Patents

Literature

169 results about "Waxing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waxing is the process of hair removal from the root by using a covering of a sticky substance, such as wax, to adhere to body hair, and then removing this covering and pulling out the hair from the follicle. New hair will not grow back in the previously waxed area for four to six weeks, although some people will start to see regrowth in only a week due to some of their hair being on a different human hair growth cycle. Almost any area of the body can be waxed, including eyebrows, face, pubic hair (called bikini waxing), legs, arms, back, abdomen, knuckles, and feet. There are many types of waxing suitable for removing unwanted hair.

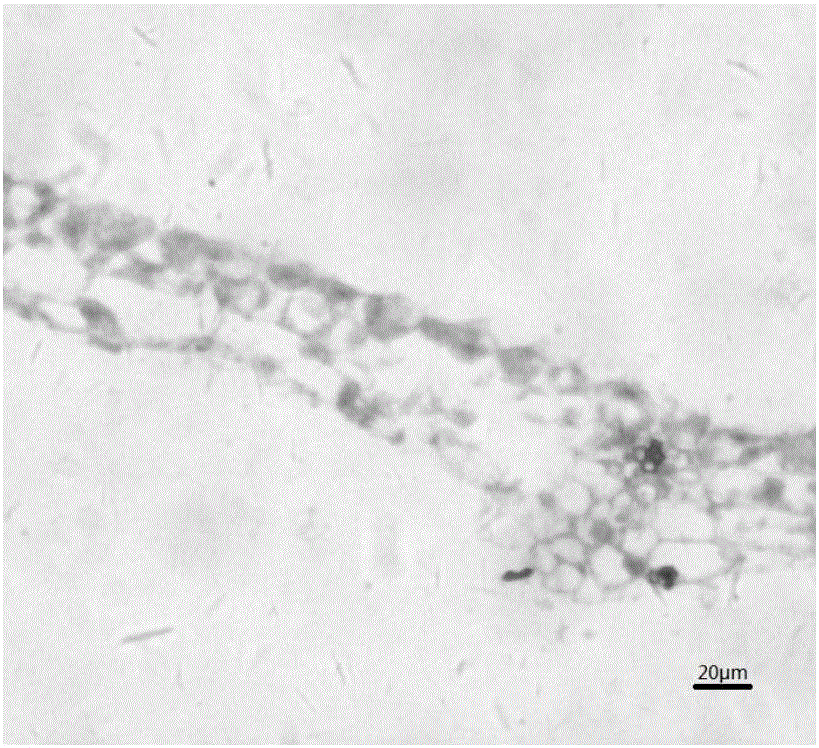

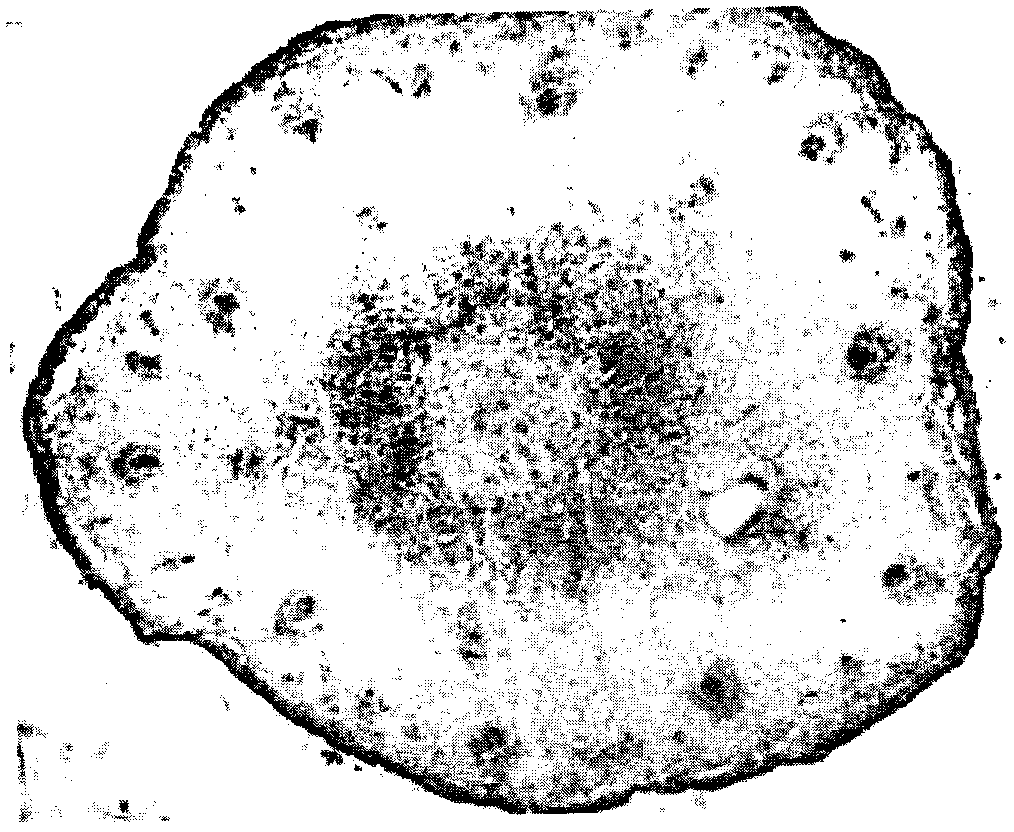

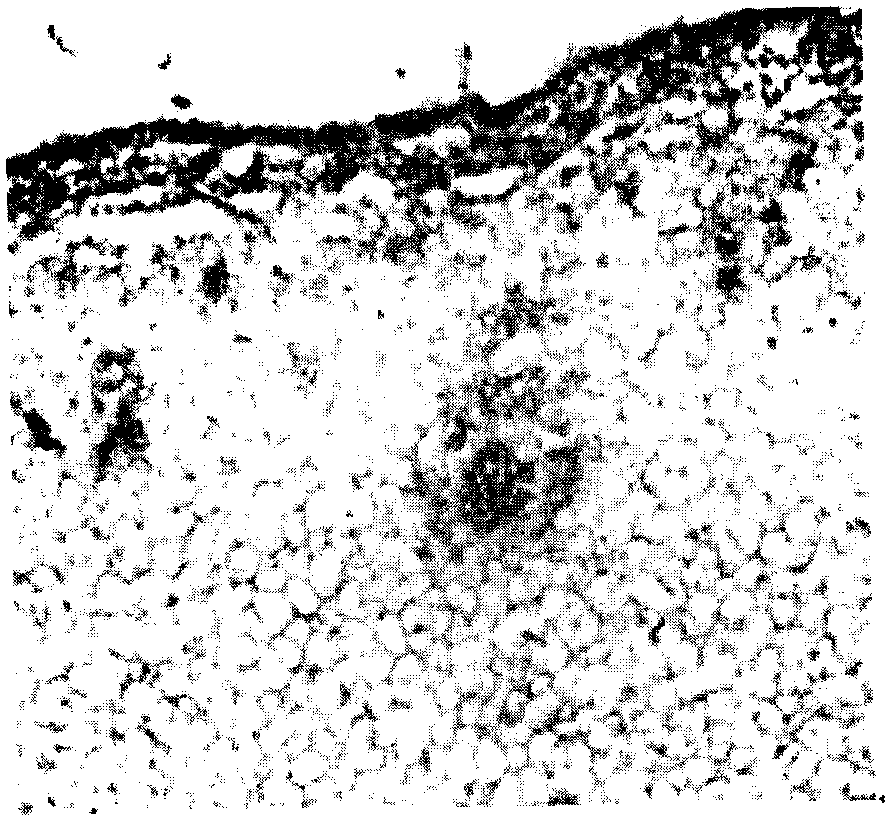

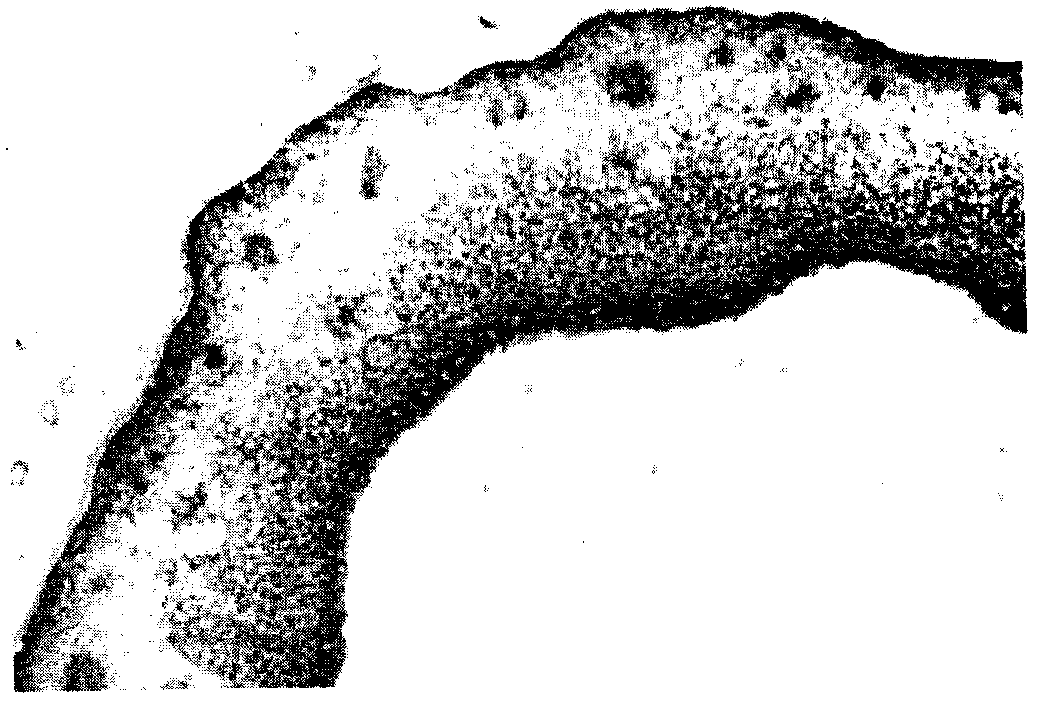

Production method for paraffin section of paeonia lactiflora mature embryo

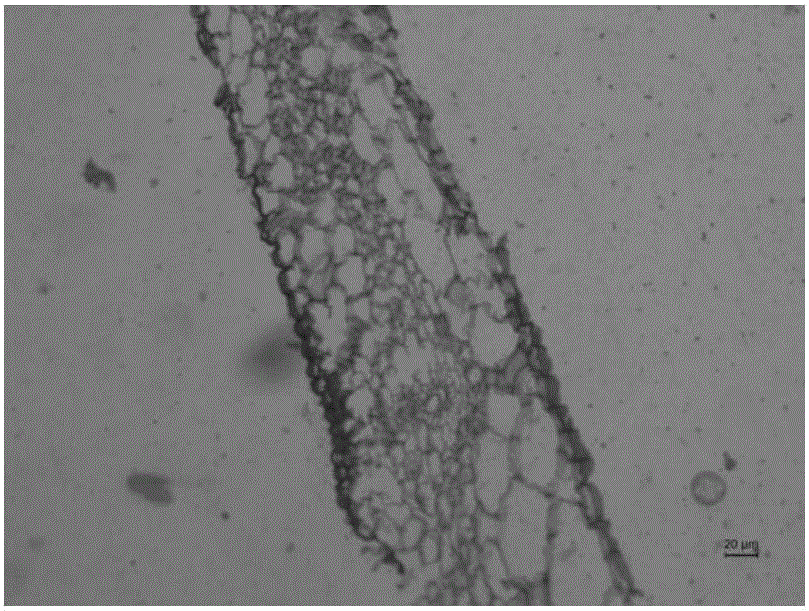

InactiveCN103630421AComplete structureClear structureWithdrawing sample devicesPreparing sample for investigationWater bathsParaffin wax

The invention discloses a production method for a paraffin section of a paeonia lactiflora mature embryo. The production method comprises the following steps: drawing materials and fixing: stripping a seed coat, cutting a seed, immersing the seed top part containing the embryo or part endosperm into a FAA stationary liquid, and fixing for more than 24 hours; dehydrating: washing in ethyl alcohol with the concentration of 70% for 3 to 5 times, and performing gradient dehydration from the ethyl alcohol with the concentration of 70%; performing hyalinization: carrying out five level hyalinization by using dimethyl benzene as a transparent reagent; waxing and embedding: pouring out one half volume of dimethyl benzene, adding wax crumbs in a bottle until saturation, staying overnight at the temperature of 40 DEG C; then changing a wax liquid every two hours for three times per day, repeating for three days, and carrying out conventional paraffin embedding; slicing; flattening and bonding: flattening a linoleum tape on an iron plate of a water bath kettle at the constant temperature of 50 DEG C, dewaxing, rehydrating, dyeing through safranine and fast green and performing hyalinization; mounting. According to the invention, the paeonia lactiflora mature embryo paraffin section of which the tissue structure is integrated and clear can be obtained, so that accurate technical support can be provided for researching paeonia lactiflora seed dormancy and germination.

Owner:SHENYANG AGRI UNIV

Cleaning polishing wax with photocatalytic performance

InactiveCN102936462ANo secondary pollutionExcellent photocatalytic environmental performanceAqueous dispersionsOil emulsionOil phase

The invention discloses a cleaning polishing wax with photocatalytic performance, particularly a wax / oil emulsion with photocatalytic function capable of being applied onto the surfaces of leather, furniture, metals, plastics, artificial boards and the like, belonging to the technical field of chemical engineering. The cleaning polishing wax with photocatalytic performance is prepared from the following raw materials in parts by weight: 1-55 parts of oil phase, 0.5-30 parts of emulsifier, 0.01-10 parts of anatase crystal form nano titanium dioxide and 10-120 parts of water. The cleaning polishing wax has the functions of cleaning, polishing and waxing, and more importantly, has environmental protection property of photocatalytically degrading organic pollutants. The cleaning polishing wax can complete cleaning, polishing and waxing at one time; and under the light irradiation, the cleaning polishing wax can continuously decompose formaldehyde, benzenes, amines, TVOC (total volatile organic compound) and other organic pollutants which are released by the substrate or float in air under the photocatalytic action. The invention does not produce irritating smell or secondary pollution.

