Patents

Literature

21194results about How to "Guaranteed to work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

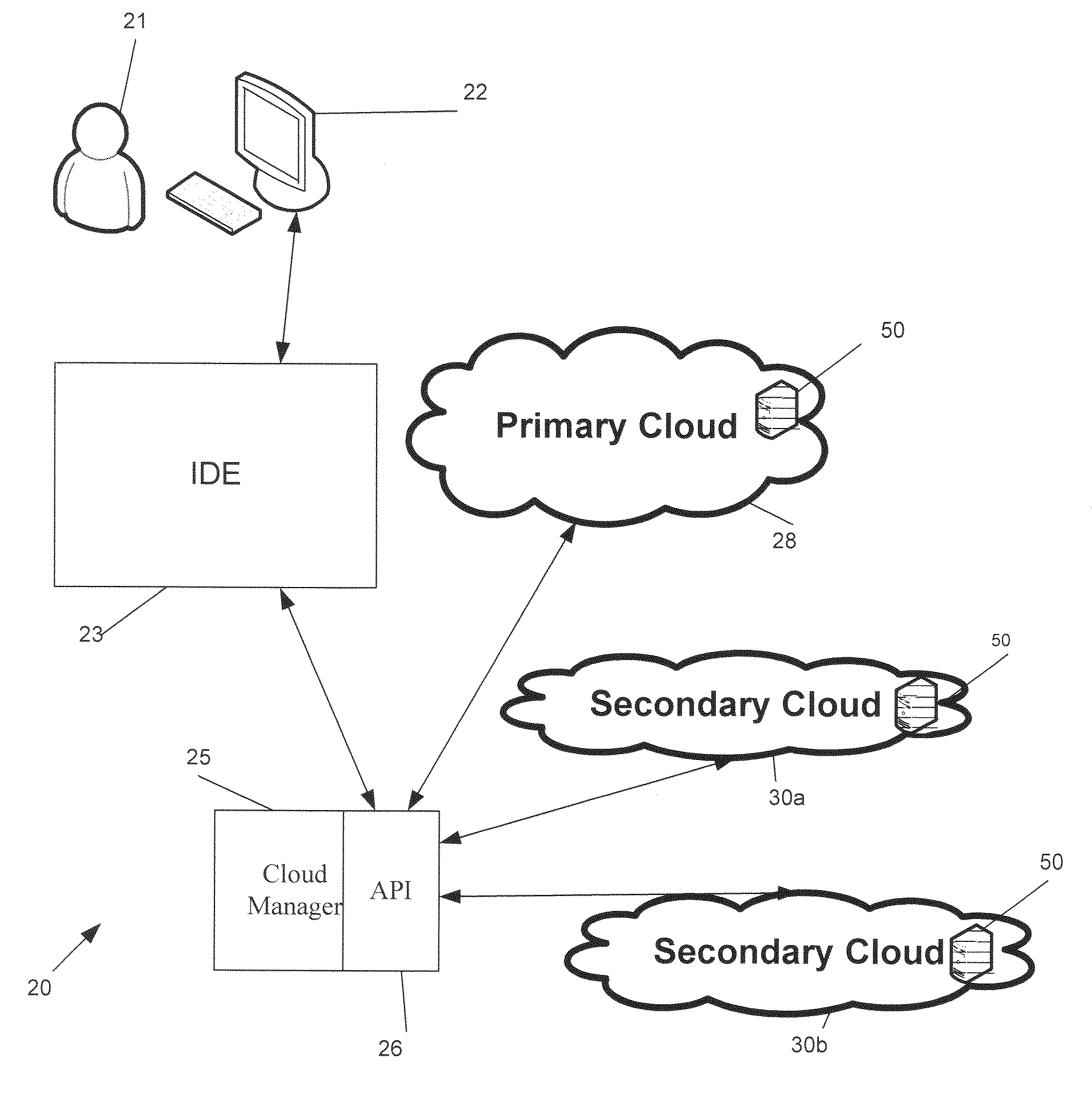

System and method for developing, deploying, managing and monitoring a web application in a single environment

InactiveUS7596620B1Guaranteed to workDigital computer detailsRequirement analysisWeb applicationThe Internet

A system and method for developing, deploying, managing and monitoring a web application in a single environment is disclosed herein. The single environment is preferably an integrated development environment (“IDE”). The system and method preferably allows for deployment to a cloud provider, and preferably allows for use of Web resources from multiple cloud providers. One preferred IDE is the APTANA® STUDIO IDE. An operator can use a user interface to access the integrated development environment and the cloud manager over the network, specifically the Internet.

Owner:APPCELERATOR

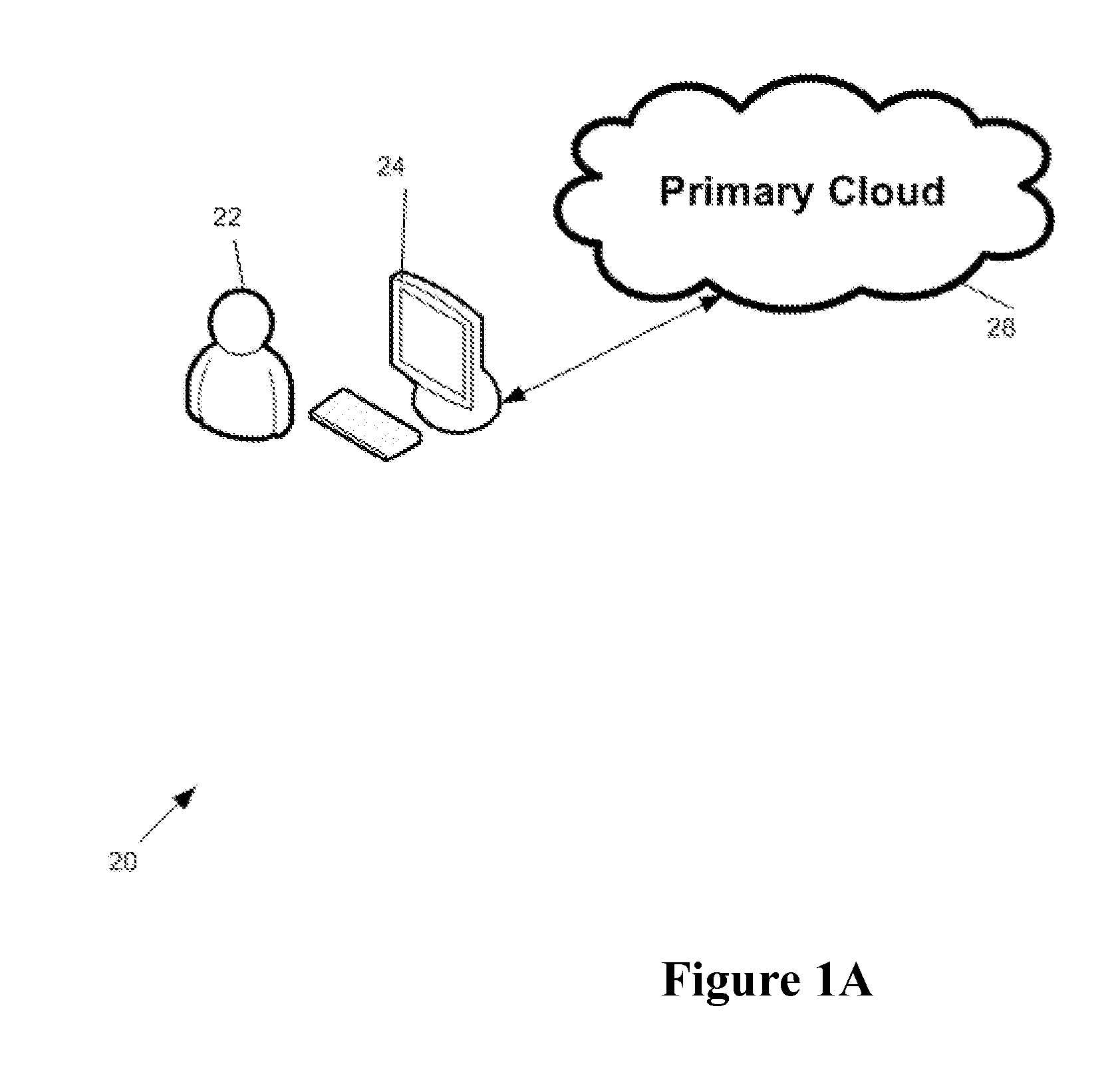

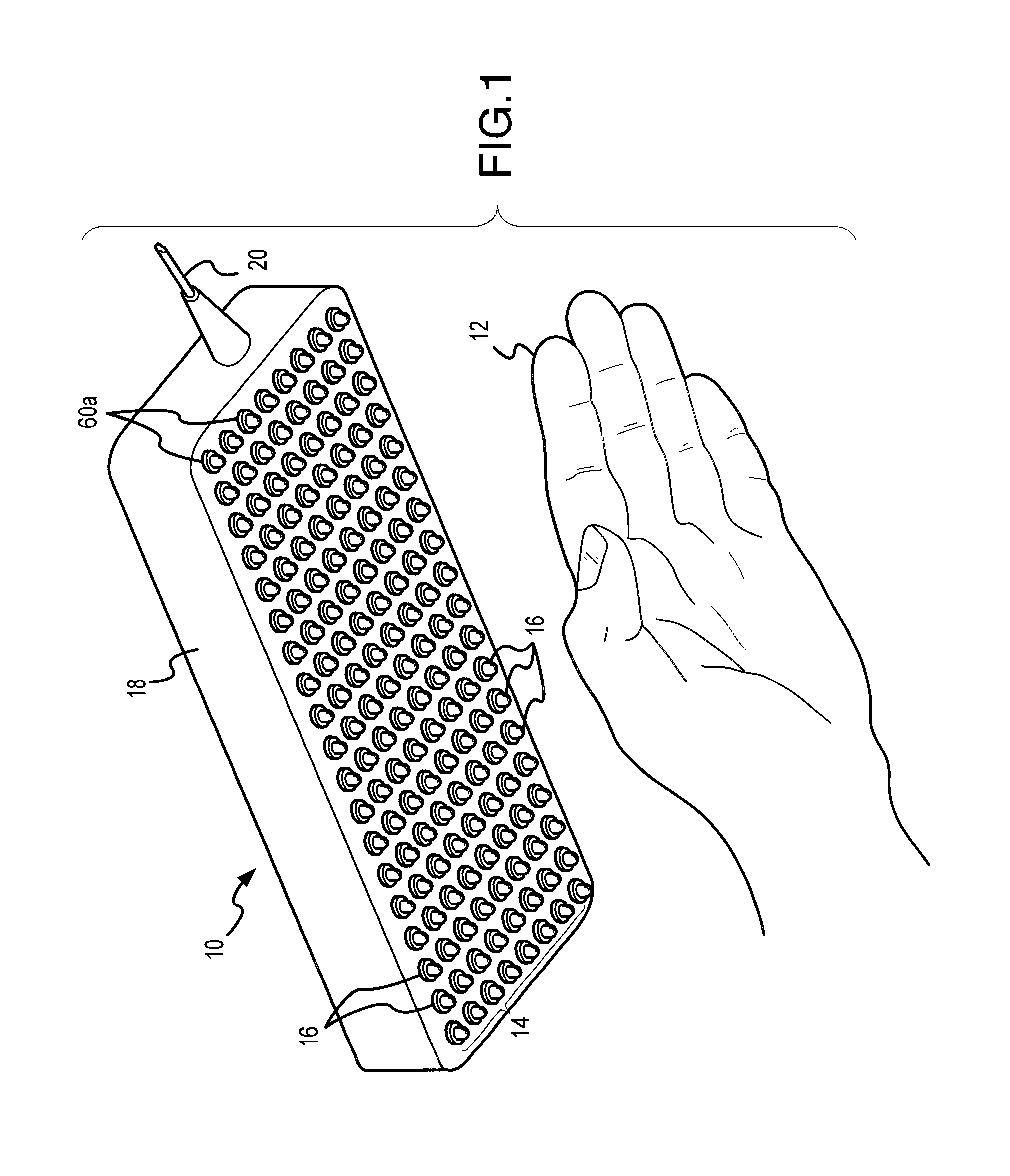

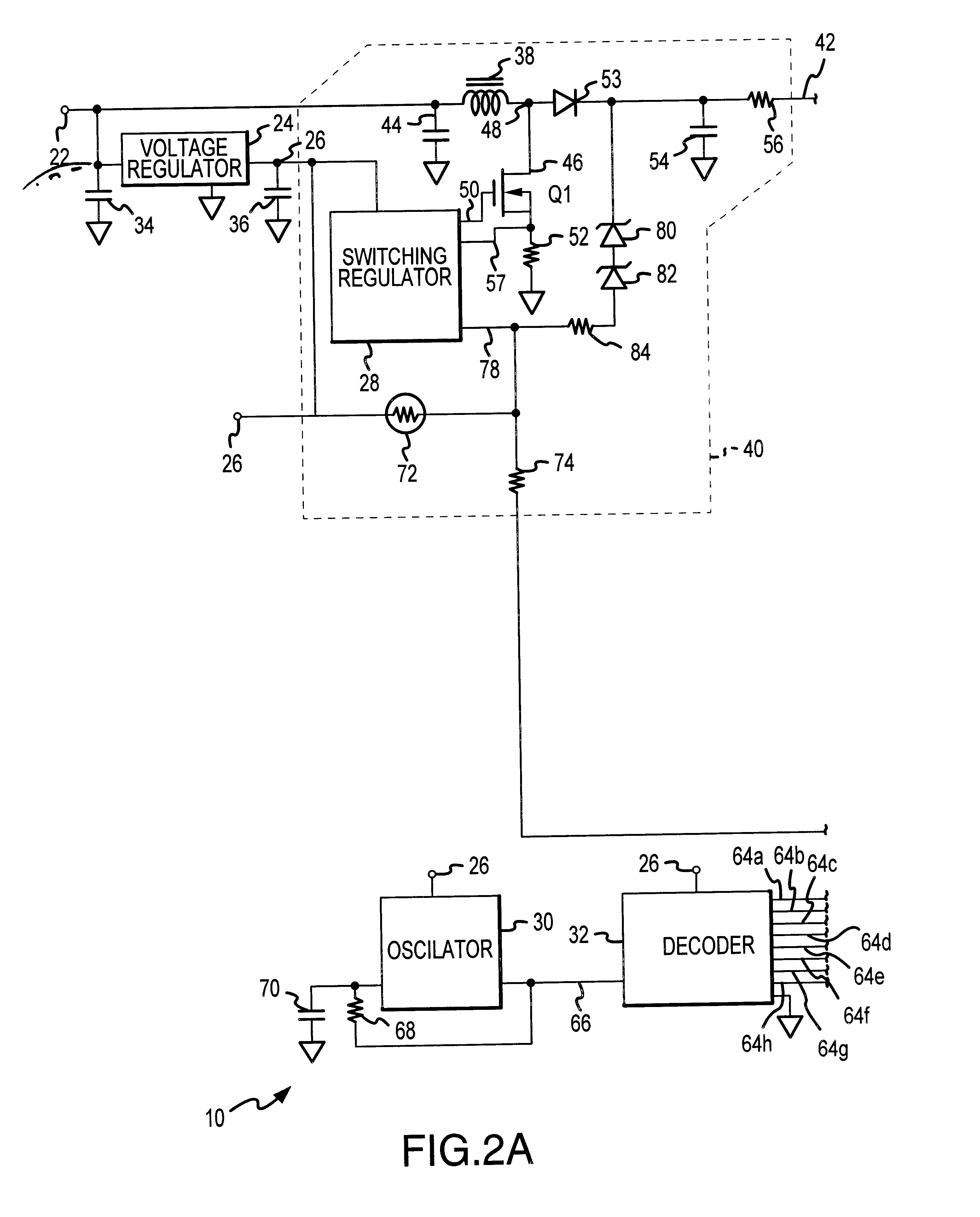

Low level light therapy method and apparatus with improved wavelength, temperature and voltage control

InactiveUS6471716B1Energy penetrationLow costDentistrySurgical instrument detailsEngineeringVoltage source

A photo-therapy device emits photo-therapeutic radiation to treat. living tissue. The device incorporates an array of emitters, the photo emissions of which is dependent on their temperature. Temperature feedback is provided to a voltage supply that supplies current to the emitters, to regulate the voltage supply level and the temperature of the emitters. Additionally, the wavelength of the radiation is dependent on the temperature of the emitters, so the wavelength is moved closer to an optimum wavelength for absorption by the tissue by controlling the temperature of the emitters. Furthermore, the useful life of the emitters is extended by pulsing the emitters on and off by sequentially applying an activation signal to one group of emitters at a time. Also, the device can operate on a wide range of voltage input levels since it utilizes a switching regulator, which can convert a voltage level in the range to the level required to drive the array of emitters. The photo-therapeutic infrared light may be used to treat insect bites and to relieve headaches in human beings. The infrared light emitters may be incorporated into a mouthpiece for treating gum tissues.

Owner:FOX SHERRY PERSONALLY

RFID scanning device

ActiveUS10482292B2Minimal costMinimal effortLogisticsSensing by electromagnetic radiationInventory managementAuthorization

