Patents

Literature

102 results about "Passive heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Passive heating. A system whereby a building’s structure or an element of it is designed to allow natural thermal energy flows, such as radiation, conduction, and natural convection generated by the sun, to provide heat. The home relies solely or primarily on nonmechanical means of heating.

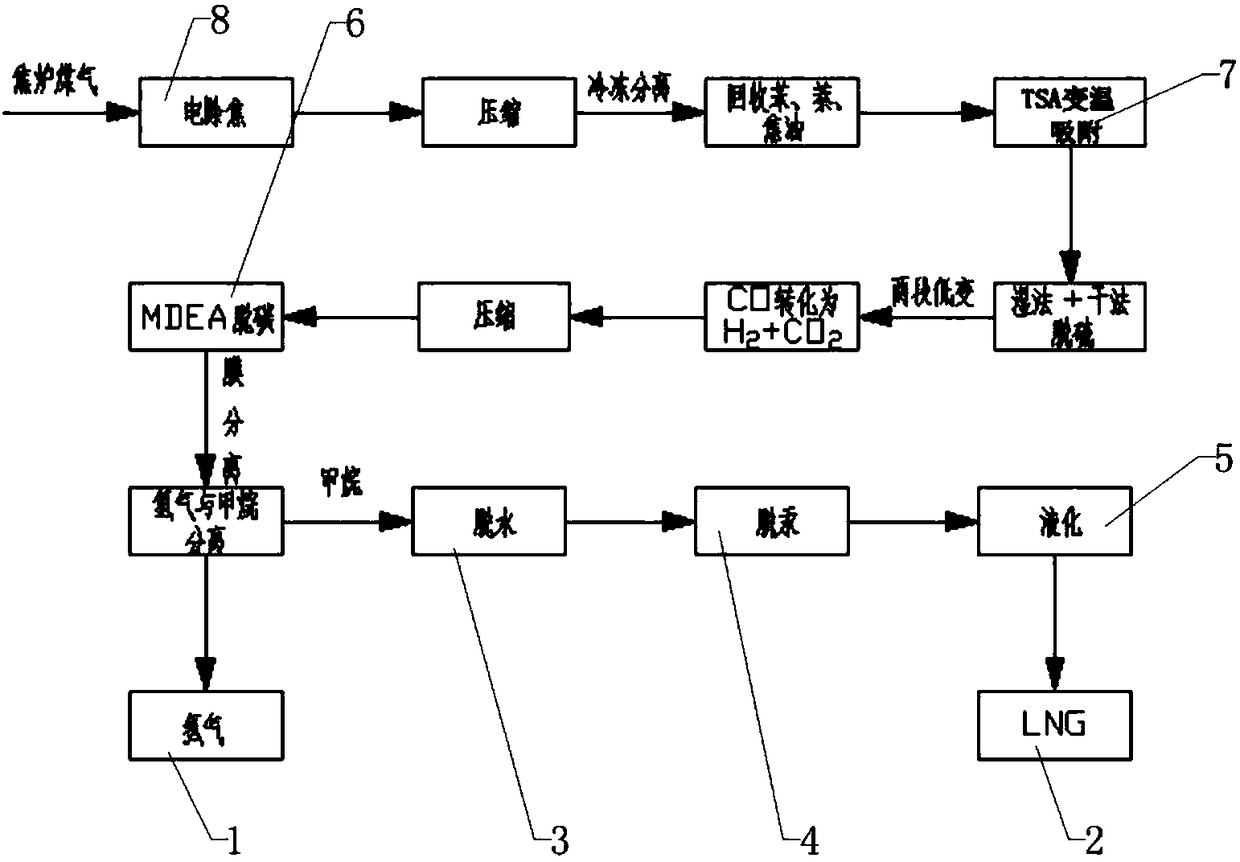

Method for preparing hydrogen and LNG from coke oven gas

InactiveCN108179046ALow investment costLow running costHydrogenGaseous fuelsHigh concentrationSeparation technology

The invention provides a method for preparing hydrogen and LNG from coke oven gas. The method comprises the following steps: electric decoking; boosting of the coke oven gas by a compression system; cooling of the raw gas coke oven gas by using the BOG gas (the BOG gas is a gas formed after the passive heating gasification of LNG) of LNG in order to further remove tar, benzene, naphthalene and like substances in the coke oven gas; and pretreatment using a TSA process to finely remove macromolecular impurities, such as tar, benzene, naphthalene and the like; wet and dry two-stage desulfurization for removing sulfides in the coke oven gas; two-stage low pressure shifting for a reaction of CO and water vapor to form CO2 and hydrogen; and pressurization using a compressor, an MDEA solution process for removing carbon dioxide, a membrane separation technology for separating hydrogen and methane, separation, concentration and purification of the hydrogen and methane, and dehydration, demercuration and liquefaction of the separated high-concentration methane to obtain the LNG. The coke oven gas is finally converted into the hydrogen and the LNG which have high values, so the energy of thecoke oven gas is fully used, and the environment is protected.

Owner:SICHUAN HENGRI GAS ENG CO LTD

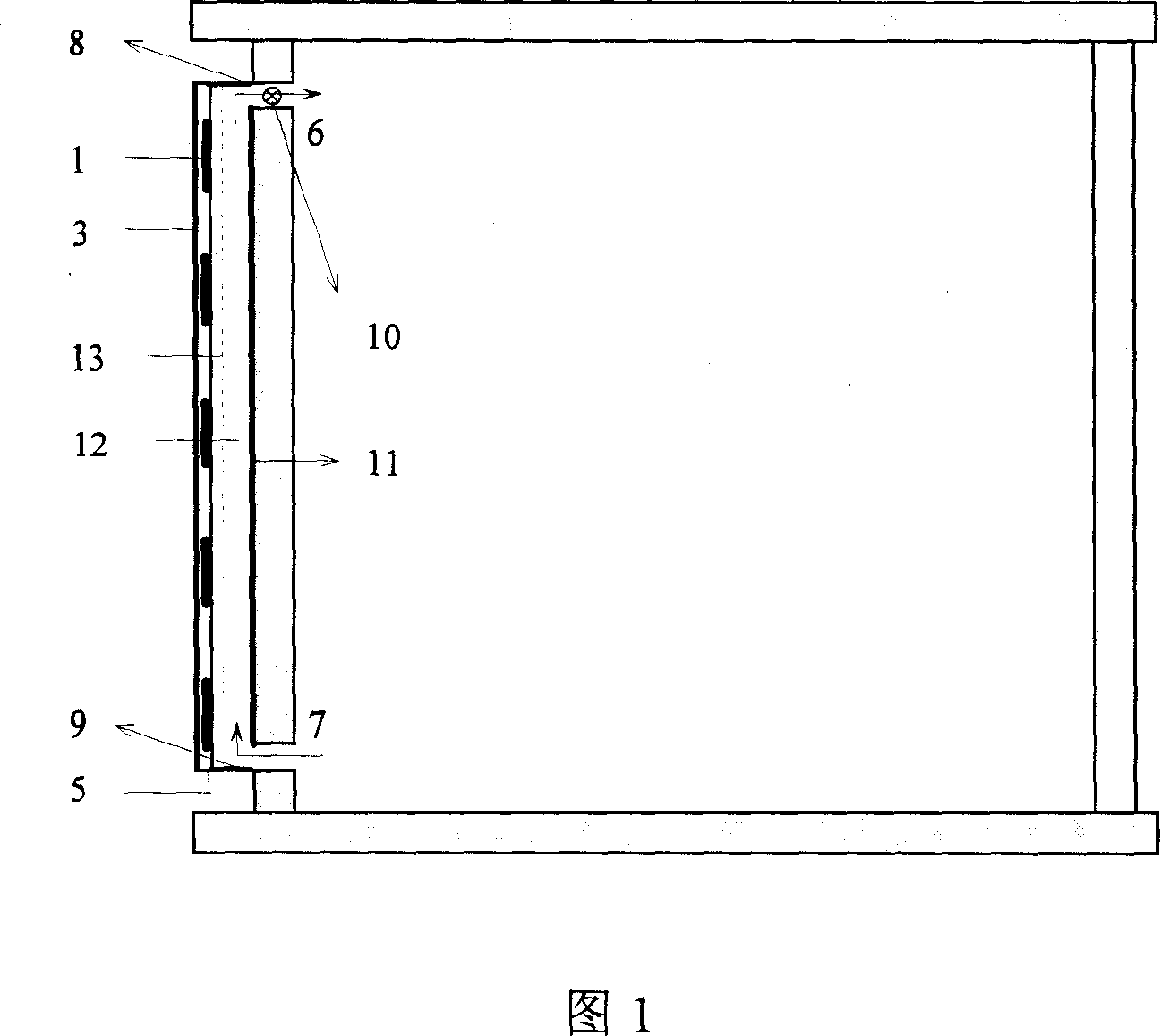

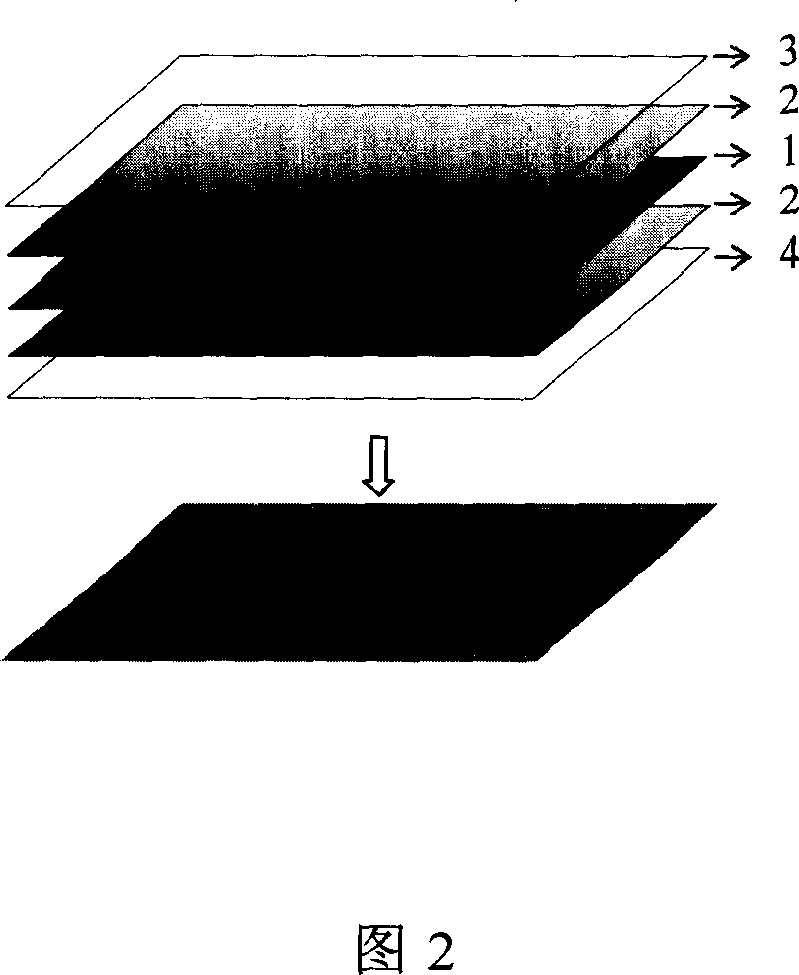

Photovoltaic passive heating wall

InactiveCN1944829AReduce indoor heat loadLess investmentHot-air central heatingWallsElectricityPassive heating

The photovoltaic passive heating wall includes glass plate with photovoltaic cells adhered to the back side, two summer ventilating openings, two winter ventilating openings, heat collecting wall, and DC blower for speeding the airflow in the airflow channel. The photovoltaic glass plate is installed on one frame parallel to the heat collecting wall, two summer ventilating openings are in the upper and the lower part of the airflow channel separately, two winter ventilating openings are in the upper and the lower part of the heat collecting wall separately, and the DC blower is installed in the winter ventilating openings or the airflow channel. The present invention has photovoltaic cells, forced airflow to lower the temperature of the cells and raised electricity generating efficiency, the electricity generating and heating functions and building appearance with fascination.

Owner:UNIV OF SCI & TECH OF CHINA

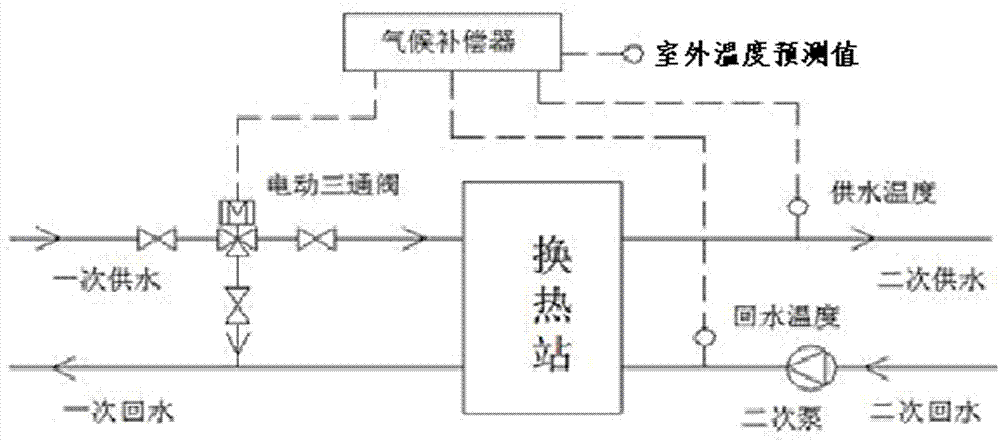

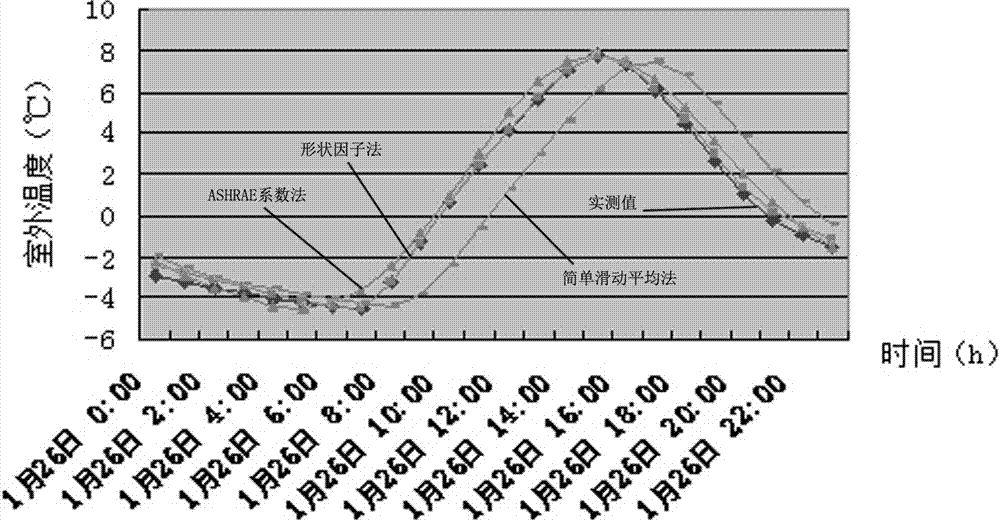

Dynamic climate compensation method for centralized heating

ActiveCN107120721AStable indoor temperatureEnsure heating qualityLighting and heating apparatusSpace heating and ventilation detailsHysteresisValue set

The invention discloses a dynamic climate compensation method for centralized heating. Firstly, the outdoor temperature is predicted, water supply and return temperatures are adjusted some time ahead according to the predicted value of the outdoor temperature, and the hysteresis of pipe network adjustment in the manner that adjustment is performed while sampling is overcome. The outdoor temperature of the next day is predicted according to local historical meteorological data and weather forecast of the meteorological department, and the value is used as basic data for prediction of a thermal load; and then the thermal load is predicted, that is, the thermal load curve of the next day is calculated according to the outdoor temperature. With the method, the outdoor temperature is reasonably predicted so as to realize advanced dynamic adjustment of a climate compensator; heating medium parameters of a heating system are adjusted by the aid of an adjusting model according to the thermal load value set in advance, a heat source is changed from original wide passive heating into active heating, on the premise that the indoor temperature for the user is stable, the operation adjusting indictor of the heating system within the specified time are given in advance, the heating efficiency is improved, and the heating energy consumption is reduced.

Owner:石家庄华浩能源科技有限公司

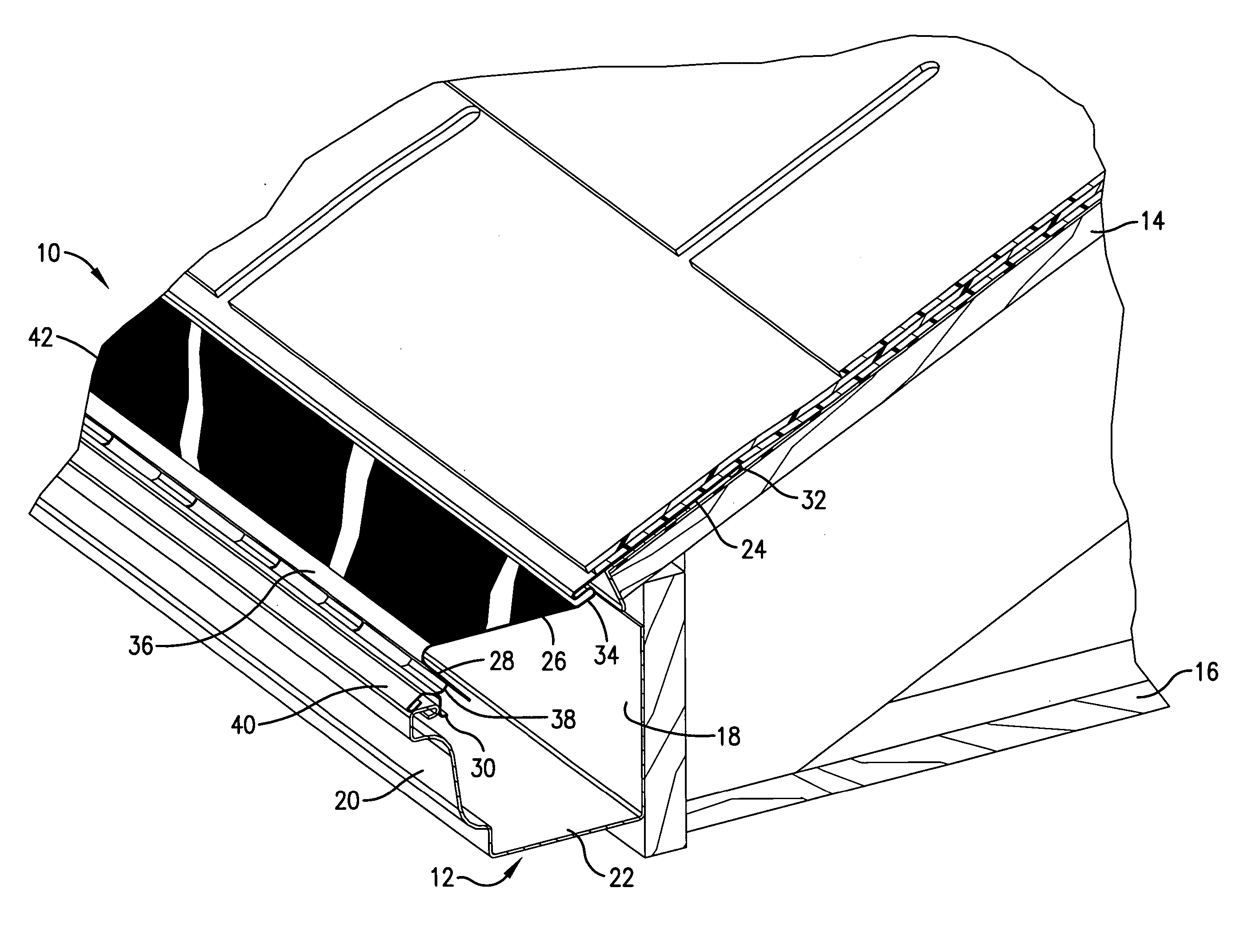

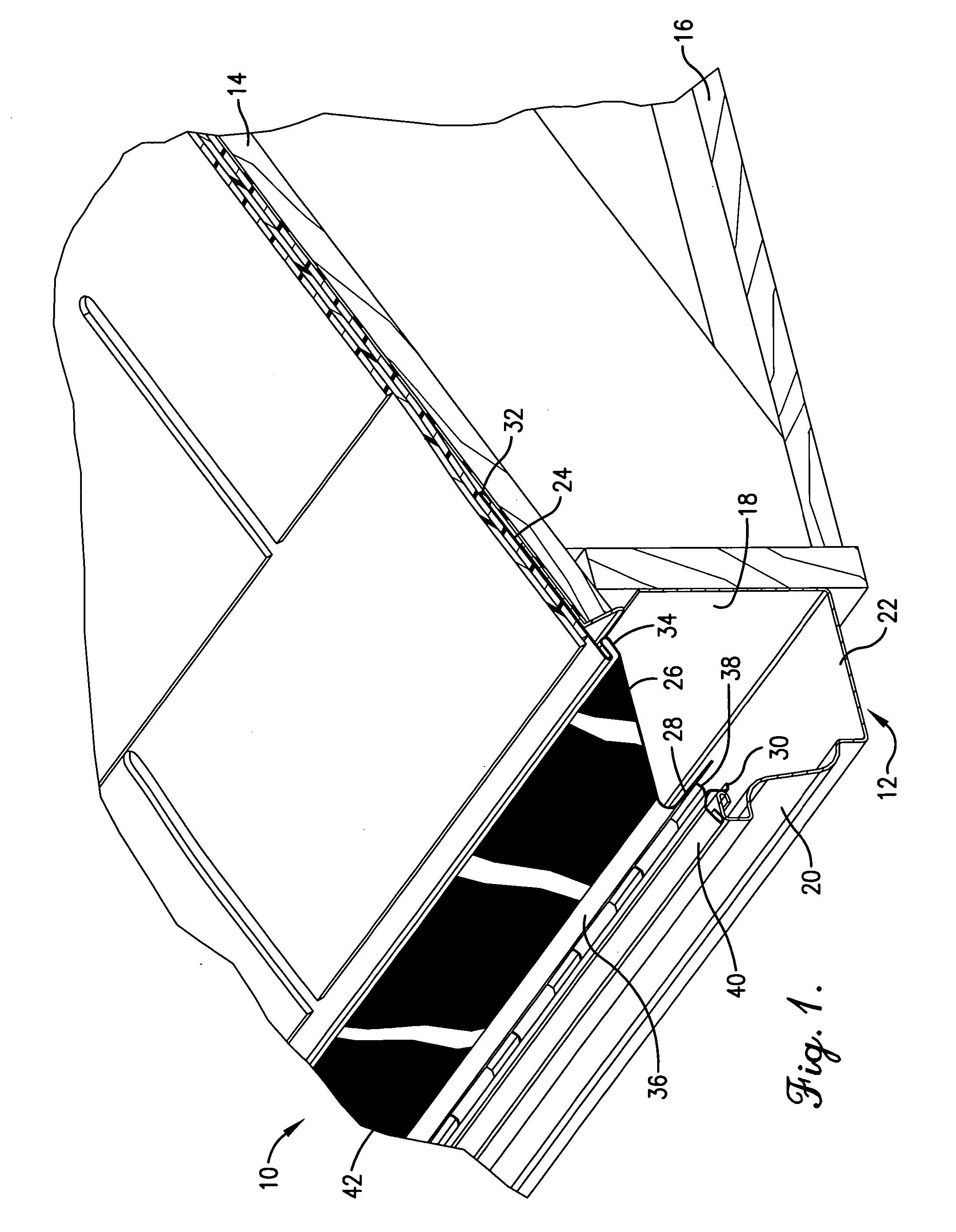

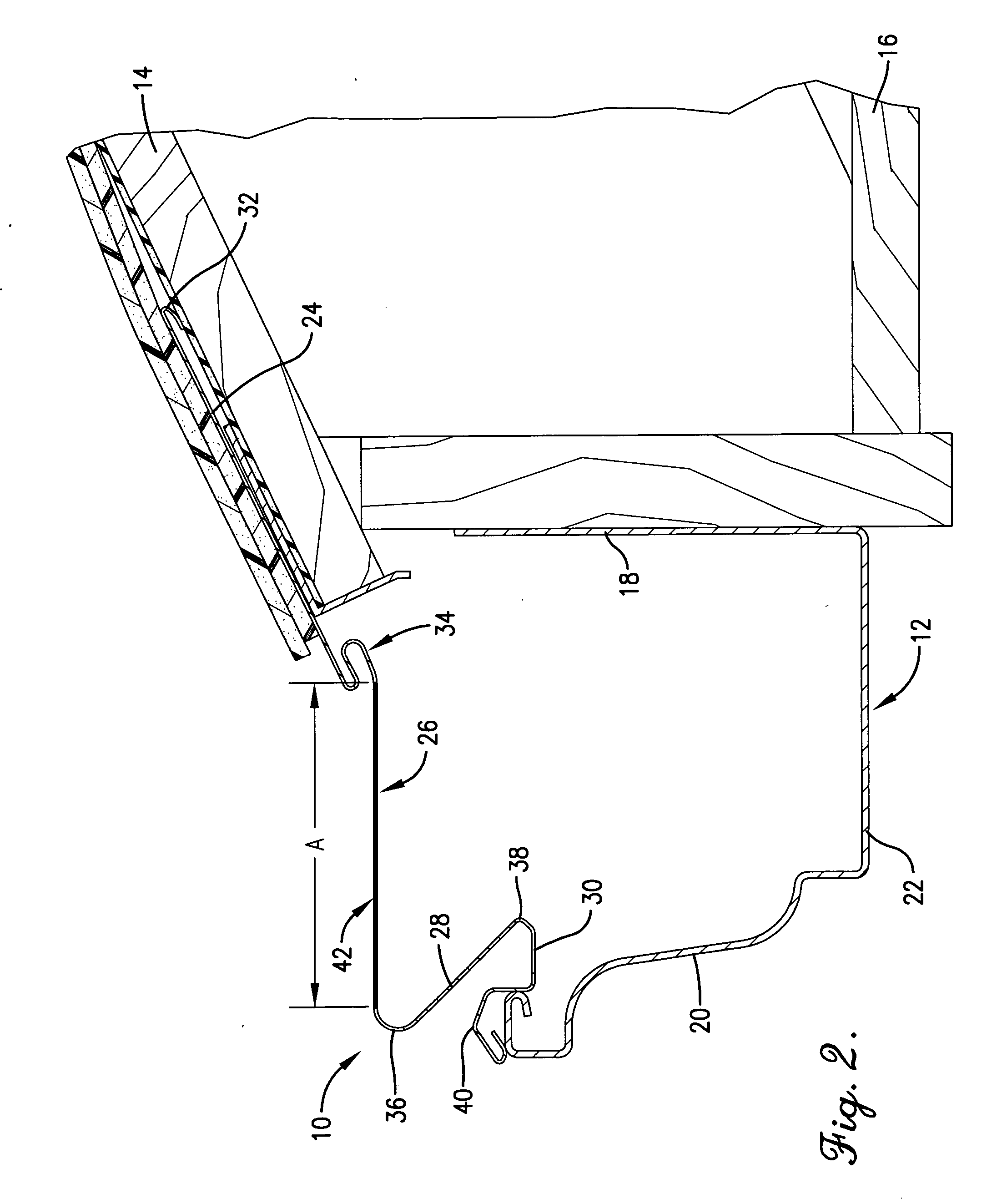

Gutter cover with passive ice and snow melt

InactiveUS20070094939A1Effectively and efficiently prevents cloggingPreventing and minimizing accumulation of snowRoof coveringPassive heatingActive component

A gutter cover which more effectively and efficiently prevents the clogging of gutters and the formation of ice dams without the use of heating cables and other active components. The gutter cover comprises a first section, a second section, and a passive heating element. The first section is adapted to be installed over or under roofing material covering the roof for directing water from the roof. The second section is attached to the first section and adapted to be installed over an open end of the gutter for directing the water from the roof into the gutter while preventing debris from entering the gutter. The passive heating element is provided for absorbing heat from sunlight and thereby preventing or minimizing accumulation of snow or ice on or near the second section without the use of heating cables or other active heating components.

Owner:BACHMAN JAMES E

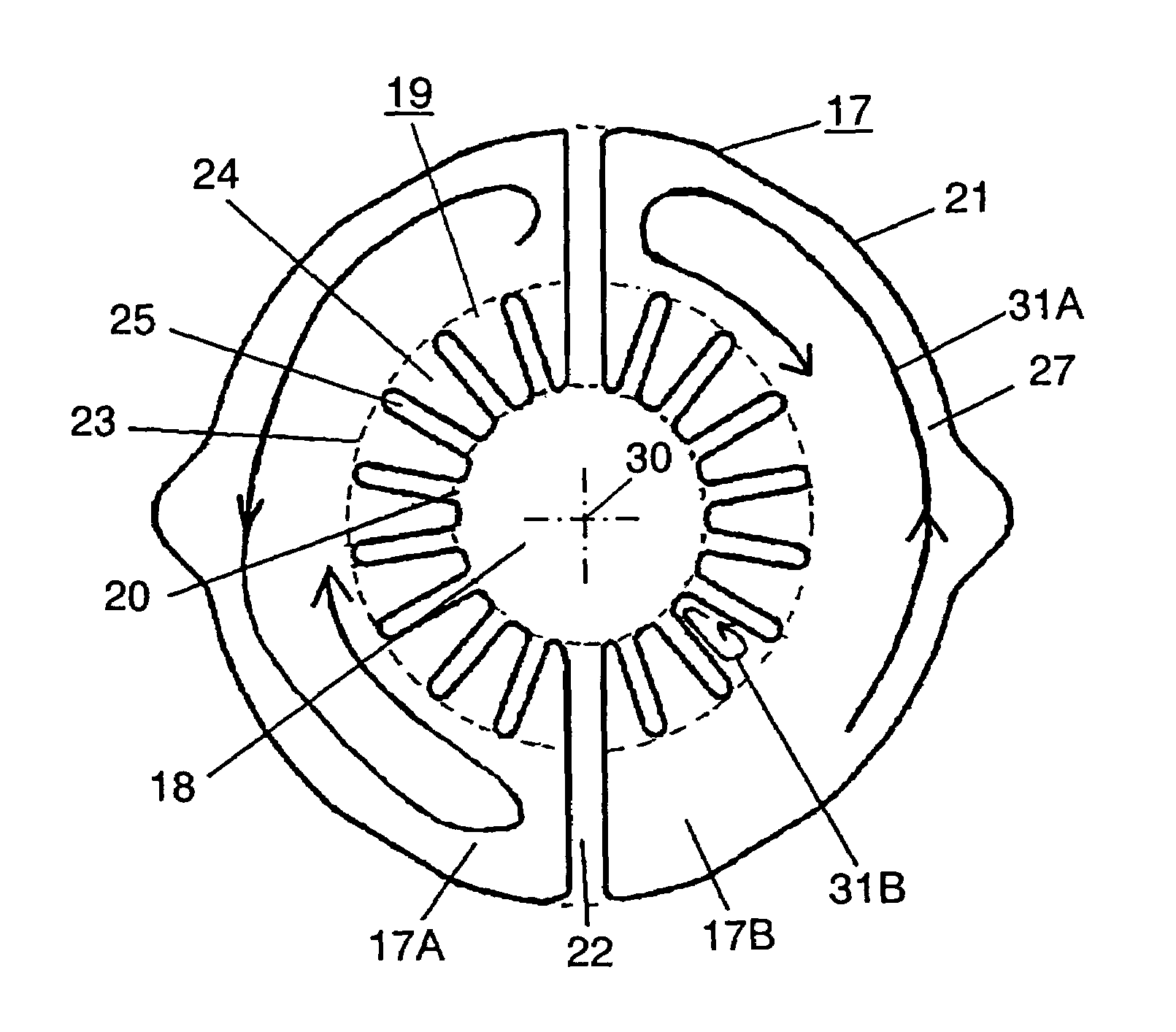

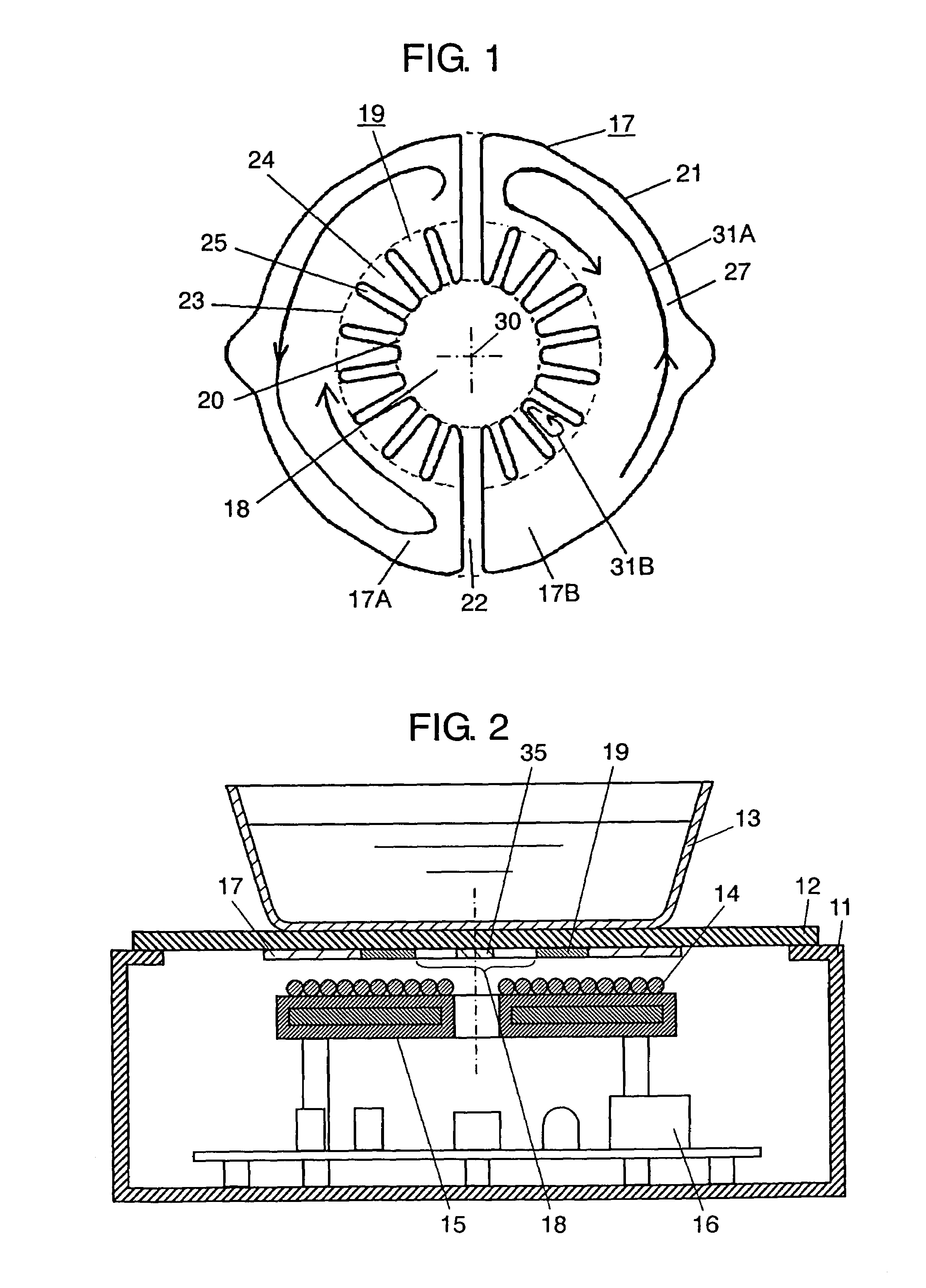

Induction cooker with heating coil and electrical conductor

ActiveUS7049563B2Reduce lifting forceImprove heating efficiencyCoil arrangementsInduction heating apparatusElectrical conductorPassive heating

An electric conductor provided for decreasing a lifting force exerted on an object being heated has an aperture of a small diameter in the center thereof, which leaves a large surface area to enhance reduction of the lifting force. The electric conductor is also provided with a comb section around the aperture for preventing a circling current induced in the electric conductor from flowing into an area around the aperture. This structure can thus alleviate excessive heating around the aperture, and allow the heating coil to produce a high output power for a long duration of time even when an inwardly concaved pan is used.

