Preparing method of internally-supported reinforced type polyvinylidene fluoride hollow fiber film

A polyvinylidene fluoride and fiber membrane technology, which is applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor bonding performance of internal support reinforced hollow fiber membranes, and achieve the goal of reducing broken wires and fouling Possibilities, extended service life, effect of good bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

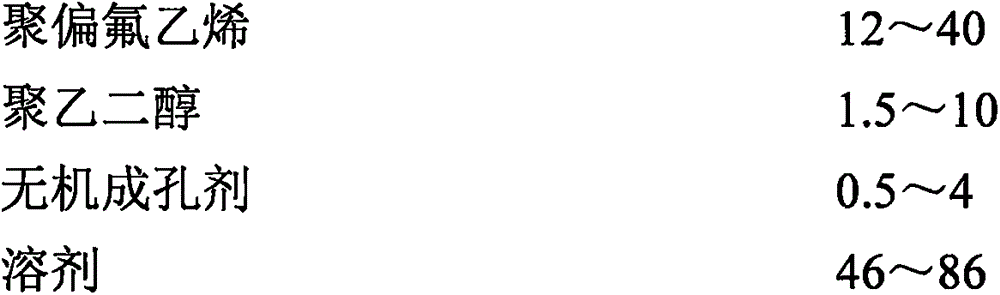

Method used

Image

Examples

Embodiment 1

[0031] 40g of polyvinylidene fluoride resin with a weight average molecular weight of 400,000, 10g of polyethylene glycol (molecular weight 600), 0.5g of anhydrous lithium chloride, and 49.5g of dimethylformamide were uniformly mixed and stirred at 90°C , dissolved, filtered and defoamed to obtain a polyvinylidene fluoride casting solution with a mass concentration of 40%. The polyester hollow braided rope with a length of 50 cm, an inner diameter of 0.5 mm, and an outer diameter of 1.2 mm was soaked in a 10% sodium hydroxide aqueous solution for 0.5 h at 80° C., and then washed and dried in water. The braided rope was treated with an aqueous solution of polyester polyether block copolymerization type hydrophilic finishing agent with a mass concentration of 10% at room temperature for 30 minutes, and then the braided rope was baked at 120° C. for 20 minutes. Then, under the condition of 60°C, the outer surface of the hollow braided rope is coated with a layer of polyvinylidene...

Embodiment 2

[0033] Mix 6g of polyvinylidene fluoride resin with a weight average molecular weight of 700,000, 0.75g of polyethylene glycol (molecular weight of 2000), 1.5g of alumina, and 41.75g of dimethylacetamide at 30°C, stir and dissolve , after filtering and defoaming, a polyvinylidene fluoride casting solution with a mass concentration of 12% was obtained. The polyester hollow braided rope with a length of 50 cm, an inner diameter of 2.2 mm and an outer diameter of 3.2 mm was soaked in a 20% sodium hydroxide aqueous solution for 1 hour at 40°C, and then washed and dried in water. The braided rope was treated with an aqueous solution of polyester polyether block copolymerization type hydrophilic finishing agent with a mass concentration of 8% at room temperature for 20 minutes, and then the braided rope was baked at 110° C. for 30 minutes. Then, under the condition of 50°C, a layer of polyvinylidene fluoride casting solution with a mass concentration of 12% was coated on the outer...

Embodiment 3

[0035] 9g of polyvinylidene fluoride resin with a weight average molecular weight of 700,000, 1.5g of polyethylene glycol (molecular weight 200), 1g of calcium chloride, and 38.5g of N-methylpyrrolidone were uniformly mixed, stirred, and dissolved at 50°C. After filtering and defoaming, a polyvinylidene fluoride casting solution with a mass concentration of 18% was obtained. The polyester hollow braided rope with a length of 50cm, an inner diameter of 1.8mm and an outer diameter of 3.0mm was soaked in 30% sodium hydroxide aqueous solution for 0.5h at 60°C, and then washed and dried in water. The braided rope was treated with an aqueous solution of polyester polyether block copolymerization type hydrophilic finishing agent with a mass concentration of 5% at room temperature for 20 minutes, and then the braided rope was baked at 110° C. for 30 minutes. Then, under the condition of 40°C, the outer surface of the hollow braided rope is coated with a layer of polyvinylidene fluorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com