Microemulsion heavy wax crystal emulsifying dispersant applied to oil well for tertiary oil recovery

A technology of emulsifying dispersant and microemulsion, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high back pressure in oil production wells, short hot washing cycle, etc., achieve stable performance, reduce condensate viscosity, etc. The effect of small wall volume and odor toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 3g compound emulsifier preparation: weigh 1.9g sodium oleate, 1.1g C 18 Mixture of unsaturated olefinic acids;

[0014] Weigh 2g of SAM, 3g of composite emulsifier, 18g of xylene, 12g of sodium sulfonate, 12g of methanol, 20g of 1009-2 type demulsifier, 33g of water, and mix to prepare a heavy wax crystal emulsifying dispersant.

Embodiment 2

[0016] 3.5g compound emulsifier preparation: weigh 2.2g sodium oleate, 1.3g C 18 Mixture of unsaturated olefinic acids;

[0017] Weigh 2g of SAM, 3.5g of composite emulsifier, 25g of xylene, 10g of sodium sulfonate, 10g of methanol, 20g of 1009-2 type demulsifier, 29.5g of water, and mix to prepare a heavy wax crystal emulsifying dispersant.

[0018] The on-site application effect evaluation of the microemulsion heavy wax crystal emulsifying dispersant applied to tertiary oil recovery oil wells is as follows:

