Patents

Literature

710results about How to "Good temperature and salt resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic associated polymer and preparation method thereof

InactiveCN105646777AGood temperature and salt resistanceImprove shear resistanceDrilling compositionSolubilityPolymer science

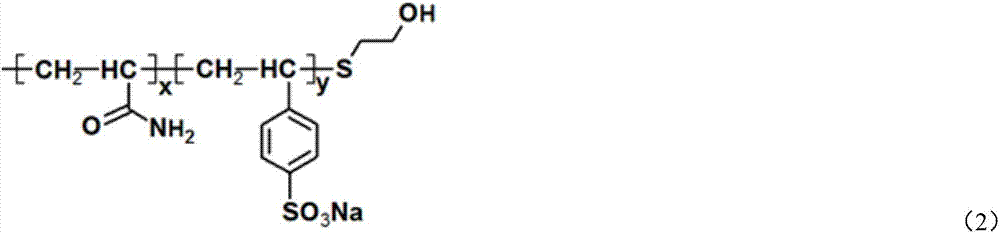

The invention provides a hydrophobic associated polymer, comprising repeating units shown in formula (I) and formula (II), wherein x: y = 1: (0.001 to 0.06); A is a monomeric unit of a hydrophobic monomer; the viscosity average molecular weight of the hydrophobic associated polymer is 5 to 35 million. Compared with the prior art, the hydrophobic associated polymer comprises two monomeric units, and a hydrophilic unit is a monomeric unit of acrylamide, can provide a hydrophilic group for a hydrophobic associated polymer, and ensures that the polymer has good water solubility; a hydrophobic unit is a monomeric unit of the hydrophobic monomer, can provide a hydrophobic side group for the hydrophobic associated polymer, and ensures that a polymer chain has a certain hydrophobic character, and hydrophobic groups gather in water due to a hydrophobic interaction to form a spatial network structure, thereby providing necessary viscoelasticity for a solution; under the combined action of the two units, the temperature resistance and salt tolerance and shear resistance of the hydrophobic associated polymer are improved.

Owner:SICHUAN GUANGYA POLYMER CHEM

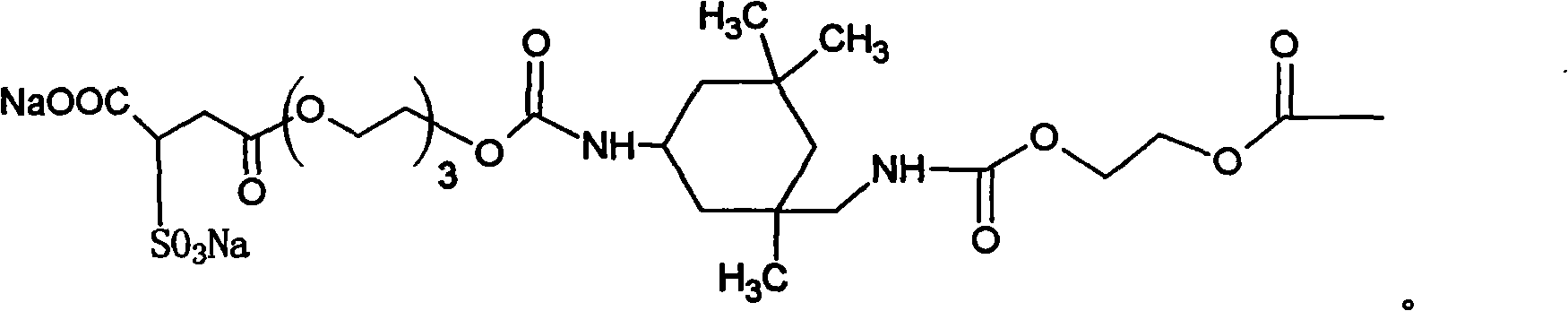

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

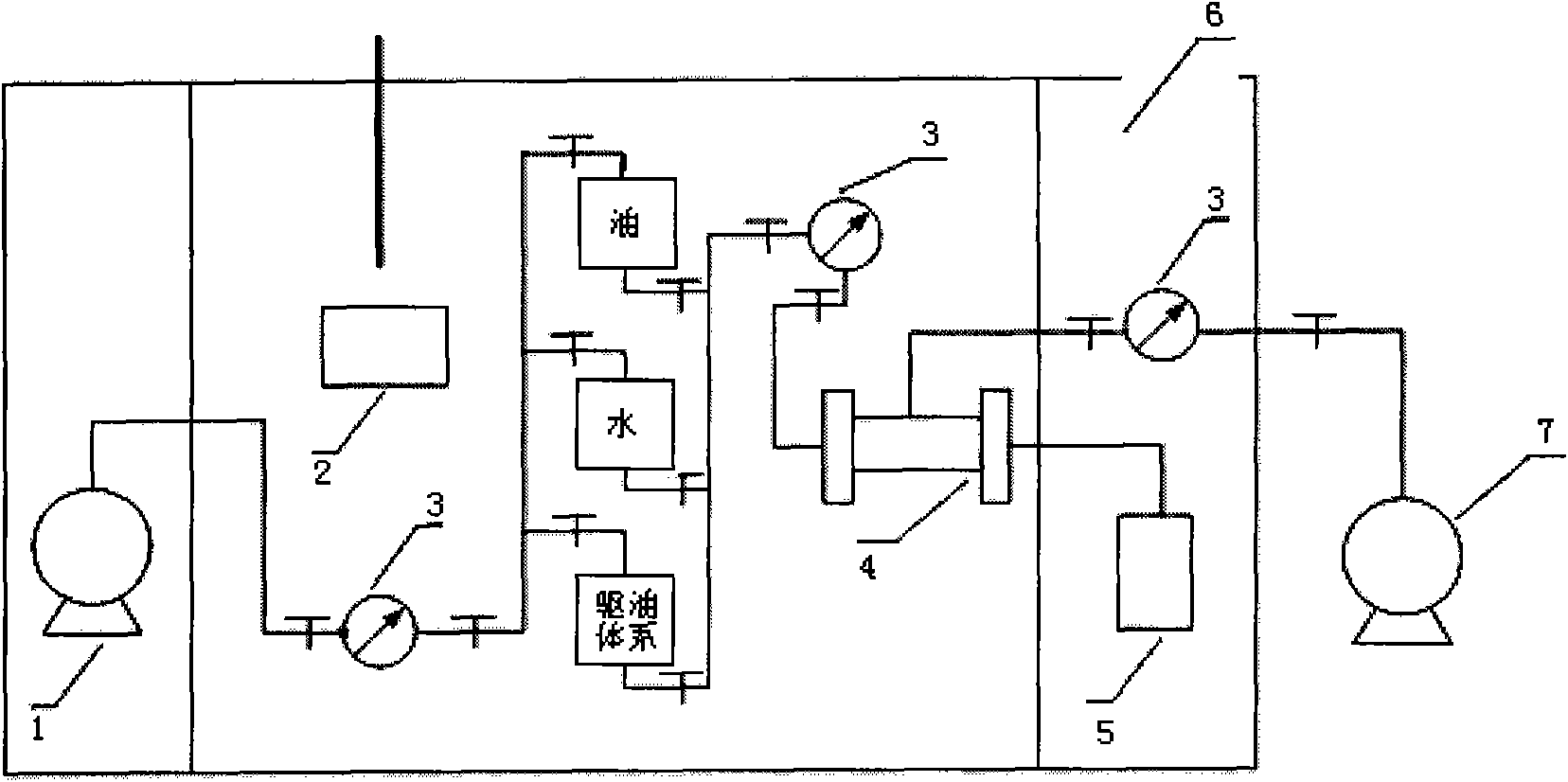

Fluorocarbon surfactant binary composite foam flooding system

ActiveCN102140338AImprove stabilityHigh apparent viscosityFluid removalDrilling compositionSulfonateFoaming agent

The invention relates to a fluorocarbon surfactant binary composite foam flooding system. The system is prepared by adopting fluorocarbon surfactant as a foaming agent, adopting a macromolecular compound as a foam stabilizer and adding water; the foaming agent is one or combination of sulphobetaine type fluorocarbon surfactant and amine oxide type fluorocarbon surfactant, or combination of alpha-alkenyl sulfonate and one of sulphobetaine type fluorocarbon surfactant and amine oxide type fluorocarbon surfactant; and the foam stabilizer is partially hydrolyzed polyacrylamide, polyvinyl pyrrolidone K30, polyvinyl pyrrolidone K90 or hydroxyethyl cellulose. An application method comprises that solution of the fluorocarbon surfactant binary composite foam flooding system and nitrogen are alternately injected into a stratum or a rock center so as to improve the recovery rate of crude oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Alkyl group polyoxyethylene ether surface active agent with Guerbet structure and preparation method and application thereof

ActiveCN101745343AGood water solubilityLow critical micelle concentrationTransportation and packagingMixingChemical structureSolubility

The invention relates to an alkyl group polyoxyethylene ether surface active agent with a Guerbet structure and a preparation method and the application thereof, which is applied to the tertiary oil recovery technology; alpha-olefin with dialkyl, which is obtained by catalyzing dimerization by the alpha-olefin with short carbon chain, is used as starting material, and after a series of the chemical reaction, the corresponding alkyl group polyoxyethylene ether surface active agent with the Guerbet structure is prepared; the surface active agent comprises a quaternary ammonium cationic surfactant of alkyl polyoxyethylene ether hydroxypropyl and a carboxylic acid oxyneurines amphoteric surfactant of alkyl group polyoxyethylene ether hydroxypropyl, a special molecular structure determines the alkyl group polyoxyethylene ether surface active agent to have good water solubility, low critical micelle concentration, good surface or interface tensile force reduction capacity and high-efficiency foaming capacity, ultra-low oil-water interface tensile force (10-3mN / m) is formed between the brine solution energy and crude oil, therefore, the alkyl group polyoxyethylene ether surface active agent which is used as an effective oil displacement agent has application potential in the tertiary oil recovery; the surface active agent has the following chemical structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Three-phase foam complex oil flooding system and application thereof

ActiveCN103980873AImprove stabilityOil displacement effect is goodFluid removalDrilling compositionFoaming agentRock core

The invention relates to a three-phase foam complex oil flooding system and application thereof. The three-phase foam complex oil flooding system consists of a foaming agent, a foam stabilizer, water and gas, wherein the foaming agent and the foam stabilizer are uniformly dispersed into the water to form an oil flooding system solution; the proportion of components is as follows: the foam stabilizer is 0.1-0.3% in percentage by mass, and the foaming agent is 0.1-0.4% in percentage by mass; the gas is nitrogen, carbon dioxide or natural gas; the volume ratio between the oil flooding system solution and the gas is 1:(1-1.5), and the oil flooding system solution and the gas are alternately injected into the stratum or rock cores. The three-phase foam complex oil flooding system disclosed by the invention can be used for reducing the liquid discharge speed of a liquid membrane, increasing the viscoelasticity and strength of the liquid membrane, and ensuring that the foam is more stable, has good oil flooding effects, and can be used for enhancing the oil recovery.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

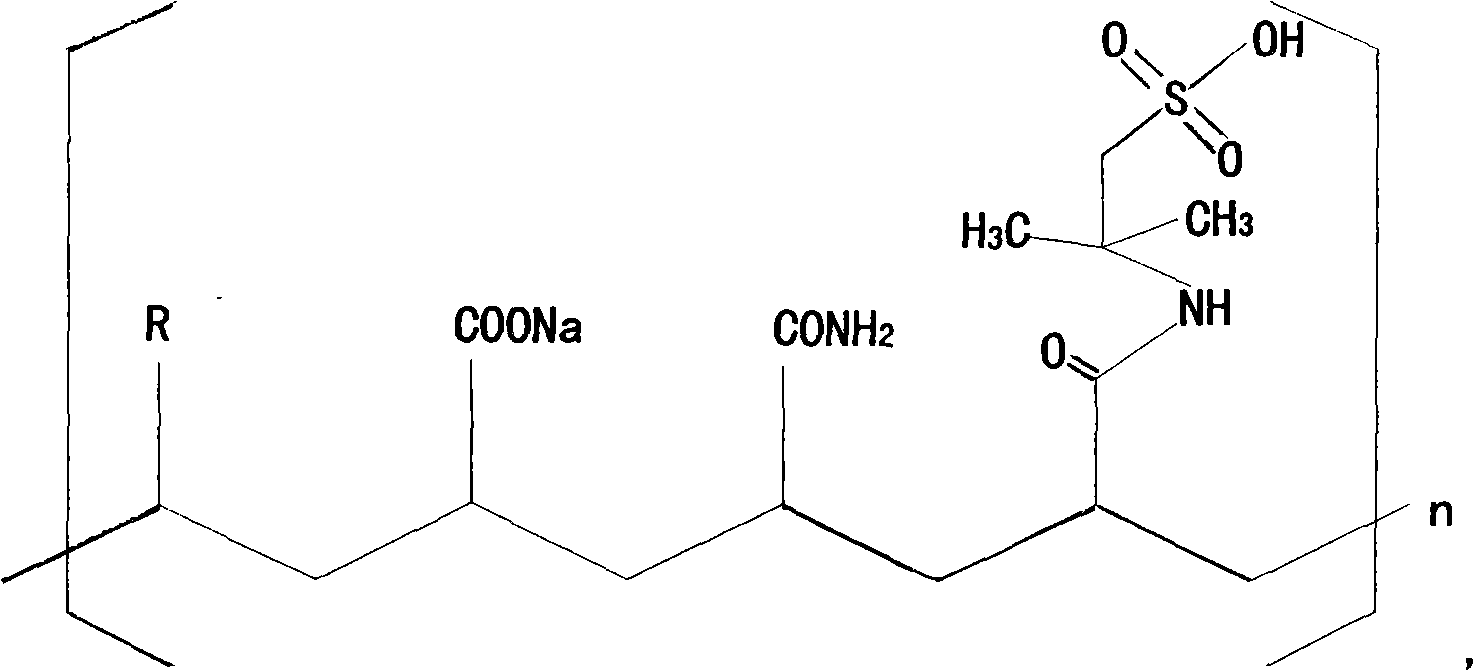

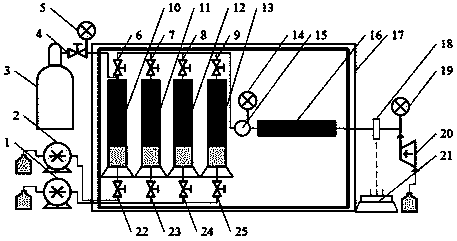

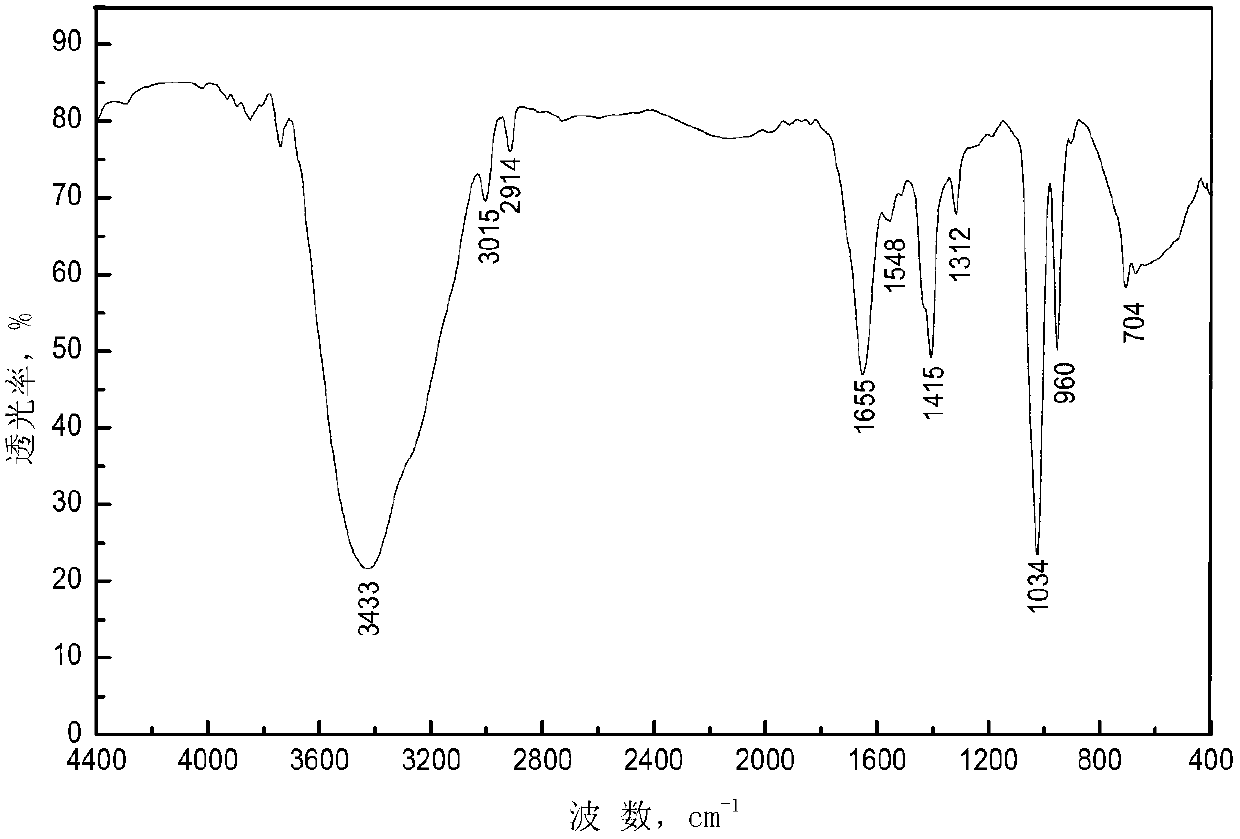

Polymer mobility control agent suitable for ultrahigh-salinity oil deposit and preparation method thereof

ActiveCN104448127AGood temperature and salt resistanceGood thermal stabilityDrilling compositionPolymer scienceWater soluble

The invention relates to a polymer mobility control agent suitable for an ultrahigh-salinity oil deposit and a preparation method thereof, and the polymer mobility control agent is mainly used for solving the problem that a polymer can not meet the requirement for tertiary oil recovery due to poor temperature resistant property, salt resistant property and shearing resistant property in the prior art. In order to better solve the problem, the technical scheme adopted by the invention is as follows: the control agent for an amphoteric hydrophobic associated polymer comprises the following components in parts by weight of the amphoteric hydrophobic associated polymer: 5-99.9 parts of nonionic water-soluble monomers, 0-50 parts of anionic monomers or / and cationic monomers, 0.1-10 parts of hydrophobic monomers with surface activity, 0.1-5 parts of inorganic substances and 1-20 parts of surface active agents. The preparation method disclosed by the invention can be used for the industrial production of the polymer mobility control agent suitable for the ultrahigh-salinity oil deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2

ActiveCN103881683AEnhanced overall recoveryOil displacement effect is goodDrilling compositionFoaming agentSURFACTANT BLEND

The invention provides a foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2. The foaming agent is composed of the following components in percentage by weight: 0.12%-0.30% of anionic surfactant, 0.06%-0.15% of imidazoline-derived ampholytic surfactant, 0.12%-0.30% of lycine-derived ampholytic surfactant, 0.02%-0.04% of foam stabilizer and the balance of water. The foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2 is characterized in that the anionic surfactant, the imidazoline-derived ampholytic surfactant, the lycine-derived ampholytic surfactant and the foam stabilizer are combined so that the obtained foaming agent is capable of forming stable foam with the CO2, and thus is strong in foaming capacity and high in stability; the foaming agent has high plugging selectivity and can be used for plugging CO2 channeling in the displacement of reservoir oil by using CO2, and therefore, the plugging effects of plugging water rather than oil and plugging large rather than small can be achieved, and the oil recovery factor and the effect of the displacement of reservoir oil by using CO2 can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amphoteric heat-resistant and salt-resistant filtrate reducer for drilling fluid and preparation method

InactiveCN107033280AMolecular weight controllableGood temperature and salt resistanceDrilling compositionHorizontal wellsPotassium hydroxide

The invention discloses an amphoteric heat-resistant and salt-resistant filtrate reducer for drilling fluid and a preparation method. The amphoteric heat-resistant and salt-resistant filtrate reducer is prepared from, by weight parts, acrylamide, alkenyl sulfoacid or alkenyl sulphonate, acrylic acid, cationic monomers, rigid monomers, sodium hydroxide, potassium hydroxide, dispersant, deionized water, a molecular weight modifier and an initiator. The preparation method includes the steps that acrylamide, acrylic acid, alkenyl sulfoacid or alkenyl sulphonate, the cationic monomers, the rigid monomers and the deionized water are added into a reactor, after the materials are dissolved, the pH value of the solution is adjusted, the dispersant is added, the materials are mixed, then the mixture is transferred into a reaction still, nitrogen is introduced for deoxygenization, the initiator is added for triggering polymerization, and jelly is taken out after the reaction is completed, dried, smashed and sieved. The molecular weight of the filtrate reducer for the drilling fluid is controllable; the filtrate reducer can adapt to complex drilling conditions, and can be used in horizontal wells, high-temperature deep wells and evaporite beds; fewer residual monomers of the filtrate reducer for the drilling fluid are generated; the filtrate reducer and other oil field chemicals are good in compatibility; the preparation method is simple; the cost is low, and popularization is promoted.

