Patents

Literature

3312 results about "Filament yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filament Yarn. There are basically two types of fibers that are used to make yarn; namely, filament and staple fibers. The fibers that are so long, and that they can work themselves as yarn are called filament fibers. As they do not require twisting to be converted into yarn, they are sometimes also referred to as filament yarn.

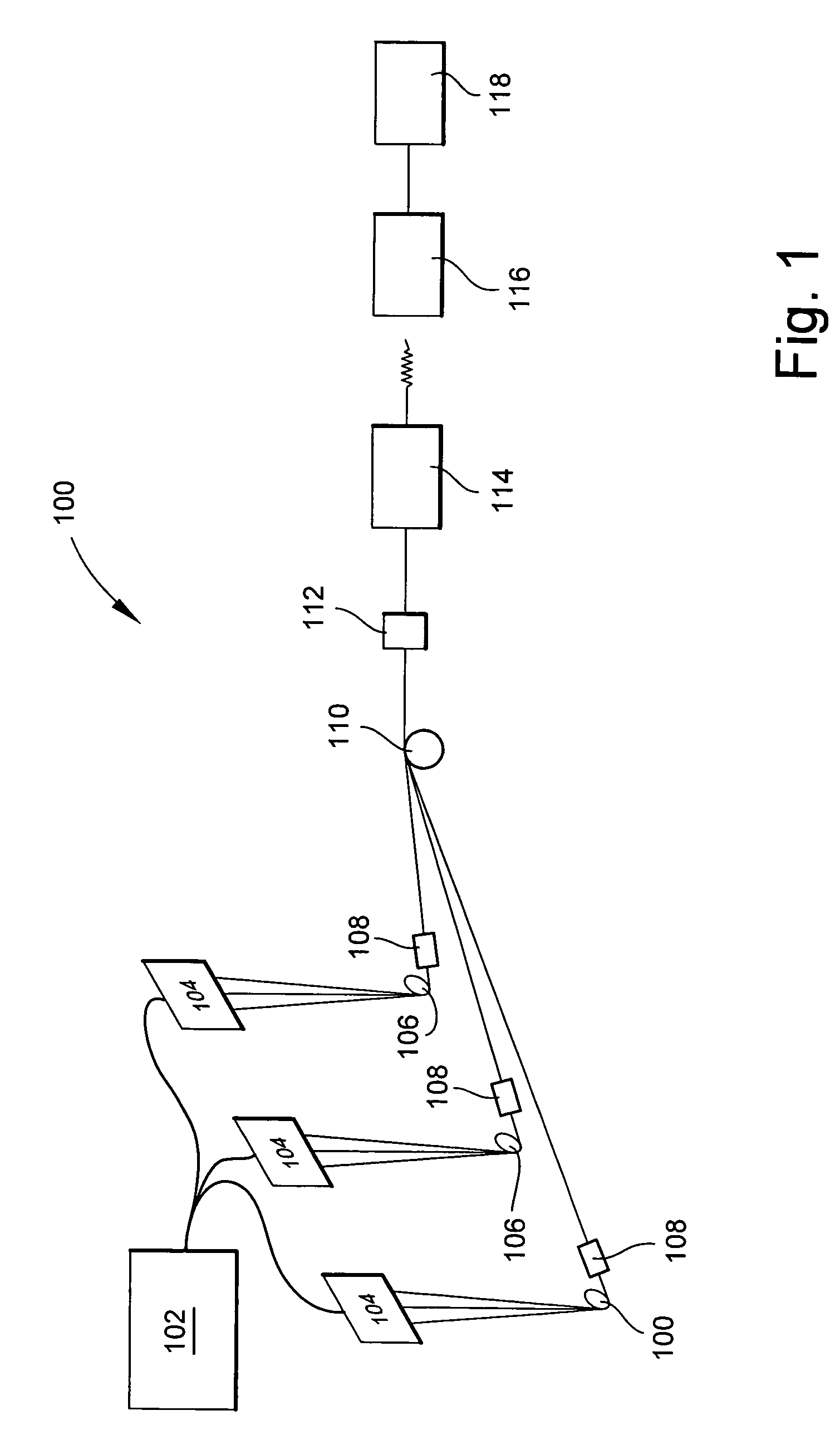

Carpet Construction and Carpet Backings for Same

Owner:PROPEX OPERATING

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

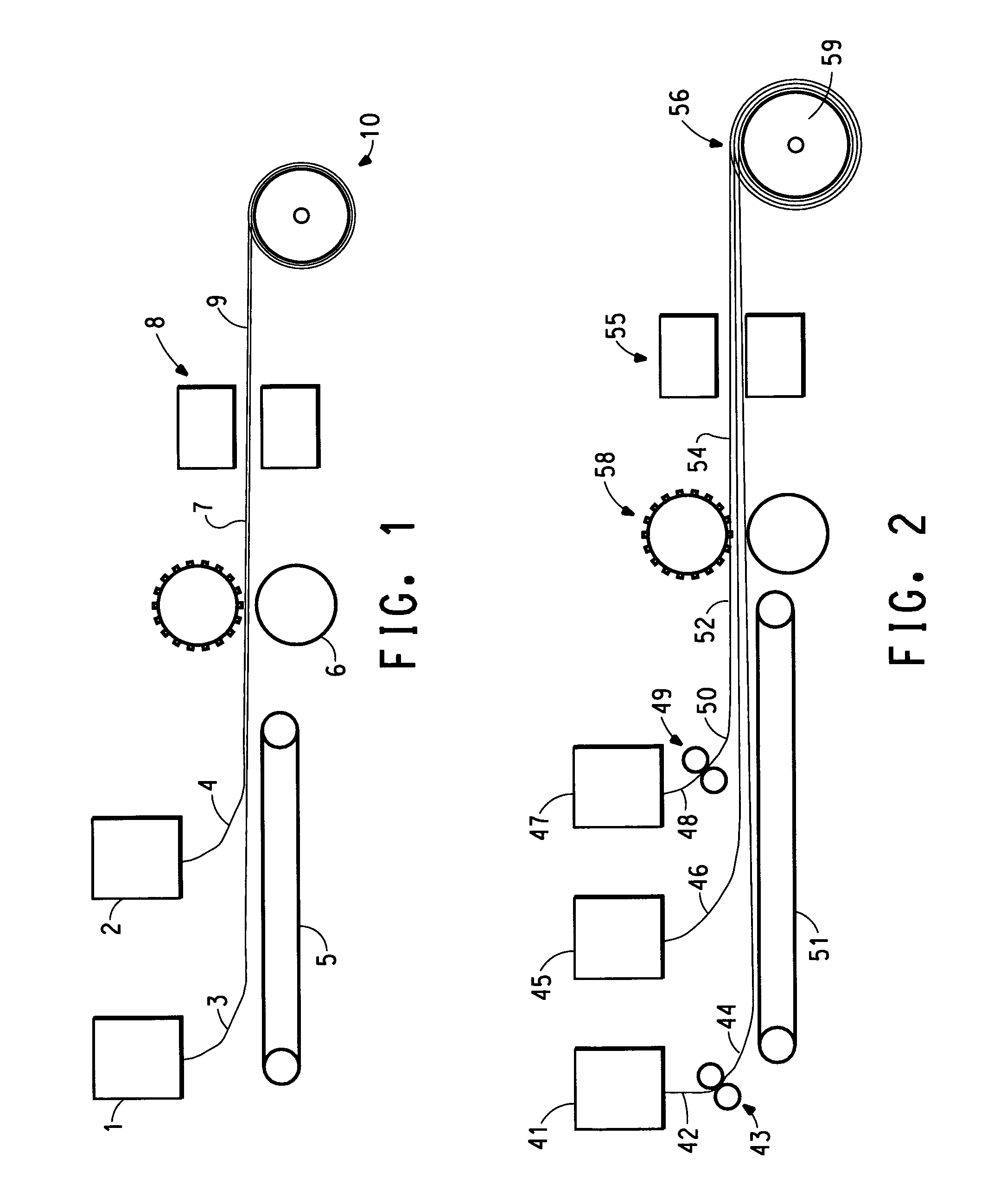

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

Soft and bulky composite fabrics

A composite fabric is provided that contains staple fibers hydraulically entangled with a nonwoven web formed from continuous filaments. A portion of the staple fibers is entangled with the web, while another portion protrudes through the web. The resulting surface topography has one surface with a preponderance of the smooth, staple fibers, and another surface with a preponderance of the continuous filaments from the nonwoven web, but also including some of the protruded smooth, staple fibers. Thus, each surface contains smooth staple fibers and is soft.

Owner:KIMBERLY-CLARK WORLDWIDE INC

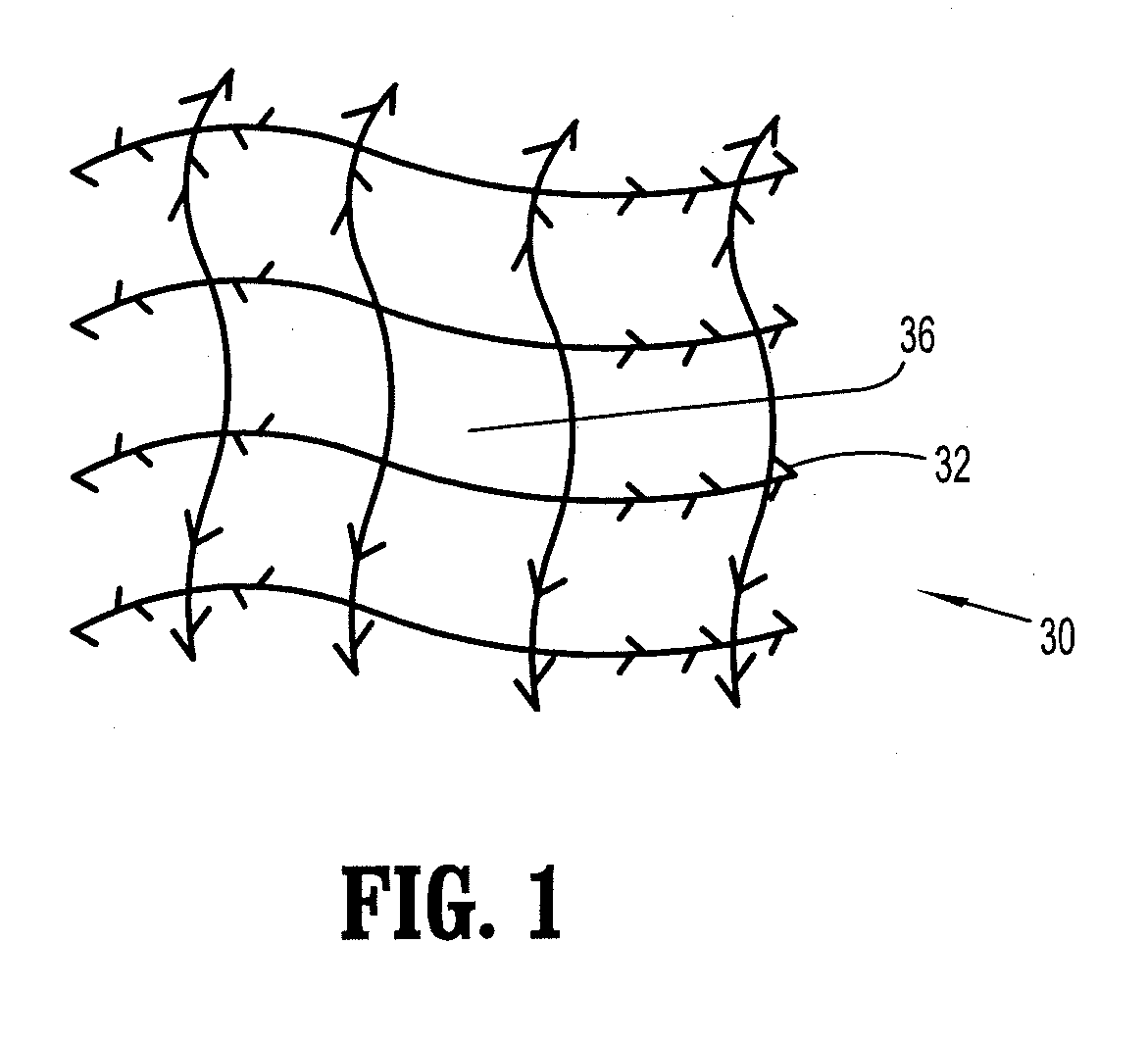

Stretchable composite sheets and processes for making

This invention relates to an improved method for preparing stretchable multiple-component bonded composite sheets which involves bonding a fibrous layer of spirally-crimpable multiple-component continuous filaments or staple fibers to one or more non-spirally-crimpable layers using an array of intermittent mechanical, chemical, or thermal bonds, and heating the bonded composite to activate the spiral crimp of the fibers in the spirally-crimpable layer. Multi-layer nonwoven fabrics prepared according to the method of the current invention have an improved combination of strength, aesthetics, stretch-recovery properties, and textile hand and drape compared to multiple-component nonwoven fabrics known in the art.

Owner:THE LYCRA CO LLC

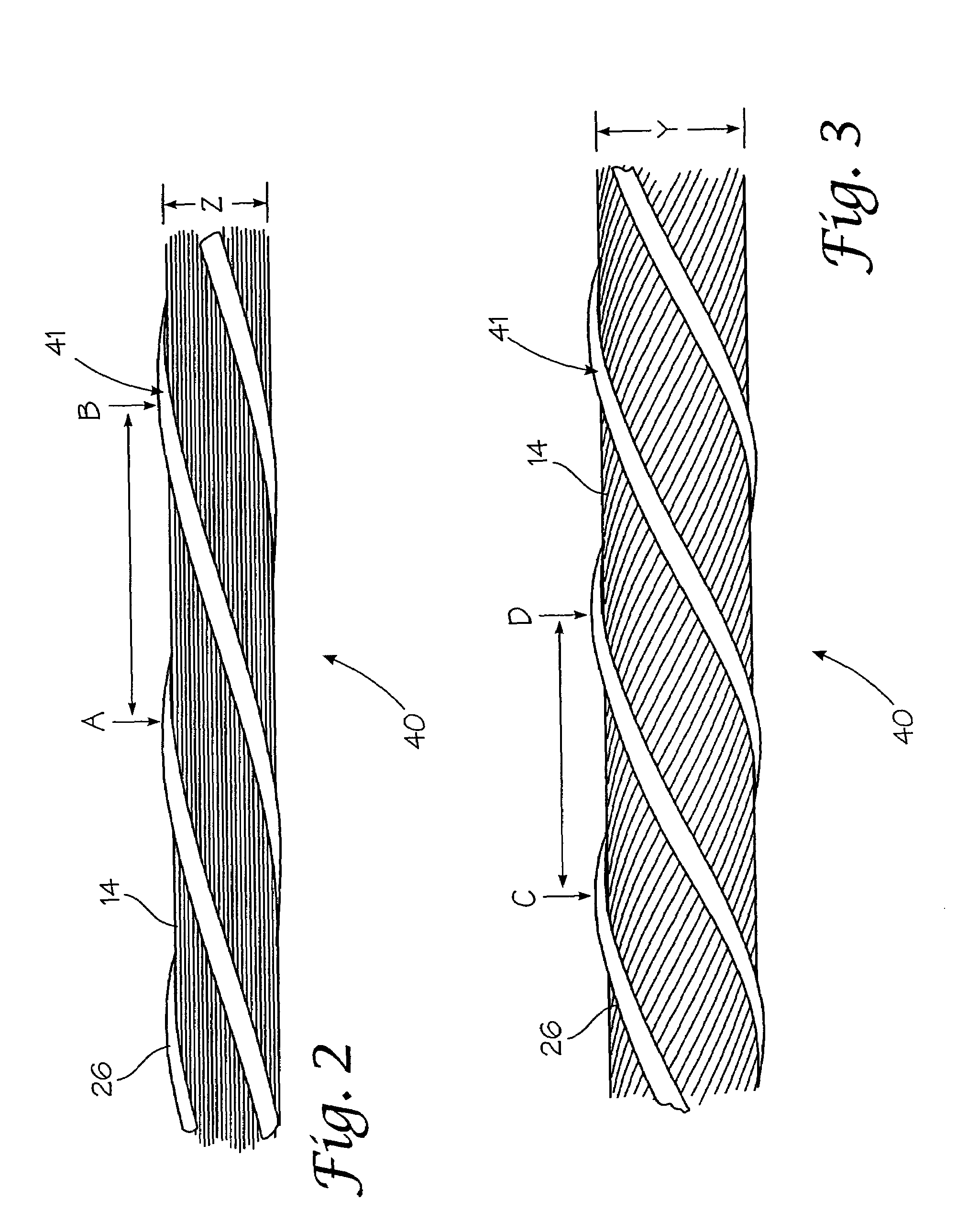

Filament-Reinforced Composite Fiber

Owner:TYCO HEALTHCARE GRP LP

Process for drawing gel-spun polyethylene yarns

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

Filaments comprising an active agent nonwoven webs and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

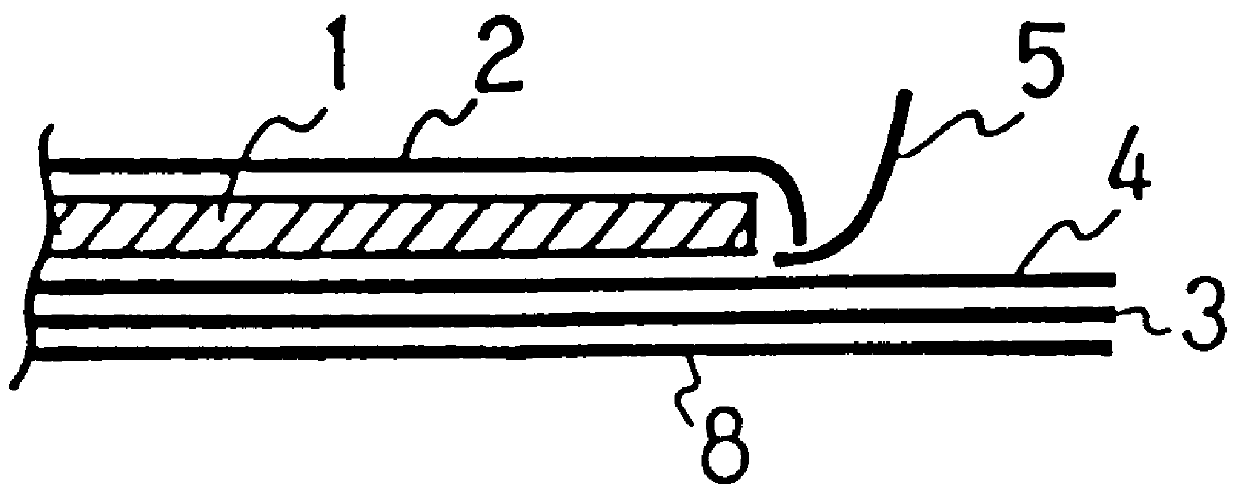

Devices for prevention of pressure ulcers

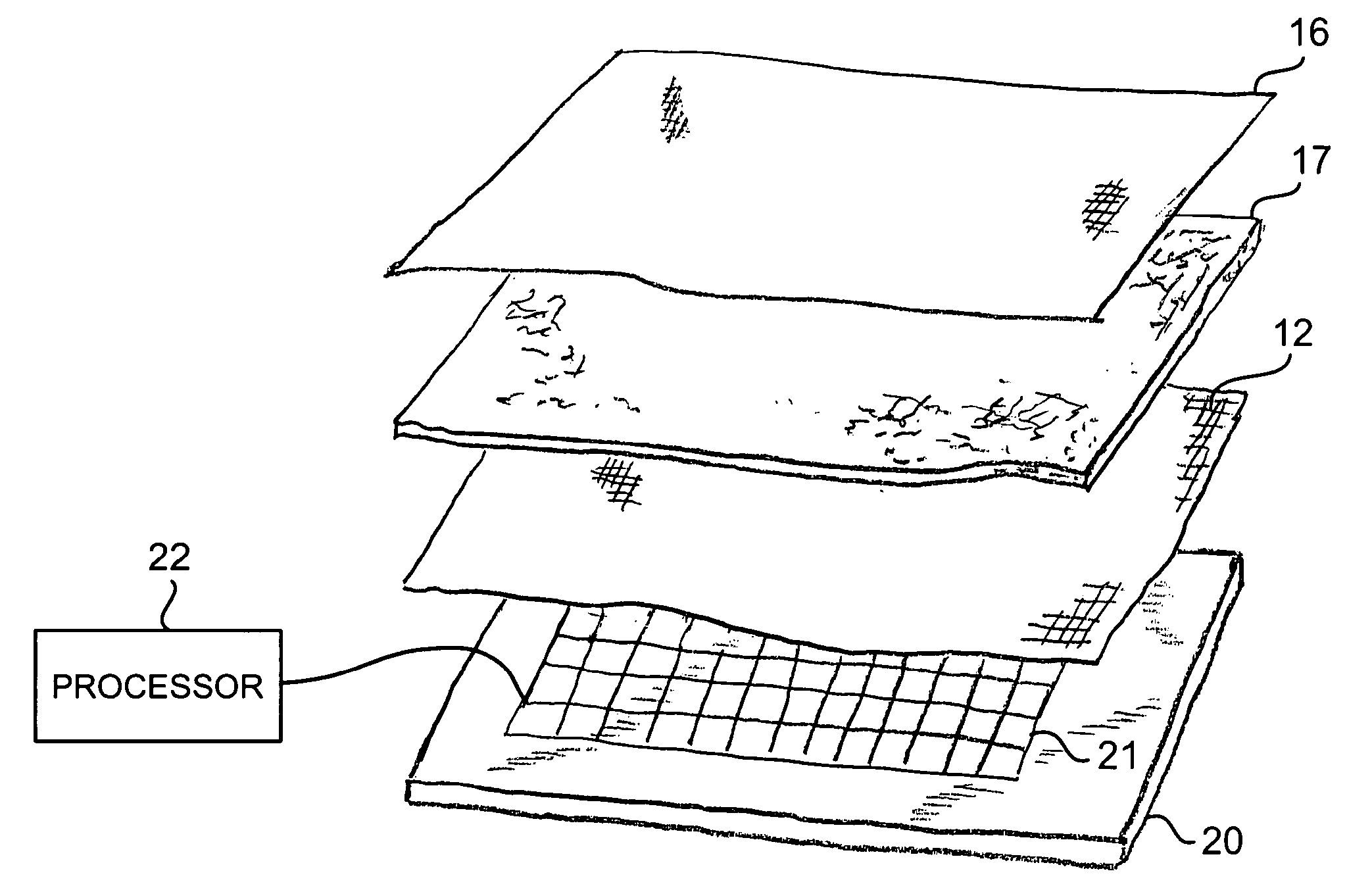

InactiveUS20090070939A1Avoid pressure soresMinimal puckeringStuffed mattressesSpring mattressesInter layerSkin contact

A support surface, such as an underpad, for preventing pressure sores in a patient is a multi-layer textile assembly having a skin contact layer formed from a fabric of synthetic filament yarns woven to provide air permeability and moisture vapor permeability and having a thickness of less than 1 mm. An absorbent middle layer is formed from a breathable microfiber fabric woven to provide for moisture transition from an upper surface of the middle layer to a bottom surface of the middle layer. The skin contact layer and the middle layer are stitched together using a stitching pattern optimized to produce an open pattern with minimal puckering. A bottom layer is formed from a breathable, waterproof fabric woven from synthetic yarn to produce a moisture vapor transfer rate within the range of 5,000 to 20,000 grams per meter squared per 24 hours. The three layers are attached together around their outer edges.

Owner:PERSIMMON SCI

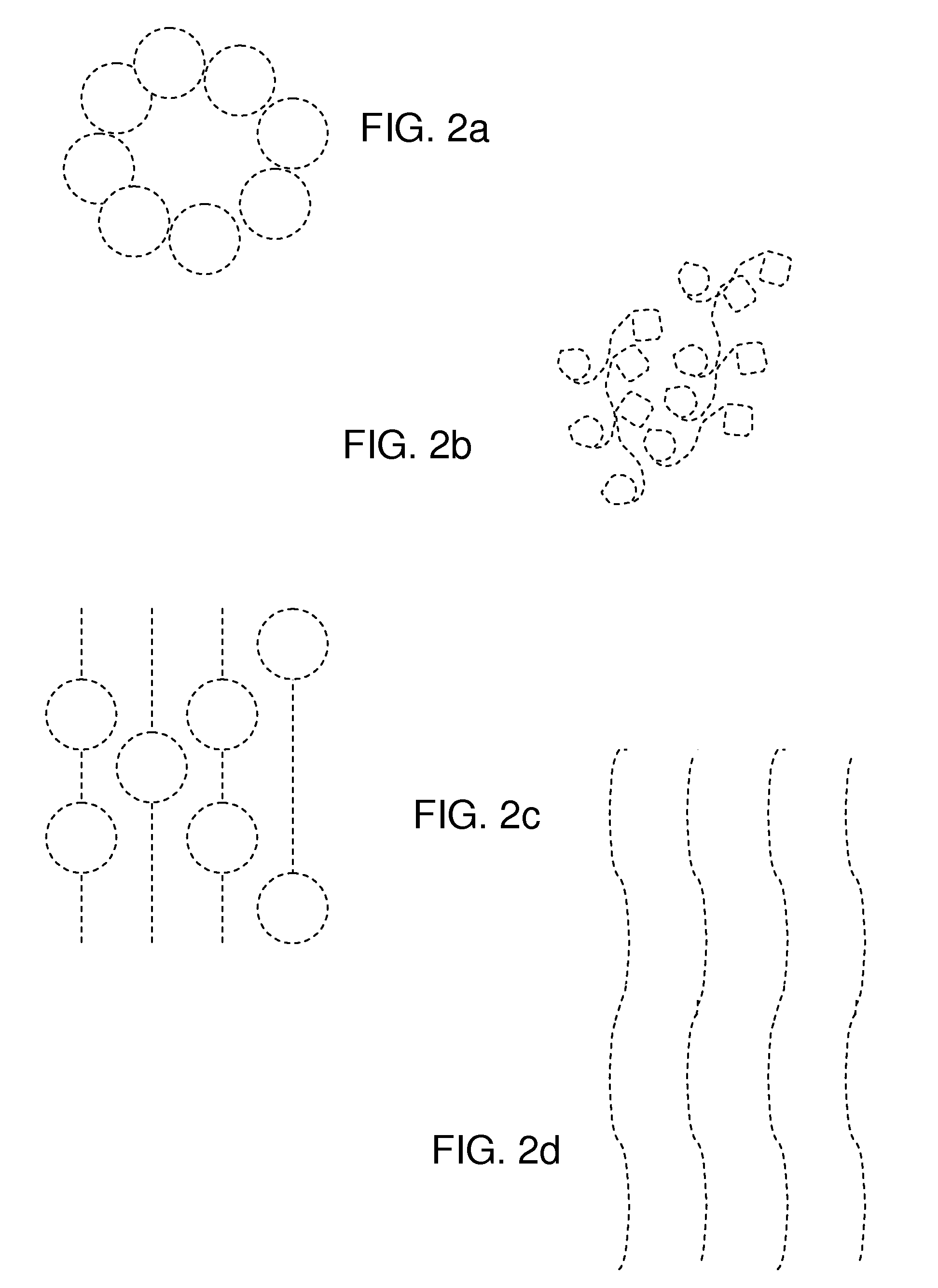

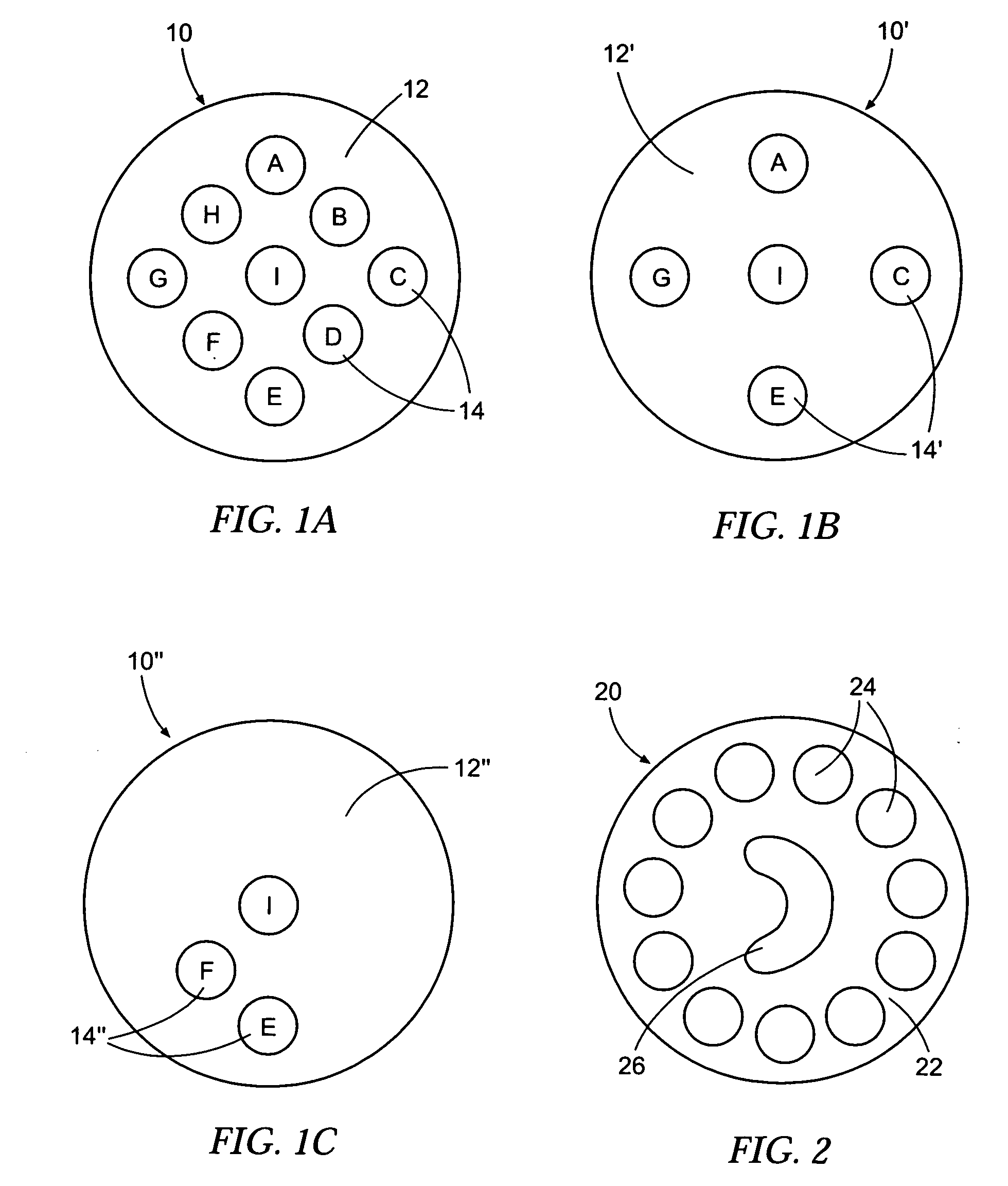

Taggant fibers

InactiveUS20050227068A1Less noticeable in useLikely to degradeMarking textilesFilament/thread formingMaterials sciencePolymer

Multicomponent fibers are provided that include a plurality of coextruded polymeric components arranged in discrete structured domains. The polymer domains have one or more identifying characteristics that can be varied to form a plurality of different identifying patterns. A plurality of islands in the sea fibers can be provided, the plurality of fibers including two or more subsets of fibers, each subset comprising a uniquely identifiable cross sectional pattern of island domains, each pattern being formed from an array comprising a predetermined number of island domains in predetermined locations within the array, wherein each pattern is determined by classifying individual island domains within the array as present or absent from the pattern. The plurality of fibers can be meltspun simultaneously to form a filament yarn or tow.

