Intermediate water recovering process in fruit and vegetable can industry

A technology for reclaimed water and canned food is applied in the field of reclaimed water reuse technology in the canned fruit and vegetable canning industry, which can solve the problems of water resource pollution and large discharge, and achieve the effects of low operating cost, stable operation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

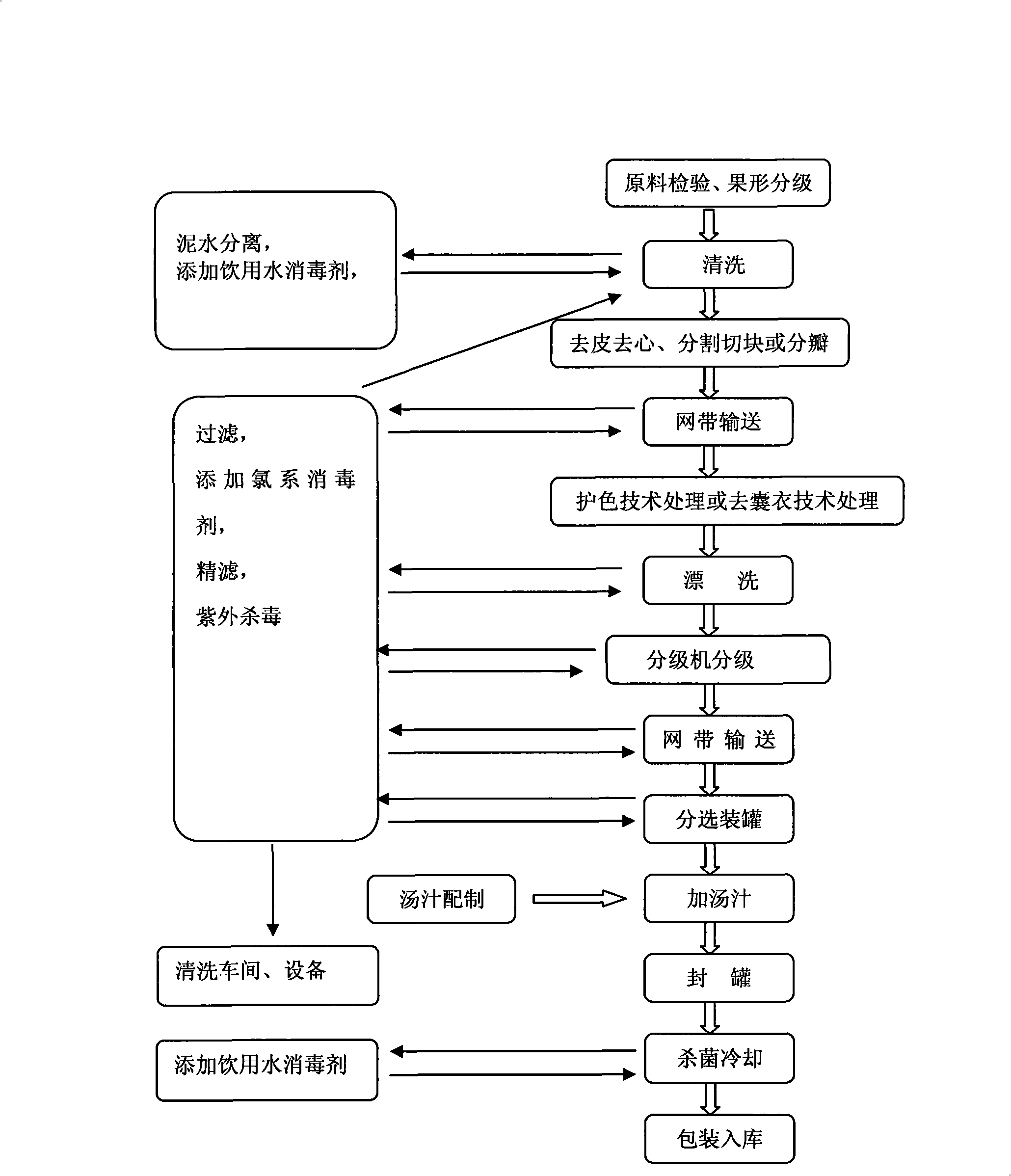

[0022] The production process of canned citrus is as follows:

[0023] Raw materials → cleaning and blanching → peeling → splitting → water immersion → mesh belt transportation → acid-base treatment → water washing → classifier classification → mesh belt transportation → canning → adding sugar juice → sealing → sterilization → cooling → finished product

[0024] (1) Washing and blanching water for recycled raw materials, the water mainly contains a small amount of sediment and orange oil, and the COD concentration is basically below 250mg / L. This part of the water is treated with a split-type ultra-high-speed mud-water separator and then added with chlorine dioxide disinfectant, so that the residual chlorine content in the water is controlled below 0.5ppm, and the recovered water after disinfection is directly reused for raw material cleaning.

[0025] (2) Citrus is generally treated with acid and alkali in an automatic temperature-controlled launder. The fruit capsules are so...

Embodiment 2

[0028] The production process of canned asparagus is as follows:

[0029] Material selection→cleaning→peeling and cutting→precooking→cooling and rinsing→grading→soup making→canning→sealing→sterilization→cooling→cleaning→storage

[0030] (1) Asparagus generally use asparagus with a stem length of 10-16 cm and an average stem diameter of 1.0-3.8 cm in thickness. It is required to be fresh, good, free from diseases and insect pests, rust spots and damage, and free from hollow, cracked and deformed asparagus as raw materials. Rinse with spray or running water. Washing with water is convenient to open the leaves and wash away the dust and silt wrapped in the leaves. Most of the water used for canned asparagus is concentrated in the raw material cleaning stage. This part of the water is treated with a split-type ultra-high-speed mud-water separator and then added with sodium hypochlorite disinfectant, so that the residual chlorine content in the water is controlled below 0.5ppm, an...

Embodiment 3

[0034] The production process of canned mushrooms is as follows:

[0035] Raw material cleaning→selection→color protection→rinsing→precooking→cooling→grading→slicing→rinsing→canning→exhaust→sealing→sterilization→cooling

[0036] (1) The cleaning water for mushroom raw materials is mainly silt and sawdust from the roots of some mushrooms, and also contains a very small amount of mushroom fragments, mushroom stalk hairs, and may also contain colored substances. After this part of the water is treated by the split-type ultra-high-speed mud-water separator, the solid matter in the water can be removed. Then add ozone to disinfect the water body. On the one hand, the ozone disinfectant can remove organic substances in the water, and on the other hand, it can decolorize the water body. The concentration of ozone is between 0.4ppm-3.0ppm. Different concentrations require different sterilization time and water storage time. For example, after 1.0ppm ozone water treatment for 2min-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com