Patents

Literature

5964 results about "Microemulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

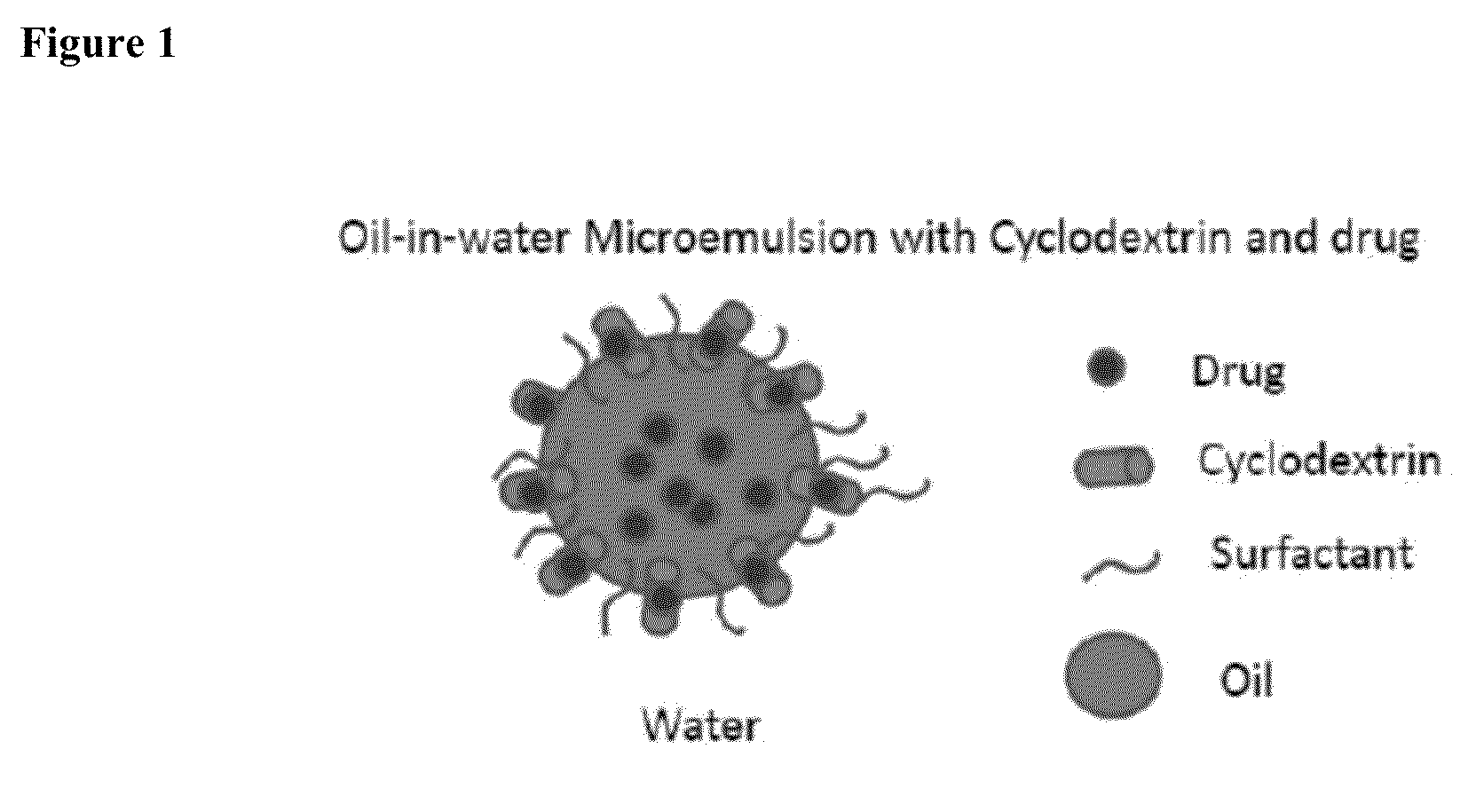

Microemulsions are clear, thermodynamically stable, isotropic liquid mixtures of oil, water and surfactant, frequently in combination with a cosurfactant. The aqueous phase may contain salt(s) and/or other ingredients, and the "oil" may actually be a complex mixture of different hydrocarbons and olefins. In contrast to ordinary emulsions, microemulsions form upon simple mixing of the components and do not require the high shear conditions generally used in the formation of ordinary emulsions. The three basic types of microemulsions are direct (oil dispersed in water, o/w), reversed (water dispersed in oil, w/o) and bicontinuous.

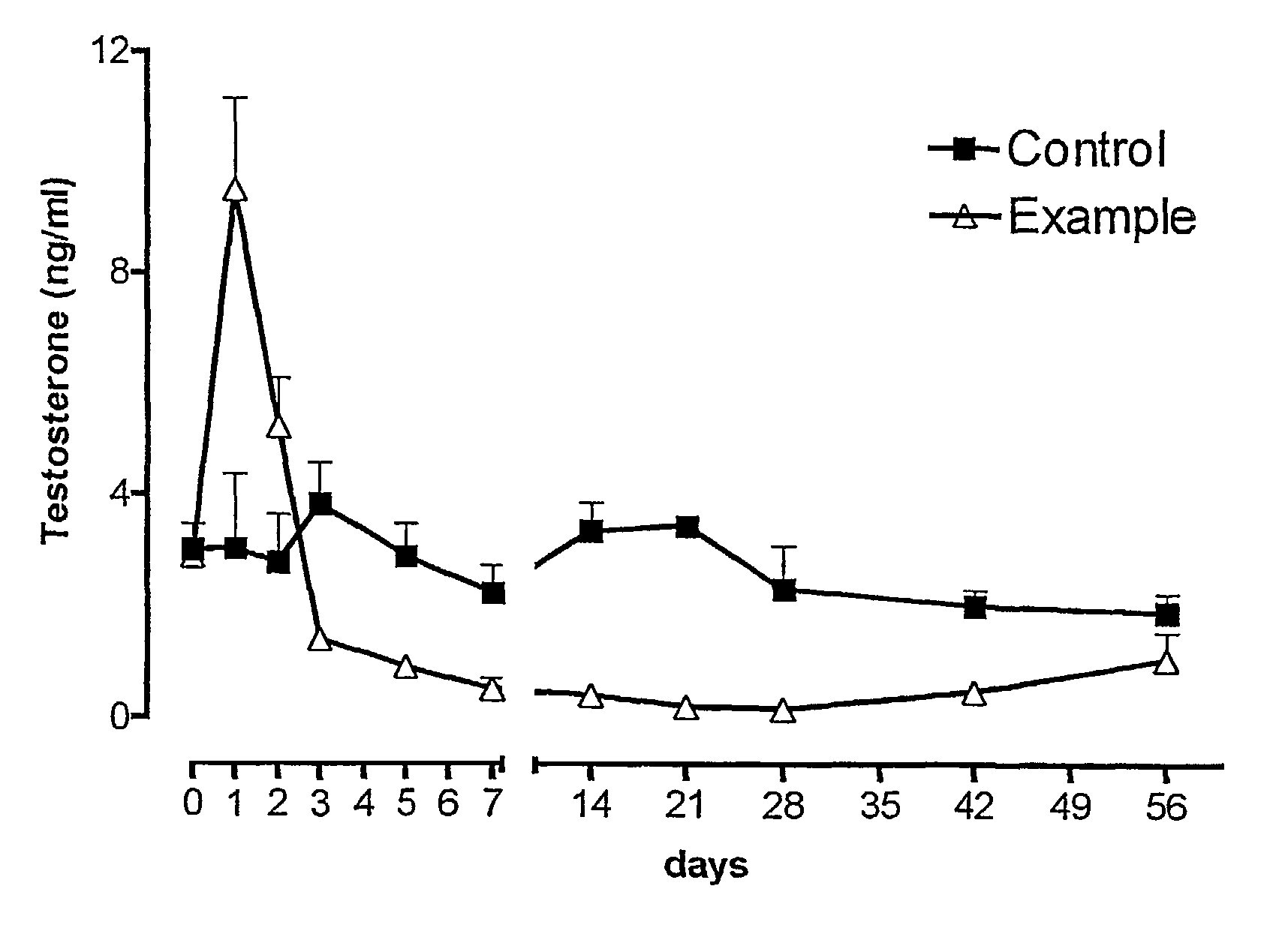

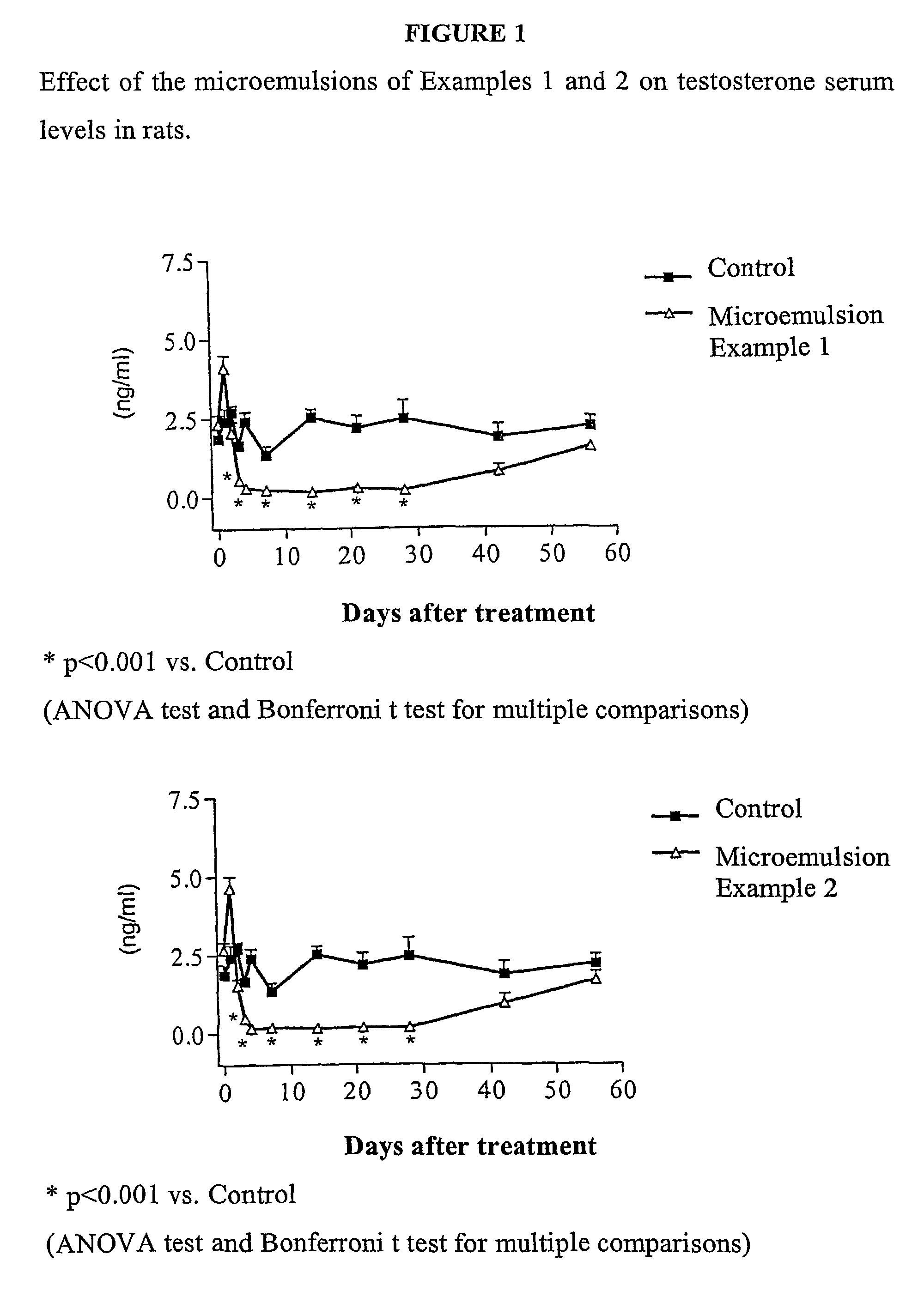

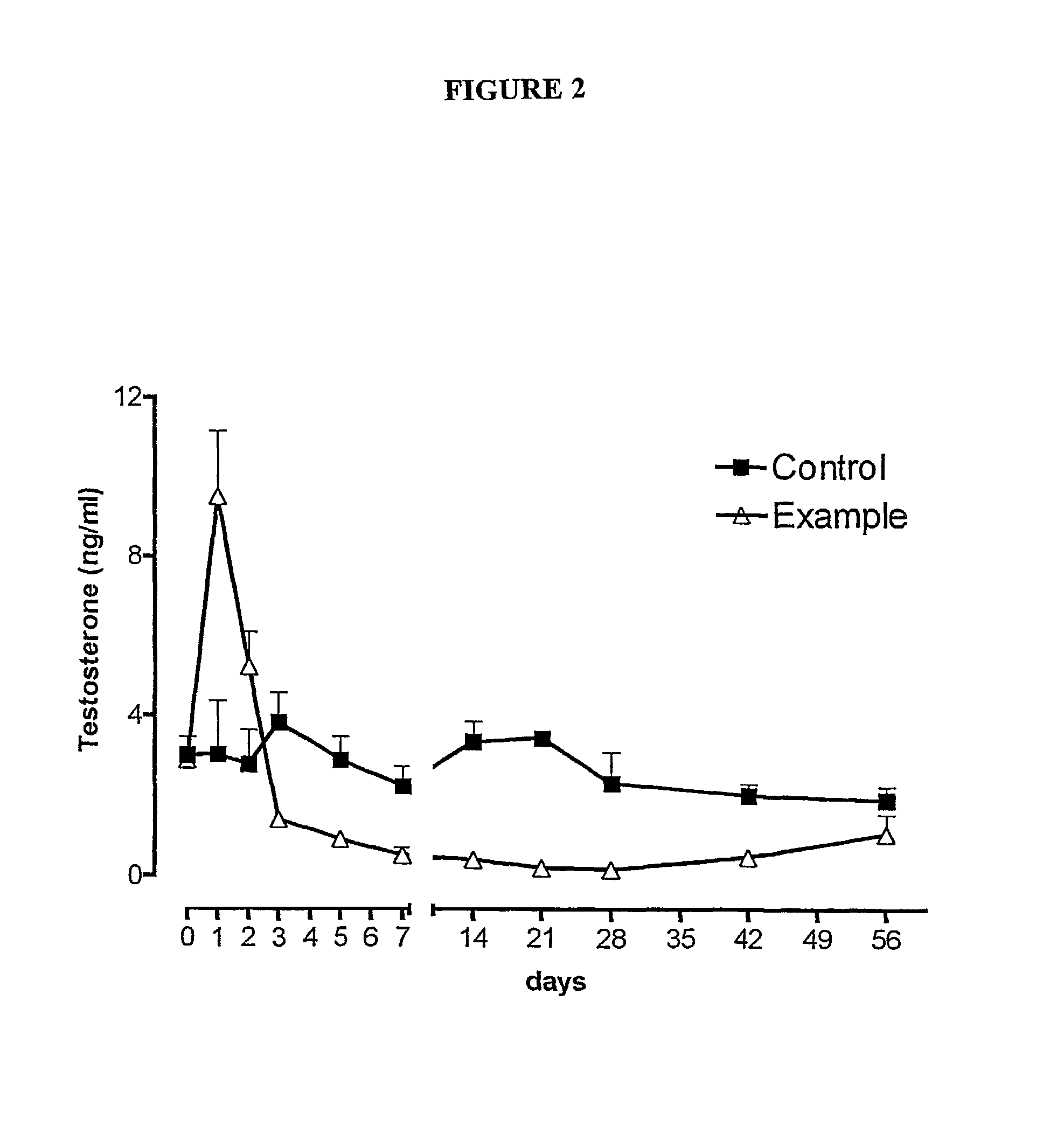

Sustained release pharmaceutical compositions for the parenteral administration of hydrophilic compounds

InactiveUS7157099B2Easy to prepareOrganic active ingredientsPeptide/protein ingredientsParenteral nutritionBULK ACTIVE INGREDIENT

