Patents

Literature

447 results about "Breaking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mimumum Breaking Force: the minimum force at which the chain, in the condition which it leaves the manufacturer’s plant, has been found by representative testing to break when a constantly increasing force is applied in direct tension. Breaking force values are not guarantees that all chain segments will endure these loads.

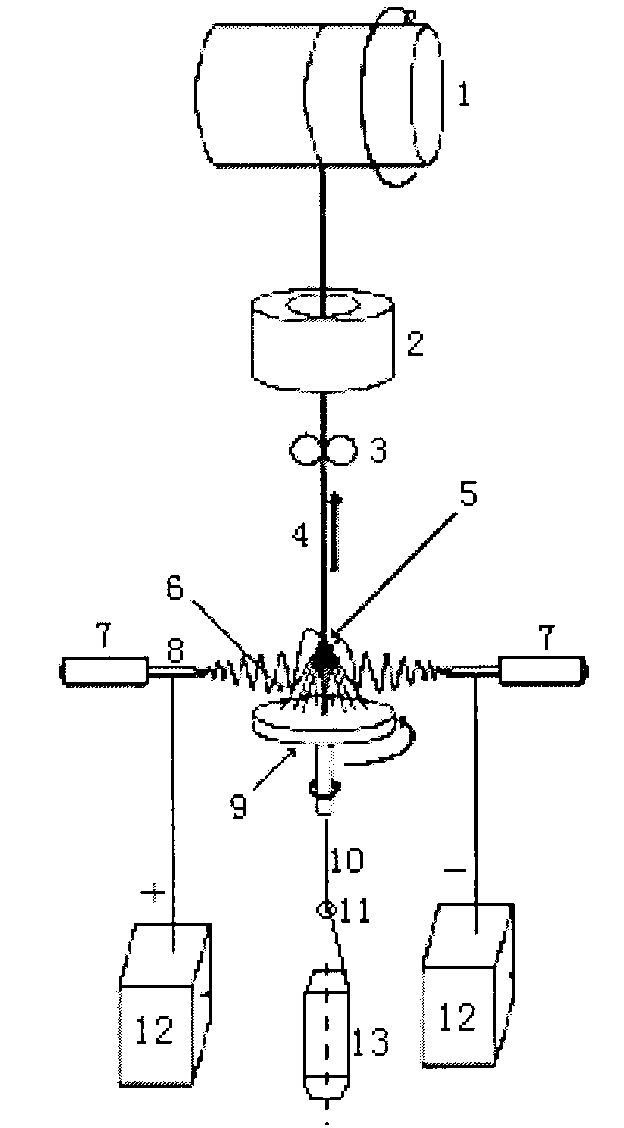

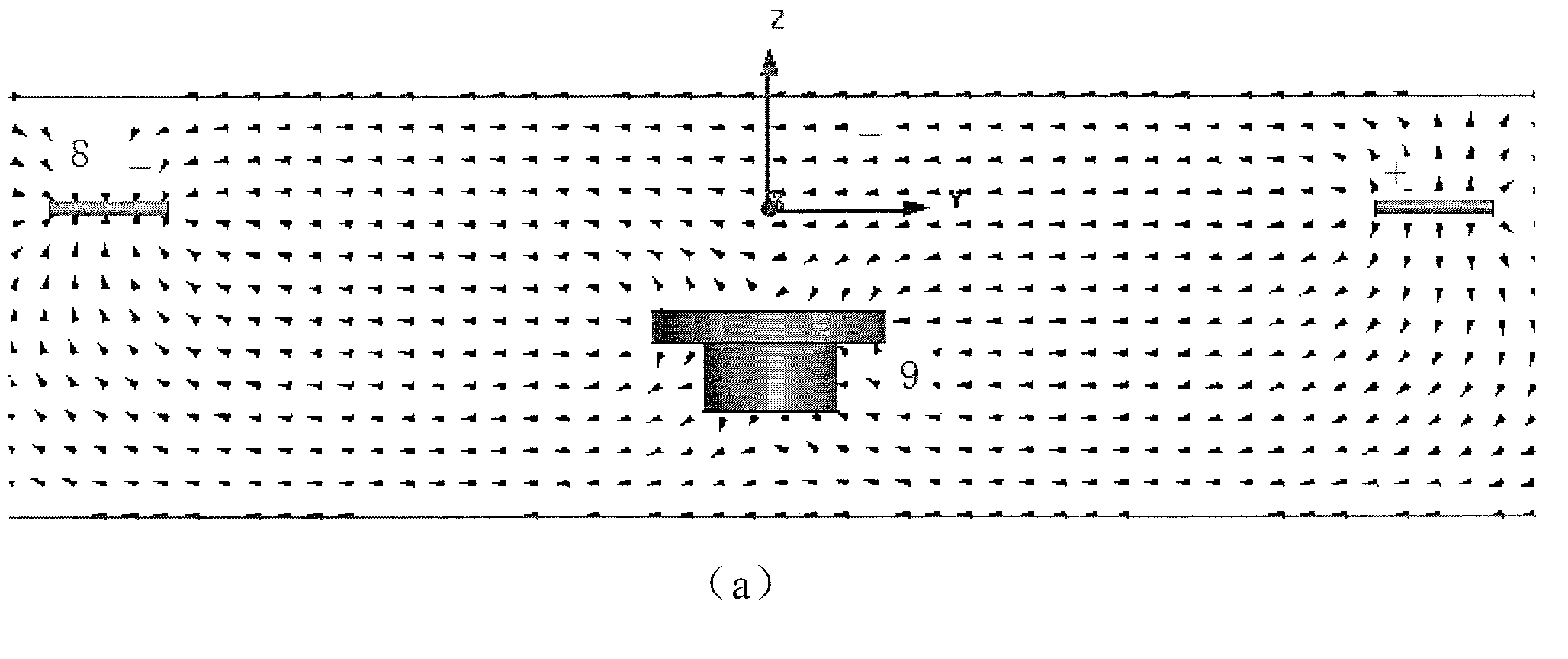

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

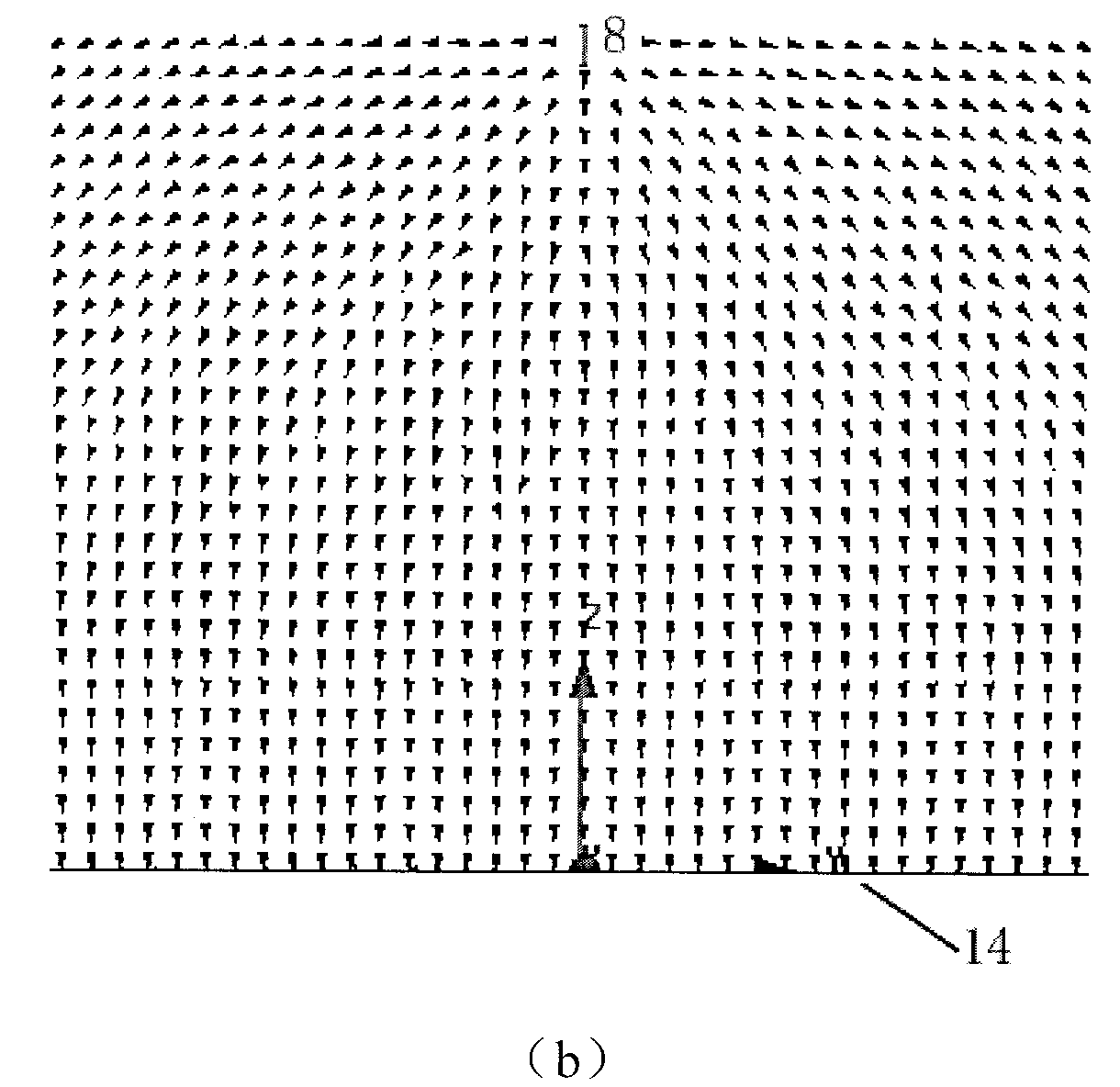

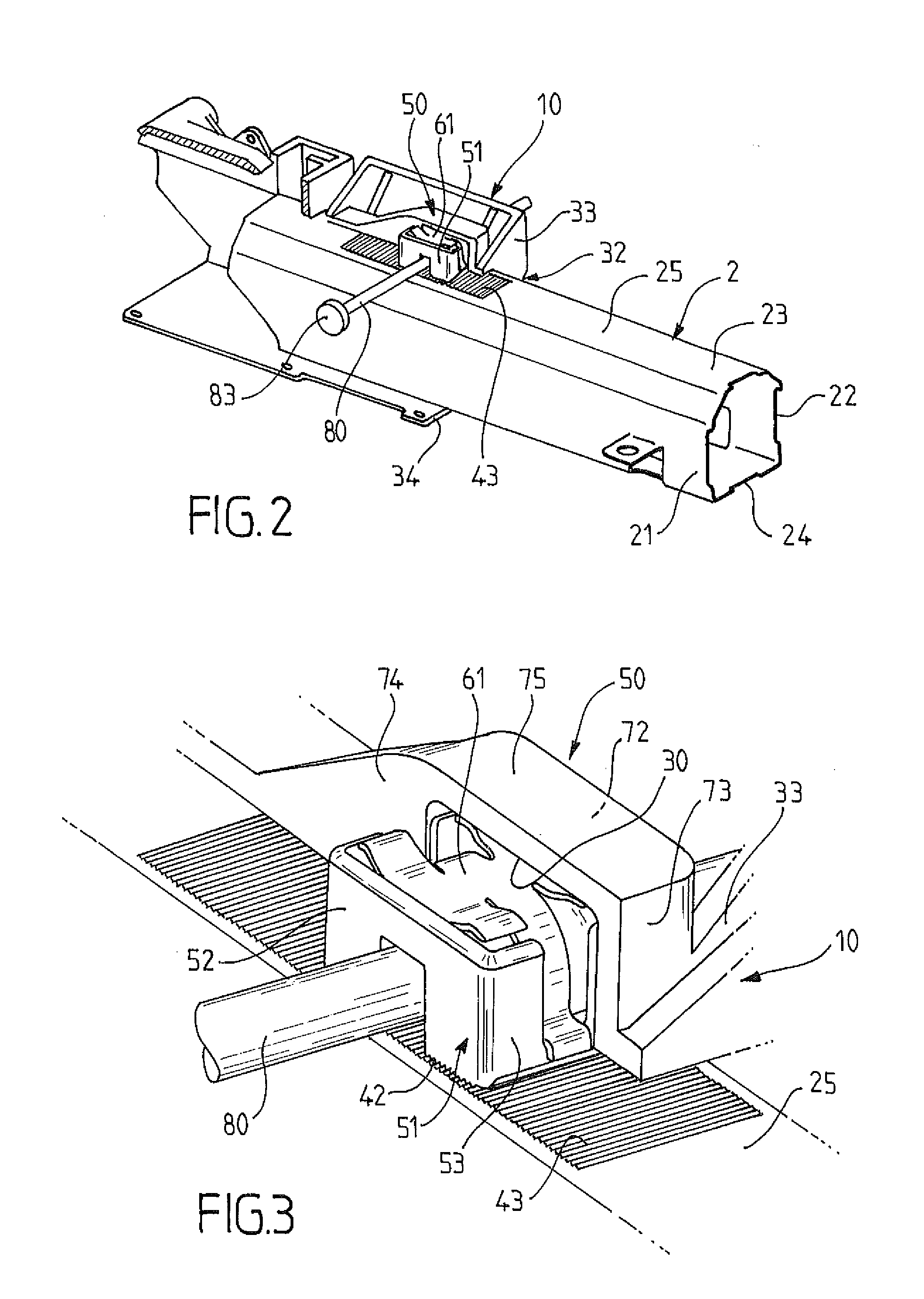

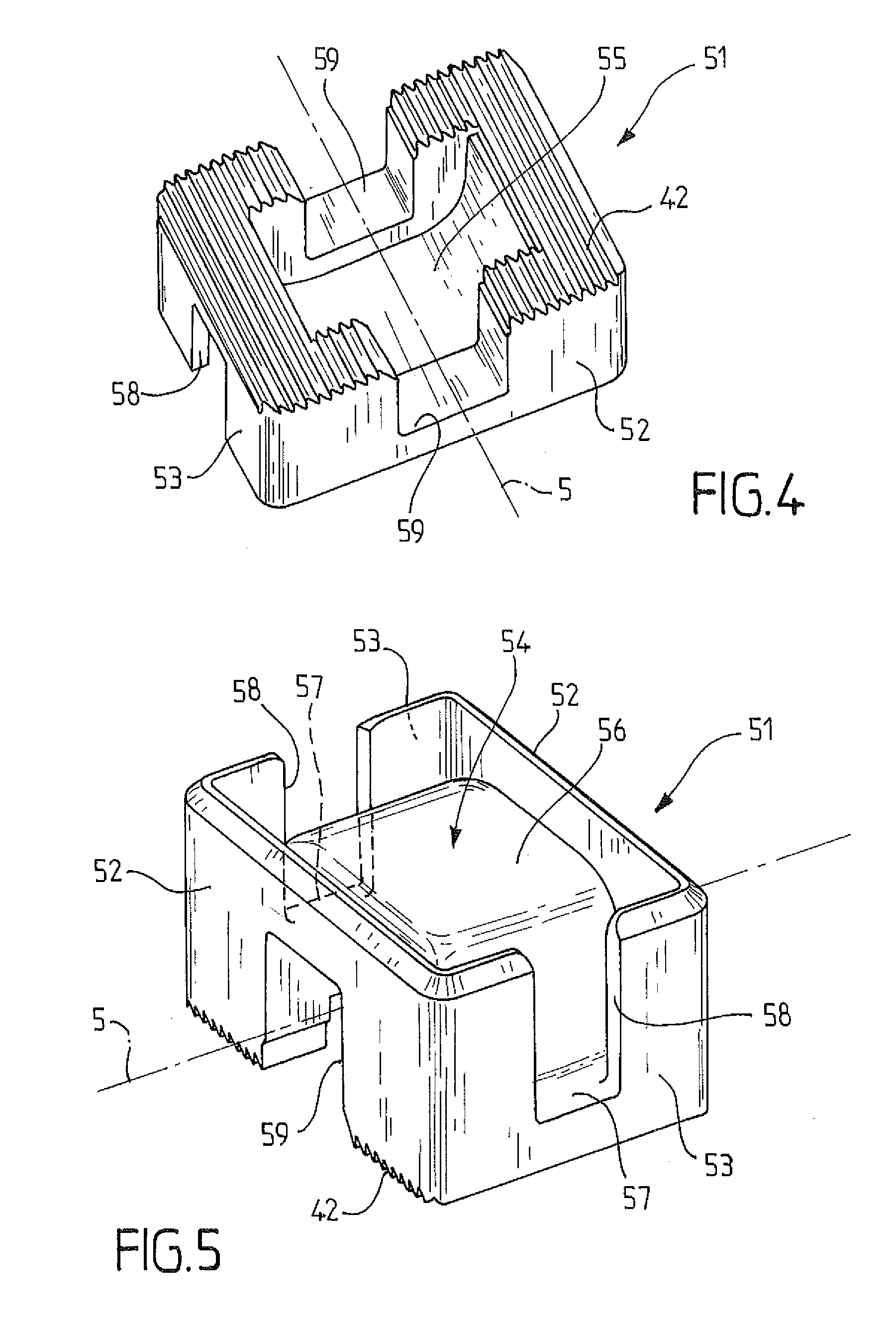

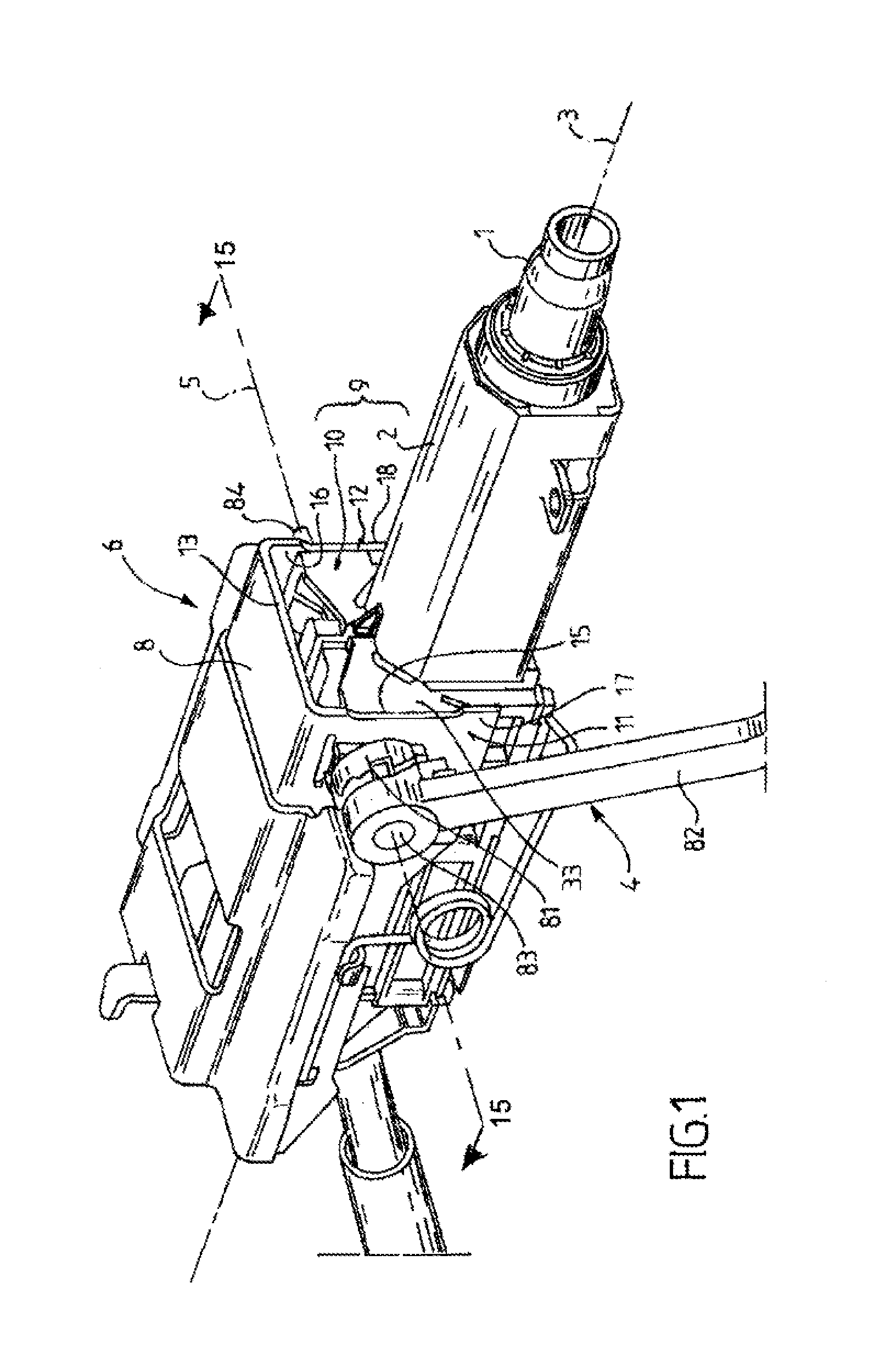

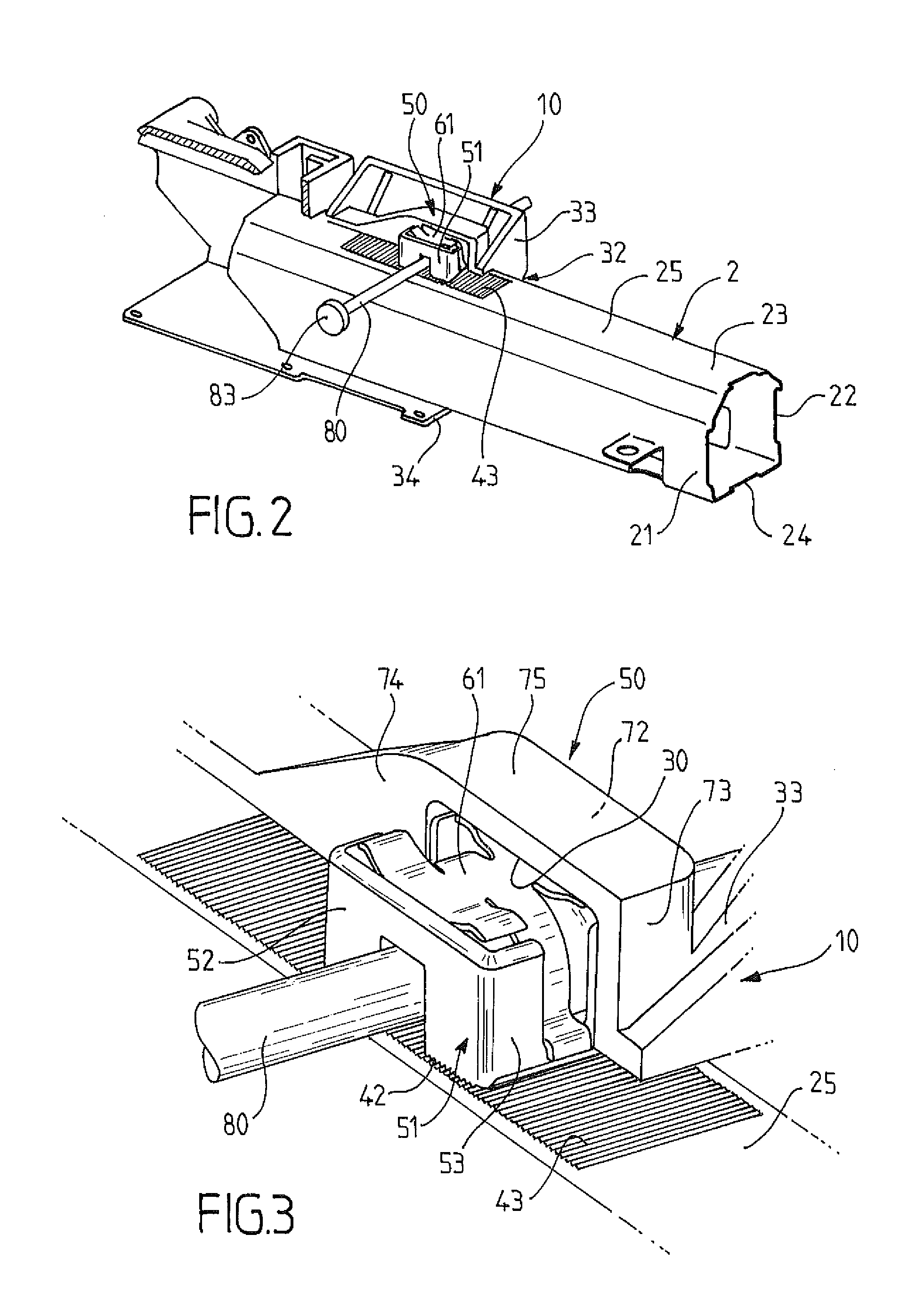

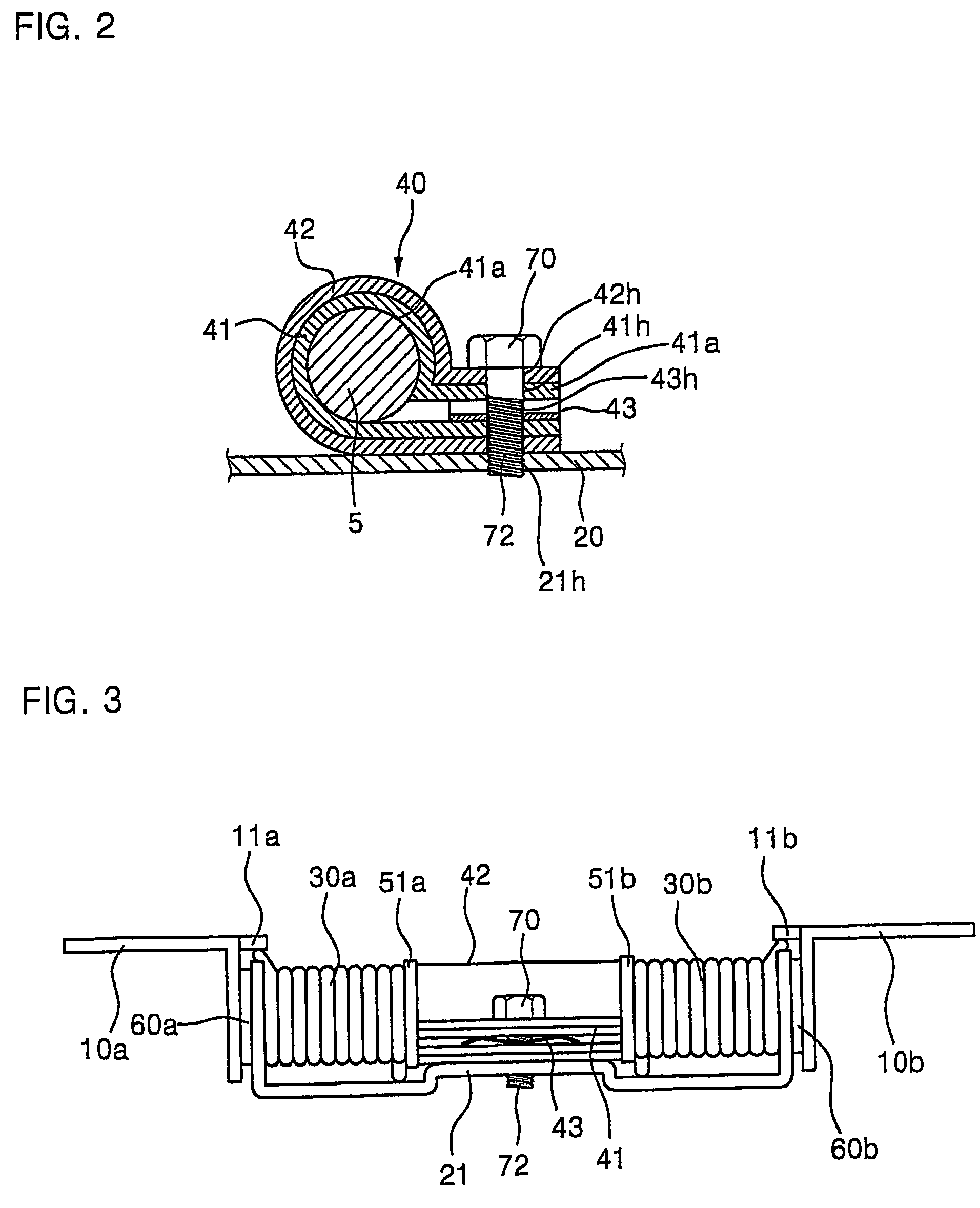

Energy absorption position-keeping device in an automotive vehicle steering column

In an adjustable steering column adjustable, a steering shaft is mounted in a body tube arranged in an intermediate carrier mounted on a fixed support member. The body tube is immobilized onto the fixed support member by a clamping system. The position-keeping device includes teeth that, in the event of an impact, are mutually engageable by means of a press system mounted in the intermediate carrier and under the action of the clamping system. The teeth belong to of the press system and are on the body tube. The teeth have characteristics defined such that in the event of an impact, the breaking force of the teeth has a predetermined value.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING VENDOME

