Patents

Literature

2376results about "Treatment with plural serial refining stages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

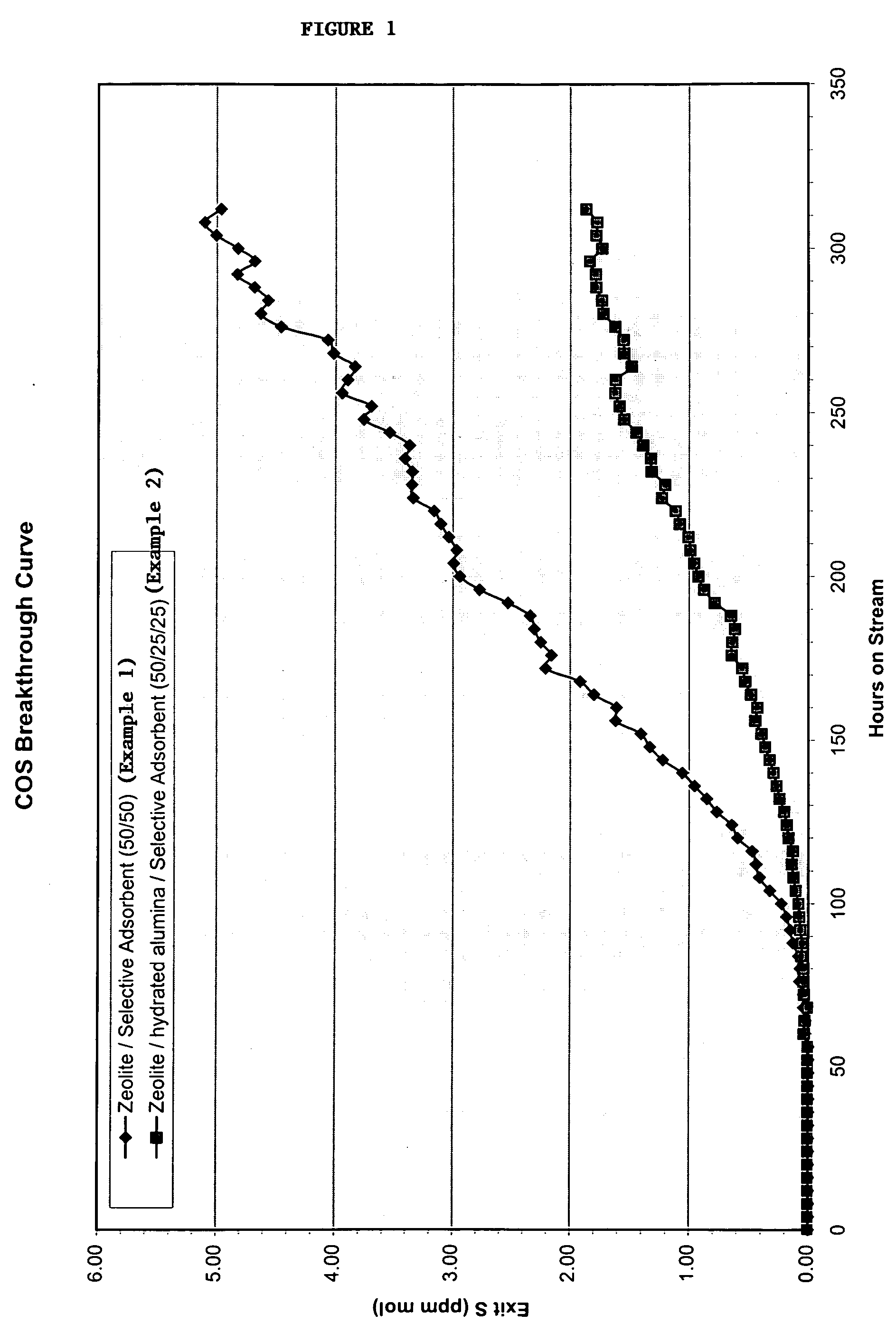

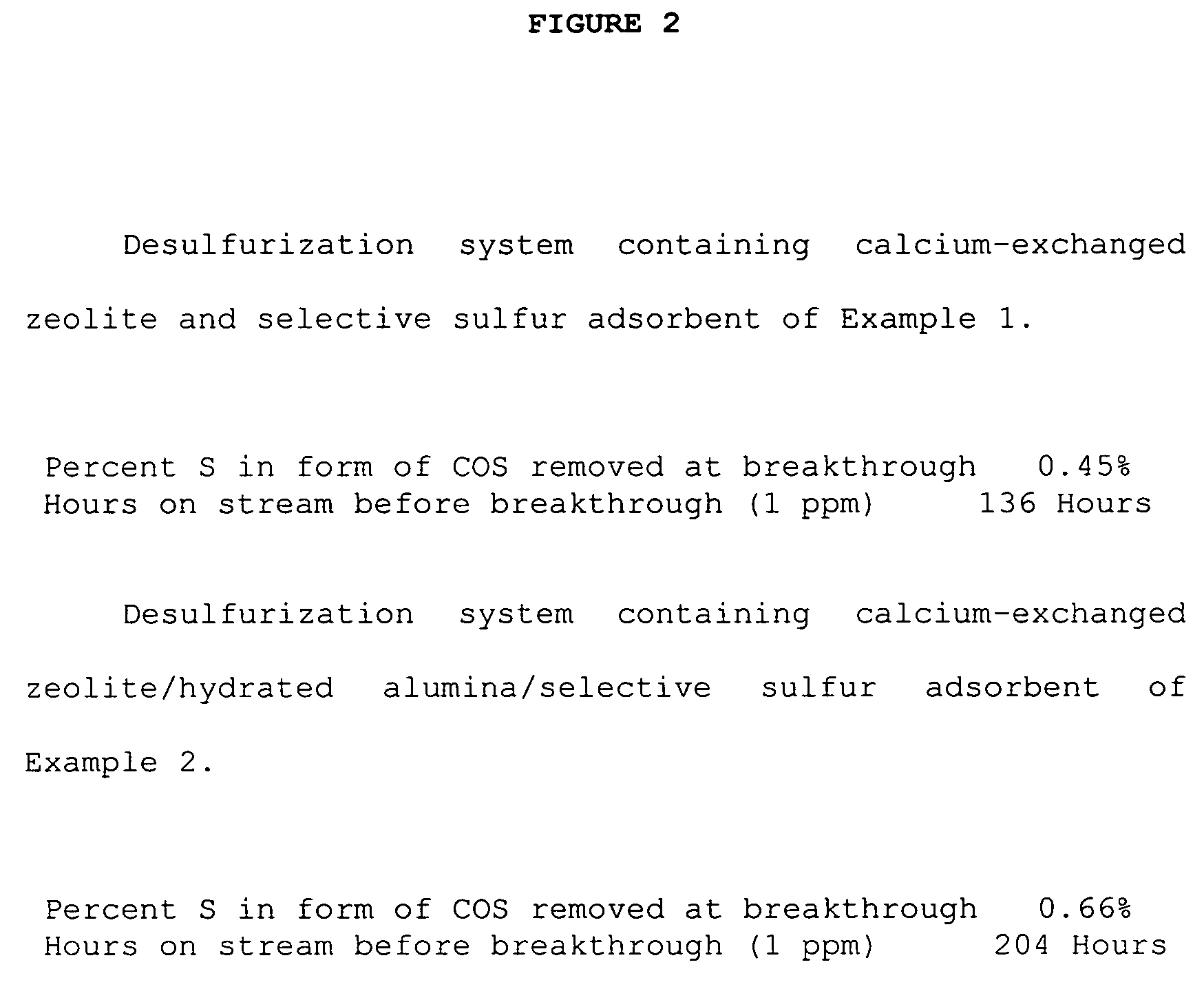

Desulfurization system and method for desulfurizing a fuel stream

A method for producing a substantially desulfurized hydrocarbon fuel stream at temperatures less than 100° C. including providing a nondesulfurized fuel cell hydrocarbon fuel stream and passing the fuel stream through a sequential sulfur adsorbent system containing calcium exchanged zeolite, hydrated alumina and a selective sulfur adsorbent placed in sequence to produce a substantially desulfurized hydrocarbon fuel stream.

Owner:SUD CHEM INC

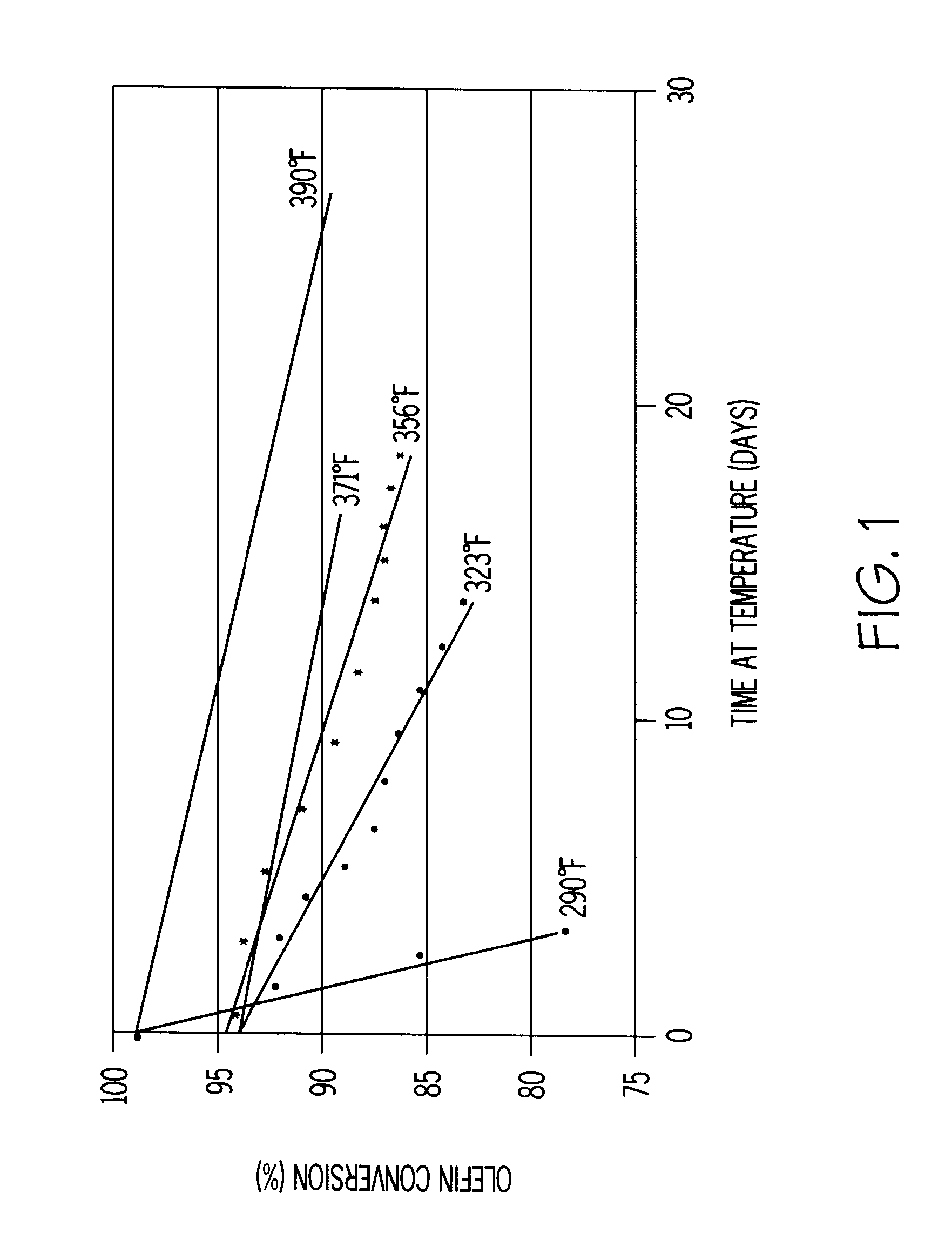

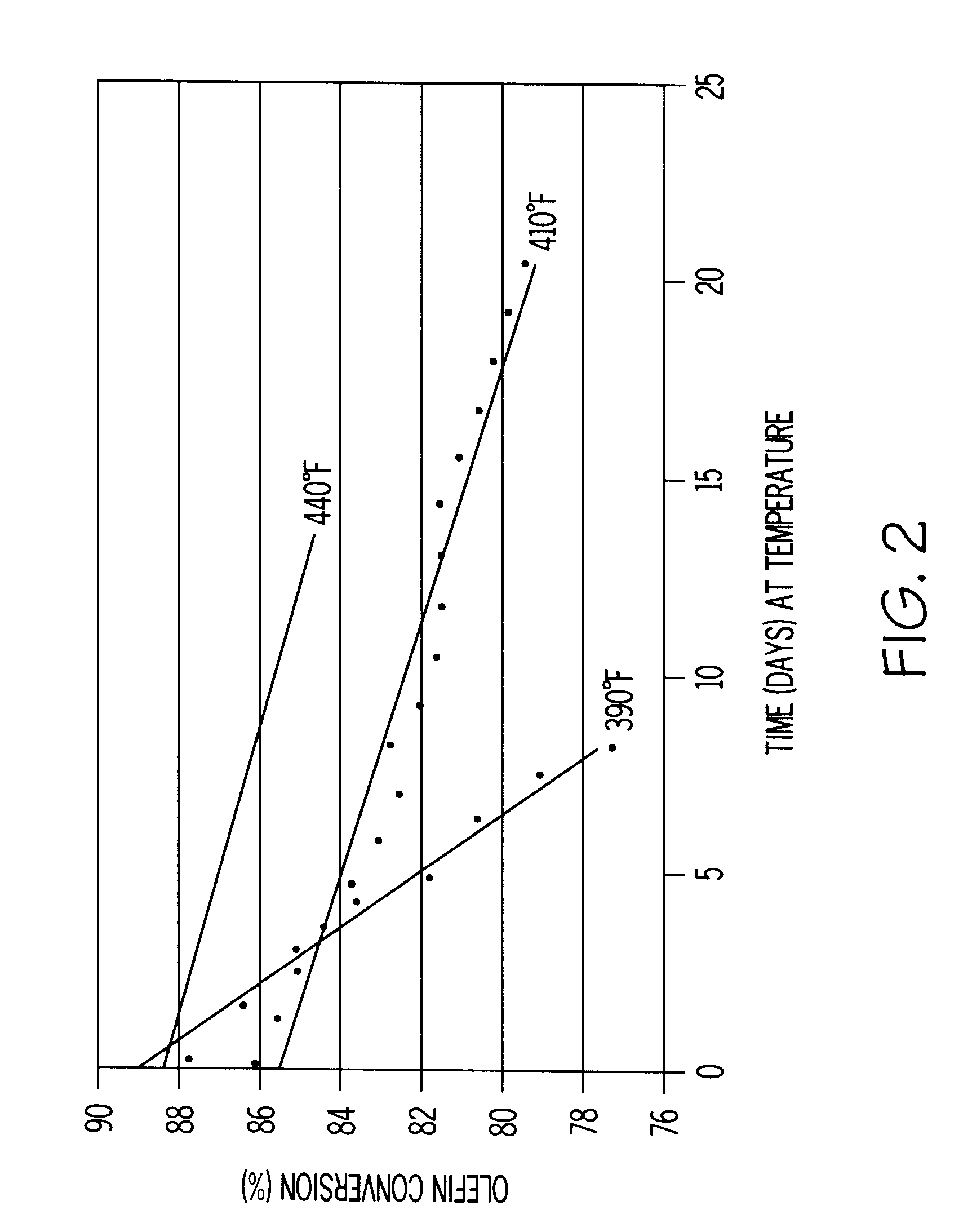

Process for BTX purification

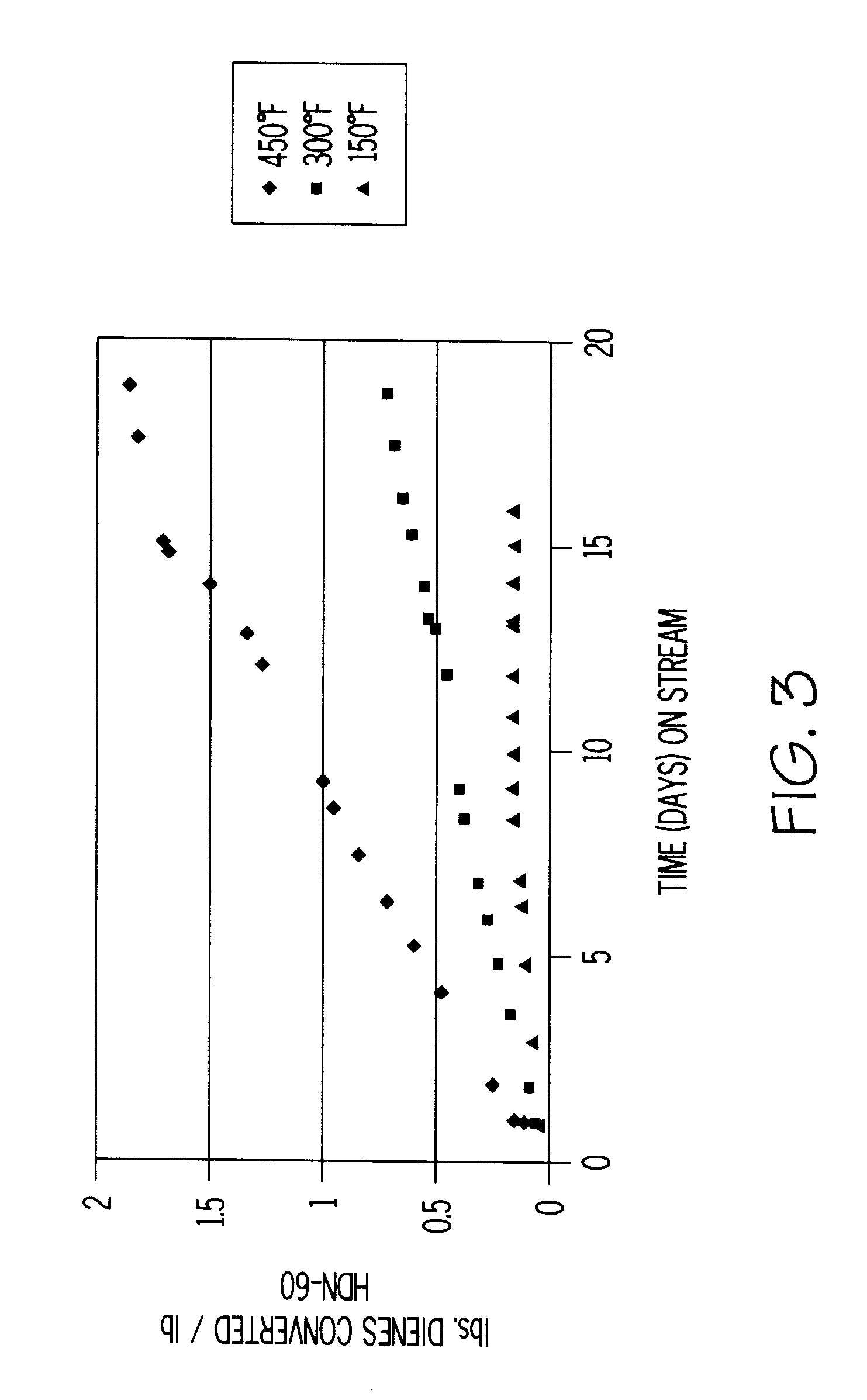

InactiveUS6500996B1Lowering indexEfficient executionOrganic chemistry methodsTreatment with plural serial refining stagesCobaltChromium

A process for the removal of hydrocarbon contaminants, such as dienes and olefins, from an aromatics reformate by contacting an aromatics reformate stream with a hydrotreating catalyst and / or a molecular sieve. The hydrotreating catalyst substantially converts all dienes to oligomers and partially converts olefins to alkylaromatics. The molecular sieve converts the olefins to alkylaromatics. The process provides an olefin depleted product which can be passed through a clay treater to substantially convert the remaining olefins to alkylaromatics. The hydrotreating catalyst has a metal component of nickel, cobalt, chromium, vanadium, molybdenum, tungsten, nickel-molybdenum, cobalt-nickel-molybdenum, nickel-tungsten, cobalt-molybdenum or nickel-tungsten-titanium, with a nickel molybdenum / alumina catalyst being preferred. The molecular sieve is an intermediate pore size zeolite, preferably MCM-22. The clay treatment can be carried out with any clay suitable for treating hydrocarbons.

Owner:EXXONMOBIL CORP (US)

Method for extraction of organosulfur compounds from hydrocarbons using ionic liquids

InactiveUS7001504B2Reduce hydrocarbon contentReduce sulfur contentTreatment with plural serial refining stagesHydrocarbon oils refiningPartial oxidationOrganosulfur compounds

A process for the removal of organosulfur compounds from hydrocarbon materials is disclosed. The process includes contacting an ionic liquid with a hydrocarbon material to extract sulfur-containing compounds into the ionic liquid. The sulfur-containing compounds can be partially oxidized to sulfoxides and / or sulfones prior to or during the extraction step.

Owner:EXTRACTICA

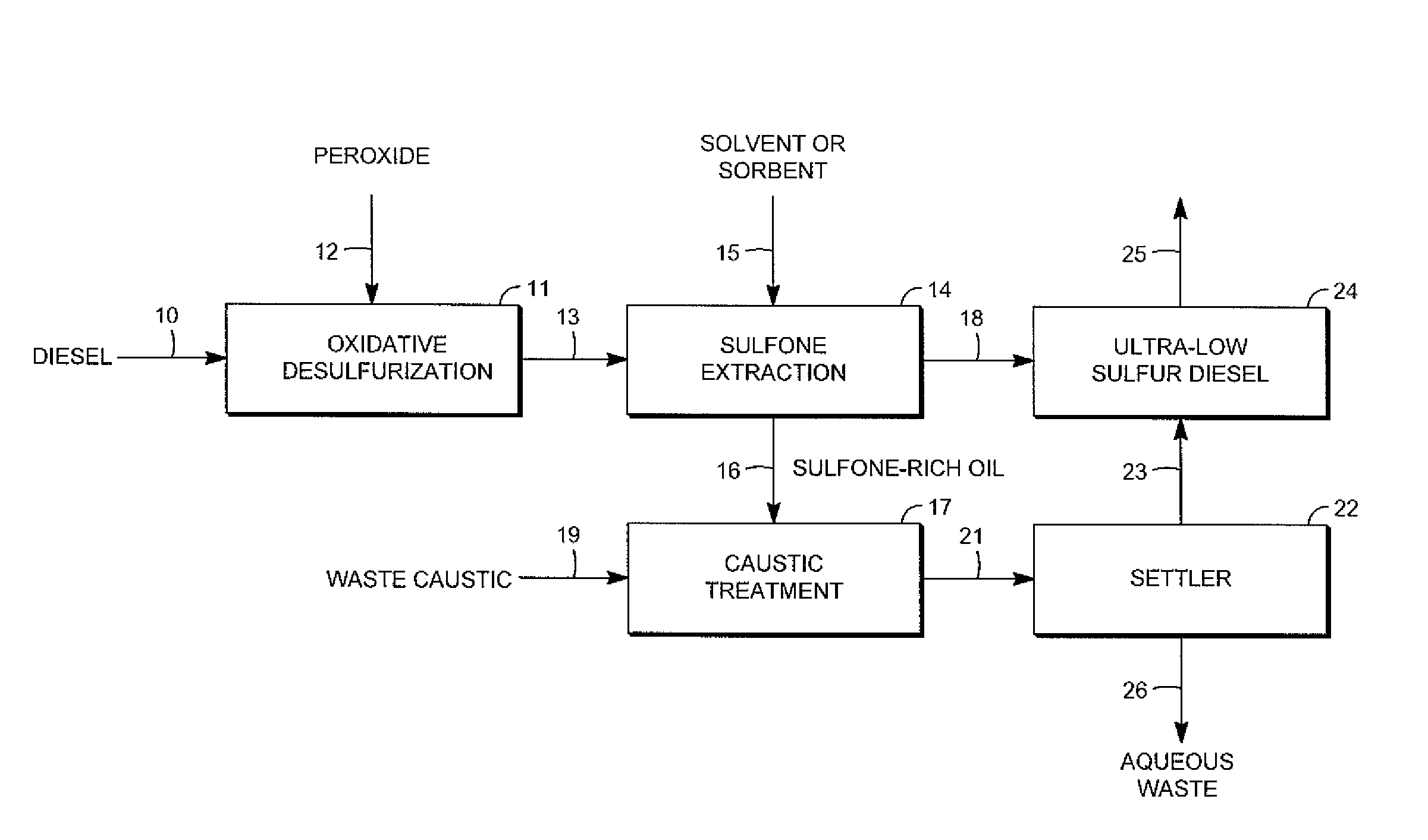

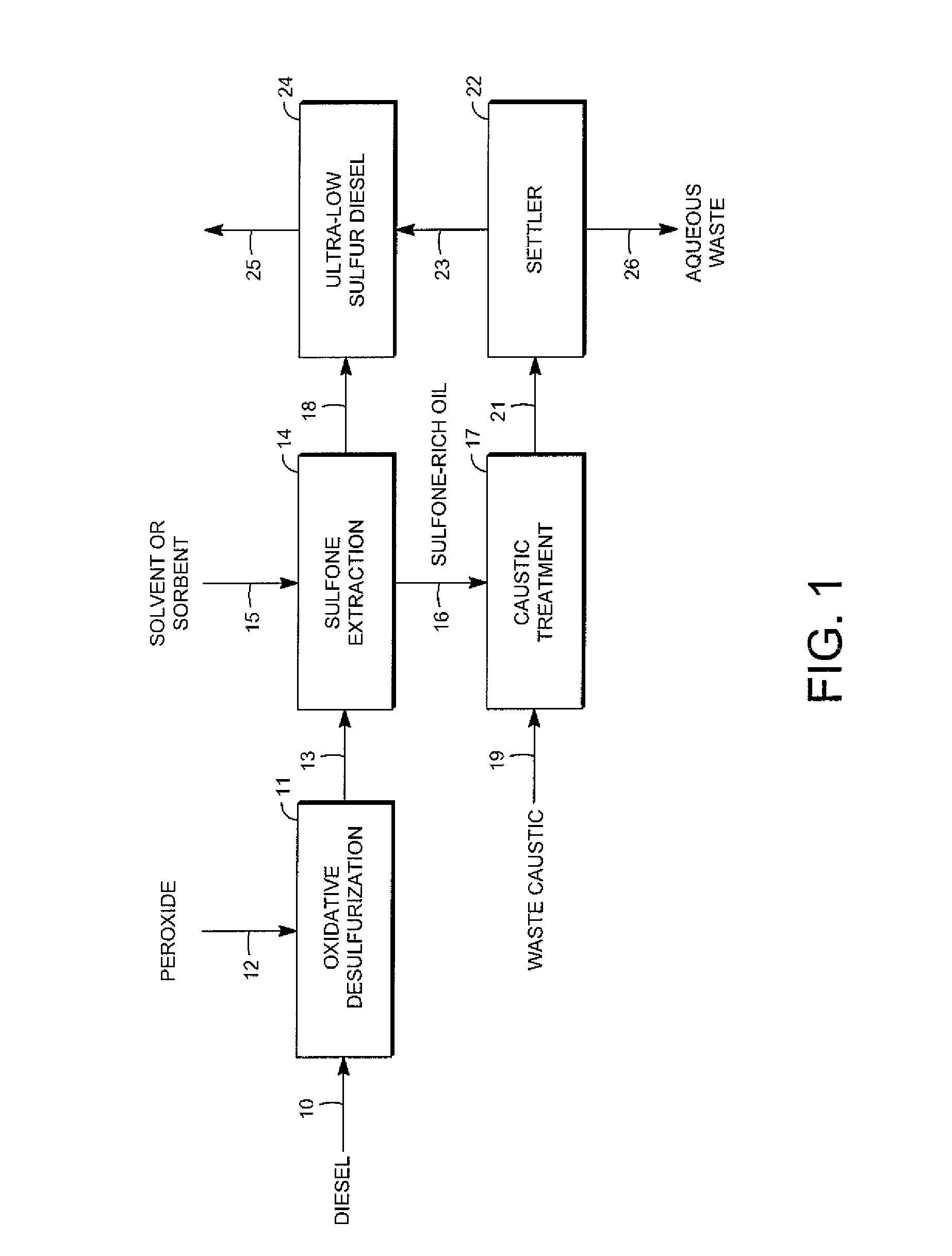

Removal of sulfur-containing compounds from liquid hydrocarbon streams

InactiveUS20090065399A1Easy to separateEasy extractionRefining with oxygen compoundsTreatment with plural serial refining stagesLiquid hydrocarbonsImproved method

An improved method for desulfurizing a fuel stream such as a diesel stream is disclosed which includes generation of a sulfone oil, the desulfurization of the sulfone oil and the recycling of the resulting biphenyl-rich stream and ultra-low sulfur diesel streams. The method includes combining a thiophene-rich diesel stream with an oxidant to oxidize the thiophenes to sulfones to provide a sulfone-rich diesel stream. Sulfone oil is extracted from the sulfone-rich diesel stream to provide sulfone oil and a first low-sulfur diesel stream The low-sulfur diesel stream is recycled. The sulfone-rich oil stream is combined with an aqueous oxidant-containing stream, such as caustic stream, which oxidizes the sulfones to biphenyls and forms sulfite to provide a second low-sulfur diesel stream

