Patents

Literature

52results about How to "Desirable mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

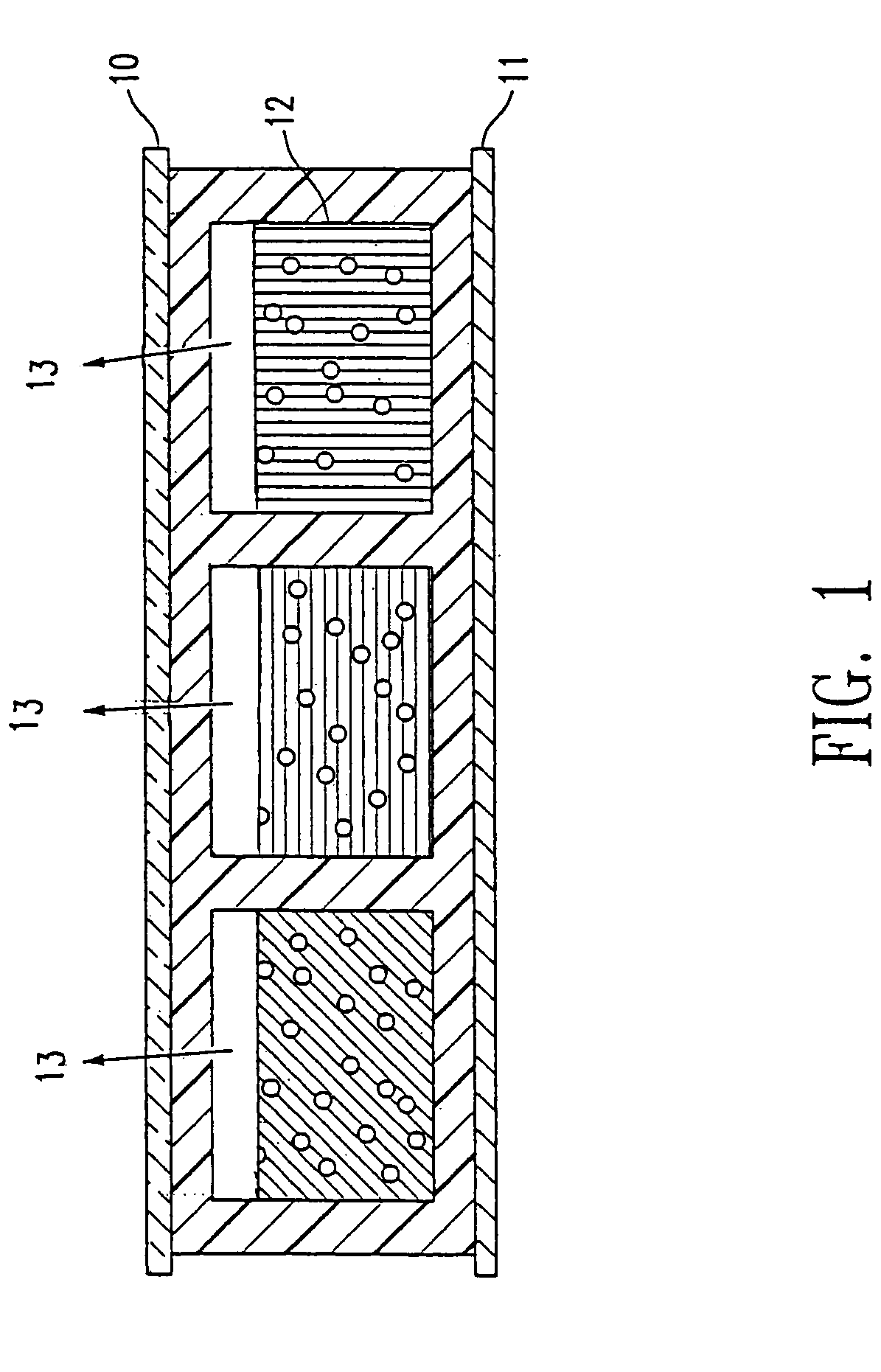

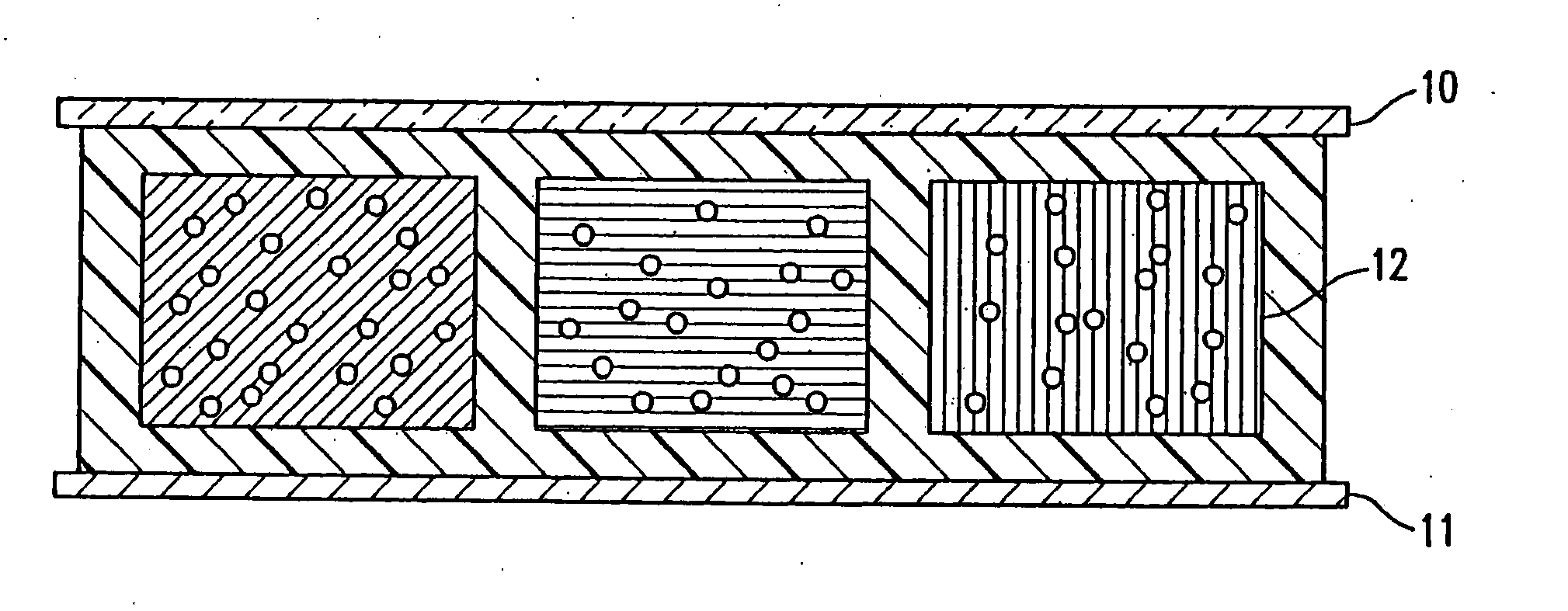

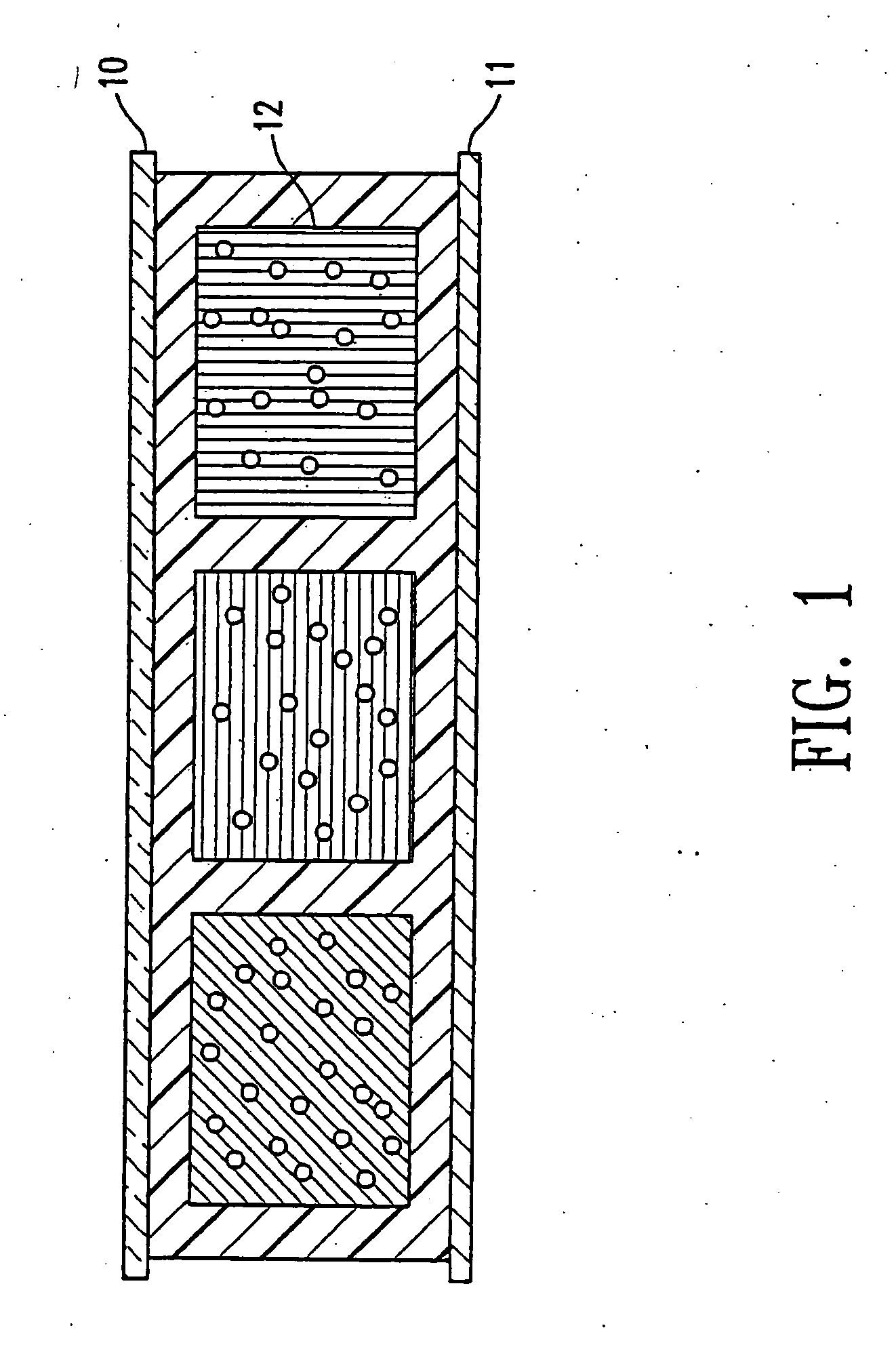

Electrophoretic display

InactiveUS7715088B2Improve adhesionImprove the display effectStatic indicating devicesNon-linear opticsElectrophoresisDisplay device

