Patents

Literature

5613 results about "Aqueous dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous Dispersions. Teflon™ aqueous dispersions are milky white dispersions of PTFE particles in water, stabilized by wetting agents. They can be further formulated to meet specific needs by adding other solid or liquid ingredients.

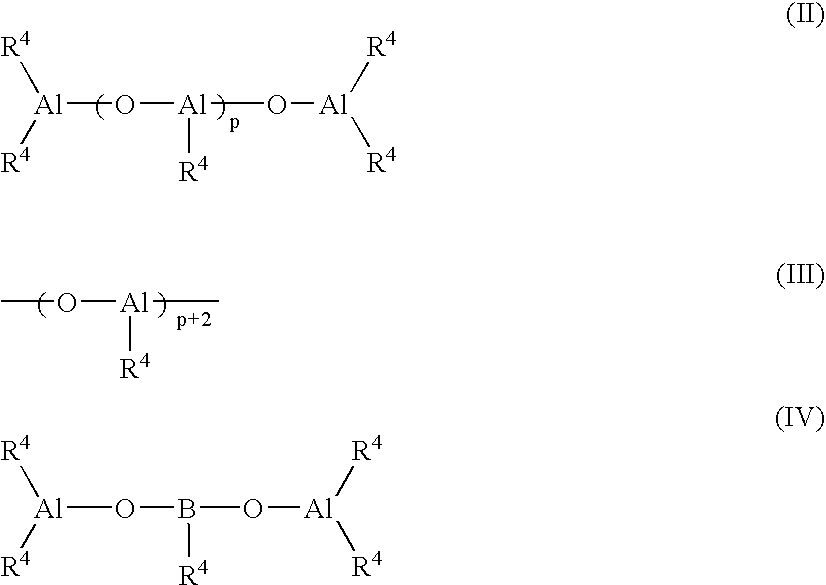

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

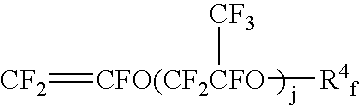

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

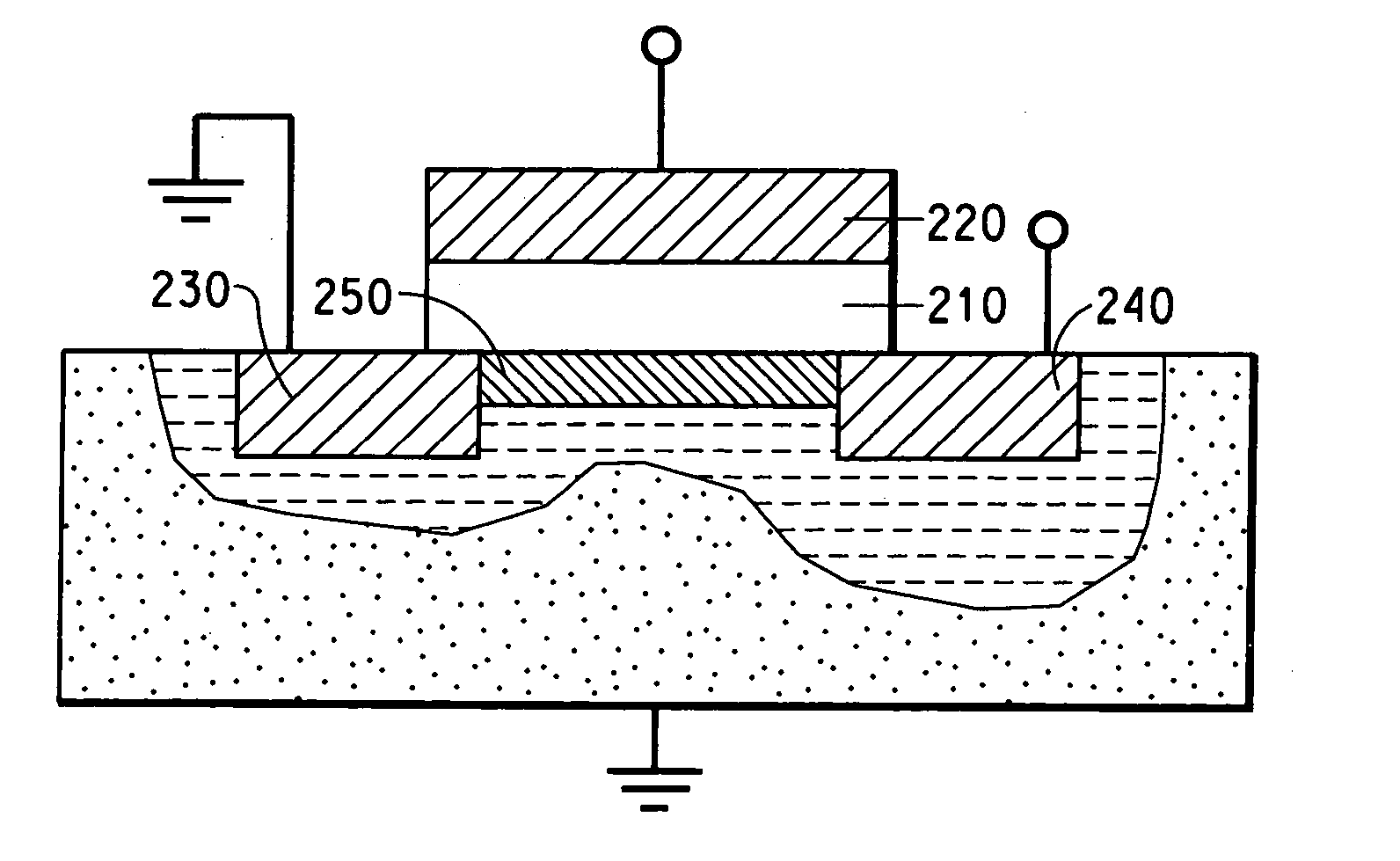

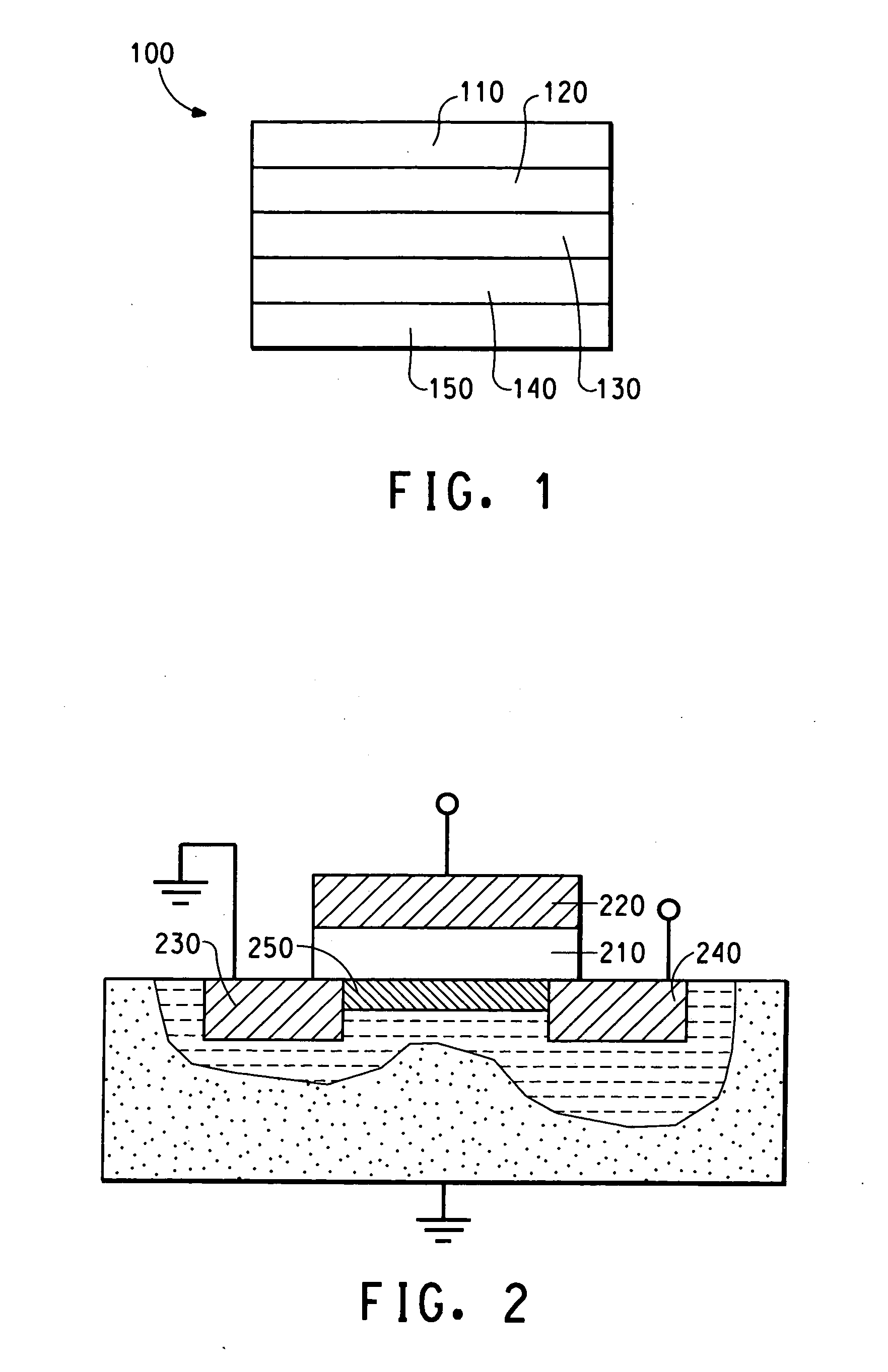

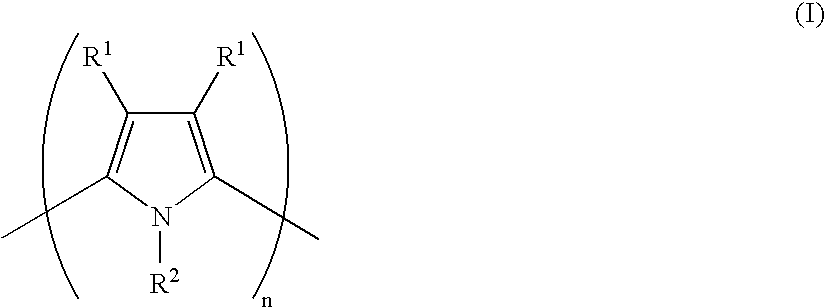

Water dispersible polypyrroles made with polymeric acid colloids for electronics applications

InactiveUS20050205860A1Material nanotechnologyHybrid capacitor electrolytesWater dispersiblePolypyrrole

Compositions are provided comprising aqueous dispersions of at least one polypyrrole and at least one colloid-forming polymeric acids at methods of making such compositions. The new compositions are useful in electronic devices including organic electronic devices such as organic light emitting diode displays, memory storage, electromagnetic shielding, electrochromic displays,and thin film transistors, field effect resistance devices.

Owner:EI DU PONT DE NEMOURS & CO

Aqueous dispersion, its production method, and its use

ActiveUS20050100754A1Liquid surface applicatorsSynthetic resin layered productsVolume averageAlpha-olefin

Aqueous dispersions including at least one thermoplastic resin; at least one dispersing agent; and water; wherein the dispersion has a pH of less than 12 are disclosed along with dispersions including at least one thermoplastic resin; at least one dispersing agent; and water wherein the dispersion has a volume average particle size of less than about 5 μm. Some dispersions include less than about 4 percent by weight of the dispersing agent based on the weight of the thermoplastic resin. Other dispersions include at least one propylene-rich alpha-olefin interpolymer; at least one dispersing agent; and water. Methods of making such dispersions are also described.

Owner:DOW GLOBAL TECH LLC

Aqueous emulsion polymerization of fluorinated monomers using a fluorinated surfactant

InactiveUS20070015866A1Low toxicityGood chemical stabilityLiquid surface applicatorsFibre treatmentEmulsion polymerizationEther

The present invention provides an aqueous emulsion polymerization of fluorinated monomers including gaseous fluorinated monomers using a perfluoro ether surfactant as an emulsifier. The perfluoro ether surfactants correspond to formula (I) Rf—O—CF2CF2—X (I) wherein Rf represents a linear or branched perfluoroalkyl group having 1, 2, 3 or 4 carbon atoms and X represents a carboxylic acid group or salt thereof. In a further aspect, the invention also provides an aqueous fluoropolymer dispersion comprising the perfluoro ether surfactant and the use of such dispersion in the coating or impregnation of substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous dispersions of polymer-enclosed particles, related coating compositions and coated substrates

ActiveUS20060251896A1Nanostructure manufactureSynthetic resin layered productsNanoparticleMaterials science

Disclosed are aqueous dispersions of polymer-enclosed particles, such as nanoparticles. Also disclosed are methods for making an aqueous dispersion of polymer-enclosed particles, polymerizable polymers useful in such a method, powder coating compositions formed from such an aqueous dispersion, substrates at least partially coated with such a composition, and reflective surfaces comprising a non-hiding coating layer deposited from such a composition.

Owner:PPG IND OHIO INC

Fluoroalkyl carboxylic acid derivative, method for producing fluorine-containing polymer, and aqueous dispersion of fluorine-containing polymer

ActiveUS20060281946A1Improve efficiencyImprove stabilityPreparation from carboxylic acid halideOrganic compound preparationHydrogen atomAcid derivative

This invention provides a novel compound which can be properly used as a surfactant, a method of producing a fluoropolymer, surfactant and a fluoropolymer aqueous dispersions using the novel compound. This invention is a fluoroalkylcarboxylic acid derivative which is represented by the general formula (i): Rf1(OCH2CF2CF2)n1OCX1X2CF2(Rf2)n2COOM (i) wherein Rf1 represents a straight or branched fluoroalkyl group containing 1 to 20 carbon atoms, which fluoroalkyl group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, Rf2 represents a straight or branched fluoroalkylene group containing 1 to 25 carbon atoms, said fluoroalkylene group may optionally contain 1 to 5 oxygen atoms in the principal chain thereof, n1 represents an integer of 0 to 3, n2 represents an integer of 0 or 1, X1 and X2 are the same or different and each represents hydrogen atom or fluorine atom, and M represents NH4 or a monovalent metal element.

