Patents

Literature

1209 results about "Low nitrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benefits of Low Nitrogen. Crops with too much nitrogen in the soil produce a lot of foliage and not as much of the actual crop. Low-nitrogen fertilizers can help plants focus on producing their fruits rather than their leaves. Veggies with low amounts of nitrogen in their fertilizers produce more antioxidants than veggies with a lot of nitrogen.

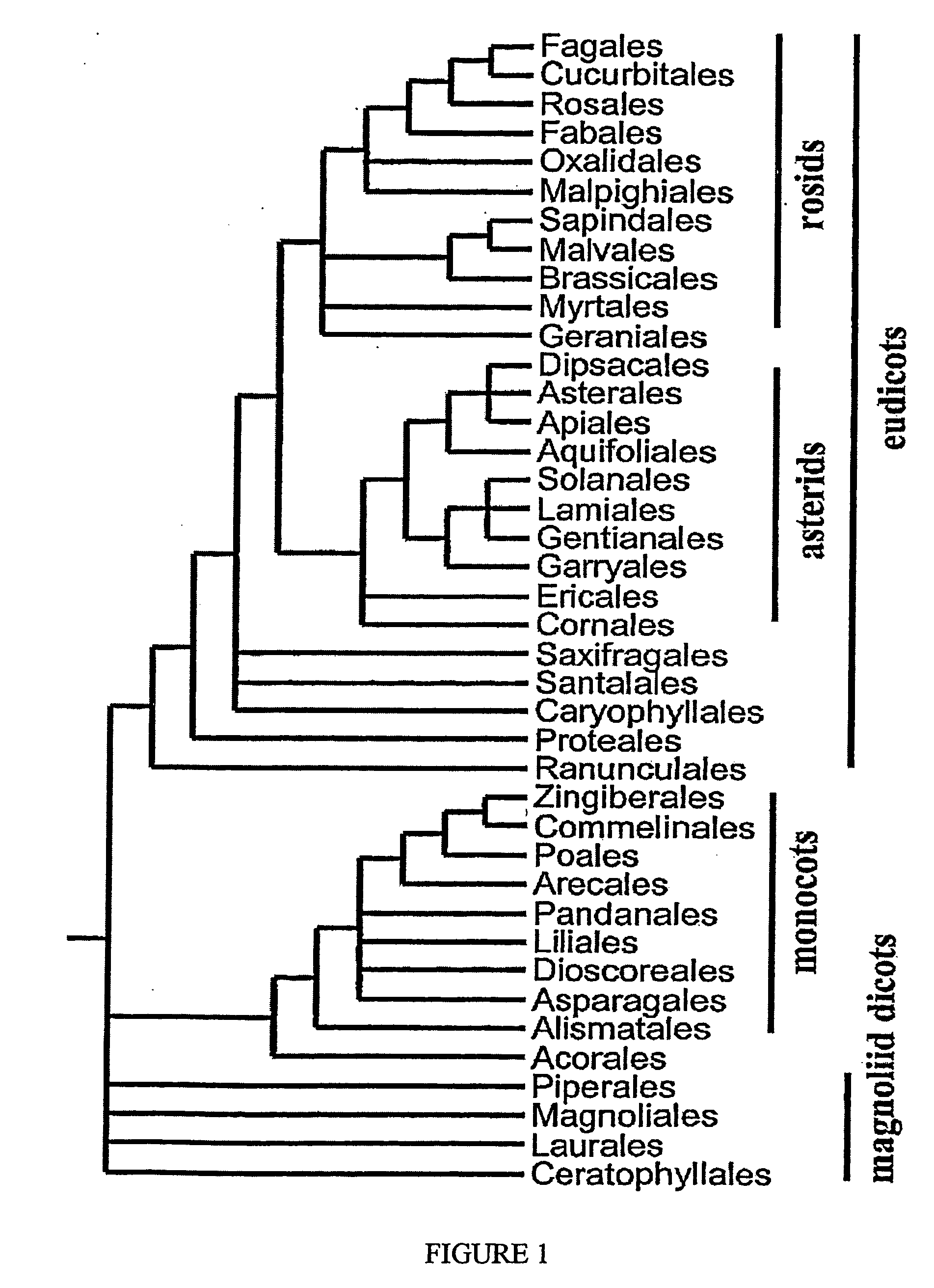

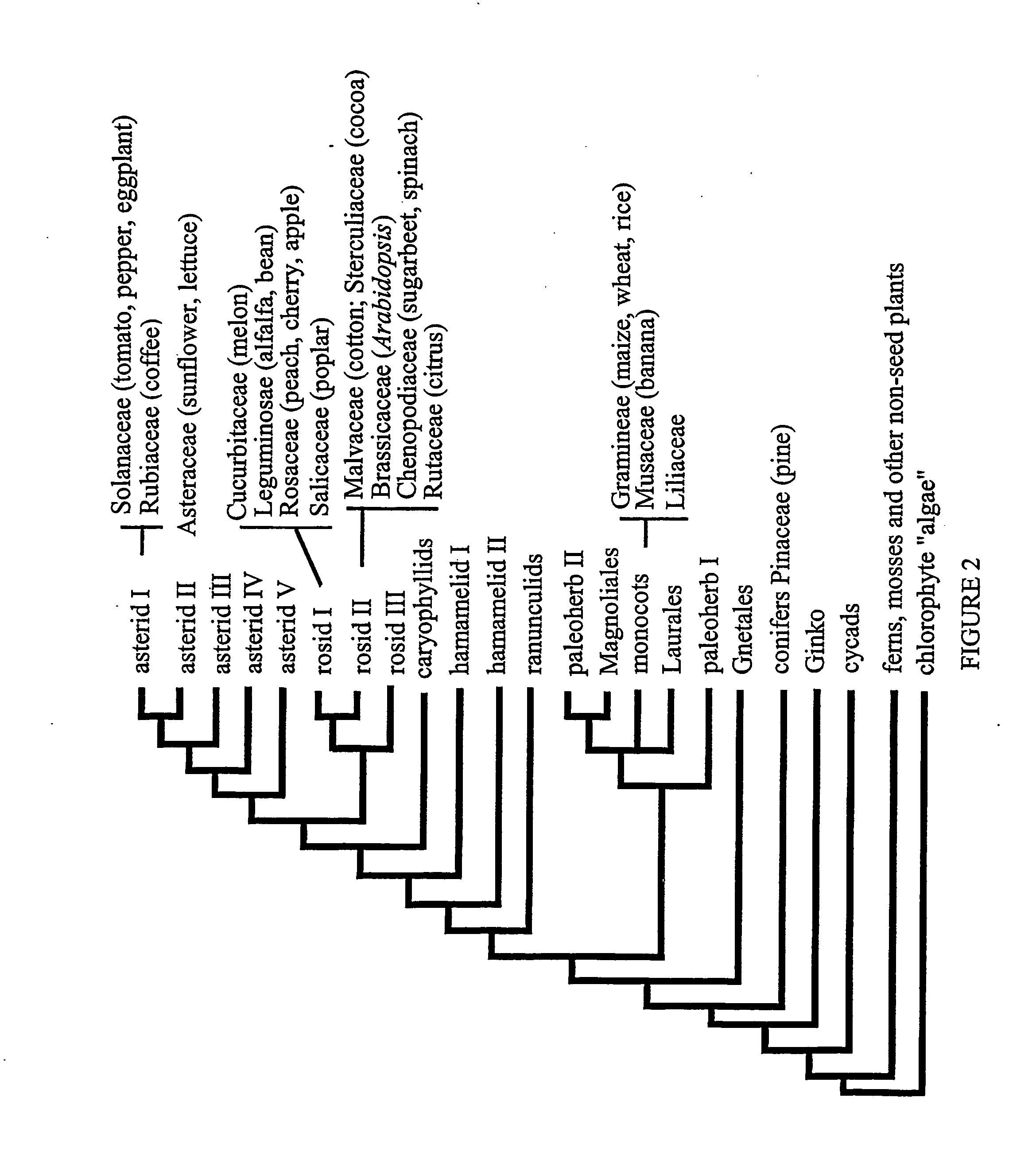

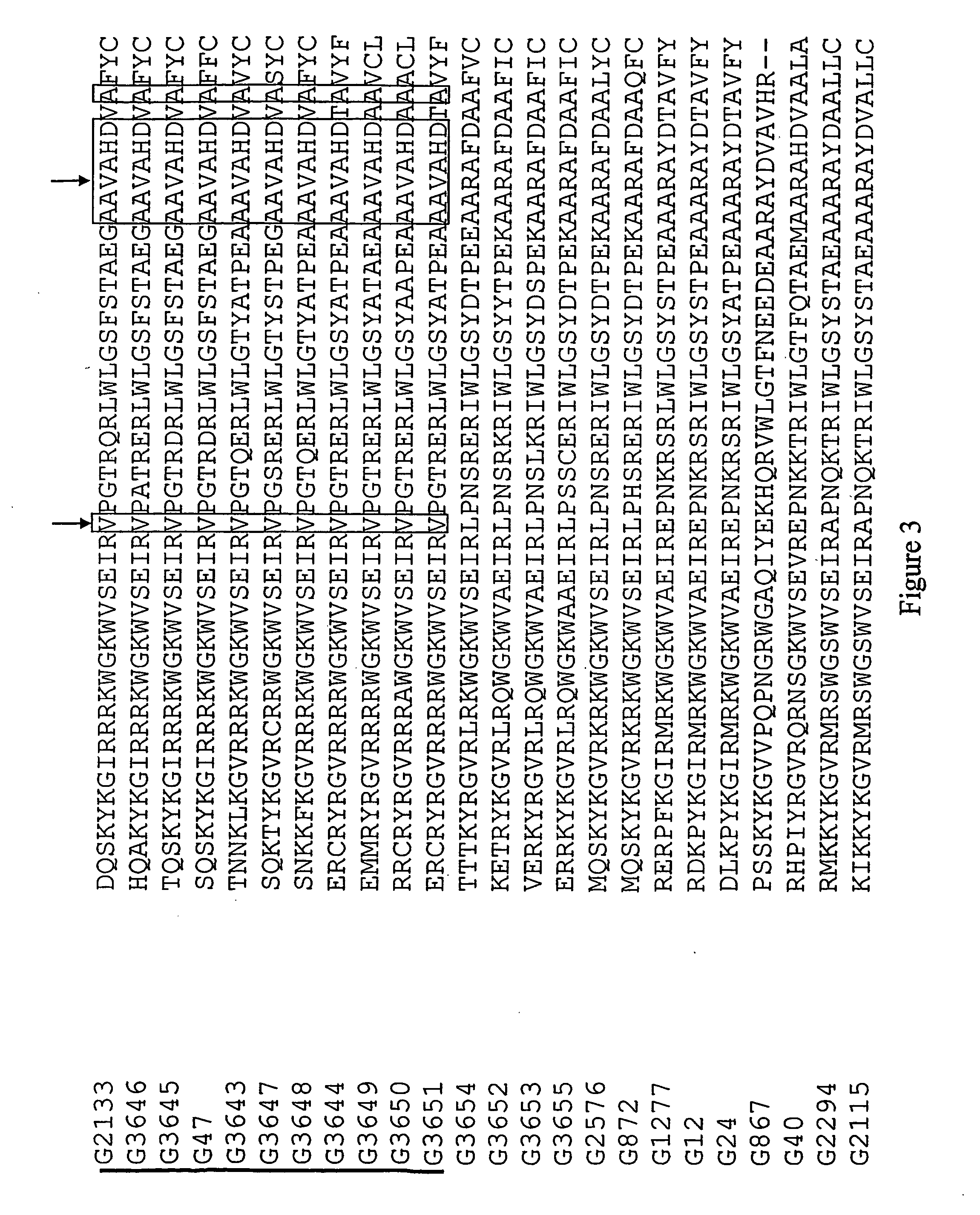

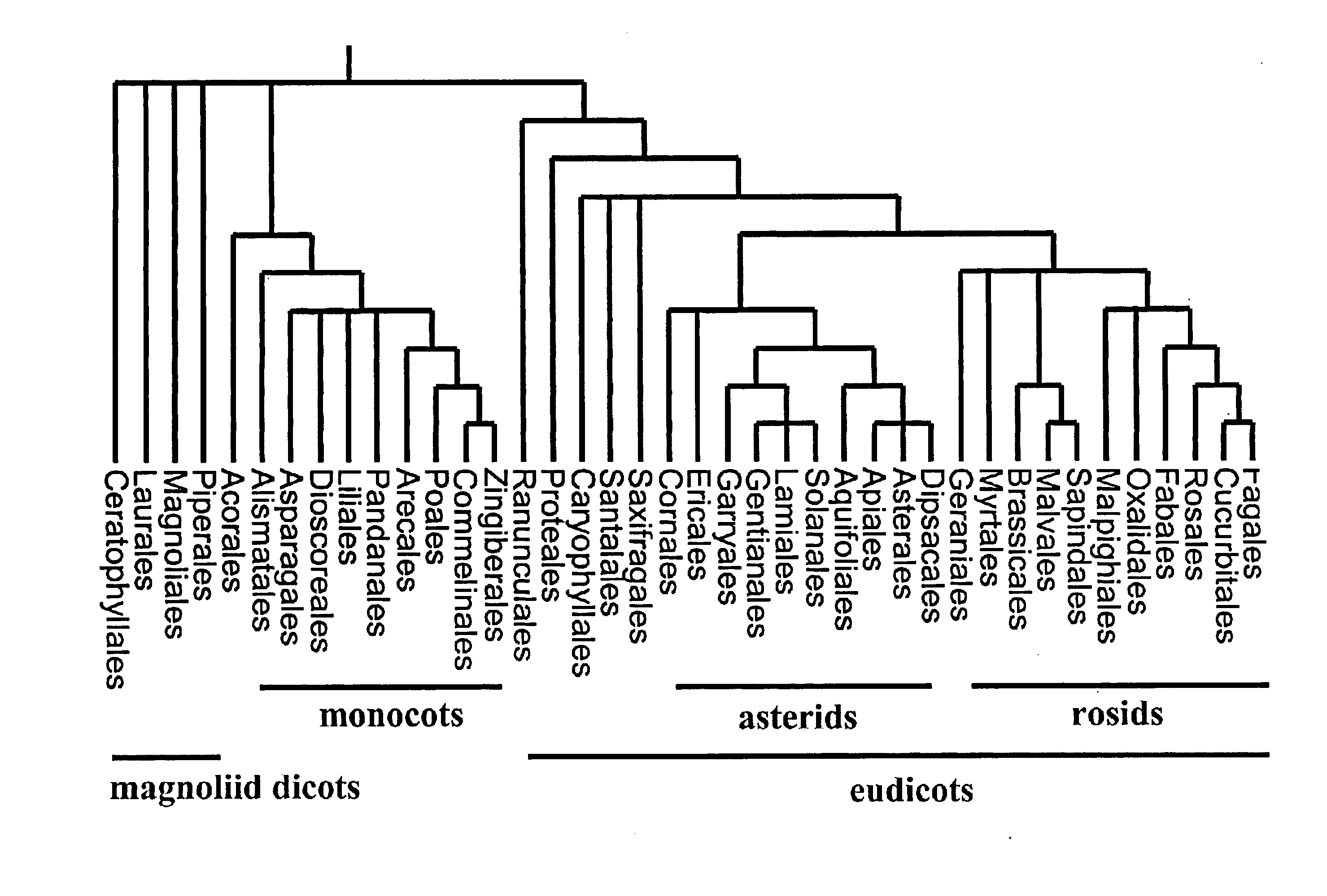

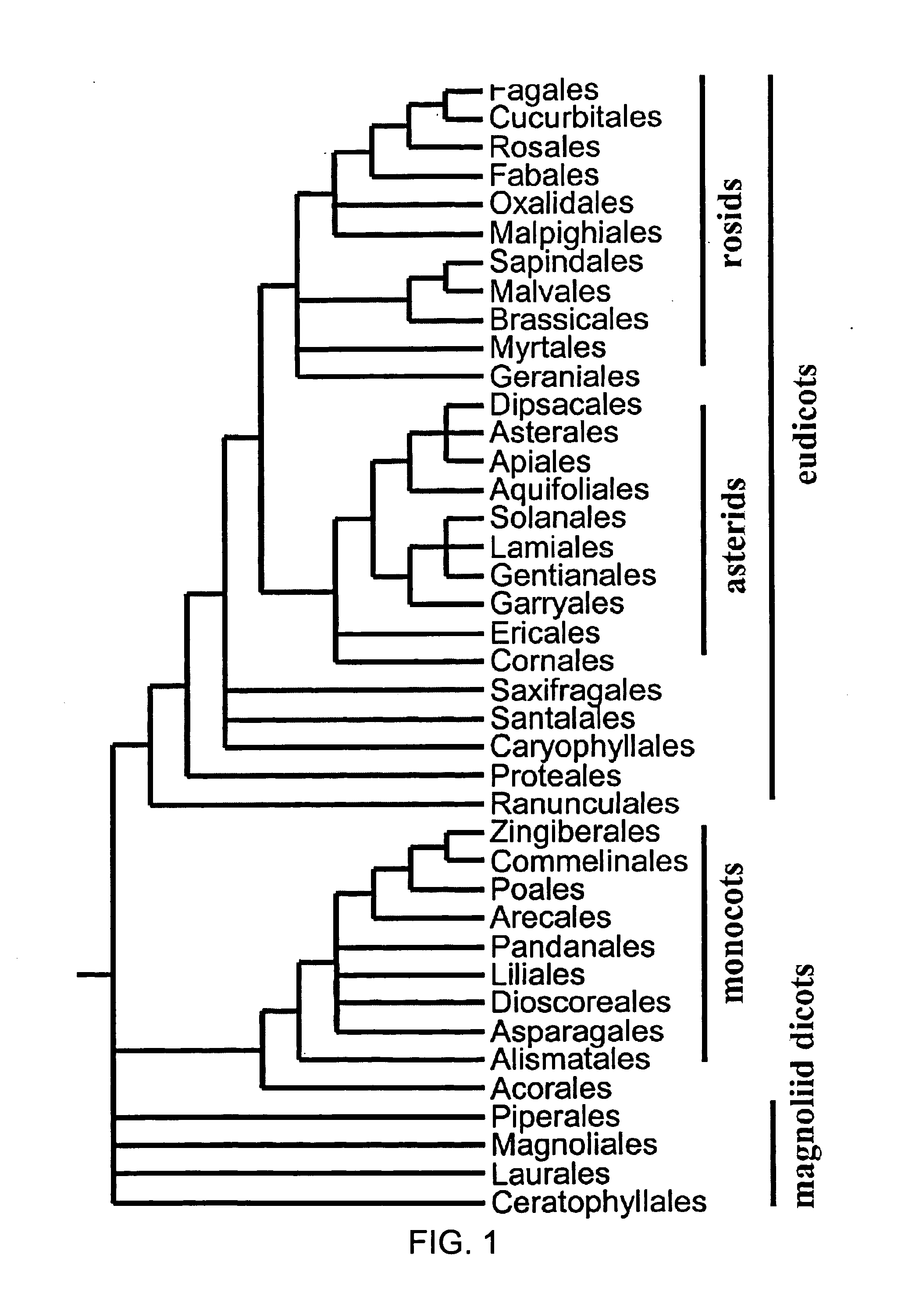

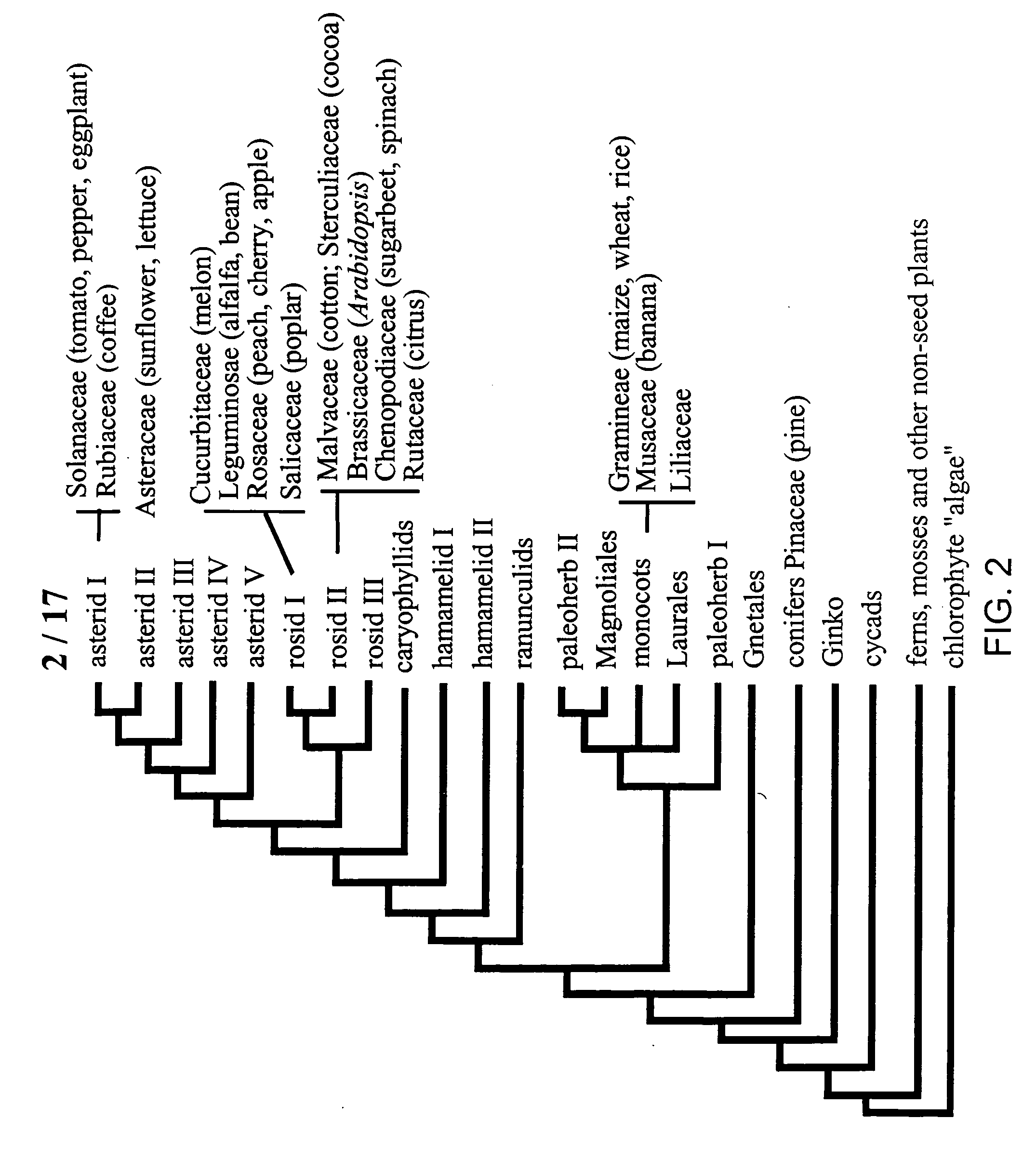

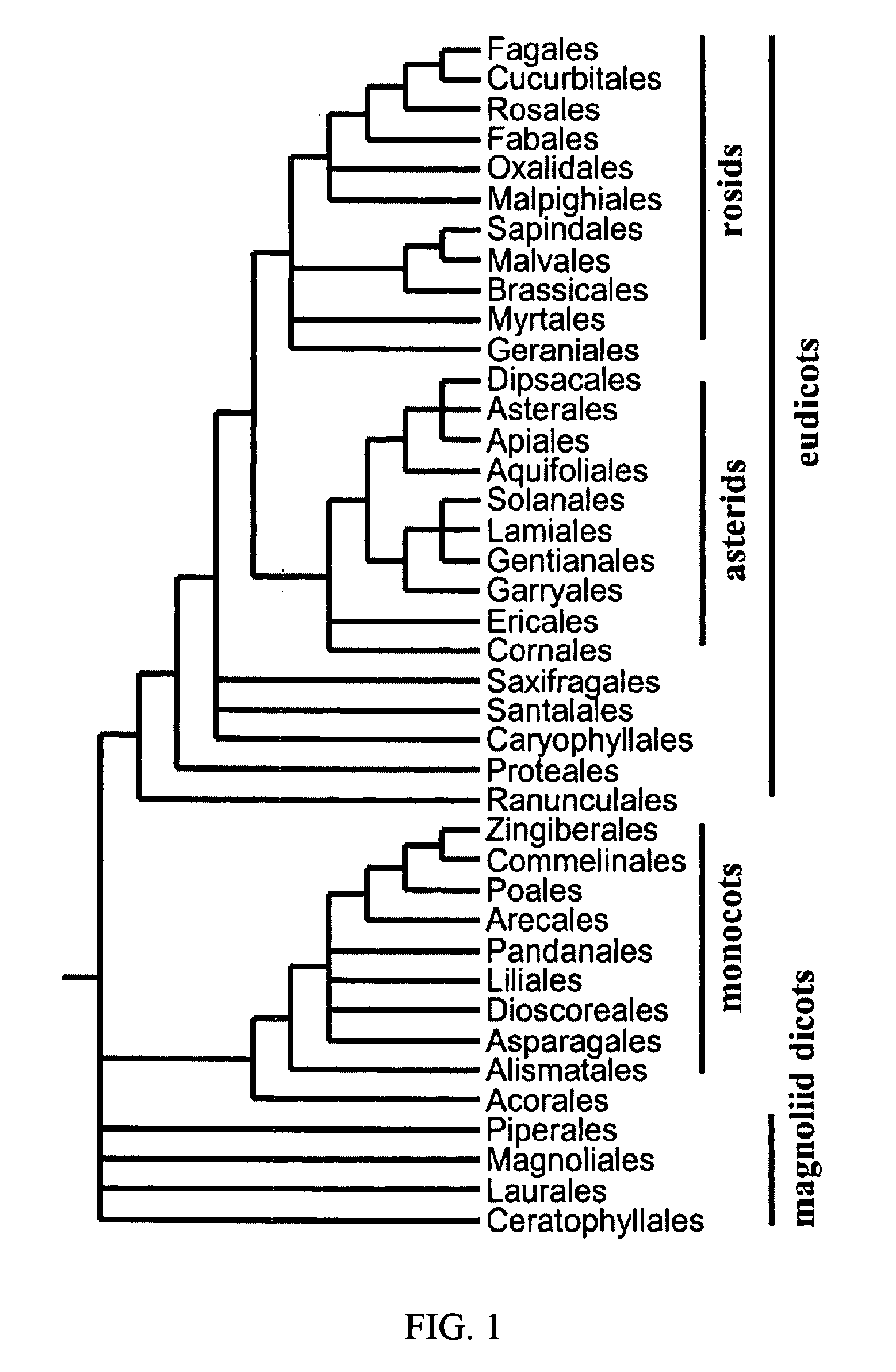

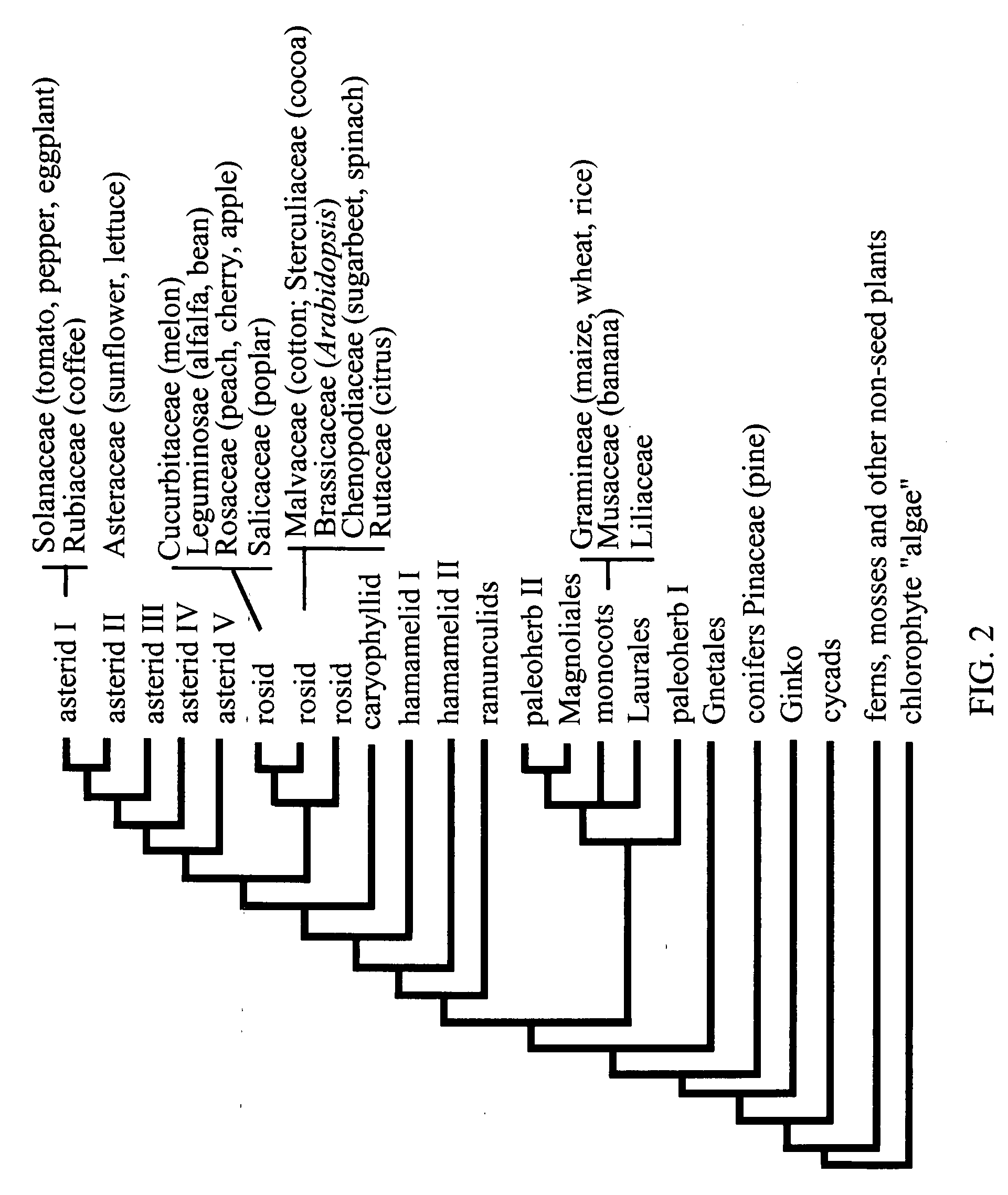

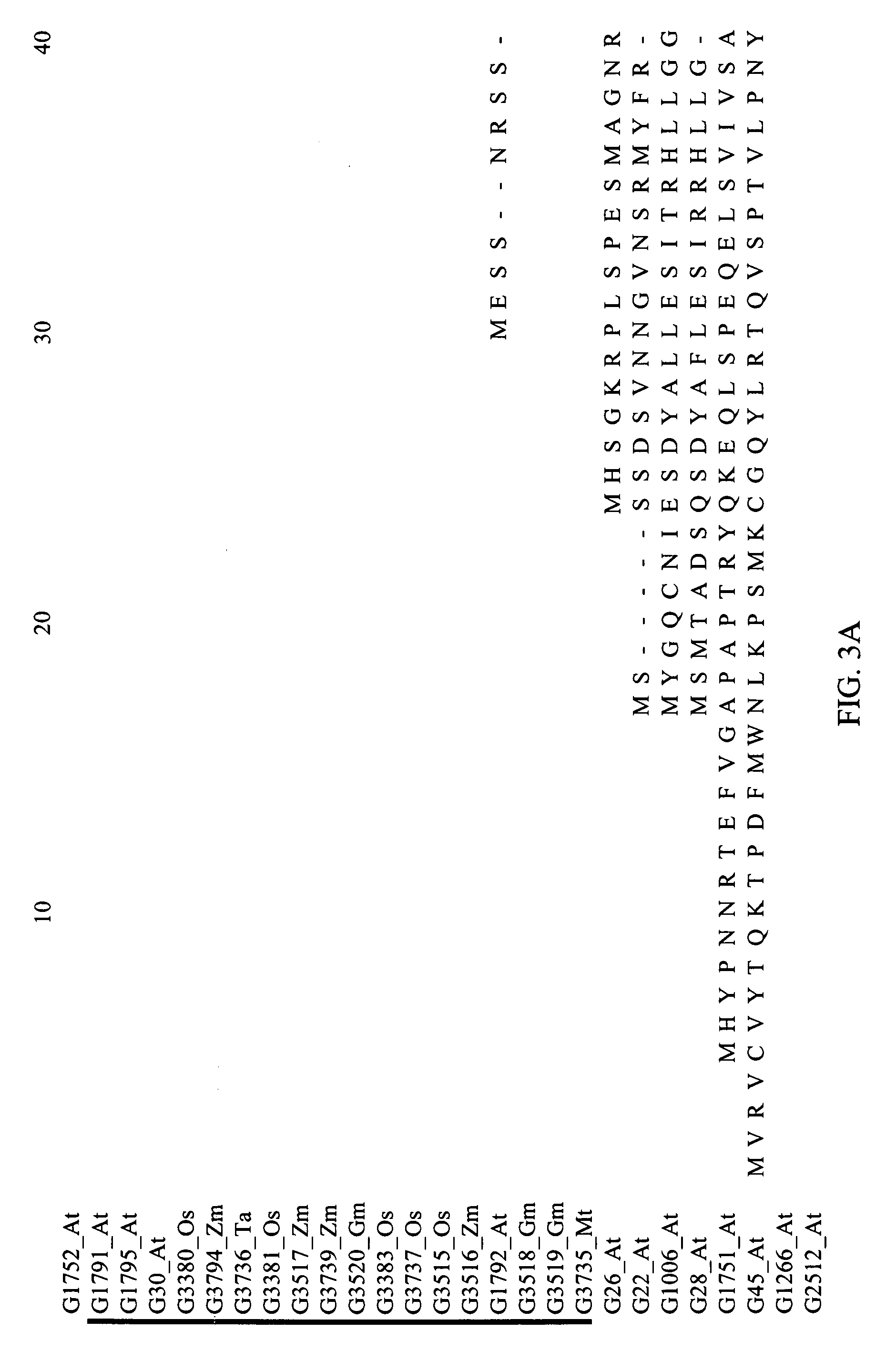

Plant transcriptional regulators

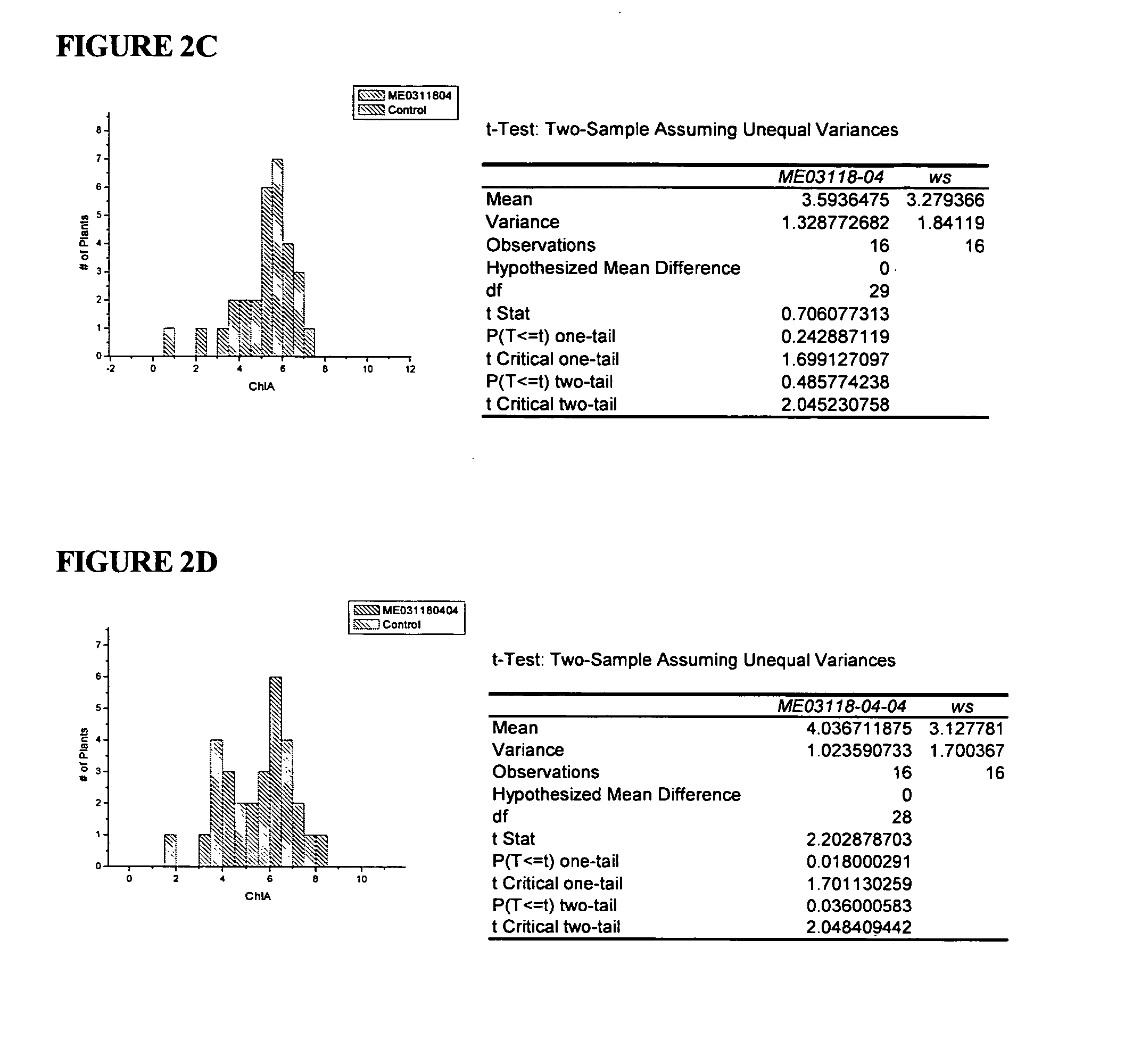

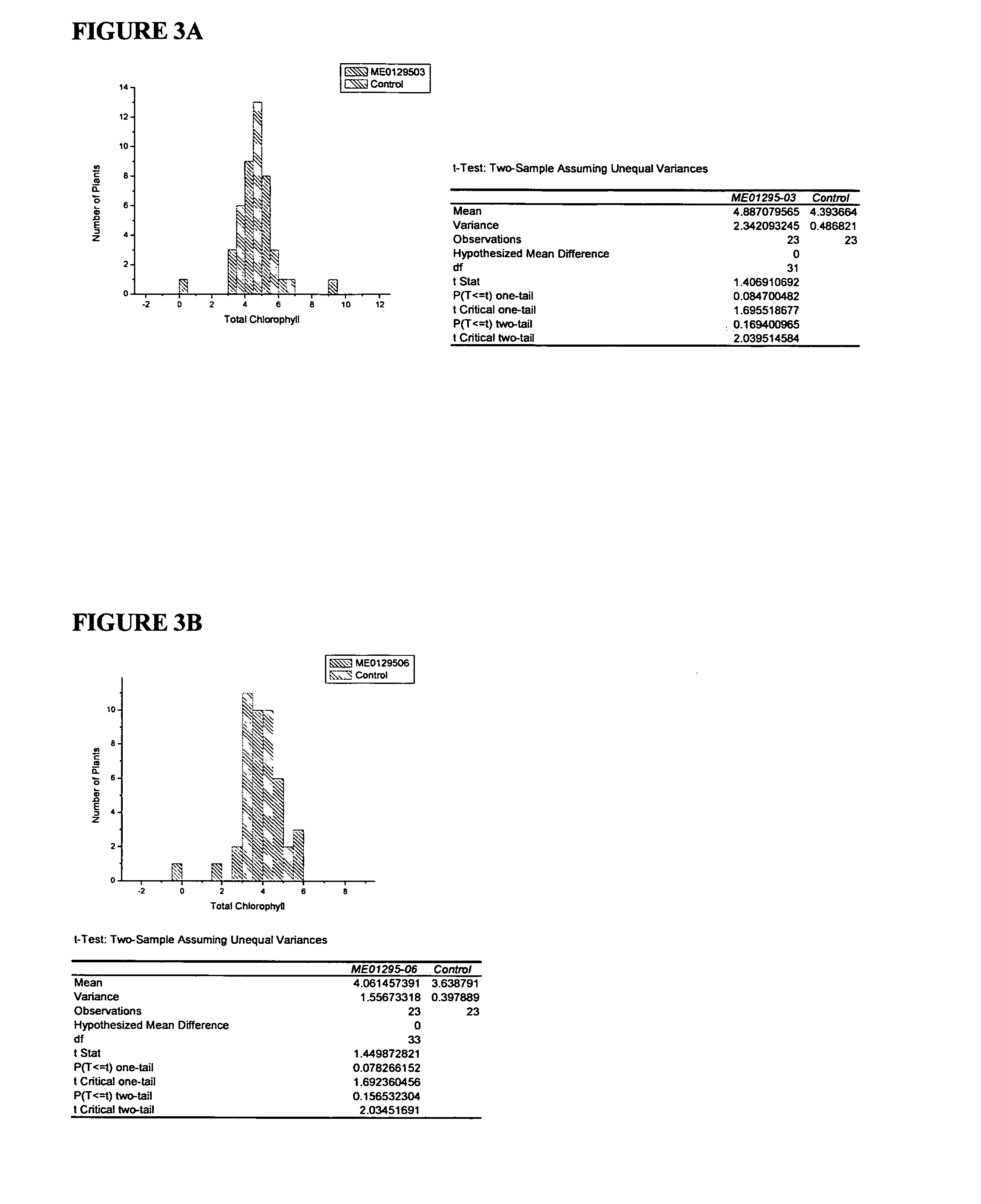