Owner:FIBER INNOVATION TECH

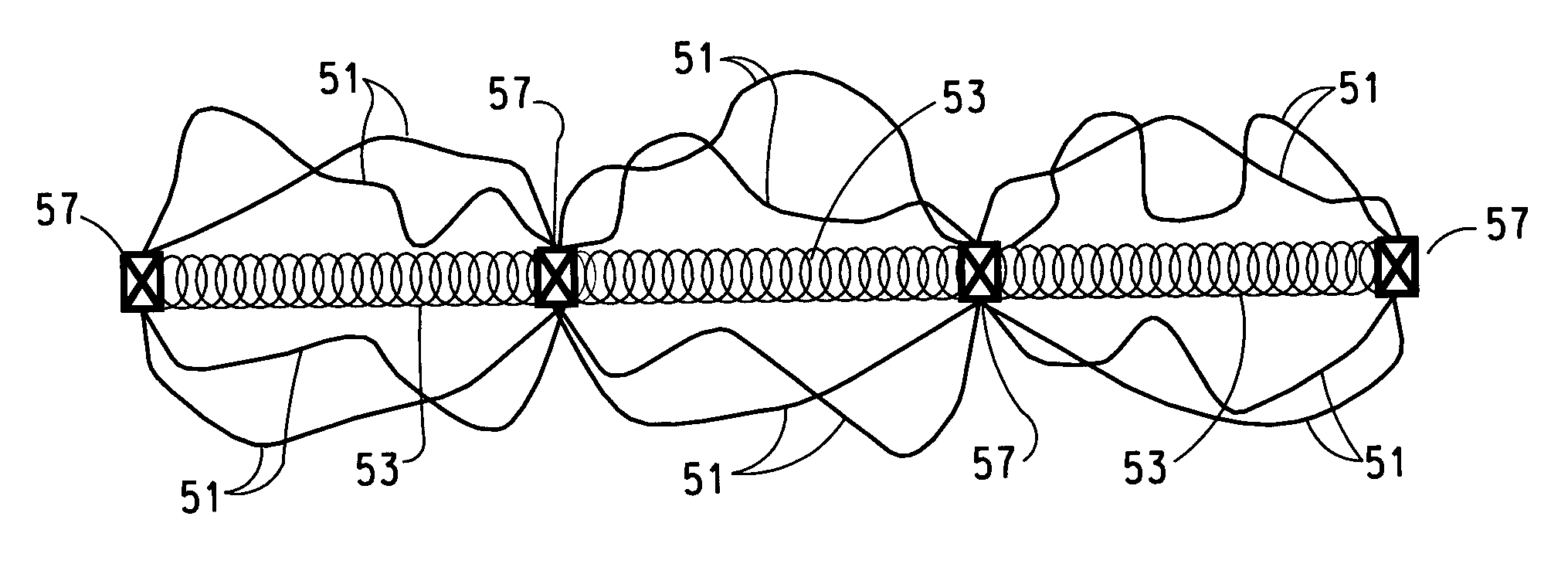

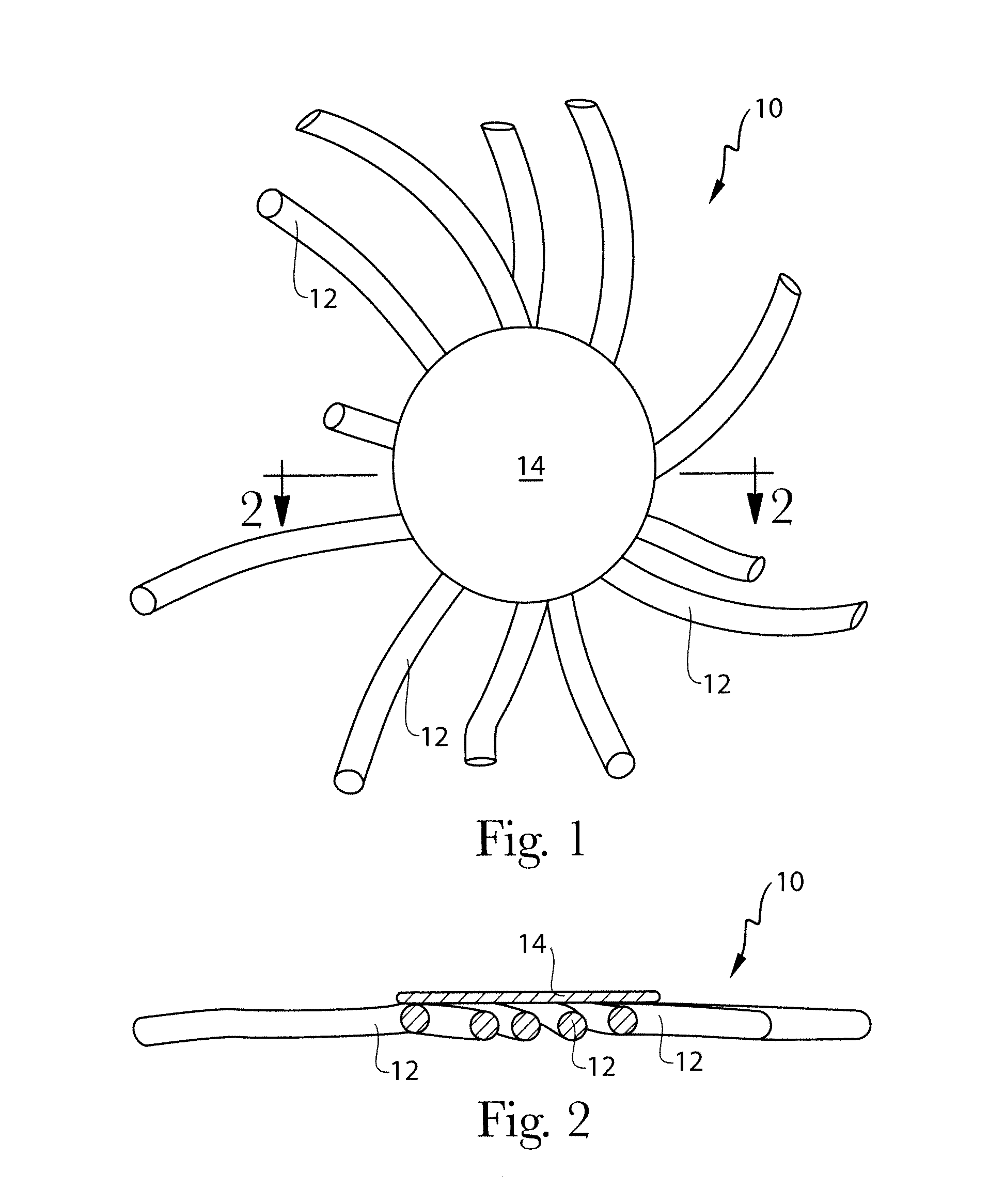

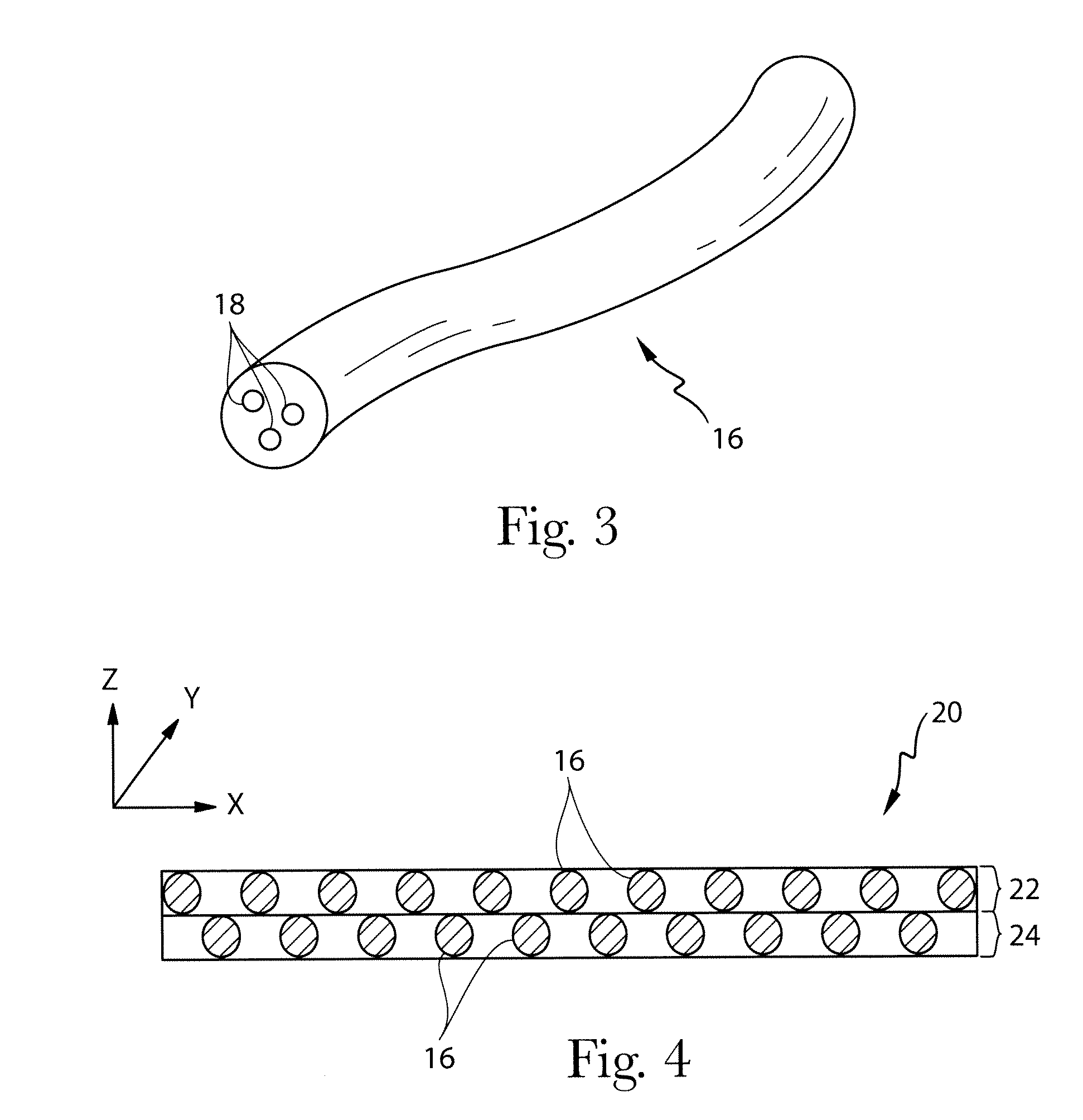

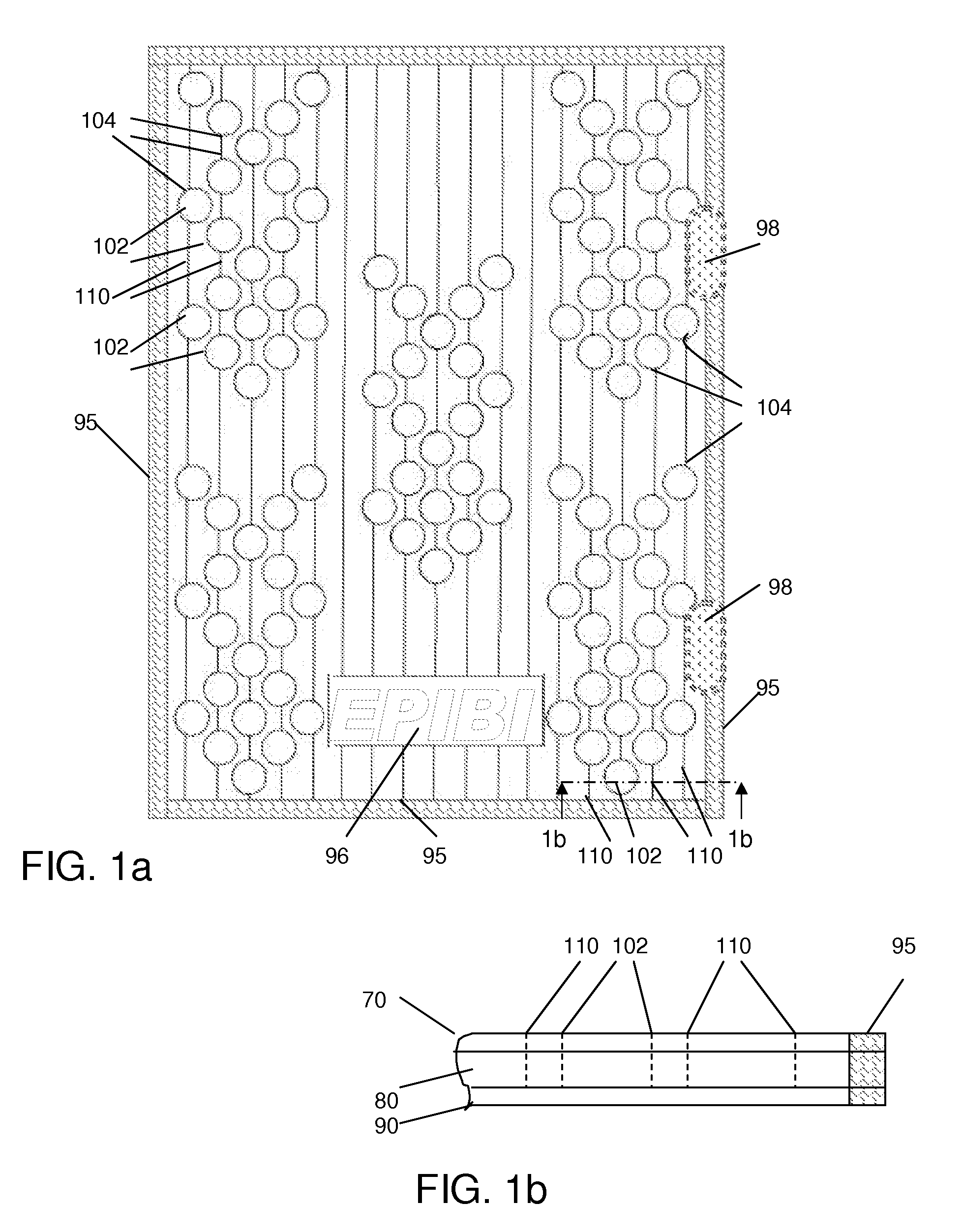

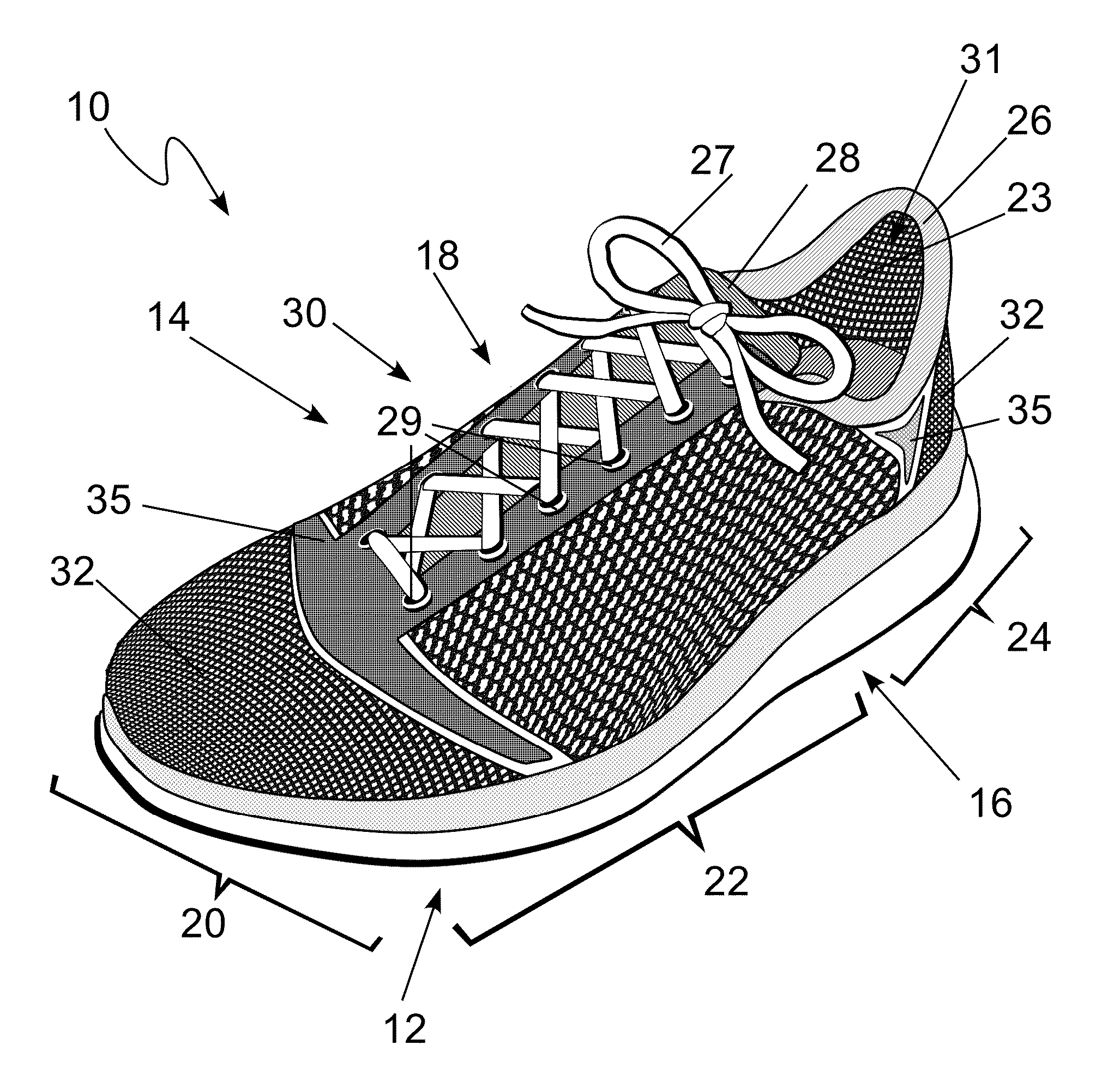

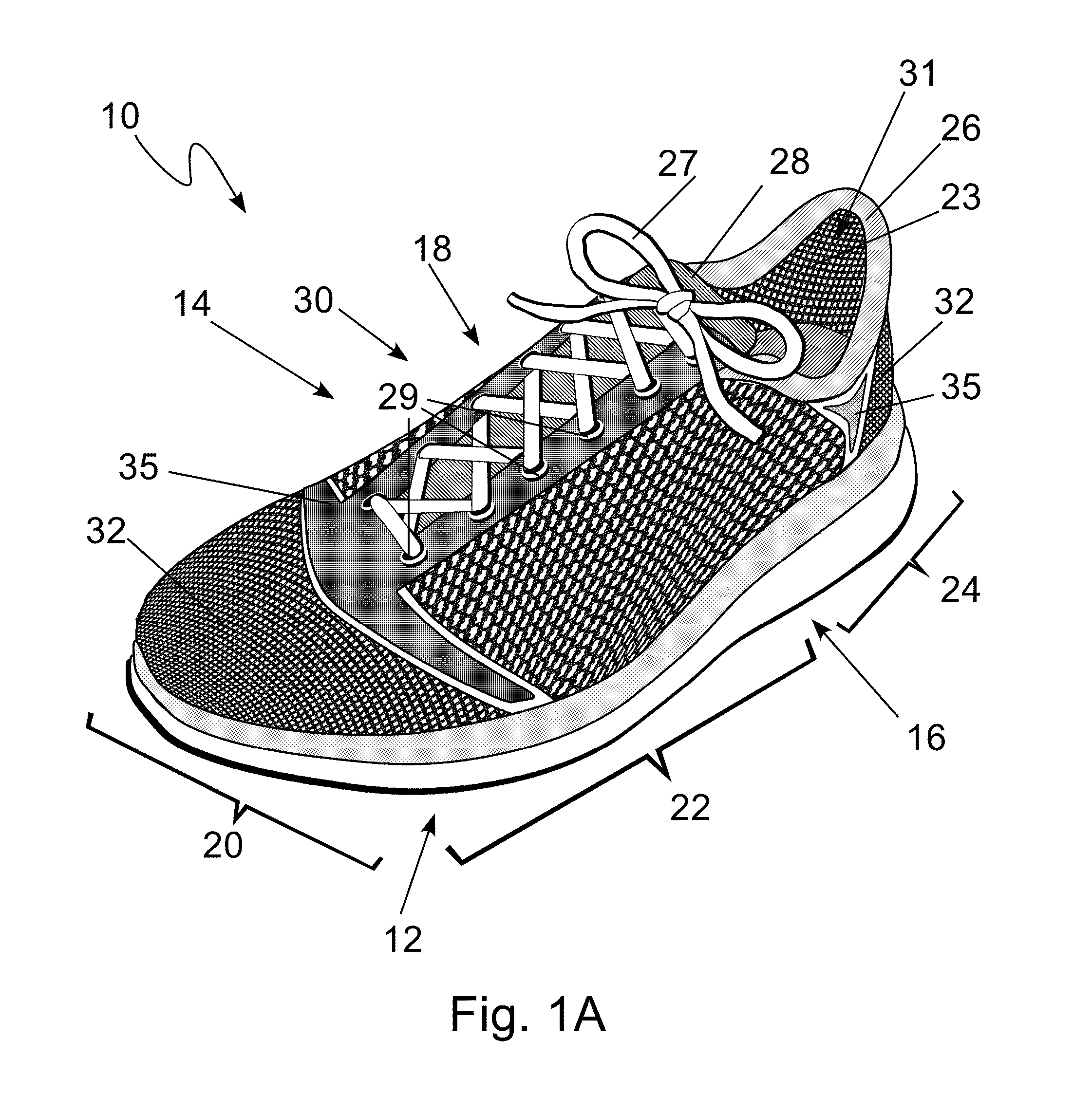

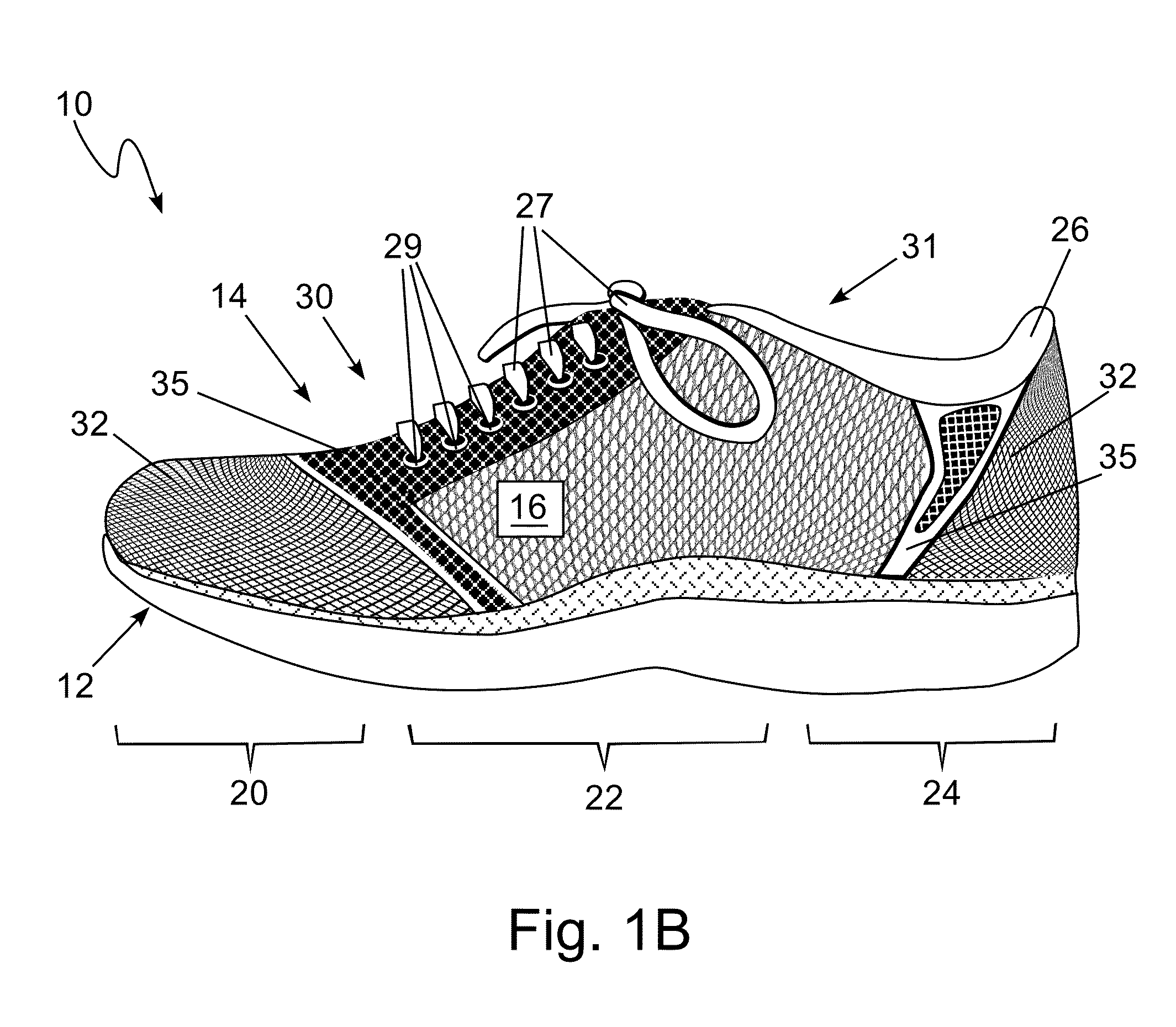

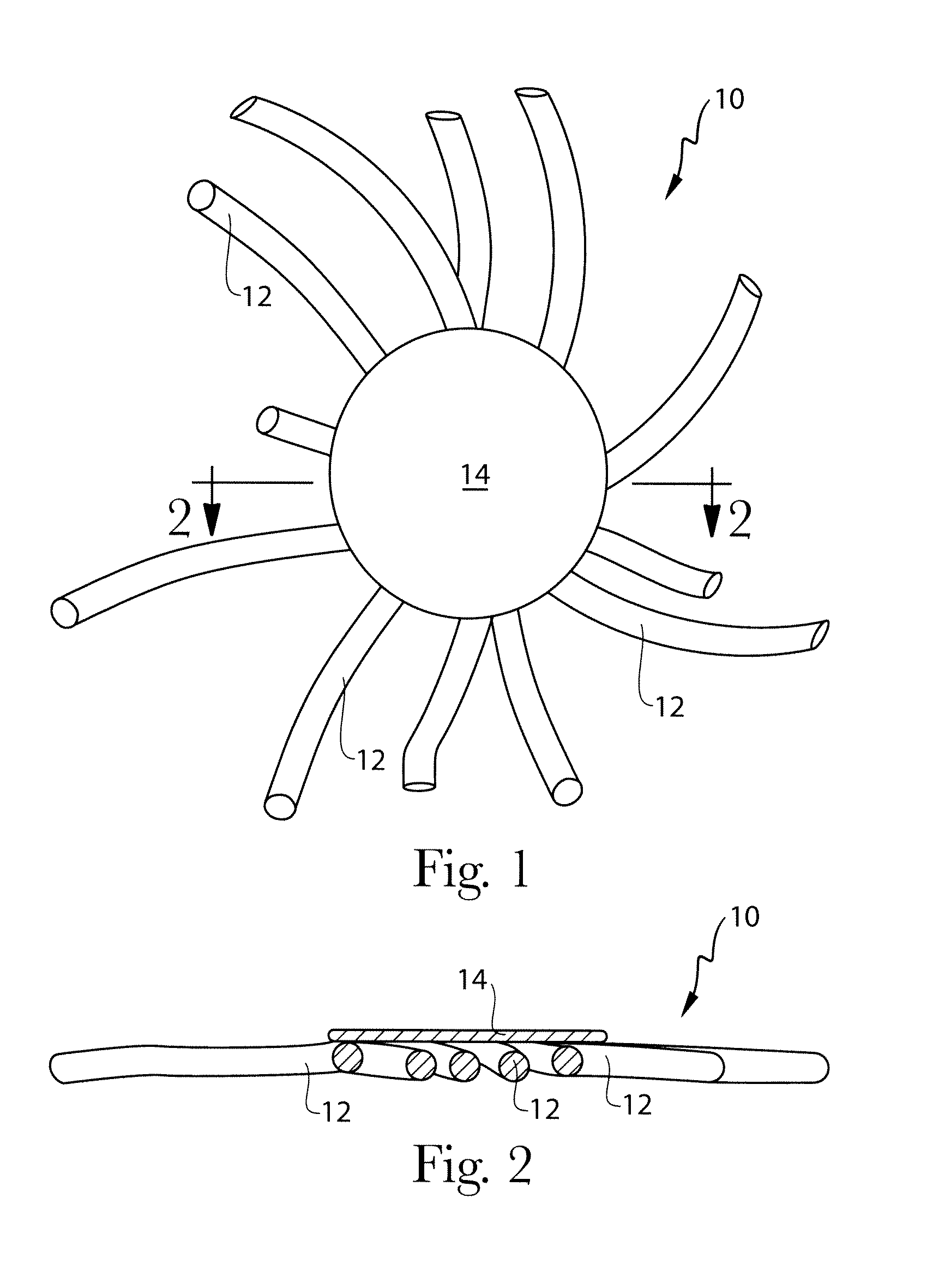

Patterned Plexus of Filaments, Method of Producing and Articles Containing Patterned Filaments

