Patents

Literature

12284 results about "Sediment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sediment is a naturally occurring material that is broken down by processes of weathering and erosion, and is subsequently transported by the action of wind, water, or ice or by the force of gravity acting on the particles. For example, sand and silt can be carried in suspension in river water and on reaching the sea bed deposited by sedimentation. If buried, they may eventually become sandstone and siltstone (sedimentary rocks) through lithification.

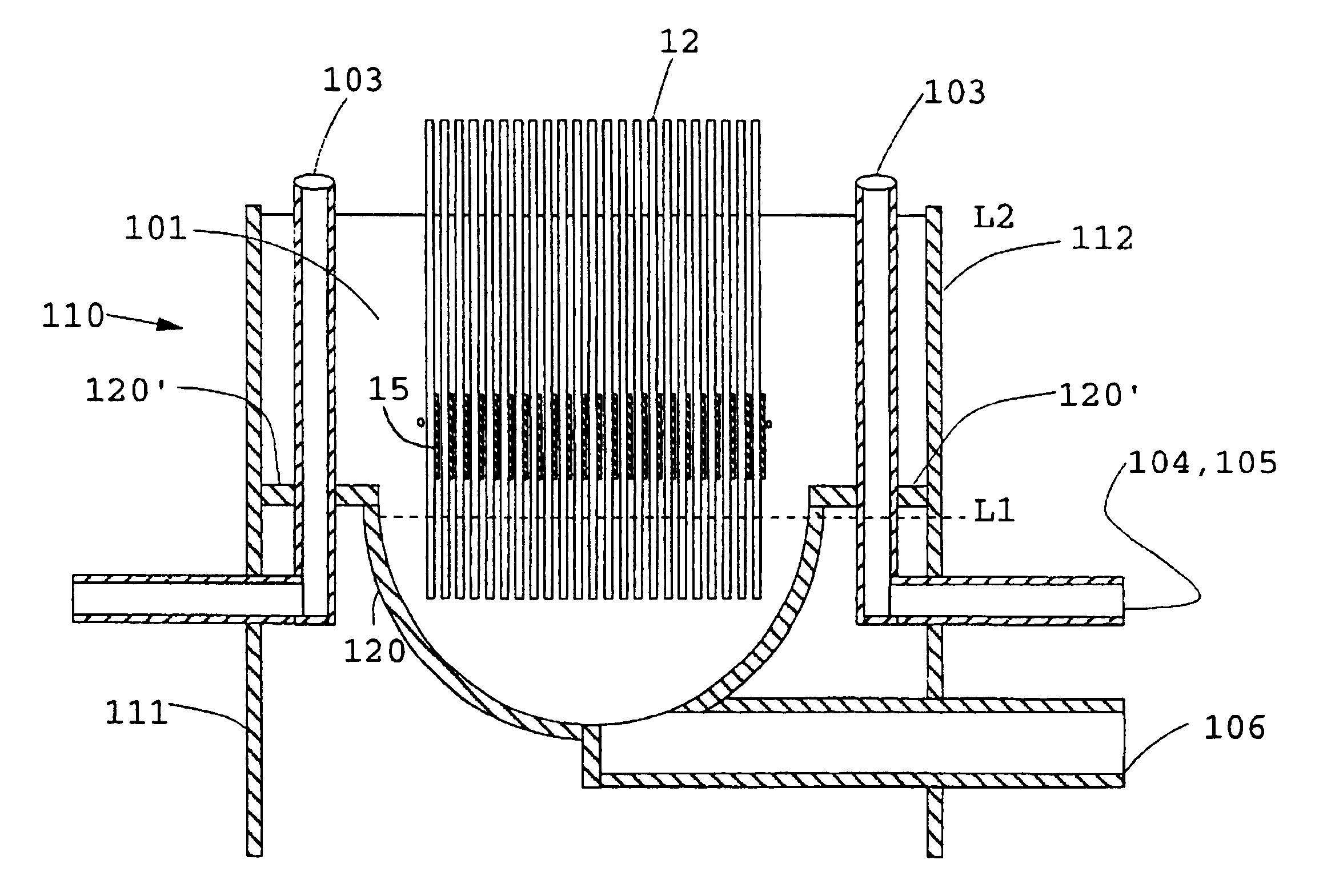

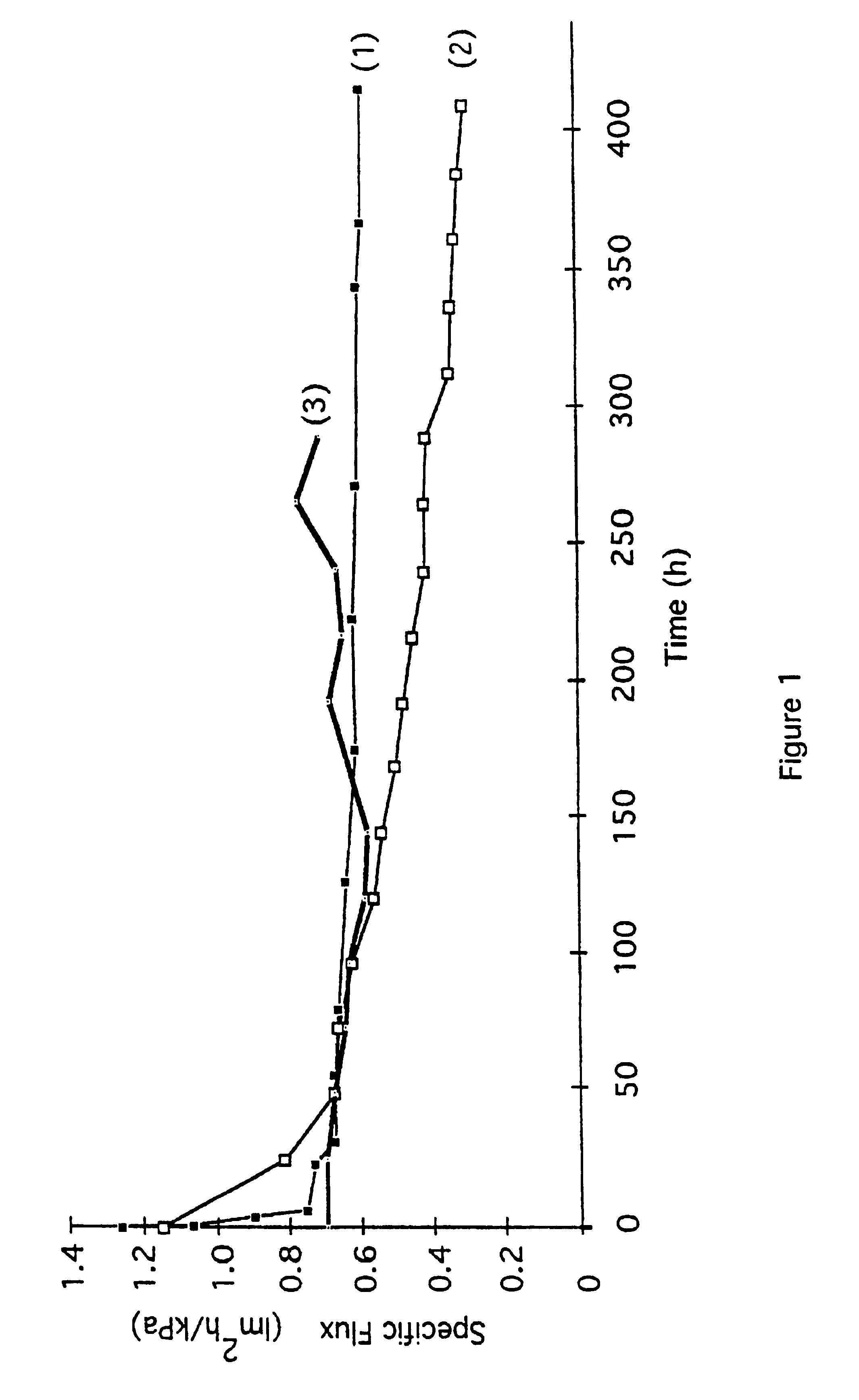

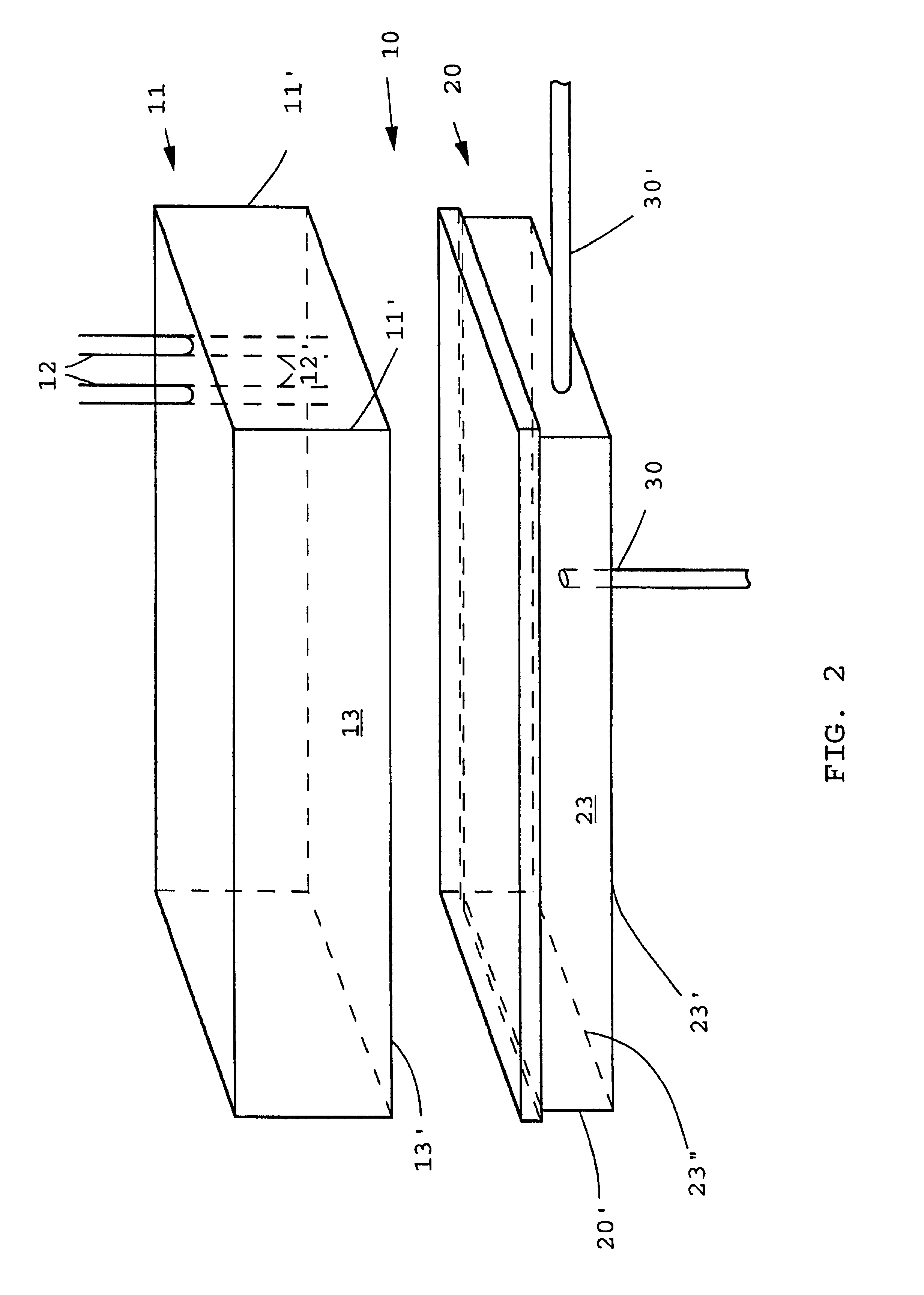

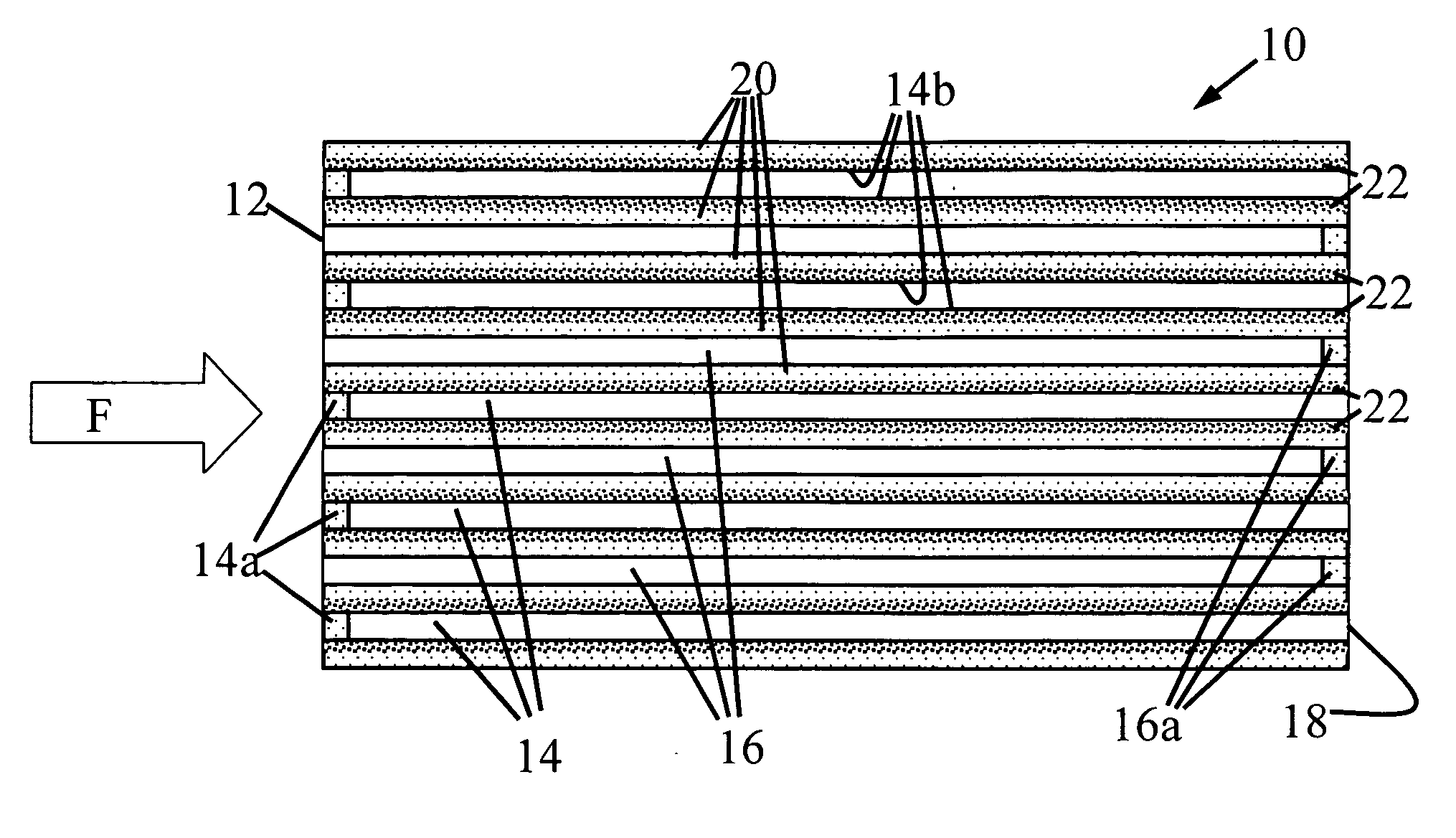

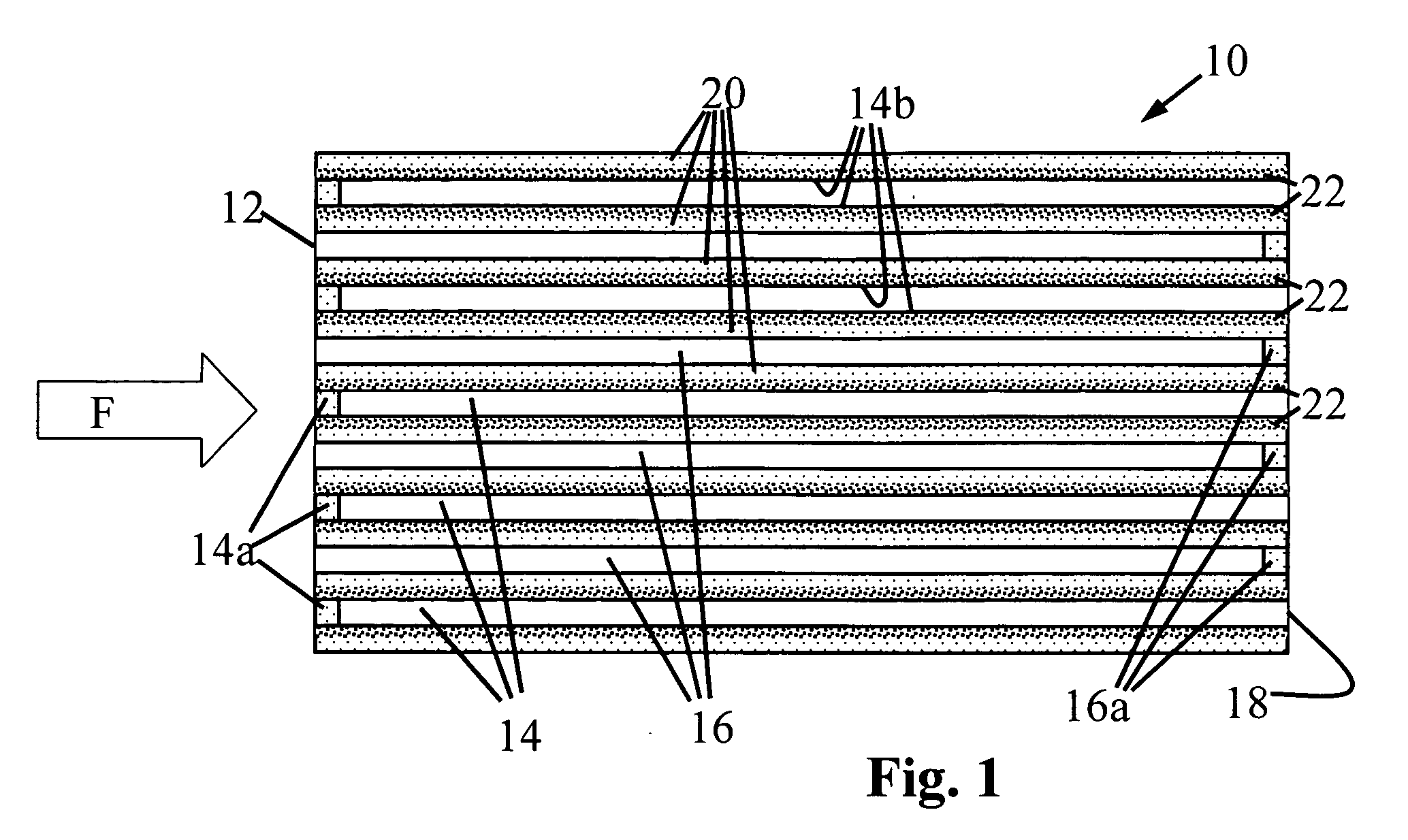

Vertical skein of hollow fiber membranes and method of maintaining clean fiber surfaces while filtering a substrate to withdraw a permeate

A vertical skein of "fibers", opposed terminal portions of which are held in headers unconfined in a modular shell, is aerated with a gas-distribution means which produces a mass of bubbles serving the function of a scrub-brash for the outer surfaces of the fibers. The membrane device is surprisingly effective with relatively little cleansing gas, the specific flux through the membranes reaching an essentially constant relatively high value because the vertical deployment of fibers allows bubbles to rise upwards along the outer surfaces of the fibers. Further, bubbles flowing along the outer surfaces of the fibers make the fibers surprisingly resistant to being fouled by build-up of deposits of inanimate particles or microorganisms in the substrate provided that the length of each fiber is only slightly greater than the direct center-to-center distance between opposed faces of the headers, preferably in the range from at least 0.1% to about 5% greater. For use in a large reservoir, a bank of skeins is used with a gas distributor means and each skein has fibers preferably >0.5 meter long, which together provide a surface area >10 m2. The terminal end portions of fibers in each header are kept free from fiber-to-fiber contact with a novel method of potting fibers.

Owner:ZENON TECH PARTNERSHIP

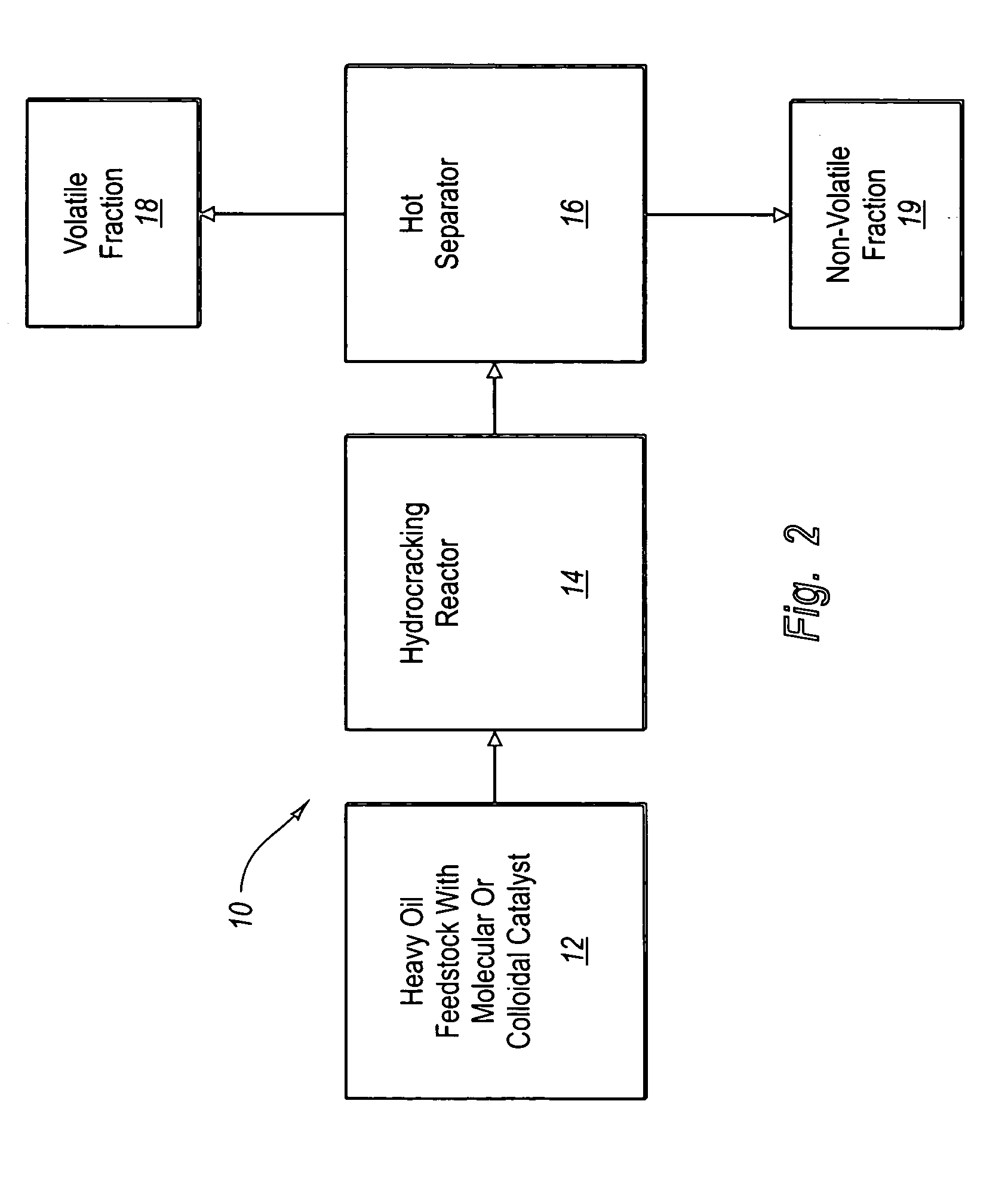

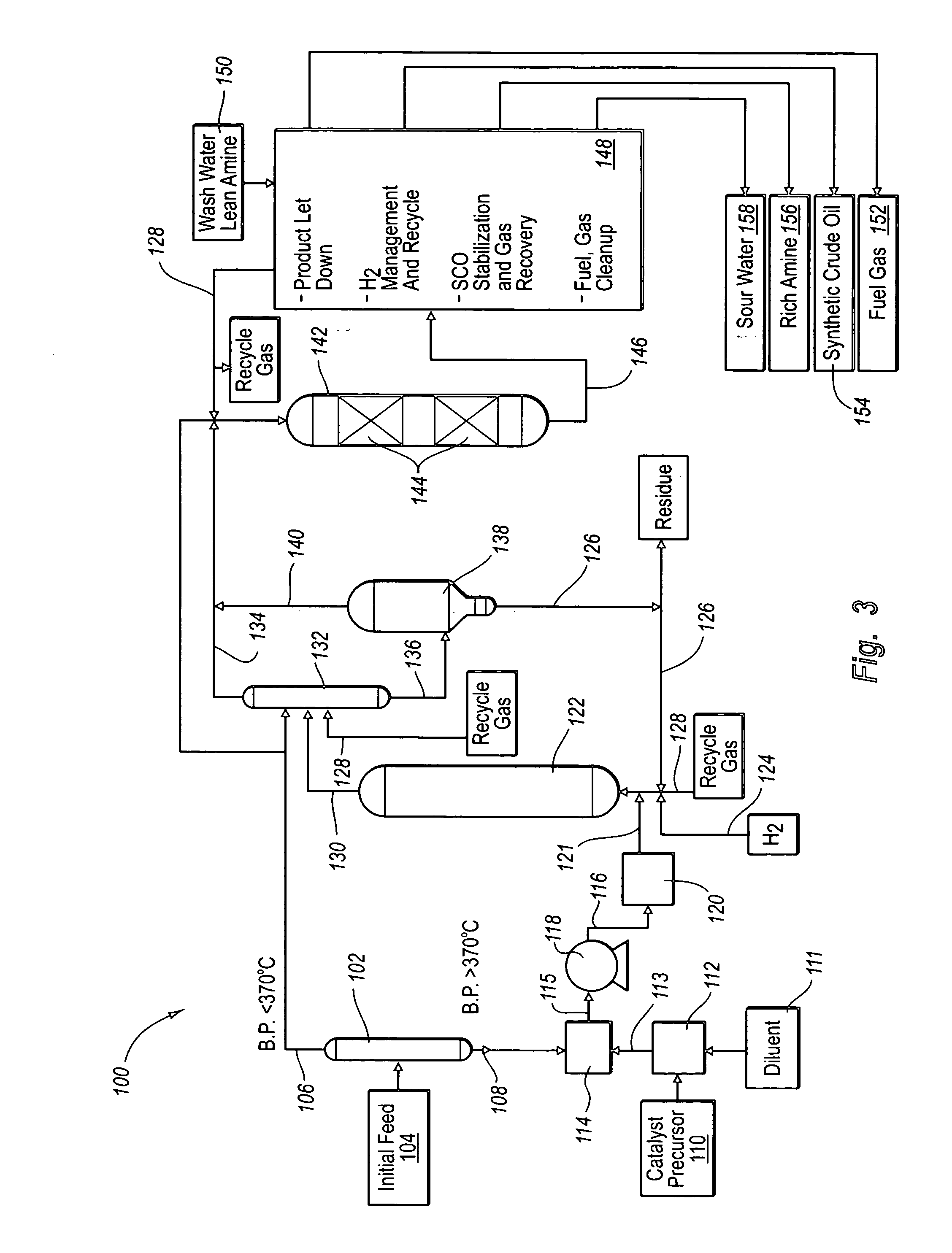

Hydroprocessing method and system for upgrading heavy oil using a colloidal or molecular catalyst

ActiveUS20050241993A1Inhibits eliminates formationEasy to useCatalyst regeneration/reactivationCatalyst activation/preparationColloidFuel oil

Methods and systems for hydroprocessing heavy oil feedstocks to form an upgraded material involve the use of a colloidal or molecular catalyst dispersed within a heavy oil feedstock, a hydrocracking reactor, and a hot separator. The colloidal or molecular catalyst promotes hydrocracking and other hydroprocessing reactions within the hydrocracking reactor. The catalyst is preferentially associated with asphaltenes within the heavy oil feedstock, which promotes upgrading reactions involving the asphaltenes rather than formation of coke precursors and sediment. The colloidal or molecular catalyst overcomes problems associated with porous supported catalysts in upgrading heavy oil feedstocks, particularly the inability of such catalysts to effectively process asphaltene molecules. The result is one or more of reduced equipment fouling, increased conversion level, and more efficient use of the supported catalyst if used in combination with the colloidal or molecular catalyst.