Owner:DAIKIN IND LTD

Controlled release formulations coated with aqueous dispersions of acrylic polymers

InactiveUS6143353ADissolution stabilityIncrease weight gainPretreated surfacesMedical devicesWater insolubleActive agent

A stable solid controlled release formulation having a coating derived from an aqueous dispersion of a hydrophobic acrylic polymer includes a substrate including an active agent selected from the group consisting of a systemically active therapeutic agent, a locally active therapeutic agent, a disinfecting and sanitizing agent, a cleansing agent, a fragrance agent and a fertilizing agent, overcoated with an aqueous dispersion of the plasticized water-insoluble acrylic polymer. The formulation provides a stable dissolution of the active agent which is unchanged after exposure to accelerated storage conditions.

Owner:PURDUE PHARMA LP

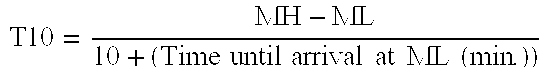

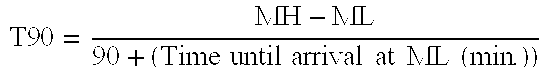

Stabilized controlled release substrate having a coating derived from an aqueous dispersion of hydrophobic polymer

InactiveUS6129933AReduce reunionLiquid surface applicatorsGranular deliveryHydrophobic polymerDissolution

A stabilized solid controlled release dosage form having a coating derived from an aqueous dispersion of ethylcellulose is obtained by overcoating a substrate including a therapeutically active with an aqueous dispersion of ethylcellulose and then curing the coated substrate at a temperature and relative humidity elevated to a suitable level above ambient conditions until the coated dosage form attains a stabilized dissolution profile substantially unaffected by exposure to storage conditions of elevated temperature and / or elevated relative humidity.

Owner:PURDUE PHARMA LP

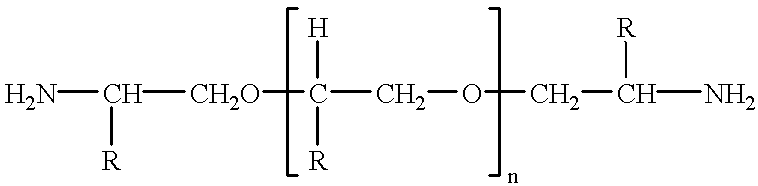

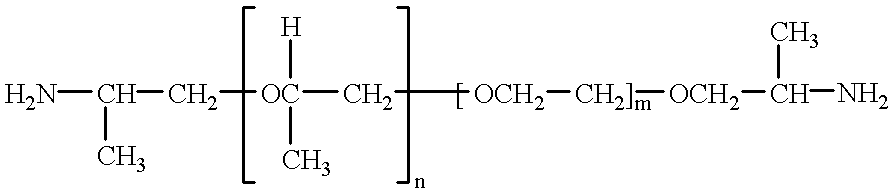

Aqueous dispersion of epoxy resin and blend of epoxy resin-polyoxyalkylene amines

PCT No. PCT / EP97 / 06364 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Nov. 14, 1997 PCT Pub. No. WO98 / 25988 PCT Pub. Date Jun. 18, 1998A blend of epoxy-amine adducts are useful as emulsifiers of aqueous epoxy resin dispersions comprises (A-1) one or more epoxy-amine adduct(s) obtained by the reaction of (i) one or more aromatic, cycloaliphatic or novolac epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (A-2) one or more epoxy-amine adduct(s) derived from the reaction of (i) one or more aliphatic epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (B-1) aromatic, cycloaliphatic or novolac polyglycidyl ethers; (B-2) optionally, polyglycidyl esters of aromatic or cycloaliphatic polycarboxylic acids; and (C) optionally, at least one of reactive thinners, pigments, filler or other addtitives.

Owner:SIKA CHEM

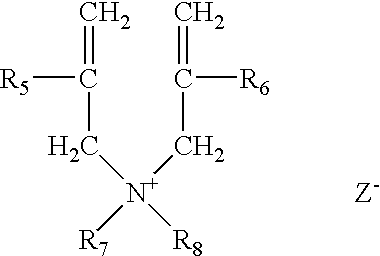

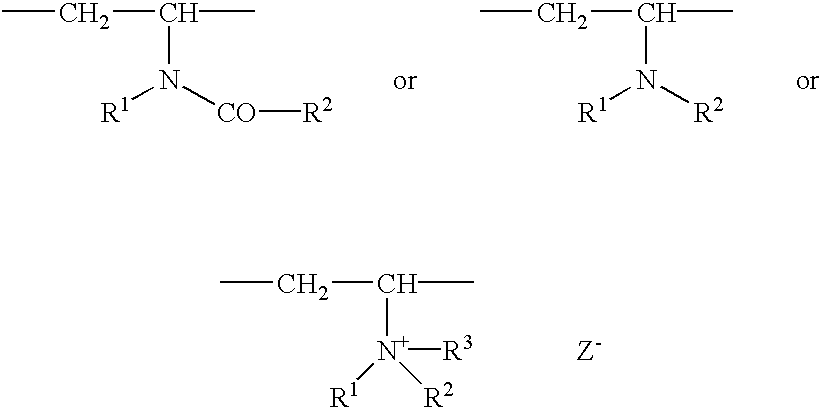

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

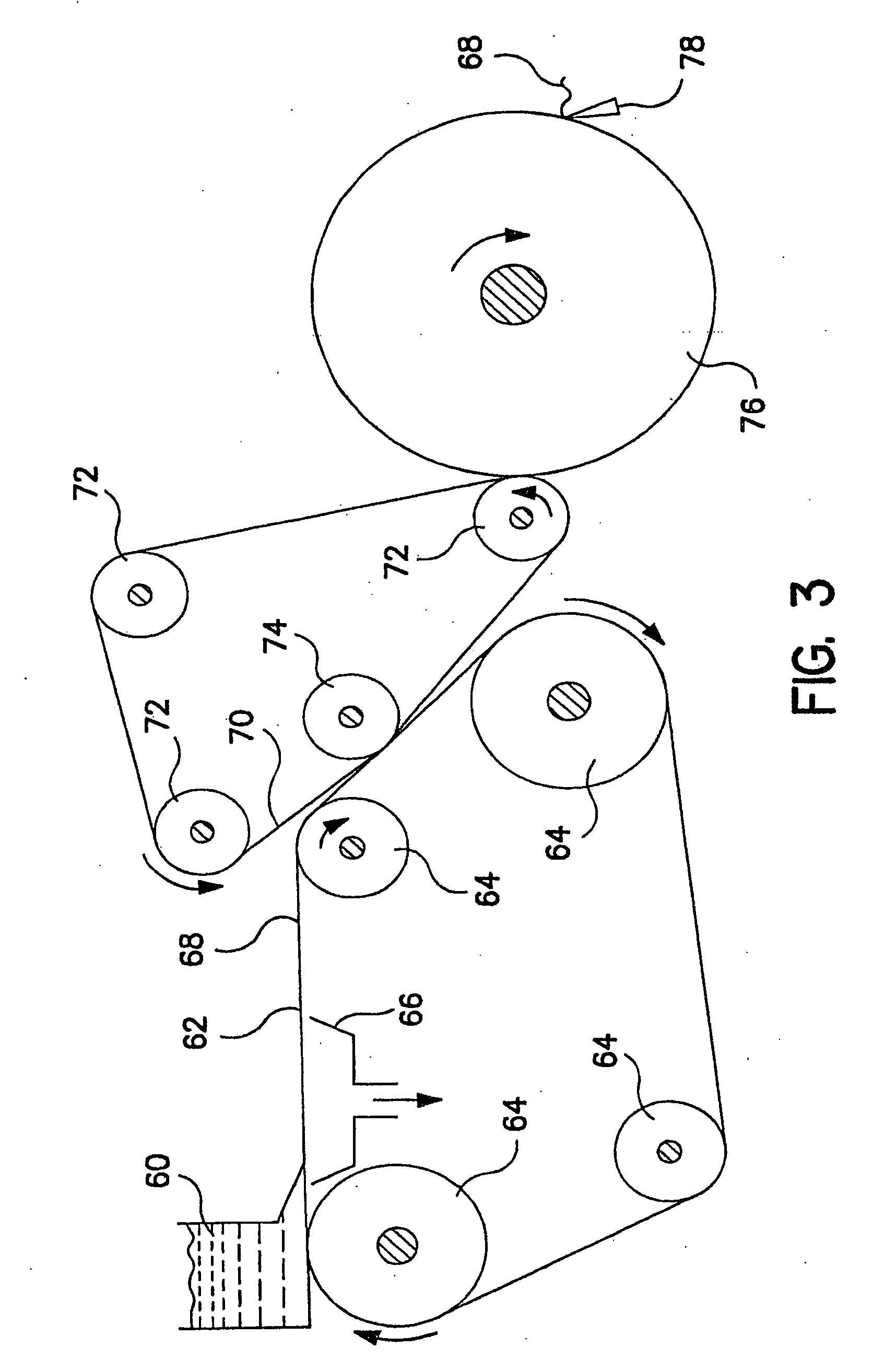

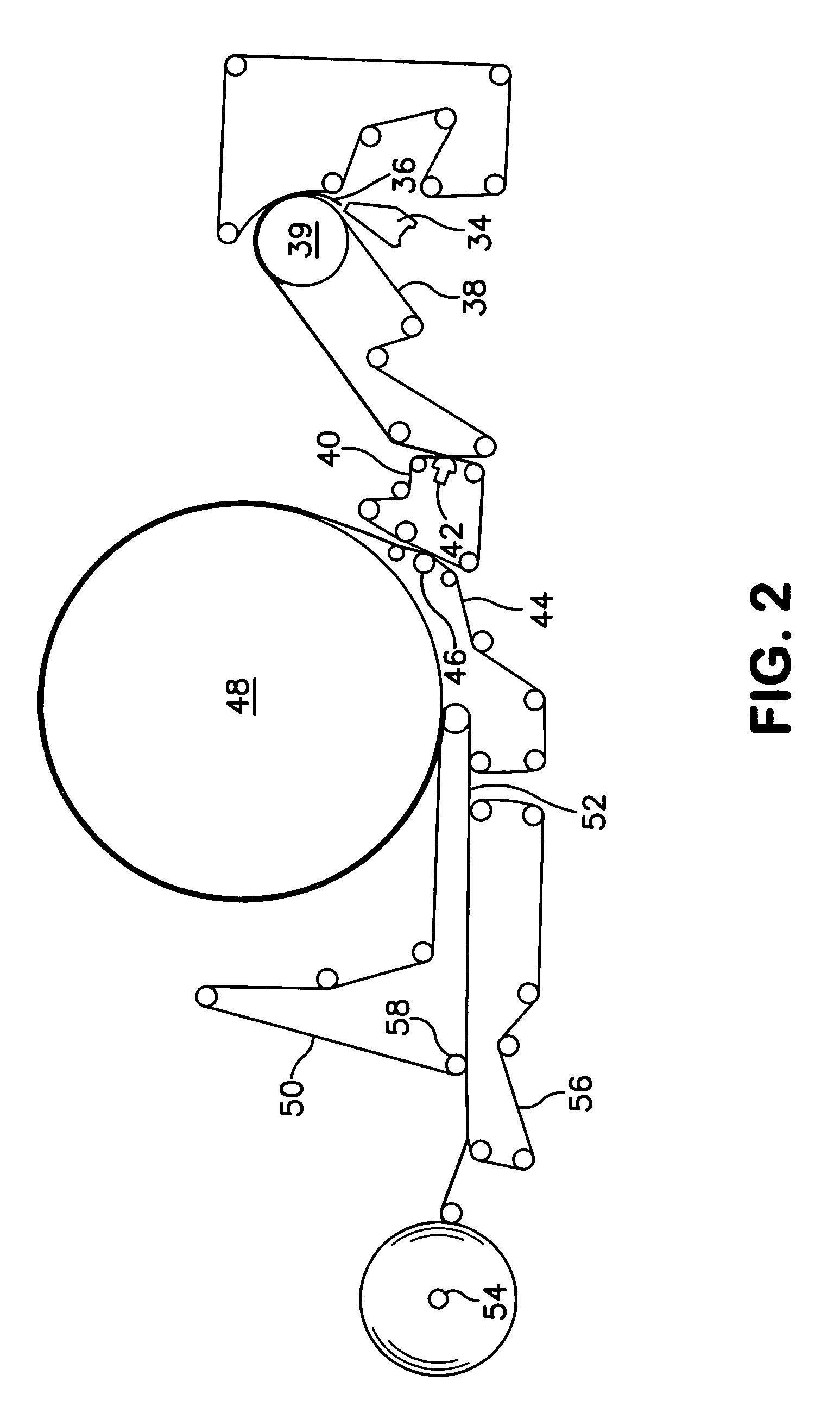

Embossed tissue products

InactiveUS20070137813A1Preserve strengthHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. After the additive composition is applied to the web or otherwise incorporated into the tissue web, the tissue web is embossed. During embossing, the additive composition forms well defined embossments in the web that are water resistant. In one embodiment, the additive composition may also be used to bond multiple tissue webs together to form a multiple ply product during the embossing operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Aqueous dispersions containing multi-stage emulsion polymers

Aqueous dispersions are disclosed, having a minimum film formation temperature no greater than about 50° C., that include a multi-stage emulsion polymer made by a process that includes a first polymerization stage, in which a first monomer mixture having a calculated glass transition temperature of at least about 50° C. is polymerized via free radical emulsion polymerization to obtain a first-stage emulsion polymer, and a second polymerization stage, in which a second monomer mixture, having a calculated glass transition temperature from about −30° C. to about 10° C., is polymerized via free radical emulsion polymerization, in the presence of the first-stage emulsion polymer. The dispersions are useful in a variety of coating compositions that exhibit improved block resistance.