Owner:SHANDONG NUOER BIOLOGICAL TECH

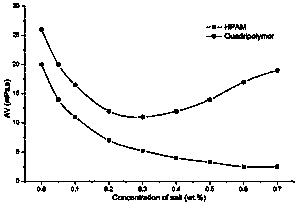

Amphoteric ionic polymer clay stabilizer and preparation method

InactiveCN102660247AIncrease molecular rigidityEnhanced encapsulationDrilling compositionSodium AcrylateAqueous solubility

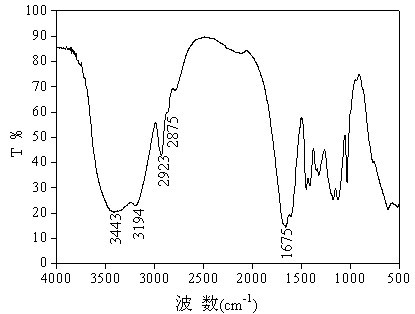

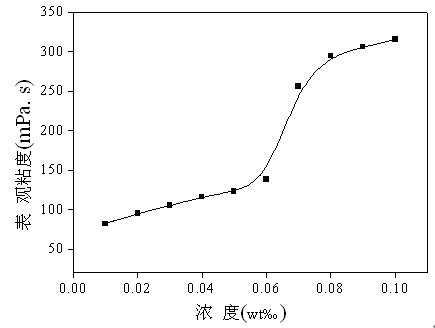

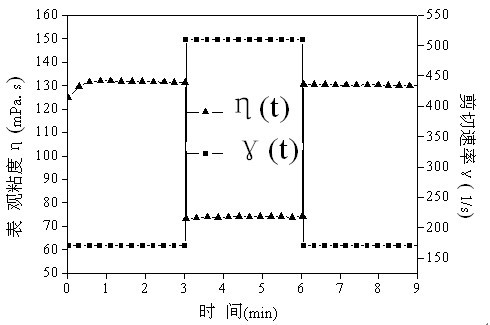

The invention relates to an amphoteric ionic polymer clay stabilizer and a preparation method thereof. The polymer has water solubility, is low in use level and shows excellent temperature resistance and shear resistance. According to the technical scheme, the amphoteric ionic polymer clay stabilizer is prepared from the following raw materials and monomers in percentage by mass: 53.5-59.9 percent of acrylamide AM; 40-45 percent of sodium acrylate NaAA (obtained from neutralization of crylic acid and sodium hydroxide), 0.1-1.5 percent of N-allyl oleamide NAO and 0.1-1.5 percent of dimethyl diallyl ammonium chloride DMDAAC. The preparation method comprises the following steps: firstly adding NAO in a reactor, then adding an emulsifier and water; after complete emulsification, adding AM, NaAA, DMDAAC to prepare a solution with the total mass percentage concentration of monomer being 10-25 percent, adjusting pH to be 6-8, and introducing N2 for 20 min; then adding an initiator, continuing to introduce N2 for 20 min, and reacting for 8-12 h at 30-70 DEG C; washing with absolute ethyl alcohol, grinding and drying to obtain AM / NaAA / DMDAAC / NAO quadripolymer. The result of an anti-swelling test of 0.2wt% solution shows that the anti-swelling rate can reach 86 percent.

Owner:SOUTHWEST PETROLEUM UNIV

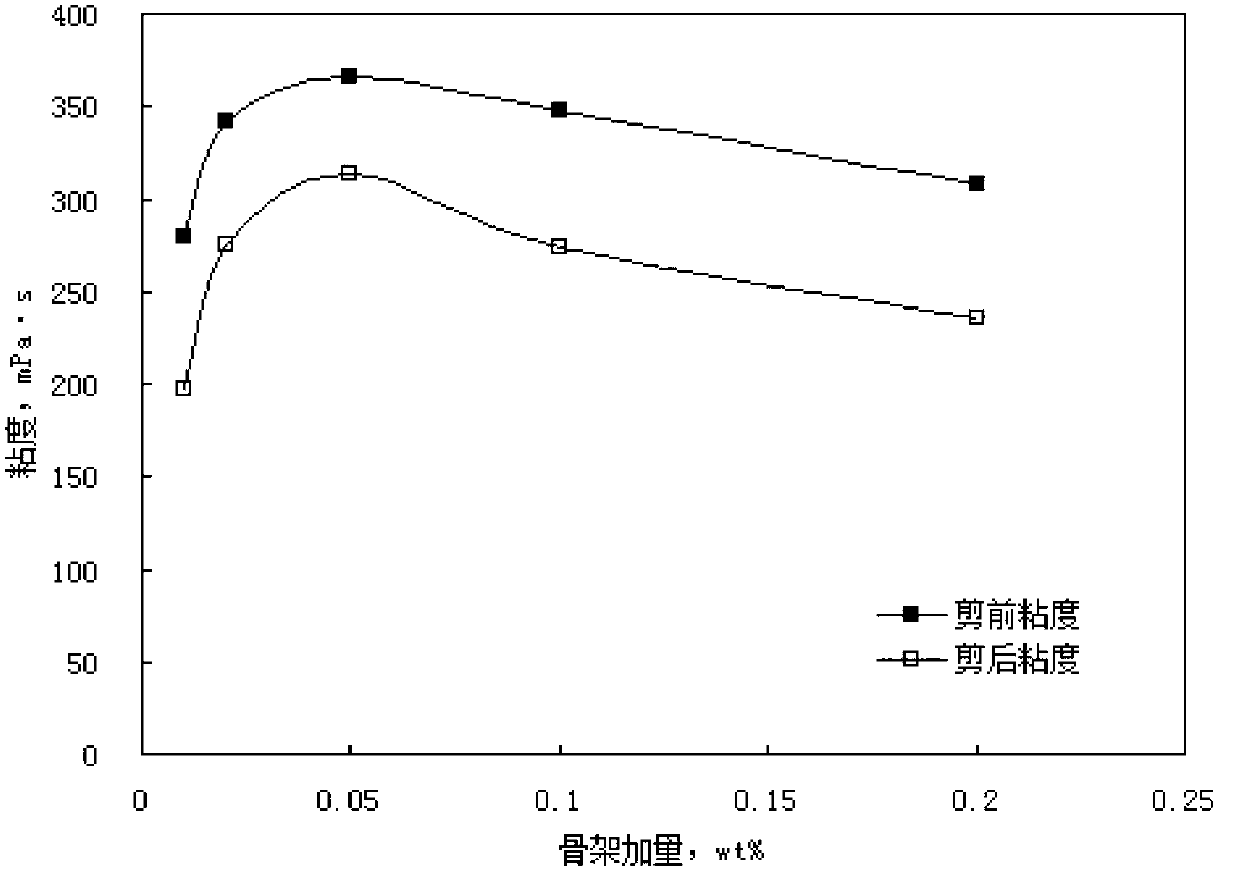

Hyperbranched hydrophobical-associating water-soluble polymer and its preparation method

InactiveCN103130967AGood viscosity increasing effectImprove solubilityDrilling compositionPolymer sciencePolyamide

The invention discloses a hyperbranched hydrophobical-associating water-soluble polymer and its preparation method. The polymer is obtained through copolymerizing acrylamide, acrylic acid, a hydrophobic monomer and functional hyperbranched macromolecules. The preparation method of the polymer comprises the following steps: 1, respectively dissolving a hyperbranched polyamide-amine macro-molecular skeleton treating diethylenetriamine as a core and maleic anhydride (or acryloyl chloride or acrylic anhydride) in dimethyl sulphoxide, slowly adding the skeleton monomer solution to the maleic anhydride solution in a dropwise manner, letting in nitrogen, placing the obtained system in an icy salt bath, stopping the dropwise addition of the skeleton monomer solution when the pH value of a reaction solution reaches 4-5, and precipitating with chloroform to obtain a functionalized skeleton monomer; and 2, carrying out free radical aqueous solution polymerization of sodium acrylate, acrylamide, the hydrophobic monomer dimethylallyl-N-alkylammonium chloride and the functional skeleton monomer. The preparation method has a reliable principle and is simple to operate, and the synthesized polymer still has a good thickening capability and a good seepage performance under a high mineralization degree and a strong shearing action.

Owner:SOUTHWEST PETROLEUM UNIV

Polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and preparation method thereof

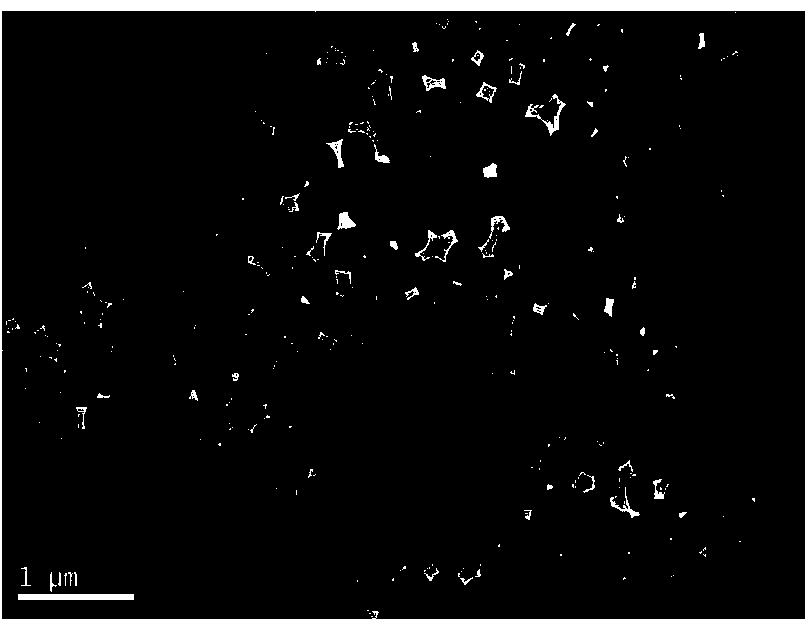

InactiveCN103525379ANew features of strong high temperature resistanceGood temperature and salt resistanceDrilling compositionPolymer scienceEmulsion polymerization

The invention discloses a polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and a preparation method thereof. According to the preparation method, in the presence of nano-silica, a polymer-base nanometer composite material with amphiphilic block hydrophobic associating polymer wrapping inorganic nano-silica is successfully synthesized by virtue of a micellar emulsion polymerization method and combines the rigidity and the heat stability of the inorganic nano-silica and the characteristics of the amphiphilic block hydrophobic associating polymer together, and the temperature resistance, the salt tolerance and the thickening property of the polymer are obviously improved by virtue of the polymer-base nanometer composite material on the basis of the existing good performances of the amphiphilic block hydrophobic associating polymer. As a temperature-resistant, salt-tolerant and fluid loss reducing agent for a drilling fluid in the drilling engineering, the polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent has a remarkable fluid loss reducing effect under high temperature and high salinity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Profile controlling and flooding composition for high-temperature oil reservoirs with high salinity

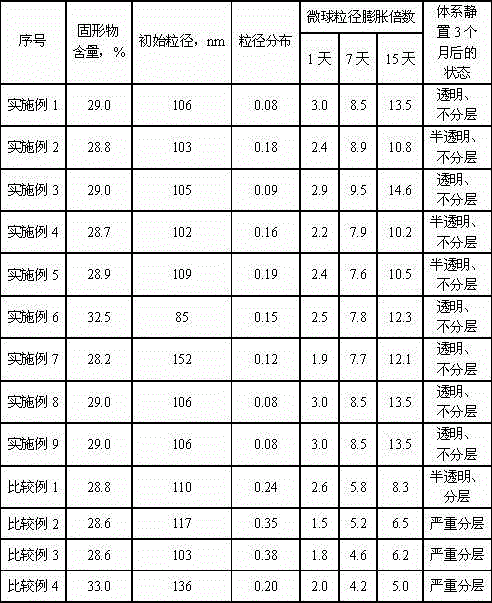

ActiveCN104559992AGood temperature and salt resistanceNarrow particle size distributionDrilling compositionThermodynamicsMicrosphere

The invention relates to a profile controlling and flooding composition for high-temperature oil reservoirs with high salinity and an application of the composition in tertiary oil recovery of the high-temperature oil reservoirs with high salinity, and mainly aims at solving the problems of poor heat resistance and salt tolerance and low oil displacement efficiency of an oil displacement agent under the conditions of high temperature and high salinity in the prior art. The problems are well solved by virtue of the following technical scheme: the profile controlling and flooding composition for high-temperature oil reservoirs with high salinity is prepared from the following components in percentage by weight: (1) 0.01-3.0% of heat-resistant and salt-tolerant polyacrylamide microspheres, (2) 0.01-5.0% of anionic-nonionic surfactant and (3) 92.0-99.98% of injected water; and the profile controlling and flooding composition can be applied to field applications for increasing the recovery rate such as depth profile controlling, water plugging and oil displacement for tertiary oil recovery of the high-temperature oil reservoirs with high salinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

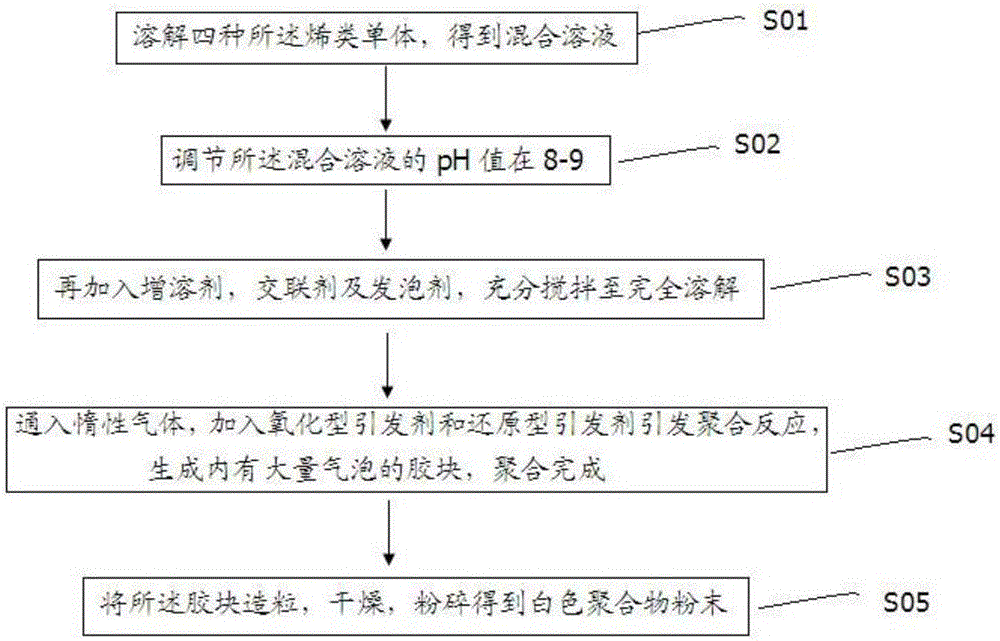

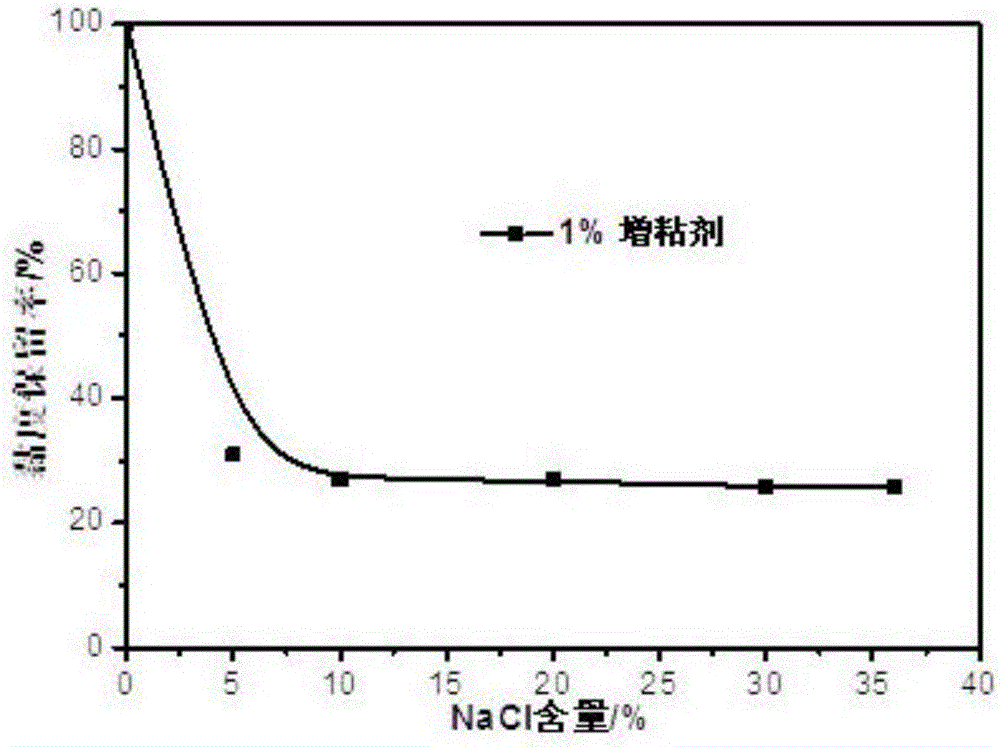

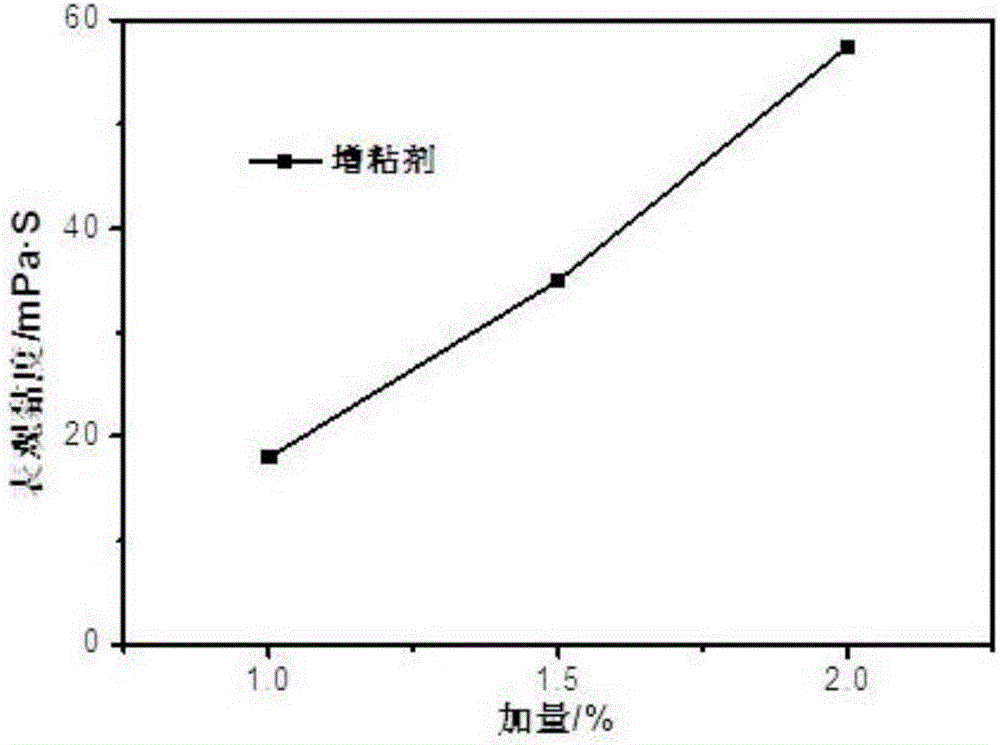

Tackifier for drilling fluid, and preparation method and application thereof

ActiveCN106243266AGood temperature and salt resistancePromote hydrationDrilling compositionAlkaneDouble bond