Owner:HEADWATERS TECH INNOVATION LLC

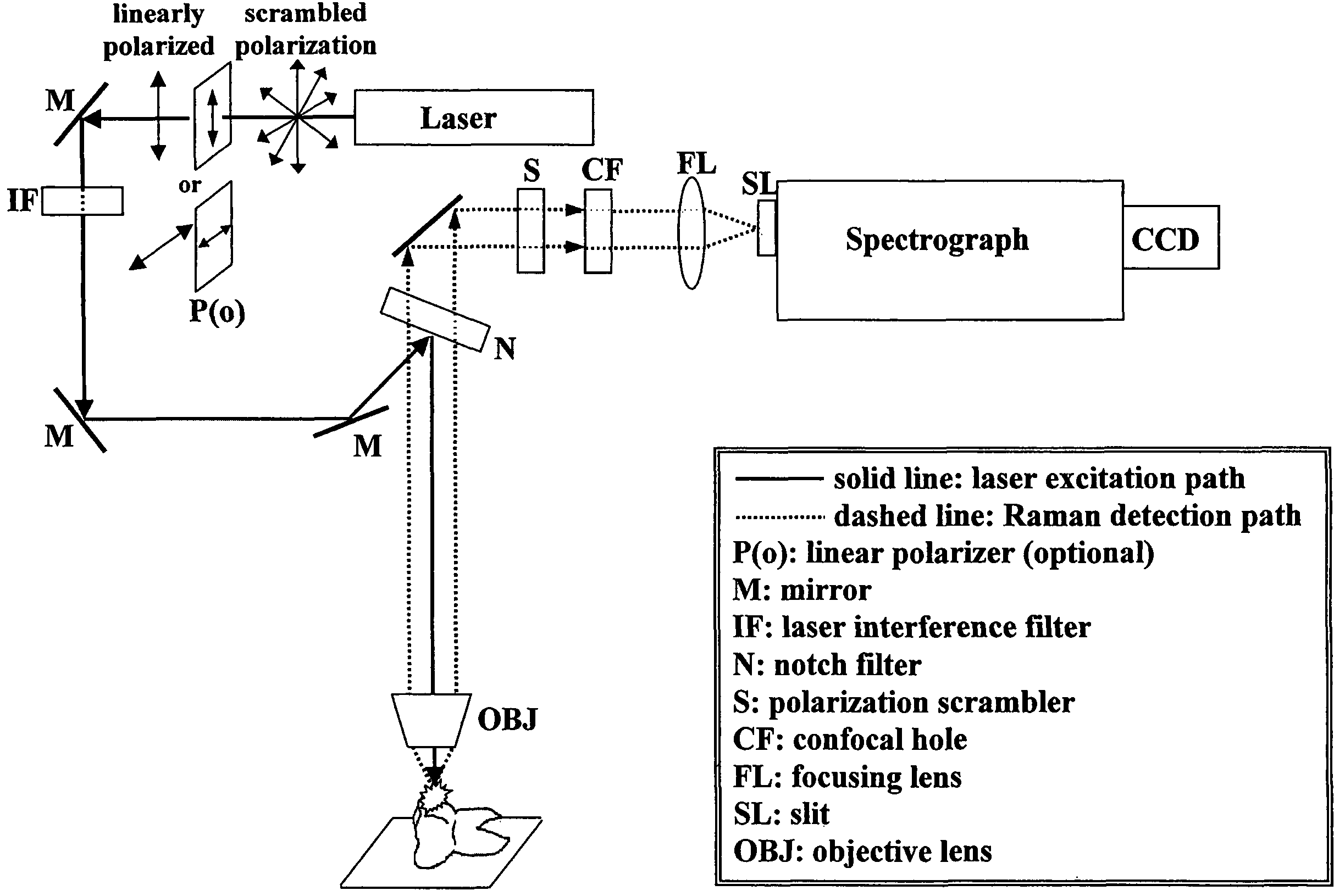

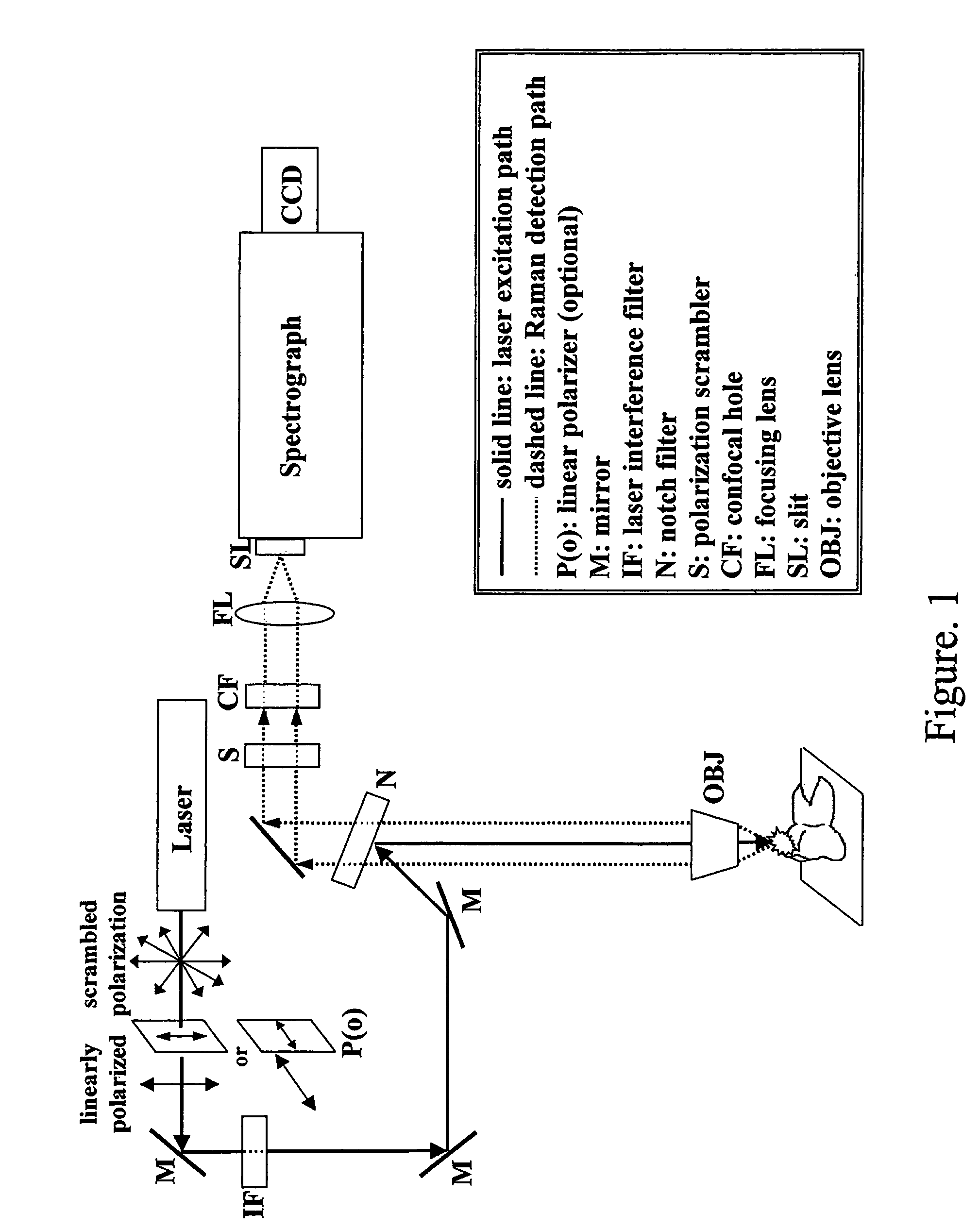

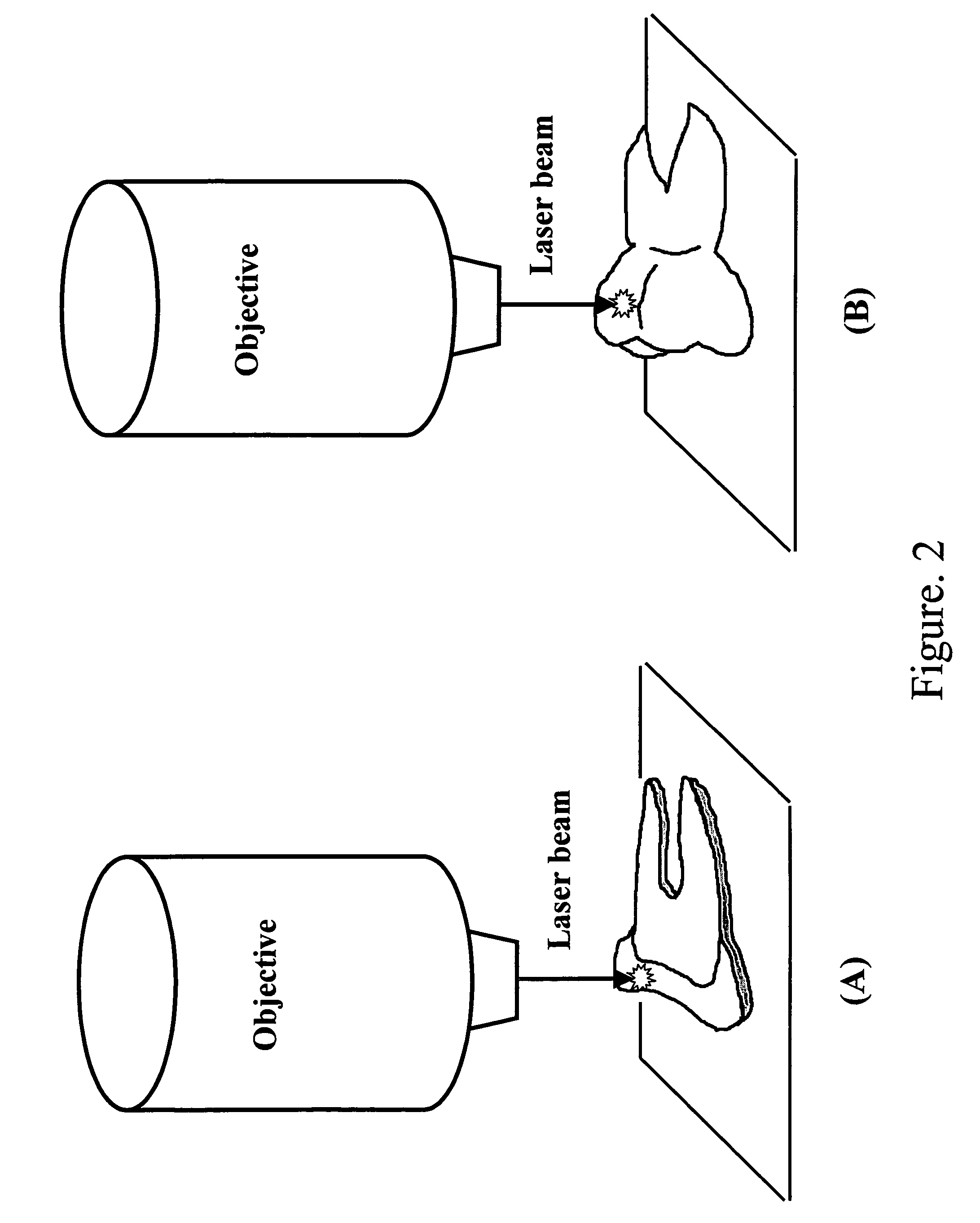

Detection and monitoring of changes in mineralized tissues or calcified deposits by optical coherence tomography and Raman spectroscopy

InactiveUS7796243B2Minimal disruptionHigh sensitivityRadiation pyrometryMaterial analysis by optical meansCarious lesionTooth Supporting Structures

Owner:NAT RES COUNCIL OF CANADA +2

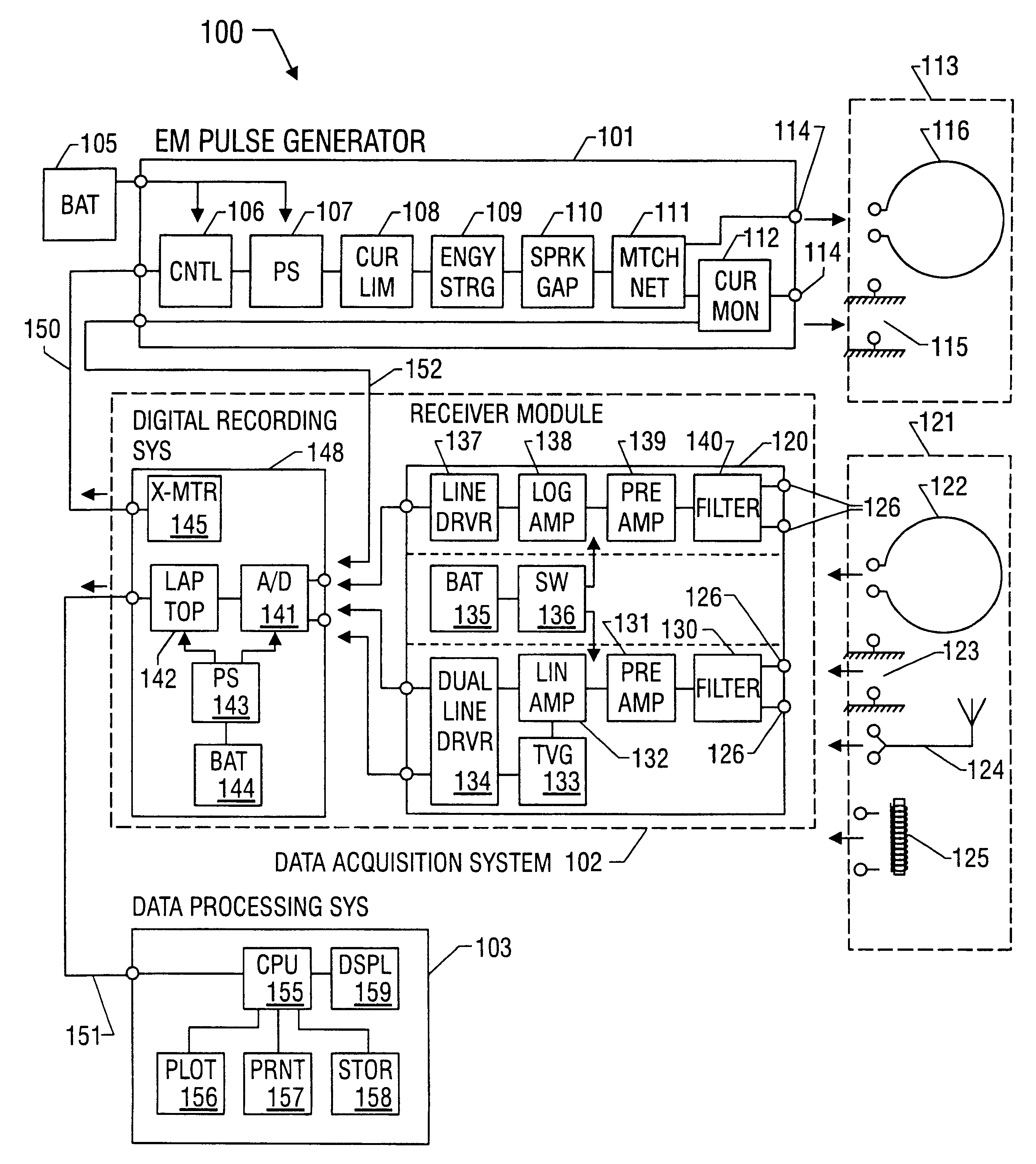

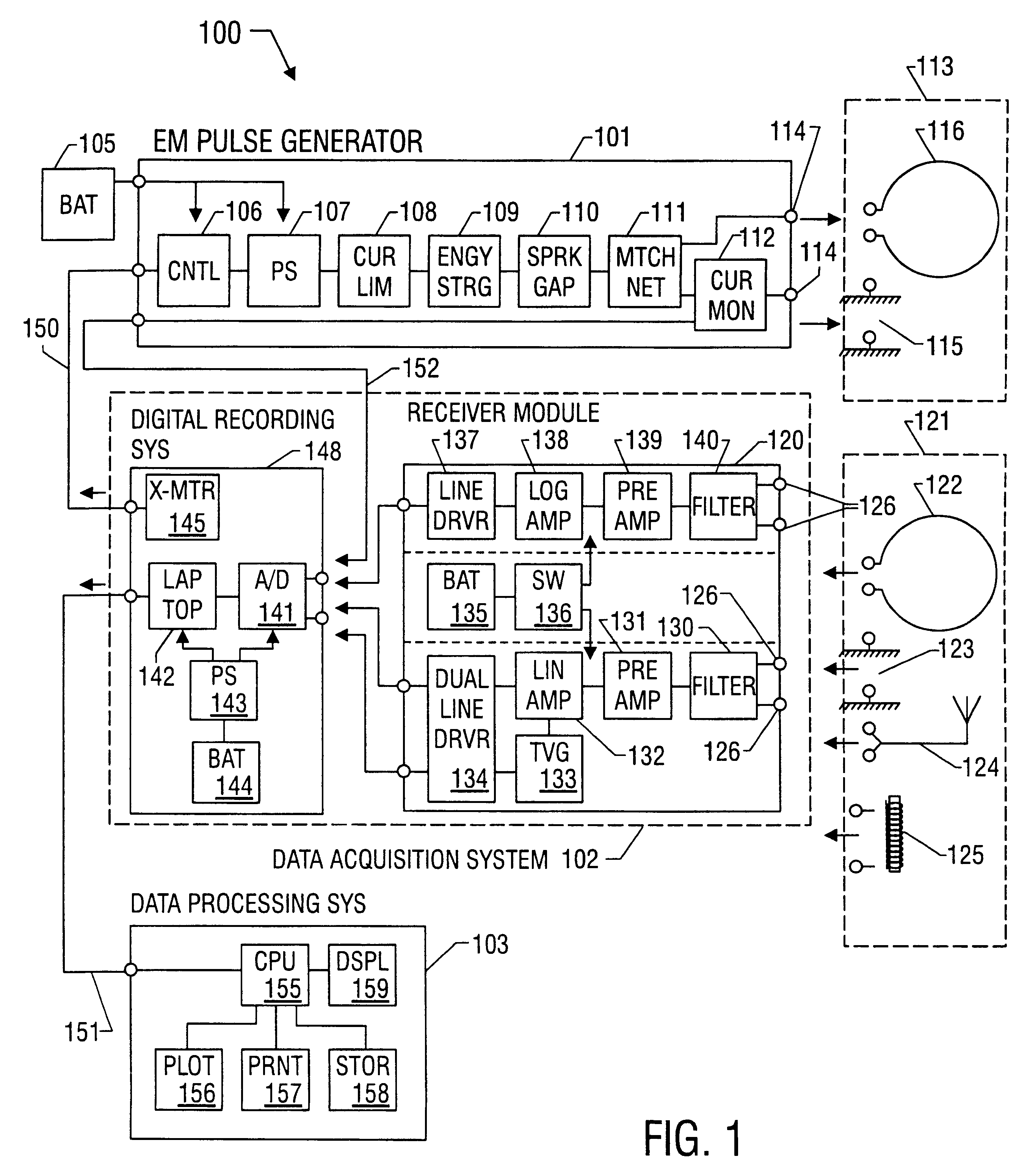

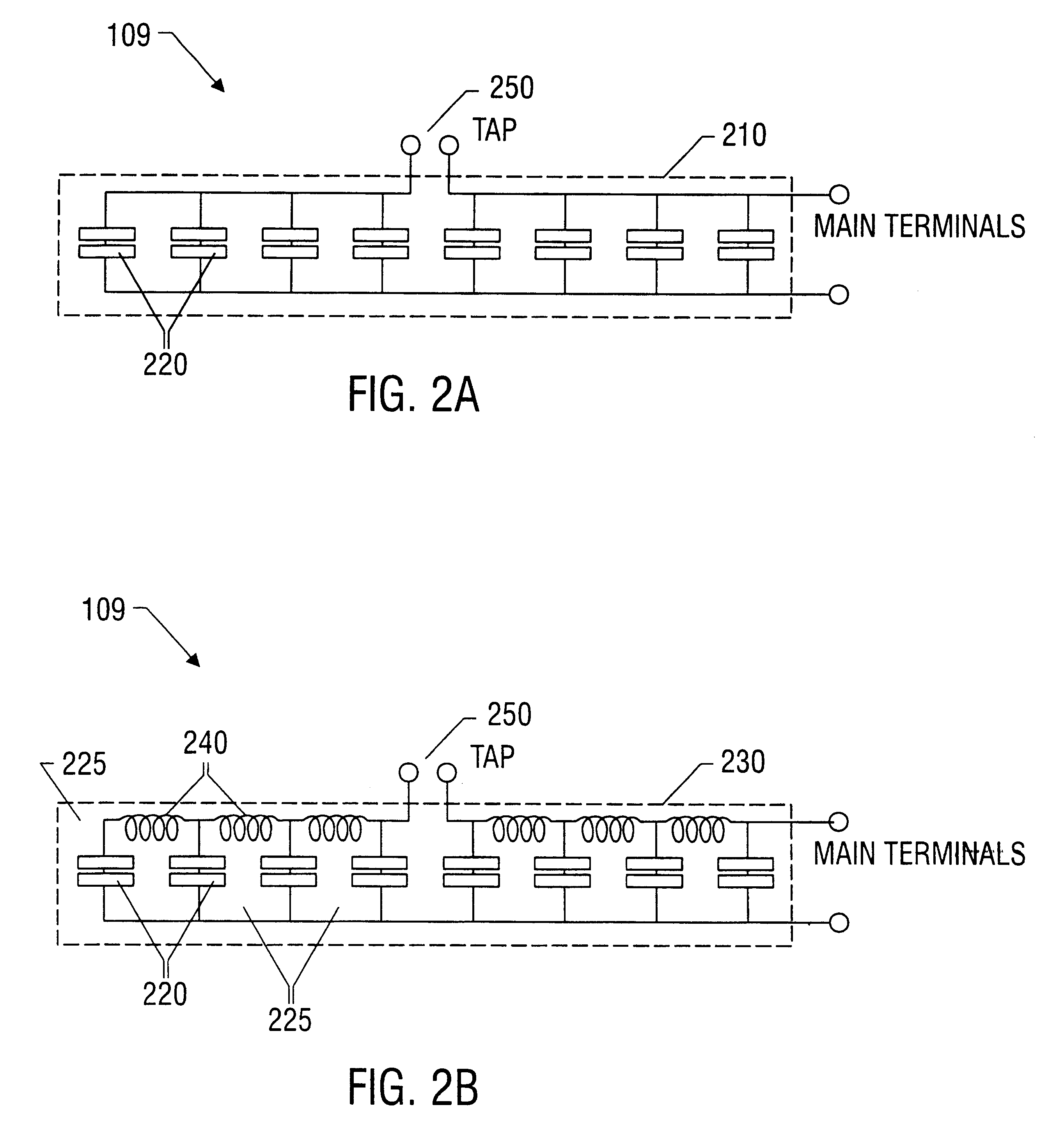

Method and apparatus for transmitting electromagnetic waves and analyzing returns to locate underground fluid deposits

InactiveUS6188221B1Detection using electromagnetic wavesRadio wave reradiation/reflectionData acquisitionData treatment

An electromagnetic (EM) survey system for determining the presence of liquid or gaseous deposits within the earth's interior. The system includes an EM pulse generator for generating the EM pulses, a data acquisition system for receiving and processing reflected signals from the earth's interior caused by the EM pulses, and a data processing system for analyzing the reflected signals to determine the presence of fluids in the earth's interior. Delivery of the EM pulses to the earth's interior can be accomplished either invasively or non-invasively. In an invasive manner, the EM pulse is delivered to the earth's interior via a set of electrodes buried shallow into the ground. In a non-invasive coupling, the EM pulse is delivered to the earth's interior via a wire loop. The reflected signals are received from the earth's interior via one of a wire loop, set of electrodes, wire antenna, or rod antenna array.

Owner:VAN DE KOP FRANZ +2

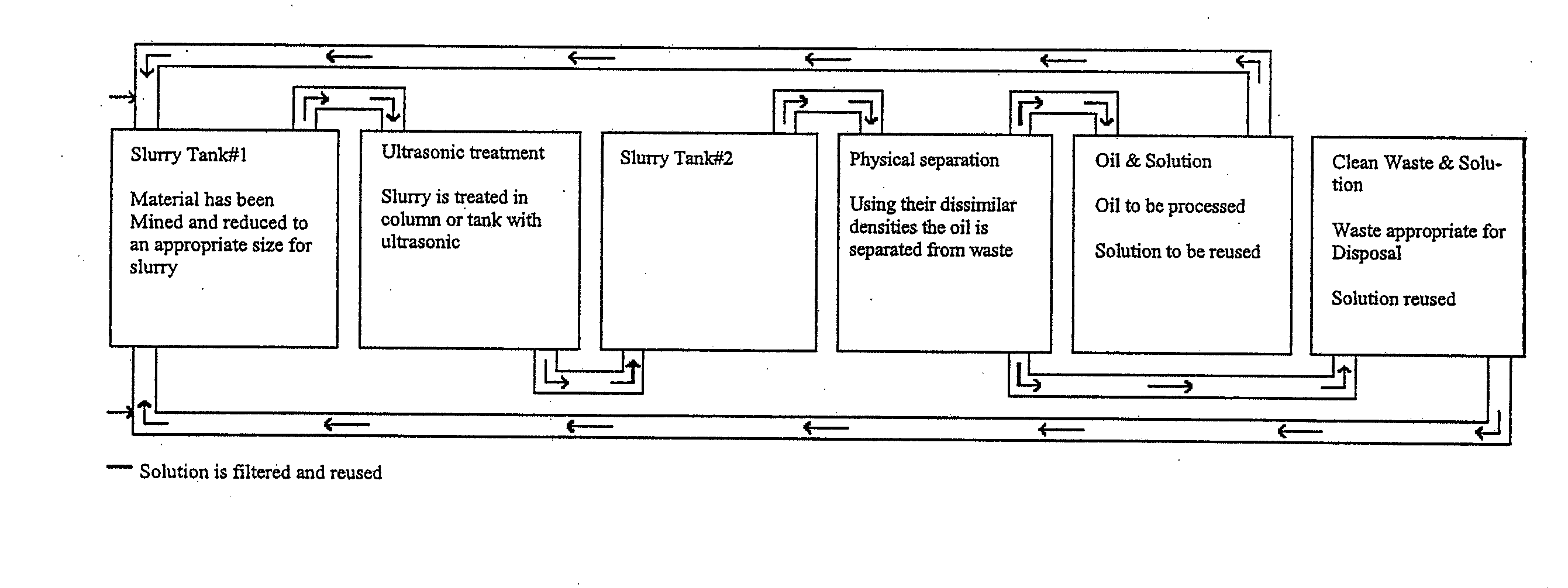

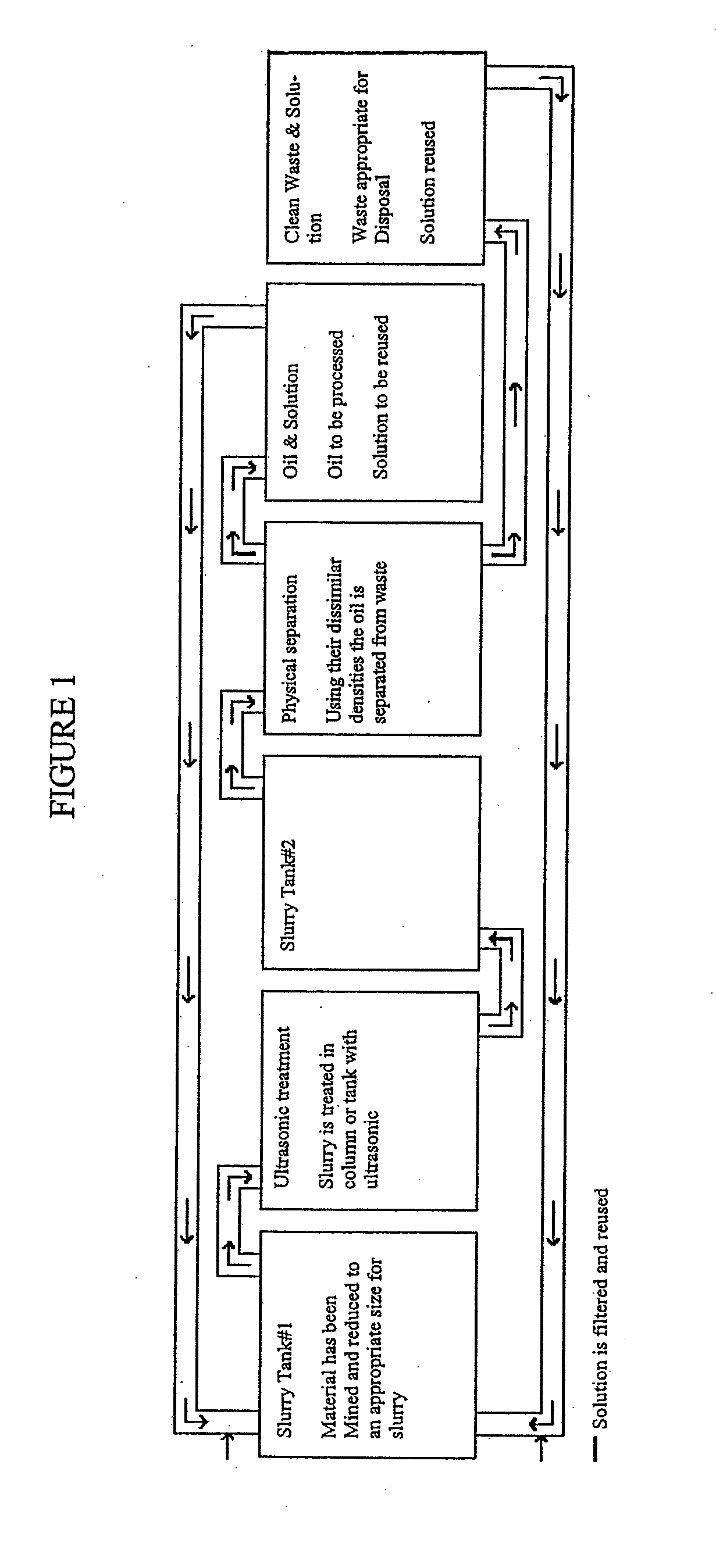

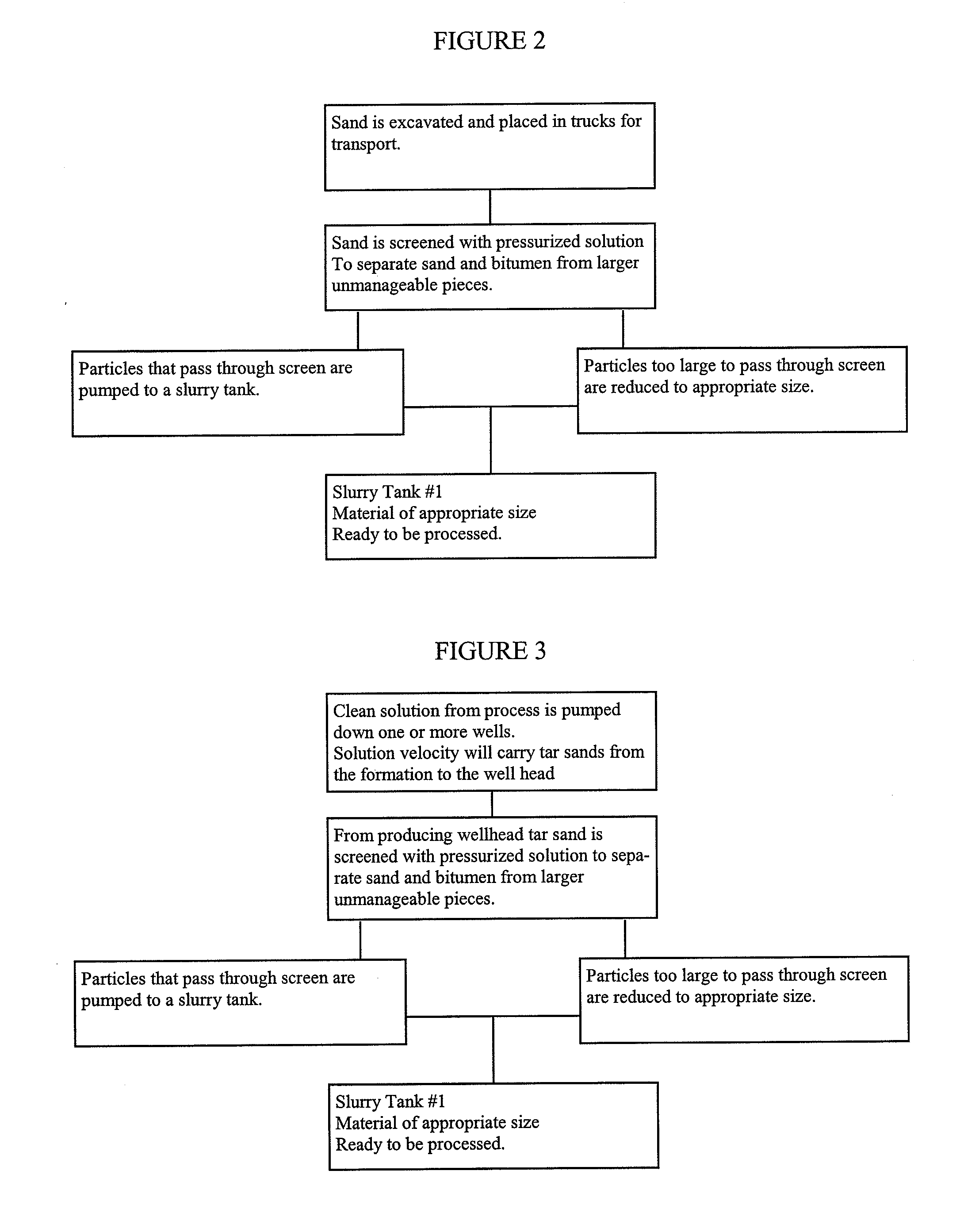

Method for extracting heavy oil and bitumen from tar sands

InactiveUS20080139418A1Removing both soluble and insoluble bitumenEfficient removalLiquid hydrocarbon mixture productionFlushingWater basedBatch processing

The use of high flash point low vapor pressure compositions for removal of crude oil deposits from tar sands by injection of products in situ or by removal of tar sands and batch processing. Processing equipment is designed for use on these compositions to maximize recovery of deposits and producing clean sand clays or other base materials for re-deposition without further treatment. The compositions consist of solvent based cleaners, solvent emulsion cleaners, and / or water based alkaline cleaners.