Owner:HEXION INC

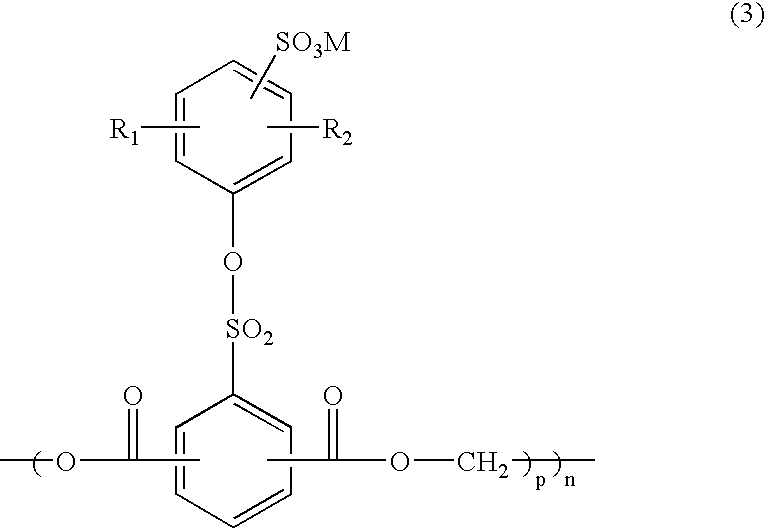

Hydrophilic coatings for medical implements

ActiveUS7015262B2Easy extractionSpeed up the flowSurgeryPretreated surfacesWater basedHydrophilic coating

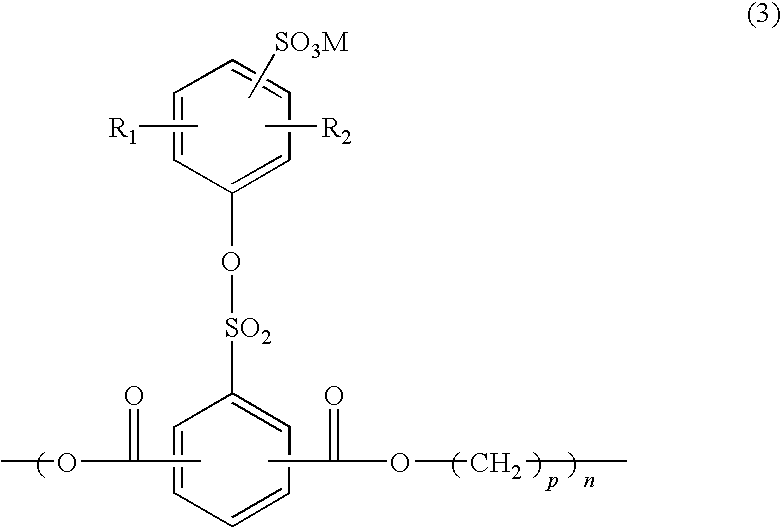

Compositions, methods, devices and kits utilizing water-based hydrophilic coating formulations on medical implements. The composition for applying a coating comprises a sulfonated polyester, water, and a surface active agent. Methods for coating a medical implement comprise providing an aqueous dispersion comprising sulfonated polyester and surface active agent, contacting the medical implement with the aqueous dispersion, and drying the medical implement. Methods for acquiring a sample of bodily fluid from a patient comprise coating a needle with a sulfonated polyester, penetrating the needle into the patient, and drawing bodily fluid through the needle.

Owner:LIFESCAN IP HLDG LLC

Liposomal products

InactiveUS6060080AHigh encapsulation efficiencyEasy to packLiposomal deliveryCholesterolWater soluble drug

A liposomal aqueous dispersion and method of making the liposomal aqueous dispersion is useful for encapsulation of drugs. The liposomal aqueous dispersion comprises: an aqueous suspension medium; multilamellar liposomes comprising an anionic phospholipid and cholesterol as essential components; neutral phospholipid in a mole ratio of 0 to 40% based on the total amount of said multilamellar liposomes; and a cation moiety-containing water-soluble drug, wherein the electrolyte concentration of said aqueous suspension medium is not more than 40 mM.

Owner:DAIICHI PHARMA CO LTD

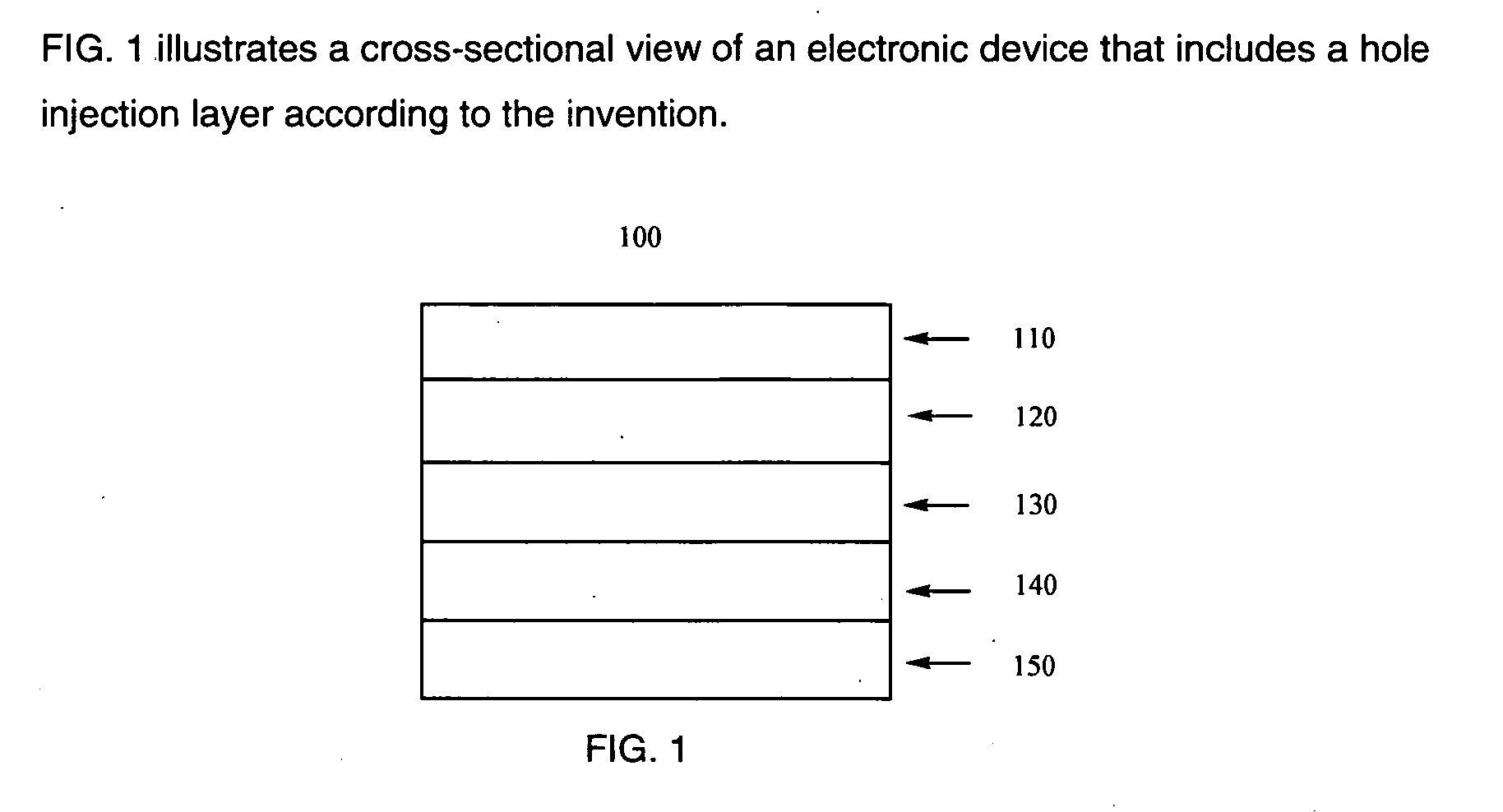

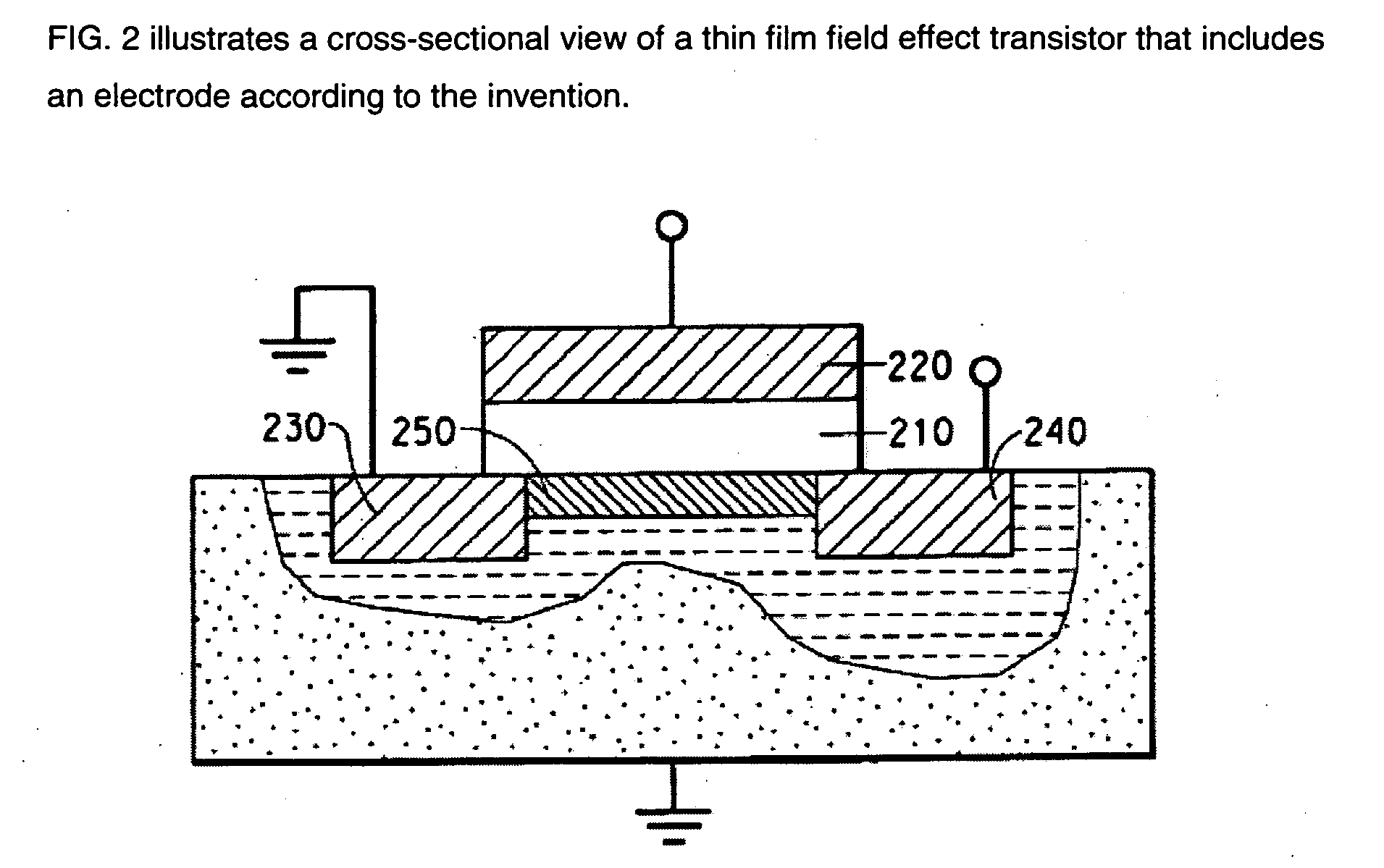

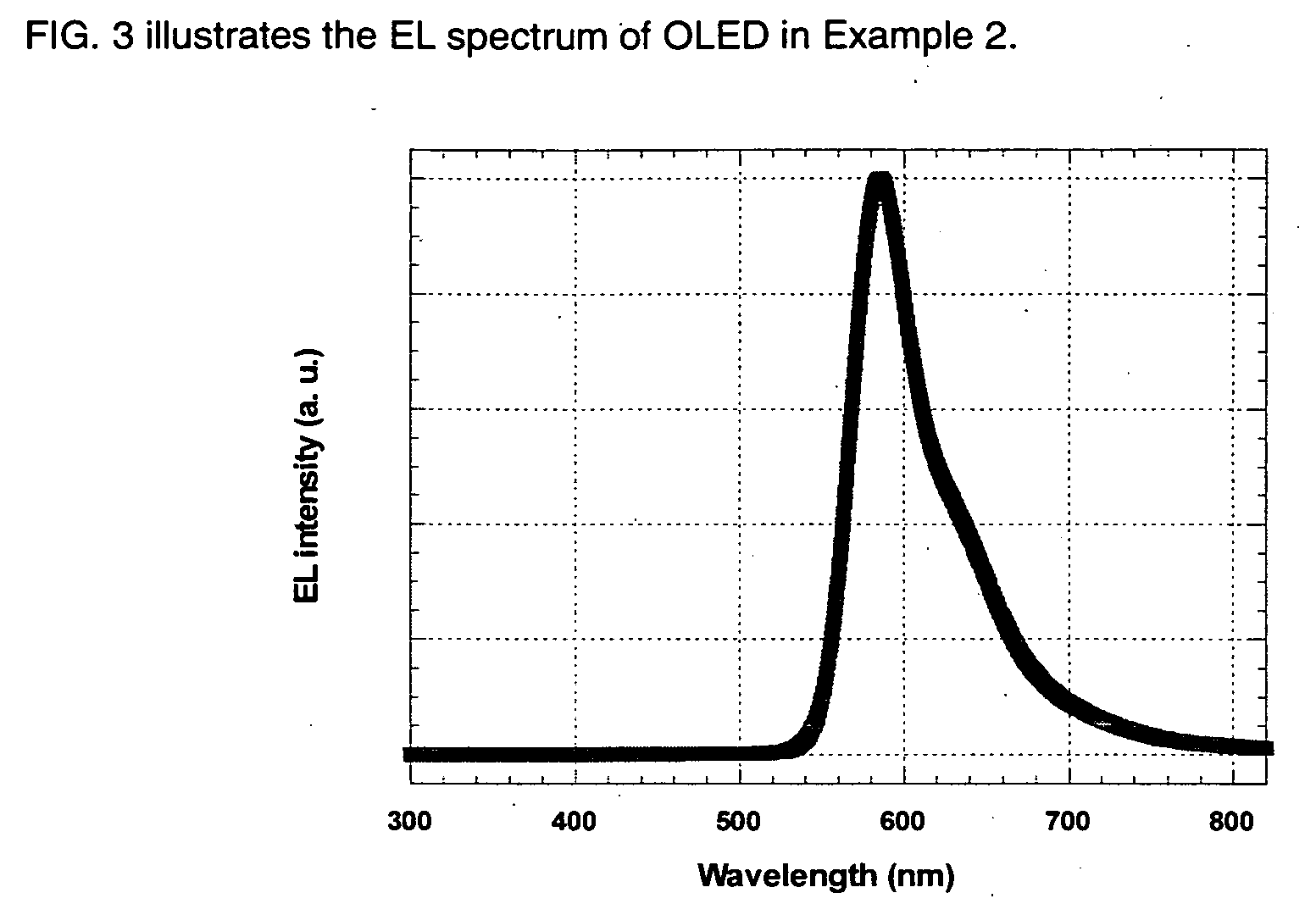

Aqueous dispersions of polythienothiophenes with fluorinated ion exchange polymers as dopants

ActiveUS20060076557A1Solve problemsMaterial nanotechnologyDischarge tube luminescnet screensCarbon nanotubeIon exchange

Compositions are provided comprising aqueous dispersions of polythienothiophenes and colloid-forming polymeric acids. Films from invention compositions are useful as hole injection layers in organic electronic devices, including electroluminescent devices, such as, for example, organic light emitting diodes (OLED) displays, as hole extraction layers in organic optoelectronic devices, such as organic photovoltaic devices, and in combination with metal nanowires or carbon nanotubes in applications such as drain, source, or gate electrodes in thin film field effect transistors.