The invention provides a tackifier for a drilling fluid, and a preparation method and application thereof. The tackifier is a quadripolymer formed by polymerization of four alkene monomers, wherein the four alkene monomers are selected from a temperature-resistant salt-tolerant monomer, a hydrated monomer and an adsorptive monomer; the temperature-resistant salt-tolerant monomer is selected from an alkenyl sulfonic acid monomer; the hydrated monomer is selected from alkenyl carboxylic acid, alkenyl alkane ketone and double-bond-containing quaternary ammonium salt compounds; and the adsorptive monomer is selected from an alkenyl amide monomer. The tackifier provided by the invention can resist a high temperature of no less than 180 DEG C, is resistant to saturated salt, has remarkable tackifying effect, is low in toxicity and environmentally friendly, and can obviously improve the dehydration and wall building capability of the drilling fluid, thereby effectively reducing the dehydration. The invention solves the downhole complexity possibly caused by the fact that the drilling fluid system can not carry and suspend rock debris and thus can not clear boreholes in time due to reduced viscosity shearing force as a result of poor temperature resistance and salt tolerance of the tackifier in deep well, ultradeep well, horizontal well and extended reach well operations.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

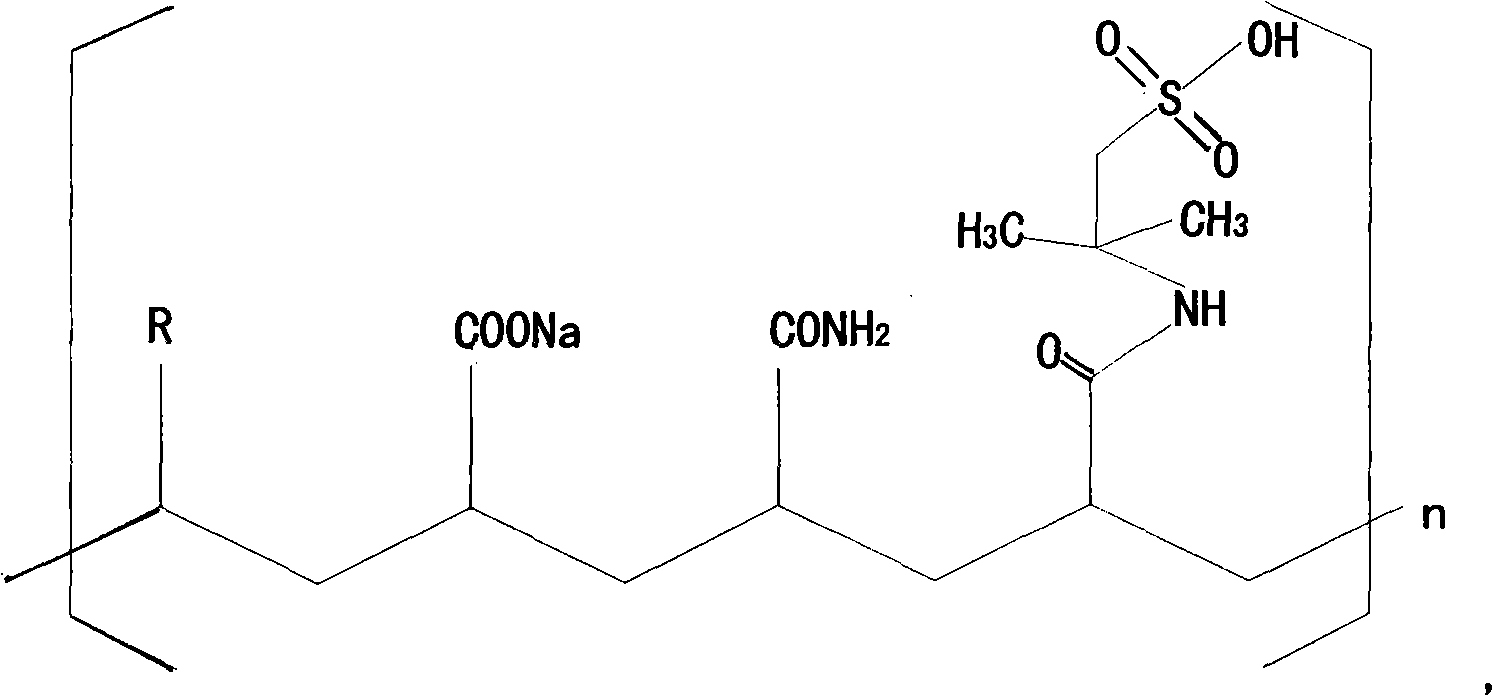

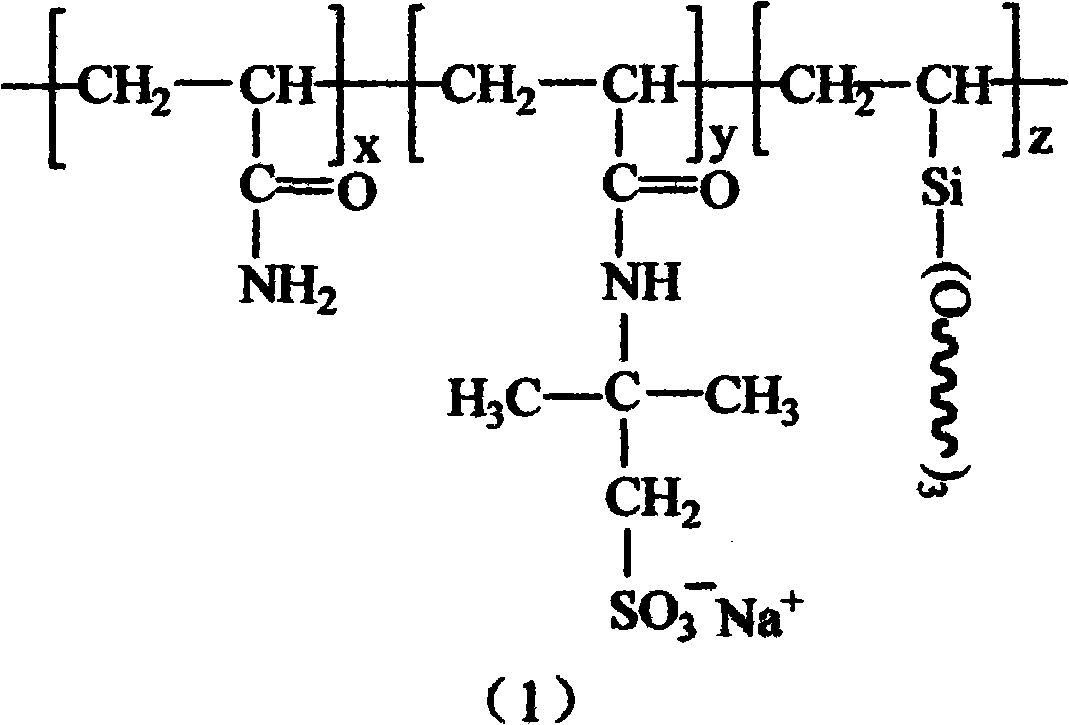

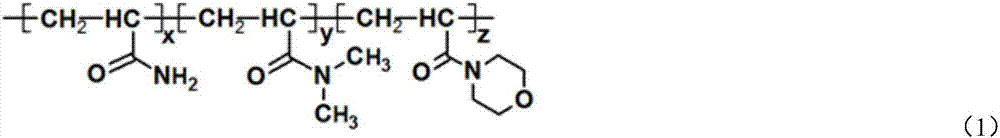

Long-branched chain polyacrylamide copolymer and preparation method thereof

ActiveCN102382241AGood temperature and salt resistanceHigh viscoelasticityDrilling compositionSalt resistancePolymer science

The invention discloses a long-branched chain polyacrylamide copolymer. The structural formula of the long-branched chain polyacrylamide copolymer is shown as formula (1). An organic silicon monomer with temperature resistance and salt resistance is introduced into an acrylamide copolymer so as to improve the temperature resistance and salt resistance of polyacrylamide; the introduction of a long-branched chain organic silicon flexible chain greatly improves the entwisting capability of a polymer molecular chain so as to improve the viscoelasticity of the polymer for reducing the interface tension of a grafting copolymer solution and improve the affinity of displacing fluid and displaced fluid in practical use; and a copolymer main chain is formed by copolymerizing the organic silicon monomer, acrylamide and monomers with temperature resistance and salt resistance, such as 2-acrylamino-2-methy propanesulfonic acid, N-vinyl pyrrolidone, N,N-dimethyl acrylyl and the like, thereby ensuring the chemical stability of the main chain.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of partially hydrolyzed polyacrylamide with improved temperature and salt resisting performances

ActiveCN102060965AImprove temperature and salt resistanceLess investment in production equipmentFunctional monomerSaline water

The invention relates to a preparation method of partially hydrolyzed polyacrylamide with improved temperature and salt resisting performances by using a template polymerization mode. The polymerization initial temperature of the partially hydrolyzed polyacrylamide is controlled to be 0-15DEG C at which template materials are more remarkably acted with functional monomers of polymerization monomers to facilitate the forming of a polyacrylamide product with a block structure; by adopting the template polymerization at the polymerization phase, polymer colloid particles have superhigh molecular weight and maintain favorable dissolving performance at the same time; and by using the temperature of the polymer colloid particles during generation, NaOH is added for hydrolysis during discharge. The number average molecular weight of the partially hydrolyzed polyacrylamide disclosed by the invention can reach 25-32 millions; meanwhile, compared with a random copolymerization product, the high polymer structure has more ordered block sequence structure, so that the partially hydrolyzed polyacrylamide has favorable dissolving performance; in addition, higher viscosity can be maintained in saline water with high temperature and high salinity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Polymer mobility control agent suitable for high-temperature and high-salinity harsh reservoir and preparation method of polymer mobility control agent

ActiveCN104448128AGood temperature and salt resistanceGood thermal stabilityDrilling compositionSalt resistancePolymer science

The invention relates to a polymer mobility control agent suitable for a high-temperature and high-salinity harsh reservoir and a preparation method of the polymer mobility control agent, and the polymer mobility control agent is mainly used for solving the problems that the polymer in the prior art is poor in heat and salt resistance and long-term stability, and cannot meet the requirements of tertiary oil recovery. In order to better solve the problems, the technical scheme adopted by the invention is as follows: an amphoteric hydrophobic association polymer is prepared from the following raw materials in parts by weight: 5-99.9 parts of a non-ionic water-soluble monomer, 0-50 parts of an anionic monomer or / and cationic monomer, 0.1-10 parts of a hydrophobic monomer with surface activity, 0-20 parts of a viscosity stabilizer and 0-20 parts of a surfactant. The preparation method can be applied to industrial production and application of the polymer mobility control agent for the high-temperature and high-salinity harsh reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

