Patents

Literature

321 results about "Canned fruit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Canned fruit may not have the fresh flavor and firm texture of recently harvested ripe fruit, but it does provide fiber, carbohydrates and essential minerals. Although fruit may lose some of its vitamin content during the canning process, its basic nutritional profile is similar to fresh fruit.

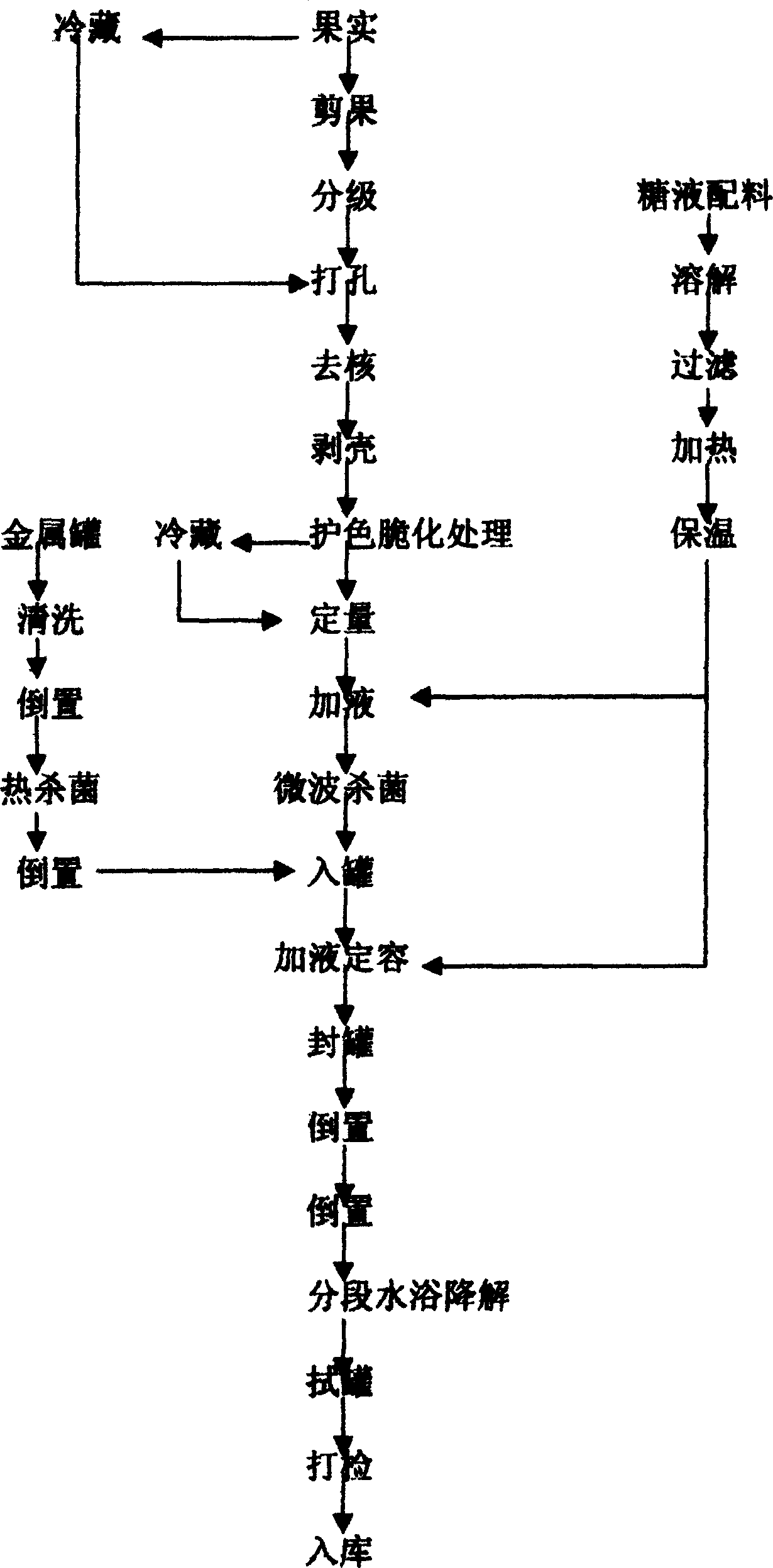

Tinned fruit production process

InactiveCN1478401AImprove completenessLess investmentFruits/vegetable preservation by heatingWater bathsTinning

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

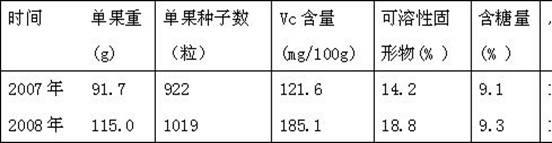

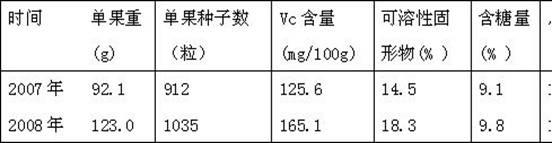

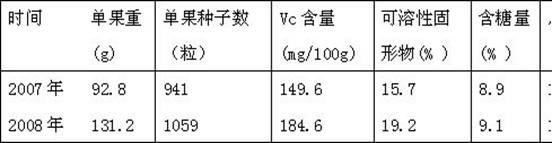

Field management method of high-end kiwi fruit during fruiting period

InactiveCN102550352AGuaranteed nutrition supplyGuaranteed qualityBio-organic fraction processingOrganic fertiliser preparationActinidiaDisease damage

A field management method of high-end kiwi fruit during a fruiting period relates to a cultivation management method which is applied after a kiwi fruit plant can fruit. By systematic treatment of the method comprising application of fertilizer prior to flowering, bud picking, pollination, fruit thinning, application of fruit expanding fertilizer, application of leaf surface fertilizer, pest control, bagging, core picking, drought resistance, drainage of stagnant water, base fertilizer application, winter pruning, winter orchard-clearing disinfection and the like, the kiwi fruit can fully and efficiently utilize light, temperature, water, air and fertilizer, the relations of branch and leaf growth and fruiting are adjusted in real time, distribution of plant nutrient is adjusted, the fruiting capability of the kiwi fruit can be brought into play as far as possible, single-fruit grain weight and the number of contained seeds are increased, pest and disease damage can be eliminated simultaneously, and the disease-resistant capability of plants is enhanced. Besides, the trophic structure of the soil can be adjusted, soil fertility is not reduced all the year round, high quality, high yield and stable yield of the kiwi fruit are achieved, and the age limit of fruiting is prolonged.

Owner:重庆信祥生态农业有限公司

Preparation process of fruit can

InactiveCN102550650AEasy to synthesizeGood colorClimate change adaptationFruits/vegetable preservation using sugarsVitamin CCanned fruit

A preparation process of a fruit can is characterized in that the formula of the fruit can includes following materials by weight: 55%-60% of fruits, 8%-10% of sugar mixture, 0.3% of citric acid, 0.2% of neotame, 0.05% of vitamin C and the balance of water, the sugar mixture includes 60%-70% of xylitol and 30%-40% of fructose, and the xylitol is a novel sweetener and an intermediate of saccharometabolism in a human body and can penetrates through a cell membrane to be absorbed and utilized by tissues without the promotion of insulin under the condition that the saccharometabolism is influenced due to the shortage of insulin in a human body, so that the glycogen is promoted to be synthesized, the nutrition and energy are provided for cells, and the blood glucose value cannot be increased. The fruit can provided by the invention is a low-sugar fruit can which has beautiful pulp color and good mouthfeel and is suitable for the old and the young.