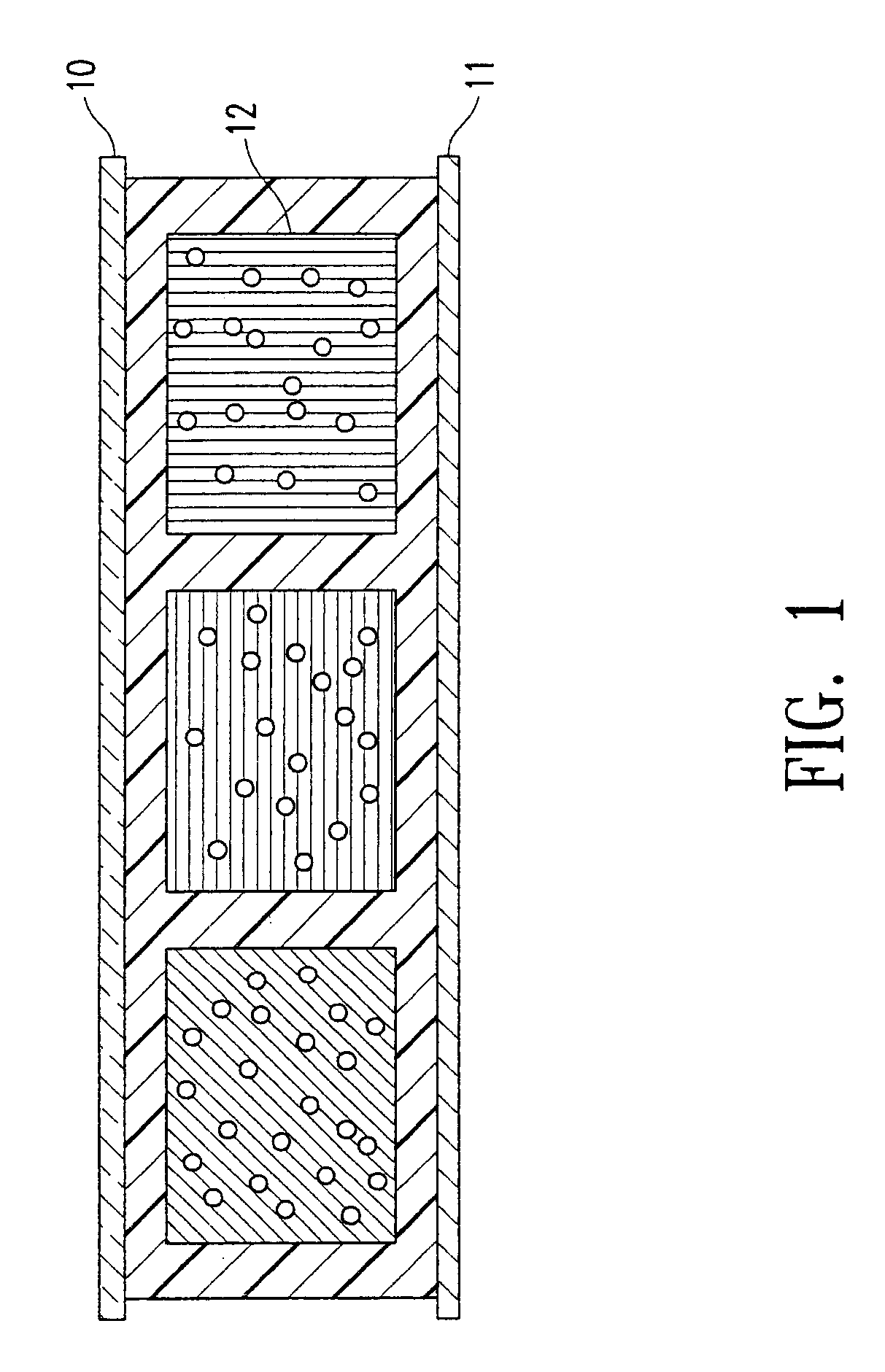

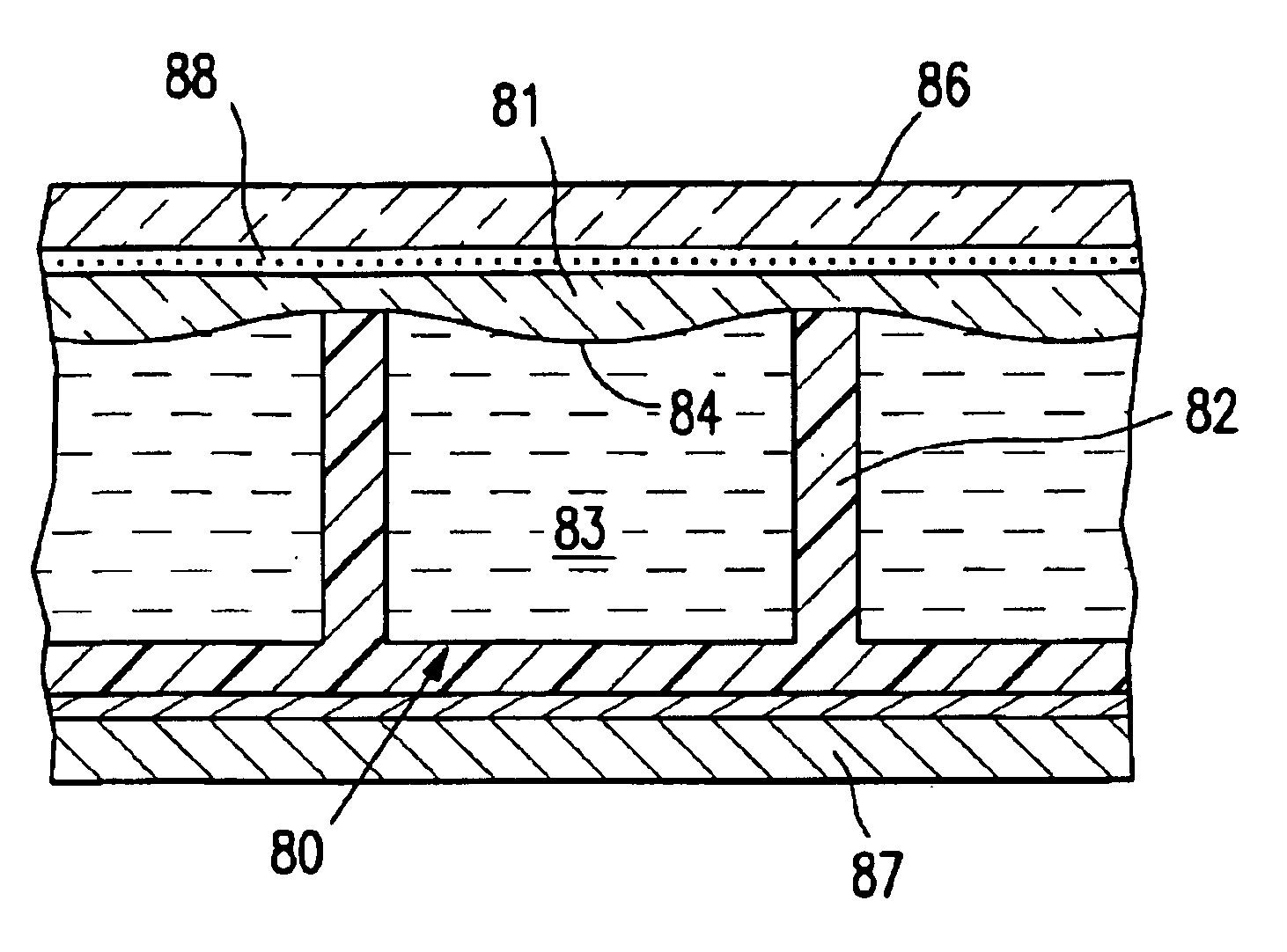

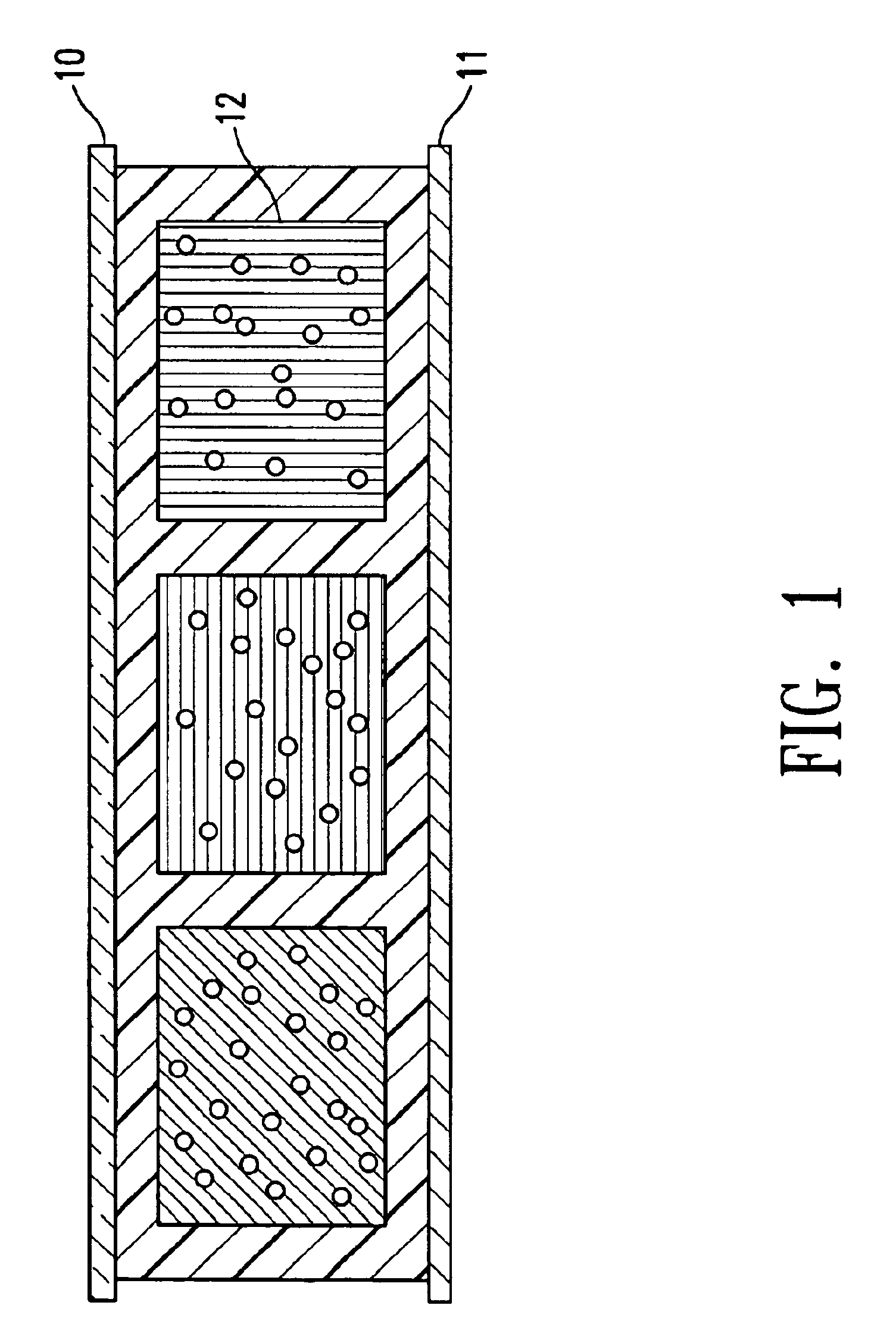

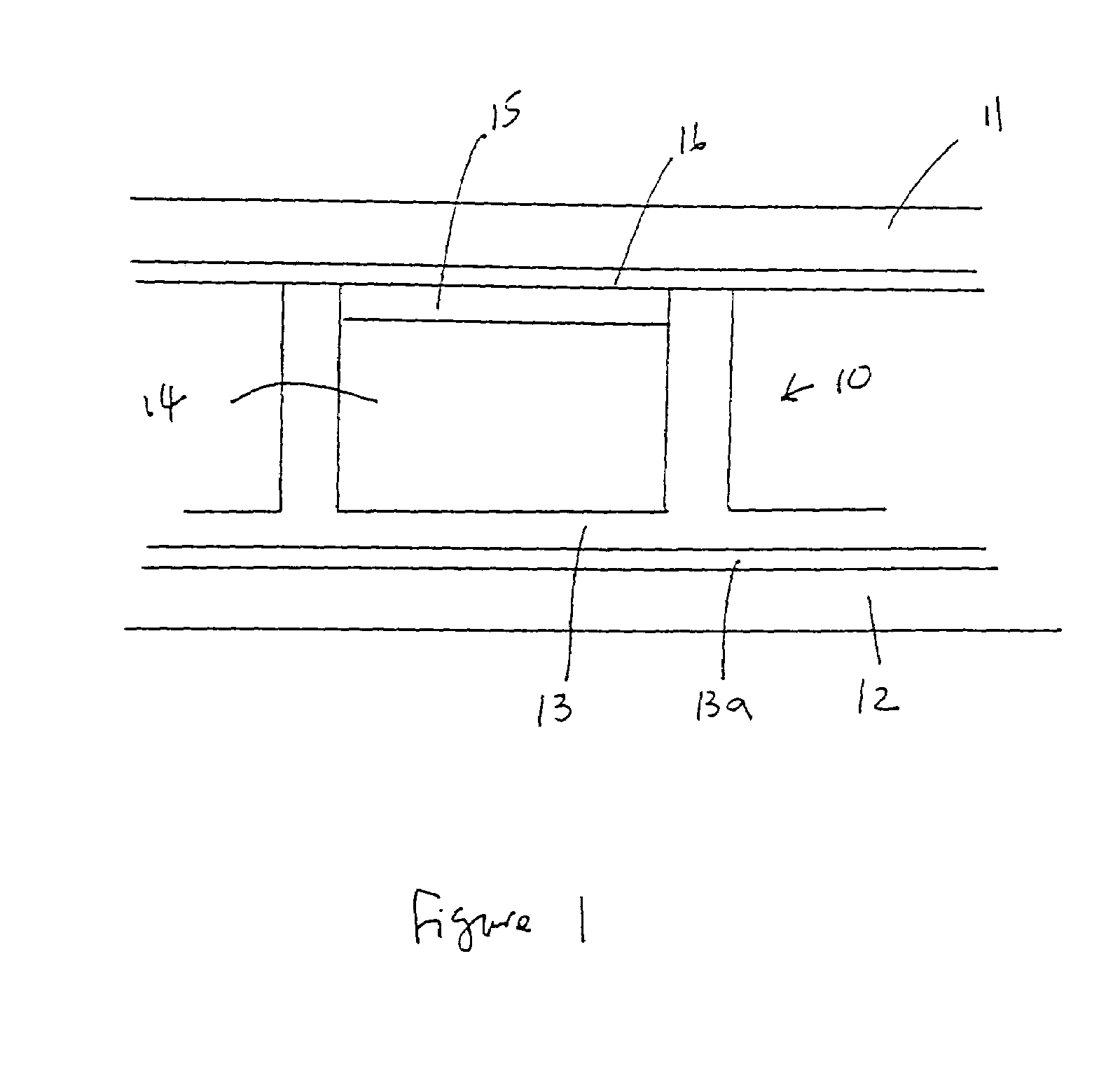

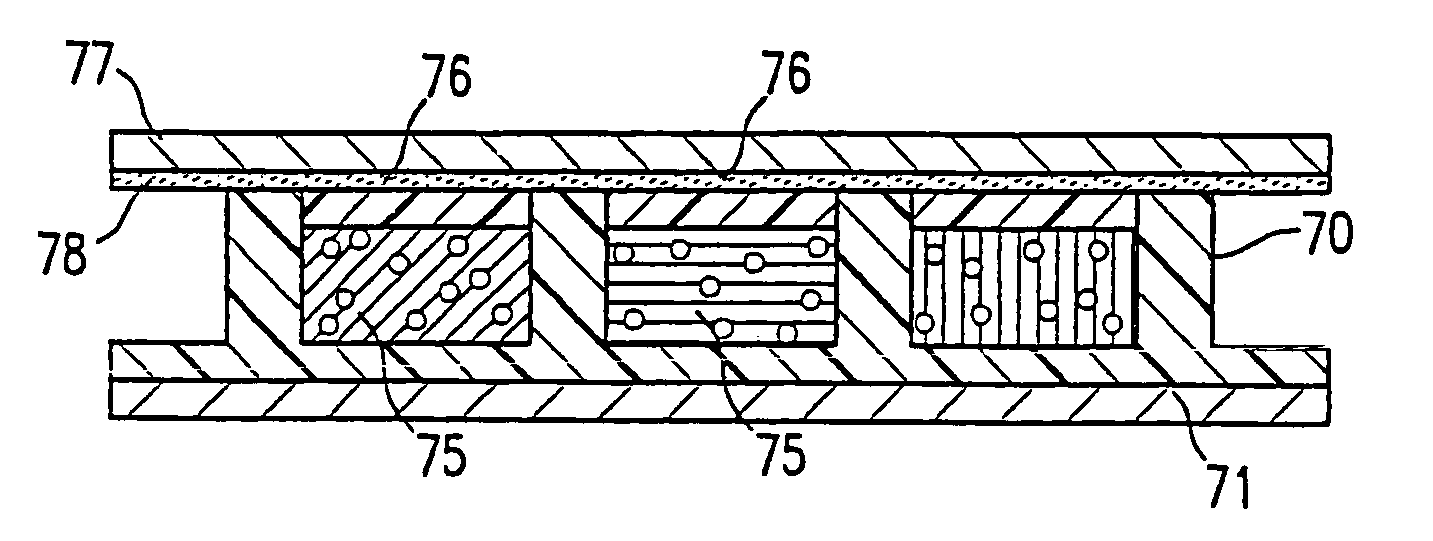

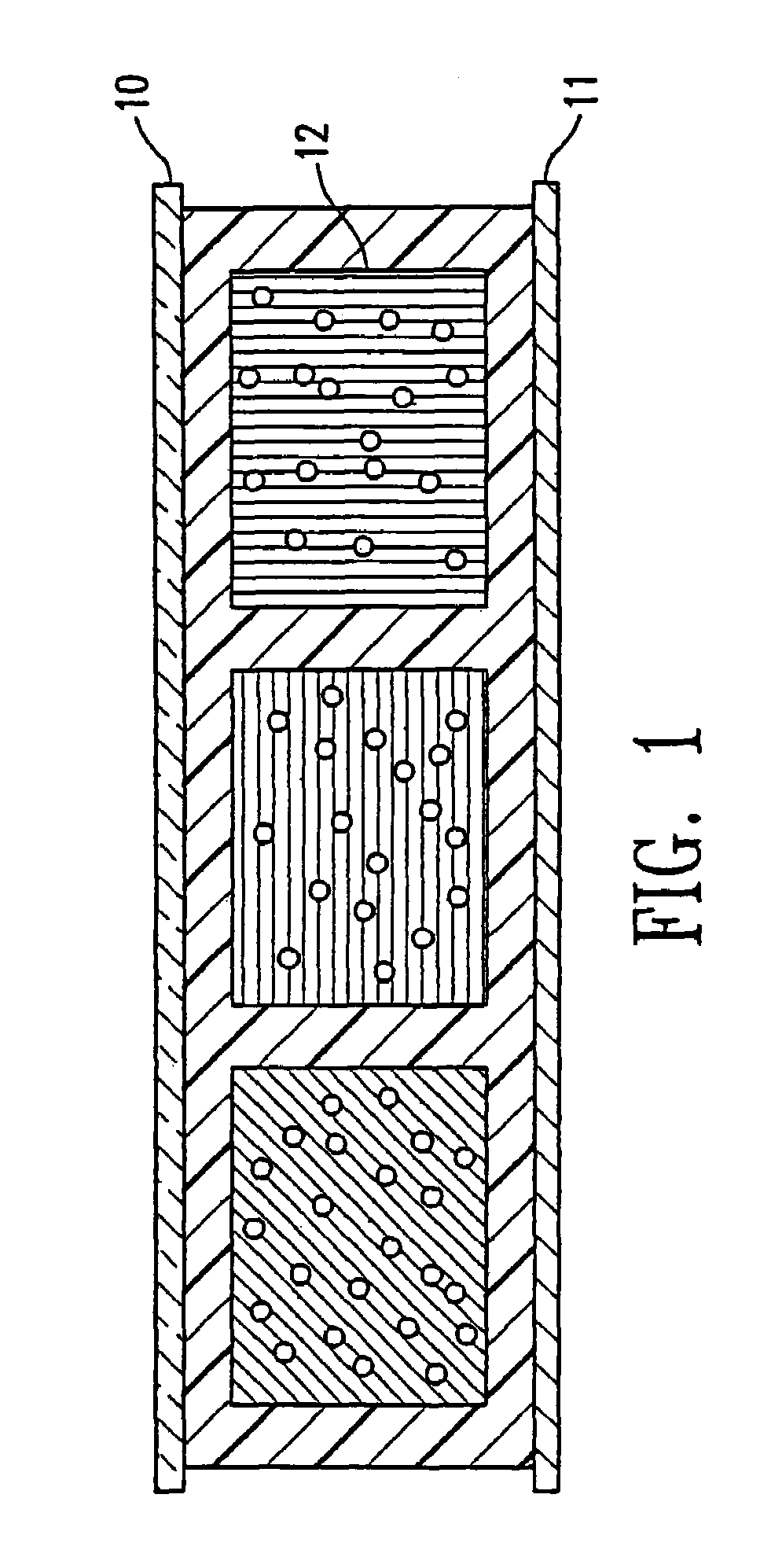

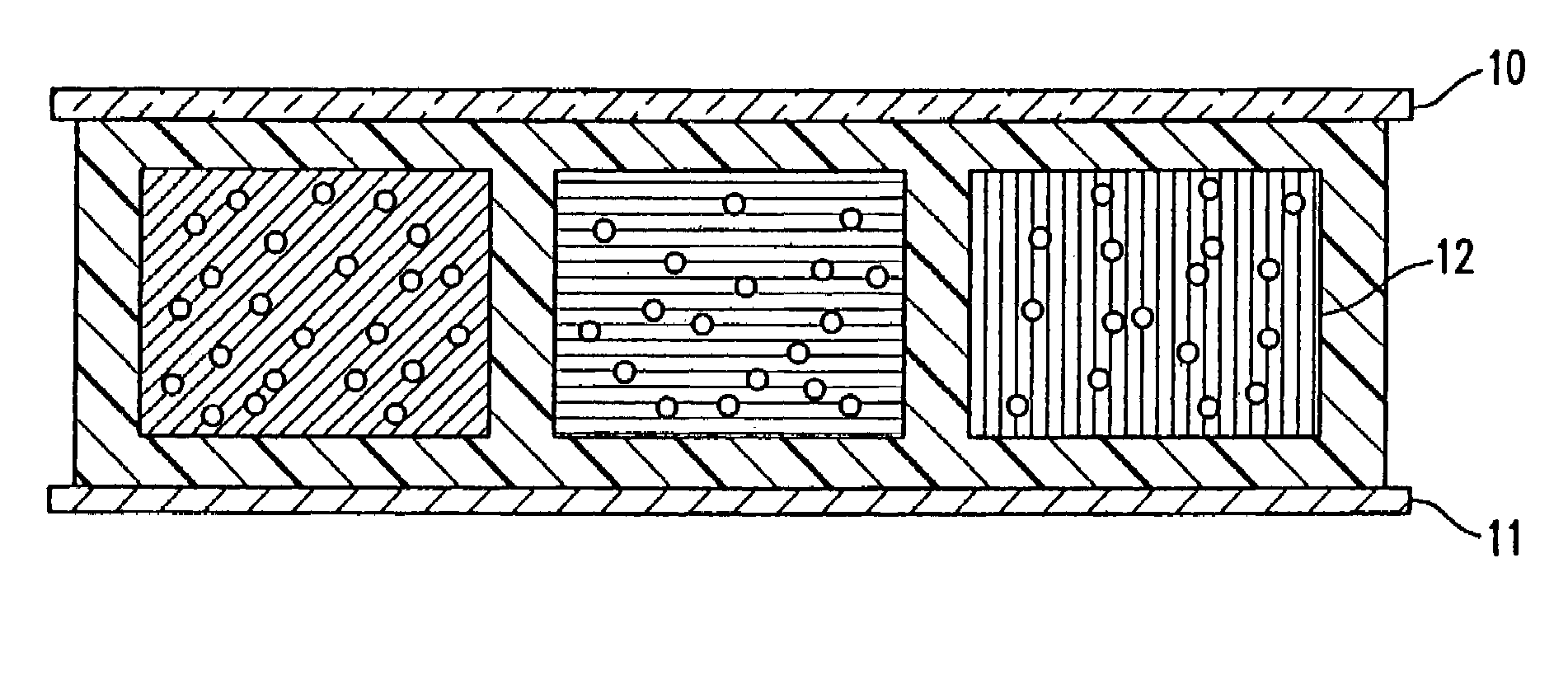

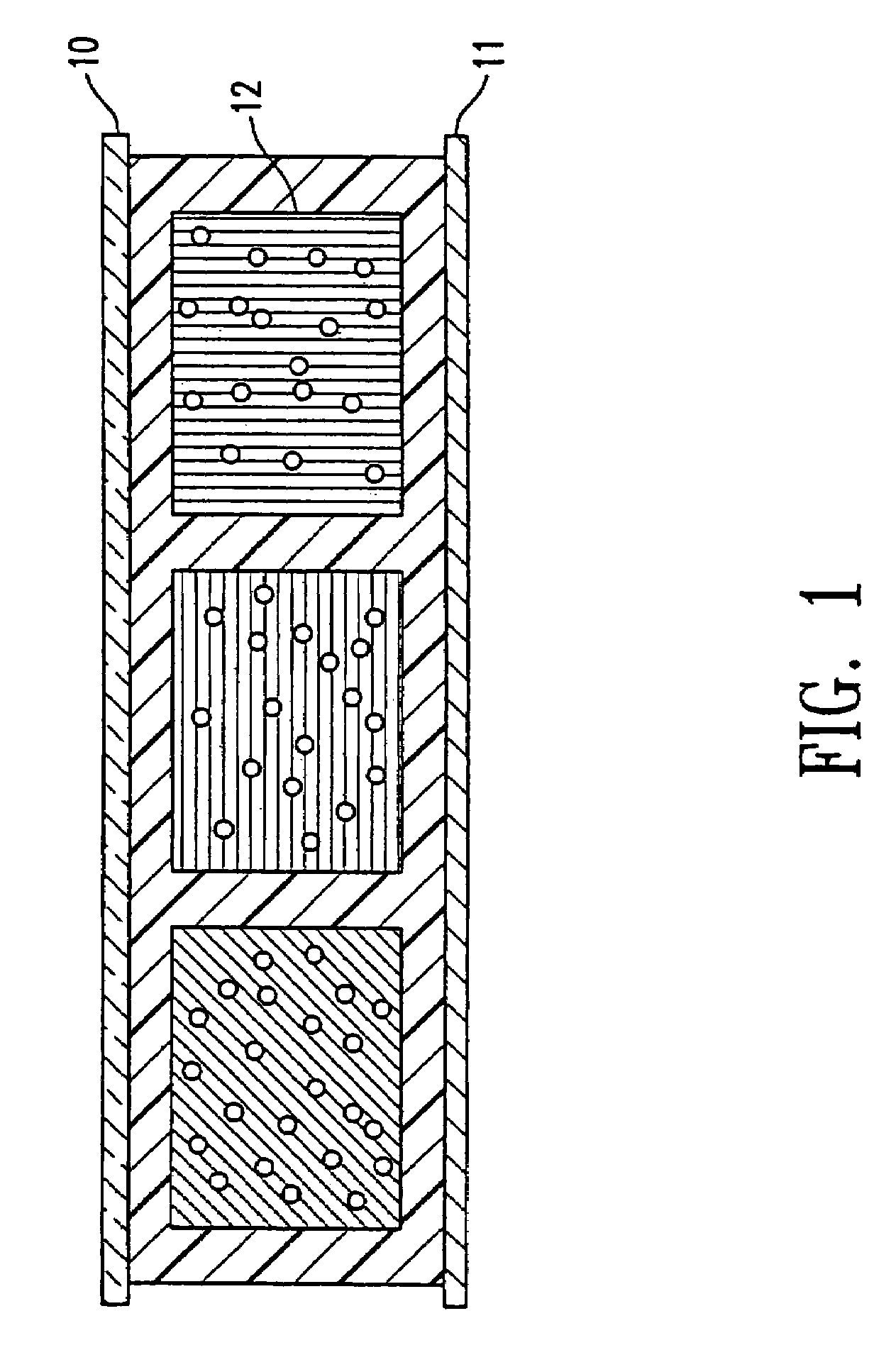

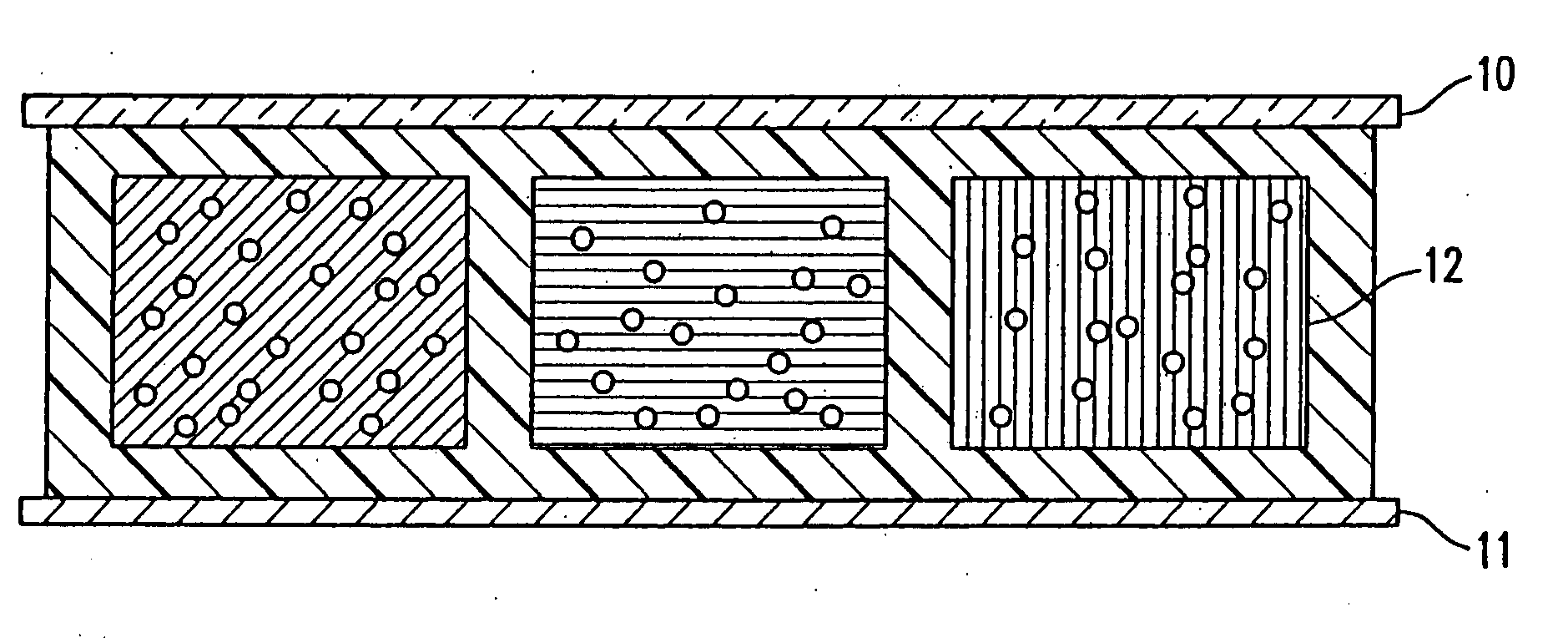

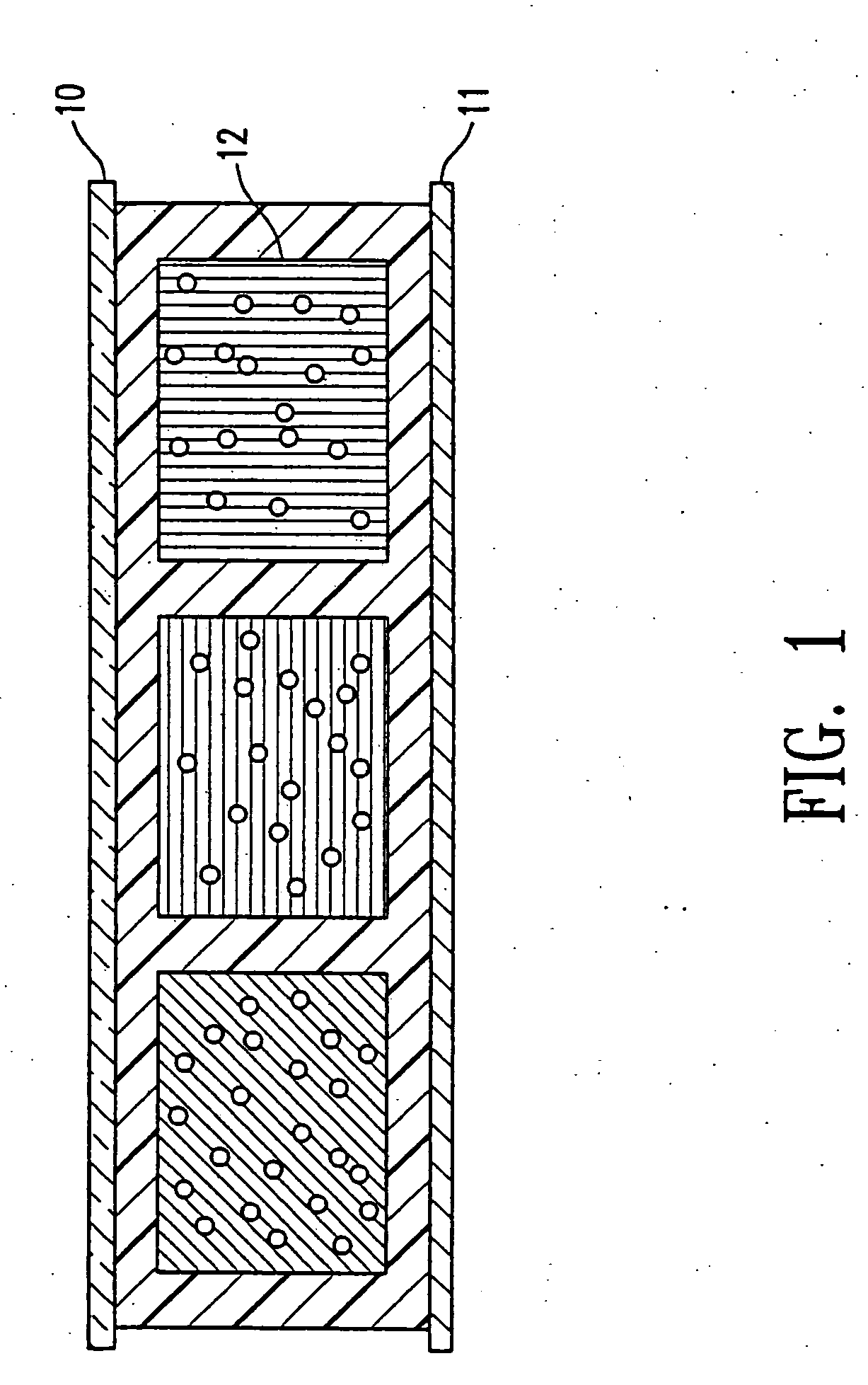

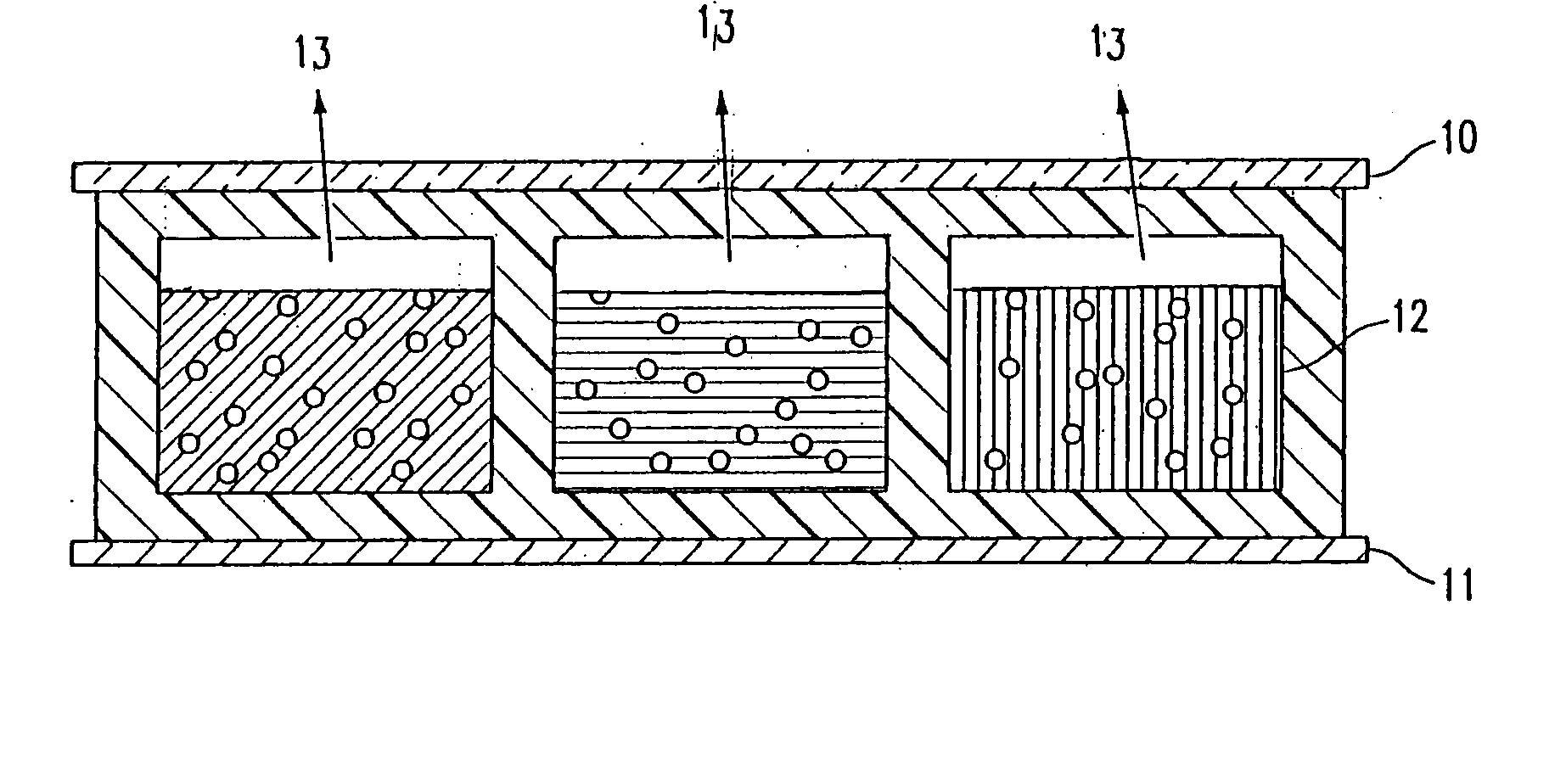

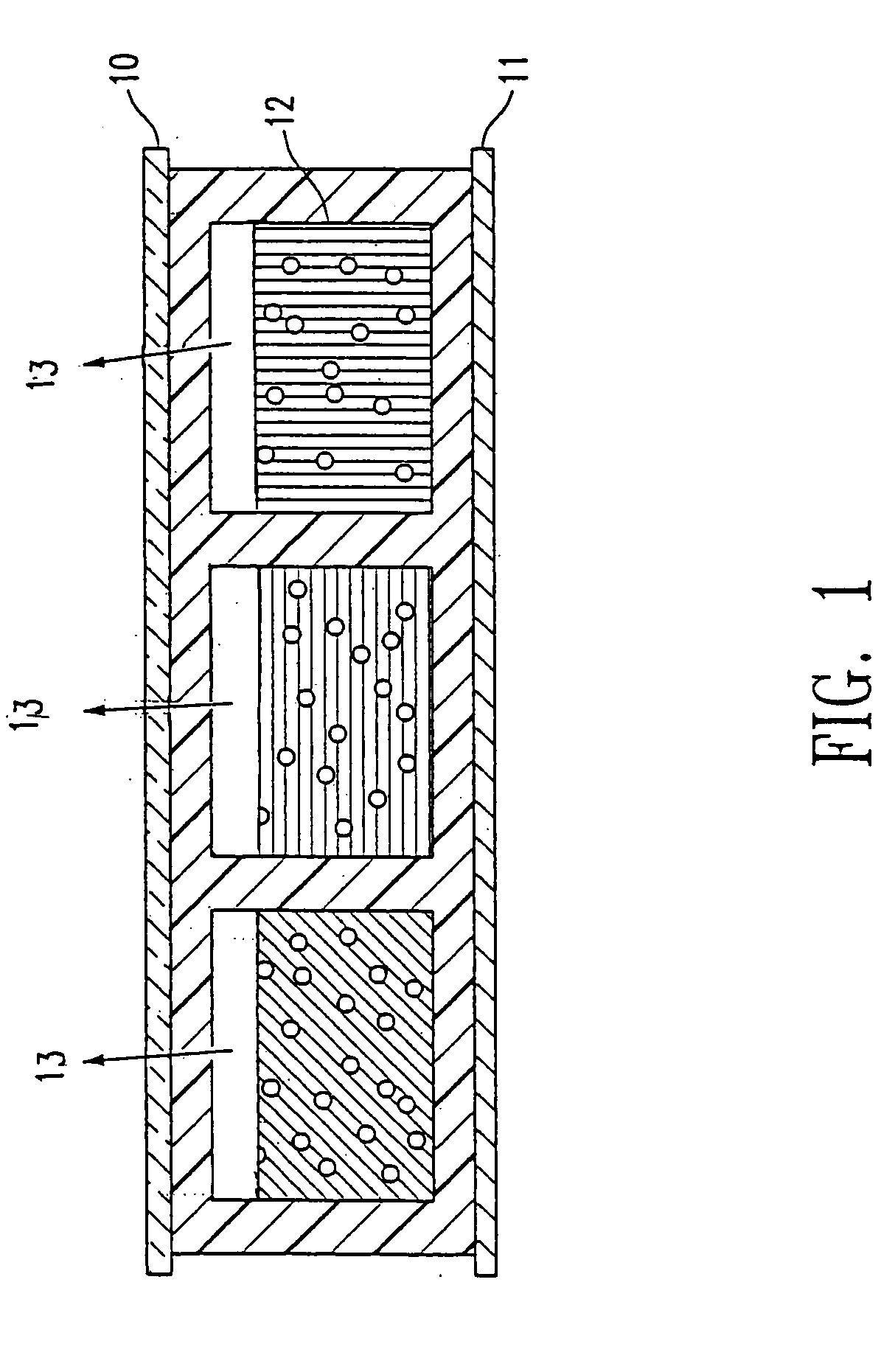

This invention relates to an electrophoretic display comprising a plurality of cells, each of said cells comprises: a) partition walls; b) an electrophoretic fluid filled therein; c) a polymeric sealing layer to enclose the electrophoretic fluid within the cell; and d) an interface between the electrophoretic fluid and the sealing layer.

