Sealed type dust removal polishing machine

A polishing machine, closed technology, used in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. problems, to reduce labor intensity, ensure physical health, and avoid noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

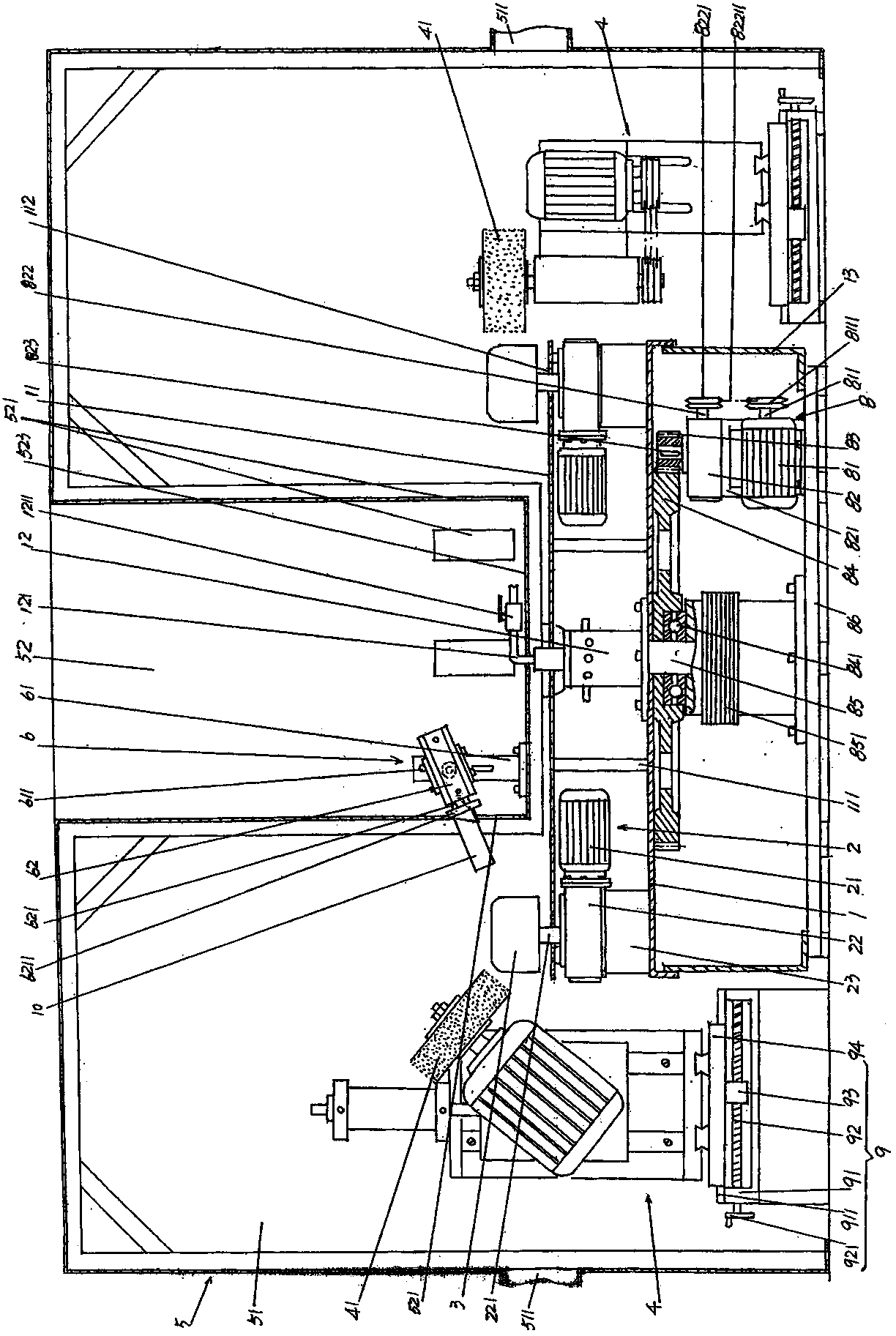

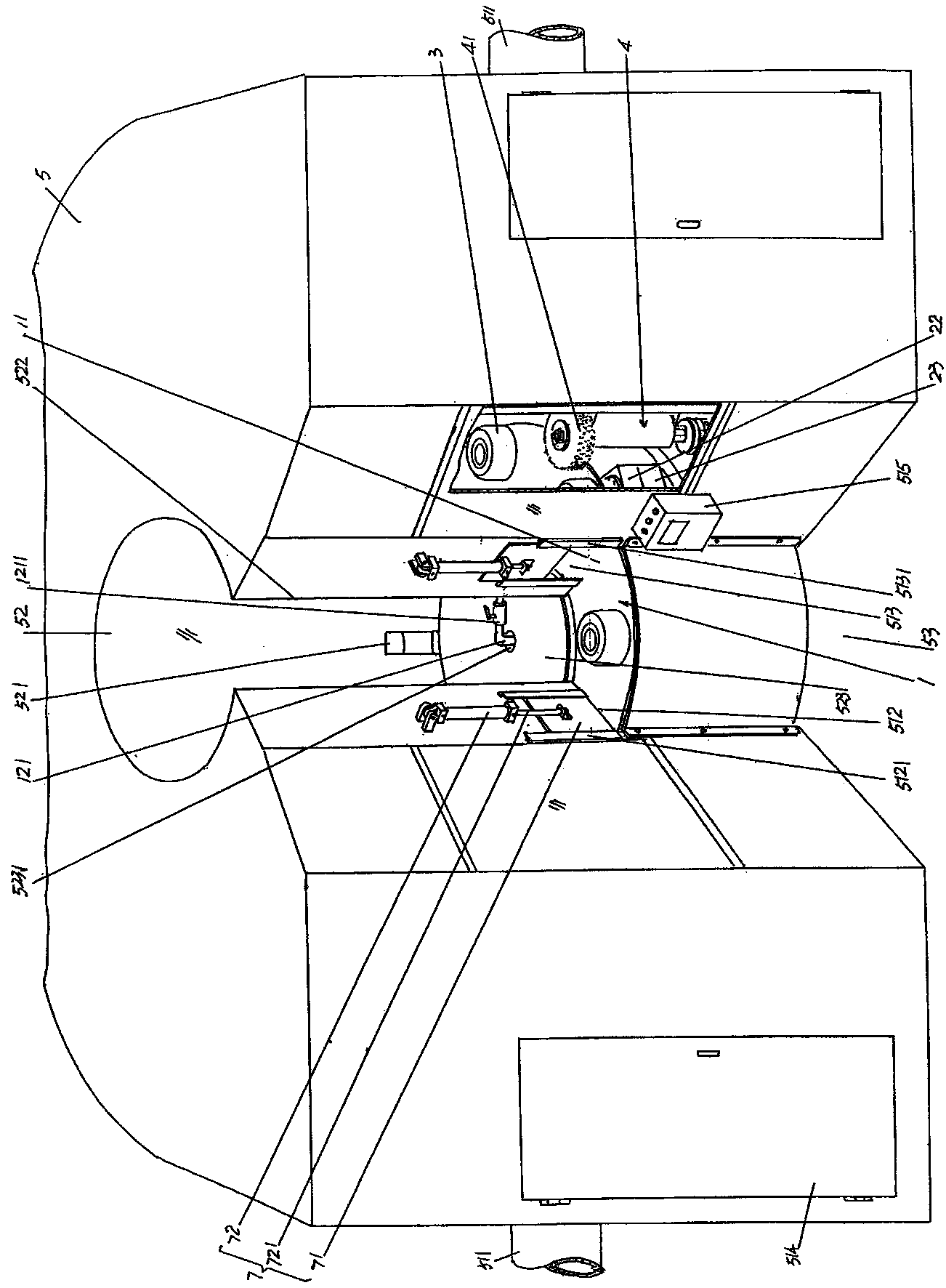

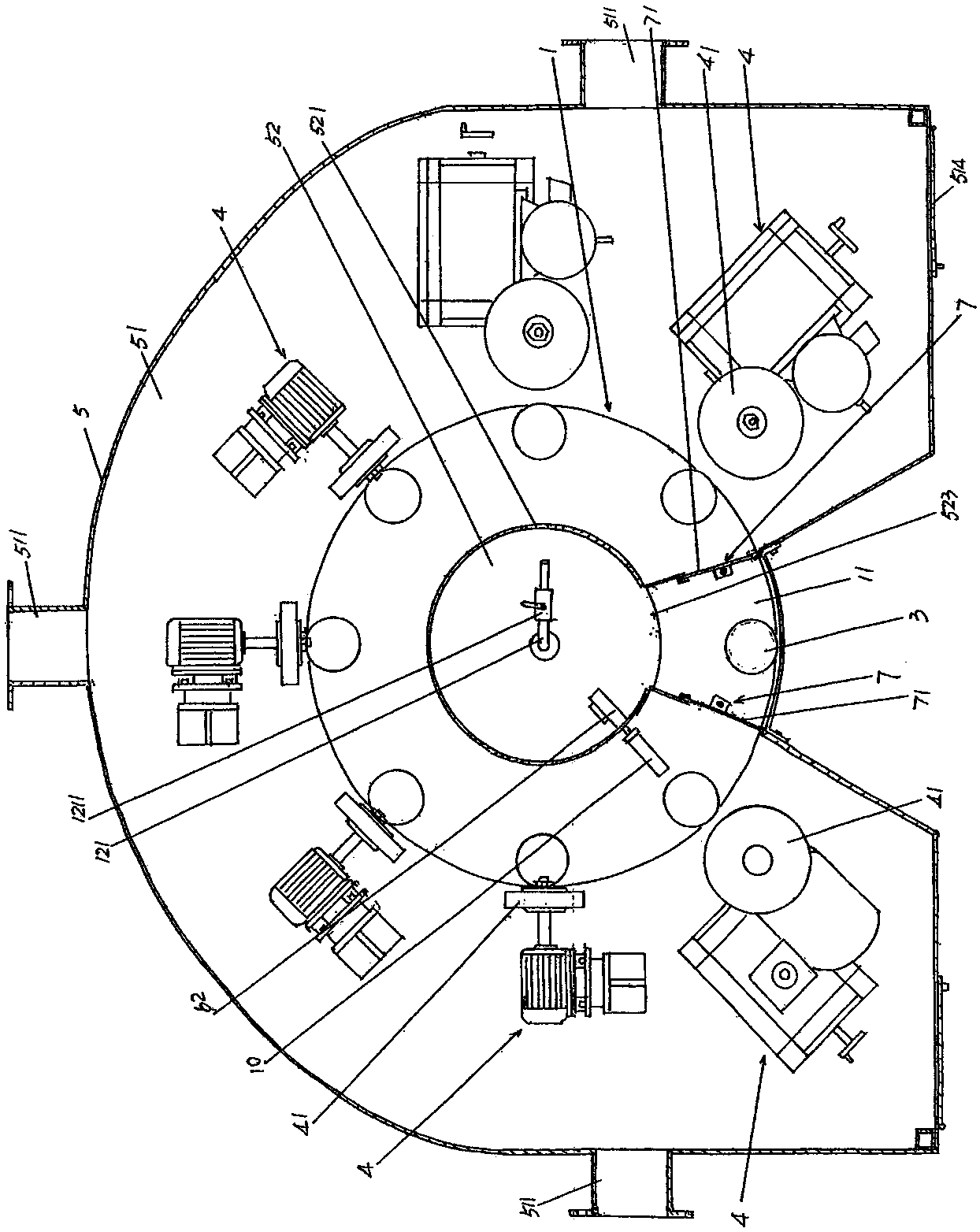

[0025] See figure 1 with figure 2 , a polishing turntable 1 is given, the polishing turntable 1 is disc-shaped, and a set of mold driving mechanisms 2 are arranged at intervals on the upward facing side of the polishing turntable 1 around the circumferential direction of the polishing turntable 1 edge position, and a set of dies 3 is provided on the upper part of the set of die drive mechanism 2, that is to say each die drive mechanism 2 is equipped with a die 3, the shape and size of the die 3 is the same as Compatible with the workpiece to be polished. Since this embodiment is aimed at the polishing of stainless steel pots made of stainless steel and food-grade stainless steel, the concept of the workpiece is a stainless steel pot, and the shape and size of the cover mold 3 are compatible with the cavity of the stainless steel pot. basin or cup, then the shape and size of cover mold 3 are adapted to the cavity of stainless steel basin or stainless steel cup.

[0026] A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com