Patents

Literature

230 results about "Draw ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

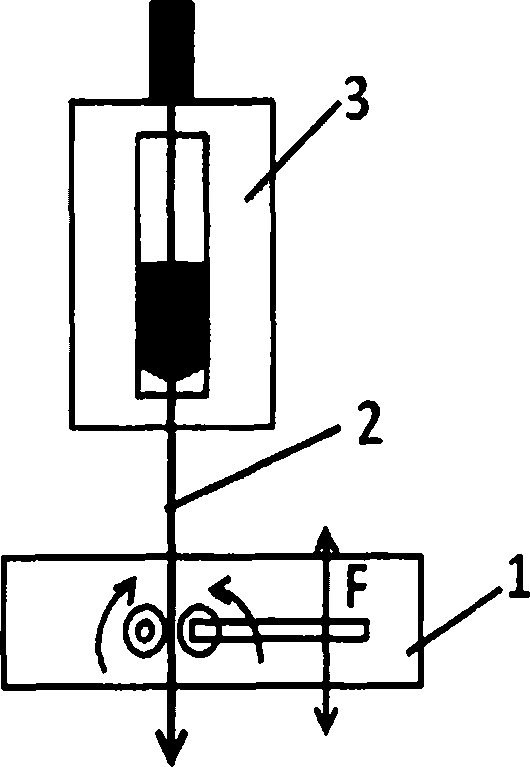

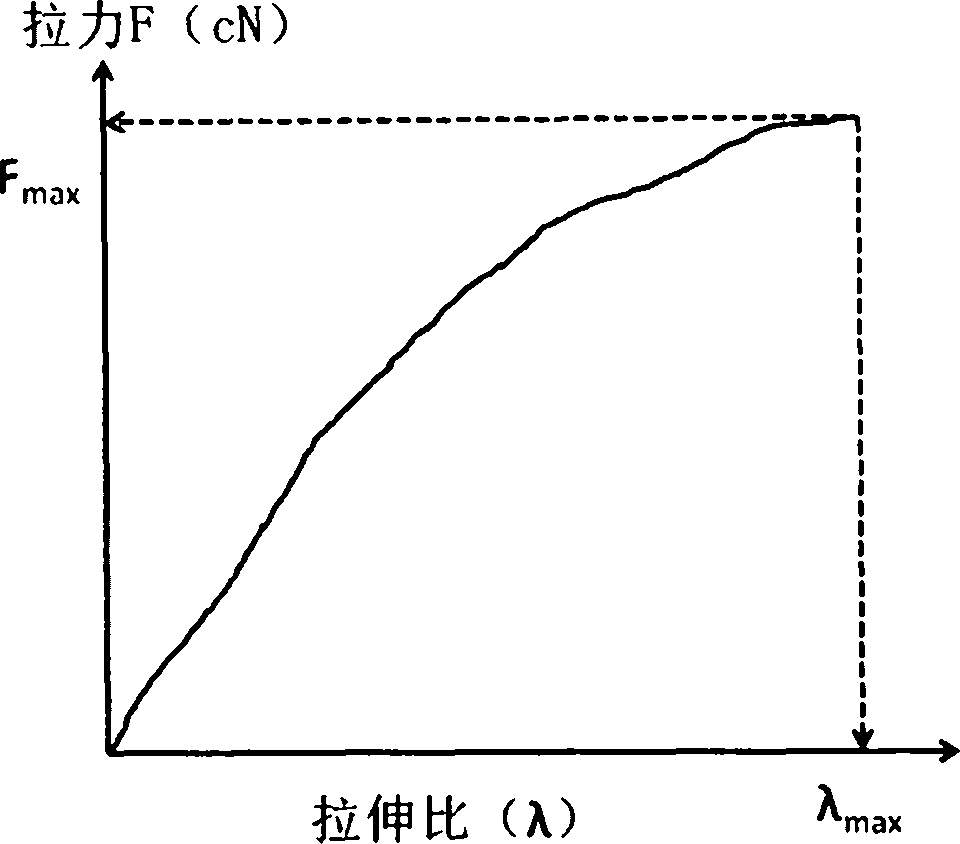

The draw ratio is the relationship between the size of the draw post and the size of the blank. The draw ratio must fall within acceptable limits to allow metal to flow. During forming, a blank is forced into circumferential compression, which creates a resistance to flow.

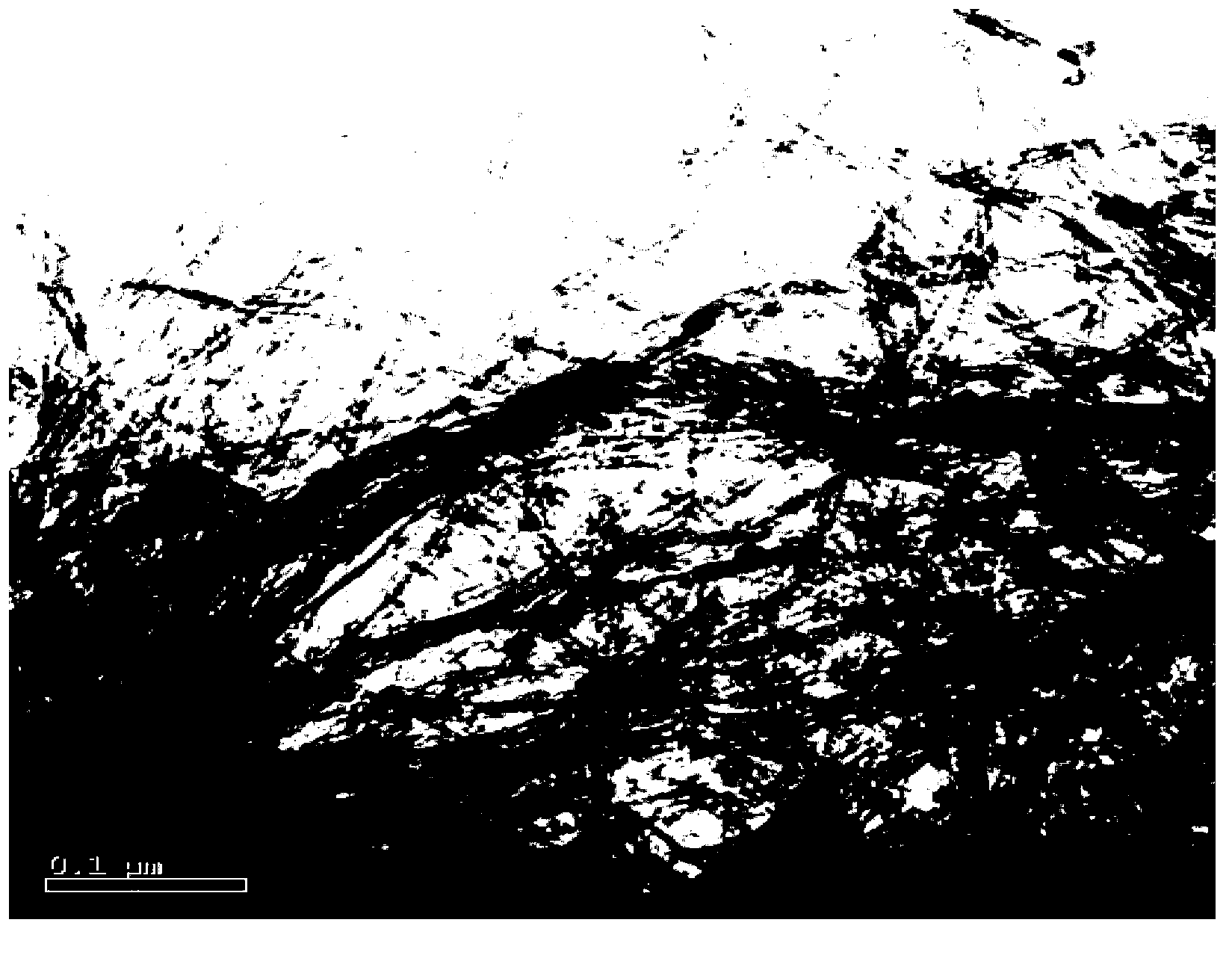

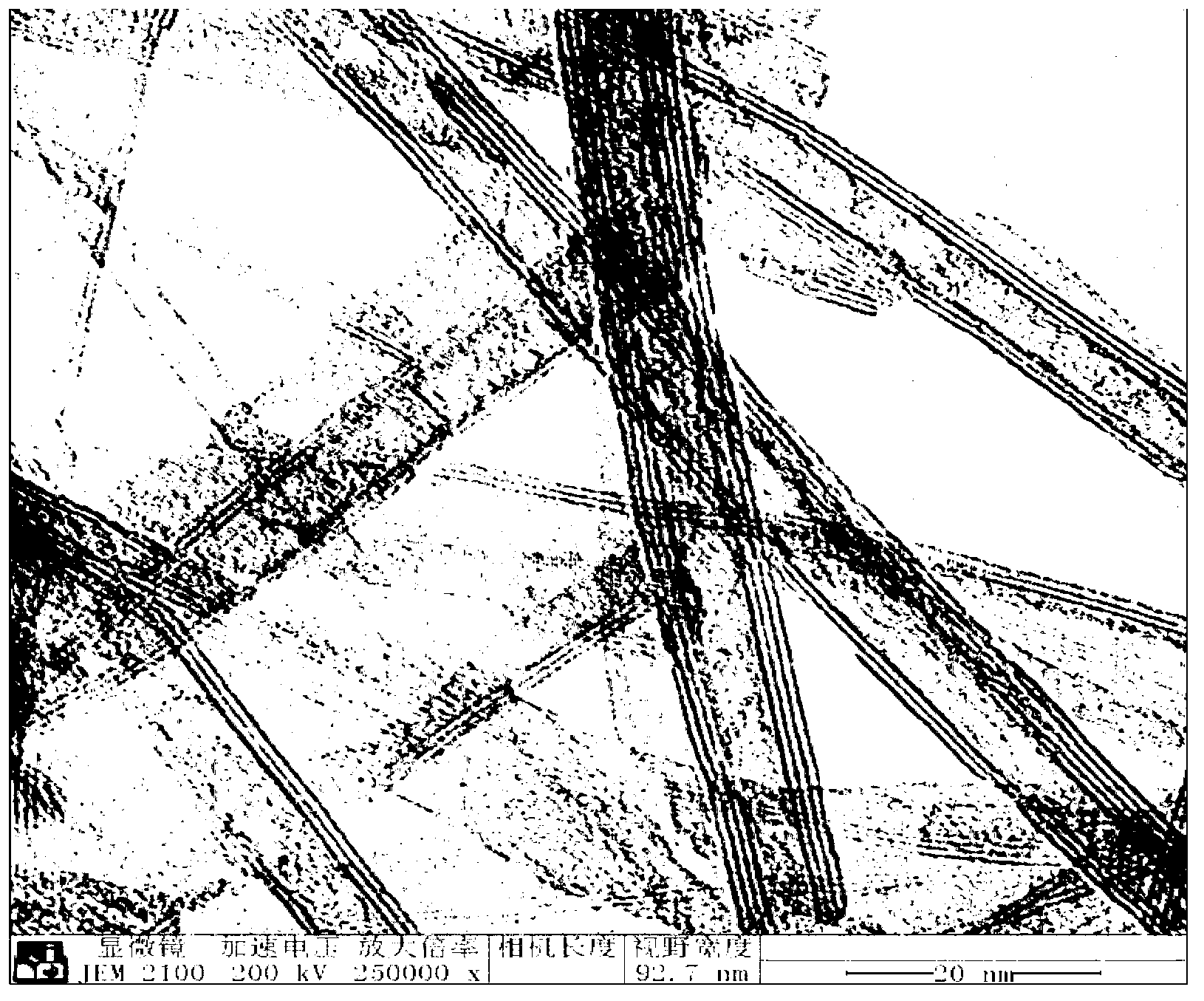

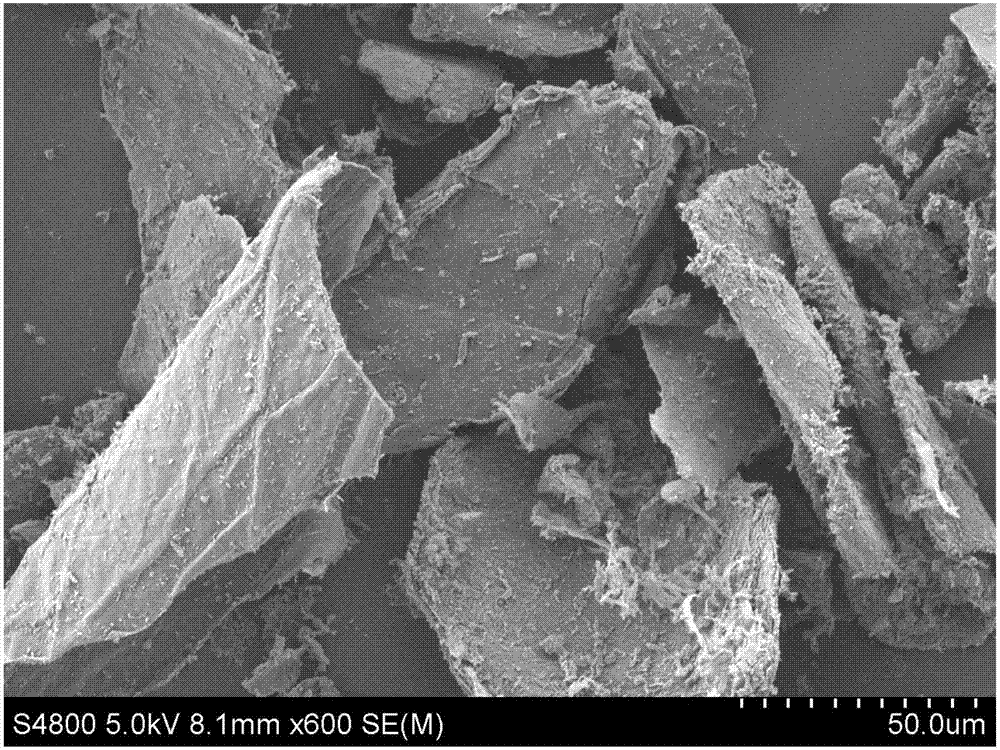

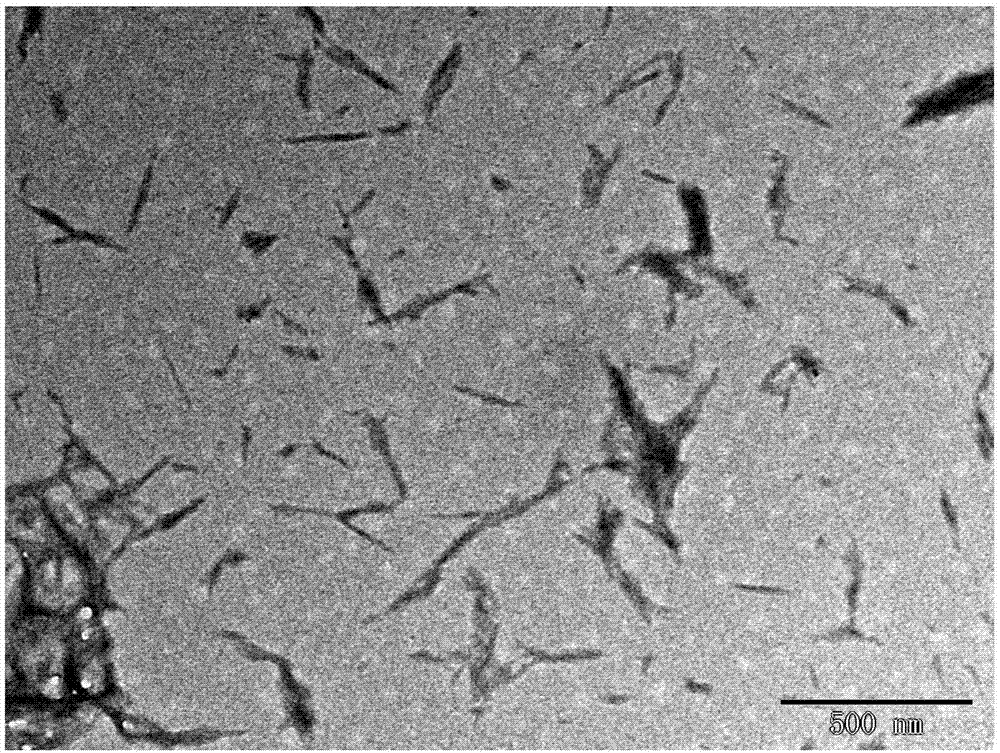

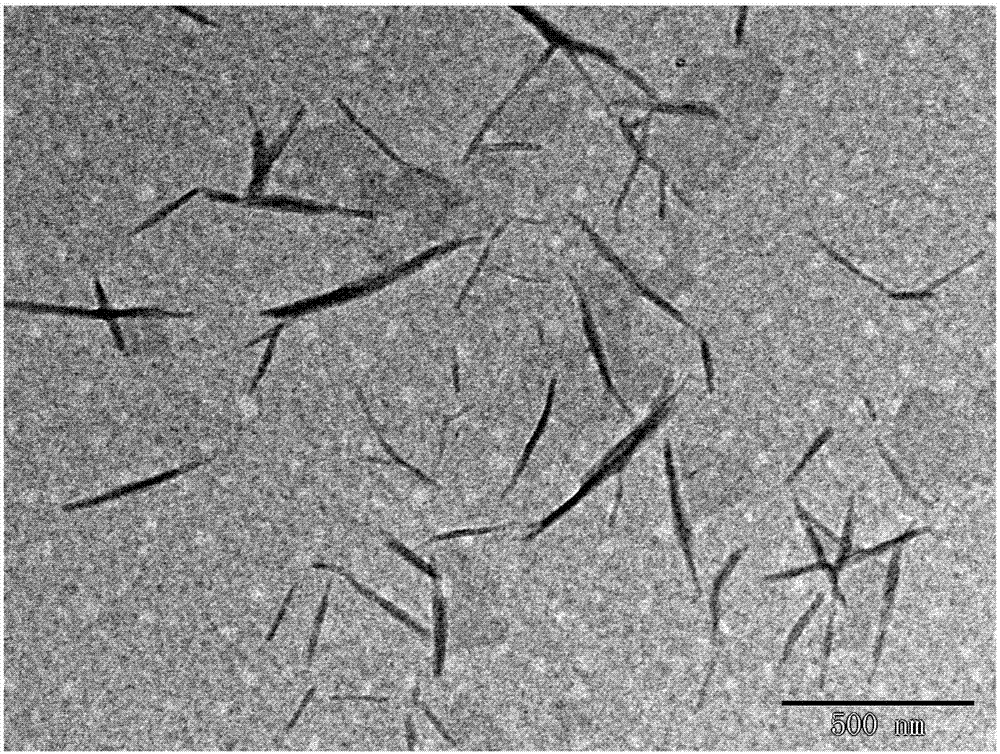

Preparation method of straw micro-nano cellulose

ActiveCN101949103AHigh aspect ratioLarge specific surface areaPaper material treatmentMicro nanoHydrolysis