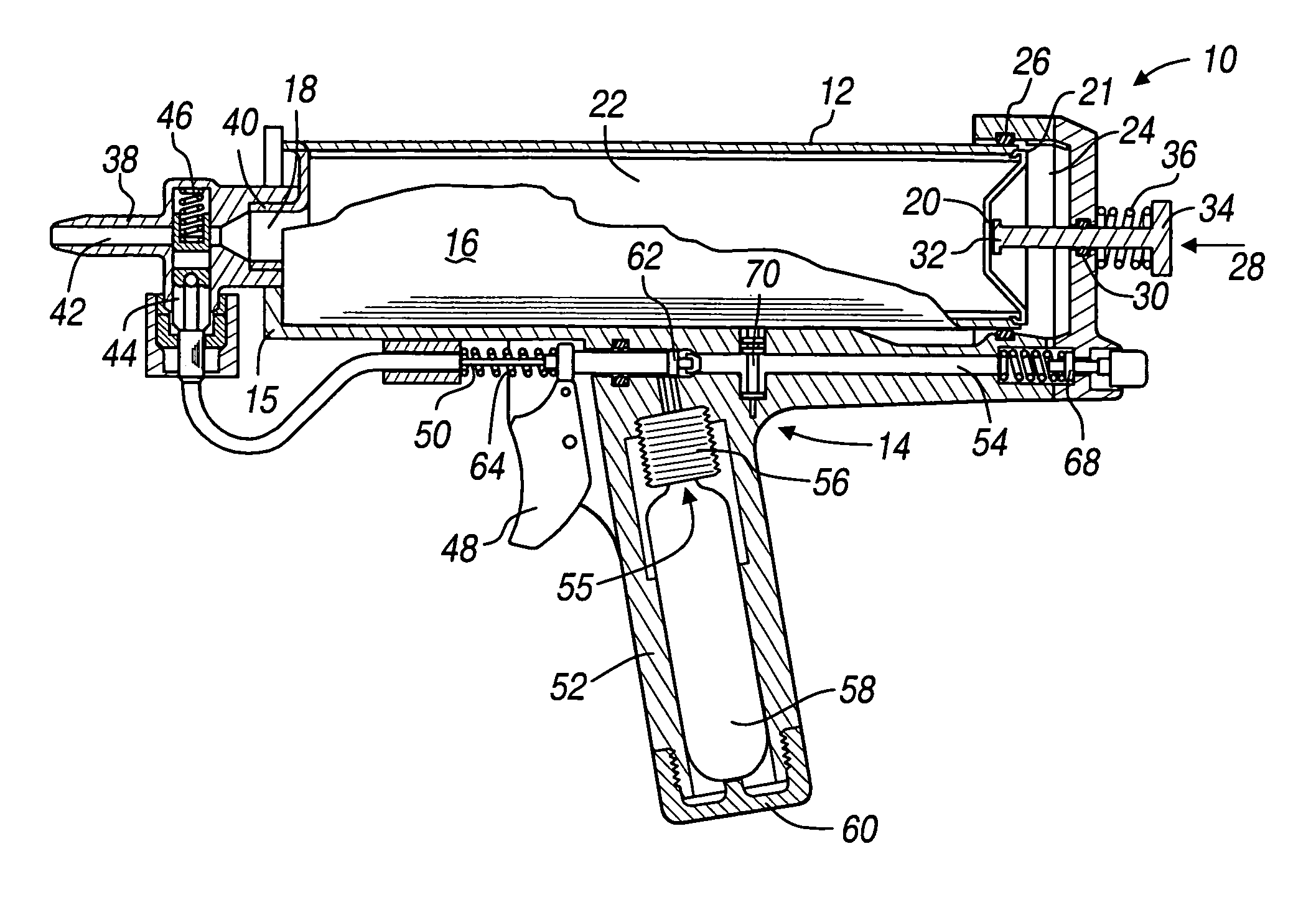

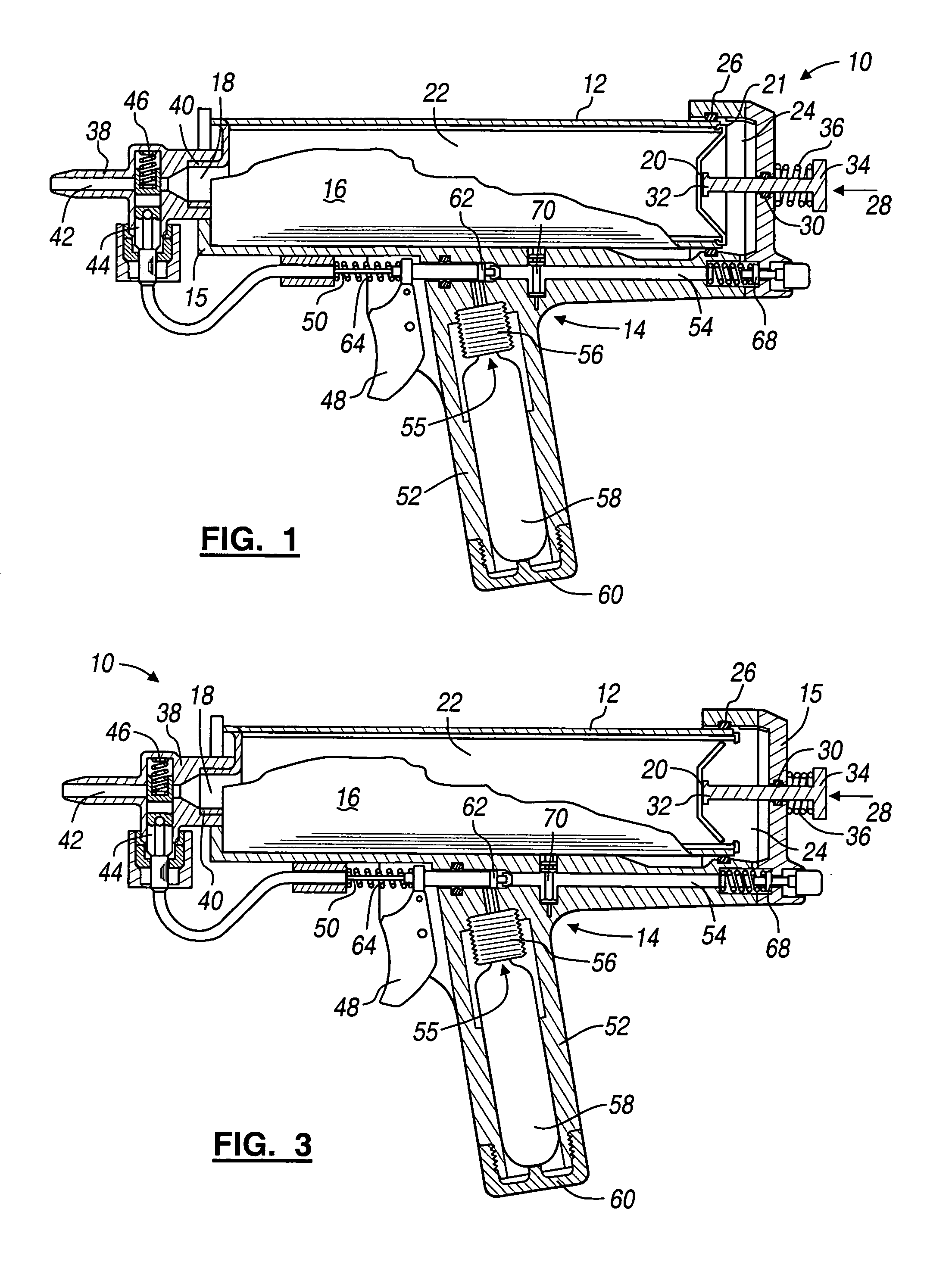

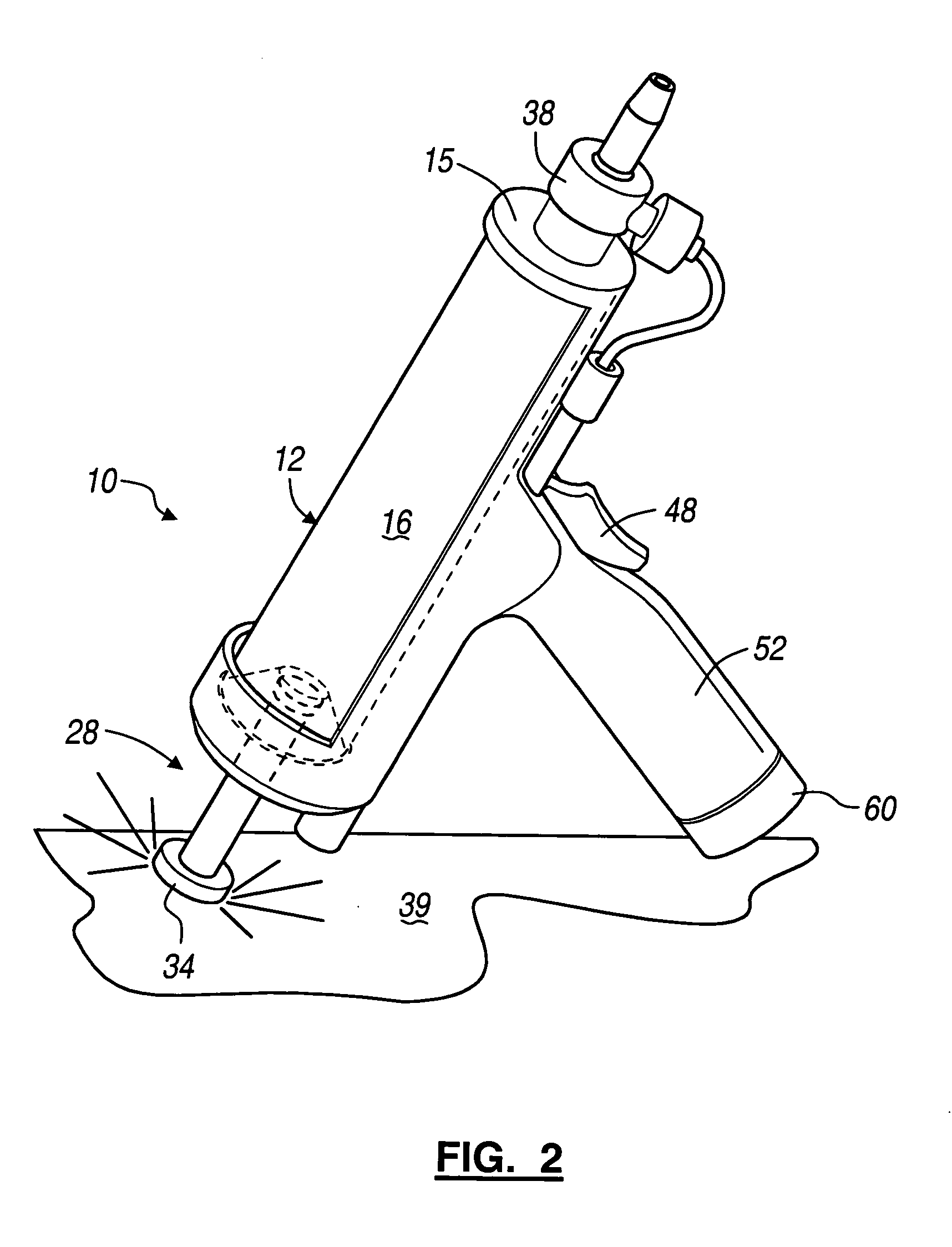

Pneumatic dispensing device with frangible seal breaker and method

Product cartridges that include a frangible seal are used for construction adhesives, sealants and caulks. A housing retains the product cartridge and cooperates therewith to form a gas enclosure separated from a product enclosure by a piston. A plunger is adapted to transfer a force to the piston to break the frangible seal of the product cartridge. In addition, the dispensing device provides pressurized gas to the gas enclosure to generate a force sufficient to dispense product from a dispensing orifice of the product cartridge. A method of enabling product to be dispensed from such cartridges includes associating a seal breaking mechanism with the dispensing device that can exert a frangible seal breaking force on the product cartridge. A separate dispensing mechanism is also associated with the dispensing device that can exert a product dispensing force on the product cartridge.

Owner:BLACK & DECKER INC

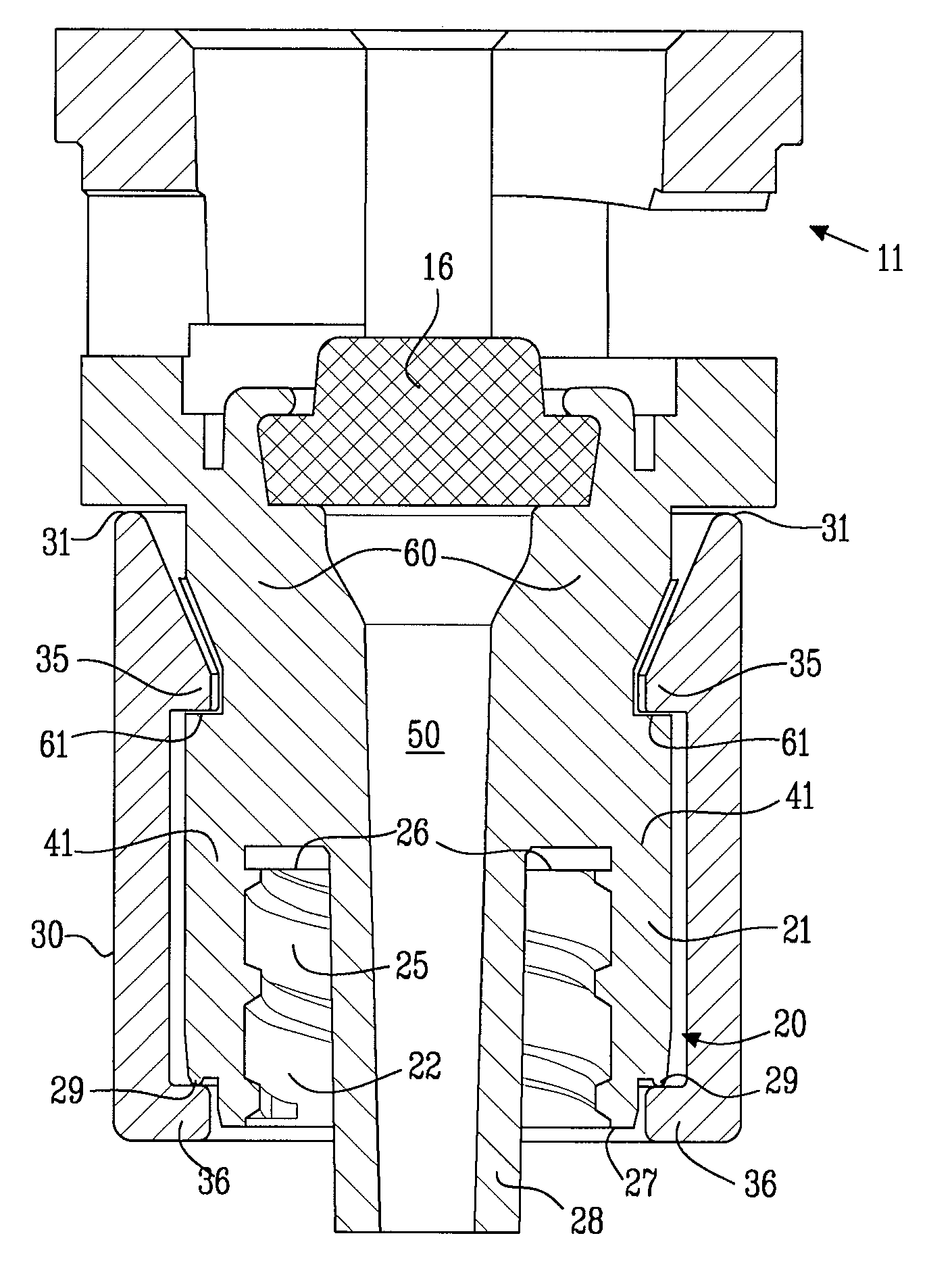

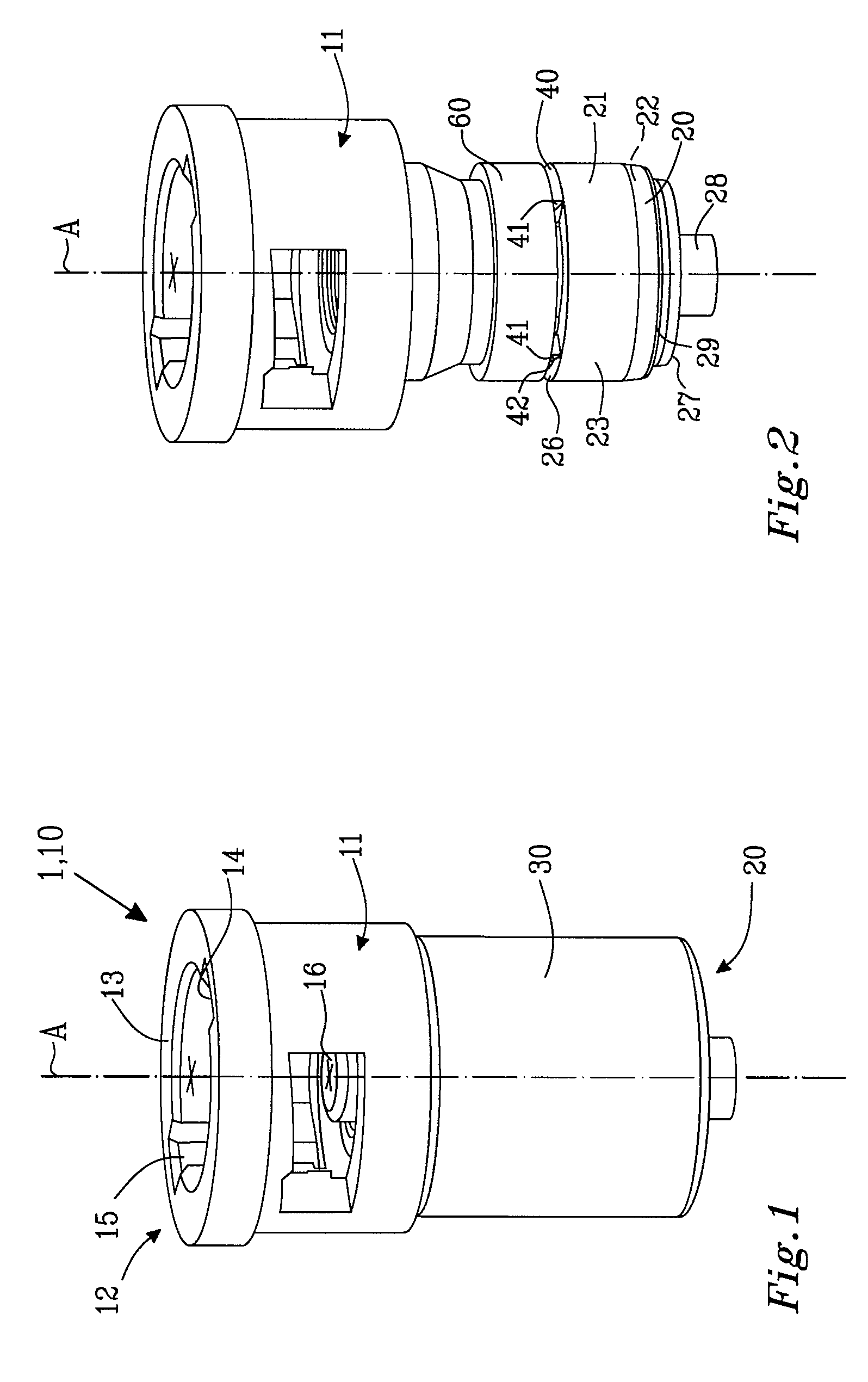

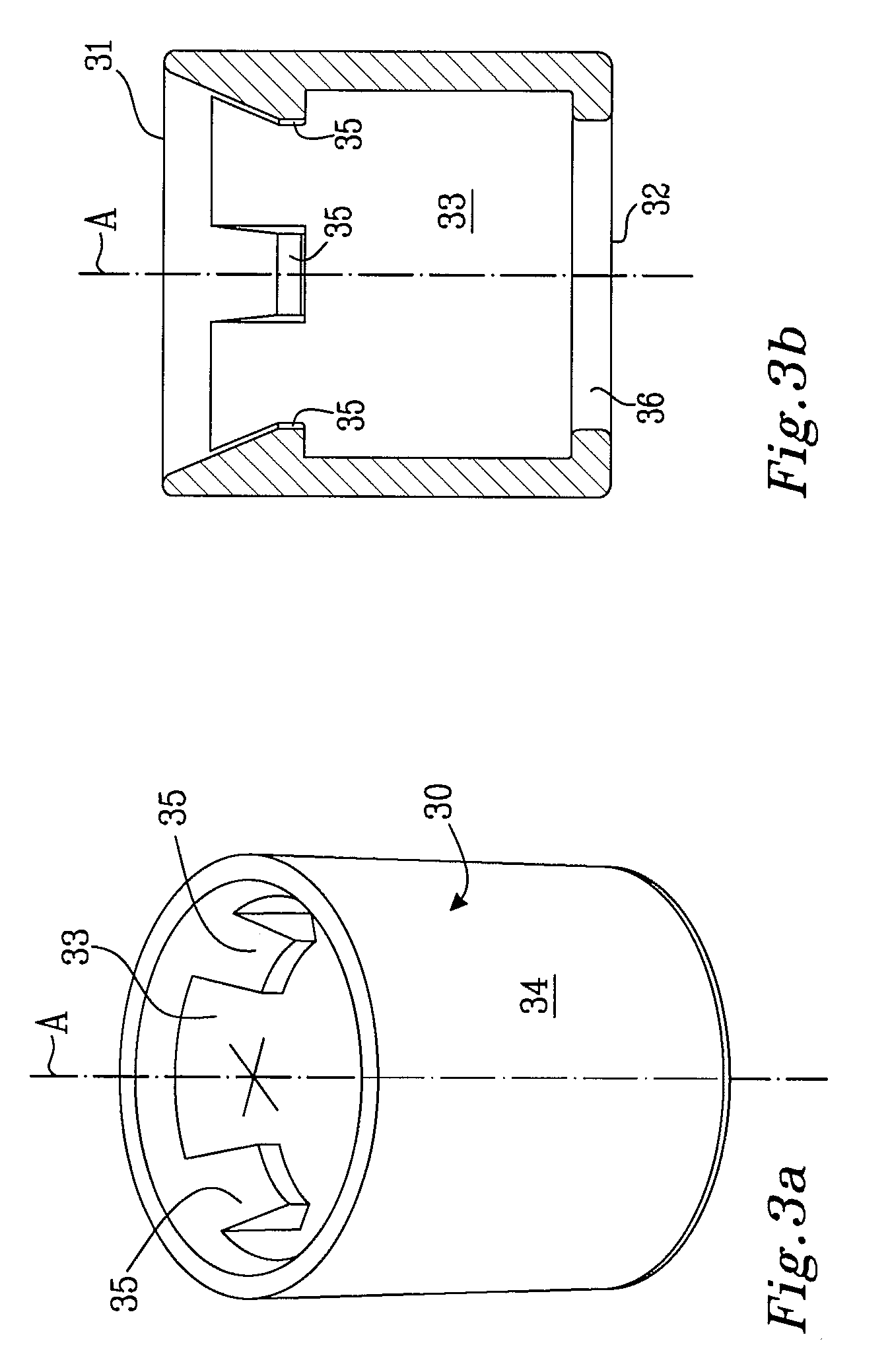

Connection arrangement and method for connecting a medical device to the improved connection arrangement

ActiveUS20100152669A1Reduce riskFirmly connectedInfusion syringesTube connectorsEngineeringSafe handling

The present invention relates to a connection arrangement and a method of assembly, for providing a substantially tamper resistant connection with at least a first medical device. The connection arrangement (1) having a centre axis (A), the connection arrangement (1) comprises; a first connection member (21,161,521,621) for connection to the first medical device by means of a rotational motion in a first direction, and a body (60,120, 504, 603). Additionally the first connection member (21,161,521,621) and the body (60,120, 504, 603) are connected directly or indirectly together via at least one designated ruptureable retaining member (41, 141, 541, 641), the designated ruptureable retaining member (41, 141, 541, 641) is arranged to rupture at a predetermined breaking force, wherein the first connection member (21,161,521,621), and thereby the first medical device after assembly, can be displaced with respect to the body (60,120, 504, 603) after rupture. The present invention provides for a substantially tamper safe connection arrangement which disables accidents such as wrongly disengage a connected medical device. A safer handling is provided for the involved user(s).

Owner:CARMEL PHARMA

Production process of contact net anchorage steel wire rope

InactiveCN102517941AHigh breaking forceGood non-rotationRope making machinesExtrusion cleaning devicesIndustrial engineeringHeat treating

The invention discloses a production process of a contact net anchorage steel wire rope. The production process comprises the following steps: carrying out surface acid cleaning and phosphating; drawing; carrying out lead bath heat treatment; galvanizing; drawing; detecting; entwisting; stranding; forging; and greasing. The production process has the advantages of convenience in operation and time-saving and labor-saving properties; and the produced contact net anchorage steel wire rope has the advantages of high breaking force, long fatigue service life, good abrasion resistance and good corrosion resistance.

