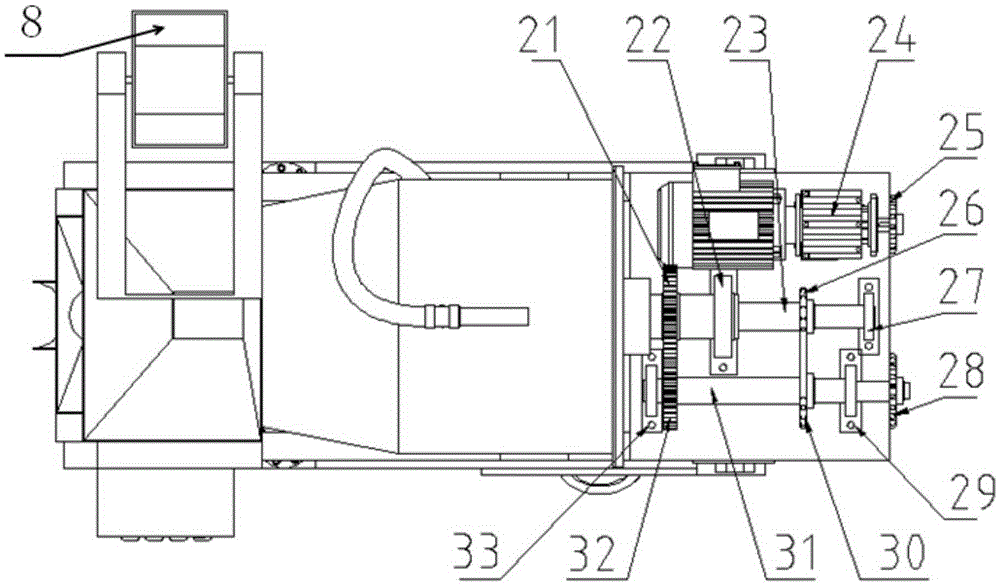

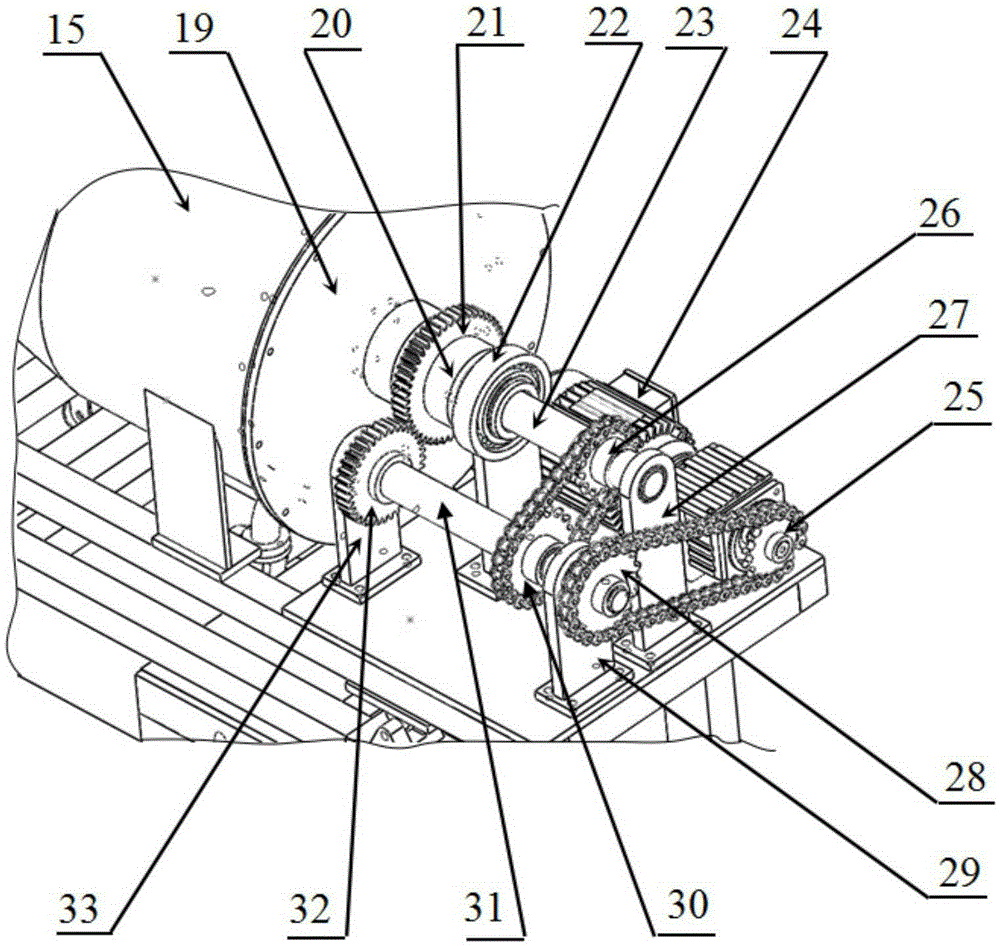

Roller type macadam screening jet flow ore washing equipment

The invention discloses a jet ore washing equipment for drum-type crushed stone screening, which comprises a water storage tank, an ore washing shell, an ore washing net cylinder, a spiral blade, a high-pressure jet hole and a hollow rotating shaft. The bottom of the ore washing shell is welded There is a water storage tank, the bottom of the water storage tank is welded on the support frame, the inner bottom of the water storage tank is set as a water storage tank, and the filter residue net is installed on both sides above the water storage tank, and the upper end of the filter residue net is connected to the separator, and the two ends of the separator are equipped with Slag drop hole; the ore washing shell is equipped with an ore washing net cylinder, and the ore washing net cylinder is respectively connected to the feeding cover and the discharge cover through the rotating guide sleeve, so that the hollow rotating shaft and the ore washing net cylinder can be driven to rotate at the same time. The hollow rotating shaft is opposite to the rotation direction of the ore washing net cylinder and is combined with the flushing of the high-pressure jet hole, which has a good cleaning efficiency and effect on the ore; after cleaning, the water flows into the water storage tank to realize water recycling; the ore washing net cylinder effectively filters out the ore The slag in the filter can improve the screening effect of the crushed stone.