Owner:E INK CALIFORNIA

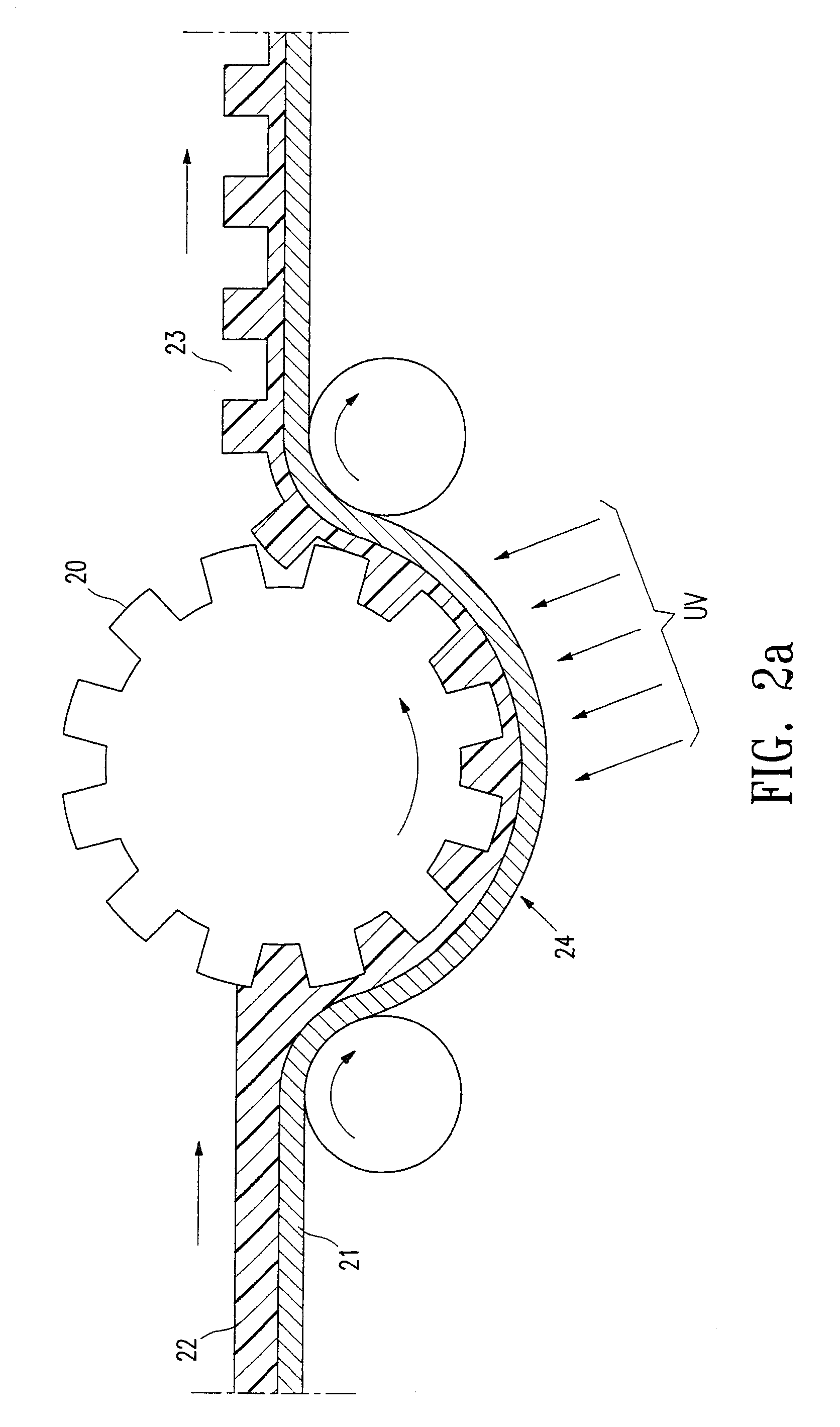

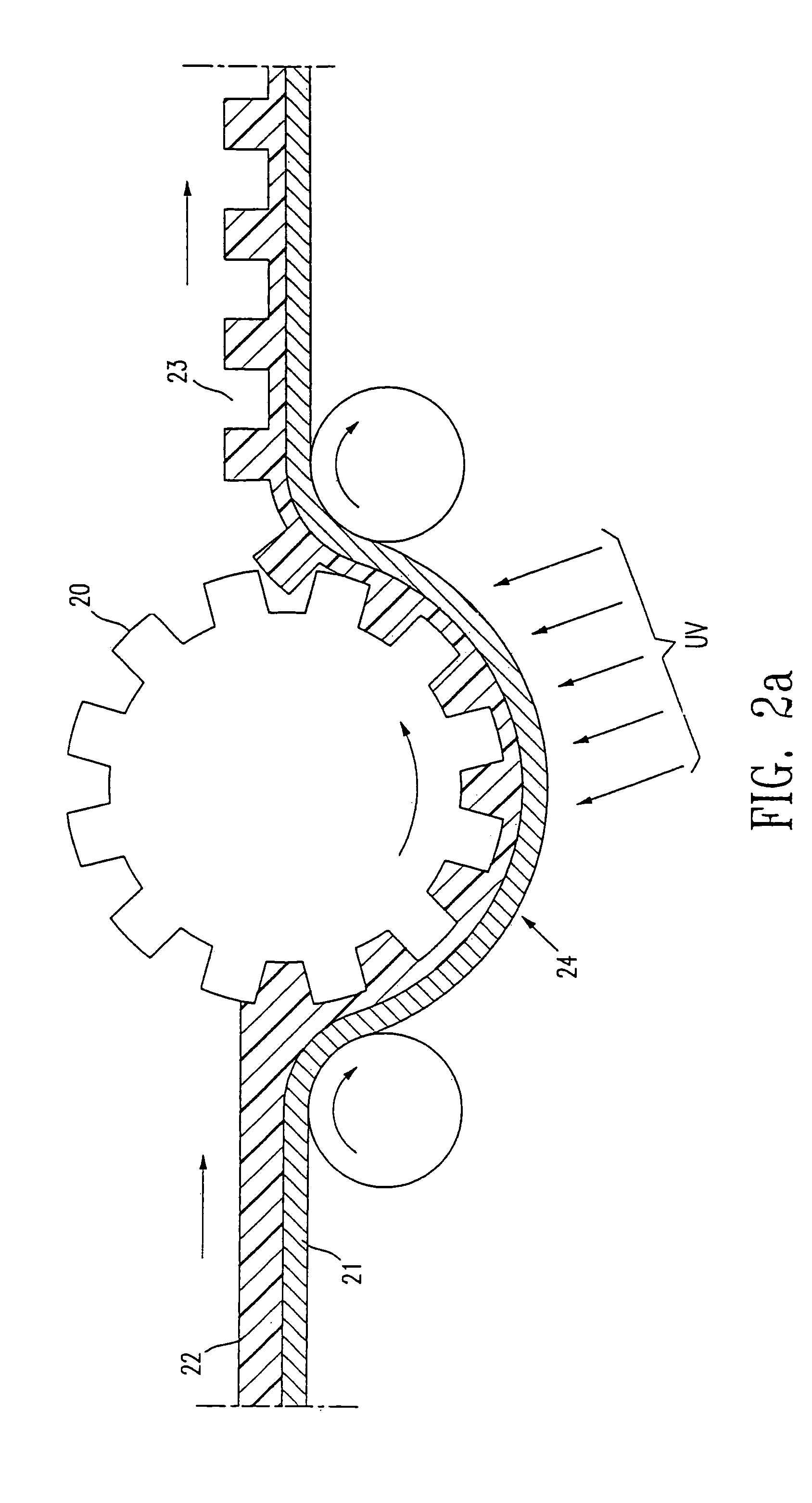

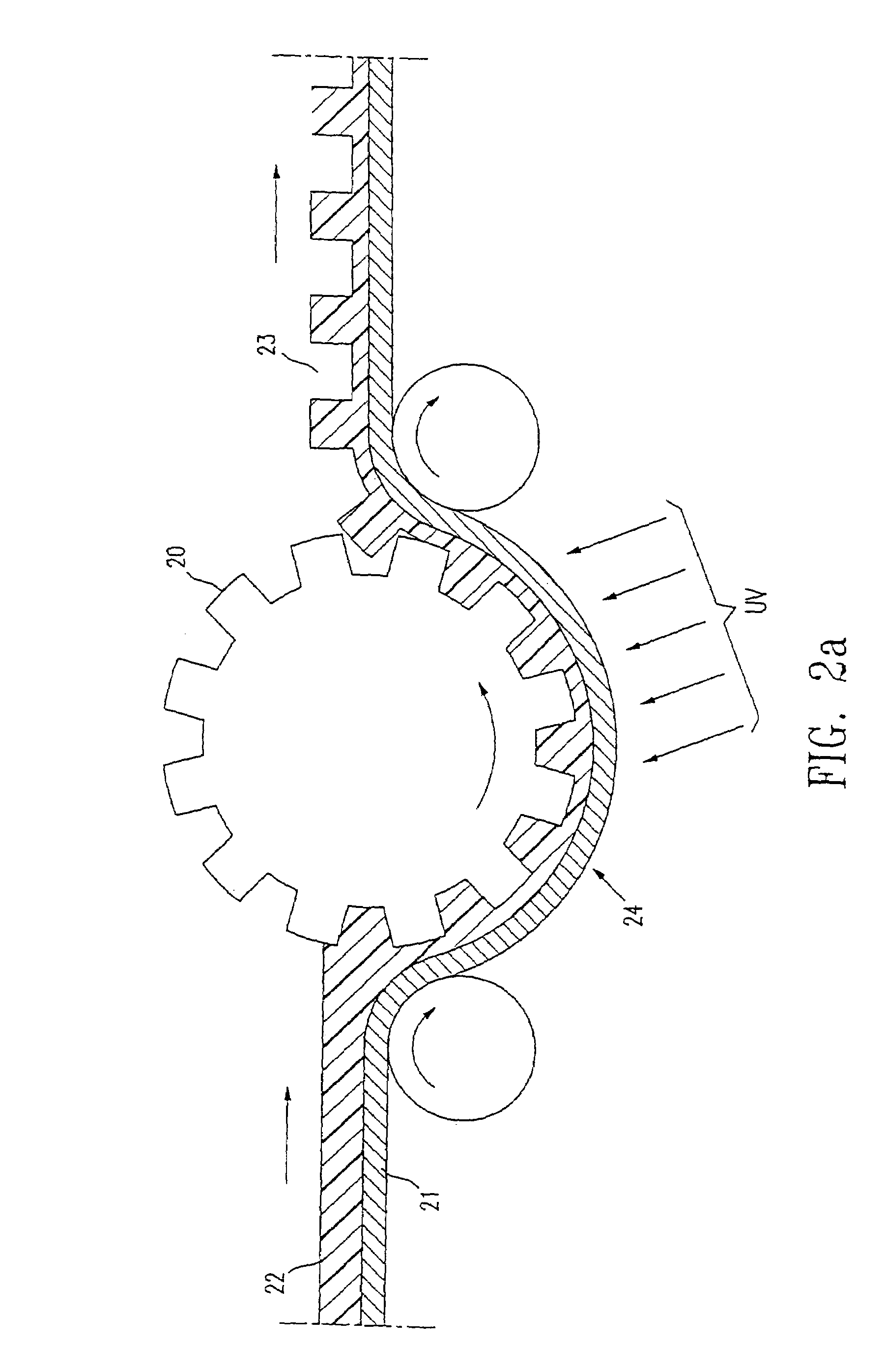

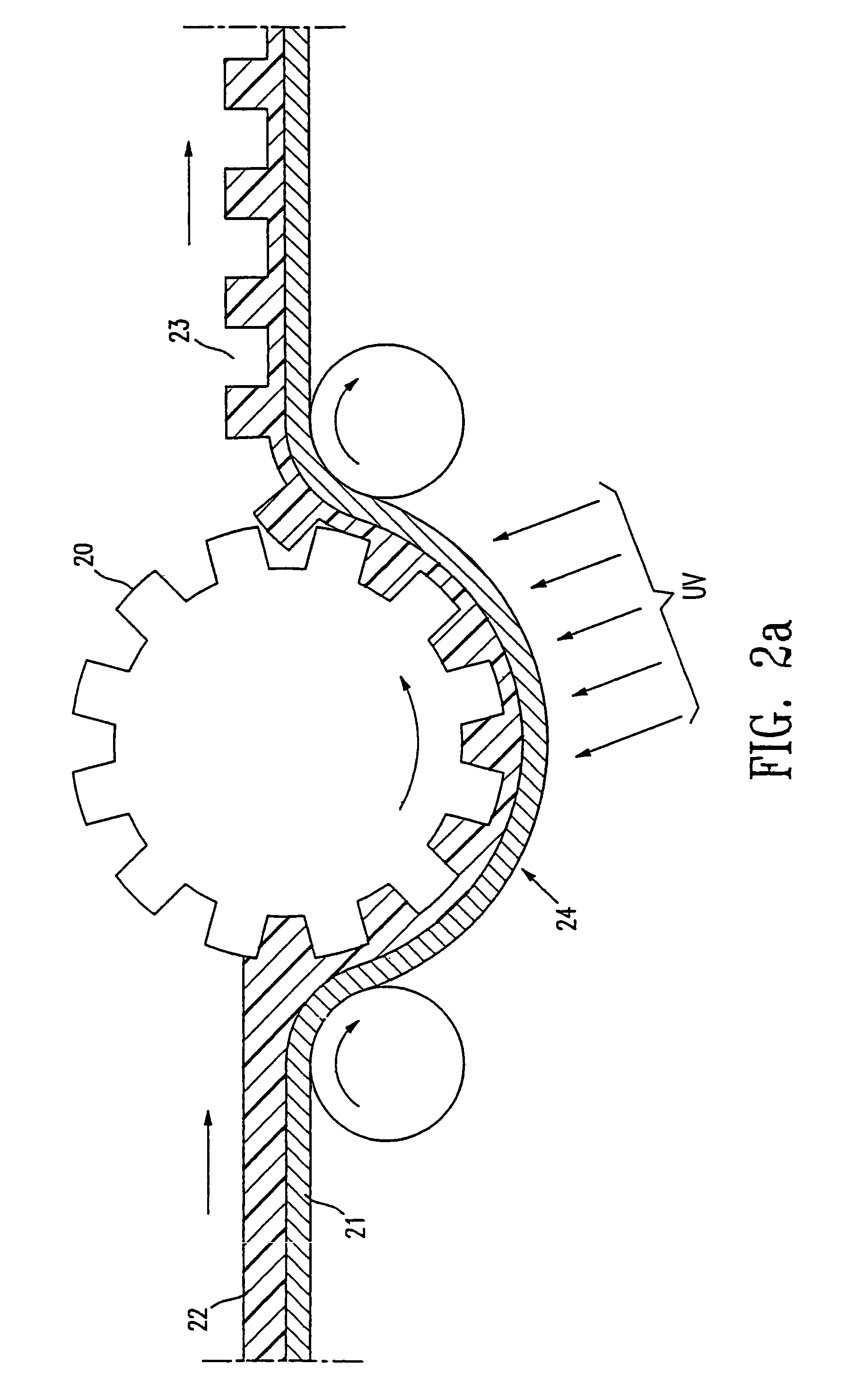

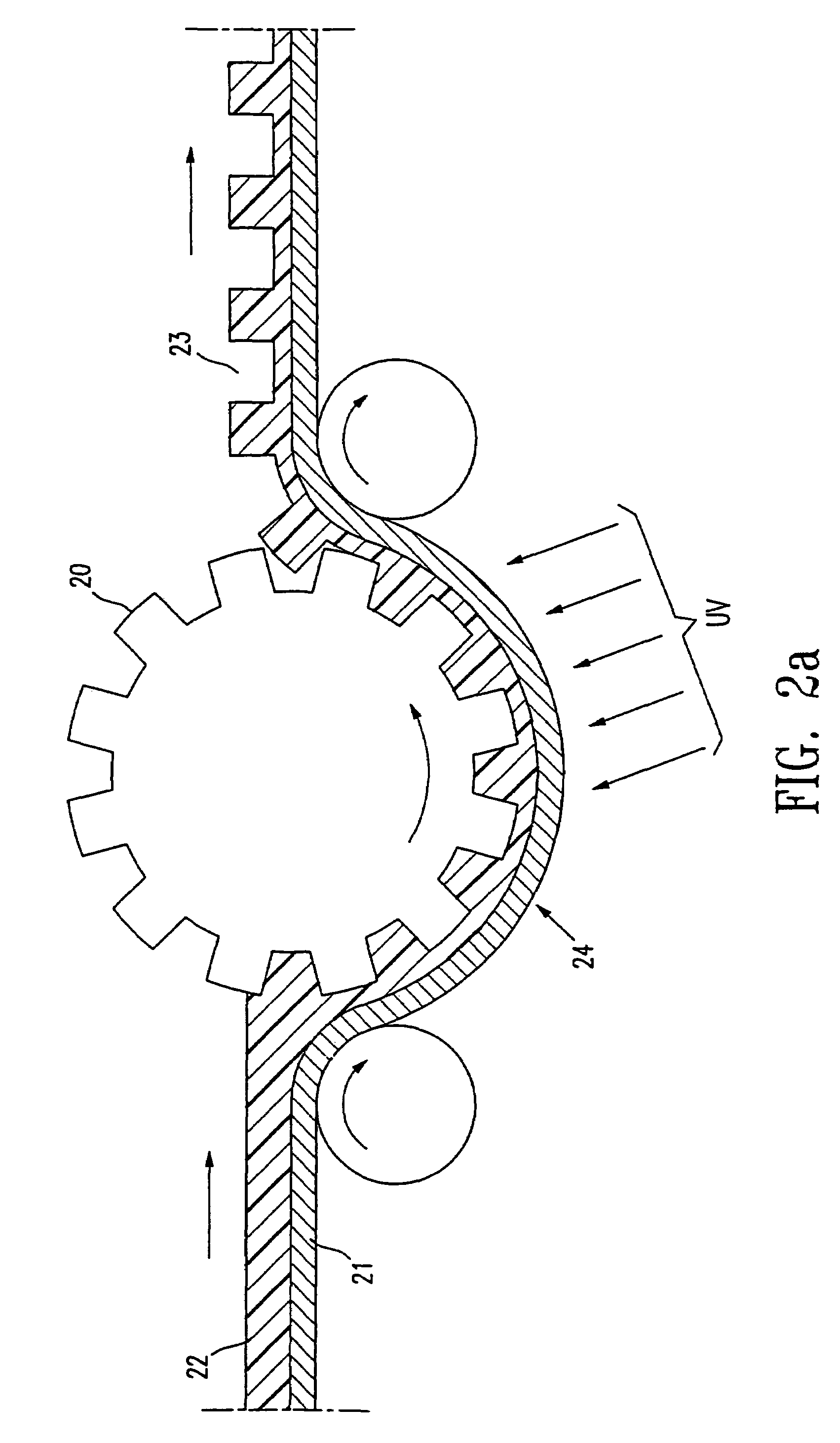

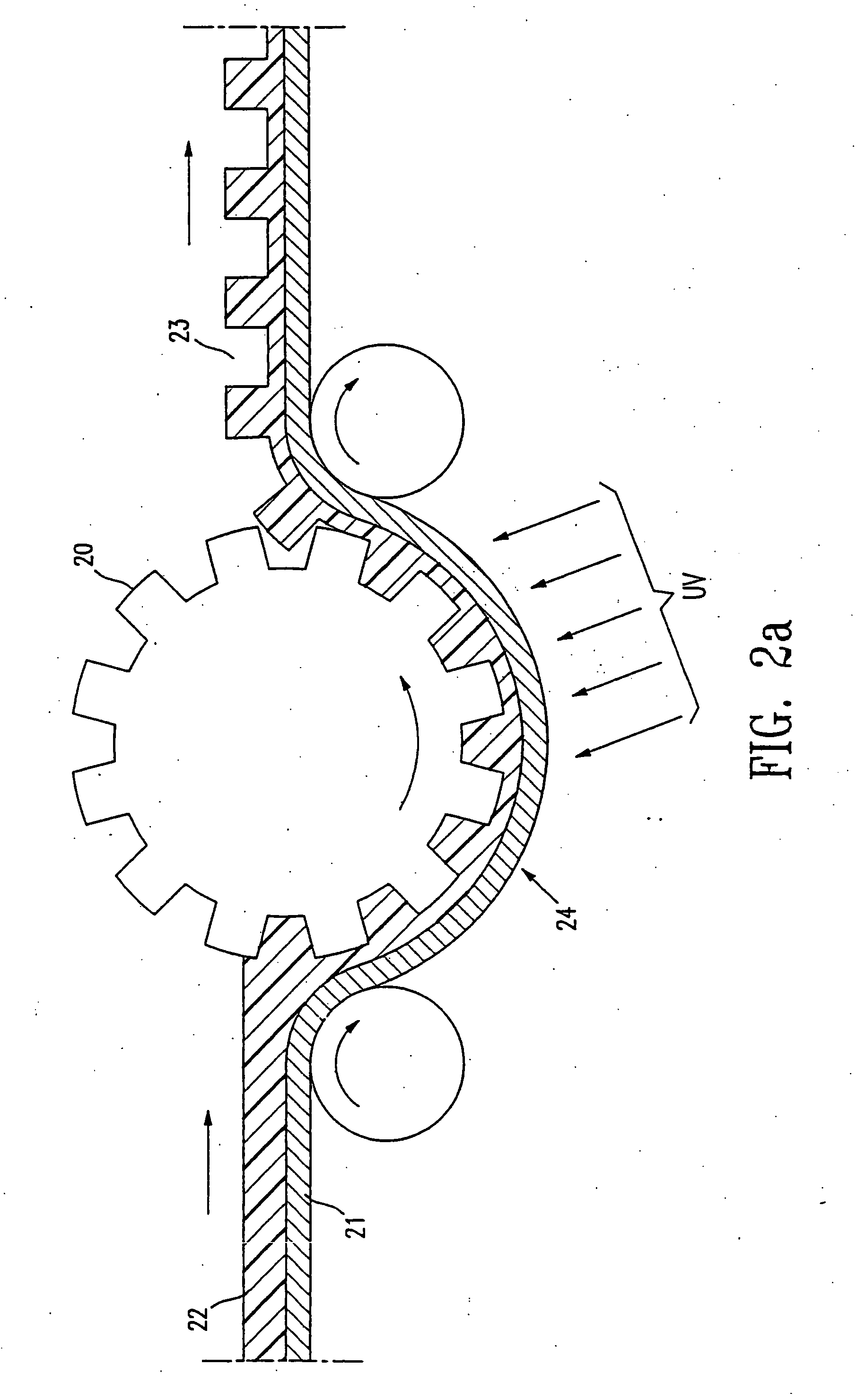

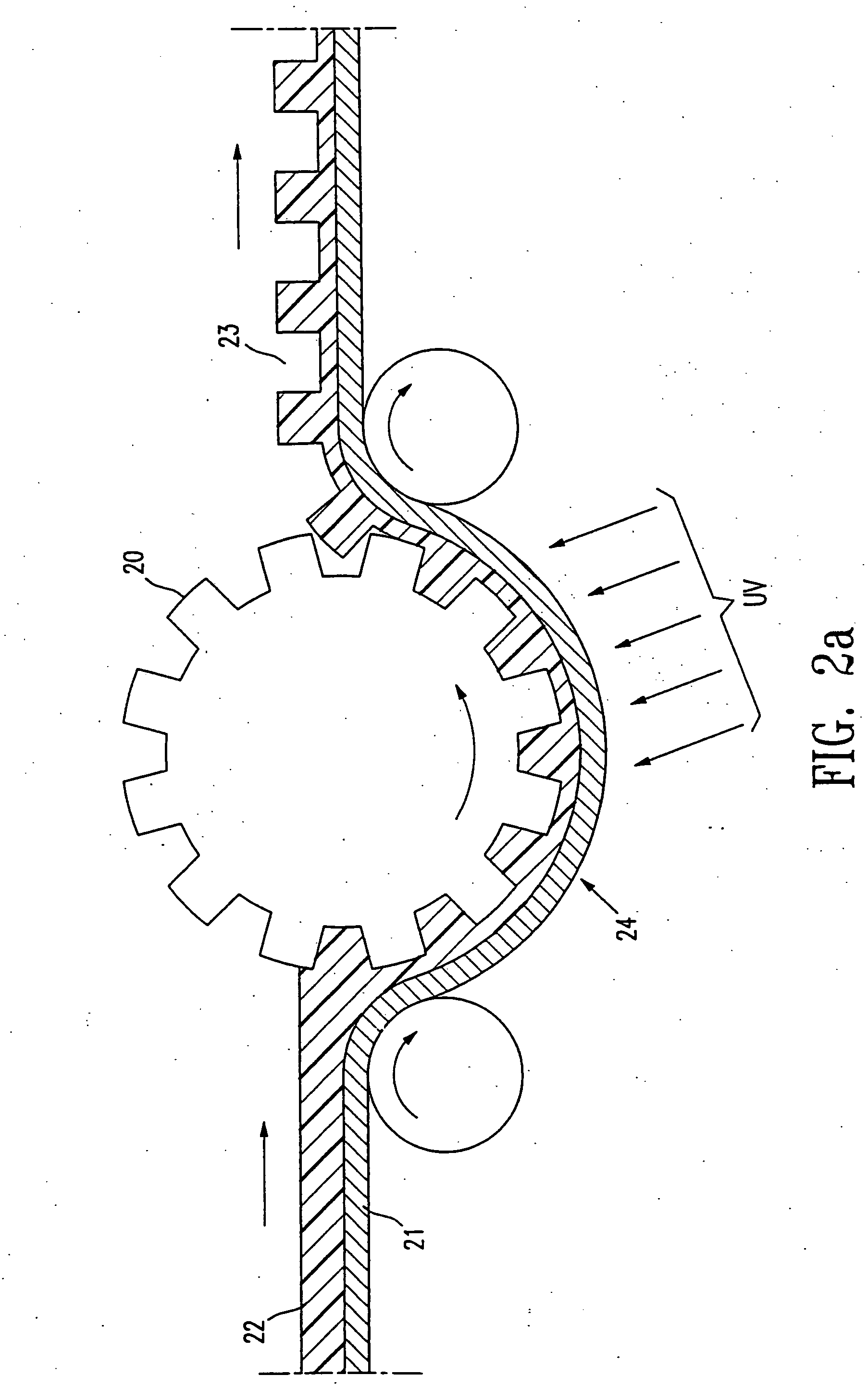

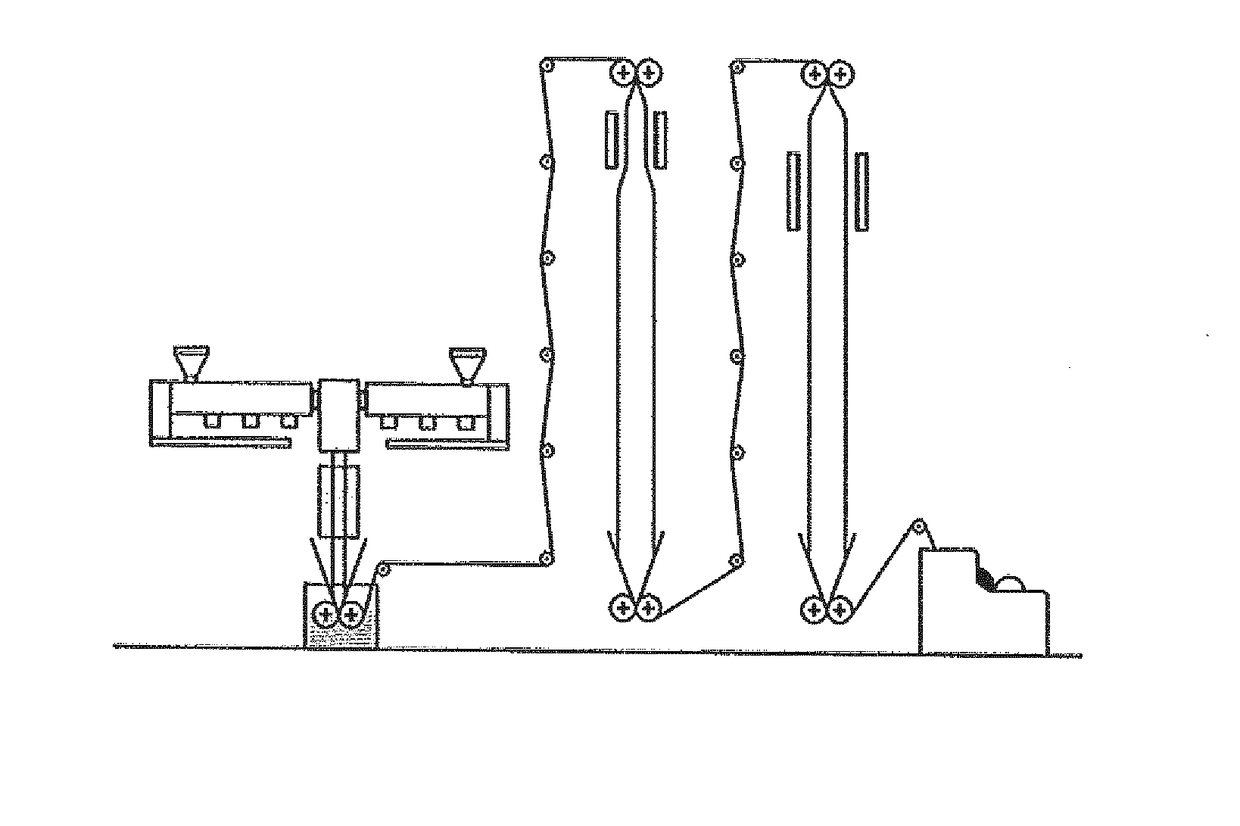

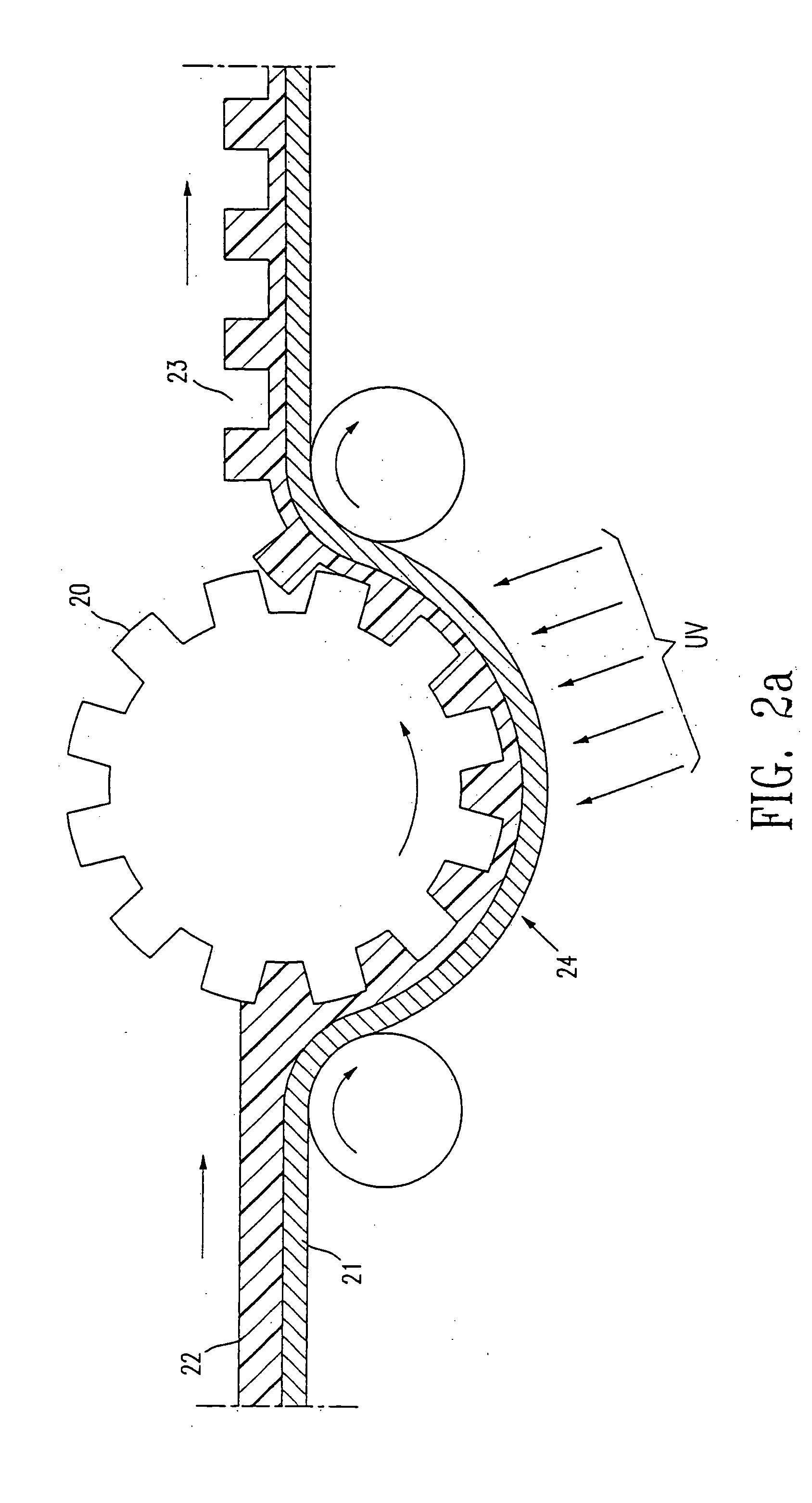

Electrophoretic display and novel process for its manufacture

InactiveUS6833943B2Improve the display effectCost effectiveStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresisElectrical battery

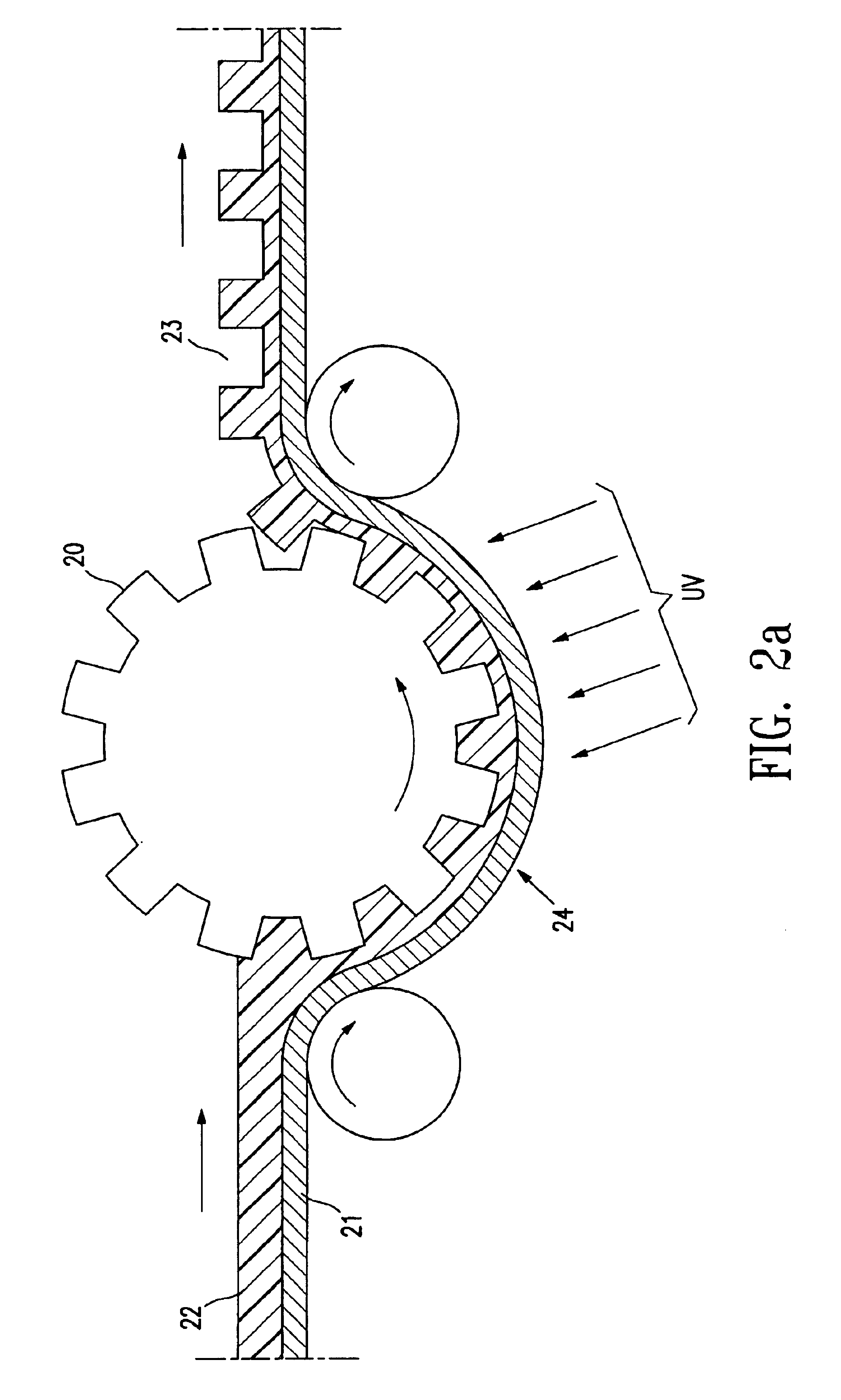

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer which is an integral part of the display and is curved.