Owner:GARY L SHARPE

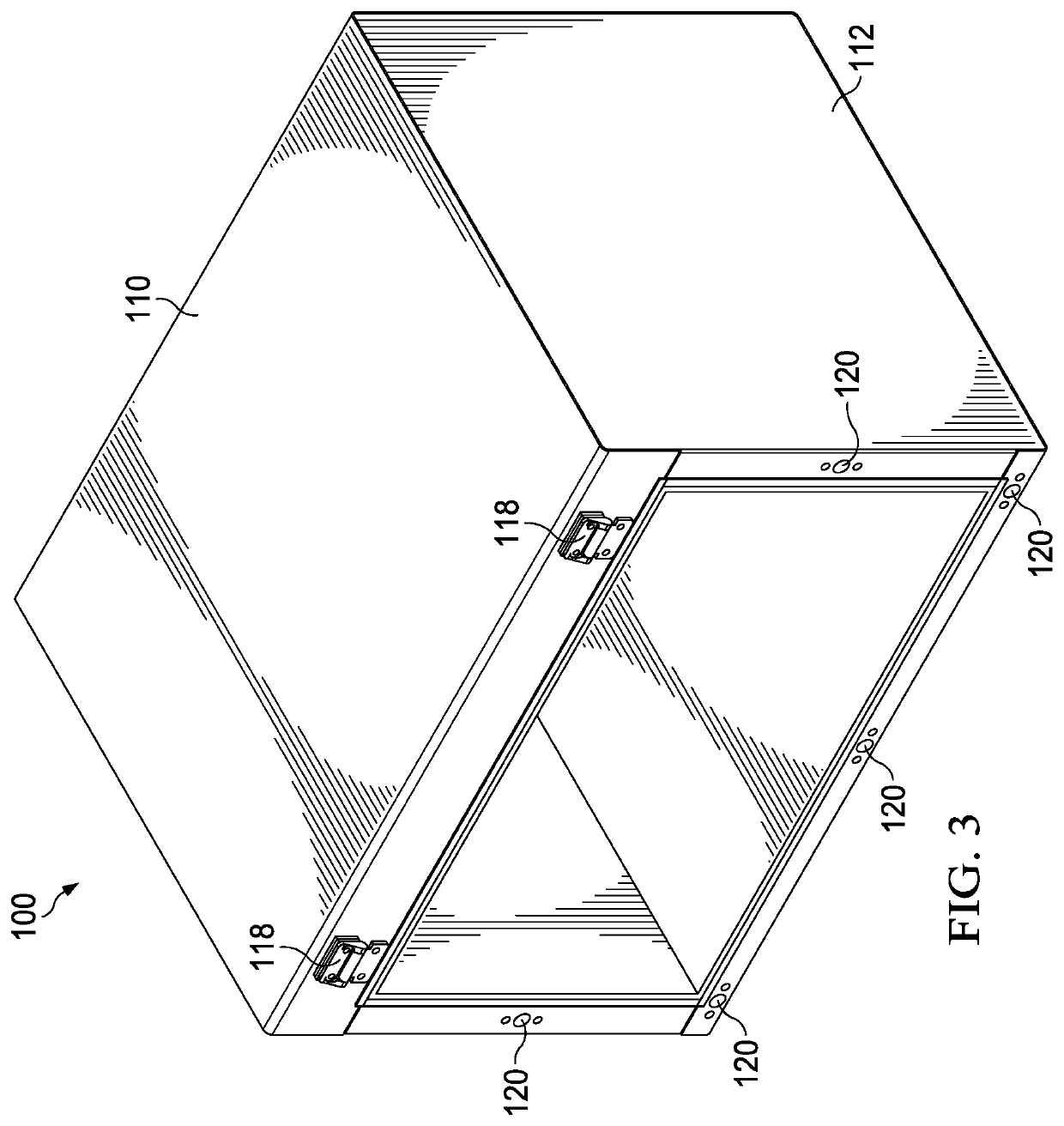

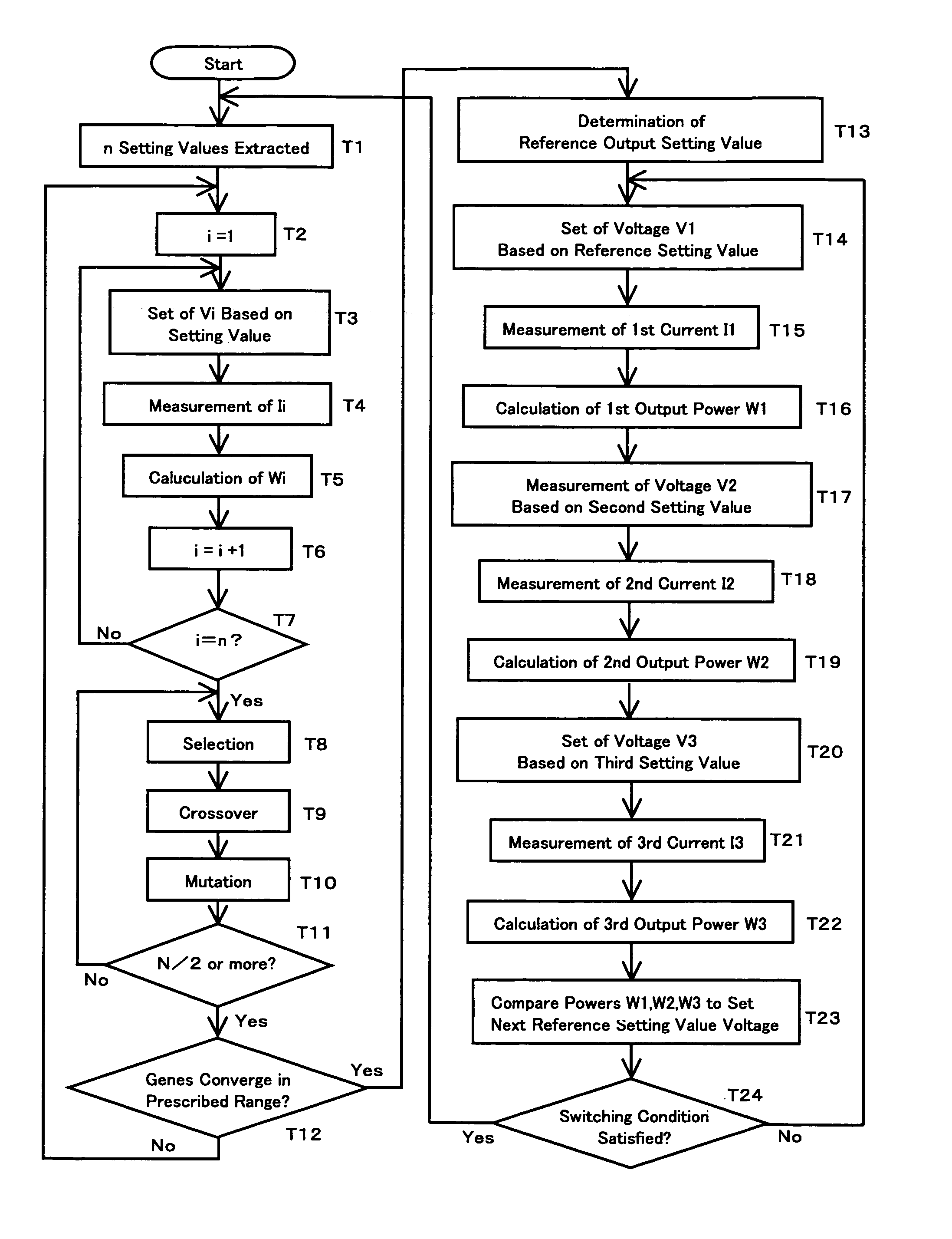

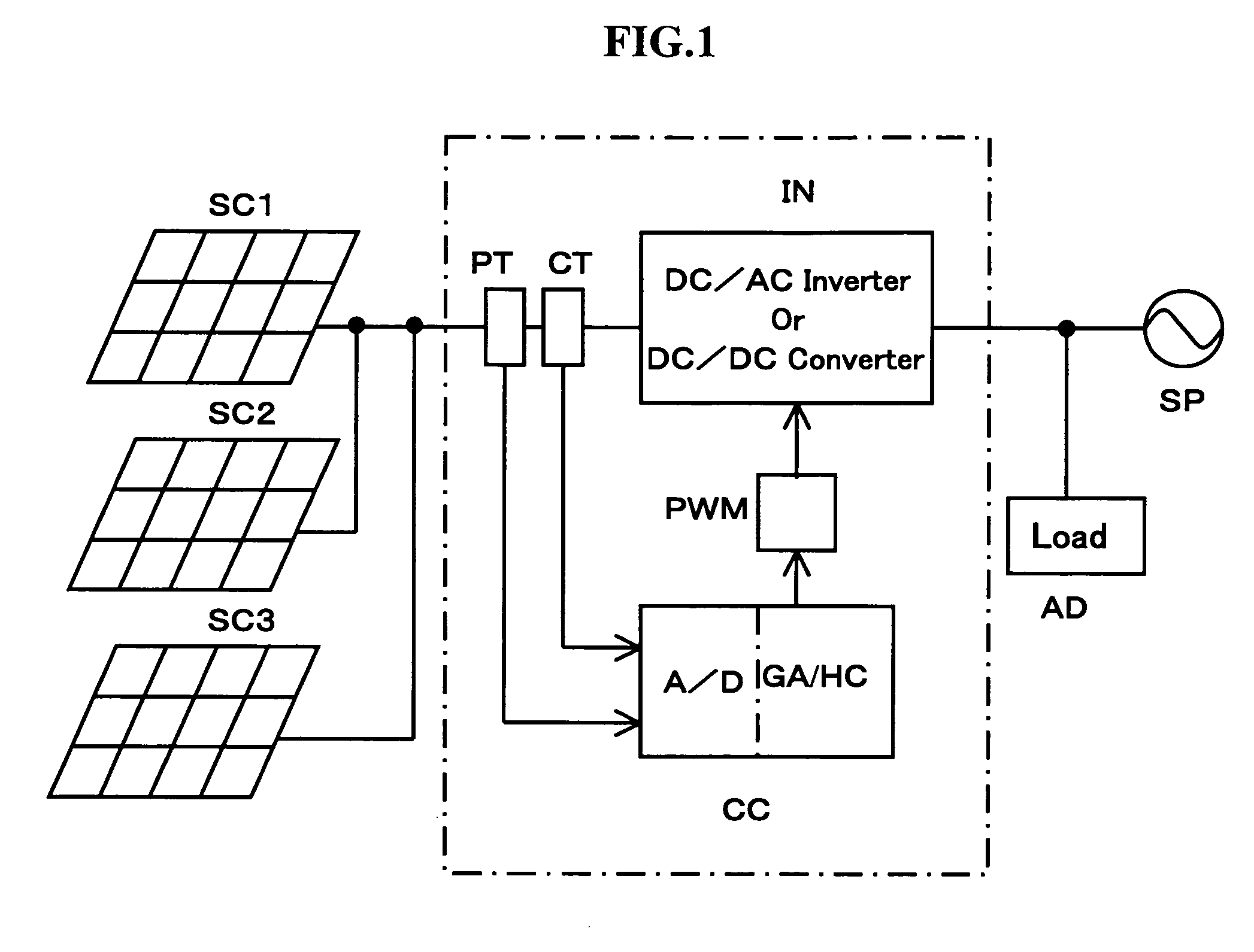

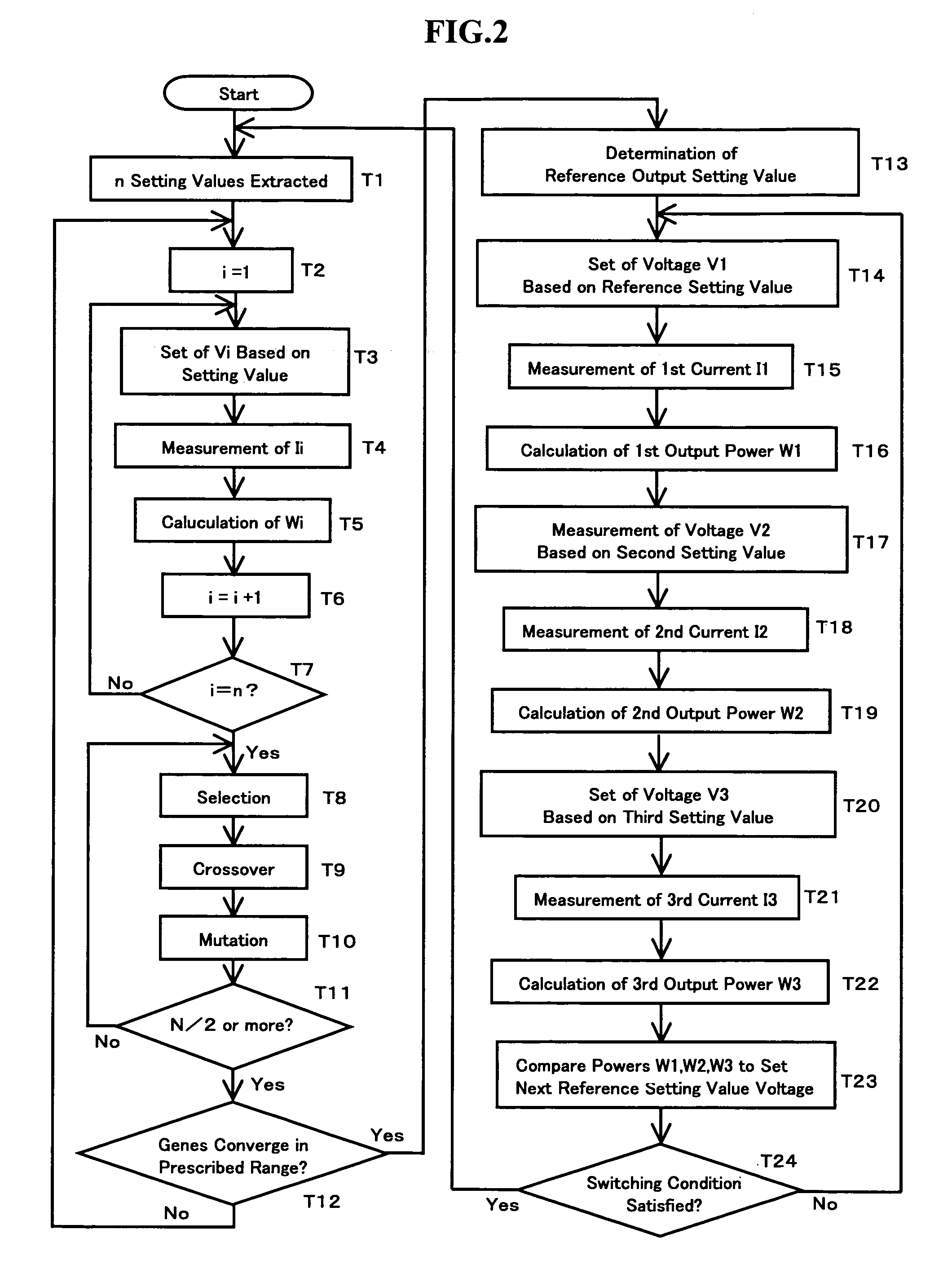

Method of controlling photovoltaic power generation system

ActiveUS7042195B2Quickly reachGuaranteed to workBatteries circuit arrangementsPhotovoltaic monitoringEngineeringSolar cell

A conventional hill climbing method is not capable of tracking a maximum power when a shadow covers a part of a solar cell panel and a plurality of maximal values is thereby developed. The invention provides a photovoltaic power generation system control method that controls a photovoltaic output setting value to be an appropriate value by following up a variation in the solar irradiation, including a genetic algorithm process of employing the photovoltaic output setting value as a gene and the output power as an evaluation value thereof; randomly extracting a plurality of genes and repeating storage, selection and crossover / mutation of the output powers which are the evaluation values of the genes, so as to converge a difference between a maximum and minimum values of the output voltages into a predetermined range; and a hill climbing process of setting the photovoltaic output setting value corresponding to the greatest value of the converged output voltages, and a greater and a lower value than the photovoltaic output setting value by a predetermined amount, so as to select the greatest output power among these values; and repeating such steps to track the maximum output power.