InactiveUS20060272060A1Improve drought toleranceIncreased tolerance to low nitrogen conditionsOther foreign material introduction processesPlant peptidesLow nitrogenNucleotide

The invention relates to plant transcription factor polypeptides, polynucleotides that encode them, homologs from a variety of plant species, and methods of using the polynucleotides and polypeptides to produce transgenic plants having improved tolerance to drought, shade, and low nitrogen conditions, as compared to wild-type or reference plants.

Owner:MENDEL BIOTECHNOLOGY INC

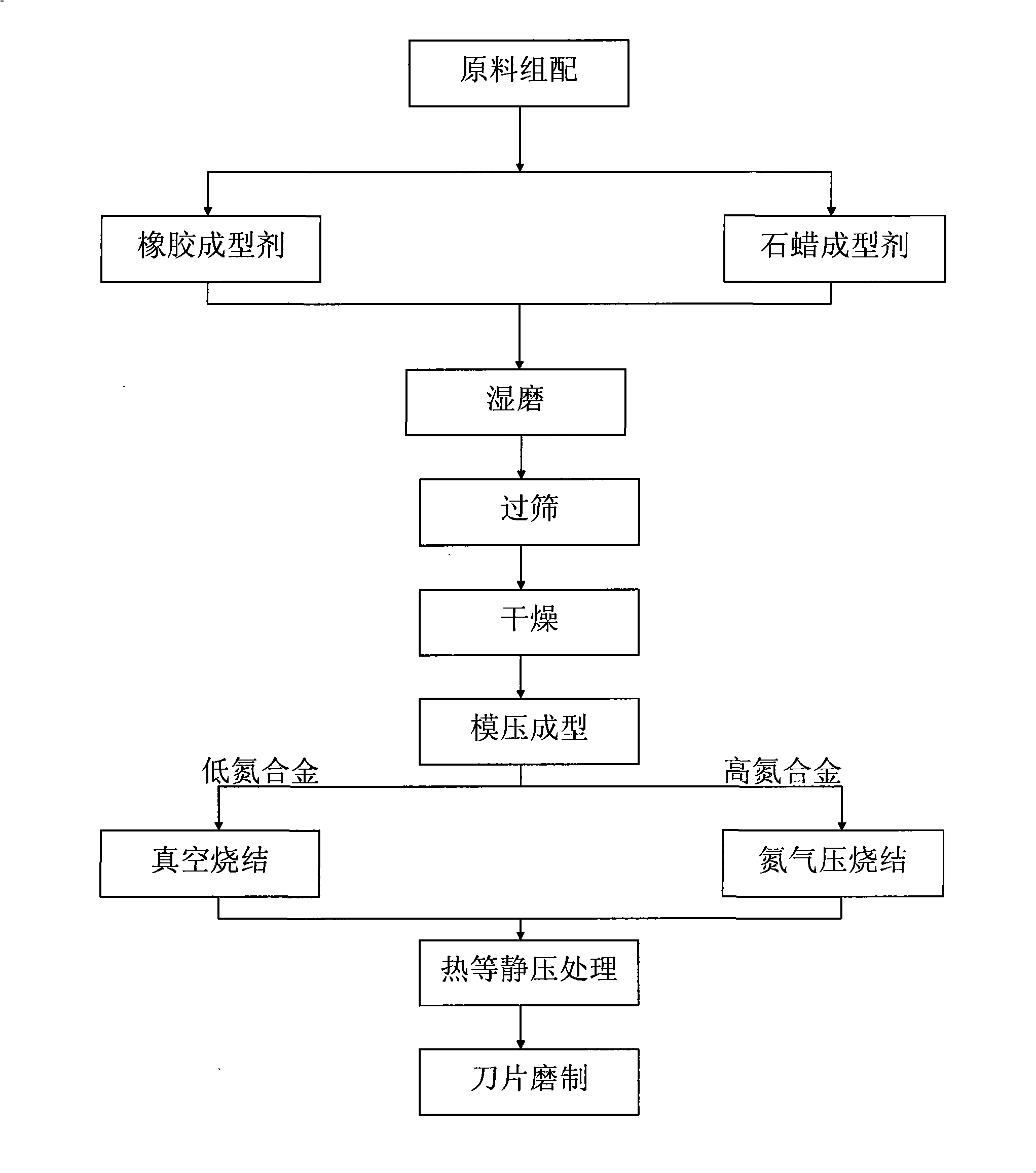

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

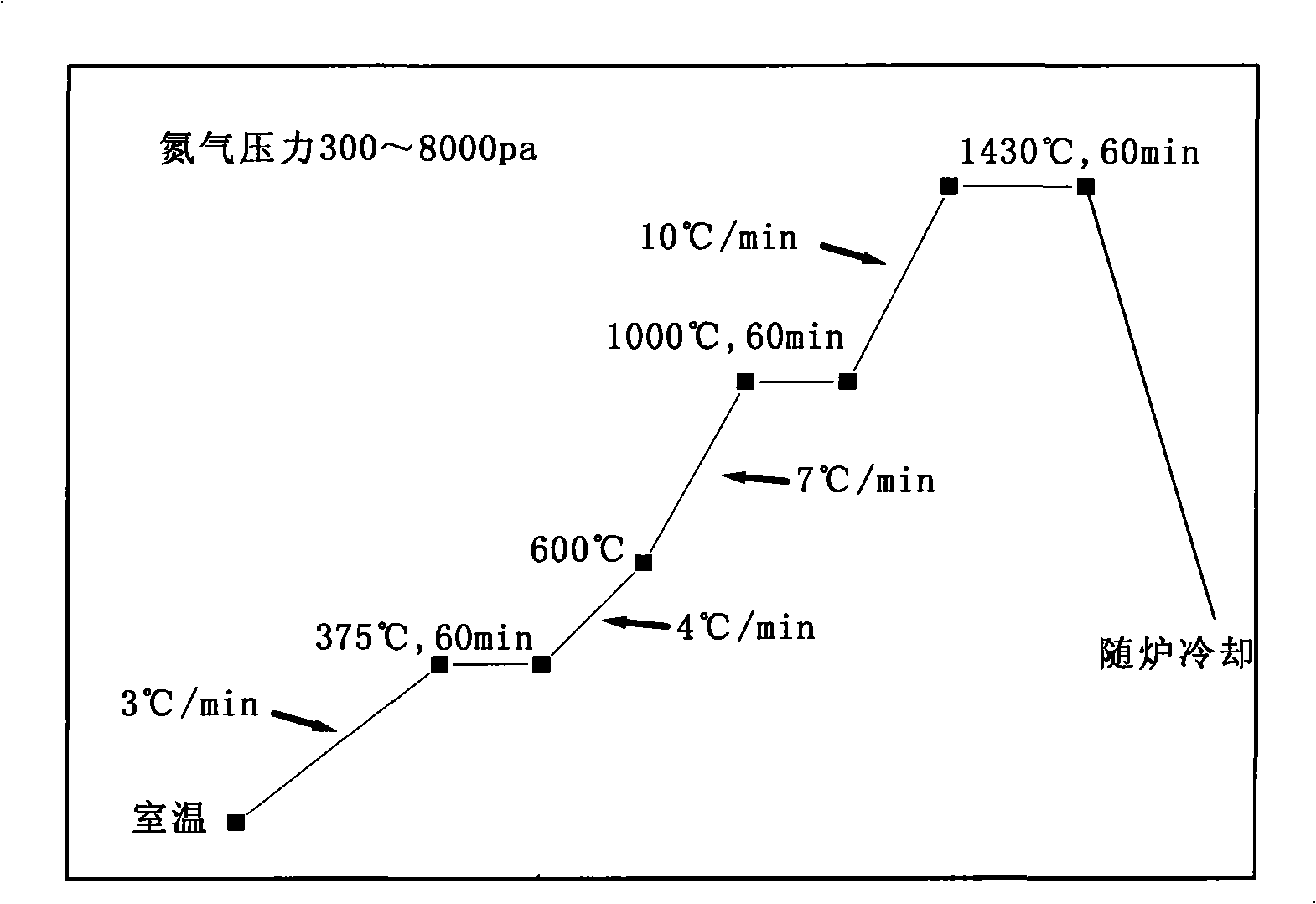

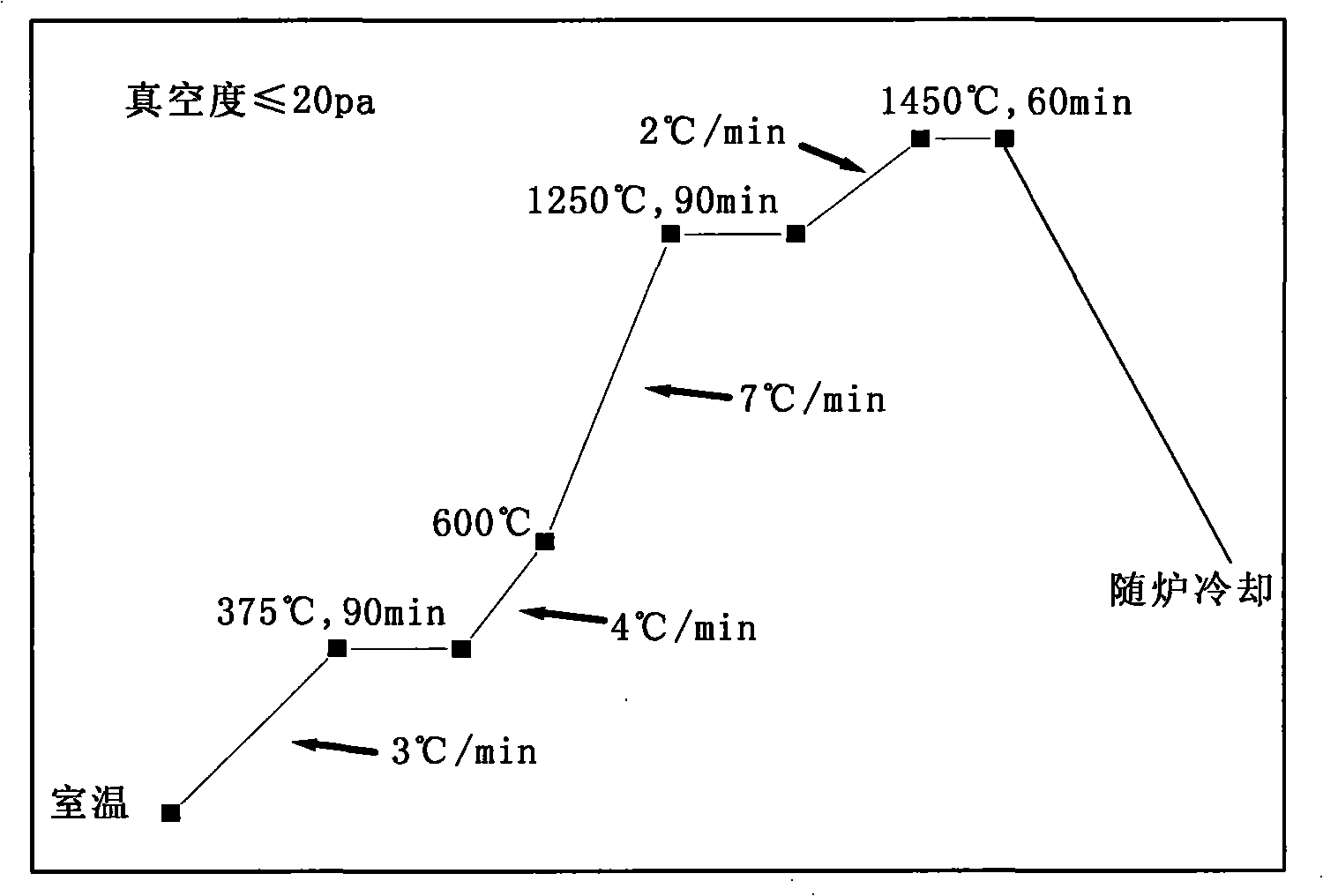

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

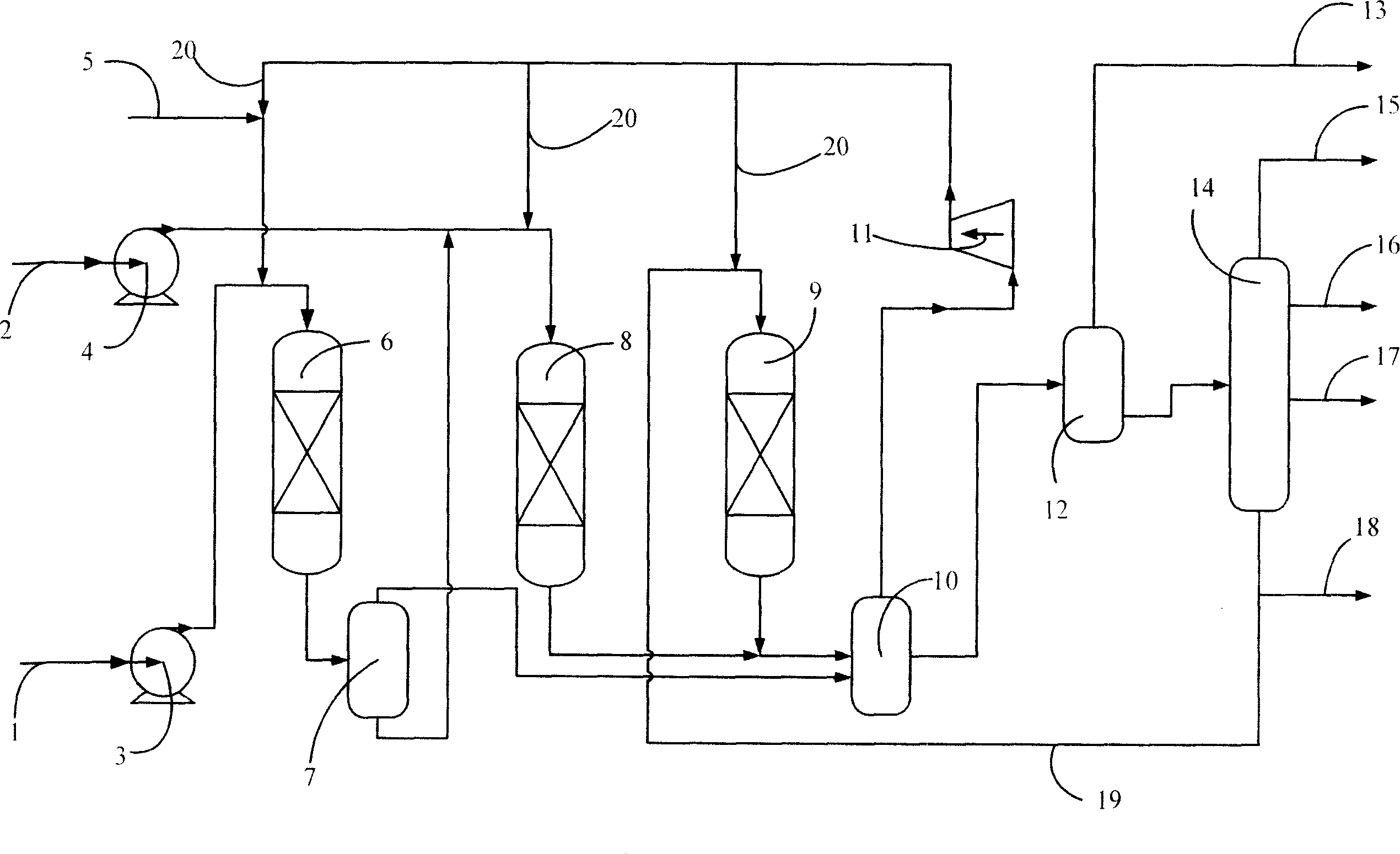

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN1903994AReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