Owner:E INK CALIFORNIA

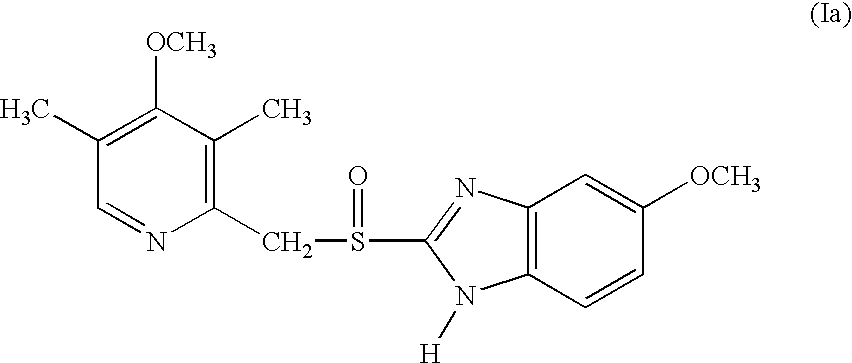

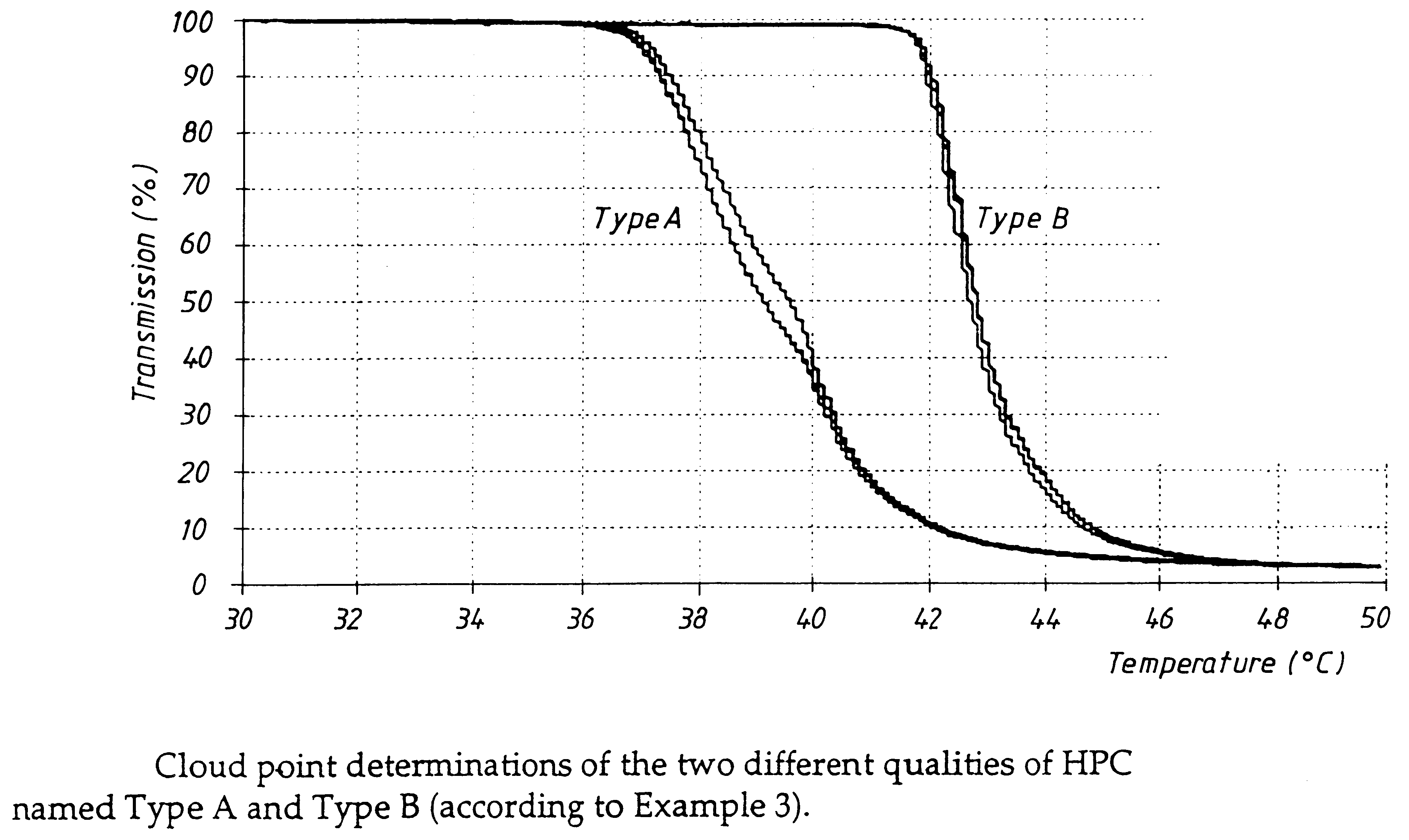

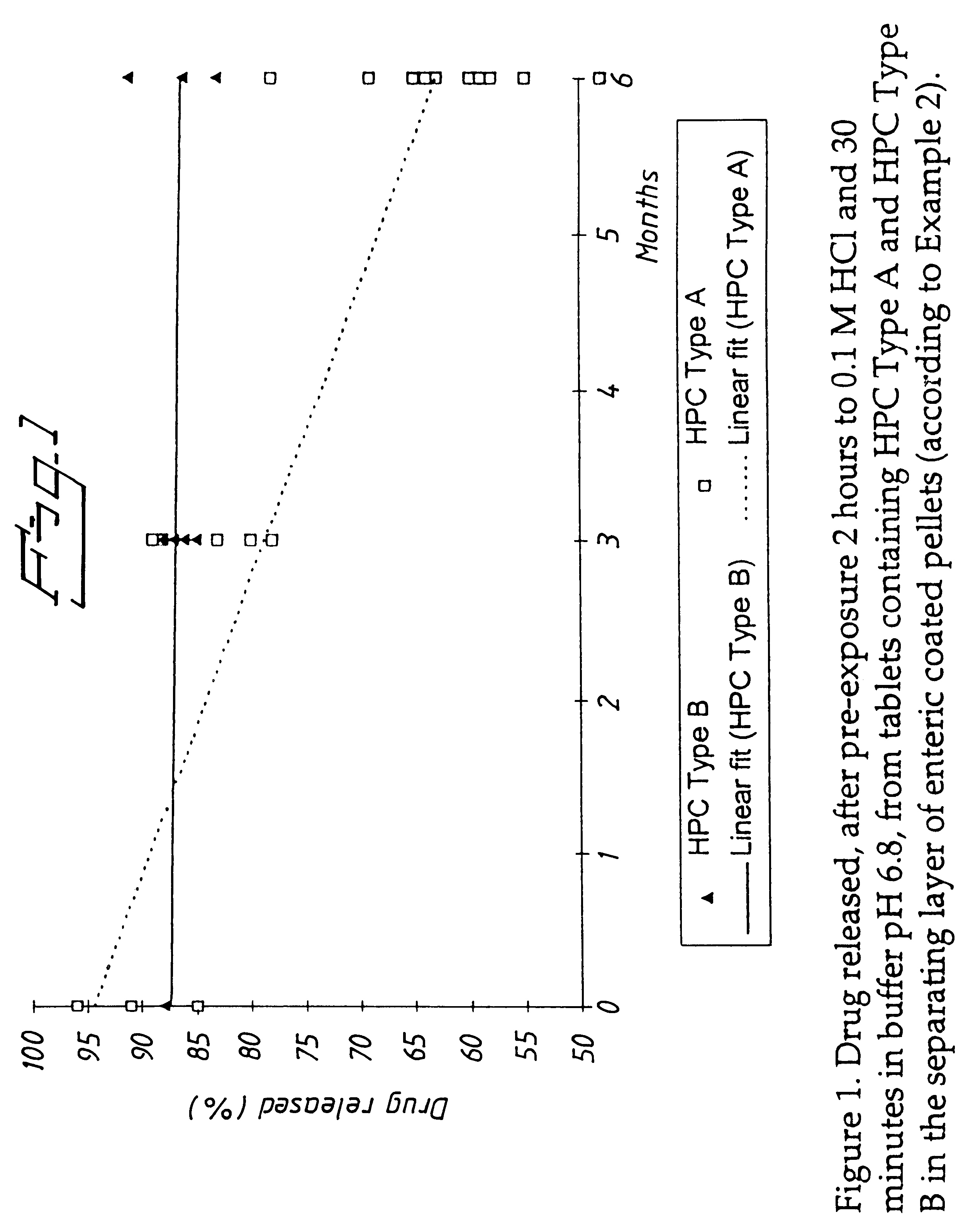

Pharmaceutical formulation comprising omeprazole

InactiveUS6428810B1Reduce diffuseHigh film thicknessOrganic active ingredientsOrganic chemistryEnantiomerOmeprazole

An enteric coated oral pharmaceutical formulation comprising as active ingredient a compound selected from the group of omeprazole, an alkaline salt of omeprazole, one of the single enantiomers of omeprazole and an alkaline salt of one of the single enantiomers of omeprazole, wherein the formulation comprises a core material that comprises the active ingredient and optionally an alkaline reacting compound, the active ingredient is in admixture with a pharmaceutically acceptable excipient, such as for instance a binding agent, and on said core material a separating layer and an enteric coating layer. A hydroxypropyl cellulose (HPC) with a specific cloud point is used in the manufacture of the claimed pharmaceutical formulations. Furthermore, the application describes the processes for their preparation and the use of the claimed formulations in medicine.

Owner:ASTRAZENECA AB

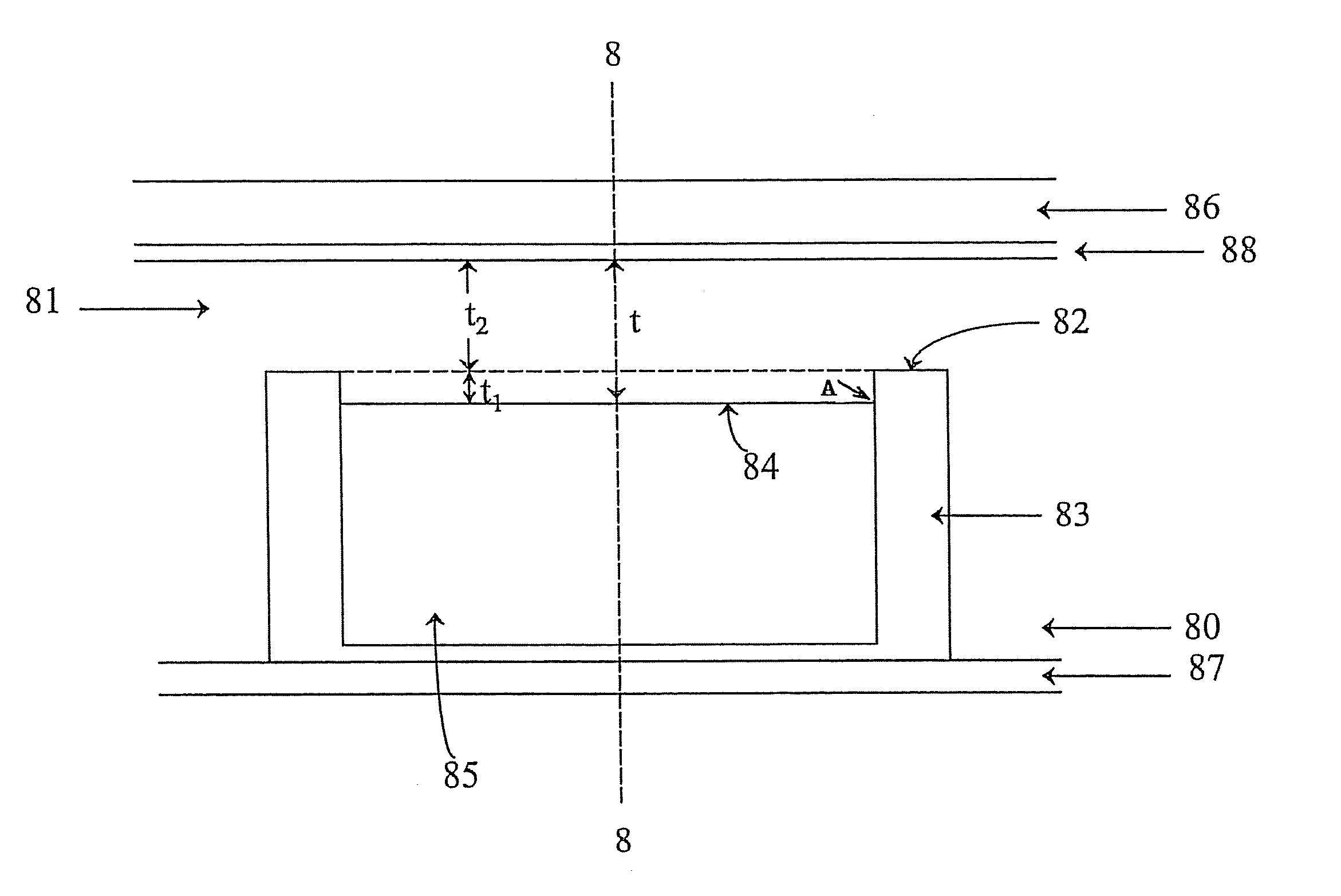

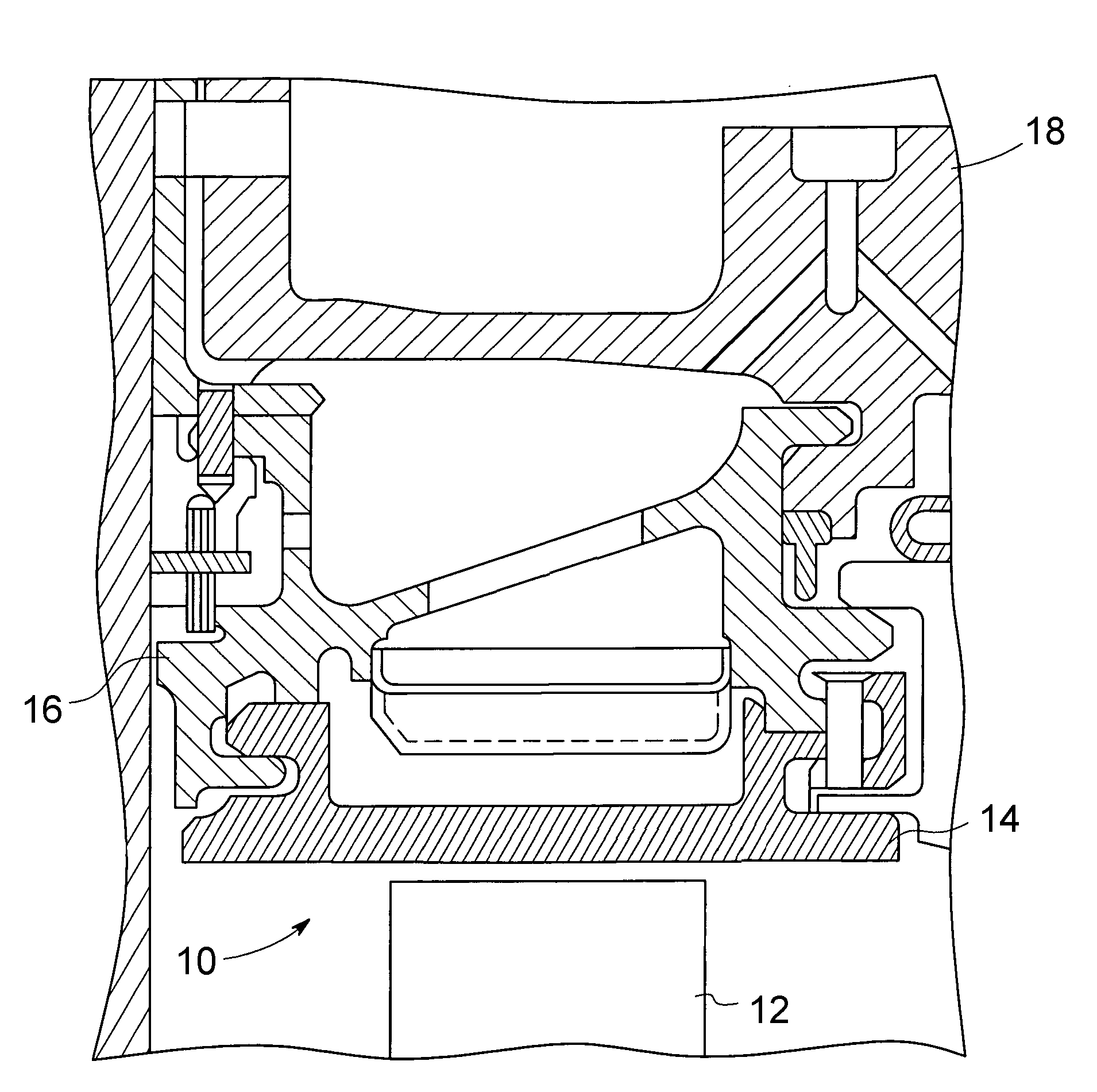

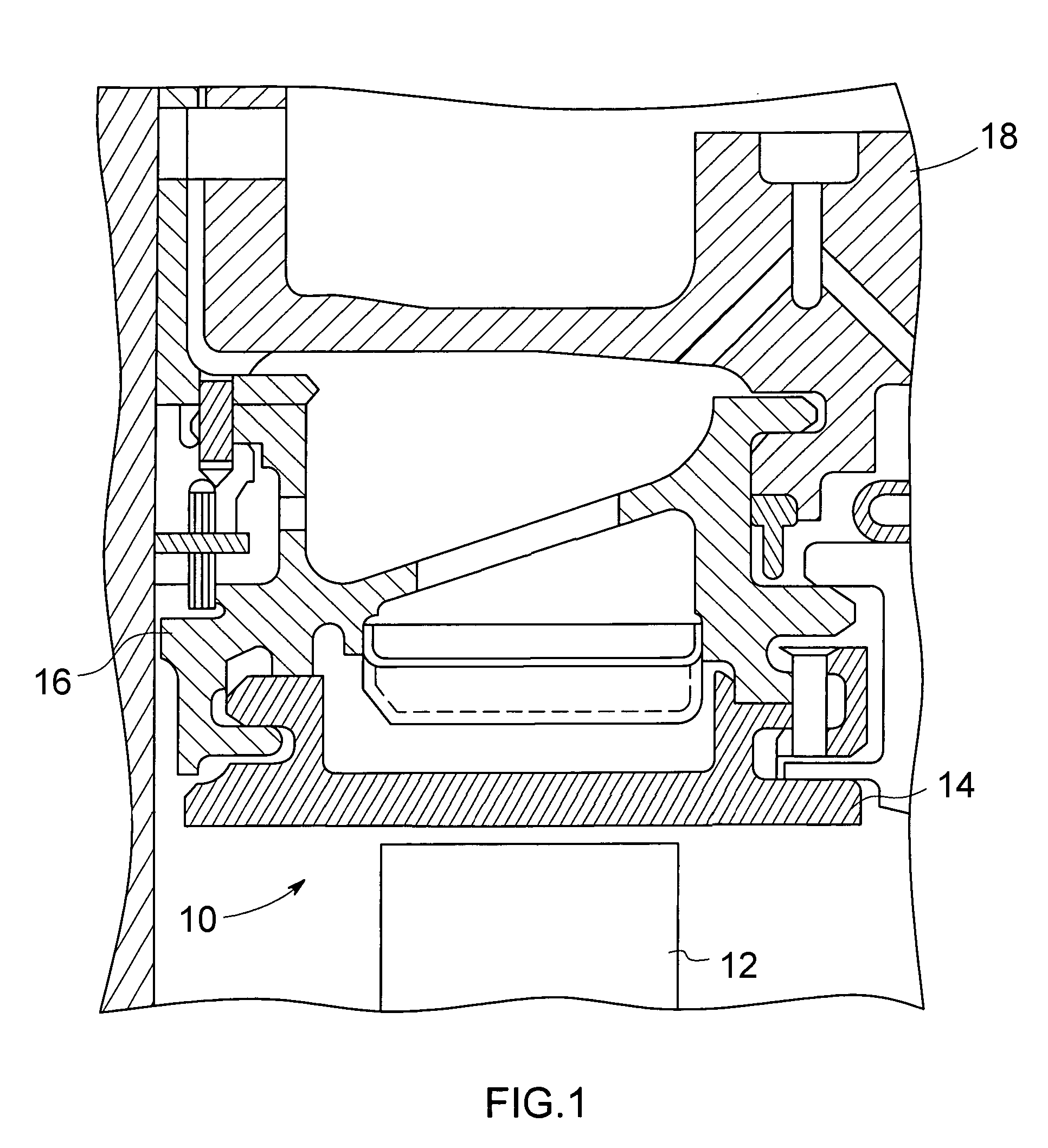

Electrophoretic display and process for its manufacture

InactiveUS7112114B2Improve the display effectImprove optical and physicomechanical propertyMaterial analysis by electric/magnetic meansVessels or leading-in conductors manufactureElectrophoresisDisplay device

Owner:E INK CALIFORNIA

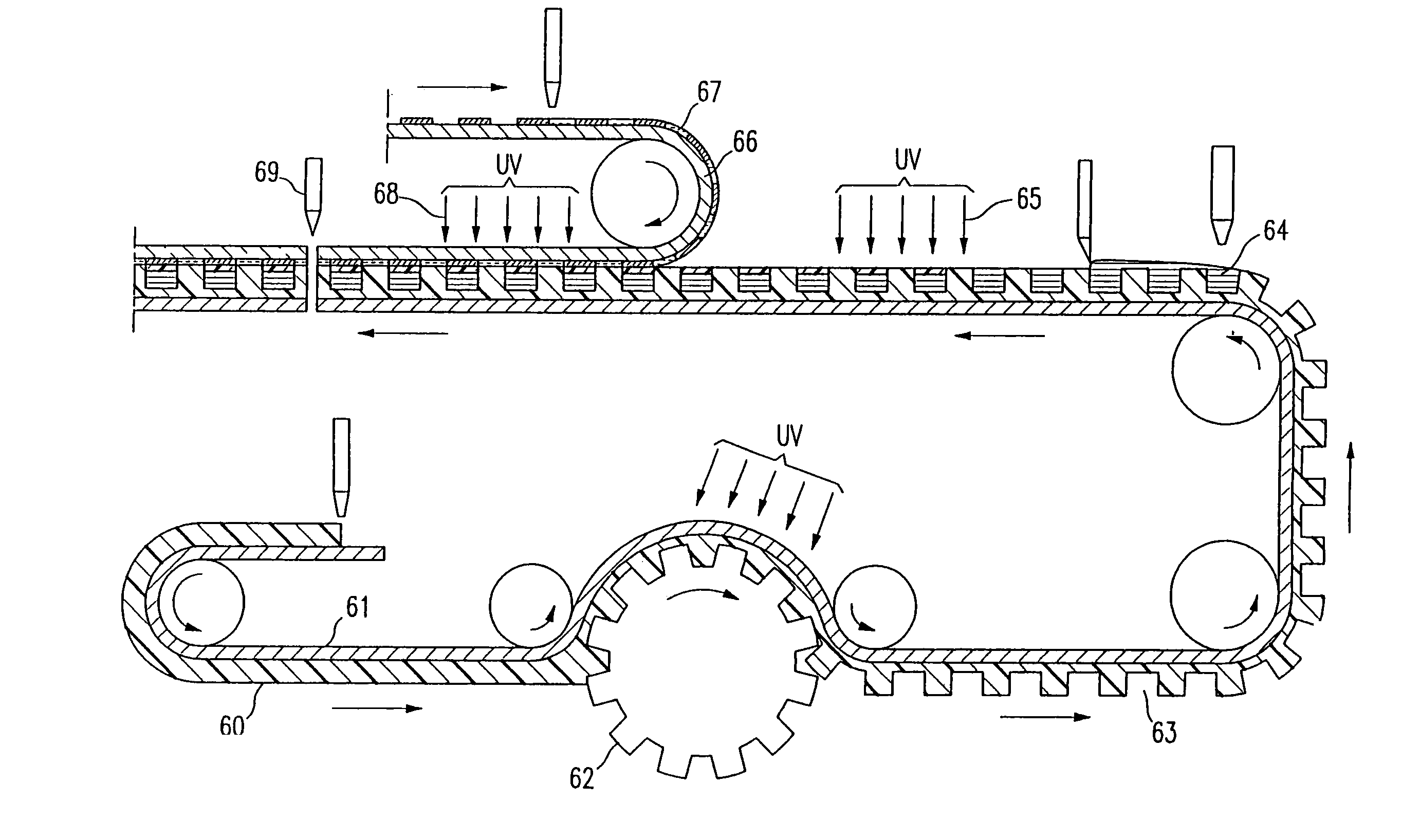

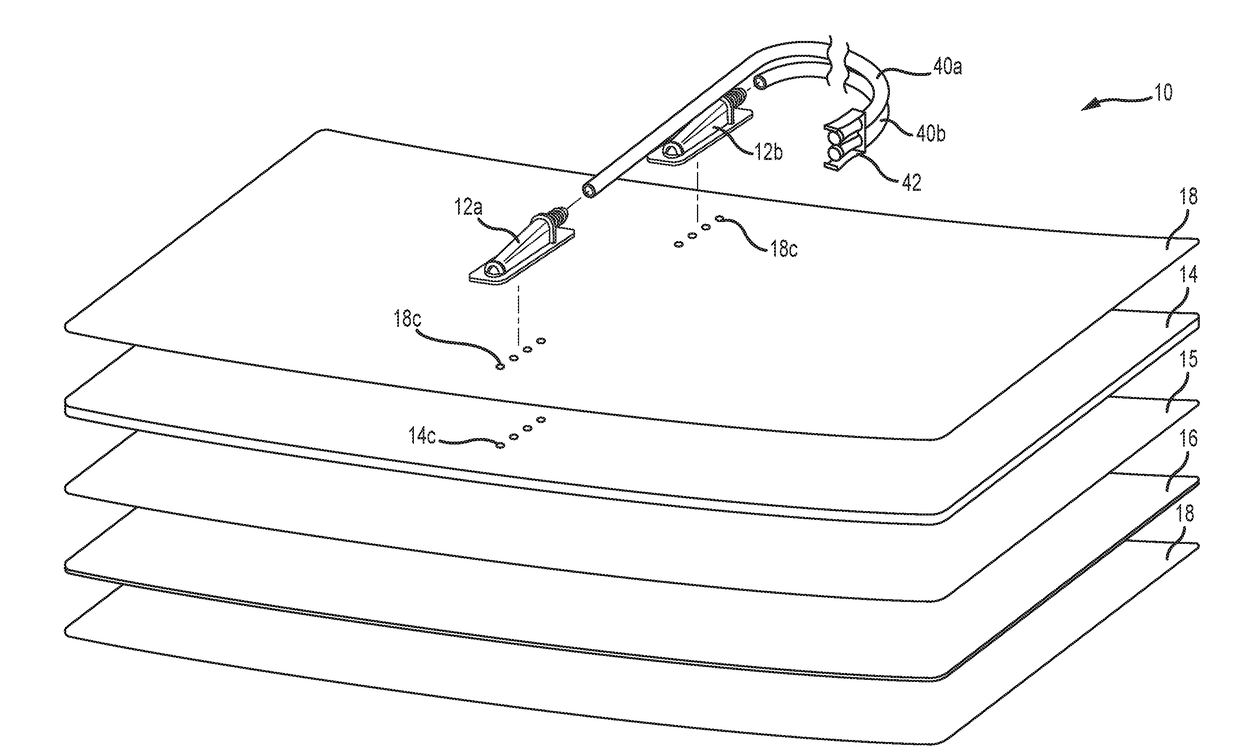

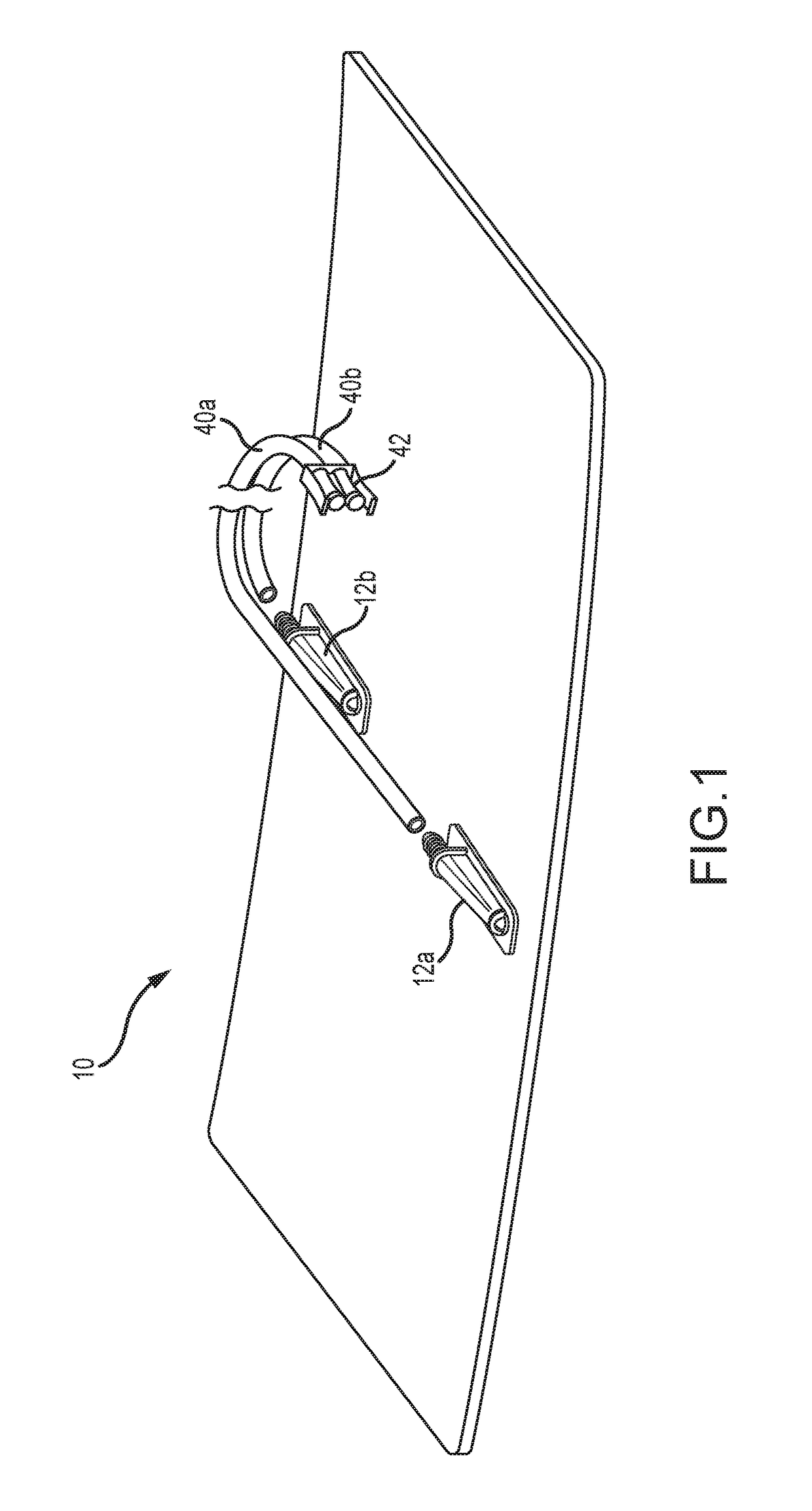

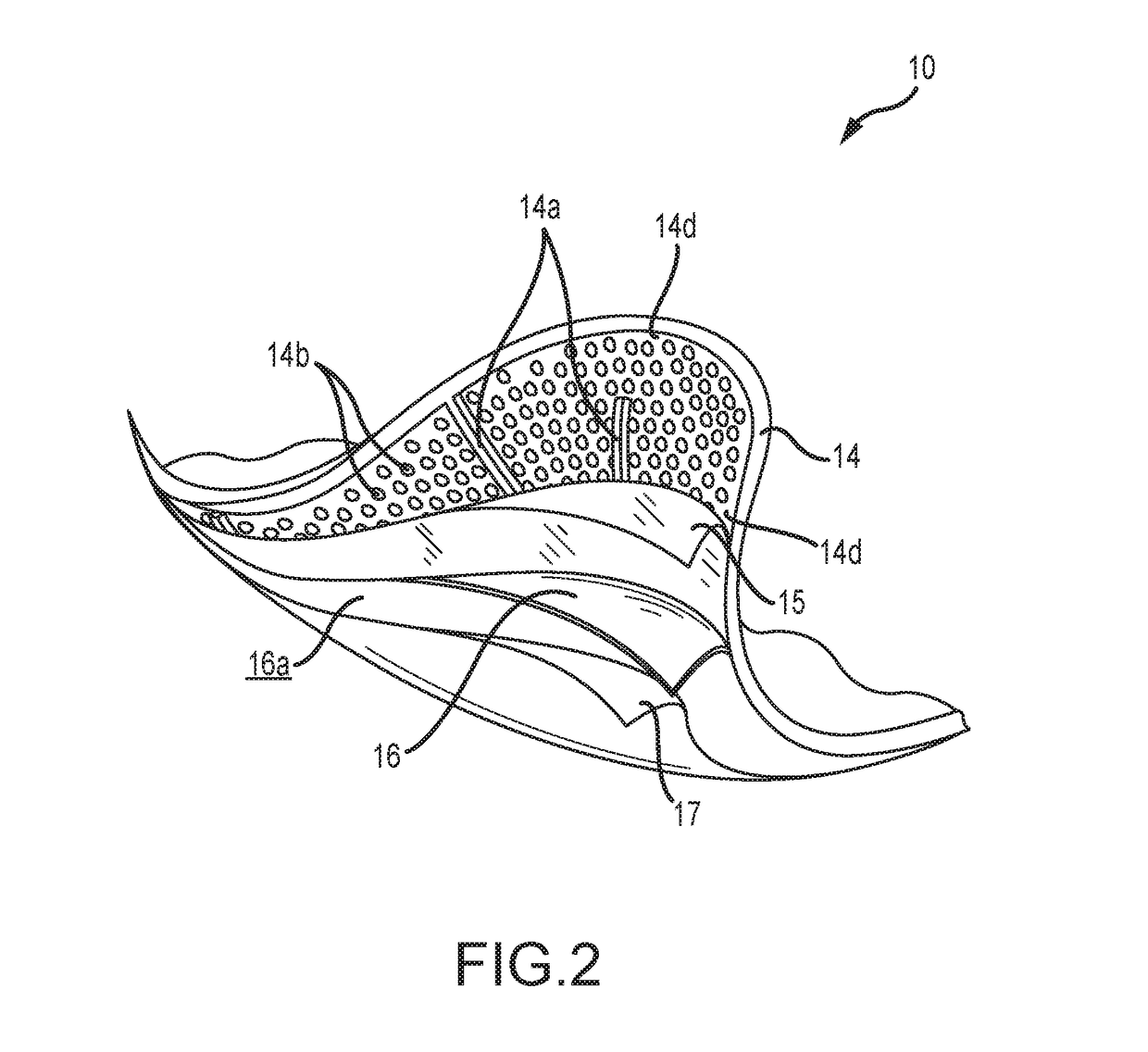

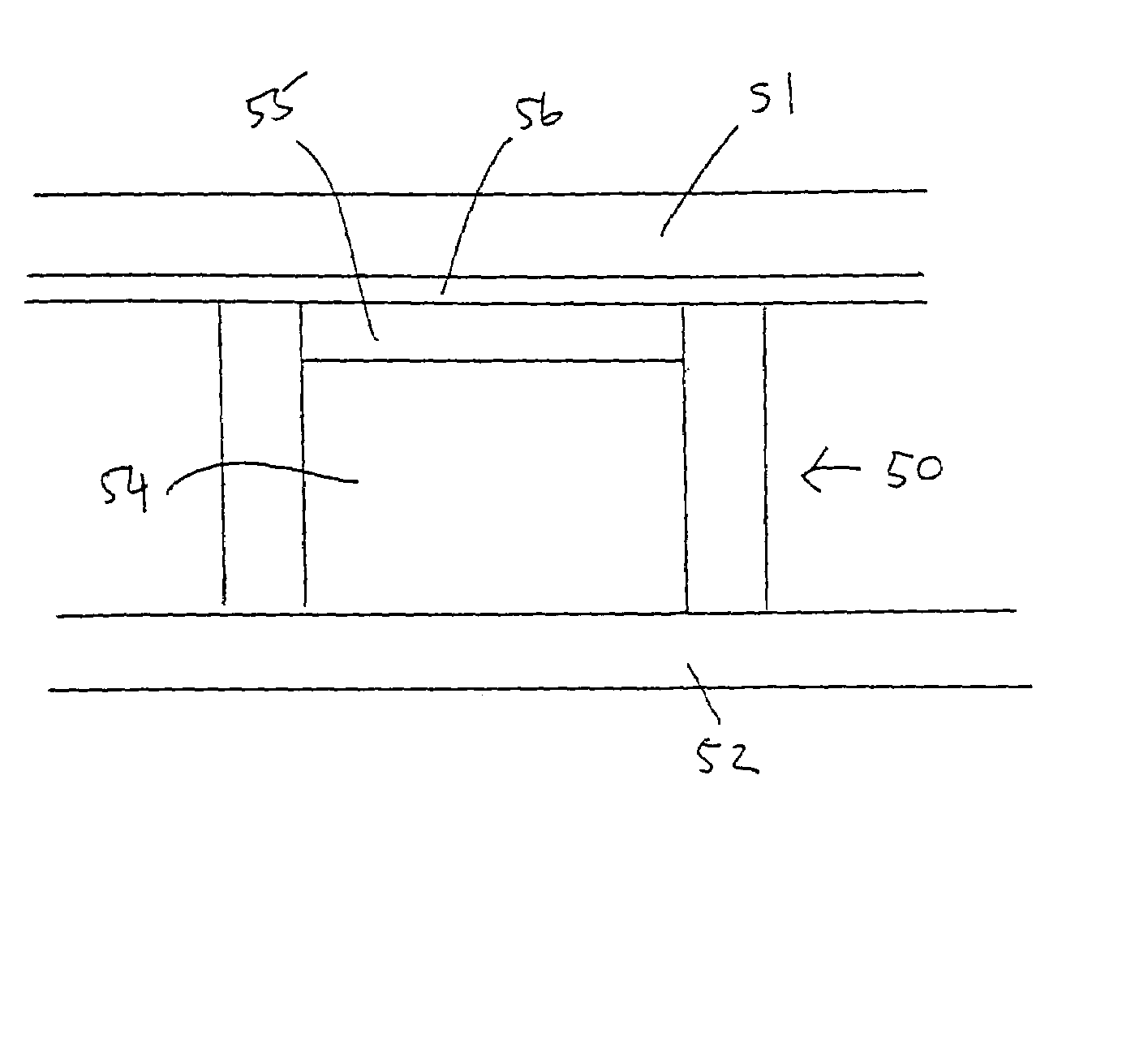

Medical pad and system for thermotherapy

ActiveUS20170189225A1Easy to implementDownsizing of facilityTherapeutic coolingTherapeutic heatingCross-linkEngineering

An improved medical pad for contact thermal exchange with a patient includes a fluid circulation layer for containing a thermal exchange fluid circulatable therethrough, a first port and a second port for circulating the thermal exchange fluid in to and out of the fluid circulation layer, and a hydrogel layer interconnected to and extending across one side of the fluid circulation layer to define an adhesive surface for adherence to a patient's skin. The hydrogel layer comprises an ultra violet light-cured composition that includes a cross-linking copolymer in an amount of between about 15% to 30% by weight of the composition, water in an amount of between about 15% to 40% by weight of the composition, and glycerol in an amount of between about 25% to 35% by weight of the composition. The hydrogel layer is provided to have a thermal conductivity of at least about 1.9 ca / / hr-cm-° C.