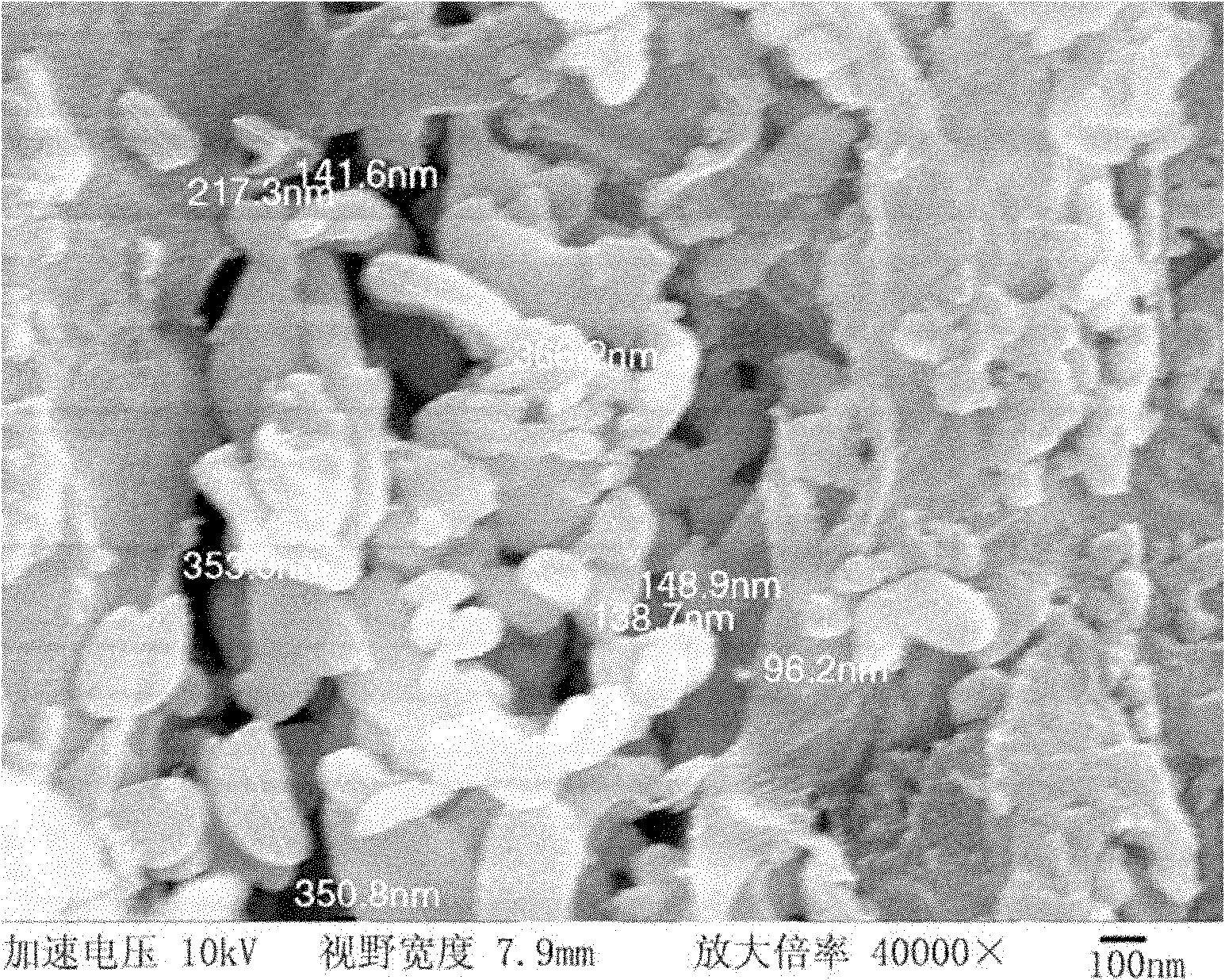

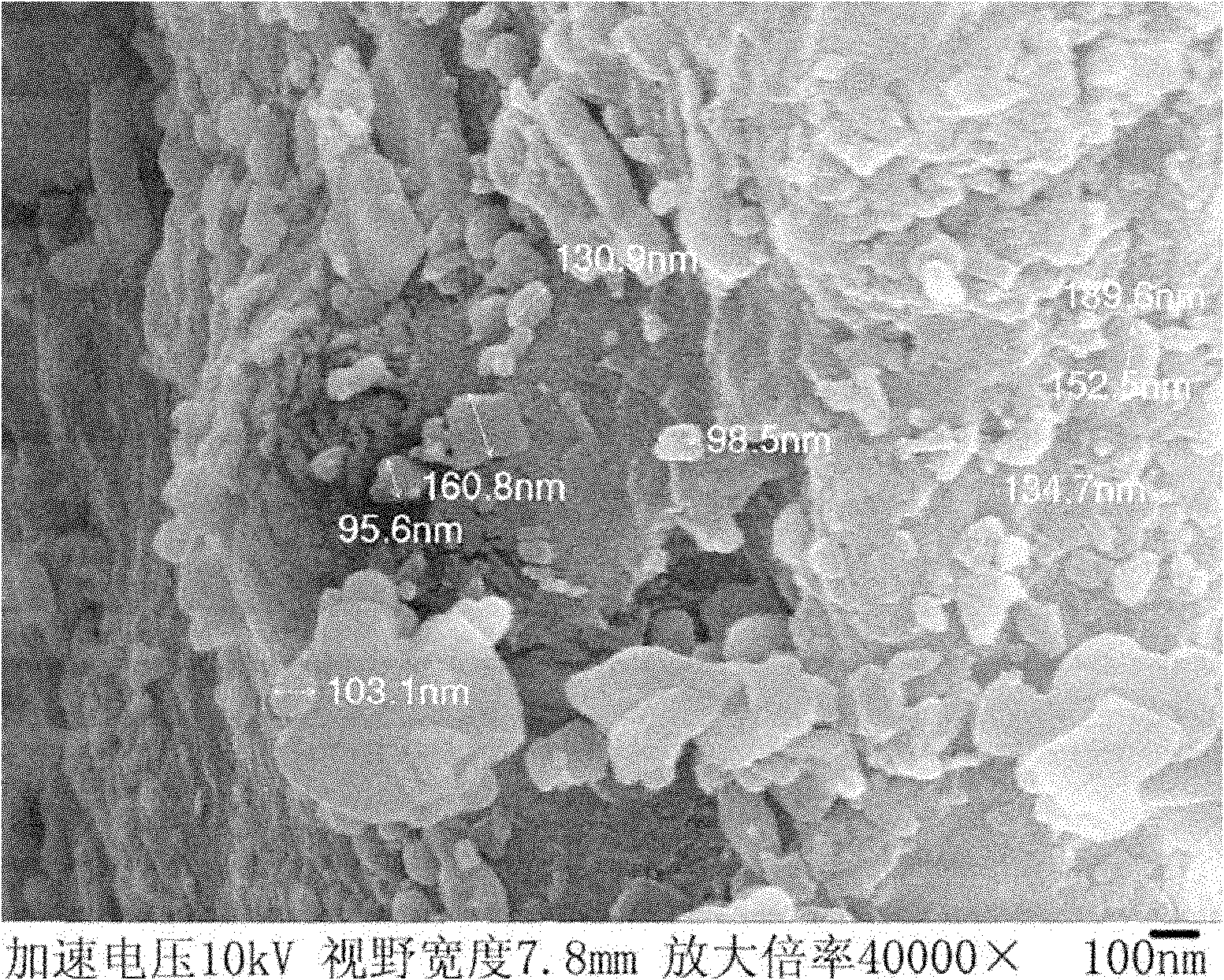

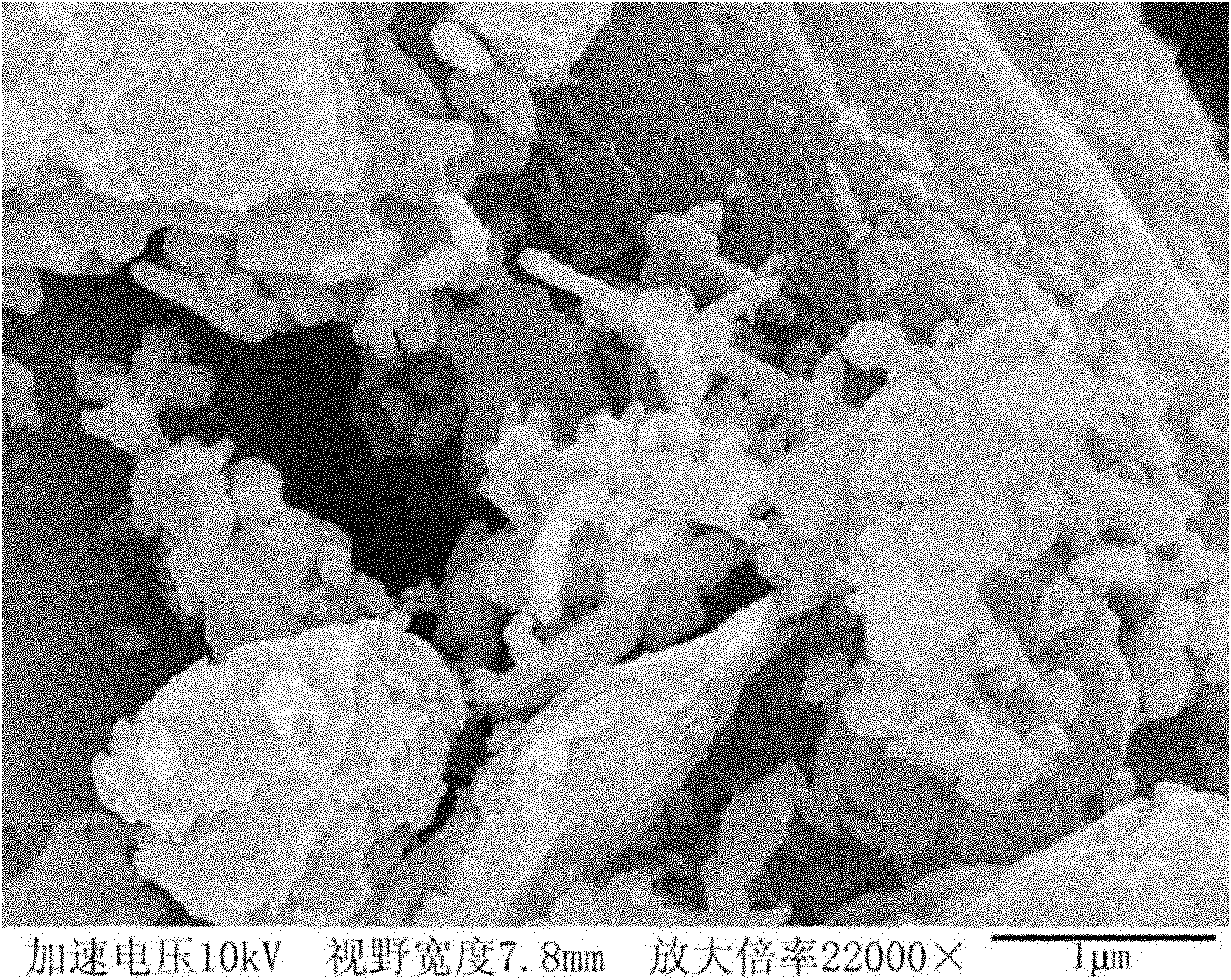

The invention discloses a preparation method of straw micro-nano cellulose, relating to a preparation method of micro-nano cellulose. The invention solves the problems that the prior art for preparing nano cellulose comprises more steps, and rodlike nano cellulose has low draw ratio. The preparation method is as follows: 1, stewing; 2, dipping and washing; 3, screening; 4, bleaching; 5, carrying out hydrolysis and supersonic treatment; and 6, neutralizing, rinsing, breaking, decentralizing and drying to obtain the straw micro-nano cellulose. The micro-nano cellulose prepared by the preparation method of the invention has fibroid appearance, has the diameter of 10-200 nm and the length of 200-10 mu m, and has high draw ratio and large specific surface area. The invention is applied to the field of composite materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Belt-creped, variable local basis weight multi-ply sheet with cellulose microfiber prepared with perforated polymeric belt

ActiveUS20120021178A1High absorbency (SAT)Eliminate needMechanical working/deformationLayered productsPaper towelEngineering

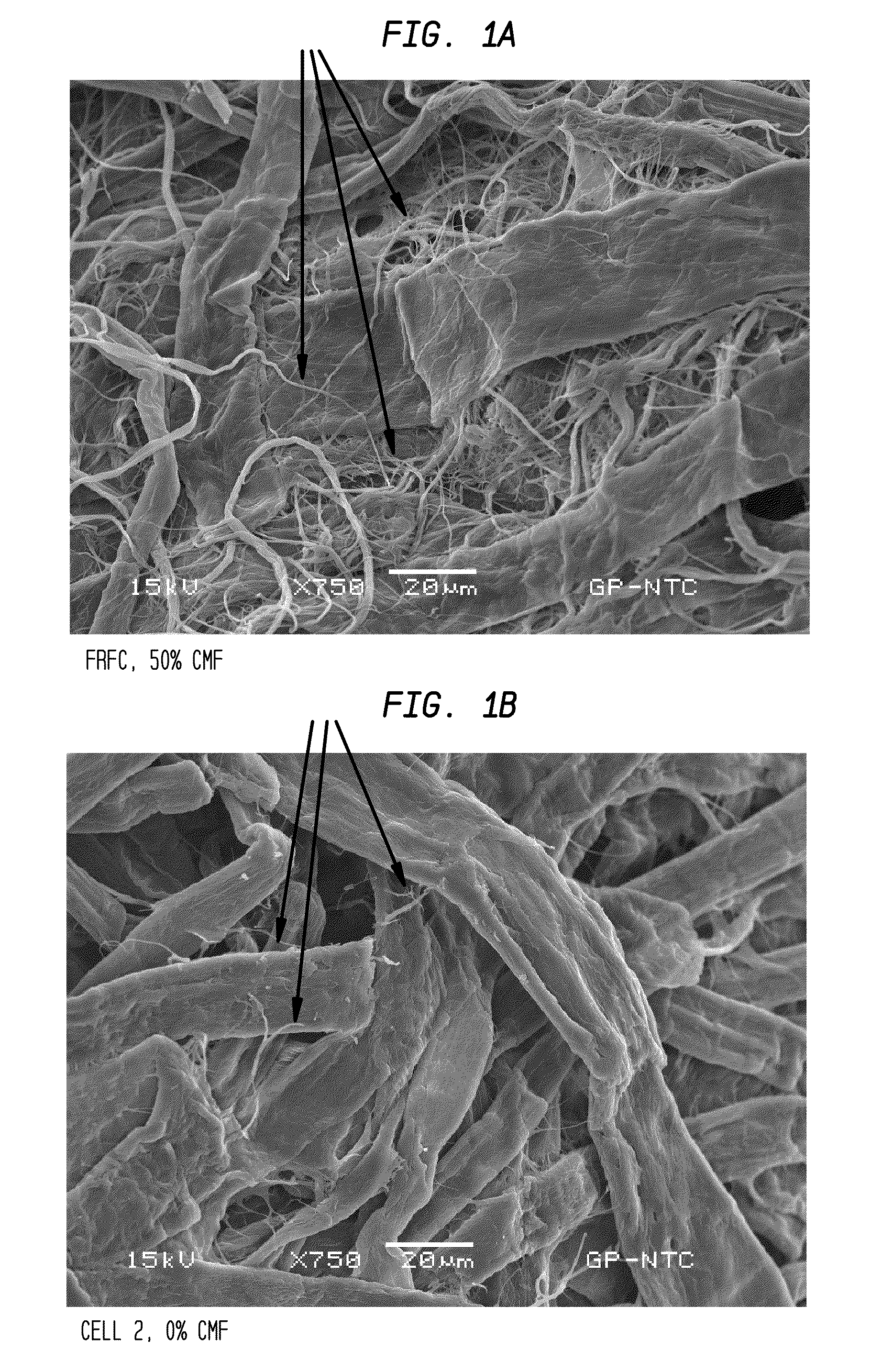

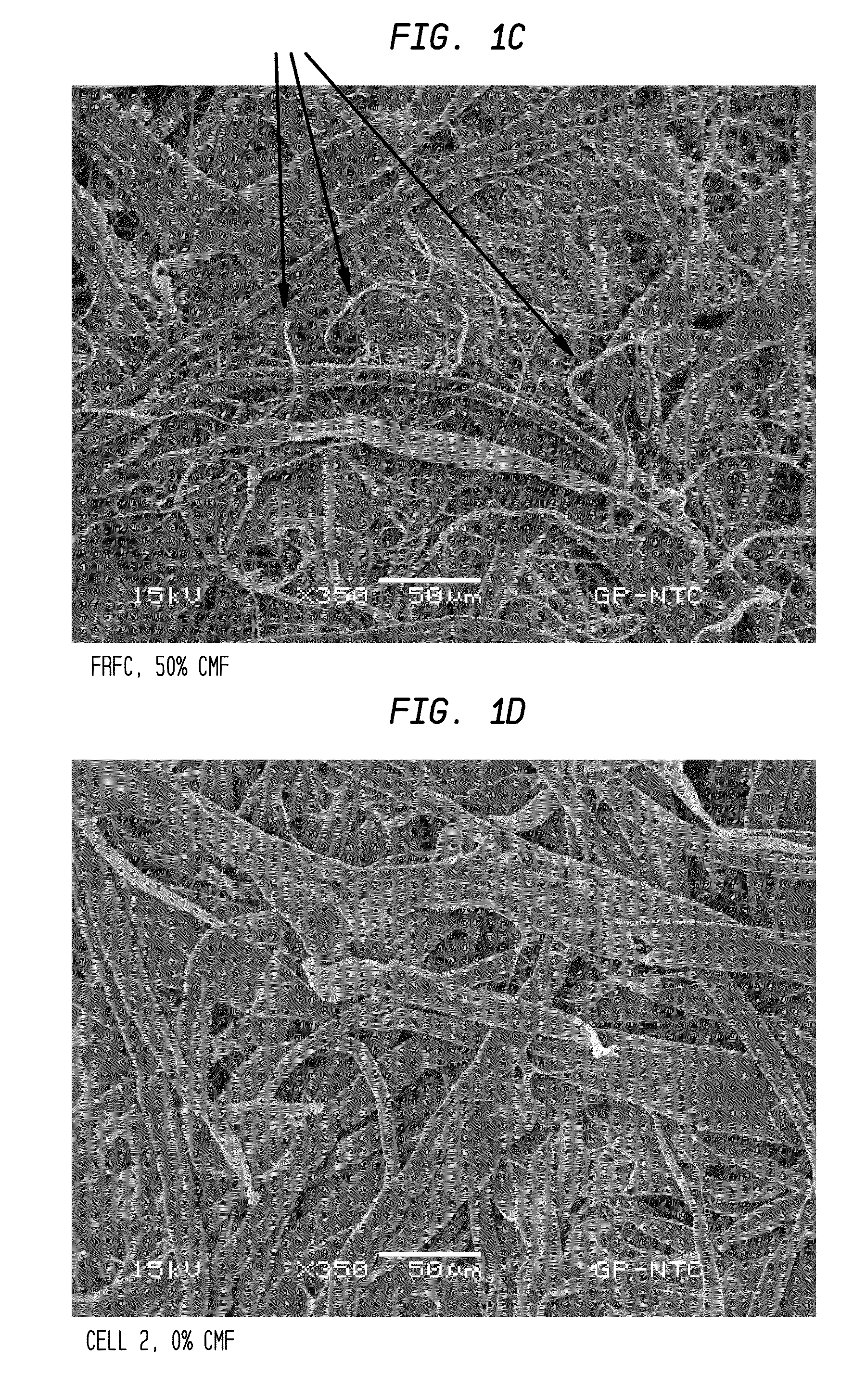

A multi-ply absorbent sheet includes at least a first and second ply bonded together. In one construction, the first and second ply are provided with from about 90% by weight to about 25% by weight pulp-derived papermaking fiber and from about 10% to about 75% by weight fibrillated regenerated cellulosic microfiber having a characteristic CSF value of less than 175 ml; the sheet having a caliper of from 180-250 mils / 8 sheets and exhibiting a wipe-dry time of less than 20 seconds, an SAT capacity in the range of 350-500 g / m2, an SAT rate in the range of 0.05-0.25 g / s0.5, a CD wet tensile in the range of 400-2500 g / 3″ and a wet / dry CD tensile ratio of from 35% to 60%. The multi-ply sheets are efficient, high capacity wipers and have enough absorbent capacity to be used as ordinary paper towels. Preferred wiper towel products exhibit a differential pore volume for pores under 5 microns in diameter of at least about 75 mm3 / g / micron.

Owner:GPCP IP HLDG LLC

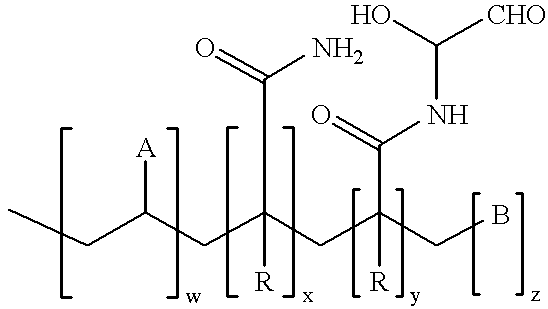

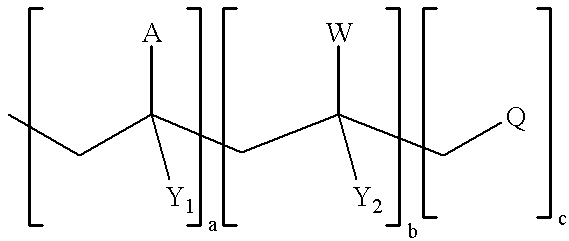

Process for making a yarn having a spin finish

InactiveUS6908579B2Enhances yarn processabilityImprove mechanical qualityFibre typesPneumatic tyre reinforcementsYarnEngineering

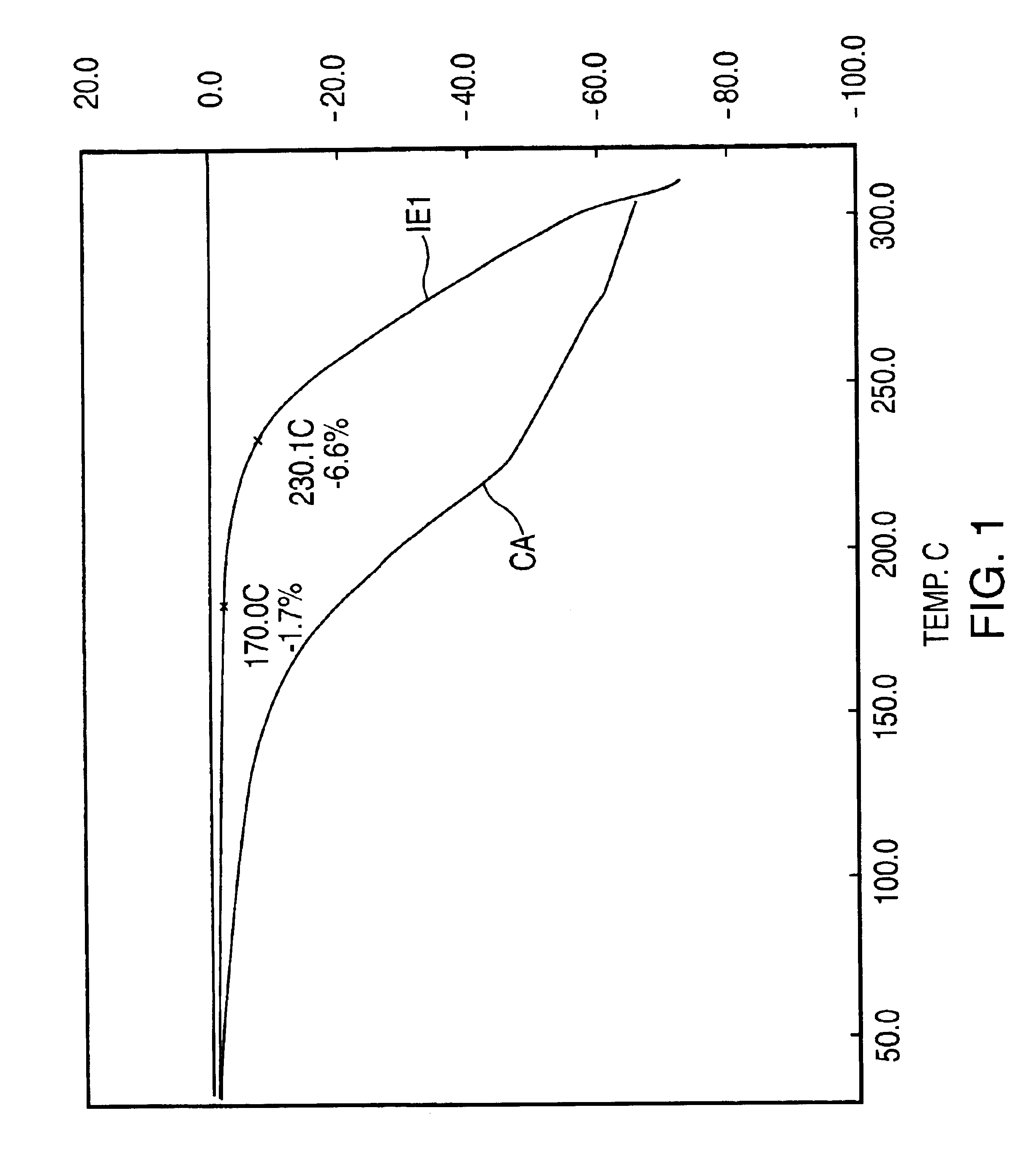

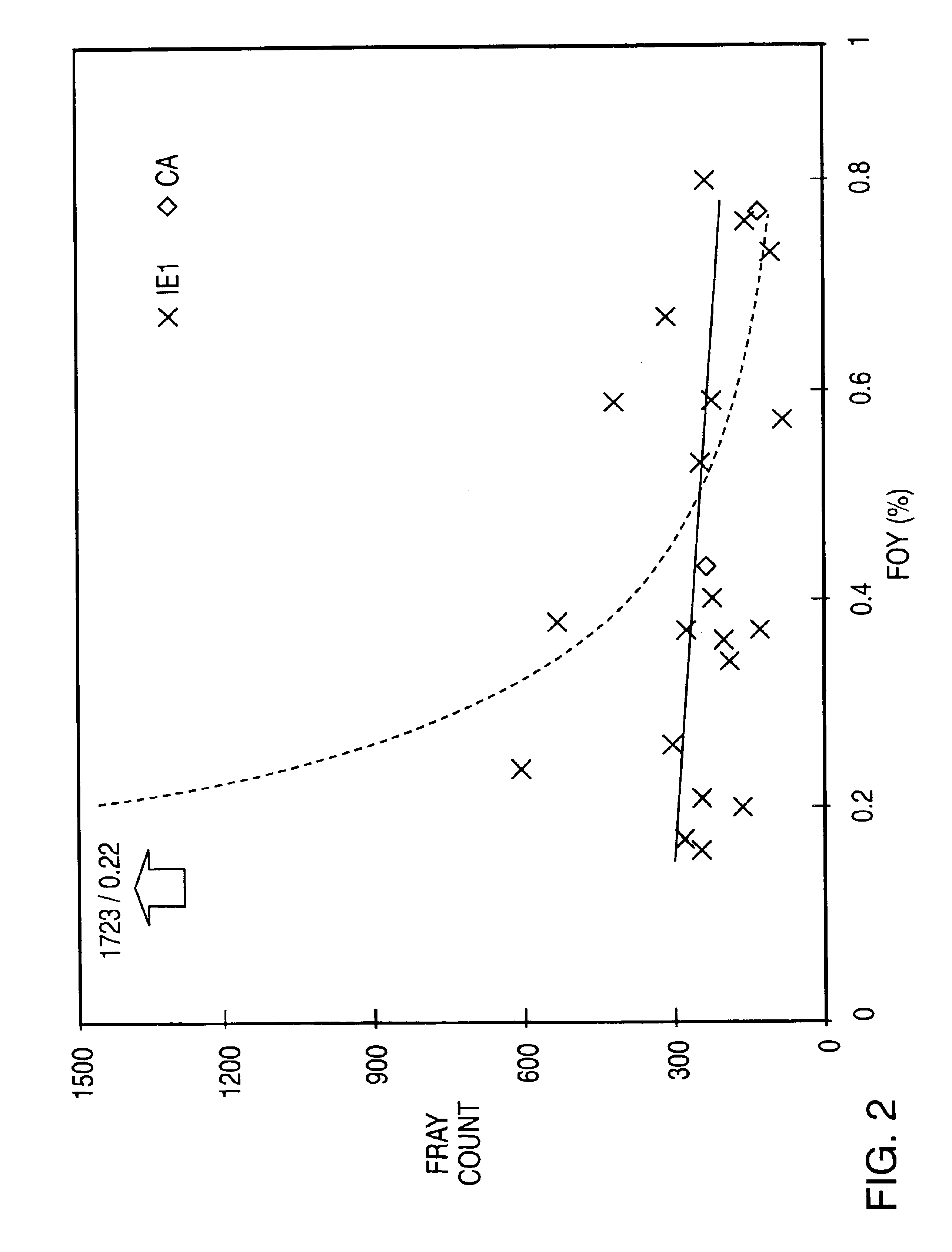

A spin finish which enhances yarn processability and contributes to improved yarn performance. The spin finish is advantageous when compared with conventional spin finishes applied to industrial yarn because the present spin finish enhances yarn processability as evidenced by low forming, improved mechanical quality at lower amounts of spin finish per yarn, improved mechanical quality at higher draw ratios, and minimal depositing. It also improves yarn performance as evidenced by improved strength and wicking.

