Patents

Literature

251 results about "Fluorinated monomers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorine-containing monomers are used in a variety of coatings applications because of their heat and chemical resistance, weatherability, low refractive index, non-cohesiveness, water and oil repellency, and electric insulating properties.

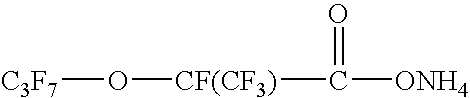

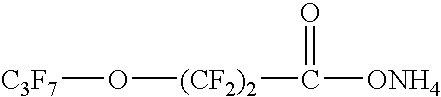

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

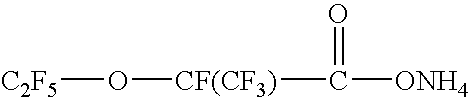

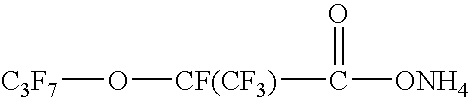

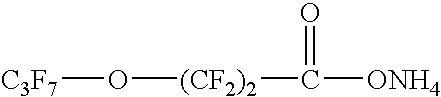

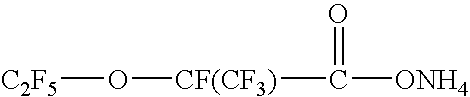

Aqueous emulsion polymerization of fluorinated monomers using a fluorinated surfactant

InactiveUS20070015866A1Low toxicityGood chemical stabilityLiquid surface applicatorsFibre treatmentEmulsion polymerizationEther

The present invention provides an aqueous emulsion polymerization of fluorinated monomers including gaseous fluorinated monomers using a perfluoro ether surfactant as an emulsifier. The perfluoro ether surfactants correspond to formula (I) Rf—O—CF2CF2—X (I) wherein Rf represents a linear or branched perfluoroalkyl group having 1, 2, 3 or 4 carbon atoms and X represents a carboxylic acid group or salt thereof. In a further aspect, the invention also provides an aqueous fluoropolymer dispersion comprising the perfluoro ether surfactant and the use of such dispersion in the coating or impregnation of substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Fluorinated surfactants for use in making a fluoropolymer

InactiveUS20070117914A1Convenient and easy preparationPrepared cost-effectivelyOrganic active ingredientsOrganic compound preparationEmulsion polymerizationCarboxylic acid

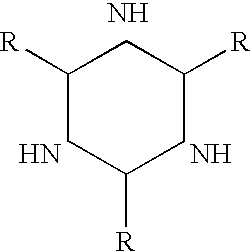

The present invention provides a fluorinated surfactant having the general formula:[Rf—(O)t—CQH—CF2—O]n—R-G (I)wherein Rf represents a partially or fully fluorinated aliphatic group optionally interrupted with one or more oxygen atoms, Q is CF3 or F, R is an aliphatic or aromatic hydrocarbon group, G represents a carboxylic or sulphonic acid or salt thereof, t is 0 or 1 and n is 1, 2 or 3. The surfactant is particularly useful in polymerizing fluorinated monomers in an aqueous emulsion polymerization.

Owner:3M INNOVATIVE PROPERTIES CO

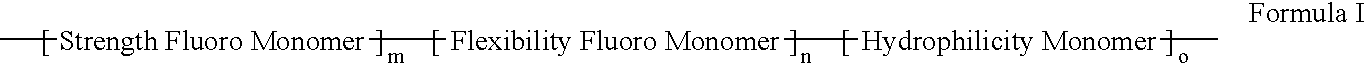

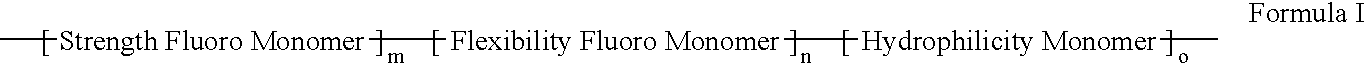

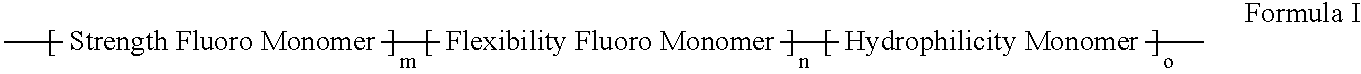

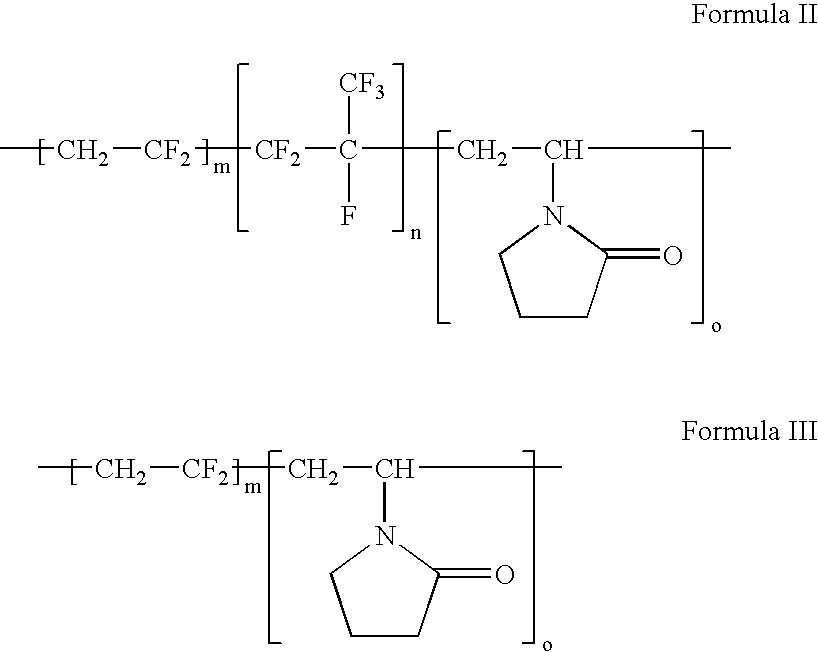

Polymers of fluorinated monomers and hydrophilic monomers

ActiveUS20060047095A1Improve propertiesProvide flexibilityFibre treatmentSurgeryDiseasePolymer science

A polymer of fluorinated monomers and hydrophilic monomers is provided. It is also provided a polymer blend that contains a polymer of fluorinated monomers and another biocompatible polymer. The polymer of fluorinated monomers or polymer blend described herein and optionally a bioactive agent can form a coating on an implantable device such as a drug-delivery stent. The implantable device can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, patent foramen ovale, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

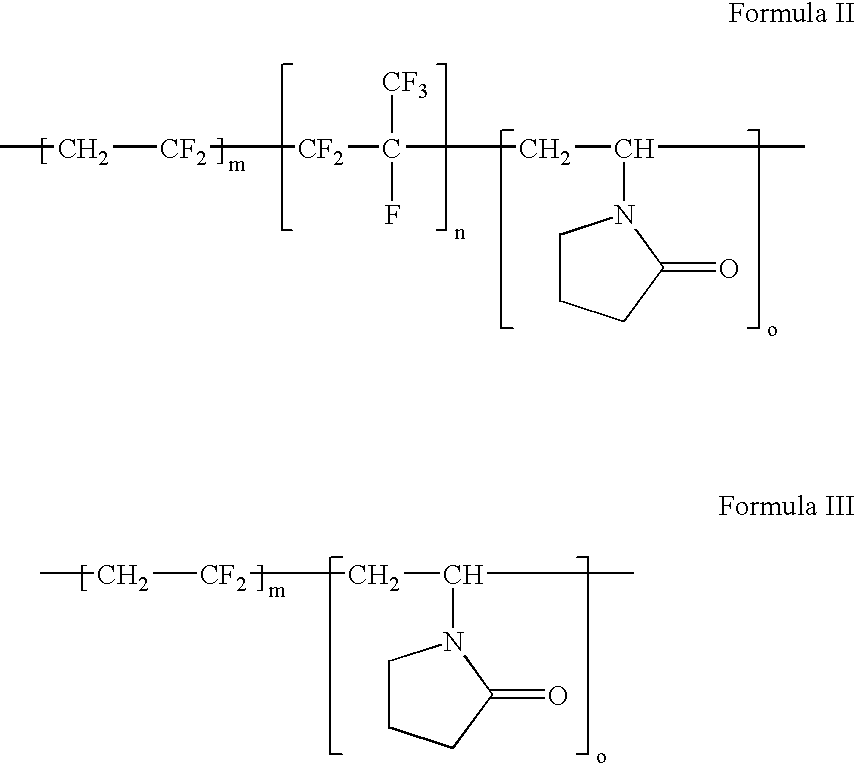

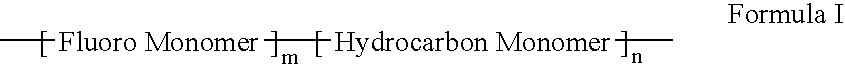

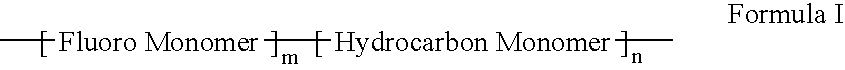

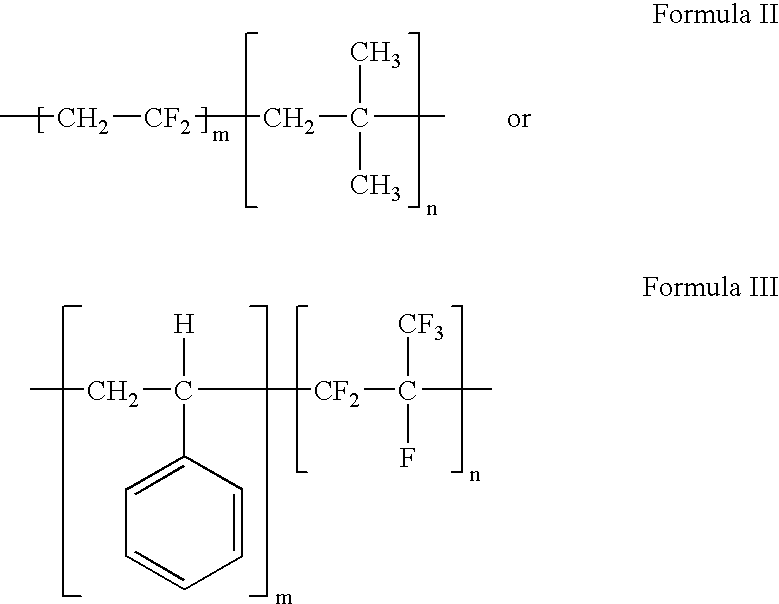

Polymers of fluorinated monomers and hydrocarbon monomers

InactiveUS20060134165A1Provide mechanical strengthGive flexibilityStentsSurgeryAbnormal tissue growthPolymer science

A polymer of fluorinated monomers and hydrocarbon monomers is provided. It is also provided a polymer blend that contains a polymer formed of fluorinated monomers and hydrocarbon monomers and another biocompatible polymer. The polymer or polymer blend described herein and optionally a bioactive agent can form an implantable device such as a stent or a coating on an implantable device such as a drug-delivery stent, which can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

Polymers of fluorinated monomers and hydrophilic monomers

ActiveUS20060269586A1Provide flexibilityProvide strengthStentsAntifouling/underwater paintsHydrophilic monomerPolymer science

A polymer blend that contains a polymer of fluorinated monomers and another biocompatible polymer. The polymer blend can form a coating on a medical device. The medical device can be used for treat, prevent or ameliorate a medical condition.