Owner:MEDIVANCE

Electrochromic or electrodeposition display and novel process for their manufacture

ActiveUS7245414B2Extend your lifeImprove throughputNon-linear opticsOptical elementsEngineeringElectrochromism

The present invention is directed to an improved electrodeposition and an electrochromic display. The display cells formed from microcups are filled with an electrolyte fluid and are individually sealed with a polymeric sealing layer.

Owner:E INK CORPORATION

Electrophoretic display and process for its manufacture

InactiveUS7557981B2Improve the display effectIntegrityNon-linear opticsOptical elementsElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

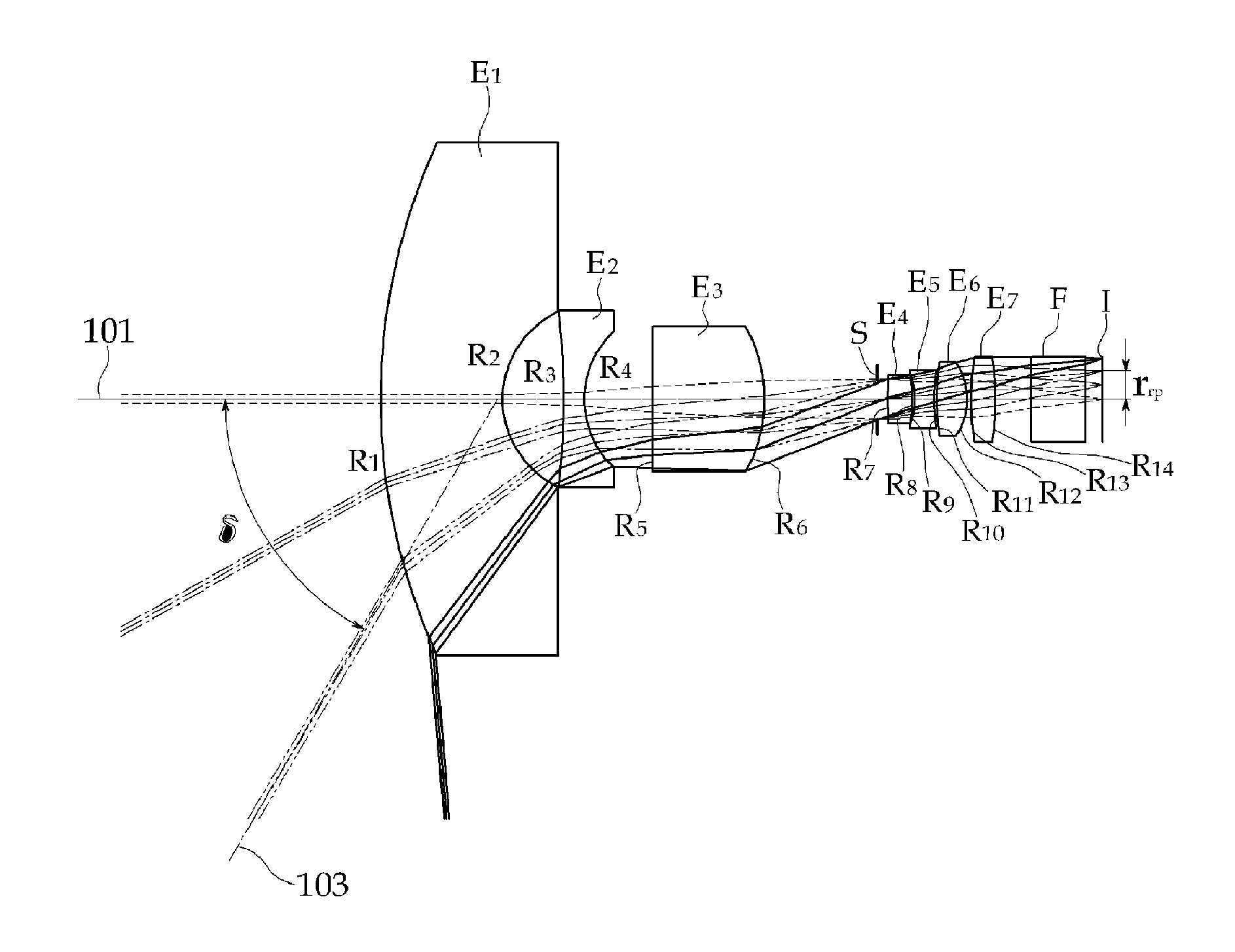

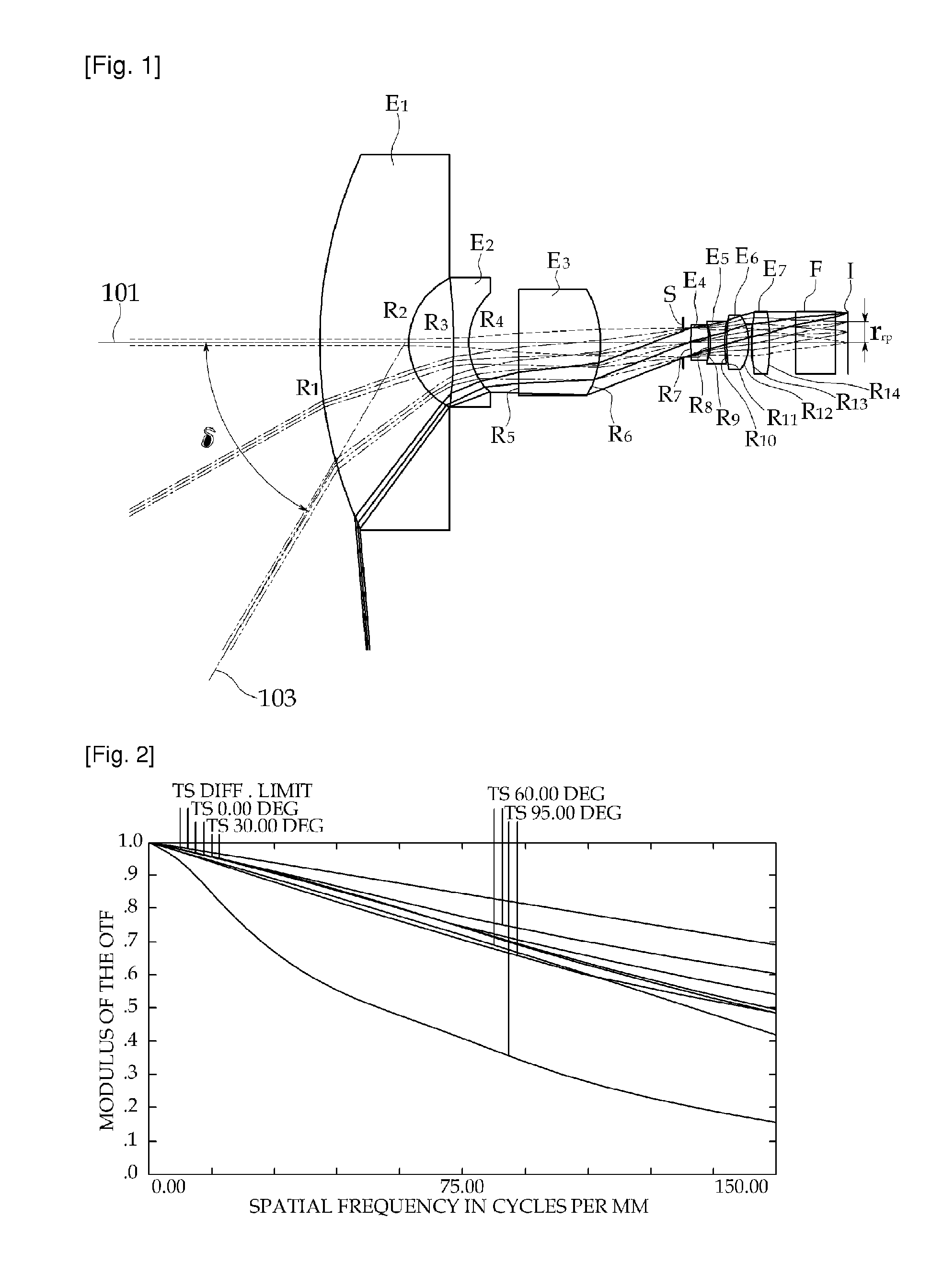

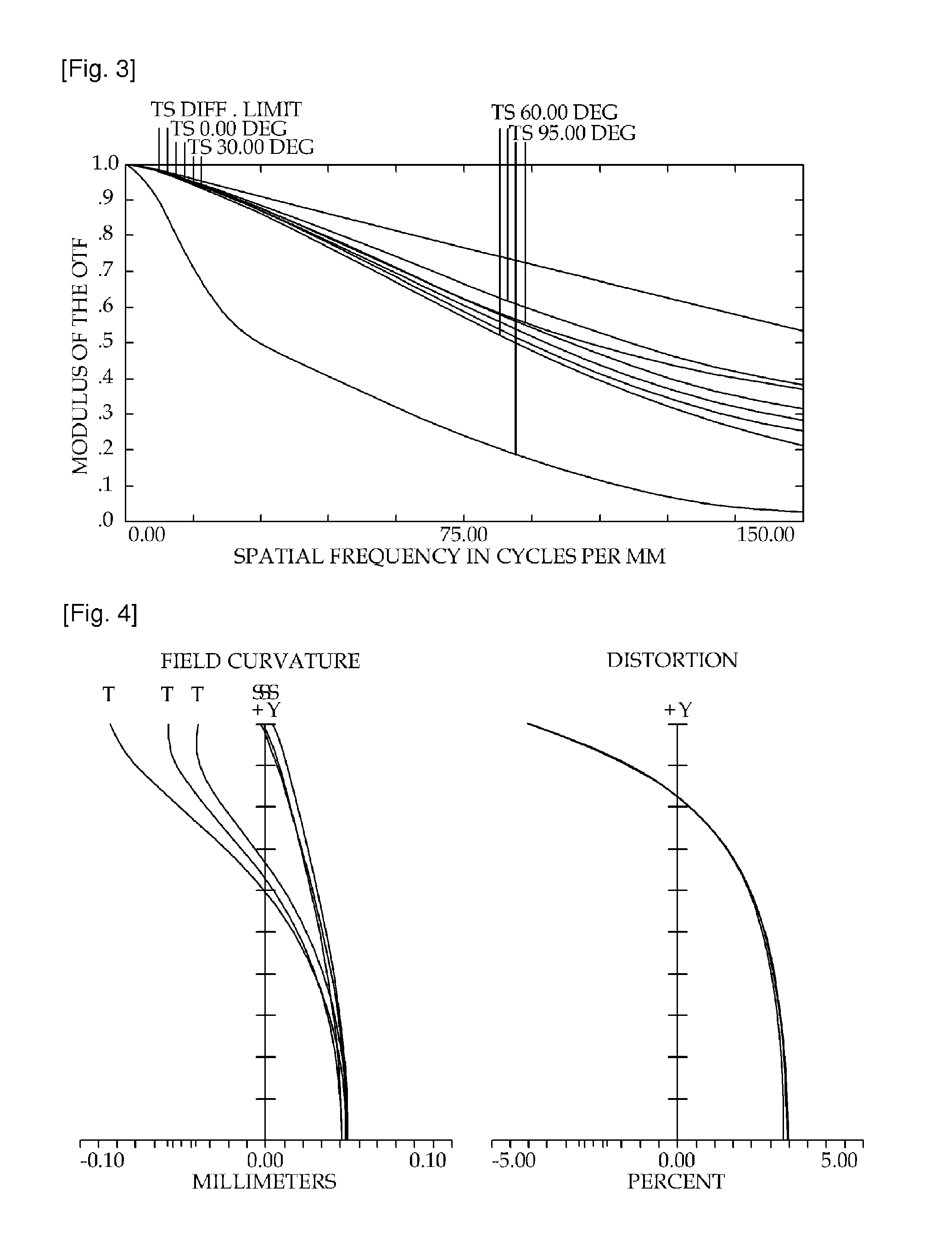

Fisheye lens

InactiveUS20100277816A1Desirable mechanical propertyDesirable optical propertyLensCamera lensIlluminance

Disclosed is a fisheye lens comprised of the first through the seventh lens elements: wherein a field of view is larger than 180° a calibrated distortion is 10% or less, a relative illumination is 80% or more, all the refractive surfaces of the lens elements are spherical surfaces, the first lens element is a negative meniscus lens element having a convex surface facing an object side, the second lens element is a bi-concave lens element, the third lens element is a positive meniscus lens element having a convex surface facing an image side, a stop is located between the third and the fourth lens elements, the fourth lens element is a bi-convex lens element, the fifth lens element is a bi-concave lens element, the sixth and the seventh lens elements are bi-convex lens elements.

Owner:NANOPHOTONICS CO LTD

Electrophoretic display and process for its manufacture

InactiveUS7522332B2Improve the display effectCost effectiveElectrographic processes using photoelectrophoresisElectrographic process apparatusElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

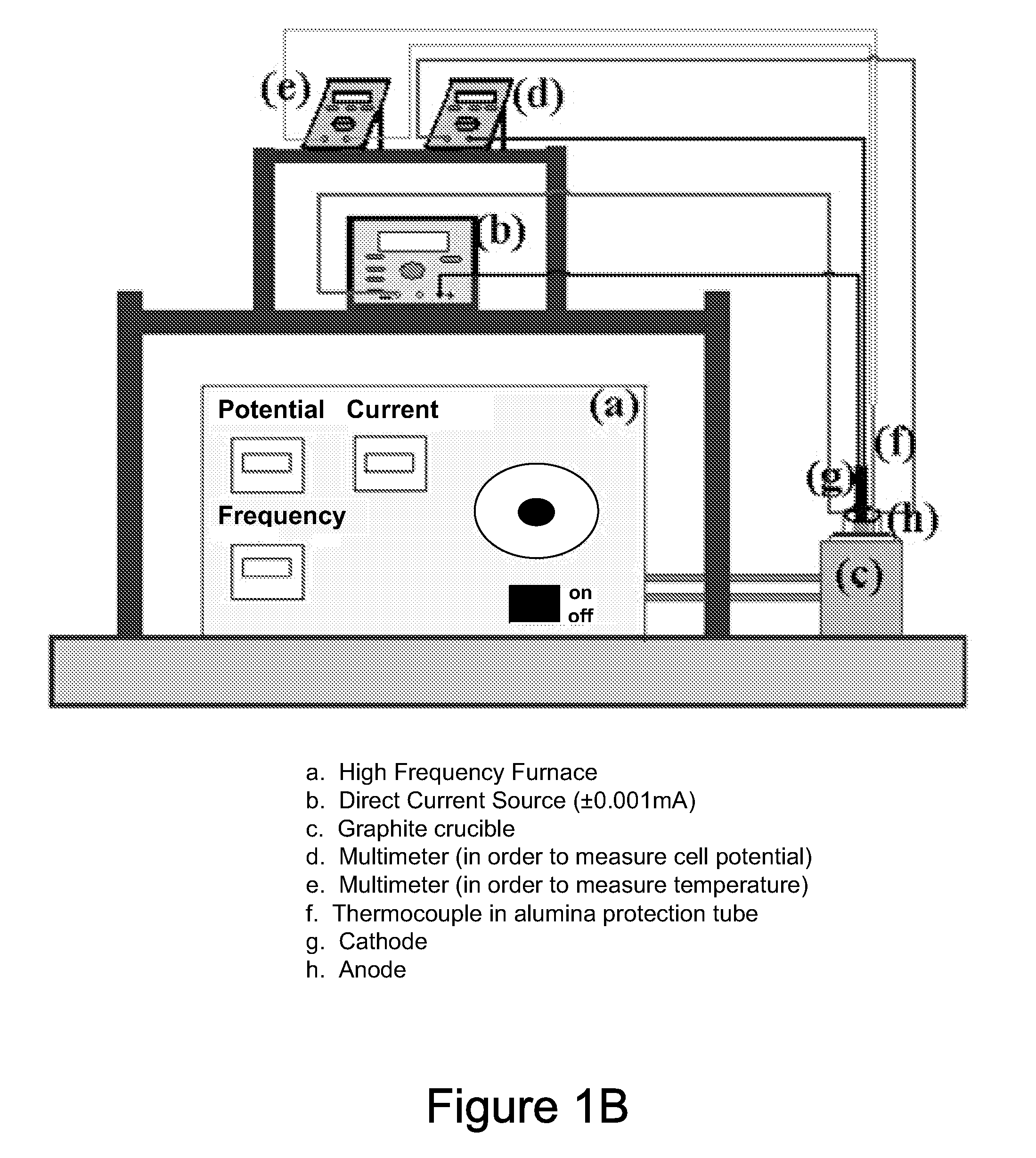

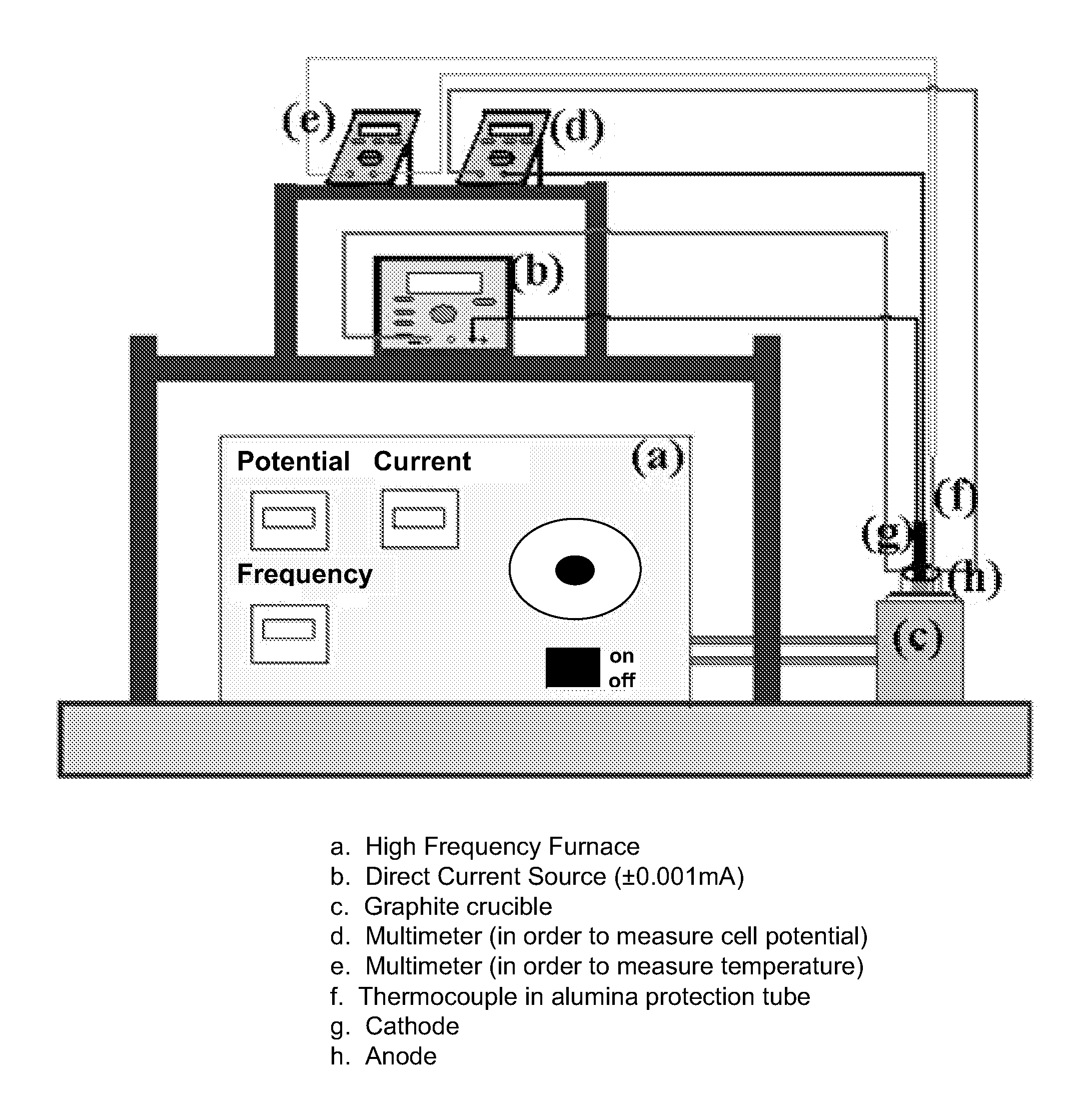

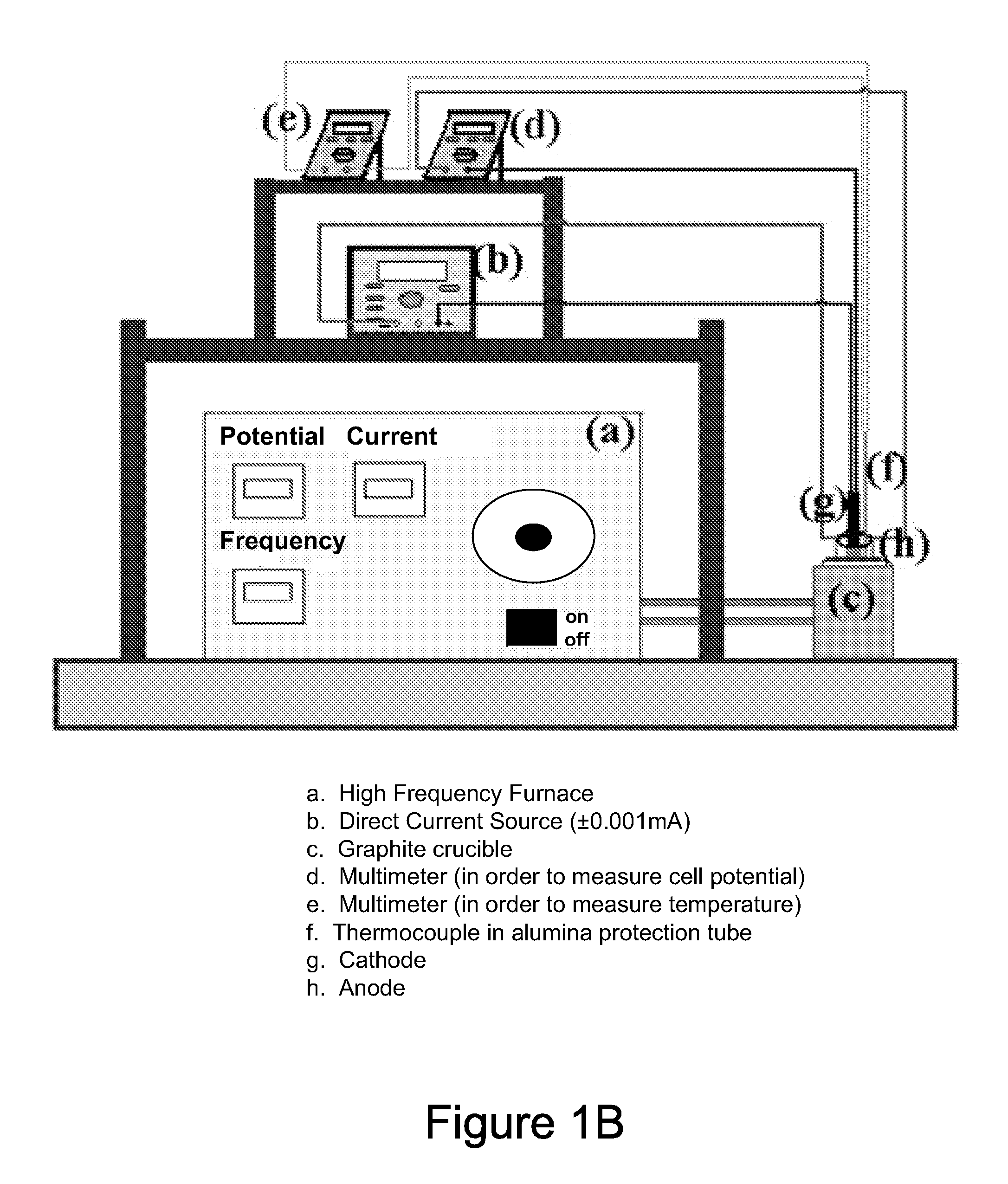

Ultra-fast boriding of metal surfaces for improved properties

InactiveUS20100018611A1Fast boridingDesirable mechanical propertySolid state diffusion coatingMetallurgyUltra fast

A method of ultra-fast boriding of a metal surface. The method includes the step of providing a metal component, providing a molten electrolyte having boron components therein, providing an electrochemical boriding system including an induction furnace, operating the induction furnace to establish a high temperature for the molten electrolyte, and boriding the metal surface to achieve a boride layer on the metal surface.

