Patents

Literature

52results about How to "Higher quality than capacitance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

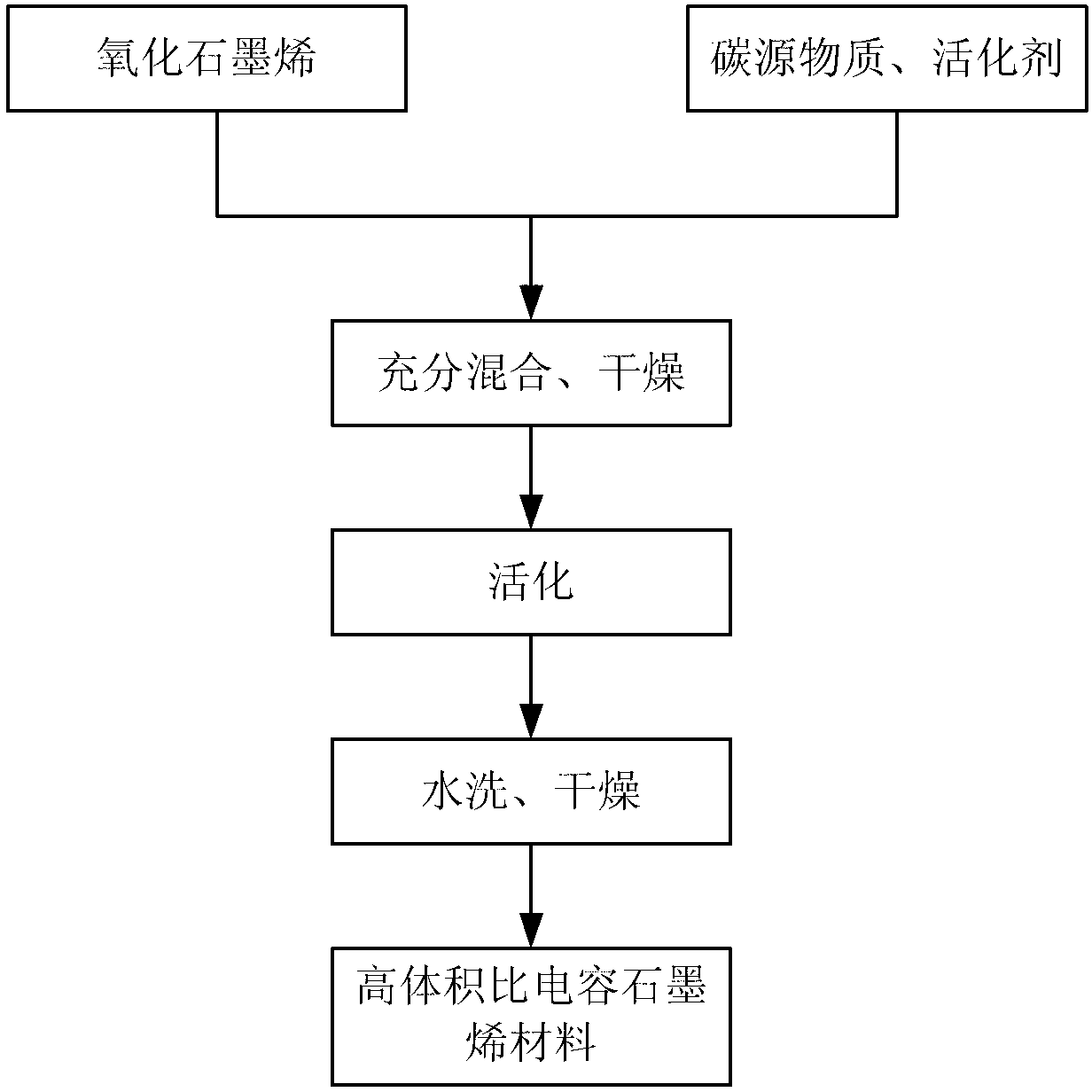

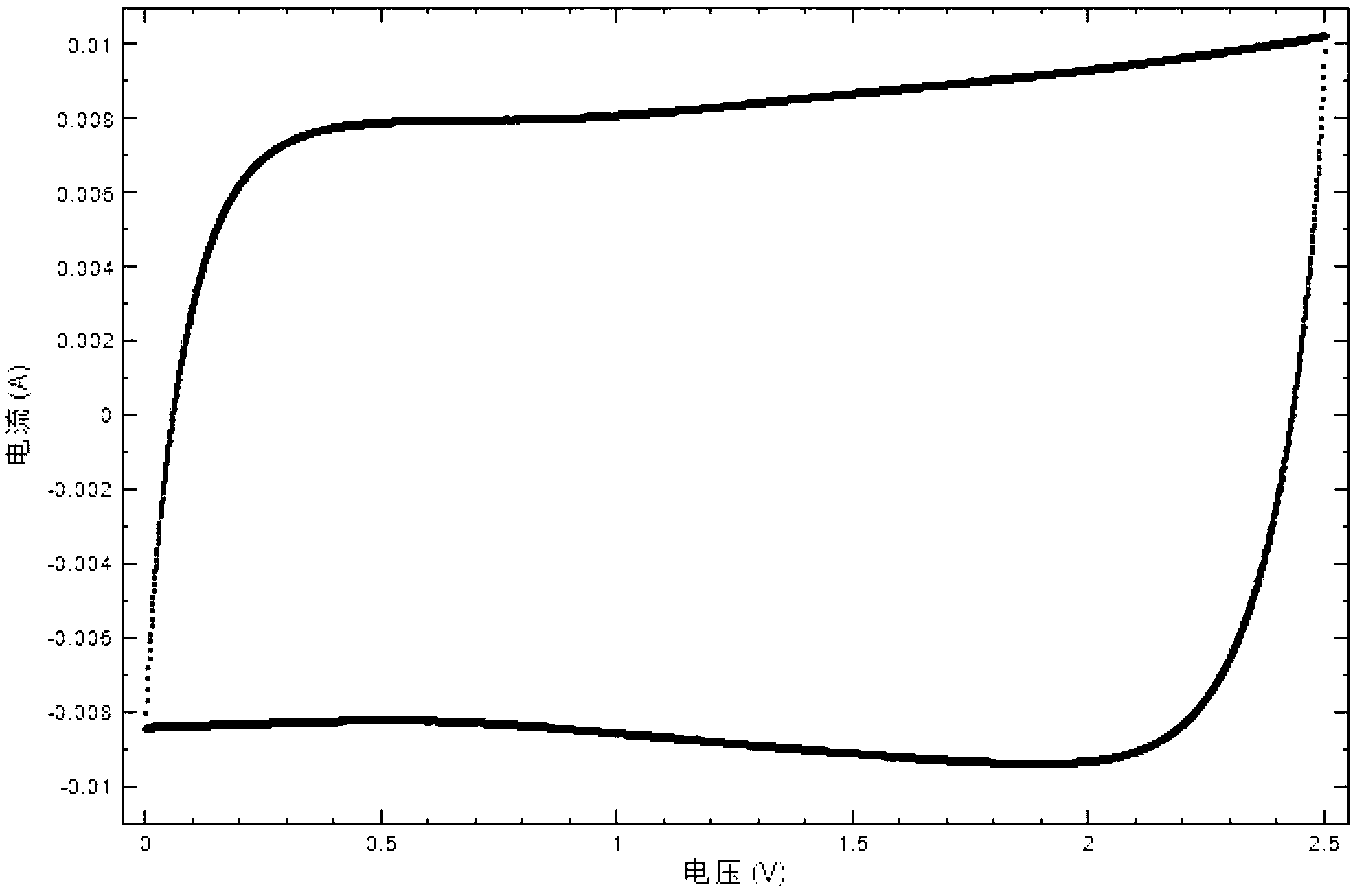

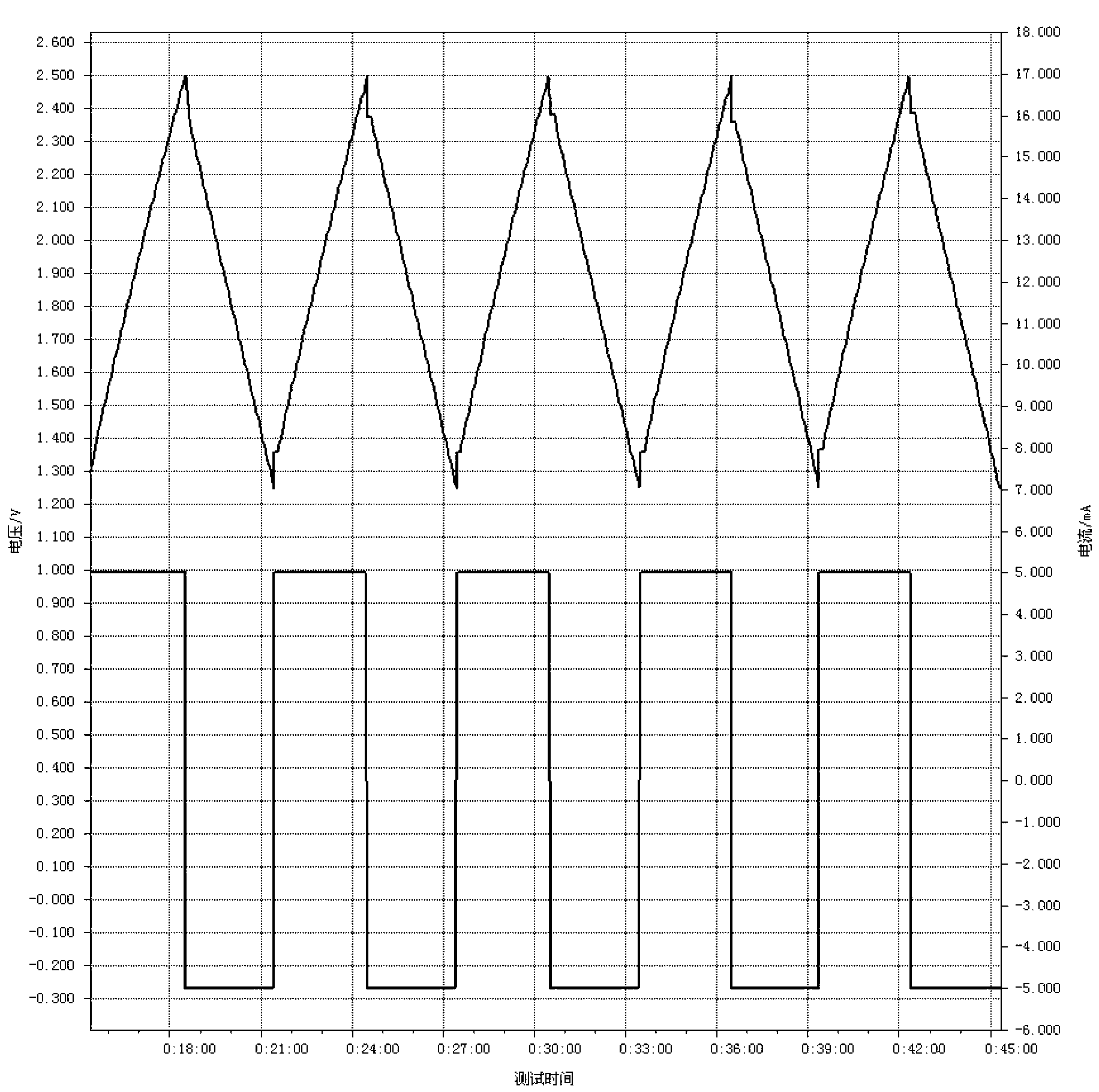

Graphene with high volumetric specific capacitance and preparation method thereof

ActiveCN103253658AHigher volume than capacitanceLarge specific surface areaGrapheneCapacitanceCvd graphene

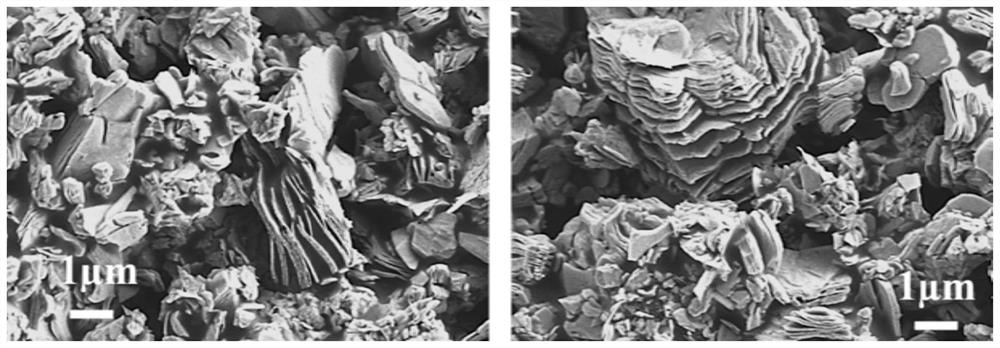

The invention relates to a type of graphene. Active carbon is doped in the graphene sheet. The invention further discloses a preparation method of the graphene. The preparation method comprises the following steps of: adequately mixing oxidized graphene with an activating agent and a carbon-source substance; activating under the protection of a protective atmosphere; and then cooling, washing and drying to obtain the graphene with a high volumetric specific capacitance. According to the graphene and the preparation method disclosed by the invention, the volumetric specific capacitance of the graphene is increased while the high specific surface area and high mass specific capacitance of graphene material are ensured, thus overcoming the technical problem that the graphene cannot be applied to a super-capacitor as an electrode material due to low volumetric specific capacitance. According to the graphene and the preparation method, massive use for chemical reagents is avoided, and the usage amount of the activating agent is reduced; and the graphene is simple in equipment, low in cost, safe and reliable, less in pollution, high in production efficiency, low in cost, capable of being produced on a large scale, very strong in market competitiveness, and wide in application prospect.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Preparation method of carbon foam with high electrochemical performances

The invention relates to a preparation method of carbon foam with high electrochemical performances, comprising the following steps of: firstly, weighing phenol formaldehyde, vanadate, surface active agent, sodium hydroxide and solvent according to mass ratio of 1:(0.6-4):(0.01-0.5):(1-20):(0.01-0.5):100, mixing uniformly and obtaining precursor solution of the carbon foam; putting the obtained solution into an environment with the temperature of 15 DEG C-60 DEG C to lead the solvent to be completely volatilized, and obtaining precursor of solid carbon foam; and solidifying the precursor of the solid carbon foam for 1 hour-24 hours at the temperature of 100 DEG C-200 DEG C, then rising the temperature to be 600 DEG C-1400 DEG C at the temperature rising speed of 1 DEG C / min-60 DEG C / min under the inert atmosphere, carbonizing for 0.5 hour-10 hours, and obtaining the carbon foam with high electrochemical performances. In the preparation method, the technology is simple, the quality is stable, vanadate introduced when the precursor solution of the carbon foam is prepared is converted into sodium vanadate nanocrystalline with a stable layer structure in the process of carbonization, and the obtained sodium vanadate nanocrystalline is embedded into a carbon foam skeleton uniformly. Compared with the existing carbon foam, the prepared carbon foam has the electrochemical performances such as high mass specific capacitance, good charging and discharging circulation and the like, and can be effectively applied in the fields such as electrode materials of electrochemical capacitors and the like.