Owner:PANASONIC CORP

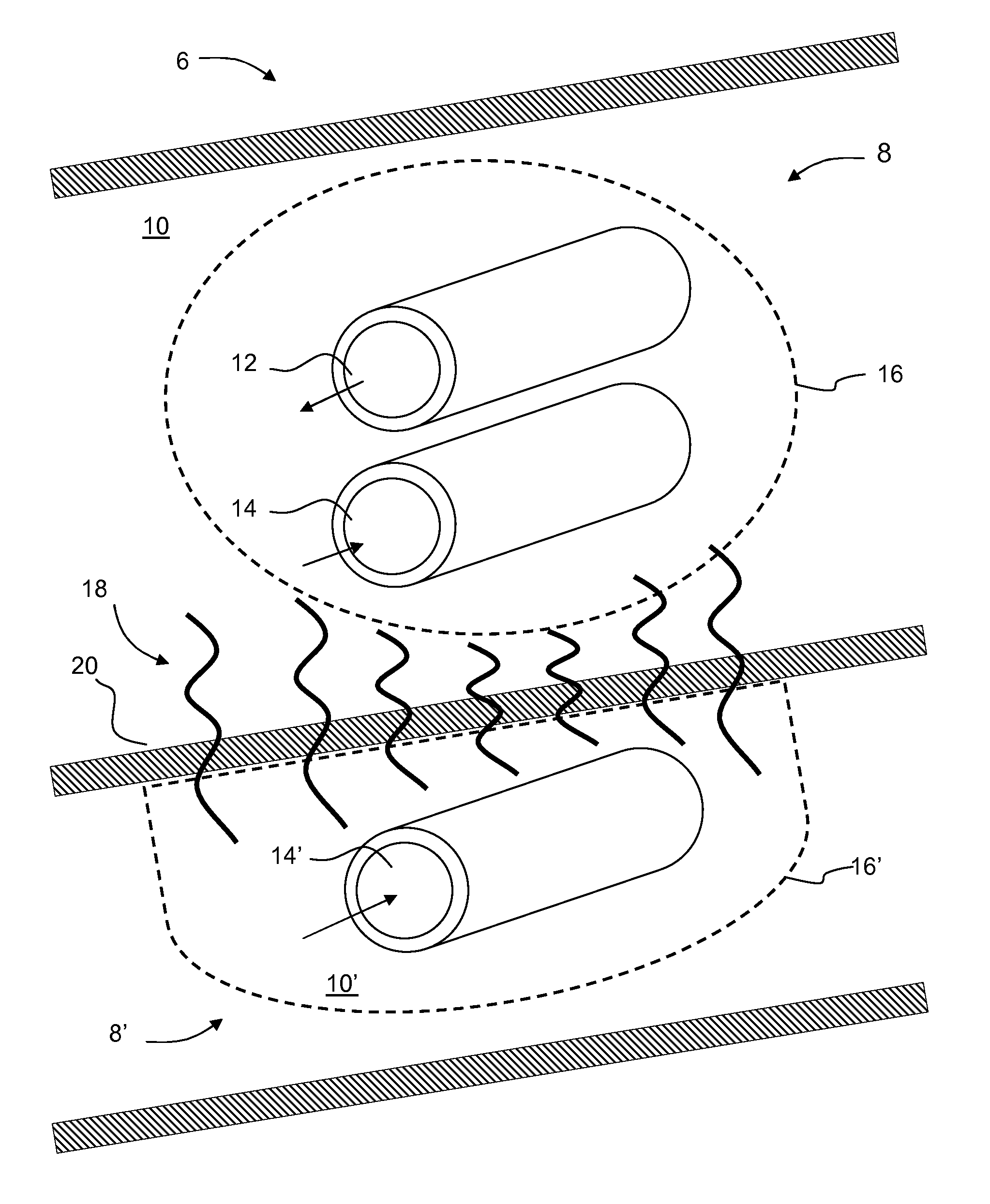

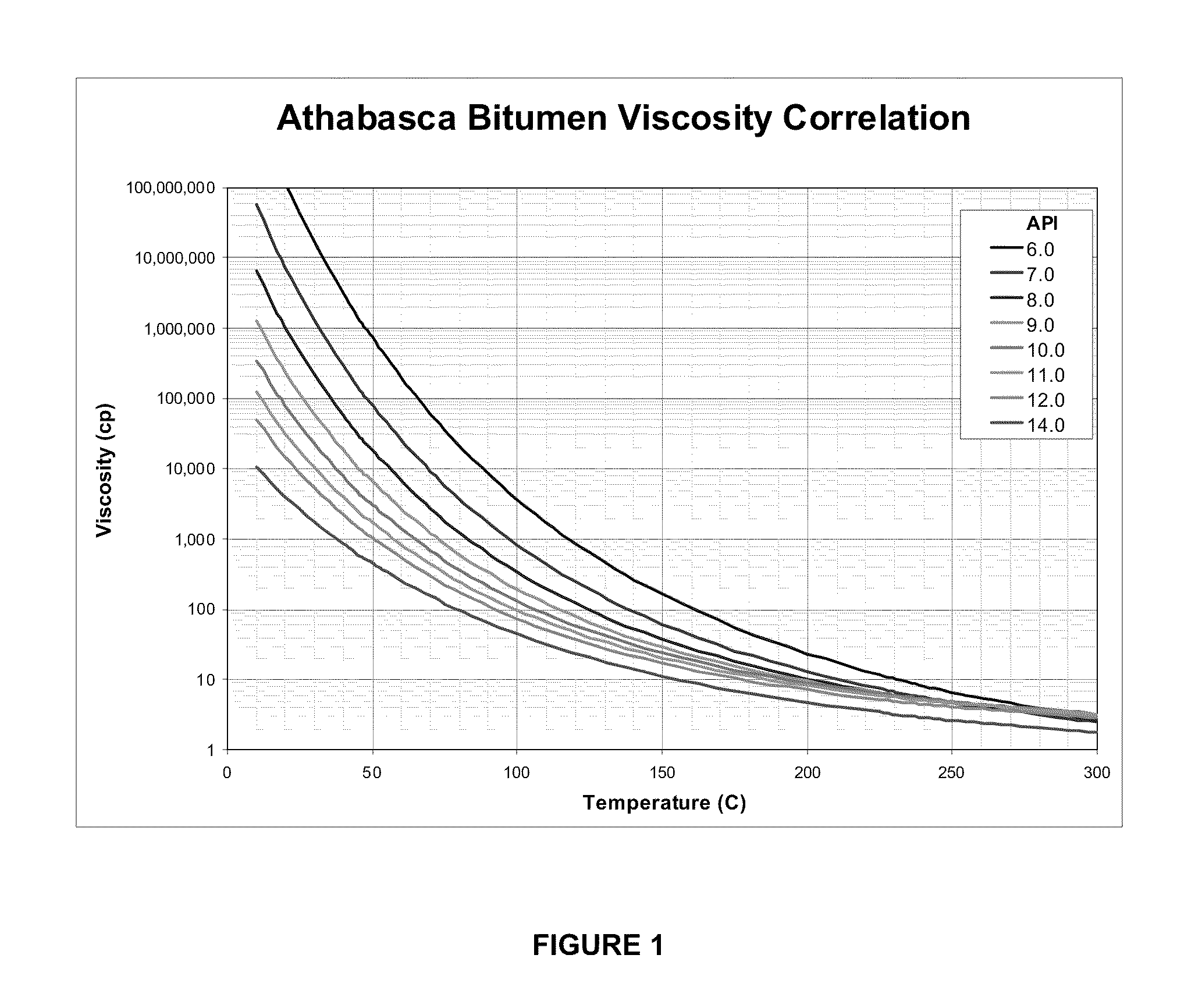

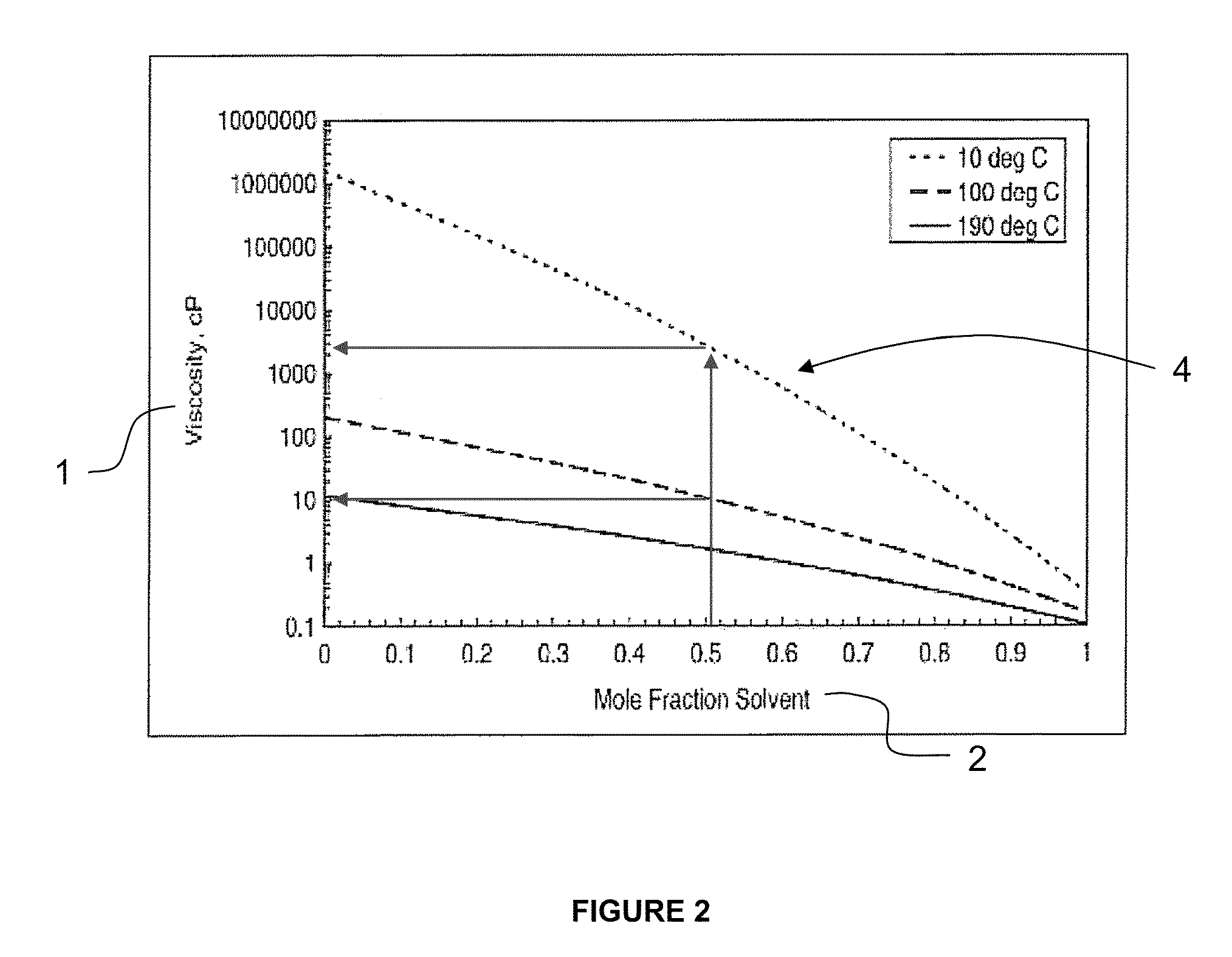

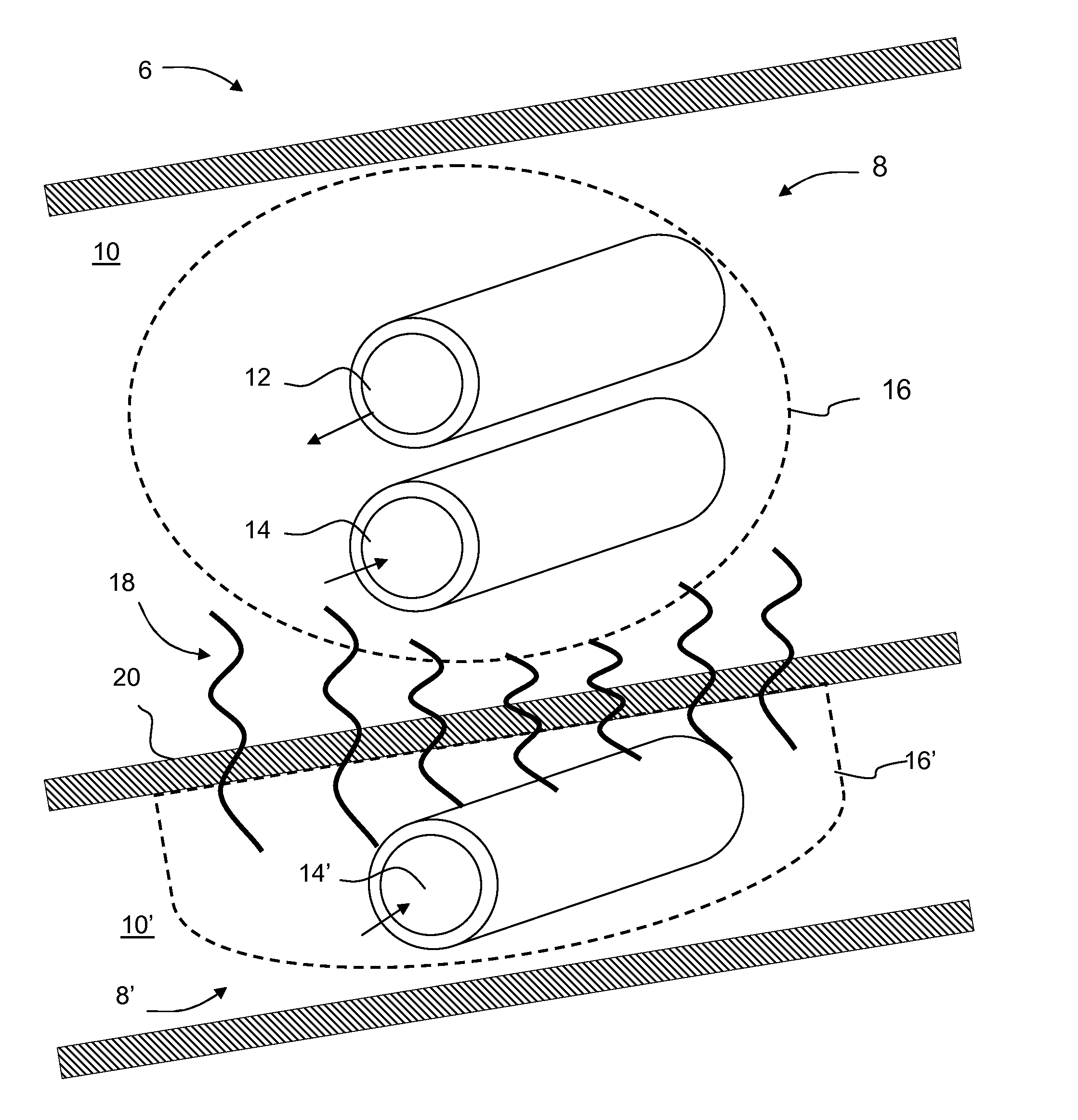

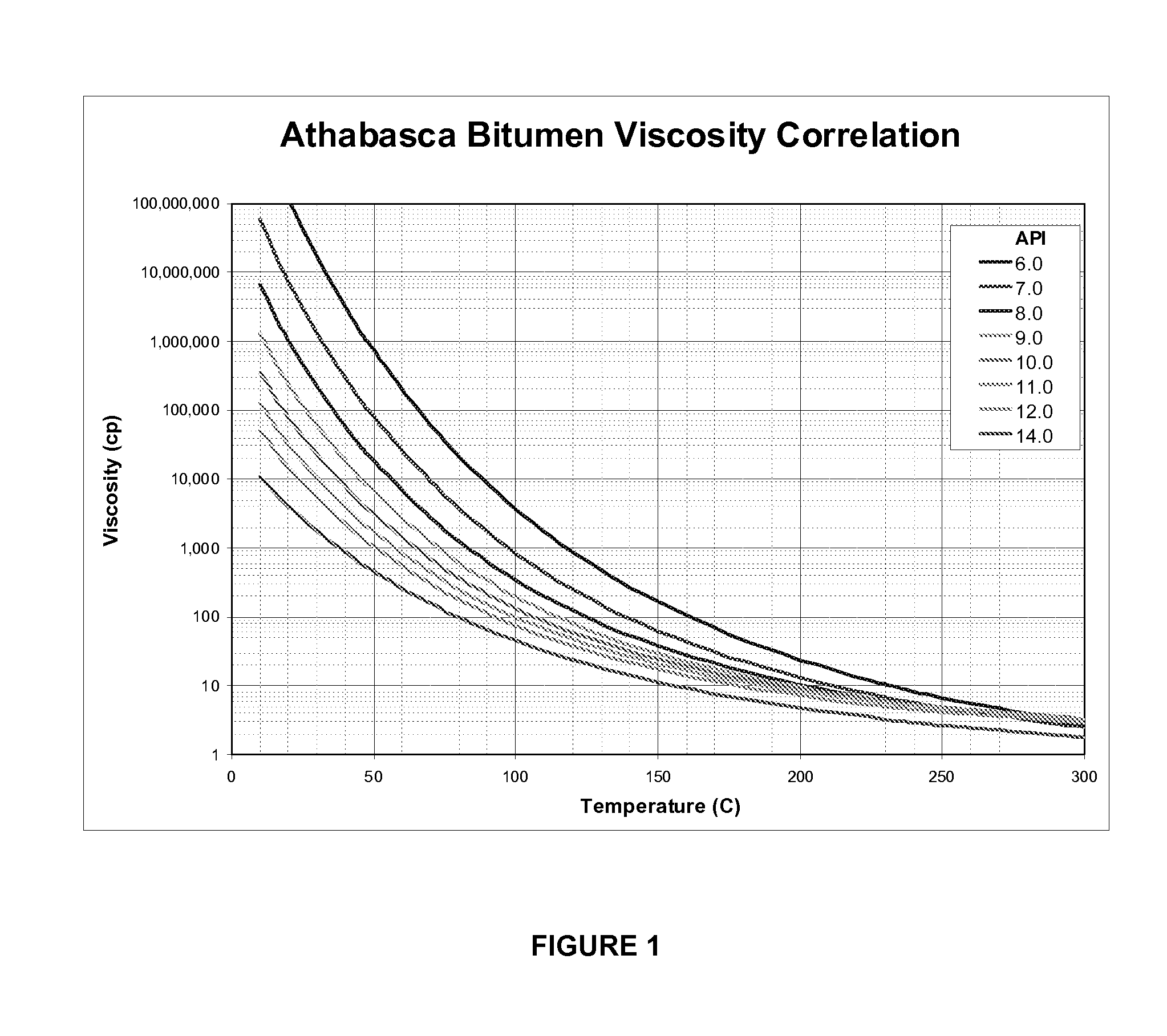

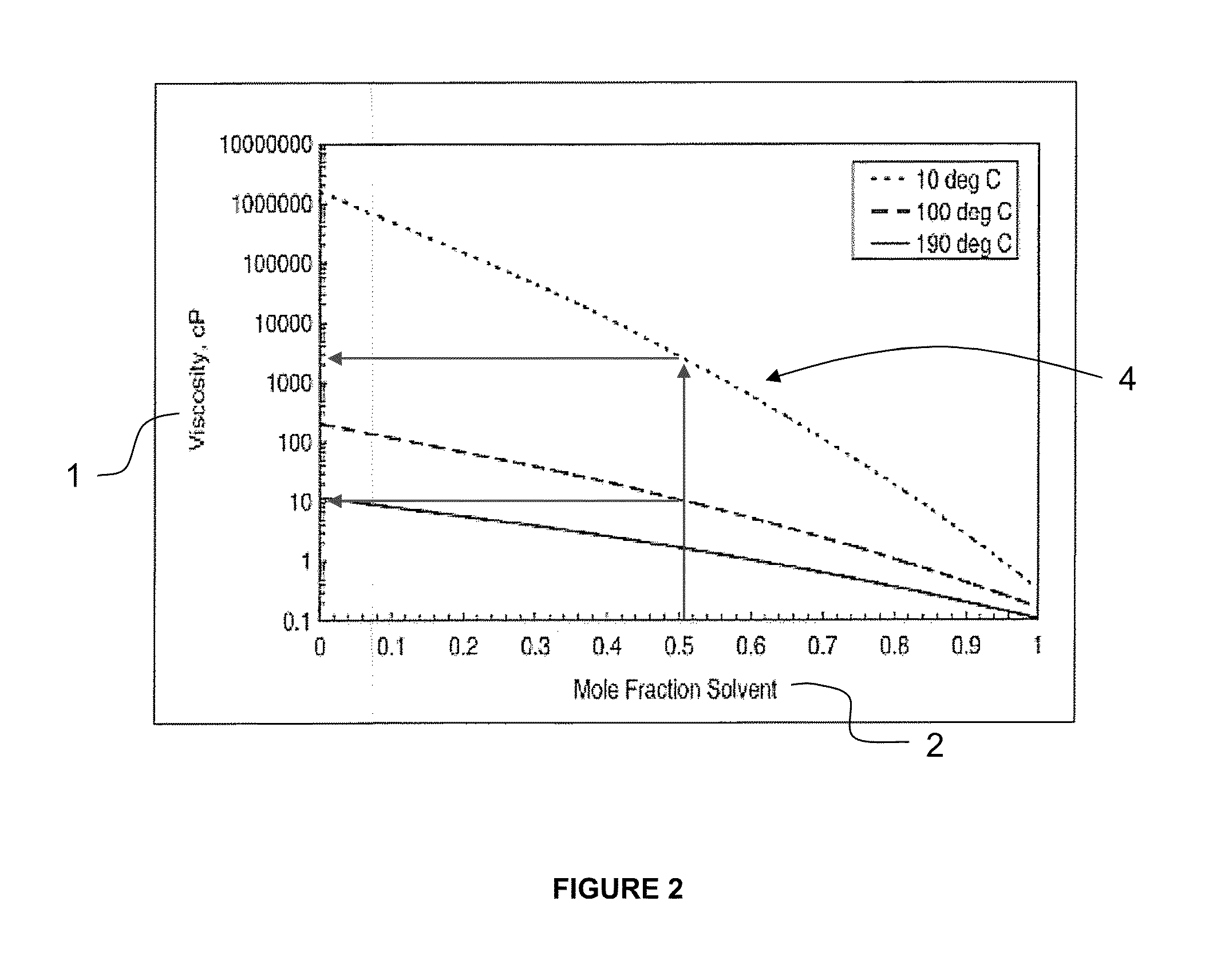

Passive heating assisted recovery methods

ActiveUS7934549B2Low viscositySufficient viscosityInsulationFluid removalRecovery methodPre-condition

A method for producing hydrocarbons from a region having adjacent strata divided by an impermeable or partially permeable barrier and, wherein at least one of the strata contains hydrocarbons, comprises of sufficiently heating one of the stratum to allow heat to be conducted to the hydrocarbon containing stratum and producing hydrocarbons therefrom. In one aspect, both strata contain hydrocarbons, such as bitumen, and heat is generated by a steam assisted gravity drainage process to the adjacent stratum. Heat may also be generated by in-situ combustion of hydrocarbons to preheat an adjacent stratum, or by electrical heating. Once pre-conditioned to a higher in-situ temperature, hydrocarbon production may be facilitated by diluting the target pre-heated hydrocarbon bearing stratum with solvent injection.

Owner:LARICINA ENERGY

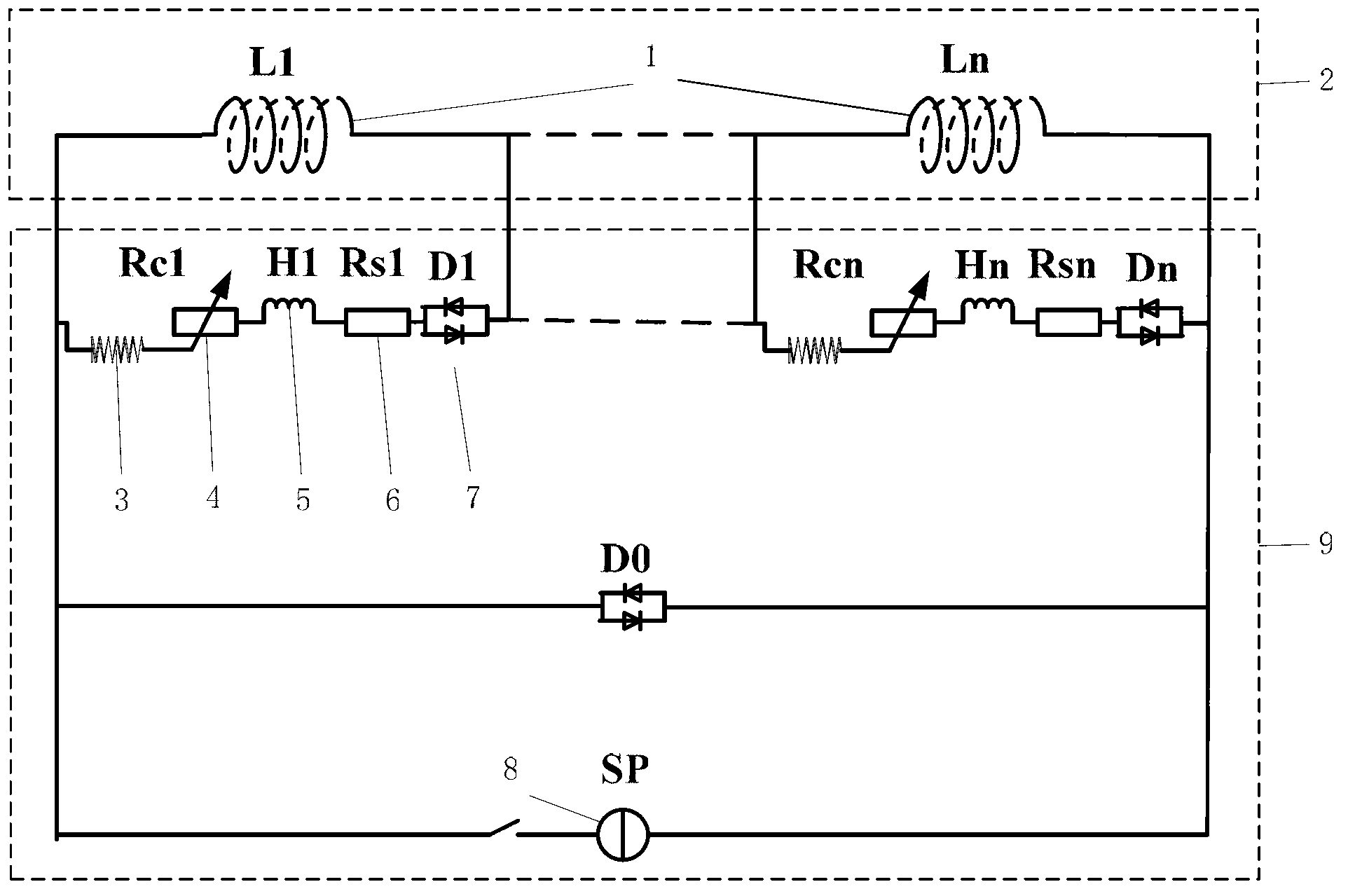

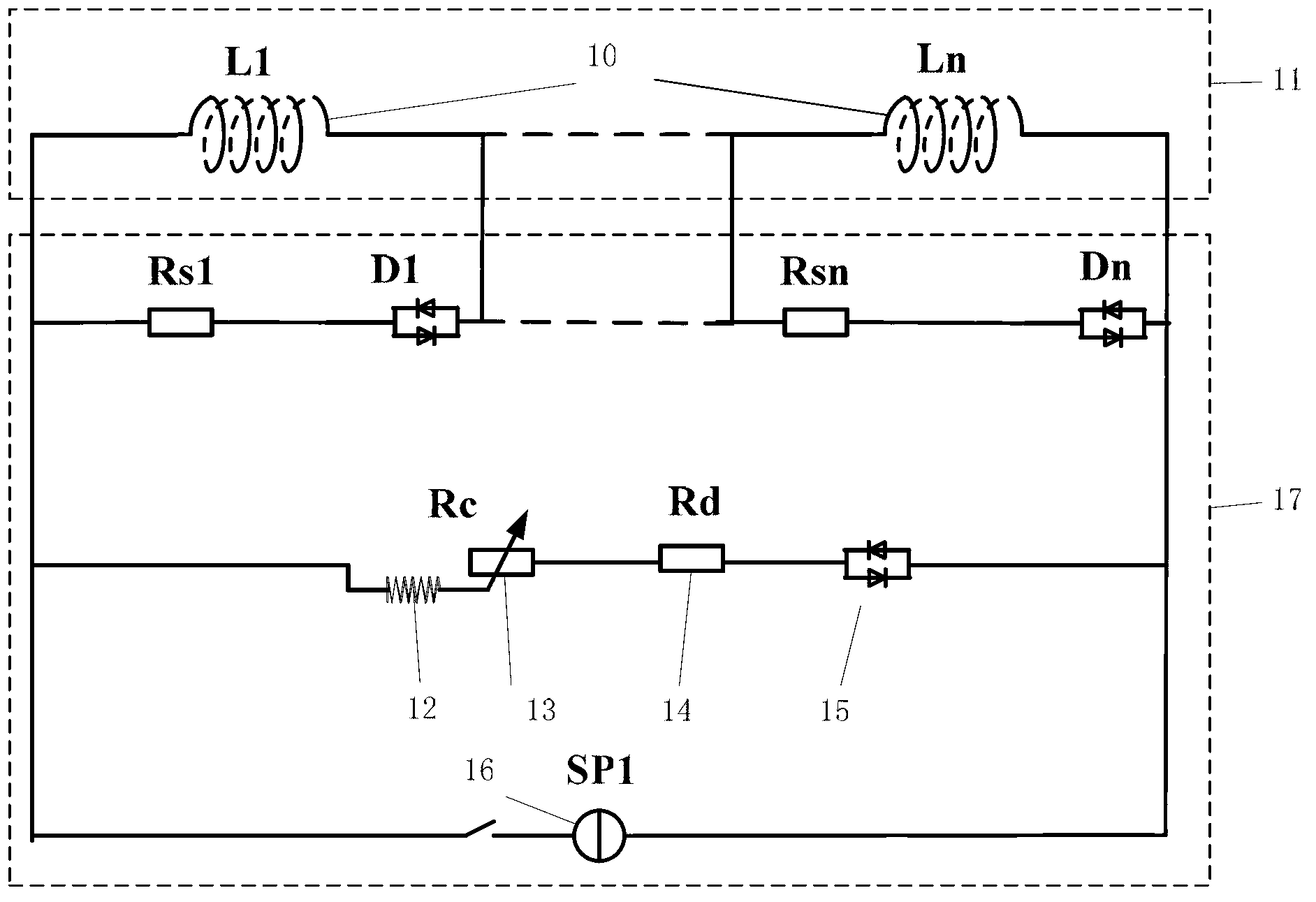

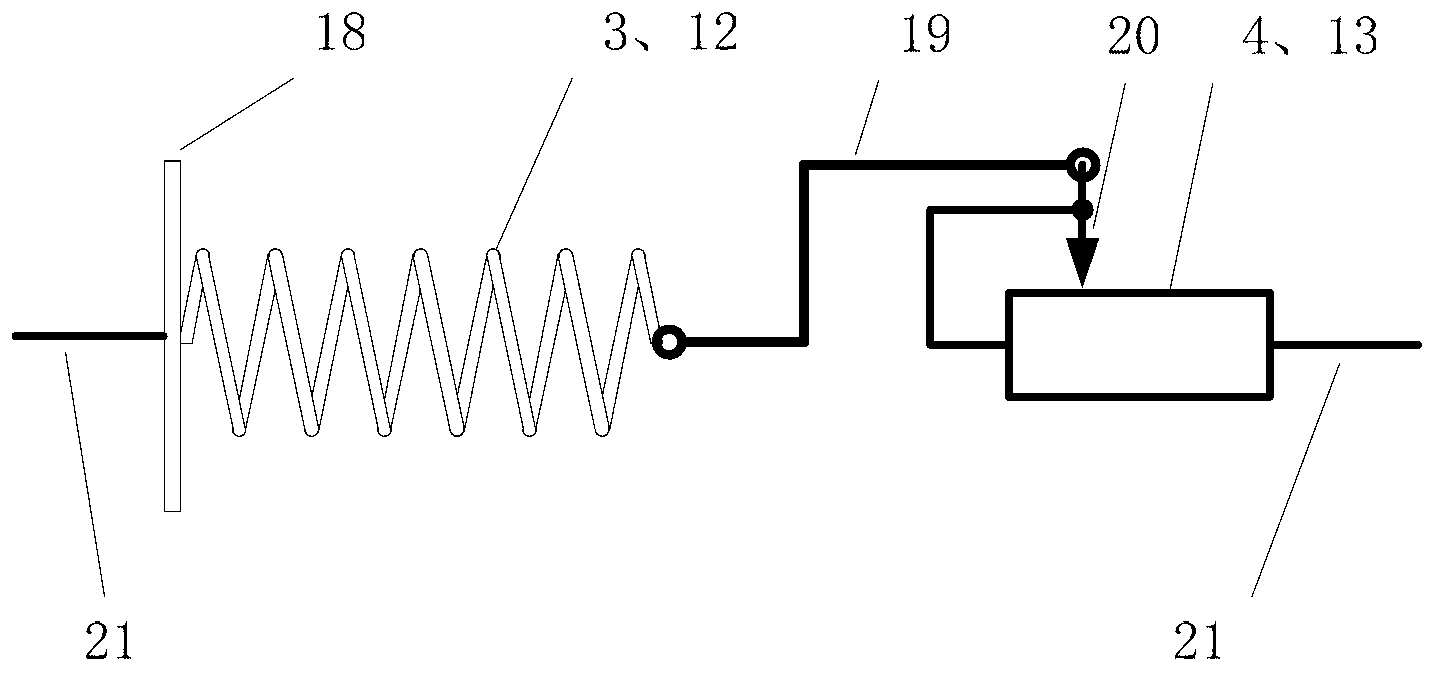

Device for protecting superconducting magnet quench

ActiveCN103022972AStable deformation propertiesStable resistance characteristicsEmergency protective arrangements for automatic disconnectionSuperconducting magnets/coilsElectrical resistance and conductancePassive heating

A device for protecting superconducting magnet quench comprises a superconducting magnet and a quench protection circuit. When the device protects passive heating of the superconducting magnet, the superconducting magnet (2) composed of a plurality of superconducting coils (1) is divided into n segments, n being not smaller than 1. Each segment includes one or a plurality of superconducting coils (1). Each segment is parallelly connected with serially connected devices such as an electrifiable spring (3), a variable resistor (4), a quench trigger heater (5), a piecewise resistor (6) and a bidirectional protection diode (7). The whole superconducting magnet (2) is connected with a power supply (8) in parallel. When the device protect energy bleeding of the superconducting magnet, the quench protection circuit further comprises a bleeder resistor (14); after sequentially connected in series, an electrifiable spring (12), a variable resistor (13), the bleeder (14) and a bidirectional protection diode (15) are parallelly connected to two ends of the superconducting magnet.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