Owner:SAMSUNG ELECTRONICS CO LTD

Photothermographic recording material coatable from an aqueous medium

InactiveUS6143488AImprove imaging effectImprove stabilityRadiation applicationsPhotothermographic systemsSilver iodideWater dispersible

A process for producing a photothermographic recording material having a support and a photo-addressable thermally developable element containing photosensitive silver halide in catalytic association with a substantially light-insensitive silver salt of an organic carboxylic acid, an organic reducing agent for the substantially light-insensitive silver salt of an organic carboxylic acid in thermal working relationship therewith and a binder including a water-soluble binder, a water-dispersible binder or a mixture of a water-soluble binder and a water-dispersible binder, comprising the steps of: (i) producing an aqueous dispersion or aqueous dispersions containing photosensitive silver halide, a substantially light-insensitive silver salt of an organic carboxylic acid, an organic reducing agent for the substantially light-insensitive silver salt of an organic carboxylic acid and a binder including a water-soluble binder, a water-dispersible binder or a mixture of a water-soluble binder and a water-dispersible binder; (ii) coating the aqueous dispersion or aqueous dispersions onto a support thereby forming a photo-addressable thermally developable element on the support, wherein at least 80 mol % of the photosensitive silver halide is silver iodide and the aqueous dispersion further contains or the aqueous dispersions further contain a diazine compound.

Owner:AGFA HEALTHCARE NV

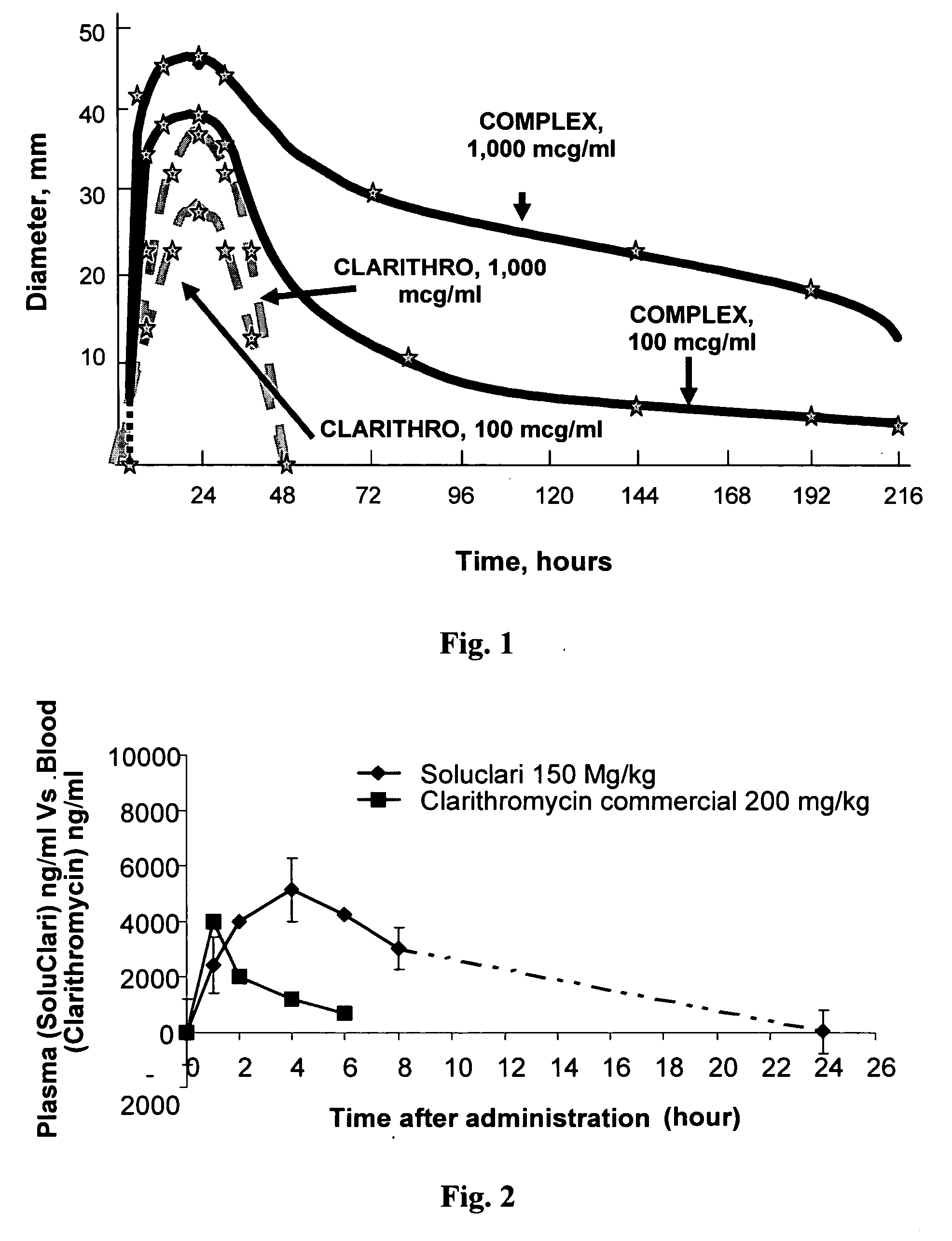

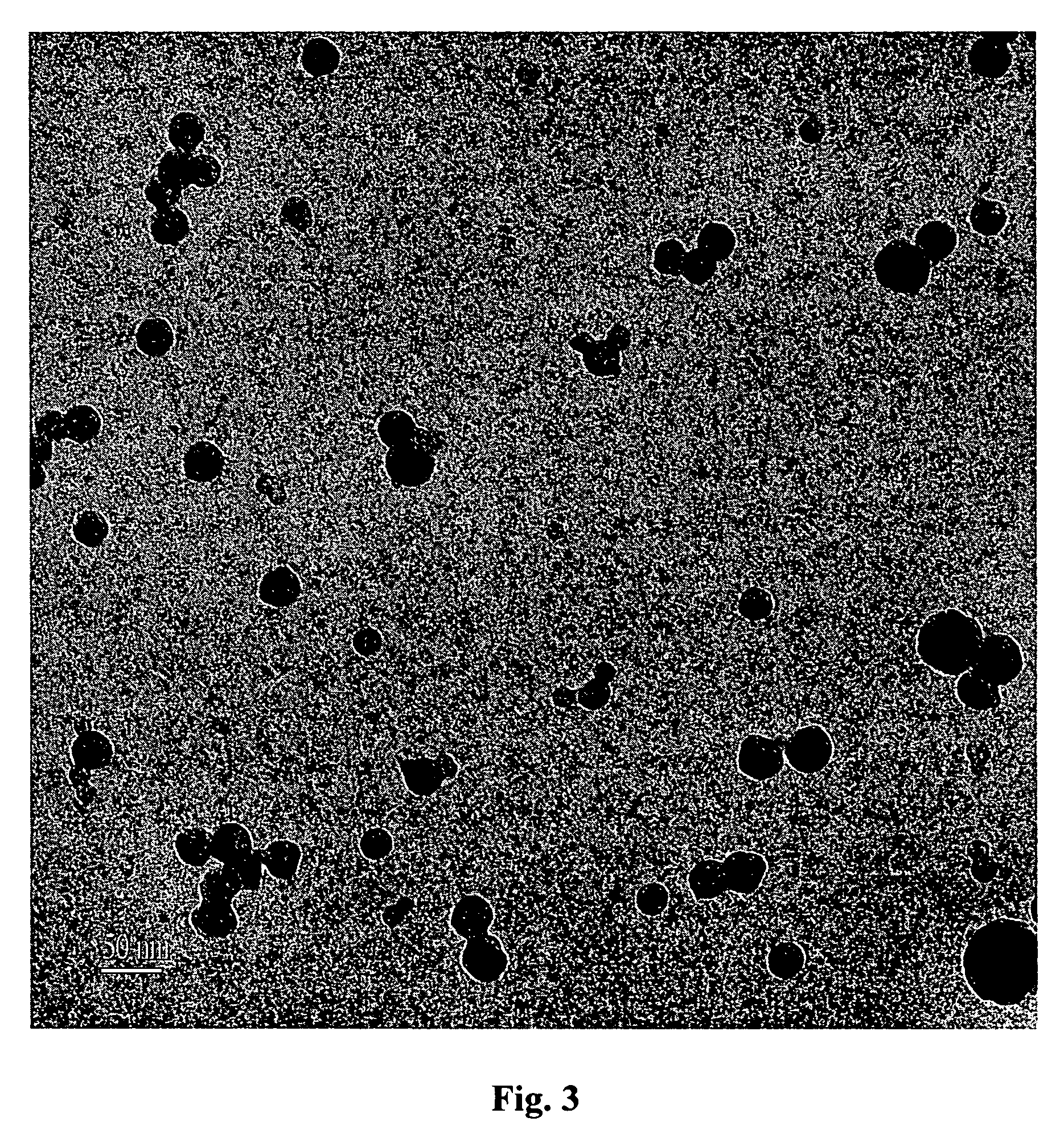

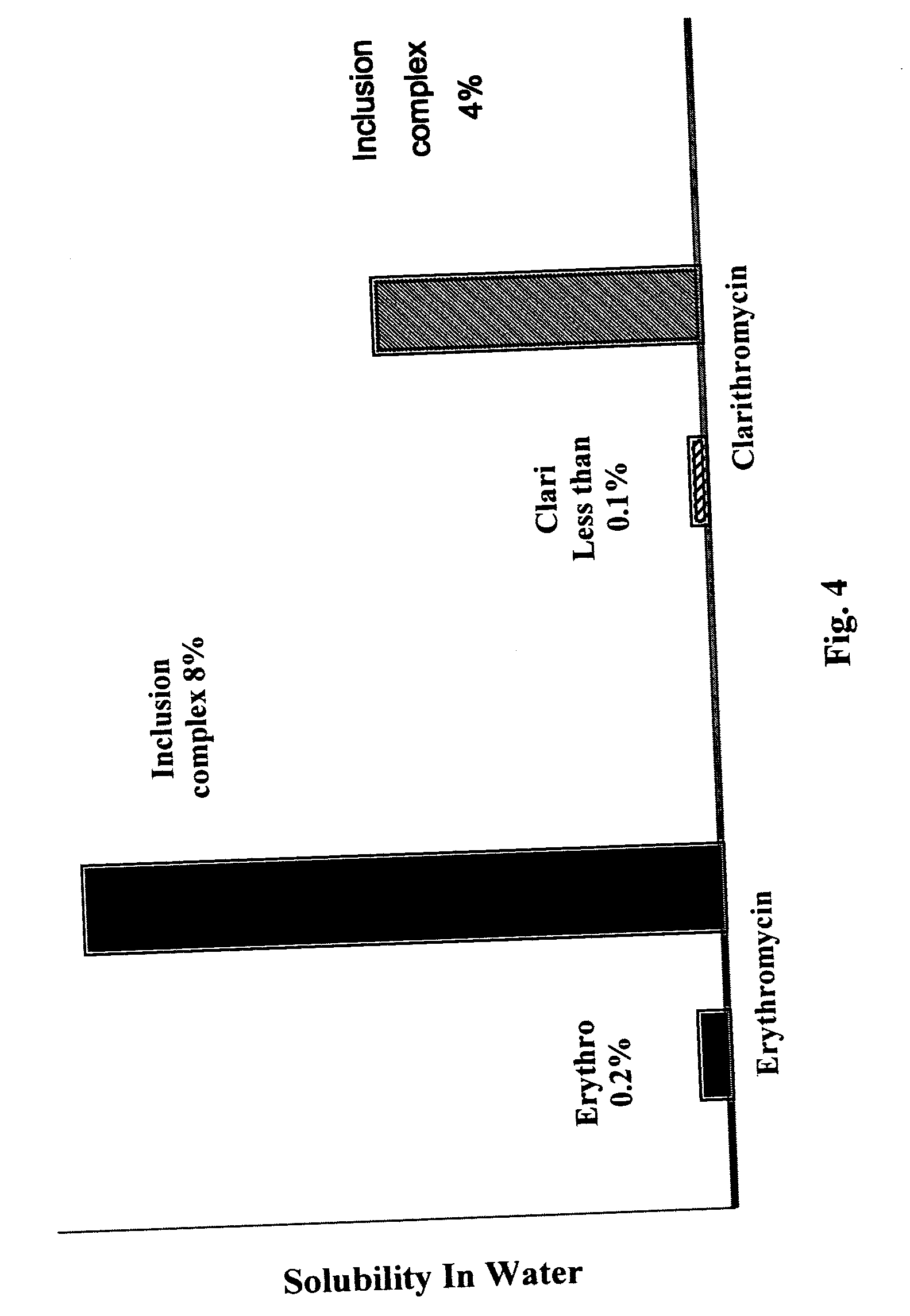

Water soluble nanoparticles and method for their production

InactiveUS20050191359A1Readily bioavailableLow costPowder deliveryBiocidePolymer scienceNanoparticle

Hydrophilic dispersions of stable nano-sized particles are provided comprising: (a) a water-insoluble or water-soluble active compound, wherein said active compound is selected from the group consisting of a macrolide antibiotic, donepezil hydrochloride, an azole compound and a taxane; and (b) an amphiphilic polymer which wraps said active compound in a non-crystalline manner to form a nano-sized molecular entity in which no valent bonds are formed.

