Machine-made sand self-compaction concrete

A technology of self-compacting concrete and machine-made sand, which is applied in the field of building materials, can solve the problems of physical injury of operators, complicated production operations, susceptibility to aspiration lung disease, etc., and achieve low cost, low slump loss, and physical health protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

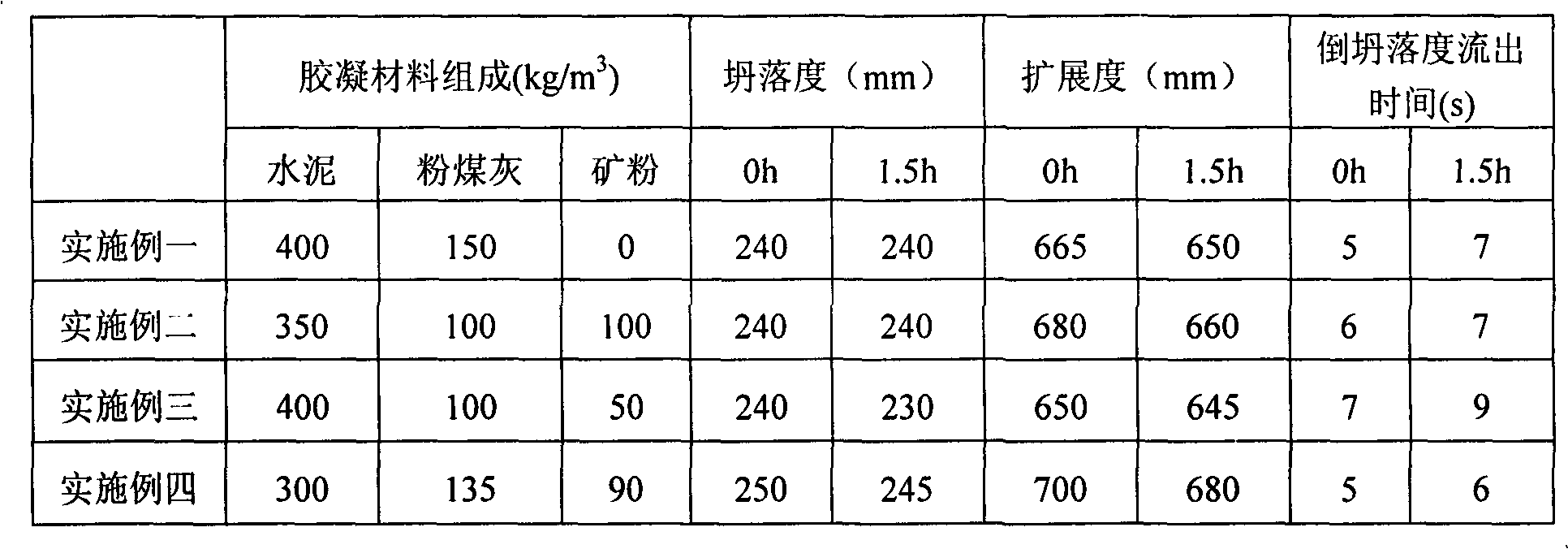

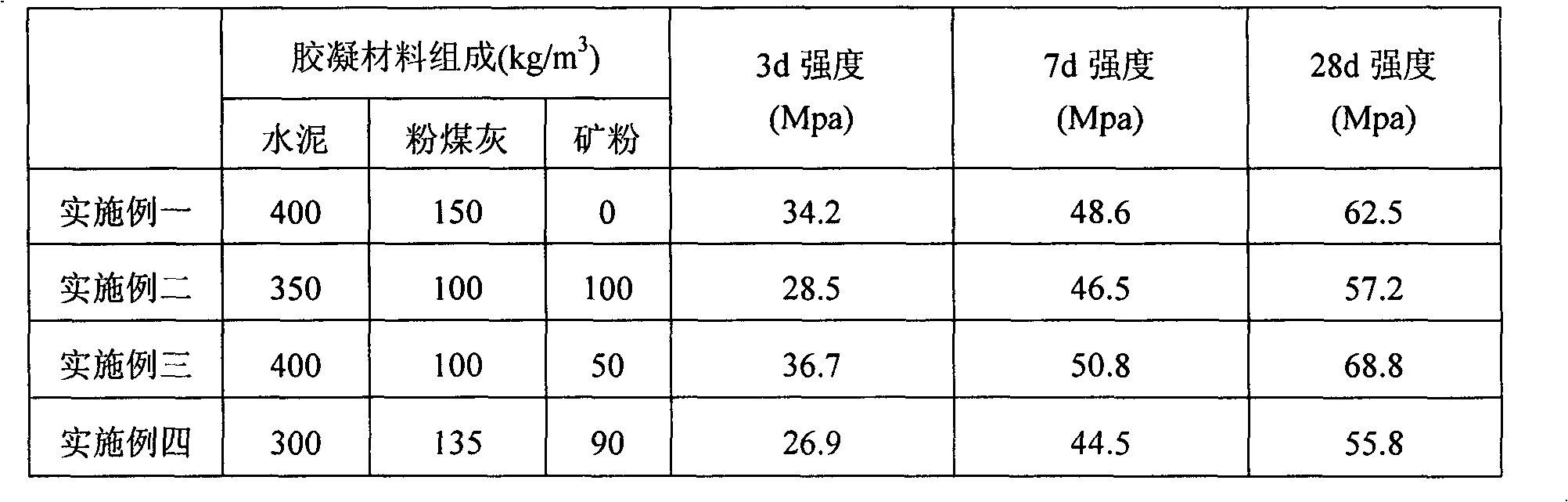

Embodiment 1

[0011] Make the machine-made sand self-compacting concrete 1m 3 , Take 400kg of cement, 150kg of fly ash, 0kg of mineral powder, 4kg of polycarboxylate superplasticizer, 920kg of machine-made sand, 560kg of pebbles, and 560kg of gravel. The machine-made sand is crushed from pebbles, with a fineness modulus of 2.8, gradation meeting the sand edge requirements in Zone II, and a stone powder content of 9%. The pebbles have a continuous gradation of 5-16mm, and the crushed stones have a continuous gradation of 10-20mm. Both the pebbles and the crushed stones have been washed with water, and the mud content is 0.4%. The cement is ordinary Portland cement with a strength grade of 42.5. The fly ash is Class I fly ash, and its water demand ratio is 100%. The mineral powder is S75 grade with a specific surface area of 360m 2 / kg, the fluidity ratio is 110%. The solid content of the polycarboxylate water reducer is 20%.

[0012] When in use, 200kg of water is mixed with the above...

Embodiment 2