Owner:DALIAN YUMAN FOOD

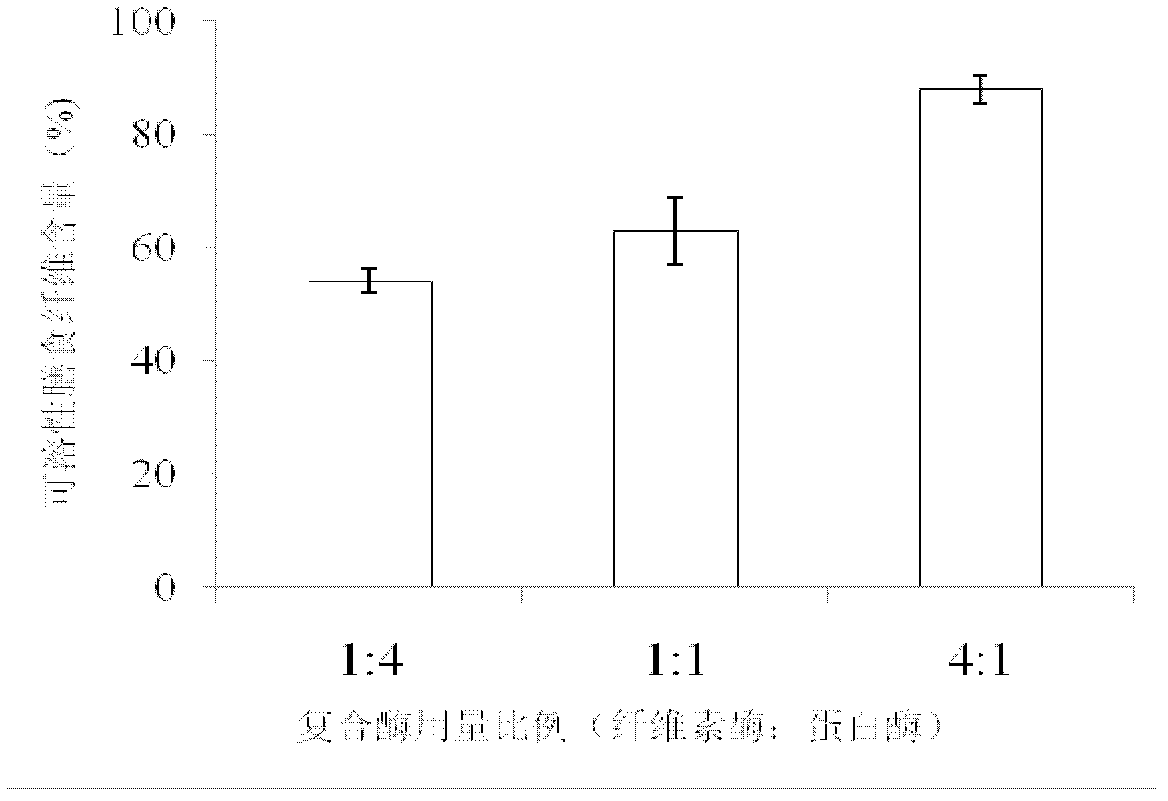

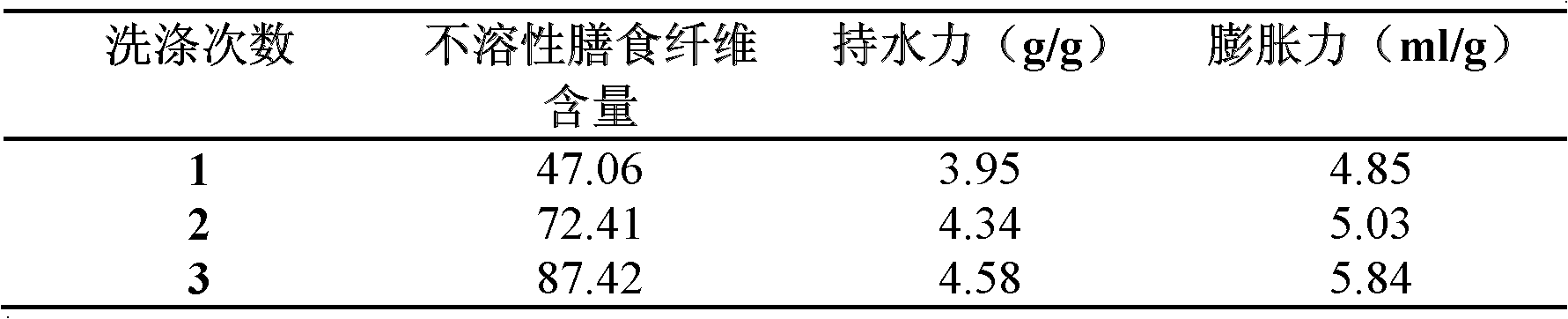

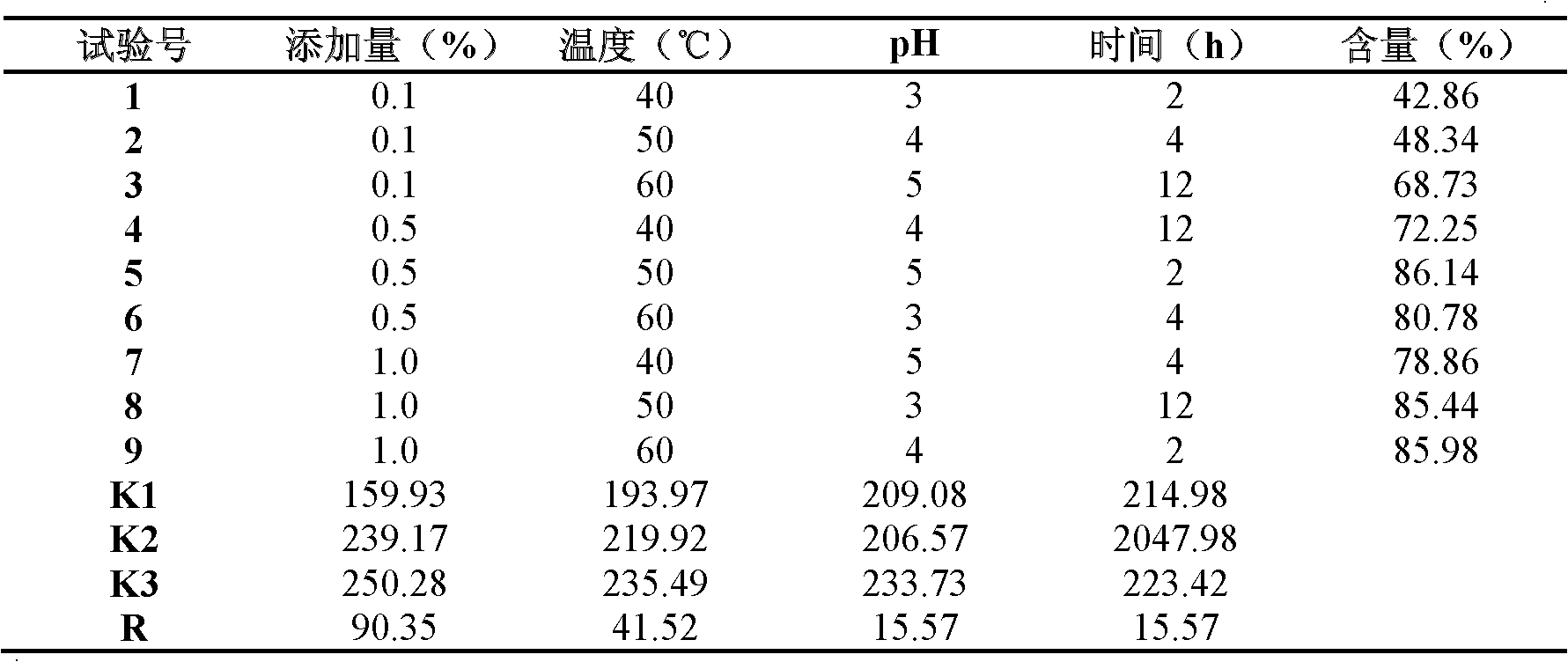

Fruit residue dietary fiber and preparation method thereof

The invention discloses fruit residue dietary fiber and a preparation method thereof. According to the preparation method, fruit peel residues and fruit flesh residues produced in the processing processes of fruit juice and fruit cans are taken as raw materials and prepared into a high-purity and high-physiological activity dietary fiber product by the process steps and equipment of impurity removal, ultrafine crushing, enzymolysis, centrifuging, concentrating, decoloring, ethanol precipitation, drying and the like. The product has the characteristics of high purity, high water holding capacity, strong swelling performance and the like.

Owner:CHINA AGRI UNIV

Production technology of low-sugar fruit can

InactiveCN102940030ALower sugar compoundDesugar technology is simple and feasibleFruit and vegetables preservationDiabetic patientShelf life

The invention relates to a production technology of a low-sugar fruit can. The production technology introduces a fruit desugaring process based on the traditional production technology and greatly reduces sugar content of a fruit can. The production technology adopts a dual-sterilization technology, is simple and effective, and greatly increases a quality guarantee period to more than 18 months. The low-sugar fruit can obtained by the production technology is suitable for being taken by diabetics or children and has a wide market prospect.