Owner:SOLUBEST

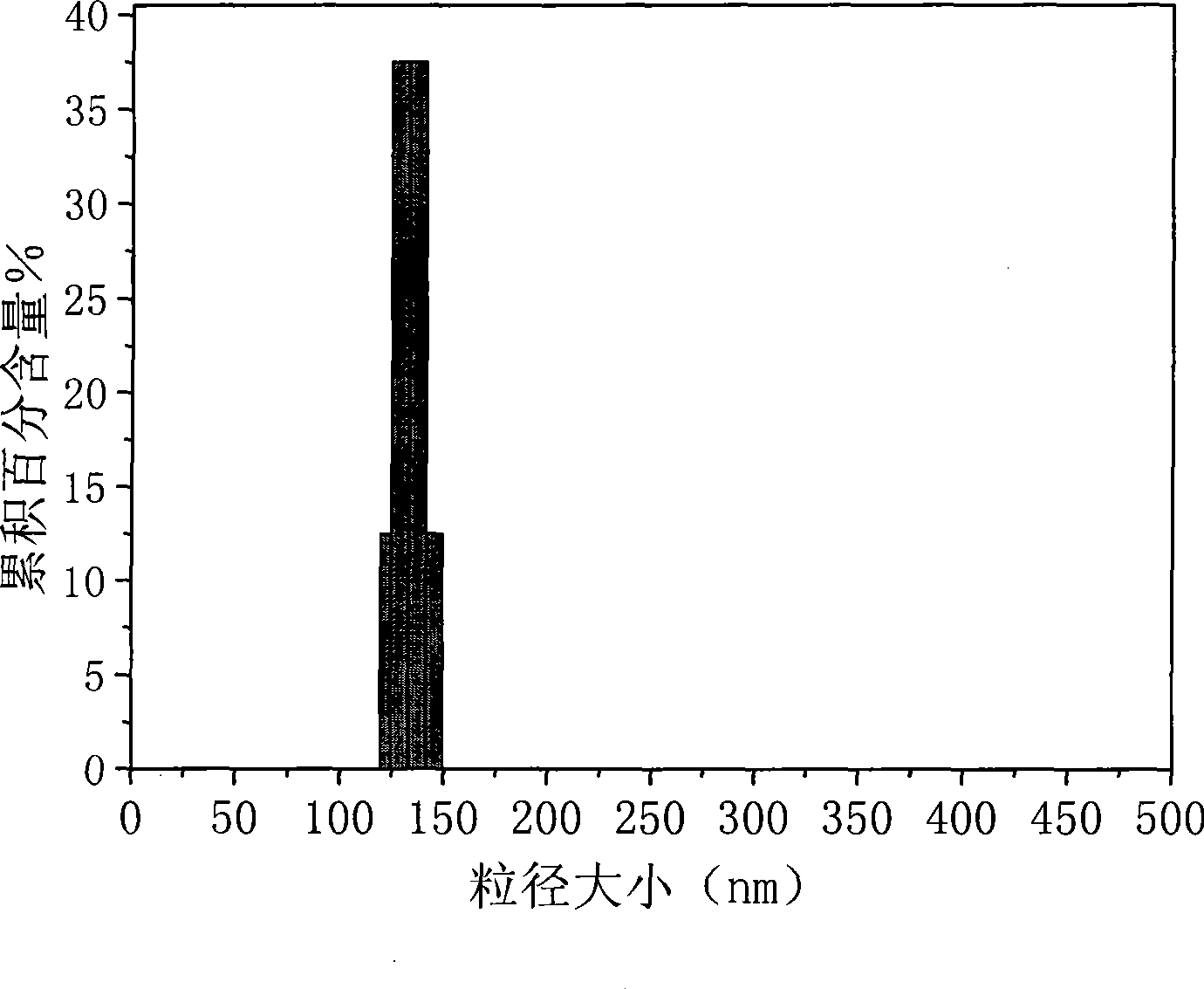

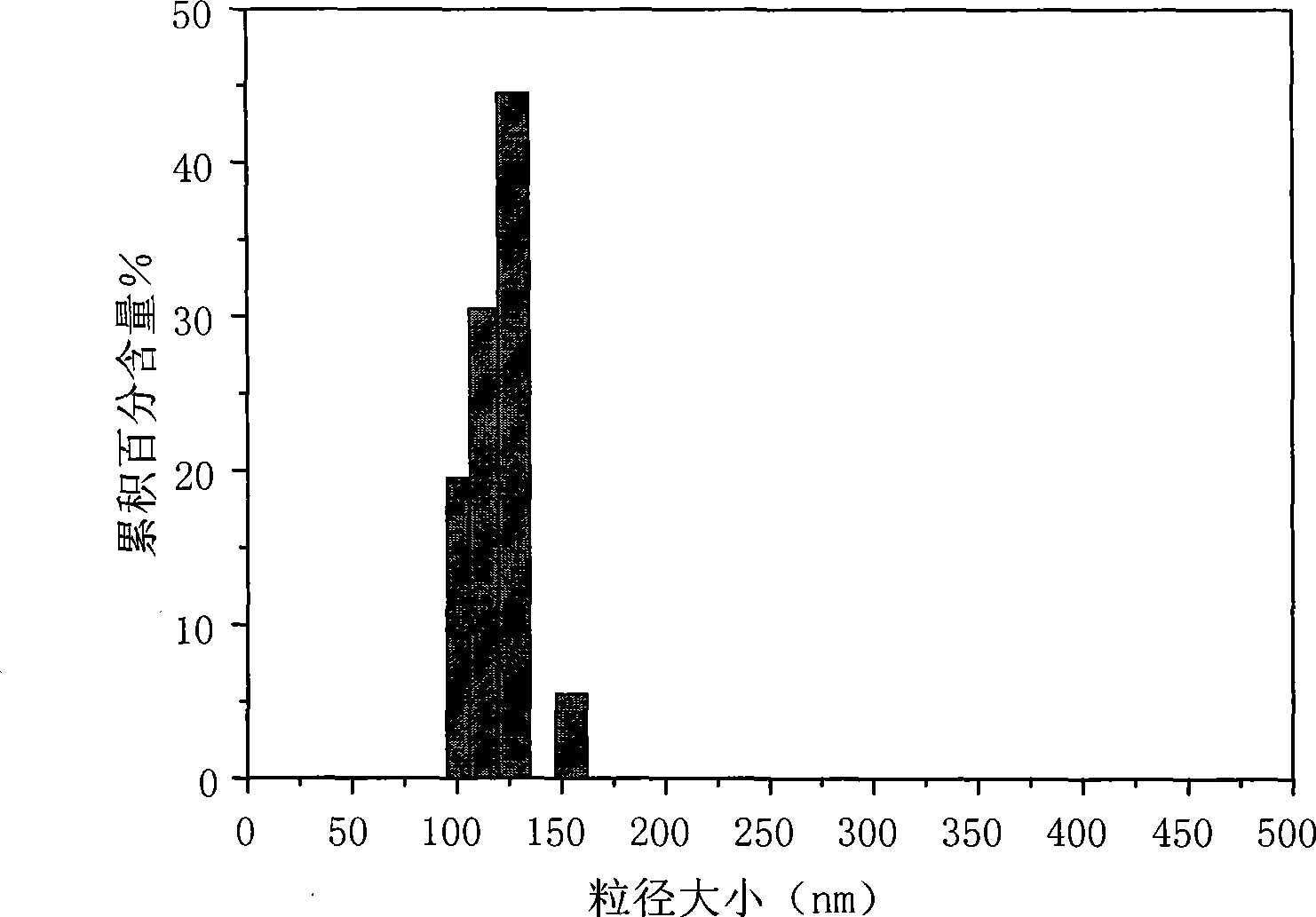

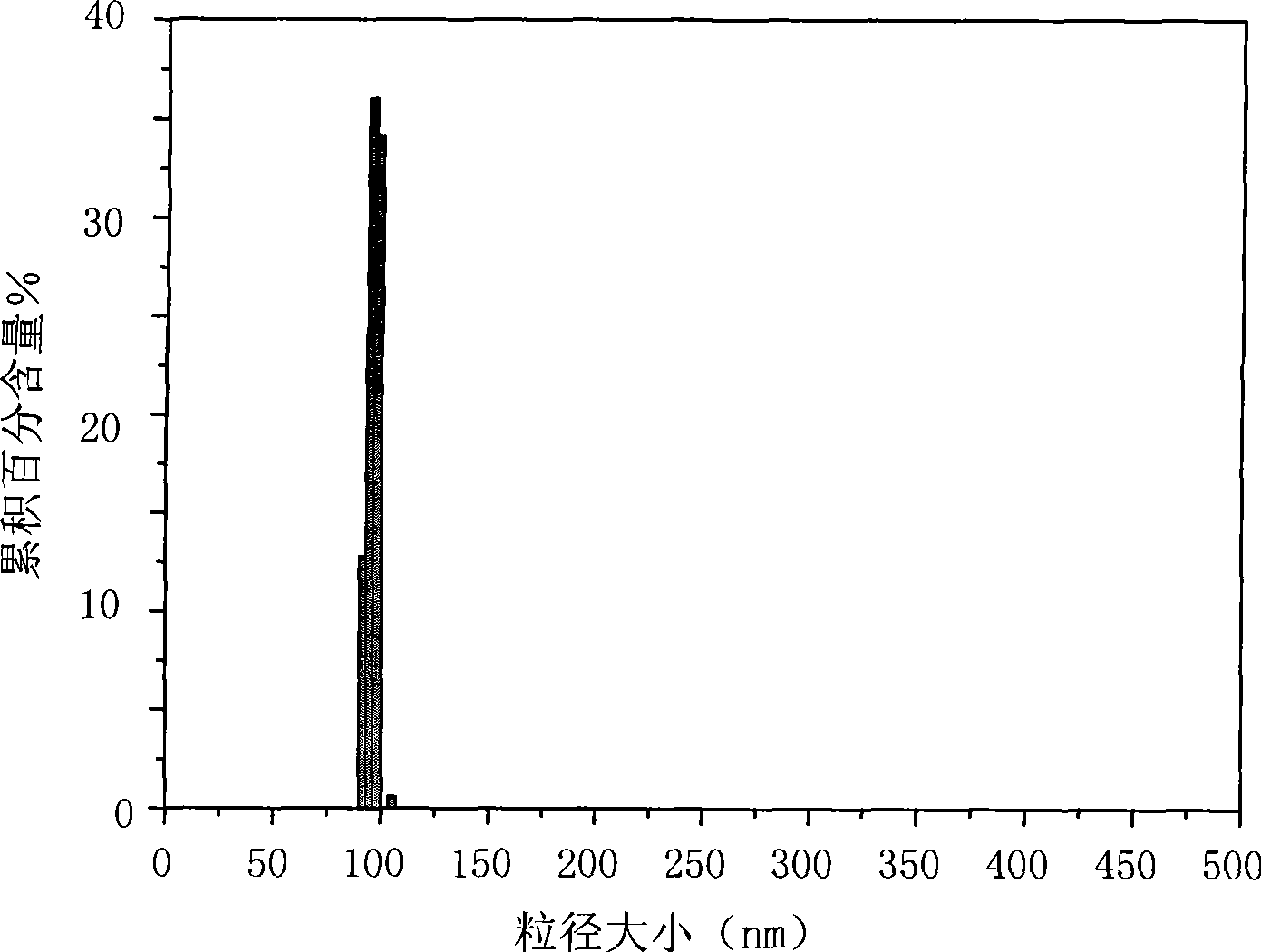

Polypropylene type aqueous dispersion, polypropylene type composite aqueous emulsion composition and its use

A polypropylene type aqueous dispersion comprising the following components (a) to (c): (a) a polypropylene type polymer100parts by weightand / or a modified polypropylene typepolymer(b) a surfactant1 to 100parts by weight, and(c) water100 to 1,000parts by weight,wherein the component (a) has a main chain having the following features (1) and (2) and dispersion particles in the dispersion have an average particle size of at most 0.5 μm, Feature (1) when observing a peak derived from a carbon atom of a methyl group in a propylene unit chain part comprising a head-to-tail bond by 13C-NMR and fixing a chemical shift of a peak top at a peak attributable to pentad expressed by mmmm to 21.8 ppm, a ratio (S1 / S) of an area S1 of a peak of a peak top at 21.8 ppm to a total area S of peaks at from 19.8 ppm to 22.1 ppm is at least 10% and at most 60%, and when an area of a peak (mmmr) of a peak top at 21.5 to 21.6 ppm is expressed as S2, 4+2S1 / S2>5, and Feature (2) a content ratio (mol ratio) of propylene unit (A): other olefin unit (B) is from 100:0 to 90:10.

Owner:MITSUBISHI CHEM CORP

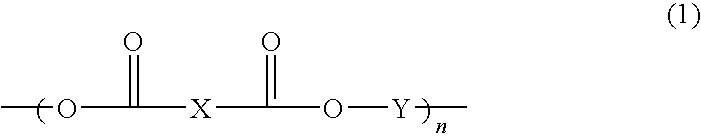

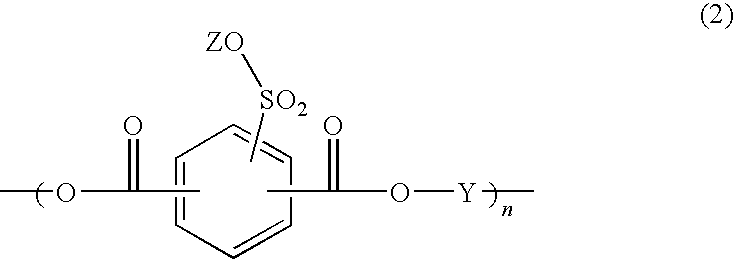

Process for forming a two-coat electrodeposited composite coating the composite coating and chip resistant electrodeposited coating composition

InactiveUS6248225B1Electrolysis componentsVolume/mass flow measurementPolyurethane coatingAqueous dispersion

A process for applying two electrodeposited coatings, one on top of the other, to an electrically conductive substrate is provided. An electrically conductive first coating is applied to provide for corrosion resistance and a second polyurethane-based coating is applied to the first coating to provide chip resistance. Also, aqueous dispersions of the polyurethane coating compositions are disclosed.

Owner:PPG IND OHIO INC

Hydrophilic coatings for medical implements

InactiveUS7553511B2Speed up the flowFree from damageGuide needlesCosmetic preparationsHydrophilic coatingPolyester

Compositions, methods, devices and kits utilizing water-based hydrophilic coating formulations on medical implements. The composition for applying a coating comprises a sulfonated polyester, water, and a surface active agent. Methods for coating a medical implement comprise providing an aqueous dispersion comprising sulfonated polyester and surface active agent, contacting the medical implement with the aqueous dispersion, and drying the medical implement. Methods for acquiring a sample of bodily fluid from a patient comprise coating a needle with a sulfonated polyester, penetrating the needle into the patient, and drawing bodily fluid through the needle.

