Patents

Literature

3664 results about "Separation technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

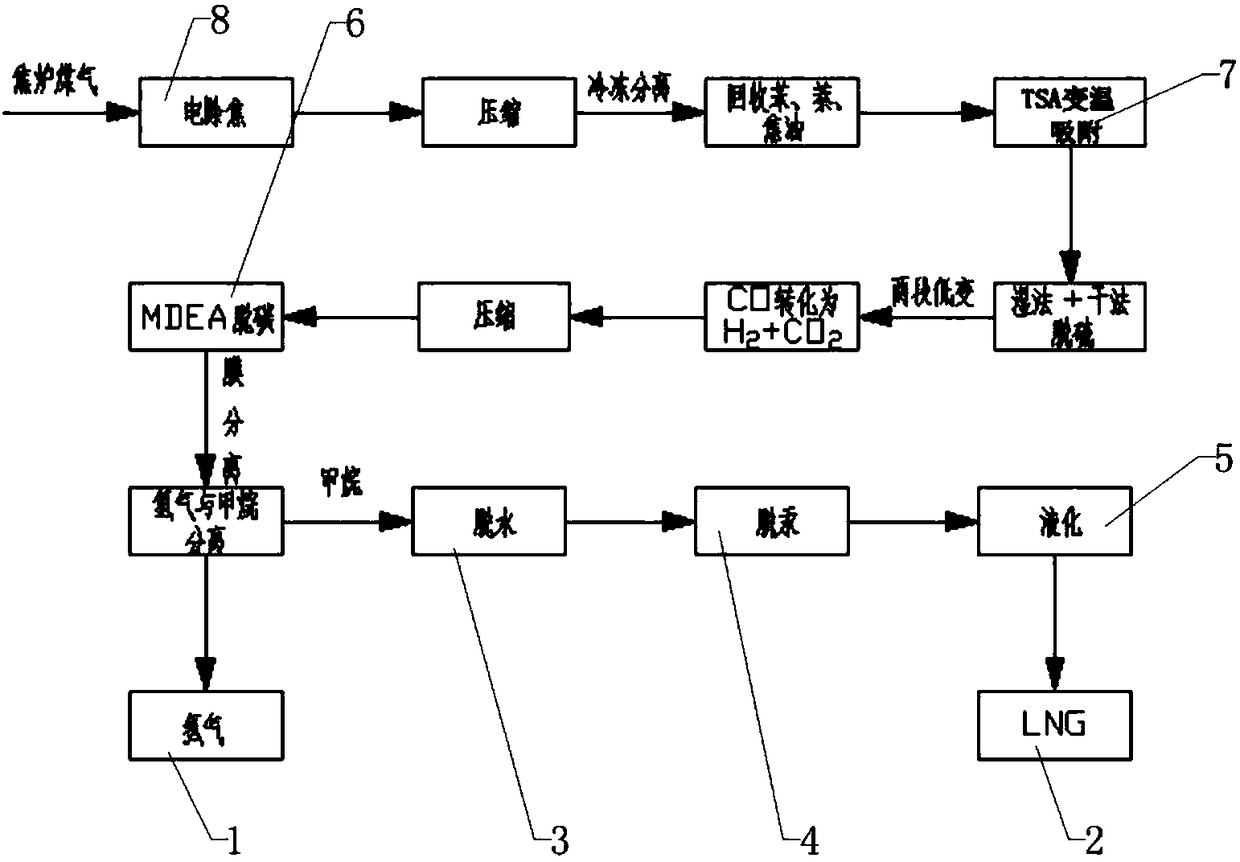

Method for preparing hydrogen and LNG from coke oven gas

InactiveCN108179046ALow investment costLow running costHydrogenGaseous fuelsHigh concentrationSeparation technology

The invention provides a method for preparing hydrogen and LNG from coke oven gas. The method comprises the following steps: electric decoking; boosting of the coke oven gas by a compression system; cooling of the raw gas coke oven gas by using the BOG gas (the BOG gas is a gas formed after the passive heating gasification of LNG) of LNG in order to further remove tar, benzene, naphthalene and like substances in the coke oven gas; and pretreatment using a TSA process to finely remove macromolecular impurities, such as tar, benzene, naphthalene and the like; wet and dry two-stage desulfurization for removing sulfides in the coke oven gas; two-stage low pressure shifting for a reaction of CO and water vapor to form CO2 and hydrogen; and pressurization using a compressor, an MDEA solution process for removing carbon dioxide, a membrane separation technology for separating hydrogen and methane, separation, concentration and purification of the hydrogen and methane, and dehydration, demercuration and liquefaction of the separated high-concentration methane to obtain the LNG. The coke oven gas is finally converted into the hydrogen and the LNG which have high values, so the energy of thecoke oven gas is fully used, and the environment is protected.

Owner:SICHUAN HENGRI GAS ENG CO LTD

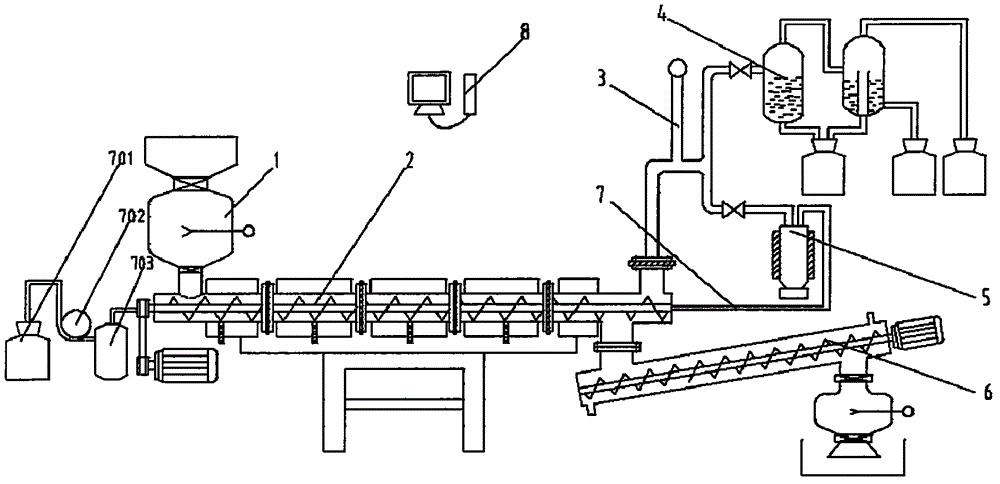

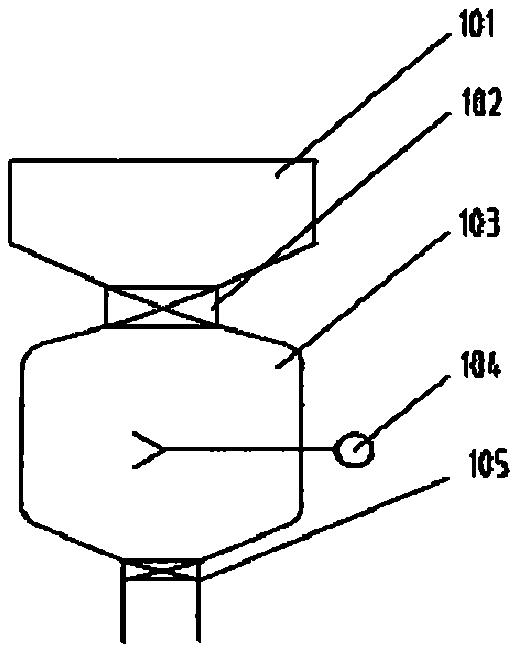

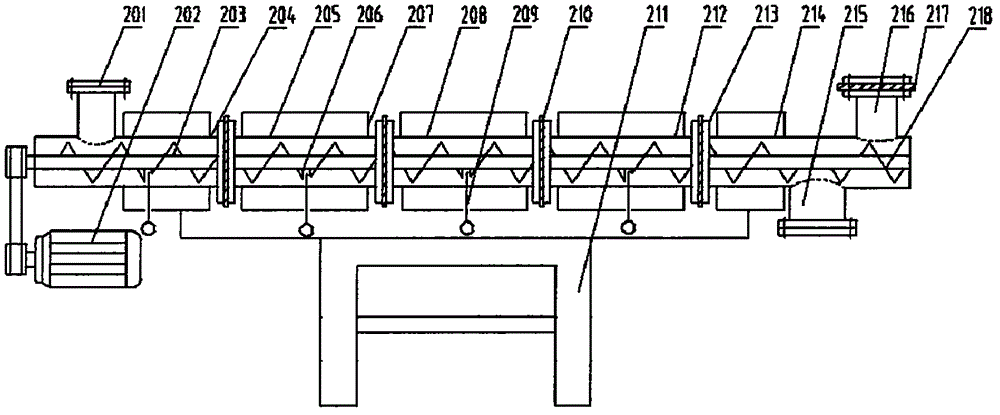

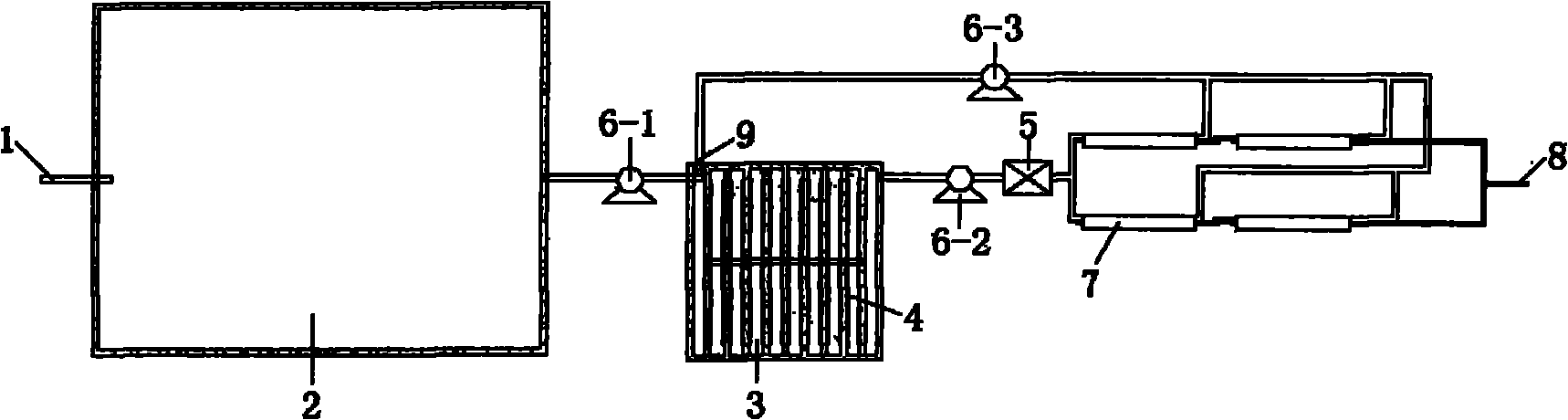

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

Process for producing sodium sulfate and sodium chloride in Na2SO4-NaCl-H2O system

InactiveCN1944256AIncrease profitReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal halide purificationInorganic saltsSeparation technology

The process of producing sodium sulfate and sodium chloride in a Na2SO4-NaCl-H2O system belongs to the field of mixed inorganic solution evaporating separation technology. Mixed solution of sodium sulfate and sodium chloride as material is first evaporated and then separated to obtain sodium sulfate, sodium chloride and evaporated mother liquor; the evaporated mother liquor is low temperature evaporated and separated to obtain sodium chloride and salt-making mother liquor; and the salt-making mother liquor is evaporated and separated to obtain sodium sulfate and saltpeter-making mother liquor. The present invention has the features of high main and side product quality, high material adaptability, low cost, low cost, no waste draining, etc.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

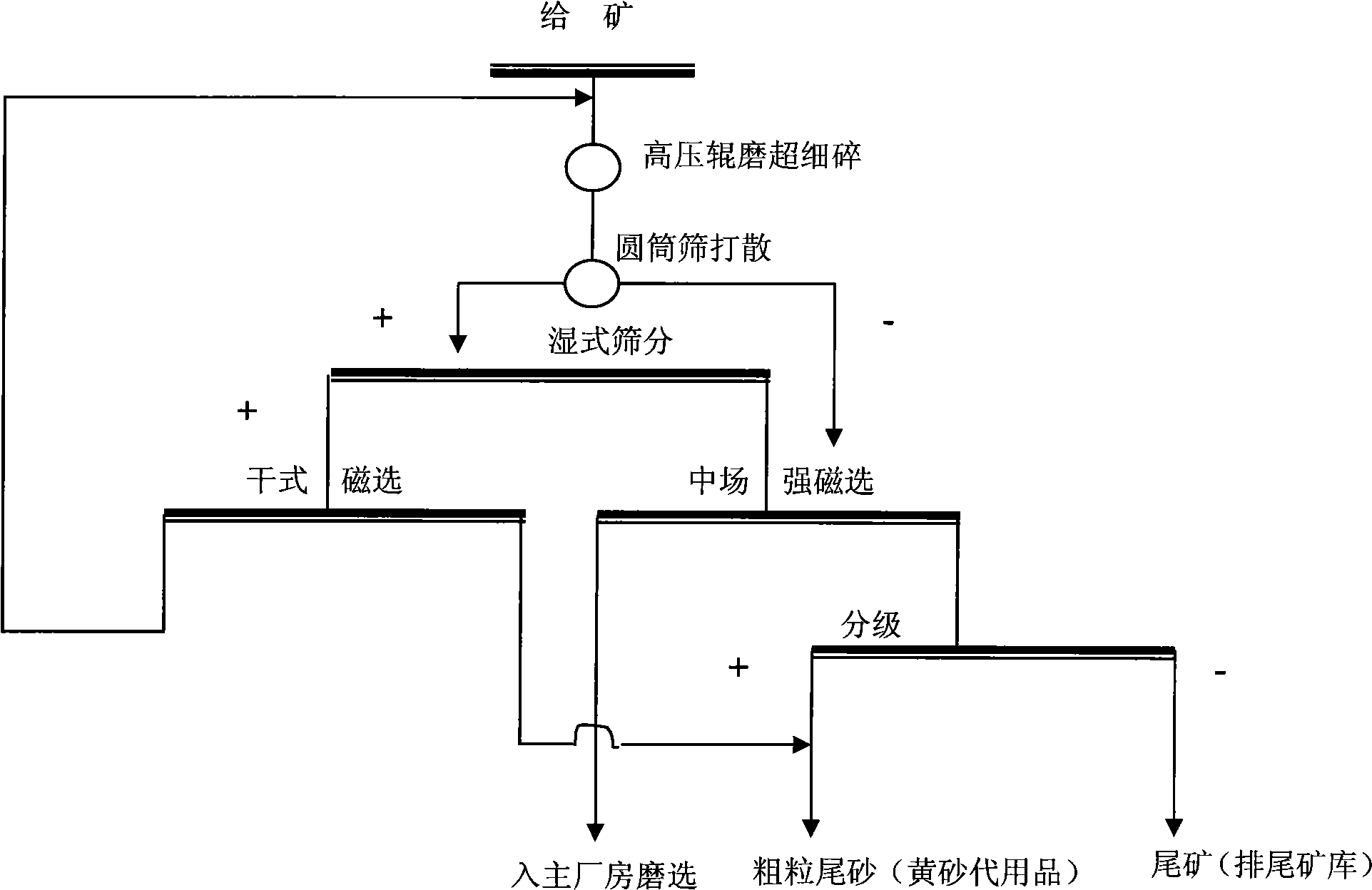

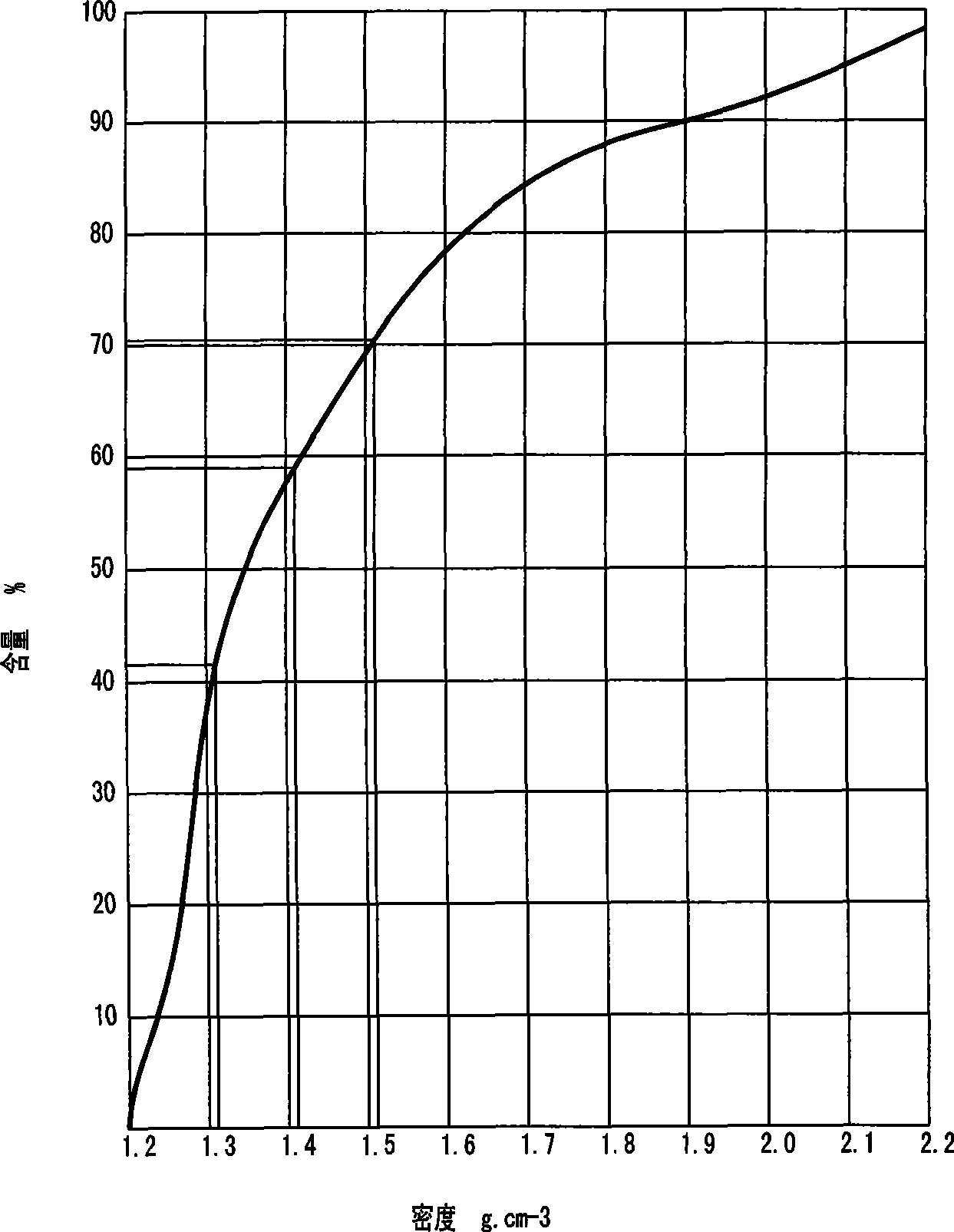

Pre-selection method of low-ore grade magnetic iron ore

InactiveCN101502819ASolve the costSolve the problem of large tailingsSievingScreeningSeparation technologyMagnetite

The invention discloses a preselecting method of low-grade magnetic iron ore, comprising the steps of crushing the raw ore of the magnetic iron ore by coarse crushing, intermediate crushing and fine crushing operations, conveying to subject to ultra-fine crushing operation, and then crushing by a high-pressure roller mill, scattering the crushed product by a wet cylindrical sieve, conveying the ore on the cylindrical sieve to the vibrating sieve by a belt to perform wet gradation, conveying the ore on the vibrating sieve to a dry magnetic separator by the belt to discard the waste, returning the ore concentrate of the dry magnetic separator to the high-pressure roller mill to crush the ore concentrate again, perform magnetic separation and discarding tailings of the ore concentrate below the vibrating sieve and the ore concentrate below the cylindrical sieve in a wet coarse grain intermediate-field intensity magnetic separator, and selecting the coarse ore concentrate of the intermediate-field intensity magnetic separator by a grinding separation technology. The invention has the advantages that the invention selects quantities of qualified mine tailings by wet magnetic separation before grinding ore, reduces ore grinding work, reduces ore grinding energy consumption and has high system processing capacity; the invention can be widely used in magnetic ore dressing plant, and in particular suitable for treatment of preselecting low-grade magnetic iron ore with the iron grade lower than or equal to 22%.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

