Patents

Literature

5249 results about "Crushed stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crushed stone or angular rock is a form of construction aggregate, typically produced by mining a suitable rock deposit and breaking the removed rock down to the desired size using crushers. It is distinct from gravel which is produced by natural processes of weathering and erosion, and typically has a more rounded shape.

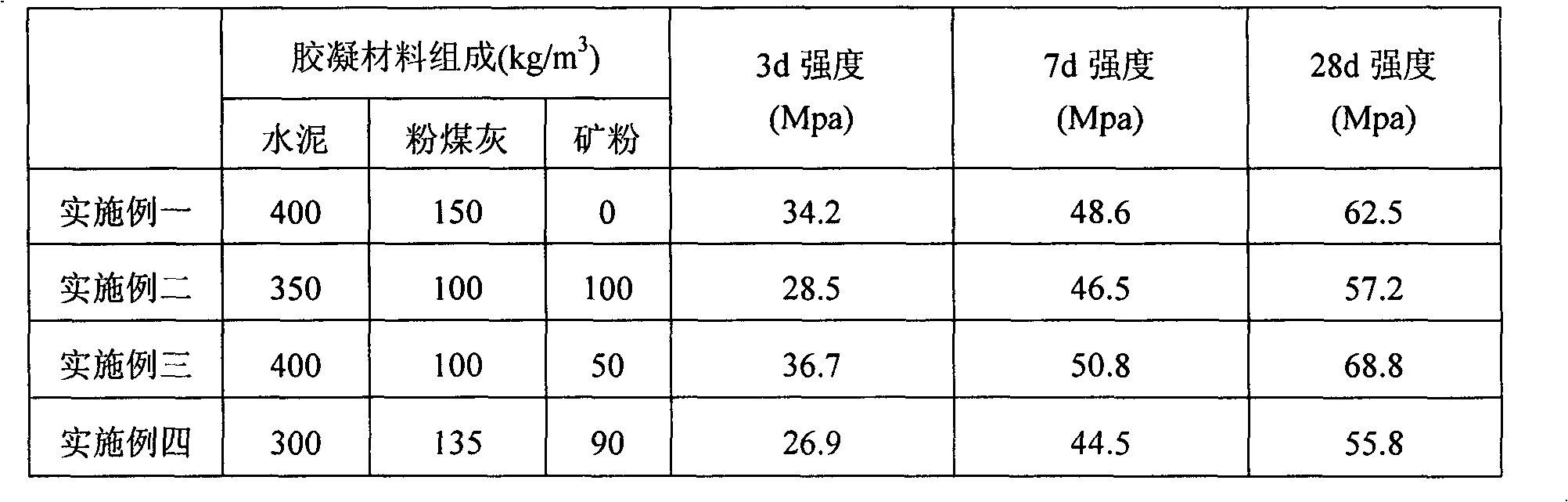

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

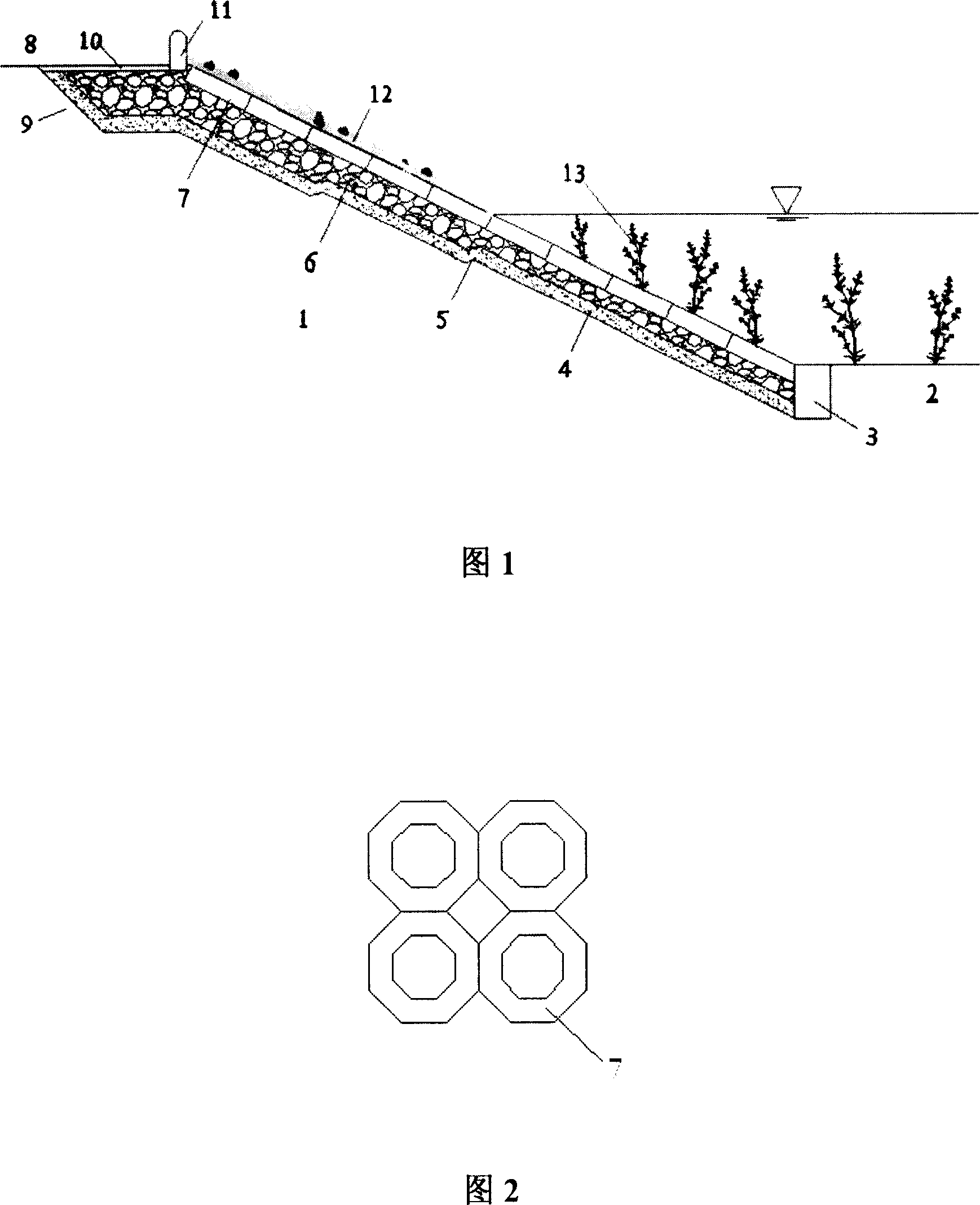

Hard reinforced concrete revetment slope biological repairing method

InactiveCN102071697AEffectively fixedPrevent landslidesSoil drainageCoastlines protectionPlant rootsRainfall runoff

The invention discloses a hard reinforced concrete revetment slope biological repairing method, which is characterized by comprising the steps of: roughing a concrete revetment and constructing drainage ditches at set intervals; digging a water collecting tank on one side of the cross of the revetment and a road, reserving an opening at the joint of the drainage ditch and the water collecting tank, and constructing a watertight concrete overflow bank; filling gravels in the water collecting tank and the drainage ditches; and welding earthwork grids by high-density polyethylene stripes on the protection slope, laying gravel cushion coats in the earthwork grids, and finally pouring biological slurry. The method has the advantages that: the whole project is stable and safe; rain flows into the water collecting tank and passes through grave areas, non-watertight sand-free concrete, a slope cushion coat, plant roots and the like to seep into rivers, so water quality is improved to a relatively large extent; when rainfall runoff is overlarge, the rain overflows from the overflow bank and passes through the graves of the drainage ditches, so the water quality is also purified to a certain extent, meanwhile the slope is protected; the biological slurry poured onto the slope is prepared from biological materials, and has certain anti-erosion strength and can be used as a substrate for plant growth, so the cost is low and the operation is simple.

Owner:HOHAI UNIV

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

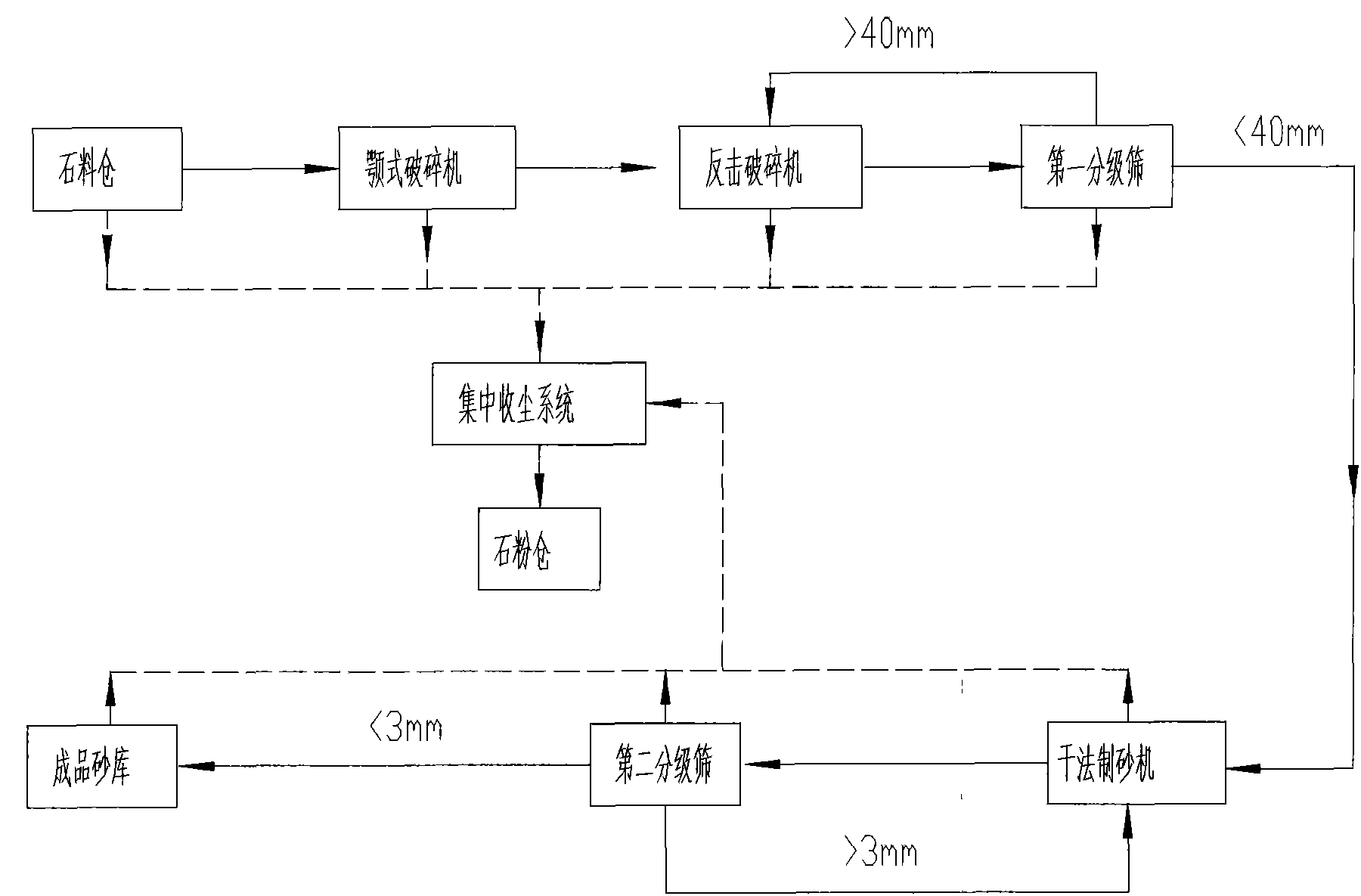

Drying-method sand making device and process

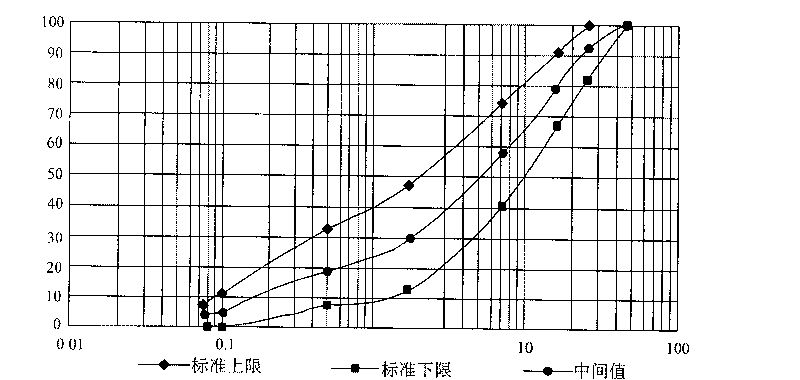

A drying-method sand making device and a process relate to the field of sand making technology. The device includes: a jaw crusher, an impact crusher, a first grading screen, a drying-method sand making machine, a second grading screen and a concentrated dust collecting system. The production process comprises the steps: a stone material in a stone material bin is evenly fed into the jaw crusher through a feeder for a first rough crushing, the crushed material is transported to the impact crusher for a second fine crushing, the crushed material goes into the first grading screen for grading, sandstones with the size of less than 40 mm are fed to the drying-method sand making machine through a conveyor for crushing and sand making, and broken stones with the size of more than 40 mm are returned to the impact crusher; the sandstones going into the drying-method sand making machine are transported to the second grading screen for grading after being crushed by the drying-method sand making machine, sand with the size of less than 3 mm is directly fed into a finished product sand bin, and a stone material with the size of more than 3 mm is afresh returned to the drying-method sand making machine for crushing. The produced machine-made sand has good particle shape and high finished product rate, and can meet the technical index of high-performance concrete on the machine-made sand.

Owner:王燕

Burning-free geology polymer material of red mud coal ash and preparation method thereof

InactiveCN101708983AGood strength performanceHigh strengthSolid waste managementCeramic shaping apparatusRed mudCrushed stone

The invention relates to a burning-free geology polymer material of red mud coal ash and a preparation method thereof, belonging to the technical field of recycling inorganic nonmetal material and industrial solid waste. Kawazu mud powder and coal ash are taken as main substrate raw materials, building fine sands and building crushed stones are taken as aggregate, solid water glass powder is taken as alkali activator to prepare the burning-free geology polymer material of red mud coal ash. The raw materials comprise the following components based on parts by weight percent: 5-98% of the kawazu mud powder, 1-65% of the coal ash, 1-96% of the building fine sands and the building crushed stones, and 1-20% of the solid water glass powder. Counting the red mud+the coal ash+the building fine sands and the building crushed stones as 100%, the raw materials further comprise the following components based on parts by weight percent: 5-45% of water and 0.1-10% of calcium lignosulphonate. The preparation method comprises the steps of: dosing, mixing, aging, shaping, maintaining and drying, etc. The invention has the advantages of the high use ratio of industrial solid waste, the less pollution, the low energy composition and the simple operation of the preparation technology, and embodies the important meanings of environment protection, energy conservation and emission reduction.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

