Patents

Literature

185results about How to "Reduce wire breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

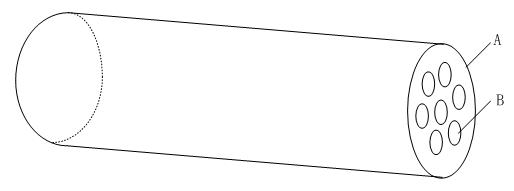

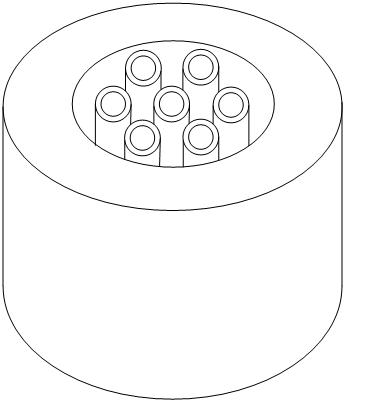

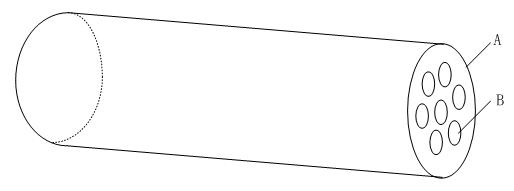

Polyether sulfone-polyurethane blend hollow fiber membrane and preparation method thereof

The invention relates to a polyether sulfone-polyurethane blend hollow fiber membrane and a preparation method thereof. In the hollow fiber membrane, polyether sulfone is taken as a main membranous material; polyurethane is added for blending; and a high molecular pore forming agent, a surfactant, a solvent and the like are added to prepare casting solution; and the polyether sulfone-polyurethane blend hollow fiber membrane is prepared by a dry-wet method, namely, a nonsolvent induced phase separation method spinning process. The prepared polyether sulfone-polyurethane blend hollow fiber membrane has seven inner bores with the inner diameter of 0.8 to 1.0mm and the outer diameter of 3.8 to 4.5mm, has high hydrophilcity, the flux of pure water of 300 to 2,900 L / M<2>.H(0.1MPa and 25 DEG C), high intensity and the tensile breaking force of 30 to 62N, has the advantages of high flexibility, the breaking elongation of 60 to 110 percent, high chemical resistance, high pollution resistance, and the like, and is easy to clean.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