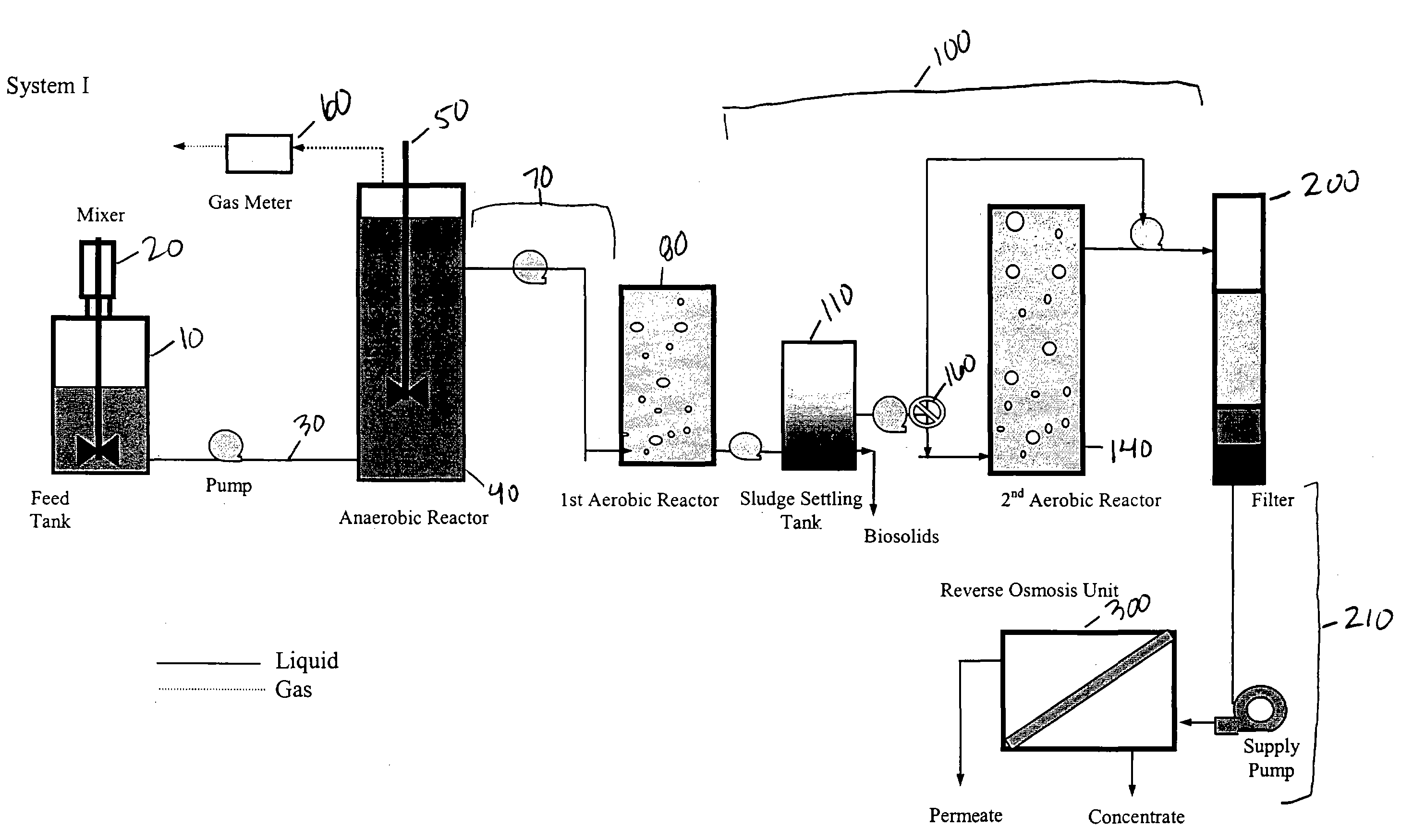

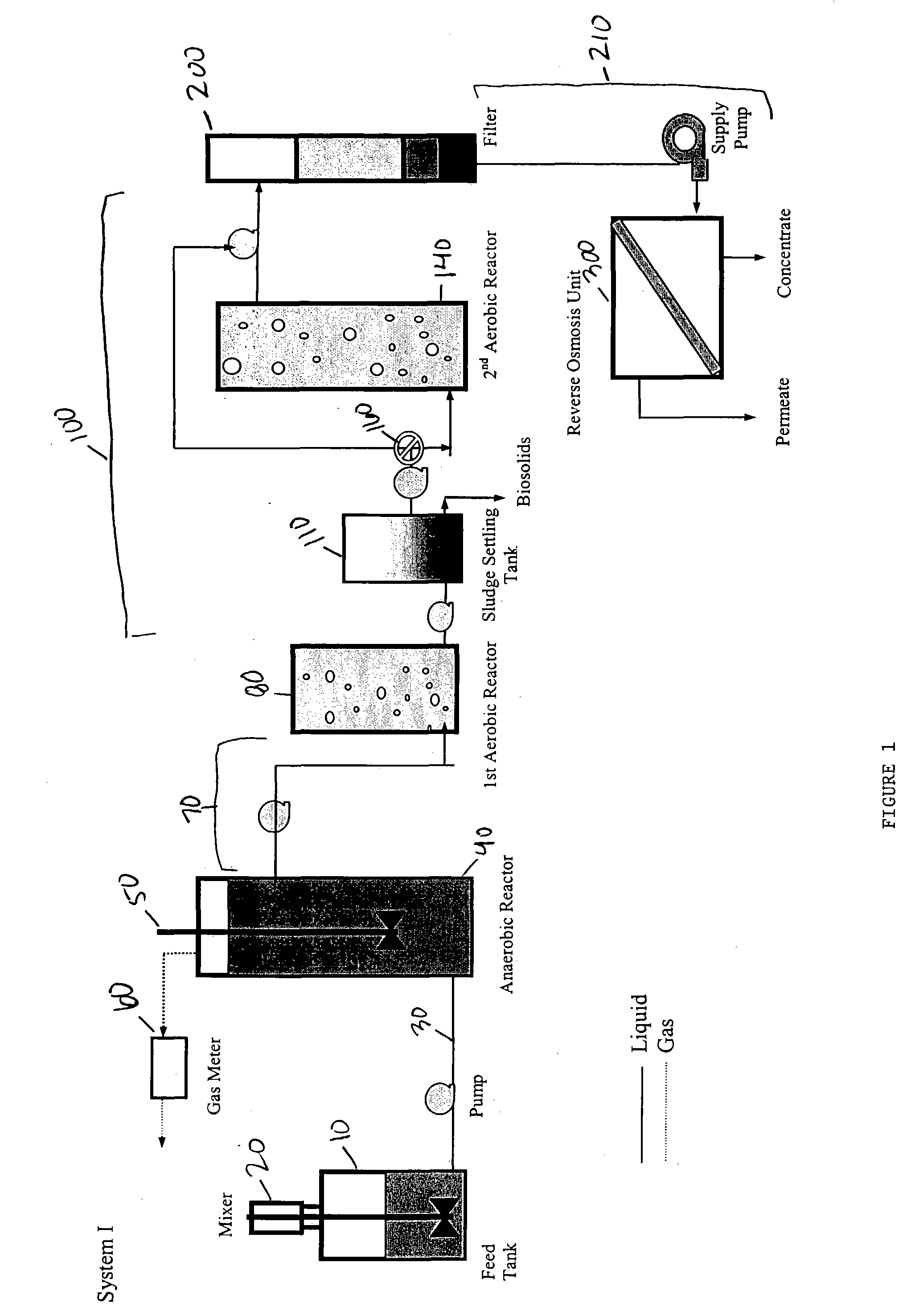

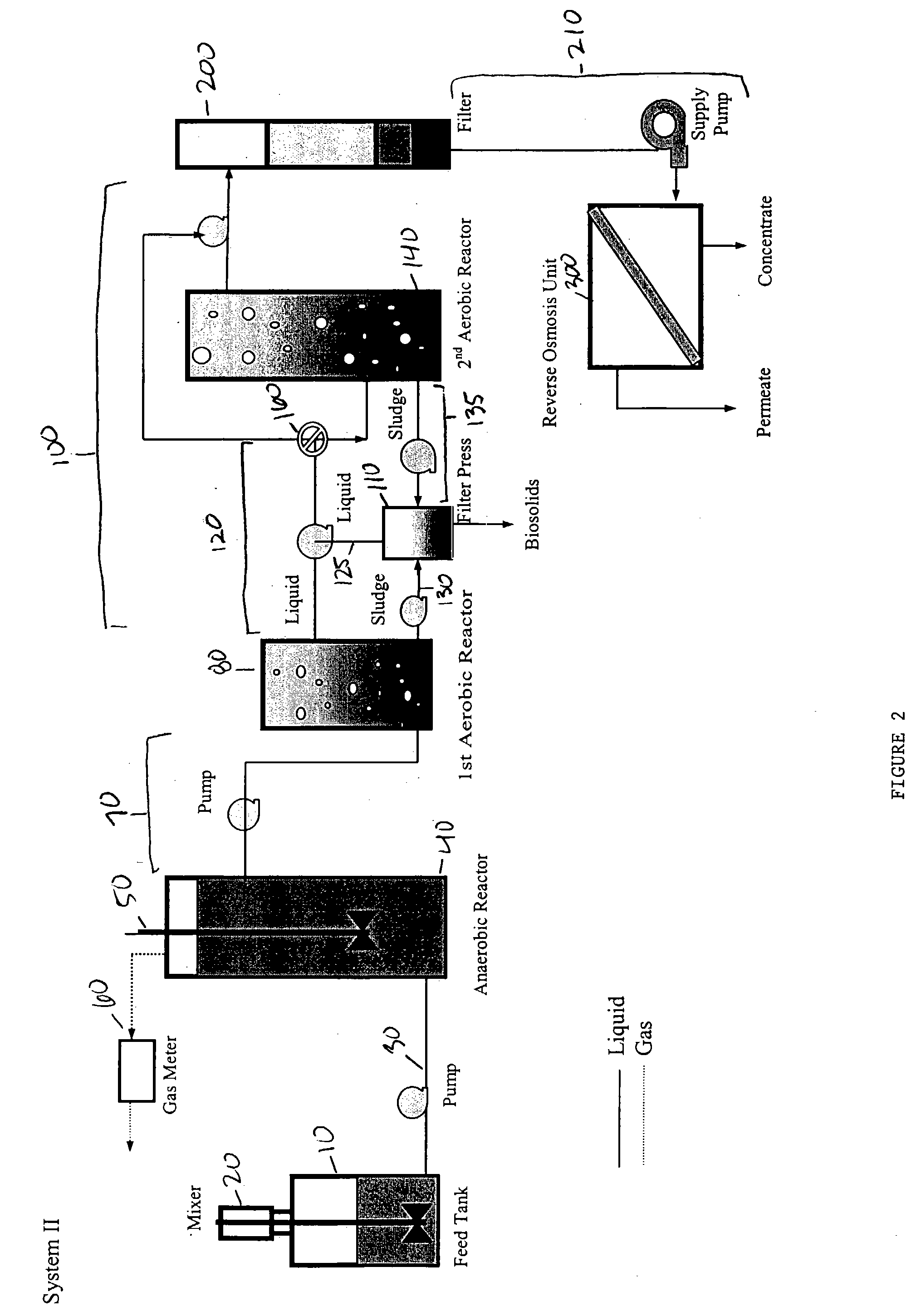

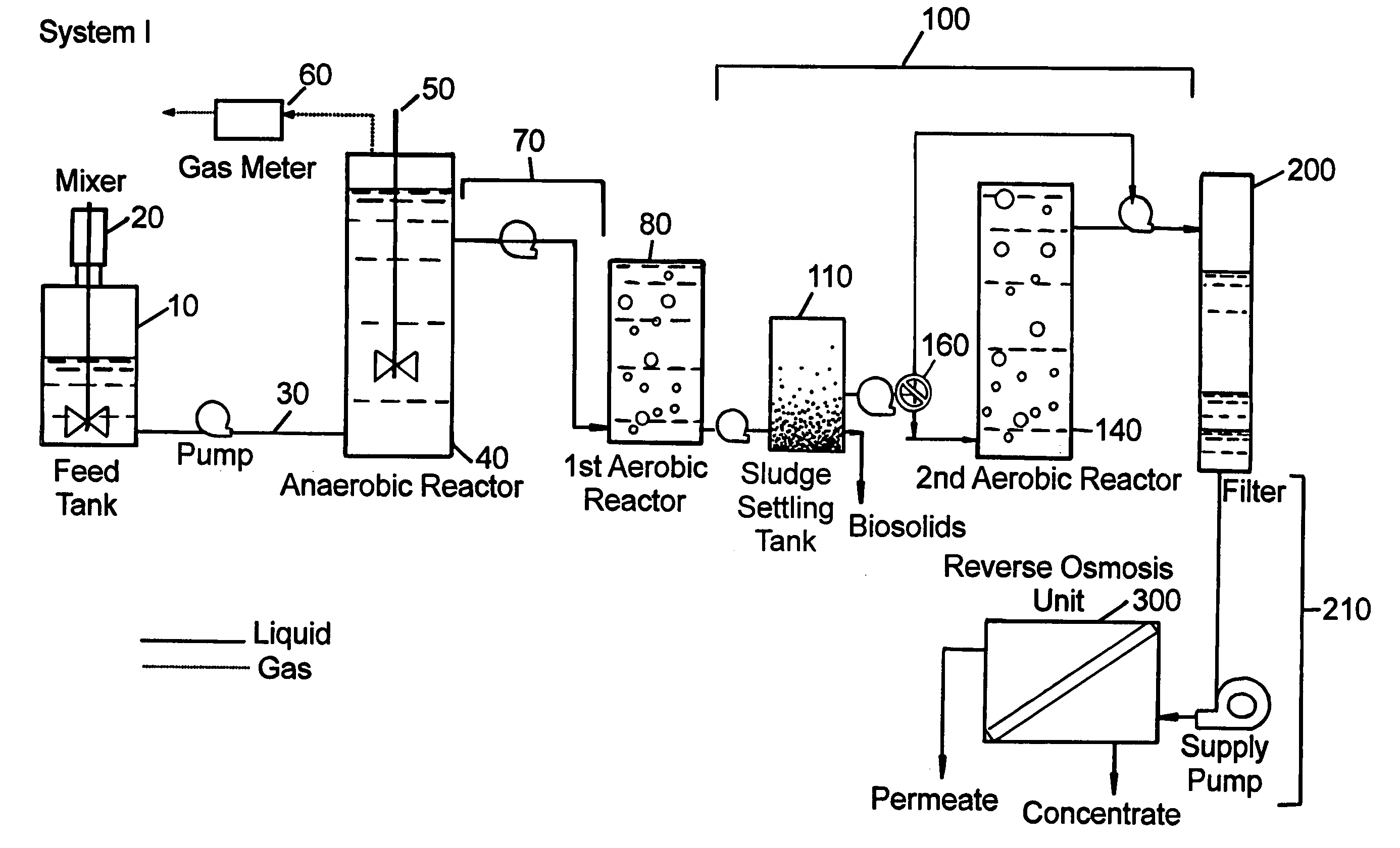

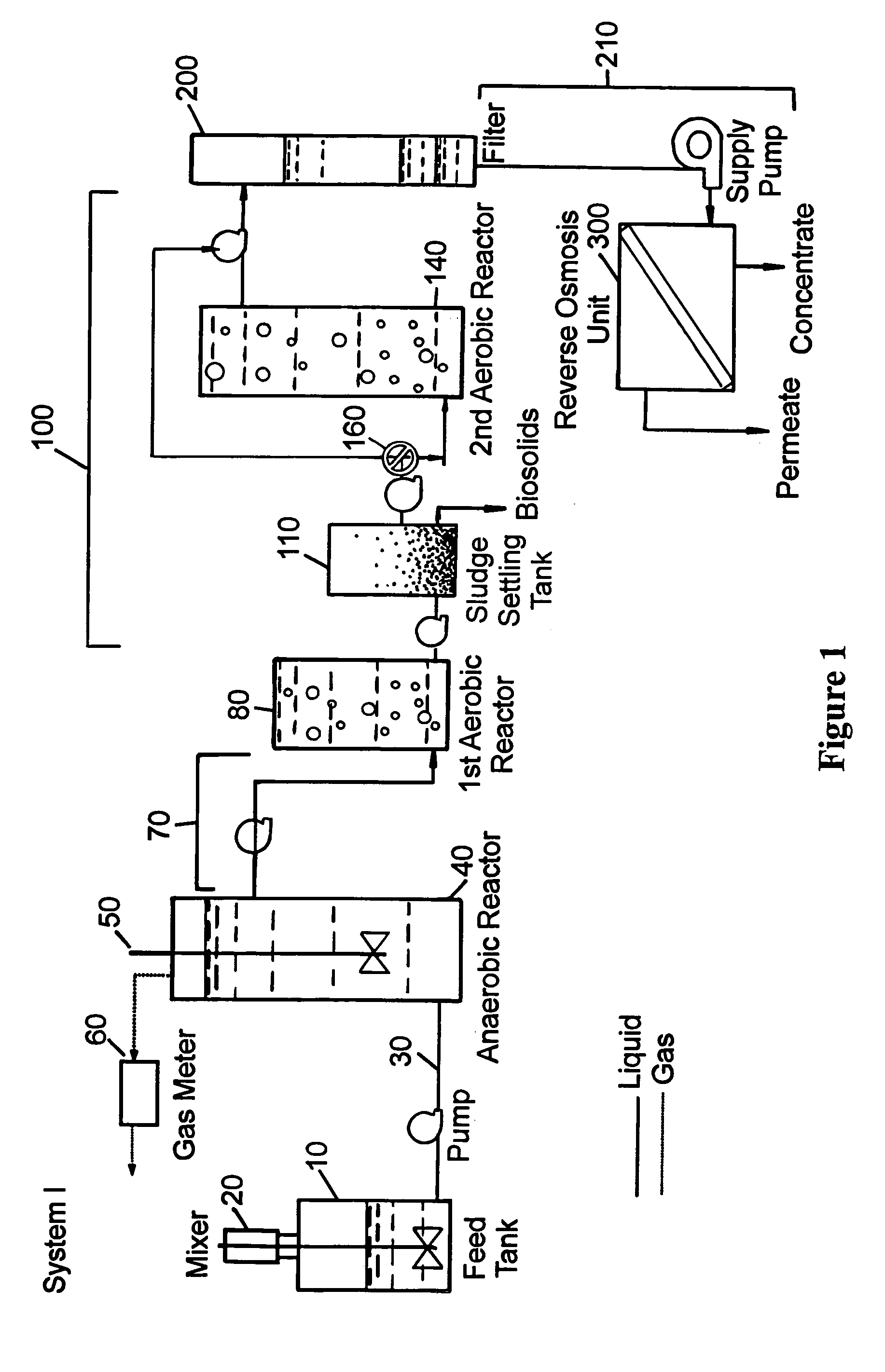

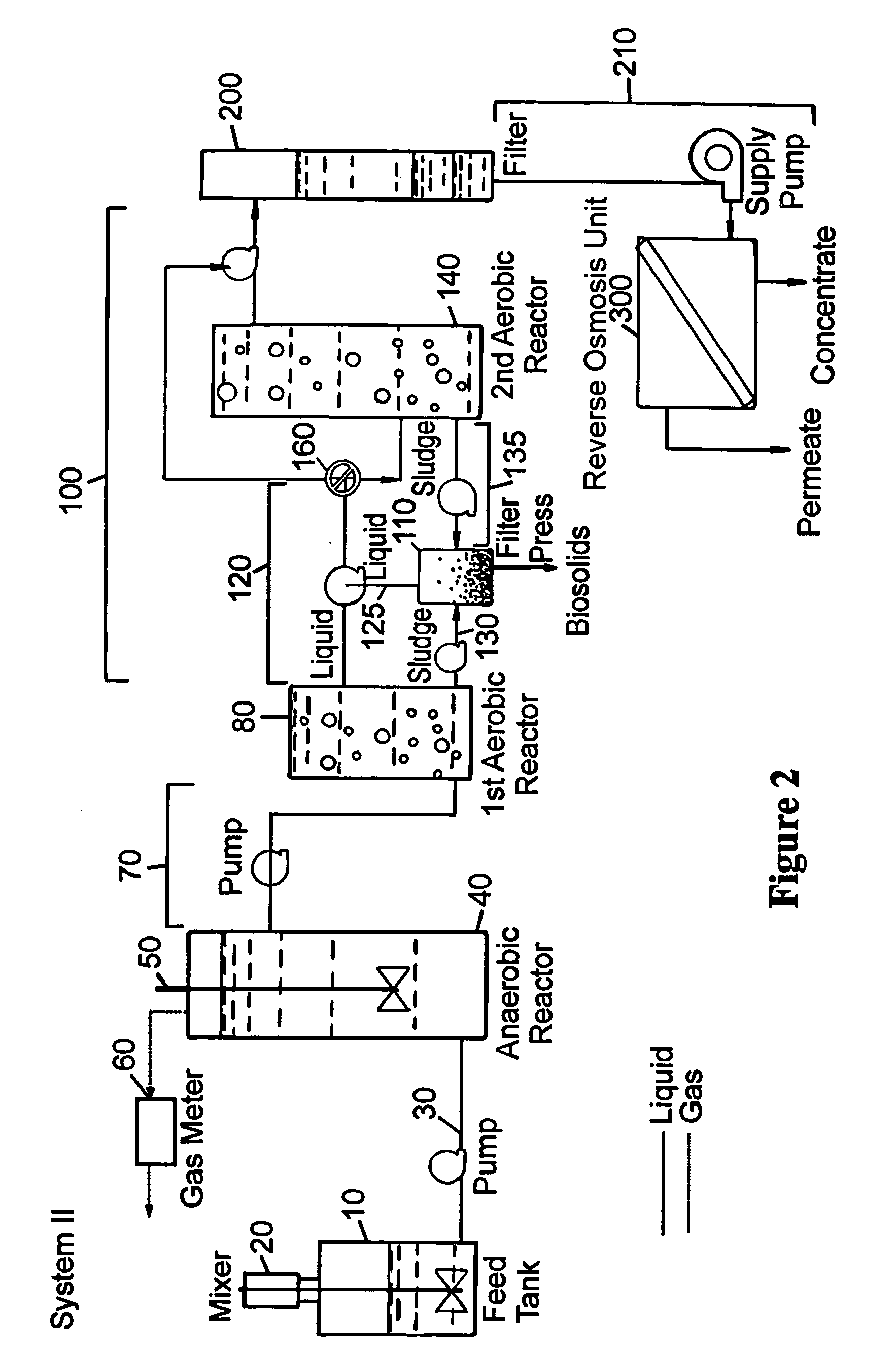

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS20050035059A1Bio-organic fraction processingWaste water treatment from animal husbandryFiltrationSeparation technology

The present invention provides an integrated system for treatment of biodegradable waste, including sewage sludge, forestry waste, food waste, agricultural waste, municipal waste, and the like. The integrated system comprises an anaerobic reactor, at least one aerobic reactor, a filtration device, and a desalinization device.