Owner:LIFESCAN IP HLDG LLC

Aqueous tetrafluoroethylene polymer dispersion,process for producing the same, tetrafluoroethylene polymer powder,and molded tetrafluoroethylene polymer

InactiveUS20070060699A1Excellent in moldability/processabilityIncrease concentrationFibre treatmentTetrafluoroethylenePolymer science

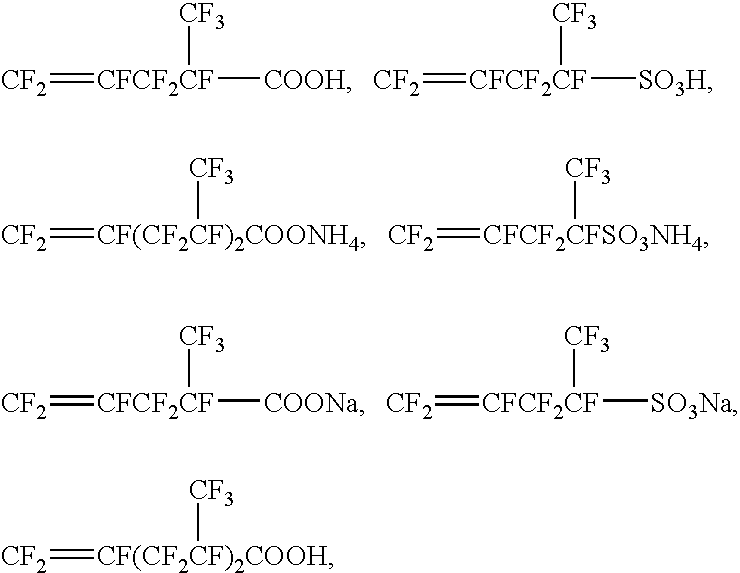

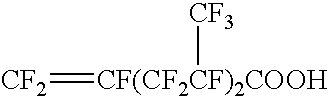

The present invention provides a tetrafluoroethylene polymer aqueous dispersion obtained by carrying out a TFE polymerization in an aqueous medium in the presence of a fluorovinyl group-containing emulsifier, wherein the TFE polymer aqueous dispersion contains a particle comprising a TFE polymer dispersed in the aqueous medium, the fluorovinyl group-containing emulsifier comprises a fluorovinyl group-containing compound, and the TFE polymer aqueous dispersion has a fluorine-containing surfactant content of not higher than 1000 ppm by mass.

Owner:DAIKIN IND LTD

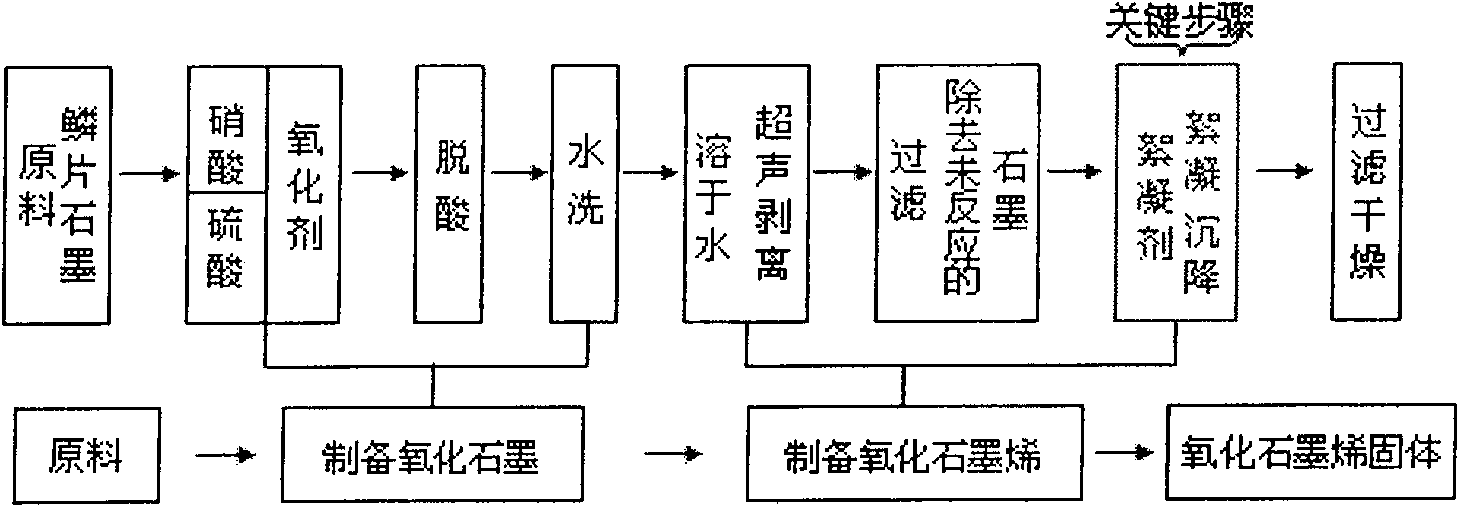

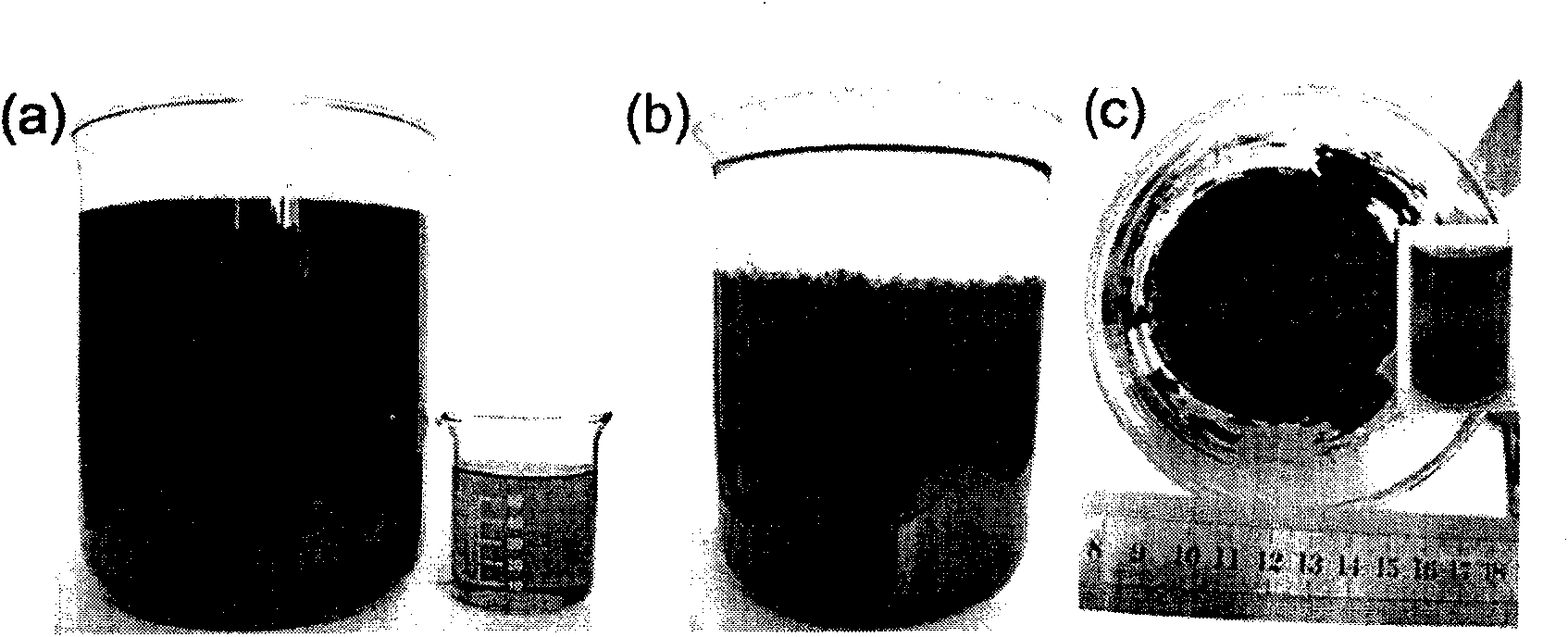

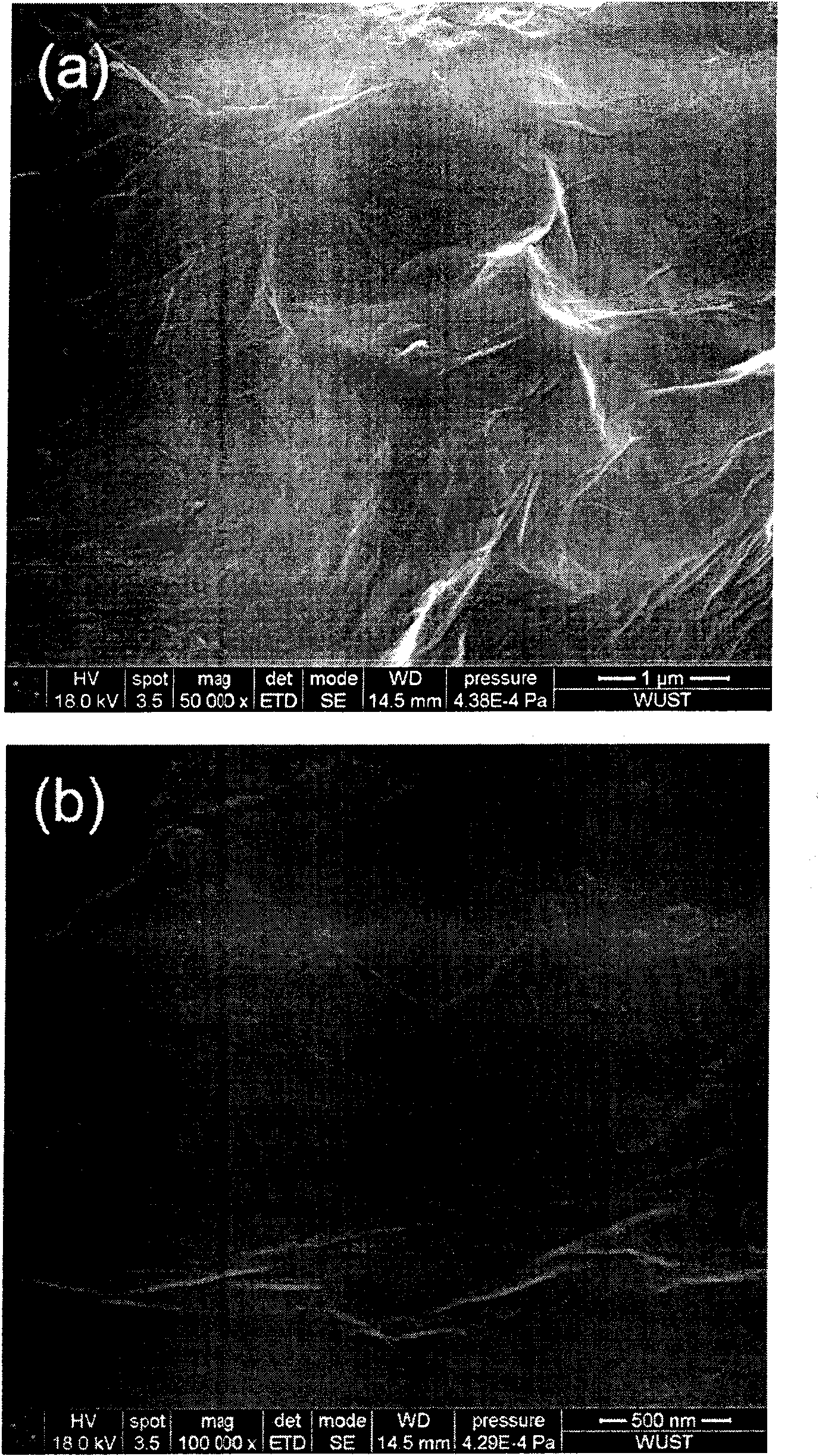

Method for realizing large-scale preparation of monolayer oxidized graphene

The invention relates to a method used for realizing large-scale preparation of monolayer oxidized graphene. The method comprises the following steps: oxidizing natural crystalline flake graphite by an oxidant to obtain oxidized graphite; after ultrasonic stripping, carrying out filtration to remove unreacted graphite and obtain the aqueous solution of oxidized graphene; and adding a flocculating agent to obtain oxidized graphene solid after settlement, filtration and drying. The method can easily separate the oxidized graphene solid from aqueous dispersion solution through flocculating settlement, thereby realizing large-scale preparation of graphene; moreover, the method has cheap and accessible raw materials, easy operation, simple process and good reproducibility, and is suitable for large-scale industrial production. The monatomic oxidized graphene prepared by the method can be used as flake reinforced phase of composite materials to prepare materials with high mechanical property and barrier property; moreover, the oxidized graphene can also be used for preparing fingerprint collecting materials, and the like. Graphene, namely the reduction product of the oxidized graphene can be used for constructing two-dimensional photoelectron components such as nano computer chips, solar battery electrodes and field effect transistors and the like.

Owner:HUBEI UNIV

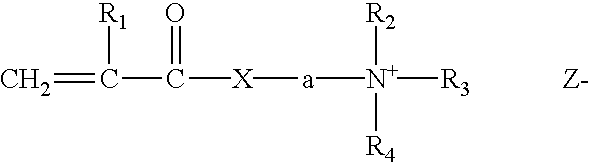

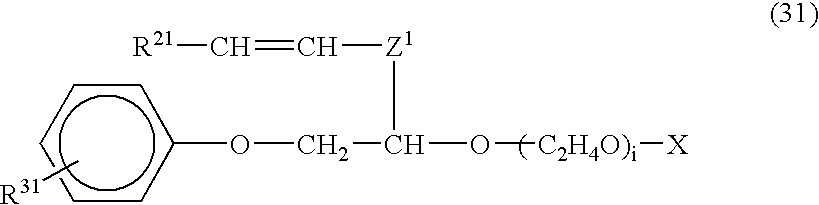

Process for preparing microencapsulated pigment, microencapsulated pigment, aqueous dispersion, and ink for ink jet recording

The present invention relates to a process for preparing a microencapsulated pigment, which comprises adding a polymerizable surfactant having a hydrophilic group, a hydrophobic group and a polymerizable group, a polymerization initiator and an aqueous medium to a wet pigment, and conducting emulsion polymerization to encapsulate pigment particles with a polymer. Also disclosed are a microencapsulated pigment obtained by using this preparation process and an ink for ink jet recording containing at least the microencapsulated pigment and water.