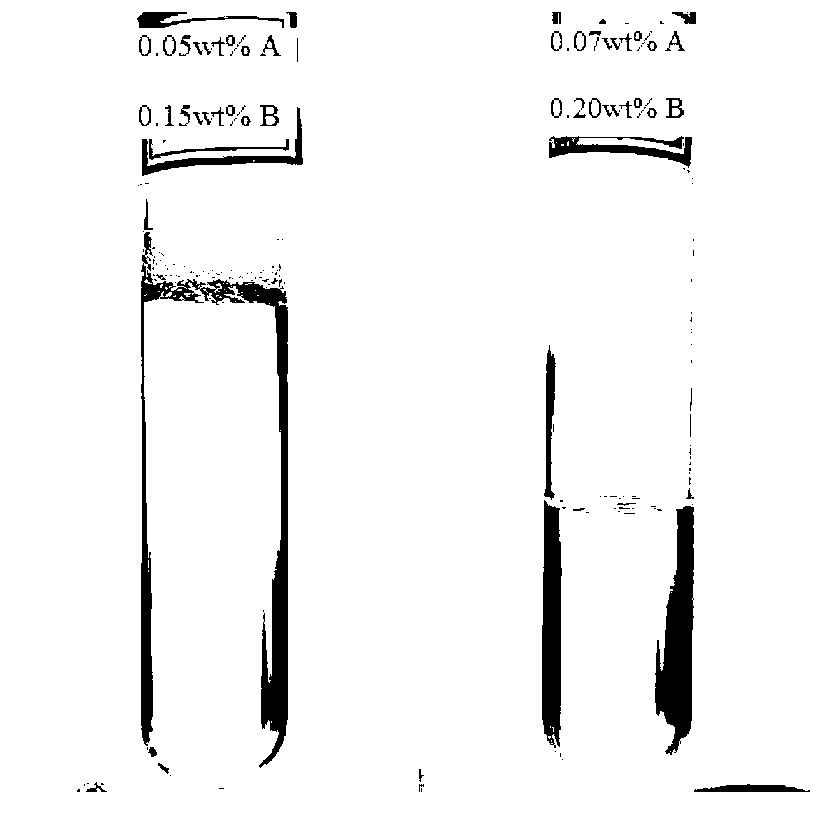

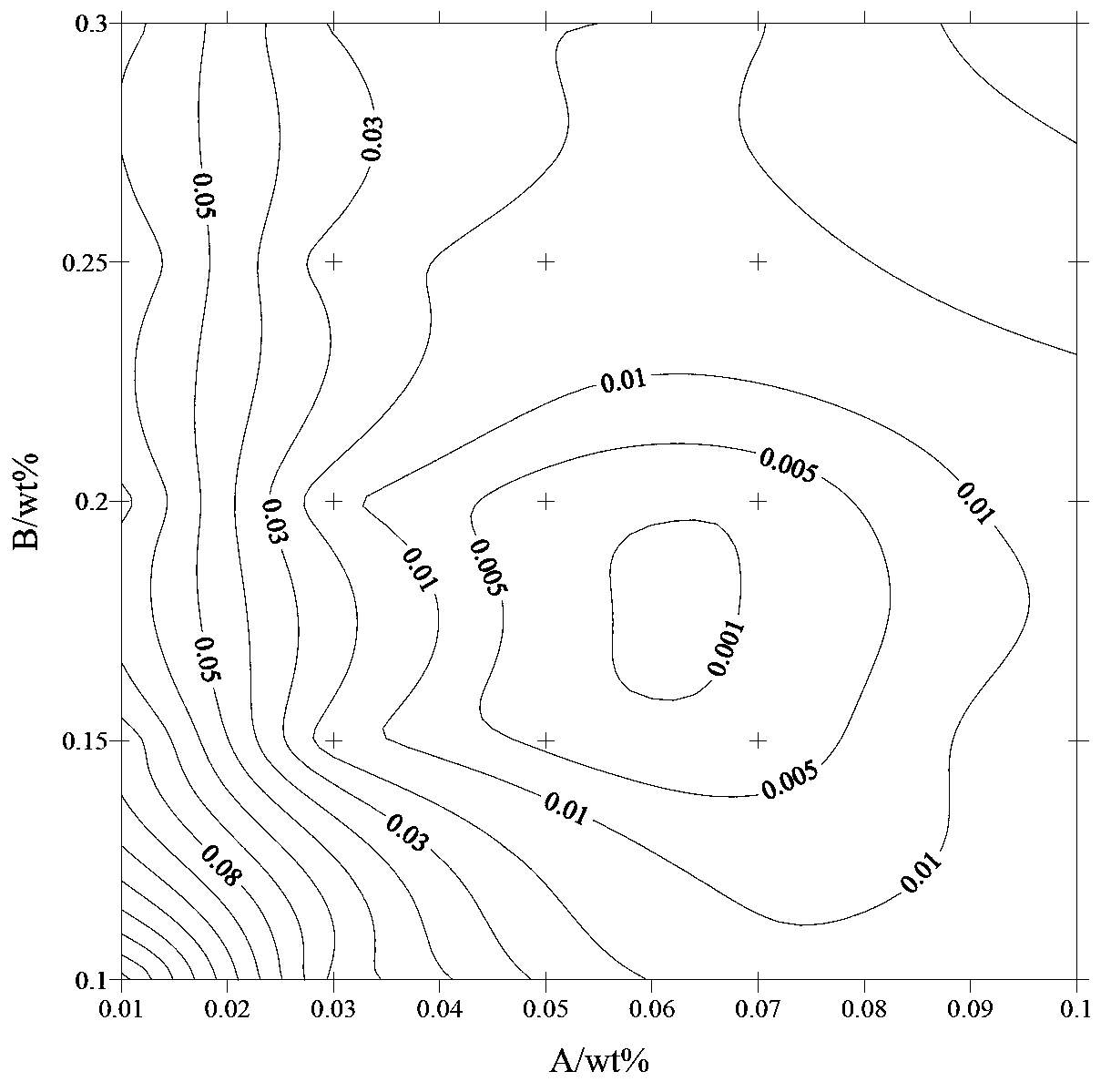

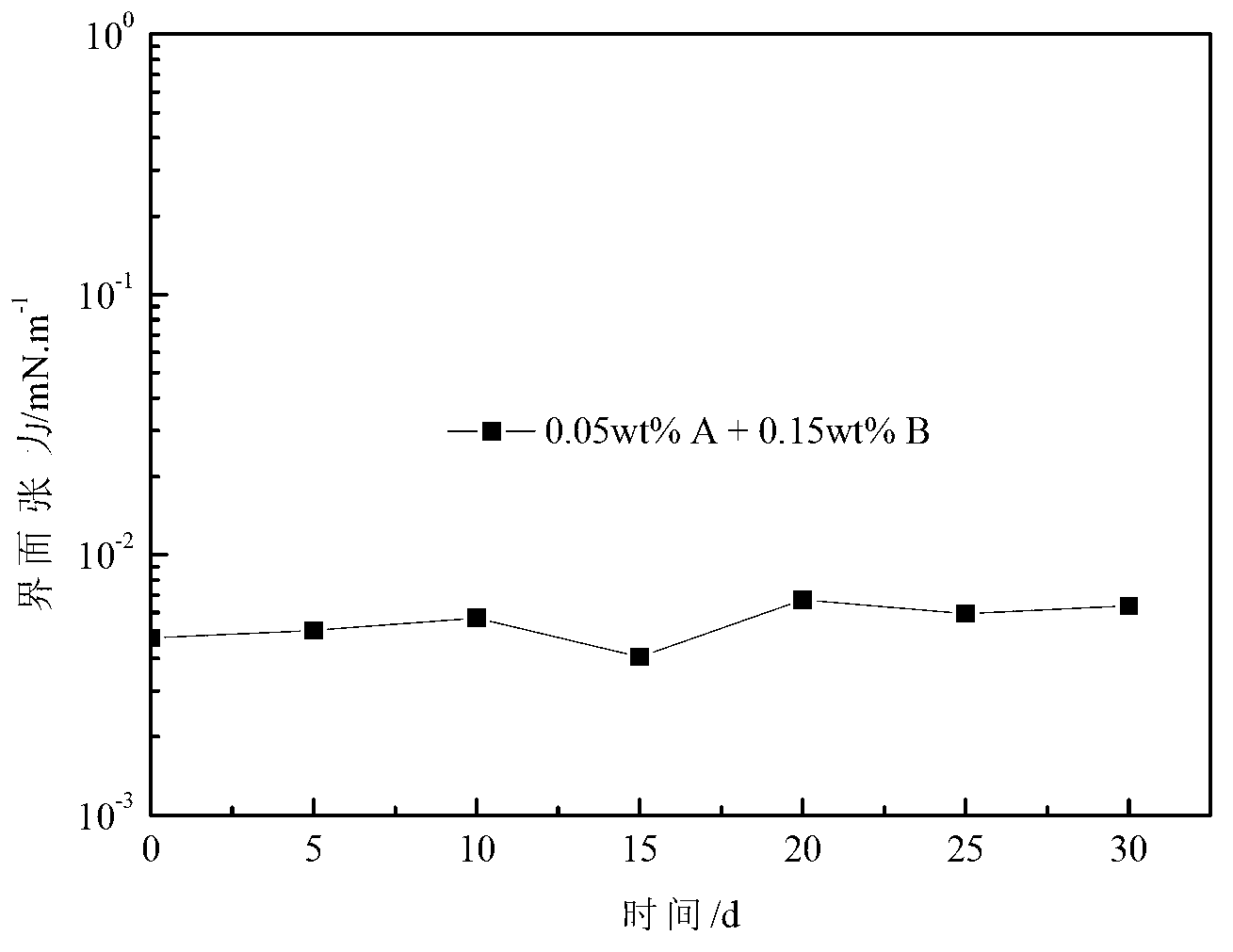

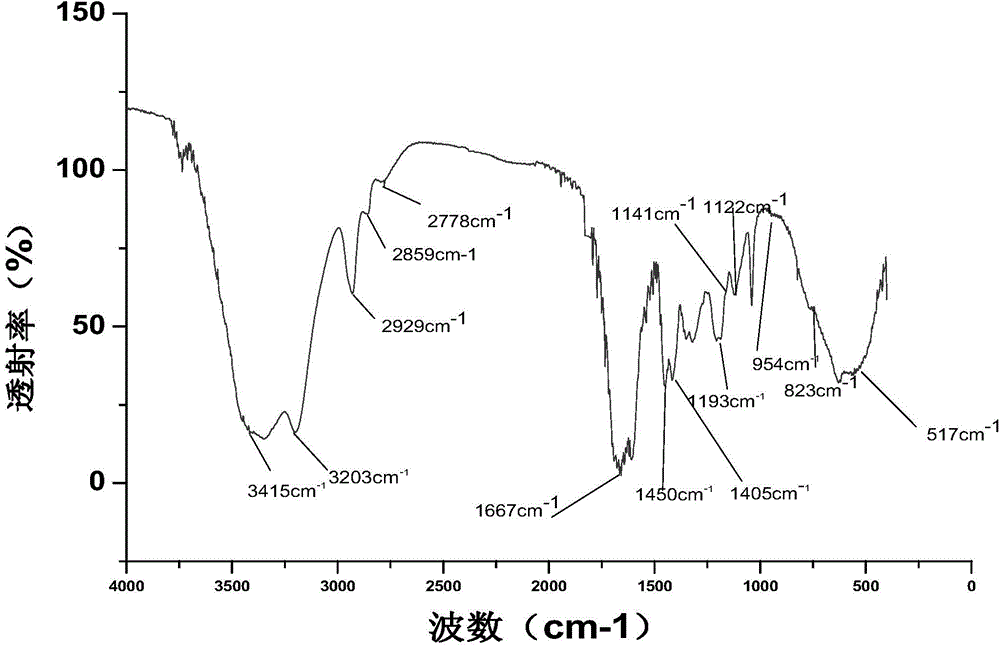

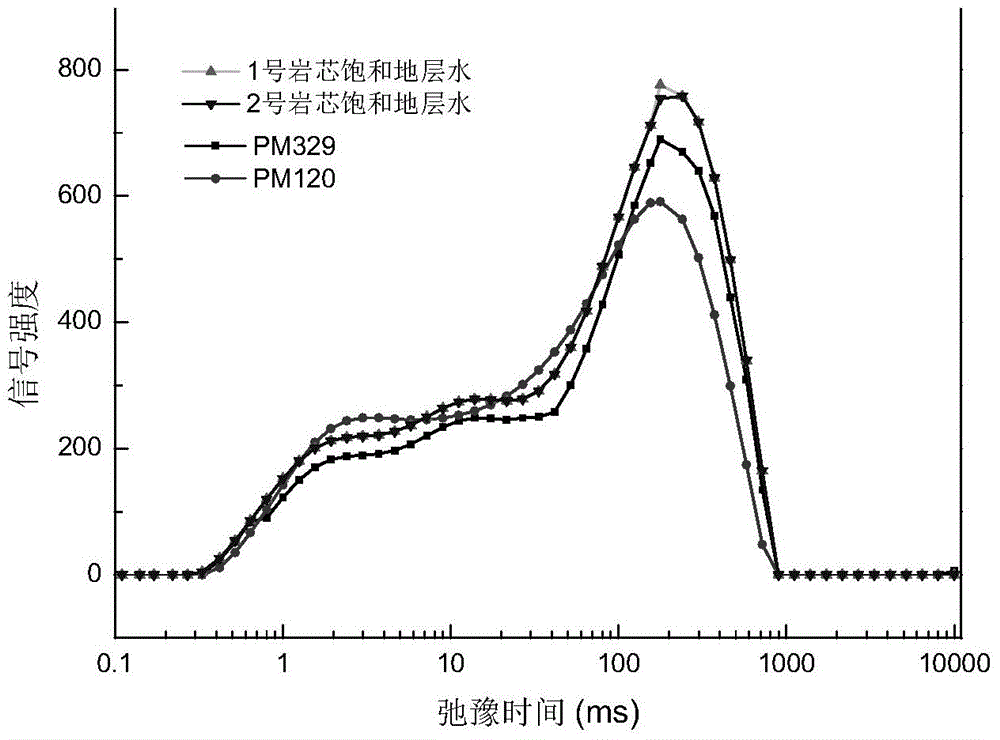

Oil-displacing agent and oil-displacing method for enhancing recovery ratio of high-temperature, high-salinity and high-hardness reservoir crude oil

ActiveCN103254883ALow critical micellar concentrationStrong ability to reduce interfacial tensionFluid removalDrilling compositionChemistryAlkylphenol

The invention relates to an oil-displacing agent and an oil-displacing method for enhancing the recovery ratio of high-temperature, high-salinity and high-hardness reservoir crude oil. The oil-displacing agent is composed of the following components in percentage by mass: A, 0.05-0.07% of an amine oxide type amphoteric surfactant; B, 0.15-0.20% of alkylphenol ethoxylate carboxylate; and C, the balance of water. The oil-displacing method disclosed by the invention is implemented through injecting the oil-displacing agent into a natural core subjected to oil-displacing under the conditions that the oil reservoir temperature is 100-120 DEG C, the total salinity of formation water is (10-15)*10<4> mg / L, and the amount of calcium-magnesium divalent metal ions is 7000-10000 mg / L, so that residual oil is in contact with the oil-displacing agent, and then the residual oil is fully displaced. The oil-displacing agent provided by the invention reaches the magnitude order of 10<-3> mN / m under the condition of high-temperature, high-salinity and high-hardness salt reservoirs, and the interfacial tension still can be maintained in an ultra-low interfacial tension state after the oil-displacing agent is aged for a long time under the condition of oil reservoirs, therefore, the oil-displacing agent is applied to the tertiary oil recovery production of oil fields.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

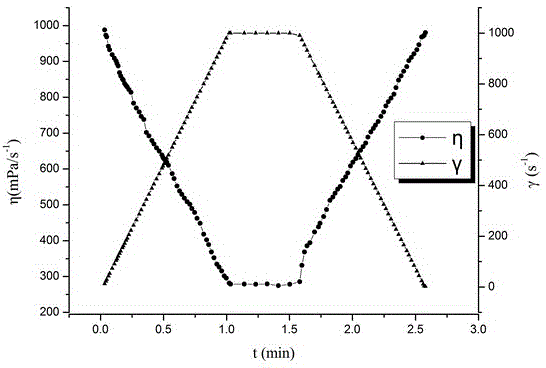

Temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer and preparation method thereof

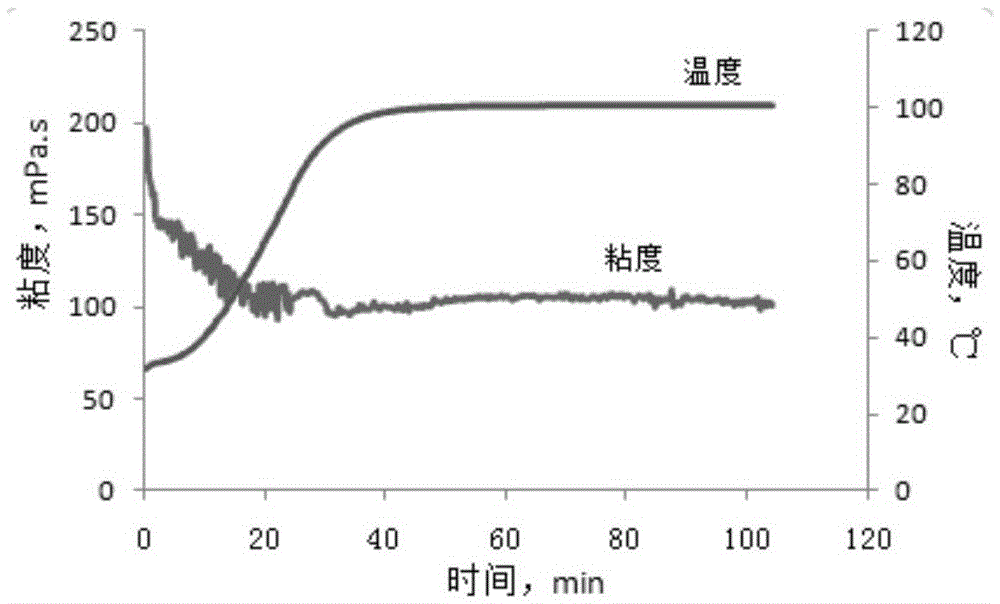

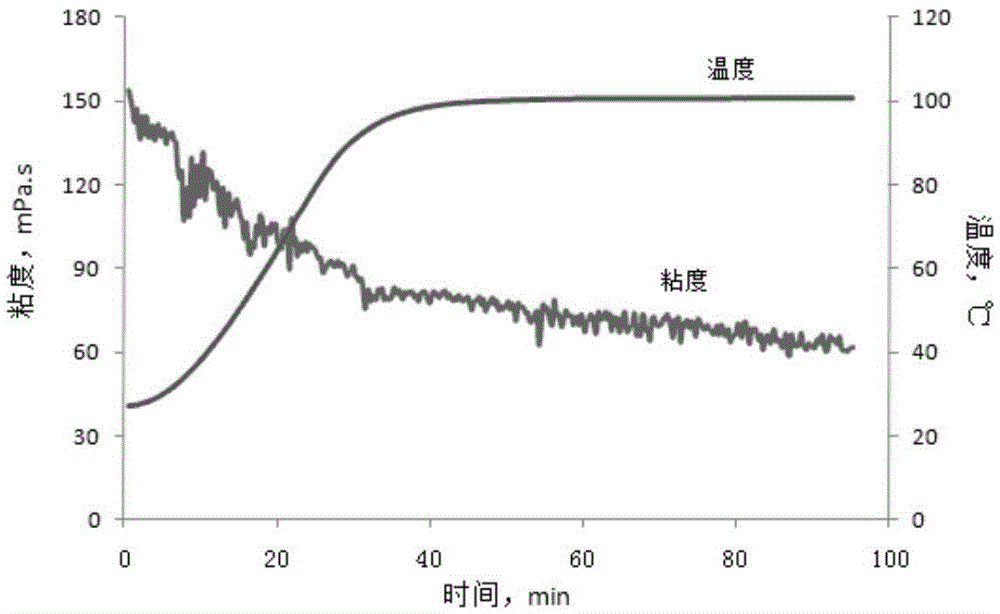

ActiveCN104892838AHigh interface activityReduce the amount of adsorptionDrilling compositionMethacrylateSolubility

The invention relates to a temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer and a preparation method thereof. The temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer is prepared by copolymerizing a monomer A, a monomer B and a monomer C, wherein the weight ratio of the monomer A to the monomer B to a monomer C is 10: (0.5-1.5): (0.05-0.15); the monomer A is acrylamide; the monomer B is 2-acrylamido-2-methyl propane sulfonate (AMPS), alpha-alkenyl sulphonate or vinyl sulfonate; the monomer C is poly(ethylene glycol) octadecyl methacrylate (OEMA). With a sulfonic acid group, the copolymer has excellent water solubility and temperature resistance; meanwhile, with a non-ionic hydrophobic unit, the copolymer has unique shear resistance and viscosifying ability; the copolymer has excellent performance, has a wide application prospect in the oil and gas resource exploitation under high temperature, high salt, low permeability, and can be used in an oil field displacement agent and a fracturing fluid thickener.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

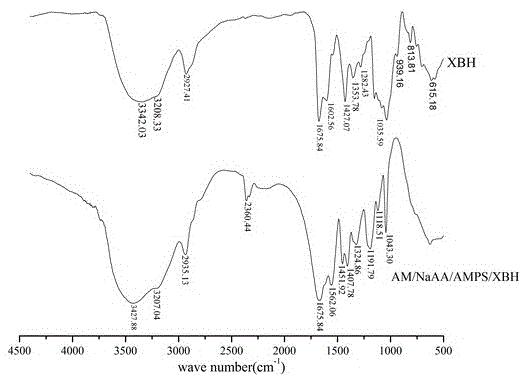

Polymer clay stabilizer containing Beta-cyclodextrin structure and synthesis method thereof

InactiveCN102618237AWith parcel landfill functionGood water solubilityDrilling compositionSolubilityPolymer science

The invention relates to a polymer clay stabilizer containing Beta-cyclodextrin structure and a synthesis method thereof, wherein the polymer clay stabilizer is used for restraining clay hydration swelling of an oil well. The technical scheme is as follows: the polymer clay stabilizer comprises the following materials and monomers in percentage by mass: 35-54.8% of acrylamide AM, 15-25% of sodium acrylate NaAA, 8-20% of 2-acryloyl-methyl-propyl sulfonate AMPS, and 0.2% of 2-O (propenyloxy-2-hydroxy-propyl)-Beta-cyclodextrin XBH; 0.02g of XBH and 2g of AMPS are added into a flask, and then 5.48g AM, 1.915g of AA and 0.585 g of NaOH are added into the flask, so a water solution with the monomer mass percentage concentration of 20% is prepared, and nitrogen is introduced into the water solution for 20 min; (NH4)2S2O8 solution and NaHSO3 solution are then added into the water solution while nitrogen is continuously introduced into the water solution for 10-20 min, and reaction is carried out at the temperature of 35 DEG C for 4-12 hours; and finally, the reacted solution is subjected to washing with absolute ethyl alcohol, smashing and drying to obtain AM / NaAA / AMPS / XBH quaternary polymer. The polymer clay stabilizer has good water solubility, viscosifying capacity, temperature resistance, salt resistance, anti-shearing capacity and clay-swelling restraining capacity, and reaches the swelling prevention rate of 84.37% towards sodium-montmorillonite.