Owner:RGT UNIV OF CALIFORNIA

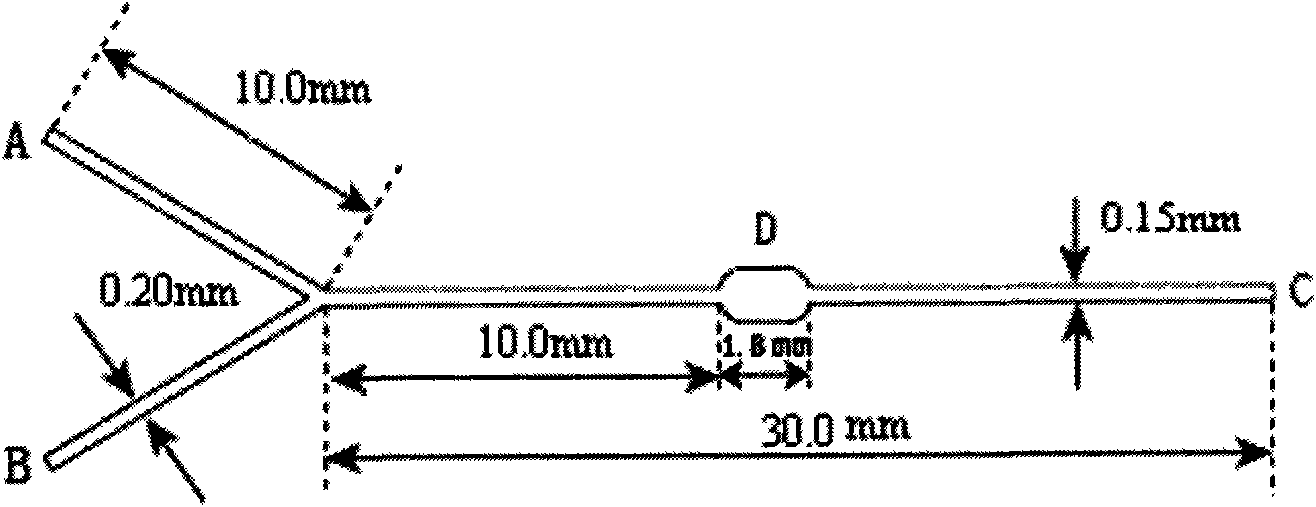

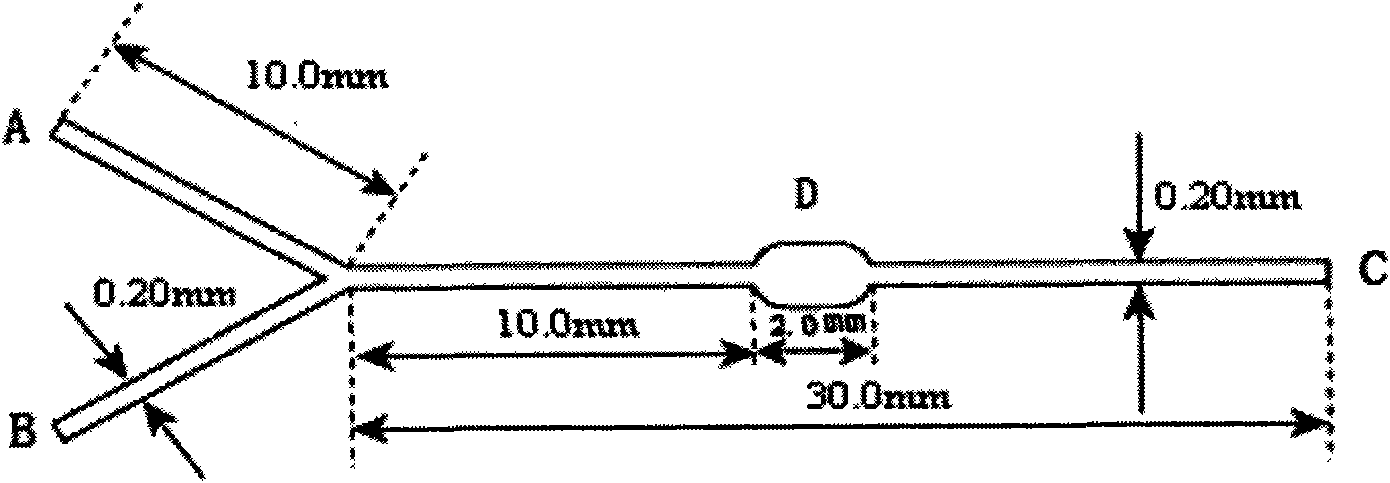

Cell sorter micro-fluidic chip based on immunomagnetic separation technology and application thereof in aspect of enrichment of rare cells

InactiveCN101643701AReduce manufacturing costEase of mass productionMicrobiological testing/measurementBiomass after-treatmentAntigenCell sorter

The invention discloses a cell sorter micro-fluidic chip based on the immunomagnetic separation technology and application thereof in the aspect of enrichment of rare cells, belonging to the technicalfield of micro-fluidic chips. The micro-fluidic chip, improved on the basis of the existing Y-type micro-fluidic chip, comprises a substrate and a cover-slip, wherein a Y-shaped micro-channel, a sample cell (1) and a buffer cell (2) respectively located at two end points of the upper part of the Y-shaped micro-channel, and an effluent cell (3) located at the end point of the lower part of the Y-shaped micro-channel are arranged on the substrate; and an antigen / antibody immunological reaction chamber (4) located on the micro-channel between the cross point (5) of the Y-shaped micro-channel andthe effluent cell (3) is further arranged on the substrate, wherein the width of the antigen / antibody immunological reaction chamber (4) is 2 to 5 times that of the micro-channel. The chip of the invention can effectively and rapidly fix the magnetic beads, increase the sample size of cells, improve the analysis flux, reduce the dead volume of sample introduction and reduce the retention and cross infection.

Owner:TSINGHUA UNIV

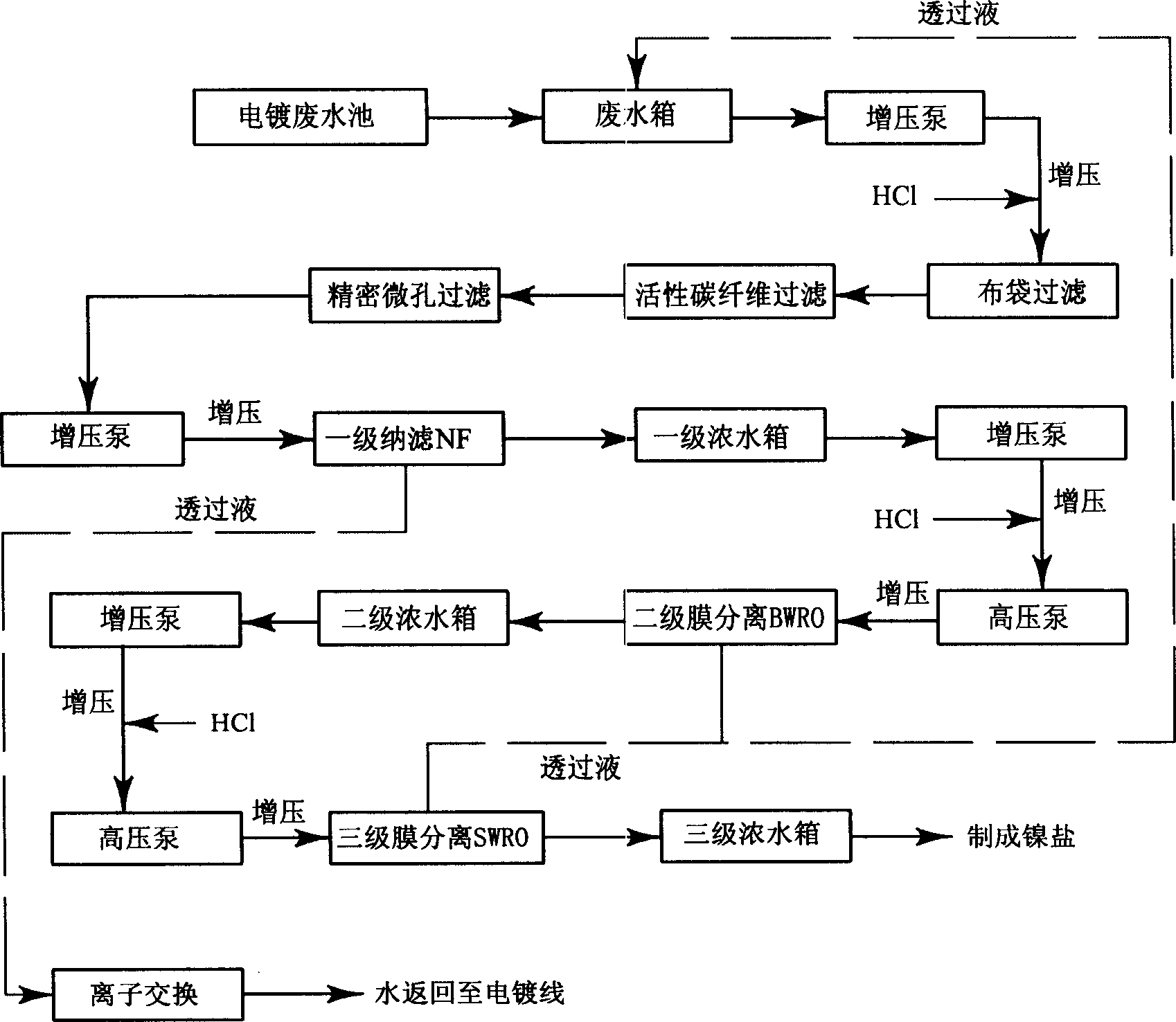

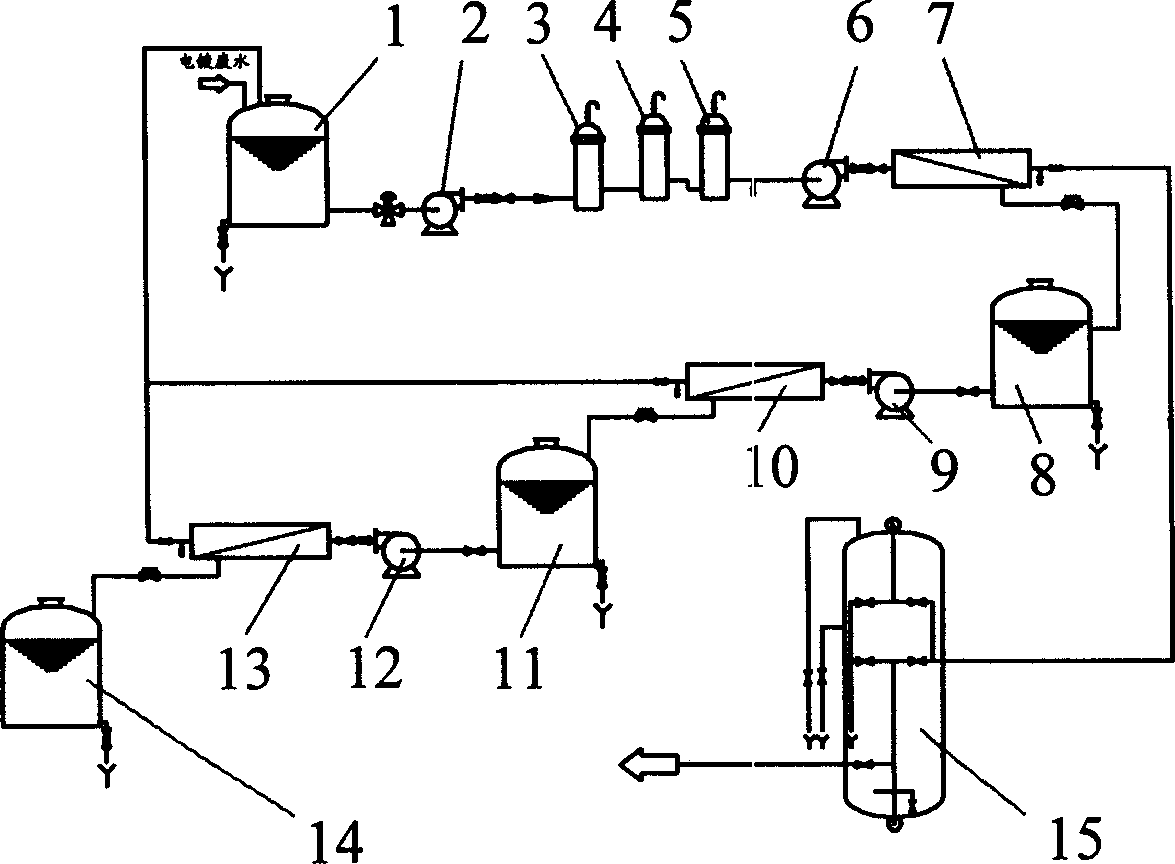

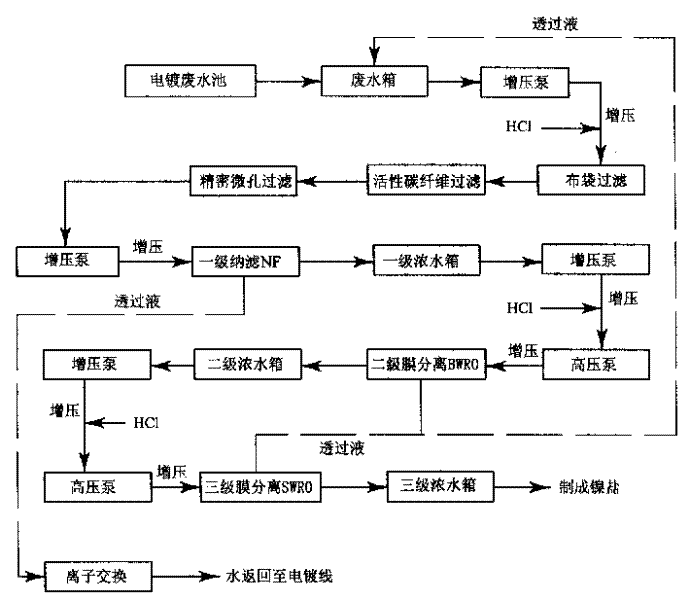

Membrane separation method of zero discharge of electroplating waste water treatment

InactiveCN1590322AAchieving zero emissionsOut of pollutionWater/sewage treatmentMultistage water/sewage treatmentSeparation technologyTreated water

A membrane separation method for reclaiming the electroplating sewage includes liqui material treating, lifting, pressurizing and delivering. It features the 3-class membrane separation to remove impurities, organic substances, fine suspended substances, Na ions, heavy metal ions, inorganic ions, etc. the regulation of pH value to prevent deposition of hydroxide, periodical automatic flushing and reuse of treated water.

Owner:HANGZHOU WATER TREATMENT TECH RES & DEV CENT NAT BUREAU OF OCEANGRAPHY

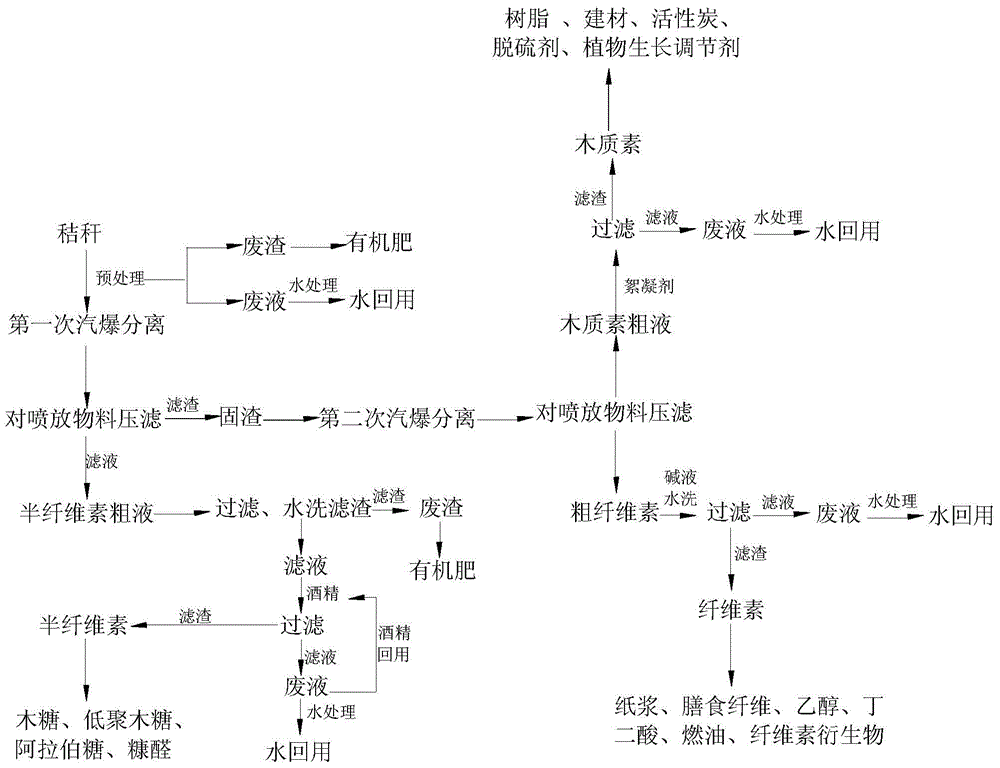

Straw component separation and straw component full utilization method

ActiveCN104404803AAchieve separationEasy to separateRaw material divisionSeparation technologyWastewater

The invention discloses a straw component separation and straw component full utilization method, and relates to the technical field of straw comprehensive utilization. According to the method, straws are subjected to a steam explosion treatment, such that hemicellulose is first separated; and the rest of the material after hemicellulose extraction is subjected to steam explosion treatment again, such that the separation of cellulose and lignin is realized. The method has the advantages of simple process, environment-friendliness, low cost, and thorough separation of hemicellulose, cellulose and lignin. With the method provided by the invention, an environment-friendly separation technology of cellulose and lignin is realized for the first time internationally, and a basis is provided for full-element, high-added-value and comprehensive utilization of straws. On the basis, products with higher added values can be derived or generated. With the production process provided by the invention, all wastewater is treated and is completely recycled, and all waste residue is used for producing organic fertilizers, such that straws are thoroughly utilized, and straw component full utilization is realized. Also, zero emission and zero pollution are realized, such that the difficulty of straw comprehensive utilization is solved.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