Owner:DAIHEN CORP

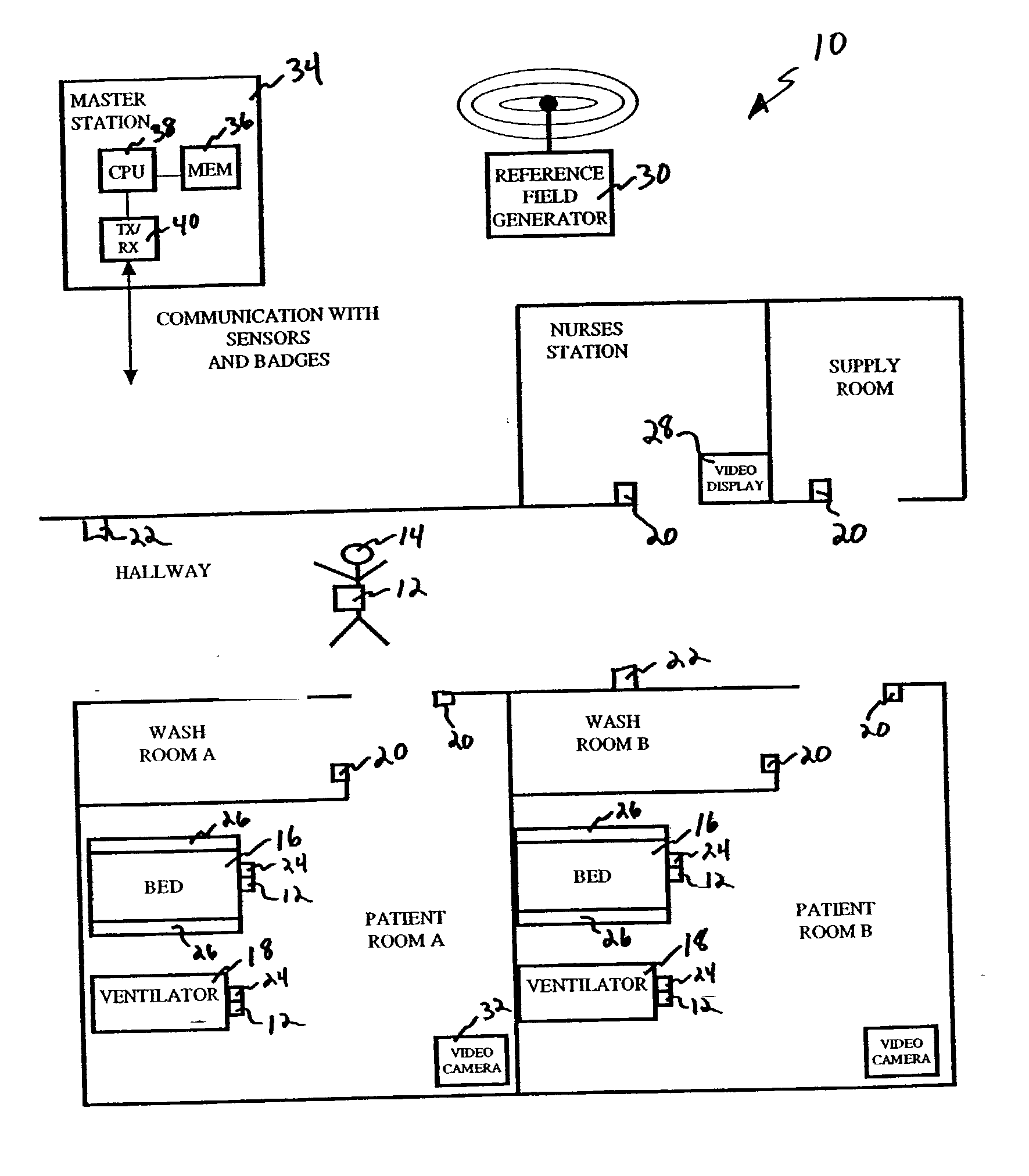

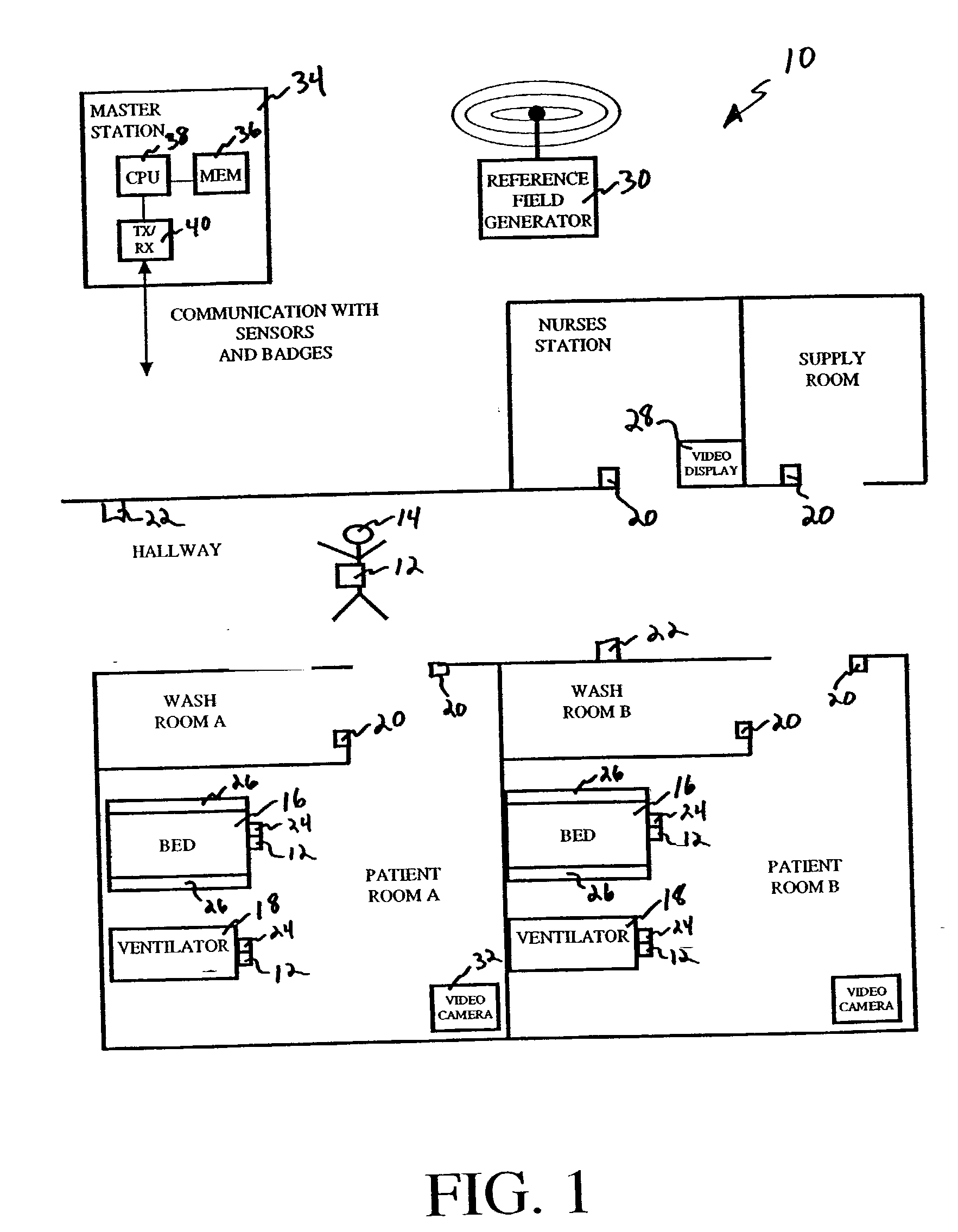

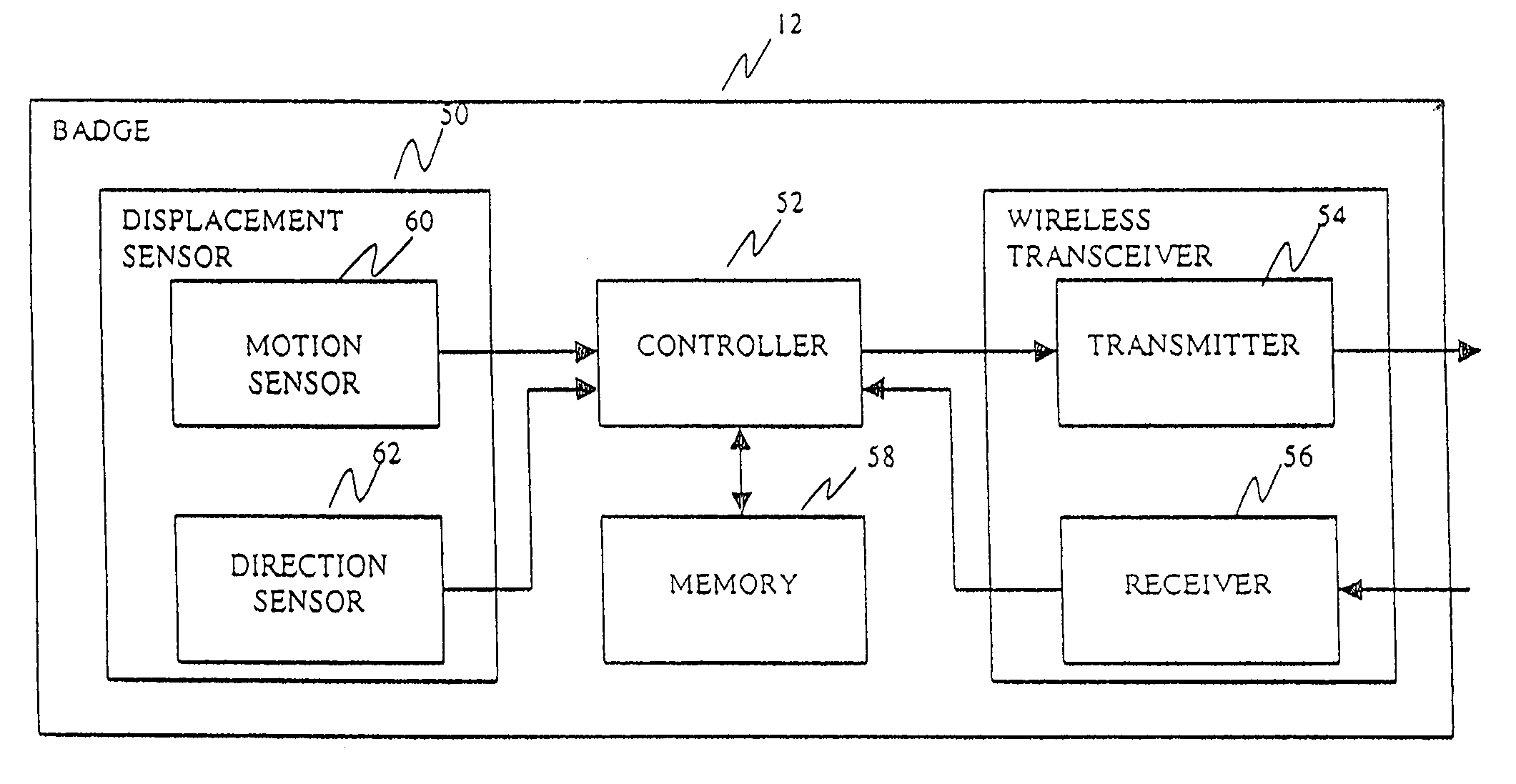

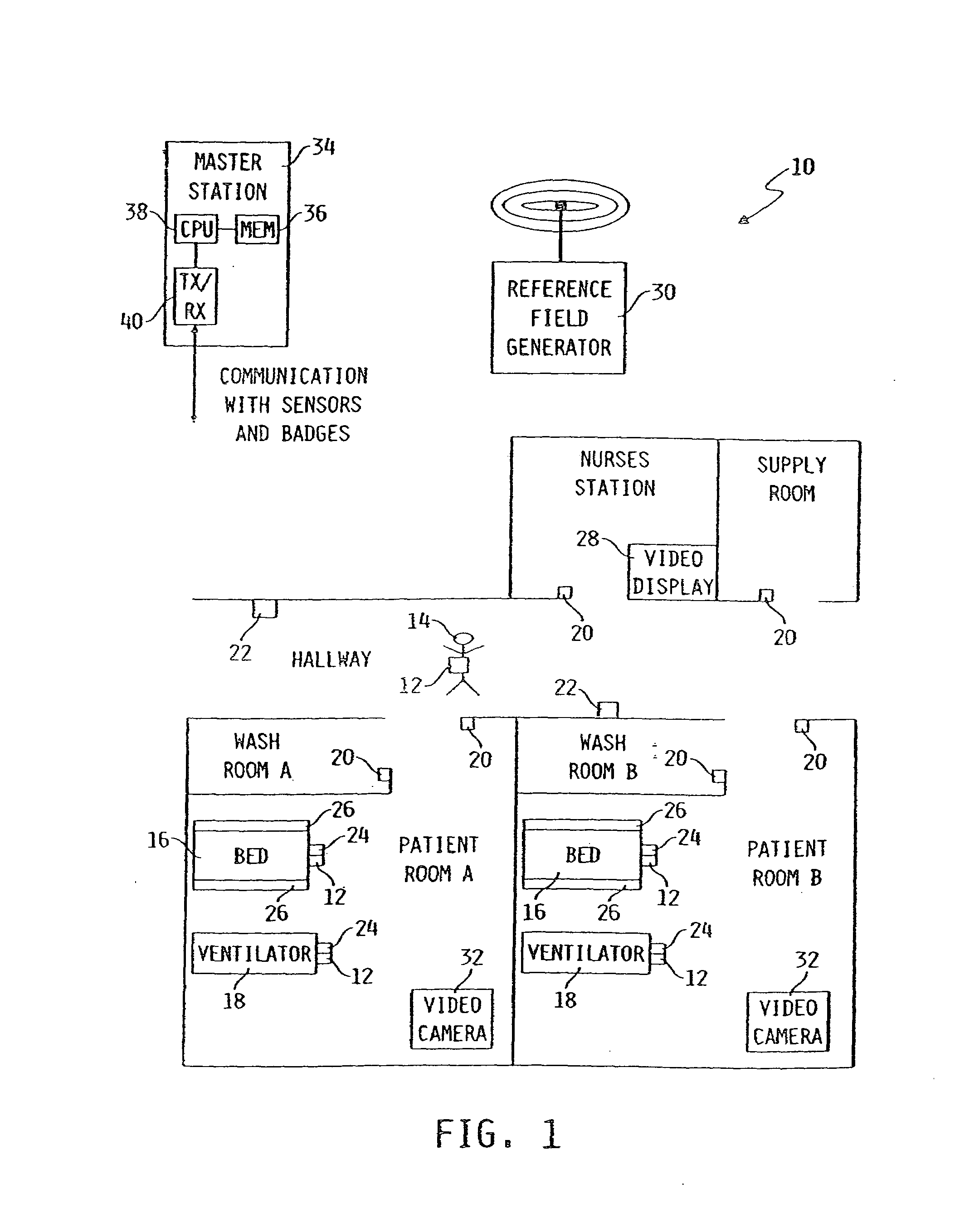

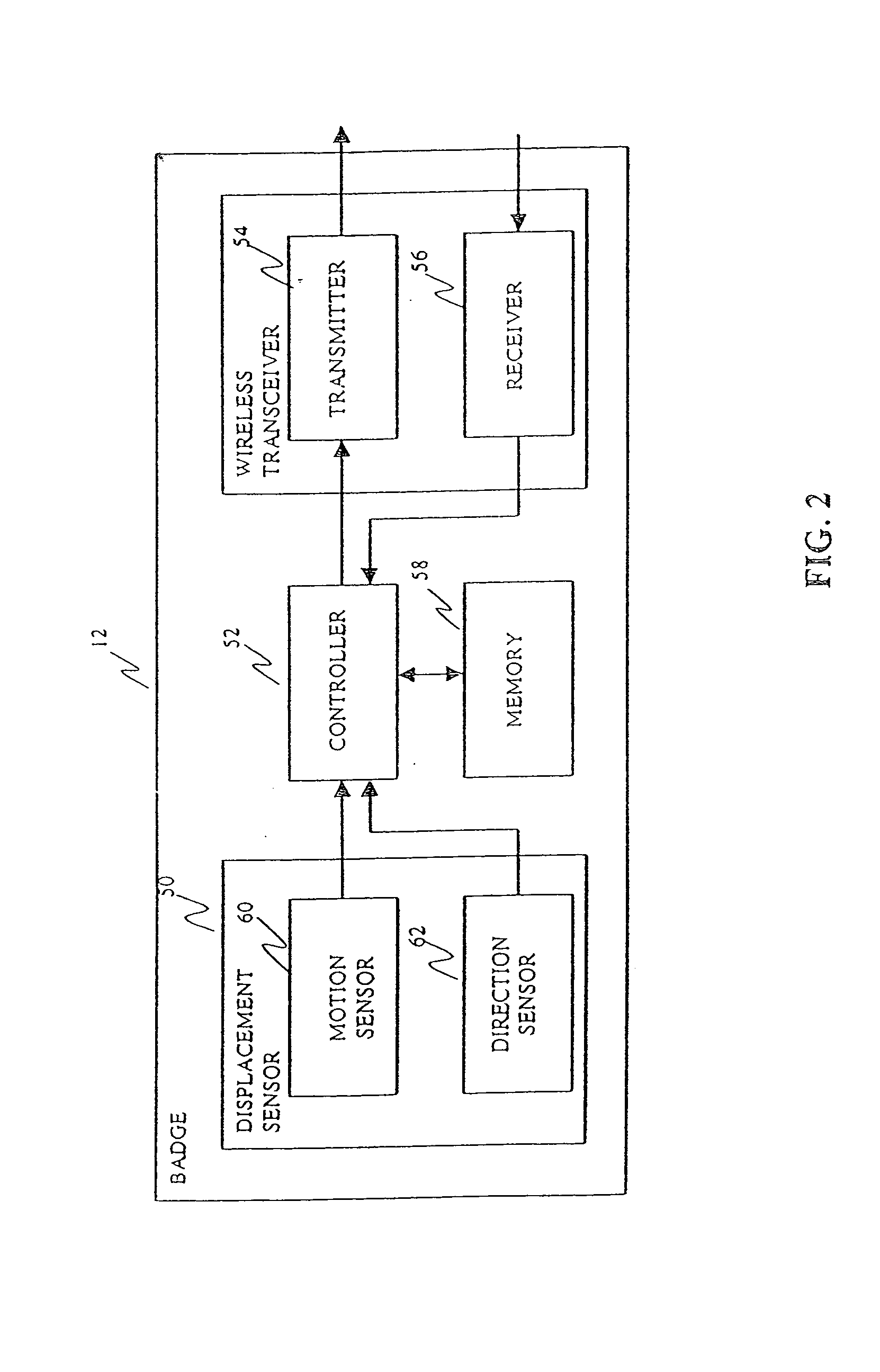

Article locating and tracking system

ActiveUS20020183979A1Reduce non-value added activityReduce in quantityRegistering/indicating time of eventsError detection/correctionTransceiverPosition dependent

A system for tracking an activity in a healthcare environment includes a master station having a processor, a memory, and a transceiver, badges coupled to objects, each transmitting a unique badge ID, and sensors disposed throughout the environment, each including a transceiver for receiving badge IDs and transmitting to the master station transceiver the badge IDs and a unique sensor ID that relates the sensor to a location. The master station processor determines object locations from the badge and sensor IDs by identifying the badge associated with the object, relating the sensor ID to the sensor location, and storing object location information in memory. Each badge also includes a displacement sensor that generates signals indicating object movement and direction for transmission to the sensor transceivers which forward displacement information to the master station. The master station processor uses the information to update the stored object location information.