Owner:NANTONG GUANGMING STEEL WIRE PROD

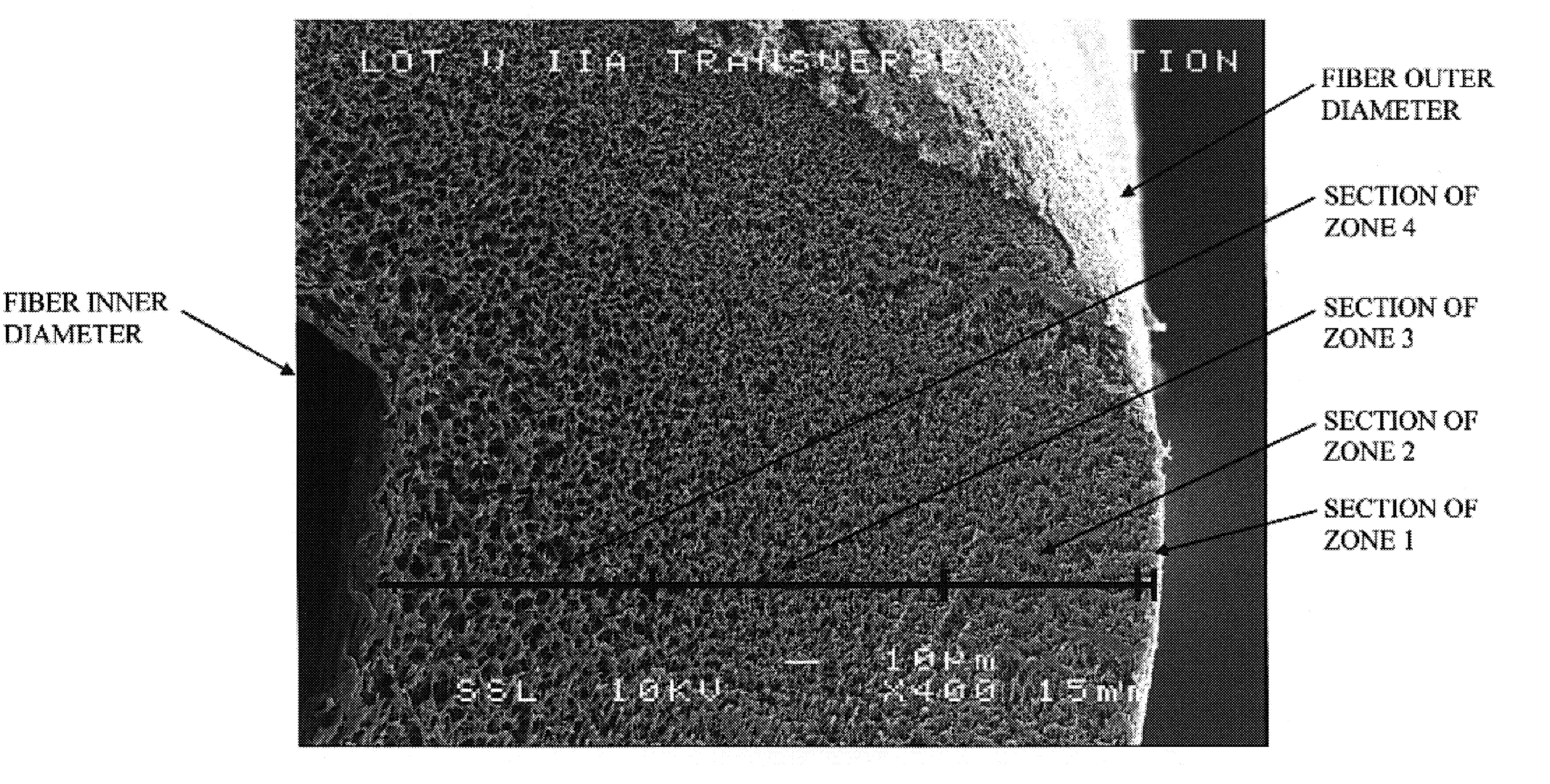

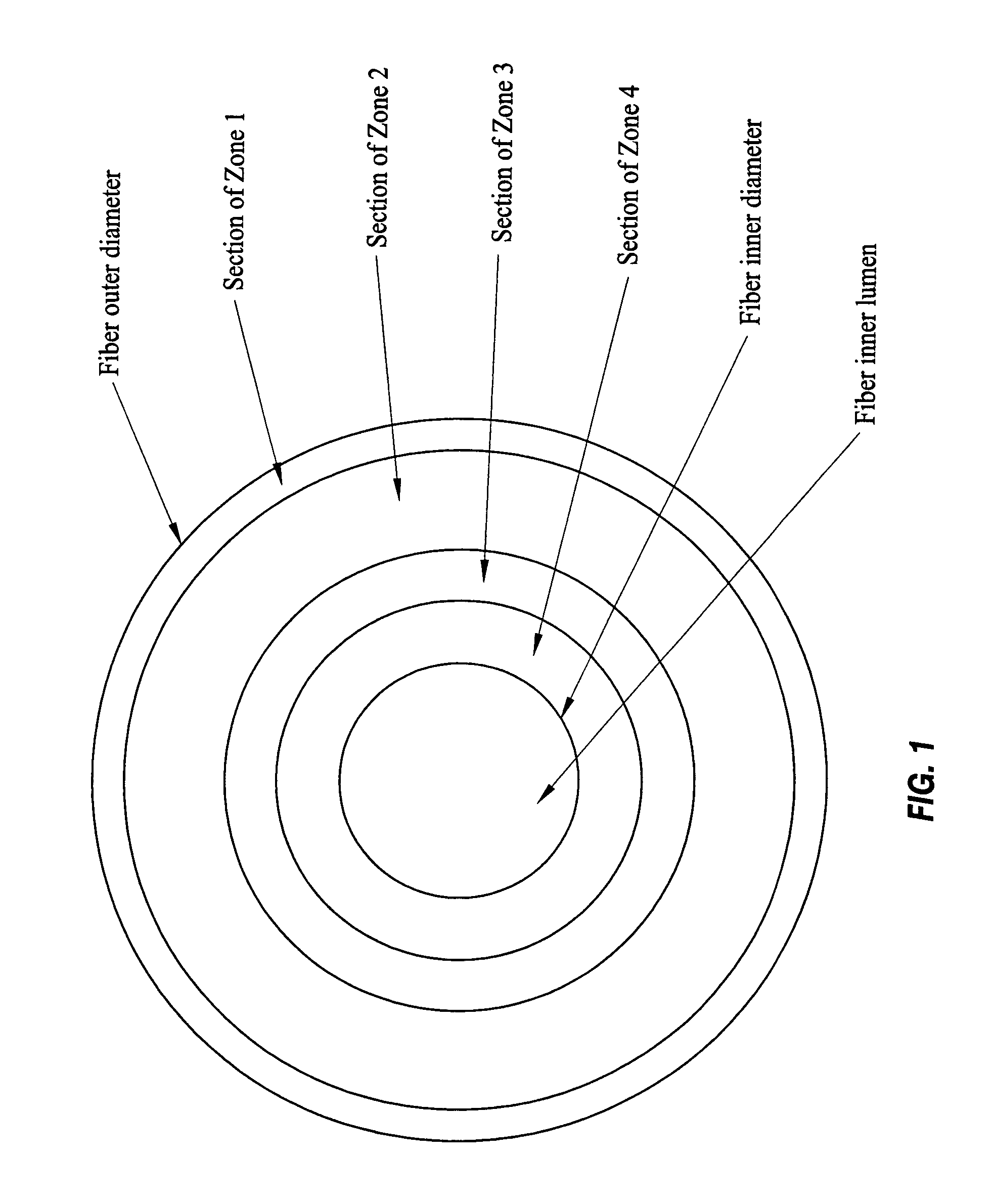

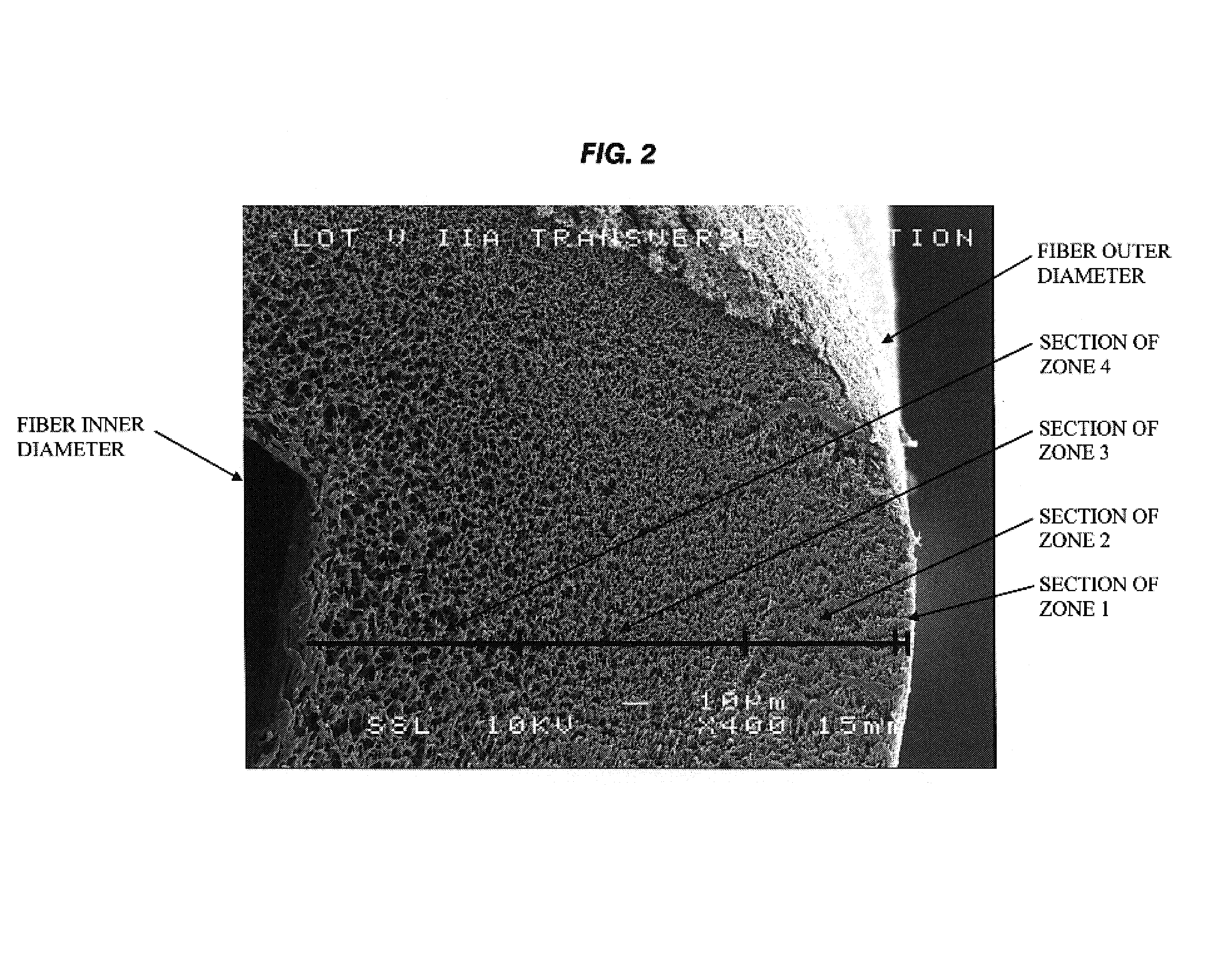

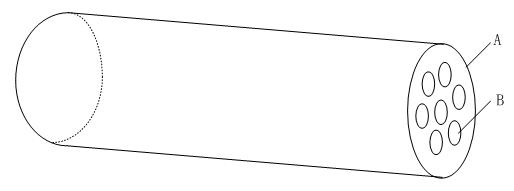

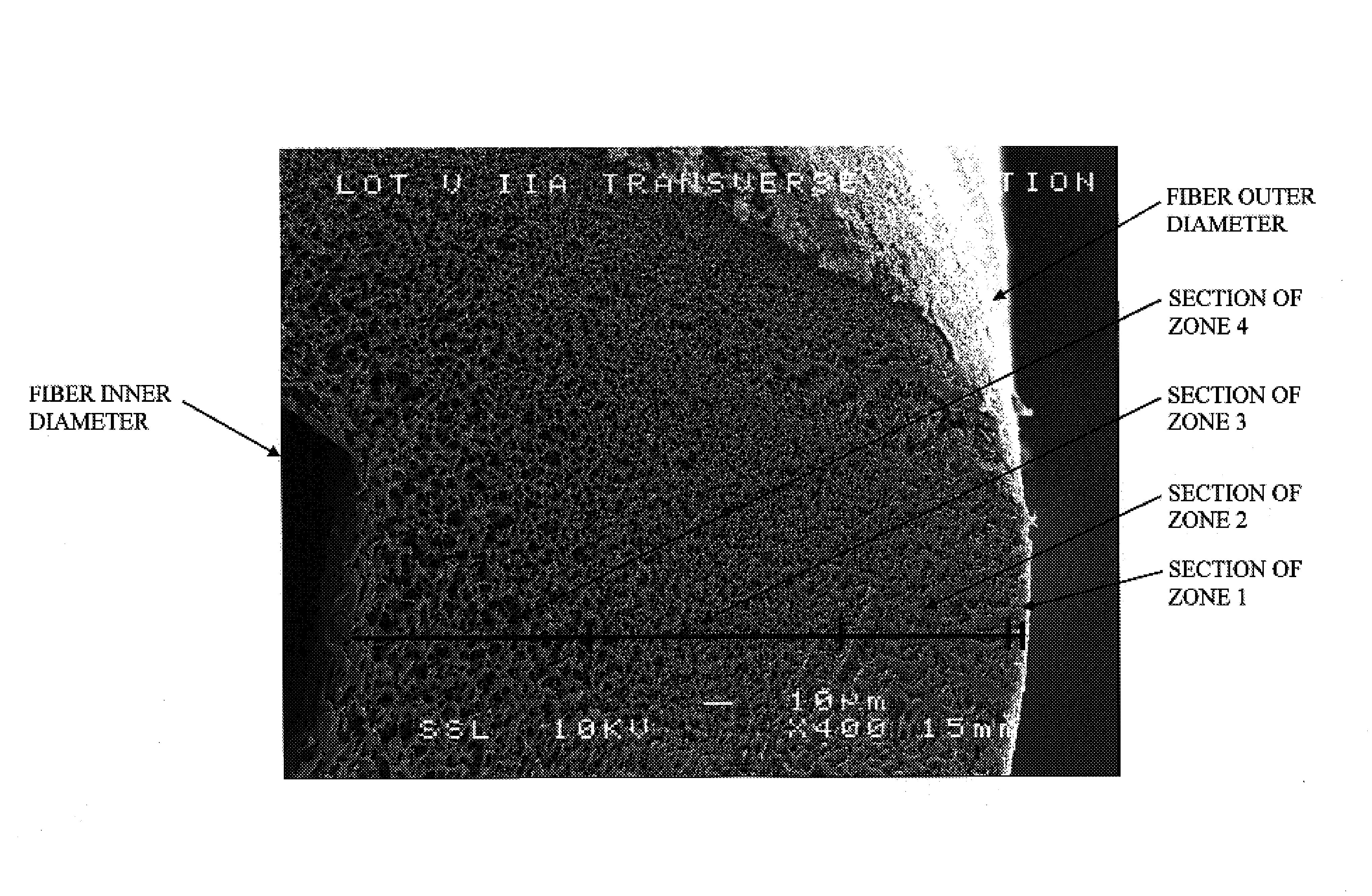

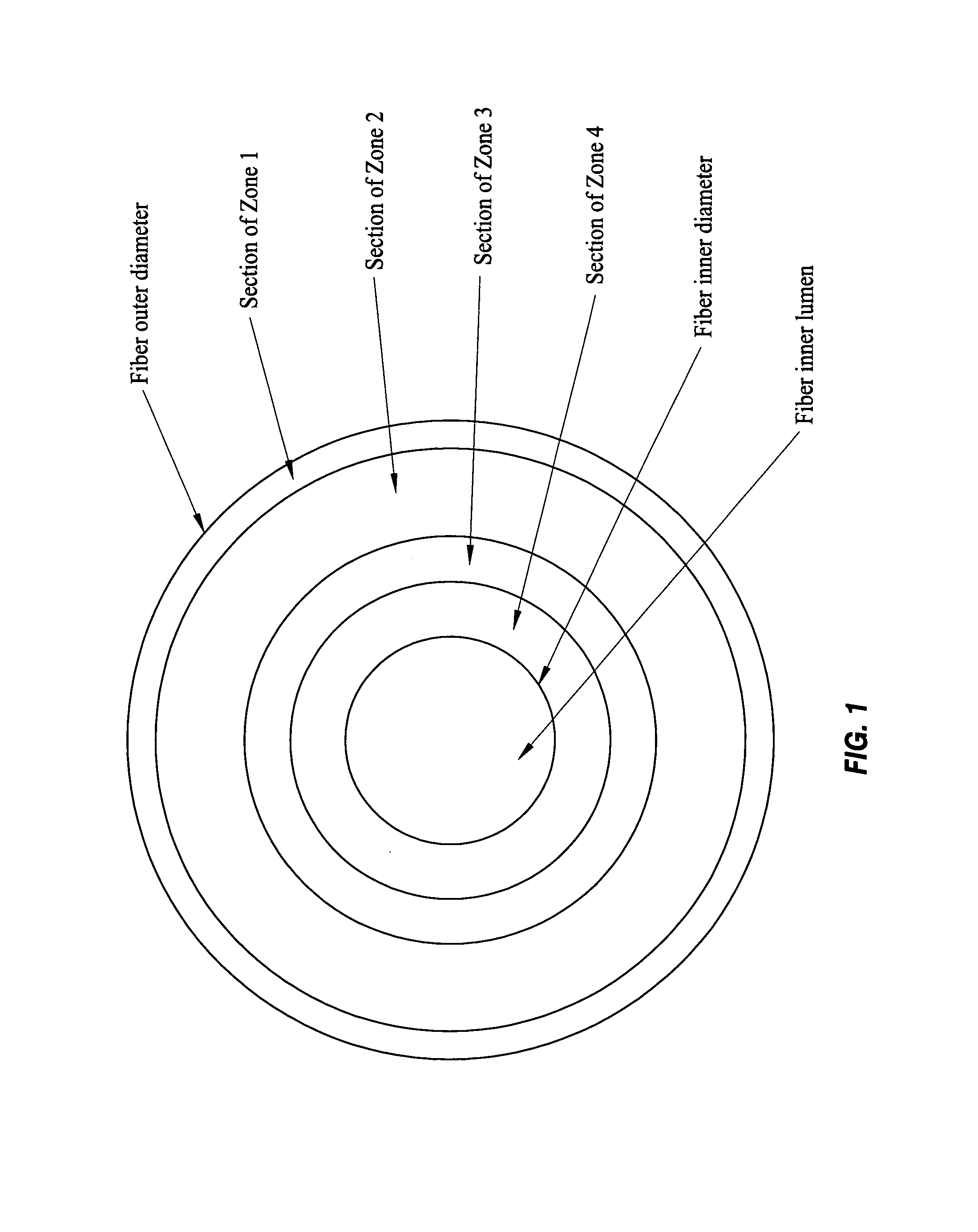

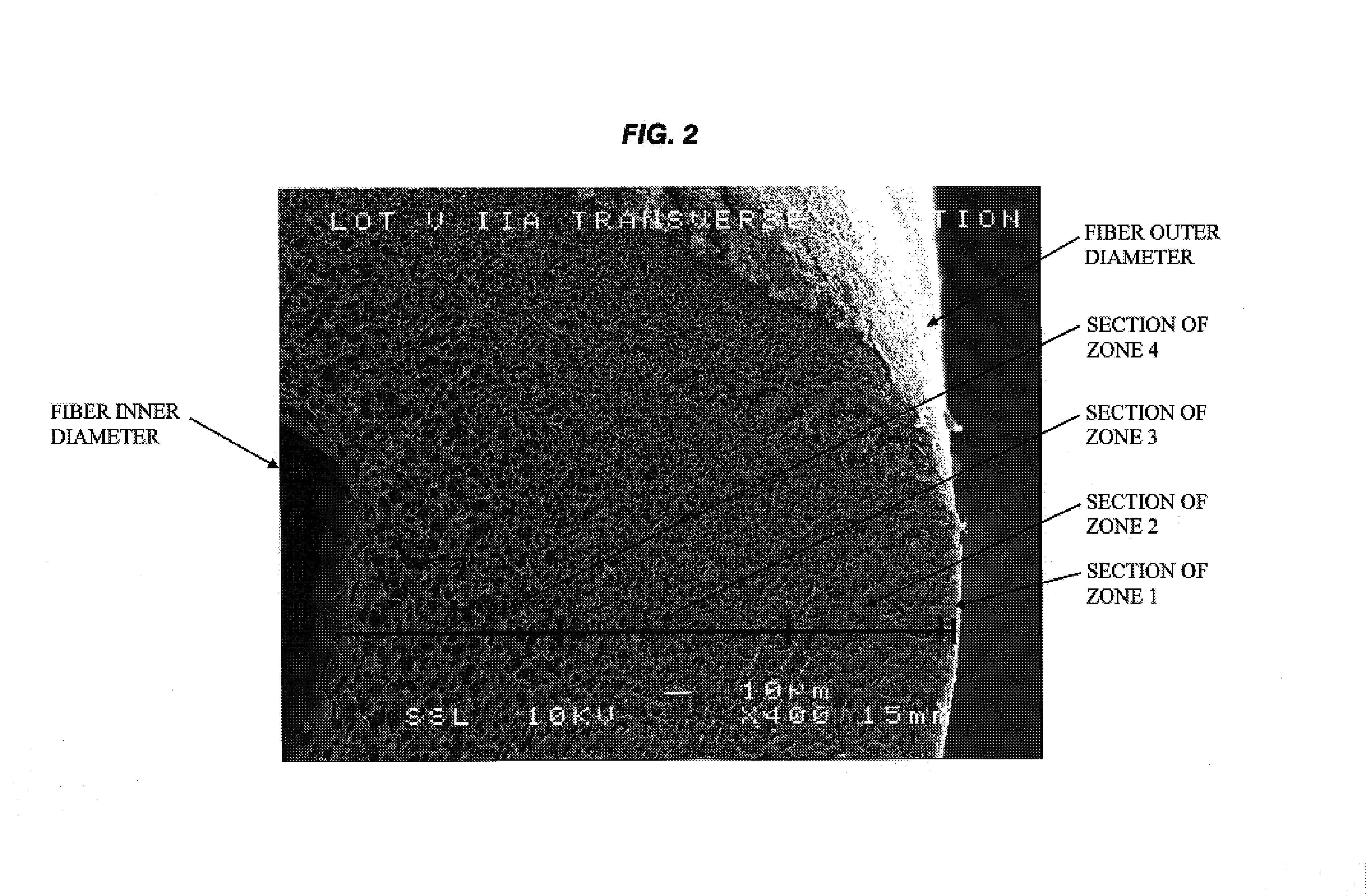

Specialized hollow fiber membranes for plasmapheresis and ultrafiltration

A plasmapheresis and / or ultrafiltration membrane comprises elongated hollow fibers each fiber having an interior lumen extending along the fiber length, the fiber wall having a plurality of zones between the inner and outer wall surfaces, each of the zones having a mass density different than the mass density of an adjacent zone. The fiber wall is characterized by having a lower mass density zone at the inner wall surface and a higher mass density zone at the outer wall surface. The fiber is further characterized by having an average elongation breaking force strength of at least about 0.2 lbs. and an average elongation of at least about 45%.