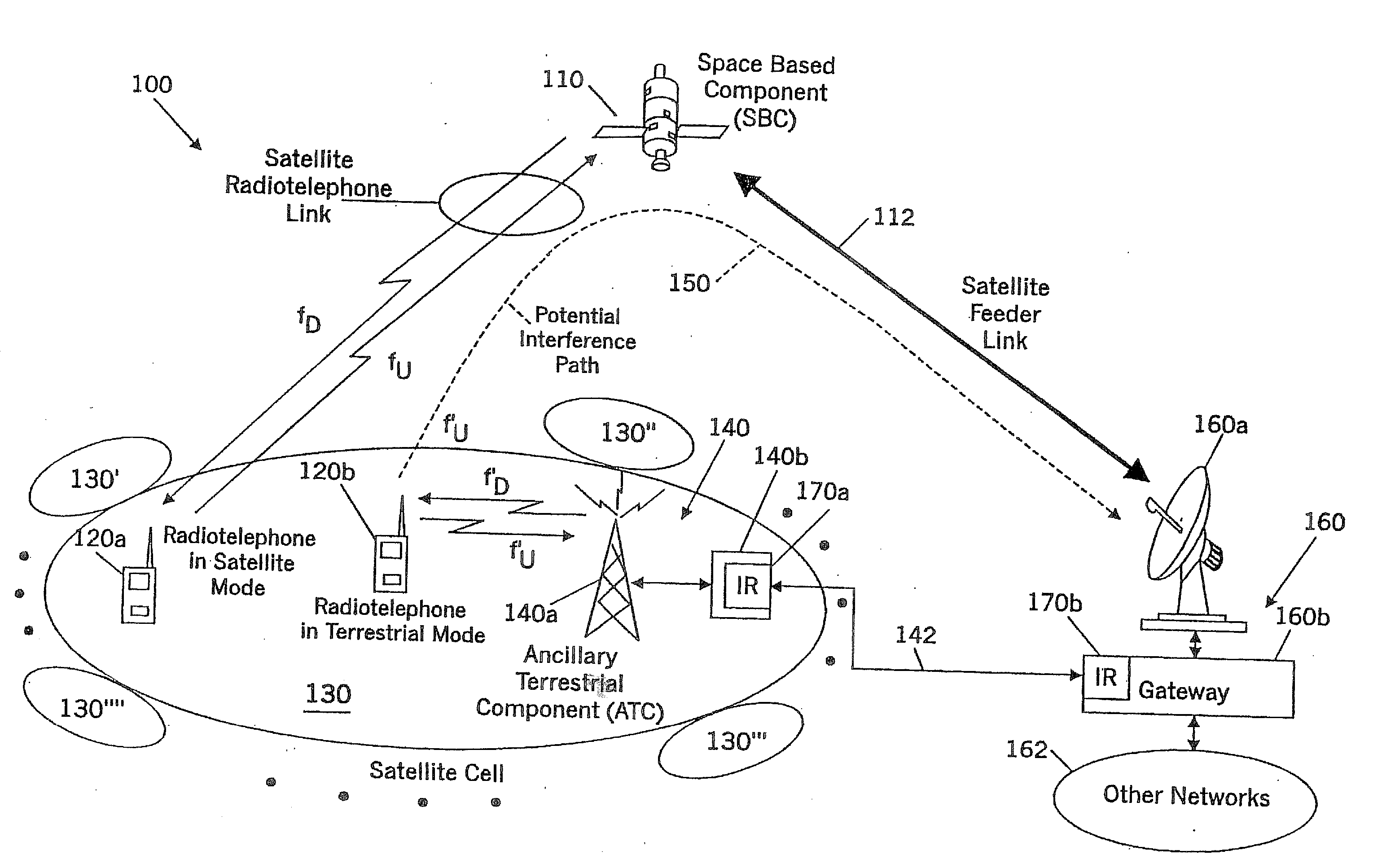

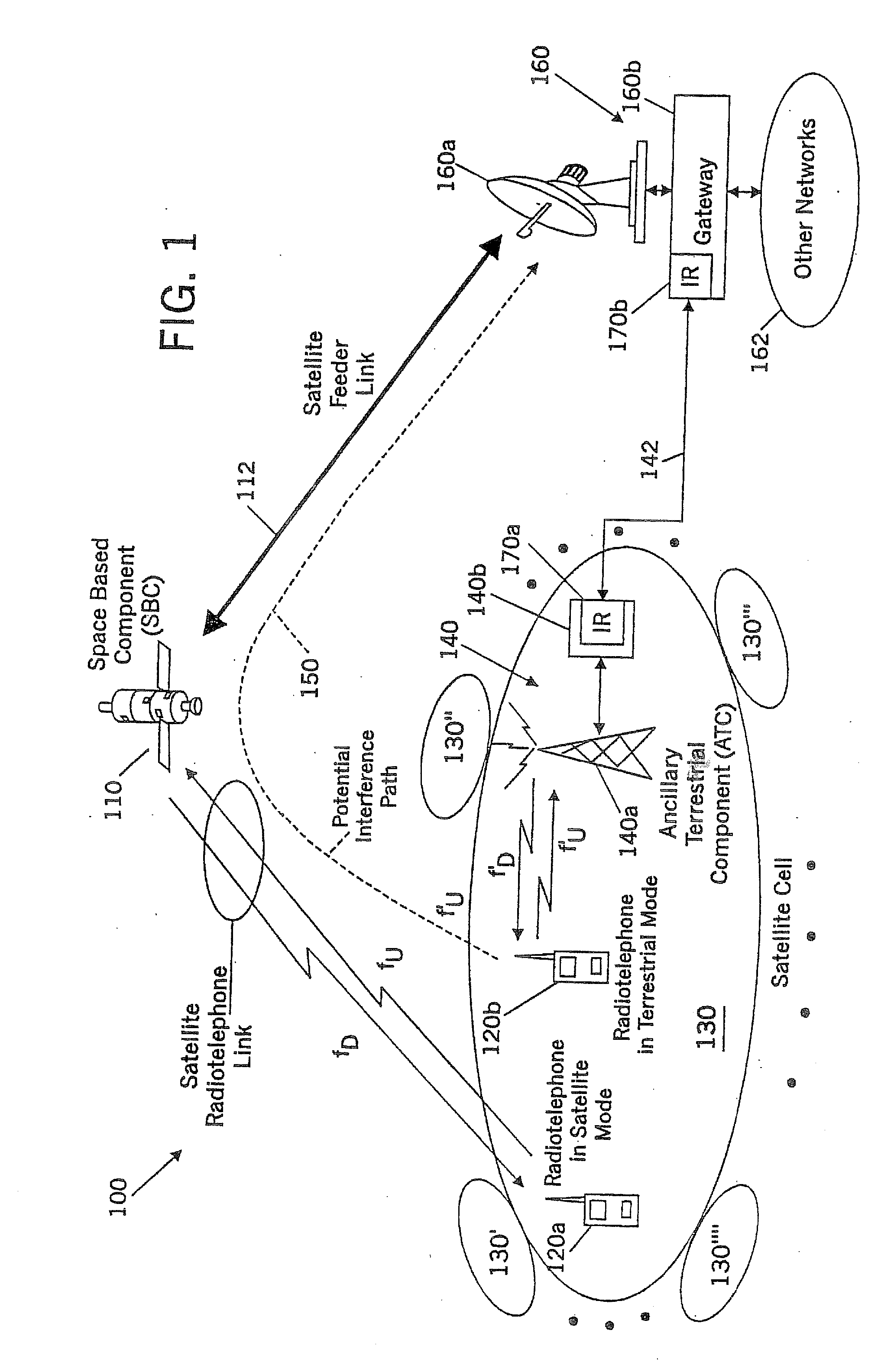

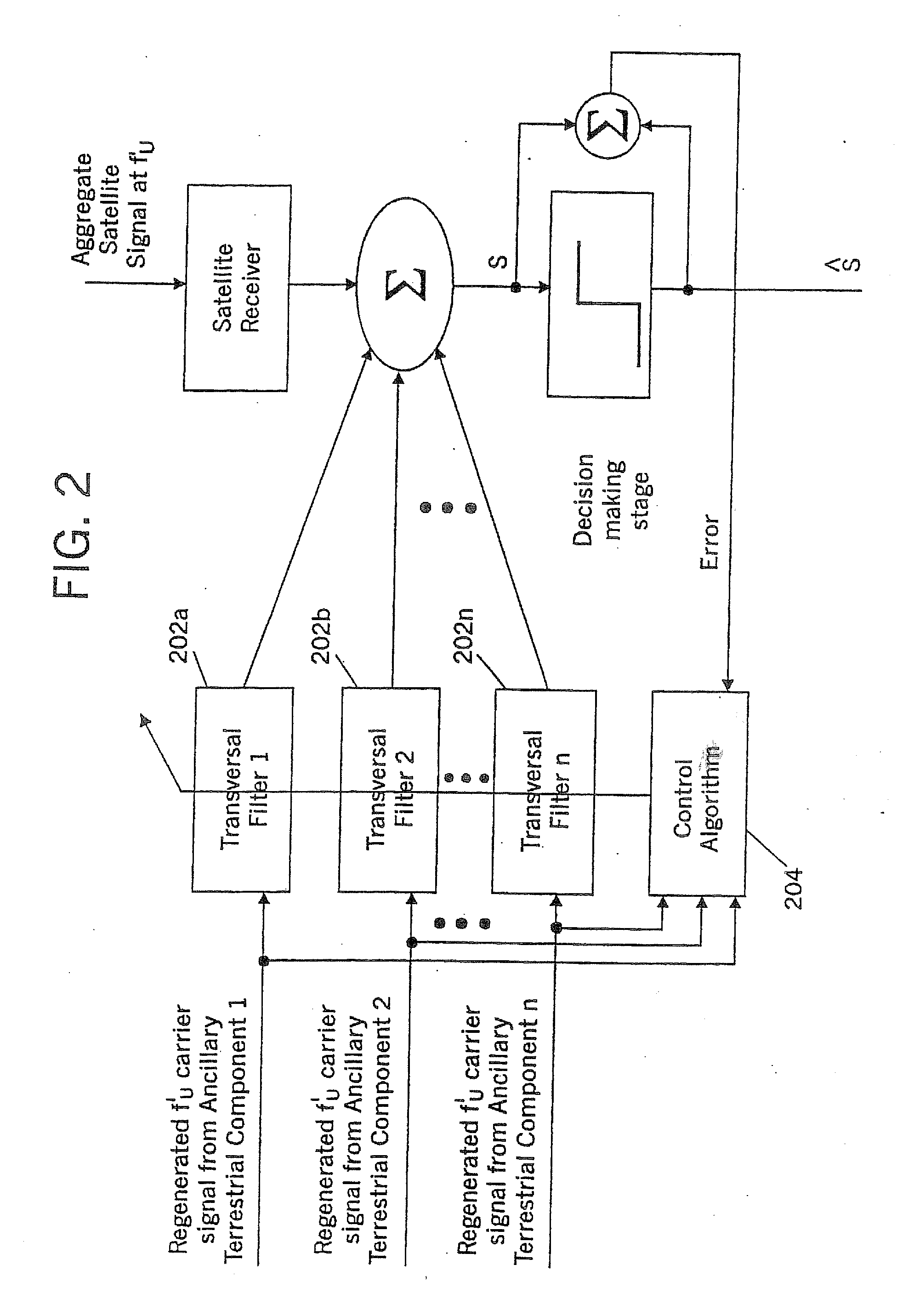

Systems and methods for terrestrial reuse of cellular satellite frequency spectrum using different channel separation technologies in forward and reverse links

ActiveUS20070232298A1Radio transmissionWireless commuication servicesCommunications systemFrequency spectrum

A wireless communications system includes a terrestrial network that is configured to receive wireless communications from radiotelephones over satellite band frequencies that are divided into channels that are separated by one of frequency or code (e.g., OFDMA or CDMA). The terrestrial network is also configured to transmit wireless communications to radiotelephones over satellite band frequencies that are divided into channels that are separated by a different one of frequency or code (e.g., CDM or OFDM). Related devices and methods are also disclosed.

Owner:ATC TECH LLC

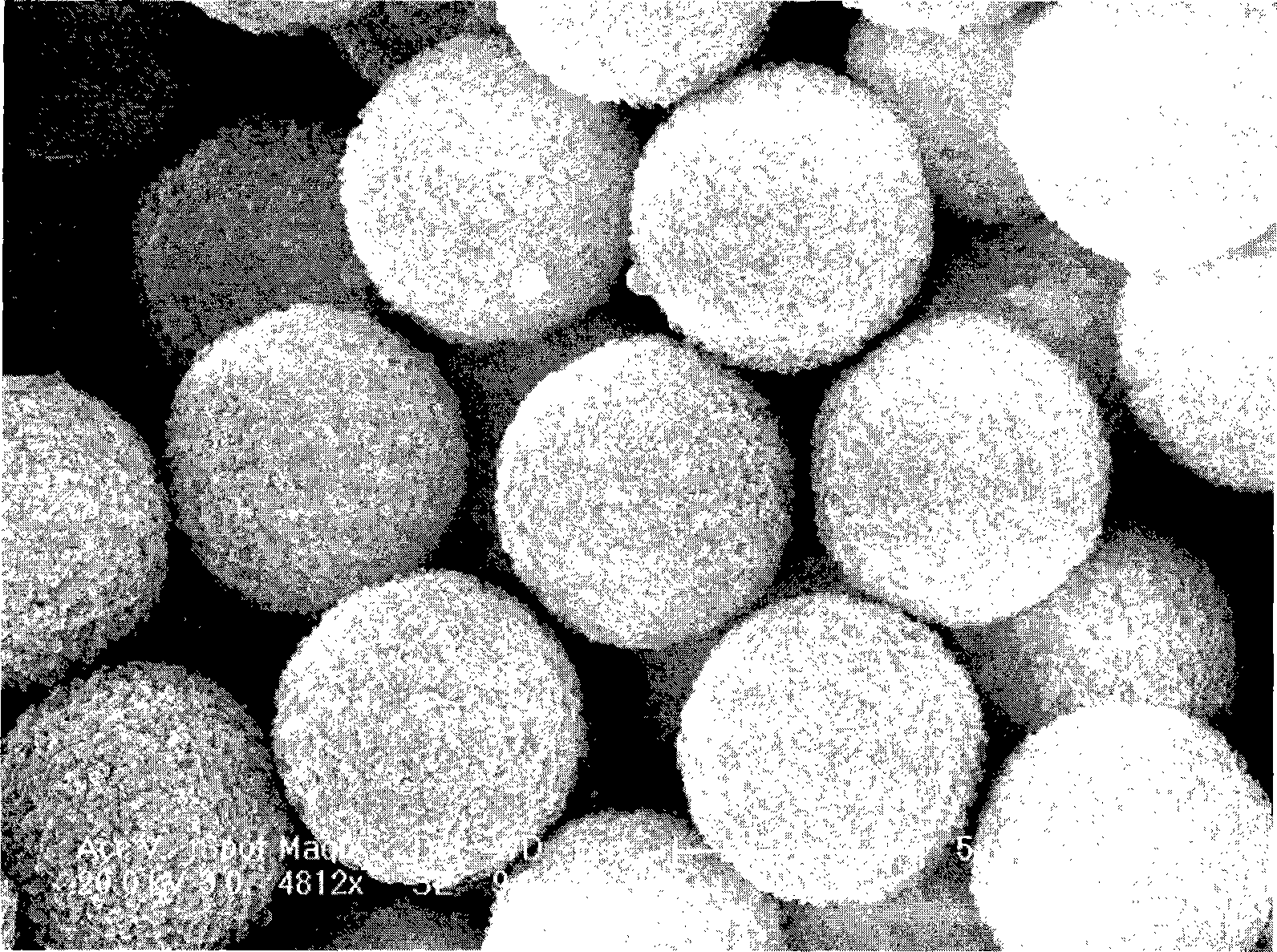

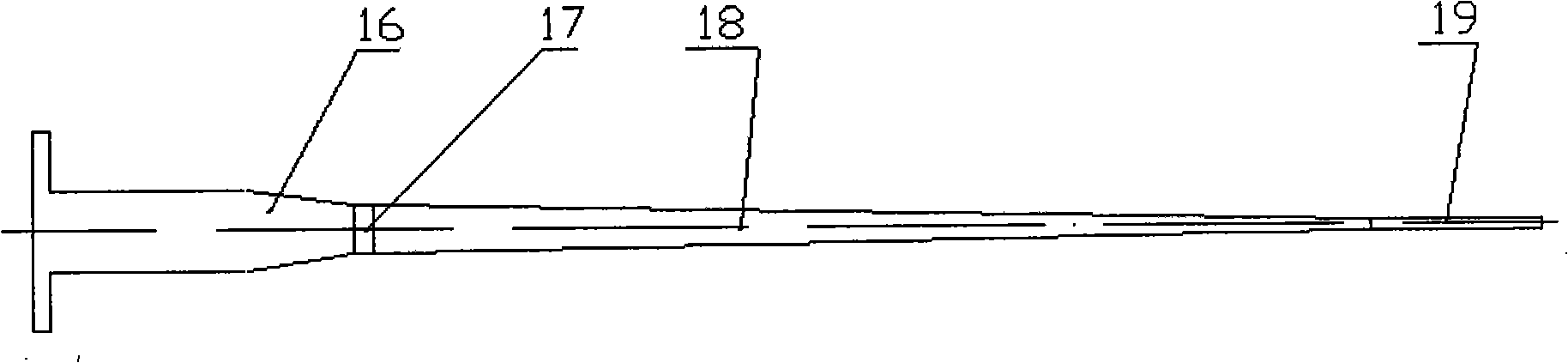

Preparation of monodisperse porous polymer microsphere

The invention provides a preparation method of a monodisperse porous polymer microsphere. After a second stage of swelling of two-stage seed swelling polymerization, remnant monomer separation technology is adopted to avoid the aggregation of the microspheres and the generation of secondary particles, thereby greatly improving the stability of preparing monodisperse porous polymer microsphere through the two-stage seed swelling polymerization. The two-stage seed swelling polymerization can stably prepare the following monodisperse porous polymer microspheres: P(St-co-DVB) (PSD for short) and P(St-co-DVB-co-MMA) (PSDA for short), wherein, St is referred to as styrene, DVB as divinybenzene, MMA as methyl methacrylate, AN as acrylonitrile and co as copolymerization. The monodisperse porous polymer microsphere PSDA prepared by the method can be seen in an attached drawing.

Owner:芜湖万隆新材料有限公司

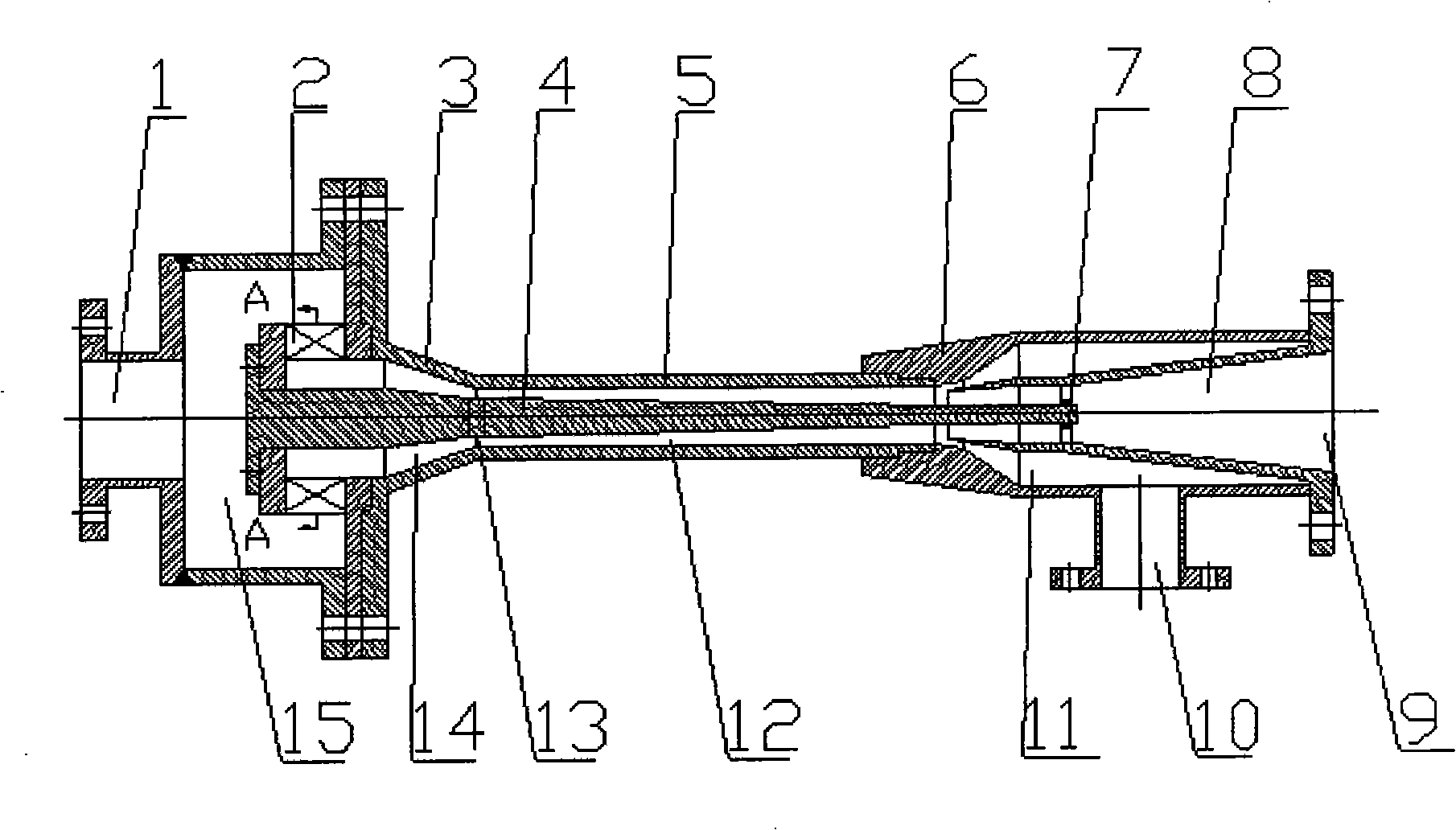

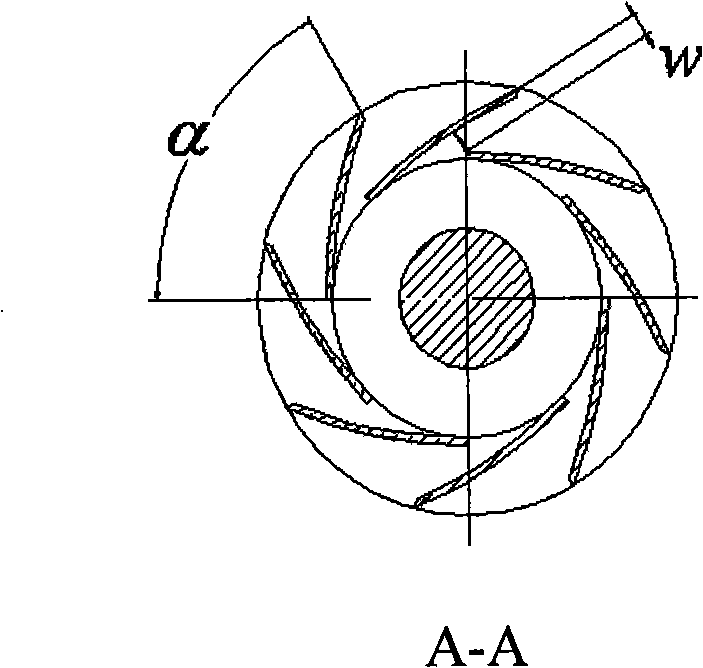

Conical core type supersonic condensing cyclone separator

ActiveCN101264470AHigh precisionEasy to separateDispersed particle separationVapor condensationCycloneSeparation technology

The invention relates to a taper core type supersonic condensation cyclone separator, belonging to the technical field of expansion refrigeration and condensation separation of pressure gas. The taper core is inserted in a passage, and the diameter of the taper core is changed at different places, so as to form the passage with a gradually decreased section part, a constant throat part and a gradually increased section part; therefore, a constant diameter inner hole can be adopted to avoid gradually increased small taper pipe passage which is difficult to be machined, so that the spin strength is not weakened due to the diameter increase. The taper core type supersonic condensation cyclone separator enables low-temperature working condition by means of pressure expansion and cooling of the gas, and reinforces spin by means of diameter decrease to generate strong centrifugal force field. The pressure can be increased after separation. The taper core type supersonic condensation cyclone separator has the advantages of no moving pieces, no need of external drive, energy saving, compact size, low cost, stable and reliable operation, and applicability to condensation separation of mixed gas with high pressure and low flow rate and separation of heavy components of natural gas and petroleum gas, in particular to offshore platform and other occasions with limited space due to compact size.

Owner:DALIAN UNIV OF TECH

Preparation method of oil-water separation material

ActiveCN103626171AImprove oil-water separation effectEasy to separateGrapheneLiquid separationSeparation technologyMechanical stability

The invention provides a preparation method of an oil-water separation material, which comprises the following steps: soaking a sponge material in a graphene oxide solution, taking out the obtained sponge material and centrifuging the sponge material, so that a graphene oxide coated sponge material is obtained; and carrying out a reduction reaction on the graphene oxide coated sponge material under the action of a reducing agent so as to obtain the oil-water separation material. The oil-water separation material prepared by using the method provided by the invention is a reduced graphene oxide coated sponge material, is coated with a graphene layer uniformly and tightly and has good rebound resilience and mechanical stability, and the reduced graphene oxide layer provides good hydrophobicity and lipophilicity, therefore, the preparation method disclosed by the invention can be applied to oil-water separation technologies.