Owner:HILL ROM SERVICES

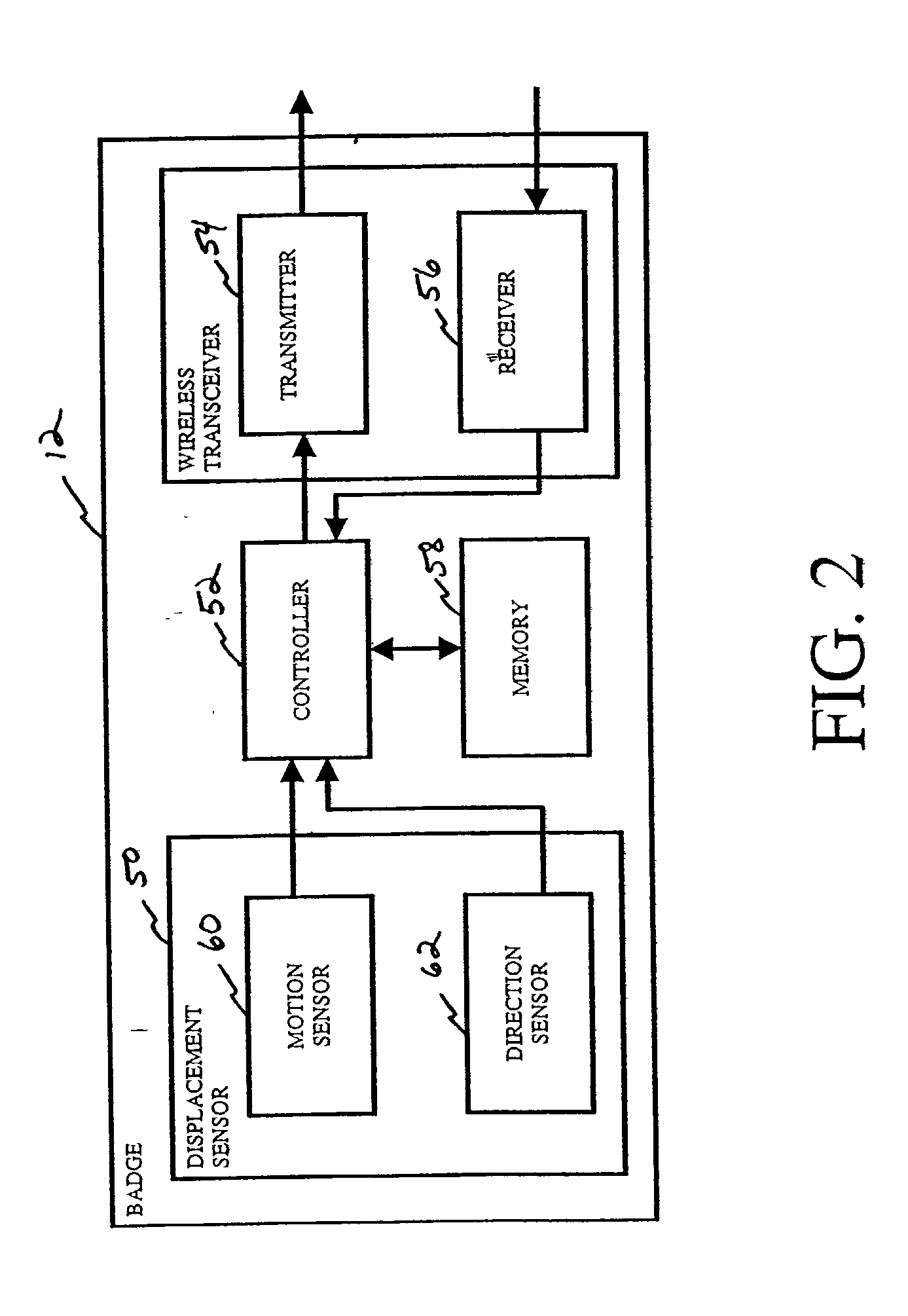

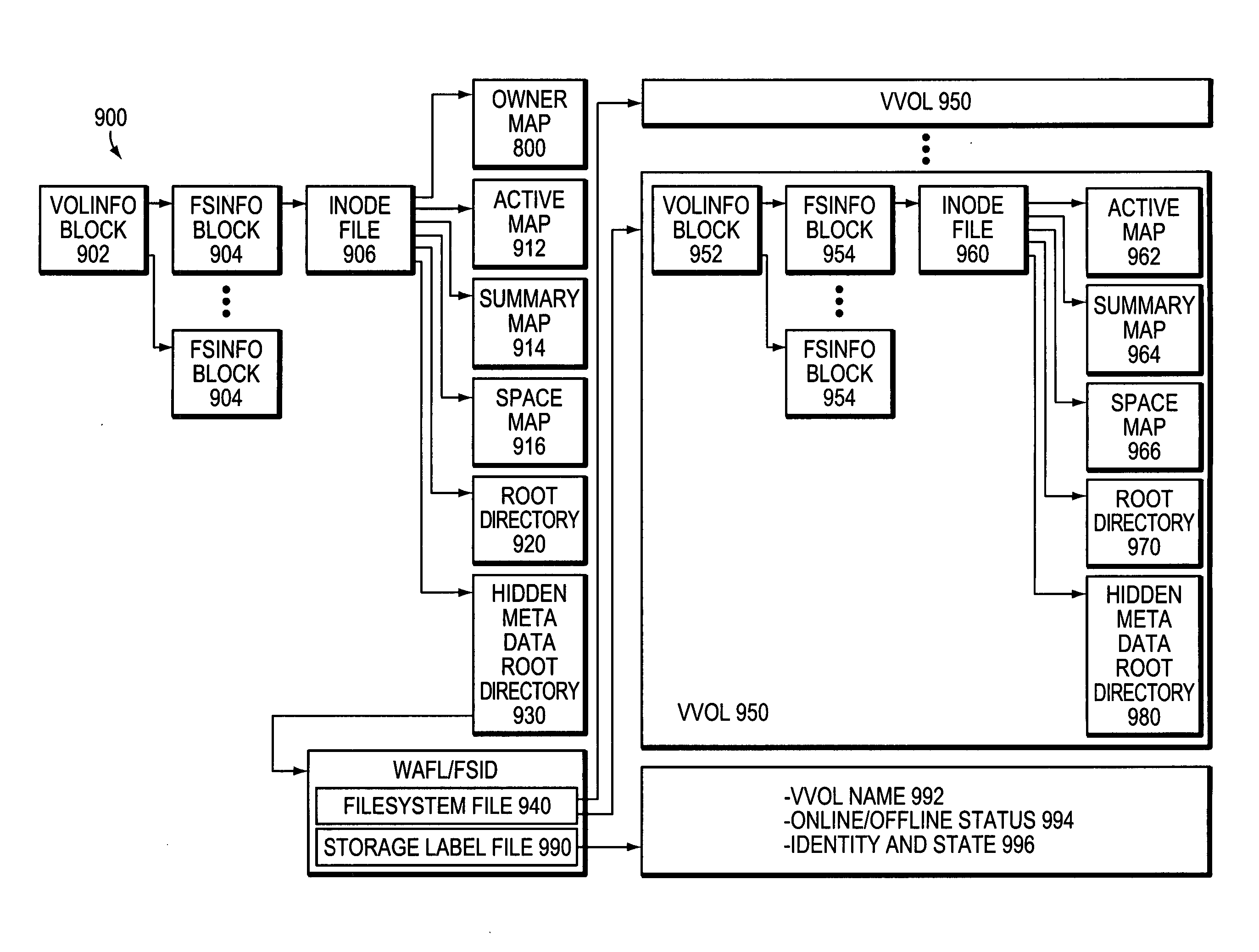

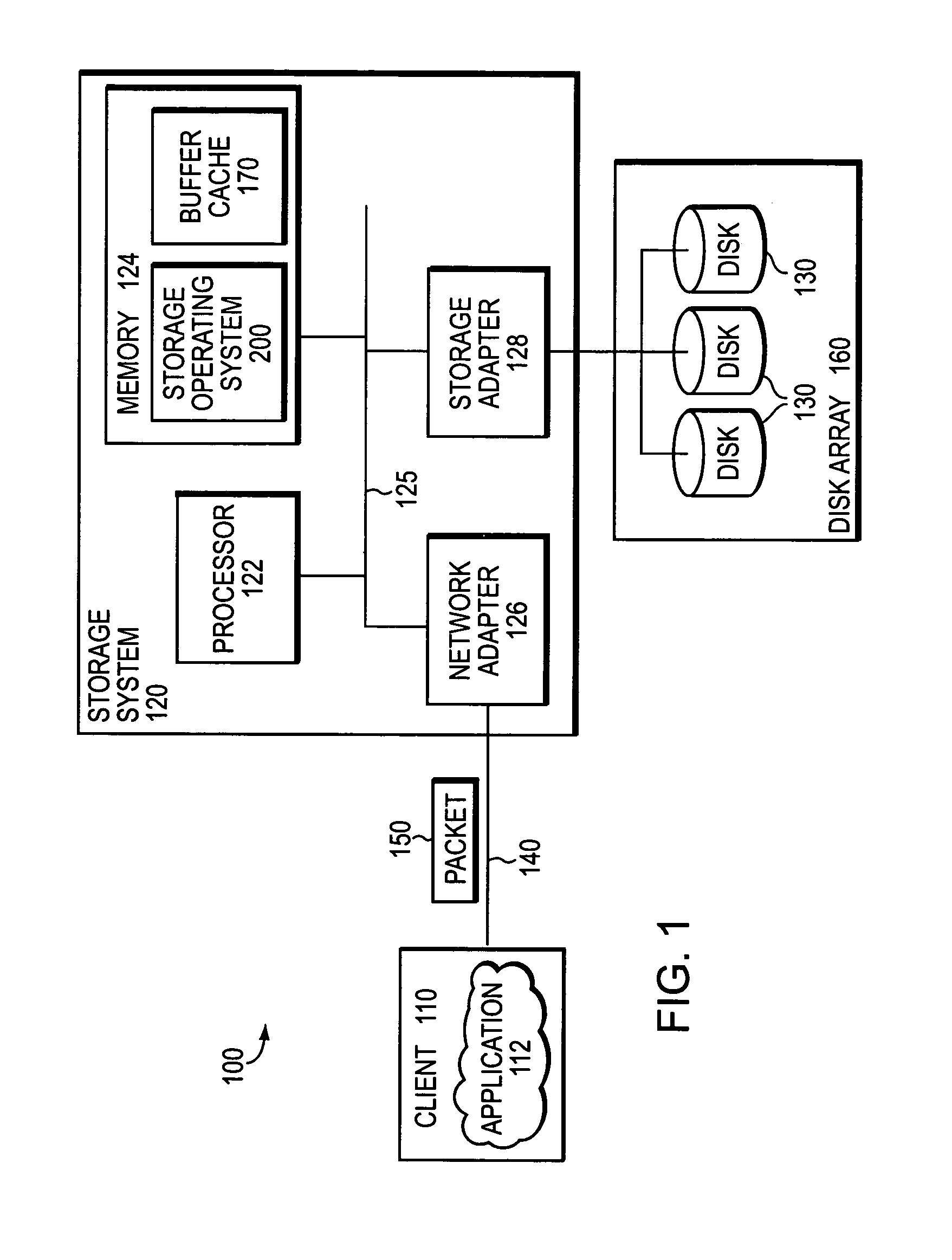

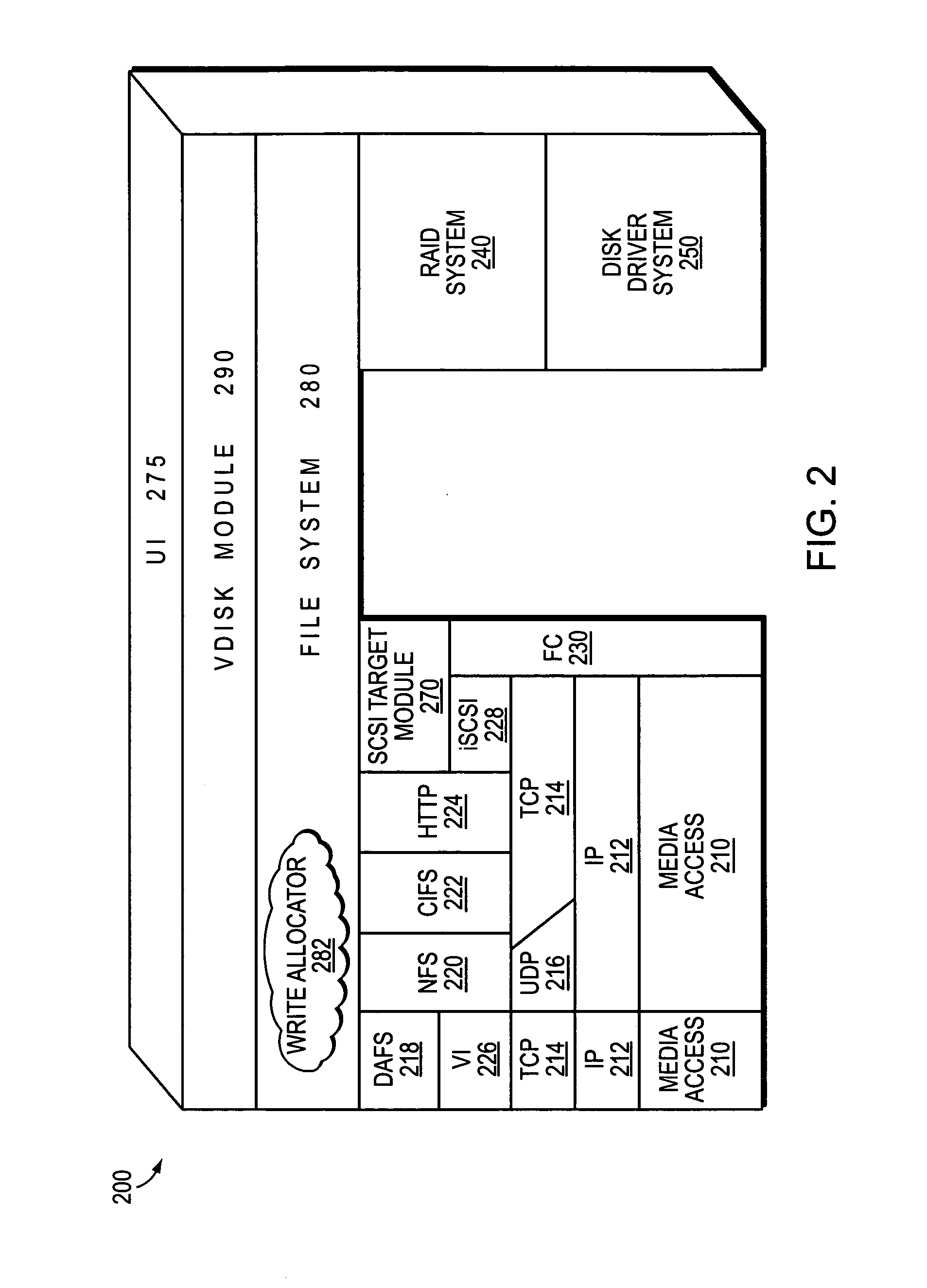

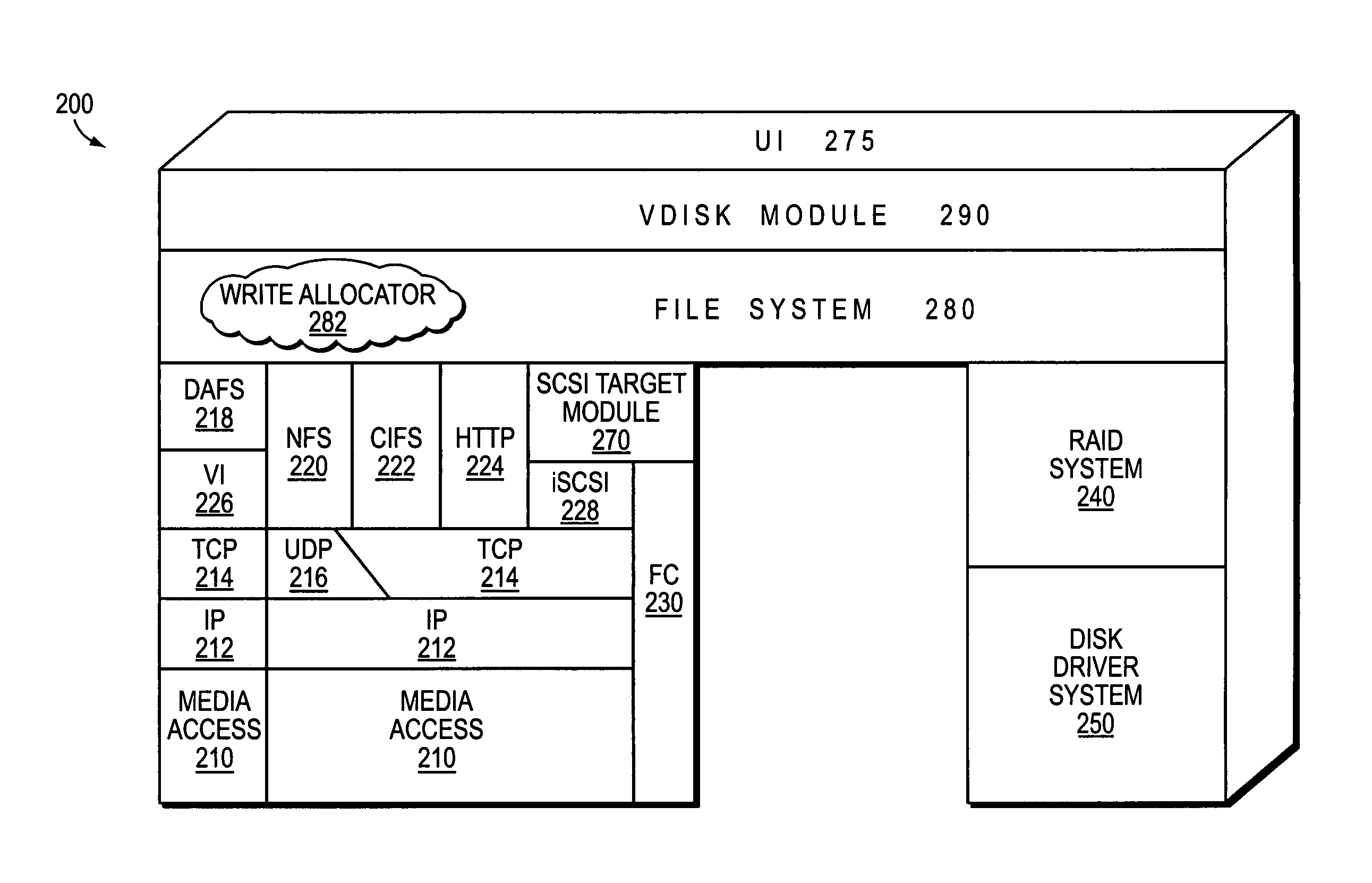

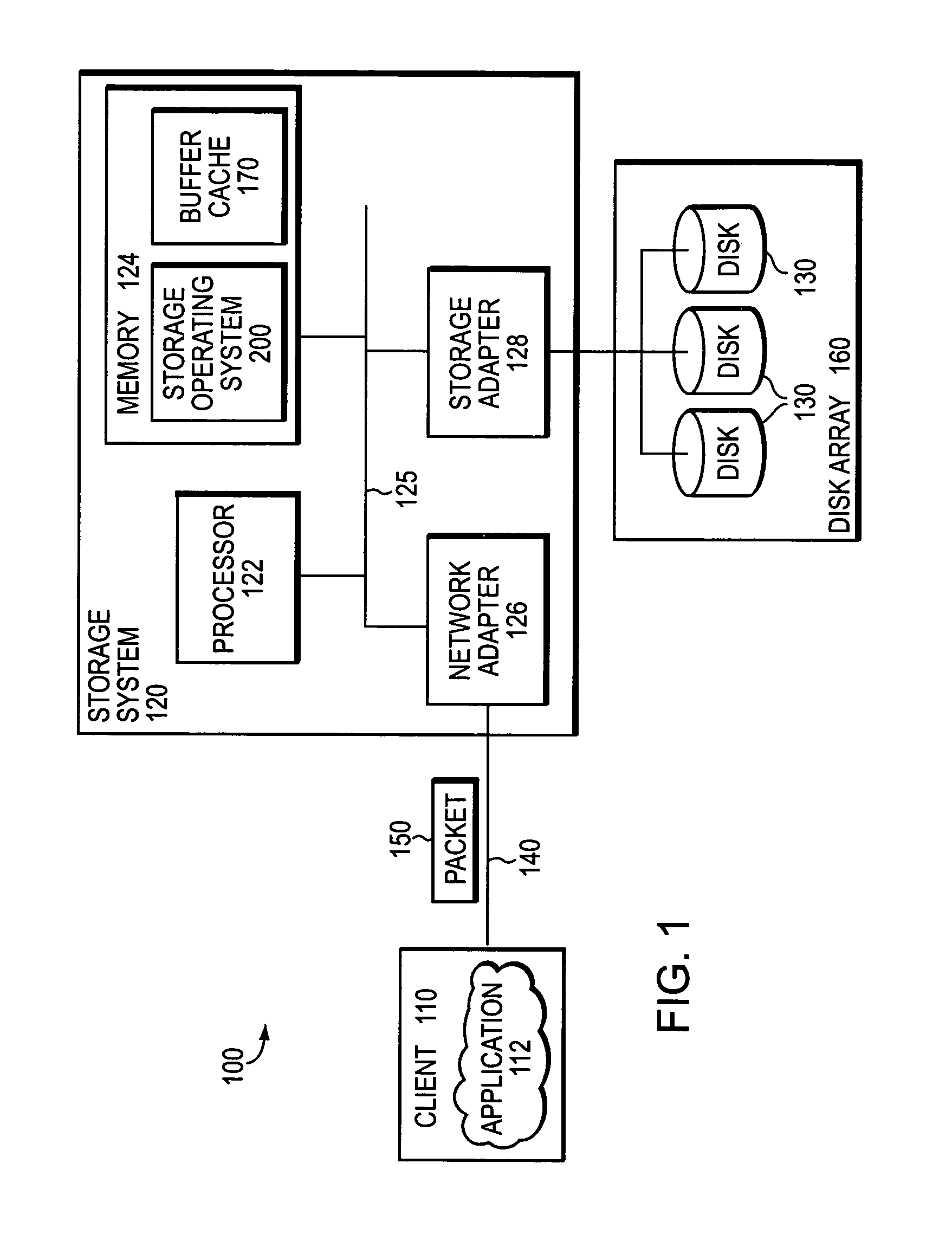

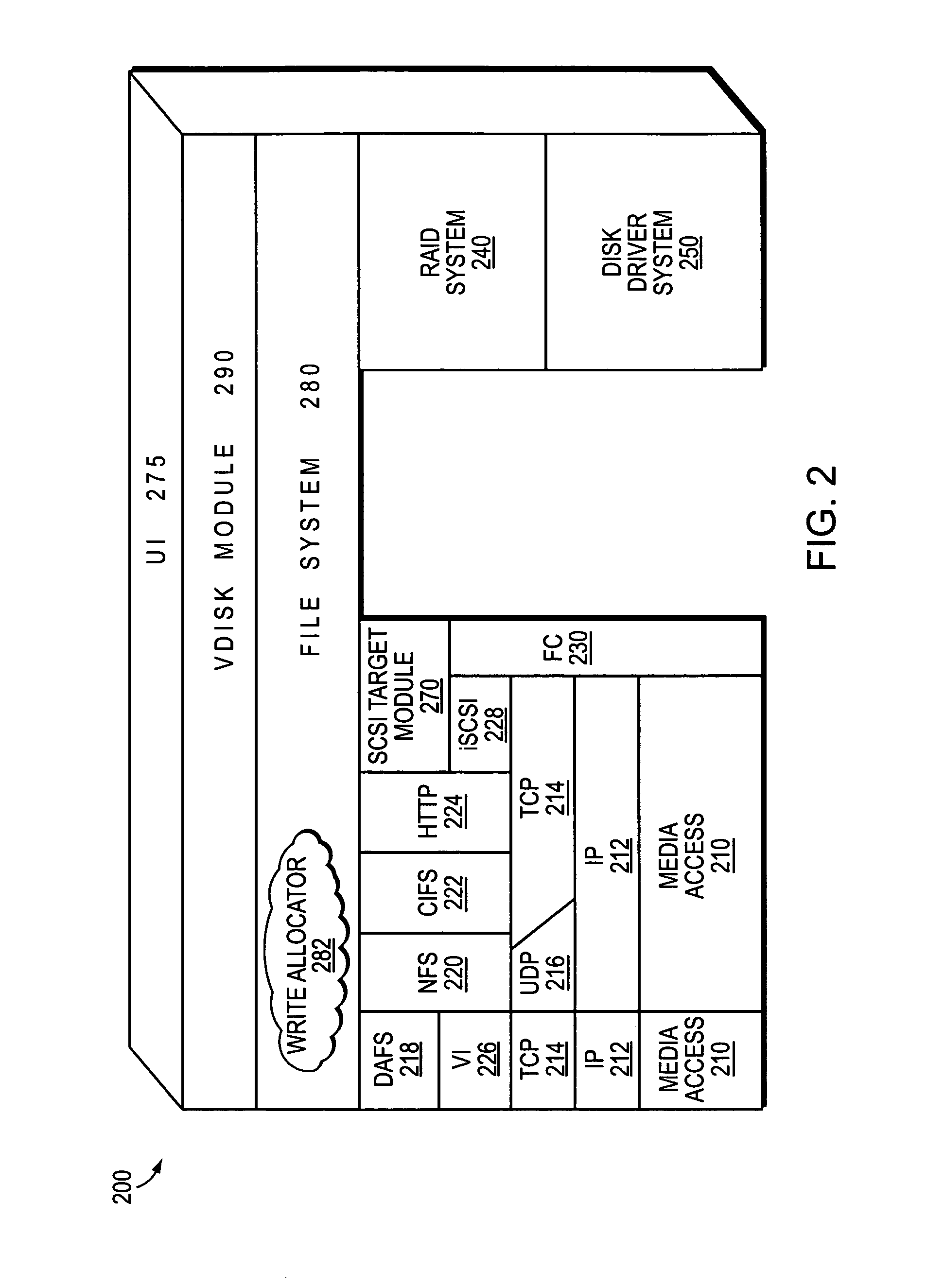

Extension of write anywhere file system layout

ActiveUS20050246401A1Avoid partialFlexible sizeDigital data information retrievalSpecial data processing applicationsRAIDFile system

A file system layout apportions an underlying physical volume into one or more virtual volumes (vvols) of a storage system. The underlying physical volume is an aggregate comprising one or more groups of disks, such as RAID groups, of the storage system. The aggregate has its own physical volume block number (pvbn) space and maintains metadata, such as block allocation structures, within that pvbn space. Each vvol has its own virtual volume block number (vvbn) space and maintains metadata, such as block allocation structures, within that vvbn space. Notably, the block allocation structures of a vvol are sized to the vvol, and not to the underlying aggregate, to thereby allow operations that manage data served by the storage system (e.g., snapshot operations) to efficiently work over the vvols. The file system layout extends the file system layout of a conventional write anywhere file layout system implementation, yet maintains performance properties of the conventional implementation.