Owner:陈鹏

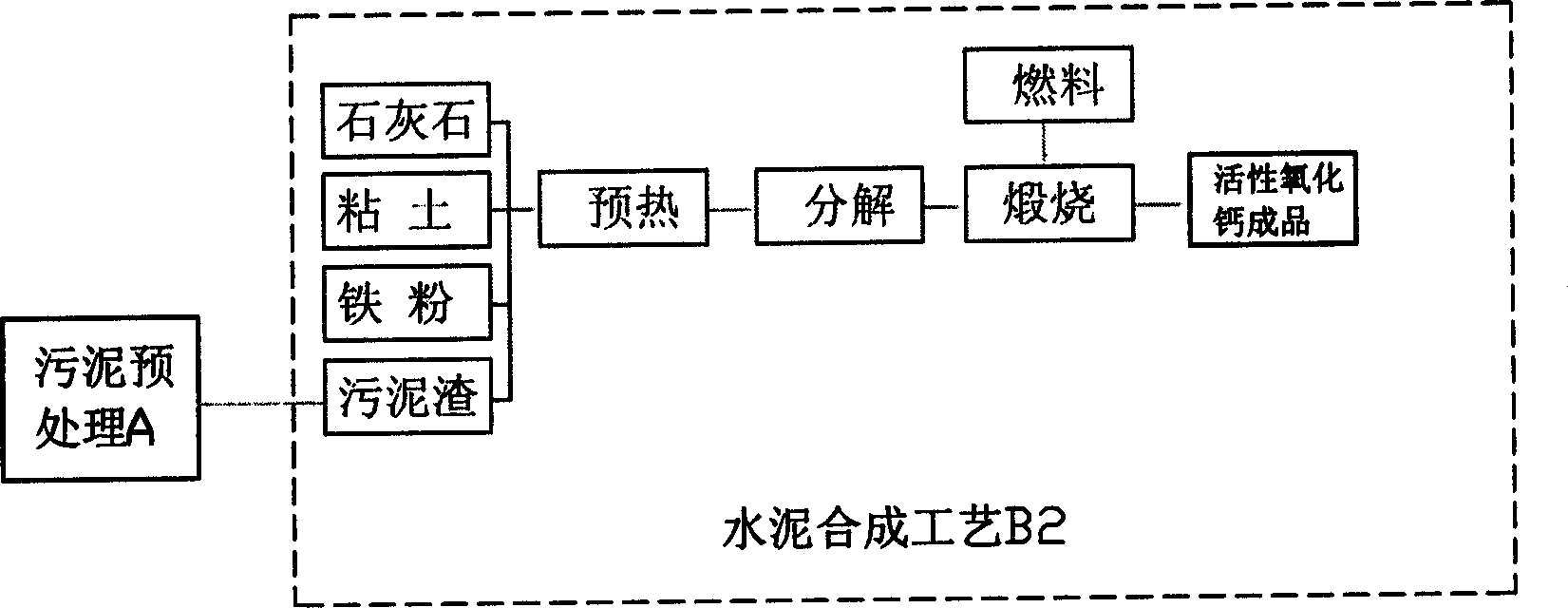

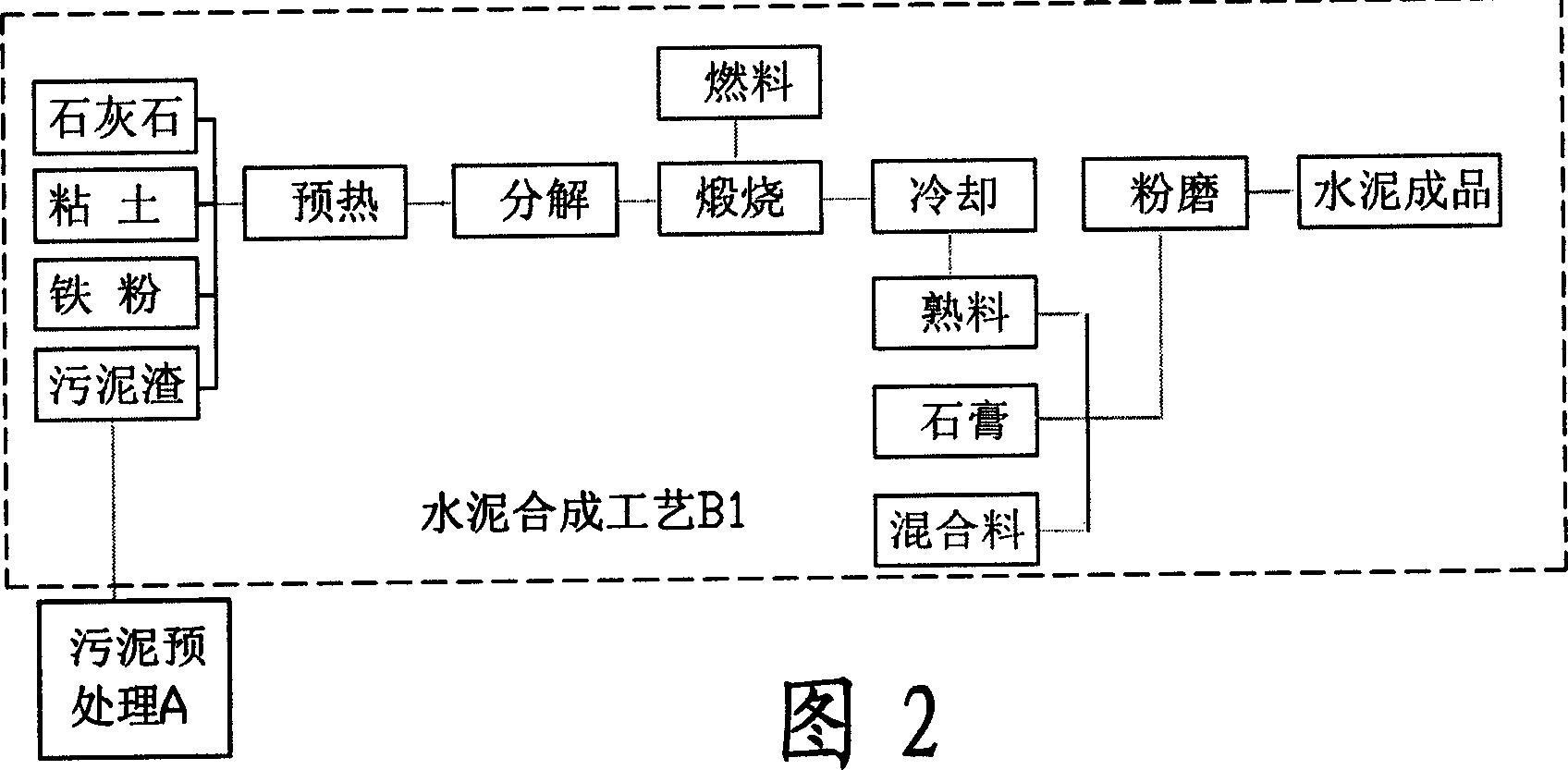

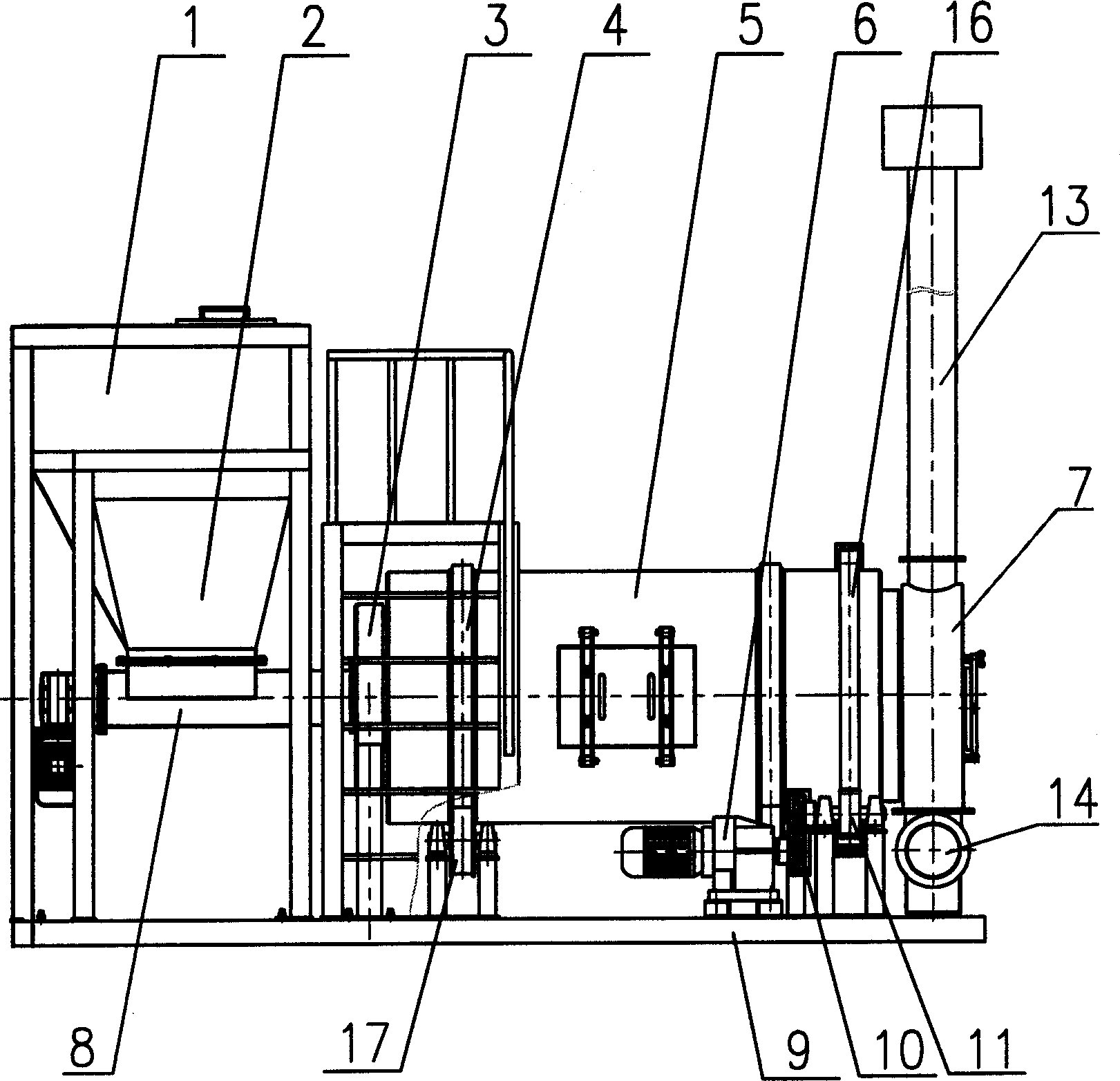

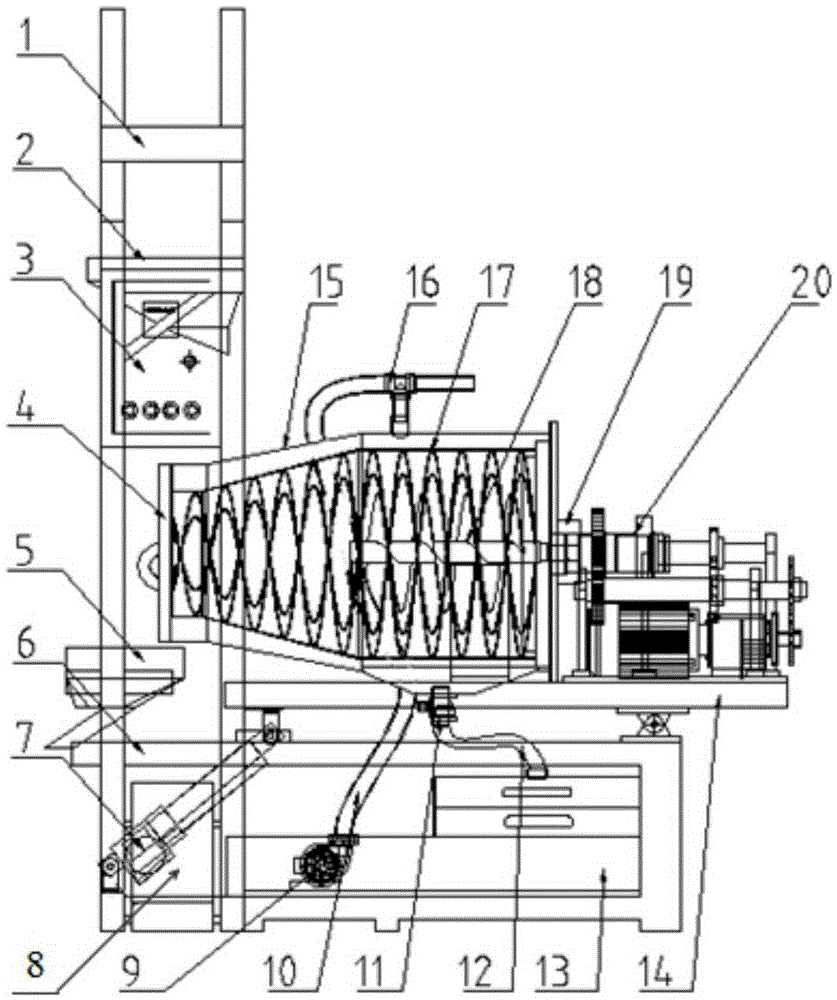

Method and device of treating urban mud by using cement rotary kiln

InactiveCN1861532AAvoid swappingAvoid lostAluminium compoundsSludge treatment by oxidationConvex structureCalcium hydroxide

A method for treating city sludge by the rotary kiln of preparing cement features that said sludge containing calcium hydroxide is calcined in said rotary kiln to become calcium oxide. Its apparatus is composed of a sludge pre-treating unit and new material synthesizing unit. The spiral blades of the screw stirring-delivering mechanism have the concave-convex structure on their edge, resulting in high stirring effect and strength.