Owner:孙强

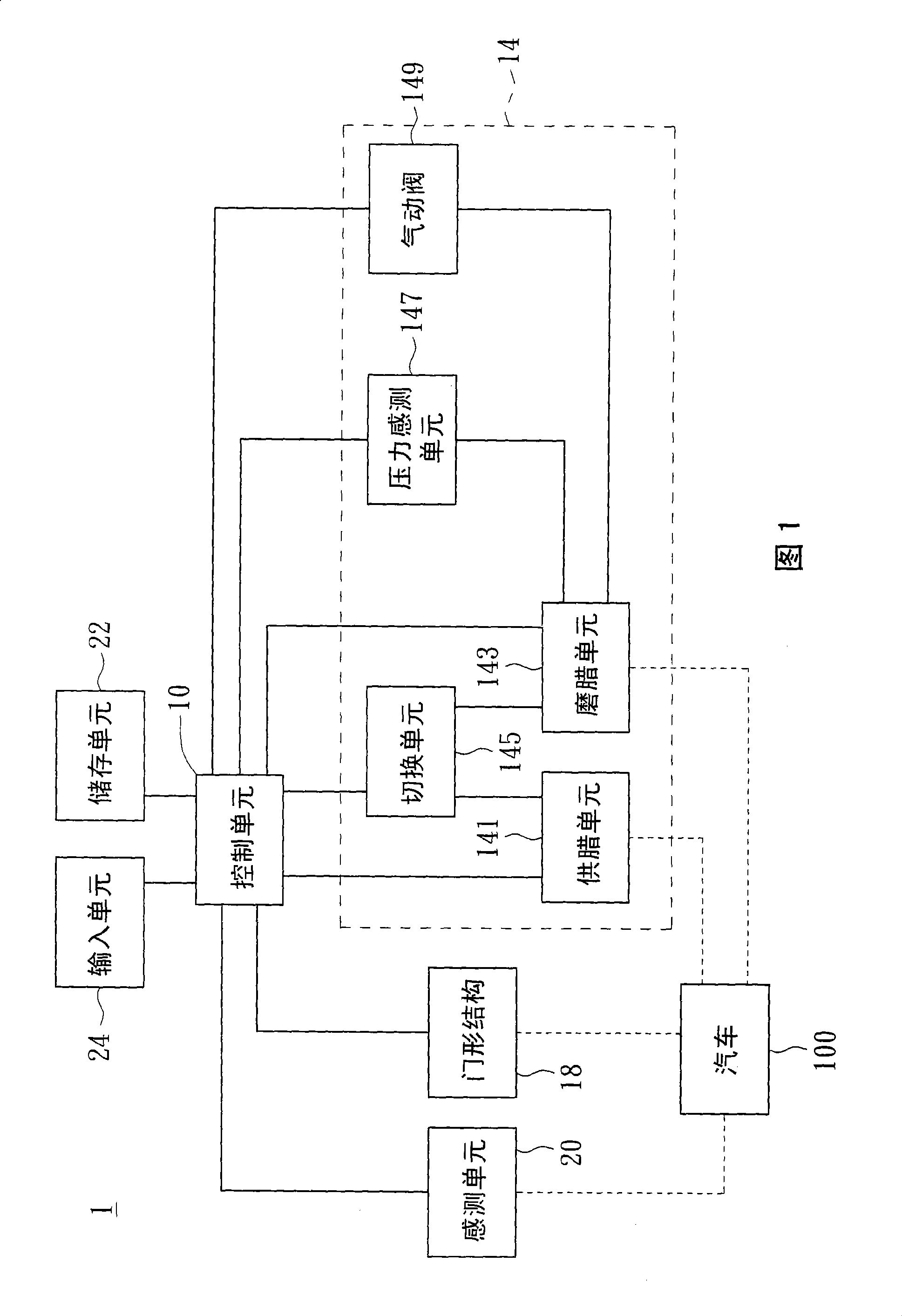

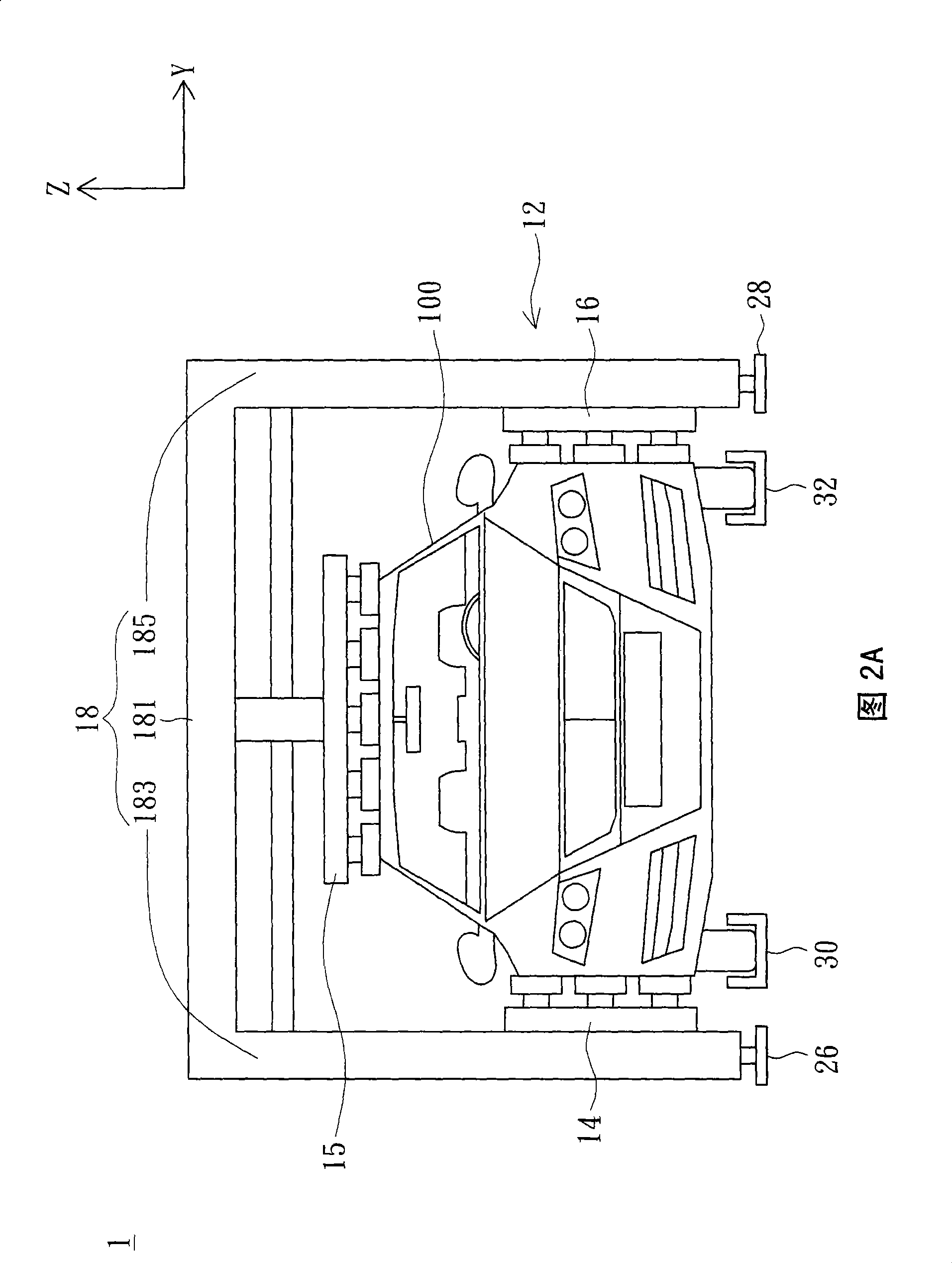

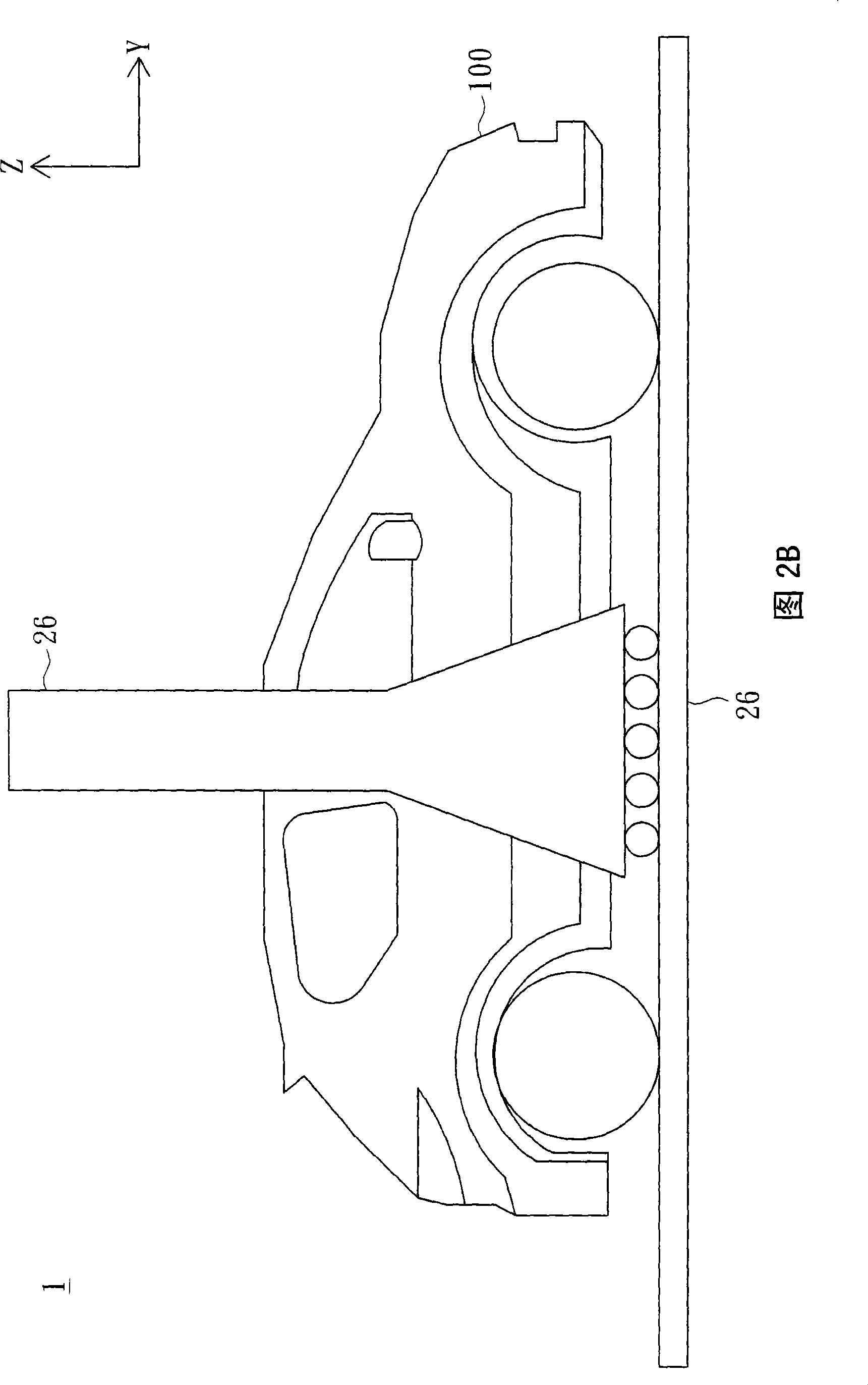

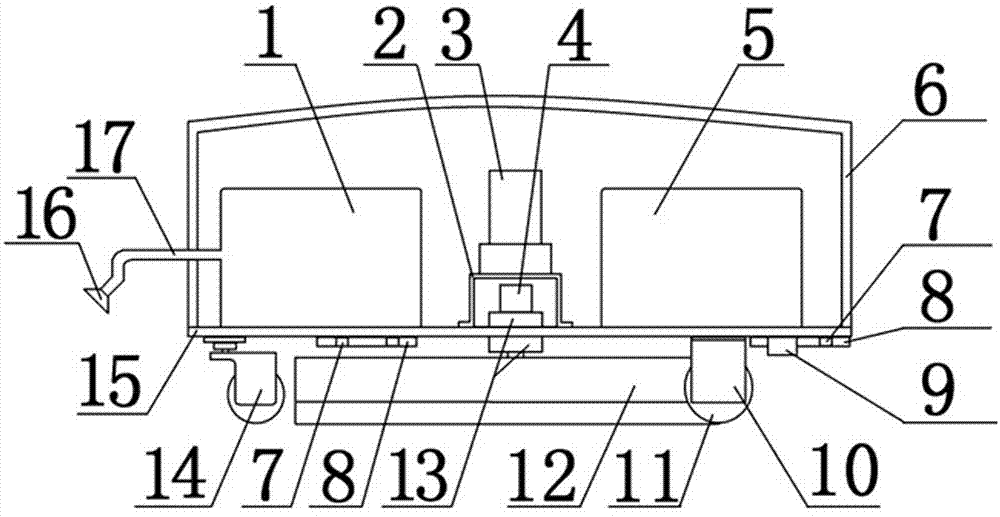

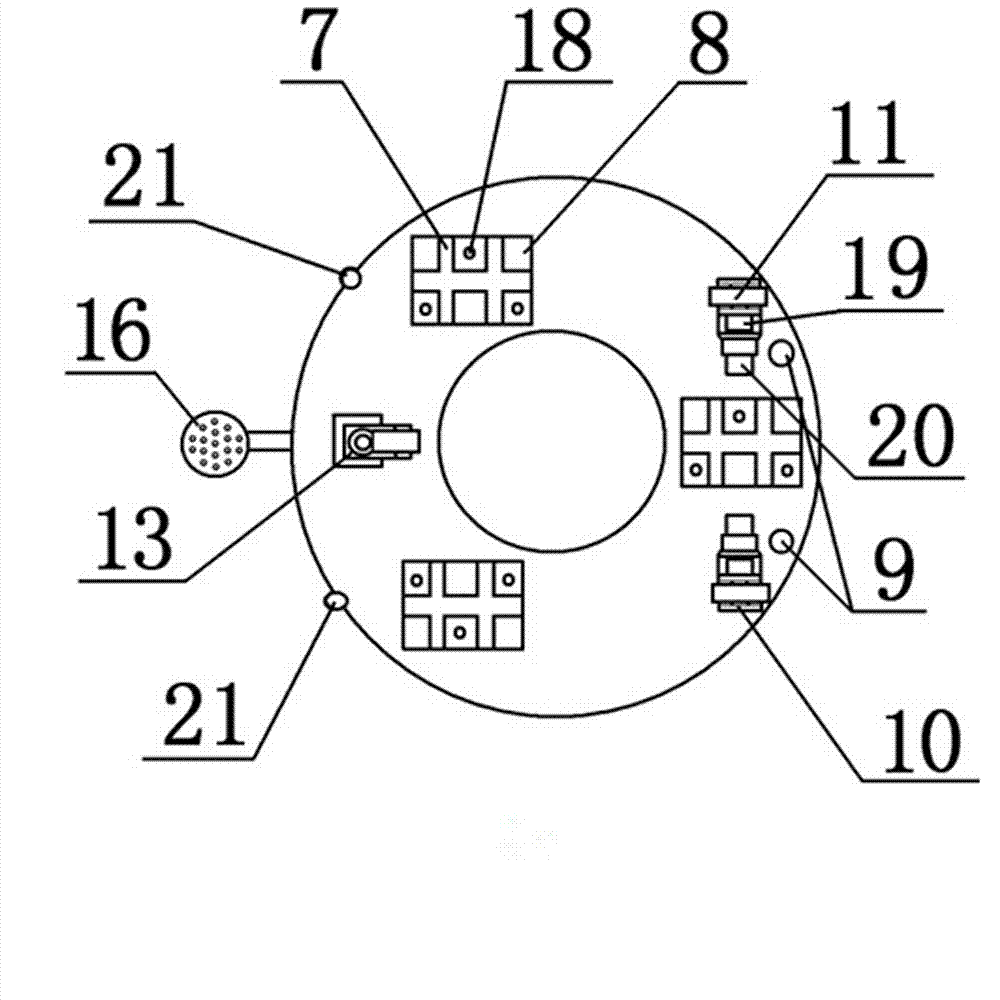

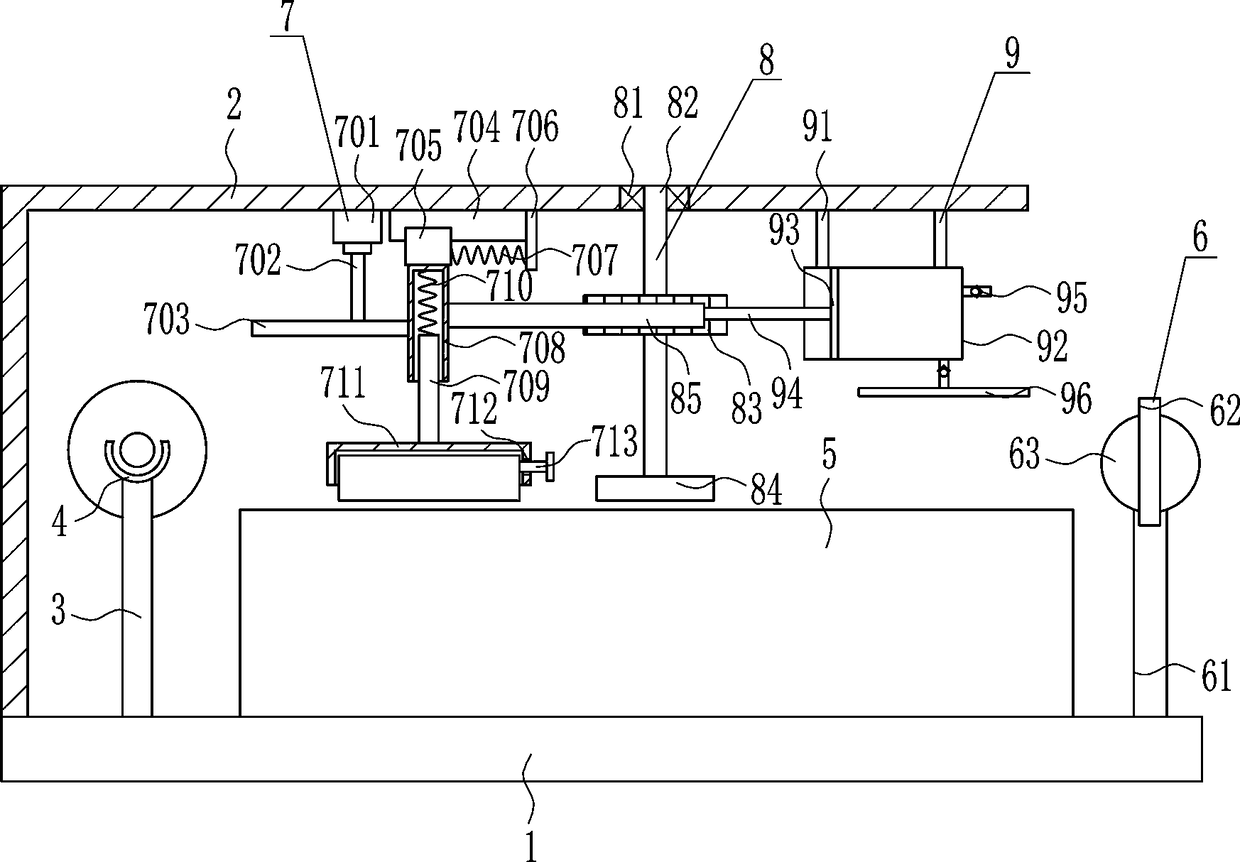

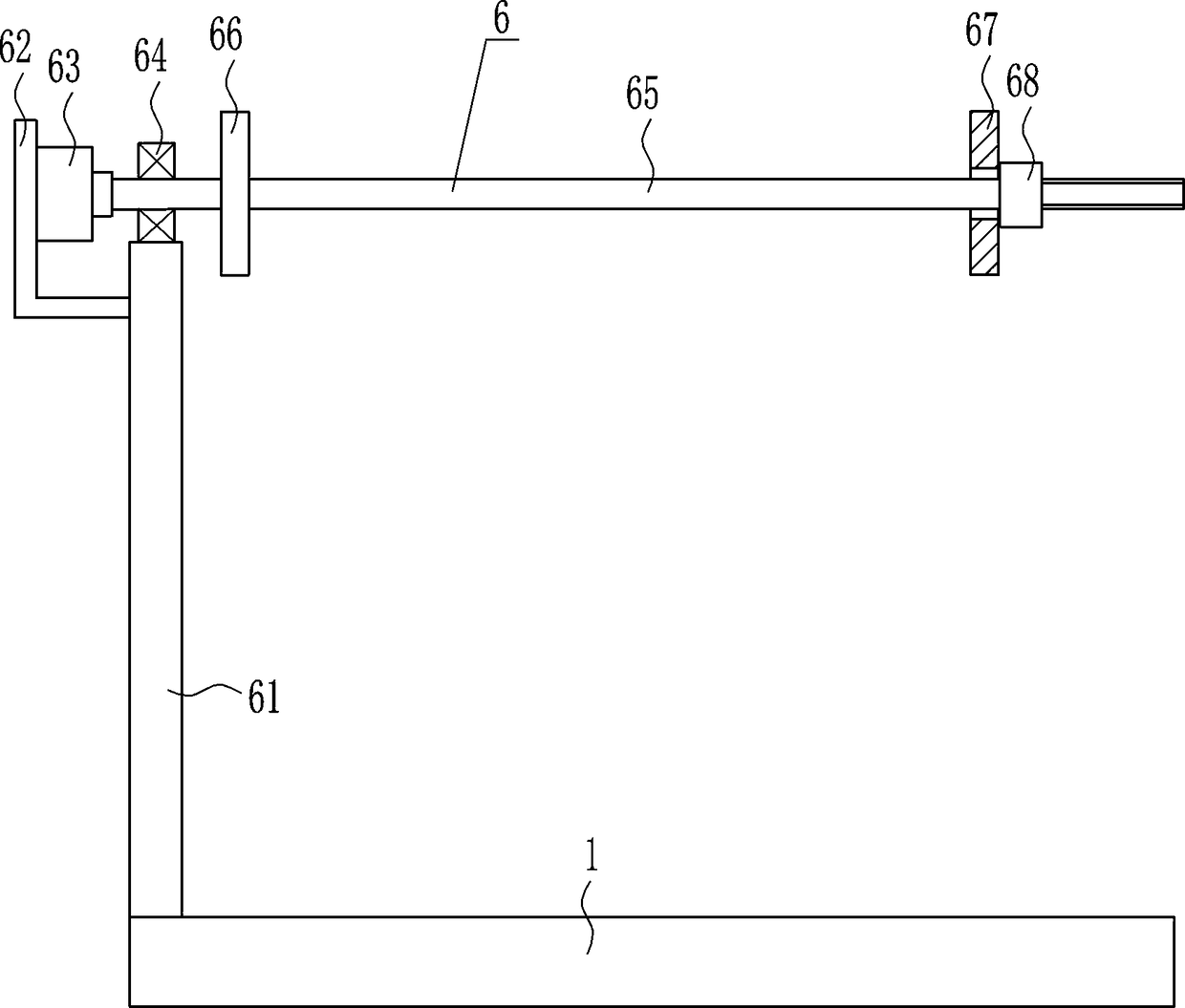

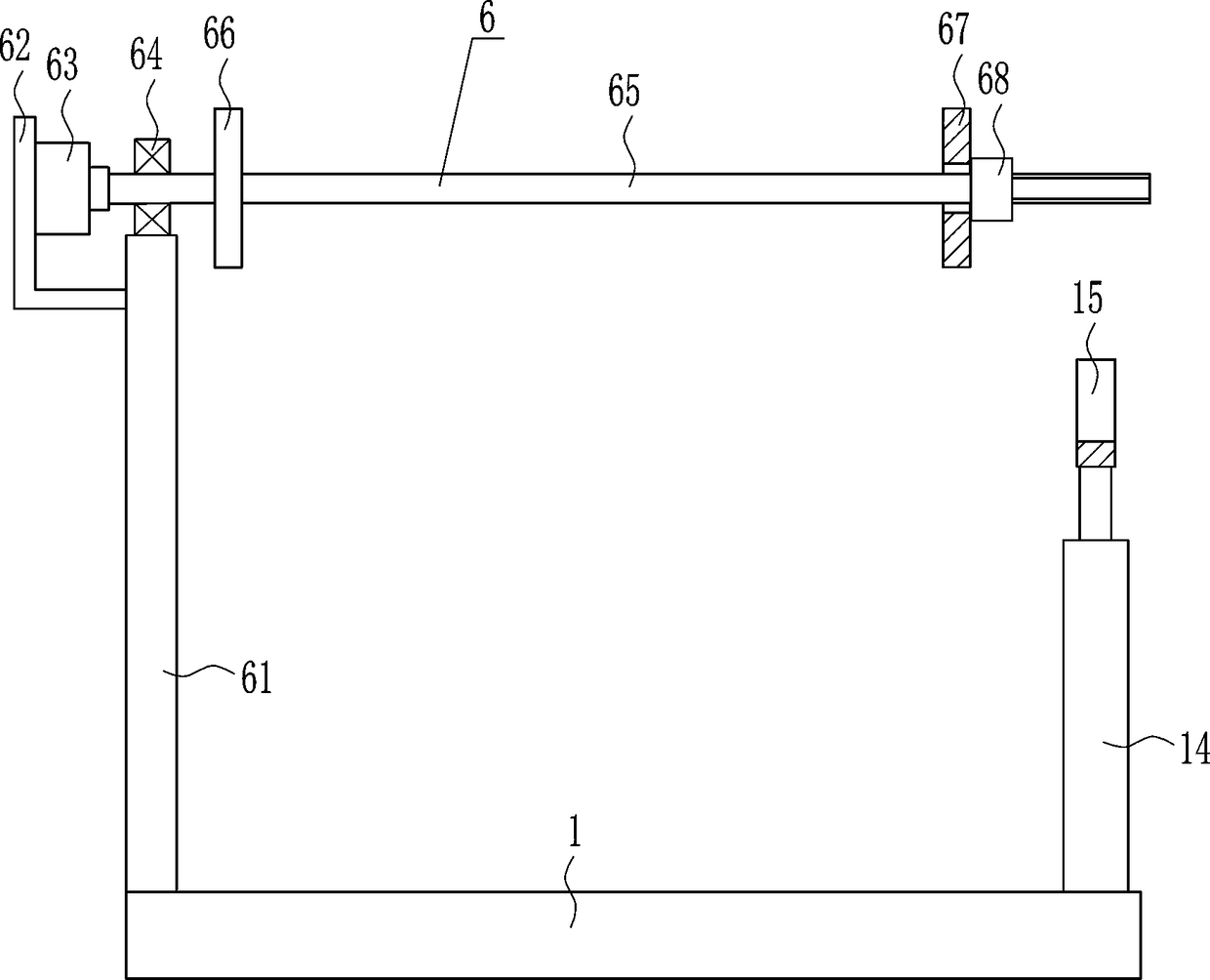

Automatic waxing device and method

ActiveCN101372004AReduce manpower expenditureReduce volumePretreated surfacesCleaning apparatus for vehicle exteriorsWaxingAutomation

The invention provides an automation wax polishing device and a method thereof, which is applied to an automobile. The automation wax polishing device comprises a mobile door-shaped module, at least a wax polishing module and a control module. The mobile door-shaped module comprises a door-shaped structure which can move corresponding to the automobile. The wax polishing module is arranged on a door-shaped structure. And the wax polishing module comprises a wax-supply unit and a wax-grinding unit. The control module is coupled with the door-shaped structure, the wax polishing unit and the wax grinding unit, wherein, the control module determines the shift motion of the door-shaped structure corresponding to the automobile according to the data of the automobile, the waxing motion of the waxing-supply unit on the automobile and the waxing-grinding motion of the waxing-grinding unit on the automobile.

Owner:IND TECH RES INST

Tissue paraffin section de-waxing method

InactiveCN1975367AOvercome operabilityOvercome the polluted environmentPreparing sample for investigationParaffin waxMedicine

This invention disclosed a de-waxing method used for paraffin-cut section. De-waxing solution was prepared by mixing distilled water and Triton X-100 by volume ratio of 99:1. It can be used by the following procedure: place the slice into the first de-wax solution and dip for 10-2 minutes at 60-70DEG C; take it out and place it to the second de-wax solution and repeat the above operation; wash it by water. The solution Triton X-100 used in this invention was safe, cost save, environmental friendly and it's easy to handle.

Owner:NANKAI UNIV

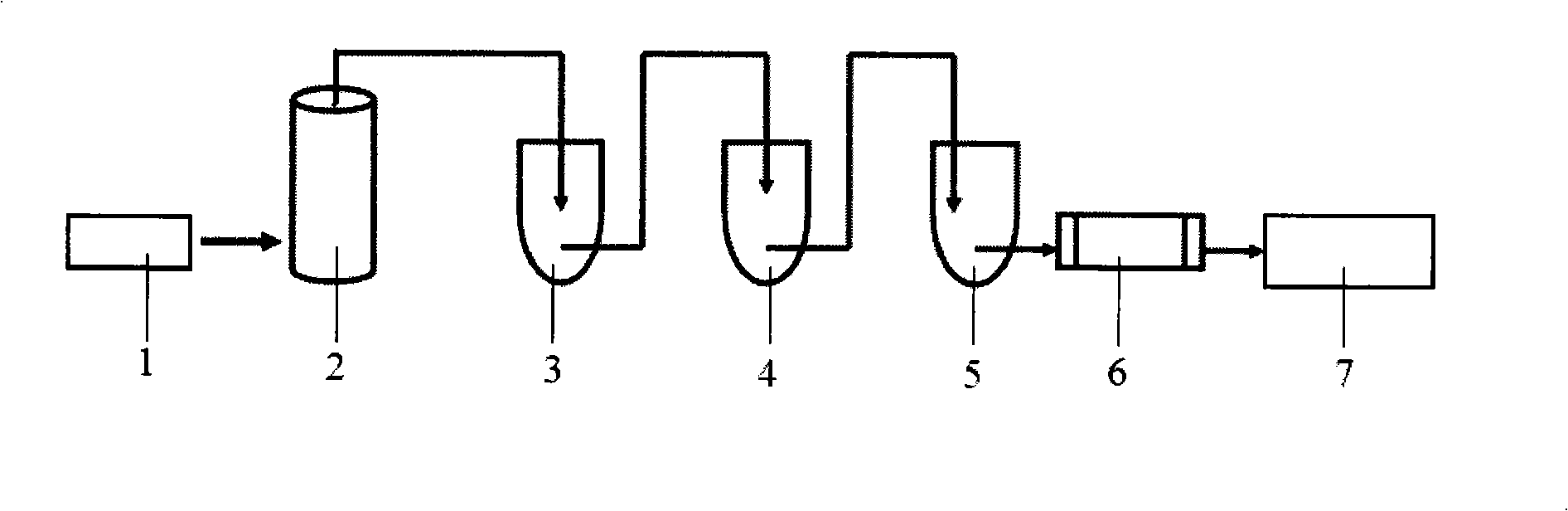

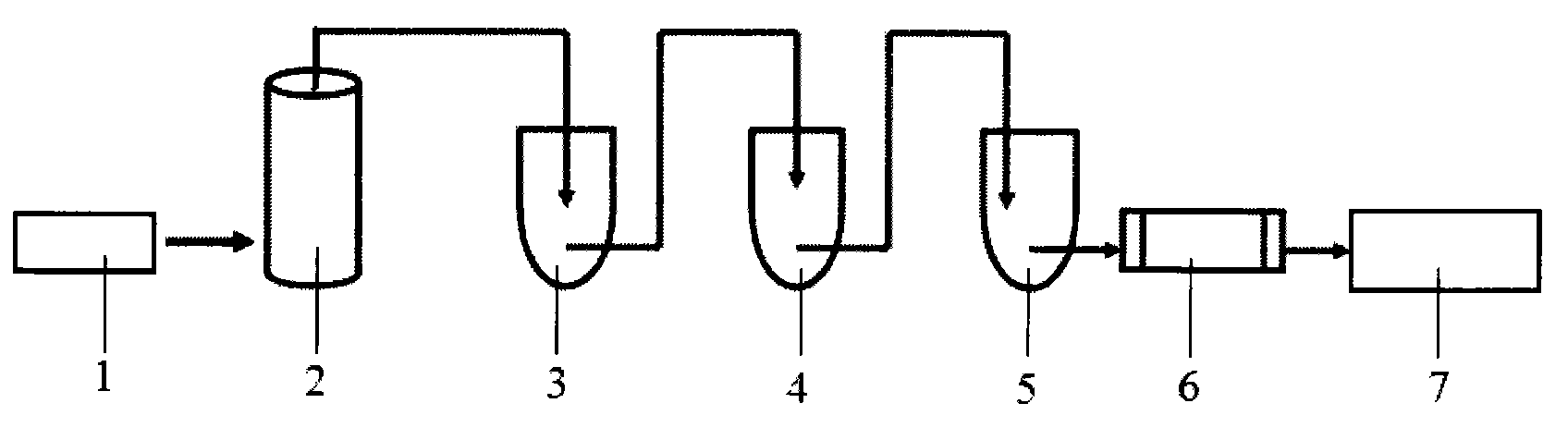

De-waxing and refining production process of corn germ oil

InactiveCN102757863AFatty-oils/fats/waxes solidificationFatty-oils/fats refiningHeating oilNational standard

The invention provides a de-waxing and refining production process of corn germ oil. The production process sequentially comprises the following steps of: 1, dissolution stage, to be specific, heating oil to be de-waxed to 45 DEG C and fully dissolving wax in the oil; 2, crystallization stage, wherein the temperature range from 35 DEG C to 28 DEG C is the main precipitation period of wax, the wax is separated out at 35 DEG C to 33 DEG C for 280 min, the wax is separated out at 33 DEG C to 30 DEG C for 200 min, and the wax is separated out at 30 DEG C to 28 DEG C for 280 min; and 3, crystal growing stage, wherein the temperature range from 25 DEG C to 12 DEG C is the main crystal growing time; the crystals are grown at 25 DEG C to 22 DEG C for 180 min, the crystals are grown at 22 DEG C to 18 DEG C for 180 min, and the crystals are grown at 18 DEG C to 15 DEG C for 160 min. Meanwhile, the stirring speed is reduced to 8-10 rpm. According to the production process, disclosed by the invention, parameters of the three key procedures including dissolution, crystallization and crystal growing and main technical indexes of the corn oil are formulated, crystallization rate is improved, corn oil quality is improved favorably and the quality of the corn oil is enabled to reach the first level of national standard.