Owner:UOP LLC

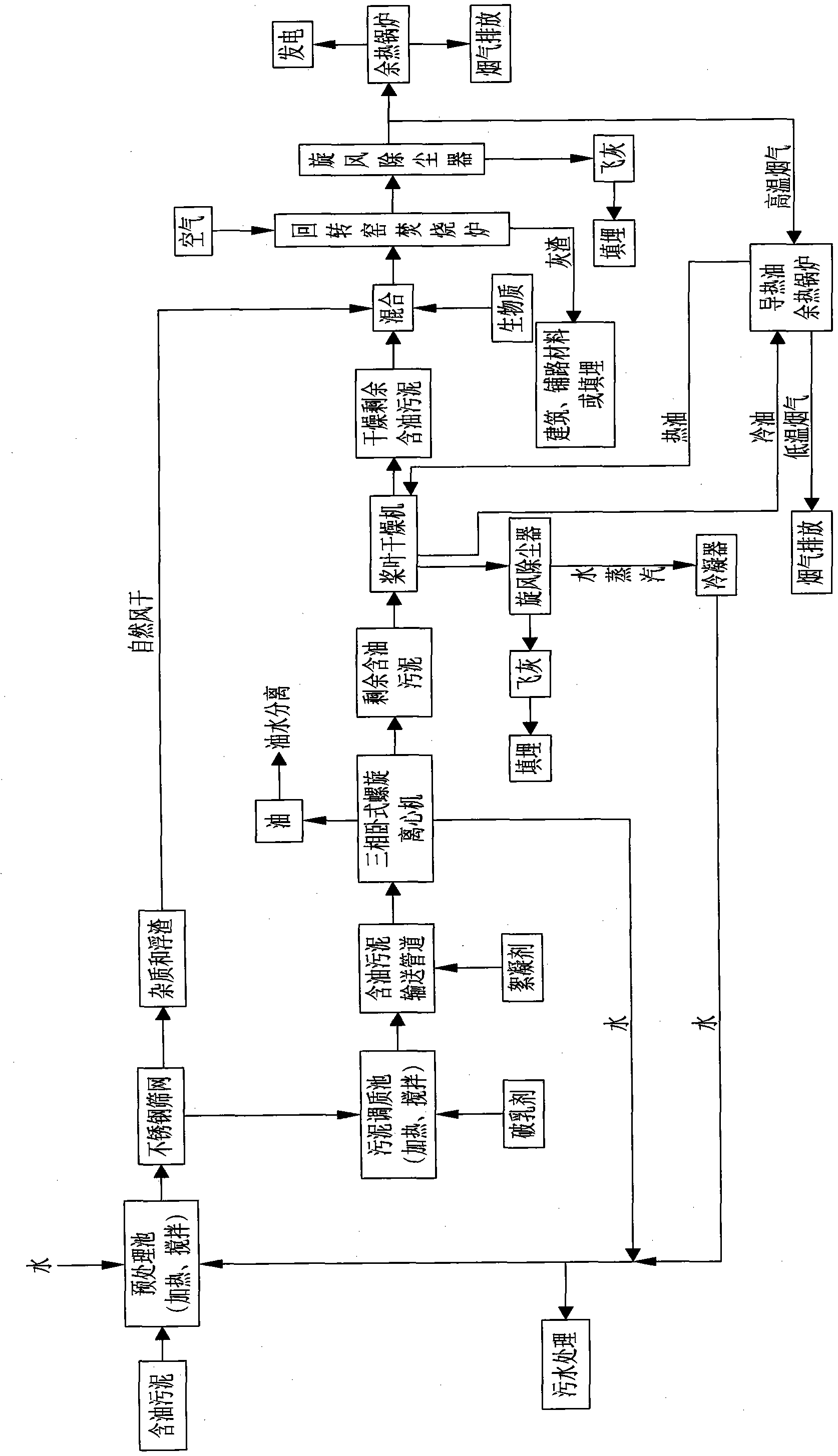

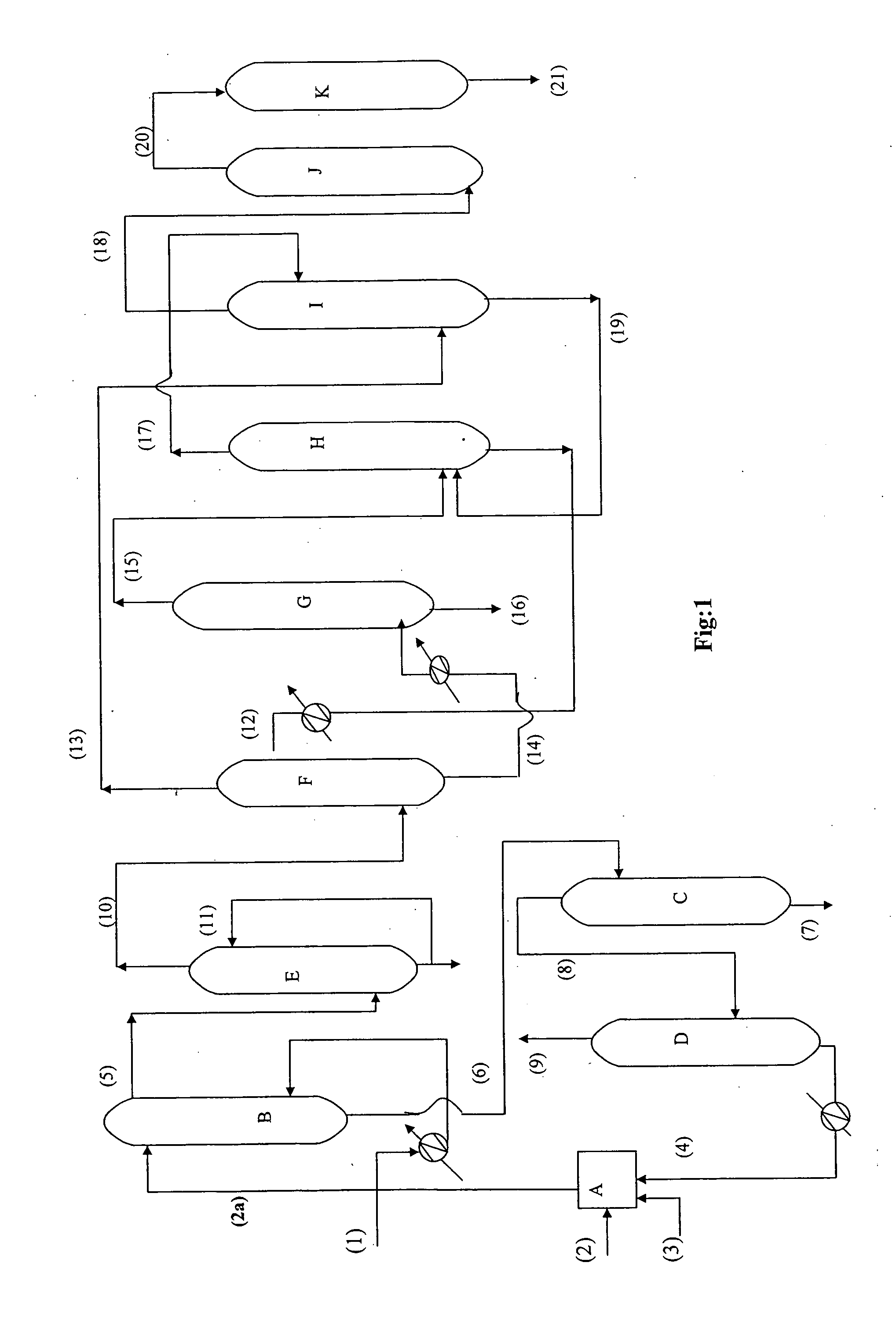

Oily sludge recycling and innocent comprehensive treatment process

InactiveCN102039301APromote resource utilizationEliminate secondary pollutionSolid waste disposalTreatment with plural serial refining stagesSlagOil sludge

The invention provides an oily sludge recycling and innocent comprehensive treatment process, which comprises the following four steps of: 1, pretreating oily sludge: adding water into the oil sludge, heating and stirring to form fluidized sludge, and separating in a stainless steel screen; 2, conditioning the oily sludge, adding a demulsifier and a flocculant into the separated fluidized sludge for conditioning the oily sludge; 3, performing centrifugal separation on three phases of the oily sludge: introducing separated oil into an oil-water separation system for recovering crude oil, conveying separated water to the oily sludge pretreatment step for recycling, drying the separated residual oily sludge, and solid impurities and floating slag which are separated in the oily sludge pretreatment, and introducing the dried substances into a rotary kiln incinerator; and 4, performing mixed combustion on the residual oily sludge and biomass, performing high temperature incineration treatment after the residual oily sludge, the separated solid impurities and floating slag, and the biomass are mixed in a rotary kiln to remove the secondary pollution of the oily sludge, and recovering afterheat from high temperature flue gas.

Owner:KUNMING UNIV OF SCI & TECH

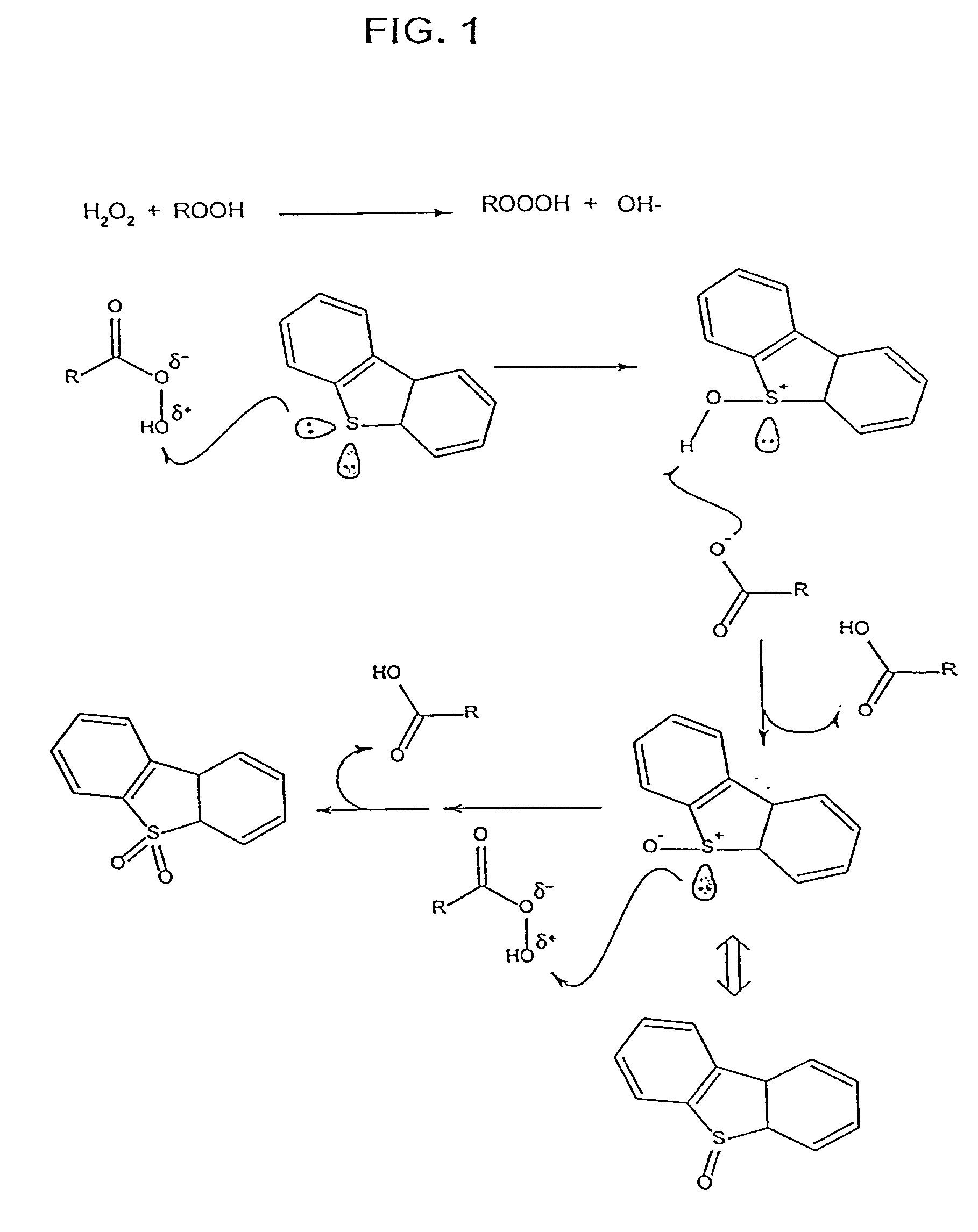

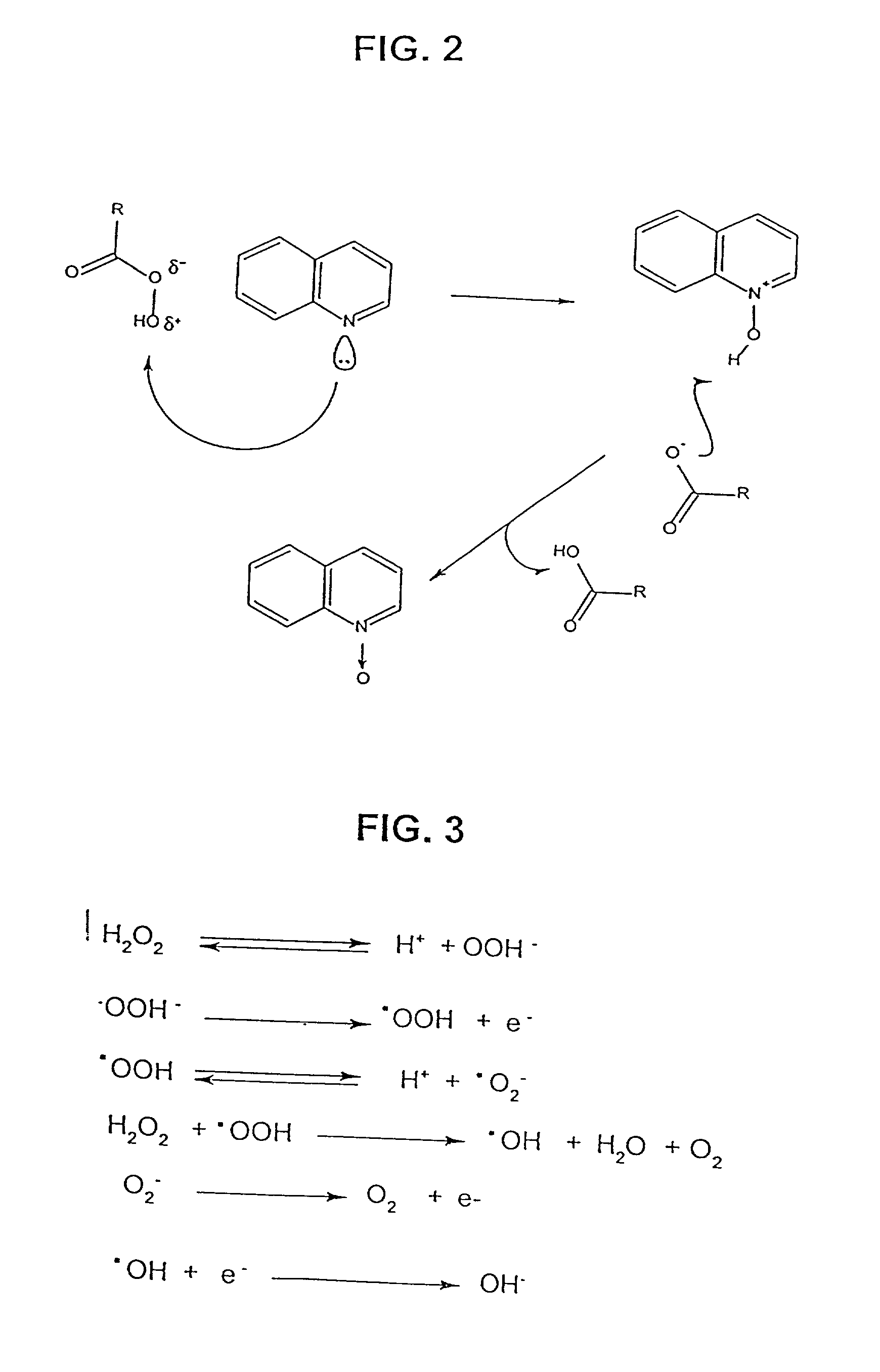

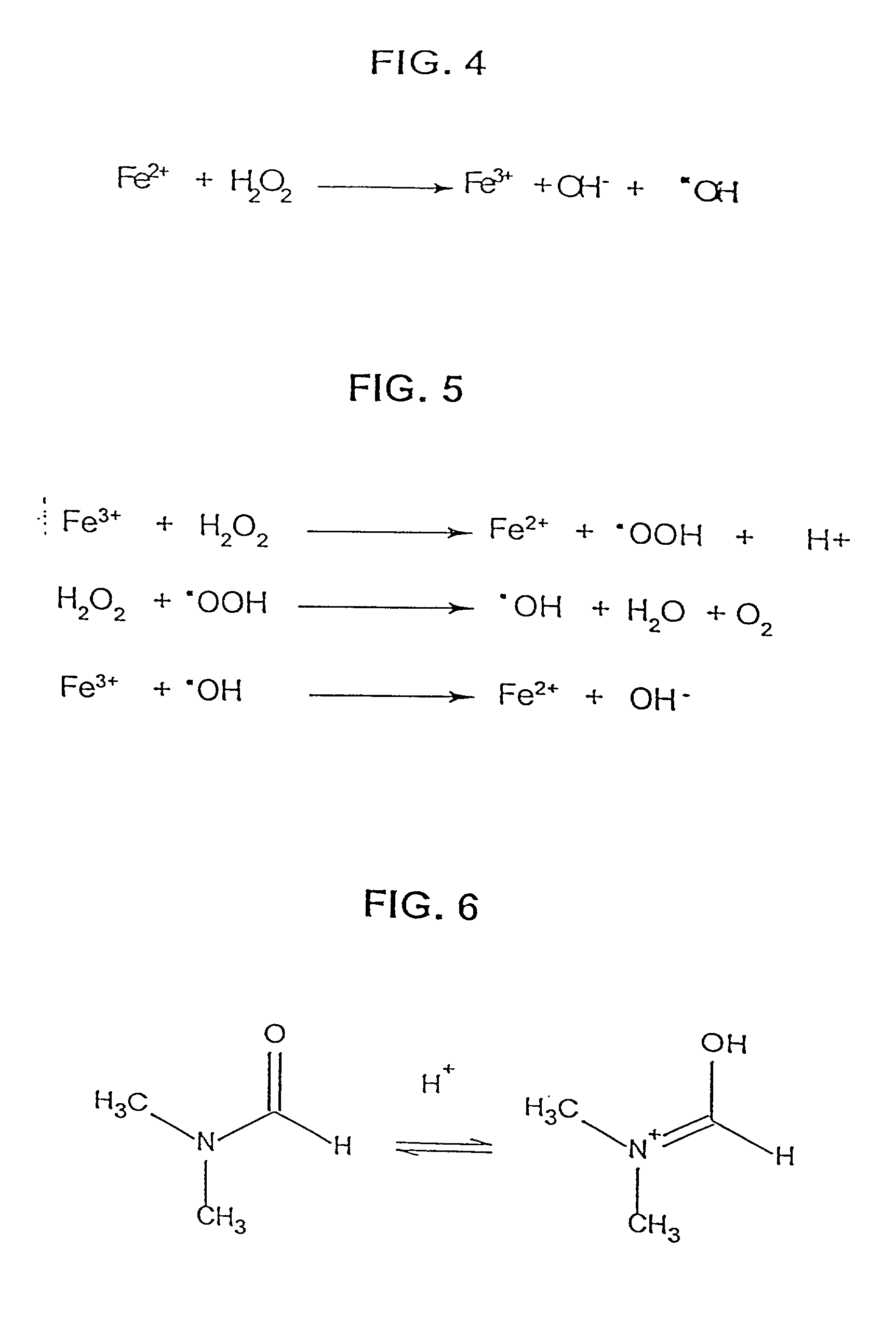

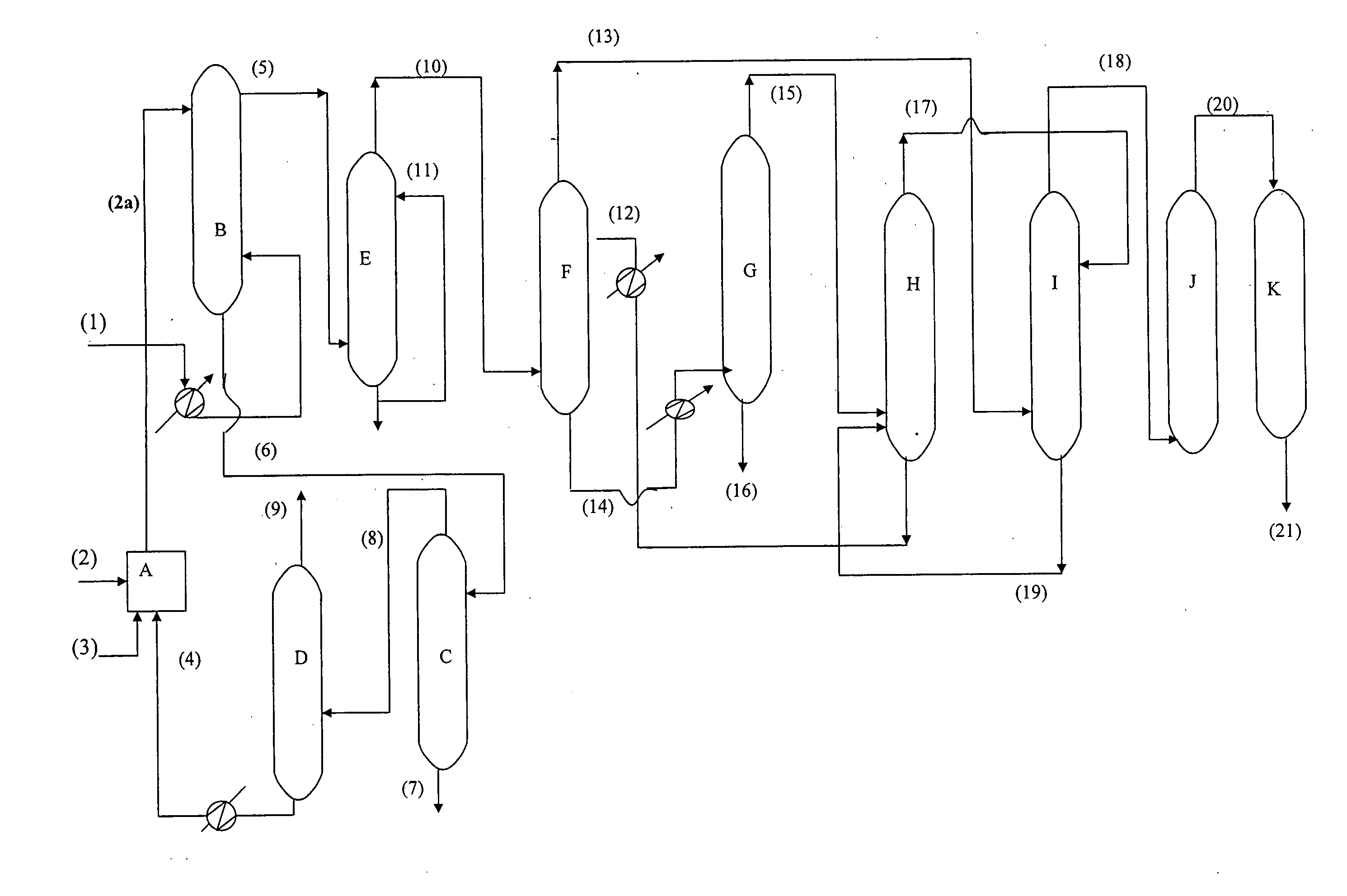

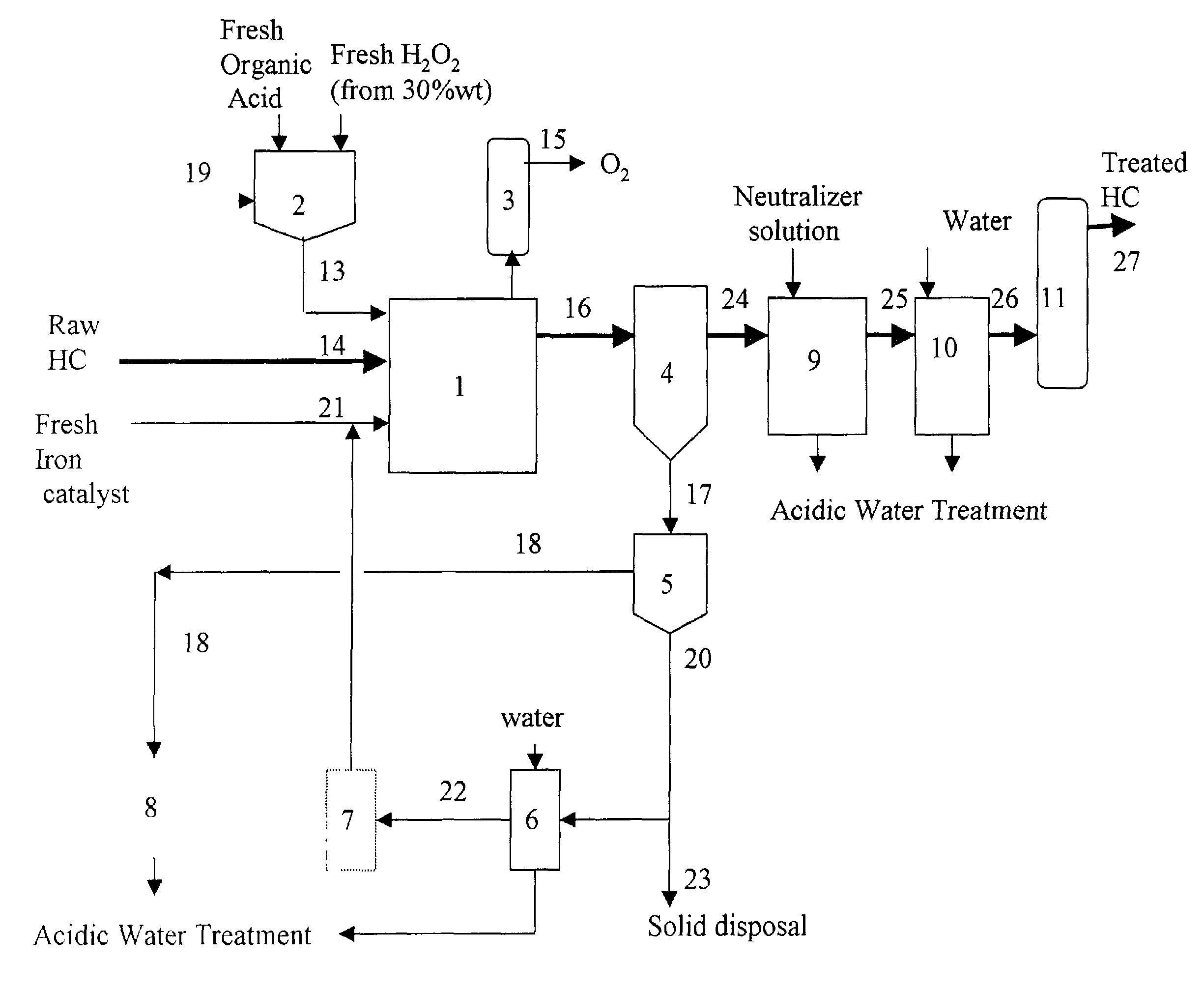

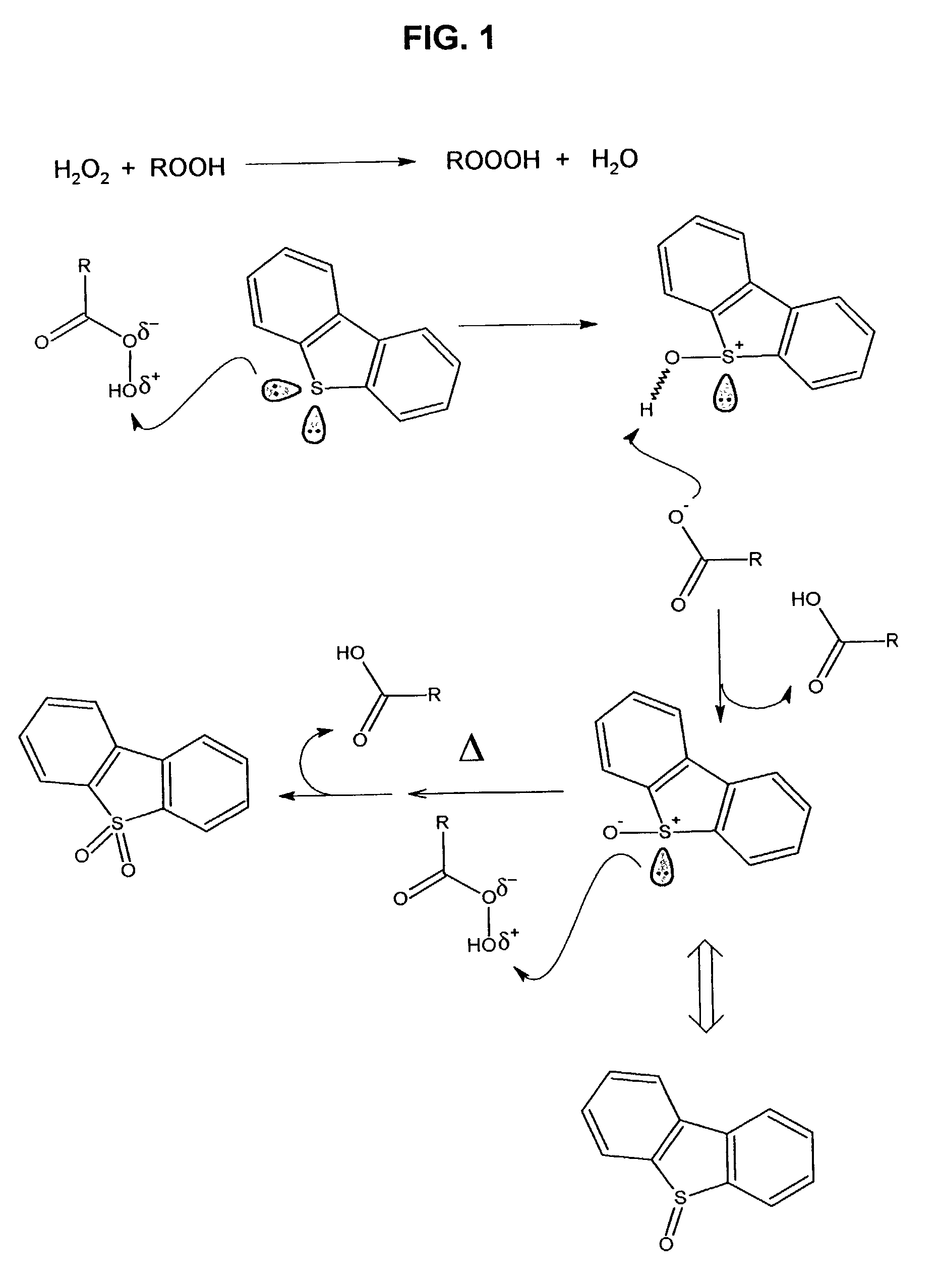

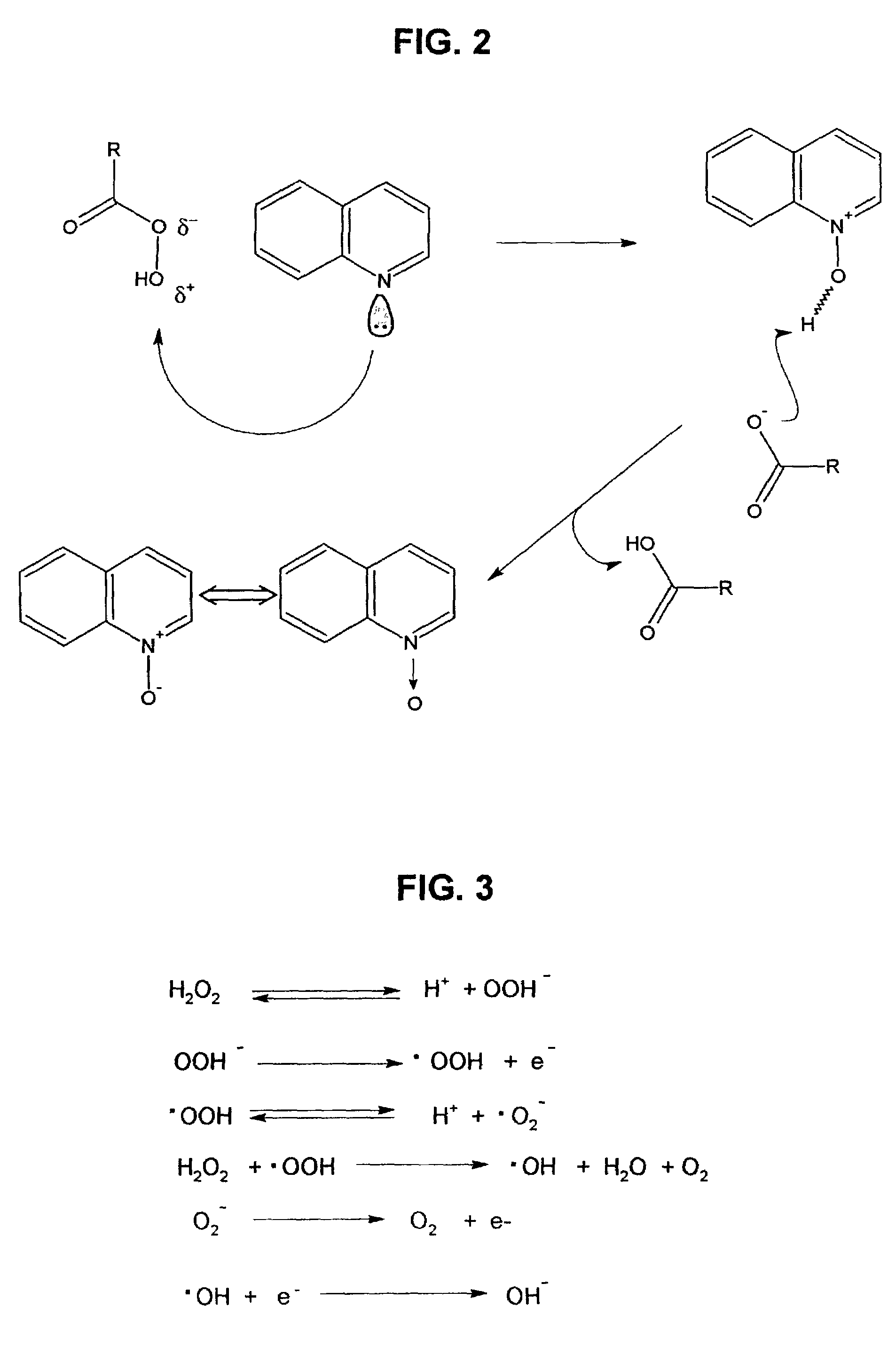

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxyacid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