Owner:李钊

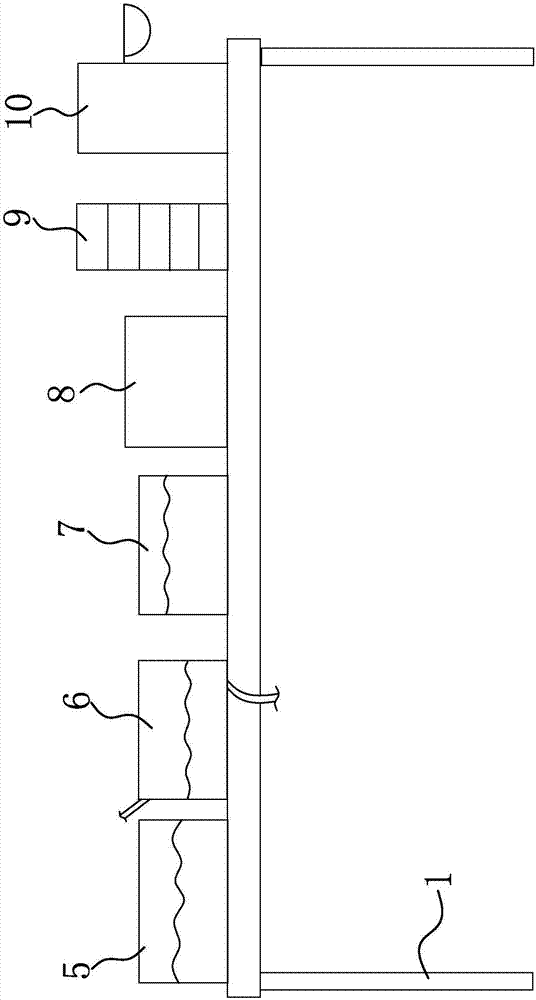

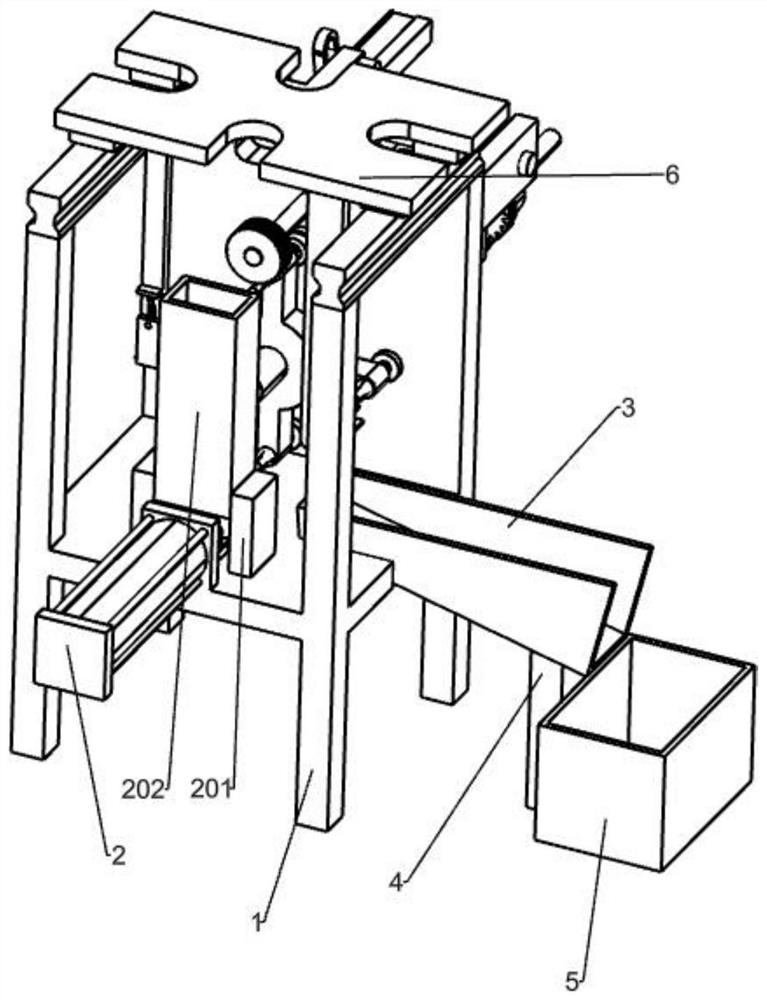

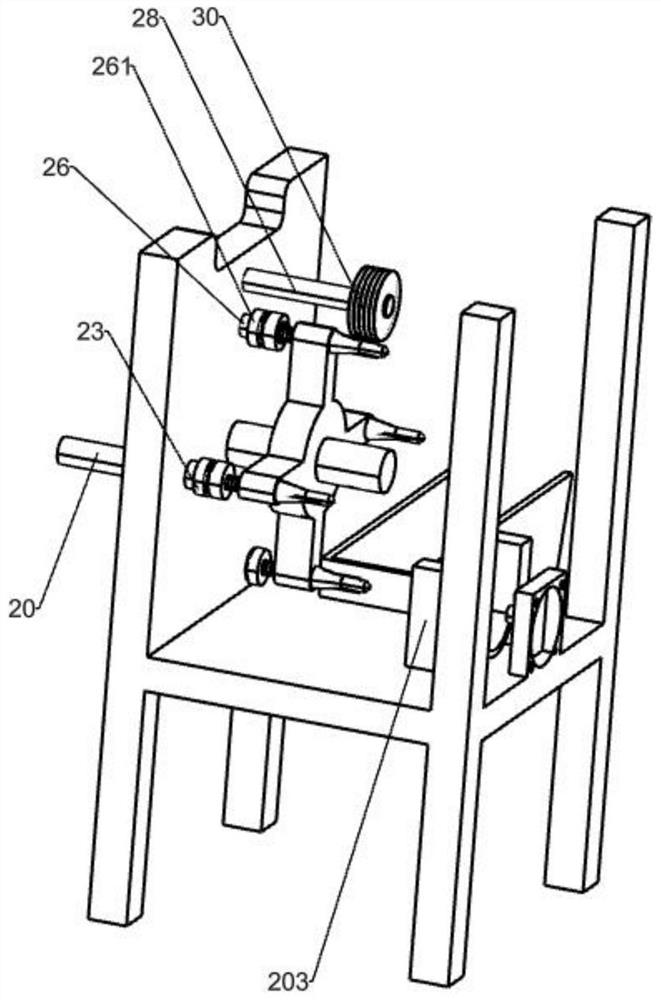

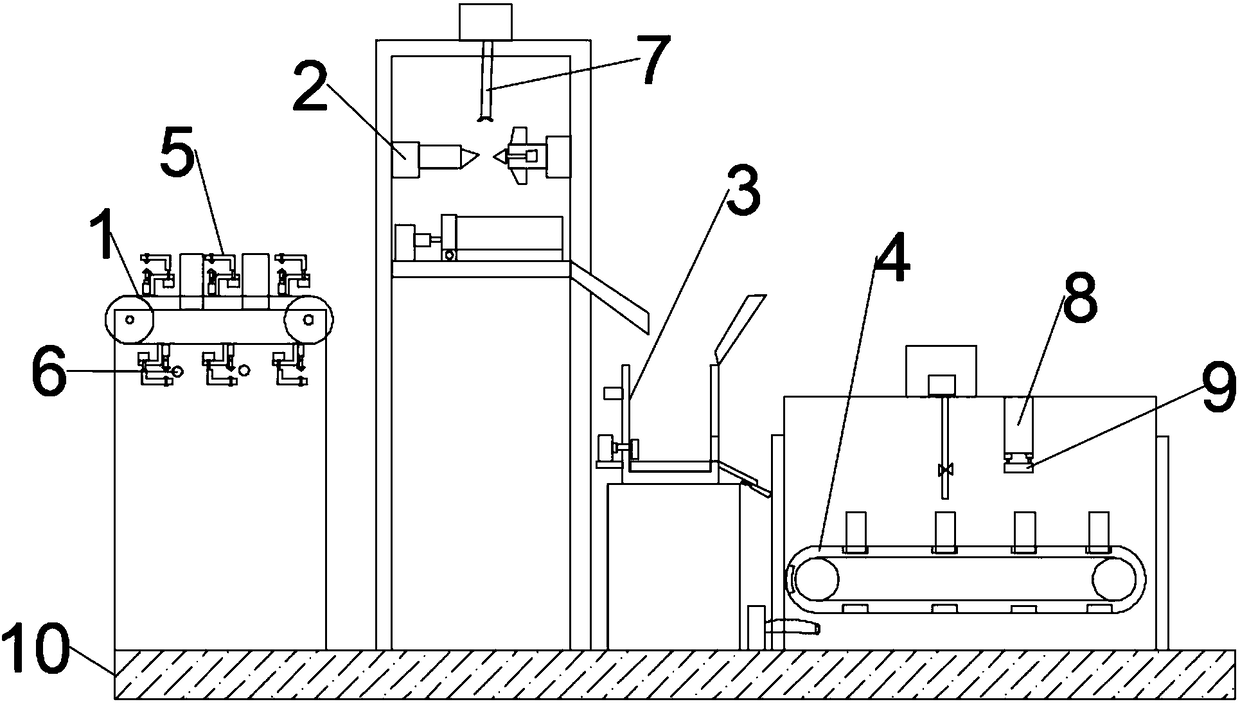

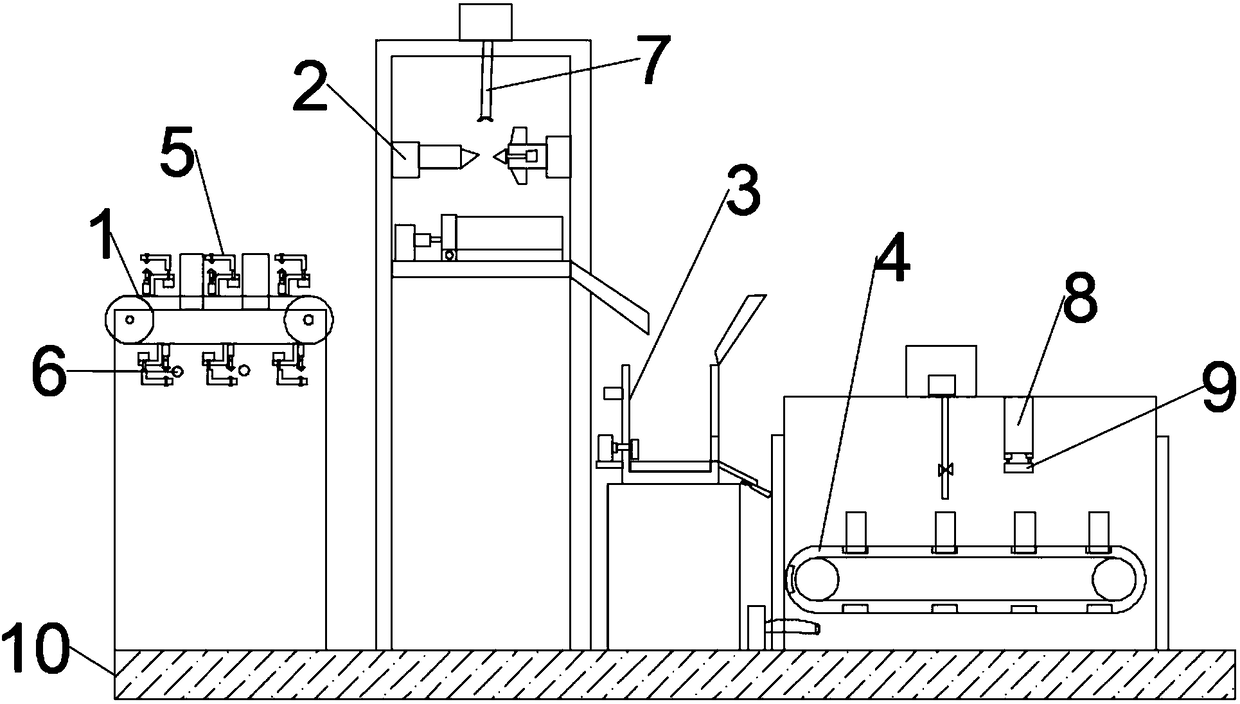

Production equipment of mixed fruit can and production method thereof

The invention belongs to the technical field of food processing, and particularly relates to production equipment of a mixed fruit can and a production method thereof. The production equipment comprises a grape processing line and a juicy peach processing line, wherein the grape processing line and the juicy peach processing line are connected with a mixing processing line; the grape processing line comprises a rack; a selecting device, a soaking and rinsing device capable of removing impurities on the grape surfaces, and a softening device capable of softening grape particles are sequentially arranged on the rack; the juicy peach processing line comprises a rack; a hair rubbing device capable of removing hair on the juicy peach surfaces, a washing device capable of washing salt water remaining on juicy peaches, a peeling device for peeling the juicy peaches, a kernel-removing and slicing device capable of carrying out kernel-removing and slicing on the peeled juicy peaches, and a food steamer for steaming the sliced juicy peaches on a plate are sequentially arranged on the rack; the mixing processing line comprises a soup-adding packaging device for jointly packaging prepared juice, grapes and the juicy peaches. The production equipment has the advantages of high processing efficiency and reasonable integrated design.

Owner:浦江兴晟食品科技有限公司

Safe food preservative

InactiveCN105077511AImprove anti-corrosion performanceFruit and vegetables preservationNatural extract food ingredientsHalobacteriumBacilli

The invention belongs to the technical field of food processing, and particularly relates to safe food preservative. The safe food preservative comprises, by mass, 2-7 parts of gingko leaf extractives, 4-9 parts of lysozyme, 12-15 parts of chitosan, 3-7 parts of spice extractives, 4-10 parts of protamines and 80-100 parts of water. According to the safe food preservative, the main inhibiting objects are pseudomonades, micrococcus, bacilli, enterobacteriaceae, vibrios, halobacterium, mycete and the like, and the application range is wide in beverages, seasoning, cooked wheaten food, cakes, sausages, canned fruit, various melons and fruits, vegetables and the like.

Owner:SICHUAN HUIQUAN CANNED FOOD

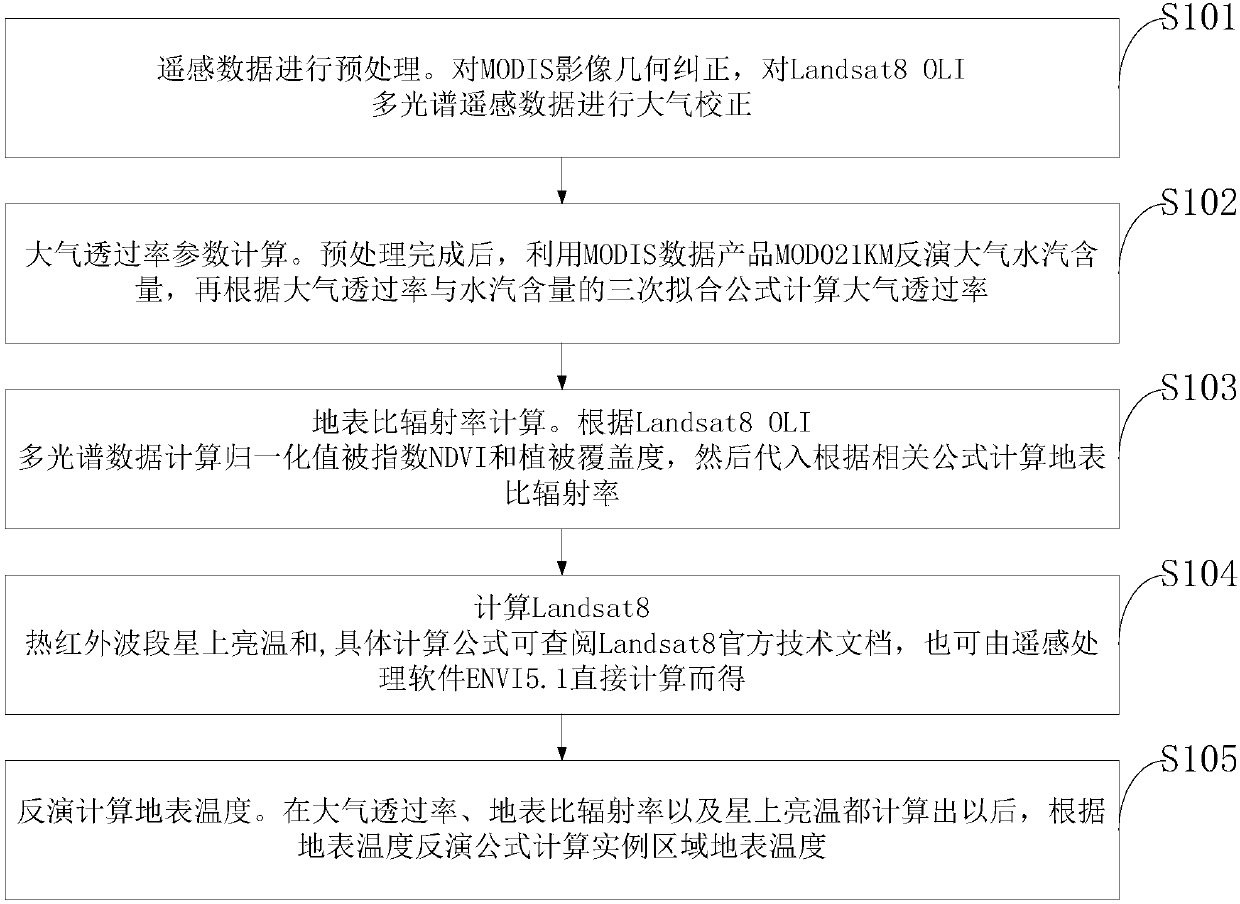

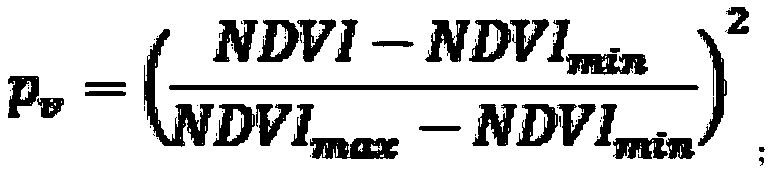

Landsat8 remote sensing ground surface temperature inversion method

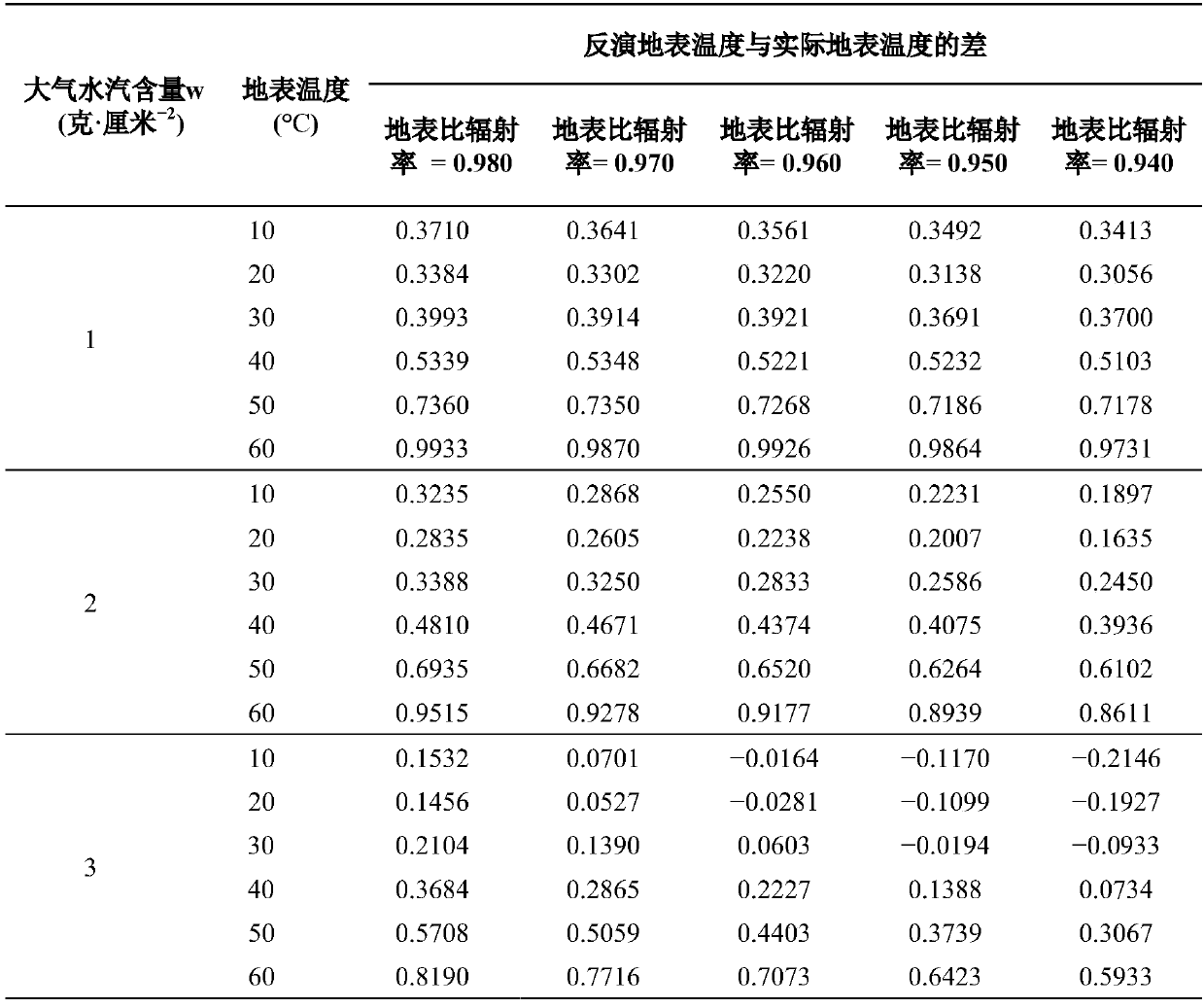

The present invention discloses a Landsat8 remote sensing ground surface temperature inversion method. The method includes the following steps that: step 1, atmospheric water vapor content w is calculated; step 2, an atmospheric transmissivity tau10 and an atmospheric transmissivity tau11 which are corresponding to two thermal infrared bands of the Landsat8 are calculated; step 3, a ground surfaceemissivity epsilon10 and a ground surface emissivity epsilon11 corresponding to the two thermal infrared bands of the Landsat8 are calculated; and step 3, ground surface temperature TS is calculatedthrough inversion: on the basis of the step 1 to step 3, the above parameter calculation results are substituted into an inversion formula to calculate a surface temperature value. According to the Landsat8 remote sensing ground surface temperature inversion method of the invention, Landsat8 remote sensing ground surface temperature inversion algorithm technology is improved and developed throughdifferent algorithm ideas, so that the accuracy of the calculation of the ground surface temperature by means of inversion through the thermal infrared bands of the Landsat8 can be improved; non-professionals can better understand and master the algorithm technology by means of simple and direct logical relationships, and therefore, the algorithm technology can be widely used and can fruit certainoverall efficiency and overall value.