Owner:UNITED ENERGY CORP

Stable compositions of nano-particulate unmodified pigments and insoluble colorants in aqueous microemulsions, and principle of stability and methods of formation thereof

If the particle size of pigments in ink-jet inks is reduced below 500 nm, then the ink compositions achieved extraordinary stability; that is, there is no visible sediment formed after three weeks at ambient temperature and there is no sediment formed after heating to 70 DEG C. for 10 min followed by cooling to 0 DEG C. for 10 min. No dispersant is necessary, and the pigment particles having such a defined size may be incorporated into microemulsions, using a suitable oil (water-immiscible organic compound), at least one amphiphile, and water.

Owner:HEWLETT PACKARD CO

Black-odor river pollution treatment method

InactiveCN101417840AEfficient removalControl and reduce the total amount receivedTreatment using aerobic processesWater aerationMicrobial agentSelf purification

The invention discloses a method for managing town black and olid river pollution in situ by utilizing biological repair technology, which takes the steps and measures of aerating and oxygenizing in riverway, adding a complex microbial agent, biologically repairing bottom sediment, arranging a bio-nest system and the like, so as to control and eliminate the exogenous and endogenous pollution of the river, purify the water quality of the river, improve the self-purification ability of the water body and achieve the purpose of eliminating black and olid. The method does not need to build structures in the riverway or lead the river water out of the riverway to be treated, or dredge the bottom sediment in the river, therefore the method is generally applicable to incomplete sewage interception and dredging or the rivers which can not be intercepted sewage or dredged temporarily, and the in situ treatment to the riverway which is affected by tide and has complicated fluid variation. Therefore, the method which can lead the water body to recover normal ecological function provides the practical, economic and convenient treatment method for various town black and olid rivers.

Owner:黎赓桓 +1

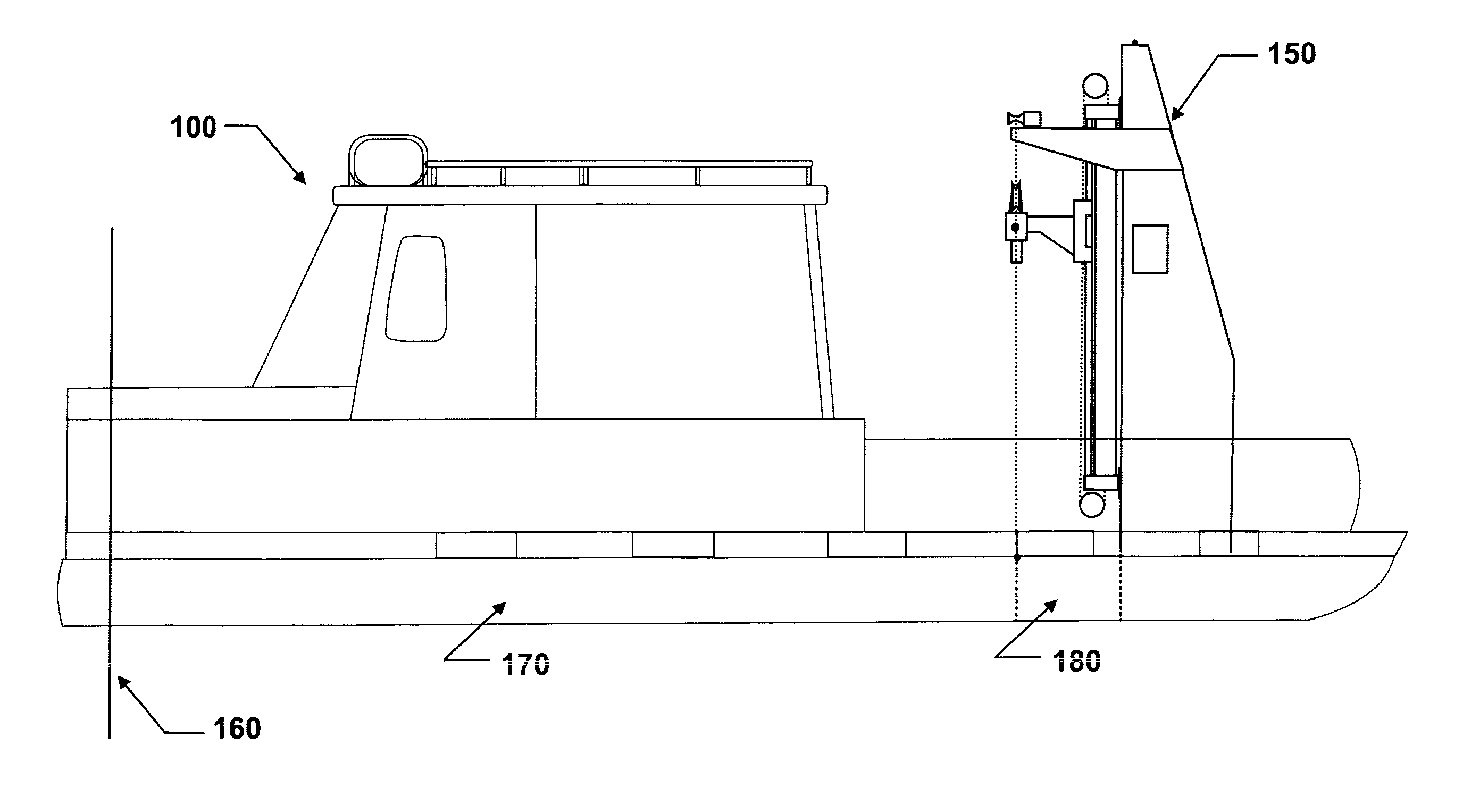

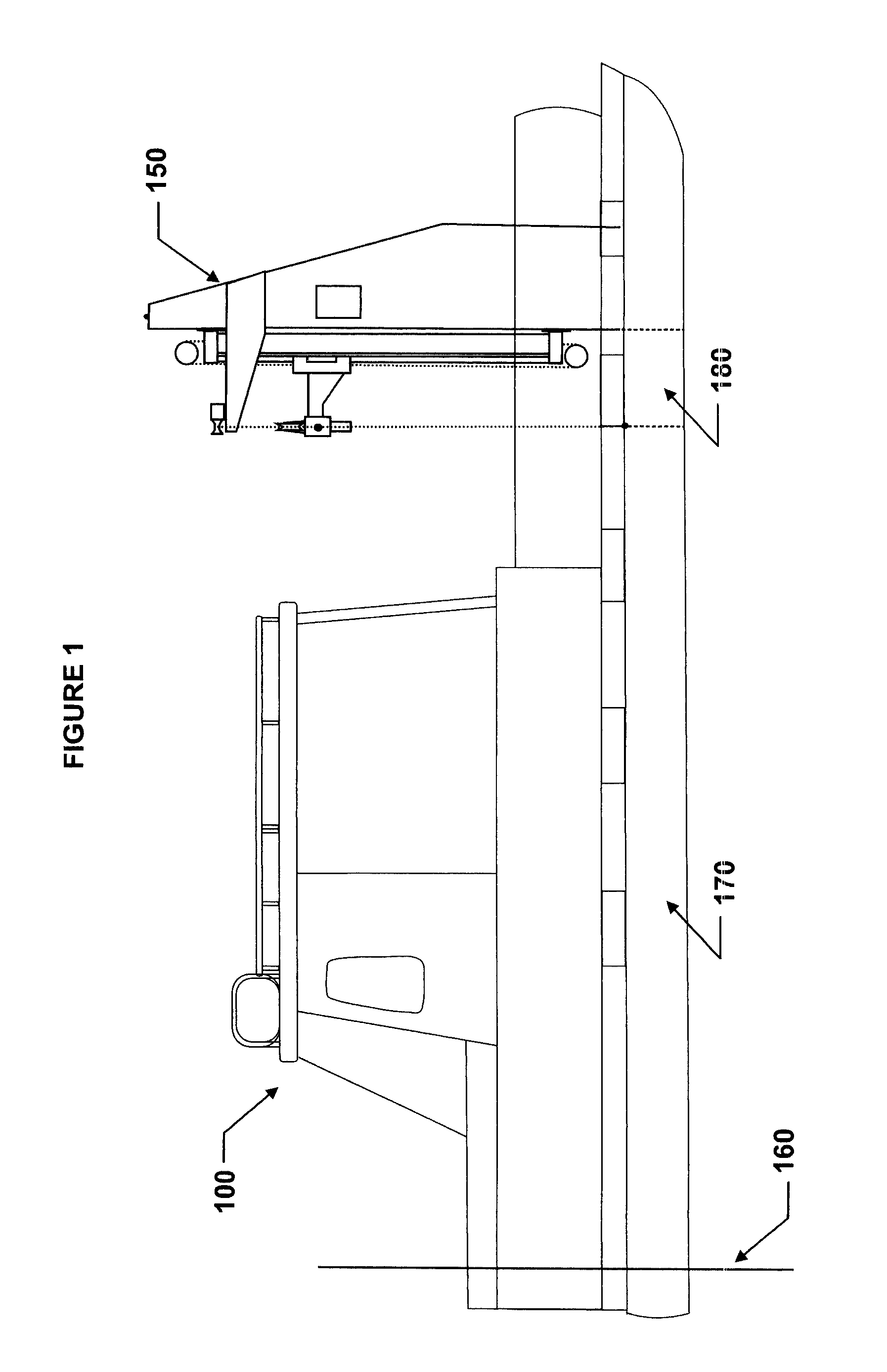

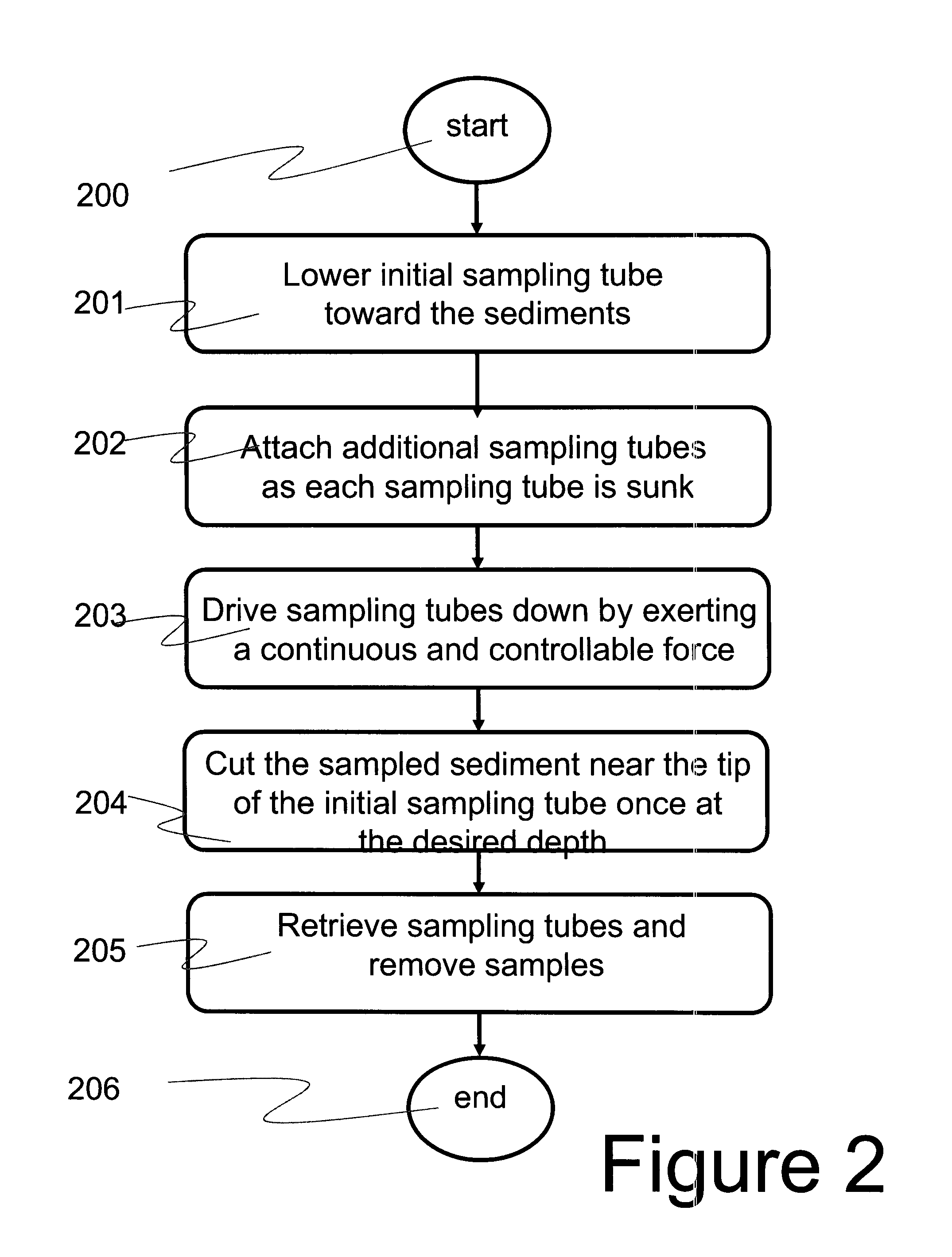

Undisturbed soil and sediment sampling

Device, system and method for sampling of soft sediments with retention of sample material and profile. A barge is anchored and stabilized in position; sampling tubes are driven through underlying sediments using continuous and controllable translational pneumatic force; a torpedo-shaped end piece leads the sampling tubes into the sediments. Once at desired depth, a rotational force is applied to sampling tubes. Fins located around torpedo prevent the torpedo from rotating and connection between leading sampling tube and torpedo is tightened. O-ring located between torpedo and leading sampling tube is squeezed as a result of such tightening and bulges inward pinching the core inside sampling tube. During retrieval, core is more likely to break at the location of the pinch which has introduced structural discontinuity; core above the pinch is capped by compacted material at the pinch. O-ring does not disturb sample integrity during descent. Winch and pulley mechanism may assist.

Owner:DANESH BIJAN

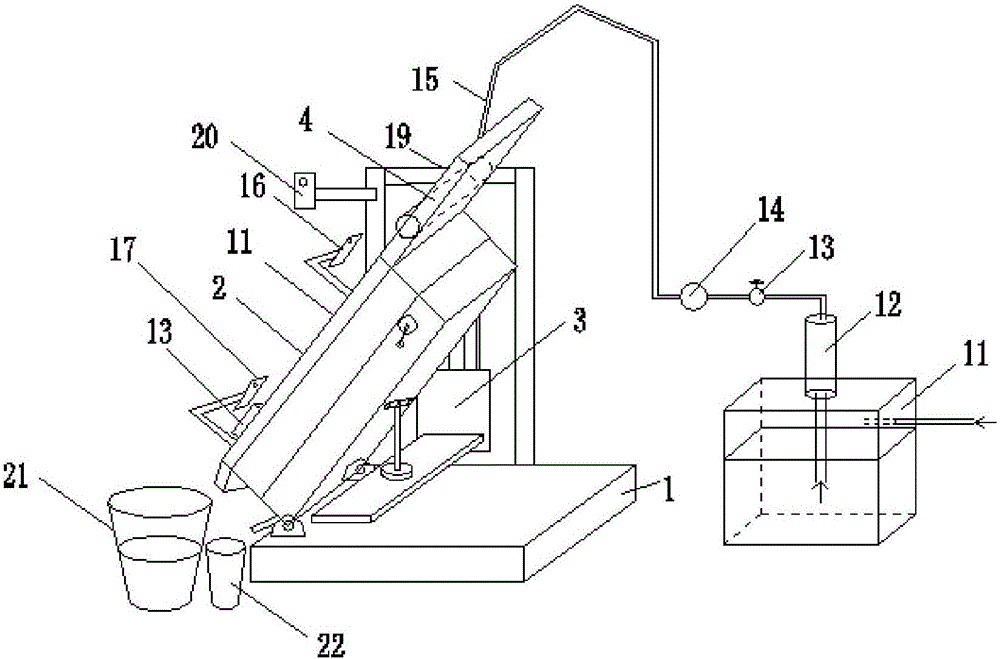

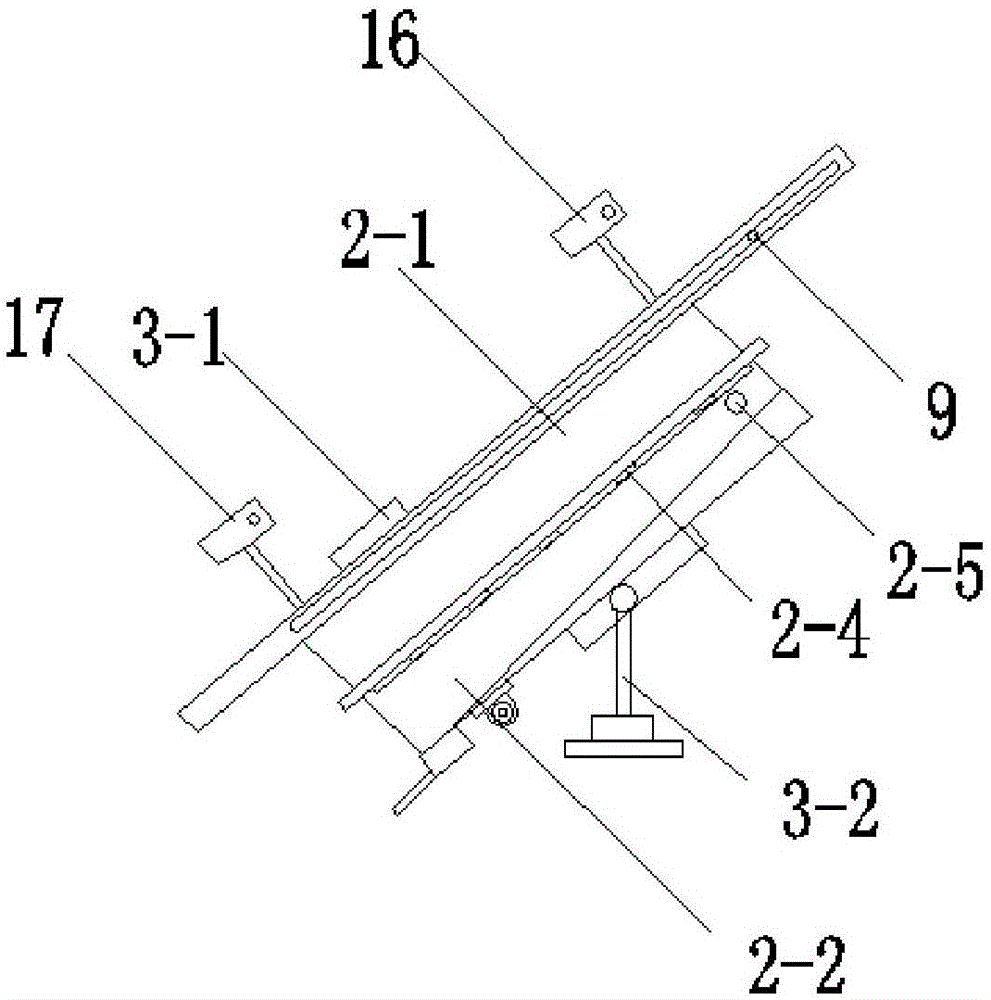

Soil slope water flow erosion resistance simulation test method and device

ActiveCN106290800AIncrease the time to gatherReduce wasteInvestigating moving fluids/granular solidsEarth material testingSoil scienceMaximum depth

The invention relates to a soil slope water flow erosion resistance simulation test method and device. The device comprises a liftable slope simulation device, a sheetflood scouring simulation device, a water and soil collecting device, a flow velocity determining device and a slope surface form camera device. According to the test method, the water flow is controlled, surface flow and seepage are formed, and sheetflood water, seepage water and sediment quantity formed by scouring slopes by sheetflood water are collected. The flow, the flow velocity, the erosion depth, the sand yield and the like of the water flow are measured quantitatively. Compacted soil is soaked in water until saturation for simulation, the efficiency of an indoor simulation test on slope scouring is improved, the test period is shortened, the test result proves the maximum depth of a slope erosion gully and the change rule of the sand yield with time, discloses the relation between the water flow erosion capacity of catchment behind slopes and the slope length, gradient and time and provides a basis for prediction of the water flow erosion scale and the need of slope protection and reinforcement. The device is simple in structure, convenient to operate and suitable for measurement of soil mechanics parameters of slope soil mass.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

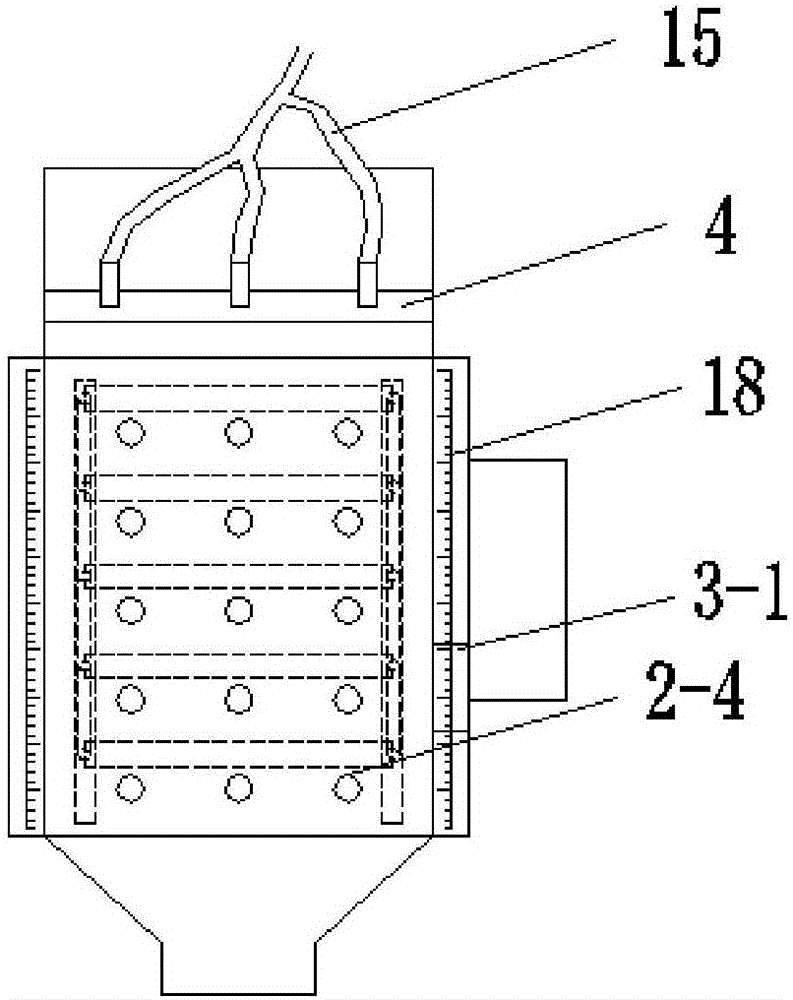

Three-axis test device and methods for sediments including gas hydrates

InactiveCN102252918AEvenly distributedSimple structurePreparing sample for investigationMaterial strength using steady shearing forcesOcean bottomNatural state

The invention discloses a three-axis test device and methods for sediments including gas hydrates, relating to a testing technology of sediments including gas hydrates. The device is used for making samples with different hydrate contents and uniform distribution by utilizing first circulation and saturation and then cooling of gas-containing saturated water in the samples and then carrying out three-axis shear on the sample in a certain confining pressure so as to determine the mechanical parameters of the samples. Based on the device, a set of methods for testing the three-axis mechanical parameters of the sediments including gas hydrates is formed, and the mechanical parameters measured by the method are closer to the natural state. The device and methods disclosed by the invention are used for carrying out an accurate simulation test on the marine gas hydrate forming process in a laboratory, providing technical assurance and support for the further study of physical and mechanical properties of the marine soil including gas hydrates, and promoting the further development of the research powerfully.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