Owner:SEIKO EPSON CORP

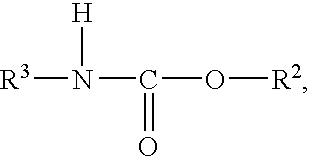

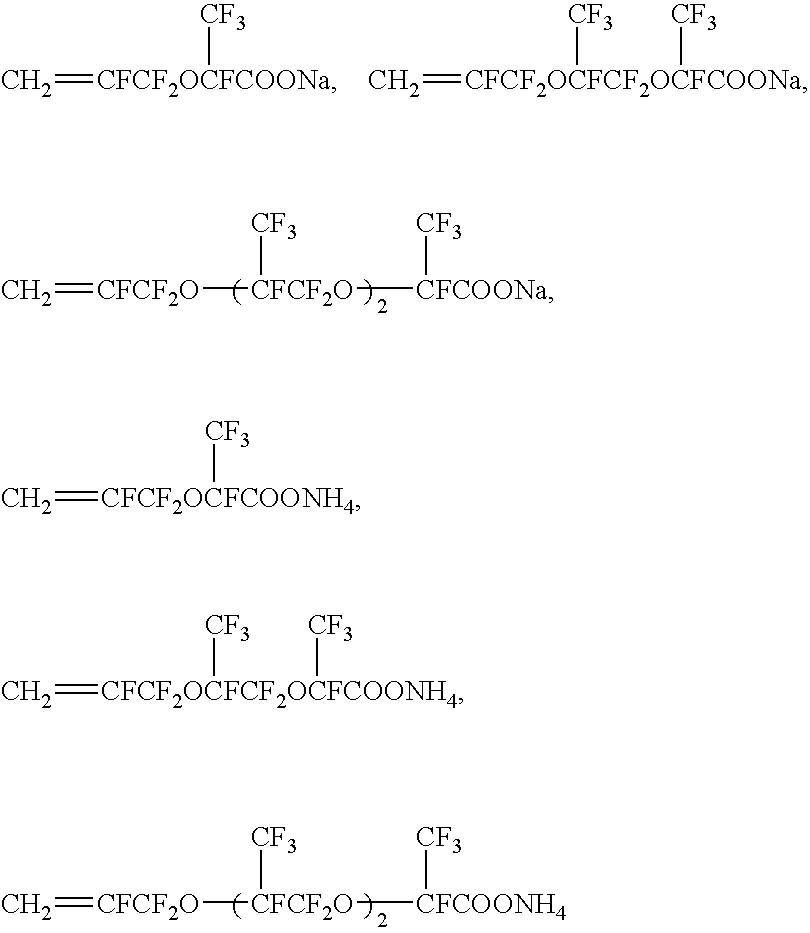

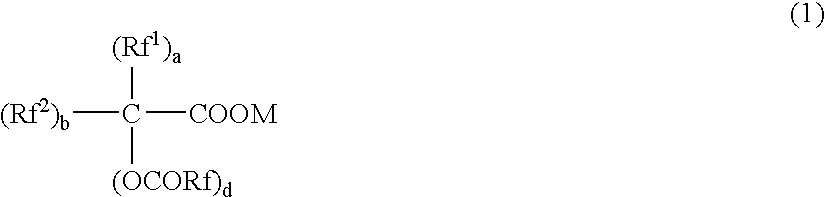

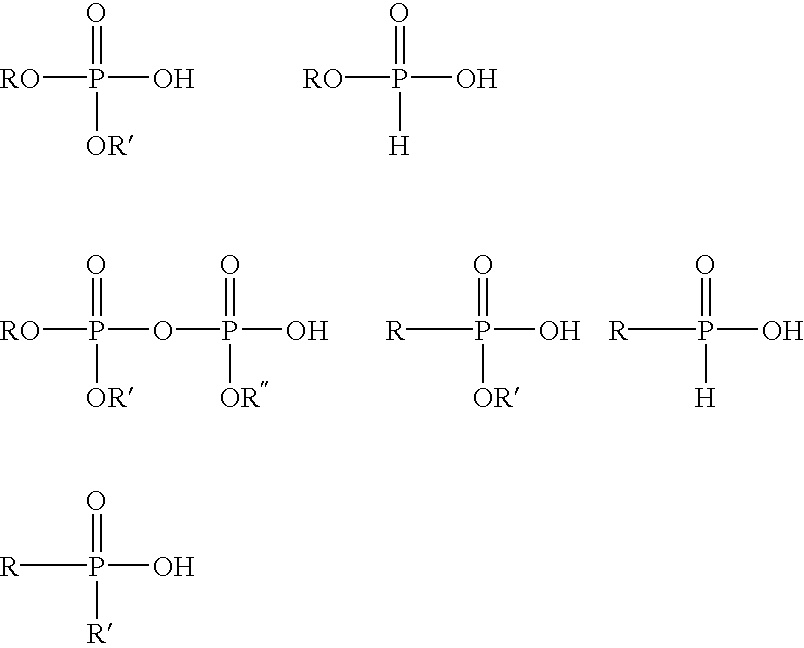

Method for producing fluorine-containing ploymer, aqueous dispersion of fluorine-containing polymer,2-acyloxycarboxylic acid derivative , and surface active agent

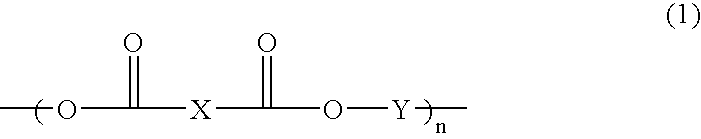

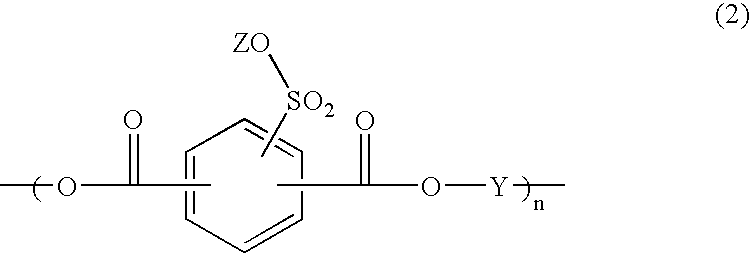

ActiveUS20060223924A1Low residual surfactant contentGood physical propertiesOrganic chemistrySynthetic resin layered productsAcid derivativeCarboxylic salt

The present invention provides a method of producing a fluoropolymer, wherein polymerization using a carboxylate ester bond-containing carboxylic acid derivative as a surfactant in an aqueous medium to give the fluoropolymer is conducted, the above carboxylate ester bond-containing carboxylic acid derivative has a carboxylate ester bond and —COOM (M representing H, NH4, Li, Na or K), the above carboxylate ester bond may optionally be substituted by fluorine atom.