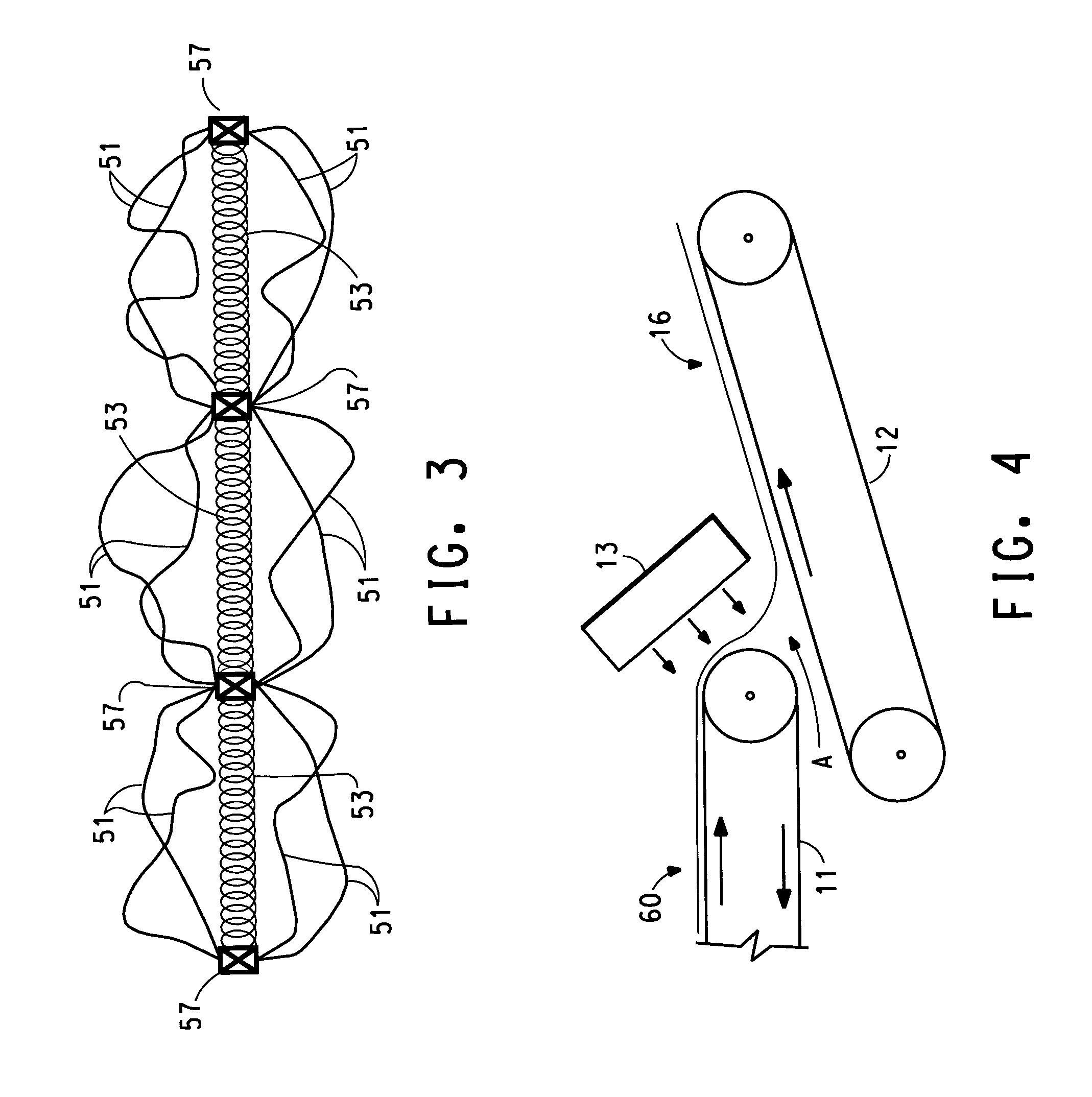

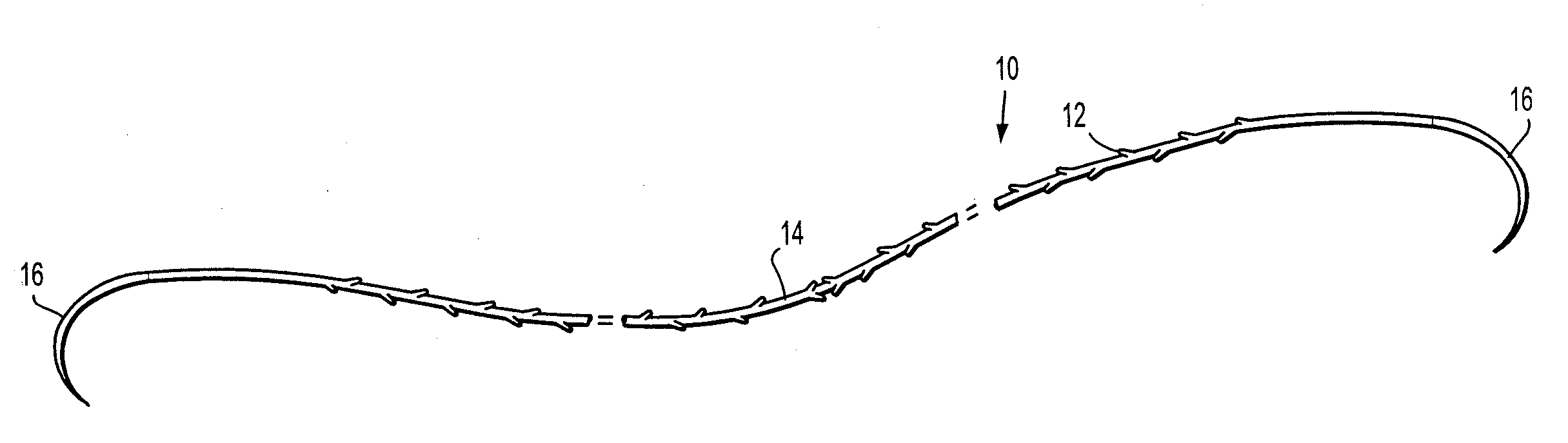

ActiveUS20140377488A1Good flexibilityOptimize load distributionSolesLayered productsEngineeringLoad distribution

Disclosed herein is a plexus of filaments which is composed of groups of filaments, whose filament members are linked together, in a repetitious pattern, and whose filaments may be interlaced or linked to bisecting groups of filaments, creating a patterned plexus whose filament members generally follow spiraling paths, while linking with neighboring filaments, creating a group, or interlaced groups, of tension distributive filaments within a plexus of filaments; said plexus exhibiting greater conformal and constrictive qualities in comparison to the prior art. Also disclosed is a method of producing filament structures for a variety of uses including composite structures with tension displacement properties, and sporting goods requiring conformal load distribution with minimal weight; such as, running shoes.