Owner:FIBER INNOVATORS INT LLC

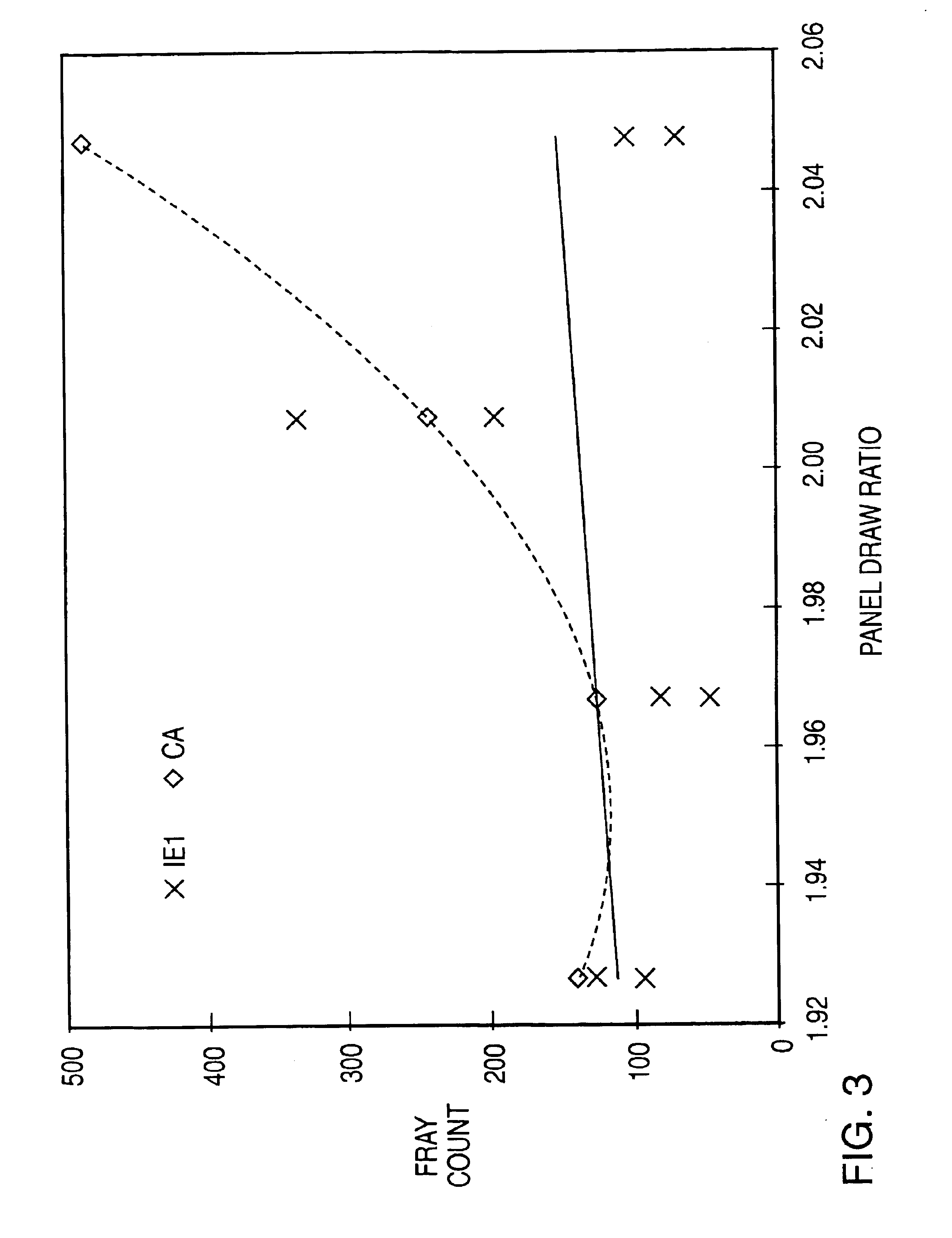

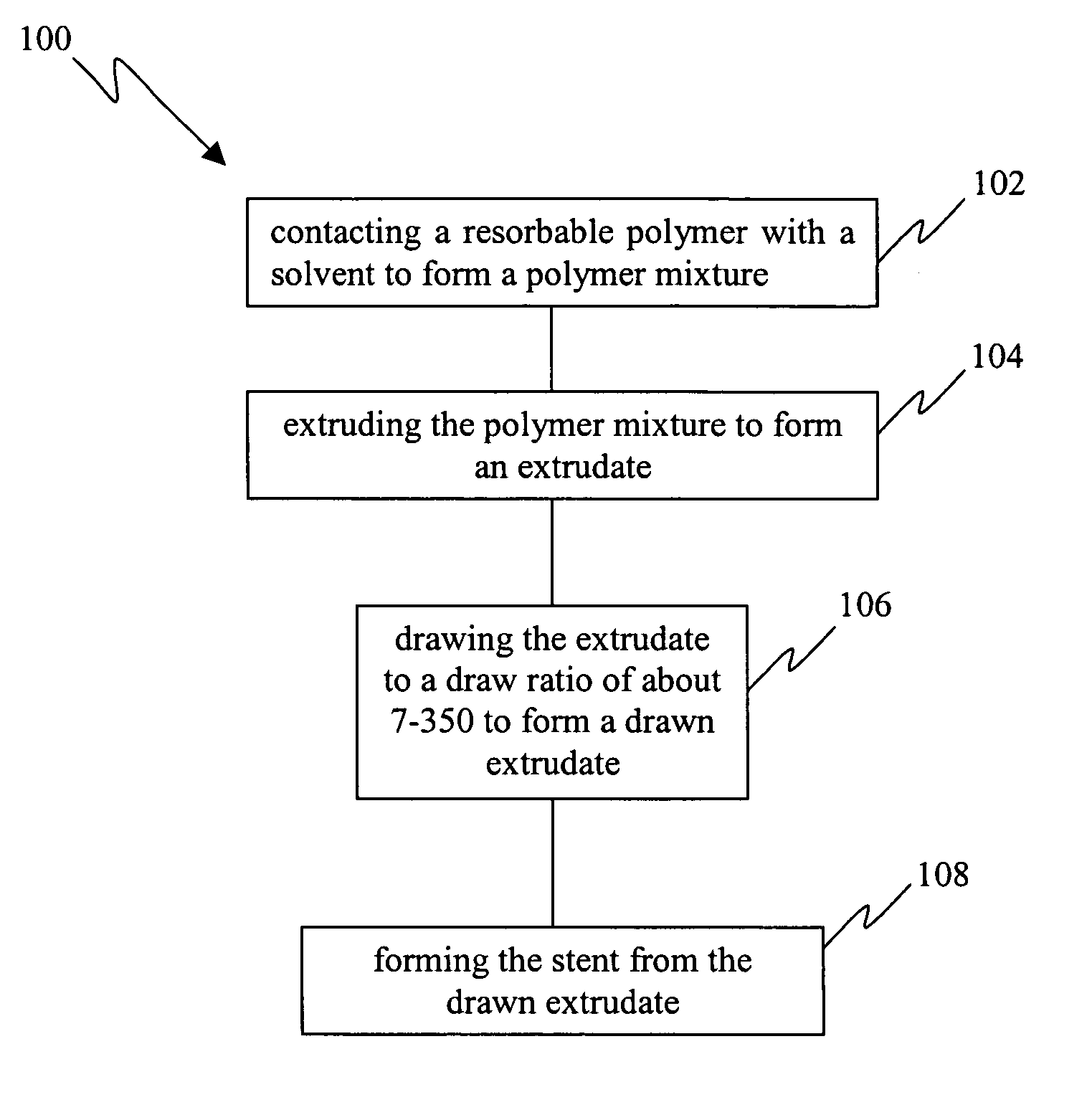

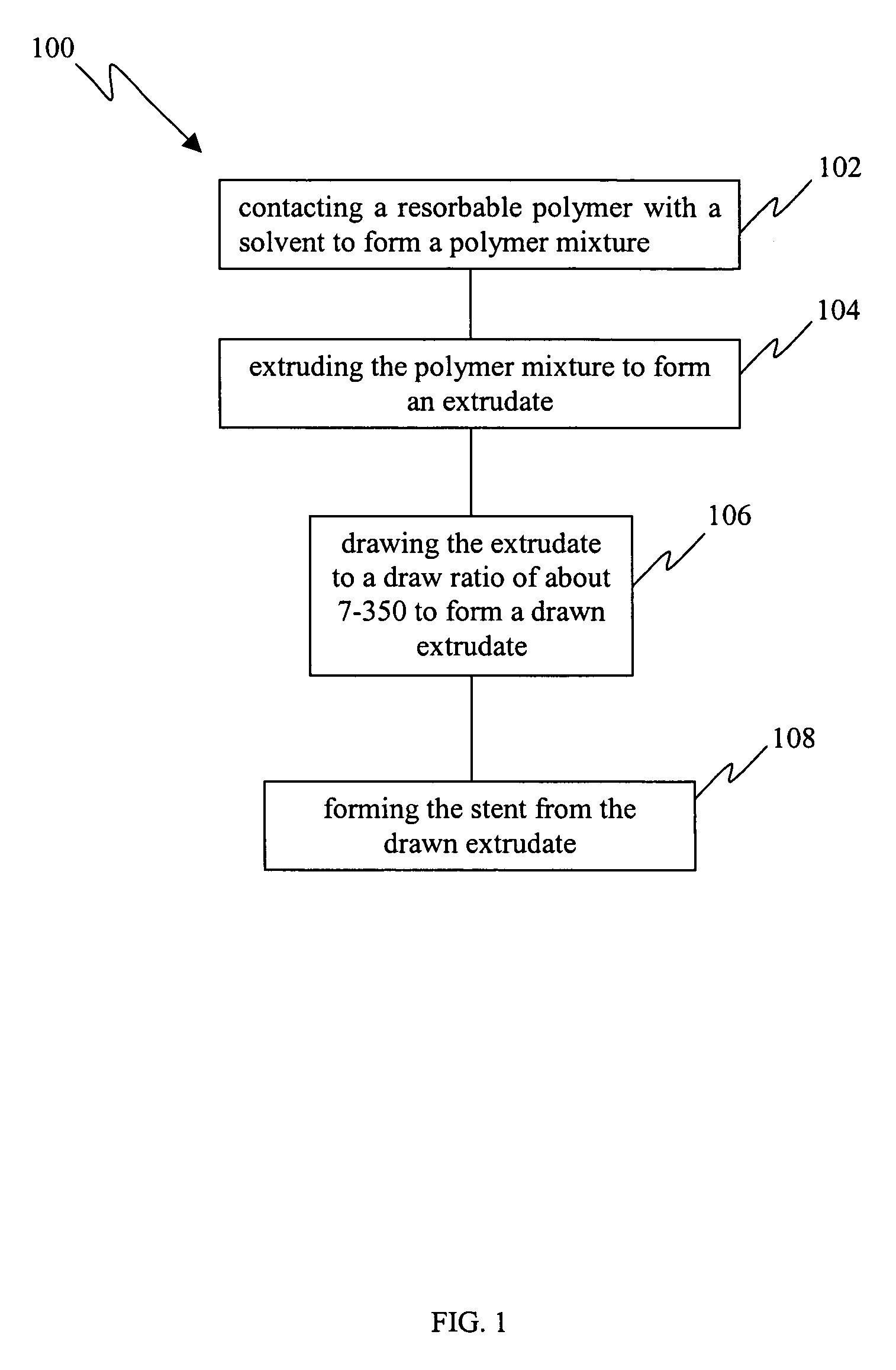

Minimal injury resorbable stent

InactiveUS20050149172A1Improved propertyMinimal injuryMonocomponent protein artificial filamentSurgeryResorbable polymersPlasticizer

A minimal injury resorbable stent comprising an oriented resorbable material drawn to a ratio about 7-350 is disclosed. The drawn materials of the present invention have tensile strength of about 50-500 MPa and Young's modulus of about 2-300 GPa. The bioresorbable stents can have cylindrical shape and optionally further comprise one or more of a solvent, plasticizer, biologically active agent and modifier. Also disclosed is a method for manufacturing a minimal injury resorbable stent. The process comprises contacting a resorbable polymer with a solvent to form a polymer mixture, extruding said polymer mixture to form an extrudate, drawing said extrudate to a draw ratio in the range of about 7-350 to form a drawn extrudate and forming said stent from said drawn extrudate. The process optionally further comprises coagulating the extrudate and annealing the extrudate and / or stent.

Owner:MEDTRONIC VASCULAR INC

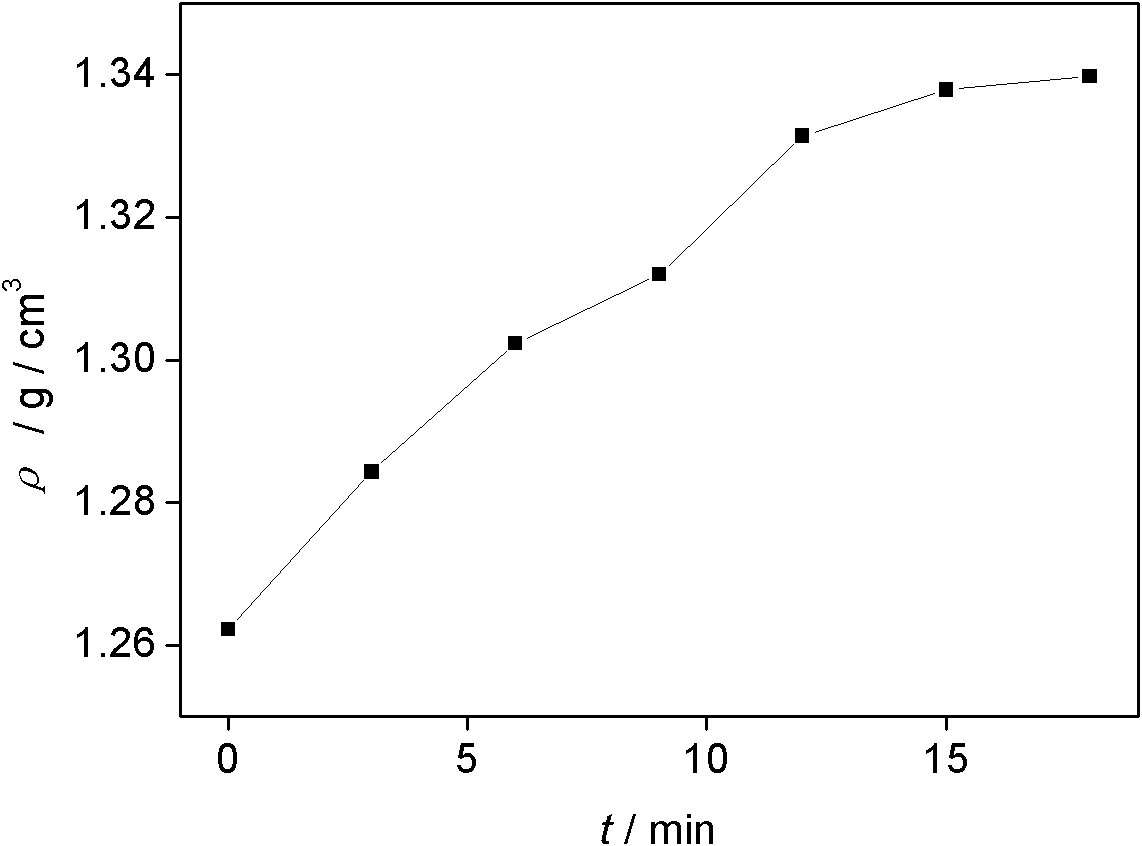

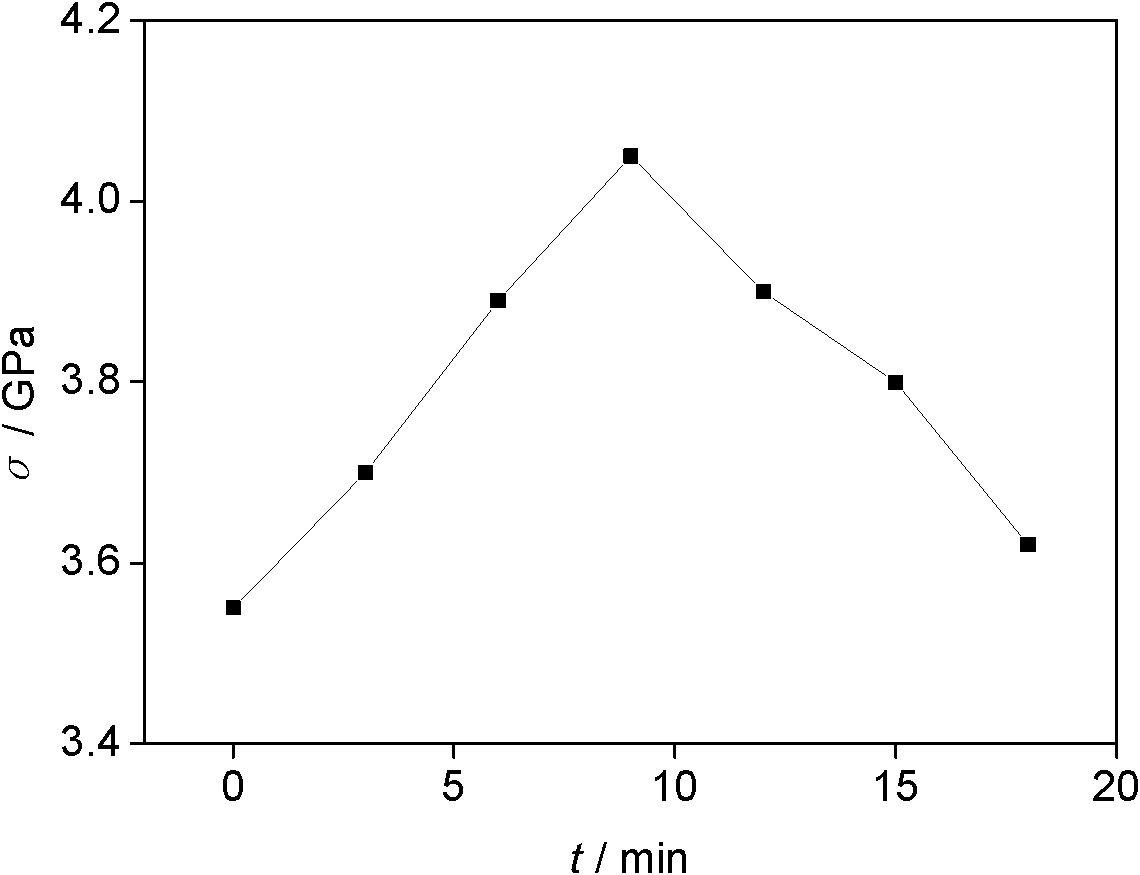

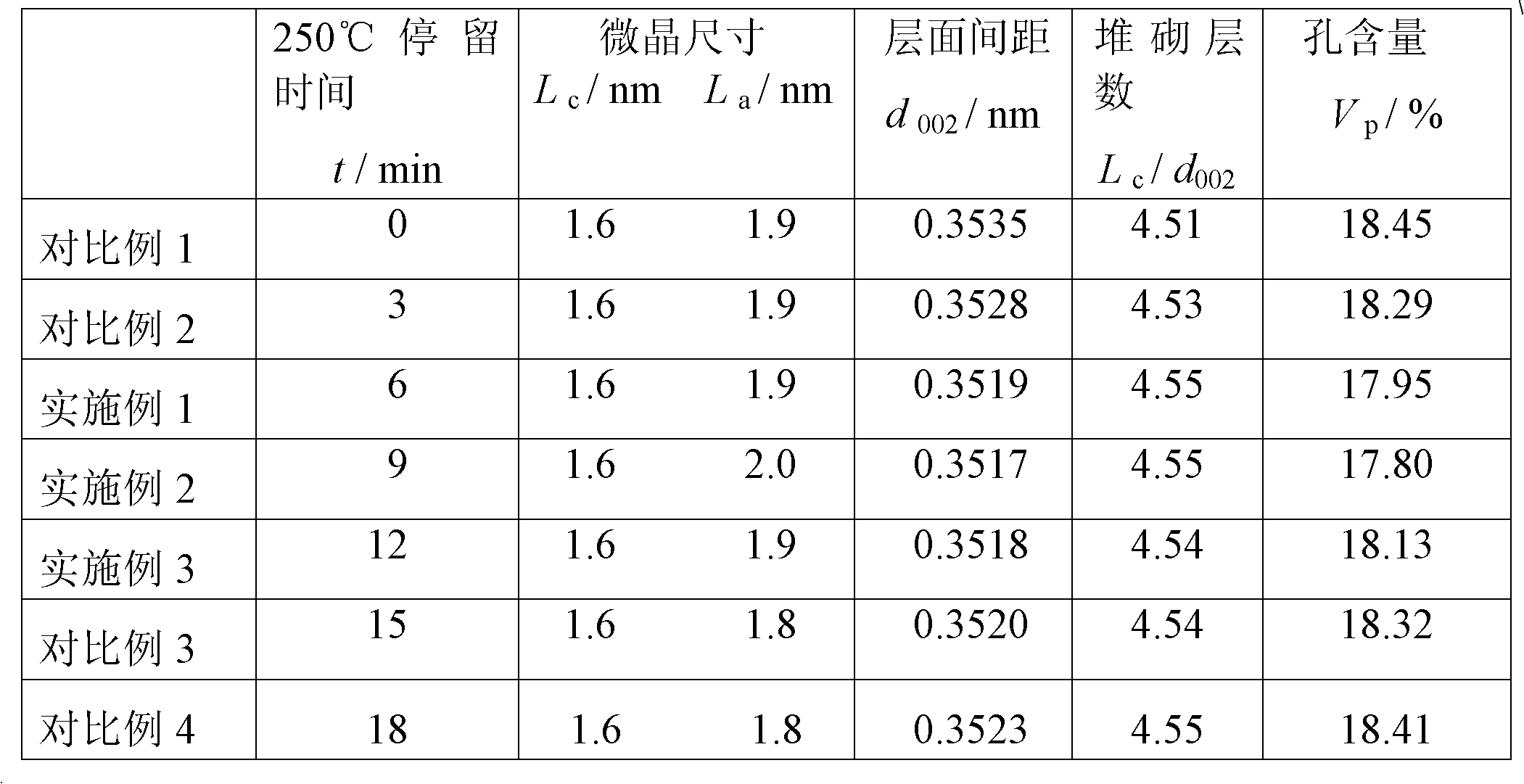

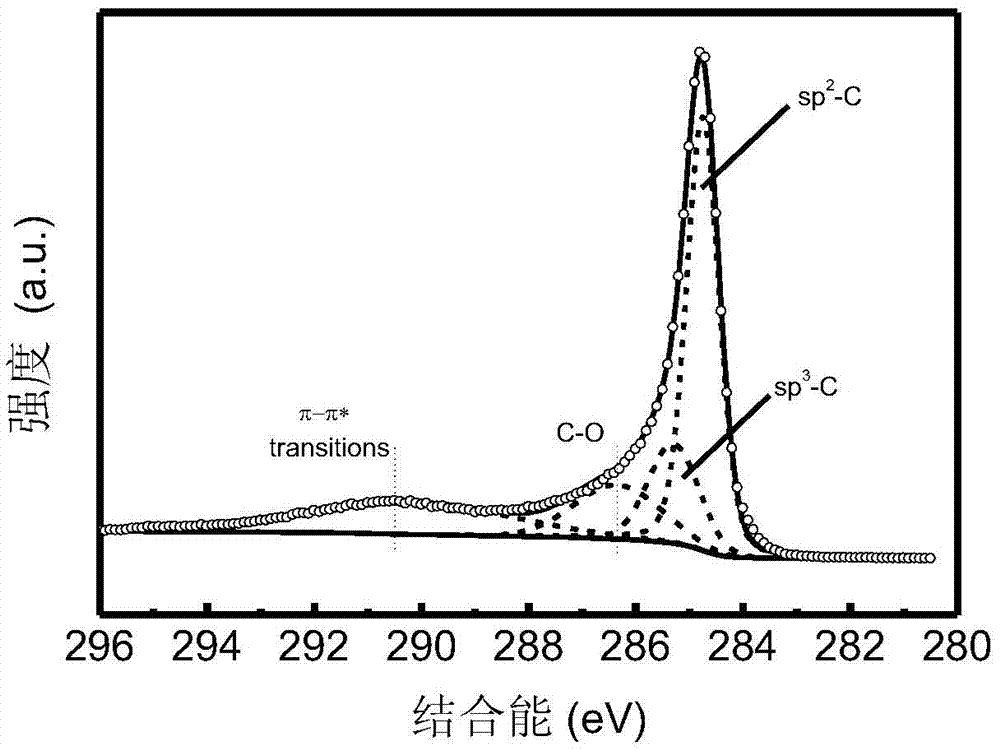

Method for preparing high-strength carbon fiber

InactiveCN102154740AImprove mechanical propertiesSimple structureFibre chemical featuresAir atmosphereHigh intensity

The invention discloses a method for preparing a high-strength carbon fiber, belonging to the technical field of the carbon fiber. The method comprises the following steps of: pre-oxidizing a polyacrylonitrile (PAN) copolymer fiber under air atmosphere at the temperature of between 200 DEG C and 280 DEG C; performing heat treatment for 50 to 70 minutes in a four-section to seven-section gradient heating mode; keeping at a temperature zone with heat treatment temperature of 250 DEG C for 9+ / -3 minutes; and carbonizing the pre-oxidized fiber under conventional carbonizing conditions, namely carbonizing the fiber under protection of a nitrogen gas at the draw ratio of -4 to +8 percent and at the low temperature of between 300 DEG C and 900 DEG C for 3+ / -1.5 minutes, and carbonizing the fiber at the high temperature of between 1,200 DEG C and 1,600 DEG C and at the draw ratio of -4 to +1 percent for 2+ / -1 minutes. The carbon fiber prepared by the method has a perfect structure and excellent mechanical property. The tensile strength of the obtained carbon fiber reaches over 3.8GPa.

Owner:BEIJING UNIV OF CHEM TECH

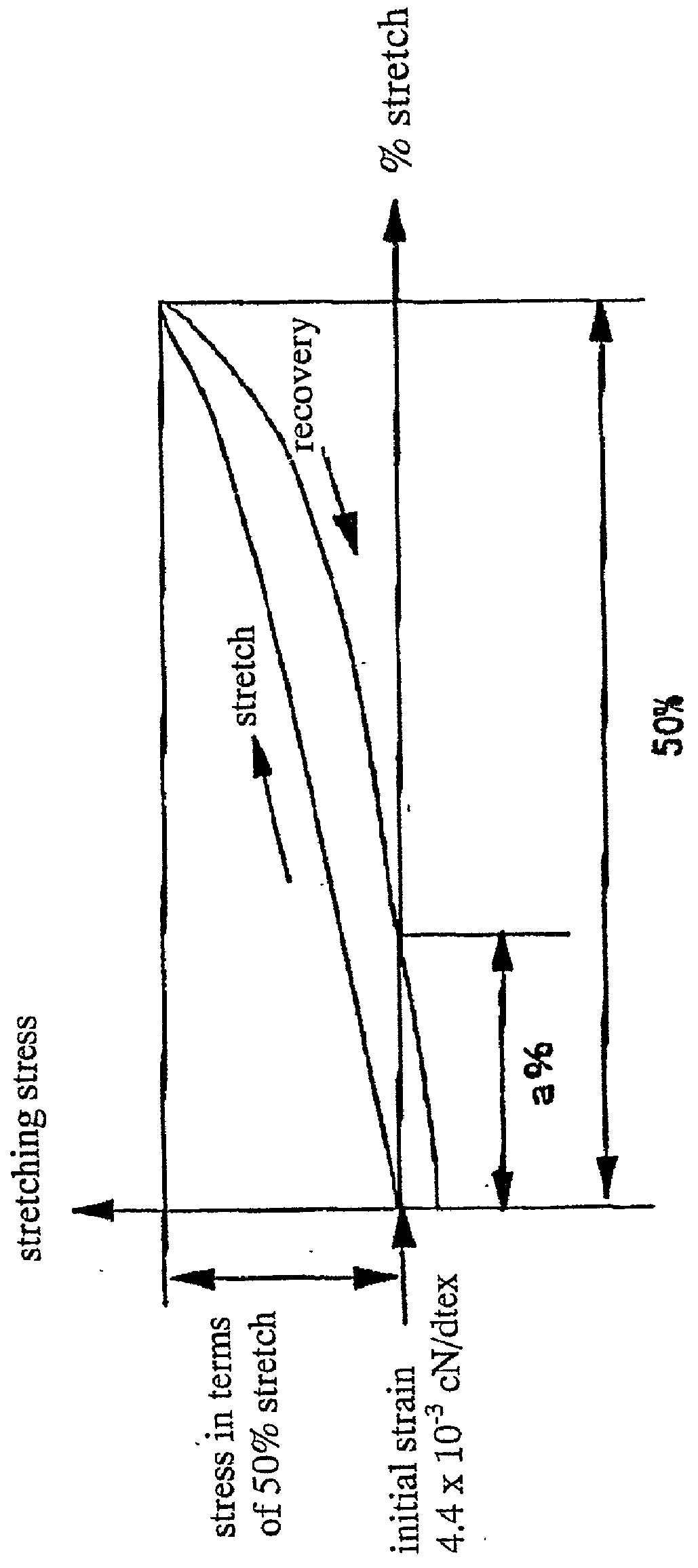

Soft stretch yarns and their method of production

InactiveUS20010055683A1Eliminate the problemImprove tensile propertiesHollow filament manufactureWoven fabricsPolyesterYarn

A soft stretch yarn substantially comprising polyester fibers has a stress, at 50% yarn stretch, of no more than 30x10-3 cN / dtex and, at the same time, a percentage recovery of at least 60%. Preferably, the Uster unevenness is no more than 2.0% and the crimp diameter is no more than 250 mum. This soft stretch yarn can be produced by spinning yarn of conjugate fibers comprising two types of polyester in which one component is PTT at a take-up velocity of at least 1200 m / min, drawing at a drawing temperature of 50 to 80° C. at a draw ratio such that the drawn yarn tensile elongation is 20 to 45%, and then heat setting.