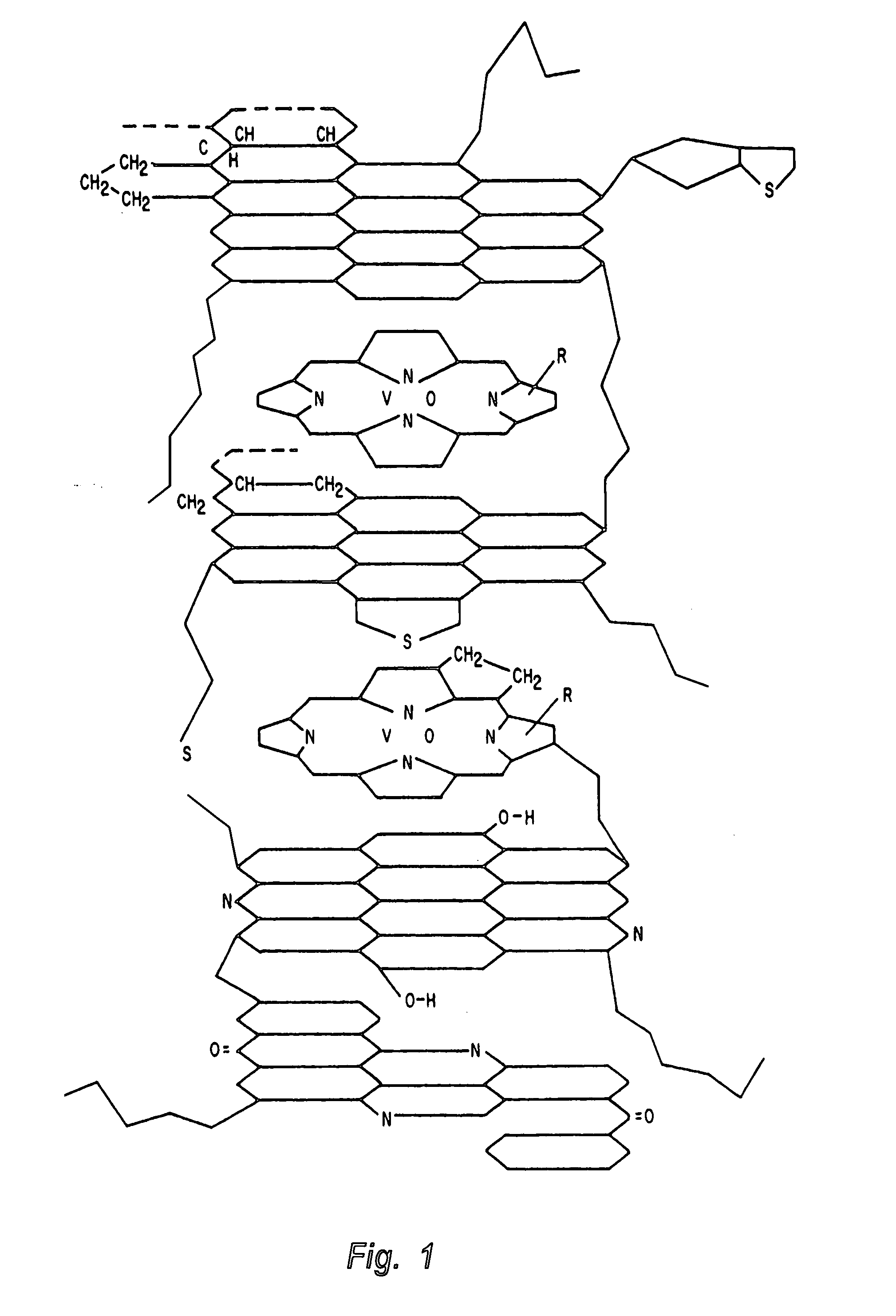

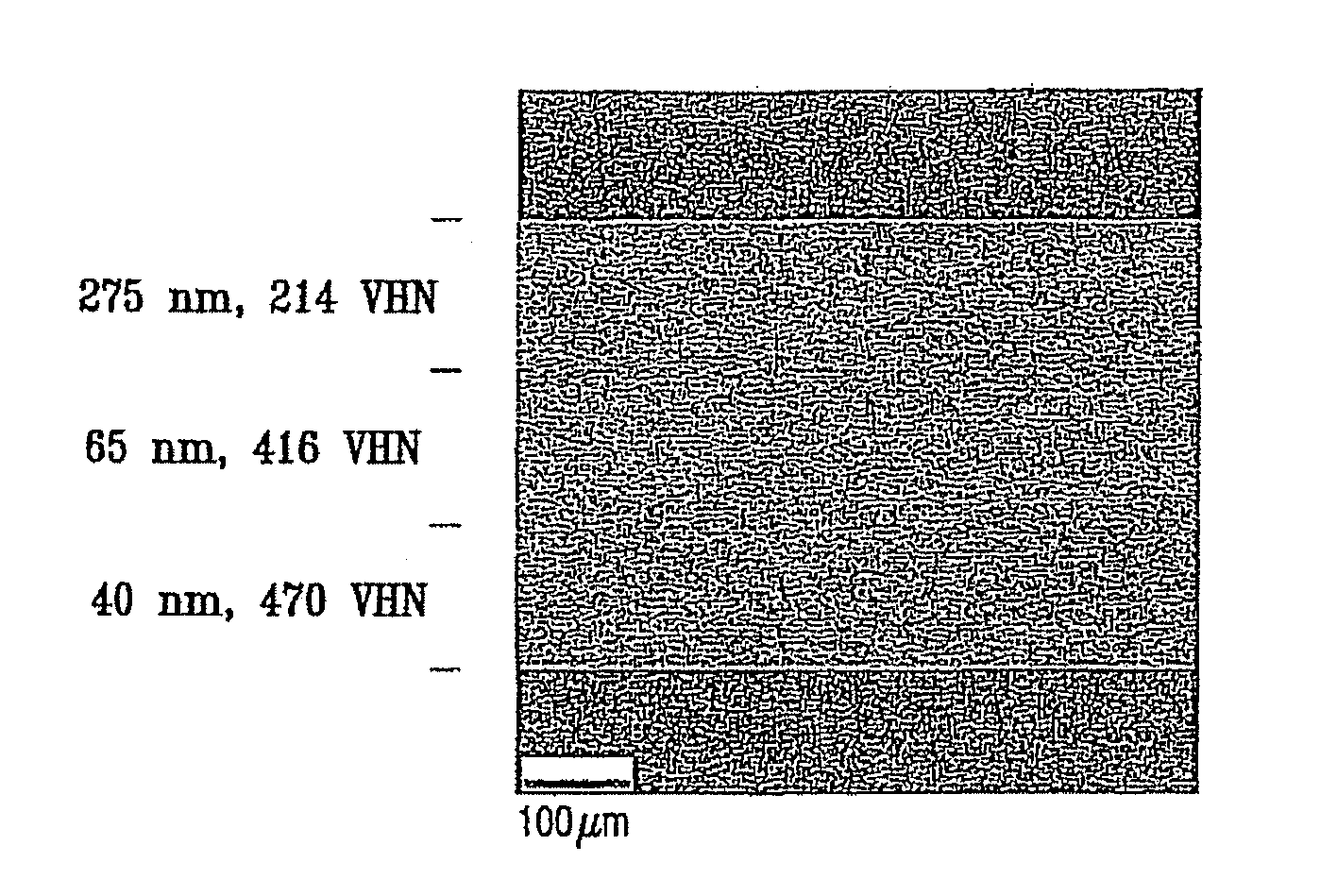

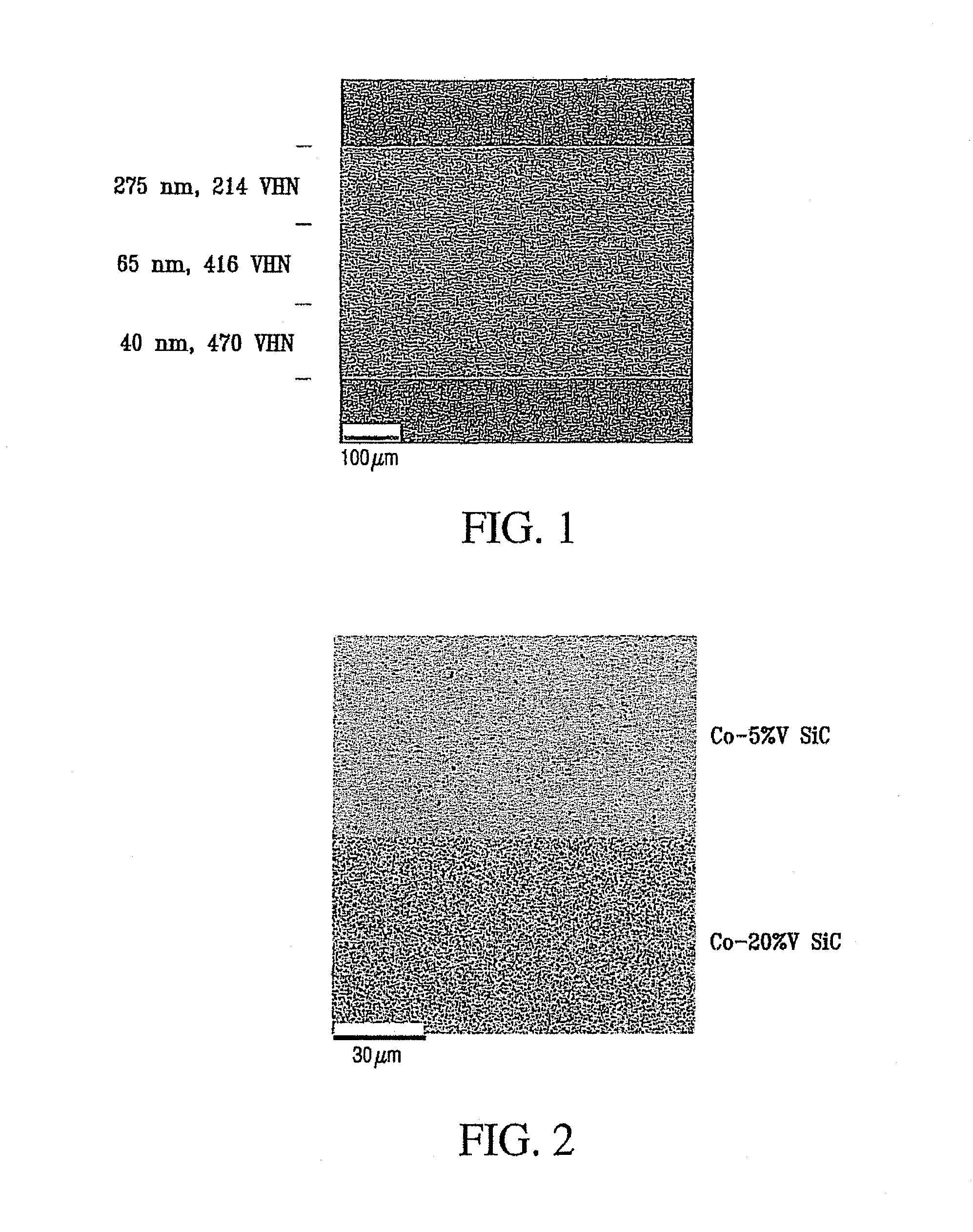

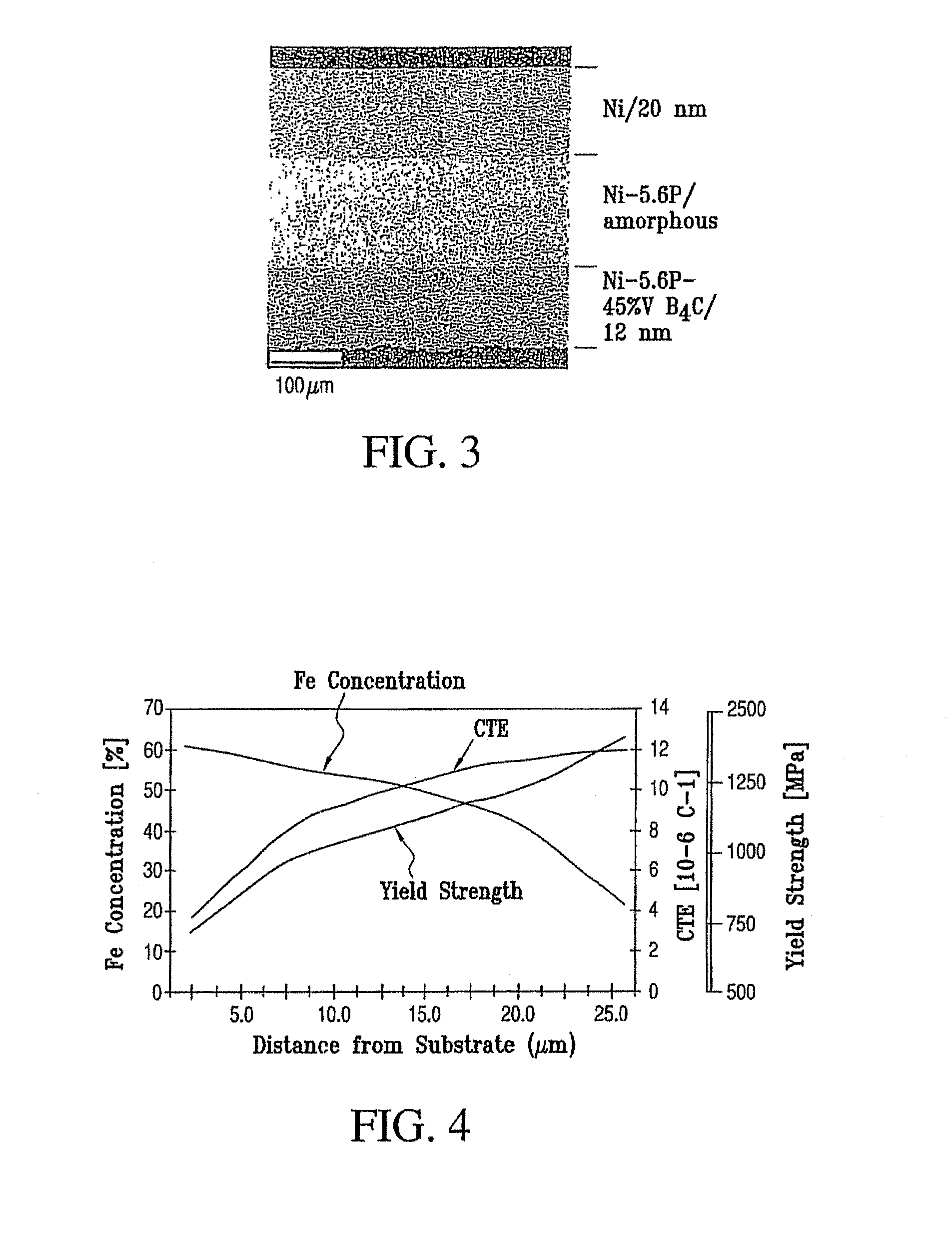

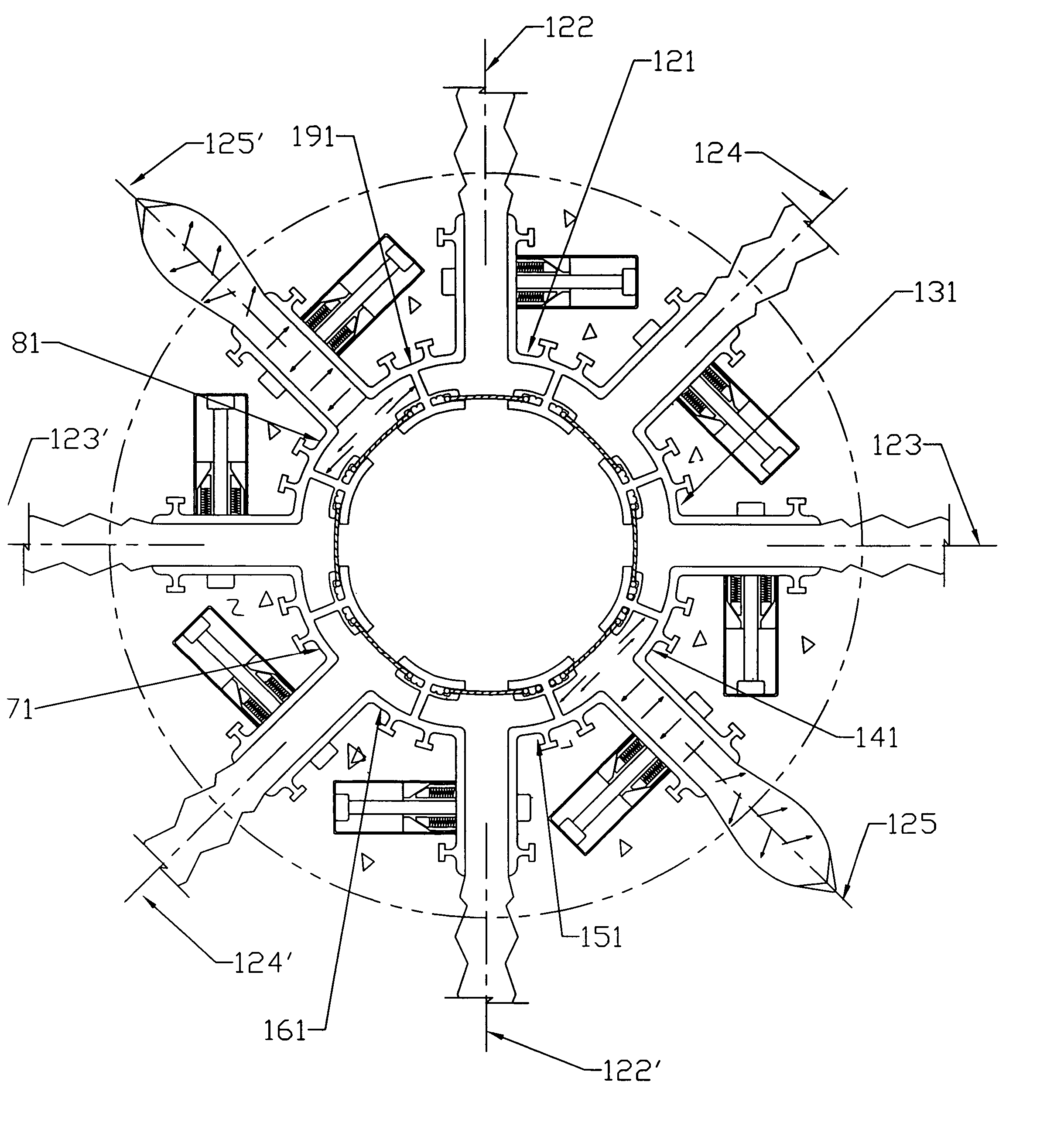

Metallic Structures with Variable Properties

InactiveUS20110256356A1Increased durabilityIncrease floor spaceVacuum evaporation coatingSputtering coatingParticulatesMetallic materials