Owner:UNIV OF SCI & TECH OF CHINA

Drainage plate for silt consolidation, filter cloth and drainage plate core

The invention is the improvement on a longitudinal drainage plate for silt consolidation, filter cloth and a drainage plate core, which is characterized in that fibrous hot-pressed microporous filter cloth is planar filter cloth hot-rolled by a flat roller, the filter cloth is adhered to the surfaces of convex ribs of the drainage plate core through thermal thawing or a chemical way, the filter cloth adopts silk reeling and hot-press forming separation technology, and the drainage plate core is made of co-polypropylene, thereby overcoming the disadvantages of the prior art; and the aperture of the filter cloth can be adjusted according to treated silt, the drainage plate is difficult to block, the engineering on a soft foundation after the treatment cannot have the settlement after the construction and has smooth drainage and high drainage efficiency, and the plate core has long effective service life.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

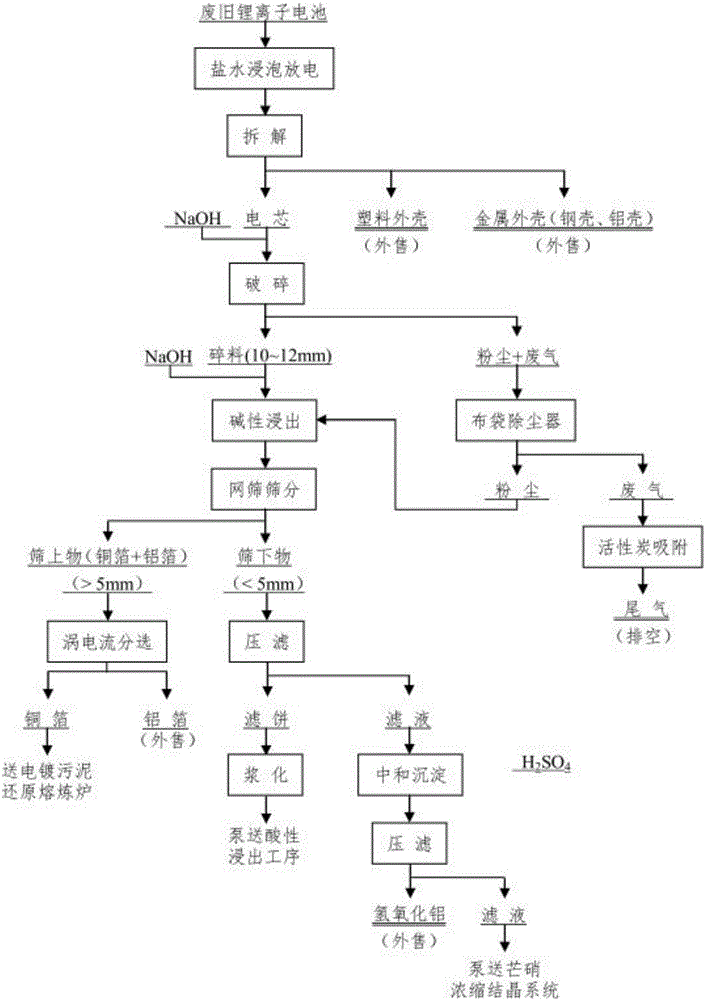

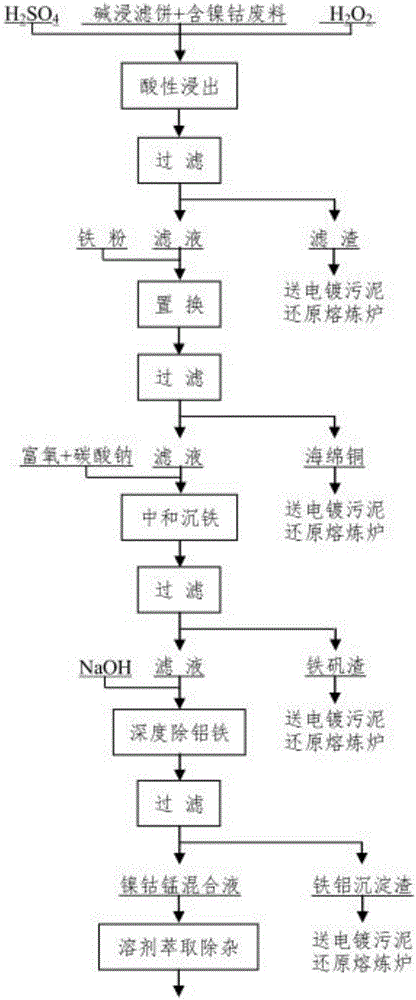

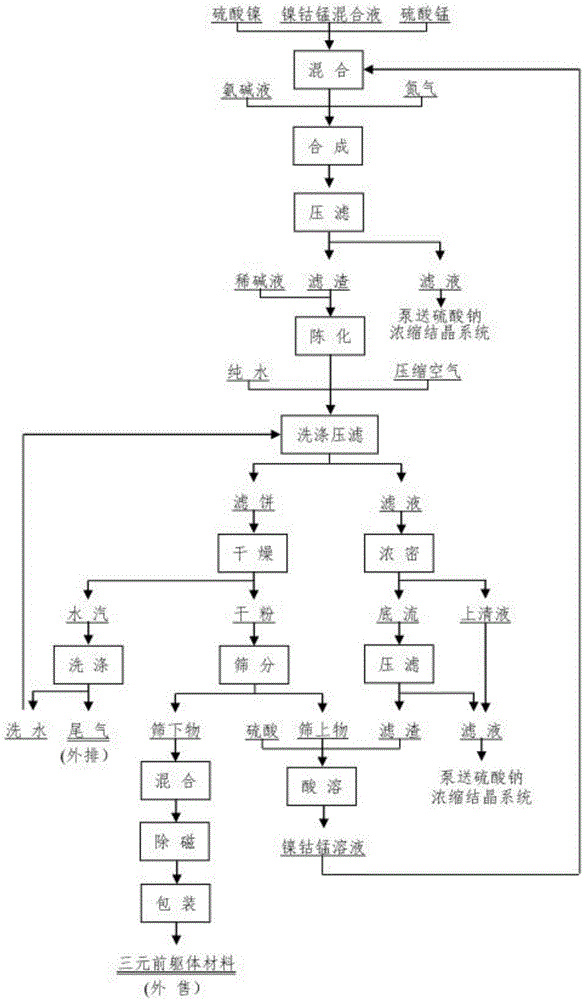

Environmentally-friendly and highly-efficient recovery and separation technology of lithium ion batteries in waste mobile phones

ActiveCN106558739ACause secondary pollutionAchieve recyclingWaste accumulators reclaimingBattery recyclingSeparation technologyLithium-ion battery

The invention discloses an environmentally-friendly and highly-efficient recovery and separation technology of lithium ion batteries in waste mobile phones. The technology mainly comprises brine discharge, disassembling and crushing, alkaline leaching, acidic leaching, iron powder displacement copper precipitation, purification and impurity removal, and precursor synthesis. The technology has the characteristics of advanced process, low cost, high efficiency, substantial economic and social benefits, no discharge of three wastes, no secondary pollution to environment, and realization of cycling of mobile phone resources, so the earth is well protected.

Owner:安徽得盈再生资源回收有限公司

Method for preparing composite nanofiltration membrane

The invention relates to a method for preparing composite nanofiltration membrane, to the field of film separating technology. The electrolyte multilayer film is assembled on the substrate film as an ultrathin separating film using layers static self-assembly technology, to obtain the composite nanofiltration membrane. The preparation method alternately immerges the substrate film into the polyanion solution and the polycation solution to alternately and repeatedly aggrade on the surface of the substrate film to get the composite nanofiltration membrane ultrathin separating layer after the assemble of a certain layers. The said polyanion solution is sodium polystyrene sulfonate or sodium polyacrylate; the said polycation solution is poly dimethyl diallyl ammonium chloride or polyallyl ammonium chloride, and the said substrate film is polyethersulfone ultrafiltration film or polysulfone ultrafiltration film. The method of the invention has a simple process, and the thickness of ultrathin separating layer is controlled. The compositenanofiltration membrane has a using foreground in the field of sea water and bitter desalination, sewage disposal and callback, ultra pure water preparation and so on.

Owner:SHANGHAI UNIV

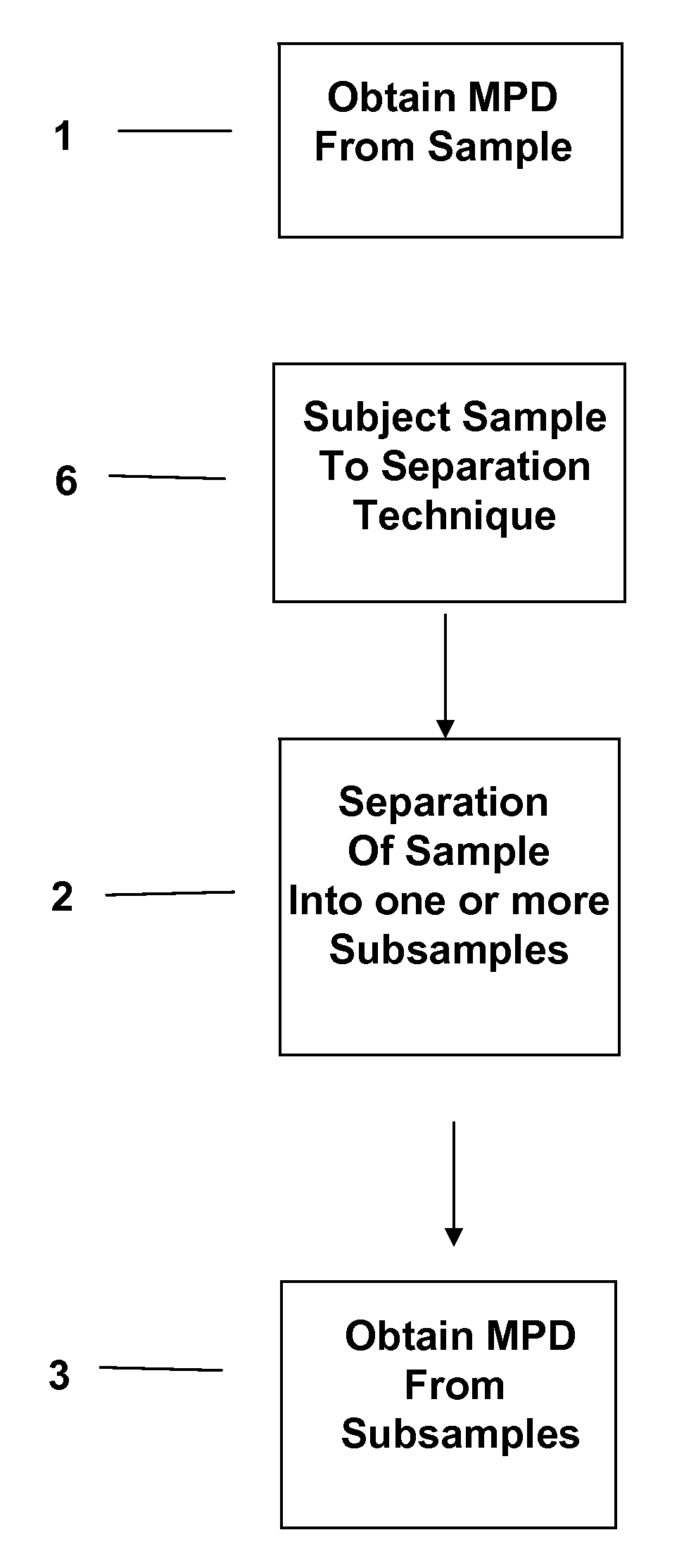

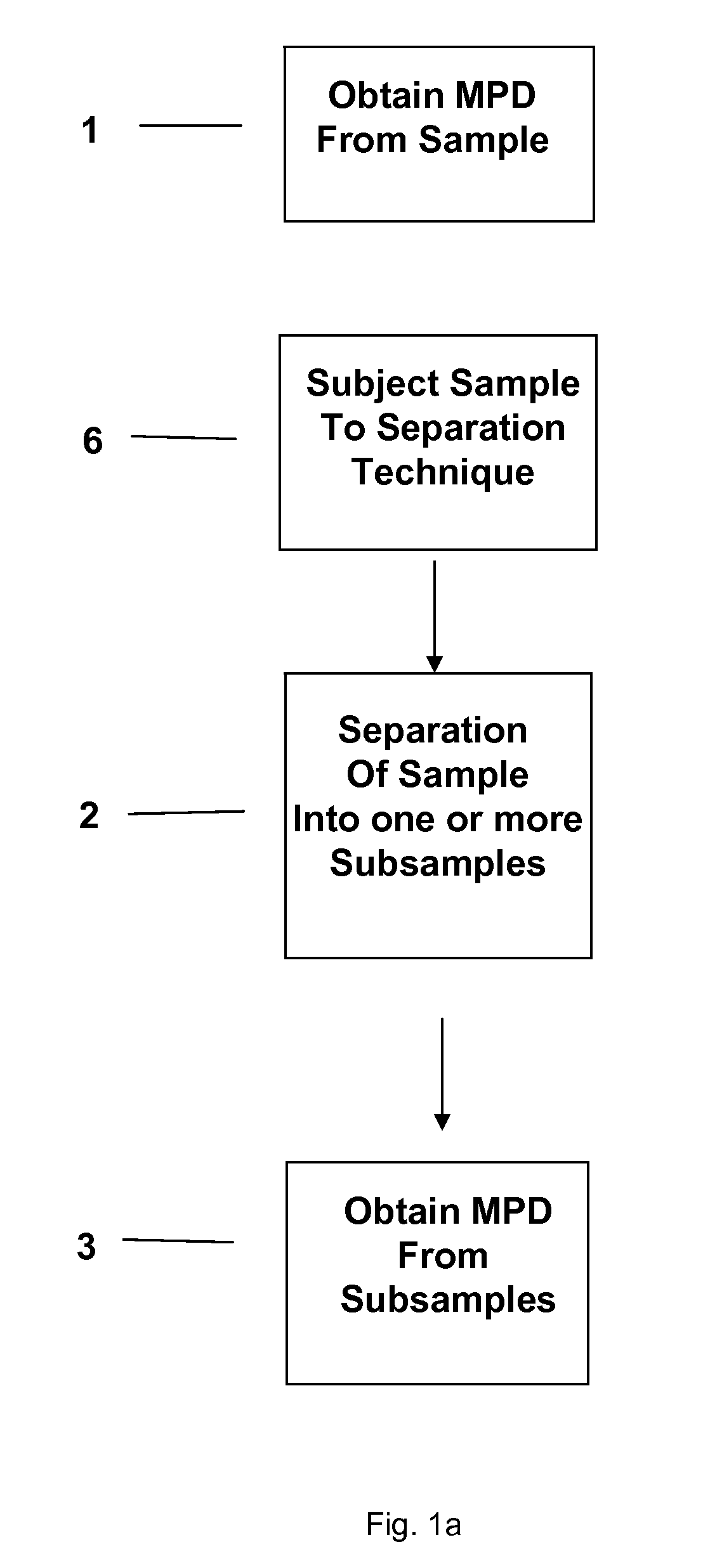

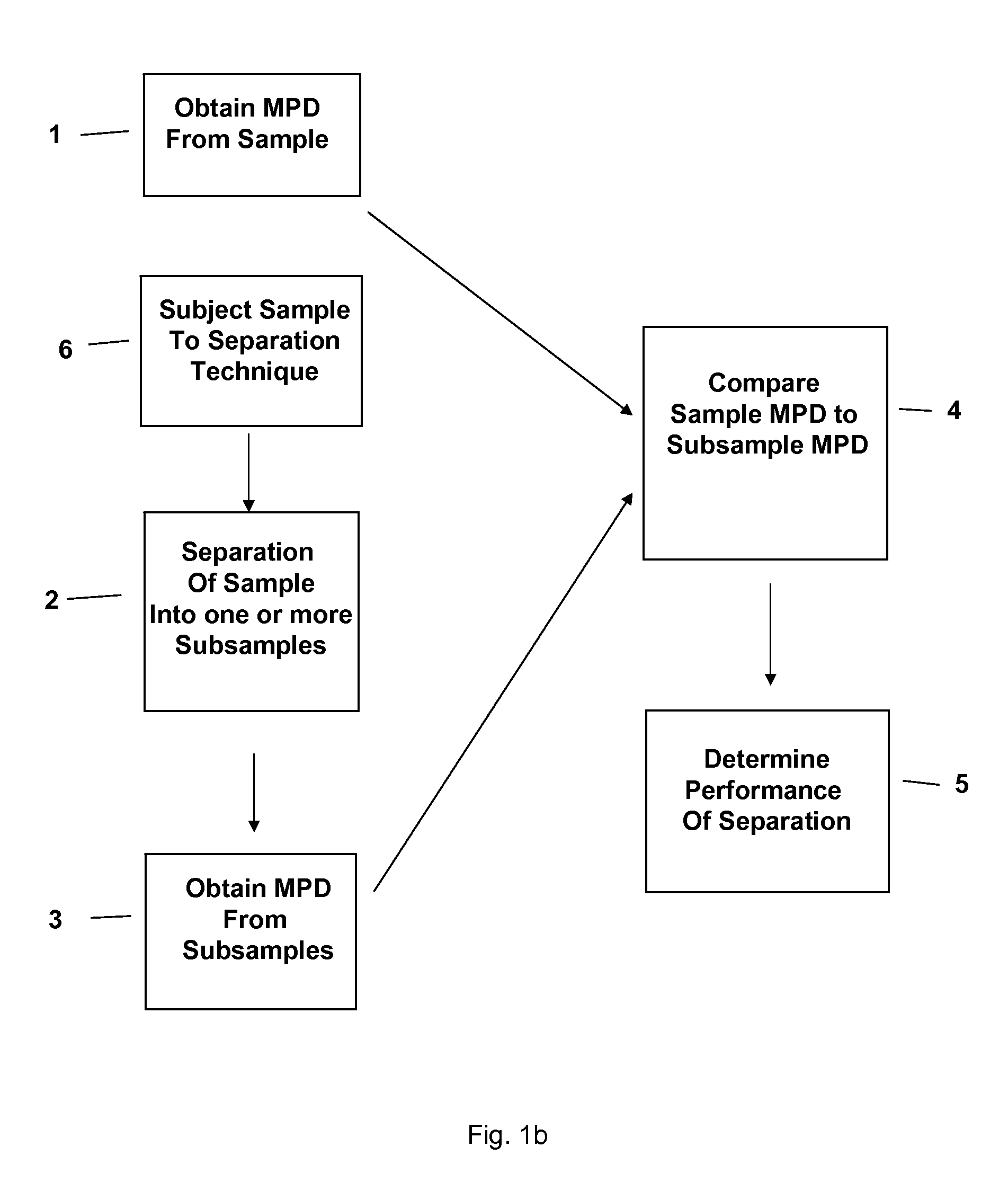

Separation technology method and identification of error

InactiveUS20100050737A1Optical radiation measurementParticle separator tubesCapillary electrophoresisElectrophoresis

The present invention relates to a method and accompanying device for separating a known or unknown sample into one or more subsamples. By comparing the subsample's measurement profile data to the sample measurement profile data, the performance of the separation can be determined. The separation could be chromatography [such as high-performance liquid chromatography (HPLC), gas chromatography (GC), or the like], electrophoresis [such as capillary electrophoresis (CE) or the like], or another separation technique. The measurement profile data could be ultraviolet / visible (UV / Vis) spectra, mass spectra (MS), or another measurement technique.