Owner:TORAY IND INC

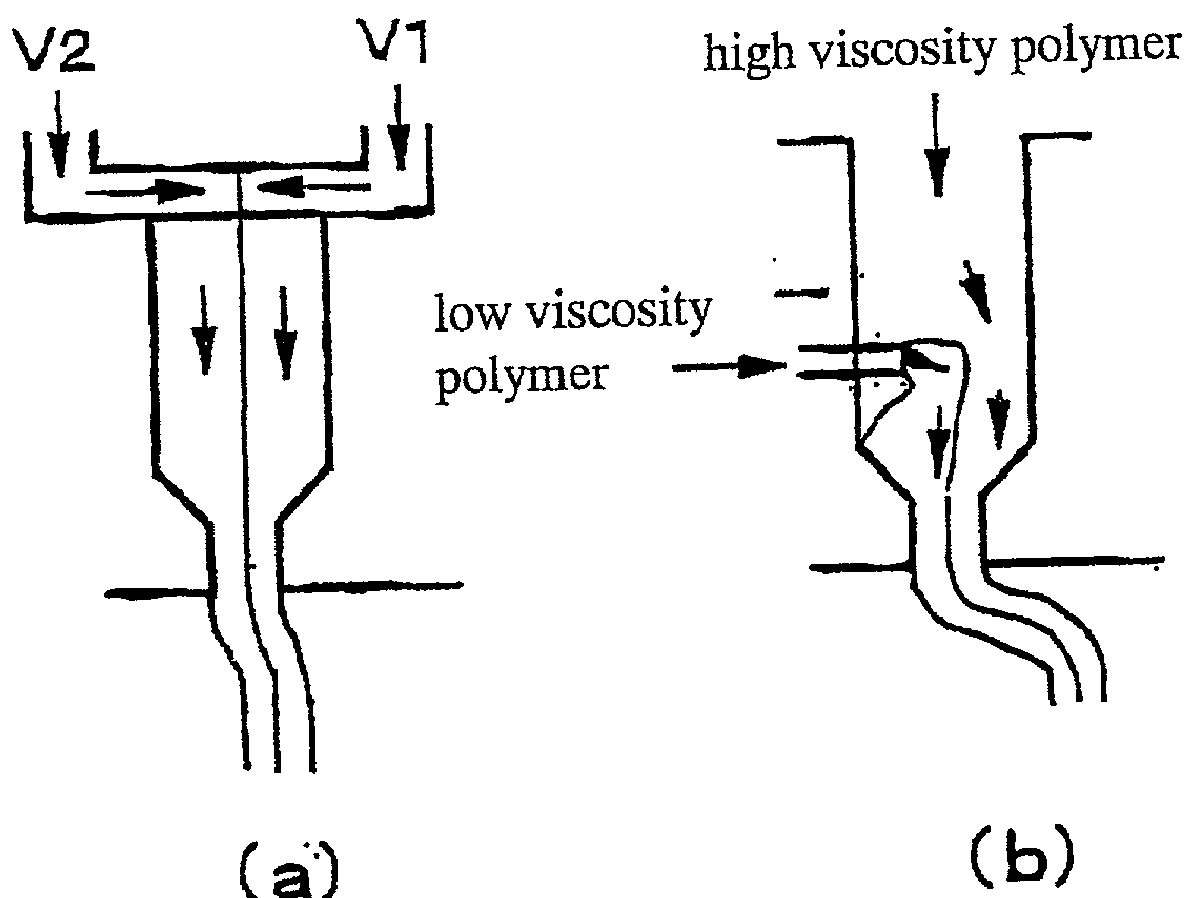

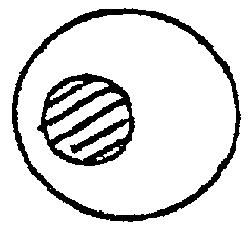

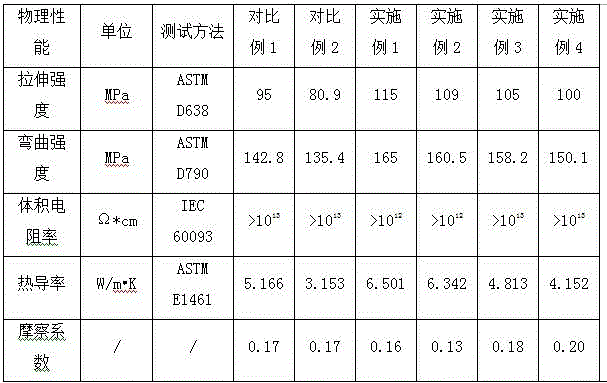

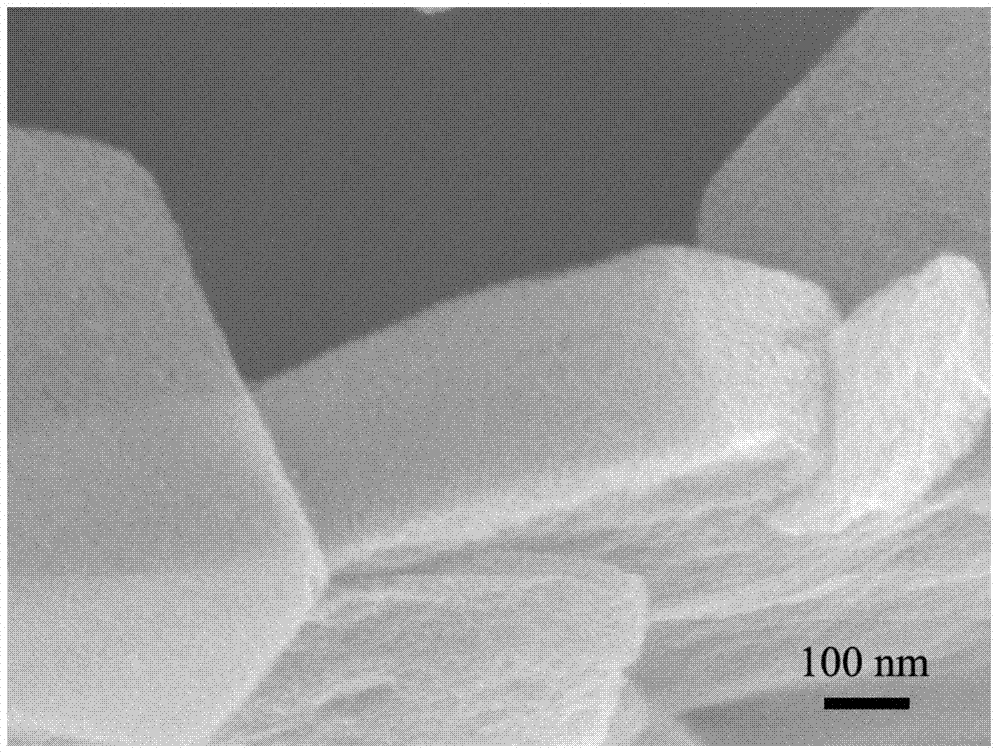

Heat-conducting, wear-resistant and insulated nylon 6 composite material and preparation method thereof

The invention relates to a heat-conducting, wear-resistant and insulated nylon 6 composite material and a preparation method thereof. The material is composed of the following raw materials in percentage by weight: 20-50% of PA 6, 10-30% of fibrous heat-conducting fillers, 15-30% of insulated heat-conducting powder A, 5-10% of insulated heat-conducting powder B, 5-15% of heat-conducting wear-resistant powder, 0.75-1.5% of coupling agent, 3-10% of compatibilizer, 0.2-0.5% of antioxidant and 0.2-0.5% of lubricant. According to the heat-conducting, wear-resistant and insulated nylon 6 composite material provided by the invention, heat-conducting fillers with different particle sizes, different shapes and different draw ratios are compounded so that the fillers are more uniformly distributed in a plastic matrix so as to form a heat-conducting network more easily. Since a low-feeding high-shearing extrusion process is used in the invention, an extruder is at a hungry state to achieve an effect of dispersing the fillers more uniformly. When the fibrous heat conducting fillers are added, a single screw extruder is used, so that the fibers can be sheared into smaller size, the damage is smaller, and meanwhile, the fillers are dispersed more uniformly by extruding the fillers by the extruder for the second time; and the heat-conducting, wear-resistant and insulated nylon 6 composite material provided by the invention has the advantages of good heat conducting effect, excellent wear resistance, easy workability, etc.

Owner:SHANGHAI UNIV

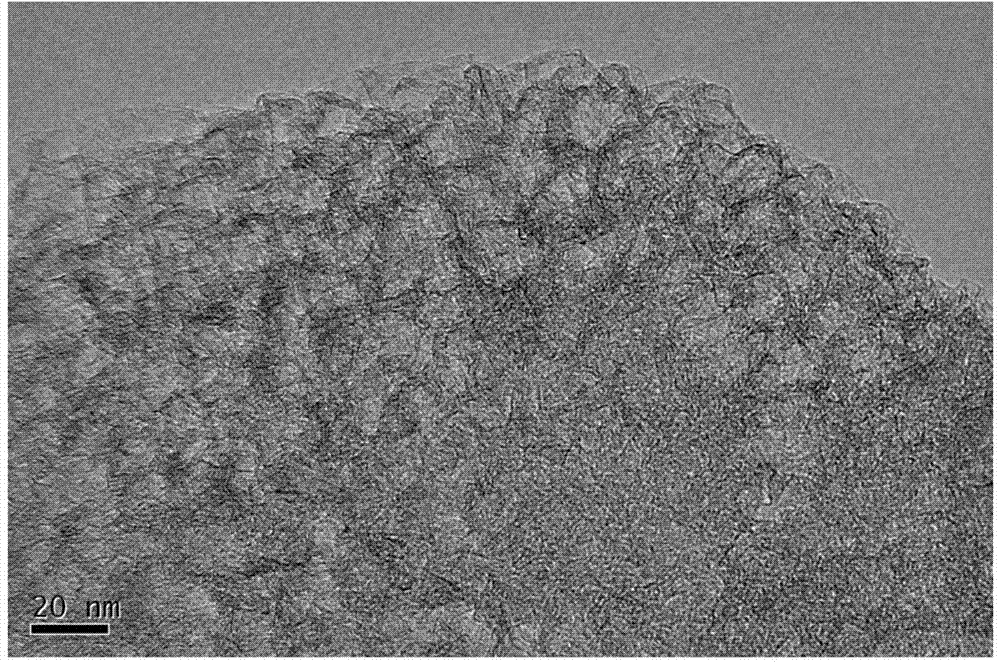

Mesoporous graphene foam as well as preparation method thereof

ActiveCN103482611AStable structureLarge specific surface areaGrapheneNanotechnologyDraw ratioElectric properties

The invention belongs to the technical fields of a novel material as well as preparation, and particularly relates to mesoporous graphene foam as well as a preparation method thereof. The invention realizes hydrothermal preparation of a magnesium oxide texture structure and preparation of the mesoporous graphene foam by using textured magnesium oxide as a template. The mesoporous graphene foam material has abundant mesoporous structures and excellent electric property and can be used as an electrode material of batteries and supercapacitors, so that the energy density and the power density of the batteries or the supercapacitors are expectedly improved to a great extent. The cycling stability of the mesoporous graphene foam material is increased, and the mesoporous graphene foam material combined with materials with high draw ratio or the mesoporous graphene foam material can soften energy storage apparatuses. The advantages have important meaning for realization of commercialization of a new generation of energy storage apparatuses for electromobiles and development of smaller, lighter and flexible portable mobile power supplies. The business prospect is wide. Meanwhile, preparation processes of the high temperature hydrothermal method and a fluidized bed can realize engineering enlargement, so that the method is expected to be industrialized.