Owner:TAIYUAN UNIV OF TECH

Liquid fruit can and processing technique thereof

InactiveCN102028019ARetain nutritionKeep it deliciousFruit and vegetables preservationVitamin CCanned fruit

The invention discloses a liquid fruit can and a processing technique thereof. The liquid fruit can mainly contains the following components in percentage by weight: 60-95 percent of fine crushing flesh, 5-40 percent of water, 0.1-0.3 percent of white granulated sugar, 0.1-0.3 percent of acesulfame potassium, 0.1-0.3 percent of citric acid and 0.1-0.3 percent of vitamin C. The liquid fruit can with the components, which is produced by preparing, beating, evacuating, canning, vacuumizing, sterilizing and other work procedures, has a protruded edible value. The liquid fruit can has the main advantages of containing no preservative, saccharin or other addictives harmful to the human body and being a real green food; breaking through the traditional idea, the liquid fruit can free from being chewed is developed, not only retains the nutrition and the deliciousness of the traditional fruit can, but also is convenient to eat and is especially suitable for old people and infants.

Owner:大连韩强食品有限公司

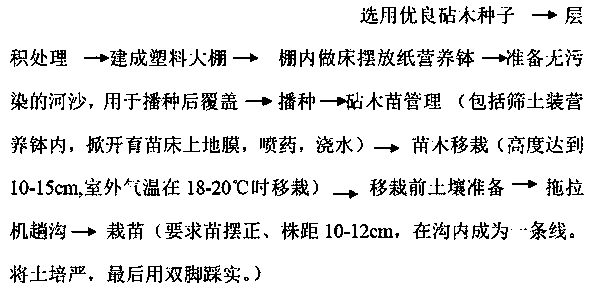

High-quality large cherry seedling cultivating method

The invention belongs to a cherry cultivating method. A high-quality large cherry seedling cultivating method comprises the following steps: culturing seedlings: directly sow germinated stock seeds in a paper nutrition bowl, placing the paper nutrition bowl in a plastic-covered tunnel nursery garden, keeping the temperature to be below 25 DEG C; transplanting: when the temperature of the nursery garden is above 20 DEG C and the height of seedlings is 10-15cm, transplanting, wherein rotary tillage is carried out to ensure that wet soil is fine and loose before transplanting, and furrows are made according to the conditions that the row spacing is 65-70cm and the furrow depth is 10-15cm, the seedling planting distance is 10-12cm, no watering is required after transplanting; grafting: breaking a stock, remaining the 40cm-long stock, and then grafting; and30 day after grafting, removing a plastic film on a budder. According to the high-quality large cherry seedling cultivating method, due to adoption of the factory-like nutrition bowl seedling cultivating mode, the seedlings are uniform, are free from meloidogynosis, and high in survival rate after being transplanted, the land can be economically utilized; the stock is broken before grafting, the plastic film is removed 30 days after grafting; the grafted seedlings grow healthy and strong, and high in adaptability. The large cherry cultured according to the method can fruit eerily, is high in yield and can create high economic benefit per unit area.

Owner:DALIAN FOLUNDE AGRI SCI & TECH

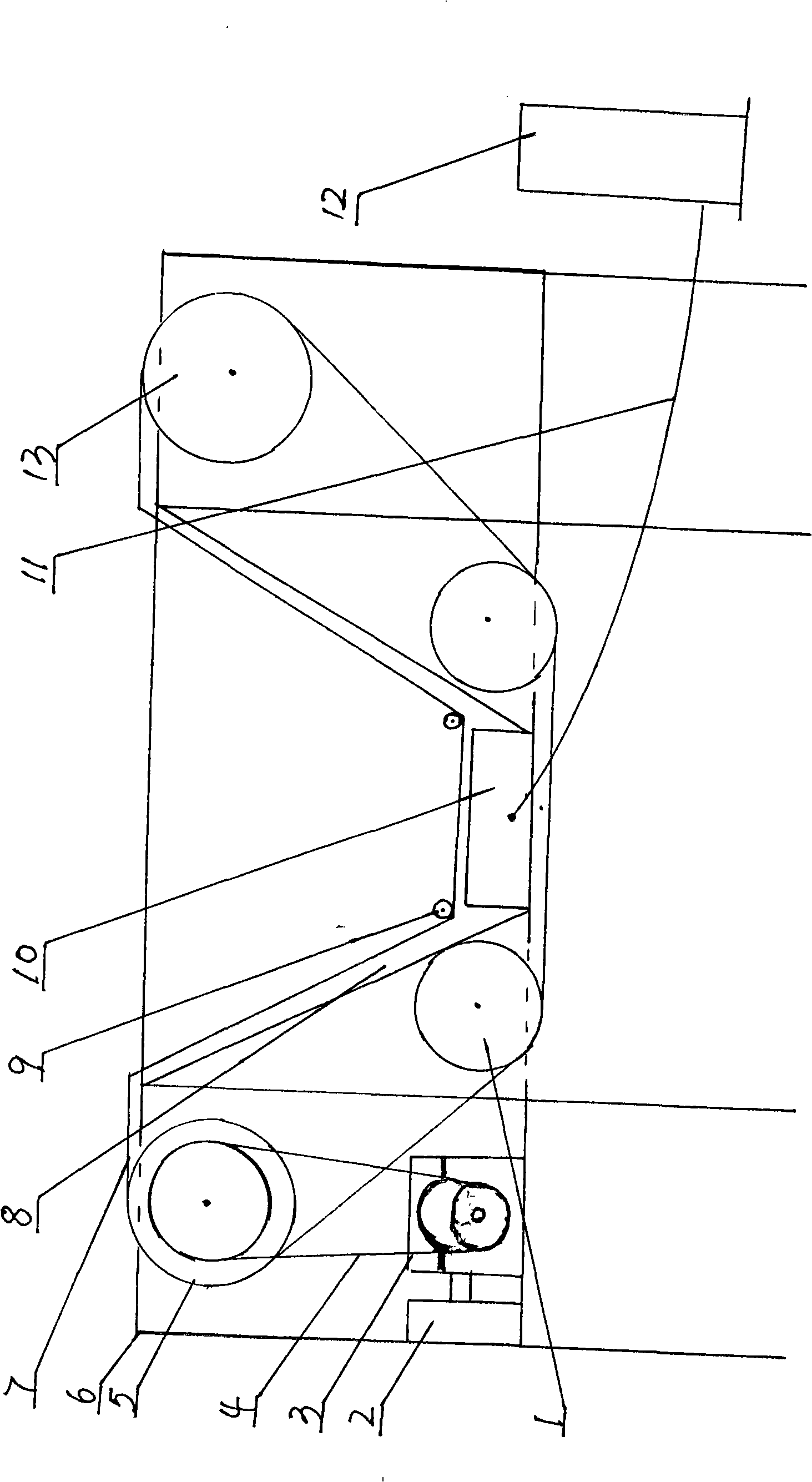

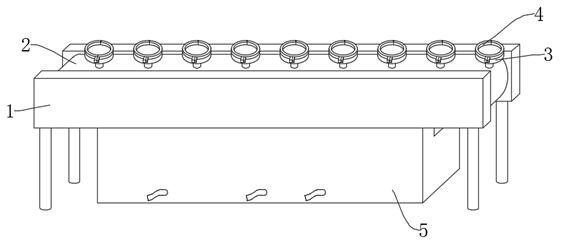

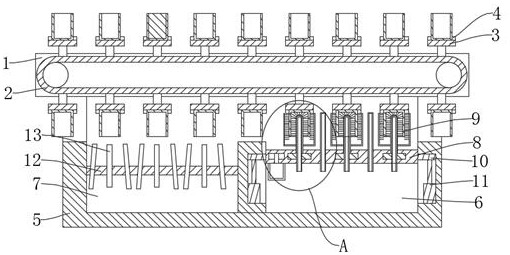

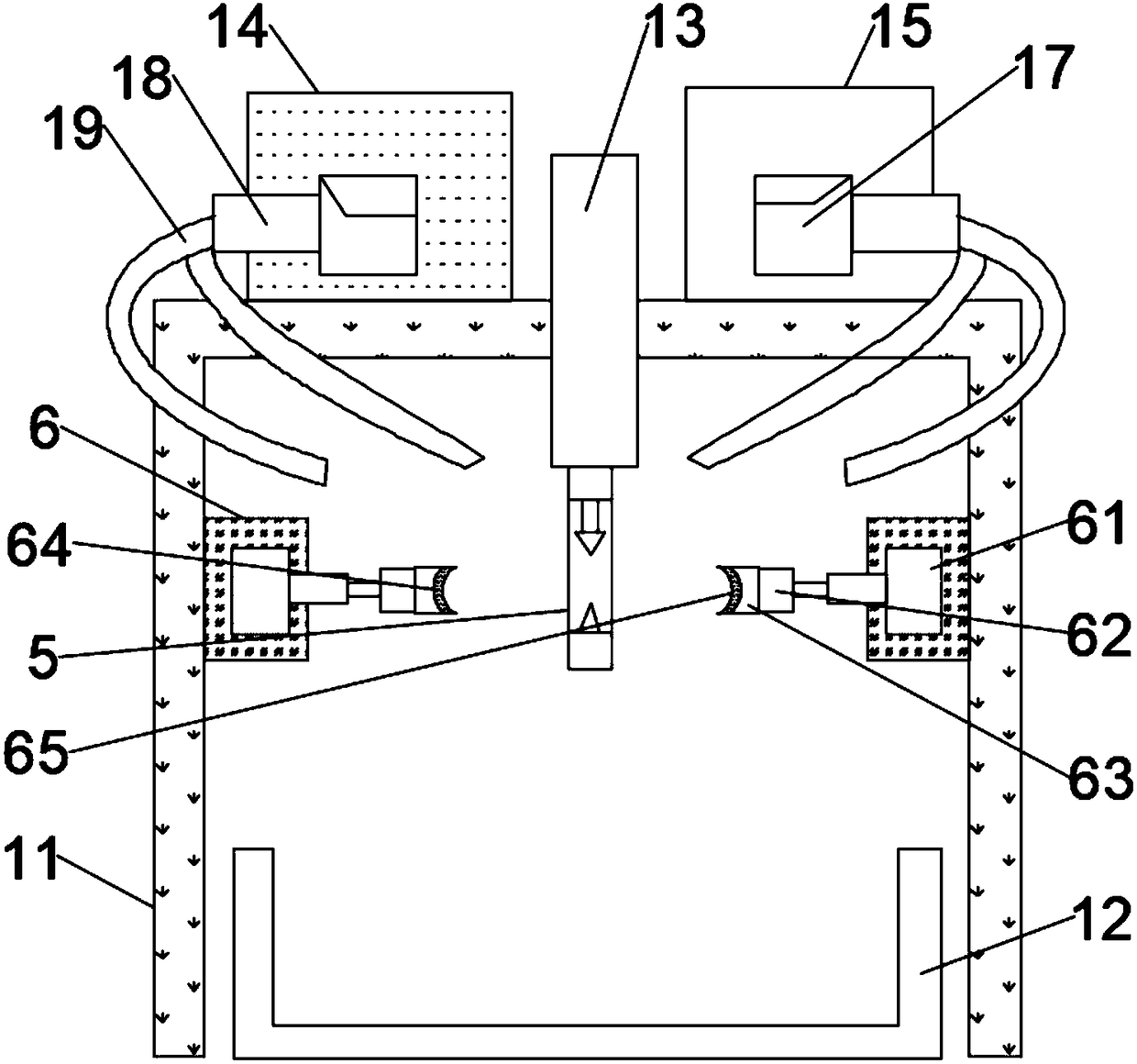

Ultrasonic sterilization machine

InactiveCN101263922AReasonable structural designEasy to manufactureFood scienceCanned fruitFruit juice

The invention discloses an ultrasonic sterilization machine, comprising a support device and a sterilization container; wherein, an ultrasonic transducer is arranged at the bottom of the sterilization container; a conveyer is positioned on the ultrasonic transducer; both ends of the conveyer are respectively arranged on a drive roller and a passive roller; a guiding device for a support roller is positioned on the conveyer between the drive roller and the passive roller; the ultrasonic transducer is connected with an ultrasonic generator through cable conductors; the drive roller is connected with a reducer through a driving belt, and the reducer is then connected with a motor. In use, the food to be sterilized is arranged on one end of the conveyer near the passive roller, and passes through the ultrasonic transducer in uniform motion, and then is output by the other end of the conveyer near the drive roller, thereby the ultrasonic sterilization machine has the advantages of rational structural design, convenient use, realizing automation of the sterilization process, and solving the technical problems in the prior art of incomplete sterilization and spoiled nutritional components, and is mainly applied for the sterilization of liquid such as canned fruits, milk, fruit juice, soy sauce, drinking water and alcohol or for the sterilization of bottled liquid or bag food.