[0014] Make the machine-made sand self-compacting concrete 1m 3 , Take 350kg of cement, 100kg of fly ash, 100kg of mineral powder, 2.8kg of polycarboxylate superplasticizer, 770kg of machine-made sand, 525kg of pebbles, and 525kg of gravel. The machine-made sand is crushed from pebbles, the fineness modulus is 2.5, the gradation meets the sand edge requirements in Zone II, and the stone powder content is 8%. The pebbles have a continuous gradation of 5-16mm, and the crushed stones have a continuous gradation of 10-20mm. Both the pebbles and the crushed stones have been washed with water, and the mud content is 0.35%. The cement is ordinary Portland cement with a strength of 52.5 strength grade. The fly ash is Class II fly ash, and its water demand ratio is 95%. The mineral powder is S75 grade with a specific surface area of 330m 2 / kg, the fluidity ratio is 108%. The solid content of the polycarboxylate water reducer is 20%.

[0015] When in use, 157.5kg of water is mix...

Embodiment 3

[0017] Make the machine-made sand self-compacting concrete 1m 3 , Take 400kg of cement, 100kg of fly ash, 50kg of mineral powder, 6kg of polycarboxylate superplasticizer, 1000kg of machine-made sand, 520kg of pebbles, and 520kg of gravel. The machine-made sand is crushed from pebbles, with a fineness modulus of 3.0, a gradation meeting the sand edge requirements in zone II, and a stone powder content of 10%. The pebbles have a continuous gradation of 5-16mm, and the crushed stones have a continuous gradation of 10-20mm. Both the pebbles and the crushed stones have been washed with water, and the mud content is 0.45%. The cement is ordinary Portland cement with a strength of 42.5R strength grade. The fly ash is Class II fly ash, and its water demand ratio is 98%. The mineral powder is S75 grade with a specific surface area of 390m 2 / kg, the fluidity ratio is 115%. The solid content of the polycarboxylate water reducer is 20%.

[0018] When in use, 240kg of water is mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com