Owner:UCHICAGO ARGONNE LLC

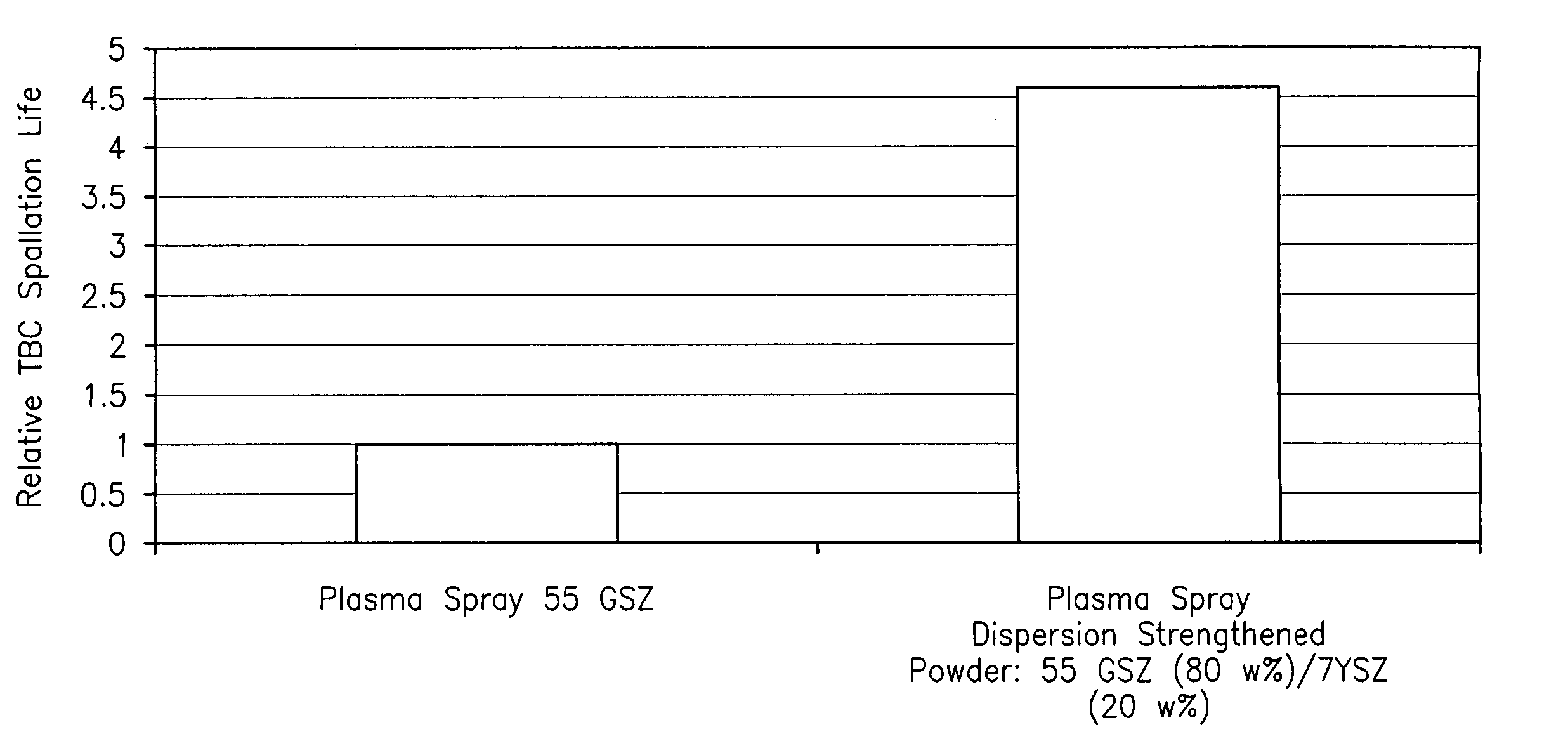

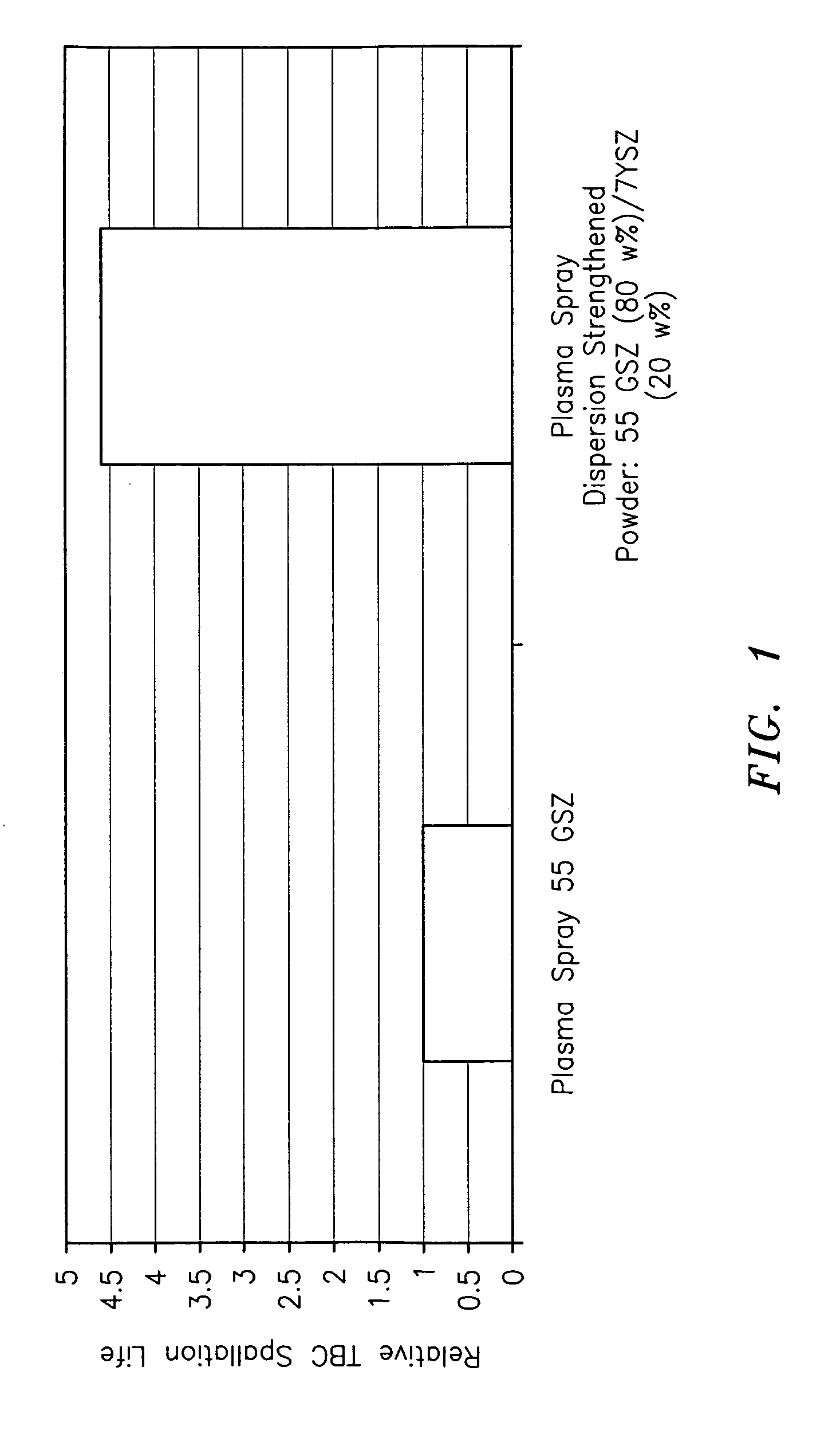

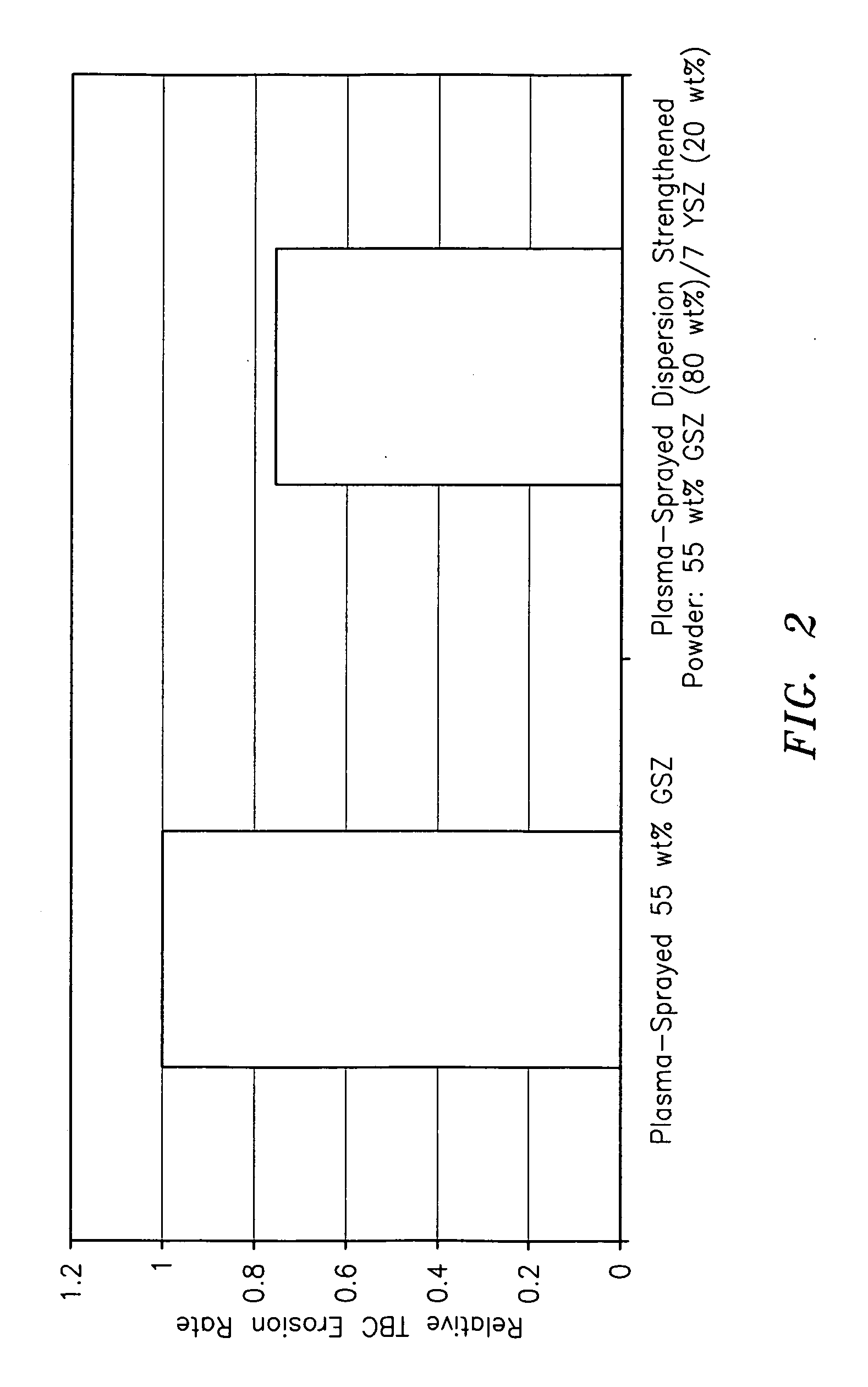

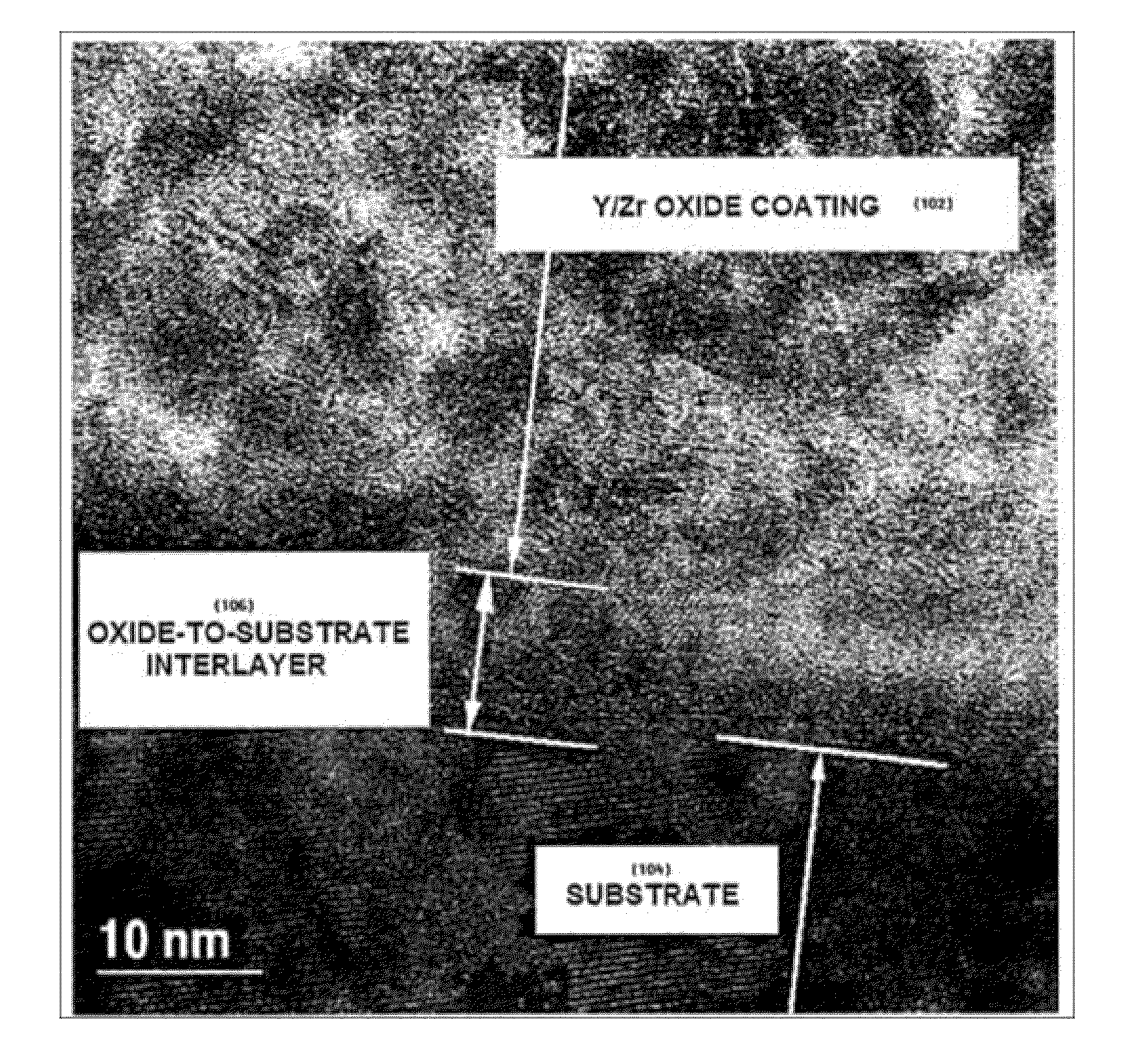

Dispersion strengthened rare earth stabilized zirconia

ActiveUS20060024513A1Desirable mechanical propertyLiquid surface applicatorsMolten spray coatingYttria-stabilized zirconiaAluminium

A process for forming a coating on a substrate, such as a turbine engine component, is provided. The process comprises the steps of providing a rare earth oxide stabilized zirconia composition, blending the first rare earth oxide stabilized zirconia composition with at least one additional constituent selected from the group consisting of TiO2, Al2O3, a blend of Al2O3—TiO2, La2Zr2O7, and 20 wt % Yttria Stabilized Zirconia; and depositing the blended powder onto the substrate. Articles having the coating formed from the above process are also described.

Owner:RAYTHEON TECH CORP

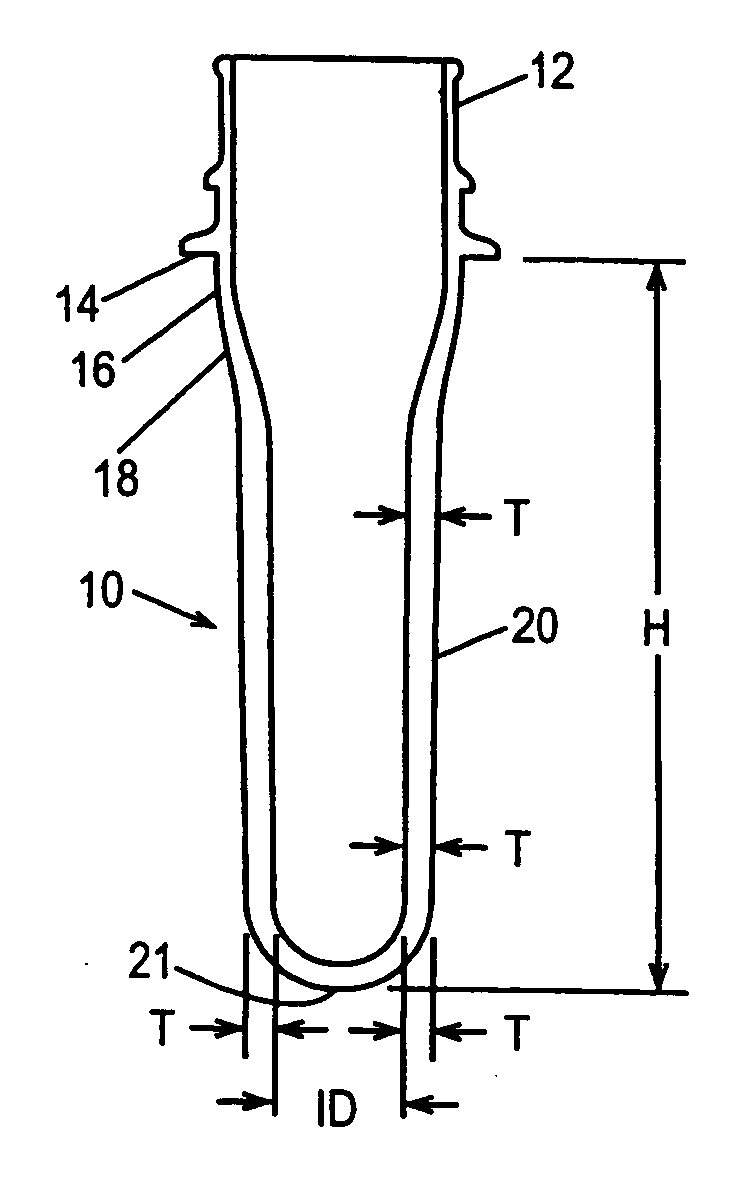

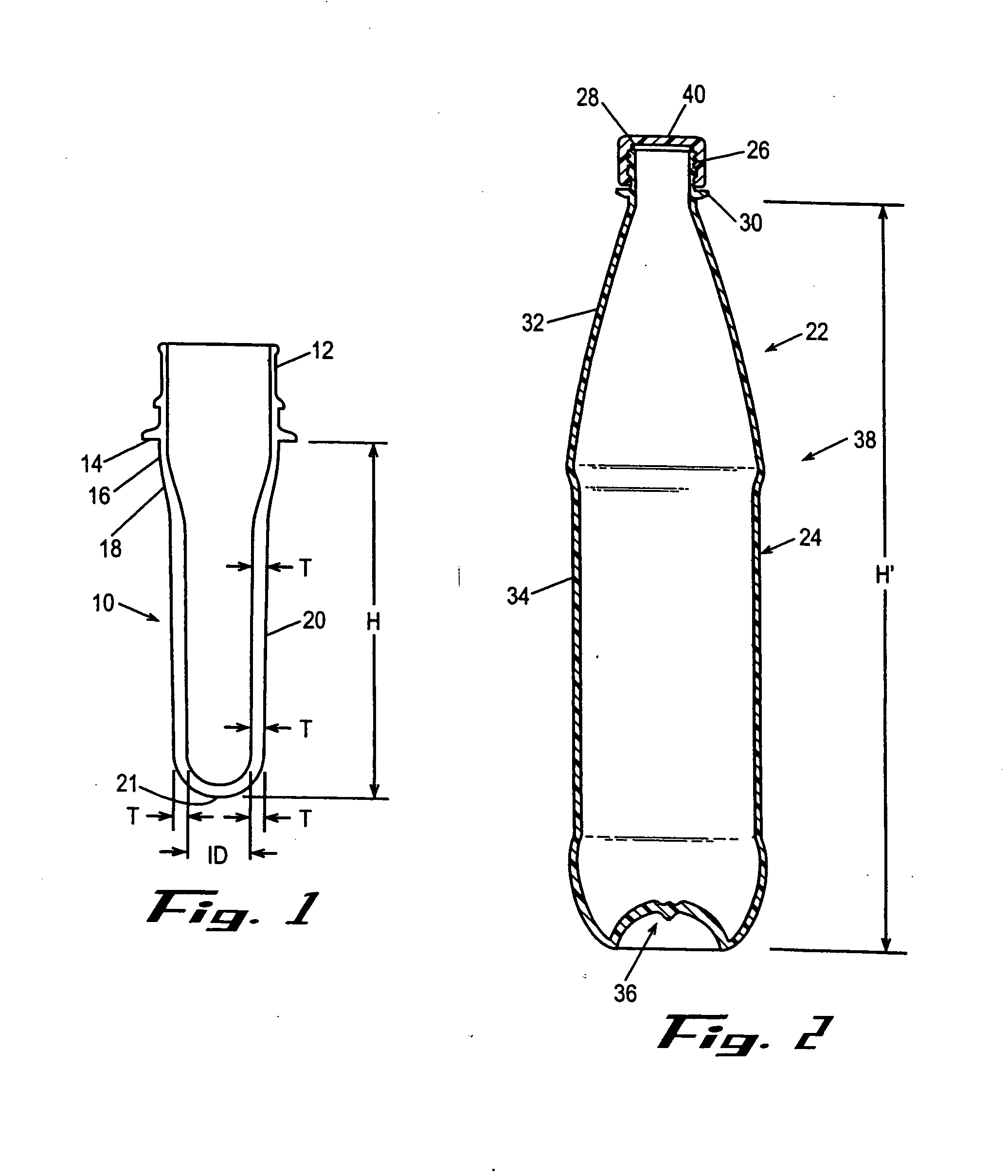

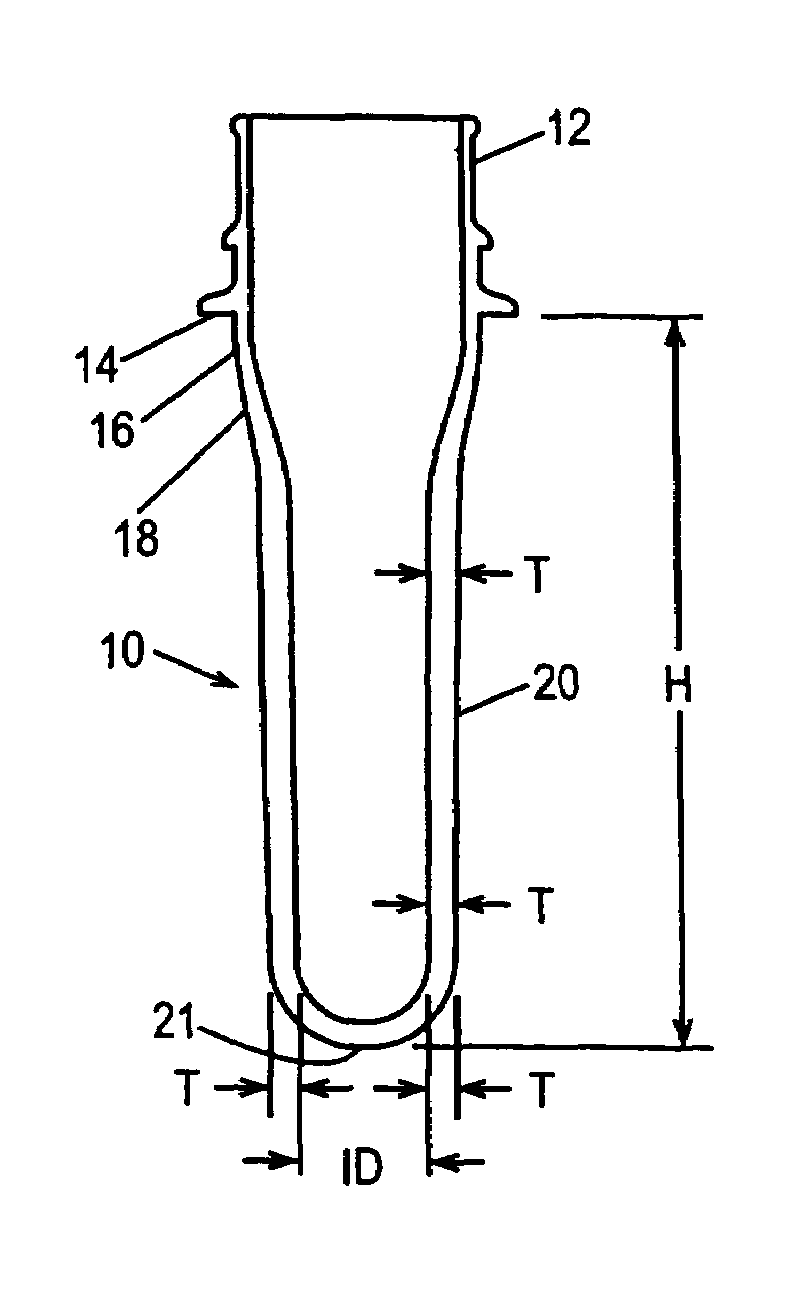

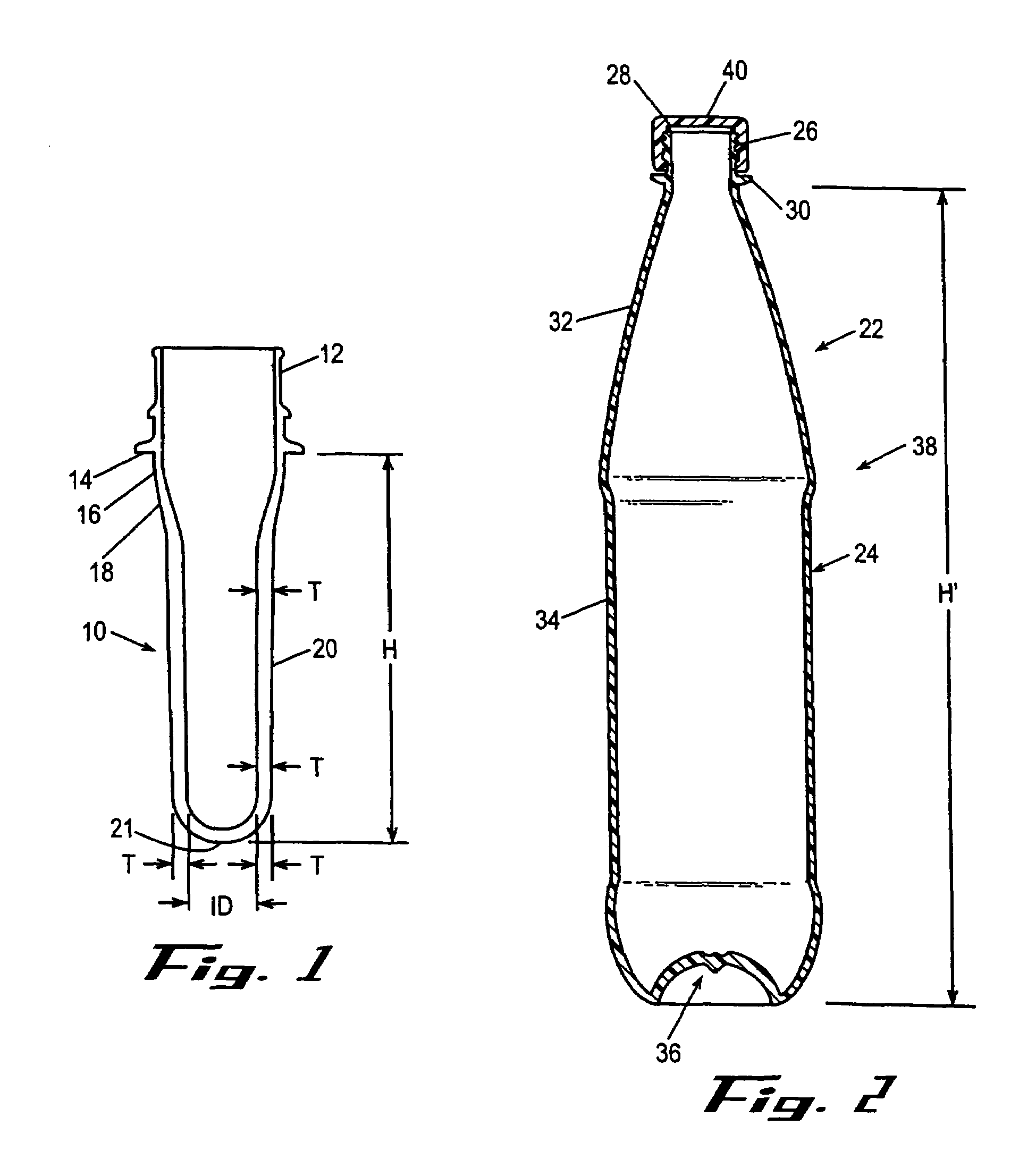

Low IV pet based copolymer preform with enhanced mechanical properties and cycle time, container made therewith and methods

InactiveUS20060257602A1Low IVRaise the draw ratioSynthetic resin layered productsThin material handlingDiethylene glycolDiol

A preform having a low IV and comprising a PET Copolymer comprising a diol component having repeat units from ethylene glycol and diethylene glycol and a diacid component having repeat units from terephthalic acid and naphthalenedicarboxylic acid. The total amount of diethylene glycol and naphthalenedicarboxylic acid is present in the poly(ethylene terephthalate) copolymer in an amount from about 0.1 mole percent to less than 2.8 mole percent. The preform is useful in making containers and corresponding methods are disclosed.