Owner:徐尉

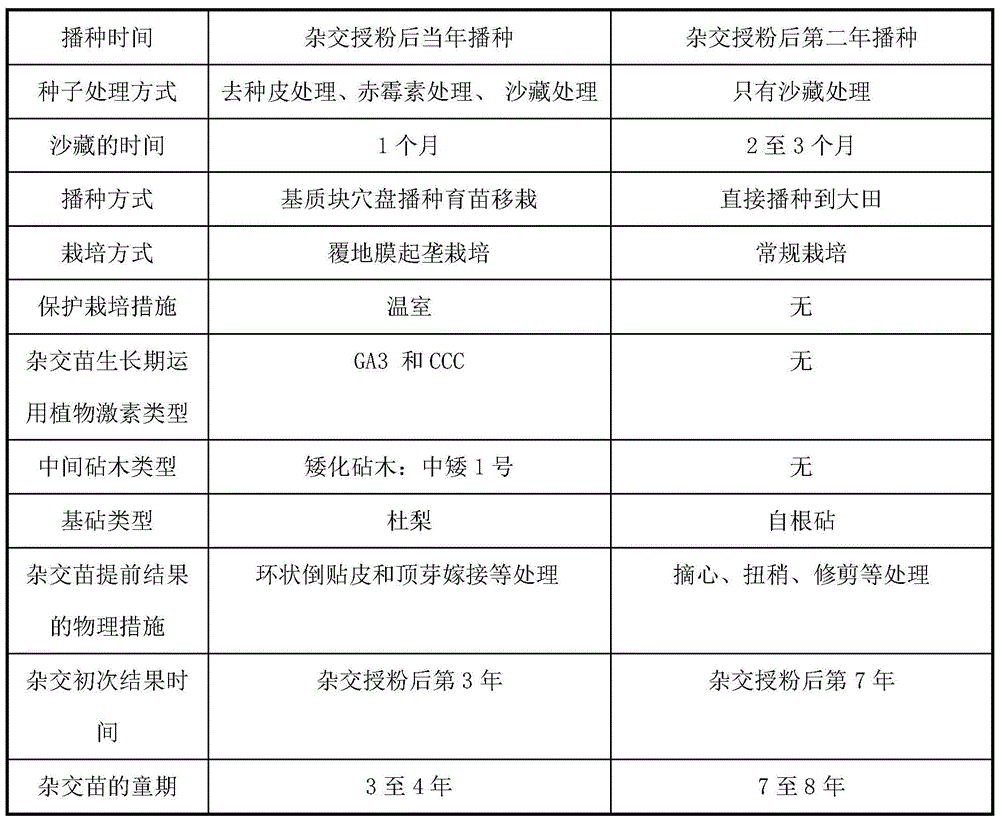

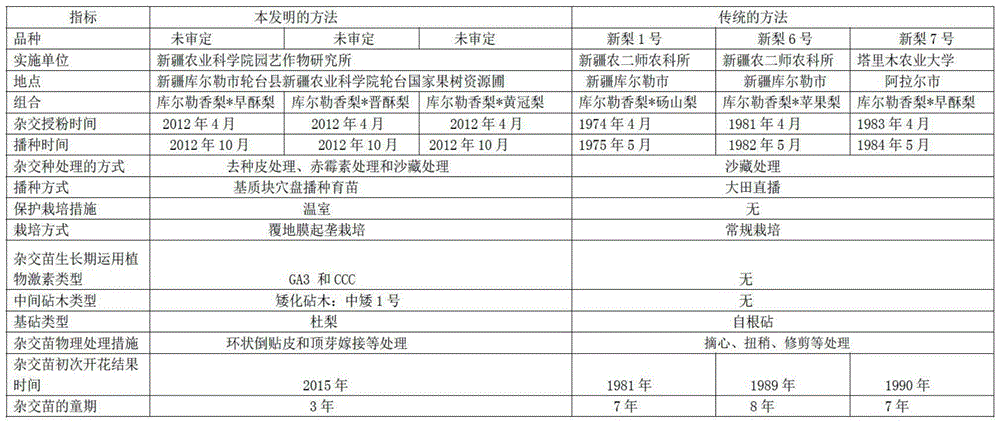

Method for shortening juvenile period of directive breeding hybrid seedlings of Pyrus bretschneideri Rehd.

InactiveCN105660237AShortened childhoodShorten the directed breeding cycleCultivating equipmentsCanned fruitGreenhouse

The invention discloses a method for shortening the juvenile period of directive breeding hybrid seedlings of Pyrus bretschneideri Rehd. The method adopts sowing and greenhouse seedling raising in the same year, and comprises the following steps: removing seed coat, carrying out gibberellin treatment, spraying GA3 in the growing period of the hybrid seedlings, conducting inversed ring-bark grafting on the hybrid seedlings sprayed with GA3, carrying out hybrid seedling terminal bud grafting, dwarfing stock, spraying chlormequat chloride (CCC), and various other technical measures, so as to shorten the juvenile period of the directive breeding hybrid seedlings of Pyrus bretschneideri Rehd. According to the method, the Pyrus bretschneideri Rehd. hybrid seedlings can bloom and fruit in the third year after being planted, and the fruiting plant rate can be 30 percent, while the conventional Pyrus bretschneideri Rehd. hybrid seedlings bloom and fruit 7 to 8 years after being planted. Being treated with the six measures, the Pyrus bretschneideri Rehd. directive breeding hybrid seedlings can fruit in the third year after being planted, that is, the juvenile period is shortened by 4 to 5 years. Therefore, the Pyrus bretschneideri Rehd. directive breeding efficiency is greatly improved; the Pyrus bretschneideri Rehd. directive breeding period is shortened; a new way and a new method are provided for breeding of new Pyrus bretschneideri Rehd. directive breeding varieties; the application value is high.

Owner:HORTICULTURE INST OF XINJIANG ACAD OF AGRI SCI

Fruit tea with honey and production method thereof

The invention discloses a fruit tea with honey and a production method thereof. The production method includes peeling cleaned pomelo and tangerine, respectively crushing and juicing pulp of the pomelo and the tangerine, shredding the pomelo peel and the tangerine peel, subjecting the shreds to steam bittering respectively, freezing the pomelo juice, the tangerine juice, the pomelo peel shreds and the tangerine peel shreds at -30 DEG C, keeping in cold storage at -18 DEG C, thawing at the room temperature, adding, by weight, 600g of honey, 180g of the pomelo juice, 125g of the tangerine juice, 30g of the pomelo peel shreds, 20g of the tangerine peel shreds and 30g of purified water per 1000g of finished product, mixing and heating to 60 DEG C, and adding 2.7g of malic acid and 2.3g of citric acid sequentially, repeating mixing, canning, performing bath sterilization at 115 DEG C-120 DEG C for 45 minutes, and cooling to obtain the canned fruit tea with honey. The fruit tea with honey is sweet and refreshing, and has the effects of moisturizing intestines and cleaning lung, lowering fire and removing freckles, smoothing skin for beauty, helping digestion, lowering blood viscosity and reducing blood clot.

Owner:ANHUI WANFENG BEE IND GROUP

Fruit jam flexible packaging can and its processing technology

InactiveCN102293237AFast penetrationLow heating temperatureFruit and vegetables preservationFood preparationCanned fruitPackaging Tank

The invention discloses a soft-packed can of fruit jam and its processing technology. The technology includes the following steps: 1) raw material pretreatment; 2) mixing ingredients; 3) vacuum cooking: sucking the raw materials and ingredients into a vacuum concentration tank and starting to stir and heat. to 60-70℃, then evacuate the vacuum concentration tank and keep the temperature at 60-70℃ for heating; 4) sterilization and filling; 5) cooling. The processing technology of the fruit jam soft packaging canning of the present invention uses vacuum cooking to replace the traditional pre-cooking process, so that the ingredients can quickly penetrate into the raw material tissue, and the food can be eaten immediately without placing it, so that the eater can feel the sweet and sour taste. Compared with the traditional process, the heating temperature of the raw materials is greatly reduced and the heating time is shortened, so that the raw materials will not be affected by the loss of nutrients in the raw materials and the taste of the raw materials due to excessive heating temperature or long heating time.

Owner:北京海泰食品有限公司

Canned fruit processing equipment

ActiveCN111844217AEasy loadingEasy to processVegetable peelingMetal working apparatusCanned fruitTeeth missing

The invention relates to the field of food processing, in particular to canned fruit processing equipment. According to the technical scheme, the canned fruit processing equipment comprises a bracketand a moving mechanism, wherein a pushing mechanism is installed on the bracket, a discharging hopper is embedded on the side, away from the pushing mechanism, of the bracket, a pillar is installed atthe bottom of the discharging hopper, and a collection box is placed on the ground of the lower side of the discharging hopper; the moving mechanism is installed at the top of the bracket, a tooth missing gear is arranged on the moving mechanism, a rotating shaft V is rotatably arranged on the side, close to the tooth missing gear, of the bracket, a spur gear is installed on the rotating shaft V,and the spur gear is matched with the tooth missing gear. According to the equipment, fruit can be inserted on a fixing rod through the pushing mechanism, so that the fruit can be convenient to feed,and through the moving mechanism, a cutting knife can move backwards to peel the fruit, so that the fruit can be convenient to process.

Owner:砀山县胜华罐头食品有限公司

High-yield planting method for watermelons

The invention discloses a high-yield planting method for watermelons, which comprises the following steps of: (1) selecting a fine variety Xincheng #1 which is suitable to be subjected to shelving cultivation; (2) appropriately selecting a watermelon land with sandy loam, ploughing the watermelon land to a depth of 28-33 cm in last autumn, and before field planting, carrying out ditching and fertilization on the land according to the line spacing of field planting; (3) inserting bamboo poles so as to form a vertical shed shelf, wherein the height of the frame is 1.5-3 meters, the diameters of the bamboo poles are 1.2-1.6 cm; inserting vertical poles firstly, then binding 3-4 transverse poles, and arranging two rows of fixed poles in each rectangular piece of land; under the condition that preferably a whole branch is put on the shelf by only having a tendrilled vine, bending tendrilled vines, binding each tendrilled vine with 3-4 rings, completely removing side vines in the early stage of growth, and after a main vine has watermelons, leaving 5-8 leaves on the watermelons, carrying out pinching, and selectively leaving a side vine at the base part, so that the side vine can fruit; and (4) pollination and fruit retention: for improving the fruit set percentage, carrying out artificial supplementary pollination in the flowering phase. The high-yield planting method for watermelons is simple in operation steps, and the yield of watermelons per mu is more than 8500 kilograms, therefore, the method has great significance in realizing the income increasing of watermelon farmers.

Owner:彭岩

Low-sugar canned strawberry and preparation method thereof

ActiveCN101548752AAvoid absorptionIt has the function of nourishing the liverFood preparationIcing sugarCanned fruit

The invention relates to a low-sugar canned strawberry and a preparation method thereof. Aiming at the problems of low performance-cost ratio, high artificial pigment content and high powdered sugar content of canned fruit in the existing market, the invention provides the low-sugar canned strawberry. The canned strawberry contains the following ingredients by weight portions: 310-340 portions of strawberry and 90-120 portions of sweet water with the pH value of 3-4 according to weight; and every 100 portions by weight of sweet water contain 22-30 portions of xylitol and 3-8 portions of blackberry juice. The preparation method of the low-sugar canned strawberry comprises the following steps of: selecting materials, cleaning, vacuuming, blending sweet water, canning, sealing and sterilizing. The low-sugar canned strawberry has the efficacies of nourishing the liver, nourishing, preventing atherosclerosis and coronary heart disease, and the like; the sugar content is low, with nutrition and health, and the strawberry reaches 72-79% of ingredients of the whole canned strawberry, with high pulp content and high performance-cost ratio; and no artificial pigment is contained, thus being pure natural healthy food.

Owner:临沂市康发食品饮料有限公司

Sugarless canned fruit

The invention is directed to a sugarless canned fruit edible for patients with diabetes, and solves the problem that a current market cannot meet the demand of the patients with diabetes on a canned fruit. The sugarless canned fruit is composed of strawberry, honey dew melon blocks, water, a colorant, vitamins, xylitol and a viscous agent, wherein the fruits account for 48-62%, the viscous agent accounts for 3%, the colorant accounts for 5-7%, the vitamins account for 0.1-0.3%, the xylitol accounts for 12-15%, and the balance is water.