Owner:哈尔滨天通农业科技开发有限公司

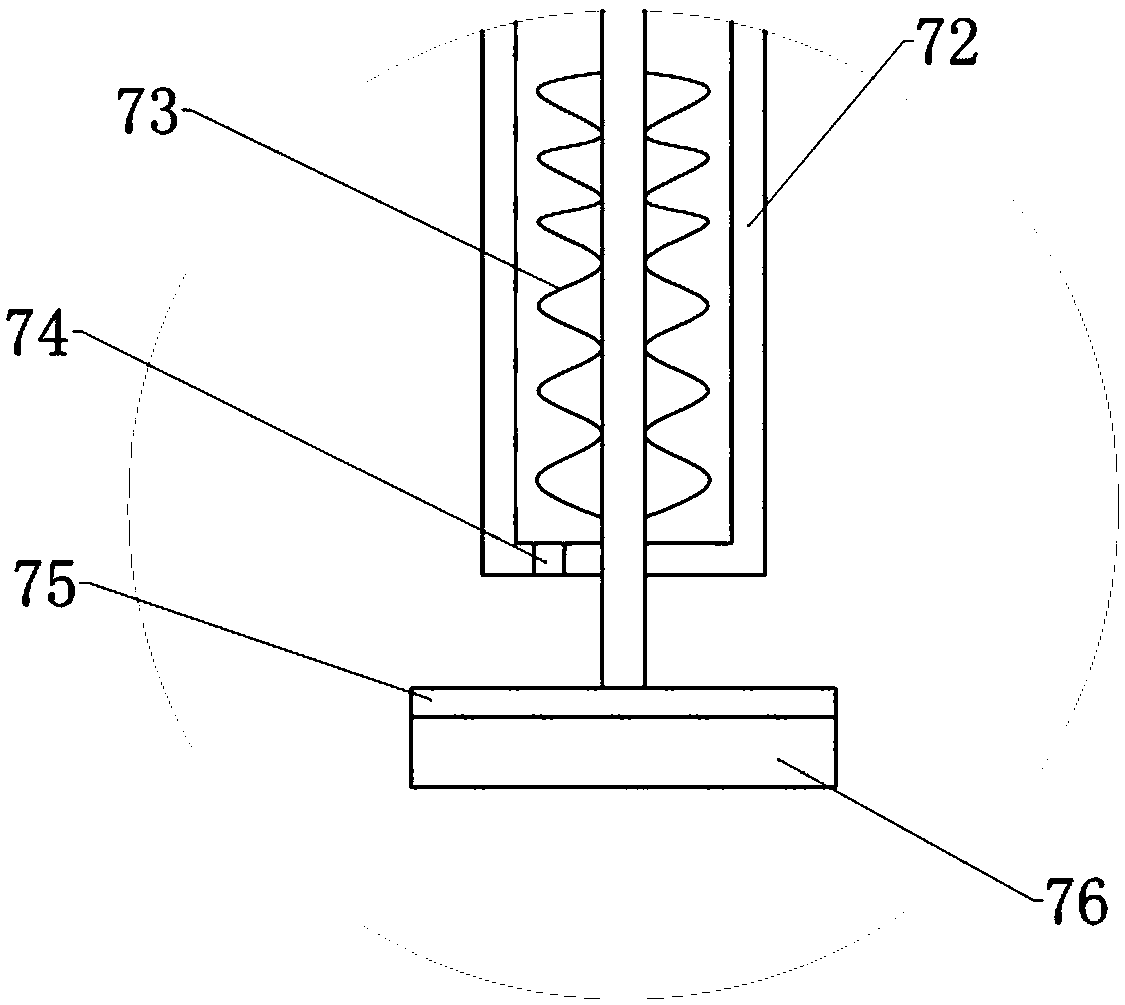

Tight type yarn waxing mechanism for spinning

The invention discloses a tight type yarn waxing mechanism for spinning. The yarn waxing mechanism comprises a first waxing component and a second waxing component; each of the first waxing componentand the second waxing component comprises a base, a supporting rod, a guiding wheel, a telescopic pipe, a supporting plate, an air pump, a fixing component and a wax block; each supporting plate is fixed to the top of the corresponding telescopic pipe; one of the two air pumps is mounted at the front end of the corresponding supporting plate; the other air pump is mounted at the back end of the corresponding supporting plate; the two air pumps are connected with telescopic rods; each of the two telescopic rods is provided with one fixing component; a groove is formed in one side of each fixingcomponent; each wax block is mounted inside the corresponding groove; and shock absorbing components are arranged on the sides, close to each other, of the two fixing components. According to the mechanism, the two wax blocks are driven by the two telescopic rods to perform extruding waxing on yarn simultaneously, the yarn can be waxed sufficiently in all directions, and thus the waxing quality of the yarn can be improved; and the shock absorbing components are arranged on the fixing components, so that vibration is reduced during working of the waxing mechanism, the yarn is more stable during waxing, and the working precision is improved.

Owner:ANHUI RUIHUA COTTON IND DEV CO LTD

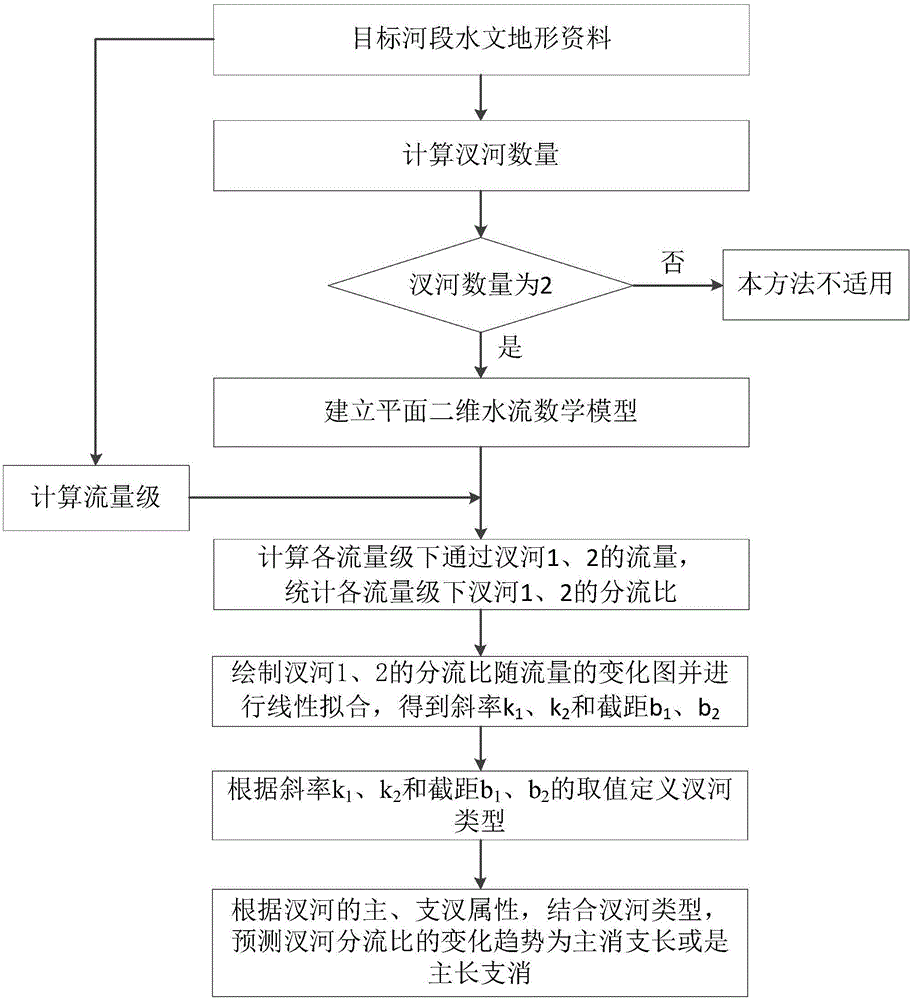

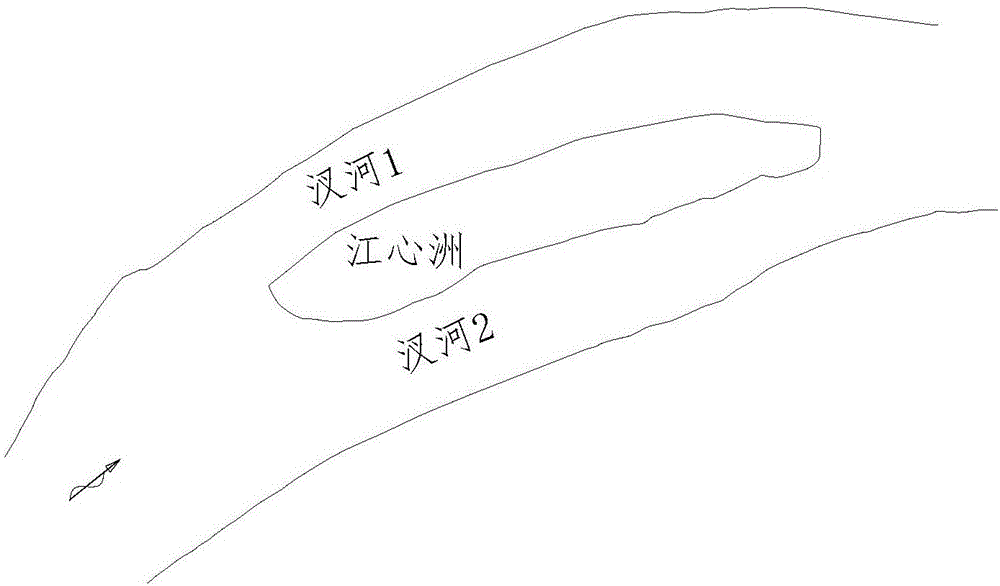

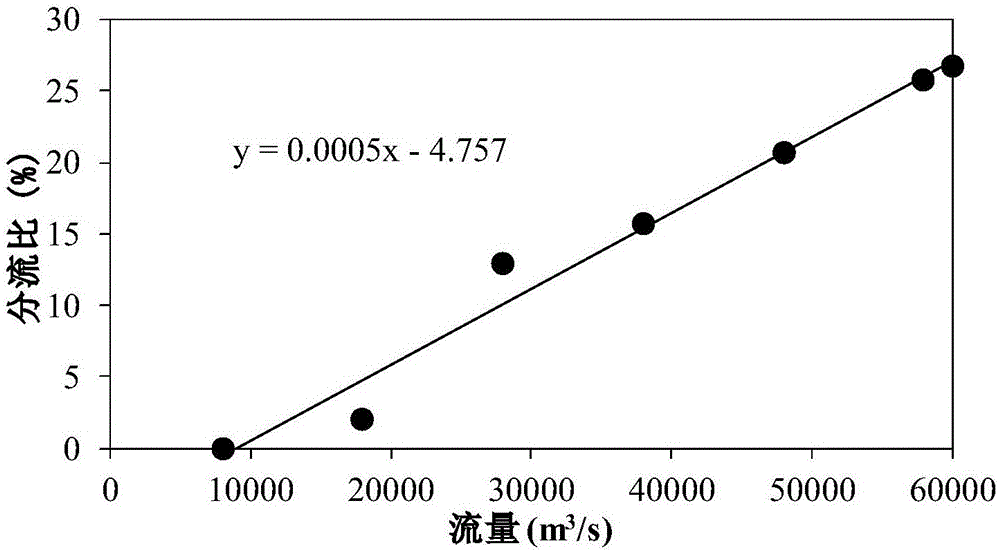

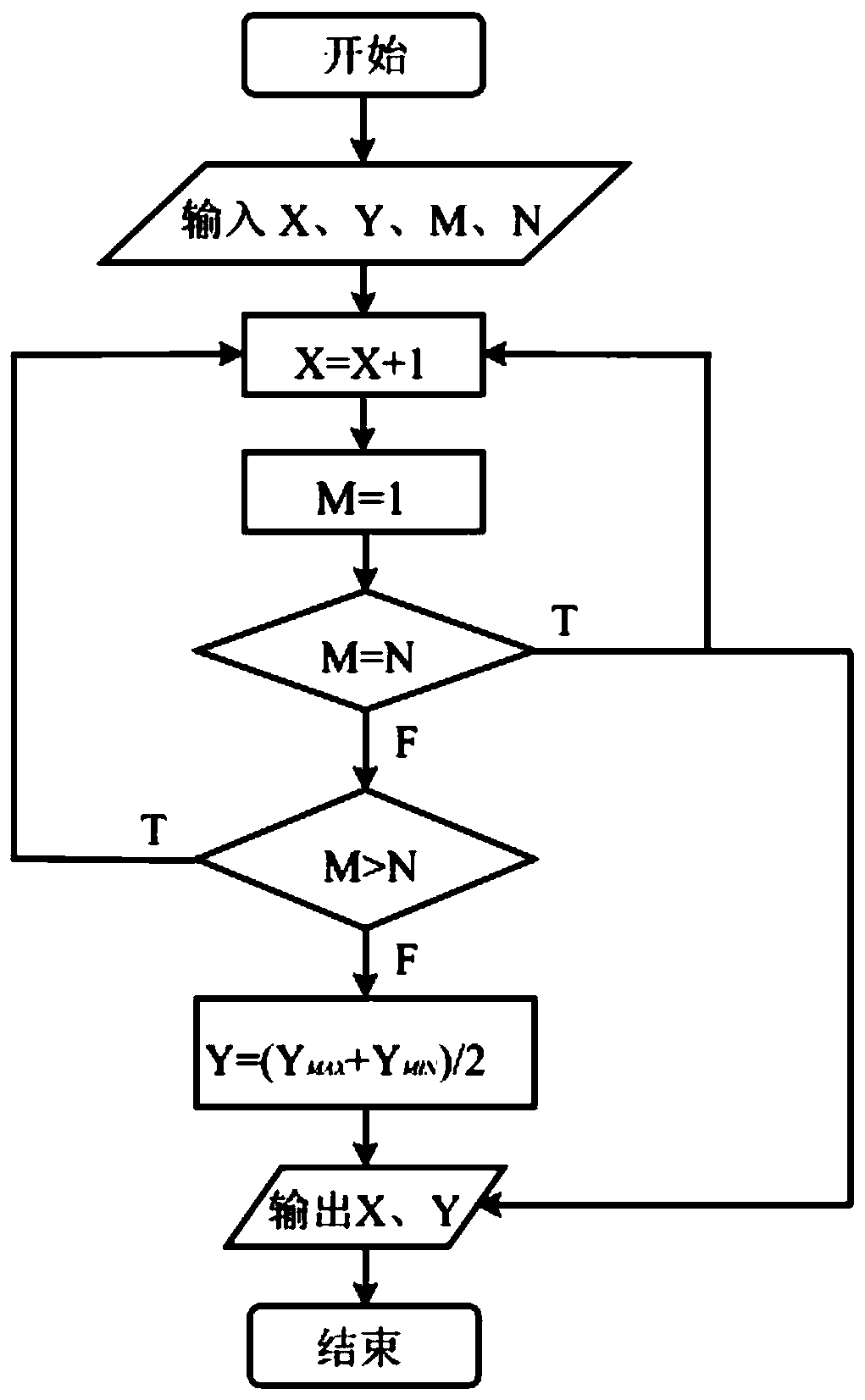

Method for predicting diversion ratio change of distributary channels of two-stage bifurcated riverway in the downstream of reservoir

InactiveCN106372375AEasy to plan and designClimate change adaptationForecastingPredictive methodsEngineering

The invention provides a method for predicting diversion ratio change of distributary channels of a two-stage bifurcated riverway in the downstream of a reservoir. The method comprises the following steps that a planar two-dimensional water flow mathematic model is established, and parameter calibration and verification are performed; the flow range from the minimum flow to maximum flow of a target river section is equally divided into multiple flow levels, and statistics is conducted on the diversion ratio of the two distributary channels at all flow levels; variation diagrams of the diversion ratio with flows of the two distributary channels are respectively drawn, and linear fitting is performed to obtain slope and an intercept; according to values of the slope and the intercept, the types of the distributary channels are defined; it is predicted that the variation trend of the diversion ratio of the two distributary channels is main waxing and distributary waning or main waning and distributary waxing. According to dynamic change indexes of the diversion ratio of the distributary channels and the flows, the distributary channel of the two-stage bifurcated riverway is divided into a flood tendency distributary channel and a water shortage tendency distributary channel, the diversion ratio of the distributary channels is dynamically related with hydrodynamic conditions, the diversion ratio change of the distributary channels of the bifurcated riverway is accurately predicted according to hydrological change characteristics of the downstream of the reservoir, and planning and design of an airway is further promoted.

Owner:WUHAN UNIV

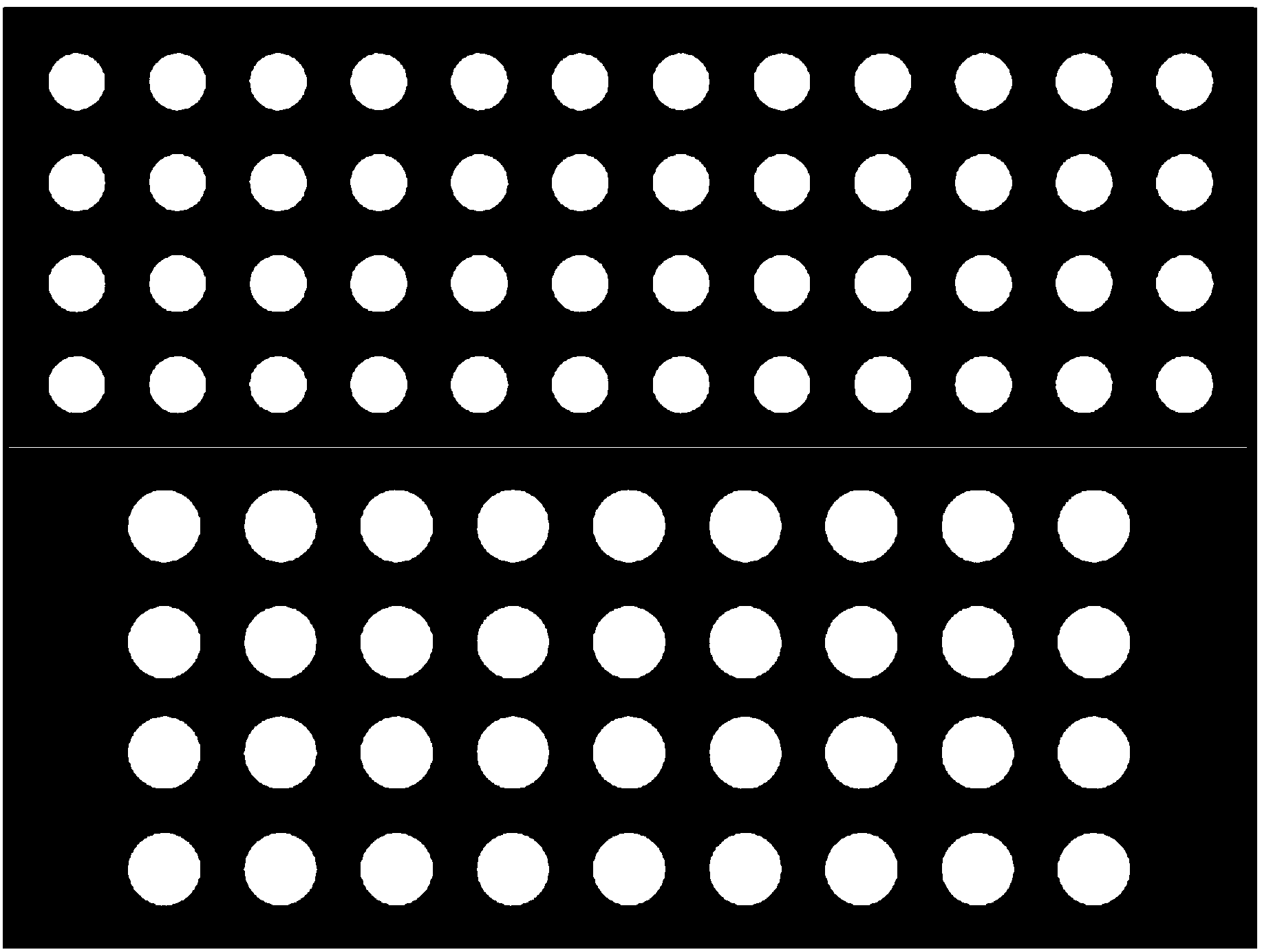

Wax screen printing processing method for cloth-based microfluidic analytical chip

ActiveCN104226389AEasy to operateThe method flow is simpleLaboratory glasswaresScreen printingHigh flux

The invention discloses a wax screen printing processing method for a cloth-based microfluidic analytical chip. The method comprises the following steps: placing cotton cloth in a container, adding water to the container and boiling; taking out the cotton cloth, drying the moisture, placing the dried cotton cloth in another container, and adding a sodium carbonate solution to soak the cotton cloth; taking out the cotton cloth, washing the cloth with water and drying; flattening the processed cotton cloth on a platform, covering a screen printing board with a designed pattern on the cotton cloth, waxing and milling; roasting the screen board and the cotton cloth together; after roasting, separating the cotton cloth from the screen board to obtain the cloth-based microfluidic analytical chip. The method disclosed by the invention is to directly coat the wax on the cotton cloth through the screen board, and then heat and fuse the wax to penetrate in the cotton cloth without other media to transfer, so that the utilization efficiency of the wax is high and the utilization effect is good. In addition, the chip prepared by the method has the characteristics of high flux and high resolution.