Owner:ITALFARMACO SPA

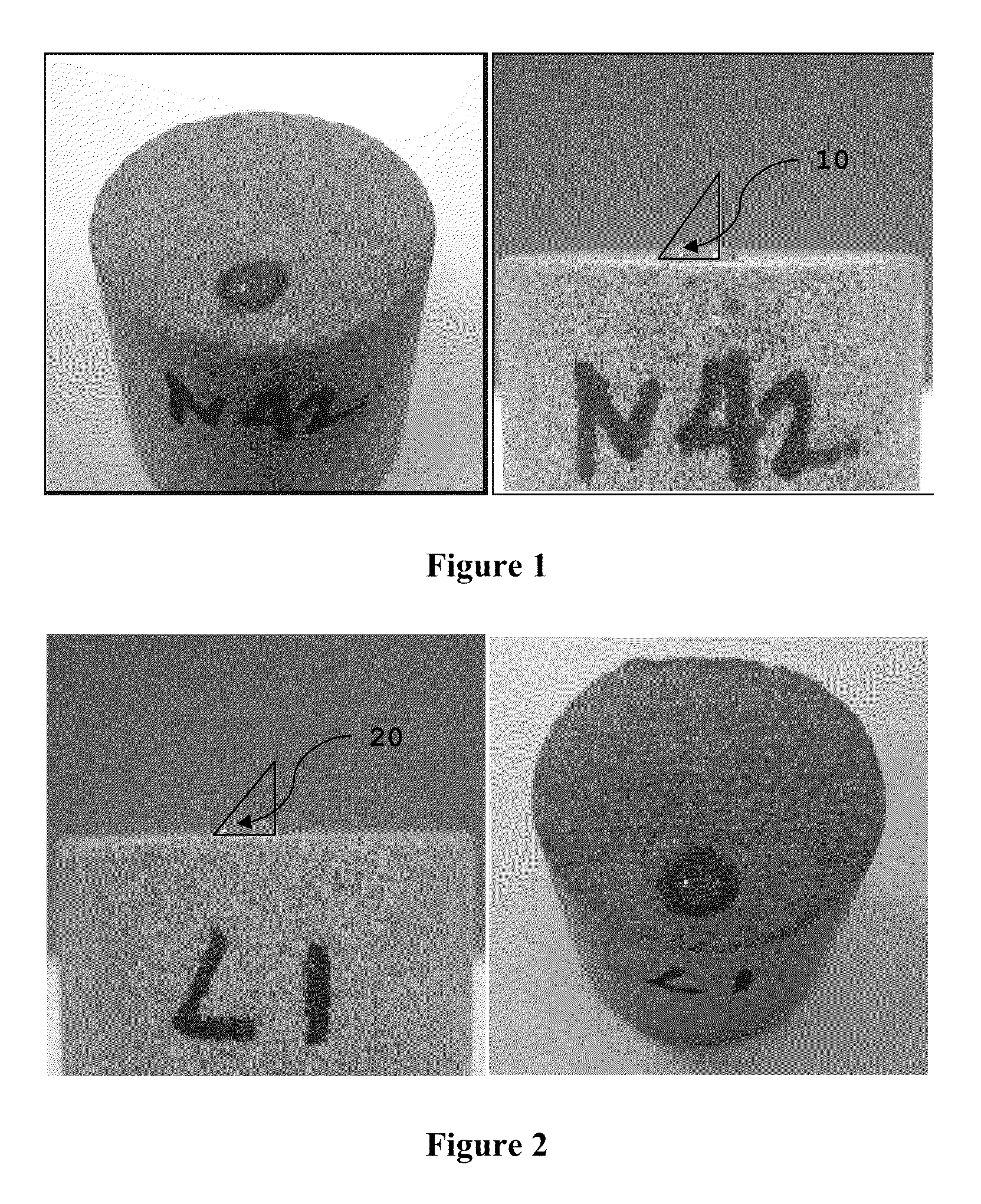

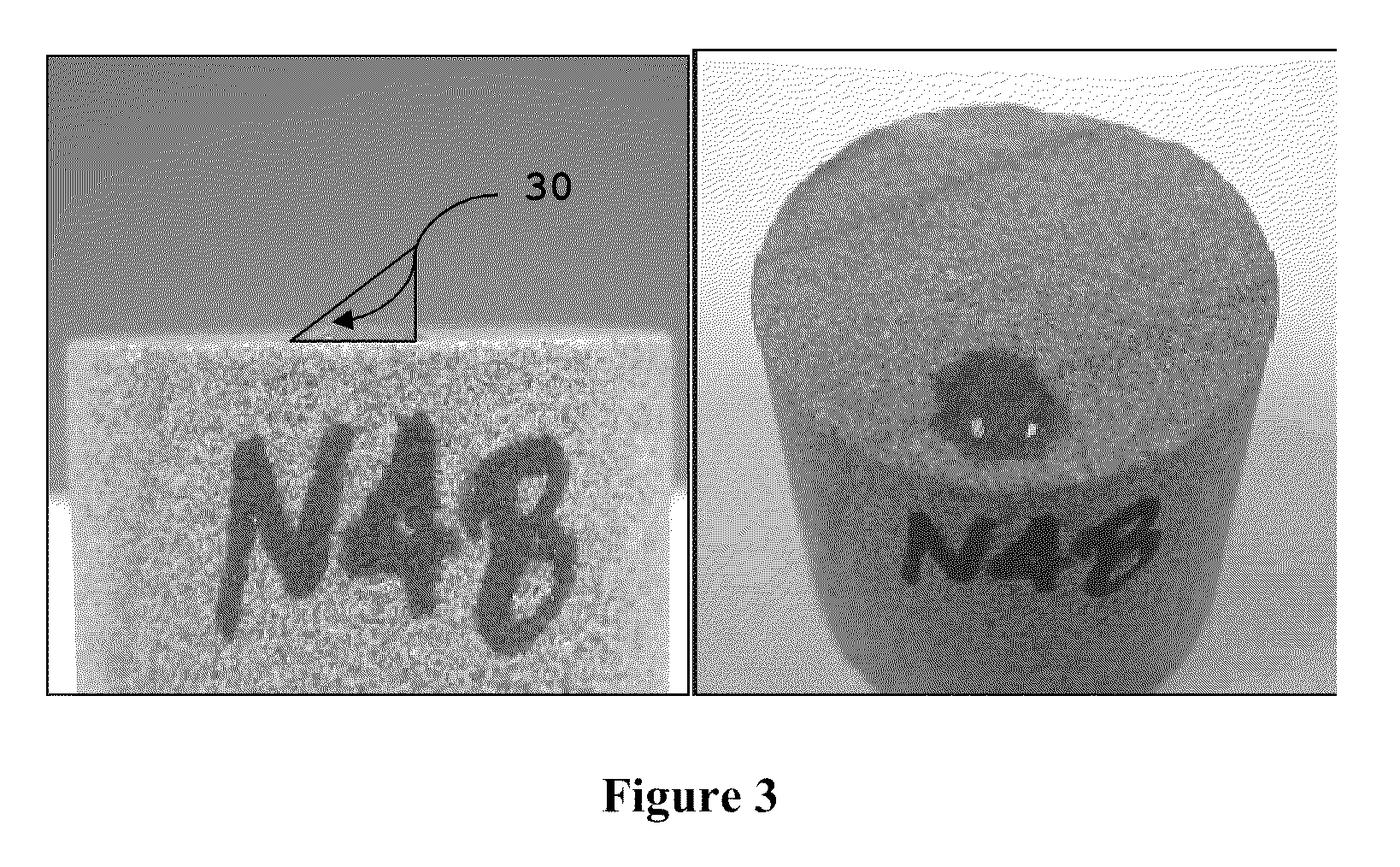

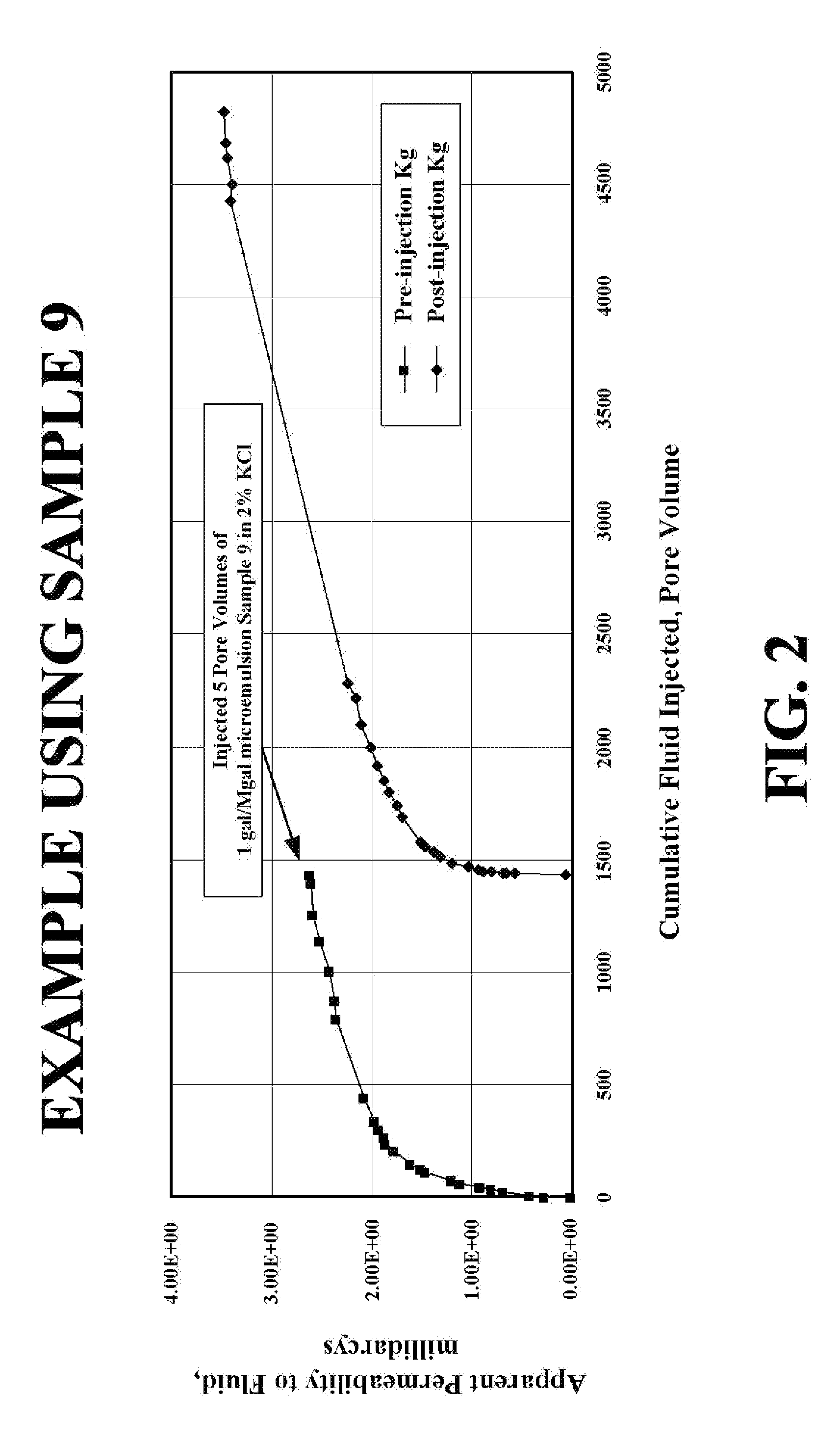

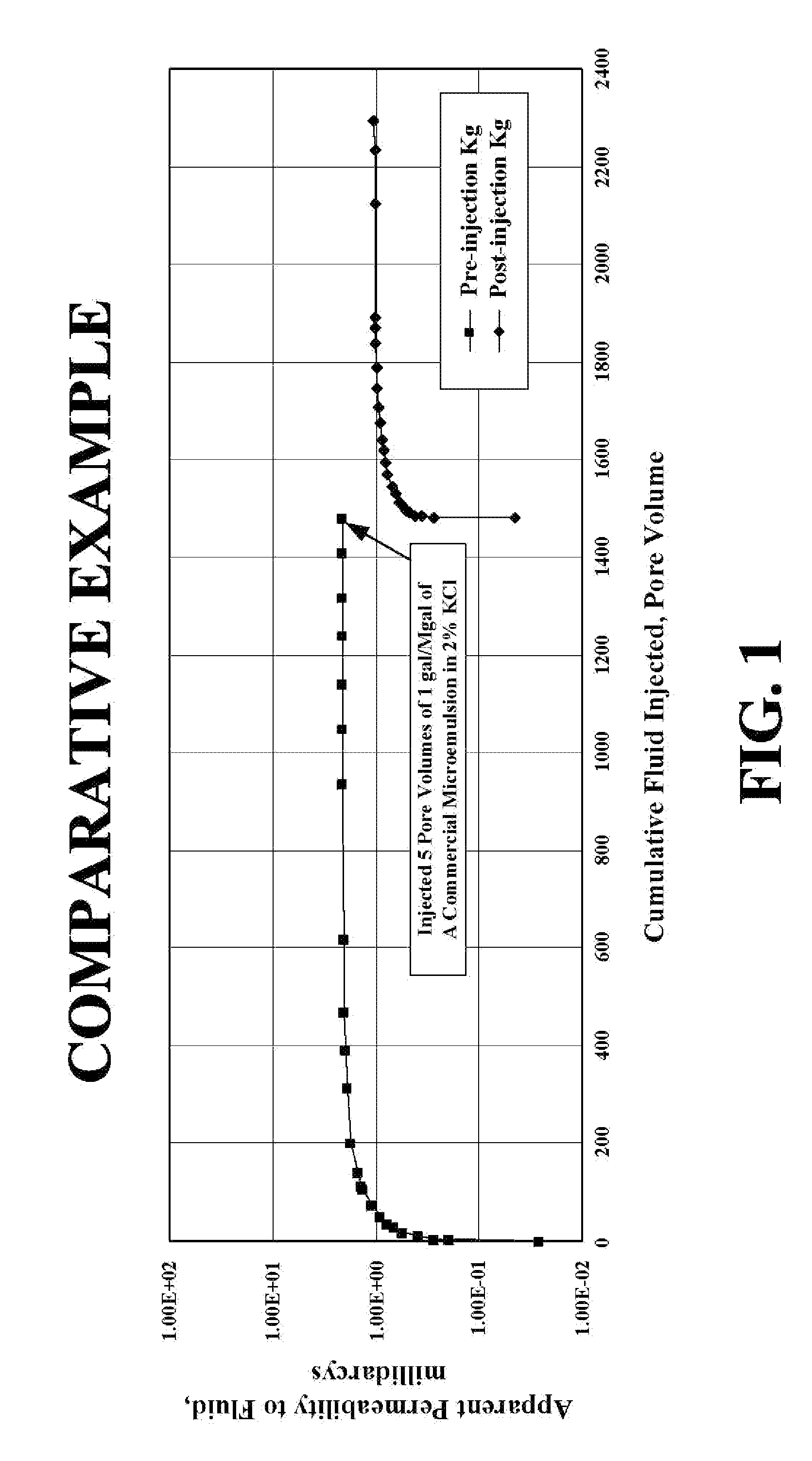

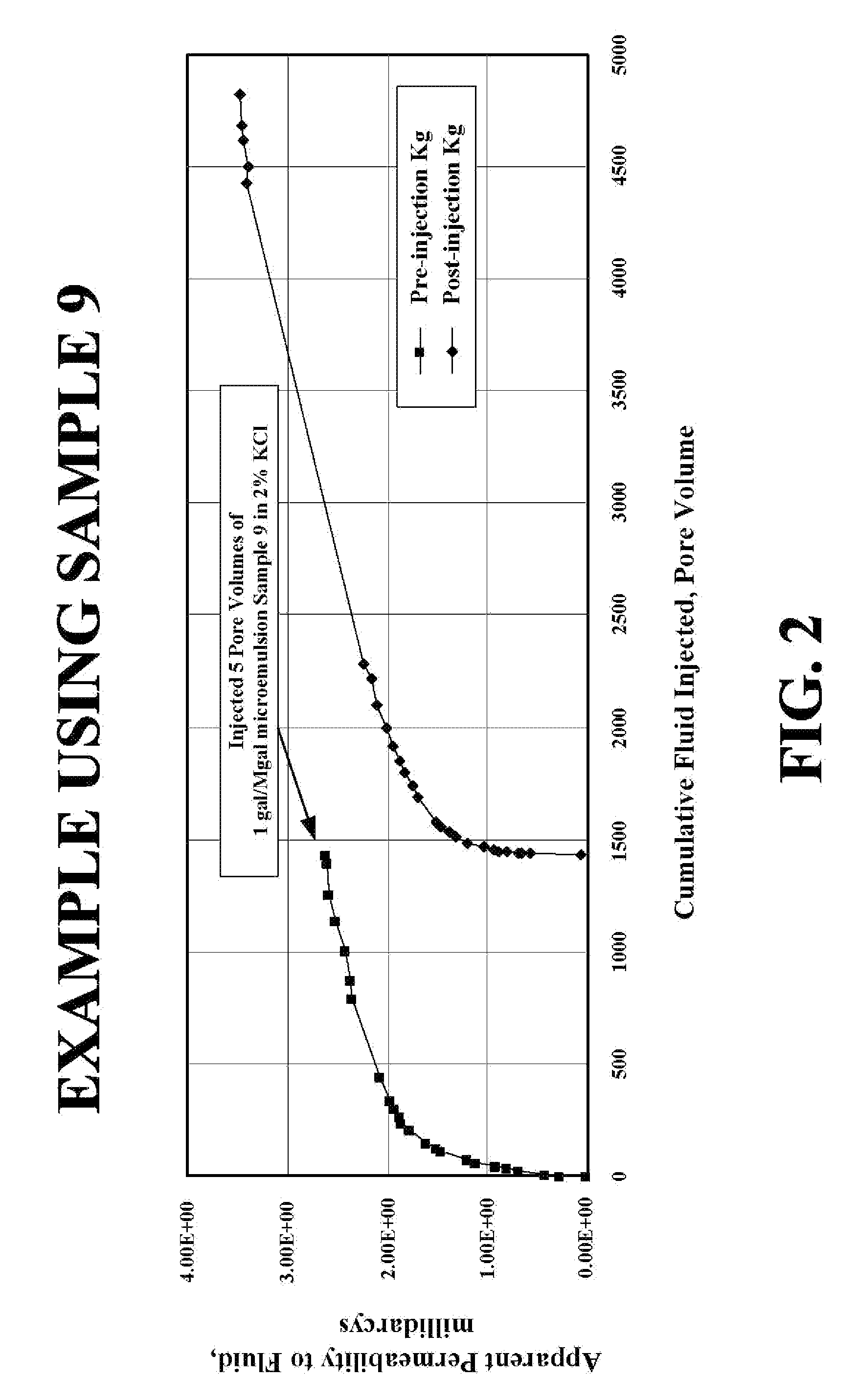

Composition and process for well cleaning

Disclosed is a microemulsion well treatment microemulsion that is formed by combining a solvent-surfactant blend with a carrier fluid. In preferred embodiments, the solvent-surfactant blend includes a surfactant and a solvent selected from the group consisting of terpenes and alkyl or aryl esters of short chain alcohols. The disclosed well treatment microemulsion can be used in well remediation, stimulation and hydrogen sulfide mitigation operations. Additionally, the well treatment microemulsion can be used in the production of benzothiophenes through interaction with hydrogen sulfide.

Owner:PNC BANK NAT ASSOC +2

Orally administrable composition capable of providing enhanced bioavailability when ingested

InactiveUS6054136AImprove solubilityImprove bioavailabilityCosmetic preparationsToilet preparationsFatty acid esterIngestion

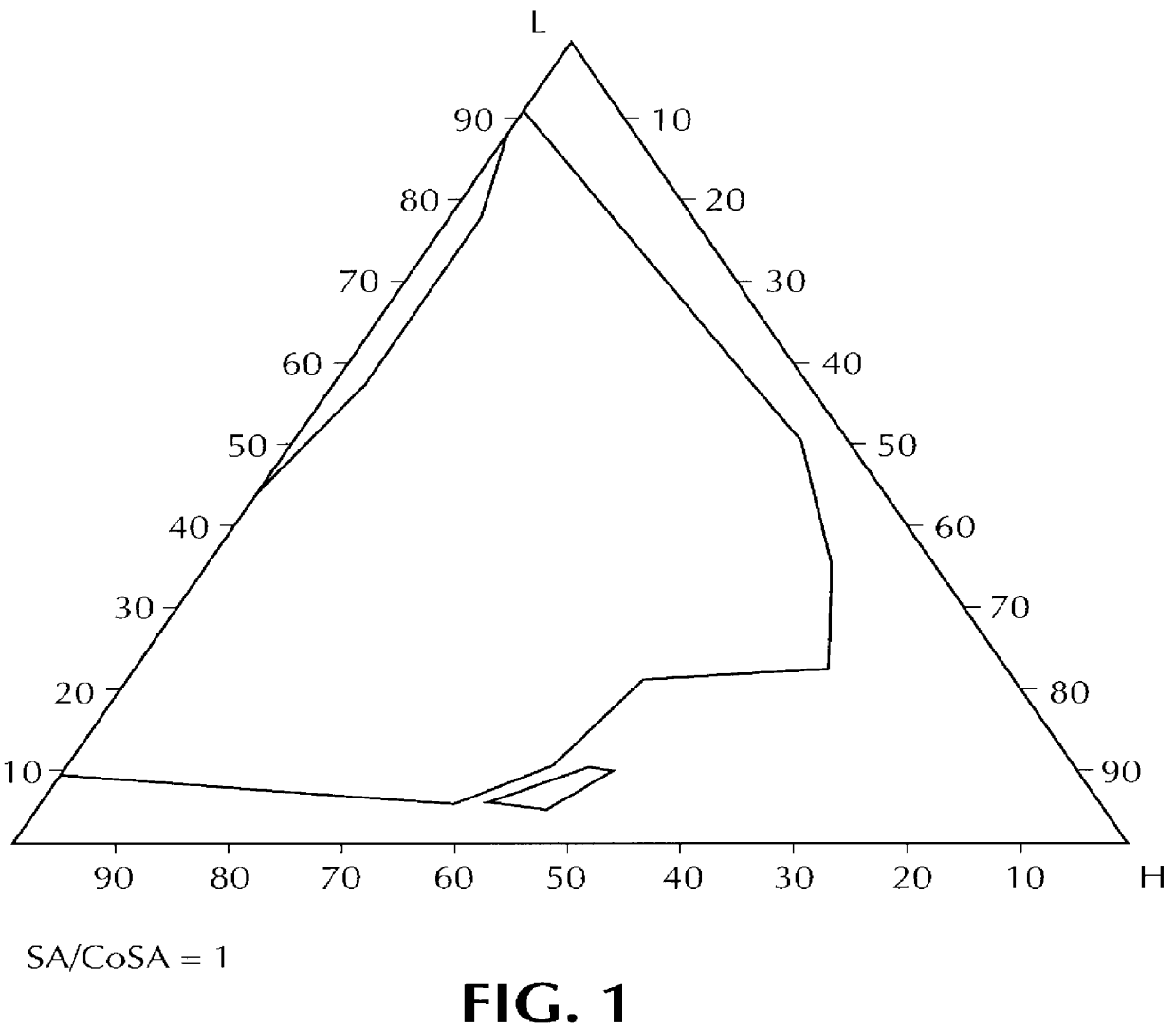

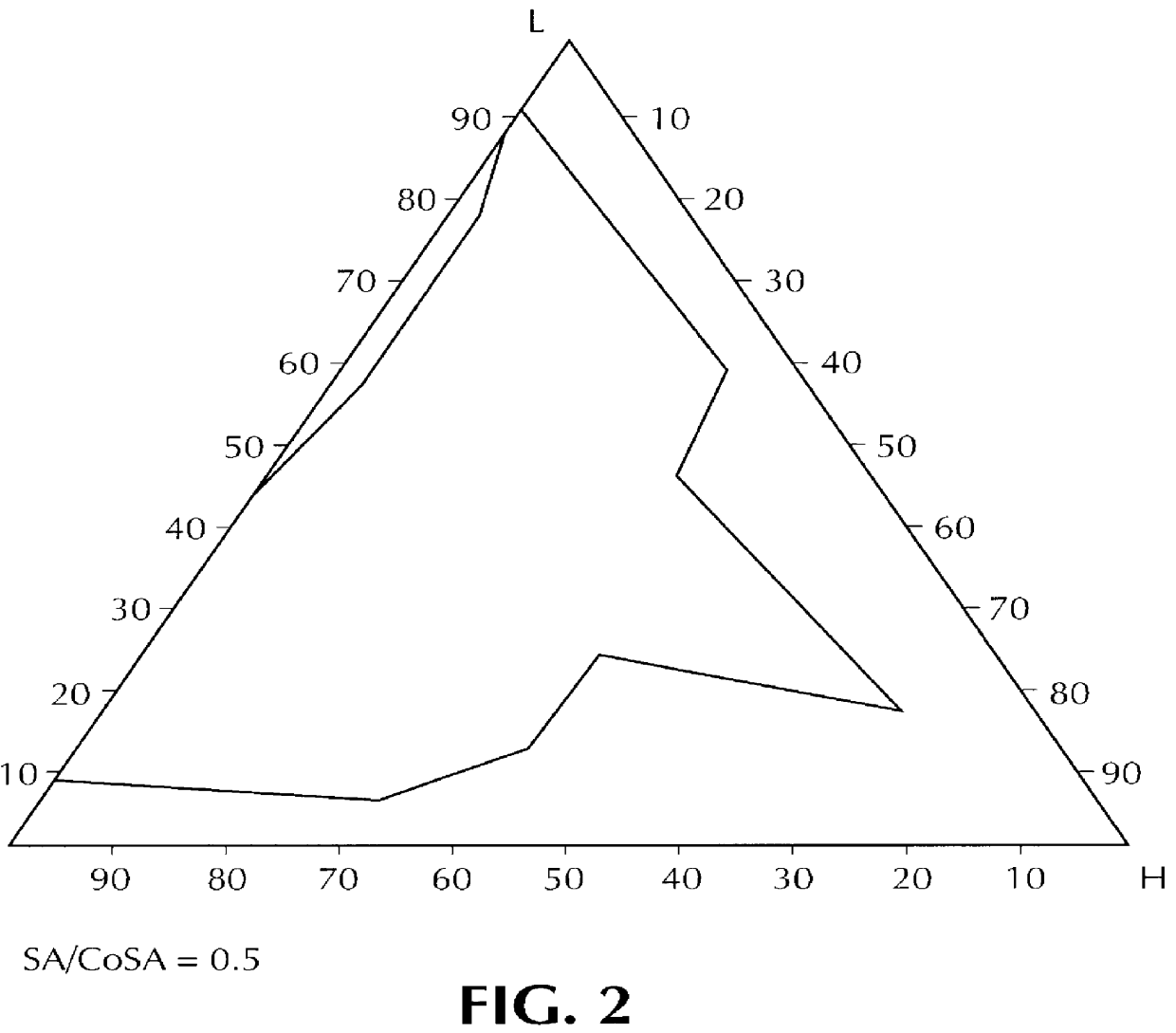

Composition for pharmaceutical or cosmetic use, capable of forming a microemulsion, comprising at least: an active principle, a lipophilic phase consisting of a mixture of fatty acid esters and glycerides, a surfactant (SA), a cosurfactant (CoSA), a hydrophilic phase, characterized: in that the lipophilic phase consists of a mixture of C8 to C18 polyglycolized glycerides having a hydrophilic-lipophilic balance (HLB) of less than 16, this lipophilic phase representing from 30 to 75% of the total weight of the composition; in that the surfactant (SA) is chosen from the group comprising saturated C8-C10 olyglycolized glycerides and oleic esters of polyglycerol, this surfactant having an HLB of less than 16; in that the cosurfactant (CoSA) is chosen from the group comprising lauric esters of propylene glycol, oleic esters of polyglycerol and ethyl diglycol; in that the SA / CoSA ratio is between 0.5 and 6; and in that the hydrophilic phase of the final microemulsion is supplied after ingestion by the physiological fluid of the digestive milieu.