Owner:NETWORK APPLIANCE INC

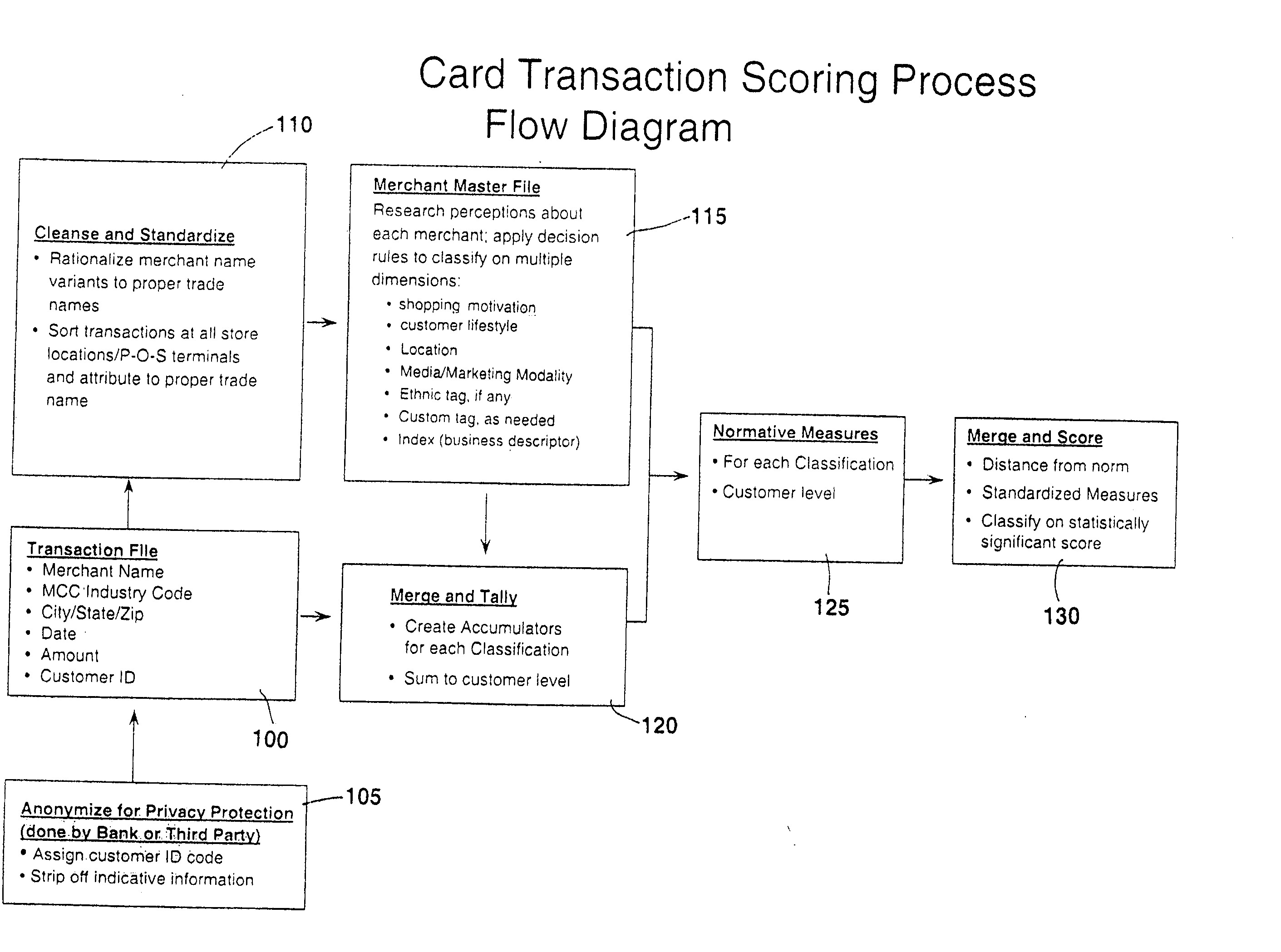

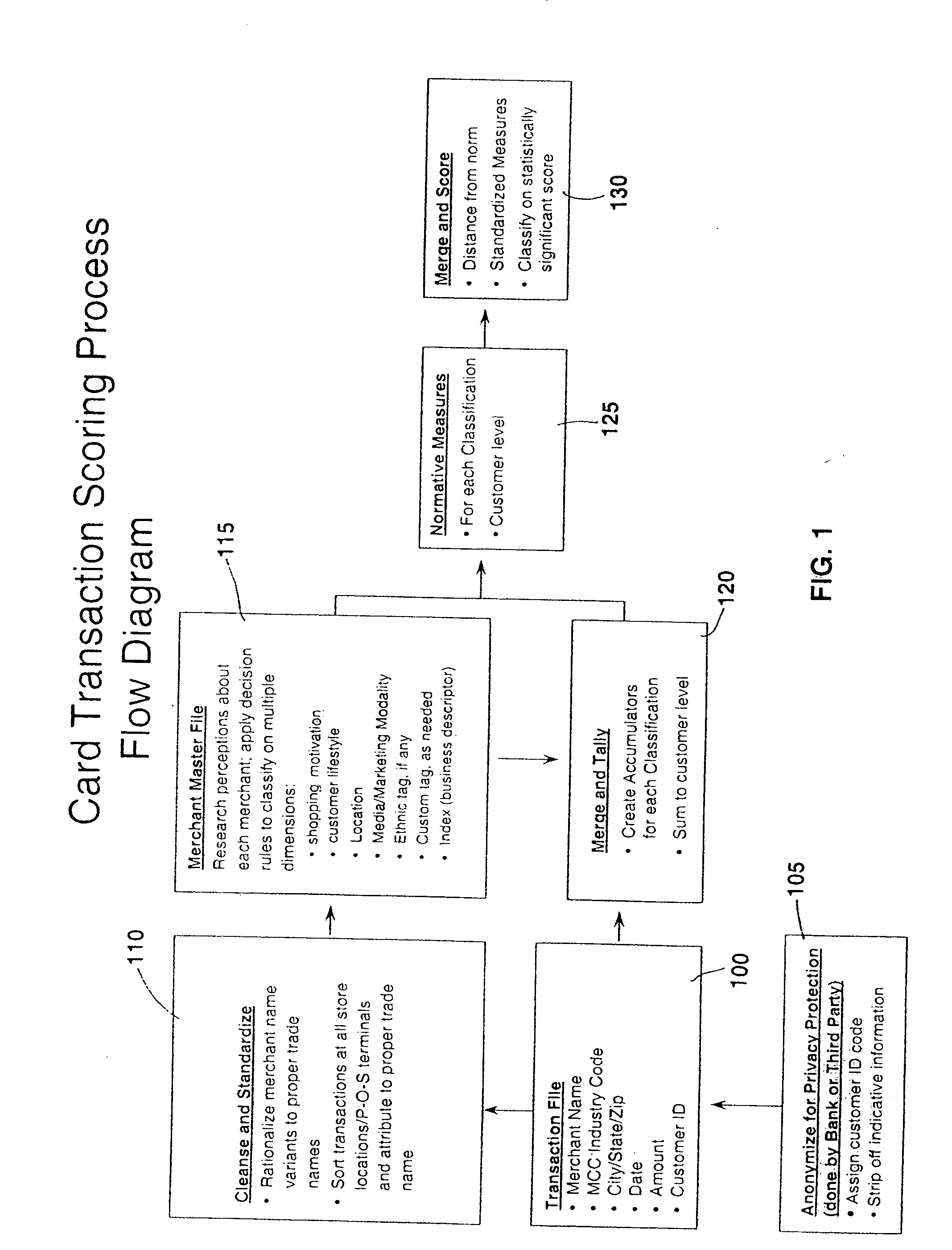

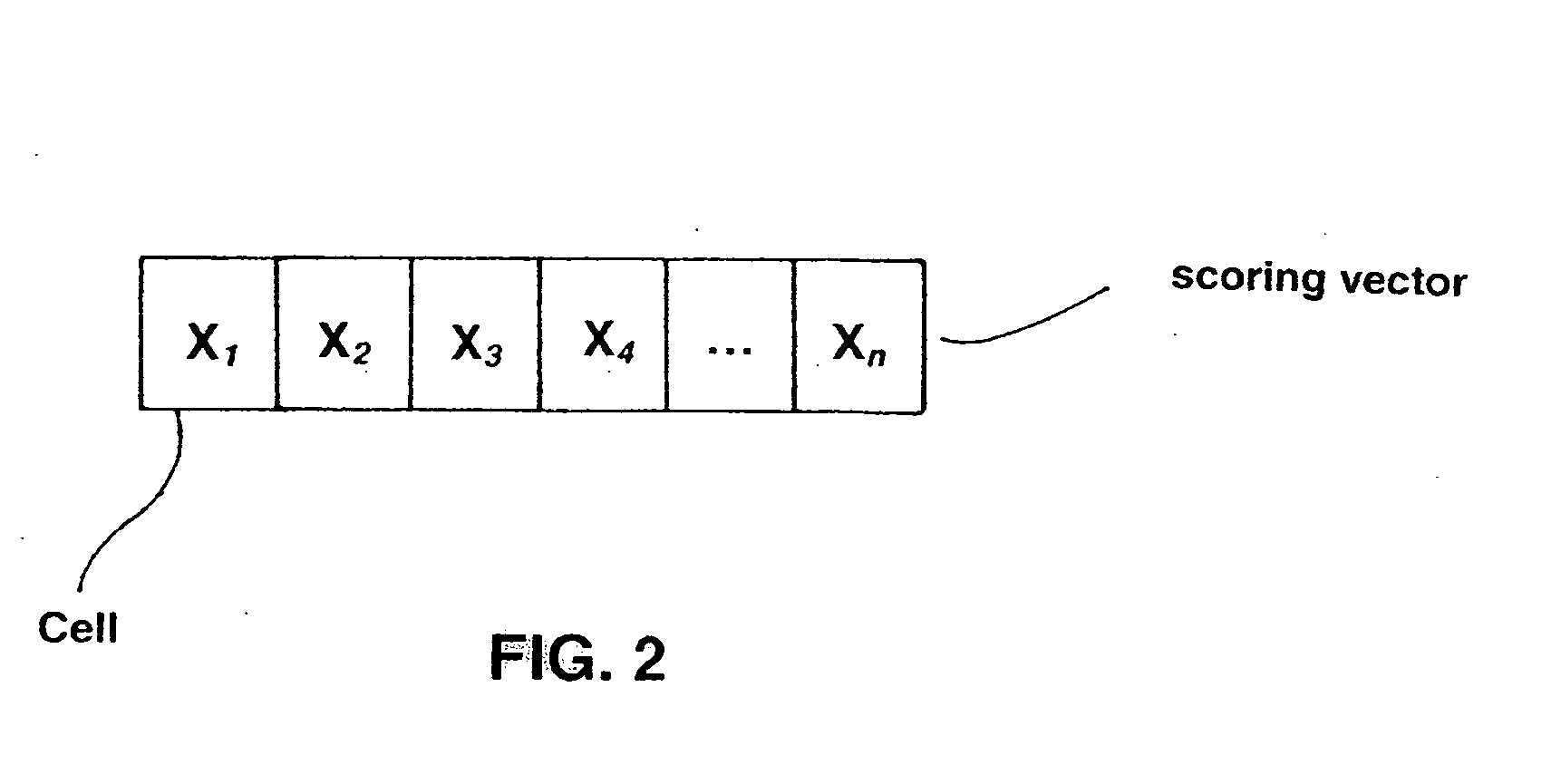

Method of analyzing credit card transaction data

InactiveUS20080086365A1Work effectivelyGuaranteed to workSpecial data processing applicationsMarketingThird partyPurchasing

A method of analyzing debit and credit card transaction data to provide interpretations of customer purchasing patterns for use by third parties, such as financial services marketers, in providing offers and incentives to targeted groups of consumers. Bulk credit card or debit card transaction data that has been gathered for a large sample of cardholders is obtained, a multi-step process is applied to prepare the data for analysis, multiple categories of marketing “intelligence” or decisions are attached to each transaction contained in the bulk transaction data, a summation of all of the different intelligence categories for each cardholder and for the entire sample is performed to create comparative normalizations, and a score in vector form is generated for each customer based on differences or variations in the way in which that customer shops relative to the bulk-derived normalized data for each field or dimension within the comparative normalization.