Owner:SOUTH CHINA NORMAL UNIVERSITY

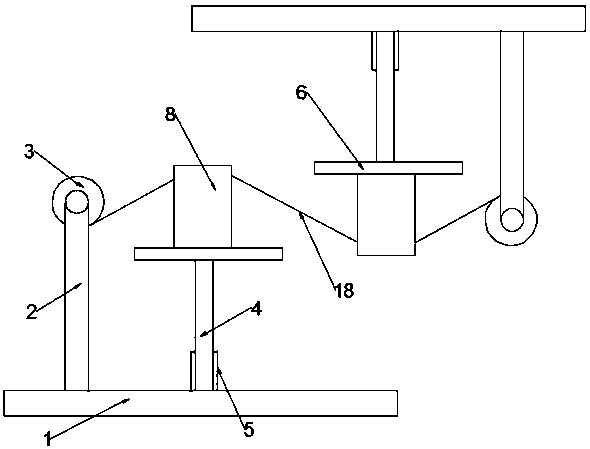

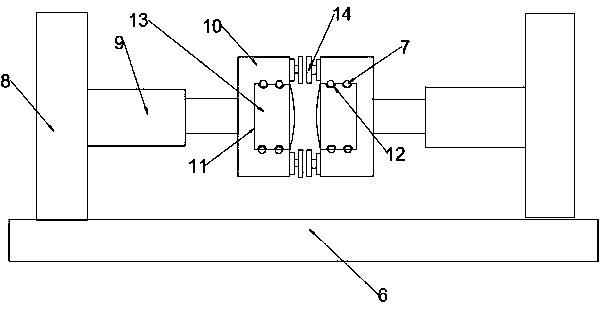

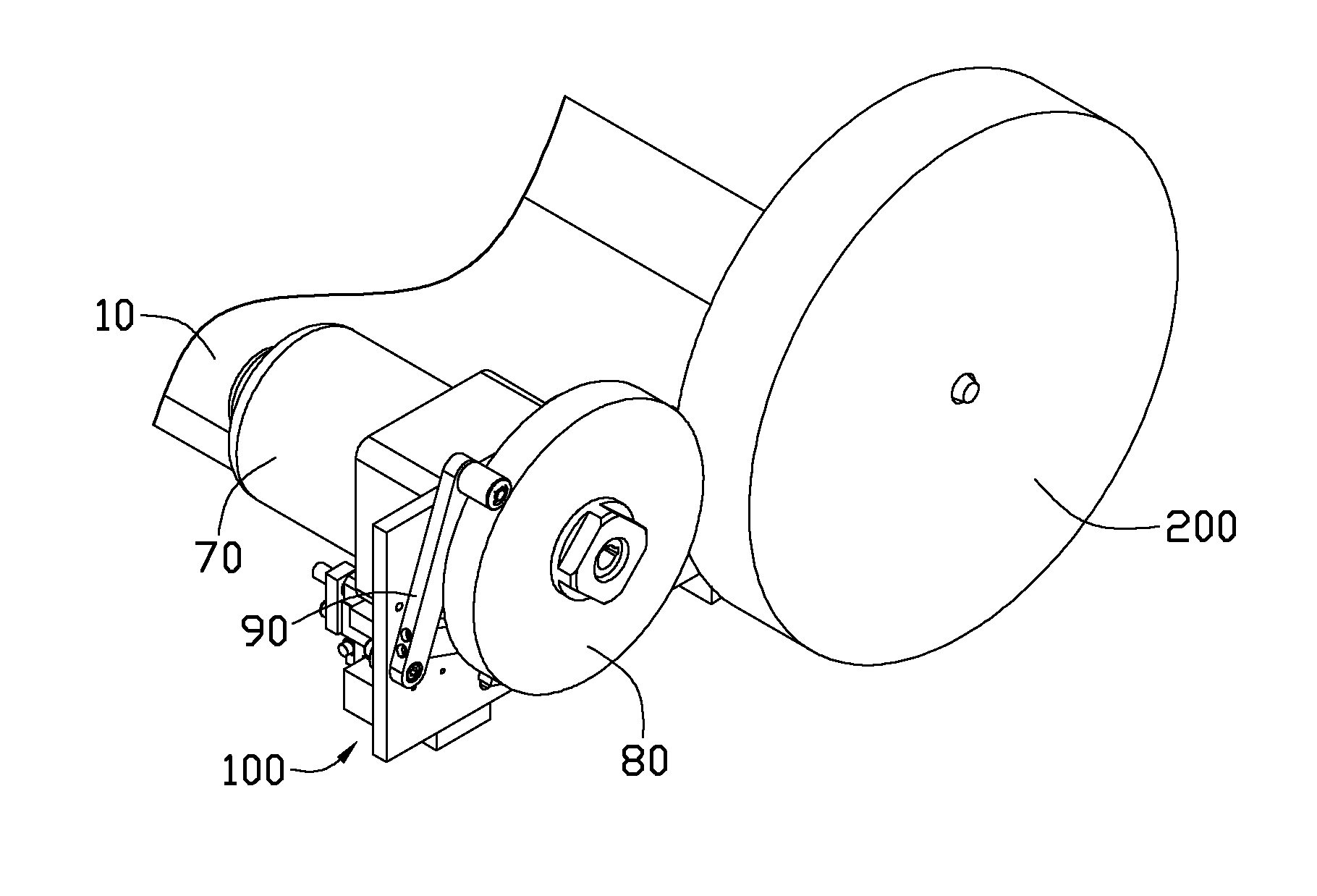

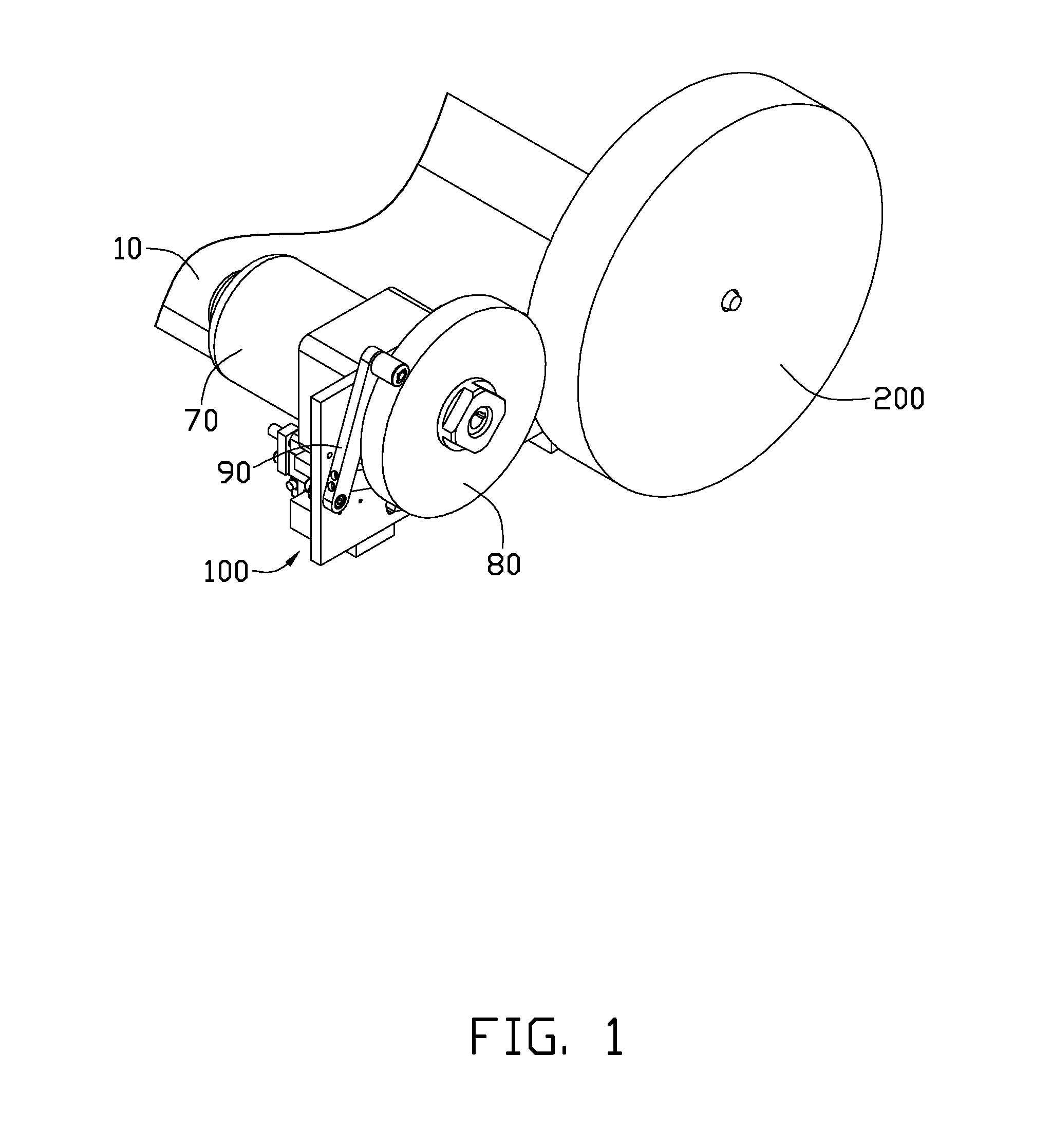

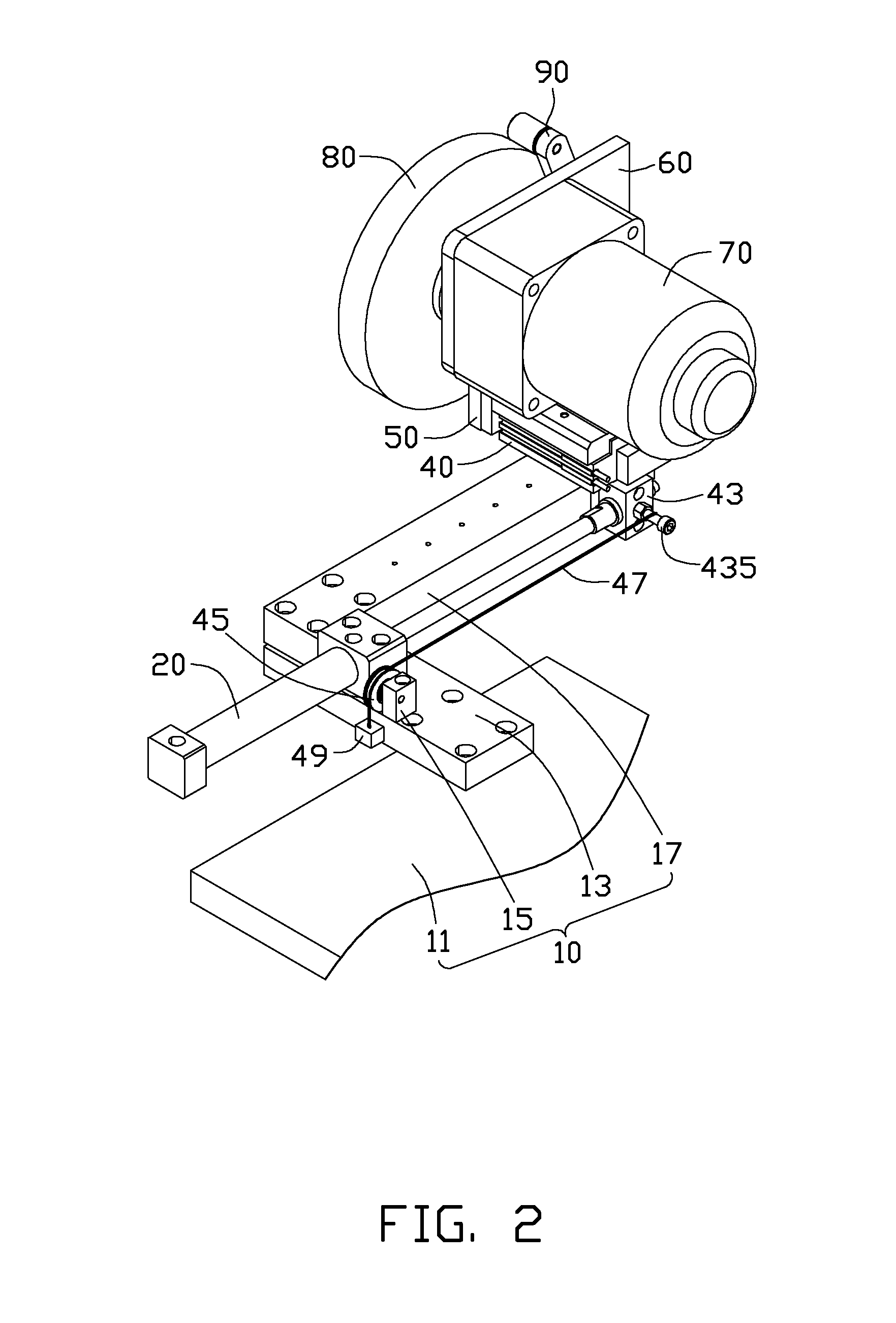

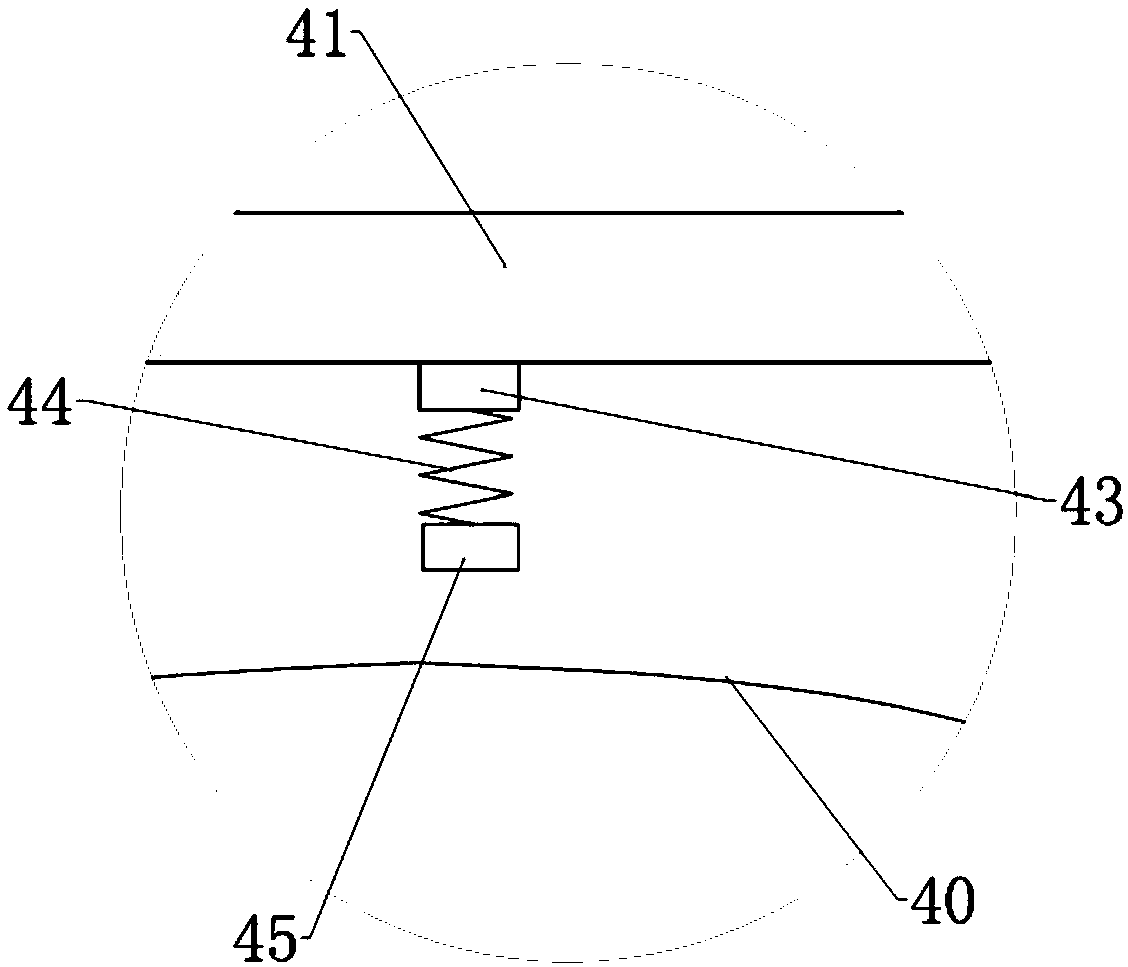

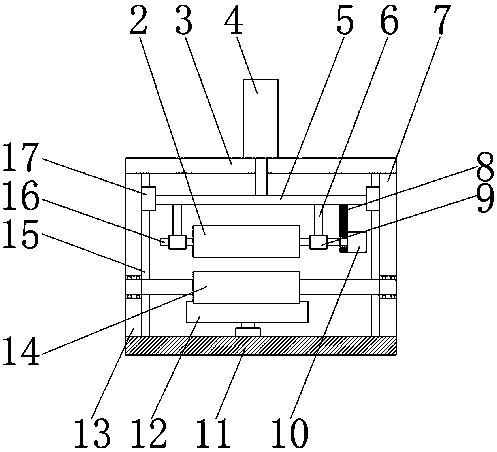

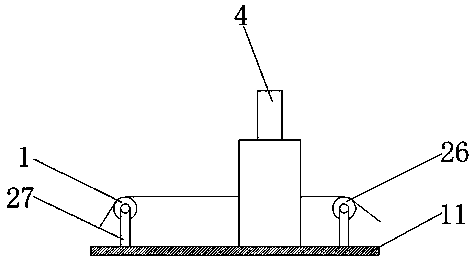

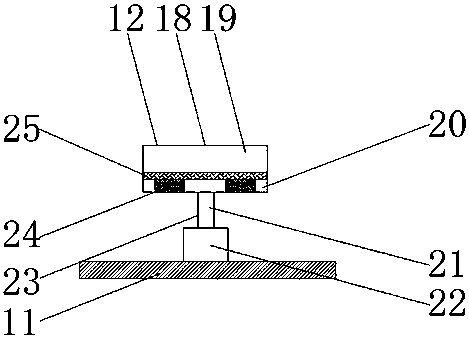

Waxing device

InactiveUS20130019800A1Time consumingLiquid surface applicatorsPolishing machinesWax treatmentElectric machinery

A waxing device is used for applying a waxing treatment to a polishing wheel, and includes a supporting assembly, an adjusting assembly, a driving mechanism, a mounting assembly, a motor, a wax block and a resisting mechanism. The supporting assembly includes a sliding rail, and the adjusting assembly is slidably positioned on the sliding rail; the driving mechanism is mounted on the adjusting assembly; the mounting assembly includes a mounting member positioned on the driving mechanism; the motor is mounted on mounting member; the wax block is positioned on the motor and rotated by the motor; the resisting mechanism is positioned on the supporting assembly and resists the adjusting assembly for adjusting a pressure applied to the polishing wheel during the waxing process.

Owner:HON HAI PRECISION IND CO LTD

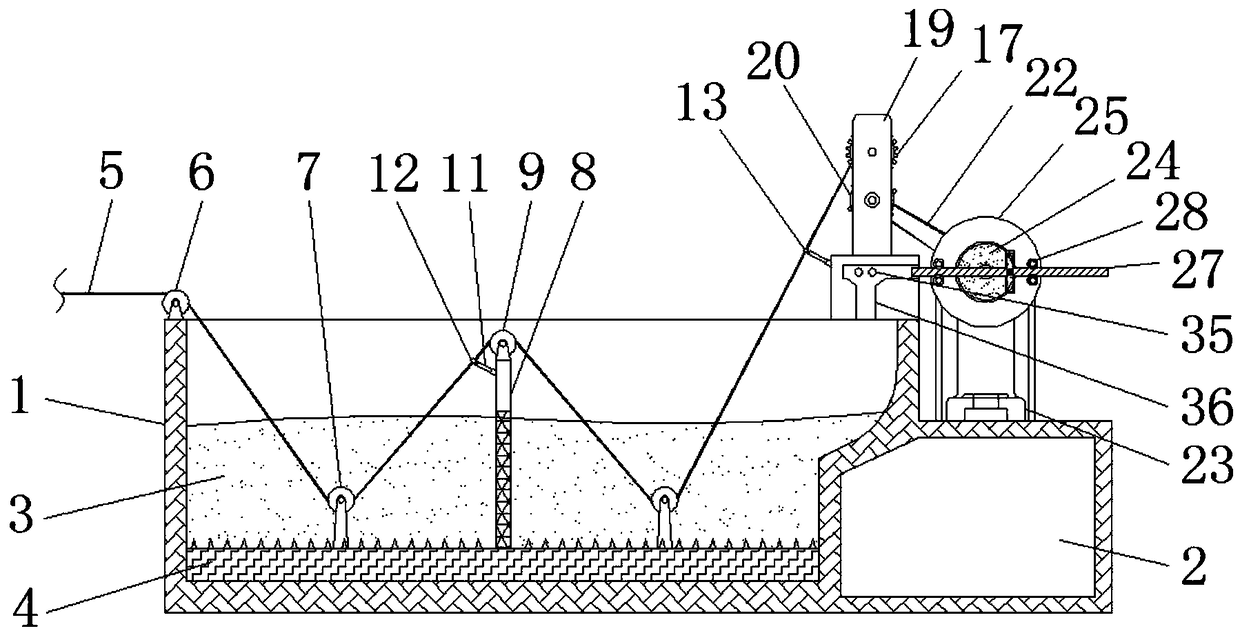

Automobile cleaning and waxing integrated device

ActiveCN109501737ASimple structureReduce manufacturing costCleaning apparatus for vehicle exteriorsVehicle servicing/repairingCold airEngineering

The invention relates to the technical field of automobile service, and particularly discloses an automobile cleaning and waxing integrated device. The device comprises a rack. A cylinder is fixedly arranged on the rack. A piston and a piston rod are arranged inside the cylinder. One end of the piston rod is fixedly connected with the piston, the other end of the piston rod is rotationally connected with a crank driven by the motor through a rotating rod, and the crank, the connecting rod, the piston rod and the piston form a crank sliding block mechanism; two inflation cylinders are formed onthe cylinder, a vortex tube is further fixed to the rack, and the two inflation cylinders are both connected with the air inlet end of the vortex tube; the cold air outlet end of the vortex tube is connected with an air storage tank, the air storage tank is connected with an air cylinder, the air cylinder is connected with a brush head, and a sponge is arranged on the brush head; a Venturi tube is connected to the hot air end of the vortex tube, and the throat part of the Venturi tube is connected with a right water tank and a detergent box separately; an outlet of the Venturi tube is connected with a nozzle. The problem that an existing automobile cleaning device cannot perform automatic cleaning or waxing is solved.

Owner:温州陆华科技有限公司

Leather fabric waxing device

InactiveCN104437957AGuaranteed to be straightEasy to apply waxPretreated surfacesLeather/skins/hides/pelt chemical treatment apparatusCold airEngineering

The invention relates to a leather fabric waxing device which comprises a conveying belt supported by a supporting frame to accommodate a leather fabric, wherein a clean sponge stick is arranged above one end of the conveying belt through an upper bracket, a water tank is arranged above the clean sponge stick, a downcomer with a valve is connected below the water tank and is connected above the downcomer, a blowpipe is arranged on one side of the clean sponge stick on the upper bracket, a rolling wheel of which an outer layer is a piece of dry cloth is hoisted on the upper bracket on one side of the blowpipe, a waxing box for accommodating wax liquid is arranged on the upper bracket, a pre-coating discharge pipe and a waxing pipe are respectively arranged below the waxing box, a hard brush is connected below the pre-coating discharge pipe, a soft brush is connected below the waxing pipe, a plurality of cold air pipes and a plurality of hot air pipes are also arranged on the upper bracket, and an upper rolling wheel and a lower rolling wheel are arranged at the other end of the conveying belt. The leather fabric waxing device has the benefits that the leather fabric is uniformly waxed, and the processing speed is high.