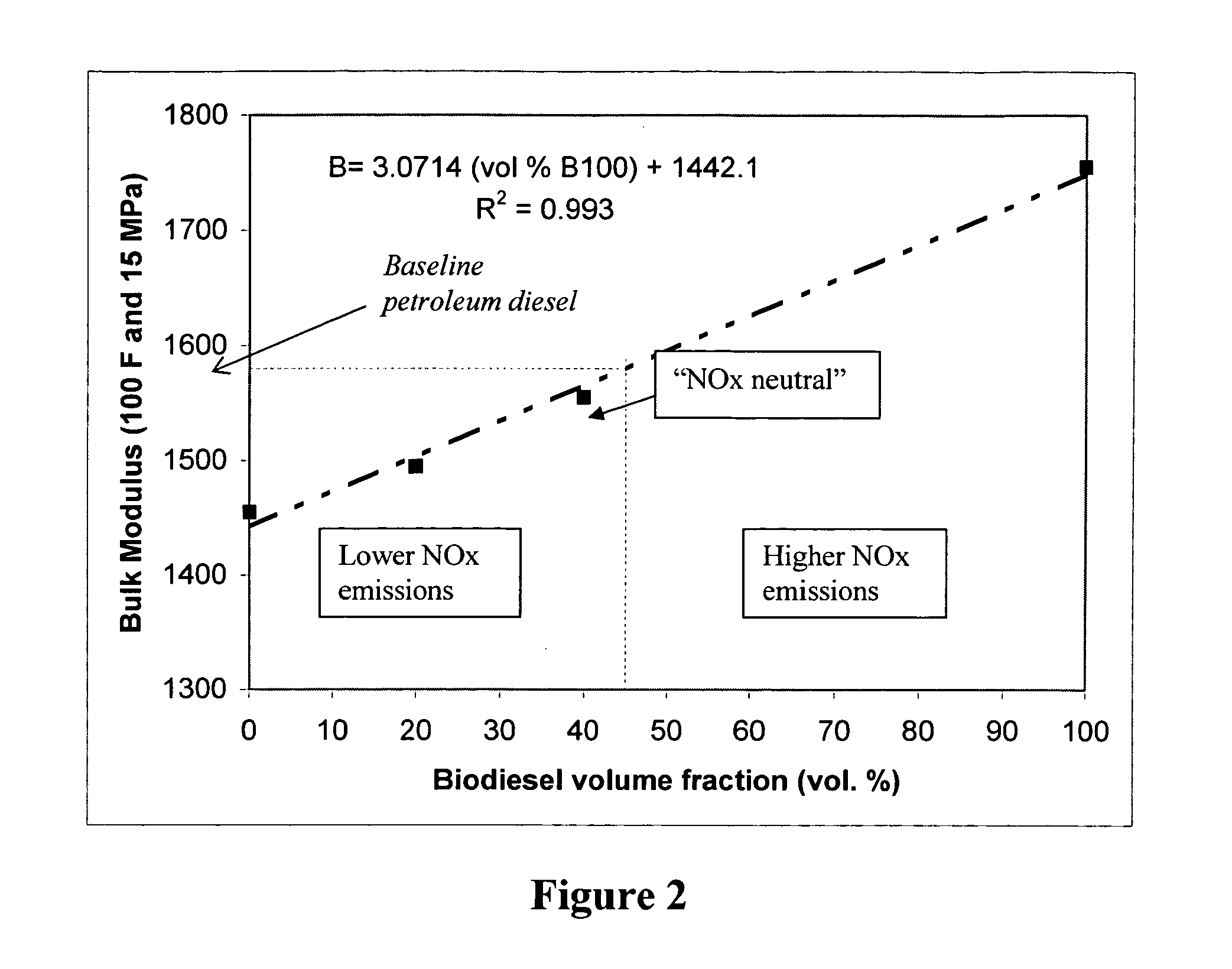

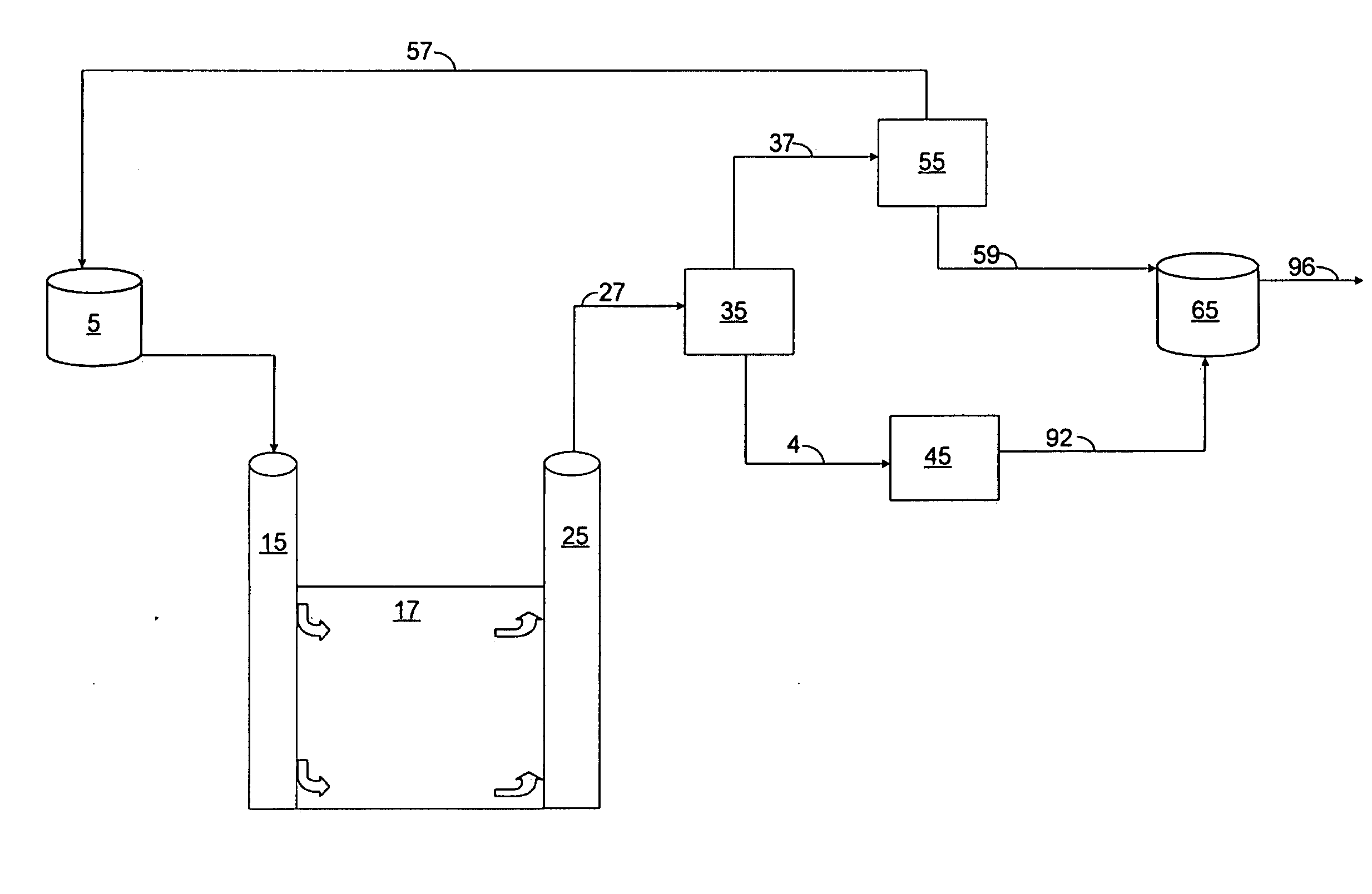

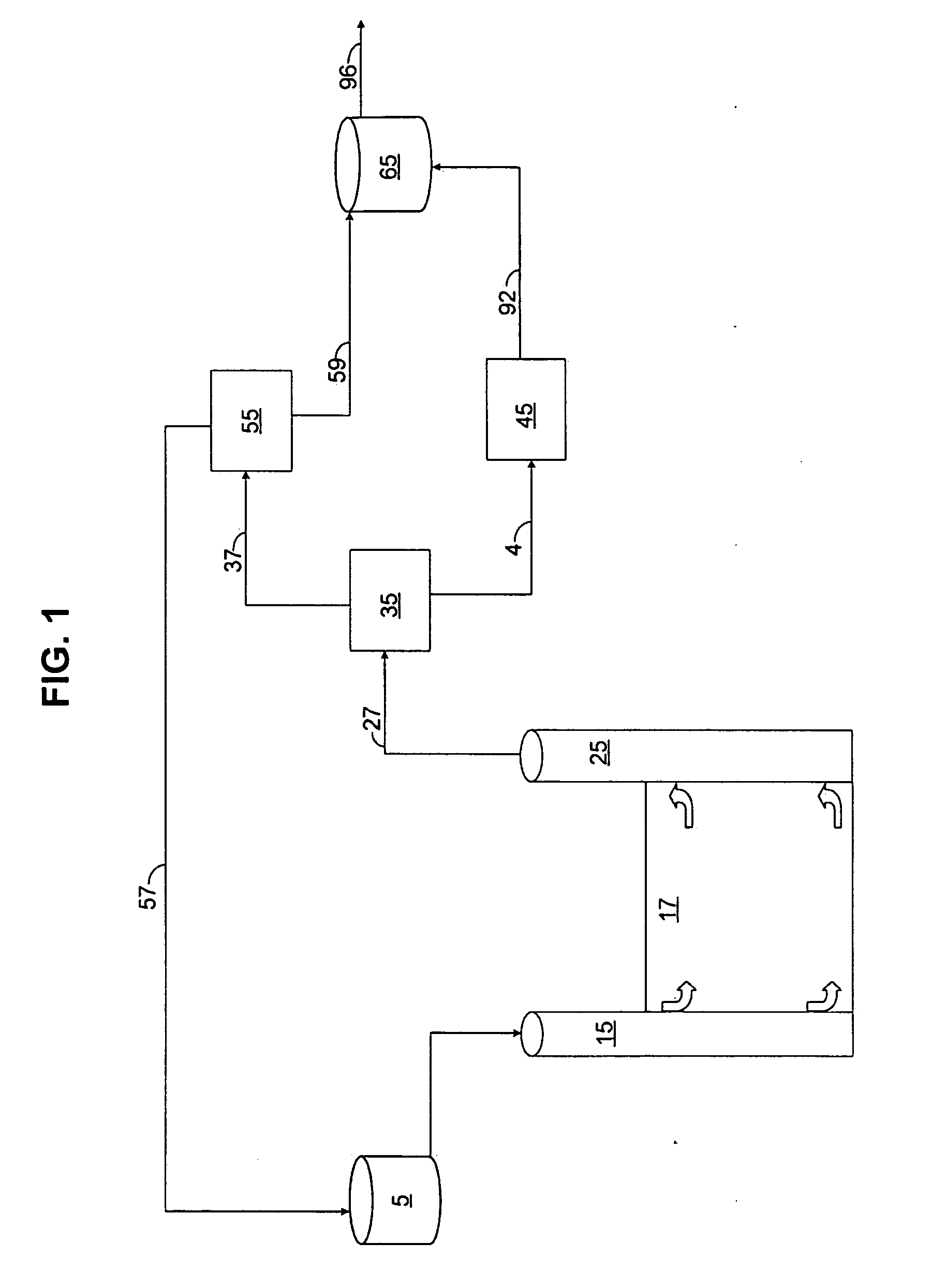

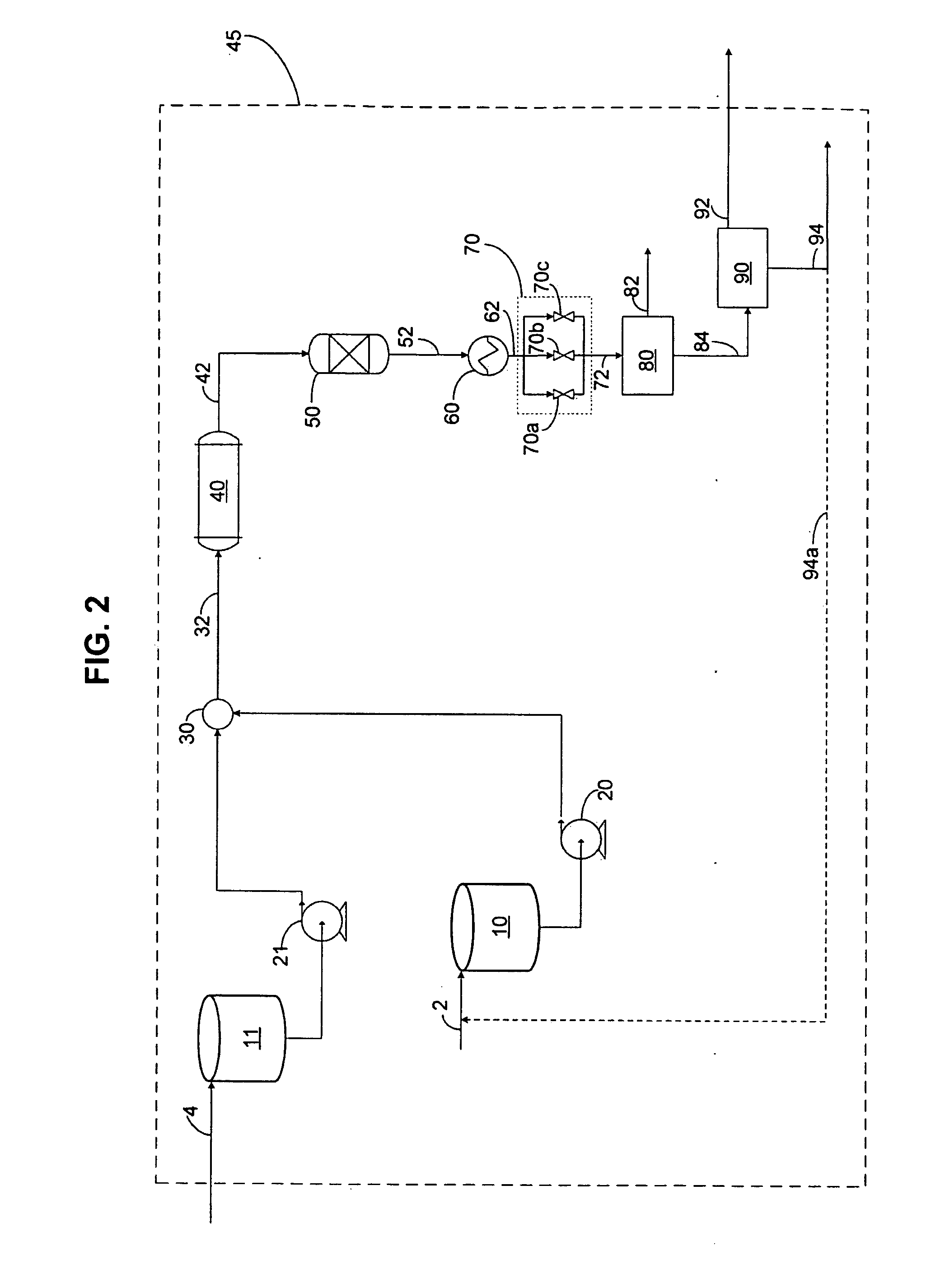

Blends of synthetic distillate and biodiesel for low nitrogen oxide emissions from diesel engines

InactiveUS20050210739A1Reduce nitrogen oxide emissionsReduced NO<sub>xBiofuelsSolid fuelsAlkaneBiodiesel

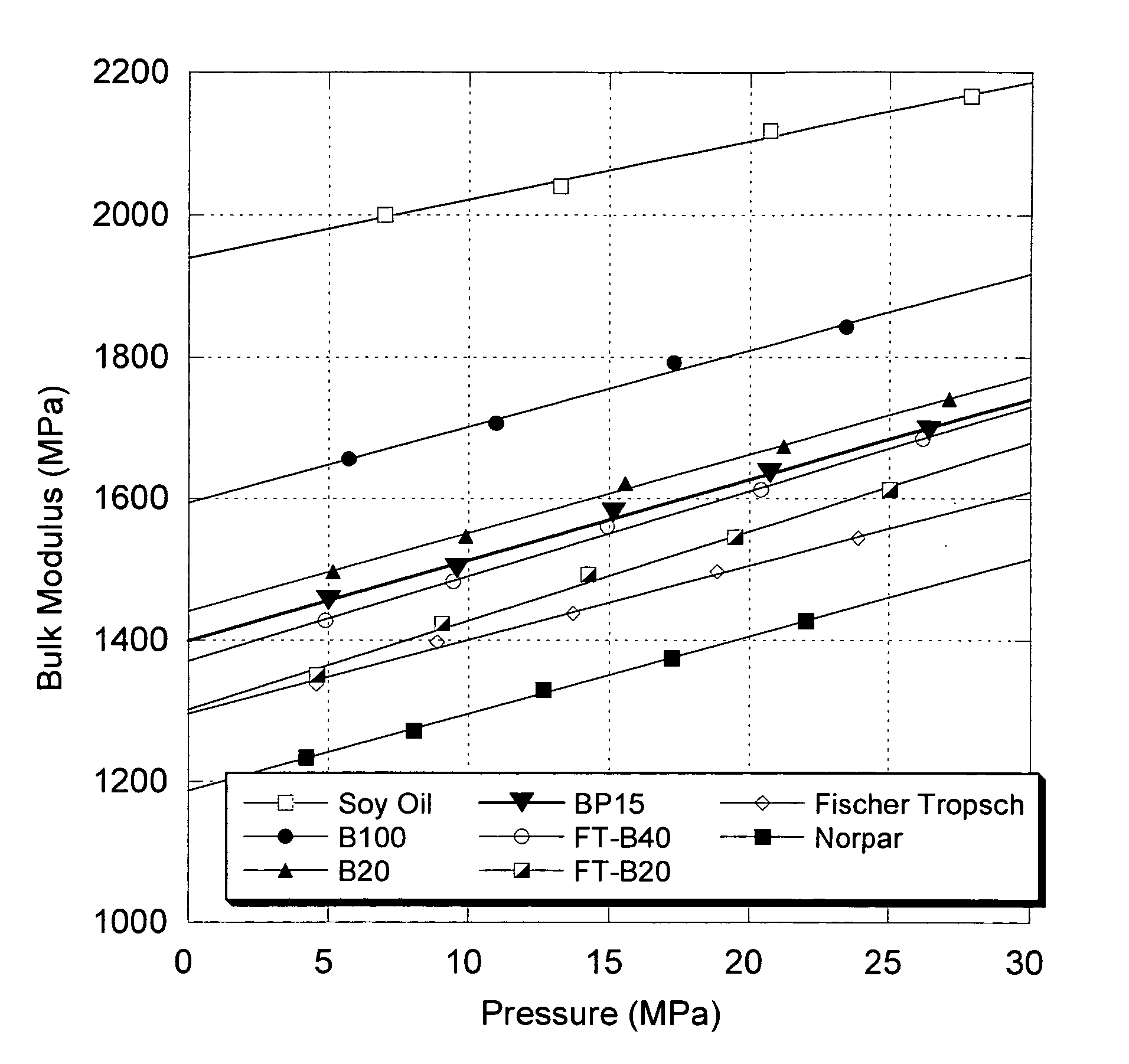

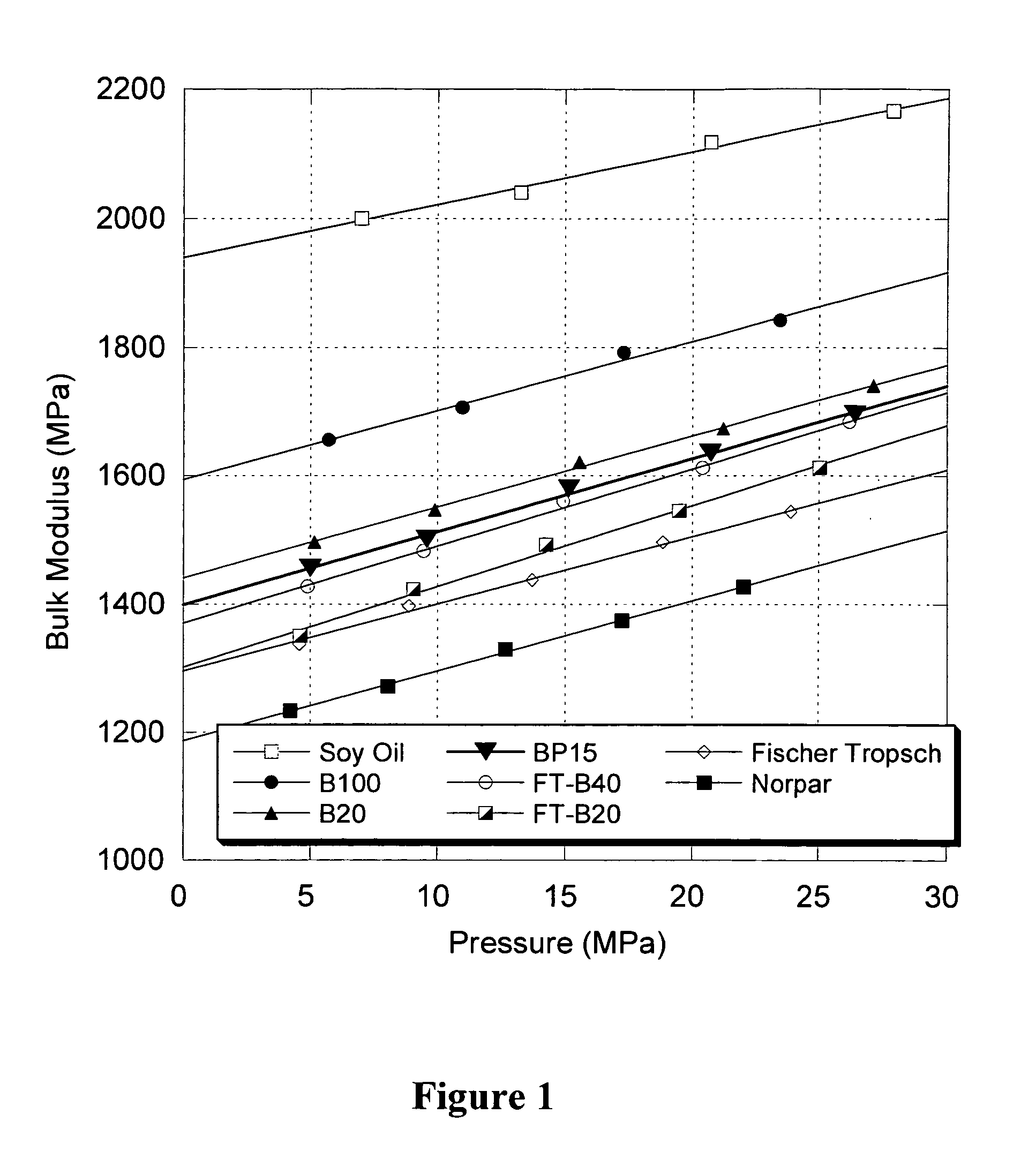

This invention shows how to make and use a biodiesel-based fuel in diesel engines without incurring the NOx penalty. Embodiments primarily relate to an optimum range of bulk modulus of compressibility for biodiesel blends, which results in generating “NOx neutral” biodiesel blends or to formulate biodiesel blends with lower NOx emissions than conventional petroleum diesel fuel. These biodiesel blends preferably comprise synthetic paraffinic middle distillate derived from a hydrocarbon synthesis to generate synthetic environmentally-friendly diesel fuels.

Owner:CONOCOPHILLIPS CO +1

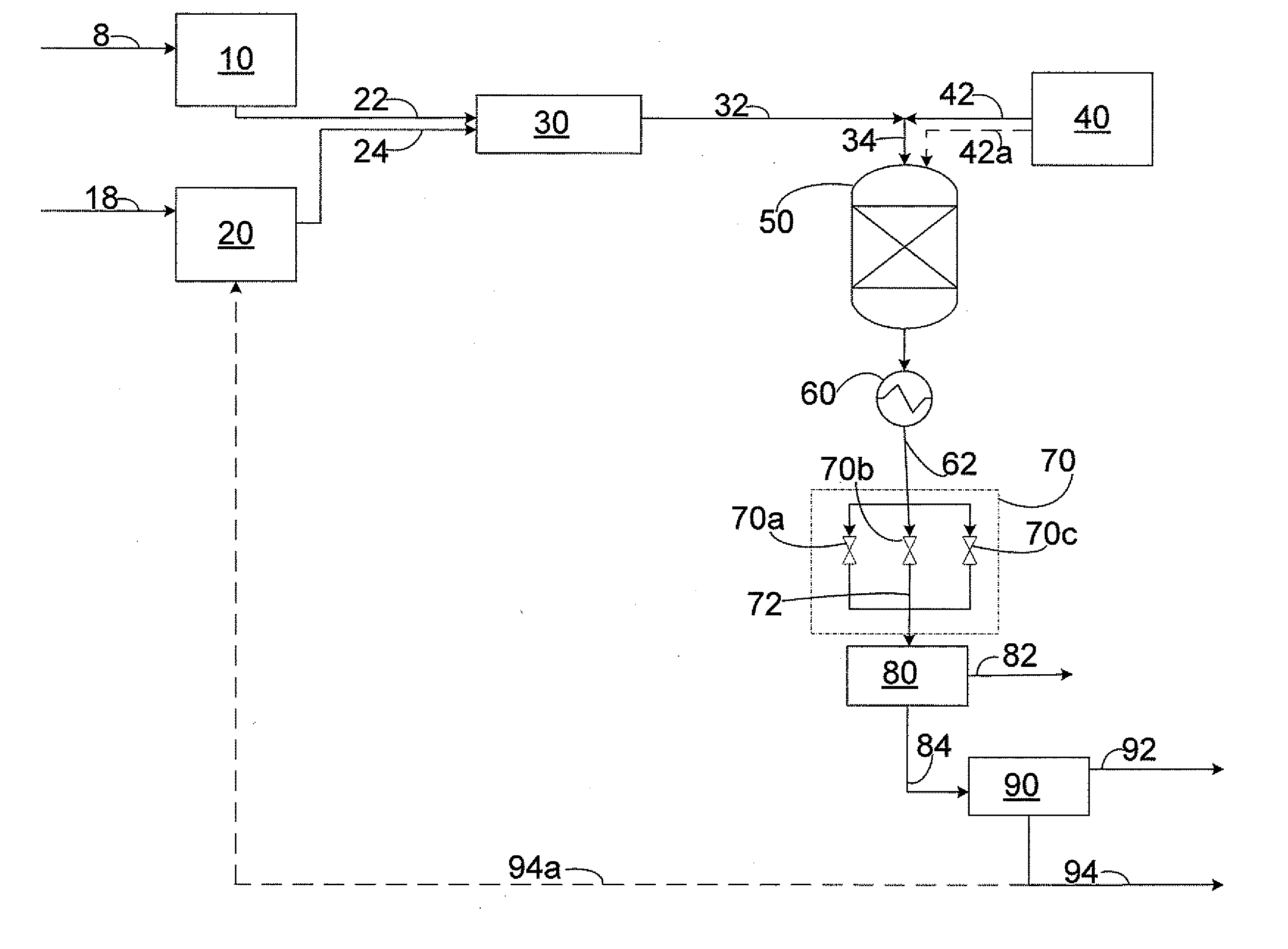

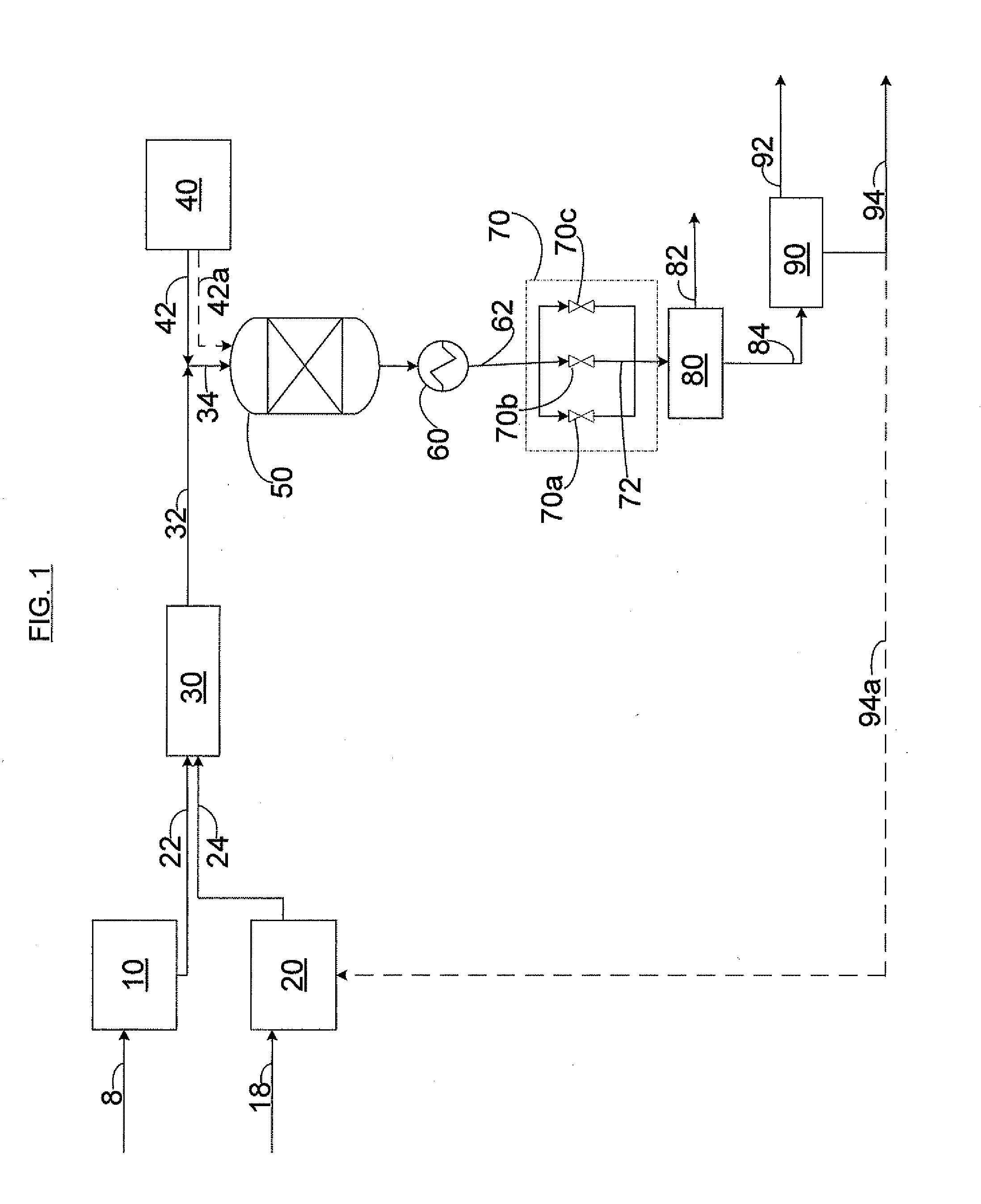

Process to upgrade whole crude oil by hot pressurized water and recovery fluid

ActiveUS20090139715A1Upgraded more easilyLess coke formationThermal non-catalytic crackingRefining by water treatmentSulfurLow nitrogen

A process for upgrading whole crude oil utilizing a recovery fluid, depressurizing an extracted whole crude oil / recovery fluid mixture in a step-wise fashion, and subsequently contacting at least a portion of the whole crude oil with supercritical water fluid to produce high value crude oil having low sulfur, low nitrogen, and low metallic impurities for use as hydrocarbon feedstock.

Owner:SAUDI ARABIAN OIL CO

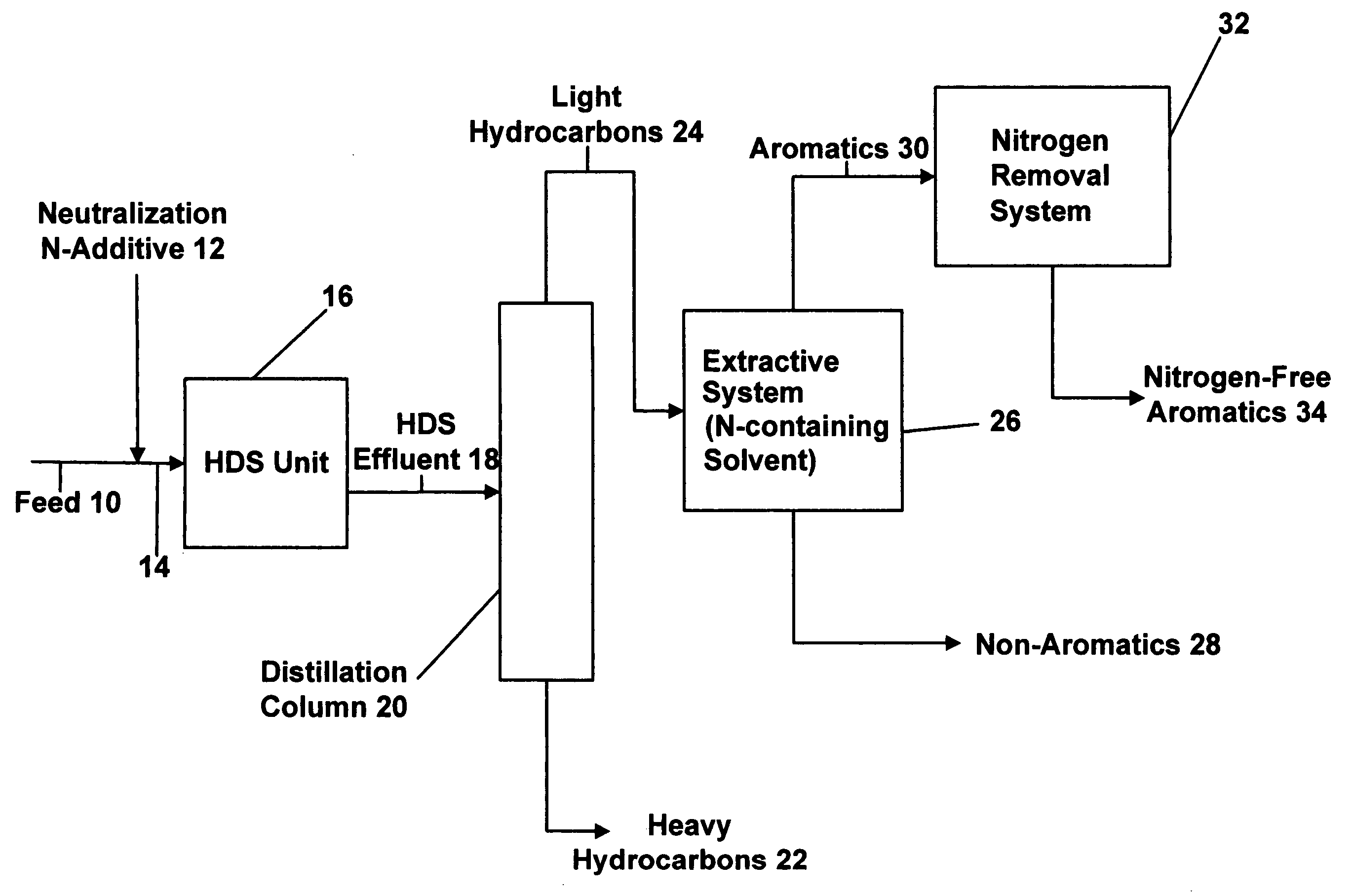

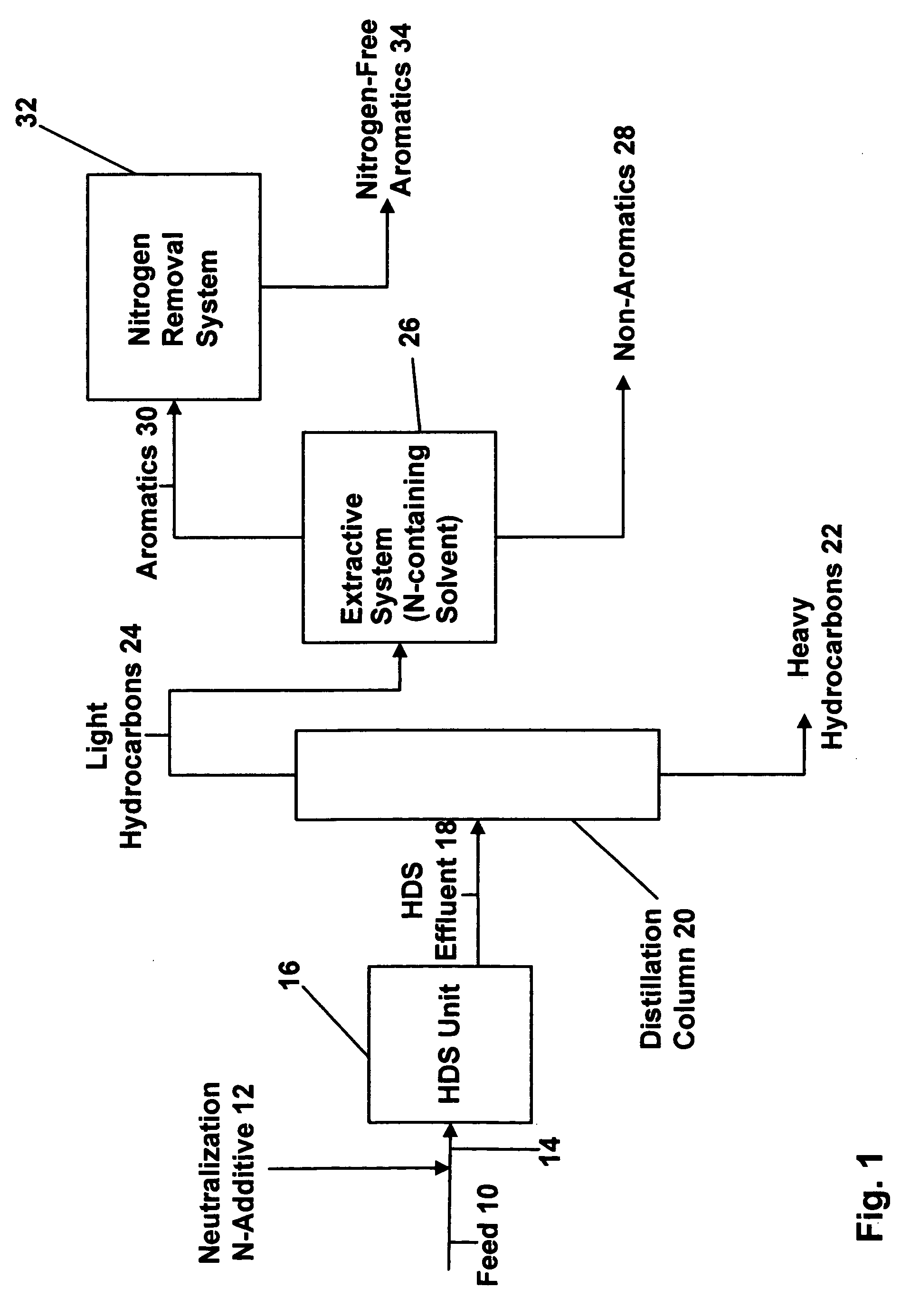

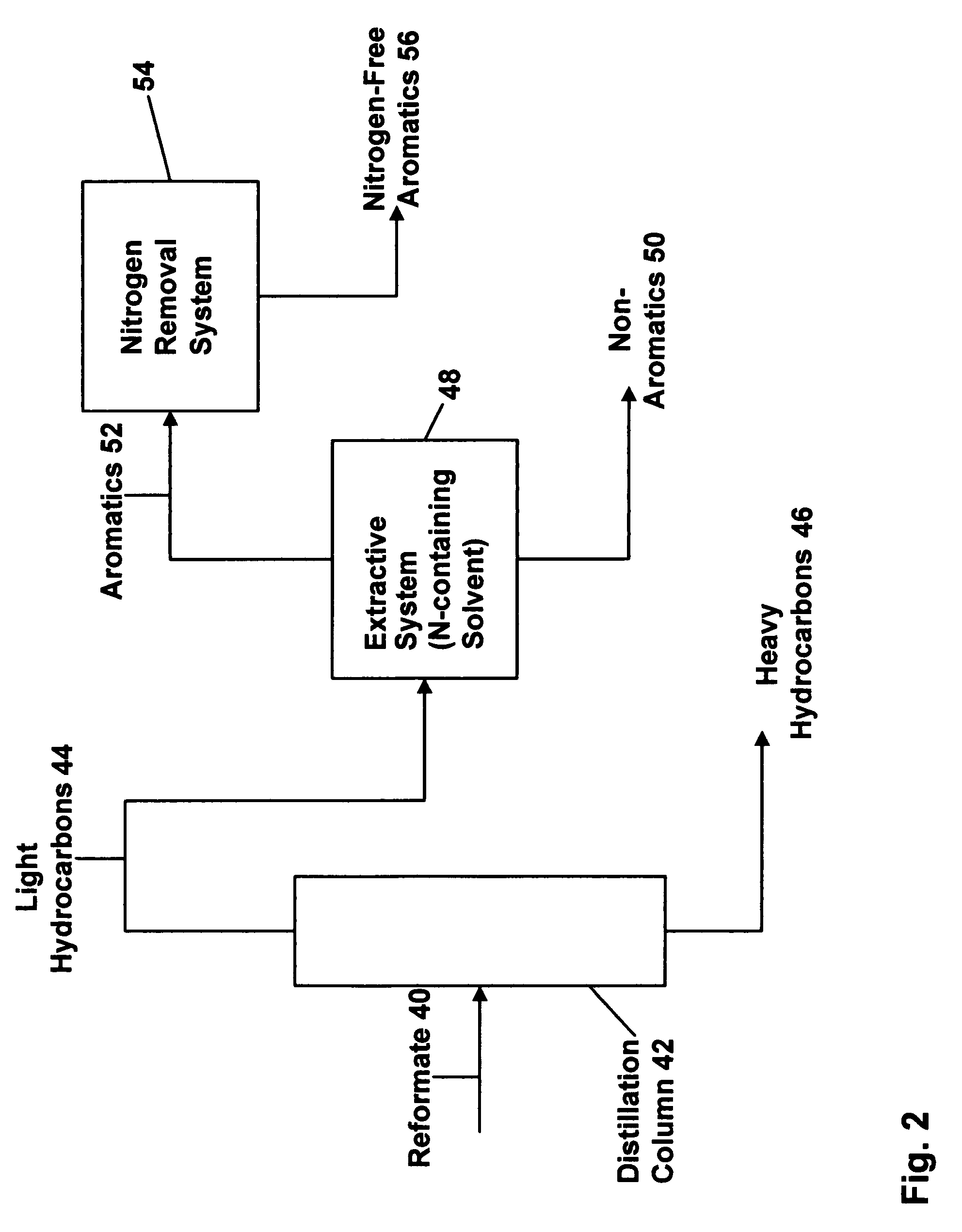

Process for producing petroleum oils with ultra-low nitrogen content

ActiveUS20070000809A1Highly effectiveSpeed up the extraction processHydrocarbon distillationTreatment with plural serial refining stagesLow nitrogenSolvent

A highly effective liquid-liquid extraction process to remove nitrogen compounds and especially basic nitrogen compounds from aromatic light petroleum oils with excellent recovery employs de-ionized water, which can be acidified, as the extractive solvent. The product is an aromatic hydrocarbon with ultra-low amounts of nitrogen poisons that can deactivate acidic catalysts. The extracted oils are suitable feedstock for the subsequent catalytic processes that are promoted with the high performance solid catalysts, which are extremely sensitive to nitrogen poison.