Owner:TRANSVIVO

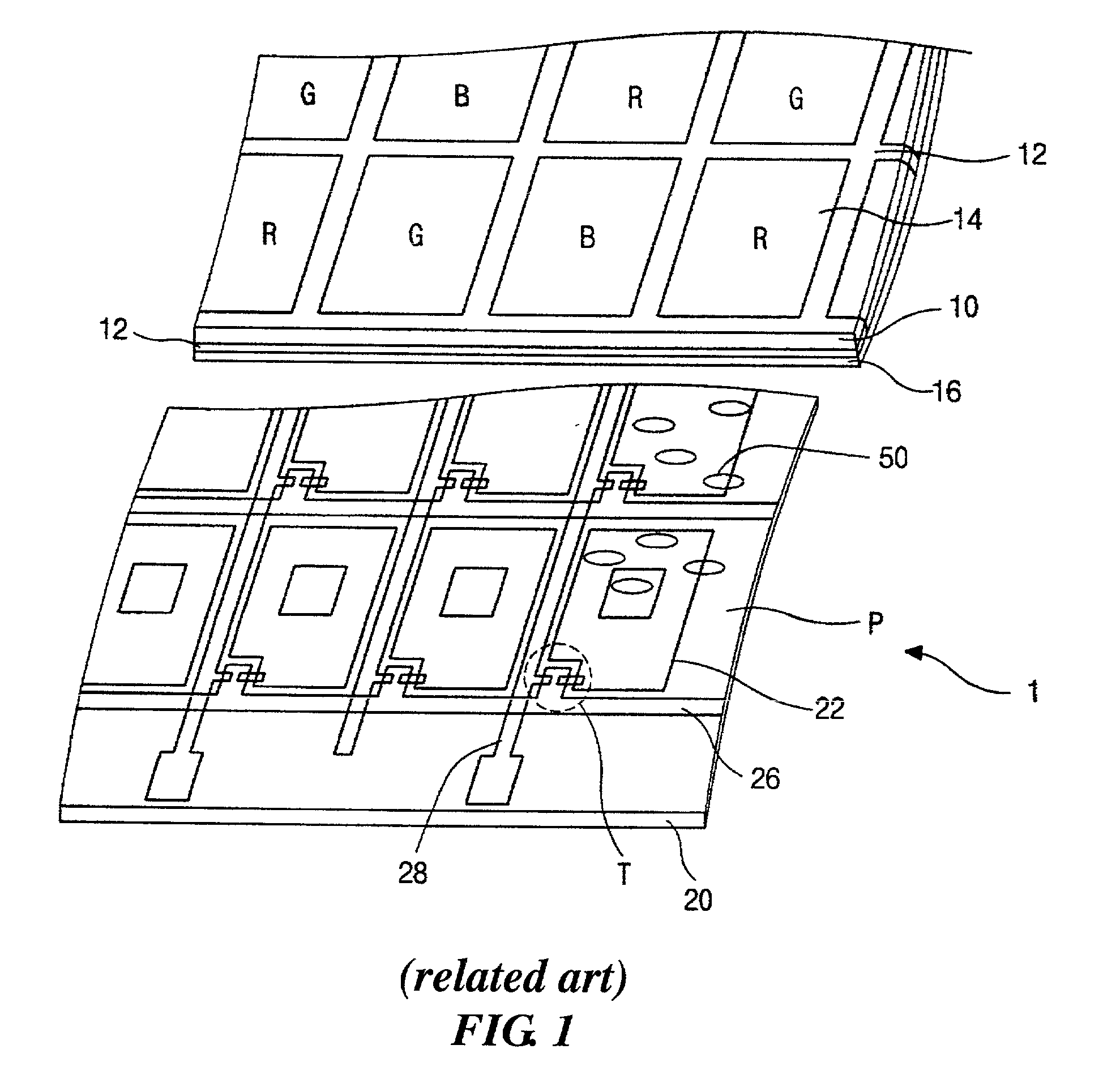

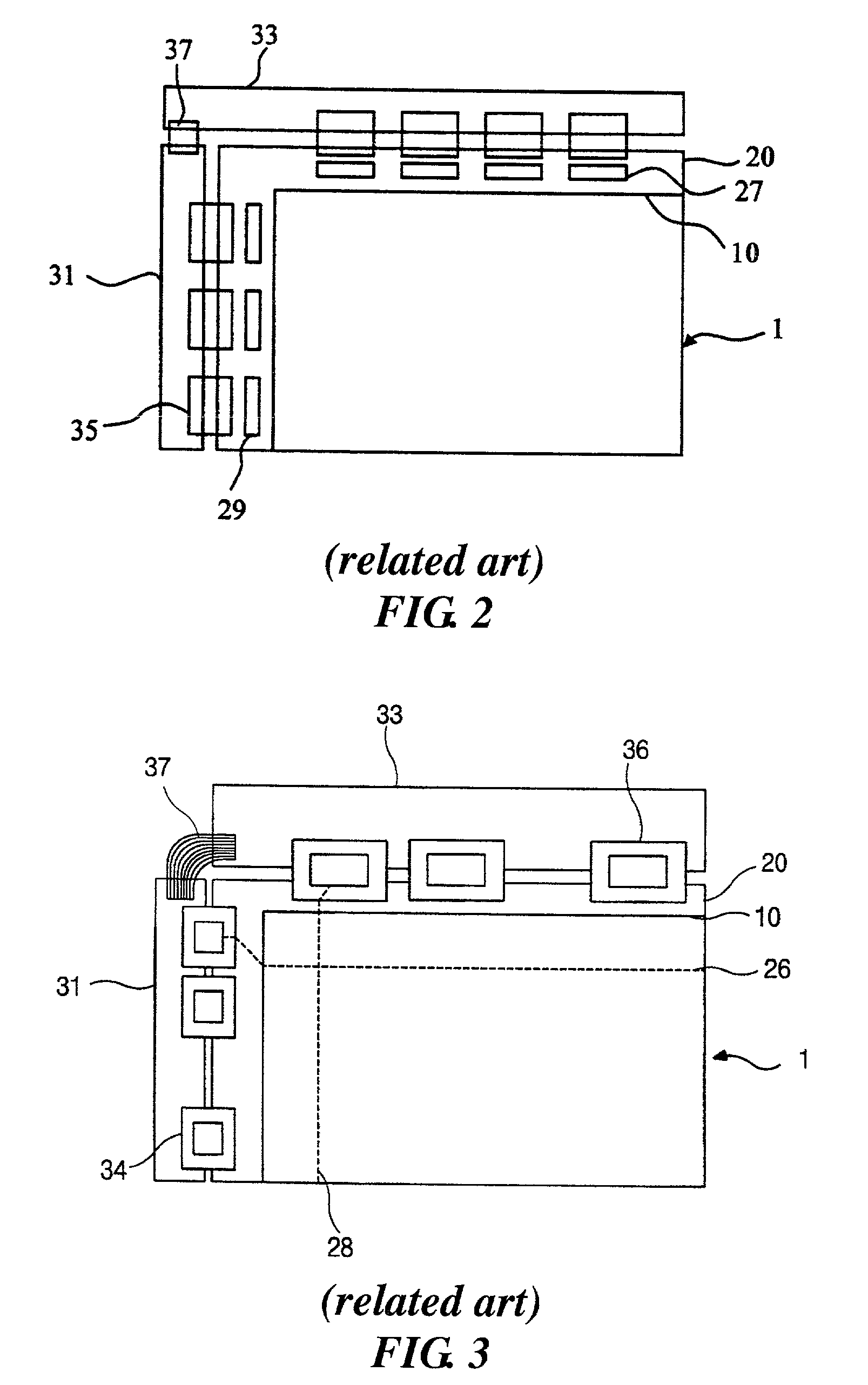

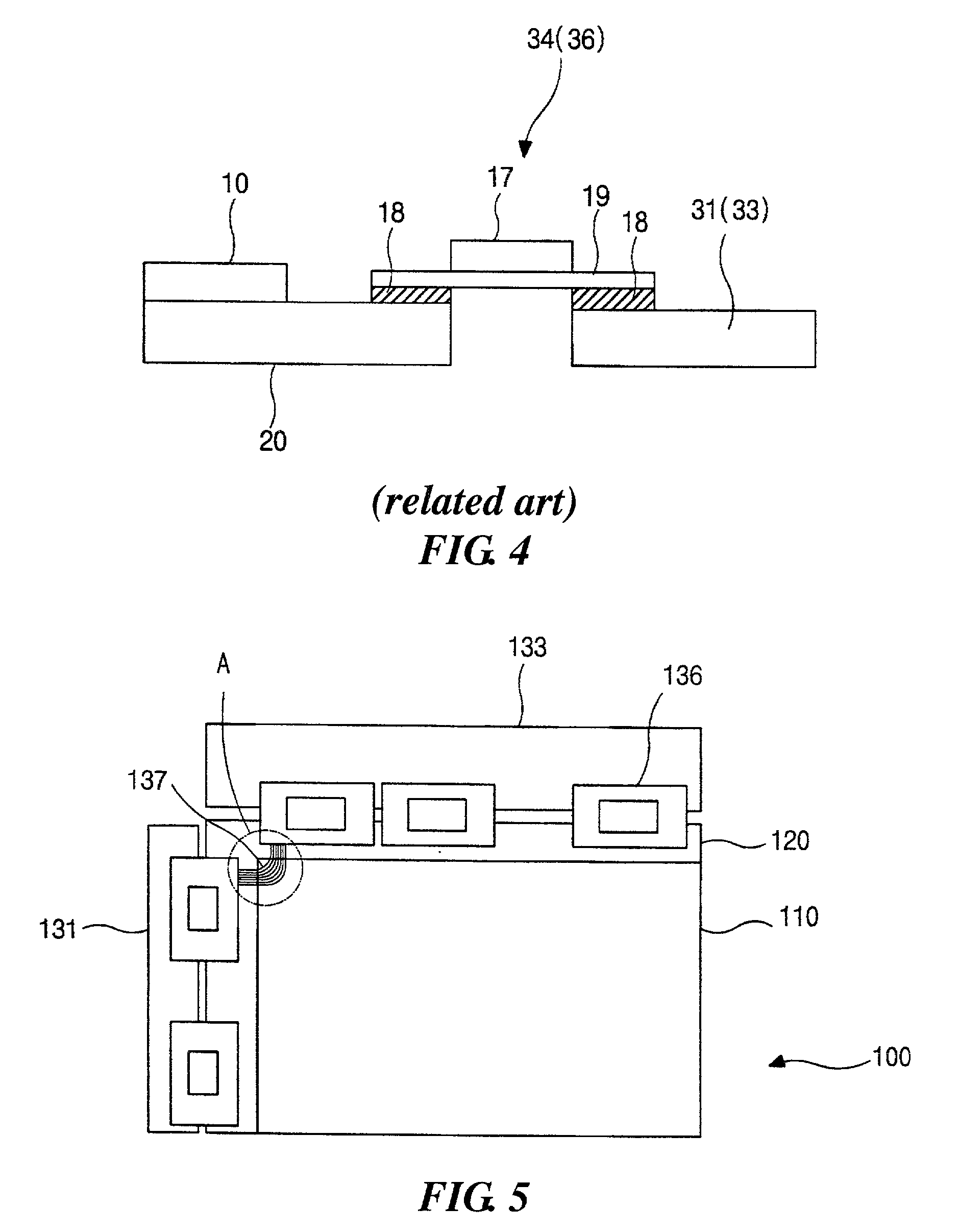

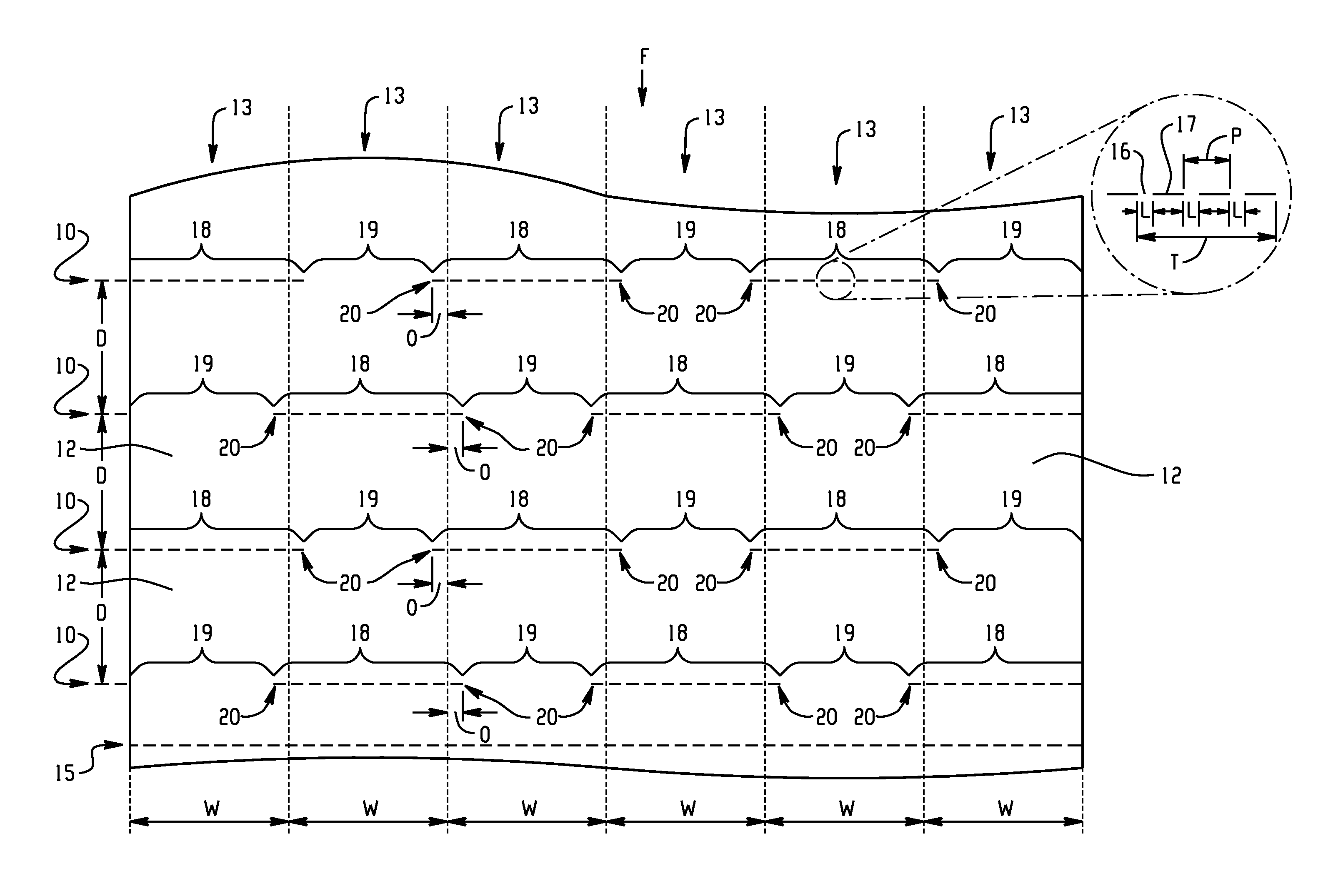

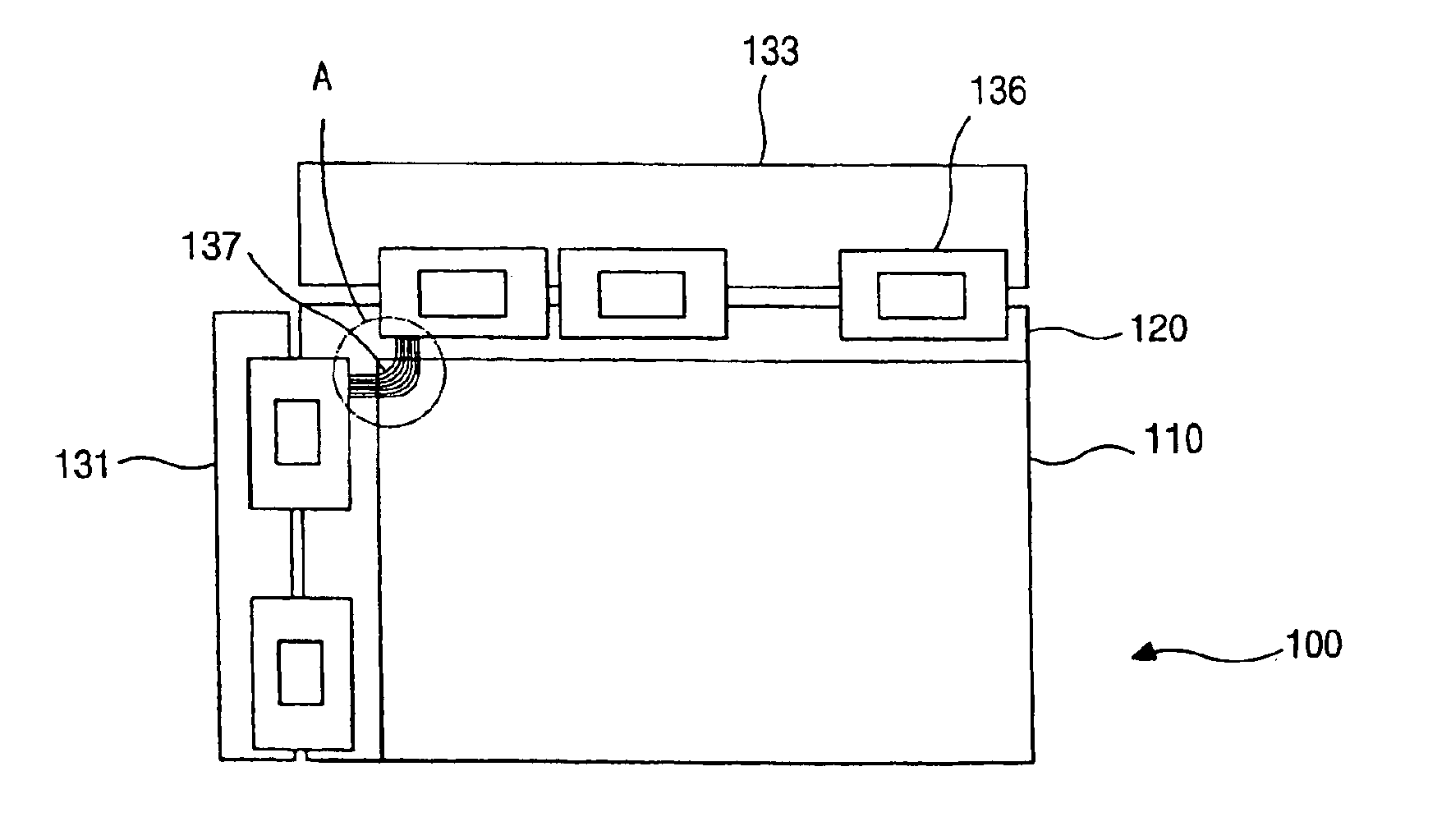

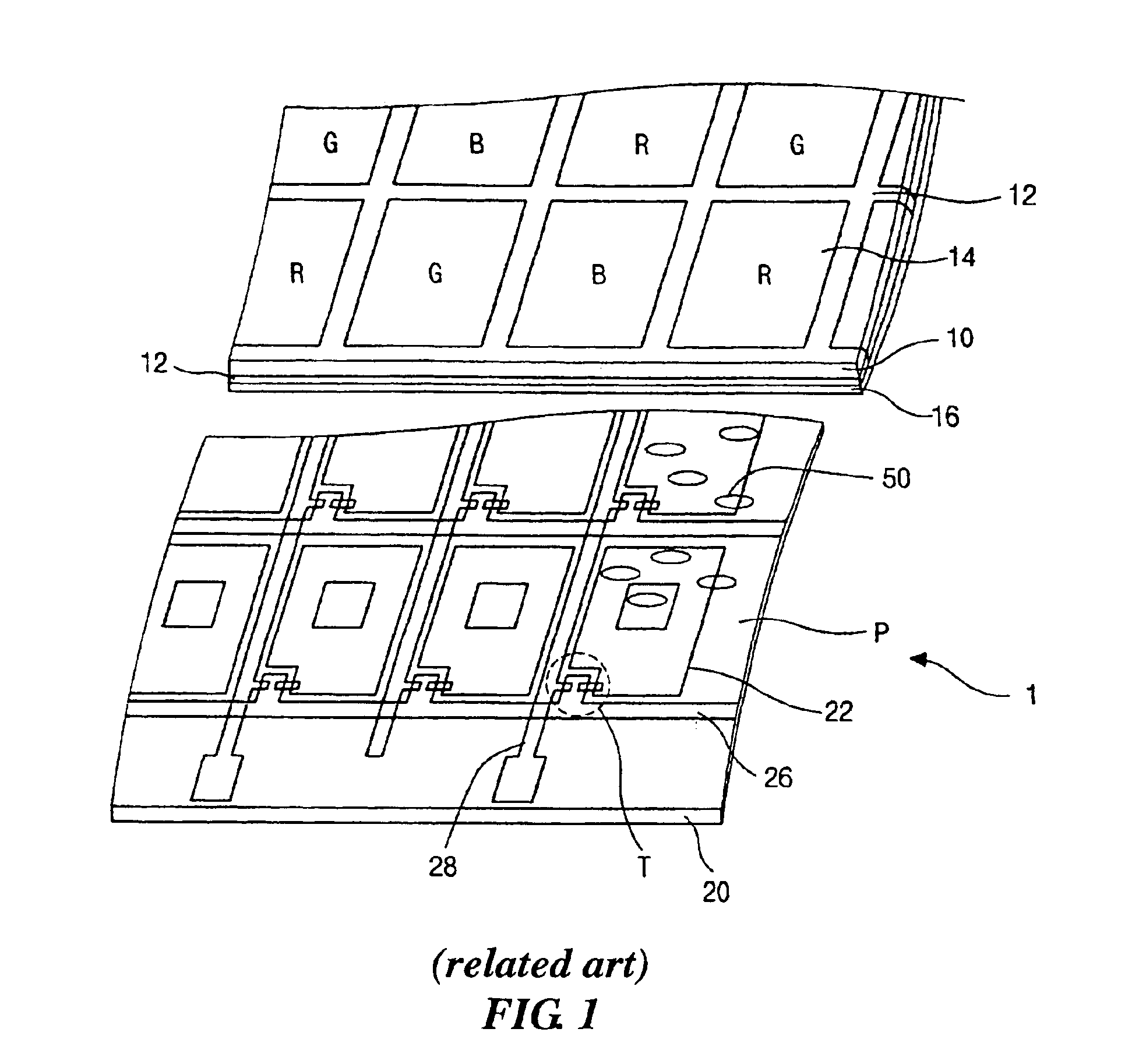

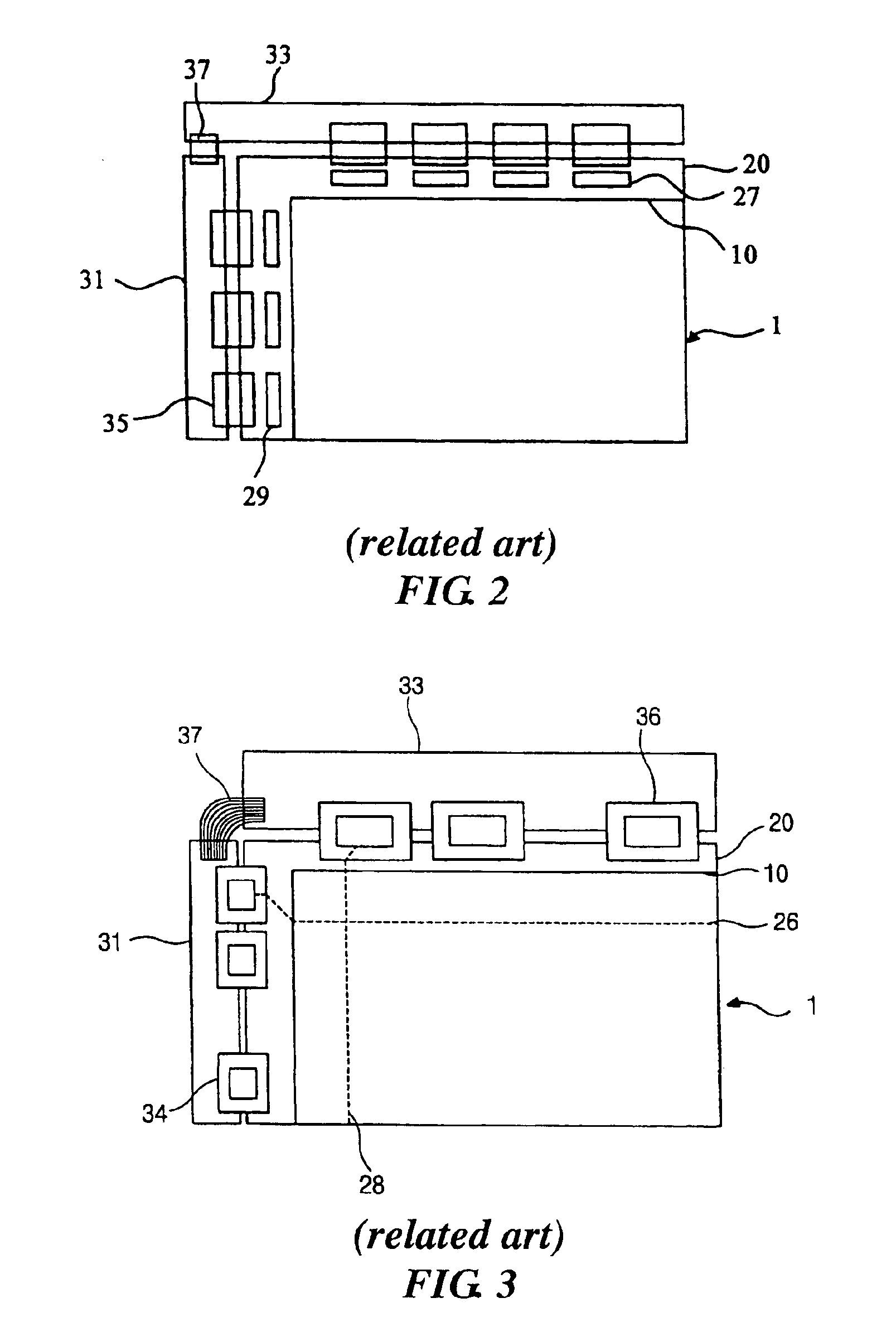

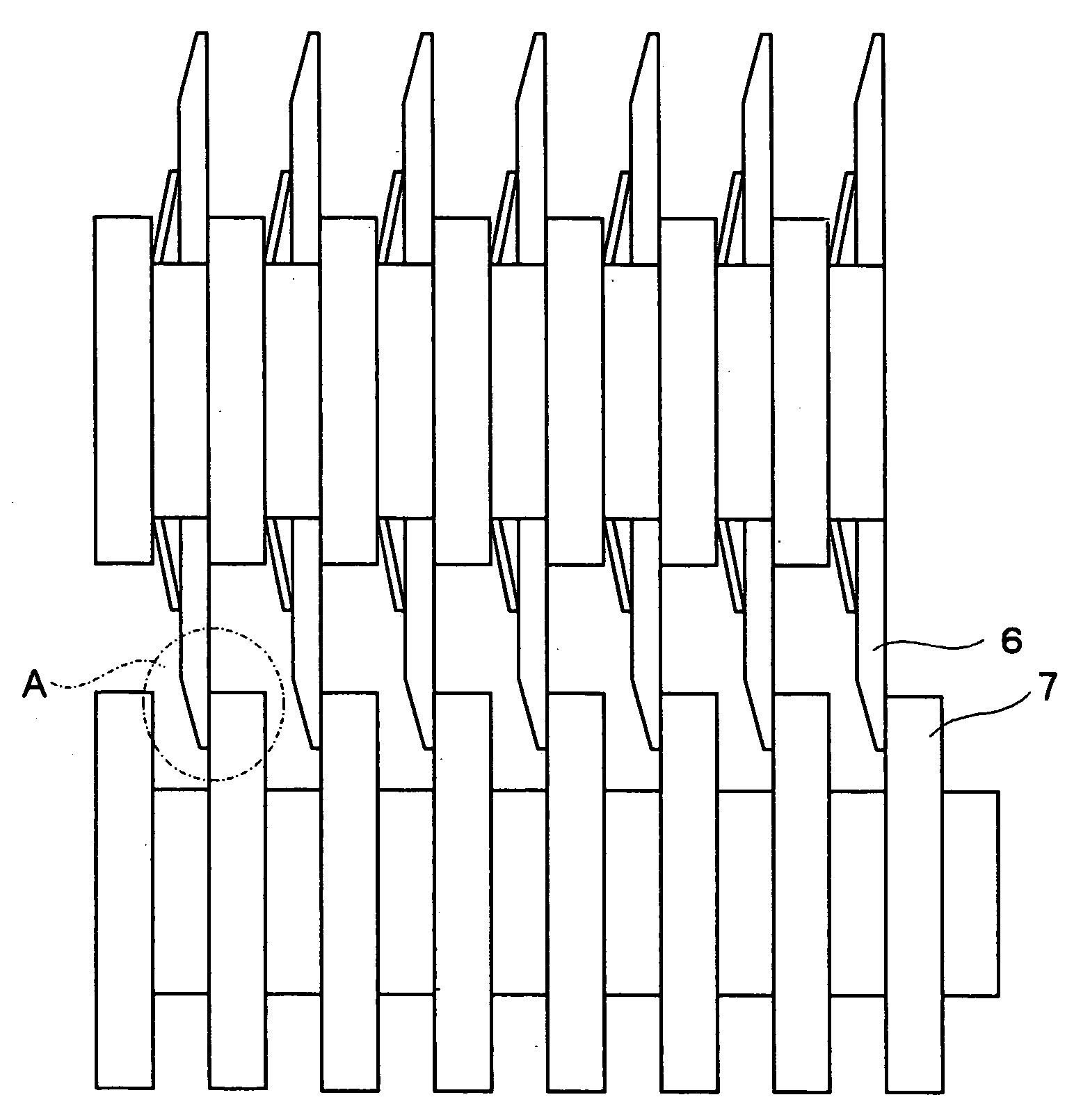

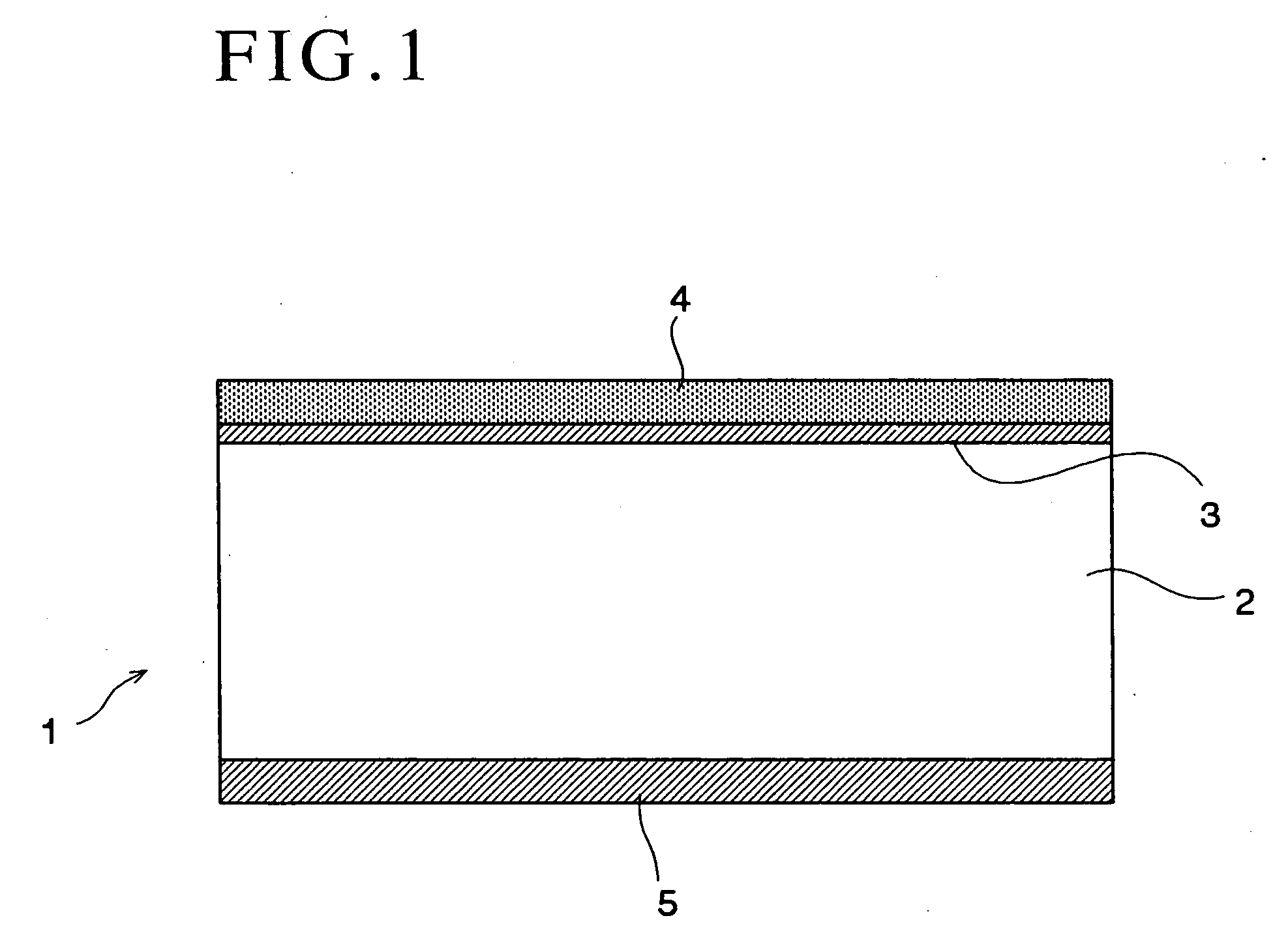

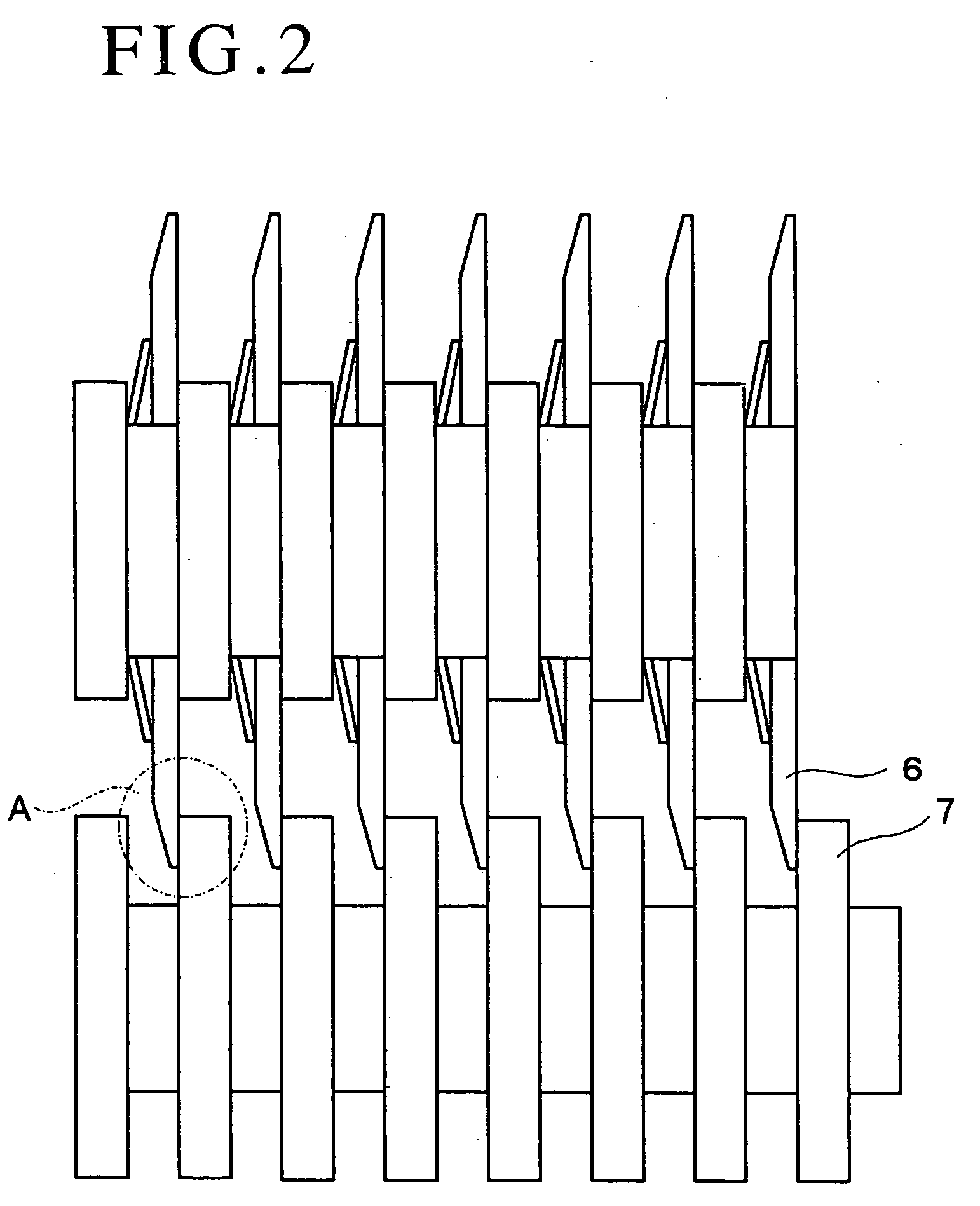

Liquid crystal display device implementing improved electrical lines and the fabricating method

The present invention discloses a liquid crystal display device, including upper and lower substrates with a liquid crystal layer interposed therebetween; a sealant between the upper and lower substrates; a plurality of source and gate pads on the lower substrate; a plurality of gate and data lines on the lower substrate, each gate line being electrically connected with the corresponding gate pad, each data line being electrically connected with the corresponding source pad; a gate insulating layer between the gate lines and the data lines; a source PCB electrically connected with the plurality of source pads; a gate PCB electrically connected with the plurality of gate pads; and a plurality of transmitting wires on the lower substrate, the transmitting wires being electrically connected with the gate and source pads across the sealant such that the source PCB is electrically connected with the gate PCB. The liquid crystal display device further includes a repair wire to repair the gate transmitting wires, and dummy patterns to protect the gate transmitting wires from a mechanical damage of a scribing and breaking force.

Owner:LG DISPLAY CO LTD

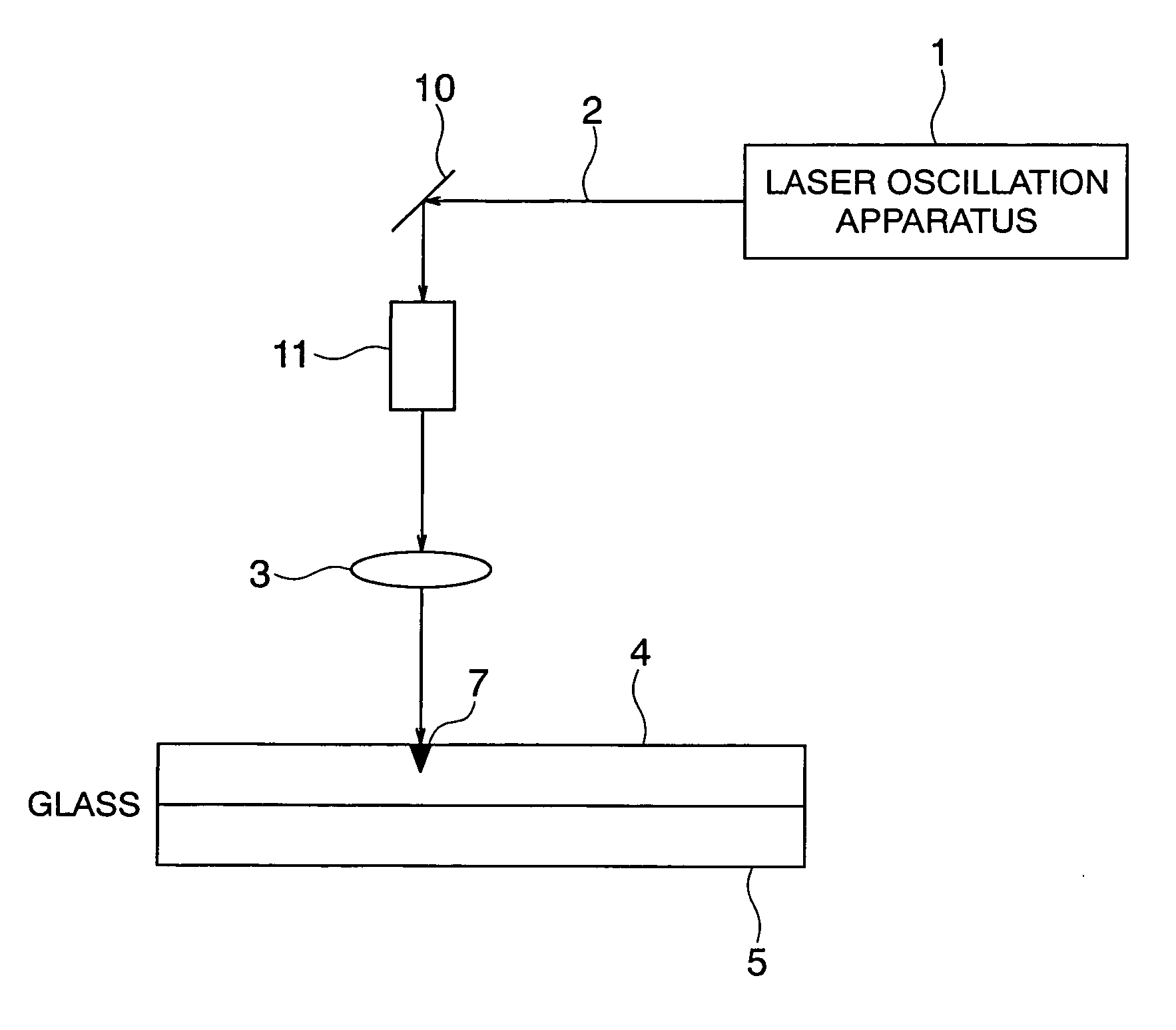

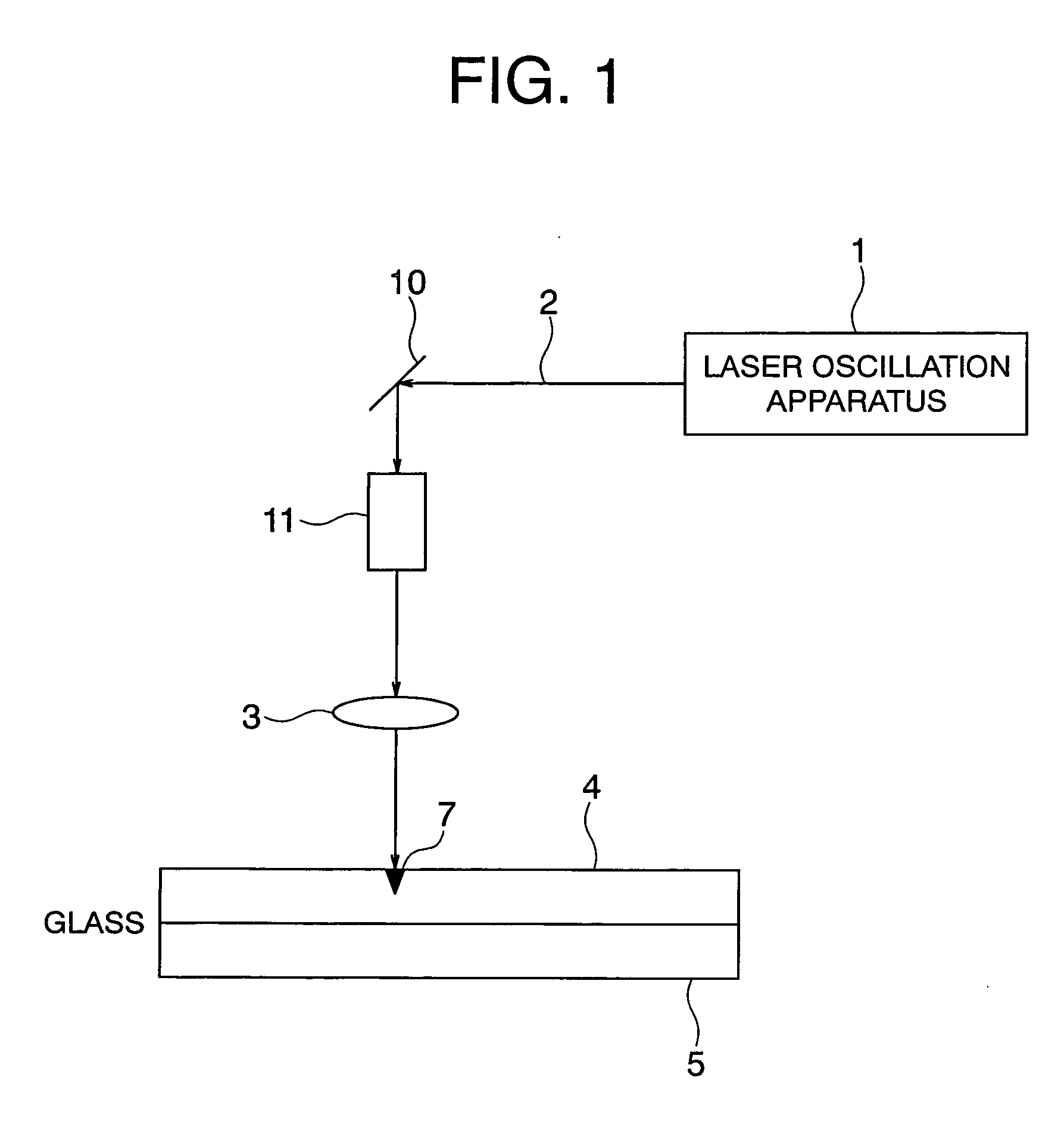

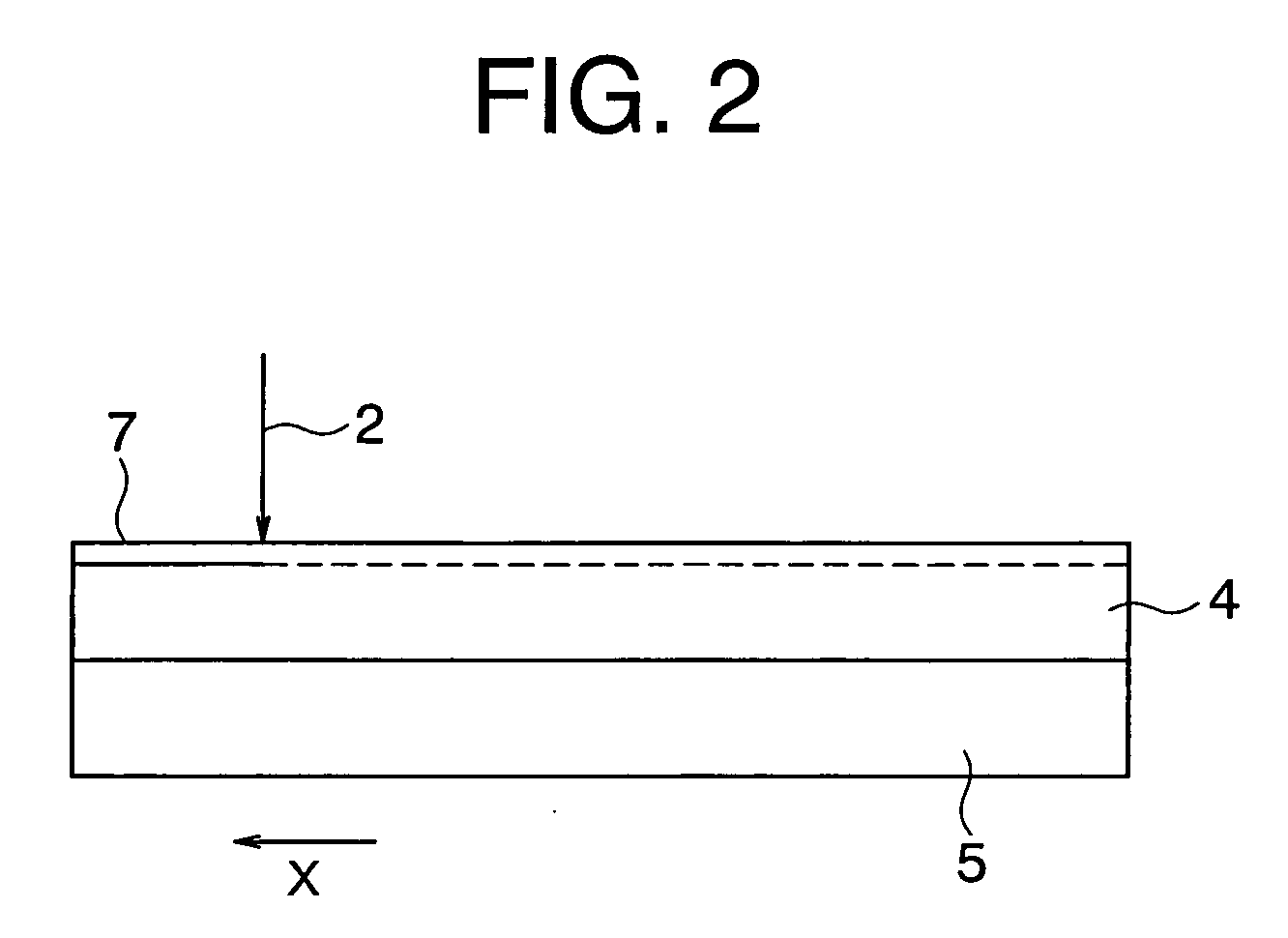

Glass cutting method and apparatus therefor

InactiveUS20070090100A1Formed rapidly and accuratelyPhoton energy is highFine working devicesGlass severing apparatusCutting glassUltraviolet

In the case of forming a scribe line by irradiating a laser in an ultraviolet range in one stroke, the glass bending strength after glass is cut is about 50 MPa or less, and the glass is likely to be subjected to crack damage during use as liquid crystal panel glass or the like. In a glass cutting method in which a portion to be cut of glass 4 is irradiated with a pulse laser 2 in one stroke of relative movement to form a scribe line 7, and then the glass is cut by applying a break force to the scribe line 7, a pulse laser of an ultraviolet range is used as the pulse laser 2, and the pulse laser 2 is irradiated while the pulse laser 2 is being relatively moved so that the total number of pulses at each irradiation portion is in a range of 2,667 to 8,000 pulses, whereby the scribe line 7 is formed to a depth of 1.8 to 6.3% of the thickness of the glass 4.