Owner:JAMISON BRADFORD C

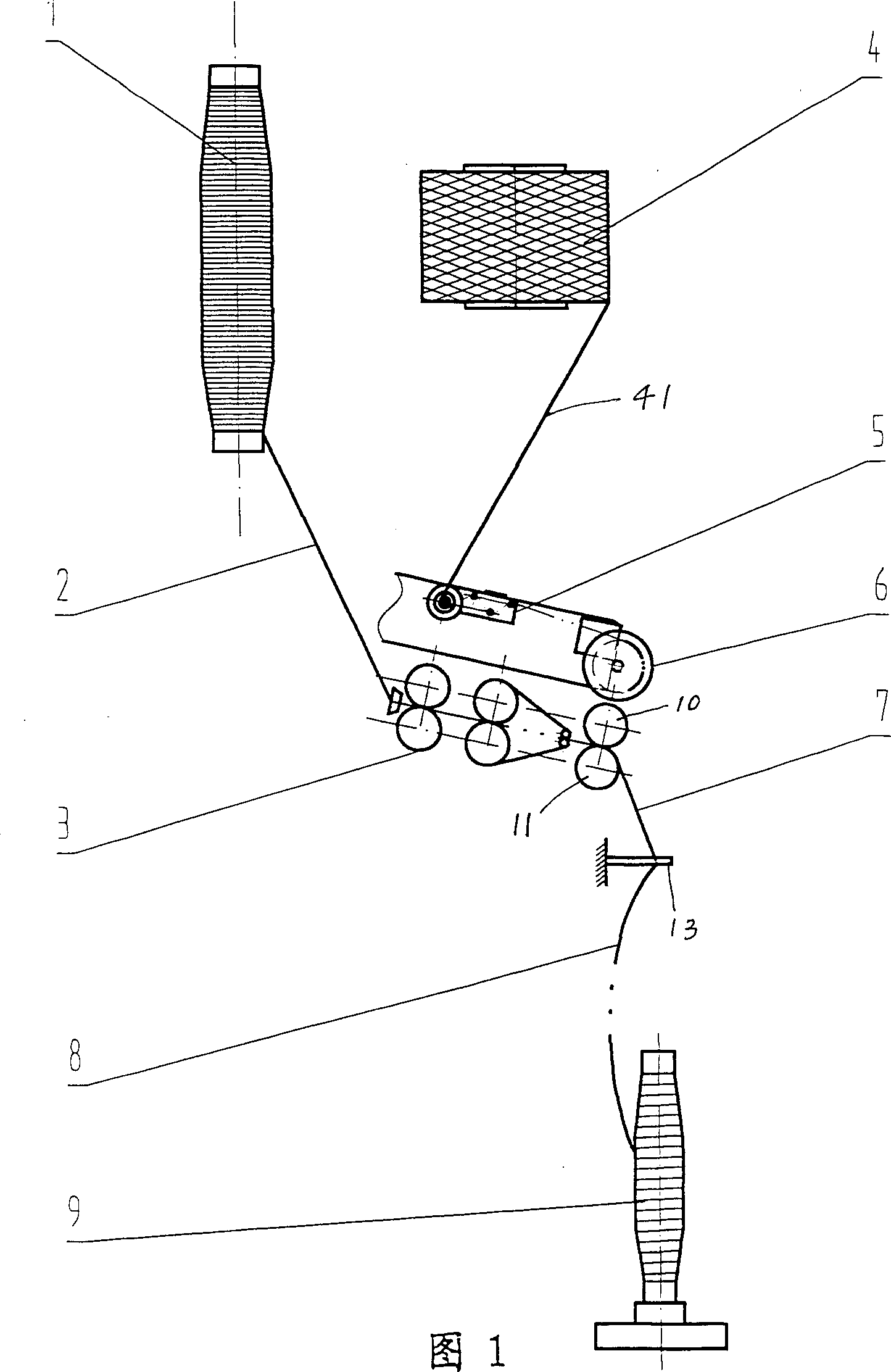

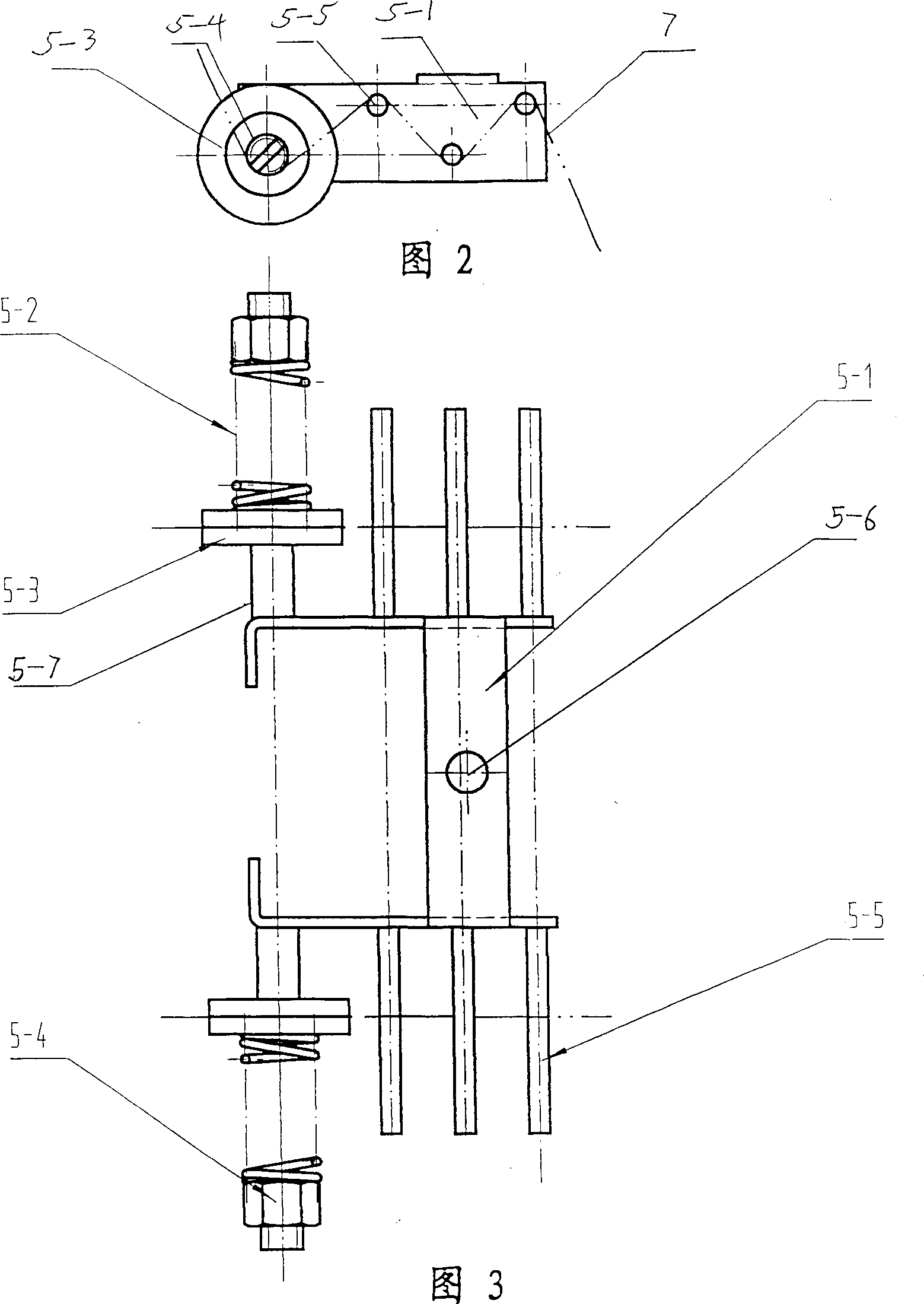

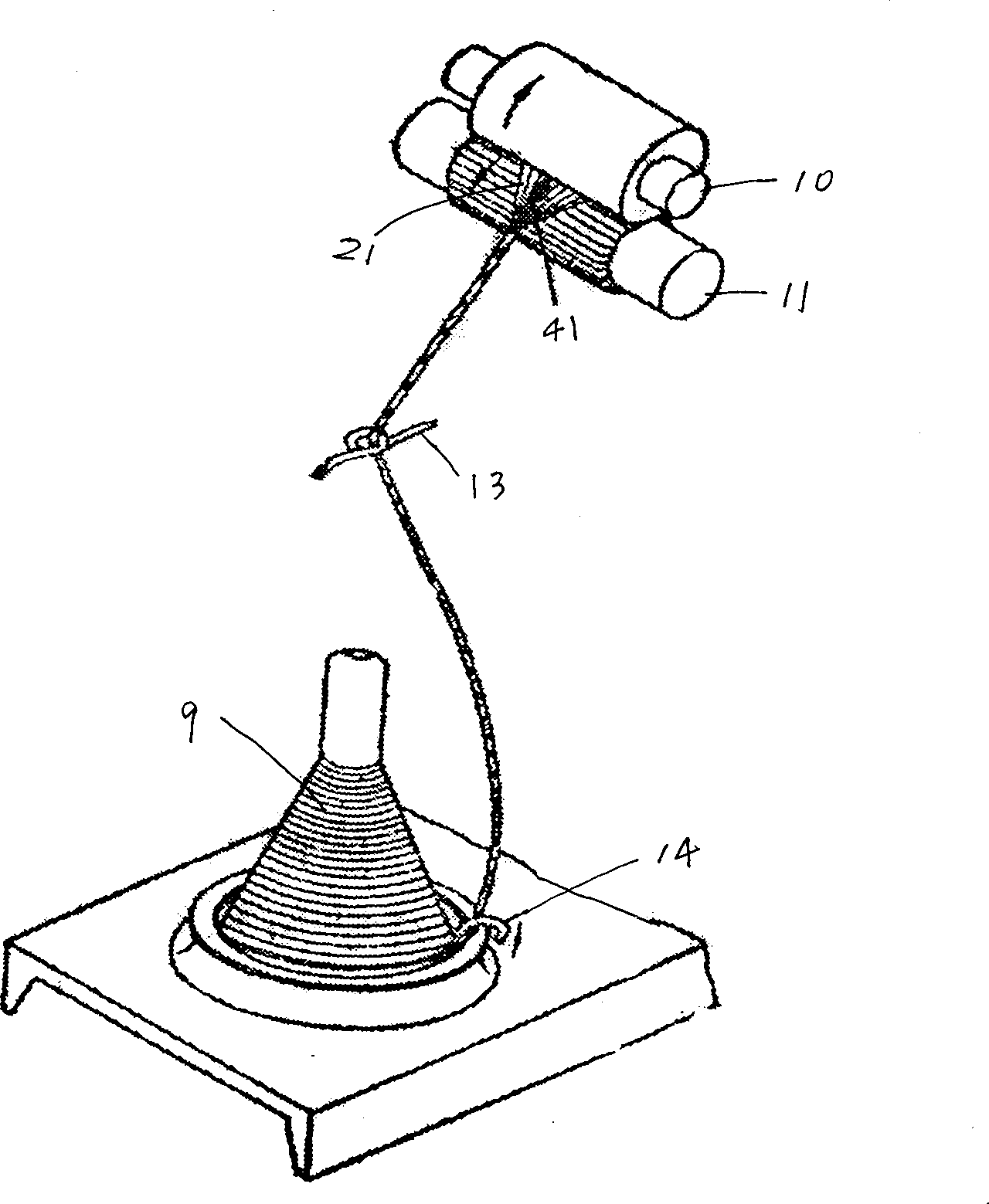

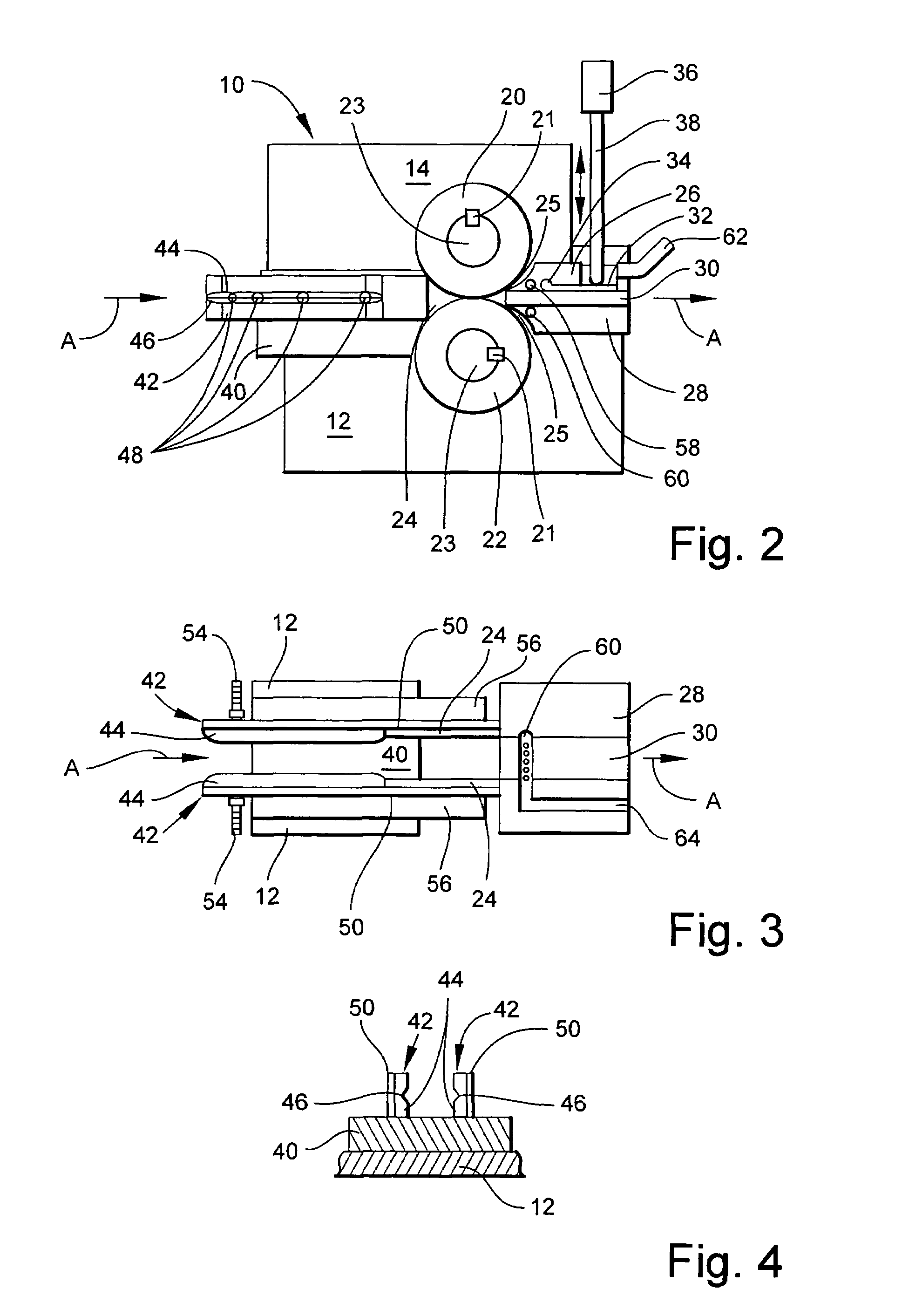

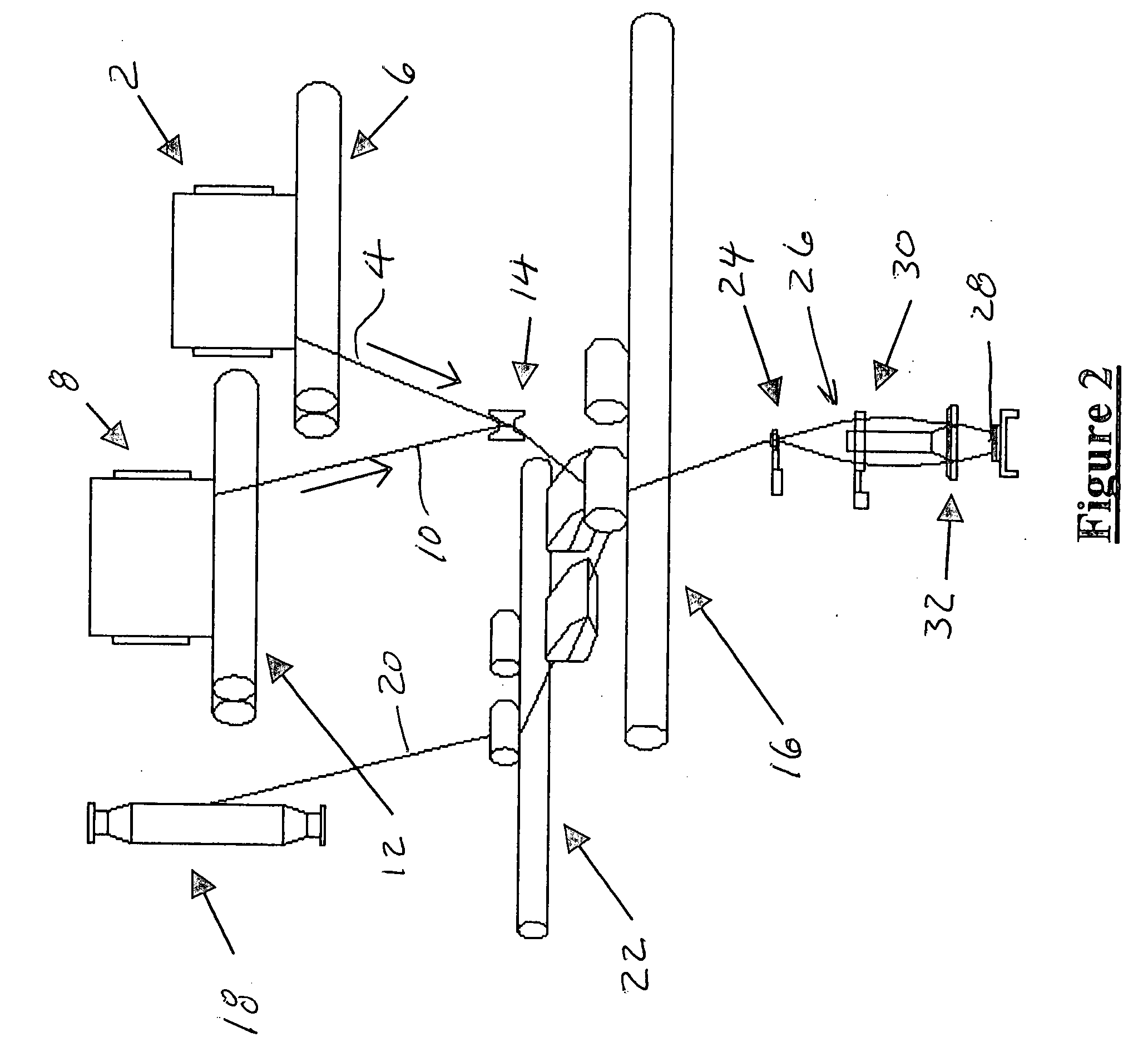

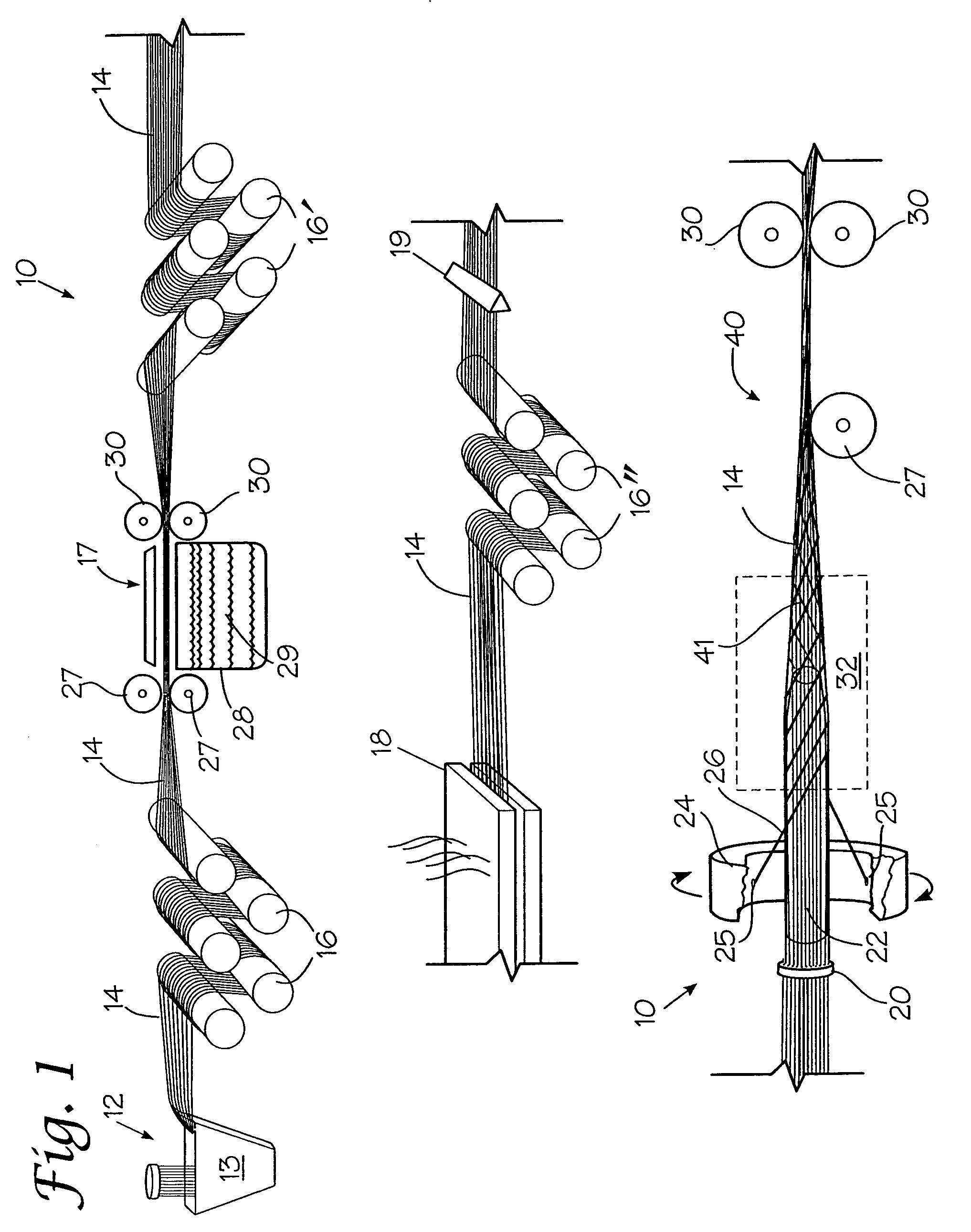

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

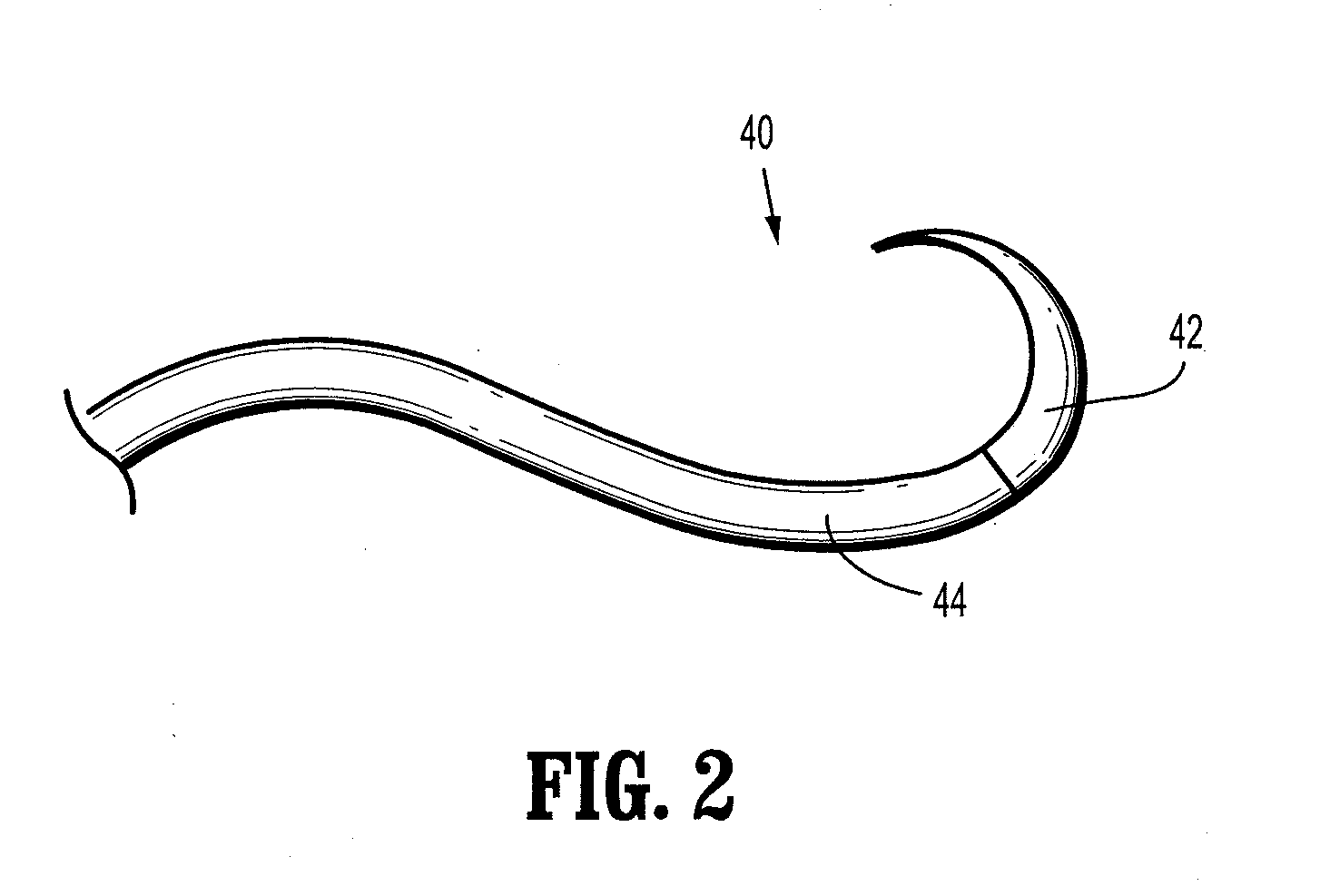

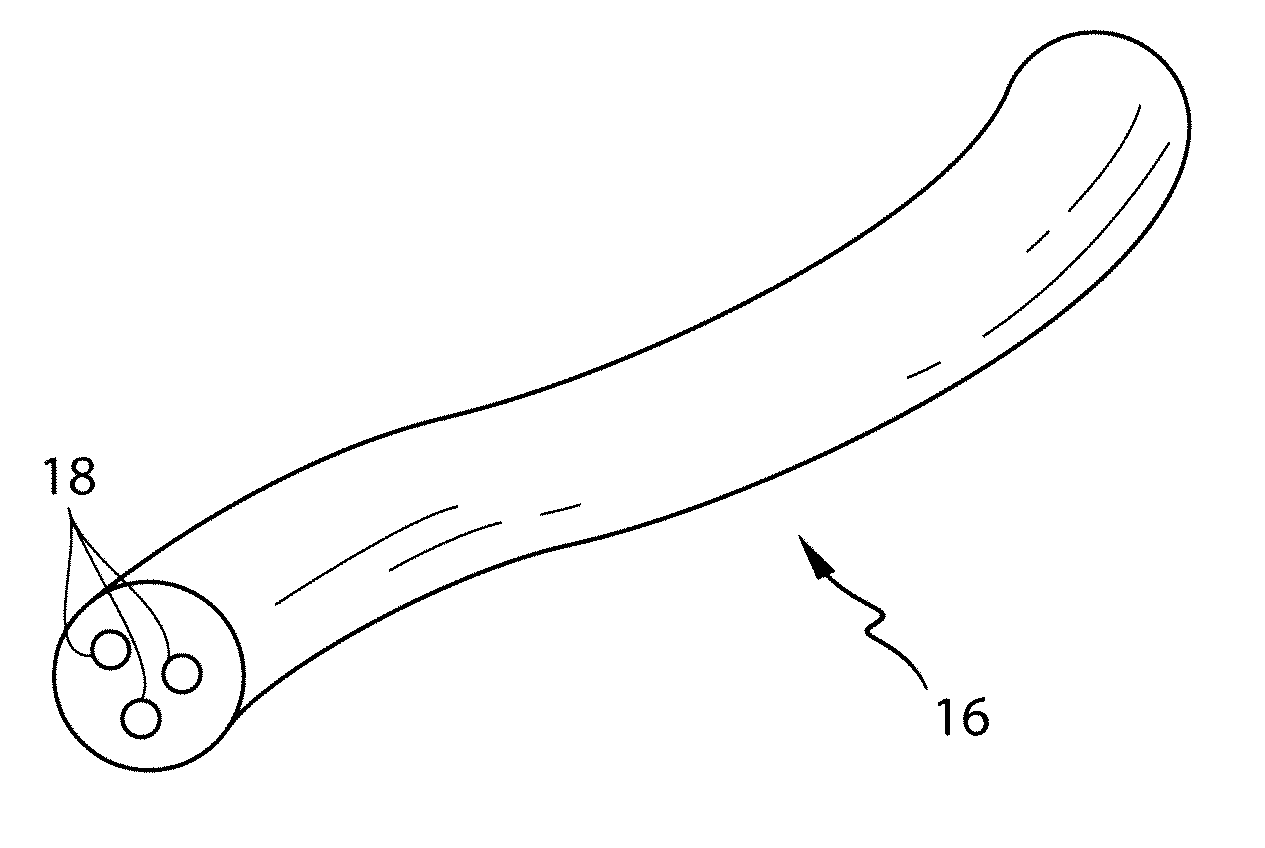

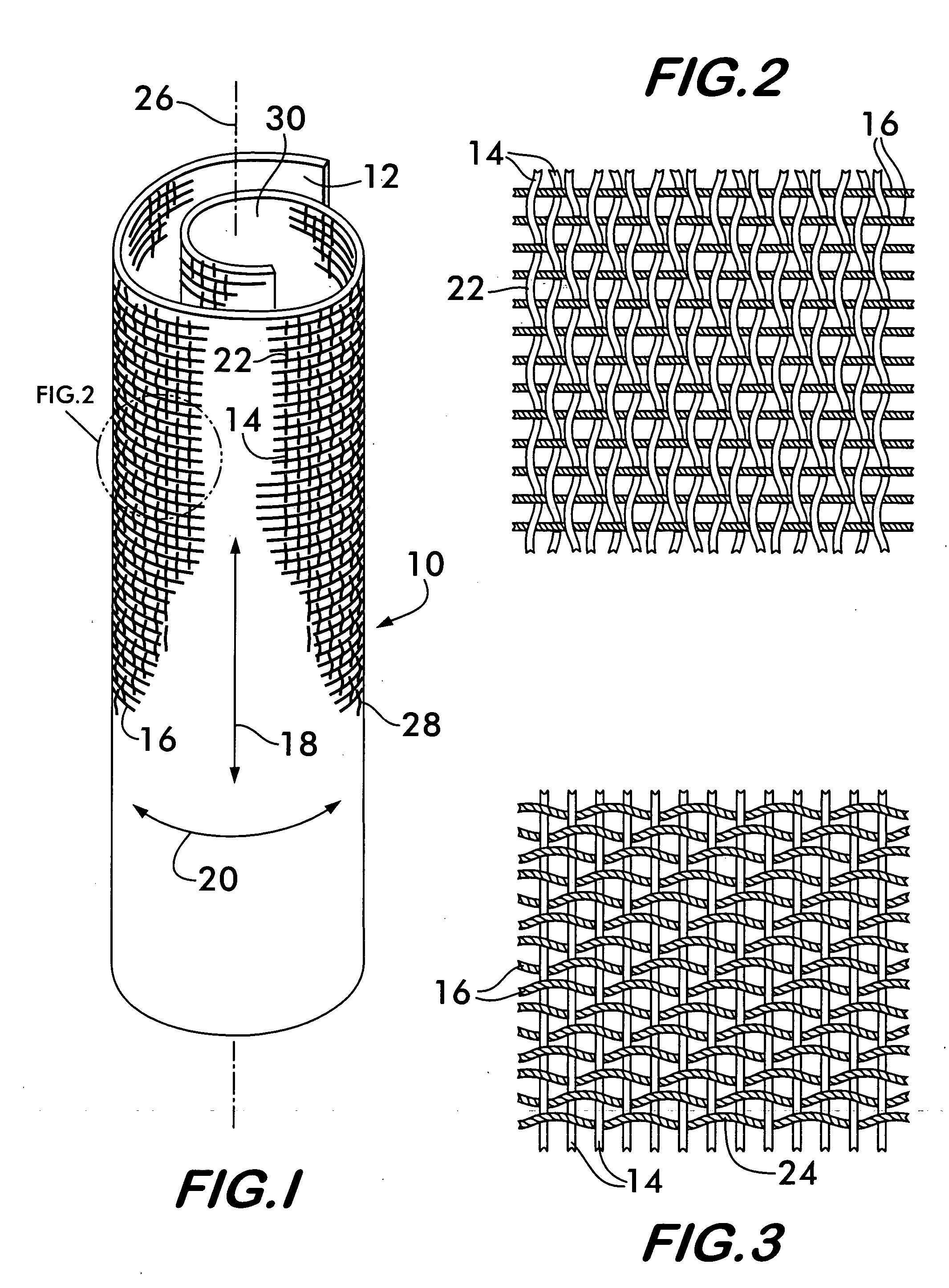

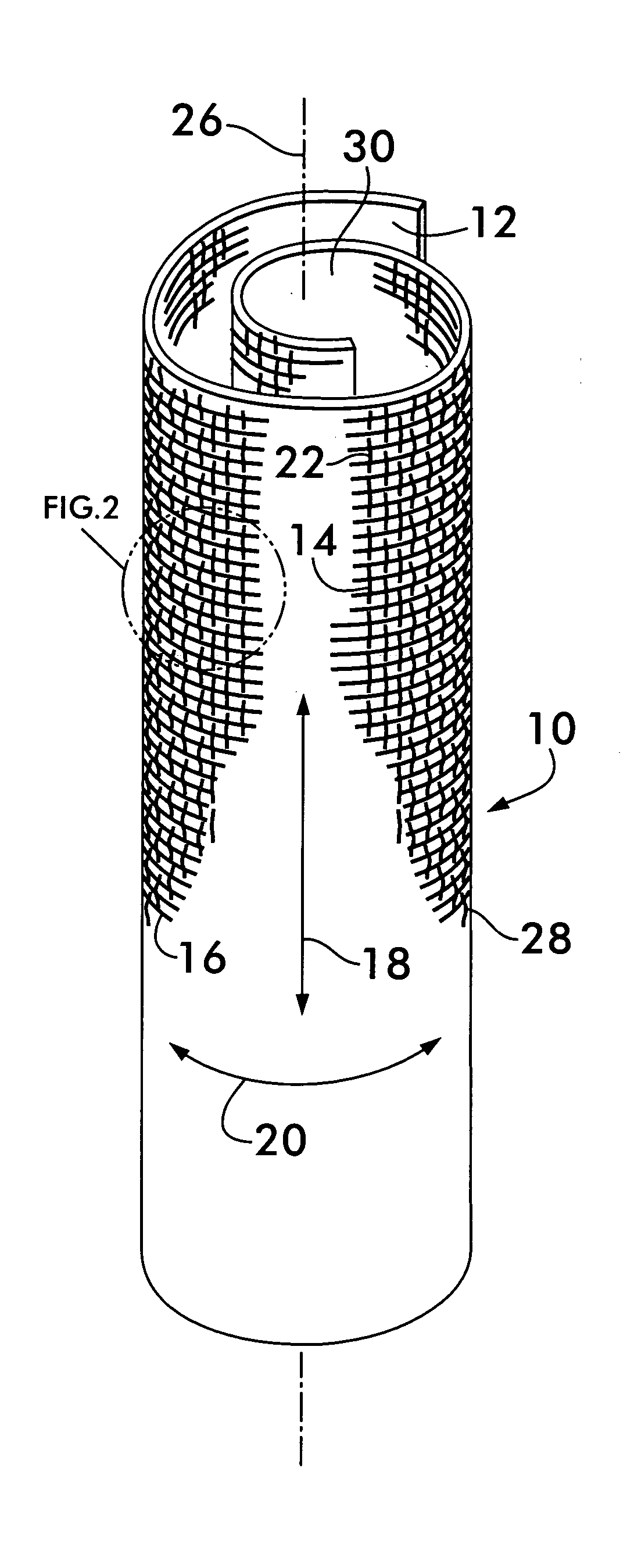

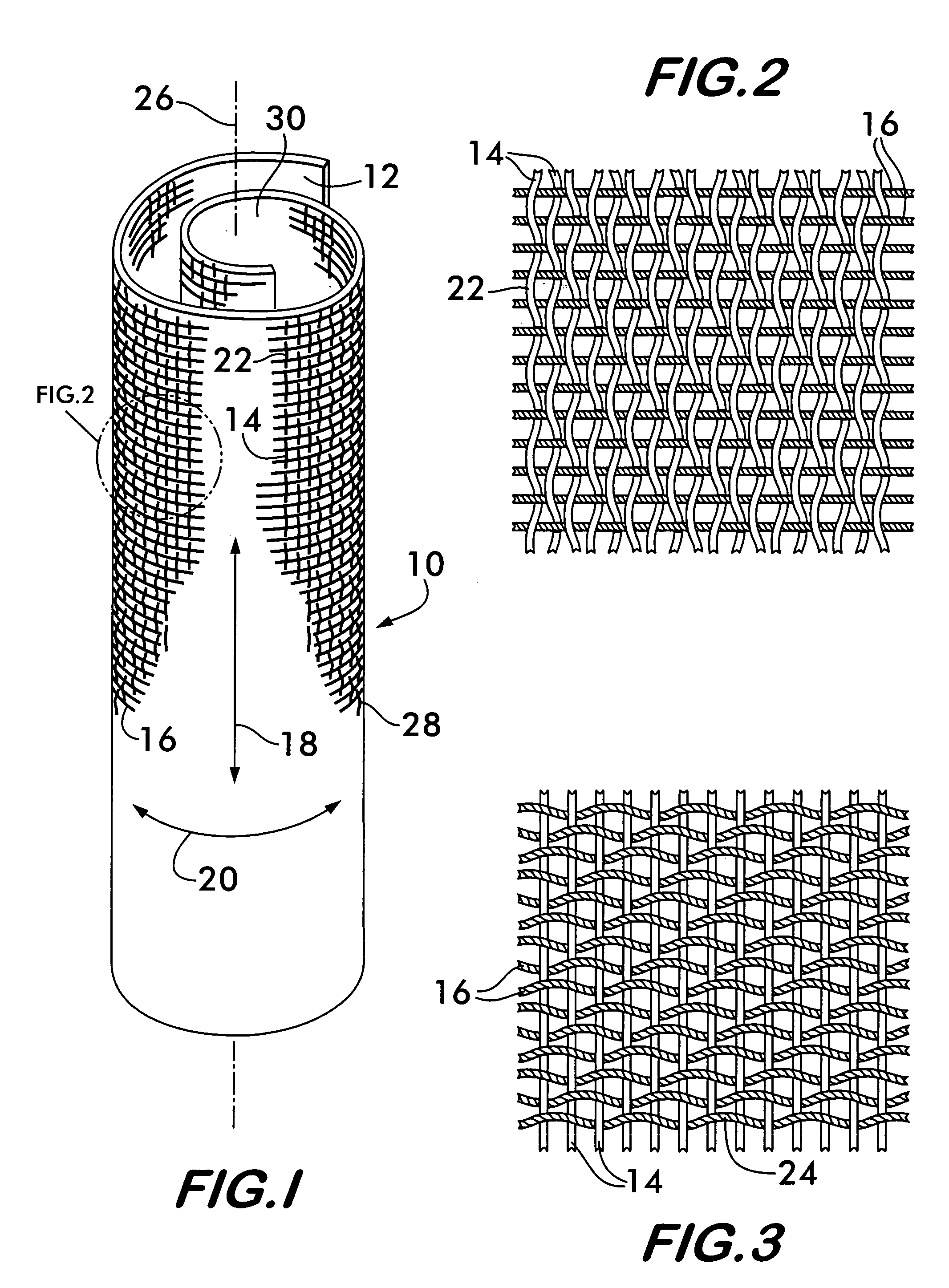

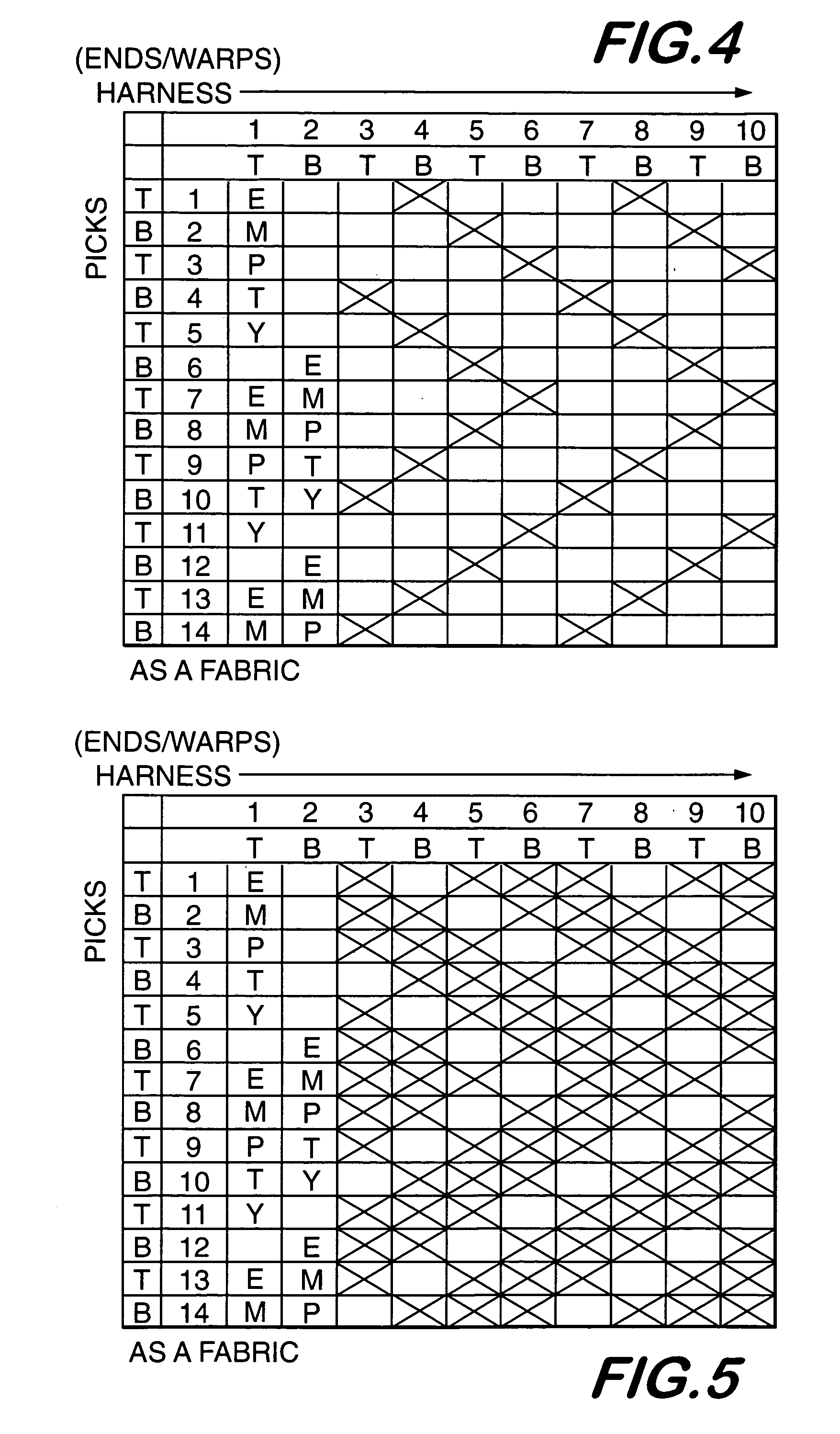

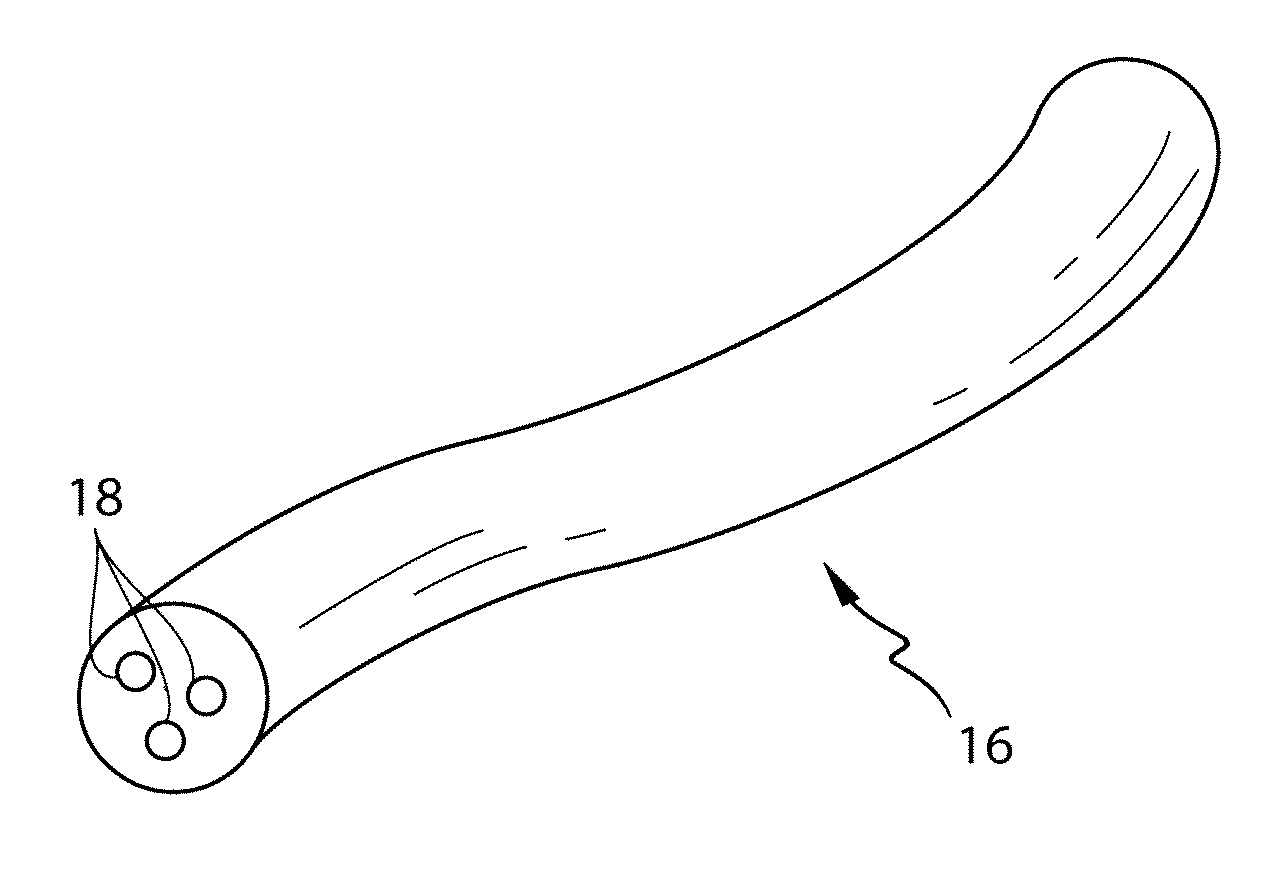

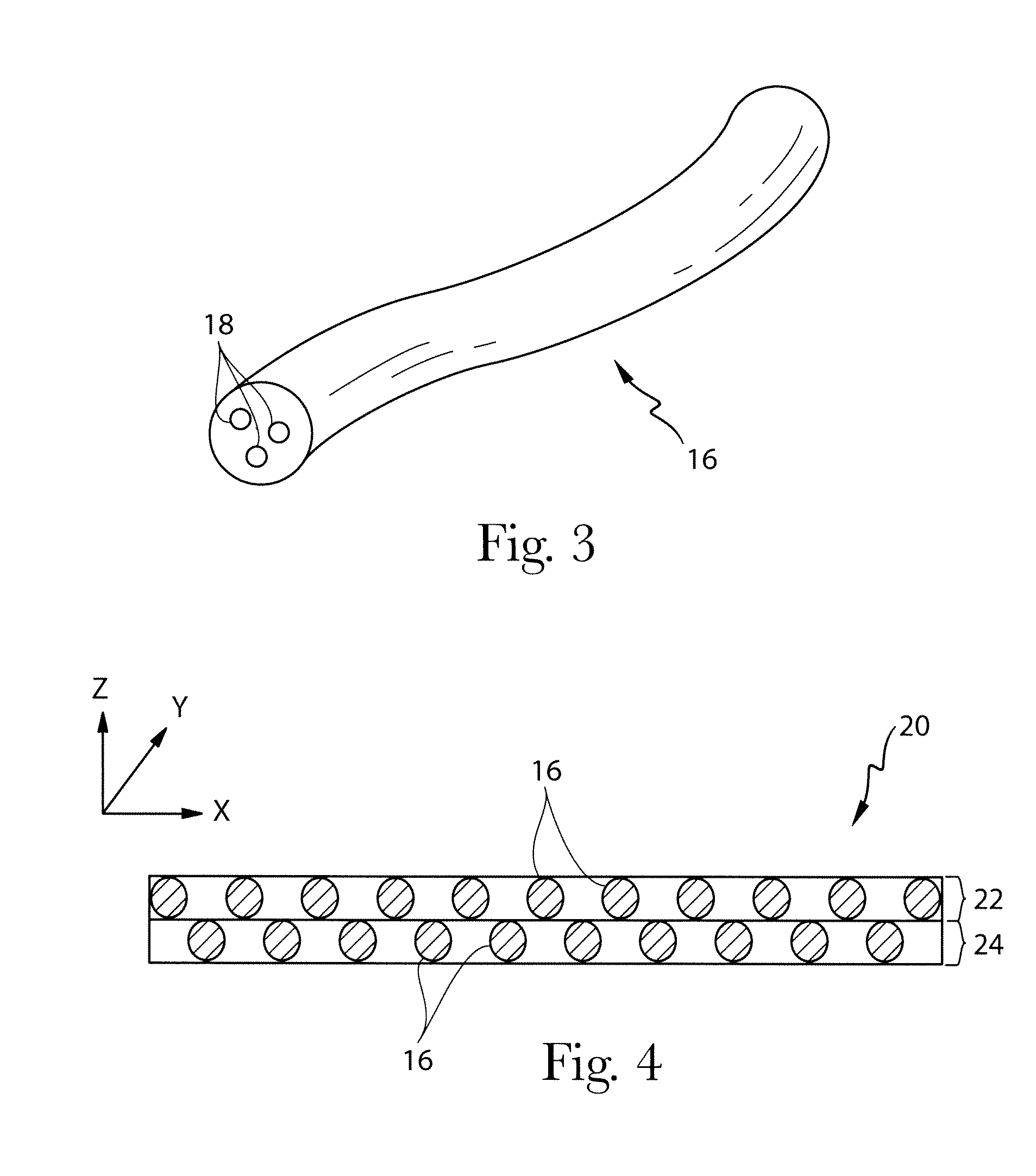

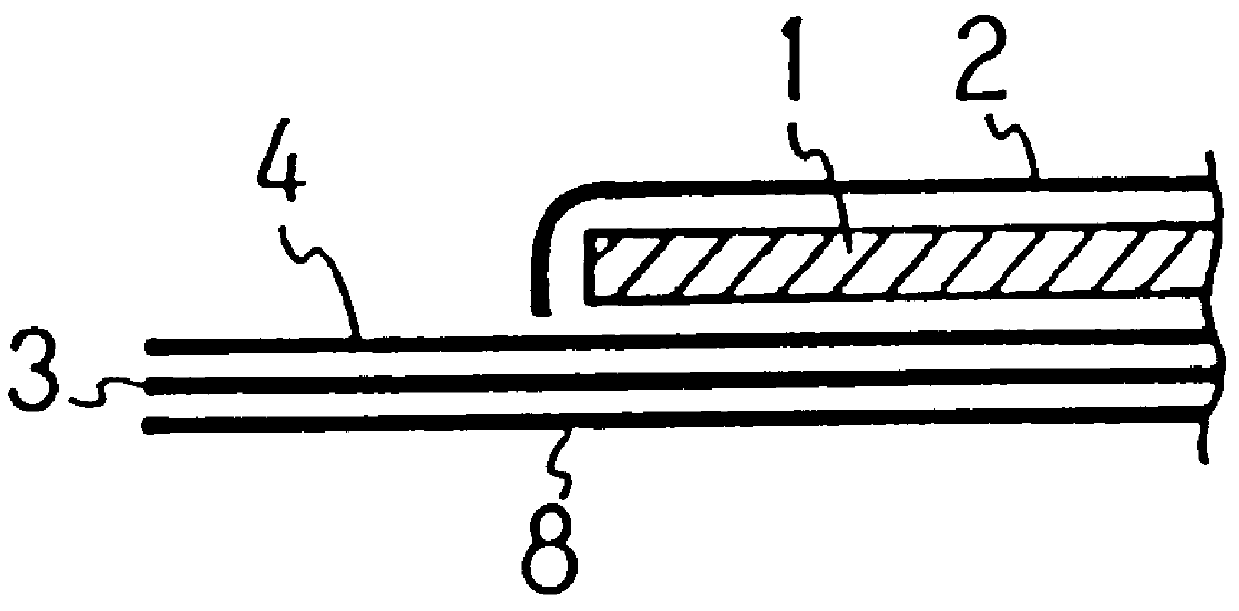

Self-curling sleeve

ActiveUS20060016507A1Thermal insulationPipe protection by thermal insulationEngineeringPerpendicular direction

A substrate including a plurality of monofilaments, or a combination of monofilaments and multi-filament yarns oriented in perpendicular directions, has a tendency to curl around a central space. When all monofilaments are used, the monofilaments along one direction may have a larger diameter than the monofilaments along the other direction. The monofilaments are woven such that the larger diameter monofilaments form floats predominantly on one side of the substrate. For the monofilament-multifilament combination the monofilaments form floats predominantly on one side of the substrate. The substrate curls about an axis parallel to the monofilaments forming the floats. The side having the floats faces outwardly away from the central space. Preferably, the monofilaments are oriented in the warp direction along the substrate. The filaments may be woven in a herringbone twill weave, a double cloth herringbone twill weave or a satin weave to provide the floats.

Owner:FEDERAL MOGUL WORLD WIDE LLC

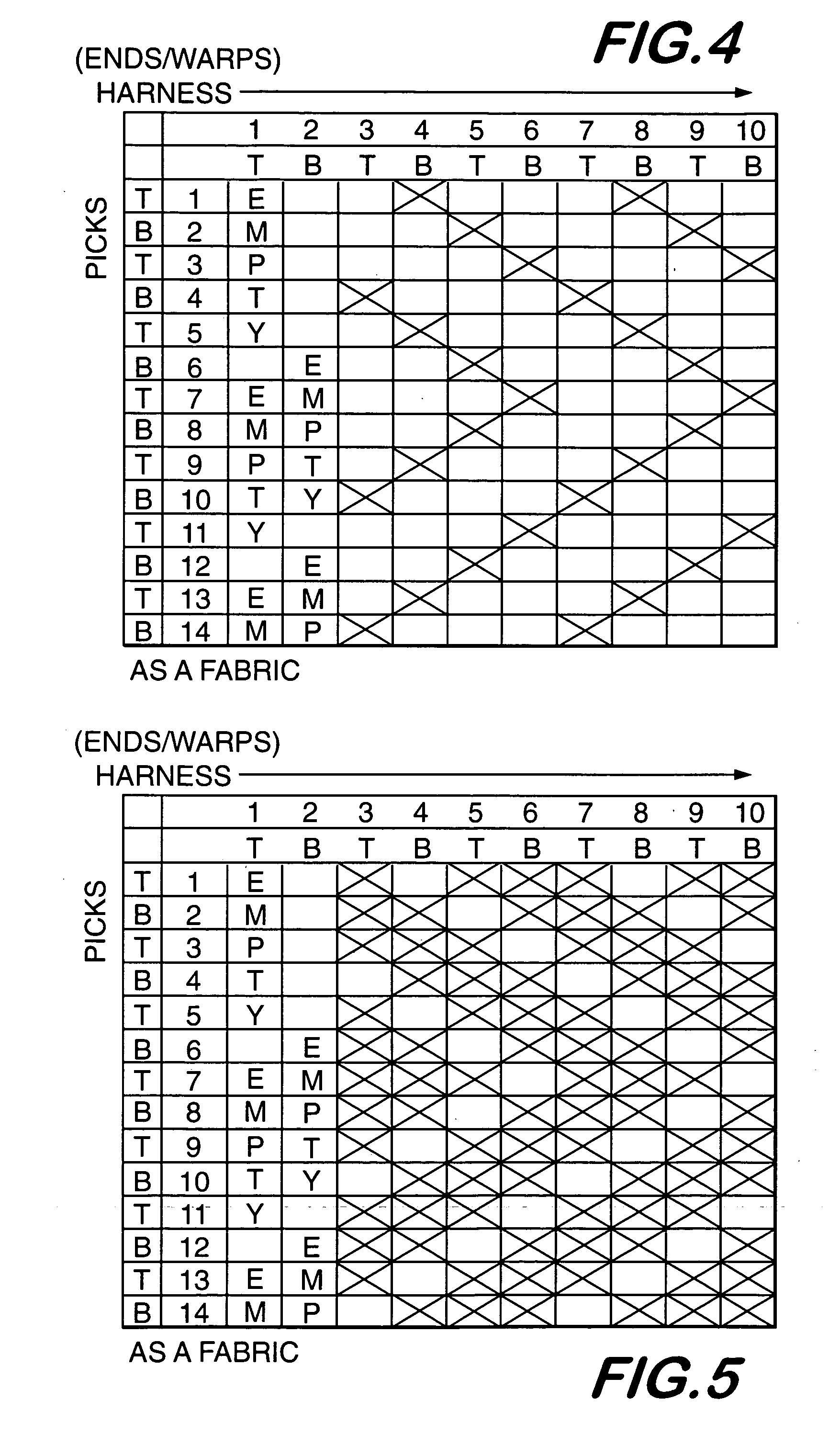

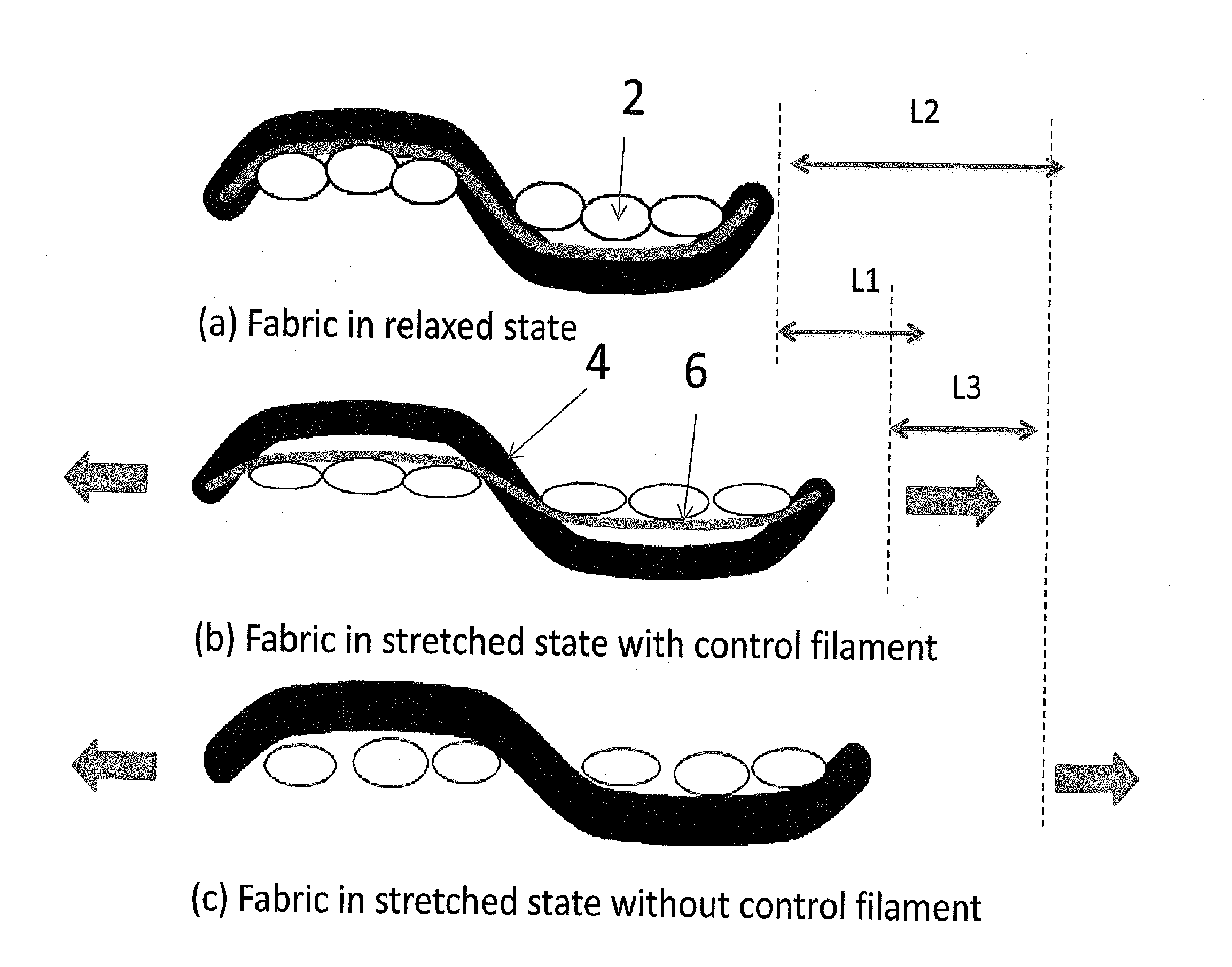

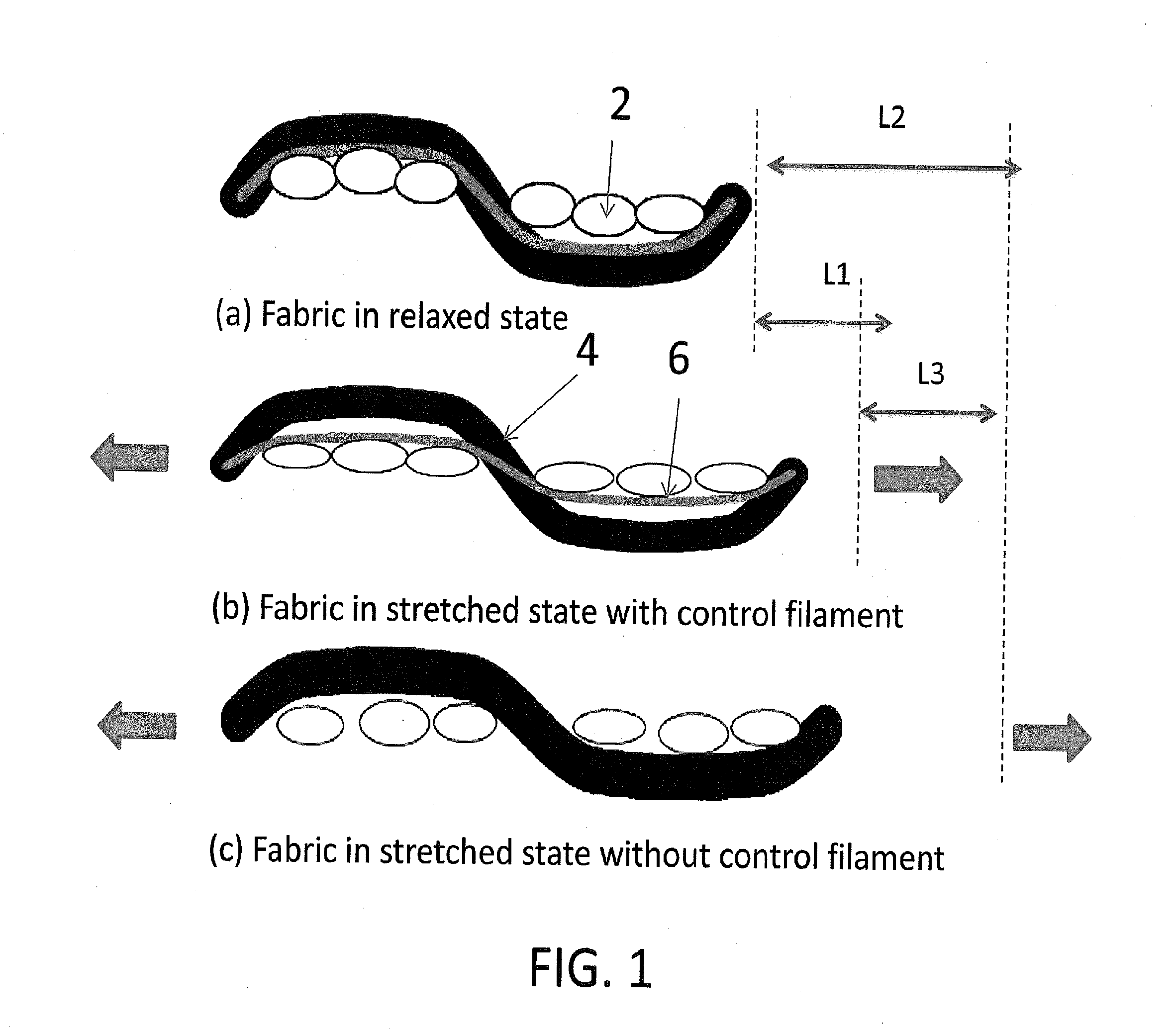

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

Self-curling sleeve

A substrate including a plurality of monofilaments, or a combination of monofilaments and multi-filament yarns oriented in perpendicular directions, has a tendency to curl around a central space. When all monofilaments are used, the monofilaments along one direction may have a larger diameter than the monofilaments along the other direction. The monofilaments are woven such that the larger diameter monofilaments form floats predominantly on one side of the substrate. For the monofilament-multifilament combination the monofilaments form floats predominantly on one side of the substrate. The substrate curls about an axis parallel to the monofilaments forming the floats. The side having the floats faces outwardly away from the central space. Preferably, the monofilaments are oriented in the warp direction along the substrate. The filaments may be woven in a herringbone twill weave, a double cloth herringbone twill weave or a satin weave to provide the floats.