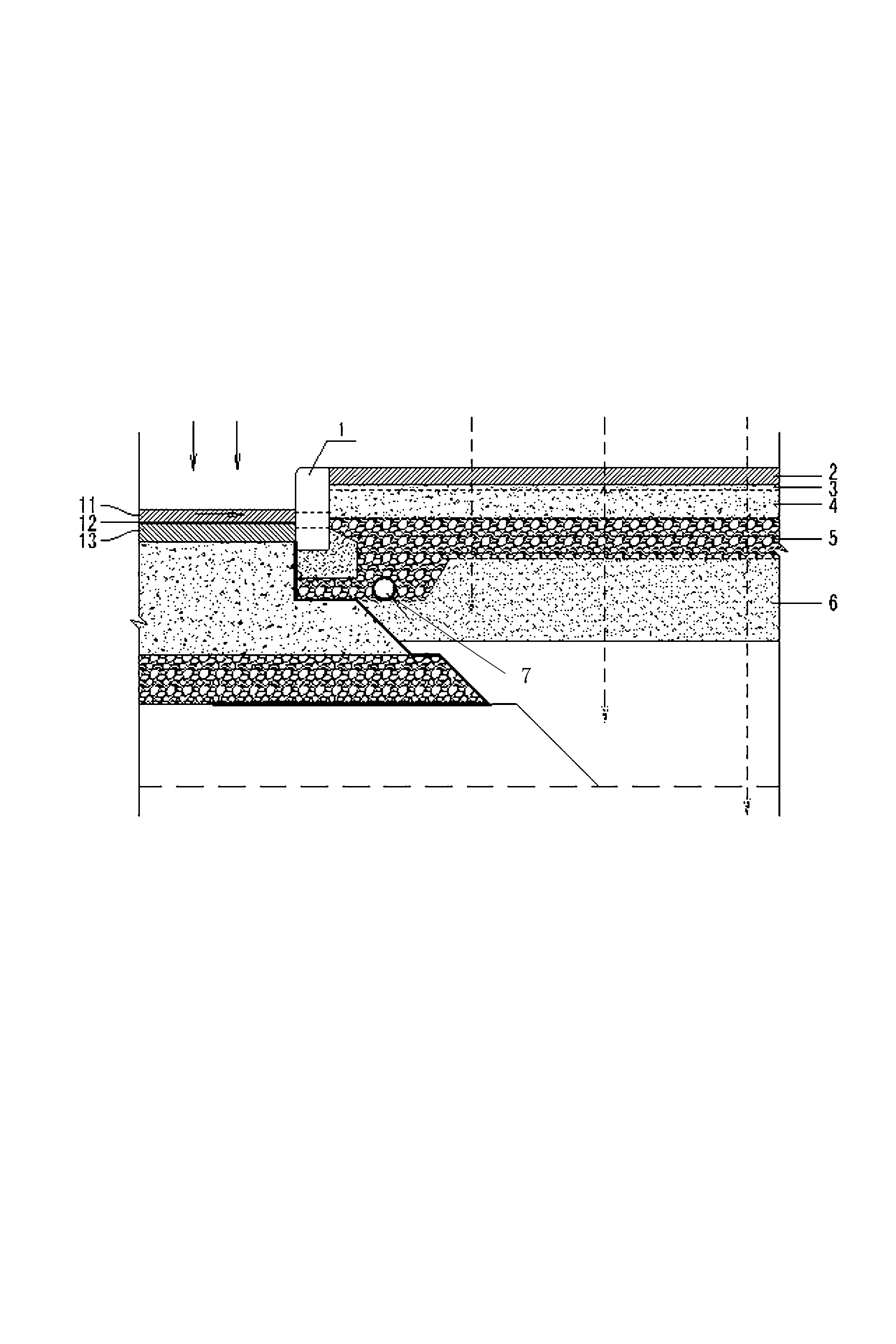

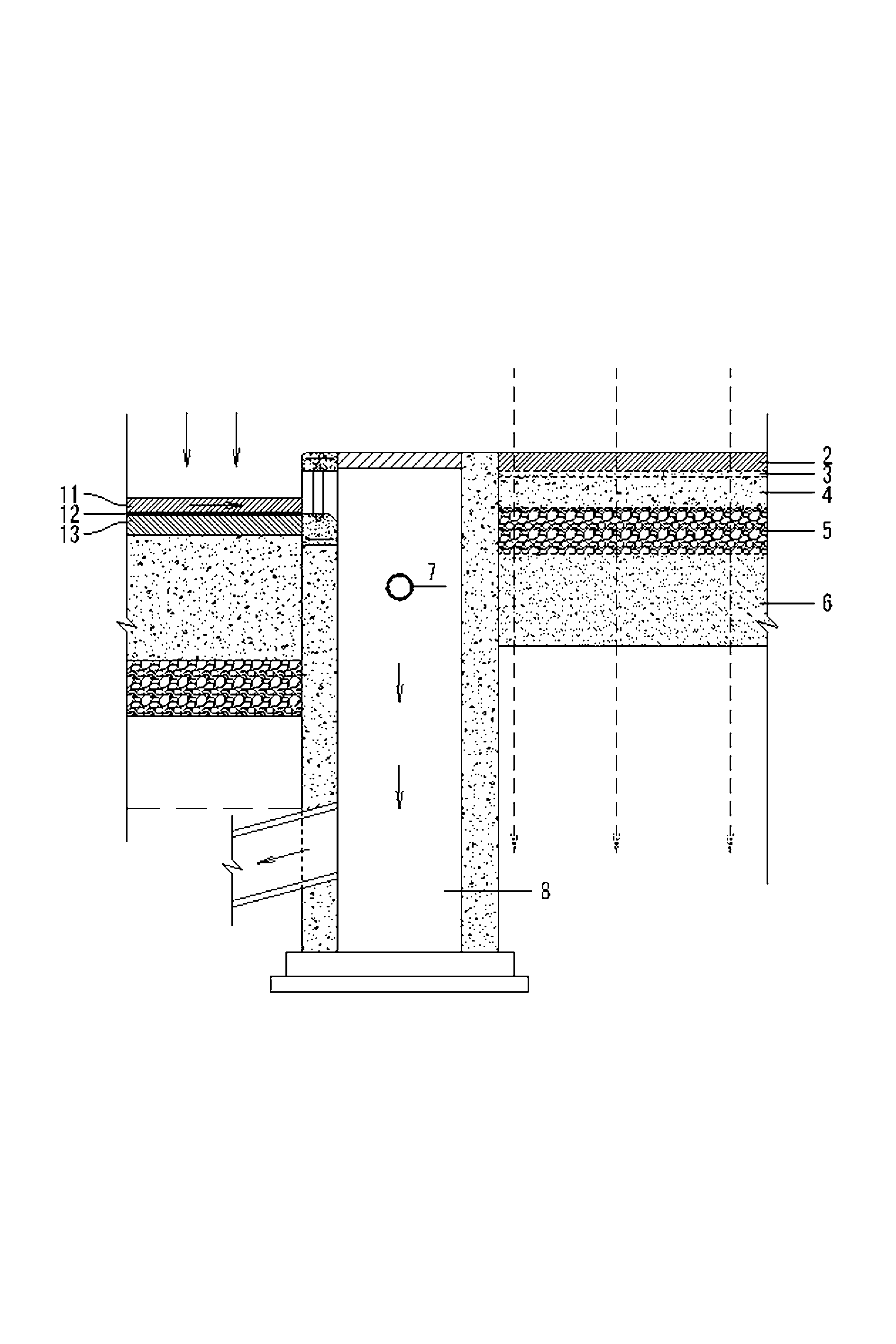

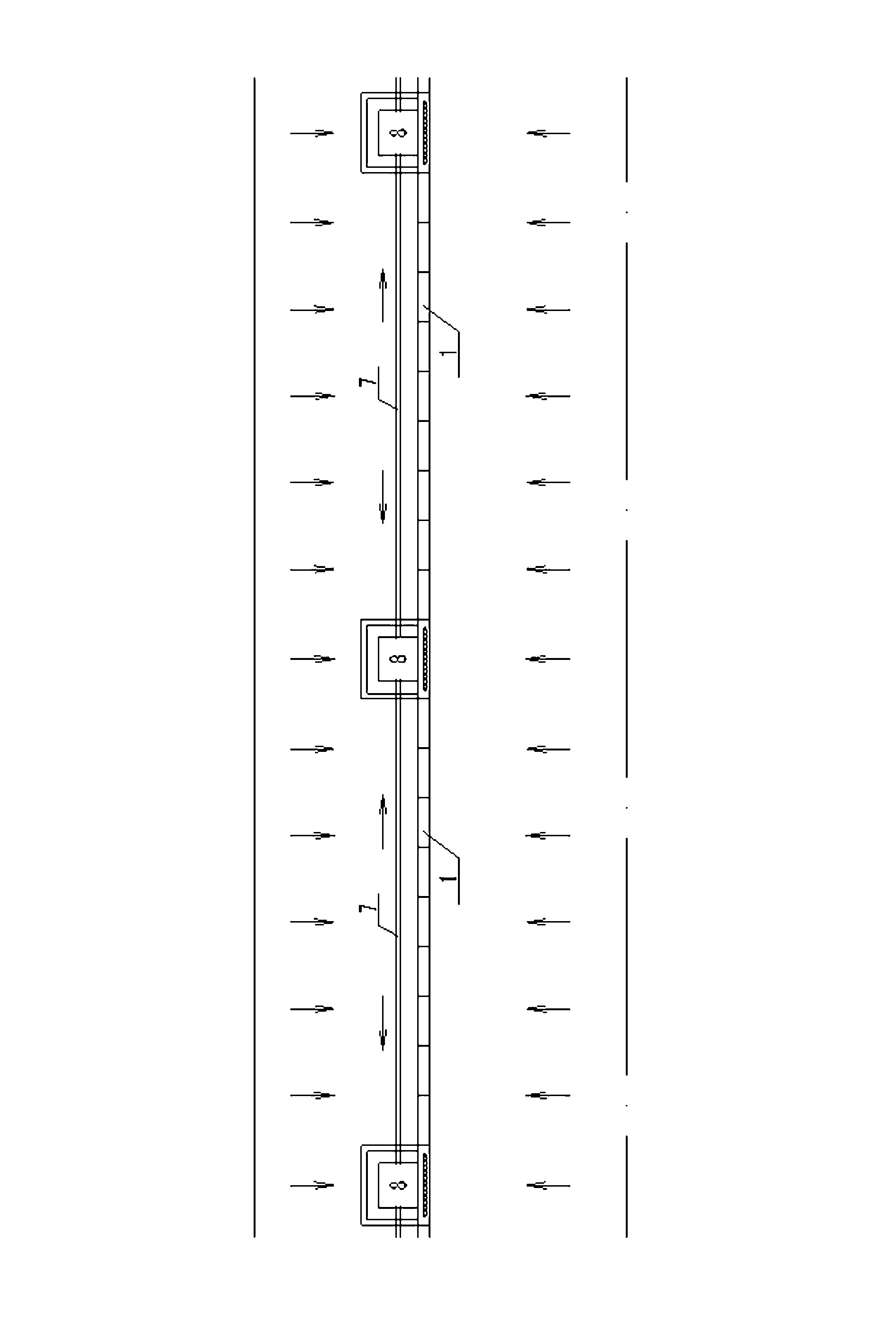

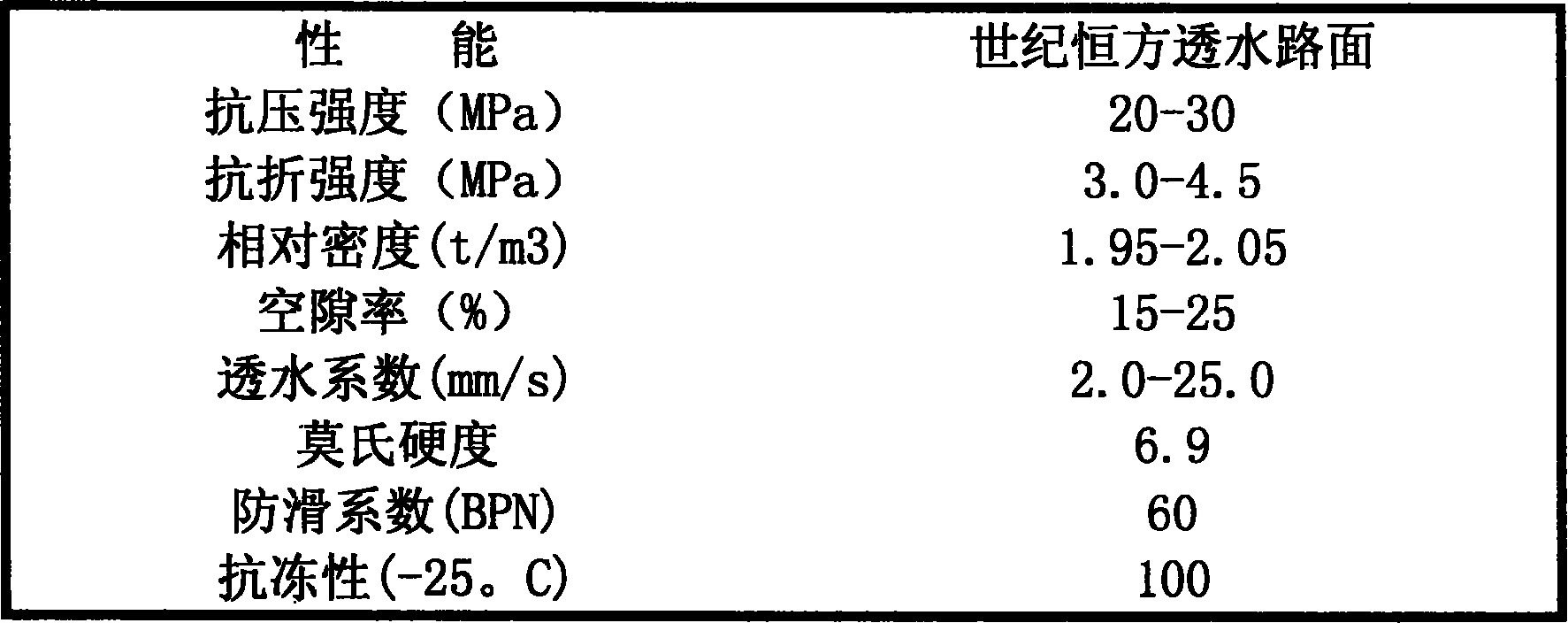

Road pavement draining method and drainage structure system

ActiveCN103103905ASolve vertical drainage problemsOvercomes the disadvantages of direct discharge into municipal pipesIn situ pavingsGround-workCrushed stoneEnvironmental engineering

The invention provides a road pavement draining method and a drainage structure system. The road pavement draining method is characterized in that water falling on a lane vertically passes through a lane water-permeable surface layer, arrives at a waterproof bonding layer preventing water penetration, and enters into a water-permeable drainage system located at outer sides of drainage curbstones by a cross slope and the drainage curbstones located at outer sides of the lane; the bottoms of the drainage curbstones are provided with water-permeable curbstone bases; the water-permeable drainage system comprises a broken stone blind drain drainage system arranged at the bottoms and the outer sides of the water-permeable curbstone bases; the bottom of the broken stone blind drain drainage system is provided with a longitudinal drainage water-permeable pipe; and most of the water discharged into the water-permeable drainage system at the outer sides permeates into soil at the outer sides and forms ground water, and the rest of the water passes through the longitudinal drainage water-permeable pipe in the broken stone blind drain drainage system and then is discharged into a municipal pipe. The road pavement draining method solves the problem that rainwater on a drainage bituminous pavement is directly discharged into the municipal pipe, and has functional advantages of good safety, ecological benefits, energy saving and good economical efficiency.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Water permeable concrete and manufacturing method thereof

InactiveCN101190833AQuality improvementHigh strengthSolid waste managementWater storageWeather resistance

The invention discloses a pervious concrete and is characterized in that the pervious concrete is made by mixing cement, aggregate, water, water reducer agent and adhesive evenly; and the cement, the aggregate, the water, the water reducer agent and the adhesive are mixed in different weight proportions of 1-1.2 to 5.5-8.5 to 0.2-0.5 to 0.01-0.2 to 0.01-0.2. The invention can solve the natural ecology problems of hardened ground in cities, atmospheric circulation as well as soil and water moisture retention, thereby forming a high-quality natural ecology environment and maintaining urban ecological balance. The pervious concrete consists of two pervious surface courses and two macadam bases in different particles so as to provide a water storage structure which can store the water until the water penetrates into the soil; meanwhile, the invention can be made into building block, which can be provided with different decorative patterns and colors on the surface, and has the advantages of artistic quality, water permeability, good water retention, skid resistance, high strength, cold resistance and weather resistance, etc.

Owner:上海恒方防腐工程有限公司

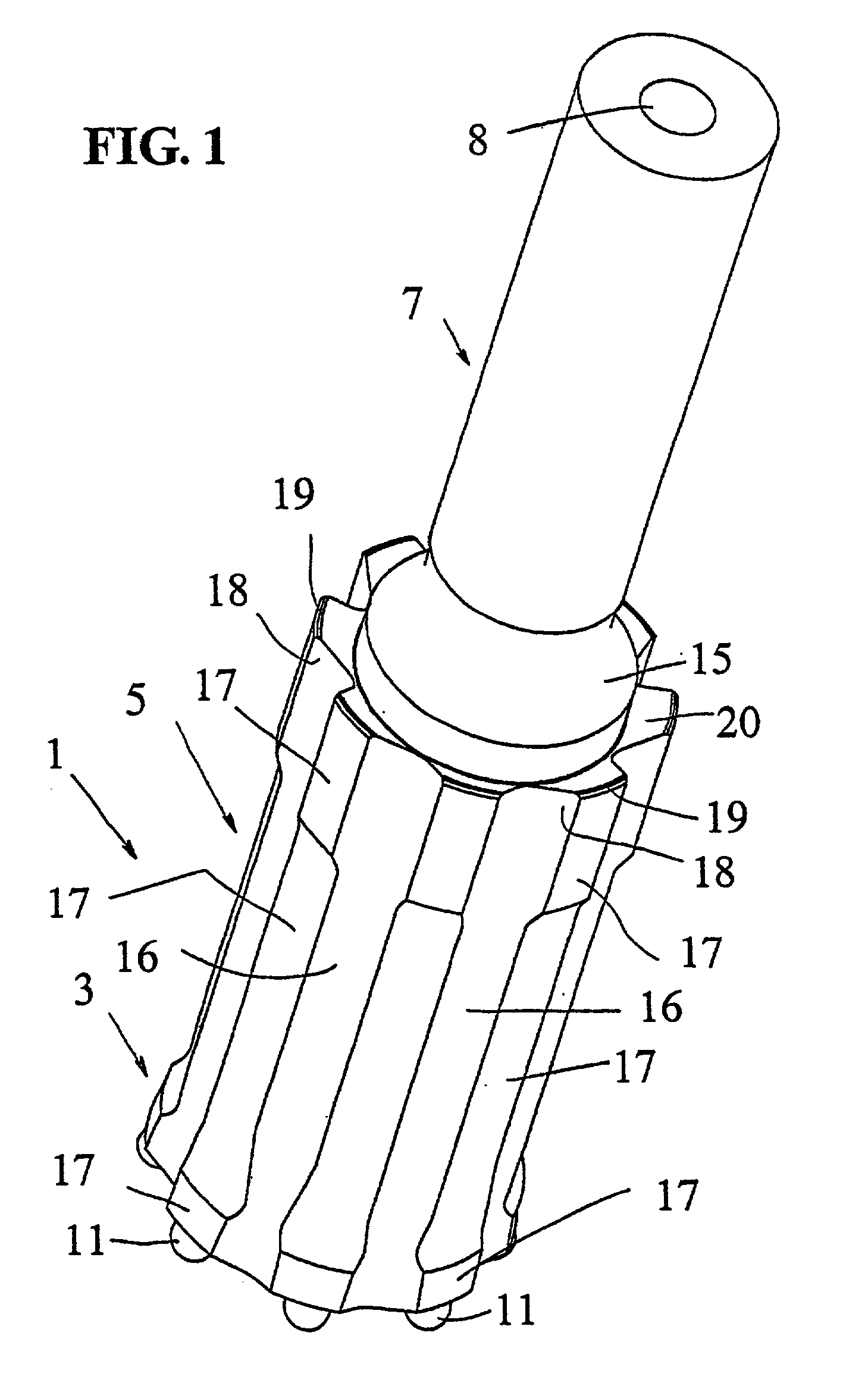

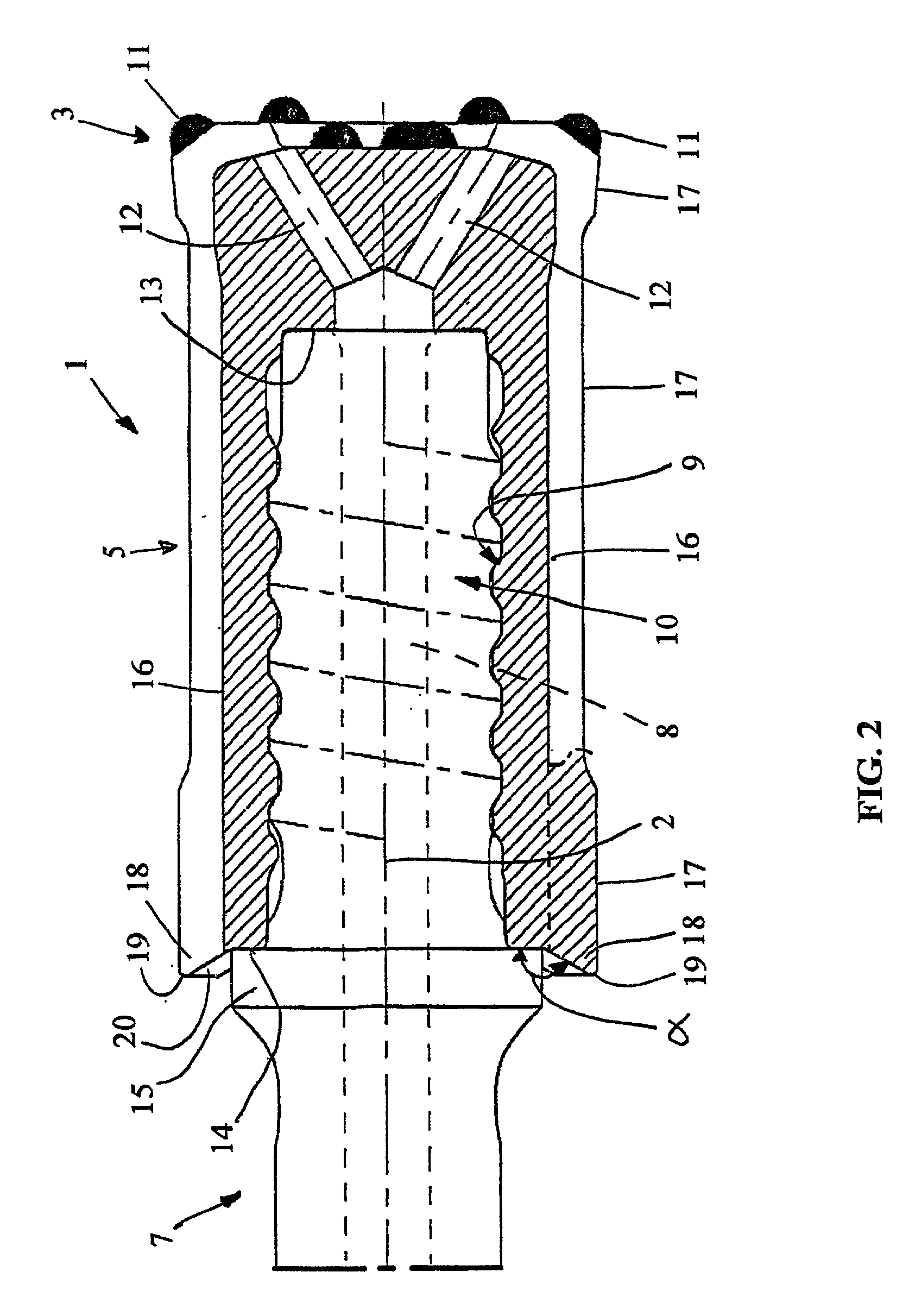

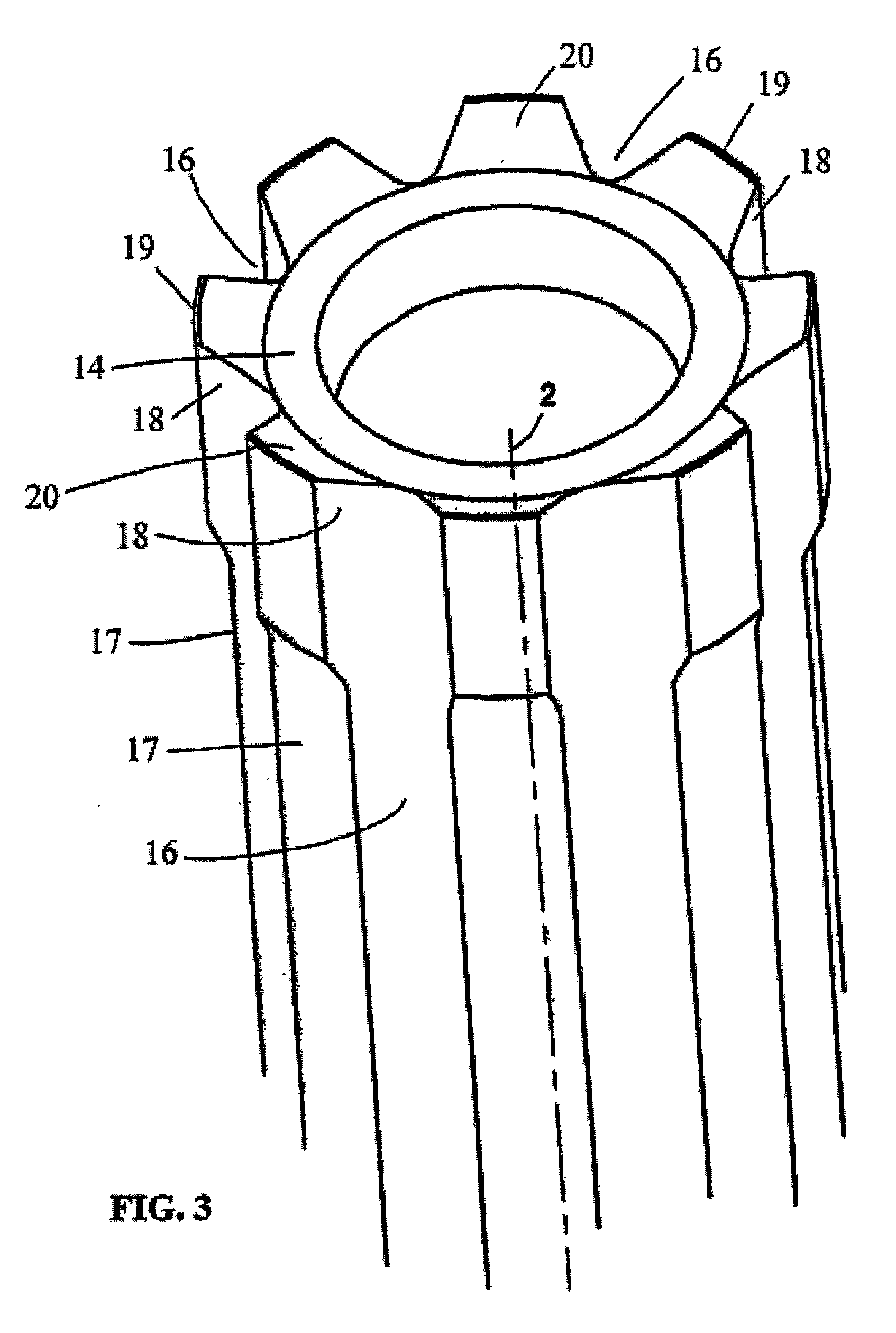

Rock drill bit having retrac teeth and method for its manufacturing

InactiveUS20010018990A1Inhibits the formation of cracksDrill bitsDrilling rodsStructural engineeringDrill bit

A rock drill bit for percussive drilling, especially top hammer drilling, includes a bit head provided with front rock crushing buttons and a skirt. The bit head is provided with a number of grooves formed in the outside of the skirt and extending in the axial direction of the drill bit. Protruding lands are defined between the grooves, which likewise extend in the axial direction. Axially rearward ends of at least some of the lands are formed with retrac teeth. Each retrac tooth has a cutting edge extending along an outer circumference of the skirt.