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

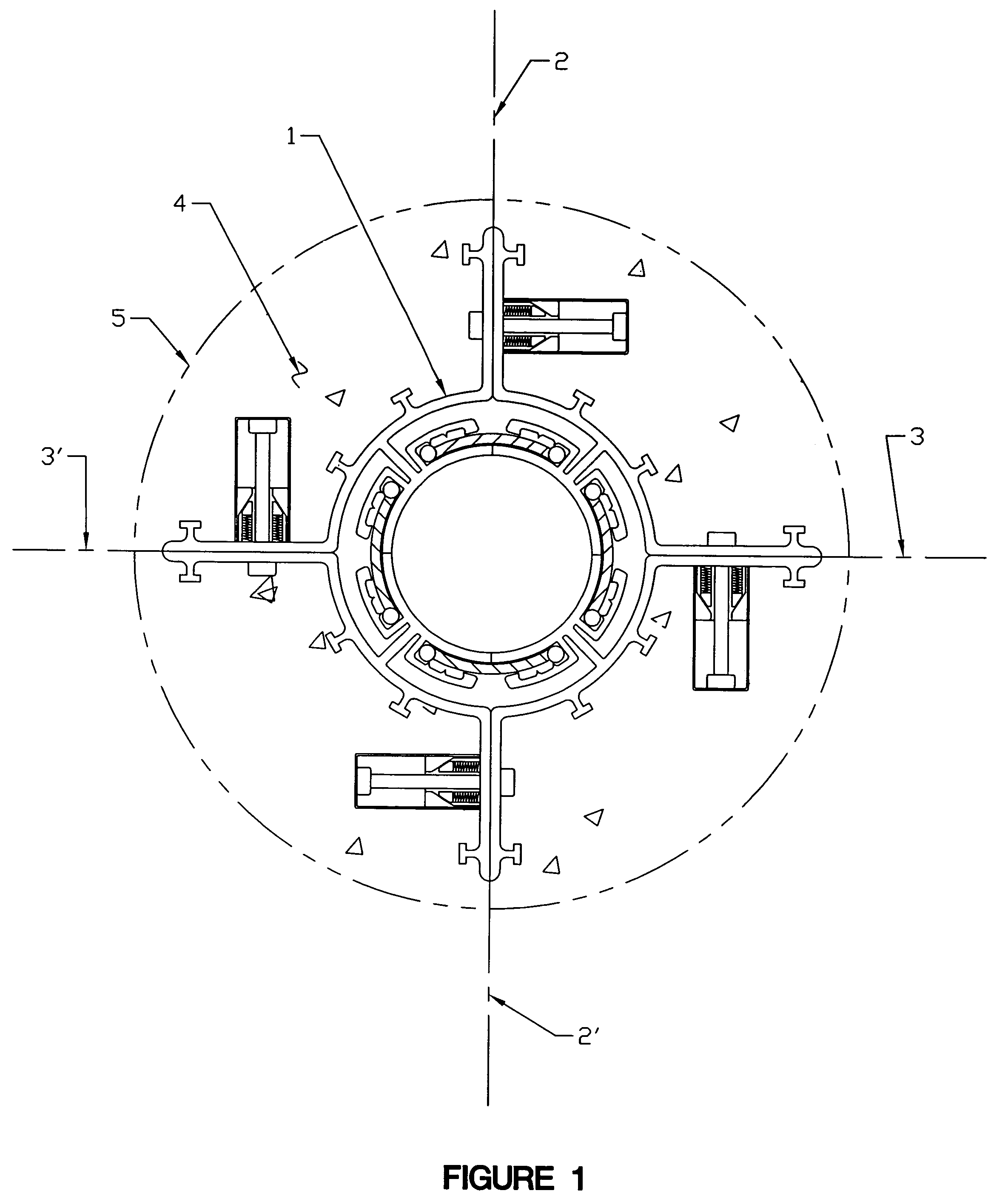

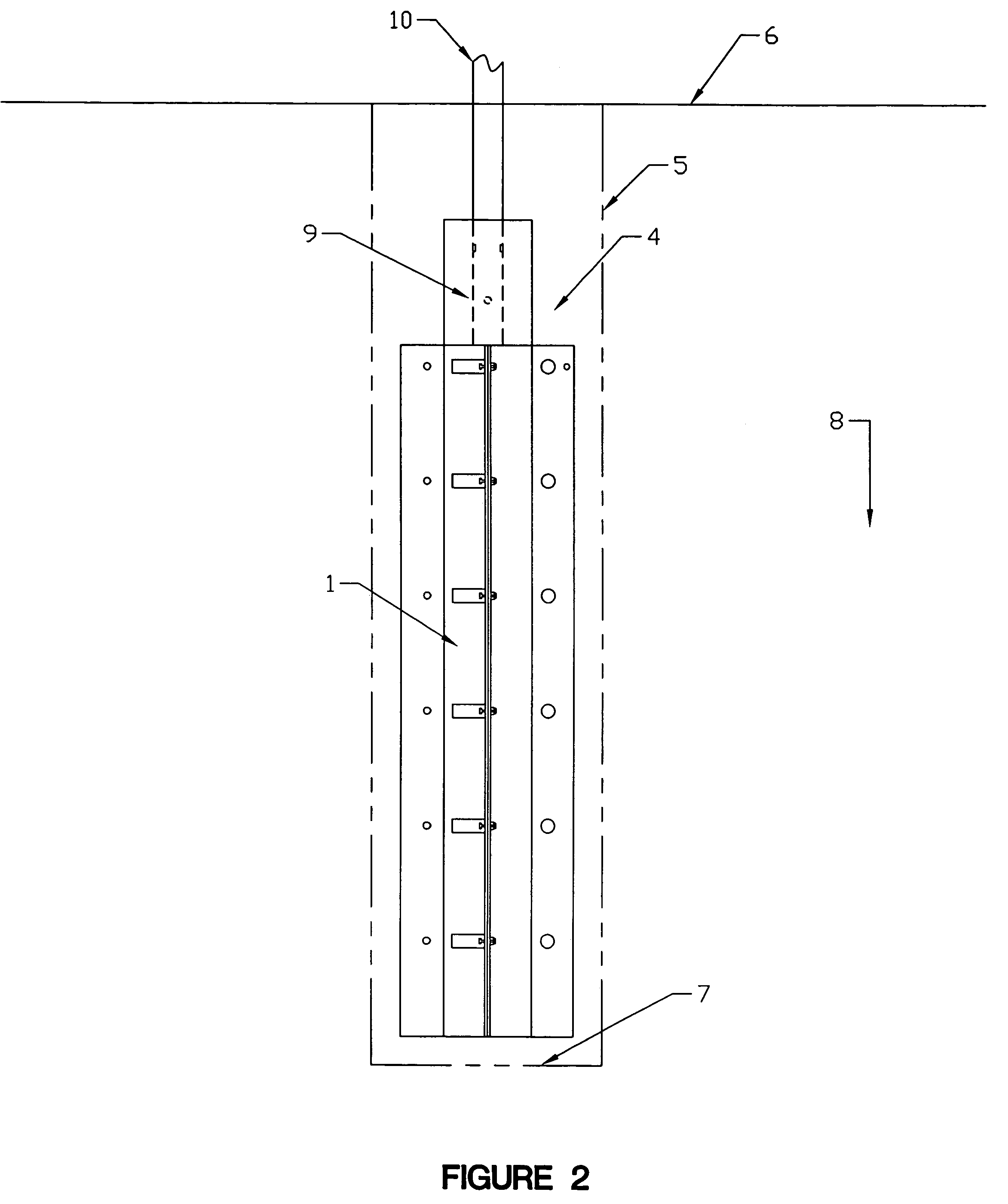

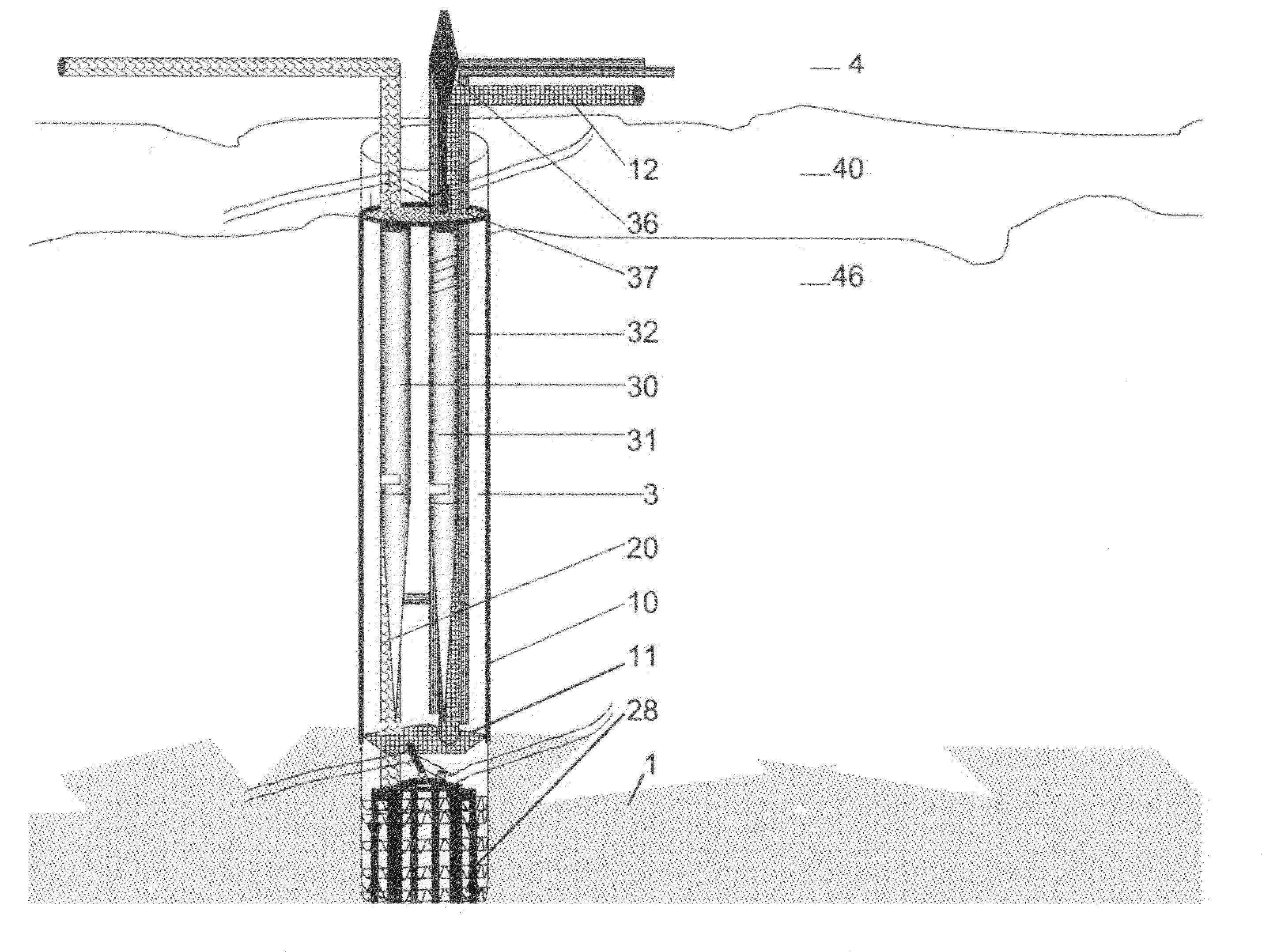

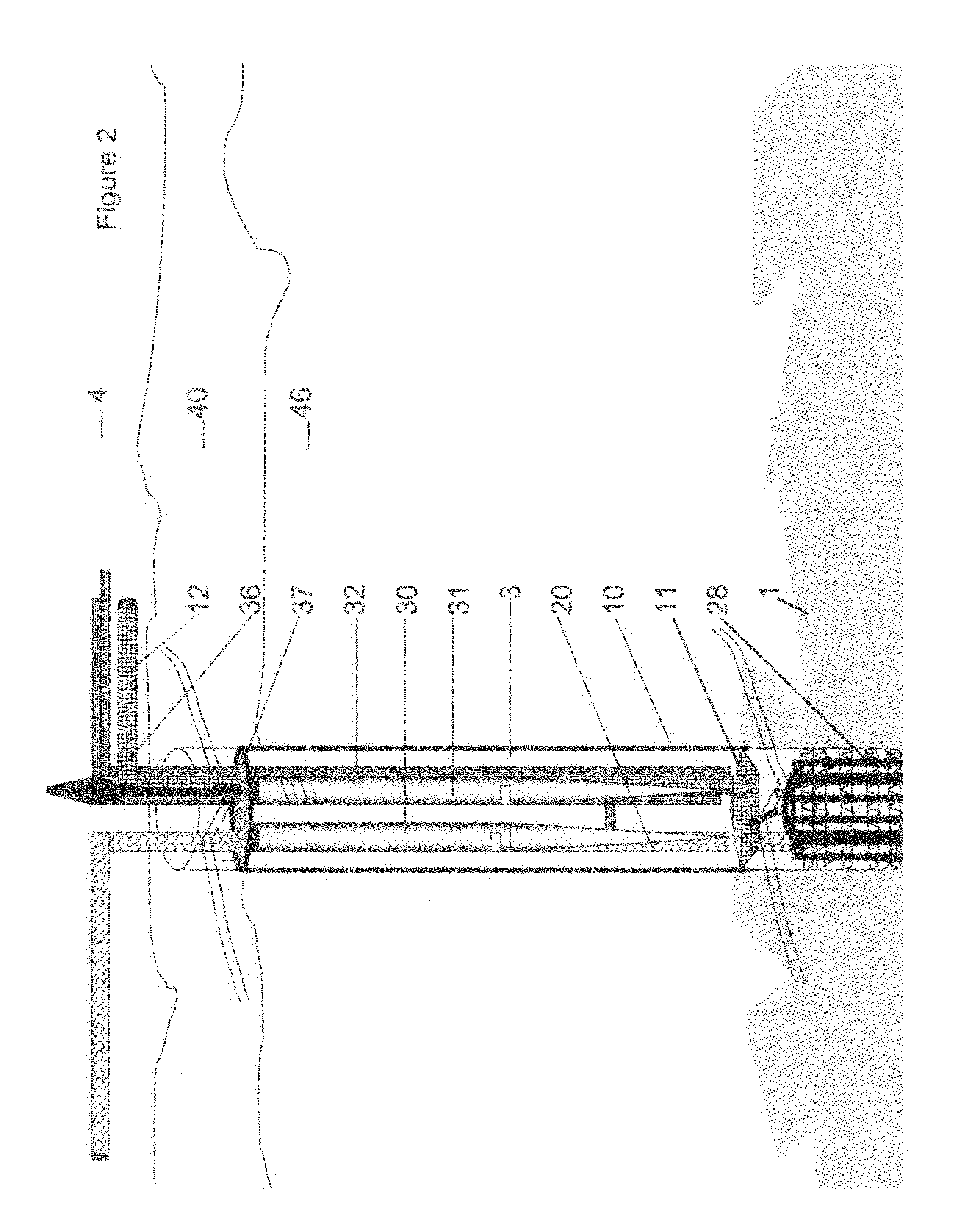

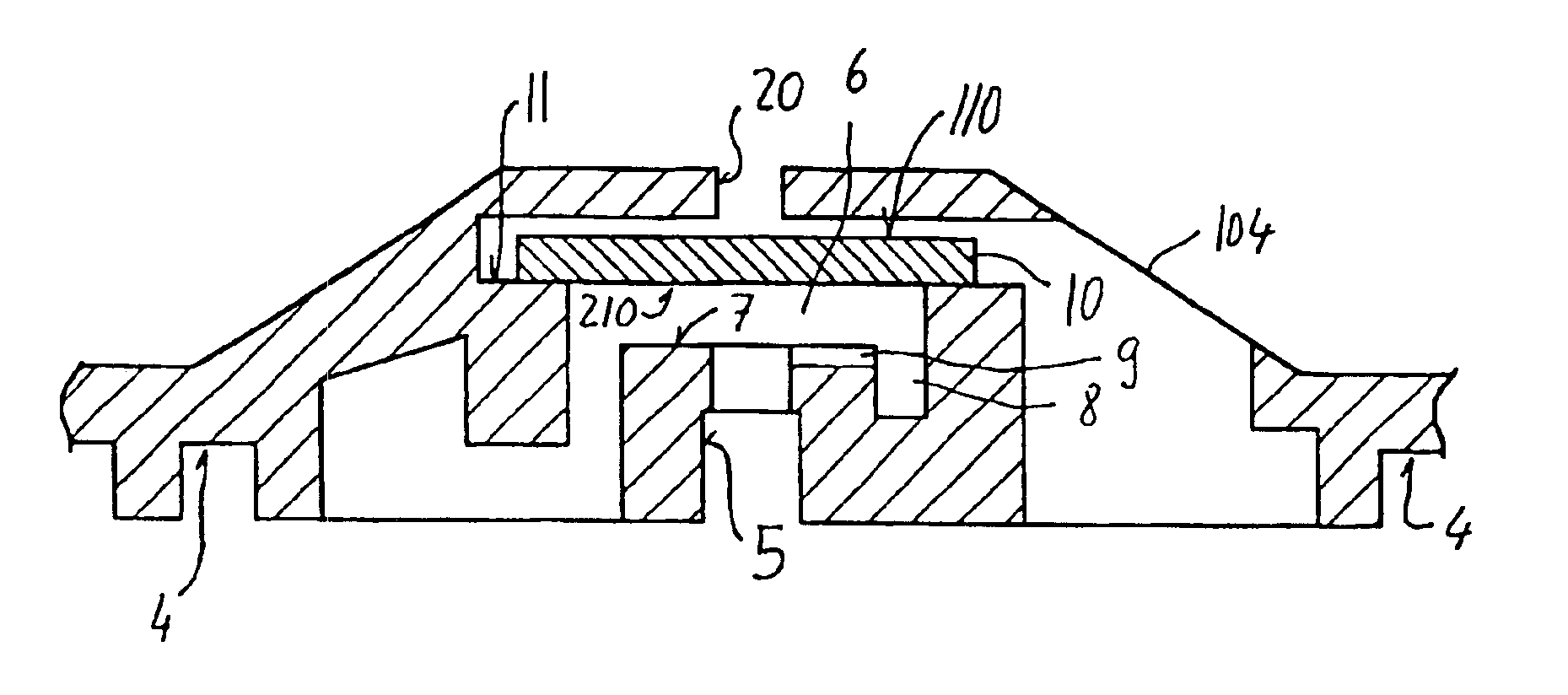

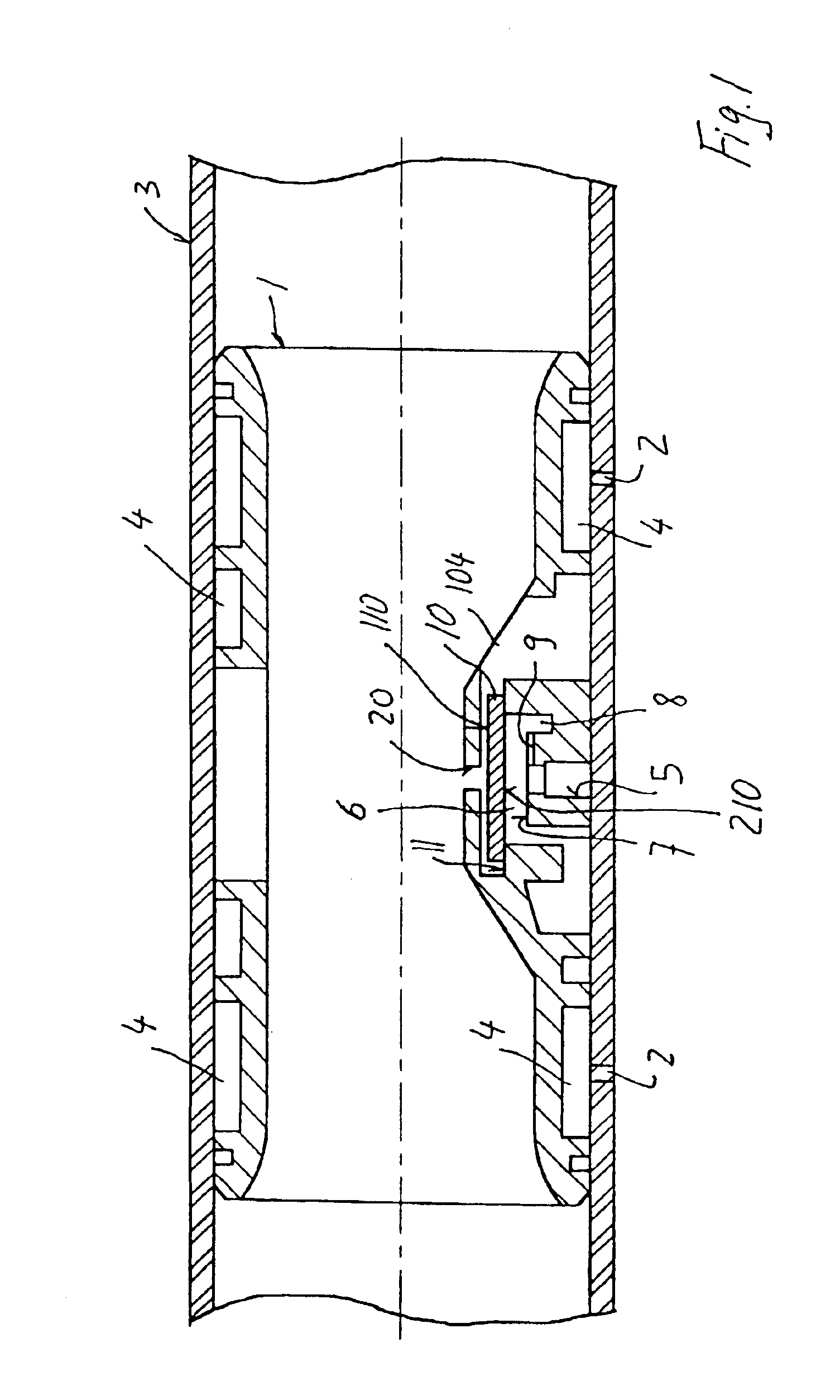

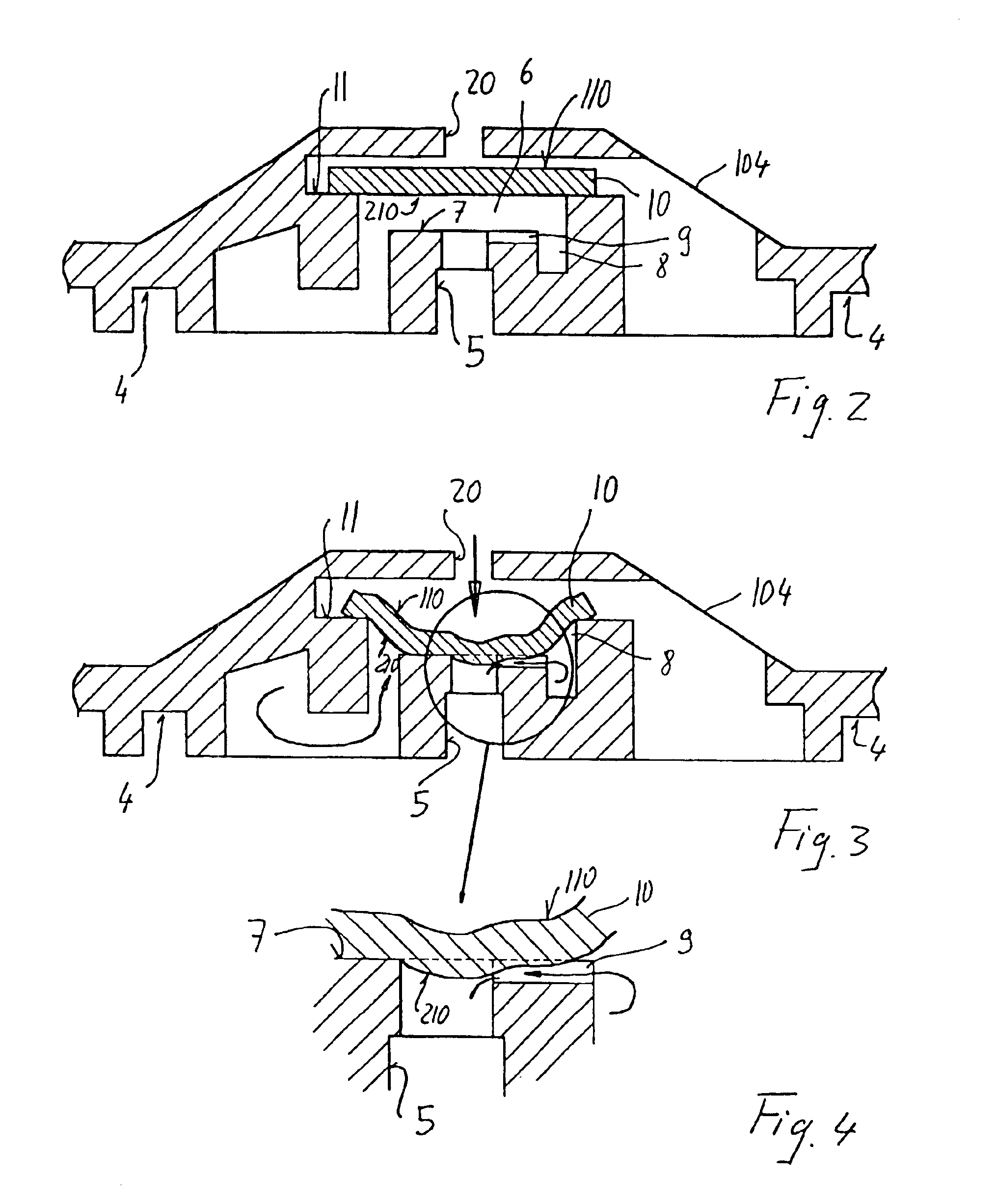

Multiple azimuth control of vertical hydraulic fractures in unconsolidated and weakly cemented sediments

InactiveUS6991037B2Increase pressureImprove stressDrilling rodsFluid removalFracturing fluidHydraulic fracturing

A method and apparatus for initiating multiple azimuth controlled vertical hydraulic fractures in unconsolidated and weakly cemented sediments from a single bore hole to control the fracture initiation and propagation of hydraulic fractures at differing azimuths, enabling greater yield and recovery of petroleum fluids from the formation. An injection casing with multiple fracture initiation sections is inserted and grouted into a bore hole. A fracture fluid carrying a proppant is injected into the injection casing and opens fracture initiation sections to dilate the formation in a direction orthogonal to the first fracture azimuth plane. Following completion of the first fracture injection, the fracture fluid is injected into the injection casing and opens a set of second and subsequent fracture initiation sections dilating the formation and initiating and propagating a second and subsequent vertical hydraulic fractures at different azimuths to the first and subsequent earlier installed fractures.

Owner:GEOSIERRA

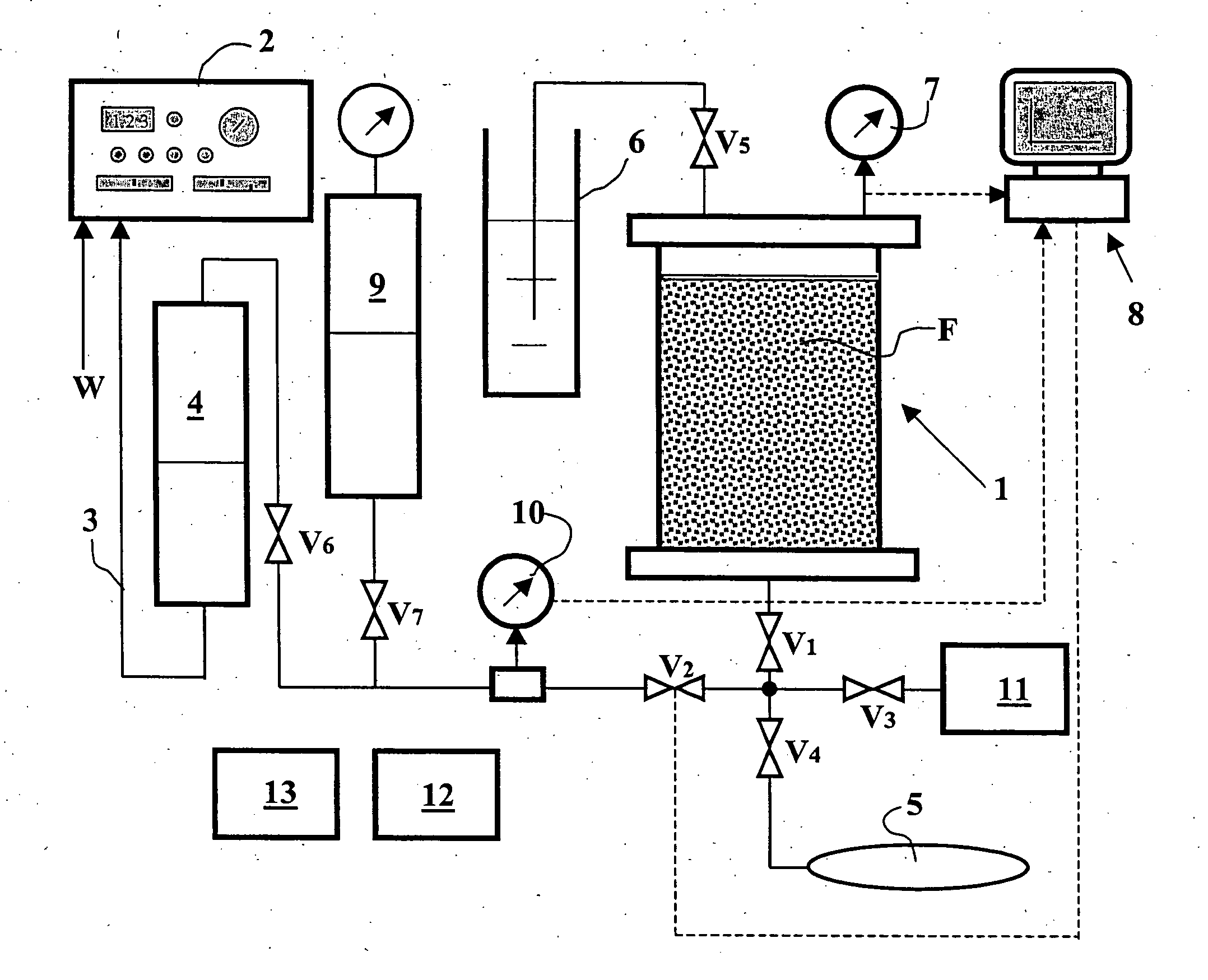

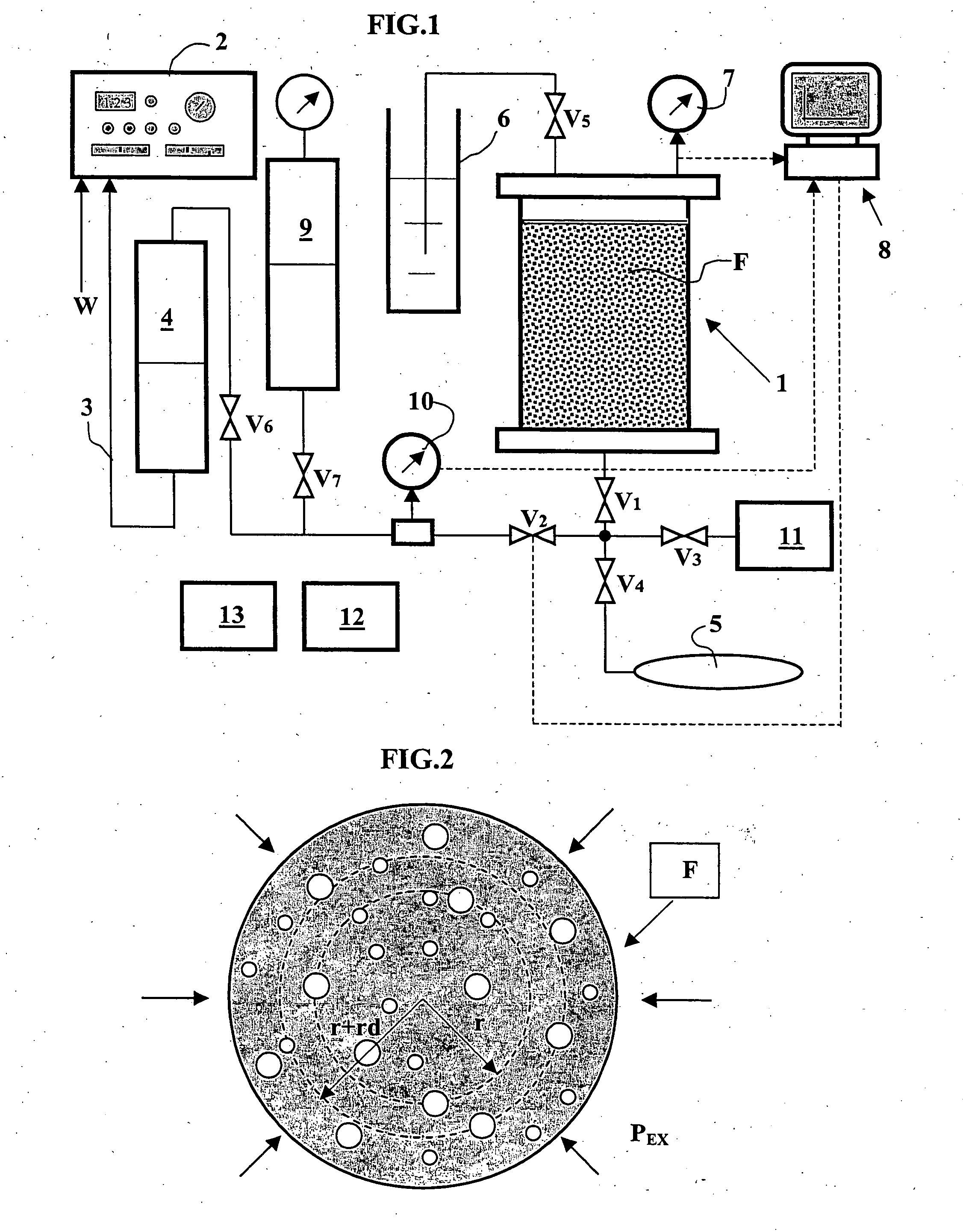

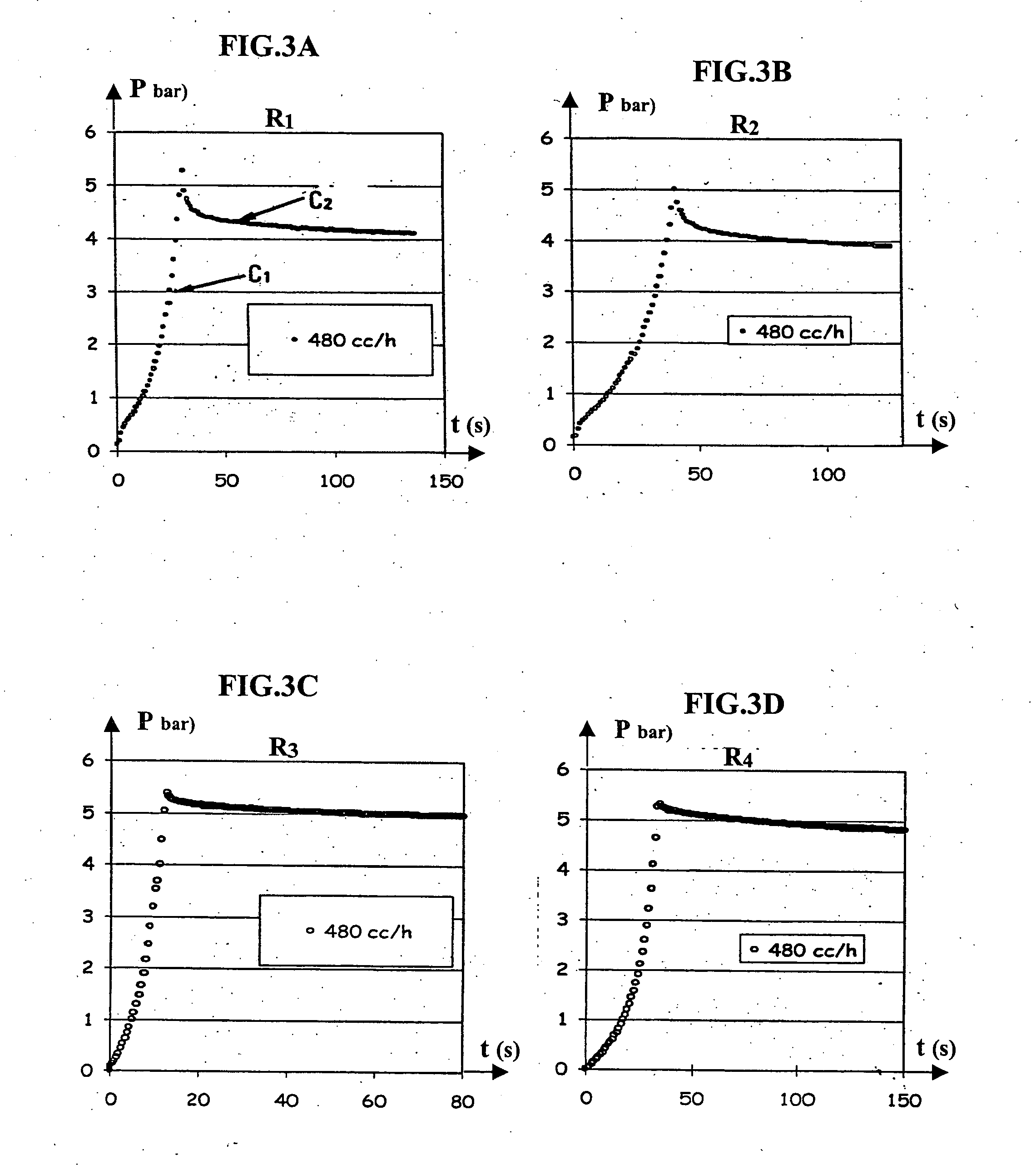

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS20050178189A1Short timeLimited spaceElectric/magnetic detection for well-loggingPermeability/surface area analysisMedicinePorous medium

Method and device for evaluating simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment. Applications: petrophysical measurements from drilling cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

Method for extracting and refining rutin

ActiveCN102718820AReduce pollutionGuaranteed withdrawal rateSugar derivativesSugar derivatives preparationAlkaline waterOrganic solvent

A method for extracting and refining rutin comprises the following steps of (1) extraction: smashing raw materials, adding organic solvent into the smashed raw materials, performing extraction for 2-4 times, mixing extracting solution and concentrating the mixed extracting solution to thick extract with organic solvent content smaller than or equal to 5wt%; (2) alkali dissolution-acid sediment: adding alkaline water into the thick extract, then heating the mixture and stirring, filtering the heated mixture, regulating pH of alkaline filtrate to be 3-4, standing, filtering, drying to obtain a rutin pure product; and (3) mother liquor treatment: enabling obtained acid mother liquor to penetrate through a chromatographic column filled with resin, after the acid mother liquor penetrates through the chromatographic column, firstly using deionized water to wash a column bed until outflow liquid is neutral and colorless, introducing eluent into the chromatographic column and collecting eluate until outflow liquid is colorless, concentrating the eluate to the volume which is 5-10% of the original volume in a pressure reduction mode, cooling the concentrated eluate to achieve crystallization, filtering, using the deionized water to elute a filter cake, and drying the eluted filter cake to obtain a mother liquor rutin product. The prepared rutin is high in yield and purity, and the quality of the rutin reaches the international standard.

Owner:湖南莱崔尔生物科技有限公司

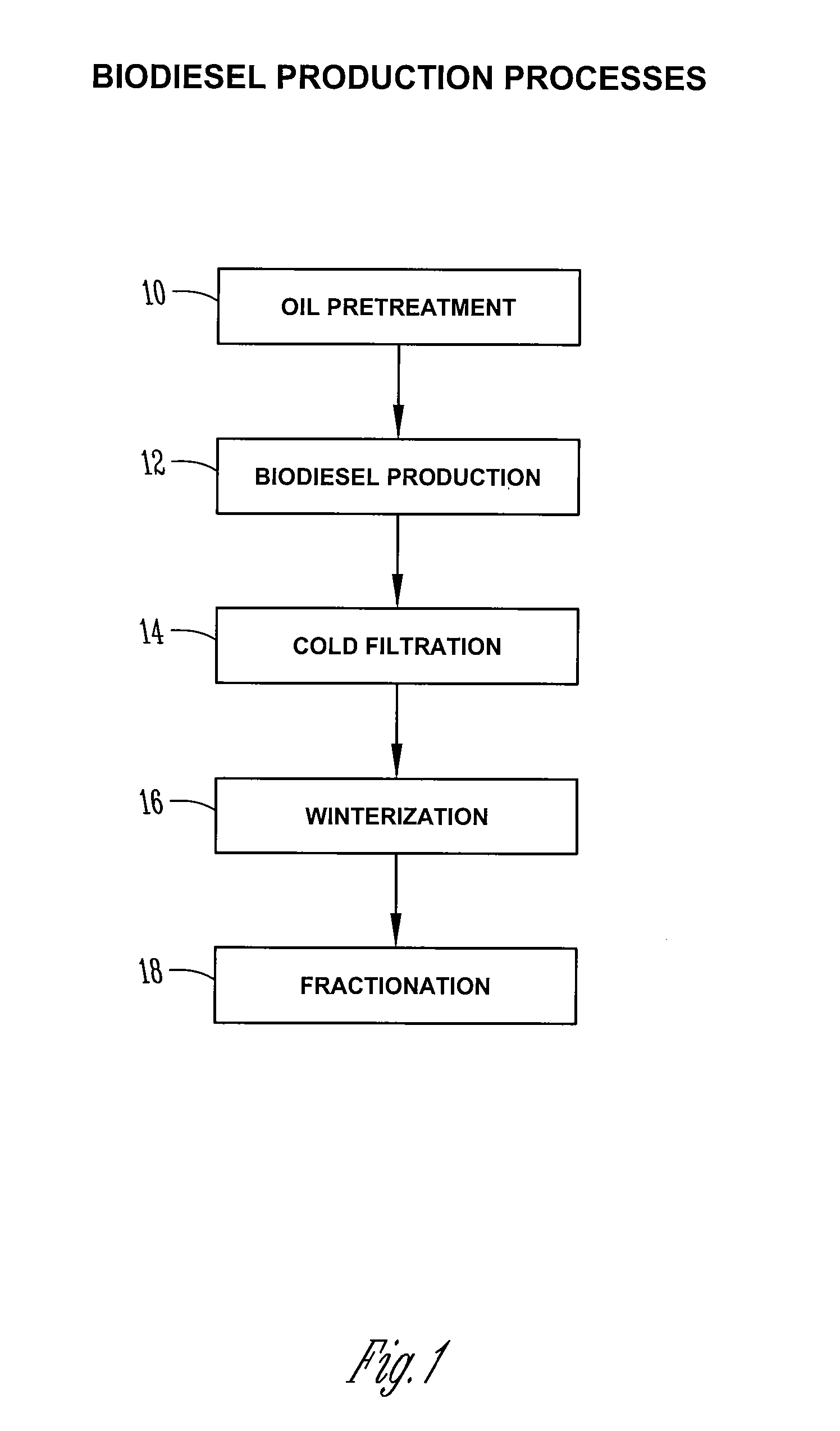

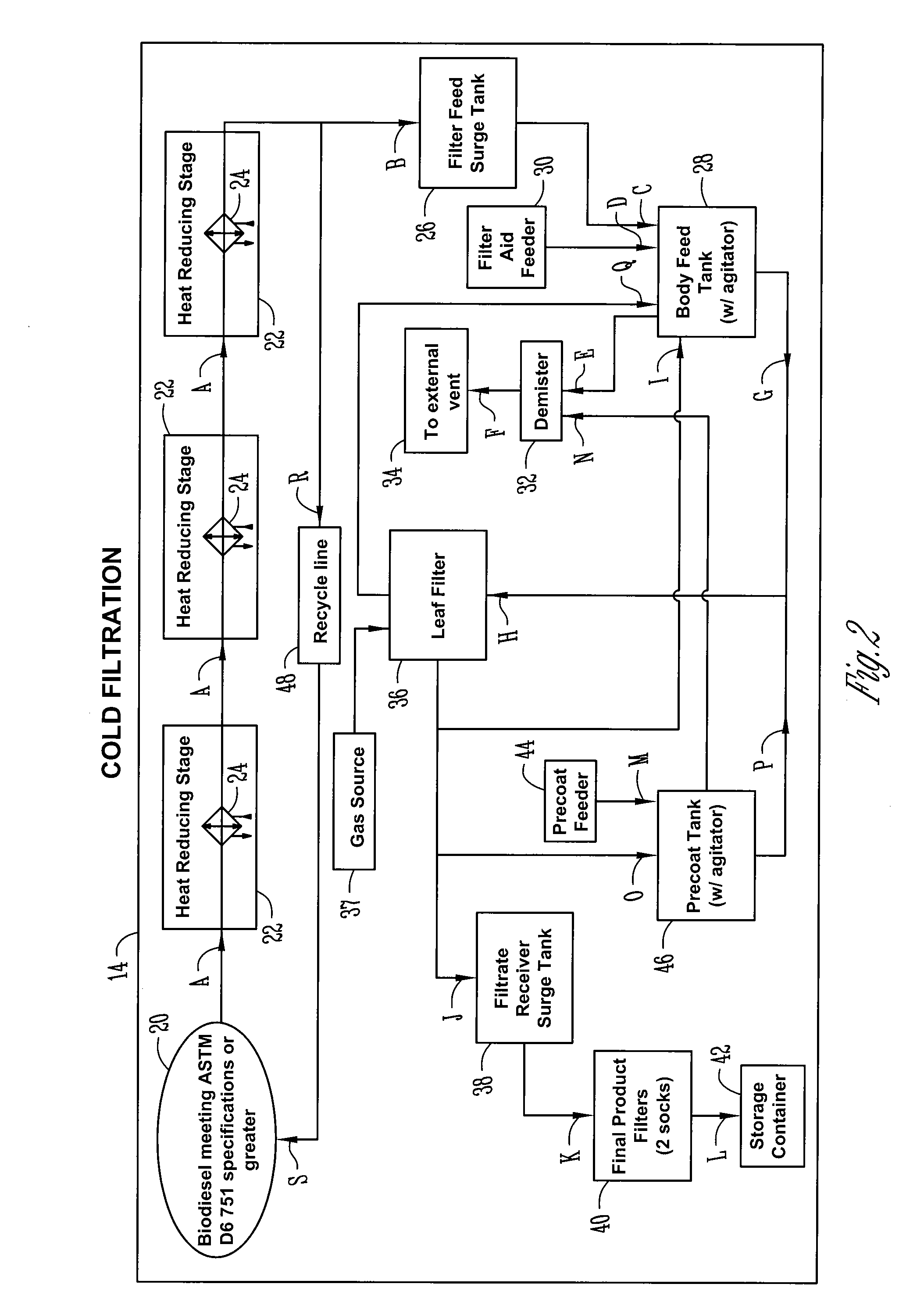

Biodiesel cold filtration process

An improved biodiesel production process includes the steps of processing a feedstock to produce biodiesel, cooling the biodiesel so as to form sediment, and filtering the biodiesel to remove the sediment. The resulting biodiesel from the cold filtration process avoids problems of sediment formation during storage and transportation.