Owner:TSINGHUA UNIV

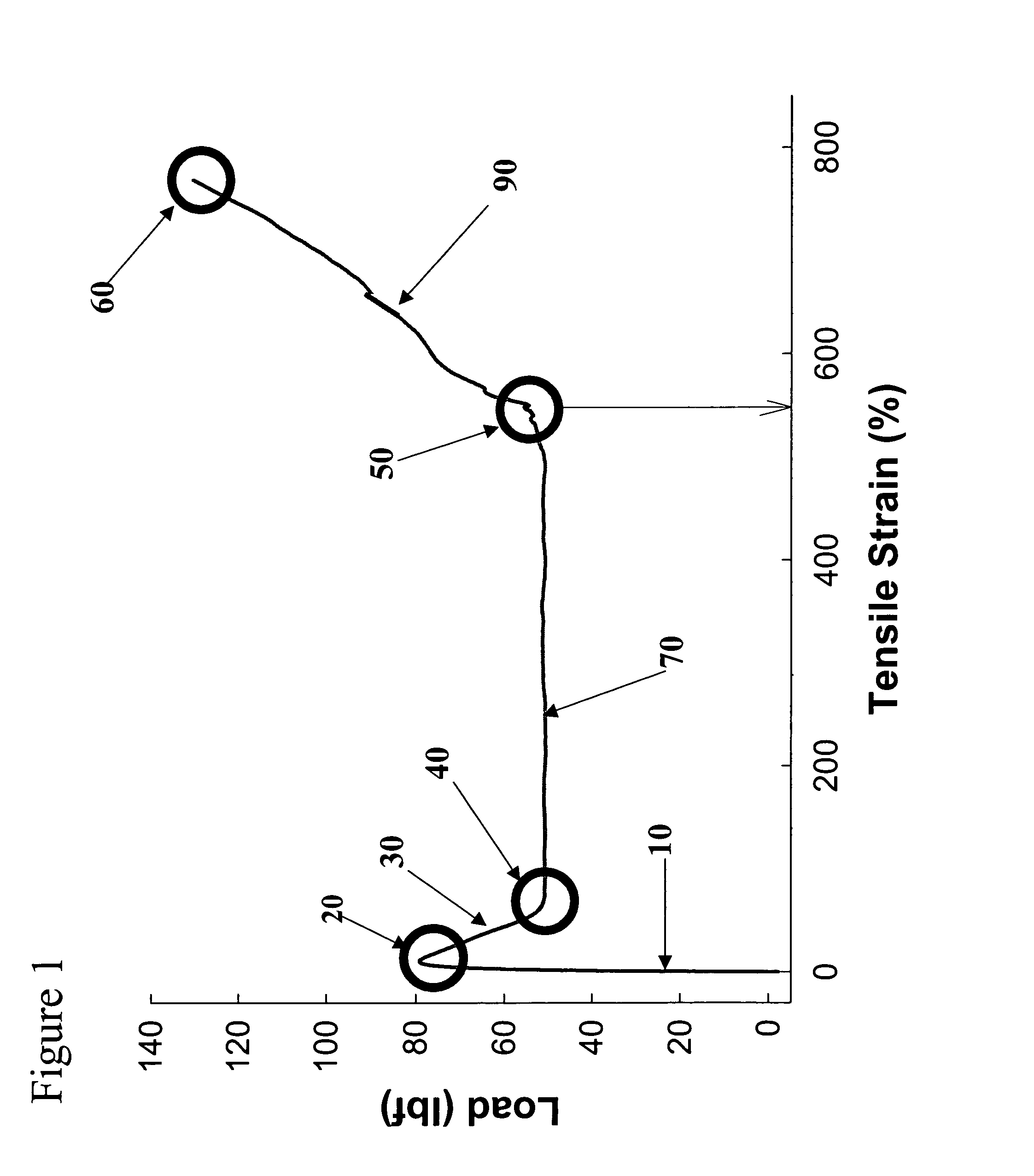

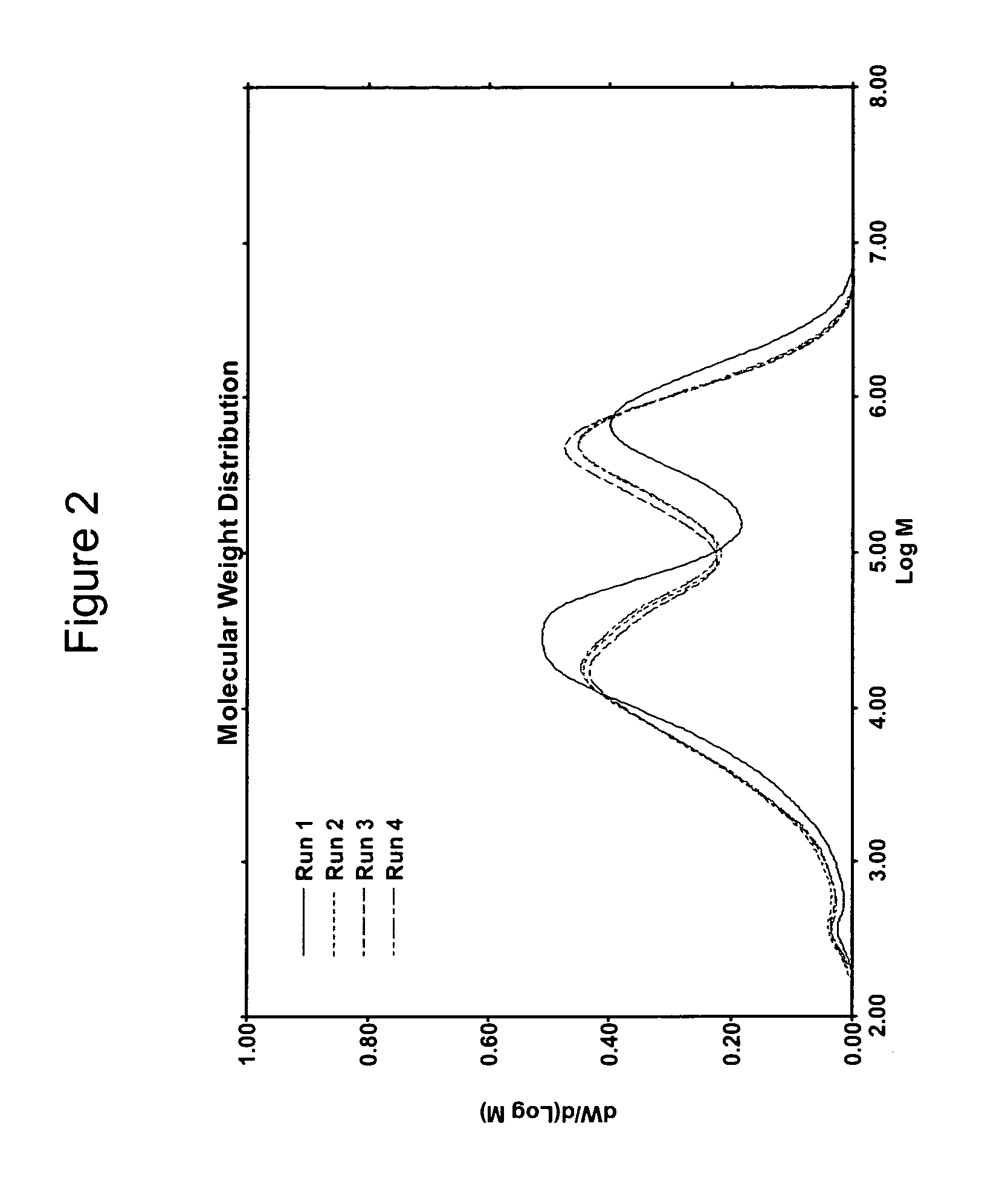

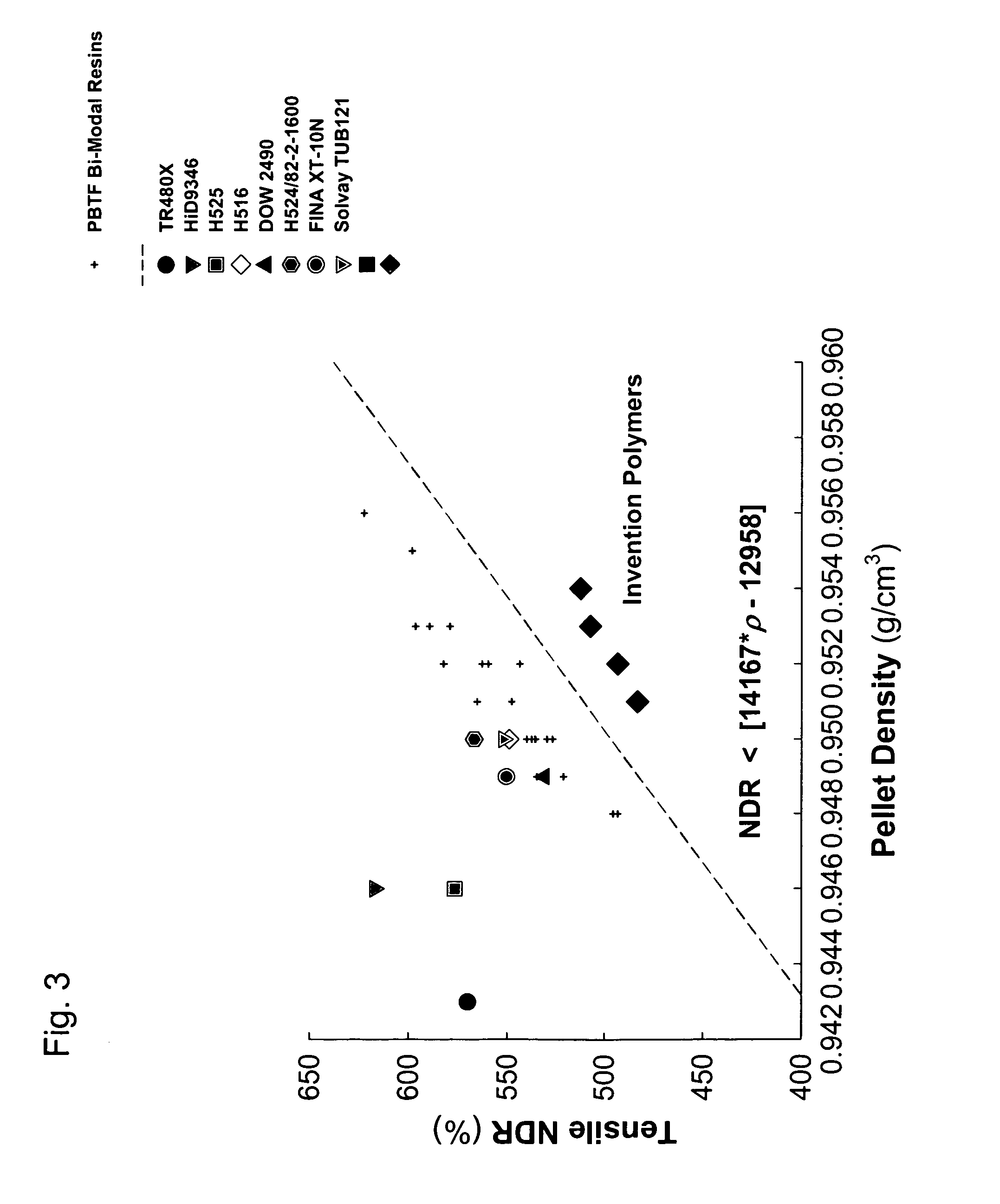

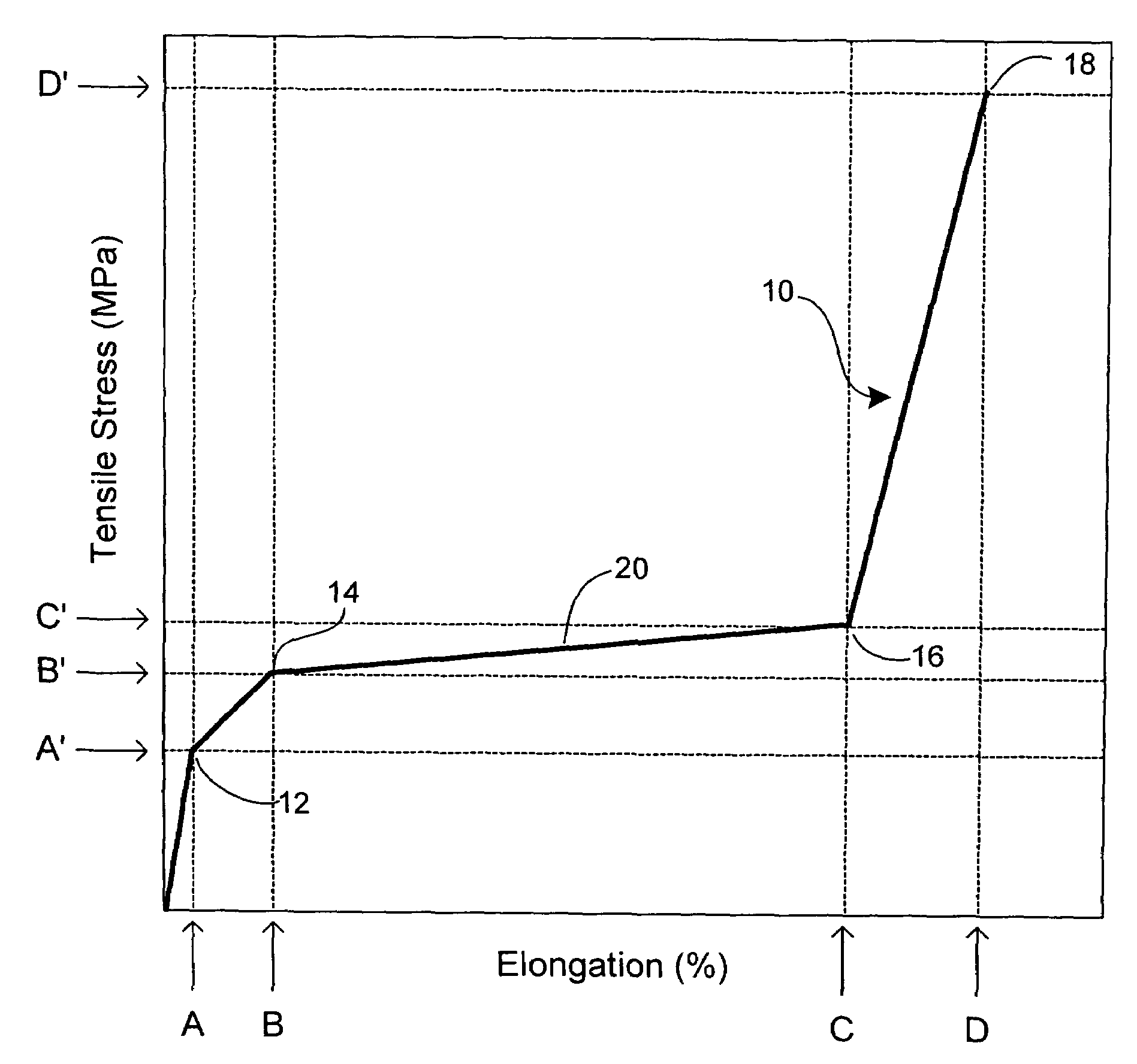

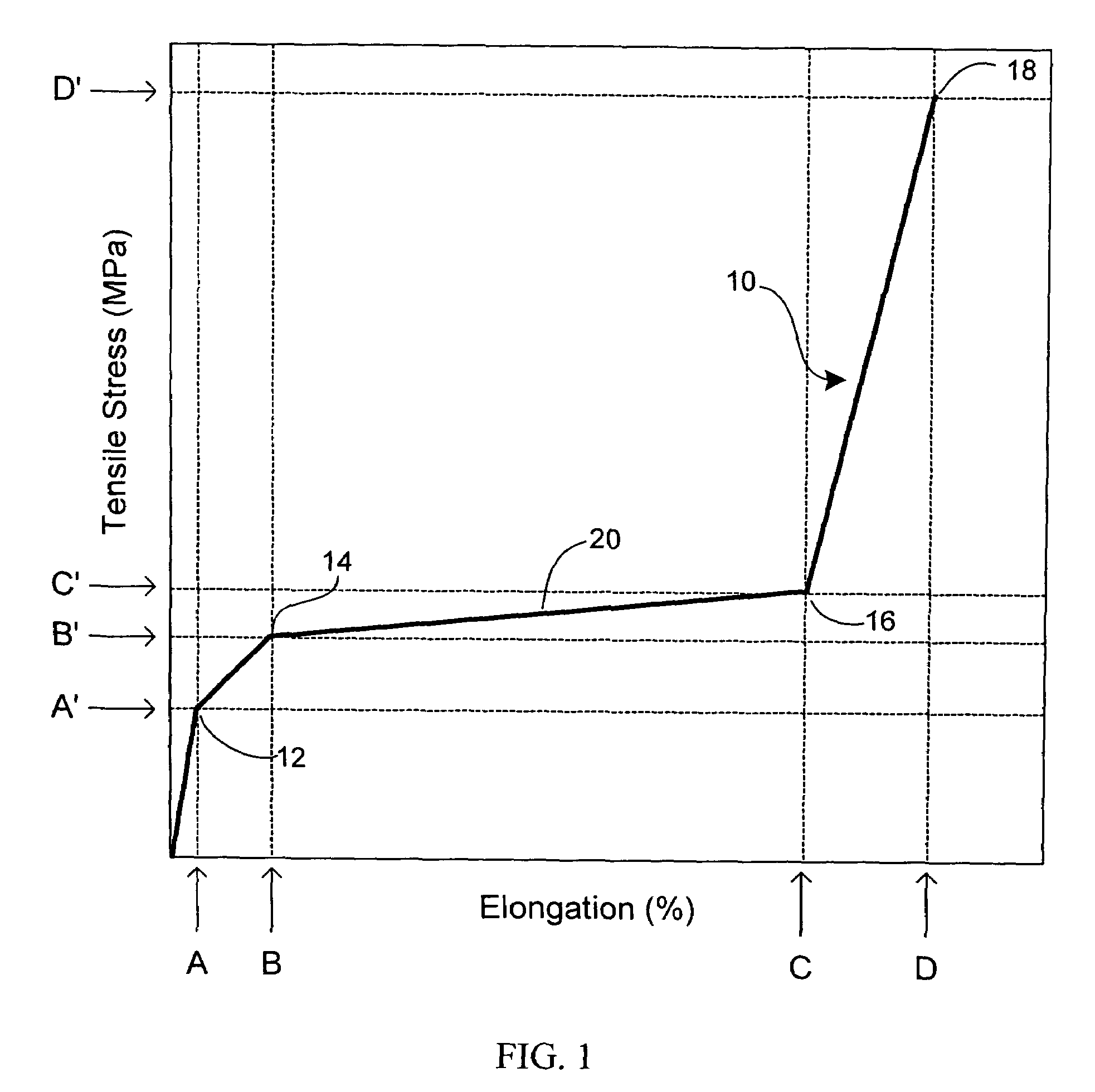

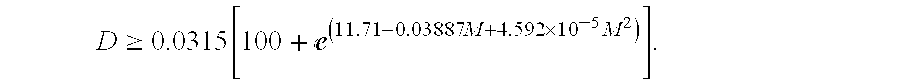

Polyethylene compositions and pipe made from same

A polymer composition comprising a density equal to or greater than about 0.947 g / cc, a high load melt index from about 1 g / 10 min to about 30 g / 10 min, and a tensile natural draw ratio less than about 14167 ρ-12958, where ρ is the density (g / cc) of the composition. A polymer composition comprising a tensile natural draw ratio less than about 14167ρ-12958, where ρ is the density (g / cc) of the composition and wherein less than about 1 weight percent of the composition comprises non-polymeric additives.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Stretch film

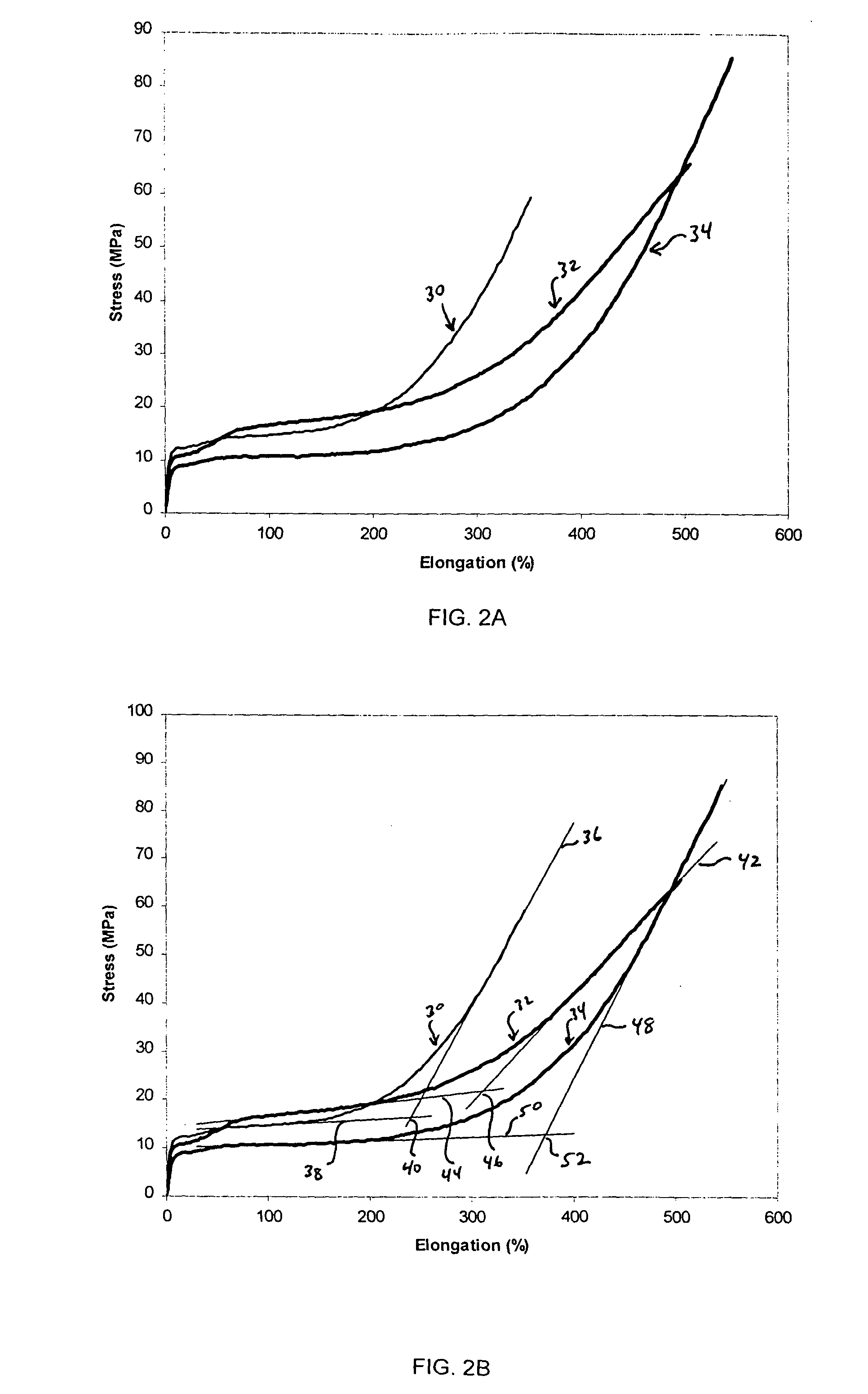

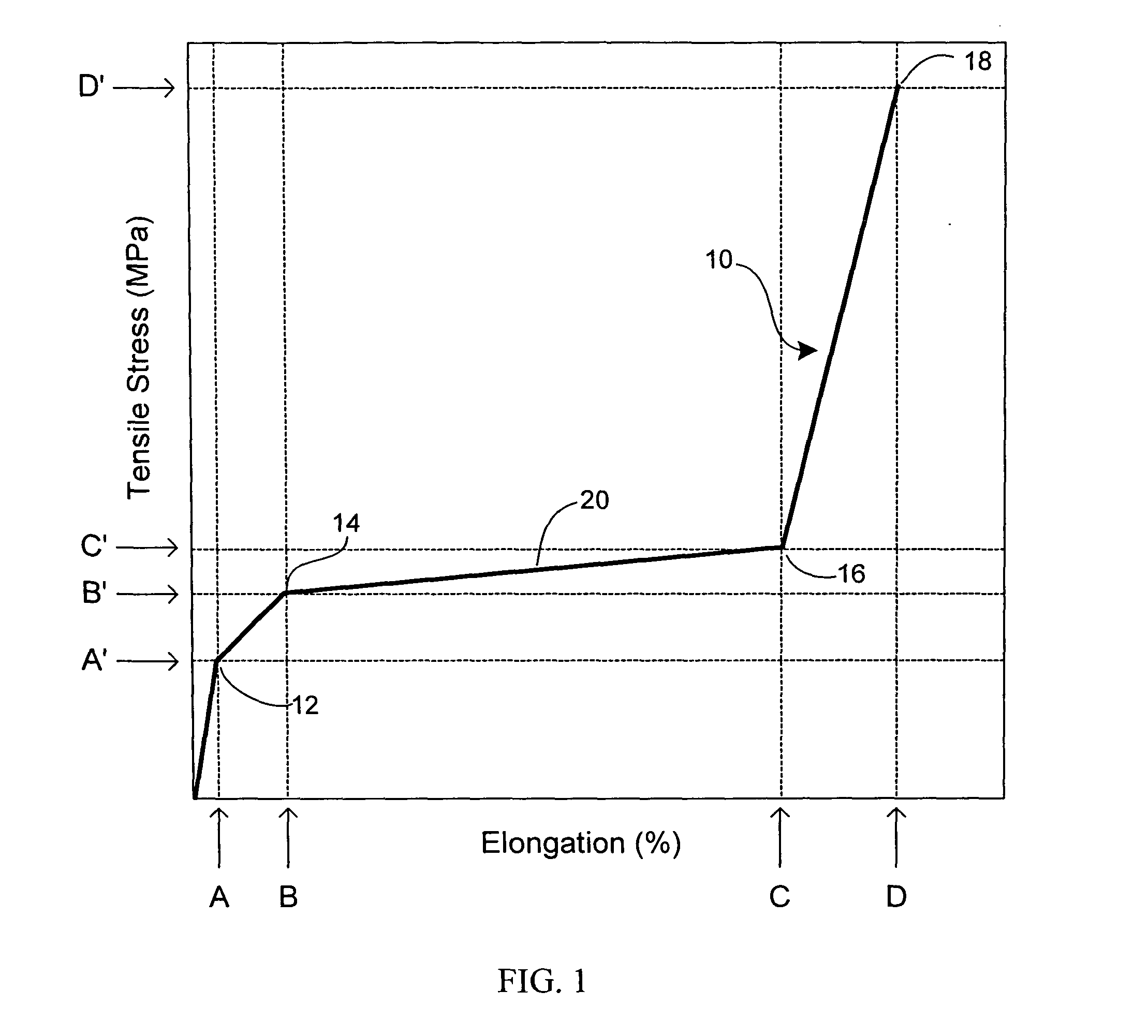

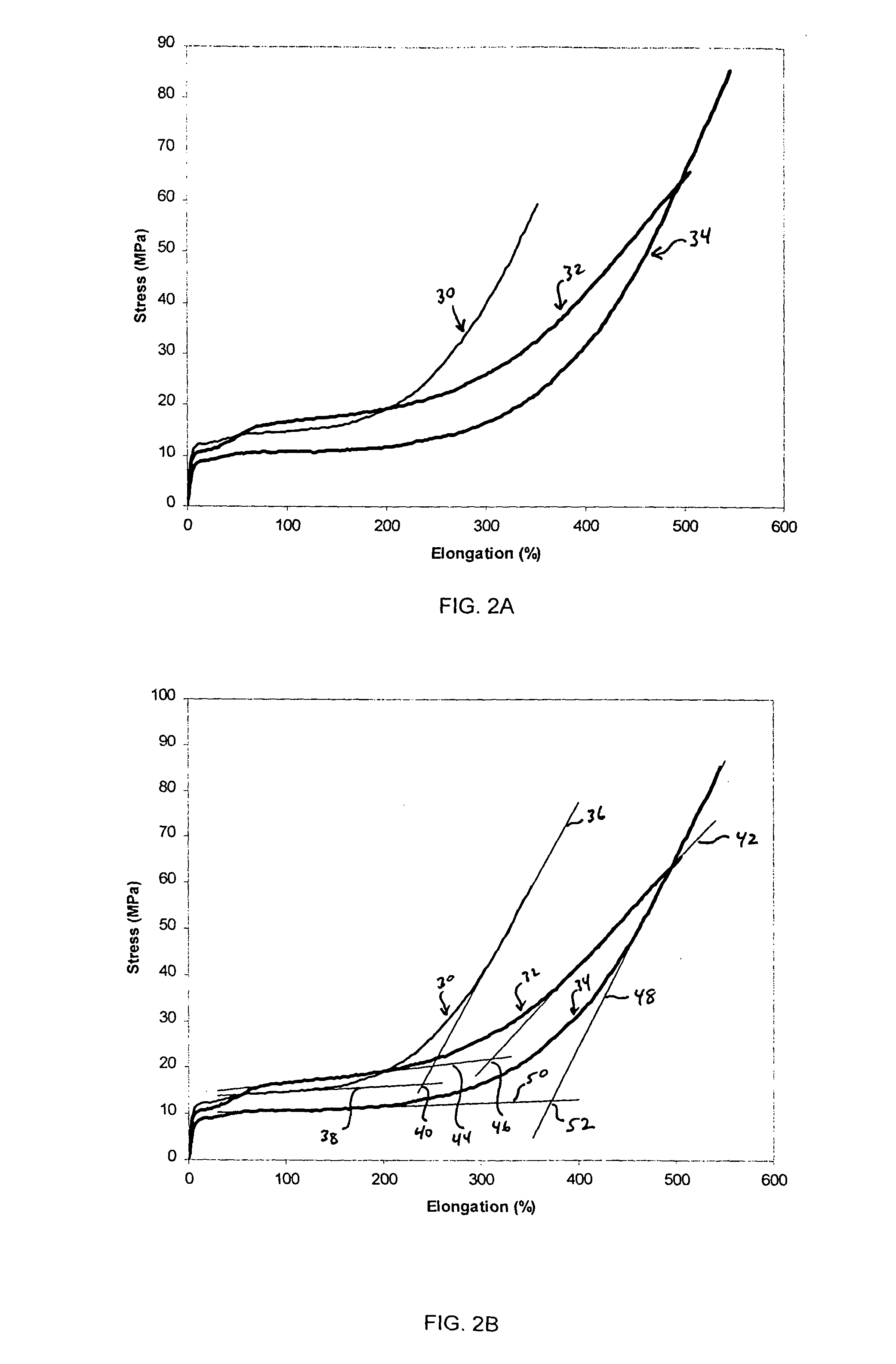

Stretch films are disclosed, the films having at least one layer formed of or including a polyethylene copolymer and having a natural draw ratio of at least 250%, a tensile stress at the natural draw ratio of at least 22 MPa, and a tensile stress at second yield of at least 12 MPa. In some embodiments, the polyethylene copolymer can have a CDBI of at least 70%, a melt index I2.16 of from 0.1 to 15 g / 10 min., a density of from 0.910 to 0.940 g / cm3, a melt index ratio I21.6 / I2.16 of from 30 to 80, and an Mw / Mn ratio of from 2.5 to 5.5. The stretch films are particularly useful in bundling and packaging applications.

Owner:EXXONMOBIL CHEM PAT INC

Stretch film

Stretch films are disclosed, the films having at least one layer formed of or including a polyethylene copolymer and having a natural draw ratio of at least 250%, a tensile stress at the natural draw ratio of at least 22 MPa, and a tensile stress at second yield of at least 12 MPa. In some embodiments, the polyethylene copolymer can have a CDBI of at least 70%, a melt index I2.16 of from 0.1 to 15 g / 10 min., a density of from 0.910 to 0.940 g / cm<3>, a melt index ratio I21.6 / I2.16 of from 30 to 80, and an Mw / Mn ratio of from 2.5 to 5.5. The stretch films are particularly useful in bundling and packaging applications.

Owner:EXXONMOBIL CHEM PAT INC

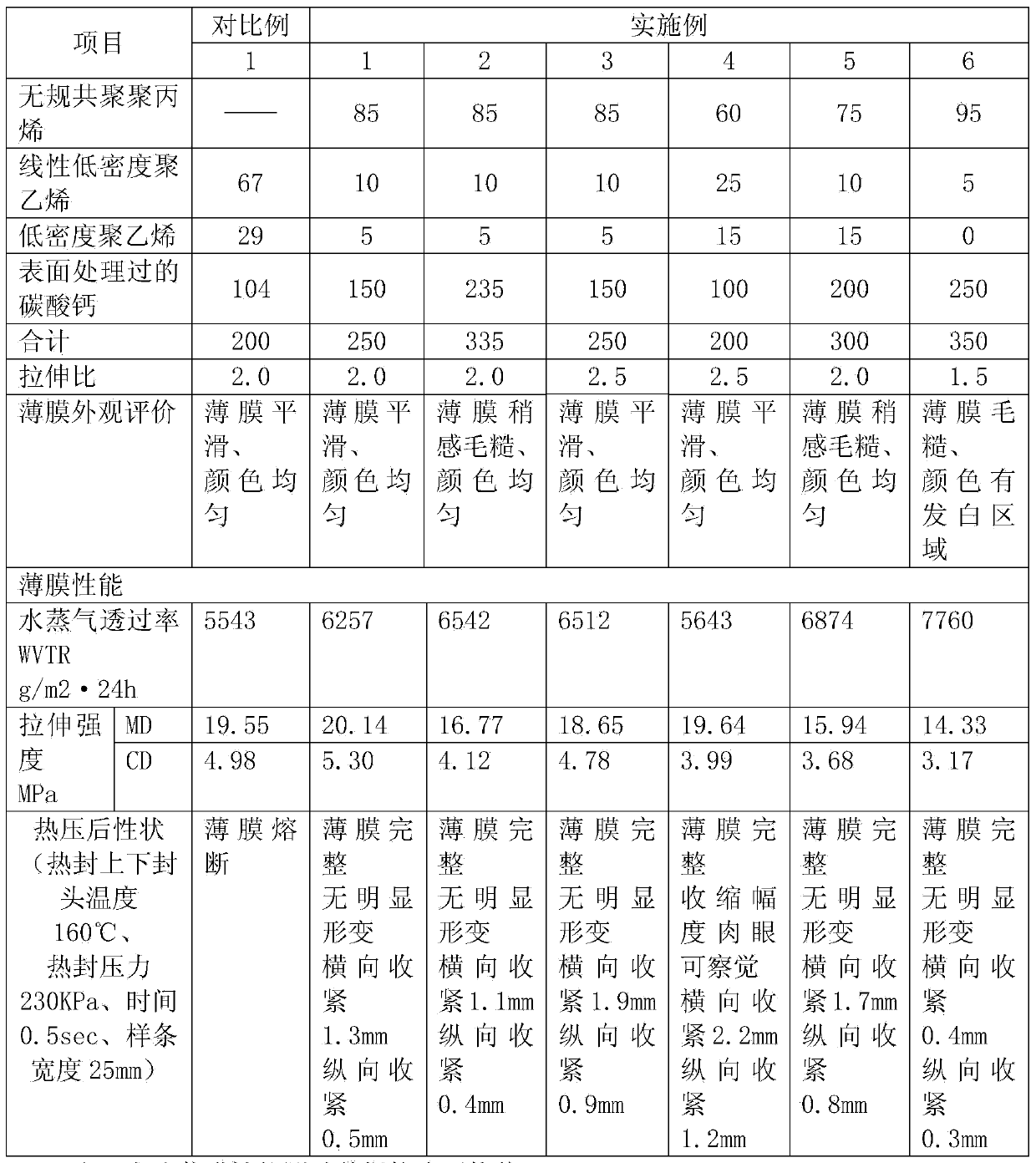

Polyolefin microporous air-permeable membrane and preparation method thereof

ActiveCN103739962AImprove process rangeDoes not affect processing performancePolymer sciencePolyolefin

The invention discloses a polyolefin microporous air-permeable membrane and a preparation method thereof. The microporous air-permeable membrane is prepared from a polyolefin substrate filled with a calcium carbonate filler with processed surface by means of casting extruding, stretching, and heat setting and film-forming. During the preparation, the polyolefin and the calcium carbonate filler with the processed surface are blended, extruded and pelletized, so as to prepare air-permeable particles; the air-permeable particles are extruded and molten by a casting extruder; the melt temperature is kept at 240-255 DEG C; the melt is continuously extruded to form a film through a die lip clearance of a T-shaped die head of a casting machine; the film is subjected to one-step or two-step stretching in a uniaxial manner; the draw ratio is controlled to be 1.5-2.5; the film obtained in the stretching manner is subjected to heat setting treatment at the heat setting temperature of 70-85 DEG C. The polyolefin microporous air-permeable membrane disclosed by the invention can ensure high air permeability and mechanical property of the microporous air-permeable membrane, meanwhile, the processing performance of the product is not affected, and the resistance to high temperature and high pressure of the film is also improved.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

Multi-layered biaxial stretch blow molded bottle and method for production thereof

InactiveUS7666486B2Improve propertiesExcellent oxygen barrier propertiesEnvelopes/bags making machinerySynthetic resin layered productsBlow moldingEngineering

A multi-layer biaxially stretched blow bottle having a 3-layer structure of PET / nylon MXD6 / PET or a 5-layer structure of PET / nylon MXD6 / PET / nylon MXD6 / PET, wherein the oxygen gas transmission coefficient of the nylon MXD6 layer is at most 6.0×10−14 cm3·cm / cm2·sec·cmHg as measured under conditions of a temperature of 23° C. and a relative humidity of 80%, and a production process of the bottle by biaxial stretch blow molding at a low stretching temperature and high draw ratios.

Owner:KUREHA KAGAKU KOGYO KK

Polyolefin fiber and method of producing the same

ActiveUS20090093180A1Desirable maintenanceDesirable of whitenessFilament/thread formingGlass/slag layered productsYarnPolymer science

A polyolefin fiber includes 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of titanium dioxide (TiO2). The polyolefin fiber may further include 0.2 to 1.0 wt % of spin finish provided on a surface thereof. The polyolefin fiber is spun to have a circular section, a modified cross-section including an X-shaped section, a Y-shaped section, a deltaic section, an oval section, a diamond section, a bladebone-shaped section, and a combined section thereof, or a combined section of the circular section and the modified cross-section. A method of producing a polyolefin fiber includes (a) melt extruding a composition which contains 93 to 99 wt % of polyolefin resin, 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of any one titanium dioxide (TiO2) of rutile titanium dioxide, anatase titanium dioxide, and brookite titanium dioxide at 240 to 300° C. and performing winding at a spin speed of 500 to 2,000 mpm to produce a undrawn yarn, and (b) drawing the undrawn yarn at a draw ratio of 1.0 to 5.0, crimping the drawn yarn to 5.5 to 9.0 ea / cm by using a crimper, attaching 0.2 to 1.0 wt % of spin finish to a surface of the fiber by spraying or dipping, heat setting the spin finish at 100 to 130° C. for 3 to 10 min, and cutting the resulting polyolefin fiber to predetermined lengths. A method of producing a polyolefin fiber includes melt extruding a composition which contains 93 to 99 wt % of polyolefin resin, 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of any one titanium dioxide (TiO2) of rutile titanium dioxide, anatase titanium dioxide, and brookite titanium dioxide at 230 to 270° C., winding at a spin speed of 40 to 300 mpm to produce a undrawn yarn, drawing the undrawn yarn at a draw ratio of 1.0 to 5.0, crimping the drawn yarn to 5.5 to 9.0 ea / cm by using a crimper, attaching 0.2 to 1.0 wt % of spin finish to a surface of the fiber by spraying or dipping, heat setting the spin finish at 100 to 130° C. for 3 to 10 min, and cutting the resulting spin finish to predetermined lengths. The polyolefin fiber has desirable maintenance of hydrophilicity and whiteness after rinsing is performed by using water and low foaming property and excellent carding workability required to produce non-woven fabrics (particularly, spunlace non-woven fabrics). The polyolefin fiber improves clearness of point and embossing patterns during thermal point bonding and thermal embossing processes.