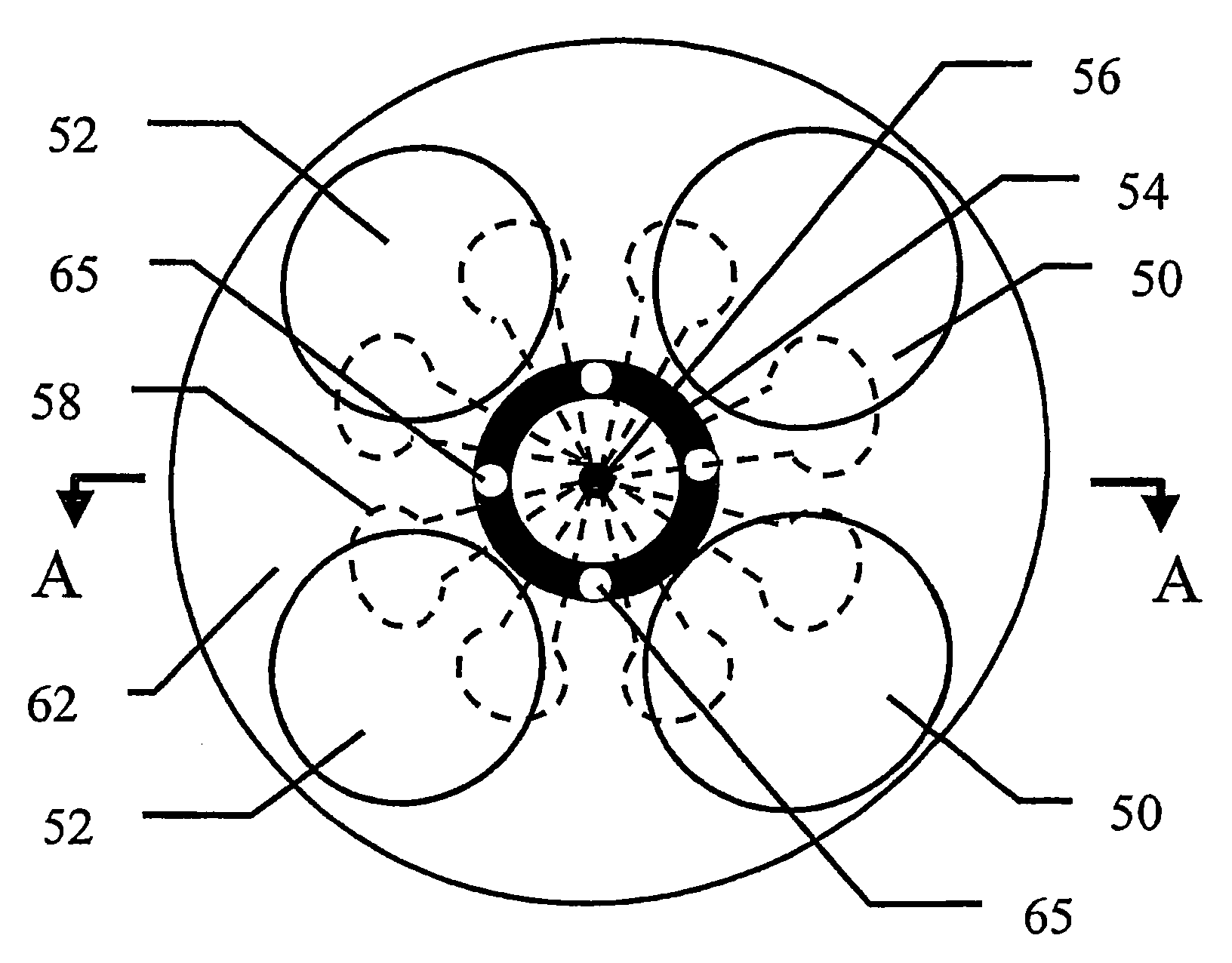

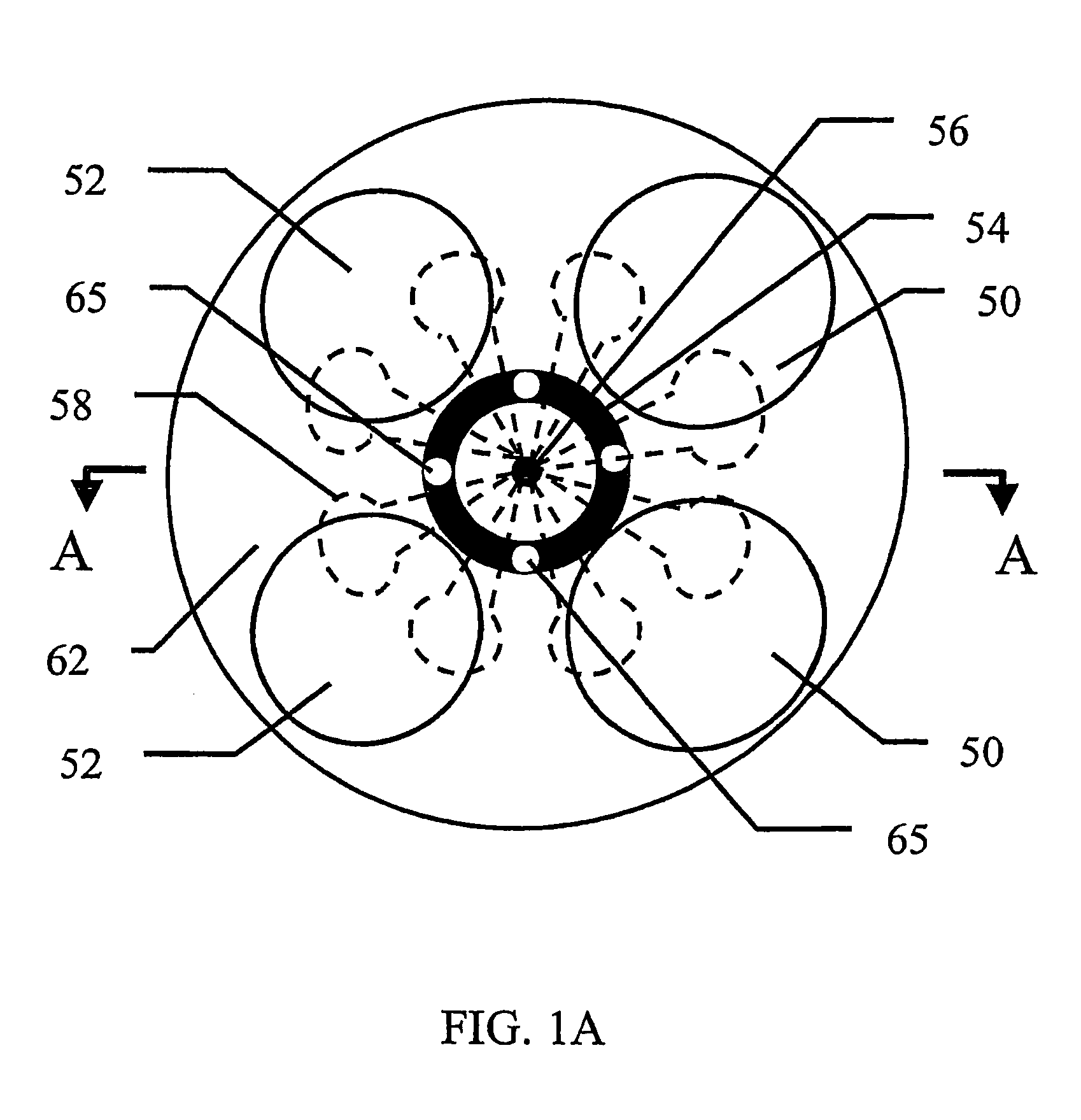

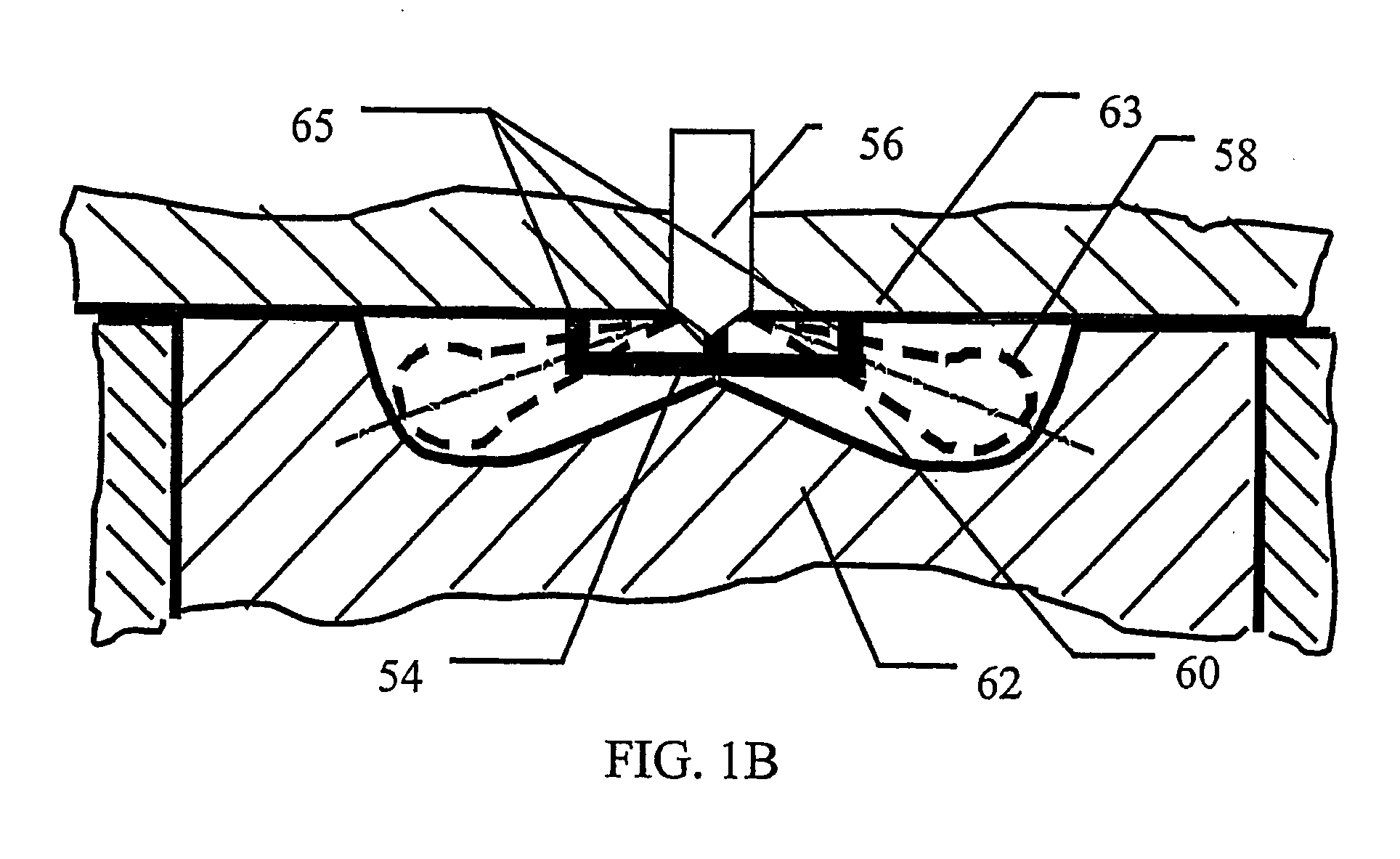

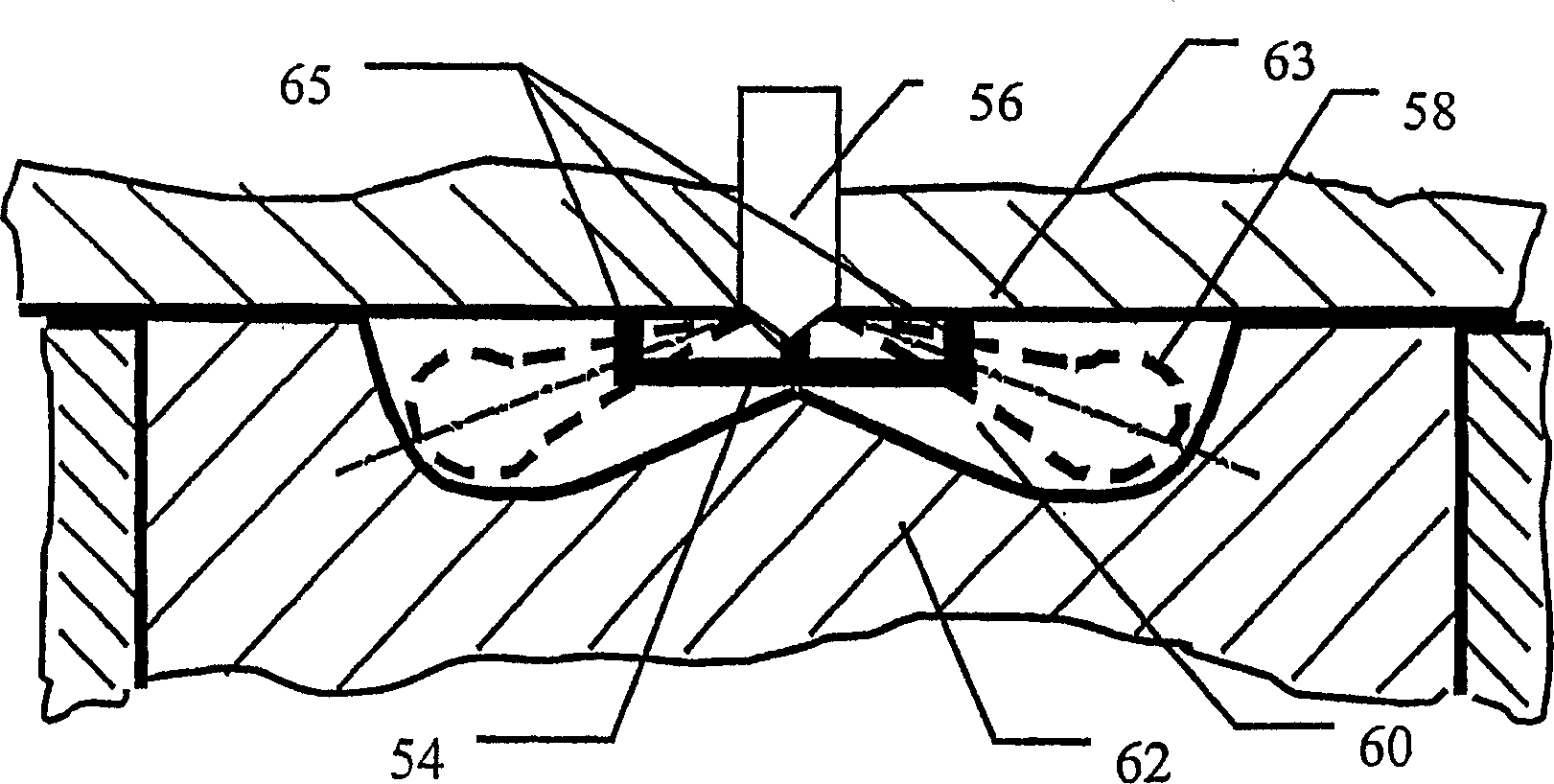

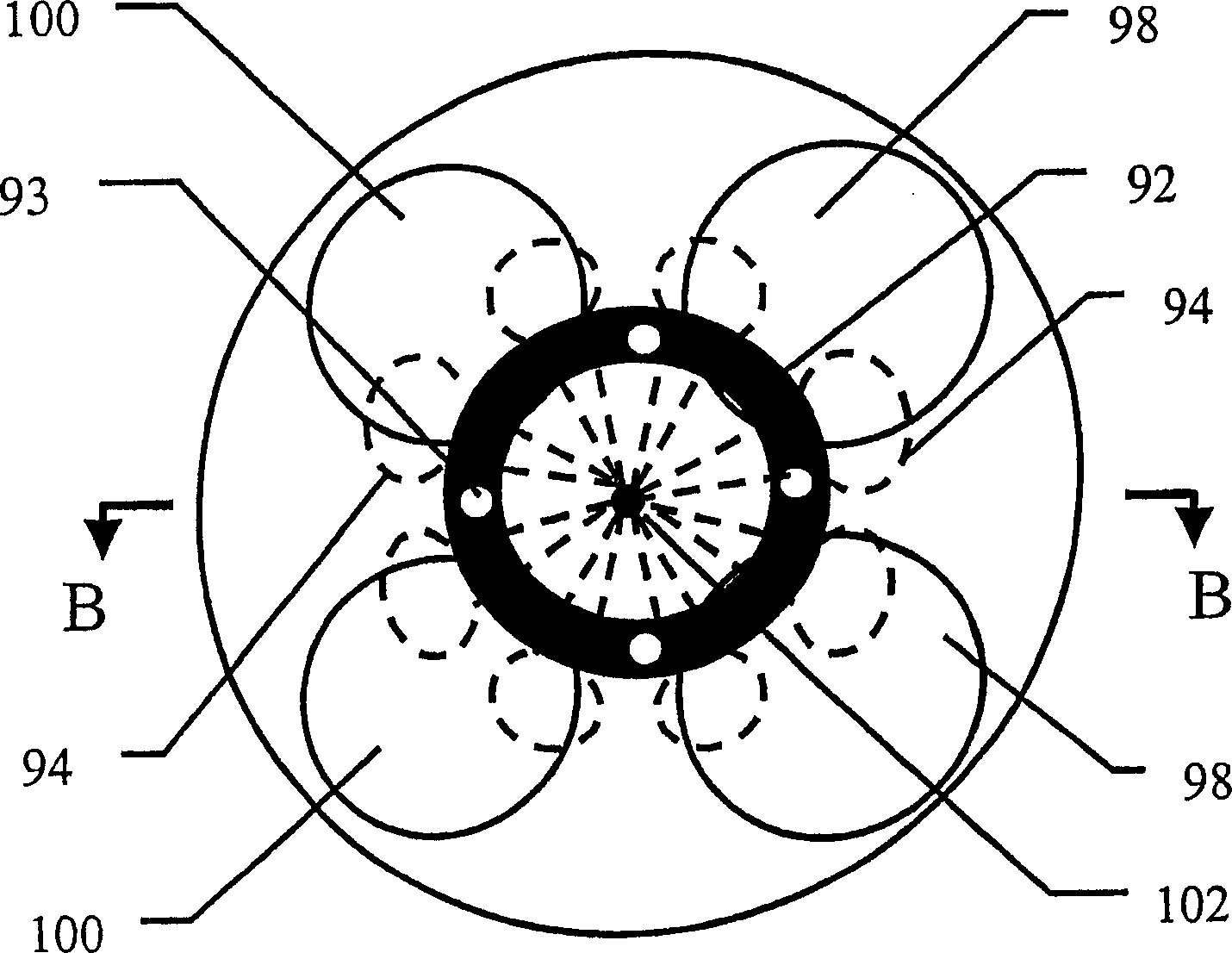

Glow ring ignition assist for internal combustion engine

InactiveUS7281514B2Increase temperatureAvoid less flexibilityElectrical controlInternal combustion piston enginesCombustion chamberPassive heating

A glow member, preferably in the shape of a ring, assists ignition and combustion of a fuel used in an internal combustion engine. A fuel injection valve injects a plurality of fuel jets directly into a combustion chamber during operation of the engine so that the fuel jets are aimed to the proximity of the glow member such that ignition of fuel in each fuel jet is assisted by the glow member. The glow member is made from high temperature materials and can include catalytic materials to further promote combustion. The glow member can be actively heated, for example by an electric current, in addition to being passively heated by the heat generated within the combustion chamber by the combustion of the fuel therein.

Owner:WESTPORT POWER

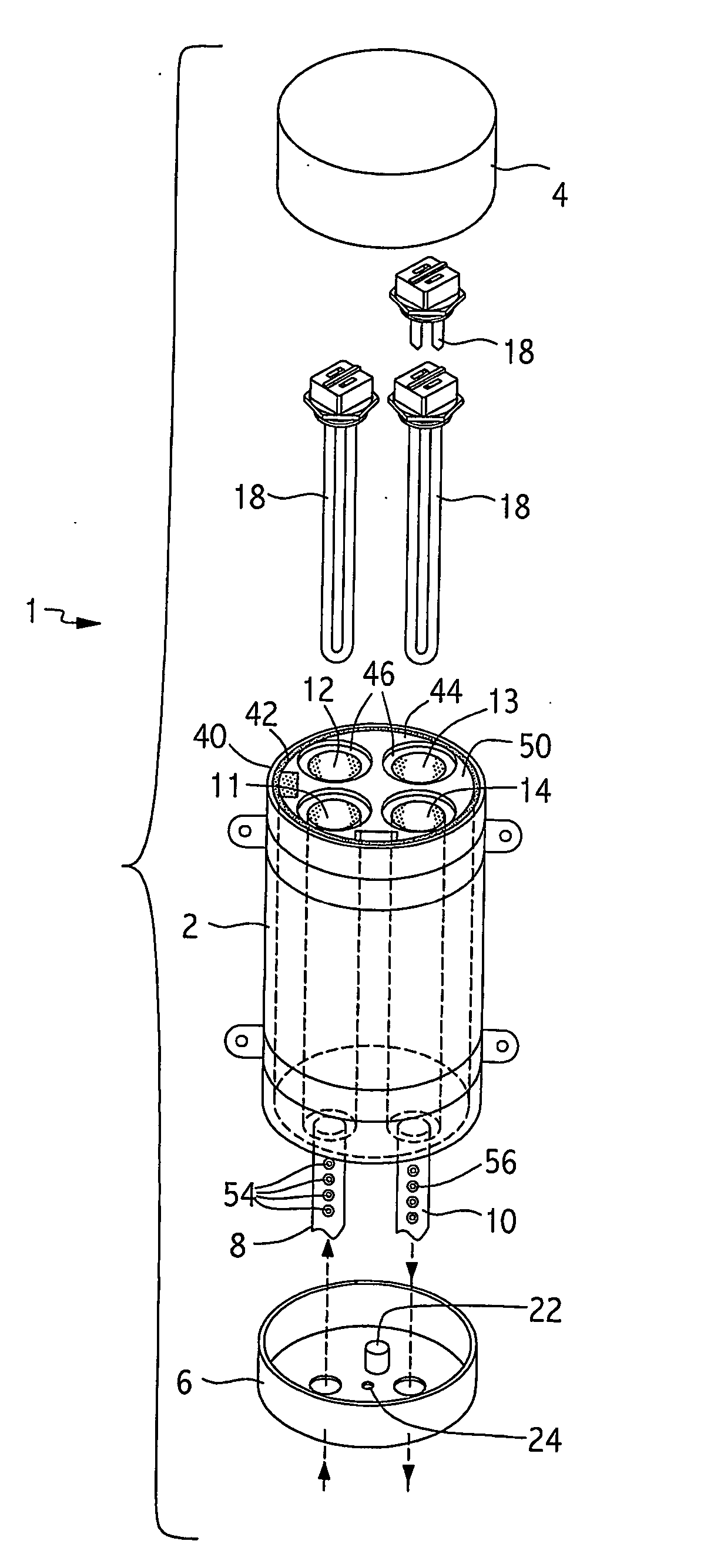

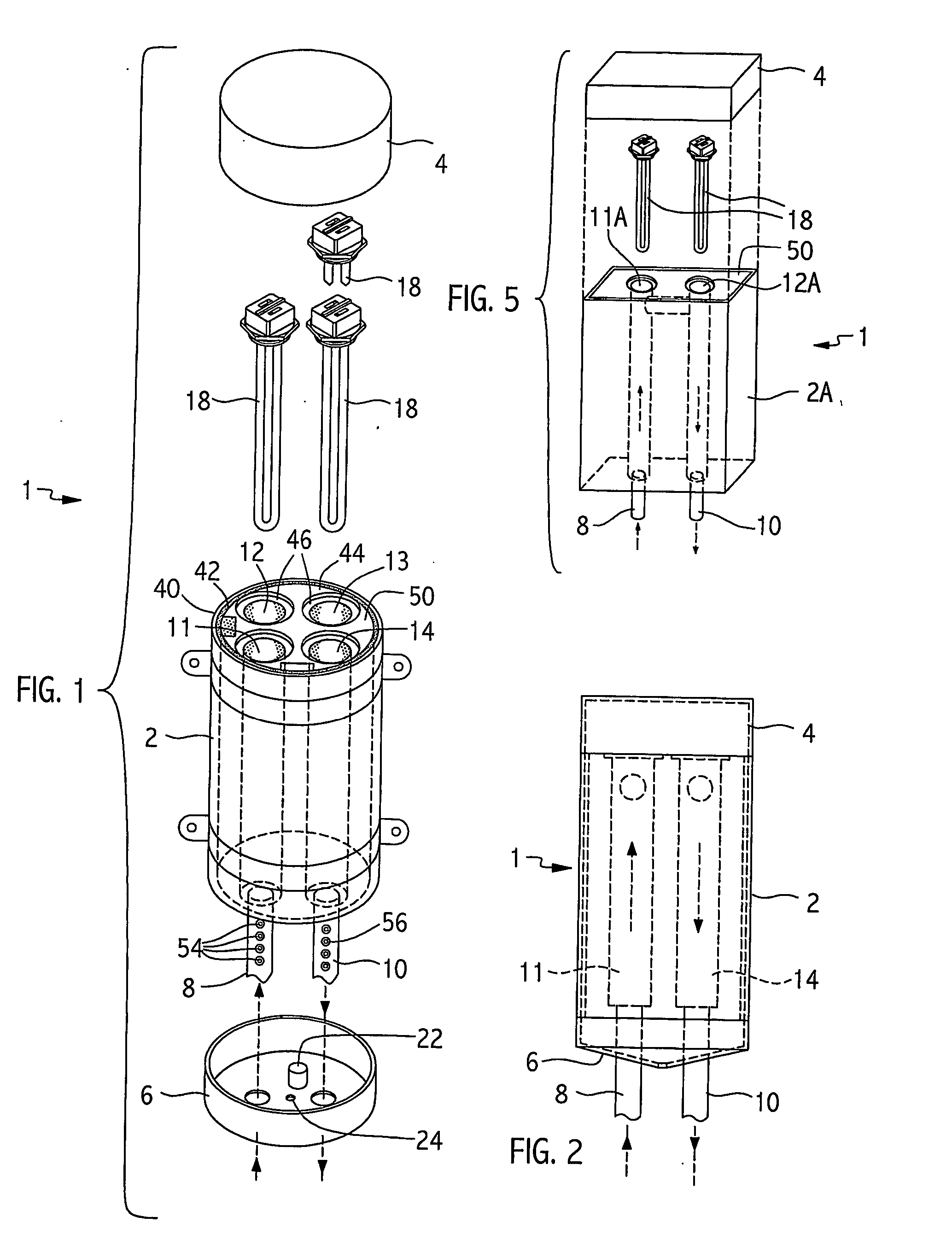

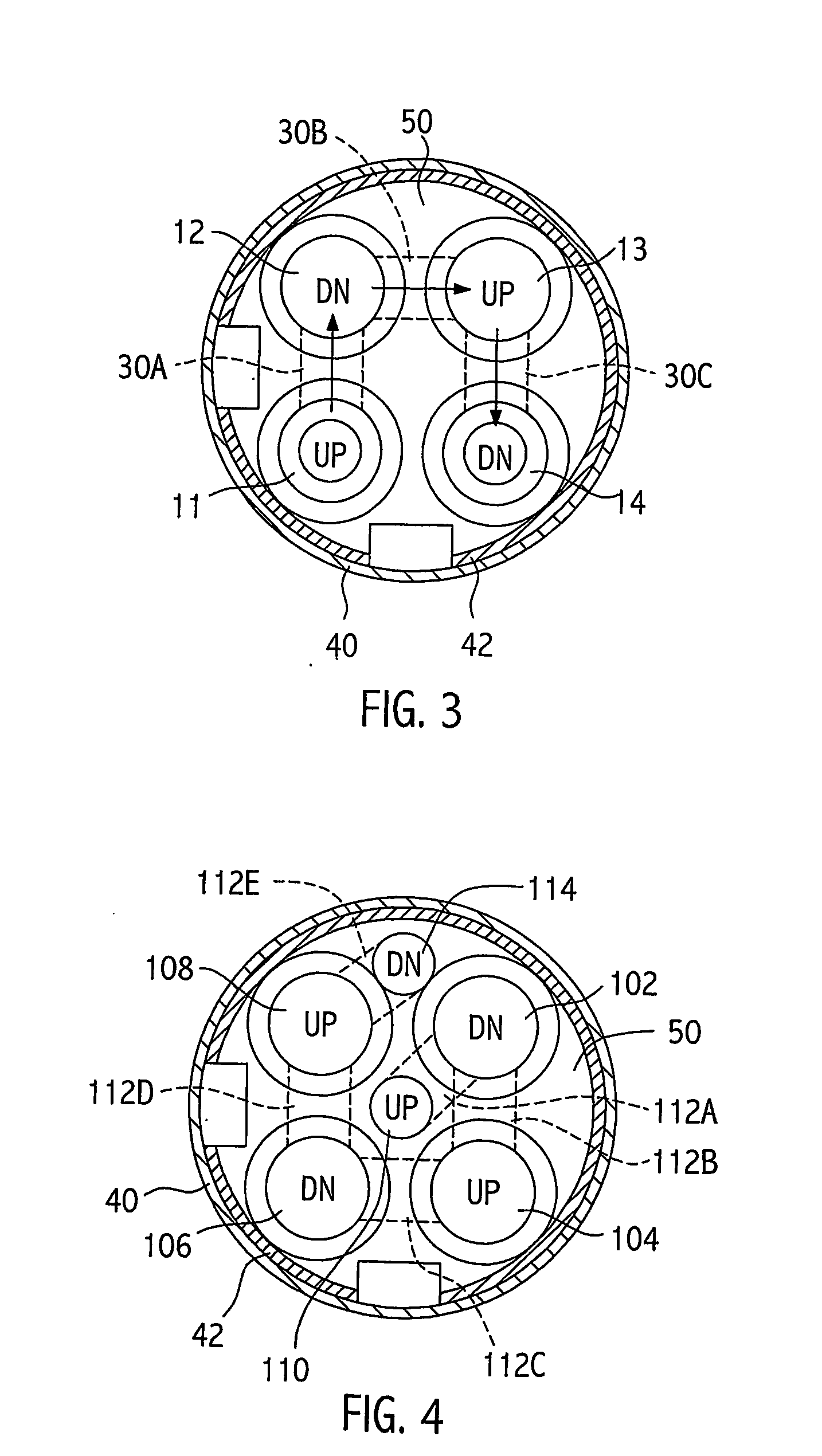

Pre-heating contiguous in-line water heater

An improved pre-heating, contiguous in-line water heater is described. The in-line water heater utilizes a passive heating means to passively heat at least a portion of the input water received by the in-line water heater. The result is a more cost efficient water heater. The in-line water heater is integrated with a means for control to receive input from at least one sensor and to regulate the operation of the in-line water heater.

