Edible supercapacitor and preparation method and application thereof

A supercapacitor and food technology, applied in the field of electrochemical energy storage, achieves the effects of high safety, wide sources of ingredients and wide sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

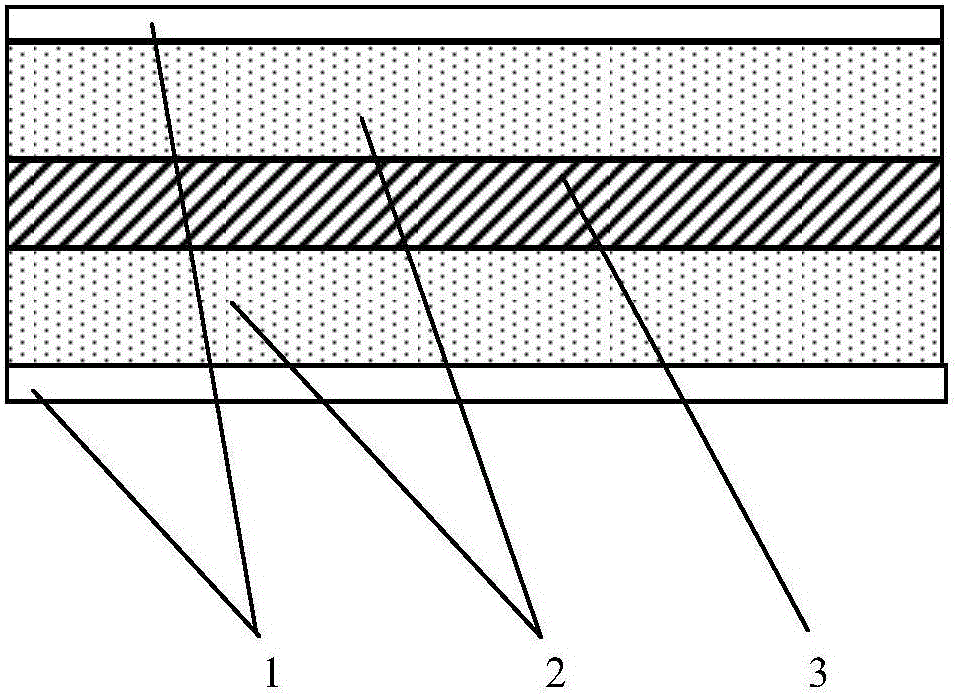

Embodiment 1

[0058] 1) Clean the titanium slices and glass slides with detergent or detergent, and dry the cleaned titanium slices and glass slides for later use. 2) Take a miscellaneous grain pancake (belonging to grain processing products) with a length of about 4.650 cm, a width of about 2.300 cm, and a thickness of about 0.526 mm. Mix two of yellow rice flour, corn flour, oat flour, buckwheat flour, barley flour, etc. in a ratio of 1:1:1. The common formula is 50 g of whole wheat flour, 50 g of flour, 50 g of cornmeal, and 230 g of water. Such as figure 1 as shown, figure 1 To illustrate the structure of the prepared edible supercapacitor, the above-mentioned multigrain pancake was selected as the material of the diaphragm 3 . The mass of the prepared pancakes was between 0.500 g and 0.900 g. 3) Take about 1.500 g of spicy sauce (a condiment), spread it evenly on a titanium sheet (4.650 cm in length, 2.300 cm in width, and 0.030 mm in thickness), and roll it into a paste. The titan...

Embodiment 2

[0065] 1) Clean the titanium slices and glass slides with detergent or detergent, and dry the cleaned titanium slices and glass slides for later use. 2) Take seaweed (aquatic product) about 6.500 cm in length, 3.200 cm in width, and 0.233 mm in thickness as the material for diaphragm 3, such as figure 1 shown. 3) Take about 0.800 g of batter (belonging to processed grain products), spread it evenly on a titanium sheet, and use the titanium sheet as metal fixture 1, and bake it at 280 °C. Do the same with the other titanium sheet. 4) Put the clean glass slide, metal fixture 1, electrode active layer 2, and diaphragm 3 in accordance with the glass slide, metal fixture 1, electrode active layer 2, diaphragm 3, electrode active layer 2, metal fixture 1, The order of the slices is fixed together, and the clean glass slide makes the overall device flat for easy testing and packaging. Canned fruit juice (belonging to canned food) is dripped into the electrode active layer 2 and th...

Embodiment 3

[0070] 1) Based on a 0.030 mm thick titanium sheet. Cut the titanium sheet into thin slices about 5.000 cm in length and 2.500 cm in width. After polishing with sandpaper, clean the titanium sheet and glass slide with detergent or cleaning agent, and clean the titanium sheet and glass slide after cleaning. Dry and set aside, the titanium sheet is used as the metal fixture 1, and the masses of two pieces are weighed to be 0.175 g and 0.189 g respectively. 2) Grind potato chips (belonging to potatoes and puffed products), and sprinkle them evenly on the surface of titanium chips. Use a hydraulic jack to press to ensure that the potato chip crumbs form a thin film and adhere to the titanium sheet, and weigh 0.859 g. Remove from heat and bake. 3) Wash the dried tofu skin (belonging to bean products), cut it into thin slices with a length of about 5.000 cm and a width of about 2.500 cm, and weigh 1.026 g, such as figure 1Shown, as the material of the diaphragm 3. 4) Put the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com