Owner:SANDVIK AB

Construction method of dewatering well under foundation slab in foundation pit

The invention discloses a construction method of a dewatering well under a foundation slab in a foundation pit, comprising the following steps of: arranging the dewatering well in the foundation pit, wherein the dewatering well is not damaged in the process of excavating a foundation pit earthwork, and the effectiveness of the dewatering well is ensured; after the foundation pit earthwork is excavated to a basement, excavating interlaced ditches along the center line of the dewatering well, and paving water-filtering type geotextile in the ditches; then paving drain pipes of the dewatering well and cables in the ditches and connecting to the outside of the pit, checking the depth of the dewatering well, an extraction pump and a pipeline thereof to ensure the integrality and the reliability; then paving granular crushed stones or cobbles in the ditches, covering asphalt felt thereon to form a blind ditch; leading the blind ditch to a water collection pit at the edge of the foundation pit and arranging a surface drain on the periphery of the foundation pit; paving a subcrust and a waterproof layer under the constructed foundation slab, gradually reducing the usage quantity and the dewatering speed of dewatering wells in the foundation pit in the construction process of underground structures and upper structures thereof, and assisting in draining by adopting the water collection pit at the periphery of the foundation pit until the dewatering operation in the foundation pit can be stopped. The invention has convenient construction, safety and reliability and low cost for dewatering in the foundation pit.

Owner:南通建工集团股份有限公司

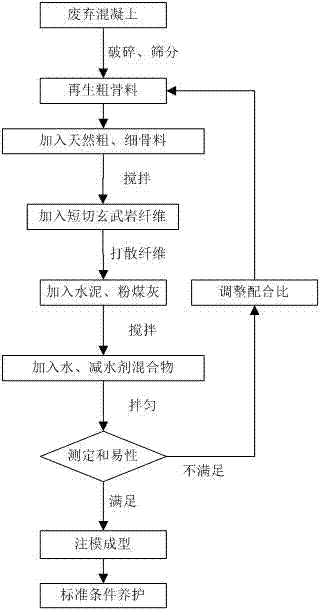

Recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate

The invention belongs to the field of building materials and in particular relates to recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate. The recycled concrete is prepared from the following raw materials in parts by weight: 100-300 parts of water, 300-500 parts of ordinary Portland cement, 500-700 parts of medium sand, 500-650 parts of natural gravels, 500-650 parts of recycled coarse aggregate, 30-50 parts of fly ash, 1-5 parts of a water reducing agent and 1-6 parts of short-cut basalt fibers. The recycled concrete provided by the invention is low in preparation cost, and the obtained concrete has high temperature resistance, corrosion resistance, tensile strength, crack resistance and better durability property.

Owner:FUZHOU UNIV

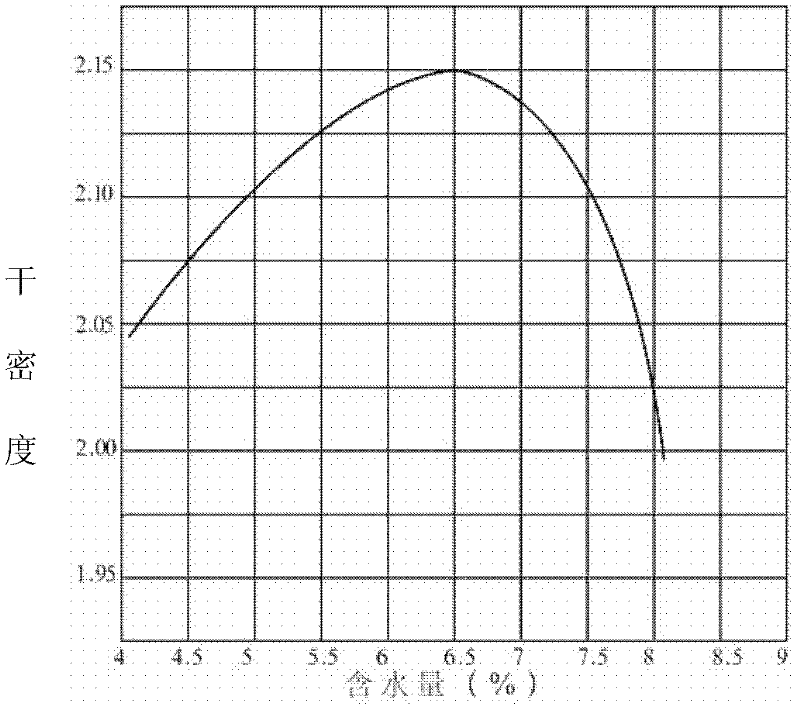

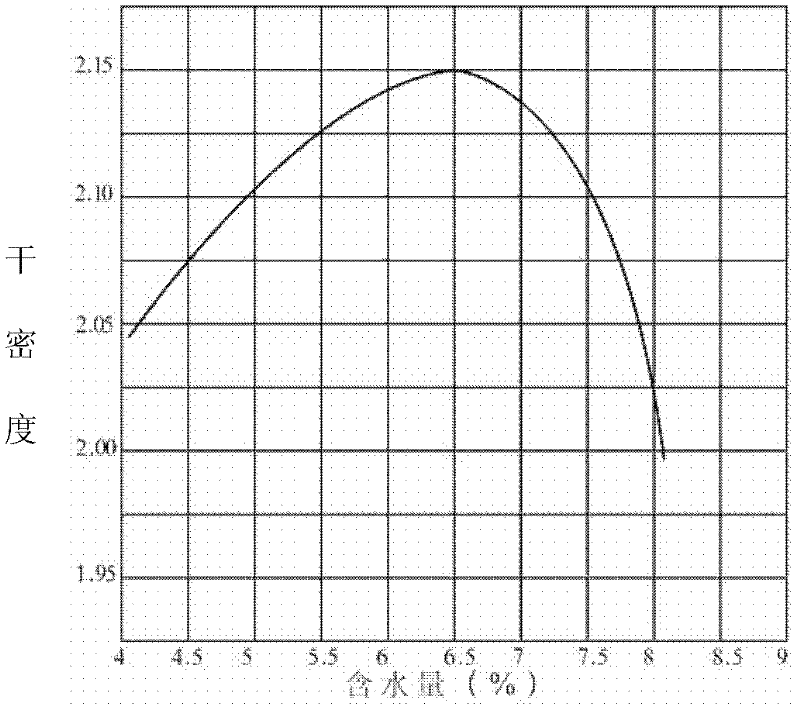

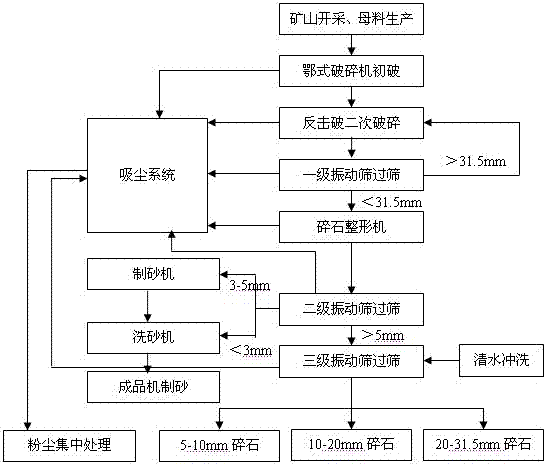

Machine-made sand processing process

ActiveCN102806133ALow stone dust contentReduce soil contentGrain treatmentsCrushed stoneProcess engineering

The invention discloses a machine-made sand processing process, which comprises the following processes that stone materials enter a jaw crusher to be decomposed into stone blocks not greater than 350mm, and then, the stone blocks enter a reverse smashing machine; the stone blocks are crushed into crush stones by the reverse smashing machine, the crushed stone enters a primary vibration sieve to be screened, the crushed stones smaller than 31.5mm enter an impact type crusher, and the crushed stones greater than 31.5mm return the reverse smashing machine to be crushed; after entering the impact type crusher to be crushed, the crushed stones enter a two-grade vibration sieve to be screened, and sand smaller than 3mm enters a sand washing machine; sand greater than 3 to 5mm enters an efficient fine crushing machine to be made into sand smaller than 3mm, and the sand smaller 3mm enters the sand washing machine after entering two-grade vibration sieve to be screened; the crushed stones greater than 5mm enter a three-grade vibration sieve; the crushed stones are screened into the crushed stones in three grades by the three-grade vibration sieve, and the crushed stones are used for material discharge in the vibration sieve after being flushed by water. The machine-made sand produced by the process provided by the invention has the advantages that each index can respectively meet the technical index of high-performance on machine-made sand, and the product quality is high, and stability and reliability are realized.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Waste and old rubber powder modifying asphalt and preparation method thereof

InactiveCN101265363AFully reflect the low temperature crack resistancePrevent slippageBuilding insulationsCrushed stoneEngineering

The invention relates to old rubber powder modified asphalt and a preparation method thereof. In the preparation method, asphalt, old rubber powder, a compatibilizer, and a dispersant are thoroughly mixed, and are cut and broken at high speed for a period of time, and are arranged in a tank for upgrowth for a period of time, thus getting the product. In the preparation method, junked tire rubber powder is used as a key component, thus improving the performance of the product, reducing the product cost, changing wastes into valuables and reducing the pollution. The product can be widely used as construction and maintenance materials of roads, such as deck waterproof layers, stress absorbed layers, synchronous crushed stone seal coat of asphalt and so on.

Owner:陕西长大博源公路养护科技有限公司

Rapid repairing materials for ultrathin layer on the surface of road and airfield runway

InactiveCN1654409AGood value for moneyMinimal disruption to daily traffic operationsWater dispersibleCrushed stone

The super thin fast repair material for highway and airport runway consists of early strengthened hydraulic cementing material 30-90 wt%, polymer resin emulsion or water dispersible polymer powder 0.1-40 wt%, fine sand 8-60 wt% and inorganic modifier 0.1-15 wt%. The repair material is suitable for thin layer and super thin layer repairing of concrete and asphalt road surface, may be also used for repairing damaged part when sand, crushed stone and other aggregate are added. It is also suitable for repairing inner and outer walls of building. The finishing super thin cement mortar layer has the breaking strength reaching 2-4 MPa in 2-3 hr and compression strength up to 20-30 MPa. The present invention can raise the antiwear performance, weather resistance and engine oil and hydraulic oil corrosion resistance.

Owner:桂永全

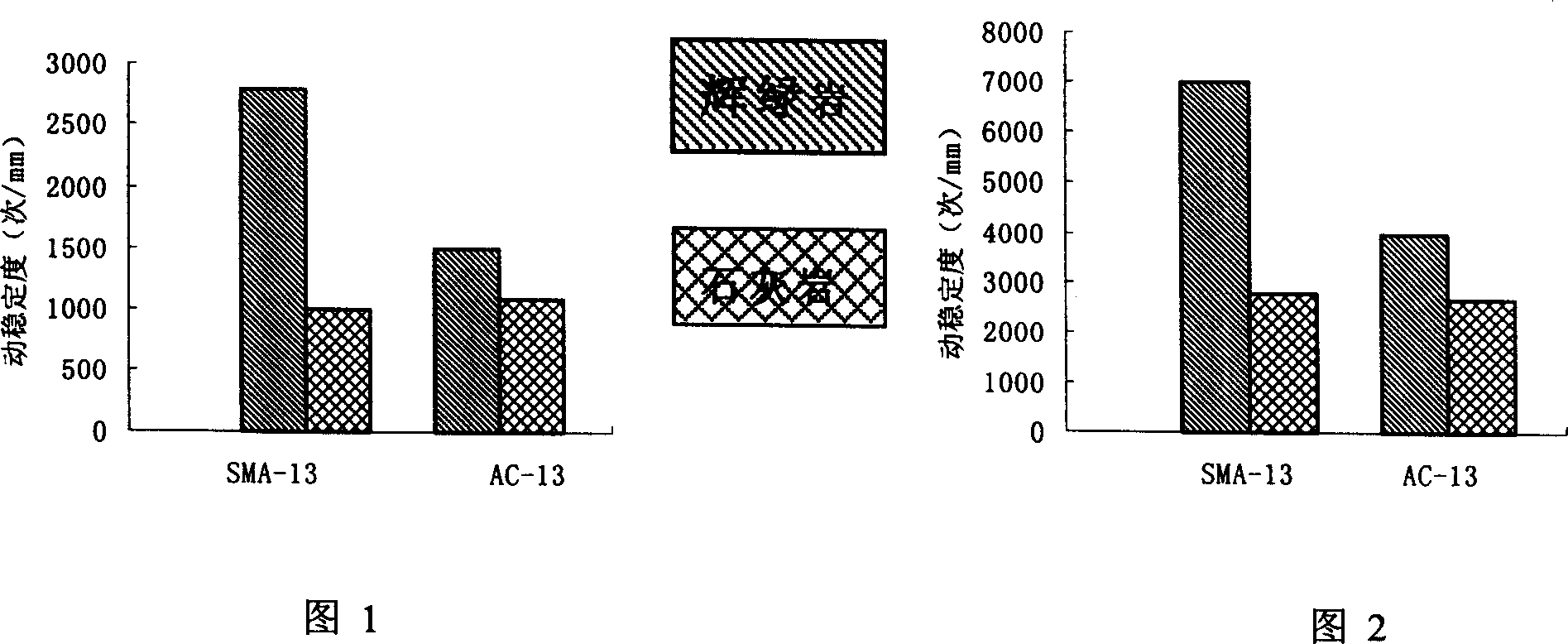

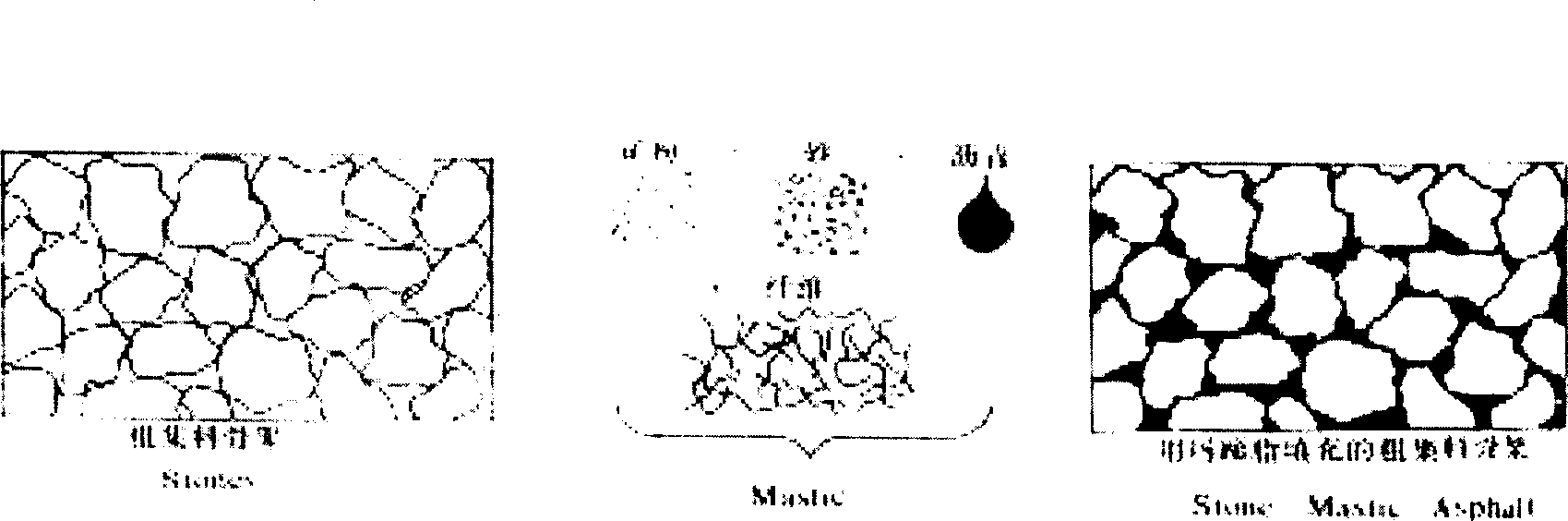

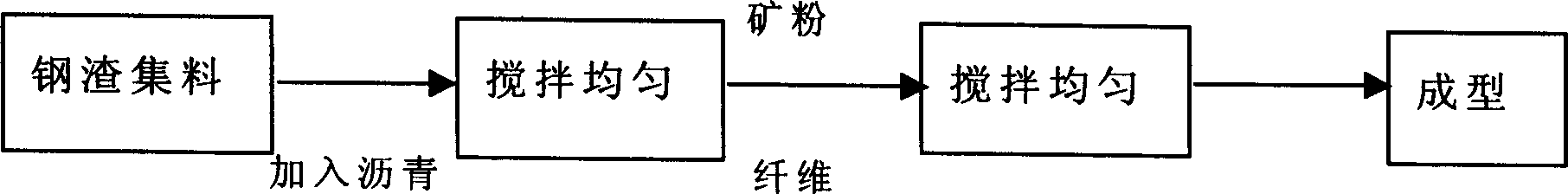

Steel scoria mastic detritus asphaltum concrete and method for preparing the same

InactiveCN1482091AImprove long-term road performanceLow costSolid waste managementCeramic shaping apparatusFiberAdhesive

Steel slag as aggregate for road engineering has not only excellent pressure resisting and wear resisting performance but also high adhesion. The asphalt concrete consists of steel slag as aggregate, mineral powder stuffing, fiber as stabilizer and asphalt as adhesive. The production process includes heating the aggregate to 170 deg.c and mixing with hot molten liquid asphalt, mixing with mineral powder, adding fiber as stabilizer, and beating the steel slag SIA asphalt mixture on two sides for 50 times each or rolling for 18 times to form. The steel slag SIA asphalt concrete has its performance indexes reaching national standard, dynamic stability up to 5846 times / mm and may be used in expressway. In addition, the use of steel slag can lower engineering cost and reduce environmental pollution.