Owner:REG BIOFUELS

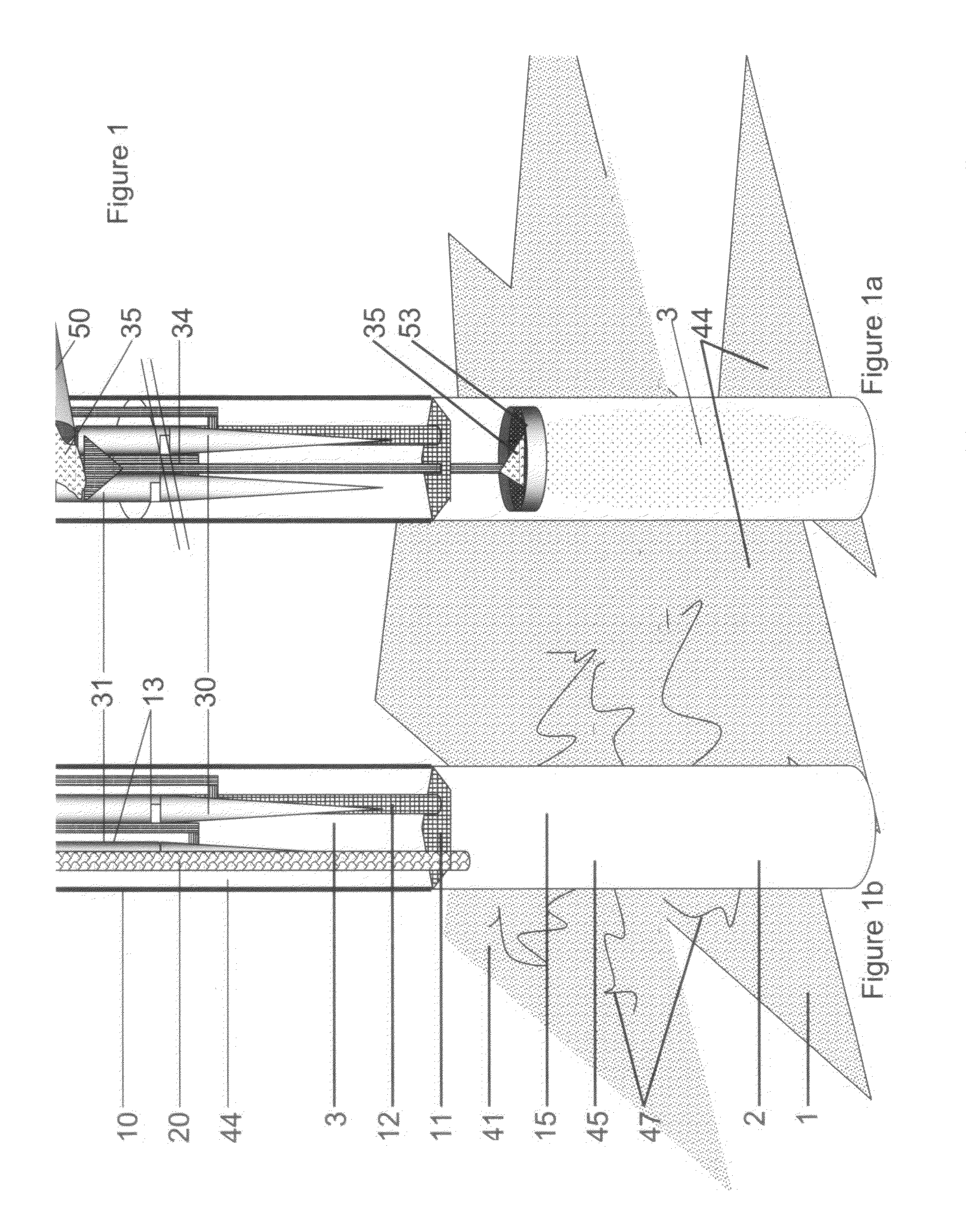

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

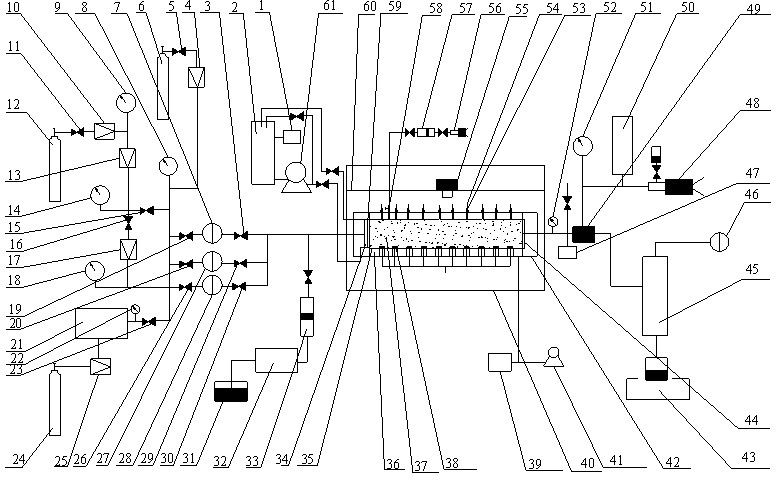

Experimental apparatus and method for researching response characteristic of natural gas hydrate stratum to drilling fluid intrusion

InactiveCN102323394ASafe and efficient exploration and developmentEarth material testingPermeability/surface area analysisDynamic monitoringTransfer mechanism

The invention relates to an experimental apparatus and a method for researching response characteristics of natural gas hydrate stratum to drilling fluid intrusion. The apparatus comprises a drilling fluid cycling mechanism, a high and low constant temperature experiment box, a gas permeability mechanism, a water / gas injection mechanism, a confining pressure tracking mechanism, a back pressure mechanism, a detection mechanism, an outlet metering mechanism, a rock core transferring mechanism, a sampling mechanism and an industrial control computer. The experimental methods based on the apparatus comprise an experimental method for hydrate deposit gas permeability, an experimental method for intrusion of drilling fluid to hydrate deposit and dynamic monitoring of response characteristics of the hydrate deposit during the intrusion process, and a method for fidelity transferring of hydrate deposit core. The invention provides an early stage indoor research on response characteristics of natural gas hydrate stratum to drilling fluid intrusion, so as to master influence rules of the drilling fluid intrusion on hydrate stratum physical properties, realize simulating fidelity transferring of a sample containing hydrate deposit and provide basis for future hydrate stratum exploitation and drilling safety and logging accuracy interpretation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Low pressure drop coated diesel exhaust filter

InactiveUS20070140928A1Promote nitrogen oxide reductionReduce and avoid obstructionCombination devicesSilencing apparatusHigh concentrationNitrogen oxides

A coated diesel exhaust filter is provided that applies a relatively low pressure drop across the exhaust system despite the buildup of soot deposits. The filter includes a porous ceramic structure having an inlet end, an outlet end, and a plurality of gas inlet and gas outlet channels disposed between the inlet and outlet ends, the channels being separated by porous ceramic walls. A catalyst is distributed at least partly within the porous ceramic walls of the structure, and is distributed at a higher concentration within portions of the ceramic walls adjacent to the outlet surfaces than within portions of the ceramic walls adjacent the inlet surfaces. Both the inlet and outlet surfaces are substantially free of the catalyst in order to maintain a gas-conducting porosity in these surfaces. The resulting filter effectively treats nitrogen oxides, carbon monoxide and unburned hydrocarbons present in the exhaust gas stream while advantageously imposing a relatively low pressure drop across the exhaust system even when soot deposits accumulate on the inlet surfaces of the ceramic walls.

Owner:CORNING INC

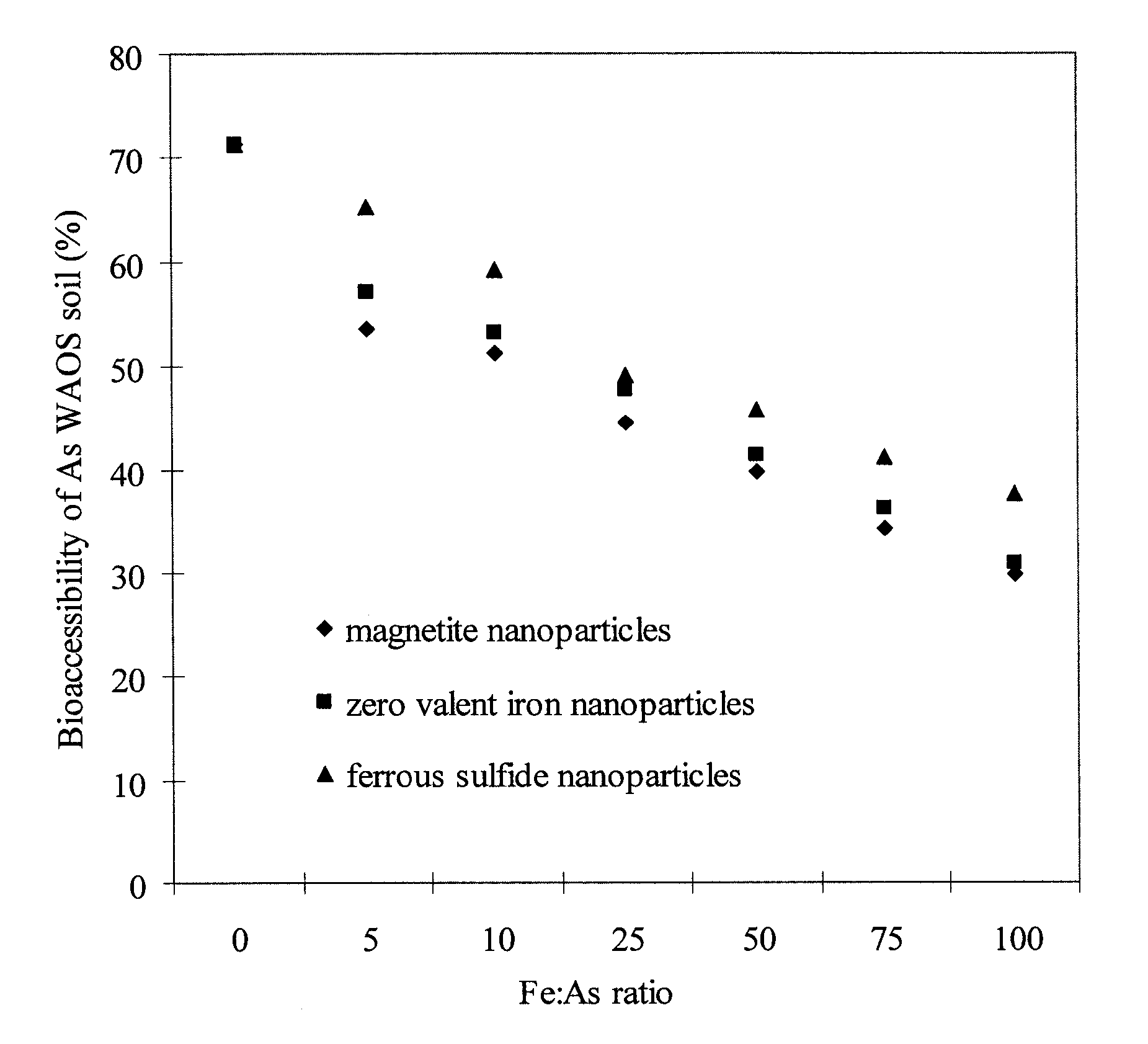

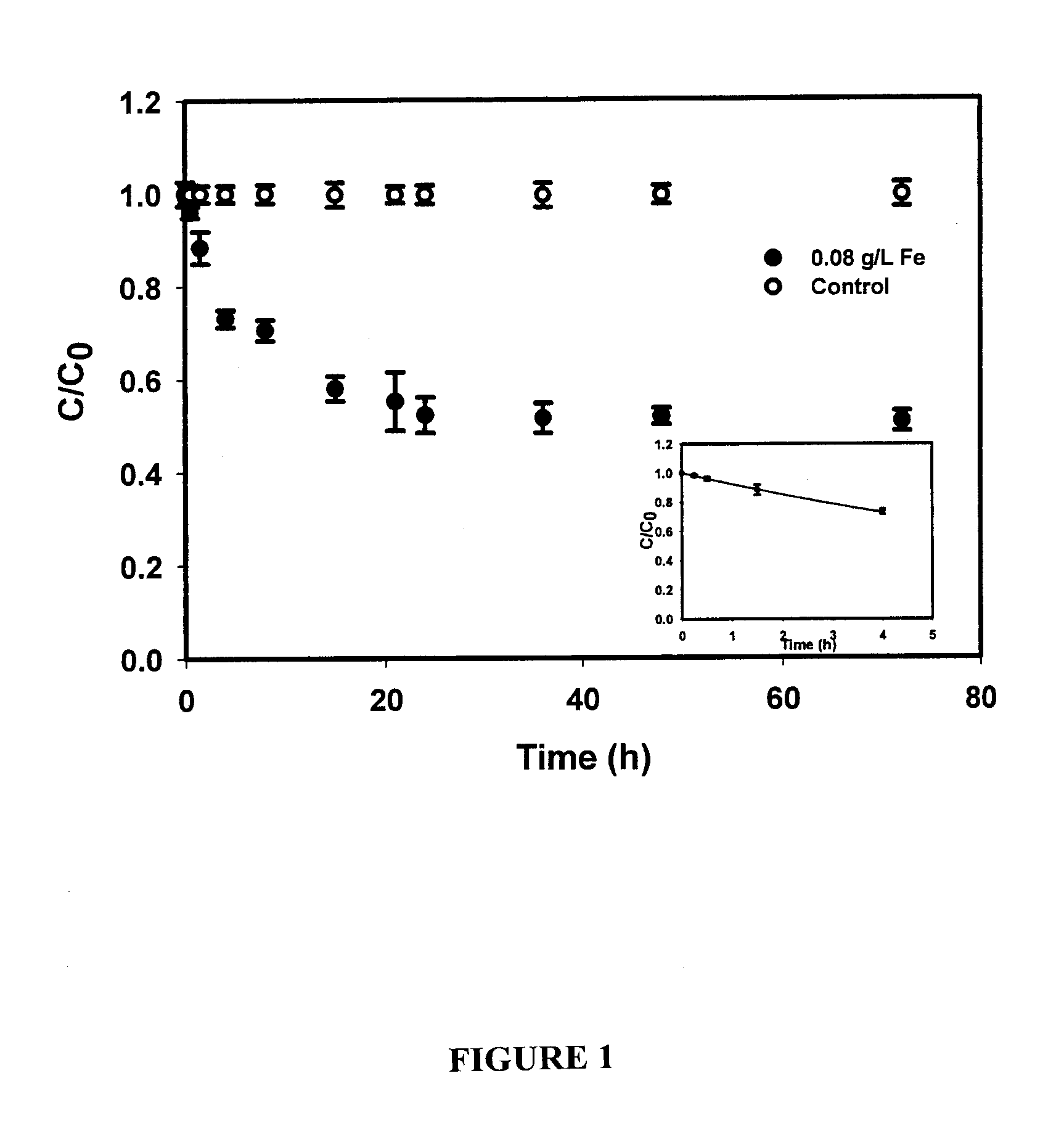

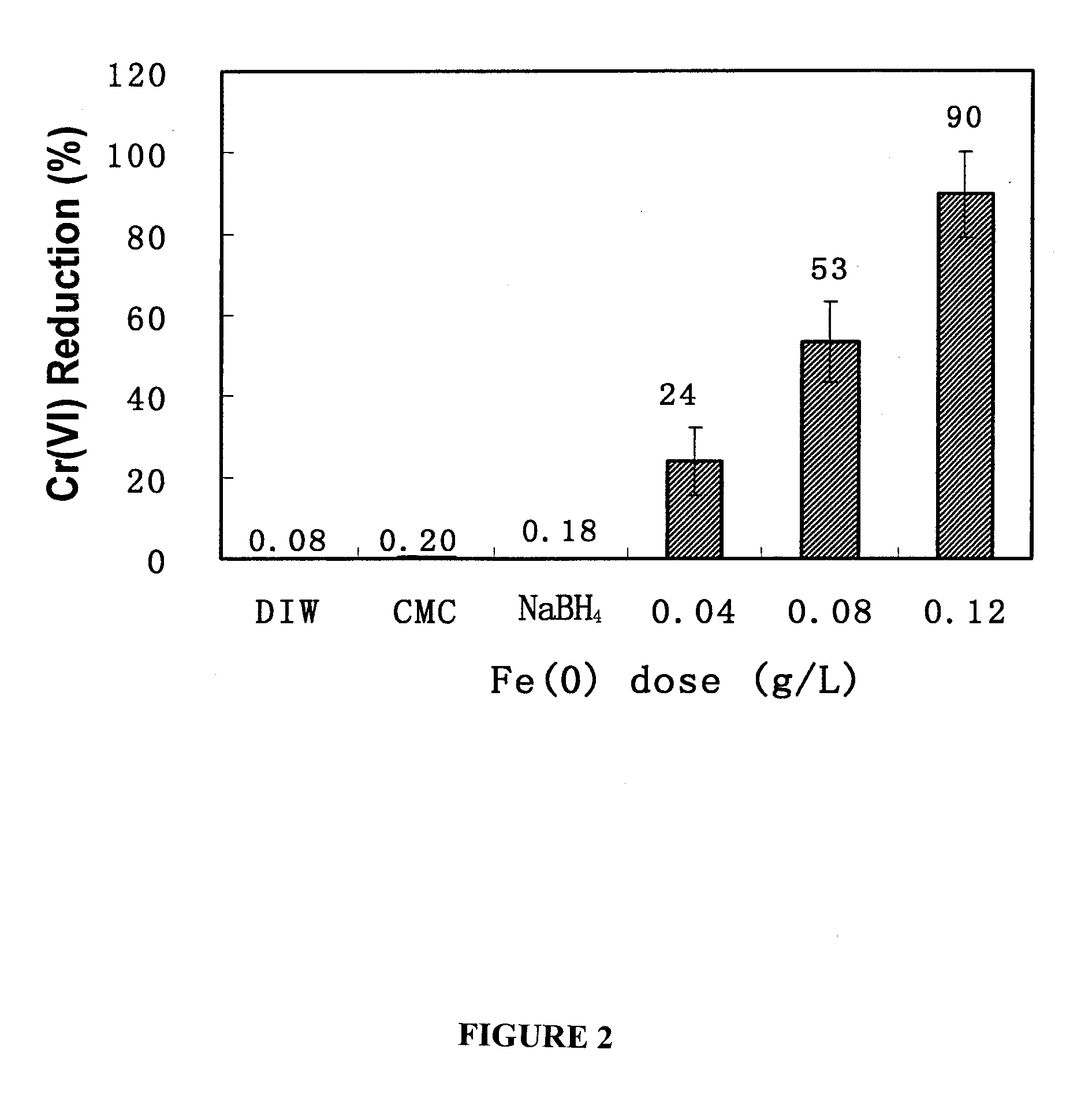

In Situ Remediation of Inorganic Contaminants Using Stabilized Zero-Valent Iron Nanoparticles

InactiveUS20070256985A1Low costProcess environmental protectionMaterial nanotechnologyWater treatment compoundsCelluloseMaterials science

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

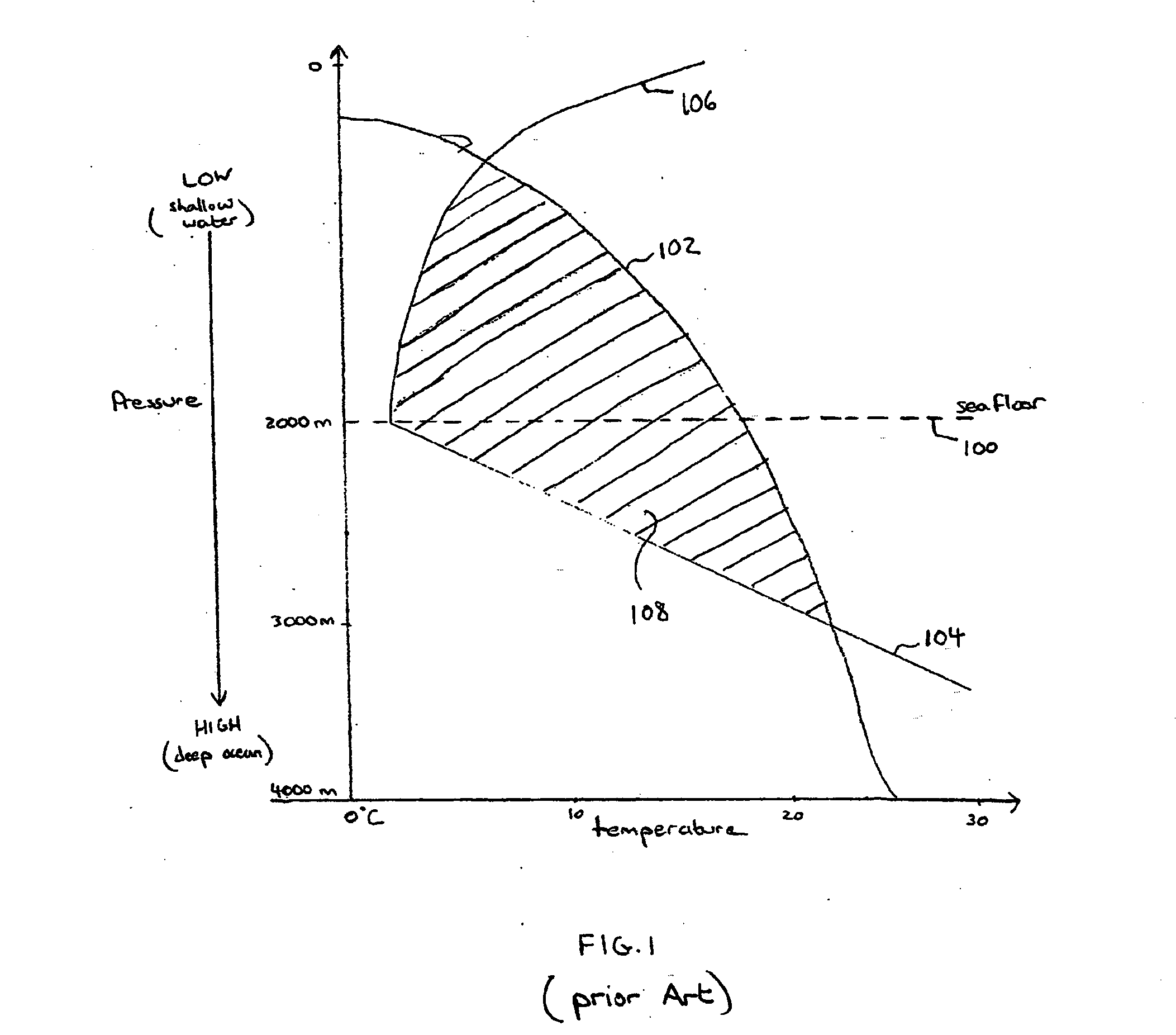

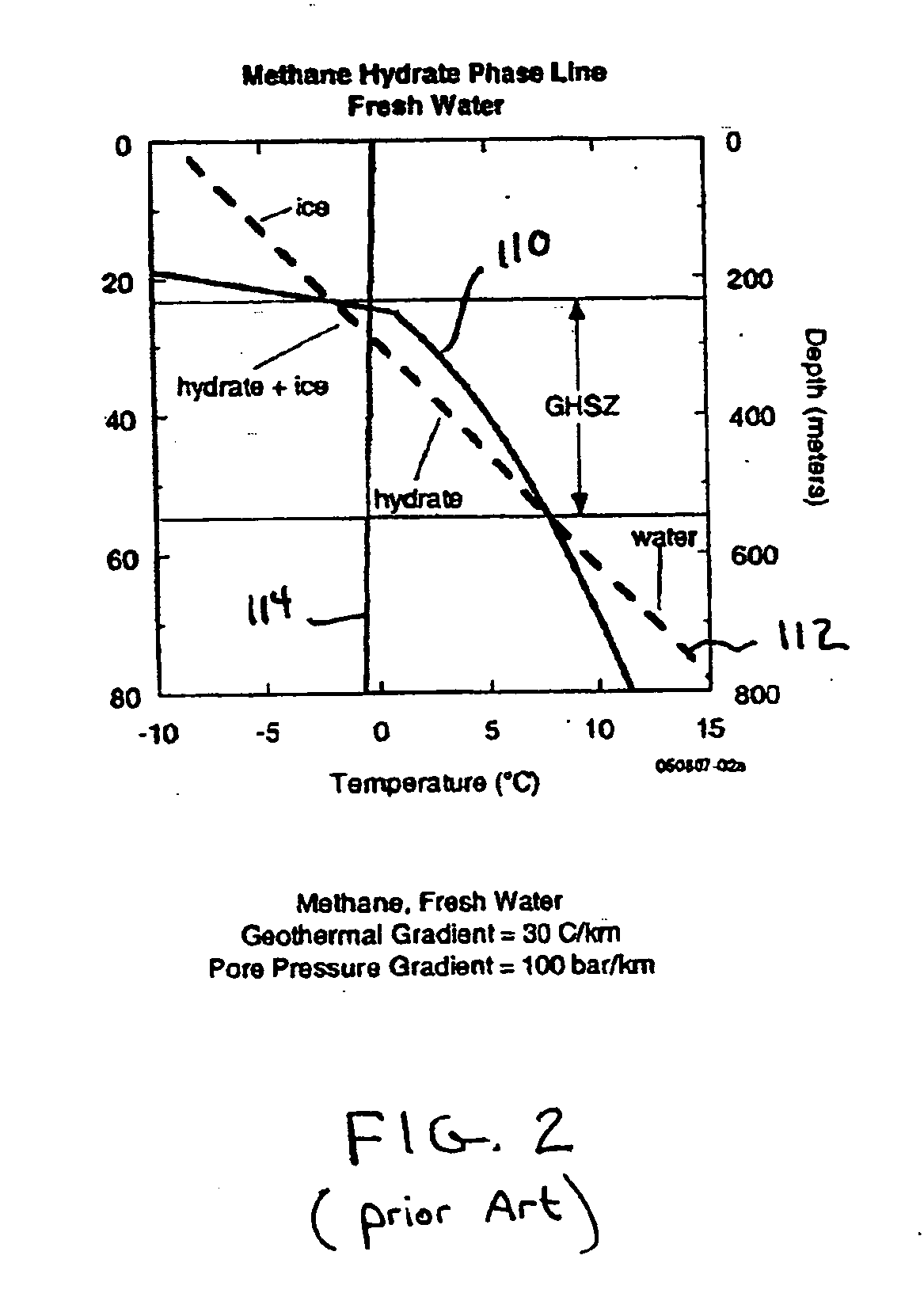

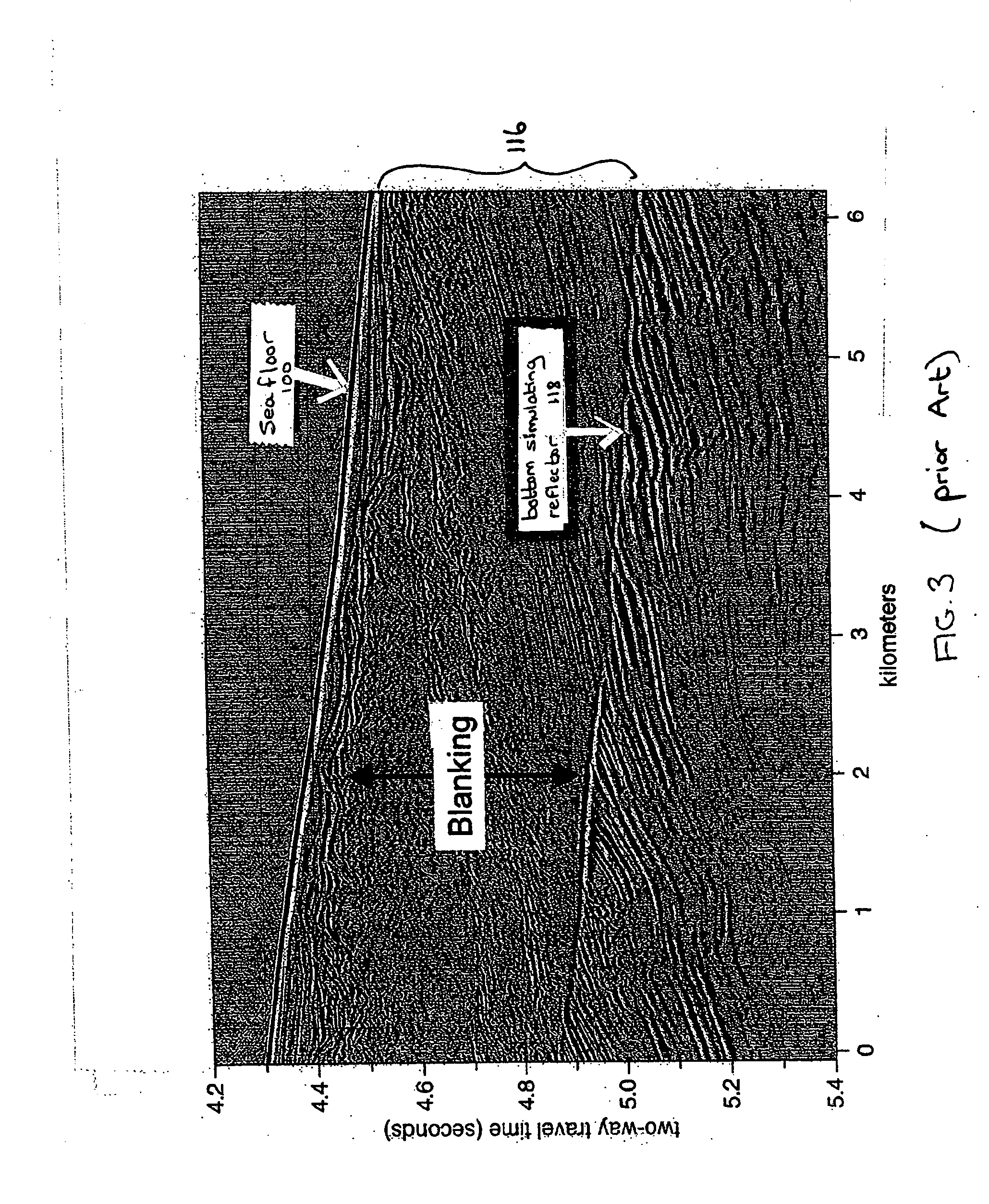

Method and apparatus for locating gas hydrate

ActiveUS20070265782A1Reduce penetrationHigh porosityElectric/magnetic detection for well-loggingMaterial analysis using sonic/ultrasonic/infrasonic wavesGas hydrate stability zoneSeismic survey

An exploration paradigm for detecting and / or characterizing gas hydrate deposits using either electromagnetic or seismic surveys, that accounts for the possibility that gas hydrate may accumulate in vertical or subvertical dikes. Geologic factors, such as the presence of the gas hydrate stability zone, indications that a prolific source of gas exists (or existed) below the gas hydrate stability zone and indications that a high flux of gas could be transported into the gas hydrate stability zone, may be considered as part of an exploration strategy. Data may be collected using seismic techniques, such as a walk-away vertical seismic profile techniques, or electromagnetic surveys that are adapted to detecting the presence of vertical or subvertical dikes. In one example, data processing and acquisition techniques may be adapted to detect hydrate dikes, and do not assume a horizontally isotropic earth model.