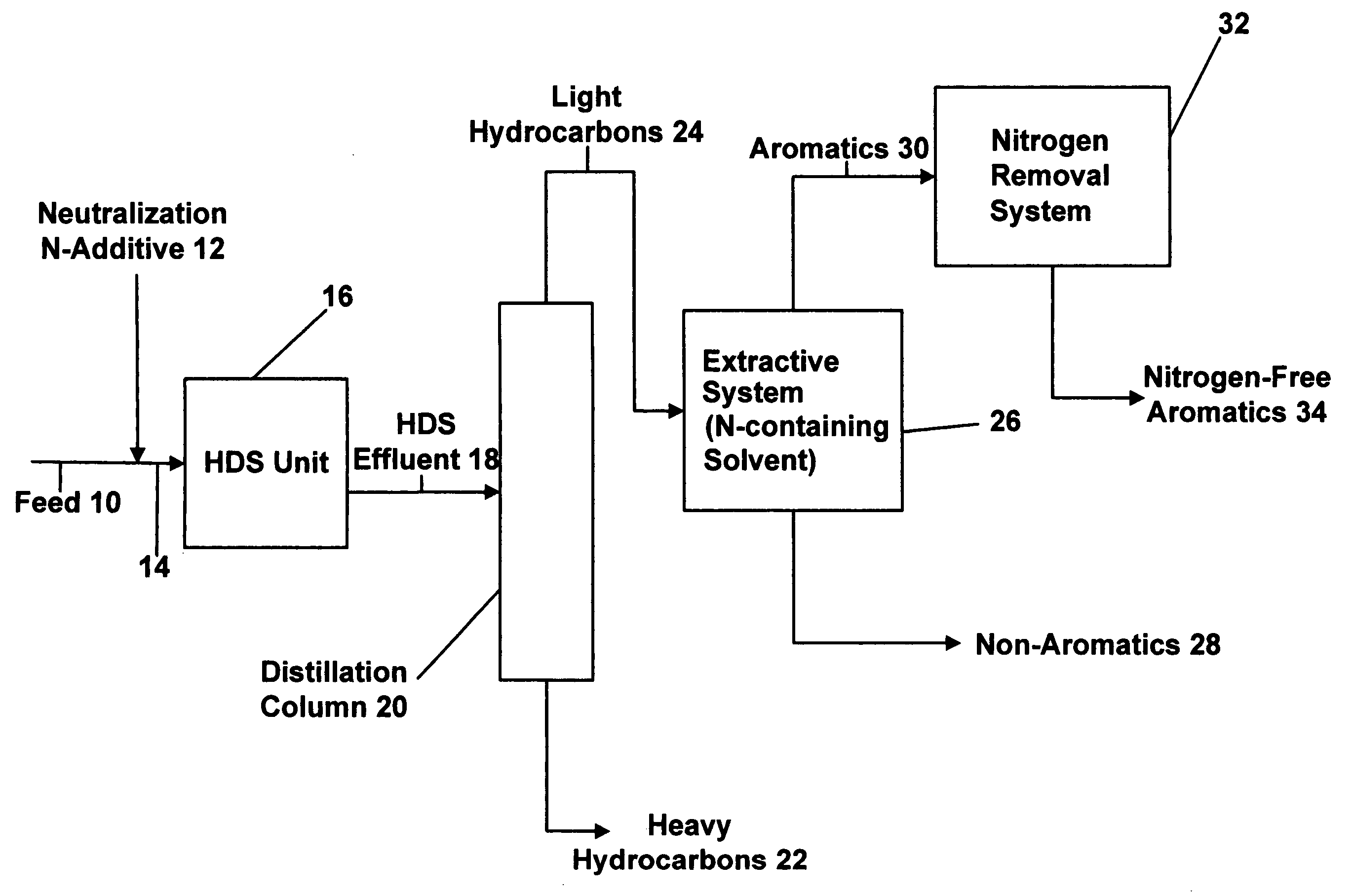

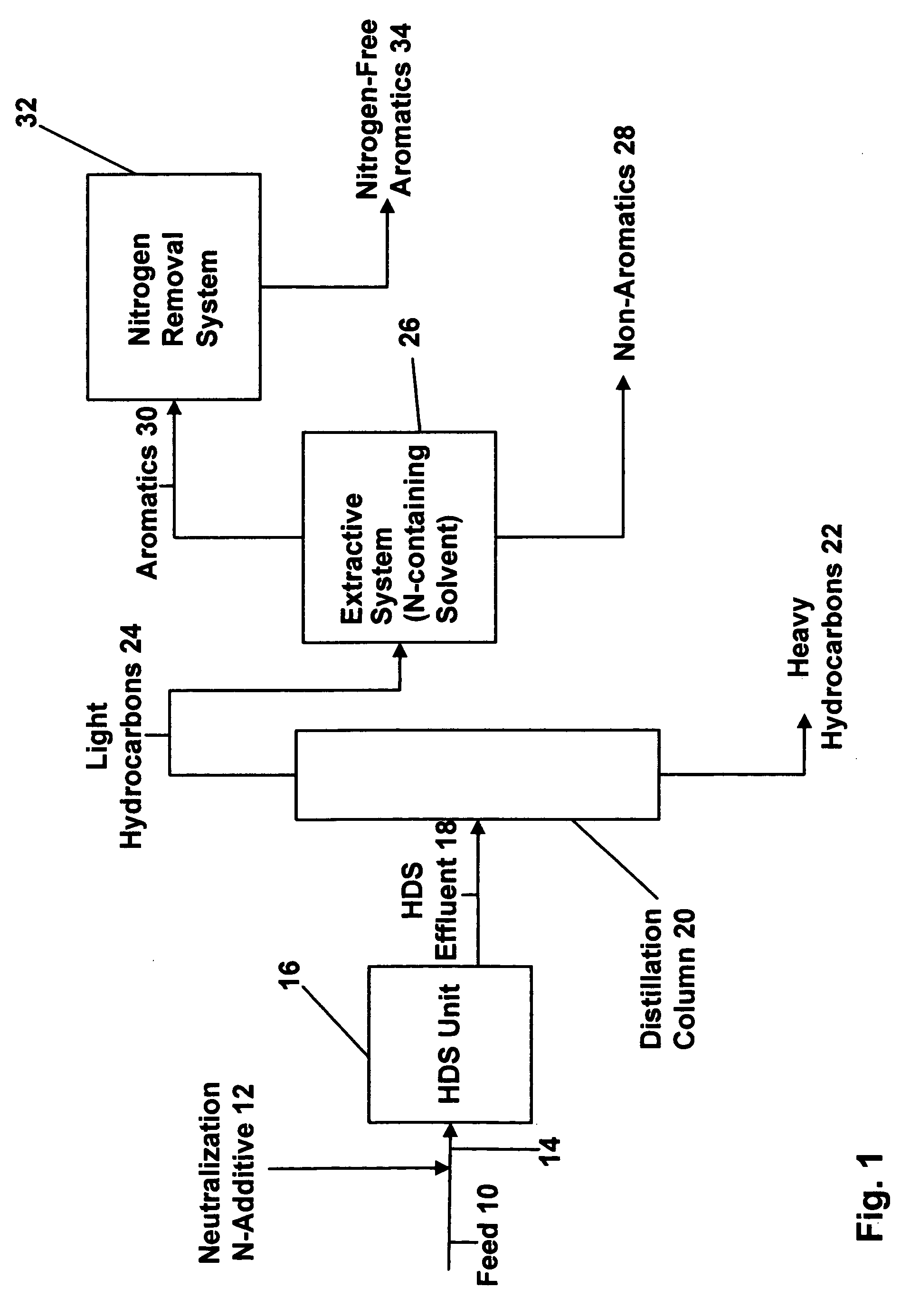

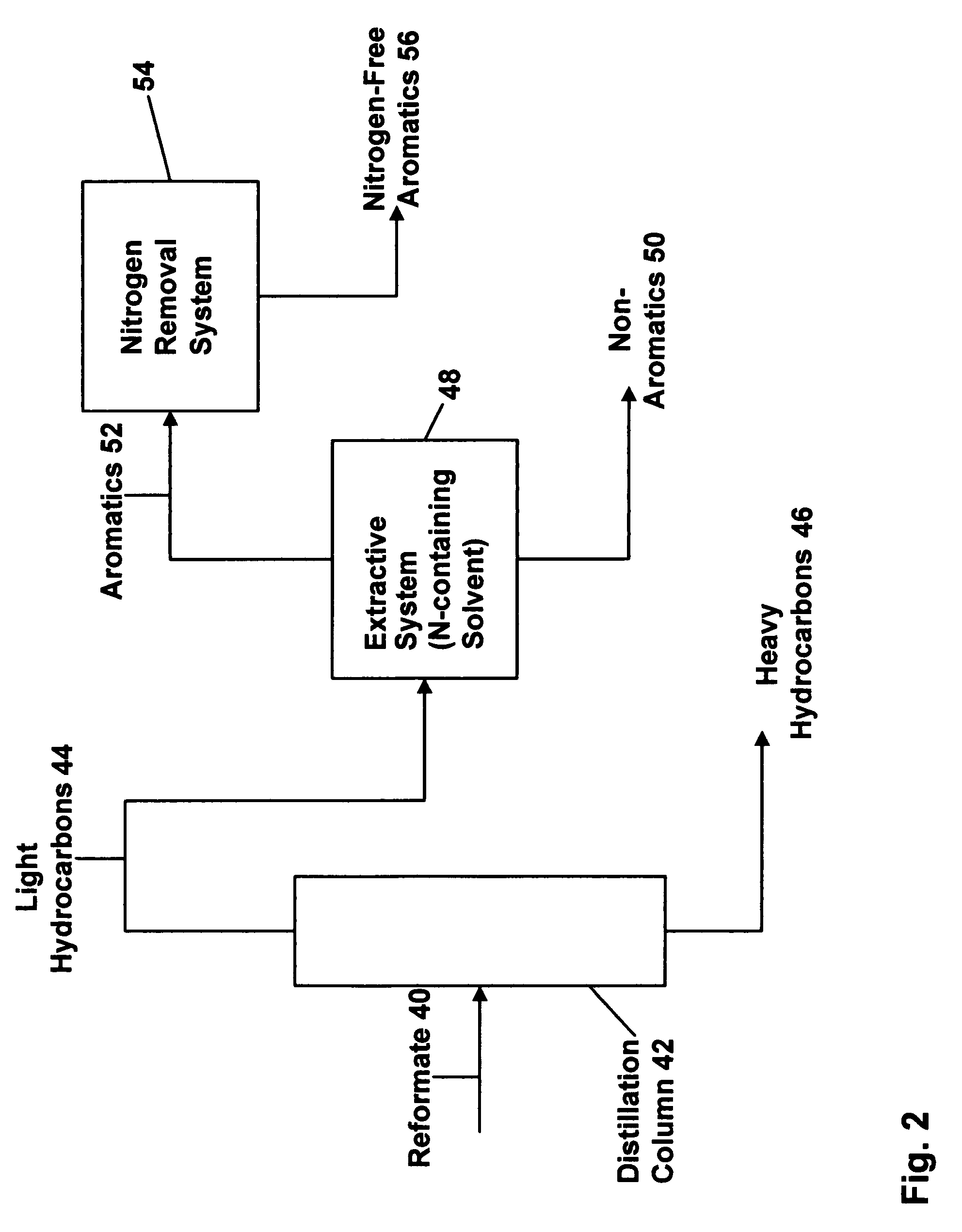

Process for producing petroleum oils with ultra-low nitrogen content

ActiveUS20070000809A1Highly effectiveSpeed up the extraction processHydrocarbon distillationTreatment with plural serial refining stagesLow nitrogenSolvent

A highly effective liquid-liquid extraction process to remove nitrogen compounds and especially basic nitrogen compounds from aromatic light petroleum oils with excellent recovery employs de-ionized water, which can be acidified, as the extractive solvent. The product is an aromatic hydrocarbon with ultra-low amounts of nitrogen poisons that can deactivate acidic catalysts. The extracted oils are suitable feedstock for the subsequent catalytic processes that are promoted with the high performance solid catalysts, which are extremely sensitive to nitrogen poison.

Owner:CPC CORPORATION +1

Process for the desulfurization of hydrocarbonacecus oil

InactiveUS20050040078A1Easily and economically reducing sulfur contentHigh recovery rateRefining with oxygen compoundsTreatment with plural serial refining stagesHydrodesulfurizationSulfur

A process for the desulfurization of hydrocarbonaceous oil wherein the hydrocarbonaceous oil is contacted with a hydrodesulfurization catalyst in a hydrodesulfurization reaction zone to reduce the sulfur level to a relatively low level then contacting the resulting hydrocarbonaceous stream from the hydrodesulfurization zone with an oxidizing agent to convert the residual, low level of sulfur compounds into sulfur-oxidated compounds. The resulting hydrocarbonaceous oil stream containing the sulfur-oxidated compounds is separated after decomposing any residual oxidizing agent by contacting the stream with an adsorbent material to adsorb the sulfur-oxidated compounds to produce a hydrocarbonaceous oil stream having a reduced concentration of sulfur-oxidated compounds. The spent adsorbent is regenerated and subsequently returned to adsorbent service.

Owner:UOP LLC

Desulfurization process

This invention is a method of purifying fuels containing organosulfur impurities. The fuel is oxidized with an organic hydroperoxide in the presence of an oxidation catalyst to form a sulfone product, followed by extraction of the sulfone product by solid-liquid or liquid-liquid extraction. The fuel is then contacted with a decomposition catalyst to remove the residual organic hydroperoxide from the fuel.

Owner:LYONDELL CHEM TECH LP

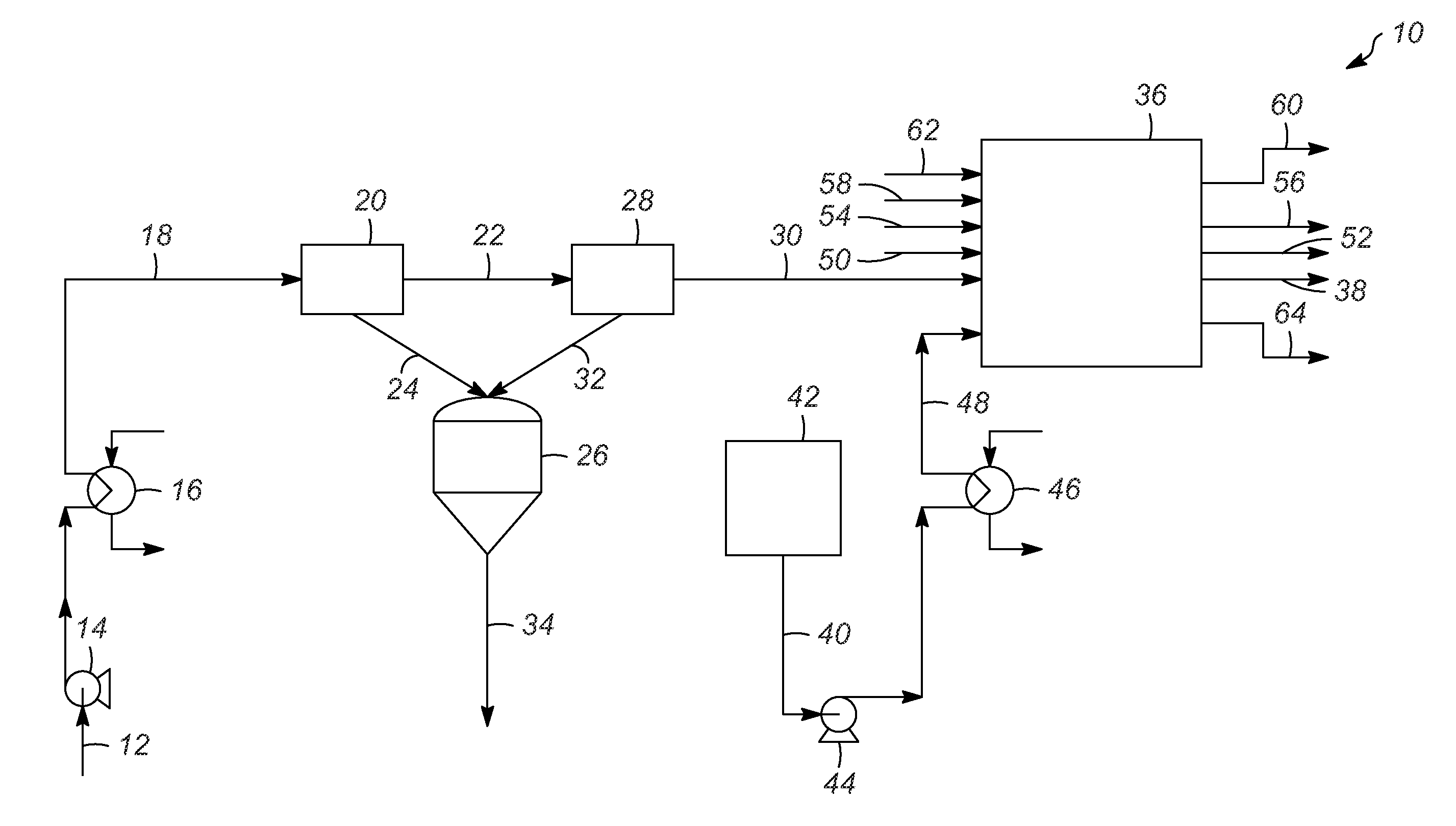

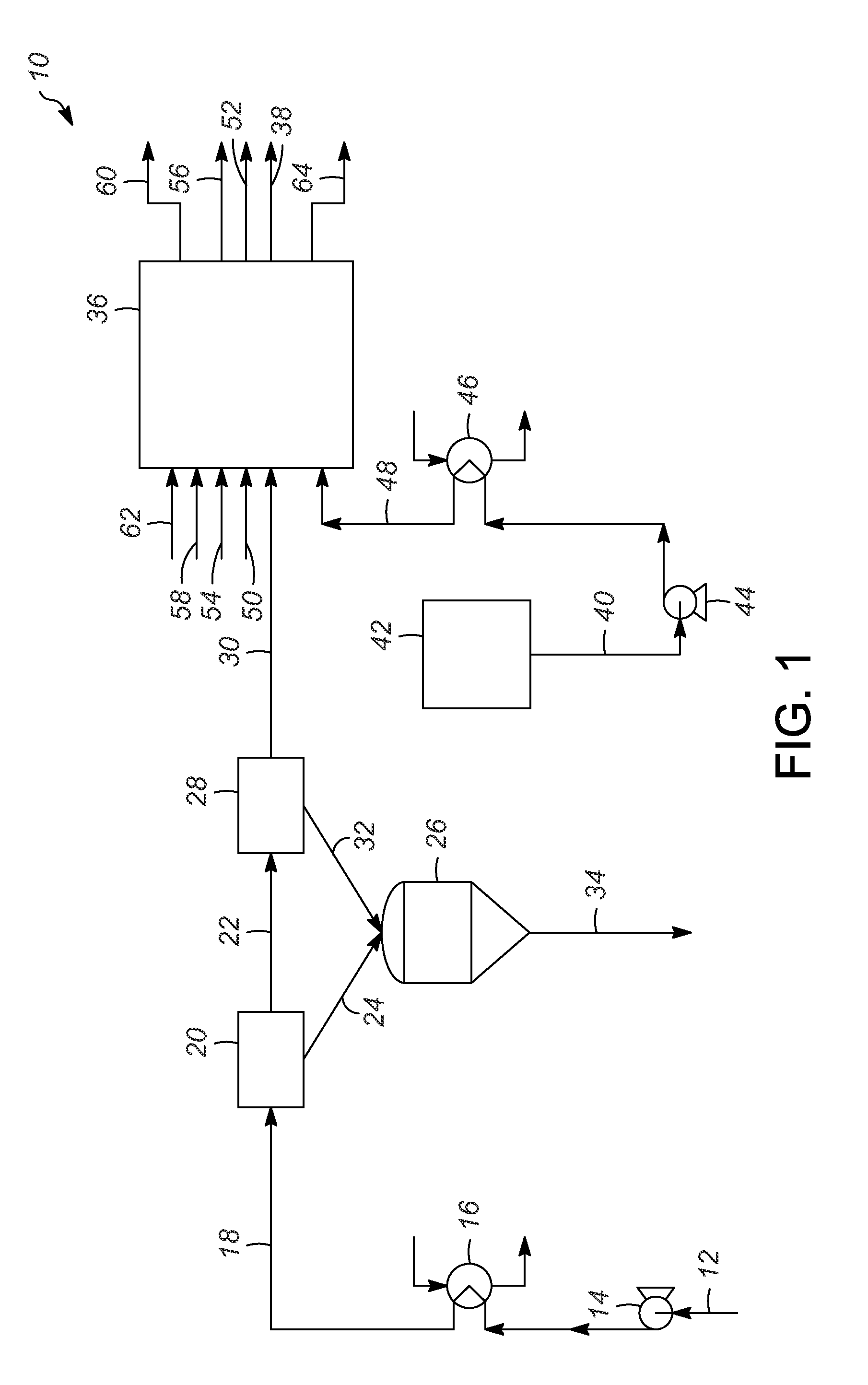

Methods and apparatuses for forming low-metal biomass-derived pyrolysis oil

Embodiments of methods and apparatuses for forming a low-metal biomass-derived pyrolysis oil are provided. The method comprises the steps of filtering a biomass-derived pyrolysis oil with a high flux rate filter arrangement having a flux rate of about 10 L / m2 / hr or greater to form a low-solids biomass-derived pyrolysis oil. The low-solids biomass-derived pyrolysis oil is filtered with a fine filter arrangement having a pore diameter of about 50 μm or less to form an ultralow-solids biomass-derived pyrolysis oil. The ultralow-solids biomass-derived pyrolysis oil is contacted with an ion-exchange resin to remove metal ions and form the low-metal biomass-derived pyrolysis oil.