Owner:CPC CORPORATION +1

Yield and stress tolerance in transgenic plants

ActiveUS20080010703A1Increase productionImprove adverse reactionsClimate change adaptationOther foreign material introduction processesIncreased toleranceLow nitrogen

Polynucleotides and polypeptides incorporated into expression vectors have been introduced into plants and were ectopically expressed. The polypeptides of the invention have been shown to confer at least one regulatory activity and confer increased yield, greater height, greater early season growth, greater canopy coverage, greater stem diameter, greater late season vigor, increased secondary rooting, more rapid germination, greater cold tolerance, greater tolerance to water deprivation, reduced stomatal conductance, altered C / N sensing, increased low nitrogen tolerance, increased low phosphorus tolerance, or increased tolerance to hyperosmotic stress as compared to the control plant as compared to a control plant.

Owner:MONSANTO CO (MONSANTO CY) +1

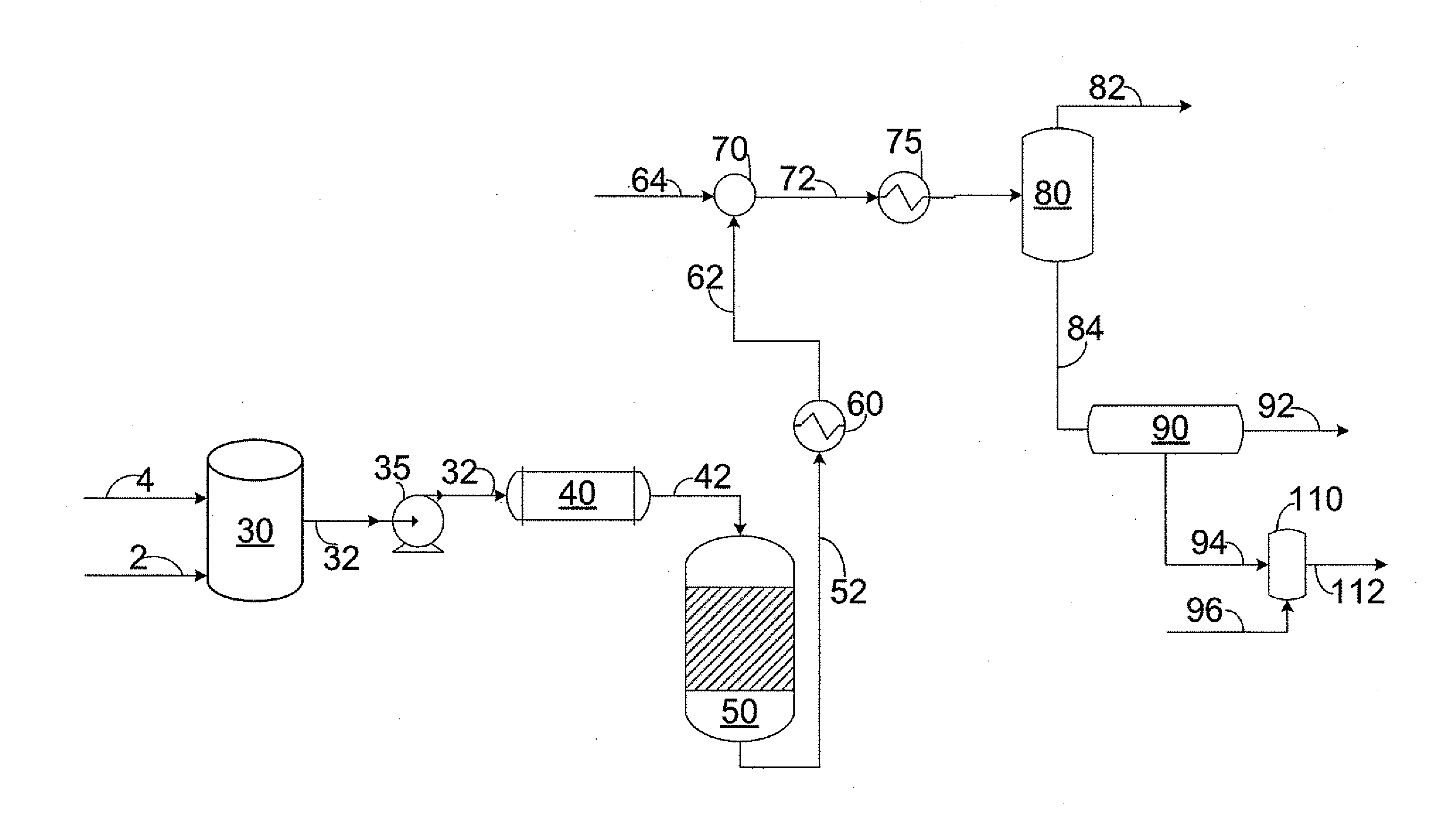

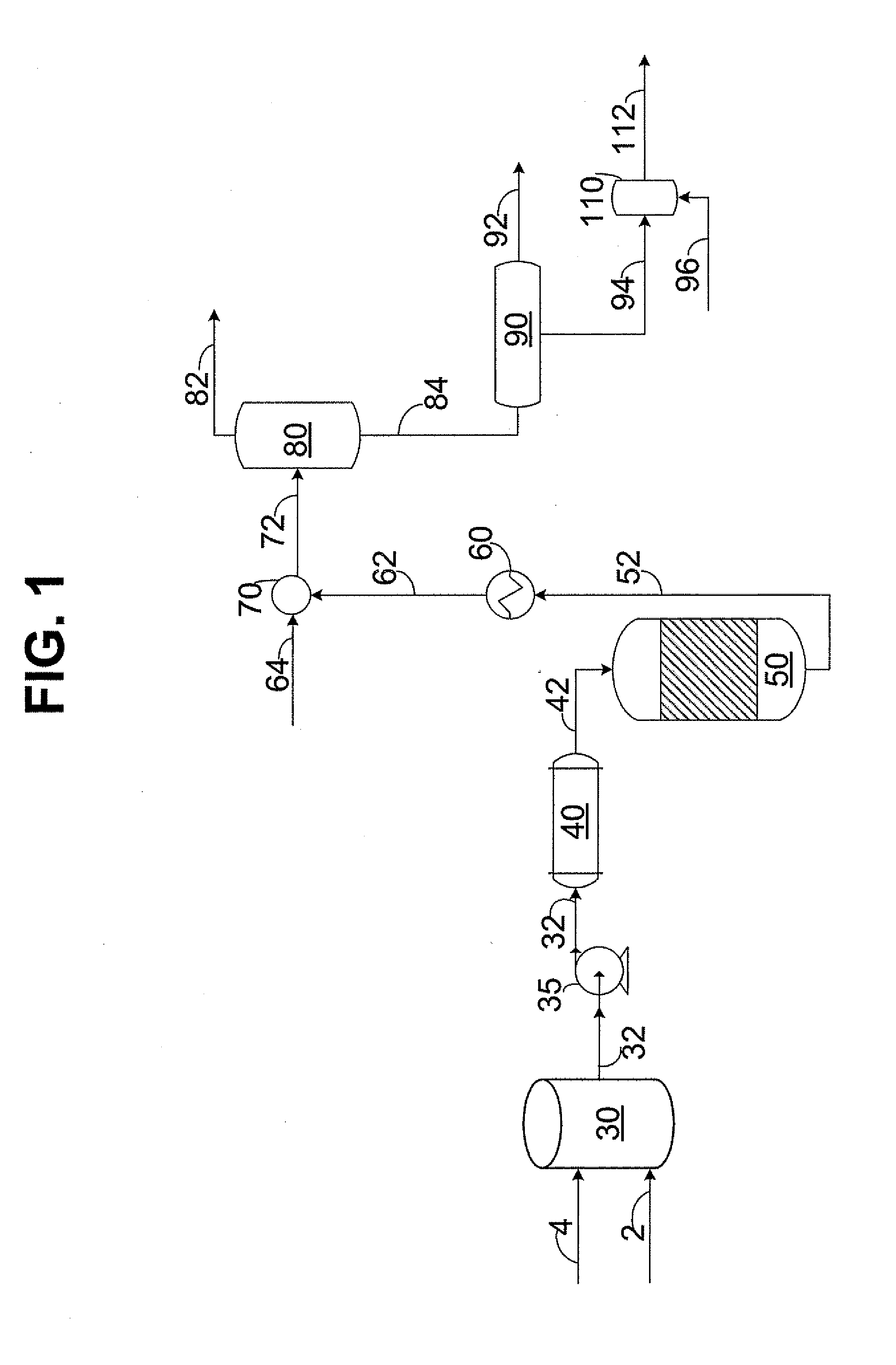

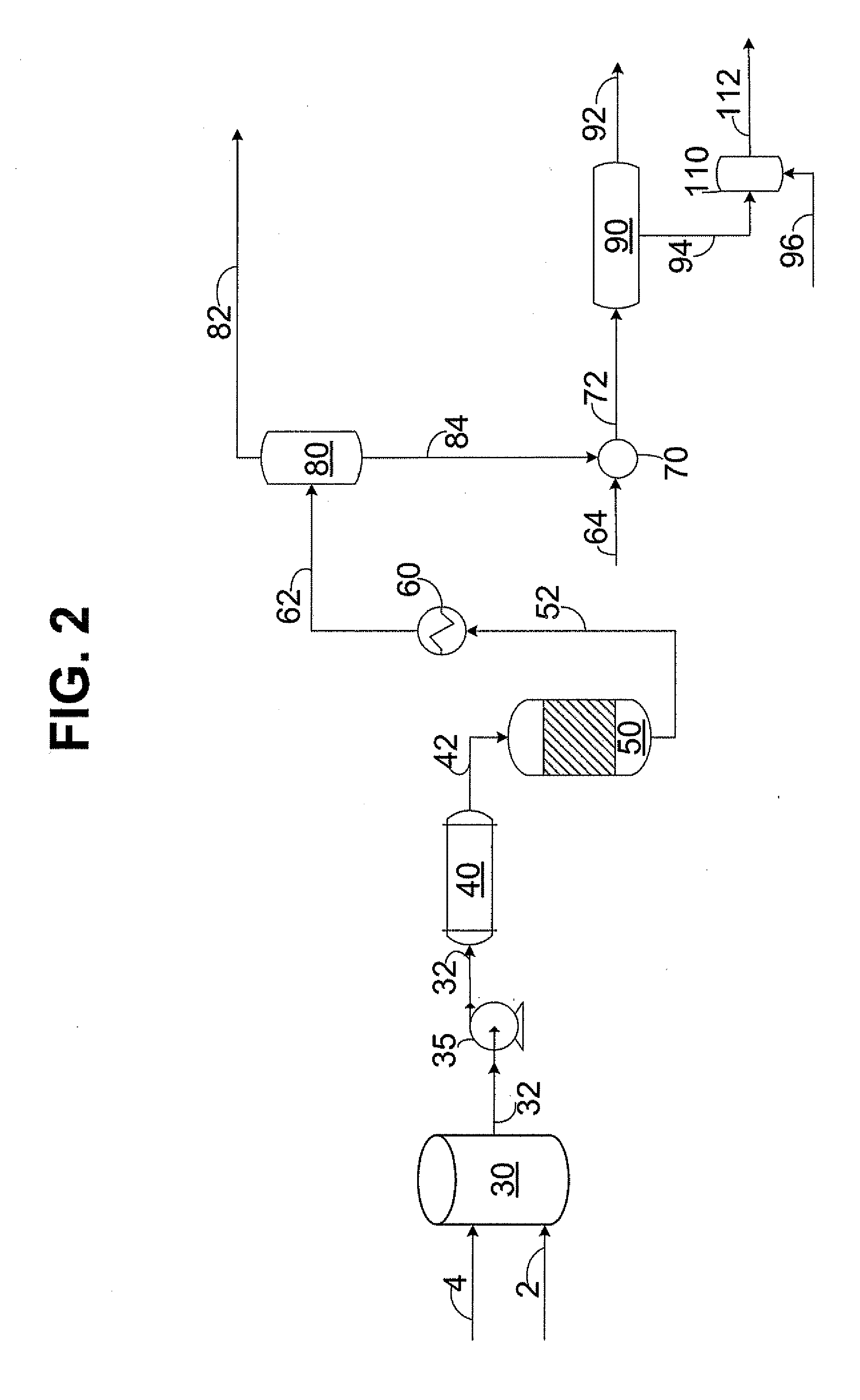

Petroleum Upgrading Process

ActiveUS20110147266A1Reduce the amount requiredIncrease gravityThermal non-catalytic crackingCatalytic crackingSulfurLow nitrogen

A process for upgrading a heavy oil stream by completely mixing the heavy oil stream with a water stream prior to the introduction of an oxidant stream. A mixture of the heavy oil stream and the water stream are subjected to operating conditions, in the presence of the oxidant stream, that are at or exceed the supercritical temperature and pressure of water. The resulting product stream is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the heavy oil stream.

Owner:SAUDI ARABIAN OIL CO

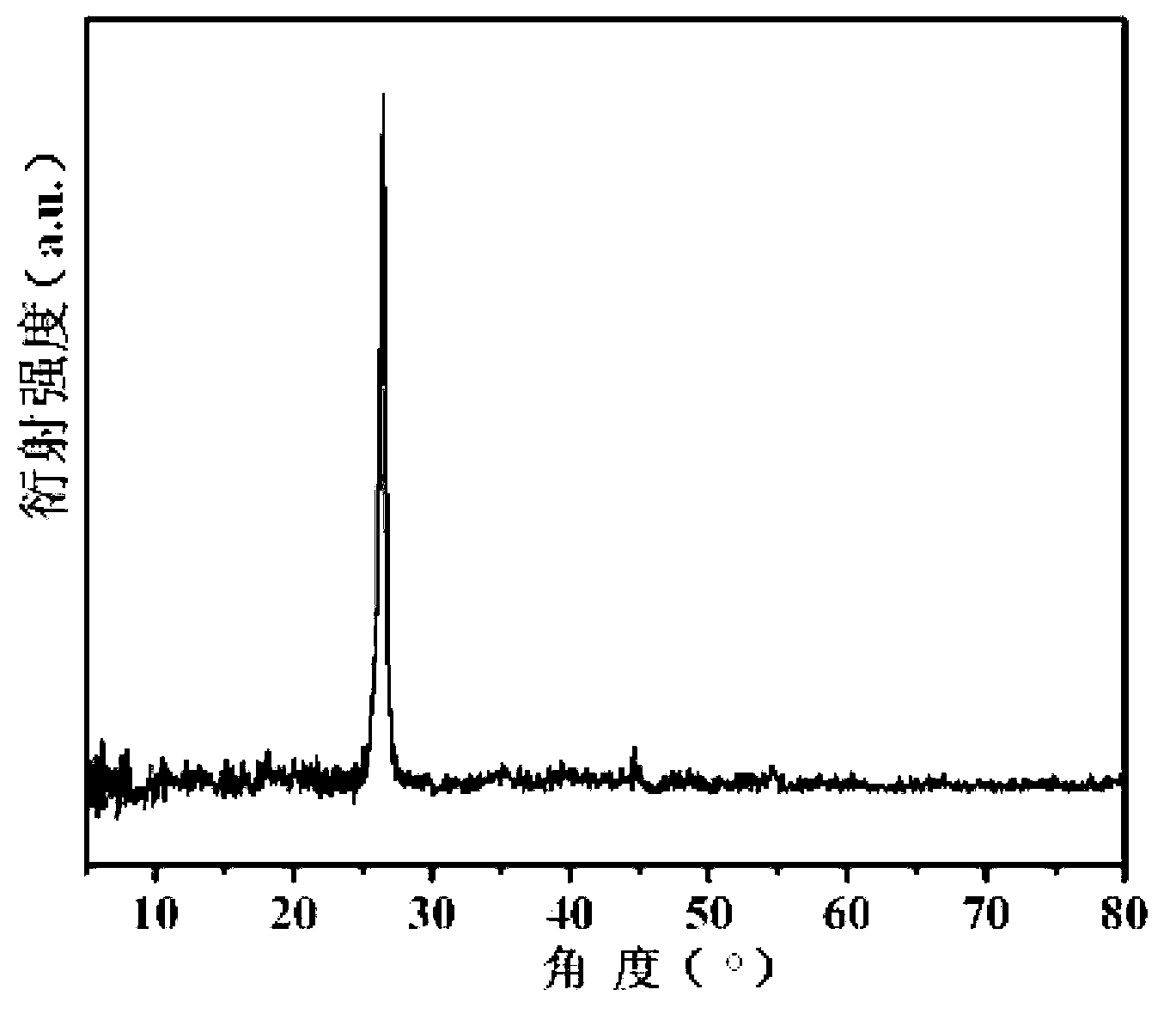

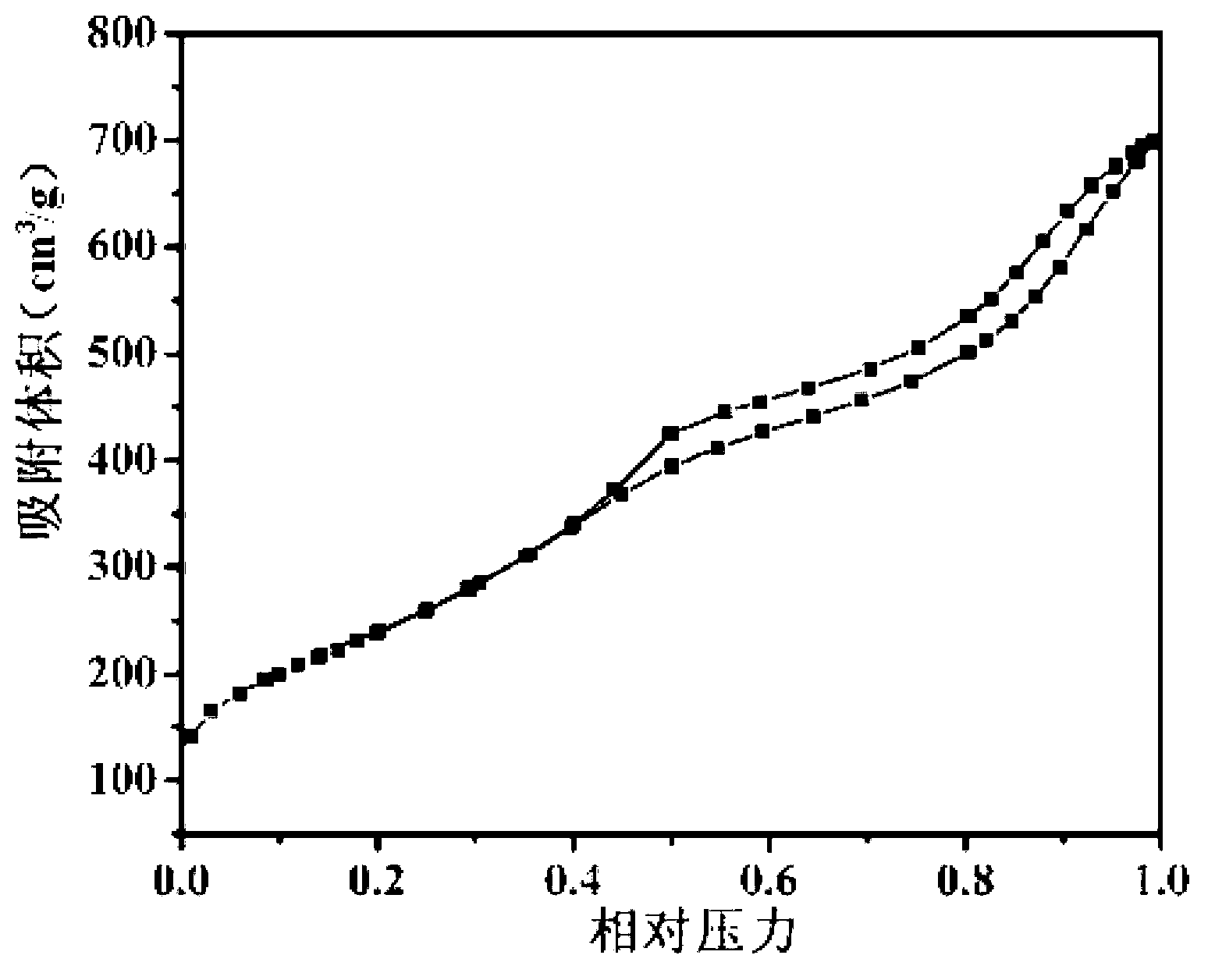

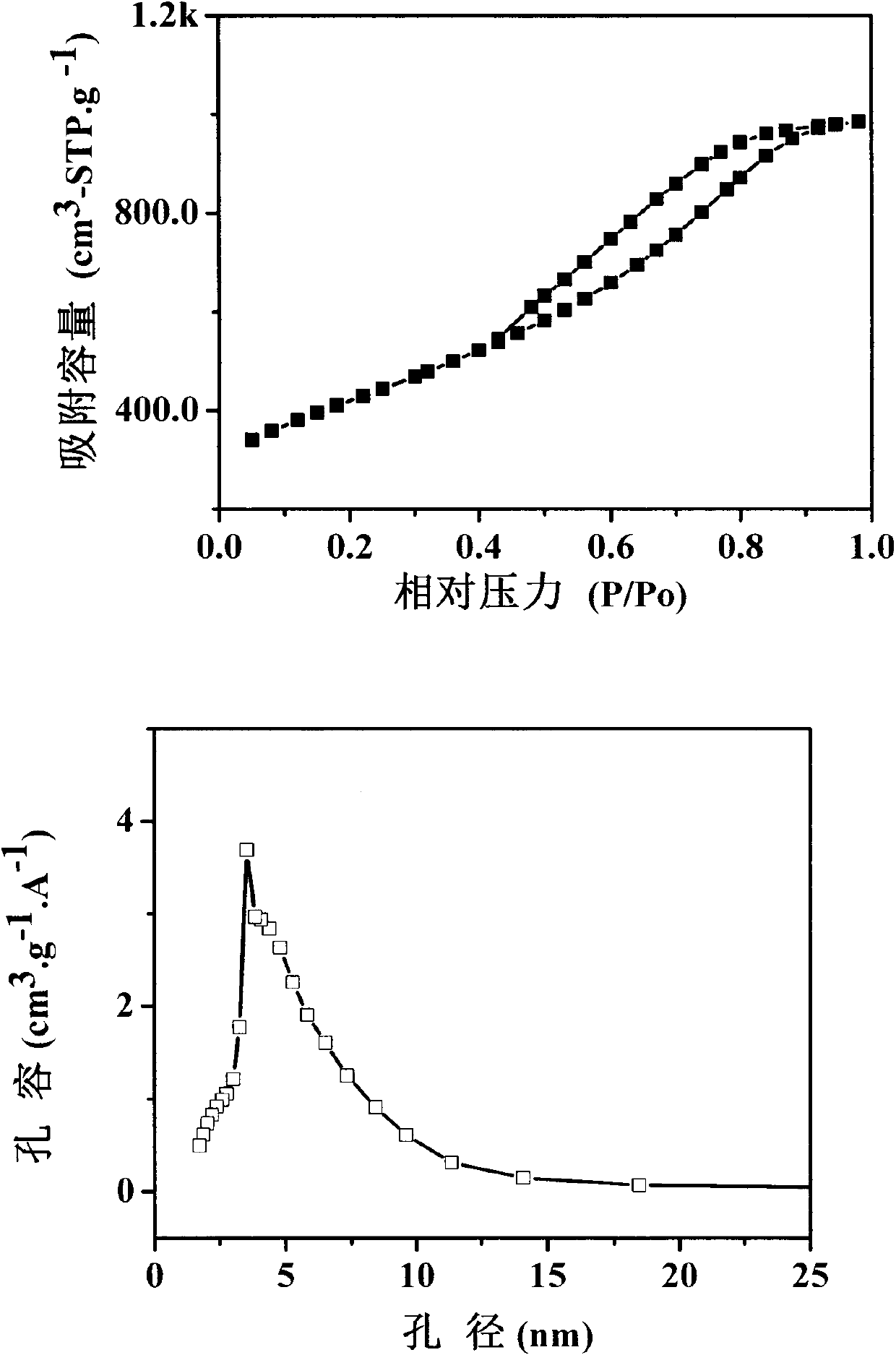

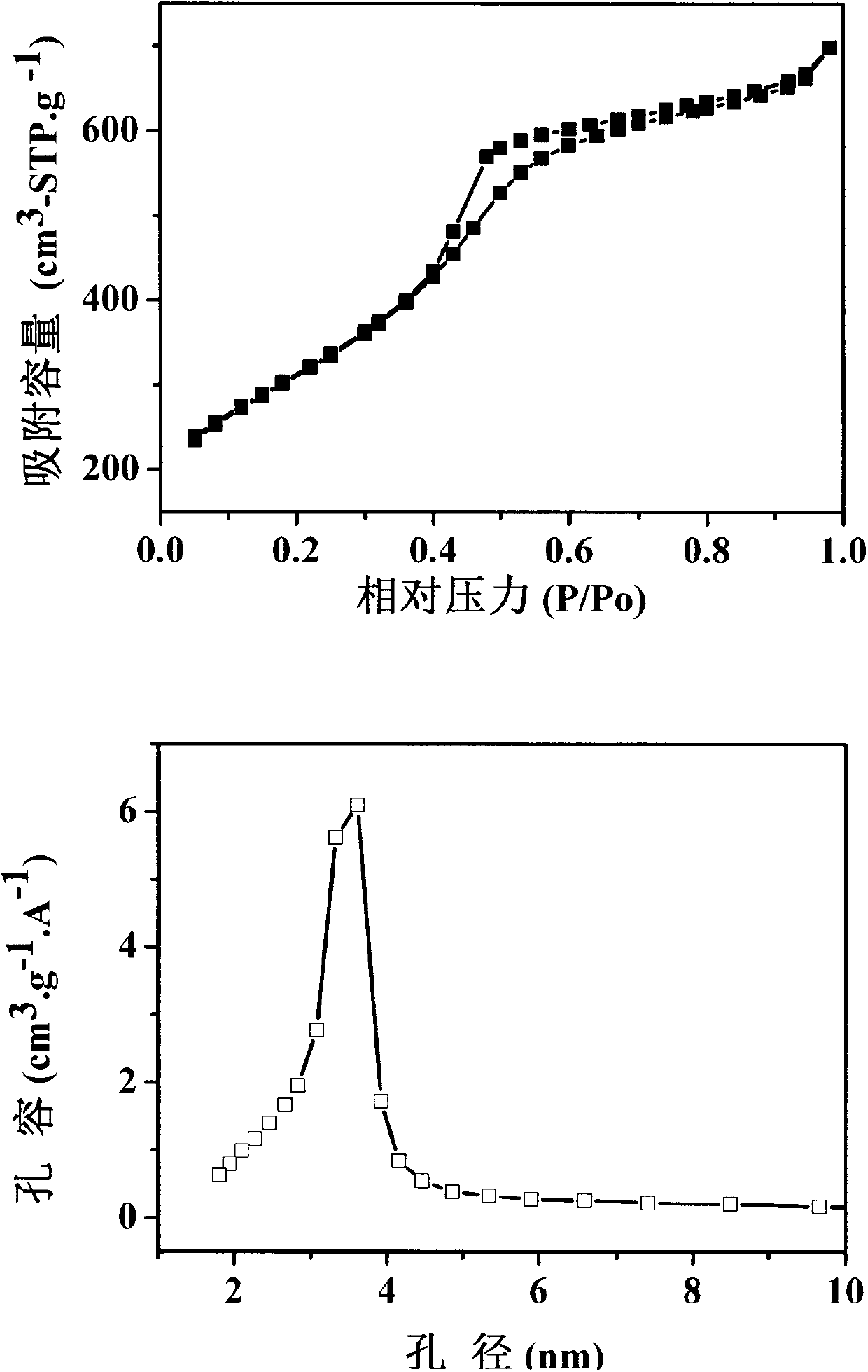

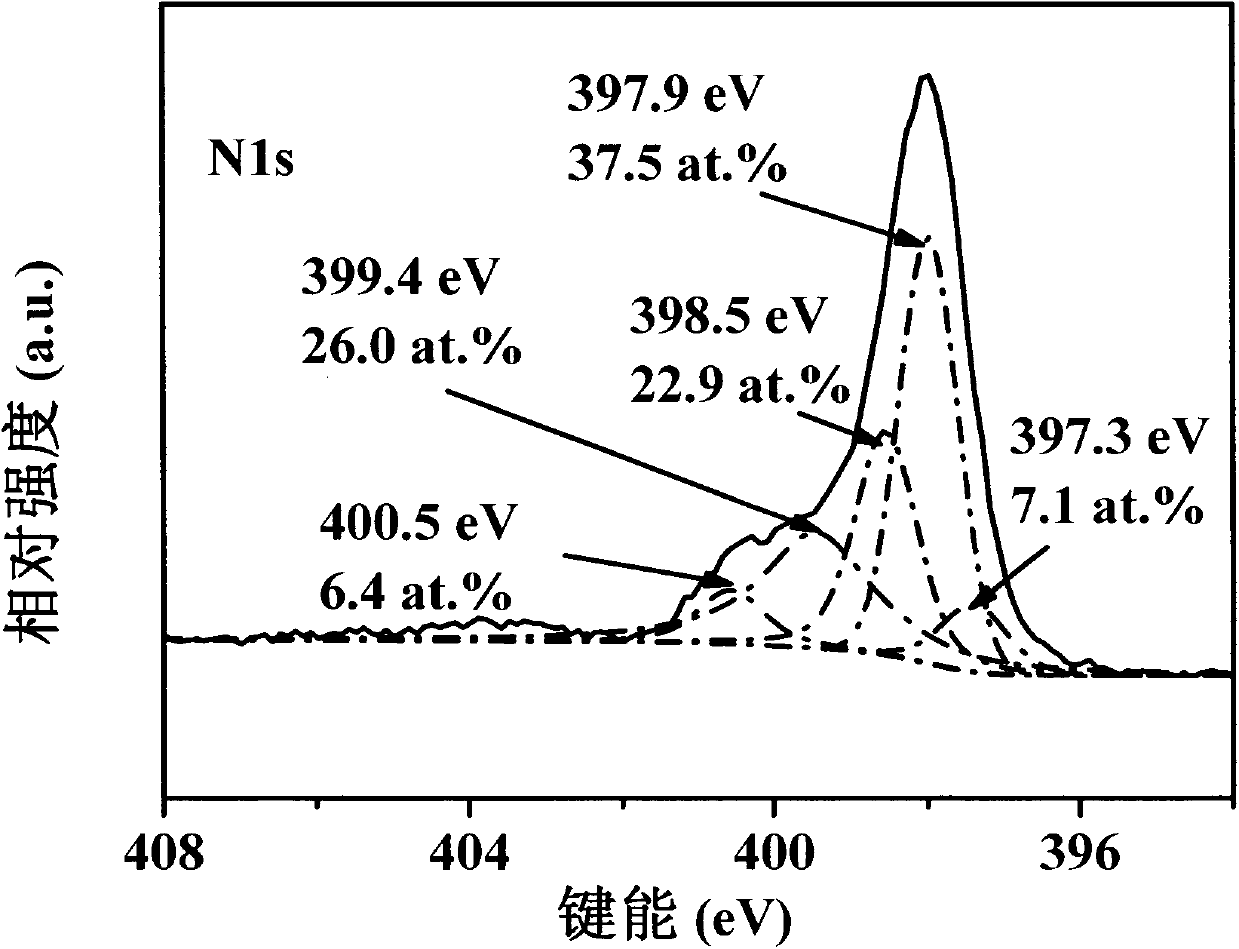

Preparation method of high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial

ActiveCN103303912AAchieve preparationHigh degree of graphitizationMaterial nanotechnologyNano-carbonLow nitrogenPore diameter

The invention discloses a preparation method of a high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial, relating to a preparation method of a carbon material and aiming at solving the problems of small specific surface area, low nitrogen content, low productivity, poor graphitizing degree and high cost of the nitrogen-doped graphitizing carbon nanomaterial prepared by the prior art. The preparation method comprises the steps of: I. preparing a complex; II. curing and carbonizing the complex; and III. carrying out acid leaching method treatment, and drying. Compared with an existing nitrogen-doped graphitizing carbon nanomaterial, the prepared high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has the advantages that the graphitizing degree is improved, the nitrogen content is increased, and the specific surface area is obviously increased, and the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has obvious pore diameter distribution. The preparation method is used for preparing the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial.