Owner:武汉钢铁集团冶金渣有限责任公司 +1

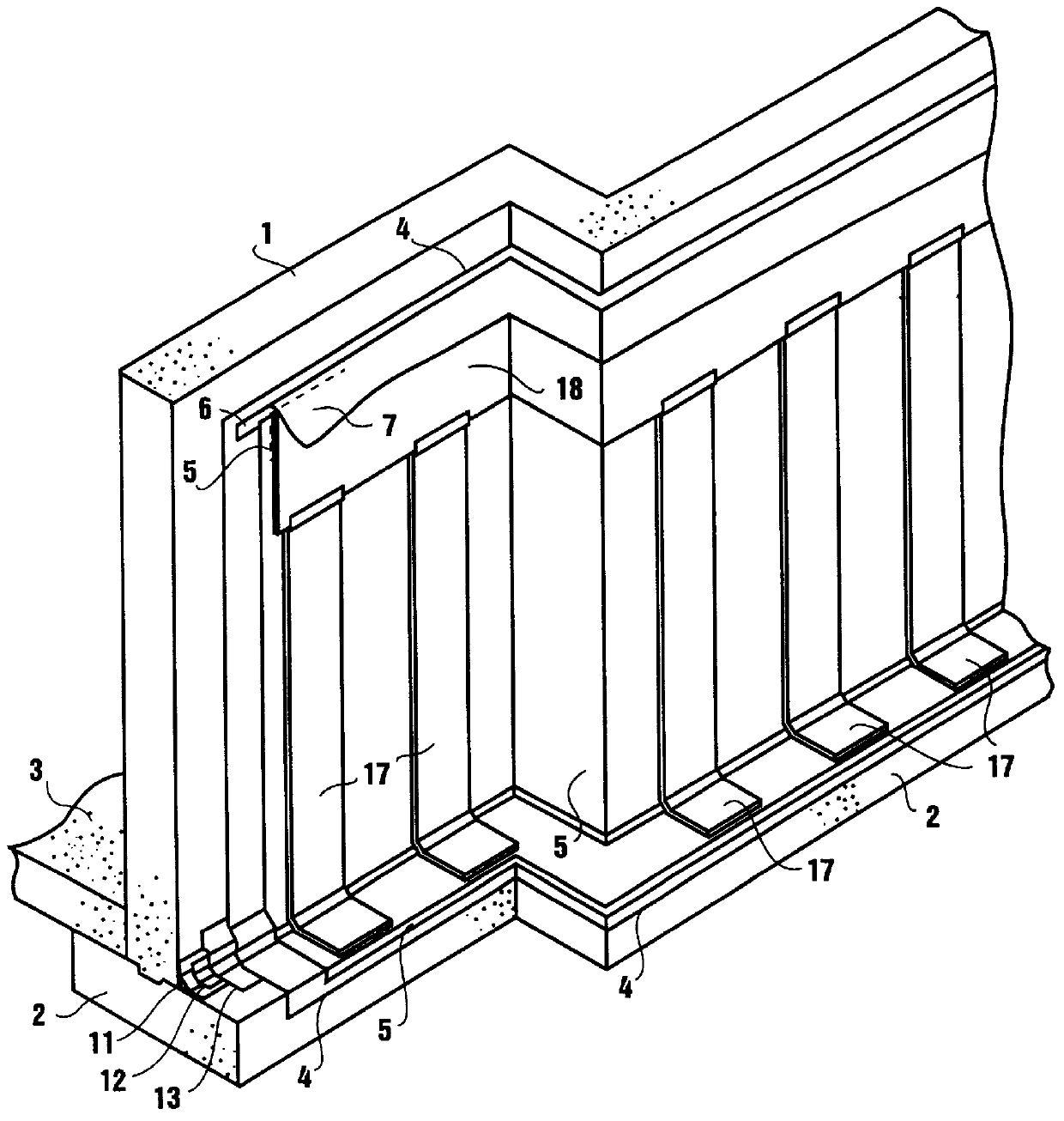

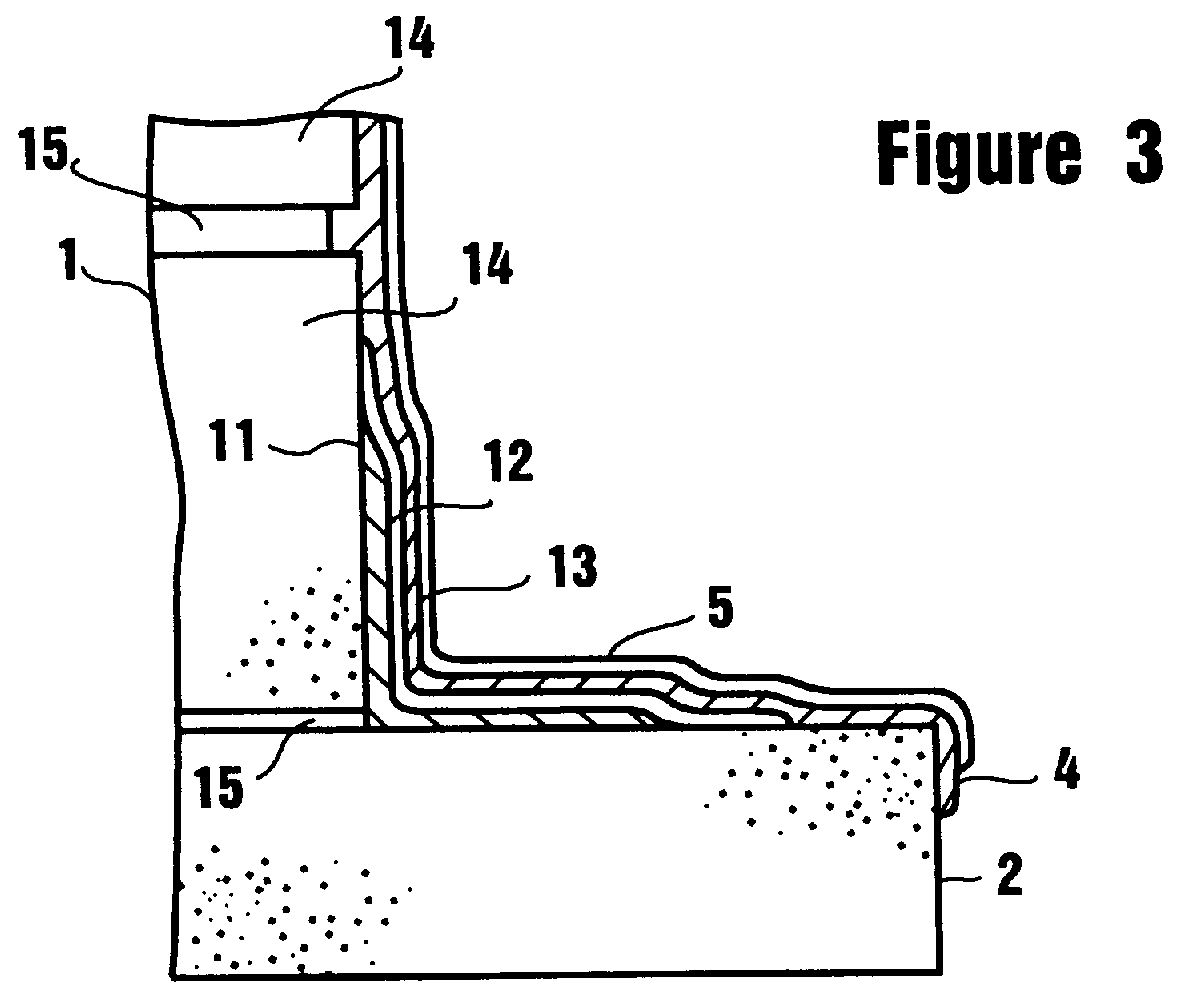

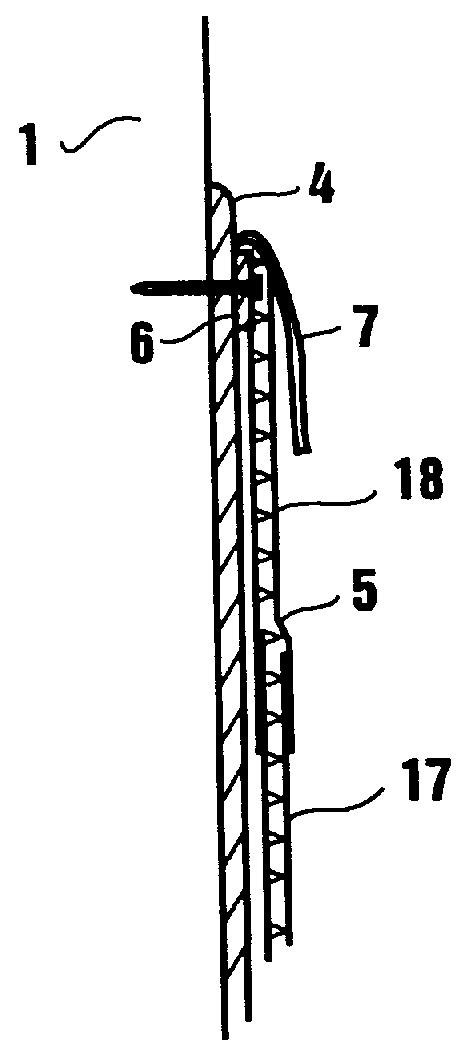

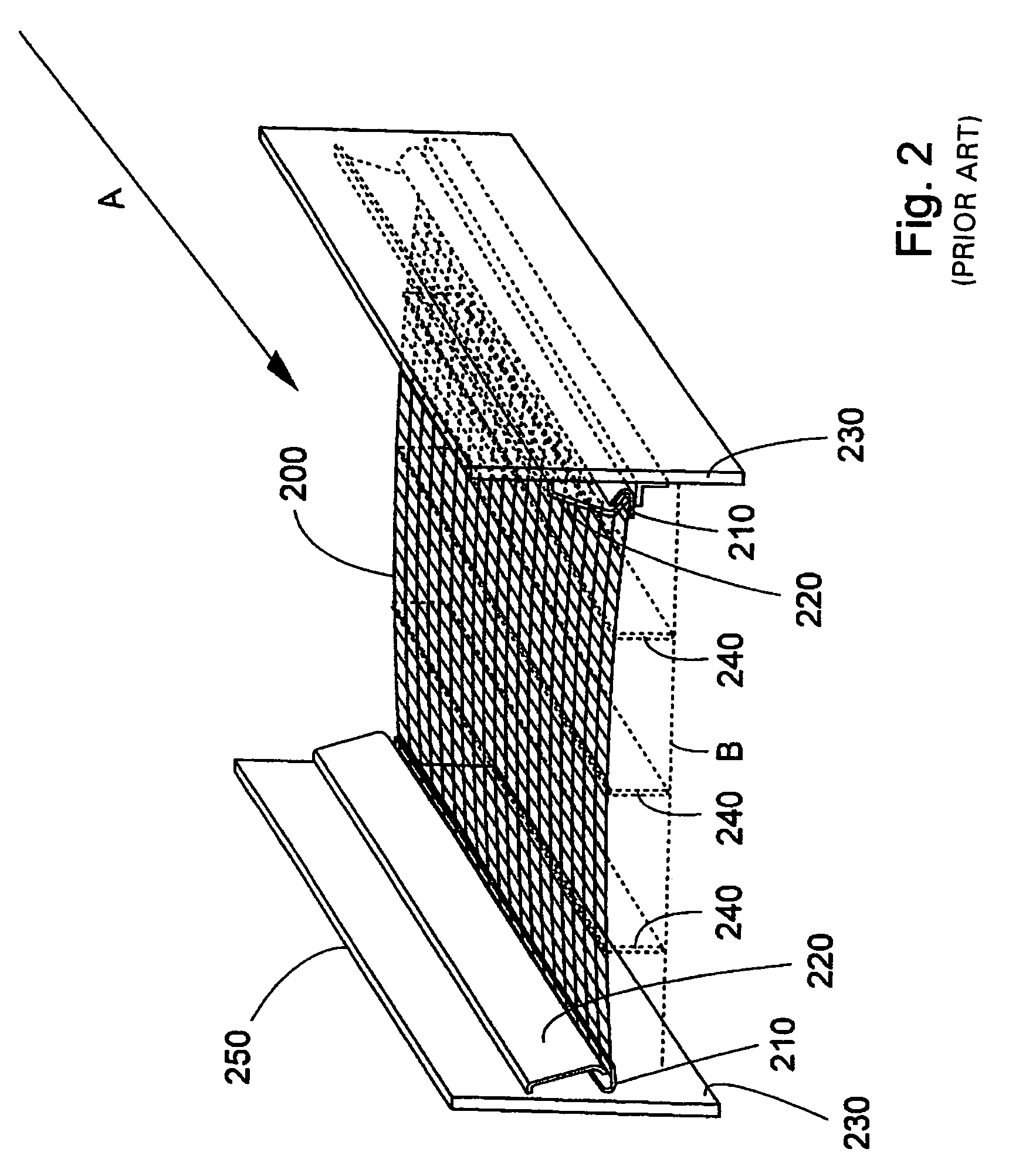

Moisture barrier protection system and method

InactiveUS6122887AImprove the immunityProtective foundationBuilding repairsSurface stressGeomembrane

A tough, high-strength geomembrane made from a custom blend of polyethylene copolymers, for protecting waterproofing courses from impact and pressure damage of debris resting against the waterproof course. A slip sheet configuration reduces surfaces stress due to earth movement and subsurface cracking thereby maintaining the protective course intact without any effect on the waterproofing layers. The geomembrane is available as lightweight rolls which can be easily be handled by one man. The film is installed horizontally in continuous sheets with few adhesive joints. Installation begins by applying a thick brush coat of the selected waterproofing membrane material (usually a rubber coat but may be any waterpoofing material). The film is unrolled along the wall, held up into position and secured using plastic self-sealing plugs and / or plastic termination bars. Concrete nails are used to attach the self-sealing plugs or termination bar to the wall. If termination bar is selected the film is extended up beyond the bar approximately 8'' and folded down over the termination bar after attachment. Staples into the termination bar can be used to hold the film down creating a nicely detailed upper edge.

Owner:SOCOPAC

Open pit coal mine mining process

ActiveCN103216237AConvenience to workGuaranteed continuity of fitUnderground miningSurface miningCoal waterMining engineering

The present invention provides an open pit coal mine mining process, which comprises the following operation steps: 1, adopting a bucket wheel excavator to dig a loess layer on the upper portion, placing the dug loess onto a conveying belt of a belt type conveyor, and discharging the loess to an outer dump; 2, adopting a single bucket truck to convey crushed stone in a rock layer on the middle portion to the outer dump, and adopting the single bucket truck to convey into an inner dump until a rock layer on the lower portion is exposed after a pit formed by the rock layer on the middle portion has a enough space; 3, adopting a casting-blasting method to blast the rock layer on the lower portion, adopting a bulldozer to flatten the top surface of the blasting stack to form a combination extension platform, adopting a dragline to inversely stack the blasting amount into the inner dump, directly discharging the blasting amount into the inner dump with matching with the single bucket until a coal layer is exposed; and 4, adopting the single bucket truck to convey coal in the coal layer to a crushing plant, and then conveying the crushed coal to a designated location with a belt conveyor.

Owner:CHINA SHENHUA ENERGY CO LTD +1

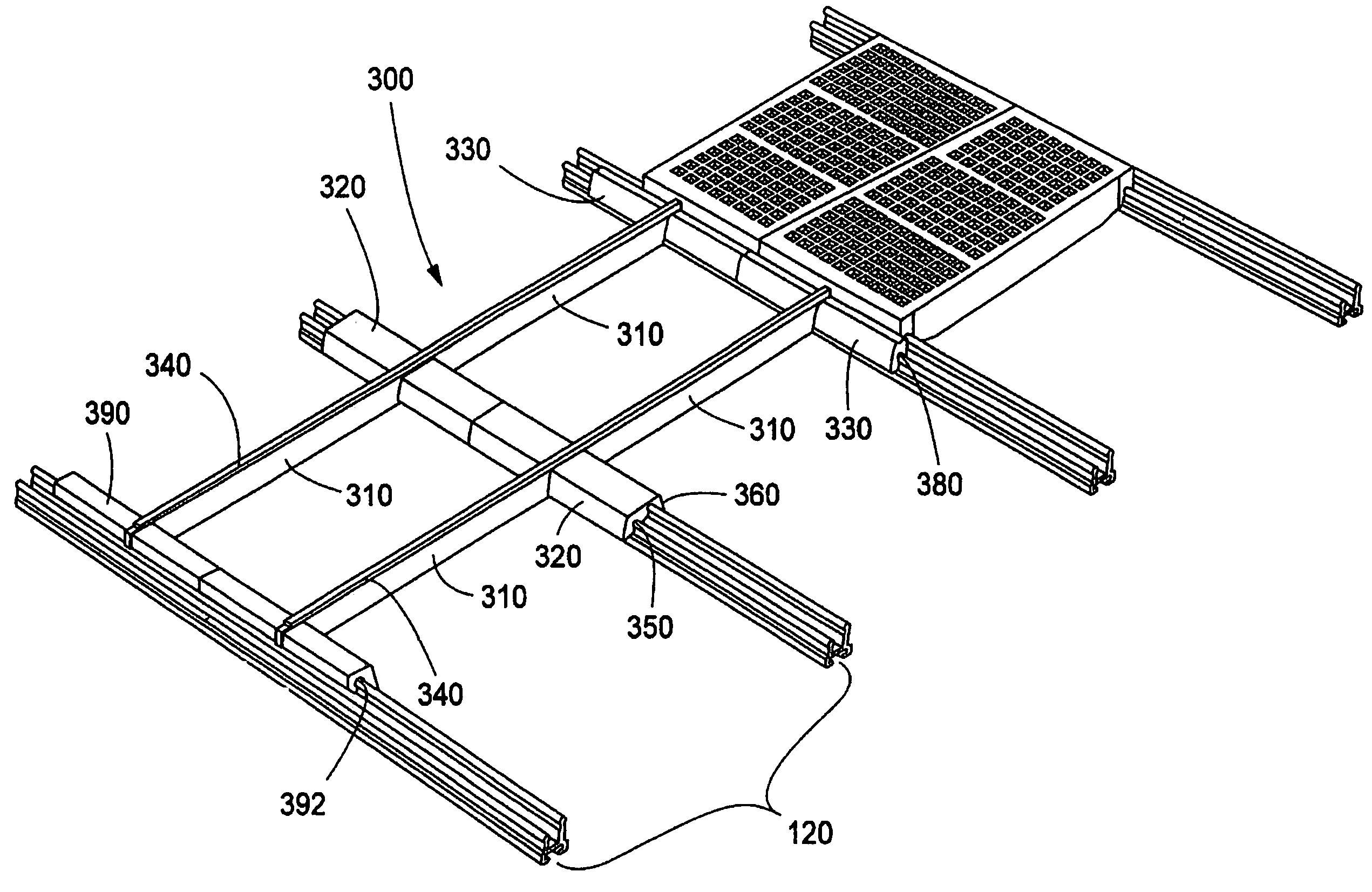

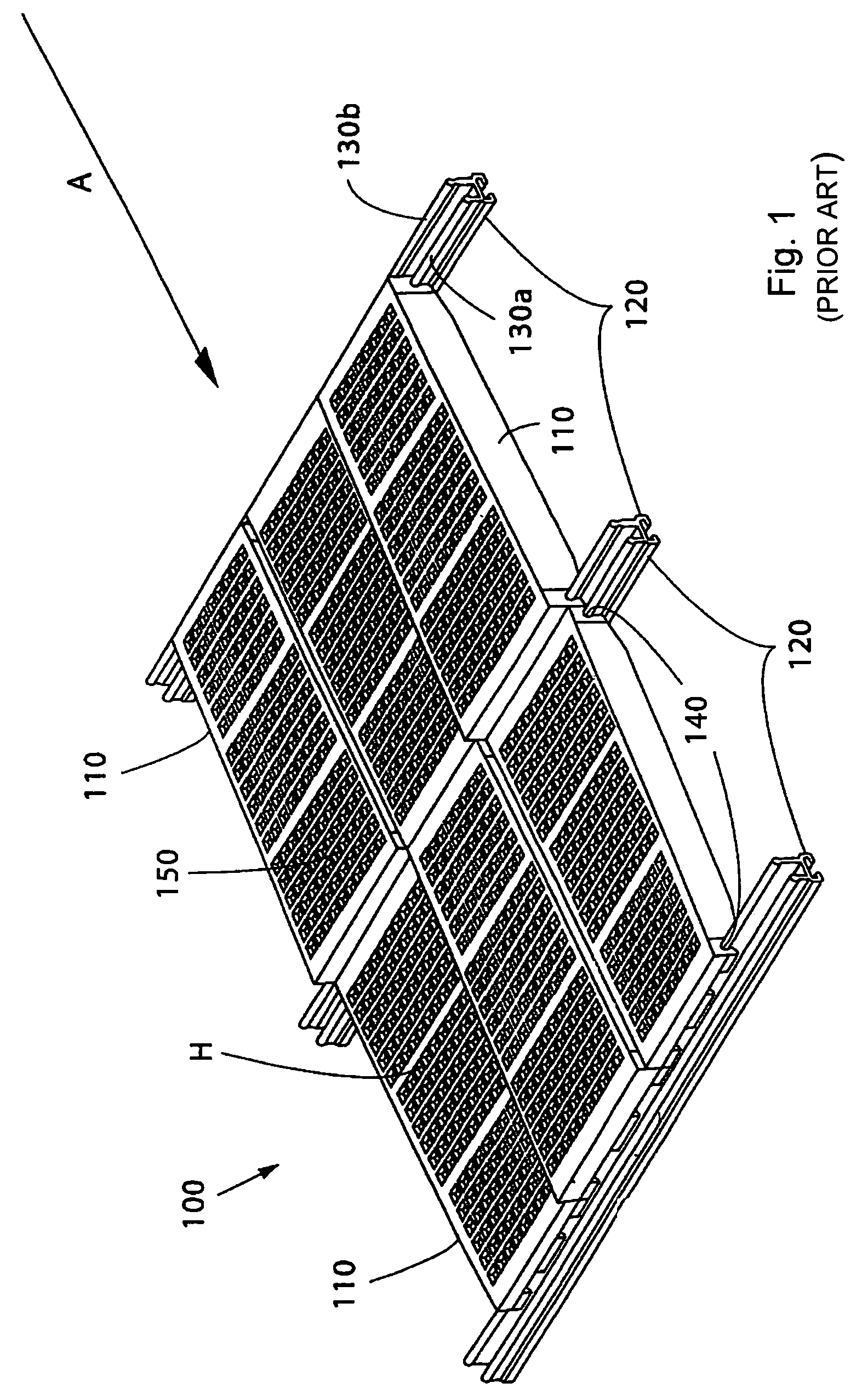

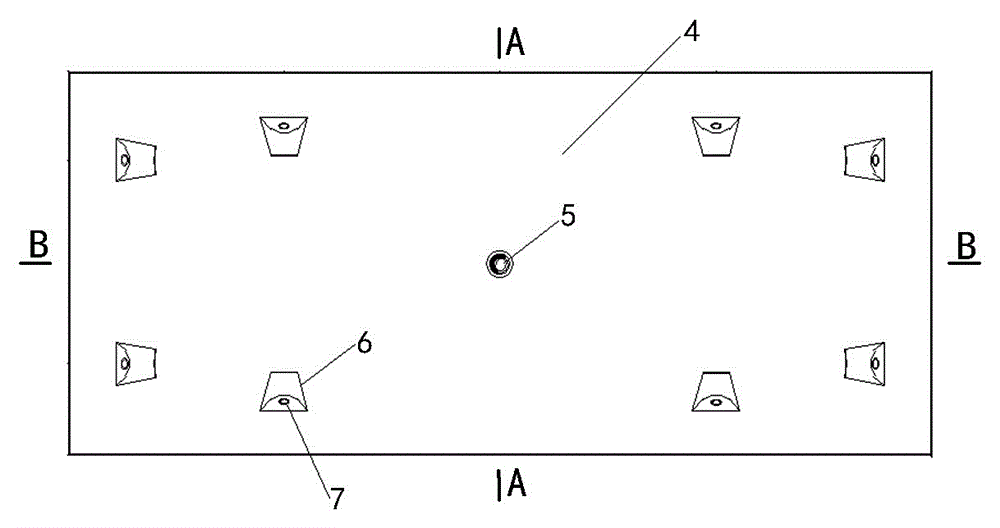

Vibrating screen for screening crushed stone and gravel

A vibrating screen for conducting material in a longitudinal direction while screening the material comprises a screening deck, exchangeable modular screening media, and an adapter arrangement for mounting the screening media on the deck. The screening deck includes transverse carriers oriented transversely of the longitudinal direction. The adapter arrangement comprises longitudinal support carriers arranged substantially in the longitudinal direction, and connecting elements oriented transversely of the longitudinal direction for interconnecting the support carriers and connecting the interconnected support carriers on the transverse carriers.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