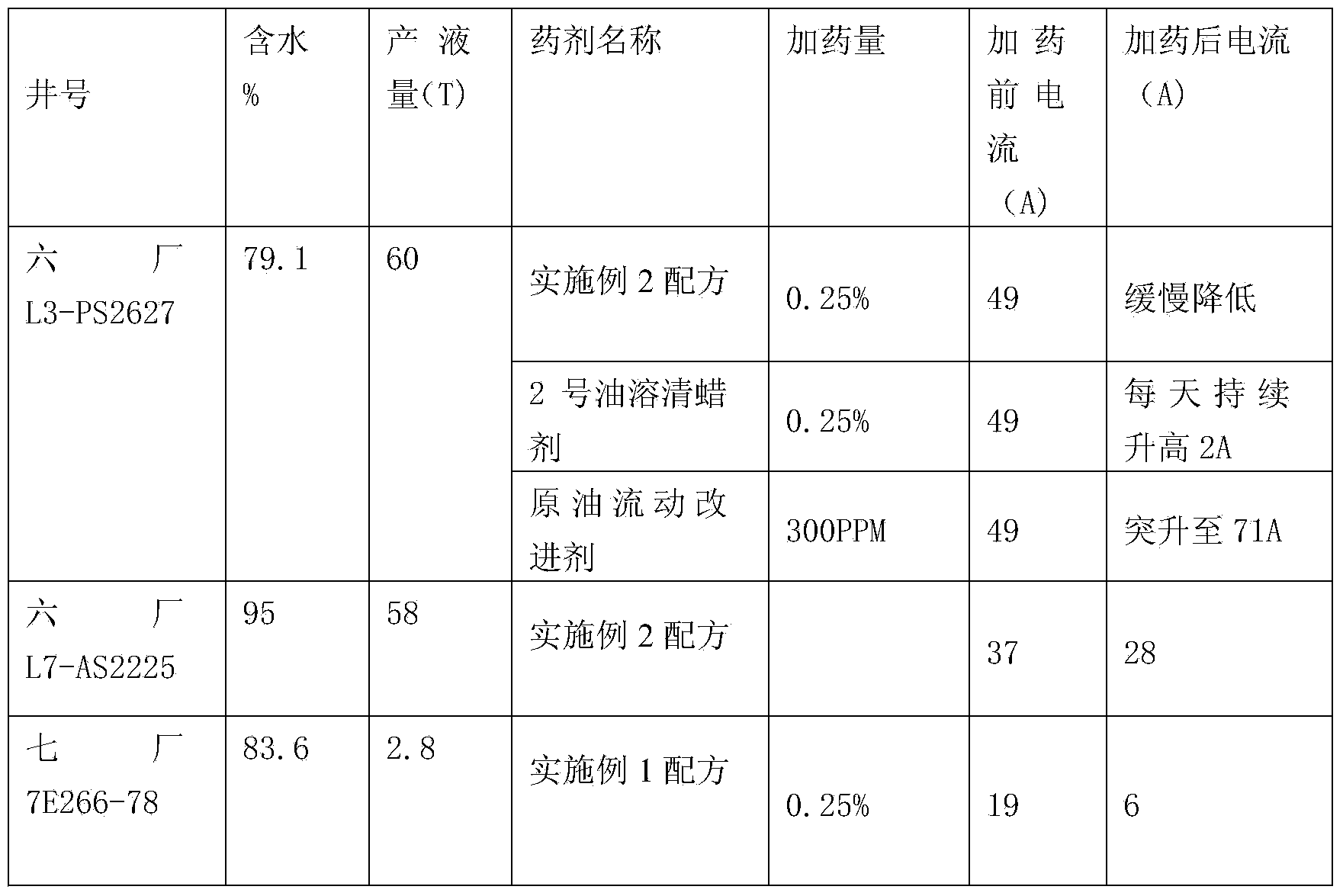

[0019] The effect of this microemulsion heavy wax crystal emulsifying and dispersing agent in Daqing Oilfield No. 6 Oil Production Plant and No. 7 Oil Production Plant compared with traditional agents is shown in Table 1:

[0020] Table 1

[0021]

[0022] The current increase of the L3-PS2627 poly-flooding screw pump oil production well of No. 6 Plant has been effectively controlled, and it can operate normally after the bottom of the well is closed and mixed with...