Owner:THE COCA-COLA CO

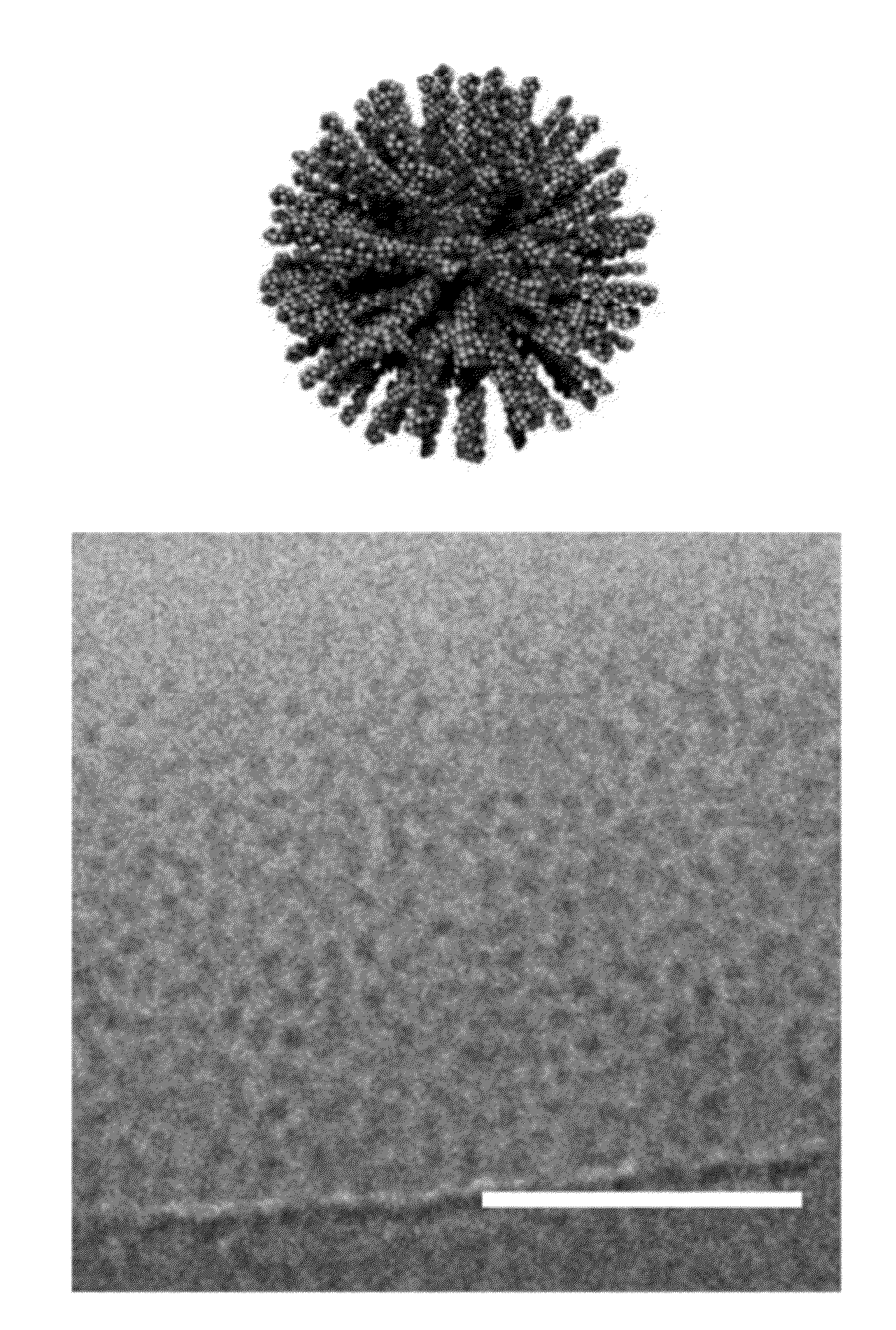

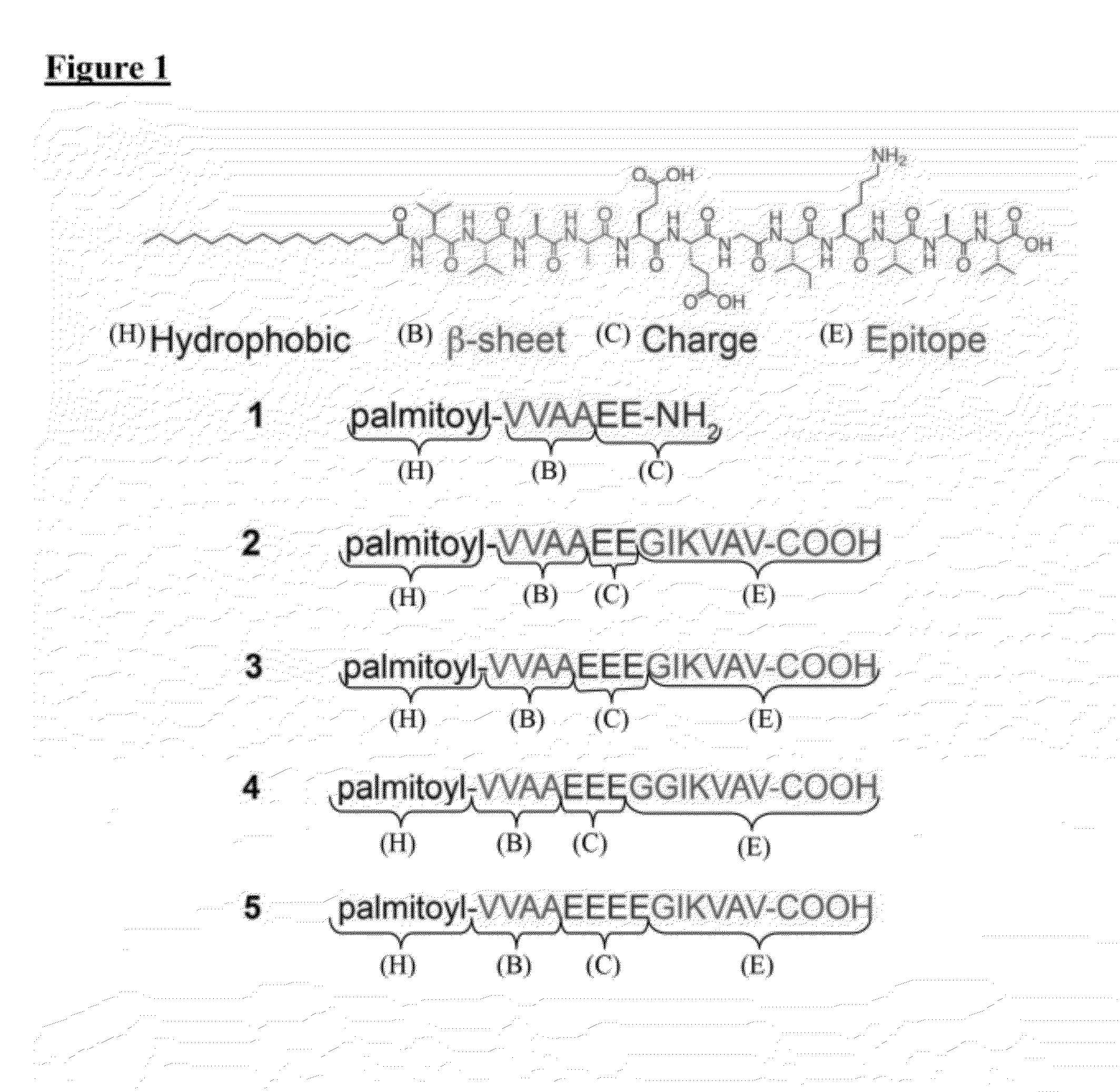

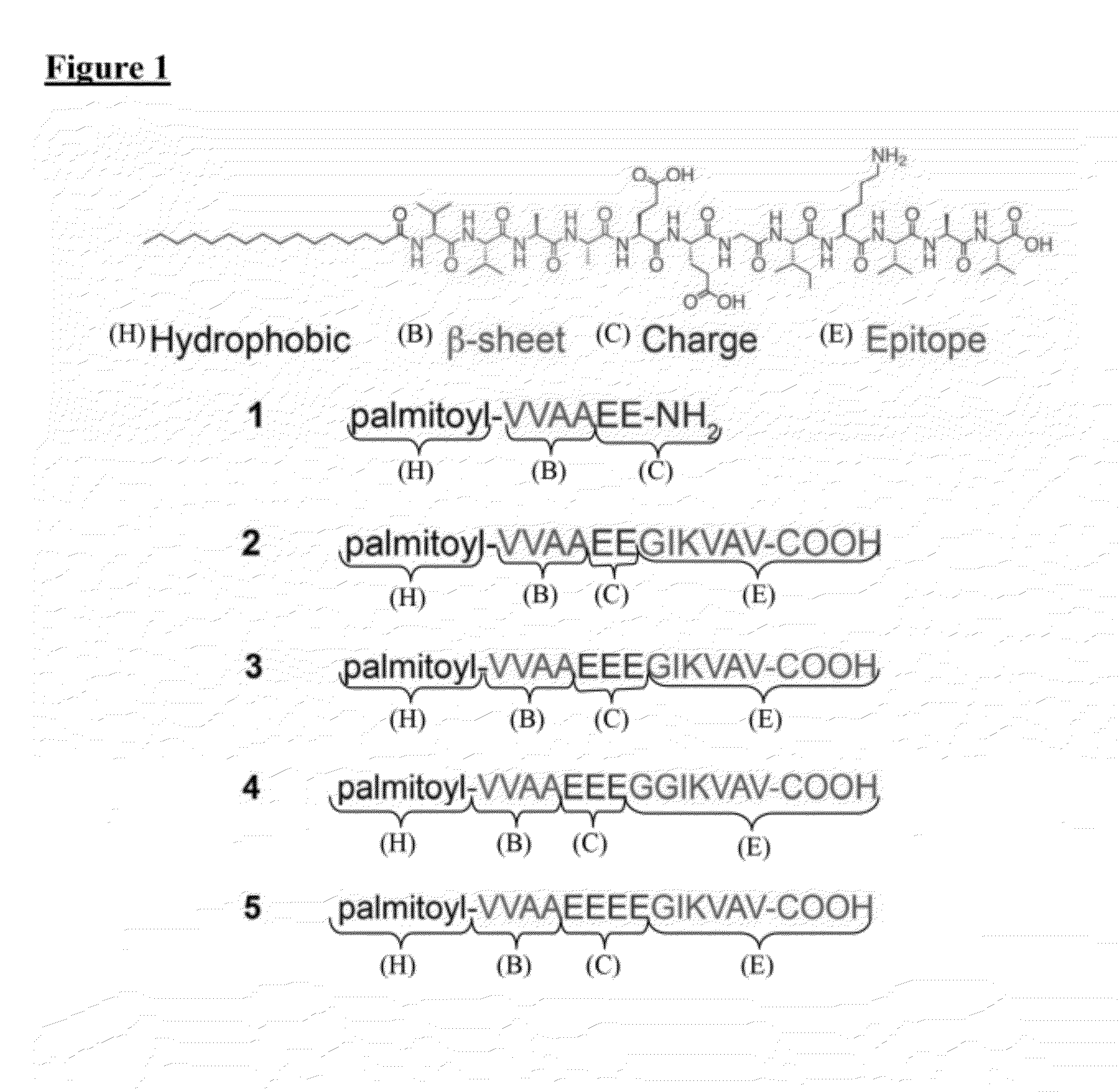

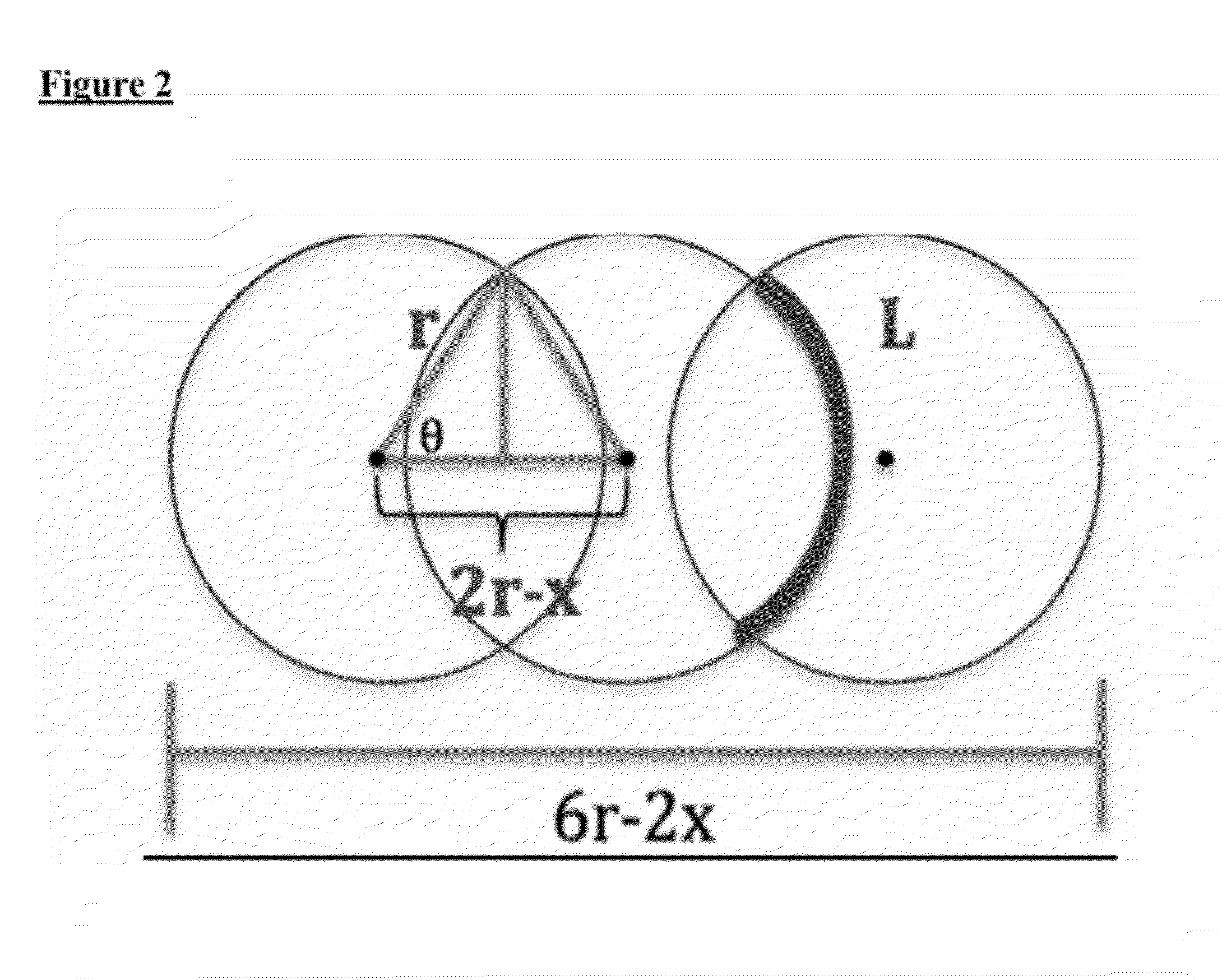

Peptide amphiphiles and methods to electrostatically control bioactivity of the ikvav peptide epitope

ActiveUS20120294902A1Superior solubility and biological activityEnhances displayConnective tissue peptidesNervous disorderChemistrySolubility

The present invention is directed to peptide amphiphile compounds, compositions and methods of use, wherein nanofiber bundling or epitope aggregation is inhibited. In certain embodiments, the peptide amphiphiles of the present invention have increased solubility and reduced nanofiber bundling. The molecules may be used in pharmaceutical applications, for example for in vivo administration to human patients, by increasing biological activity of the compositions toward neurite outgrowth and nerve regeneration.

Owner:NORTHWESTERN UNIV

Electrophoretic display and process for its manufacture

InactiveUS20060238489A1Desirable mechanical propertyImprove the display effectStatic indicating devicesNon-linear opticsSolventEngineering

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

Sealant having improved dynamic durability

ActiveUS7294669B2Increased durabilityDesirable mechanical propertySpecial tyresMixingPlasticizerSealant

An object of the present invention is to provide a low-modulus, high elongation sealant having improved dynamic durability, desirable mechanical properties, and good workability. The present invention provides a sealant containing an oxyalkylene polymer (A) having a number-average molecular weight of 20,000 to 50,000 and 0.8 or more of reactive silicon groups per molecule on average; 10 parts by weight or more of a plasticizer (B) per 100 parts by weight of the polymer (A); a filler (C); and a curing catalyst (D). This sealant has an improved durability and can achieve the above-described object.

Owner:KANEKA CORP

Sulfonated poly(arylene ether) copolymers and related polymer electrolyte membranes and fuel cells

ActiveUS20110136040A1Desirable mechanical propertyImprove conductivitySolid electrolytesIon-exchanger regenerationPolymer electrolytesFuel cells

Owner:HYUNDAI MOTOR CO LTD

Forged austenitic stainless steel alloy components and method therefor

InactiveUS20090129967A1Suitable for useDesirable mechanical propertyStatorsFurnace typesNiobiumManganese

A forgeable austenitic stainless steel alloy and forging process capable of producing forged components that exhibit mechanical and environmental properties and metallurgical stability suitable for use in thermally and chemically hostile environments, such as the environment of a component of a gas turbine engine shroud assembly. The alloy contains, by weight, 18.0 to 22.0% chromium, 8.0 to 14.0% nickel, 4.0 to 7.0% manganese, 0.4 to 0.6% silicon, at least 0.2 up to 1.0% nitrogen, at least 0.05 up to 0.075% carbon; up to 0.3% molybdenum, up to 1.0% niobium, up to 0.2% cobalt, up to 4.5% aluminum, up to 0.1% boron, up to 0.1% vanadium, up to 1.0% tungsten, and up to 5.0% copper, with the balance iron and incidental impurities.

Owner:GENERAL ELECTRIC CO

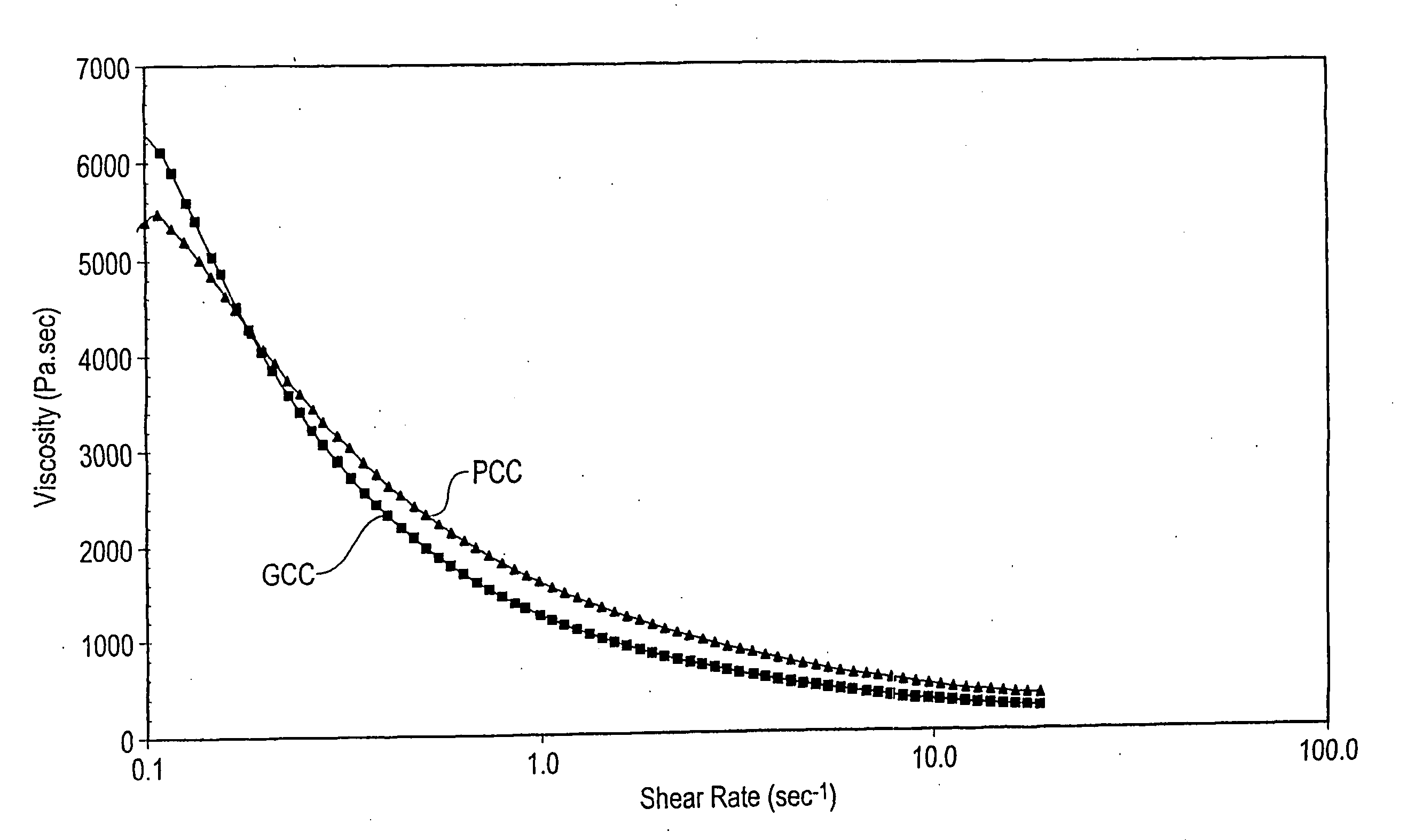

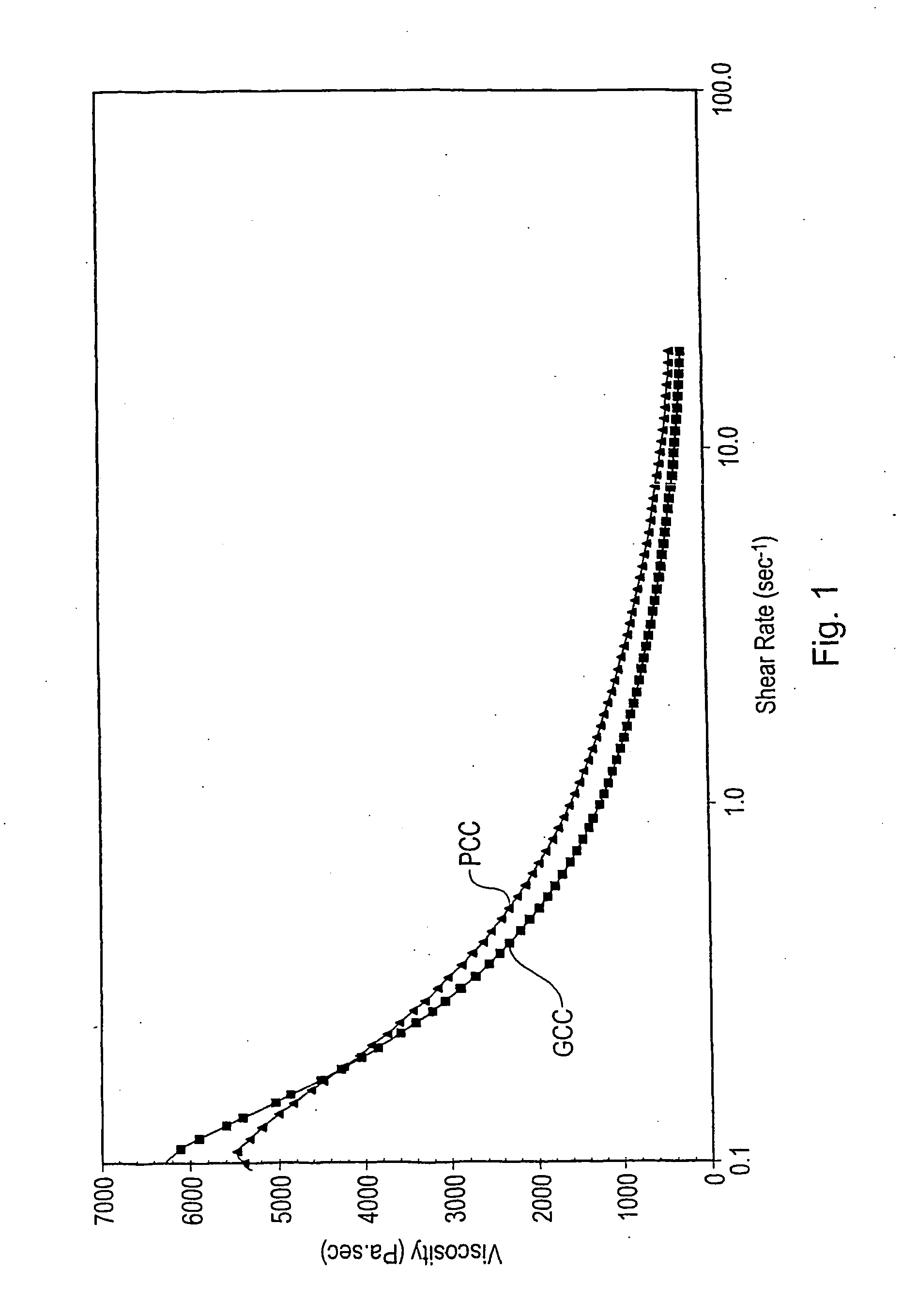

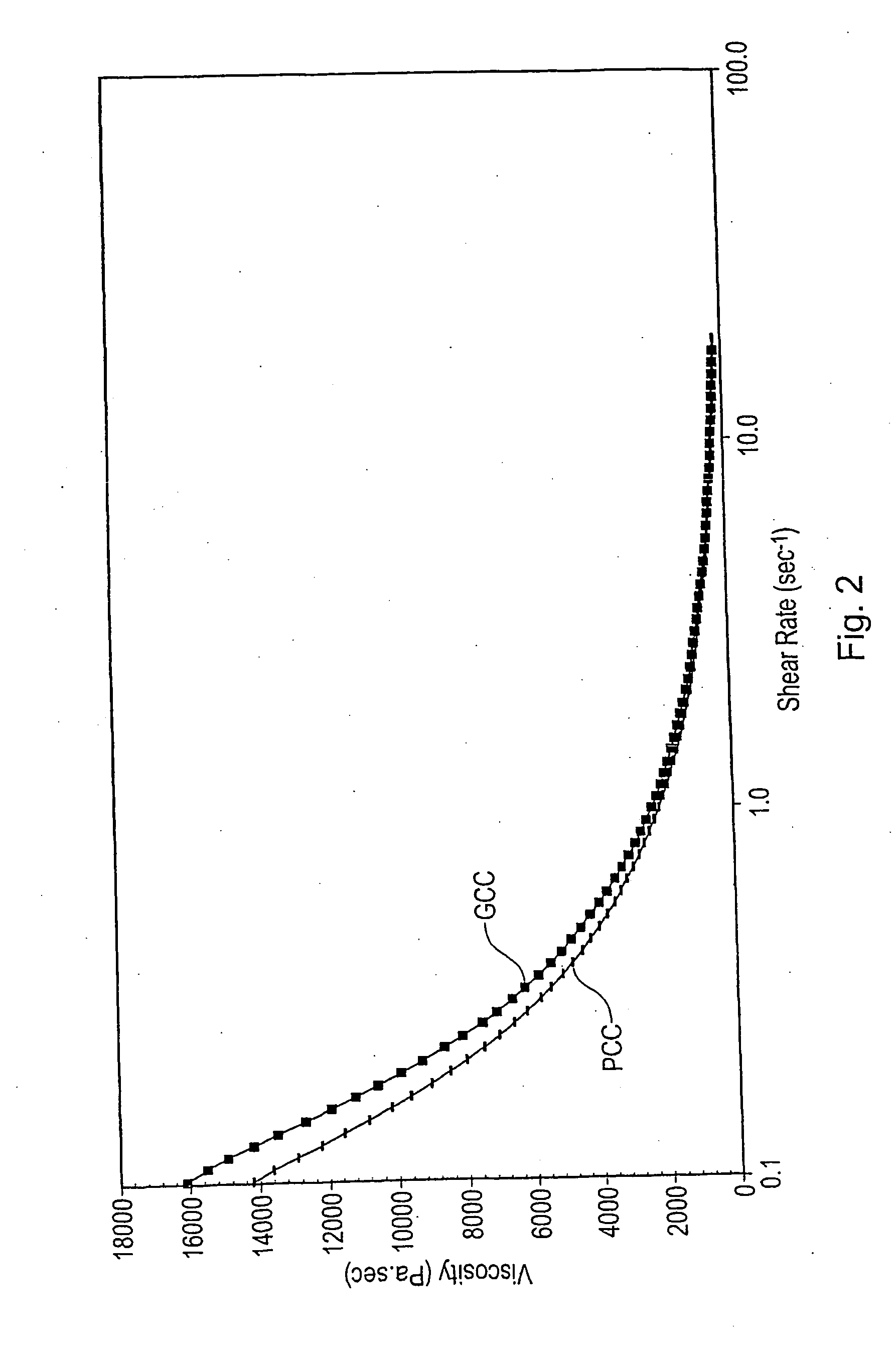

Natural particulate carbonate

InactiveUS20070167531A1Desirable mechanical propertyDesirable rheological propertyCalcium/strontium/barium carbonatesOther chemical processesParticulatesAlkaline earth metal