Owner:ABBOTT CARDIOVASCULAR

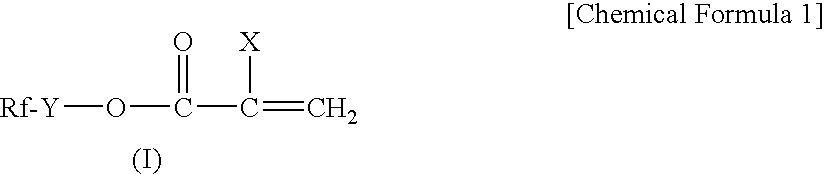

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

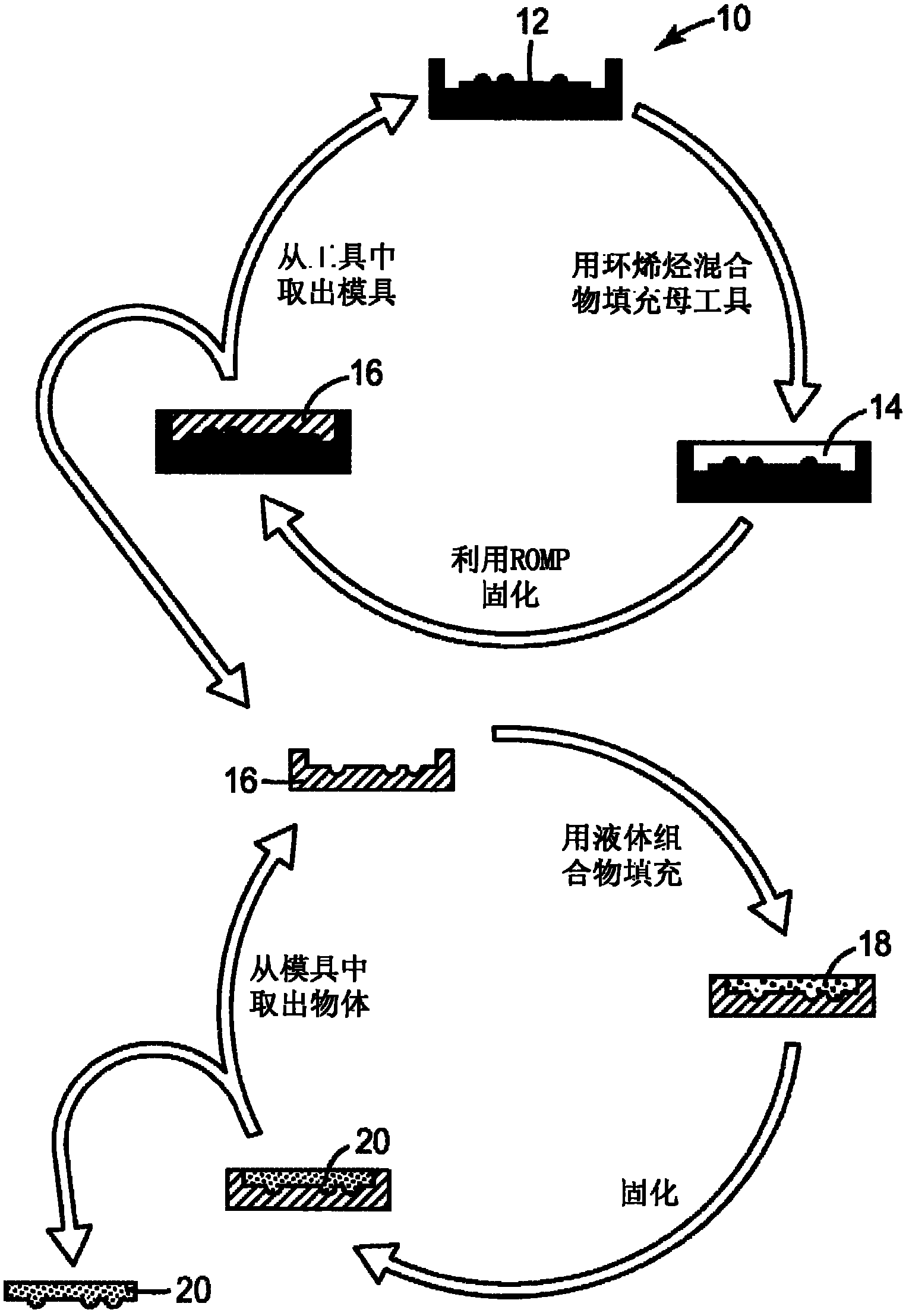

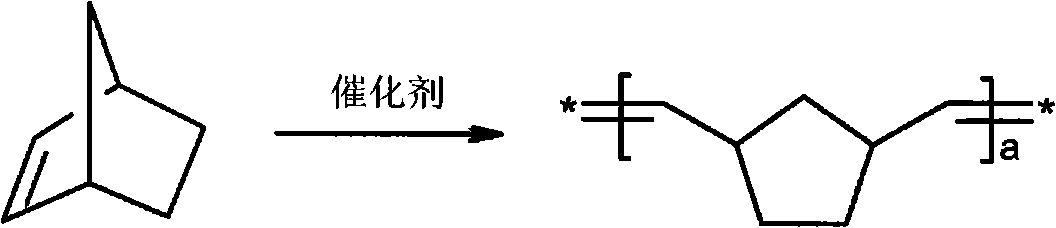

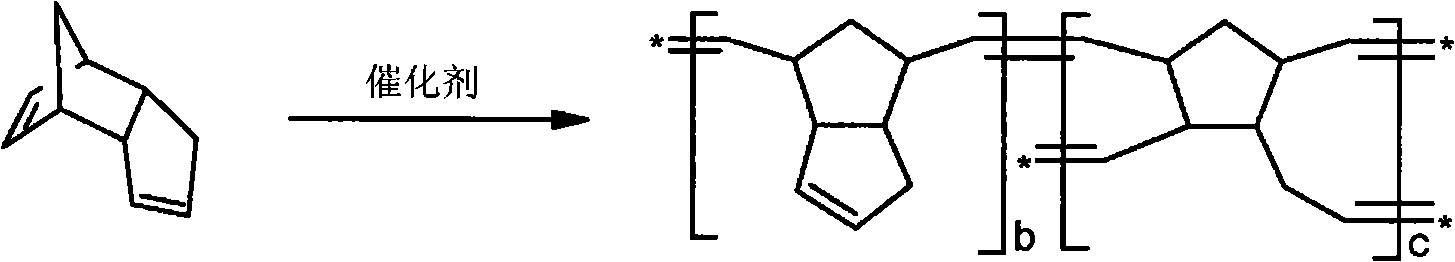

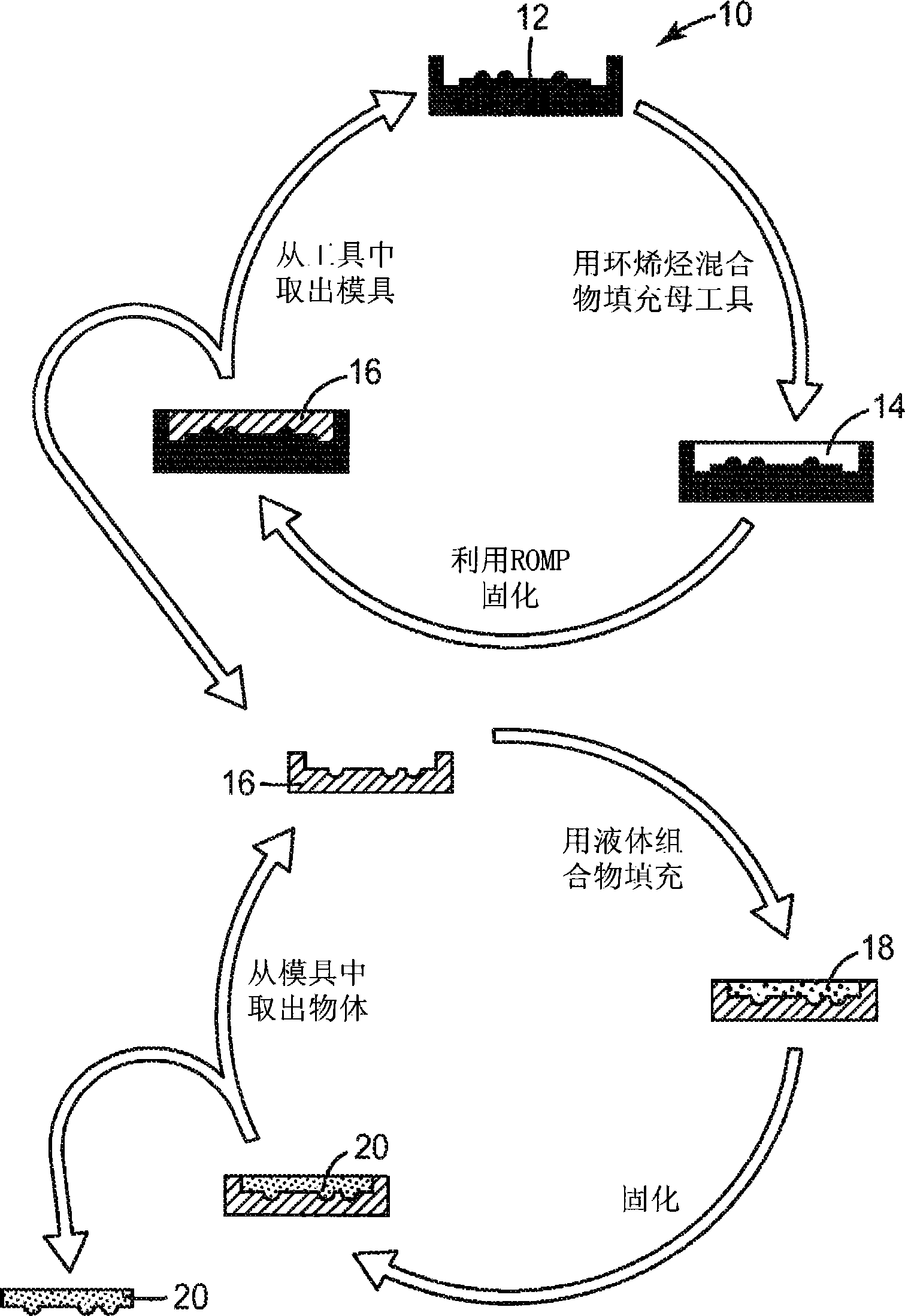

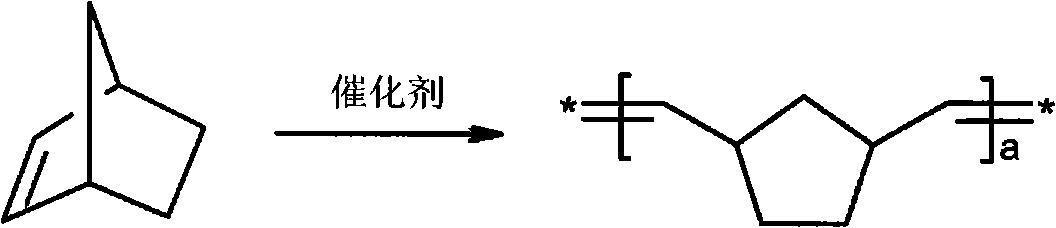

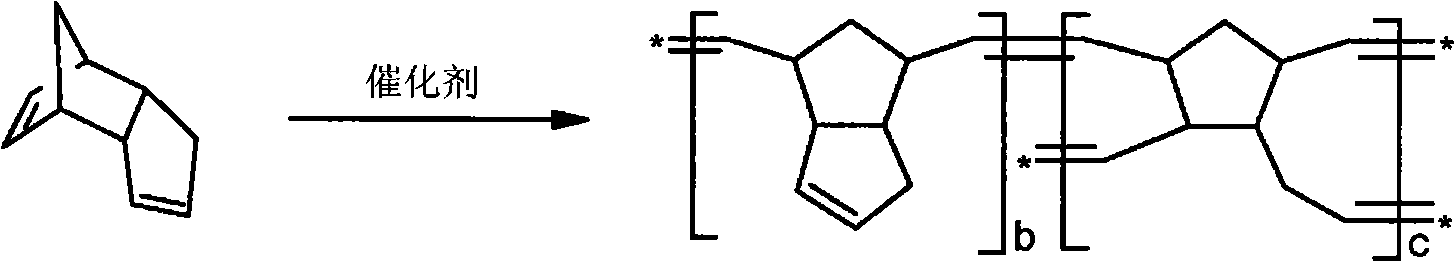

Polymeric molds and articles made therefrom

Disclosed herein are polymeric molds that can be used to make molded articles. The polymeric molds are made from cyclic olefin polymers that may be formed by ring opening metathesis polymerization (ROMP) of a polycyclic monomer having two or more reactive double bonds and a cyclic monomer comprising one reactive double bond. Fluorinated monomers may be used. The polymeric molds may be structured molds in that they have at least one microstructured feature having a dimension of less than about 2 mm, or less than about 500 um. The polymeric molds may also have a plurality of such microstructured features. Also disclosed herein are methods of making the polymeric molds, methods of making molded articles therefrom, and the molded articles.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous Polymerization of Fluorinated Monomer Using Polymerization Agent Comprising Fluoropolyether Acid or Salt and Short Chain Fluorosurfactant

ActiveUS20080269408A1Group 5/15 element organic compoundsFibre treatmentCarboxylic saltFluoropolymer

A process comprising polymerizing at least one fluorinated monomer in an aqueous medium containing initiator and polymerization agent to form an aqueous dispersion of particles of fluoropolymer, the polymerization agent comprising: fluoropolyether acid or salt thereof having a number average molecular weight of at least about 800 g / mol; and fluorosurfactant having the formula: [R1—On-L-A−]Y+wherein: R1 is a linear or branched partially or fully fluorinated aliphatic group which may contain ether linkages; n is 0 or 1; L is a linear or branched alkylene group which may be nonfluorinated, partially fluorinated or fully fluorinated and which may contain ether linkages; A− is an anionic group selected from the group consisting of carboxylate, sulfonate, sulfonamide anion, and phosphonate; and Y+ is hydrogen, ammonium or alkali metal cation; with the proviso that the chain length of R1—On-L- is not greater than 6 atoms.

Owner:THE CHEMOURS CO FC LLC

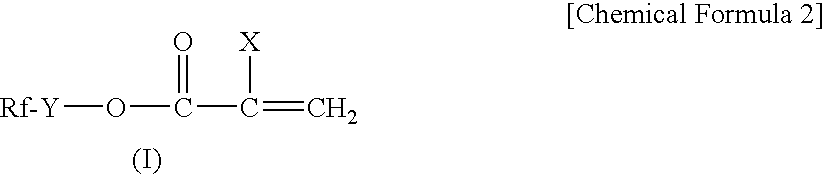

Method of treatment of a textile or non-woven substrate to render same water and oil repellent

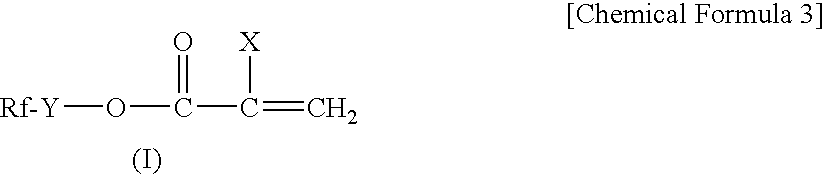