Owner:ZOLLINO RICHARD +1

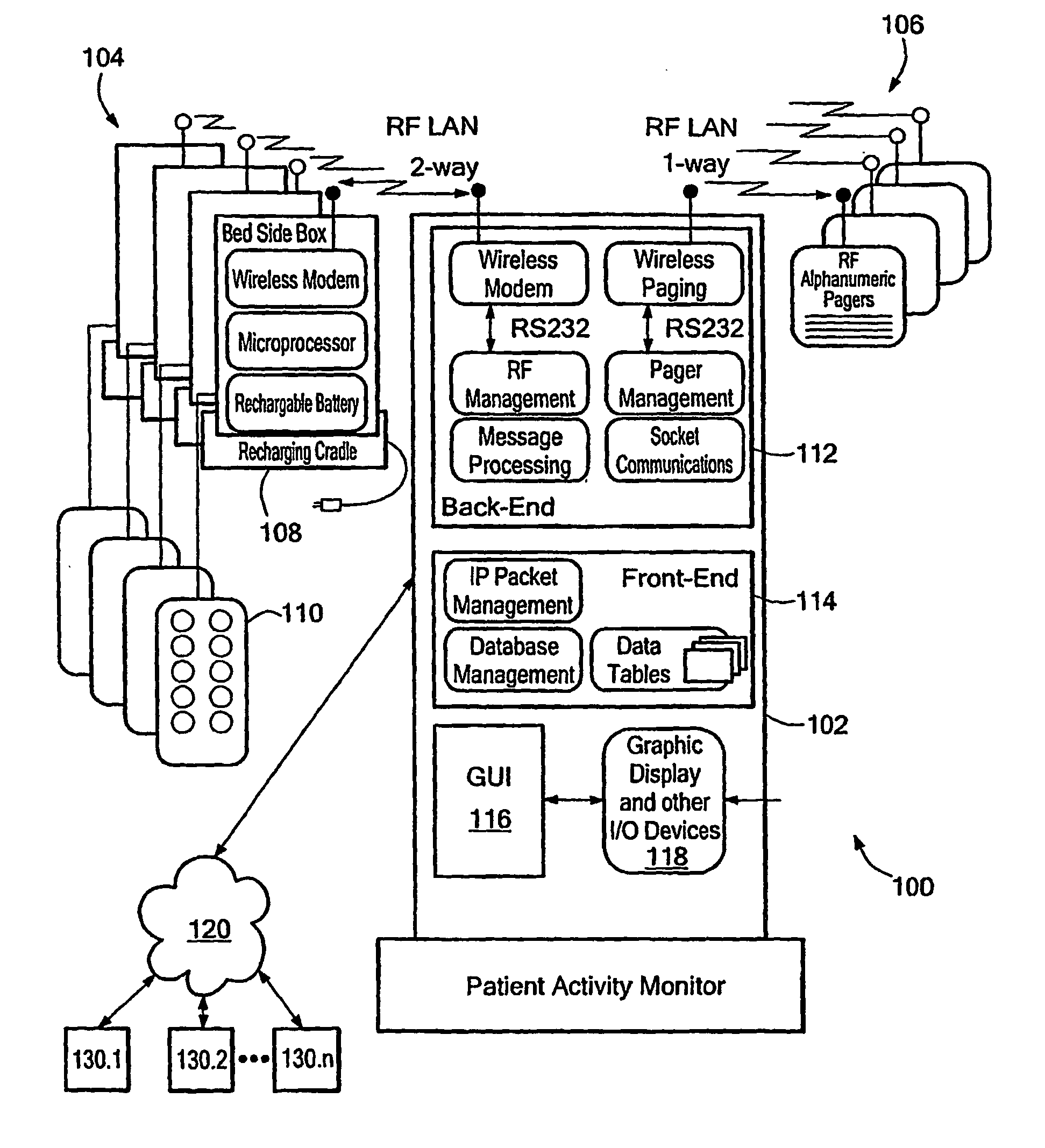

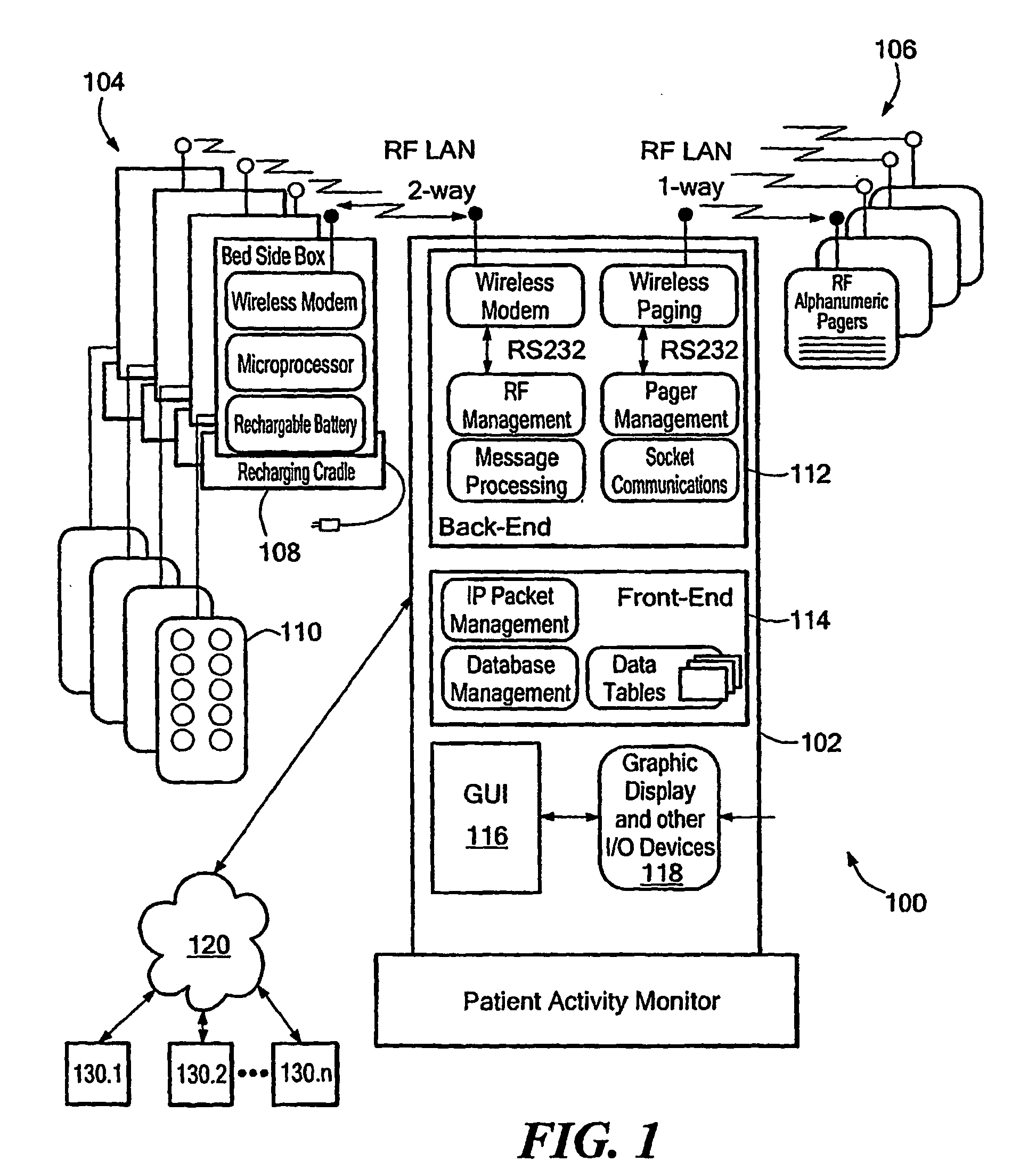

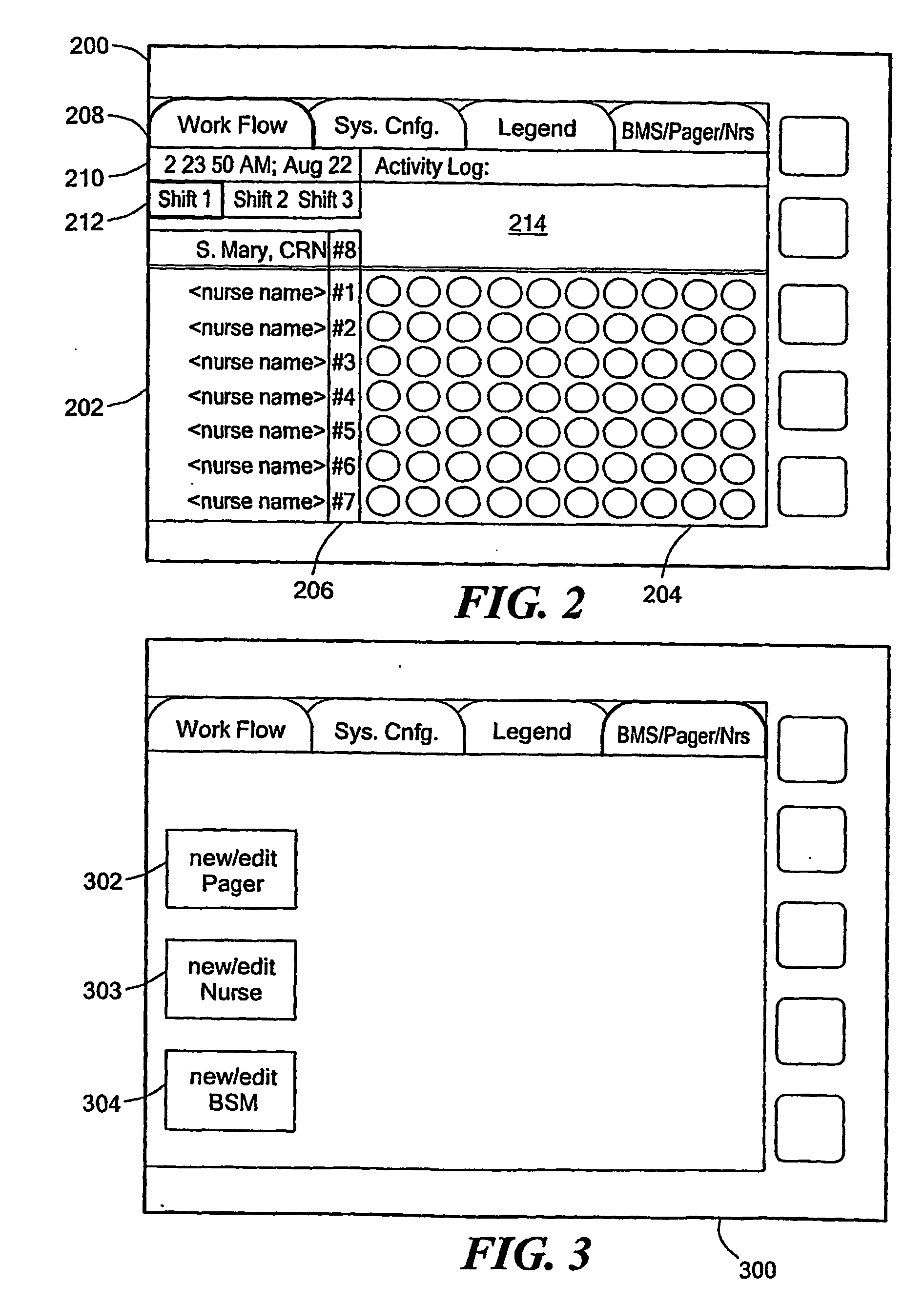

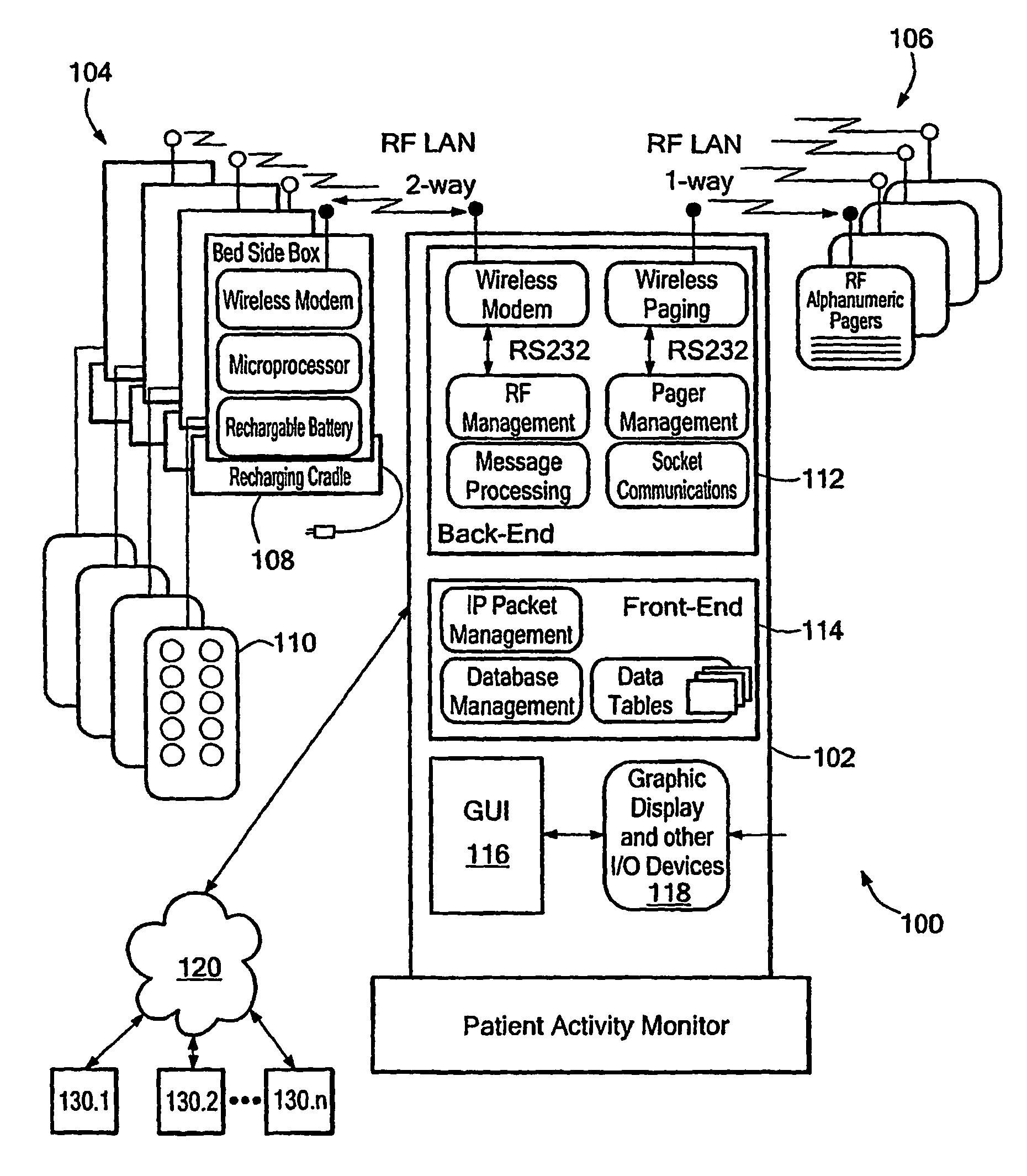

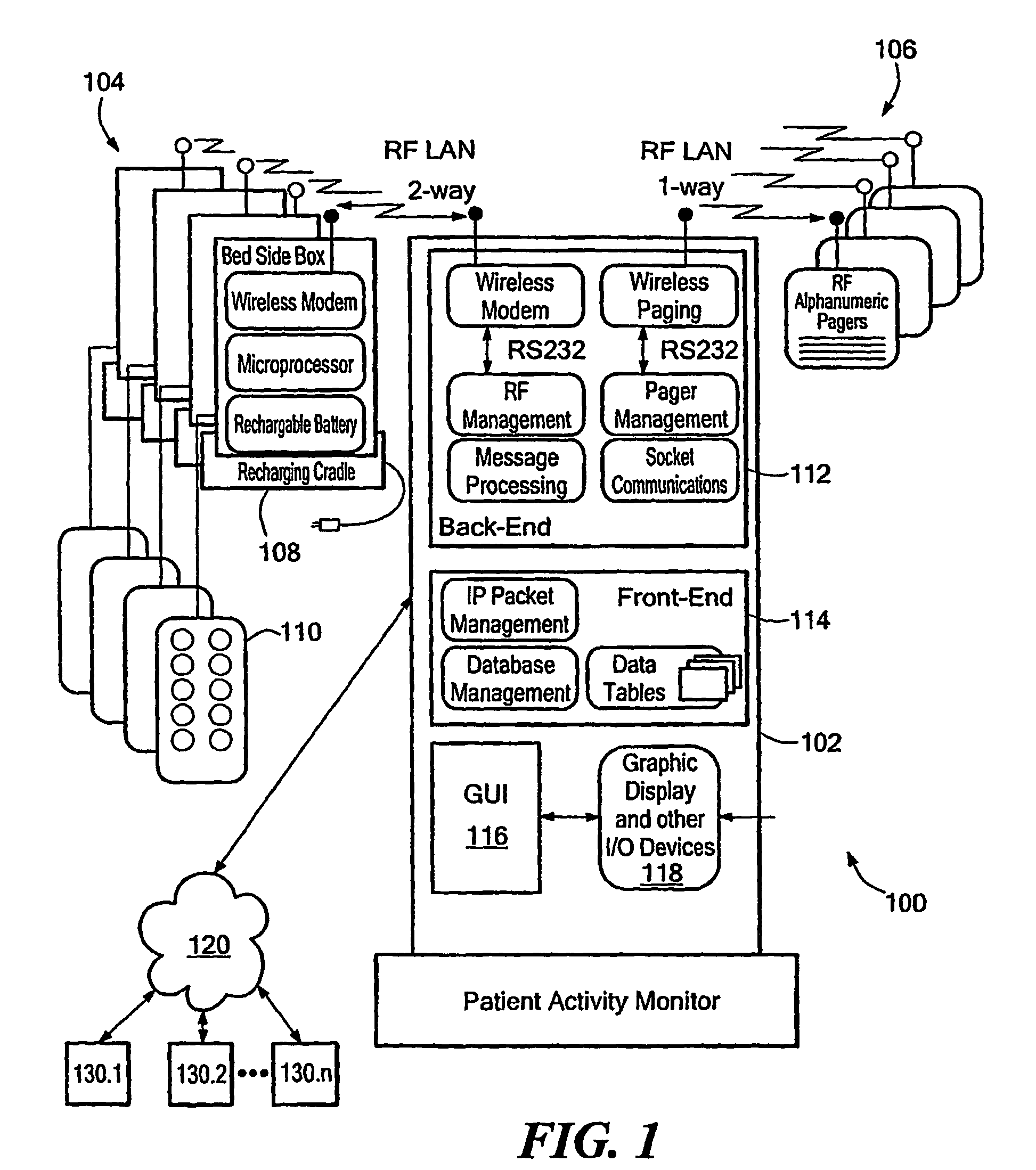

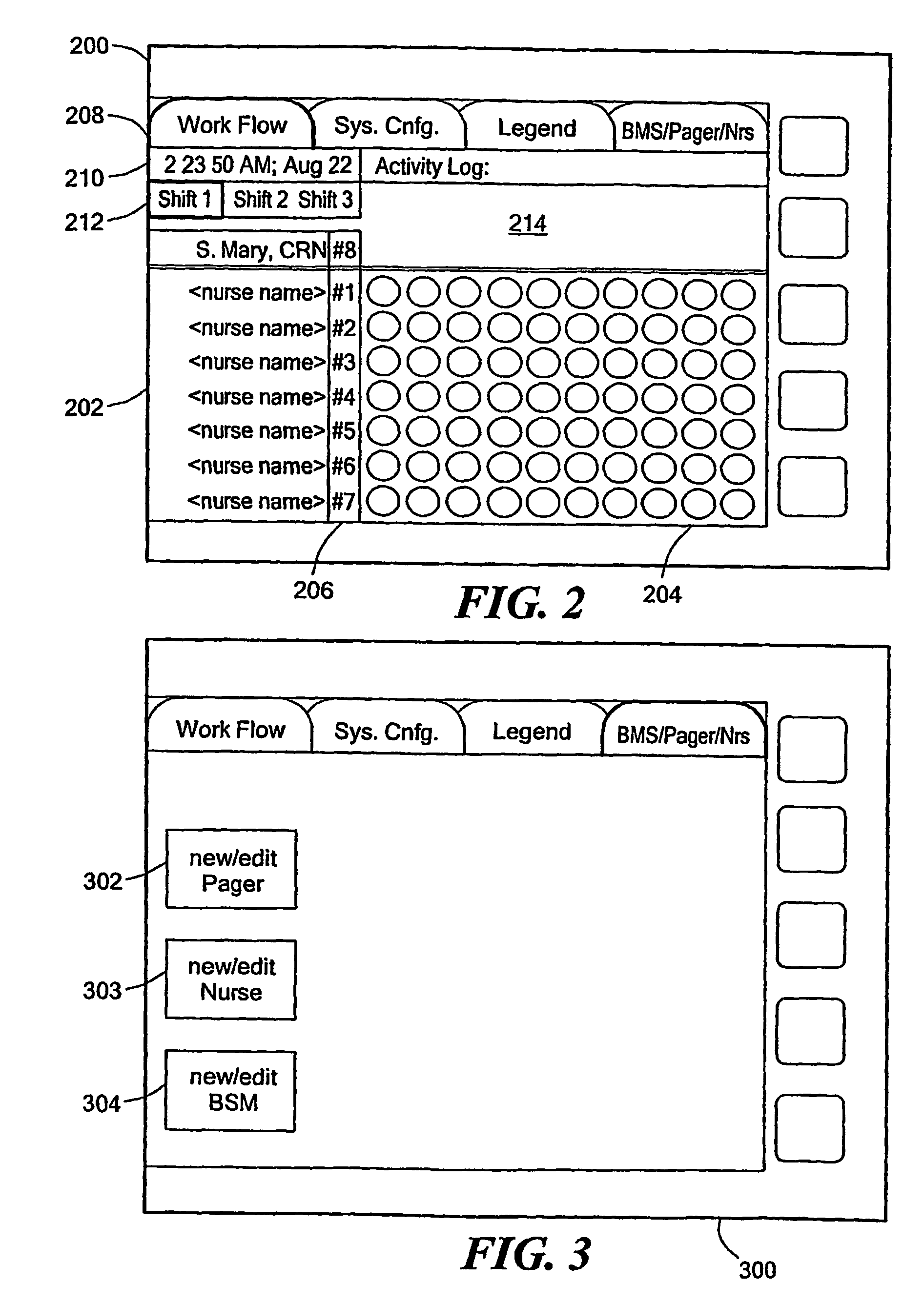

Patient activity monitor

ActiveUS20050242946A1Improve quality of careIncreasing quality and levelFrequency-division multiplex detailsSurgeryPatient careGraphical user interface

A patient activity monitoring system that allows caregivers of multiple patients to work more efficiently and with reduced cost, while increasing the quality and level of patient care. The system includes a plurality of remote monitoring subsystems, a plurality of user notification units, and a central monitoring unit with a Graphical User Interface (GUI) communicably coupled between the remote monitoring and user notification units. Each remote monitoring subsystem includes a remote monitoring unit, and a sensor device associated with a respective patient that detects one or more activity and / or physiological parameters of the patient. A simplified user interface including the GUI and the user notification units provides indications of the type and level of assistance required by one or more patients to caregivers at centralized and remote locations.

Owner:SOTERA WIRELESS

Article locating and tracking system

ActiveUS7248933B2Reduce non-value added activityReduce in quantityRegistering/indicating time of eventsError detection/correctionTransceiverMaster station

A system for tracking an activity in a healthcare environment includes a master station having a processor, a memory, and a transceiver, badges coupled to objects, each transmitting a unique badge ID, and sensors disposed throughout the environment, each including a transceiver for receiving badge IDs and transmitting to the master station transceiver the badge IDs and a unique sensor ID that relates the sensor to a location. The master station processor determines object locations from the badge and sensor IDs by identifying the badge associated with the object, relating the sensor ID to the sensor location, and storing object location information in memory. Each badge also includes a displacement sensor that generates signals indicating object movement and direction for transmission to the sensor transceivers which forward displacement information to the master station. The master station processor uses the information to update the stored object location information.