Owner:DAIKIN IND LTD

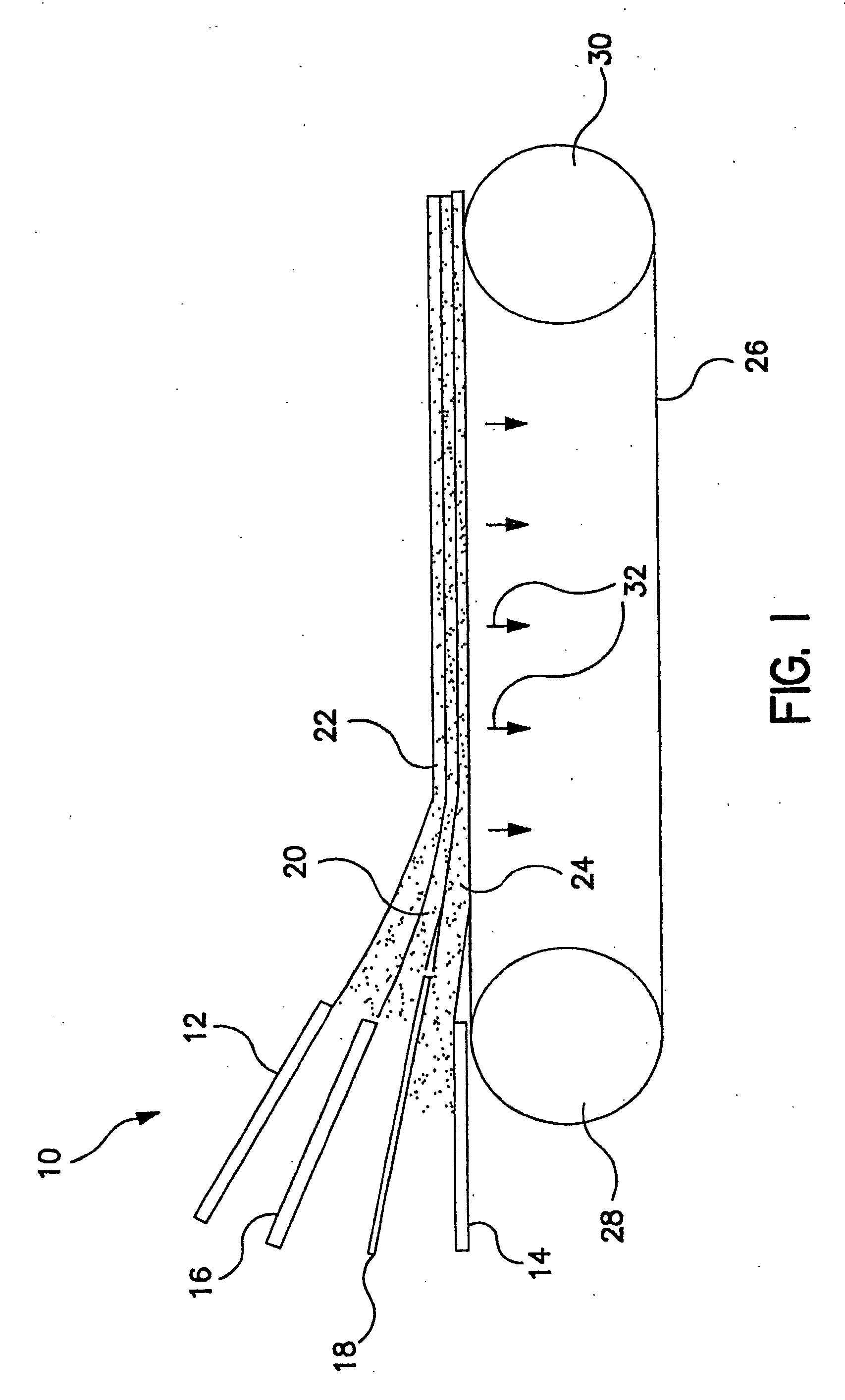

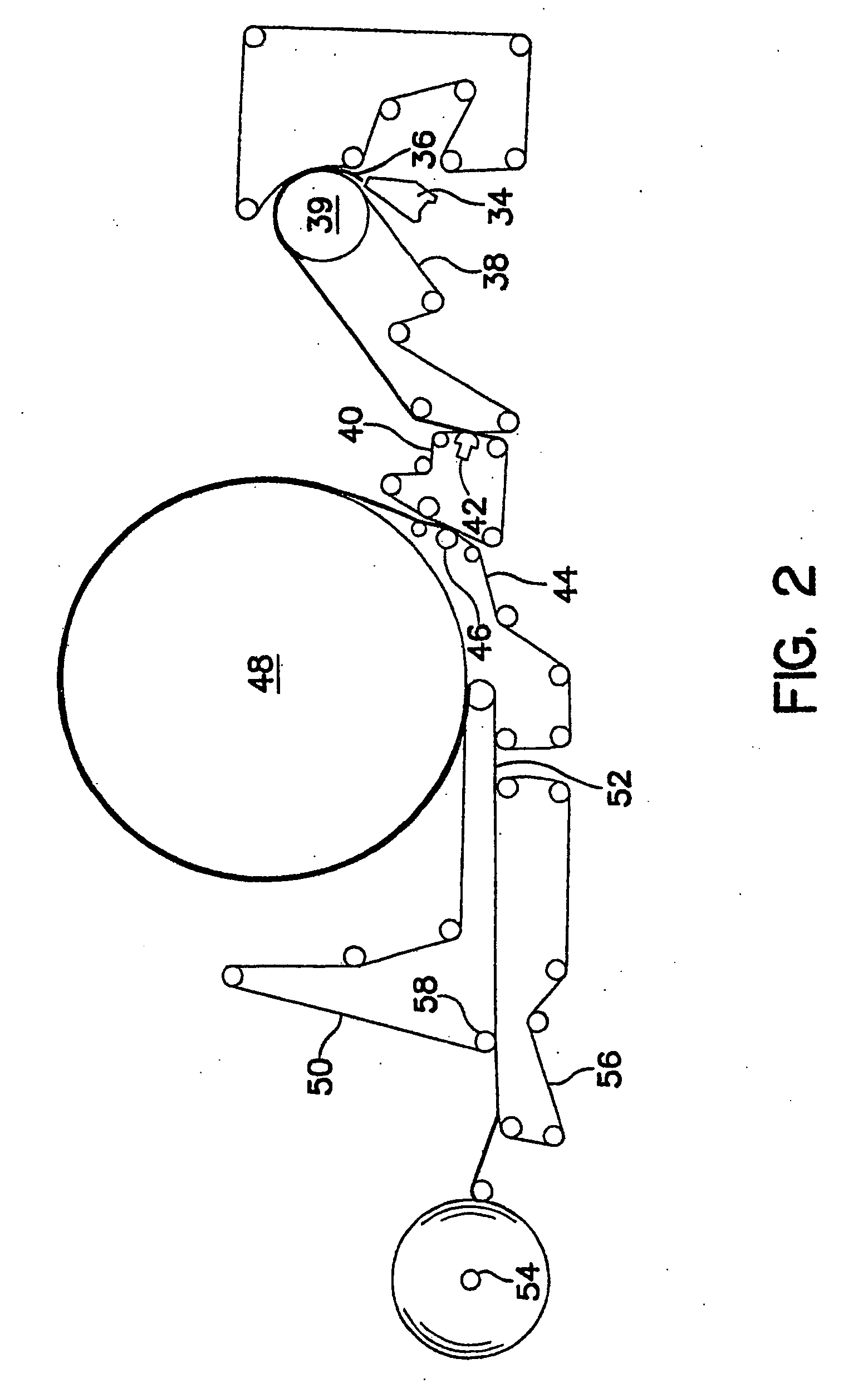

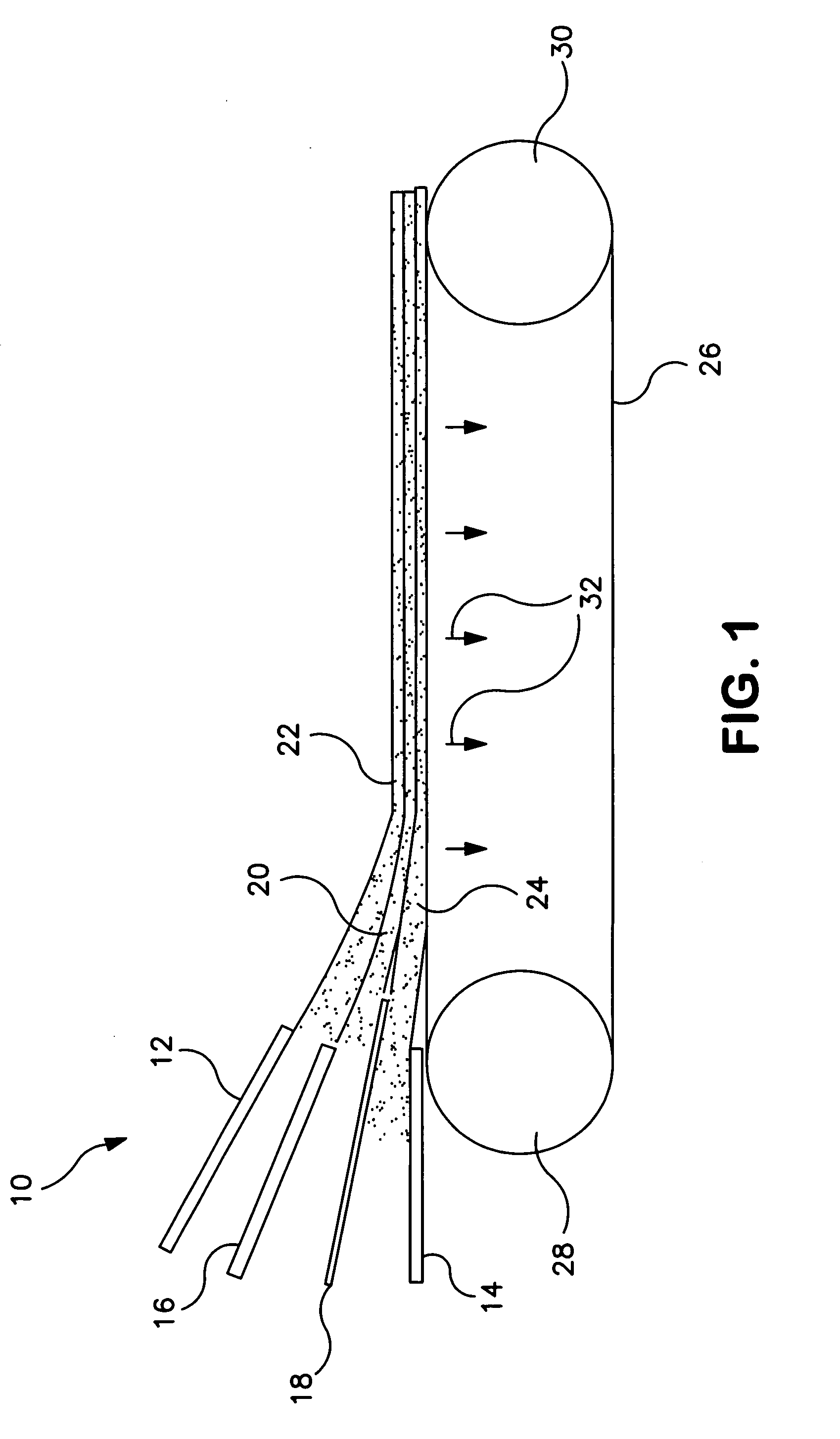

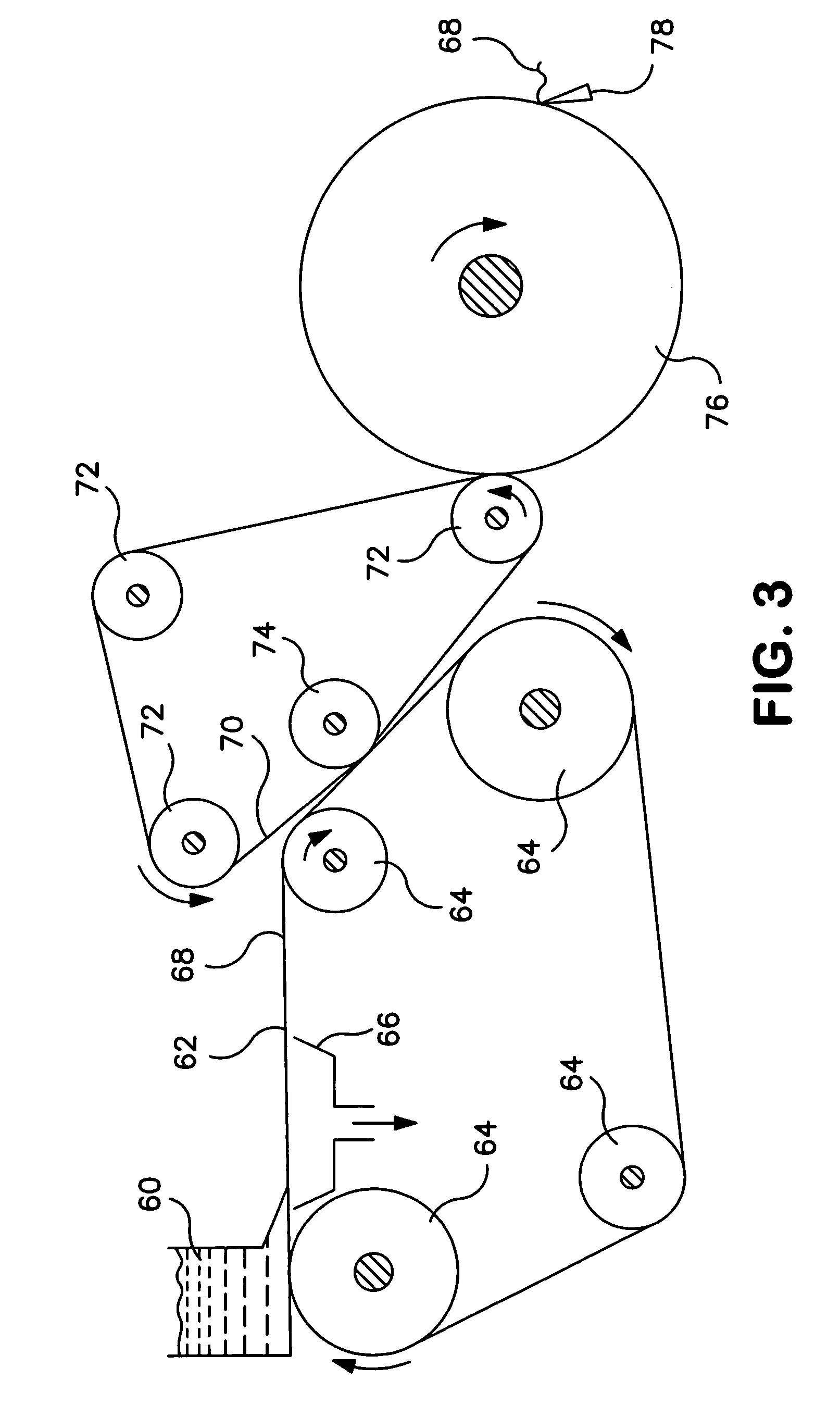

Creping process and products made therefrom

ActiveUS7883604B2Reduced strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Surfactant, method of producing a fluoropolymer, fluoropolymer aqueous dispersion

The present invention provides a surfactant making it possible to obtain particles comprising a fluoropolymer at a size smaller in diameter in an aqueous dispersion obtained by polymerization in the presence of the same. The present invention is a surfactant comprising a fluorine-containing-sulfobutanedioic-acid-ester derivative represented by the general formula (i): Y—Rf1—(CH2)m—OCOCH(SO3M)-CH2COO—(CH2)n—Rf2—Y (i) wherein Y represents hydrogen atom or fluorine atom; when Y is hydrogen atom, one of Rf1 and Rf2 is —(CF2CF2)3— and the other is —(CF2CF2)2— or —(CF2CF2)3— and, when Y is fluorine atom, Rf1 and Rf2 are the same or different and each is a divalent hydrocarbon group containing 1 to 4 carbon atoms and containing at least one fluorine atom; m and n are the same or different and each represents an integer of 1 to 3; and M represents NH4, Li, Na, K or H.

Owner:DAIKIN IND LTD

Treated tissue products having increased strength

InactiveUS20070137808A1Reduced strengthHigh strengthBiocideNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Stabilized controlled release substrate having a coating derived from an aqueous dispersion of hydrophobic polymer

InactiveUS6316031B1Reduce reunionStable productionLiquid surface applicatorsGranular deliveryHydrophobic polymerDissolution

A stabilized solid controlled release dosage form having a coating derived from an aqueous dispersion of ethylcellulose is obtained by overcoating a substrate including a therapeutically active with an aqueous dispersion of ethylcellulose and then curing the coated substrate at a temperature and relative humidity elevated to a suitable level above ambient conditions until the coated dosage form attains a stabilized dissolution profile substantially unaffected by exposure to storage conditions of elevated temperature and / or elevated relative humidity.

Owner:PURDUE PHARMA LP

Method for preparing hydroxyl acrylic acid water dispersoid

InactiveCN101457005AModerate molecular weightNarrow molecular weight distributionPolyurea/polyurethane coatingsPolyurethane adhesiveAcrylic resin

The invention relates to a preparation method for the hydroxyl acrylic aqueous dispersion of high performance and two-component waterborne polyurethane, which comprises four steps: synthesizing hydroxyl acrylic resin, removing a solvent, a neutralization salt forming reaction and deionization and aqueous dispersion. The hydroxyl acrylic aqueous dispersion prepared by the invention has proper molecular weight and the molecular weight is distributed much narrower, thus being beneficial for forming a uniform coating, reducing the plasticizing effect of small molecule substance to the coating, and increasing the comprehensive performance of the coating. The dispersion can be combined with an isocyanate curing agent to be used as wood coatings, corrosion protective coatings, industrial maintenance coatings, floor coatings and the like, and also can be used for preparing a two-component waterborne polyurethane adhesive, etc.

Owner:ZHEJIANG HUANDA PAINT IND GROUP +1

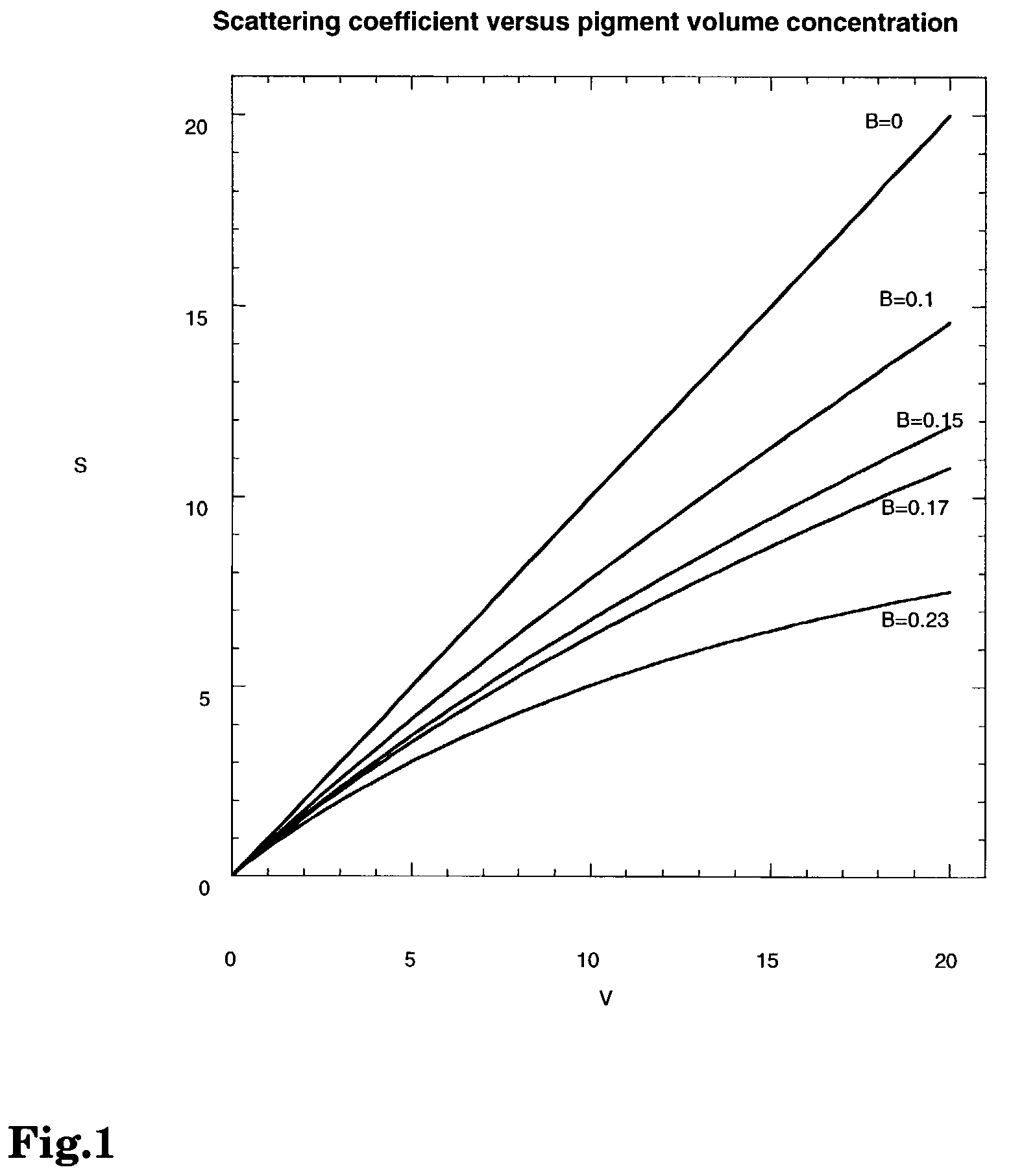

Coating with improved hiding, compositions prepared therewith, and processes for the preparation thereof

InactiveUS7081488B2Low levelIncreased hiding levelMaterial nanotechnologyConductive materialLinear relationshipVolume concentration

A coating containing pigment particles and a polymer matrix is provided. The coating contains pigment particles that have a scattering coefficient with a linear or quasi-linear relationship to the pigment volume concentration of those pigment particles. The coating has improved hiding and is useful as a protective coating or an aesthetic coating on an underlying substrate. Also provided are compositions useful for preparing the coating, including covalently bonded composite particles and aqueous dispersions containing composite particles. The composite particles each contain a pigment particle with a plurality of polymer particles attached by adsorption on the outer surface of the pigment particle or by covalent bonding to the pigment particle through a coupling agent. Methods to prepare the composite particles and coating compositions containing the composite particles are also provided.

Owner:ROHM & HAAS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com