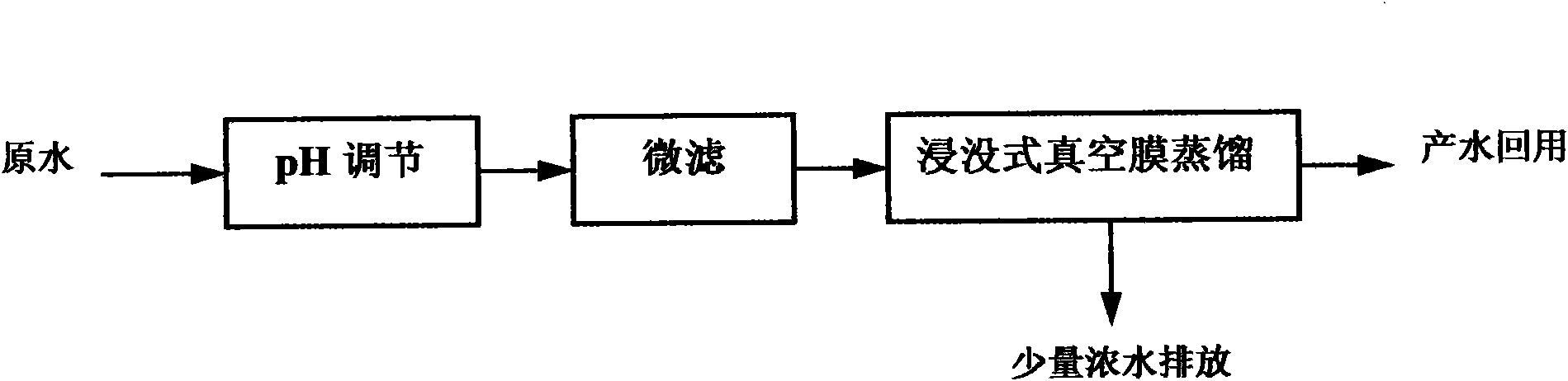

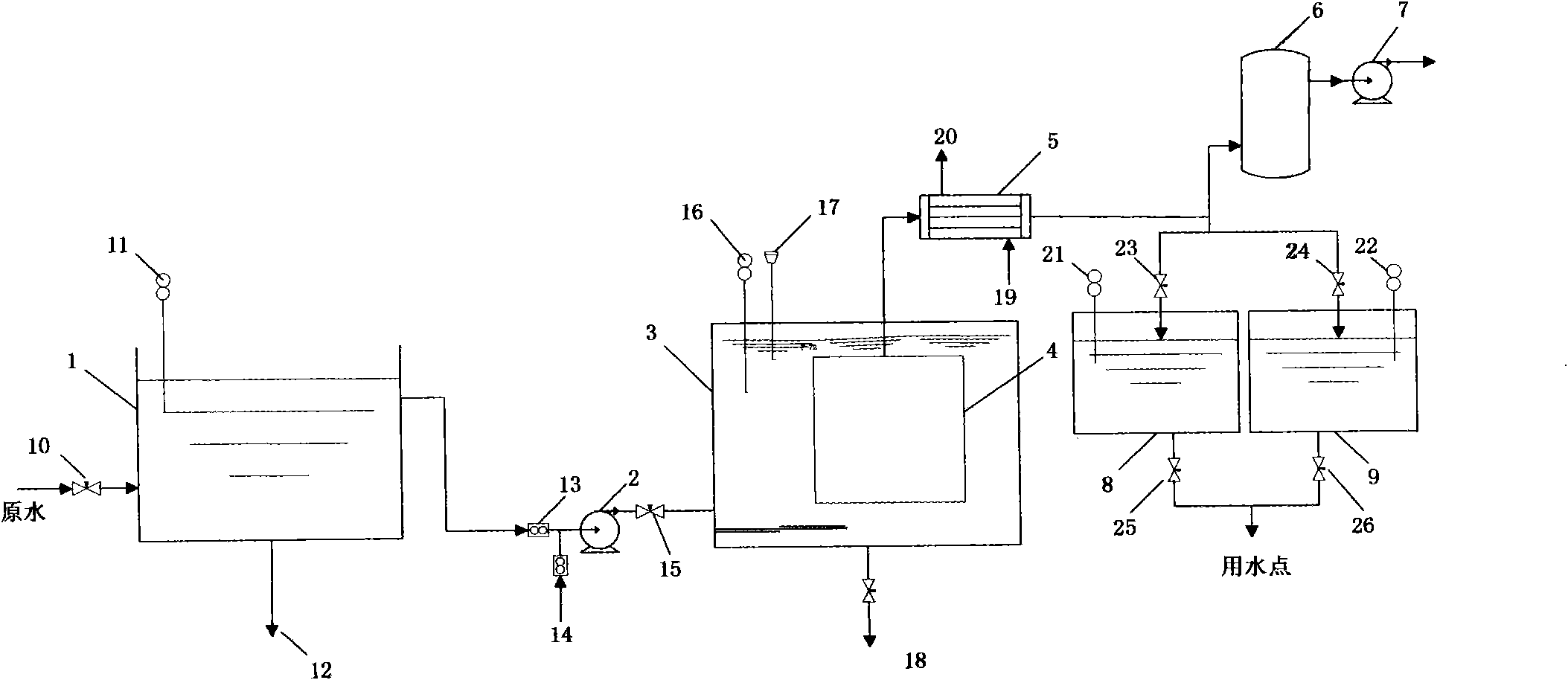

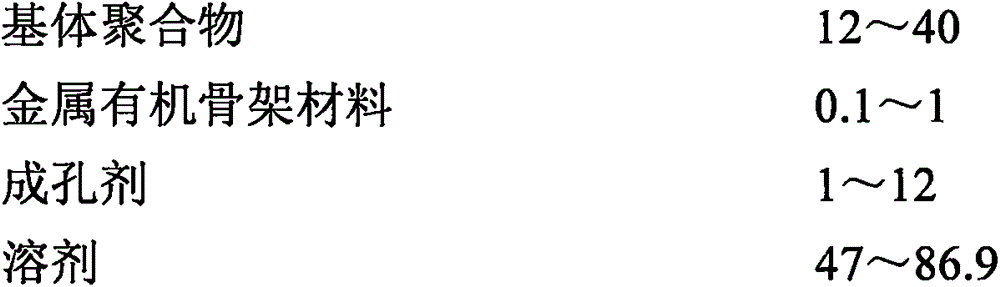

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

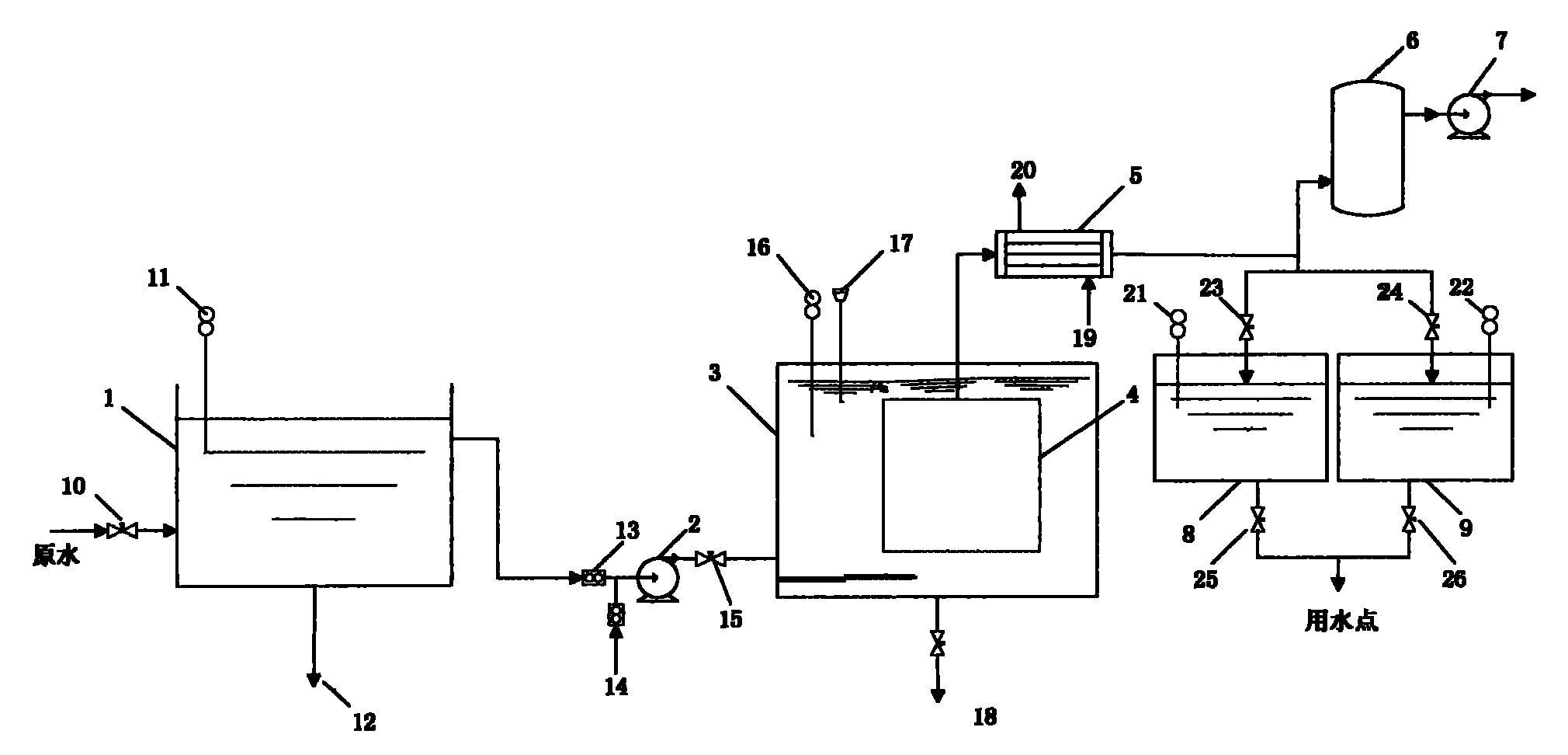

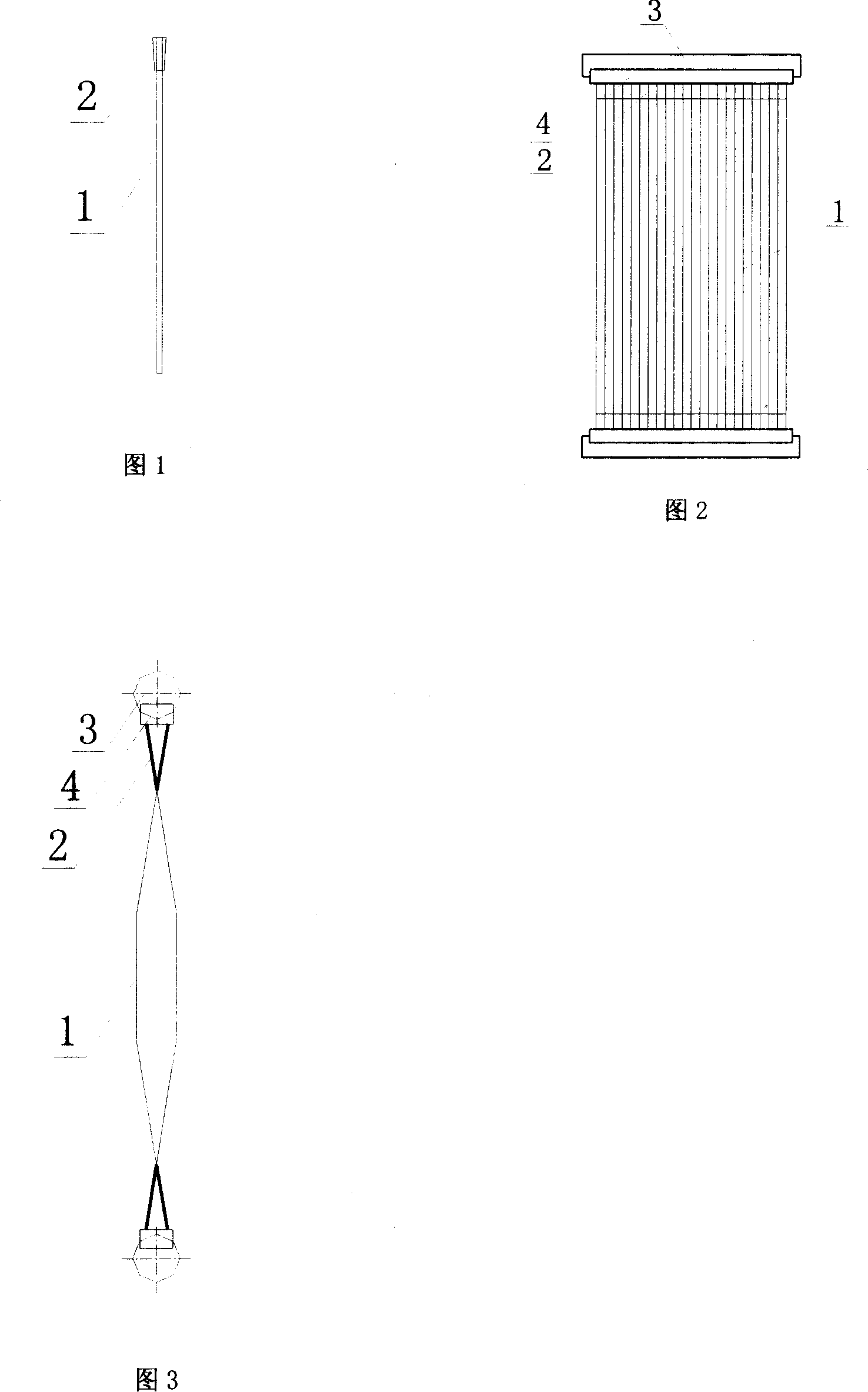

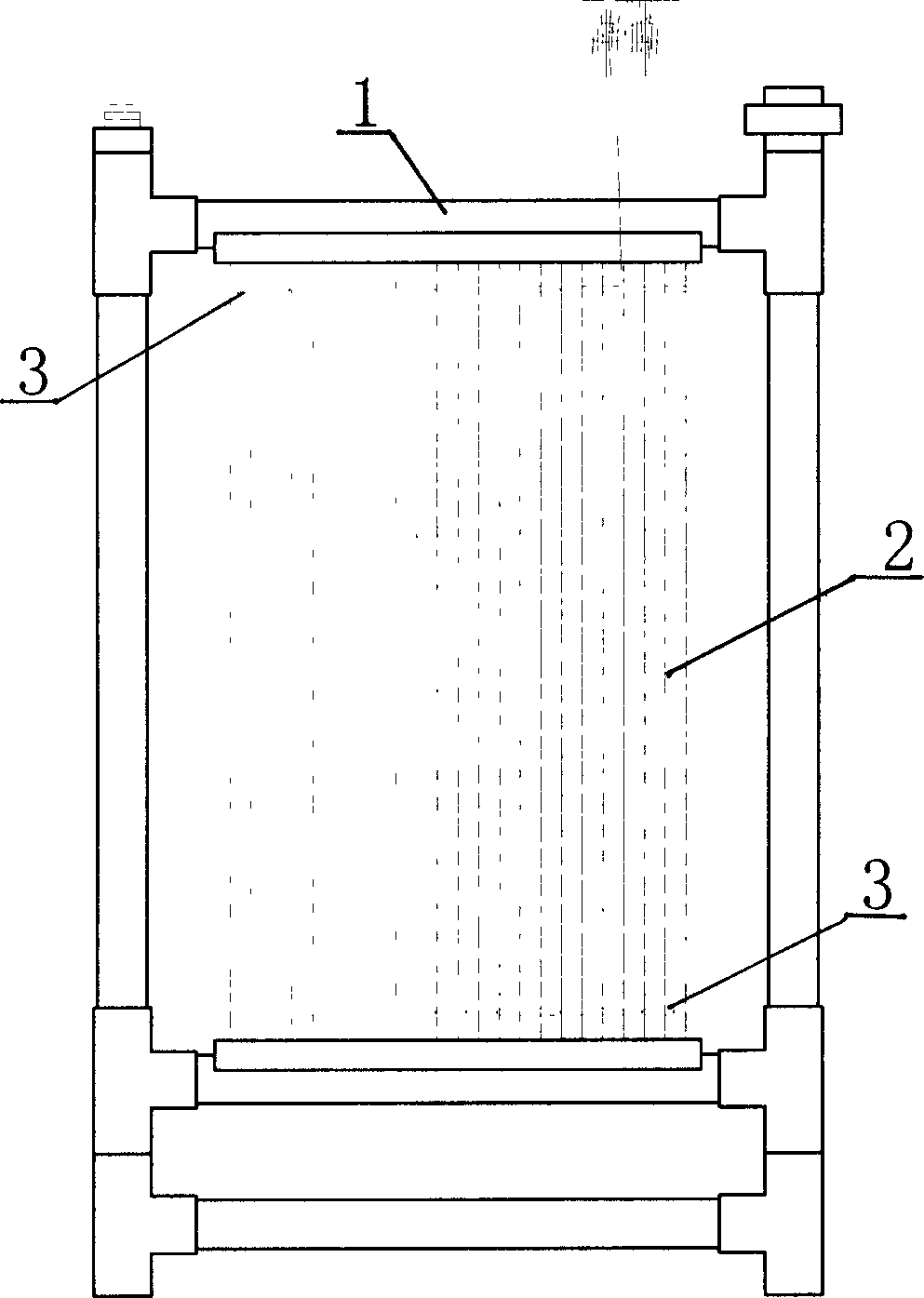

Inner support hollow fibrous membrane and preparation method and application thereof

InactiveCN106076127AHigh porosityIncrease the areaSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberYarn

The invention relates to an inner support hollow fibrous membrane which adopts a hollow braided rope as an inner supporting material. A base body polymer, a metal organic framework material and a pore forming agent are mixed together to be dissolved with a solvent, a membrane casting solution is obtained, the membrane casting solution coats the hollow braided rope, and solidification forming is performed to obtain the inner support hollow fibrous membrane. The metal organic framework material is adopted for improving the porosity and water flux of the inner support membrane; the proper proportion of the metal organic framework material to the pore forming agent in the membrane casting solution, organic coordination and synergism of the components are utilized, the interface wettability of the membrane casting solution and a coagulating bath can be effectively controlled, a coagulator and solvents in the membrane casting solution are easily dispersed and penetrate into the interface, effective combination of the membrane casting solution formula and the pore forming conditions is utilized, and the inner support hollow fibrous membrane of different pore diameters and different rejection performances can be spun; the obtained inner support hollow fibrous membrane can be used for an MBR and an immersed ultrafiltration assembly, the probability of broken yarn and sewage plugging is lowered, and the service life of the membrane is prolonged.

Owner:盐城海普润科技股份有限公司

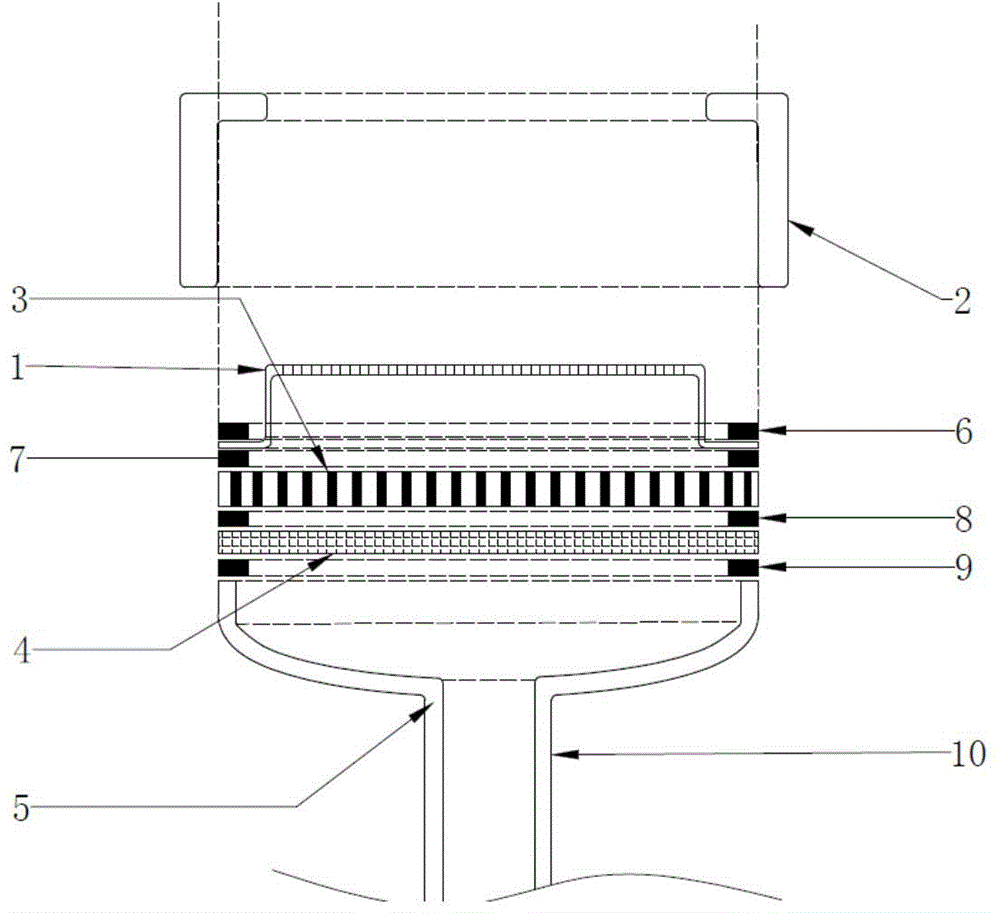

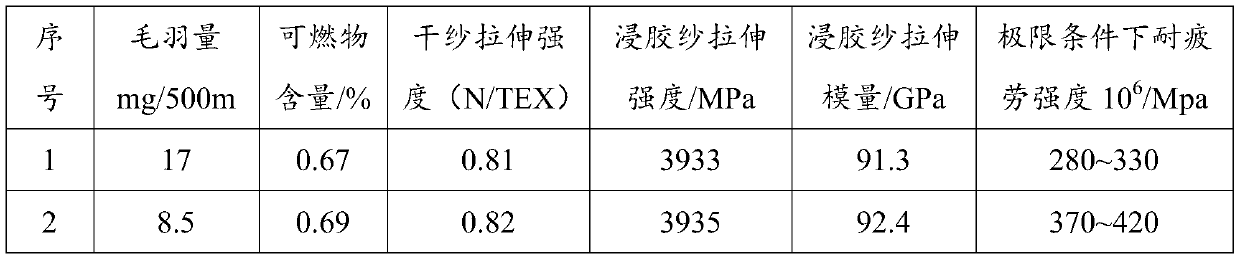

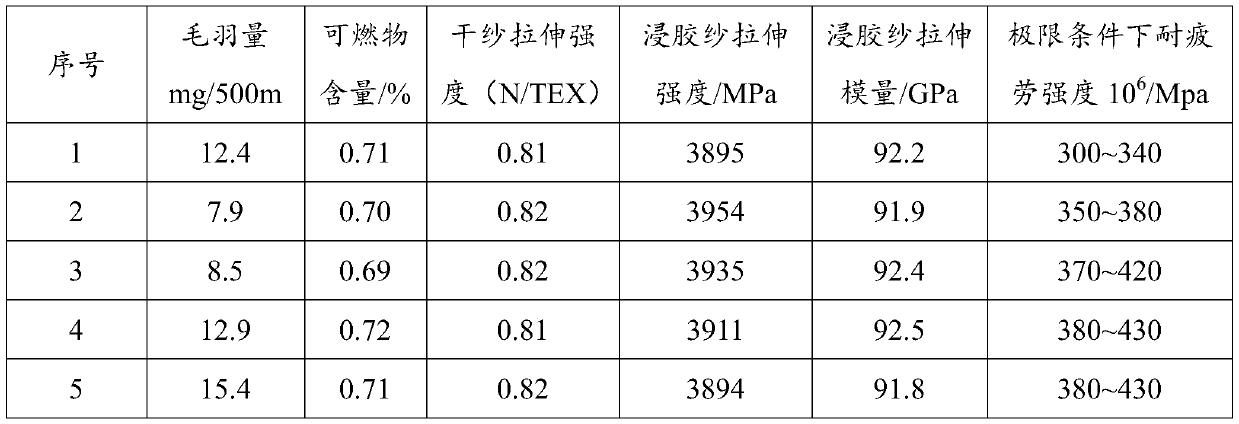

Polyacrylonitrile-based carbon fibers as well as preparation method and application thereof

ActiveCN103572411AReduce wire breakageImprove mechanical propertiesSynthetic polymer filament chemical after-treatmentYarnCarbon fibers

The invention discloses polyacrylonitrile-based carbon fibers as well as a preparation method and an application thereof. The preparation method comprises the following steps: dissolving an oxygen-rich matter, siloxane and boric acid ester in water so as to prepare a humidifying solution; immersing polyacrylonitrile precursor fibers in an immersion device filled with the humidifying solution so as to obtain humidified polyacrylonitrile fibers; carrying out thermal treatment on the humidified polyacrylonitrile fibers in an oxidizing furnace; carbonizing the polyacrylonitrile fibers subjected to the thermal treatment so as to obtain the polyacrylonitrile-based carbon fibers. The invention also provides the polyacrylonitrile-based carbon fibers prepared from the method and the application of the polyacrylonitrile-based carbon fibers. The preparation method has the advantages that the yarn breakage phenomenon and the formation of a skin-core structure are reduced, and the mechanical property of the polyacrylonitrile-based carbon fibers is improved.