Owner:WOLTERS ANDREW MARK

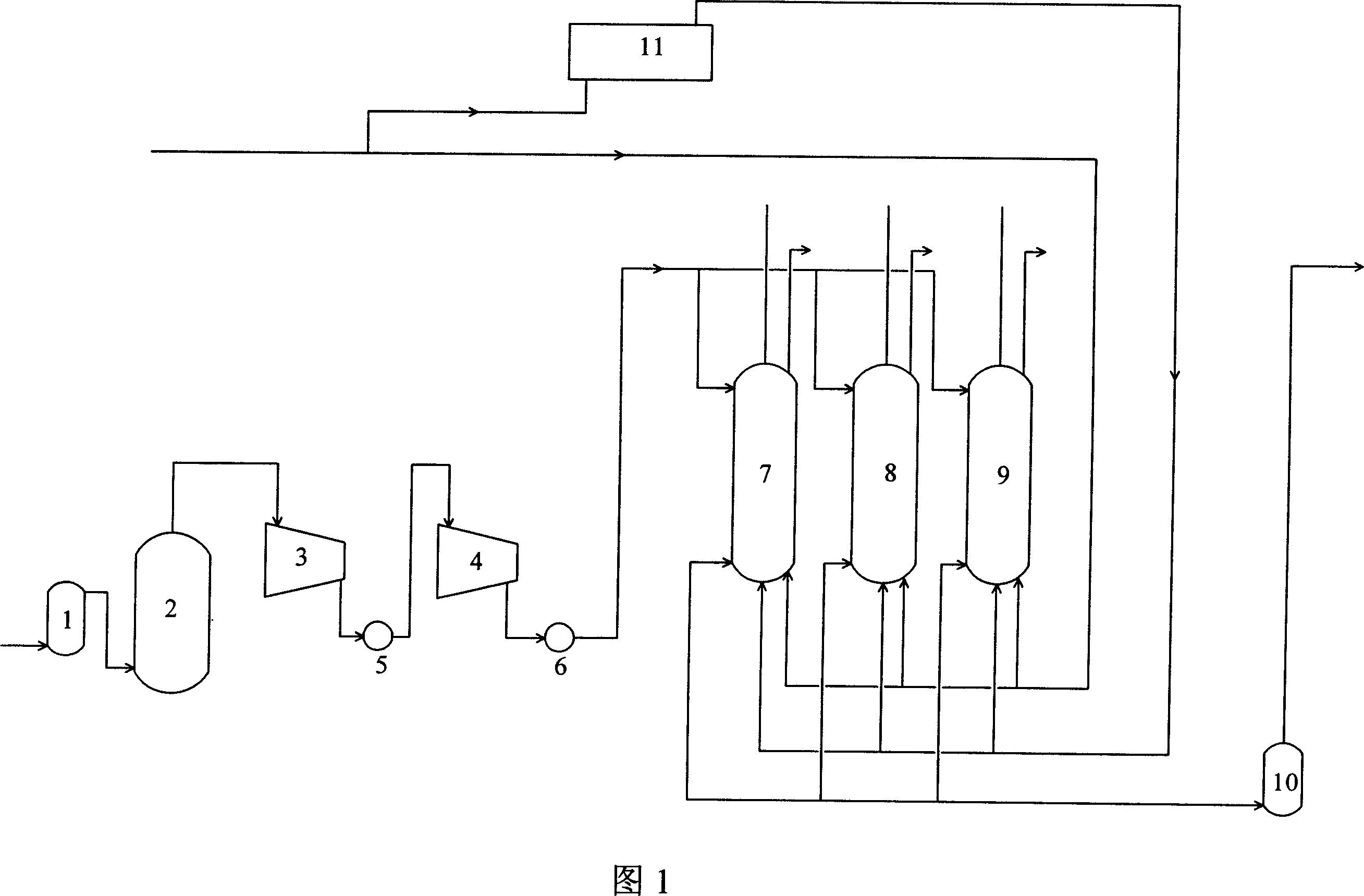

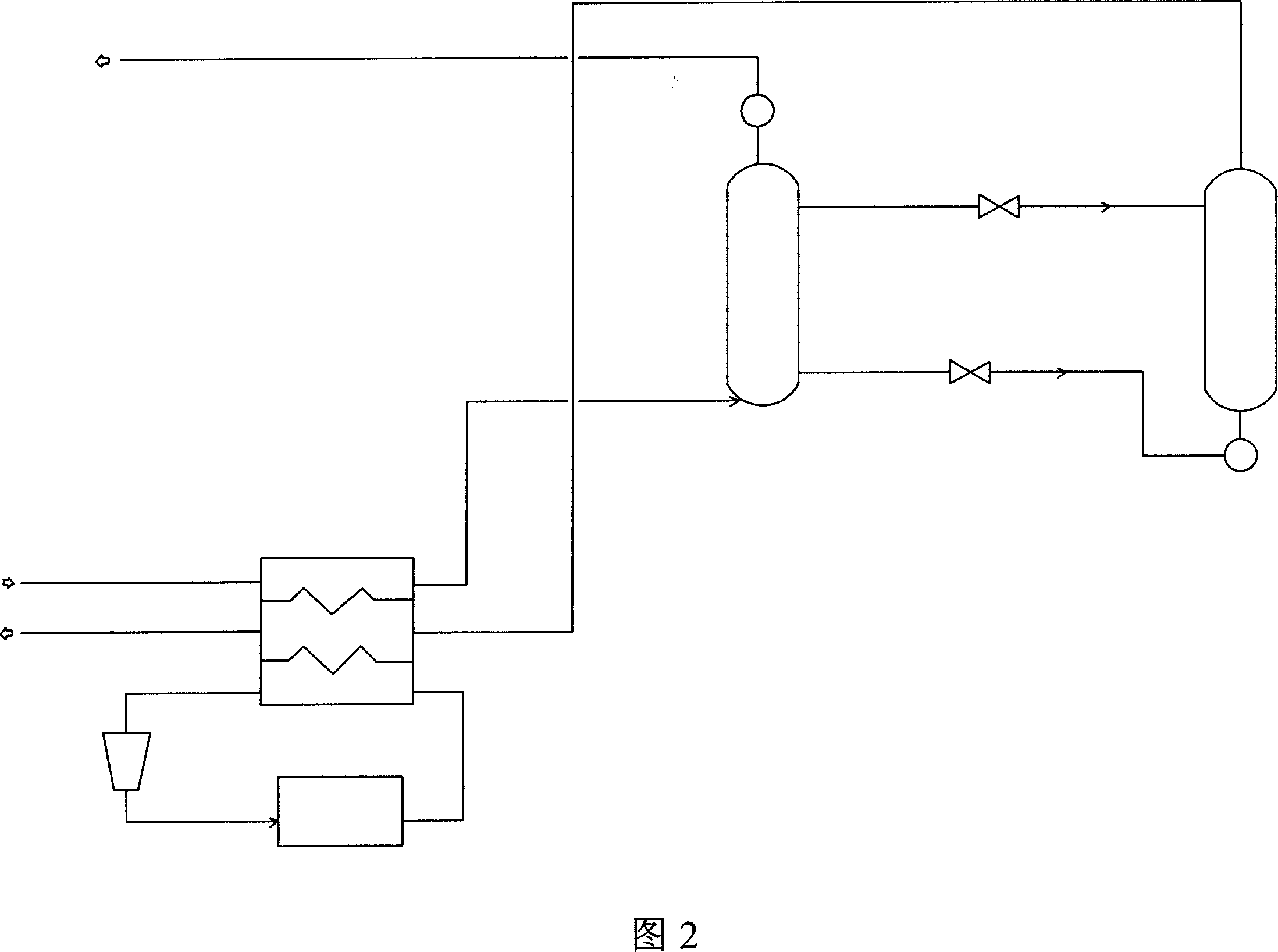

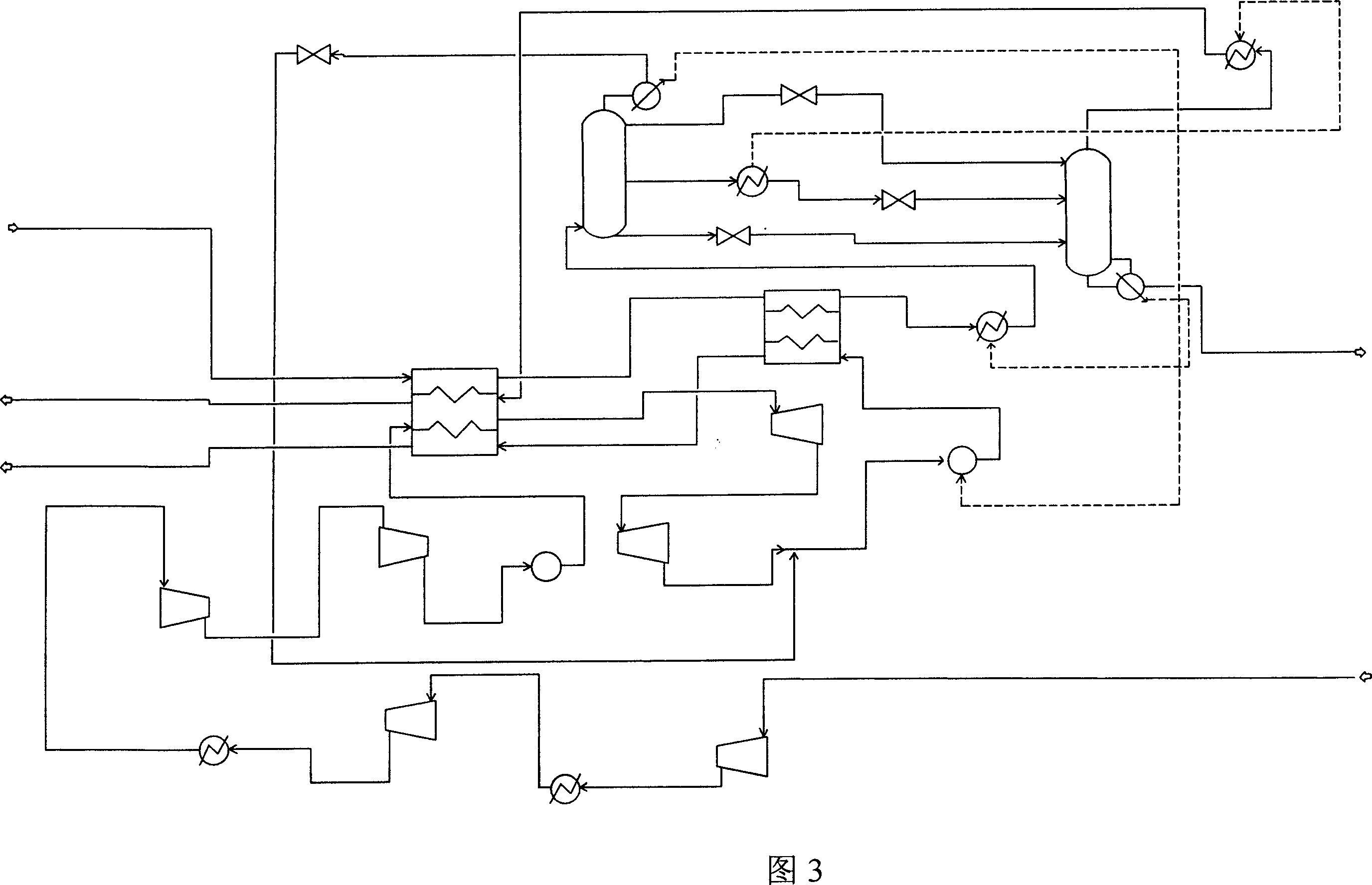

Process and equipment for liquefying air-containing coal-bed gas

InactiveCN1952569AEfficient use ofAvoid pollutionSolidificationLiquefactionSeparation technologyPhysical chemistry

The invention discloses a liquefaction technology for coal-bed gas with air, comprising compressing and purifying technology, refrigeration technology and liquefaction and separation technology. Double-grade rectifying method in low temperature is applied in the liquefaction and separation technology. Liquefaction and separation are carried out in low temperature and it is provided with high separation purity and good safety. The purity of liquefied natural gas can achieve more than 99% and the content of firedamp drained in air is only 1% or so. The resource is recycled efficiently. The invention also provides liquefaction equipment for the coal-bed gas with air.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS7045063B2Bio-organic fraction processingExcrement fertilisersSeparation technologyFiltration

Owner:RGT UNIV OF CALIFORNIA

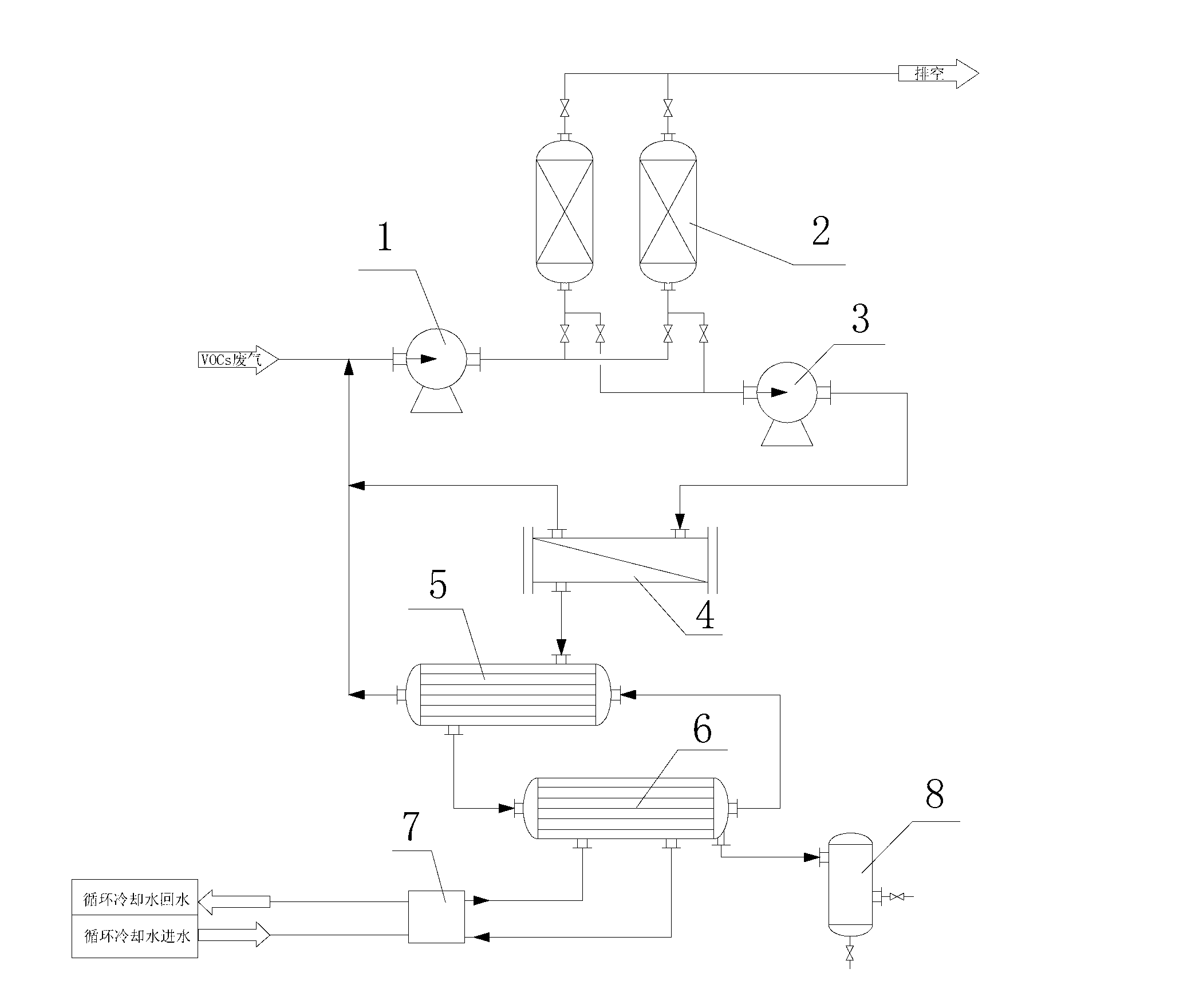

System and technology for processing low-concentration VOCs (volatile organic chemicals) waste gas

InactiveCN102794079AReduce consumptionImprove automationDispersed particle separationVapor condensationSeparation technologySewage

The invention provides a system and technology for processing low-concentration VOCs (volatile organic chemicals) waste gas. In the invention, the adsorption technology, the membrane separation technology and the condensation technology are combined, wherein the VOCs waste gas is subjected to primary concentration by the adsorption technology and secondary concentration by the membrane separation technology, and the VOCs waste gas after concentration is condensed by the condensation technology; and the aim of saturation precipitation of organic components can be achieved with relatively little consumption of cold. The system and technology provided by the invention integrate the adsorption technology, the membrane separation technology and the condensation technology, and are mainly used for processing the VOCs waste gas in the occasions with relatively low concentration such as the truck loading process of oil products and chemical products, storage tanks, sewage pools and the like; and the processed waste gas can meet the requirements of the effluent gas emission standard of the country.

Owner:JIANGSU WISDOM ENG TECH

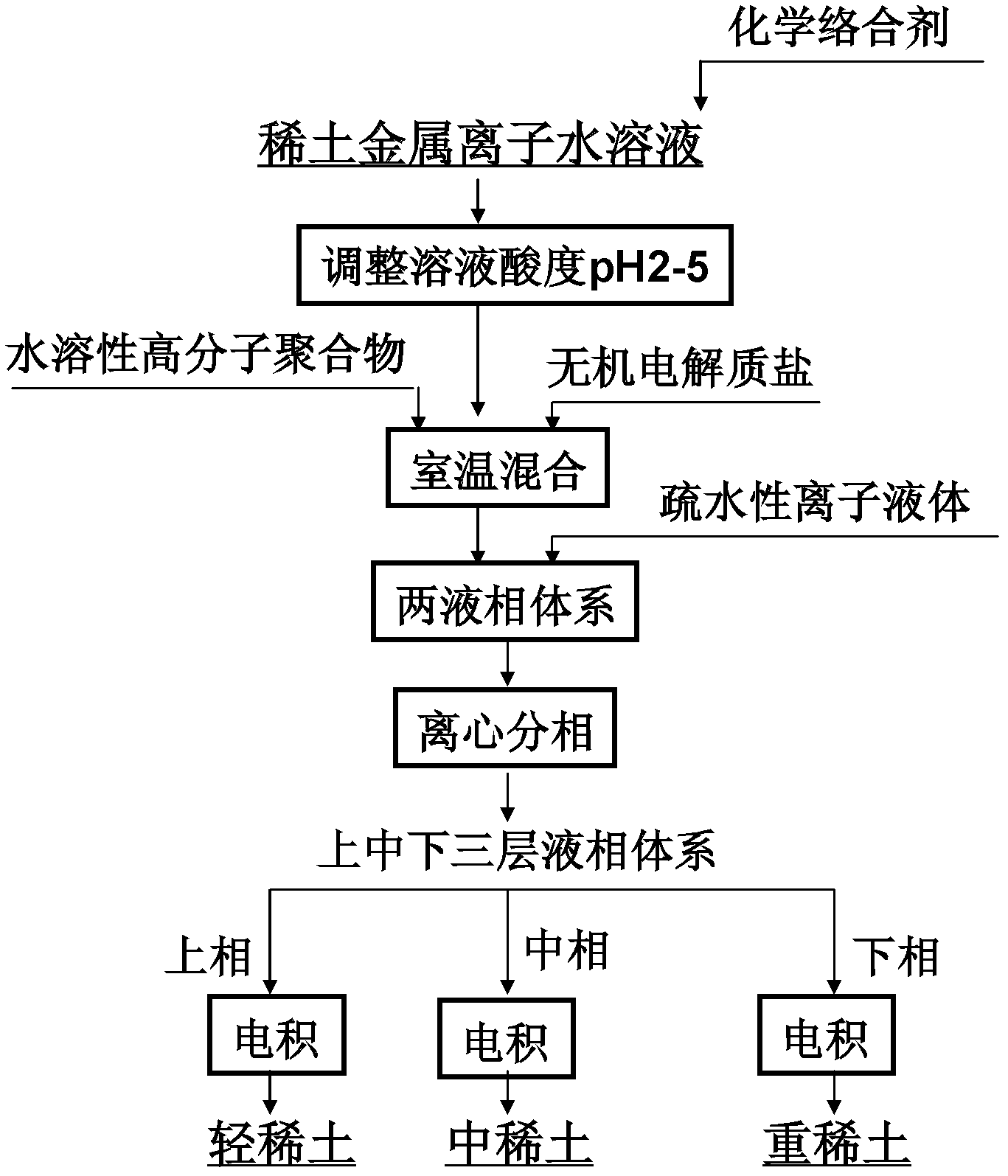

Method for separating rare earth ions by extraction of liquid-liquid-liquid three-phase system

InactiveCN102382982ASpeed up clarification and phase separationReduce usageProcess efficiency improvementSeparation technologyIonic liquid

The invention relates to a method for separating rare earth ions by extraction of a liquid-liquid-liquid three-phase system, and belongs to the technical field of rare earth extraction and separation. The method comprises the following steps of: adding a chemical complexing agent into an aqueous solution containing the rare earth ions, regulating the acidity of the solution, adding a water-soluble high polymer and an inorganic electrolyte salt, oscillating and mixing at room temperature, and obtaining a liquid phase system of upper and lower layers; adding a hydrophobic ionic liquid, fully mixing the solution at room temperature, and obtaining an insoluble three-liquid phase coexistence system of upper, middle and lower layers; and respectively taking the upper, middle and lower phases ofthe three-liquid phase system, and reclaiming the rare earth ions by using an electro-deposition method. According to the method, a volatile organic solvent is not used, so that the phase forming behavior and the phase separation process of the three-phase system are easily artificially controlled; and light, medium and heavy rare earth ions are selectively enriched or grouped and separated in three different liquid phases respectively. Compared with conventional oil-water two-phase separation, the method has the advantages that: the process flow is greatly simplified, the method is quick in phase separation and avoids emulsifying, and the hydrophilic and hydrophobic properties of the ionic liquid three-phase system are easily controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

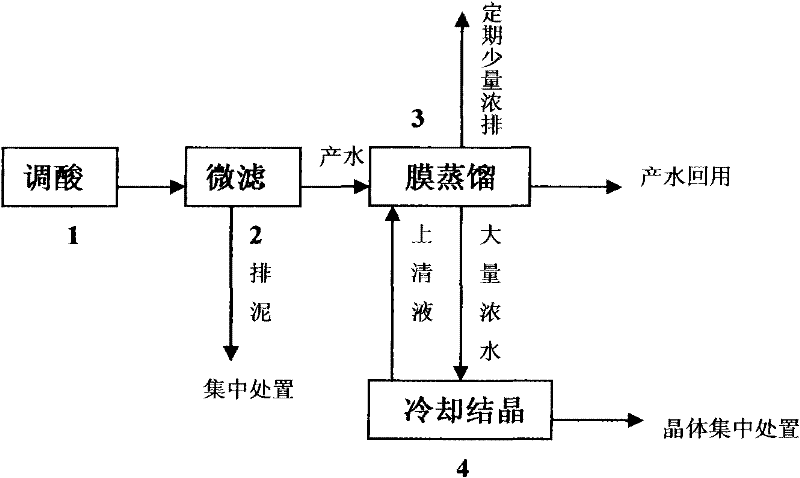

A method for the treatment and reuse of ammonia-nitrogen-containing high-salt catalyst wastewater

ActiveCN102295378ATake advantage of highly concentrated processingHigh salt contentWater contaminantsWater/sewage treatment bu osmosis/dialysisSocial benefitsSeparation technology

The invention relates to a recycling method for treating ammonia nitrogen containing high-salt catalyst wastewater by adopting a membrane separation technology. The process flow of 'acid regulation, micro-filtration, membrane distillation, cooling and crystallization' is adopted in the method. By adopting the process flow, salts, ammonia nitrogen and metal ions in the wastewater can be effectively removed, and deep treatment and recycle of the ammonia nitrogen containing high-salt catalyst wastewater are realized. The process flow makes full use of the technical advantages of membrane distillation, solves the problem that the discharge of high salts, ammonia nitrogen and metal ions of the ammonia nitrogen containing high-salt catalyst wastewater does not reach the standards, and realizes recycle of the produced water. After the ammonia nitrogen containing high-salt catalyst wastewater is treated by the process flow, the reclamation rate of the wastewater is more than 90 percent, and high recycle of the ammonia nitrogen containing high-salt catalyst wastewater is realized; and the method accords with the development strategies of energy conservation and emission reduction, and has remarkable social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