Owner:TONGJI UNIV

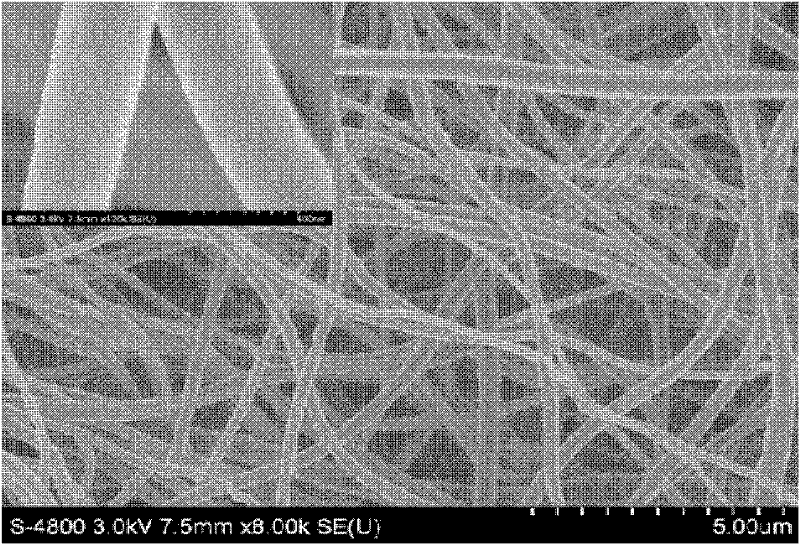

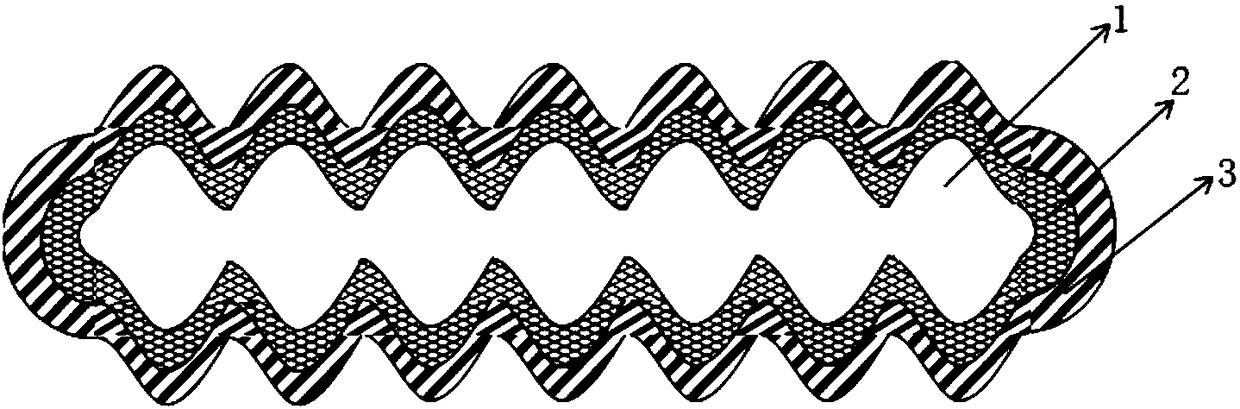

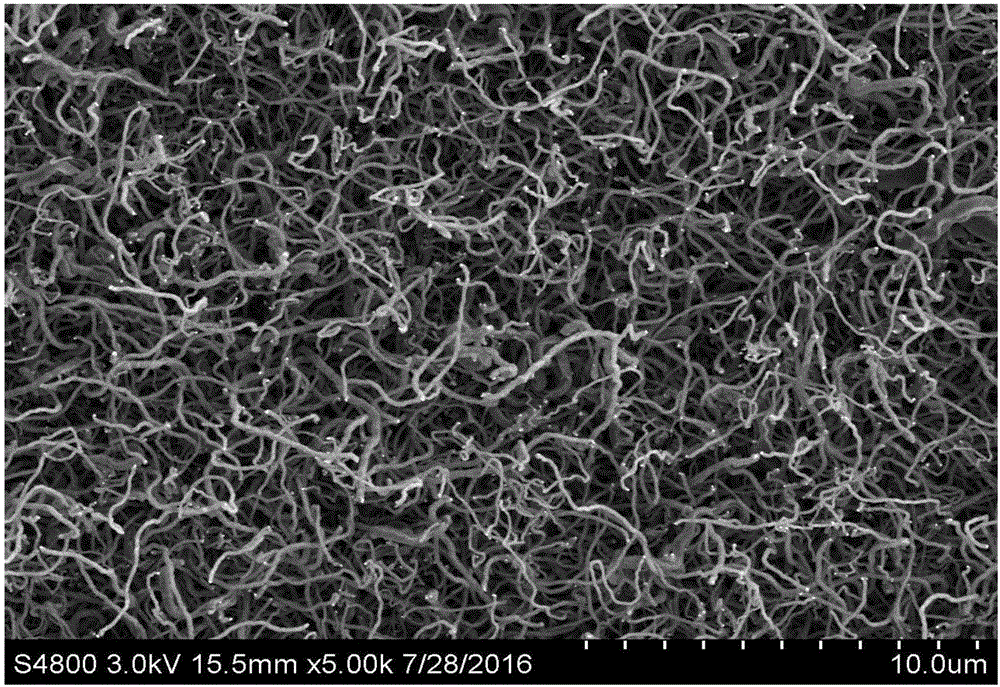

A preparation method of monolithic polyacrylonitrile carbon fiber electrode for desalination

InactiveCN102285706AHas a macroscopic integrityFine fiber diameterWater/sewage treatment by electrochemical methodsDispersed particle separationCapacitanceCarbonization

The invention relates to a preparation method for an integral polyacrylonitrile carbon fiber electrode for desalination, belonging to the technical field of novel carbon material preparation and water treatment. The method is based on an electrostatic spinning technique. Polyacrylonitrile is electro-spun into a film and then preoxidation, carbonization and activation are conducted. The prepared carbon fiber material has the characteristics of good macro integrity, small fiber diameter, large mass specific capacitance, high desalination capacity and the like. When electro-adsorption treatment is conducted to NaCl solution with initial concentration being 70mg / l under 1.6V direct-current voltage, the adsorption capacity of the carbon fiber electrode reaches 4.64mgNaCl / g and therefore a strong desalination capacity is reflected. The novel carbon fiber electrode can be widely used in fields such as bitter saline water and seawater desalination, water softening, heavy metal ion removal andthe like.

Owner:DALIAN UNIV OF TECH

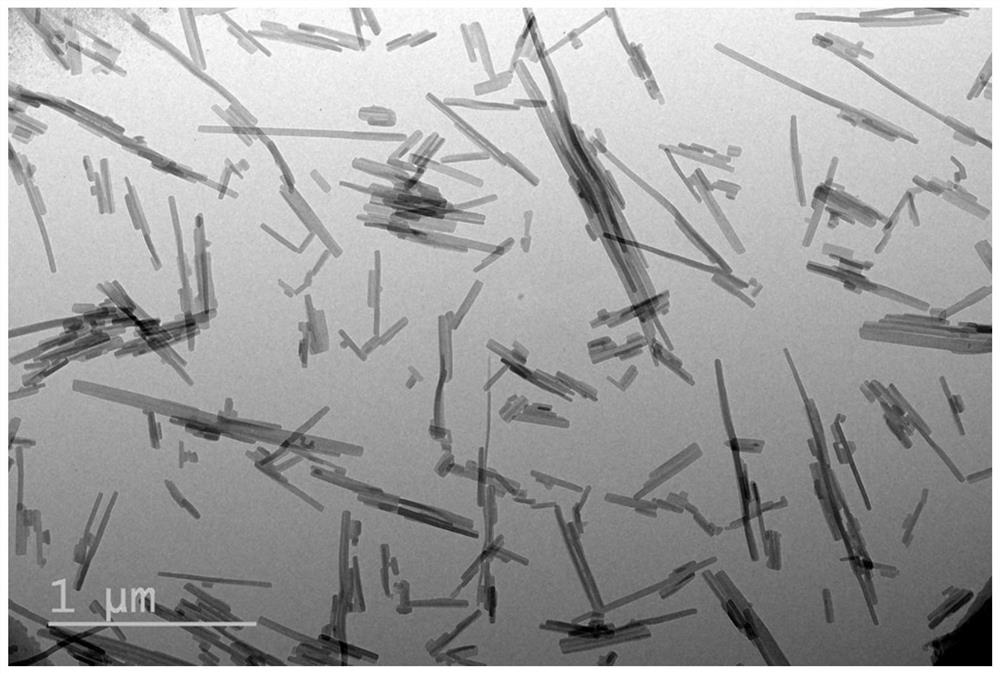

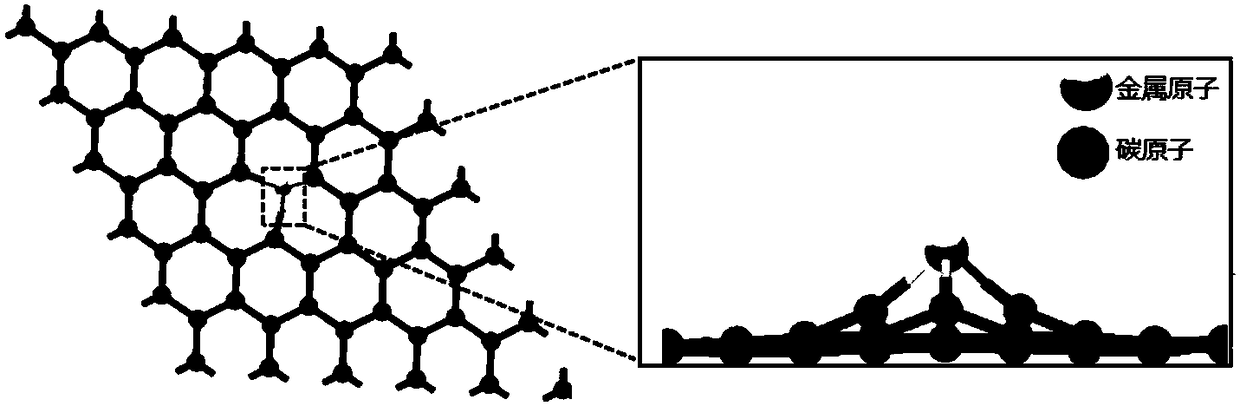

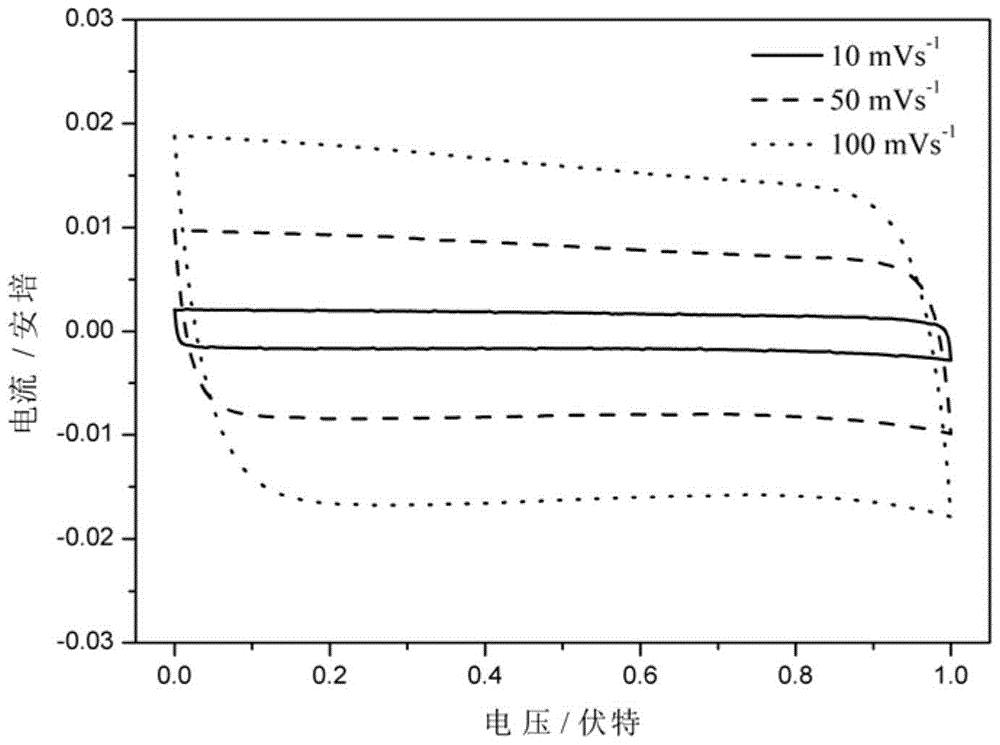

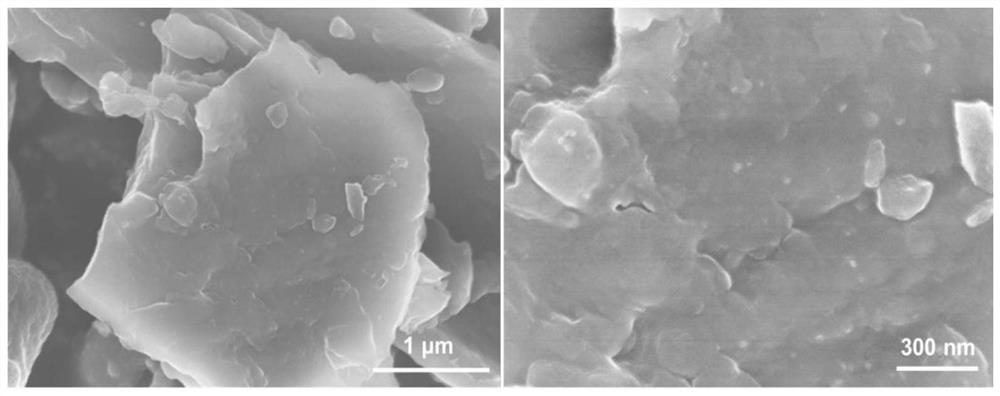

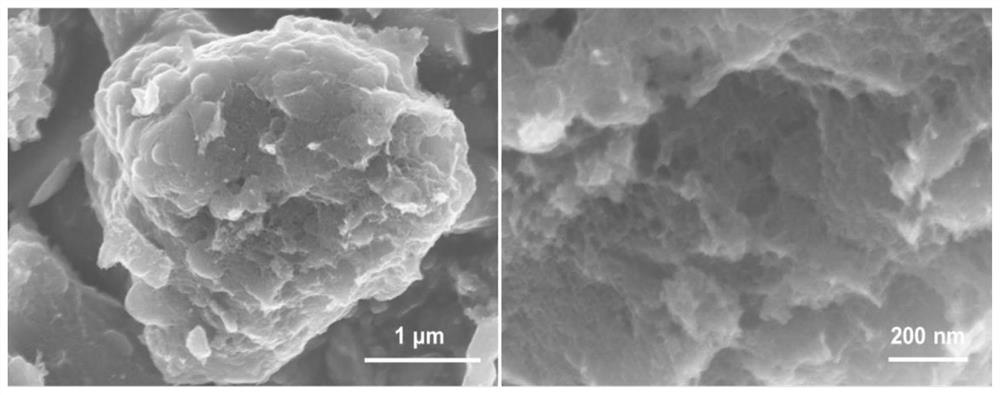

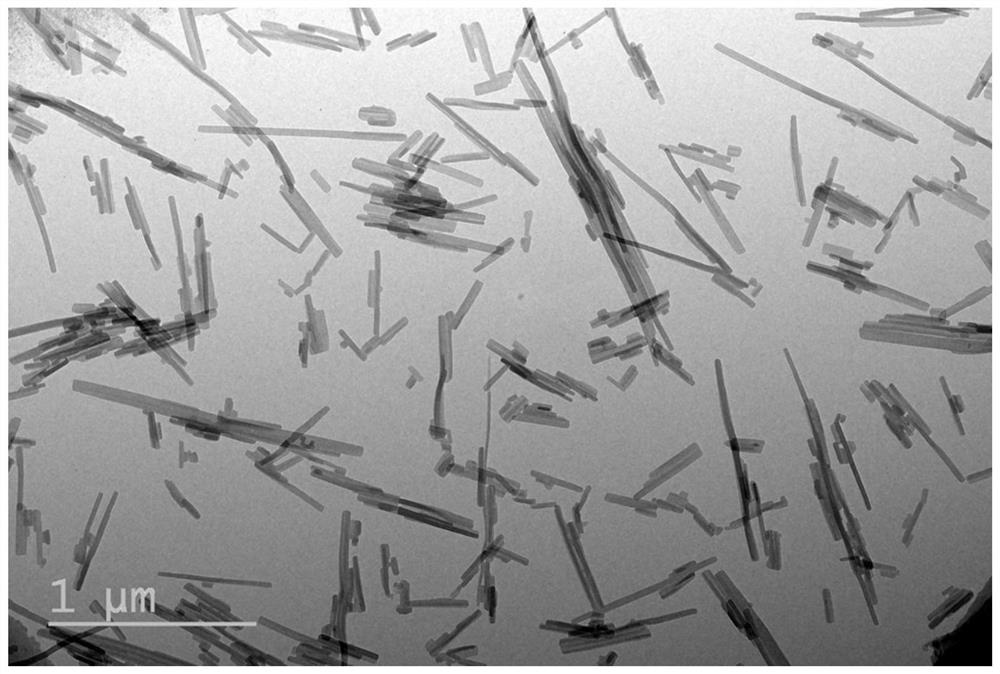

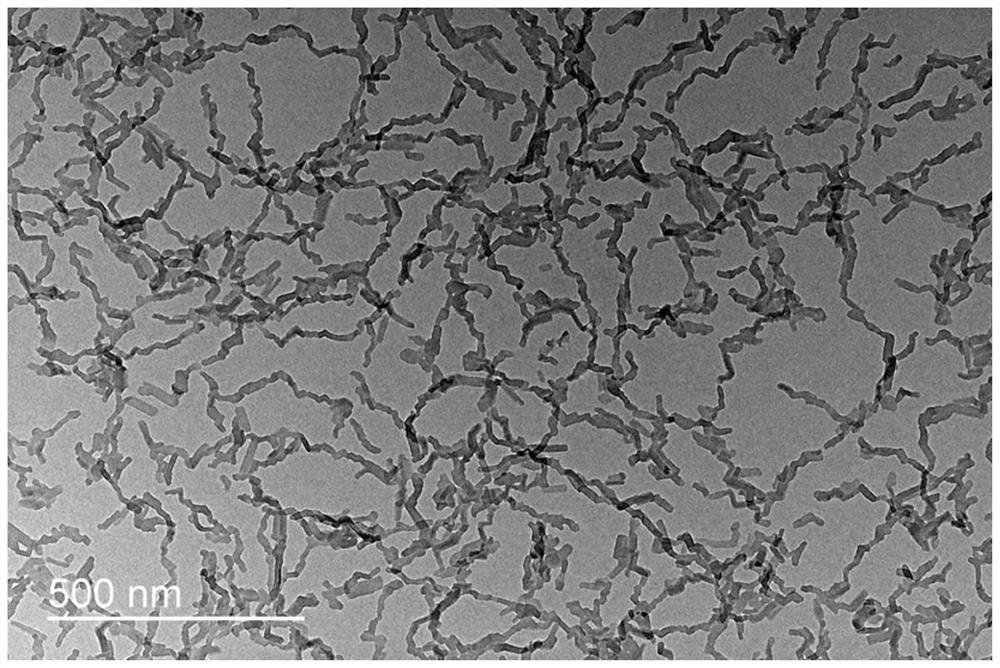

Metal phthalocyanine-MXene composite material, supercapacitor and preparation method thereof