Owner:CEZAYIRLI CEM +2

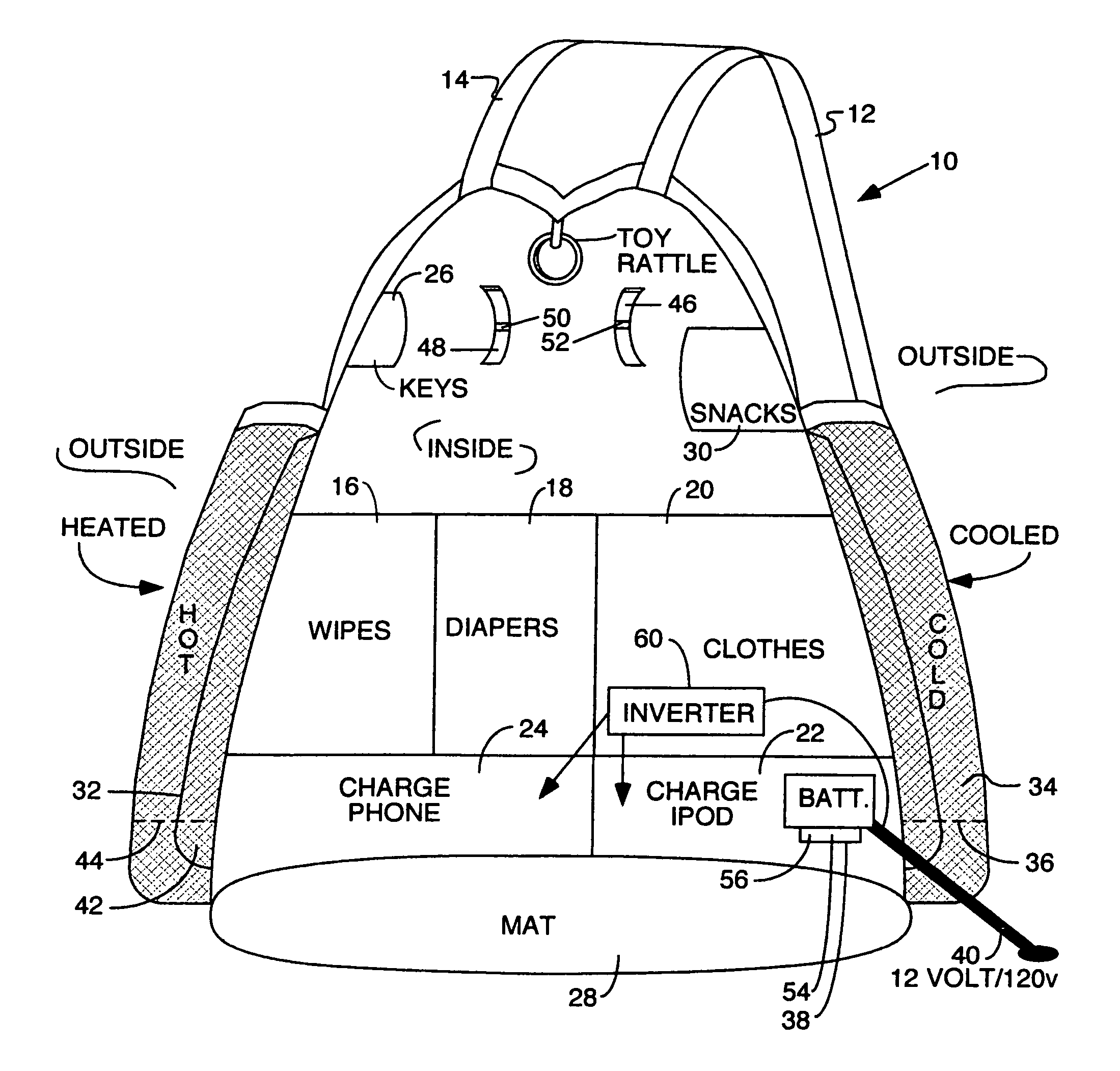

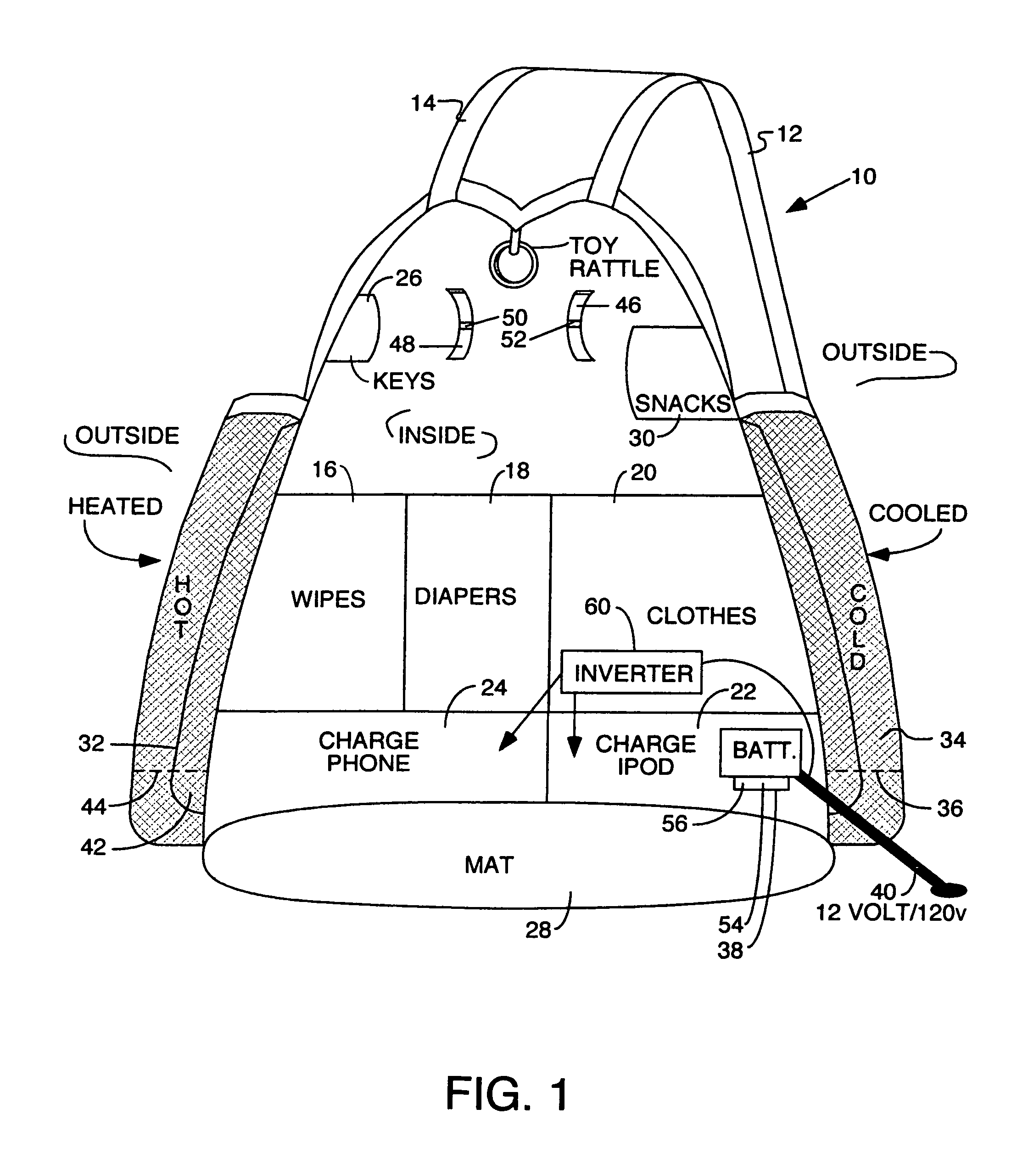

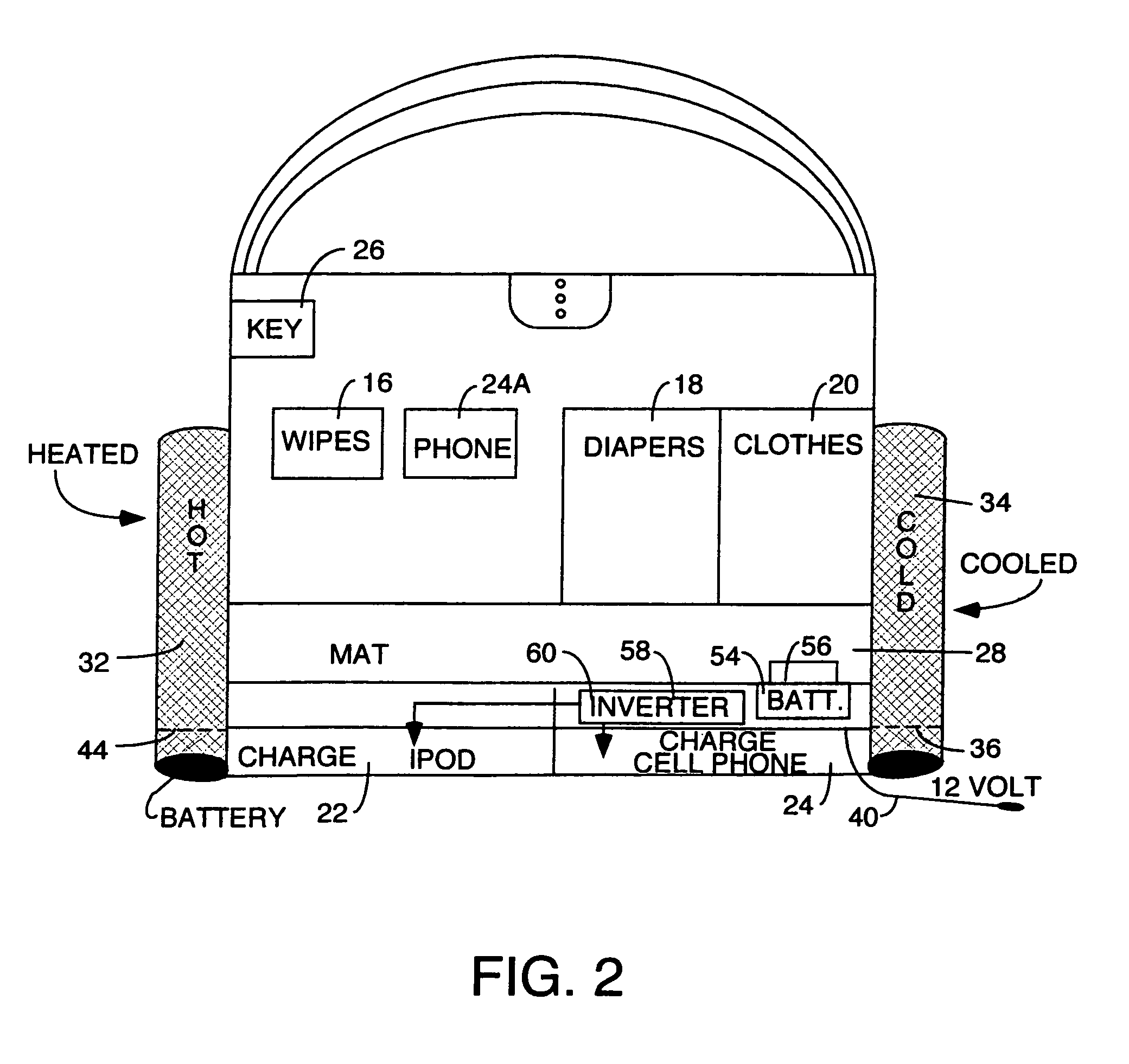

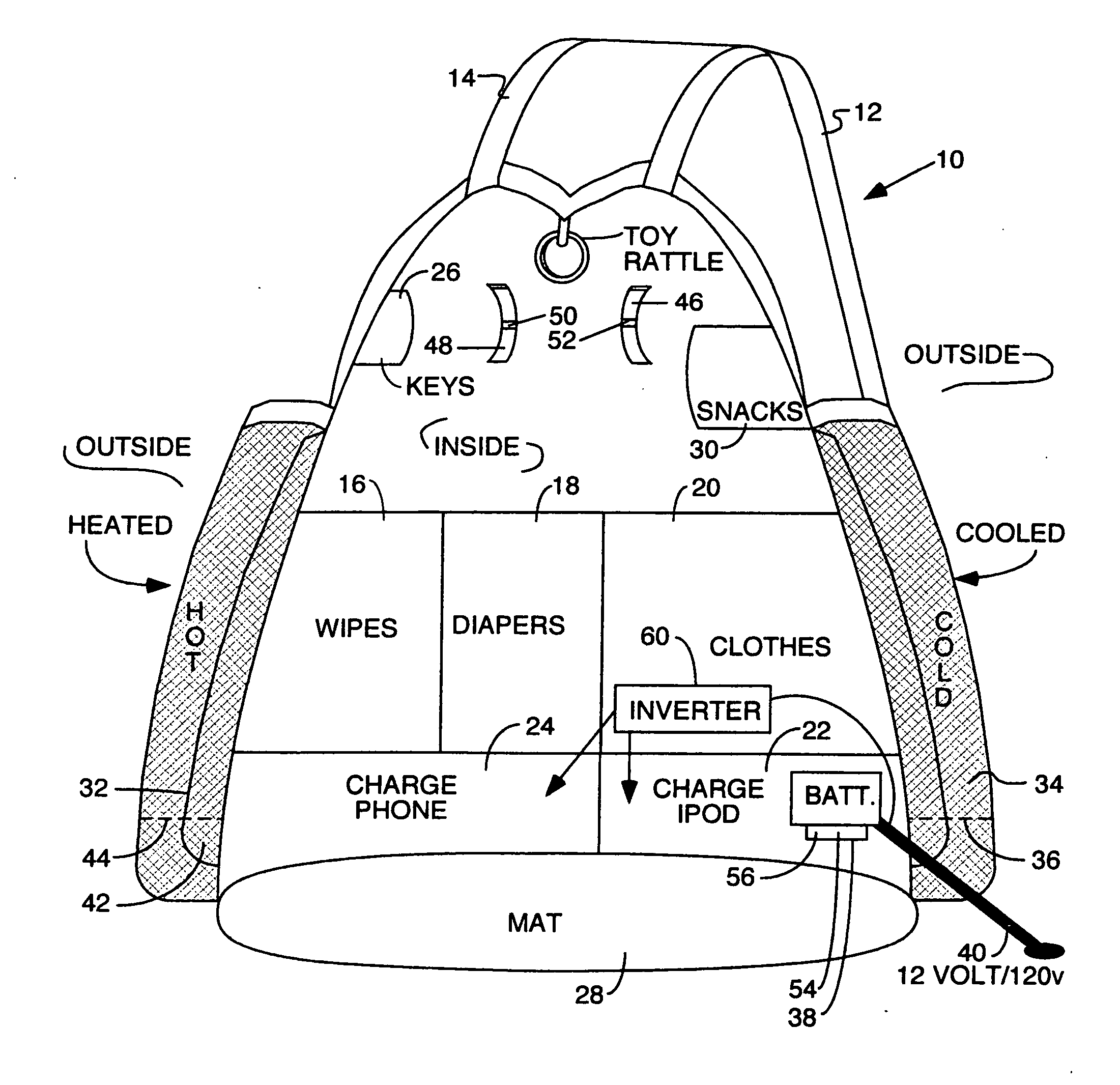

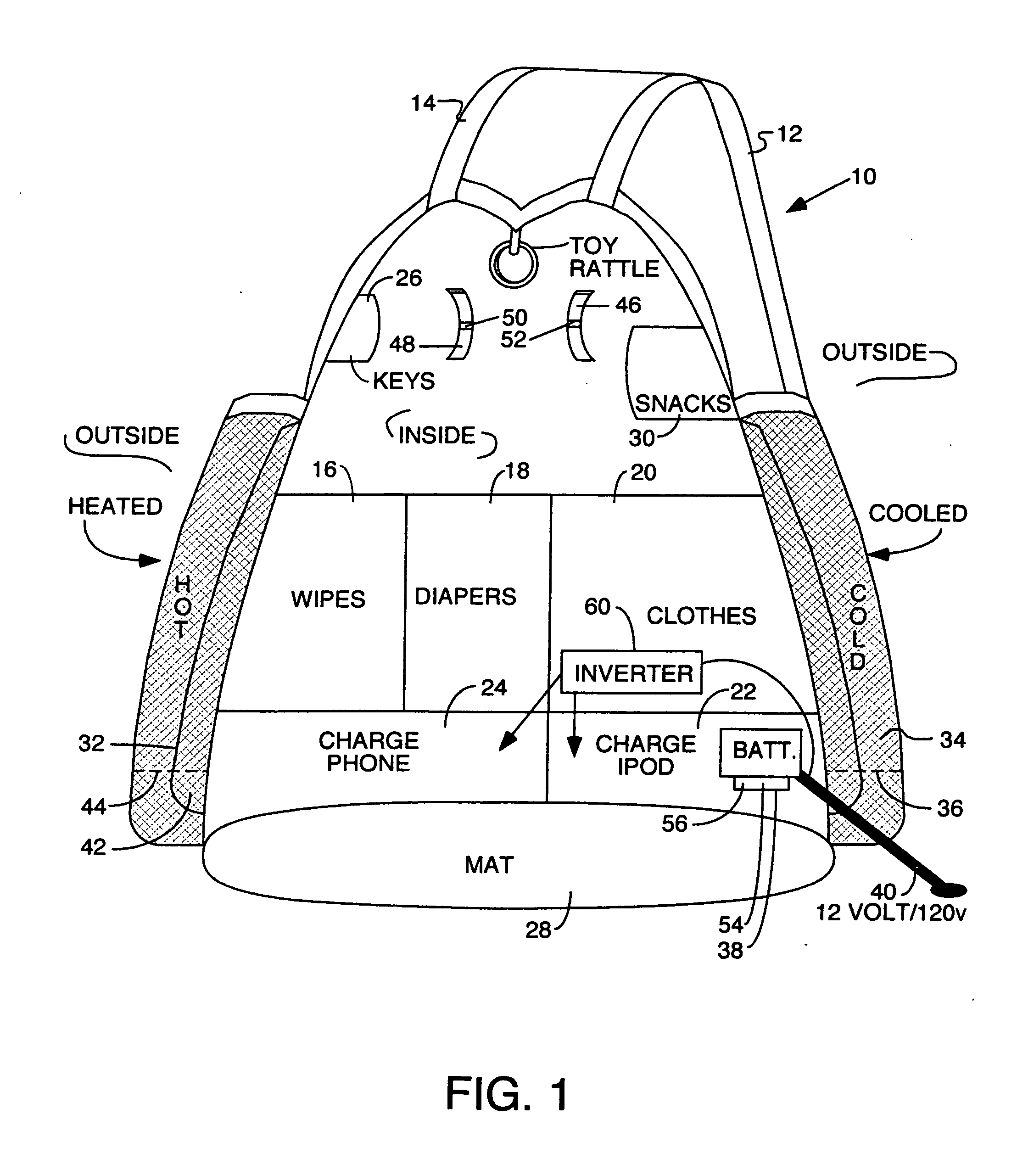

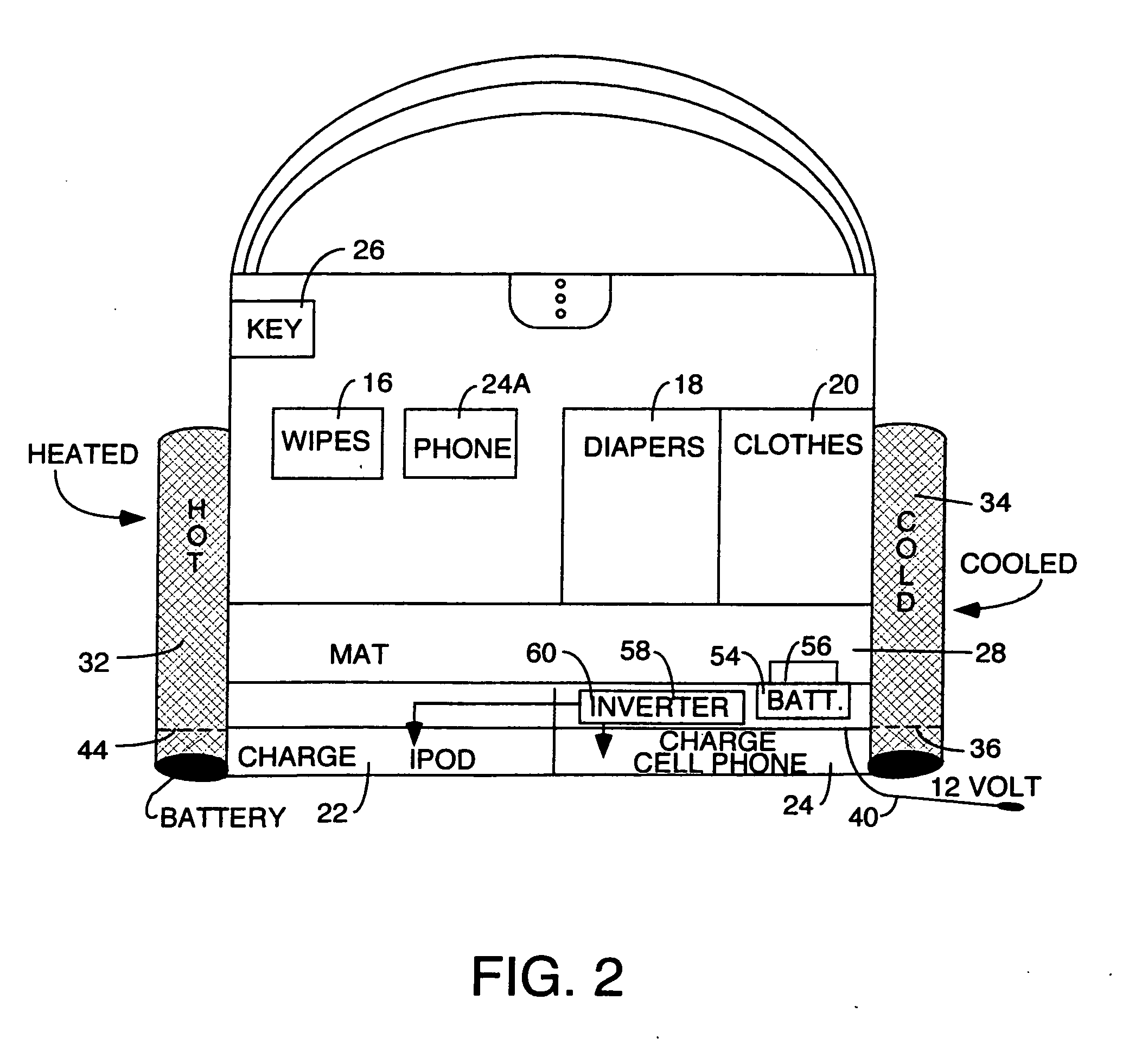

Diaper bag with heated and cooled compartments

A diaper bag having a major compartment with pockets on the walls or bottom thereof for one or more of the following accessories needed either by the mother or baby for travel: wipes, diapers, spare clothes, Mom's ipod, cell phone, keys and / or wallet, a changing mat, snacks, formula, baby food, and having actively or passively heated and cooled insulated compartments for formula, baby food included on the inside or outside of the main compartment.

Owner:KANAGAKI DEBRA BARKER

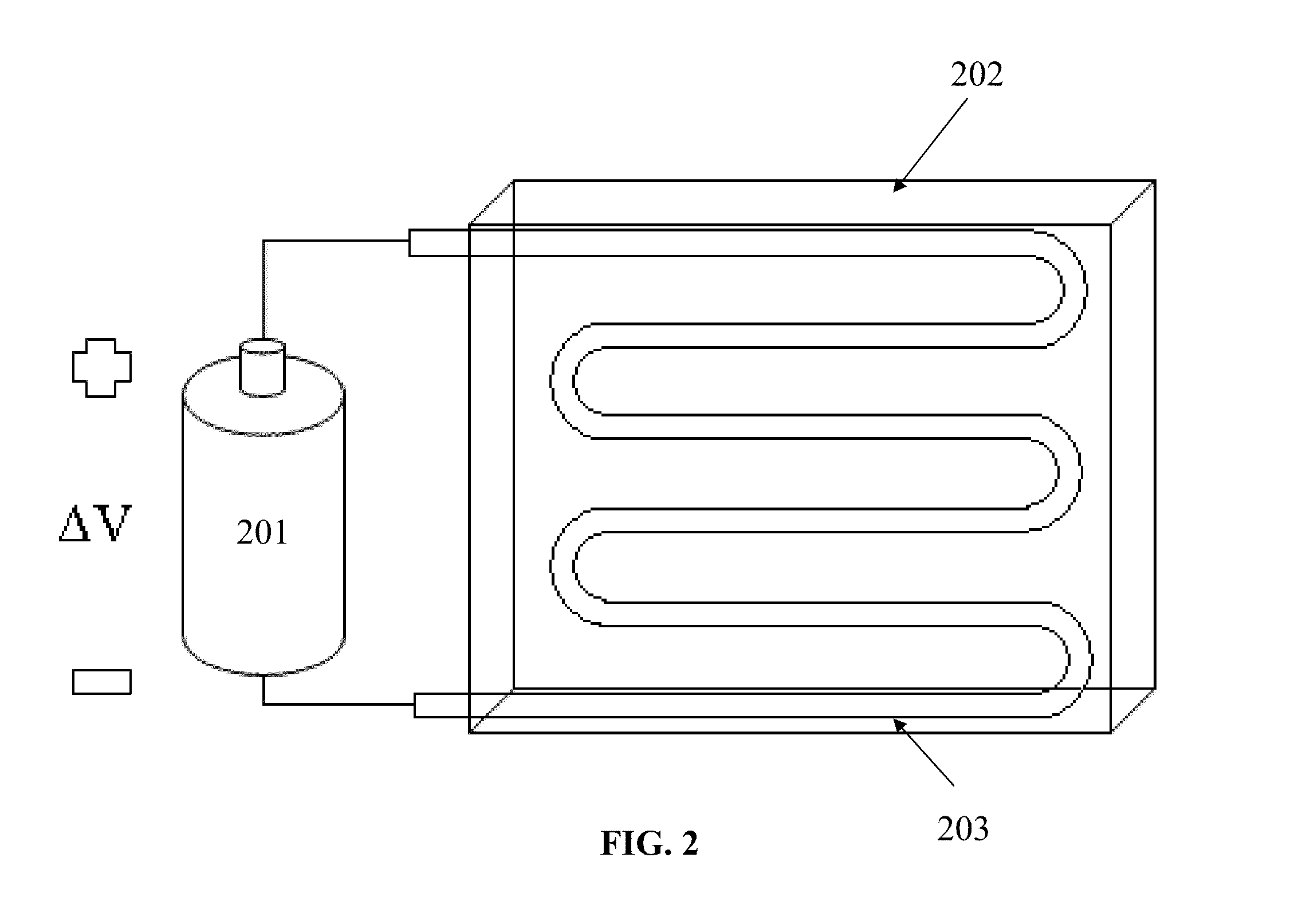

Device for active heating of transparent materials

InactiveUS20130043233A1Problem be addressTransparent/reflecting heating arrangementsOhmic-resistance heating detailsVisibilityElectrical resistance and conductance

A device for removing condensate from a surface of a transparent material is disclosed. The device uses a power supply to conduct an electrical current through and thereby heat a transparent thermo-resistive element embedded within the transparent material. As the transparent thermo-resistive element is heated, heat transfers to a surface of the transparent material, thereby heating such surface to a temperature above the dew point of the condensing liquid which in turn prevents fogging on the surface of the transparent material. Embodiments of the present invention have utility in performance eyewear where fogging has the potential to reduce visibility.

Owner:ELSER JEREMY ALAN +1

Diaper bag with heated and cooled compartments

A diaper bag having a major compartment with pockets on the walls or bottom thereof for one or more of the following accessories needed either by the mother or baby for travel: wipes, diapers, spare clothes, Mom's ipod, cell phone, keys and / or wallet, a changing mat, snacks, formula, baby food, and having actively or passively heated and cooled insulated compartments for formula, baby food included on the inside or outside of the main compartment.

Owner:KANAGAKI DEBRA BARKER

Passive Heating Assisted Recovery Methods

ActiveUS20100108317A1Reduces viscosity of oilEffective strategyInsulationFluid removalRecovery methodCombustion

A method for producing hydrocarbons from a region having adjacent strata divided by an impermeable or partially permeable barrier and, wherein at least one of the strata contains hydrocarbons, comprises of sufficiently heating one of the stratum to allow heat to be conducted to the hydrocarbon containing stratum and producing hydrocarbons therefrom. In one aspect, both strata contain hydrocarbons, such as bitumen, and heat is generated by a steam assisted gravity drainage process to the adjacent stratum. Heat may also be generated by in-situ combustion of hydrocarbons to preheat an adjacent stratum, or by electrical heating. Once pre-conditioned to a higher in-situ temperature, hydrocarbon production may be facilitated by diluting the target pre-heated hydrocarbon bearing stratum with solvent injection.

Owner:LARICINA ENERGY

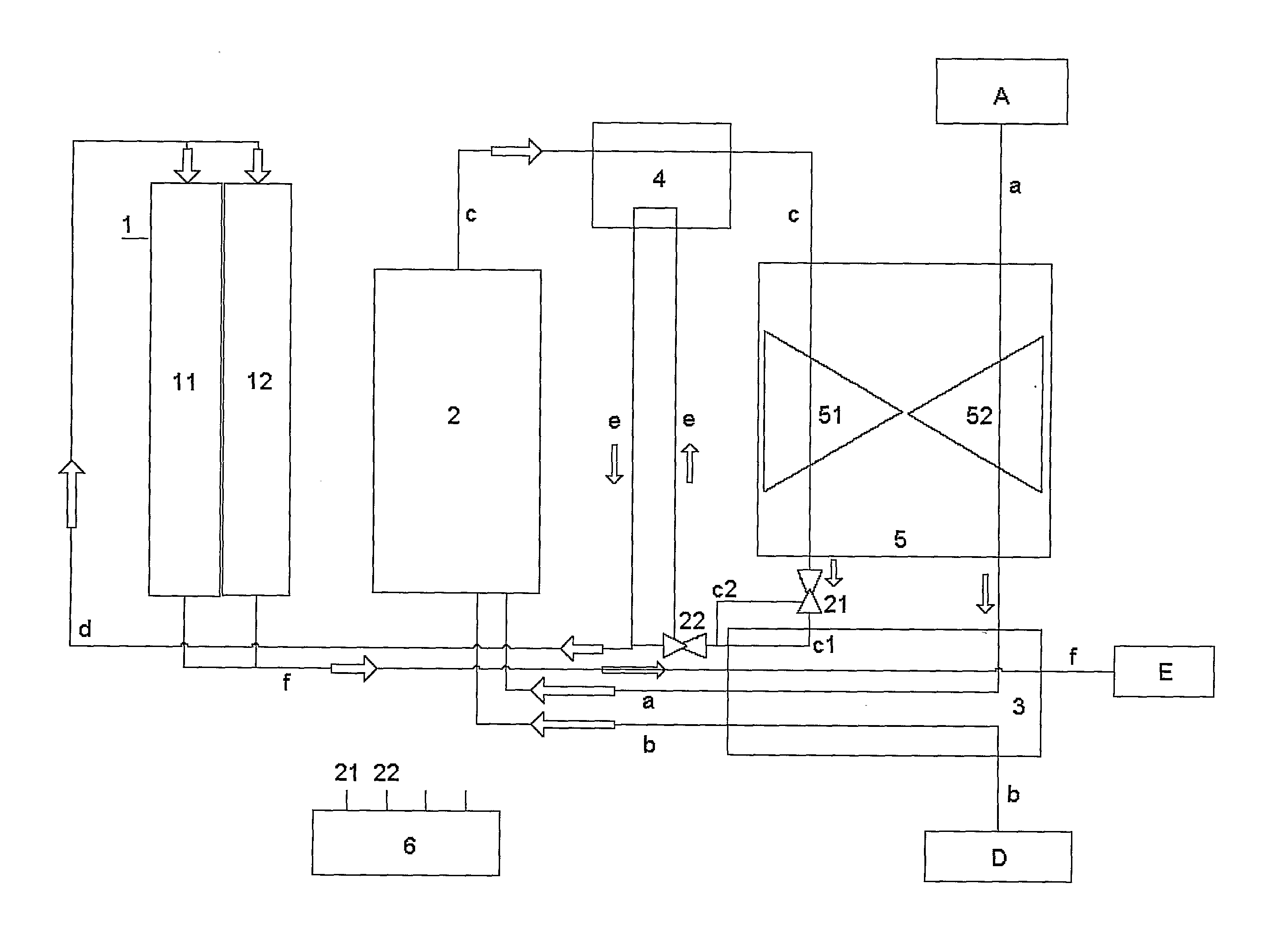

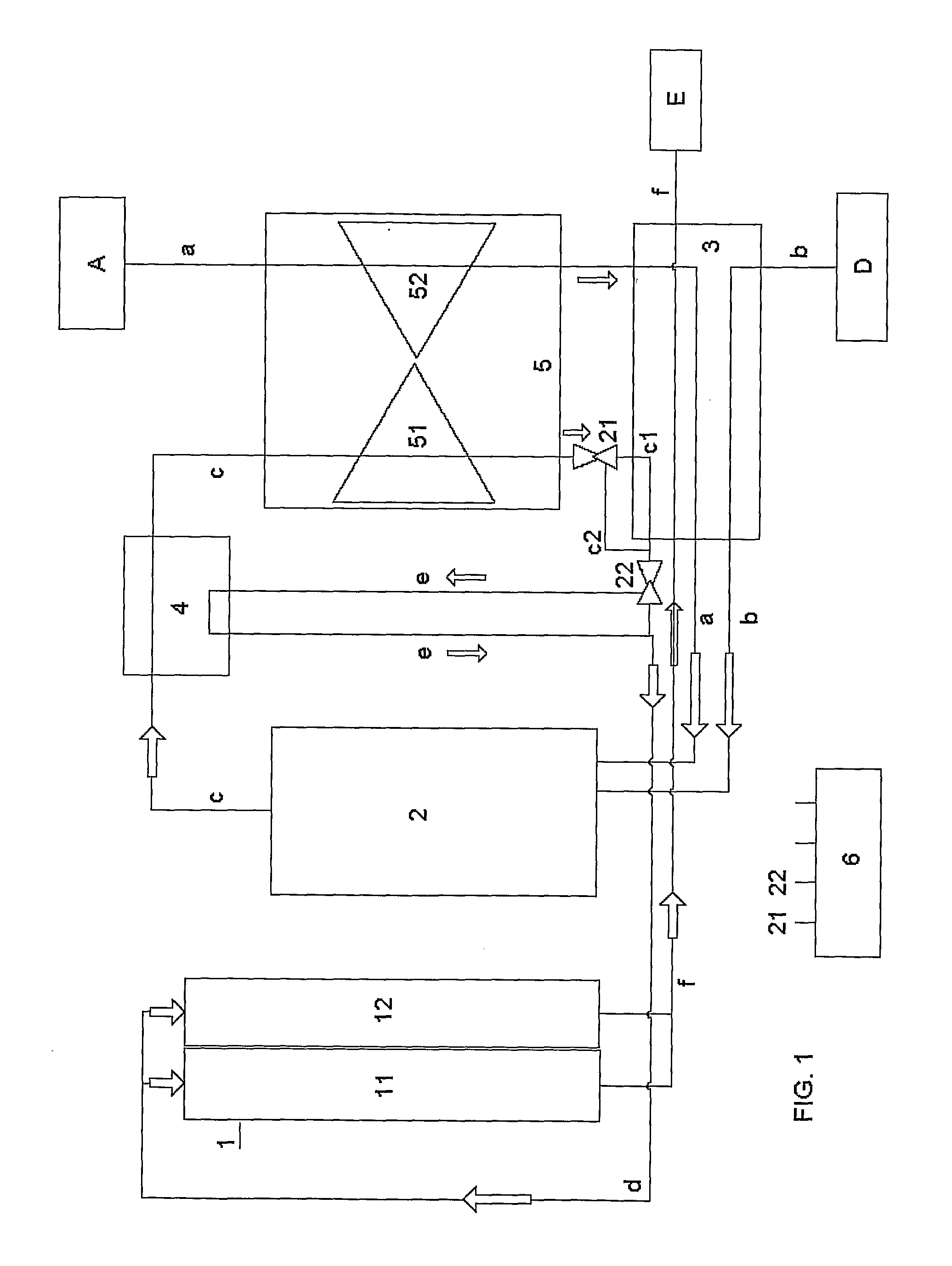

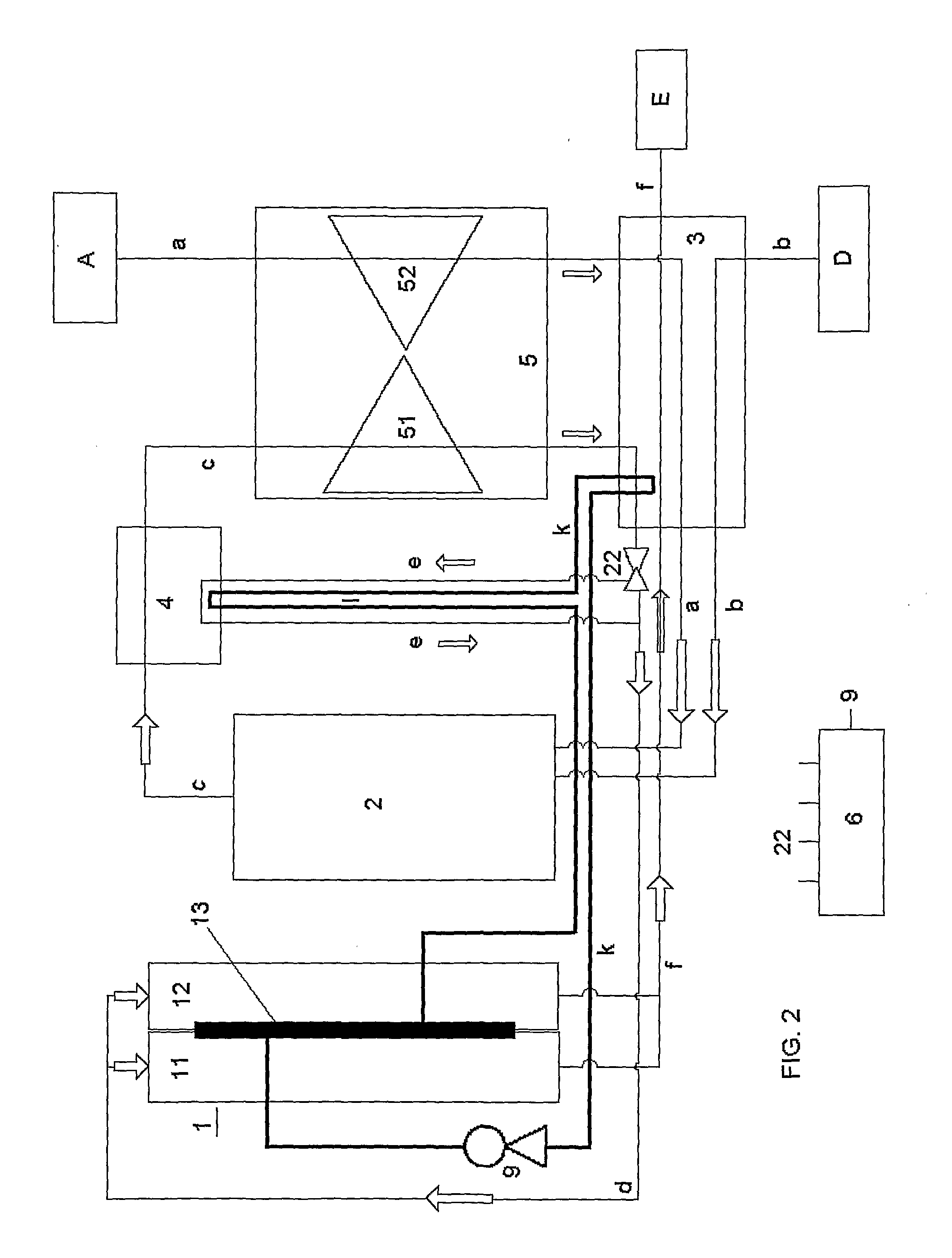

Method for operating a fuel cell and a fuel cell arrangement

ActiveUS20110053023A1Reduce riskExtended service lifeFuel cell auxillariesGas turbine plantsFuel cellsPassive heating

A method for operating, especially for starting, a fuel cell such as a solid oxide fuel cell (SOFC) is disclosed which method includes a starting operation with a first or initial start phase and an optional second or intermediate start phase which is initiated when the fuel cell has reached a predetermined medium temperature below a steady state operational temperature range, before a steady state operation is activated. During the first or initial start phase fuel is subjected to an exothermic reaction with oxygen in a burner unit and output gases from the burner unit are used to warm up and passively heat the fuel cell. Furthermore, a fuel cell arrangement comprising a fuel cell, especially a SOFC hybrid system, for conducting this method is disclosed.

Owner:VOLVO LASTVAGNAR AB

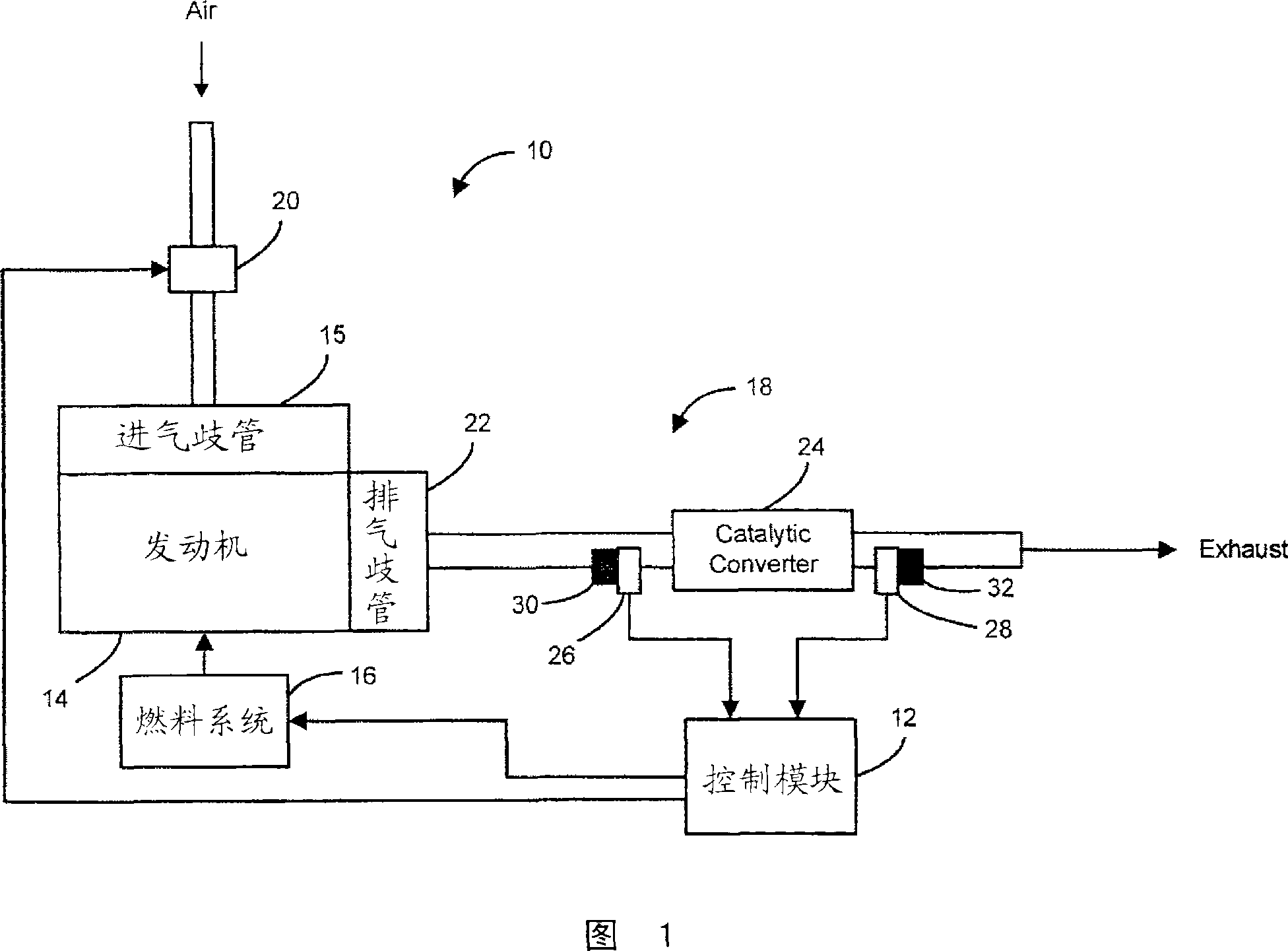

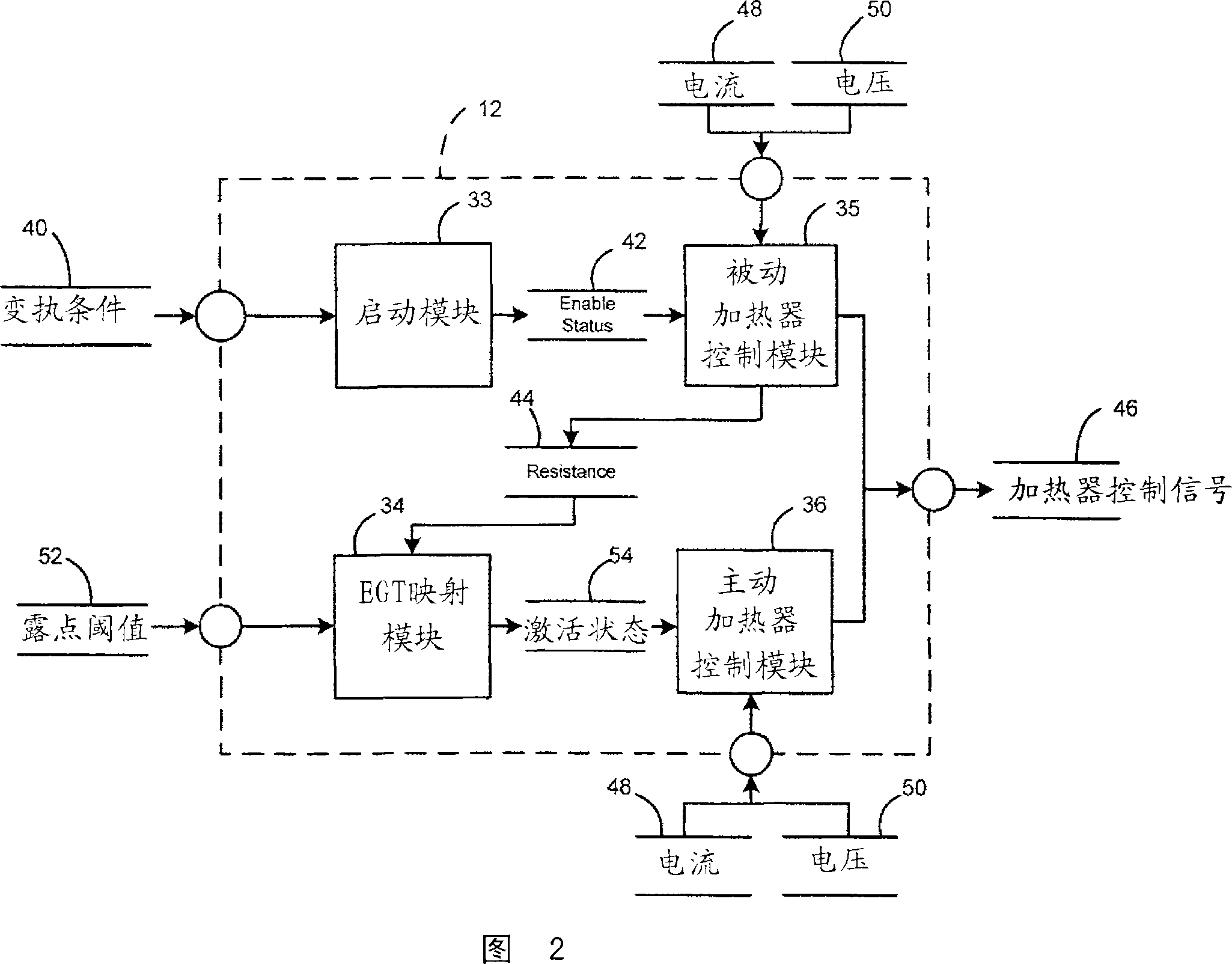

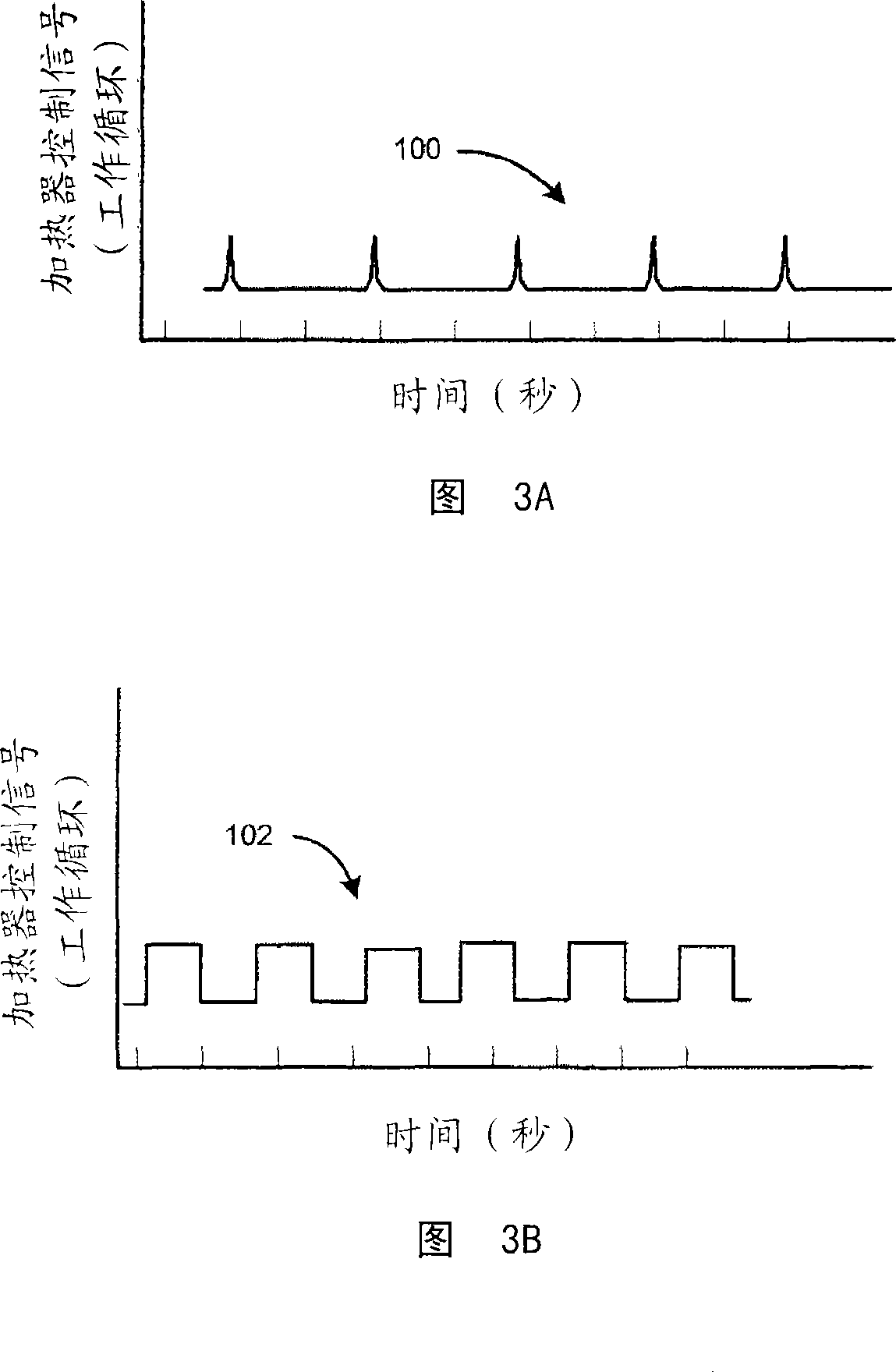

Oxygen sensor heater control methods and systems

InactiveCN101235757AElectrical controlMaterial analysis by electric/magnetic meansPassive heatingControl signal

A control system for an oxygen sensor heater is provided. The control system includes a passive heater control module that generates a heater control signal and measures resistance of the oxygen sensor heater during a first duty cycle. An exhaust temperature mapping module maps the impedance to exhaust temperature. An active heater control module generates a heater control signal based on the exhaust gas temperature during the second duty cycle.