Owner:SOUTHWEST PETROLEUM UNIV

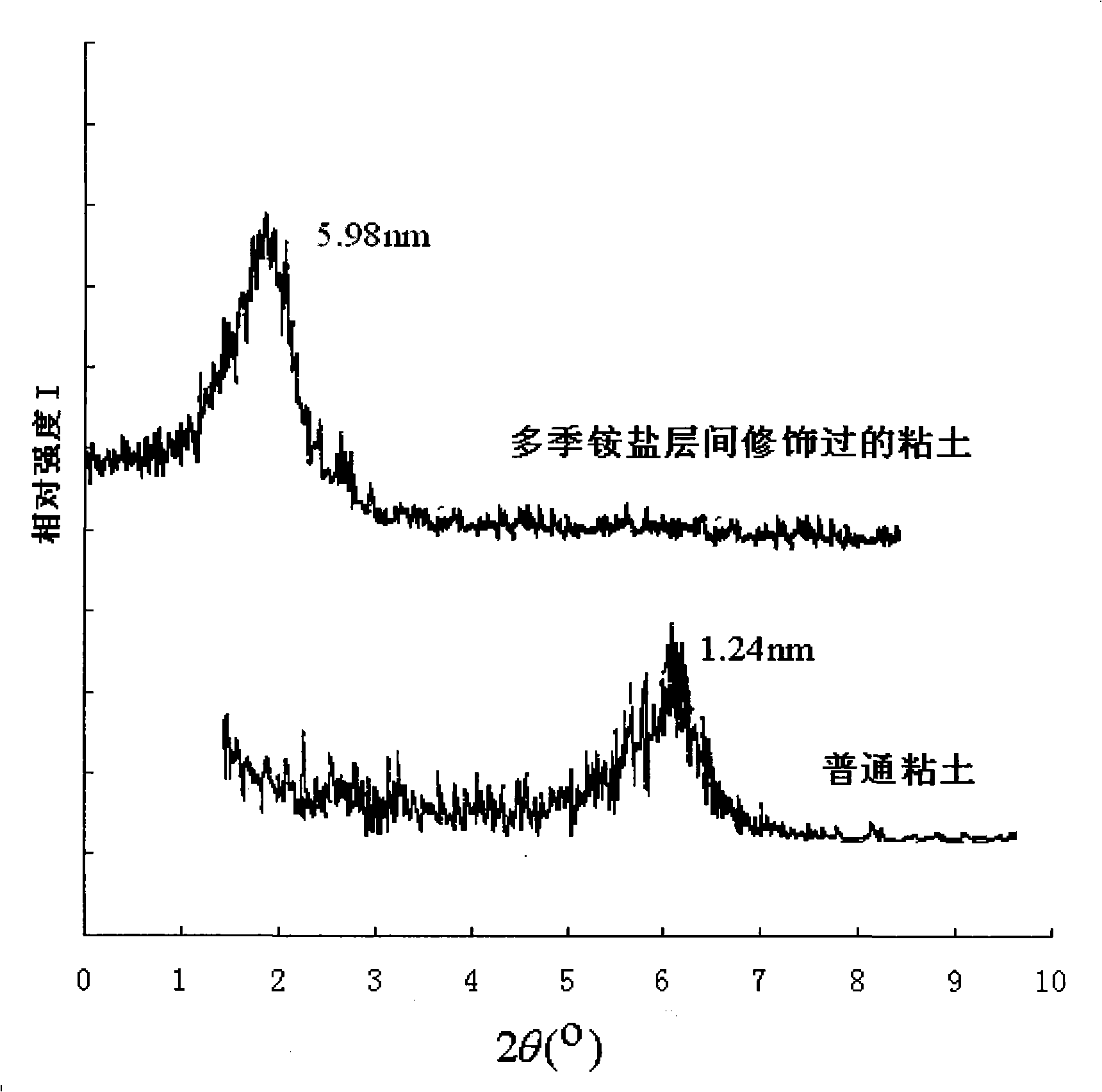

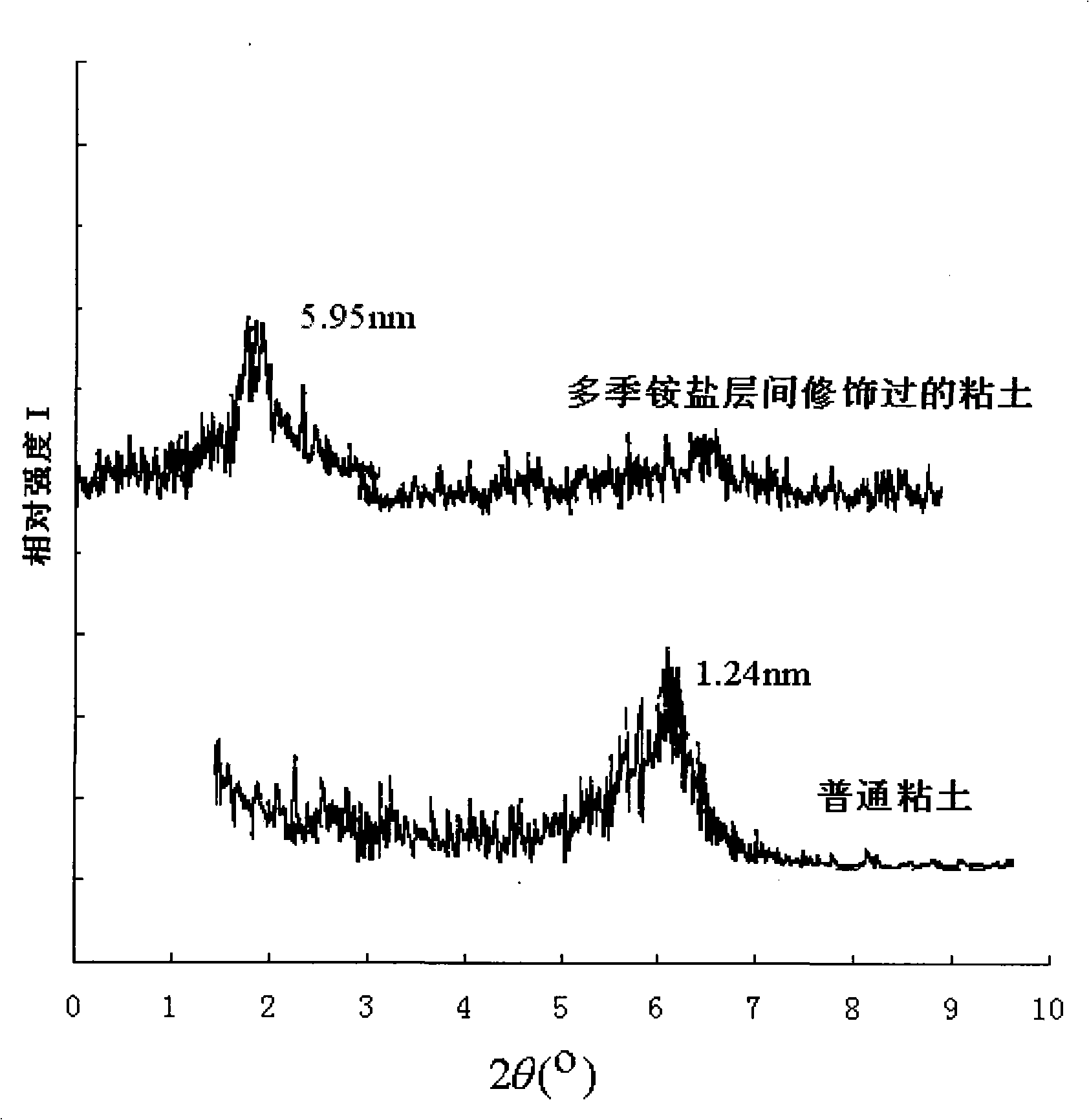

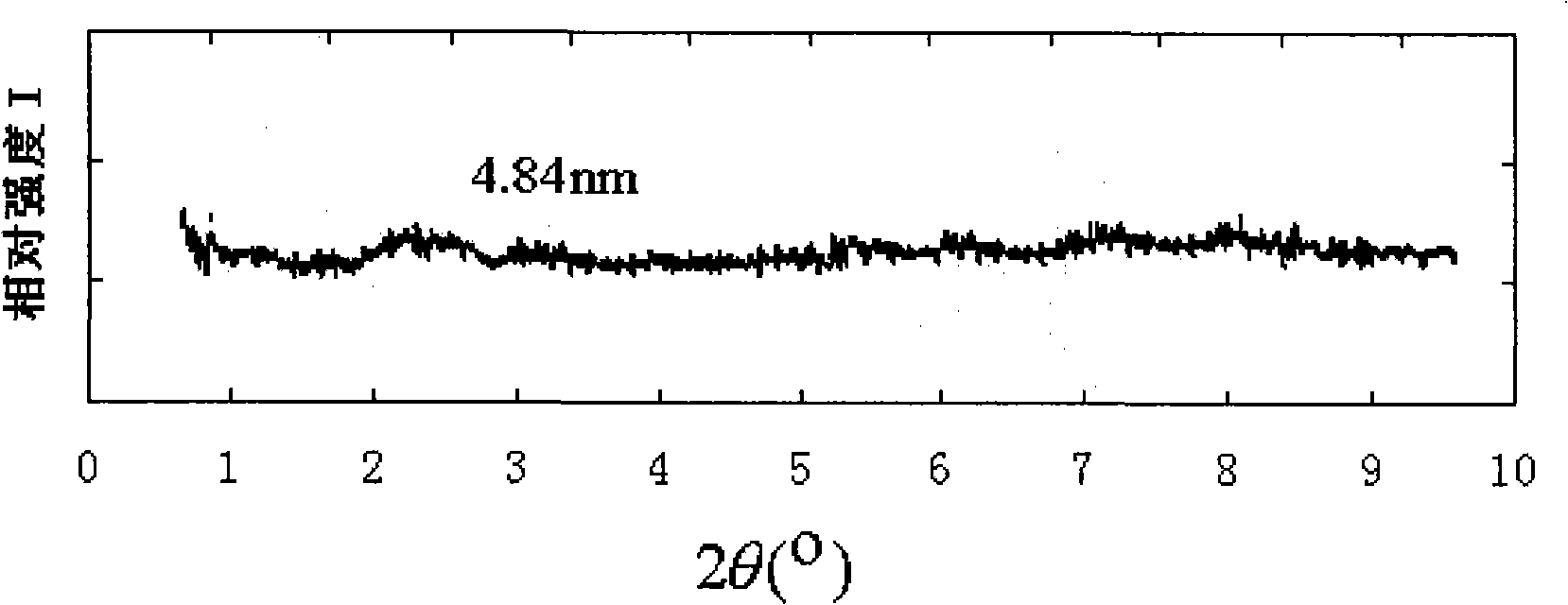

In-situ polymerization intercalated composite gel material and its preparation method and application

ActiveCN101260163AEstablishing the idea of in situ polymerization reactionSolve the problem that in-situ polymerization cannot occur to form intercalated compositesDrilling compositionRandom combinationPolymer science

The invention discloses an in-situ polymerization intercalation-type composite gel material and a preparation method and application thereof. The preparation method comprises the following steps: (1) interlayer dressing agent and clay are dissolved in water and are stirred 40 minutes to 60 minutes at a stirring speed of 10,000 to 15,000 r / min till the mixture is mixed evenly, thereby obtaining the mixing solution of the clay; (2) water-soluble monomer and initiator are added in the solution and are stirred 20 to 40 minutes at a stirring speed of 500 to 1,000 r / min till the mixture is mixed evenly; and (3) the reaction of the mixture is carried out under 80 to 140 DEG C for 6 hours to 12 hours. Moreover, the water-soluble monomer is one of or the random combination of acrylamide monomer, acrylic acid monomer, acrylonitrile monomer, acrylic ester monomer, allyl alcohol monomer, allyl urea monomer, allyl ether monomer, allyl ester monomer, allyl ether ester monomer and allyl azide monomer. Because the interlayer dimension of the composite gel material is between 4.5 nm and 6.0 nm, the composite gel material has excellent mechanical strength, injection performance, temperature resistance, salt resistance and plugging performance, thereby having a broad application prospect in the preparation of material for profile control and water shutoff.

Owner:CHINA NAT OFFSHORE OIL CORP +1

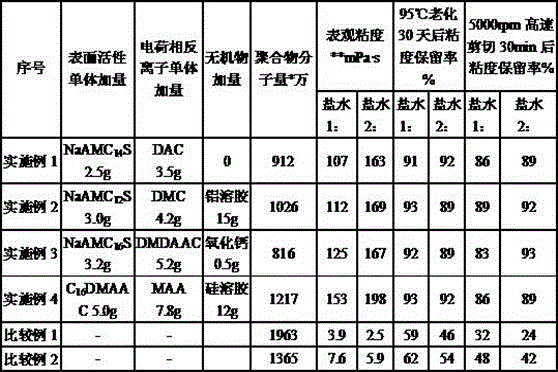

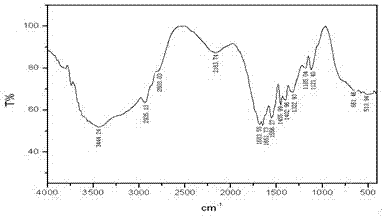

Method for preparing temperature-resistant anti-salt amphoteric polymer filtrate reducer

The invention relates to a method for preparing a temperature-resistant anti-salt amphoteric polymer filtrate reducer used for drilling fluid. In the filtrate reducer, C6 to C10 paraffin hydrocarbons are used as a continuous phase; Span and Tween are used as a compound non-ionic surface active agent, wherein the mass ratio of the Span to the Tween is 2-4:1-3; three monomers, namely acrylamide(AM), acrylic acid(AA) and styrene sulfonic sodium(SSS), are used as raw materials in a mass ratio of 10:3-6:1-4; and an initiator of ammonium persulphate or redox initiator of ammonium persulphate-sodium bisulphite is added for copolymerization by adopting an opposite micro-emulsion polymerization method to obtain the filtrate reducer. The filtrate reducer provided by the invention has the advantages of higher temperature resistance, salt resistance and filtrate-reducing property, simple preparation method, mild and controllable reaction conditions, high polymerization stability, high reaction speed and high conversion rate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

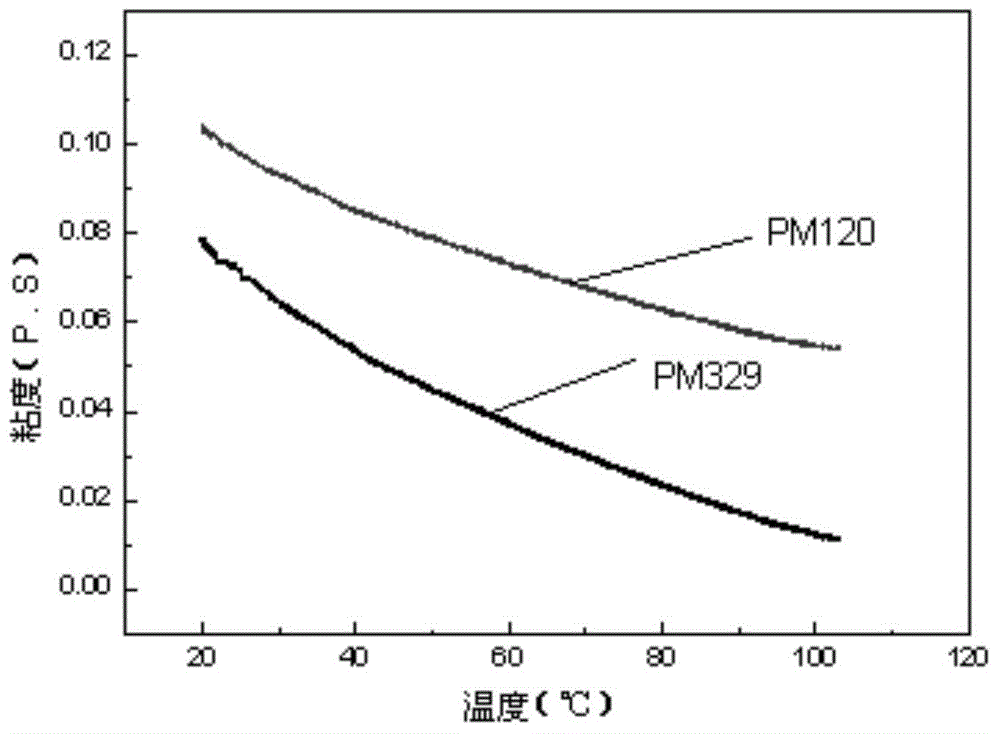

Preparation method of water-soluble anion polymer-type thickened oil viscosity reducer

ActiveCN107880214ARaw materials are cheap and easy to getSimple processDrilling compositionReduction rateEnd-group

The invention relates to a preparation method of a water-soluble anion polymer-type thickened oil viscosity reducer. The thickened oil viscosity reducer comprises a component A and a component B; thecomponent A is an acrylamide copolymer containing acryloyl morpholine blocks; the component B is an acrylamide copolymer containing active end groups. A thickened oil viscosity reducer solution is mixed with thickened oil; it is proved through viscosity reduction tests that when the dosage reaches 0.2 mg / mL, the viscosity reducer can achieve high-temperature stirred emulsification and viscosity reduction in pure water and salt water, the viscosity reduction rate is greater than 93%, and stirred demulsification is stopped at room temperature. The thickened oil emulsification viscosity reducer is obvious in viscosity reduction effect and high in environmental adaptability, the emulsification and viscosity reduction behaviors of the thickened oil viscosity reducer have temperature and shearing responsiveness, and convenience is provided for application and post-treatment in oil fields.

Owner:CHINA NAT OFFSHORE OIL CORP +2

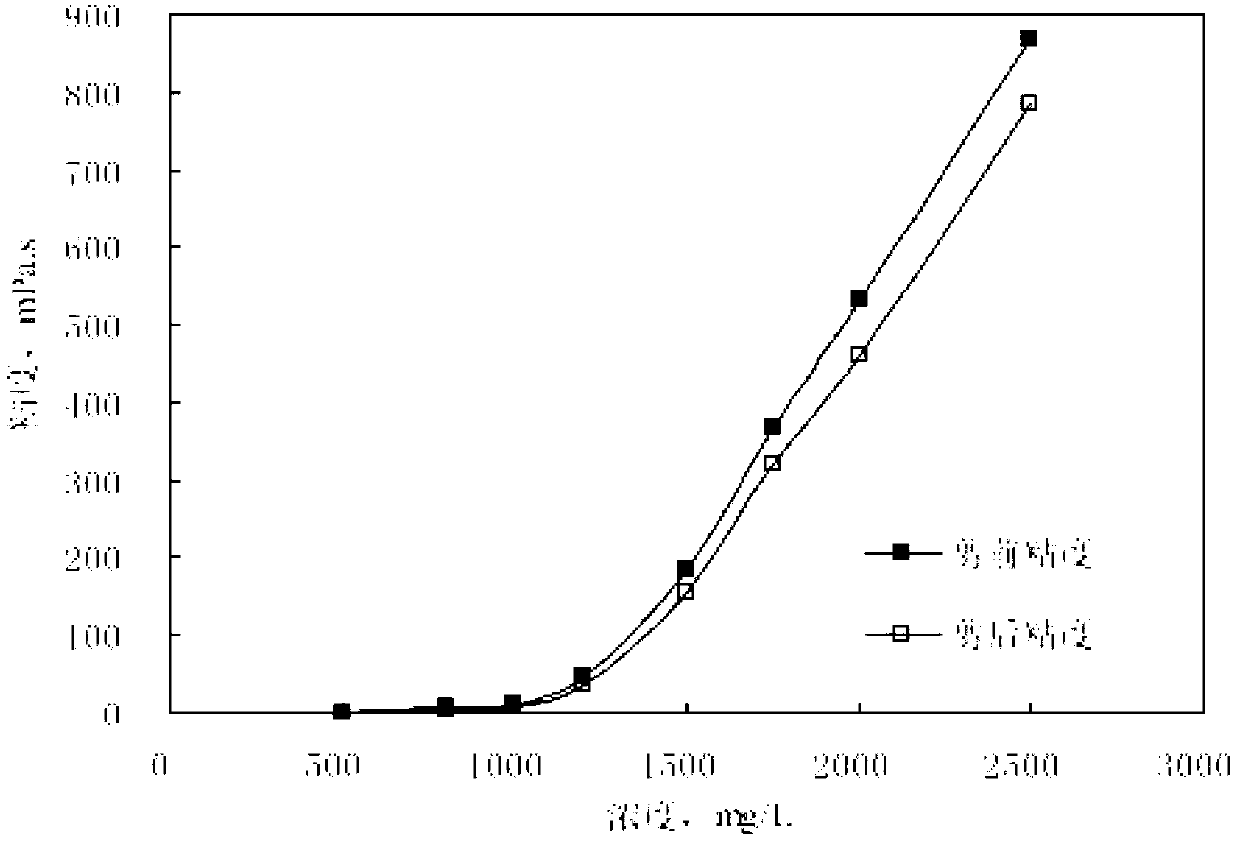

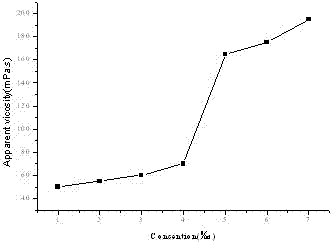

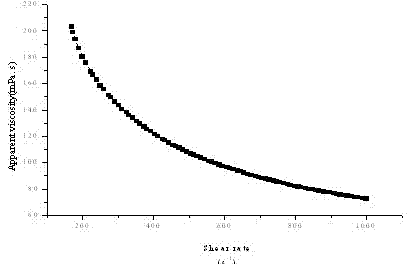

Hydrophobically associating water-soluble polymer (HAWSP) oil displacement agent and preparation method thereof

InactiveCN102391417ASoluble in waterGood temperature and salt resistanceDrilling compositionPolymer sciencePolymer flood

The invention relates to a hydrophobically associating water-soluble polymer (HAWSP) oil displacement agent and a preparation method thereof. The technical scheme is that: the HAWSP oil displacement agent comprises the following monomers and monomers in percentage by mass: 53.5 to 59.9 percent of acrylamide (AM), 40 to 45 percent of sodium acrylate (NaAA) and 0.1 to 1.5 percent of N-allyl oleylamine (NAO); and the preparation method comprises the following steps of: adding the NAO into a reactor; adding OP-10 and water; adding the AM, AA and NaOH after emulsification is performed completely to prepare a solution with the monomer total mass percentage concentration of 10 to 25 percent; adjusting the pH value to 7.5 to 11; introducing N2 for 20 minutes; adding an initiator; continuously introducing N2 for 20 minutes; reacting at the temperature of between 30 and 70 DEG C for 4 to 12 hours; washing by using absolute ethanol; and crushing and drying to prepare AM / NaAA / NAO terpolymer. The polymer has water solubility and high temperature tolerance, salt tolerance and shearing resistance, and can increase a crude oil recovery rate by over 10 percent simulatively.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing high-stability heat-resistance and salt-tolerance air foam oil displacing agent