ActiveCN111763213APrevent restacking effectIncreased electrochemical active sitesOrganic chemistryHybrid capacitor electrodesElectrochemical responseSupercapacitor

The invention discloses a metal phthalocyanine-MXene composite material as well as a preparation method and application thereof. The method for preparing the metal phthalocyanine-MXene composite material comprises the following steps of: (1) mixing metal phthalocyanine with a first solvent to obtain a metal phthalocyanine solution, and adding the metal phthalocyanine solution into water to obtaina metal phthalocyanine nano structure; and (2) mixing the metal phthalocyanine nano structure, an MXene material and a second solvent to obtain the metal phthalocyanine-MXene composite material. The method is simple in technological process and good in repeatability; the adopted materials are easy to synthesize and low in price; large-scale preparation is easy; and commercialization of the materials and devices is facilitated. With the method adopted, the metal phthalocyanine nano structure can be introduced between MXene layers to serve as an interlayer spacer, therefore, the restacking effect of the MXene is effectively prevented, electrochemical active sites on the surface of the MXene are increased, the ion mobility in an electrochemical oxidation reduction process is remarkably enhanced, and then the electrochemical response to charge storage can be improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

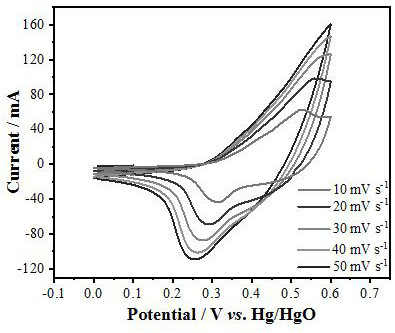

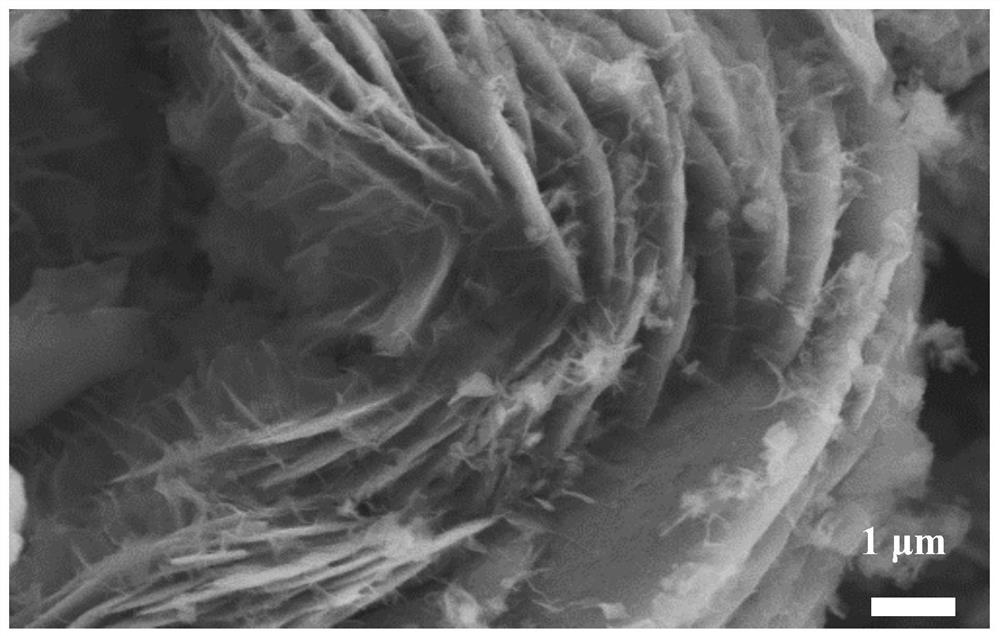

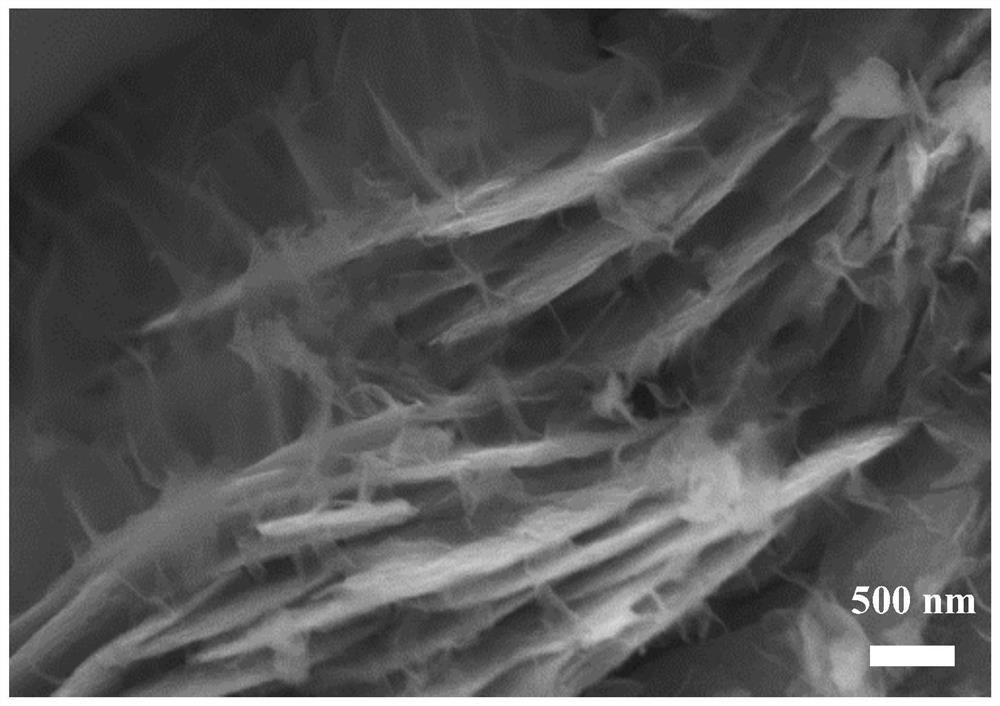

Composite electrode and preparation method and application

ActiveCN108172407AImprove bindingImprove mechanical stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceCarbon layer

The invention belonging to the fields of electronic materials and devices discloses a composite electrode comprising a substrate. A carbon layer is electroplated on the surface of the substrate; and atransition metal oxide layer is electroplated on the surface of the carbon layer. The composite electrode has a three-dimensional porous fold structure; and the maximum mass specific capacitance of the composite electrode can reach up to 1783F.g-1. The preparation method of the composite electrode comprises: step one, preparing a substrate; step two, preparing a solution; step three, electroplating a carbon layer; step four, electroplating a transition metal oxide layer; and step five, carrying out cleaning and drying. Meanwhile, an application of the composite electrode in a super capacitoris also provided. The composite electrode has the high conductivity and high mass specific capacitance and cycle stability; and the maximum mass specific capacitance of the composite electrode can reach up to 1783F.g-1; the electrode can work circularly for 2000 times under the current density of 6A.g-1; and the specific capacitance can be kept to be 84.4% of the initial value. The composite electrode has the broad application prospects.

Owner:ANHUI UNIVERSITY

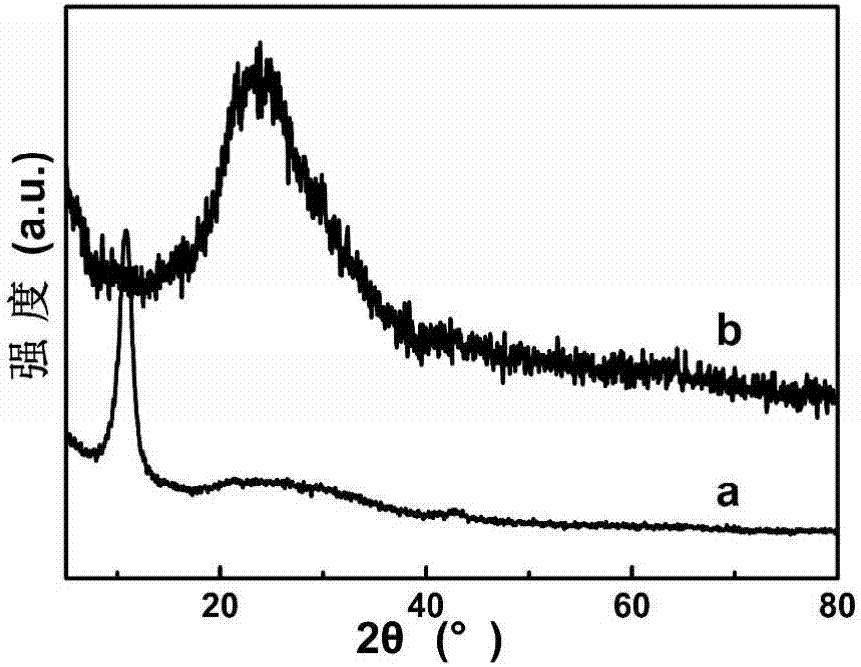

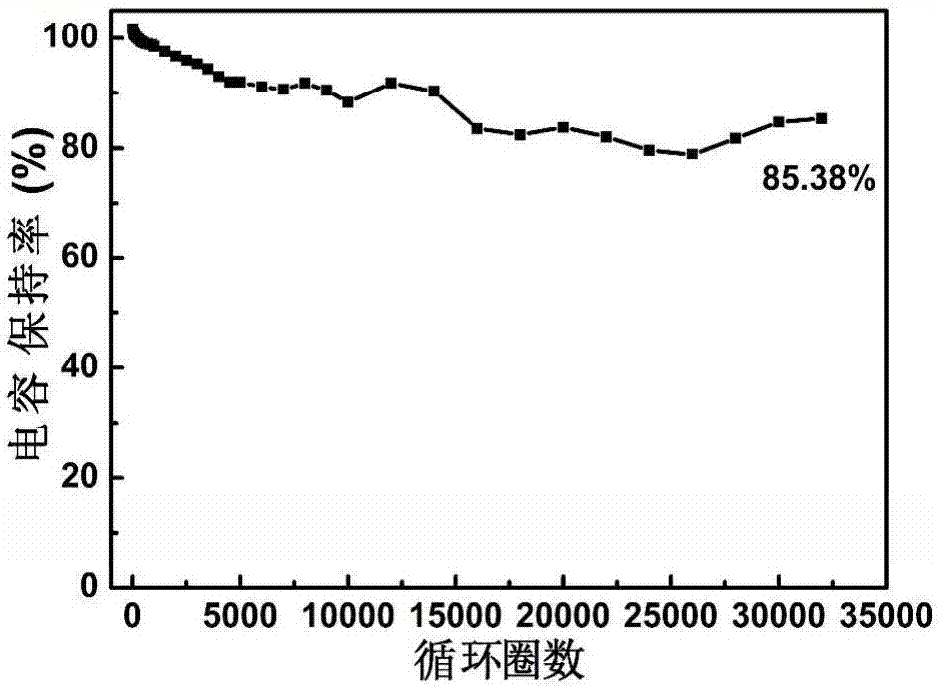

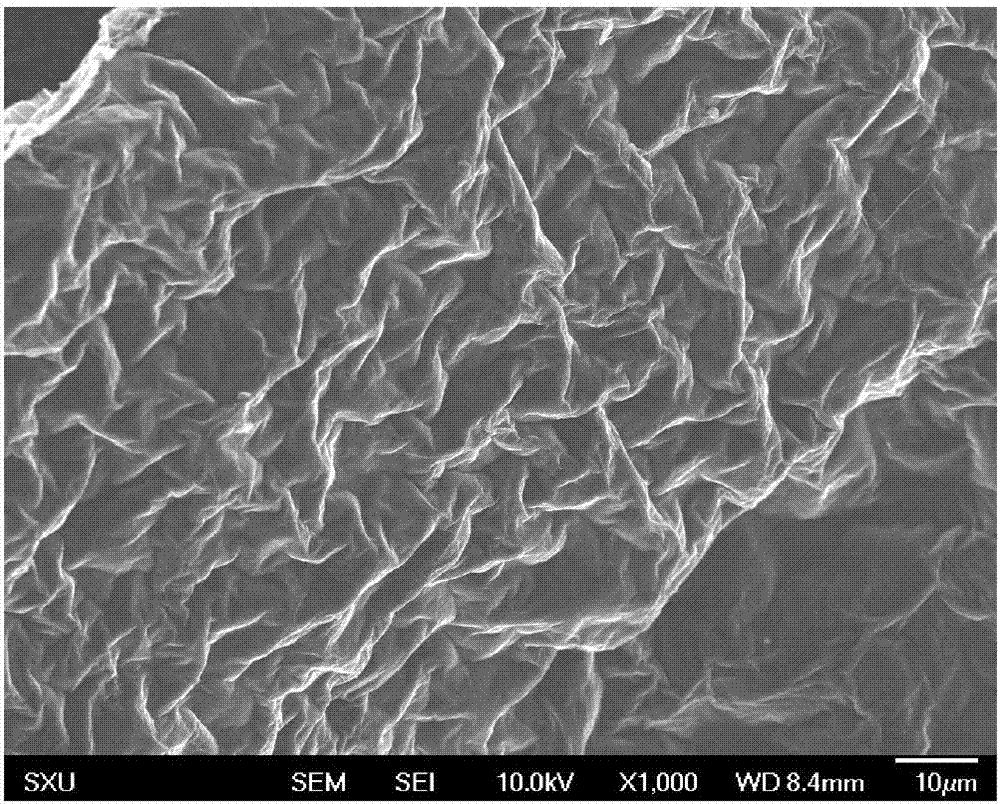

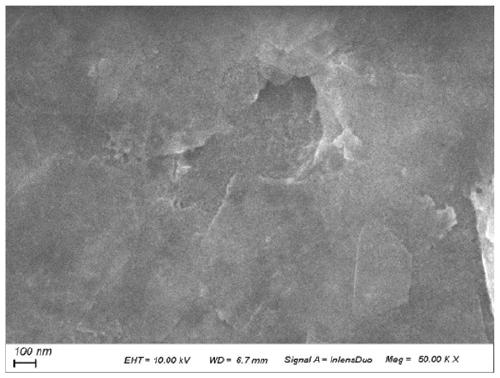

Preparation method for graphene membrane electrode material of supercapacitor

InactiveCN107337199AImprove Capacitive PerformanceReduce dosageHybrid capacitor electrodesGrapheneDistilled waterRoom temperature

The invention provides a preparation method for a graphene membrane electrode material of a supercapacitor. The preparation method comprises the following steps: thoroughly soaking a graphene oxide membrane or reduced graphene oxide membrane in a polytetrafluoroethylene reaction vessel filled with concentrated sulfuric acid; carrying out a reaction at 120 to 180 DEG C for 3 to 24 h; and then carrying out cooling at room temperature, washing with distilled water and drying so as to prepare the graphene membrane electrode material. A supercapacitor assembled from the graphene membrane electrode material has good capacitive performance, especially superior cycle stability. The preparation method provided by the invention is convenient to operate. The prepared graphene membrane electrode material is applicable as an electrode material to symmetric or asymmetric supercapacitors.