Owner:SCHLUMBERGER TECH CORP

Self-compensating drip irrigation emitter

InactiveUS6945476B2Simple and inexpensive arrangementAvoid easy cloggingClimate change adaptationWatering devicesDrip irrigationEngineering

The invention relates to a self-compensating drip irrigation emitter. A plurality of novel embodiments are provided, wherein the emitter of the invention is capable of always supplying a substantially constant flow within a range of pressures of a fluid flowing in a pipe (3), from very low to very high pressures. Furthermore, the emitter of the invention has such characteristics as to prevent any accidental and undesired clogging thereof by sediments or debris.

Owner:IRRITEC

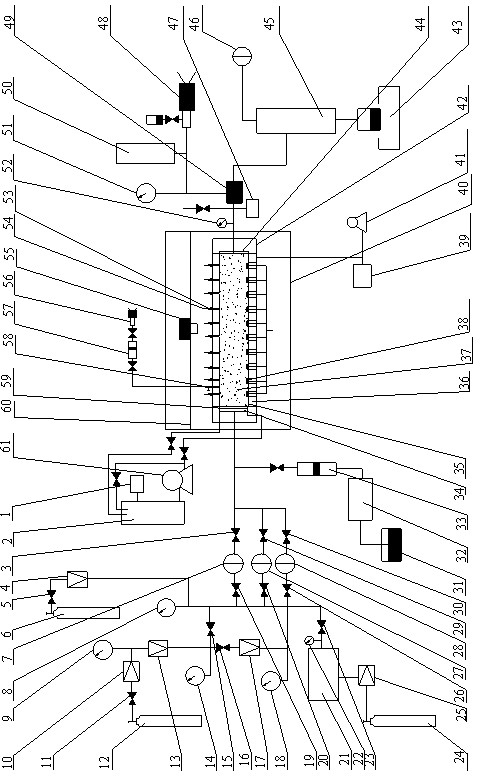

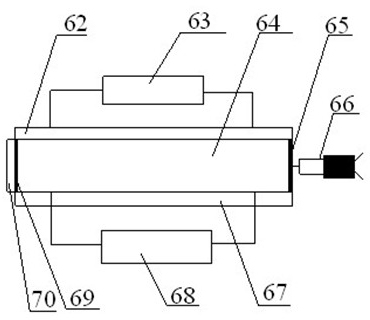

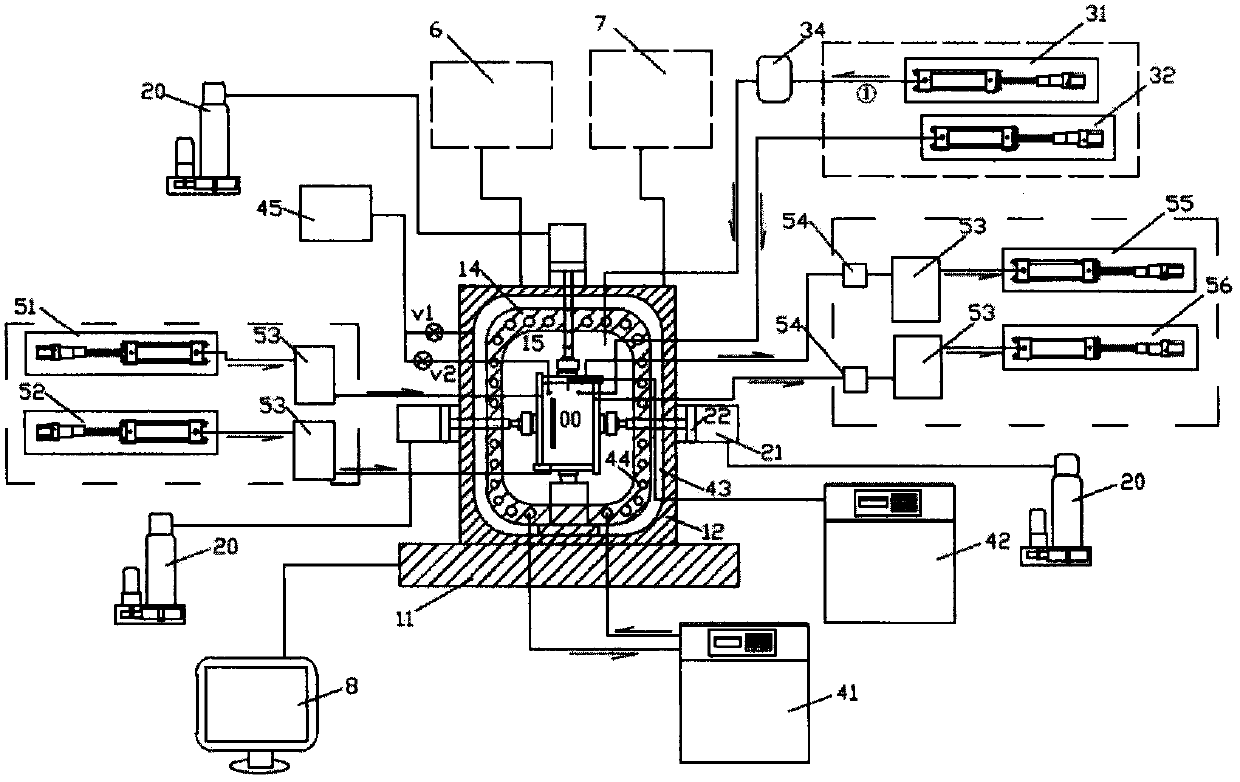

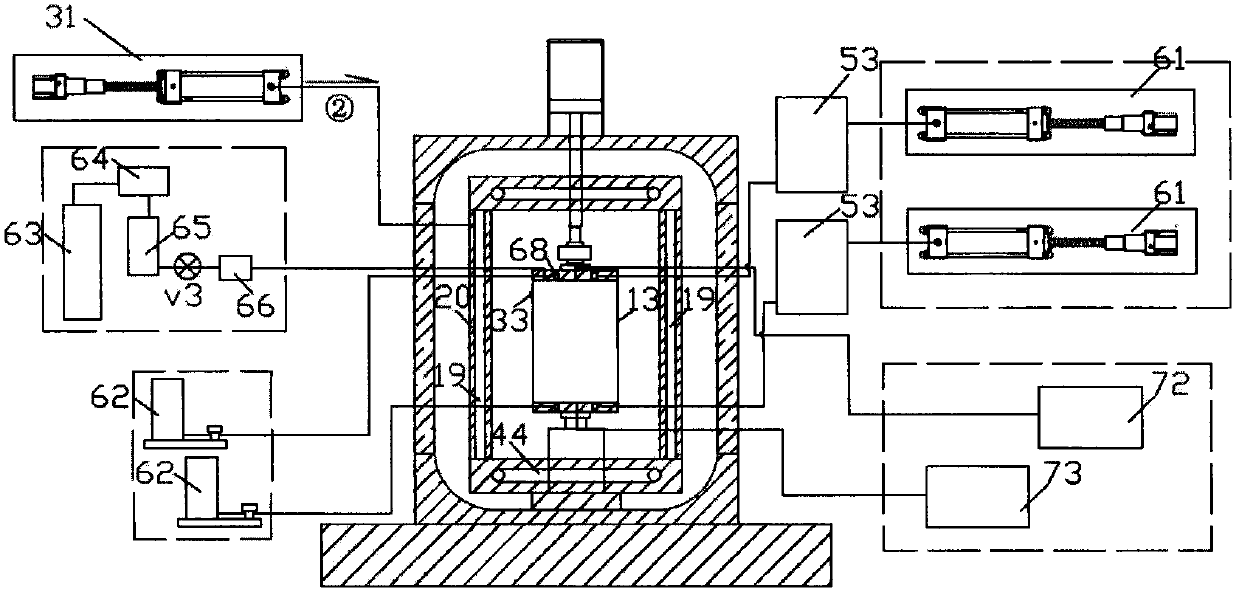

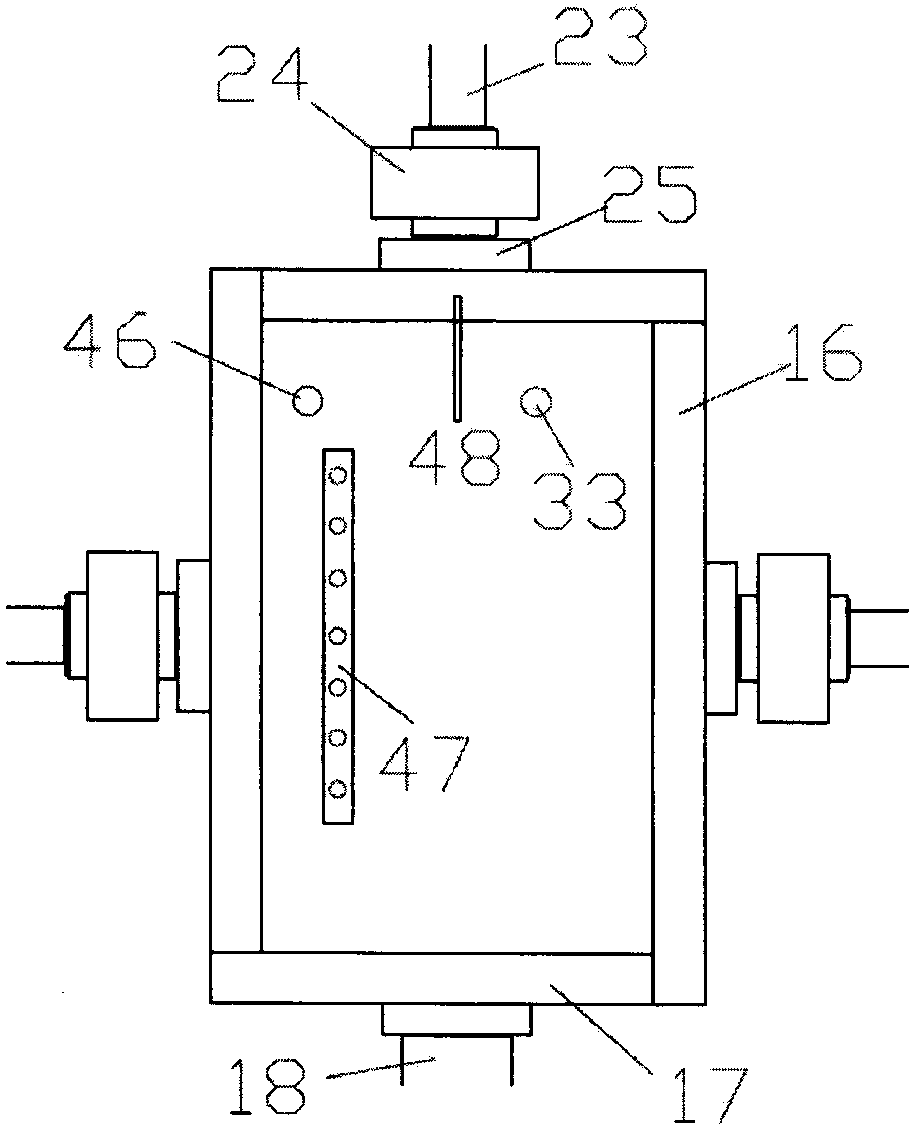

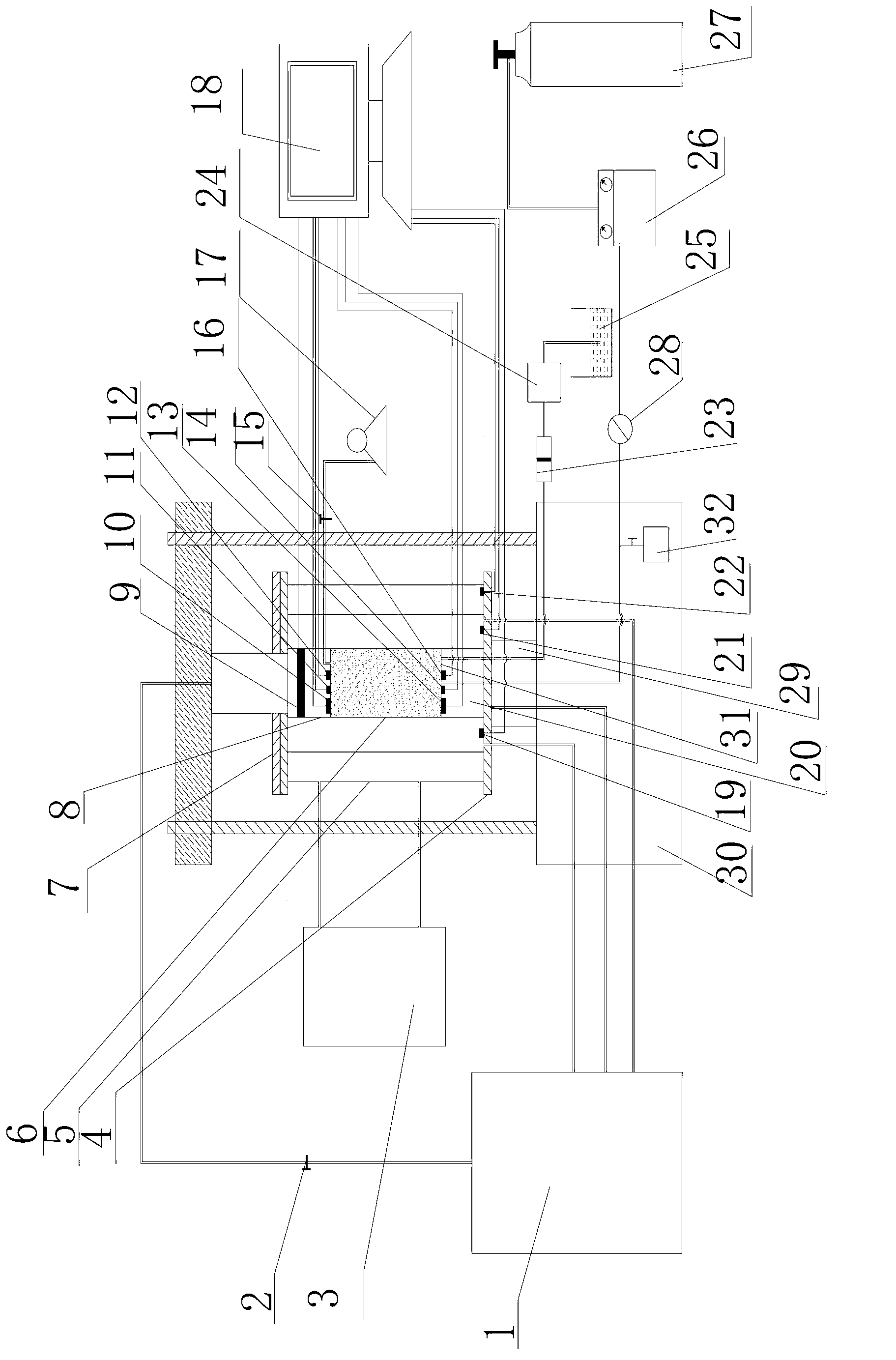

Multi-field coupling true triaxial test system and experiment method implemented by same

ActiveCN107576562AImprove accuracyRealize dockingMaterial strength using tensile/compressive forcesPermeability/surface area analysisDecompositionMulti field

The invention discloses a multi-field coupling true triaxial test system and an experiment method implemented by the same. The multi-field coupling true triaxial test system is characterized by comprising a true triaxial double-cavity pressure chamber (1), an axial loading system (2), a confining pressure / back pressure loading system (3), a temperature control system (4), a permeation control system (5), a gas loading system (6), a bending element experiment system (7) and a computer (8). The multi-field coupling true triaxial test system and the experiment method have the advantages that stress fields and seepage fields are controlled, and accordingly simulation research can be carried out on seepage anisotropy of rock and soil mass; influence of environmental factors on freezing nucleusor frozen soil samples can be simulated under the effects of temperature fields, the seepage fields and the stress fields; research can be carried out on the physical and mechanical properties of unsaturated frozen soil under the effects of the temperature fields and the stress fields; simulation research can be carried out on change of the physical and earth properties of sediments in generationand decomposition procedures of natural hydrates under multi-field coupling conditions, and simulation research can be carried out on mutual displacement effects between hydrate gas in the sediments and underground water; simulation research can be carried out on the physical and mechanical properties of unsaturated soil under the multi-field coupling conditions.

Owner:南京泰克奥科技有限公司

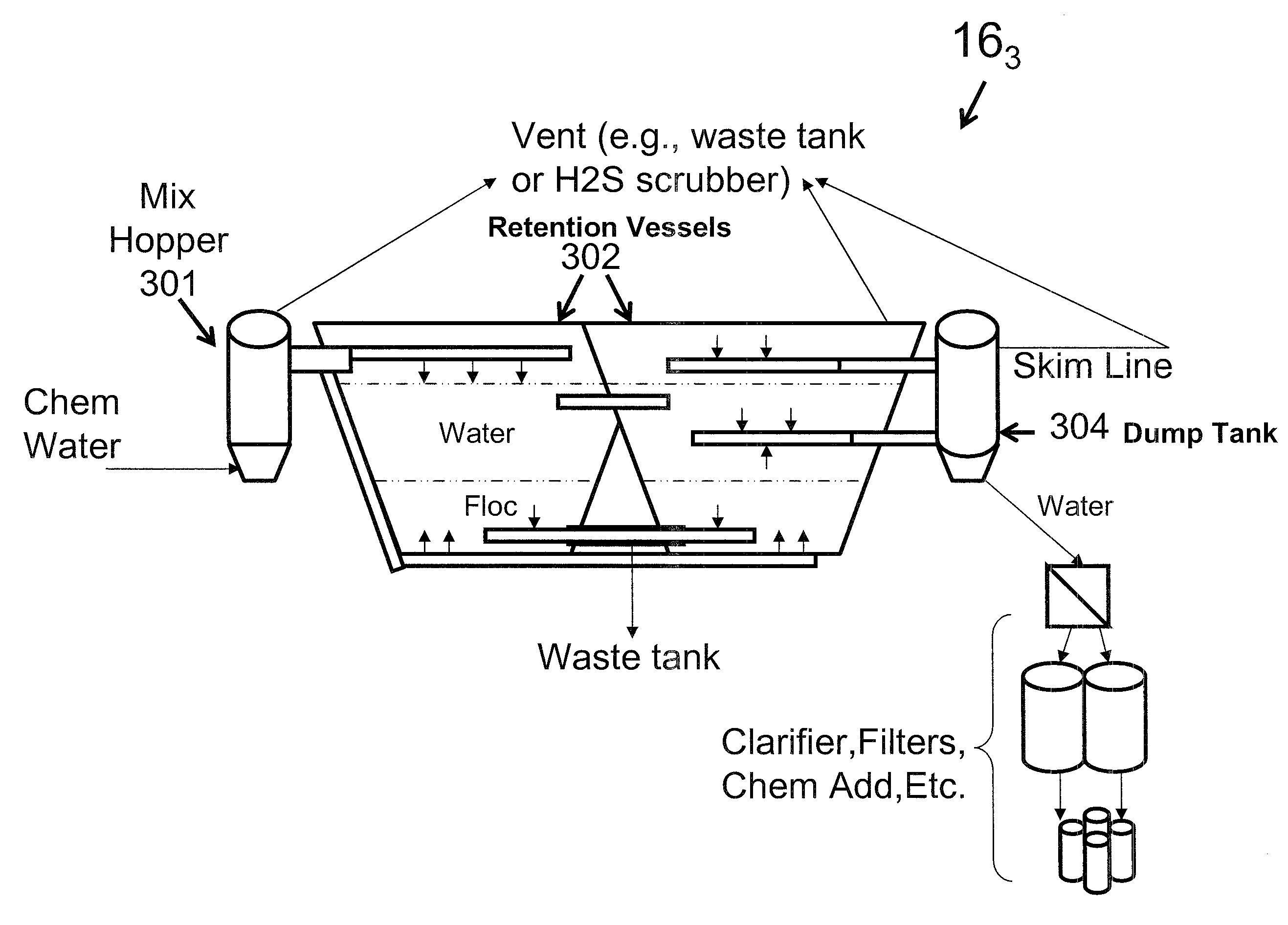

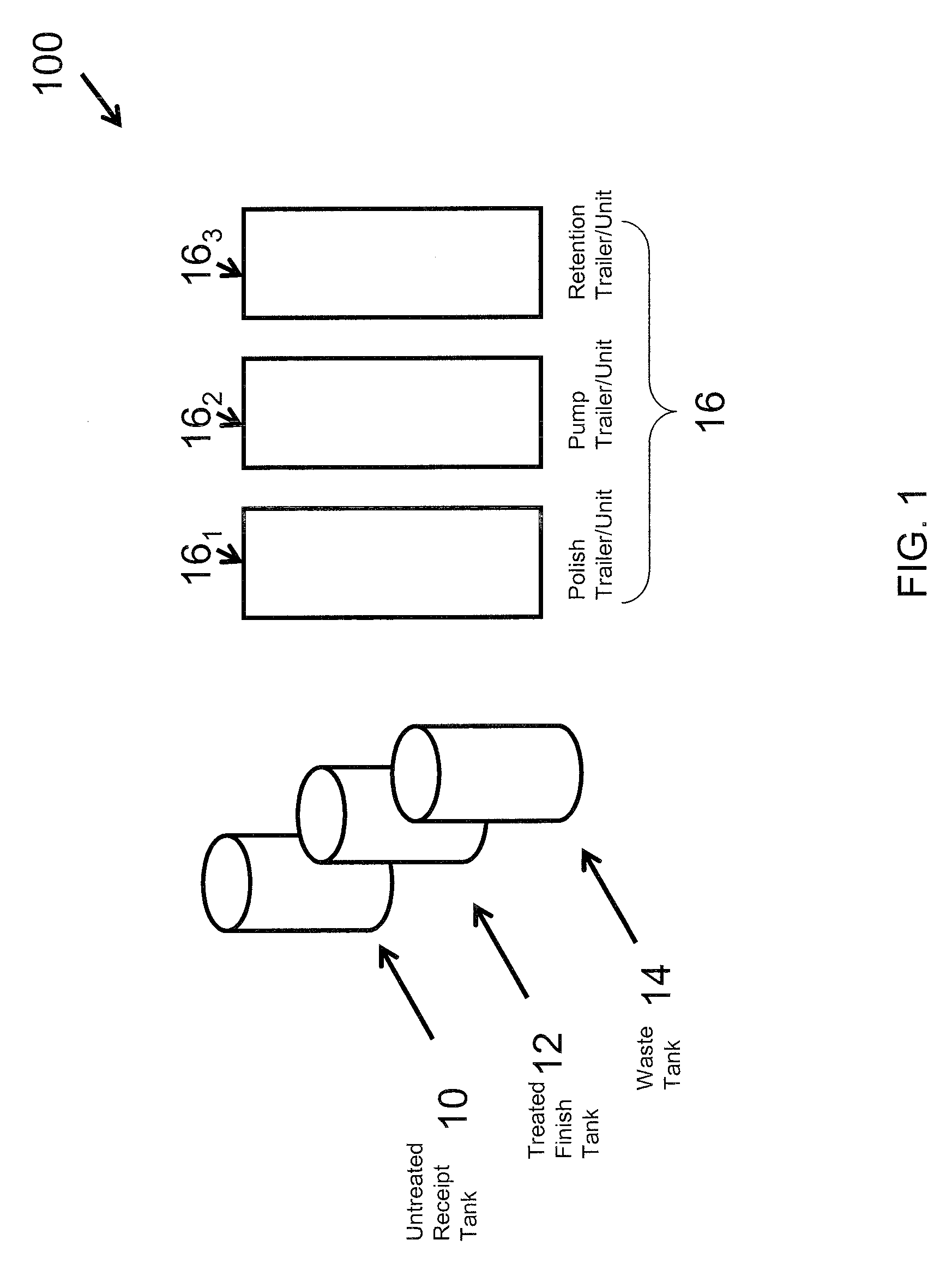

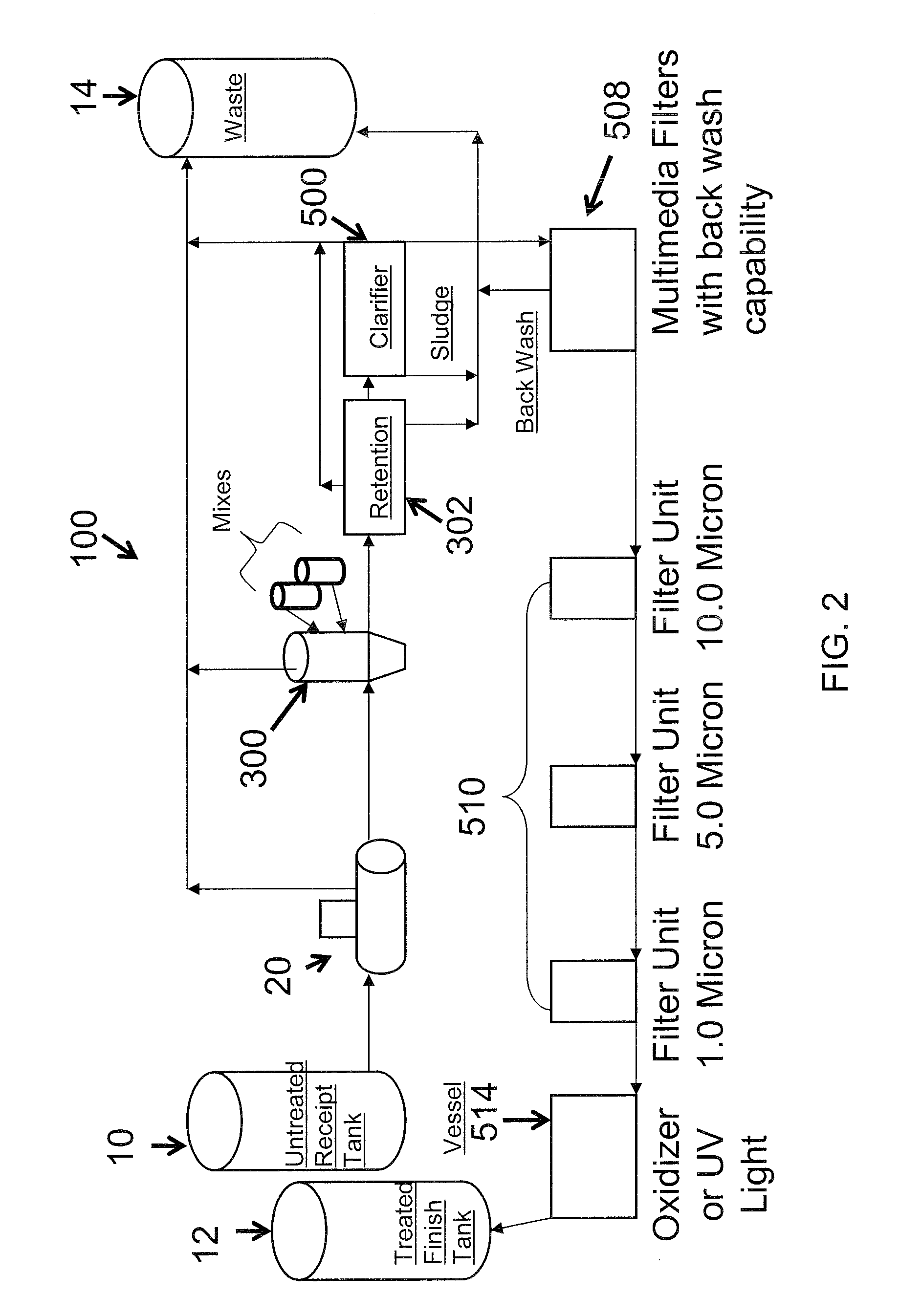

Recycling and treatment process for produced and used flowback fracturing water

ActiveUS20110005999A1Easy to assembleWater cleaningWater/sewage treatment by irradiationSedimentTreatment system

A portable water recycling and treatment system and process for used and produced flowback frac water pumps the water from a collection tank through a series of dedicated hydration, retention and filtering tanks and vessels that provide treatment for the removal of chemicals, sediments and other containments. The system, which is enclosed, can be readily assembled on-site by interconnecting the dedicated tanks, vessels and pumps. The tanks and vessels may be situated in a plurality of trailers / units that are transported separately to the site.