Owner:KOLON GLOTECH INC

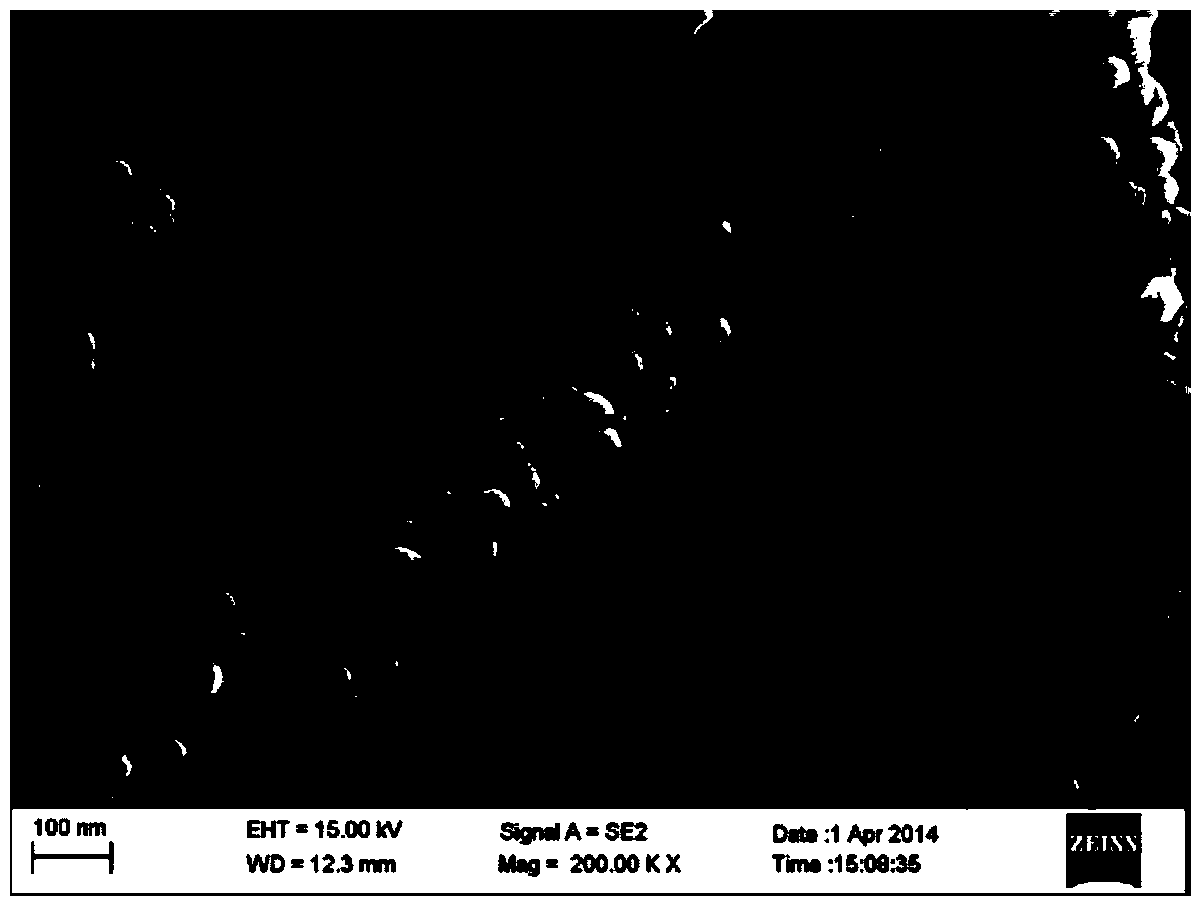

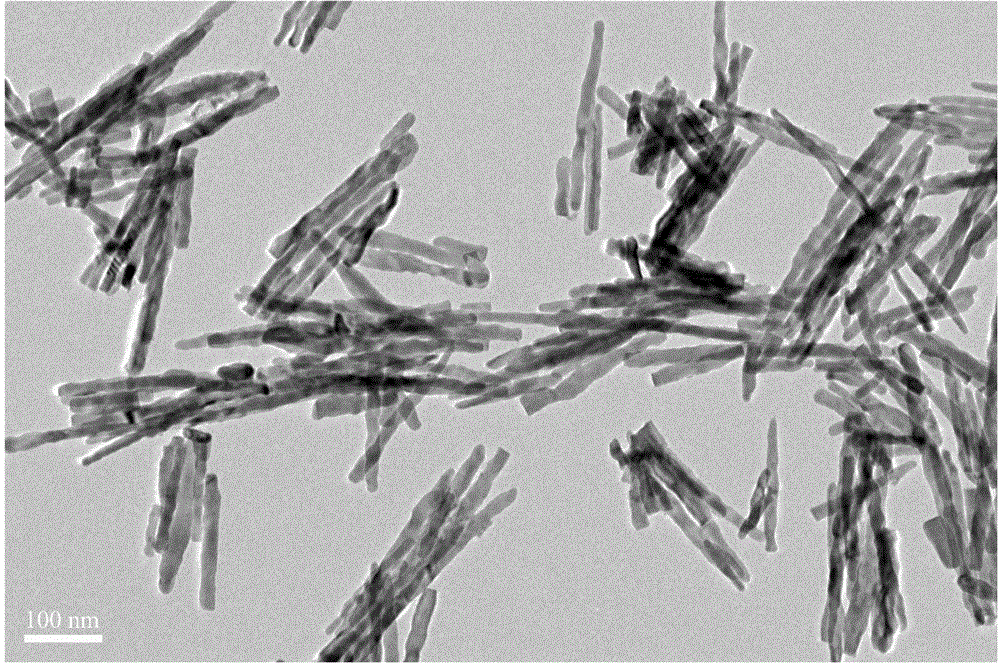

Method of preparing titanium dioxide nanotube with assistance of cationic surface active agent

InactiveCN103288126AHigh tube forming efficiencyUniform diameterNanotechnologyTitanium dioxideAdditive ingredientSurface-active agents

The invention discloses a method of preparing a titanium dioxide nanotube with assistance of a cationic surface active agent. The method comprises: adding titanium dioxide powder and hexadecyl trimethyl ammonium bromide into a polytetrafluoroethylene hydrothermal reaction kettle filled with a strong base solution according to a weight ratio of 1:1-1:5, uniformly mixing the ingredients, reacting at 100-200 DEG C for 15-30hours, performing acid treatment, washing, filtering, drying and burning the ingredients to obtain the titanium dioxide nanotube. The titanium dioxide nanotube is efficiently prepared by a soft template combining with a hydrothermal method. The length of the prepared titanium dioxide nanotube is hundreds of nanometers, the outside diameter is about 10nm, the inside diameter is about 5nm, the titanium dioxide nanotube contains 2-5 layers of tube walls and two open ends. Compared with the titanium dioxide nanotube prepared by a common hydrothermal method under the same condition, the tube length is obviously increased, the tube diameter is more uniform, the draw ratio is large, the tube forming efficiency is high and the aggregation condition is alleviated, thereby being very beneficial for application of the titanium dioxide nanotube in various fields.

Owner:HARBIN ENG UNIV

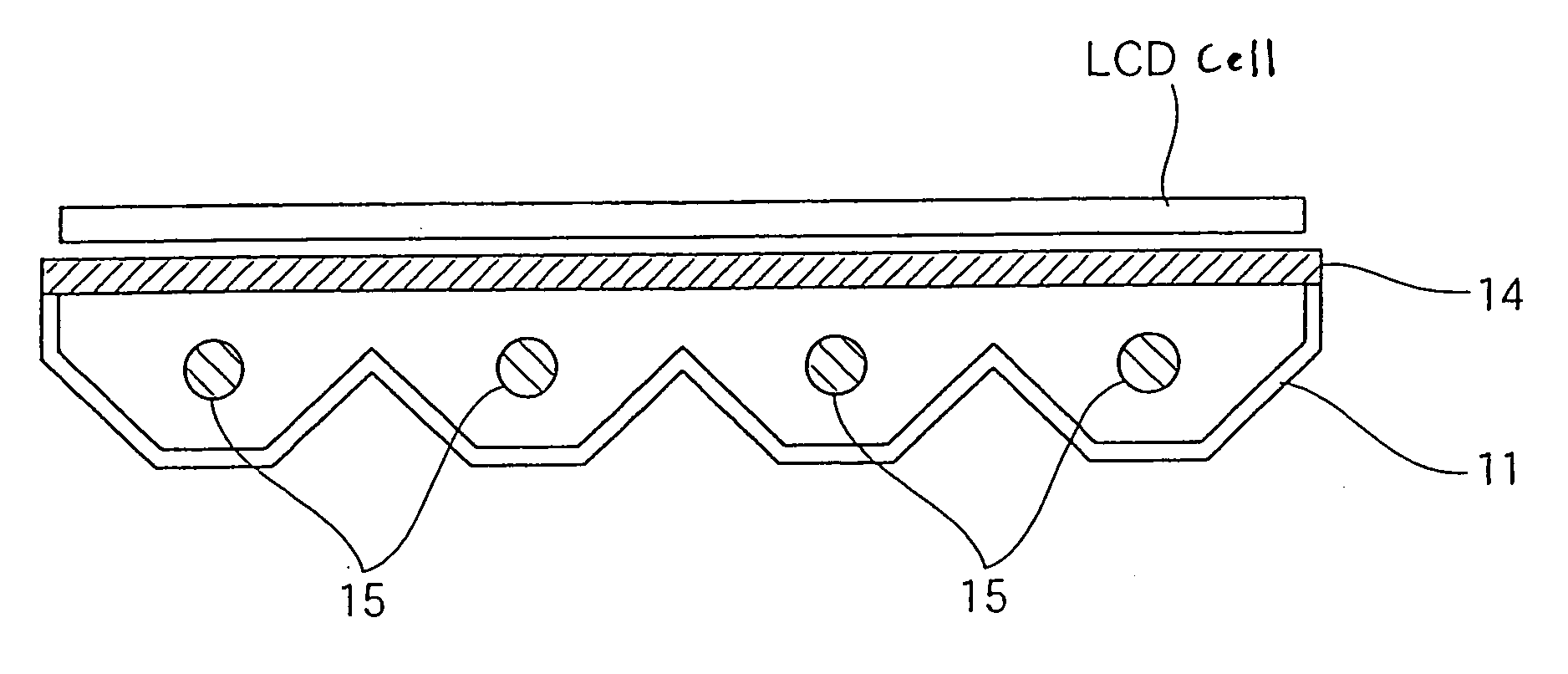

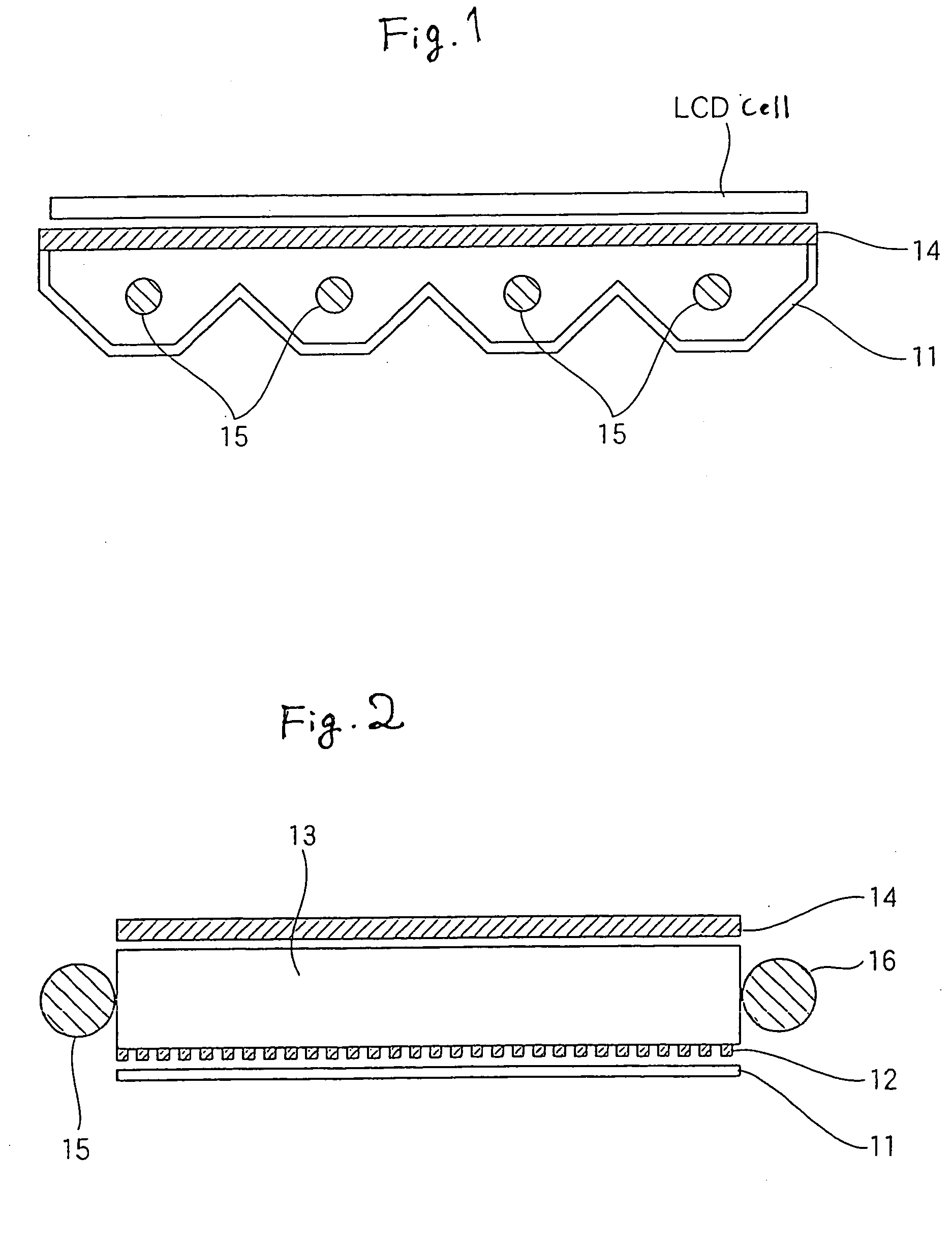

Light reflector

InactiveUS20050191464A1Reduced illuminance dropMirrorsSynthetic resin layered productsPolyesterEngineering

An object of the present invention is to provide a light reflector, which causes no unevenness in luminance in the surface direction due to deflection in use. The present invention is a light reflector comprising: an olefin-based resin film 1 comprising a filler and having a total ray reflectance of 90% or more, which is stretched at least monoaxially at an area stretch ratio of from 1.5 to 80; and at least one of the following substrates (1) to (4): (1) Film 2 comprising at least one of olefin-based resin and polyester-based resin as a main component; (2) Woven cloth 3 or non-woven cloth 4; (3) Metal plate 5; and (4) Molded material 6 comprising a thermoplastic resin composition (a1) containing a foaming agent and having a foaming ratio of from 1.05 to 10 as calculated by the following equation (1): Foaming ratio=ρo / ρ (1) where ρo represents the density before foaming; and ρ represents the density after foaming.

Owner:YUPO CORP

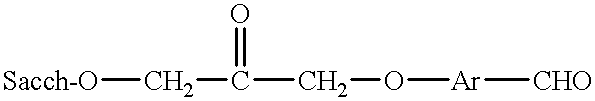

Chitin nano crystal whisker, chitin nanofiber and preparation method thereof

InactiveCN106868631AReduce manufacturing costScale controllableMaterial nanotechnologyFibre chemical featuresOrganic acidAcid hydrolysis

The invention relates to a chitin nano-whisker, a chitin nano-fiber and a preparation method thereof. In the present invention, chitin is added to the organic acid aqueous solution, stirred and heated to obtain a dispersion liquid and centrifuged to obtain a solid mixture, which is added to an alkali solution for neutralization and then left to stand for centrifugation; water is added for washing, centrifuged, left to stand for stratification, and the upper suspension is collected to obtain chitin nanocrystals The whisker dispersion liquid, the solid precipitate in the lower layer is quantitatively diluted with water and then homogeneously treated to obtain the chitin nanofiber dispersion liquid. The present invention uses chitin as a raw material to directly prepare two-scale chitin nanomaterials, that is, its nano whiskers and nanofibers, which expands the application space of chitin materials, and prepares chitin nanomaterials homogeneously through weak acid hydrolysis and a homogenizer , the process acid recovery rate is high, environmental protection, low cost, it is a new way to prepare chitin nano-materials, and can produce two kinds of nano-chitin materials with different aspect ratios in the same process, which is the application of chitin And quantitative production provides new prospects and ways.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

Soft, bulky single-ply absorbent paper having a serpentine configuration and methods for its manufacture

InactiveUS20010042606A1Easy to optimizeSuitable levelNatural cellulose pulp/paperMechanical working/deformationEngineeringDraw ratio

Single-ply absorbent tissue paper wherein of the fibers incorporated in the web: (a) at least 20% by weight have a coarseness exceeding 23 mg / 100 m; (b) at least about 20% by weight have a coarseness of less than about 12 mg / 100 m; and (c) the weight average fiber coarseness to length ratio is less than about 8.5 mg / 100 m / mm. The single-ply tissue having: a serpentine configuration; low sidedness; a basis weight of at least about 12.5 lbs. per 3000 square foot ream; specific total tensile strength between 40 and 200 g / 3 inches / lb per 3000 square foot ream; a cross direction specific wet tensile strength between 2.75 and 20.0 g / 3 inches / lb per 3000 square foot ream; an MD tensile to CD tensile ratio between 1.25 and 2.75; a specific geometric mean tensile stiffness between 0.5 and 3.2 g / inch / % strain per pound per 3000 square foot ream; a friction deviation less than 0.250; and a sidedness parameter less than 0.30.

Owner:GPCP IP HLDG LLC

Double perovskite type inorganic nano fiber and preparation method thereof

InactiveCN104313729AStable one-dimensional structureLarge specific surface areaInorganic material artificial filamentsFiberNickel salt

The invention relates to double perovskite type inorganic nano fiber and a preparation method thereof and belongs to the field of inorganic nano fiber materials. The preparation method comprises the following steps: mixing polyvinylpyrrolidone with a solvent to obtain a spinning precursor solution, and performing electrostatic spinning, preoxidation and carbonization to the spinning precursor solution to obtain the double perovskite type inorganic nano fiber; the spinning precursor solution comprises the following components in mass percent: 10% to 20% of inorganic salt, 10% to 30% of polyvinylpyrrolidone and the balance of solvent, wherein the inorganic salt is the mixture of lanthanum salt, cobalt salt and metal salt III, the molar ratio of the lanthanum salt, the cobalt salt and the metal salt III is 2:1:1, and the metal salt III is nickel salt, ferric salt or manganese salt. The invention has the advantages that the preparation method is simple and easy to implement, the raw material consumption is low, the product purity is high, and the obtained double perovskite type inorganic nano fiber has a stable one-dimensional structure, is relatively high in draw ratio and uniform in diameter.

Owner:DALIAN JIAOTONG UNIVERSITY

High strength, high toughness, high carbon steel wire rod and method of production of same