Owner:SHANXI UNIV

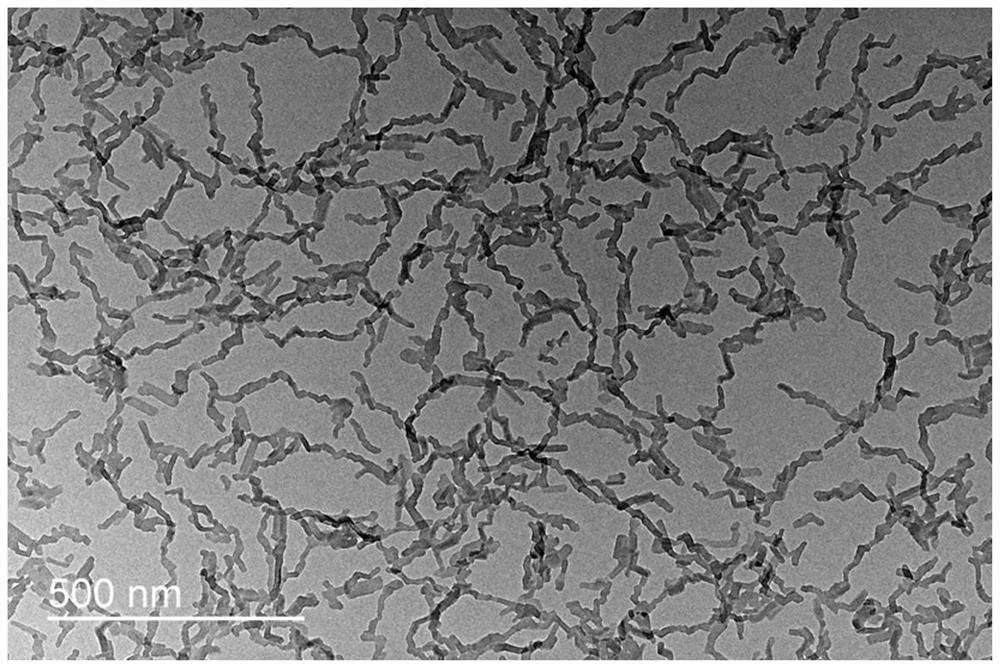

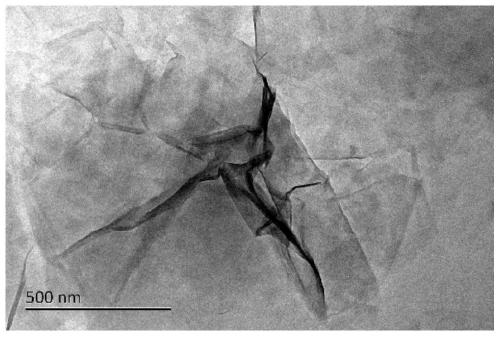

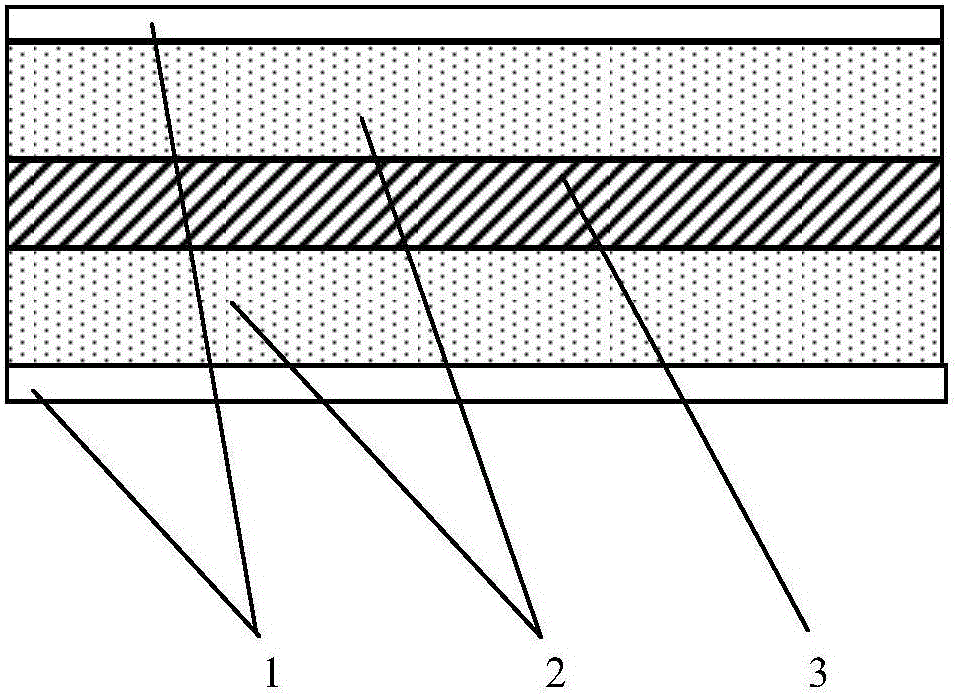

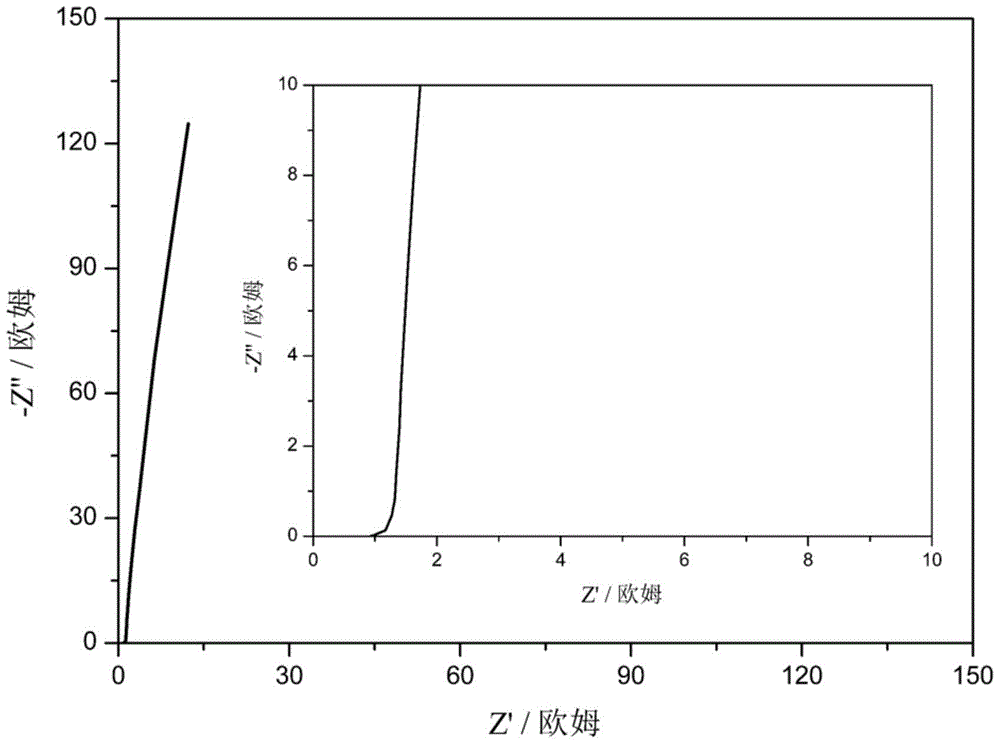

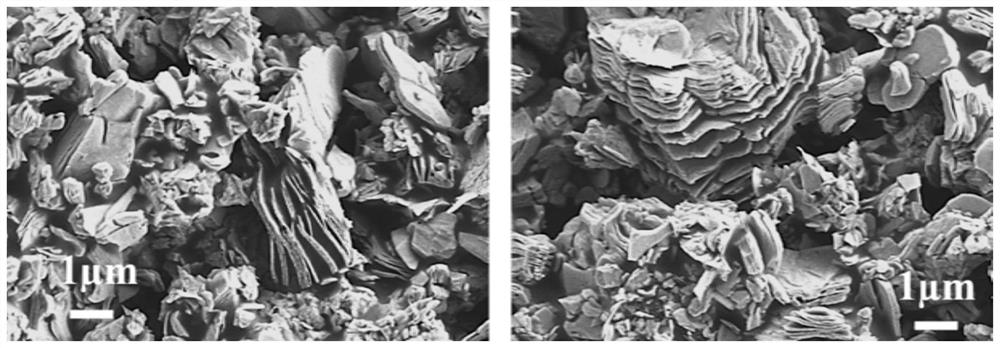

MXene/ZnMnNi LDH Van der Waals heterostructure, preparation method and application thereof

ActiveCN111599603ASolve conductivity problemsSolve the disadvantages of easy self-stackingHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMetallurgy

The invention relates to an MXene / ZnMnNi LDH Van der Waals heterostructure, a preparation method and application thereof. The preparation method comprises: 1, preparing a single-layer ZnMnNi LDH nanosheet (F-ZnMnNi LDH); 2, preparing a single-layer MXene nanosheet (F-MXene); and 3, alternately stacking the F-ZnMnNi LDH and the F-MXene to form the F-MXene / F-ZnMnNi LDH Van der Waals heterostructure.The application comprises an electrode prepared by using the F-MXene / F-ZnMnNi LDH Van der Waals heterostructure, and a super capacitor prepared from the electrode. The F-MXene / F-ZnMnNi LDH Van der Waals heterostructure shows excellent electrochemical performance, the actual specific capacitance and the cycling stability of an electrode material are improved, and the F-MXene / F-ZnMnNi LDH Van der Waals heterostructure has good application in the field of supercapacitors.

Owner:NANJING UNIV OF SCI & TECH

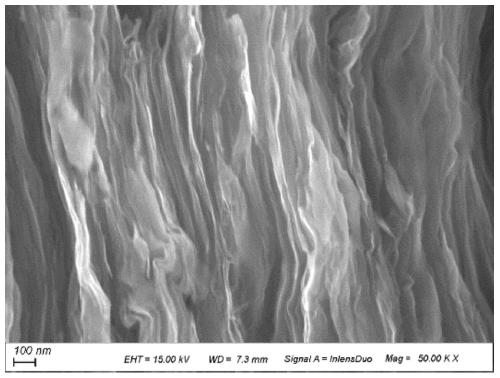

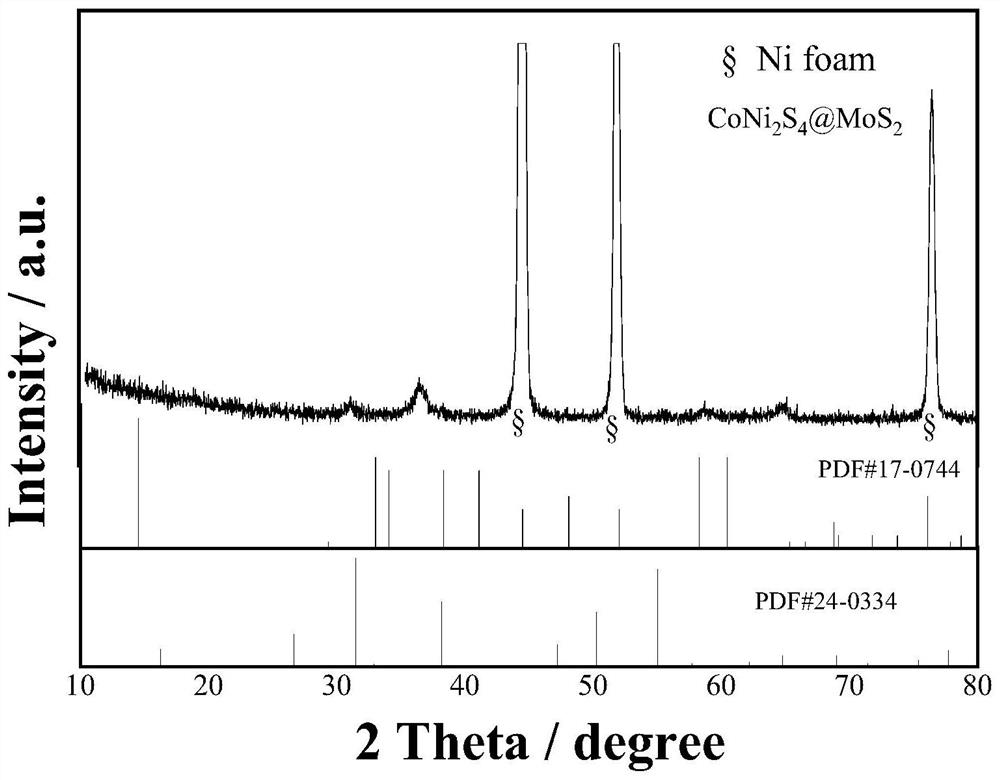

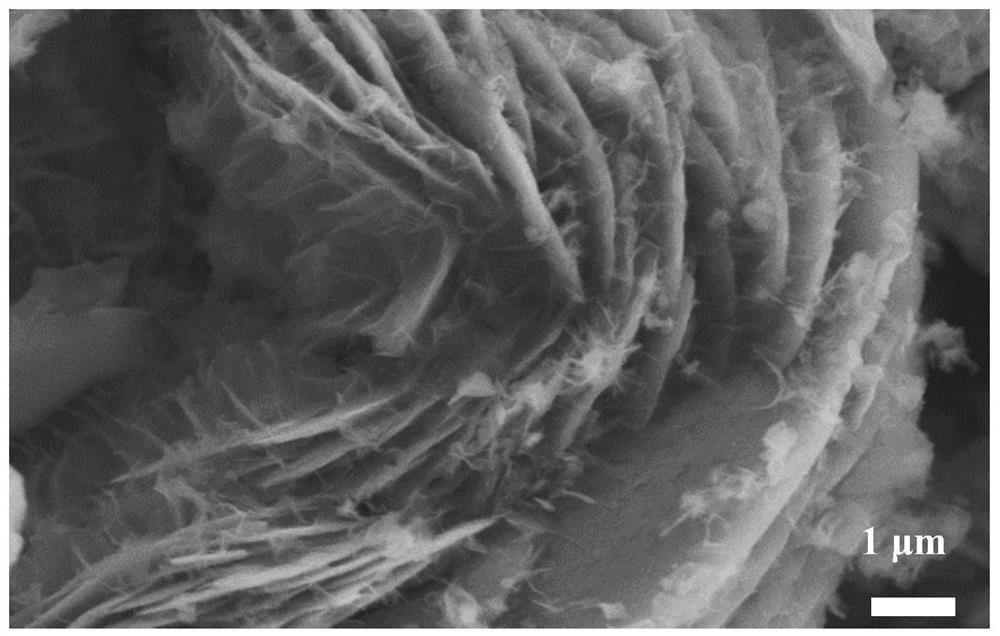

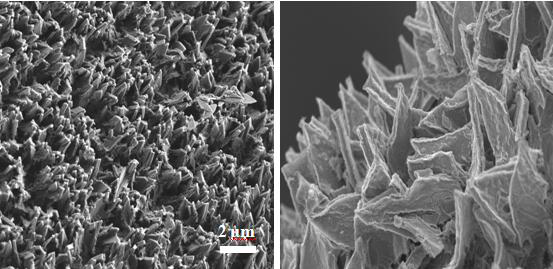

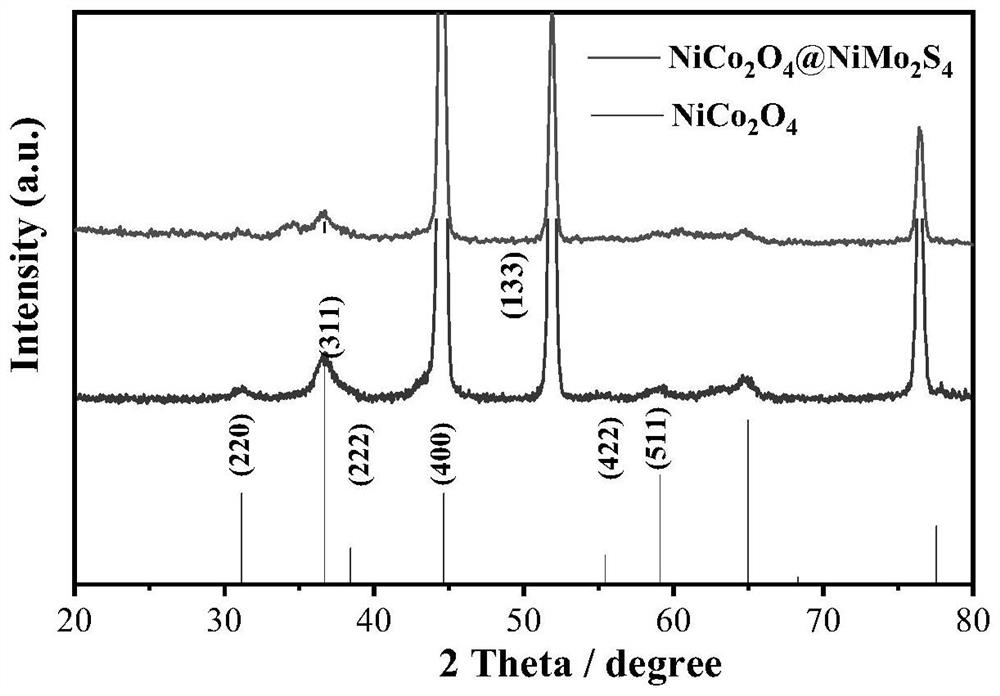

Preparation method of high-performance cabbage-shaped heterostructure electrode material

ActiveCN112863887ALow electrochemical performanceImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureHeterojunctionSodium molybdate

The invention belongs to the field of electrode material preparation, and particularly relates to a preparation method of a high-performance cabbage-shaped heterostructure electrode material. The method comprises the following steps of pretreating foamed nickel, dissolving 2-3 mmol of nickel acetate, 4-5 mmol of cobalt acetate, 2-3 mmol of sodium molybdate, 30-40 mmol of ammonium fluoride and 2-5 g of urea into 60-100 ml of water, stirring, reacting, cooling, cleaning and drying to obtain a prepared sample, dissolving 8-9 mmol of sodium sulfide in 60-70 ml of deionized water, magnetically stirring for 45 minutes, transferring the prepared sample into the solution, transferring into a reaction kettle, keeping the temperature at 80-90 DEG C for 12 hours, naturally cooling to room temperature, cleaning for three times by using absolute ethyl alcohol and deionized water, keeping the temperature of the prepared sample at 60 DEG C for 6 hours, and drying to obtain a finished product. The problems that the material morphology is not uniform, the synthesis method cannot be accurately controlled, the conductivity is poor, and the adhesion with a current collector is poor are solved.