Owner:UOP LLC

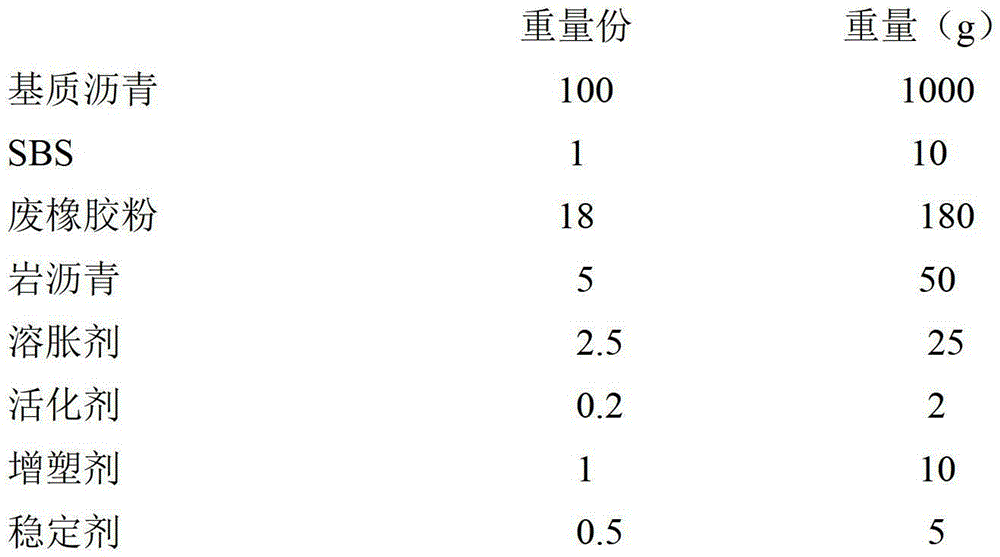

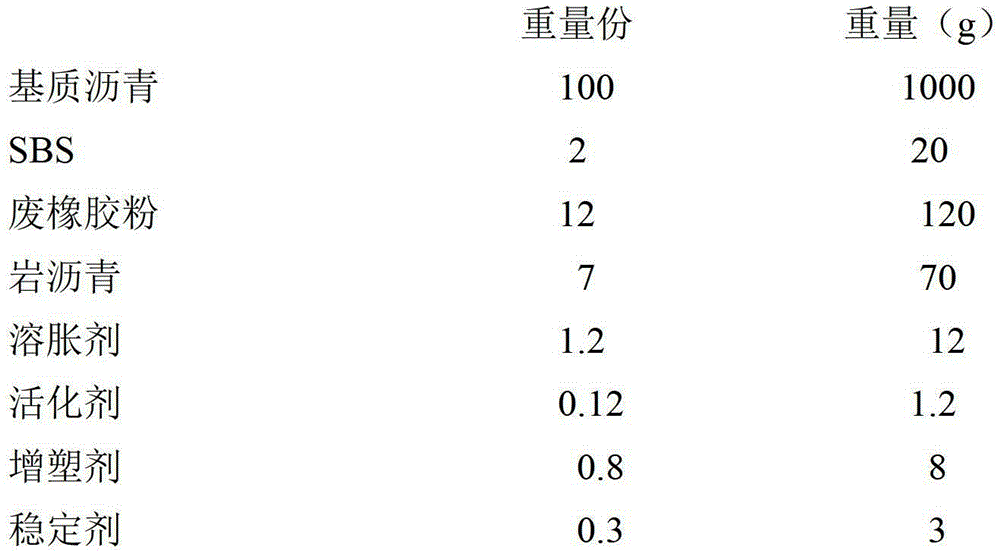

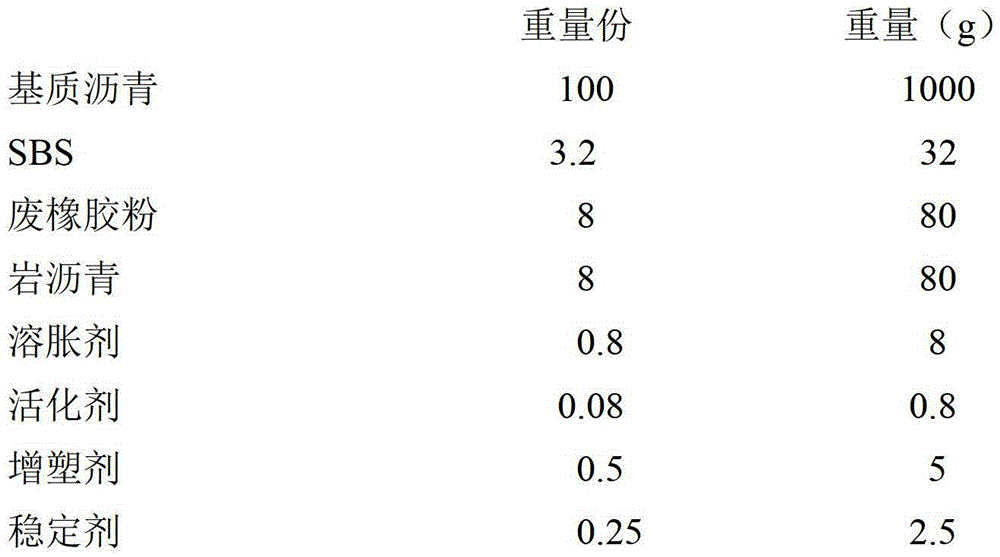

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

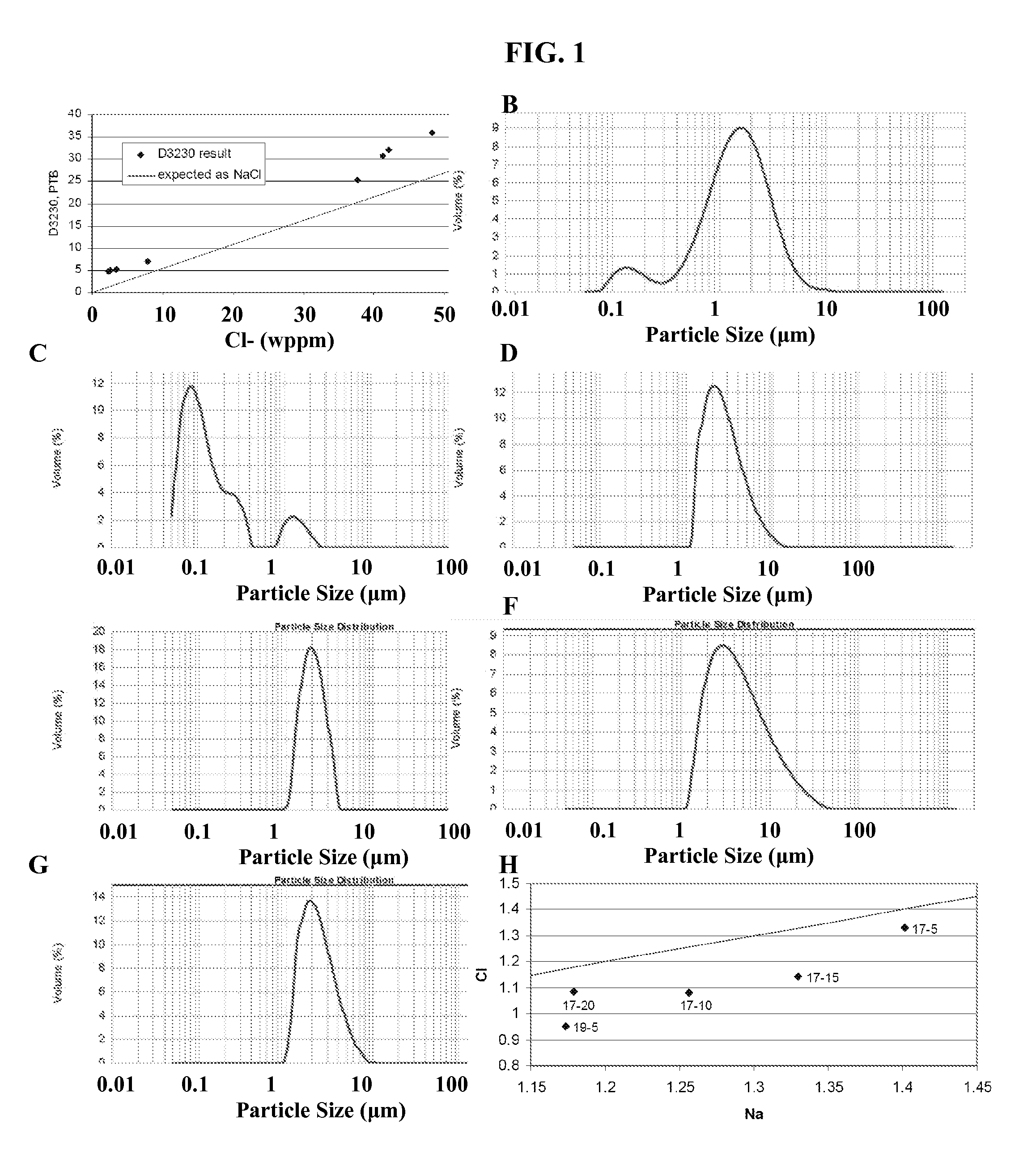

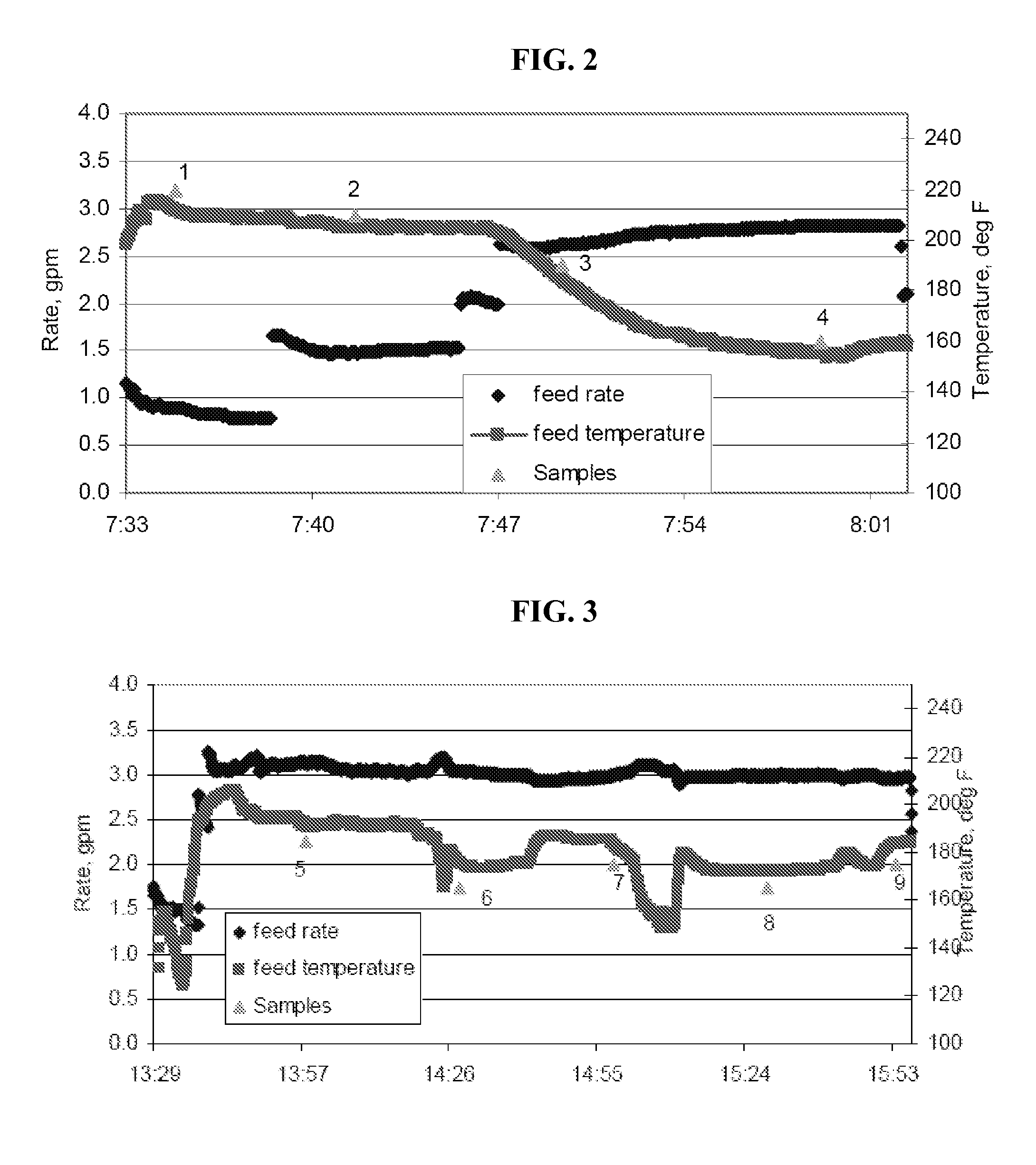

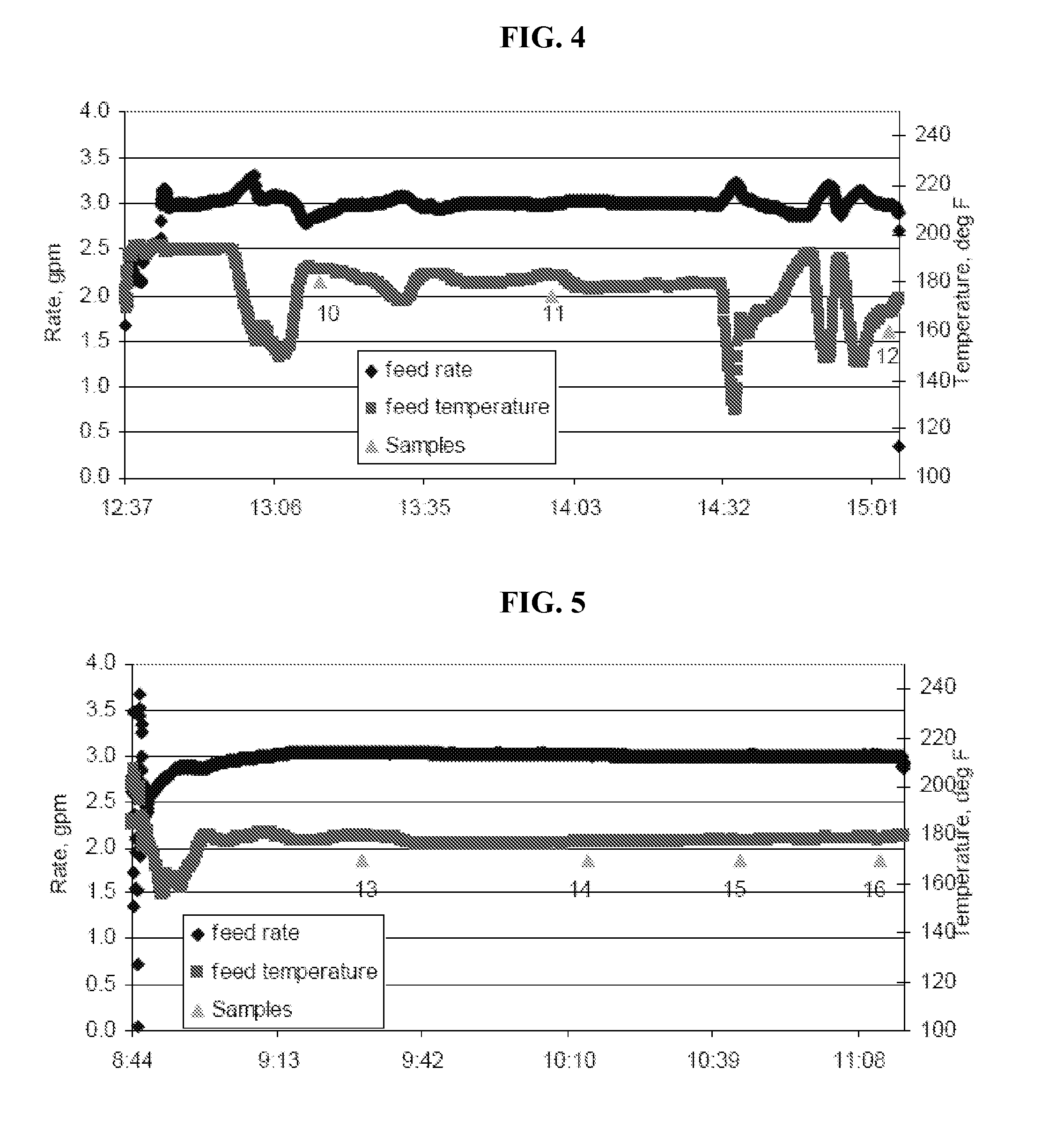

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

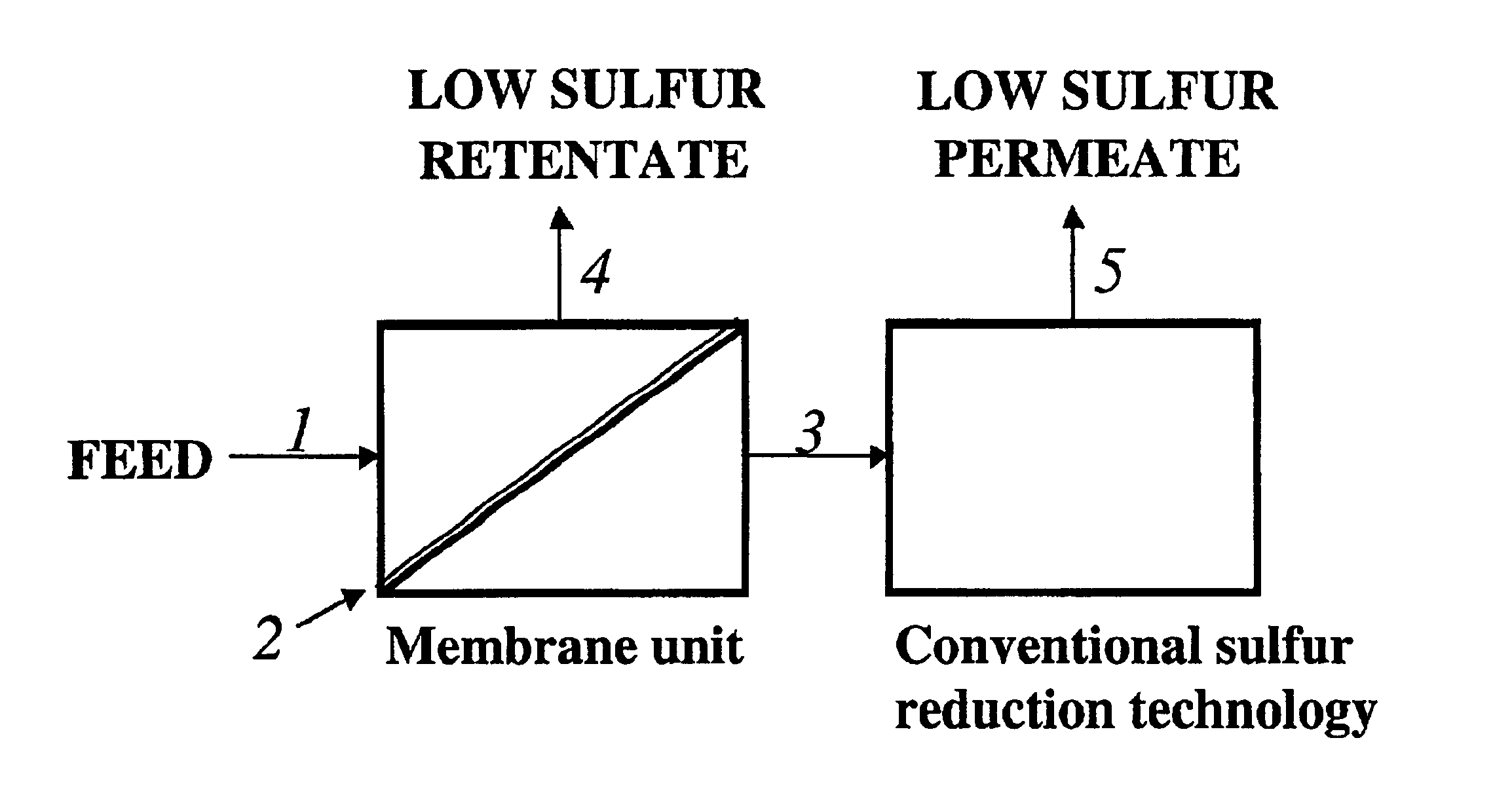

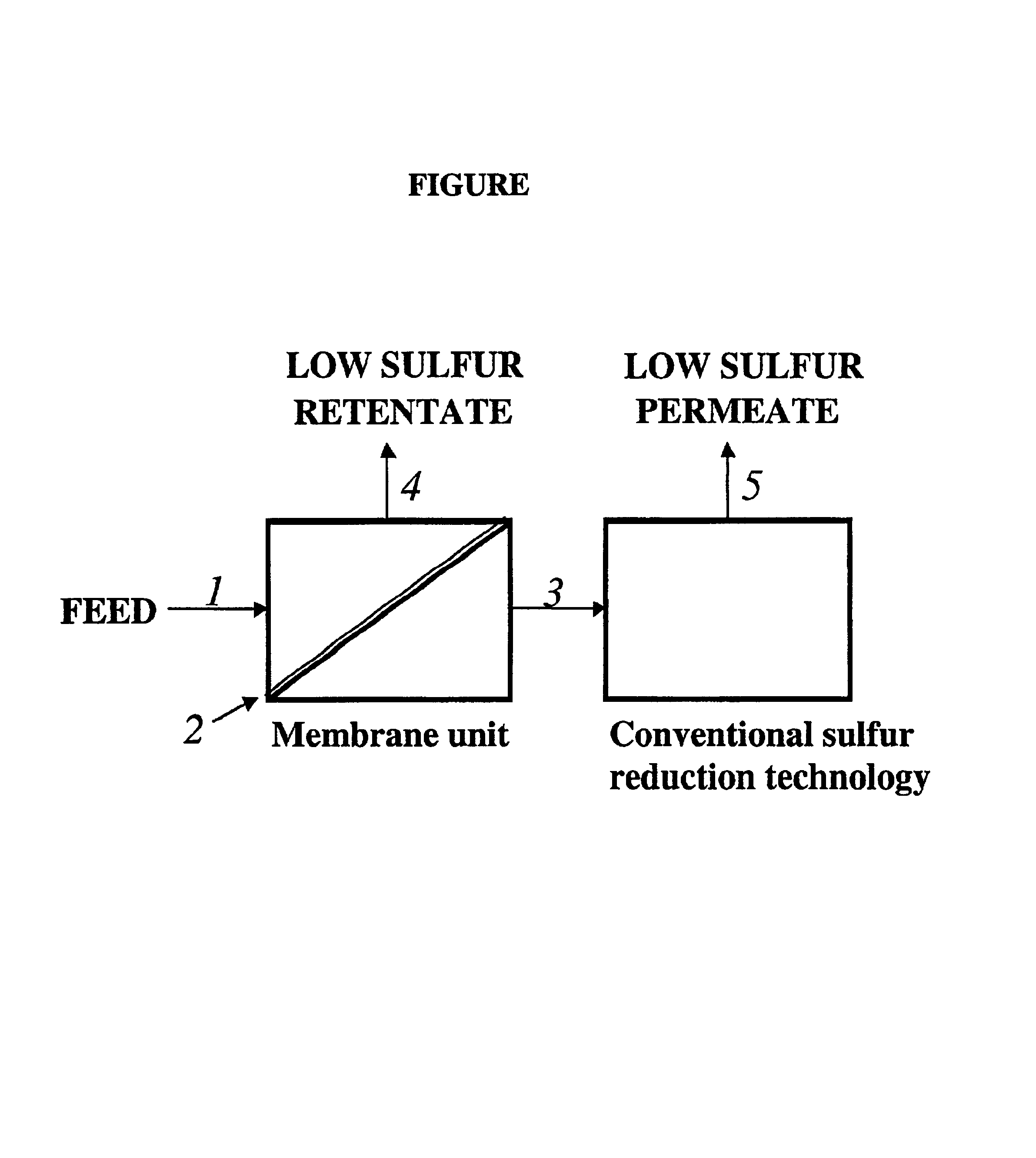

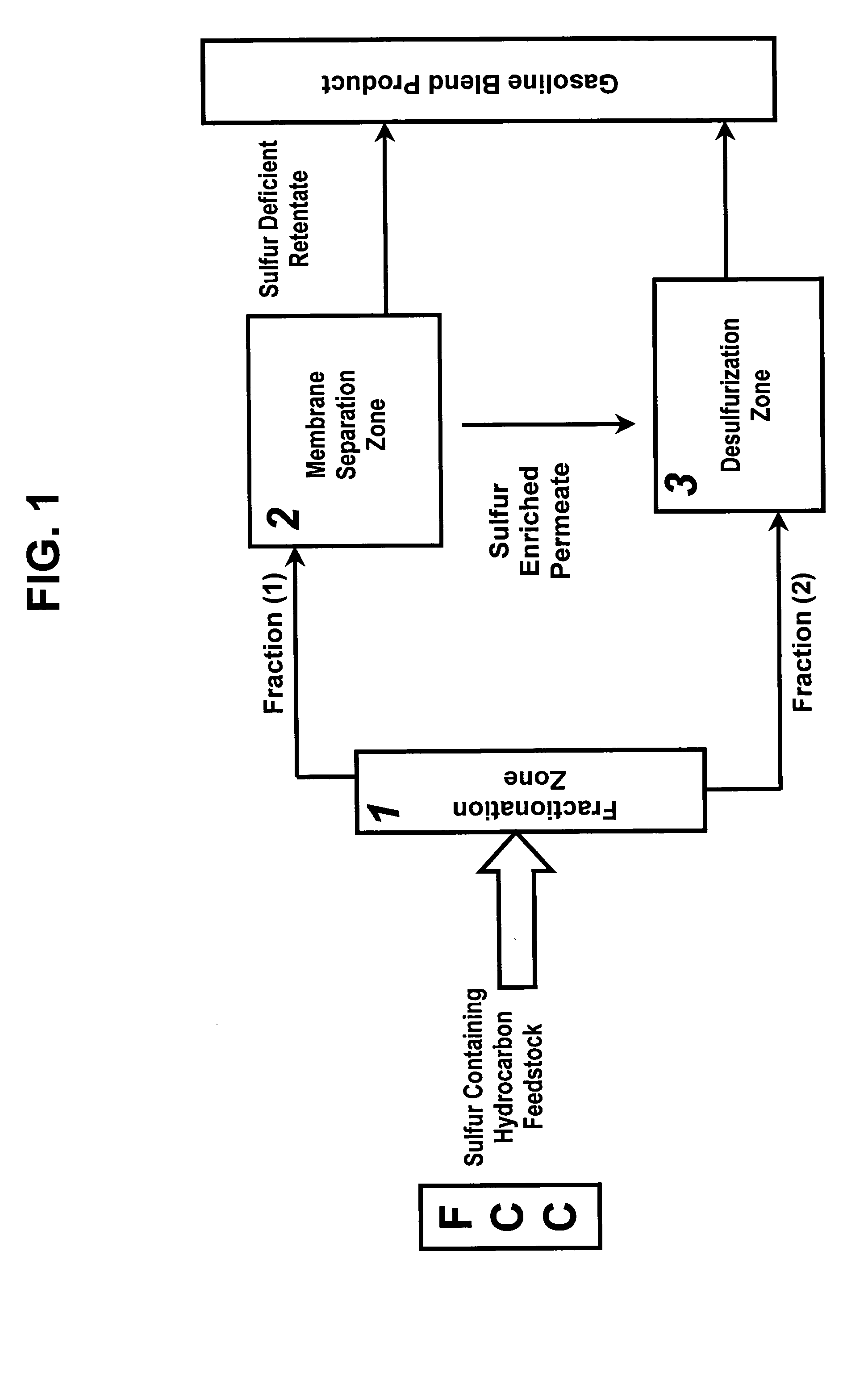

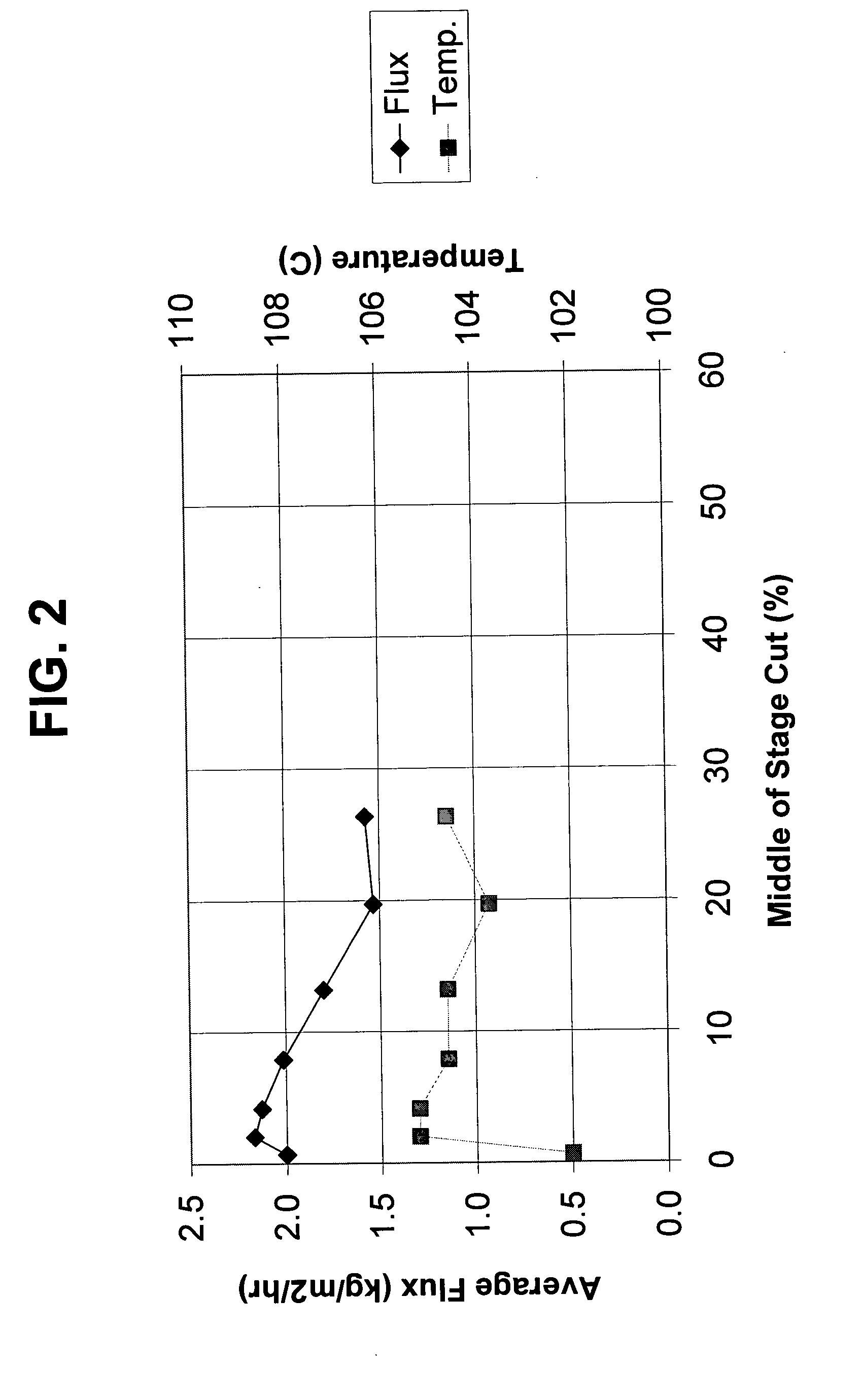

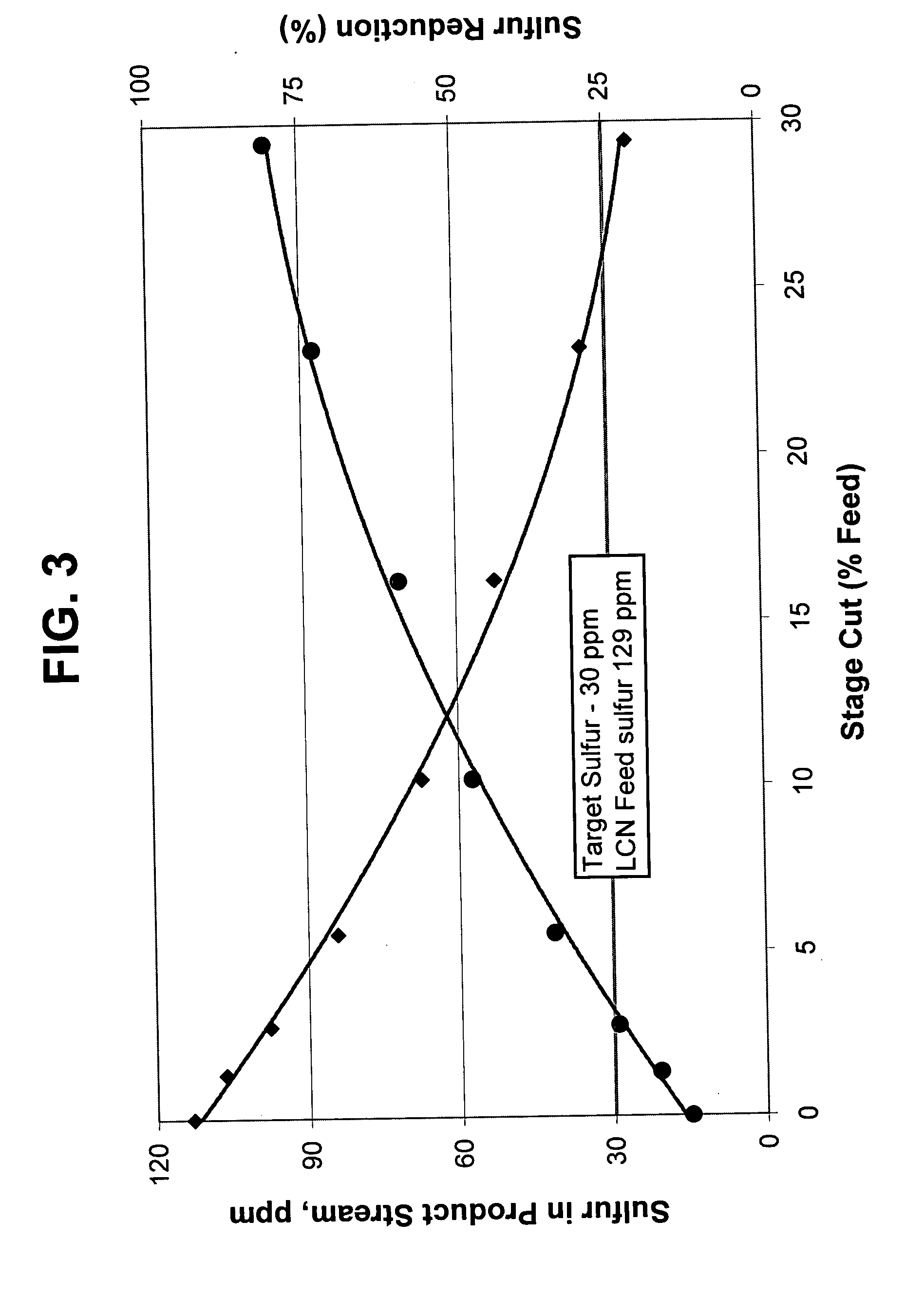

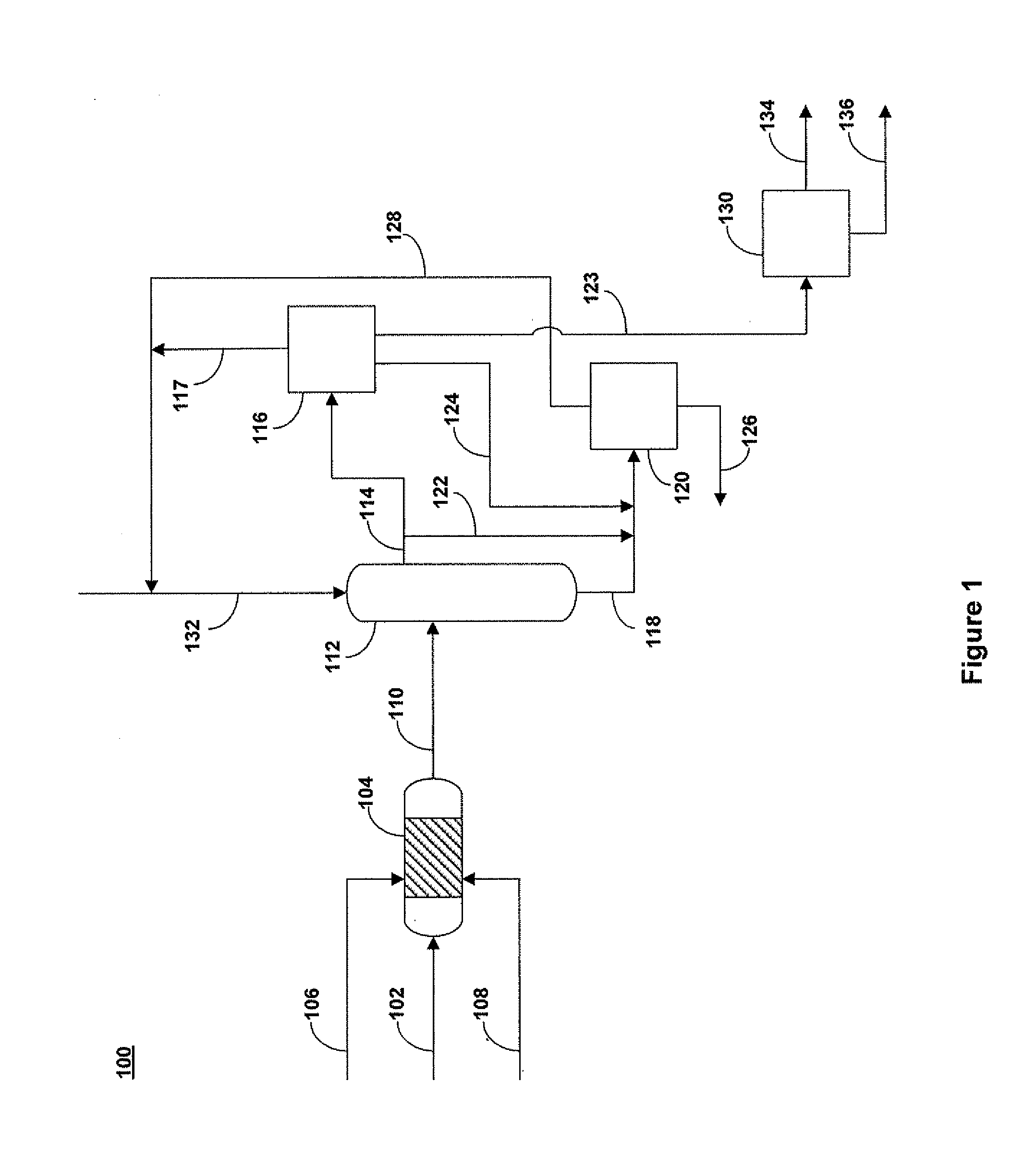

Membrane separation for sulfur reduction

InactiveUS6896796B2Improve economyMinimized volumeDialysisTreatment with plural serial refining stagesNaphthaGasoline

A membrane process for the removal of sulfur species from a naphtha feed, in particular, a FCC light cat naphtha, without a substantial loss of olefin yield is disclosed. The process involves contacting a naphtha feed stream with a membrane having sufficient flux and selectivity to separate a sulfur deficient retentate fraction from a sulfur enriched permeate fraction, preferably, under pervaporation conditions. Sulfur deficient retentate fractions are useful directly into the gasoline pool. Sulfur-enriched permeate fractions are rich in sulfur containing aromatic and nonaromatic hydrocarbons and are further treated with conventional sulfur removal technologies, e.g. hydrotreating, to reduce sulfur content. The process of the invention provides high quality naphtha products having a reduced sulfur content and a high content of olefin compounds.