The present invention relates to a method of treating a non-woven substrate or textile, comprising the step of applying to said non-woven substrate or textile a fluorochemical composition comprising a fluoropolymer that comprises:(a) between 10 and 97 mole % of units that can be derived from fluorinated monomer selected from the group consisting of monomers according to the general formula: Rf-X—OC(O)—C(R)═CH2 wherein Rf represents a perfluorinated aliphatic group having 3 or 4 carbon atoms, X is an organic divalent linking group and R represent hydrogen or a lower alkyl group having 1 to 4 carbon atoms; (b) between 3 and 75 mole % of units derived from a chlorine containing comonomer selected from the group consisting of vinylidene chloride, vinyl chloride and mixtures thereof; and (c) optionally further units derived from monomers other than a fluorinated monomer and said chlorine containing comonomers; wherein the amount of units (a), (b) and (c) adding up to 100%, whereby said fluorochemical composition is applied in such amount that the weight of fluoropolymer on said non-woven substrate or textile is not more than 3% by weight based on the weight of said non-woven substrate or textile.

Owner:3M INNOVATIVE PROPERTIES CO

Emulsion polymerization of fluorinated monomers

InactiveUS7045571B2Good chemical stabilityEasy to cleanCosmetic preparationsToilet preparationsIonomerPolymer science

The use of perfluorinated polymers and / or fluorinated ionomers as surfactant emulsifiers in emulsion polymerization of fluorinated monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous polymerization of fluorinated monomer using polymerization agent comprising fluoropolyether acid or salt and short chain fluorosurfactant

A process comprising polymerizing at least one fluorinated monomer in an aqueous medium containing initiator and polymerization agent to form an aqueous dispersion of particles of fluoropolymer, the polymerization agent comprising: fluoropolyether acid or salt thereof having a number average molecular weight of at least about 800 g / mol; and fluorosurfactant having the formula:[R1—On-L-A−] Y+wherein: R1 is a linear or branched partially or fully fluorinated aliphatic group which may contain ether linkages; n is 0 or 1; L is a linear or branched alkylene group which may be nonfluorinated, partially fluorinated or fully fluorinated and which may contain ether linkages; A− is an anionic group selected from the group consisting of carboxylate, sulfonate, sulfonamide anion, and phosphonate; and Y+ is hydrogen, ammonium or alkali metal cation; with the proviso that the chain length of R1—On-L- is not greater than 6 atoms.

Owner:THE CHEMOURS CO FC LLC

Polymer for masonry treatment and treating agent

InactiveUS20070197717A1Excellent in water and oil-repellencyMaintain good propertiesOther chemical processesFibre treatmentPhosphateCarboxyphosphate

A treating agent containing a fluoropolymer for use in masonry treatment obtained from (A) a fluoromonomer, (B) a monomer having at least one acid group selected from the group consisting of carboxy, phosphate, phosphonate, phosphinate, sulfate, sulfo, and sulfino groups, and (C) a non-fluorinated monomer containing a hydrophobic group. The treating agent imparts to a masonry excellent water- and oil-repellency and excellent unsusceptibility to fouling.