Owner:GM GLOBAL TECH OPERATIONS LLC

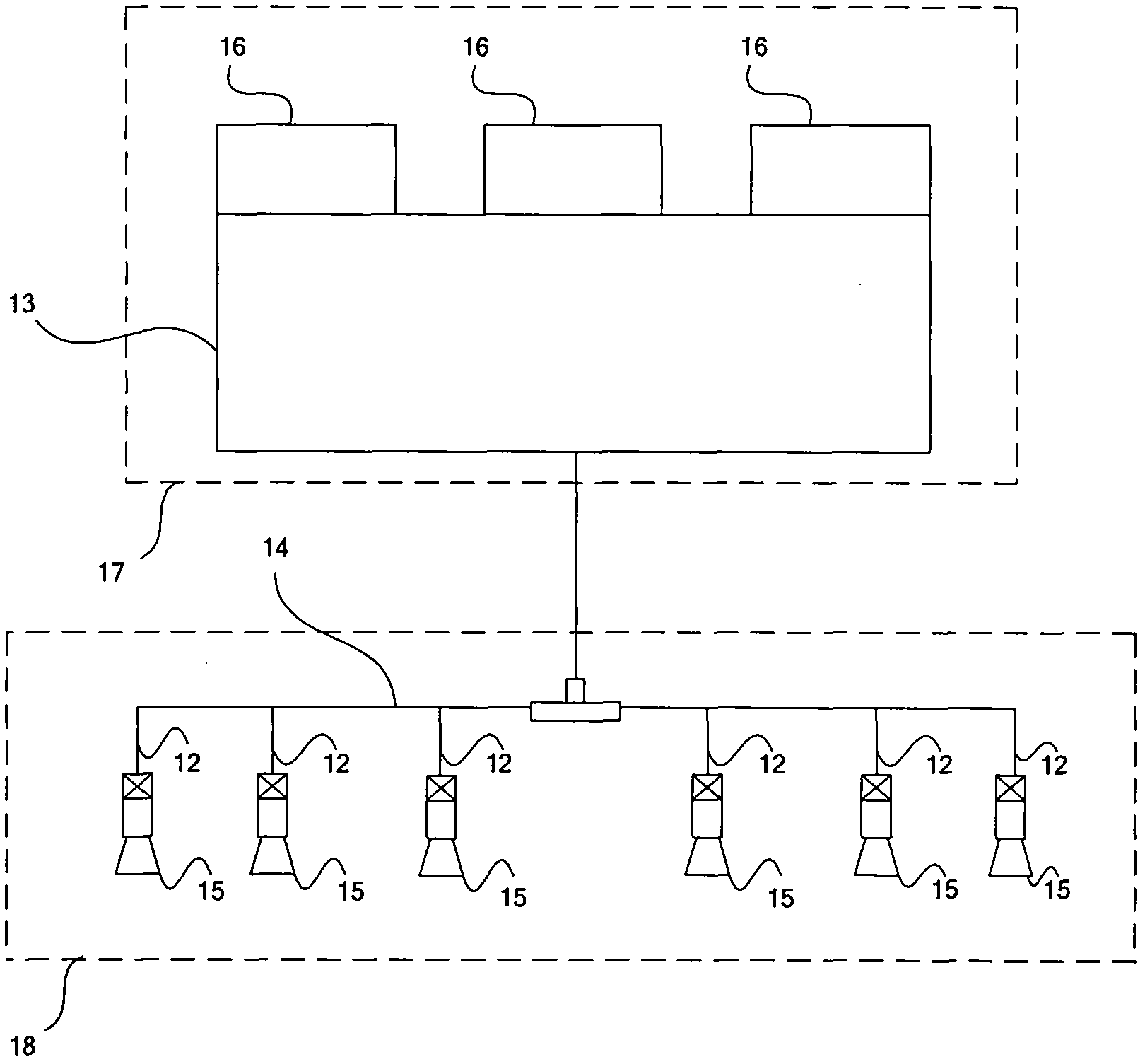

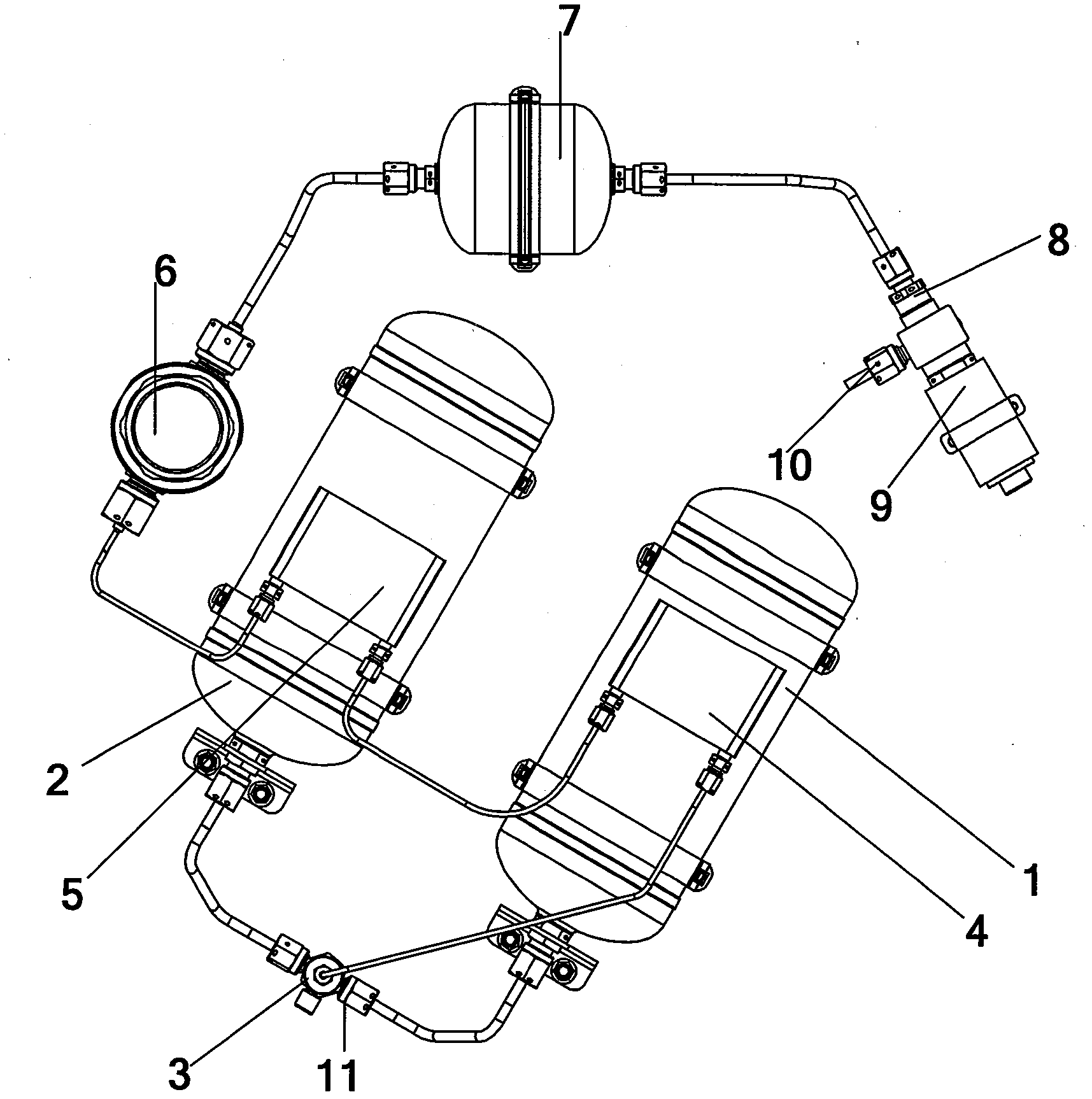

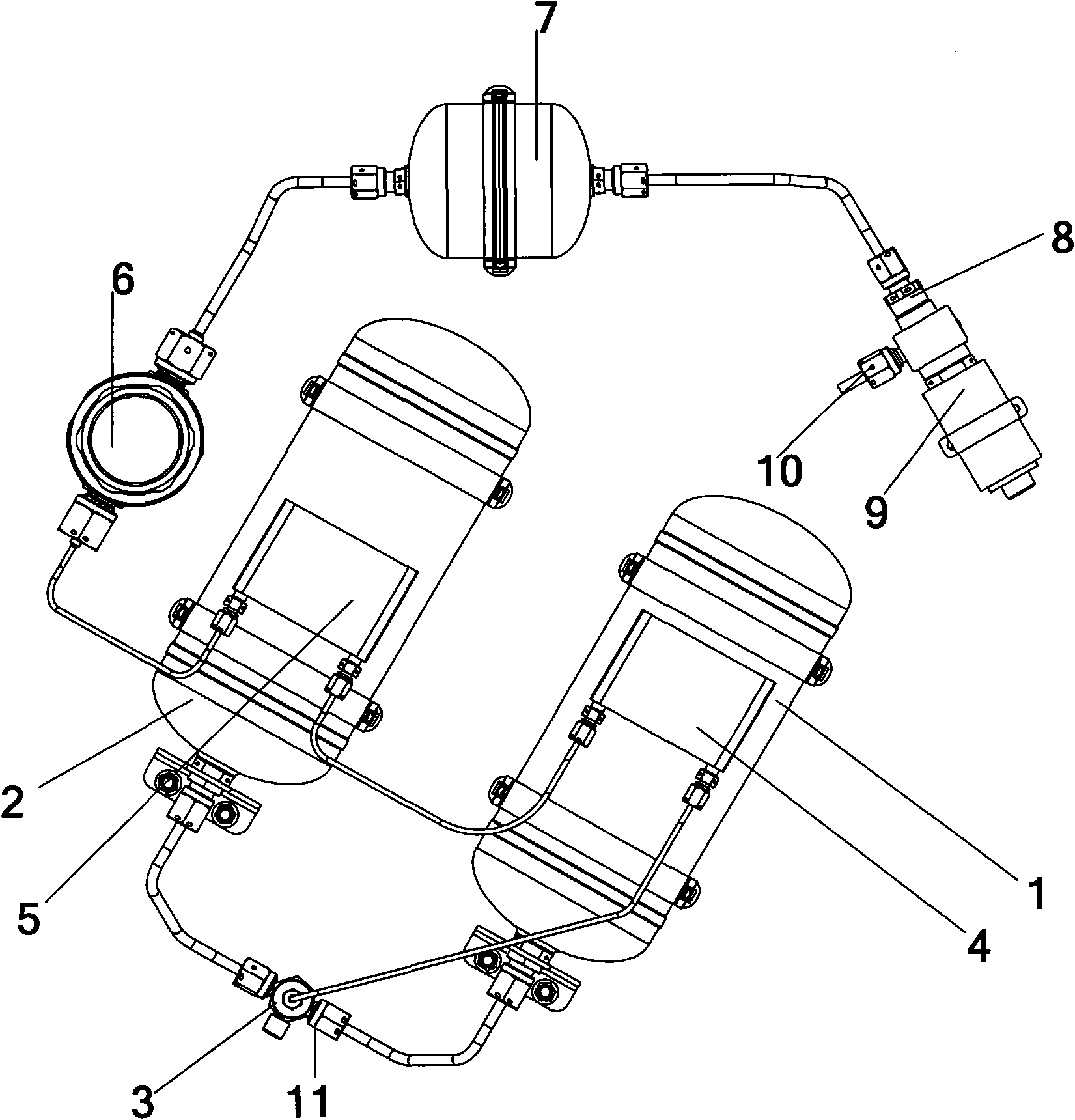

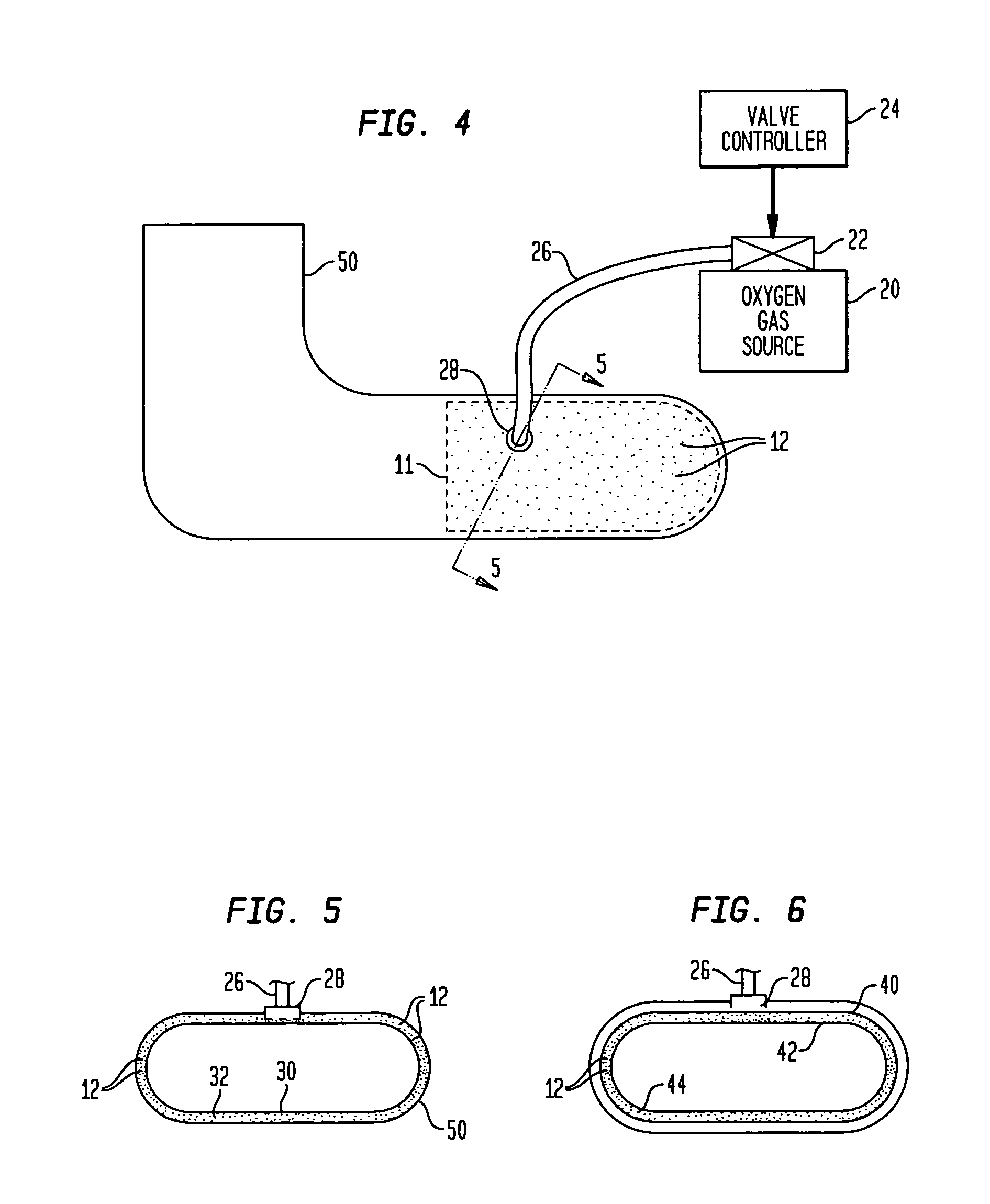

Heating gasification device for liquefied gas micro-propulsion system

InactiveCN101943082ASimple structureLight in massCosmonautic propulsion system apparatusRocket engine plantsPassive heatingHeat conducting

The invention discloses a heating gasification device for a liquefied gas micro-propulsion system. The device comprises a first propellant storage box, a second propellant storage box, a first heat conducting module, a second heat conducting module, a pressure reducer, a pressure stabilizing tank, a safety valve, a pressure sensor and a filter. In the device, a passive heating mode is adopted, and a satellite internal heat dissipation unit is used as a heat source, so that extra power consumption is not needed; and the gasification device has the advantages of reducing the production cost, fully gasifying the propellant and ensuring that the propellant completes work in the form of gas state, along with simple structure, a few elements and devices and high reliability and safety.

Owner:BEIHANG UNIV +1

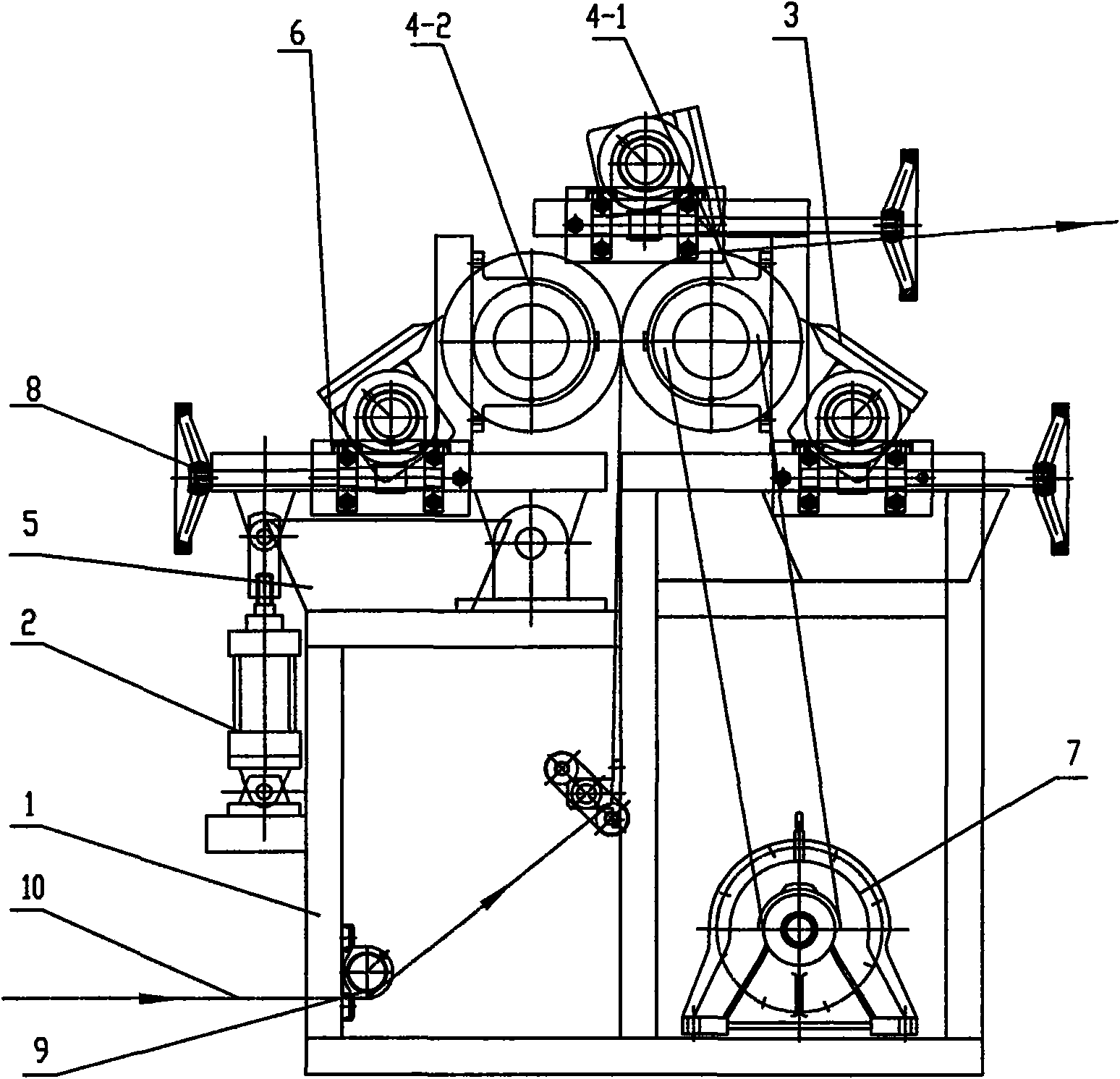

Recovery unit for reversible hot melt adhesive waste material

InactiveCN101570041AEfficient recyclingReasonable structurePlastic recyclingPassive heatingComposite substrate

The invention provides a recovery unit for a reversible hot melt adhesive waste material, which comprises a stander, a motor, a fabric guide roller, heating rollers, scrapers and an adhesive-gathering groove, wherein two heating rollers are correspondingly arranged on the stander, and one heating roller is connected with the motor and is taken as an active heating roller to drive the other passive heating roller contacted with the active heating roller to rotate; the fabric guide roller is arranged on the stander to guide a composite substrate waste coiled material to pass through between the two heating rollers; the stander is also provided with three scrapers which are contacted with the surfaces of the two heating rollers and a glue surface of the composite substrate waste coiled material; and the below of the scrapers is provided with the adhesive-gathering groove. During work, the two heating rollers heat and melt an reversible hot melt adhesive on the surface of the composite substrate waste coiled material; the scrapers scrape away the reversible hot melt adhesive adhered to the surfaces of the active heating roller, the passive heating roller and the composite substrate waste coiled material; and the reversible hot melt adhesive falls into the adhesive-gathering groove. The recovery unit has a reasonable structure, and can effectively recover the reversible hot melt adhesive on the surface of the composite substrate waste coiled material, save resources and reduce the cost.

Owner:JIANGSU HONGYE MACHINERY

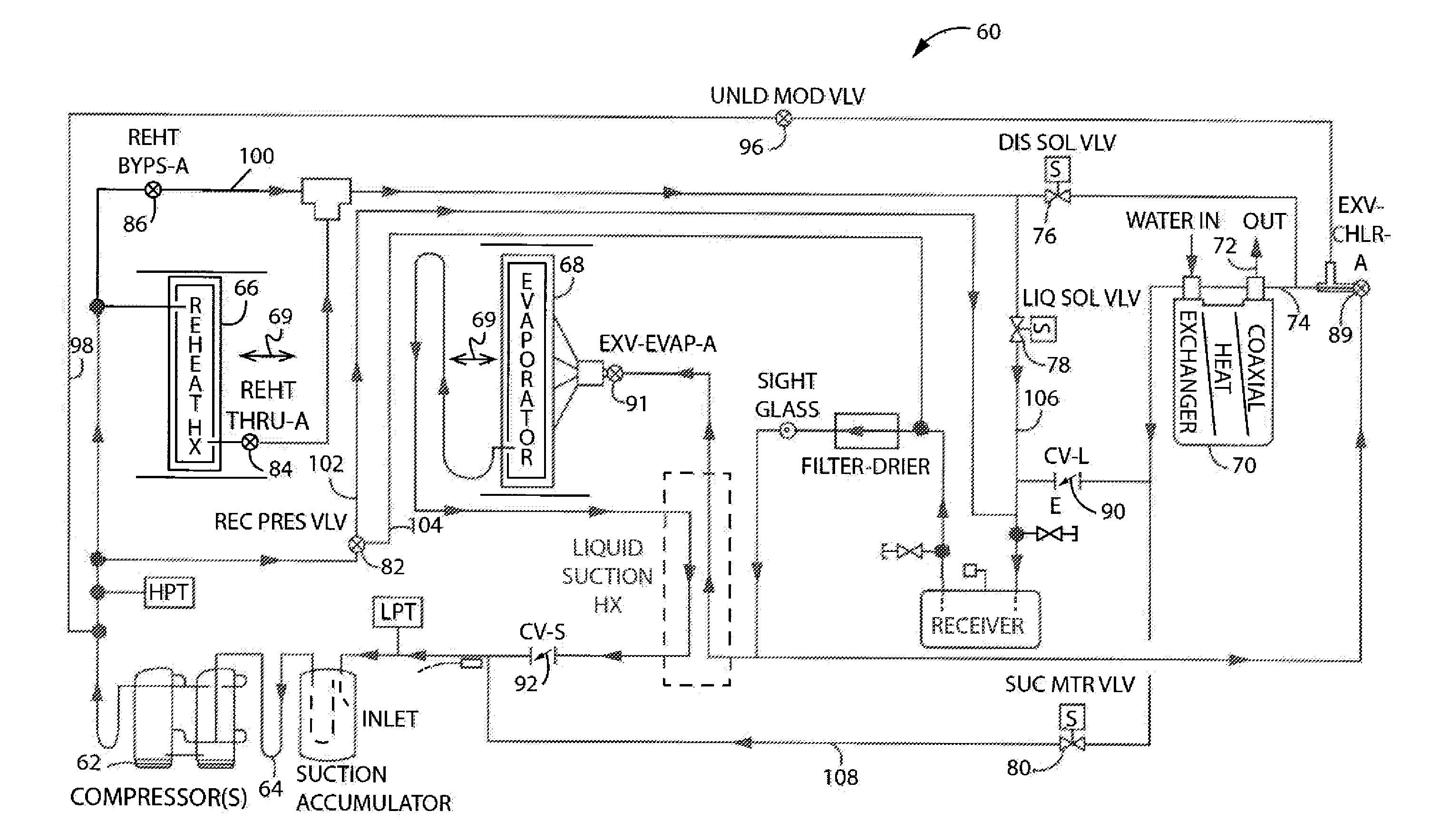

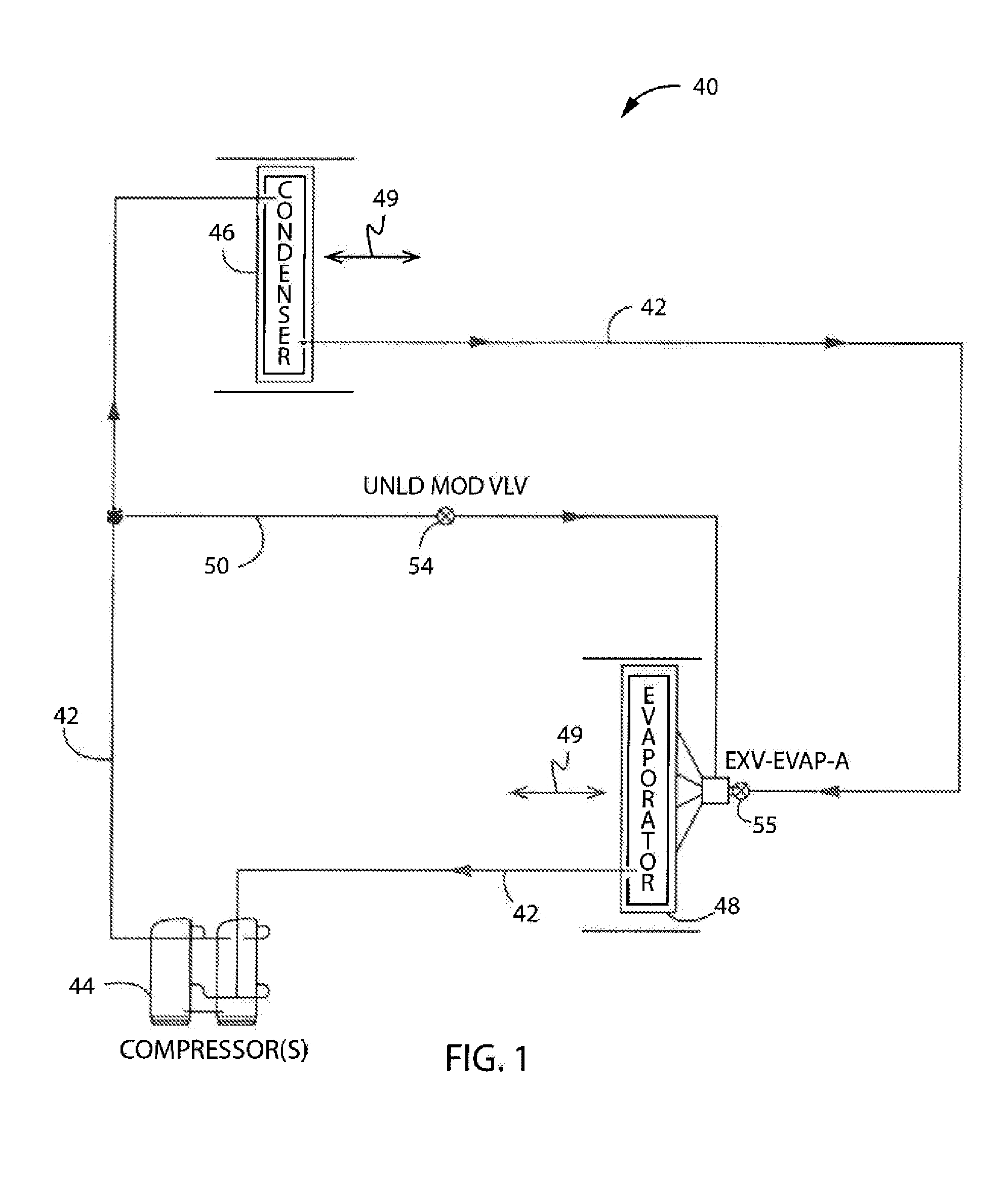

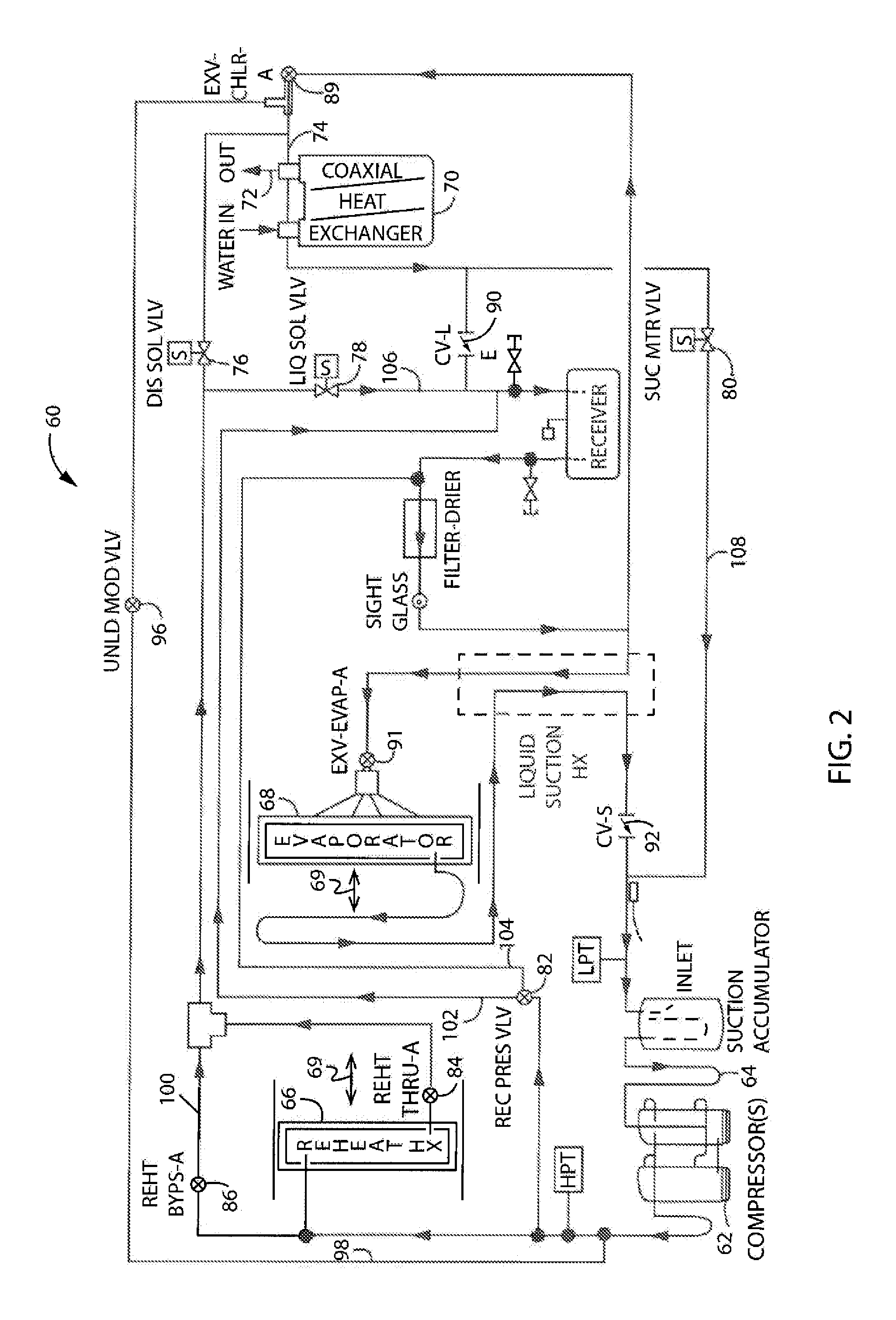

Heat Pump Temperature Control

ActiveUS20150204591A1Reduce overshootEasy to controlMechanical apparatusHeat pumpsTemperature controlPassive heating

A heat pump system that can be selectively utilized to discharge excessive heating and cooling capacity toward secondary devices of the system to maintain operation of the heat pump system to better manage the respective temperatures associated with the fluid flows in a manner that reduces the need for cycling the heat pump system ON and OFF to attain desired fluid output temperature manipulations.