Owner:WR GRACE & CO CONN

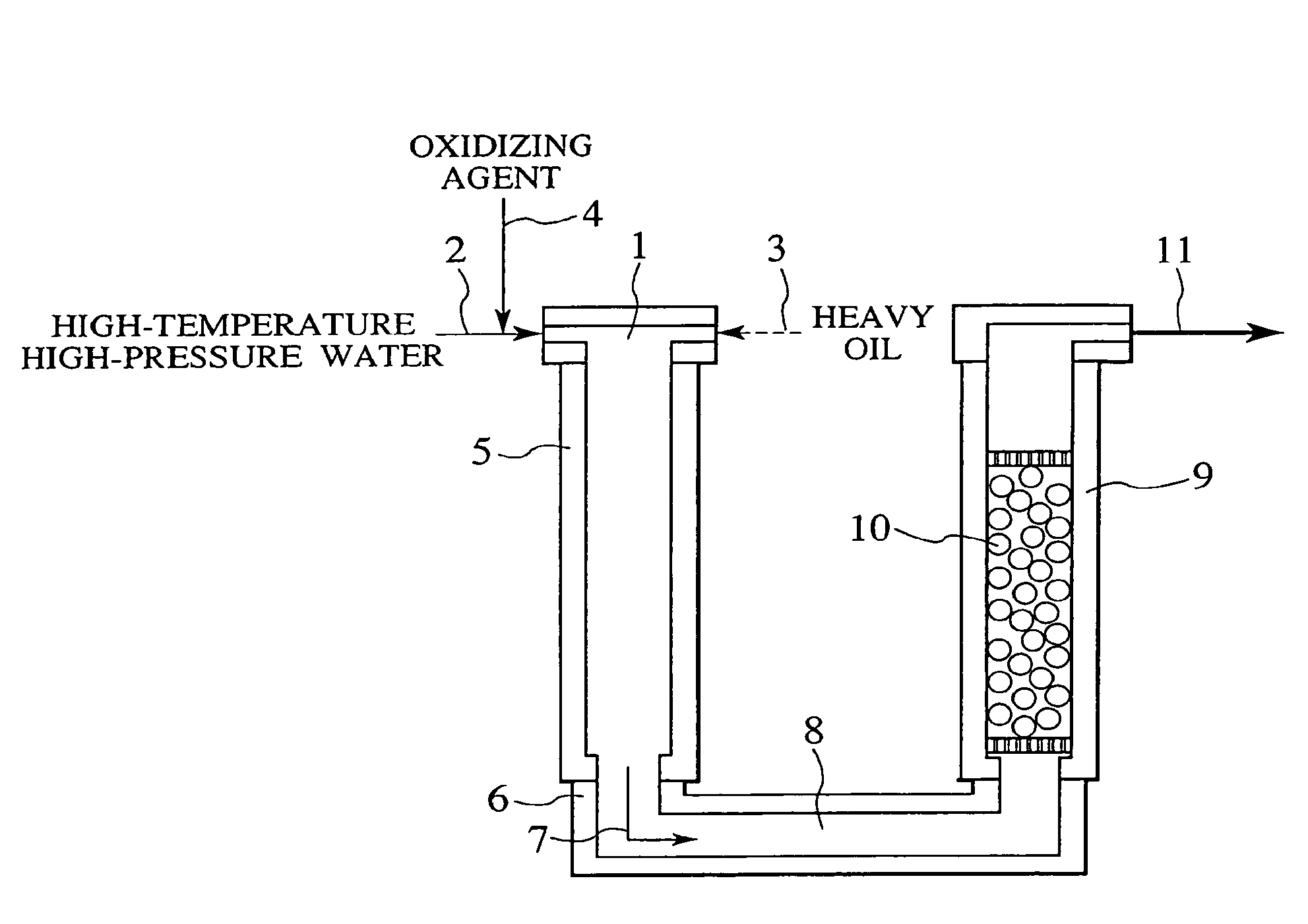

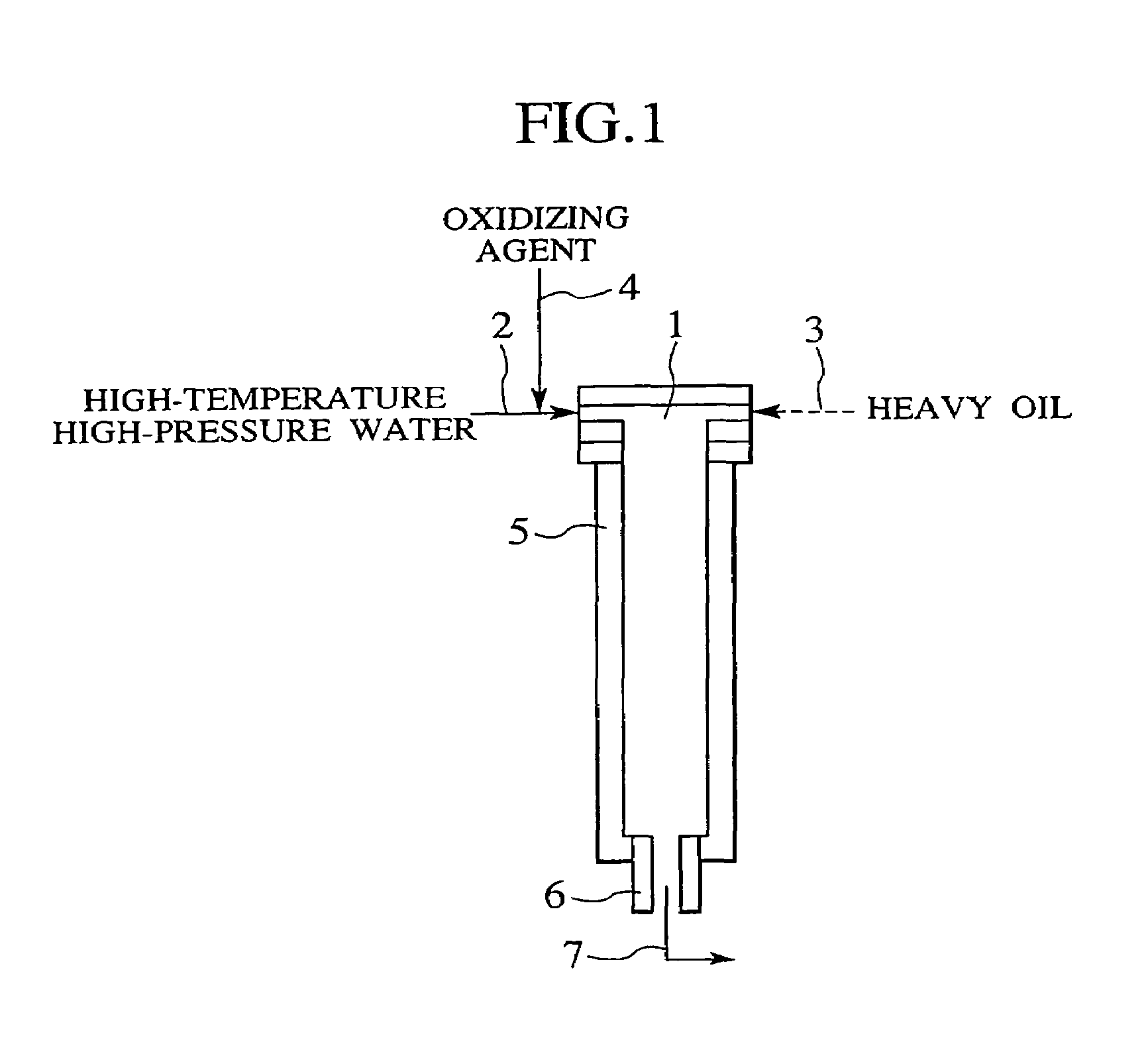

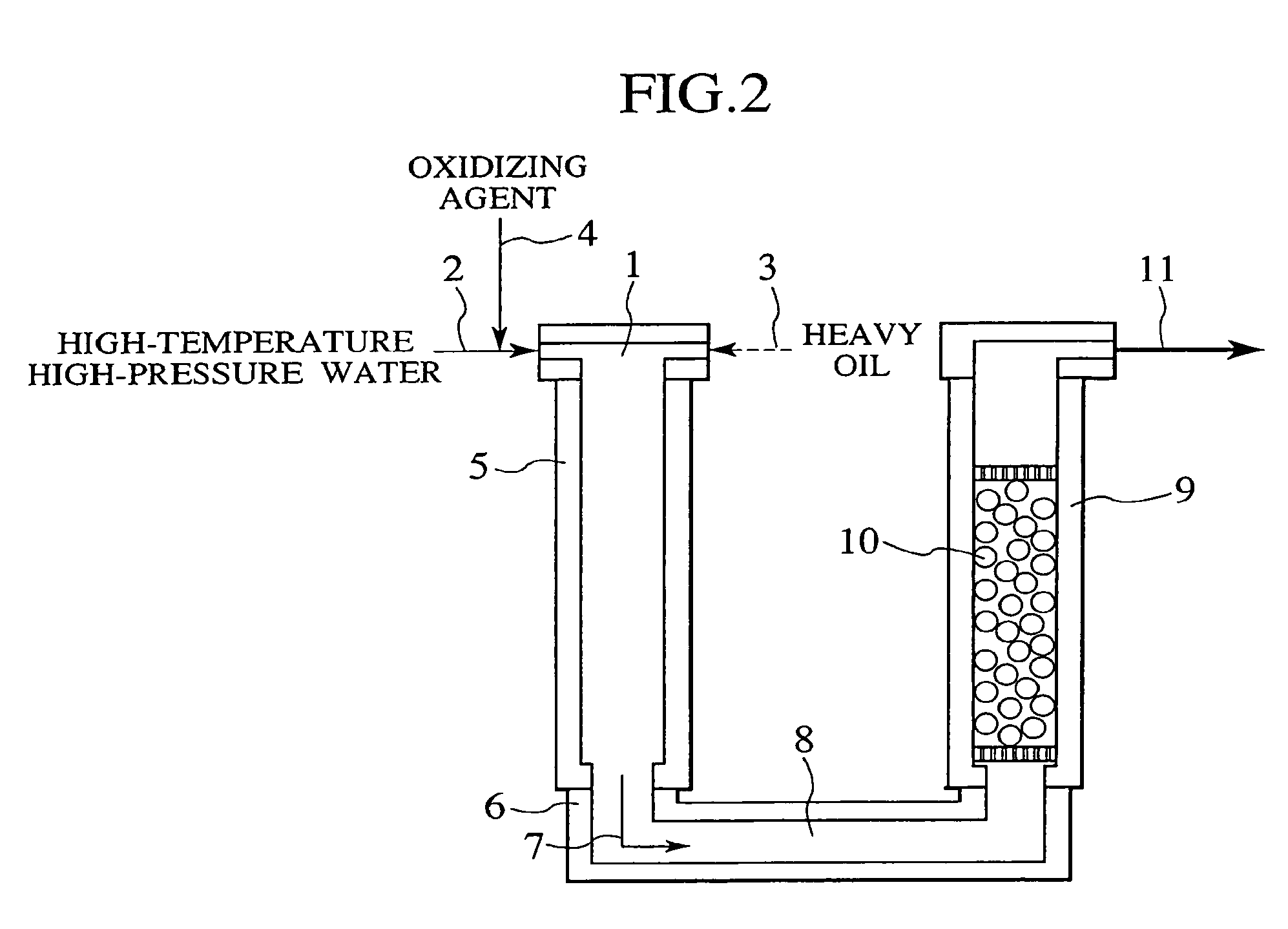

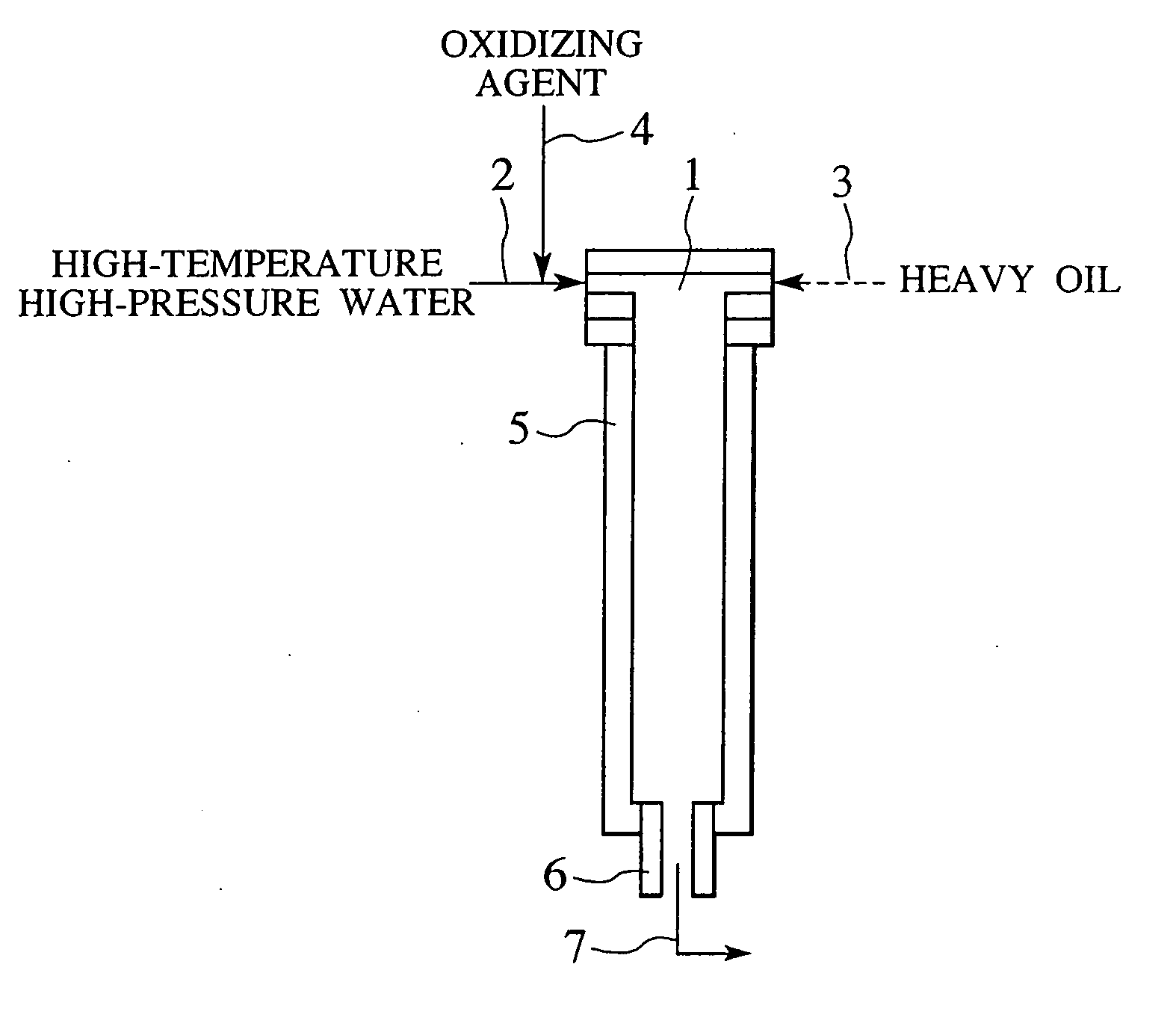

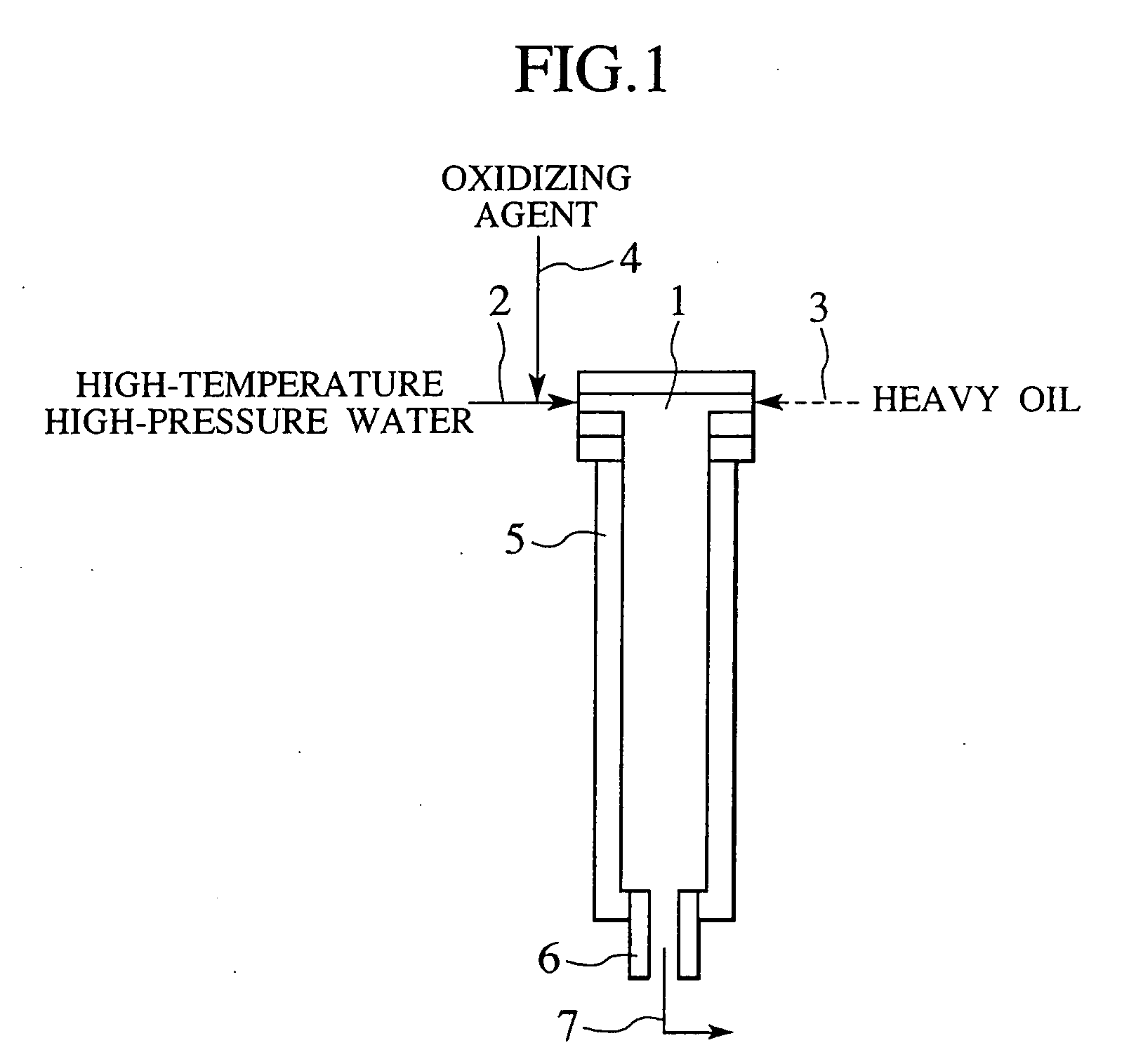

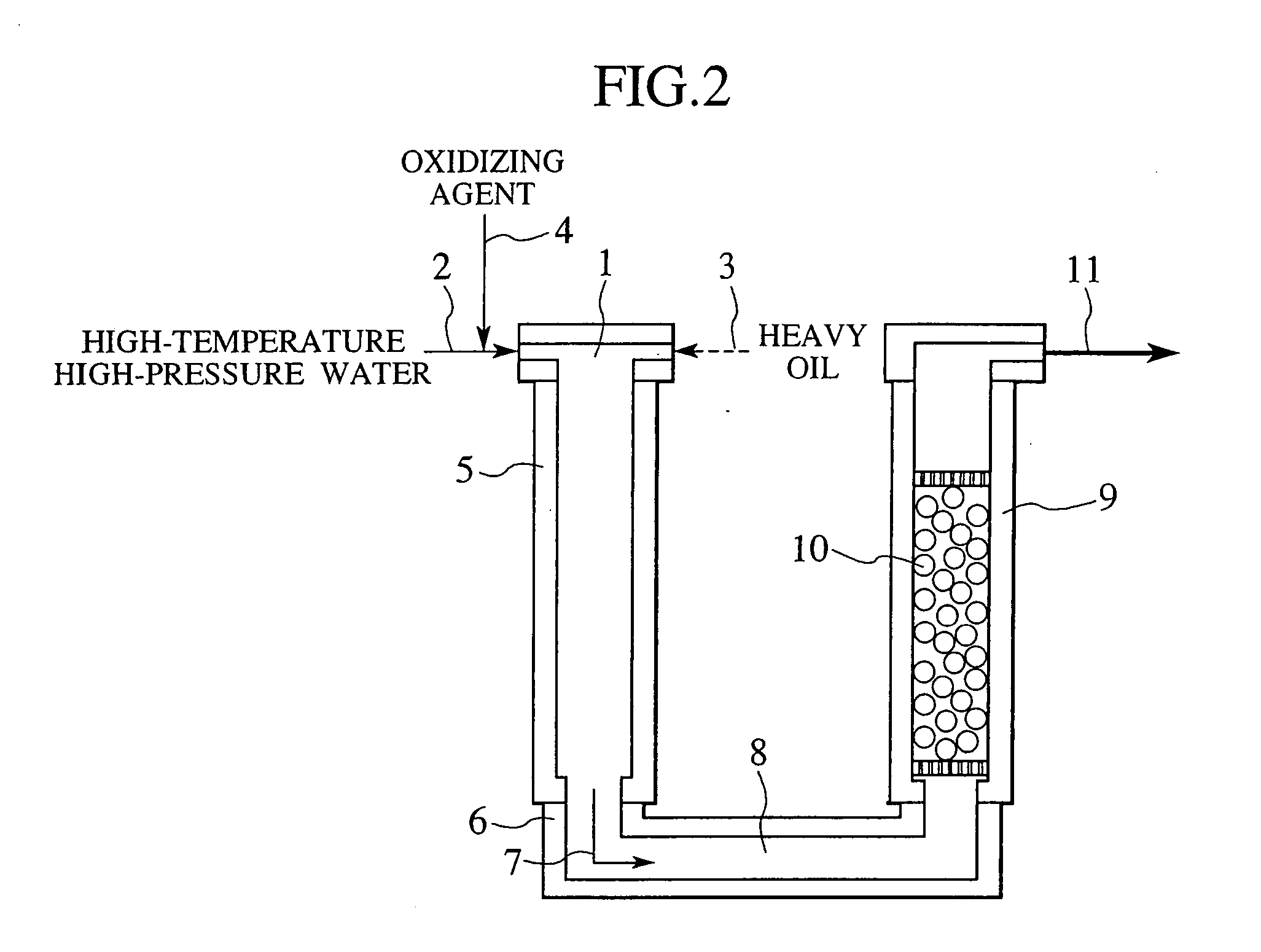

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

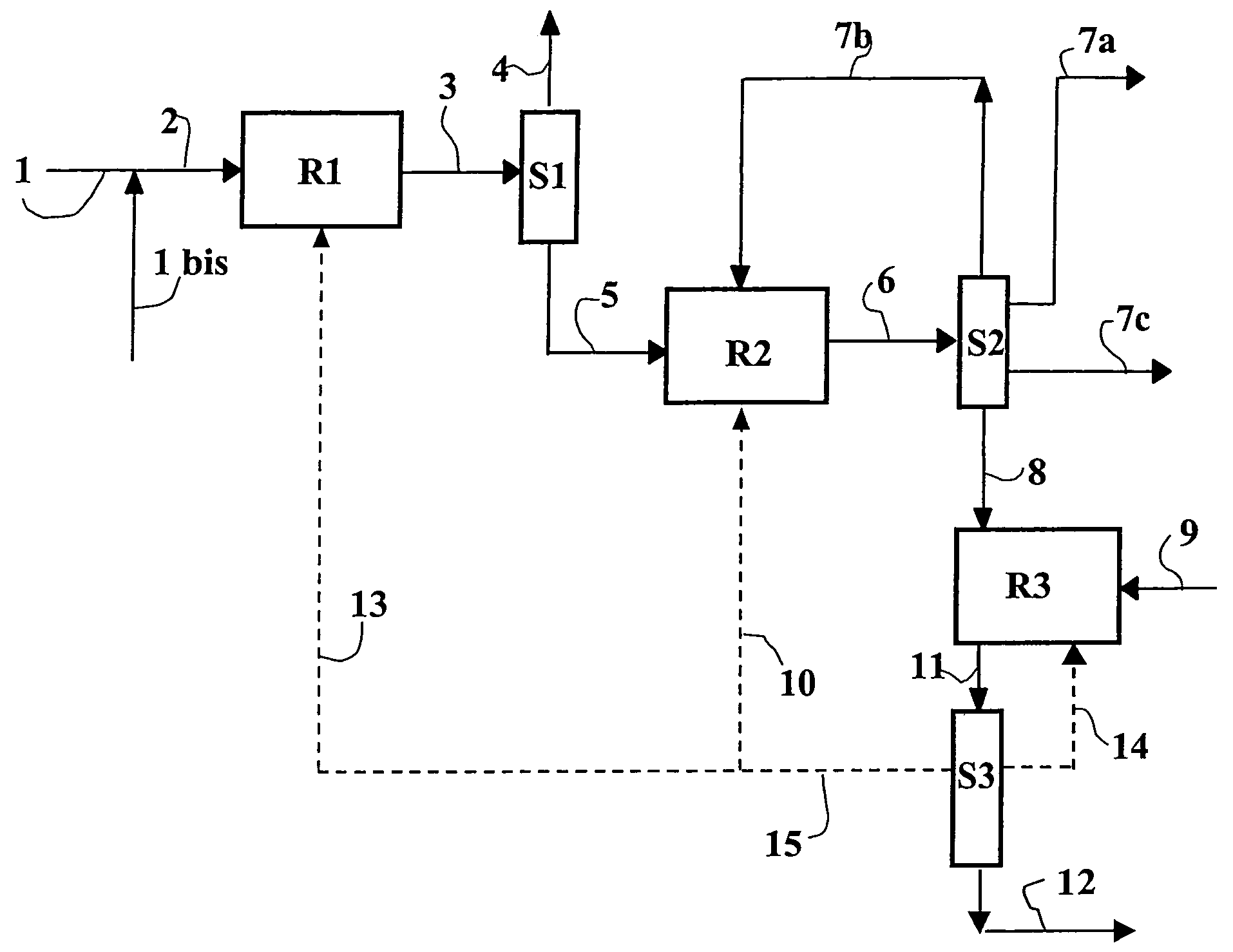

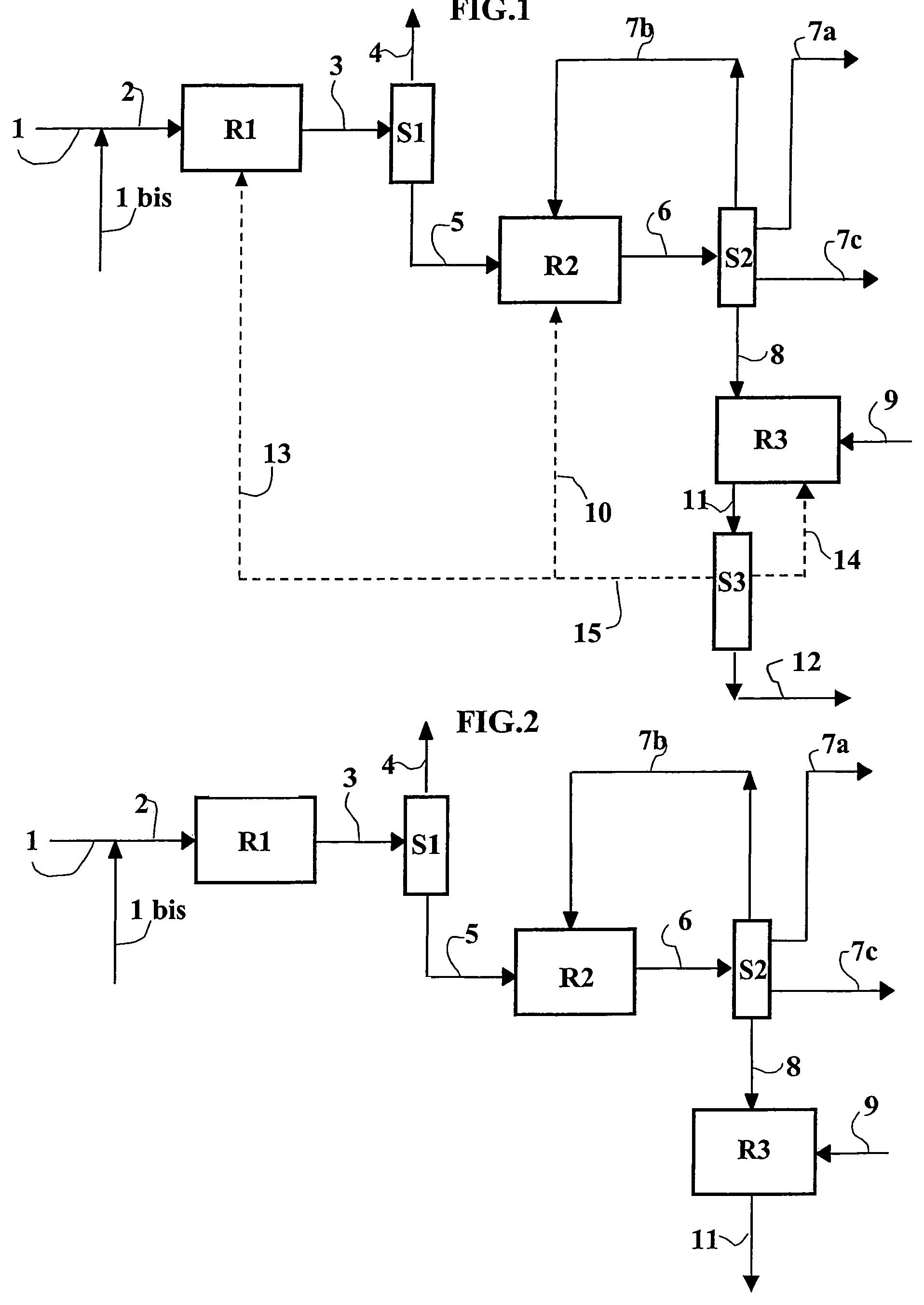

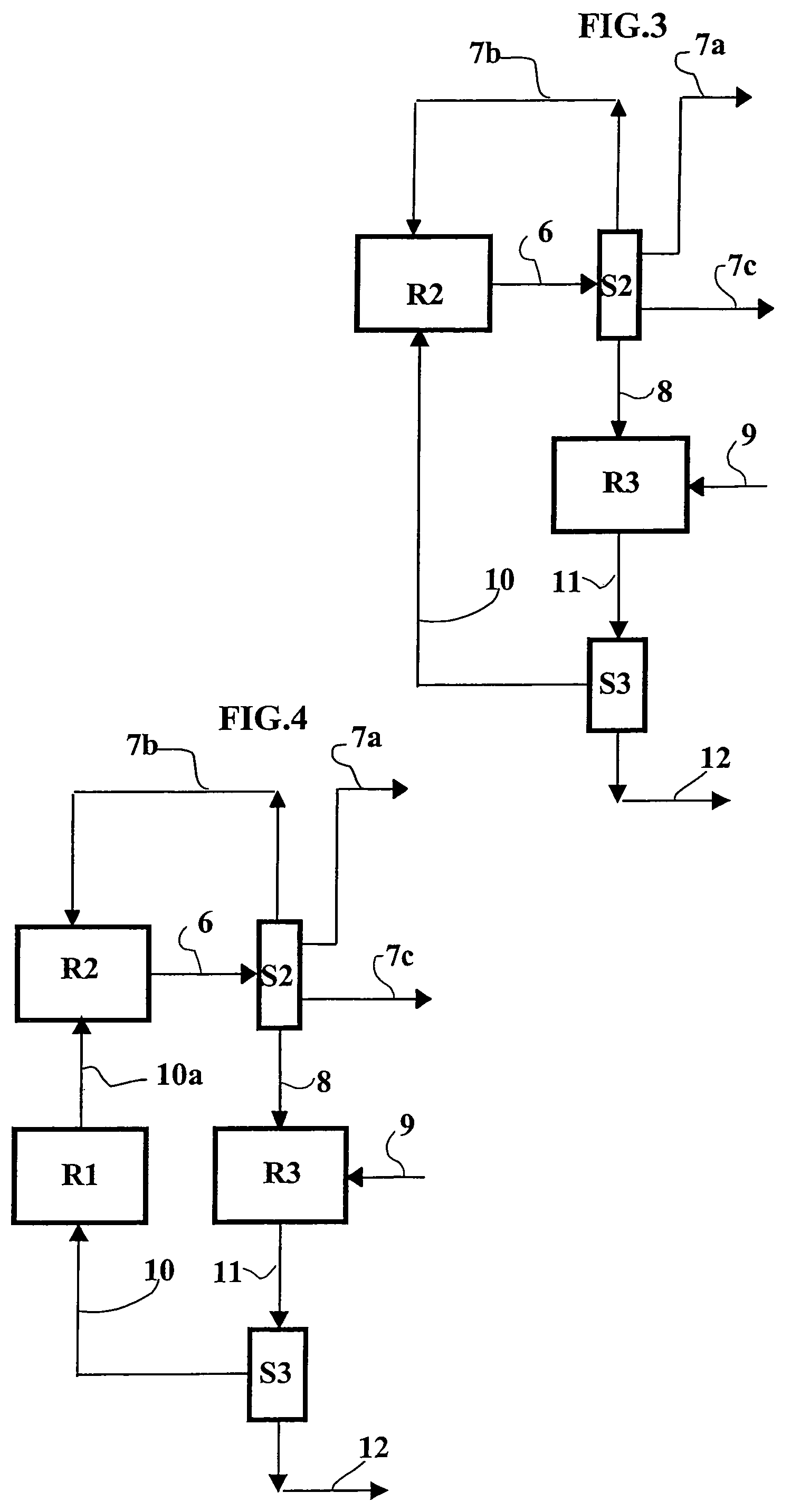

Process for desulphurisation of liquid hydrocarbon fuels

InactiveUS20070151901A1Eliminate needRefining with oxygen compoundsTreatment with plural serial refining stagesPetroleum productSulfur

The present invention provides a process for oxidative desulphurization of liquid hydrocarbon fuels, such as diesel fuel, gasoline, jet fuel, fuel oils, coal liquids and similar petroleum products to ultra low sulphur hydrocarbon fuels with sulphur content less than 10 ppm. In this process, the sulfur compounds present in hydrocarbon fuel are first oxidised to more polar sulphones / sulphoxides and then removed by solvent extraction with NMP containing antisolvent followed by final polishing by passing through adsorption column.

Owner:COUNCIL OF SCI & IND RES +1

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS7374662B2Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerFluidized bed

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein,the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst,the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Method of reducing sulfur in hydrocarbon feedstock using a membrane separation zone

ActiveUS20050067323A1Reduce sulfur contentEasy to operateTreatment with plural serial refining stagesTreatment with plural parallel refining stagesNaphthaHydrodesulfurization