Owner:JAPAN STEEL WORKS LTD

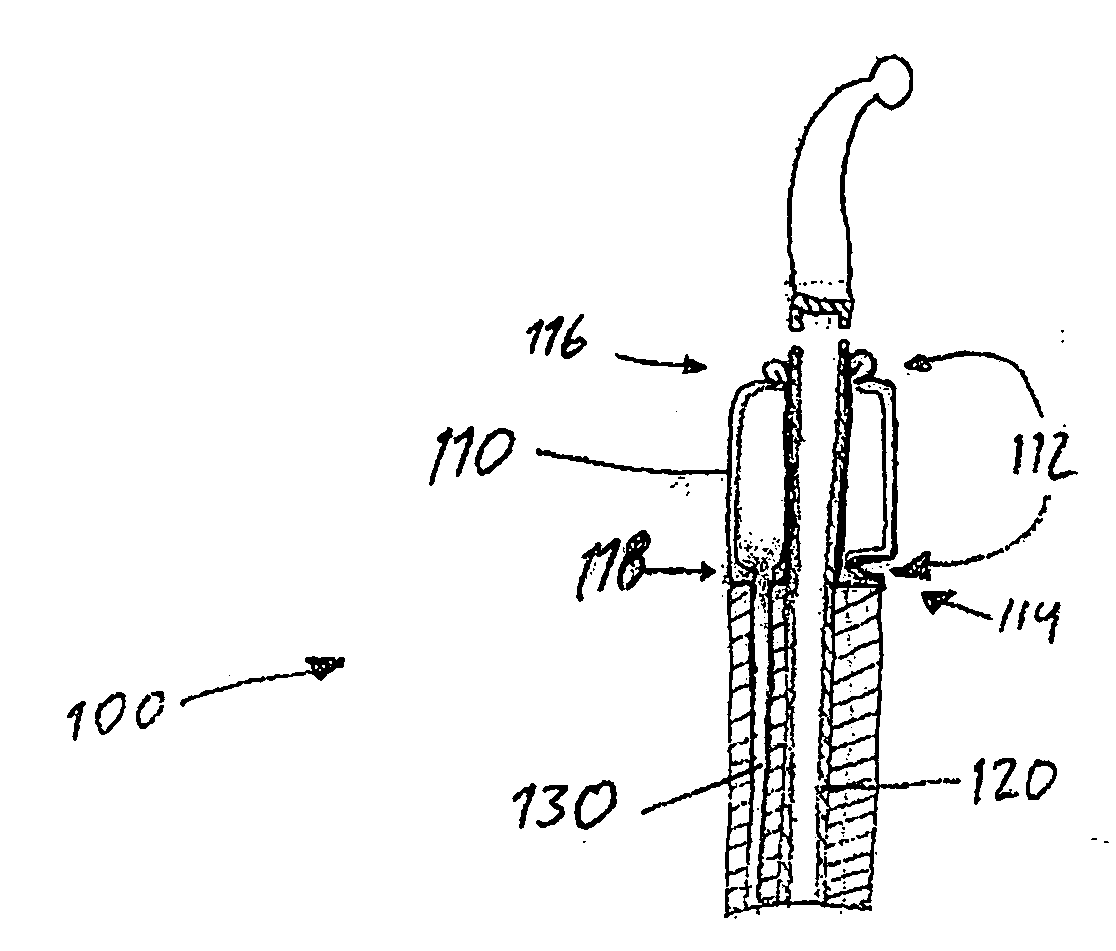

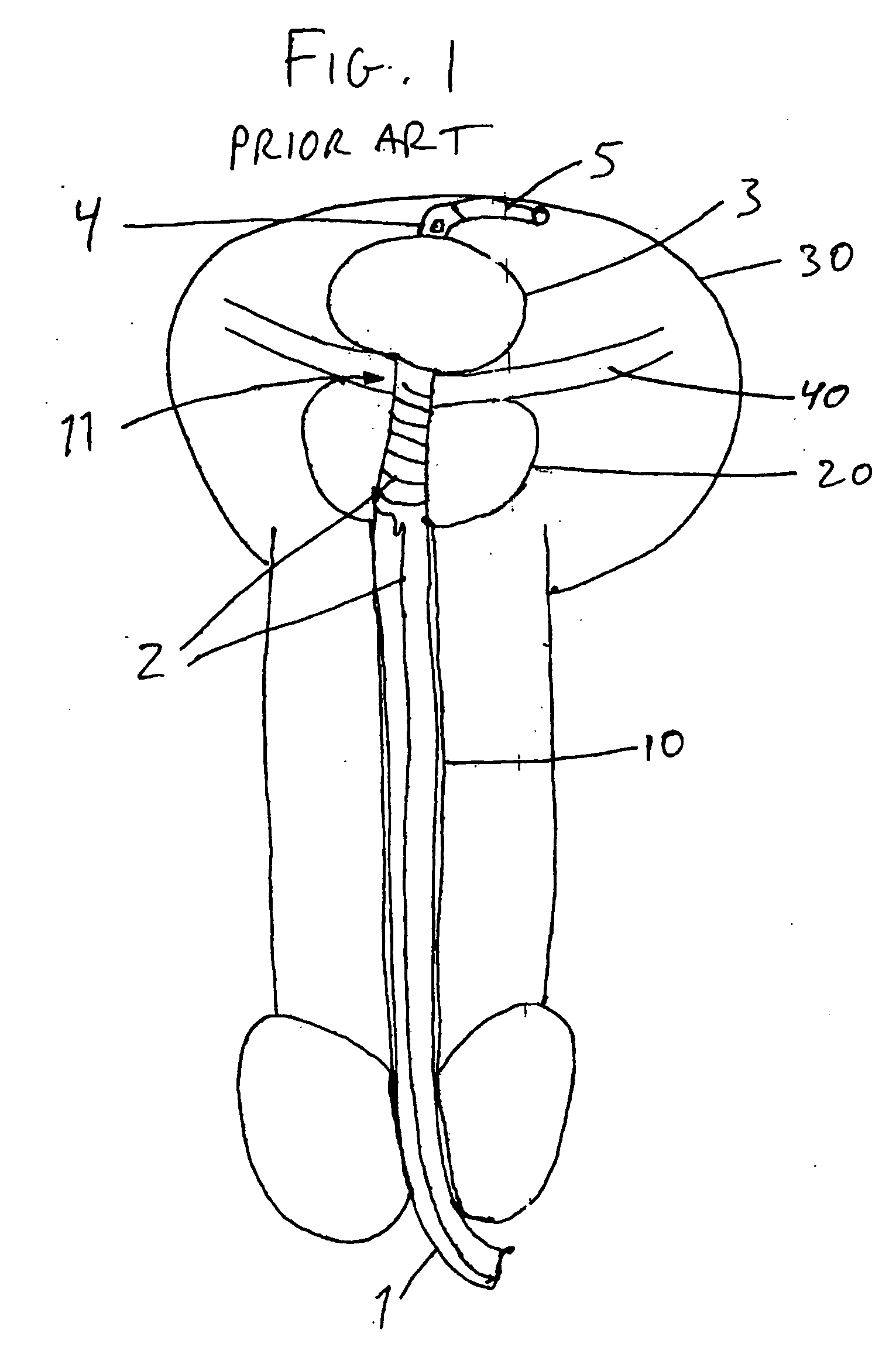

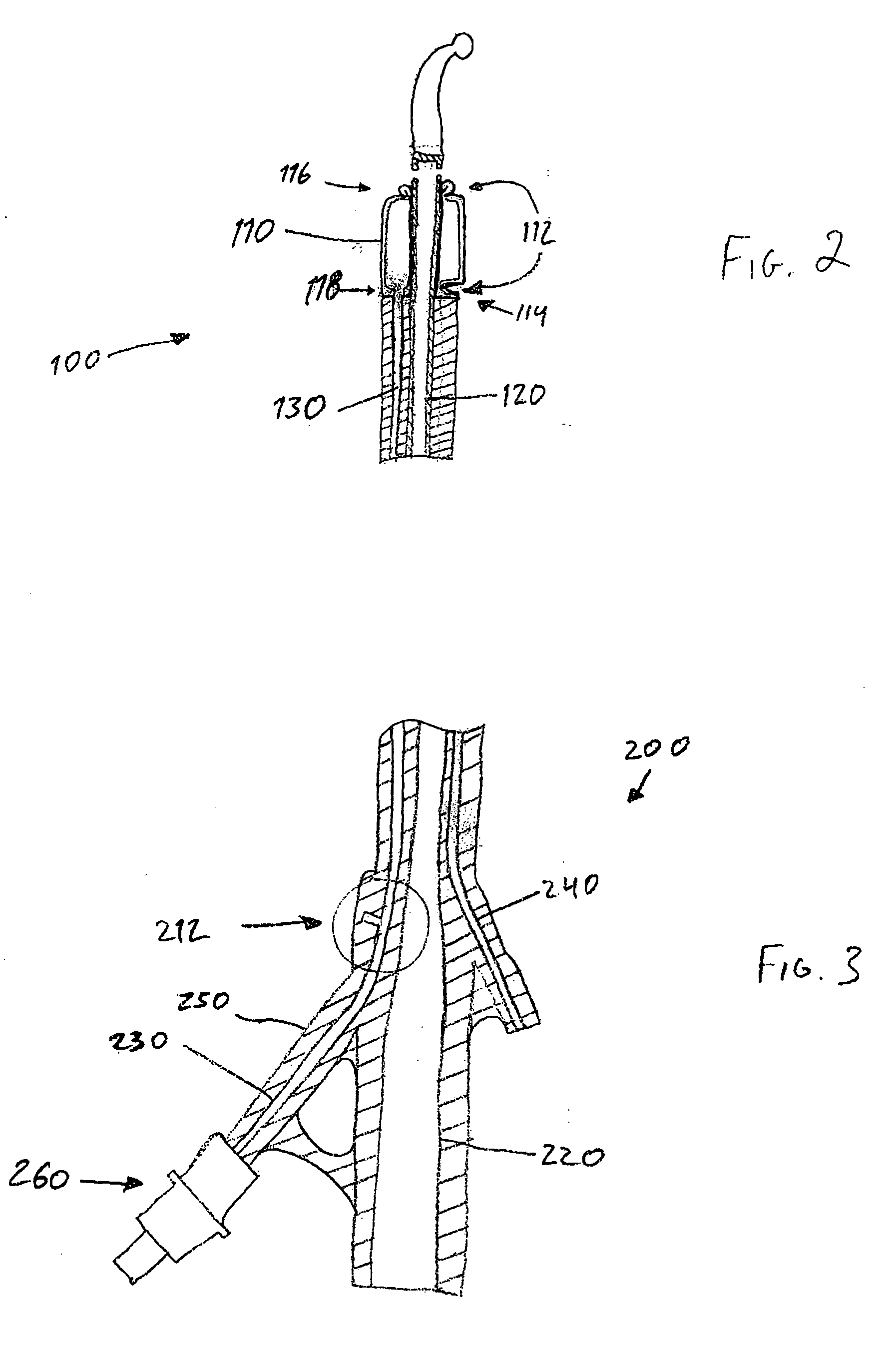

Pressure-limiting balloon catheter and method for using the catheter

InactiveUS20060167438A1Quick deflationAvoid injuryBalloon catheterSurgeryBalloon catheterSafety valve

A pressure-limiting or breakaway catheter includes a multi-lumen shaft having a distal end and a hollow balloon portion disposed at the distal end of the shaft. The balloon portion has a distal end and an interior. The shaft and / or the balloon portion has a balloon safety valve formed to open to the environment outside the shaft and / or the balloon portion when greater than a given bursting pressure exists within the shaft and / or the interior of the balloon portion. The safety valve can be formed to burst at a first breaking force less than a second breaking force required to burst the balloon portion and / or the shaft. Also provided is a breakaway catheter kit including a set of the breakaway catheters, each having the balloon safety valve with different safety valve breaking constants.

Owner:KALSER GARY +1

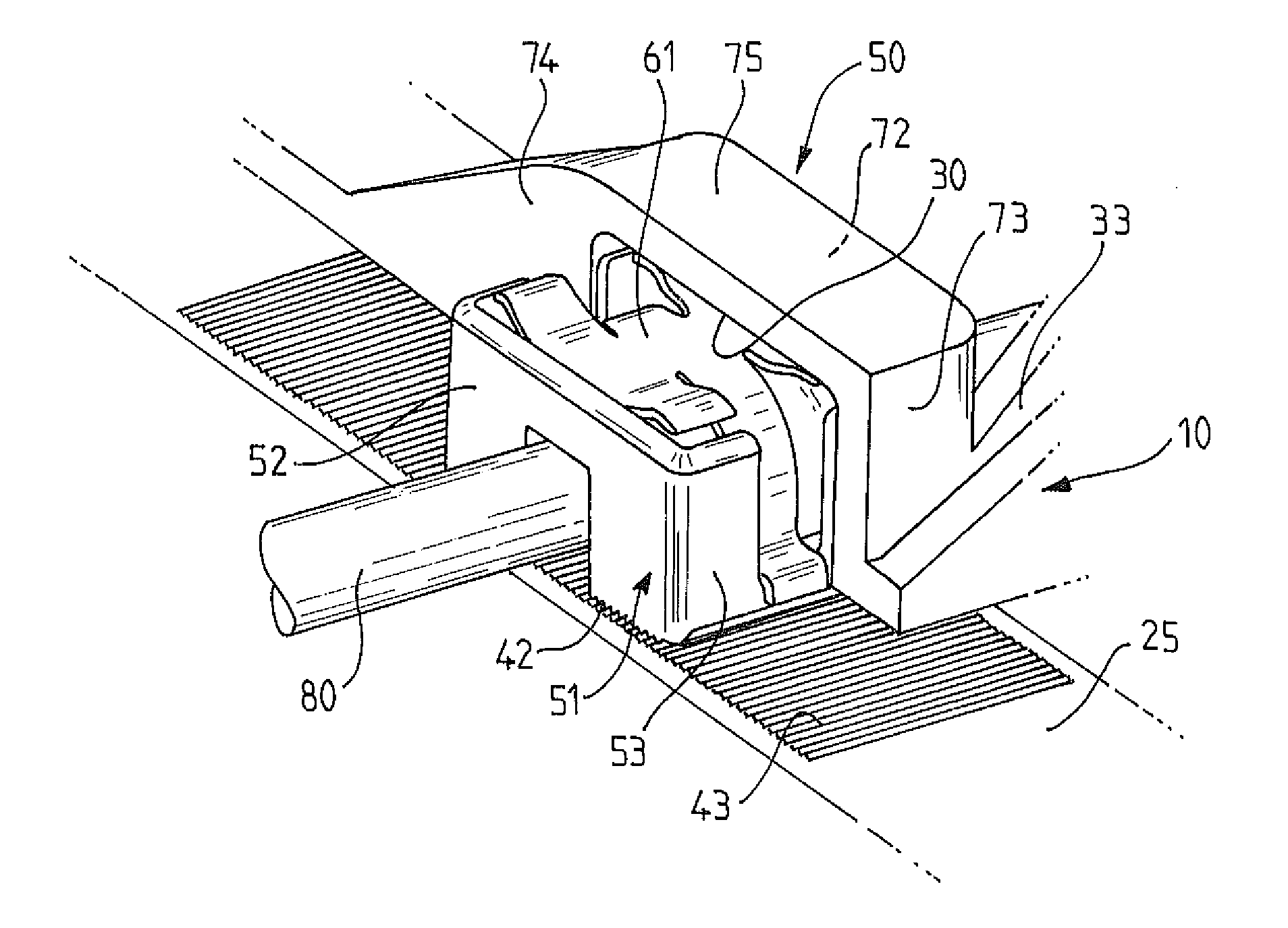

Energy absorption position-keeping device in an automotive vehicle steering column

In an adjustable steering column adjustable, a steering shaft is mounted in a body tube arranged in an intermediate carrier mounted on a fixed support member. The body tube is immobilized onto the fixed support member by a clamping system. The position-keeping device includes teeth that, in the event of an impact, are mutually engageable by means of a press system mounted in the intermediate carrier and under the action of the clamping system. The teeth belong to of the press system and are on the body tube. The teeth have characteristics defined such that in the event of an impact, the breaking force of the teeth has a predetermined value.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING VENDOME SAS

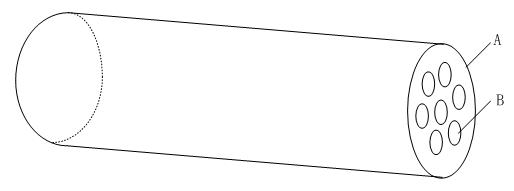

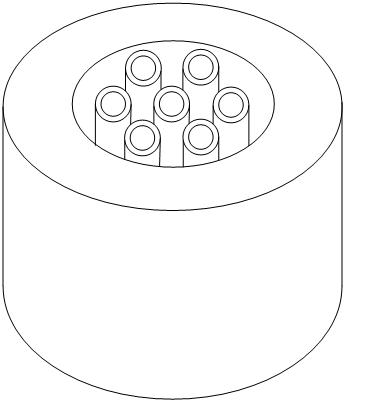

Polyether sulfone-polyurethane blend hollow fiber membrane and preparation method thereof

The invention relates to a polyether sulfone-polyurethane blend hollow fiber membrane and a preparation method thereof. In the hollow fiber membrane, polyether sulfone is taken as a main membranous material; polyurethane is added for blending; and a high molecular pore forming agent, a surfactant, a solvent and the like are added to prepare casting solution; and the polyether sulfone-polyurethane blend hollow fiber membrane is prepared by a dry-wet method, namely, a nonsolvent induced phase separation method spinning process. The prepared polyether sulfone-polyurethane blend hollow fiber membrane has seven inner bores with the inner diameter of 0.8 to 1.0mm and the outer diameter of 3.8 to 4.5mm, has high hydrophilcity, the flux of pure water of 300 to 2,900 L / M<2>.H(0.1MPa and 25 DEG C), high intensity and the tensile breaking force of 30 to 62N, has the advantages of high flexibility, the breaking elongation of 60 to 110 percent, high chemical resistance, high pollution resistance, and the like, and is easy to clean.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

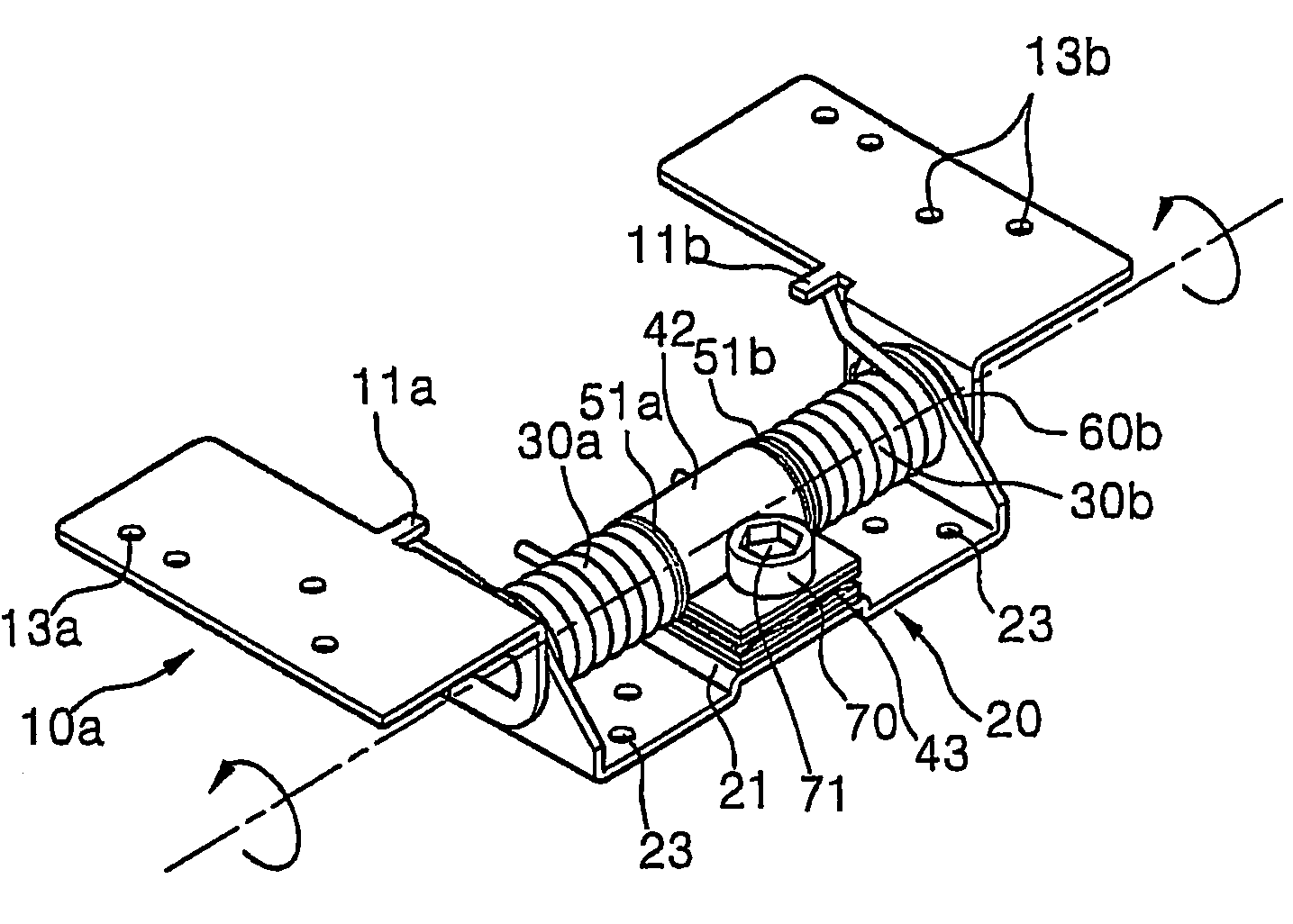

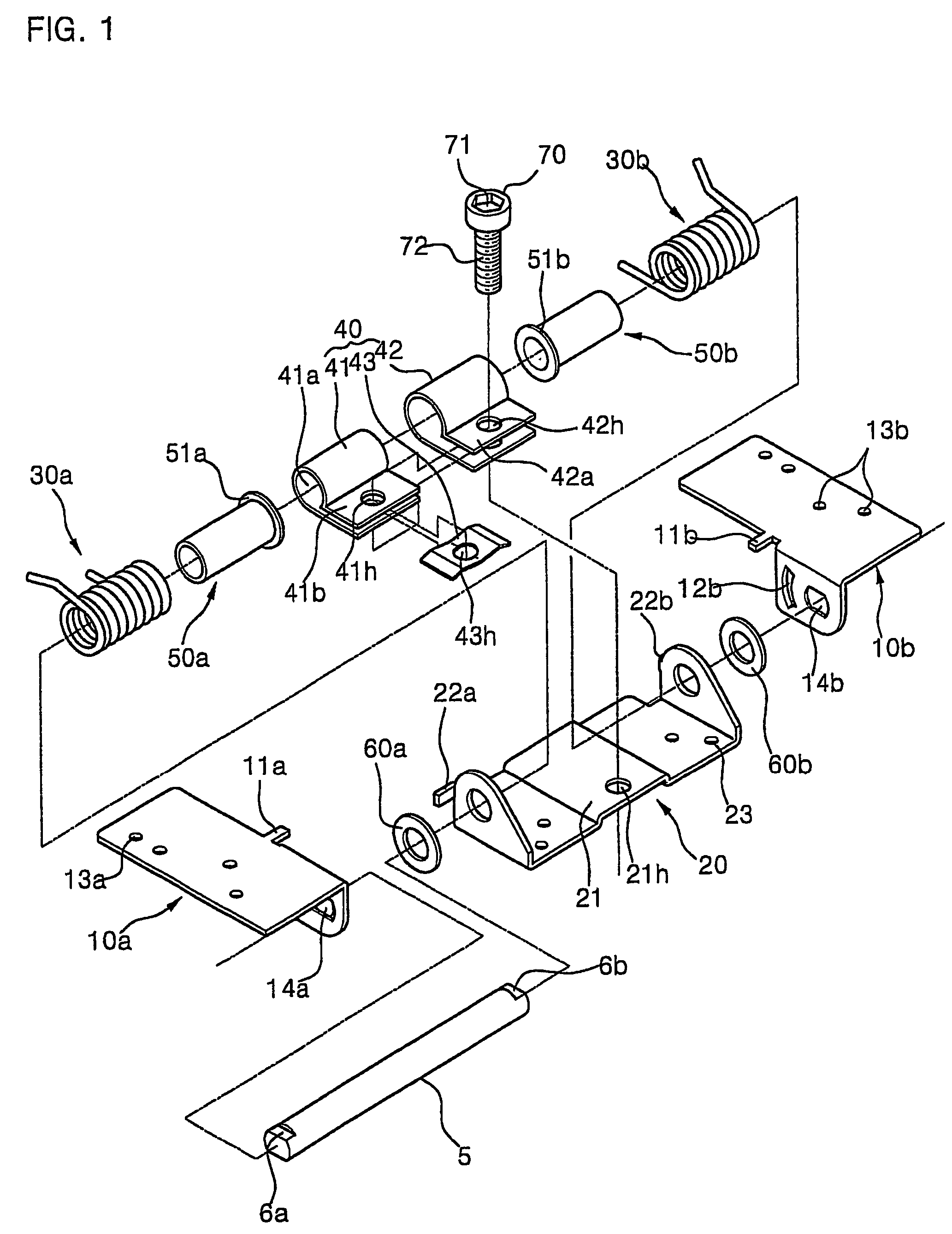

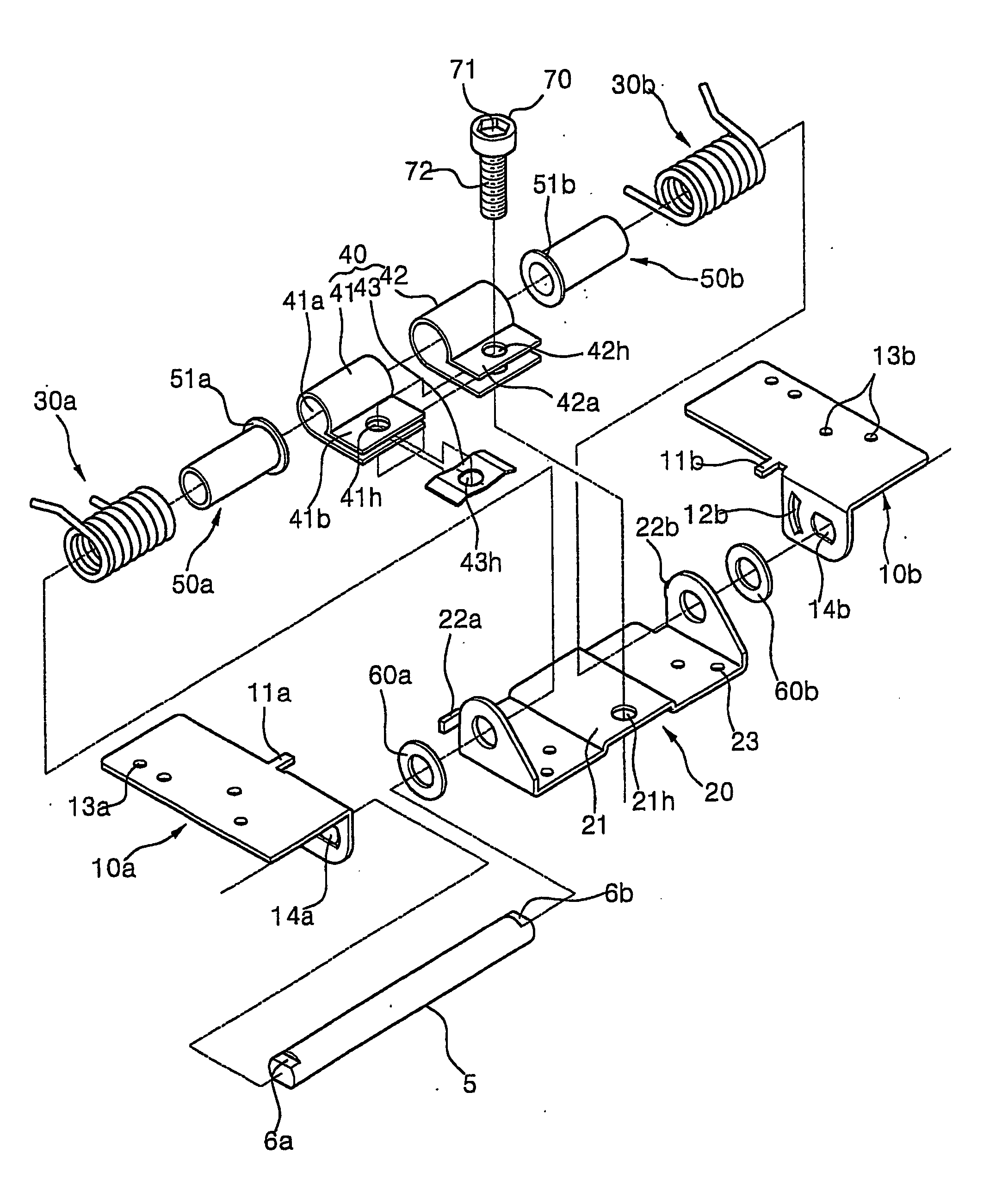

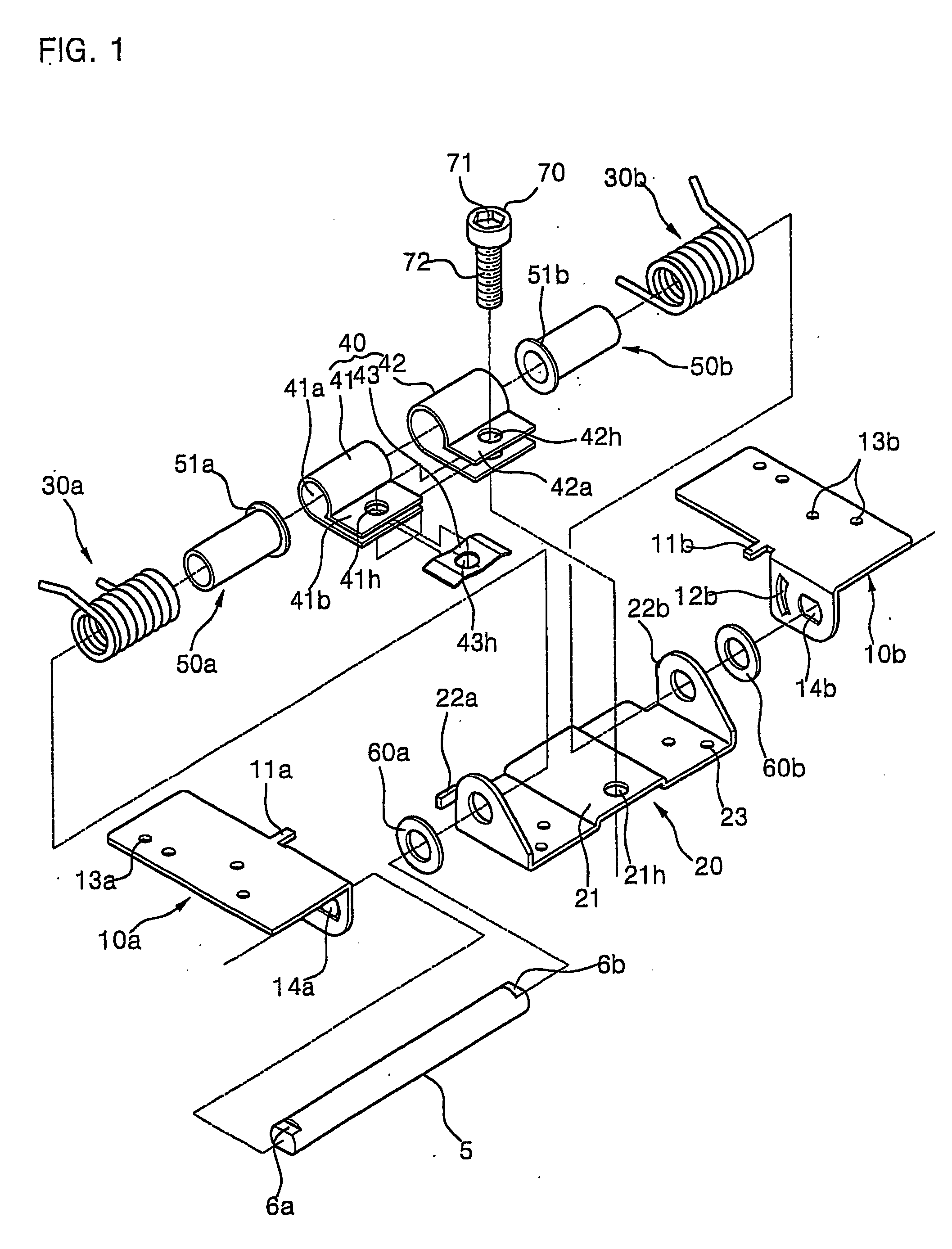

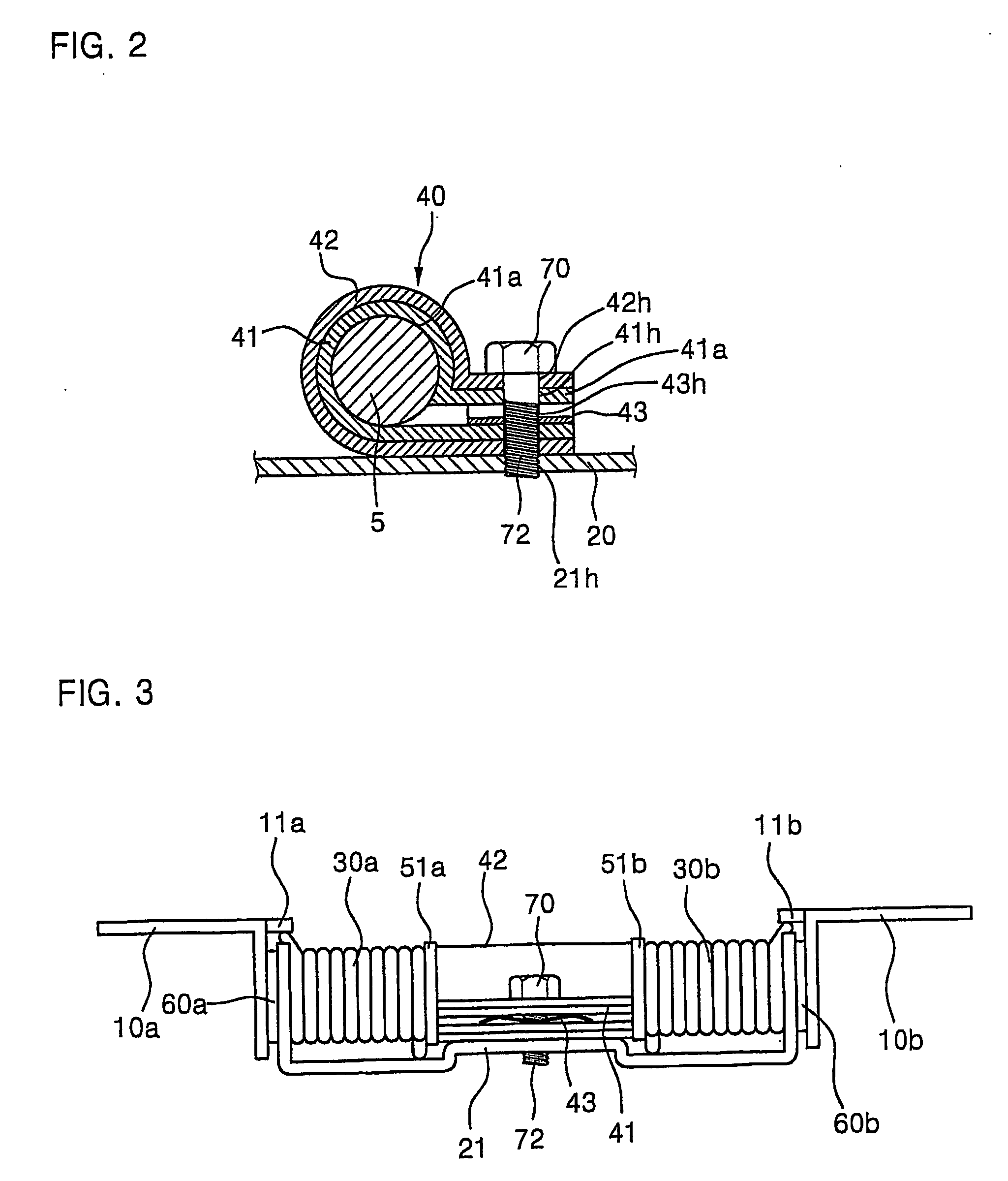

Hinge structure for flat visual display device

InactiveUS7472459B2Evenly distributedAdjusting operationDigital data processing detailsWing fastenersVertical planeDisplay device