Owner:DCI INVESTMENTS LLC

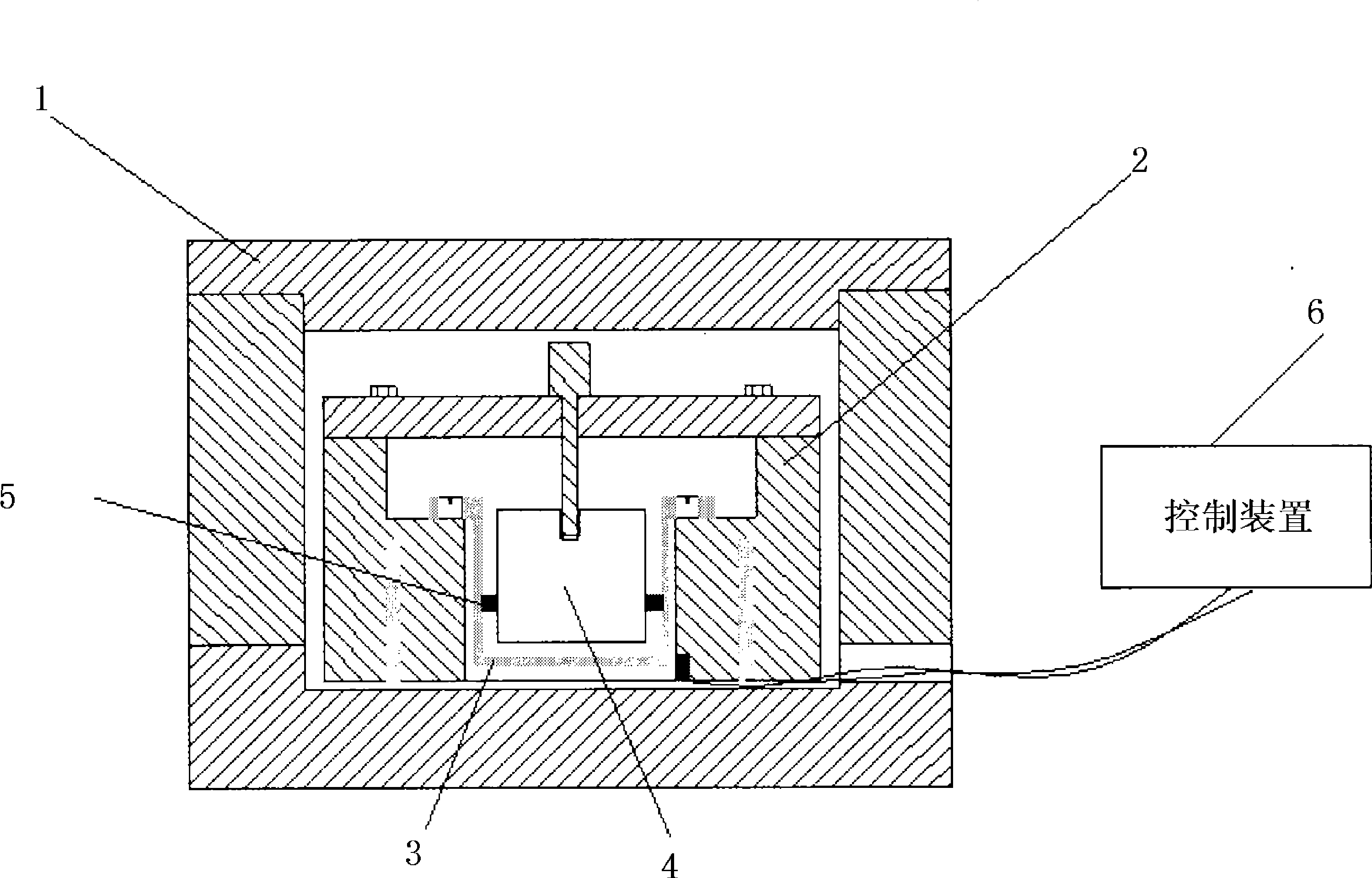

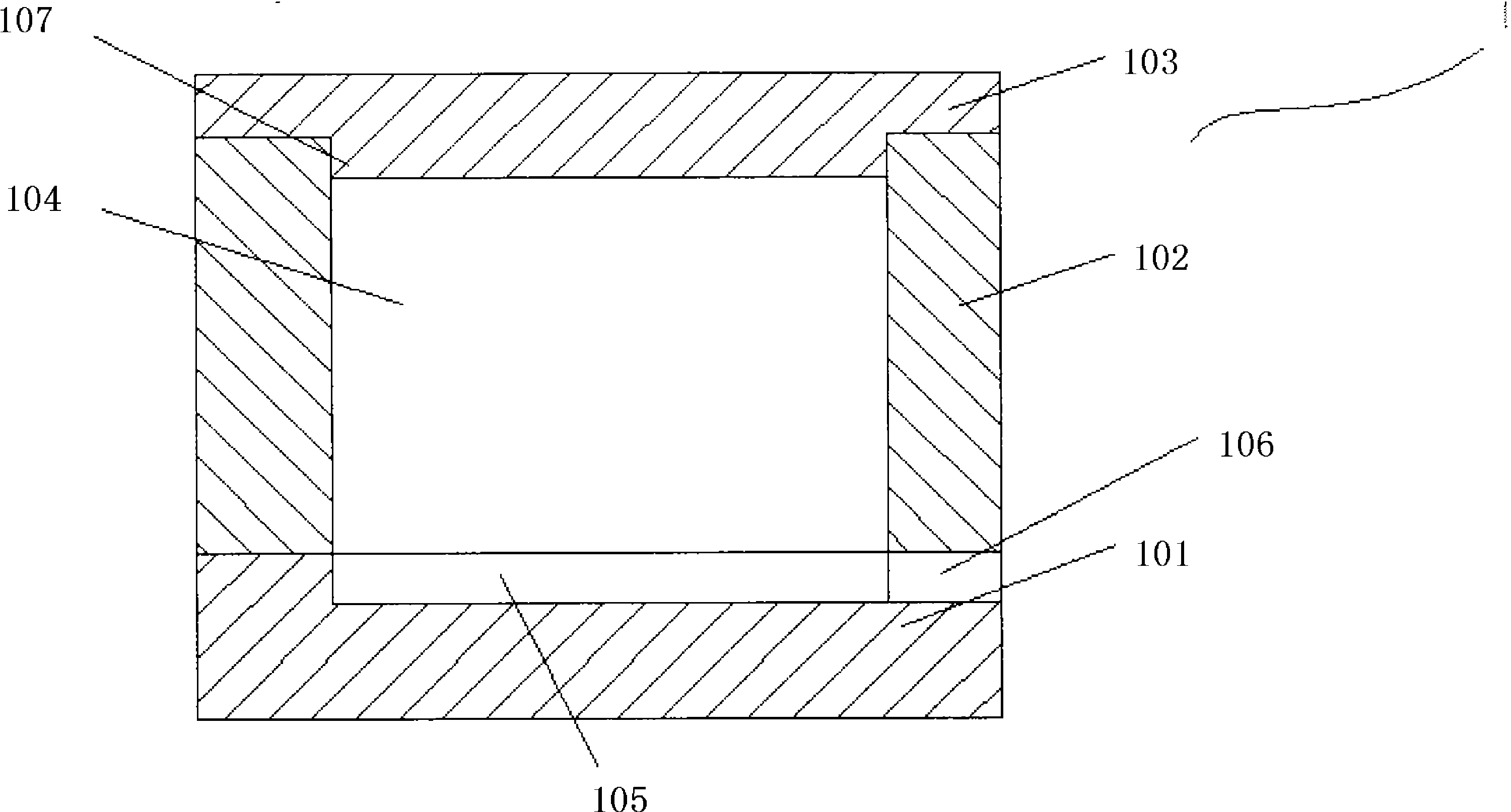

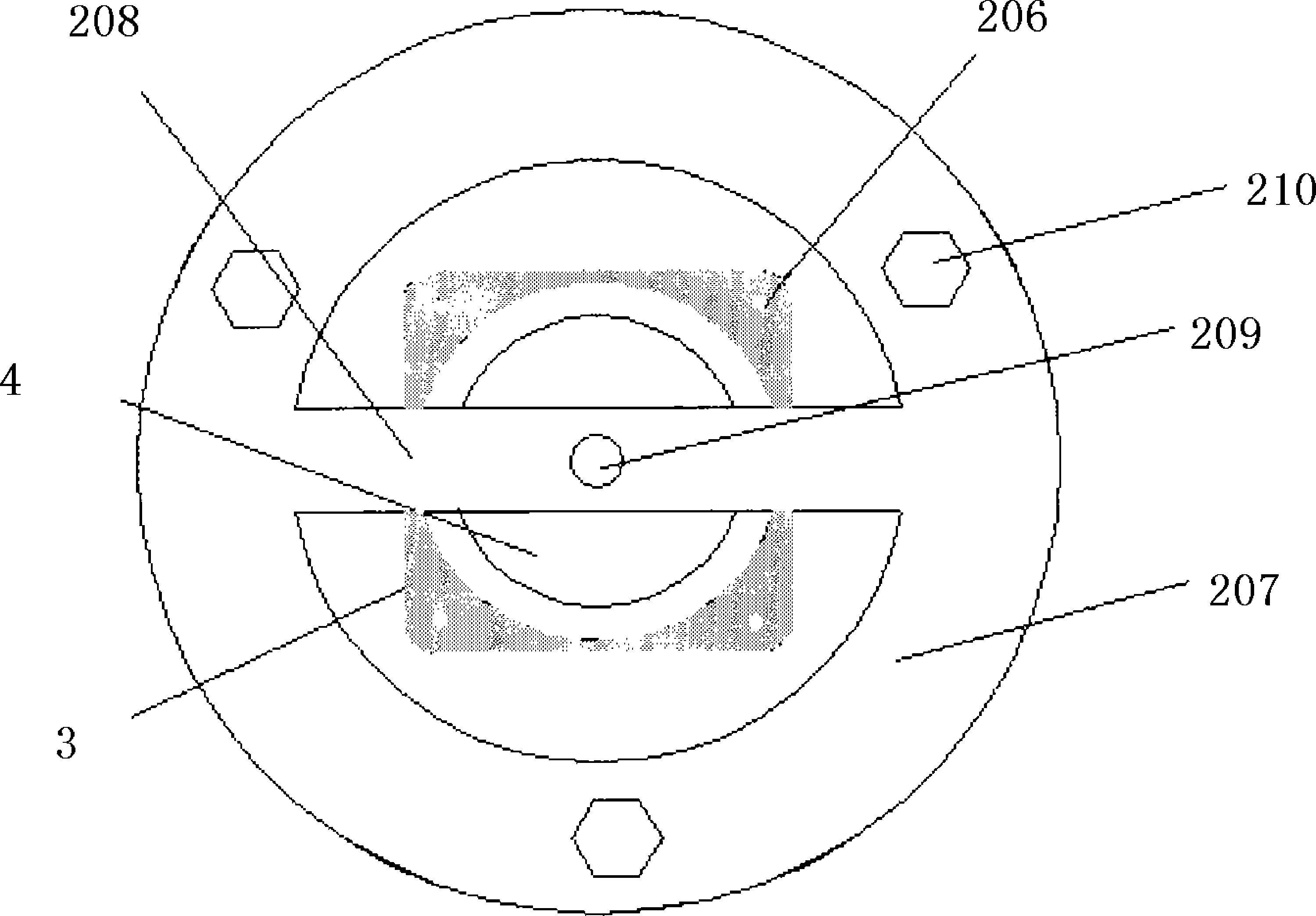

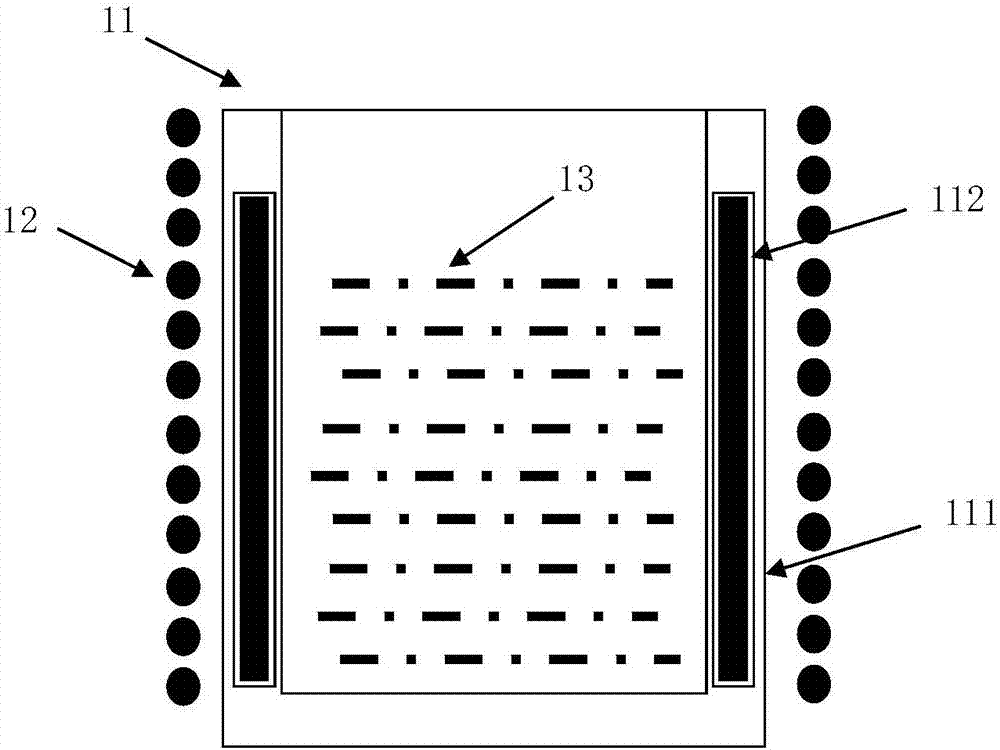

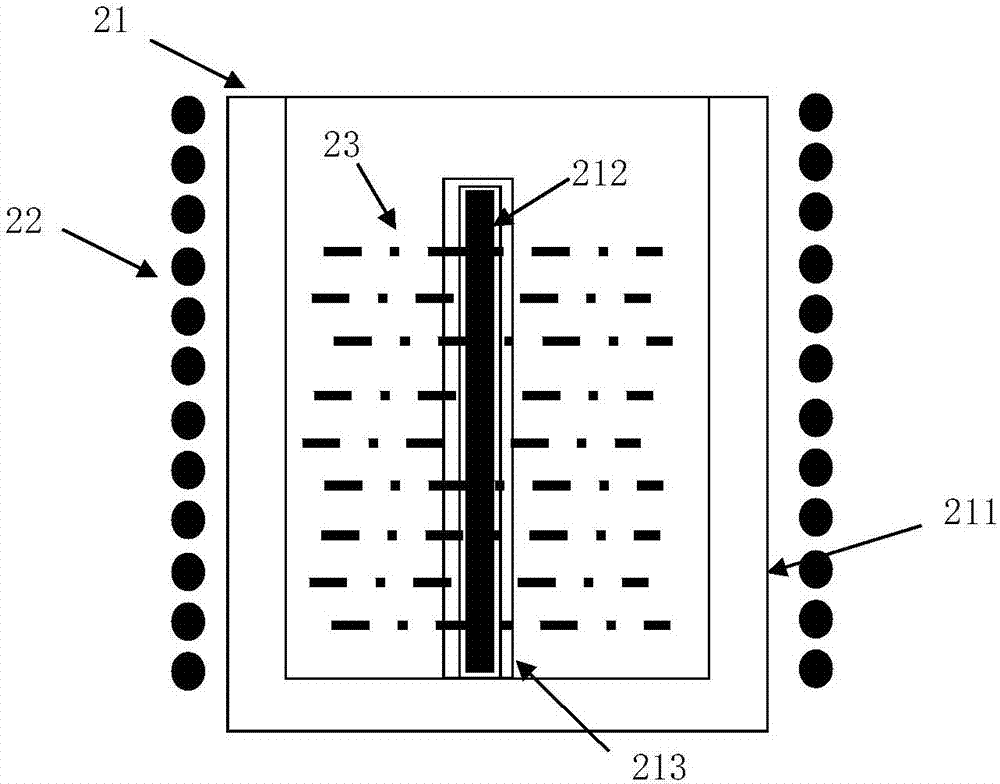

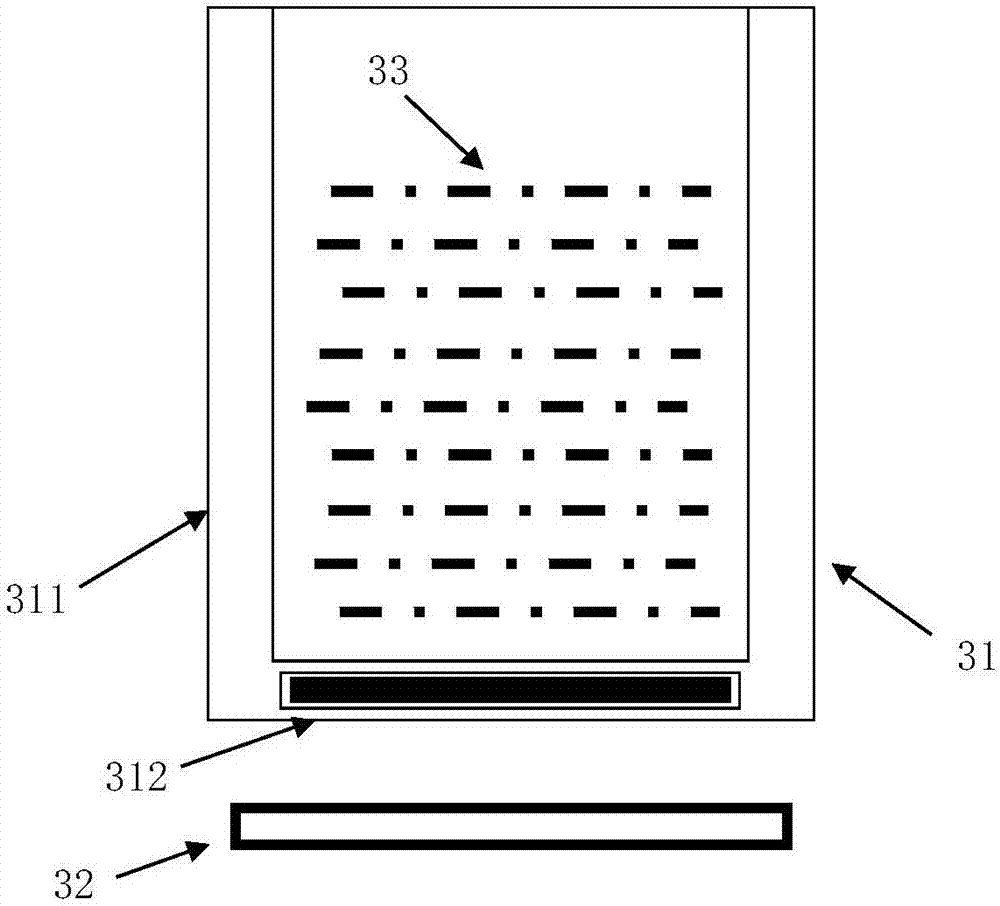

Adhesive heating and temperature control device used in accelerometer assembling process

ActiveCN104298275AEvenly heatedExtended service lifeTemperatue controlTemperature controlPassive heating

The invention provides an adhesive heating and temperature control device used in the accelerometer assembling process. The adhesive heating and temperature control device comprises a heat preservation mold, a heating device arranged in the heat preservation mold and used for evenly heating adhesive between a meter shell and a meter core in the accelerometer assembling process, and a control device connected with the heating device and used for controlling heating temperature and heating time in the heating process. Due to the fact that the adhesive between the meter shell and the meter core is evenly heated in the accelerometer assembling process, the adhesive of a single accelerometer is evenly heated in the solidification process, and the service life of the accelerometer is prolonged; heat is preserved through the heat preservation mold, the heating temperature and the heating time can be controlled through the control device in the heating process, the heating temperature and the heating time for solidification of the adhesive on meter heads of the accelerometers of the same batch are the same, and the accelerometers of the same batch are prevented from being different.

Owner:航天科工惯性技术有限公司

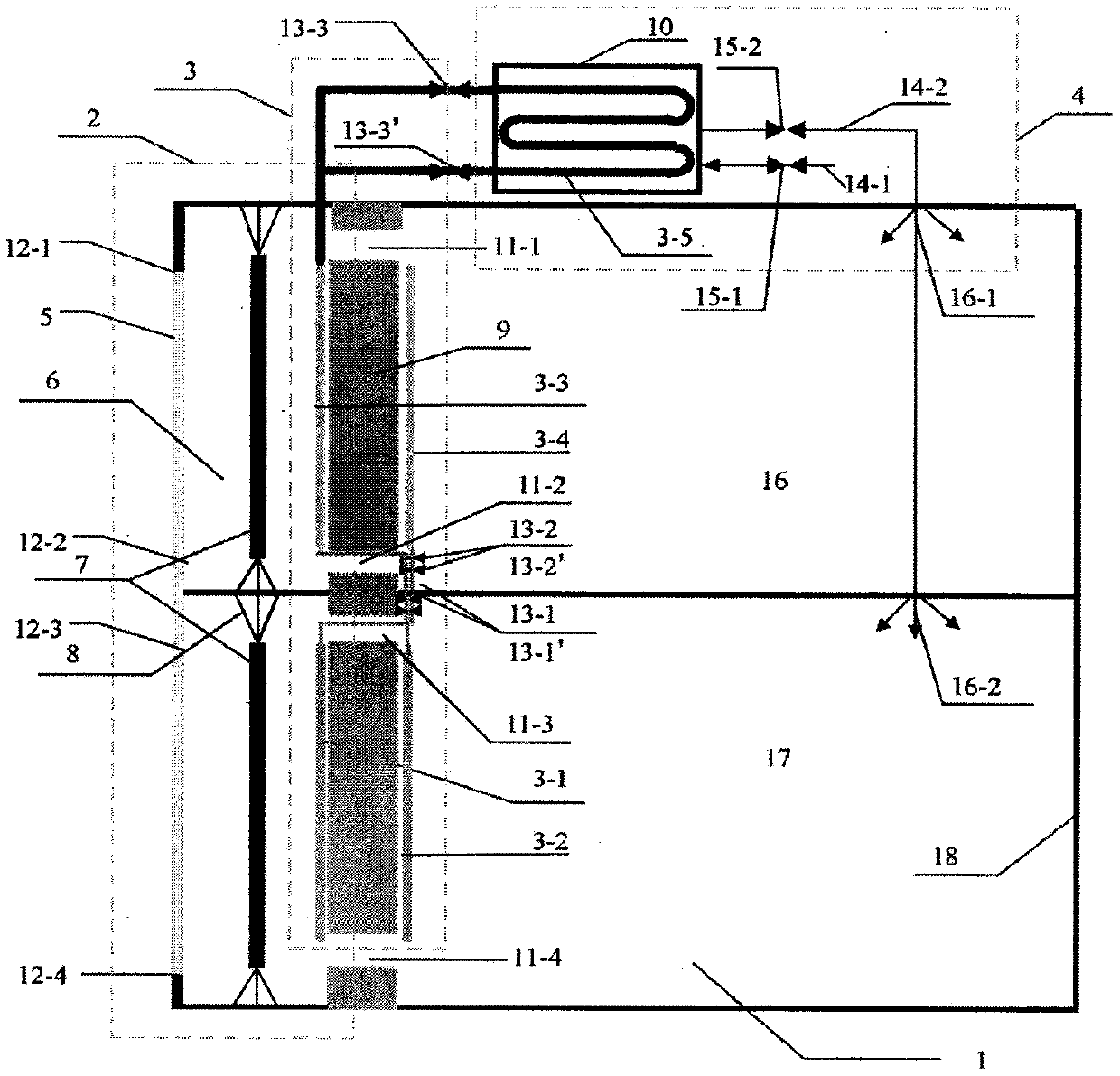

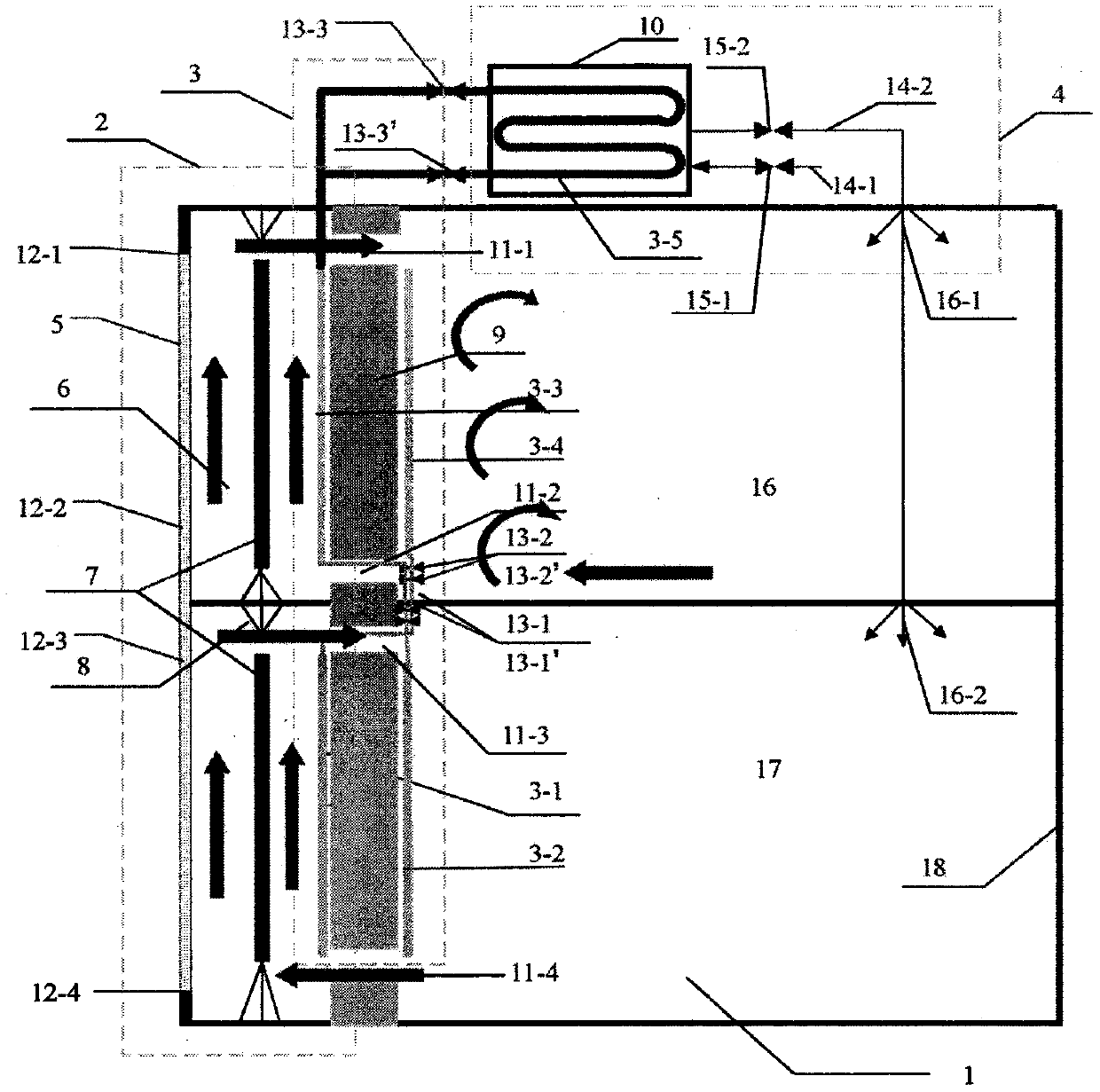

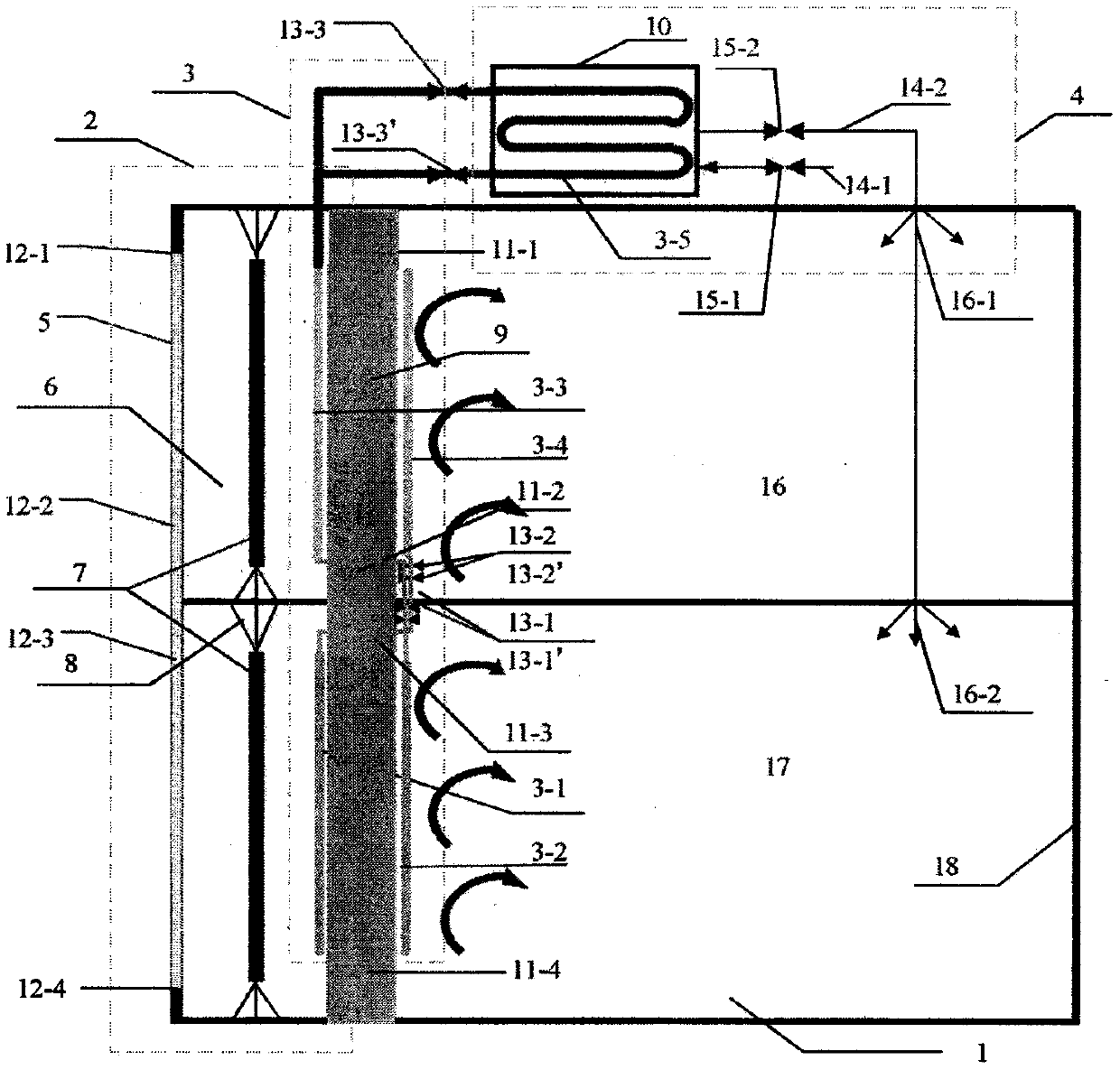

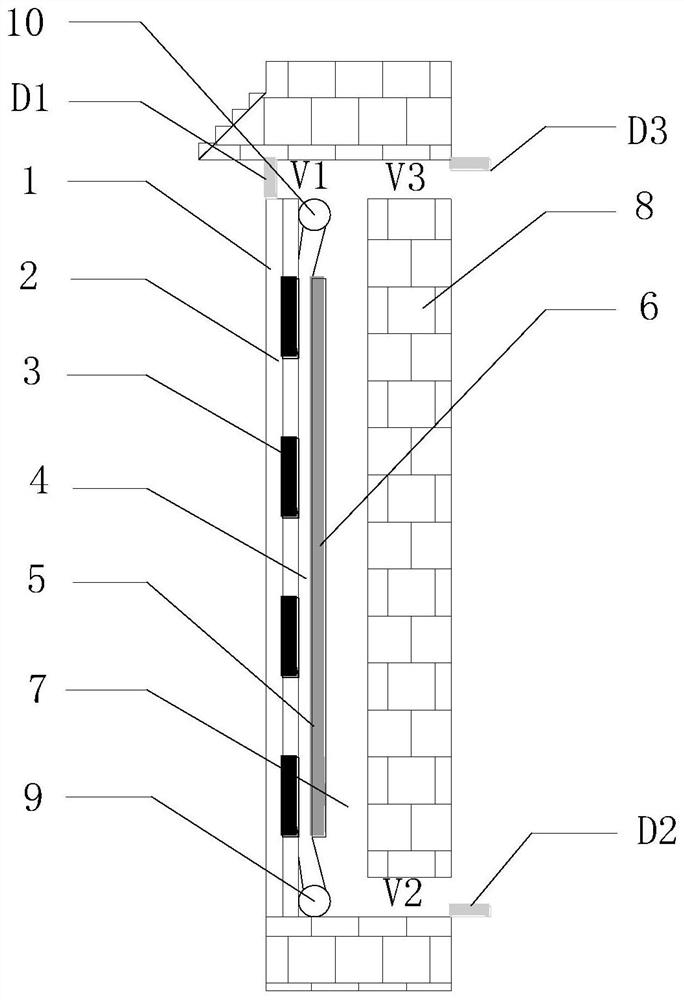

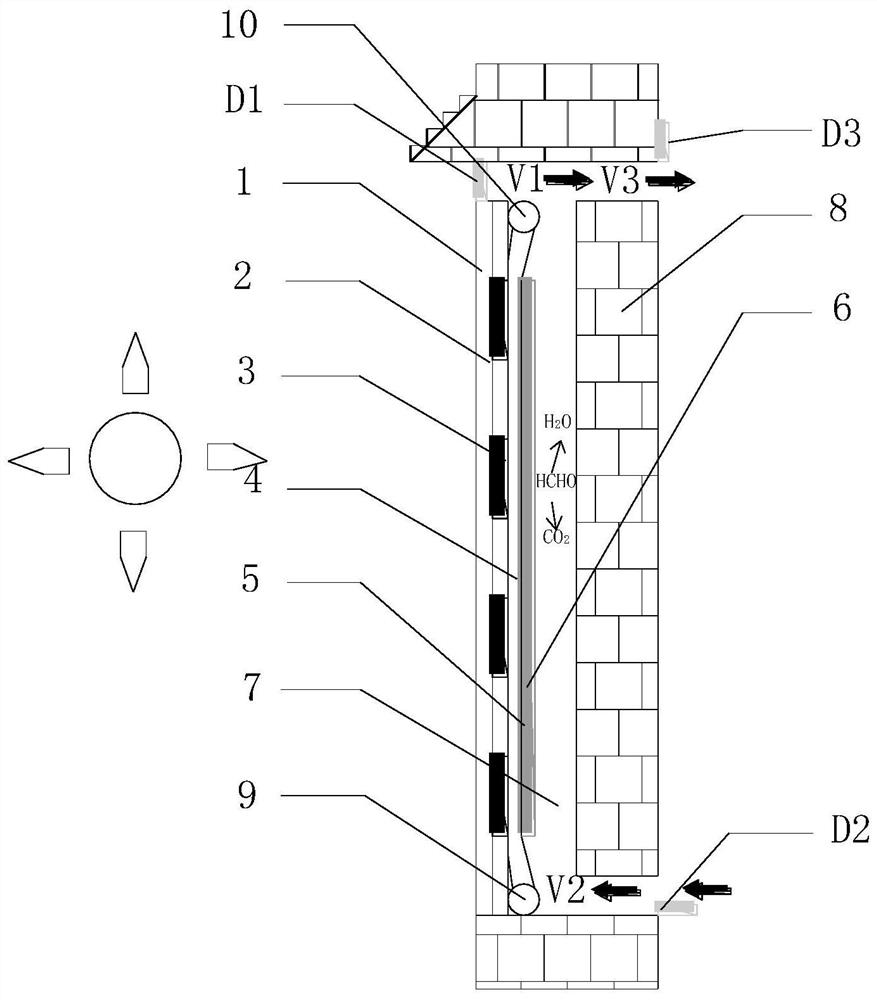

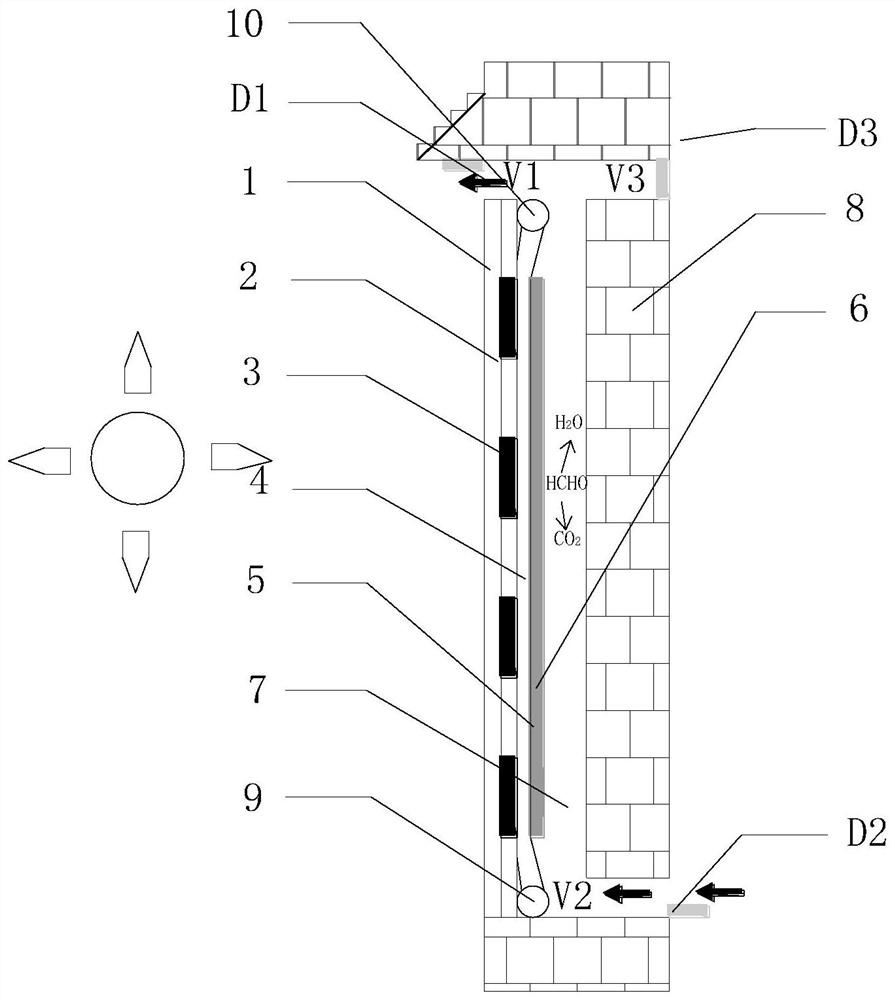

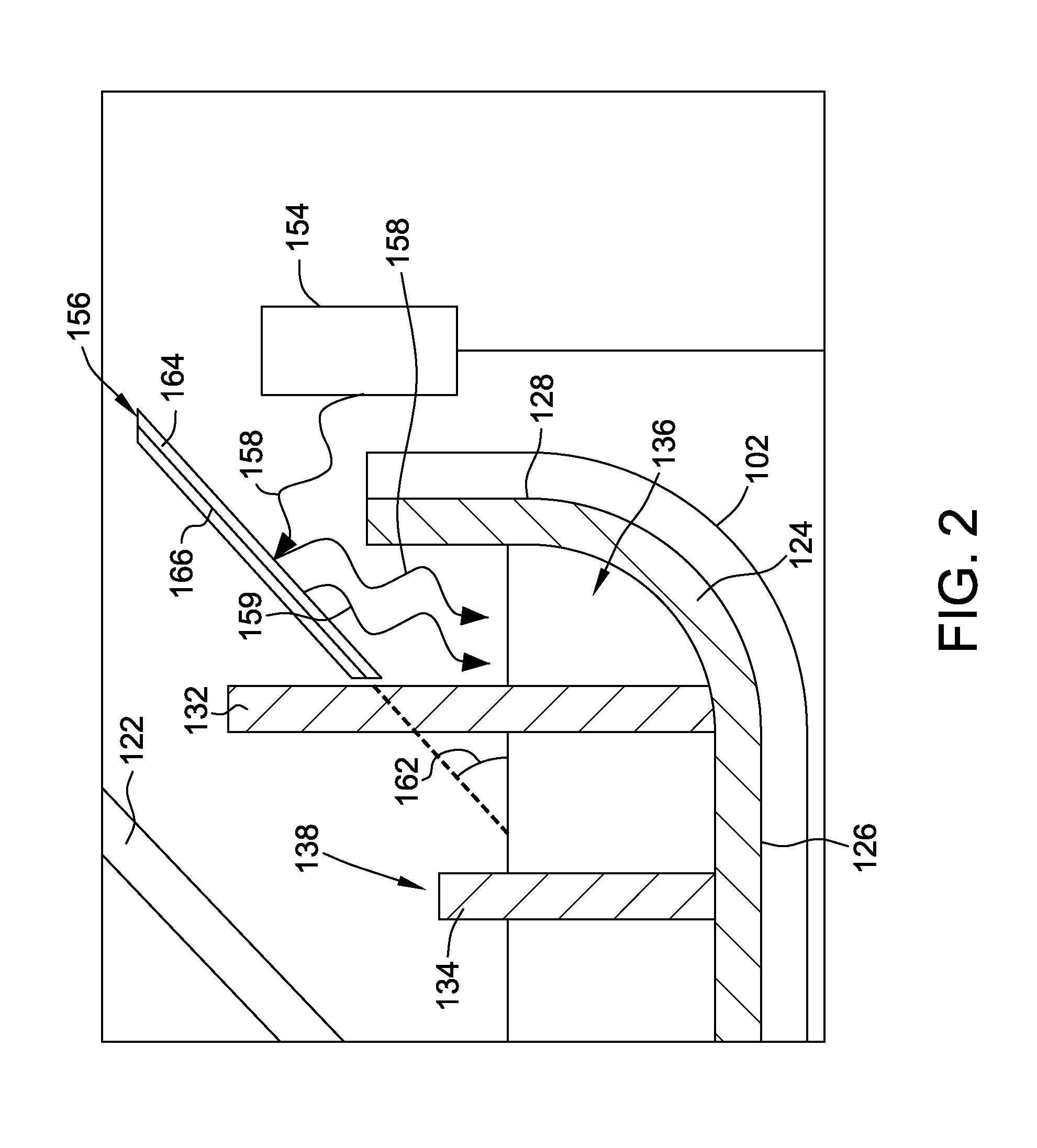

Passive heating and ventilation system for coupling solar chimney and separated type heat pipe

InactiveCN110160196AImprove indoor thermal environmentEnhanced hot pressing effectWallsIndirect heat exchangersGlass coverPassive heating

The invention discloses a passive heating and ventilation system for coupling a solar chimney and a separated type heat pipe. The passive heating and ventilation system is composed of four subsystemsincluding a passive solar house, the solar chimney, the separated type heat pipe and domestic hot water. The passive house is a two-storey or multi-storey building; the solar chimney includes a double-layer transparent glass cover plate, an air interlayer, a heavy wall, an air valve, an air inlet, an air outlet and a heat absorbing plate; and the separated heat pipe is composed of an evaporator, acondenser, a rising air pipe, a descending liquid pipe and a control valve. The passive heating and ventilation system can overcome the shortcomings that a traditional passive solar house heating andventilation system is single in function and low in efficiency, causes overheating in summer and the like, and has the advantages of the good heating and ventilation effect, the various functions, the large use range and the improvement of the indoor thermal environment. Heat can be dissipated to the outside in summer to prevent indoor overheating caused by the solar chimney, meanwhile, domestichot water is produced, and the heating effect can be maximized in winter.