Owner:FEDERAL MOGUL WORLD WIDE LLC

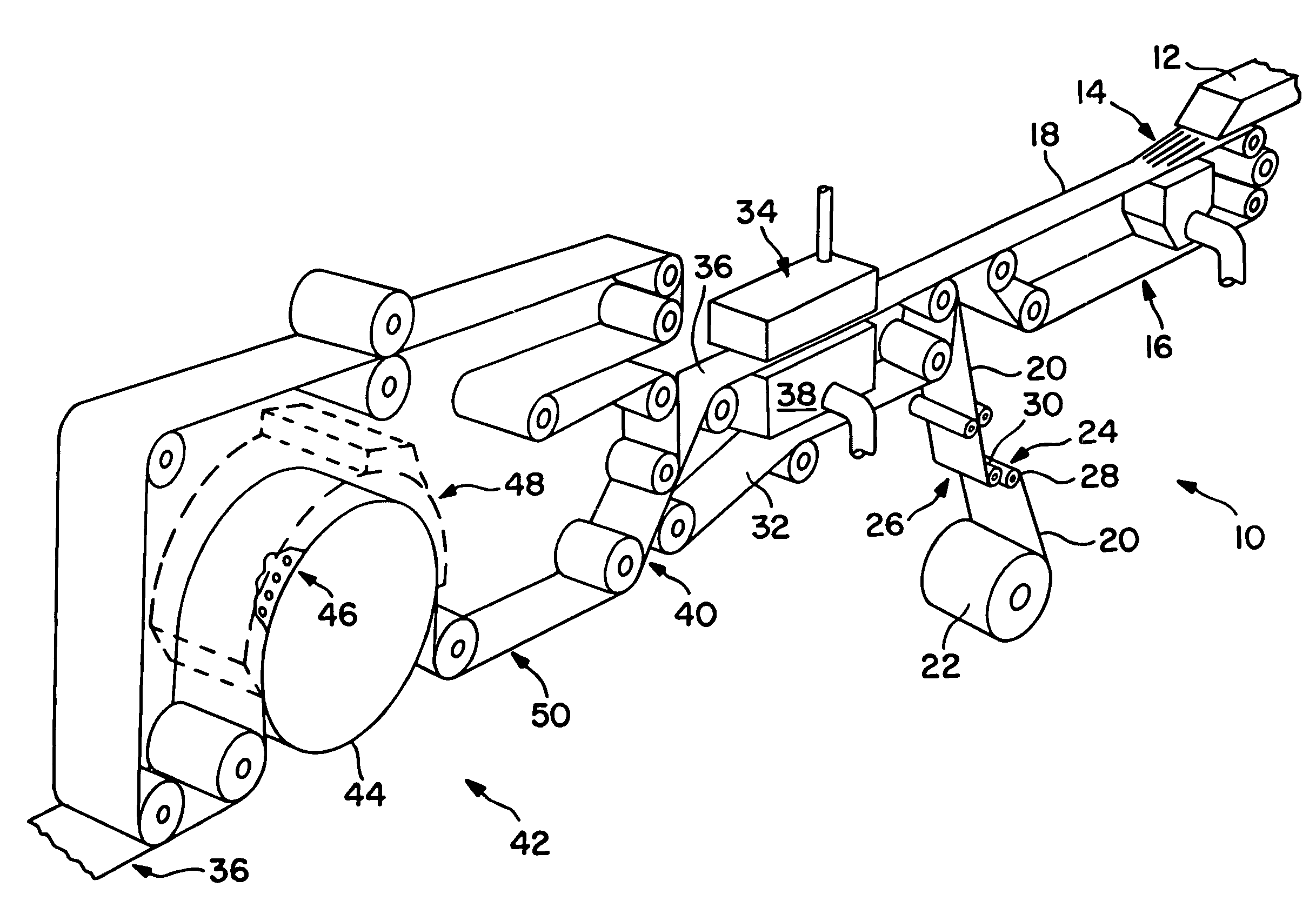

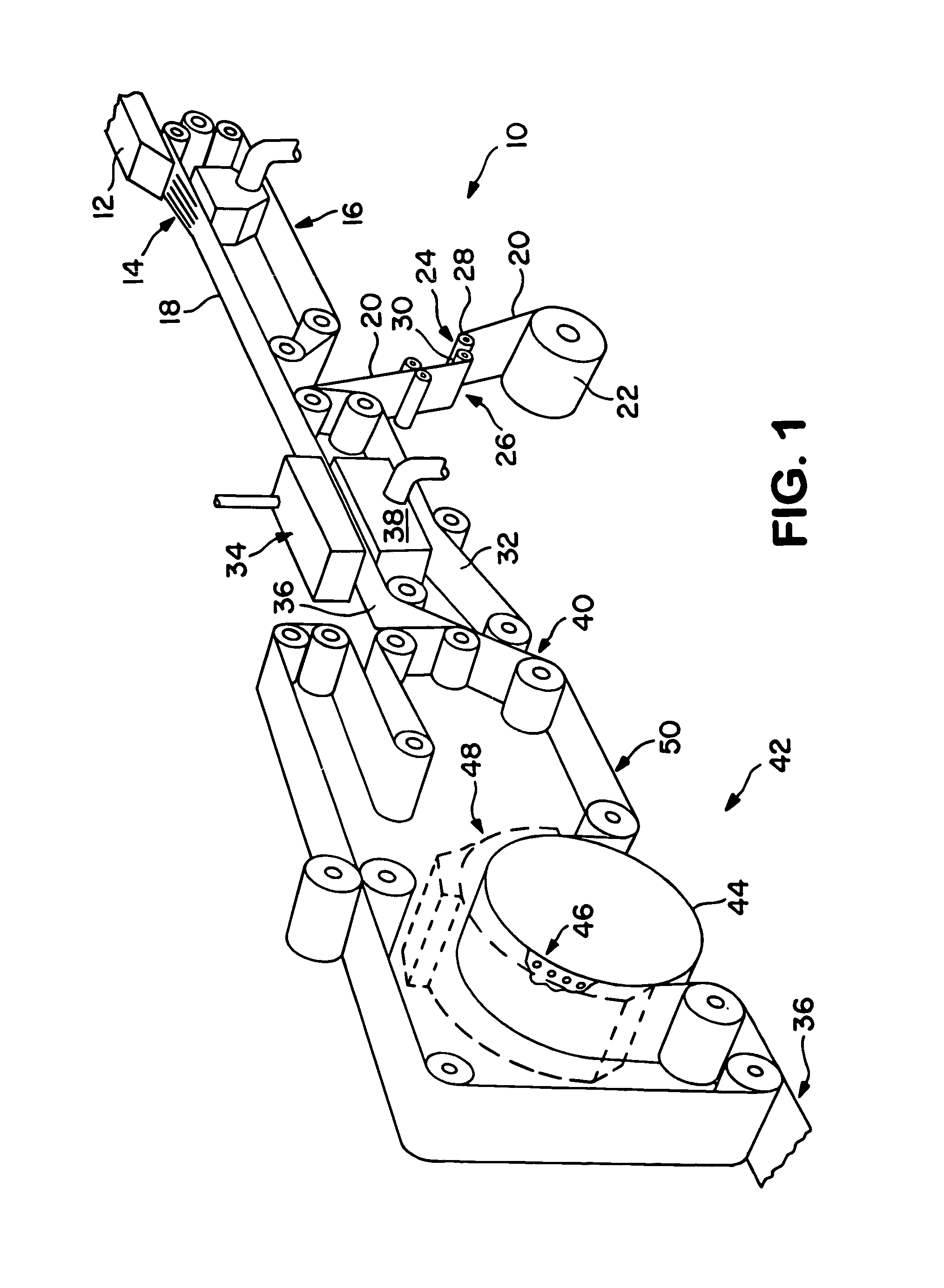

Process for making cellulose acetate tow

A process for making a cigarette tow comprising: spinning a dope; taking-up the as-spun cellulose acetate filaments; lubricating the filaments; forming a tow from the filaments; crimping the tow with a stuffer box crimper; drying the crimped tow; and baling the dried crimped tow. The process further comprises at least two of the following:A. crimping further comprising one roller of the pair of nip rollers being adapted to induce crimp into the tow;B. crimping further comprising one roller of the pair of nip rollers being made of a solid ceramic material;C. crimping further comprising a pair of tow edge lubricators;D. crimping further comprising a steam injector;E. further comprising plasticizing the tow;F. lubricating the filaments further comprises a finish consisting of a water emulsion.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

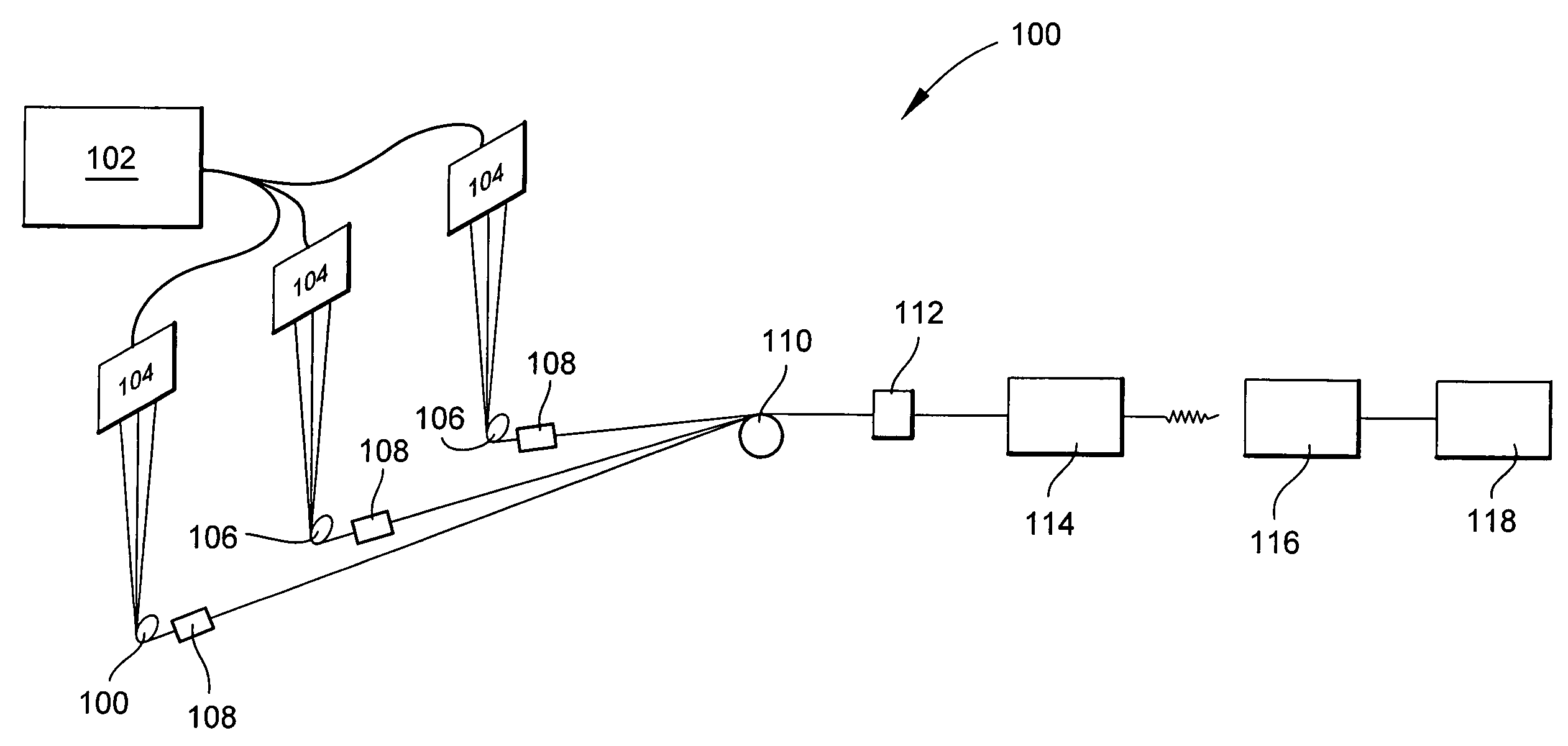

Nonwoven fabric for cylindrical bag filter, process for producing the same, and cylindrical bag filter therefrom

InactiveUS20100180558A1Excellent characteristicsImprove rigidityElectric discharge heatingDispersed particle filtrationEngineeringNonwoven fabric

The present invention provides a nonwoven fabric for cylindrical bag filter, wherein a long-fiber nonwoven fabric made of a synthetic fiber is used and the long-fiber nonwoven fabric is a long-fiber nonwoven fabric which is made of a thermoplastic continuous filament and is partially thermocompression-bonded. It is preferable that the circular arc flexural rigidity per basis weight is 0.050 to 1.000 ((cN / 2 cm) / (g / m2)) and the air permeation rate per basis weight is 0.010 to 0.500 ((cc / cm2 / sec) / (g / m2)). Further, there is provided a method for producing a nonwoven fabric for cylindrical bag filter including the steps of: melt-extruding a thermoplastic polymer through a spinneret; sucking and drawing the extrudate with an air sucker to form a thermoplastic continuous filament; allowing the filament to be subjected to electrification opening and to be piled on a moving collection surface to form a fiber web; and allowing the fiber web to be subjected to pressure welding treatment with a flat roll and partially thermocompression-bonding the fiber web with hot embossing rolls to form a long-fiber nonwoven fabric.