A hinge structure for a flat visual display device comprising: a pivotal plate connected to the flat visual display device; a fixing plate connected to a supporting portion for supporting the flat visual display device; a rotational shaft inserted to vertical planes of the pivotal plate and the fixing plate, for rotation of the flat visual display device in one degree of freedom; a frictional member which is formed on an outer periphery of the rotational shaft for enclosing the rotational shaft, and whose both ends have a frictional member tightening plane of a planar shape on which a second inserting hole is formed; and a tightening member inserted to the second inserting hole, for tightening the frictional member tightening plane, thereby tightening the rotational shaft by means of the frictional member, and generating strong breaking force accordingly.

Owner:LG ELECTRONICS INC

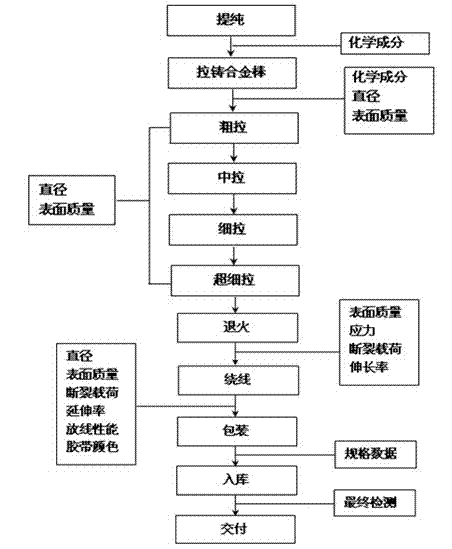

Preparation method of bonded gold-silver alloy wire

ActiveCN102776405AImprove conductivityStable chemical propertiesSemiconductor/solid-state device detailsSolid-state devicesCeriumTechnical design

The invention relates to a preparation method of a bonded gold-silver alloy wire, and belongs to the technical field of bonded wire processing processes. The bonded gold-silver alloy wire comprises the following metal materials by weight: 20-30% of silver, 5-1000 ppm of palladium, 5-1000 ppm of calcium, 5-1000 ppm of beryllium, 5-1000 ppm of cerium and the balance of gold; the preparation method comprises the following steps: 1), preparing materials; 2) smelting an alloy ingot; 3) pulling and casting an alloy rod; 4) wire-drawing; 5) annealing; 6) coiling; and 7) packaging. The preparation method of the bonded gold-silver alloy wire, provided by the invention, has the advantages of reasonable and standard technical design, and simple operation, the produced bonded gold-silver alloy wire has the advantages of strong conductivity, stable chemical performance, good oxidation resistance, flowability and plasticity, higher breaking force and better elongation, and moderate cost, and requirements of semiconductor package industry and LED (Light Emitting Diode) illumination technology on the performances of the bonded gold-silver alloy wire can be completely satisfied.

Owner:烟台招金励福贵金属股份有限公司

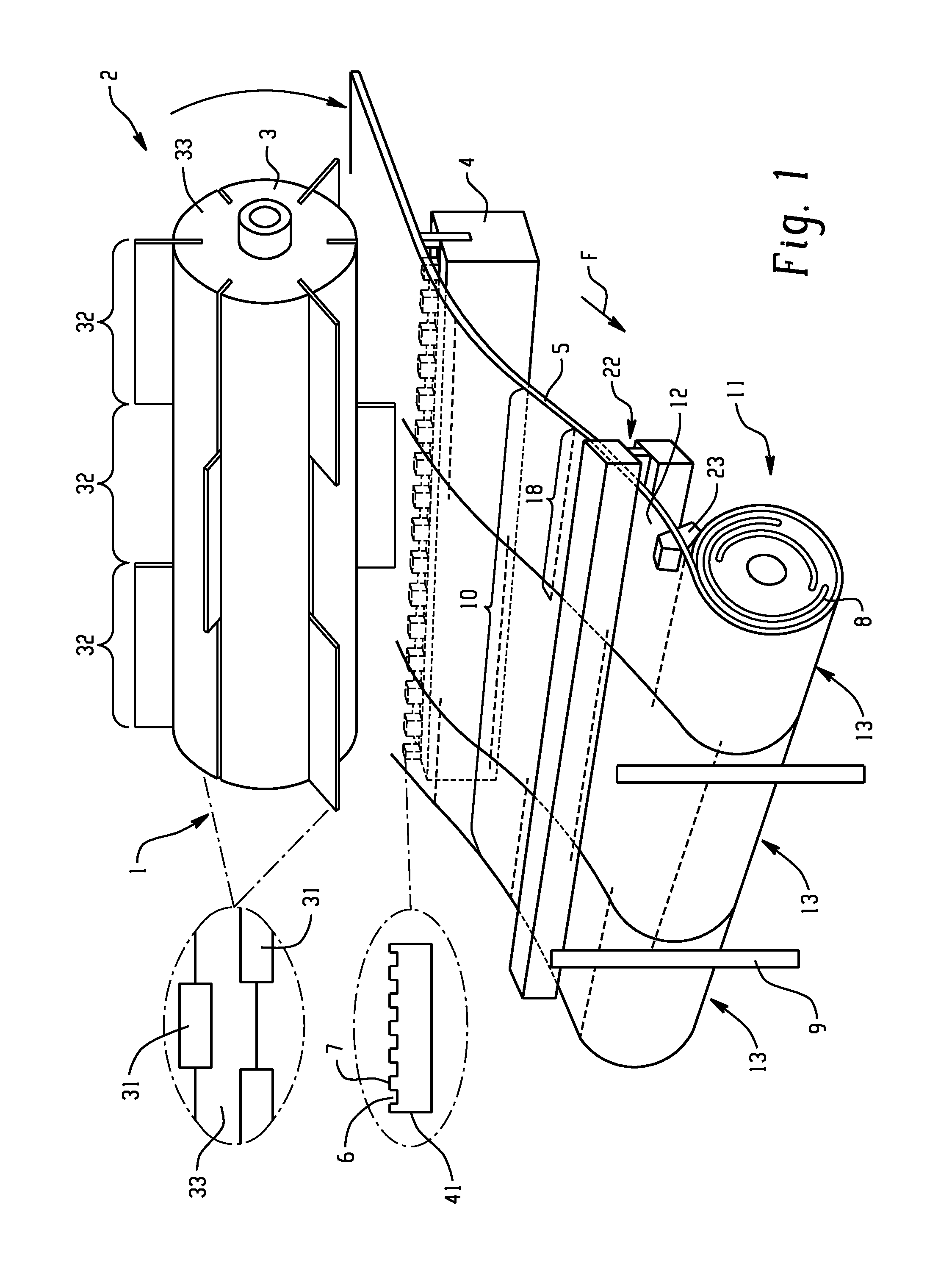

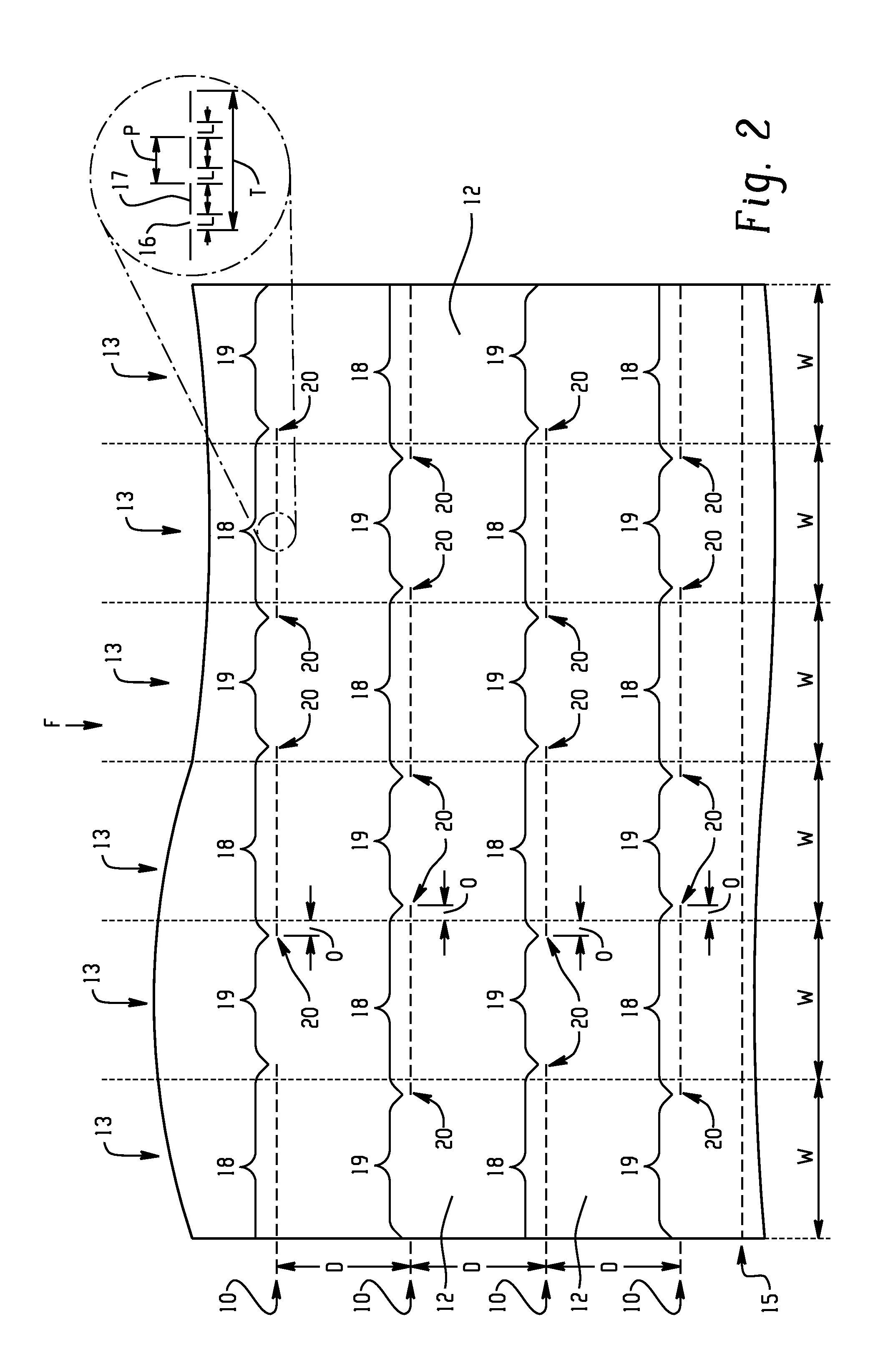

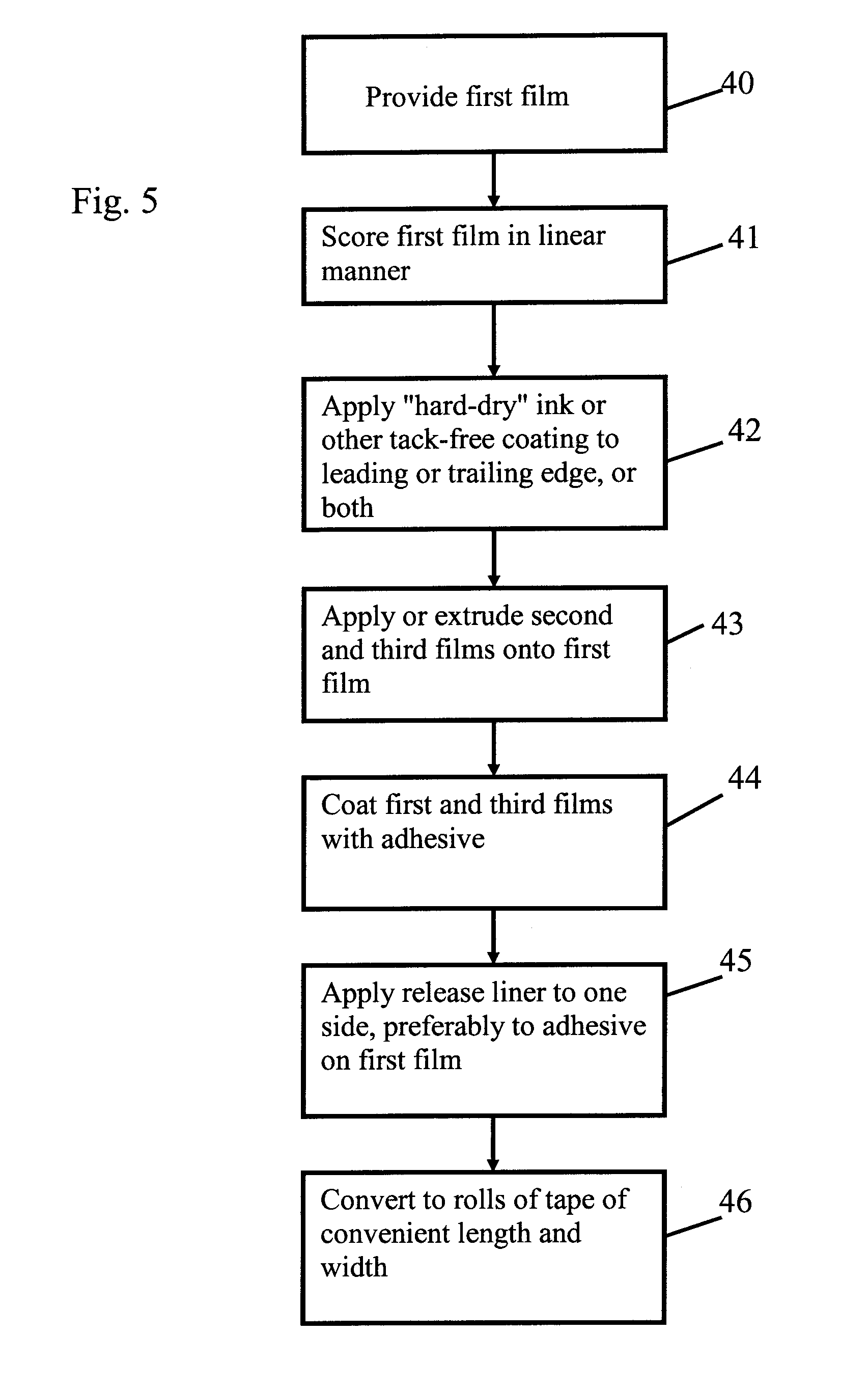

Method for Manufacturing a Sheet Product for Use in a Dispenser and Strip of Sheet Product

ActiveUS20120237711A1Reduction in perforation breaking strength of stripNot adversely affectingStampsMechanical working/deformationBreaking strengthUltimate tensile strength

The invention relates to a method of manufacturing a web of sheet product, with a discontinuous perforation arrangement such that manufacture of a web of sheet product provides for an increase in the breaking strength of the web of sheet product while feeding the web in a machine direction, thereby reducing the risk of breaking and maintaining the yield and throughput of the production of the perforated web as an intermediate product, yet providing a low breaking force for individual strips produced from the web.

Owner:GPCP IP HLDG LLC

Hinge structure for flat visual display device

InactiveUS20050102796A1Way fastEvenly distributedDigital data processing detailsWing fastenersVertical planeDisplay device

A hinge structure for a flat visual display device comprising: a pivotal plate connected to the flat visual display device; a fixing plate connected to a supporting portion for supporting the flat visual display device; a rotational shaft inserted to vertical planes of the pivotal plate and the fixing plate, for rotation of the flat visual display device in one degree of freedom; a frictional member which is formed on an outer periphery of the rotational shaft for enclosing the rotational shaft, and whose both ends have a frictional member tightening plane of a planar shape on which a second inserting hole is formed; and a tightening member inserted to the second inserting hole, for tightening the frictional member tightening plane, thereby tightening the rotational shaft by means of the frictional member, and generating strong breaking force accordingly.

Owner:LG ELECTRONICS INC

Liquid crystal display device implementing improved electrical lines and the fabricating method

The present invention discloses a liquid crystal display device, including upper and lower substrates with a liquid crystal layer interposed therebetween; a sealant between the upper and lower substrates; a plurality of source and gate pads on the lower substrate; a plurality of gate and data lines on the lower substrate, each gate line being electrically connected with the corresponding gate pad, each data line being electrically connected with the corresponding source pad; a gate insulating layer between the gate lines and the data lines; a source PCB electrically connected with the plurality of source pads; a gate PCB electrically connected with the plurality of gate pads; and a plurality of transmitting wires on the lower substrate, the transmitting wires being electrically connected with the gate and source pads across the sealant such that the source PCB is electrically connected with the gate PCB. The liquid crystal display device further includes a repair wire to repair the gate transmitting wires, and dummy patterns to protect the gate transmitting wires from a mechanical damage of a scribing and breaking force.

Owner:LG DISPLAY CO LTD

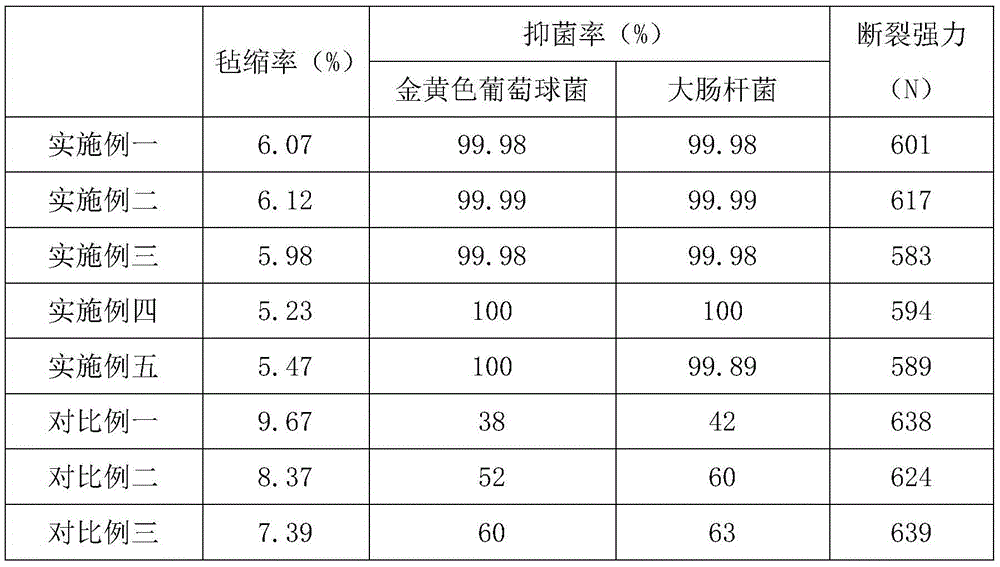

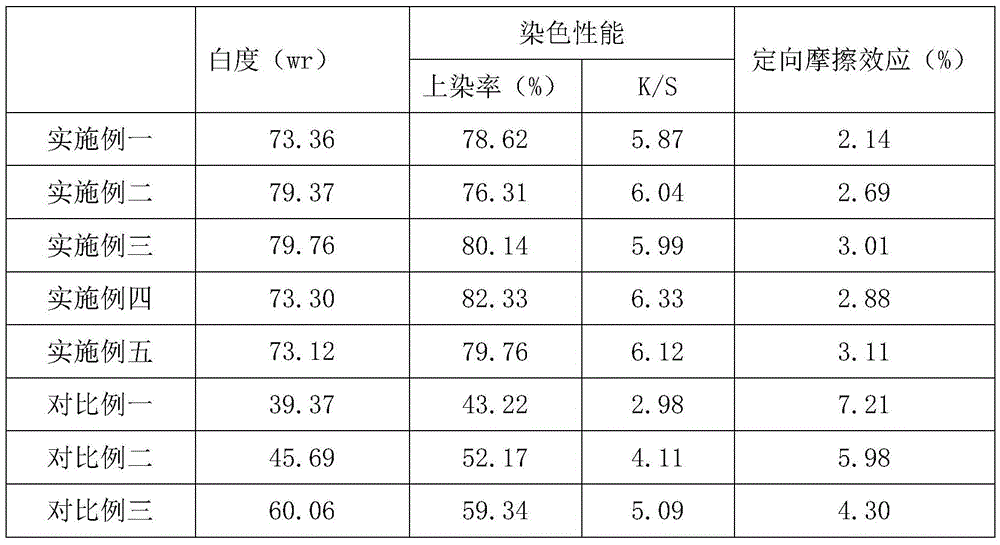

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

Multifunctional high-strength composite fabric coating agent, coating, and preparation method and application of multifunctional high-strength composite fabric coating agent

InactiveCN107254248AHigh strengthImprove scratch resistanceAntifouling/underwater paintsBiochemical fibre treatmentMoisture penetrationFilm-forming agent

Owner:JIANGNAN UNIV

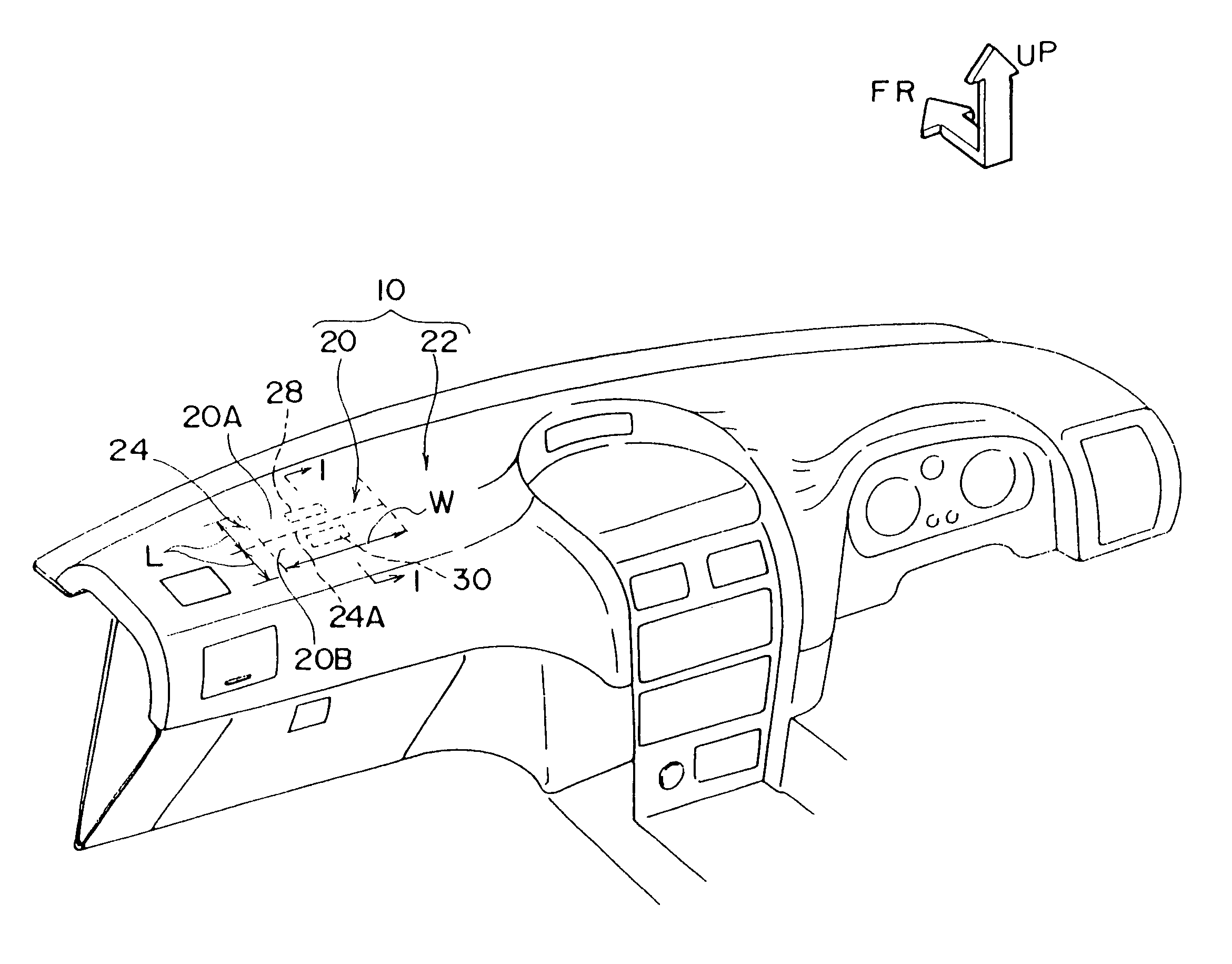

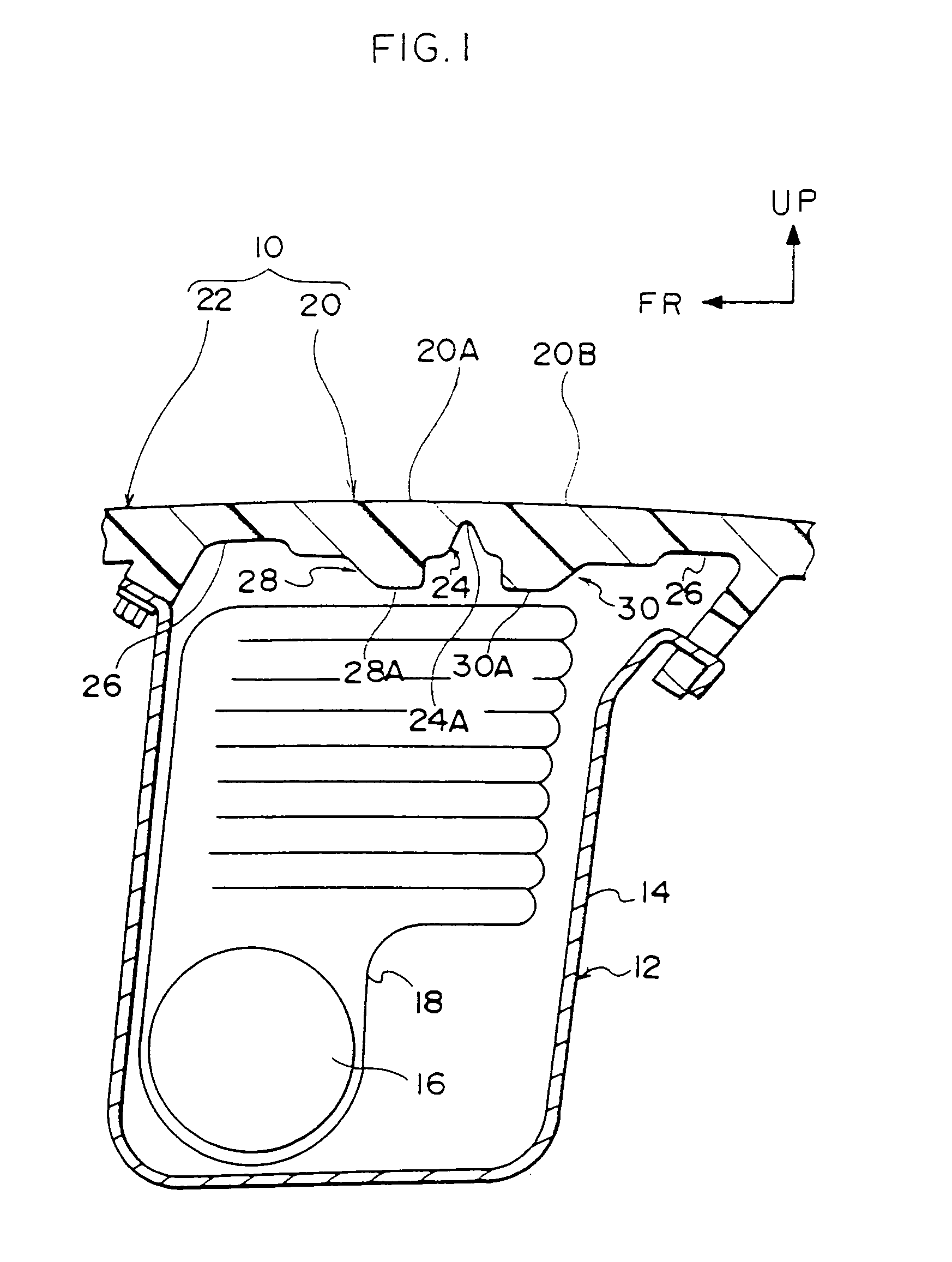

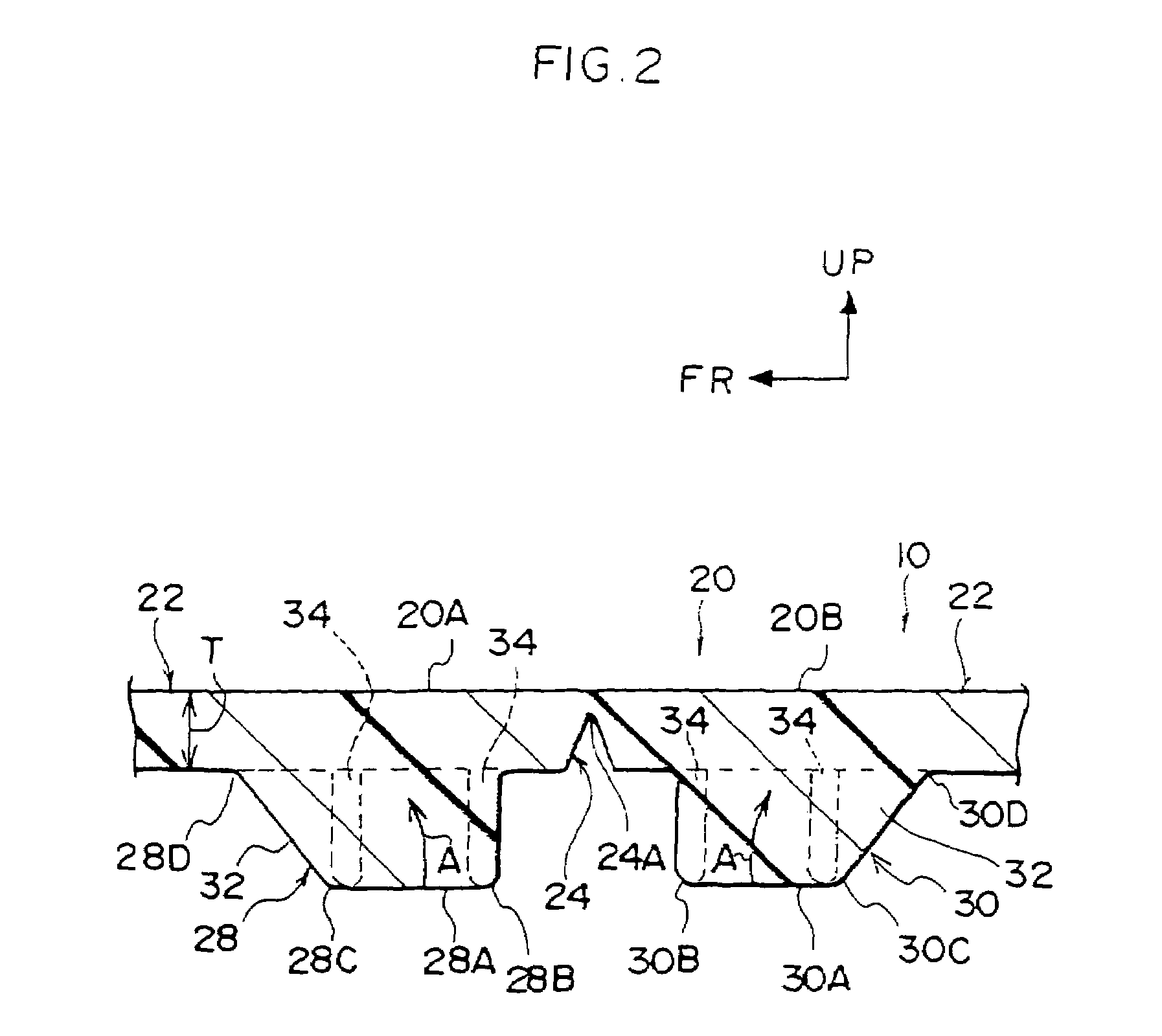

Interior member having an airbag door section for use in vehicles, and its molding method