InactiveCN104059625AReduce formulation costsEasy to useDrilling compositionFoaming agentApparent viscosity

The invention discloses a method for preparing a high-stability heat-resistance and salt-tolerance air foam oil displacing agent. According to the method, a nanometer and nanometer modification technology is adopted, and nanometer hectorite is used as a foam stabilizer and a high-temperature stabilizer to prepare the high-stability heat-resistance and salt-tolerance air foam oil displacing agent. The technology includes the following steps that the hectorite is added into deionized water at the temperature of 50-90 DEG C, stirred and dispersed evenly, cooled to the room temperature and stewed and aged for a period of time to obtain hectorite aqueous dispersion, quantitative cationic surface active agents are added, evenly stirred, stewed and aged, finally, foaming agents are added, high-speed stirring is conducted on a high-speed emulsification machine, and the high-stability heat-resistance and salt-tolerance air foam oil displacing agent is obtained. The foam half-life period reaches up to 768 hours, the high foam stability is achieved, the foam half-life period reaches up to 70 hours under the condition that the degree of mineralization is 30000 mg / L, the good salt tolerance is achieved, the apparent viscosity reaches up to 2000 mPa.s, the heat resistance performance reaches 90 DEG C, the high foam strength and the heat resistance are achieved, the shearing rate is 170 per second, the foam apparent viscosity reaches 800 mPa.s after shearing is conducted for 60 minutes, the good shearing performance is achieved, and the method is suitable for exploration and development of conventional and unconventional oil fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

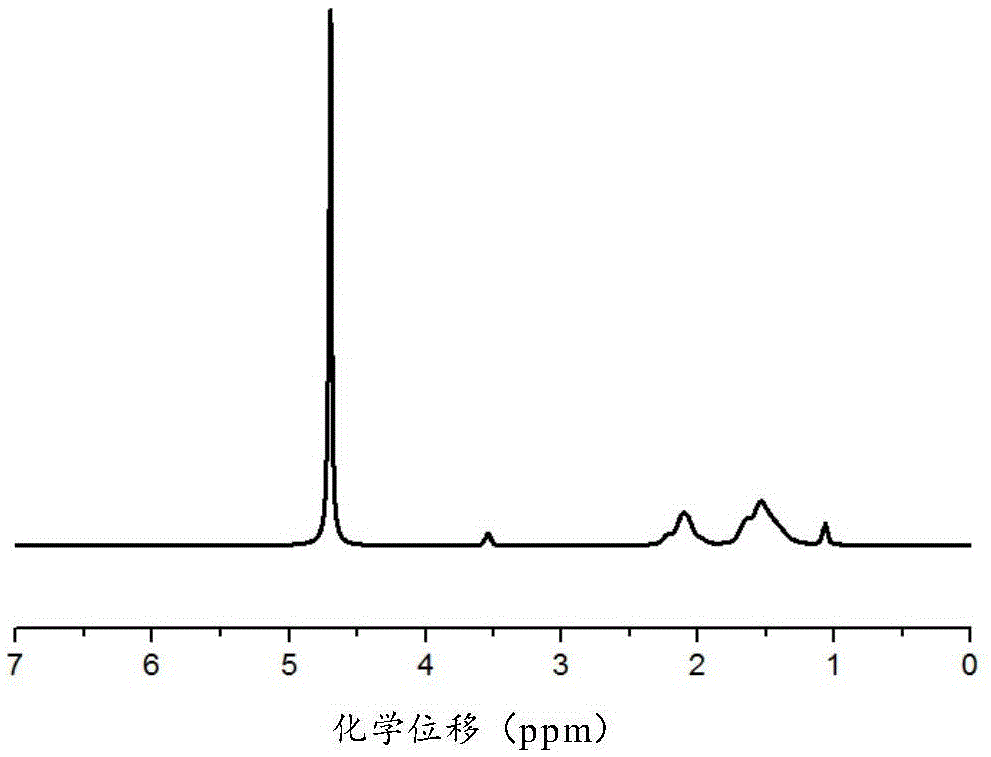

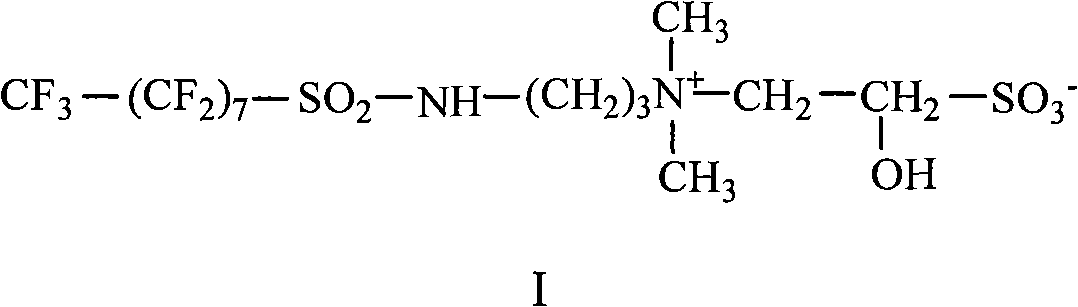

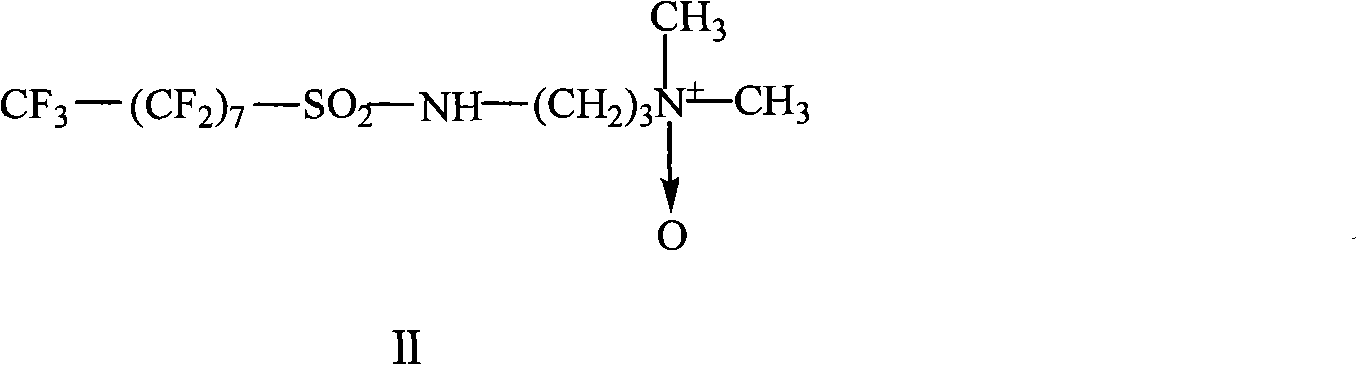

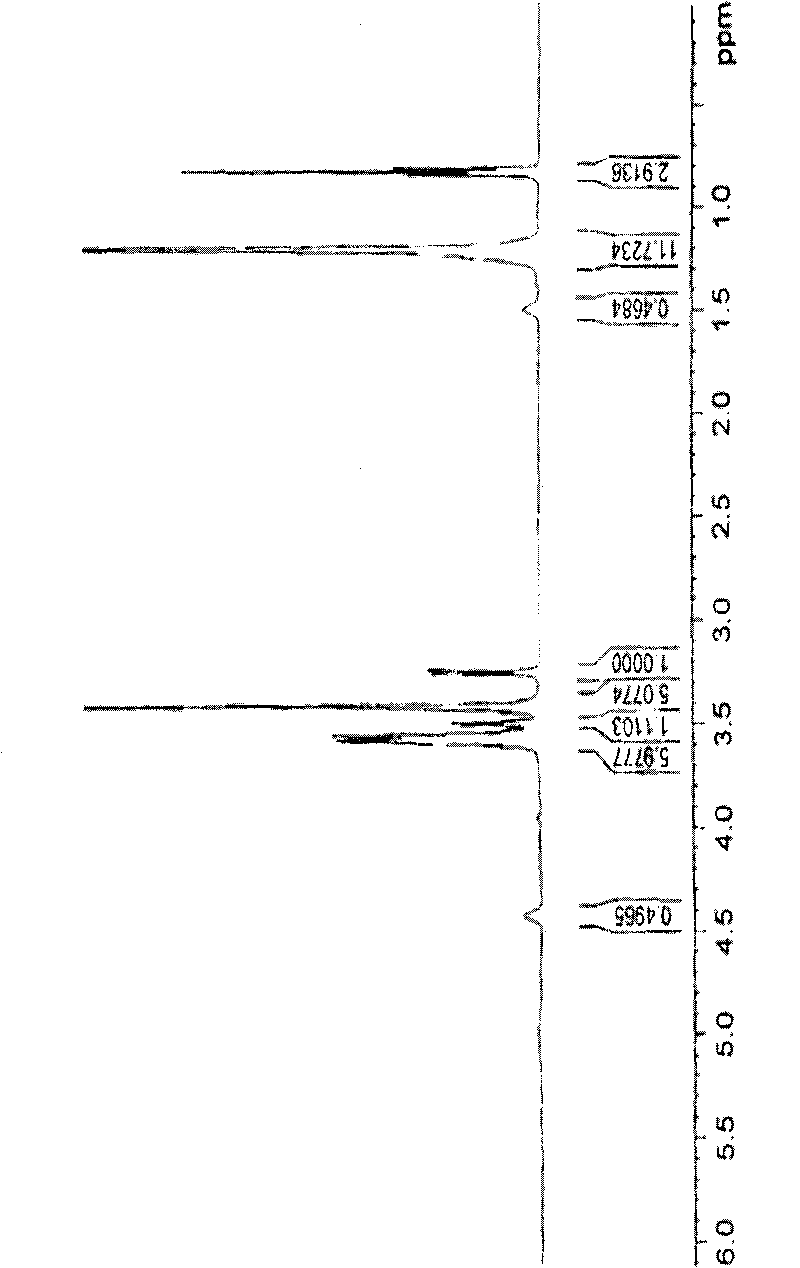

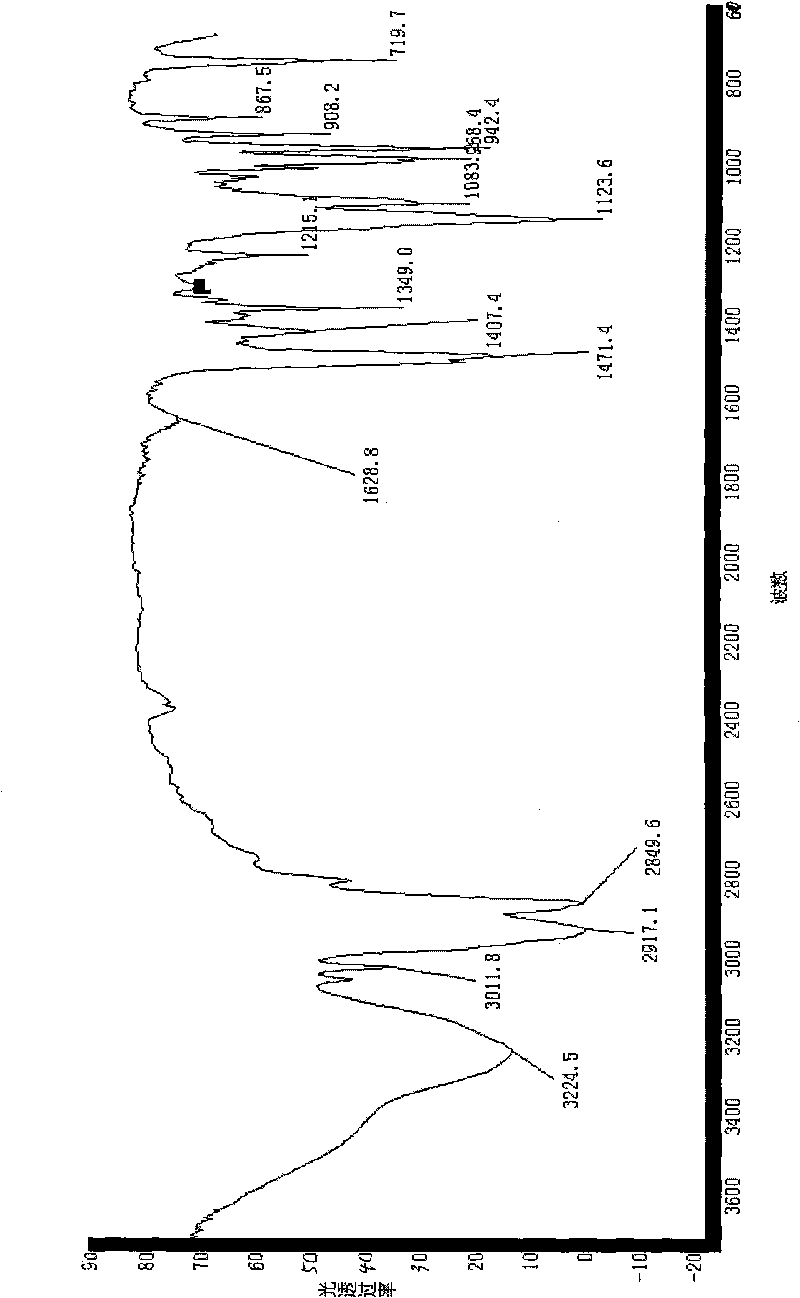

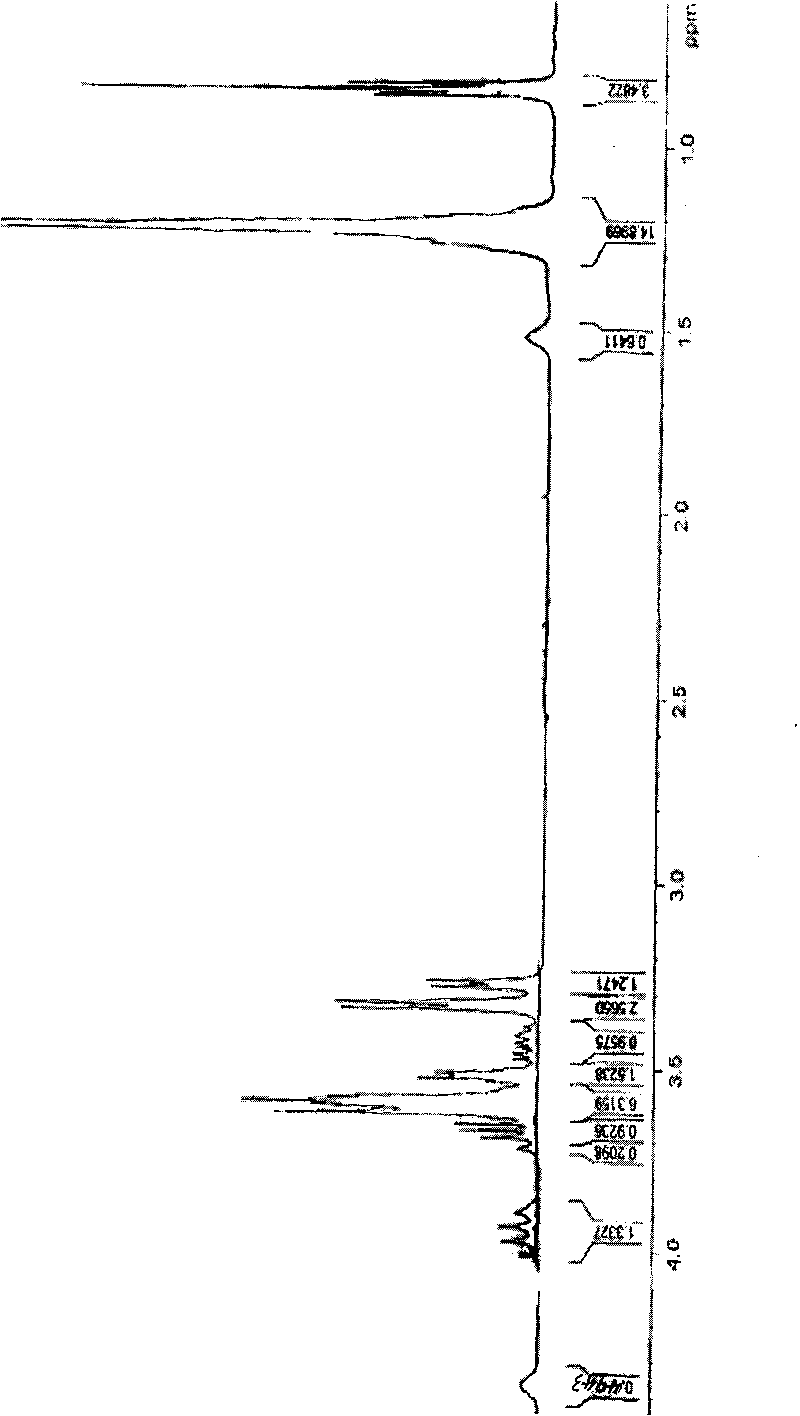

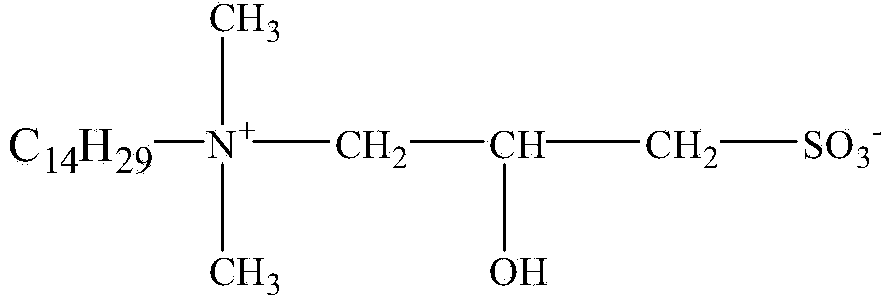

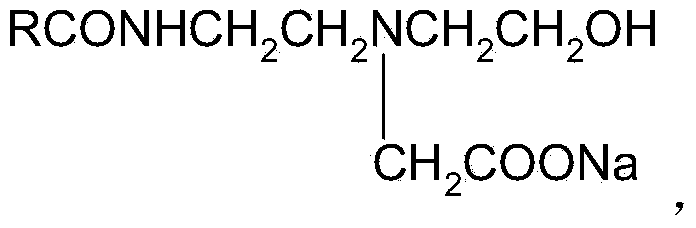

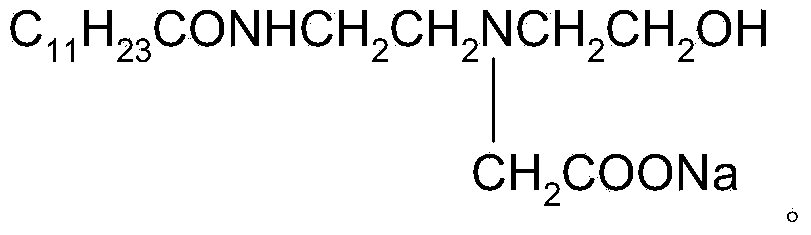

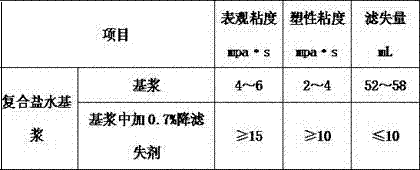

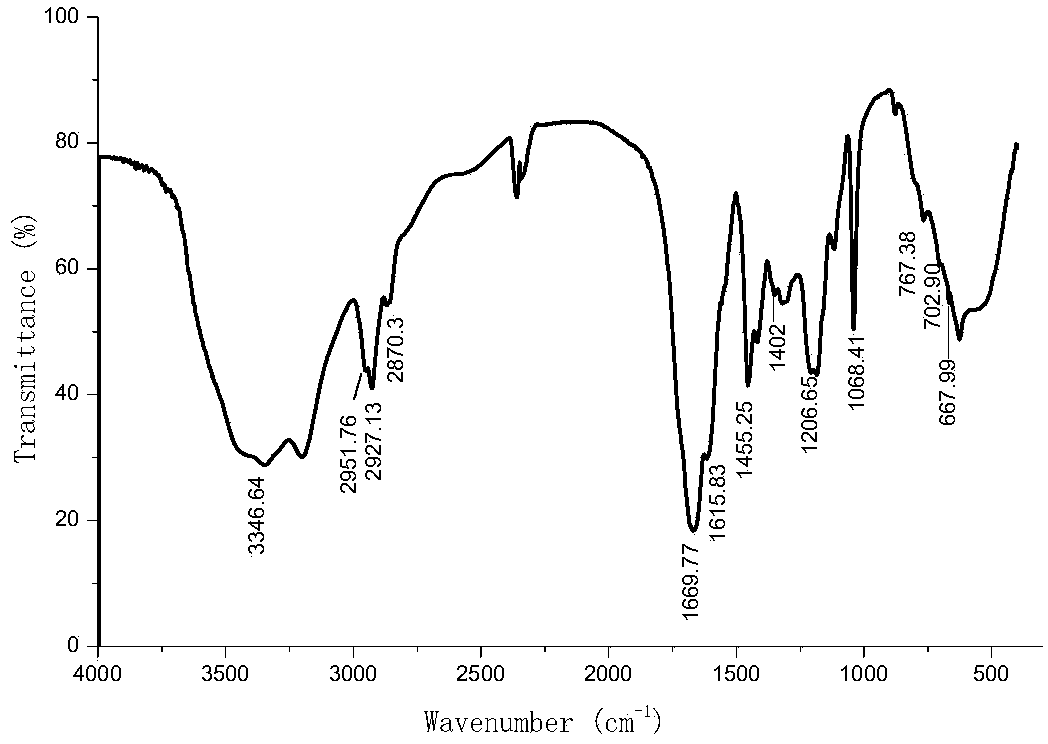

Amphipathic polymerizable monomer and amphipathic tackifying copolymer and preparation method and application thereof