Owner:孙瑞

Xinjiang Korla bergamot pear fructose syrup and production method thereof

The invention discloses Xinjiang Korla bergamot pear fructose syrup and a production method thereof. The production method comprises the following steps of: selecting raw materials, namely selecting, washing, crushing and beating; preheating to inactivate enzymes, namely preheating the crushed bergamot pear syrup to inactivate the enzymes; performing enzymolysis, namely compounding pectinase, cellulase, amylase, invertase and a juice clarifying enzyme and performing the enzymolysis; inactivating the enzymes, namely inactivating extra enzyme preparations; performing ultrafiltration to obtain clear and transparent bergamot pear juice; and separating, purifying, and performing low temperature vacuum concentration, namely concentrating the fructose syrup by a low temperature vacuum concentration technology at the temperature of between 55 and 65 DEG C and under the pressure of -300 to -650KPa until the concentration is 70Brix. The product is prepared from natural fruits, various functional nutrient factors are stored to the greatest extent, other additives are not added in the production process, quality is safe and reliable, various physical and chemical indexes meet the national standard, and the product can meet the requirements of juice and canned fruit industries.

Owner:新疆冠农股份有限公司

Lyophyllum connatum(schum.txFr.)Sing js39 strain and use thereof

ActiveCN102204475AHigh nutritional valueImprove breathabilityCultivating equipmentsSoilless cultivationLand resourcesCulture fungus

The invention relates to a Lyophyllum connatum(schum.txFr.)Sing js39 strain and use thereof. The collection number of the Lyophyllum connatum(schum.txFr.)Sing js39 strain is CCTCCNo.M2011018. The Lyophyllum connatum(schum.txFr.)Sing can be cultivated in fermented material on ground or in bags, the finished Lyophyllum connatum(schum.txFr.)Sing has high nutritional value, and according to tests, the Lyophyllum connatum(schum.txFr.)Sing contains various nutrients including 18 amino acids, calcium, iron, zinc, phosphorus, fat, proteins, polysaccharides and selenium. The ground Lyophyllum connatum(schum.txFr.)Sing cultivation method has the advantages of high breathability and high fruiting speed. At 20 to 25 DEG C, the Lyophyllum connatum(schum.txFr.)Sing can fruit within 20 to 25 days normally. Packaging bags and labor are saved, and land resources are fully utilized. The feed amount, yield, production value and pure profit are three times more than those achieved by the conventional method. The feed amount, yield, production value and pure profit of the bag Lyophyllum connatum(schum.txFr.)Sing cultivation method are 7 times more than those achieved by the conventional method. In the method, crop straw such as rice straw, corncobs, broomcorn straw, wheat straw, cotton straw, sunflower straw, cottonseed hull and the like can be utilized.

Owner:卢凤忠

Method for processing flexible packaged fresh canned fruit

InactiveCN101884347AStay nourishedKeep the flavorFruit and vegetables preservationCanned fruitVacuum pack

The invention provides a method for processing flexible packaged fresh canned fruit. The vacuum-packed fruit slices are subjected to pressure increase, pressure maintenance and pressure release for 1 to 3 times by adopting the super-high pressure technology; and the pressure of between 100 and 1,000 MPa is applied at the temperature of between 4 and 60 DEG C for 1 to 20 minutes. Therefore, the flexible packaged fresh canned fruit prolongs the quality guarantee period on the premise of not adding any extra preservative, and cannot damage nutrient components of the fruit.

Owner:LIAOCHENG UNIV

Formula and preparation method of canned fruit and vegetable with function of reducing blood pressure

InactiveCN102187983ASteady drop in blood pressureImprove dizzinessFood preparationCarrageenanCanned fruit

The invention relates to a formula and a preparation method of canned fruit and vegetable with a function of reducing blood pressure. The formula of the canned fruit and vegetable comprises 30-40% of fruit and vegetable, 20-30% of fruit and vegetable juice, 5-10% of lucid ganoderma fine powder, 1-3% of albumen powder, 0.1-0.15% of trehalose, 0.1-0.15% of stevioside, 0.1-0.25% of citric acid, 0.2-0.4% of carrageenan, and the balance of pure drinking water. The preparation method comprises the steps of: 1) preparing fruit and vegetable blocks; 2) pre-boiling and weighing the fruit and vegetableblocks in ratio for later use; 3) juicing: juicing the fruit and vegetable same as the fruit and vegetable of the fruit and vegetable blocks, and filtering with a 150-mesh filtering net; 4) preparingcanning liquid: mixing fruit and vegetable juice, lucid ganoderma fine powder, albumen powder, trehalose, stevioside, carrageenan and drinking water in ratio in the formula; 5) canning; 6) injecting liquid; 7) sealing; and 8) sterilizing and cooling to finally obtain the canned fruit and vegetable with a function of reducing blood pressure. If the canned fruit and vegetable is taken for a long time, the blood pressure can be stably decreased, the symptoms such as dizziness, tinnitus, palpitation, cardiopalmus and the like can be obviously improved, and simultaneously large amount of dark urine can be discharged.

Owner:NANCHANG JINXUAN TECH CO LTD

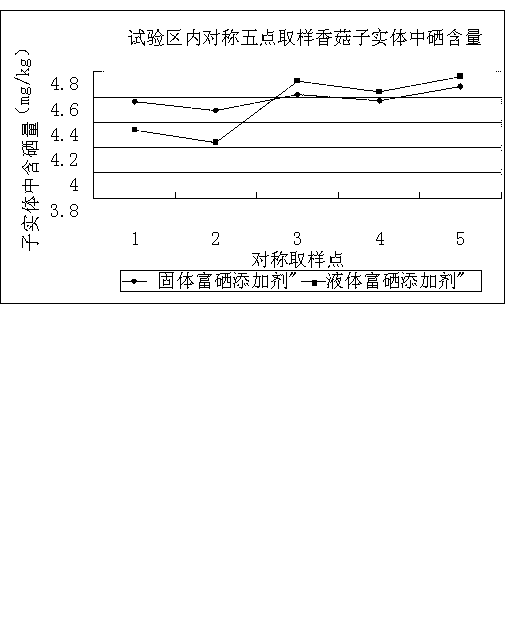

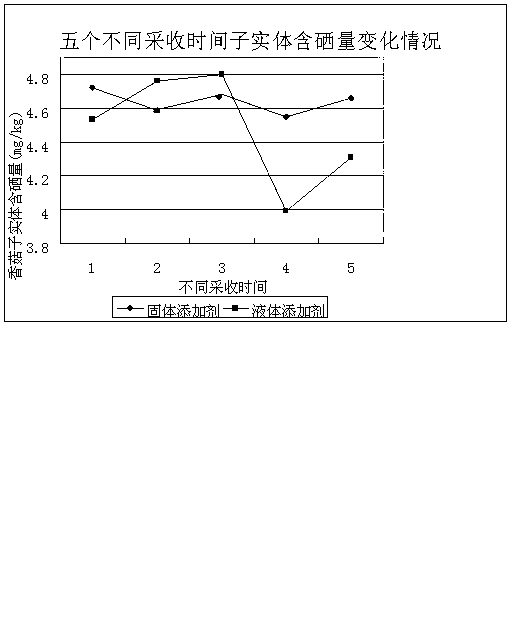

Selenium-rich additive for anti-season field-cultivated mushroom and application thereof

InactiveCN103011948APromote growthPromote growth and developmentHorticultureFertilizer mixturesSulfate zincActivated carbon

The invention relates to a selenium-rich additive for anti-season field-cultivated mushroom and an application thereof. The additive is prepared by taking sawdust of 20-40 meshes as an adsorbent and active carbon of 40-60 meshes as a sustained-release agent in combination with sodium selenite and zinc sulfate, and the preparation comprises the following steps of: preparing sodium selenite and zinc sulfate into an aqueous solution; uniformly mixing and stirring the uniformly-mixed sawdust and active carbon with the selenium solution; and stacking for 1.5-2 hours, and naturally drying. The selenium-rich additives accounting for 0.8-1% and 1.5-2.5% of the drier weight respectively are added into the compost and cultivation material of the second-level and third-level strains of mushroom. Through the invention, the needs for selenium element in the whole growth period of anti-season field-cultivated mushroom can be met, and the mushroom can fruit in May to November; the solid additive is slowly-released and long-acting, has good dispersibility, can be easily mixed with the solid compost of edible mushroom, and can promote mycelial growth, reduce stem rot and improve the stress resistance and output of the mushroom; and by adopting the additive, the cultivation time in a cultivation bag is shortened by 4 days in average, the squaring time is shortened by 2 days in average, the selenium content in the fruiting body is over 10 times that of the control group, the biological conversion rate is improved by 11.4%, and the rate of high-quality mushroom is 5.9% higher than that of the control group.