Owner:GATTEFOSSE HLDG

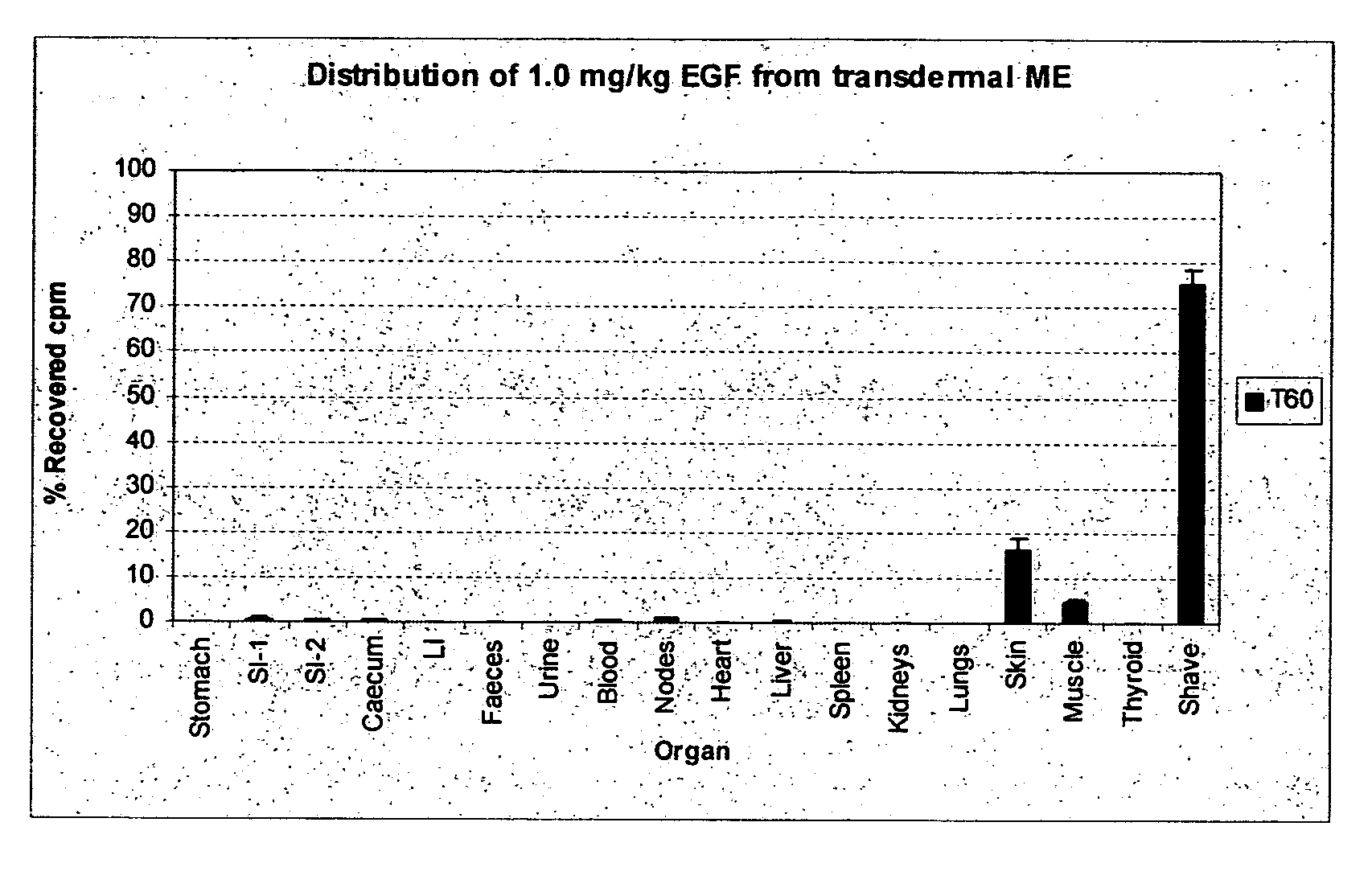

Transdermal delivery of pharmaceutical agents

InactiveUS20070243132A1Improve permeabilityEfficient use ofAntibacterial agentsOrganic active ingredientsActive agentGenetic molecular

The present invention generally relates to a vehicle useful for delivering a pharmaceutically active compound including a genetic molecule or composition. More particularly, the present invention provides microemulsions for transdermal delivery of pharmaceutically active agents to a subject.

Owner:APOLLO LIFE SCI

Microemulsion process and composition

ActiveUS20060057168A1Quality improvementCosmetic preparationsOrganic active ingredientsVegetable oilSilanes

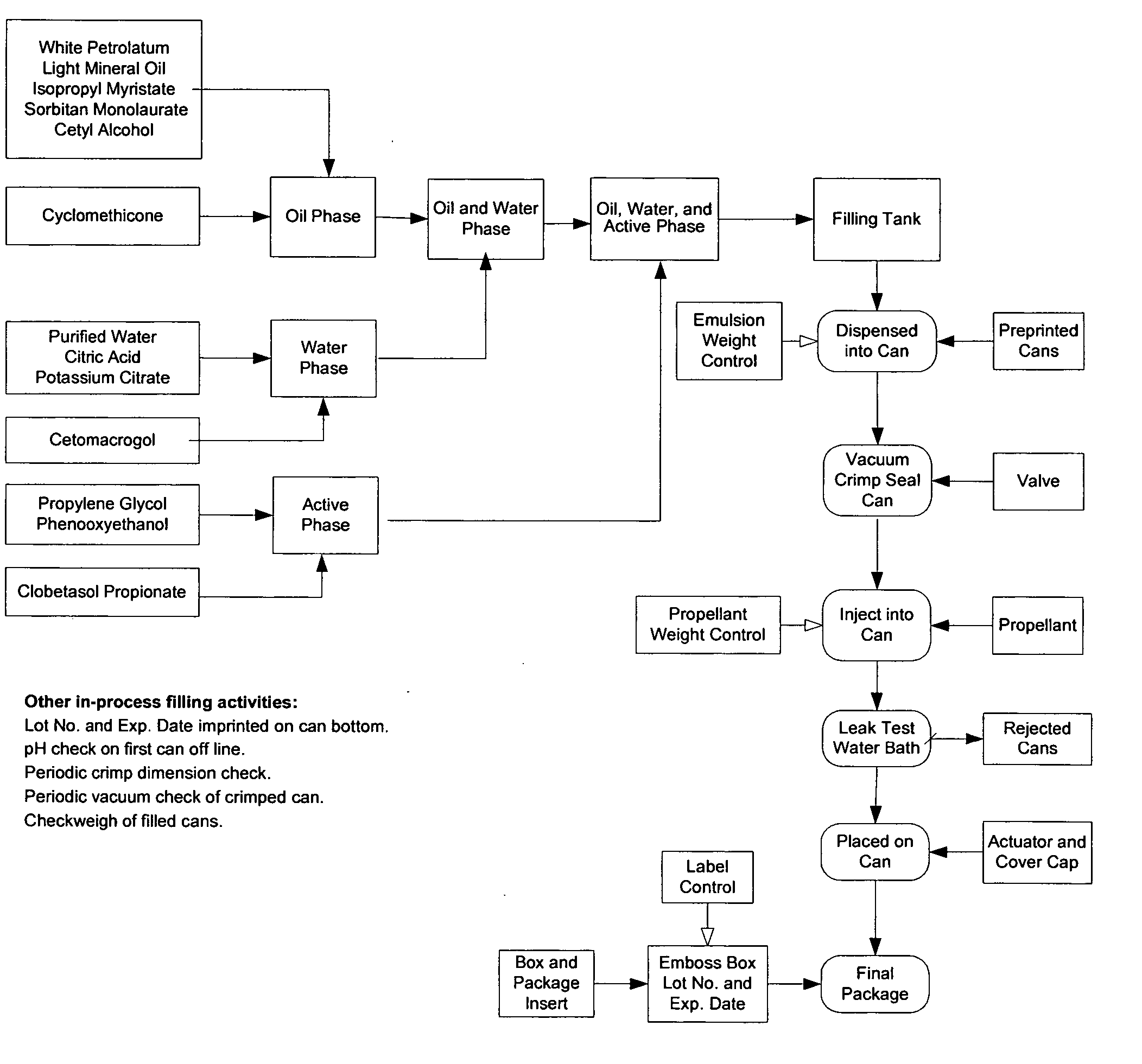

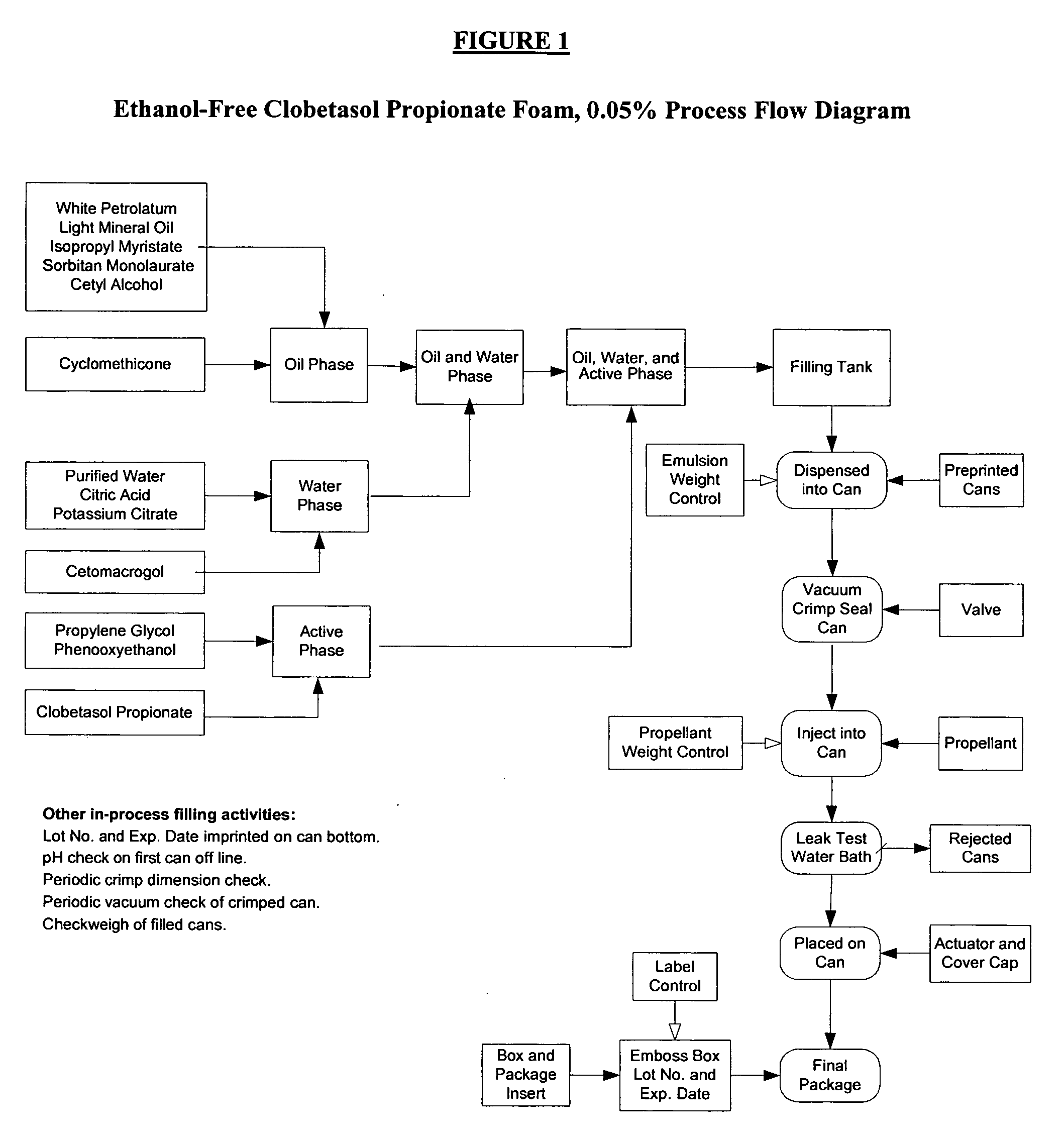

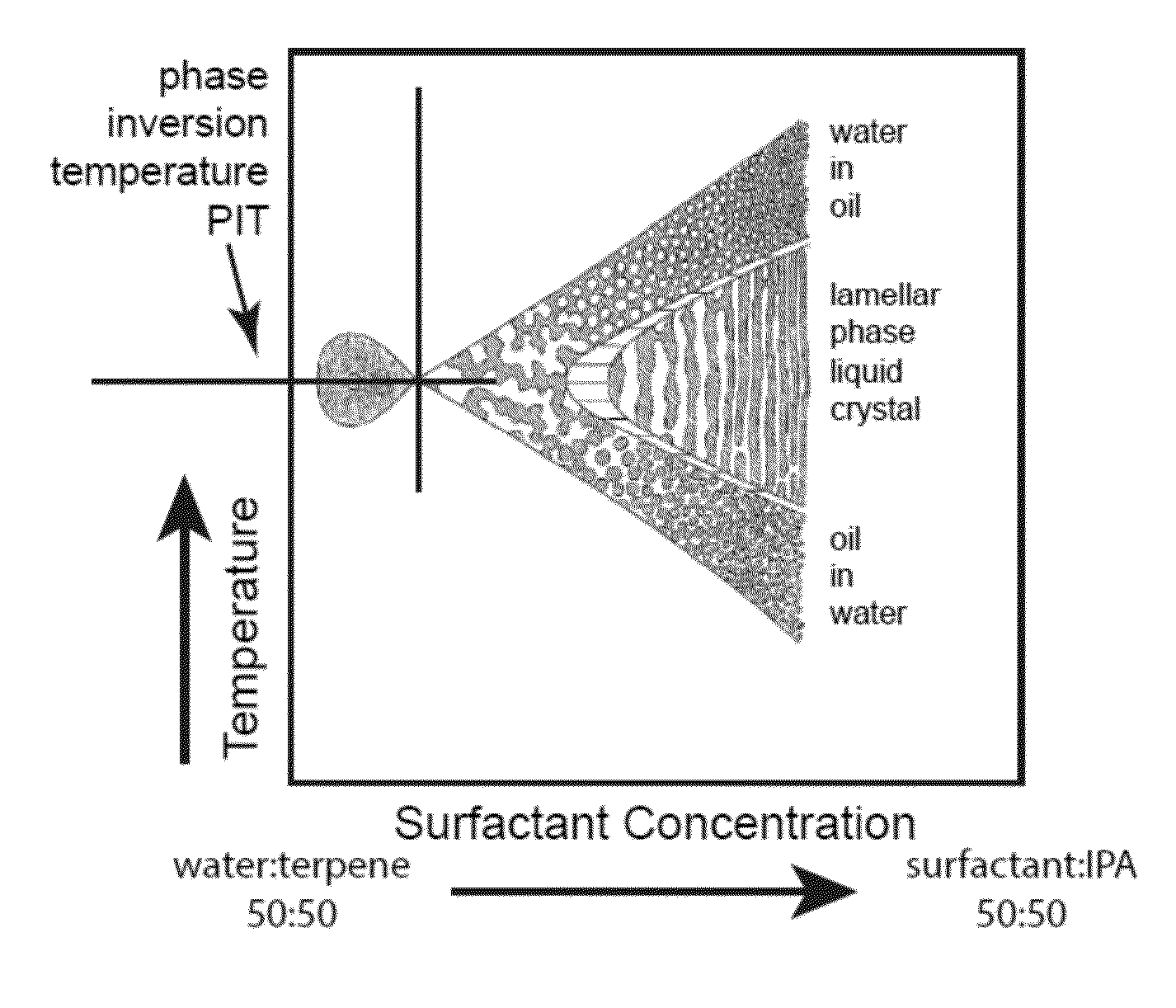

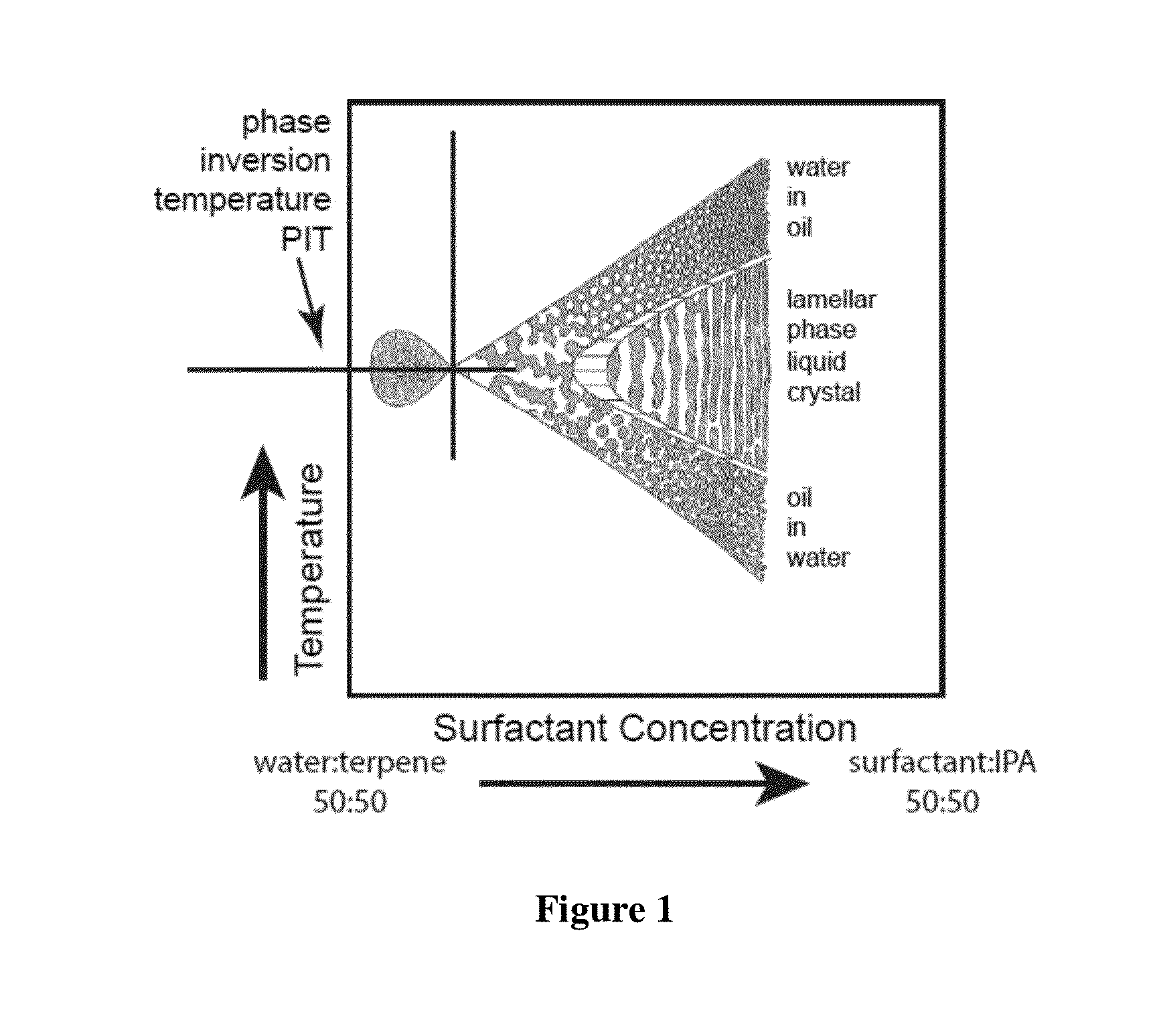

There is provided a process for the preparation of an oil in water (O / W) microemulsion or sub-micron emulsion composition for dermal delivery of at least one pharmaceutically active ingredient, the method including the steps of a) Admixing a first part including at least one of the group consisting of animal, mineral or vegetable oils, silanes, siloxanes, esters, fatty acids, fats, halogen compounds or alkoxylated alcohols; and one or more lipophilic surfactants, and a second part including water and at least one hydrophilic surfactant to achieve homogeneity, b) heating the mix of step a) to a phase assembly temperature in the range of 40-99° C., preferably 45-95° C., more preferably 65-85° C. with continuous mixing to obtain a microemulsion or sub-micron emulsion, c) allowing said microemulsion or sub-micron emulsion to cool, and d) adding a third part to said microemulsion or sub-micron emulsion at a temperature between 2° C. and said phase assembly temperature, said third part if necessary being premixed and heated until the components are dissolved and including at least one component selected from the group consisting of non-surfactant amphiphilic type compound, surfactant and water with the proviso that when the third part includes water it also includes a non-surfactant amphiphilic type compound and / or surfactant. The phase assembly temperature can be determined visually by the achievement of translucence in the composition or by measures such as conductivity which peaks and then is maintained at a plateau whilst phase assembly occurs. It has been found that whilst if a non-surfactant amphiphilic type compound such as the polyol is added together with the second part as would conventionally be the case, a microemulsion or sub-micron emulsion is not formed, by adding the so called third part, phase assembly occurs at a lower temperature than would be expected and moreover, this phase appears to assist in maintaining the microemulsion or sub-micron emulsion characteristics of the formulation during storage at normal temperatures.