Owner:KINGFA SCI & TECH CO LTD +1

Curtain type hollow fiber membrane yarn end fastening technique

InactiveCN1962038ALow mechanical strengthReduce wire breakageSemi-permeable membranesEpoxyHollow fibre membrane

The invention relates to a method for improving the mechanical strength of end of film filament, wherein it uses corrosion-resistant macromolecule organic material to coat the top and bottom filament of hollow fiber film. And the invention is characterized in that: the it coast she filament at 10-40cm from the adhesive end, as local coat or integrated coat. And the organic material can be silica gel, epoxy resin, etc.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

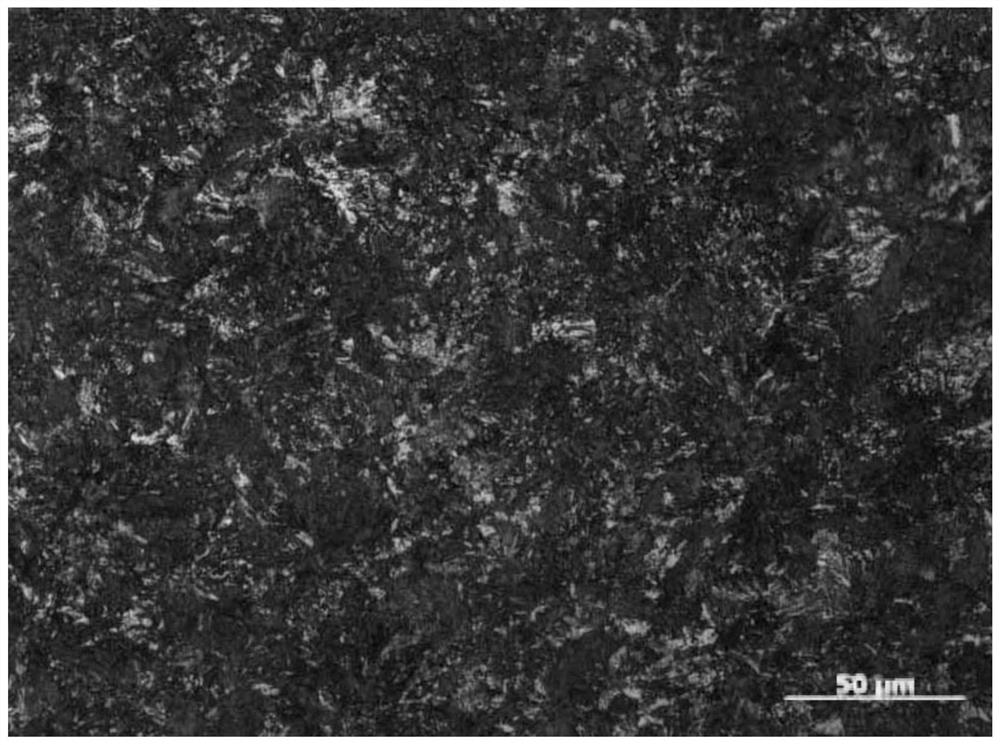

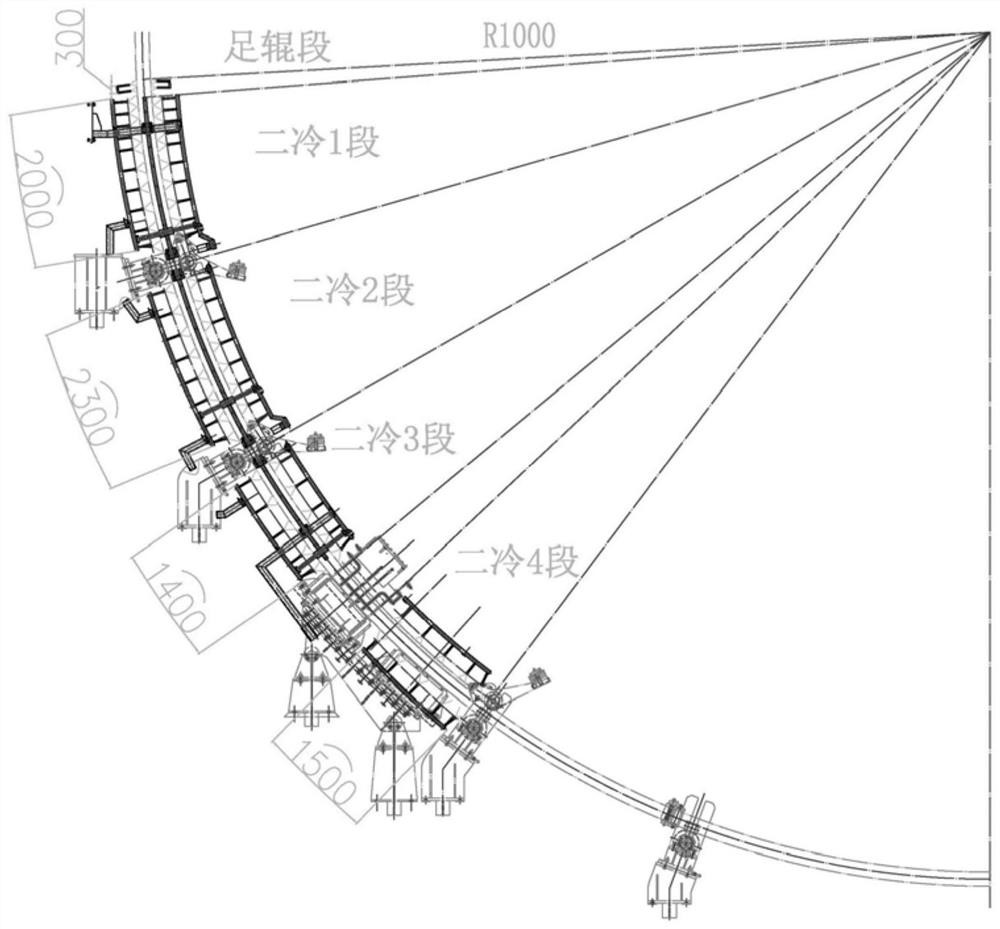

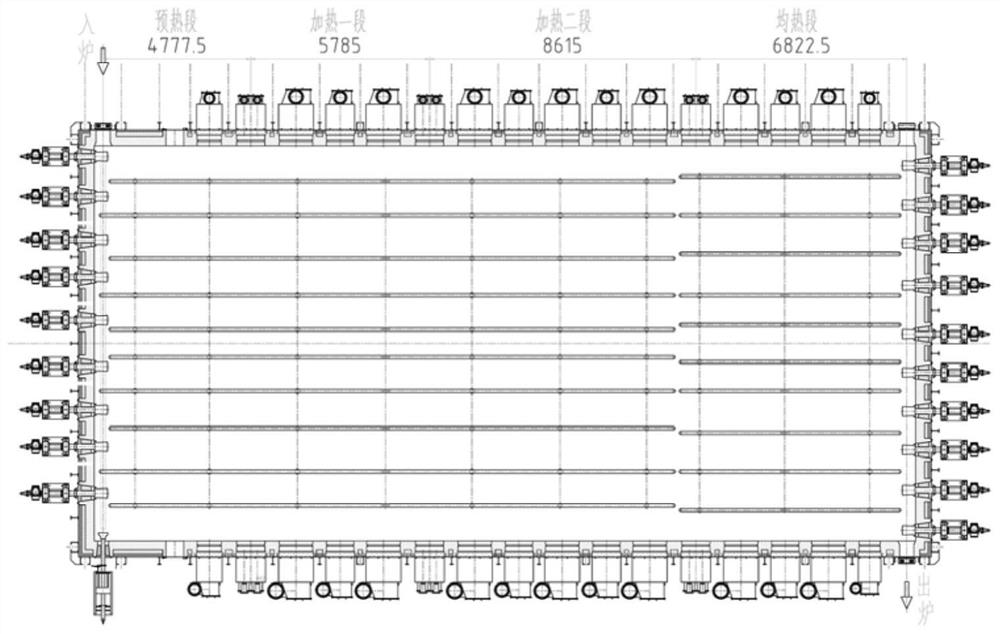

Control method for segregation and net carbon of 86-grade high-strength cord steel wire rod

ActiveCN112359277AImprove segregationImprove mesh carbonProcess efficiency improvementWire rodContinuous casting

The invention discloses a control method for segregation and net carbon of an 86-grade high-strength cord steel wire rod. The control method comprises the following steps of: KR molten iron pre-desulfurization, BOF converter smelting, LF furnace refining, continuous casting CC, casting blank surface treatment, casting blank heating, controlled rolling and controlled cooling procedures which are carried out in sequence. The 86-grade high-strength cord steel wire rod comprises the following components in percentage by weight: 0.85-0.90% of C, 0.15-0.35% of Si, 0.40-0.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.010% of Cr, less than or equal to 0.005% of Al and the balance Fe. According to the control method, the segregation and netcarbon of the wire rod are improved by combining continuous casting of small square billets with wire rolling, the period and cost are greatly reduced, the sorbitizing rate of the prepared wire rod is larger than or equal to 90%, the center segregation of the wire rod is slight, no net-shaped cementite exists in the center, and the drawing use requirements of users are met.

Owner:ZENITH STEEL GROUP CORP +1

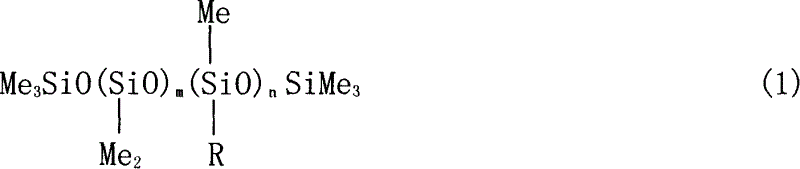

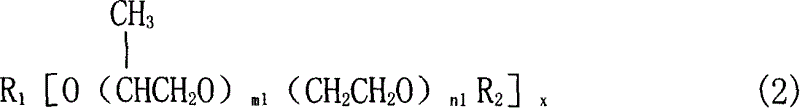

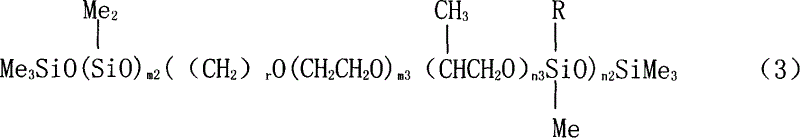

Oil preparation agent in use for spinning in urethane elastic fiber

The invention discloses a polyurethane fibre spinning oil. Its composition includes (by wt%) 5-80% of mineral oil, 10-75% of silicone oil, 0.5%-30% of epoxyethane and epoxypropane copolyether, 0.5%-50% of polyether silicone oil, 0.5-15% of antistatic agent and 0.1-10% of anti-sticking property improving agent.

Owner:CHINA PETROCHEMICAL CORP +1

Spinning technology of two-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409824AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsSpinningMachine

The invention relates to a spinning technology of a two-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of semicontinuous spinning machines. The spinning technology comprises the steps of glue supplying, thread-line forming, spinning and winding, wherein the spinning is carried out through a spinning device. The spinning device comprises two spinning rollers which are transversely arranged relative to an operating surface of a spun surface, thread lines surround the spinning rollers, and drafting, solidifying and deacidification in the spinning steps are achieved when the spinning rollers rotate. The spinning technology solves the problems that thread lines of a semicontinuous spinning machine in the prior art are insufficient in reaction, the spinning process cannot be accelerated, and production efficiency and the product quality cannot be taken into consideration. The arrangement direction of the spinning rollers is changed so that the thread lines can walk for a longer distance while the spinning process of the spinning machine is accelerated and the structures of other components of original equipment are not changed, the thread lines can be reacted with acid bath more fully, and both production efficiency and product quality are taken into consideration.

Owner:YIBIN HIEST FIBER +2

Hollow fiber ultrafilter membrane and its preparation method

InactiveCN102489170AImprove mechanical strengthExtended service lifeSemi-permeable membranesHollow fibreSolvent

The invention provides a hollow fiber ultrafilter membrane, which is obtained by a following mixture after film forming treatment: 14wt%-25wt% of film forming polymer, 0.1wt%-15wt% of meta aramid fiber, 6wt%-10wt of pore forming agent and 59wt%-80wt% of solvent. The invention also provides a preparation method of the hollow fiber ultrafilter membrane. The meta aramid fiber possesses high strength, and enables mutual interpenetration of different polymer chains, is capable of enhancing the mechanical strength of the film forming polymer, so that the hollow fiber ultrafilter membrane possesses high mechanical strength without wire facture, thereby the service life can be prolonged, the daily maintenance frequency can be minimized, and the water treatment cost can be reduced; The meta aramid fiber can increase the hydrophilic performance of the hollow fiber ultrafilter membrane, so that the contamination resistance is good, the flux is high and the attenuation speed is slow. The meta aramid fiber can enhance the heat resistance of the hollow fiber ultrafilter membrane and is more suitable for usage under rigorous condition.