Owner:SHENYANG POLYTECHNIC UNIV

Preparation method of highly flexible composite electrode

ActiveCN110136997AFiber Mechanical PropertiesImprove flexibilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePolypyrrole

The invention discloses a preparation method of a highly flexible composite electrode, comprising the following steps: weighing and taking dimethylimidazole and pyrrole monomer in turn and dissolvingdimethylimidazole and pyrrole monomer in the water / methanol mixed solution to obtain a solution A; weighing and taking zinc nitrate hexahydrate and anhydrous ferric trichloride in turn, dissolving zinc nitrate hexahydrate and anhydrous ferric trichloride in the water / methanol mixed solution, and stirring the substances evenly to obtain a solution B; soaking filter paper in the solution A for 1-4h;taking the filter paper out and sucking the surface filtrate; putting the filter paper in the solution B for 20s and taking the filter paper out, and putting the filter paper in the solution A for 20s; repeating the previous step 10 times; soaking and washing the filter paper in de-ionized water to remove the surface residual; and drying the filter paper to a constant weight to obtain a highly flexible filter paper / ZIF-8 / polypyrrole functional composite material. The composite material obtained has excellent flexibility and high mass specific capacitance, and can be directly used as a workingelectrode without any binder. The size and thickness of the electrode material are controllable. The preparation process is simple, feasible, green and economical.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of NiO@CoMoO4/NF capacitor electrode

ActiveCN113421775AImprove conductivityFacilitated DiffusionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrolytic agent

The invention discloses a preparation method of a NiO@CoMoO4 / NF capacitor electrode. The NiO@CoMoO4 / NF capacitor electrode is prepared by taking NF, COCl2.6H2O, Na2MOO4.2H2O, glucose and a tough material as raw materials through the steps of preparation of NiO@CoMoO4 / NF, loading of NiO@CoMoO4 / NF carbon quantum dots, coating of the NiO@CoMoO4 / NF tough material loaded with the carbon quantum dots and the like. The NiO@CoMoO4 / NF has a higher specific capacitance value, meanwhile, the conductivity of the electrode can be greatly improved, on the other hand, the NiO@CoMoO4 / NF electrode is treated by a ductile material, so that the NiO@CoMoO4 / NF electrode can adapt to volume change in the charging and discharging process, meanwhile, the corrosion effect of an electrolyte can be prevented, finally, the product is good in cycling stability, and after 10000 times of charging and discharging cycles, the capacity is not attenuated, 100% of the maximum capacity is still kept, the mass specific capacitance is greatly increased, the mass specific capacitance of the electrode at 1 A / g can reach 1457 F / g, the electrochemical energy storage is excellent, and the electrode is worthy of market popularization.

Owner:CHONGQING UNIV OF ARTS & SCI

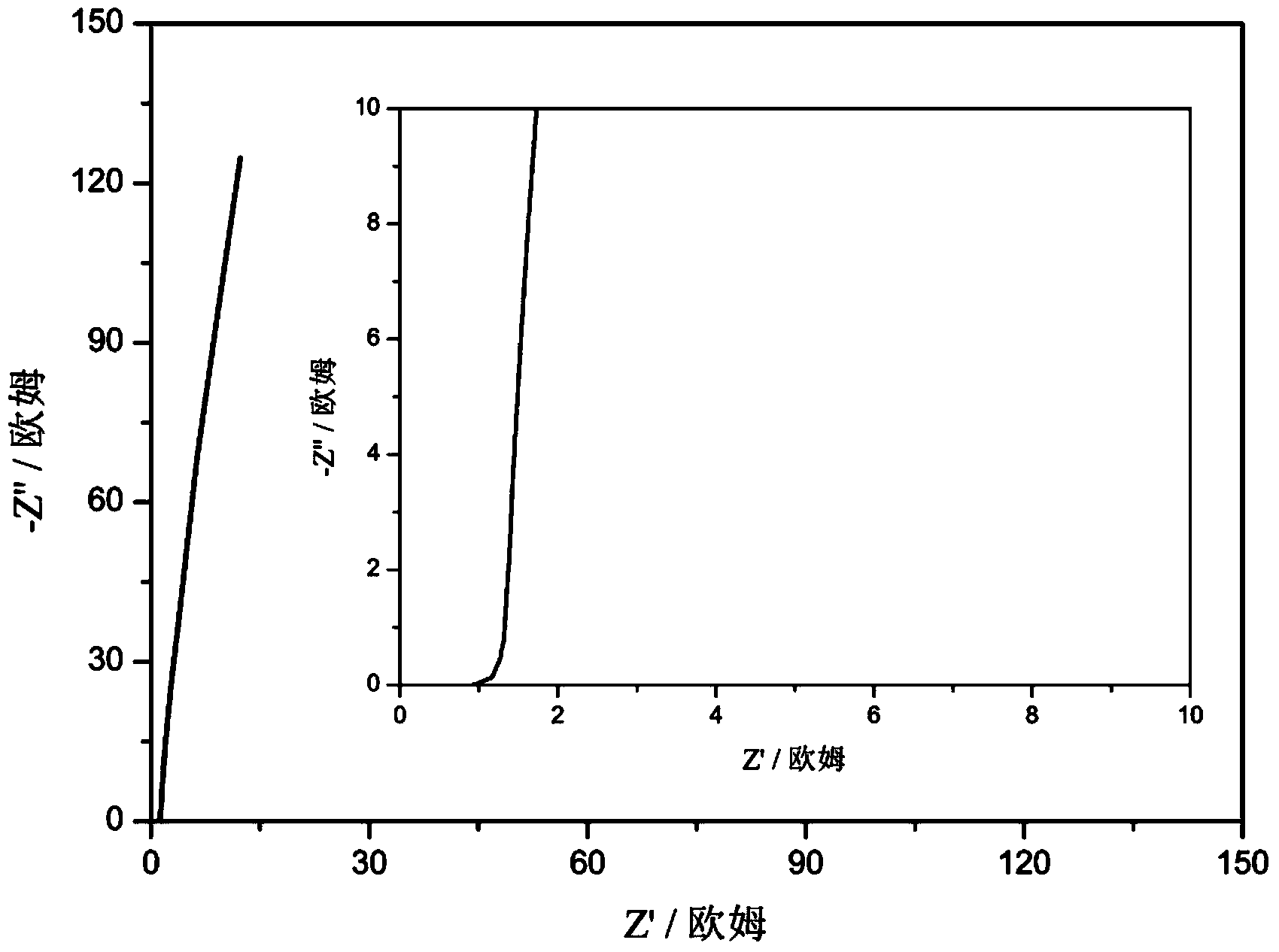

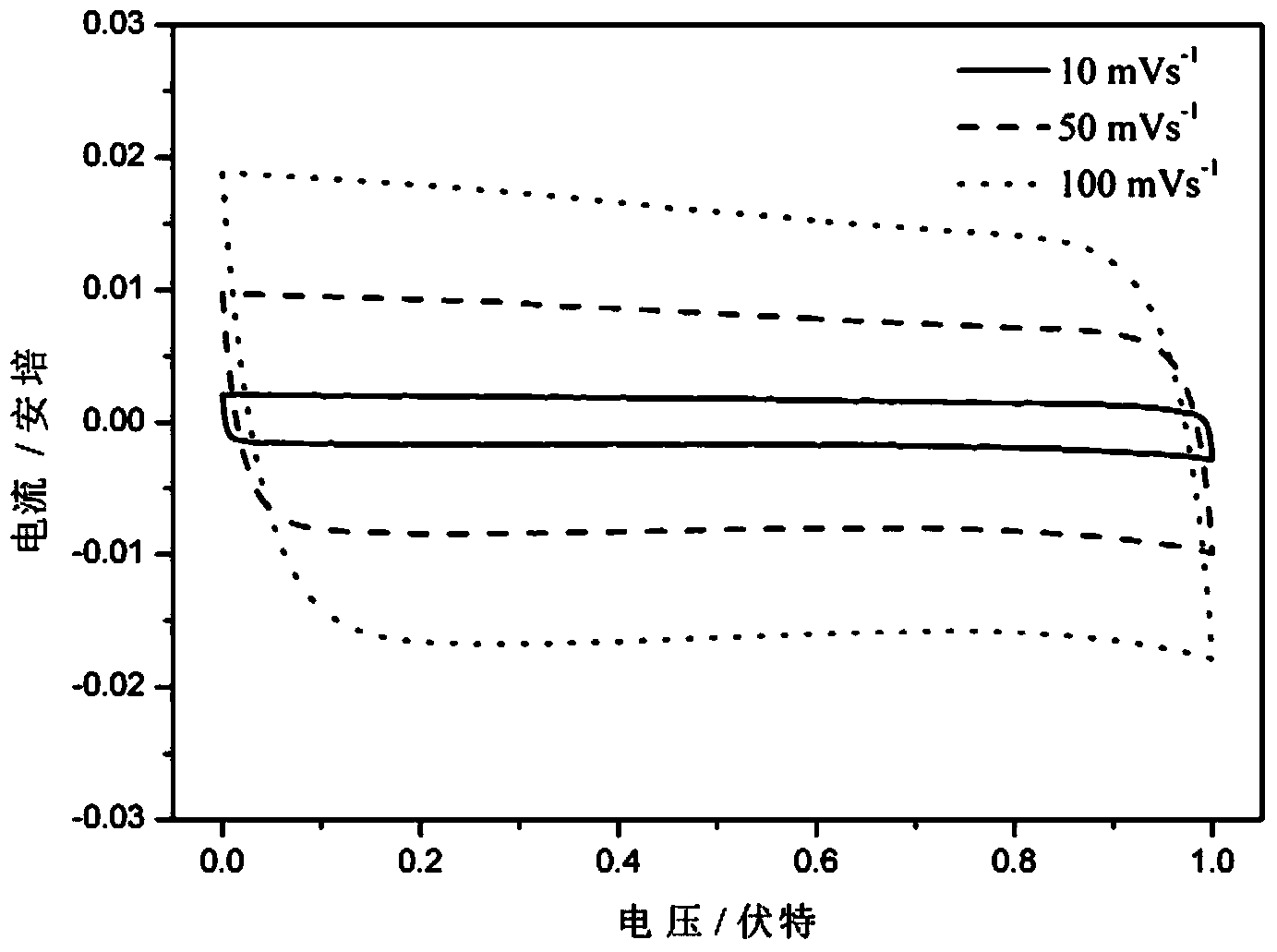

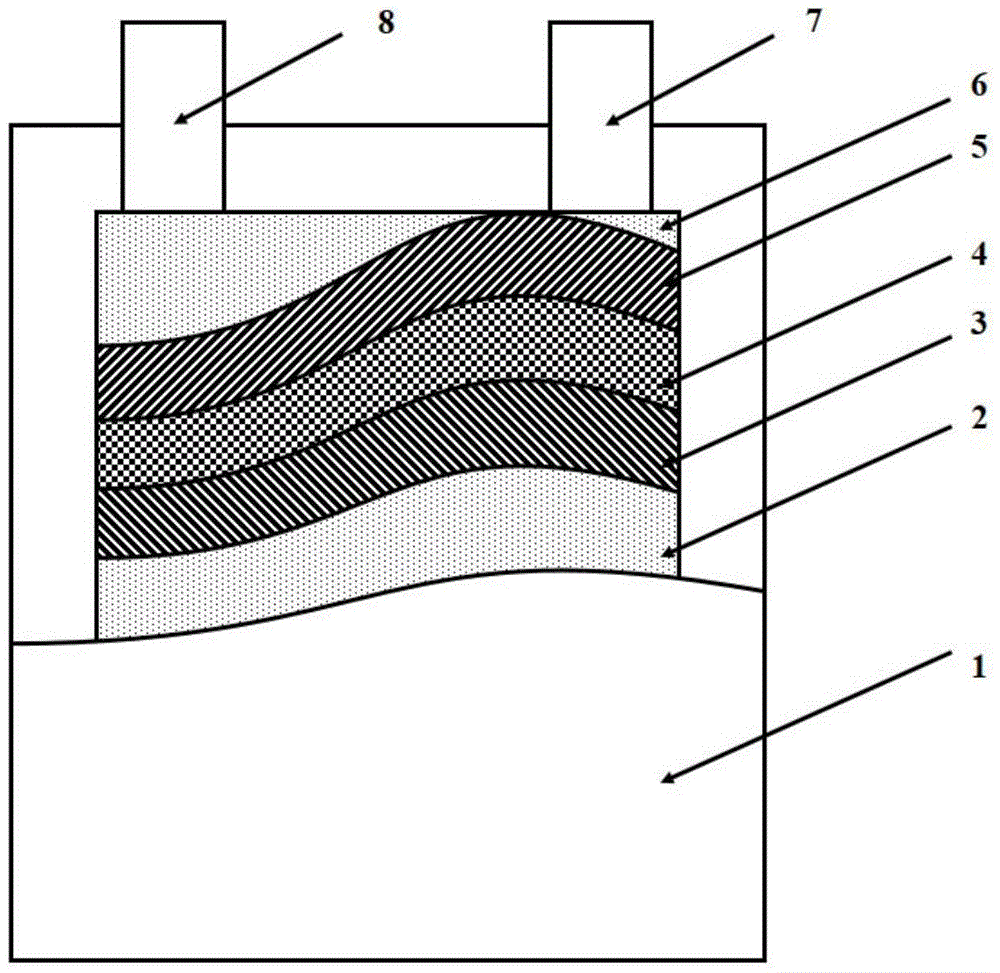

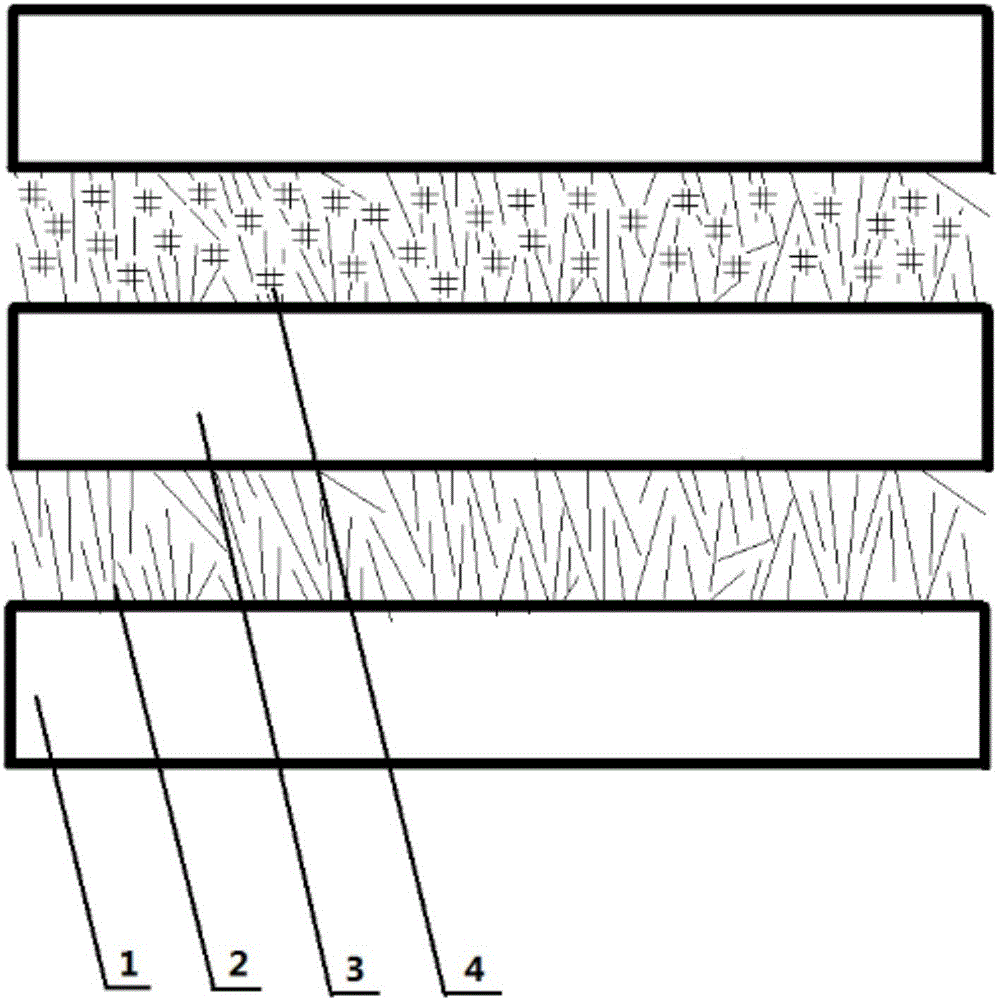

Polyarylether/ hydrophilic resin composite diaphragm for supercapacitor and preparation method of diaphragm

ActiveCN104072794AHigher quality than capacitanceImprove securityHybrid capacitor separatorsHybrid/EDL manufactureElectric vehicleVacuum drying

The invention relates to a polyarylether / hydrophilic resin composite diaphragm for a supercapacitor and a preparation method of the diaphragm, which belongs to the technical field of the super-capacitor. The preparation method is characterized by comprising the steps: blending a brooethyl polyarylether solution with a hydrophilic resin solution, casting the mixed solution on a clean and tidy glass plate, and drying the glass plate in a vacuum drying box so as to form a membrane on the glass plate; and ammoniumizing and alkalizing the obtained brooethyl polyarylether / hydrophilic resin composite membrane, and cleaning the residual alkaline liquid in the membrane by utilizing deionized water to obtain the polyarylether / hydrophilic resin composite diaphragm. The supercapacitor manufactured by adopting the polyarylether / hydrophilic resin composite diaphragm prepared through the method is high in electrolyte adsorption volume, low in contact resistance, high in ion conductivity and high in mass specific capacity; moreover, the large weight and large size of the single supercapaictor caused by vast electrolyte can be avoided, the safety of the supercapacitor is improved, an assembling space can be reduced, and the potential application value is high in the fields such as electronic devices and hybrid electric vehicle.