InactiveUS7063349B2Reduce breaking forcePedestrian/occupant safety arrangementDomestic articlesMobile vehicleIn vehicle

Owner:TOYOTA JIDOSHA KK

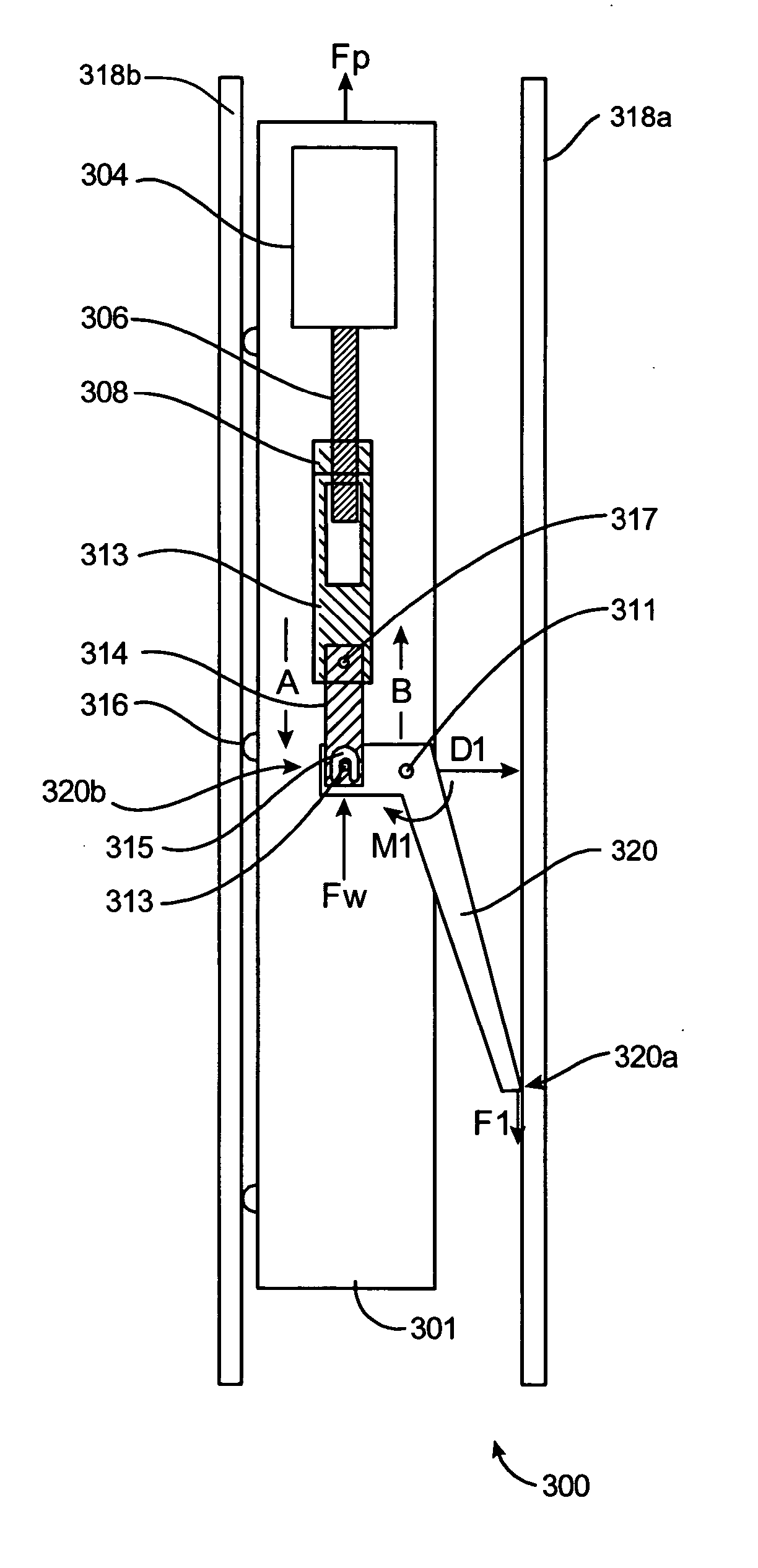

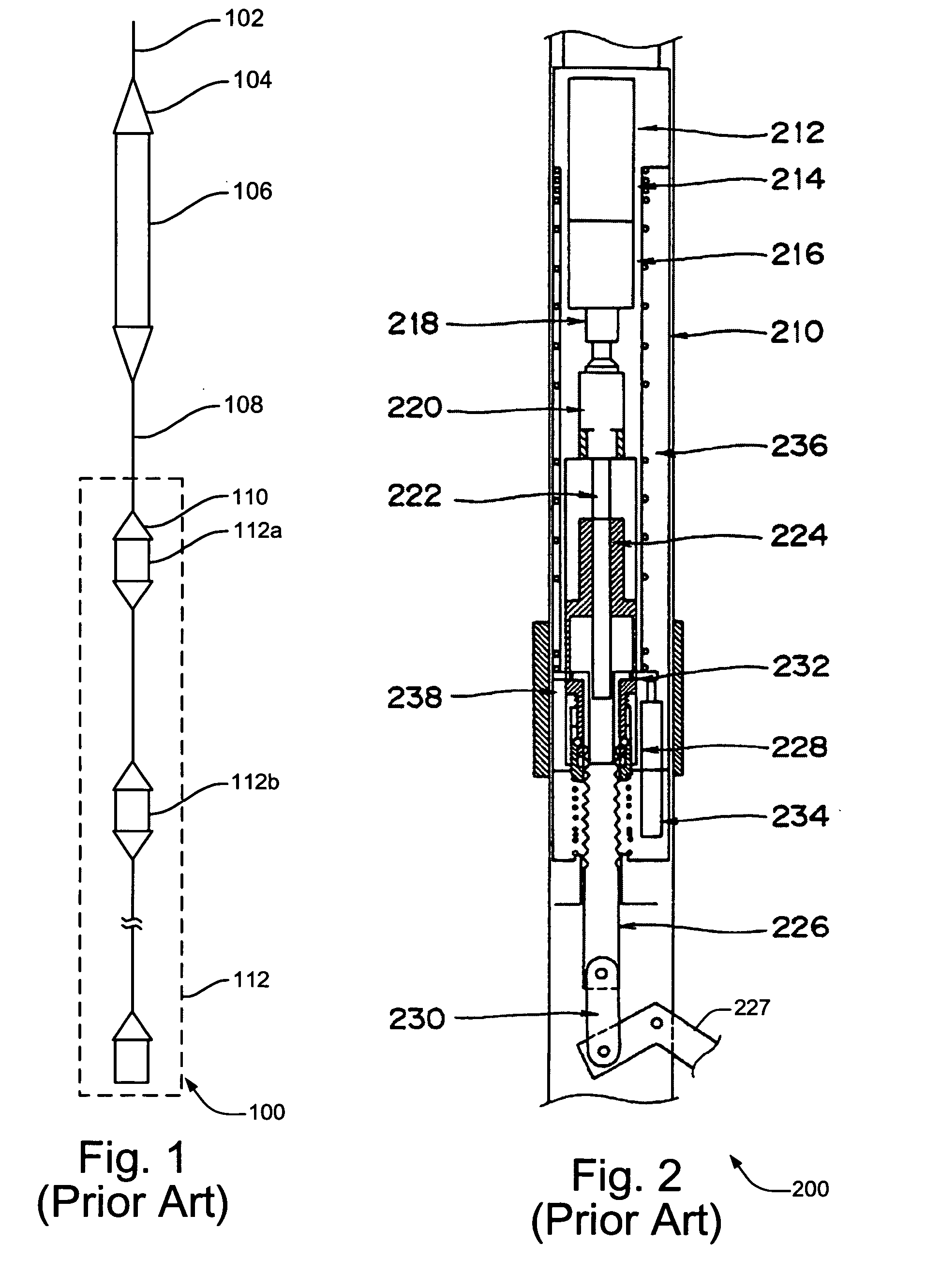

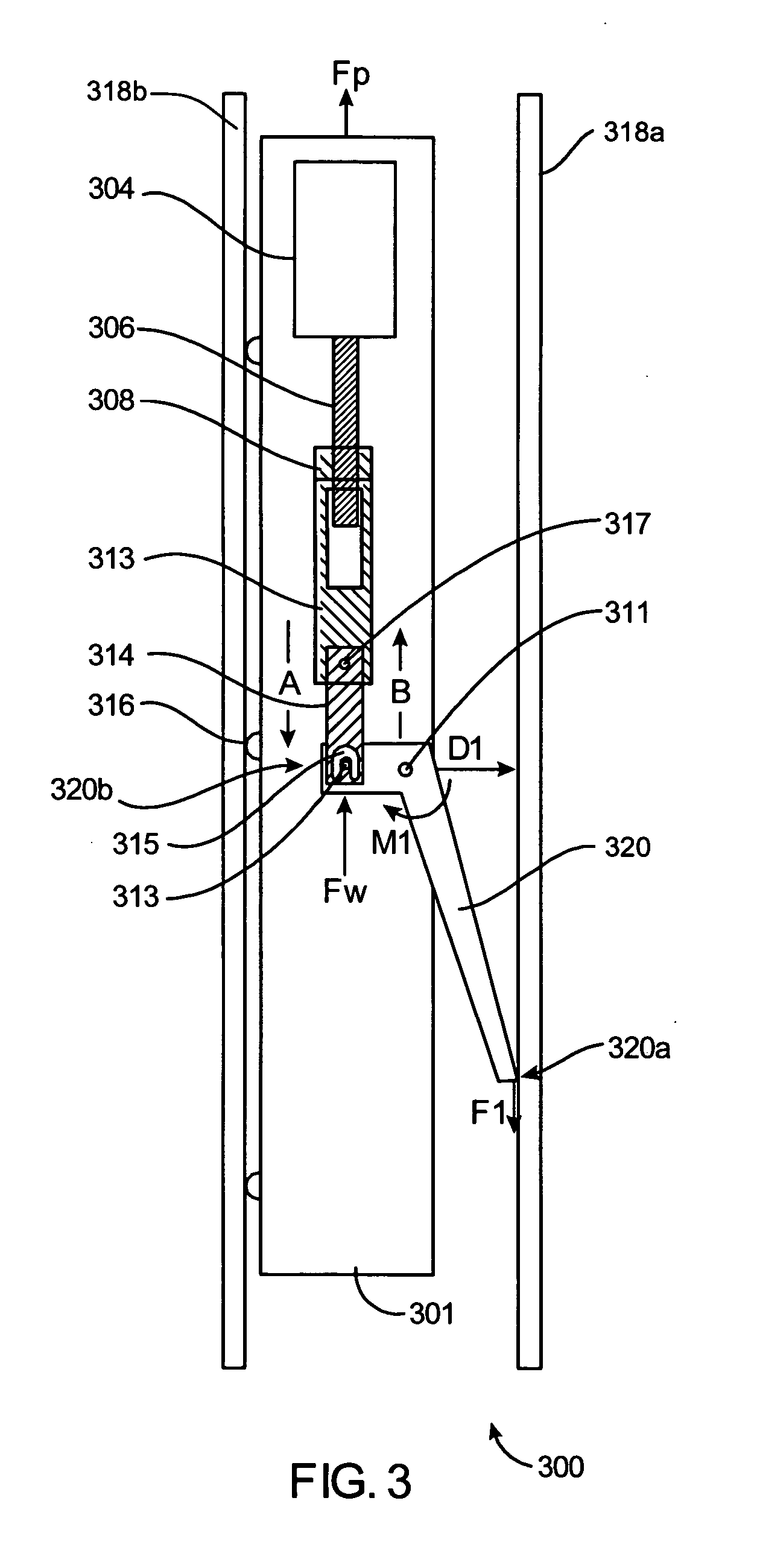

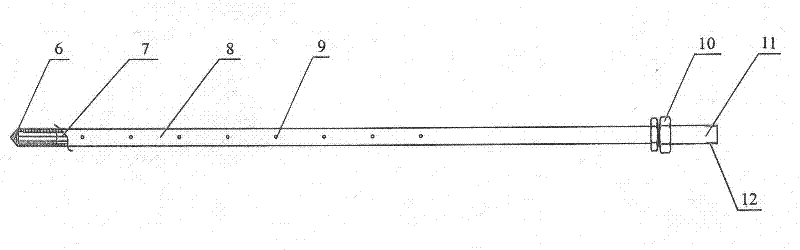

Anchor arm for seismic logging tool

A technique is described for releasing a borehole seismic acquisition tool from a stuck position within a borehole. The borehole seismic acquisition tool includes a tool body having at least one sensor package. The borehole seismic acquisition tool further includes an anchoring arm, and anchoring arm linkage adapted to connect the anchoring arm to the tool body. The anchoring arm linkage includes a weakpoint mechanism adapted to break in response to a minimum threshold amount of breaking force being applied upon the weakpoint mechanism. The anchoring arm includes a first end and a second end. The second end of the anchoring arm is pivotally attached to the anchoring arm linkage. The first end of the anchoring arm includes a tip portion which defines a slot. The anchoring arm also includes a movable cam inserted into the slot and removably secured to the first end via a first connector pin inserted through an aperture in the cam. According to at least one implementation, the cam is at least partially rotatable about the first connector pin. An exposed portion of the cam is engaged with the surface of borehole wall. When a failure of retraction of the anchoring arm is detected, the cam may be caused to rotate against the borehole wall surface in response. The rotation of the cam against the borehole wall surface causes a force to be exerted upon the weakpoint mechanism, which, in turn, causes the weakpoint mechanism to break. The breaking of the weakpoint mechanism results in a release of the borehole seismic acquisition tool from the stuck position. According to a specific embodiment, rotation of the cam against the borehole wall surface may be caused by a pulling force applied to a top portion of the borehole seismic acquisition tool.

Owner:SCHLUMBERGER TECH CORP

A preparation method for high-fiber recombinant asparagus chips

The present invention discloses a preparation method for high-fiber recombinant asparagus chips, and belongs to the deep processing field of fruits and vegetables. The asparagus chips use discarded scraps of old stems and old roots from asparagus production enterprises as raw materials, and are prepared by the following steps: pre-treating the raw materials, blanching the materials in hot water, preserving color, conducting beating, mixing the materials with adjuvant materials, cooking the mixture for a short time, placing the mixture on plates, drying the mixture under vacuum by two section-type microwave to a moisture content of 10% -15%, drying the mixture by short- and medium-wave infrared method under vacuum to a moisture content below 5%, and packaging the mixture to obtain the end products. The dietary fiber content of the asparagus chips is 8.35% - 10.27%, and every 100g of the chips contains flavonoids 12.73-16.86 mg, polysaccharide 9.34-11.28 mg. The preservation rate of chlorophyll is 70% to 75% after processing, and the chip breaking force is 1123-1443 g. The preparation method provides a novel method for taking full advantage of asparagus scraps, and the microwave vacuum drying and the short- and medium-wave infrared vacuum drying have advantages of quick drying, low temperature and higher nutrient retention rate, etc. The asparagus chips are high in cellulose content, rich in flavonoids, polysaccharide and other active substances, crispy and delicious in taste and high in nutritional value. Therefore, the asparagus chips are leisure crisps for people of all ages.

Owner:JIANGNAN UNIV +1

Method for detecting integrally breaking force for steel wire rope

InactiveCN102636389AHigh breaking forceBreaking force responsePreparing sample for investigationMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a method for detecting integrally breaking force for a steel wire rope. The method includes spreading apart two ends of the steel wire rope and cleaning the spread ends by detergent; placing one of the two ends into a mold, filling liquid zinc into the mold and taking out the end after the liquid zinc is solidified; placing the other end into the mold, filling zinc liquid into the mold, taking out the end after the liquid zinc is solidified, and obtaining a steel wire rope test sample with solidified zinc slabs at the ends; and carrying out stretching test for the steel wire rope test sample. The method has the advantages that detection steps can be simplified, detection cost is lowered, and the integral breaking force of the steel wire rope can be increased and is truly reflected effectively.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Specialized hollow fiber membranes for in-vivo plasmapheresis and ultrafiltration

An in-vivo plasmapheresis and / or in-vivo ultrafiltration membrane comprises elongated hollow fibers each fiber having an interior lumen extending along the fiber length, the fiber wall having a plurality of zones between the inner and outer wall surfaces, each of the zones having a mass density different than the mass density of an adjacent zone. The fiber wall is characterized by having a lower mass density zone at the inner wall surface and a higher mass density zone at the outer wall surface. The fiber is further characterized by having an average elongation breaking force strength of at least about 0.2 lbs. and an average elongation of at least about 45%.

Owner:TRANSVIVO

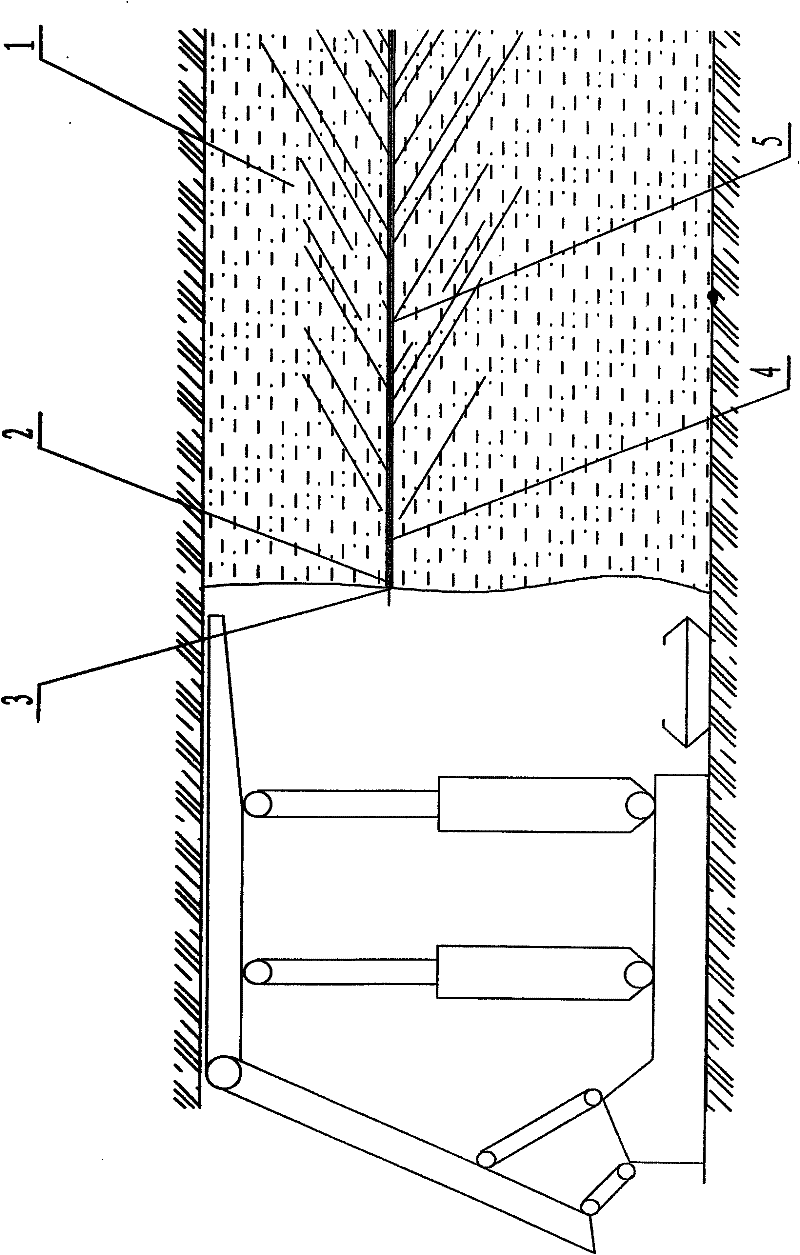

Method for reinforcing working surface of loose and soft coal bed by utilizing nonmetal grouting anchor cable

The invention discloses a method for reinforcing a working surface of a loose and soft coal bed by utilizing a nonmetal grouting anchor cable. The grouting anchor cable is made of a high-strength composite material carbon fiber / glass fiber. The reinforcement of the working surface of the loose and soft coal bed is realized through the processes of surveying and lofting, drilling holes in a coal body, manufacturing and arranging the grouting anchor cable, sealing an anchor cable hole, and grouting chemical grout in the hole and the like. As the grouting anchor cable is made of nonmetal materials, no sparks are generated when a coal-winning machine cuts, and the grouting anchor cable has the characteristics of flame retardancy, anti-static electricity, safety and reliability in use and hightensile strength, higher breaking force, light weight, and capability of being bent and coiled, and is higher than steel and convenient in transportation; and by utilizing the method, deep hole reinforcement and support on the working face can be carried out under the condition that the coal face can not be supported by using a metal anchor cable, the grouting support operation can be carried outon the working surface on site by combining a chemical grouting method, and the coal body of the working surface can be reinforced at the upper and lower tunnels of the working face by combining the chemical grouting in advance.

Owner:HEBEI TONGCHENG MINING TECH

Method for preparing plasticised wheat gluten compositions for petfood and pet treat applications

InactiveUS20090110802A1Animal feeding stuffVegetable proteins working-upSpecific mechanical energyCompanion animal

A method for manufacturing plasticised gluten compositions for pet food and pet treat applications, the method comprising the steps of: mixing at least gluten and a plasticiser wherein the mixing equipment is set to a value below 500C and the SME (Specific Mechanical Energy) applied to the mix is less than 600 kj / kg, wherein the gluten content is between 20 and 85% by weight wherein the plasticiser content is less than 40% by weight. The invention also relates to the use of plasticised gluten for the manufacture of a chewy pet food having a high breaking force.

Owner:NESTEC SA +1

Preparation method of pyrohydrolysis-resistant meta-position aramid fiber material

ActiveCN102628222AAvoid hydrolysisMembrane structure intactFibre typesSynthetic resin layered productsWater vaporDifferential pressure

The invention relates to a preparation method of a pyrohydrolysis-resistant meta-position aramid fiber material. The preparation method is characterized in that: a meta-position aramid fiber three-layer structural body made by adopting a no-weaving technology is taken as a filter material green body, the meta-position aramid fiber three-layer structural body is subjected to padding by pyrodydrolysis-resistant finishing liquor which contains polytetrafluoroethylene and epoxy phenolic resin mainly and then is subjected to low temperature antimigrant primary drying and high temperature crosslinking, thus a membrane structure which is completely coated and is uniformly distributed with polytetrafluoroethylene particles, high temperature water vapor is isolated from contacting fibers, retention rate of longitudinal and transverse breaking forces of hydrolysis at higher continuous working temperature are 100-107%, water repellency level and oil repellency level are obviously improved, the filter material is difficult to damage, is easy to clean ash, does not paste bag and does not harden, differential pressure of a dust removal system is small, service life of a filter bag is prolonged, and the filter material can be widely applied to high temperature flue gas dedusting and filtering of steel and iron, electricity generation, cement, a coal-fired boiler and the like. The preparation method disclosed by the invention can directly use the traditional production equipment and has a simple process and low production cost.