Owner:DAIKIN IND LTD

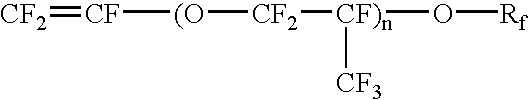

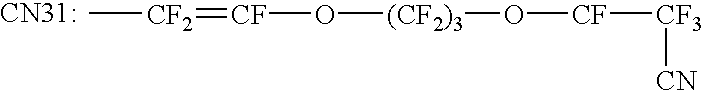

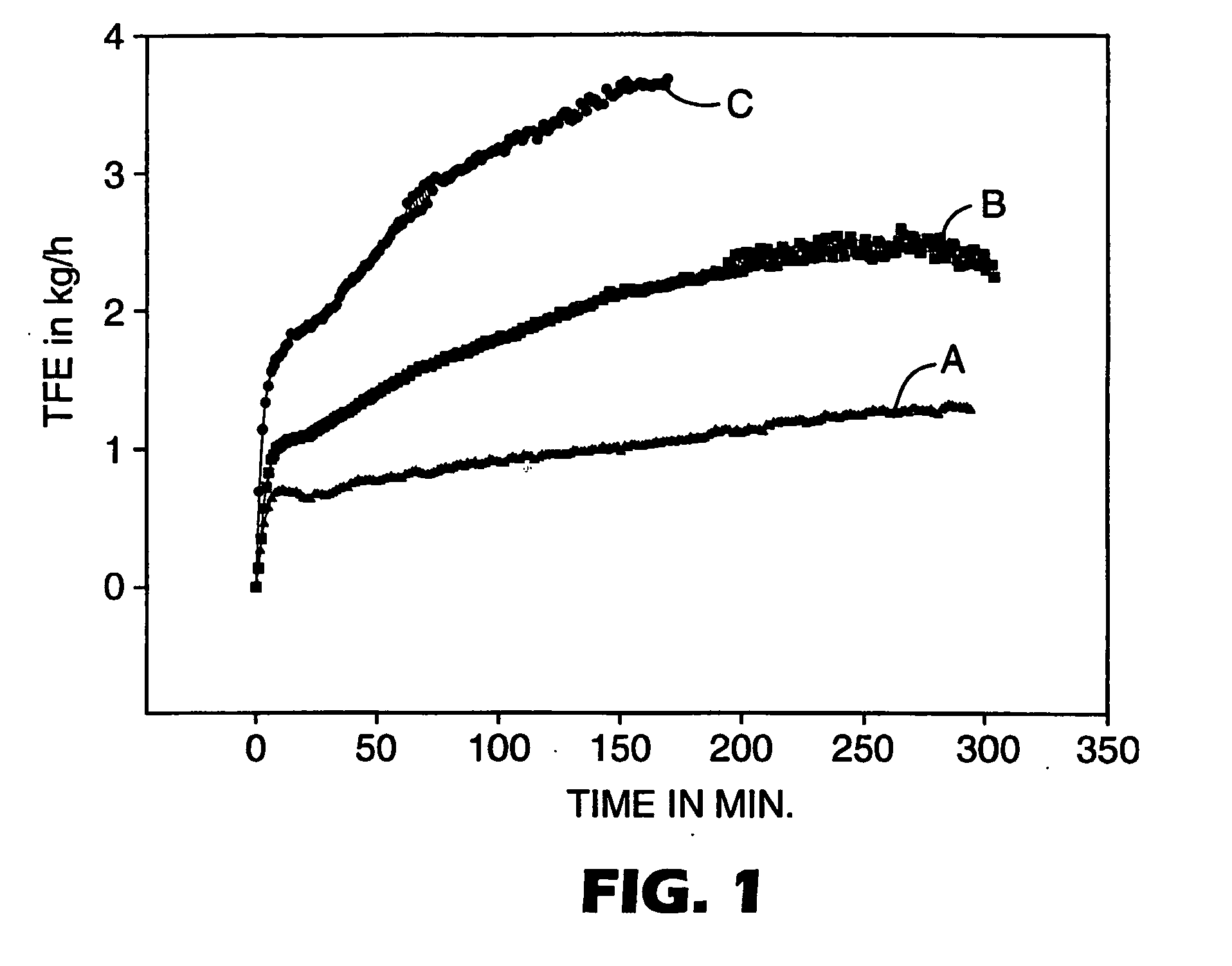

Perfluoroelastomers having a low glass transition temperature and method of making them

InactiveUS6730760B2The polymerization reaction is fastDesirable mechanical propertyVinyl etherVitrification

A method of making a curable fluoroelastomer is disclosed. The method comprises the steps ofpreemulsifying at least one perfluorovinylether in water, andcopolymerizing the preemulsified perfluorovinylether with a gaseous fluorinated monomer in the presence of a cure site monomer. The method provides a fluoroelastomer having a glass transition temperature of less than -10° C. Also disclosed is a fluoroelastomer that consists essentially of a perfluorovinylether of formula (I) as defined below, a cure site component, perfluoromethylvinylether, and tetrafluoroethylene and / or chlorotrifluoroethylene.

Owner:3M INNOVATIVE PROPERTIES CO

Emulsion Polymerization of Fluorinated Monomers

InactiveUS20060160947A1Good chemical stabilityEasy to cleanTransportation and packagingOrganic dyesIonomerPolymer science

The use of perfluorinated polymers and / or fluorinated ionomers as surfactant emulsifiers in emulsion polymerization of fluorinated monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Fluoropolymer of fluorinated short chain acrylates or methacrylates and oil-and water repellent compositions based thereon

InactiveUS20050027063A1Good to excellent repellency propertyMaintain good propertiesFibre treatmentMethacrylatePolymer science

The present invention relates to compositions based on a fluoropolymer comprising repeating units derived from (i) one or more fluorinated monomers selected from the group consisting of monomers according to the general formula: Rf—X—OC(O)—C(R)═CH2 wherein Rf represents a perfluorinated aliphatic group having 3 or 4 carbon atoms, X is an organic divalent linking group and R represents hydrogen or a lower alkyl group having 1 to 4 carbon atoms; and (ii) one or more non-fluorinated comonomers. The fluoropolymer has a weight average molecular weight between 3000 and 55000. The compositions may be solvent born or aqueous born and are particularly useful to provide good oil- and / or water repellency properties to the substrate.

Owner:3M INNOVATIVE PROPERTIES CO

Method of rendering substrates oil and water repellent with a fluorochemical oligomeric silane

InactiveUS7166329B2Lower levelIncreased durabilityOther chemical processesFibre treatmentArylPolymer science

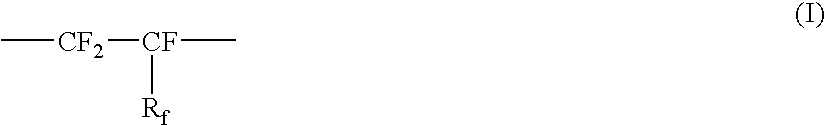

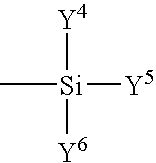

A fluorochemical composition comprising of organic solvent and fluorochemical oligomer represented by the general formula:X-MfnMhmMar-Gwherein X represents the residue of an initiator or hydrogen; Mf represents units derived from fluorinated monomers; Mh represents units derived from a non-fluorinated monomers; Ma represents units having a silyl group represented by the formula:wherein each of Y4, Y5 and Y6 independently represents an alkyl group, an aryl group or a hydrolyzable group; G is a monovalent organic group comprising the residue of a chain transfer agent; n represents a value of 1 to 100; m represents a value of 0 to 100;r represents a value of 0 to 100; and n+m+r is at least 2.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous emulsion polymerization of fluorinated monomers in the presence of a partially fluorinated oligomer as an emulsifier

InactiveUS20070004848A1Increase speedSmall particle sizeTransportation and packagingFibre treatmentPolymer scienceOligomer

The present invention relates to a method for making a fluoropolymer comprising an aqueous emulsion polymerization of one or more fluorinated monomers wherein said aqueous emulsion polymerization is carried out in the presence of an oligomer that comprises one or more ionic groups, has a partially fluorinated backbone, a number average molecular weight of not more than 2000 g / mol and that has a combination of repeating units different from that of the fluoropolymer that is being produced by the polymerization of said one or more fluorinated monomers. Since the polymerization of the one or more fluorinated monomers to produce the desired fluoropolymer is carried out in the presence of the oligomer, the resulting dispersion will contain the oligomer in addition to the fluoropolymer. Thus, in a further aspect, the invention relates to an aqueous dispersion of a fluoropolymer comprising the oligomer.

Owner:3M INNOVATIVE PROPERTIES CO

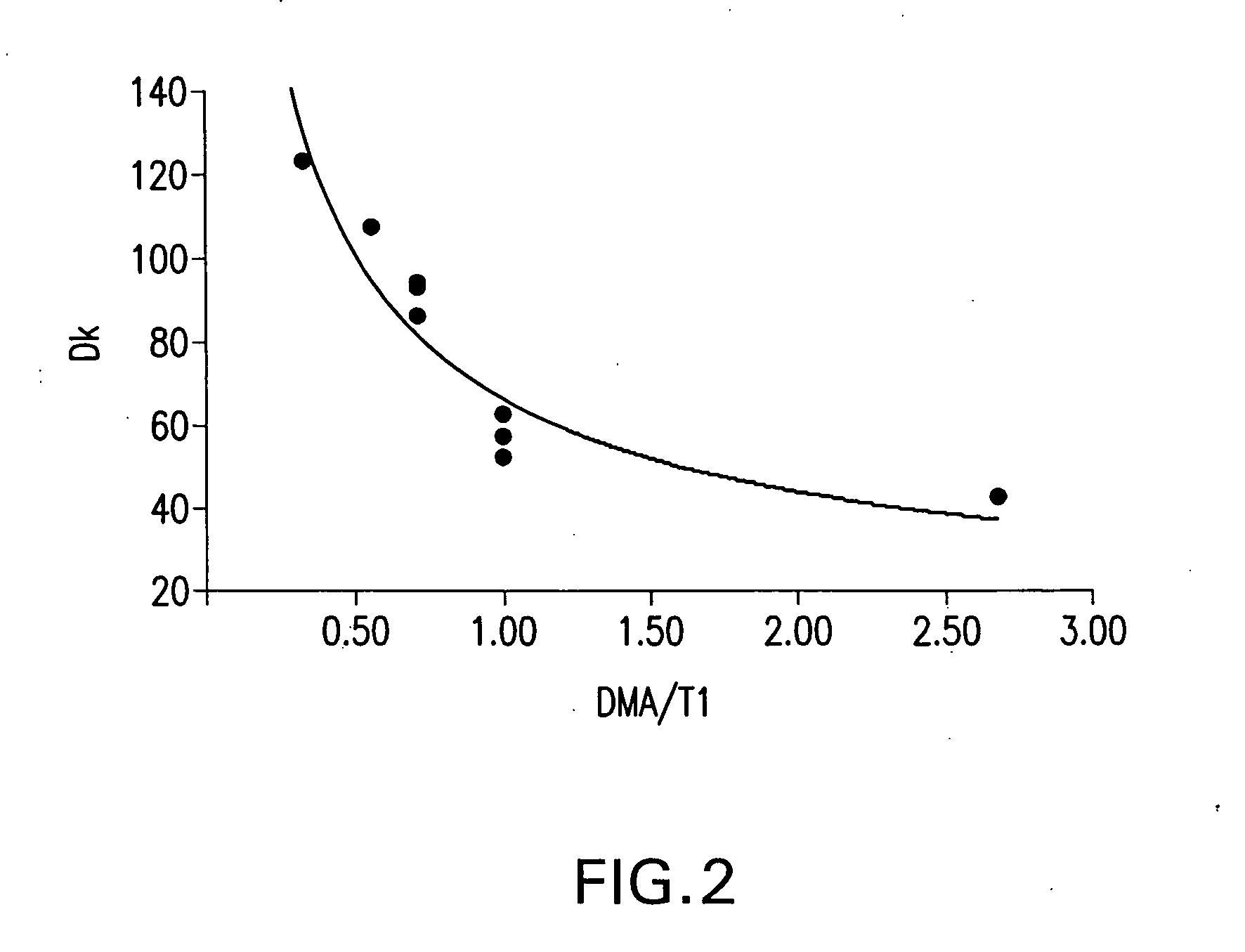

Aqueous emulsion polymerization in the presence of ethers as chain transfer agents to produce fluoropolymers

The present invention provides a method of making a fluoropolymer comprising repeating units derived from one or more gaseous fluorinated monomers. The method comprises an aqueous emulsion polymerization of gaseous fluorinated monomers in the presence of an ether selected from the group consisting of dimethyl ether (DME), methyl tertiary butyl ether (MTBE) and mixtures thereof.