Owner:倪国权

Mechanical yarn waxing device used for spinning machine and beneficial to rapid production

The invention discloses a mechanical yarn waxing device used for a spinning machine and beneficial to rapid production. The mechanical yarn waxing device used for the spinning machine and beneficial to rapid production comprises a main body, a textile yarn and a driving disc. A storage bin is fixedly welded to the right side of the main body. A supporting device is connected to the tail end of a winding shaft. A connecting rod is arranged on the front side of a driven disc. A shifting rod is mounted on the outer side of the driving disc. A wax box is arranged on the left side of a scraping device. A mounting groove is formed in the wax box. A fixing base is mounted at the top end of a spring. A fixing hole is formed in the outer side of the top of a wax rod. According to the mechanical yarn waxing device used for the spinning machine and beneficial to rapid production, yarns can be protected and can be kept in order; the yarns can be sufficiently soaked in liquid wax, so that the waxing uniformity is ensured; and the liquid wax can be kept sufficient all the time in use and can be kept in the liquid state, so that rapid waxing is facilitated, and the production efficiency is improved.

Owner:吴子侠

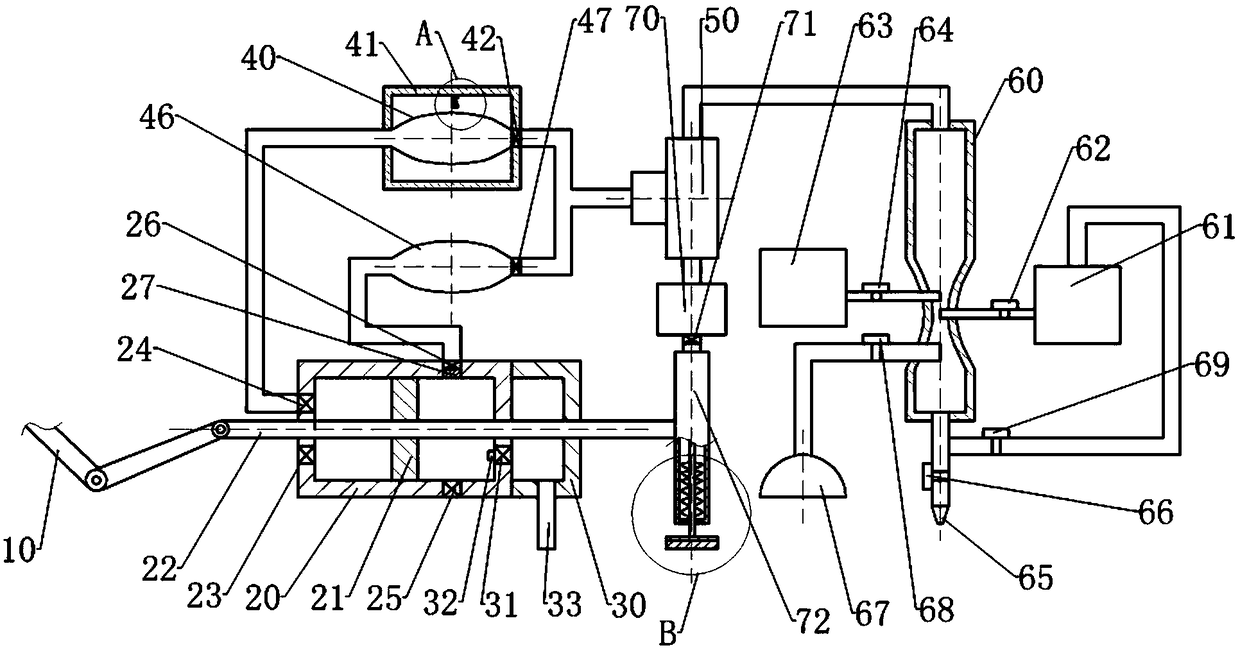

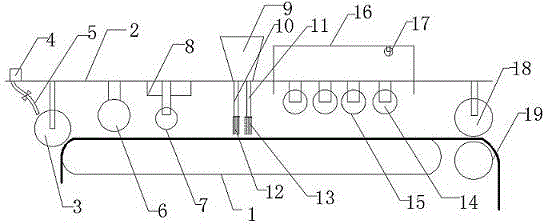

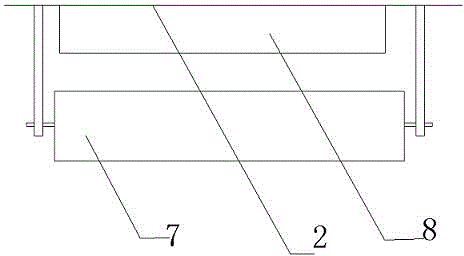

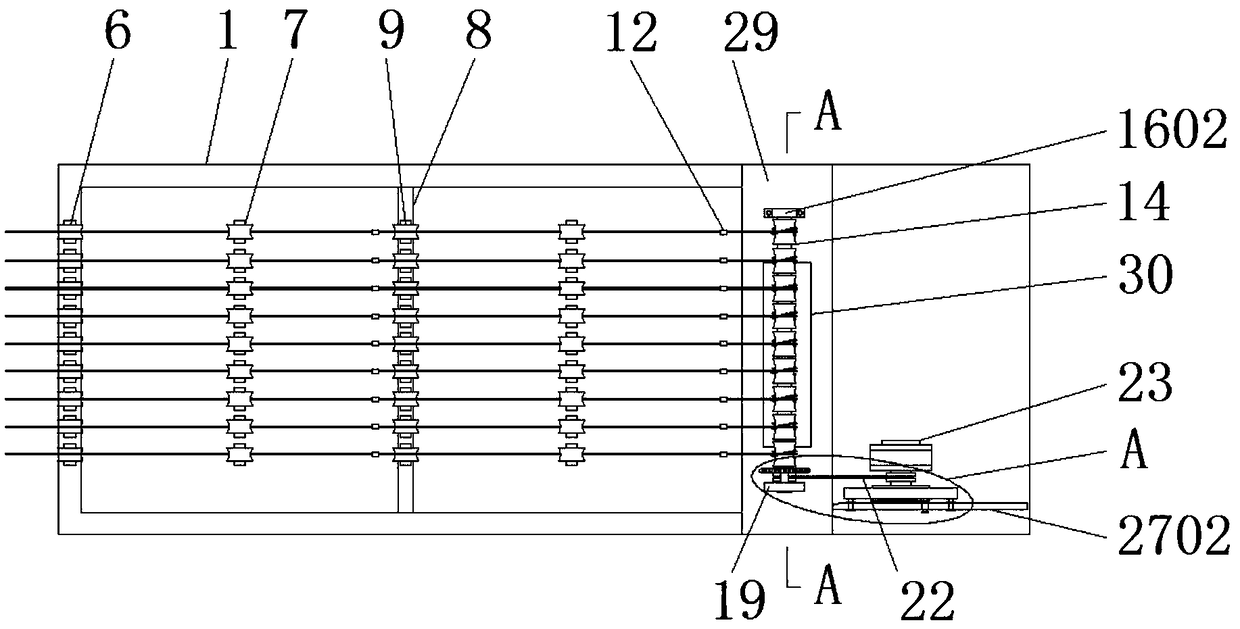

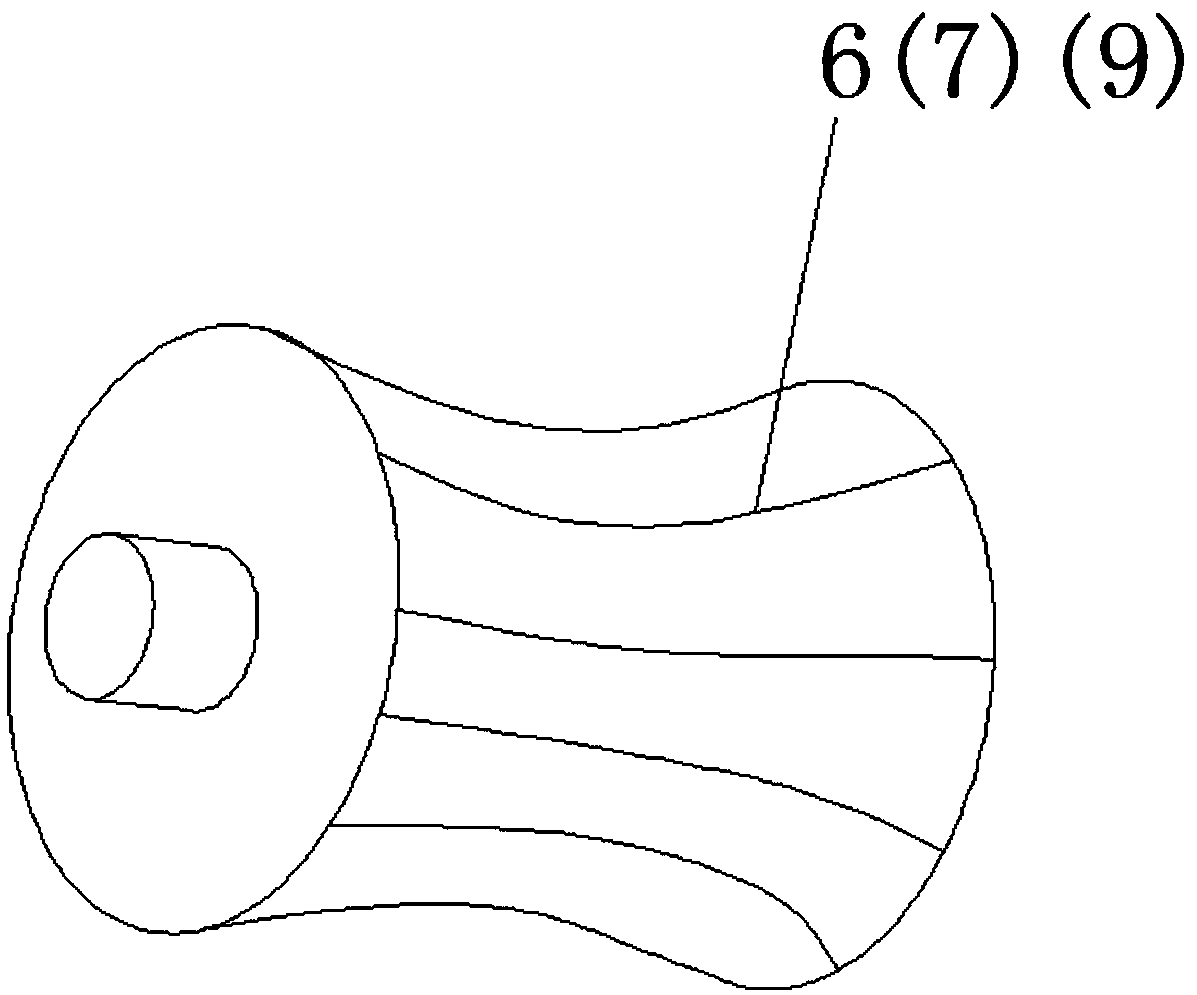

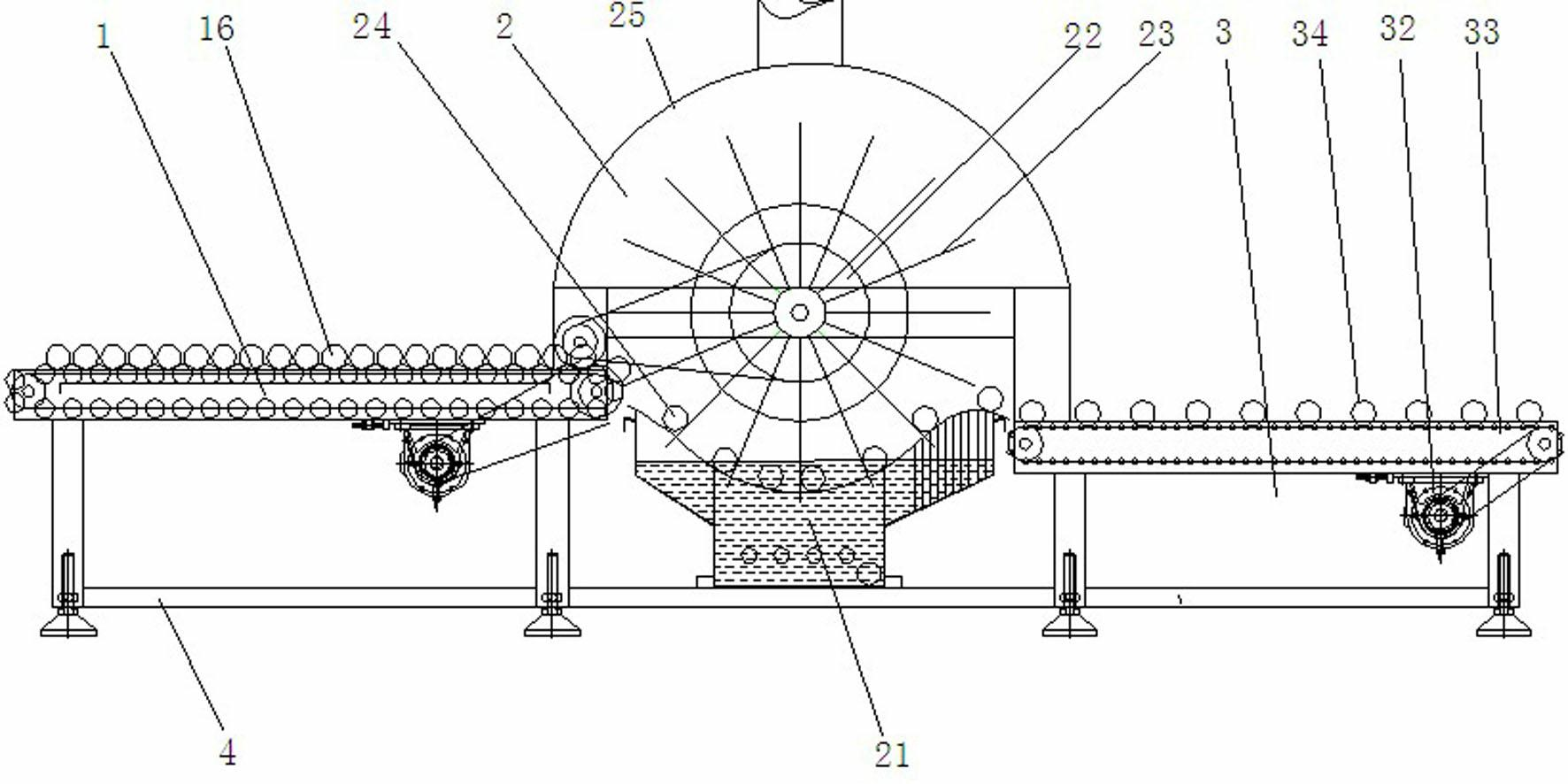

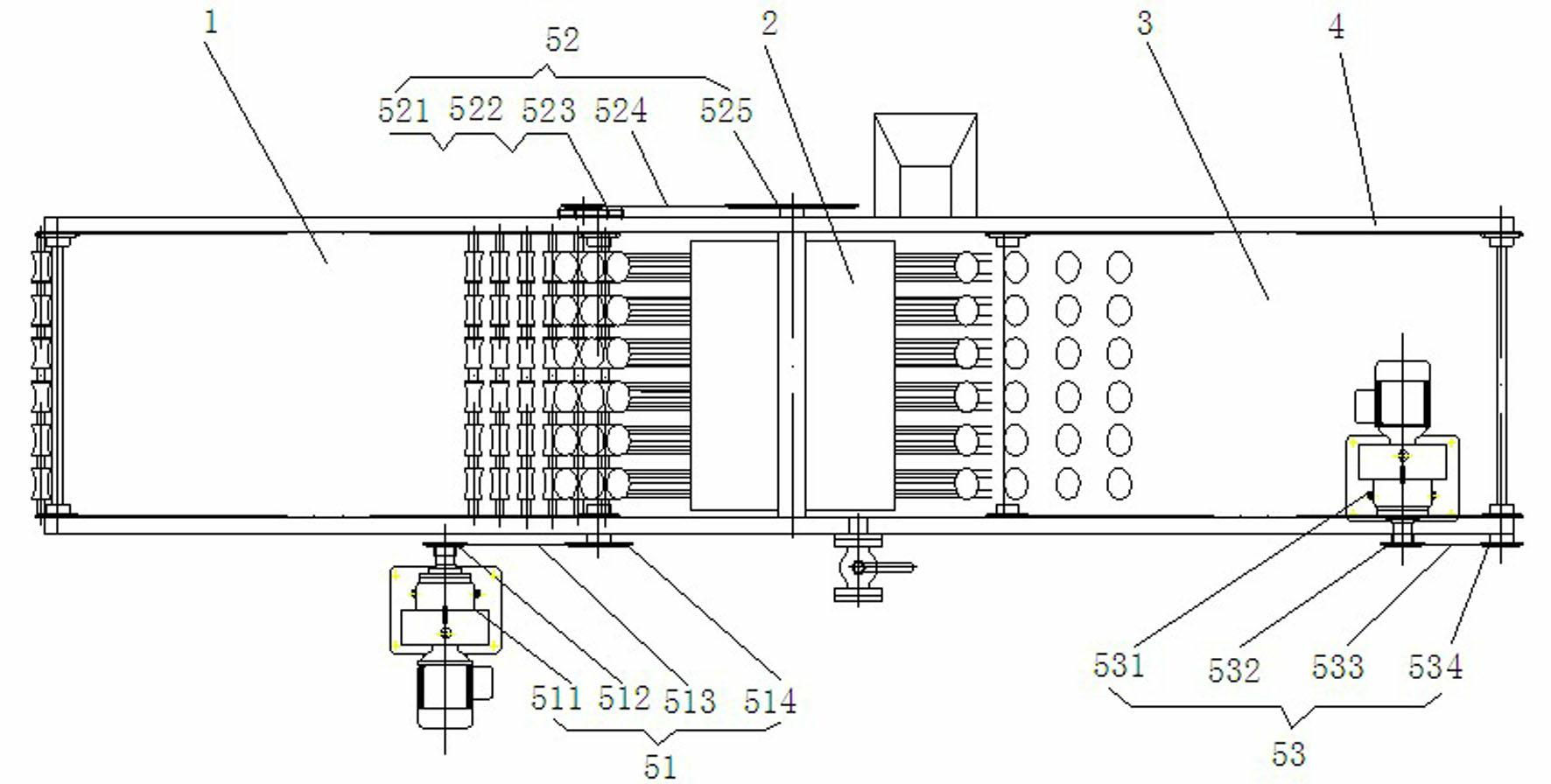

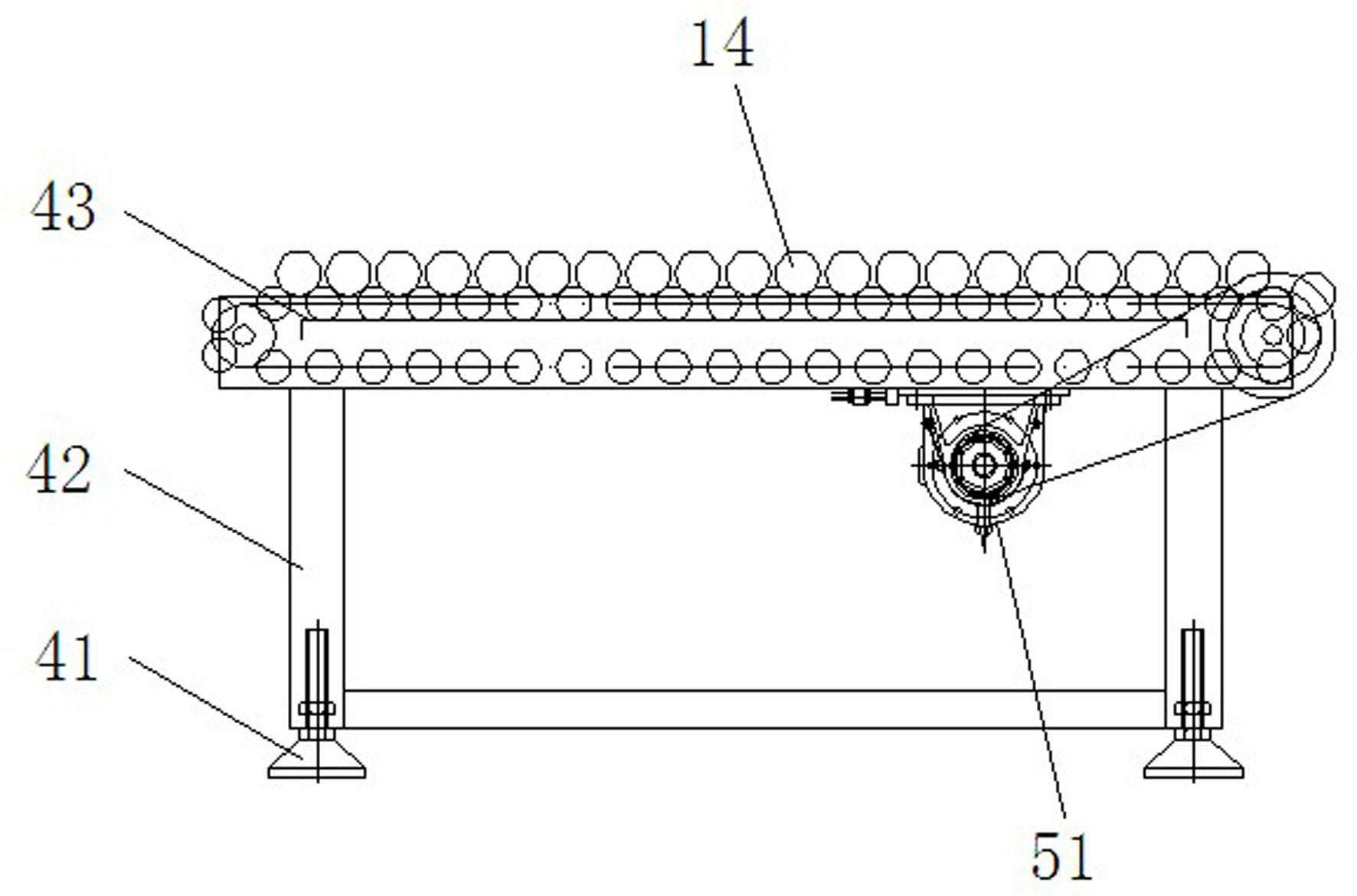

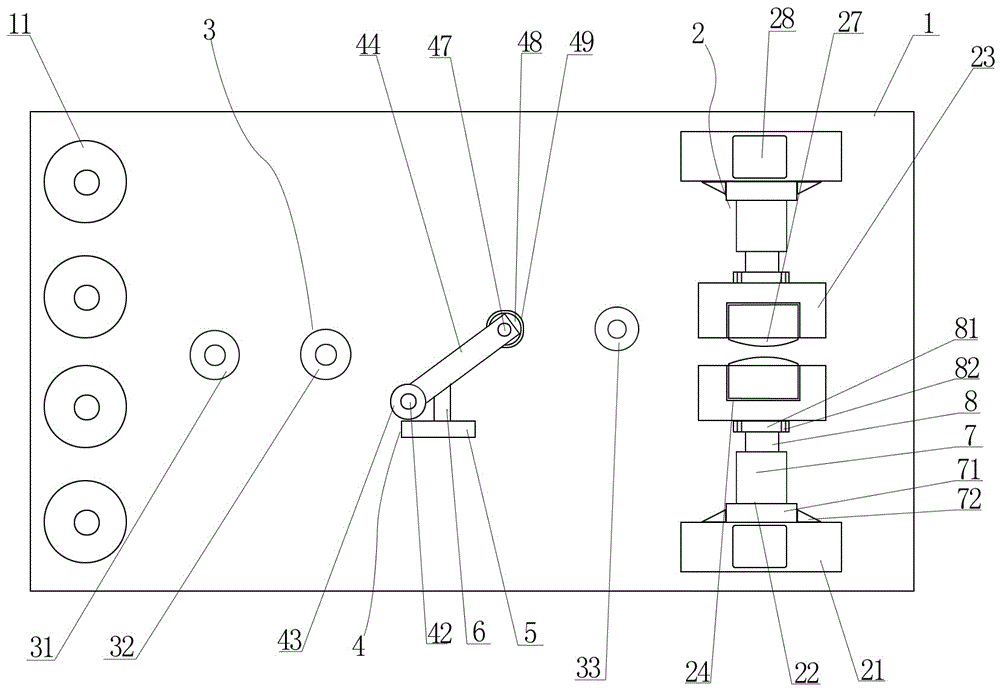

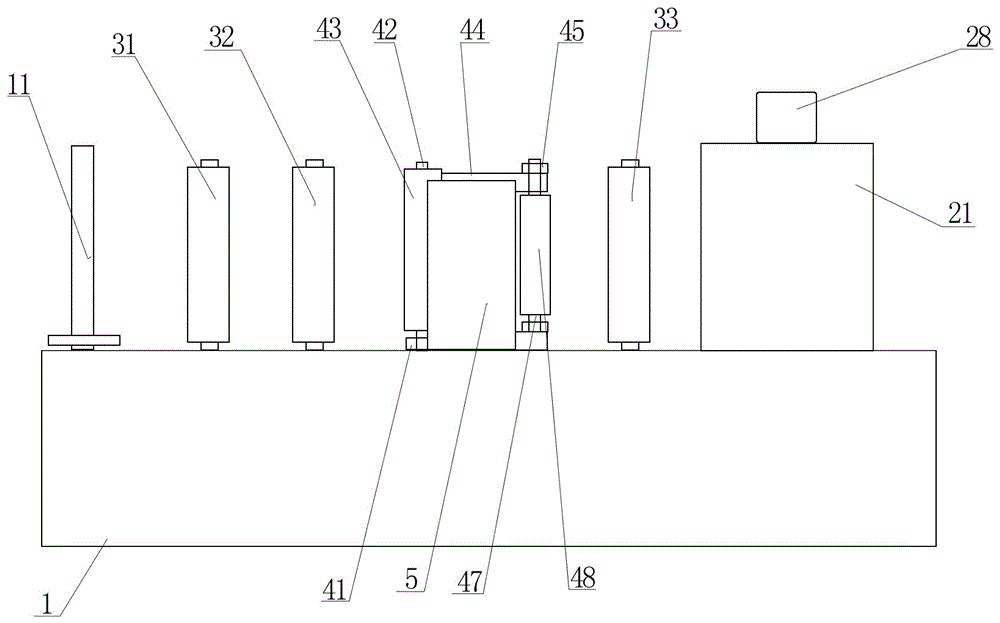

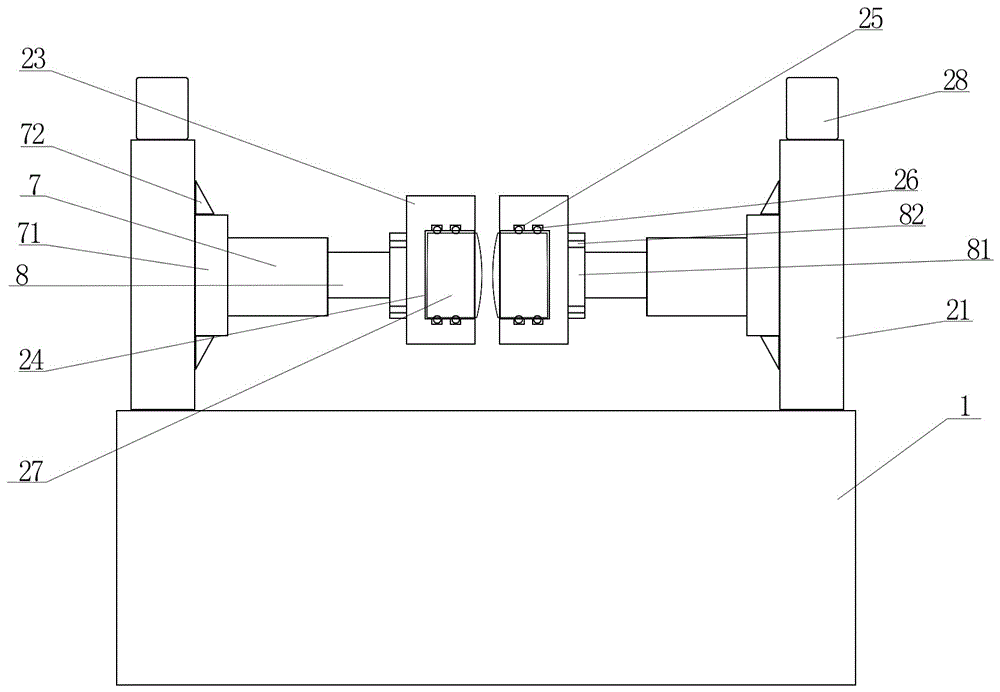

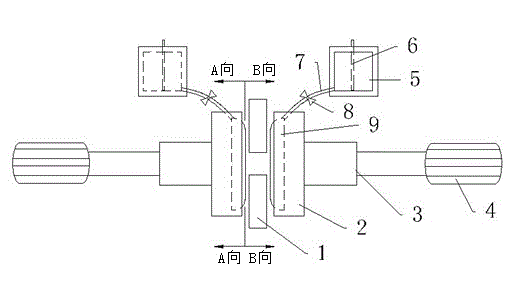

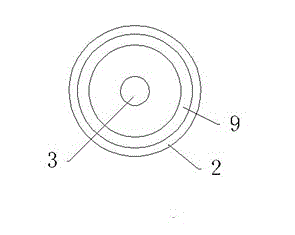

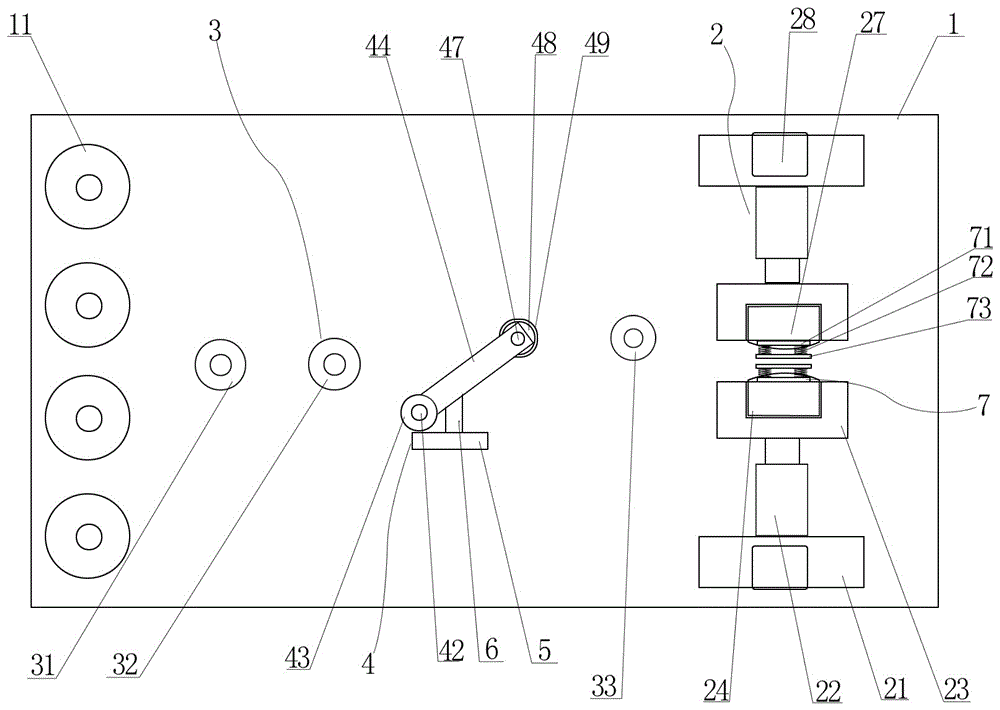

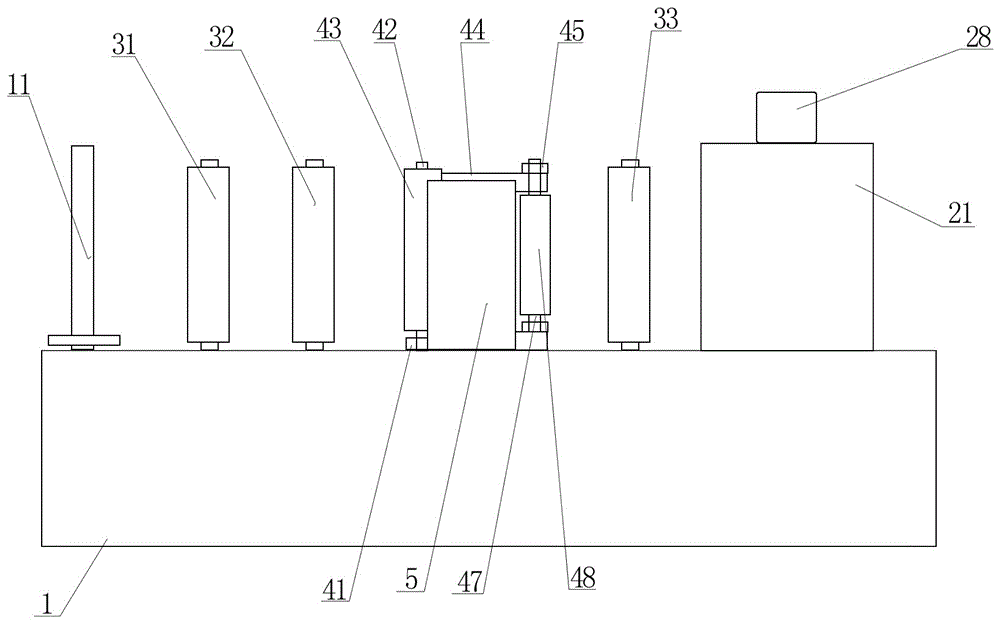

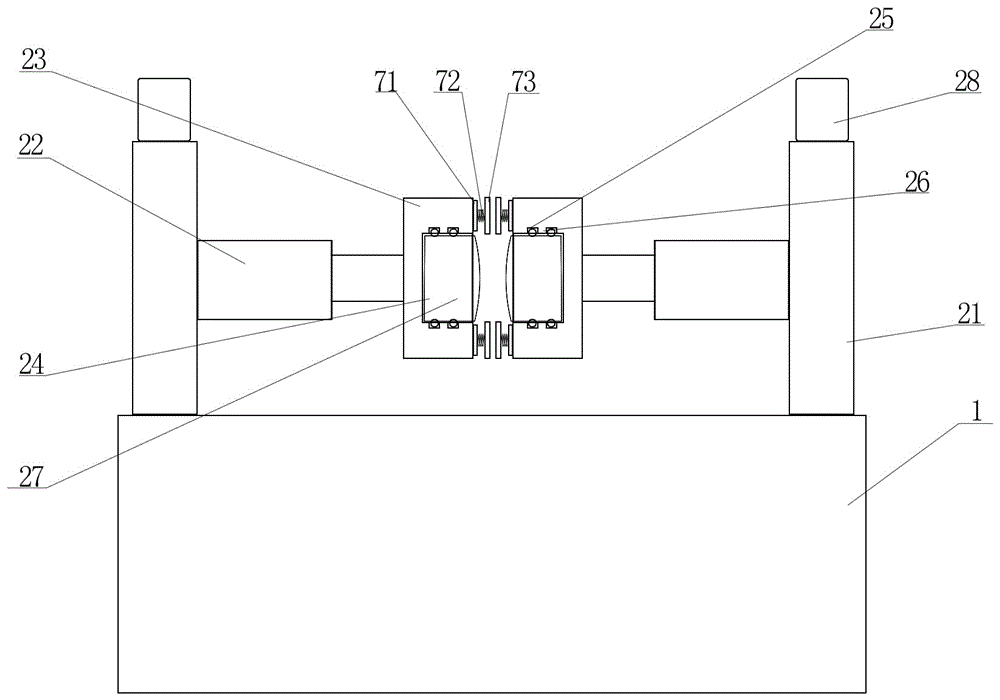

Pulling wheel type egg product waxing machine

ActiveCN102630739AGuaranteed liquidityPrevent superheated evaporationEggs preservation by coatingDrive wheelChain type

The invention provides a pulling wheel type egg product waxing machine comprising a chain type egg feeding and conveying device (1), a waxing device (2), a belt type egg unloading device (3), a rack (4) and a power transmission device, wherein the chain type egg feeding and conveying device (1) comprises a driving wheel (11), a driven wheel (12), chains (13) and a plurality of egg rollers (14) which are horizontally arranged between two chain type conveying chains (13); the waxing device (2) comprises a wax melting box (21), and a pulling wheel (23) and an air exhausting cover (25) which are arranged above the wax melting box (21); an egg guide groove (213) is arranged above the wax melting box (21), and a heating pipe (211) is arranged below the wax melting box (21); and the egg unloading device (3) comprises a driving rotary drum (31), a driven rotary drum (32) and a conveying belt (33). The pulling wheel type egg product waxing machine has the advantages of simple structure, convenience in use, no need of a pump, a pipeline and a valve system, and no generation of sputtered wax foams; and the machine is simple in operation, can continuously work and has high efficiency.

Owner:深圳市振野蛋品智能设备股份有限公司

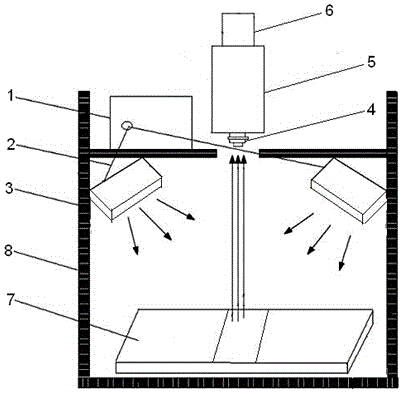

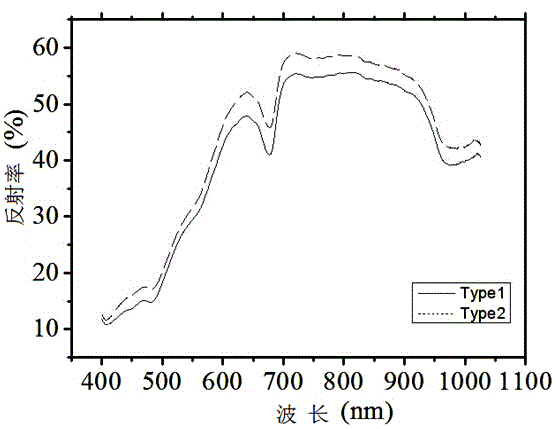

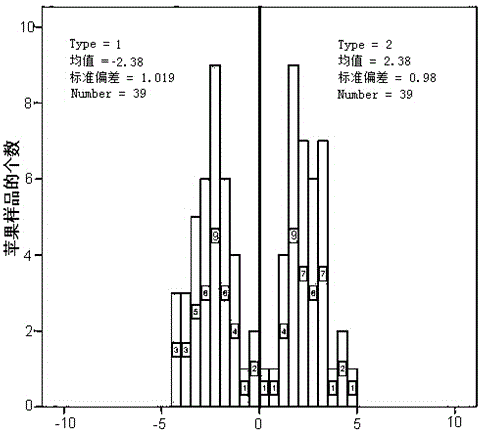

Method for realizing non-destructive test of waxing kinds of apple surfaces

InactiveCN104406928ANo need to damageRealize detectionColor/spectral properties measurementsSpectral responseVisible near infrared

The invention relates to a method for realizing non-destructive test of waxing kinds of apple surfaces. The method comprises the following steps: shooting hyperspectral images of the apple surfaces by using a visible near infrared hyperspectral imaging system, so that the image information and the spectral information of apples can be obtained at the same time, transforming spectral response under each wave length to corresponding reflectivity by using black and white plate correction, extracting the characteristic wave length for identifying the waxing types of the apple surfaces by using a continuous projection algorithm SPA, establishing a typical discriminant function by a linear discriminant analysis (LDA) method, and realizing the non-destructive test of the apples with unknown waxing types by combining matlab programming. The method disclosed by the invention has the advantages that the operation is simple, apple tissue is not required to be destructed, the test is quick and accurate, a scientific basis is provided for identifying the waxing types of the apple surfaces, and before the apples appear on the market, an on-line test is performed, so that the quality of the apples sold in the market is ensured.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Hardwood furniture waxing method

InactiveCN105944942AHigh glossImprove the decorative effectPretreated surfacesCoatingsCotton clothImpurity

The invention discloses a hardwood furniture waxing method. The hardwood furniture waxing method comprises the following steps: (a) the surface of hardwood furniture is roughly grinded in a grain direction by a 180-meshes abrasive paper; (b) the surface of the furniture is lightly wiped by hot cotton cloth to remove such impurities as wood residues and dust; (c) the surface of the hardwood furniture is grinded with water in the grain direction by a 320-meshes abrasive paper; (d) a proper amount of active dye is added in hot molten wax for uniformly mixing; (e) a brush is dipped in a proper amount of hot molten wax to disperse on the surface of the hardwood furniture in a dot manner; (f) the surface of the hardwood furniture is baked by a hot air gun; and cotton cloth is used for uniformly wiping when melting the wax; (g) redundant wax condensed on the surface of the hardwood furniture is scraped off by a flat shovel; and (h) the cotton cloth is used for wiping with strength in the grain direction until no redundant wax exists. The hardwood furniture waxing method can realize better gloss and better decoration effect.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for producing and preparing artificial jade