Owner:STIEFEL WEST COAST

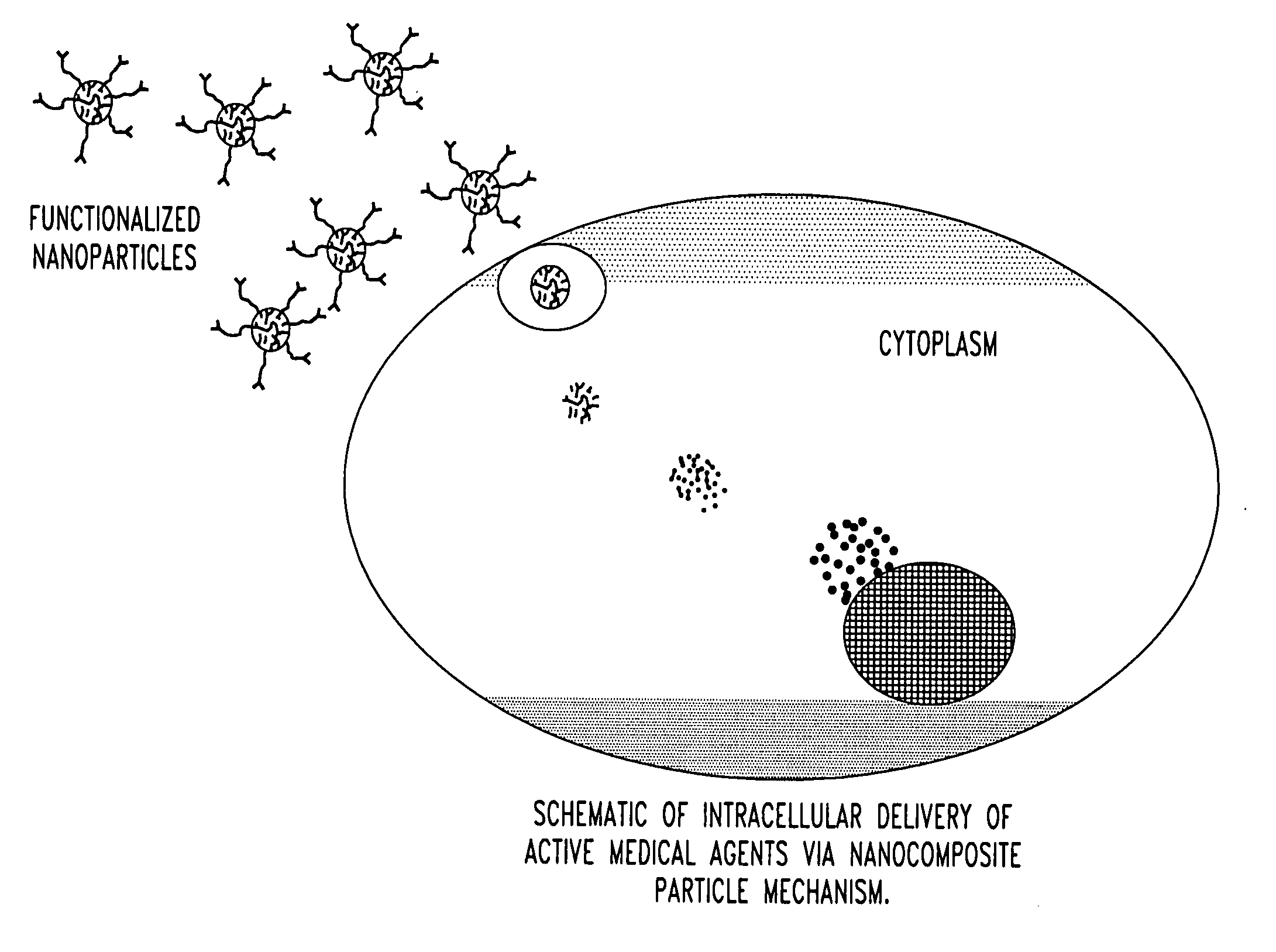

Nanoparticles for drug-delivery

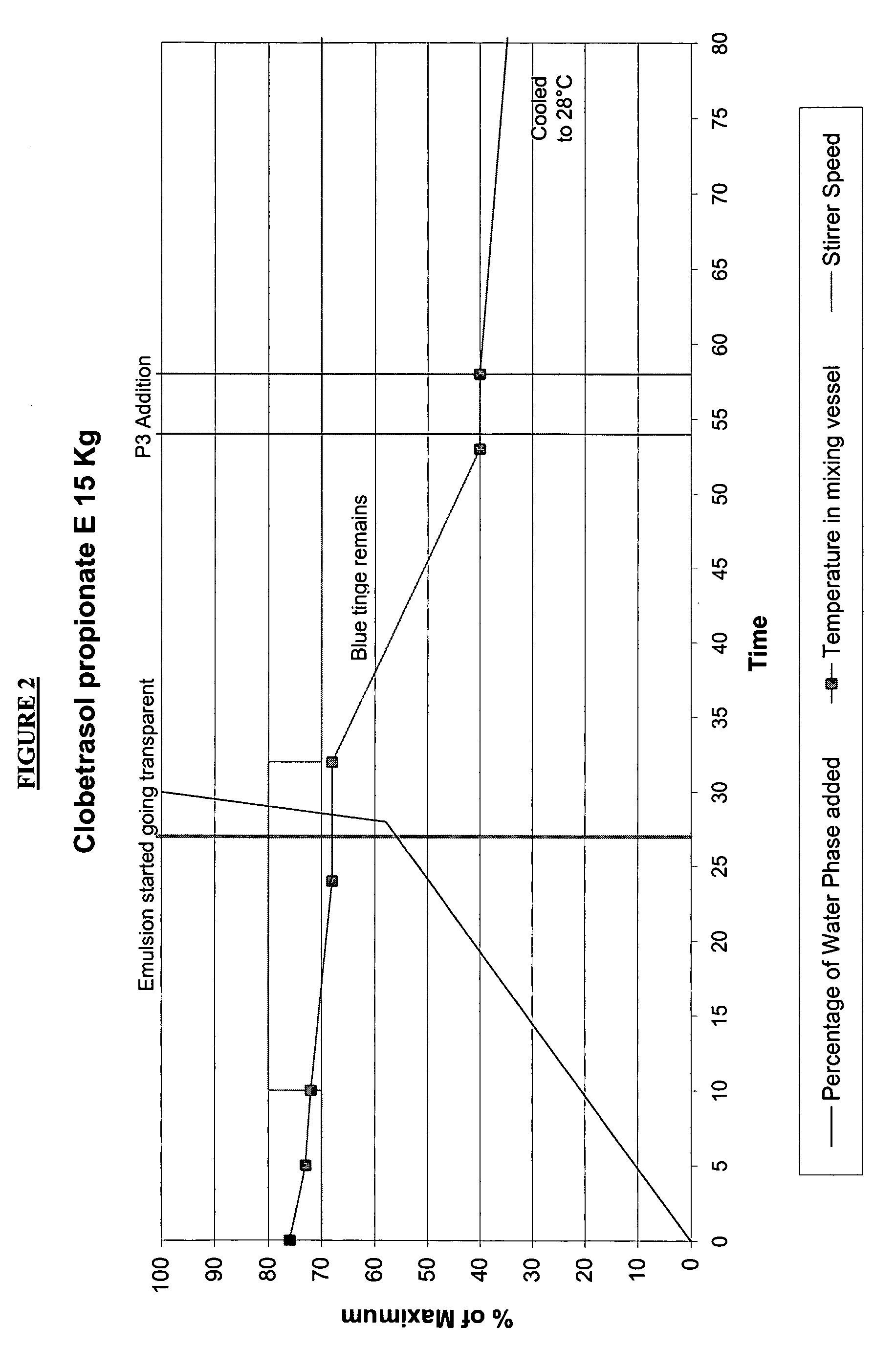

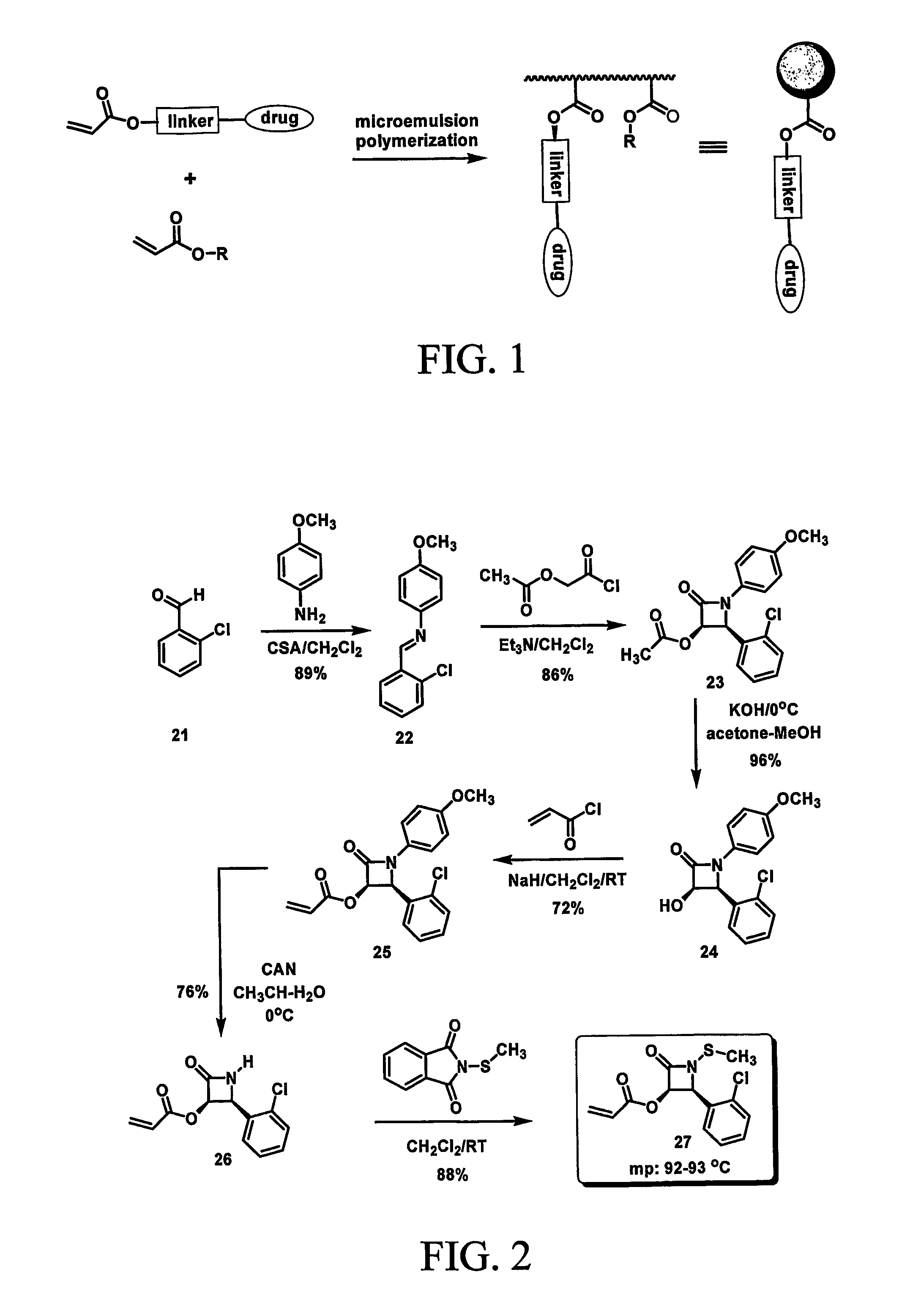

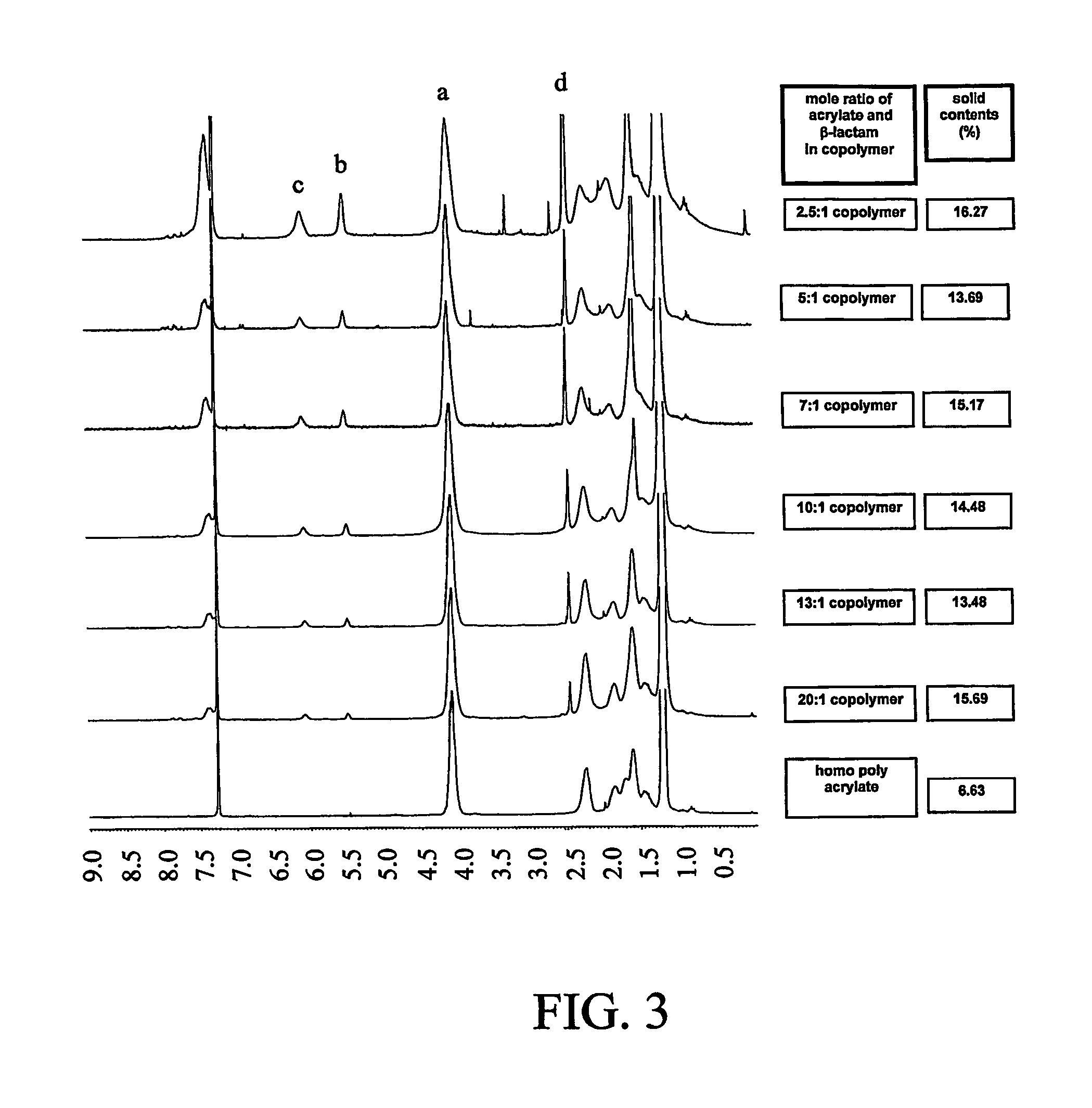

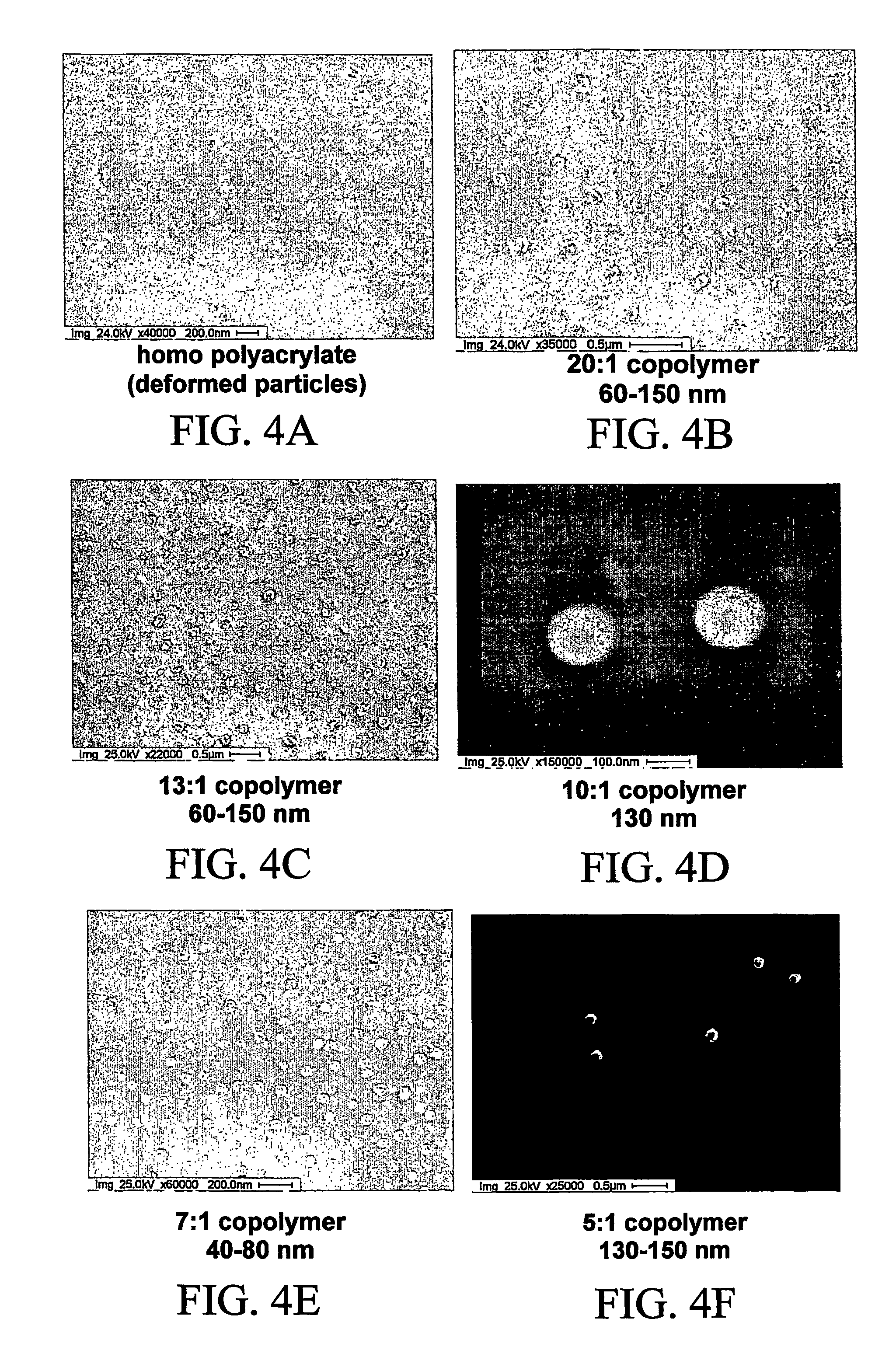

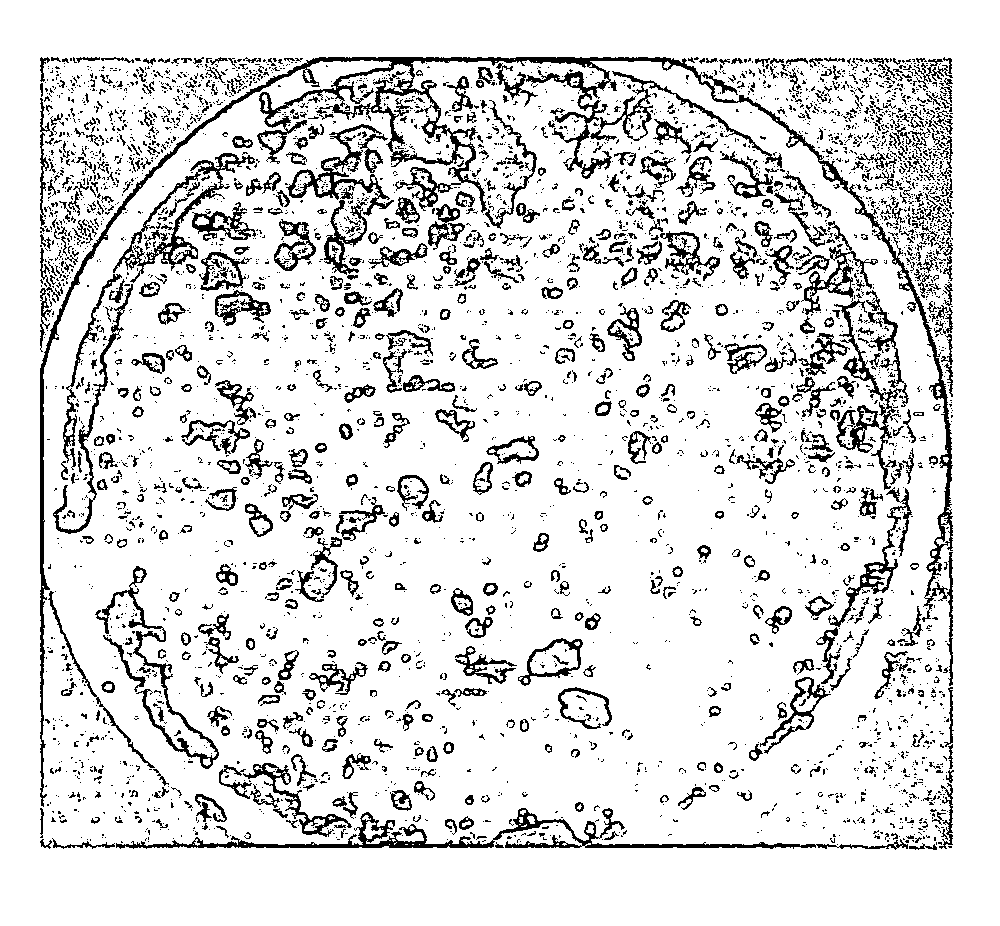

This invention relates to polymeric nanoparticles useful for drug delivery with target molecules bonded to the surface of the particles and having sizes of up to 1000 nm, preferably 1 nm to 400 nm, more preferably 1 nm to 200 nm, that are dispersed homogeneously in aqueous solution. The target drug / target substance is covalently bonded to the novel polymeric nanoparticles to secure them from outer intervention in vivo or cell culture in vitro until they are exposed at the target site within the cell. This invention also relates to microemulsion polymerization techniques useful for preparing the novel nanoparticles.

Owner:UNIV OF SOUTH FLORIDA

Method of removing an invert emulsion filter cake after the drilling process using a single phase microemulsion

Owner:BAKER HUGHES HLDG LLC

Composition and method for fluid recovery from well

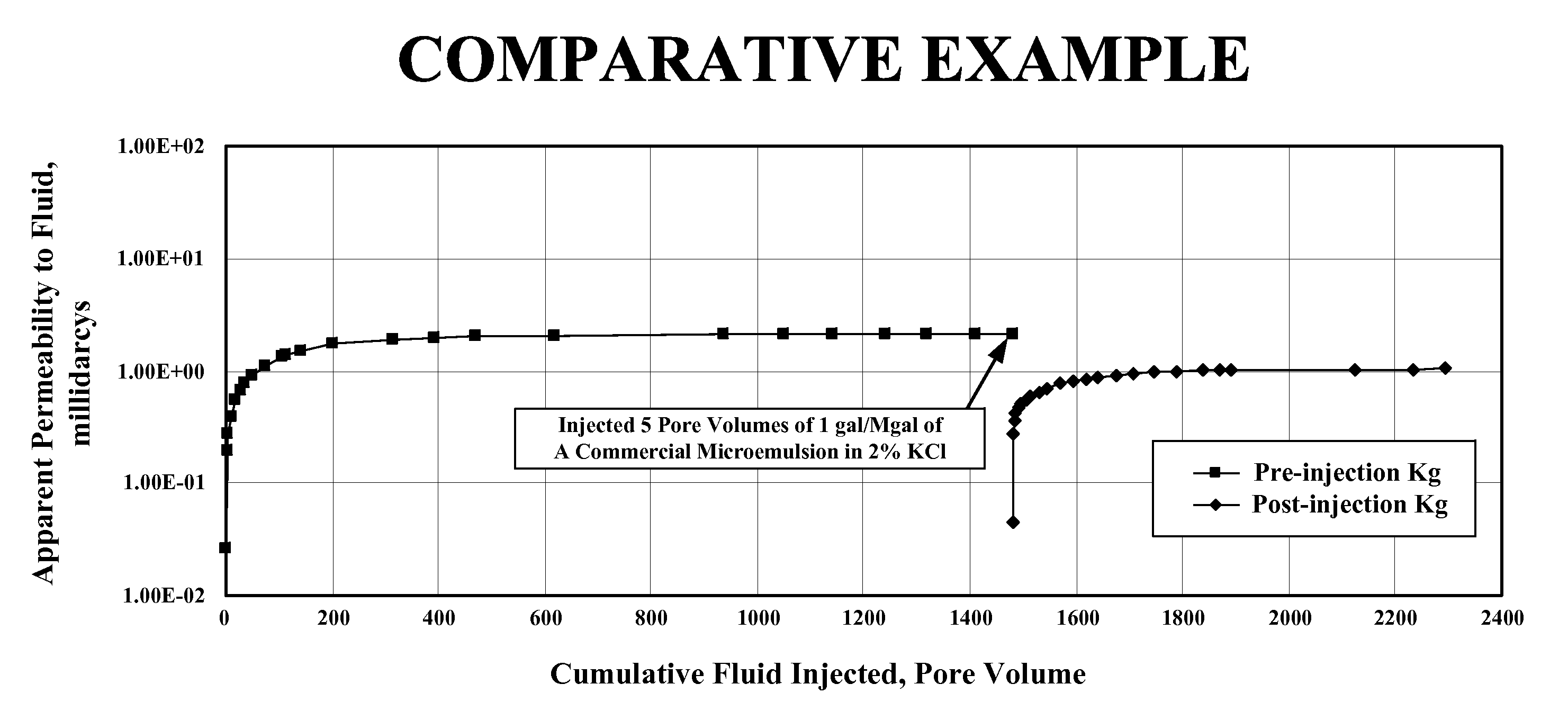

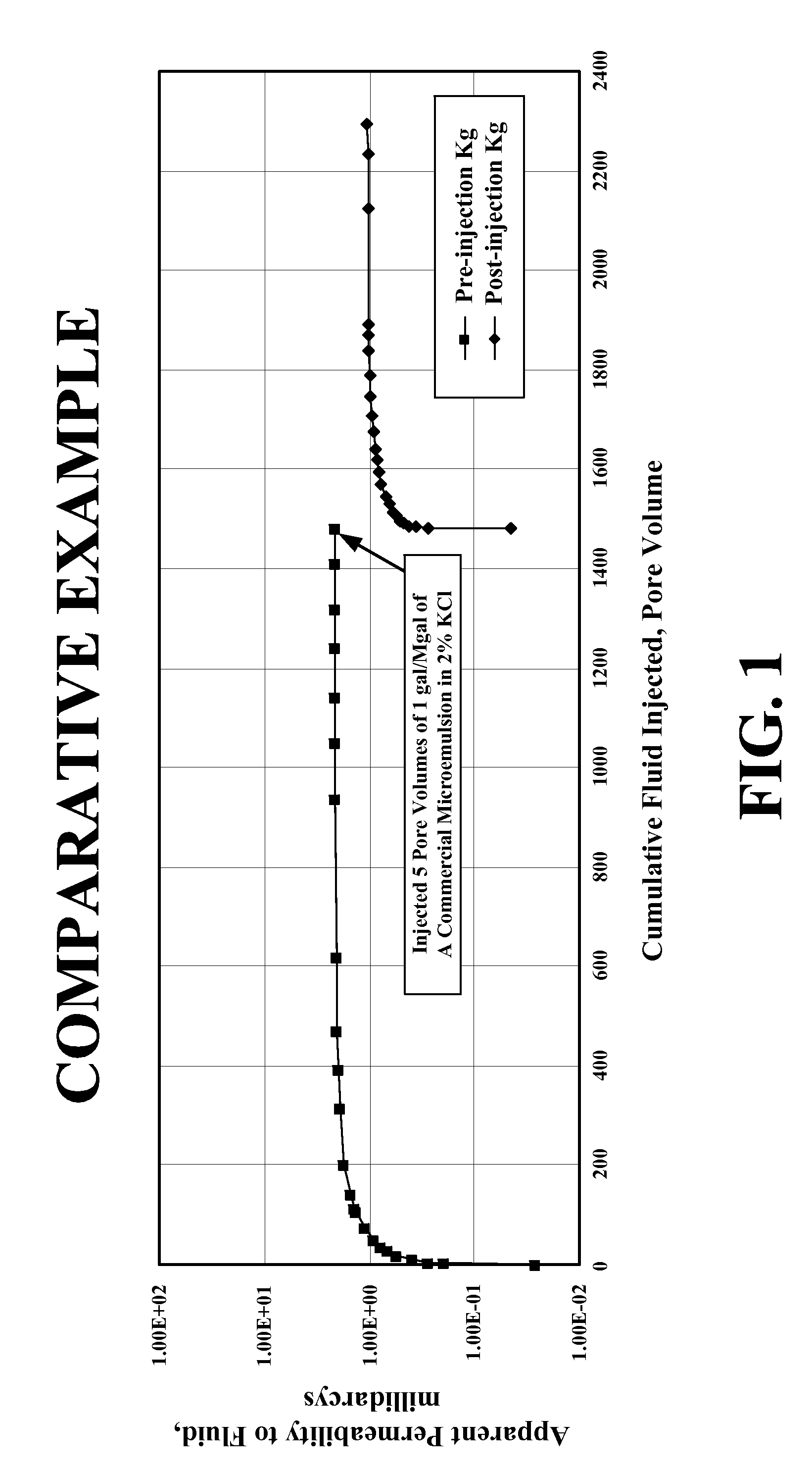

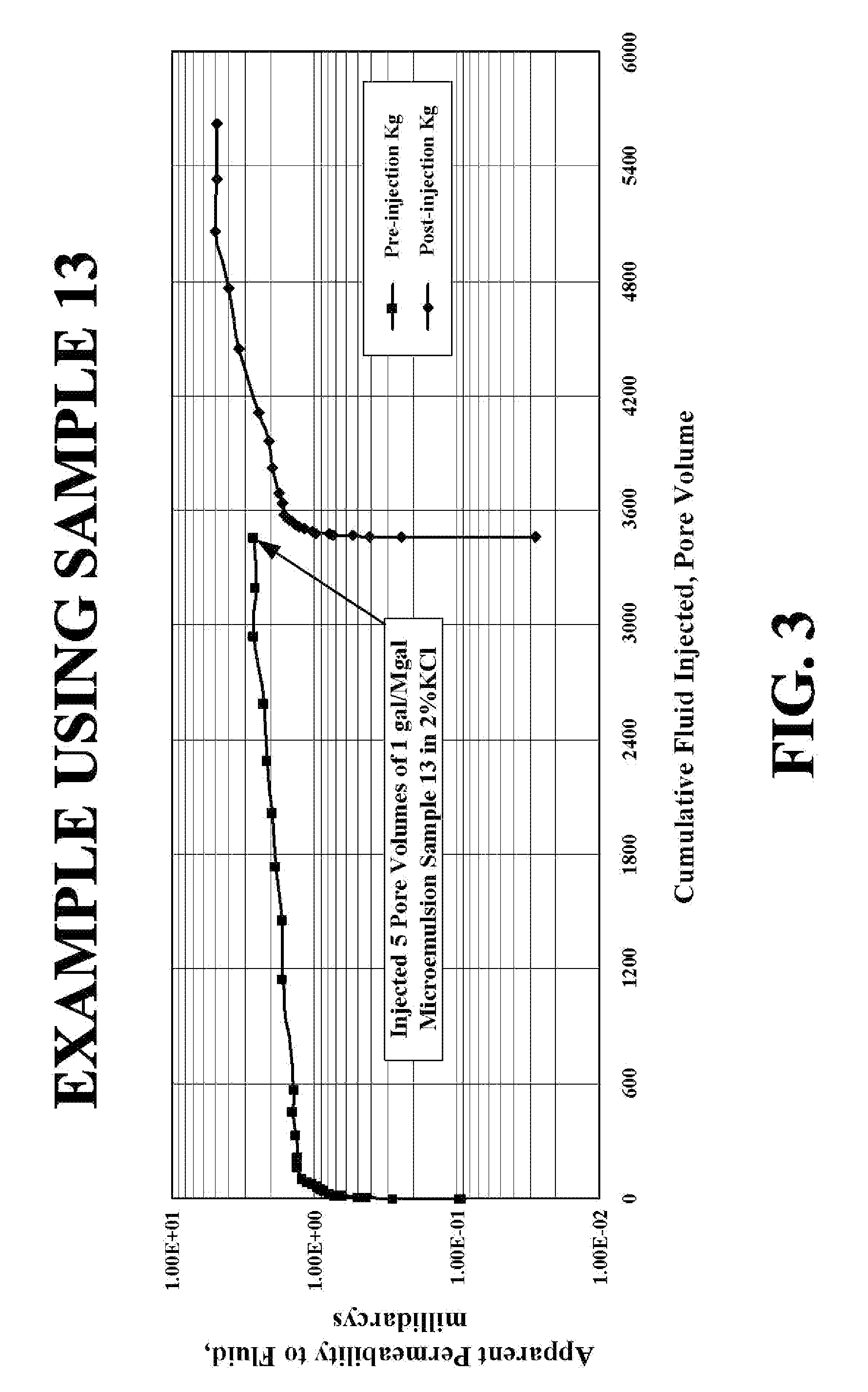

InactiveUS7893010B2Effective in permeabilityEffective recoveryOther chemical processesMixing methodsAlcoholCarrier fluid

Owner:SCHLUMBERGER TECH CORP

Method for making polysiloxane emulsions

A method for making oil free polysiloxane standard, fine and microemulsions using emulsion polymerization is disclosed. The method comprises reacting a cyclicsiloxane in the presence of a catalyst, ionic surfactant and nonionic surfactant within a certain operating window. Emulsions containing silicone copolymers can also be produced using the method of the instant invention.

Owner:DOW SILICONES CORP

Method of treating an oil or gas well with biodegradable low toxicity fluid system

InactiveUS7231976B2Well remediationIncrease stimulationCleaning apparatusFluid removalMETHYL SOYATEFluid system

A method of treating a well consists of introducing into the wellbore a biodegradable fluid system containing a blend of lactic acid ester, such as ethyl lactate, and a fatty acid ester, such as methyl soyate. The fluid system may be further in the form of a microemulsion that is formed by combining a blend with one or more emulsifiers, an alcohol, and water. The fluid system may be used in displacement, well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:BAKER HUGHES HLDG LLC