A membrane is used in combination with fractionation and hydrodesulfurization to reduce the sulfur content of hydrocarbon feeds, preferably sulfur-containing naphtha feeds. A membrane separation zone is employed to treat a fraction of effluent from a fractionation zone containing sulfur-containing non-aromatic hydrocarbons to produce a sulfur rich permeate and sulfur deficient retentate. The sulfur rich permeate and a second fraction of the fractionation zone, which contains sulfur-containing aromatic hydrocarbons, are further treated in a hydrodesulfurization zone. The stream from the hydrodesulfurization zone and the sulfur deficient retentate from the membrane separation zone are then processed as low sulfur hydrocarbon streams, especially those streams being processed in the manufacture of gasoline when the initial hydrocarbon stream is naphtha from a fluidized catalytic cracking unit.

Owner:WR GRACE & CO CONN

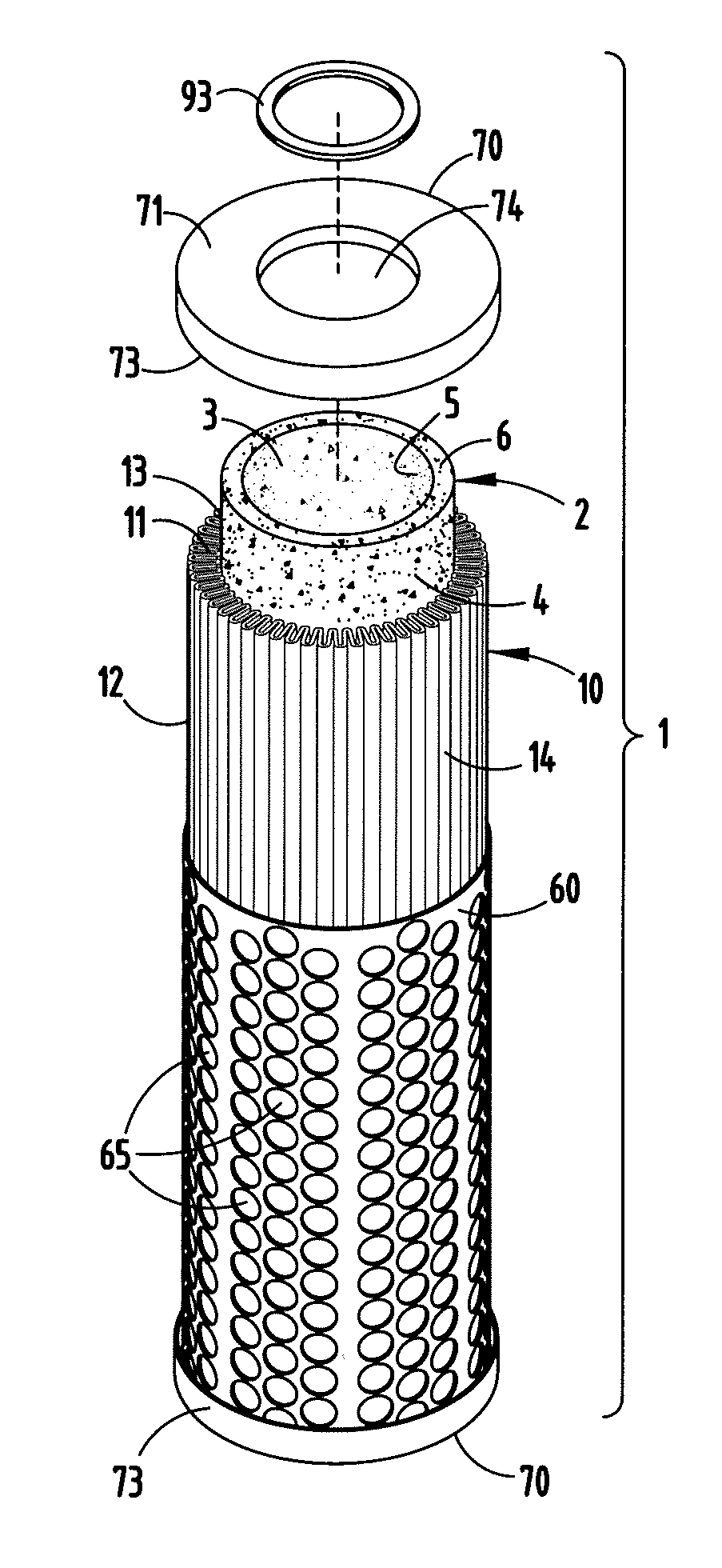

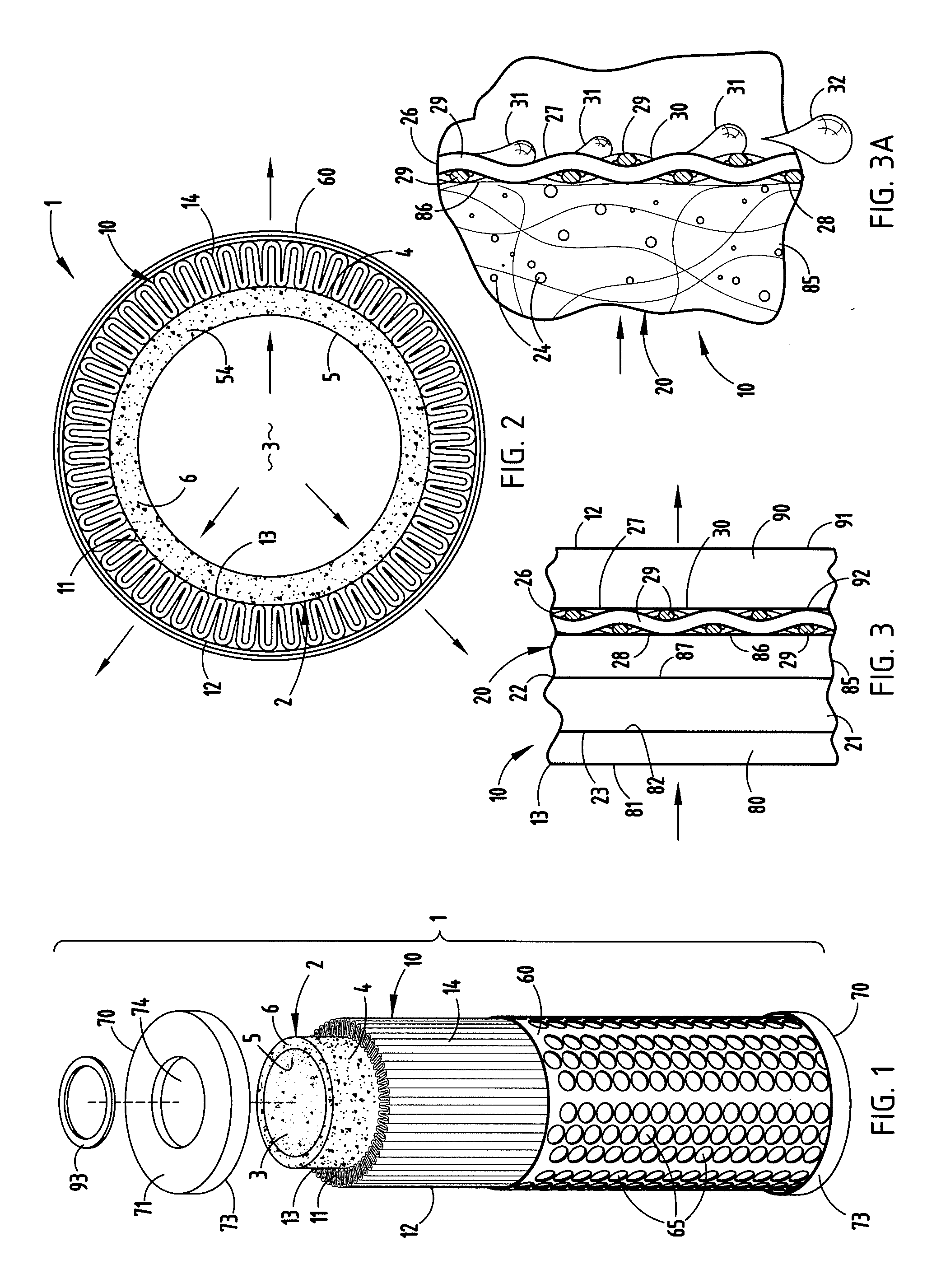

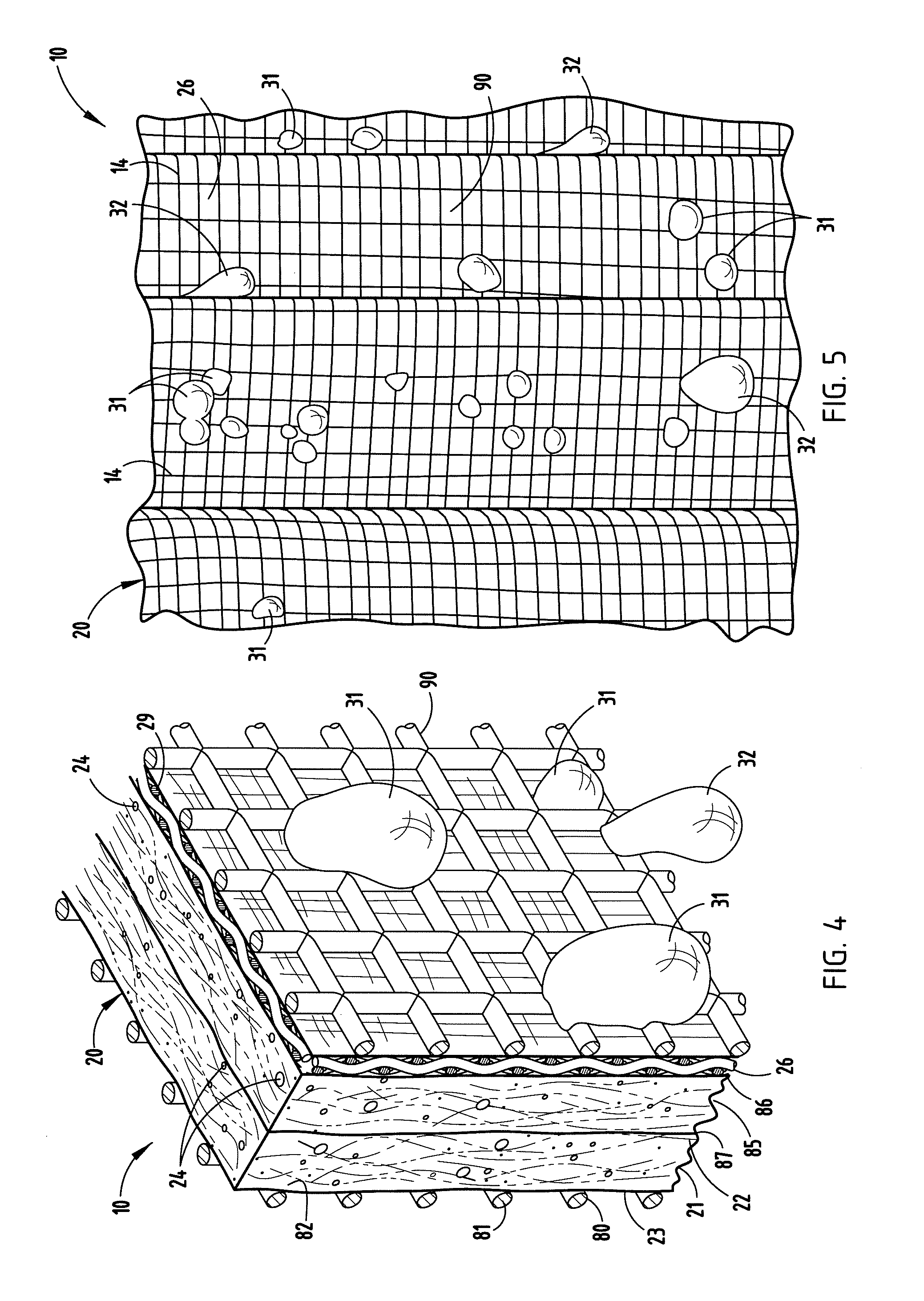

Apparatus and method for removing contaminants from industrial fluids

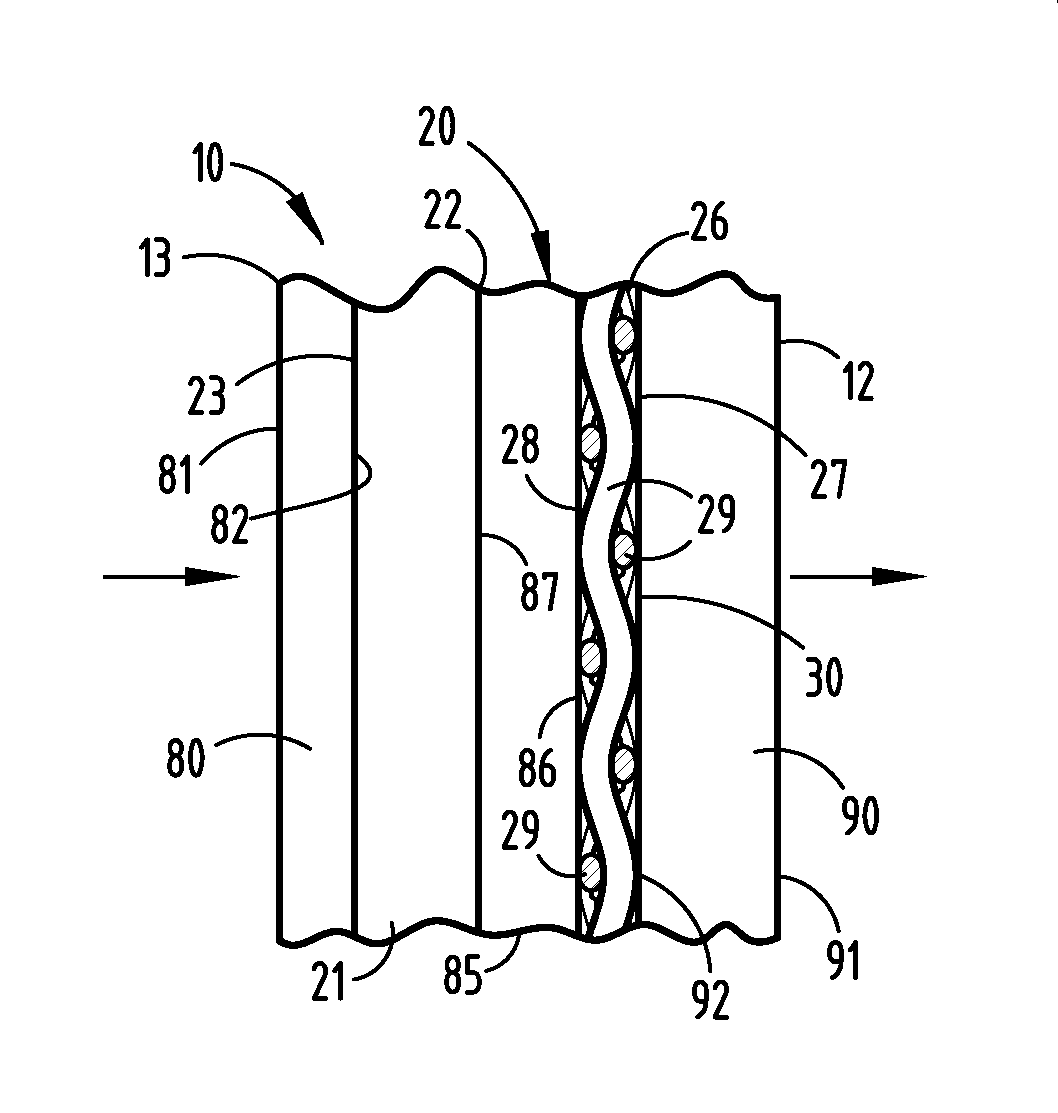

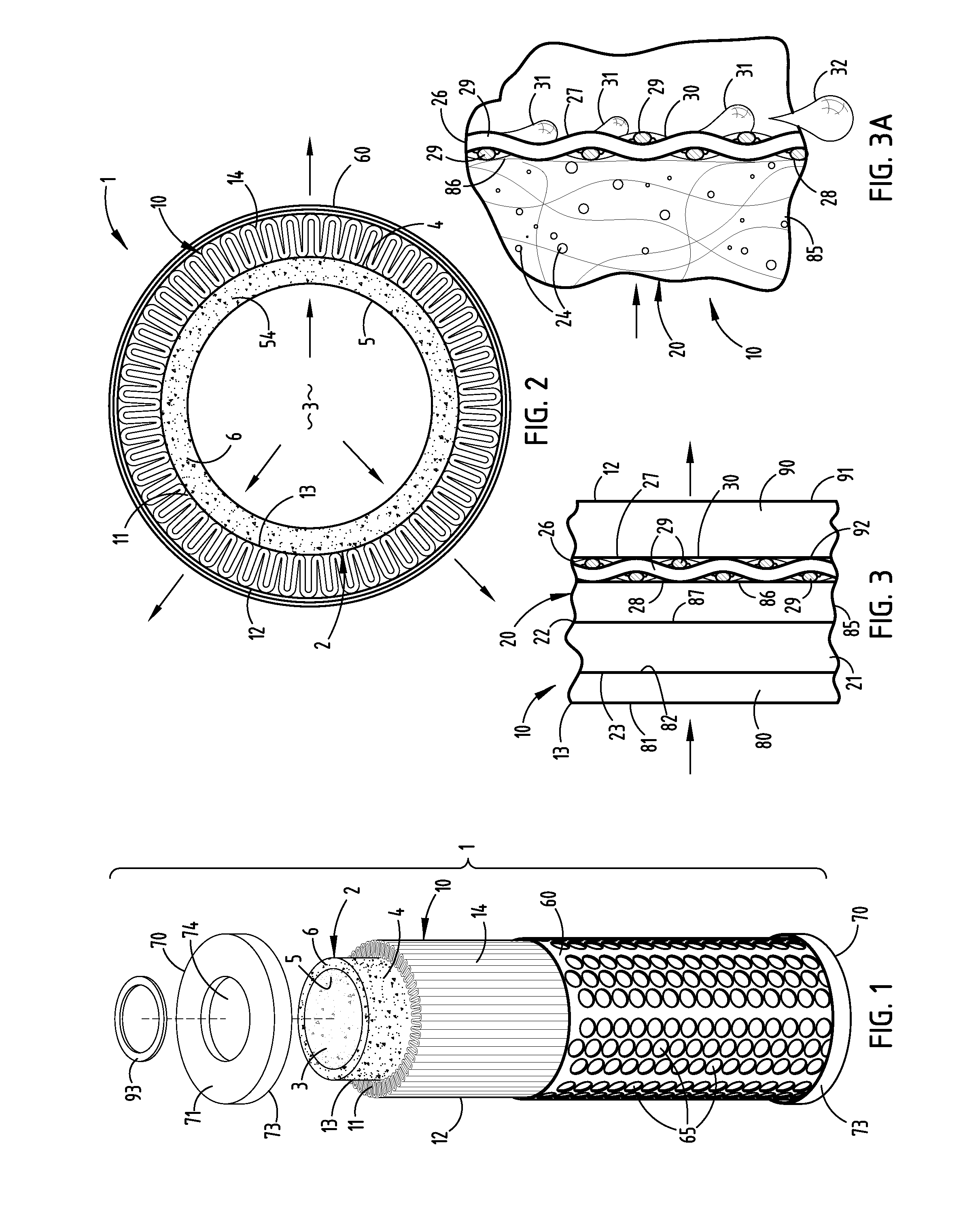

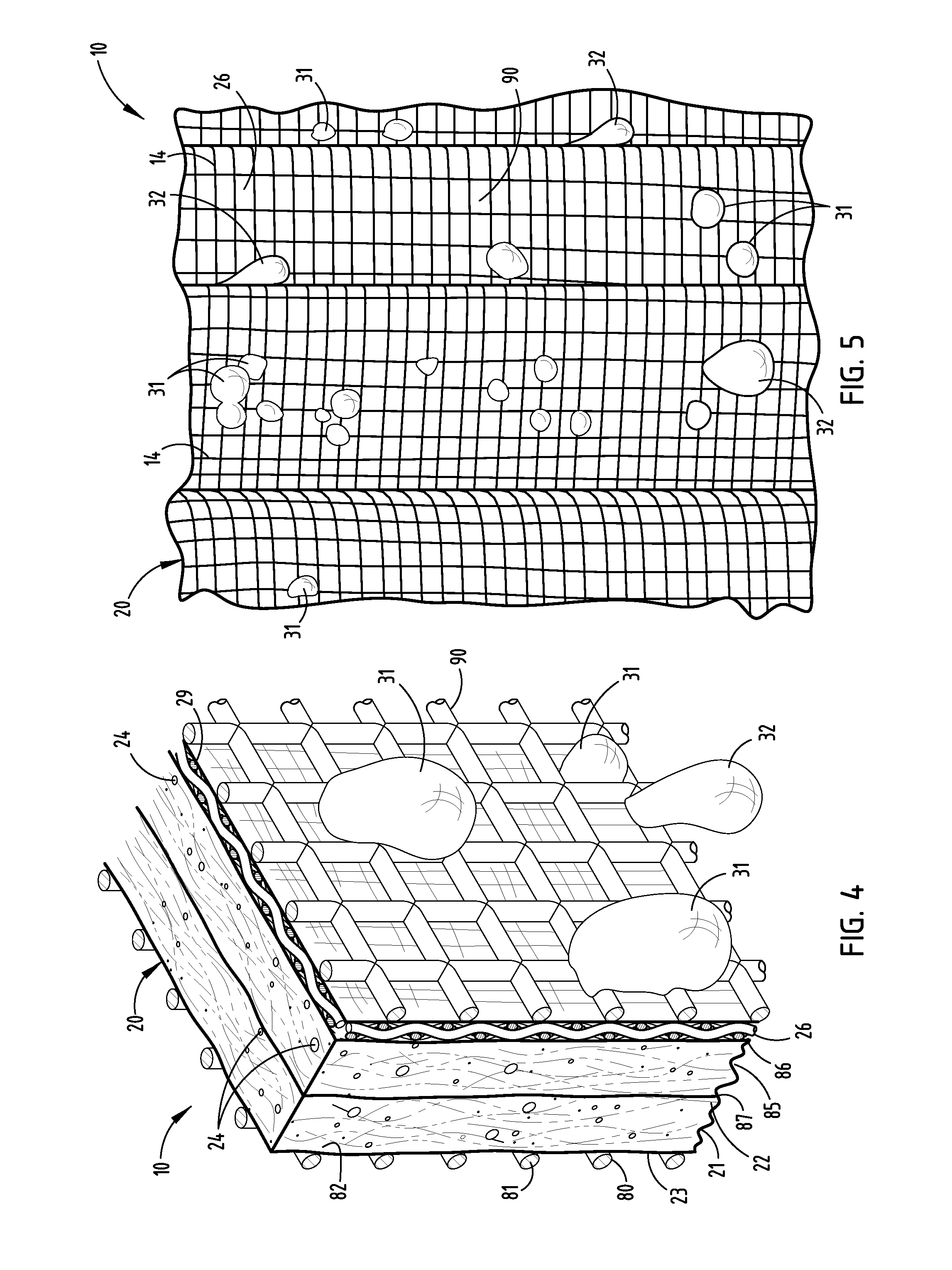

InactiveUS20110259796A1Efficiently and effectively removedReduce manufacturing costSemi-permeable membranesDewatering/demulsification with mechanical meansFilter systemEngineering

A filter system for removing contaminants from oil based industrial liquids and the like includes a support tube with a permeable sidewall through which the industrial liquid flows in an inside out direction. A multilayer coalescence media surrounds the support tube, and includes at least one layer of a non-woven fibrous material that is partially wettable by the dispersed water in the industrial liquid, and commences coalescence of the same to form small primary water droplets, and at least one sheet of a precisely woven monofilament fabric stacked on the downstream side of the non-woven material. The woven fabric is substantially wettable by the dispersed water, and has a fixed open mesh with uniformly sized and spaced apart pore openings which continue to coalesce the primary water droplets into large water drops which fall from the filter for collection along the bottom of the apparatus.