The invention discloses a method for producing man-made jade, using polyester resin as main ingredient, hydrafil as filler and accelerator, using curing agent, flame retardant, coupling agent, defoamer, antioxidant, light stabilizer, color paste, noctilucence powder, flash powder as auxiliary material, wherein the materials can be used at one time and can choose several kinds to use, thereby having flexibility. Production steps are as follows: 1, coating demoulding wax on the surface of a mould, 2, painting a well-prepared gel coat resin with a brush on the surface of the mould, 3, stirring evenly the materials in proportion, 4, pouring the mixxed materials to the mould, 5, vacuumizing in a vacuum-pumping room, 6, solidifying, 7, demoulding, 8, polishing, 9, polishing and waxing, 10, making out the product. The product has the advantages of luxury style, realistic jade, rich color, high permeability, smooth surface, wearing resistance, hard, scale resistance, anti-ultraviolet, simple production, easy implementation.

Owner:金纪德

Efficient waxing device for textile machinery

InactiveCN107601171AImprove waxing effectGuaranteed waxing effectFilament handlingYarnPulp and paper industry

The invention discloses an efficient waxing device for textile machinery. The efficient waxing device includes a motor, an air cylinder, a wax block storing bin, a waxing roller and a height adjustingdevice. Upper layer wax blocks rotate in the direction opposite to the direction of yarn by using rotation of the motor, frictional force between the upper surface of the yarn and the upper layer waxblocks is further increased, the effect of yarn waxing is improved, meanwhile, the upper layer wax blocks are always in contact with the upper surface of the yarn by using the air cylinder to drive amoving rod to move on a sliding rail, separating of the upper surface of the yarn and the upper layer wax blocks is avoided, thus the effect of waxing of the upper surface of the yarn is ensured, frictional force between the waxing roller and the wax blocks is decreased by softening the wax blocks in the wax block storing bin, the purpose of waxing on the lower surface of the yarn is achieved byusing rotation of the waxing roller, the height of the wax block storing groove is adjusted by arranging the height adjusting device, so that the waxing roller is always in contact with the softened wax blocks in the wax block storing bin.

Owner:长兴宝诺纺织科技有限公司

Special vibration absorber oil for railway locomotive and preparation method thereof

InactiveCN101955842AImprove seismic performanceImprove the lubrication effectTreatment with plural serial refining stagesLubricant compositionViscosity indexBase oil

The invention discloses special vibration absorber oil for a railway locomotive and a preparation method thereof. The vibration absorber oil comprises the following components in part by weight: 86.77 to 89.187 parts of special base oil, 10 to 12 parts of viscosity index improver, 0.8 to 1.2 parts of complexing agent, 0.003 to 0.01 part of extreme pressure enhancing agent and 0.01 to 0.02 part of composite defoaming agent. The method comprises the following steps of: distilling and cutting refined low-viscosity mineral oil serving as a raw material into narrow fraction base oil, performing deep de-waxing and clay refining on the narrow fraction base oil to obtain the special base oil, and then adding the viscosity index improver, the complexing agent and the defoaming agent into the special base oil to obtain the vibration absorber oil. The special vibration absorber oil for the railway locomotive has good vibration absorption, lubricating property, low-temperature liquidity, shearing safety and anti-oxidation rustproof performance, and particularly has high viscosity index (more than 190); and the function of the vibration absorber oil is not affected by extremely cold regions and hot regions. The special vibration absorber oil for the railway locomotive is oil mainly applied to vibration absorbers of trains and railway locomotives, can obviously improve the vibration absorption effect and lubricating property after being used, meanwhile prolongs the service life of machinery, and improves the safety factors of vehicles.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

Fastening-type yarn waxing mechanism for spinning

The invention discloses a fastening-type yarn waxing mechanism for spinning. The mechanism comprises a rack, wherein a waxing assembly and a yarn transmission assembly are disposed on the rack; the waxing assembly comprises vertical plates disposed on two sides of the rack; each of the adjacent sides of the vertical plates is correspondingly connected to an expansion rod; the expansion rods are disposed horizontally; each expansion rod comprises a fixed rod and a movable rod; the fixed rod is connected to the vertical plate; a fixation ring sleeves the fixed rod; four notches are formed at equal intervals on the fixation ring; the fixation ring is connected to a triangular plate by the notches; the triangular plates are connected to the vertical plates; one end of each of the two movable rods is correspondingly equipped with a fixation box; a fixation disk sleeves each movable rod; multiple installation holes are formed in the fixation disk; the fixation disk is firmly connected to the fixation box by the installation holes; a groove is formed correspondingly on each of the adjacent sides of the two fixation boxes; a wax block used for yarn waxing is disposed in each groove; multiple round grooves are formed in the upper side and the lower side of the groove; hoodles are disposed in the round grooves; gas pumps are disposed on both of the vertical plates; and each gas pump is connected to the expansion rod on the corresponding side.