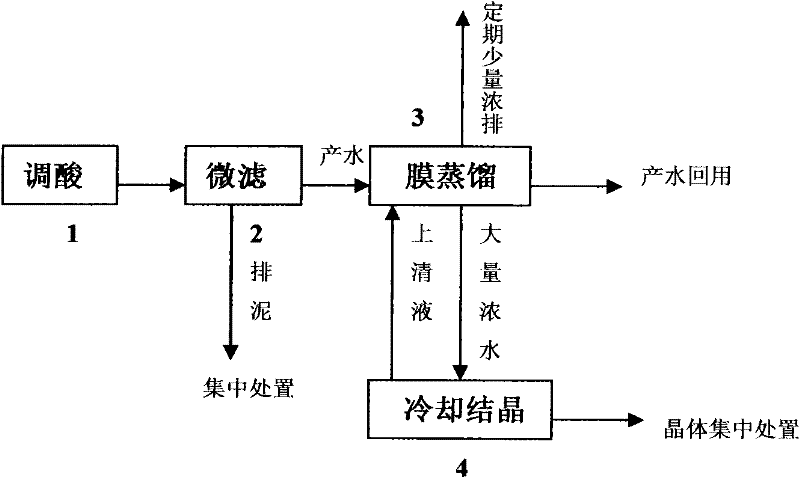

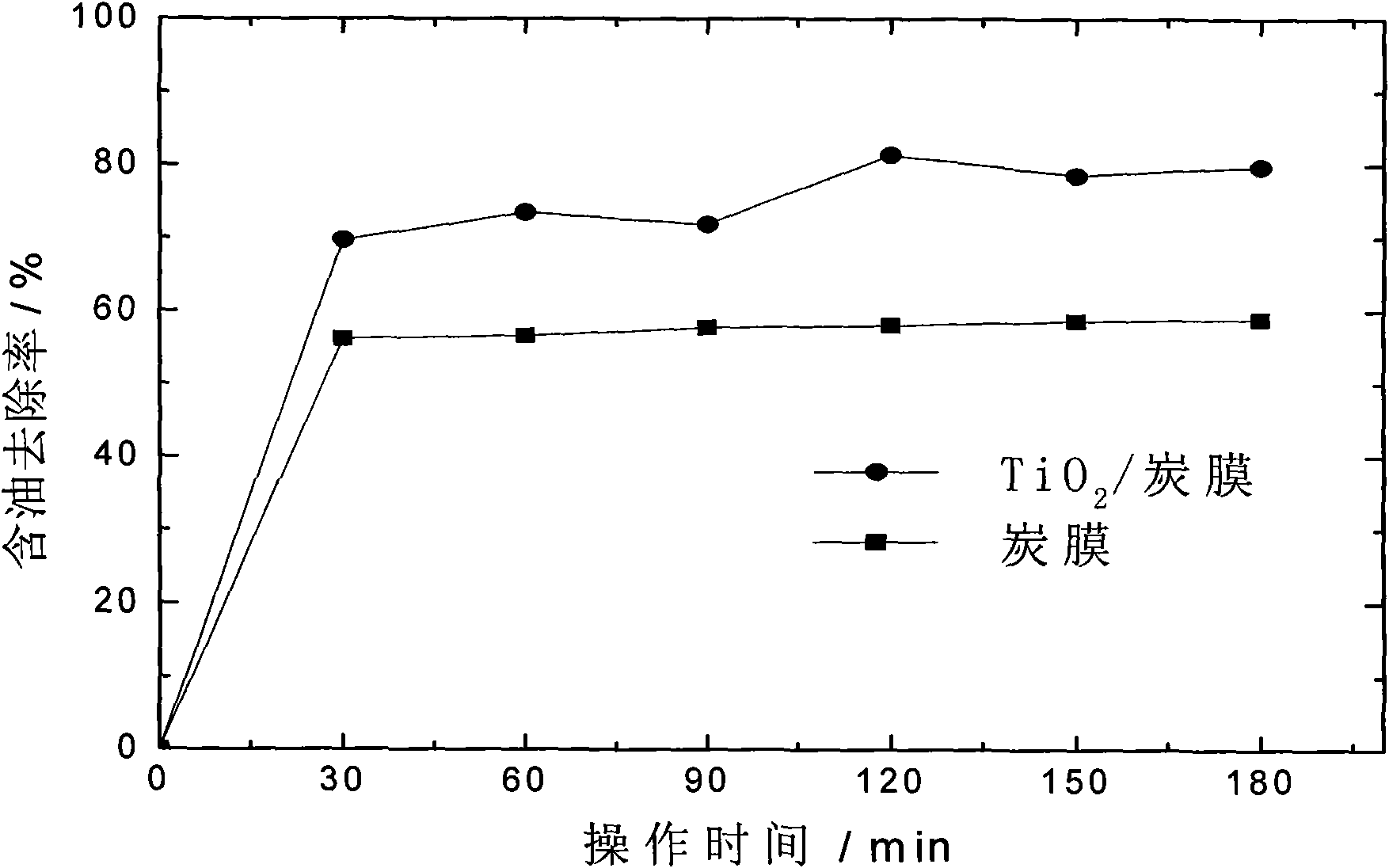

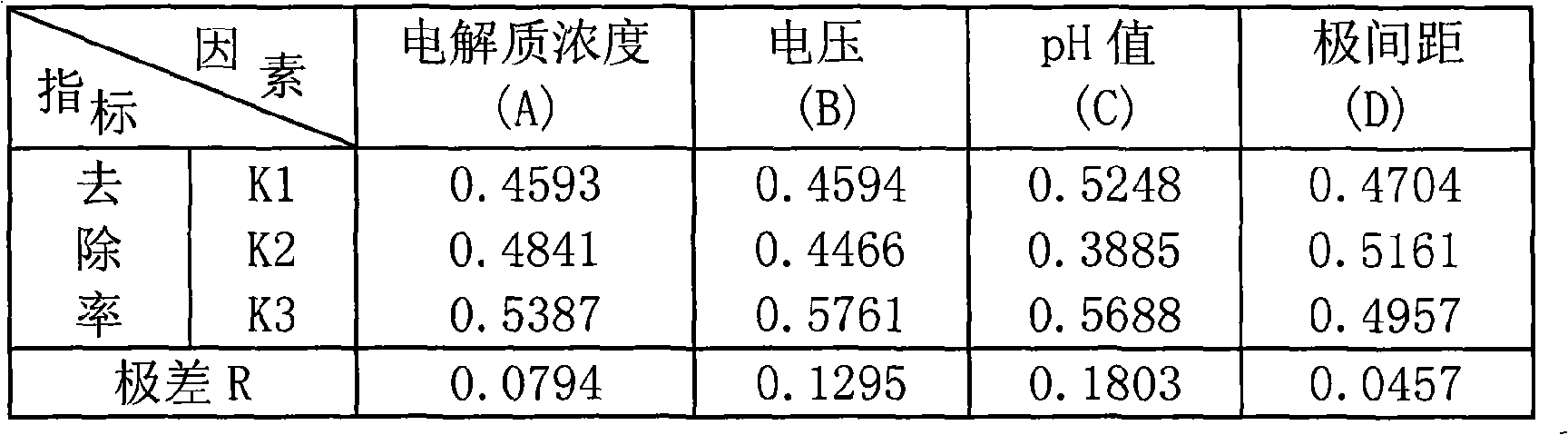

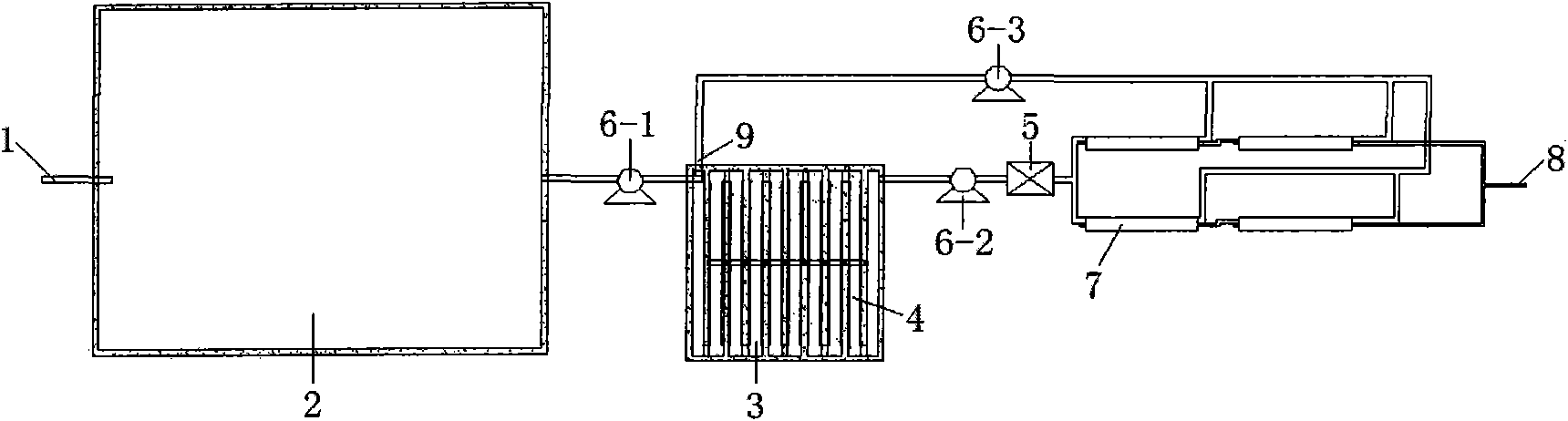

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

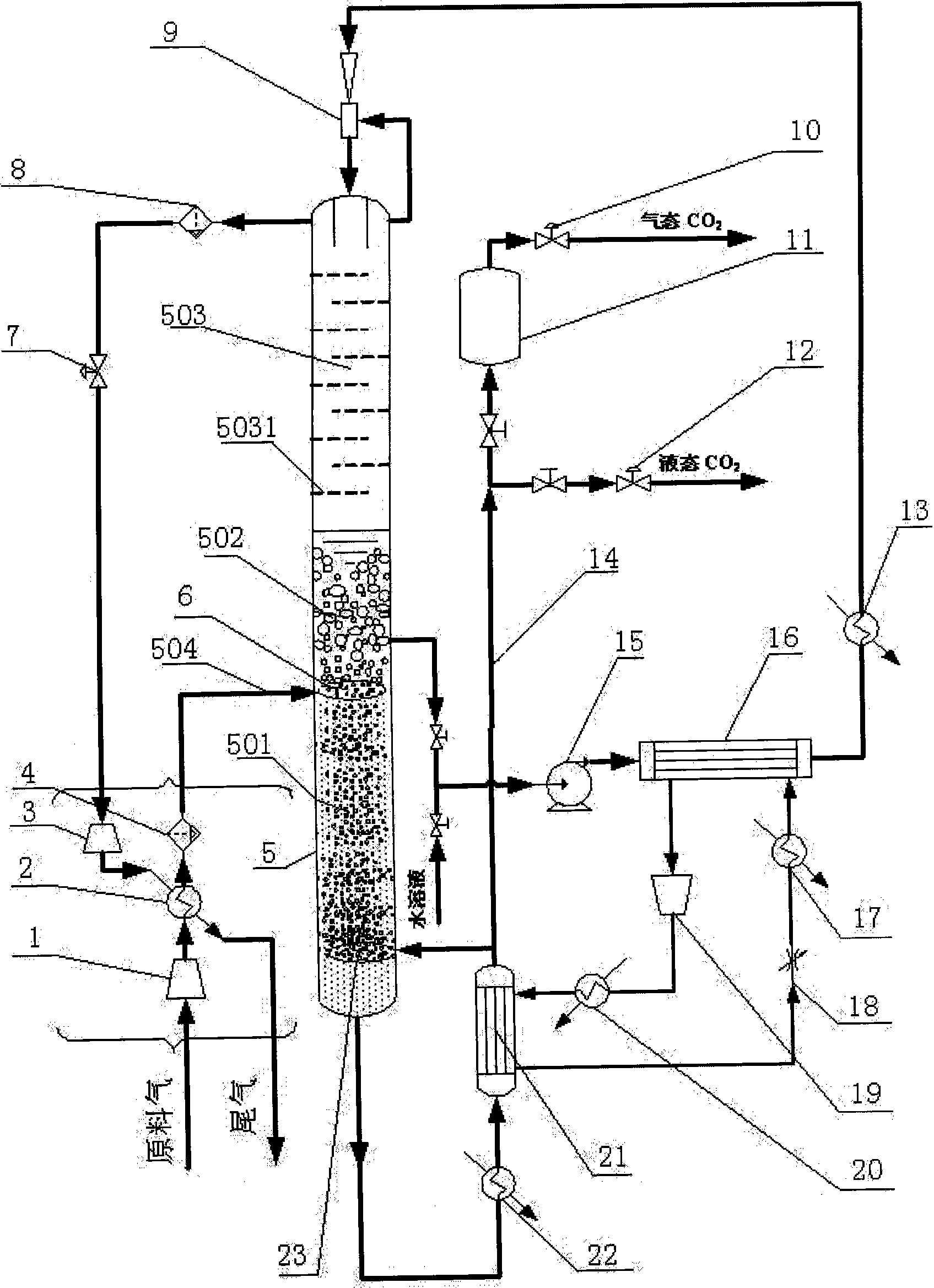

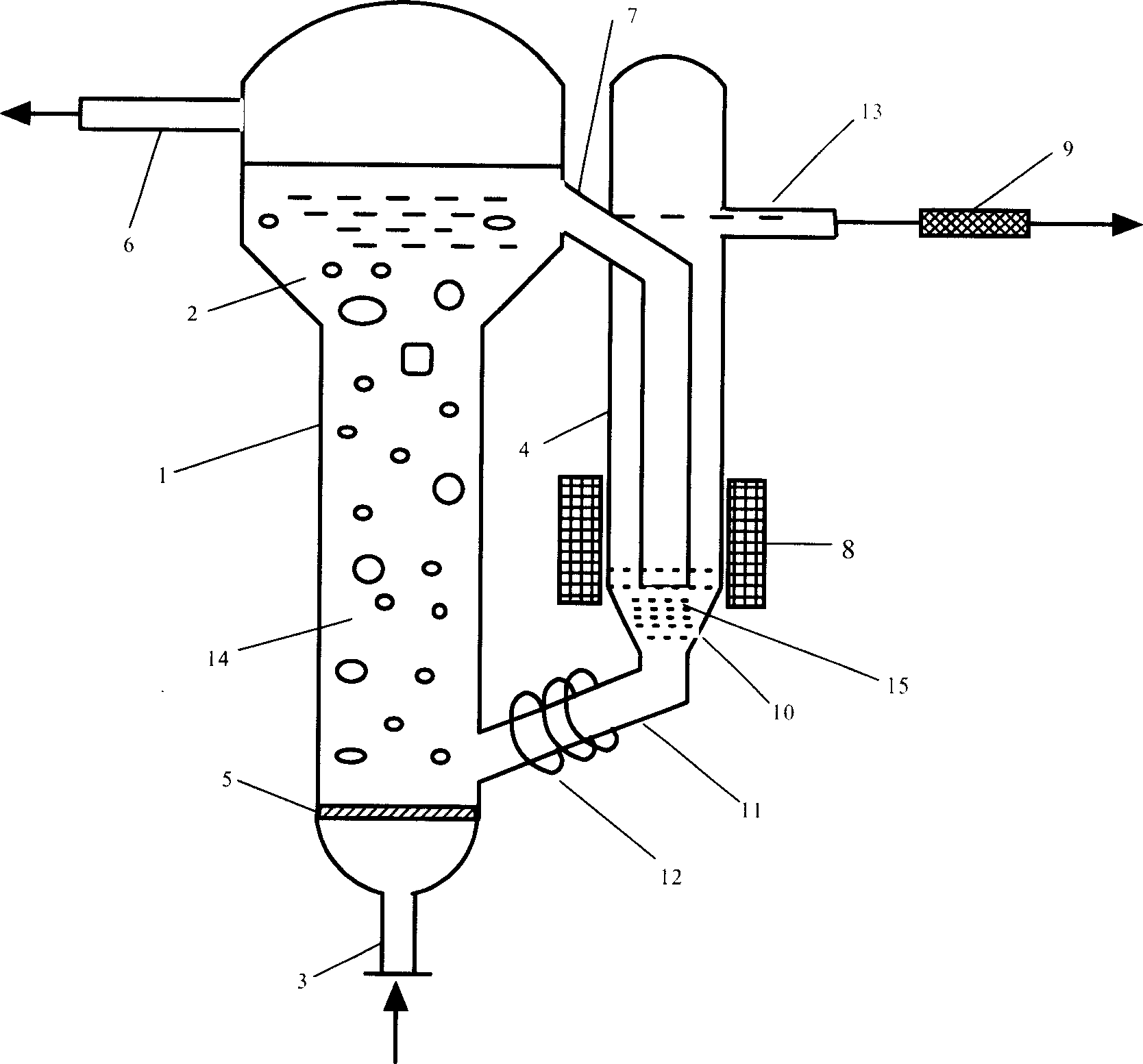

Carbon dioxide industrial-scale separation and purification system and method in mixture gas by hydrate method

ActiveCN101456556AIncrease concentrationIncrease separation rateProductsCarbon compoundsCollection systemFractionation

The invention discloses a system and a method for industrially separating and purifying CO2 in mixed gas by a hydrate method. The system consists of a feed gas pretreatment system, a hydrate separation tower, a micro-bubble jet-loop reaction system, a column bottom hydrate decomposition system, a CO2 product collection system, a hydrate formation and decomposition heat comprehensive utilization system and a tail gas energy recovery system. The method integrates hydrate bubbling reaction technology, spraying reaction technology and micro-bubble jet reaction technology, adopts CO2 reflux displacement fractionation technology to improve the concentration of the CO2 in a hydrate phase, has simple separation technology and device and high separation rate and efficiency, comprehensively utilizes the formation heat and decomposition heat of the hydrate during refrigeration cycle, simultaneously recovers compression work of tail gas and cold energy for feed gas pretreatment, and has low energy consumption and cost during separation. The system and the method can be applied to industrial and continuous separation and purification of the CO2 in the mixed gas such as flue gas (CO2 / N2), IGCC synthetic gas (CO2 / H2), biomass synthetic gas (CO2 / H2), natural gas (CO2 / CH4), coalbed gas and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Dendrobium candidum instant powder and preparation method thereof

InactiveCN101700361ALow extraction temperatureIncrease usageDigestive systemFood preparationEffervescent tabletSeparation technology

The invention relates to a dendrobium candidum instant powder and a preparation method of various related formulations thereof. The preparation method of the dendrobium candidum instant powder comprises the steps of: combining low-temperature extract of the dendrobium candidum with raw materials such as maltodextrin and dietary fiber, and the like, wherein the low-temperature extract of the dendrobium candidum is prepared by modern extraction and separation technologies such vacuum exploding, reverse film permeating, freeze drying and spray drying, and the like; and further preparing into formulations such as granules, effervescent tablets, capsules and oral liquid, etc. The invention improves the extraction efficiency of the dendrobium candidum, maximally guarantees the bioavailability of the dendrobium candidum, remains the primary smell of the dendrobium candidum, and leads the dendrobium candidum is conveniently taken.

Owner:刘宏源 +1

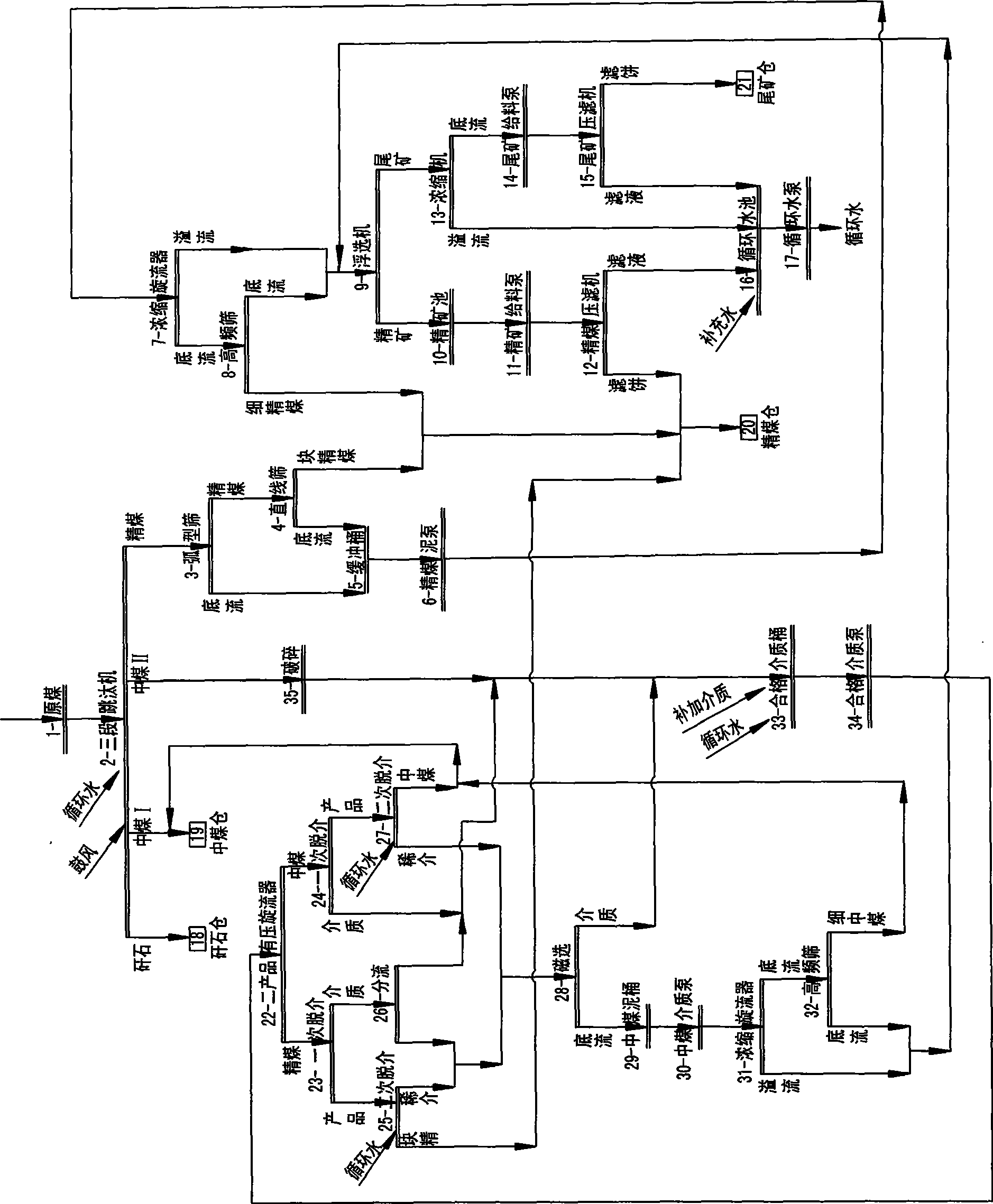

A coal dressing method and system of four-product jigging primary cleaning, secondary head coal small simplified heavy medium reelecting

ActiveCN101530824AReduce investmentLow operating costSievingScreeningTotal investmentSeparation technology

The invention discloses a coal dressing method and system of four-product jigging primary cleaning and secondary head coal small simplified heavy medium reelecting. The invention is a coal dressing method and system that selects the secondary head coal product through the four-product jigging technique and then reelects the secondary head coal with small simplify heavy medium separation technology. The adoption of the invention to select coal is characterized by less total investment, simpler system and lower operational expense, which can improve the stability of the system, reduce the powerconsumption, simplify the managing and maintaining work. The method can be easily realized with present technical merits, which is beneficial to be popularized in the middle and small coal washeries where the management level is low and if the method is used in oversize coal washeries, the cost for washing is lower.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

Variable cascade temperature regulation biomass charring device

InactiveCN104861995AMeet the requirements of different heating ratesSolve the problem that the heating rate cannot be adjustedBiofuelsEnergy inputControl systemSeparation technology

The invention discloses a variable cascade temperature regulation biomass charring device. The device mainly comprises a feeding unit, a segmented pyrolysis unit, an oil-gas separation unit, a secondary catalytic cracking unit and a waste heat reuse unit. The whole process is regulated through a reaction control system, and the continuous performing of the pyrolytic reaction is guaranteed through continuous sealed feeding and discharging. According to the pyrolysis portion, a variable cascade segmented heating principle is used, so that multi-stage regulation among different heating sections of a pyrolyzing furnace is achieved, and the requirement for different heating speeds during pyrolysis is met. Meanwhile, the pyrolysis gas condensation separation technology, the secondary catalytic cracking tar removing technology, the charcoal continuous cooling technology, the high-temperature pyrolysis gas waste heat reuse technology, the internal and external combined heating pyrolysis charring technology and the like are integrated. The device is applicable to pyrolysis charring of various biomasses in different conditions.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Slurry ¿Cbed reaction unit and method of use thereof

ActiveCN101116803AImprove space utilizationSave spaceHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSeparation technologyProduct gas

A slurry bed reaction equipment and method of using the same is provided, wherein the equipment comprises an ascending tube reactor 1 and a settling tube 4; the lower part of the ascending tube reactor 1 is a reacting region 14, while the upper part of the ascending tube reactor is a settling region 2 with tube diameter enlarged; the top of the settling region 2 is provided with an exhaust port 6; the bottom of the ascending tube is provided with a feed port 3 and a gas distributor 5; a pipeline 7 is used for connecting the settling region 2 with the settling tube 4, of which the opening position is arranged at the inside of the settling tube 4; the lower part of the settling tube 4 is a magnetic separation region 15, of which the lower end is communicated with the lower end of the ascending tube reactor 1 through a conical spout 10 and a reflux pipe 11; the upper part of the settling tube 4 is provided with a liquid discharging hole 13. The space utilization ratio of the reactor is improved by adopting the equipment and the separation method of the present invention; meanwhile, the separation technology combining settling, magnetic separation and filtering are adopted, making the separation part small in equipment volume, high in efficiency and space saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