Owner:IMERYS MINERALS

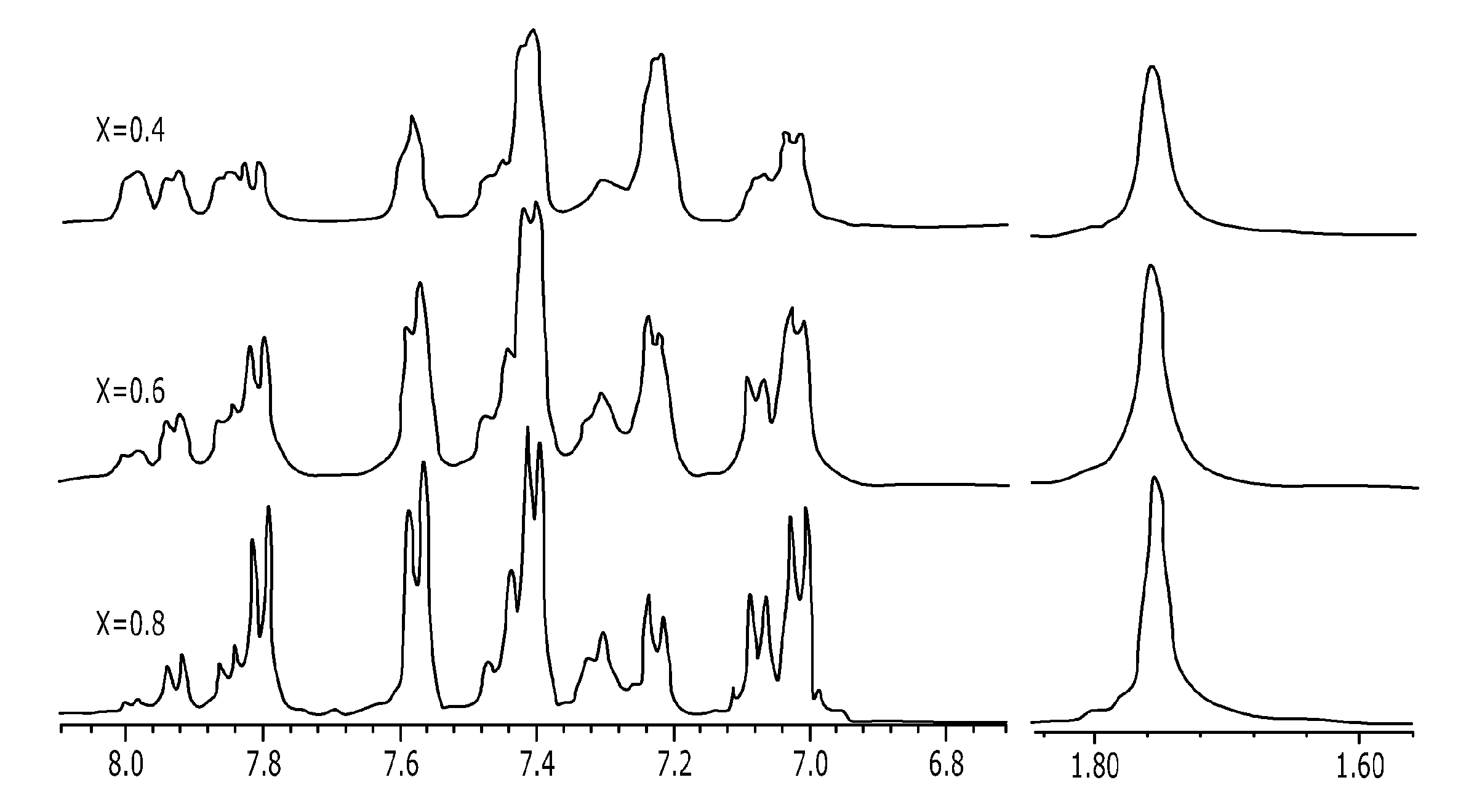

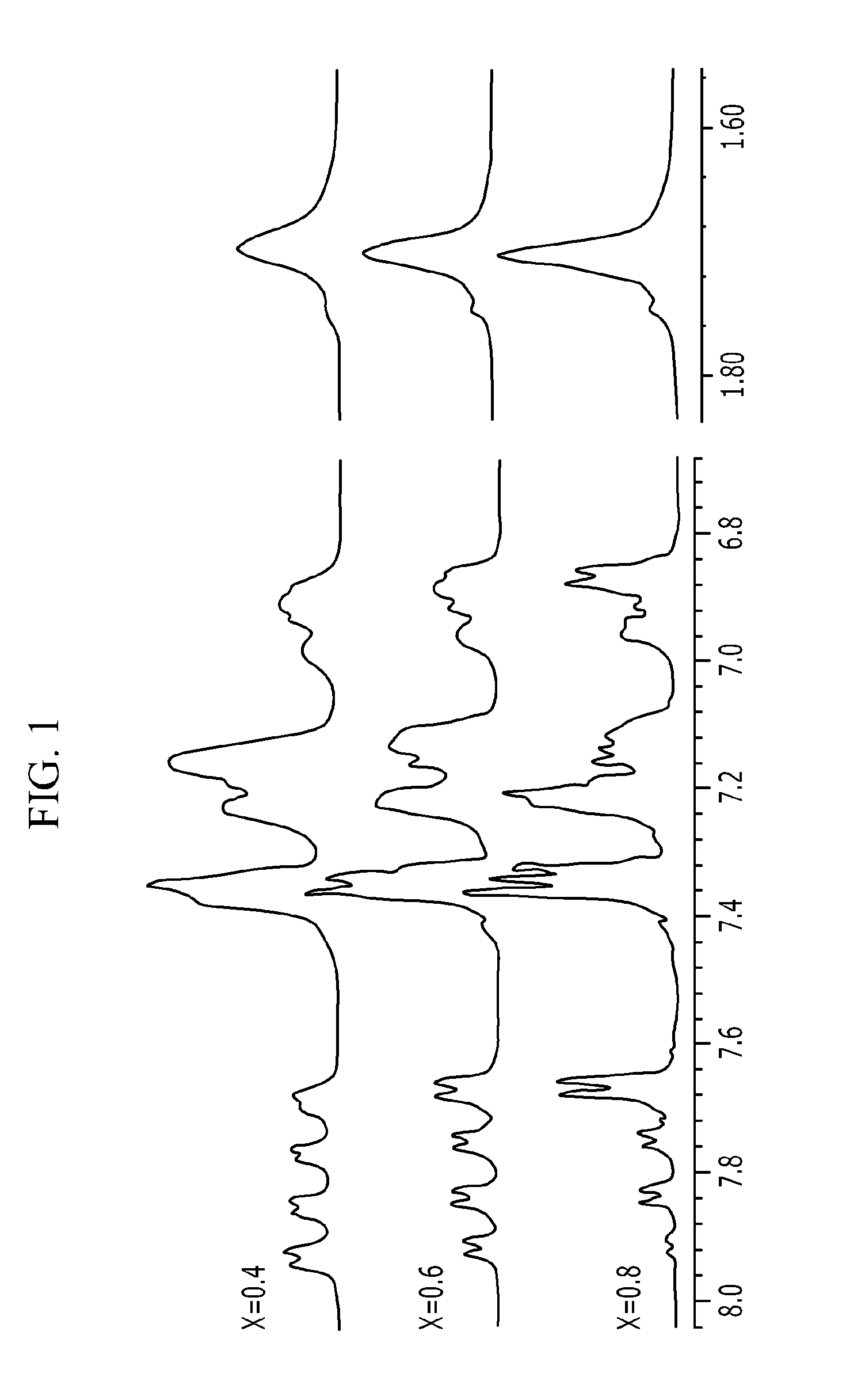

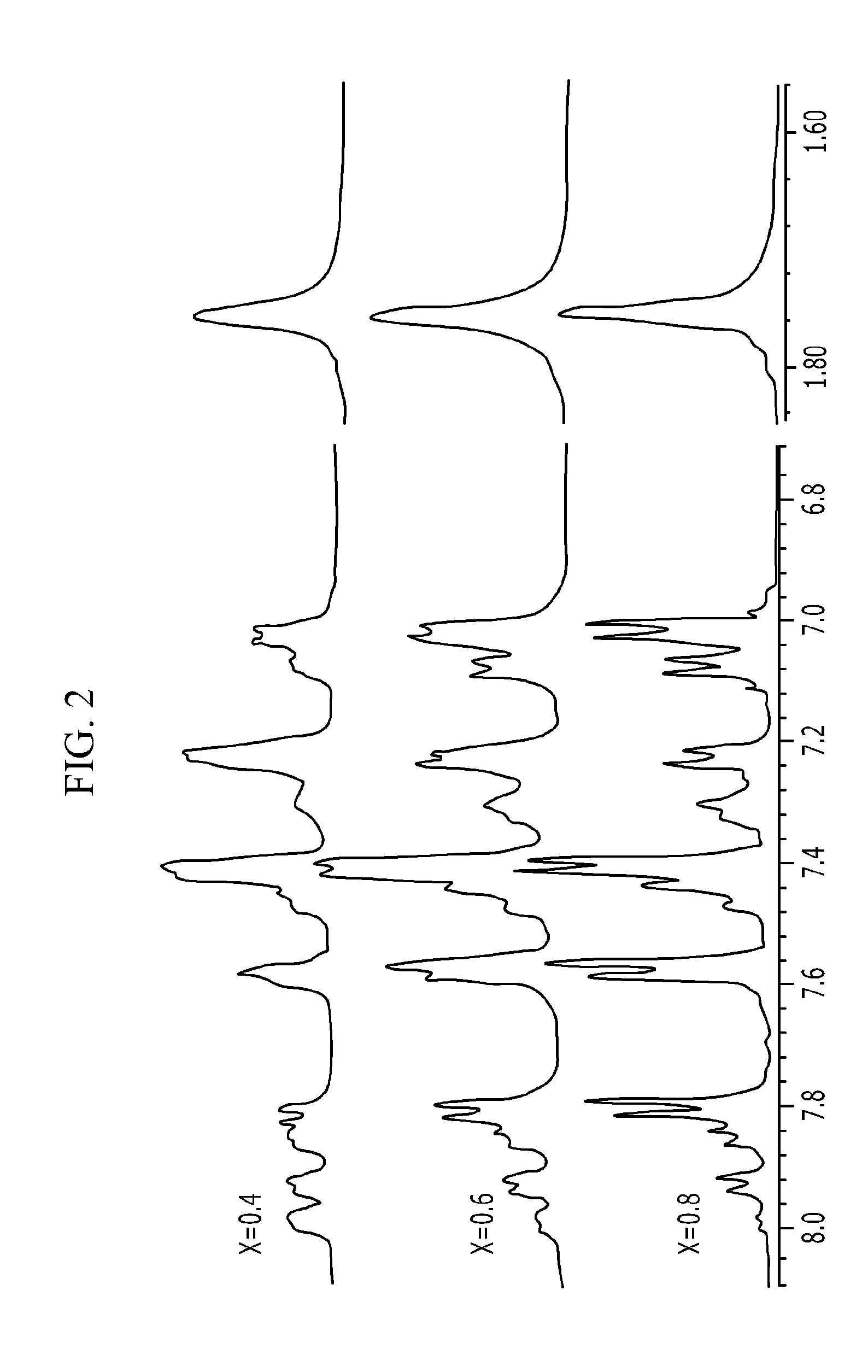

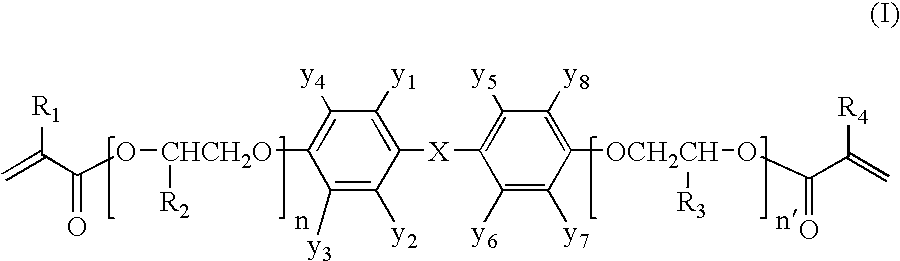

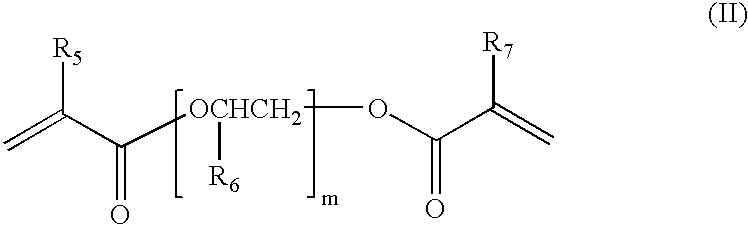

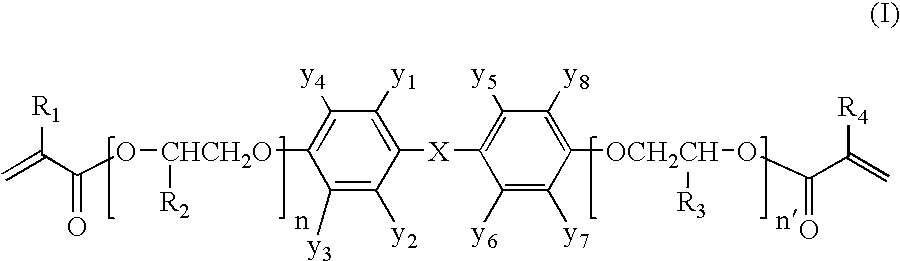

High index curable photochromic composition and its process

InactiveUS6933325B2Excellent optical propertiesDesirable mechanical propertyImpression capsDiffusing elementsRefractive indexPhotoinitiator

A high refractive index, curable, synthetic resin composition comprising a core resin composition composed of a mixture of ethylenically unsaturated compounds, and an initiation system containing both photo and thermal initiators, particularly a photochromic resin composition which further includes at least one photochromic dye. Also a curing process, which includes a combination of multi-step radiation curing and thermal annealing. Articles produced of cured composition exhibit superior physical and, in appropriate cases, photochromic properties and can be easily mass produced on a commercial scale due to short processing time and use of readily available chemicals.

Owner:RODENSTOCK GMBH +1

Electrophoretic display and process for its manufacture

InactiveUS20060164715A1Continuous preparationCost-effectiveMicroballoon preparationNon-linear opticsElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

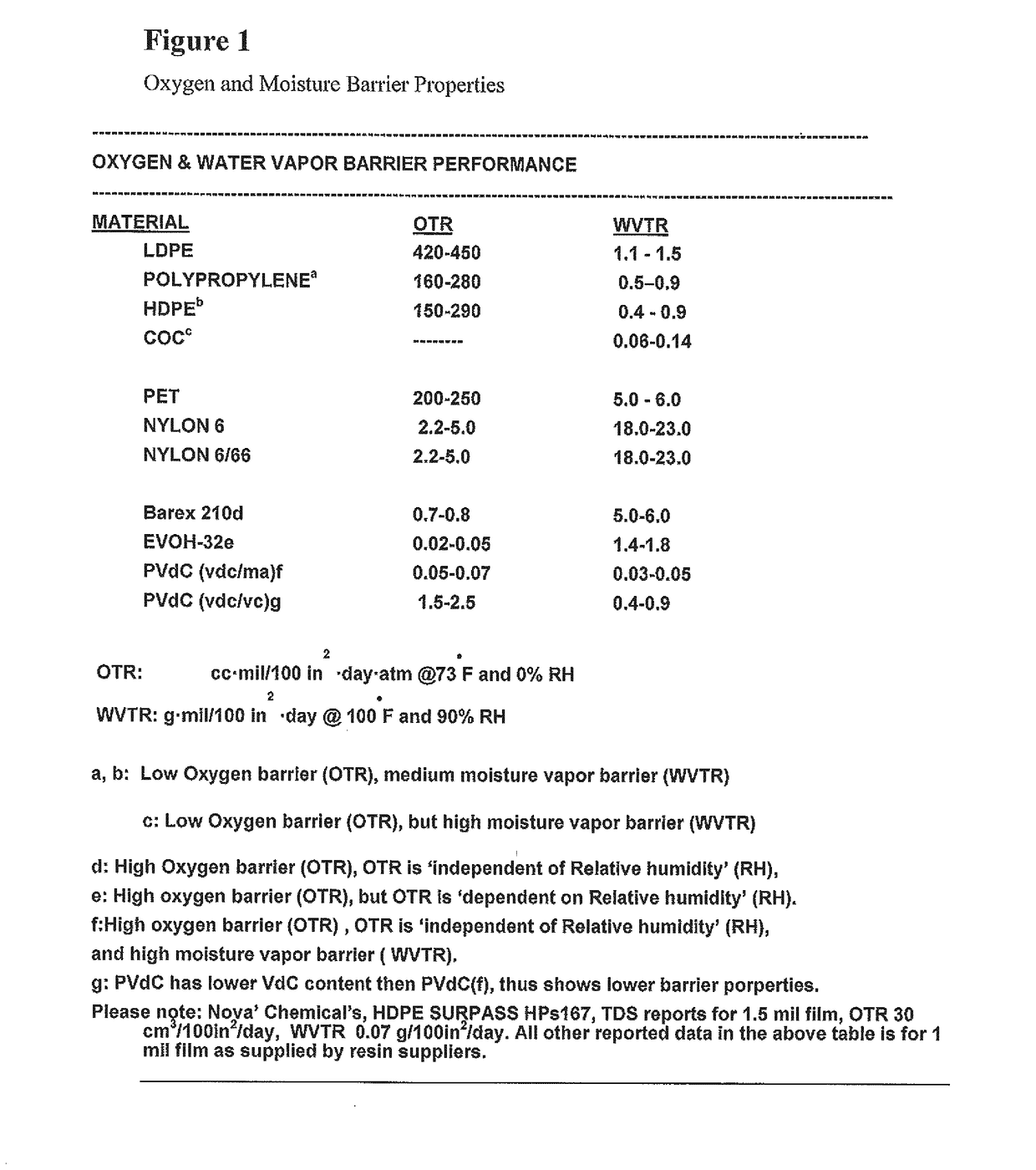

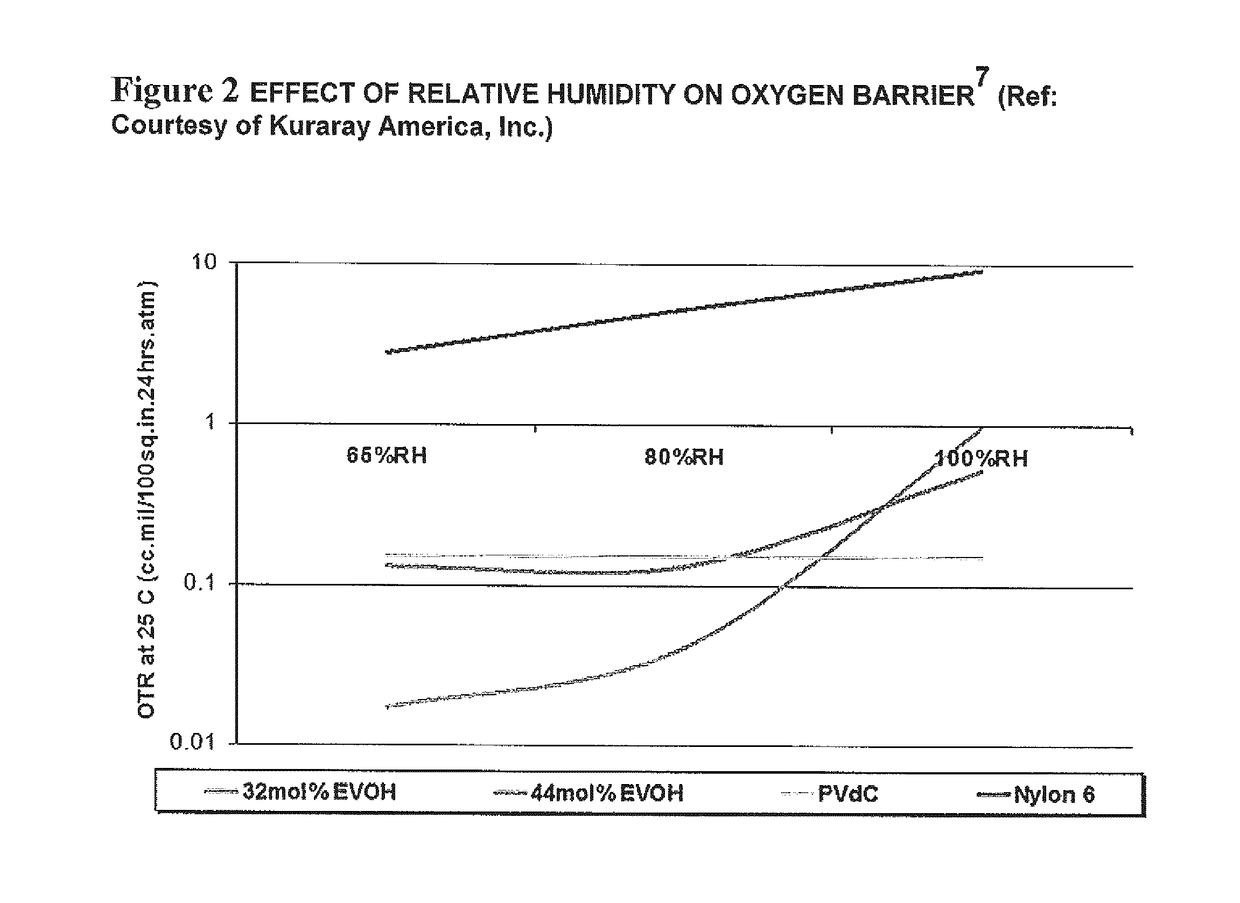

Multilayer plastic film

InactiveUS20170361582A1High strengthDesirable mechanical propertyFlexible coversWrappersPlastic filmSealant

A novel multilayer plastic film is provided comprising a series of component layers and optionally bonding layers to tie said component layers together, said component layers comprising: a central oxygen barrier layer, a first polymeric barrier layer on a first side of said central oxygen barrier layer, a second polymeric barrier layer on a second side of said central oxygen barrier layer, an outer layer adjacent the first polymeric barrier layer for providing mechanical strength, and a sealant layer adjacent the second polymeric barrier layer. At least one layer comprises two different polymers.

Owner:MACRO TECH

Peptide amphiphiles and methods to electrostatically control bioactivity of the ikvav peptide epitope

ActiveUS8748569B2Improve the display effectDecrease of bioactivityNervous disorderPeptide/protein ingredientsSolubilityIn vivo

The present invention is directed to peptide amphiphile compounds, compositions and methods of use, wherein nanofiber bundling or epitope aggregation is inhibited. In certain embodiments, the peptide amphiphiles of the present invention have increased solubility and reduced nanofiber bundling. The molecules may be used in pharmaceutical applications, for example for in vivo administration to human patients, by increasing biological activity of the compositions toward neurite outgrowth and nerve regeneration.

Owner:NORTHWESTERN UNIV

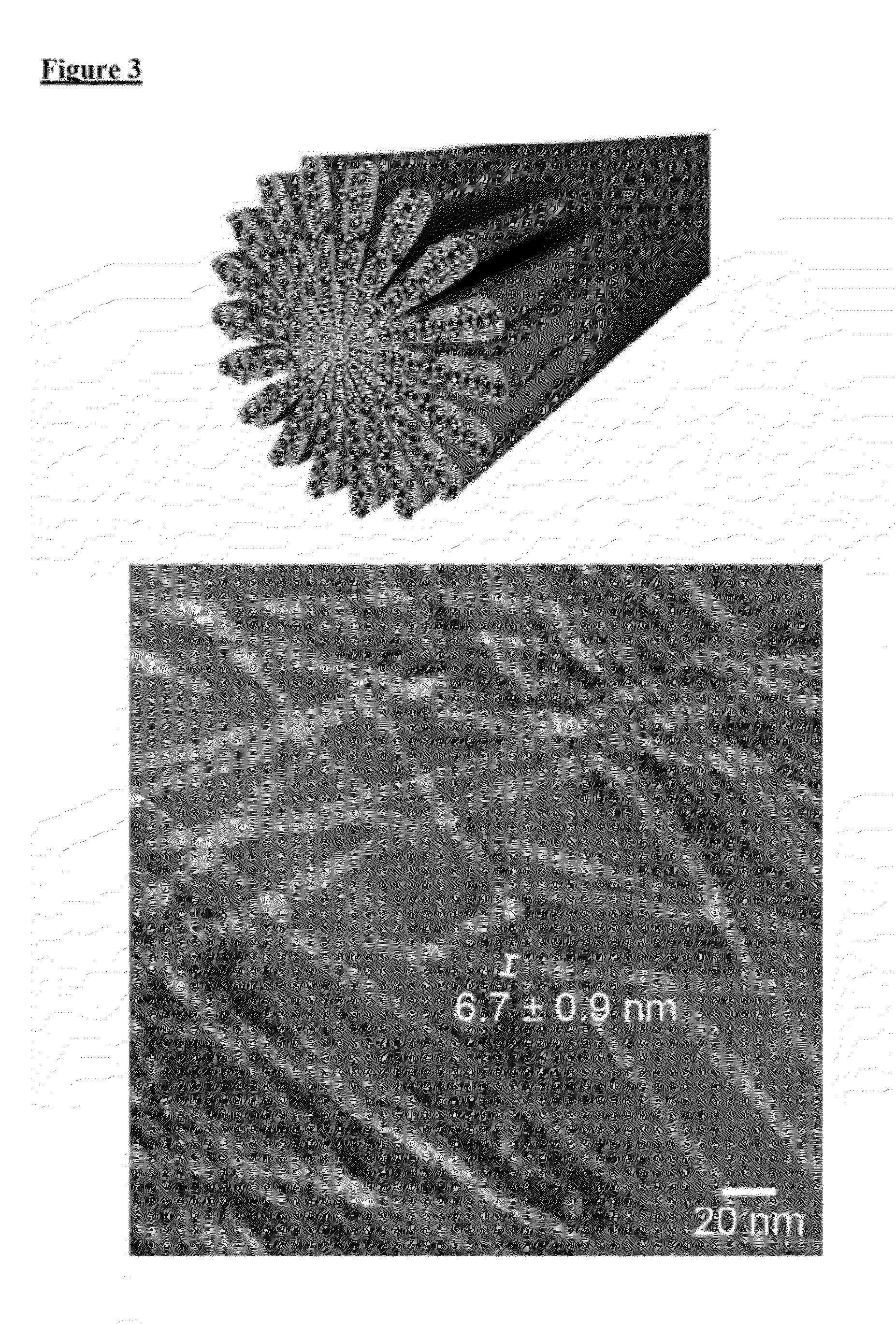

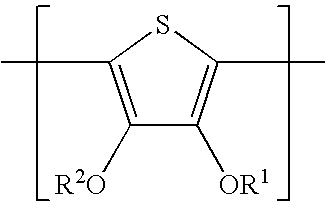

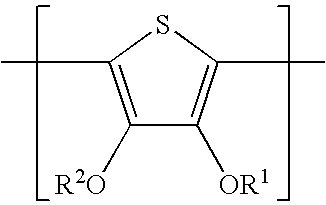

Conductive polymers on acicular substrates

InactiveUS7163746B2High aspect ratioLow costNon-insulated conductorsLiquid surface applicatorsConductive polymerMonomer

The present invention relates to an electronically conductive particle comprising an acicular substrate in contact with an electronically conductive polymer. Another embodiment comprises an article comprising electronically conductive particles comprising an acicular substrate in contact with an electronically conductive polymer. A further embodiment comprises a method for making electronically conductive particles comprising providing at least one acicular substrate, combining at least one monomer with said at least one acicular substrate, and mixing at least one catalyst with said at least one acicular substrate and said at least one monomer.

Owner:EASTMAN KODAK CO

Ultra-fast boriding of metal surfaces for improved properties

ActiveUS20130056363A1Fast boridingDesirable mechanical propertySolid state diffusion coatingBoridingUltra fast

A method of ultra-fast boriding of a metal surface. The method includes the step of providing a metal component, providing a molten electrolyte having boron components therein, providing an electrochemical boriding system including an induction furnace, operating the induction furnace to establish a high temperature for the molten electrolyte, and boriding the metal surface to achieve a boride layer on the metal surface.

Owner:UCHICAGO ARGONNE LLC

Low IV pet based copolymer preform with enhanced mechanical properties and cycle time, container made therewith and methods

InactiveUS7572493B2Raise the draw ratioDesirable mechanical propertyEnvelopes/bags making machineryBottlesDiethylene glycolDiol

A preform having a low IV and including a PET Copolymer including a diol component having repeat units from ethylene glycol and diethylene glycol and a diacid component having repeat units from terephthalic acid and naphthalenedicarboxylic acid. The total amount of diethylene glycol and naphthalenedicarboxylic acid is present in the poly(ethylene terephthalate) copolymer in an amount from about 0.1 mole percent to less than 2.8 mole percent. The preform is useful in making containers and corresponding methods are disclosed.

Owner:THE COCA COLA CO

Binder for mineral wool products

InactiveUS7459490B2Increase temperatureDesirable mechanical propertyCosmetic preparationsToilet preparationsCarboxylic acidCOTTON WOOL

Process for providing a binder for mineral wool products, said process comprising the steps of: mixing together under reactive conditions a carboxylic acid with an alkanolamine, whereby optionally these are firstly mixed to provide a resin, which resin is subsequently reacted with a separate carboxylic acid group containing polymer.

Owner:ROCKWOOL INT AS

Electrophoretic display and process for its manufacture

InactiveUS20060082864A1Improve the display effectImprove optical and physicomechanical propertyMaterial analysis by electric/magnetic meansNon-linear opticsElectrophoresisDisplay device

Owner:E INK CALIFORNIA

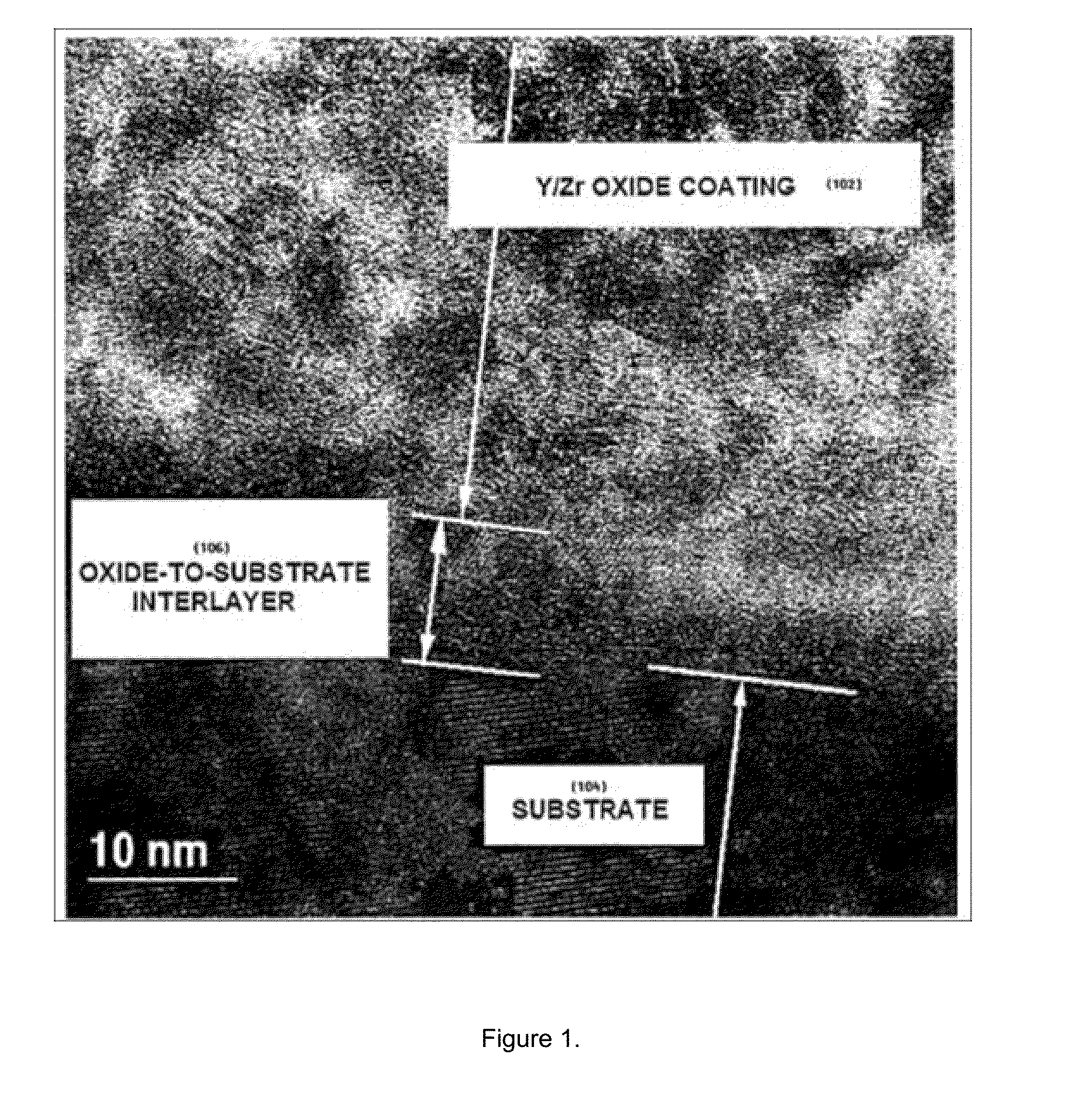

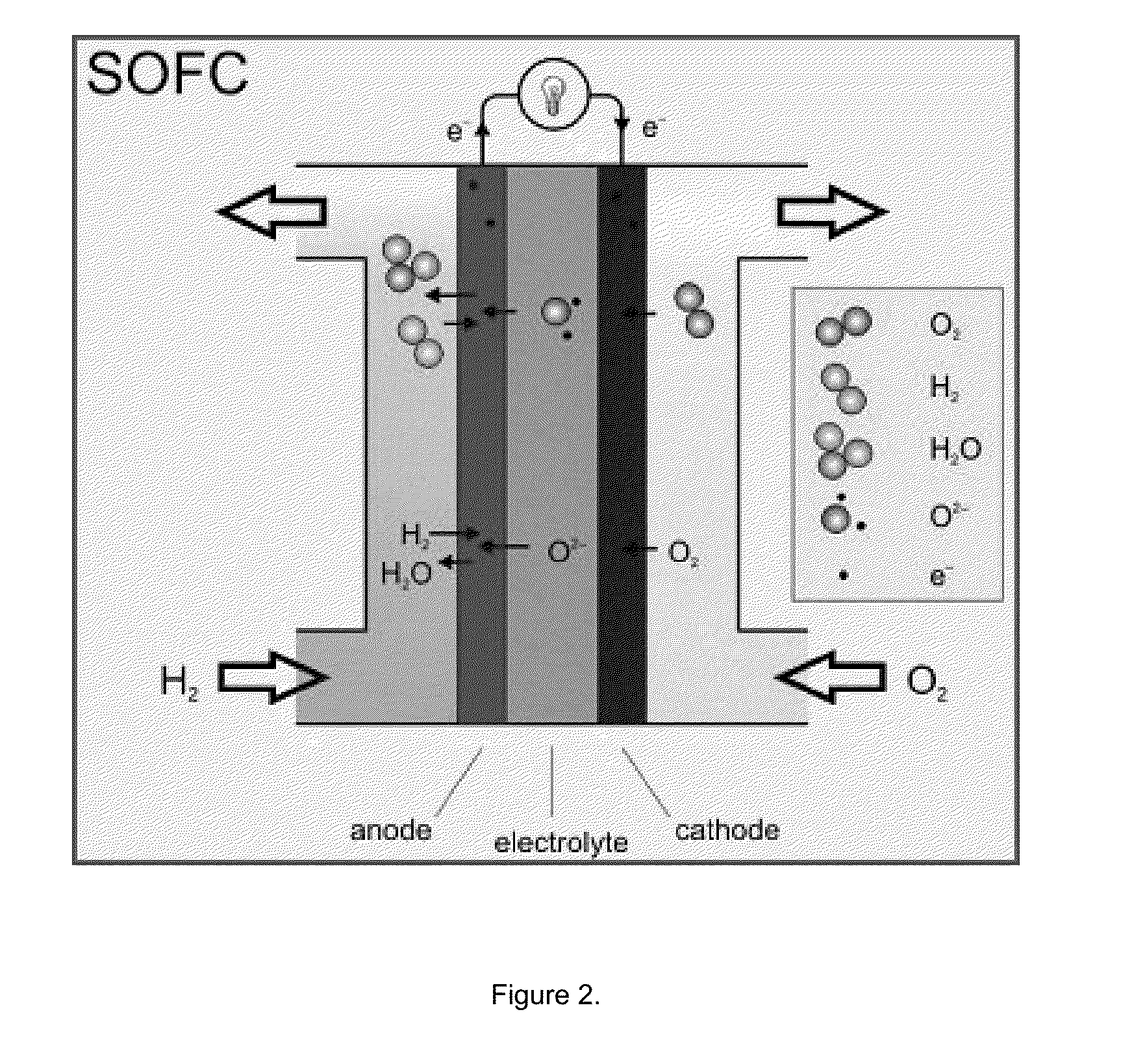

Low Temperature Electrolytes for Solid Oxide Cells Having High Ionic Conductivity

InactiveUS20160168734A1Simpler and less-expensive materialImprove ionic conductivityCellsFuel cell shape/formFuel cellsMaterials science

Methods for forming a metal oxide electrolyte improve ionic conductivity. Some of those methods involve applying a first metal compound to a substrate, converting that metal compound to a metal oxide, applying a different metal compound to the metal oxide, and converting the different metal compound to form a second metal oxide. Electrolytes so formed can be used in solid oxide fuel cells, electrolyzers, and sensors, among other applications.

Owner:FCET +1

Multi-layered films oriented in the machine direction and articles comprising the same

InactiveUS20180134012A1Desirable mechanical propertyDesirable tear strengthSynthetic resin layered productsDomestic containersDrawing ratioSingle site

The present invention provides uniaxially oriented films and packages formed from such films. In one aspect, a uniaxially oriented film comprises (a) a first layer comprising a polyolefm plastomer having a density of 0.865 to 0.908 g / cm3 and a melt index (I2) of 0.5-6 g / 10 minutes, and at least one of a single-site catalyzed linear low density polyethylene having a density of 0.912 g / cm3 to 0.935 g / cm3 and a melt index (I2) of 0.5 to 6 g / 10 minutes, or a Ziegler-Natta catalyzed ultra low density polyethylene having a density of 0.880 g / cm3 to 0.912 g / cm3, a melt index (I2) of 0.5 to 6 g / 10 minutes, and a MWD of 6.0 or less; (b) a second layer comprising a Ziegler-Natta catalyzed ultra low density polyethylene having a density of 0.880 g / cm3 to 0.912 g / cm3, a melt index (I2) of 0.5 to 6 g / 10 minutes, and a MWD of 6.0 or less; and (c) at least one inner layer between the first layer and the second layer comprising at least one polyolefin. The film is oriented in the machine direction at a draw ratio of between 4:1 and 10:1, and can exhibit a machine direction 2% secant modulus of 85,000 psi or more when measured as per ASTM D882.

Owner:DOW GLOBAL TECH LLC

Sealant having improved dynamic durability

ActiveUS20050234170A1Improved dynamic durabilityExcellent dynamic durabilitySpecial tyresMixingPolymer sciencePtru catalyst

An object of the present invention is to provide a low-modulus, high elongation sealant having improved dynamic durability, desirable mechanical properties, and good workability. The present invention provides a sealant containing an oxyalkylene polymer (A) having a number-average molecular weight of 20,000 to 50,000 and 0.8 or more of reactive silicon groups per molecule on average; 10 parts by weight or more of a plasticizer (B) per 100 parts by weight of the polymer (A); a filler (C); and a curing catalyst (D). This sealant has an improved durability and can achieve the above-described object.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com