Owner:CHONGQING DELING TECH

Preparation method of carbon fiber precursor fiber and application of carbon fiber precursor fiber

ActiveCN109440214AImprove performanceStable productionMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberCarbon fibers

The invention discloses a preparation method of carbon fiber precursor fiber and application of the carbon fiber precursor fiber. The carbon fiber precursor fiber is obtained by the steps as follows:dissolving an acrylonitrile polymer by utilizing a solvent to obtain a uniform spinning solution, allowing the spinning solution to pass through a spinneret hole to form a spinning flow which enters acoagulation bath component at the temperature lower than a gel temperature spot of the spinning solution and forms nascent fiber, and subjecting the nascent fiber to drafting, washing, drying and oiling post-treatment process. The carbon fiber precursor fiber is pre-oxidized and carbonized to obtain pre-oxidized fiber or carbon fiber. The carbon fiber precursor fiber has the advantages of low cost, good fiber performance and stable production under high-drafting conditions.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

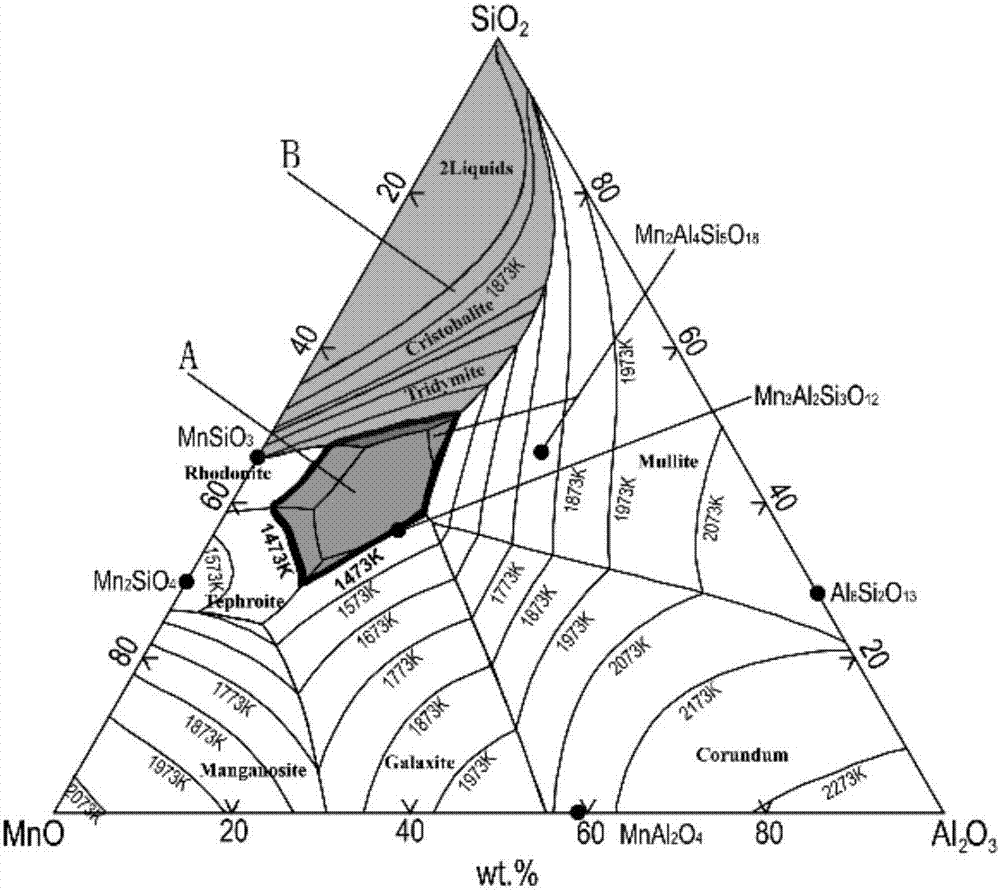

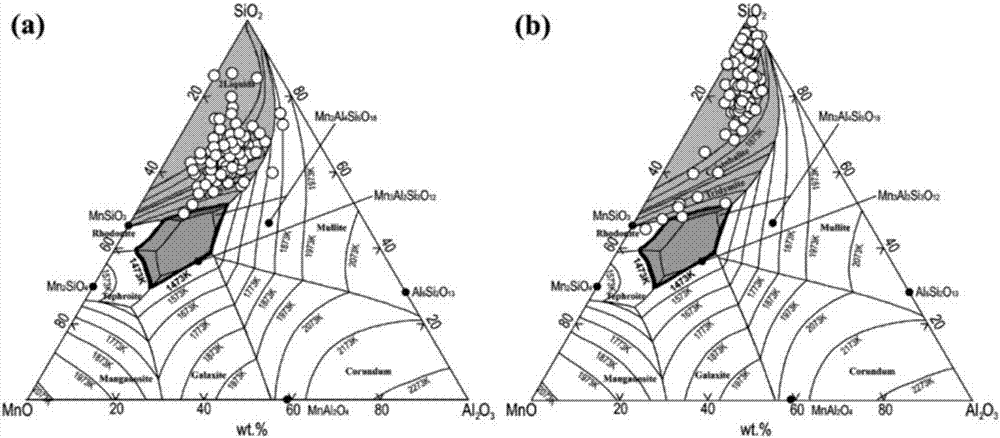

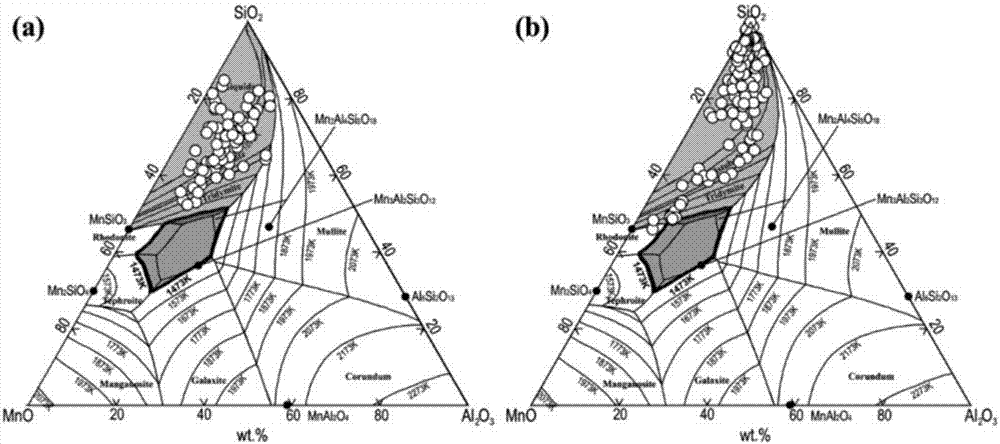

Method for realizing low Young's modulus of oxide inclusion in tire cord steel

InactiveCN108004374AEasily brokenReduce wire breakageManufacturing convertersProcess efficiency improvementWire rodSteelmaking

The invention discloses a method for realizing low Young's modulus of oxide inclusion in tire cord steel. The method comprises a converter steelmaking process, an LF refining process, a soft blowing process and a continuous casting process; the converter steelmaking process comprises the step that refining premelting slag of 6-8kg / t of steel is added in the steel after tapping is finished, whereinthe premelting slag comprises, by weight, 40-50% of CaO, 40-45% of SiO2, 5-10% of Al2O3 and 5-10% of MgO, and CaO / SiO2 is controlled to be less than or equal to 1.0. By designing special smelting operation, the oxide inclusion in steel has lower Young's modulus, the inclusion can better adapt to the following drawing process characteristics of a cord steel wire rod, the inclusion can be broken and separated by the huge pressure stress and compression ratio of steel in the drawing process, and fine control of the oxide inclusion can be realized. The method for realizing low Young's modulus ofthe oxide inclusion in the tire cord steel solves the problem of wire breaking caused by large-size non-deformation inclusions in the tire cord steel, and significantly improves the drawing and stranding performance of the cord steel wire rod.

Owner:XINGTAI IRON & STEEL

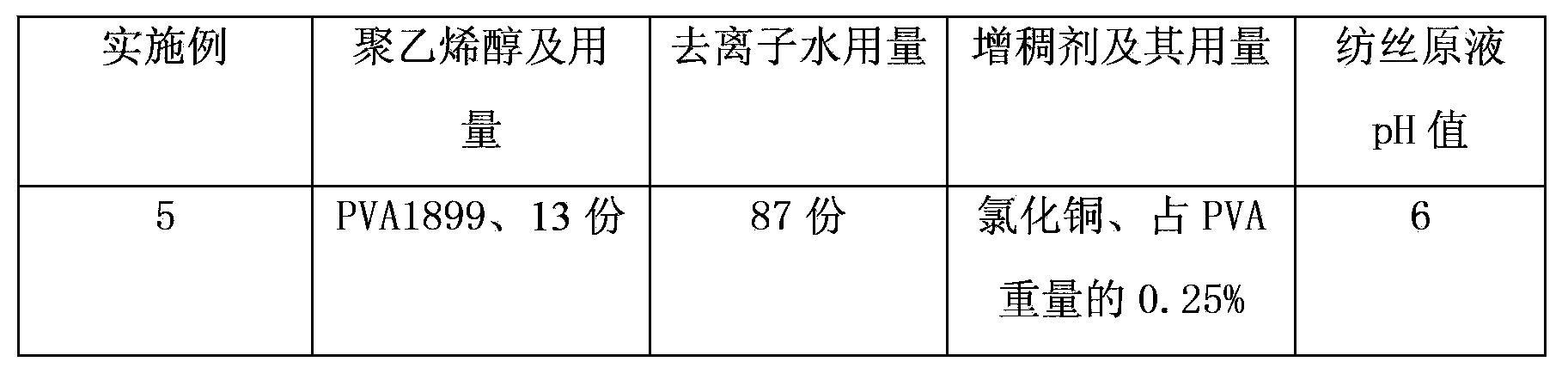

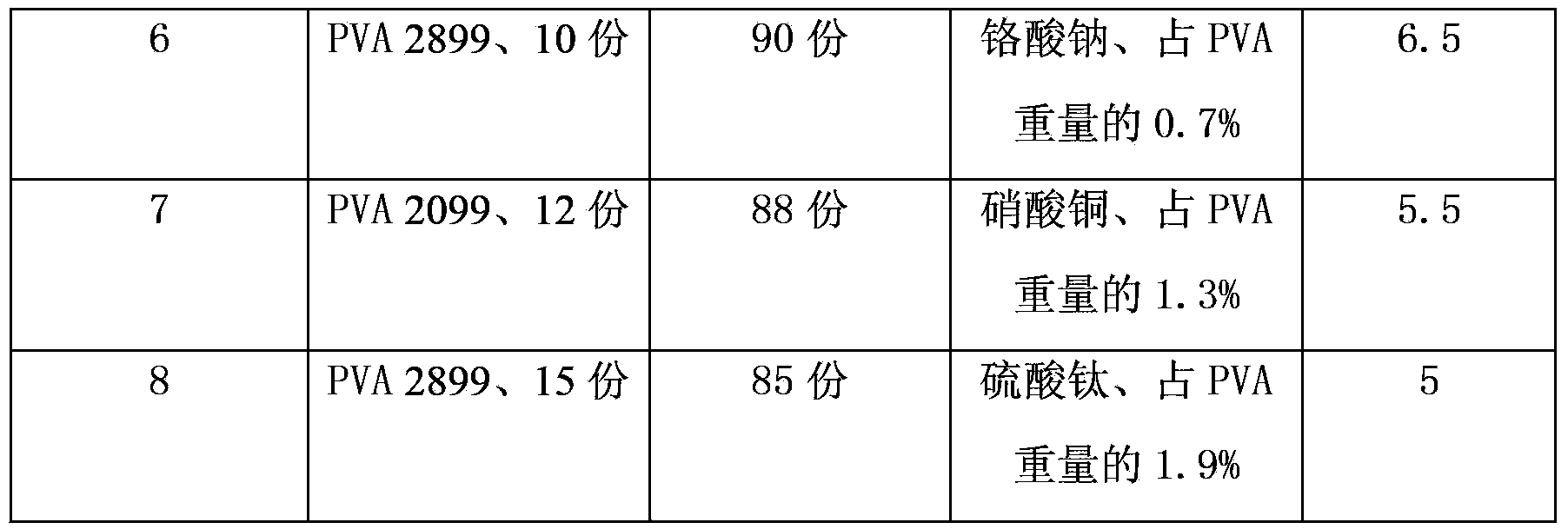

Fine-denier or superfine-denier polyvinyl alcohol fiber and preparation method thereof

ActiveCN103388189AImprove spinnabilityReduce the amount addedArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberCopper nitrate

A preparation method of a fine-denier or superfine-denier polyvinyl alcohol fiber comprises the following steps: dissolving 10-15 parts of polyvinyl alcohol in 85-90 parts of deionized water at 95-98DEG C for 2-5h to form a homogeneous solution, adding a thickening agent having a weight being 0.1-2% of the weight of polyvinyl alcohol, adjusting the pH value of the homogeneous solution to 3-6.5 through using acetic acid, and allowing the viscosity of the homogeneous solution to 5000-30000cp in order to prepare a polyvinyl alcohol spinning stock solution, wherein the thickening agent comprises anyone of boric acid, borax, copper sulfate, copper chloride, copper nitrate, sodium chromate, potassium chromate and titanium sulfate; moulding the spinning stock solution to obtain a nascent fiber; and post-processing the nascent fiber to prepare the polyvinyl alcohol fiber. The low-concentration polyvinyl alcohol spinning stock solution has the advantages of good spinnability, good storage stability, stable and continuous spinning process, and relatively few phenomena of broken filaments; and the yield is above 95%. The obtained fiber has a low linear density in a range of 0.16-1.00dtex, a tensile strength of 5-8cN / dtex and an elongation at break of 5-15%, and the Rp value of the obtained formalized fiber is 110-125DEG C.