Owner:HEILONGJIANG UNIV

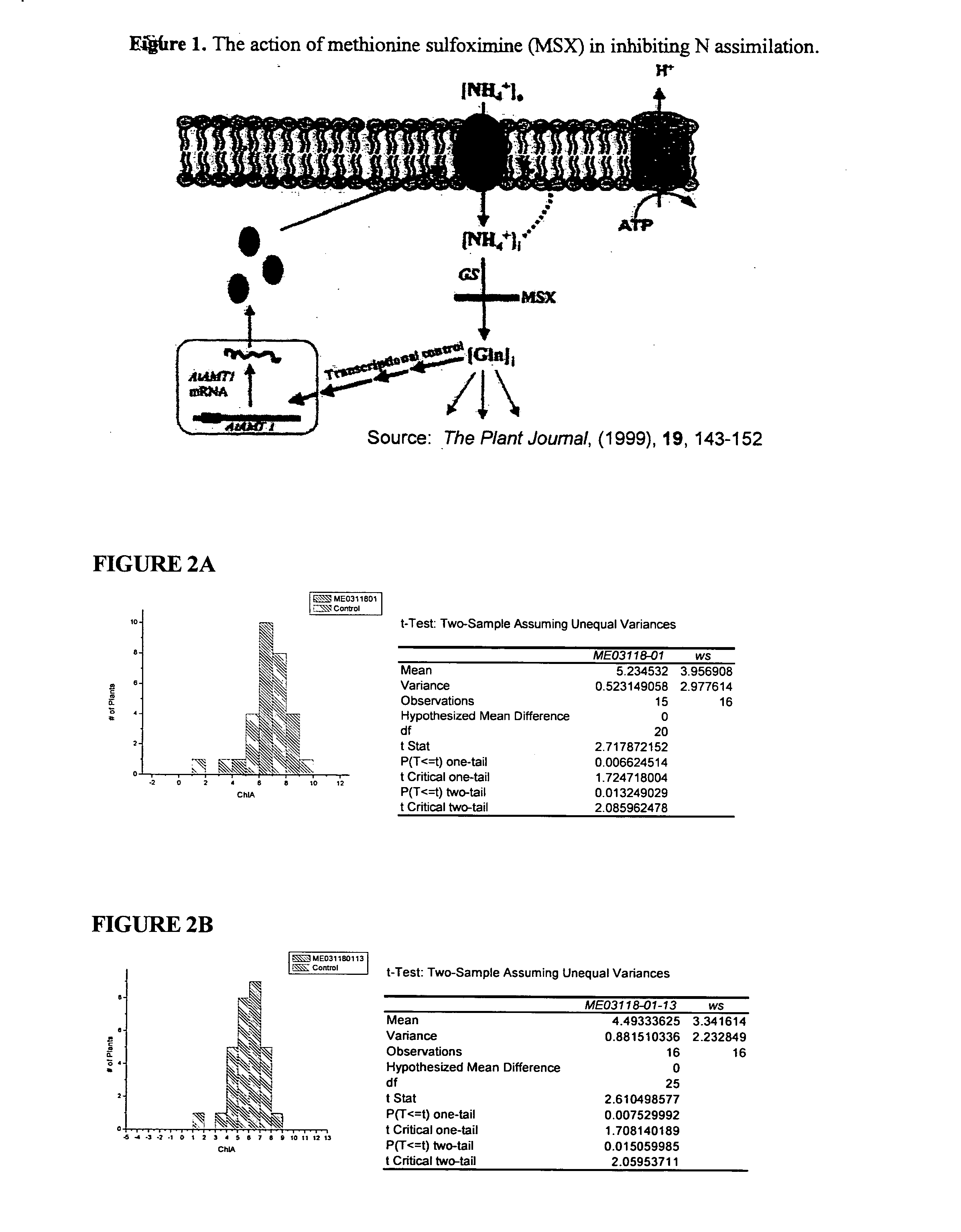

Nucleotide sequences and polypeptides encoded thereby useful for modifying nitrogen use efficiency characteristics in plants

ActiveUS20070044172A1Improve scalabilityPromote recoverySugar derivativesMicrobiological testing/measurementLow nitrogenNitrogen assimilation

Isolated polynucleotides and polypeptides encoded thereby are described, together with the use of those products for making transgenic plants with increased nitrogen use efficiency. The present invention further relates to nucleotide sequences and the use of those nucleotide sequences in the genetic-engineering of plants to display enhanced nitrogen assimilatory and utilization capacities, grow larger, more efficiently or rapidly, and / or have enriched nitrogen contents in vegetative and / or reproductive plant parts and / or increased biomass. More particularly, this invention relates to producing transgenic plants engineered to have altered expression of key components in the nitrogen assimilation and utilization pathways. The engineered plants may be productively cultivated under conditions of low nitrogen fertilizer input or in nitrogen poor soils. Alternatively, the engineered plants may be used to achieve faster growing or maturing crops, higher crop yields and / or more nutritious products under ideal cultivation conditions.

Owner:CERES INC

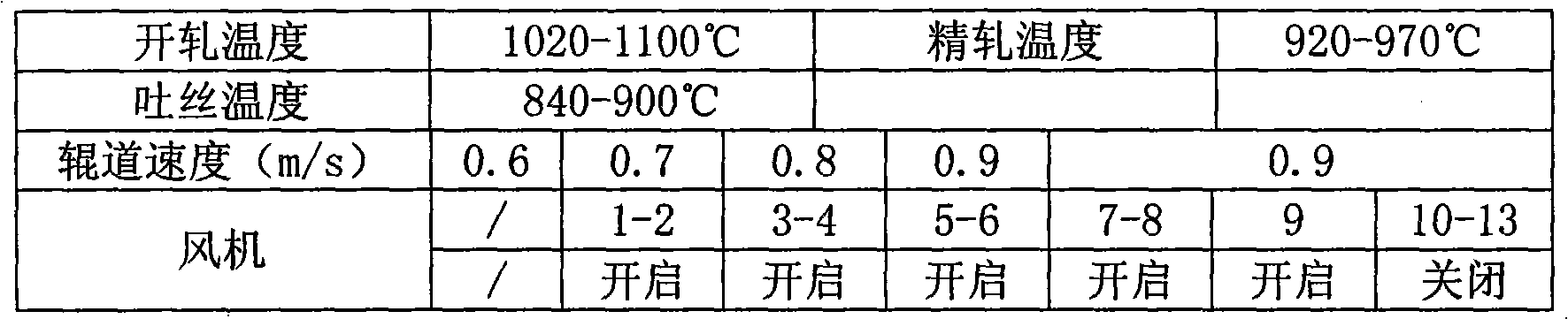

Micro alloying SWRH87B hot rolled wire rod and manufacturing method thereof

InactiveCN101597713AQuality improvementEasy to useTemperature control deviceManufacturing convertersTemperature controlWire rod

The invention provides a micro alloying SWRH87B hot rolled wire rod and a manufacturing method thereof, belonging to the technical field of hot rolled wire rod. In the invention, Cr and V micro alloying are adopted; double slag process high drawing carbon operation is used in a converter; end-point carbon is controlled at 0.40-0.60%, the steel tapping temperature is 1580-1620 DEG C, and the slag-blocked tapping is used; low nitrogen carburant is used for recarburization; Si-Ca-Ba is used for deoxidation; 600-800kg synthetic slag is added into each converter; oxygen activity is controlled below 10ppm by entering into an LF refining station, and the refined finishing slag sum of FeO and MnO is no more than 3%; inclusion modification treatment is carried out on the Ca-Si line; a billet in the size of 160mm*160mm is used, a casting mould is used for coordinating with final electromagnetic stirring (F-EMS); continuous casting machine whole protection, constant drawing speed casting and proper secondary cooling system are adopted; the initial rolling temperature is controlled at 1020-1150 DEG C which is conductive to welding the drawholes and increasing the probability of the drawholes welding; the water pre-cooling and phase transformation strengthening cooling technology is used to control the texture and the performance. The invention has the advantages that the aging time of the wire rod before the follow-up processing is shortened, the tensile strength thereof after aging time is larger than 1280MPa, and the area reduction rate is larger than 25%.

Owner:SHOUGANG CORPORATION

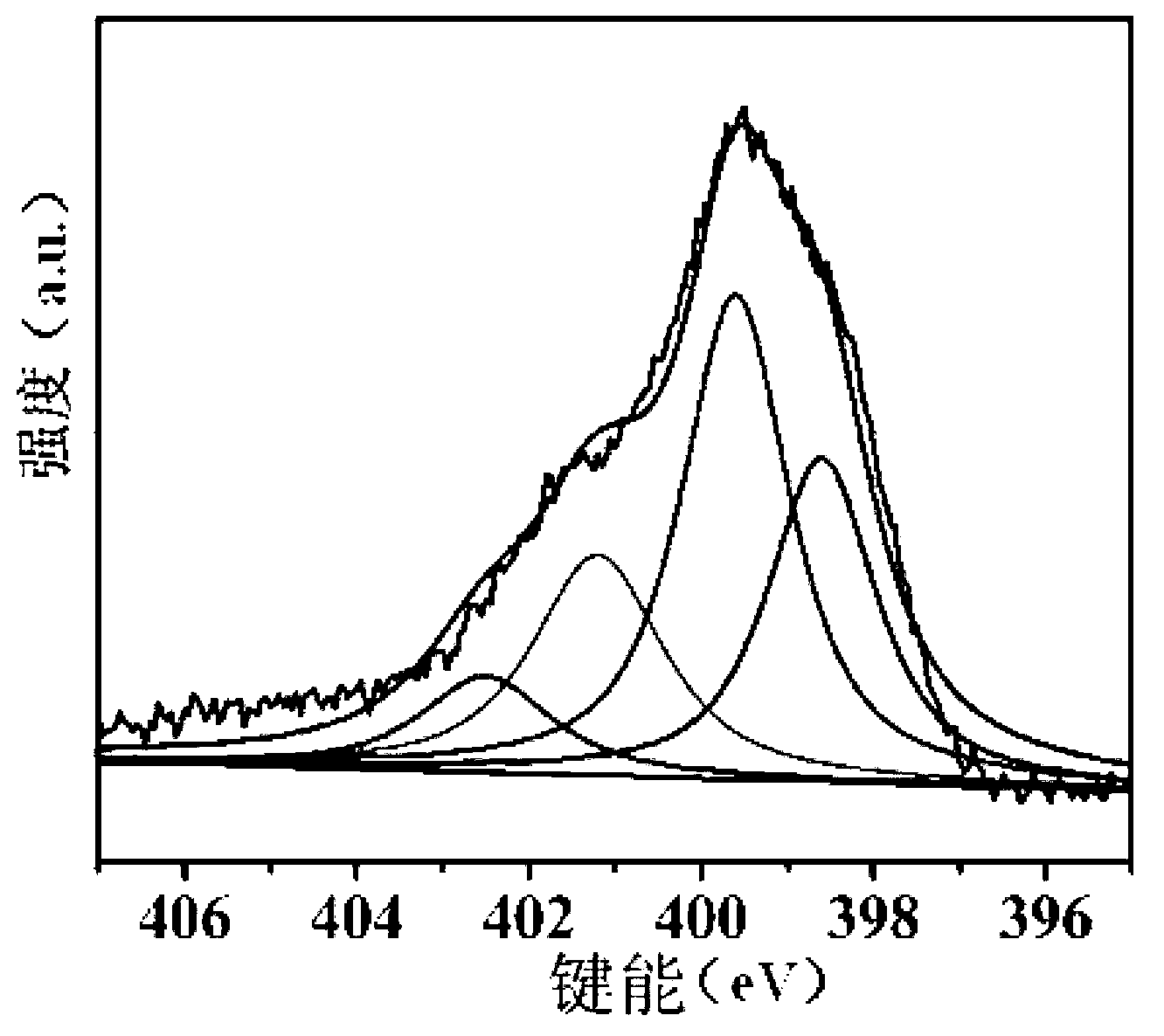

Preparation method of nitrogenous porous carbon

InactiveCN103626150AHigher quality than capacitanceSolve the low nitrogen contentPhysical/chemical process catalystsOther chemical processesPorous carbonLow nitrogen

The invention relates to a preparation method of nitrogenous porous carbon, which comprises the following steps: preoxidizing porous carbon with an oxidizer; and in a closed environment, depositing a nitrogenous substance in the preoxidized porous carbon pore canals by a chemical vapor deposition process by using melamine / dicyandiamide as a nitrogenous precursor, thereby obtaining the nitrogenous porous carbon. The method overcomes the defects of low nitrogen content in the product, high time consumption and the like in the existing nitrogenous porous carbon preparation method, obviously enhances the nitrogen content in the nitrogenous porous carbon (the maximum nitrogen content is up to 17%at), has the advantages of simple technique, abundant raw material sources and low production cost, and can easily implement industrialization; and the obtained nitrogenous porous carbon product has excellent properties, and has favorable application prospects in the fields of adsorptive separation, catalysis, electrode materials and the like.

Owner:NANJING INST OF TECH

Removal of sulfur compounds from petroleum stream

ActiveUS20110315600A1Reduce the amount requiredIncreasing API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyThiolLow nitrogen

A process for upgrading an oil stream by mixing the oil stream with a water stream and subjecting it to conditions that are at or above the supercritical temperature and pressure of water. The process further includes cooling and a subsequent alkaline extraction step. The resulting thiols and hydrogen sulfide gas can be isolated from the product stream, resulting in an upgraded oil stream that is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the oil stream.

Owner:SAUDI ARABIAN OIL CO

Conferring biotic and abiotic stress tolerance in plants

The invention relates to plant transcription factor polypeptides, polynucleotides that encode them, homologs from a variety of plant species, and methods of using the polynucleotides and polypeptides to produce transgenic plants having advantageous properties, tolerance low nitrogen, cold and water deficit conditions, and resistance to disease, as compared to wild-type or other control plants.

Owner:MENDEL BIOTECHNOLOGY INC

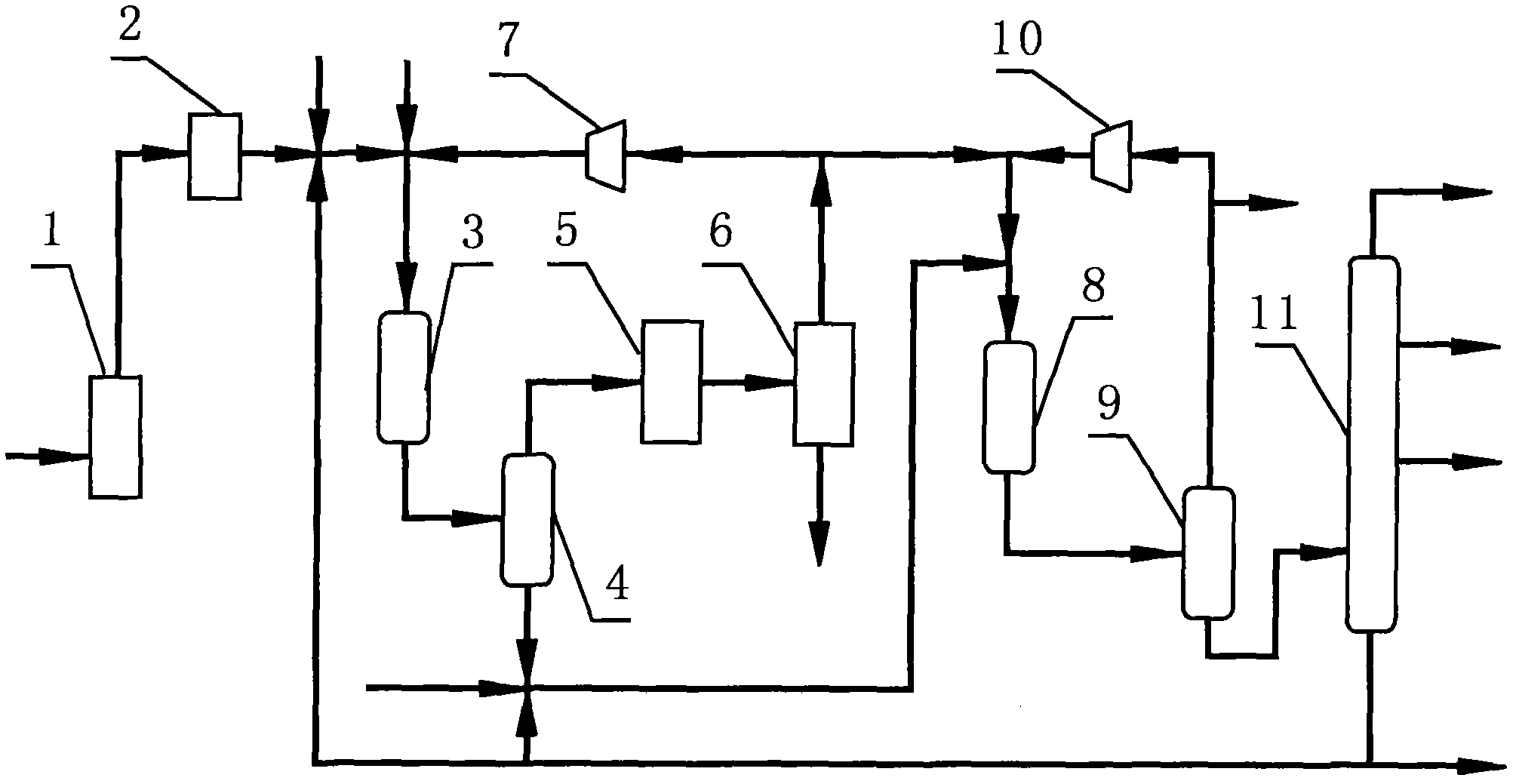

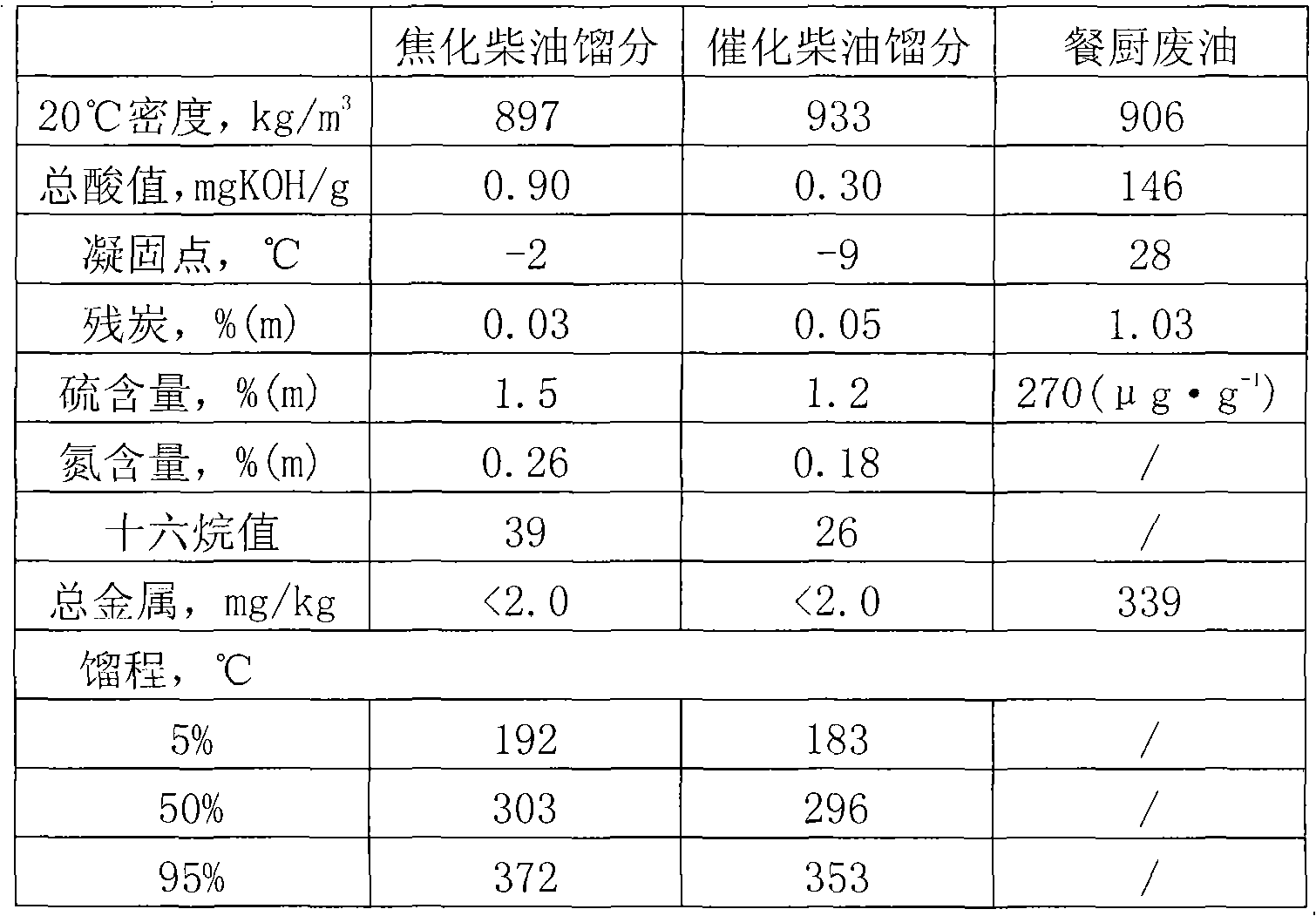

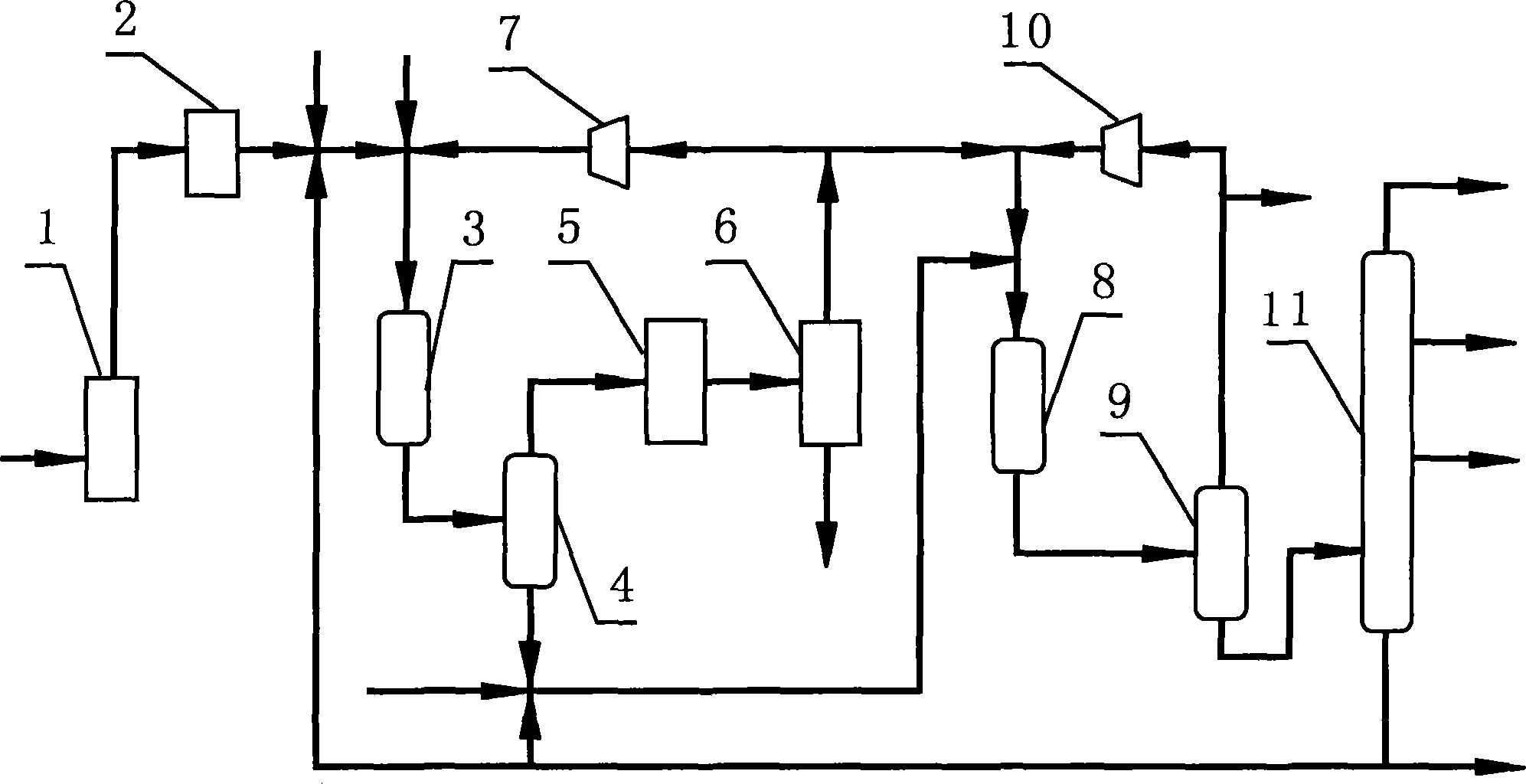

Method for preparing biodiesel by mixing waste edible oil with mineral diesel oil and hydrogenization

ActiveCN102504866AHigh activityConcentration effective controlBiofuelsEfficient propulsion technologiesOil and greaseVegetable oil

The invention relates to a method for preparing biodiesel by mixing waste edible oil with mineral diesel oil and hydrogenization. The method comprises the steps as follows: pretreatment of waste edible oil, a first stage of hydrogenization process, a second stage of hydrogenization process, and a product fractionation process. The method adopts the waste edible oil and the mineral diesel oil as raw materials for preparing high-quality biodiesel and biological aviation kerosene components which have low polycyclic aromatic hydrocarbon contents, high cetane values, low sulfur contents and low nitrogen contents, effectively solves the problems of blockage of a catalyst bed caused by the settlement of metal and gelatine in the animal and vegetable hydrogenization process, influence on the activity of catalyst from H2O, CO2 and CO produced in reaction, sulfur supplement of a hydrogenization system, and influence on the service life of the catalyst caused by centralized release of reaction heat, can realize the continuous hydrogenization and industrial production of materials containing animal and vegetable oils, and has practical significance.