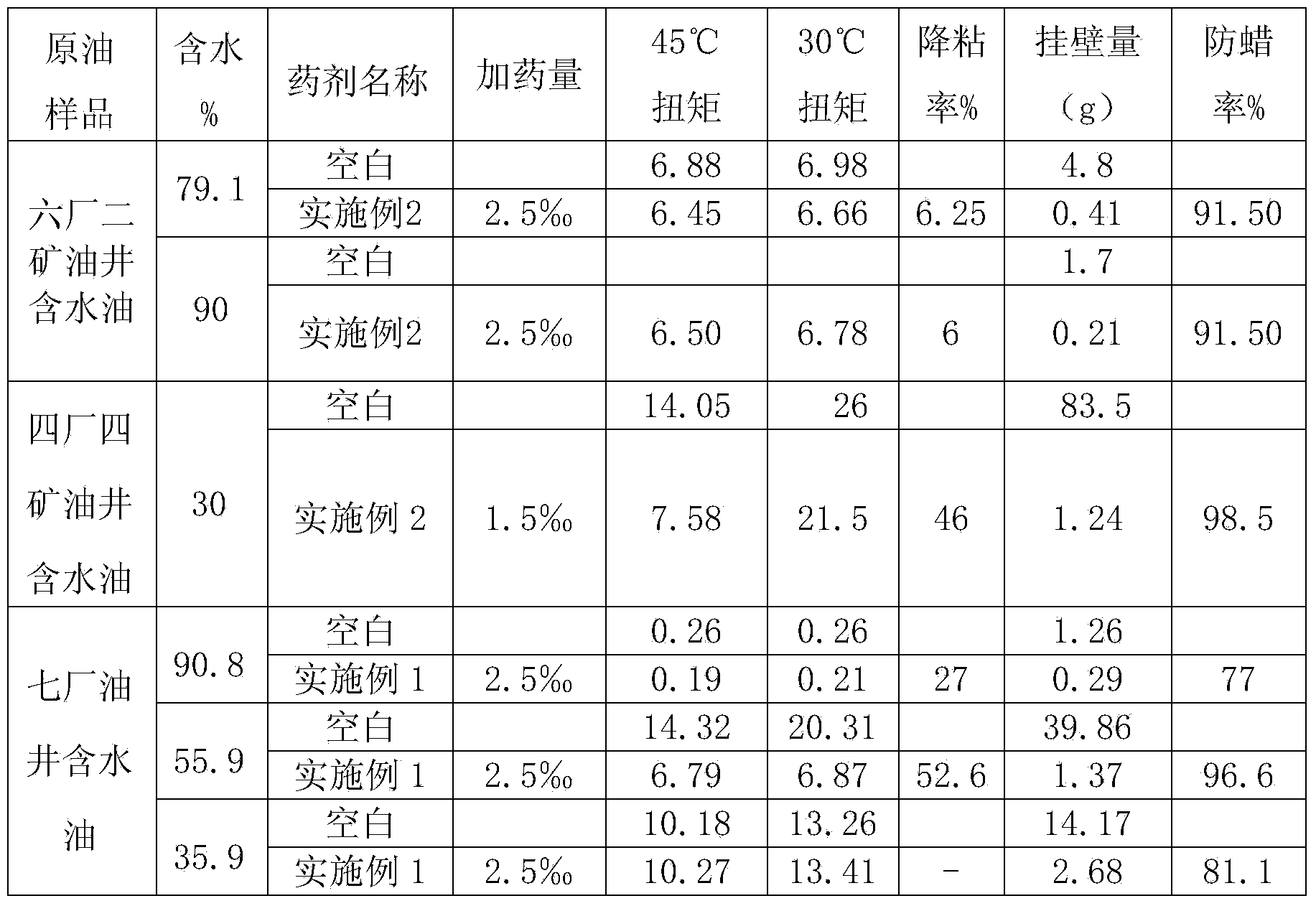

example 1

[0027] Example 1 and Example 2 have good application effects. Example 2 is applied to the polymer flooding of Plant No. 6 and Plant No. 4, and the wax control rate is greater than 91.5%. Example 1 is applied to water flooding pumping wells in peripheral oil fields. The wax control rate is greater than 77%.

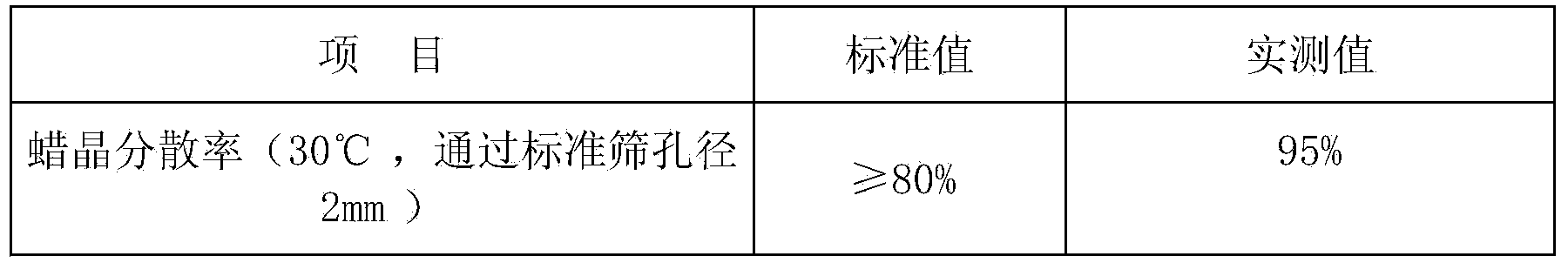

[0028] 2. See Table 3 for the evaluation of the dispersion performance of wax crystals

[0029] Triangular flask with lid, constant temperature water bath, 10-mesh standard sieve (aperture 2mm), electronic balance, 58 # Industrial white wax

[0030] table 3

[0031]

[0032] The wax crystal dispersion rate of the microemulsion wax crystal emulsifying dispersant is 95%, which is higher than the standard value of more than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com