Owner:3M INNOVATIVE PROPERTIES CO

Contact lens

InactiveUS20060012751A1Sufficient oxygenPromote hydrationOptical articlesEye diagnosticsHydrophilic monomerSilylene

This invention is directed to ophthalmic materials and ophthalmic lenses that are a co-polymerization product of a (a) hydrophilic monomer with (b) a tris(siloxy)silyl group-containing monomer, (c) a wide variety of hydrophobic monomers (both aliphatic and aromatic) and usually a (d) polyfluorinated monomer, as well as optional monomers or monomer mixtures that can include a cationic monomer, a non-aromatic hydrophobic monomer and a poly(dimethylsiloxy)silyl group-containing monomer. A contact lens prepared from such a co-polymer exhibits enhanced water content, while maintaining exceptional oxygen permeability, thereby providing a lens that can be worn comfortably for prolonged periods of time. A process for the preparation of such lenses is also disclosed.

Owner:ALCON INC

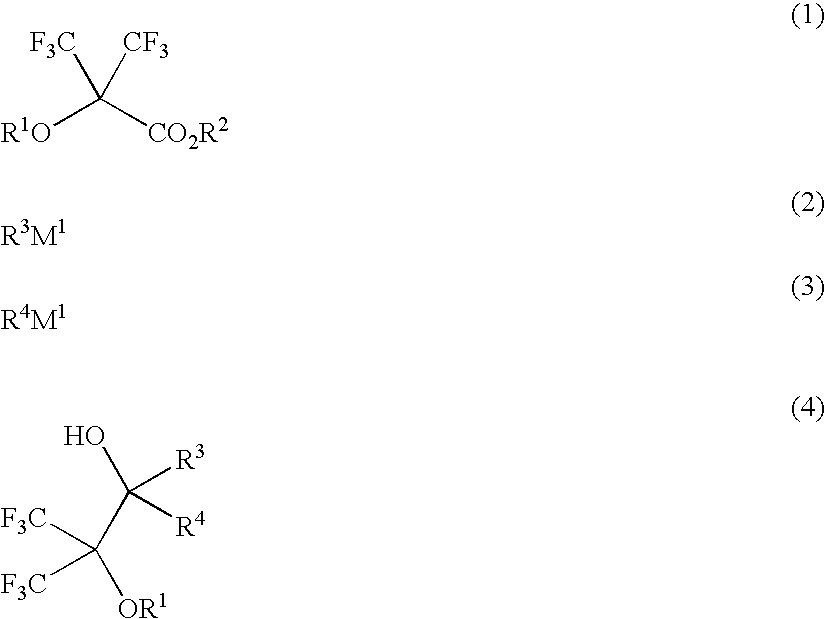

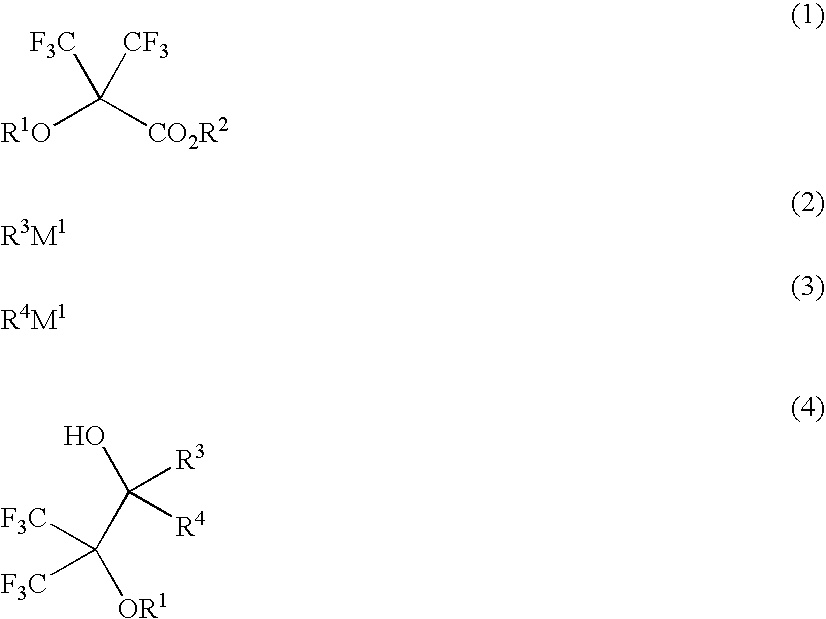

Fluoroalcohol preparation method, fluorinated monomer, polymer, resist composition and patterning process

ActiveUS20070179309A1Organic compound preparationPhotosensitive materialsPolymer scienceChemical compound

Fluoroalcohol compounds of formula (4) are prepared by reacting a fluorine compound of formula (1) with reducing agents or organometallic reagents of formulas (2) and (3) wherein R1 is H or a monovalent C1-C20 hydrocarbon group in which any —CH2— moiety may be replaced by —O— or —C(═O)—, R2 is H or a monovalent C1-C6 hydrocarbon group, R3 and R4 are H or a monovalent C1-C8 hydrocarbon group, and M1 is Li, Na, K, Mg, Zn, Al, B, or Si. From the fluoroalcohol compounds, fluorinated monomers can be produced in a simple and economic way, which are useful in producing polymers for the formulation of radiation-sensitive resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