Owner:JILIN UNIV

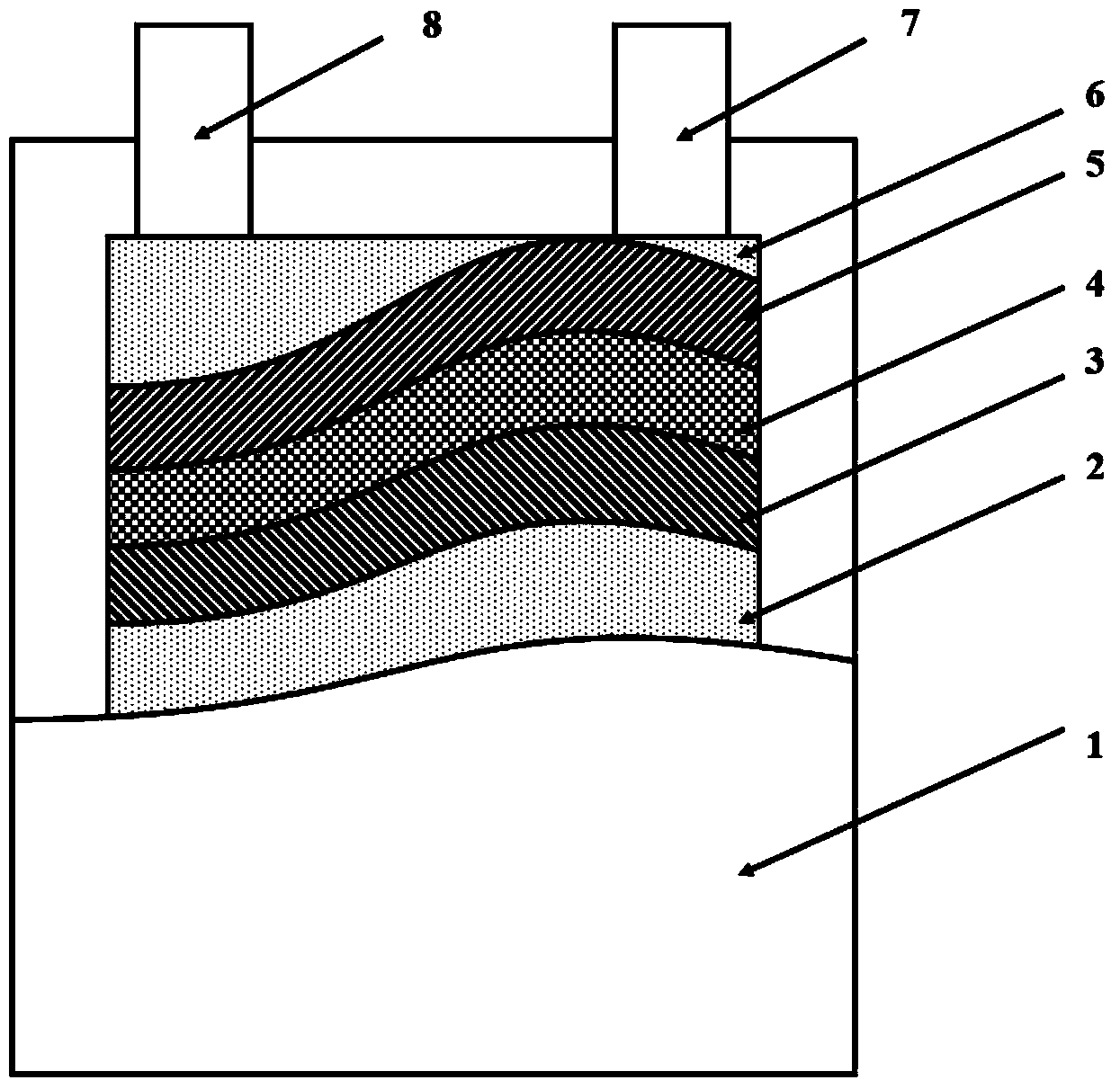

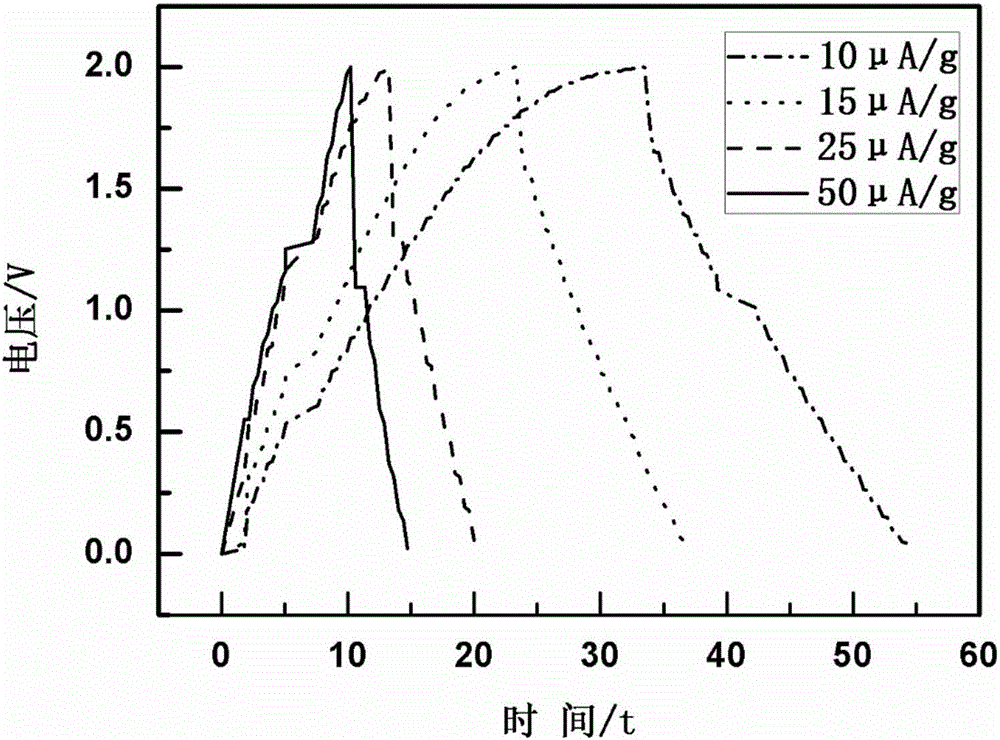

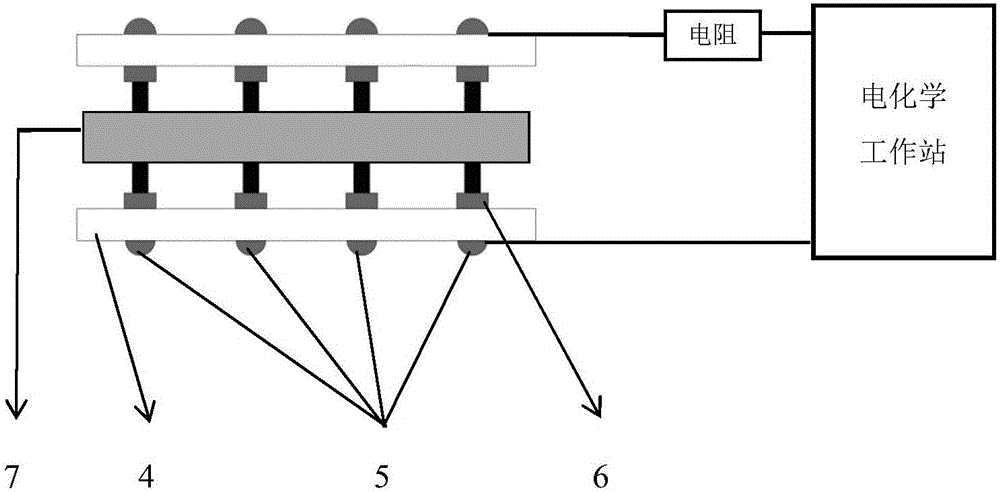

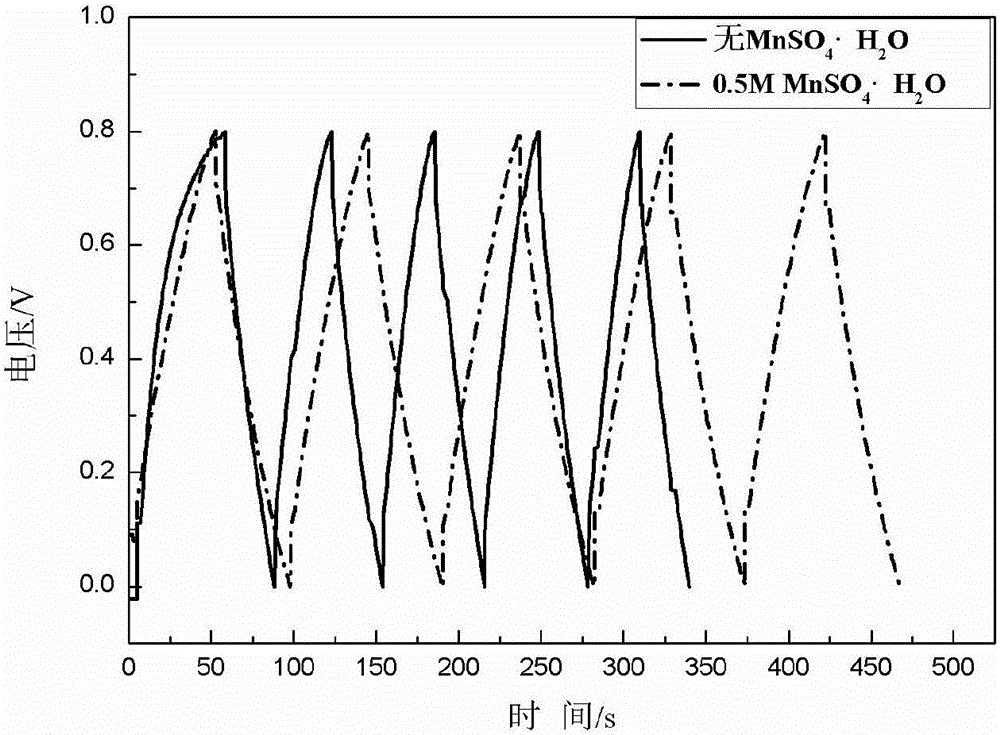

Edible supercapacitor and preparation method and application thereof

InactiveCN106504911AIncrease the output voltageImprove securityHybrid capacitor separatorsHybrid capacitor electrolytesCapacitanceEngineering

The invention discloses an edible supercapacitor and a preparation method and an application thereof. A metal clamp is adopted as an electrode substrate; and an active material layer, a diaphragm and an electrolyte of the capacitor are all made from food, and can be directly ate and digested easily by a human or an animal before or after charging. The food adopted by the supercapacitor is wide in resource; the maximum output voltage of the prepared supercapacitor can be 2.000V while the maximum mass specific capacitance can be 2.693 mF / g; and the supercapacitor has the characteristics of high charging speed, high safety, environment friendliness, and no pollution. When the edible supercapacitor is ate, the current released by the capacitor can provide electric stimulation for taste bud of a patient with dysgeusia so as to generate gestation; based on the electricity storage characteristic, the supercapacitor can supply power for a medical micro robot so as to prolong the power supply time; and the discharge current also can be utilized to kill bacteria in a human body, and the like, so that the edible supercapacitor has wide application prospect.

Owner:ANHUI UNIVERSITY

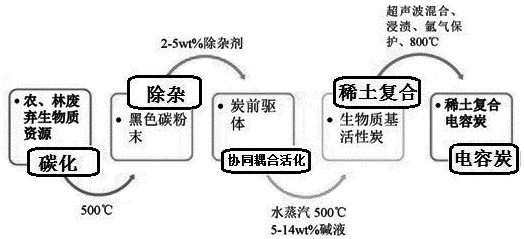

Preparation method of rare earth composite biomass-based capacitor carbon material

ActiveCN111968863AHigher quality than capacitanceHigher volume than capacitanceCarbon compoundsHybrid capacitor electrodesCarbonizationMaterials science

The invention discloses a preparation method of a rare earth composite biomass-based capacitor carbon material, which comprises the following steps: by using rice husk, straw, straw, folium cycas andbamboos as raw materials, and carrying out low-temperature carbonization, alkali liquor low-temperature impregnation, alkali liquor etching activation and rare earth high-temperature compounding by using a chemical activation method to prepare the rare earth composite capacitor carbon material. By mastering the action mechanism of rare earth ions or rare earth compounds and adopting trace doping compounding, the capacitor carbon material is modified, and the specific capacitance, cycle life and other properties of the capacitor carbon are further improved. Finally, the advantages of the rare earth material are utilized to the maximum extent, the cost is reduced, and the application prospect of the rare earth material in the future energy storage field is wider. According to the method, agricultural and forestry waste biomass resources which are rich in reserves, cheap and easy to obtain are used as raw materials, the biomass resources are reasonably utilized, and the method has great significance in stabilizing agricultural ecological balance, improving the energy structure and relieving environmental pressure.

Owner:NANCHANG NORMAL UNIV

Preparation method of nitrogen-doped porous biochar and method for preparing electrode material

PendingCN114212790AImprove surface microstructureImprove electrochemical performanceCarbon compoundsHybrid capacitor electrodesCarbonizationBiochar

The invention relates to the technical field of capacitor electrode production, in particular to a preparation method of nitrogen-doped porous biochar and a method for preparing an electrode material, and the method comprises the following steps: (1) raw material pretreatment: mixing and pretreating algae biomass and terrestrial biomass; (2) adding an activating agent: mixing the pretreated raw materials with the activating agent; and (3) carbonizing and pickling: carbonizing the mixture obtained in the step (2) under the protection of inert gas, pickling the obtained biochar until the biochar is neutral after the reaction is finished, and drying to obtain the nitrogen-doped porous biochar.

Owner:JIANGSU TAIHU BOILER

Preparation method of modified graphite electrode material and application thereof

ActiveCN107017096ALarge specific surface areaHigher quality than capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceCarbonization

The invention discloses a preparation method of a modified graphite electrode material and an application thereof. The process comprises the steps of oxidizing graphite to acquire a graphite oxide, then enabling the graphite oxide to be mixed with ammonia water and performing heating processing, subsequently performing high-temperature processing under the protection of nitrogen to acquire an activated product, then performing modification, putting the modified graphite oxide into a reactor, adding a mixed solvent of deionized water and absolute ethyl alcohol, polyvinylpyrrolidone and tetrapropyl orthosilicate, performing high-temperature processing to acquire an intermediate compound, carrying out solidification processing, ball-milling processing and carbonization processing on the intermediate compound, finally adding sodium dodecylbenzene sulfonate, magnet powder, nickel hydroxide, a conductive agent and a binding agent, and preparing an electrode piece through the steps of stirring, coating, drying, rolling and the like. The prepared modified graphite electrode material is large in specific surface area, high in mass specific capacitance and high in power density, and has good application prospects. Meanwhile, the invention further discloses an application of the modified graphite electrode material prepared according to the process in preparation of a supercapacitor.