Owner:CHINA PETROCHEMICAL CORP +2

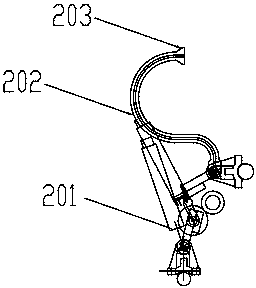

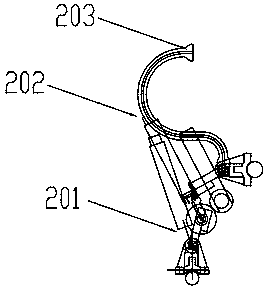

Hollow fiberous-membrane assembly root braiding reinforcing technology

InactiveCN1853763AReduce stressPrevent wire breakageSemi-permeable membranesHollow fibre membraneFiber

A braiding technique for reinforcing the root part of hollow fiber membrane module features that the anticorrosion and hydrophobic cord threads or nylon wires are used to be braided at the adhered positions on the top or bottom sides of hollow fiber membrane module to increase its strength. The number of the braided fibers in a bundle is 10-50 and the number of the braided lines is 1-5.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Low-cost preparation method of carbon fiber precursor fibers, preoxidized fibers or carbon fibers

ActiveCN109440230AUniform structureStable structureWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberCarbon fibers

A low-cost preparation method of carbon fiber precursor fibers, preoxidized fibers or carbon fibers is characterized in that an acrylonitrile polymer is dissolved through a solvent to obtain a uniformspinning solution; the spinning solution forms fine spinning flow through spinning pores, and then the fine spinning flow enters a coagulating bath component which is below the spinning solution geltemperature point to obtain primary fibers; the primary fibers are processed by stretching, washing, drying and oiling to obtain the carbon fiber precursor fibers; and the carbon fiber precursor fibers are pre-oxidized and carbonized to obtain the preoxidized fibers or carbon fibers. The method has the advantages of being low in cost, high in fiber performance and stable to produce in a high-powerstretching condition.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method for multihole fine denier spandex

ActiveCN104357943AIncrease productivityReduce manufacturing costFilament manufactureMonocomponent synthetic polymer artificial filamentDiaminePolyurea

The invention relates to a preparation method for multihole fine denier spandex. The preparation method is characterized by comprising the steps of (1) in a preparation process, polymerizing polytetramethylene ether glycol PTMG, 4,4-diphenylmethane diisocyanate (4,4-MDI) and diamine which serve as raw materials step by step to obtain a polyurea-based formic ether DMAC solution, adding functional auxiliary agents such as an antioxidant, a lubricating agent, a flatting agent, an ultraviolet absorbing agent and an antiblocking agent, performing spin-stretching, high-temperature drying and oil applying on the polyurea-based formic ether solution containing the auxiliary agents through a multihole spinning plate to obtain multihole fine denier spandex in which single fibers are not adhered to one another, and winding the multihole fine denier spandex to obtain a multihole spandex fiber roll; (2) in a use process, dividing the multihole fine denier spandex into single spandex fibers one by one under a certain stretching condition through a fiber separator, and putting the single spandex fibers into corresponding weaving units to be woven.