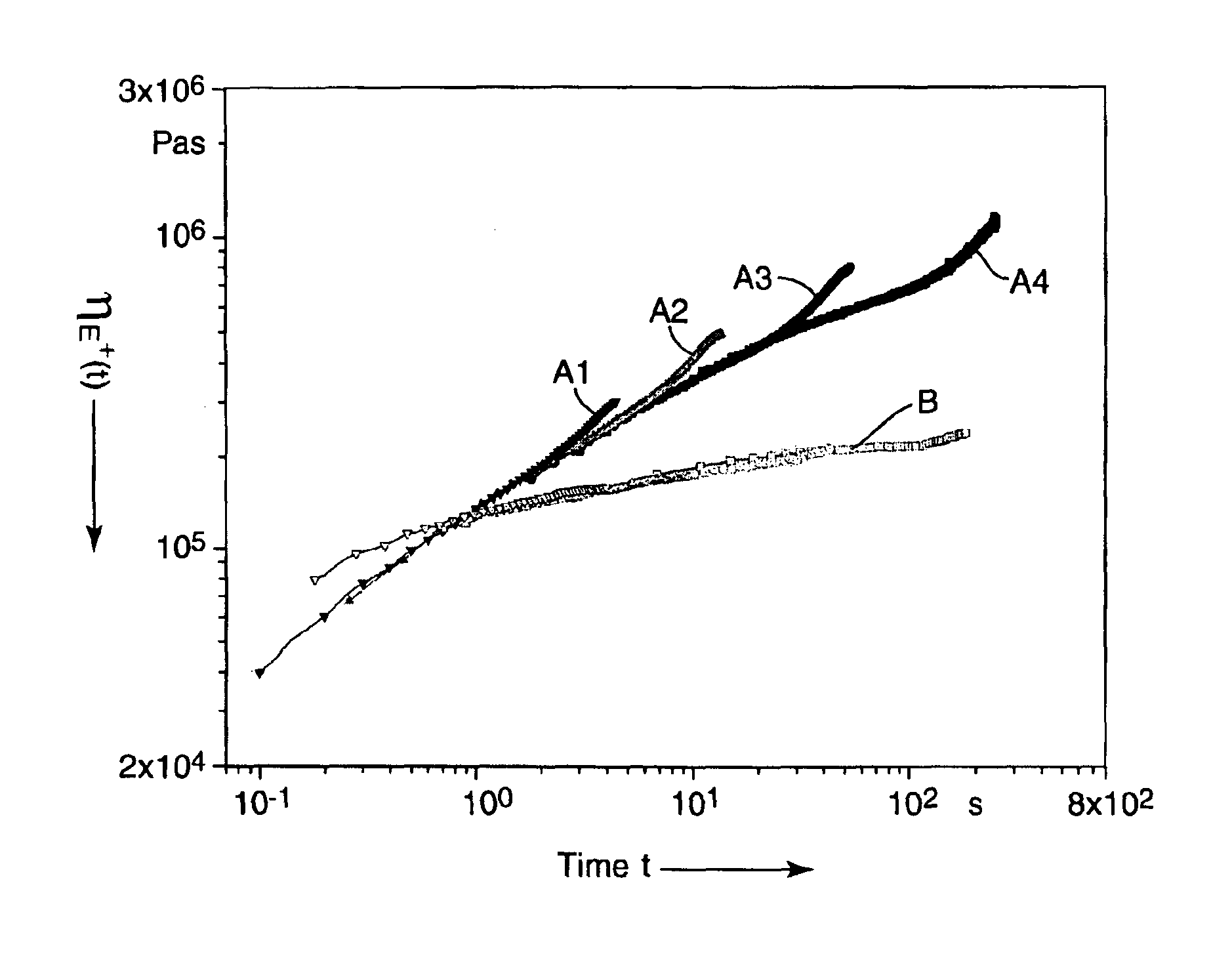

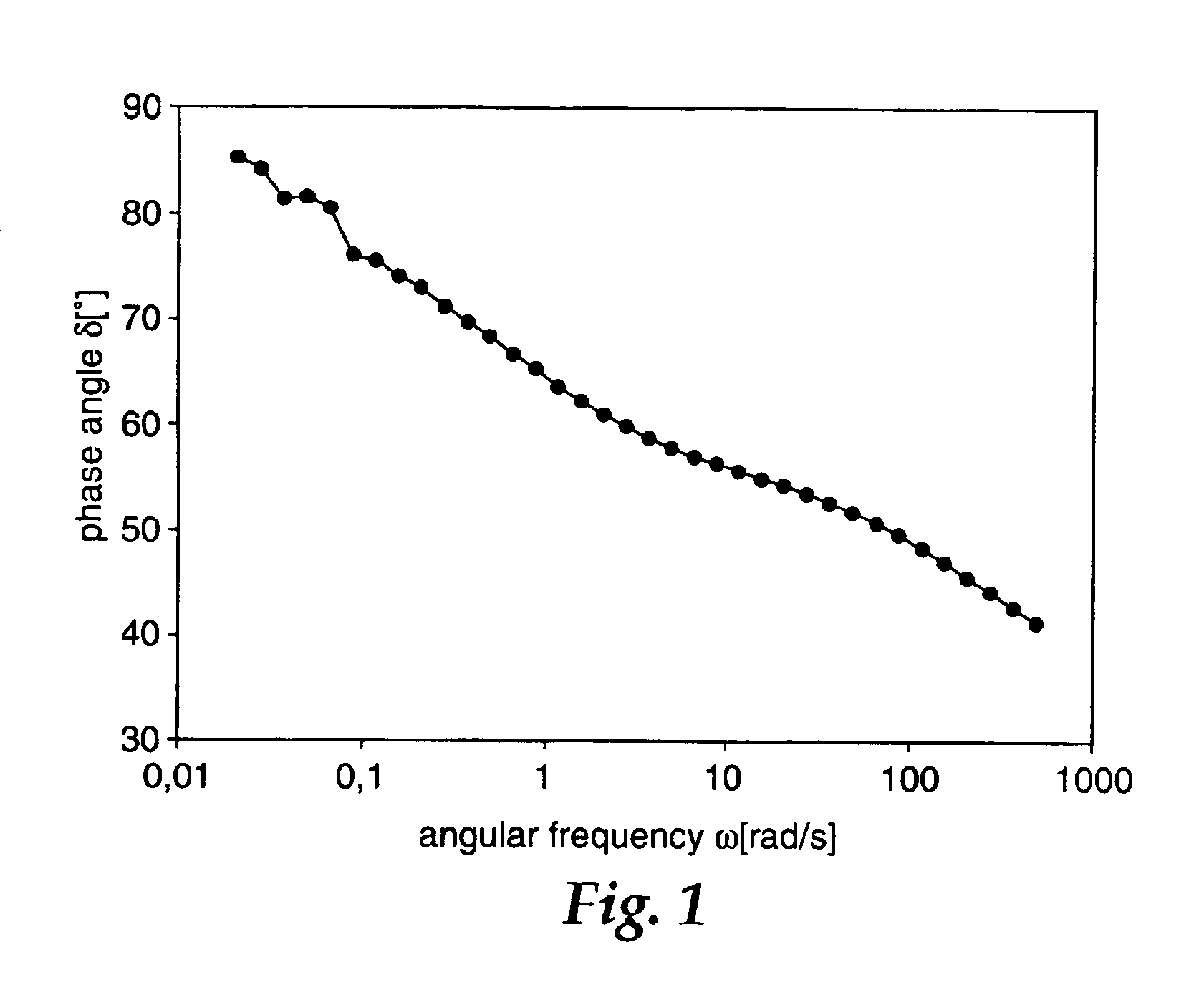

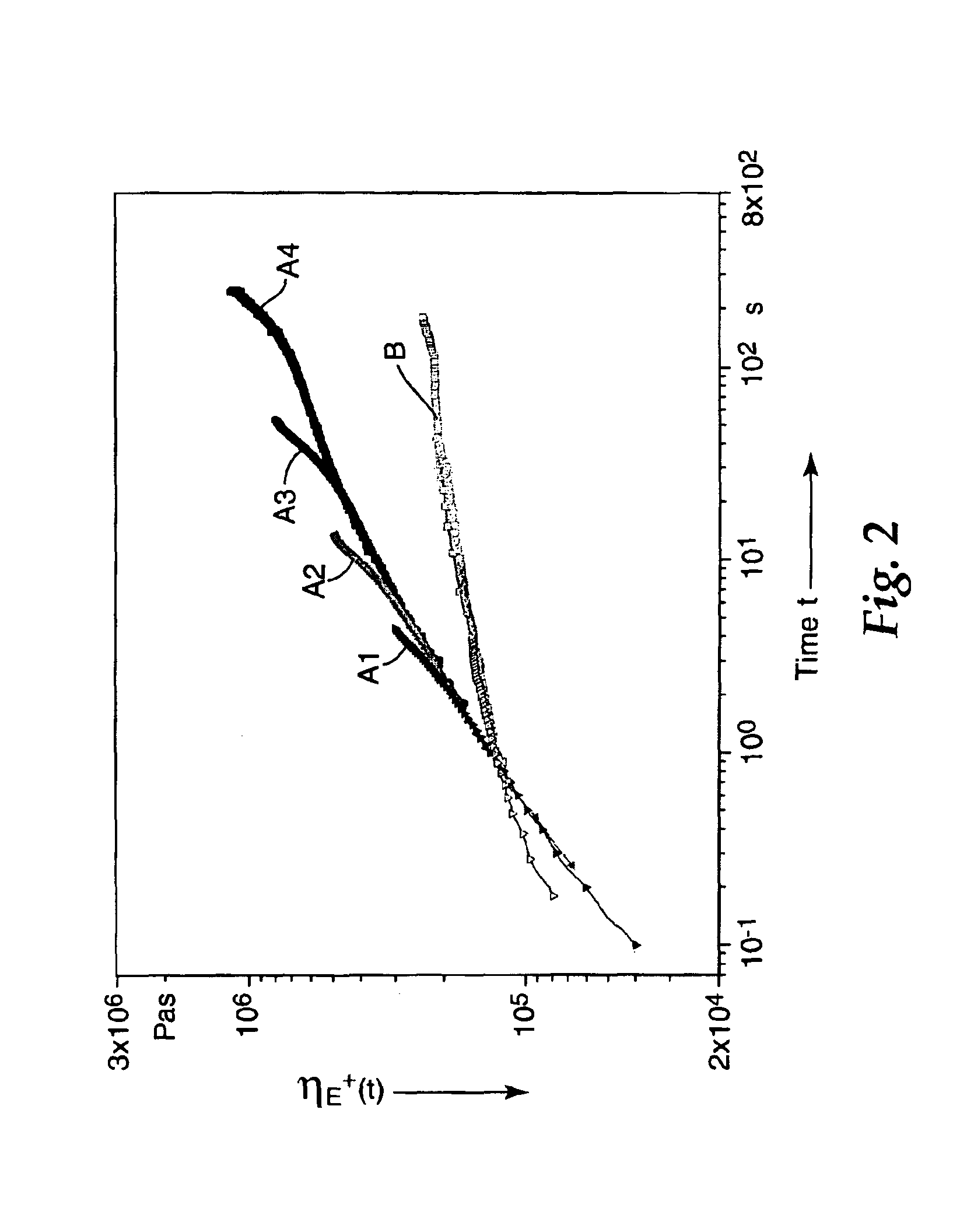

Melt-processible thermoplastic fluoropolymers having improved processing characteristics and method of producing same

ActiveUS6927265B2Increased critical shear rateSimple processPlastic/resin/waxes insulatorsFibre treatmentThermoplasticPolymer science

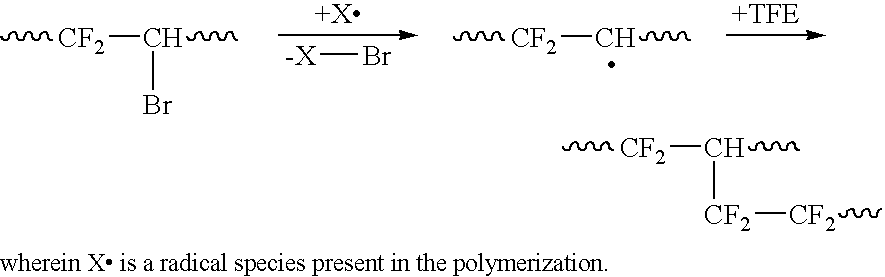

The present invention provides a fluoropolymer that is melt-processible and thermoplastic and that has a melting point between 100° C. and 320° C. The fluoropolymer is derived from (a) one or more gaseous fluorinated monomers, (b) one or more modifiers selected from (i) olefins having a bromine or iodine atom bonded to a carbon of the double bond of the olefin, (ii) olefins corresponding to formula (I):Xa2C═CXa—Rf—Br (I)wherein each Xa independently represents hydrogen, fluorine, bromine, chlorine or iodine, Rf is a perfluoroalkylene group, typically having 1 to 8 carbon atoms, a perfluorooxyalkylene group or a perfluoropolyether group and (iii) mixtures thereof; and (c) optionally one or more comonomers selected from non-gaseous fluorinated monomers and non-fluorinated monomers. The resulting fluoropolymer has long chain branches. The invention further provides a method for making these polymers.

Owner:3M INNOVATIVE PROPERTIES CO

Polymeric molds and articles made therefrom

Disclosed herein are polymeric molds that can be used to make molded articles. The polymer mold is made of a cyclic olefin polymer that can be formed from a polycyclic monomer having two or more reactive double bonds and a cyclic monomer containing one reactive double bond. Ring metathesis polymerization (ROMP) formation. Fluorinated monomers can be used. The polymeric molds may be structured molds in that they have microstructured features with at least one dimension less than about 2 mm or less than about 500 μm. The polymer mold can also have many of these microstructured features. Also disclosed herein are methods of making polymeric molds, methods of making molded articles therefrom, and molded articles.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous emulsion polymerization process for producing fluoropolymers

InactiveUS20040072977A1Reduced coagulumThe polymerization process is simpleFibre treatmentPolymer scienceEmulsion polymerization

The present invention provides a method of making a fluoropolymer through emulsion polymerization of one or more fluorinated monomers in an aqueous phase in the presence of a fluorinated surfactant. At least part of the fluorinated surfactant is added to the aqueous phase as an aqueous mixture with at least one organic liquid that is not miscible with water and that is selected from halogenated and non-halogenated organic liquids, the mixture having droplets having an average droplet diameter of not more than 1000 nm and the mixture being added to the aqueous phase in such an amount that the total amount of the fluorinated surfactant is not more than 1% by weight based on the weight of the aqueous phase and the total amount of said organic liquid is not more than 1% by weight based on the weight of said aqueous phase. The invention allows for an improvement of the efficiency of an aqueous emulsion polymerization process. In particular, the polymerization time can be reduced and the polymer yield may be improved.