Owner:KAYDON CUSTOM FILTRATION CORP

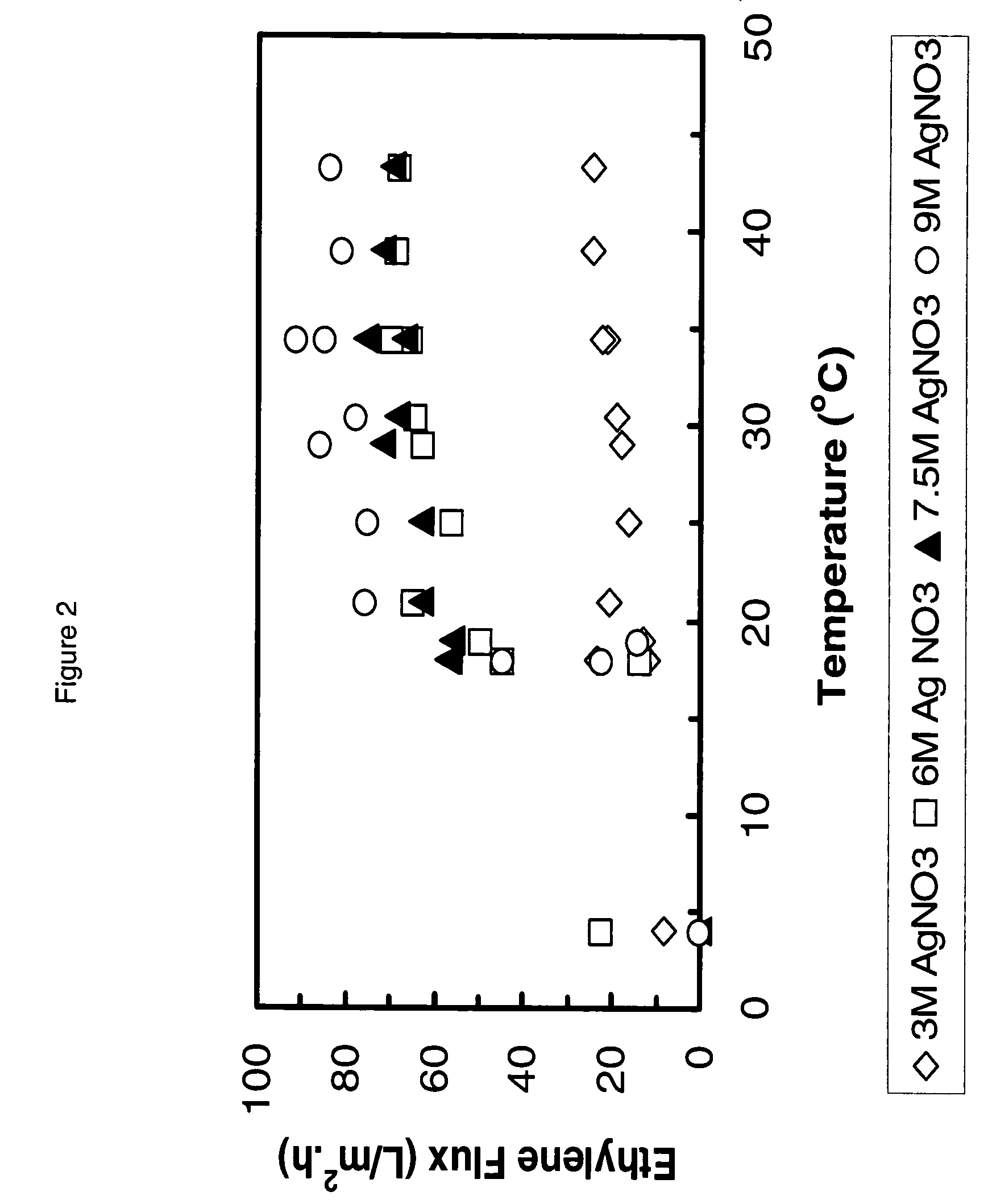

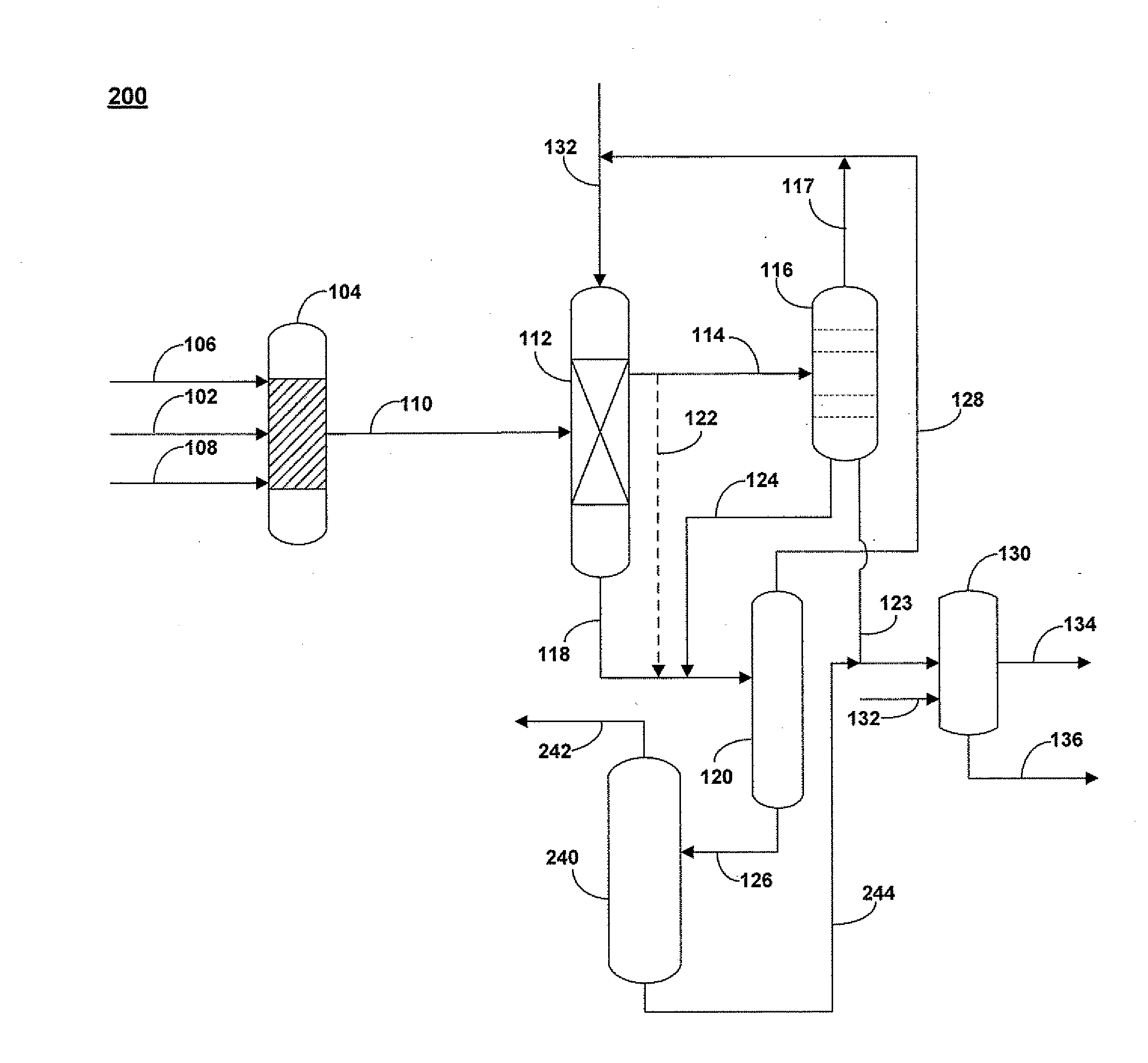

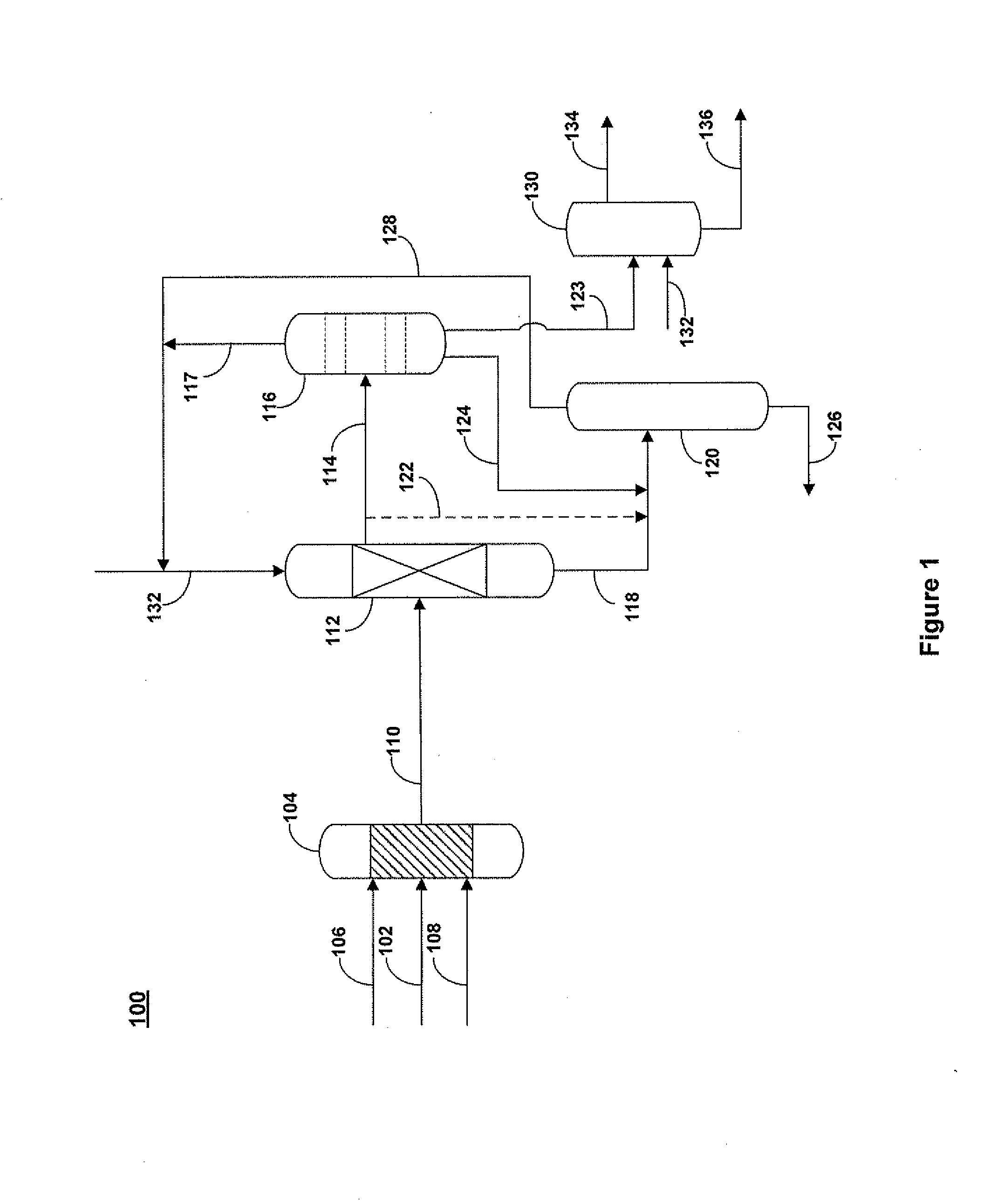

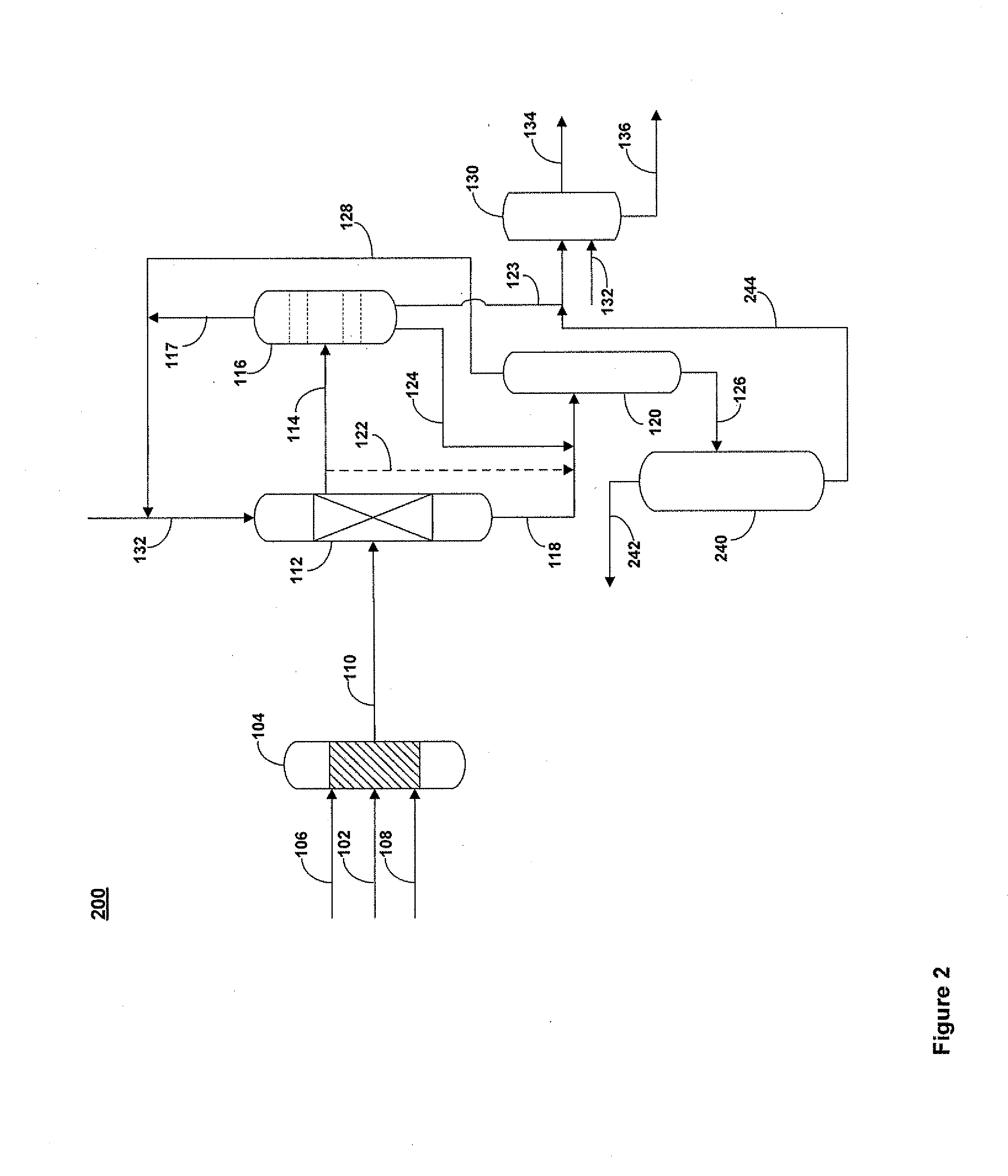

Process for the separation of olefins from paraffins using membranes

Chitosan membranes chelated with silver or cuprous material may be used to separate olefins from a mixture of olefins and paraffins. The feed stream is humidified, demisted, treated to remove sulfur compounds and passed to a cell having a chitosan membrane containing chelated silver or cuprous compounds. The process has a reasonable flux rate and is operable at reasonable temperatures and pressures. The process could be used in an olefin separation train.

Owner:IMTEX MEMBRANES CORP

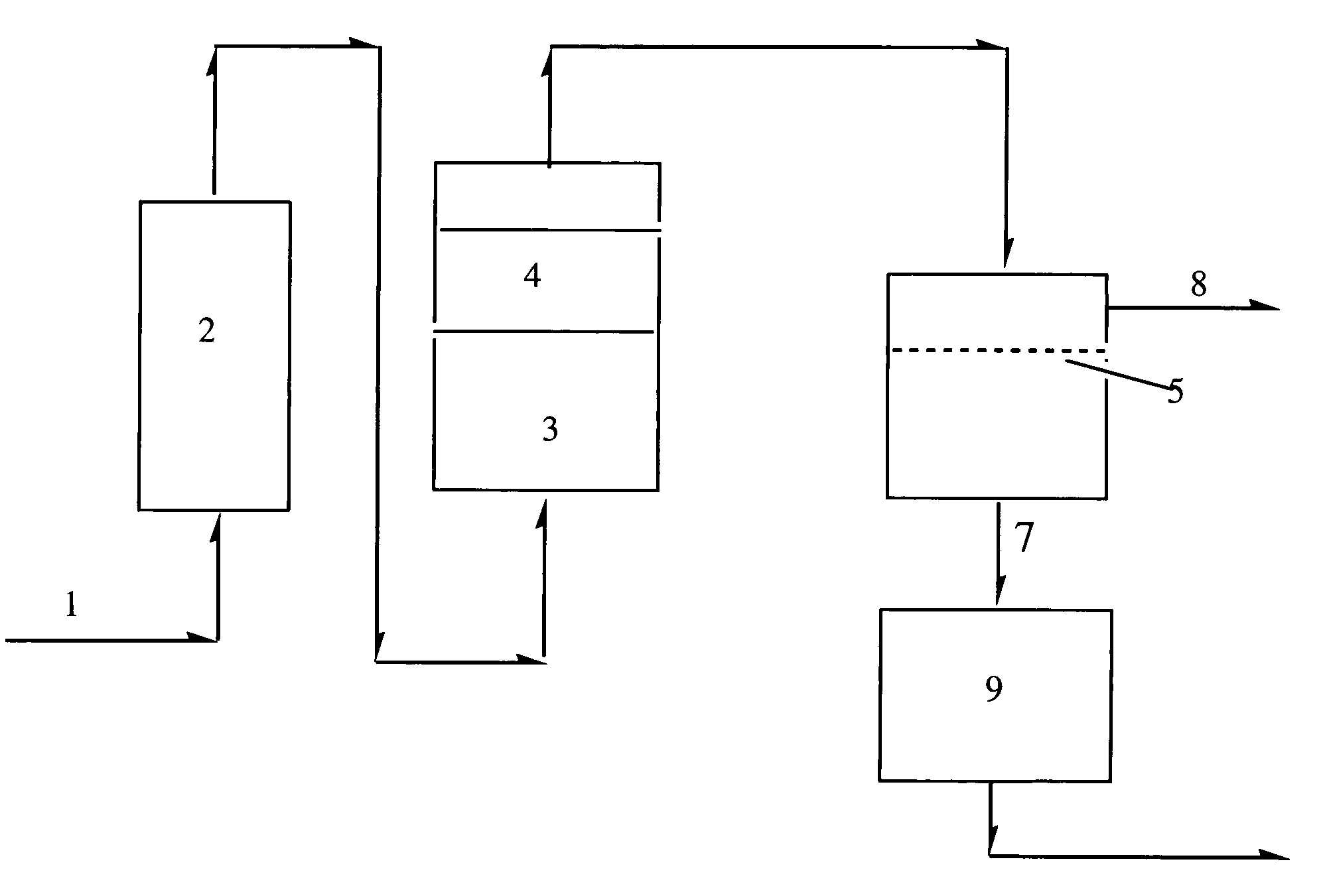

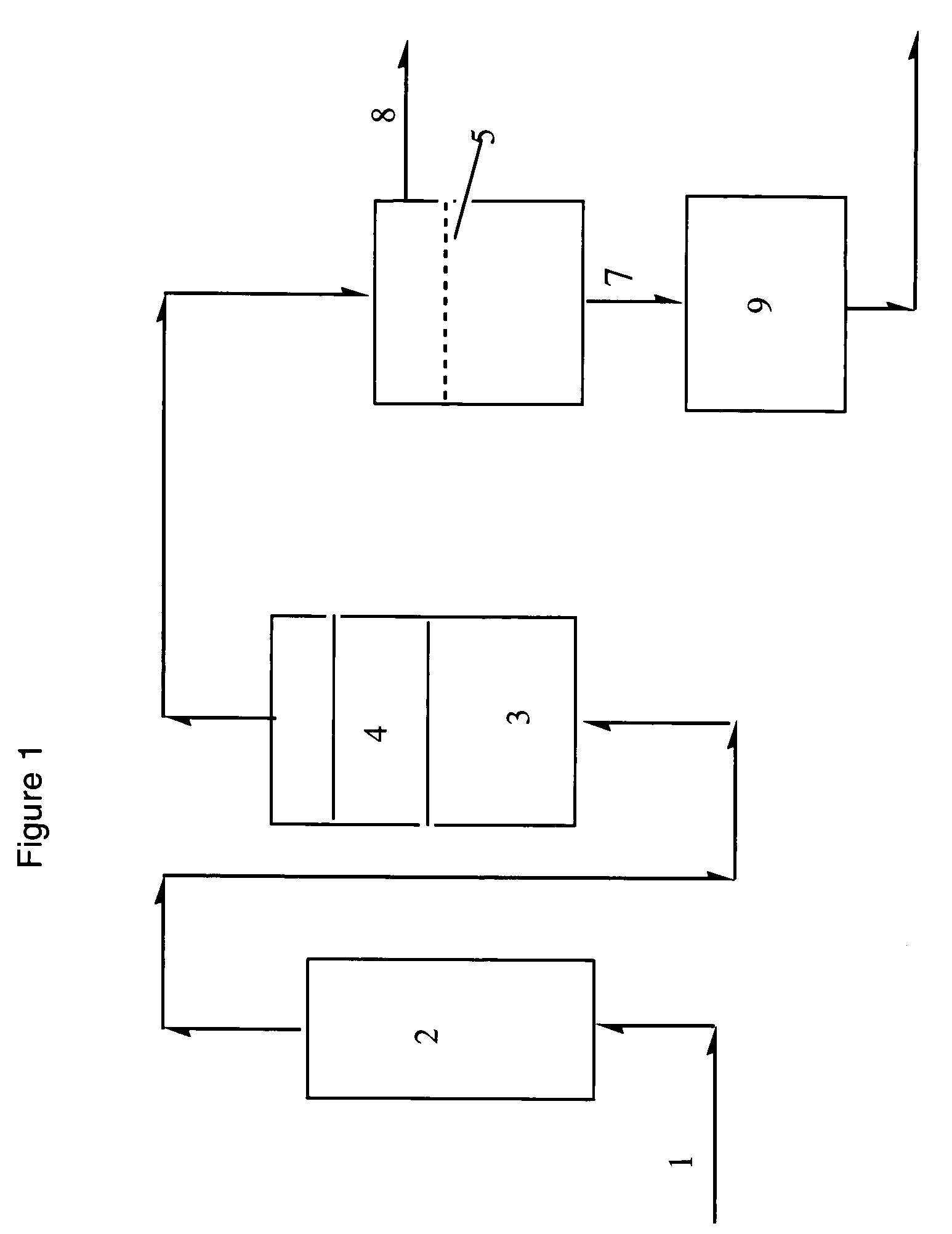

Desulfurization and Sulfone Removal Using A Coker

ActiveUS20120055845A1Refining with oxygen compoundsTreatment with plural serial refining stagesSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a coker to produce coker gases and solid coke.

Owner:SAUDI ARABIAN OIL CO

Apparatus and method for removing contaminants from industrial fluid

InactiveUS20140034580A1Efficiently and effectively removedReduce manufacturing costDewatering/demulsification with mechanical meansWater/sewage treatmentFilter systemEnvironmental engineering

A filter system for removing contaminants from oil based industrial liquids and the like includes a support tube with a permeable sidewall through which the industrial liquid flows in an inside out direction. A multilayer coalescence media surrounds the support tube, and includes at least one layer of a non-woven fibrous material that is partially wettable by the dispersed water in the industrial liquid, and commences coalescence of the same to form small primary water droplets, and at least one sheet of a precisely woven monofilament fabric stacked on the downstream side of the non-woven material. The woven fabric is substantially wettable by the dispersed water, and has a fixed open mesh with uniformly sized and spaced apart pore openings which continue to coalesce the primary water droplets into large water drops which fall from the filter for collection along the bottom of the apparatus.

Owner:KAYDON CUSTOM FILTRATION CORP

Desulfurization process

InactiveUS7144499B2Refining with oxygen compoundsTreatment with plural serial refining stagesSulfurSorbent

Owner:LYONDELL CHEM TECH LP

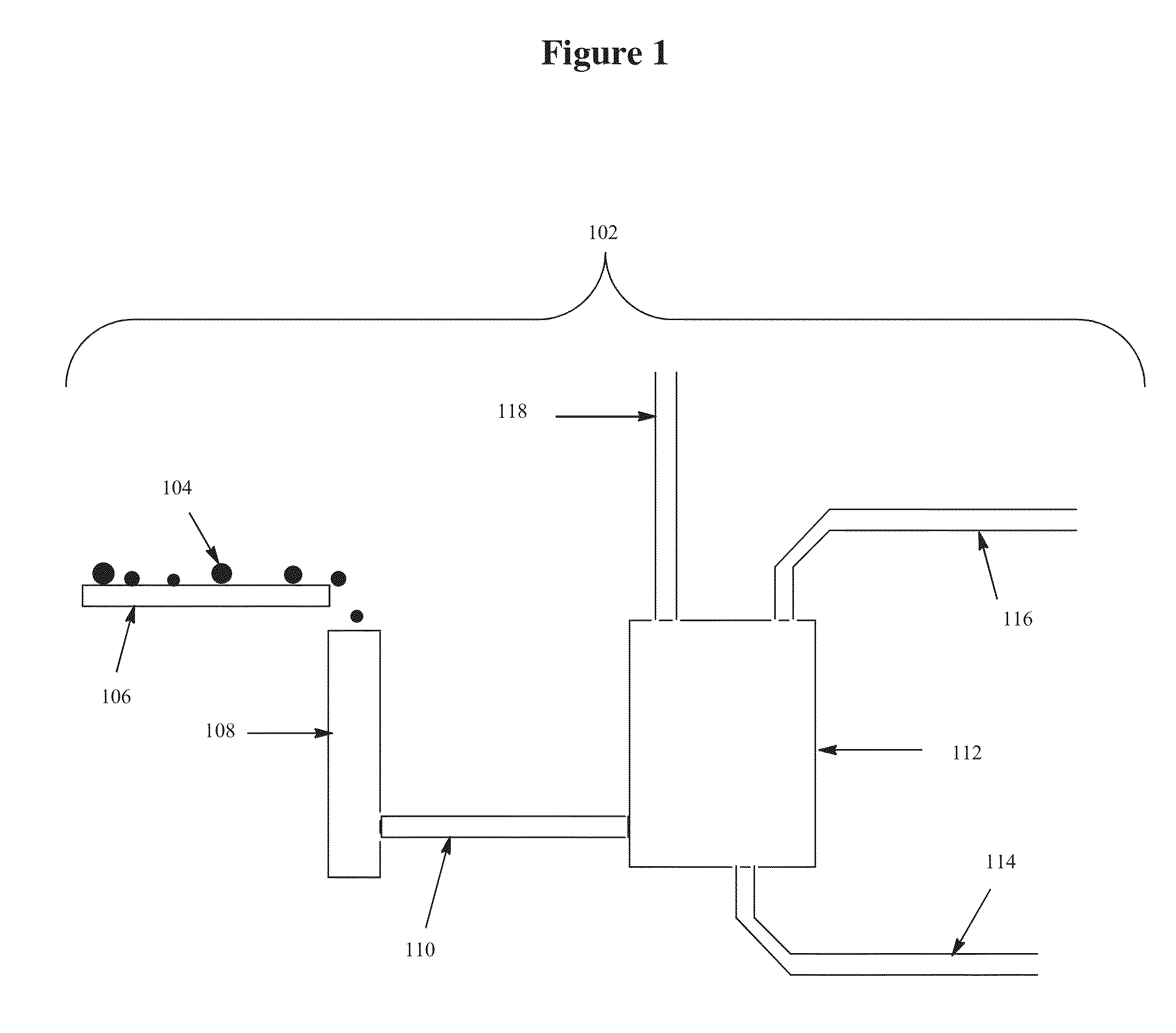

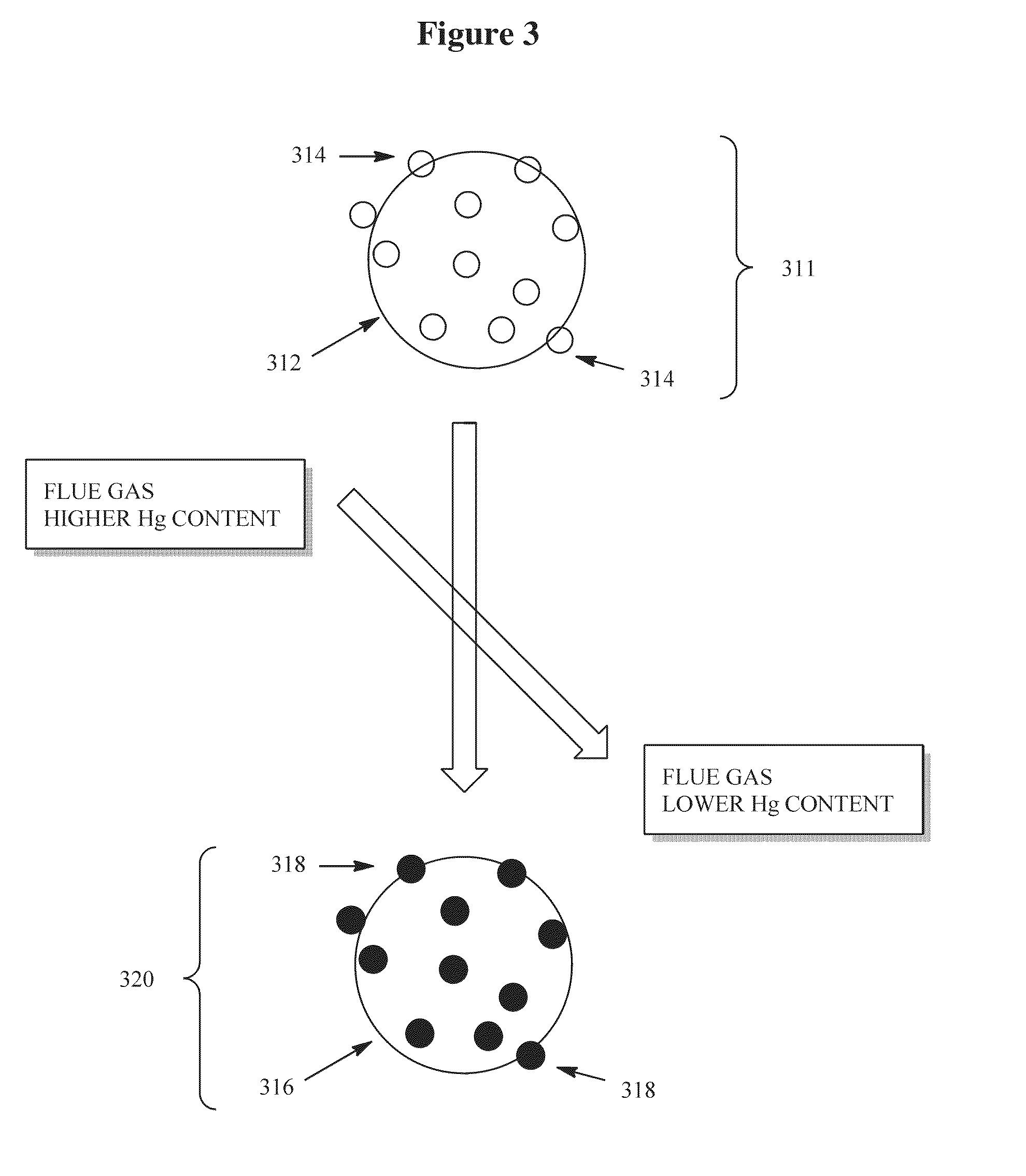

Particle-based systems for removal of pollutants from gases and liquids

InactiveUS20140252270A1Reduce total mercury contentReduce contentCombination devicesGas treatmentPetrochemicalRefinery

Systems, compositions, and methods for removing a substance or substances from a material, such as a gas or liquid material, are described. The compositions can comprise composite removal particles. In some embodiments, the composite removal particles can be comprised of support particles made from an inexpensive carrier material, and a reactive particle borne on the support particle. The reactive particle reacts with the substance or substances in the material. The reacted composite removal particles can then be removed from the material, which reduces the amount of the substance or substances present in the material. The composite removal particles are useful for removing pollutants, such as mercury, from exhaust gases, such as flue gas from a power plant combustion unit, and from other materials such as natural gas, liquefied natural gas, fuels, hydrocarbons, petrochemicals, and refinery streams.