Owner:ZHEJIANG HUAFENG SPANDEX

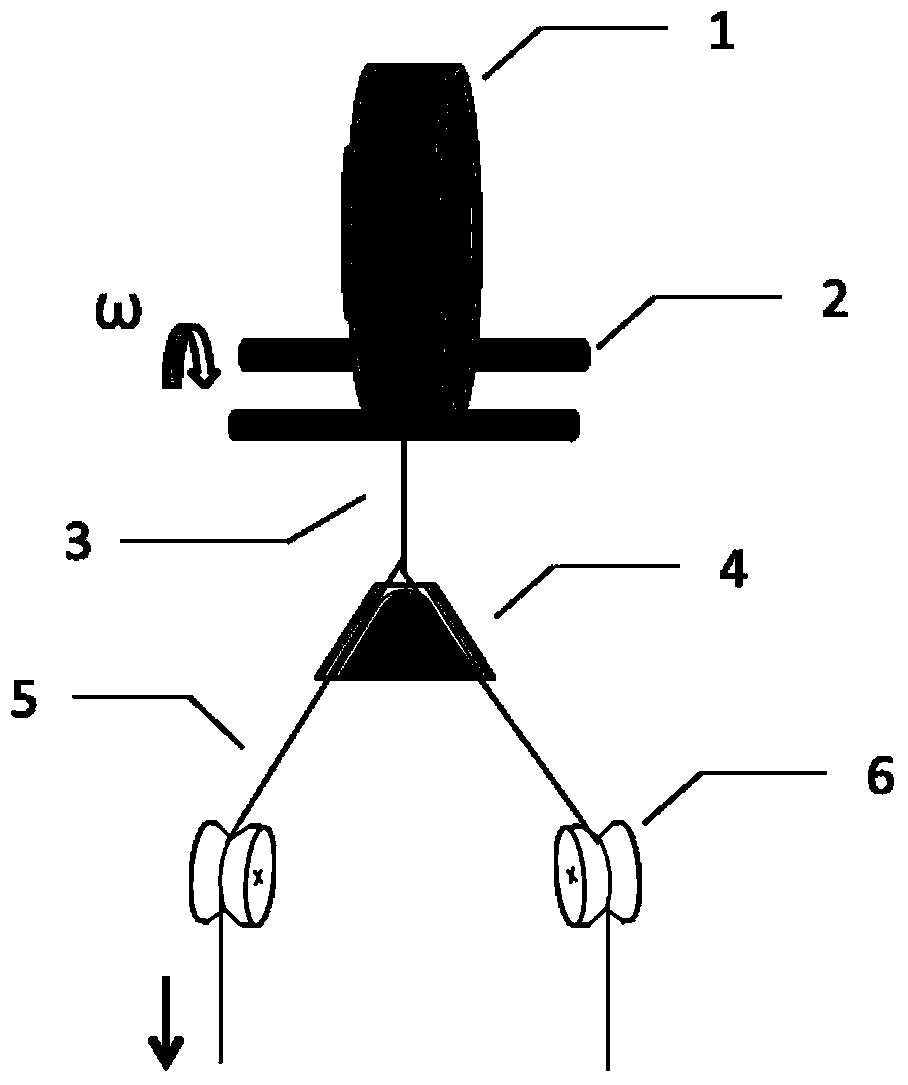

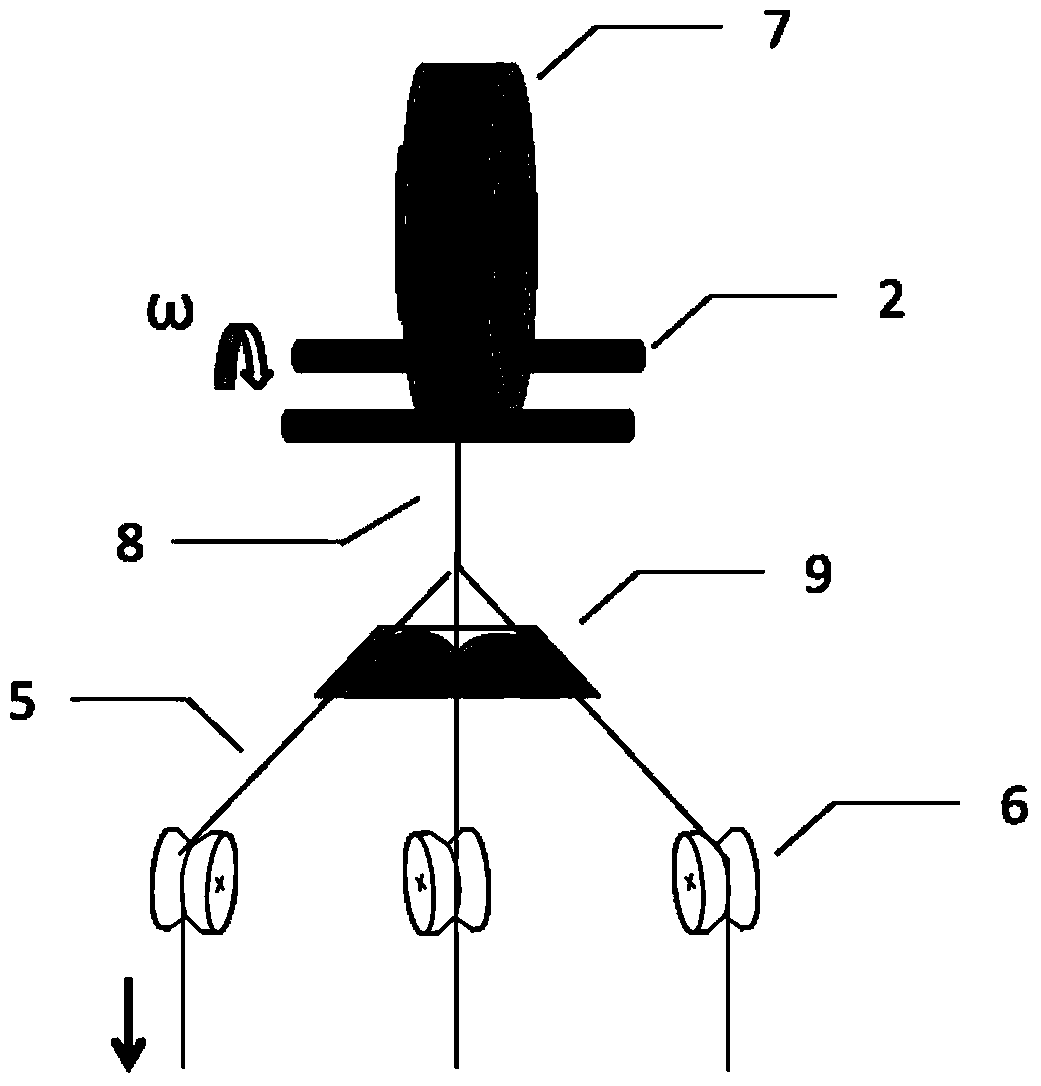

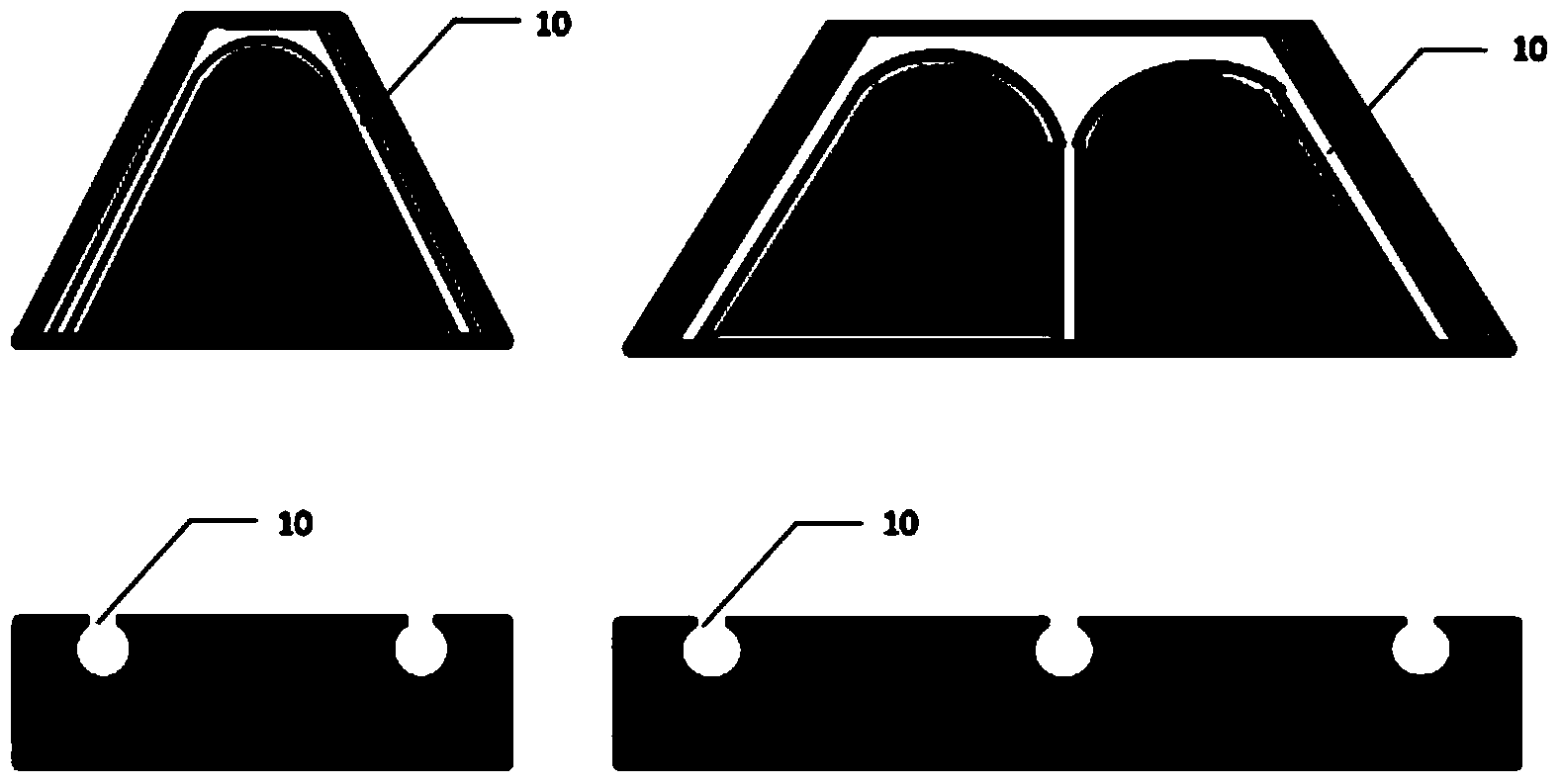

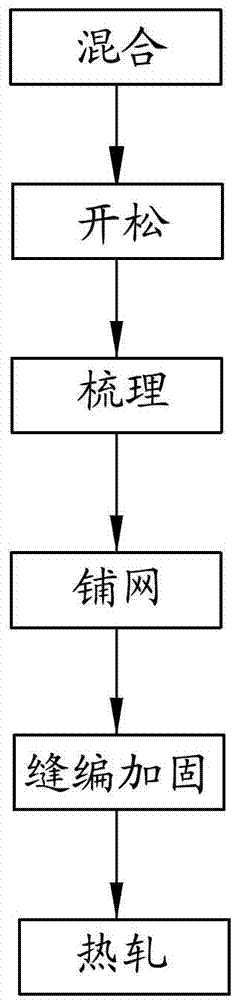

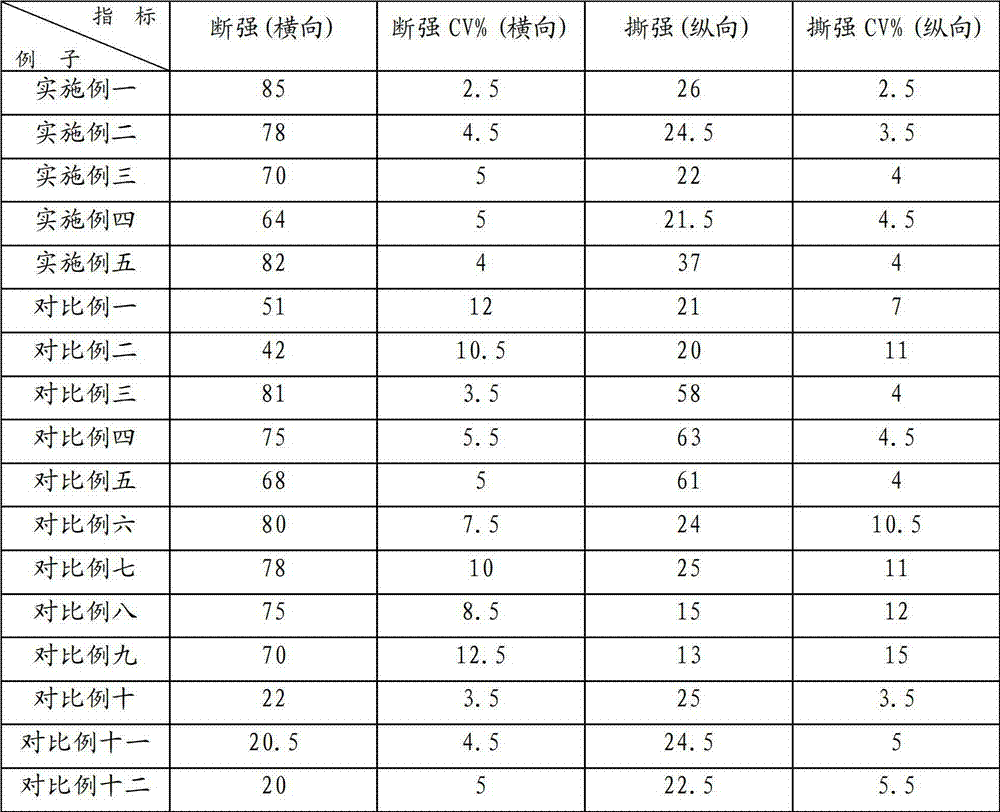

Stitch knitting non-weaving cloth for electrical tape base cloth and production method thereof

InactiveCN102965852AImprove transverse breaking strengthEasy to processNon-woven fabricsBreaking strengthGram

The invention discloses stitch knitting non-weaving cloth for electrical tape base cloth and a production method thereof. The production method comprises the following steps of: oploosening and carding polyester staple fibers with specified fineness and paving and laminating the carded polyester staple fibers to form a fiber web with specified monomer gram weight; reinforcing stitches with fine denier polyester filaments formed by a specified warping mode by adopting an active warp let-off mode; and carrying out stitching knitting and reinforcing on a stitch knitting machine adjusted by a process and then carrying out hot pressing to form the stitch knitting non-weaving cloth. Compared with a general product, the stitch knitting non-weaving cloth produced by adopting the production method disclosed by the invention has the characteristics that transverse breaking strength is great so as to facilitate the next coating processing of the product; longitudinal tearing strength is small so as to ensure the advantage of convenience for tearing with hand in actual application of next terminal product; the service performance of products is greatly improved; and the stitch knitting non-weaving cloth can be widely applied to base cloth of electrical tapes and the like of various cables and electronic elements and has wide popularization significance.

Owner:海东青非织工业(福建)有限公司 +1

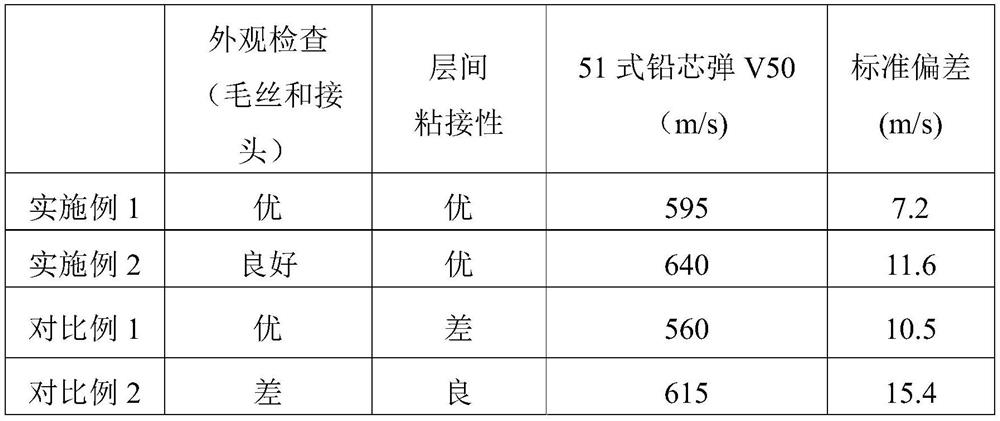

Polyethylene fiber composite cloth with high protection performance and preparation and application thereof

ActiveCN112848569AReduce joint defectsReduce fuzzLamination ancillary operationsProtective equipmentPolymer sciencePolymer chemistry

The invention relates to a polyethylene fiber composite cloth with high protection performance and preparation and application thereof, a preparation method comprises the following steps: 1) high-fineness ultra-high molecular weight polyethylene fibers are sequentially subjected to unwinding and tiling, heating and drafting, gluing and drying to obtain unidirectional polyethylene fiber cloth; (2) carrying out cross lamination and compounding on multiple layers of unidirectional polyethylene fiber cloth, rolling together with an isolating layer, and then carrying out vacuum hot-pressing shaping treatment, so as to obtain polyethylene fiber composite cloth; wherein the activation temperature of the glue is 50-150 DEG C, and the glue content is 5-30wt%; and the polyethylene fiber composite cloth is used in a soft bulletproof armor or a hard bulletproof armor. Compared with the prior art, the preparation method has the advantages that conventional high-denier monofilament and bunched ultra-high molecular weight polyethylene fibers are adopted, heating and drafting are carried out after unwinding and tiling, the activation temperature and the gluing amount of glue are controlled, and vacuum hot-pressing shaping treatment is carried out after compounding, so that the prepared polyethylene fiber composite cloth is good in appearance quality, high in bulletproof performance and small in discreteness.

Owner:SHANGHAI RES INST OF CHEM IND

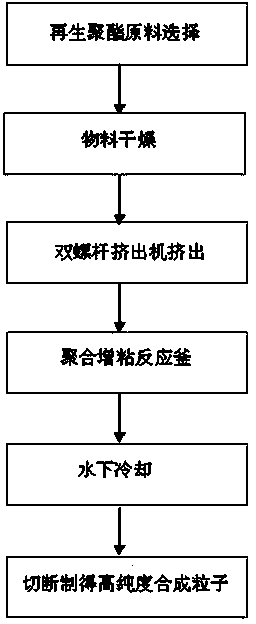

Method for preparing recycled polyester high-purity synthetic particle

The invention relates to a method for preparing recycled polyester high-purity synthetic particle. The method comprises the following steps: firstly, selecting recycled polyester raw materials, drying the materials, melting and extruding the recycled polyester raw materials through a double-screw extruder, putting in a viscosity increasing reaction kettle to carry out viscosity increasing reaction, filtering out small-particle impurities in the high viscosity melt after the reaction through a melt filter and carrying out underwater cooling and pelletizing to obtain the recycled polyester high-purity synthetic particle. The method disclosed by the invention has the advantages that the phenomena such as filament break and filament ossification in fore-spinning process of fiber can be reduced and the fiber finished product quality is increased, so that the production cost is saved and the purposes of low carbon and environmental protection are realized; when being used for spinning recycled multifunctional polyester staple fiber products, the recycled polyester high-purity synthetic particle produced by adopting the method is capable of reducing the phenomena such as the filament break and the filament ossification and in the fore-spinning process of fiber and increasing the quality index of fiber finished products; in the meantime, the method disclosed by the invention is capable of effectively utilizing various recycled chemical fibers and textile wastes, so that the cost is reduced and the purposes of comprehensive utilization of resources and more environmental protection are realized.

Owner:扬州天富龙集团股份有限公司

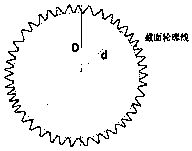

High-speed dry-spray spinning method for preparing deformed section carbon fiber precursor fiber, pre-oxidized fiber or carbon fiber

The invention discloses a high-speed dry-spray spinning method for preparing deformed section carbon fiber precursor fiber, pre-oxidized fiber or carbon fiber. An acrylonitrile polymer is dissolved byusing a solvent to obtain a uniform spinning solution, the spinning solution enters into a coagulating bath component of which the temperature is lower than the gelation temperature point of the spinning solution to form nascent fiber after passing through spinneret orifices to form a spinning trickle, and the working procedures of drafting, washing, drying and oil application aftertreatment arecarried out on the nascent fiber to obtain the carbon fiber precursor fiber. The carbon fiber precursor fiber is pre-oxidized and carbonized to obtain pre-oxidized fiber or carbon fiber. The method has the advantages of low cost and good fiber performance since fiber with similar straight toothed spur gear shape section characteristics is prepared in the condition of high-power drafting.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

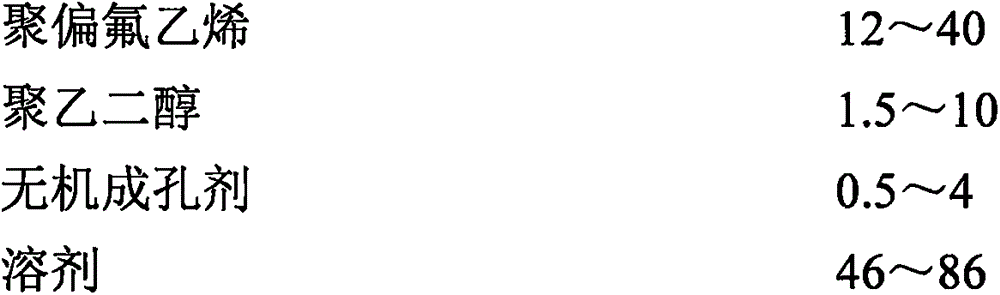

Preparing method of internally-supported reinforced type polyvinylidene fluoride hollow fiber film

The invention relates to a preparing method of an internally-supported reinforced type polyvinylidene fluoride hollow fiber film. The preparing method comprises the steps that a sodium hydroxide aqueous solution is used for removing grease dirt on the surfaces of braided ropes, and then the hollow braided ropes are treated with a polyester-polyether block copolymerization type hydrophilic finishing agent; then, the outer surfaces of the treated braided ropes are coated with a thin layer of a polyvinylidene fluoride film casting solution, solidifying and forming are carried out, and the internally-supported reinforced type polyvinylidene fluoride hollow fiber film is obtained. Polyether soft segments and polyester hard segments exist in molecules of the adopted polyester-polyether block copolymerization type hydrophilic finishing agent, and according to the similarity and mutual attraction principle, the polyester hard segments can generate co-solubility and co-crystallization effects with polyester in the heated process to enable the hydrophilic finishing agent to be preserved on the braided ropes for long; meanwhile, the polyether soft segments can generate a co-solubility effect with the film casting solution to enable the polyester braided ropes and the polyvinylidene fluoride film layer to have good binding performance; the prepared internally-supported reinforced type polyvinylidene fluoride hollow fiber film can be used in MBR and immersion type ultrafiltration assemblies.