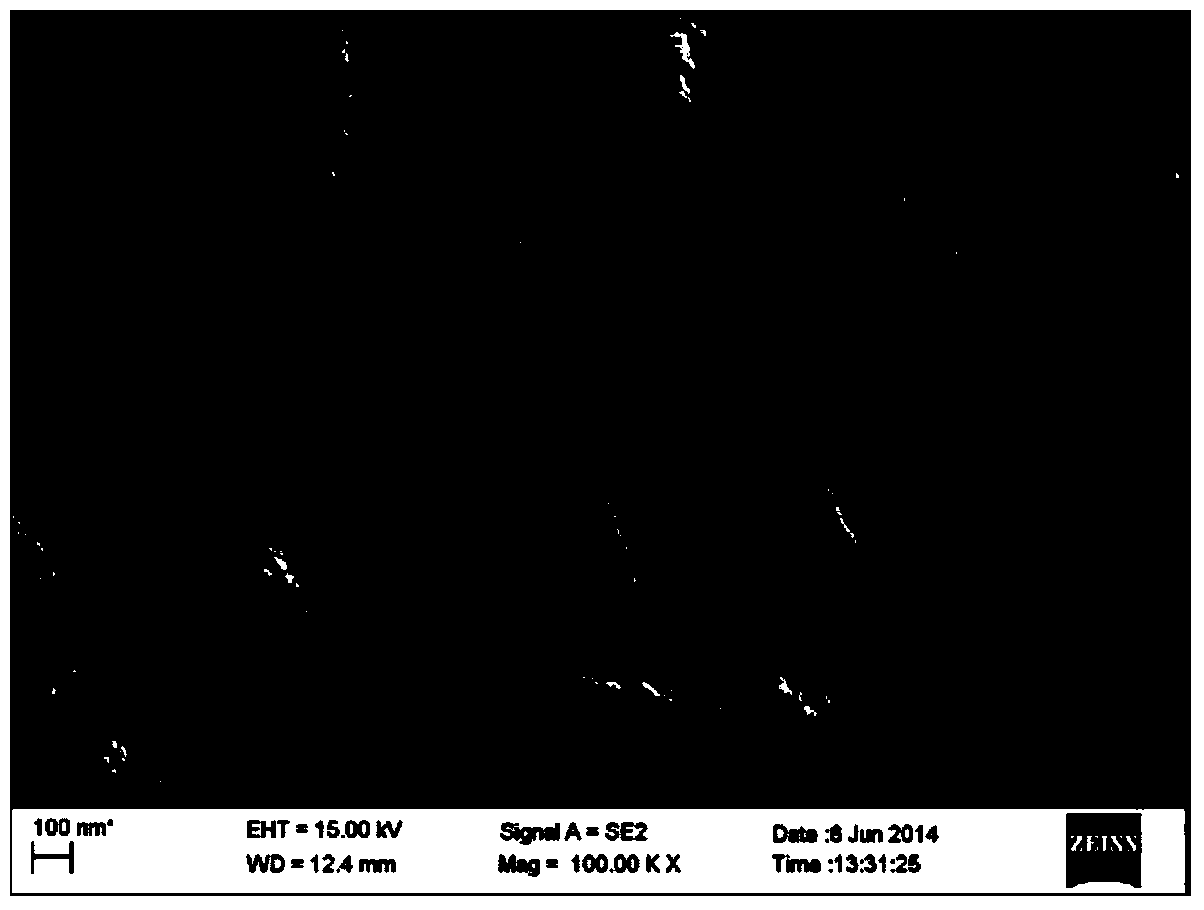

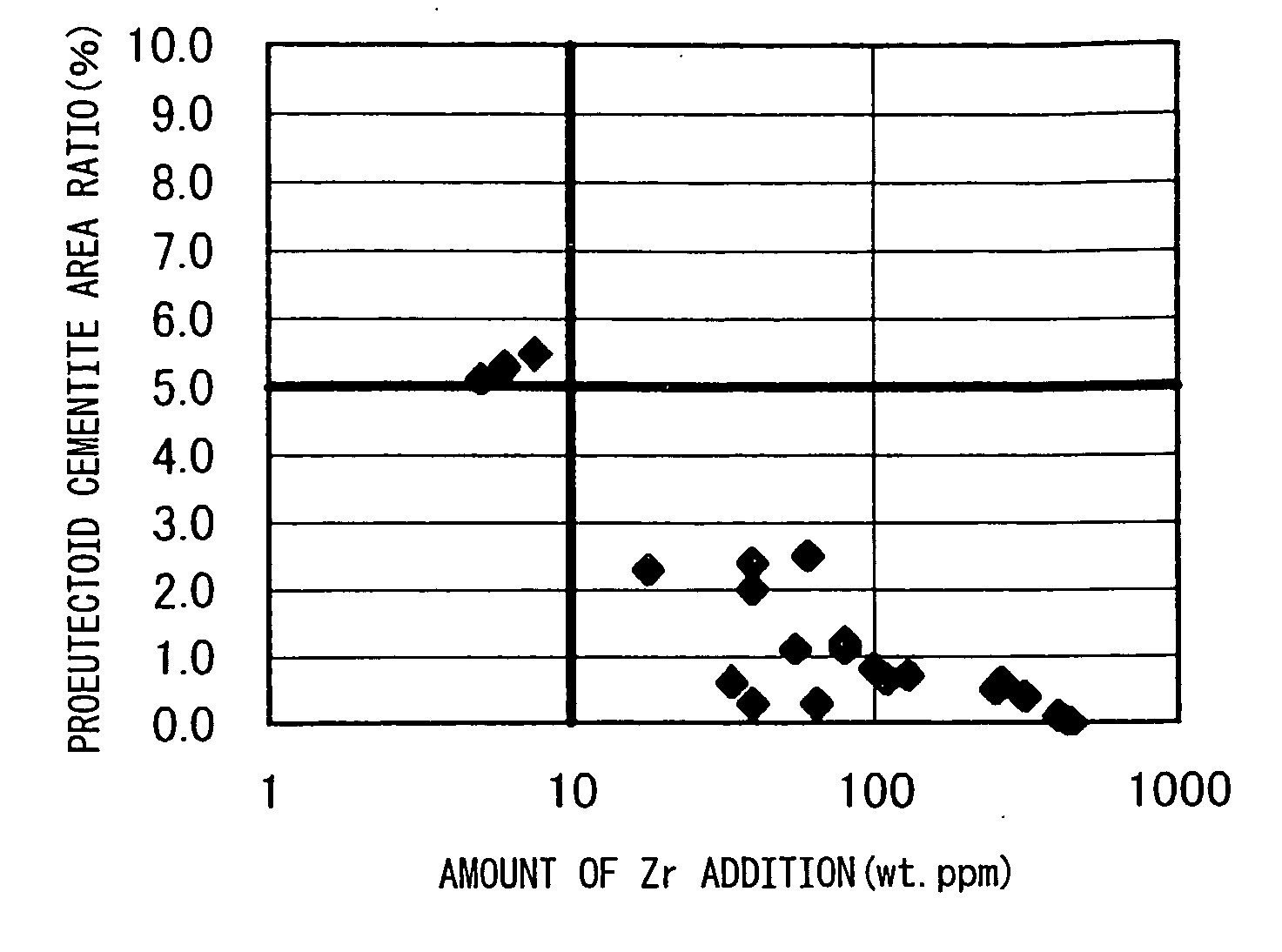

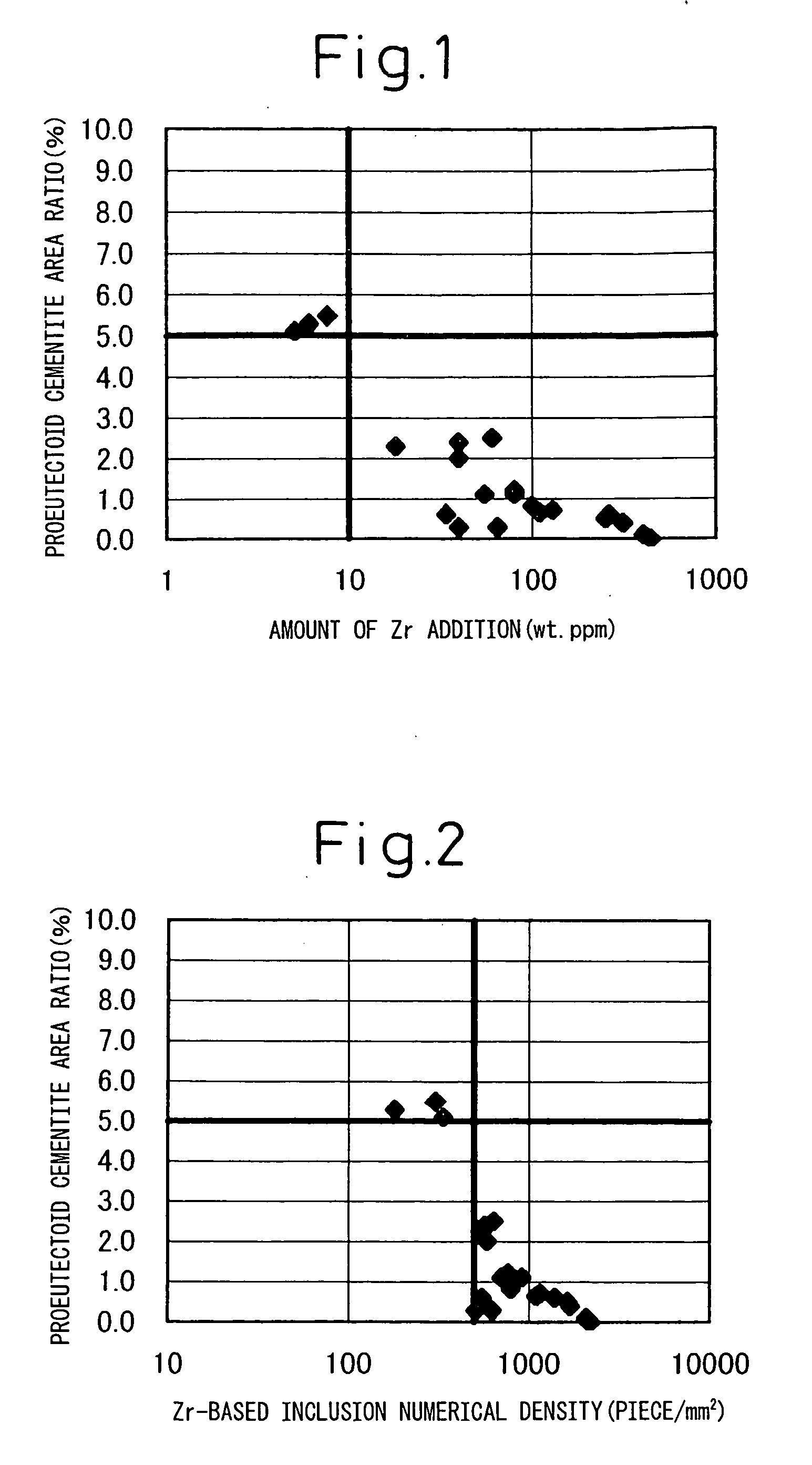

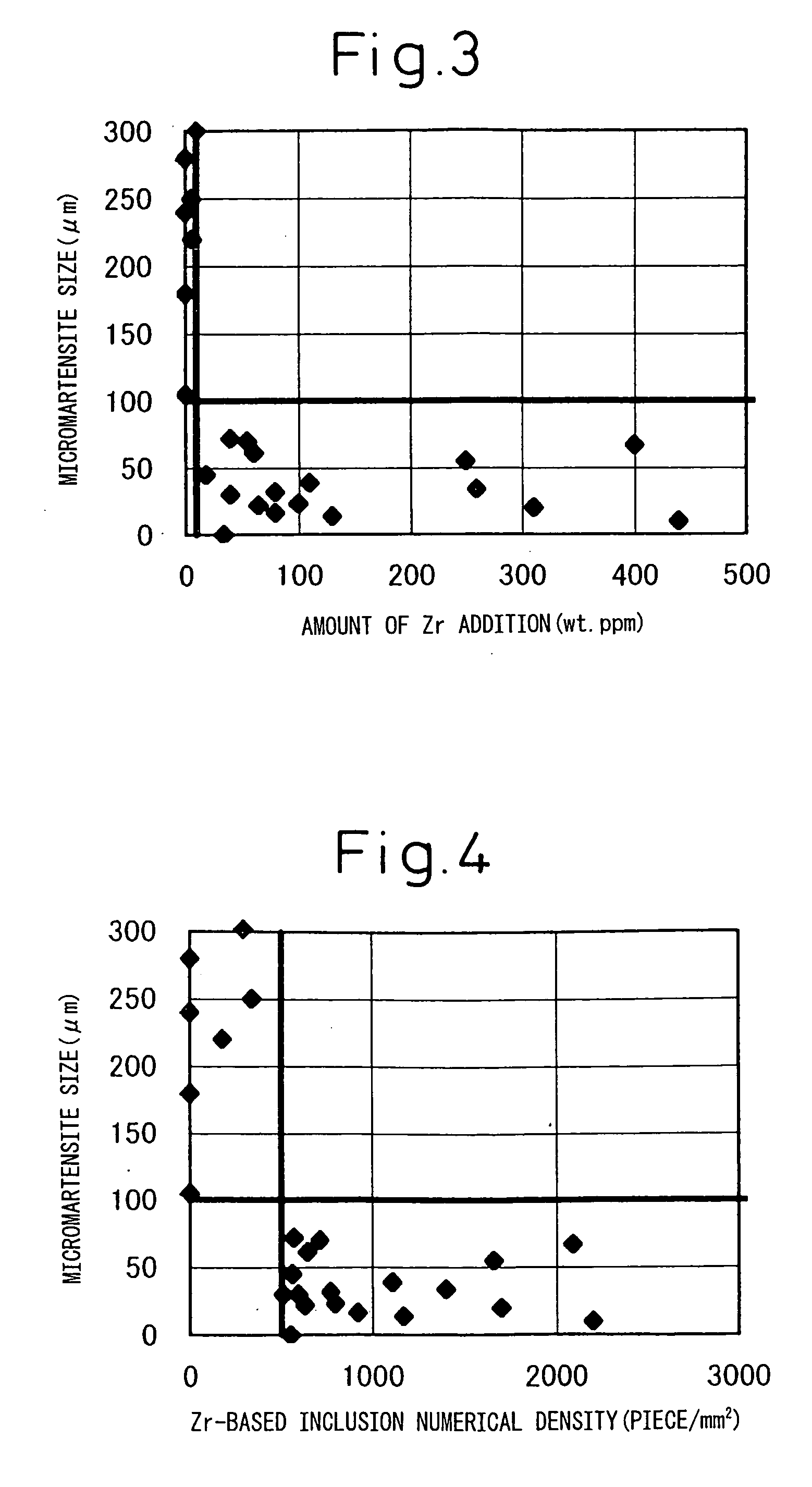

InactiveUS20060137776A1High strengthImprove toughnessHot-dipping/immersion processesFurnace typesHigh carbonNumerical density

The present invention provides a high strength, high toughness steel wire rod useful for a PC steel wire, galvanized steel strands, spring use steel wire, cables for suspension bridges, etc. By hot rolling, then directly patenting or reaustenitizing, then patenting a high carbon steel wire rod of a specific chemical composition of the steel and chemical composition, size, and numerical density of inclusions, piano wire rod or high carbon steel wire rod having a structure of mainly pearlite, having an average value of the proeutectoid cementite area ratio of 5% or less in a center region of less than 20% of the wire rod diameter from the center of the wire rod, having a micromartensite size of the C section of 100 μm or less, having a tensile strength of the 170 kgf / mm2 class or more, and having a drawing ratio at break of 30% or more is obtained.

Owner:NIPPON STEEL CORP

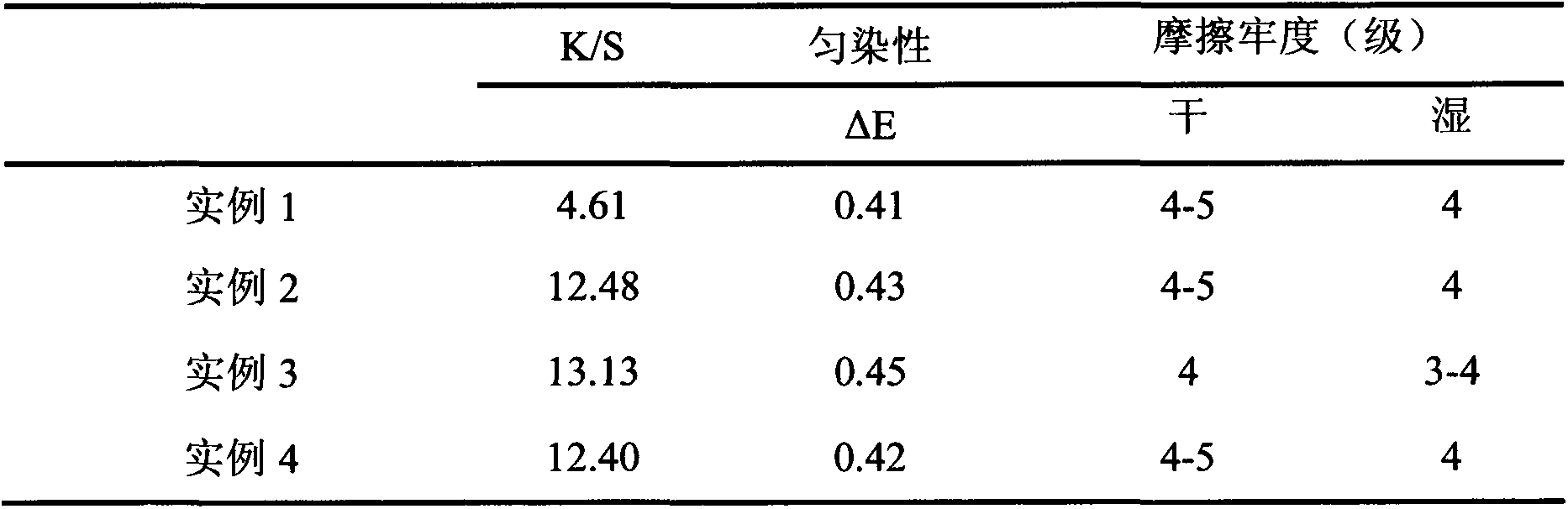

Method for coloring alginate fibers by nano pigment

ActiveCN103556301AIncrease profitAddressing Defects in StainingAlginate artificial filamentsPigment addition to spinning solutionWater resourcesRoom temperature

The invention discloses a method for coloring alginate fibers by a nano pigment. The method comprises the following steps: adding a certain quantity of superfine aqueous nano pigment into an alginate fiber spinning solution; agitating for uniformly dispersing pigment grains; filtering and defoaming; and carrying out wet-method spinning at room temperature to prepare colored alginate fibers, wherein the draw ratio of the fibers is 100%-300%. The alginate fibers prepared by the method are uniformly colored, is washable and has high sunlight fastness; water resources and energy consumption are saved and clean production is realized; the method for coloring the alginate fibers by the nano pigment has good application prospects in the fields of clothes and environmental protection.

Owner:吴江山湖颜料有限公司

Polypropylene/doped oxide composite functional fiber preparation method

ActiveCN101597810ASimple production equipmentEase of industrial productionElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentMasterbatchEmissivity

The invention relates to a polypropylene / doped oxide composite functional fiber preparation method, comprising the following steps: (1) mixing the dried polypropylene matrix and the oxide powder evenly; (2) adjusting the temperature of a twin-screw extruder to 160-220 DEG C, adding the mixed powder, squeezing out, cooling, cutting into grains and obtaining spinning masterbatch; (3) adding the masterbatch in a spinning machine to obtain freshly formed filament; (4) drafting the freshly formed filament with a extension drawing ratio of 2-6 times to obtain the composite functional fiber of the invention. The preparation method of the invention has simple production equipments and easy-realizable industrialized production, the composite functional fiber prepared by the invention has the functions of absorbing electromagnetic wave, reducing infrared emissivity, restraining bacteria, resisting ultraviolet radiation, preventing aging and the like, and the fiber can be widely used in various fields such as textiles with the functions of preventing electromagnetic wave radiation, restraining bacteria, resisting aging and resisting static electricity and the like.

Owner:GUANGDONG MODERN HIGH TECH FIBER CO LTD

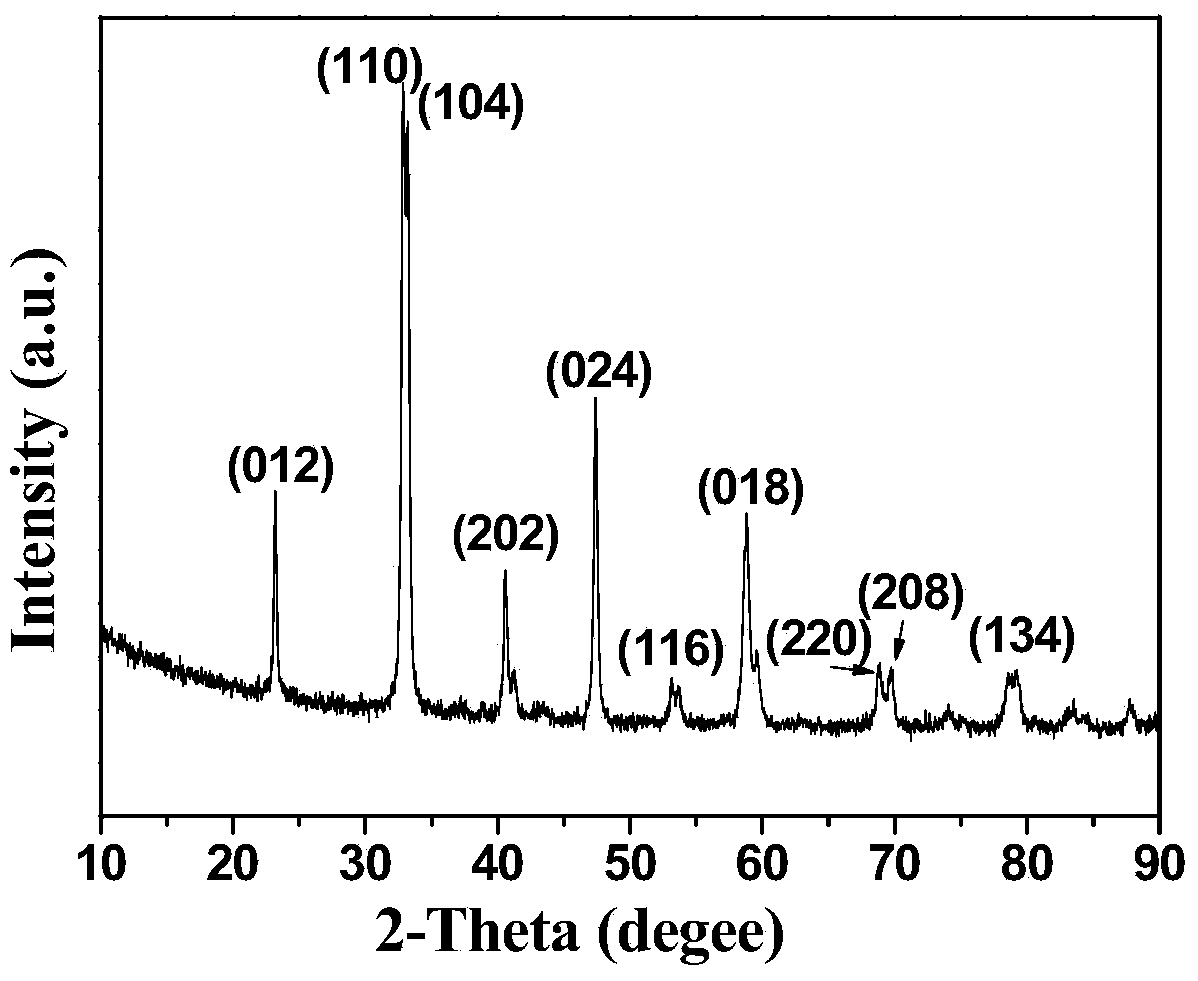

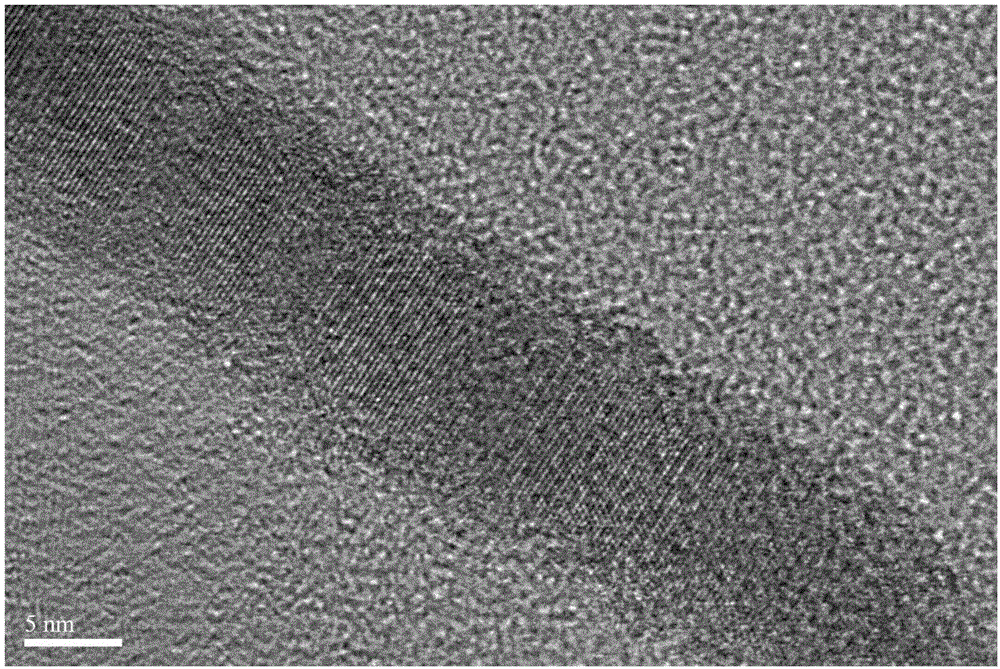

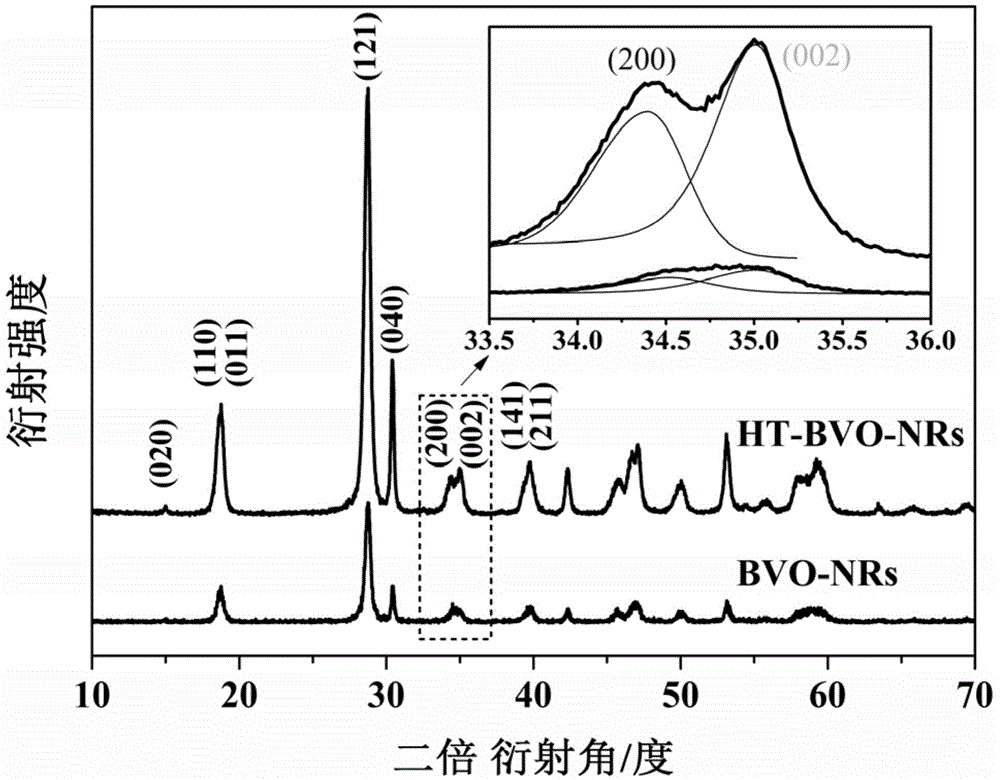

Efficient photocatalyst for bismuth vanadate nanorod and preparation method of catalyst

InactiveCN104014326ALarge specific surface areaHigh crystallinityMetal/metal-oxides/metal-hydroxide catalystsBismuth vanadateSynthesis methods

The invention relates to an efficient photocatalyst for a bismuth vanadate nanorod and a preparation method of the catalyst. The morphology of the catalyst is rodlike, the size is nano-scale, the diameter of the nanorod is 15-30nm, the draw ratio is 5-40, the specific surface area is 28.2m<2>.g<-1>, the crystal phase is a monoclinic scheelite phase, and the growth direction is [010] direction. The preparation method comprises the following steps: firstly, dissolving bismuth nitrate pentahydrate, and sodium oleate or oleic acid into water, acutely stirring, and then adding ammonium metavanadate to a mixed solution; carrying out water heating for 6-48 hours under the condition at 70-200 DEG C, and centrifugally washing and drying to obtain the bismuth vanadate nanorod. Compared with the prior art, the synthesis method adopted by the invention is simple in equipment, convenient to operate, short in synthesis cycle, high in repeatability, few in raw material species, low in cost, environmental friendly, free of pollution and high in yield, the prepared bismuth vanadate nanorod is high in adsorption capacity, and the toxic pollutants and decomposition water can be abnormally efficiently degraded under radiation of an ultraviolet light, a visible light and a natural light.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing polypropylene melt with high melt strength

The embodiment of the invention discloses a method for preparing polypropylene melt with high melt strength, which uses alkadiene as a modified monomer, thus improving the tensile property of the polypropylene melt with high melt strength due to good compatibility of the alkadiene and polypropylene resin. In addition, the alkadiene monomers can perform grafting reaction with the polypropylene melt, and the alkadiene monomer has lower activity, thus inhibiting cross-linkage reaction so as to expedite the grafting reaction in a certain degree and ensure polypropylene to have higher melt strength. Therefore, the polypropylene melt with high melt strength prepared by the method provided by the invention not only has higher melt strength, but also has larger draw ratio and excellent melt ductility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Applications of PHBV as novel natural antibacterial material in textile product preparation

InactiveCN107385541AImprove antibacterial propertiesLow costConjugated cellulose/protein artificial filamentsMonocomponent copolyesters artificial filamentYarnPolymer science

The present invention discloses applications of PHBV as a novel natural antibacterial material in textile product preparation. According to the present invention, the mixture of pure PHBV or a PHBV copolymer and other polymers or copolymers is injected into extrusion equipment with a heating device, melting is performed, fibers are collected at a temperature of 170-225 DEG C under 300-3000 m / min, and FDY long fibers are prepared according to a drawing ratio of 2-4, or short fibers are prepared according to a conventional short fiber process; during the preparation of fabrics, the fabric can be prepared completely from the PHBV long yarn or the short-fiber yarn, and can further be prepared by carrying out mixed weaving or blending on the PHBV fibers and other fiber materials; PHBV as the completely bio-based novel natural environmentally-friendly antibacterial material has characteristics of high antibacterial rate, lasting antibacterial property, no toxicity, no harm, good biocompatibility and the like; and various fabrics having different PHBV fiber contents of the present invention have excellent antibacterial property, and can maintain the good antibacterial function after water washing 20 times.