Owner:辽宁省微生物科学研究院

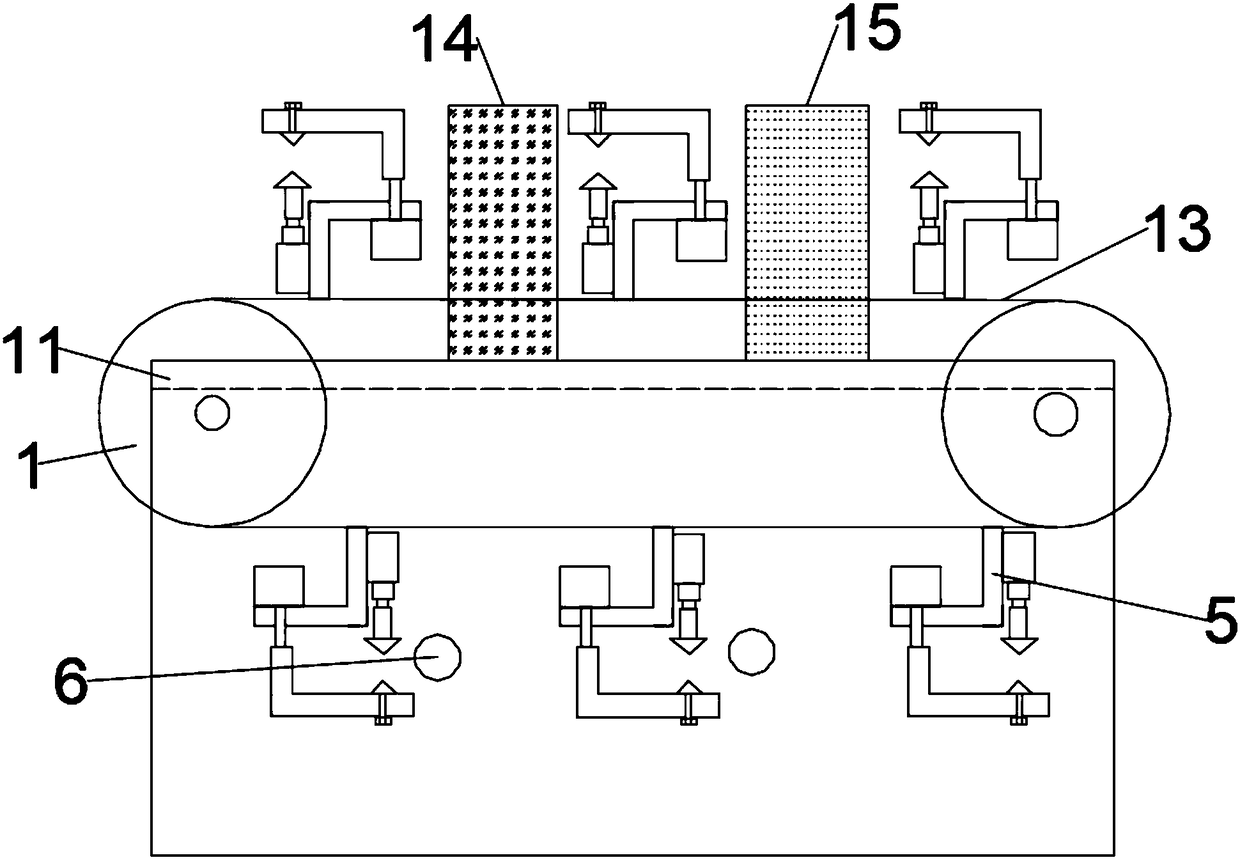

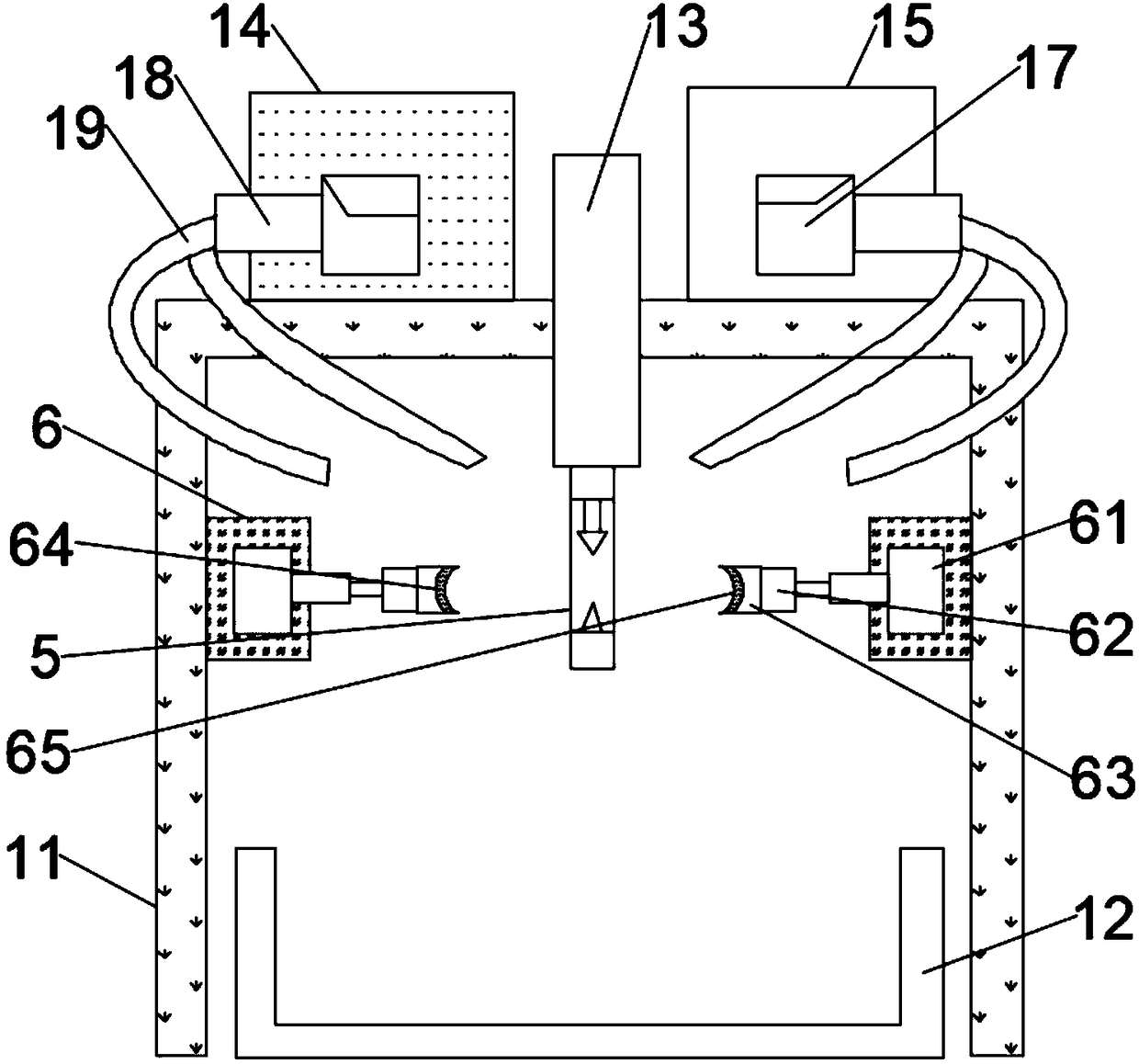

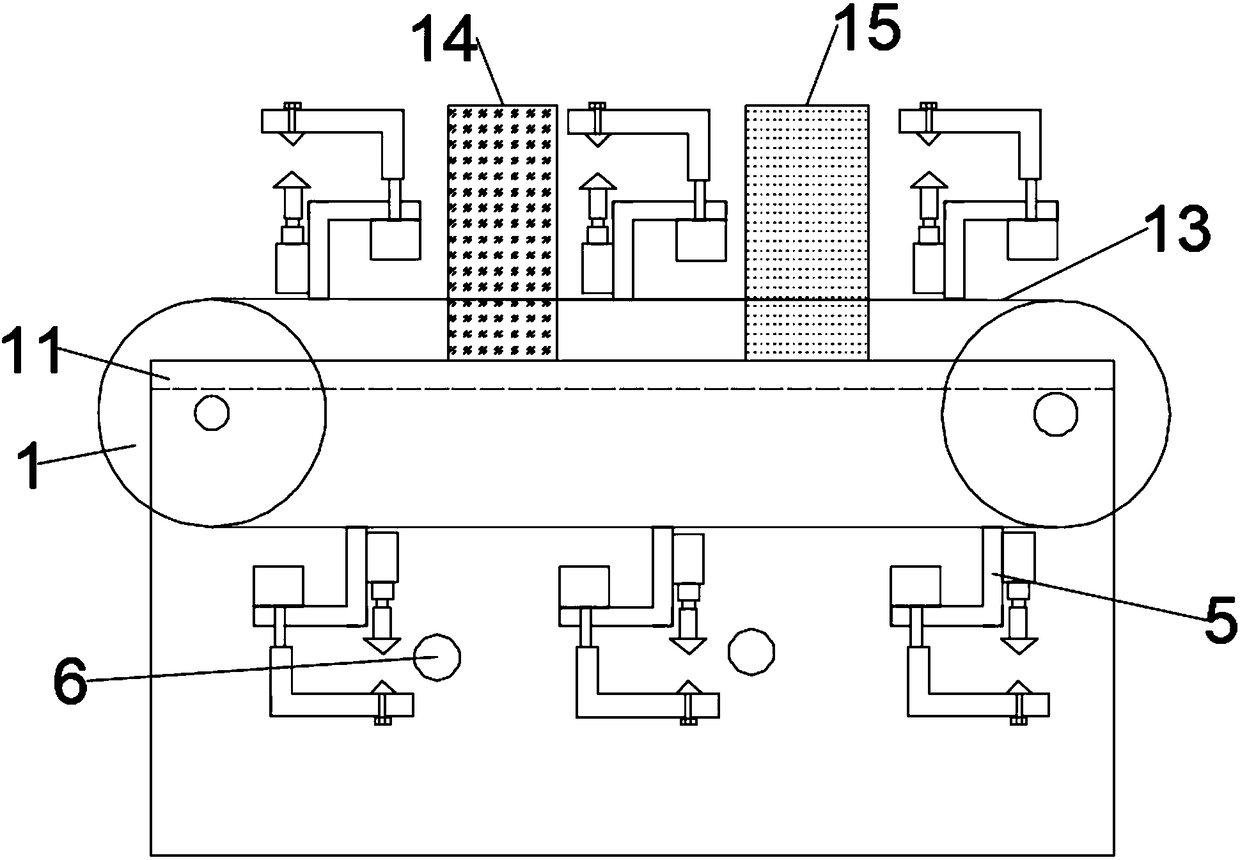

Canned fruit cleaning and air-drying equipment

InactiveCN112090902AEasy and quick placementEasy and fast operabilityHollow article cleaningDrying gas arrangementsCanned fruitProcess engineering

The invention discloses canned fruit cleaning and air-drying equipment which comprises supports, and a conveying belt is installed between the supports. A plurality of fixing disks are installed on the conveying belt, and clamping mechanisms are installed on the fixing disks. A treatment box is installed at the bottoms of the supports. A cleaning cavity and an air-drying cavity are formed in the treatment box. A first supporting plate is clamped between the inner walls of the two sides of the cleaning cavity, and a scrubbing mechanism is installed on the first supporting plate. A second supporting plate is installed between the inner walls of the two sides of the air-drying cavity, and a plurality of air blowing pipes are connected to the second supporting plate. Canned bottles are placedon the fixing disks through the clamping mechanisms to be clamped and fixed, the conveying belt drives the canned bottles to be moved into the cleaning cavity gradually, the scrubbing mechanism brushes the interiors and the exteriors of the canned bottles fully, and cleaning is made cleaner; and the conveying belt moves to enable the scrubbed canned bottles to enter the air-drying cavity, and meanwhile the subsequent canned bottles enter the cleaning cavity. The air blowing pipes blow air to quickly air-dry the inner walls and the outer walls of the canned bottles. And finally, the canned bottles are moved to the upper portions of the supports again along with the conveying belt, the canned bottles are manually and rapidly taken down, and continuous cleaning and air drying of the canned bottles are achieved.

Owner:宿州皇冠食品有限公司

Production technology of green and red grape

The invention relates to a production technology of canned fruits, in particular to a production technology of green and red grape cans, mainly solving the problem of the compatibility of a fruit system, acidophilus milk and baking foods. Since the water content of canned sweet fruits is higher, if the canned sweet fruits are directly used in the acidophilus milk or cake, the water eduction of the canned sweet fruits are easy to break the system of the foods and change the texture of the foods so as to influence the flavor and the taste of the foods and further to influence the quality guarantee period of the foods. The production technology of the invention enables green and red grapes to be directly used in fruits paste acidophilus milk and for ornamenting the baked foods. The production technology and a formula of the green and red grapes comprise the following steps: selecting the green and red grapes; peeling the green and red grapes; removing seeds of the green and red grapes; protecting the colors of the green and red grapes; washing the green and red grapes; selecting the green and red grapes again; repairing the green and red grapes; blanching the green and red grapes; preheating the green and red grapes; preparing soup liquid; canning and sealing. The invention has the advantages that the green and red grapes can change colors difficulty and can also be used in the acidophilus milk to enrich the flavor of the acidophilus milk; the taste of grape pulp is sweet, crisp and delicious; in addition, the quality guarantee period is long.