Owner:AUREUS ENERGY SERVICES INC

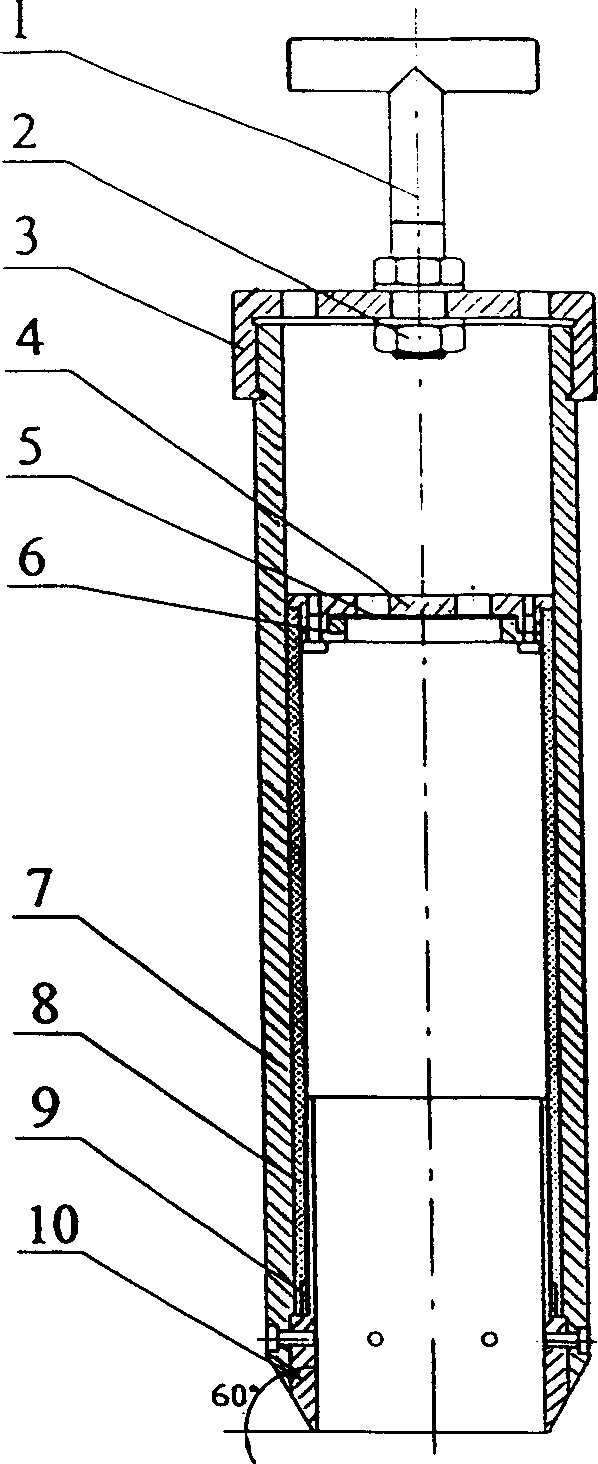

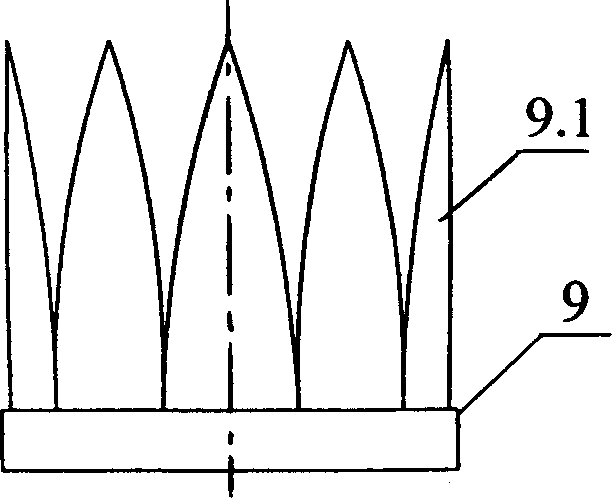

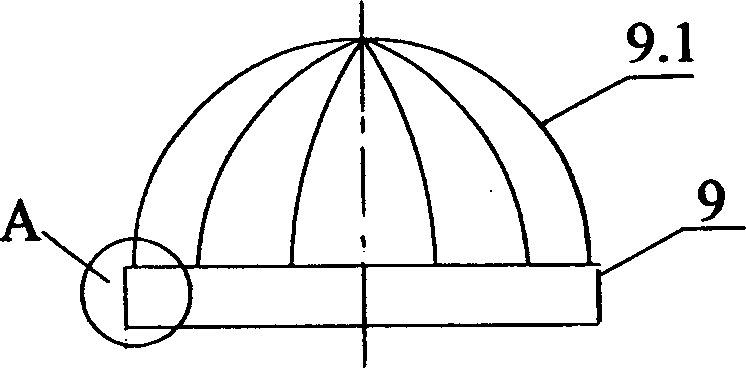

Mechanical hand hold type deposit sediment sampler without boundary disturbance

A mechanical handheld type deposit sampler consists of a knife pot assembly and a bush assembly. The knife pot assembly includes the hand bar, the upper end cover, the knife pot and the inserting tube. The bush assembly installed in the knife pot assembly includes the brush cover, the filter screen and the bush, and the claw petal. The manipulator grasping the T type hand bar inserts the sampler down into the marine deposits vertically. In the inserting procedure, the seawater through the filter screen and the drain hole is discharged outside. With the deposit touching the cover of the bush, the bush is brought to move upwards. When the cover touching the locknut, the claw petal is closed to cut off the deposit, sealing the opening so as to complete the sampling operation.

Owner:ZHEJIANG UNIV +1

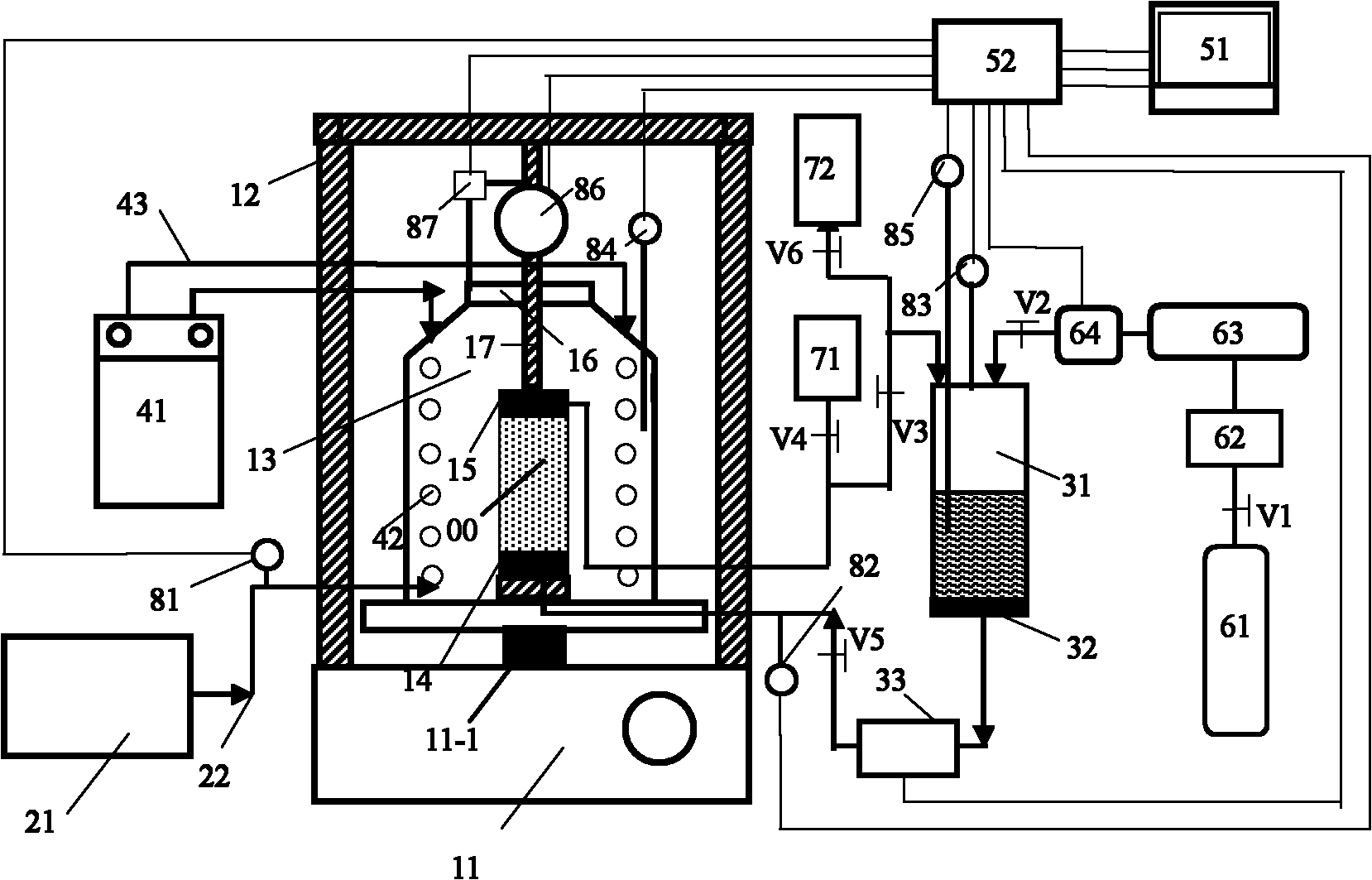

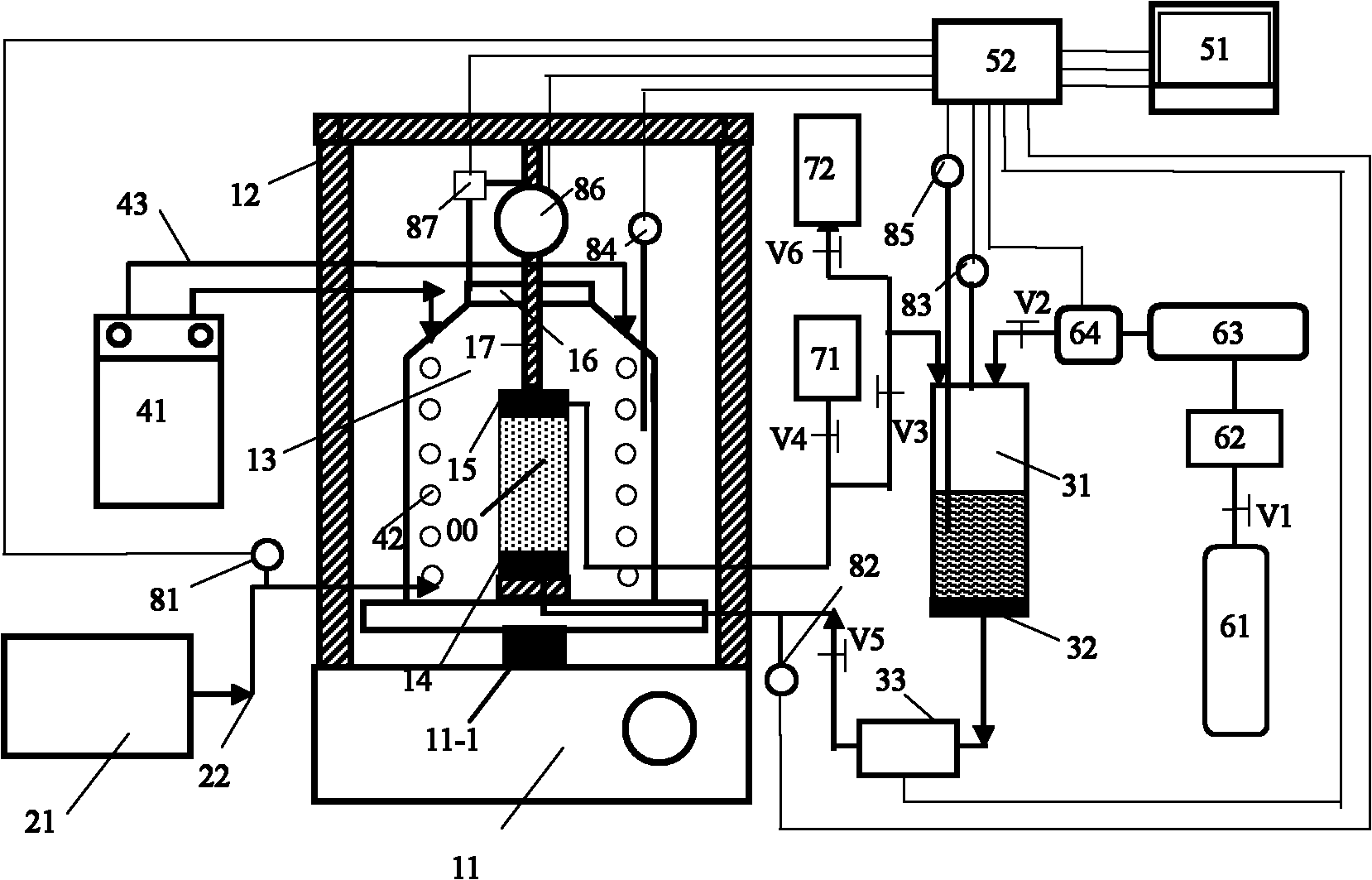

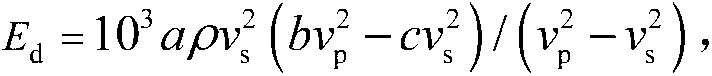

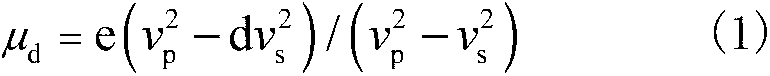

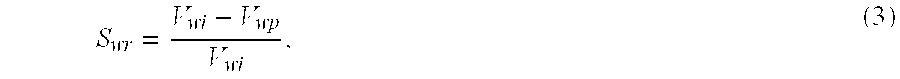

Natural gas hydrate deposit dynamic triaxial mechanic-acoustic-electrical synchronous test experimental device and method

ActiveCN103323352AImplement dynamic loadingScientific experiment dataAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using repeated/pulsating forcesTest fixtureWave velocity

The invention provides a natural gas hydrate deposit dynamic triaxial mechanic-acoustic-electrical synchronous test experimental device, and a test method. The natural gas hydrate deposit dynamic triaxial mechanic-acoustic-electrical synchronous test experimental device comprises an acoustic wave receiving device, an acoustic wave transmitting device, and a resistivity testing device. The natural gas hydrate deposit dynamic triaxial mechanic-acoustic-electrical synchronous test experiment method comprises the steps that: step A, a hydrate sample is synthesized; step B, the synthesized hydrate sample is subjected to dynamic loading, and electric-acoustic-mechanical property tests are simultaneously carried out, until the sample is subjected to shearing damage. The invention provides a mechanical response characteristic research of indoor hydrate deposit under dynamic load. With the device and the method, mechanical, electrical, and acoustic parameter synchronous testing of hydrate deposit under dynamic load can be realized. With the test data, a relationship between mechanical parameters and wave velocity can be obtained by fitting.

Owner:PETROCHINA CO LTD

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Method for stabilizing the gas flow in water-bearing natural gas deposits or reservoirs

The invention relates to a method for stabilizing the gas flow in water-bearing natural gas deposits or reservoirs which produce at least 50 l of water per 1000 m3 (Vn) of extracted natural gas. According to the method, a dispersion comprising the following components is injected into the water-bearing rock: A) an organosilicon compound as the dispersed phase; B) a hydrophilic dispersion agent, which can be mixed with water, and, if needed, C) a dispersing additive.

Owner:WACKER CHEM GMBH

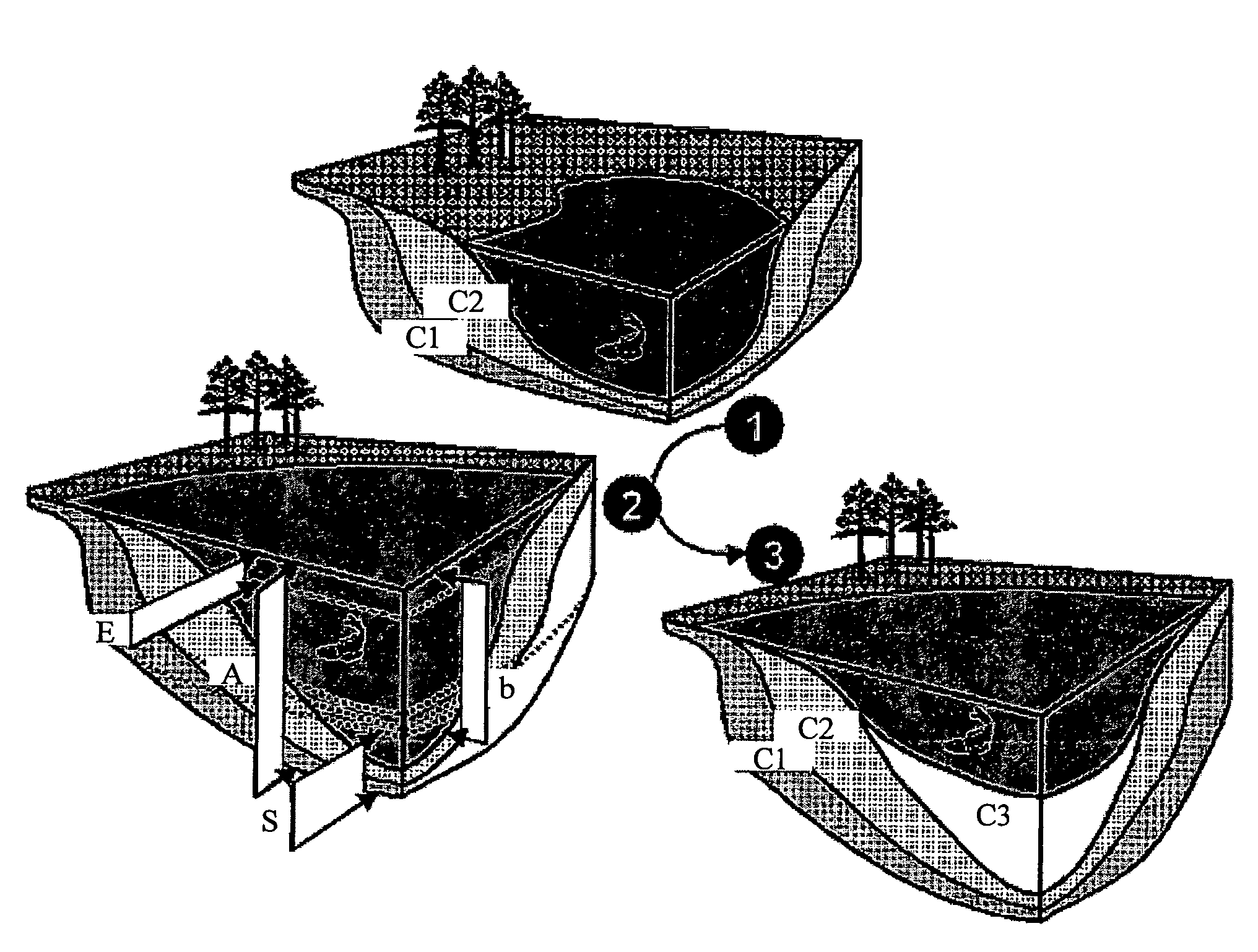

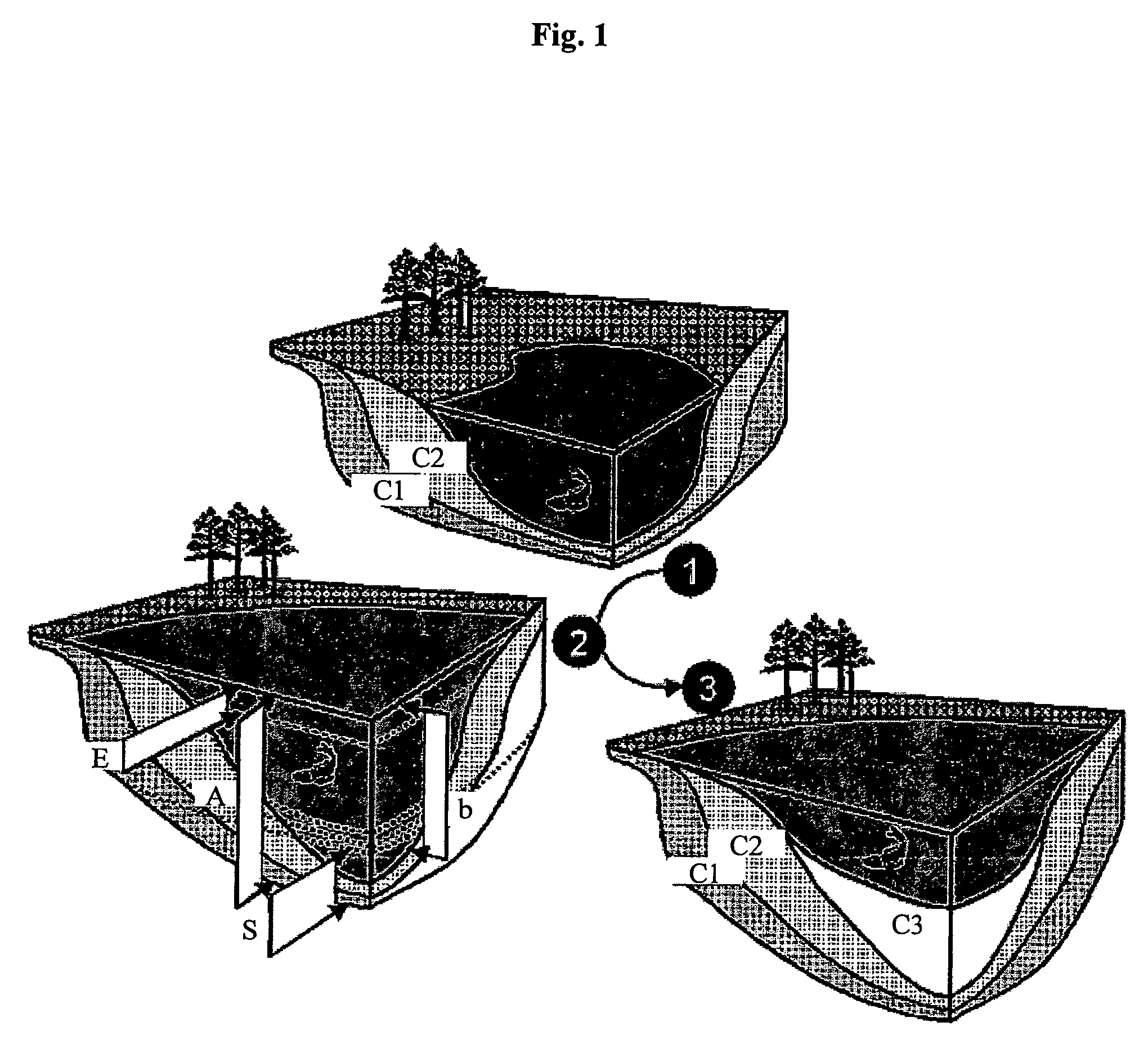

Method of simulating the sedimentary deposition in a basin respecting the thicknesses of the sedimentary sequences

ActiveUS7337069B2Seismic signal processingSpecial data processing applicationsLithologyFixed point algorithm

The method of the invention allows, by means of an iterative inversion algorithm, prediction of the spatial distribution of the lithologic composition of sediments deposited in a sedimentary basin during a geologic time interval, and the temporal evolution of the depositional profile throughout filling of the basin, while respecting exactly the thicknesses of the sedimentary sequences measured otherwise which is useful for locating hydrocarbon reservoirs. Input data of thickness maps of the sedimentary layer, location and composition of the sediment supply at the boundaries of the sedimentary basin, and physical parameters characterizing transport of the sediments during the period of consideration are applied to an iterative inversion loop initialized by the accommodation provided by a stationary multilithologic diffusive model which works as a fixed-point algorithm correcting the accommodations by means of a preconditioning of the residue on the sequence thicknesses obtained by an instationary model.

Owner:INST FR DU PETROLE

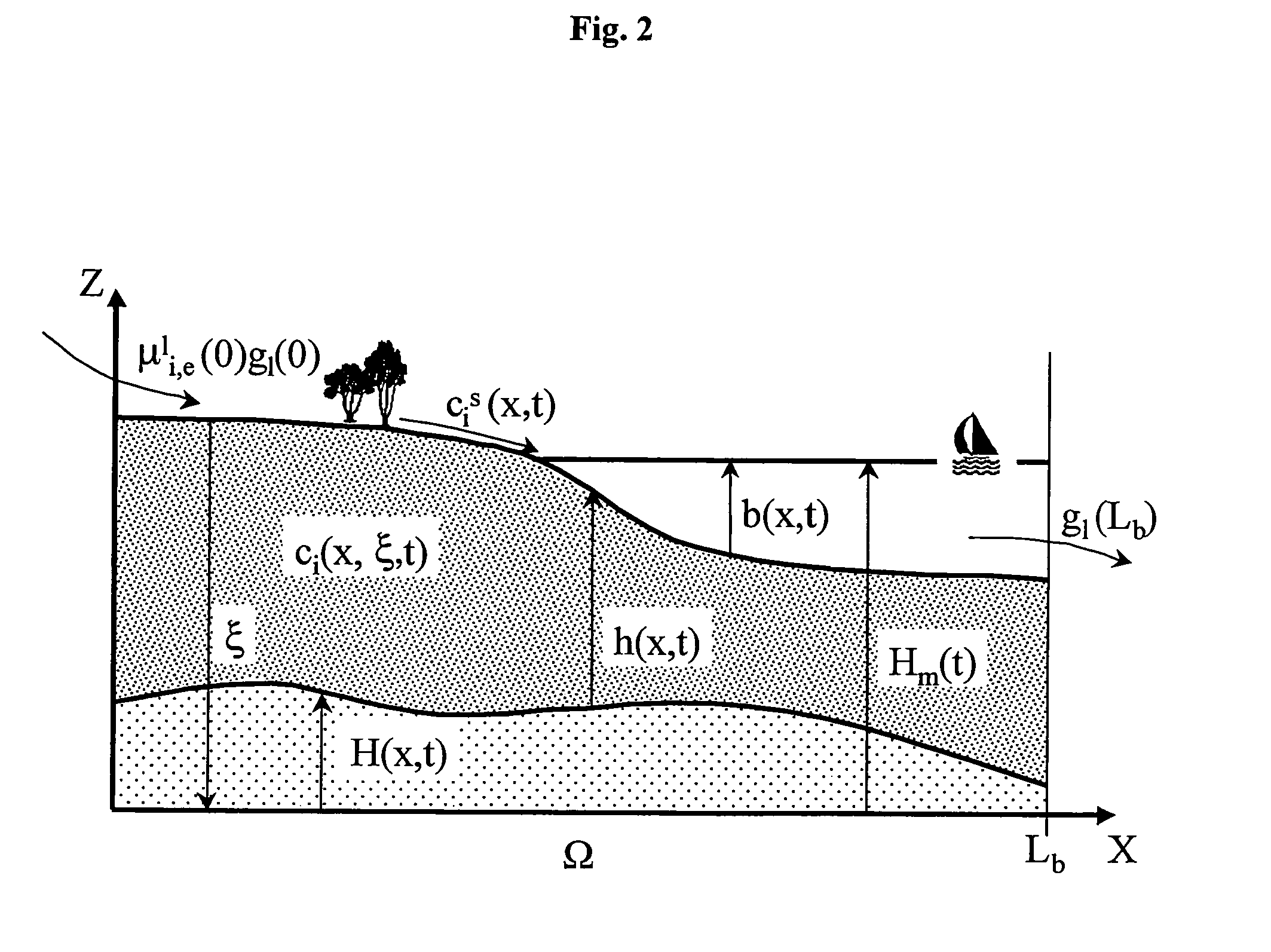

Method for separating and recovering lithium from waste lithium ion battery

ActiveCN103035977AEasy to recycleHigh purityWaste accumulators reclaimingBattery recyclingRecovery methodPhysical chemistry

The invention discloses a method for separating and recovering lithium from a waste lithium ion battery. The method comprises the following steps: dismounting after discharging the waste lithium ion battery, and removing a battery case; crashing a battery cell; leaching and filtering the crushed battery cell with inorganic acid and oxidant to obtain a filter liquor; regulating the pH of the filter liquor to be more than or equal to 8, then filtering to remove impurities and sediment to obtain a recovery liquor containing lithium ions; adsorbing the lithium ions in the recovery liquor through resin; and desorbing the resin to obtain the separated and recovered lithium salt. The recovery method provided by the invention is simple and efficient, has high purity of lithium and brings no pollution.

Owner:深圳市泰力废旧电池回收技术有限公司

Microemulsion heavy wax crystal emulsifying dispersant applied to oil well for tertiary oil recovery

InactiveCN103614128AUnique penetrationImprove permeabilityDrilling compositionHigh carbonAromatic solvents

The invention relates to a microemulsion heavy wax crystal emulsifying dispersant applied to an oil well for tertiary oil recovery, and is mainly used for solving the problem that the oil production rate is influenced due to the high return pressure and the short thermal washing period of the oil recovery well caused by that serious wax precipitations are generated by the oil well which contains thickened oil and is high in polymer flooding and viscosity. The emulsifying dispersant is prepared from the following components by weight percent: 1% to 3% of high-molecular polymer wax inhibitor, 13% to 25% of organic aromatic solvent, 1% to 3.5% of emulsifying agent, 8% to 12% of sulfonate, 10% to 12.5% of alcohol, 10% to 20% of demulsifier and 25% to 35% of water. The emulsifying dispersant has the dual effects of eliminating and preventing the waxy bitumen colloid precipitations with long molecular chains or high carbon number in crude oil from being precipitated, so that the wall sticking quantity of condensate oil is greatly decreased; the running load of the oil well is reduced; and the well washing period is prolonged. Thus, the oil production rate is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com