InactiveCN102452964ASelf-solubilizingImprove solubilitySulfonic acids salts preparationDrilling compositionSolubilityHydrogen

The invention provides an amphipathic polymerizable monomer with a structure shown as a formula (I), and further provides a preparation method for the amphipathic polymerizable monomer and an amphipathic tackifying copolymer. The amphipathic polymerizable monomer has high amphipathy, and has a self-solubilizing function when used for preparing a polymer; a copolymer with an amphipathic micro block structure and high solubility can be obtained without adding any surfactant; the amphipathic polymerizable monomer belongs to a derivative of acrylamide, and is easy to copolymerize with an acrylamide monomer; and two hydrogen atoms on acidamide N are substituted, so that the hydrolytic resistance of the acidamide N and the copolymer are enhanced, and the high-temperature stability of the copolymer is enhanced. The amphipathic tackifying copolymer has a simple preparation process, and can be prepared without adding a large quantity of surfactants, and the production cost is greatly lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

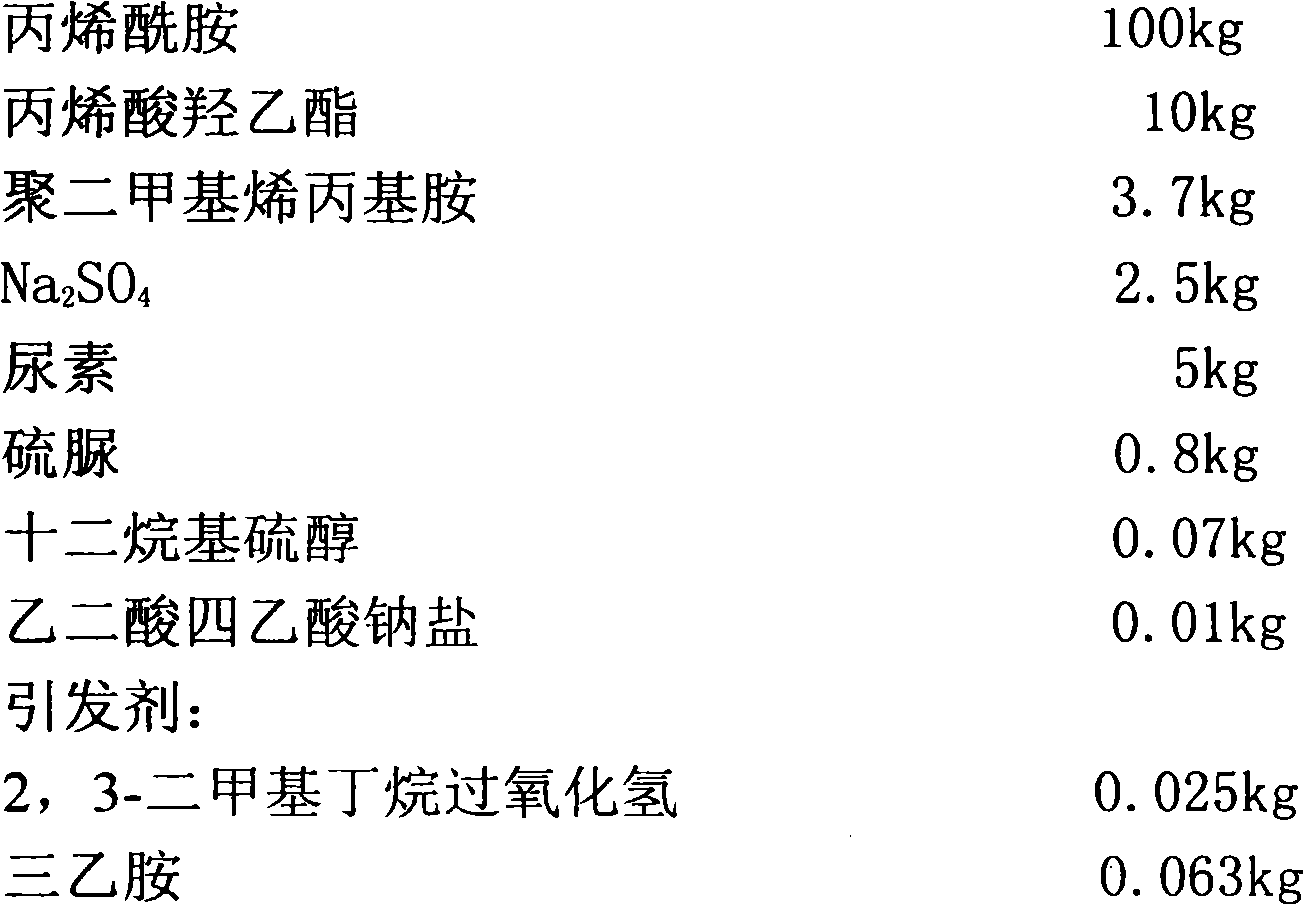

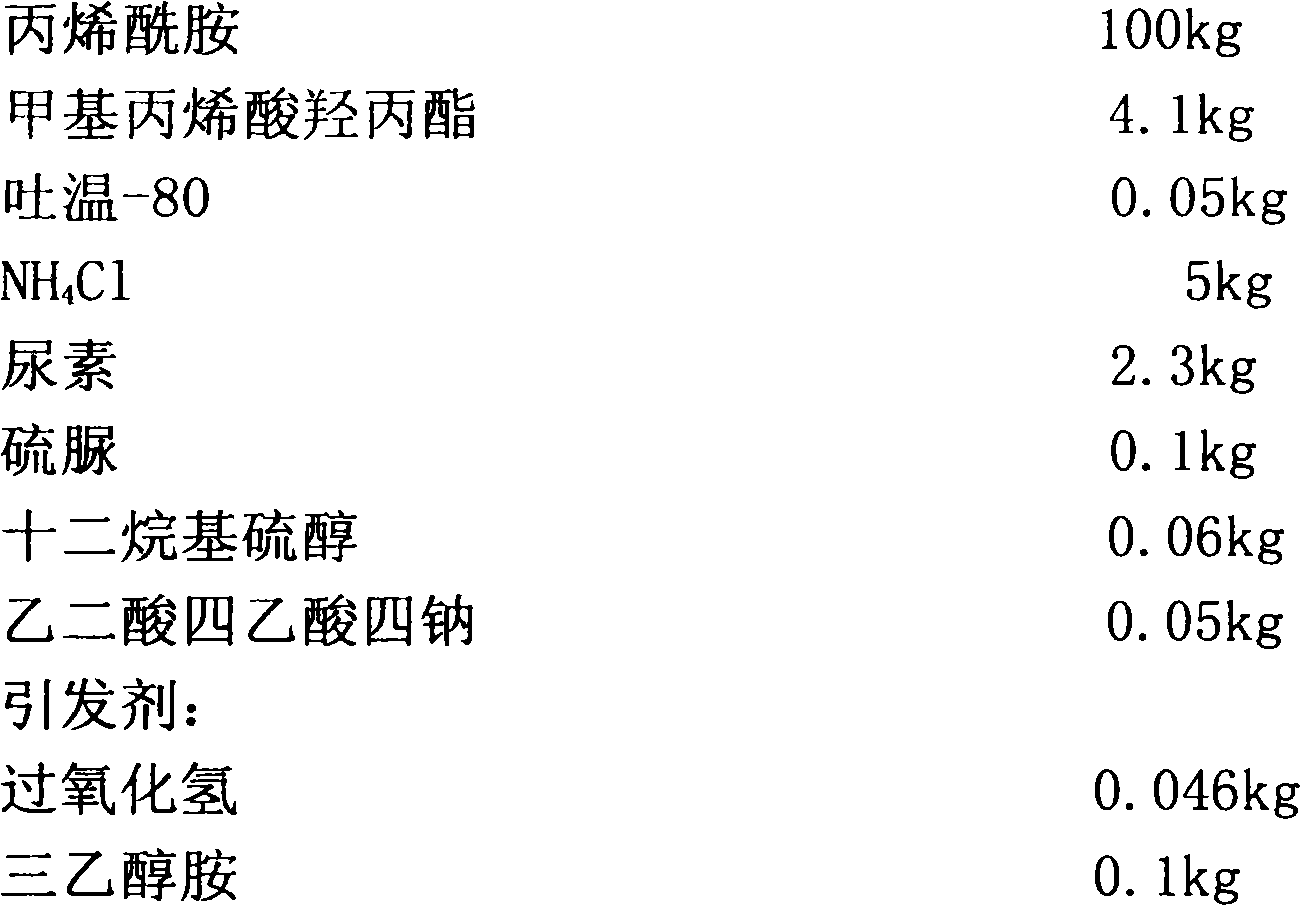

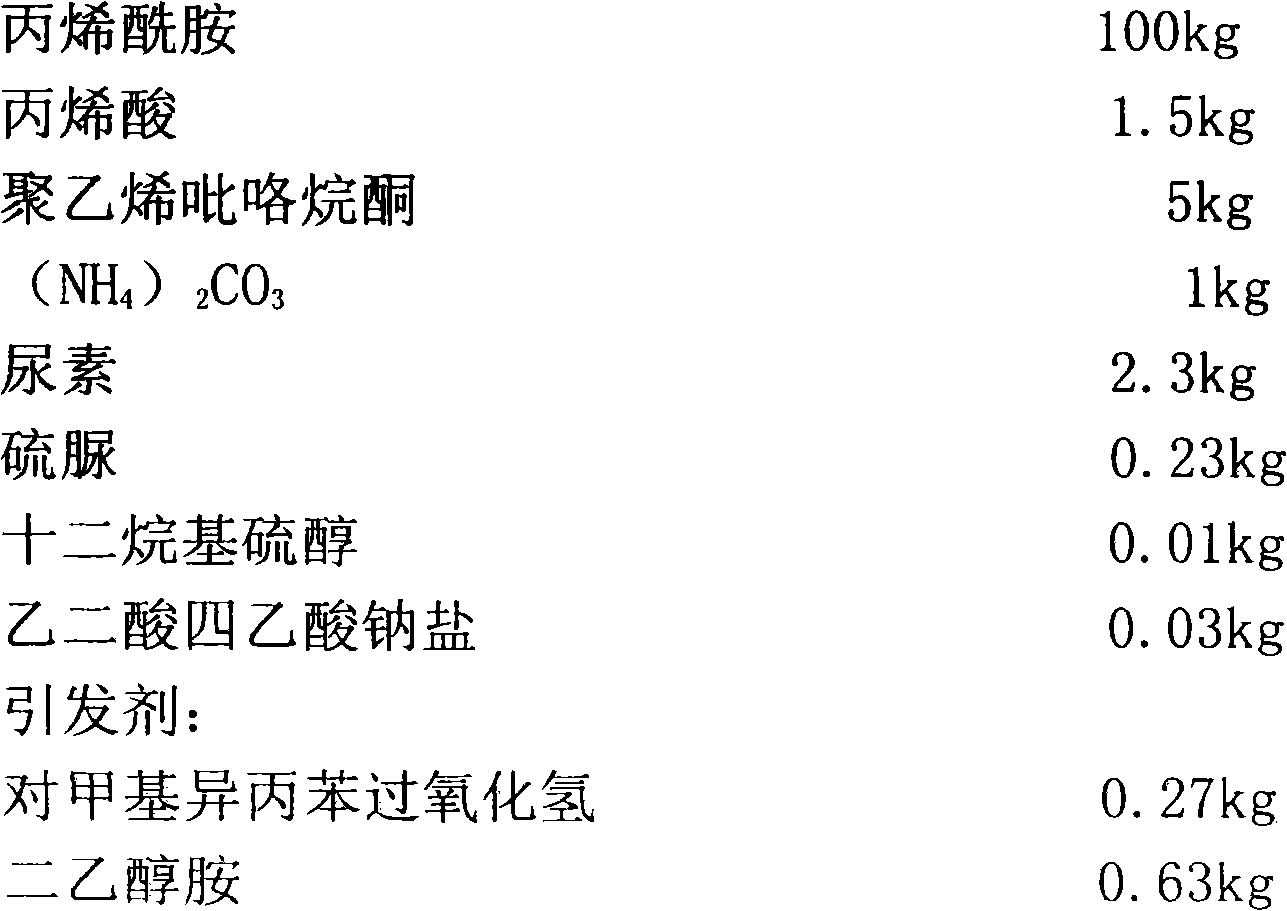

Initiator composition used for synthesizing polyacrylamide capable of displacing oil