Owner:海南环宇新能源有限公司

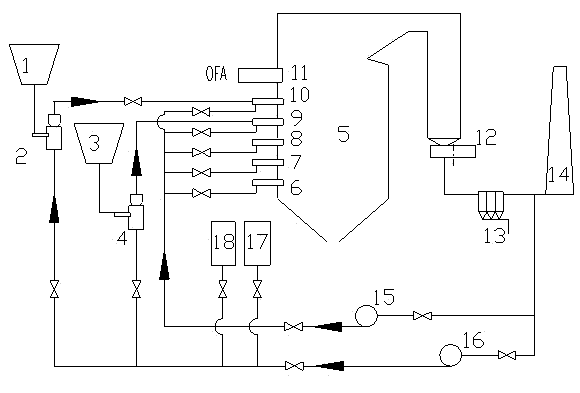

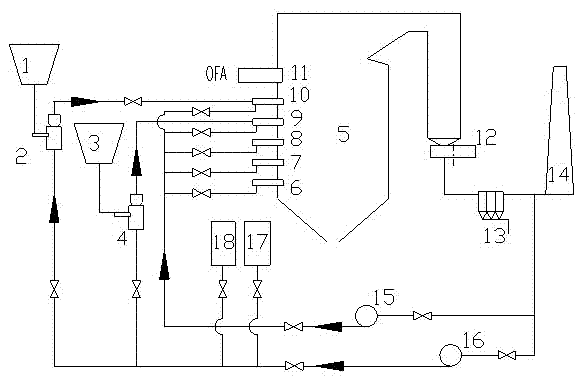

Method for combusting fuel reburning low-nitrogen oxide

ActiveCN102252324AImprove the mixing effectLong reduction reaction timeCombustion apparatusLow nitrogenEvaporation

The invention discloses a method for combusting a fuel reburning low-nitrogen oxide and belongs to a clean combustion method for a coal-fired boiler. Secondary medium air is used as a powder conveying medium of a combustor on the upper layer of the main combustion area of the boiler, coal powder used as a reburning fuel is conveyed into the boiler, the secondary medium air is used as distributed air of the combustor, the secondary air of the combustor on the upper layer is reduced correspondingly, the distributed air in the reburning area is reduced correspondingly, low excess air combustion is formed, the distributed air in a hearth is not enough, and finally over fire air (OFA) complements the required air; and the mixed medium of air and fuel gas is used as the conveying medium of the coal powder of the combustor of the upper layer, and the coal powder with the conventional fineness is conveyed into the boiler from the combustor on the upper layer by using a coal mill and a powder making system and is re-burnt and denitrated, and is burnt out by OFA. The problem that the reburning fuel and the fuel gas are not mixed uniformly, the reduction time is short, and the denitration efficiency is low is solved, the original design working conditions of maximum continuous evaporation capacity of the boiler and the like are not influenced, transformation is easy to realize, and the running cost is low.

Owner:徐州燃烧控制研究院有限公司

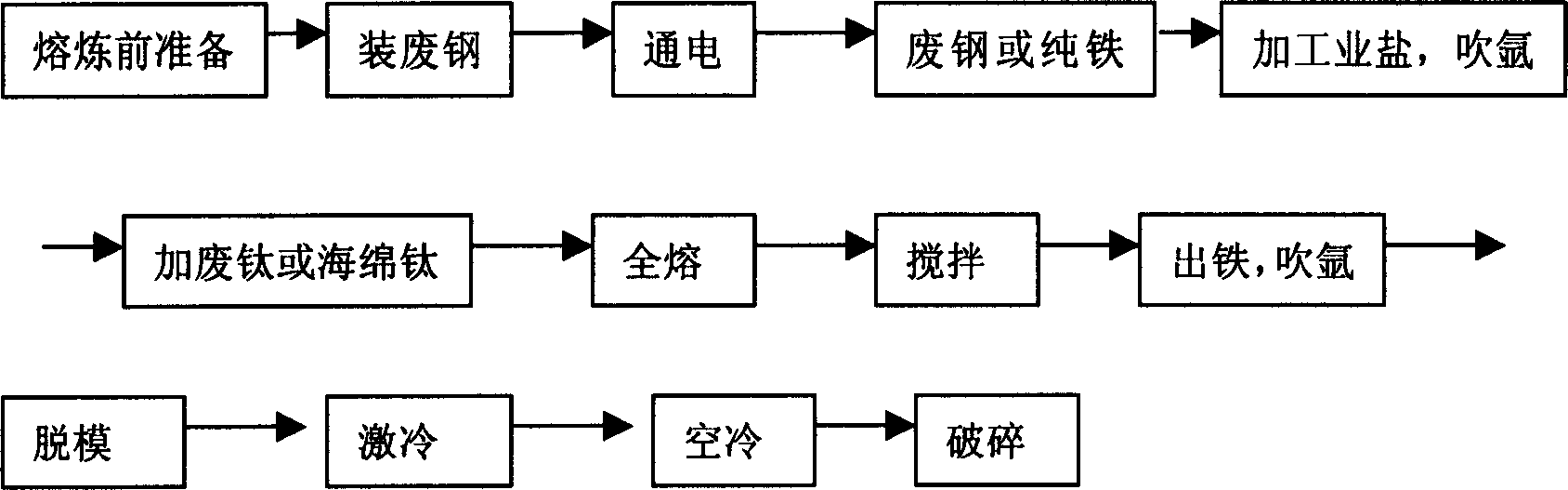

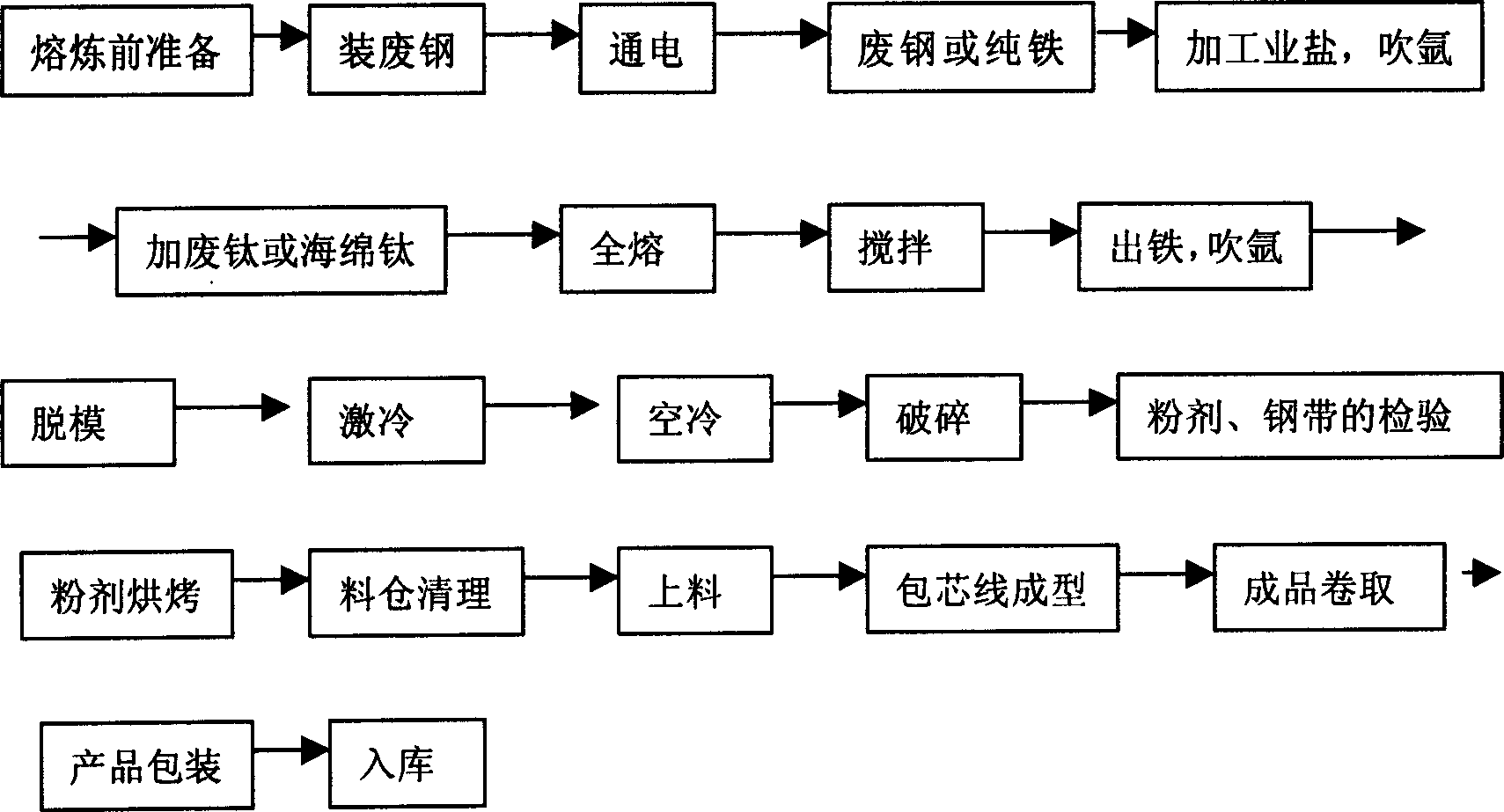

Low-nitrogen ferrotitanium, its manufacturing method and cored wire

The manufacture method for low-nitrogen ferrotitanium 70Fe-Ti comprises: selecting material from industrial salt as slag-forming agent, titanium sponge, waste titanium, and high-grade waste steel or pure iron while ensuring 60-80% Ti, N íœ0.15%, Al <3%, Si íœ0.5%, C íœ0.1%, P íœ0.04%, S íœ0.03%, and Fe; melting; tapping; during process, using argon gas for protection. This invention can manufacture different high-grade stainless steel with super properties, well notch sensitivity, cooling speed effect and size effect by low cost.

Owner:上海马腾新型材料厂

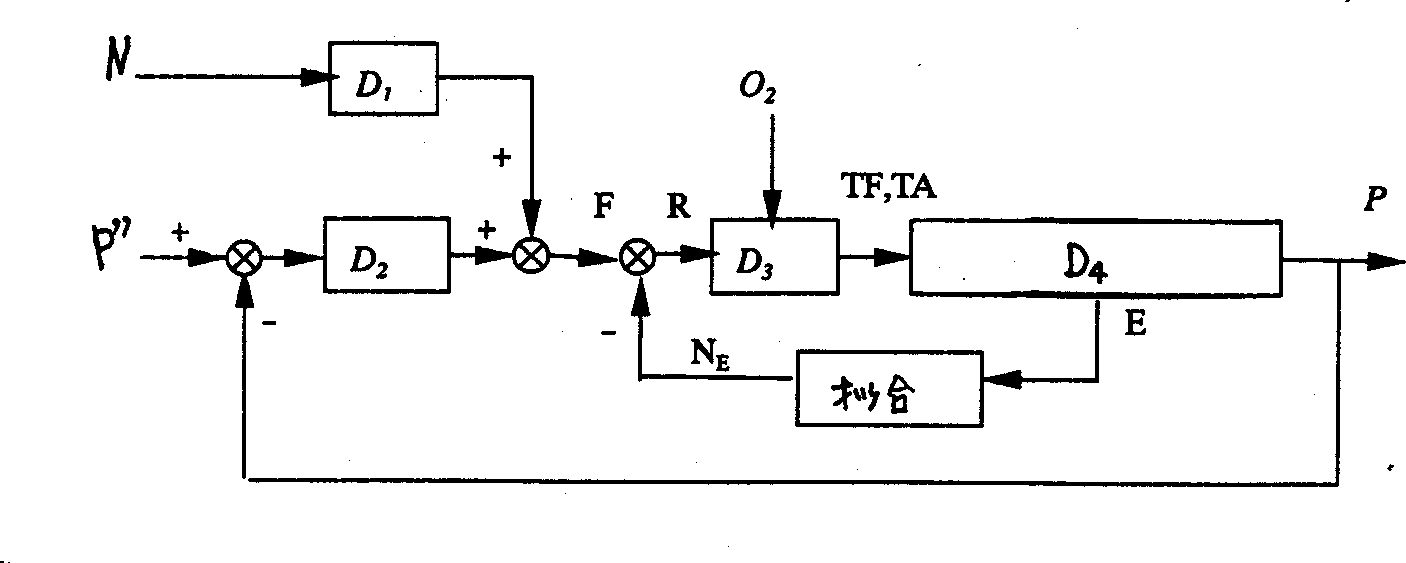

Optimized control method of combustion in multiple fire nozzle hearth of boiler

The present invention belongs to the combustion controlling technology of boiler hearth, especially of multiple fire nozzle hearth, and is suitable for the combustion monitoring of combustion in a four corner-rounded boiler. The present invention relates optimized efficient low nitrogen oxide exhaust control by arranging several flame image detectors to obtain the 3-D temperature distribution in hearth and through fitting the expression between radiation energy E and power generating load NE of the poer set, measuring the flame center height and the change rules of flame section temperature center with fuel amount and blast distribution proportion in different layers and different corners, and giving control command of fuel amount and blast distributino proportion in different layers and different corners according to boiler load, fuel amount and blast amount.

Owner:HUAZHONG UNIV OF SCI & TECH

Solid acid assisted deep desulfurization of diesel boiling range feeds

InactiveUS20090065398A1Improve efficiencyRefining with acid-containing liquidsTreatment with hydrotreatment processesLow nitrogenSulfur

The instant invention relates to a process to produce low sulfur diesel products through the hydrodesulfurization of low nitrogen diesel boiling range feedstreams in the presence of solid acidic materials.

Owner:EXXON RES & ENG CO

Coated low-nitrogen sand and its prepn

ActiveCN101088659AReduce usageReduce nitrogen contentFoundry mouldsFoundry coresLow nitrogenTetramine

The present invention discloses one kind of coated low-nitrogen sand and its preparation process. The coated low-nitrogen sand consists of phenolic resin 1.5-4.0 wt% of the material, hexamethylene tetramine in 0-6 wt% of the phenolic resin, lubricant in 3-7 wt% of the phenolic resin, and raw sand for the rest. It has greatly lowered hexamethylene tetramine consumption, low nitrogen content and capacity of ensuring the surface quality of the casting. During its heated formation, the thermosetting phenolic resin can speed the curing, raise the hardening rate and raising the hot strength of the sand mold.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

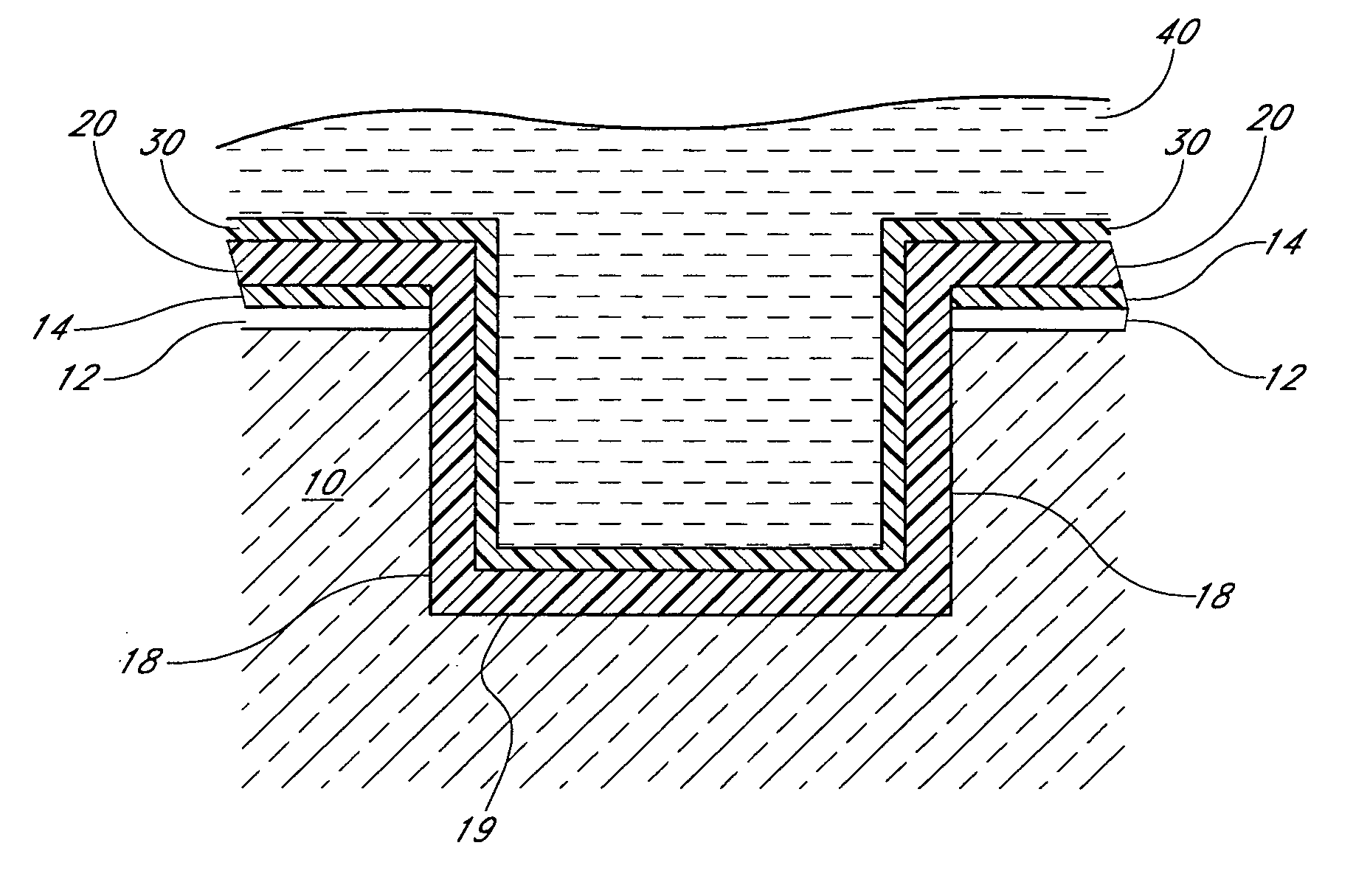

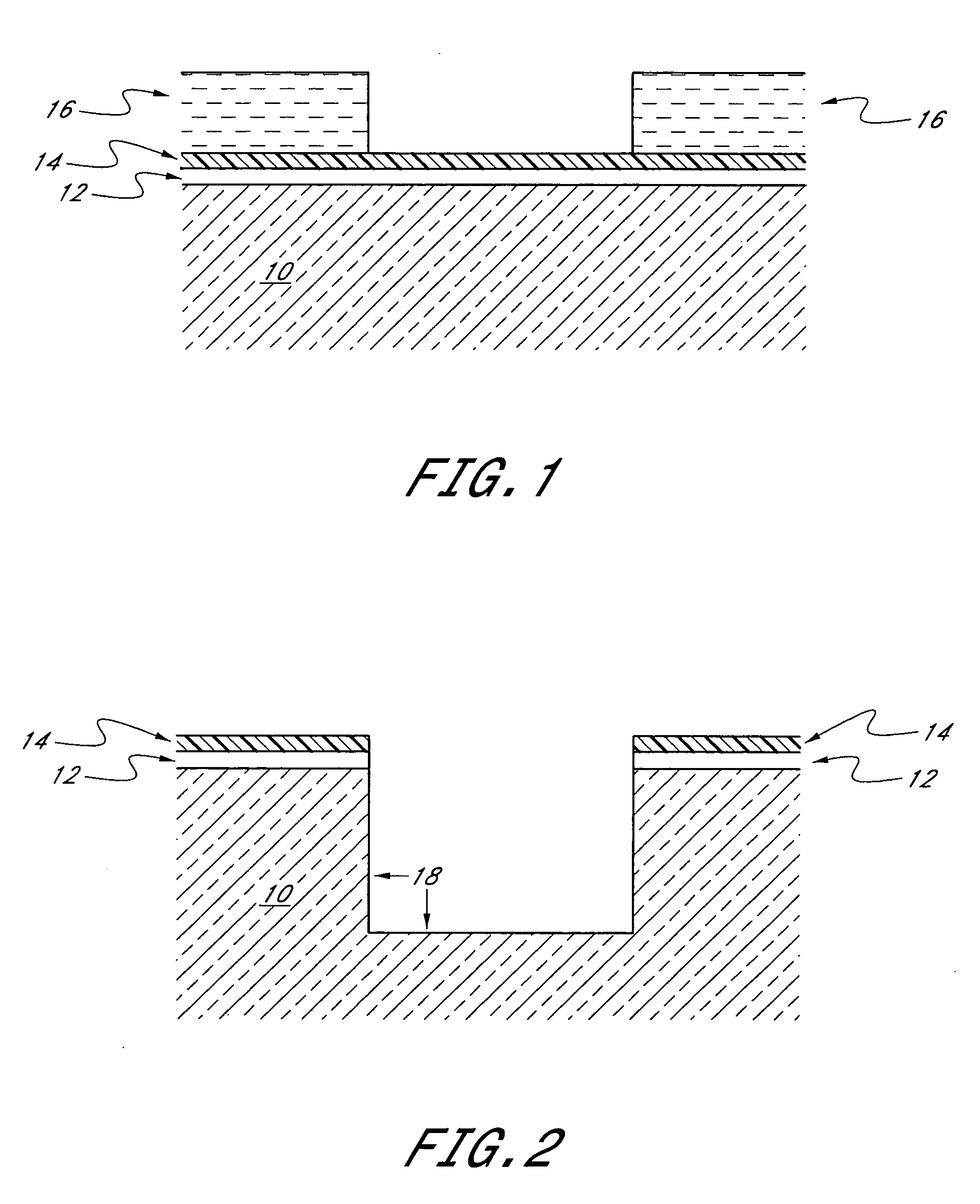

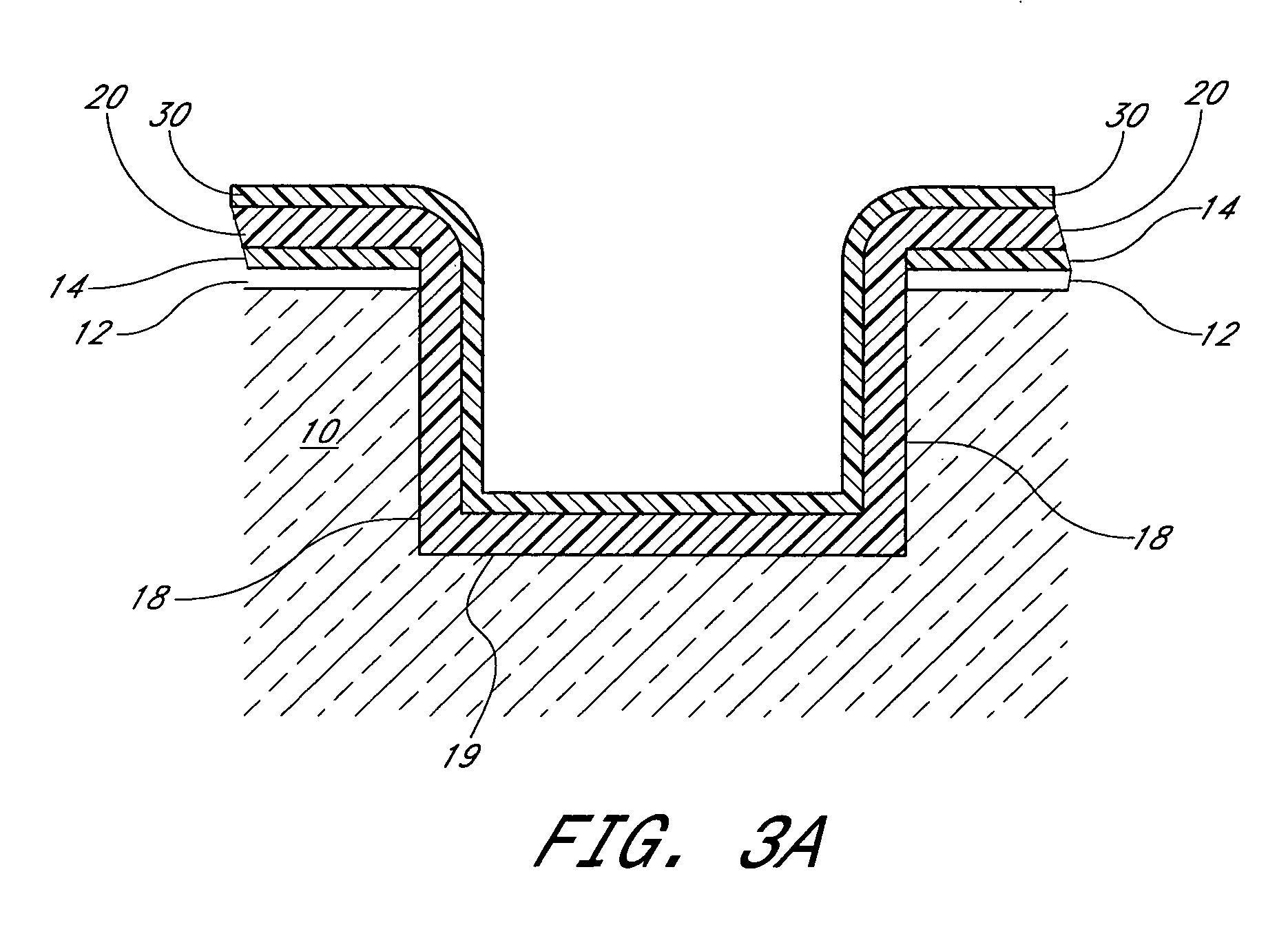

Liner for shallow trench isolation

ActiveUS20060043521A1Semiconductor/solid-state device manufacturingSemiconductor devicesLow nitrogenSilicon nitride

A method of depositing dielectric material into sub-micron spaces and resultant structures is provided. After a trench is etched in the surface of a wafer, a silicon nitride barrier is deposited into the trench. The silicon nitride layer has a high nitrogen content near the trench walls to protect the walls. The silicon nitride layer further from the trench walls has a low nitrogen content and a high silicon content, to allow improved adhesion. The trench is then filled with a spin-on precursor. A densification or reaction process is then applied to convert the spin-on material into an insulator. The resulting trench has a well-adhered insulator which helps the insulating properties of the trench.

Owner:MICRON TECH INC

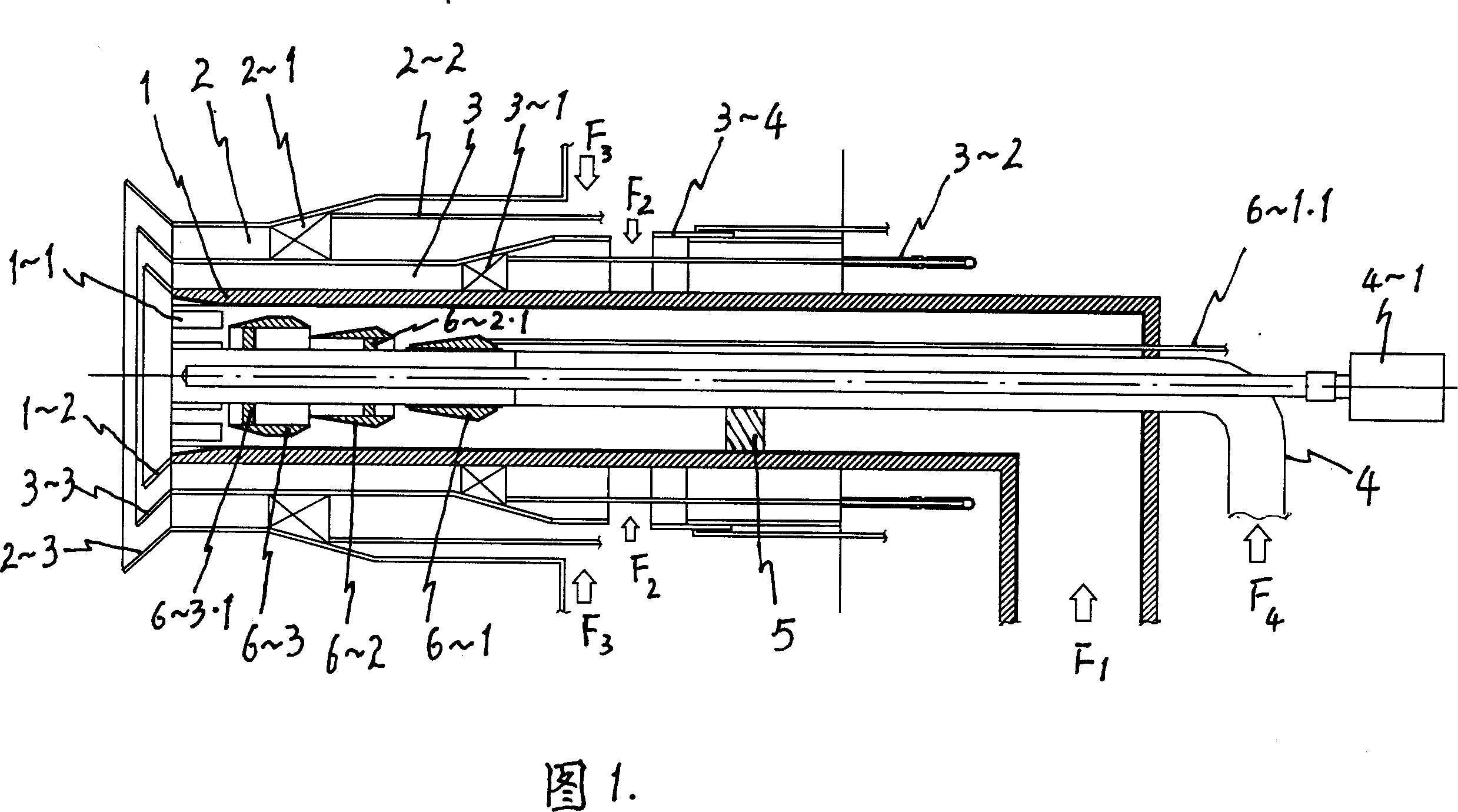

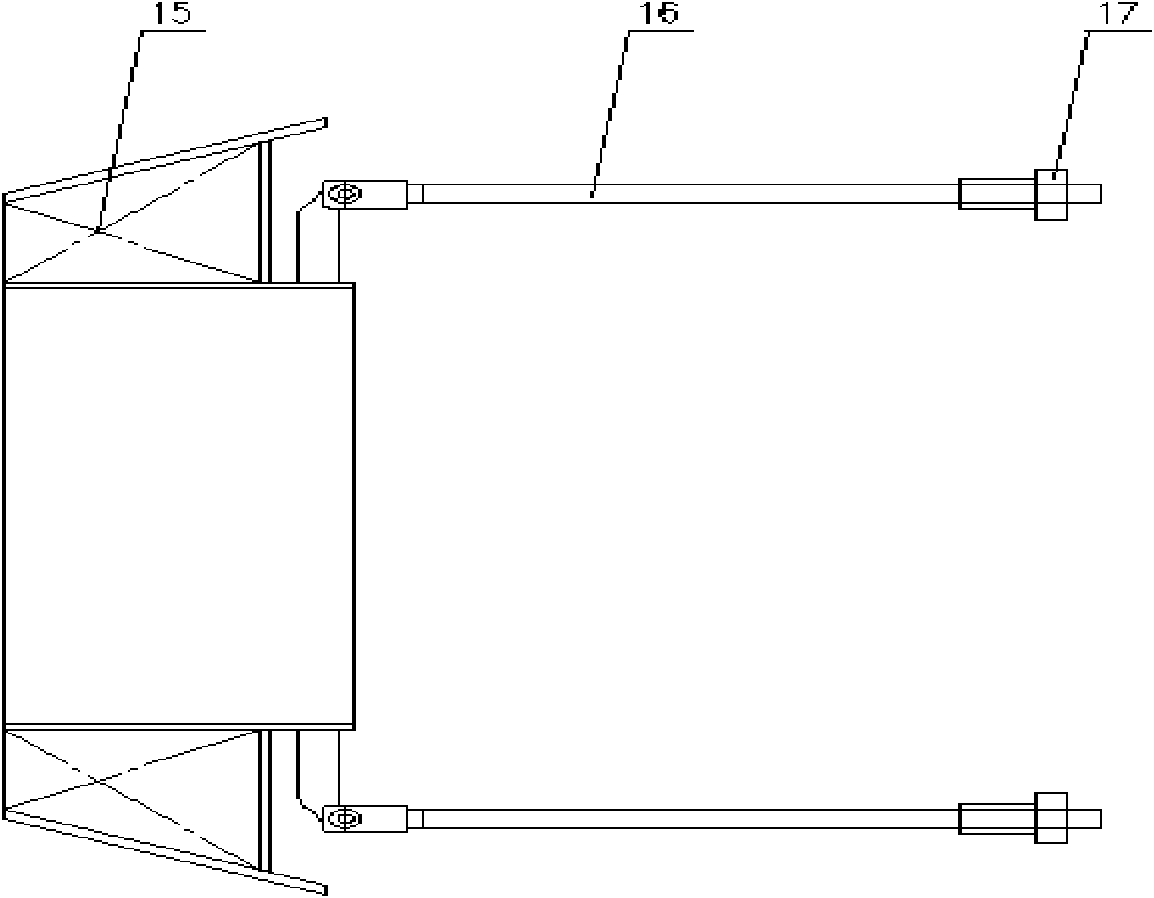

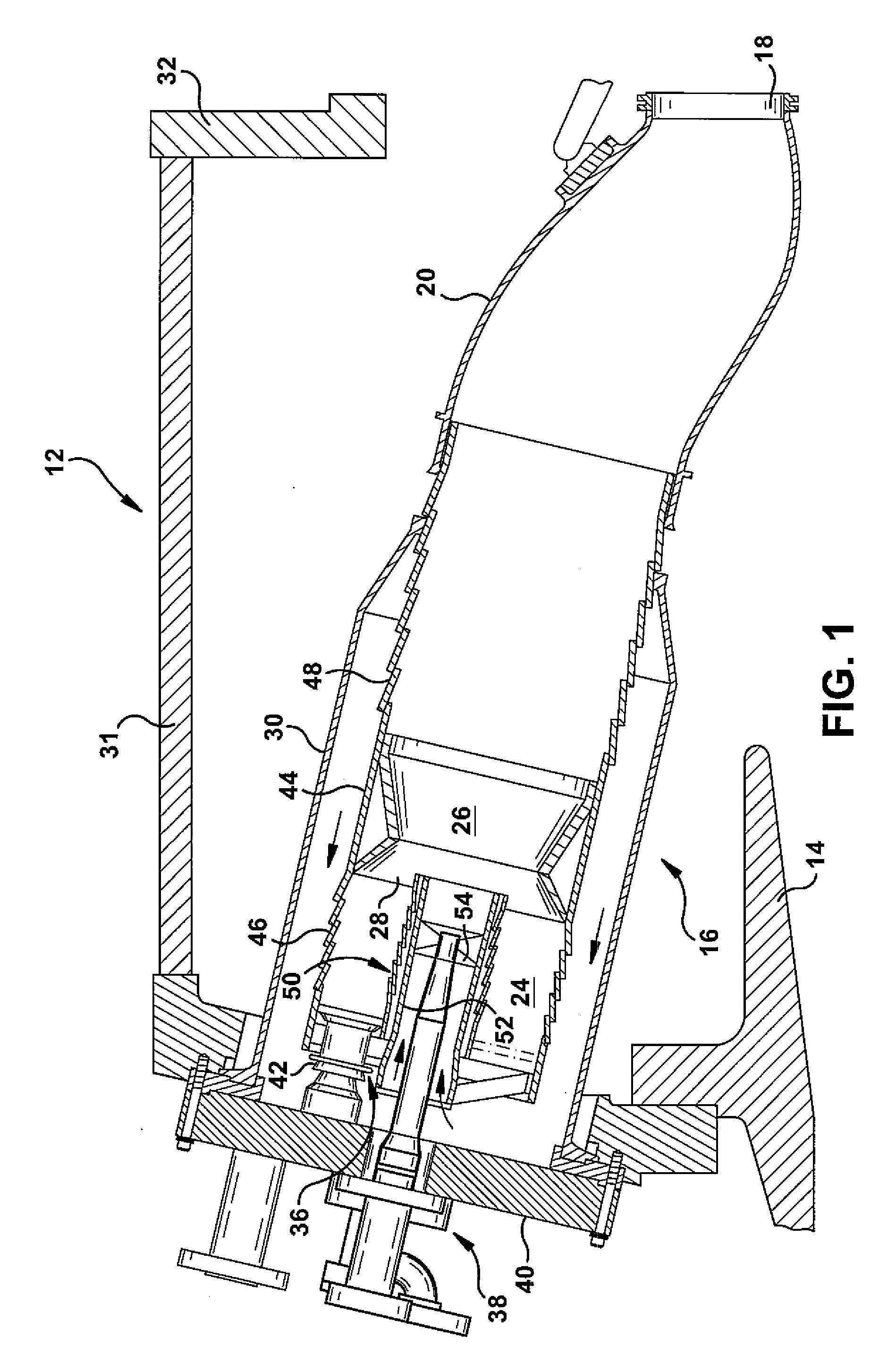

Rotational flow pulverized coal burner

ActiveCN1920382AGood concentration separation effectImprove adaptabilityPulverulent fuel combustion burnersCyclonePower station