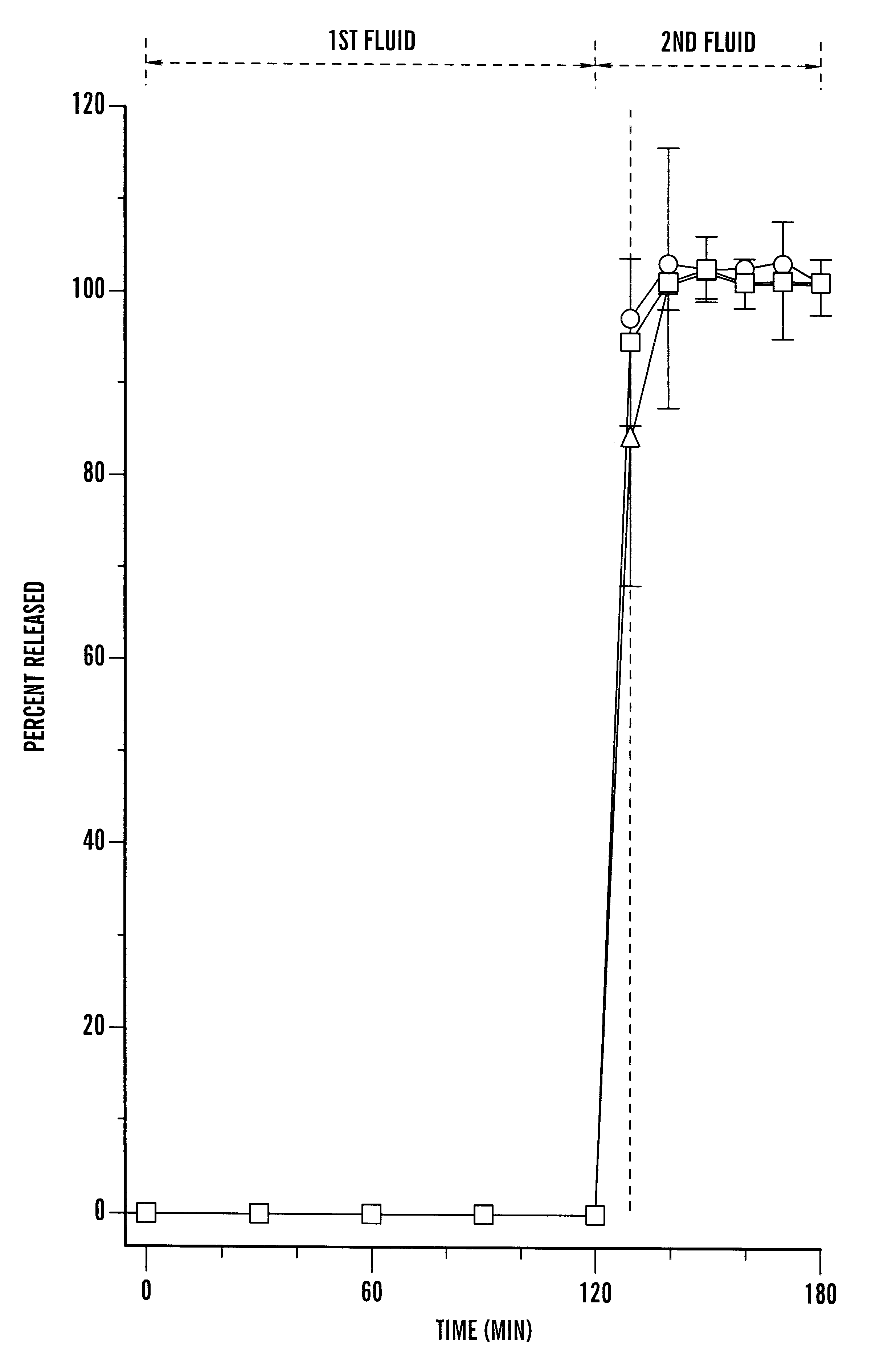

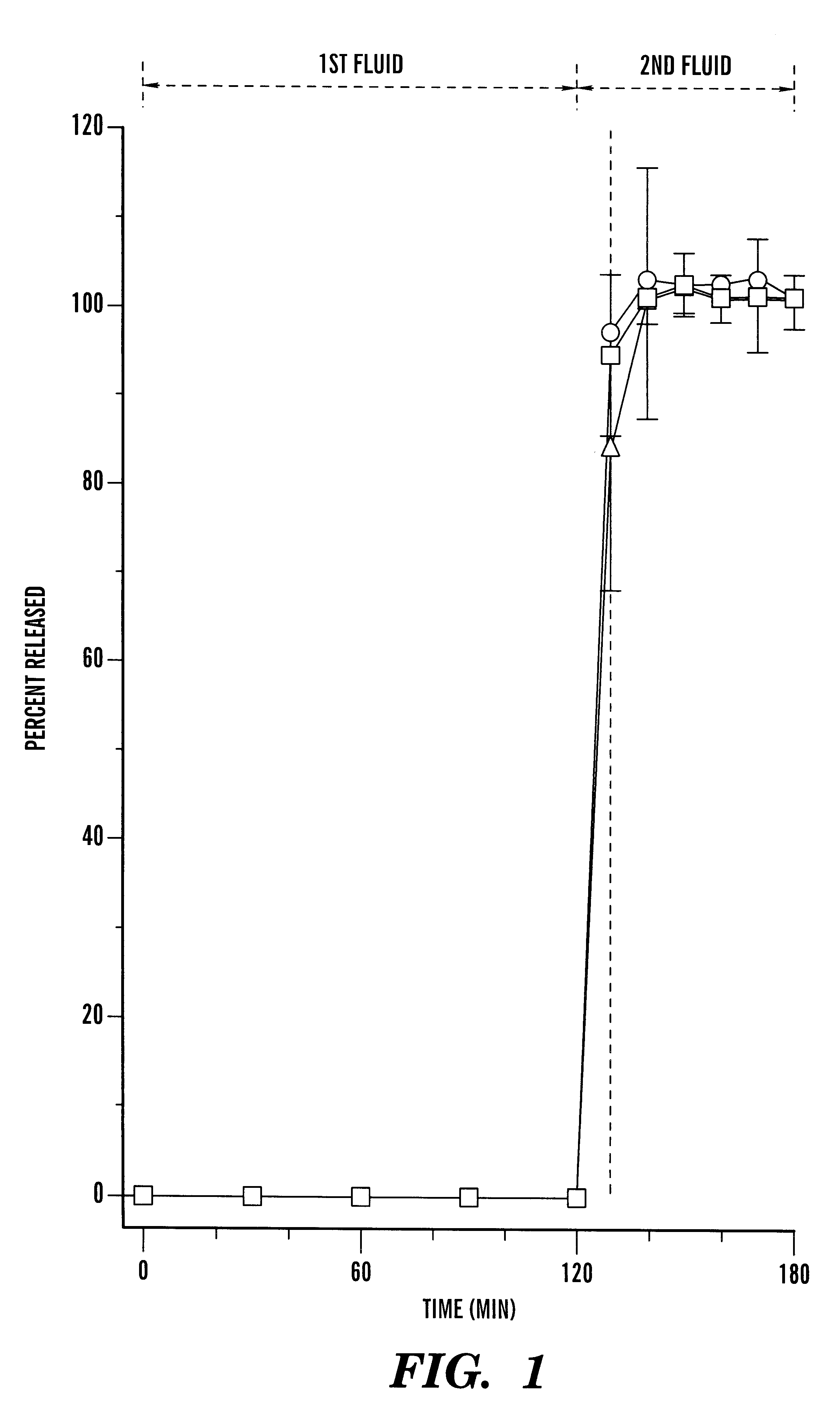

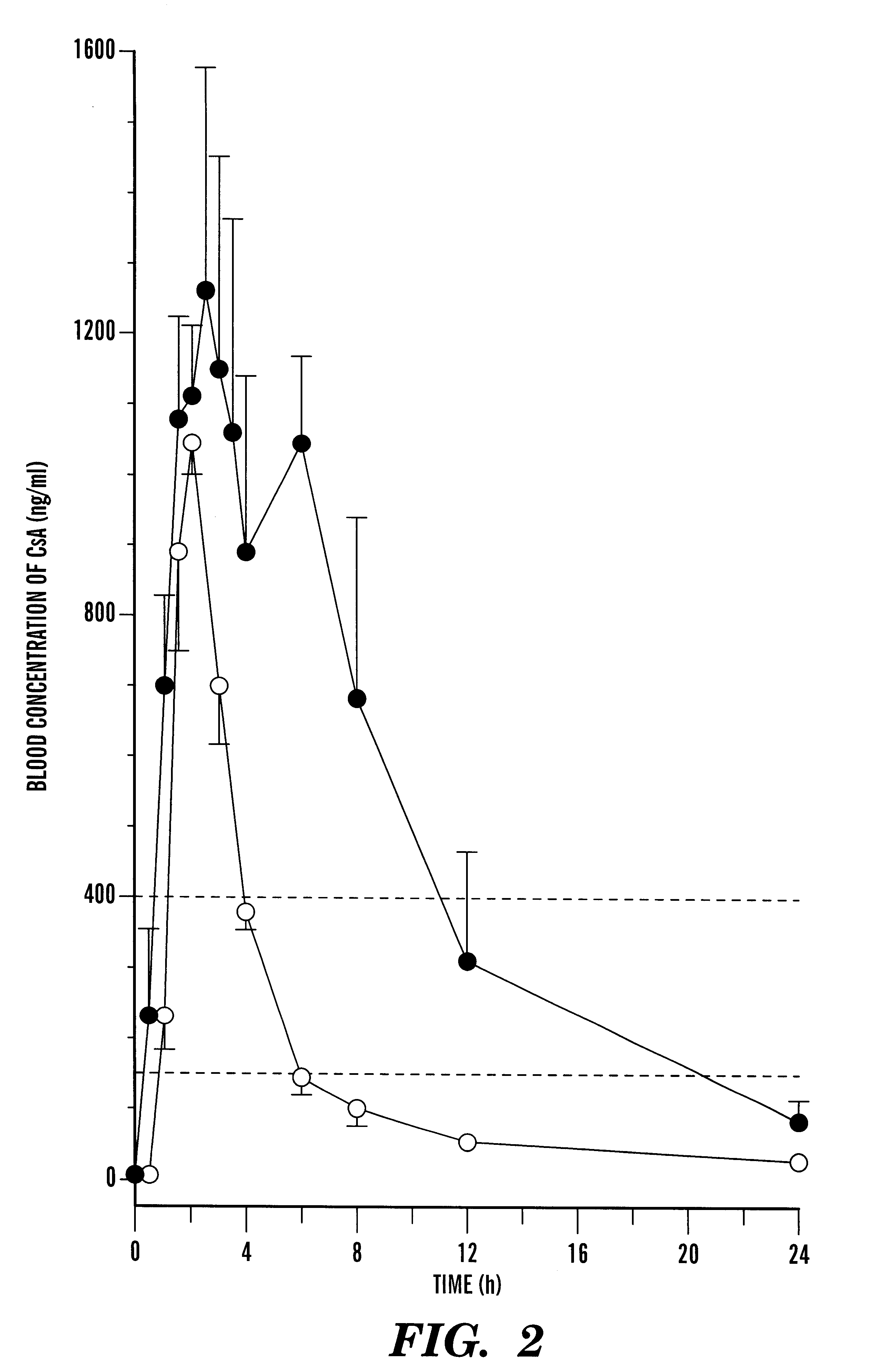

Pharmaceutical composition comprising cyclosporin solid-state microemulsion

InactiveUS6306434B1Easy to controlMaintaining blood concentrationPowder deliveryCyclic peptide ingredientsIntestinal fluidBlood concentration

A pharmaceutical composition comprising a cyclosporin solid-state microemulsion is disclosed. In a preferred embodiment, the composition comprises a cyclosporin microemulsion dispersed in an enteric carrier. The composition does not dissolve in external phases such as artificial gastric fluid, but dissolves rapidly in artificial intestinal fluid, whereby it releases the cyclosporin microemulsion, providing rapid delivery of cyclosporin. The composition effectively maintains a therapeutic blood concentration of cyclosporin with once a day dosing, providing for convenience of administration and avoiding adverse effects induced by increasing peak blood cyclosporin concentrations associated with conventional cyclosporin formulations.

Owner:CHONG KUN DANG PHARMA CORP

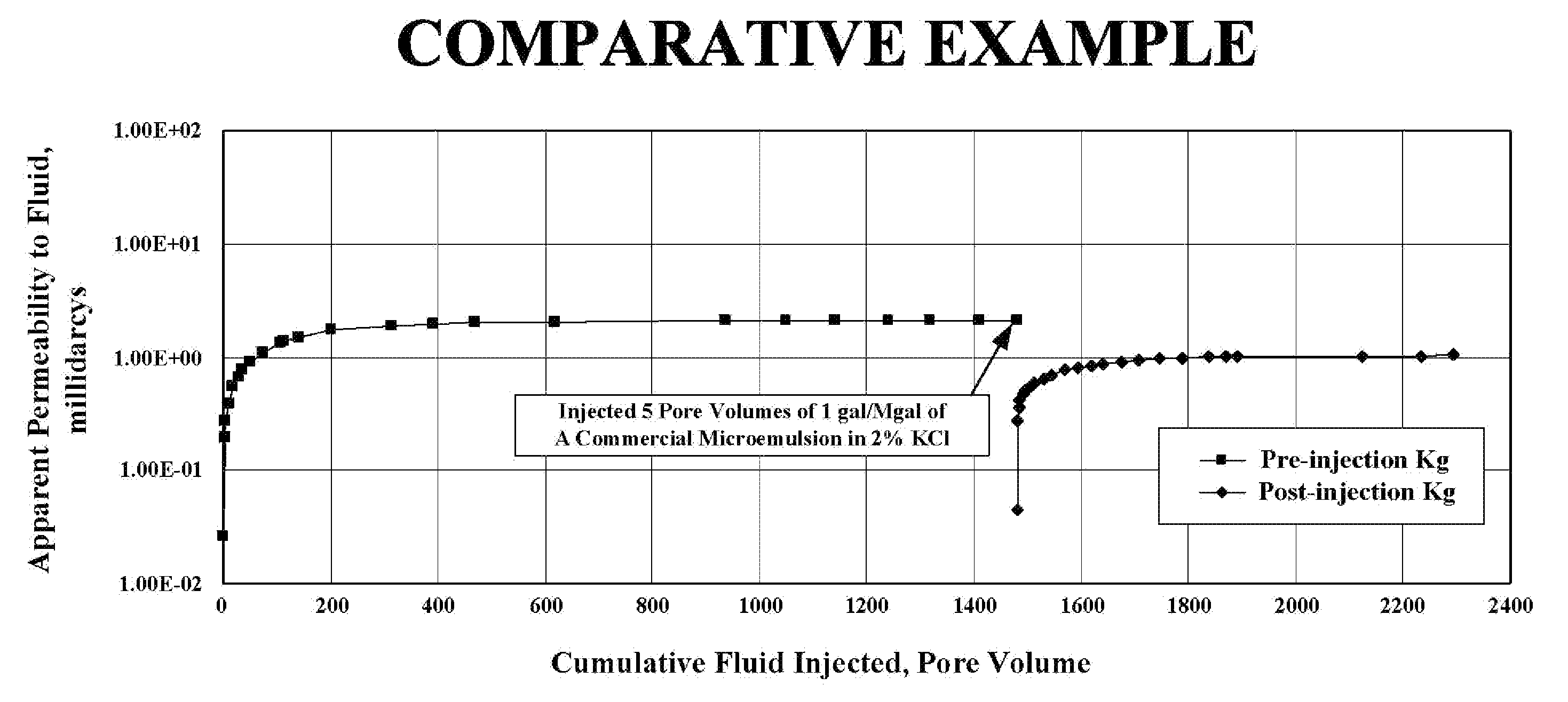

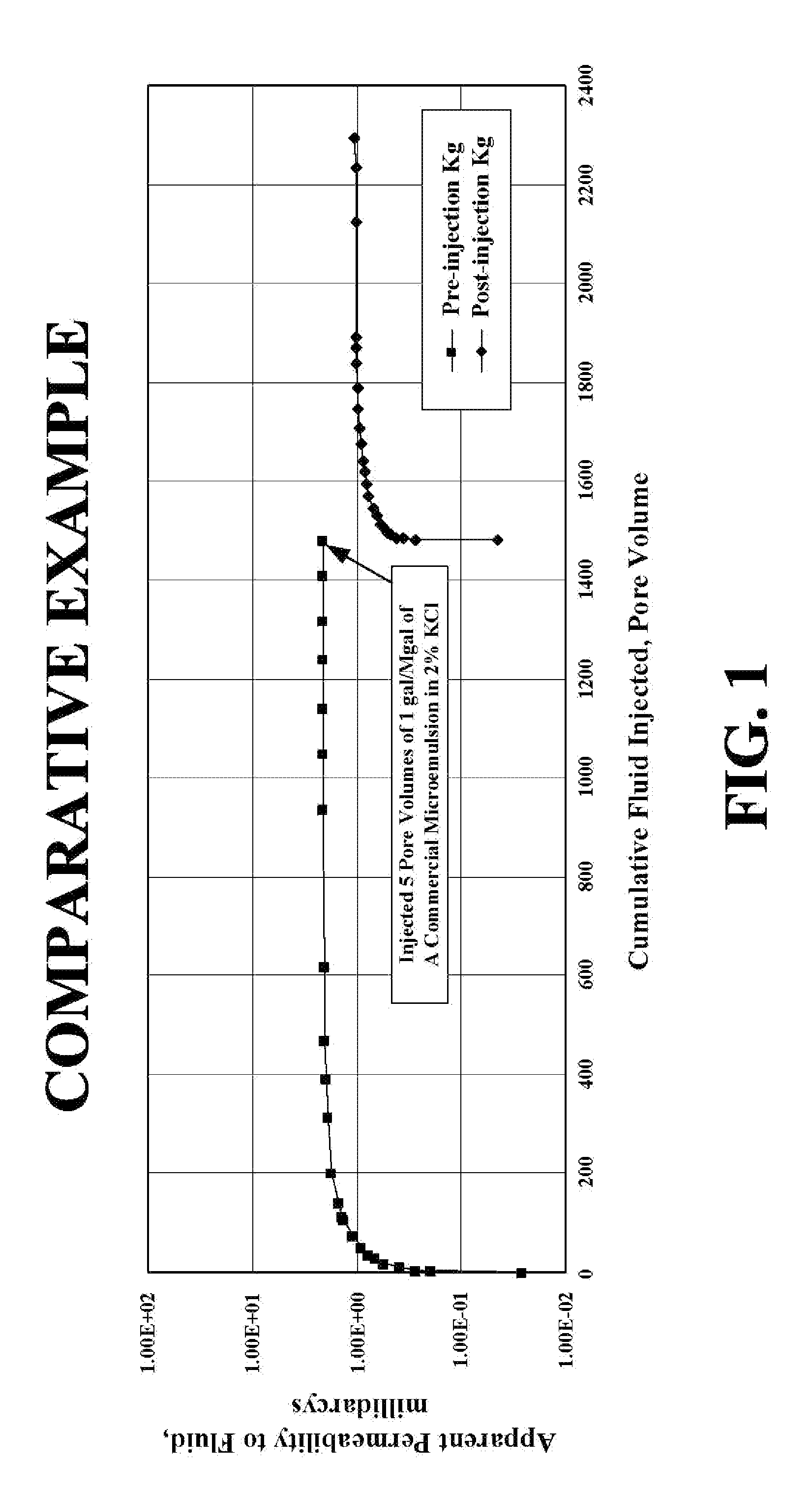

Composition and Method for Fluid Recovery from Well

InactiveUS20090281004A1Improve propertiesEffective in permeabilityOther chemical processesMixing methodsAlcoholCarrier fluid

A well treatment microemulsion for use in a subterranean formation is disclosed, the microemulsion comprises a solvent blend comprising a solvent and a co-solvent; a surfactant blend comprising a surfactant, wherein the surfactant blend is able to give formation intermediate wettability properties; an alcohol; and a carrier fluid; wherein the alcohol, the solvent and surfactant blends are combined with the carrier fluid to produce the well treatment microemulsion. By intermediate wettability it is meant that the water has an advancing contact angle on the surface between 62 and 133 degrees. The associate method of treating a subterranean formation of a well with the microemulsion and the associate method of modifying the wettability of the formation with the microemulsion are also disclosed.

Owner:SCHLUMBERGER TECH CORP

Compositions and methods for gas well treatment

ActiveUS20090200033A1Increase productionFully removedSurveyOther chemical processesSulfateWater block

A microemulsion system is disclosed which comprises a solvent subsystem, a co-solvent subsystem and a surfactant subsystem comprises at least one monoalkyl branched propoxy sulfate anionic surfactant, where the microemulsion system are useful in drilling, producing, remediation, and fracturing application to reduce water blocks and water blocking in formation of a producing formation.

Owner:THE LUBRIZOL CORP

Stable compositions of nano-particulate unmodified pigments and insoluble colorants in aqueous microemulsions, and principle of stability and methods of formation thereof

If the particle size of pigments in ink-jet inks is reduced below 500 nm, then the ink compositions achieved extraordinary stability; that is, there is no visible sediment formed after three weeks at ambient temperature and there is no sediment formed after heating to 70 DEG C. for 10 min followed by cooling to 0 DEG C. for 10 min. No dispersant is necessary, and the pigment particles having such a defined size may be incorporated into microemulsions, using a suitable oil (water-immiscible organic compound), at least one amphiphile, and water.

Owner:HEWLETT PACKARD CO

Shampoo compositions comprising and emulsified silicone an a microemulsified silicone

An aqueous shampoo composition comprising, in addition to water:i) at least one cleansing surfactant;ii) a cationic deposition polymer, andiii) a silicone component consisting of a blend of:(a) emulsified particles of an insoluble silicone, in which the emulsified particles of insoluble silicone are incorporated into the shampoo composition as a preformed aqueous emulsion having an average silicone particle size in the emulsion and in the shampoo composition of from 0.15 to 30 microns, and(b) microemulsified particles of an insoluble silicone, in which the microemulsified particles of insoluble silicone are incorporated into the shampoo composition as a preformed aqueous microemulsion having an average-silicone particle size in the microemulsion and in the shampoo composition of less than 0.10 microns.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

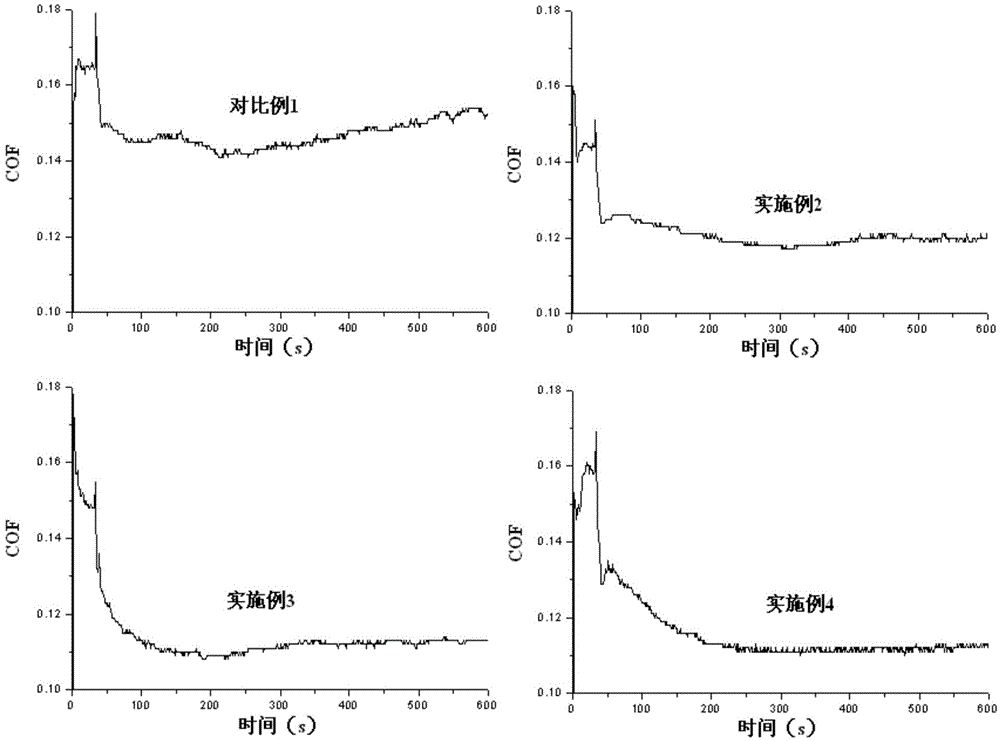

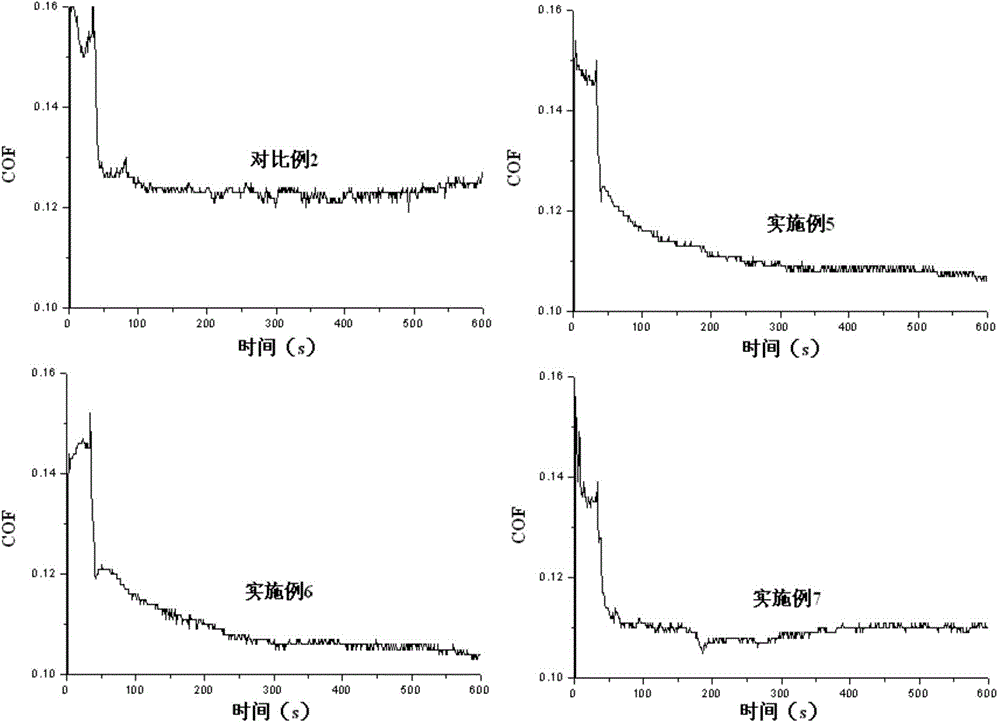

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

Compositions and methods for gas well treatment

ActiveUS7886824B2Increase productionImprove productivityTransportation and packagingCleaning apparatusSulfateWater block