Owner:HILL ROM SERVICES

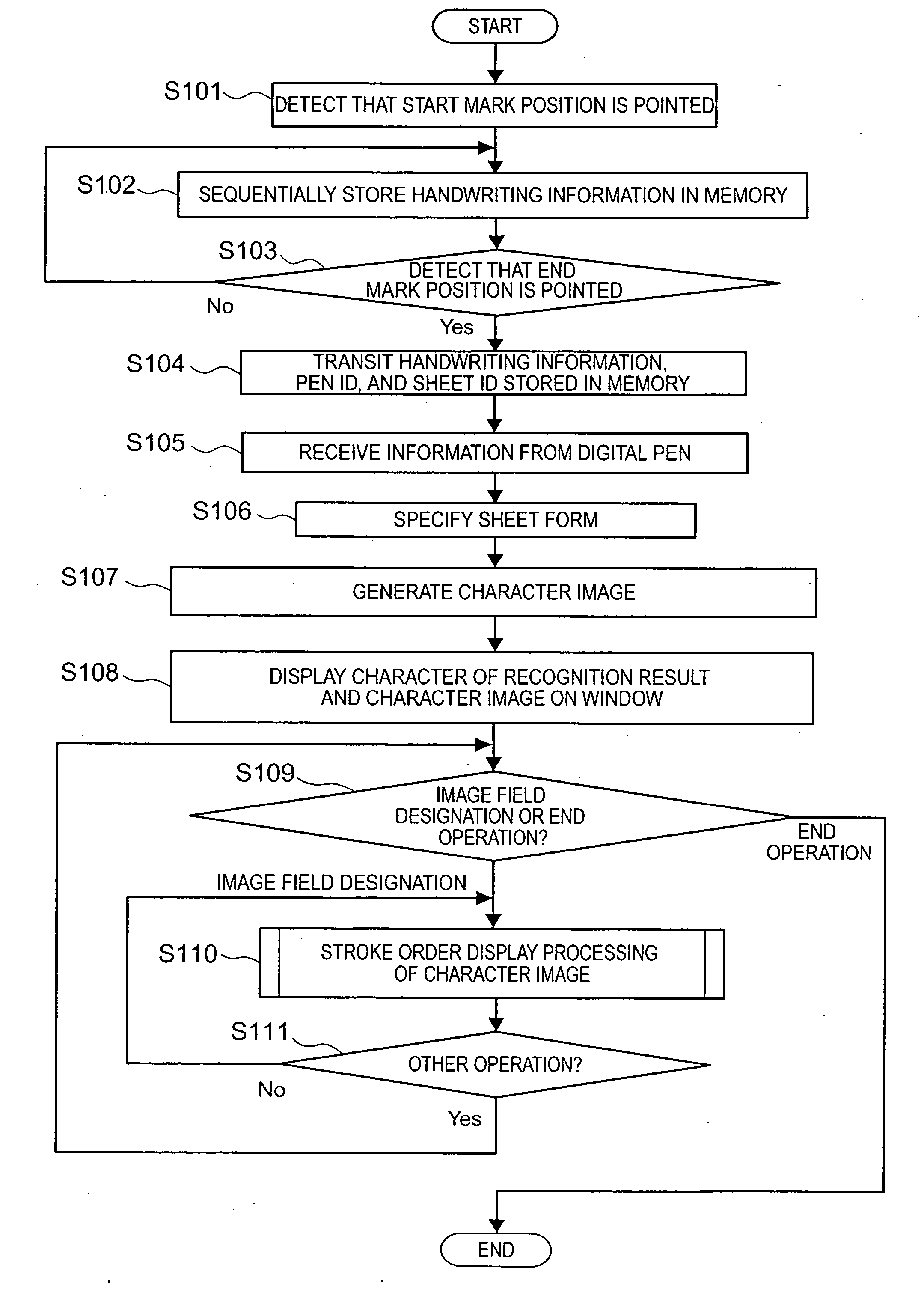

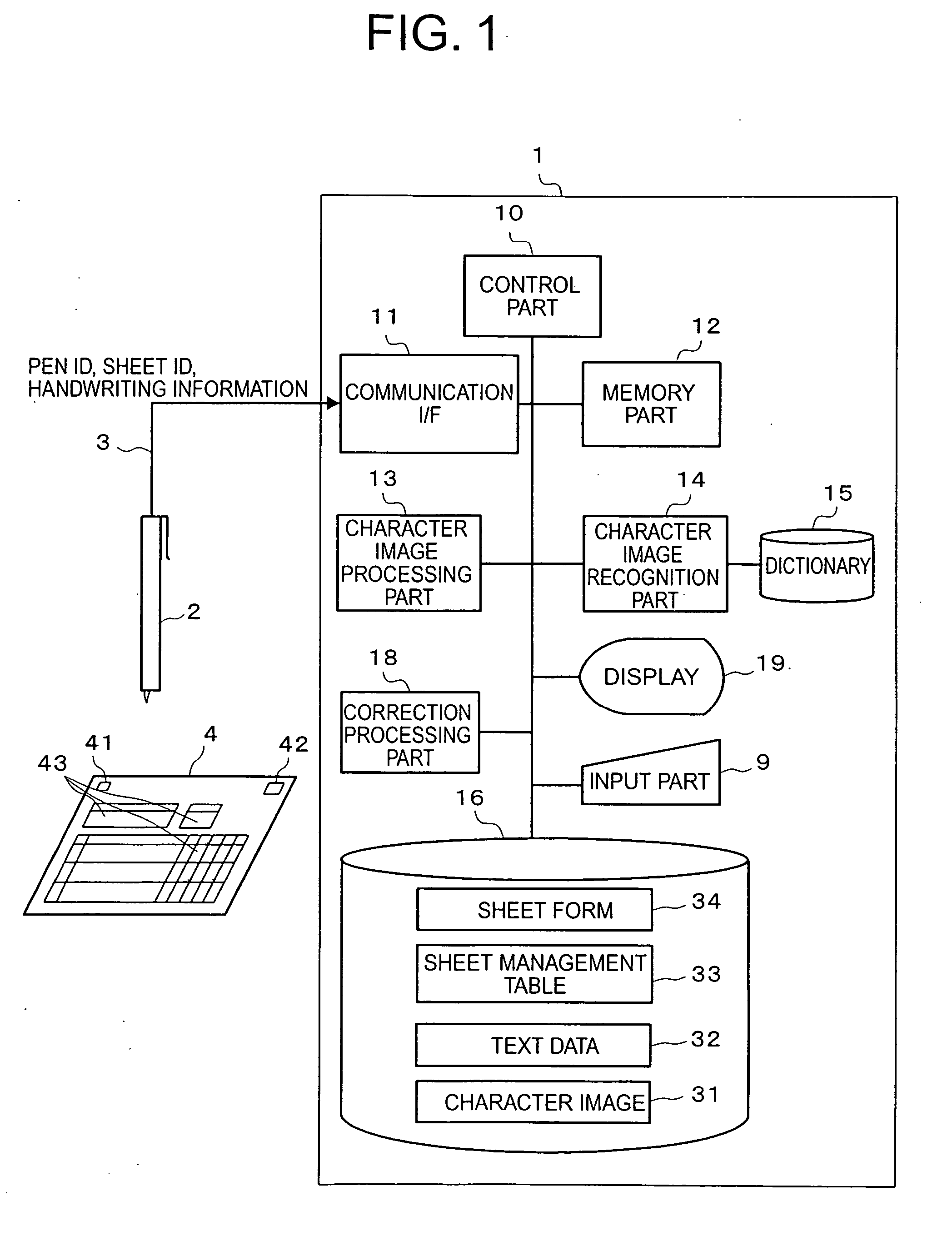

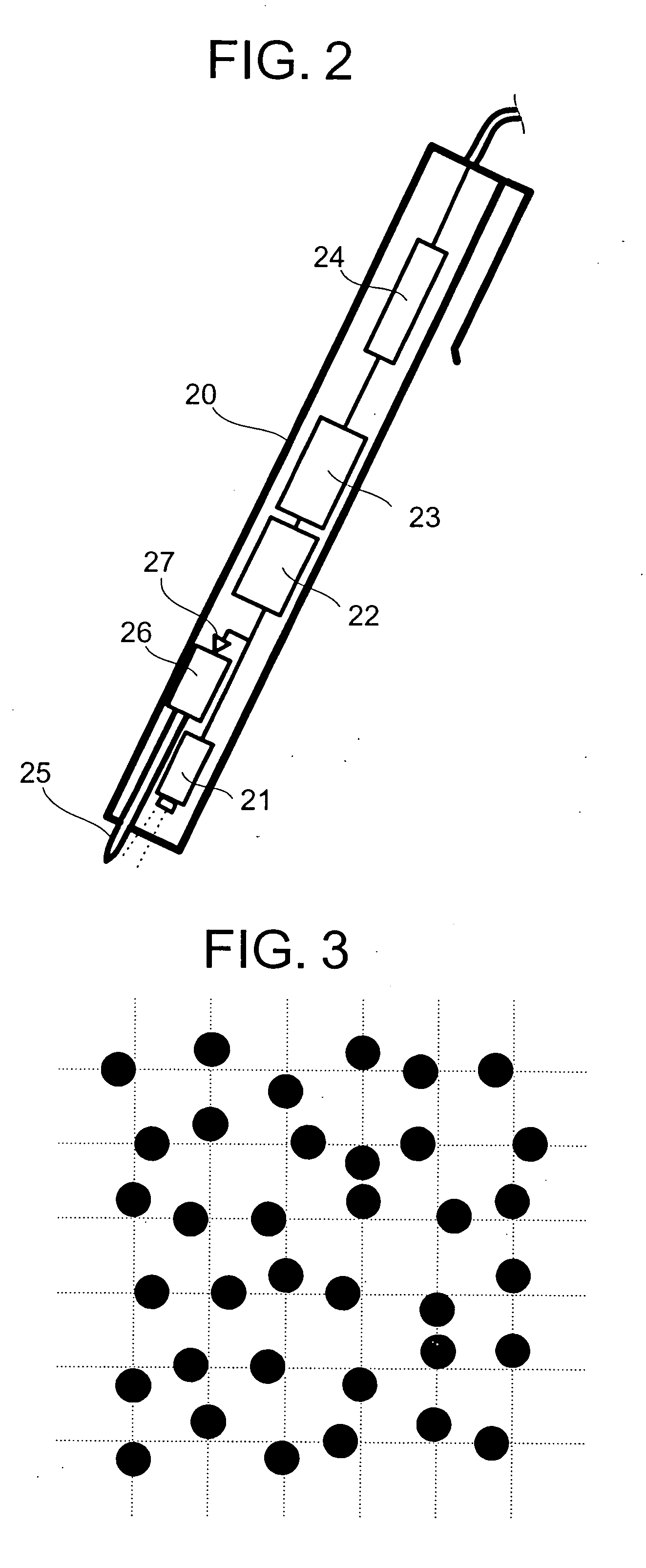

Character reader, character reading method, and character reading program

InactiveUS20070058868A1Work efficientlyGuaranteed to workCharacter and pattern recognitionCathode-ray tube indicatorsHandwritingStroke order

A character reader 1 includes: a handwriting information obtaining part that obtains handwriting information of a character which is handwritten on a sheet 4 with a digital pen 2; a character image generating part that generates partial character images in order in which the character is written, based on the obtained handwriting information of the character; and a stroke order display part that displays the generated partial character images in sequence at predetermined time intervals.

Owner:KK TOSHIBA +1

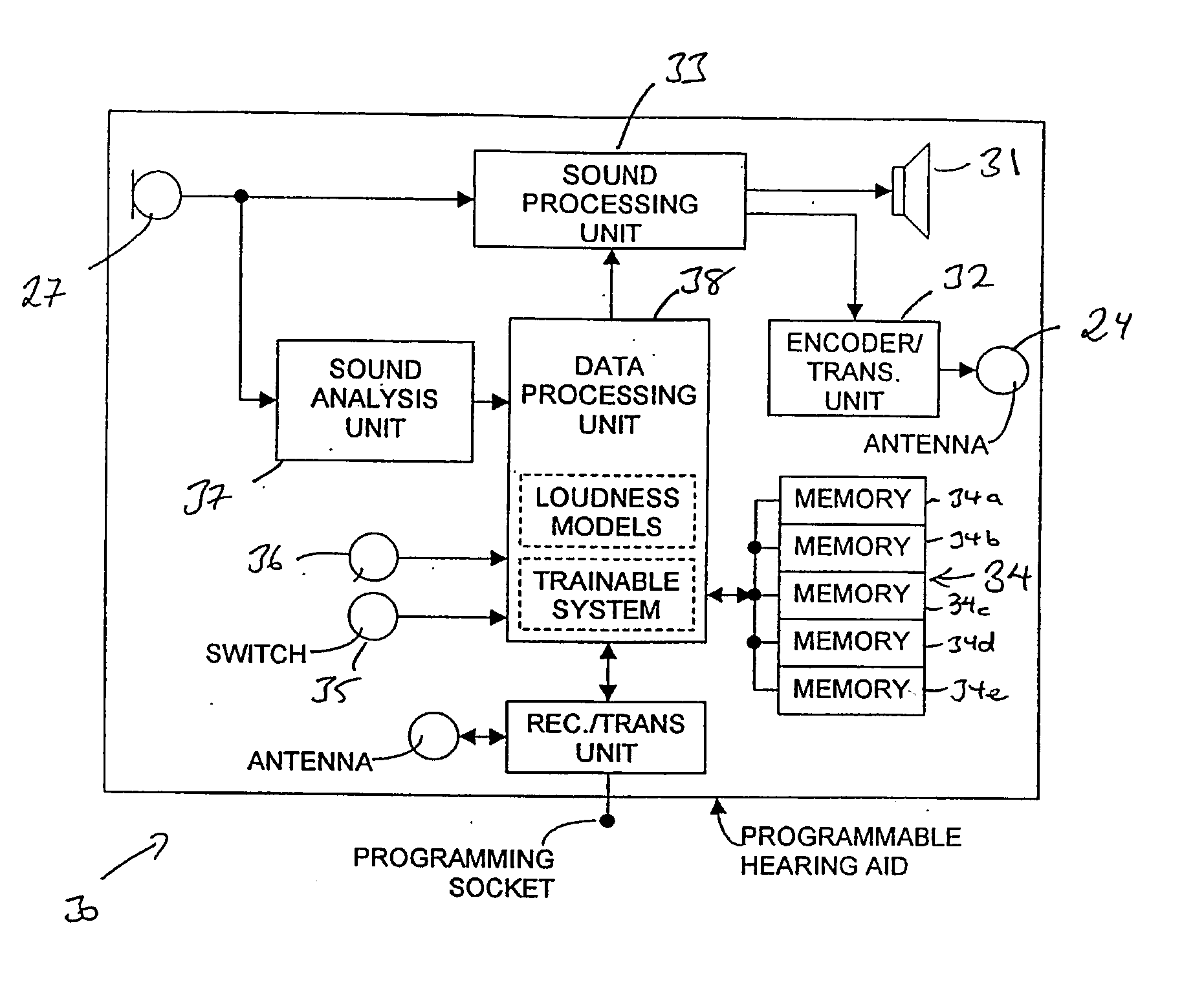

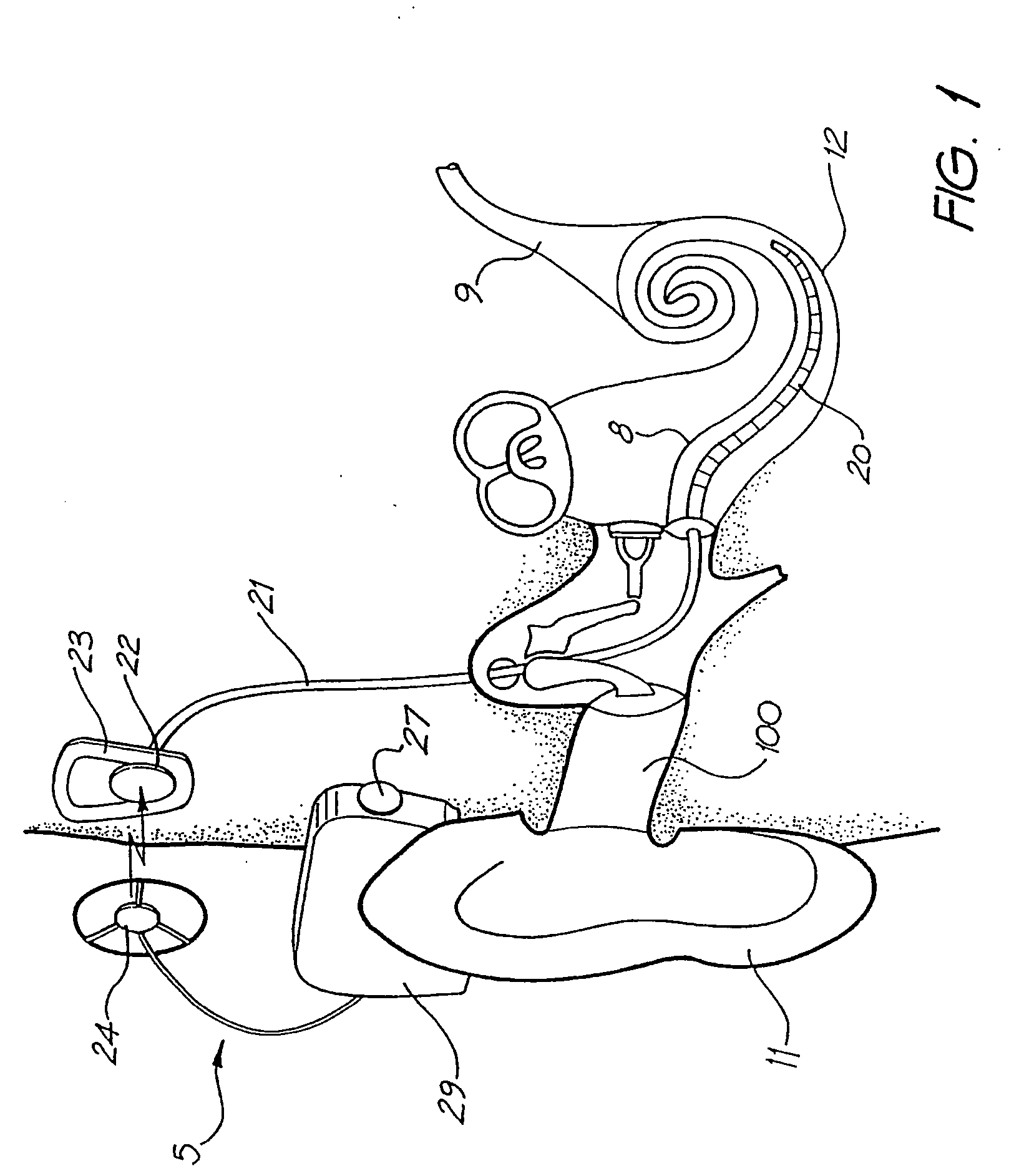

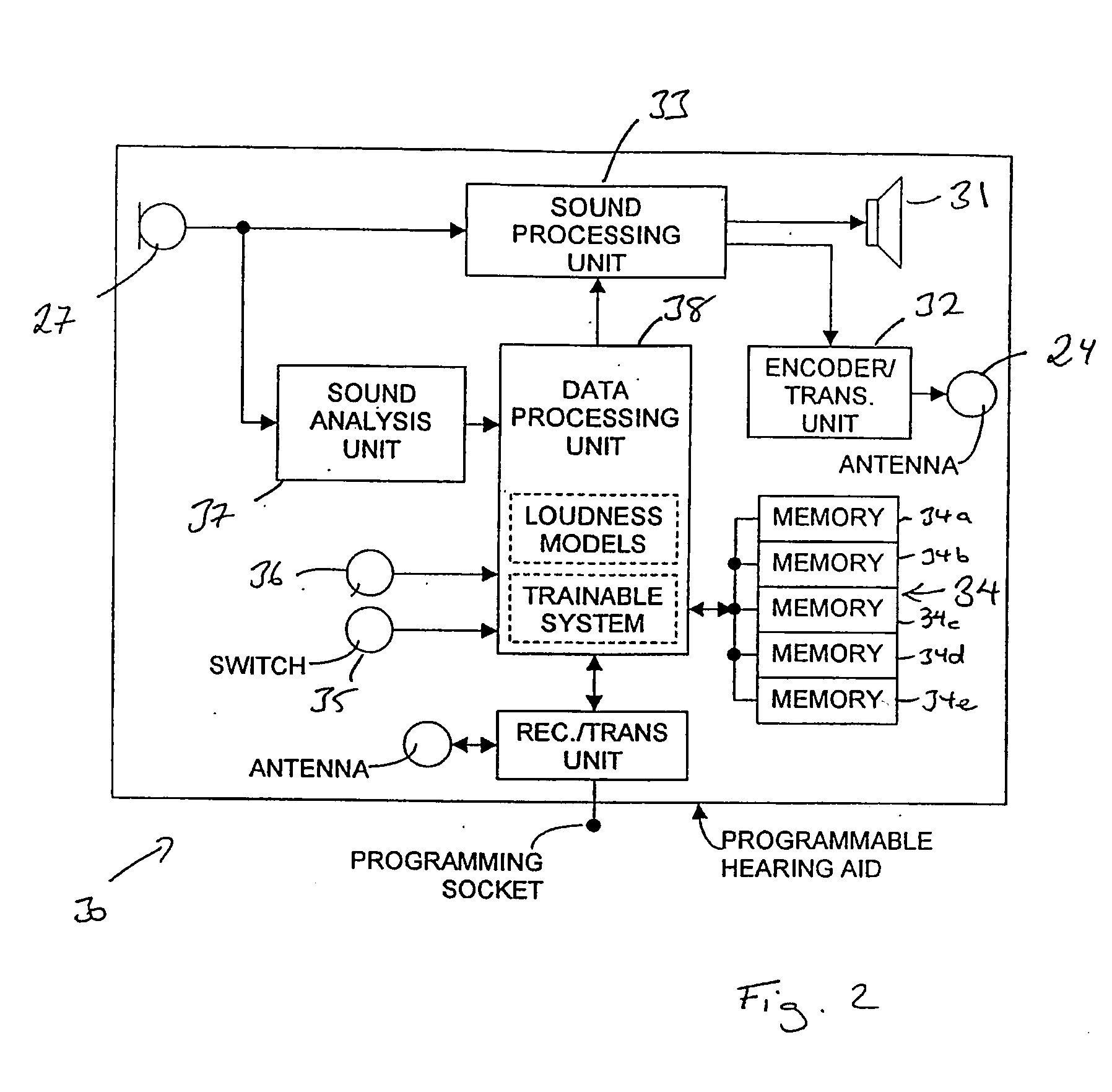

Programmable auditory prosthesis with trainable automatic adaptation to acoustic conditions

An auditory prosthesis (30) comprising a microphone (27) for receiving the sound and producing a microphone signal responding to the received sound, an output device for providing audio signals in a form receivable by a user of the prosthesis (30), a sound processing unit (33) operable to receive the microphone signal and carry out a processing operation on the microphone signal to produce an output signal in a form suitable to operate the output device, wherein the sound processing unit (33) is operable in a first mode in which the processing operation comprises at least one variable processing factor which is adjustable by a user to a setting which causes the output signal of the sound processing unit (33) to be adjusted according to the preference of the user for the characteristics of the current acoustic environment.