Owner:TORAY IND INC

Core spun yarn and woven stretch fabric

InactiveUS20080318485A1Increase draftContinuous wound-up machinesWoven fabricsPolyethylene terephthalateEthylene

A core spun yarn comprising a bi-component polyester filament and an elastomeric fiber. The polyester filament has a denier from about 20 to about 150 and the elastomeric fiber has a denier from 20 to 140. The polyester filament is about 2 weight percent to about 60 weight percent, based on total weight of the yarn and the elastomeric fiber is from about 1 percent to about 40 percent, based on total weight of the yarn. The elastomeric fiber may have higher draft than the bi-component polyester fiber. The polyester filament comprises poly (trimethylene terephthalate) and at least one polymer selected from the group consisting of poly (ethylene terephthalate) and poly (tetramethylene terephthalate) and said elastomeric fiber is spandex. The yarn may include a sheath of at least one staple fiber. The disclosure also includes a fabric of the bi-component polyester filament and an elastomeric fiber.

Owner:CENT TEXTILES HK

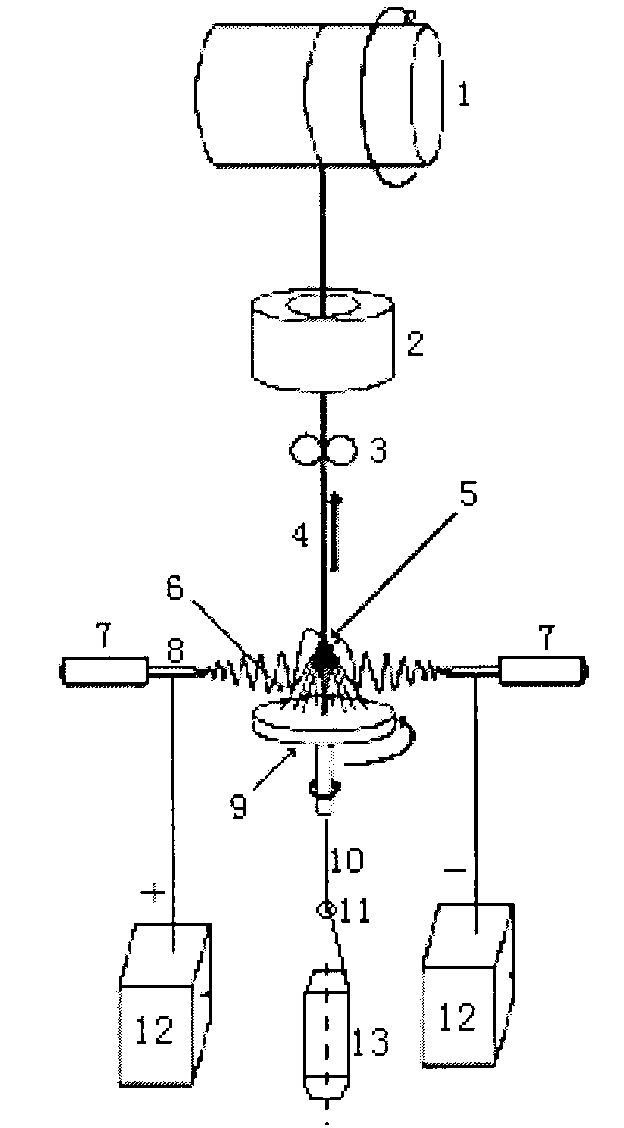

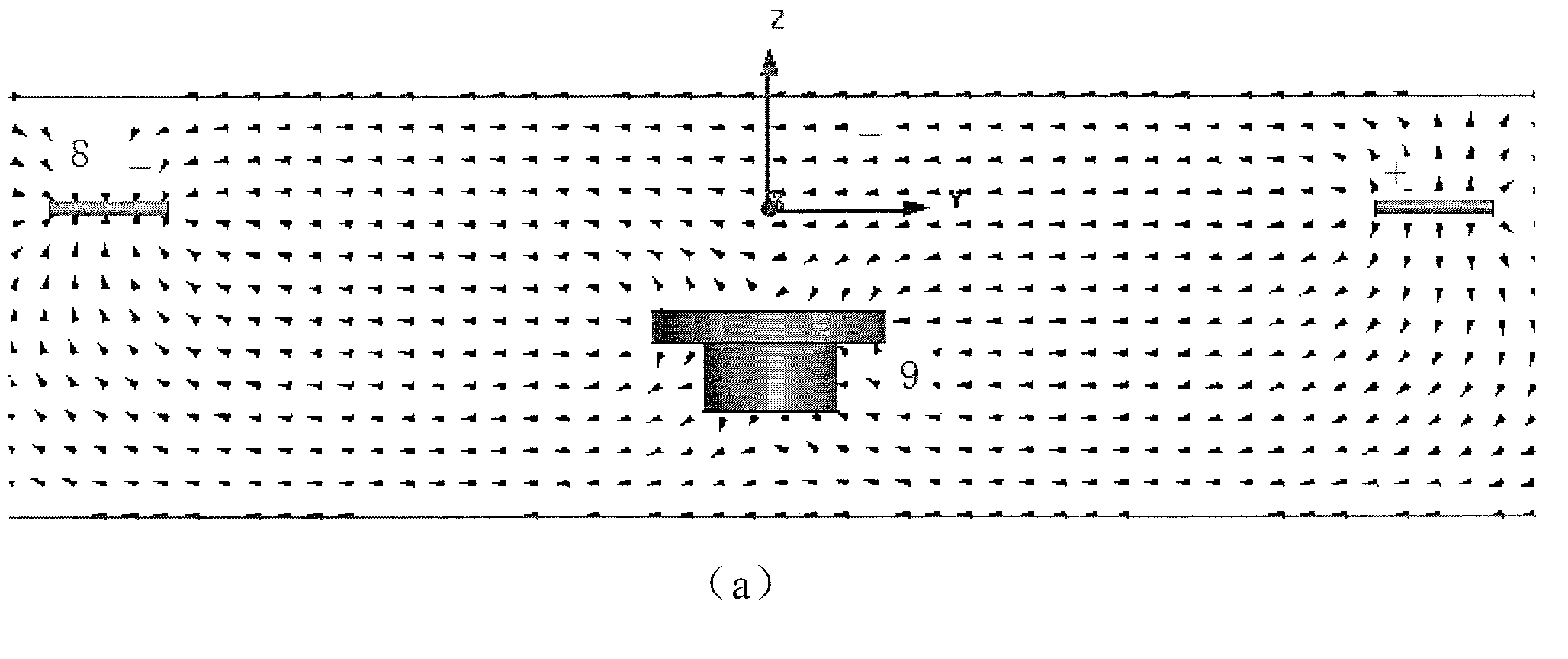

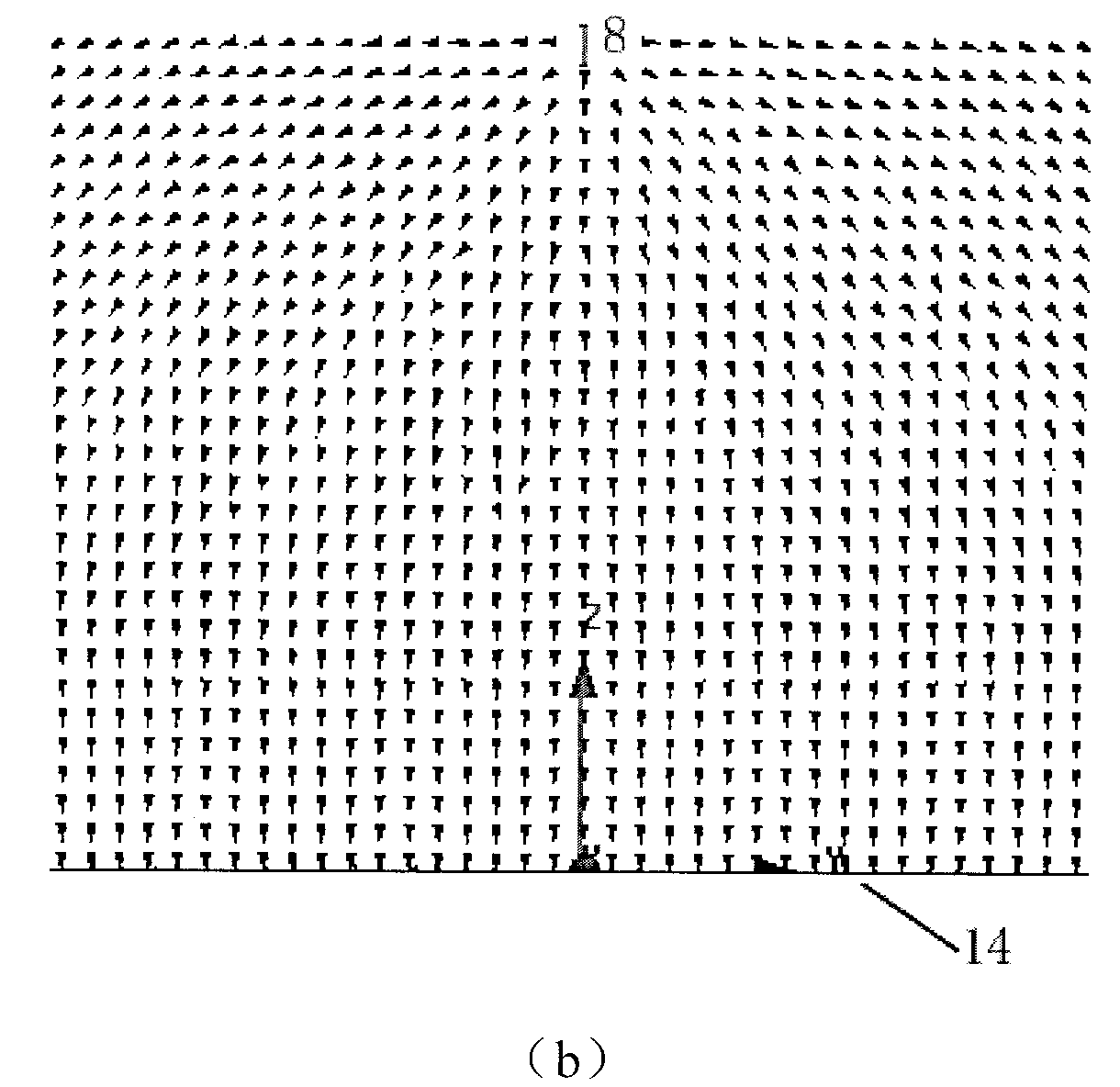

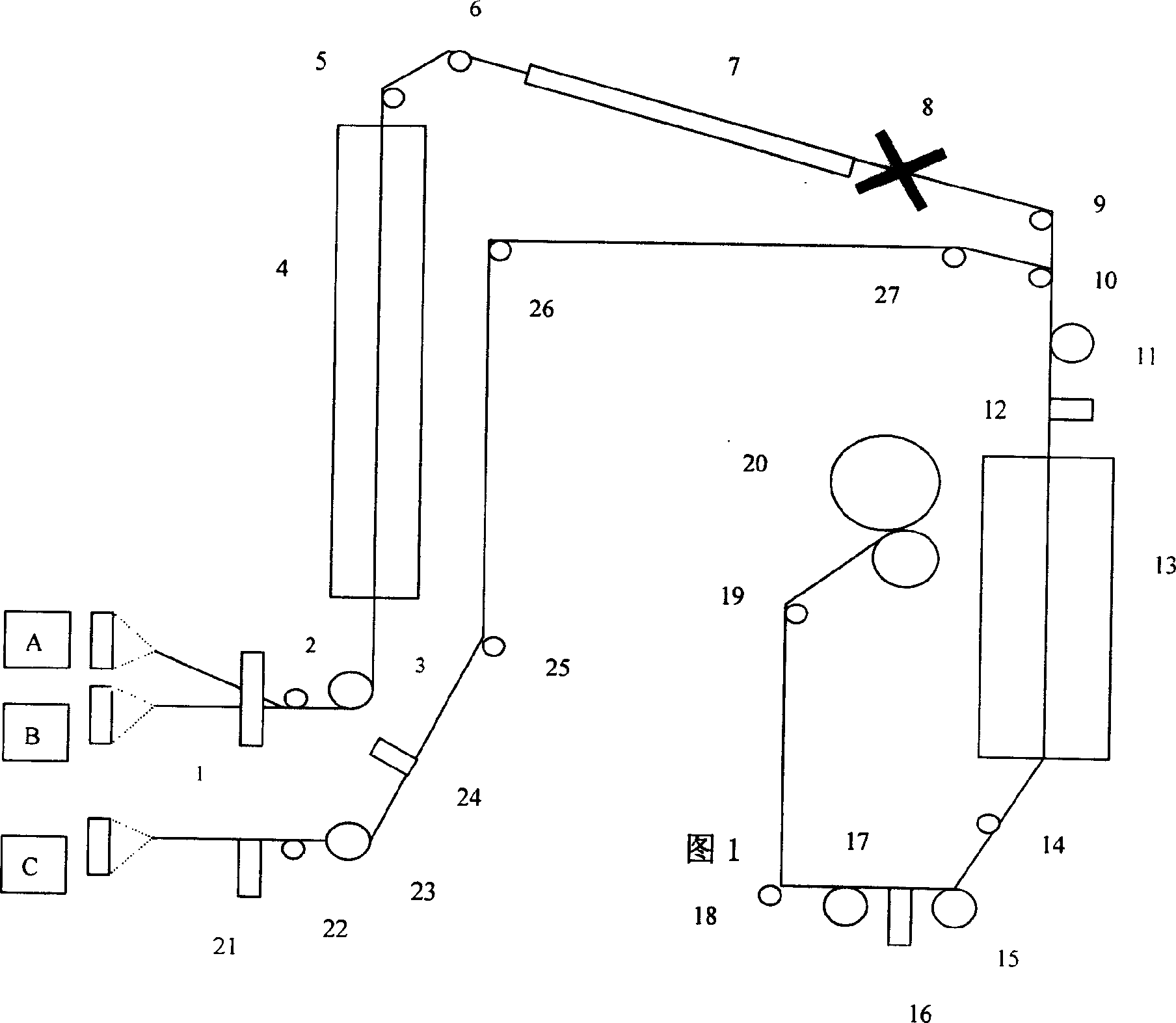

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

Filaments comprising a non-perfume active agent nonwoven webs and methods for making same

Owner:GLENN JR ROBERT WAYNE +11

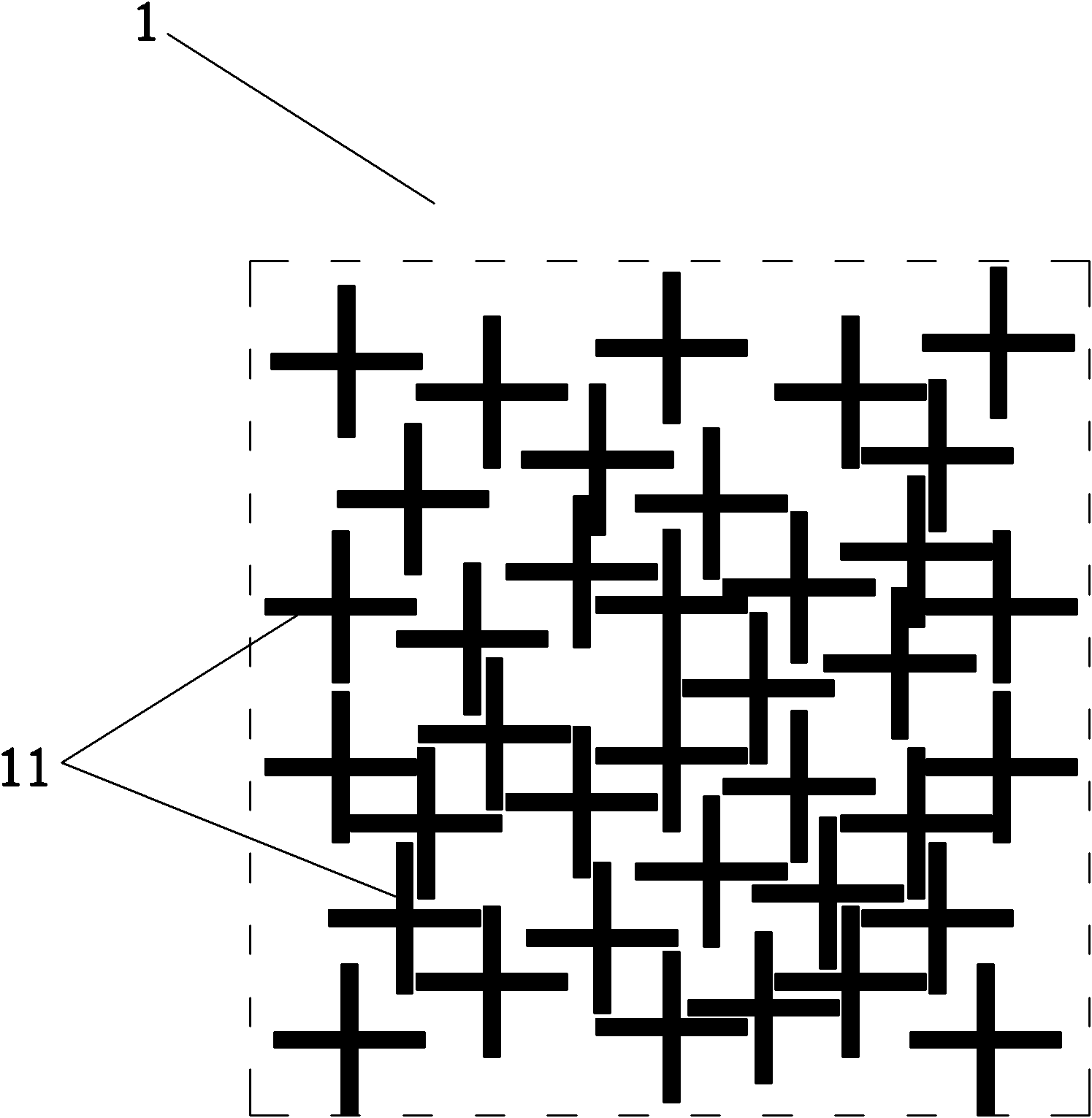

A kind of super imitation cotton polyester filament and its production process

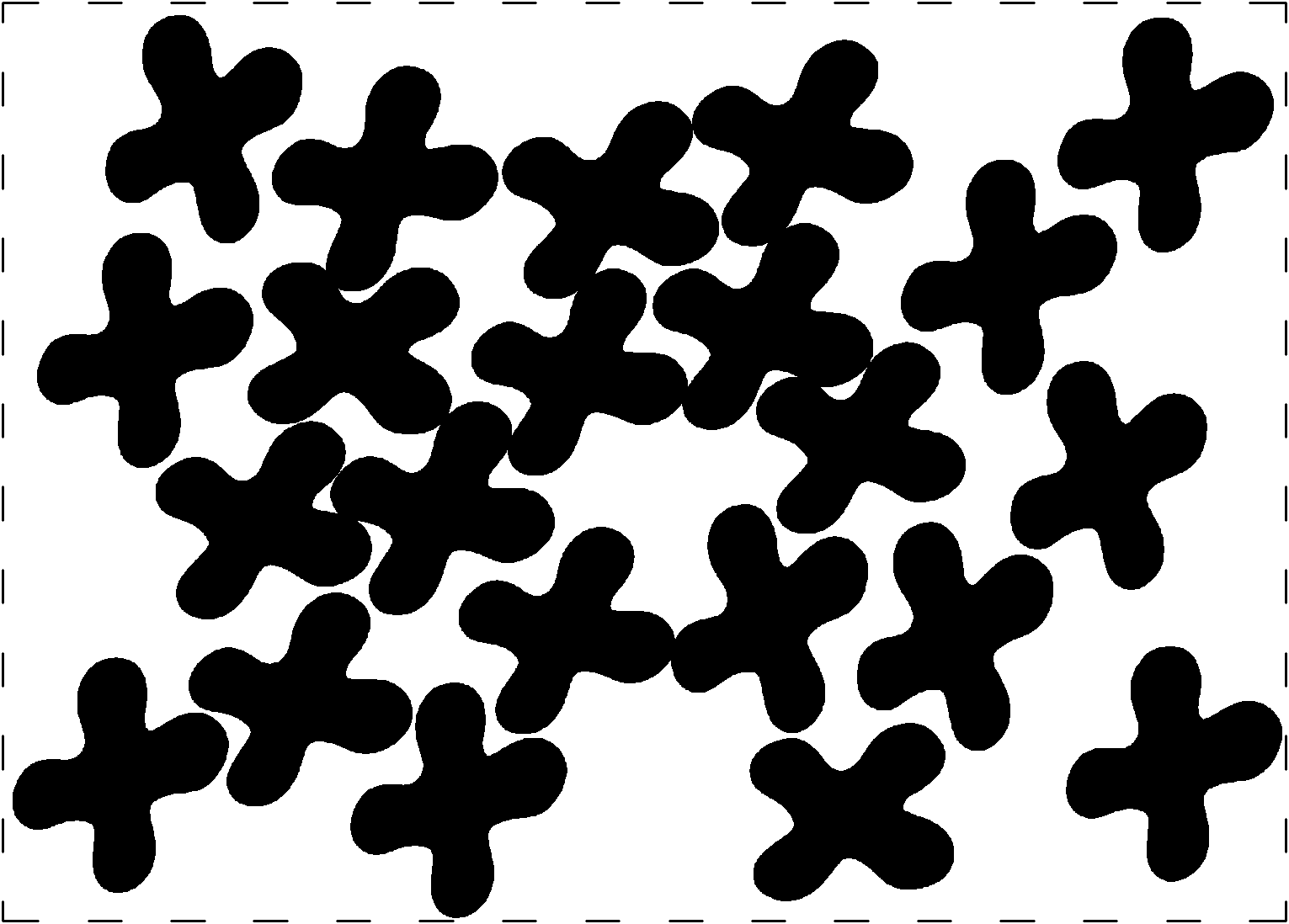

The invention provides a kind of super imitation cotton polyester filament, comprising polyester FDY yarn and superfine polyester POY yarn, polyester FDY yarn and superfine polyester POY yarn are composited together through false twist deformation processing, and the polyester FDY yarn has a fineness of 0.5-1.5D, semi-dull polyester FDY yarn with elongation at break of 25%-35%, the semi-dull polyester FDY yarn is a tow composed of several monofilaments, and the cross-sectional shape of the monofilament is cross-shaped; Superfine polyester POY yarn is full-dull superfine polyester POY yarn, the fineness of the full-dull superfine polyester POY yarn is 0.5-1.5D, and the elongation at break is 100%-135%. It is a tow composed of several monofilaments, and the cross-sectional shape of the monofilaments is circular. The beneficial effect of the present invention is that its softness, water absorption, moisture permeability and quick-drying property are all superior to those of pure cotton fiber, which can achieve the purpose of replacing cotton fiber, greatly reducing the dependence of the textile industry on natural cotton, and alleviating The problem of shortage of cotton resources.