Owner:SHANGHAI YIFANG RURAL TECH HLDG +1

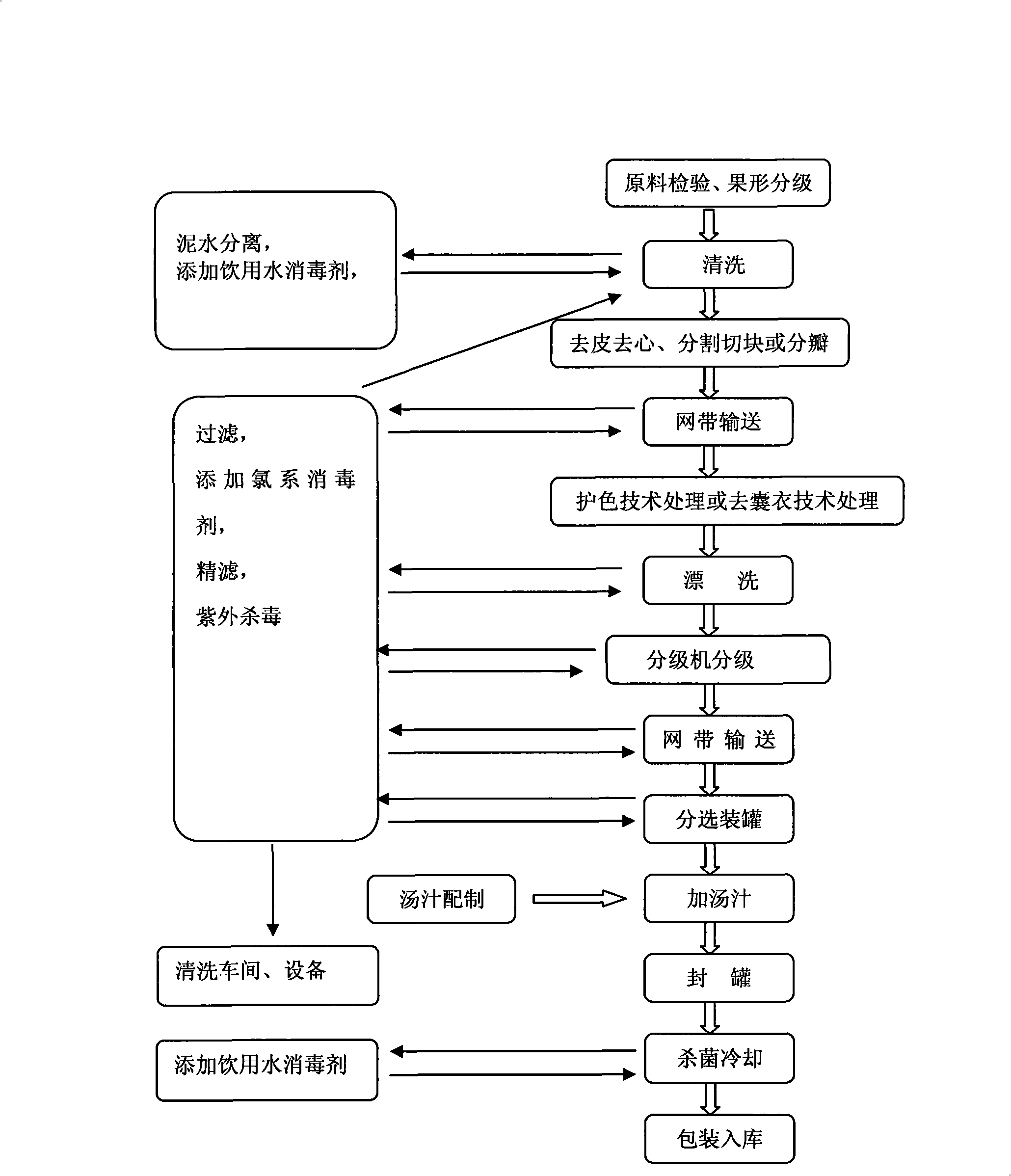

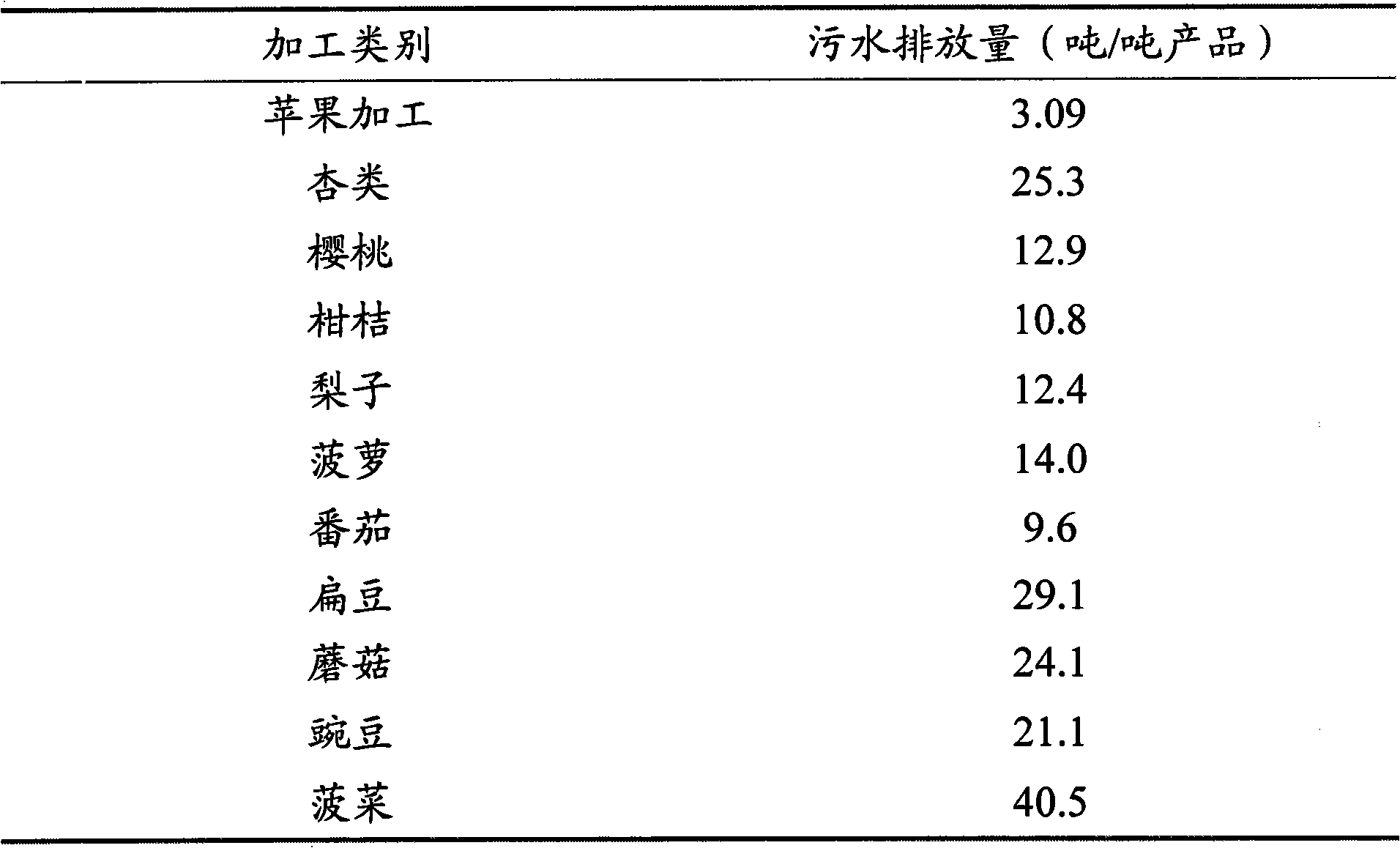

Intermediate water recovering process in fruit and vegetable can industry

InactiveCN101306897AEmission reductionIncrease profitWater/sewage treatment by irradiationMultistage water/sewage treatmentWater useDisinfectant

The invention discloses a reclaimed water recycling technique in the canned fruit and vegetable industry, comprising the following steps that: firstly, water used for cleaning raw materials is reclaimed; after slurry is separated, the water is added with drinking water disinfectant and then directly used for cleaning the raw materials; secondly, mesh-belt conveying water, rinsing water, grading water of a grader and separating and canning water are reclaimed, filtered by a filter screen and further intensively filtered, and ultraviolet sterilization is performed on the water which is then used in other can production technological flows except sterilization and cooling, and for cleaning equipment and workshops; thirdly, sterilization and cooling water is reclaimed, cooled and added with the drinking water disinfectant, and is then used for sterilization and cooling. The reclaimed water recycling technique has stable system operation, simple operation and low operating cost. The water conservation rate can reach between 30 and 60 percent according to different canned fruit and vegetable manufacturing procedures, and the reclaimed water recycling technique has great significance in energy conservation and emission reduction in the canned fruit and vegetable industry.

Owner:ZHEJIANG UNIV

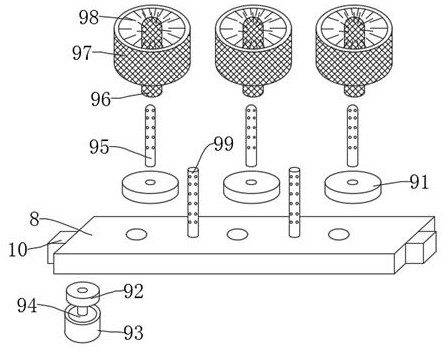

Screw cap mechanism for vacuum filling of fruit cans

ActiveCN108584838ADoes not damage the epidermisGuaranteed tasteCapsThreaded caps applicationBottle capScrew cap

The invention discloses a screw cap mechanism for vacuum filling of fruit cans. The screw cap mechanism for vacuum filling of the fruit cans comprises a base, a vacuum tinning device is installed on the base, and a vacuum tinning device comprises a bottle clamping device and an automatic screw cap device. The automatic screw cap device comprises a vertical mounting column fixed at the top end of the inner portion of a frame-shaped shell, and a cylindrical bottle cap placing groove and a bottle cap lowering groove are separately formed inthe bottom ends of the left side and right side of the vertical mounting column. A lifting cylinder is installed on the right side of the top end of the vertical mounting column. The right side of the cylindrical bottle cap placing groove is connected withthe bottle cap lowering groove. A horizontal telescopic rod and a push rod are arranged on the left side of the bottom end of the cylindrical bottle cap placing groove. A sealing top cover is movablyinstalled on the bottle cap placing groove. The bottom end of the lifting cylinder is connected with an absorbing magnetic column through a piston rod. A screw cap clamp is arranged at the bottom endof the absorbing magnetic column. Each time only one bottle cap is allowed to enter the bottle cap lowering groove 812, and then the bottle cap is screwed on the bottle body, the processing is more stable, the bottle cap is clamped in both directions, and the clamping force is more reliable.

Owner:福建泉州台商投资区莉沓科技有限公司

Broken fruit heat treatment device of universal production line of canned fruits

InactiveCN108477469ADoes not damage the epidermisGuaranteed tastePackaging under special atmospheric conditionsLiquid bottlingProduction lineCanned fruit

The invention discloses a broken fruit heat treatment device of a universal production line of canned fruits. The broken fruit heat treatment device comprises a base, wherein a fruit block heating device is mounted on the base; the fruit block heating device is fixed to a steam kettle above a bottom plate by a support block; the top end of the steam kettle is hinged with a sealing cover; one end of the steam kettle is connected with a steam pipe; a cushion is fixed to the bottom end of the inner part of the steam kettle; a fruit outlet is formed at the right end of the steam kettle; a feedingair cylinder is arranged on the left side of the cushion; the right end of the feeding air cylinder is connected with a push shovel by a piston rod; an oblique discharging plate is arranged at the bottom end of the right side of the fruit outlet; the fruit outlet is hinged with a movable door; an oblique oil cylinder is fixed to the bottom side of the oblique discharging sheet; and the bottom endof the oblique oil cylinder is connected with an extended guide plate by a piston rod. Blocky fruits can directly slide in a groove channel, and the bottom end of the extended guide plate can extend into a canning jar and directly deliver fruit blocks subjected to heat treatment into the jar, thereby saving canning time.

Owner:北京乾淳知识产权运营有限公司

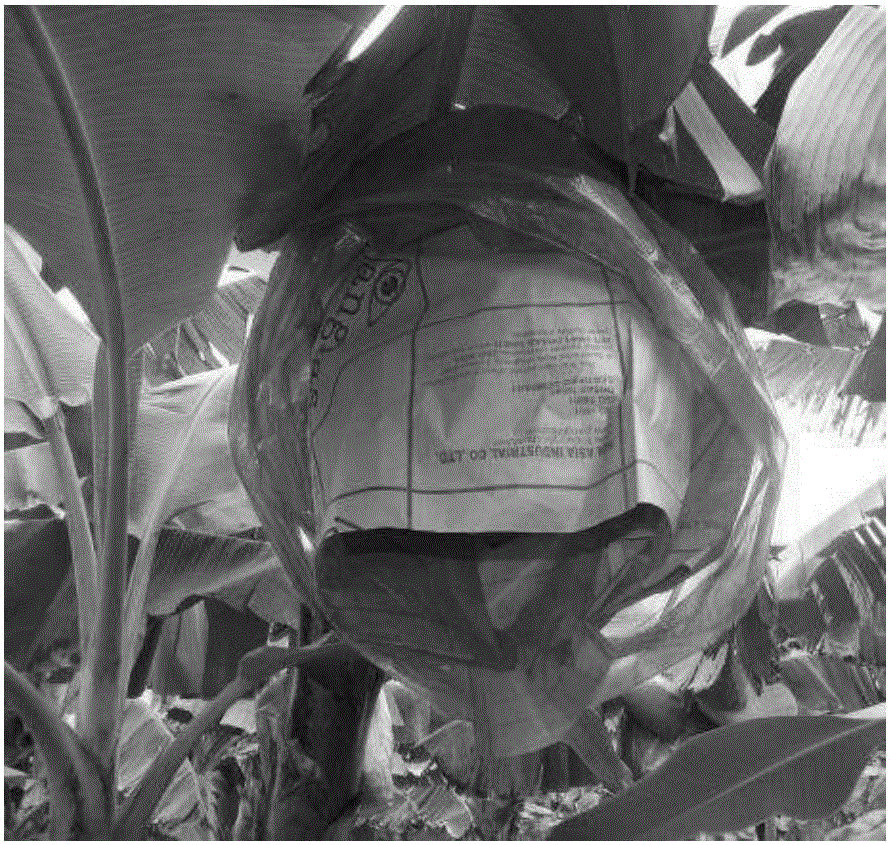

High-yield and high-quality cultivation method for anti-wilt banana variety

ActiveCN105993782AImprove efficiencyAvoid coldClimate change adaptationCultivating equipmentsBanana PlantCanned fruit

The invention discloses a high-yield and high-quality cultivation method for an anti-wilt banana variety. The method comprises the steps that the low-order planting anti-wilt banana variety is adopted for tissue culture seedlings; when the low order means soil preparation or planting, the ground of a planting hole is lower than a garden bed face, a step is formed, the paddy field banana garden level difference is 8-15 cm, and the mountain land banana garden is 14-22 cm; when banana plant corms begin to appear, earthing is performed to protect corms, and root growth is promoted. During early spring planting, the low planting density is adopted, plants can fruit earlier, and plants are prevented from fruiting or being frozen in winter; in summer and autumn, high planting density is adopted for planting, the yield per unit area can be increased, and meanwhile fruit quality is not affected; paper bags and nutritional agents are used for plant ears, so that the problem that fruits become green physiologically can be solved. According to the high-yield and high-quality cultivation method customized for the anti-wilt banana variety, the culture technology can achieve high yield, good quality and high benefits and achieves the great production significance.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Sugar-free fruit can and preparation method thereof

InactiveCN103652704ALow in sugarFull of nutritionFood ingredient functionsFood preparationCanned fruitTangerine Fruit

The invention provides a sugar-free fruit can and a preparation method thereof. The sugar-free fruit can comprises the following materials in parts by weight: 5 to 8 parts of tangerines, 3 to 7 parts of oranges, 1 to 3 parts of lemons, 1 to 4 part of shaddocks, 1 to 3 parts of ginseng fruit, 3 to 6 parts of dragon fruit, 1 to 3 parts of hawthorns, 1 to 3 parts of carambola, 3 to 6 parts of honey, 4 to 9 parts of isomaltulose, 3 to 7 parts of high maltose syrup, and 20 to 50 parts of purified water. The preparation method comprises the steps of firstly feeding the honey, the isomaltulose and the high maltose syrup into the purified water, boiling the mixture, so as to obtain sweet water, then washing, peeling and slicing the fruits, so as to obtain fruit blocks, and finally feeding the fruit blocks into the sweet water, so as to obtain the sugar-free fruit can. The method adopts the honey, the isomaltulose and the high maltose syrup as main sources of sweetening agent, which completely replace rock candy adopted in the traditional fruit can formula, and remarkably lowers the sugar content of the fruit can; moreover, as the multiple kinds of fruits are added, the sugar-free fruit can is rich in nutrition and delicious, beautifies appearance, and keeps young.

Owner:NANTONG SHUANGHE FOOD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com