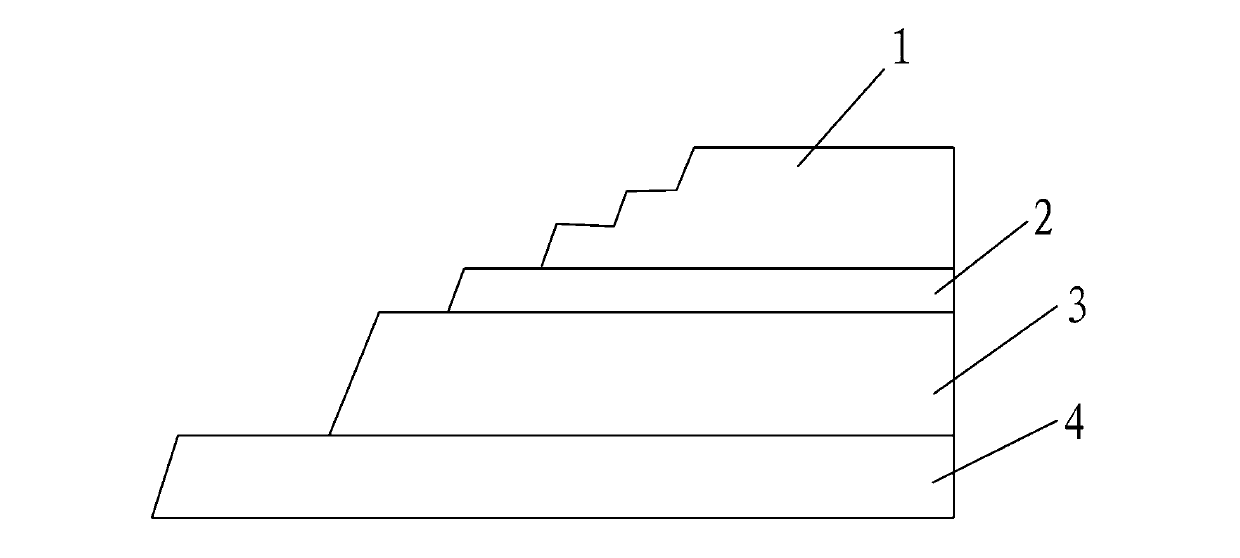

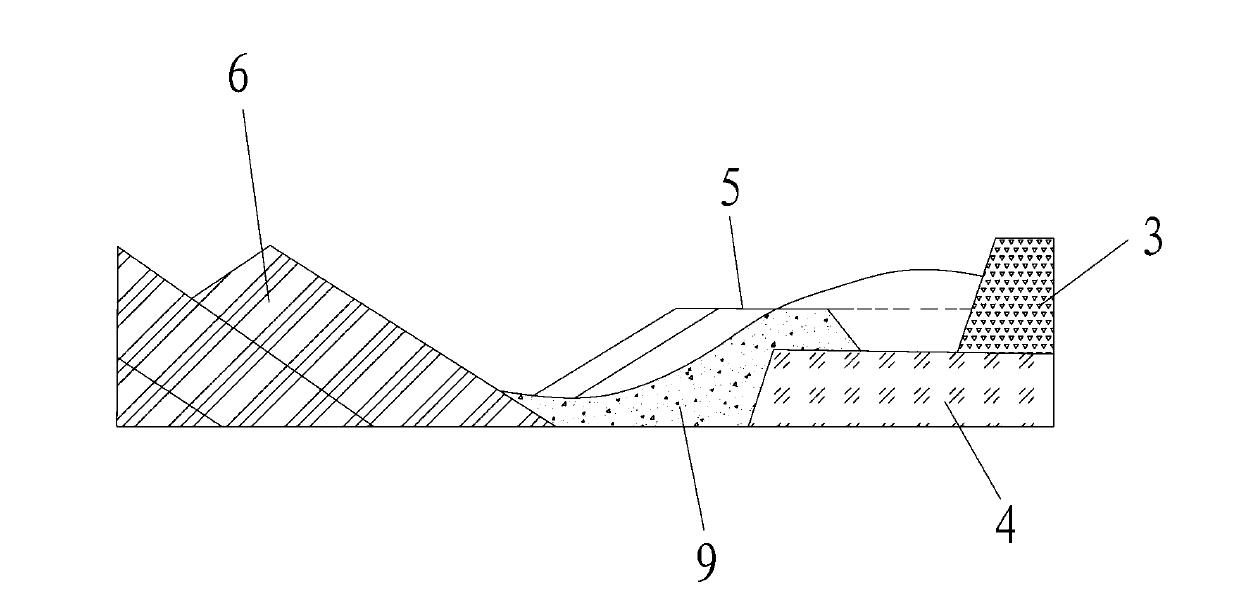

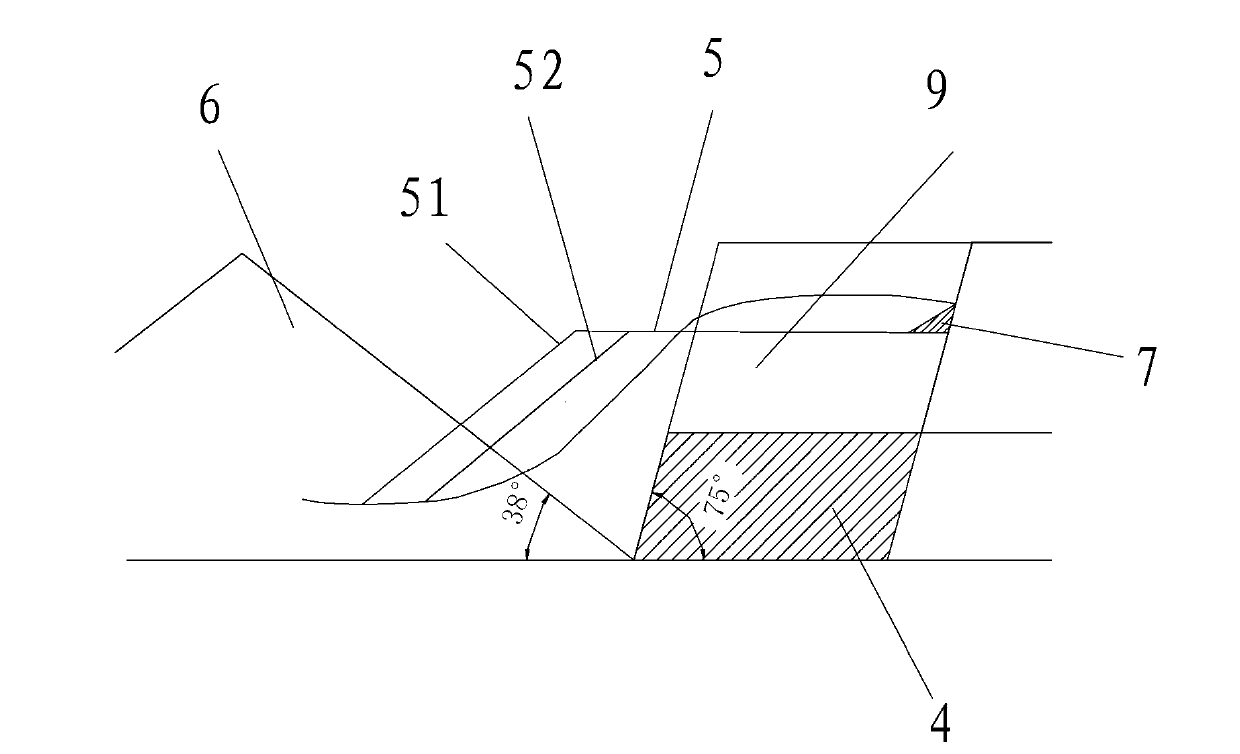

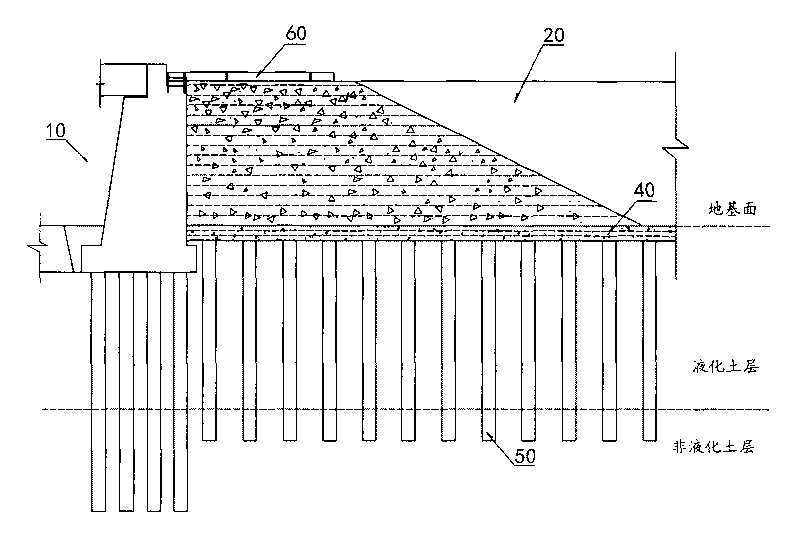

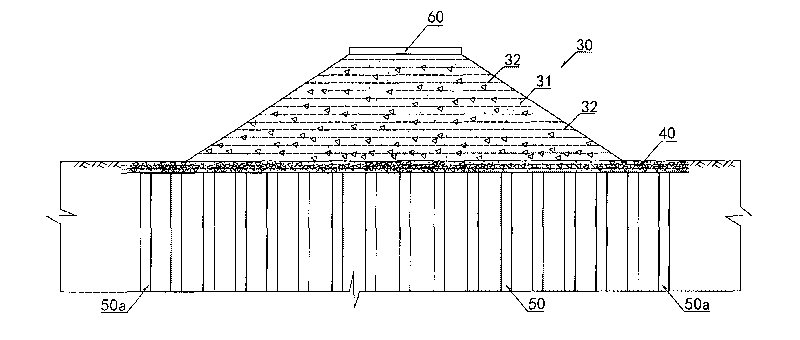

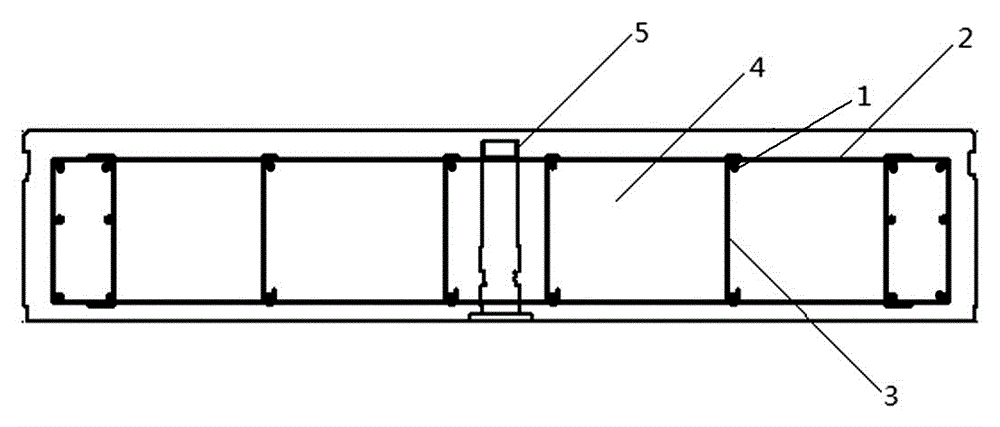

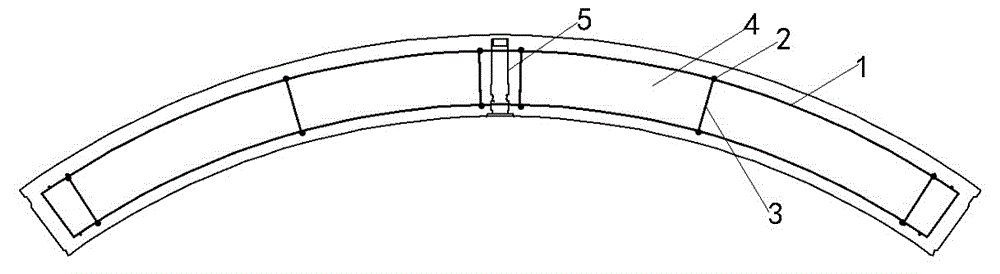

Liquefied soil foundation quake-proof road-bridge transition section structure of ballastless track of high-speed railway

InactiveCN101691724ALower fill longitudinalReduce lateral deformationRailway tracksBridge structural detailsReinforced concreteCrushed stone

The invention discloses a liquefied soil foundation quake-proof road-bridge transition section structure of a ballastless track of a high-speed railway, and aims to improve the stability and the integrity of the roadbed at the transition section and meet the quake-proof design requirements of lines. The structure comprises a concrete bridge abutment (10) and a soil roadbed (20). A reinforced grading gravel transition section (30) is arranged between the concrete bridge abutment (10) and the soil roadbed (20), wherein the longitudinal section of the transition section is wedge-shaped and the transverse section of the transition section is right trapezoidal. Rows of reinforcing piles (50) are arranged in the liquefied soil foundation at intervals along the longitudinal and transverse directions under the transition section (30). The pile ends of the reinforcing piles (50) pass through the liquefied soil layer of the foundation and enter a non-liquefied soil layer. A cement grading gravel reinforced cushion layer (40) is paved between the foundation surface and the pile top of the reinforcing pile (50). A reinforced concrete lap plate (60) is arranged on the top surface of the reinforced grading gravel transition section (30). One end of the reinforced concrete lap plate (60) is simply supported or fixedly supported on the concrete bridge abutment (10), while the other end is placed on the soil roadbed (20).

Owner:SOUTHWEST JIAOTONG UNIV +1

Method for constructing tunnel by utilizing shield empty-pushing crossing mine method

ActiveCN102425427AShort construction periodReduce workloadUnderground chambersTunnel liningArchitectural engineeringCrushed stone

The invention discloses a method for constructing a tunnel by utilizing a shield empty-pushing crossing mine method. Gravels are paved in advance on an empty-pushing section, thereby being short in construction period; the gravels are stacked and filled in front of a cutter, a counter force is provided when the shield is in a tunneling process, and duct pieces are not fixed by structural steel; most clearances between the duct pieces and rock are filled with the gravels, thereby reducing work load and promoting tunneling efficiency; enough counter force is supplied by a jack for splicing the duct pieces, a water-stopping bar is excellently pasted and a waterproof effect is excellent; the duct pieces can be filled and compacted in time, the duct pieces after being spliced cannot float upward, and damaged and over-loaded staggered slabs do not exist; the grout amount on the back of the duct pieces is reduced and the construction cost is saved; and the tunneling efficiency is greatly promoted, the production value within a unit time is high and the economic benefit is excellent.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

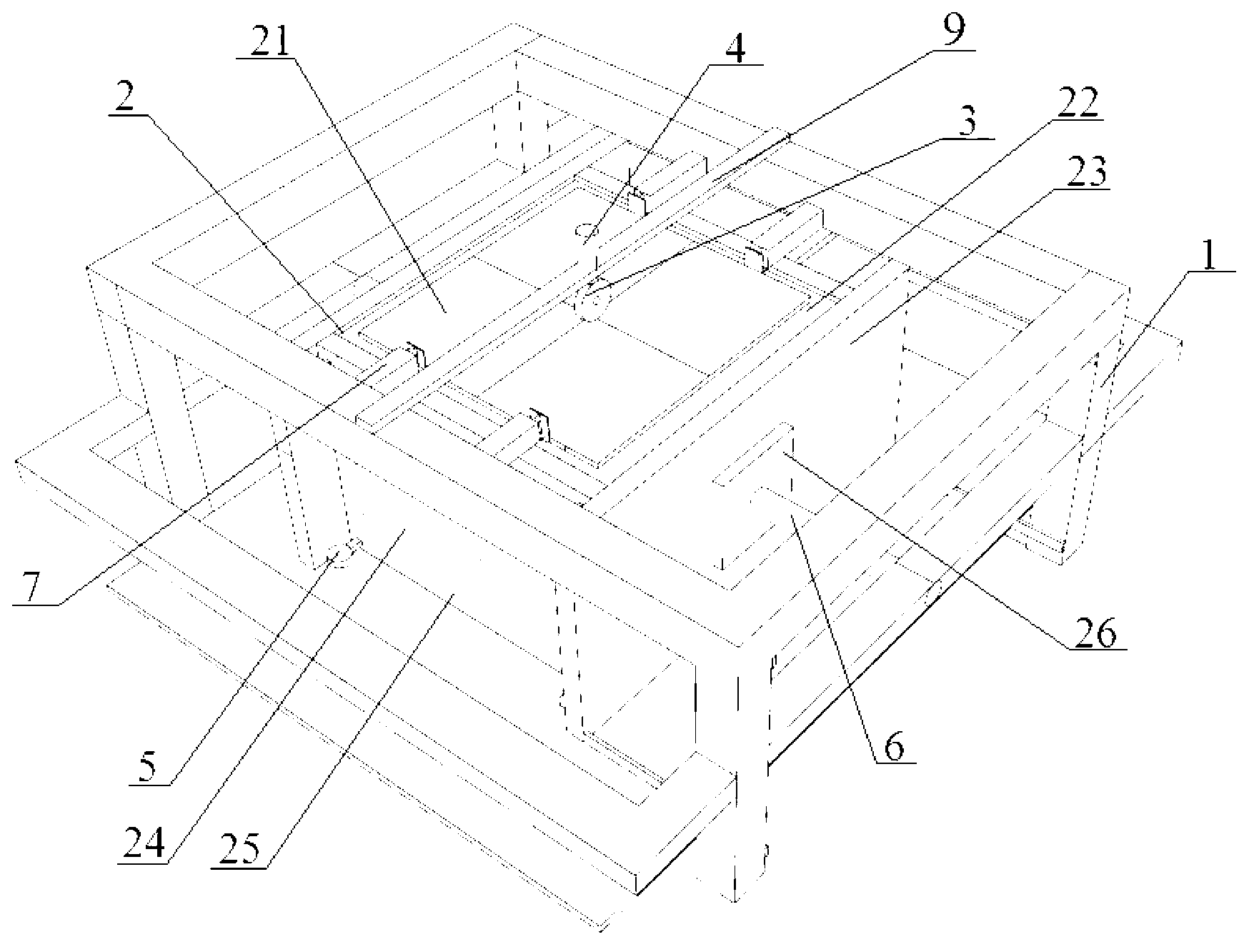

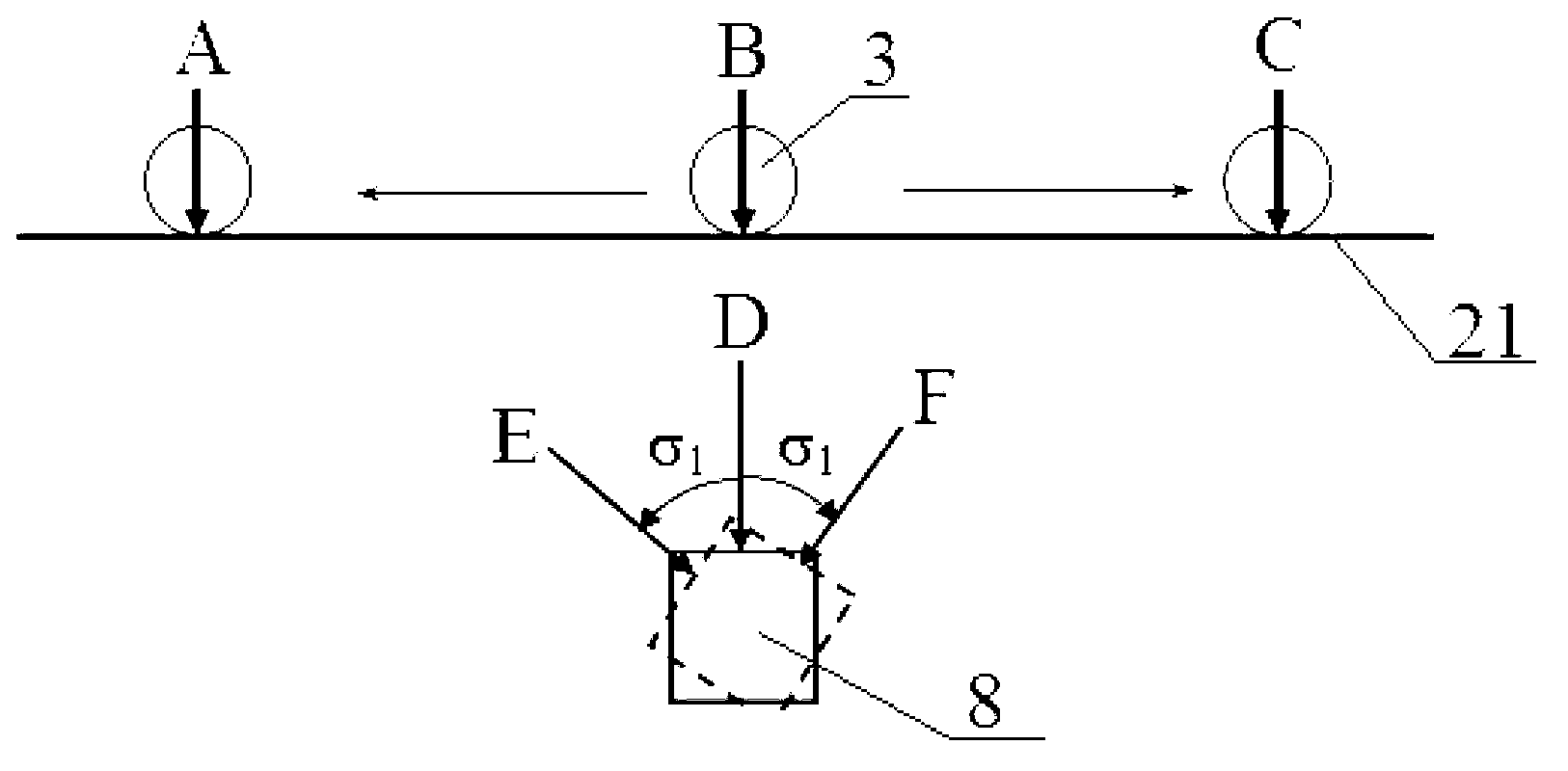

Testing device for simulating mechanical behaviors of gravel soil subgrade under reciprocating traffic moving load

InactiveCN103217348AGuaranteed stabilitySimple structureMaterial strength using repeated/pulsating forcesReciprocating motionRoad engineering

The invention relates to a testing device for simulating mechanical behaviors of a gravel soil subgrade under reciprocating traffic moving load. The device comprises a peripheral framework, a test sample box, an axial loading unit, a horizontal loading system and a data acquisition system, wherein the test sample box is arranged in the peripheral framework, a gravel soil subgrade test sample is filled in the test sample box, a road slab is paved above the gravel soil subgrade test sample, the axial loading unit comprises a trundle and a hydraulic loading system, the trundle is arranged on the road slab, the hydraulic loading system applies an axial pressure to the trundle, the horizontal loading system maintains the horizontal reciprocating movement of the trundle, and the data acquisition system is arranged at the four corners of the side wall of the test sample box. Compared with the prior art, the device disclosed by the invention can simulate the mechanical behaviors of the gravel soil subgrade under the reciprocating traffic moving load to obtain the relationship between gravel soil subgrade deformation settlement and parameters of loading time, loading frequency, axial load and the like, thereby reasonably guiding the engineering practice of road engineering construction and ensuring the stability of the gravel soil subgrade.