Owner:3M INNOVATIVE PROPERTIES CO

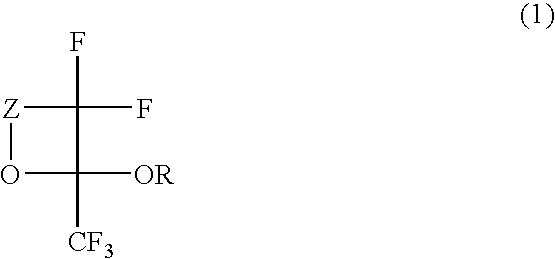

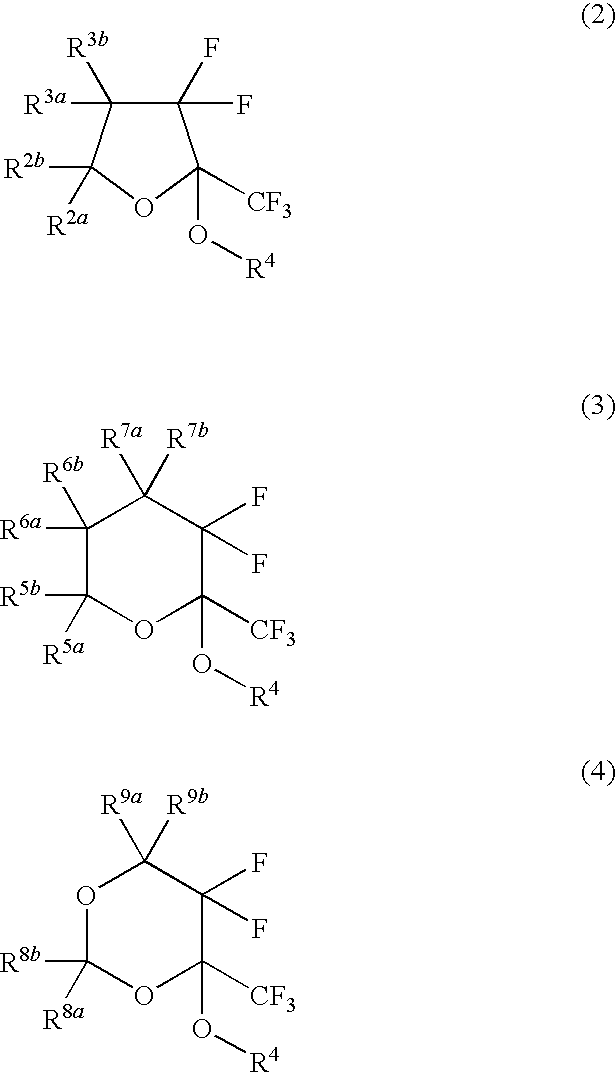

Fluorinated monomer of cyclic acetal structure, polymer, resist protective coating composition, resist composition, and patterning process

ActiveUS20100112482A1Readily availableEasy to handleOrganic chemistryPhotosensitive materialsResistHalogen

A fluorinated monomer of cyclic acetal structure has formula (1) wherein R is a C1-C20 alkyl group which may be substituted with halogen or separated by oxygen or carbonyl, and Z is a divalent organic group which forms a ring with alkylenoxy and contains a polymerizable unsaturated group. A polymer derived from the fluorinated monomer may be endowed with appropriate water repellency, water sliding property, lipophilicity, acid lability and hydrolyzability and is useful in formulating a protective coating composition and a resist composition.