Owner:盐城海普润科技股份有限公司

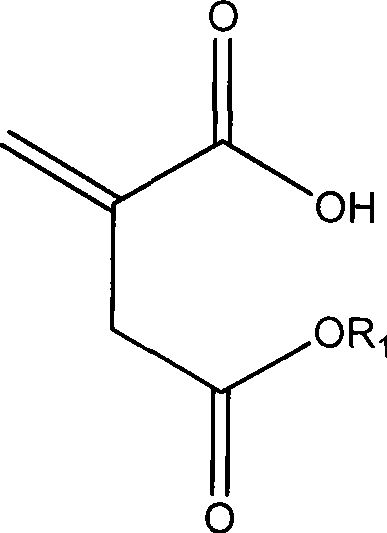

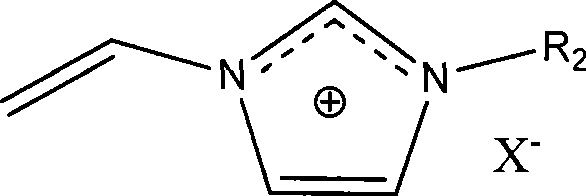

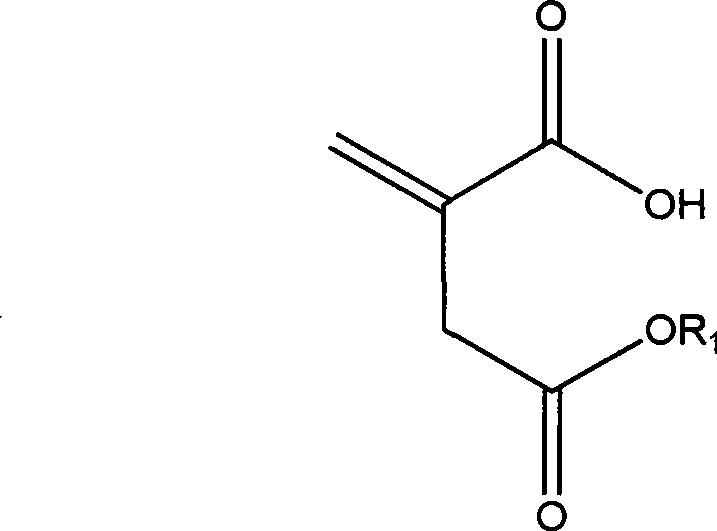

Acrylonitrile terpolymer spinning fluid containing hydrophilic group and preparation thereof

InactiveCN101413152AHigh molecular weightImprove spinnabilityMonocomponent synthetic polymer artificial filamentChain structureAcrylonitrile

The invention relates to an acrylonitrile terpolymer spinning solution containing hydrophilic groups and a preparation method. The preparation method comprises the following steps: in dimethyl sulfoxide solution, using azo-bis-iso-heptonitrile to initiate acrylonitrile, itaconate beta-monoester and vinyl imidazole salt to carry out copolymerization reaction, using small amount of chain transfer agent to adjust molecular weight of the copolymer, and synthesizing the acrylonitrile terpolymer at a temperature of between 25 and 45 DEG C, wherein the molecular weight of the acrylonitrile terpolymer is controllable to between 100, 000 and 500, 000, and distribution index of the molecular weight is lower than 2.3. The acrylonitrile terpolymer spinning solution has the characteristics of controllable molecular weight, even chain structure, narrower molecular weight distribution, and excellent hydrophilicity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

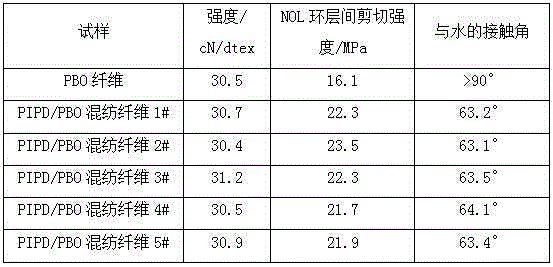

Preparation method of PIPD/PBO (poly(dihydroxyphenylene pyridobisimidazole)/poly-p-phenylene ben-zobisthiazole) blend fiber

ActiveCN104862826AGood compatibilityImprove wettabilityArtificial thread manufacturing machinesFilament/thread formingPropanolaminePolymer chemistry

The invention relates to a preparation method of a PIPD / PBO (poly(dihydroxyphenylene pyridobisimidazole) / poly-p-phenylene ben-zobisthiazole) blend fiber and belongs to the technical field of blend fibers. The technology comprises the steps of preparation of a PIPD / PPA (phenyl-propanolamine) polymer solution, preparation of a PBO / PPA polymer solution, mixed preparation of a PIPD / PBO polymer, preparation of freshly formed filaments, drawing, solidification, water washing and drying. According to the PIPD / PBO blend fiber prepared by the method, the PIPD polymer is introduced into a PBO fiber, that is to say, a little PIPD is added into a PBO polymer matrix. The wettability and bonding performance of the PBO fiber with a resin matrix are improved on the premise that the excellent mechanical property, high-temperature resistance and flame resistance of the PBO fiber are not reduced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

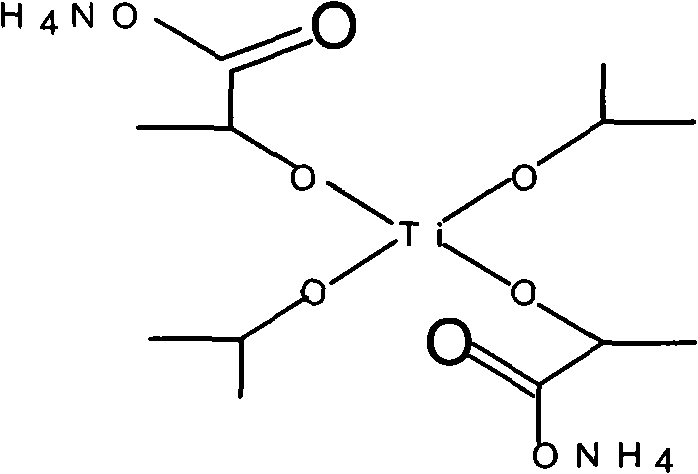

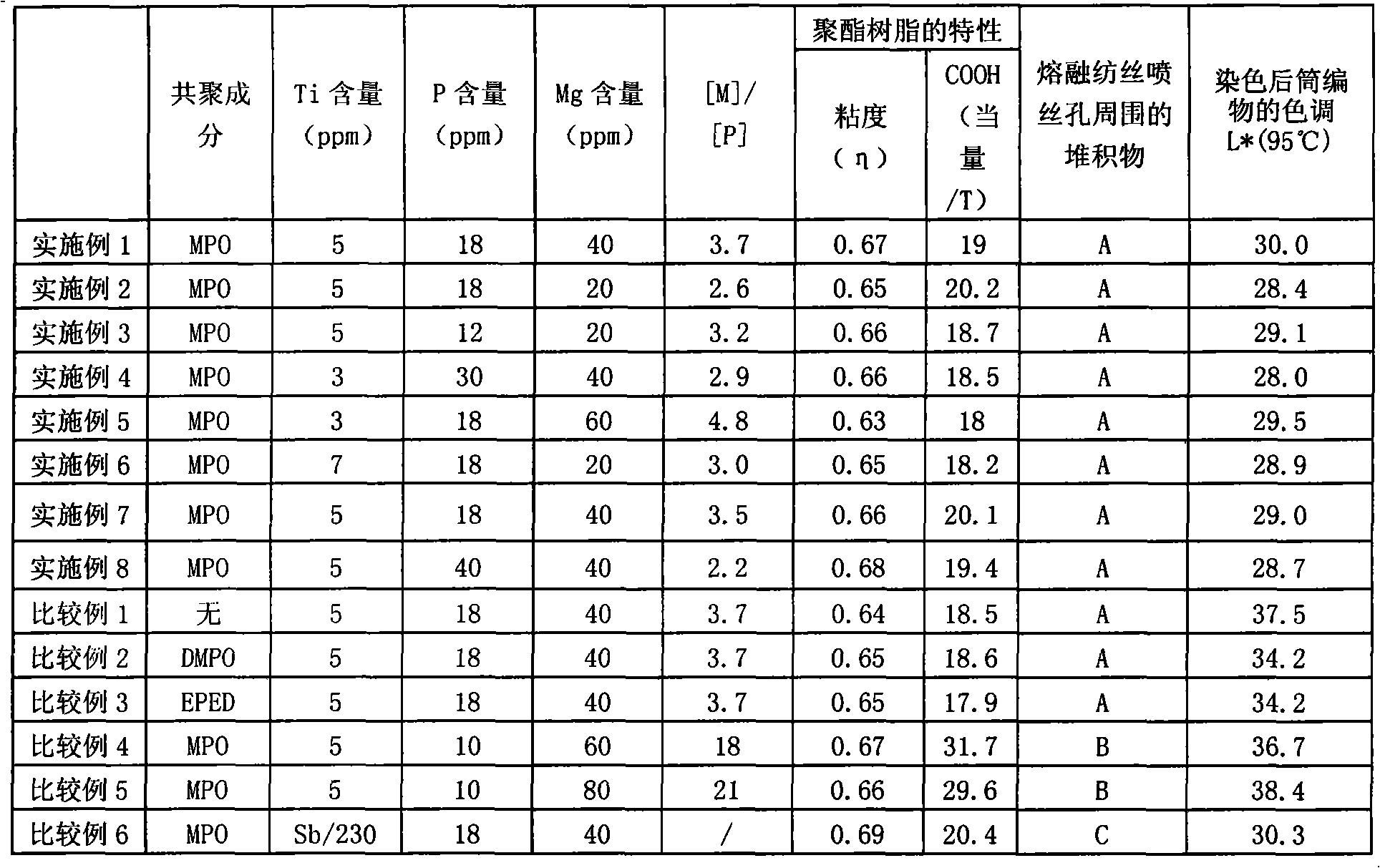

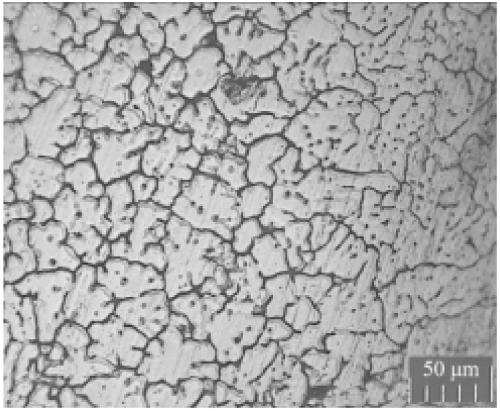

Copolyester and application thereof

InactiveCN102030890AImprove dyeing effectImprove stabilityMonocomponent polyesters artificial filamentFiberSide chain

The invention relates to copolyester and application thereof. The copolyester is prepared from diacid and dihydric alcohol through polymerization reaction in the presence of a catalyst. In components of diacid for forming the copolyester, the content of terephthalic acid structural unit is over 90 mol percent; in components of dihydric alcohol for forming the copolyester, the content of glycol structural unit is 70 to 99 mol percent, the content of aliphatic diol structural unit is 1 to 30 mol percent; and the content of antimony element is less than or equal to 5ppm in based on the total weight of the copolyester. In the polymerization process, a non-antimony catalyst is used and environment-friendly, reduces pollution on spinneret orifices in the spinning process and has environmental safety; the polymer has excellent tone; and the obtained copolyester fibers are high in heat resistance and good in dyeing property.

Owner:TORAY IND INC

Preparing process of welding wire suitable for fusion welding of spray-formed ultrahigh-strength aluminum alloy plate

InactiveCN111069609AShort production processImprove yieldWelding/cutting media/materialsSoldering mediaWeld seamFusion welding

The invention provides a preparing process of a welding wire suitable for fusion welding of a spray-formed ultrahigh-strength aluminum alloy plate. The process includes the steps of material preparing, vacuum smelting, powder atomizing, powder screening, ball-milling and powder mixing, vacuum canning, hot isostatic pressing, lathing, hot extruding and the like. The welding wire produced through the method does not need to be homogenized, saves energy and shortens the welding wire production process. Surplus crystal-phase particles in the prepared welding wire are small in size and are evenly dispersed and distributed, drawing breakage of the wire is reduced, the yield of the welding wire is increased, production cost is reduced, the welding performance of the welding wire and the metal strength of a weld joint can be improved, and the welding wire is particularly suitable for fusion welding of the spray-formed ultrahigh-strength aluminum alloy plate.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

Polyvinyl Chloride Fiber and Process for Production Thereof

InactiveUS20070270532A1High productivityManufacturing cost be reduceWigsFilament/thread formingChemistryPlasticizer

The polyvinyl chloride-based fiber of the present invention is formed of a vinyl chloride-based resin composition obtained by blending, with respect to (a) 100 parts by weight of a vinyl chloride-based resin, (b) 0.1 parts by weight to 0.6 parts by weight of a hydrotalcite-based thermostabilizer, (c) 0.1 parts by weight to 0.5 parts by weight of β-diketone, (d) 0.2 parts by weight to 0.5 parts by weight of a calcium soap and a zinc soap, (e) 0.7 parts by weight to 1.7 parts by weight of a lubricant, and (f) 0.5 parts by weight to 5 parts by weight of a plasticizer. Thereby, the present invention provides a polyvinyl chloride-based fiber that has an excellent touch feeling as a fiber for hair, excellent transparency and a vivid color tone, and can be obtained by stable melt spinning with less occurrence of filament breakage.