Owner:TONGJI UNIV

High-strength plant growing type porous concrete and preparation method thereof

InactiveCN102010155AGuaranteed compressive strengthHigh porositySolid waste managementEcological environmentCrushed stone

The invention discloses a high-strength plant growing type porous concrete and a preparation method thereof. The concrete comprises the following ingredients in proportioning by weight: water, cement, waste concrete or natural crushed stone aggregate, water reducing agents and rice straw. The preparation method comprises the steps of: firstly crushing the waste concrete or the natural crushed stone aggregate to be used as aggregate for later use; smashing the fully dried rice straw for later use; stirring the aggregate and a proper amount of water for a period of time; putting a proper amount of cement, the smashed rice straw and the water reducing agents into a stirrer for stirring; and finally, adding rest water and cement to be stirred. The high-strength plant growing type porous concrete can replace masonry flagstone with the strength of lower than M15, is applied to engineering projects such as raceways, parking lots, side slopes, riverbanks and the like and helps the growth of plants and restores the ecological environment destroyed by construction under the application condition.

Owner:孙学军 +1

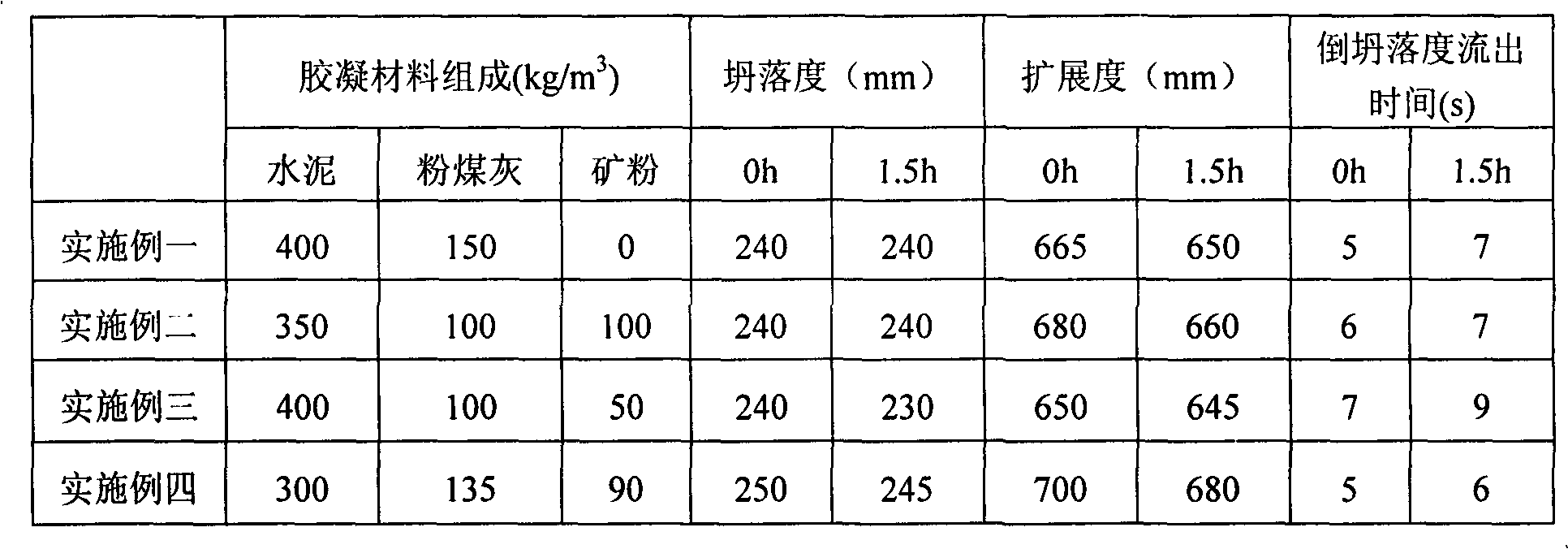

Machine-made sand self-compaction concrete

The invention discloses a machine-made sand self-compacting concrete. The concrete is made from the following components according to parts by weight: 100 parts of cement, 25-45 parts of fly ash, 0-30 parts of mineral powder, 0.8-1.5 parts of a polycarboxylic acid water reducing agent, 220-250 parts of machine-made sand, 130-150 parts of cobble and 130-150 parts of crushed stone. The concrete saves natural resource as well as has high fluidity, high stability and low slump loss; compared with equivalent effects, the concrete has the advantages of lower cost and simpler production, meanwhile, silicon dust is not applied to the concrete, therefore, the health of operators is better guaranteed.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

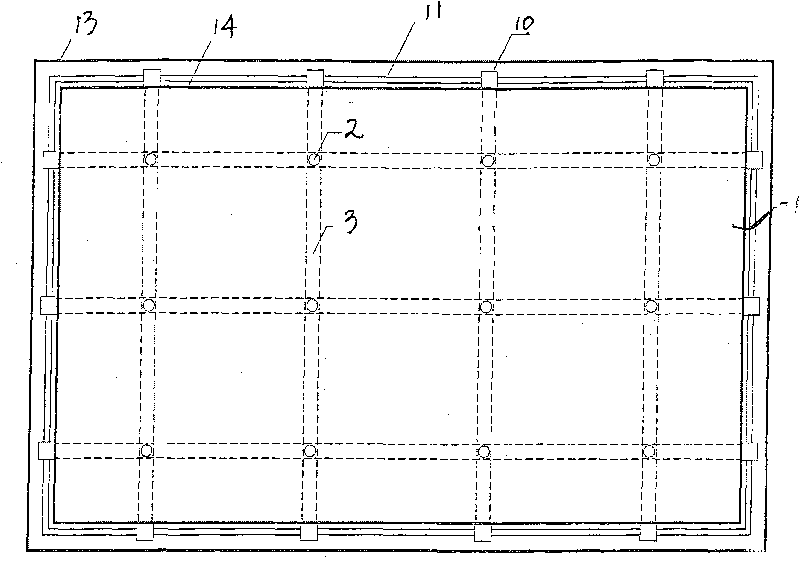

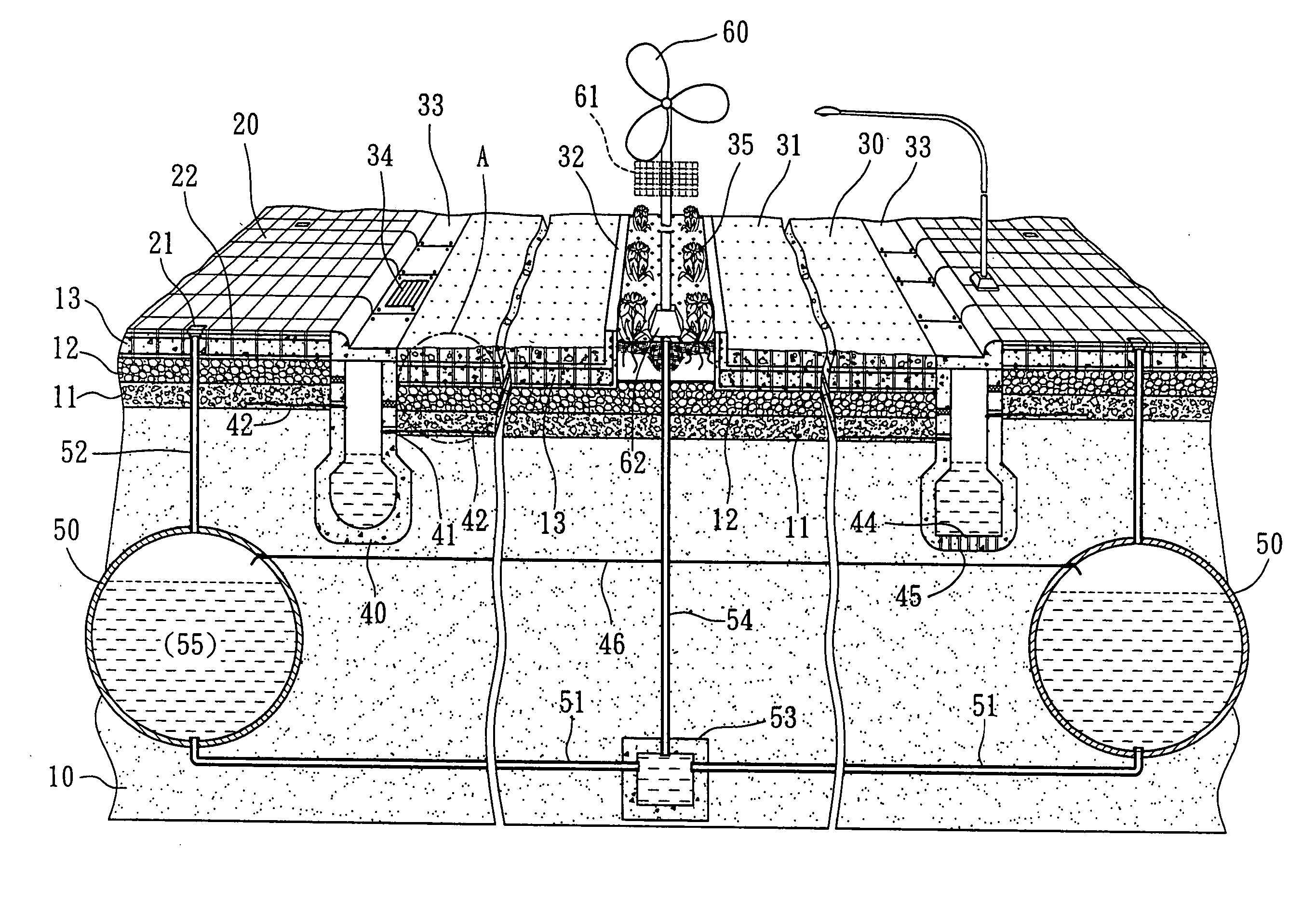

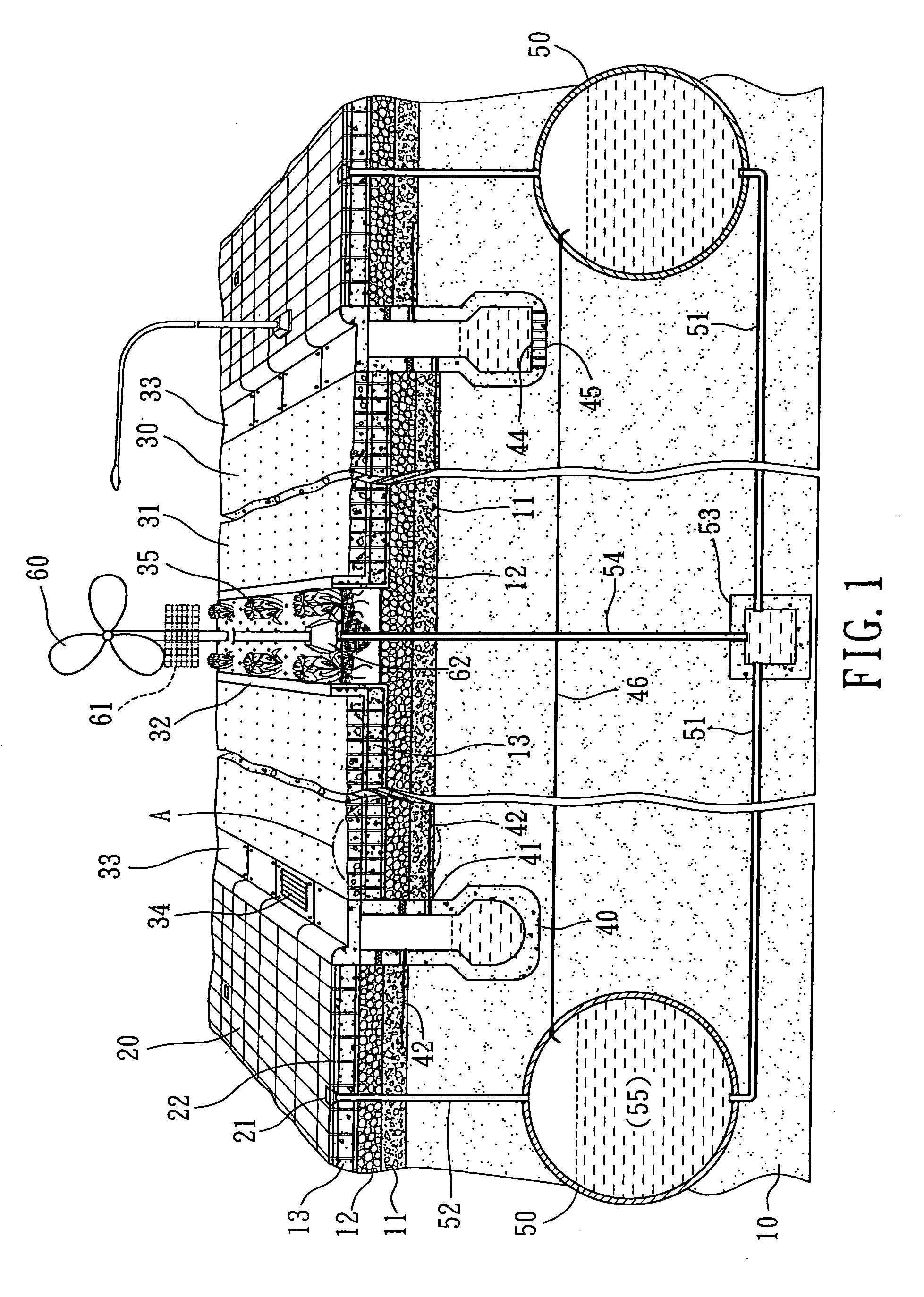

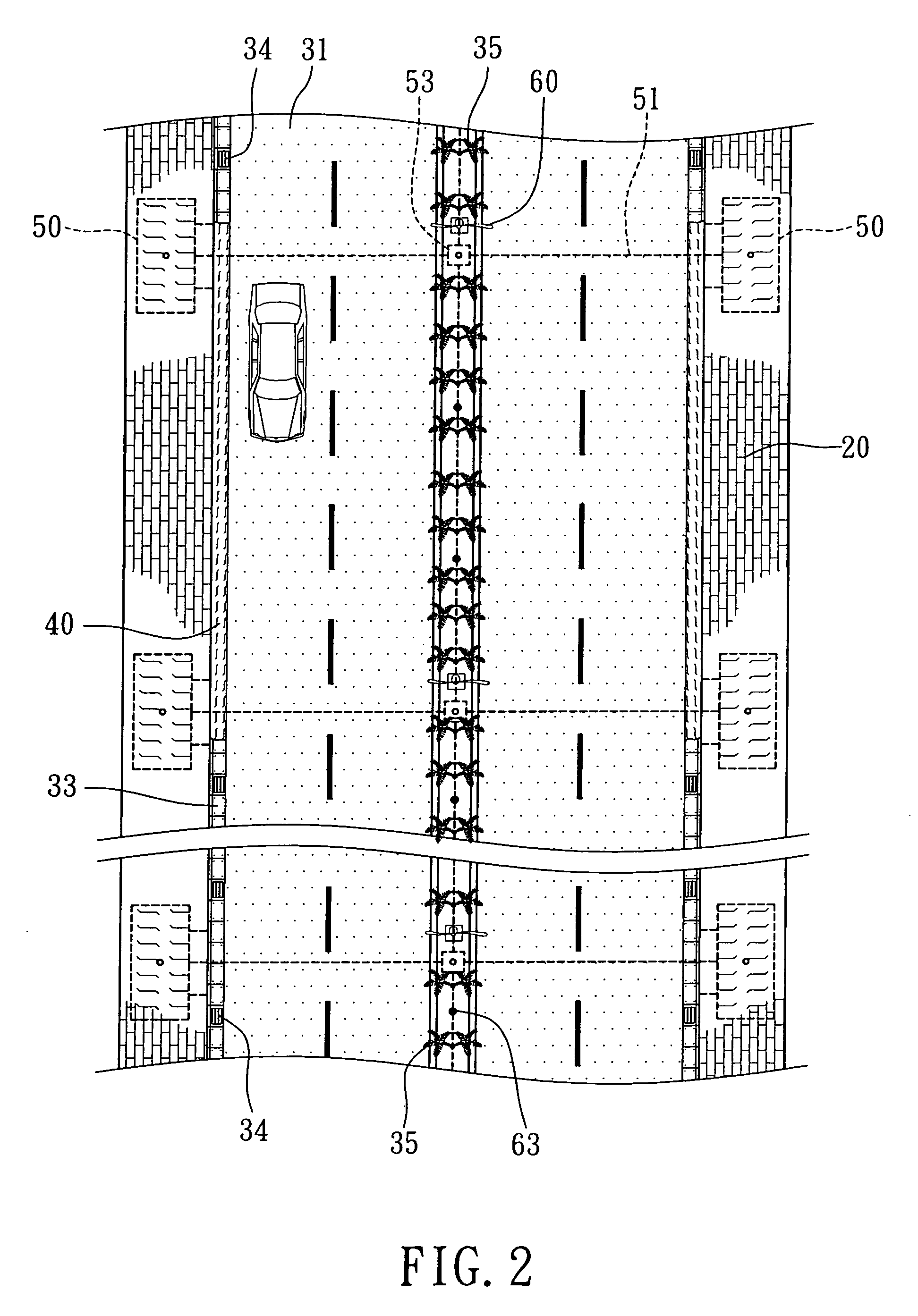

Constructive water resource recycling method

InactiveUS20060210358A1Effective maintenanceInhibition effectGround-workGeneral water supply conservationWater resourcesCrushed stone

A constructive water resource recycling method is characterized in that great-sized water reservoirs, each of which has a drainpipe provided above for connecting to the ground surface, are buried in the underground soil; deep drainage trenches are selectively provided under the macadam stratum; the side walls of the deep drainage trenches have water inlets such that the rain can be led down to the soil via drainage bands, while trenches are covered by trench covers; the water contained in the water reservoirs can be drawn by water-drawing pipes to the ground surface for further utilization through a water pump of natural power; the great-sized water reservoirs are covered by soil and macadam stratum, and then an instantly permeable layer which is composed of macadam, pebbles or sand; finally, the instantly permeable layer is covered a concrete pavement and then drilled through to complete a constructive permeable pavement, thereby efficiently recycling the rain for fully utilization.