Owner:SDC MATERIALS

Process for Oxidative Desulfurization and Sulfone Disposal Using Solvent Deasphalting

ActiveUS20120055843A1High purityWorking-up pitch/asphalt/bitumen by selective extractionSulfur-dioxide/sulfurous-acidSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a deasphalting unit.

Owner:SAUDI ARABIAN OIL CO

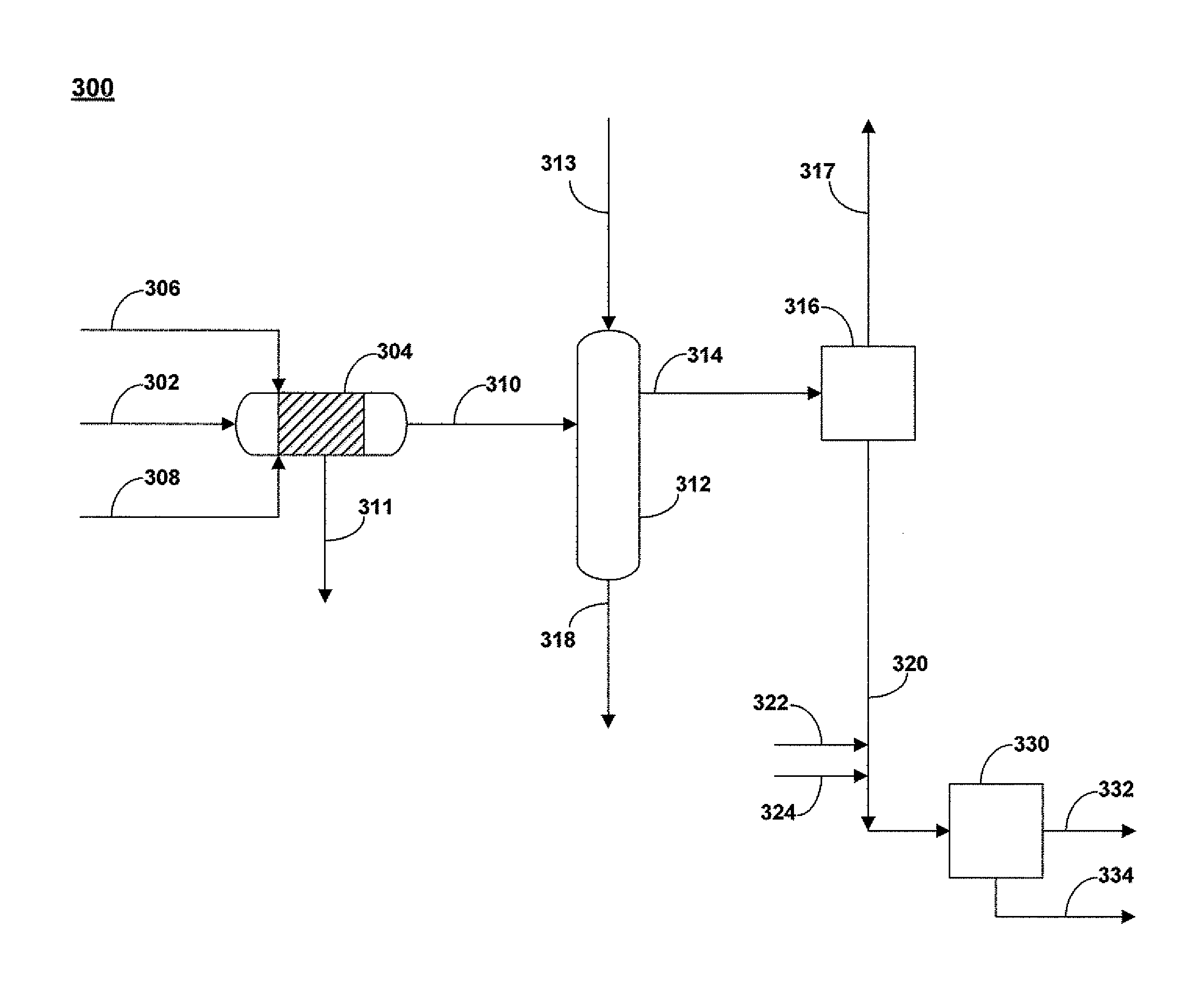

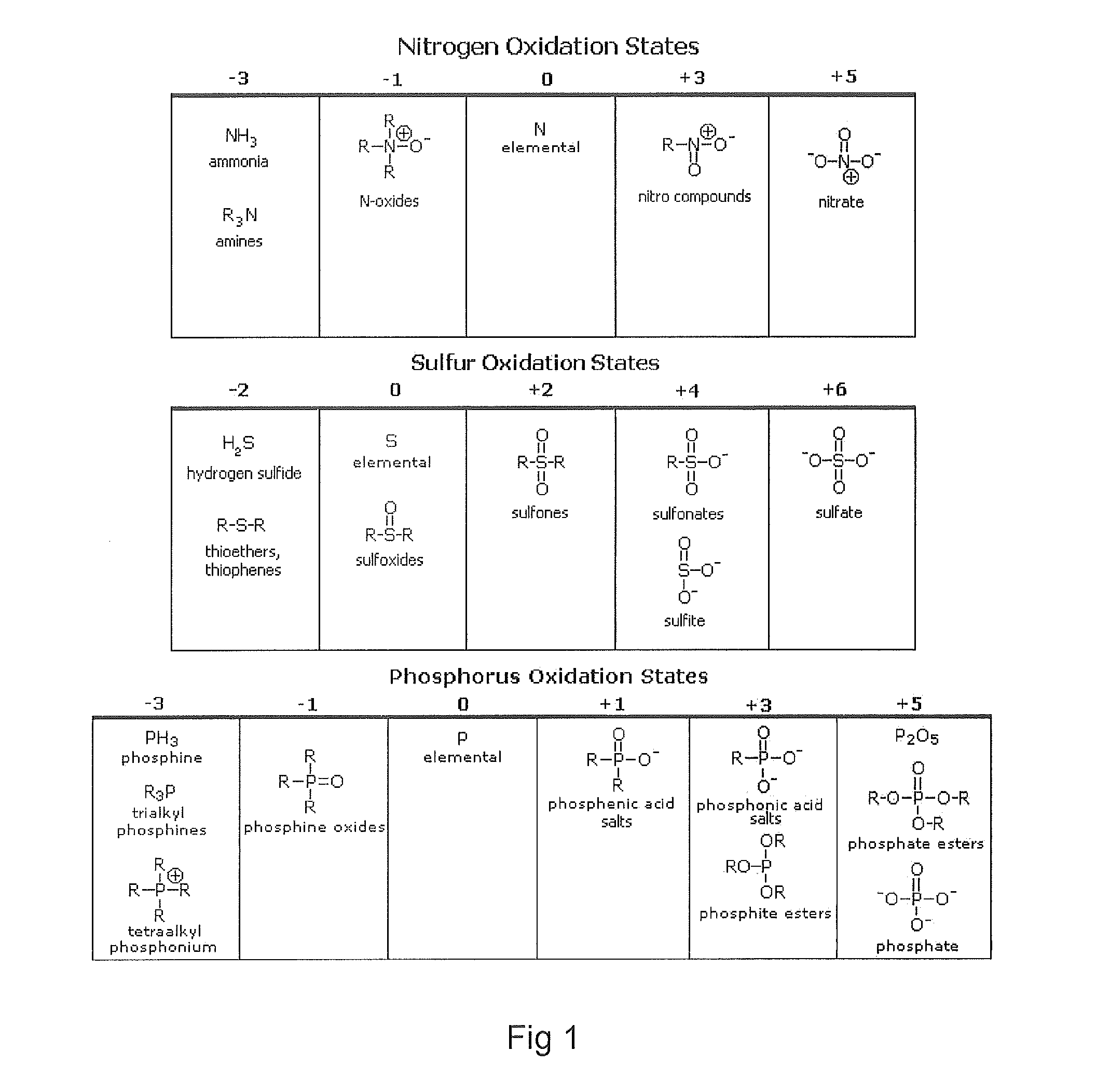

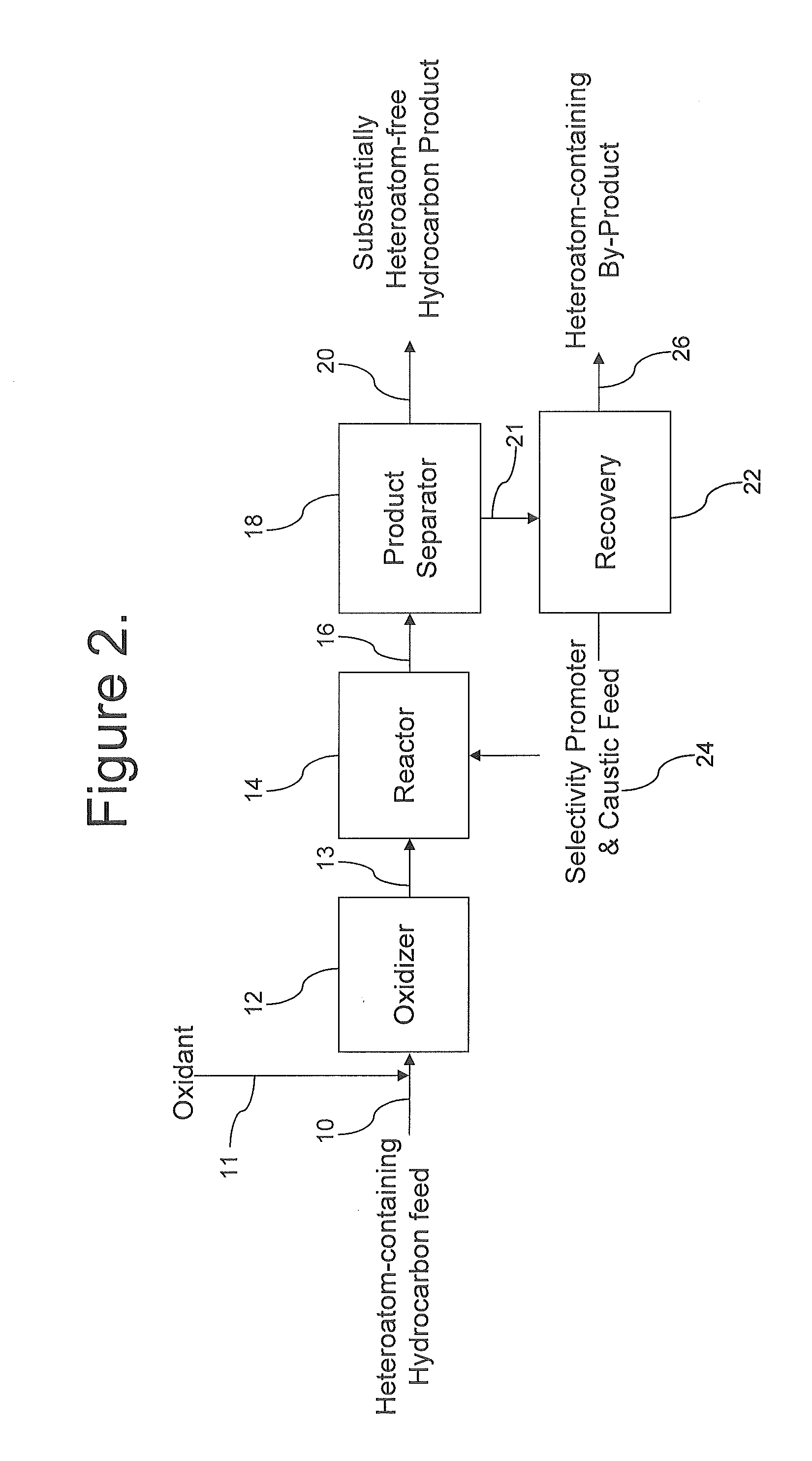

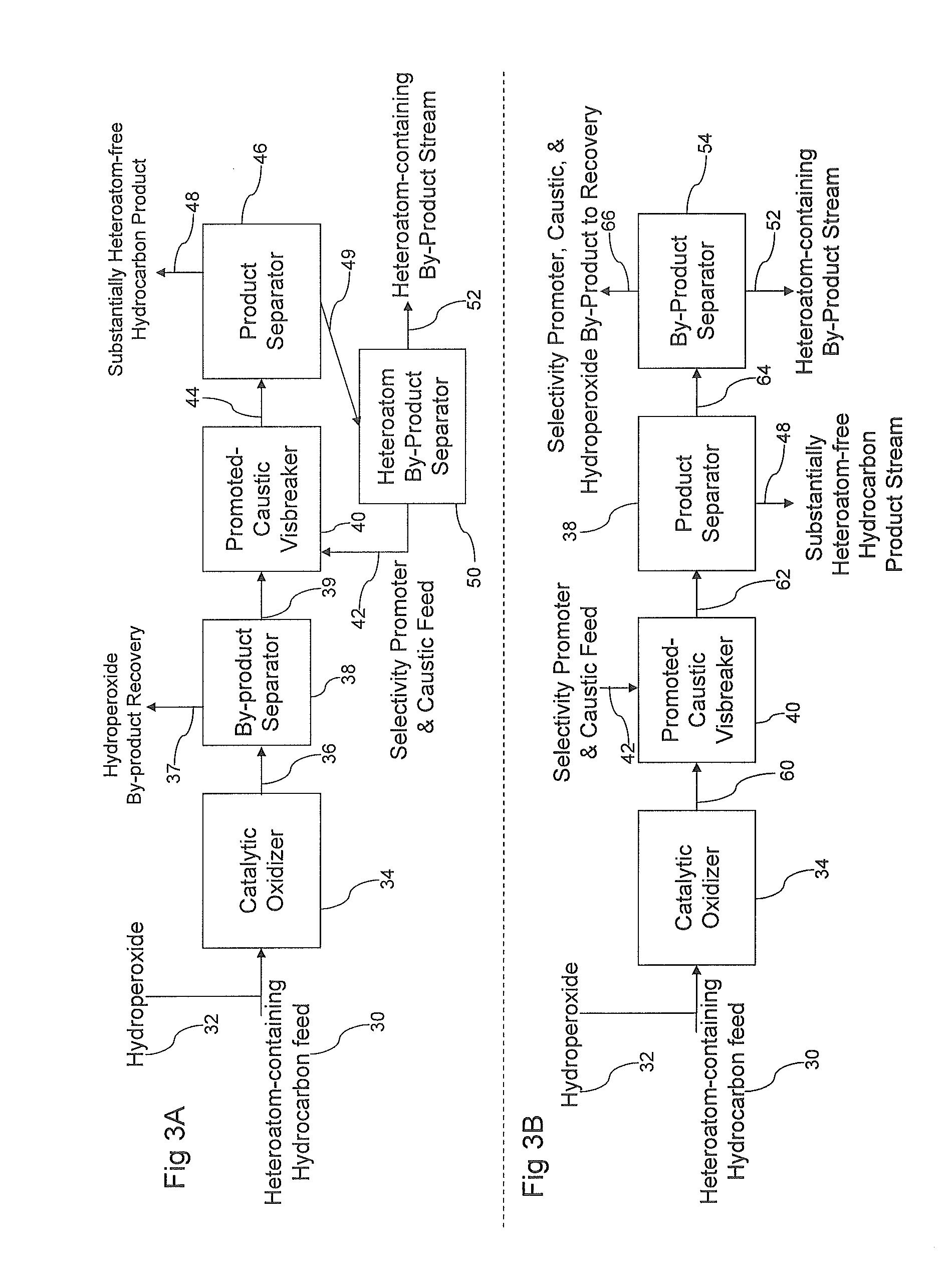

Methods for upgrading of contaminated hydrocarbon streams

A method of upgrading a heteroatom-containing hydrocarbon feed by removing heteroatom contaminants is disclosed. The method includes contacting the heteroatom-containing hydrocarbon feed with an oxidant to oxidize the heteroatoms, contacting the oxidized-heteroatom-containing hydrocarbon feed with caustic and a selectivity promoter, and removing the heteroatom contaminants from the heteroatom-containing hydrocarbon feed. The oxidant may be used in the presence of a catalyst.

Owner:AUTERRA INC

Process for the upgrading of raw hydrocarbon streams

InactiveUS7153414B2Increase polarityPromote oxidationRefining with metalsRefining with oxygen compoundsTotal nitrogenSlurry

A process for the upgrading of raw hydrocarbon streams rich in heteroatomic polar compounds and / or unsaturated moieties involving the extractive oxidation of sulfur, nitrogen, conjugated dienes and other unsaturated compounds from said streams, the said process comprising treating said streams with a peroxide solution / organic acid couple and an iron oxide catalyst which is a limonite ore, under an acidic pH, atmospheric pressure and ambient or higher temperature. As a result of the reaction, the oxidized heteroatomic compounds, having strong affinity for the aqueous slurry phase, are extracted into said aqueous phase, while the oxidized hydrocarbon is separated from catalyst by decanting, neutralizing, water washing and drying, the resulting end product being a hydrocarbon stream from which have been removed 90% or more of total nitrogen compounds and basic nitrogen up to 99.7%, both calculated as mass contents.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS20070144941A1Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercritical water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

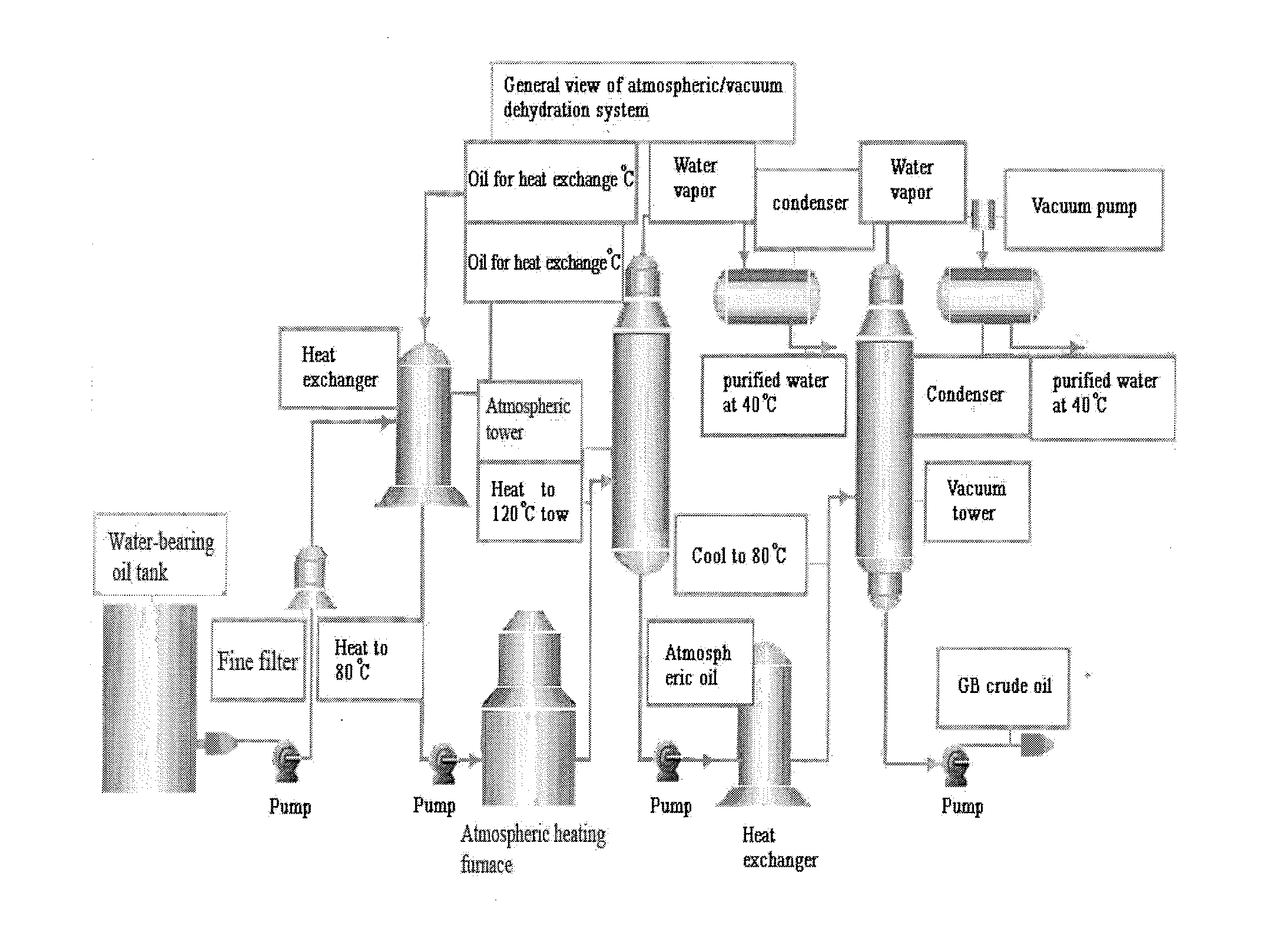

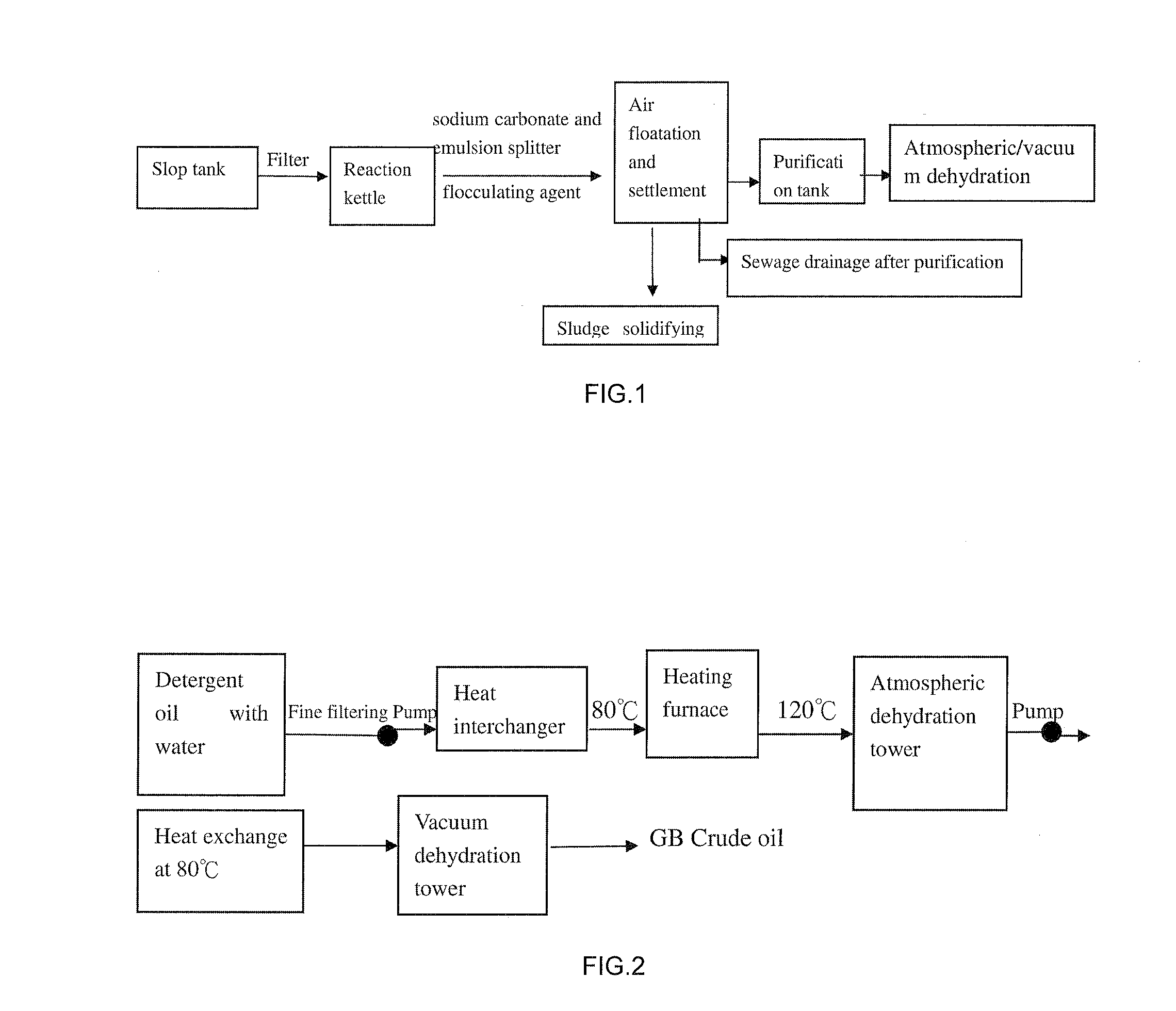

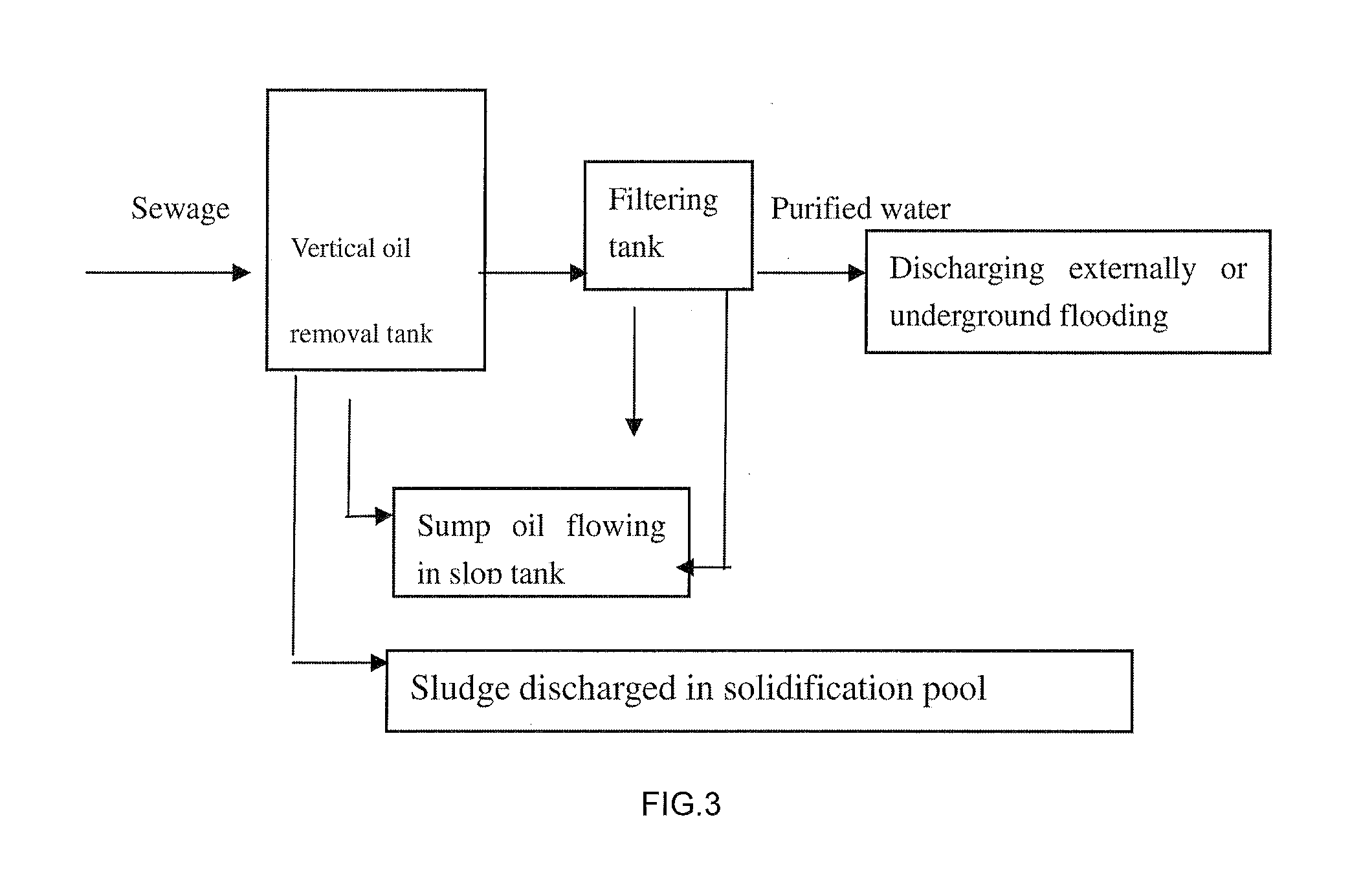

Centralized Sump Oil and Acid Oil treatment process and System

InactiveUS20120103914A1Easy to separateLow cost of treatmentSludge treatmentVacuum distillation separationSludgePollution

This invention reveals to the public the centralized sump oil and acid oil treatment process and system. The process consist of (1) the filter; (2) entry to reaction kettle, the sodium carbonate solution added at the time of air floatation till PH value keeps about 6.0-8.0; and emulsion splitter and flocculating agent added for further reaction; (3) suspension of air floatation and static settlement; (4) the international crude oil is collected after the detergent oil at the upper level of the reaction kettle is dehydrated under normal and reduced pressure; the wastewater is drained after filtering by the natural oil removal tank and the oil-water filter; the sludge is solidified by the cement and the quick lime and aluminium oxide are used as the coagulant aid for solidifying the sludge. The centralized treatment process of sump oil and acid oil not only greatly lowers the pollution of surroundings of the oilfield and corrosion of equipment, but also changes waste into valuable, reuses a great amount of crude oil and improves the economic benefits of the oilfield. The sludge solidified can be directly used for buildings.

Owner:YUAN GANG

Preparation of components for refinery blending of transportation fuels

InactiveUS20060021913A1Refining with oxygen compoundsTreatment with plural serial refining stagesChemical compositionSulfur

The process of the present invention involves reducing the sulfur and / or nitrogen content of a distillate feedstock to produce a refinery transportation fuel or blending components for refinery transportation fuel, by contacting the feedstock with an oxygen-containing gas in an oxidation zone at oxidation conditions in the presence of an oxidation catalyst comprising a zeolitic material, TIQ-6, whose chemical composition corresponds to the formula, expressed as oxides, SiO2:z ZO2:m MO2:x X2O3:aH2O Wherein Z is Ge, Sn,z is between 0 and 0.25 mol.mol−1 M is Ti or Zr, M has a value between 0.00001 and 0.25, preferably between 0.001 and 0.01, and a=has a value between 0 and 2.

Owner:BP CORP NORTH AMERICA INC

Popular searches

Multistage water/sewage treatment Stationary filtering element filters Refining to eliminate hetero atoms Hydrocarbons Treatment with hydrotreatment processes Naphtha treatment Refining by selective hydrogenation Chemical modification purification/separation Naphtha reforming Hydrocarbon preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com