Owner:SUZHOU HAILINGDA EIECTRONIC TECH CO LTD

Preparation method of fiber/graphene/carbon quantum dot/cobalt nickel sulfide flexible electrode material

ActiveCN110164709ASmall particle sizeIncrease transfer rateHybrid capacitor electrodesCvd grapheneNickel salt

The invention discloses a preparation method of a fiber / graphene / carbon quantum dot / cobalt nickel sulfide flexible electrode material, which comprises the following steps: A, soaking a pretreated fiber fabric in a suspension containing graphene oxide, drying, and repeating the step for multiple times to obtain a fiber / graphene oxide material; and B, immersing the material obtained in the step A into a hydrothermal reaction kettle containing carbon quantum dots, and carrying out heating reaction synthesis to obtain the fiber / graphene / carbon quantum dot flexible electrode material. And C, immersing the material obtained in the step B into a hydrothermal reaction kettle containing nickel salt, cobalt salt and a sulfur-containing precursor solution, and carrying out heating reaction synthesisto obtain the fiber / graphene / carbon quantum dot / cobalt nickel sulfide flexible electrode material. The material prepared by the method disclosed by the invention has relatively high area specific capacitance and power characteristics, and is excellent in cycle performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

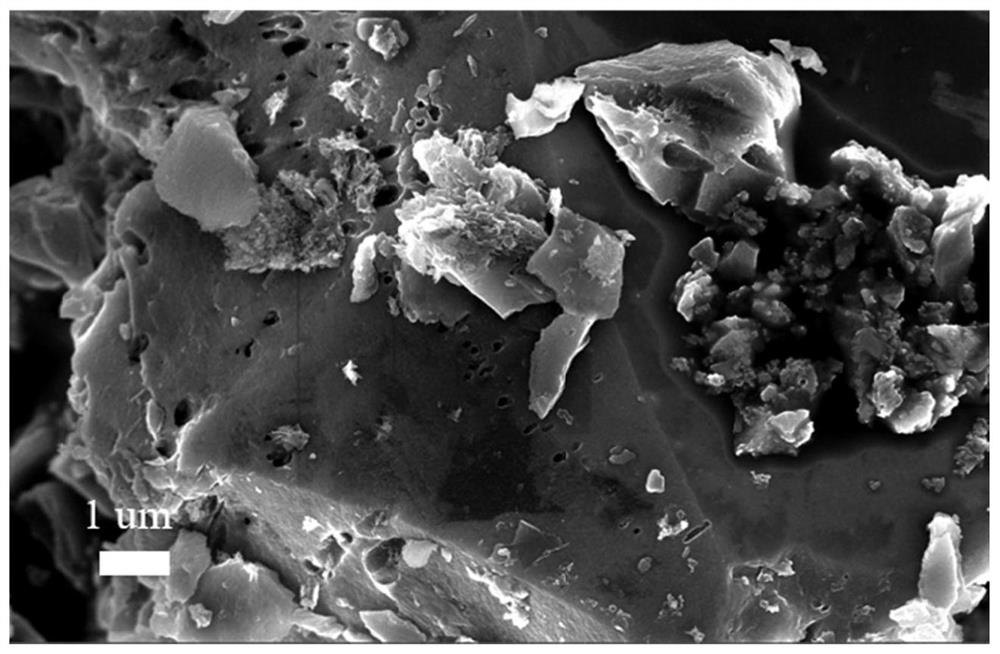

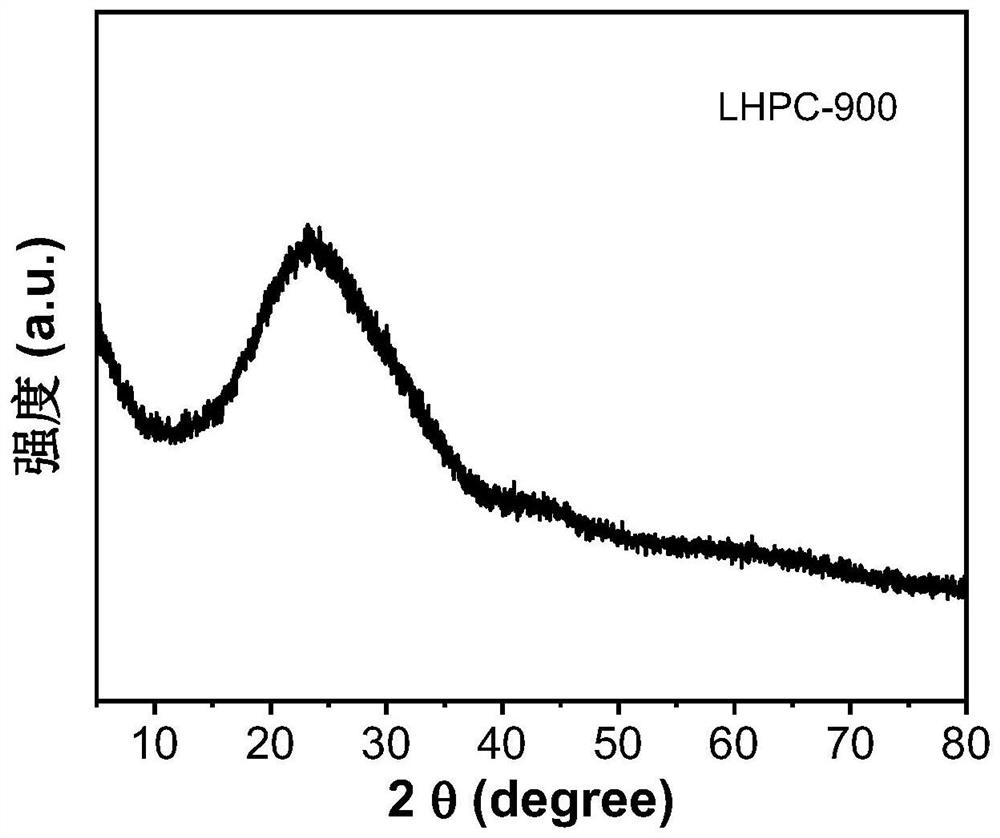

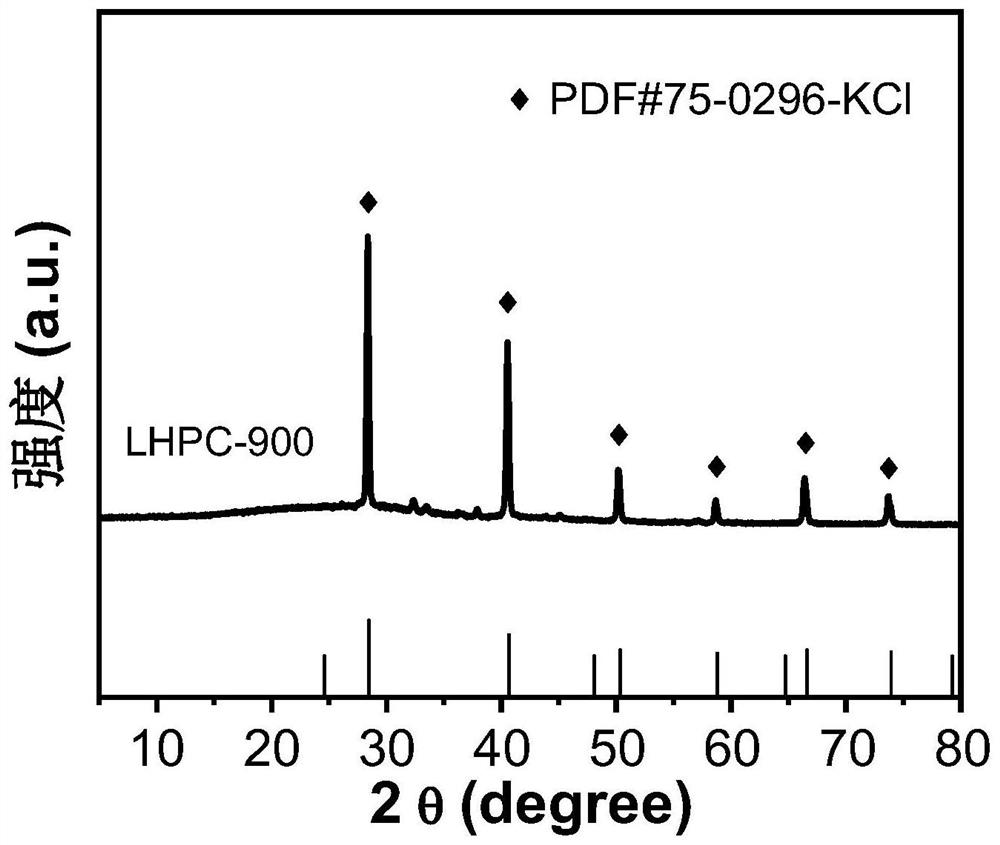

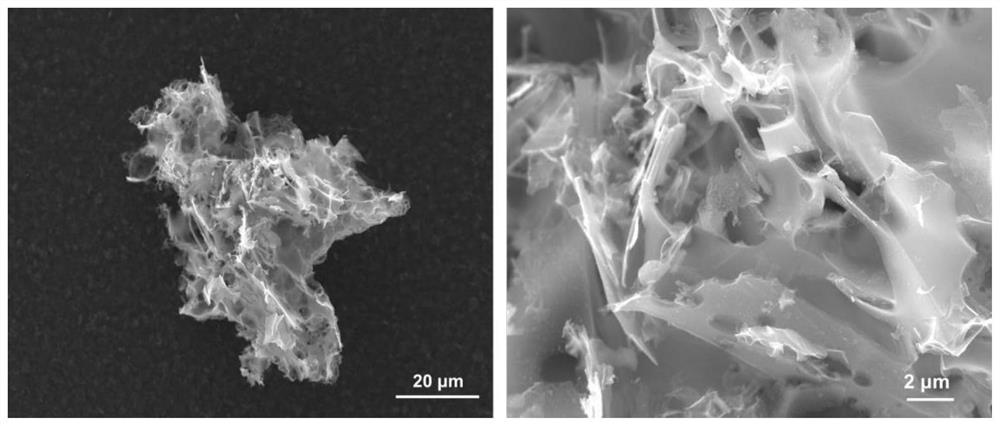

Preparation and application of lignin-based hierarchical porous carbon based on direct carbonization method

The invention discloses preparation of lignin-based hierarchical porous carbon based on a direct carbonization method and application of the lignin-based hierarchical porous carbon to an electrochemical supercapacitor. Under the condition that a small amount of KOH is introduced, lignin is subjected to carboxylation and phenolic hydroxylation modification by utilizing the advantage of rich functional groups of lignin, and potassium atoms are grafted to carboxyl or phenolic hydroxyl. According to the method, the effect of assisting chemical activation with physical activation is achieved, under the condition that no template agent is added, template salt KCl or carbonate is formed in the pyrolysis carbonization process to achieve the self-template effect, and the obtained porous carbon not only has the high specific surface area and the developed pore channel structure, but also has the excellent super-capacitor performance. The rich pore structure of the lignin-based hierarchical porous carbon can effectively improve the mass specific capacitance, coulombic efficiency and rate capability of the supercapacitor.

Owner:GUANGDONG UNIV OF TECH

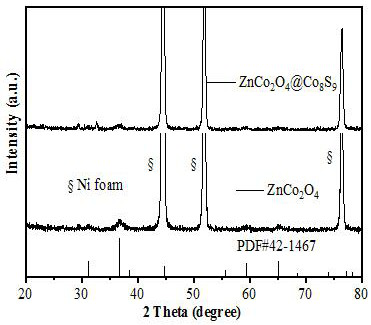

Preparation method of high-performance supercapacitor heterostructure electrode material

InactiveCN113140412AImprove electrochemical performanceExcellent rate performanceMaterial nanotechnologyCobalt sulfidesCOBALTOUS NITRATEElectrode material

The invention belongs to the field of electrode material preparation, and mainly relates to a preparation method of a high-performance supercapacitor heterostructure electrode material. The method comprises the following steps: pretreating foamed nickel, dissolving 1 mmol of nickel nitrate, 2 mmol of cobalt nitrate, 8-10 mmol of ammonium fluoride and 1-2 g of urea into 55 ml of water, and carrying out heat preservation at 120 DEG C for 6 hours; dissolving 1 mmol of cobalt nitrate, 8 to 10 mmol of ammonium fluoride and 0.5 to 1 g of urea into 50 ml of water; transferring the solution into a reaction kettle, and keeping the temperature at 110 DEG C for 6 hours; dissolving 0.35 g of sodium sulfide in 55 ml of deionized water, magnetically stirring for 20 min, preserving heat at 120 DEG C for 6 h, naturally cooling to room temperature, preserving heat of the prepared sample at 60 DEG C for 12 h, and drying to obtain the prepared electrode material. The problems that the structure of the material is unstable, the size is uniform, the synthesis method cannot be accurately controlled, the conductivity is poor, and the contact property with a current collector is poor are solved.

Owner:SHENYANG INST OF ENG

Preparation method of fiber/graphene/carbon quantum dots/FeOF flexible electrode material

ActiveCN110136976ASmall particle sizeIncrease transfer rateHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneCapacitance

The invention discloses a preparation method of a fiber / graphene / carbon quantum dots / FeOF flexible electrode material, which comprises the following steps: A, impregnating pretreated fiber fabric in asuspension containing graphene oxide and drying the fiber fabric, and repeating the step several times to obtain a fiber / graphene oxide material; B, immersing the material obtained in step A in a hydrothermal reaction vessel containing carbon quantum dots, and synthesizing a fiber / graphene / carbon quantum dots flexible electrode material by heating reaction; and C, immersing the material obtainedin step B in a hydrothermal reaction vessel containing FeF3.3H2O and alcohol solution, and synthesizing a fiber / graphene / carbon quantum dots / FeOF flexible electrode material by heating reaction. The material prepared by the method of the invention has higher area specific capacitance and power characteristics and superior cycle performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

A polyarylether/hydrophilic resin composite diaphragm for supercapacitor and preparation method thereof

ActiveCN104072794BHigher quality than capacitanceImprove securityHybrid capacitor separatorsHybrid/EDL manufactureCapacitanceHybrid car

A polyarylether / hydrophilic resin composite diaphragm for supercapacitors and a preparation method thereof belong to the technical field of supercapacitors. It is to blend the bromomethyl polyarylether solution with the hydrophilic resin solution, cast it on a clean and tidy glass plate, and dry it in a vacuum oven to form a film; the obtained bromomethyl polyarylether / hydrophilic resin The resin composite membrane is further ammonized and basified, and the residual lye in the membrane is washed with deionized water to finally obtain a polyarylether / hydrophilic resin composite membrane. The supercapacitor manufactured by the polyarylether / hydrophilic resin composite diaphragm prepared by the present invention improves the adsorption capacity of the electrolyte, reduces the contact resistance, improves the ion conductivity, improves the mass specific capacitance, and avoids a large amount of electrolysis The high weight and large volume of the supercapacitor monomer brought by the liquid improves the safety of the supercapacitor, which is beneficial to the saving of assembly space, and has a wide range of potential application values in the fields of electronic equipment and hybrid vehicles.

Owner:JILIN UNIV

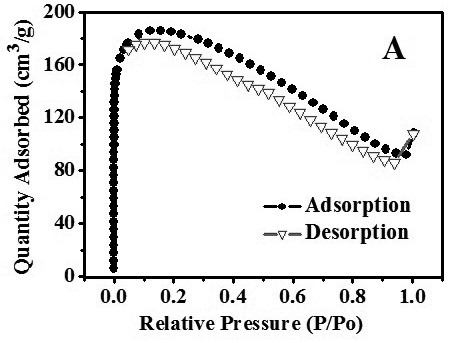

Porous carbon material based on high-temperature thermal shock carbonization and KOH activation of coconut shell material, preparation method and application

PendingCN114408919AMany poresNarrow pore size distributionCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention discloses a porous carbon material based on high-temperature thermal shock carbonization and KOH activation of a coconut shell material as well as a preparation method and application of the porous carbon material. The preparation method comprises the following steps: grinding the coconut shell material into particles, and then carrying out first thermal shock carbonization to obtain a coconut shell pre-carbonized material; the coconut shell pre-carbonized material and KOH powder are mixed and ground uniformly and then subjected to secondary thermal shock carbonization to obtain the porous carbon material, the preparation steps are simple, the consumed time is short, and the porous carbon material can be applied to a supercapacitor. When the proportioning ratio of the coconut shell pre-carbonized material to KOH is 1: 3, the prepared porous carbon electrode material shows the structural characteristics of large specific surface area, narrow pore size distribution and abundant pores, the electrochemical performance of the electrode material is improved, the specific performance is high specific capacitance of 225.15 F g <-1 > and good rate capability, and after the current density is increased by 10 times, the specific capacitance of the electrode material is greatly improved. And the specific capacitance can still reach 140.45 F g <-1 >. The preparation method is low in cost and simple and convenient to operate, has high specific capacitance and good rate capability, and is a promising electrode material applied to supercapacitors.