Owner:TIANAN BIOLOGIC MATERIAL NINGBO

Method of producing lighting terylene short fiber

InactiveCN101289769AImprove uniformityReduce the number of times of spinning and trimmingSpinnerette packsFilament/thread formingPolyesterNonwoven fabric

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

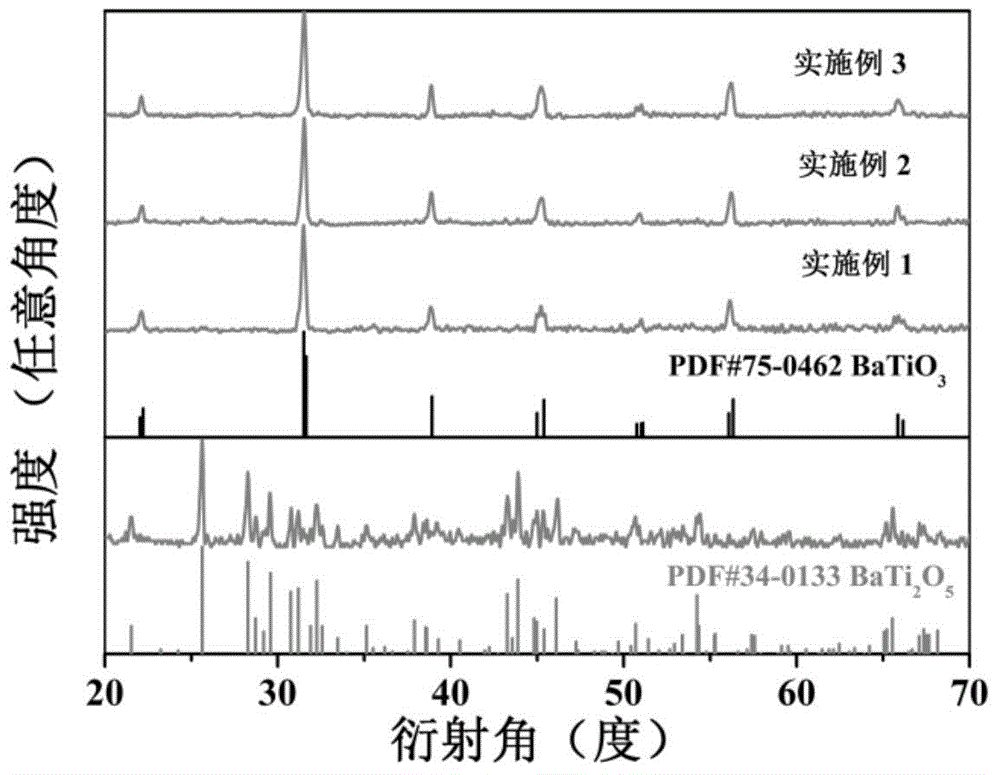

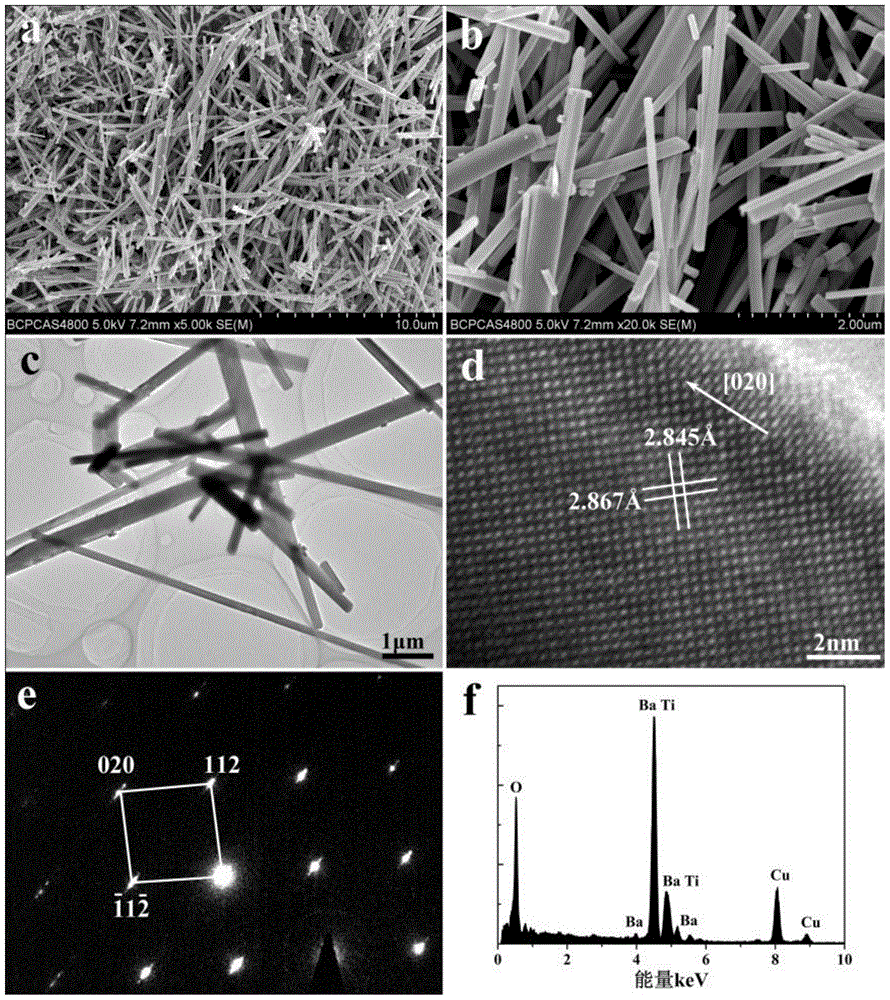

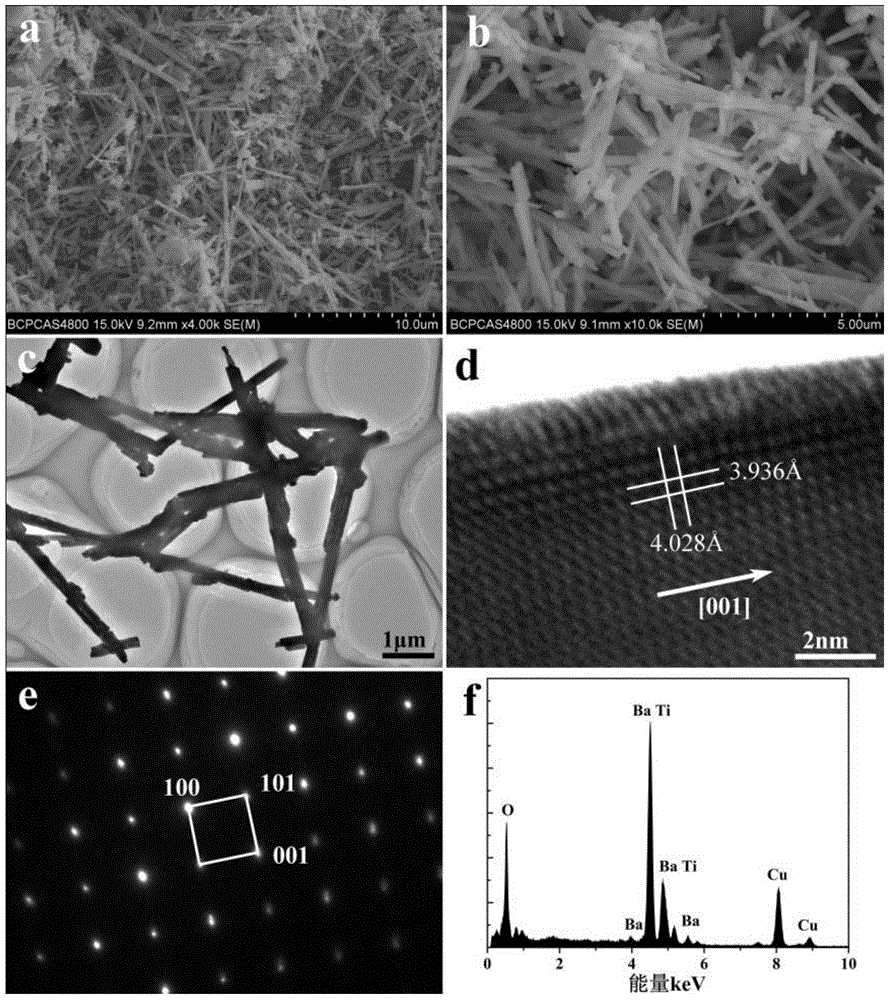

Method for preparing BaTiO3 nanowire through two-step salt melting method

InactiveCN104925856ASimple processGood repeatabilityMaterial nanotechnologyTitanium compoundsNanowireMolten salt

The invention relates to a method for preparing a BaTiO3 nanowire through a two-step salt melting method and belongs to the technical field of BaTiO3 nanowires. The two-step salt melting method is adopted, the first step salt melting process is carried out, BaCO3 and TiO2 are taken as raw materials, NaCl and KCl eutectic salt with the ratio of the NaCl and the KCl being 1:1 serves as a medium, a BaTi2O5 nanowire is obtained and serves as a template, the second step of salt melting process is carried out, and a pure-phase BaTiO3 nanowire material with the large draw ratio is synthesized. The production method is simple in process and low in energy consumption, the BaTiO3 nanowire has the large draw ratio and the even appearance. A new approach capable of massively preparing the BaTiO3 nanowire is provided.

Owner:BEIJING UNIV OF TECH

Sparkling bamboo joint terylene fibre

The invention relates to a glitter slub polyester filament yarn, wherein, triangular pre-oriented yarns (POY) are produced by modification of spinning filaments through a spinneret plate and the yarns have the characteristic of glitter; the triangular pre-oriented yarns are processed into slub yarns by adoption of a special drafting technique during the post processing process of the POY; and the post processing drafting technique is to adopt a small draw ratio (between 1.4 and 1.46) and a relatively high setting temperature to process the slub yarns into finished products DTY, namely the glitter slub polyester filament yarn. Textile fabrics woven by fibers have flowery color and can be widely used for manufacturing an evening dress, a performance costume, an ornament, a fashion dress and so on.

Owner:SUZHOU LONGJIE SPECIAL FIBER

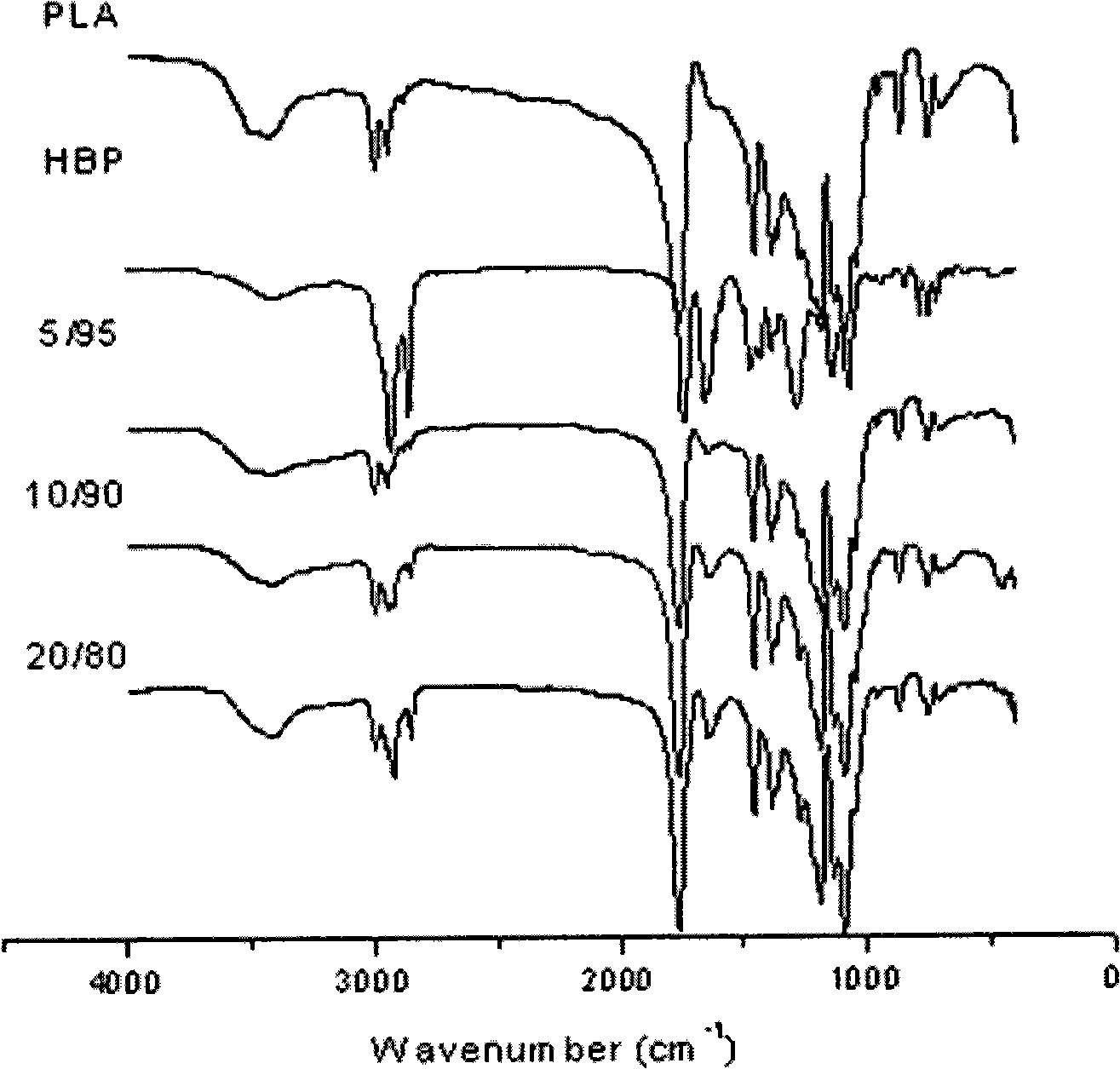

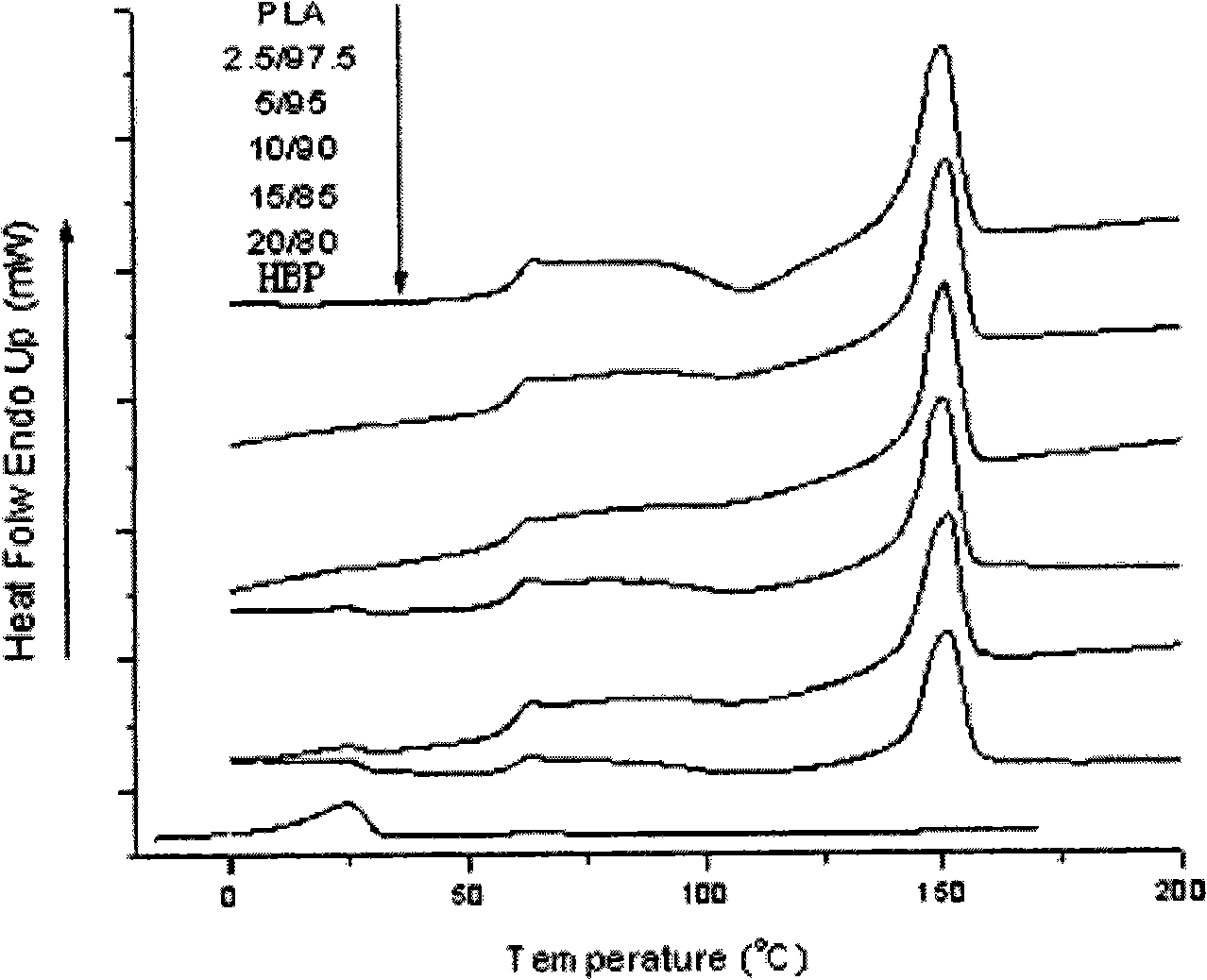

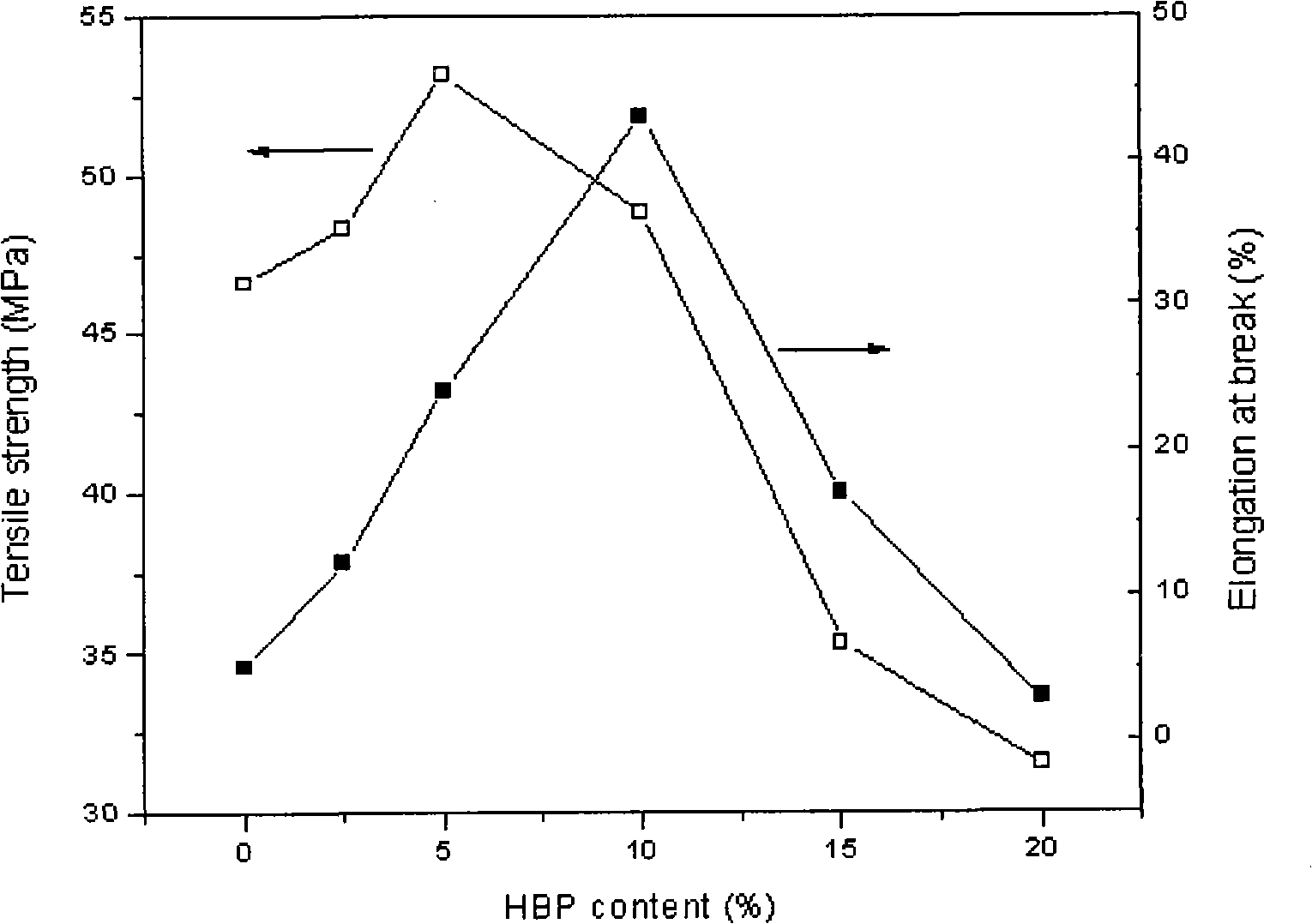

Shape memory material based on polylactic acid, manufacturing and using process thereof

InactiveCN101319088AOvercome the disadvantage of brittlenessControl performanceCrystallinityDraw ratio

The invention provides a shape memory material on the basis of polylactic acid and a preparation method thereof. The shape memory material is characterized by consisting of the polylactic acid and hyper branched polyesteramide, wherein, the weight portion of the polylactic acid is between 80 and 98 portions and the weight portion of the hyper branched polyesteramide is between 2 and 20 portions. The shape memory material has the advantage that various performances of a product such as the mechanical intensity, the breaking elongation and the degree of crystallinity can be controlled by changing the ratio of the hyper branched polyesteramide to the polylactic acid and mixing the two. The general polylactic acid material is easy to rupture when subject to a stretching or bending stress. The polylactic acid material overcomes the shortcoming of brittleness of the pure polylactic acid and has high toughness and elongation at break. Therefore, the polylactic acid material does not break at a high draw ratio, can restore to the prior shape by being heated and has good shape memory effect.

Owner:DONGHUA UNIV

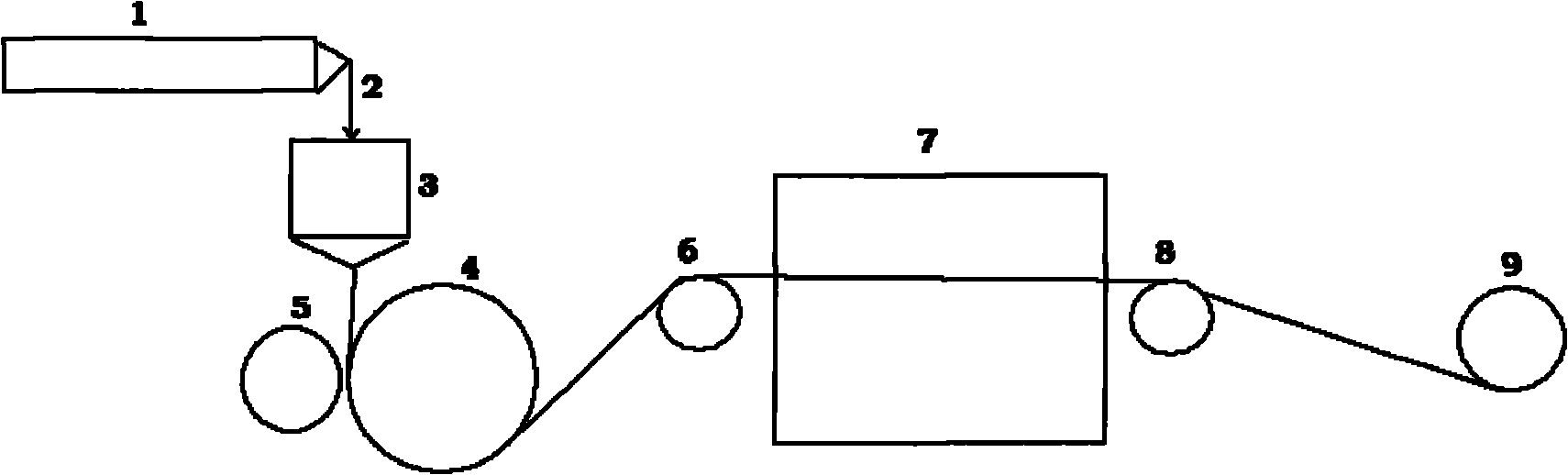

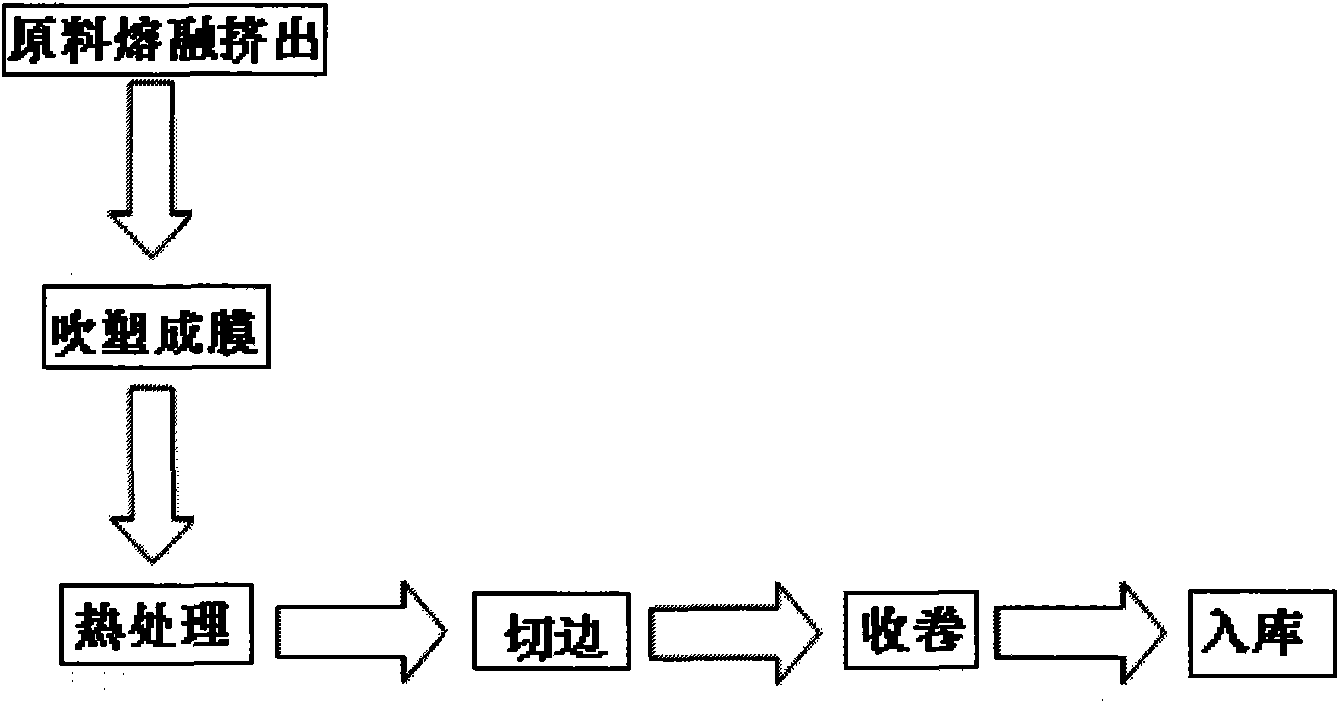

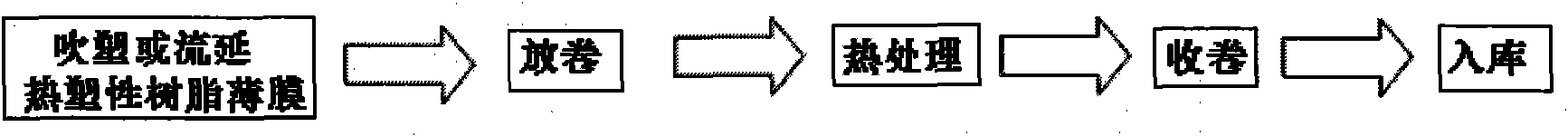

Method for preparing thermoplastic resin film

ActiveCN101767465AImproved optical properties and gas permeabilityLateral orientation is smallFlat articlesDrawing ratioMolecular geometry

The invention discloses a method for preparing a thermoplastic resin film, wherein, the film is not stretched or extended to a micro-stretch film with drawing ratio 0.1-60 per cent through melting cast film or blow molding, and then transferred to a heat treatment device for heat treatment more than 0.1s and less than 1200s under the condition of convey tension range of 0.1-300 N / cm<2> and in therange of heat treatment temperature below thermoplastic resin melting point Tm and above glass transition temperature (Tg+50 DEG C). The method of the invention combines the advantages of melting cast or blow molding and heat treatment. The resulting thermoplastic resin film has reasonable internal molecular structure and orientation, perfect and controllable mechanical property, dimension stability, temperature range, optical property and air permeability.

Owner:FOSHAN KING WONDER HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com