The invention relates to a cyclone power coal burner used in the boiler of power station, wherein it comprises: oil gun, or central cylinder, 2-3 step power coal separator, the main nozzles of wedge groove and horn open; 2-3 air nozzles with cyclone generator and horn open, nozzles and gas inlet of central cylinder; at the surface of inner chamber of main nozzle, the inner and outer surfaces of separator, and at the surface of support plate, there are abrasion-resistant layer. The invention has better dense-thin separation effect, while the ratio between dense and thin is 3-7:1; the cyclone strength at 2-3 step nozzle is high with simple adjustment; the resistance of main nozzle is 1 / 3 of background technique to reduce 55-65% of energy consumption, with low nitrogen oxide discharge and stable burning.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

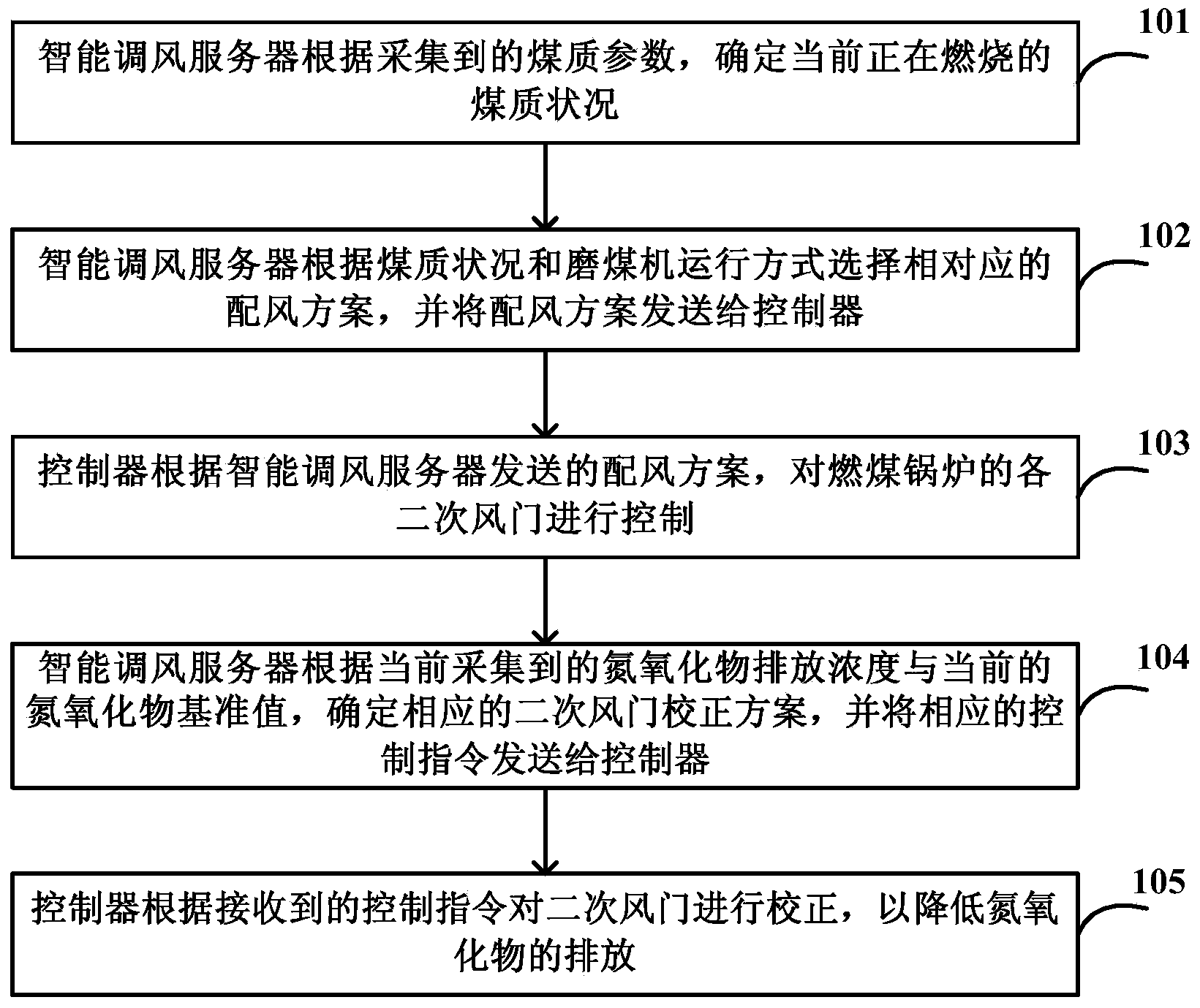

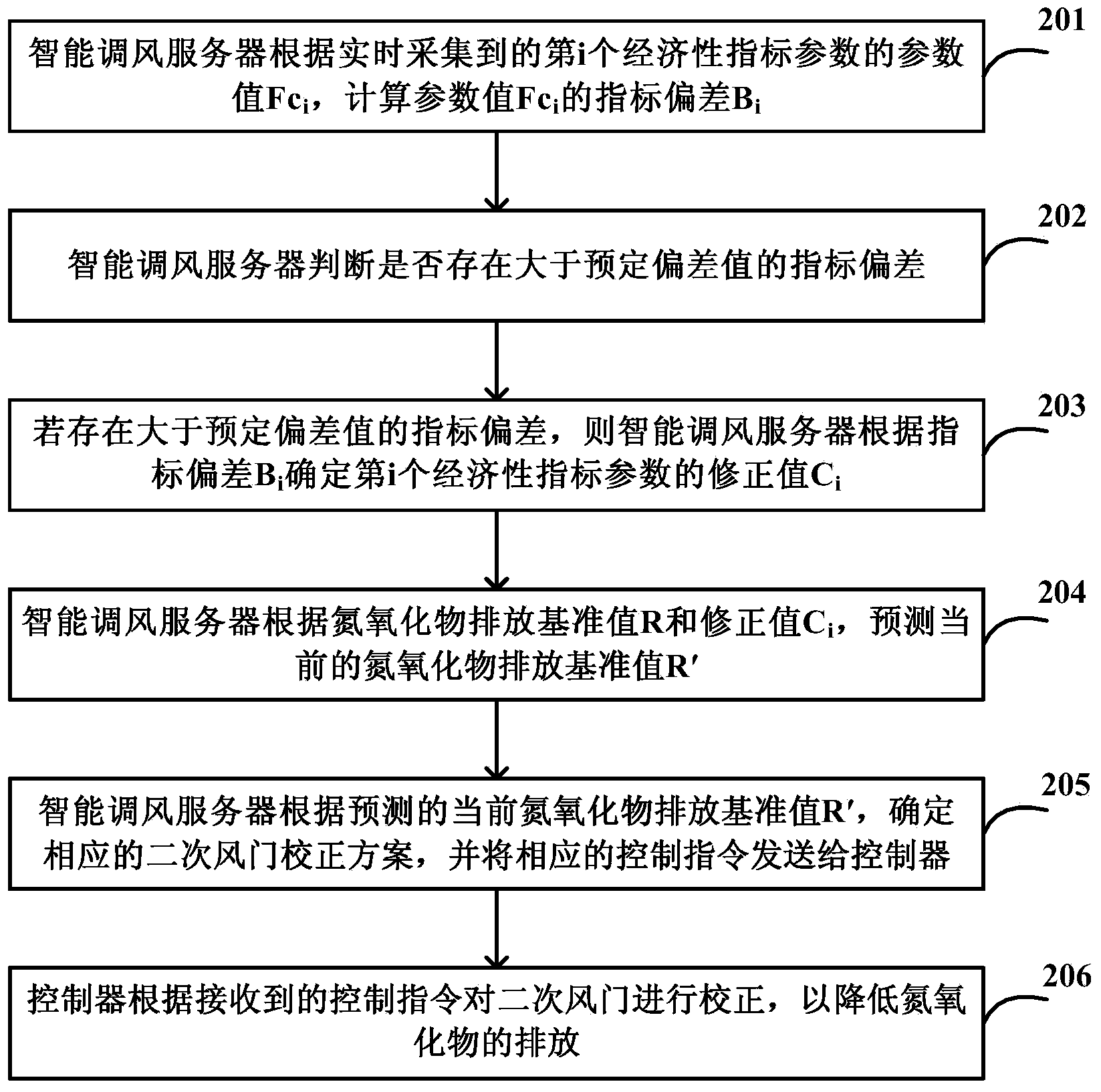

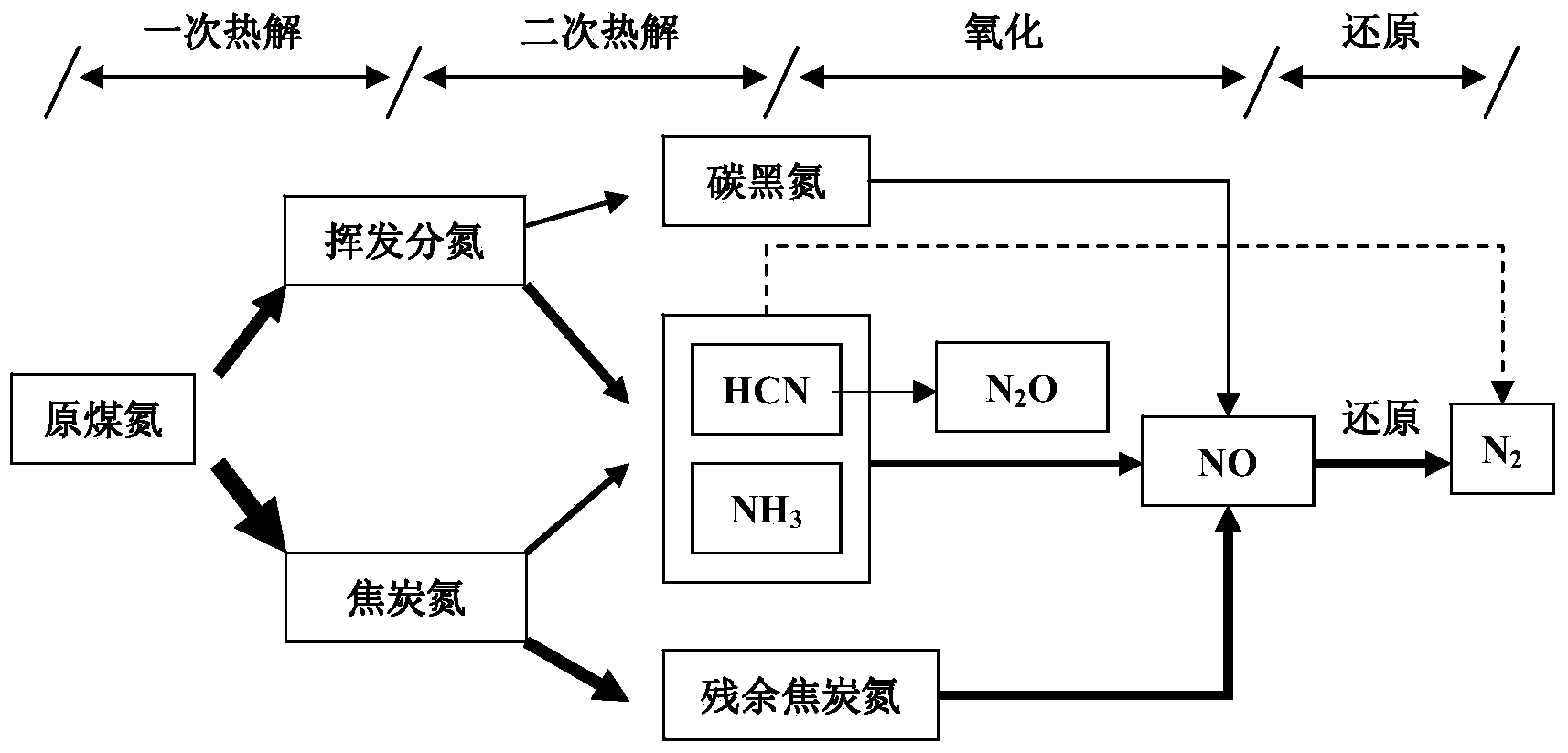

Low-nitrogen combustion control method and system based on secondary air door air regulation control

ActiveCN104061588AAchieve low nitrogen combustion controlAir supply regulationNitrogen oxidesLow nitrogen

The invention discloses a low-nitrogen combustion control method and system based on secondary air door air regulation control. An intelligent air regulation server determines the quality state of coal burned at present according to collected coal quality parameters, selects a corresponding air distributing scheme according to the quality state of the coal and an operating mode of a coal mill and sends the air distributing scheme to a controller; the controller controls all secondary air doors of a coal-fired boiler according to the air distributing scheme sent by the intelligent air regulation server; the intelligent air regulation server determines a corresponding secondary air door correcting scheme according to collected current nitrogen oxide emission concentration and a current nitric oxide reference value, and sends corresponding control instructions to the controller; the controller corrects the secondary air doors according to received control instructions so as to reduce the emission of nitric oxide. The secondary air doors are controlled according to the operating state of the coal-fired boiler, and thus low-nitrogen combustion control is effectively achieved.

Owner:YANTAI LONGYUAN POWER TECH

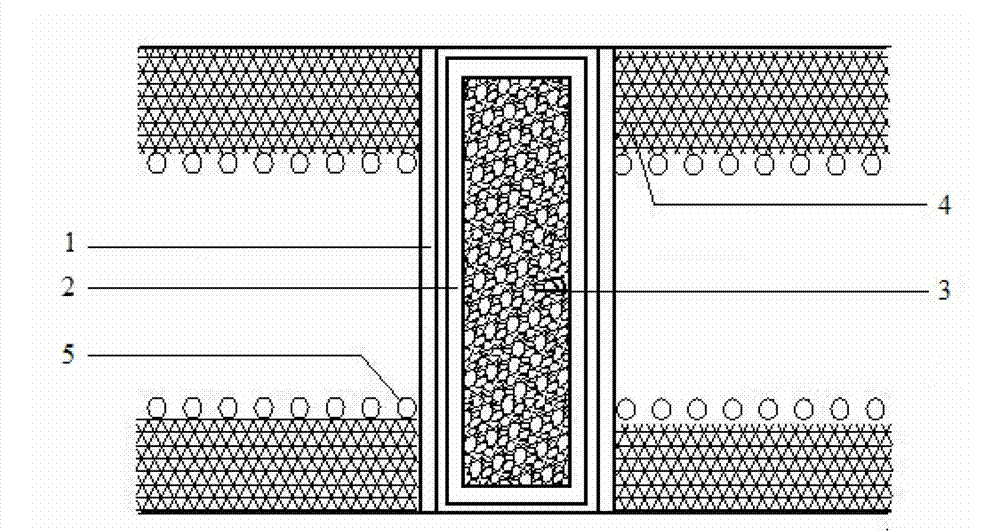

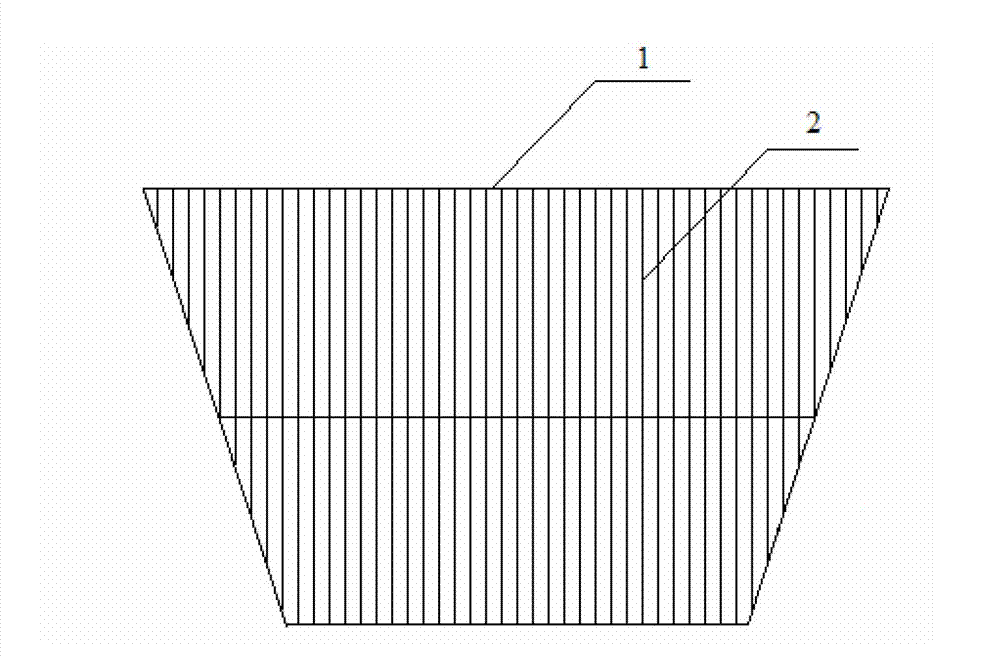

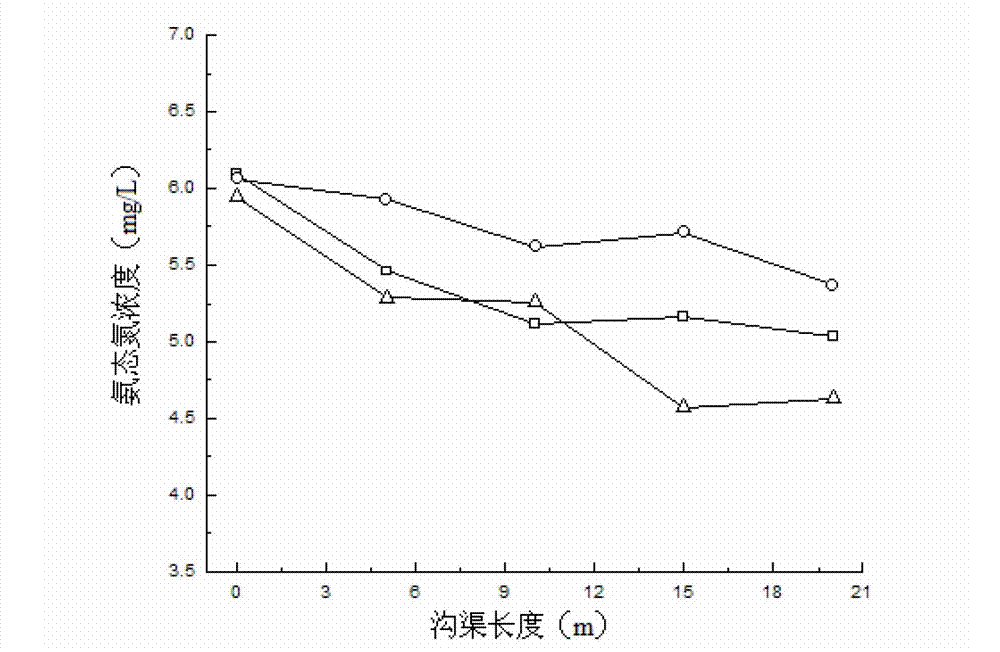

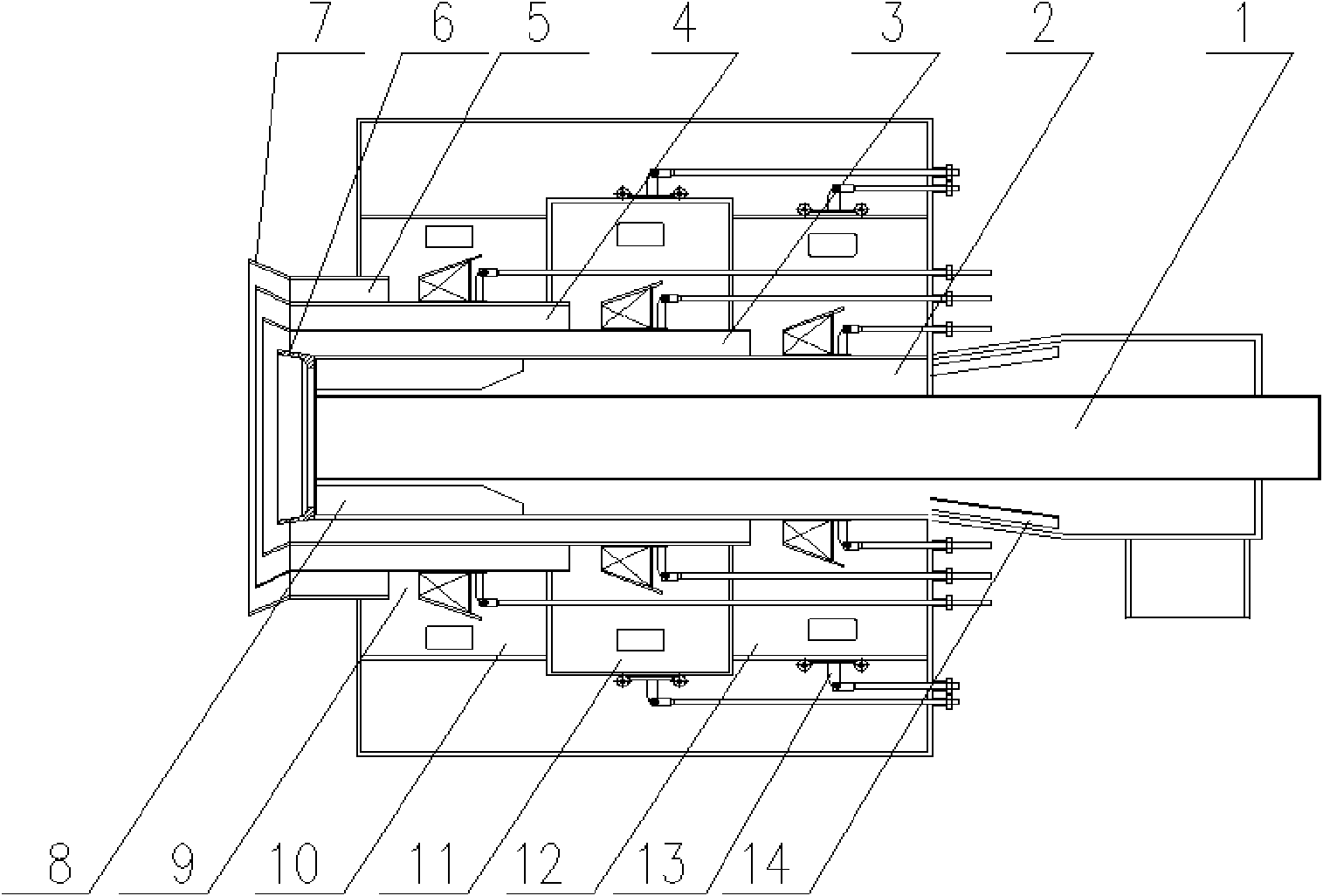

Ecological ditch constructing method for controlling nitrogen and phosphorus in farmland drainage

InactiveCN102966083AIncrease diversityReduce washoutConstructionsSoil drainageLow nitrogenSoil conservation

The invention provides an ecological ditch constructing method for controlling nitrogen and phosphorus in farmland drainage and relates to an ecological ditch constructing method for the farmland drainage. The purpose of the invention is to solve technical problems of poor water flushing resistance and low nitrogen and phosphorus intercepting and purifying capacity in the traditional ecological ditch constructing method for controlling nitrogen and phosphorus in the farmland drainage through arranging an ecological interceptor; and the ecological ditch constructing method provided by the invention is carried out in the following steps: first, planting plants on ditch walls and at ditch bottoms; and then arranging PVC pipes with holes at junctions of the ditch walls and the ditch bottoms; and arranging matrix intercept dams capable of replacing matrices at the ditch bottoms. The ecological ditch constructing method provided by the invention has the advantages as follows: without affecting normal drainage, the hydraulic retention time is prolonged, excessive water flushing is resisted, and soils in the ditches are uneasy to slip; compared with the traditional ditch, the comprehensive nitrogen and phosphorus purifying capacity of the ecological ditch is enhanced by 6-15 %; the capacity of intercepting and purifying nitrogen and phosphorus is strong; moreover, filled matrix of the matrix dam is solid wastes, so that a purpose of controlling waste by waste is achieved; and the ecological ditch constructing method provided by the invention can be applied to the field of environmental pollution prevention and water and soil conservation.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Three-layer secondary air low nitrogen oxide swirling burner

InactiveCN102434878AImprove circumferential unevennessConducive to stable combustionPulverulent fuel combustion burnersAir volumeCombustor

The invention discloses a three-layer secondary air low nitrogen oxide (NOx) swirling burner which comprises a central air pipe as well as a primary air pipe, an inner secondary air pipe, a middle secondary air pipe and an outer secondary air pipe which are concentrically arranged at the periphery of the central air pipe from inside to outside, wherein the air inlets of the inner secondary air pipe, the middle secondary air pipe and the outer secondary air pipe are provided with swirling adjusting mechanisms for generating straightly-flowing secondary air or secondary air with variable swirling intensity by virtue of the respective secondary air pipes; three independent air boxes are sleeved outside each secondary air pipe; and the air volume of each secondary air pipe can be adjusted by air box baffle plate adjusting mechanisms on the air boxes. By adopting the structure of the low NOx swirling burner, the partial grading burning effect of the burner is enhanced and the high temperature smoke reflow is increased, thus finally achieving the aim that the burner burns coals stably and reduces the NOx generated by burning. The three-layer secondary air low NOx swirling burner has a simple structure, is easy to manufacture and install, is high in industrial applicability, is applicable to various coals and guarantees the burning stability and the burning economy of a boiler.