Owner:山东润生生物科技有限公司

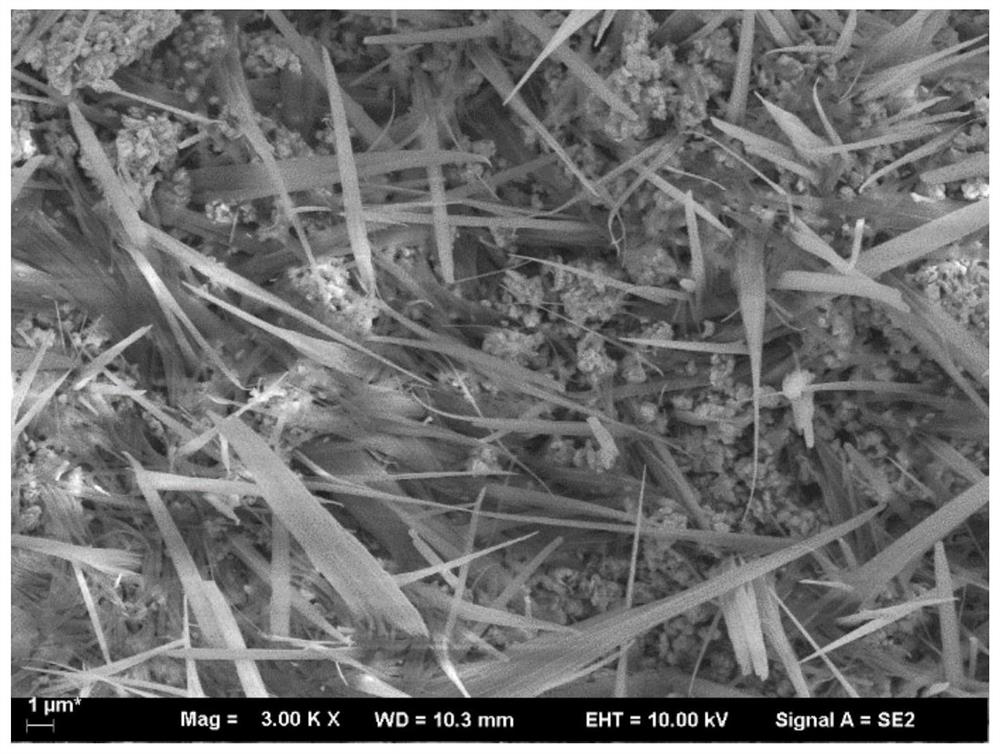

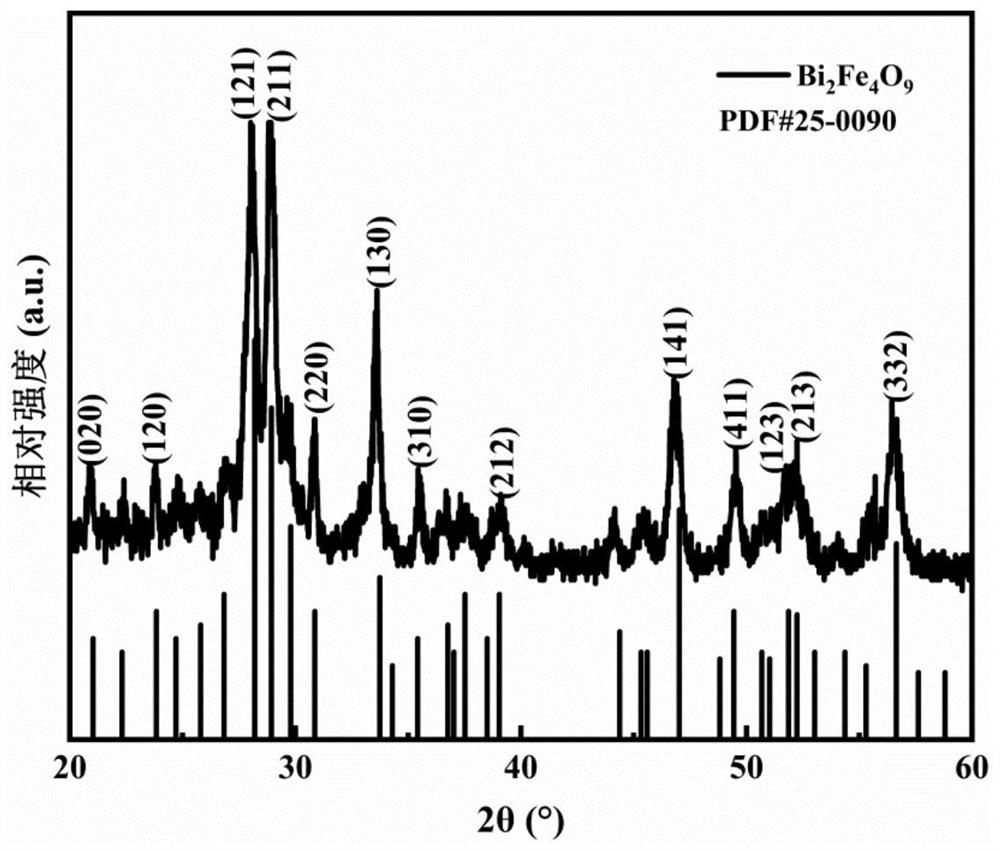

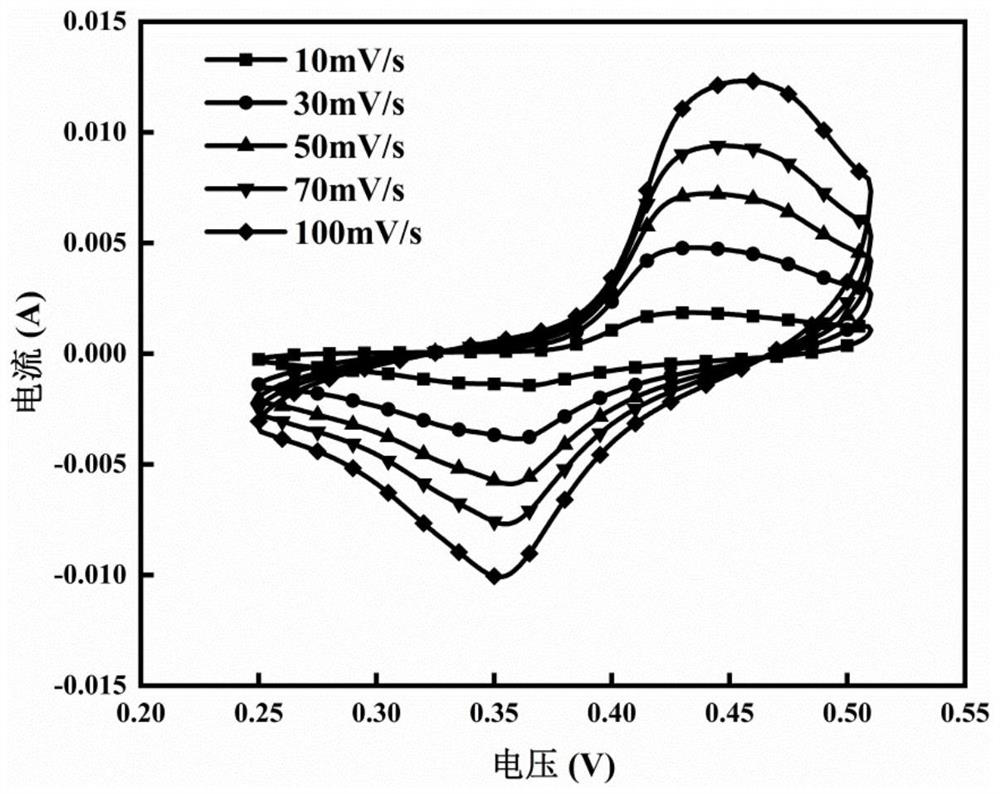

Preparation method of Bi2Fe4O9 material and application thereof

PendingCN114084911AIncrease contact areaChemically stableHybrid capacitor electrodesIron compoundsCapacitanceActive agent

The invention discloses a preparation method of a Bi2Fe4O9 material and an application thereof, and the method comprises the following steps: (1) adding bismuth salt, ferric salt and a surfactant into acid for dissolving, and titrating with an alkaline solution to obtain a precursor suspension; (2) carrying out a hydrothermal reaction on the precursor suspension; and (3) centrifuging, washing and drying the solution obtained by the reaction in the step (2) to obtain the Bi2Fe4O9 material. The Bi2Fe4O9 material obtained by the method is applied to a supercapacitor electrode and shows relatively high mass specific capacitance and relatively good electrochemical performance; by controlling the concentration of sodium hydroxide and the use amount of polyvinylpyrrolidone, a flower-shaped and strip-shaped Bi2Fe4O9 interlaced and nested structure can be obtained, and the special structure and more gaps provide a convenient conductive channel for charge transfer, so that the Bi2Fe4O9 material has the advantages of high specific capacity, stable charge and discharge and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method of high-performance supercapacitor heterostructure electrode material

PendingCN114360918AImprove electrochemical performanceOptimize electrode materialHybrid capacitor electrodesHybrid/EDL manufactureSodium molybdatePhysical chemistry

The invention belongs to the field of electrode material preparation, and mainly relates to a preparation method of a high-performance supercapacitor heterostructure electrode material. The method comprises the following steps: pretreating foamed nickel, and dissolving nickel nitrate, cobalt nitrate, ammonium fluoride and urea into water to prepare a precursor; dissolving cobalt nitrate, sodium molybdate, ammonium fluoride and urea into 50ml of water; and transferring the solution and the precursor into a reaction kettle to obtain the prepared electrode material. The problems that the structure of the material is unstable, the size is uniform, the synthesis method cannot be accurately controlled, the conductivity is poor, and the contact property with a current collector is poor are solved.

Owner:SHENYANG INST OF ENG

Supercapacitor capable of eating and preparation method thereof

InactiveCN106558426AHigher quality than capacitanceIncrease the output voltageHybrid capacitor separatorsHybrid capacitor electrolytesElectrolyteMetal

The present invention discloses a supercapacitor capable of eating and a preparation method thereof. The supercapacitor comprises an electrode active layer, a diaphragm and electrolyte which are all edible, the supercapacitor employs a metal clamp as an electrode conductive substrate, and the assembling is performed according to the sequence from the metal clamp, the electrode active layer, the diaphragm, the electrode active layer and the metal clamp. The active materials employ spicy sauce or flour. The metal clamp is taken as the electrode substrate, the active materials, the diaphragm and the electrolyte of the capacitor are formed by food, the source of the food materials is wide, the cost is low, and the prepared capacitor has high safety and is environmentally friendly and pollution-free.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

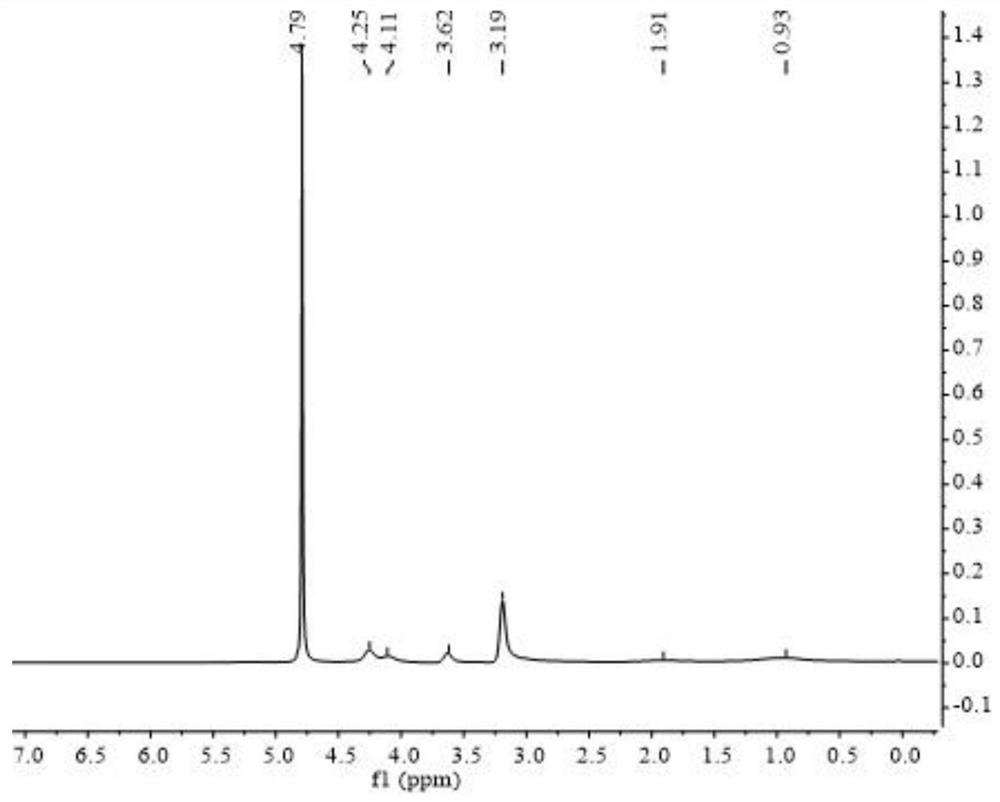

Polymer electrolyte containing zwitter-ionic groups and redox groups and preparation method of polymer electrolyte

ActiveCN112048036AEasy to prepareImprove electrochemical performanceHybrid capacitor electrolytesPolymer electrolytesRedox

The invention discloses a polymer electrolyte containing zwitter-ionic groups and redox groups. The structural general formula of the polymer electrolyte is shown in the specification. The polymer electrolyte disclosed by the invention has excellent electrochemical performance; the preparation method of the polymer electrolyte is simple and suitable for industrial production.

Owner:SHANGHAI UNIV

Preparation method of carbon foam with high electrochemical performances

The invention relates to a preparation method of carbon foam with high electrochemical performances, comprising the following steps of: firstly, weighing phenol formaldehyde, vanadate, surface active agent, sodium hydroxide and solvent according to mass ratio of 1:(0.6-4):(0.01-0.5):(1-20):(0.01-0.5):100, mixing uniformly and obtaining precursor solution of the carbon foam; putting the obtained solution into an environment with the temperature of 15 DEG C-60 DEG C to lead the solvent to be completely volatilized, and obtaining precursor of solid carbon foam; and solidifying the precursor of the solid carbon foam for 1 hour-24 hours at the temperature of 100 DEG C-200 DEG C, then rising the temperature to be 600 DEG C-1400 DEG C at the temperature rising speed of 1 DEG C / min-60 DEG C / min under the inert atmosphere, carbonizing for 0.5 hour-10 hours, and obtaining the carbon foam with high electrochemical performances. In the preparation method, the technology is simple, the quality is stable, vanadate introduced when the precursor solution of the carbon foam is prepared is converted into sodium vanadate nanocrystalline with a stable layer structure in the process of carbonization, and the obtained sodium vanadate nanocrystalline is embedded into a carbon foam skeleton uniformly. Compared with the existing carbon foam, the prepared carbon foam has the electrochemical performances such as high mass specific capacitance, good charging and discharging circulation and the like, and can be effectively applied in the fields such as electrode materials of electrochemical capacitorsand the like.

Owner:TONGJI UNIV

Metal phthalocyanine-mxene composite material, supercapacitor and preparation method thereof

ActiveCN111763213BPrevent restacking effectIncreased electrochemical active sitesOrganic chemistryHybrid capacitor electrodesElectrochemical responseSupercapacitor

The invention discloses a metal phthalocyanine-MXene composite material, a preparation method and an application thereof. Wherein, the method for preparing metal phthalocyanine-MXene composite material comprises: (1) metal phthalocyanine is mixed with first solvent, obtains metal phthalocyanine solution; Said metal phthalocyanine solution is added into water, obtains metal phthalocyanine nanostructure (2) mixing the metal phthalocyanine nanostructure, MXene material and the second solvent to obtain the metal phthalocyanine-MXene composite material. The process of the method is simple and repeatable, and the materials used are easy to synthesize, low in price, and easy to be prepared on a large scale, which is conducive to realizing the commercialization of materials and devices. By adopting this method, metal phthalocyanine nanostructures can be introduced between MXene layers to act as interlayer spacers, thereby effectively preventing the restacking effect of MXene and increasing the electrochemically active sites on the surface of MXene, which is useful for the electrochemical redox process. There is also a significant enhancement of the ion mobility, which in turn can improve the electrochemical response to charge storage.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A kind of nio@comoo 4 Preparation method of /nf capacitance electrode

ActiveCN113421775BImprove conductivityFacilitated DiffusionHybrid capacitor electrodesHybrid/EDL manufactureElectrolytic agentCapacitance

A kind of NiO@CoMoO 4 The preparation method of / NF capacitance electrode is based on NF, C O Cl 2 .6H 2 O, Na 2 m O o 4 .2H 2 O, glucose, and tough materials are used as raw materials, respectively, after NiO@CoMoO 4 Preparation of / NF, NiO@CoMoO 4 / NF carbon quantum dot loading, NiO@CoMoO loaded with carbon quantum dots 4 / NF toughness material wrapping and other steps are prepared. The present invention NiO@CoMoO 4 / NF has a higher specific capacitance value, and can also greatly improve the conductivity of the electrode. On the other hand, NiO@CoMoO 4 / NF electrodes are treated with tough materials, which can make NiO@CoMoO 4 The / NF electrode adapts to the volume change during the charging and discharging process, and at the same time can prevent the corrosion of the electrolyte, which ultimately makes the product cycle stable. After 10,000 charging and discharging cycles, the capacity of the present invention does not decay, and still maintains 100% of the maximum capacity. The mass specific capacitance has been greatly increased, and the mass specific capacitance of the electrode can be as high as 1457F / g at 1 A / g. The electrochemical energy storage is excellent, and it is worthy of market promotion.

Owner:CHONGQING UNIV OF ARTS & SCI

Preparation method of a high-performance cabbage-like heterostructure electrode material

ActiveCN112863887BReduce usageLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureHeterojunctionNickel(II) acetate

The invention belongs to the field of electrode material preparation, in particular to a preparation method of an electrode material with a high-performance cabbage-shaped heterostructure. The method comprises: pretreatment of foamed nickel, 2-3mmol nickel acetate, 4-5mmo cobalt acetate, 2-3mmol sodium molybdate, 30-40mmol ammonium fluoride, 2-5g urea dissolved in 60-100ml water, stirring, Reaction, cooling, cleaning and drying obtain the prepared sample; 8-9mmol sodium sulfide is dissolved in 60-70ml deionized water, magnetically stirred for 45min, then the prepared sample is transferred to this solution, transferred to the reaction kettle, and Insulate at 80‑90°C for 12 hours, cool naturally to room temperature, wash with absolute ethanol and deionized water three times, and dry the prepared sample at 60°C for 6 hours to obtain the finished product. Solve the problems of uneven material morphology, inability to accurately control the synthesis method, poor electrical conductivity, and poor adhesion to current collectors.

Owner:SHENYANG POLYTECHNIC UNIV

Fabrication method of supercapacitor electrode

InactiveCN106373787AImprove charge and discharge performanceEasy to operateMaterial nanotechnologyHybrid capacitor electrodesCapacitanceManganese oxide

The invention discloses a fabrication method of a supercapacitor electrode, and belongs to the field of an electronic material and a device. The fabrication process comprises the steps of preparing a substrate; adding a manganese salt, sodium dodecyl sulfate or a sodium dodecyl benzene sulfonate solution in a transition metal salt solution, coating the mixture on the substrate, and naturally drying the substrate; placing the substrate in an inner flame of an alcohol lamp flame, and heating the substrate for 2 minutes; and performing annealing for 60-300 minutes at 400 DEG C. In the fabrication process, a three-dimensional micro-nano porous nanocarbon-manganese oxide composite material will be formed from a precursor solution coated on the substrate during flame synthesis and has excellent conductivity and electrochemical activity; when the composite material is applied to an active material of the supercapacitor electrode, the mass-to-capacitance range can reach 10.99-322.60F / g; and moreover, the method for fabricating the supercapacitor electrode is simple and is low in cost, and thus, the method has a wide market application prospect.

Owner:ANHUI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com