Owner:福建百宏聚纤科技实业有限公司

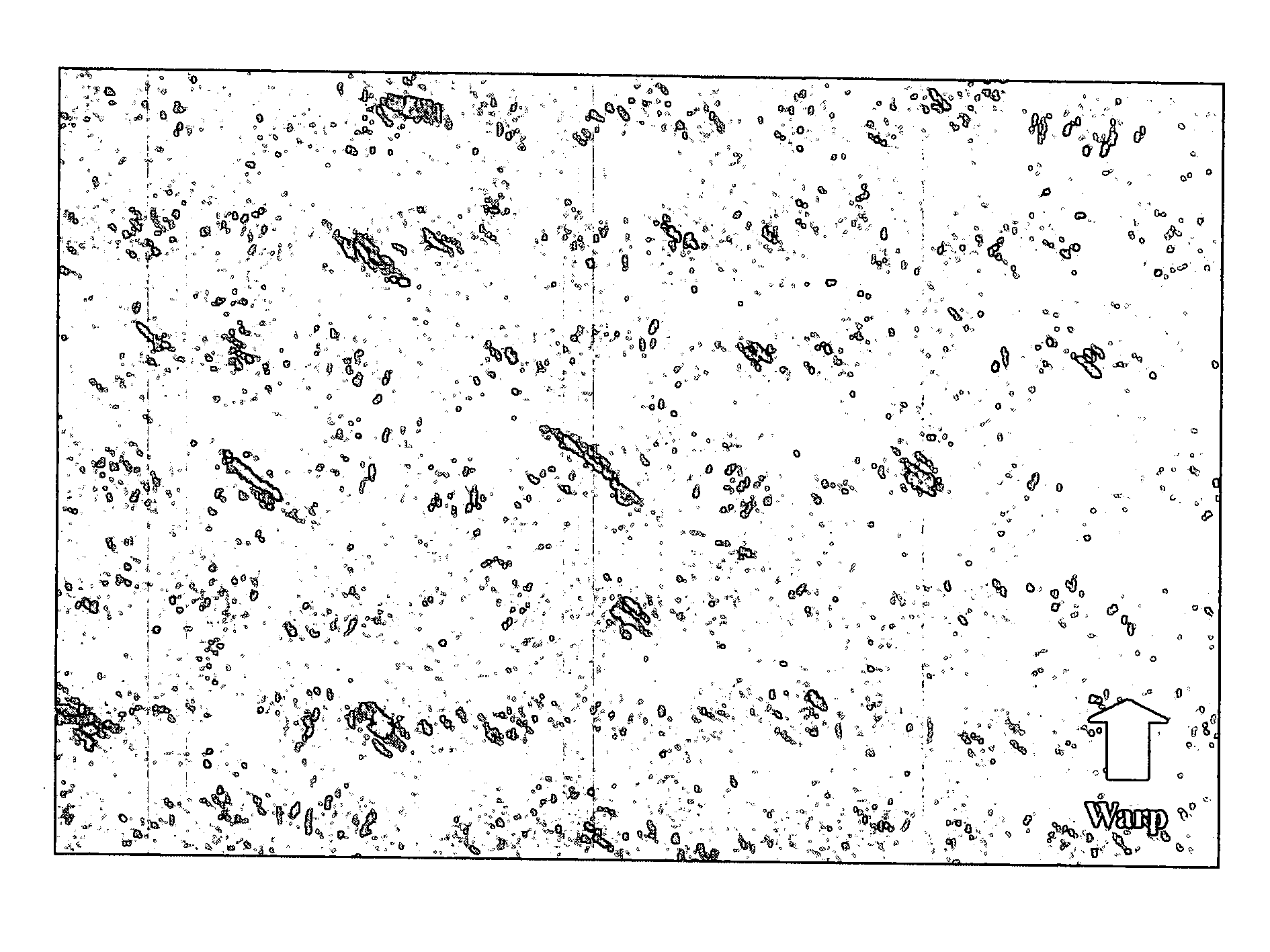

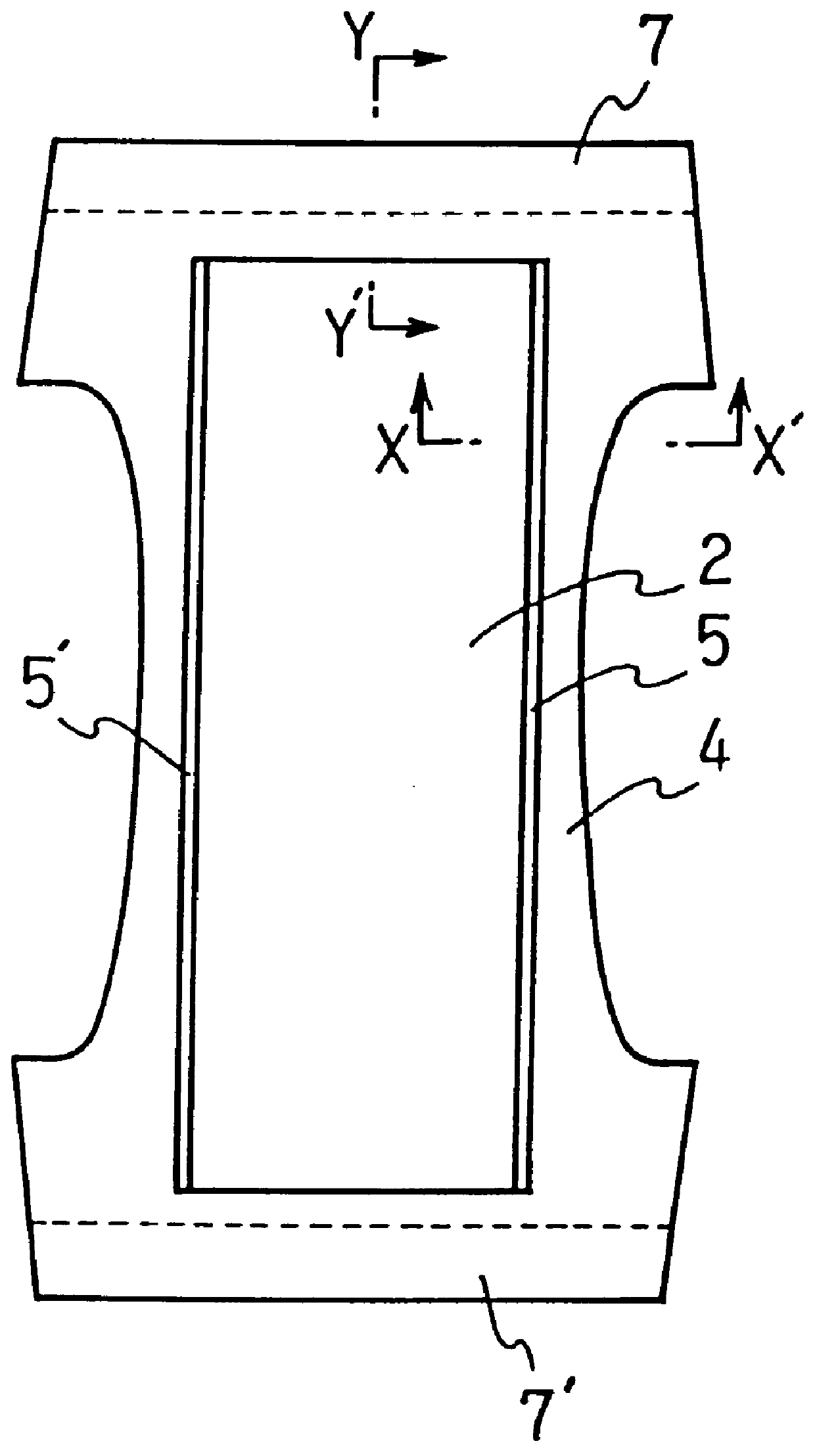

Filament nonwoven fabric and absorbent article using the same

A filament nonwoven fabric comprising thermoplastic fibers with a fineness of 0.1 to 10 d / f, having a basis weight of 5 to 35 g / m2, and having thermally press bonded portions, in which the conditions (A), (B), and (C) below are satisfied: (A) the area rate of the thermally press bonded portions being from 5 to 25%; (B) X< / =2.0 (mm) X: the average value of the distance between adjacent thermally press bonded portions in the mechanical direction of the nonwoven fabric; Y< / =2.5 (mm) Y: the average value of the distance between adjacent thermally press bonded portions in the direction perpendicular to the mechanical direction of the nonwoven fabric; and (C) the average value of the ratio between the maximum diameters of the thermally press bonded portions satisfying 1< / =y / x< / =15, wherein x: the average value of the maximum diameter of the thermally press bonded portions in the mechanical direction of the nonwoven fabric; and y: the average value of the maximum diameter of the thermally press bonded portions in the direction perpendicular to the mechanical direction of the nonwoven fabric.

Owner:CHISSO CORP

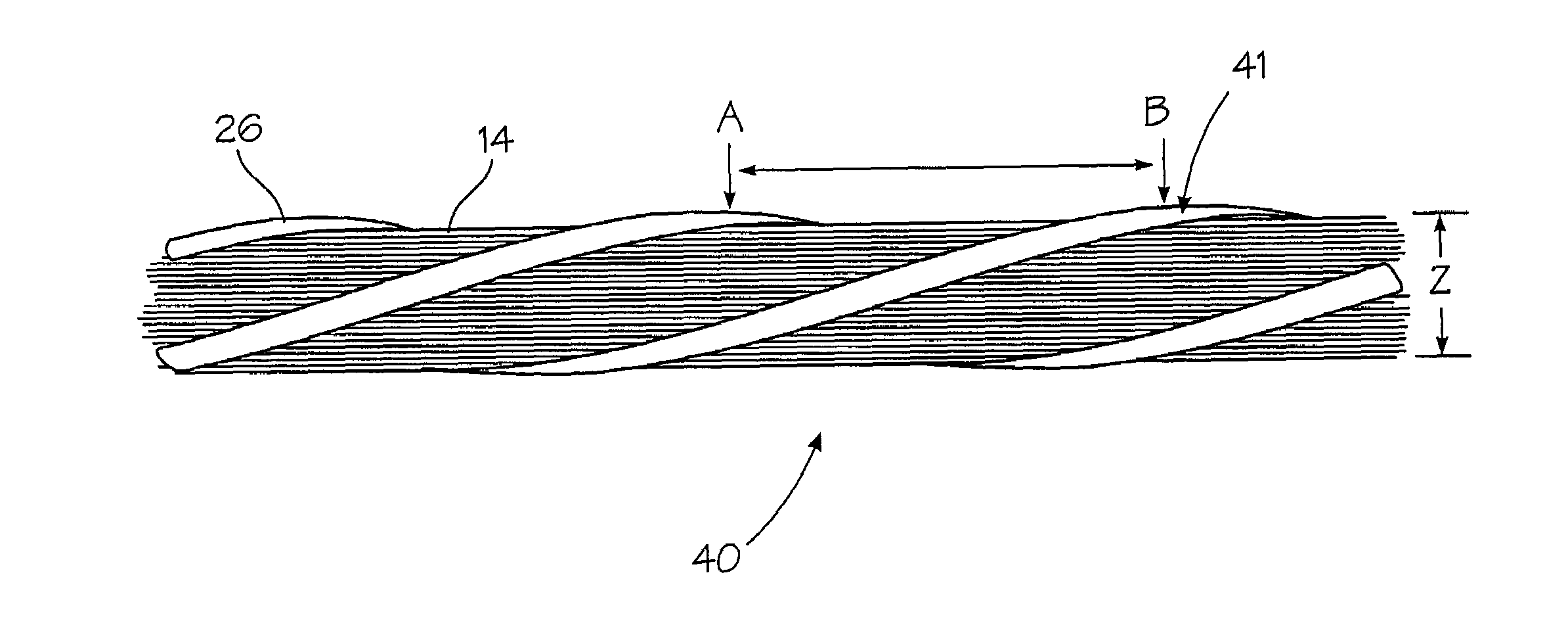

Process for producing wool-like polyester composite filament yarn

The present invention discloses the production process of composite wool-like polyester filament yarn. Very fine sea island polyester fiber and conventional polyester fiber are stretched, false twisted and combined to form composite fiber filament, and the composite fiber filament is then combined with high shrinkage polyester fiber with boiling water shrinkage over 20 % via air spray twisting to form the composite wool-like polyester filament yarn. The composite filament yarn is woven, and processed through fiber opening, post finishing and light roughing to form soft and fine wool-like fabric with excellent rebound resilience.

Owner:厦门翔鹭化纤股份有限公司

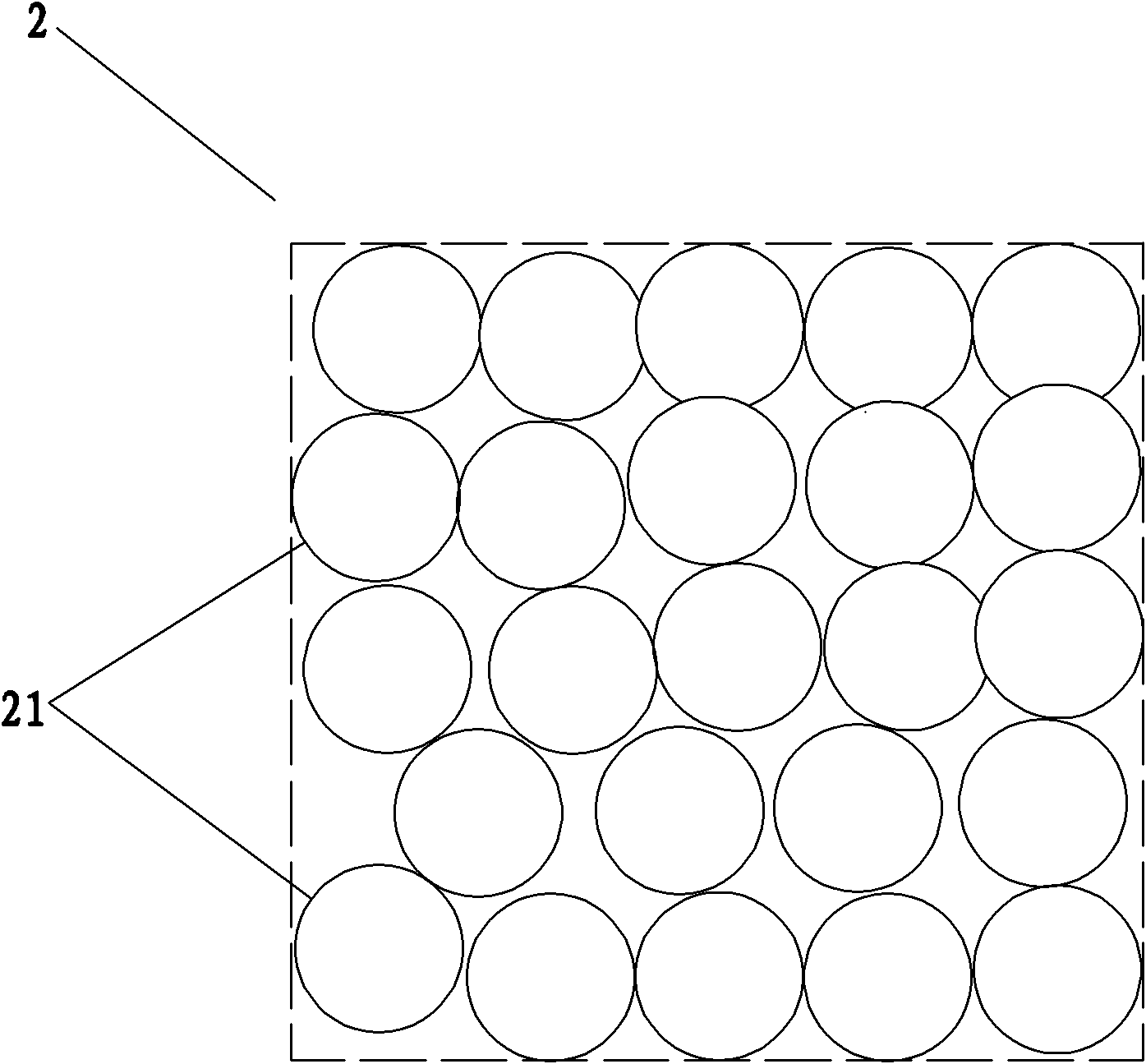

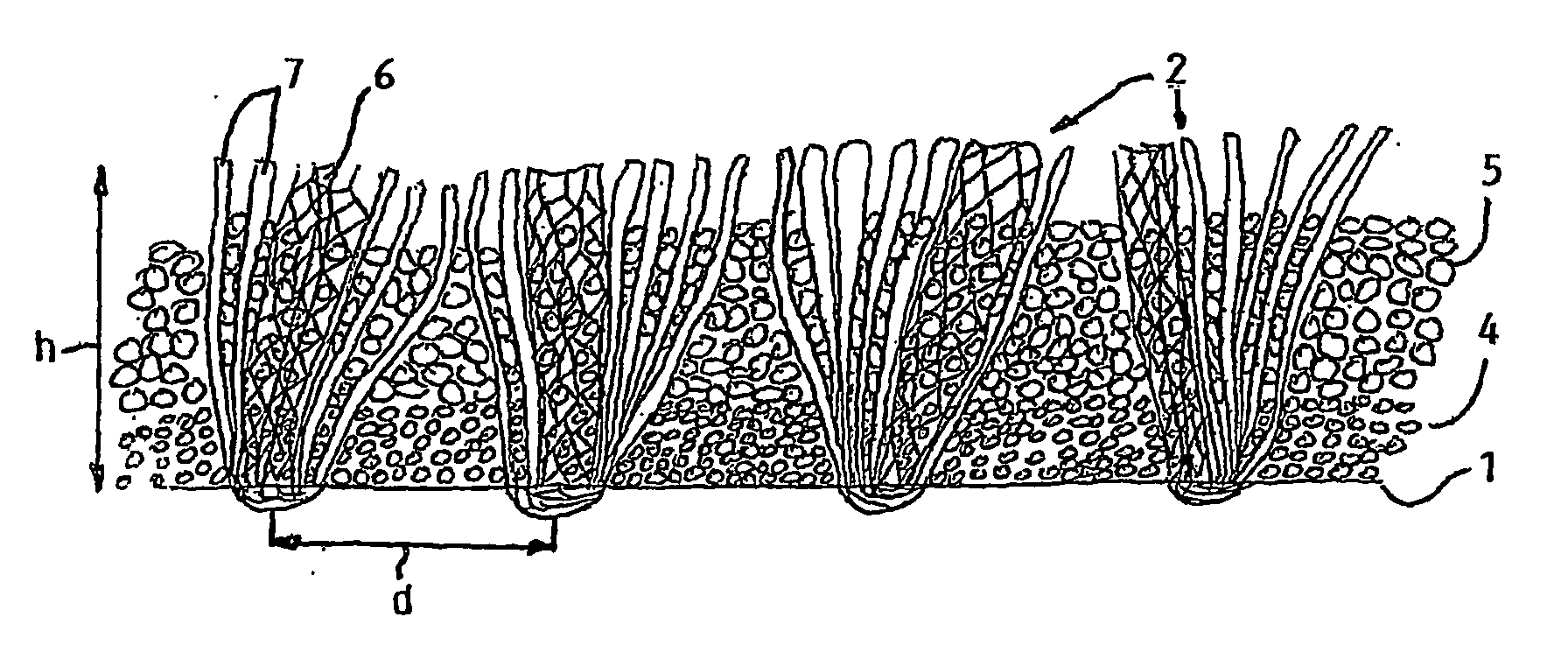

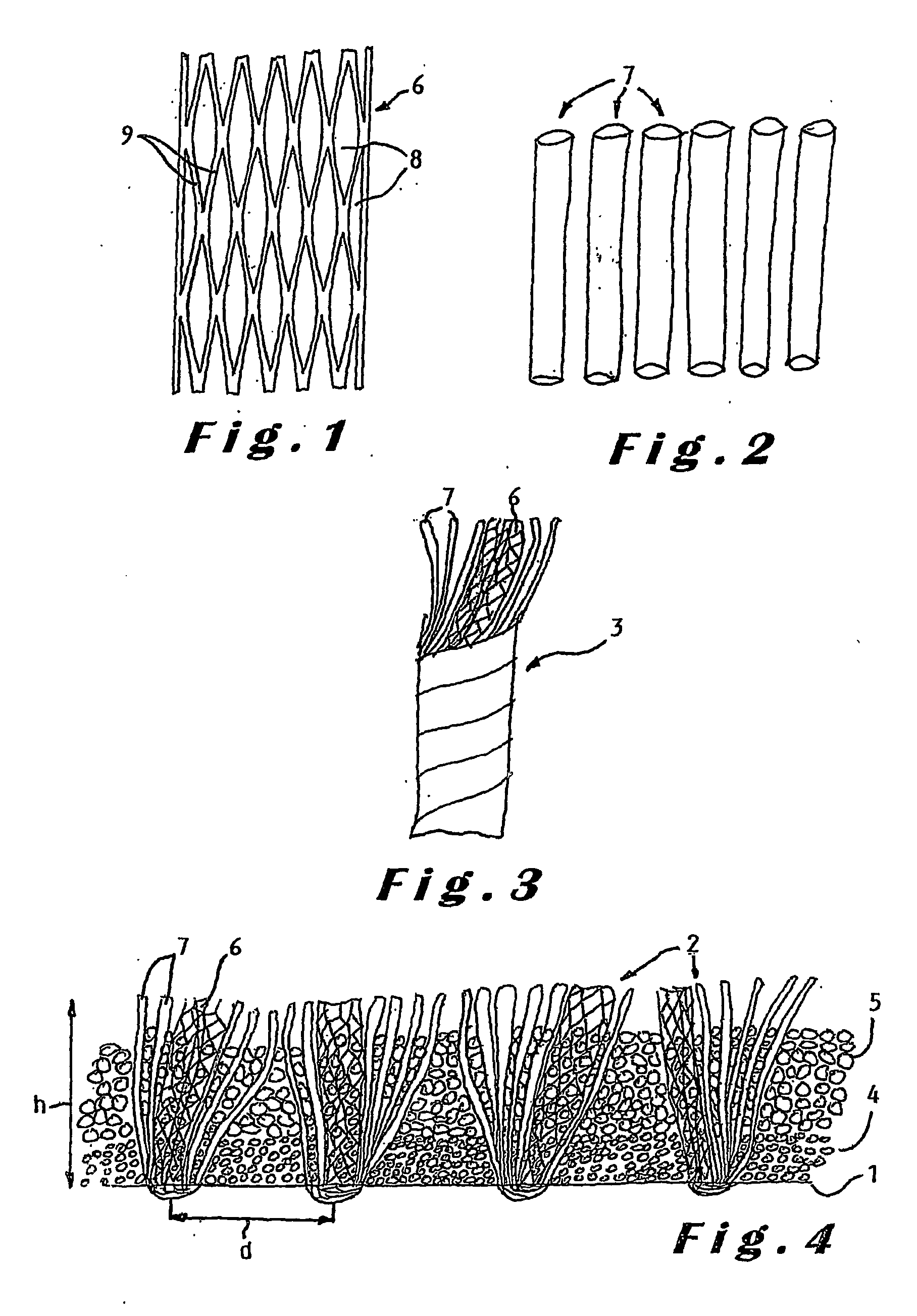

Synthetic turf

InactiveUS20060093783A1Increase elasticityEasy to recycleDead plant preservationArtificial flowers and garlandsInfillWear pattern

The present invention provides new types of synthetic turf. The synthetic turf includes a pile fabric having a backing (1) and tufts (2) projecting therefrom. In one embodiment, at least a number of the tufts are made of a composite yarn formed by at least one fibrillated yarn (6) together with a number of individual filament yarns (7), in particular with so-called monofilament or monotape yarns. The fibrillated yarn and the individual filament yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. In another embodiment, at least a number of the tufts are made of a composite yarn formed by monotape yarns twisted together with a number of the monofilament yarns. The monofilament and monotape yarns are preferably made of polyethylene so that the synthetic turf is sliding-friendly. The combination of a fibrillated yarn and individual filament yarns or the combination of monofilament and monotape yarns in a composite yarn allows immediate achievement of the look of natural grass, that is, without post-fibrillation, and avoids any visible difference in wear pattern between the different types of yarns. In another embodiment, the invention also provides improved particulate material for use as infill material for top-dressing a synthetic turf.

Owner:DOMO ZELE

Bamboo-charcoal viscose fiber and method for making same

InactiveCN1607271AStrong ability to absorb odorMonocomponent cellulose artificial filamentWet spinning methodsEmulsionEngineering

Said invention discloses a bamboo charcoal viscose fiber and producing method. The bamboo charcoal is finely selected, coarse cracked, dust removed, trash extracted, and pulverized to less than 0.5 micrometer, the bamboo charcoal micropowder and dispersant are put in water to made into aqueous emulsion slurry, filtered four times by two-layer of poplin filter fabric, respectively spinning in filament spinning machine and shorts spinning machine to obtain said bamboo charcoal viscose fiber which has bacteriostasis and antibiotic effect.