Owner:CHEN JUI WEN

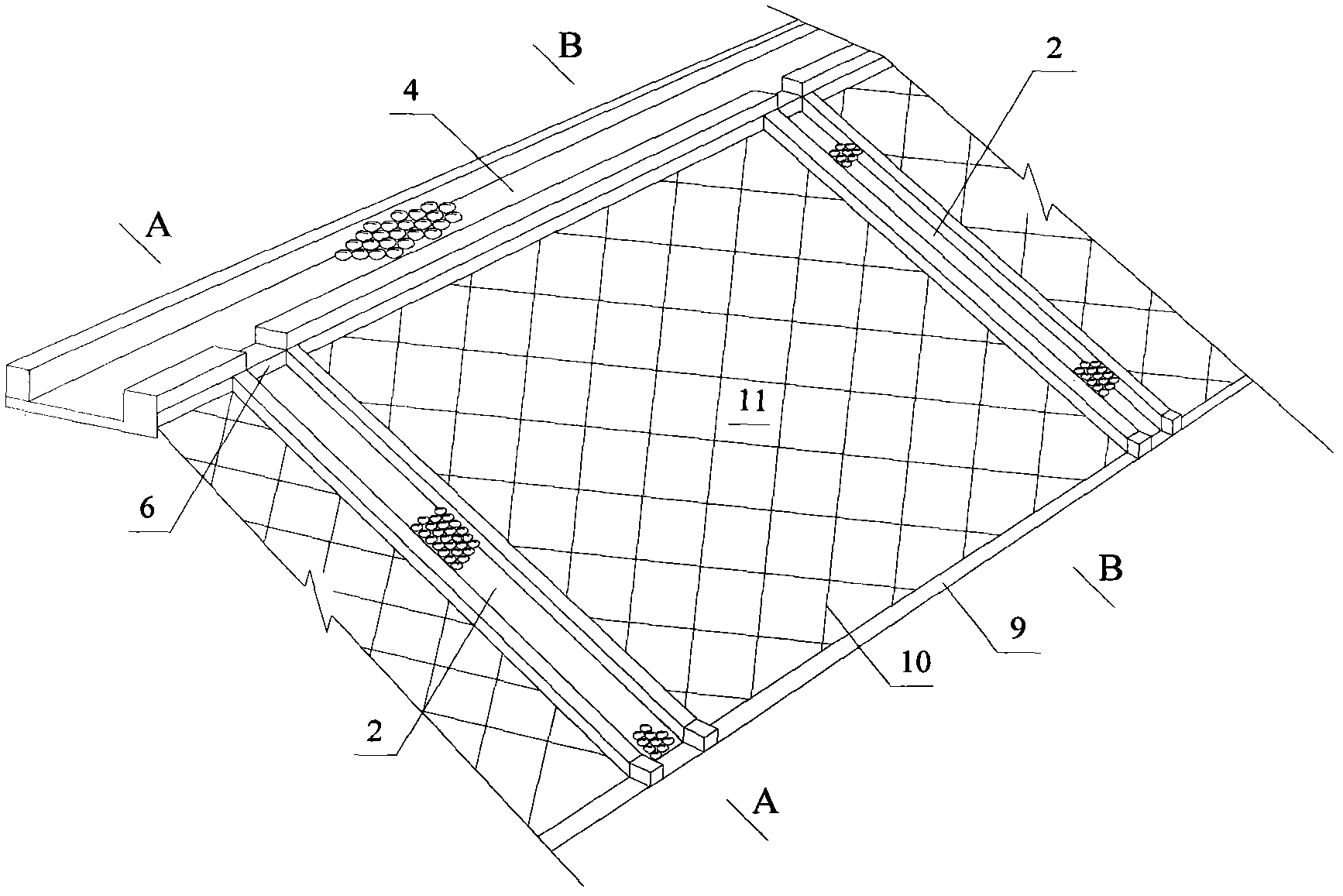

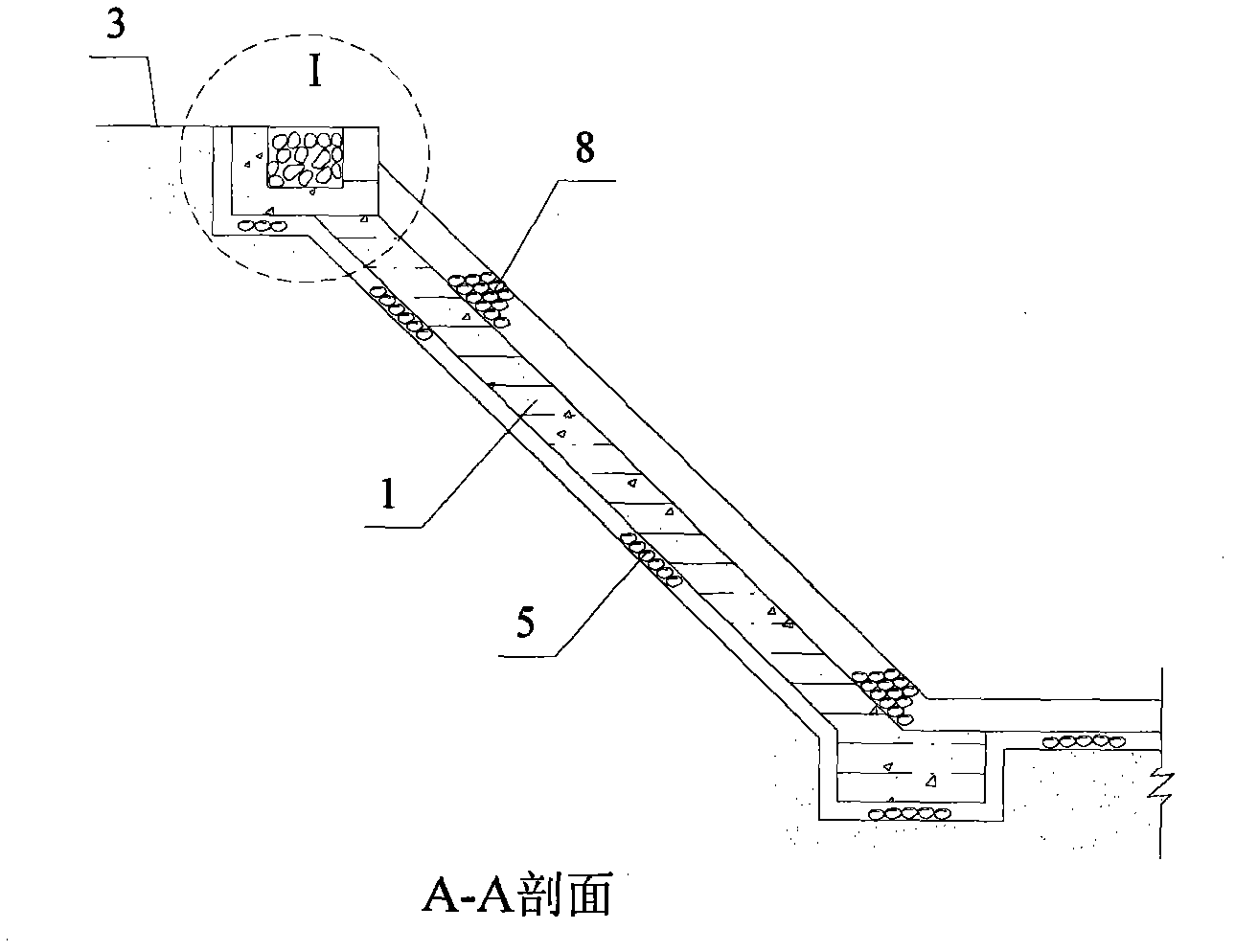

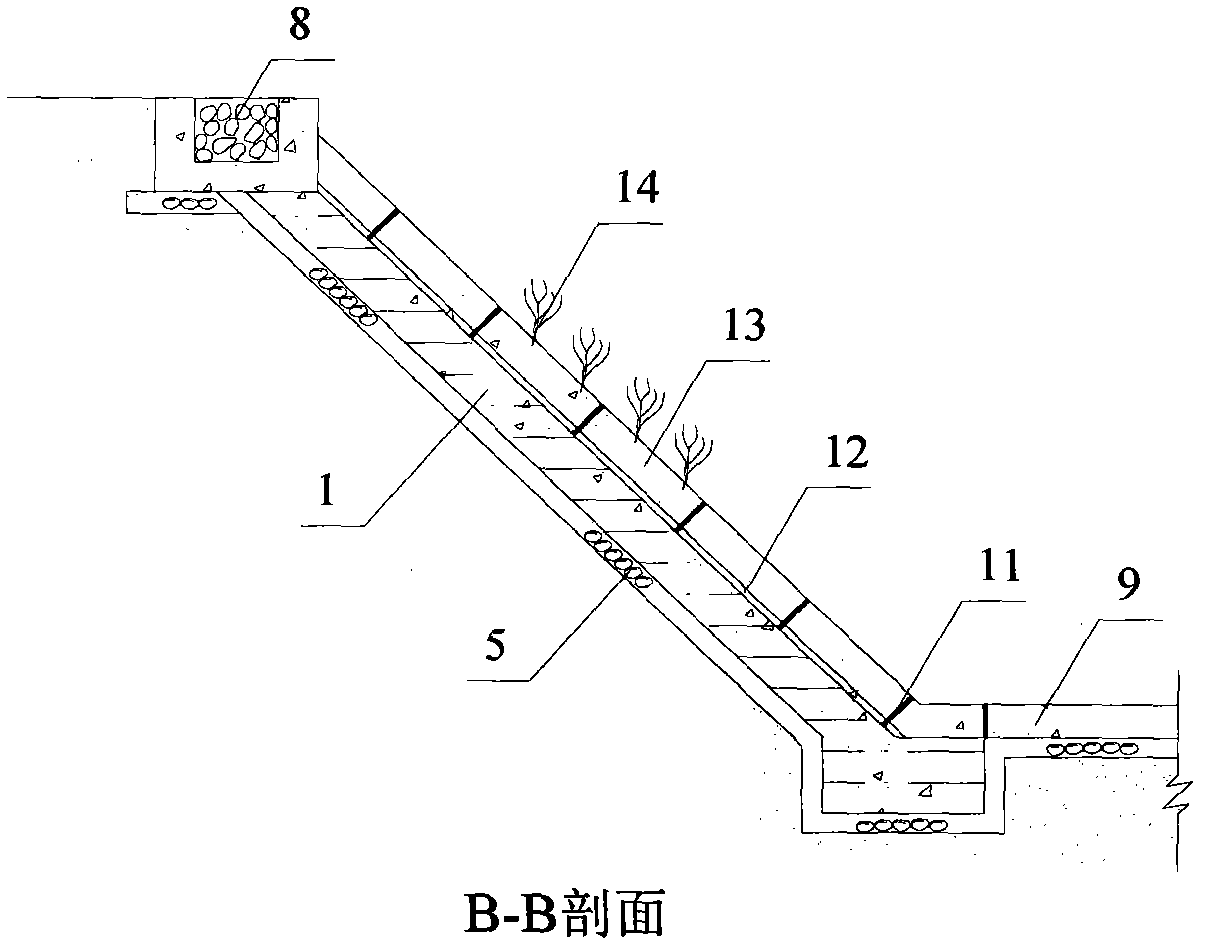

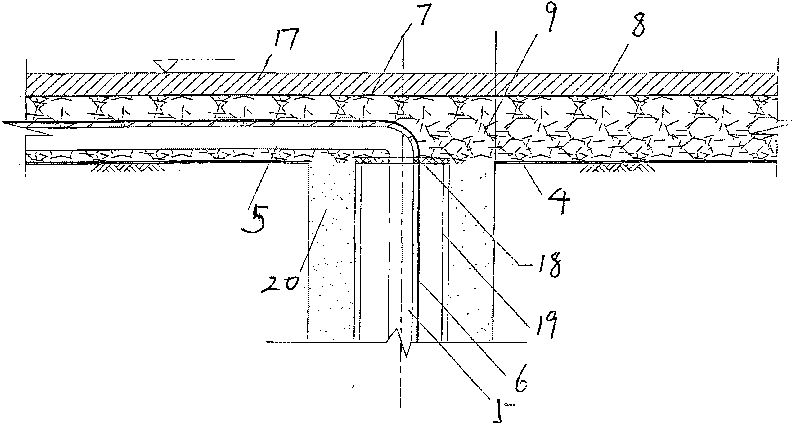

Impurifying ecological bank-protection combined system

InactiveCN1936190AGood interception and purification effectEfficient retentionCoastlines protectionRainfall runoffBrick

The invention relates to revetment combination system that has cutoff purifying function to the river rainfall runoff surface contaminating material. It sets non-sand concrete curbstone at the intersection of road and bank slope, a catch water channel is set at one side of intersection road, where coarse sand bedding is paved. Crushed stones are filled in the channel, and the top of channel is sealed by non-sand concrete. On the band slope toward water side paves coarse sand, crushed stone of different thickness, and ecology brick. Cement laid stone masonry breast wall is set at basal slope, and growing plant at the bank slope. It increases the residence time for runoff in the system and takes purification to it.

Owner:HOHAI UNIV

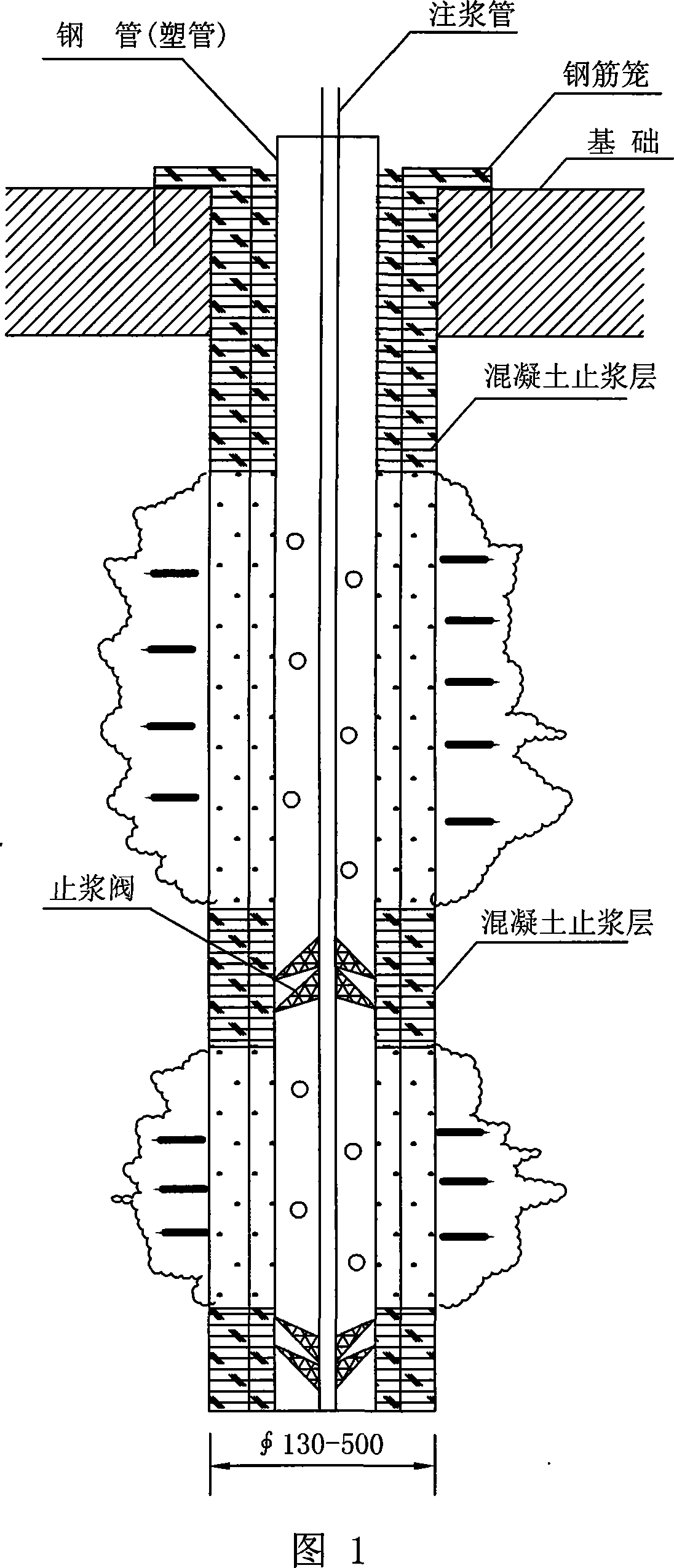

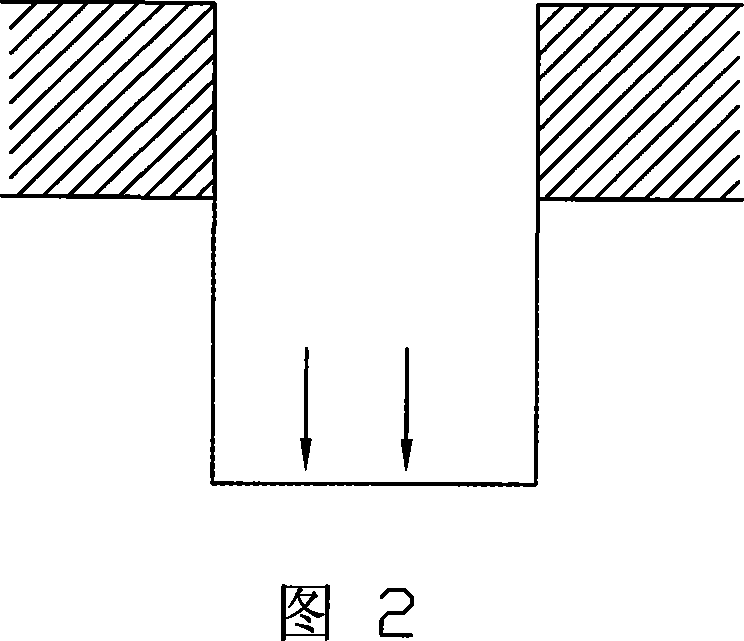

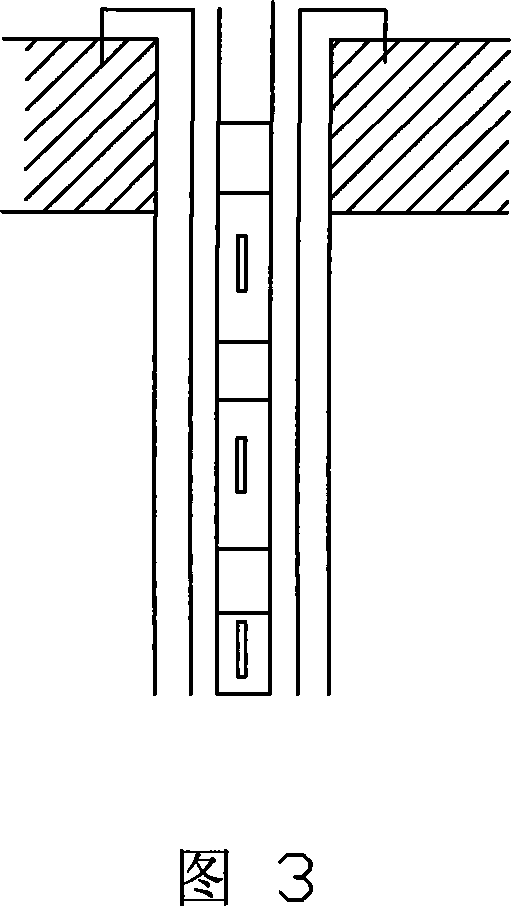

Construction method for pulling-resistant and pressure-resistant slip casting pipe pile

InactiveCN101058979ASolve the problem of insufficient pullout resistance of pullout pilesImprove pull resistanceBulkheads/pilesCrushed stoneWater table

A construction method of casting pipe pile plucking with resistance to plucking and pressing, The invention relates to a construction method of pipe pile. The purpose of the invention is: solving the insufficient problems of resistance to plucking and pressing happened in the buildings which are built under complex geological conditions or under higher groundwater level geological strata and the problems are generated by bottom board percolating water due to buildings bottom board plucking resistance is insufficient, declination due to excessive eccentricity when design buildings and when design the resistance to plucking of new buildings. The invention drills hole downward on the buildings basic layer according the design height mark and bore diameter of pipe pile, lifts downward steel pipes or plastic pipes with slip casting hole after the drilled hole is completed, lifts downward reinforcement bar or reinforcement cage in the hole out the steel pipes or plastic pipes, lifts downward sands and broken stone between the outer wall of the steel pipes or plastic pipes and the hole wall. The invention has extremely distinctive action in buildings plucking-resistance and reinforcement, buildings declination correction and the foundation reinforcement project of house floors addition and reconstruction. The pile type in the invention is suitable for various geological strata, it can be used for the plucking-resistance, reinforcement and foundation reinforcement of prior buildings and the resistance-plucking pile construction of new buildings.