Owner:THE LUBRIZOL CORP

Method of treating an oil or gas well with biodegradable low toxicity fluid system

InactiveUS20060096757A1Increase stimulationWell remediationCleaning apparatusFluid removalMETHYL SOYATEAlcohol

A method of treating a well consists of introducing into the wellbore a biodegradable fluid system containing a blend of lactic acid ester, such as ethyl lactate, and a fatty acid ester, such as methyl soyate. The fluid system may be further in the form of a microemulsion that is formed by combining a blend with one or more emulsifiers, an alcohol, and water. The fluid system may be used in displacement, well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:BAKER HUGHES INC

Unagglomerated core/shell nanocomposite particles

ActiveUS20050281884A1Improve stabilityPromote absorptionPowder deliveryMaterial nanotechnologyAlcoholMicroemulsion

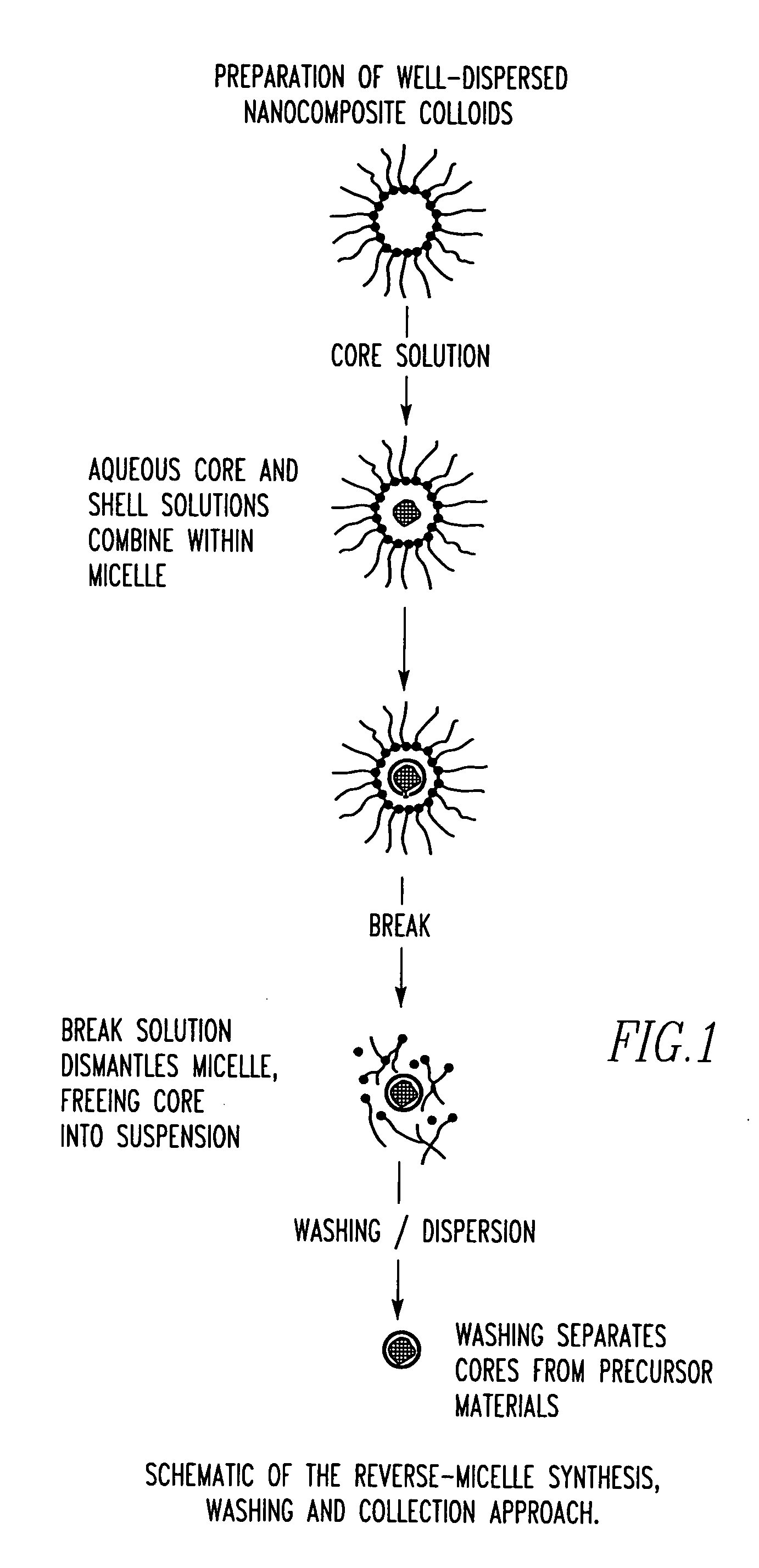

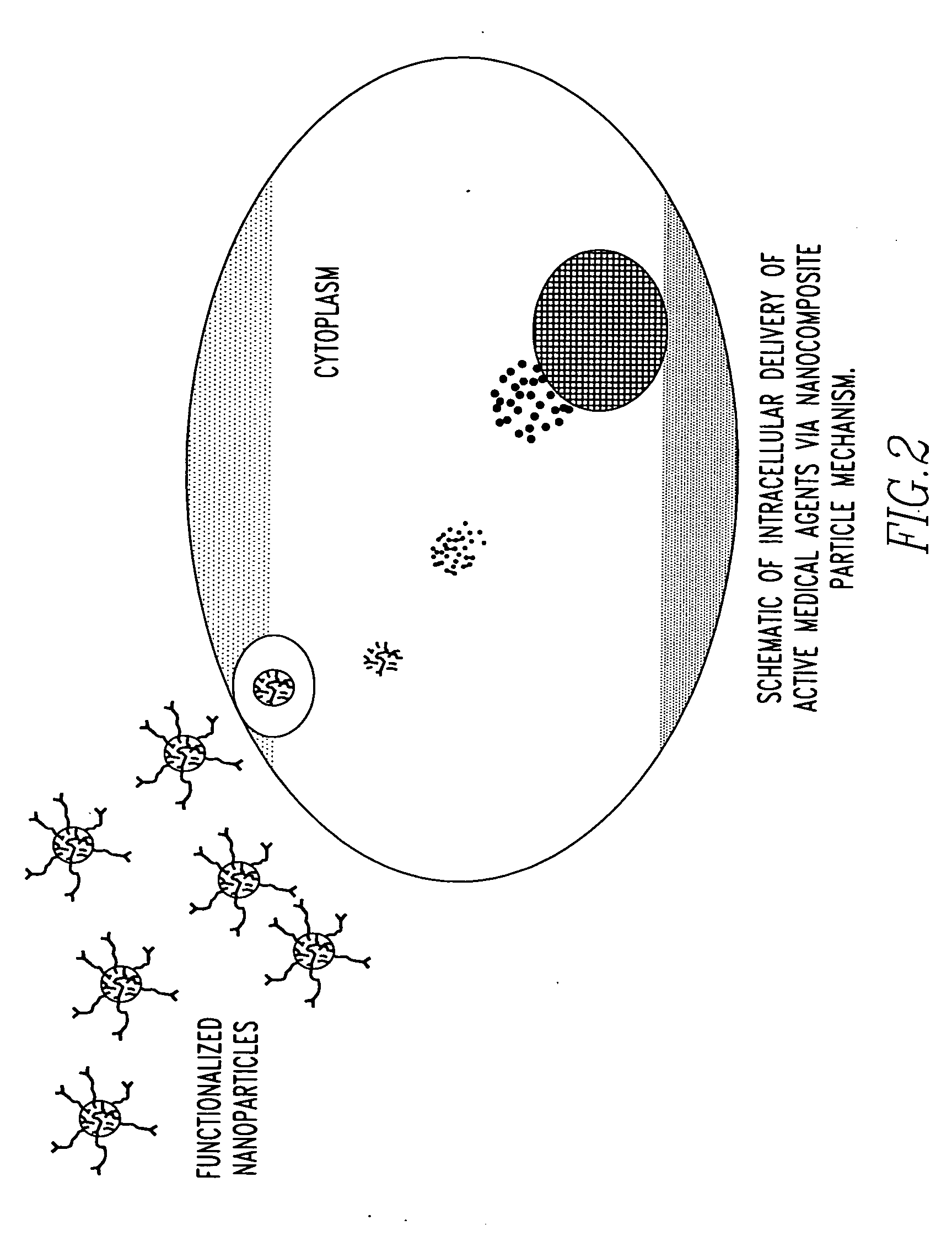

The present invention provides a method for the synthesis of unagglomerated, highly dispersed, stable core / shell nanocomposite particles comprised of preparing a reverse micelle microemulsion that contains nanocomposite particles, treating the microemulsion with a silane coupling agent, breaking the microemulsion to form a suspension of the nanocomposite particles by adding an acid / alcohol solution to the microemulsion that maintains the suspension of nanocomposite particles at a pH of between about 6 and 7, and simultaneously washing and dispersing the suspension of nanocomposite particles, preferably with a size exclusion HPLC system modified to ensure unagglomeration of the nanocomposite particles. The primary particle size of the nanocomposite particles can range in diameter from between about 1 to 100 nm, preferably from between about 10 to 50 nm, more preferably about 10 to 20 nm, and most preferably about 20 nm.

Owner:PENN STATE RES FOUND

Compositions and methods for gas well treatment

ActiveUS20090200027A1Increase productionFully removedTransportation and packagingCleaning apparatusSulfateWater block

A microemulsion system is disclosed which comprises a solvent subsystem, a co-solvent subsystem and a surfactant subsystem comprises at least one monoalkyl branched propoxy sulfate anionic surfactant, where the microemulsion system are useful in drilling, producing, remediation, and fracturing application to reduce water blocks and water blocking in formation of a producing formation.

Owner:THE LUBRIZOL CORP

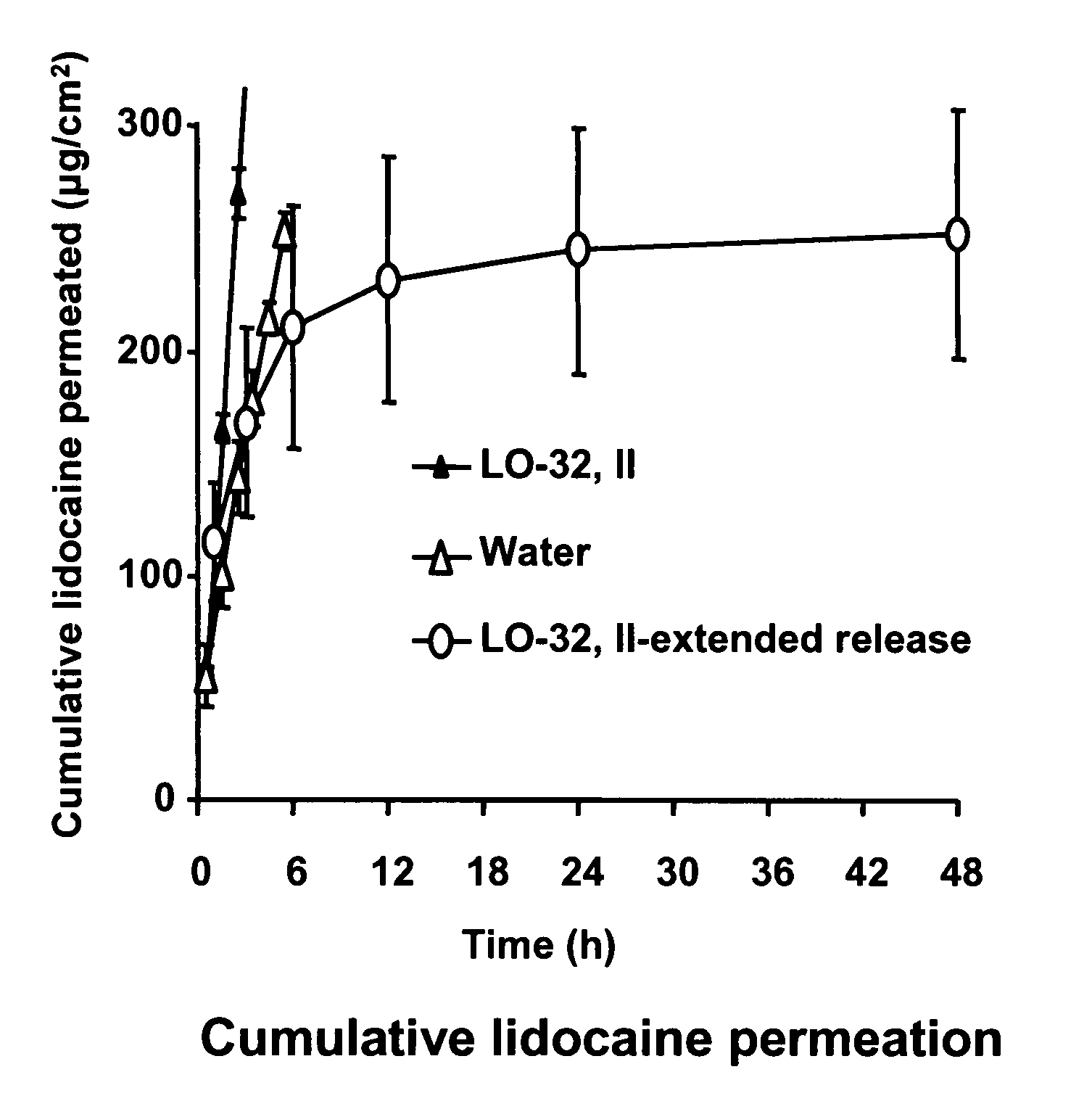

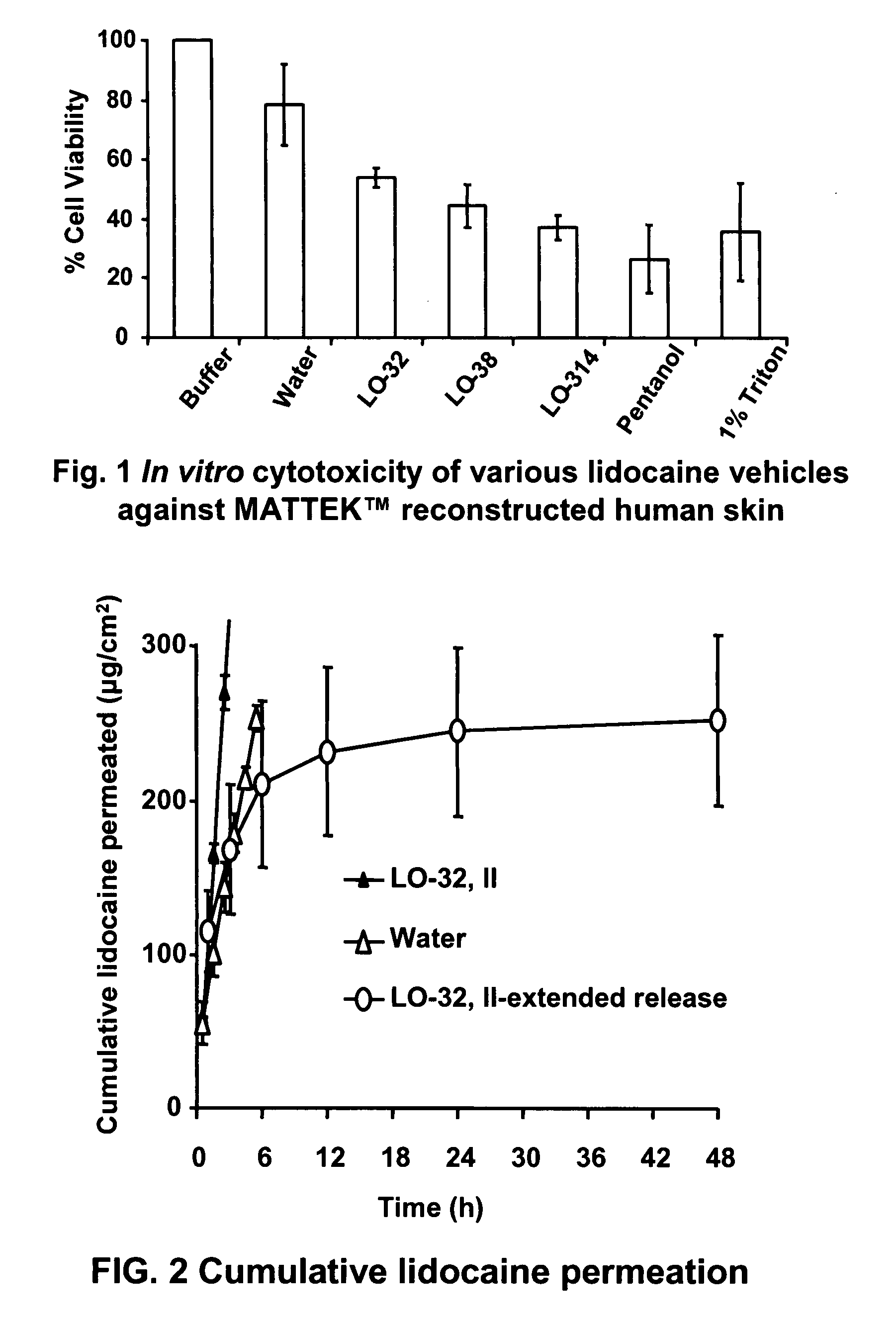

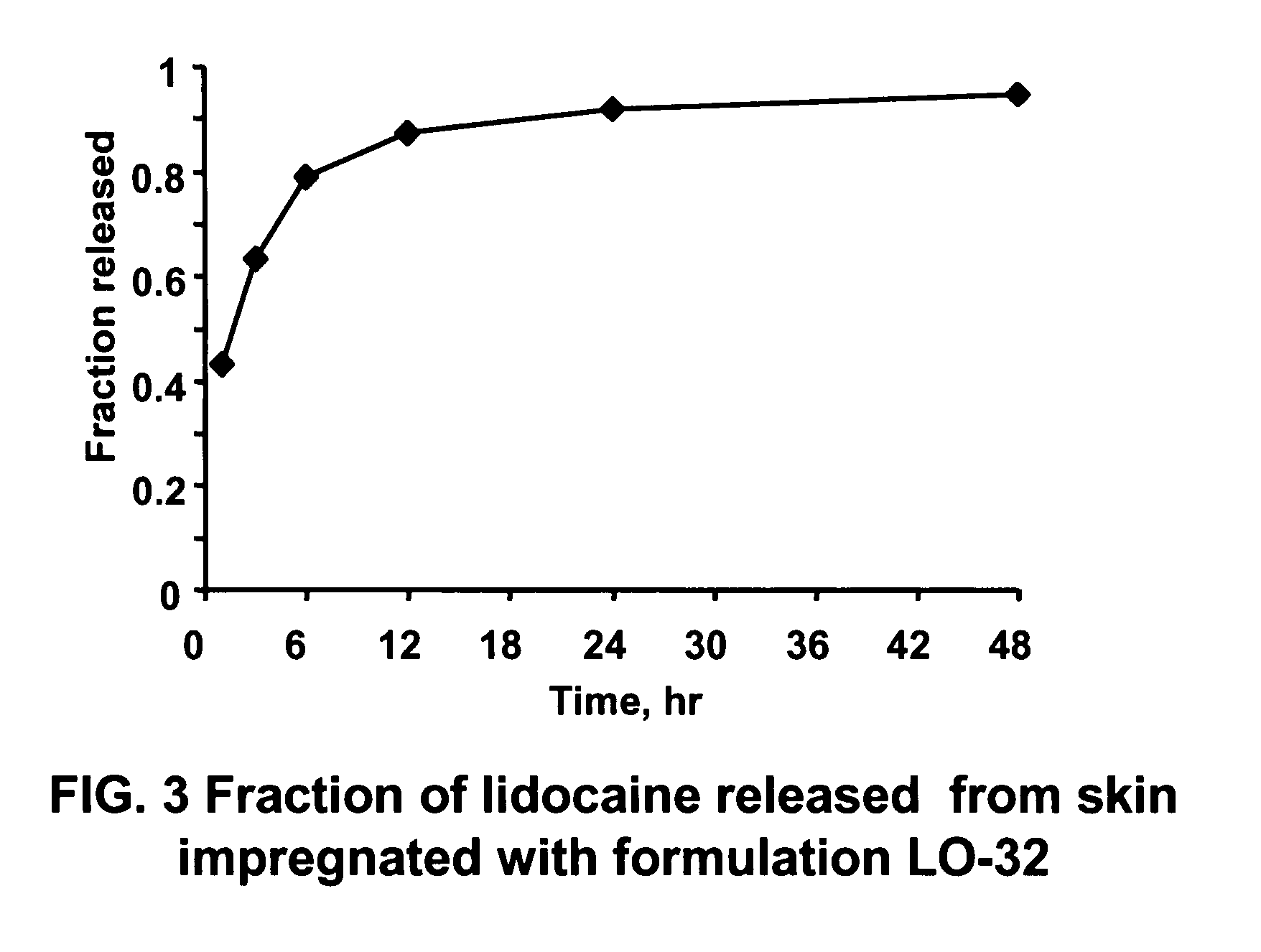

Linker-Based Lecithin Microemulsion Delivery Vehicles

ActiveUS20080139392A1Improve solubilityPromote absorptionBiocideTransportation and packagingHigh concentrationSide effect