Owner:SHIN ETSU CHEM IND CO LTD

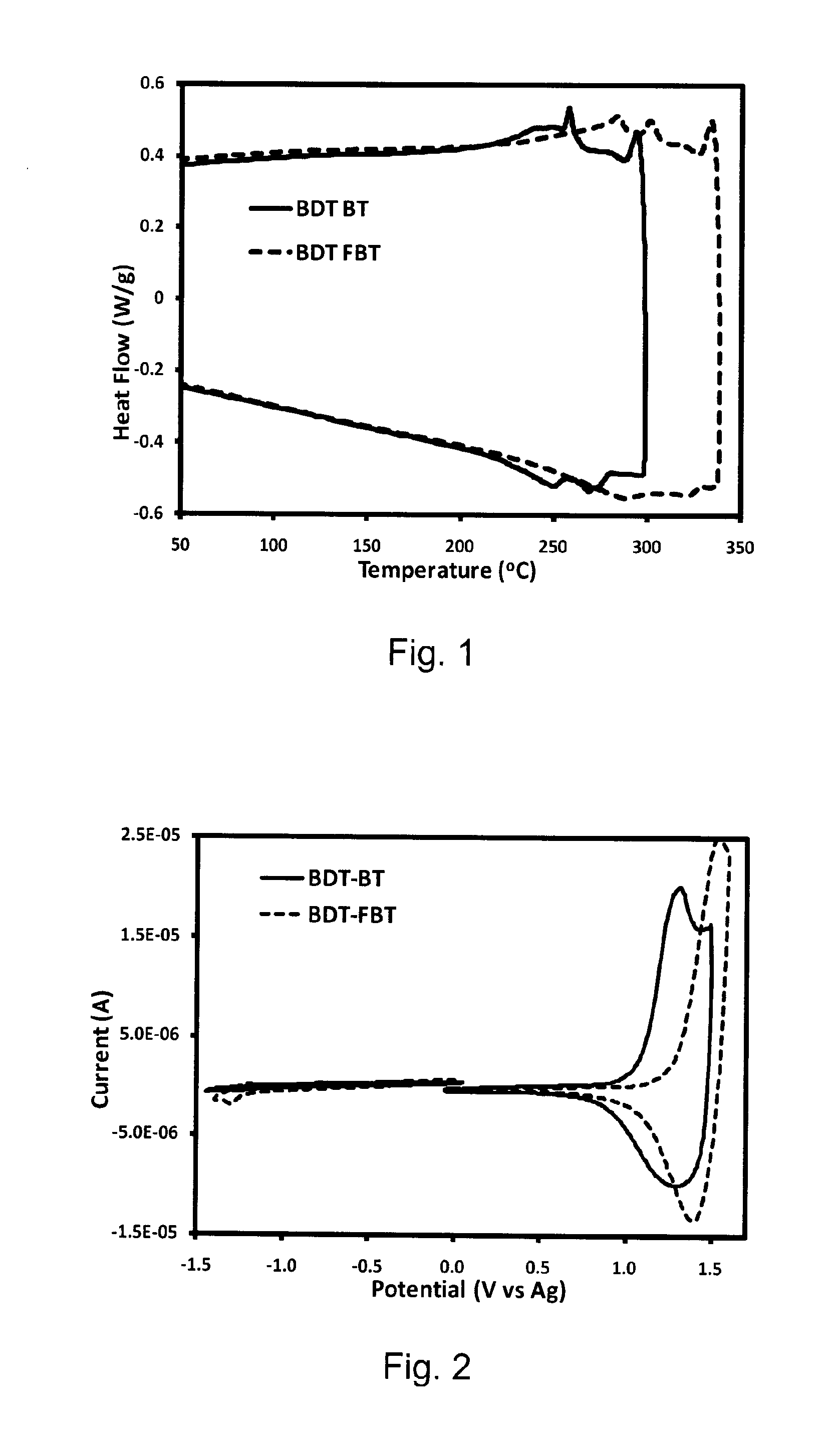

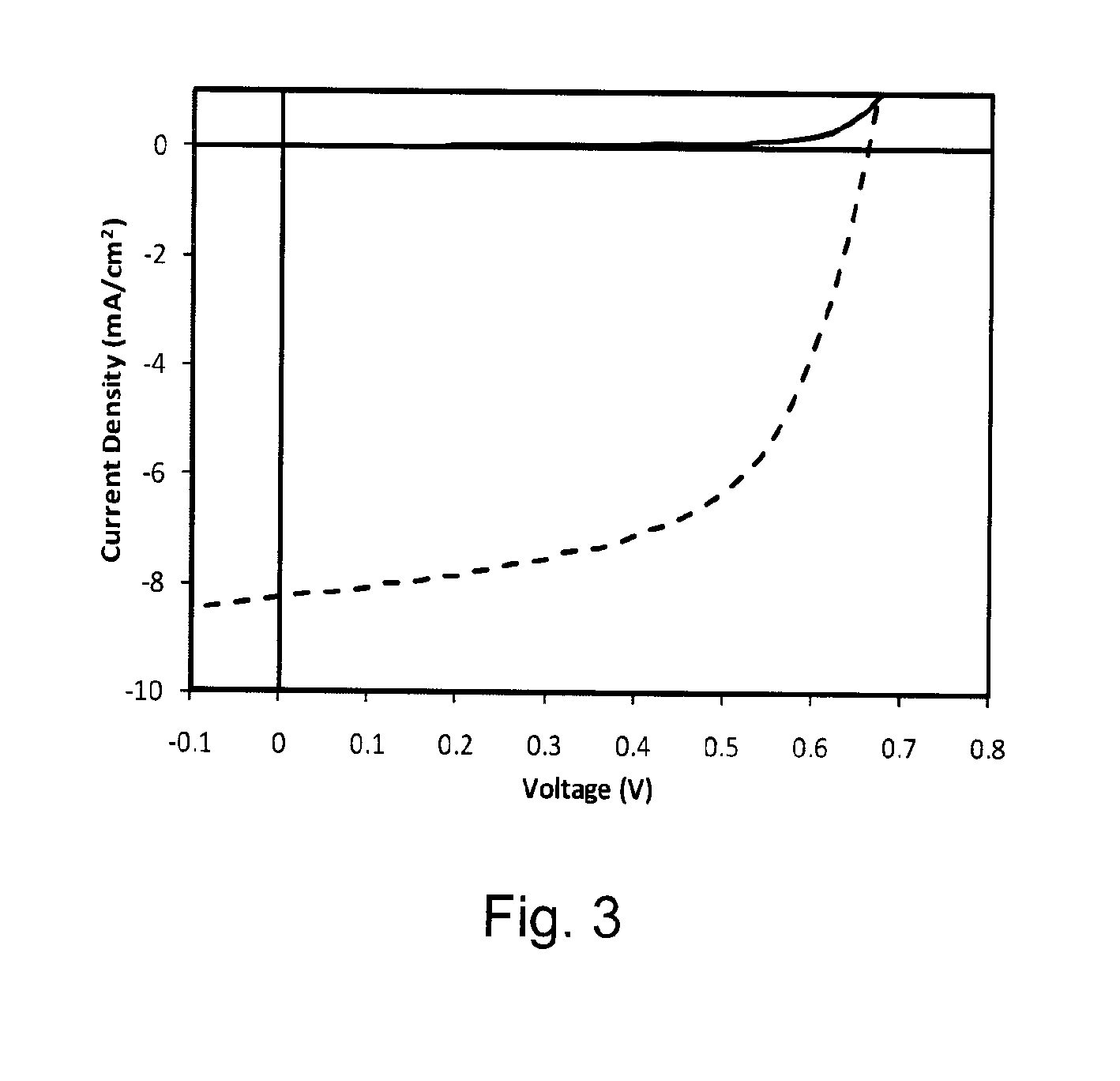

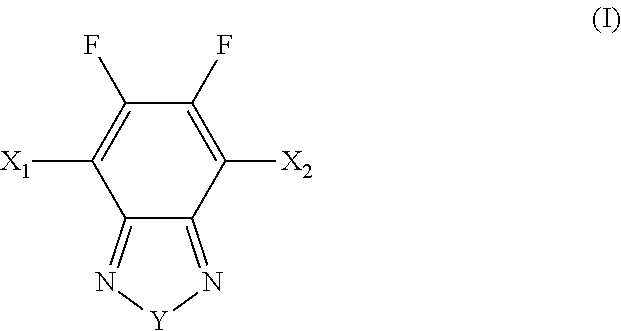

Fluorinated Monomers, Oligomers and Polymers for Use in Organic Electronic Devices

ActiveUS20120232237A1Maintain good propertiesEnhanced π-stackingOrganic chemistryNanoinformaticsArylOligomer

Compounds of Formula (I): (formula (I)) where: X1 and X2 are the same or different and each is independently Cl, Br, I, a substituted or unsubstituted aryl group or a substituted or unsubstituted heteroaryl group; and, Y is O, S, Se, NR1, R1C—CR2 or R1C═CR2, wherein R1 and R2 are the same or different and are each independently H or an organic group, are useful as monomers to produce oligomers or polymers that are useful in organic electronic devices.

Owner:NAT RES COUNCIL OF CANADA

Aqueous emulsion polymerization in the presence of ethers as chain transfer agents to produce fluoropolymers

The present invention provides a method of making a fluoropolymer comprising repeating units derived from one or more gaseous fluorinated monomers. The method comprises an aqueous emulsion polymerization of gaseous fluorinated monomers in the presence of an ether selected from the group consisting of dimethyl ether (DME), methyl tertiary butyl ether (MTBE) and mixtures thereof.

Owner:3M INNOVATIVE PROPERTIES CO

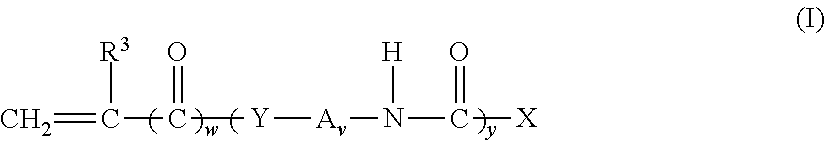

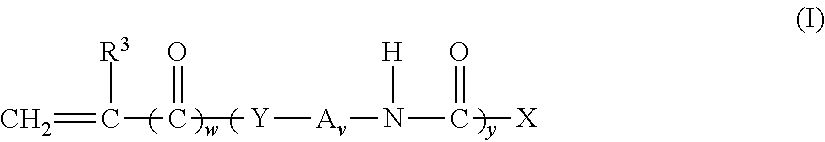

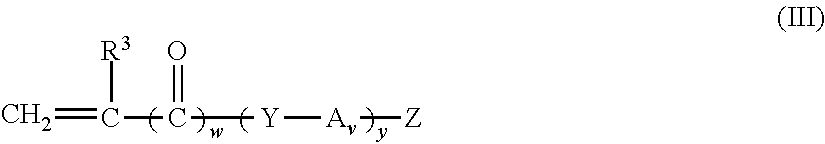

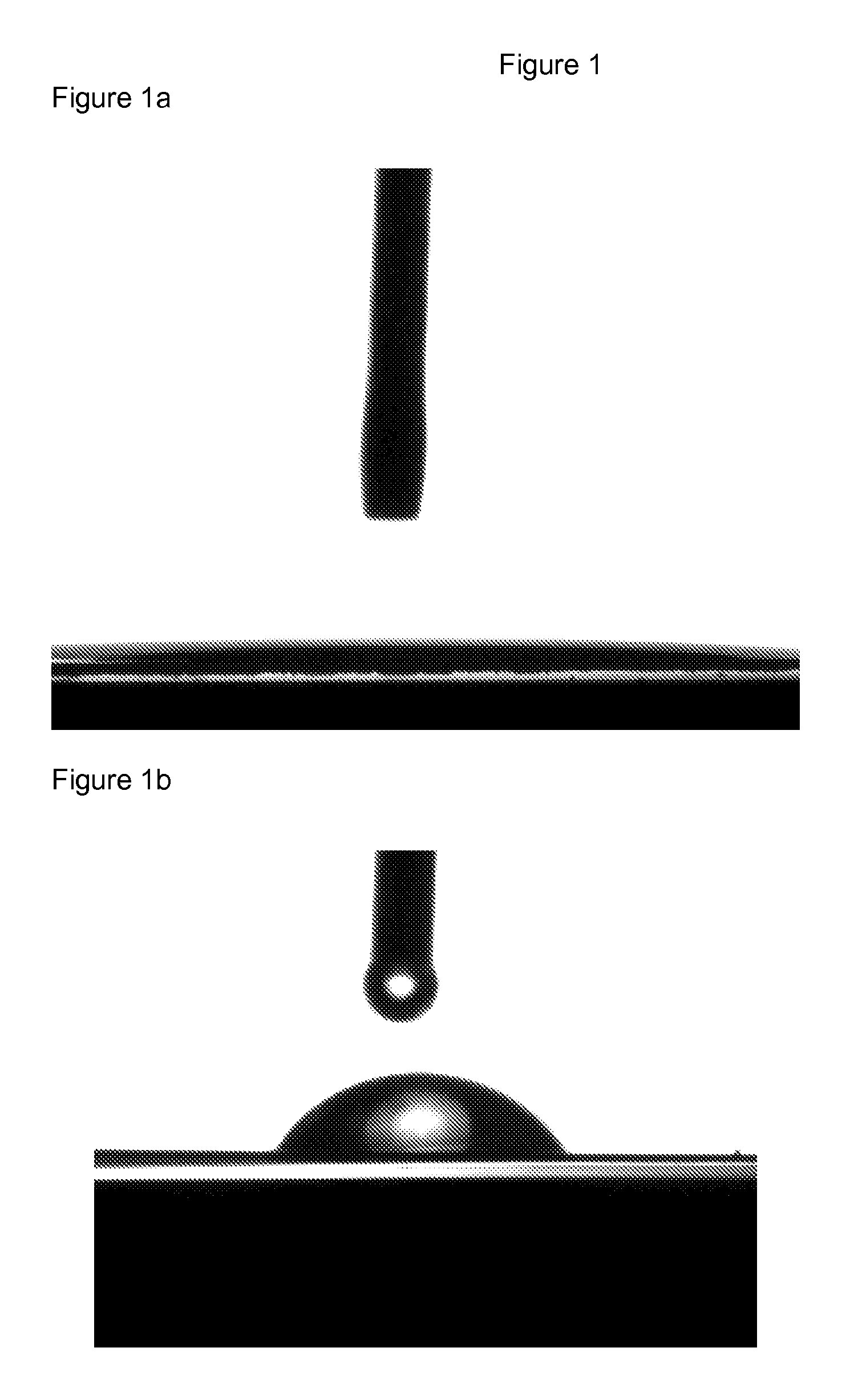

Non-fluorinated monomers and polymers for surface effect compositions

The present invention relates to monomers and polymers of Formula (I):where R3 is selected from H or a C1 to C4 alkyl group; Y is selected from O or a substituted or unsubstituted arylene group; A is a linear or branched C1 to C10 alkylene group; w is 0 or 1; v is 0 or 1; y is 0 or 1; X is the residue of a cyclic or acyclic sugar alcohol which is substituted with at least one —R1; —C(O)R1; —(CH2CH2O)n(CH(CH3)CH2O)mR2; —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1; each n is independently 0 to 20; each m is independently 0 to 20; each R1 is independently a linear or branched alkyl group having 9 to 29 carbons optionally comprising at least 1 unsaturated bond; and each R2 is independently —H, a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof.

Owner:THE CHEMOURS CO FC LLC

Polyester films with improved oil repellency

InactiveUS20110218316A1Organic compound preparationSynthetic resin layered productsCopolyesterChemistry

Owner:EI DU PONT DE NEMOURS & CO

Melt-processible thermoplastic fluoropolymers having improved processing characteristics and method of producing same

ActiveUS20040192868A1Increase the critical shear rateHigh melt tensionPlastic/resin/waxes insulatorsFibre treatmentFluorinated monomersBromine

The present invention provides a fluoropolymer that is melt-processible and thermoplastic and that has a melting point between 100° C. and 320° C. The fluoropolymer is derived from (a) one or more gaseous fluorinated monomers, (b) one or more modifiers selected from (i) olefins having a bromine or iodine atom bonded to a carbon of the double bond of the olefin, (ii) olefins corresponding to formula (I): X2C=CX-Rf-Br (I) wherein each Xindependently represents hydrogen, fluorine, bromine, chlorine or iodine, Rf is a perfluoroalkylene group, typically having 1 to 8 carbon atoms, a perfluorooxyalkylene group or a perfluoropolyether group and (iii) mixtures thereof; and (c) optionally one or more comonomers selected from non-gaseous fluorinated monomers and non-fluorinated monomers. The resulting fluoropolymer has long chain branches. The invention further provides a method for making these polymers.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com