Owner:SUZHOU KANGJIAN TEXTILE

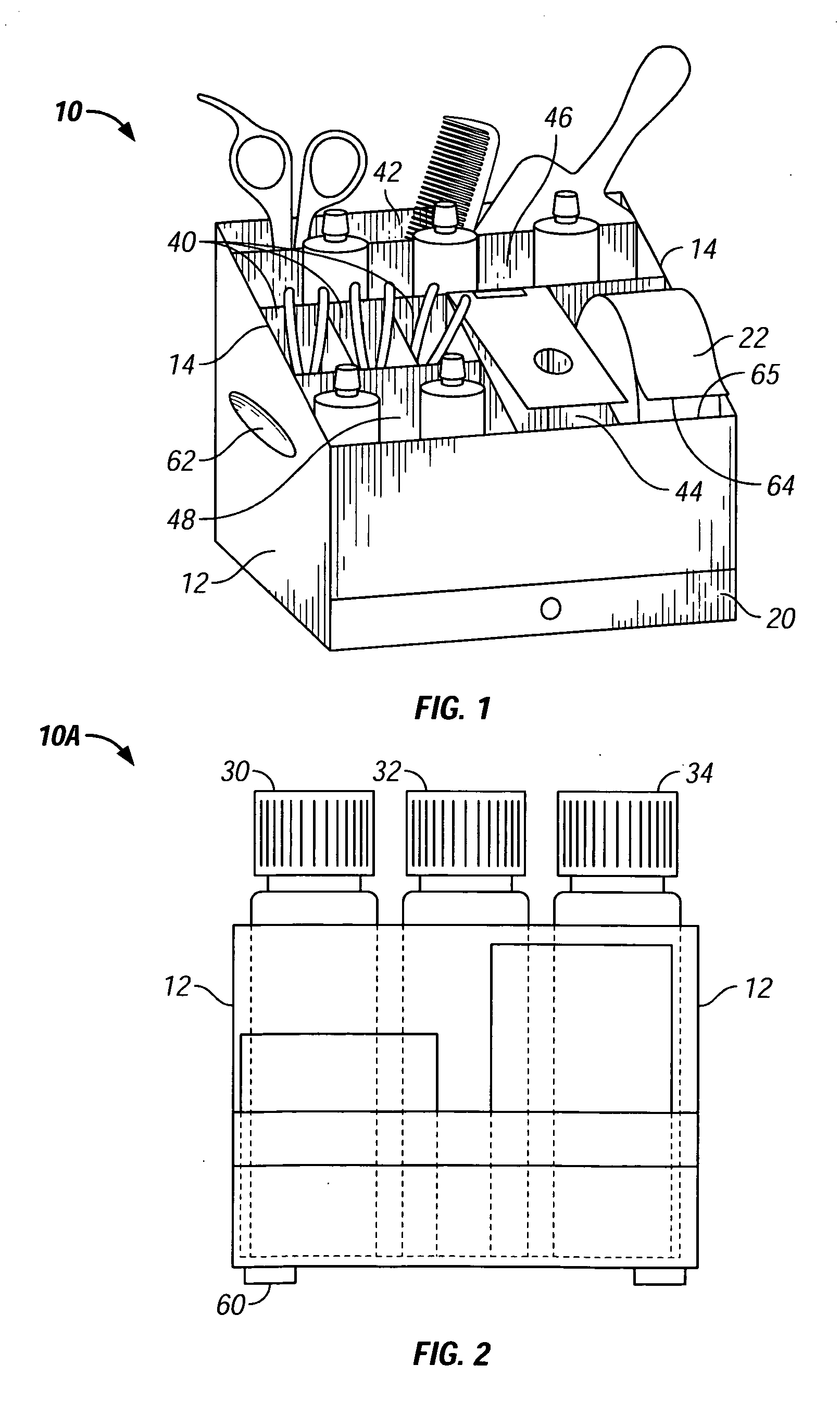

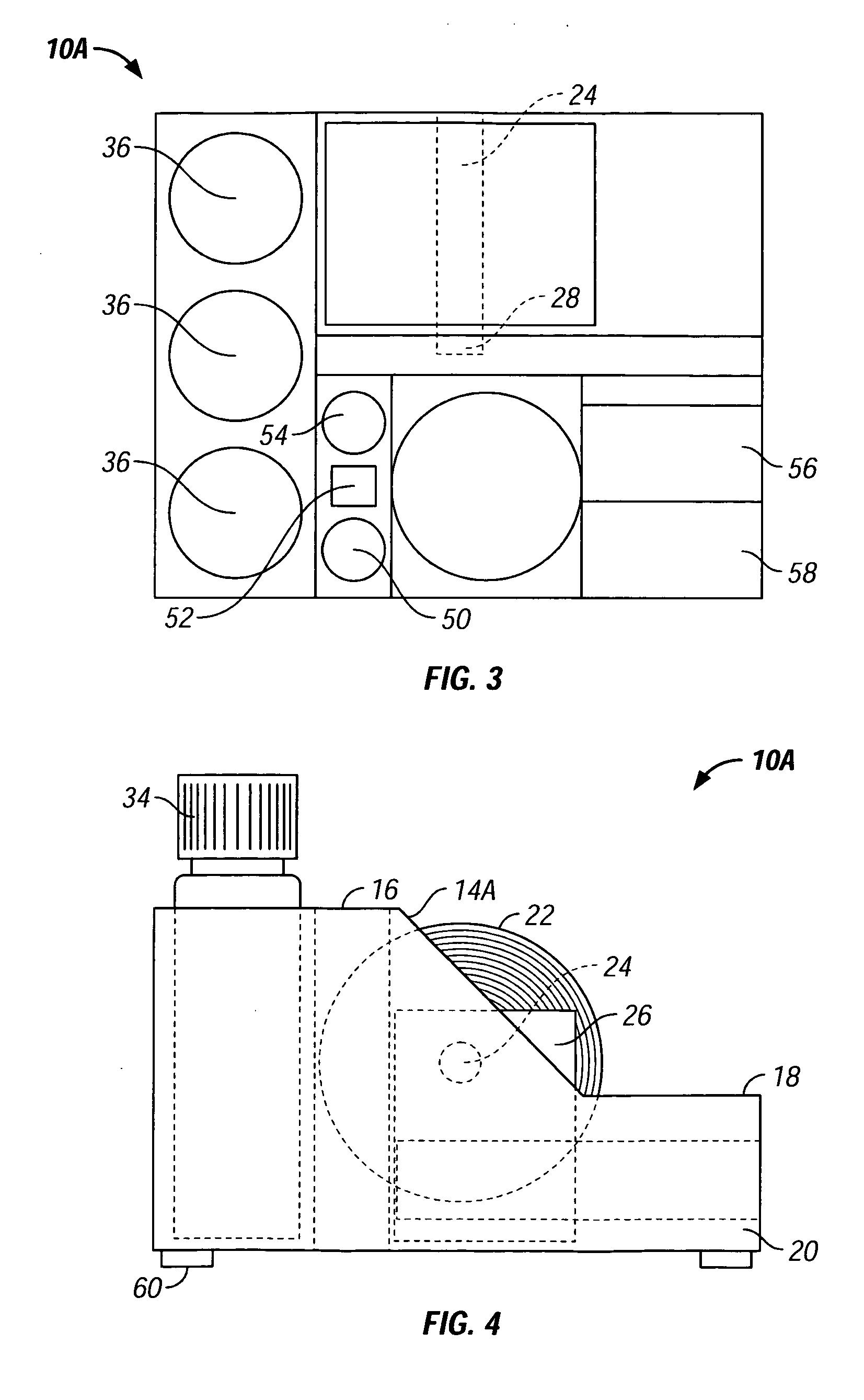

Hair removal waxing product organizer and method

InactiveUS20060186015A1Shorten the timeReduce confusionSmall article dispensingHair-singeingCleansers skinHair removal

A process and / or apparatus for organizing a plurality of articles utilized in hair removal waxing procedures. The plurality of articles utilized in hair removal procedures may comprise bottles of pre-wax cleanser, cooling gel, and other sundry accessories. The process may comprise steps such as forming a one-piece organizing container and / or providing sidewalls for the one piece organizing container with a sloping portion and / or mounting a tape roll dispenser within the one piece organizing container and within the sloping portion of the sidewalls such that the tape roll is easily accessible. Other steps may comprise providing different sized compartments within the one piece organizing container for receiving the plurality of bottles, sundry articles such as cotton and alcohol, and tools such as scissors and tweezers. A preferred embodiment includes forming handles on the one piece organizing container which comprise lips or indentations.

Owner:ABSHIRE DARLENE W

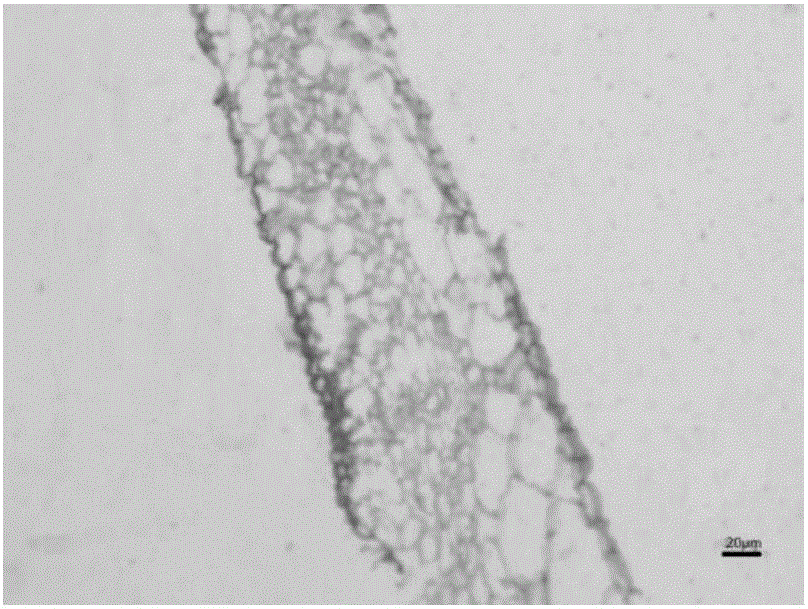

Paraffin slicing method for corydalis saxicola blades

ActiveCN106501053ACross-cut structure is clearLong-term storage and usePreparing sample for investigationAcetic acidParaffin wax

The invention discloses a paraffin slicing method for corydalis saxicola blades. The method comprises the following steps: fixing a sample, dehydrating, transparently processing, waxing, embedding, slicing and unfolding slices, de-waxing, dyeing and sealing slices. The dyeing step further comprises the following steps: before transparently processing, putting the dehydrated corydalis saxicola blades into a safranine solution in volume concentration of 0.8-1.2%, and dip-dyeing for 8-12h; rehydrating a slide carrying the corydalis saxicola blades in the dyeing step; after rehydrating, putting into an alcoholic solution for separating colors; adding acetic acid at the volume ratio of 1 / (800-1000) into the alcoholic solution used for separating colors; and finally, putting into a fast green solution in volume concentration of 0.8-1.2%, and dyeing for 5-15 seconds. The corydalis saxicola blades prepared according to the invention are clear in outline tissues and are suitable for identification of medicinal materials.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Paper tube waxing machine

InactiveCN102909154AImprove waxing efficiencyQuality is easy to controlLiquid surface applicatorsCoatingsFuel tankPulp and paper industry

A paper tube waxing machine comprises a paper tube fixing clamp, wherein wax cloth rings are arranged at two ends of the paper tube fixing clamp and are fixed at a periphery groove of the surface of a rotary disc, the groove is communicated with a wax oil tube, and telescopic rods are arranged outside the rotary disc and are connected with a motor by a transmission element; and the other end of the wax oil tube is communicated to a wax oil box which adopts a thermostat and is internally provided with a heating tube, and a flow valve is arranged in the wax oil tube. According to the paper tube waxing machine, two ends of a paper tube can be mechanically and continuously waxed, the paper tube waxing efficiency is improved, the waxing time is shortened, and the waxing quality is convenient to control.

Owner:吴江久升纸业有限公司

Embedded waxing and polishing machine for vehicles

InactiveCN104118399ANot easy to scratchSolve the problem of high intensity of manual waxing workCleaning apparatus for vehicle exteriorsVehicle servicing/repairingDrive wheelSprayer

The invention relates to a waxing device, in particular to an embedded waxing and polishing machine for vehicles. The embedded waxing and polishing machine for the vehicles comprises a liquid wax storage bin, a liquid wax sprayer, a liquid wax pipe, a brush disk motor bracket, a brush disk motor, a brush disk transmission shaft, a brush disk bearing pedestal, a brush disk, a control box, a shell, a base plate, permanent magnets, yokes, adjusting bolts, effect detection sensors, wheel racks, driving wheels, a universal wheel, infrared sensors, traveling motors, traveling motor shafts and the like. Through arrangement of multi-body coupling surface gap type permanent magnet attraction systems, the embedded waxing and polishing machine can be attracted onto a vehicle body and can move on the vehicle body. The embedded waxing and polishing machine for the vehicles can automatically complete large-area waxing and polishing operation on the vehicle body, solves the problem of high working intensity of manual waxing, is simple in structure, low in hardware cost, good in polishing effect, light in vehicle body, stable in attraction and convenient to operate and control, and can not scratch the vehicles easily.

Owner:赵文俊

Preparation method of paraffin section of pear flower tissue

InactiveCN109060468AImprove post-embedding qualityImprove embedded qualityPreparing sample for investigationParaffin waxPetal

The invention relates to the technical field of biological histology, in particular to a preparation method of paraffin section of pear flower tissue, which comprises the following steps: taking out the pear flowers preserved in a 4-5 degree Celsius refrigerator and washing them with distilled water, removing the center of the flower, stamen, calyx, petals, and the 3 mm portion below the base of the stalk to obtain the treated pear flower tissue; putting the obtained pear flower tissue into a FAA fixing solution of a fixing container, and evacuating the fixing container until the FAA fixing solution no longer appears bubbles, fixing 1-2days after evacuating; placing the pear flower tissue obtained after evacuating on a gauze to absorb the FAA fixing solution, and carrying out dehydration,transparency, waxing, embedding, slicing, sticking, dewaxing, dyeing and de-floating treatment in turn. According to the preparation method of paraffin section of pear flower tissue, the problem thatthe traditional paraffin section has no strict requirements on material processing, which causes the tissue to be too large when slicing, thereby having a great influence on the experimental result issolved, and the quality of the paraffin section obtained is high.

Owner:TARIM UNIV

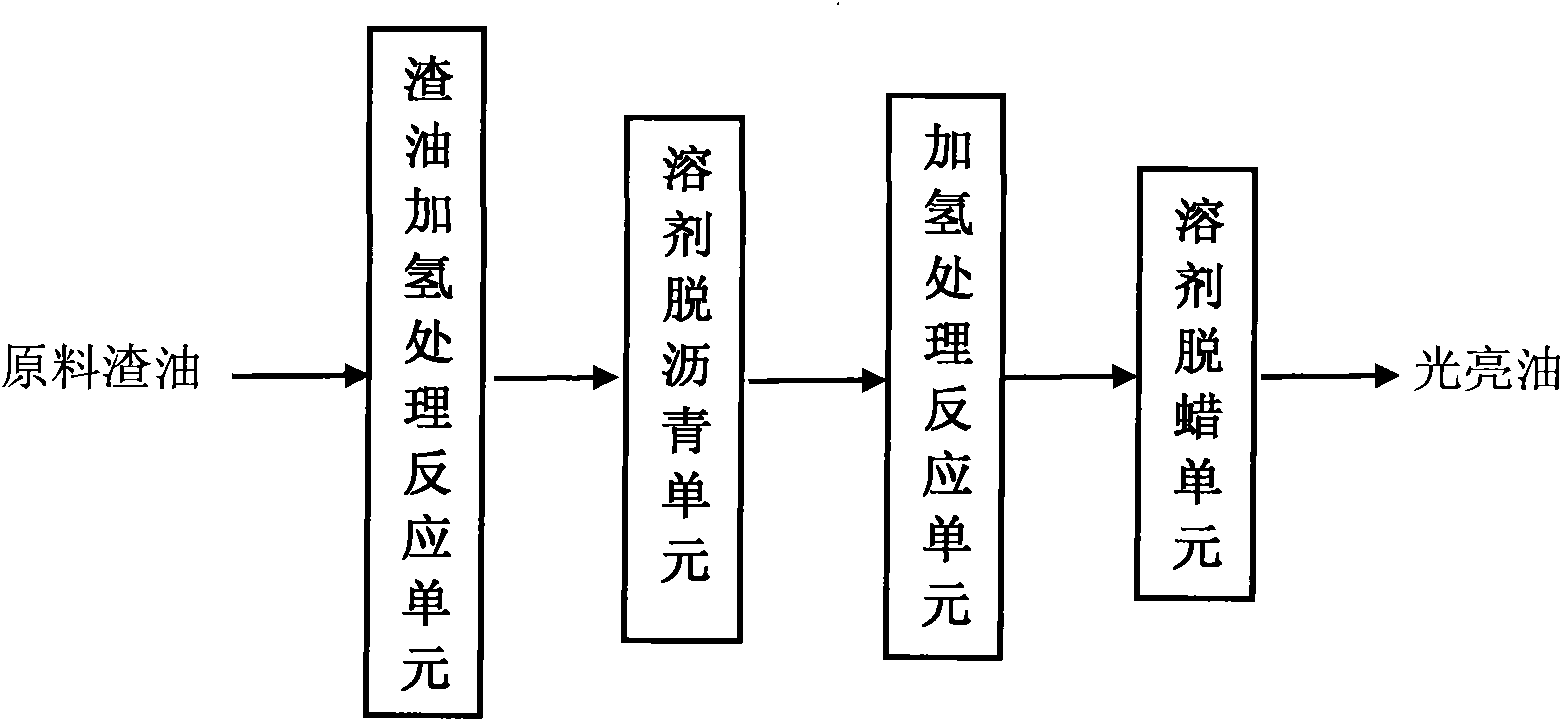

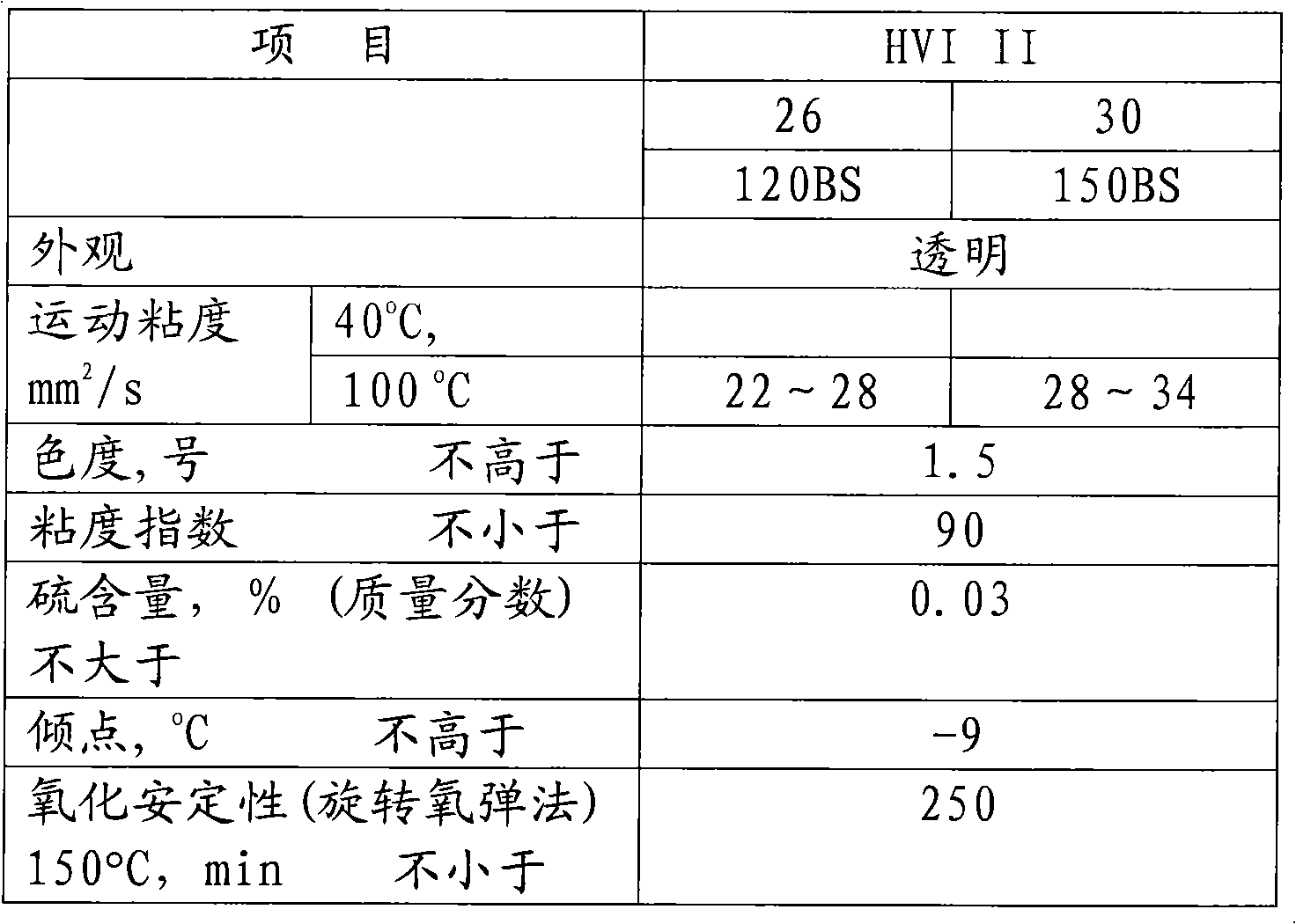

Production method of bright stock

A production method of bright stock comprises the following steps of: (1) under the conditions of a residuum hydrotreatment reaction unit and a residuum hydrotreatment reaction, performing a contact reaction between hydrogen and the residuum raw material in the presence of a catalyst for residuum hydrotreatment, and separating to obtain hydrogenated residuum with its distillation range being more than 470 DEG C; (2) under the solvent deasphalting condition and in a solvent deasphalting unit, carrying out solvent refining on the hydrogenated residuum which is obtained from the step (1) with its distillation range being more than 470 DEG C, so as to obtain residuum which has undergone solvent refining; (3) in a hydrotreatment reaction unit and under the condition of hydrotreatment reaction, performing a contact reaction between the residuum which has undergone solvent refining and is obtained from the step (2) and a hydrotreatment catalyst, and separating to obtain hydrotreated oil with its distillation range being more than 470 DEG C; and (4) in a solvent de-waxing unit and under the condition of solvent de-waxing, carrying out solvent dewaxing on the hydrotreated oil which is obtained from the step (3) with its distillation range being more than 470 DEG C, so as to obtain the product oil, namely bright stock.

