Heating gasification device for liquefied gas micro-propulsion system

A gasification device and micro-propulsion technology, which is applied in the directions of jet propulsion device, space flight vehicle propulsion system device, rocket engine device, etc., can solve the problems of high power, waste of energy, etc., and achieves low mass, reduced consumption and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

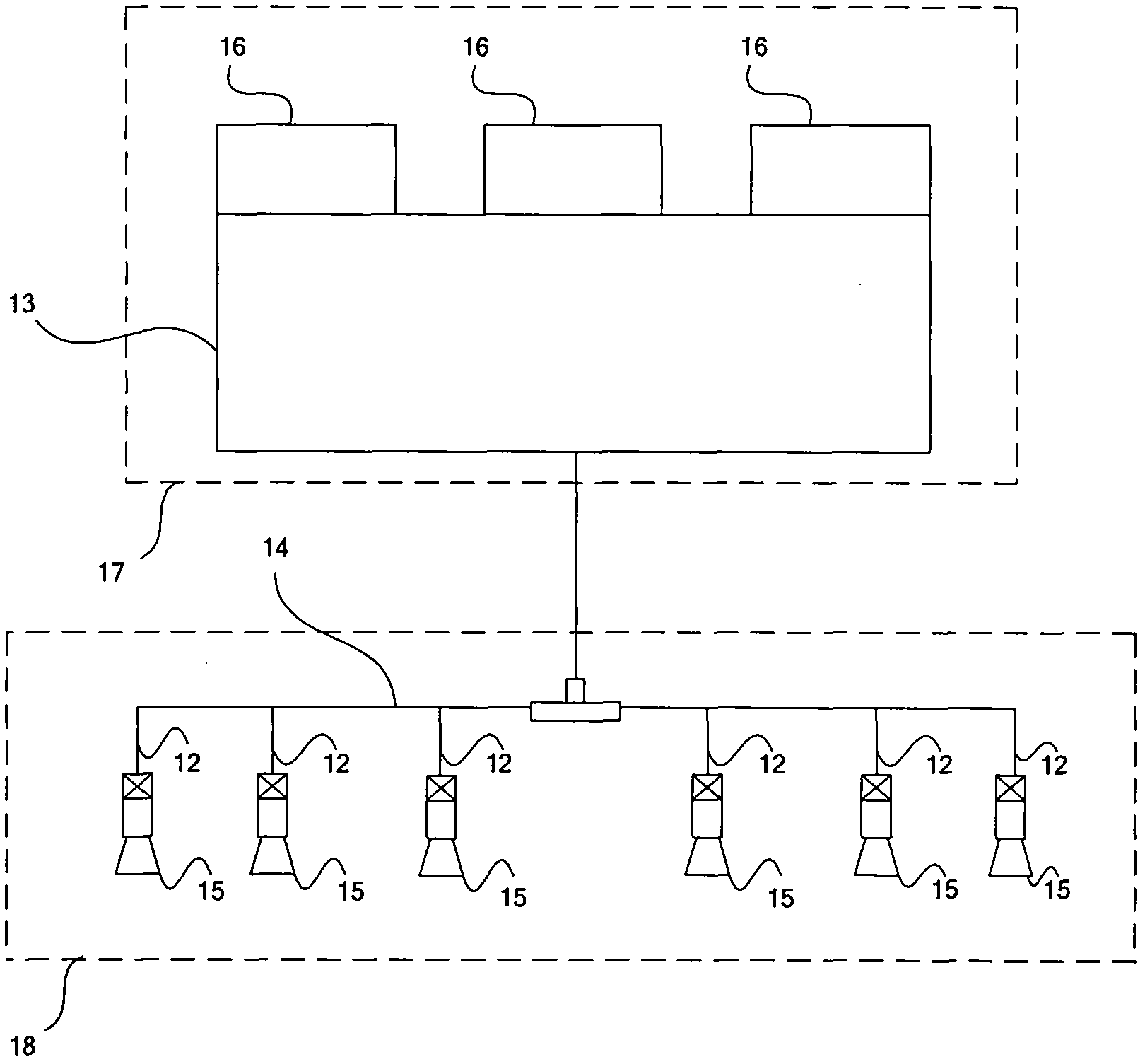

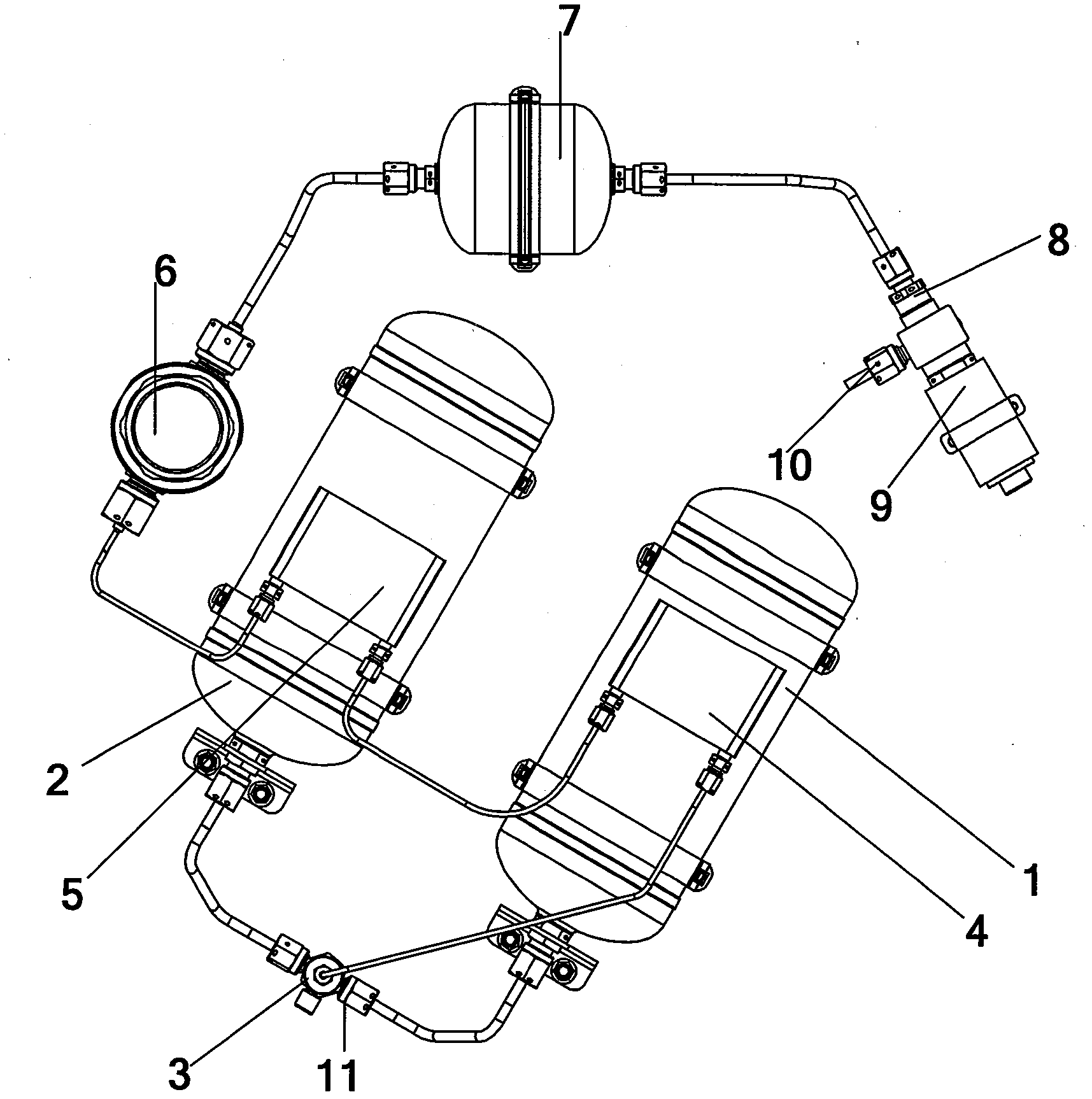

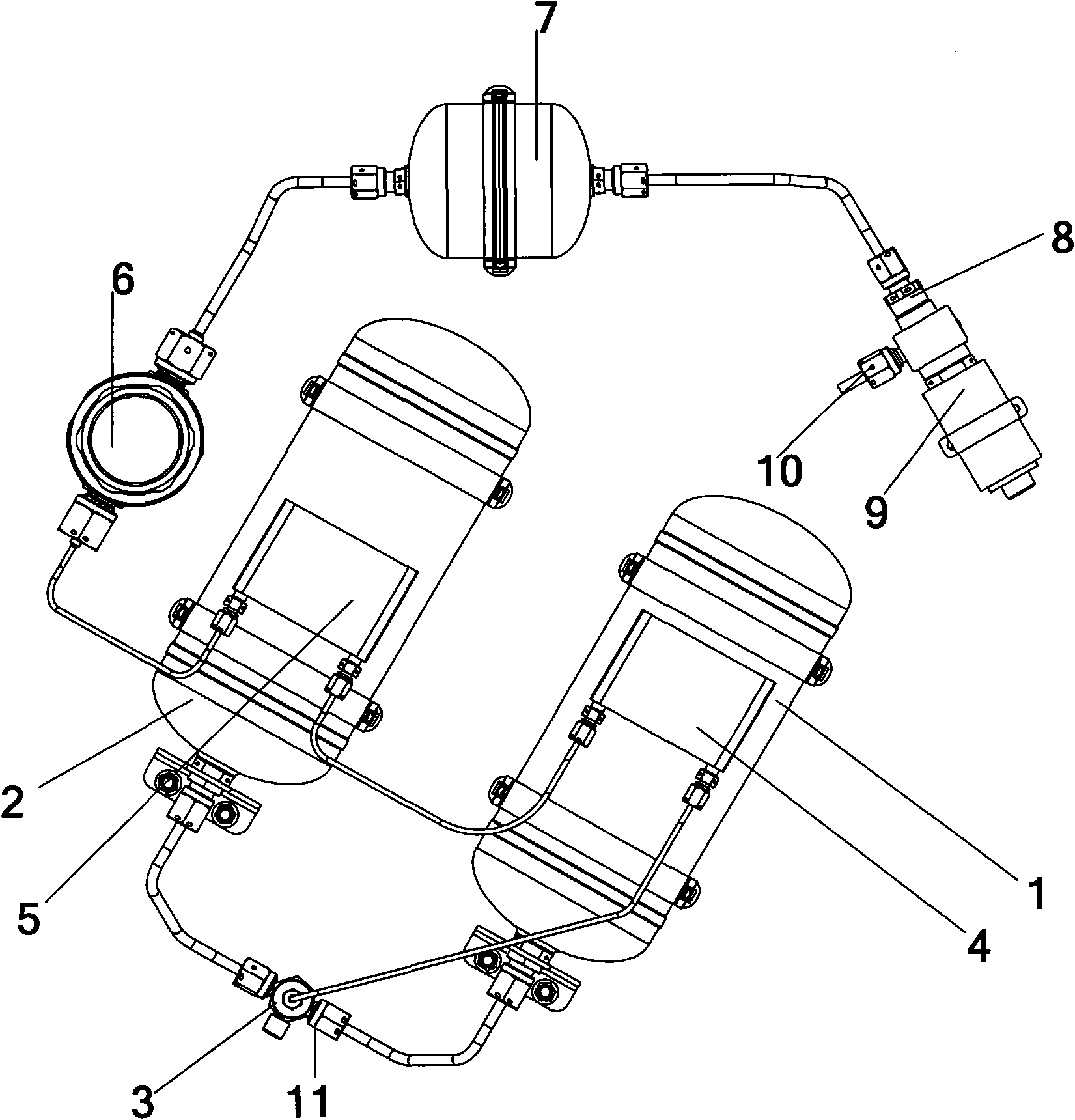

[0023] The present invention is a heating gasification device for a liquefied gas micro-propulsion system, comprising a first propellant storage tank 2, a second propellant storage tank 1, a first heat conduction module 5, a second heat conduction module 4, and a pressure reducer 6 , Surge tank 7, safety valve 3, pressure sensor 9 and filter 8, such as figure 2 Shown.

[0024] The first propellant tank 2 and the second propellant tank 1 are used to fill the liquid propellant. The liquid propellant is stored in the first propellant tank 2 and the second propellant tank 1 in liquid form. The stored pressure It is 0.84MPa, the total mass of liquid propellant is 0.6kg, and the mass of liquid propellant can be changed according to different mission requirements. A first heat conduction module 5 and a second heat conduction module 4 are installed on the first propellant tank 2 and the second propellant tank 1, respectively, the propellant inlet of the first heat conduction module 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com