Owner:XINXIANG CHEM FIBER

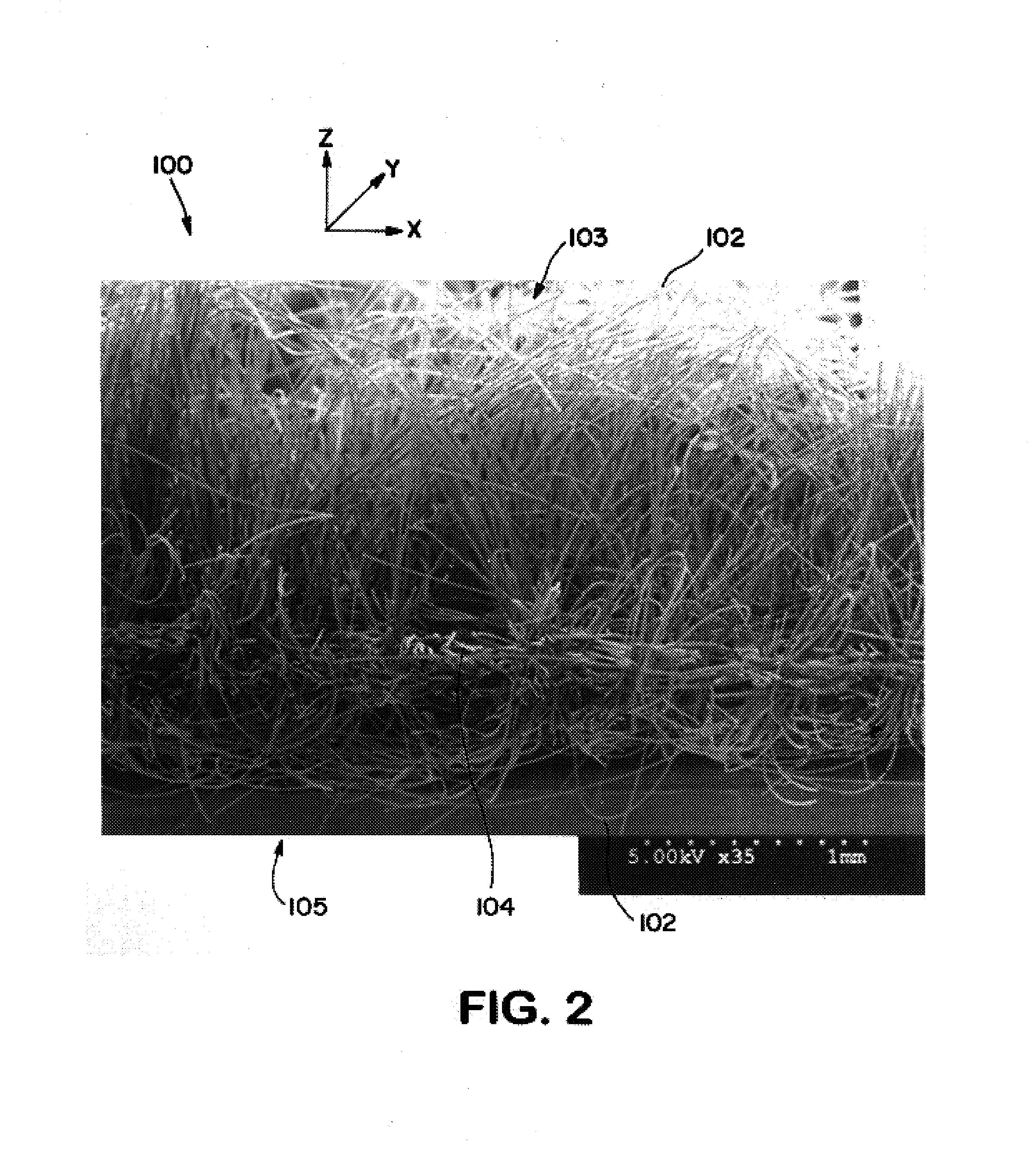

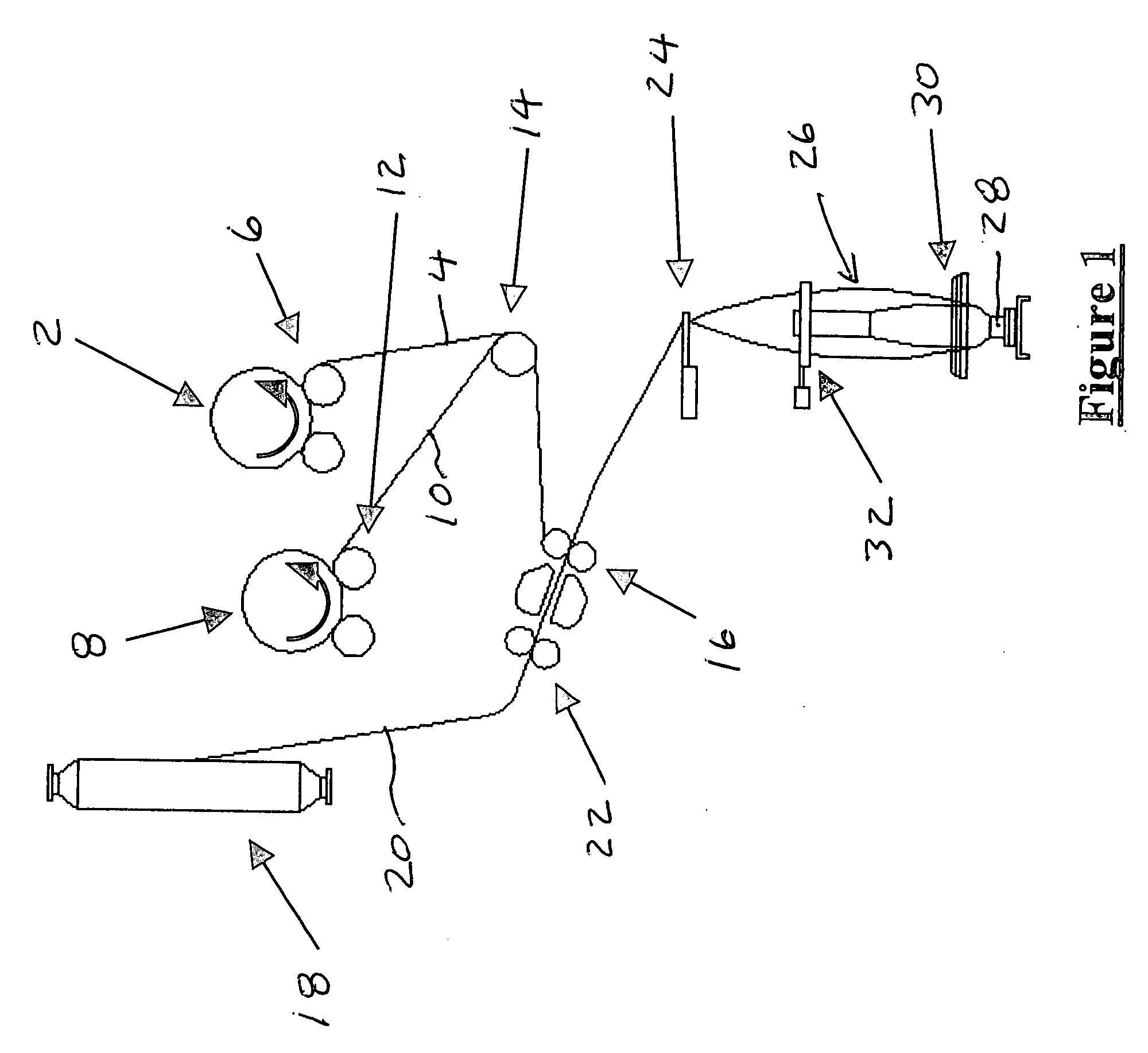

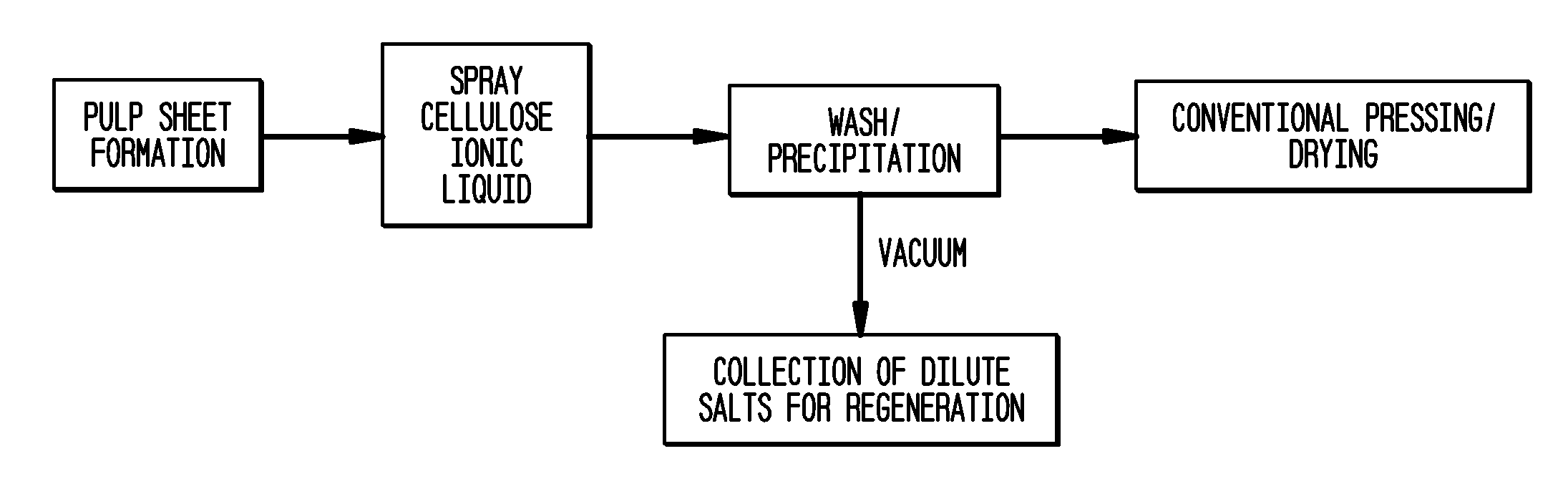

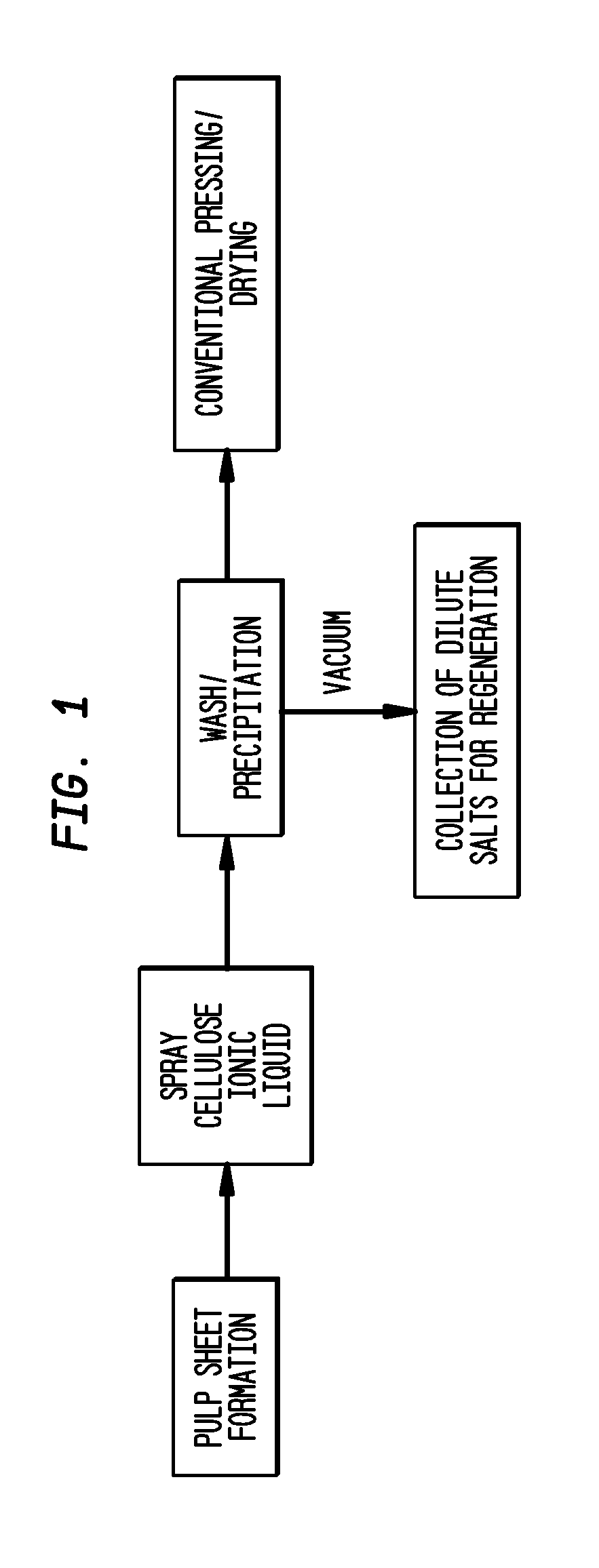

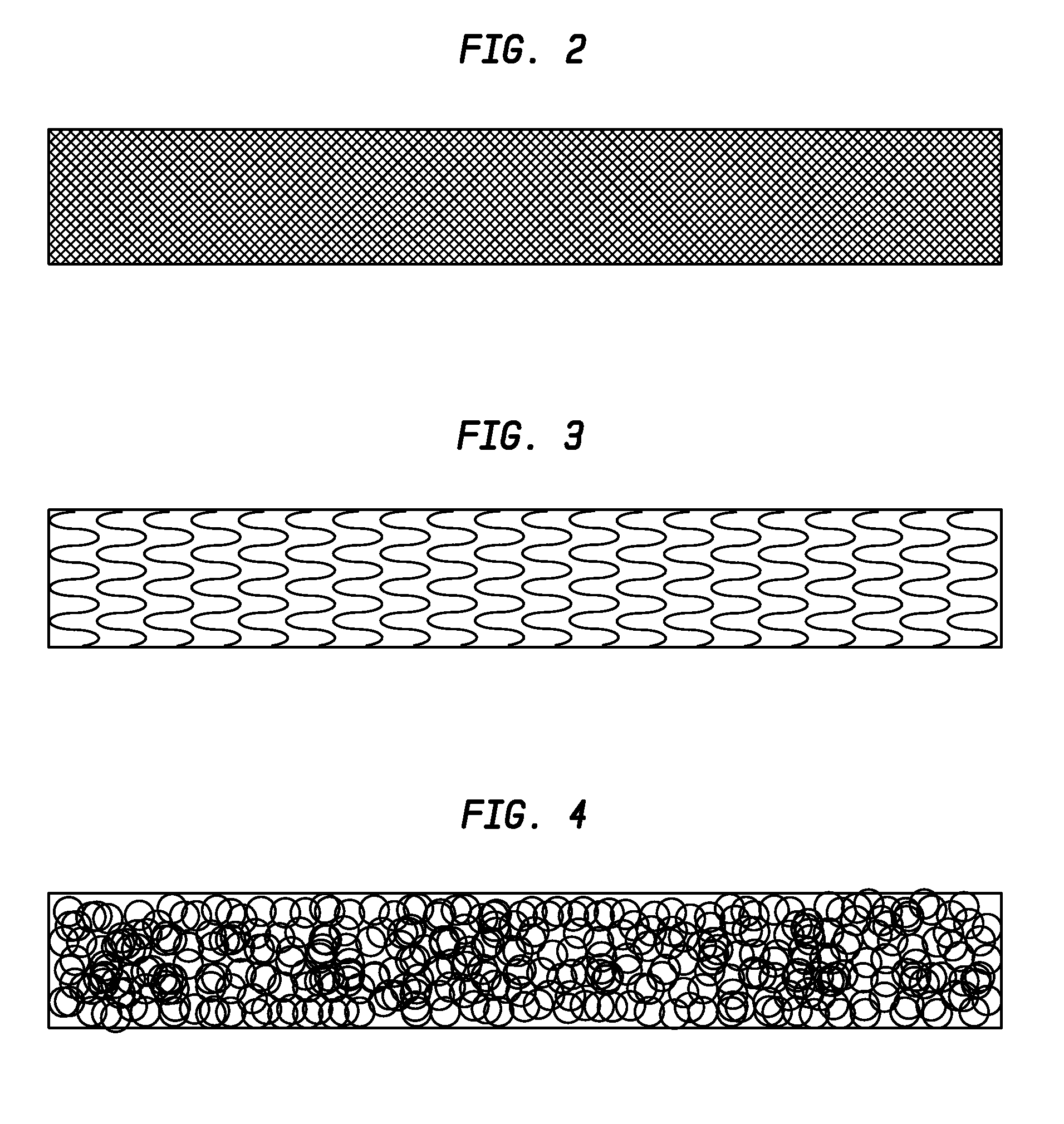

Absorbent Cellulosic Products with Regenerated Cellulose Formed In-Situ

A method of making absorbent cellulosic sheet includes forming a web of papermaking fibers, extruding a cellulosic dope of underivatized cellulose, disposing the dope upon the web and regenerating the cellulose in-situ. Regenerated filaments may have a denier of from about 0.05 to about 20.

Owner:GPCP IP HLDG LLC

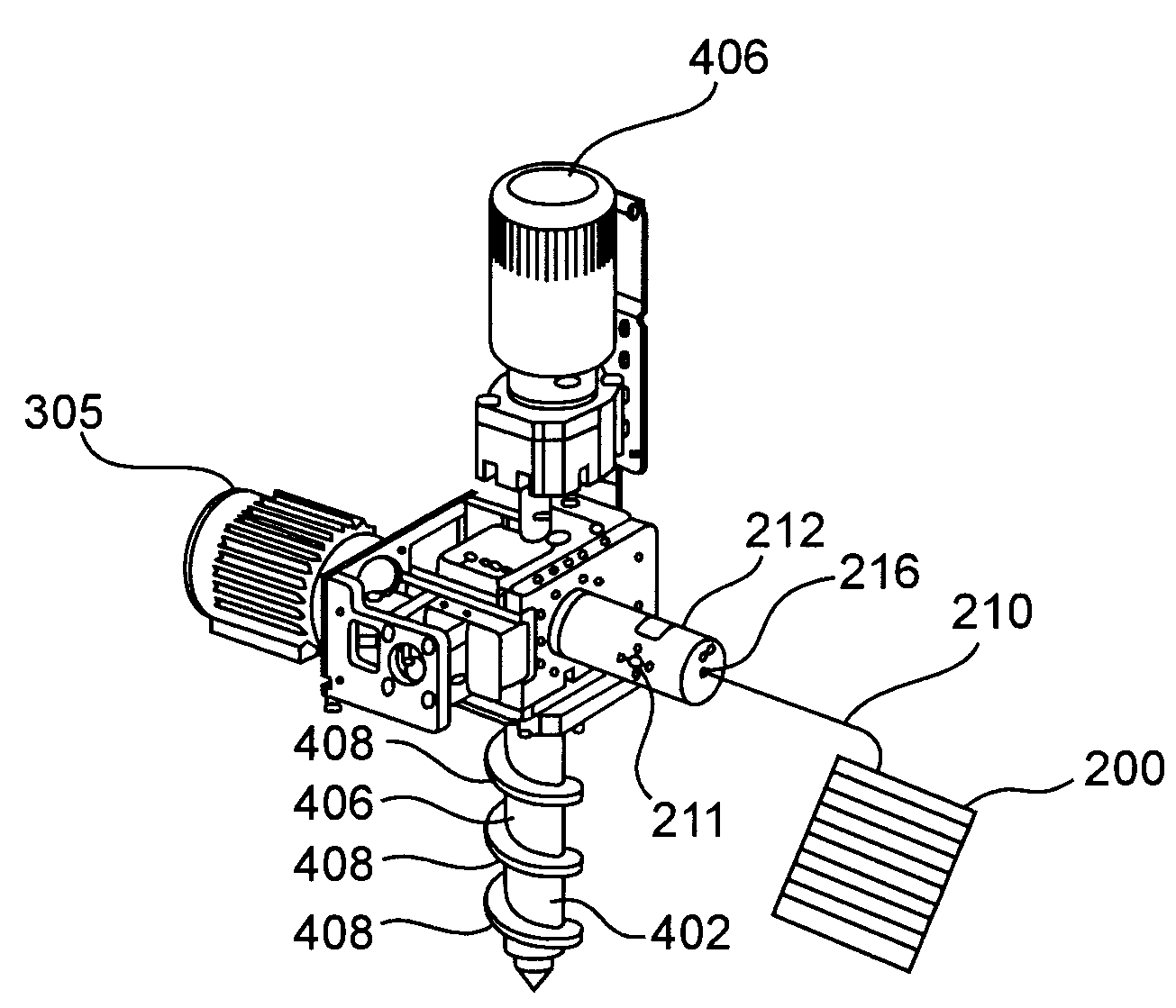

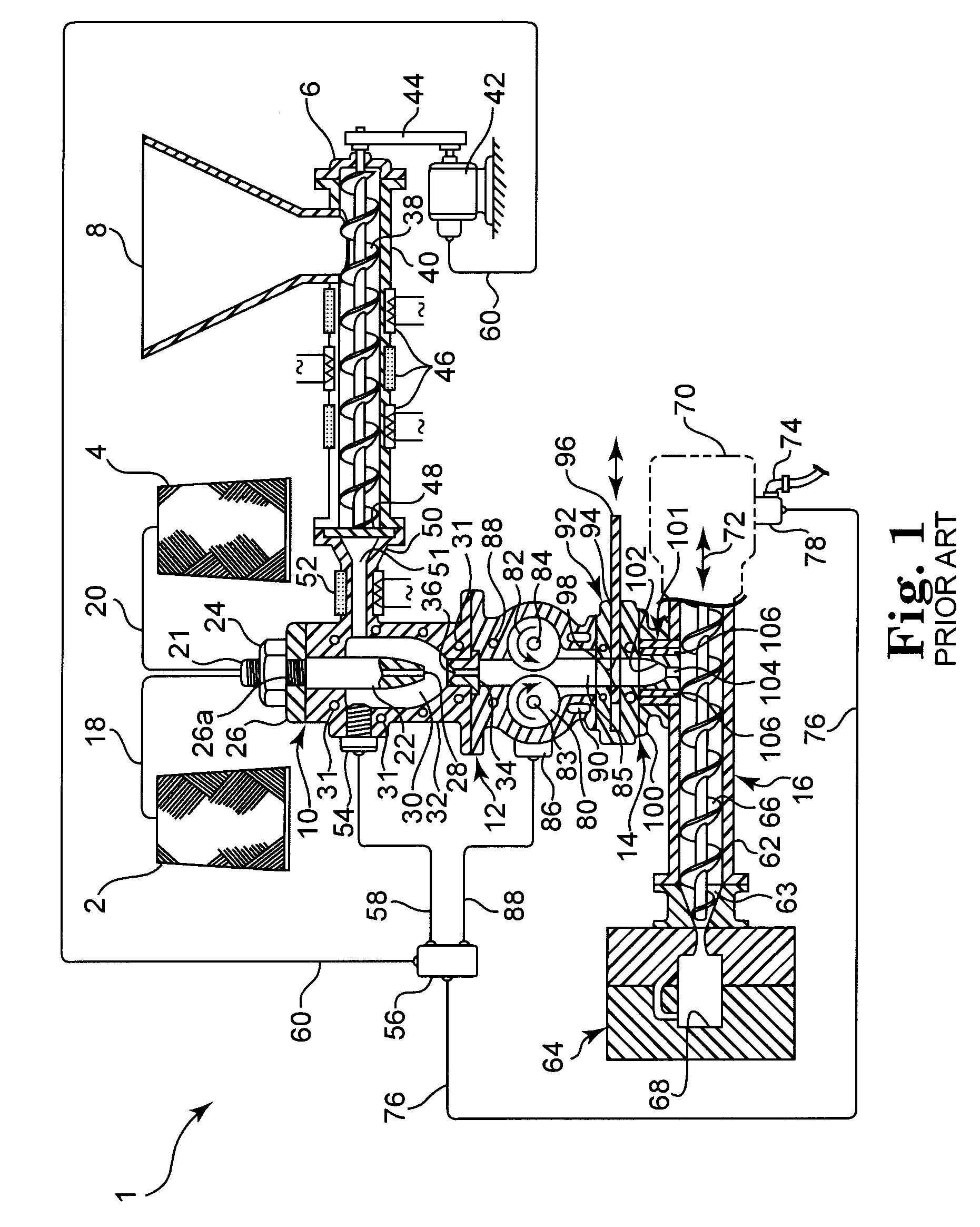

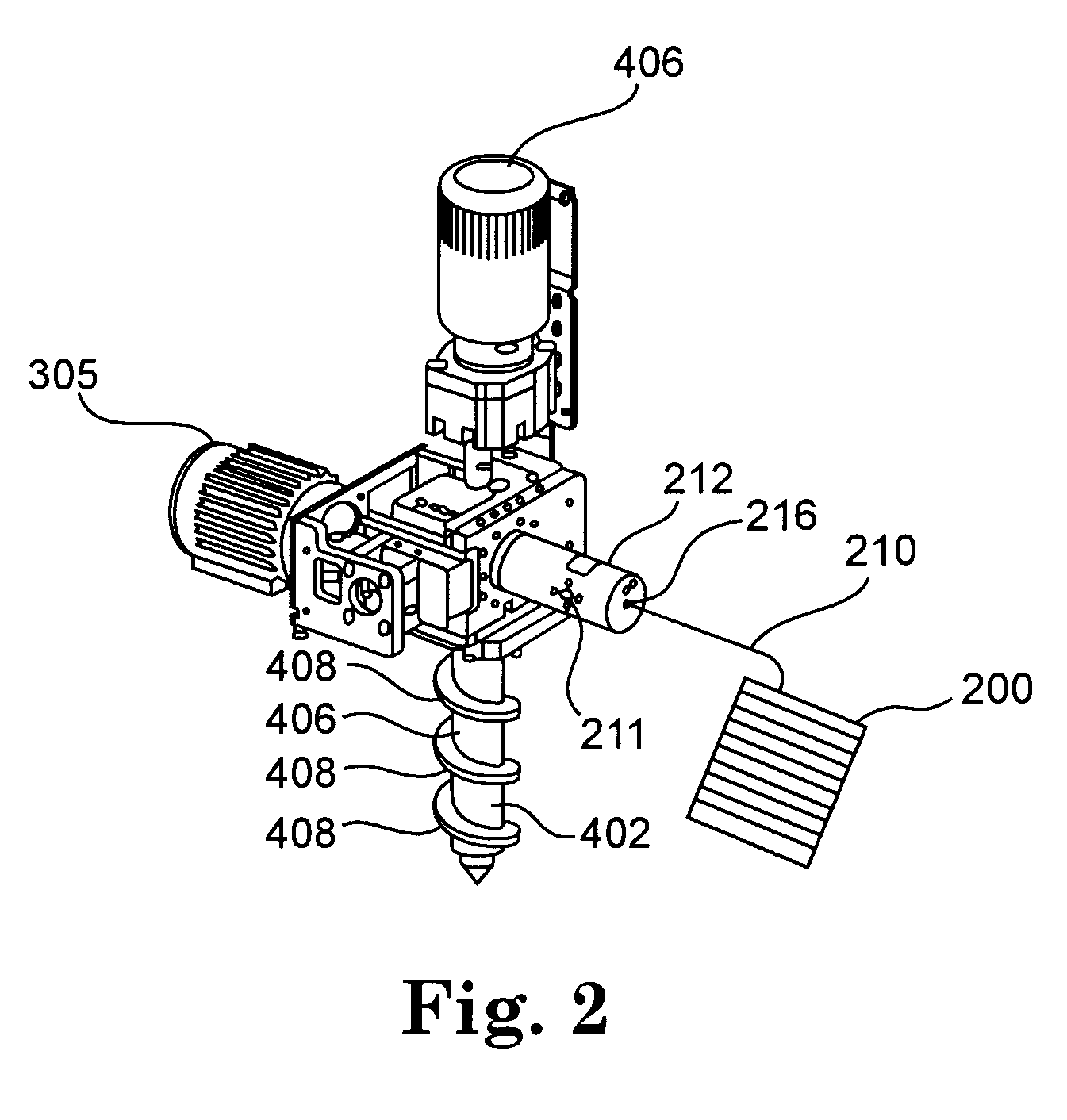

Reinforced thermoplastic resin and device and method for producing very long fiber reinforced thermoplastic resins

Improved reinforced thermoplastic resin, and devices and methods for producing the improved reinforced thermoplastic resin. The invention comprises complete fiber strand dispersion and wet out without breaking fiber filaments after cutting the fiber to a designated length. Certain embodiments of the present invention may comprise a zero-shear down screw which rotates very slowly. Thus, the resin and glass fiber bundles are slowly kneaded and the individual filaments unbundled from the fiber bundles resulting in complete wet-out of each filament without creating a pressure flow path for the substrate material and the entrained glass fibers and unbundled filaments. Optimized geometrically-controlled openings may be provided at the end of the down screw, providing further breakage-free kneading of the individual filaments. Certain embodiments may comprise an extended length cutting chamber which allow cutting very long individual fiber lengths. Temperature reduction mechanisms may be provided which provide a thermal block between the down screw assembly and the main frame assembly.

Owner:PLASTICOMP

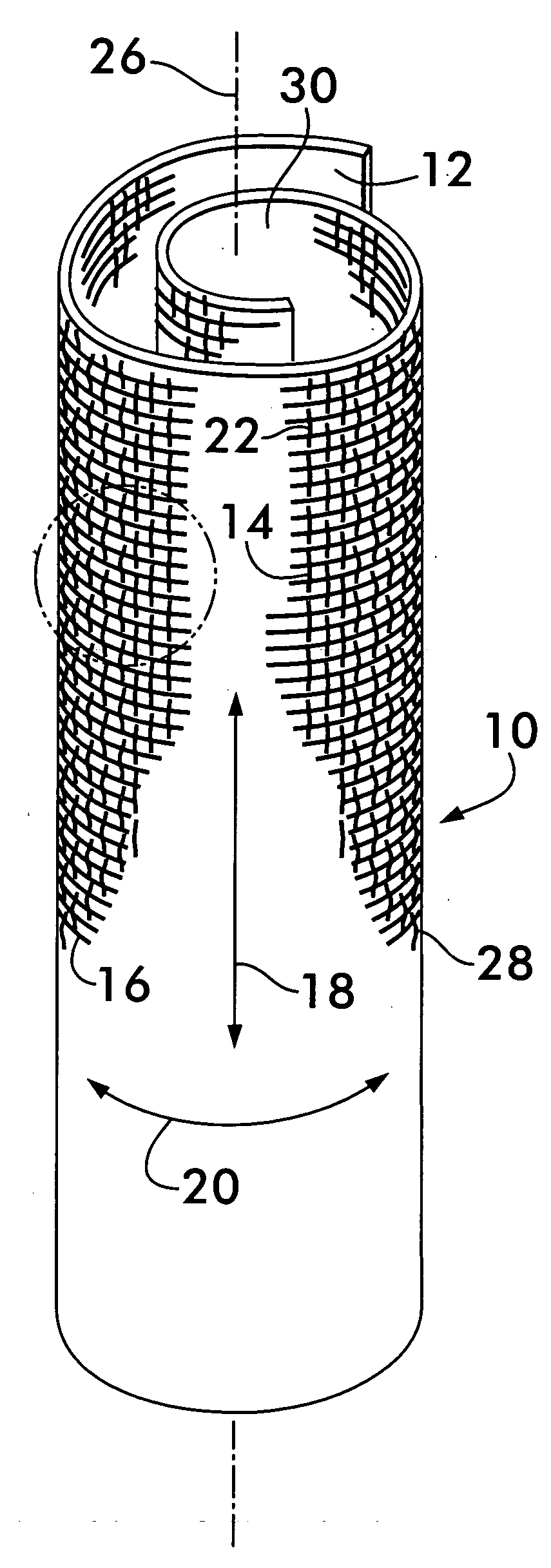

Expandable tubular fabric

Owner:EVELYN FLORENCE

Bonded-fiber fabric for producing clean-room protective clothing

InactiveUS6815382B1Woven fabricsConjugated synthetic polymer artificial filamentsEngineeringNonwoven fabric

A nonwoven fabric for manufacturing repeatedly re-usable clean-room protective clothing, made of super microfilaments having a titer of less the 0.2 dtex that are produced by water jet splitting multicomponent multisegment filaments having a titer of less than 2 dtex, the primary filaments being spun from the melt, aerodynamically stretched, laid to form a nonwoven fabric, and subjected to water-jet prebonding prior to splitting.

Owner:CARL FREUDENBERG KG

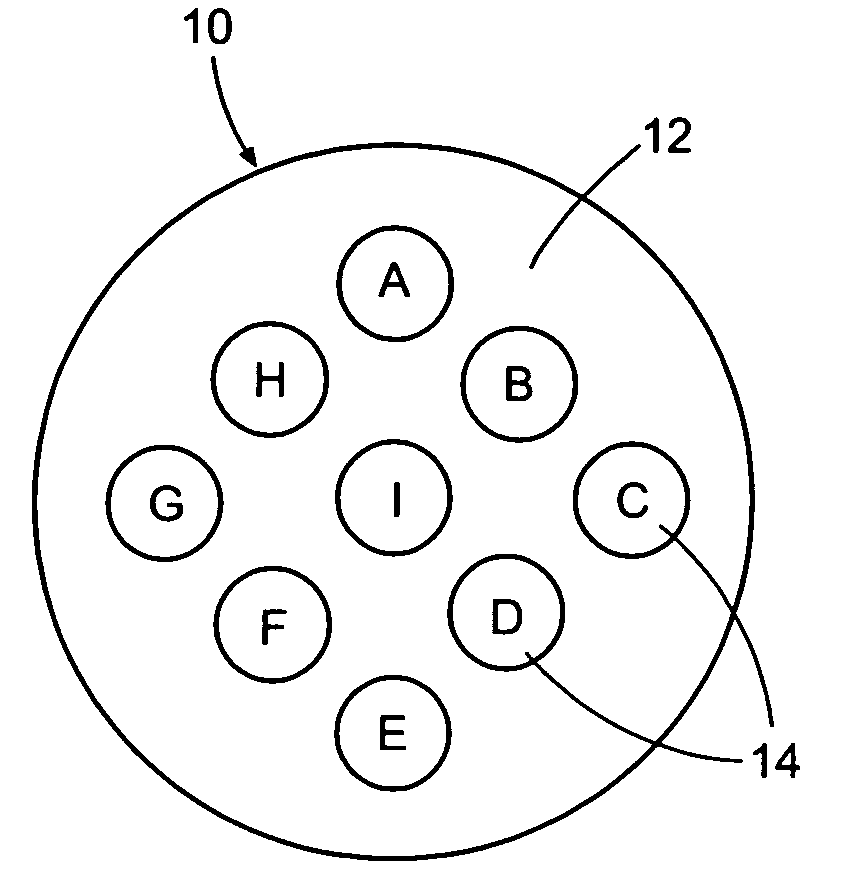

Precursor silk feedstock for forming filaments

InactiveUS7041797B2Contamination of the silk feedstock solution by other body fluids is substantially reduced or preventedImprove mechanical propertiesPeptide/protein ingredientsMonocomponent fibroin artificial filamentZoologyArthropod

The application relates to a method of obtaining silk feedstock solution from a gland of a silkworm or another silk-producing arthropod in which the body of the silkworm or the other silk-producing arthropod is cut open and the gland removed. The silk feedstock solution is subsequently extracted from the gland and used for extrusion, spinning or moulding of objects.

Owner:SPINTECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com