Owner:CHINA PETROLEUM & CHEM CORP +1

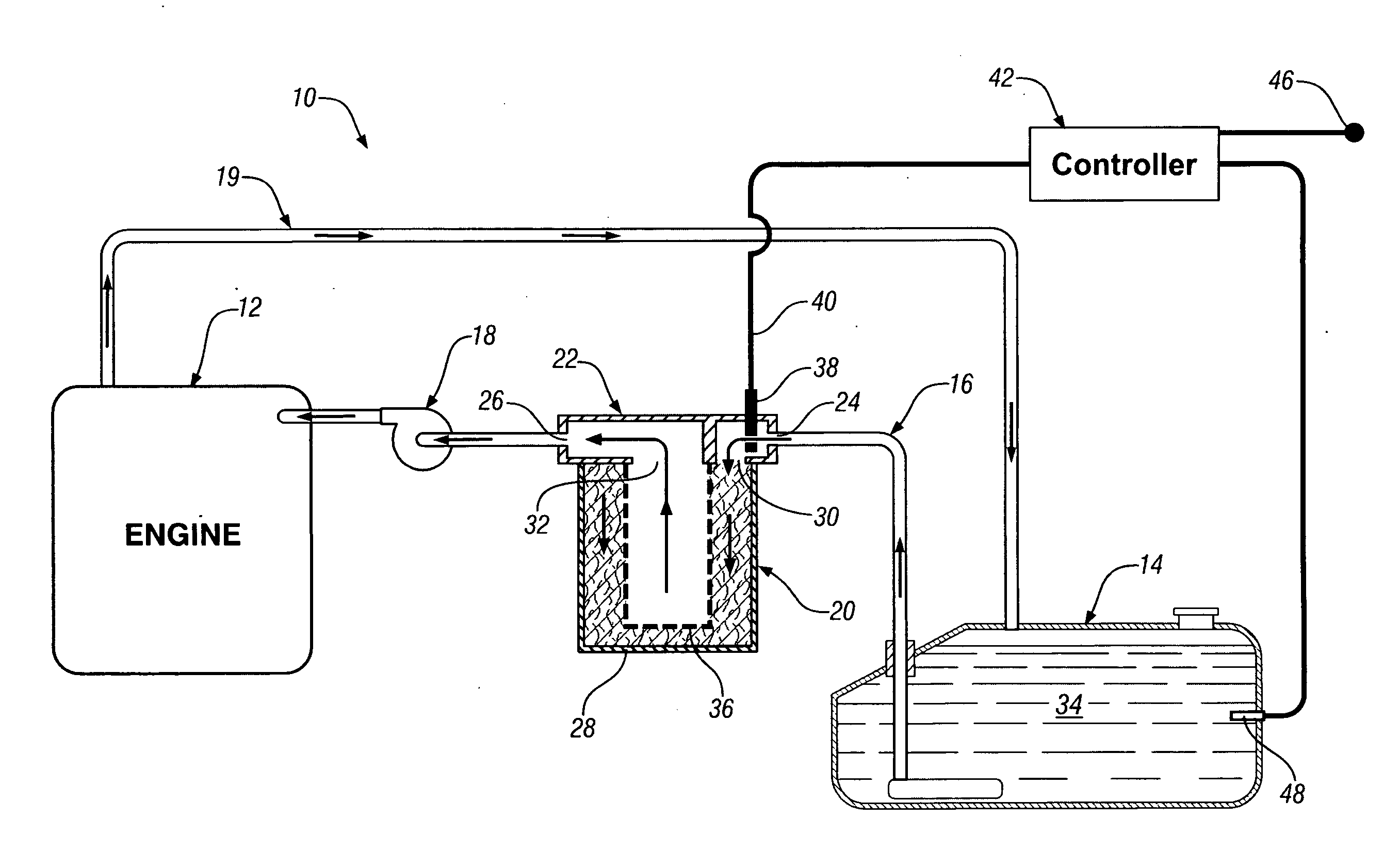

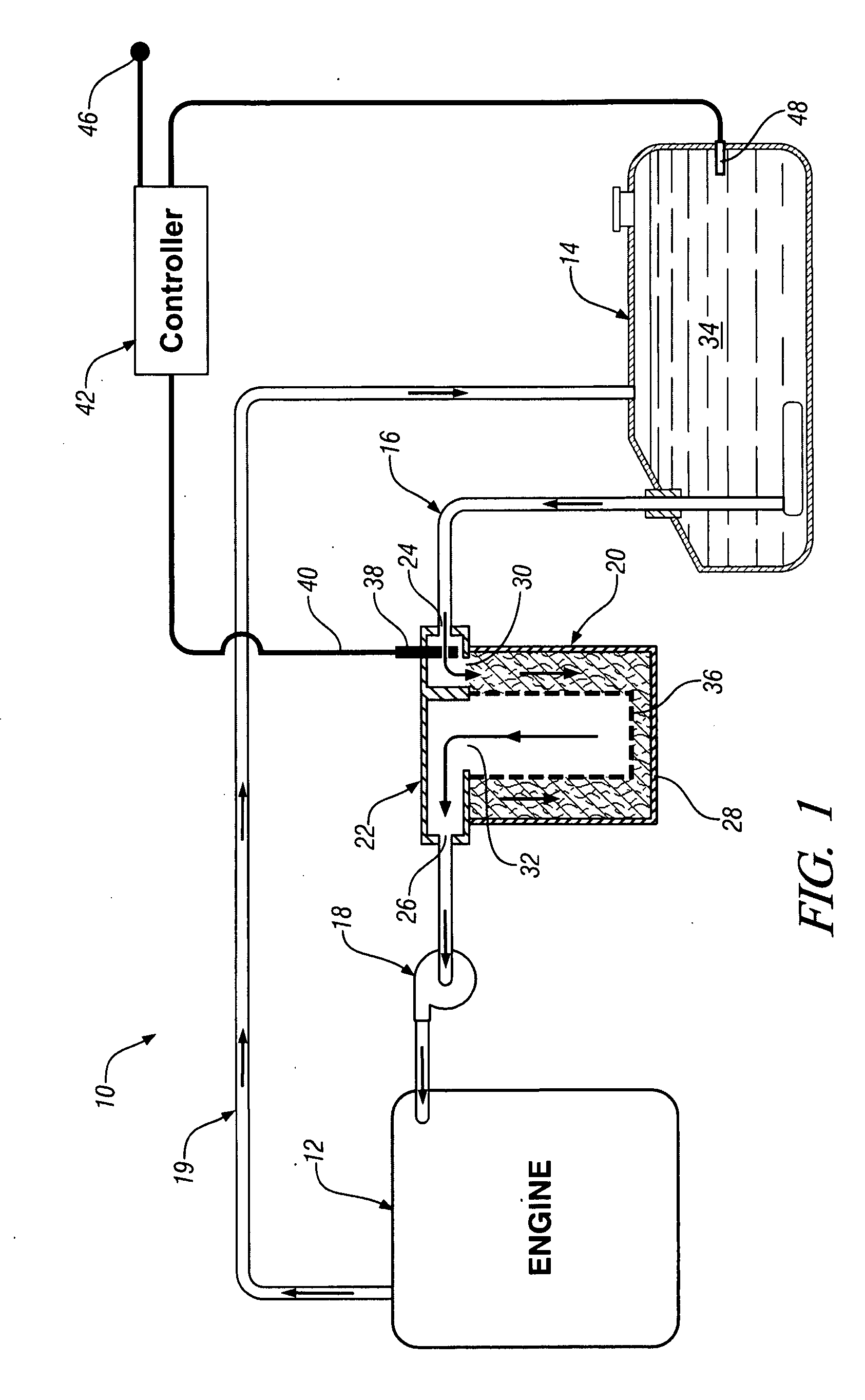

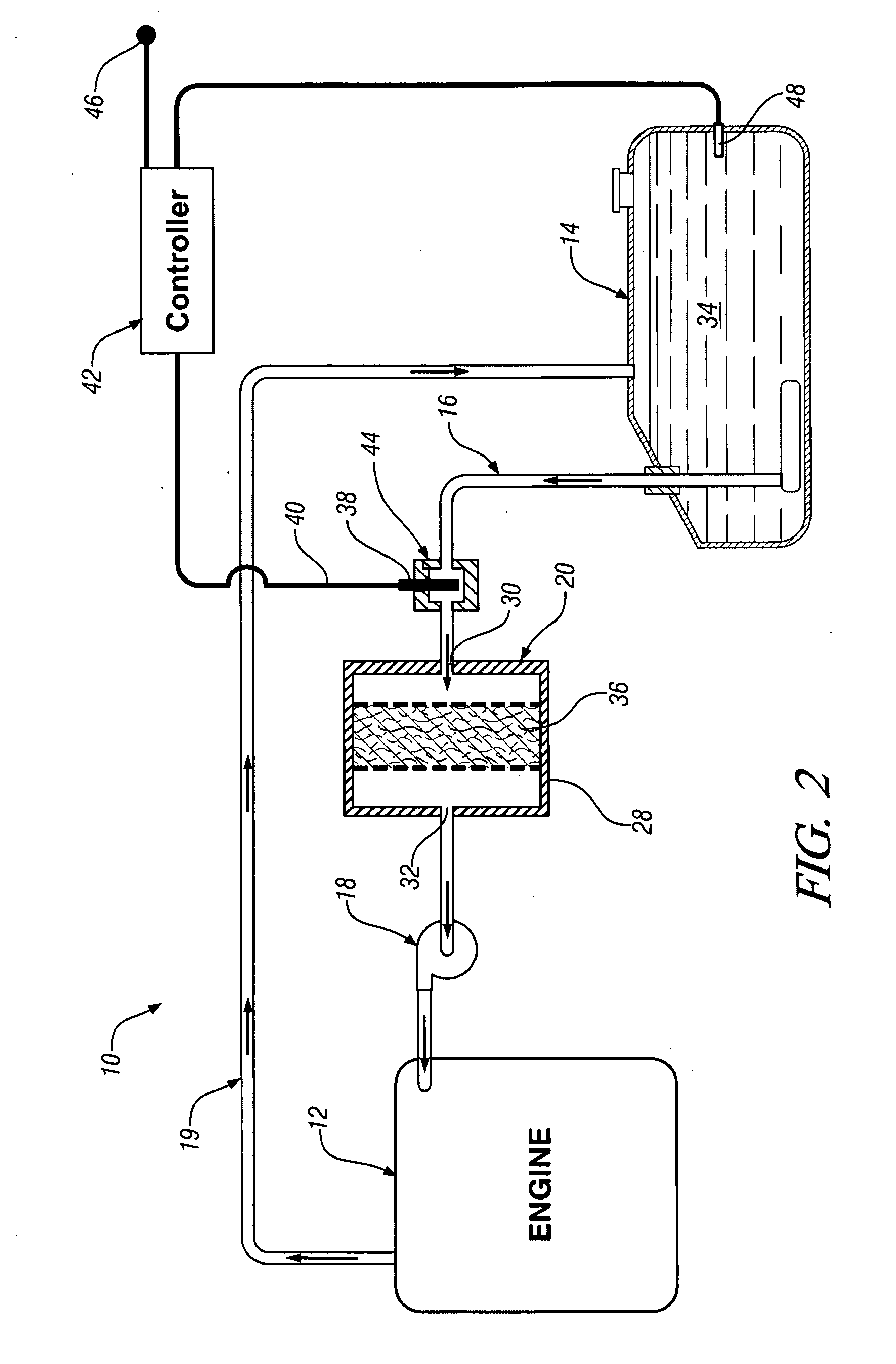

Apparatus For Reducing Fuel Waxing

InactiveUS20100258091A1Combustion-air/fuel-air treatmentSedimentation separationEngineeringFuel filter

A fuel filter is configured to filter fuel for an internal combustion engine and is associated with an electromagnetic wave generator configured to emit high frequency electromagnetic waves operable on the fuel to heat and thereby melt wax crystals suspended in the fuel.

Owner:GM GLOBAL TECH OPERATIONS LLC

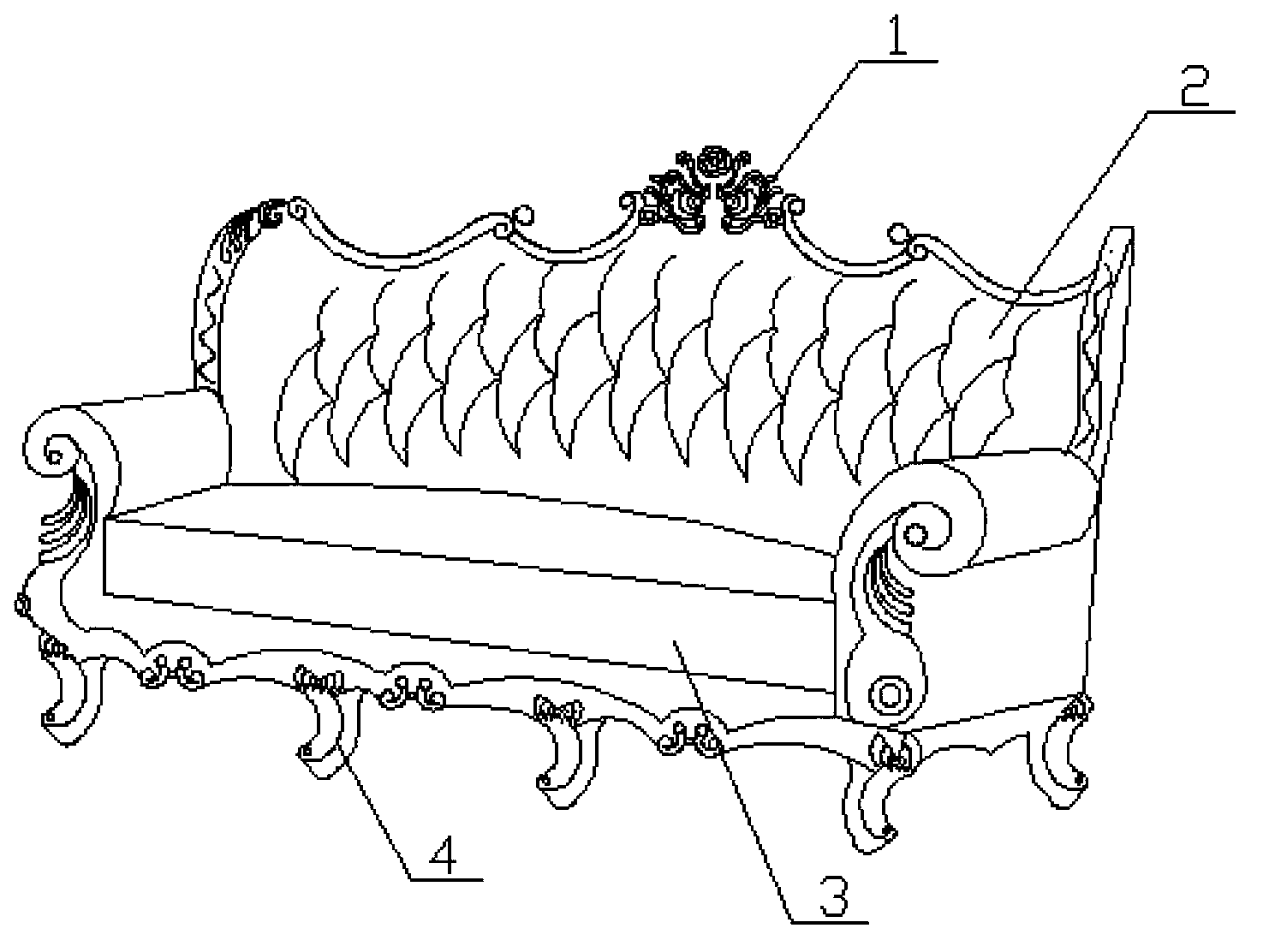

European-style furniture processed by rosewoods and manufacturing method thereof

The invention relates to European-style furniture processed by rosewoods, and further relates to a manufacturing method of the European-style furniture processed by the rosewoods. The method comprises the steps: A, taking the rosewoods as base materials, and designing a sculpt according to the grains of the rosewoods; B, according to the designed sculpt, preparing various connecting members of the furniture along with the grains of the rosewoods, performing curved sculpt processing, and carving various carved patterns; and C, connecting the prepared connecting members through a mortise and tenon joint structure, wherein in the step C of the three steps of the European-style furniture processed by the rosewoods, gold, silver and pearls can be further embedded and varnishing or waxing can be performed. The rosewood furniture can combine the craftsmanship with national characters and a humanistic culture and the magnificent style of the European-style furniture, so that the European-style furniture processed by the rosewoods has a Davidoff Champion and further has a revolutionary meaning on the manufacturing method of the European-style furniture.

Owner:朱东海

Leather waxing device for leather shoe production

ActiveCN108315510AImprove waxing effectWon't wrinkleLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringWaxing

The invention relates to a waxing device, in particular relates to a leather waxing device for leather shoe production and aims to solve the technical problem of providing the leather waxing device for time shortening and waxing for leather shoe production. To solve the technical problem, the invention provides the leather waxing device which comprises a bottom plate, a 7-shaped plate, first support rods, first arc-shaped clamping blocks, a waxing table, and the like, wherein the 7-shaped plate is mounted on the left side of the top of the bottom plate; the first support rods are mounted on the left side and the right side of the top of the bottom plate; the first support rods are positioned inside the 7-shaped plates; the first arc-shaped clamping blocks are mounted at the tops of the twofirst support rods; the waxing table is mounted in the middle of the top of the bottom plate; a coiling mechanism is arranged on the right side of the top of the bottom plate; the coiling mechanism is positioned on the right side of the waxing table. By adopting the leather waxing device, leather can be collected through the coiling mechanism, the leather can be waxed through the waxing mechanism, and the effects of time saving and sufficient and uniform waxing can be achieved.

Owner:嘉兴市南湖区余新振涛五金喷涂厂(普通合伙)

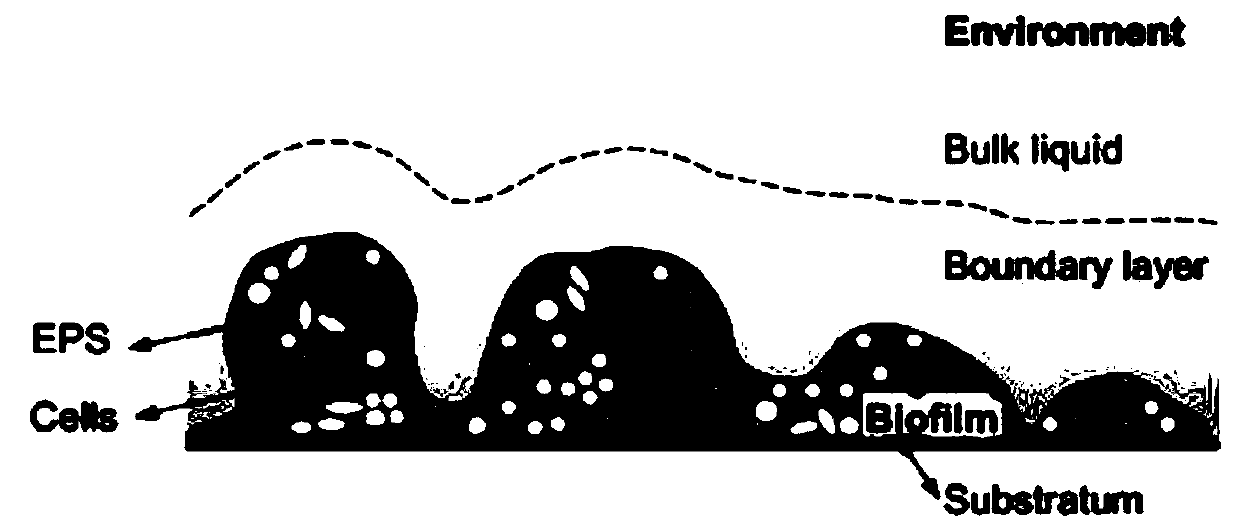

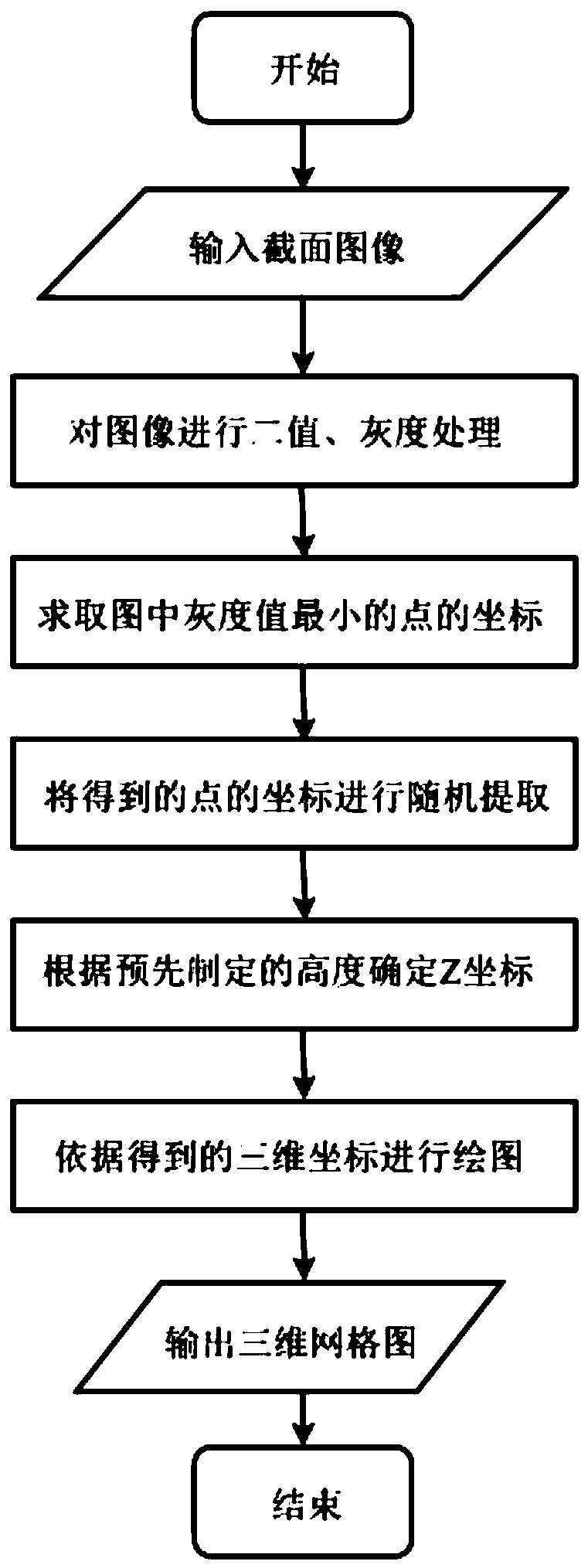

Three-dimensional curved surface reconstruction method suitable for biological membrane

ActiveCN109884019AEffective refactoringGuaranteed refactoringPreparing sample for investigationFluorescence/phosphorescenceCooking & bakingLaser light

The invention relates to a three-dimensional curved surface reconstruction method suitable for a biological membrane, and belongs to the technical field of biology. The main technical scheme is as follows: cleaning and sampling, fixing, rinsing, dehydrating, permeabilizing, waxing, embedding, slicing, sticking and baking, dewaxing, dyeing and sealing; adjusting the wavelength of emitted light, adjusting the amplification factor, photographing and storing images; and building a three-dimensional model. The three-dimensional curved surface reconstruction method suitable for the biological membrane provided by the invention is proposed for a biological membrane with the thickness greater than 0.1 mm, and in order to avoid the problem that a dye and a laser light beam cannot effectively enterthe interior of the biological membrane due to the fact that the biological membrane is excessively thick, thus the characterization is difficult. By using the technology, the complex physical form ofthe biological membrane can be effectively reconstructed, meanwhile, a relatively high reduction degree is ensured, and a feasible means is provided for researching the form change of the biologicalmembrane and influence factors.

Owner:DALIAN UNIV

Damping yarn waxing mechanism for spinning

The invention discloses a damping yarn waxing mechanism for spinning. The mechanism comprises a rack, wherein a waxing assembly and a yarn transmission assembly are disposed on the rack; the waxing assembly comprises vertical plates which are disposed on two sides of the rack; each of the adjacent sides of the vertical plates is correspondingly connected to an expansion rod respectively; the expansion rods are disposed horizontally; one end of each expansion rod is correspondingly equipped with a fixation box respectively; each of the adjacent sides of the two fixation boxes is correspondingly equipped with a groove; a wax block used for yarn waxing is disposed in each groove; multiple round grooves are formed in upper and lower sides of the groove; a hoodle is disposed in each round groove; a gas pump is disposed on each vertical plate; the gas pump is connected to the expansion rod on the corresponding side; each of the adjacent sides of the two fixation boxes is equipped with a damping assembly; each damping assembly comprises two connecting plates which are disposed on side faces of the fixation box respectively; the two connecting plates are disposed on upper and lower sides of the groove respectively; two sunk holes are formed in each connecting plate; a high-pressure spring is disposed in each sunk hole; and the two high-pressure springs are connected to a buffer plate respectively.

Owner:SUZHOU KANGJIAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com