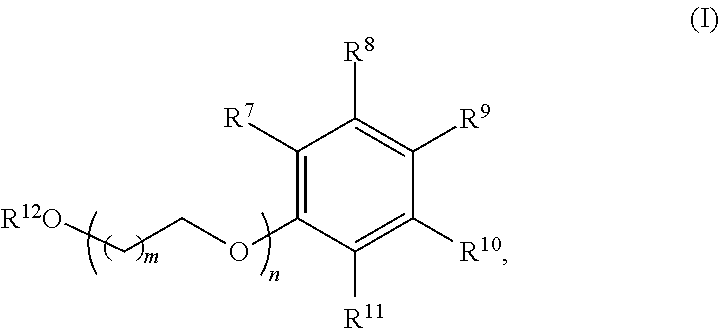

The present invention relates to biocompatible microemulsion systems designed for controlled release drug delivery applications formulated with phospholipids such as lecithin (surfactant), a lipophilic additive (linker) containing 9 or more carbons in their alkyl group and hydrophilic-lipophilic balance (HLB) of 5 or less, and a surfactant-like hydrophilic additive (linker) containing between 6 to 9 carbon atoms in their alkyl tail. The combination of linkers and phospholipids produce formulations capable of delivering high concentrations of poorly soluble drugs into epithelial tissue using low surfactant concentrations, with minimum cytotoxic side effects.

Owner:ACOSTA ZARA EDGAR JOEL +1

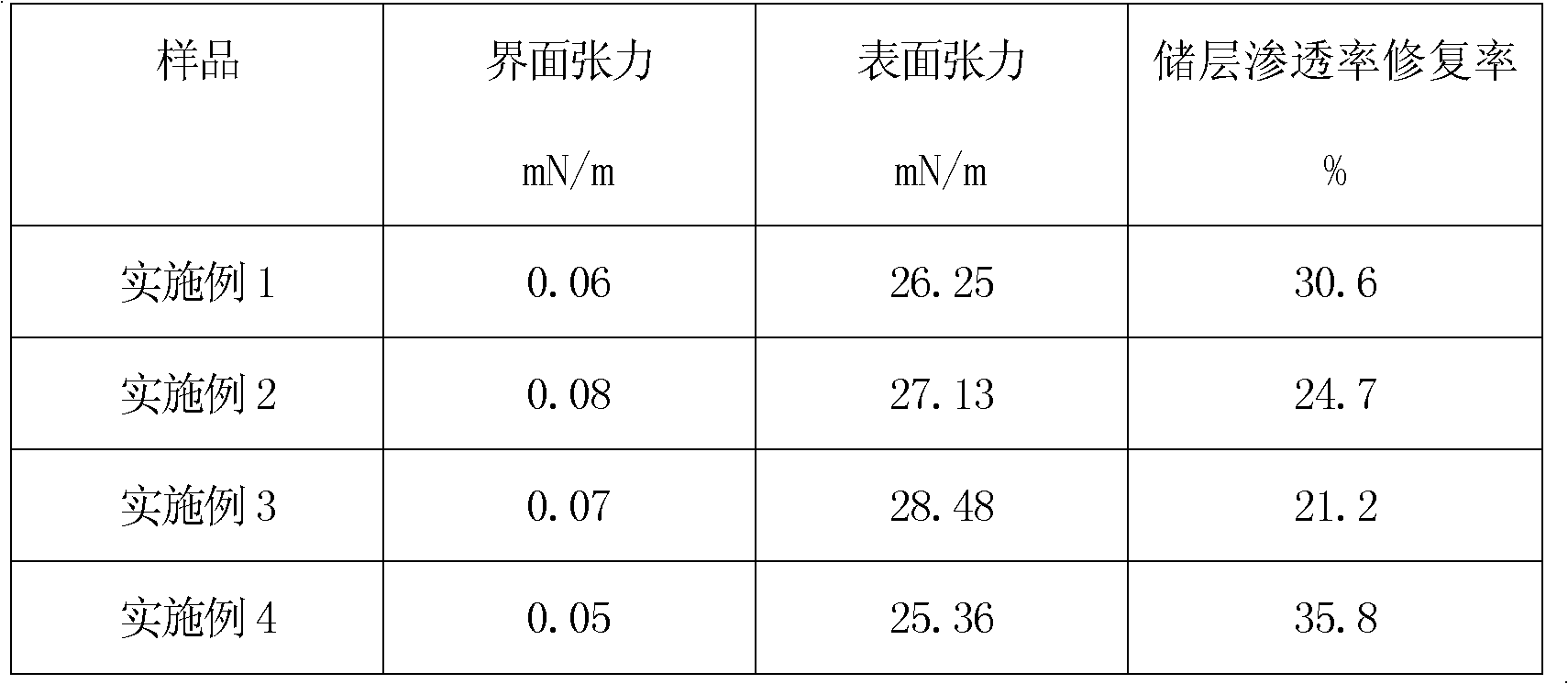

Microemulsion-type fracture acidizing cleanup additive, and preparation method and application thereof

InactiveCN102127414APerformance is not affectedGood compatibilityDrilling compositionType fracturePetrochemical

The invention relates to a microemulsion-type fracture acidizing cleanup additive, and a preparation method and application thereof, belonging to the technical field of petrochemical industry. The microemulsion-type fracture acidizing cleanup additive is prepared from the following components in percentage by weight:5-10% of surfactant, 2-8% of cosurfactant, 35-45% of oil phase, 35-45% of water phase and 3-10% of inorganic electrolyte. The microemulsion-type fracture acidizing cleanup additive provided by the invention has a function of restoring reservoir permeability; and compared with the existing cleanup additive system, the microemulsion-type fracture acidizing cleanup additive provided by the invention can reduce the degree of reservoir damage, which is caused by incompatibility of water locks, residues and formation fluids in the wellbore area of an oil well in the fracture acidizing process of an oil and gas well, by more than 50%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Nano-water soluble microgel oil displacing material and its preparation method

The present invention belongs to the field of water-soluble functional high-molecular nano material, in particular, it relates to a nano water-soluble microgel oil displacement material and method for preparing said nano water-soluble microgel oil displacement material by adopting inverse microemulsion ligh-polymerization process. It is characterized by that said invention utilizes acrylamide / anionic monomer / third monomer to synthesize ternary copolymer nano-size microgel oil displacement material. Besides, said invention also provides the concrete steps of its preparation method.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

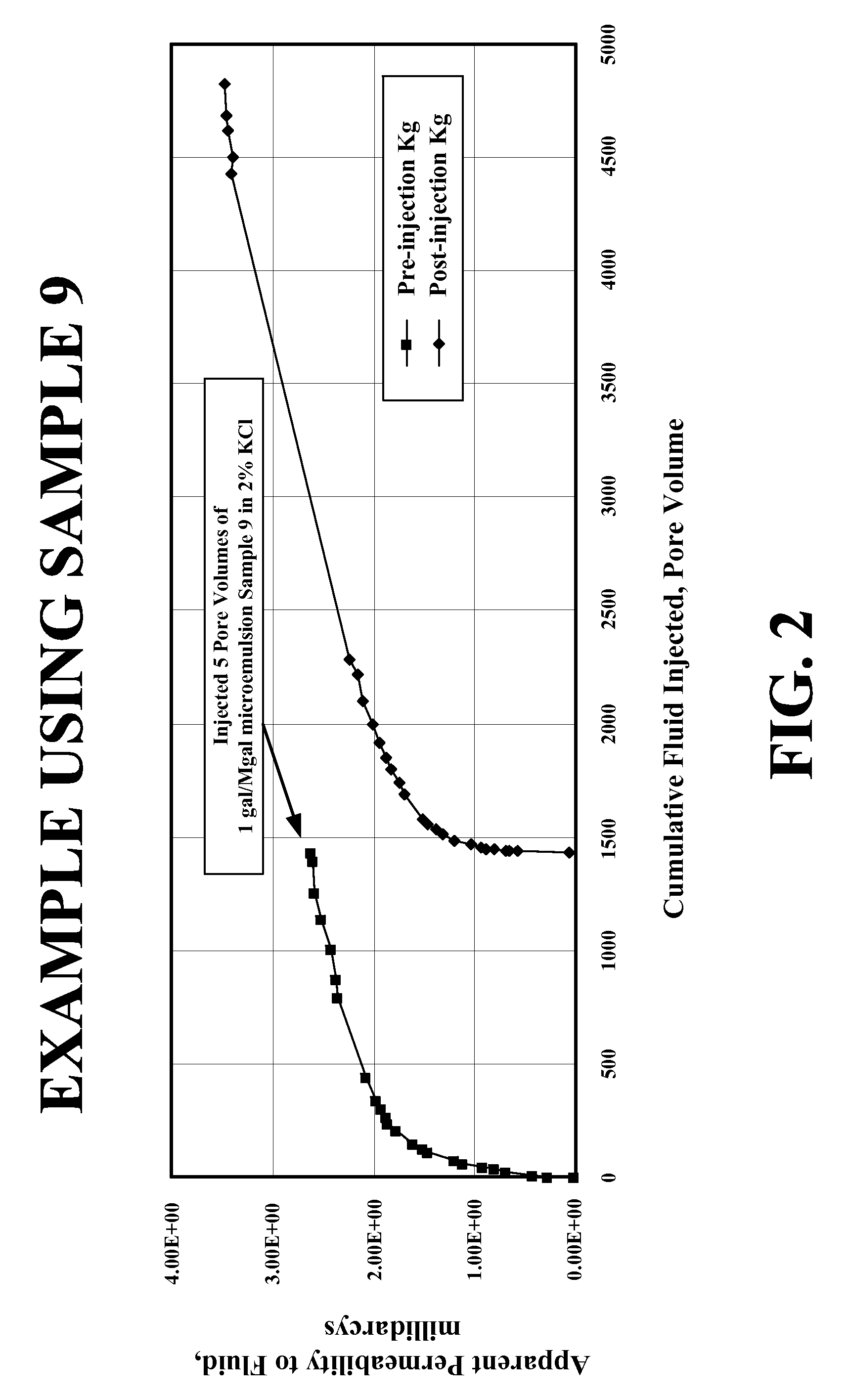

Microemulsion flowback aid composition and method of using same

ActiveUS20130261033A1Improve permeabilityImprove breathabilityFlushingDrilling compositionWater dispersibleWater soluble

Disclosed and claimed is a microemulsion flowback aid composition and a method of enhancing recovery of oil or gas during fracturing or stimulation processes. The microemulsion flowback aid composition includes (i) an oil-like phase comprising at least one nonionic surfactant having a hydrophilic-lipophilic balance (HLB) of less than about 9; (ii) a coupling agent capable of stabilizing the microemulsion flowback aid composition; (iii) at least one water-soluble or dispersible nonionic surfactant that is different from the at least one nonionic surfactant in the oil-like phase; (iv) at least one additional surfactant selected from anionic, cationic, amphoteric, and combinations thereof; and (v) water.

Owner:CHAMPIONX USA INC

Harsh oil deposit reversed-phase microemulsion profile-control flooding system and preparation method thereof

ActiveCN104448126AImprove stabilityGood temperature and salt resistanceDrilling compositionMicrosphereOil phase

The invention relates to a harsh oil deposit reversed-phase microemulsion profile-control flooding system and a preparation method thereof. The problems in the prior art that the initial particle size of the product is improper and polymeric microspheres are poor in expansibility under high-temperature high-salt conditions are mainly solved. The harsh oil deposit reversed-phase microemulsion profile-control flooding system disclosed by the invention comprises the following components in parts by weight of microemulsion: 20-70 parts of an oil-soluble solvent, 5-20 parts of an emulsifier and a co-emulsifier, 20-70 parts of a polymer aqueous phase containing acrylamide and other temperature-resistant salt-resistant comonomers. According to the technical scheme, a semi-continuous reaction method is adopted, the aqueous phase containing acrylamide and other temperature-resistant salt-resistant comonomers is added into an oil phase containing the emulsifiers in batches, and a hydrophobic monomer is added, so that the problems are solved, the prepared polyacrylamide reversed-phase microemulsion is directly compounded or is compounded with other oil field chemicals to be applied to such field applications for improving oil recovery as depth profile control, water plugging and displacement in tertiary oil recovery of a harsh oil deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microemulsions for use as vehicles for administration of active compounds

InactiveUS20010007663A1Improve solubilityReduce solubilityDrug compositionsEmulsion deliverySolubilityMicroemulsion

A non-toxic oil-in-water or bicontinous microemulsion used as a pharmaceutically acceptable vehicle for administration of one or more active compounds having a low solubility in water as well as a process for the preparation and the use thereof.

Owner:ASTRAZENECA AB

Pharmaceutical compositions based on a microemulsion

InactiveUS20100034880A1Efficient deliveryIncrease concentrationOrganic active ingredientsPowder deliveryPropylene carbonateBiological membrane

The invention provides a transdermal, transmucosal pharmaceutical composition suitable for substantially extra-vascular application of at least one biologically active substance to biological membranes of a mammal, comprising a pharmaceutical or cosmetic composition comprising propylene carbonate at least one oil or source of fatty acid or surfactant; and water; in combination with the at least one biologically active substance wherein the propylene carbonate is adapted to enhance the bioavailability of the at least one biologically active substance.

Owner:NANODERMA

Preparation method of profile control and oil displacement system of polyacrylamide nanometer microsphere with low interfacial tension

InactiveCN101759838AReduce interfacial tensionEnhanced overall recoveryDrilling compositionOrganic acidMicrosphere

The invention relates to a preparation method of a profile control and oil displacement system of polyacrylamide nanometer microsphere with low interfacial tension, which comprises the steps of: inversely preparing microemulsion with oil phase, combined emulsifying agents and water phase containing crosslinking agents, initiating polyreaction with a redox initiation system used as initiating agents, neutralizing the obtained polyacrylamide nanometer microsphere with alkali, and preparing highly active sulphonate or carboxylate surfactants with the reaction of the alkali and the substance of organic acid in the combined emulsifying agents; the oil water interfacial tension can be greatly reduced by the surfactants. The profile control and oil displacement system is applied to enhancing enhanced recovery ratio, has good effect on enhancing oil cleaning efficiency, and is a novel profile control and oil displacement system with the dual functions of profile control and oil displacement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Methods and compositions for use in oil and/or gas wells

Methods and compositions comprising an emulsion or a microemulsion for use in various aspects of the life cycle of an oil and / or gas well are provided. In some embodiments, the emulsion or the microemulsion comprises water, a solvent, and a surfactant, and optionally, one or more additives.

Owner:FLOTEK CHEM LLC

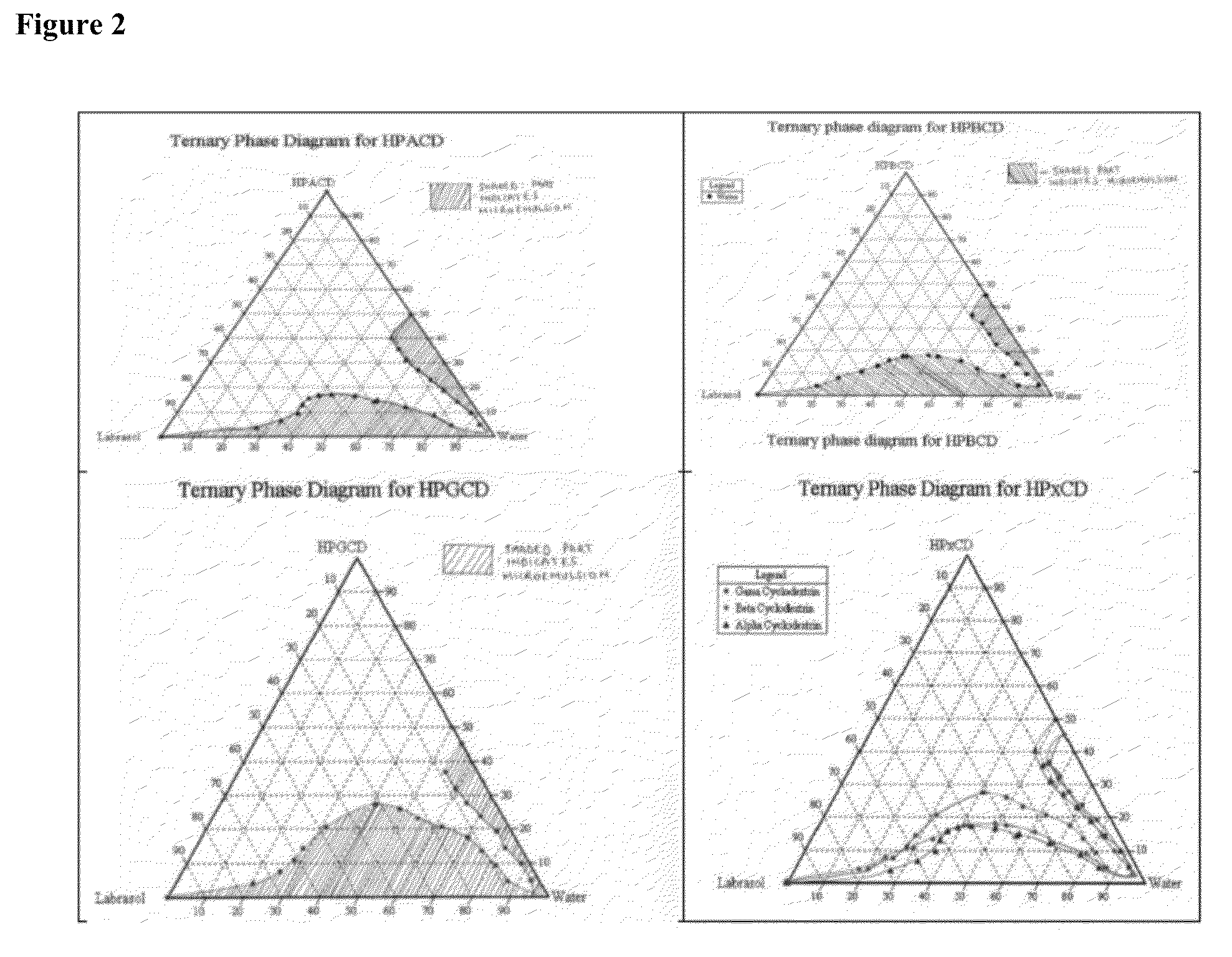

Cyclodextrin-Based Microemulsions, and Dermatological Uses Thereof

InactiveUS20130251644A1Large average pore sizeUneven skinBiocideCosmetic preparationsSolubilityActive agent

Described herein are cyclodextrin-stabilized microemulsion systems useful for increasing the solubility, stability, bioavailability, or safety of an active agent for delivery to the skin. The microemulsions may reduce the occurrence of skin irritation or odor upon application. In certain embodiments, the active agent is substantially insoluble in water. The microemulsions may be formulated as semi-solids, for example creams, or as aerosol or non-aerosol foams. Also described are methods of treating skin disorders, comprising the step of applying to an affected area of a subject in need thereof a therapeutically-effective amount of an inventive microemulsion.

Owner:PRECISION DERMATOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com