Owner:NANJING TECH UNIV

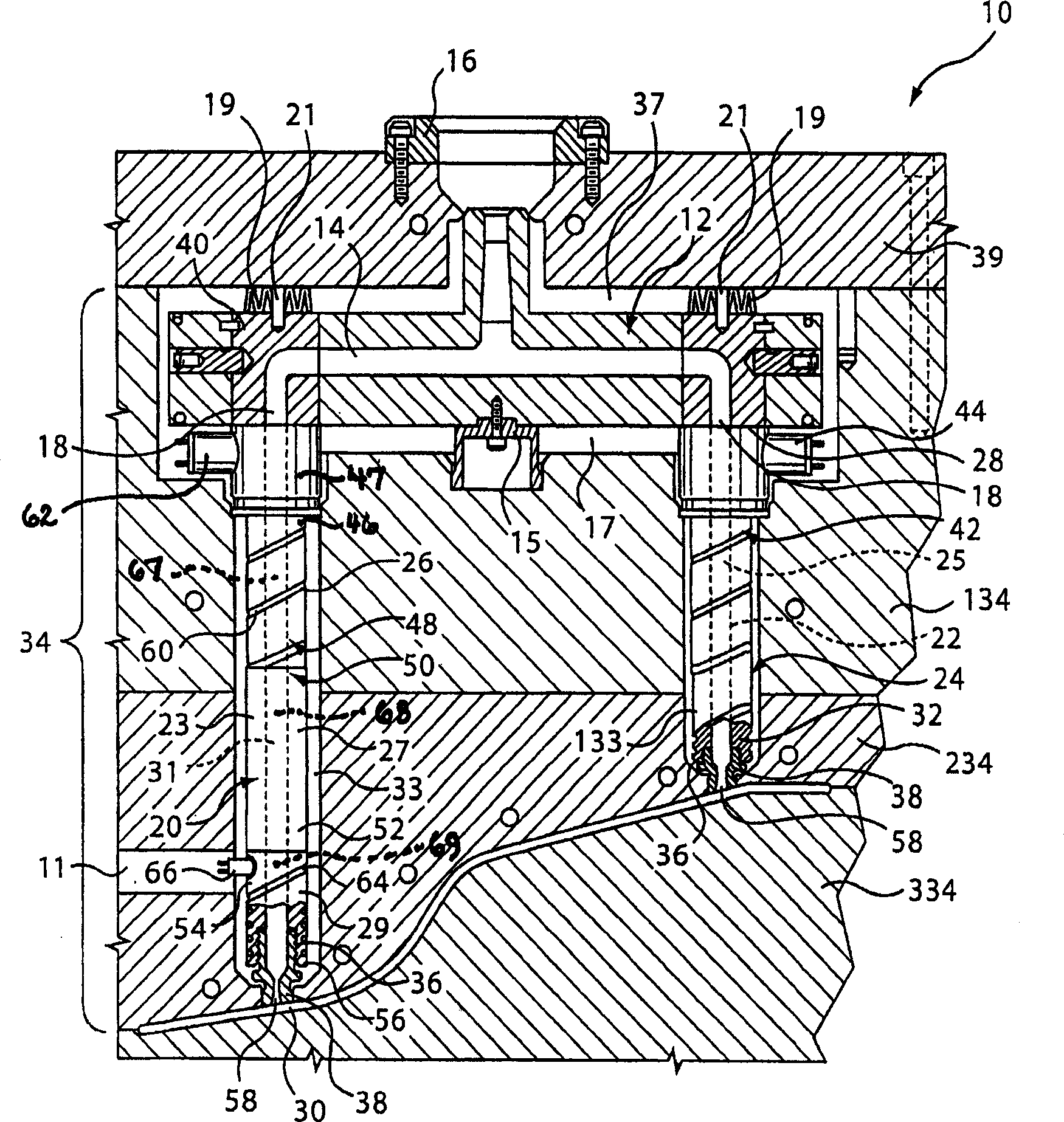

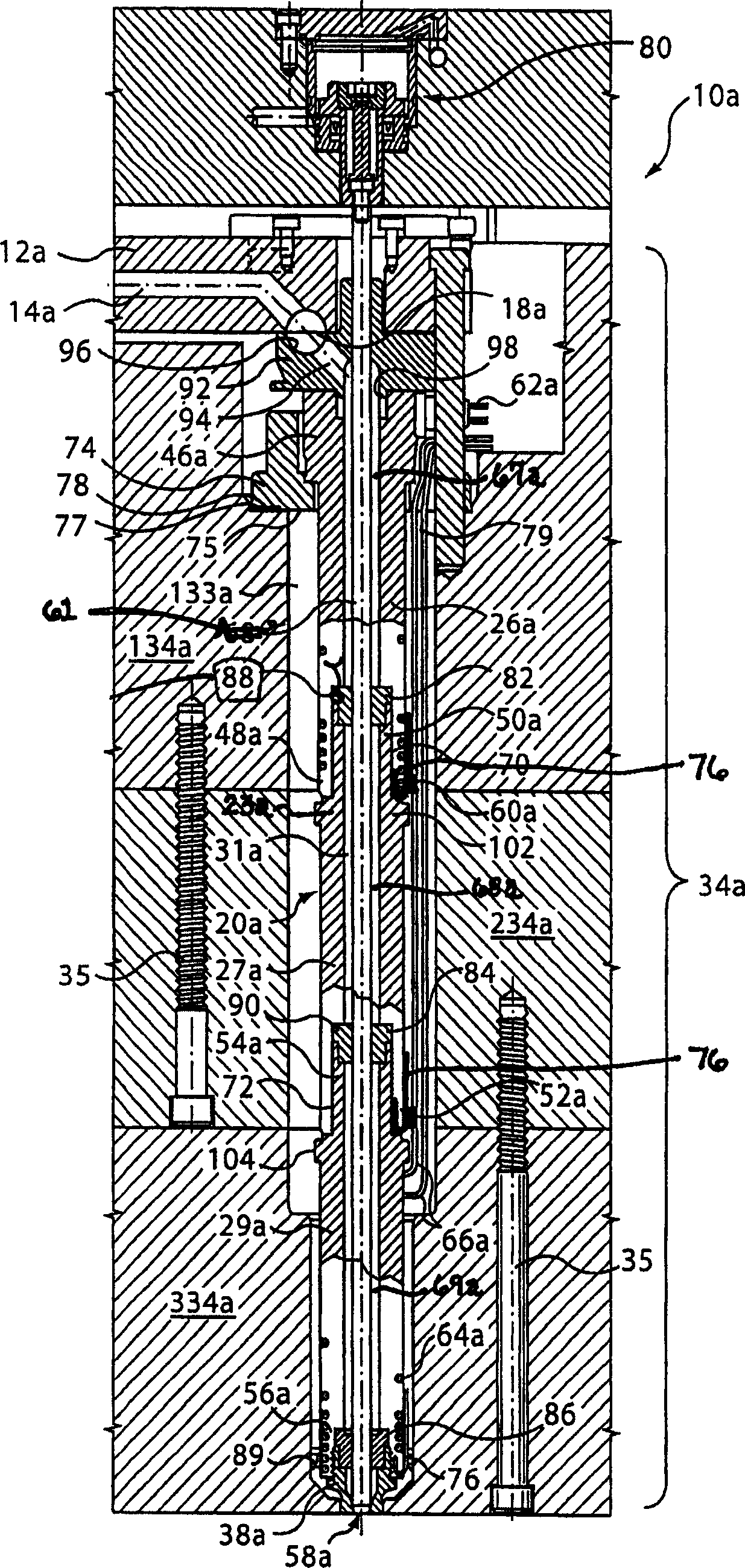

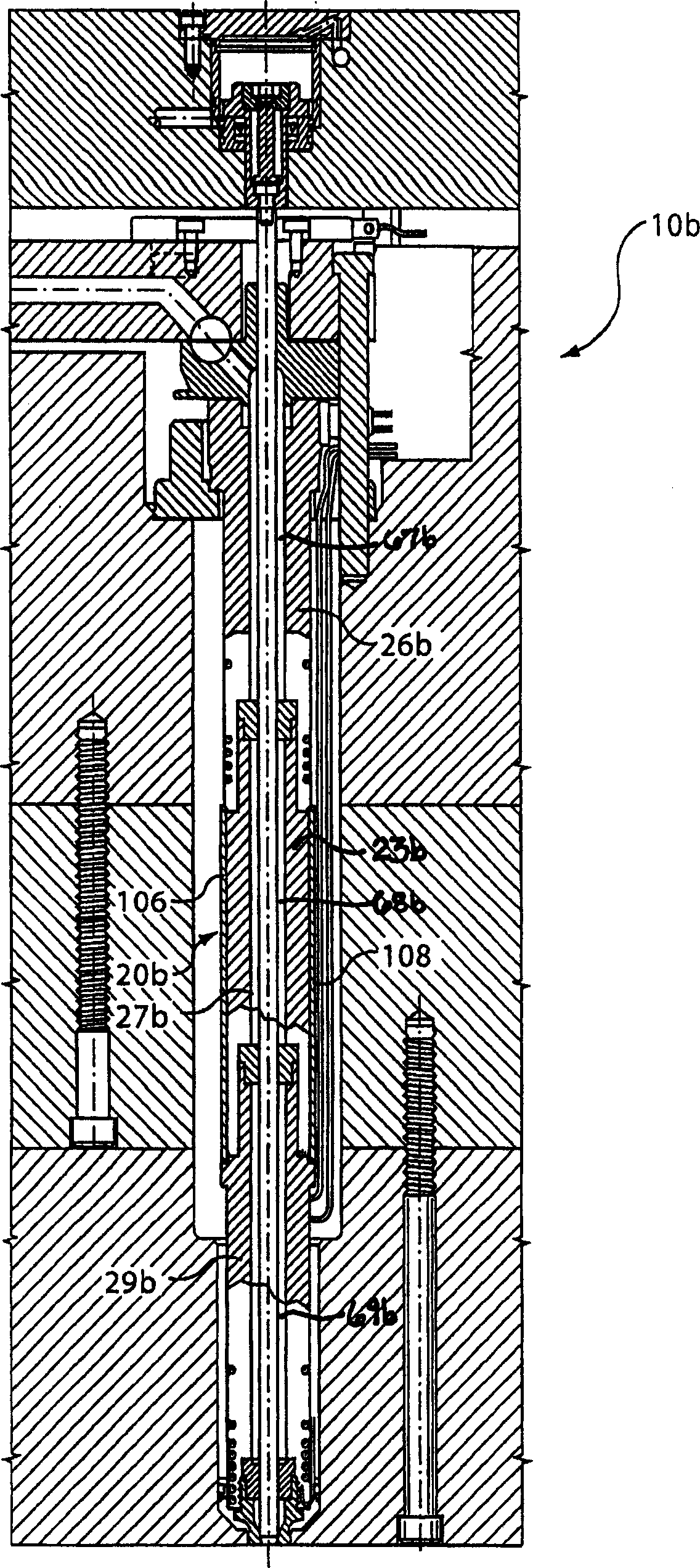

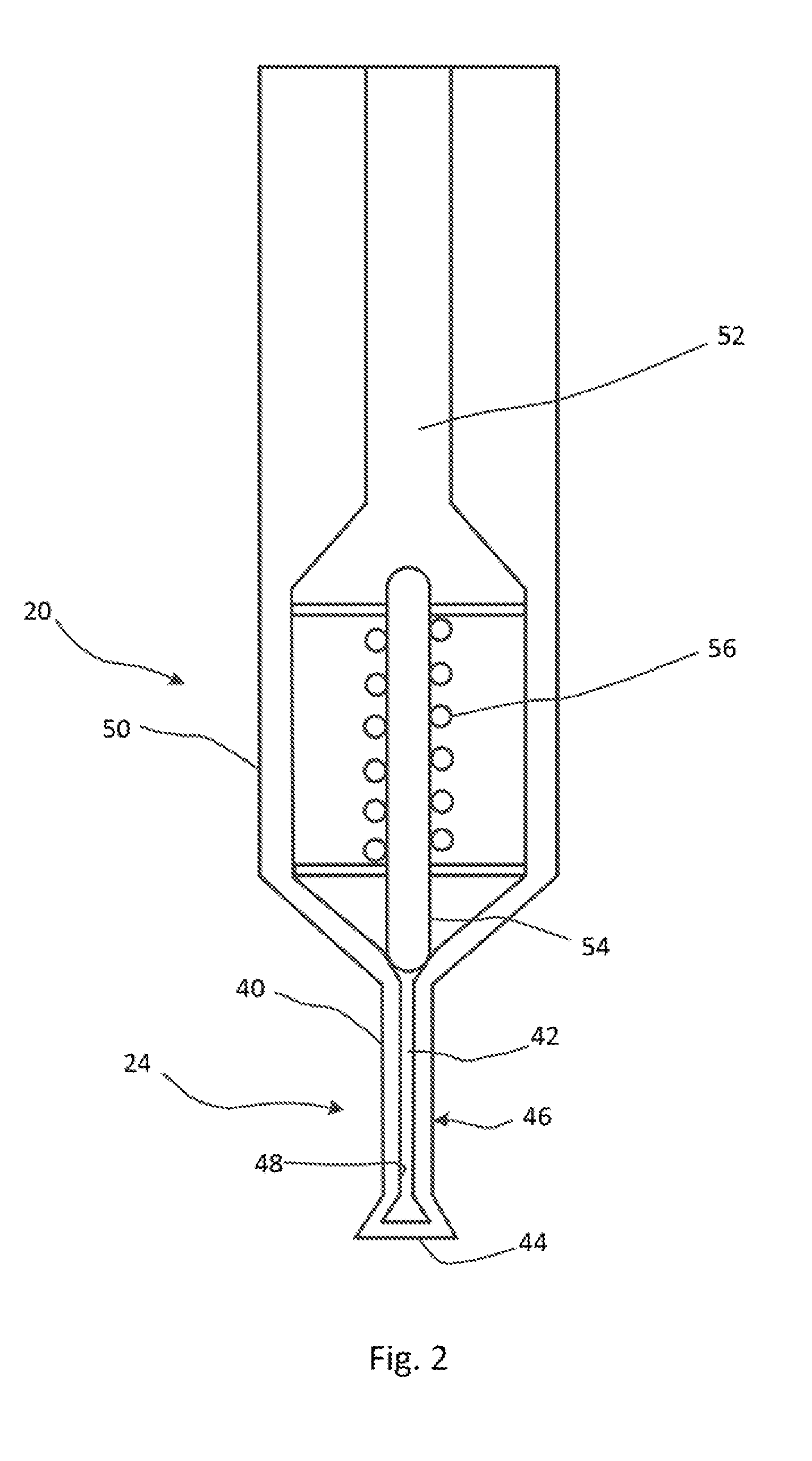

Nozzle having a nozzle body with heated and unheated nozzle body segments

A nozzle for an injection molding apparatus includes a nozzle body having a first nozzle body portion, a second nozzle body portion, and a third nozzle body portion, the second nozzle body portion movably connected to at least one of the first nozzle body portion and the third nozzle body portion, the first nozzle body portion and the third nozzle body portion being heated by the first and second nozzle heaters, respectively, or by a heater jacket tube heating, the heater sleeve has a cutout along the length of a second nozzle body portion that is substantially free of nozzle heaters to allow the second nozzle body portion to pass through with the first nozzle body The portion is passively heated in contact with the third nozzle body portion.

Owner:标准模具(2007)有限公司

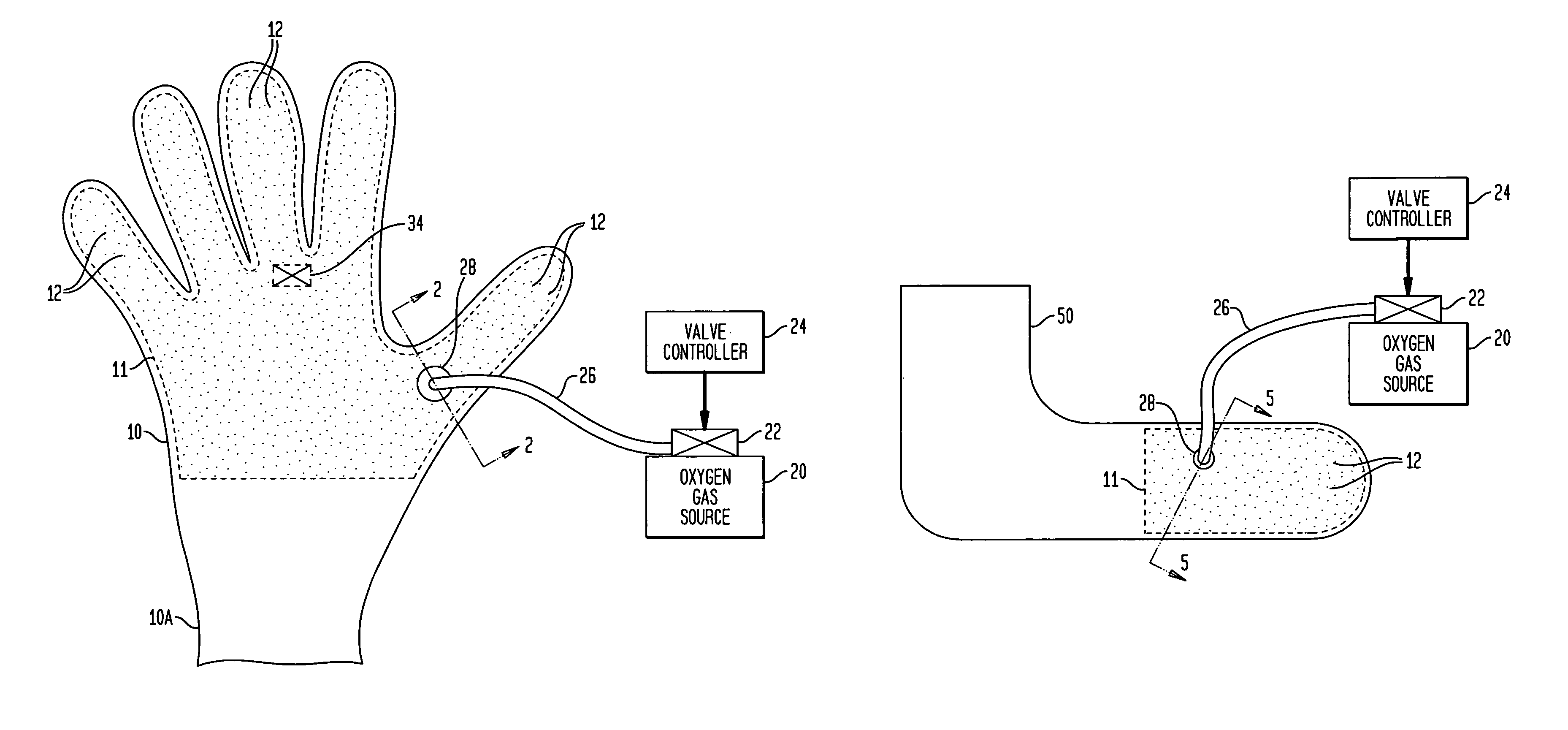

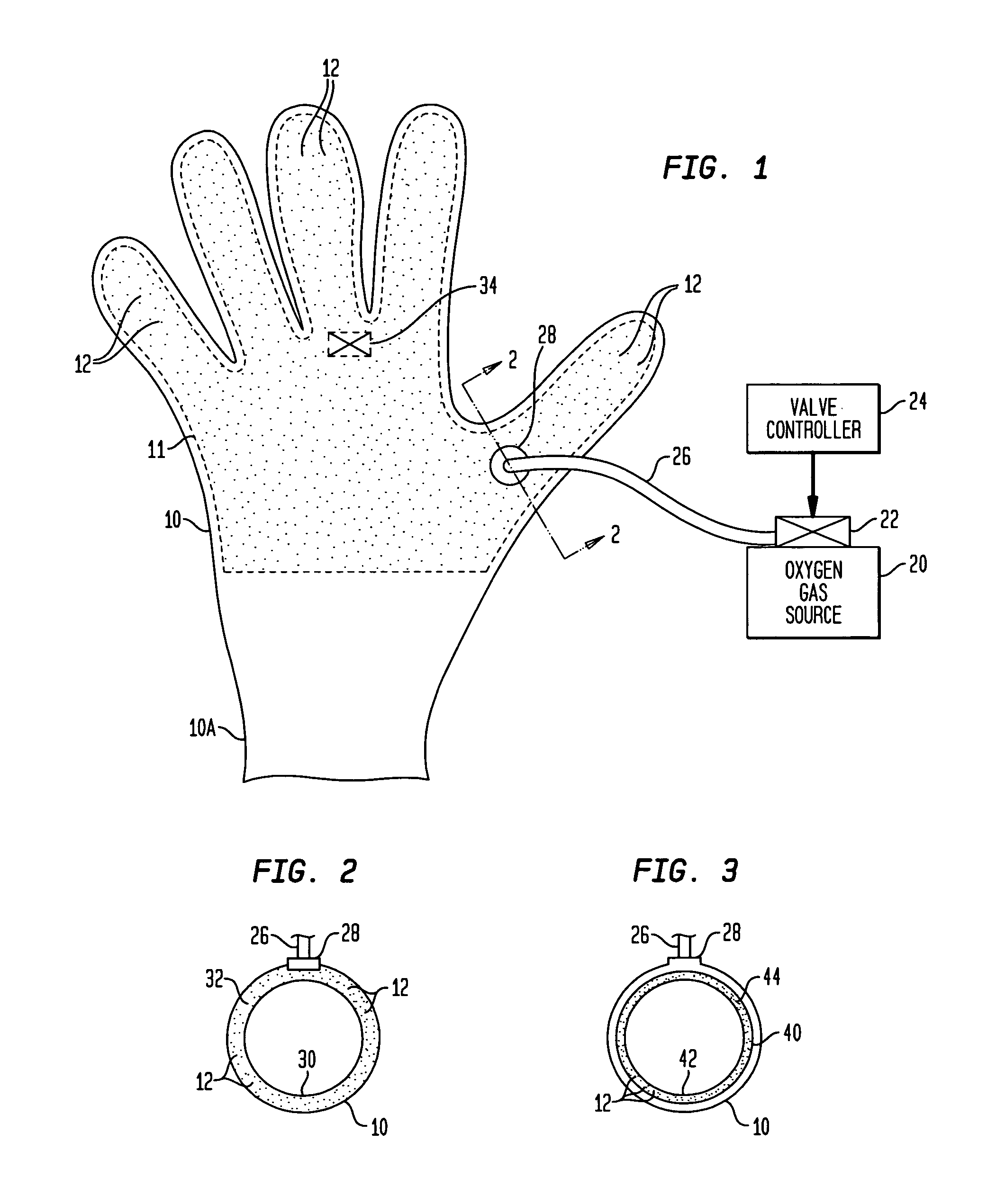

Active heating system for underwater diver

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

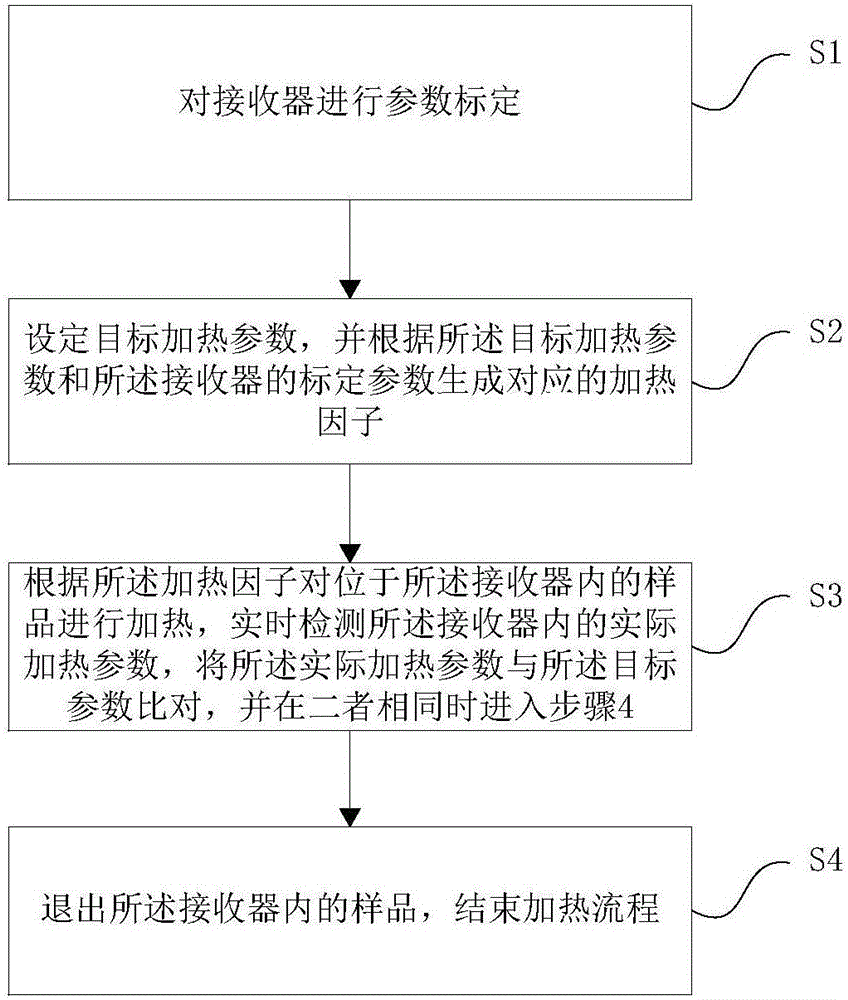

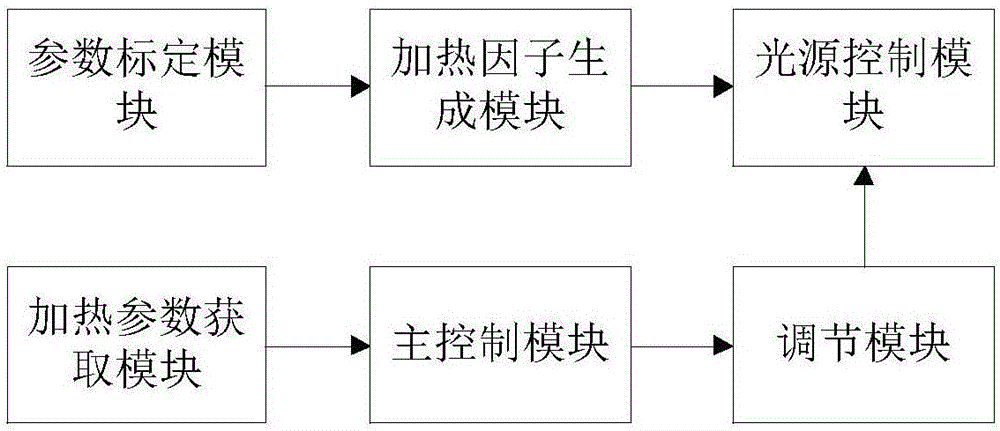

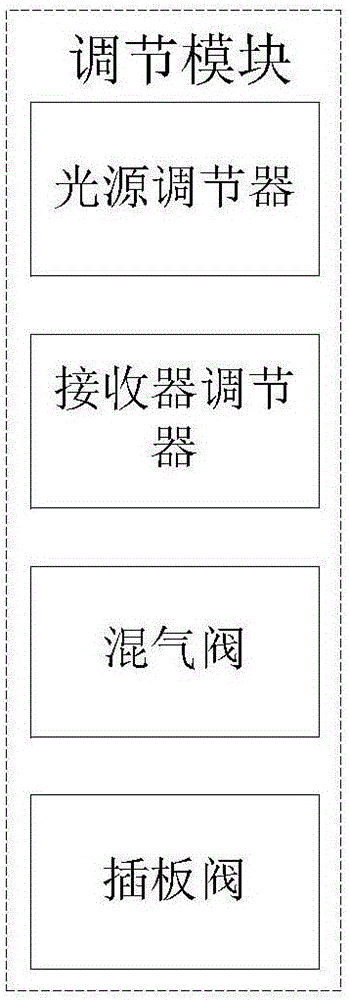

Fast heating-up control method and device based on photo-thermal type and heating furnace

The present invention relates to a fast heating-up control method and device based on a photo-thermal type and a heating furnace. The method comprises the following steps: performing parameter calibration of a receiver putting samples; setting a target heating parameter, and generating corresponding heating factors according to the target heating parameter and the calibration parameter received by the receiver; performing illumination heating of the samples in the receiver according to the heating factors, detecting an actual heating parameter in the receiver in real time, comparing the actual heating parameter and the target heating parameter, quitting the samples in the receiver when the actual heating parameter is the same as the target heating parameter, and finishing a heating flow. Corresponding heating factors are generated according to the target heating parameter and the calibration parameter of the receiver, active heating of the samples in the receiver are performed according to the corresponding heating factors, and the samples are not directly heated so as to realize fast heating up and ensure accurate control of the heating process.

Owner:HUAZHONG UNIV OF SCI & TECH

Use of noncontact inductive heating body for preparing fog and/or smoke generating device

PendingCN107454700AEasy to cleanEasy to replaceTobacco devicesInduction heating apparatusPassive heatingSource material

The invention discloses the use of a noncontact inductive heating body for preparing a fog and / or smoke generating device. The heating body comprises a passive heating body capable of being inductively heated in an alternating electric field and / or magnetic field; and a packaging body having an accommodating cavity for packaging the passive heating body. The shape of the accommodating cavity matches the shape of the heating body. When the heating body is in operation, a source material for generating fog and / or smoke is in direct contact with the packaging body so as to be heated, and the passive heating body is not in direct contact with the source material and is not in wire connection with a circuit and a power supply. The operating temperature range of the passive heating body does not exceed the withstand temperature of the packaging material. The invention also discloses a fog and / or smoke generating device which is high in heating efficiency, safe and highly efficient in energy, detachable and easy to clean.

Owner:苏州固韧纳米材料技术有限公司

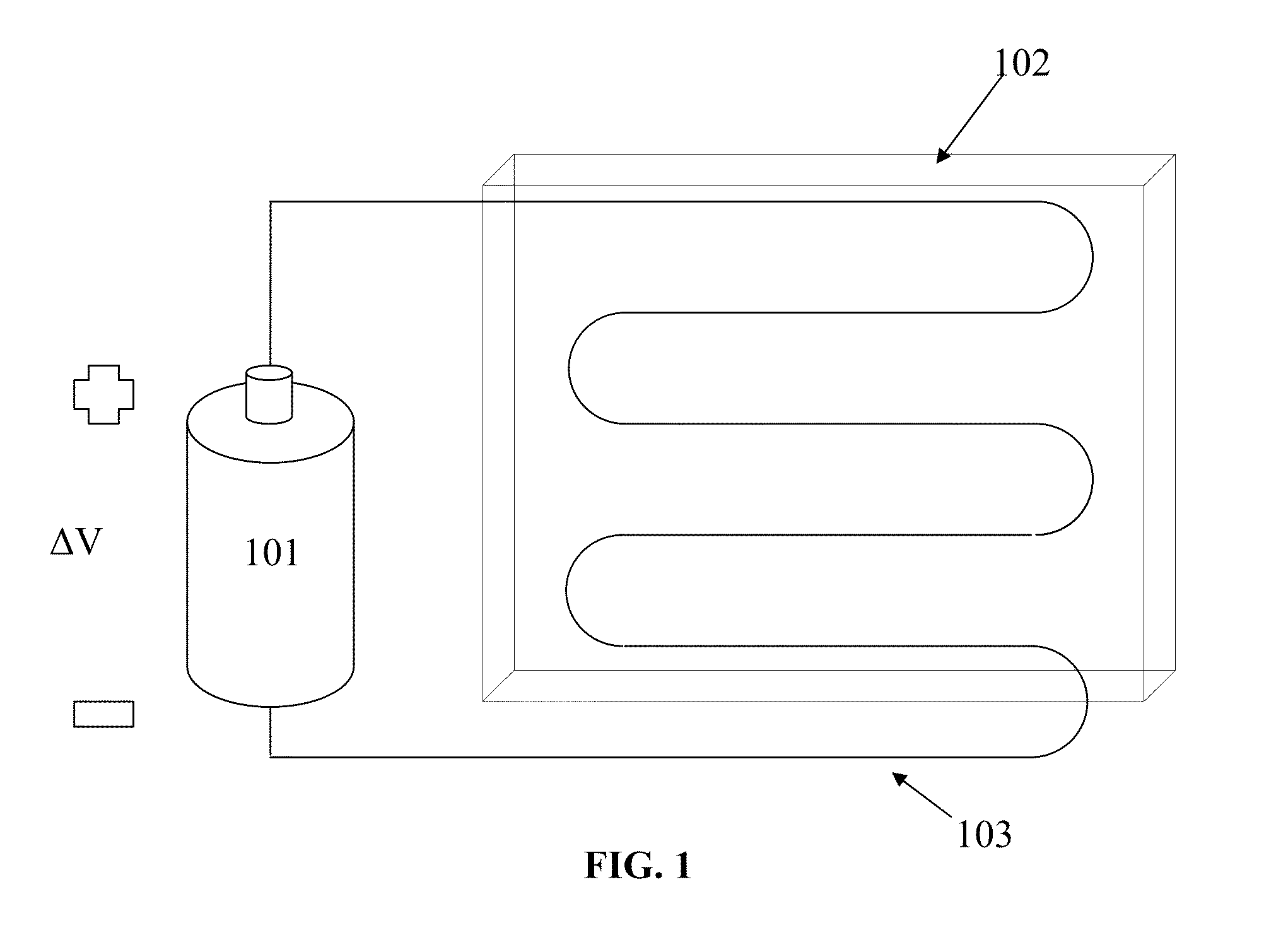

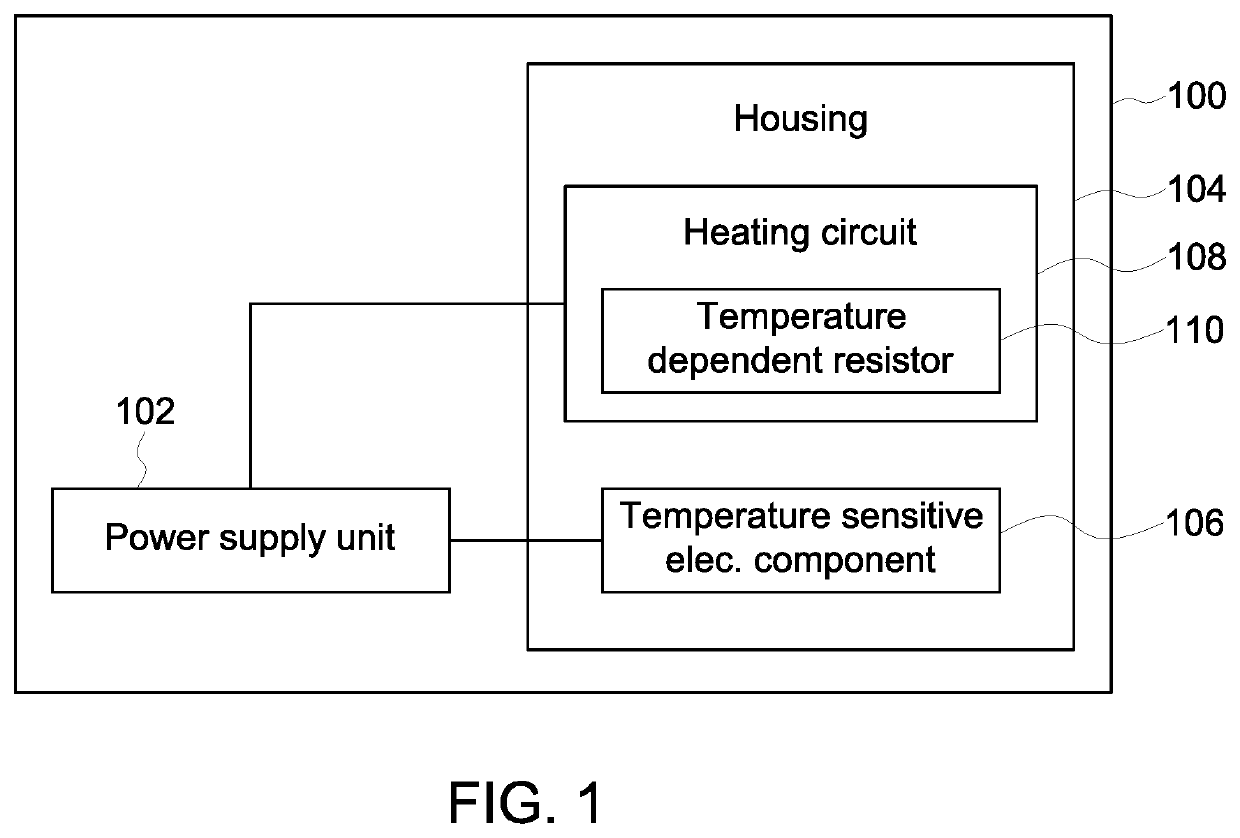

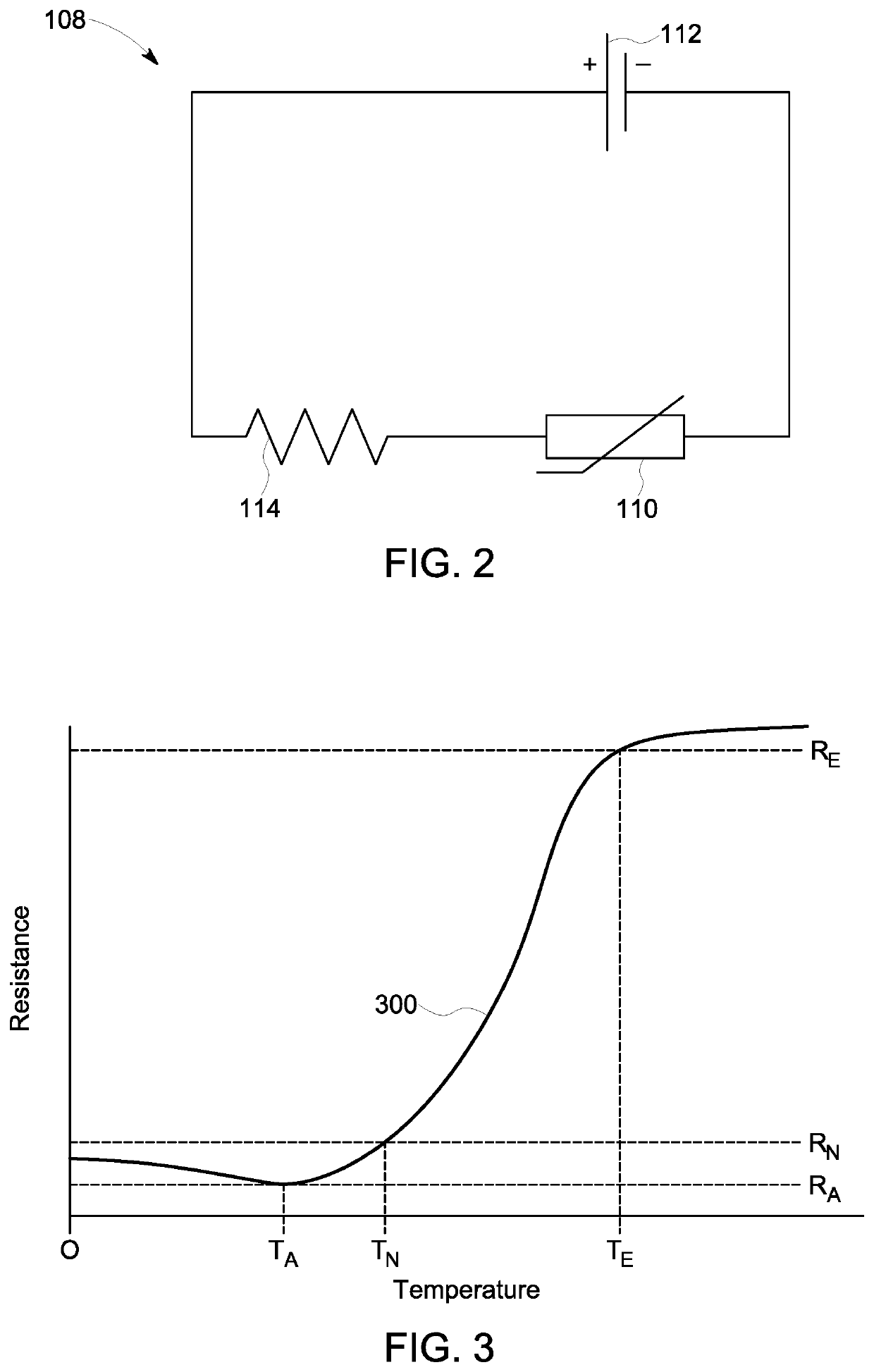

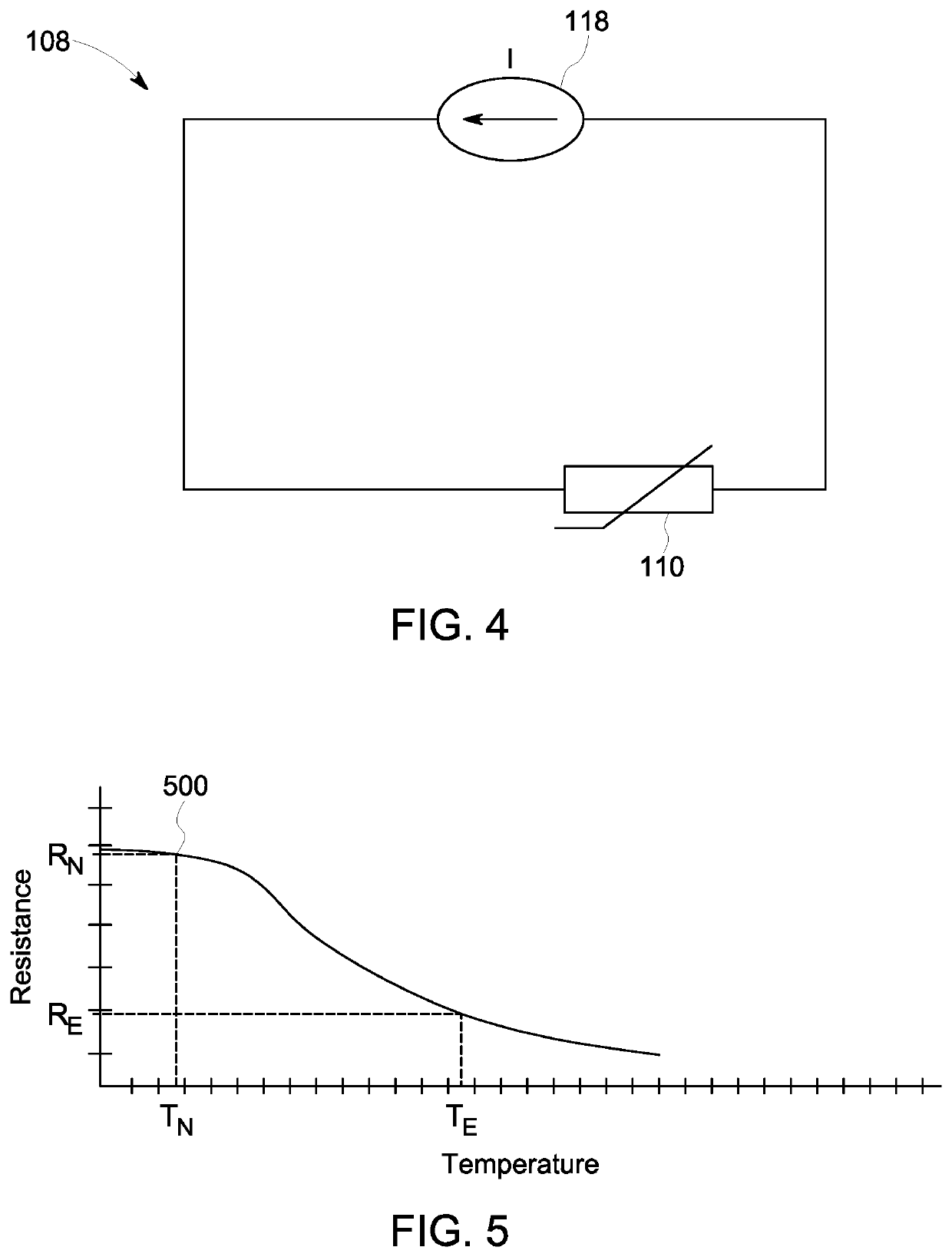

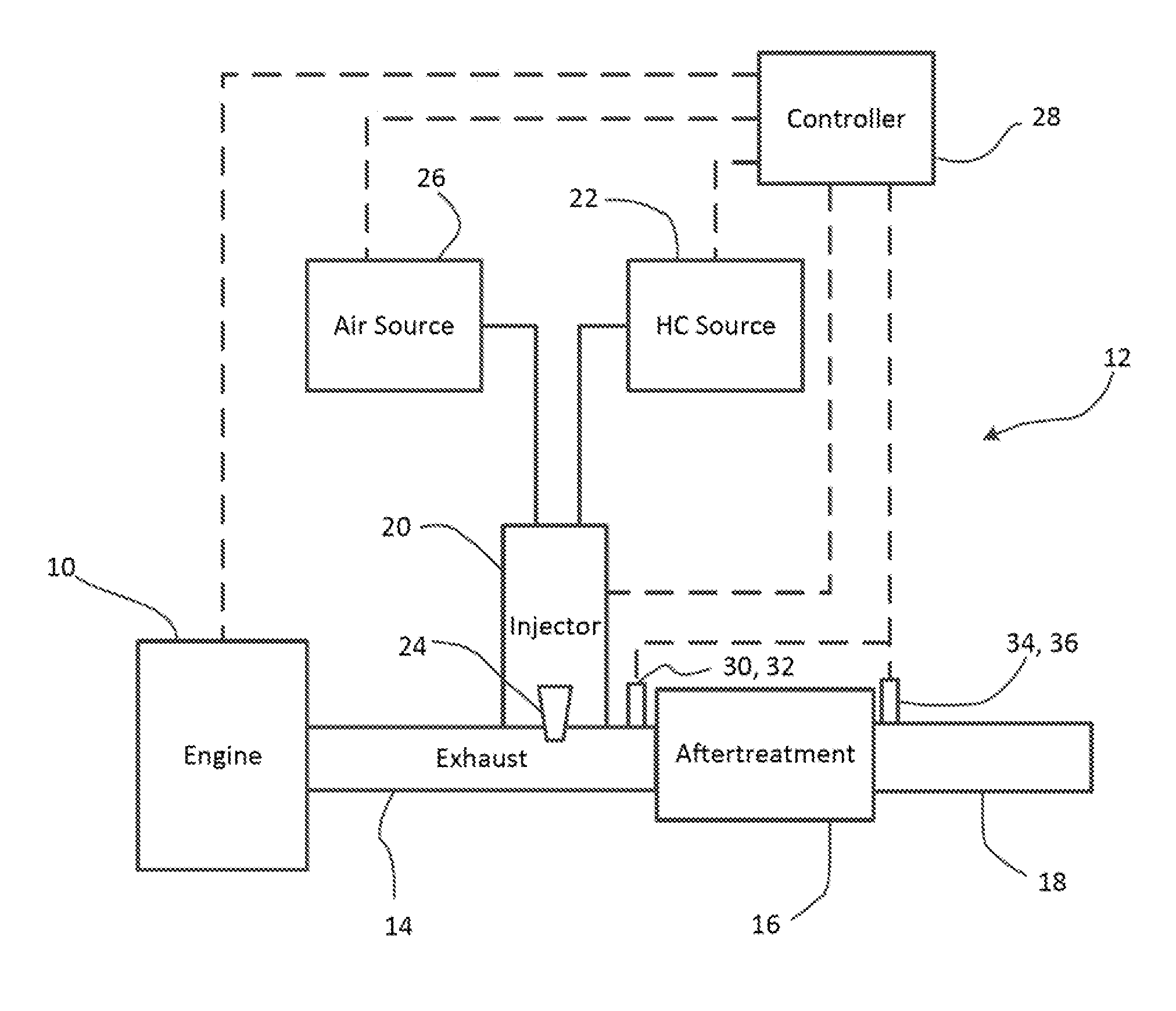

Systems and methods for passive heating of temperature-sensitive electronic components