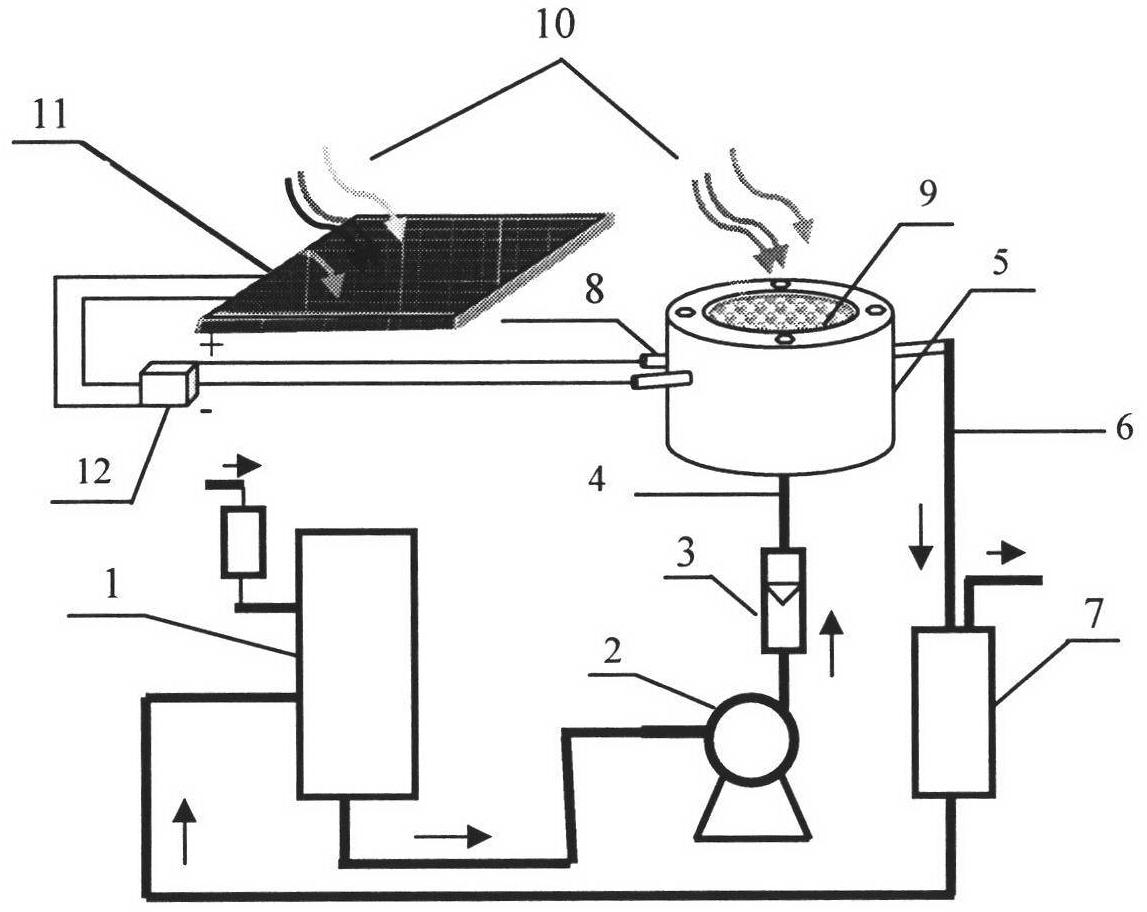

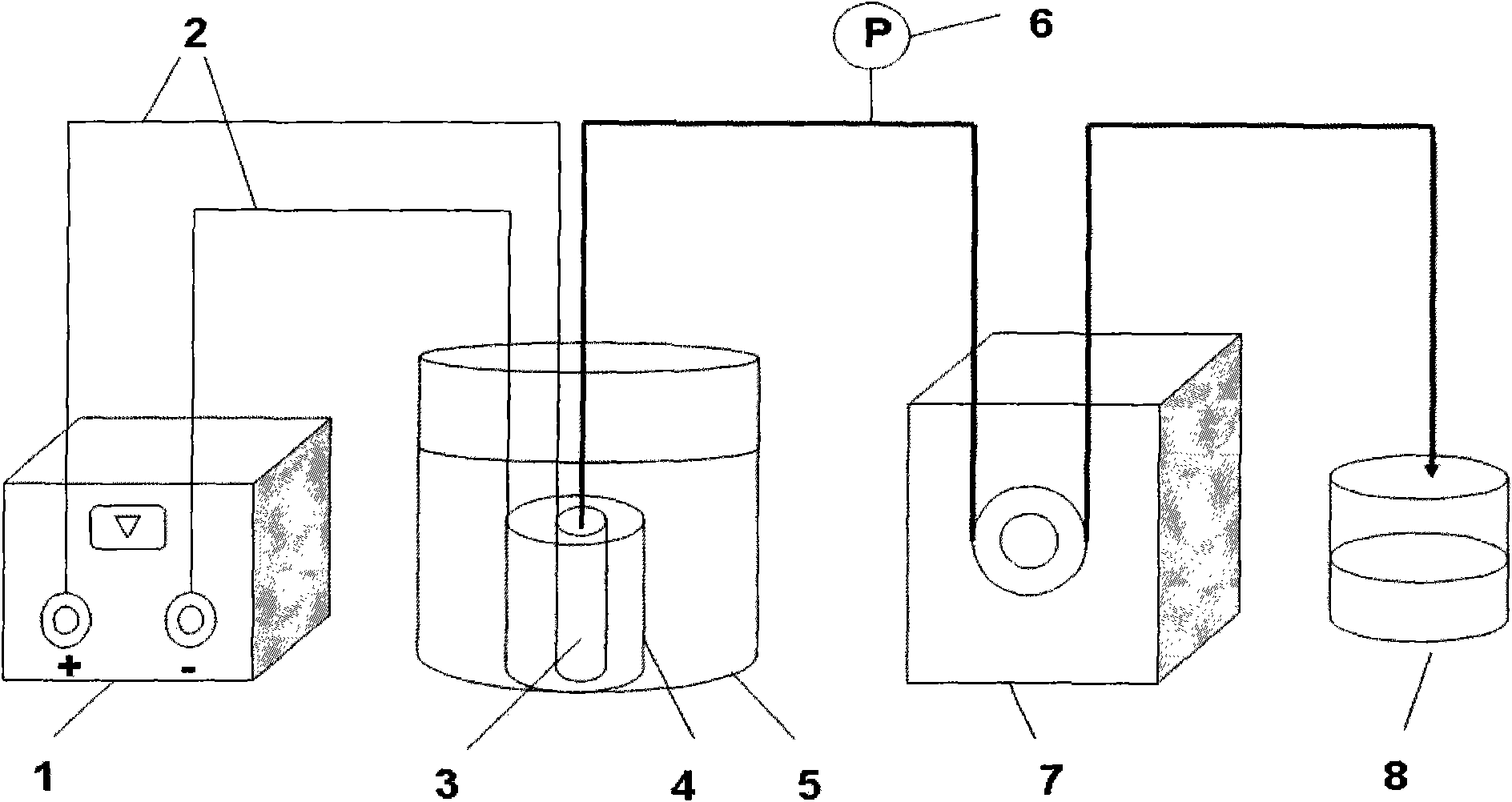

Electro-catalytic membrane reactor device

InactiveCN101597096AImprove electrocatalytic activitySimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPeristaltic pumpElectrolysis

The invention describes an electro-catalytic membrane reactor device, which is characterized in that the device can couple the membrane separation technology and electro-catalysis technology for wastewater treatment, thereby solving the problem of membrane pollution and realizing self-cleaning function of the membrane. The reactor device comprises a feed liquid tank, an electro-catalytic composite membrane, an auxiliary electrode, a regulated power supply, a vacuum gauge, a peristaltic pump and the like; wherein, the electro-catalytic composite membrane is a novel membrane material prepared by taking a microporous carbon membrane as a matrix and a metal or metallic oxide as a catalytic coating layer; one end of the electro-catalytic membrane is closed and the other end thereof is connected with the peristaltic pump through a pipeline; the pump continuously supplies negative pressure so that the feed liquid permeates a separation membrane and seeps from outside to inside along the pipeline; meanwhile, the electro-catalytic composite membrane is taken as the anode and the auxiliary electrode is taken as the cathode; the electro-catalytic composite membrane and the auxiliary electrode are respectively connected with the regulated power supply by leads to form an electrolysis device. By applying voltage to the composite membrane in the process of membrane separation, the organic pollutants deposited on and adhered to the surface and holes of the membrane are electrolytically oxidized to realize antipollution of the membrane. The reactor device has the advantages of simple device, convenient operation, high efficiency, small energy consumption and the like, and can be widely used for treatment and reuse of such industrial wastewater as oily wastewater, dye wastewater, papermaking wastewater and the like.

Owner:大连华鑫源科技发展有限公司

Electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater

InactiveCN101921032AEfficient use ofLess investmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectricityElectrolysis

The invention discloses an electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater, comprising a liquid inlet pipe, an adjusting tank, an electrolytic deposition device, a three-dimensional fixed bed device, a safety filter, three circulating pumps, a membrane assembly, a clear water outlet and a condensed liquid reflex hole, wherein the connection of various components is detailed in the description. The invention has the advantages that: by combining the electrolytic deposition technology with the membrane separation technology, the device has the advantages of less investment, high handle capacity, low energy consumption, high benefit, easy industrialization and easy implementation of the comprehensive utilization of resources; the effluent discharge after reaching standards and the recycling are realized, the heavy metal resources in the wastewater are effectively recycled; and automation degree is high and manual operation is simple and convenient, the complete recovery and zero discharge of heavy metals can be basically realized and water resources are completely recycled and the wastewater is deeply purified.

Owner:PEKING UNIV

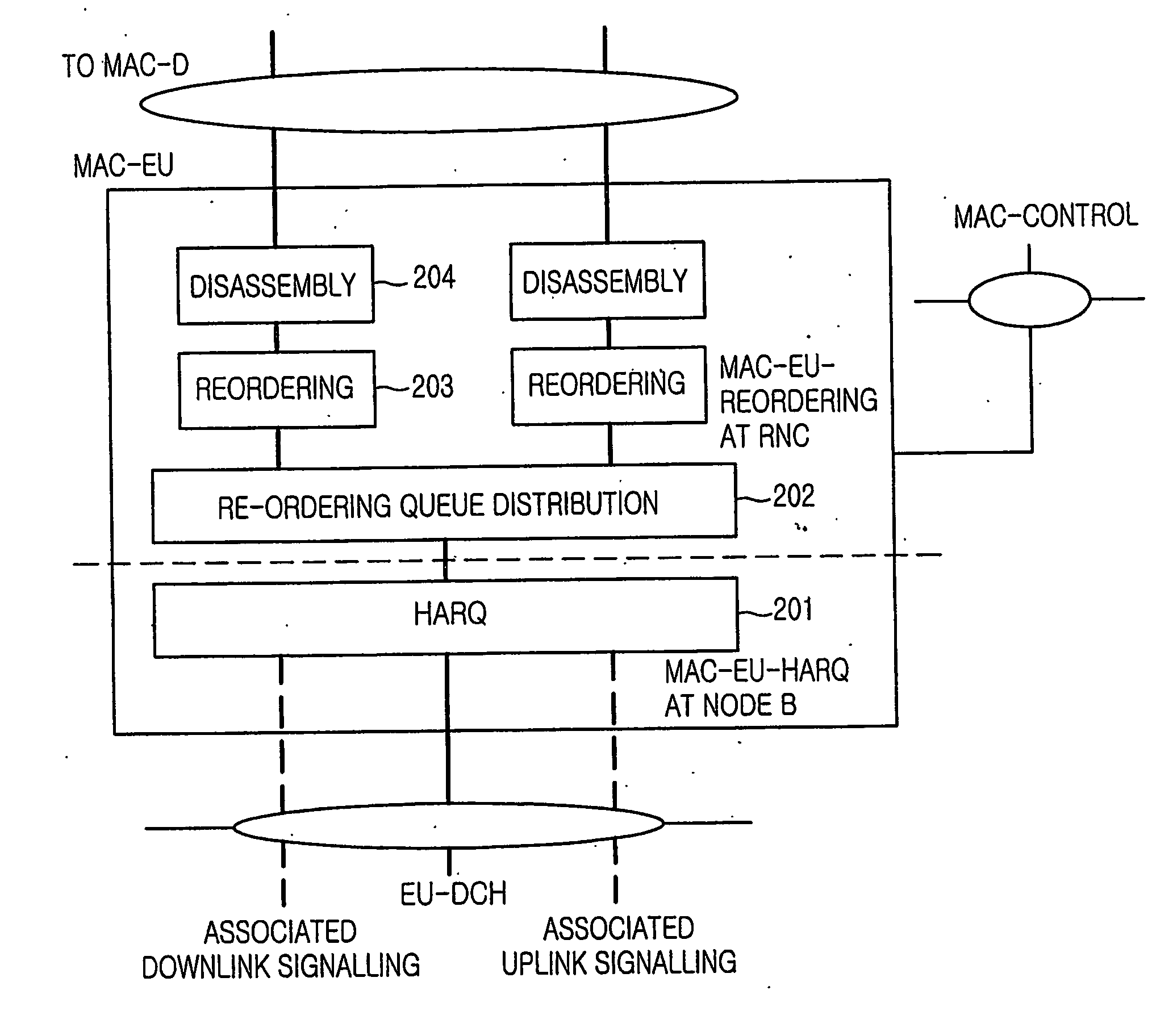

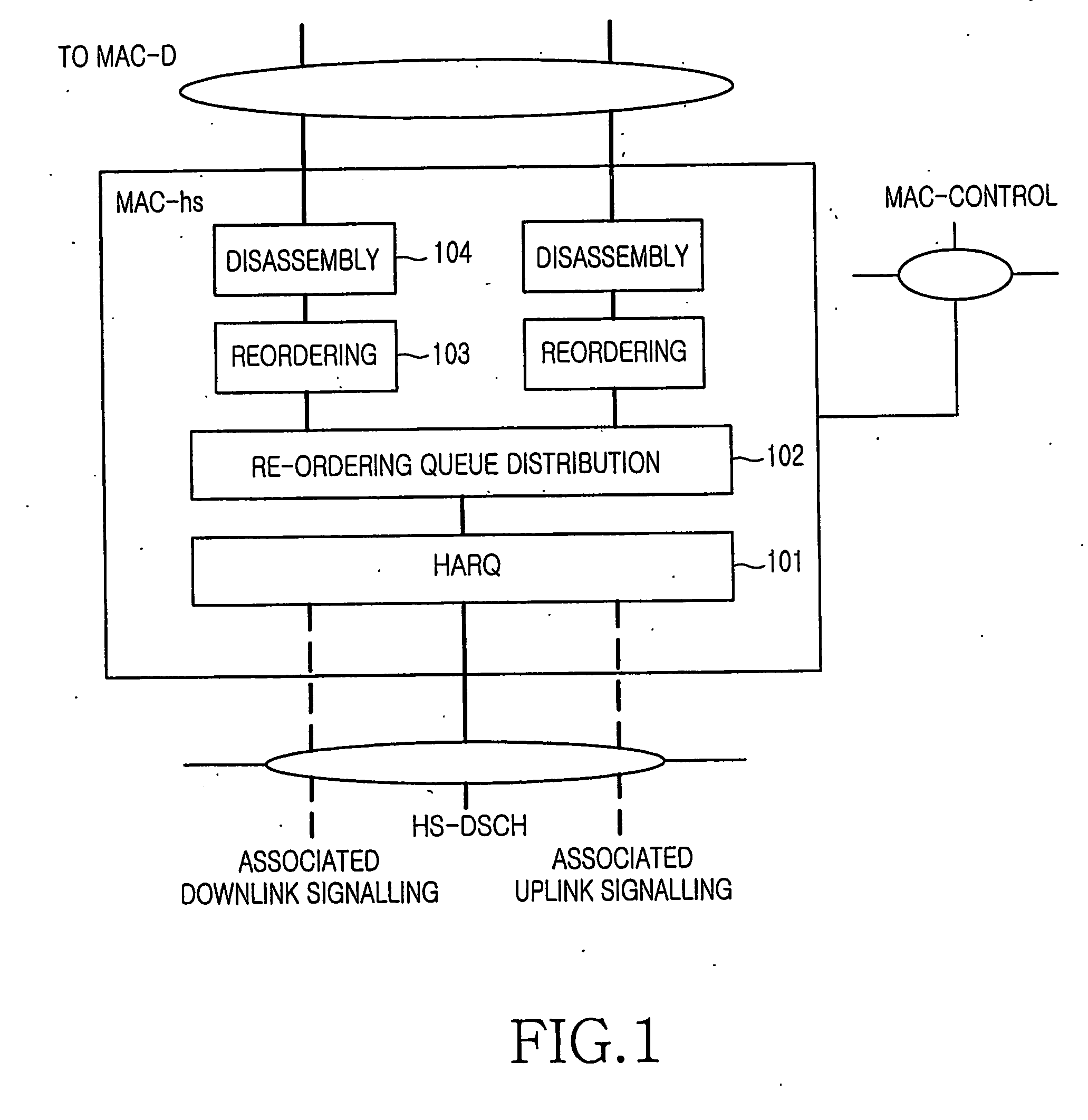

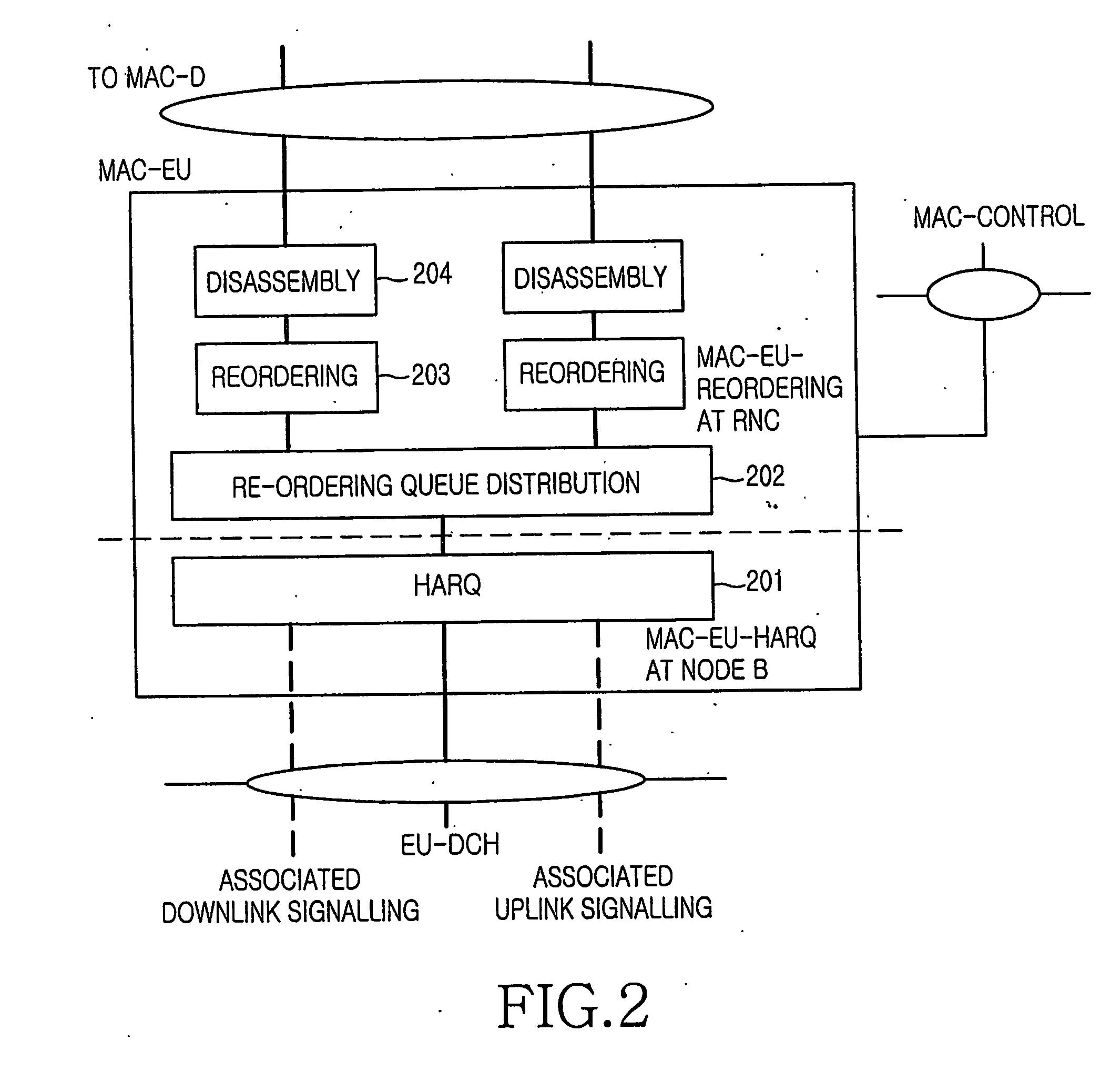

Harq reordering method for wcdma enhanced uplink dedicated channel

ActiveUS20070042782A1Reduce receiving delaySave buffer spaceError prevention/detection by using return channelNetwork traffic/resource managementSeparation technologySnubber

A method for HARQ reordering in Enhanced Uplink Dedicated Channel of WCDMA system includes following steps: locating the soft combination buffer in the Node B and the reordering buffer in the SRNC; locating the HARQ entity in the Node B; locating the reordering queue distribution entity, the reordering entity and the disassembly entity in the SRNC. This invention adopts the separation technology of the soft combination buffer and the reordering buffer, the separation model can not only ensure the diversity gain, but also reduce the receiving delay and save the buffer space. Three mechanisms (timer mechanism, window mechanism and SBI mechanism) are proposed to prevent the blocking of the reordering buffer, which degrades the blocking to the least level, improves the receiving efficiency and the system performance. Aiming at the SBI mechanism, the invention proposes the new DCH data frame structure on the Iub interface and the Iur interface.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com