Owner:北控东方(北京)环保技术有限公司

Roller type washing and peeling machine

InactiveCN105410958AImprove efficiencyImprove sexual functionVegetable peelingFood treatmentSpiral bladePulp and paper industry

The invention discloses a roller type washing and peeling machine. A roller type washing device comprises a roller, wherein the roller is horizontally put on a machine frame, and one end of a feed port of a roller body can be pushed up or put down. The roller comprises a closed outer cylinder and a closed inner cylinder, wherein the closed outer cylinder and the closed inner cylinder are coaxial with each other and separated from each other. Hollow spiral blades axially and spirally extending are arranged on the inner side of the inner cylinder. A spiral blade shaft which is horizontally suspended along the central axis of the roller is arranged at the center of the hollow spiral blades of the inner cylinder. The spiral blade shaft and the hollow spiral blades are opposite in spiral direction and are arranged in the cylinder in a 180-degree staggered mode. The inner cylinder and the spiral blade shaft are both connected with a power device and coaxially rotate in reverse directions. A water circulating system is communicated with the interior of the inner cylinder through a water inlet pipe. The bottom of the inner cylinder is communicated with a filtering device of the water circulating system through a drain outlet. The roller type washing and peeling machine has the advantages of being simple in structure, compact in mechanism, convenient to operate and control, convenient to detach and maintain in the later period and the like; potatoes, sweet potatoes, pinellia ternate and other crops can be effectively washed and peeled in all directions.

Owner:WUHAN UNIV OF SCI & TECH

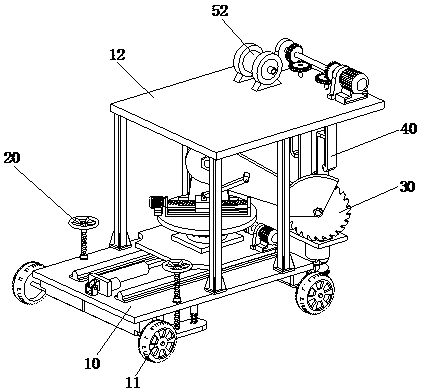

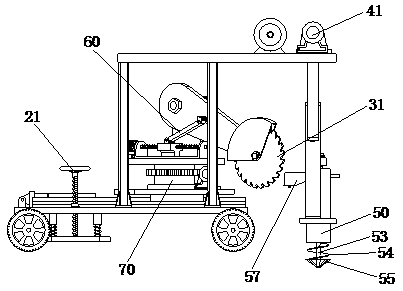

Sampling device for geotechnical exploration

InactiveCN110308010AAutomatic cuttingAutomatic crushing operationWithdrawing sample devicesDrive wheelSpiral blade

The invention discloses a sampling device for geotechnical exploration, and belongs to the technical field of geological exploration equipment. The sampling device comprises a base, a stabilizing mechanism, a rock cutting mechanism and a drilling and sampling mechanism; four driving wheels are arranged at the bottom of the base; a supporting frame is arranged on the top of the base; the drilling and sampling mechanism comprises a lifting assembly, a lifting plate and a drilling and sampling assembly; the drilling and sampling assembly comprises a sampling barrel and a connecting frame; a rotating shaft is arranged on the connecting frame; a spiral blade is arranged on the rotating shaft in a sleeved mode; and a drilling head is arranged at the bottom end of the rotating shaft in a sleevedmode. The sampling device has the beneficial effects that the lifting operation of the drilling and sampling assembly can be realized, and the sample can be conveyed to a material collecting hopper byvirtue of the drilling and sampling mechanism; the automatic cutting assembly can be used for cutting and crushing rock samples; and a rotary assembly can drive the automatic cutting assembly to rotate to a proper position, so that the interference of the automatic cutting assembly on the operation of the drilling and sampling mechanism is avoided.

Owner:胡立宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com