Owner:何新东

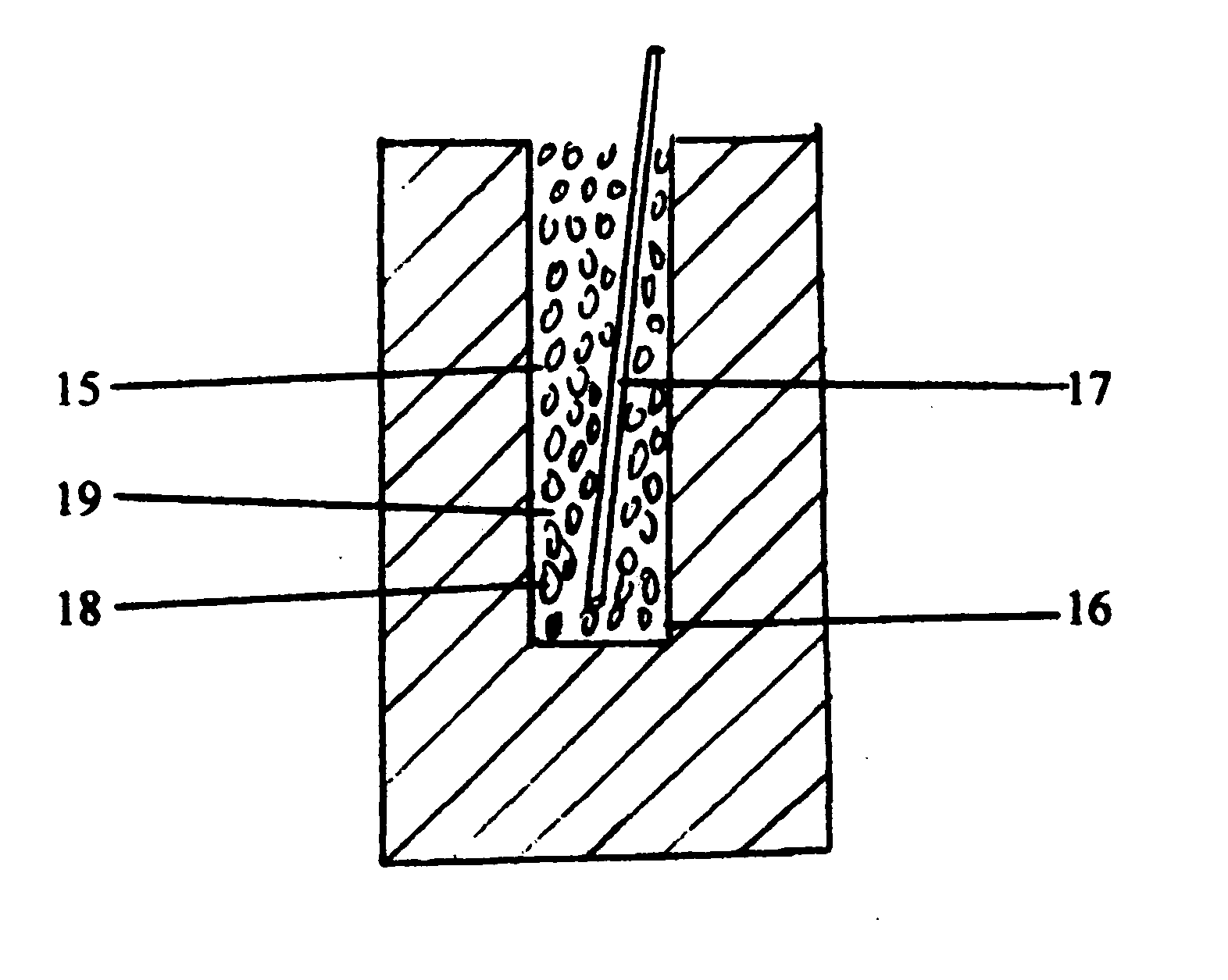

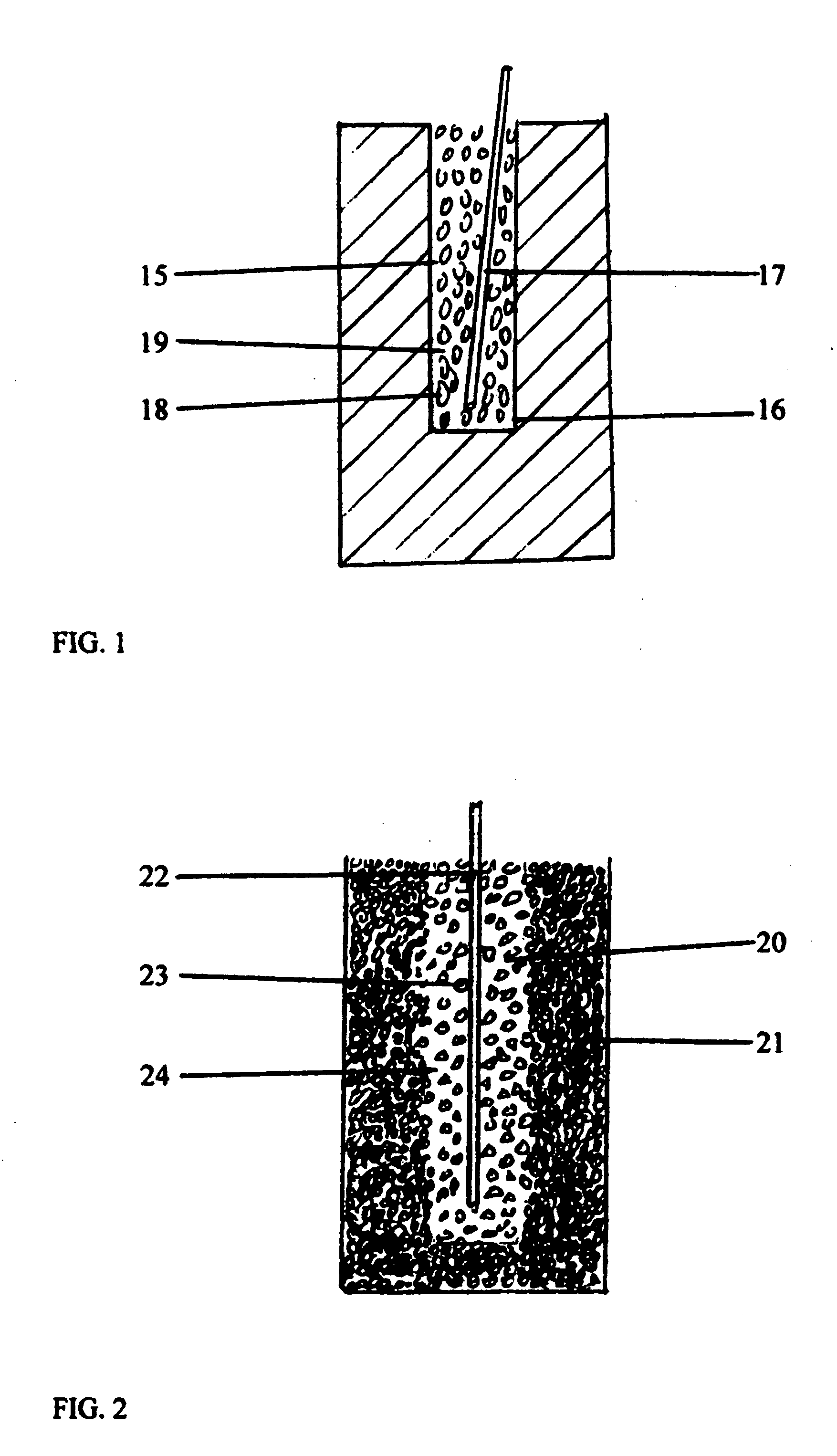

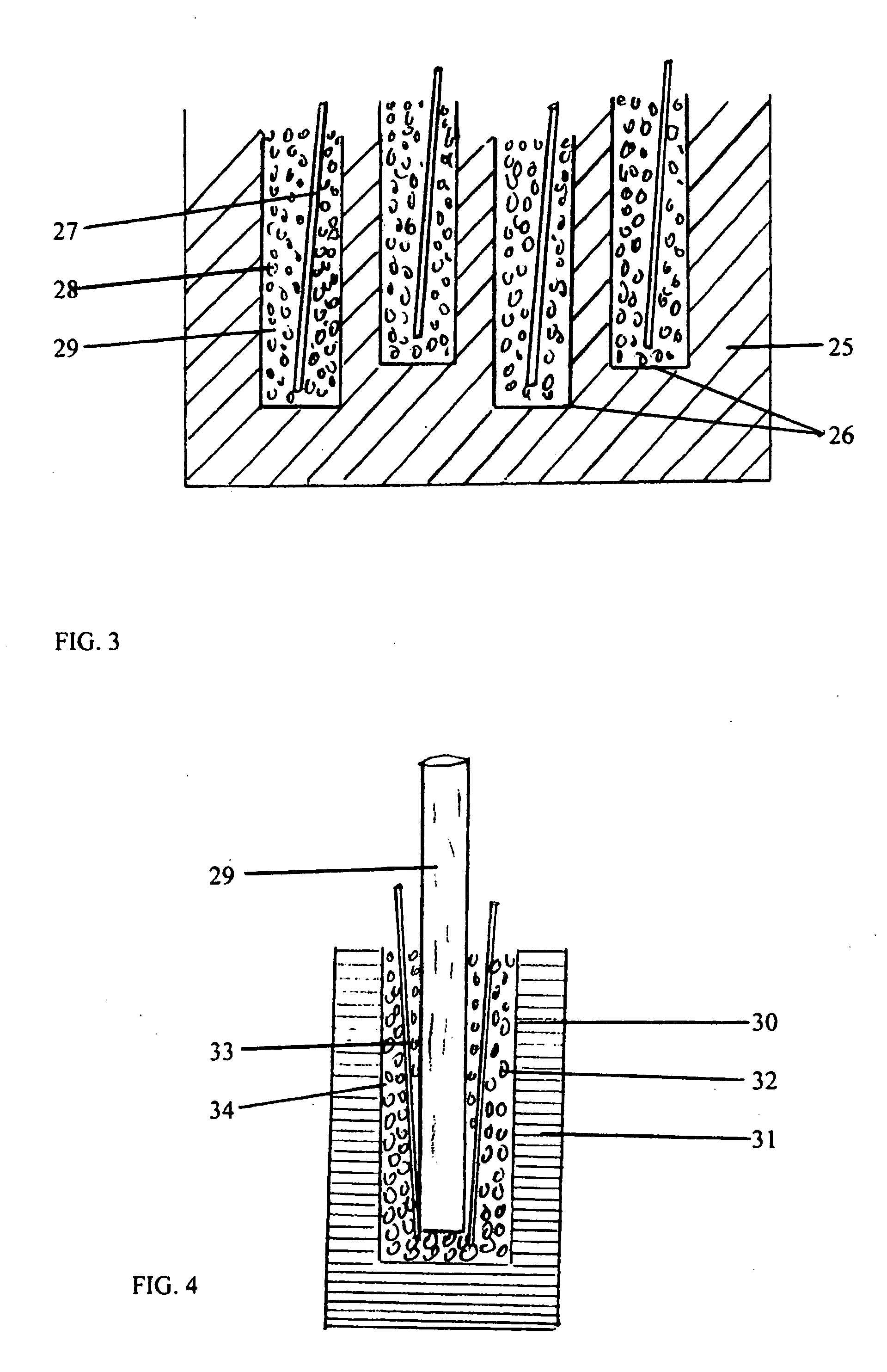

Foam pile system

ActiveUS20050081459A1Inhibit sheddingProtective foundationBuilding constructionsGlass fiberHigh density

In this invention, after a hole has been drilled or excavated, injection probe(s) are placed at appropriate depth(s), the excavated native materials are replaced with appropriately sized crushed rock or other natural or synthetic materials, and then a polymeric resin is injected through the probe(s) to encapsulate and bind the fill material, whereby upon curing the polymeric resin and fill material forms a foam friction pile. Such friction piles drilled or excavated adjacent to each other will form a foam sheet piling system. The foam piles can also be re-enforced using nylon, polypropylene, fiberglass, other synthetic or non-synthetic materials or combinations of these materials. The polymeric resin typically would comprise a high density closed cell, water resistant expanding two component polyurethane foam system.

Owner:POLY-MOR CANADA INC

Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

InactiveCN105041336AReduce dosageReduce consumptionUnderground chambersTunnel liningCrack resistanceReinforced concrete

The invention discloses an ultra-high performance hybrid fiber concrete shield segment and a preparation method thereof. The ultra-high performance hybrid fiber concrete shield segment is of a reinforced concrete structure which consists of a steel skeleton and concrete, wherein the reinforcement ratio of used main reinforcements is 0.5%-1.0%, the distances of the main reinforcements are 150-300mm, the grades of steel reinforcements are not less than three, the smallest steel reinforcement distance of distributed reinforcements is 400mm, the biggest steel reinforcement distance of used distributed reinforcements is 2000mm, and the grades of the steel reinforcements are not less than two. The ultra-high performance hybrid fiber concrete shield segment is made from ultra-high performance hybrid fiber concrete, and comprises cementitious materials, sands, crushed stones, steel fibers, synthetic fibers, water reducer, defoamer and water. The ultra-high performance hybrid fiber concrete shield segment is less in dosage of the steel reinforcements and concrete and high in early strength, can prevent steam preservation, reduces energy consumption, and is green, energy-saving and environmentally friendly. The ultra-high performance hybrid fiber concrete shield segment is strong in anti-burst performance when having a fire, excellent in toughness and crack resistance and excellent in durability, enables edge joints not to easily break, and overcomes the defects of traditional segments.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Concrete pile and preparation method thereof

InactiveCN102491702ASolve processing problemsHarm reductionSolid waste managementShaping reinforcementsSlagResource utilization

The invention discloses a concrete pile formed by concrete casting; the concrete comprises the components including cementing material, fine aggregate, crushed stones, water-reducing agent and water, wherein the fine aggregate is a mixture of sand and industrial waste slag, and the weight the industrial waste slag is 10 to 50% of that of the fine aggregate; the volume weight of the concrete is 2400 to 2600 kg / m<3>; the use amount of the cementing material is 300 to 600 kg / m<3>, the water-binder ratio is 0.2 to 0.4, and the sand percentage is 27 to 44%; and the weight of water-reducing agent is 10 to 50% of that of the cementing material. The invention further discloses a preparation method of the concrete pile. According to the invention, 10 to 50% of sand is replaced by industrial waste slag, moreover, the resource of the industrial waste slag is relatively ample, and the quality is relatively stable, so that under the premise of ensuring the quality of the concrete pile, through resource utilization of the waste material, not only the pollution problem is solved, but also great economic benefits and social benefits can be produced.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

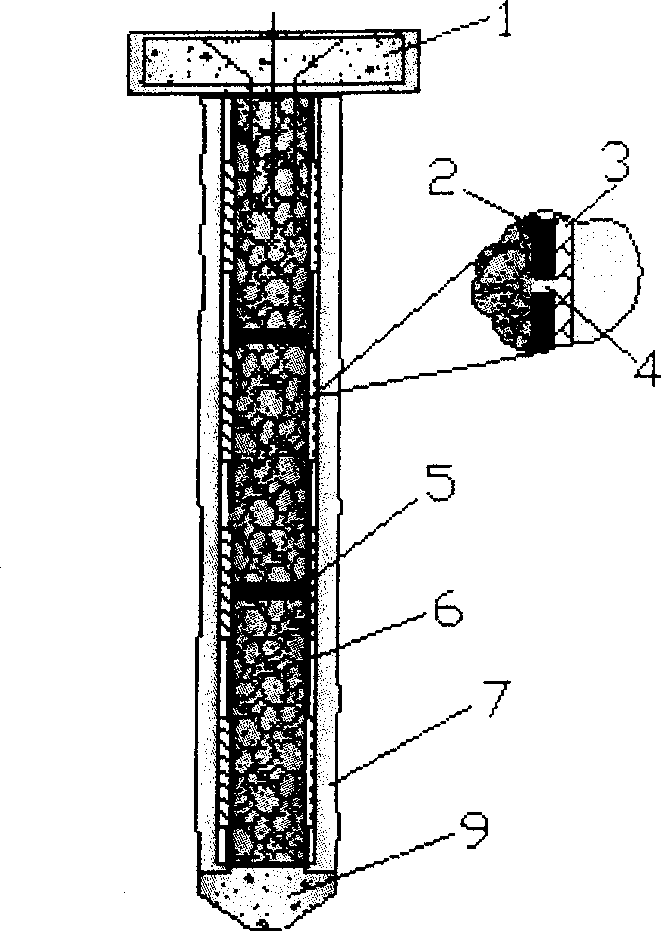

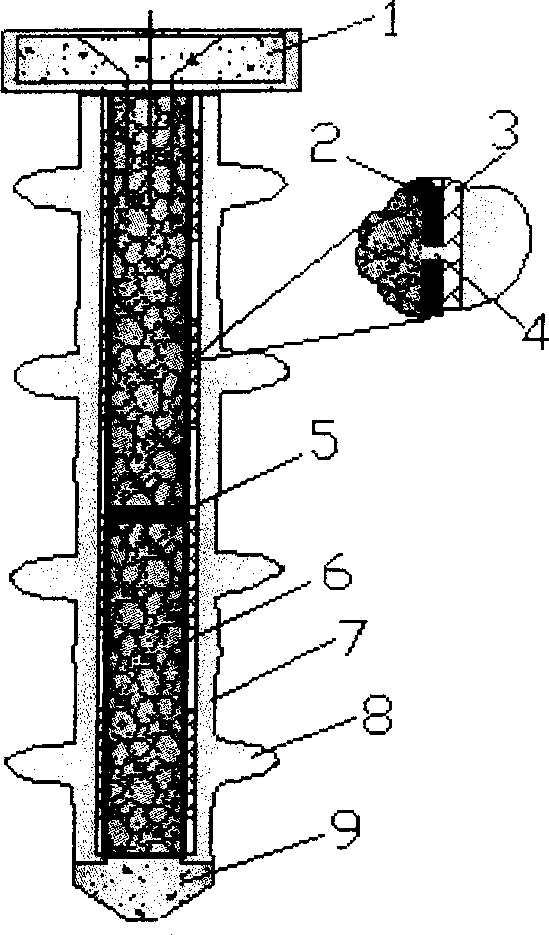

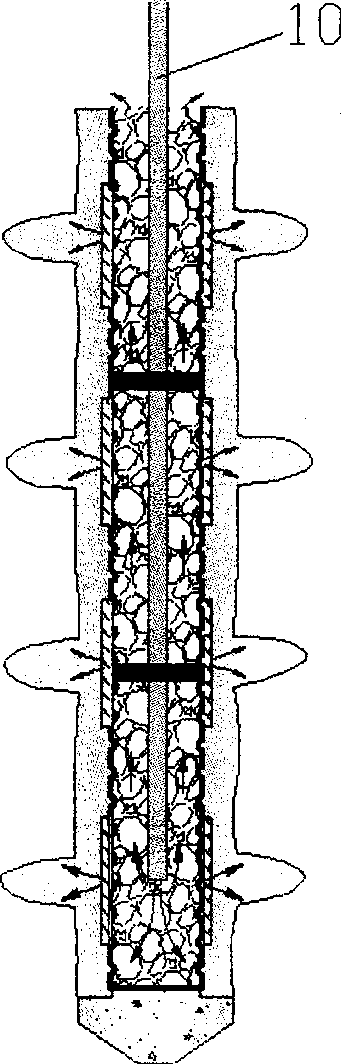

Granule grouting pile of ripple plastic sleeve with hole for strengthening soft soil foundation and strengthening method

The invention discloses a grouting pile of a plastic sleeve for strengthening a soft soil foundation and a pile-forming strengthening construction method thereof. The pile consists of a pile cap, a thread sleeve, an earthwork cloth, a joint, a pile body and a pile tip; the top of the sleeve is connected with the pile cap and the bottom of the sleeve is connected with the pile tip, the side wall of the sleeve is provided with an opening hole, the outside of the sleeve is packed by the earthwork cloth, each section of the sleeve is connected by the joint, and the sleeve is filled with granules and grouted with slurry inside so as to form the pile body and a pile periphery as a slurry spreading zone. The pile-forming strengthening method comprises: connecting the sleeve to the depth of the pile length by the joint and then to the pile tip, placing the sleeve and the pile tip into an immersed tube together, beating the sleeve into a foundation by a beating machine, leaving the sleeve and the pile tip in the foundation, feeding the granules into the sleeve and grouting the sleeve to form a slurry scattered material column, spreading a slurry liquid on the pile periphery to form a spreading zone under the grouting pressure or expanding the earthwork cloth outwards to form a gourd pile body, pouring the pile cap on the pile top, and paving a reinforced material and a gravel cushion after the pile body and the pile cap are dried so as to form a composite foundation. The pile type can strengthen the contact action between the pile and the soil, can improve the bearing capacity of the pile body greatly, and is an ideal pile type for strengthening the soft soil foundation.

Owner:HOHAI UNIV

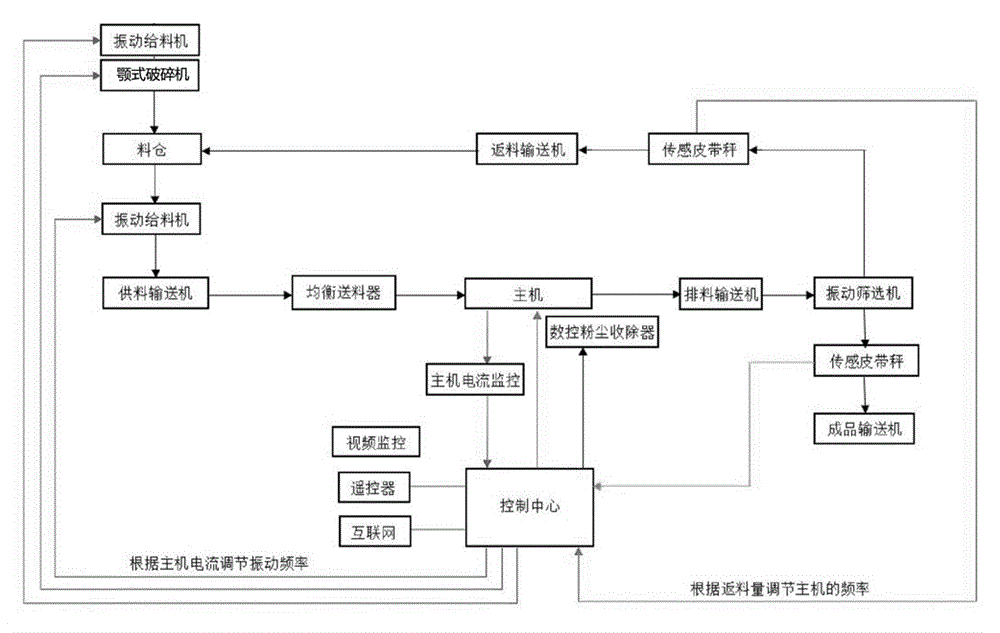

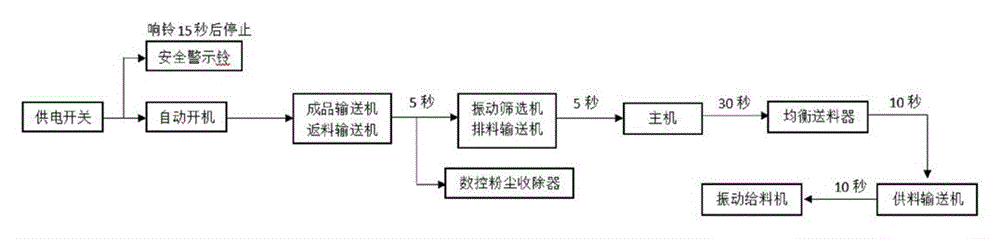

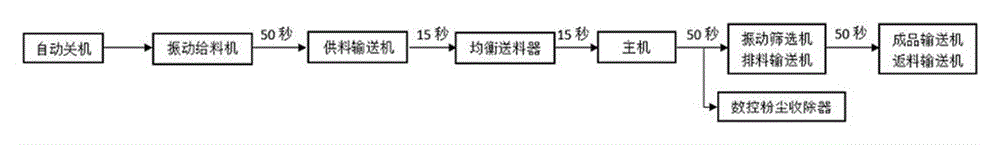

Intelligent control system for stone-crushing and sand-making machine

ActiveCN105032594AAutomatic speed adjustmentMake sure to work at full capacityGrain treatmentsElectric machineFrequency conversion

The invention relates to an intelligent control system for a stone-crushing and sand-making machine. The intelligent control system for the stone-crushing and sand-making machine comprises a control center, and the control center is connected with a whole system of the stone-crushing and sand-making machine and controls all devices of the stone-crushing and sand-making system to work simultaneously; the control center is connected with the Internet and a remote controller to conduct real-time monitoring on the equipment of the whole stone-crushing and sand-making system, and meanwhile, the control center has two startup control modes, namely, a manual adjustment mode and an automatic adjustment mode. The frequency conversion technology is adopted, the rotor speed and the discharging granularity are automatically adjusted, and the requirements for crushing stone with different hardness and making sand are met; the feed quantity is automatically adjusted, full-load work of a main machine is guaranteed, and the stone-crushing and sand-making yield is over 200% of that of a vertical-type impact sand-making machine under the same main machine motor power; monitoring is conducted on the Internet through a computer or a mobile phone, and remote monitoring operations are achieved.

Owner:SHAOGUAN HELI HEAVY IND MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com