Owner:KANEKA CORP

Fibre spinning method for polyacrylonitrile solution

ActiveCN105603543AEasy to installImprove sealingSpinning head liquid feederWet spinning methodsEngineeringViscosity

The invention relates to a fibre spinning method for a polyacrylonitrile solution, and mainly solves the technical problems in the prior art that a fibre spinning assembly has poor sealing property, fiber spinning pressure is high, and coagulating bath nascent fibre breakage is more. The invention adopts the technical scheme that the fibre spinning method for the polyacrylonitrile solution comprises the following steps: for a polyacrylonitrile / dimethyl sulfoxide solution with the molecular weight of 80 thousands to 200 thousands and viscosity of 60Pa.s to 120Pa.s, adopting an embedded fibre spinning assembly, filtering by a multi-layer combined filter net, distributing by a distributing plate, extruding by a spinneret plate, entering a coagulating bath, and coagulating to form coagulated filaments. The problems are better solved, and the fibre spinning method can be used in industrial production of polyacrylonitrile-based carbon fiber protofilaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

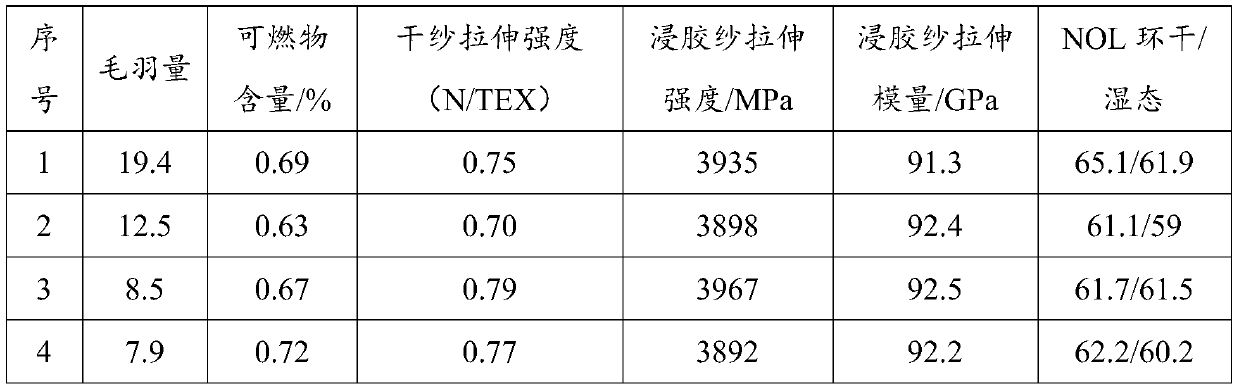

Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

The invention relates to the technical field of impregnating agents, and discloses a film forming agent suitable for glass fibers, an impregnating agent comprising the same, and a preparation method and applications of the impregnating agent. The film forming agent comprises emulsified bisphenol A type epoxy resin and polyester type polyurethane. Through the emulsification effect of a surfactant, the interfacial energy of a system is reduced, the stability of epoxy resin emulsion is improved, and thus the function of the epoxy resin emulsion can be better exerted. The polyester polyurethane film forming agent has a large molecular weight and a strong yarn-wrapping performance and easily forms a compact film on the surface of glass fibers, thus the glass fibers are isolated from the external environment, water will not enter the cracks of the glass fibers, the elasticity and wear resistant performance of yarns are improved, the anti-fatigue performance of yarns is strengthened, at the same time, the bundling force is high, and the phenomenon of yarns such as natural draping, non-uniform tension force, and the like, is effectively relieved.

Owner:SINOMA SCI & TECH

Aqueous cutting fluid for hard and brittle material multi-line cutting and preparation method thereof

InactiveCN106318592AImprove performanceExtended service lifeLubricant compositionBatch processingGlycerol

The invention discloses an aqueous cutting fluid for hard and brittle material multi-line cutting and a preparation method thereof. The aqueous cutting fluid comprises, by weight, 5-20% of ammonium carboxylate, 5-25% of a water-soluble lubricant, 10-20% of an antirust agent, 0.5-4% of a bactericide, 10-20% of a water-soluble anti-wear reagent at extreme pressure, 10-20% of triethanolamine, 0.1-4% of a settling agent, 0.01-0.1% of benzotriazole, 0.01-0.5% of an antifoaming agent and the balance water. The water-soluble lubricant is a mixture of poly(ether ester), glycerol and sulfurized fatty acid according to a weight ratio of (10-45): (3-18): (2-20). The cutting fluid has good integrated performances such as cooling performances, lubricity, settlement performances, defoaming performances, antirust properties and cleaning effects and satisfies hard and brittle difficult-to-cut material batch processing requirements of a multi-line cutting machine. The preparation method of the aqueous cutting fluid has simple processes, can be operated easily, realizes a low cost and can be finished at the normal temperature.

Owner:浙江模德科技有限公司

Closure gap bed protection method by using nylon net bag stone ballast

InactiveCN102747709AThe production process is simpleImprove construction efficiencyBarrages/weirsPolypropyleneEngineering

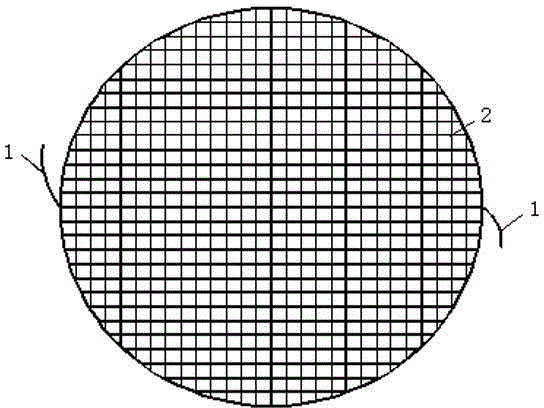

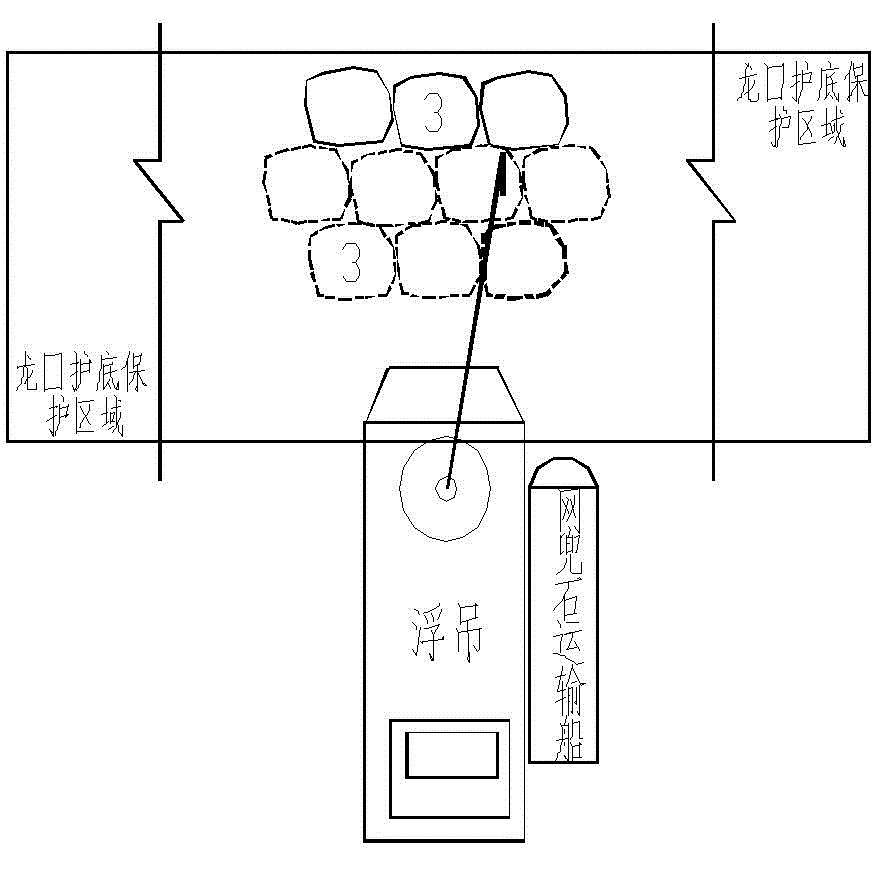

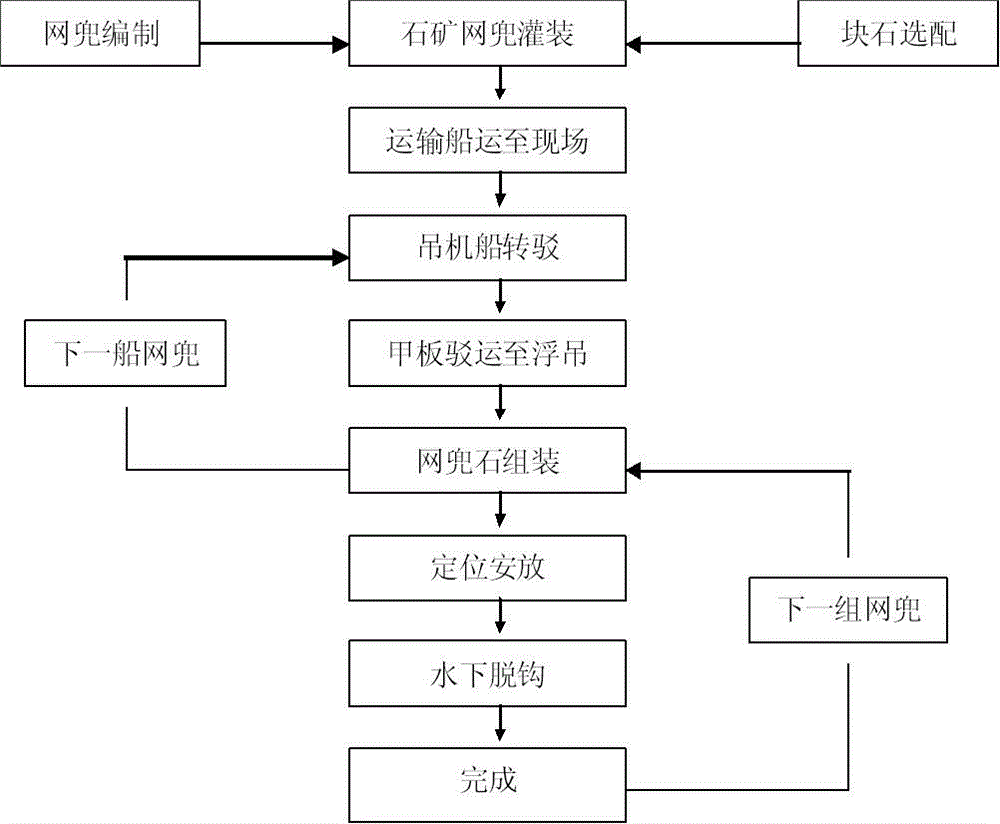

The invention discloses a closure gap bed protection method by using nylon net bag stone ballast and relates to a reservoir or coast reclamation work closure gap ballast method. A nylon net bag stone filling method is adopted. After nylon net bag stones are shipped and transferred, the nylon net bag stones are lifted and placed through a construction vessel. The closure gap bed protection method by using nylon net bag stone ballast is characterized in that the length of each side of each mesh of each nylon net bag is 20cm, phi 16mm polypropylene nylon ropes are used for knitting a circle with radius being 7m and the edge of the circle is serially connected for a turn by using phi 22mm polypropylene nylon ropes; the nylon net bag is placed in a 40m<3> filling bucket for filling block stones, the grain size of the block stones is required to be larger than the length of each side of the mesh of the nylon net bag and 10t of block stones are filled into each nylon net bag; before underground lifting and placing, six nylon net bags with 10t stones respectively are combined into a group of nylon net bags with 60t stones, and adjacent nylon net bags are serially and integrally connected by using phi 16mm polypropylene nylon ropes; and the construction vessel conducts uncoupling for underground placing through positioning according to the determined position, and during underground placing, the nylon net bags are closely placed in a staggered way to ensure close contact.

Owner:CCCC SHANGHAI DREDGING +2

Heavy-denier-yarn spinning technology of semi-continuous and high-speed spinning machine

ActiveCN103409821AReduce in quantityLow manufacturing costWet spinning methodsYarnManufacturing engineering

The invention relates to a heavy-denier-yarn spinning technology of a semi-continuous and high-speed spinning machine, and belongs to the technical field of spinning of the semi-continuous and high-speed spinning machine. The technology comprises the steps of glue supplying, thread-line forming, spinning and winding. The spinning is finished through the spinning device, the spinning device comprises three spinning rollers which are transversely arranged relative to an operation face of a spinning surface, the three spinning rollers are respectively a drafting roller, a solidifying roller and a disacidifying roller, thread-lines sequentially surround the drafting roller, the solidifying roller and the disacidifying roller, and the drafting, the solidifying and the disacidifying in the spinning steps are finished under the rotation of the spinning rollers. The heavy-denier-yarn spinning technology of the semi-continuous and high-speed spinning machine solves the problems that due to the fact that response of thread-lines of a semi-continuous spinning machine in the prior art is insufficient, the spinning speed can not be accelerated, and the production efficiency and the product quality can not be improved at the same time; by changing the arrangement direction of the spinning rollers, the thread-lines can walk a longer distance while the spinning speed of the spinning machine is accelerated and structures of other parts of original equipment are not changed, the thread-lines and acid bath react more fully, and the production efficiency and the product efficiency can be improved at the same time.

Owner:YIBIN HIEST FIBER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com