Owner:江苏东方滤袋股份有限公司 +1

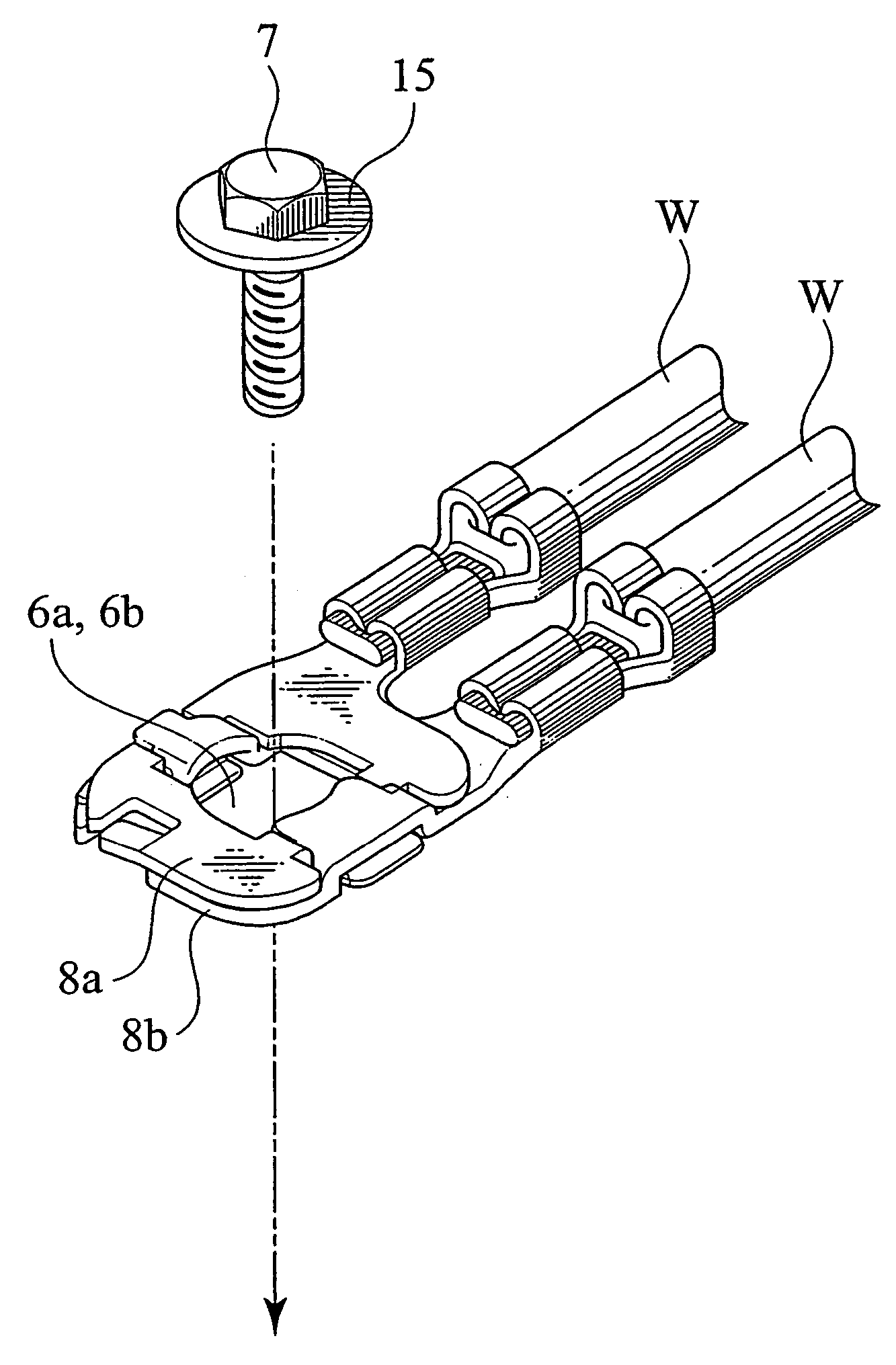

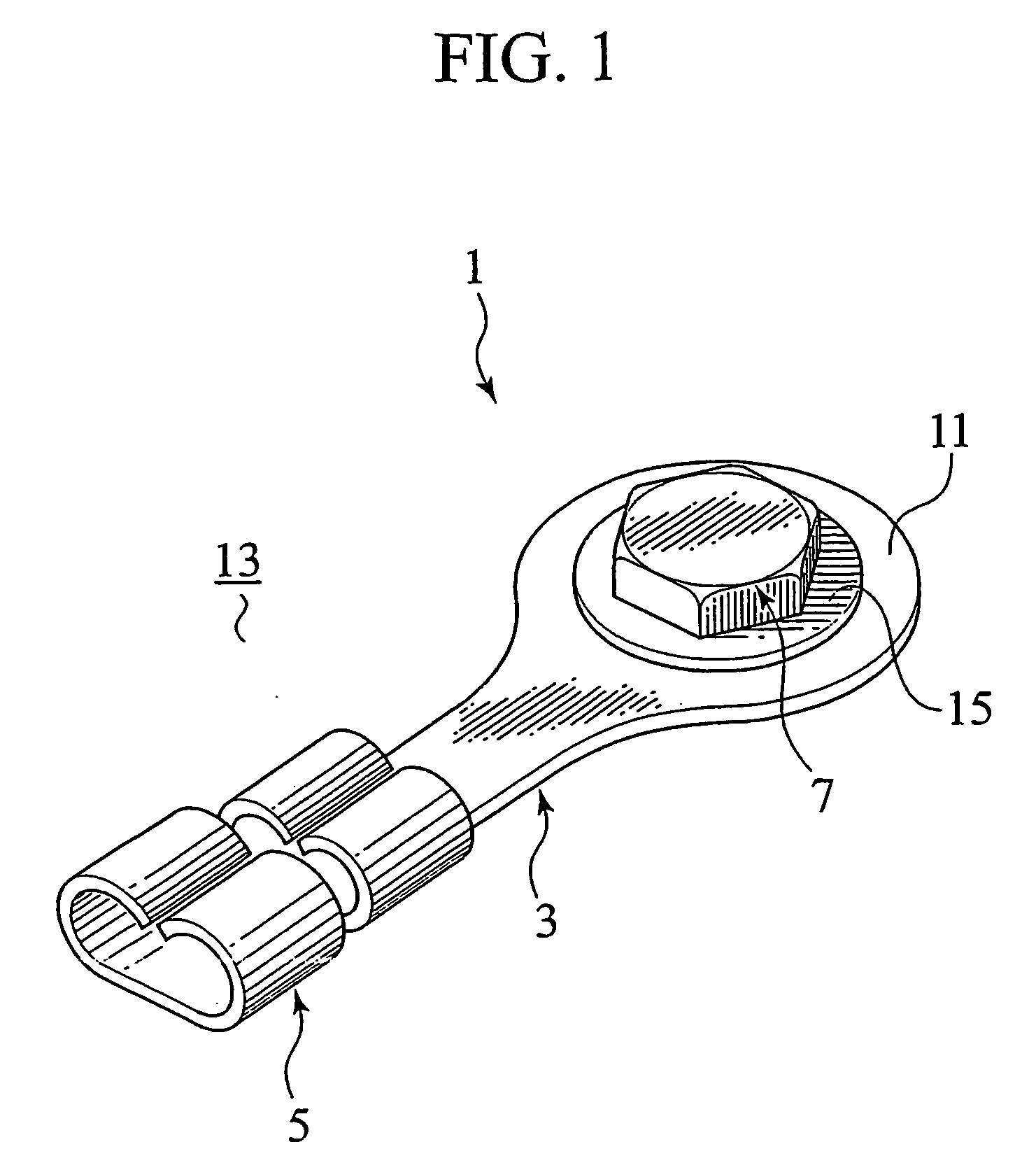

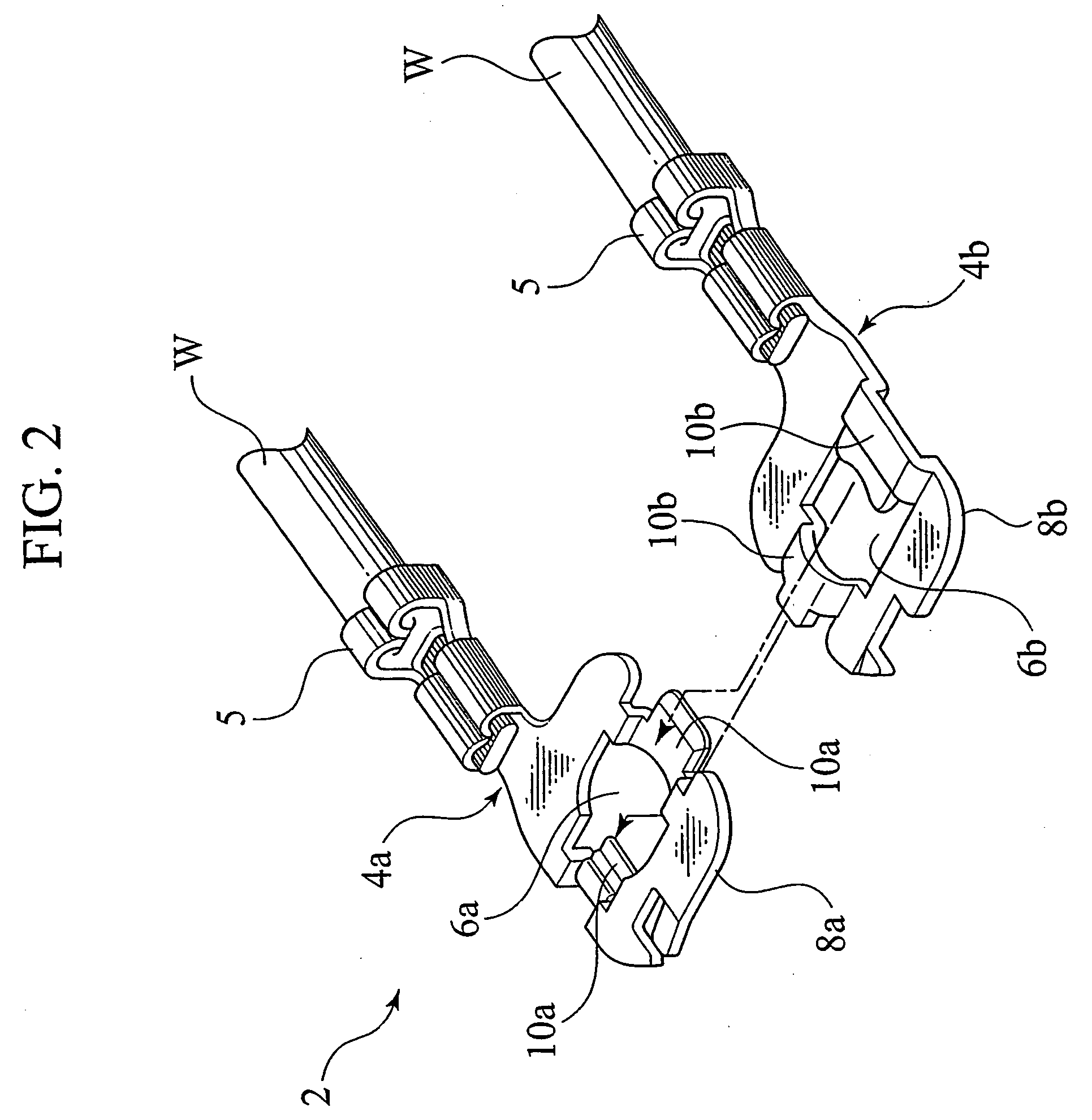

Metal terminal with weakened part

InactiveUS20050003703A1Increase electrical massImprove rigidityRelieving strain on wire connectionCoupling contact membersMechanical engineeringMetal

A metal terminal has a terminal body (19) having a crimp part (5) crimped to a wire and a fastening part (25) connected to the terminal body (19) through breaking parts (21, 21). The fastening part (25) has a through-hole (23) for passage of a bolt (7). The metal terminal further includes a co-fastening part (27) formed in the terminal body (19). The tip side of the co-fastening part (27) is fastened to a vehicle body (13) by the bolt (7), together with the fastening part (25). When detaching terminal body (19) from the vehicle body (13), one side of the one terminal body (19) is pulled up in a direction opposite to the fastening direction of the bolt (7) under condition that the fastening part (25) and the co-fastening part (27) are together fastened by the bolt (7). Consequently, the co-fastening part (27) is released from its fastened condition and a breaking force is applied on the breaking parts (21, 21).

Owner:YAZAKI CORP

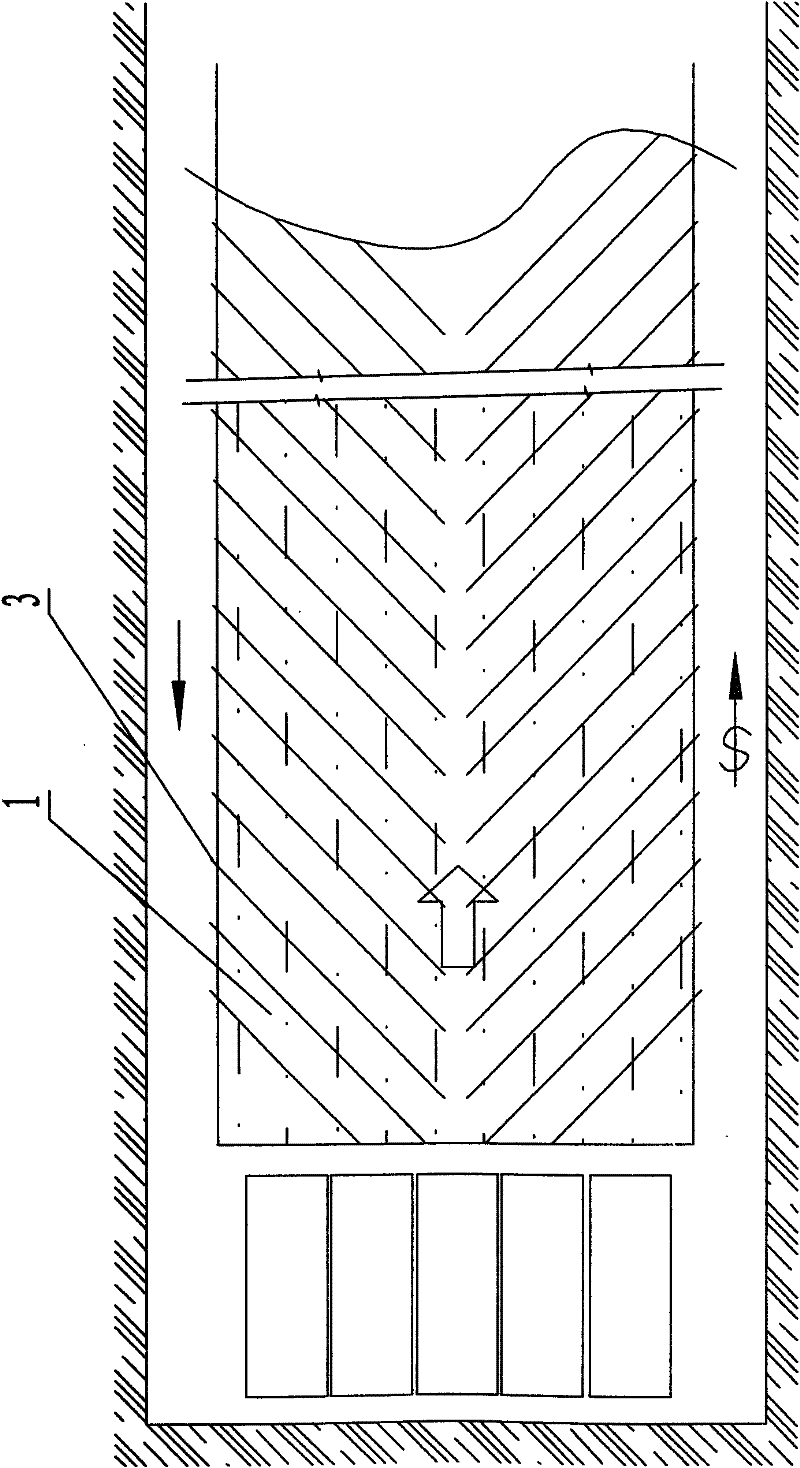

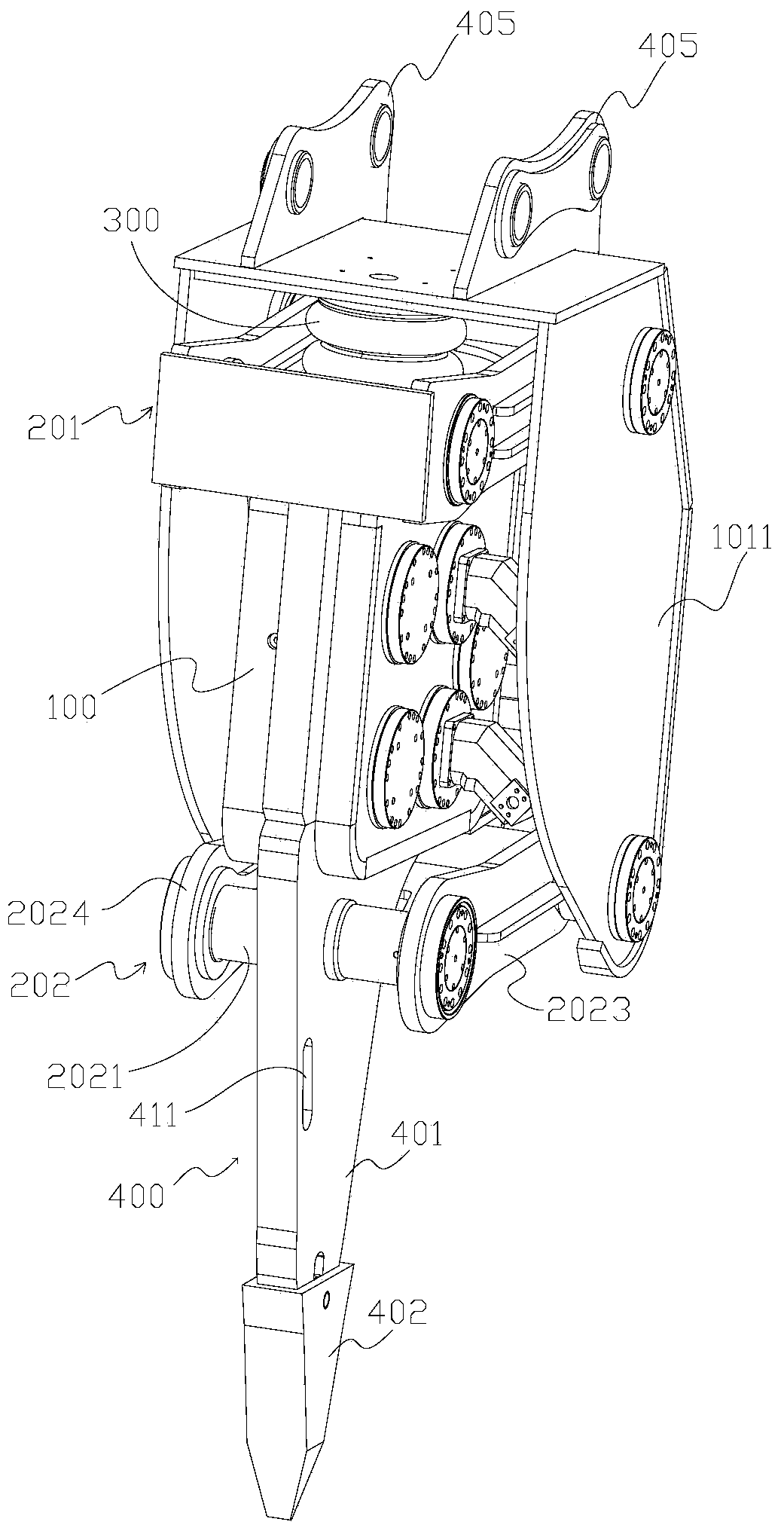

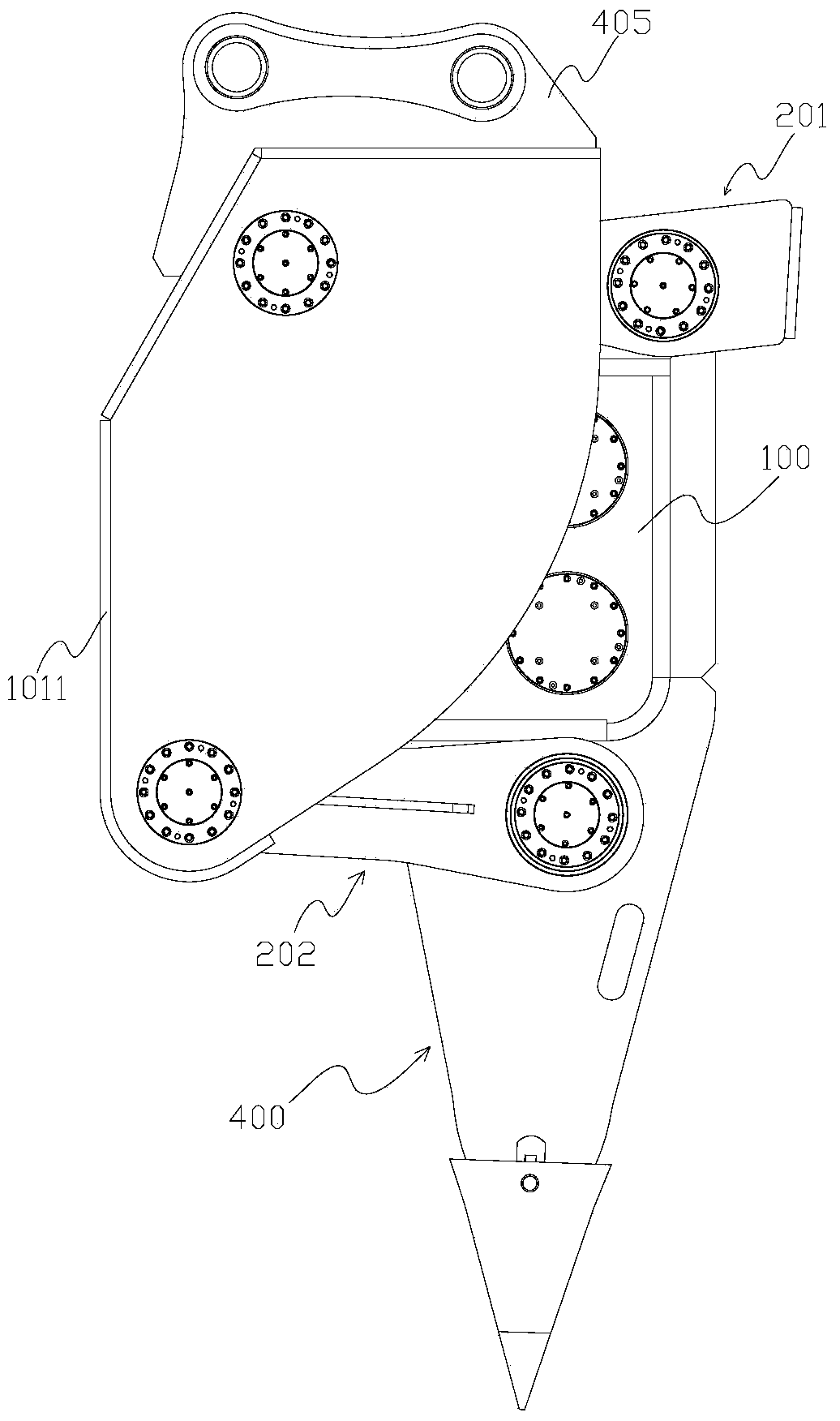

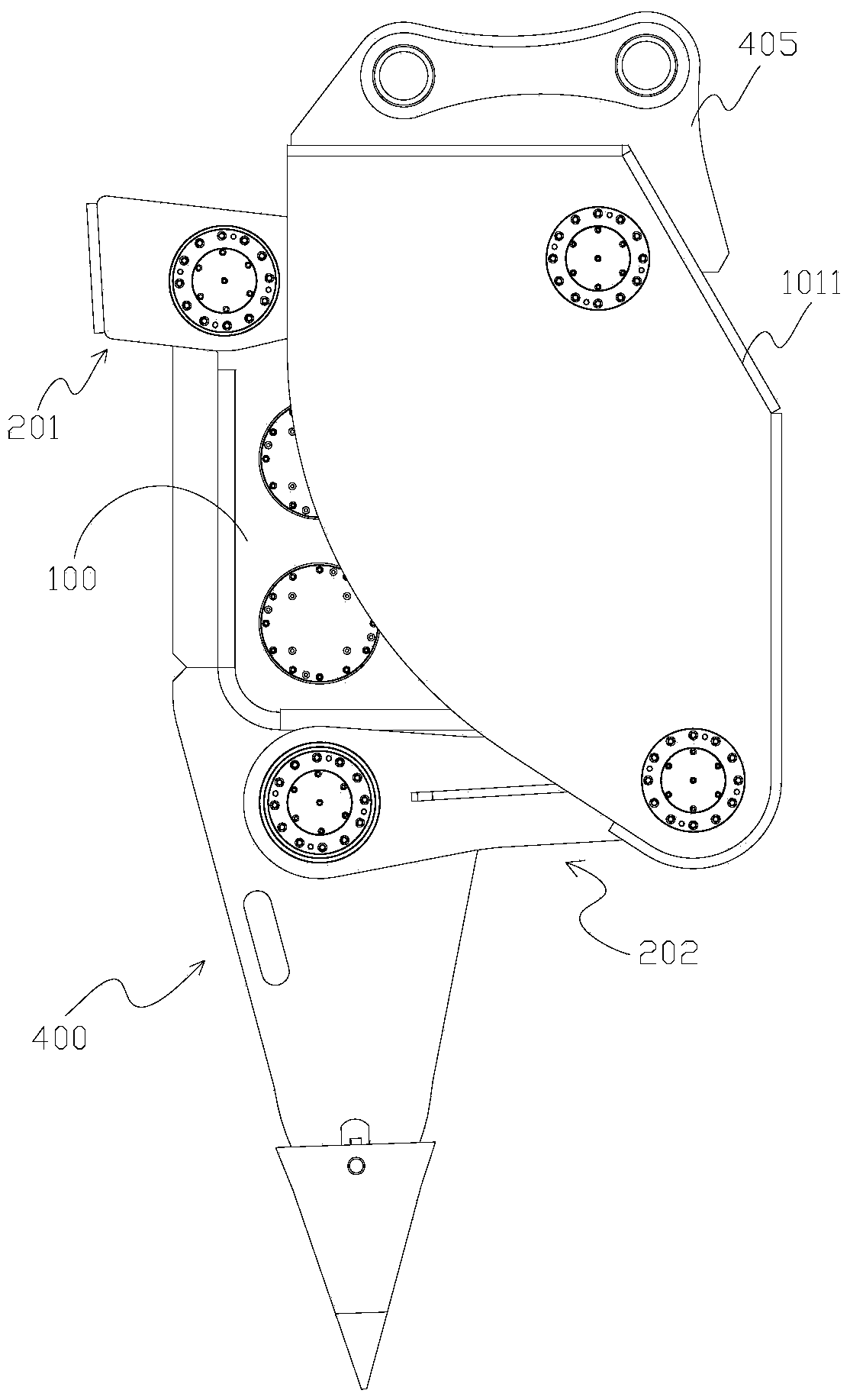

High-frequency breaking hammer

ActiveCN103706451AStrong crushingHigh crushing precisionSoil-shifting machines/dredgersGrain treatmentsDrive shaftEngineering

The invention discloses a high-frequency breaking hammer which comprises an installation shell, a vibration exciter, a four-bar mechanism and a vibration knife bar, wherein the vibration exciter comprises a shell, a first drive shaft arranged in the shell, a first driven shaft mutually meshed with the first drive shaft through a gear, a second drive shaft, a second driven shaft mutually meshed with the second drive shaft through a gear, and a bridging shaft arranged between the first drive shaft and the second drive shaft, wherein a first drive motor and a second drive motor are respectively arranged at one ends of the first drive shaft and the second drive shaft; central axes of the first drive shaft and the second drive shaft are positioned on the same vertical surface; and the first drive shaft, the first driven shaft, the second drive shaft and the second driven shaft are positioned on the same horizontal plane. According to the high-frequency breaking hammer, two groups of drive shafts are adopted and are matched with two drive motors; and compared with a breaking hammer driven by one motor, the high-frequency breaking hammer has the advantages of large breaking force, high breaking precision, small noise and strong breaking capability, thereby prolonging the working time of the breaking hammer and increasing the breaking efficiency.

Owner:苏州鸣尼克重工机械有限公司

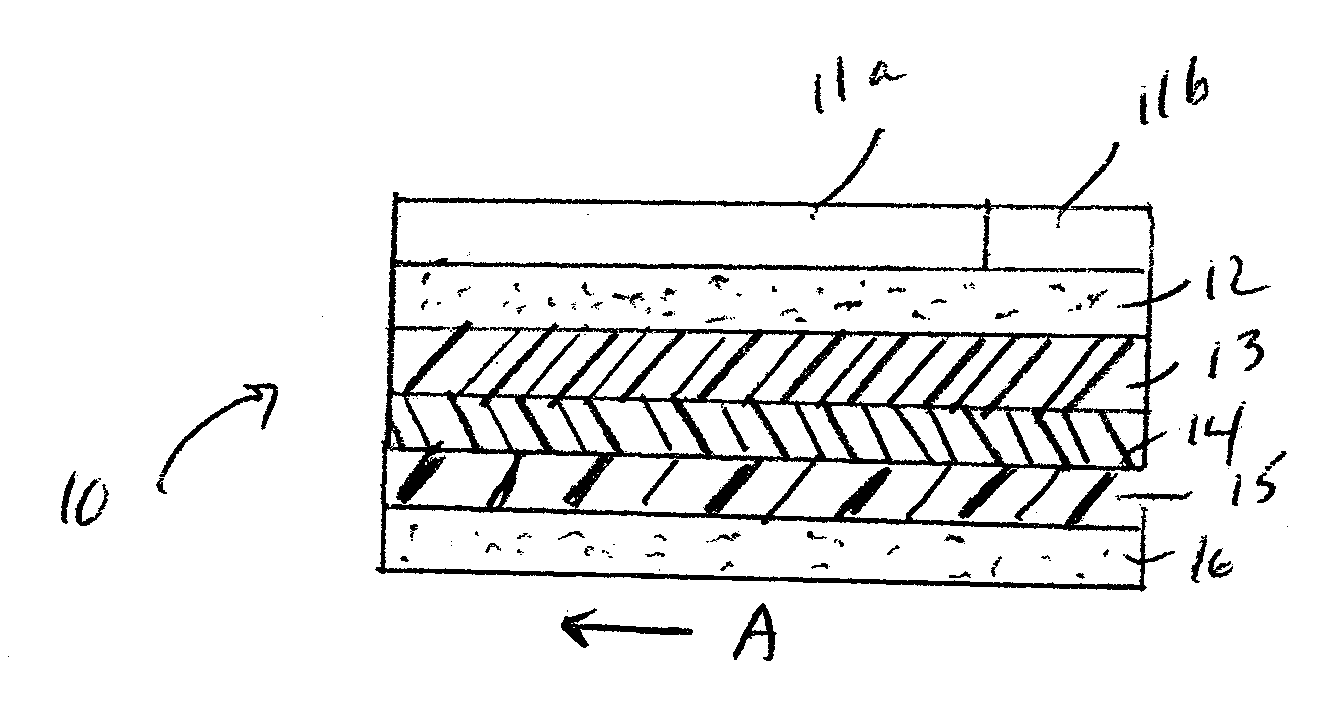

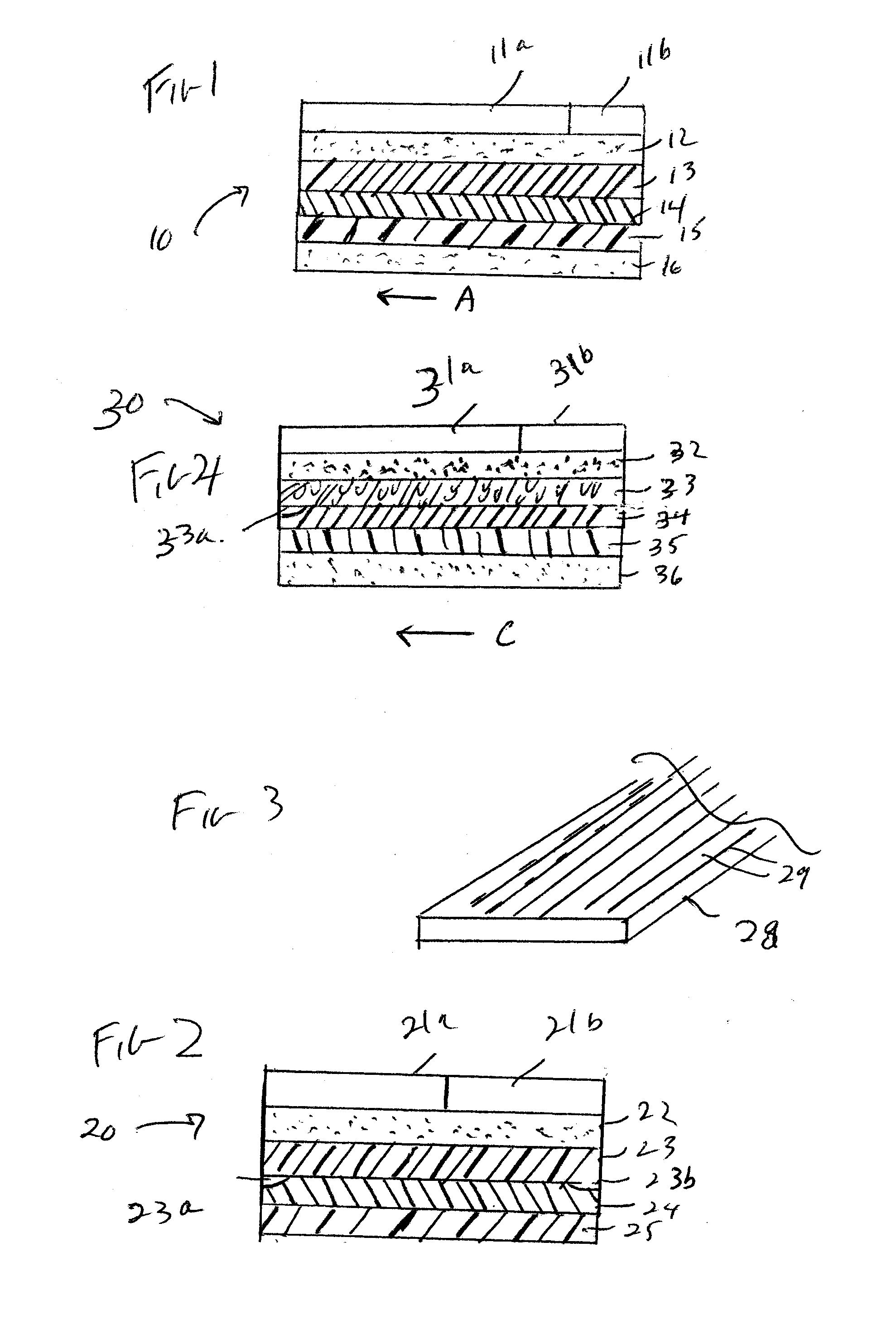

Splicing Tape

InactiveUS20080087370A1High surface energyLower surface energyMechanical working/deformationLayered productsCentral layerWell control

A splicing tape for making a running splice is disclosed. A running splice is needed for web-fed type continuous processes involving rolls of material. Materials are typically paper or thermoplastic rolls to be printed or coated. The layered splicing tape includes three central layers or films with a controlled breaking force that allows better control over the force required to separate the central layers and allow a replacement roll to be fed into the web on the tail of the roll that has almost been consumed. Pressure-sensitive or other adhesives adhere the splice to the roll and the cohesive failure of the splice then enables the splice to be made without stopping the process.

Owner:CUSTOM ADHESIVE PRODS

Magnetic tape and method for manufacturing the same

InactiveUS20040173069A1Improve adhesionMagnetic materials for record carriersRecord information storageMagnetic tapeRecording layer

A method for manufacturing a magnetic tape includes the steps of feeding a broad magnetic tape including a broad support formed with a magnetic recording layer on one side thereof and a back coat layer on the other surface thereof to a portion between a disk-like upper blade and a disk-like lower blade overlapping each other and rotating in opposite directions and cutting the broad magnetic tape into magnetic tapes each having a predetermined width, which method for manufacturing a magnetic tape further includes a step of setting a cutting start angle between the disk-like upper blade and the disk-like lower blade overlapping each other and rotating in opposite directions at the time that cutting of the broad magnetic tape fed to a portion between the upper blade and the lower blade by the upper blade and the lower blade is started so that a lower blade side cut surface of the magnetic tape to be formed by cutting the broad magnetic tape includes 40% to 65% of a region formed by cutting the magnetic tape by a breaking force, thereby cutting the broad magnetic tape. According to the above method, it is possible to manufacture a magnetic tape which can minimize an irregular raised and depressed pattern of a cut surface of a magnetic tape.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com