A system configured for operation below a threshold temperature system includes a power supply, a housing, a temperature-sensitive electronic component, and a heating circuit. The temperature-sensitive electronic component is enclosed within said housing and electrically connected to the power supply, wherein the temperature-sensitive electronic component becomes susceptible to failure when the temperature of said temperature-sensitive electronic component decreases and crosses the threshold temperature. The heating circuit is at least partially enclosed within the housing and comprising a temperature-dependent resistor, the heating circuit electrically connected to the power supply and configured to generate heat energy within the housing when the temperature within the housing decreases and approaches the threshold temperature in order to maintain the temperature of the temperature-sensitive electronic component above the threshold temperature.

Owner:GENERAL ELECTRIC CO

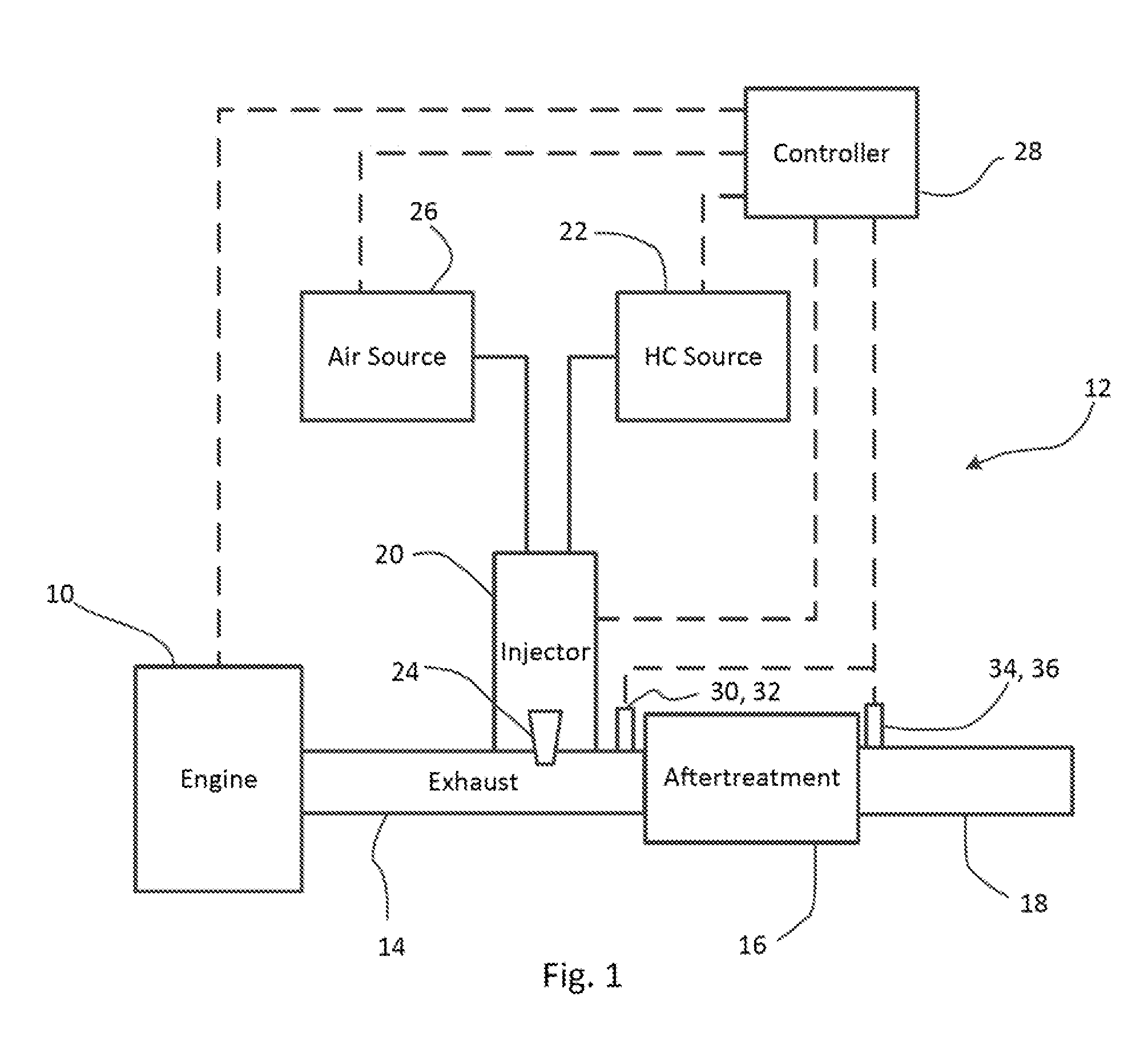

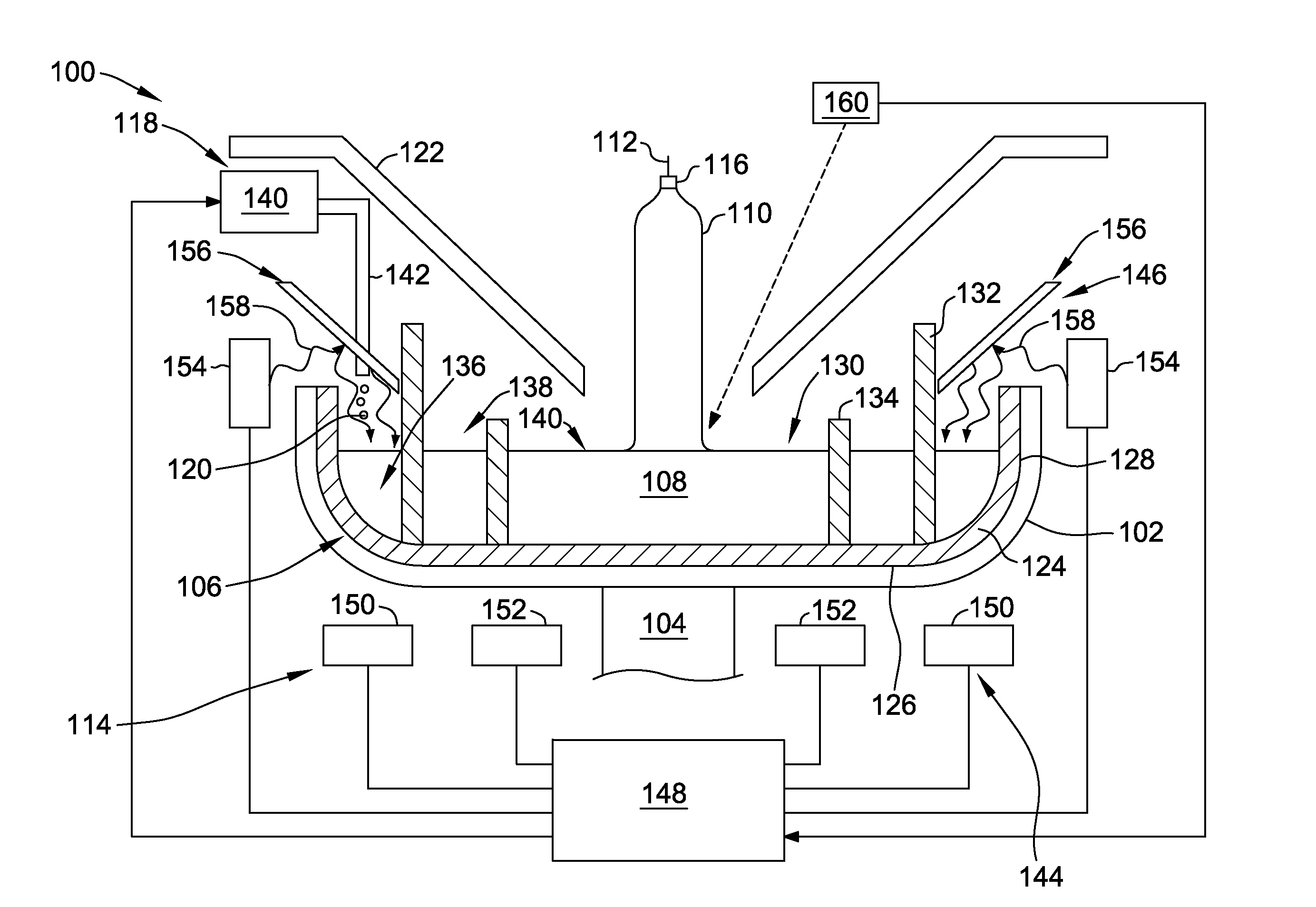

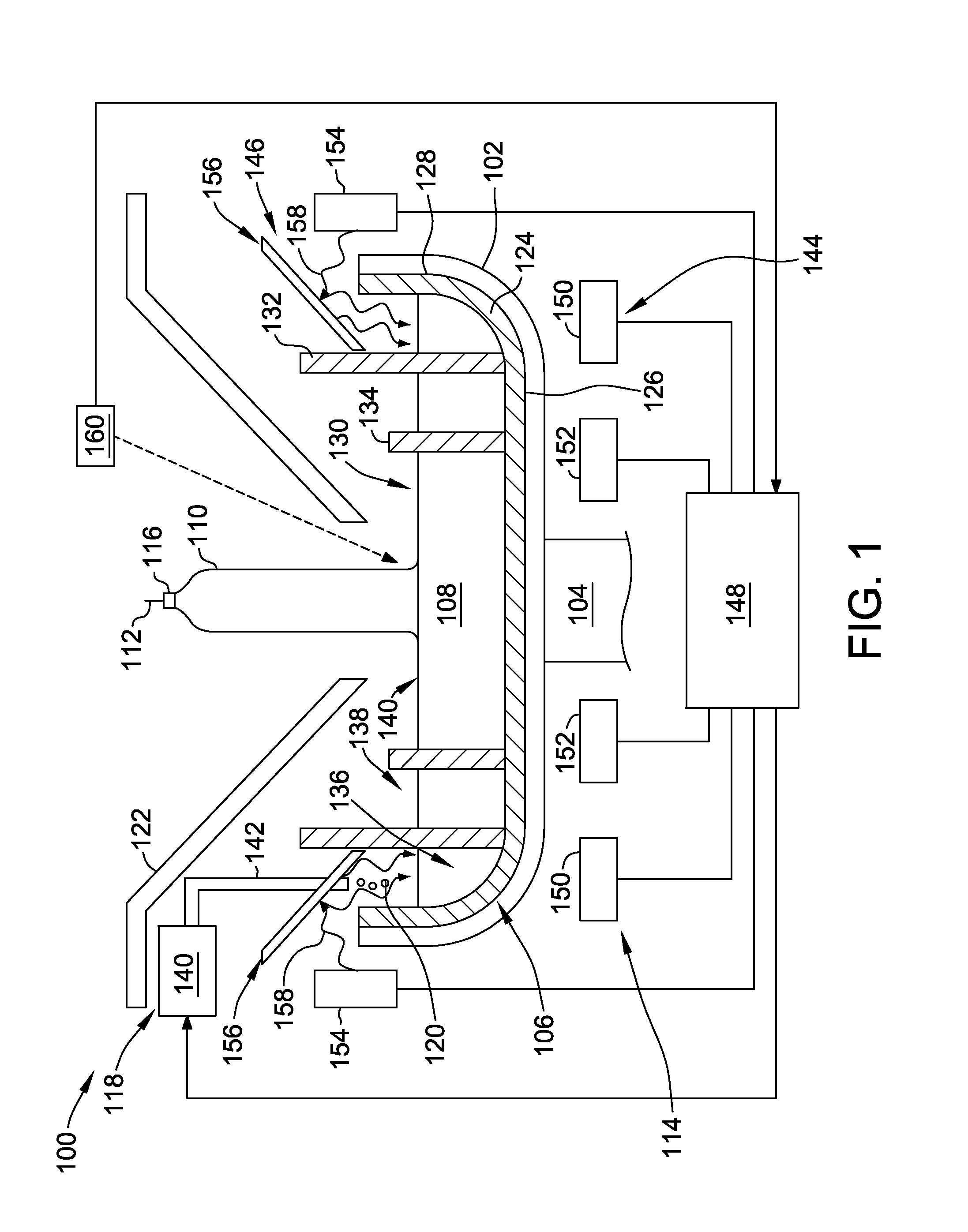

Apparatus and method of operating an injector for an exhaust gas aftertreatment apparatus

InactiveUS20150192050A1Internal combustion piston enginesExhaust apparatusPassive heatingExhaust fumes

A method for operating an exhaust aftertreatment system injector to prevent coking includes steps of injecting fuel for heating the aftertreatment devices, when not injecting fuel, flowing air to purge and cool the nozzle to prevent carbon deposits when exhaust gas temperature is low, and substantially stop air flow to allow passive heating of the nozzle by the exhaust for oxidation of any accumulated carbon when exhaust temperature is high enough to support oxidation. Preferably, the nozzle has a catalytic material coating to reduce the temperature necessary for oxidation of the coking material.

Owner:MACK TRUCKS

Catalytic purification-sterilization disinfection type multifunctional photovoltaic passive ventilation wall

PendingCN112049280AFlexible implementation of preparationFlexibility to achieve activityPhotovoltaic supportsSolar heating energyHeating seasonPassive ventilation

The invention discloses a catalytic purification-sterilization disinfection type multifunctional photovolatic passive ventilation wall. Different modes are switched by controlling opening and closingof baffles at all ventilation openings. The ventilation baffles comprise an outdoor ventilation baffle (D1), an indoor lower ventilation baffle (D2) and an indoor upper ventilation baffle (D3). The ventilation openings comprise an outdoor ventilation opening (V1), an indoor lower ventilation opening (V2) and an indoor upper ventilation opening (V3). The back face of a heat absorption plate (5) issprayed with an adsorption-thermal catalysis coating. According to the catalytic purification-sterilization disinfection type multifunctional photovolatic passive ventilation wall, the thermal catalysis technology, the thermal sterilization disinfection technology and the solar photovolatic photo-thermal technology are innovatively combined and utilized, the functions of power generation in the heating season, passive heating ventilation, air purification and thermal sterilization disinfection can be achieved, and the functions of power generation in the non-heating season, domestic hot waterpreparation, passive cooling, purification and thermal sterilization disinfection are achieved; and in the transition season, according to the building requirements, the functions of domestic hot water preparation and passive heating can be flexibly achieved by adjusting the ventilation baffles while power generation, thermal catalytic degradation of formaldehyde and thermal sterilization disinfection are conducted.

Owner:UNIV OF SCI & TECH OF CHINA

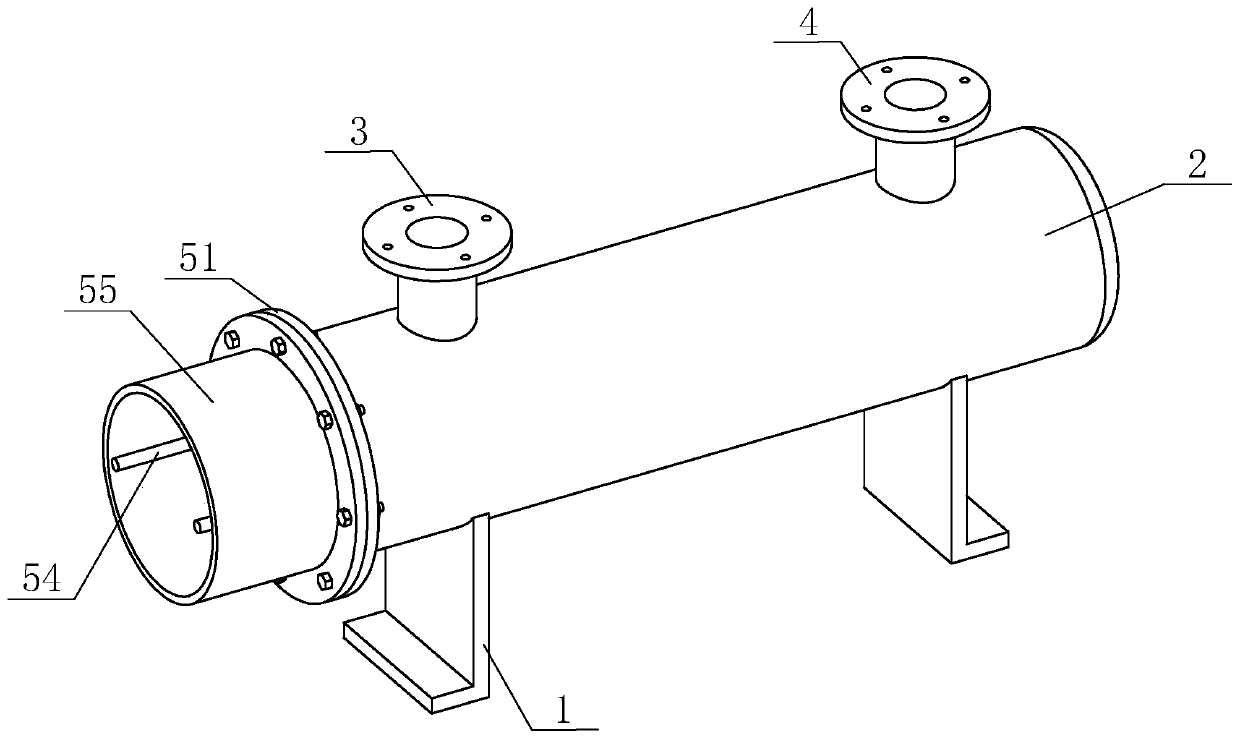

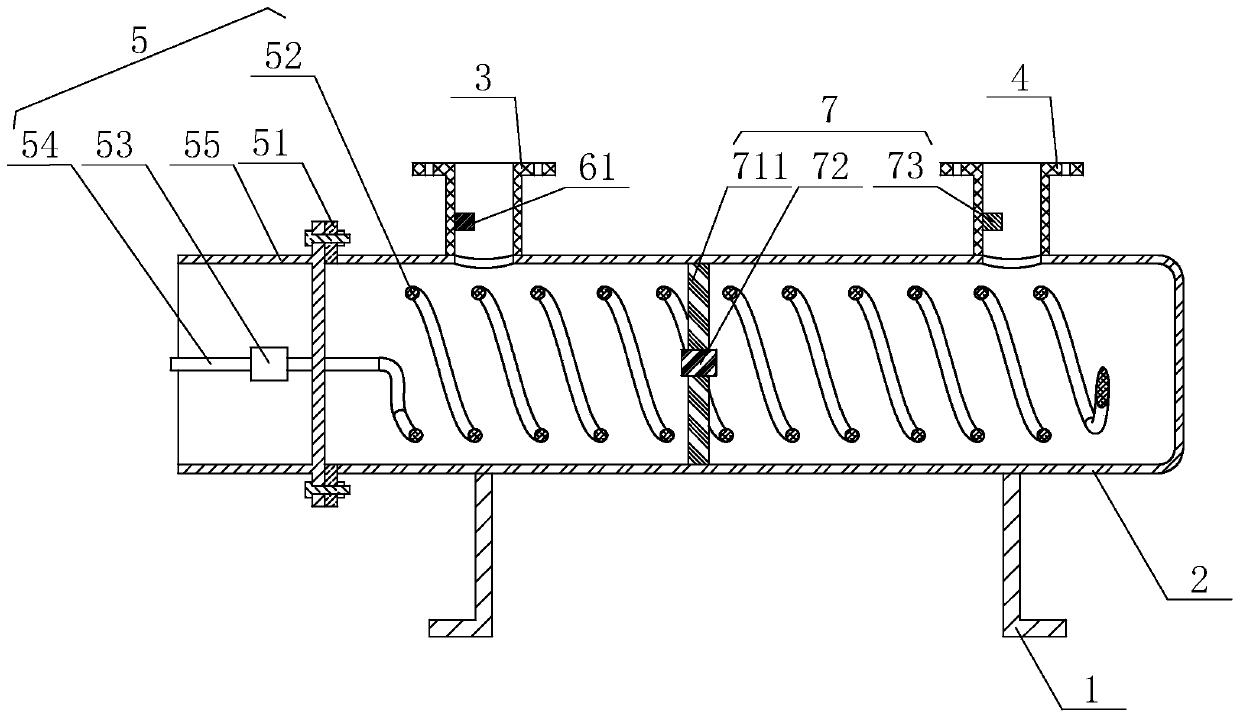

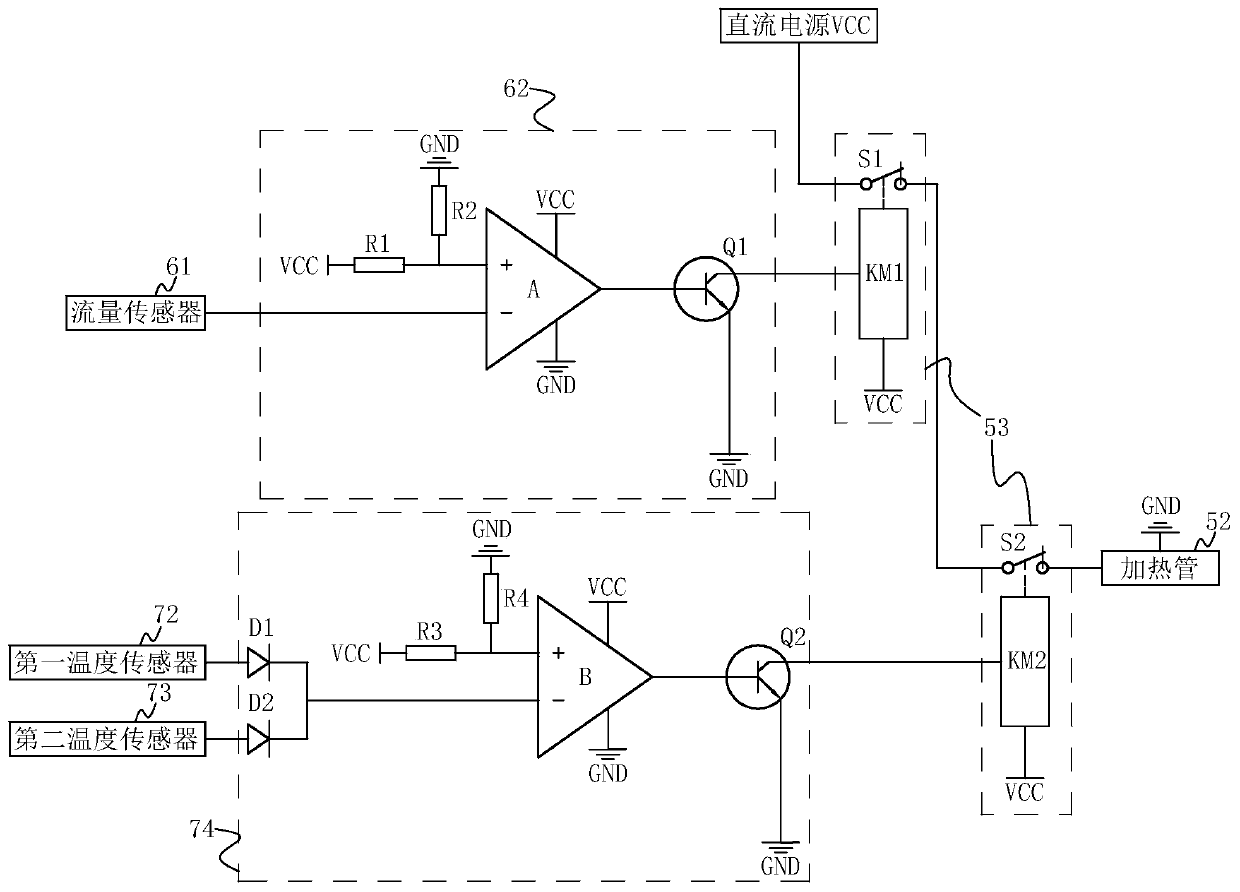

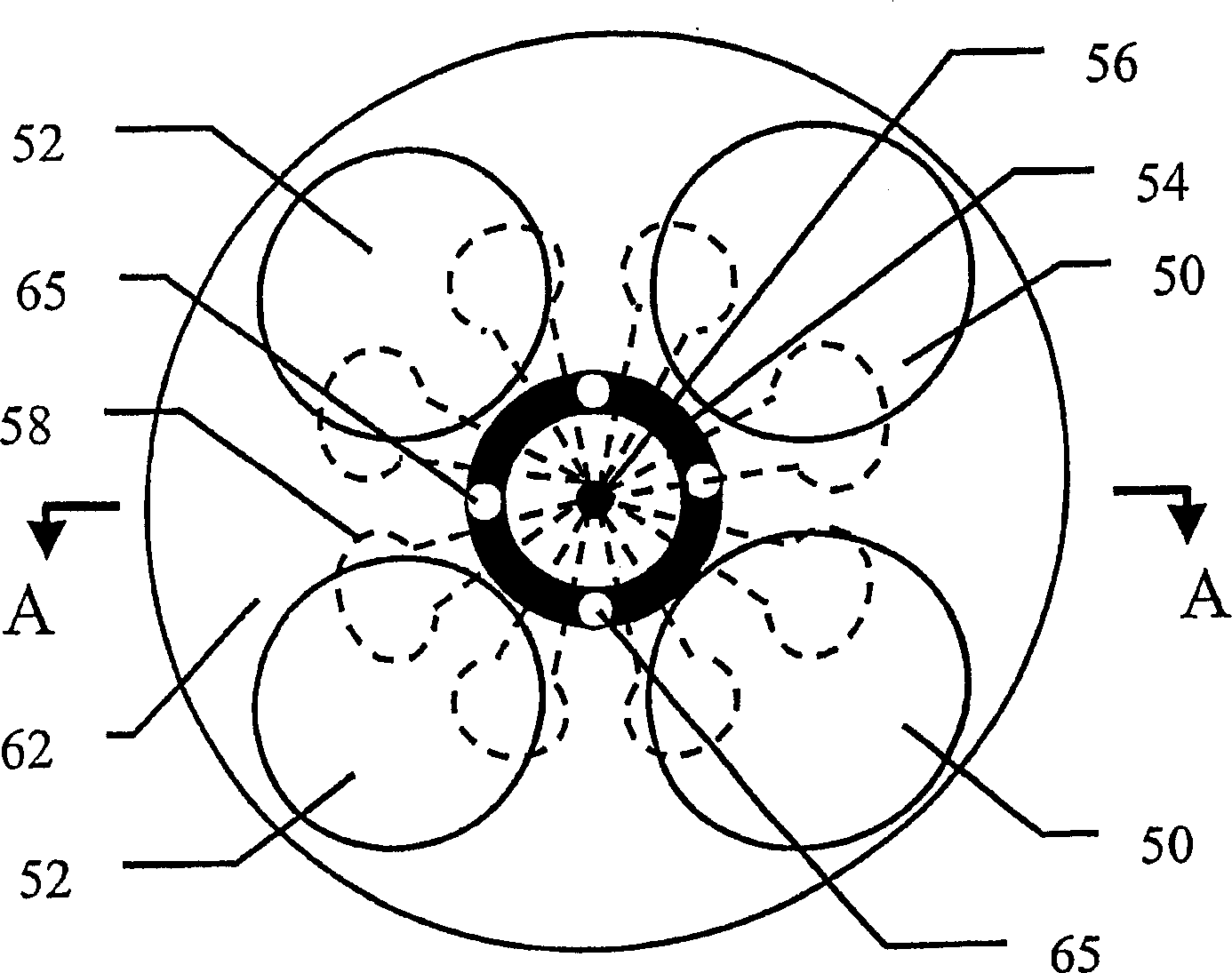

Intelligent fluid type electric heating box

ActiveCN109916079AAffect your own lifeAffect usabilityAir heatersWater heatersElectricityPassive heating

The invention relates to the technical field of heaters, and discloses an intelligent fluid type electric heating box which comprises a base and a shell fixed onto the base. A feeding pipe and a discharging pipe communicating with the inner part of the shell are arranged on the side surfaces, close to two ends, of the shell; a heating assembly is fixed to one end, close to a feed inlet, of the shell; a part, used for heating, of the heating assembly is arranged in the shell; a flow monitoring assembly electrically connected with the heating assembly is fixedly connected into the feeding pipe;temperature monitoring assemblies electrically connected with the heating assembly are fixedly connected to the discharging pipe and the middle part in the shell; the heating assembly is used for heating a fluid medium entering from the feeding pipe; and the flow monitoring assembly and the temperature monitoring assemblies are used for monitoring and controlling the flow speed and the temperatureof the fluid medium, and can stop the heating operation of the heating assembly when the flow speed of the fluid medium is too low or the temperature is too high, so that the occurrence of the phenomenon that the service life of the electric heating box and the follow-up use of the fluid medium are influenced due to dry burning or excessive heating of the heating assembly is avoided.

Owner:上海庄昊电热电器有限公司

Glow ring ignition assist for internal combustion engine

A glow member, preferably in the shape of a ring, assists ignition and combustion of a fuel used in an internal combustion engine. A fuel injection valve injects a plurality of fuel jets directly into a combustion chamber during operation of the engine so that the fuel jets are aimed to the proximity of the glow member such that ignition of fuel in each fuel jet is assisted by the glow member. The glow member is made from high temperature materials and can include catalytic materials to further promote combustion. The glow member can be actively heated, for example by an electric current, in addition to being passively heated by the heat generated within the combustion chamber by the combustion of the fuel therein.

Owner:WESTPORT POWER

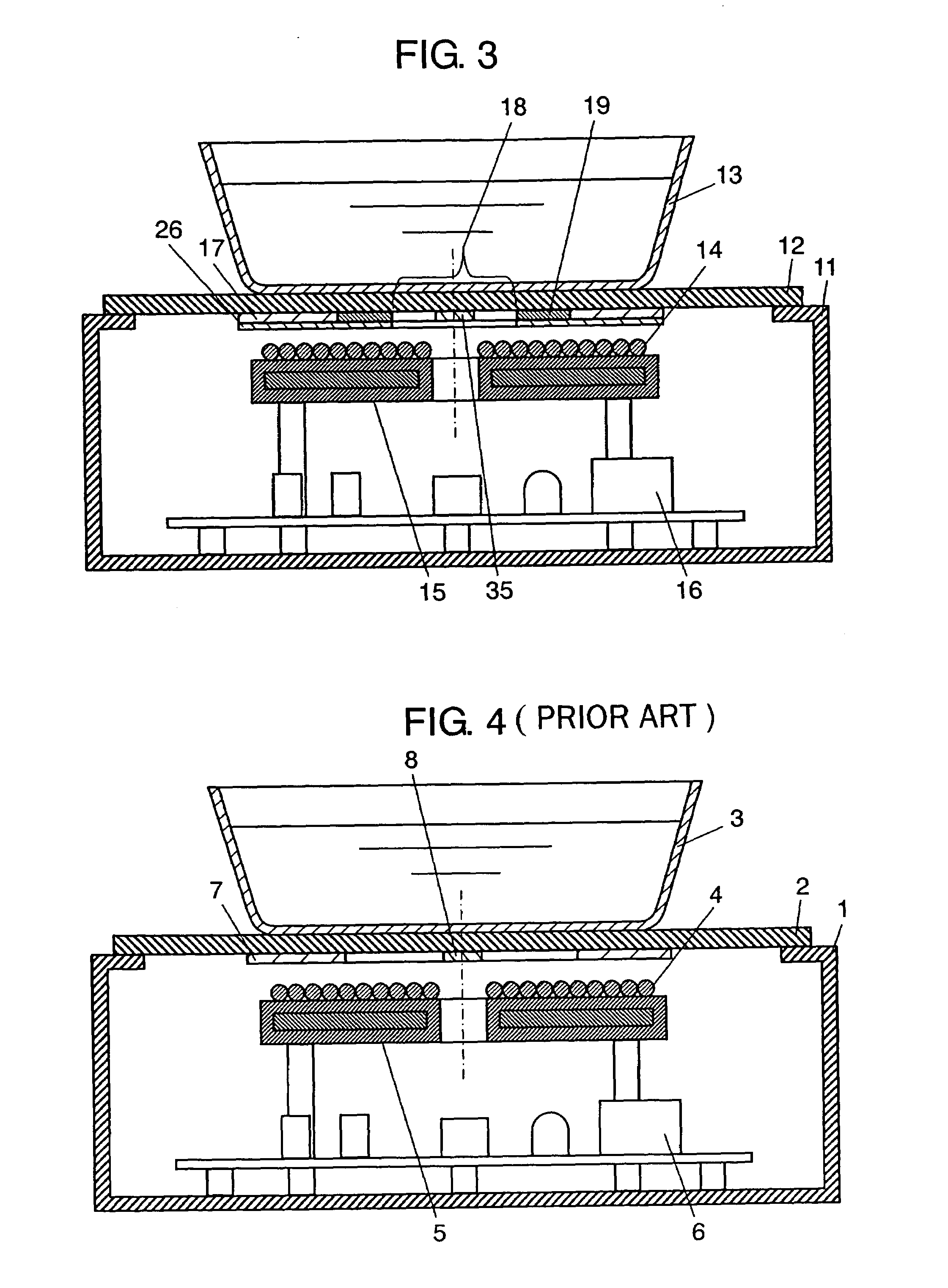

Crystal growing systems and methods including a passive heater

ActiveUS20160024685A1Polycrystalline material growthBy pulling from meltThermal energyPassive heating

A system for growing a crystal ingot from a melt is provided. The system includes a crucible assembly, a first heater, a second heater, and a passive heater. The crucible assembly includes a crucible and a weir separating an outer melt zone of the melt from an inner melt zone of the melt. The first heater is configured to supply thermal energy to the melt by conduction through the crucible. The second heater is configured to generate thermal radiation. The passive heater is configured to supply thermal energy to the outer melt zone by transferring thermal radiation generated by the second heater to the outer melt zone.

Owner:CORNER STAR LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com