Owner:HUAZHONG UNIV OF SCI & TECH

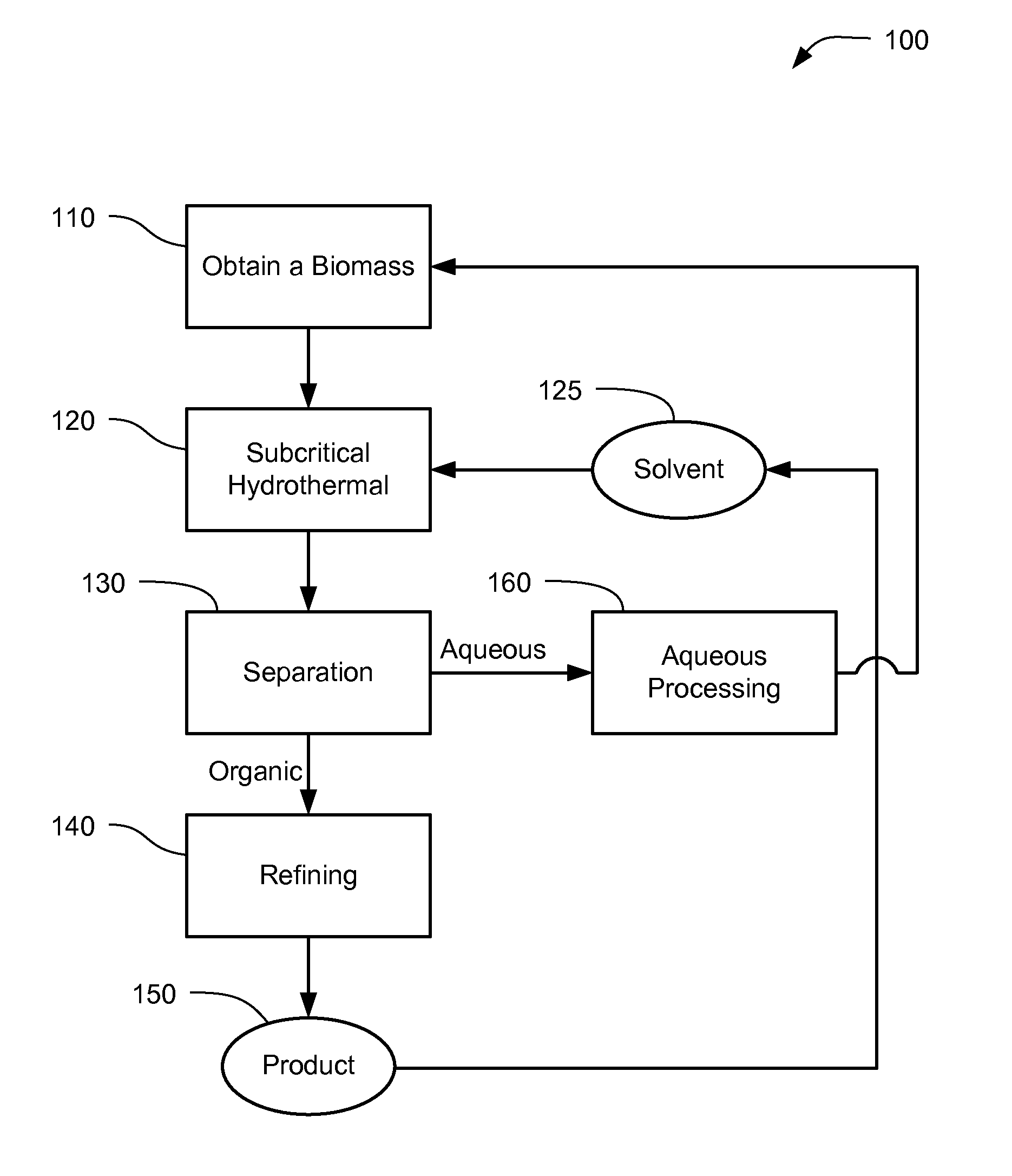

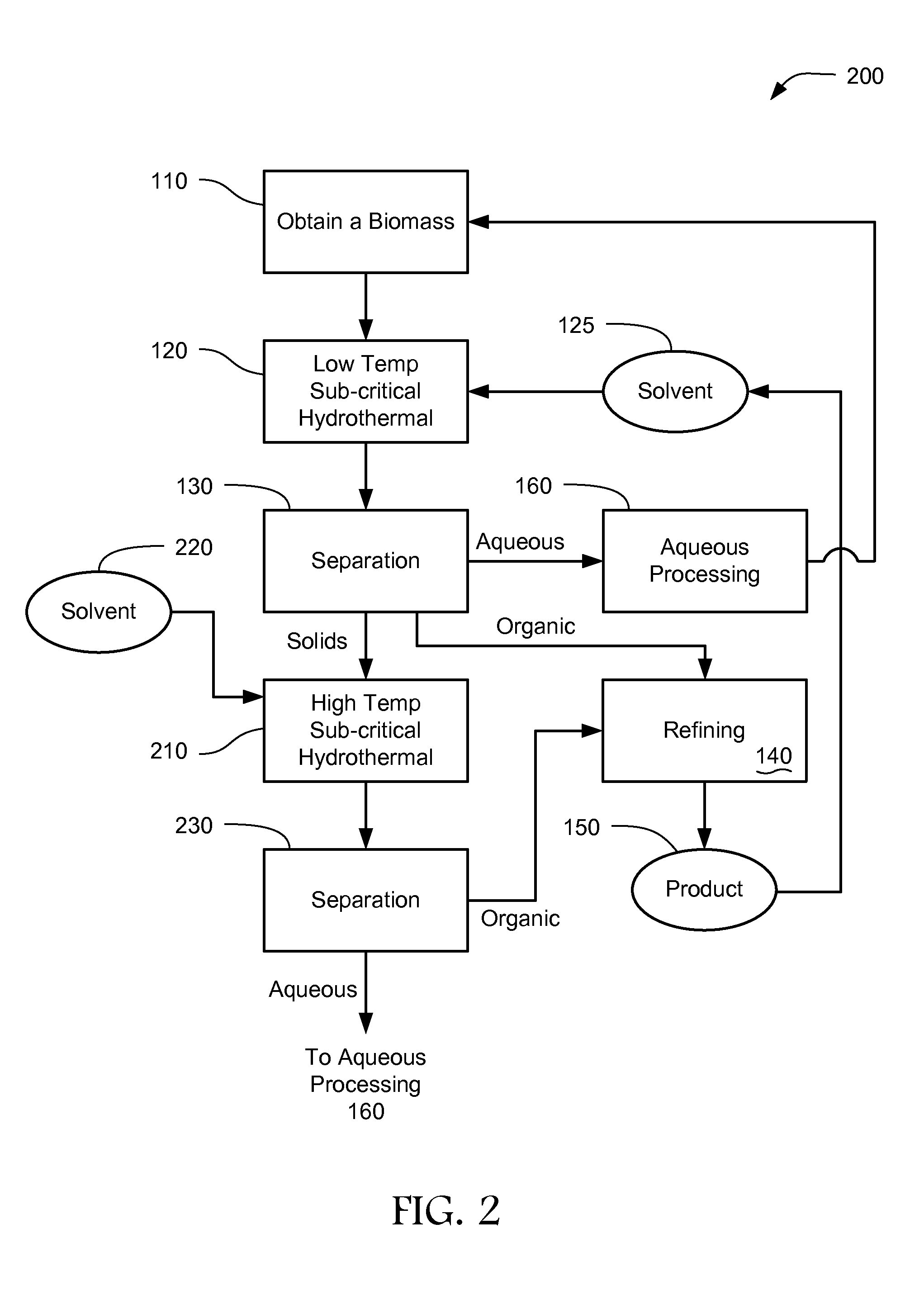

Systems and Methods for Hydrothermal Conversion of Biomass

InactiveUS20140275299A1Reduce total nitrogen concentrationLiquid hydrocarbon mixture productionHydrogen/synthetic gas productionLow nitrogenGas phase

Systems and methods are provided for synthesizing low nitrogen concentration organic liquids from biomass, such as algae, the organic liquids being suitable for refining into fuels and other chemicals. The biomass together with a solvent that is immiscible with water at room temperature are subjected to a subcritical hydrothermal treatment to disrupt cell structure and transform the biomass into a gas phase, a bio-oil phase, an aqueous phase and a solid phase. The aqueous phase contains most of the nitrogen. The resulting multi-phasic mixture can be separated into four phases, including an aqueous phase and the organic liquid which consists of bio-oil dissolved in the solvent. Refined organic liquid can be recycled into the hydrothermal treatment as the solvent. The subcritical hydrothermal treatment can be performed at a generally low temperature and followed by a second hydrothermal treatment at a higher temperature.

Owner:IHI INC +1

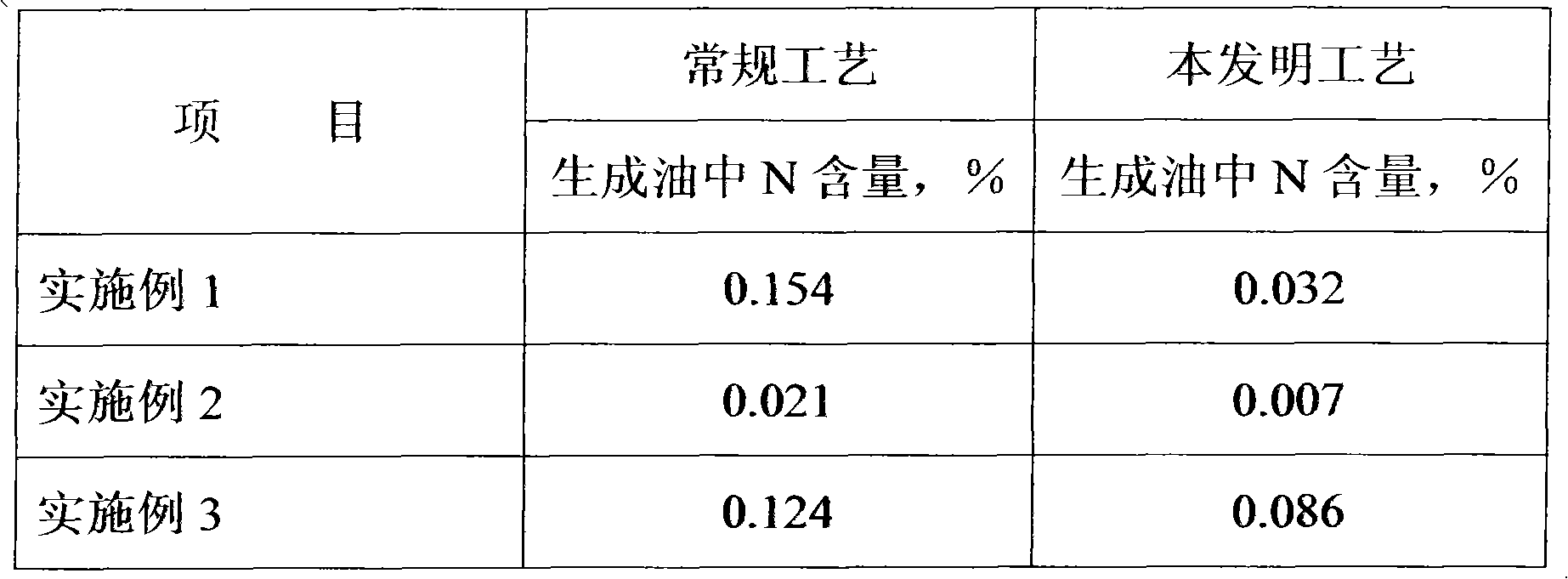

Shale oil hydrogenation process

The invention relates to a shale oil hydrogenation process method. Shale oil raw material is added into a reactor from the upper part of the reactor, hydrogen enters the reactor from the lower part thereof, the gas and oil reversely pass through a hydrobon catalyst bed for oil hydrogen refining, gas phase after reaction is exhausted from the upper part of the reactor, and liquid phase after reaction is the refined shale oil and is discharged from the lower part of the reactor. Compared with the prior art, the method of the invention does not require additional process, hydrogenation process alone can process the shale oil with high nitrogen content into the refined shale oil with low nitrogen content.

Owner:CHINA PETROLEUM & CHEM CORP +1

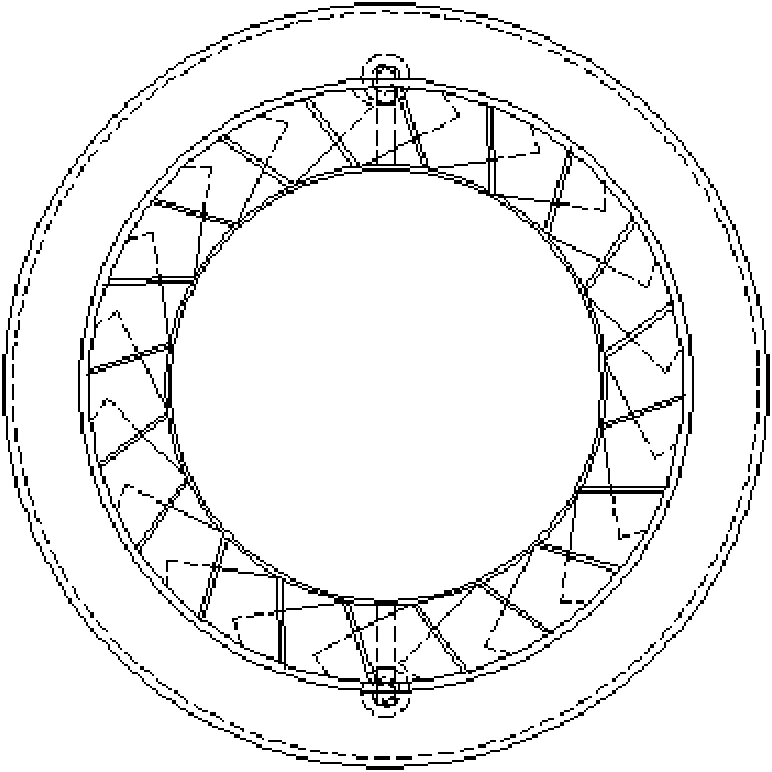

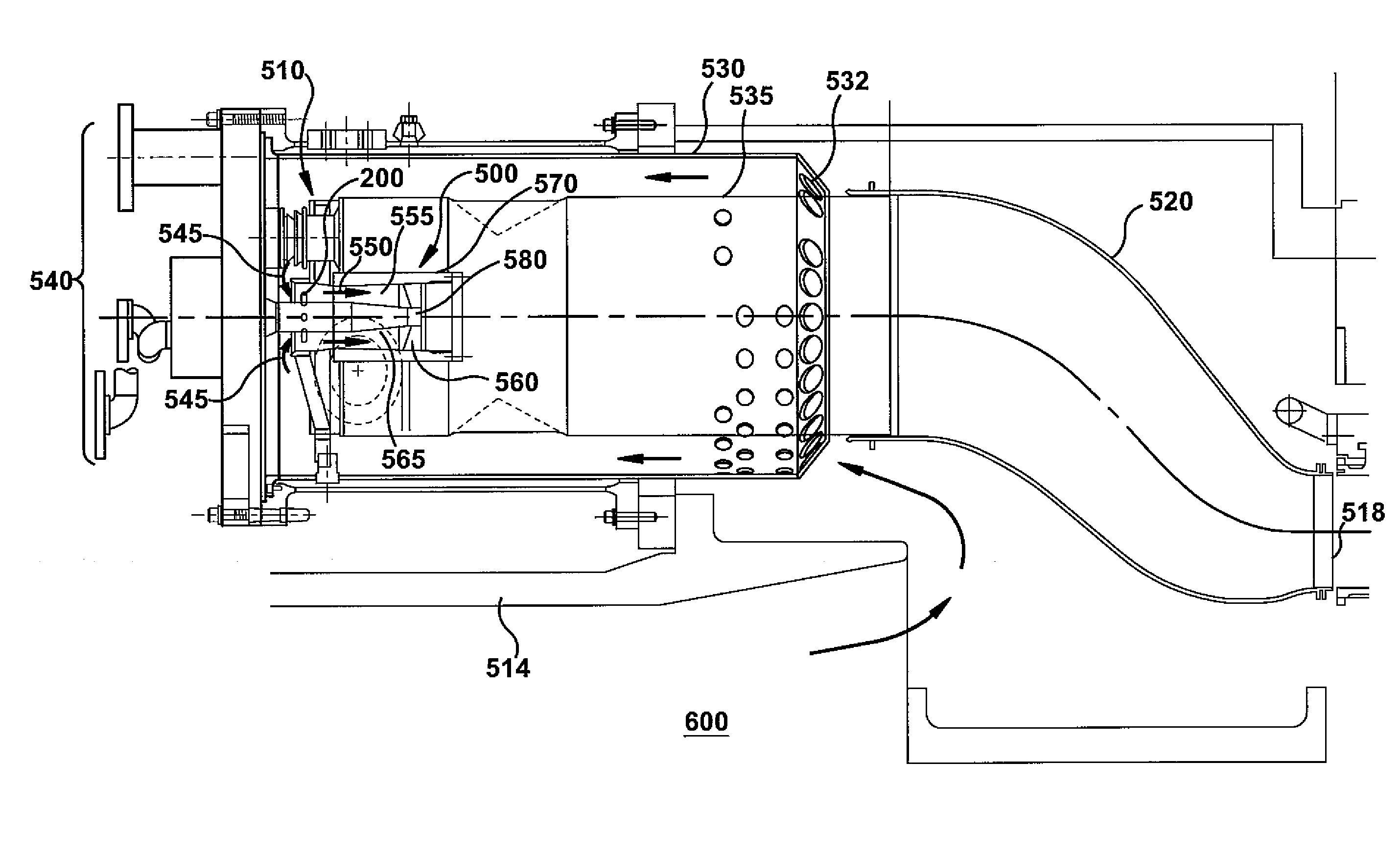

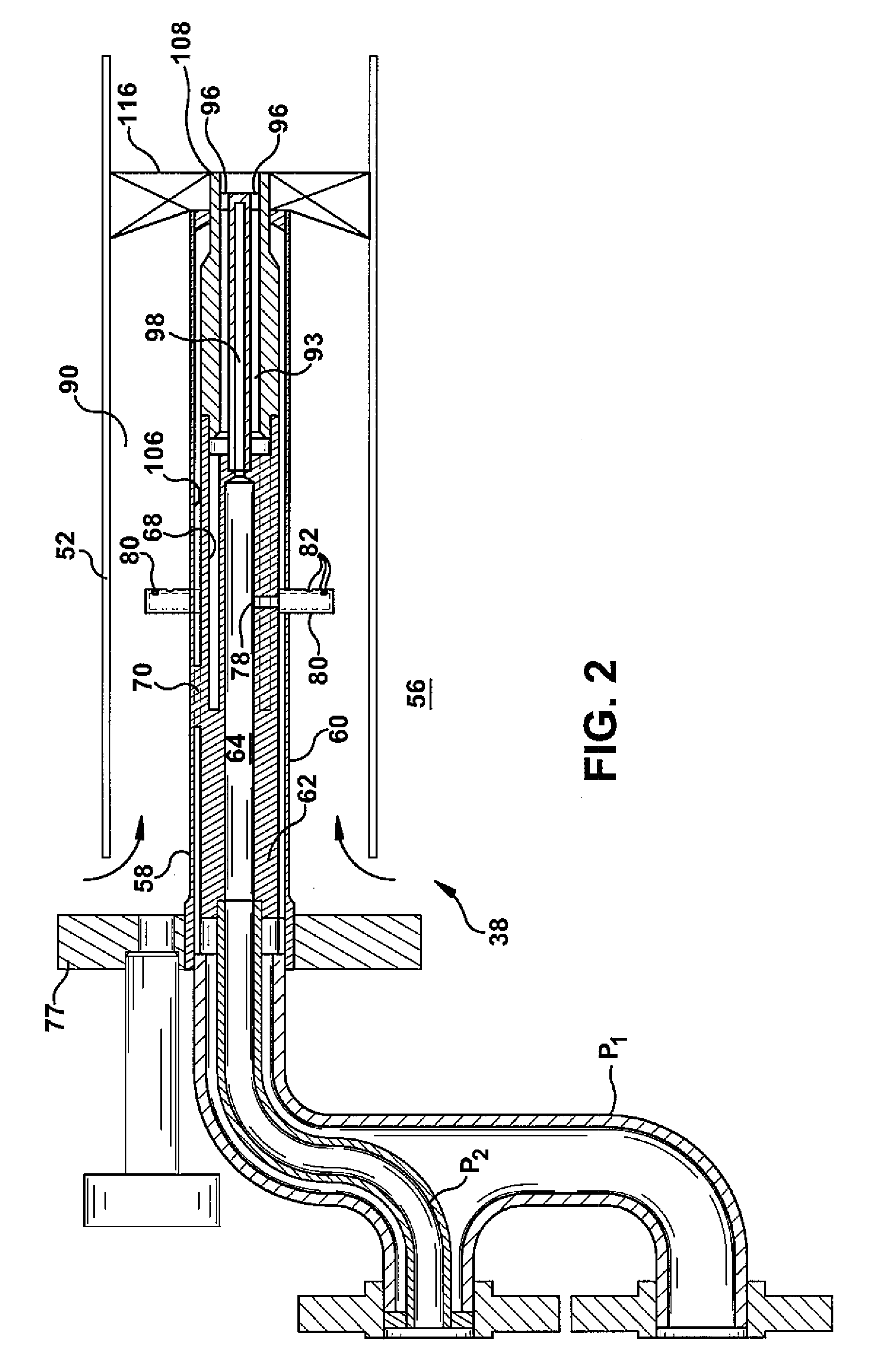

Toroidal ring manifold for secondary fuel nozzle of a dln gas turbine

InactiveUS20090077972A1Emission reductionIncrease combustion dynamicContinuous combustion chamberEngine manufactureCombustorLow nitrogen

A toroidal ring manifold for effectively dispersing premixing fuel with air in the secondary fuel nozzle of a combustor for a Dry Low NOx (DLN) gas turbine, thereby providing stable combustion with low nitrogen oxide (NOx) emissions. The toroidal ring manifold is centered around a centerbody hub of a secondary fuel nozzle assembly in a premixing volume between the nozzle centerbody hub body and a centerbody cap. The ring manifold receives fuel from the nozzle body and dispenses premix fuel from a plurality of rows of individual holes on its downstream surface into an axial airstream. The number and location of the rows, the number, size and spacing of holes in each row, and the radial position of the toroidal ring manifold within the premixing volume are optimized to promote premixing.

Owner:GENERAL ELECTRIC CO

Hydrogenation cracking method of high-output diesel oil from high-nitrogen content heavy raw material

ActiveCN1940030AAvoid cracking reactionsHigh yieldTreatment with hydrotreatment processesNaphthaLow nitrogen

Hydrogenation cracking method for qualified diesel oil from high-nitrogen content heavy raw oil is carried out by reacting by the first hydrogenation refining reactor, entering the reactant into thermal flash pot to gas-liquid separate, entering the separated liquid-phase flow and low-nitrogen content heavy raw oil into the second hydrogenation refined reactor, hydrogenation refine reacting, mixing effluent of the second hydrogenation refining reactor with effluent hydrogenation cracking reactor, entering into high-pressure separator, low-pressure separator and fractionating tower sequentially, separating out naphtha fraction, diesel fraction and tail-oil fraction, circulating all or part tail-oil fraction to hydrogenation cracking reactor for reacting. It's efficient and saves resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

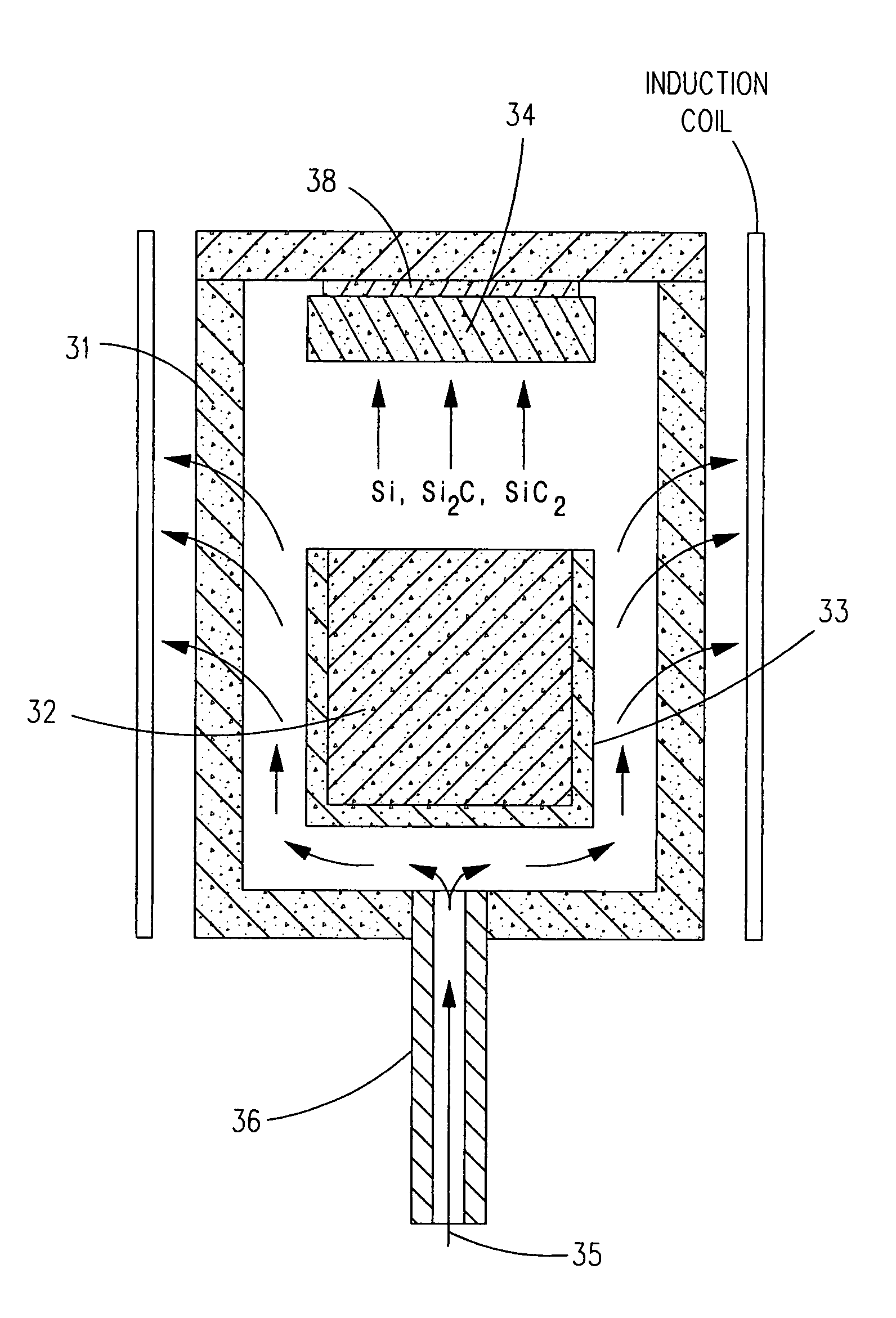

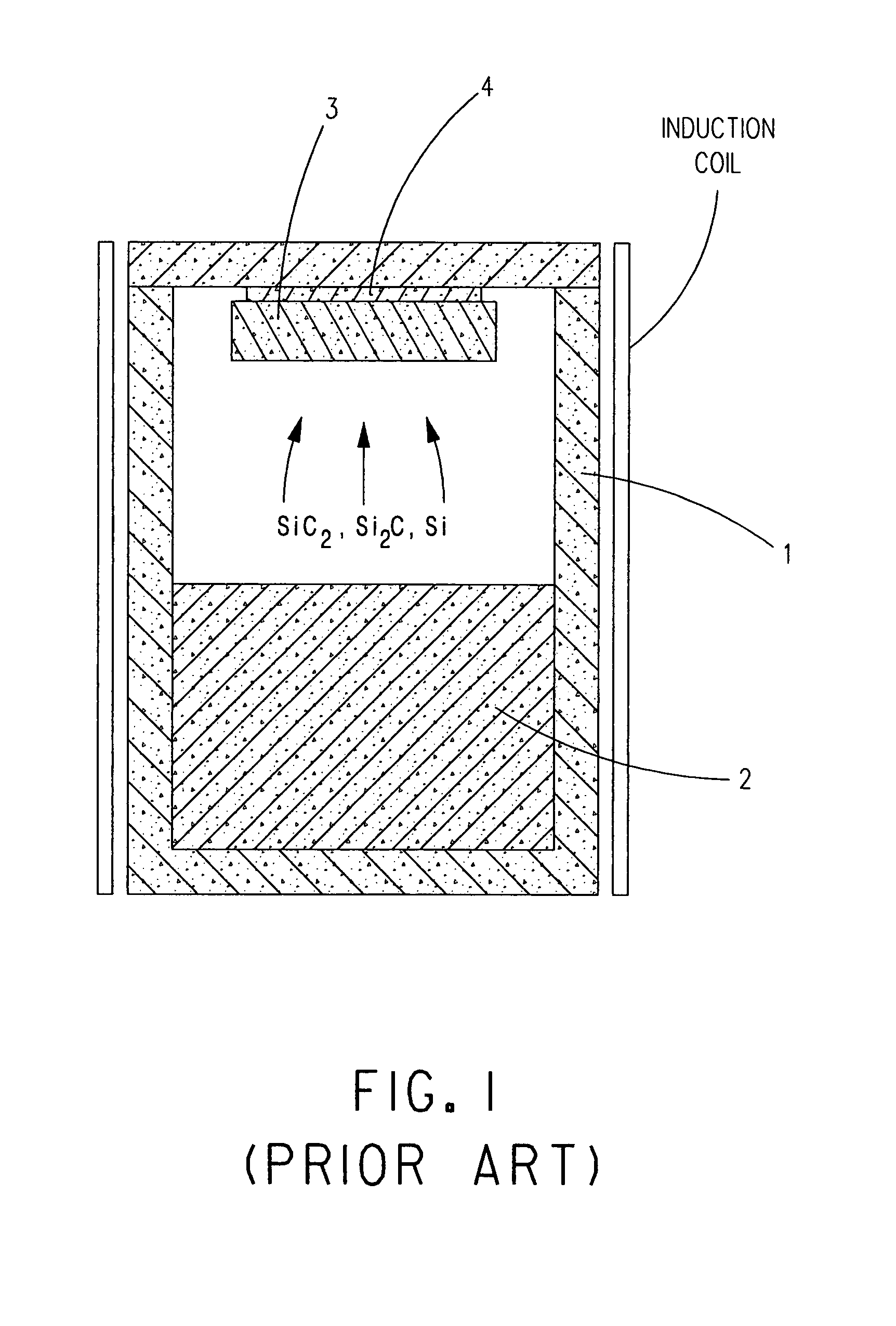

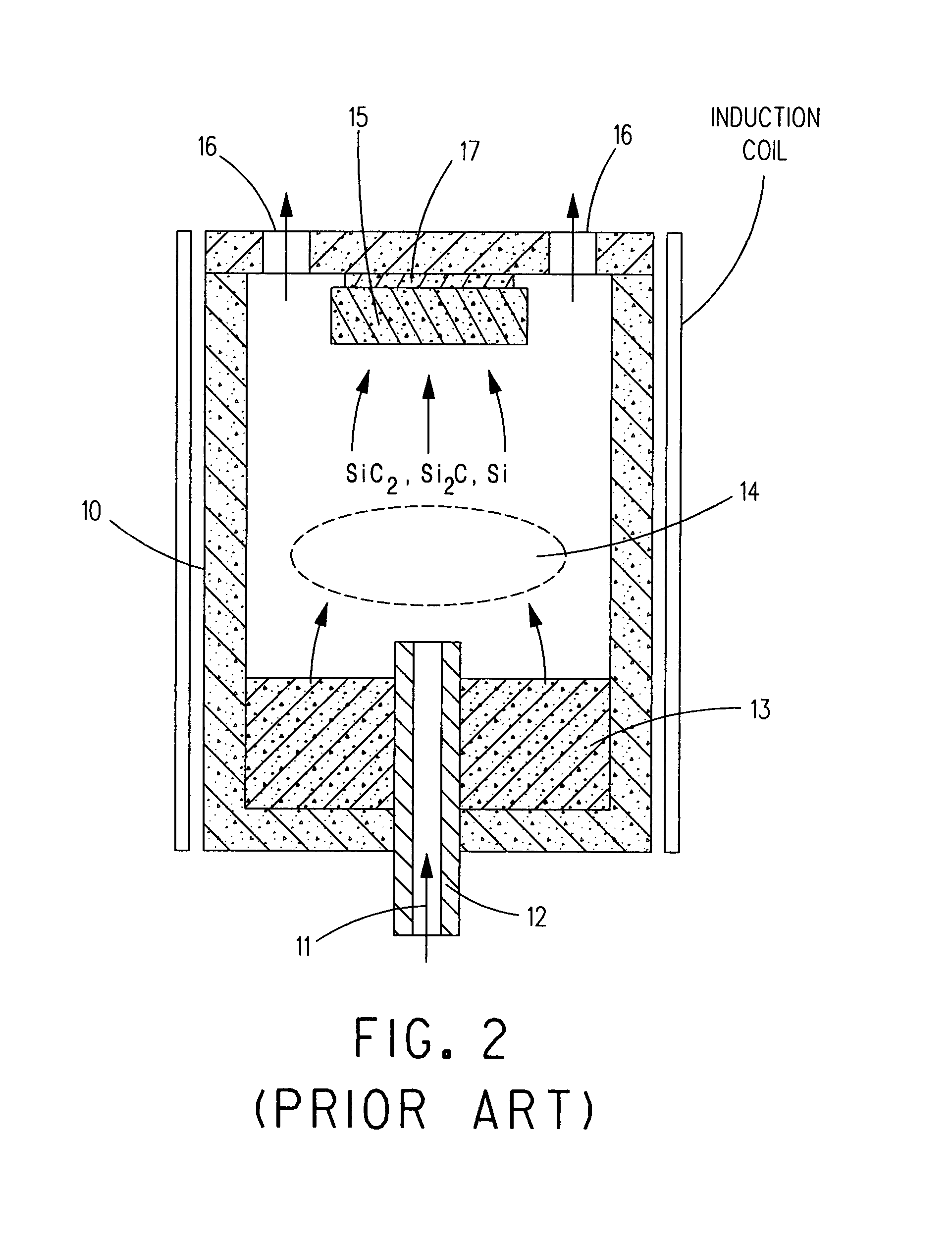

Silicon carbide with low nitrogen content and method for preparation

ActiveUS8858709B1Sufficient permeabilityReduce presencePolycrystalline material growthFrom frozen solutionsSource materialCrucible

A physical vapor deposition method of growing a crystal includes providing a seed crystal and a source material in spaced relation inside of a growth crucible that is at least in-part gas permeable to an unwanted gas. The growth chamber is heated whereupon the source material sublimates and is transported via a temperature gradient in the growth chamber to the seed crystal where the sublimated source material precipitates. Concurrent with heating the growth chamber, a purging gas is caused to flow inside or outside of the growth crucible in a manner whereupon the unwanted gas flows from the inside to the outside of the growth crucible via the gas permeable part thereof.

Owner:II VI DELAWARE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com