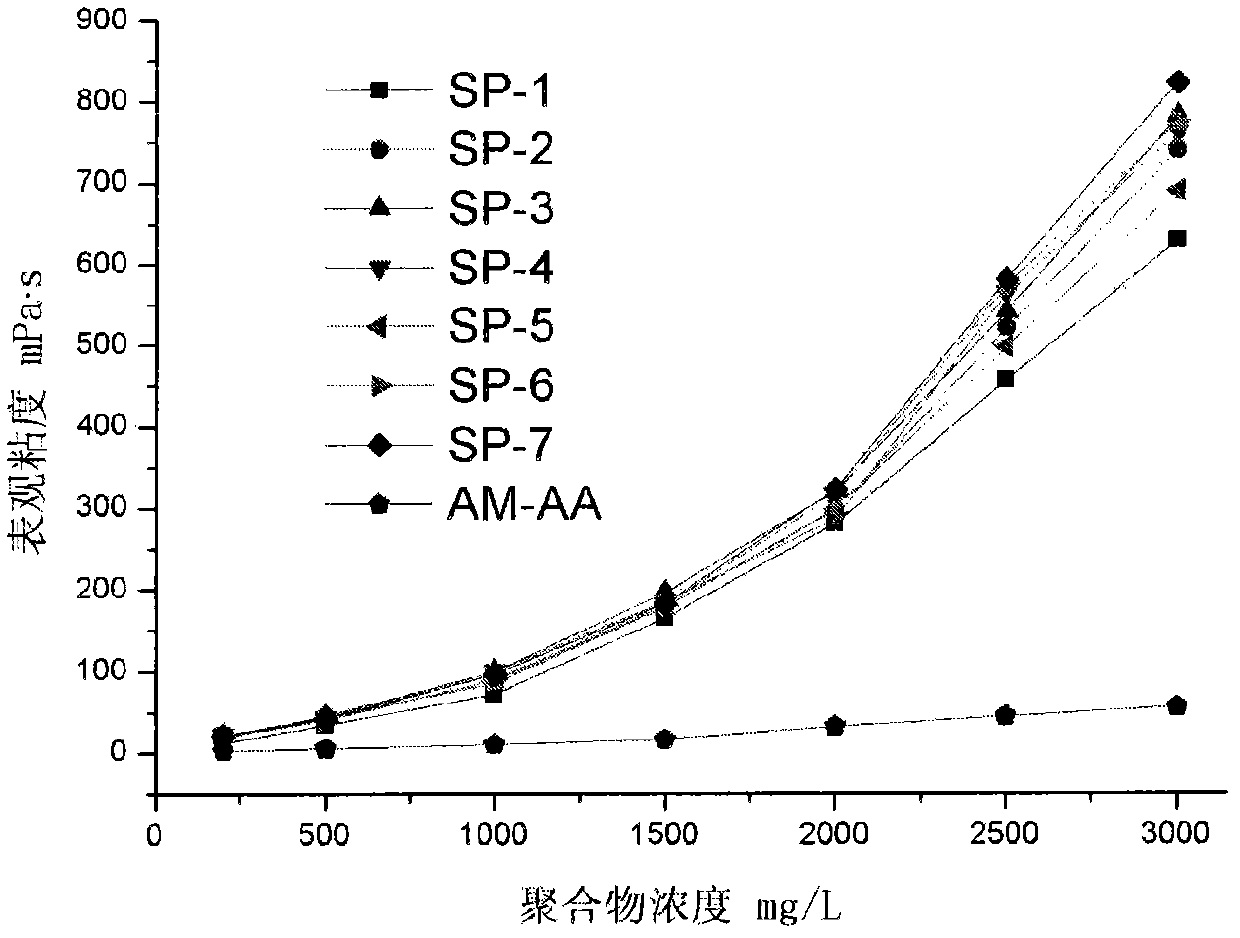

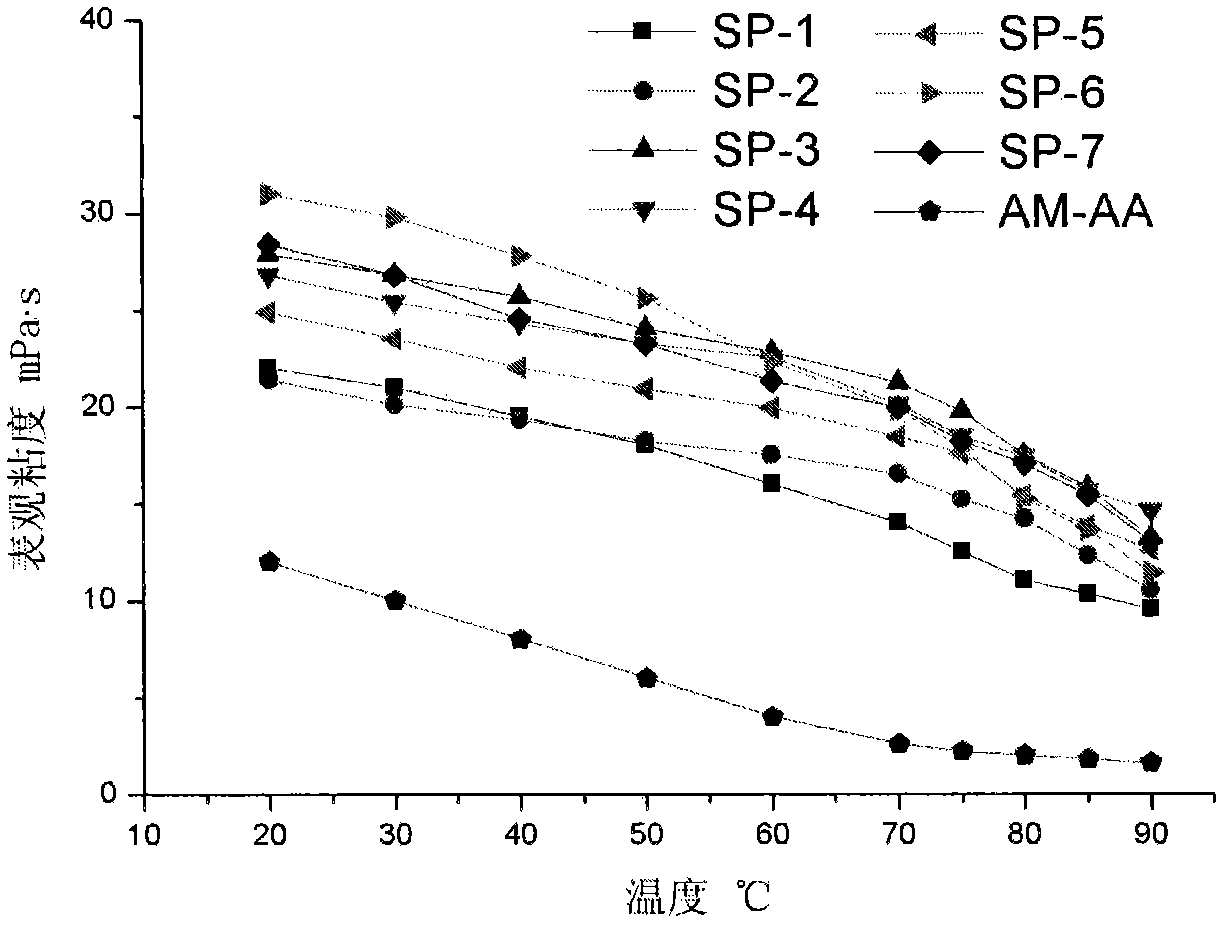

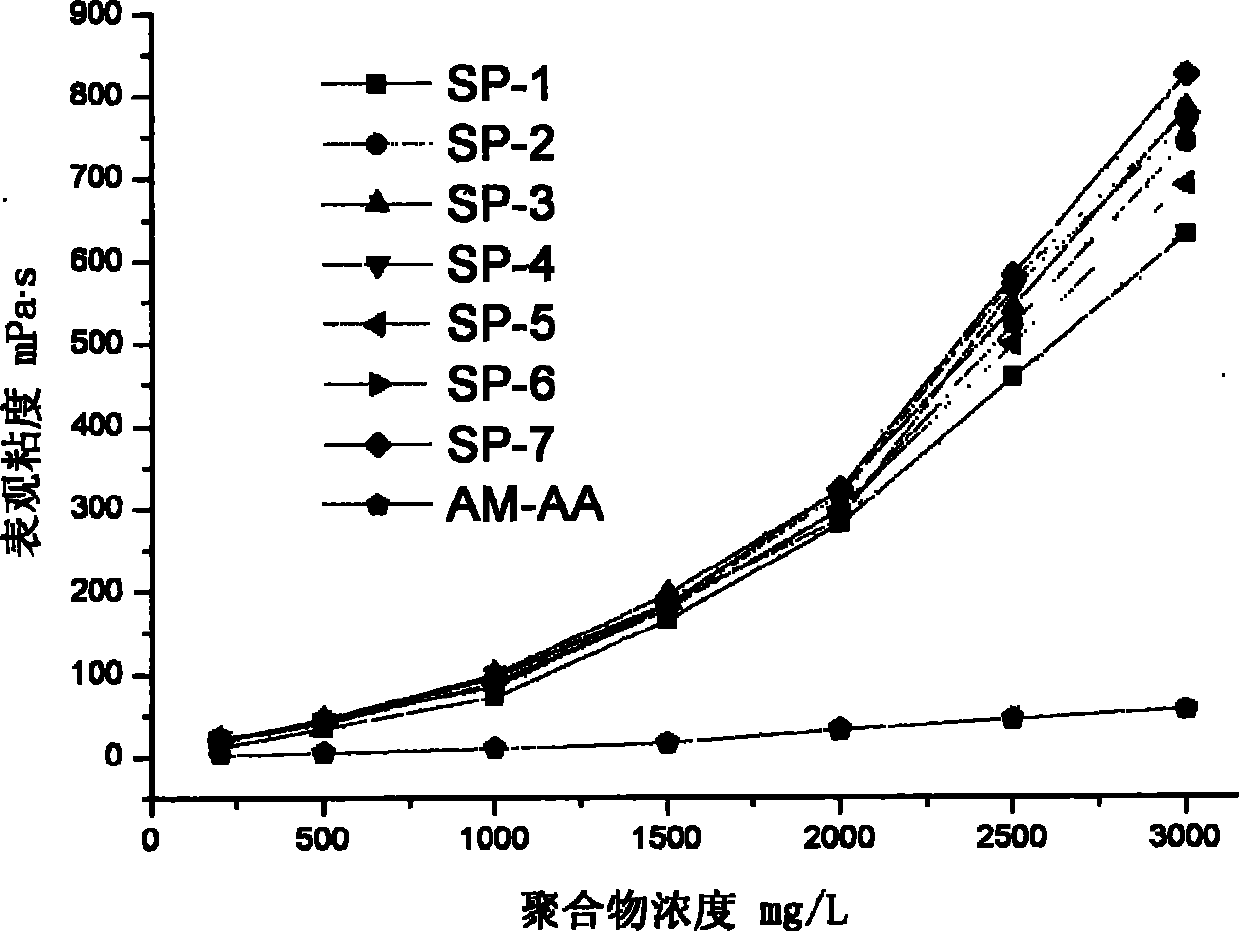

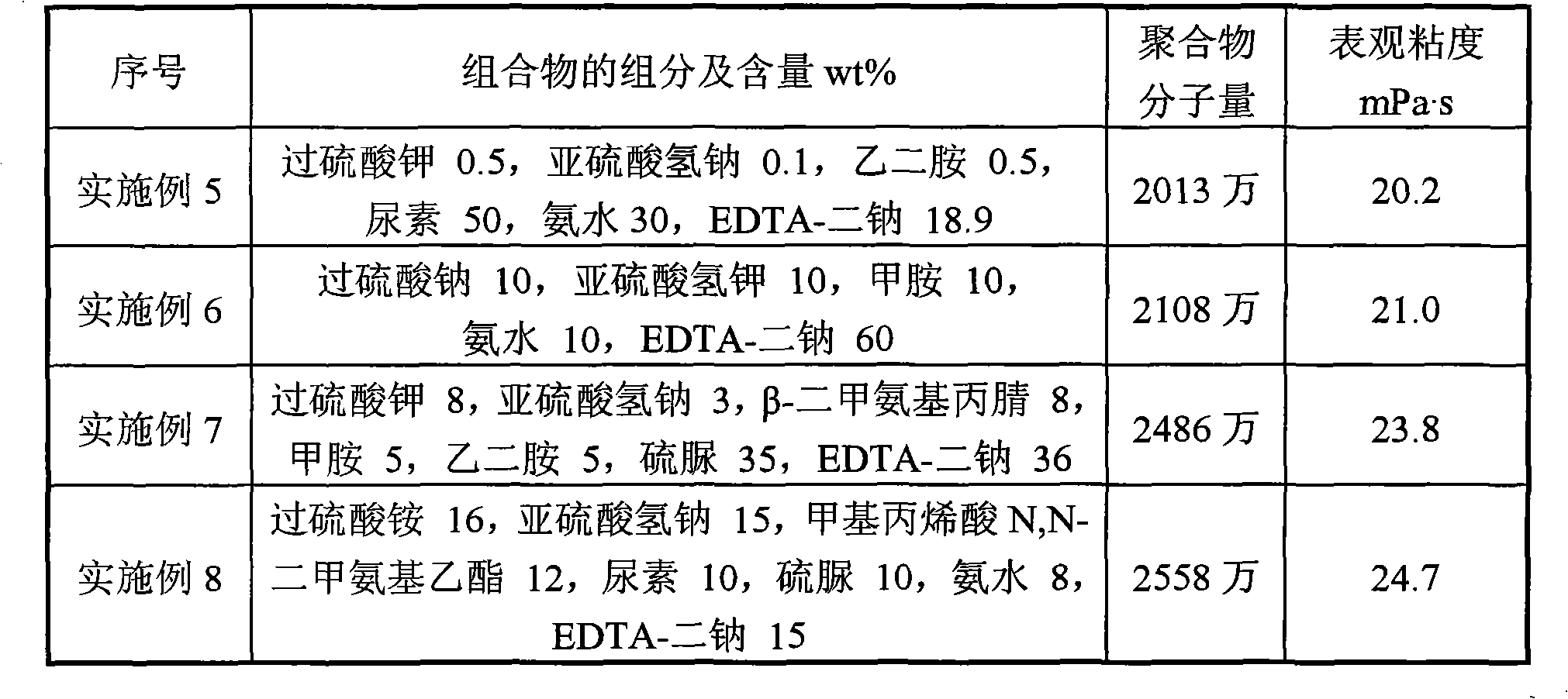

ActiveCN102372806AImprove solubilityEven growthDrilling compositionEthylenediamineAmmonium compounds

The invention relates to an initiator composition used for synthesizing polyacrylamide capable of displacing oil, which mainly solves the problems of low polyacrylamide molecular weight, poor heat resistance and salt resistance performances and difficult satisfaction for technical requirement of tertiary oil extraction. The initiator composition used for synthesizing polyacrylamide capable of displacing oil comprises the following ingredients by weight percentage: (a) 0.5-20% of persulfate; (b) 0.1-40% of sulfite or acid sulfite; (c) 0.5-20% of NR1R2R3-represented trialkylamine compounds or N<+>R4R5R6R7-represented quaternary ammonium compounds or NH2R8-represented aliphatic amine compounds, wherein R1-R7 in the formula are selected from C1-C14 straight chain or branched chain alkyl or alkyl derivatives, R8 is selected from straight chain or branched chain alkyl or alkyl derivatives; (d) 10-80% of urea, thiourea or ammonia liquor; (e) 5-60% of ethylenediaminetetraacetic acid. The technical scheme of the invention better solves the problems and can be used in industrial production of oil displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Temperature-resistant salt-resistant profile control plugging agent and preparation method thereof

InactiveCN106675540AImprove thermal stabilityImprove salt resistanceDrilling compositionSalt resistanceRoom temperature

The invention discloses a temperature-resistant salt-resistant profile control plugging agent and a preparation method thereof. The temperature-resistant salt-resistant profile control plugging agent is prepared from the following raw materials in parts by weight: 1-3 parts of temperature-resistant salt-resistant polyacrylamide, 0.15-1.2 parts of crosslinking agent A, 0.03-0.1 part of crosslinking agent B, 0.01-0.1 part of setting retarder, 1-7.5 parts of pH regulator and 988-997 parts of water. The preparation method comprises the following steps: adding the pH regulator into the water, sufficiently dissolving, adding the temperature-resistant salt-resistant polyacrylamide, stirring for 2-4 hours, adding the setting retarder and crosslinking agent B, stirring at normal temperature for 1-2 hours, adding the crosslinking agent A, stirring uniformly, and standing at the constant temperature of 70-90 DEG C for 3-5 days. The profile control plugging agent has the characteristics of temperature resistance, salt resistance, high gel strength, adjustable gelling time and the like, has selectivity for oily water plugging, and can enter the deep part of the oil reservoir after being injected to plug the high-transmissibility paths, thereby improving the waterflooding development effect and enhancing the recovery ratio of the oil reservoir.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Oil displacing agent for increasing oil recovery in high temperature high salt mid-low permeability oil reservoir, preparation method and applications thereof

ActiveCN105505364AGood temperature and salt resistanceGood thermal stabilityDrilling compositionChemistryChromatographic separation

The invention relates to an oil displacing system for increasing oil recovery in high temperature high salt mid-low permeability oil reservoir, and a preparation method thereof, and aims to solve the problems that in the prior art, hydrophobic associated polymer can easily obstruct the holes of sandstone formation, the injection performance of oil displacing agent is bad in the immediate vicinity of wellbore, the oil displacing agent can only applied to mid-high permeability oil reservoirs, and the hydrophobic associated polymer can easily react with oil displacing surfactant to generate chromatographic separation. The oil displacing agent comprises the following components in parts by weight: 0.01 to 1 part of adsorption resisting agent, 0.05 to 3 parts of hydrophobic associated polymer, 0.2 to 5 parts of oil displacing surfactant, and 91 to 99.8 parts of water; wherein the adsorption resisting agent is one or more of nonionic surfactant and anionic surfactant. The provided oil displacing agent well solves the problems mentioned above, and can be applied to the onsite oil displacing in a mid-low permeability oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

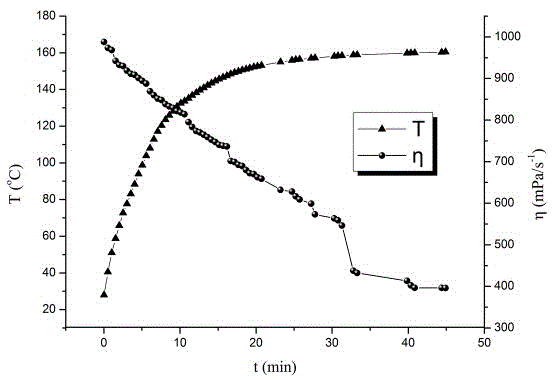

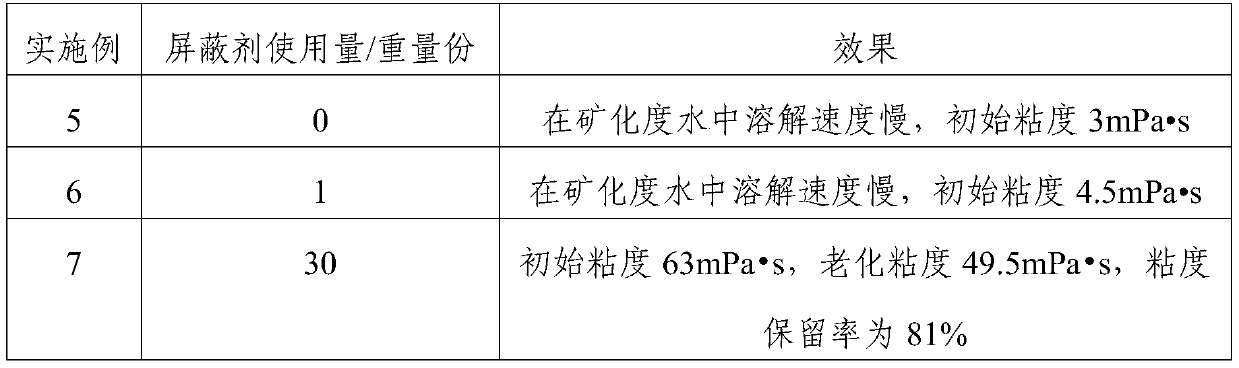

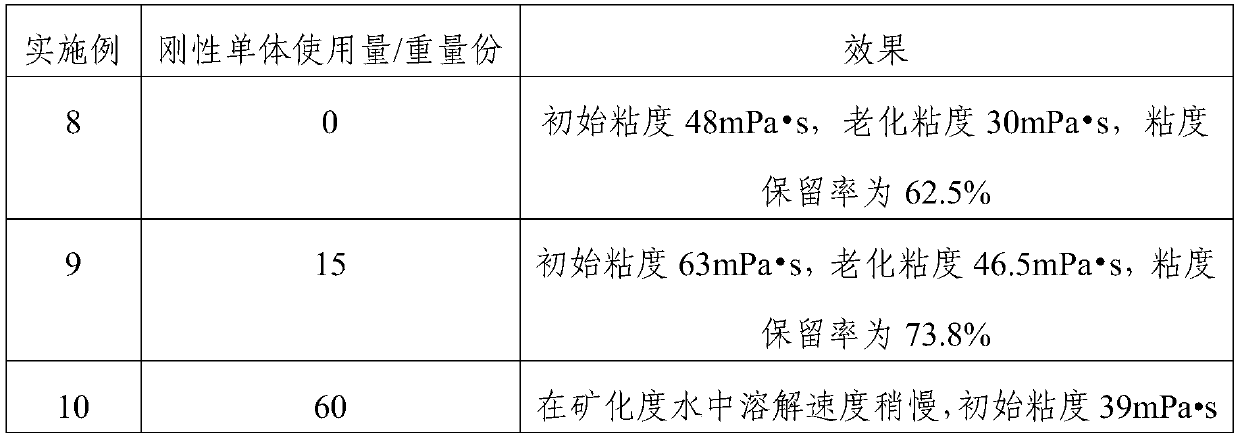

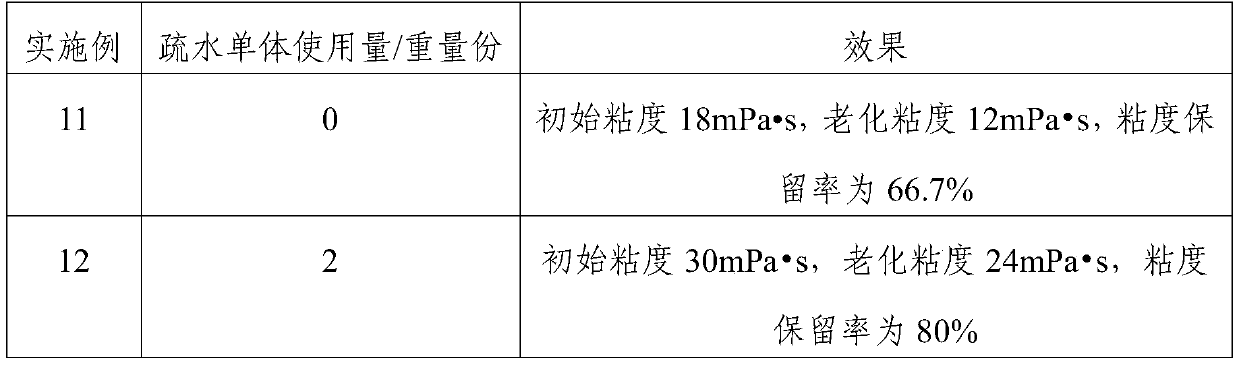

Composition, temperature-resistant salt-resistant fracturing fluid thickening agent prepared from composition, and preparation method thereof

ActiveCN109705834AGood suspension effectImprove shear resistanceDrilling compositionSaline waterSalt resistance

The invention relates to a composition used for preparing a temperature-resistant salt-resistant fracturing fluid thickening agent, the temperature-resistant salt-resistant fracturing fluid thickeningagent prepared from the composition, and a preparation method thereof. The composition comprises following components: acrylamide, acrylic acid, a hydrophobic monomer, 2-acrylamido-2-methylpropane sulfonic acid, a rigid monomer, a surfactant, and a shielding reagent. According to the temperature-resistant salt-resistant fracturing fluid thickening agent, excellent sand suspension effect can be achieved without crosslinking with a crosslinking agent, the temperature resistance and salt resistance are better; after 2h of aging in a simulated brine with total mineralization degree of 50000mg / L at 160 DEG C, the viscosity retention rate of the temperature-resistant salt-resistant fracturing fluid thickening agent is equal to or larger than 80%. Solution gel breaking of the temperature-resistant salt-resistant fracturing fluid thickening agent is complete, no water insoluble substance is left, flowback is complete, the ground is not destroyed, and no oil layer pollution is caused.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com