Owner:SIVANTOS PTE LTD

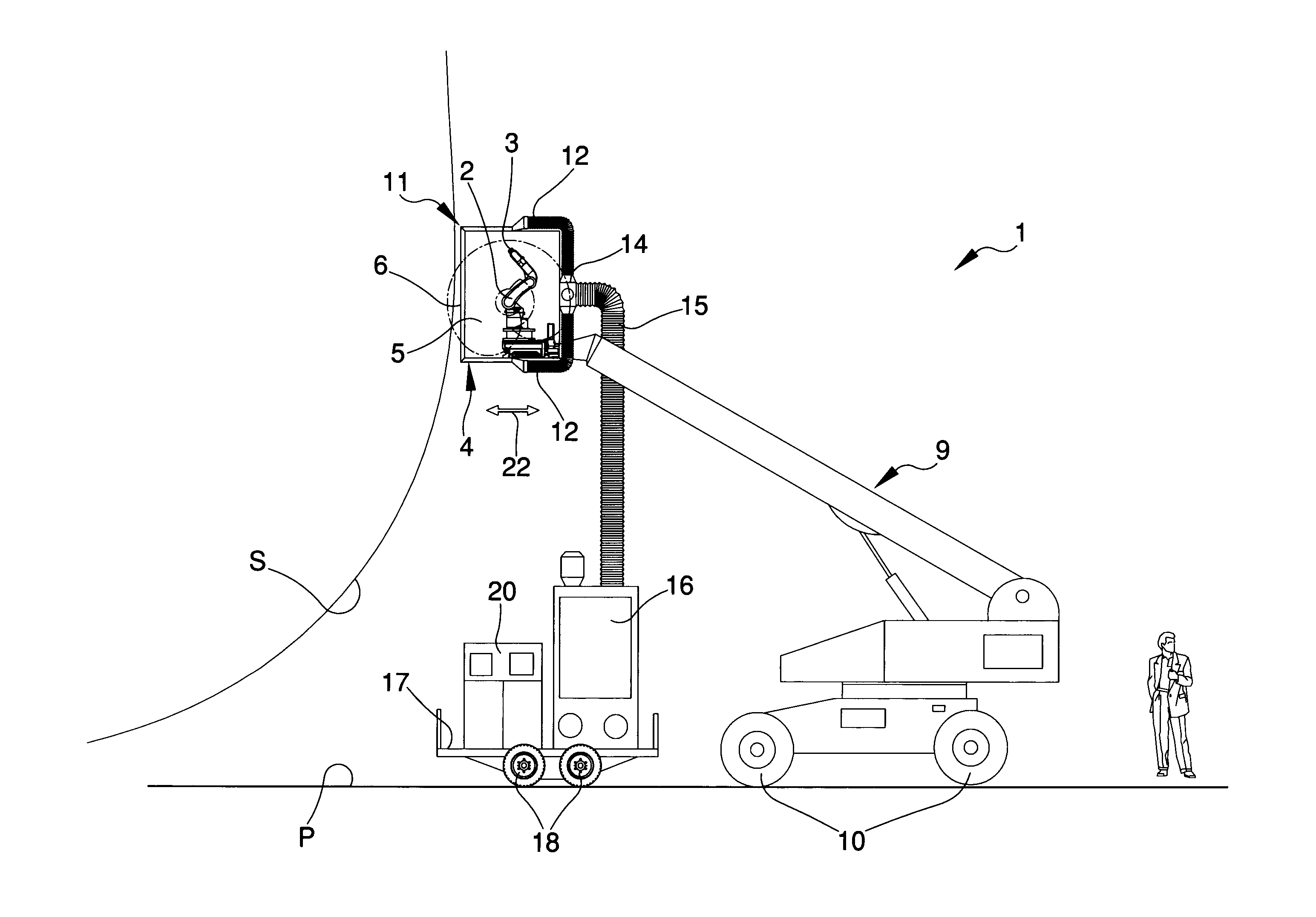

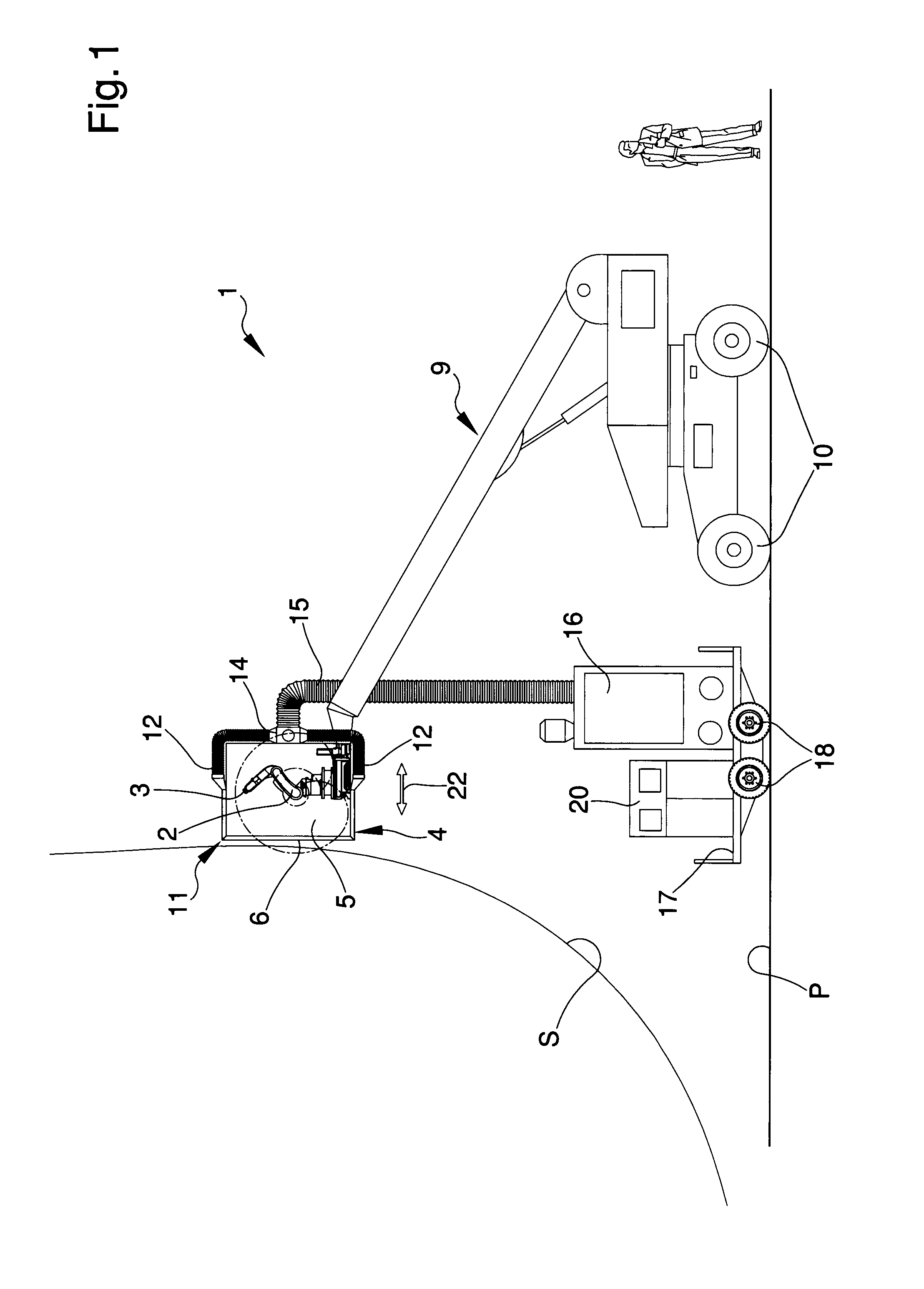

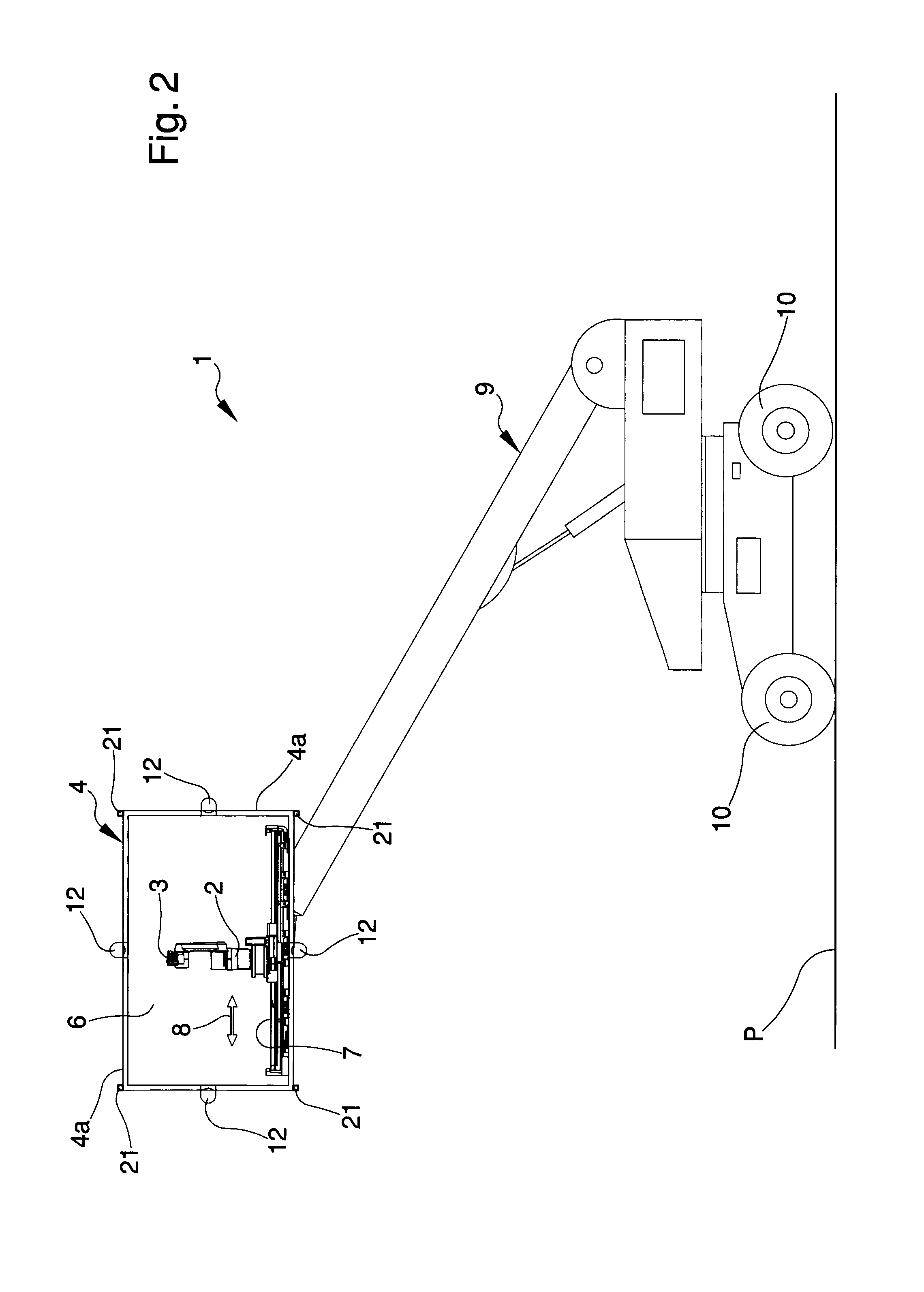

Apparatus and method for the painting of hulls of boats or the like

ActiveUS20130243963A1Reduce in quantityGuaranteed to workDry-dockingSlipwaysCommand and controlControl engineering

Apparatus for painting hulls of boats includes at least an anthropomorphic robot having paint dispensing elements, at least a supporting body which defines a chamber for containing the robot and which includes at least an opening for applying paint on a reference surface, handling elements of the body along at least a direction of moving close to / away from the surface, air suction elements to form a suction stream substantially along the entire surrounding edge of the opening, according to a preset suctionable air flow, command and control elements operatively connected to the handling elements to control movement of the body along the moving direction, sensor elements associated with the body to detect the distance of the surrounding edge from the reference surface and operatively connected to the command and control elements, the latter being programmed to adjust the distance of the surrounding edge of the opening from the reference surface.

Owner:RINA VINCENZO

Extension of write anywhere file system layout

ActiveUS7409494B2Guaranteed to workOvercome disadvantagesDigital data information retrievalRedundant operation error correctionRAIDFile system

A file system layout apportions an underlying physical volume into one or more virtual volumes (vvols) of a storage system. The underlying physical volume is an aggregate comprising one or more groups of disks, such as RAID groups, of the storage system. The aggregate has its own physical volume block number (pvbn) space and maintains metadata, such as block allocation structures, within that pvbn space. Each vvol has its own virtual volume block number (vvbn) space and maintains metadata, such as block allocation structures, within that vvbn space. Notably, the block allocation structures of a vvol are sized to the vvol, and not to the underlying aggregate, to thereby allow operations that manage data served by the storage system (e.g., snapshot operations) to efficiently work over the vvols. The file system layout extends the file system layout of a conventional write anywhere file layout system implementation, yet maintains performance properties of the conventional implementation.

Owner:NETWORK APPLIANCE INC

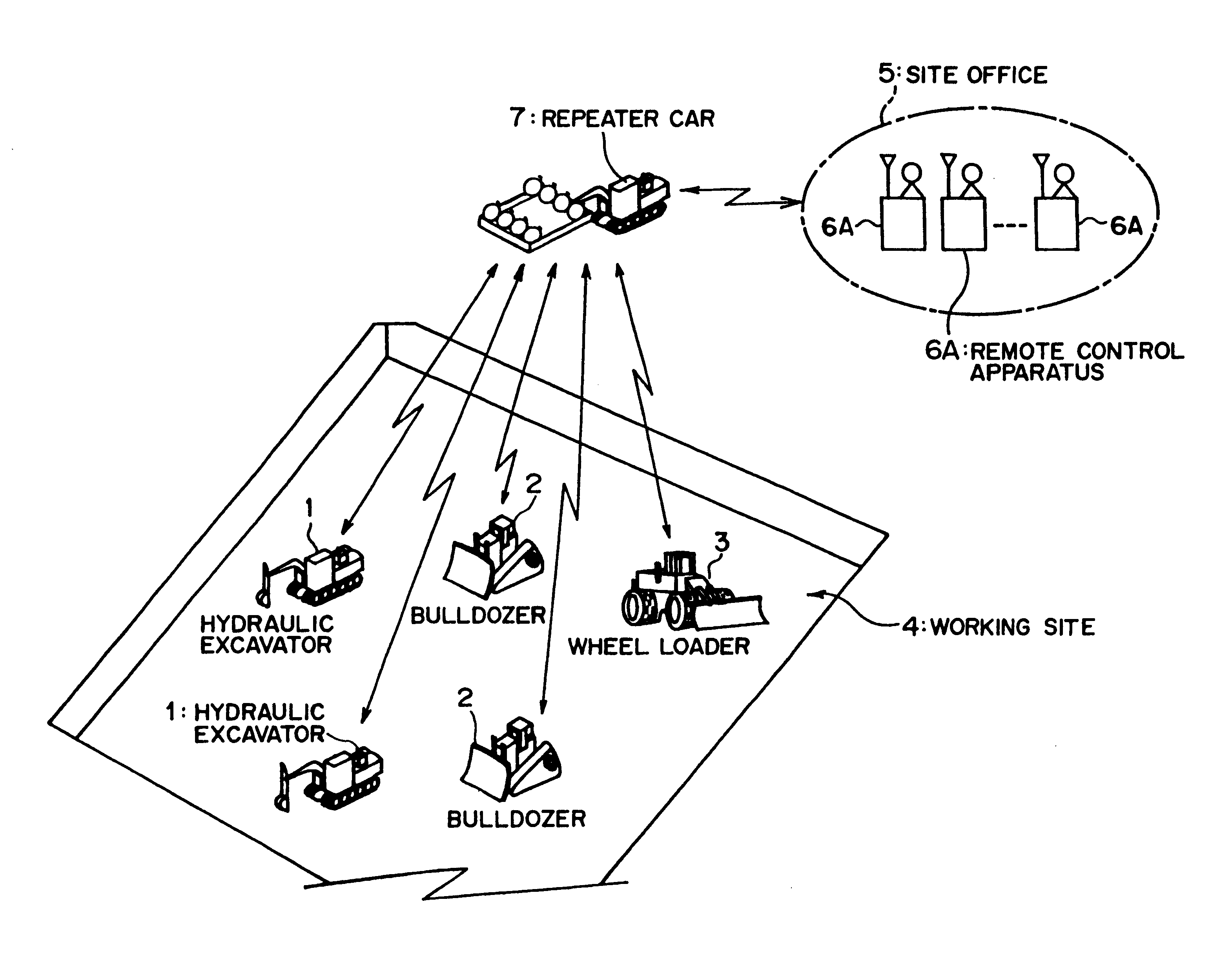

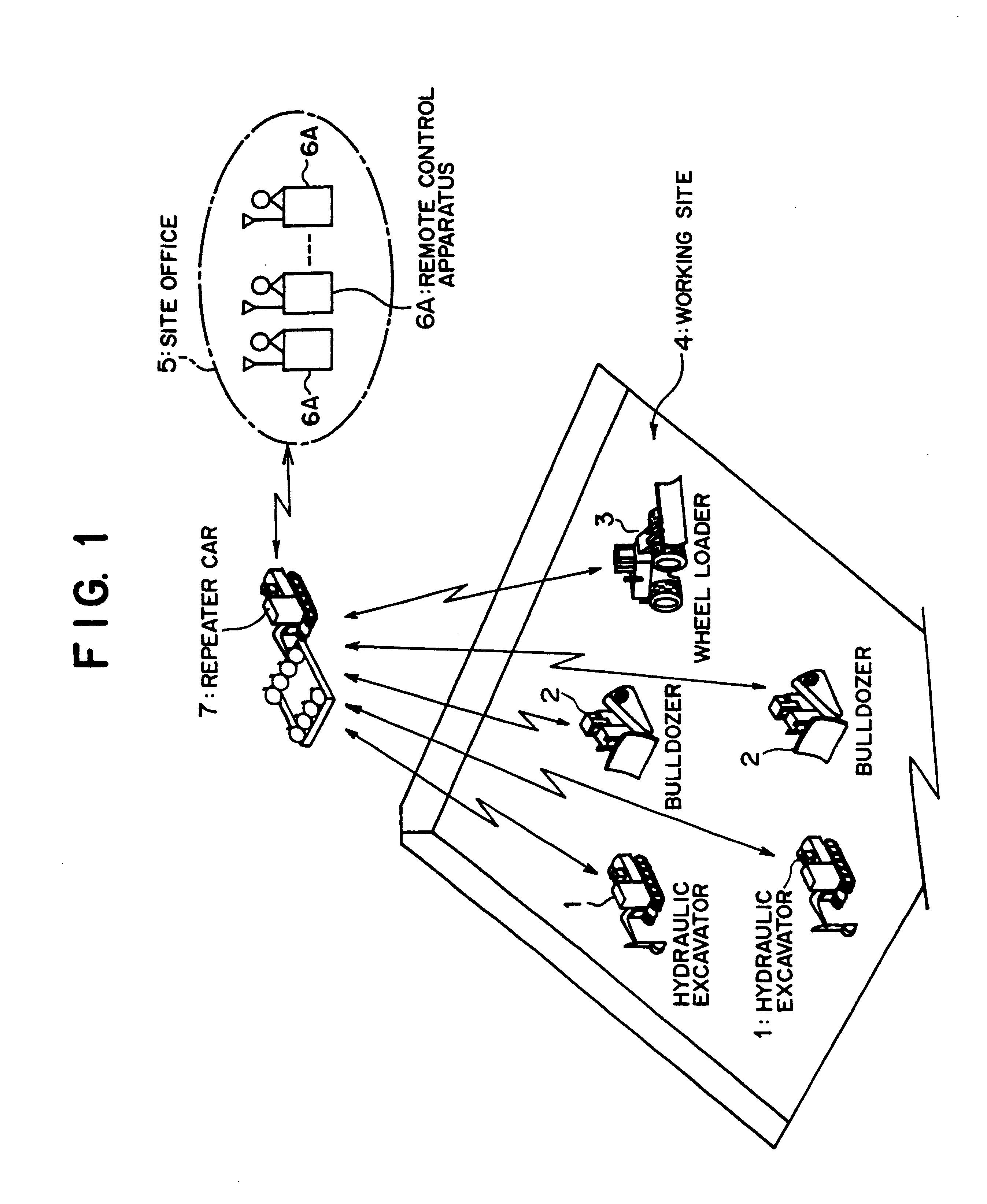

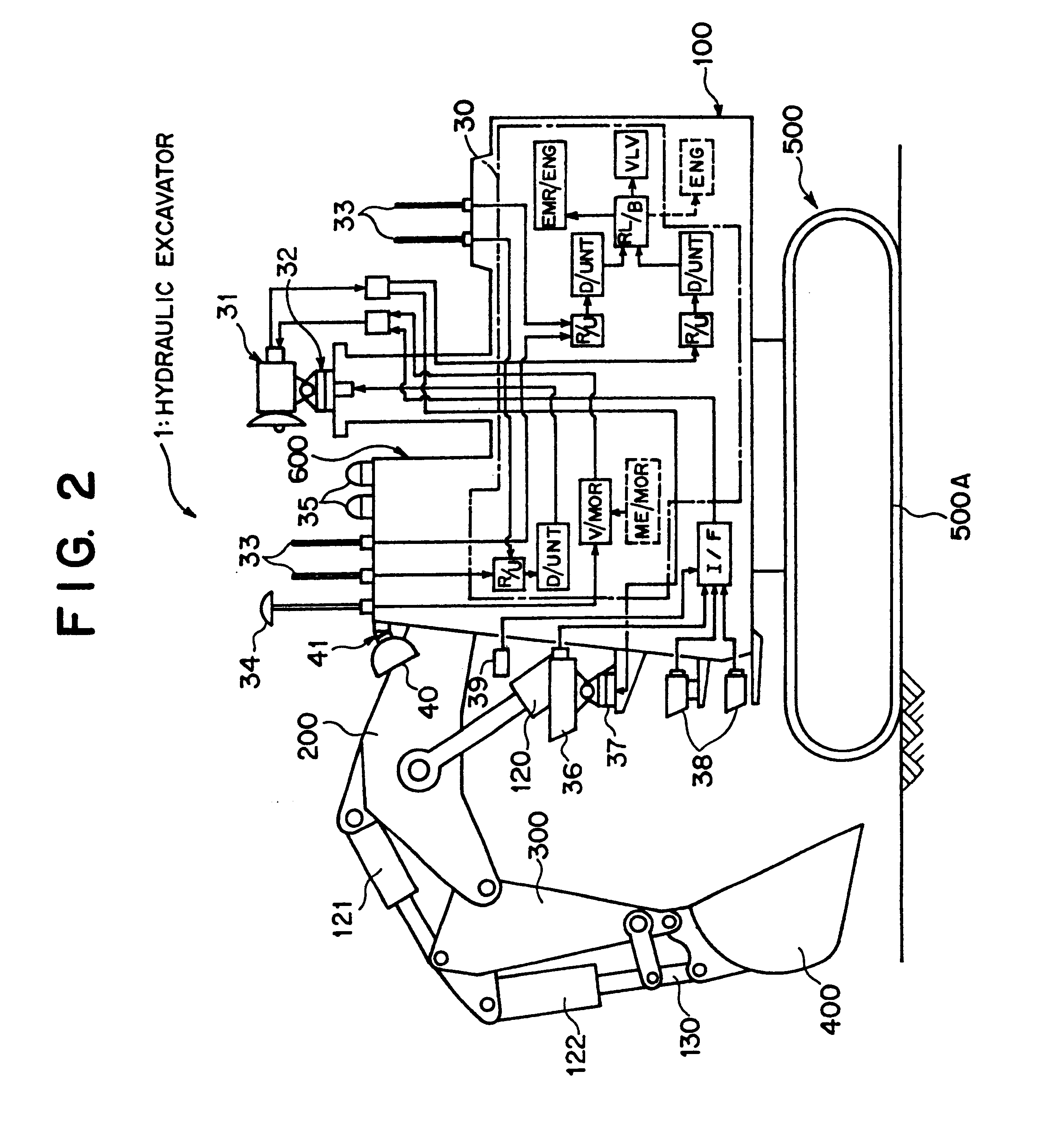

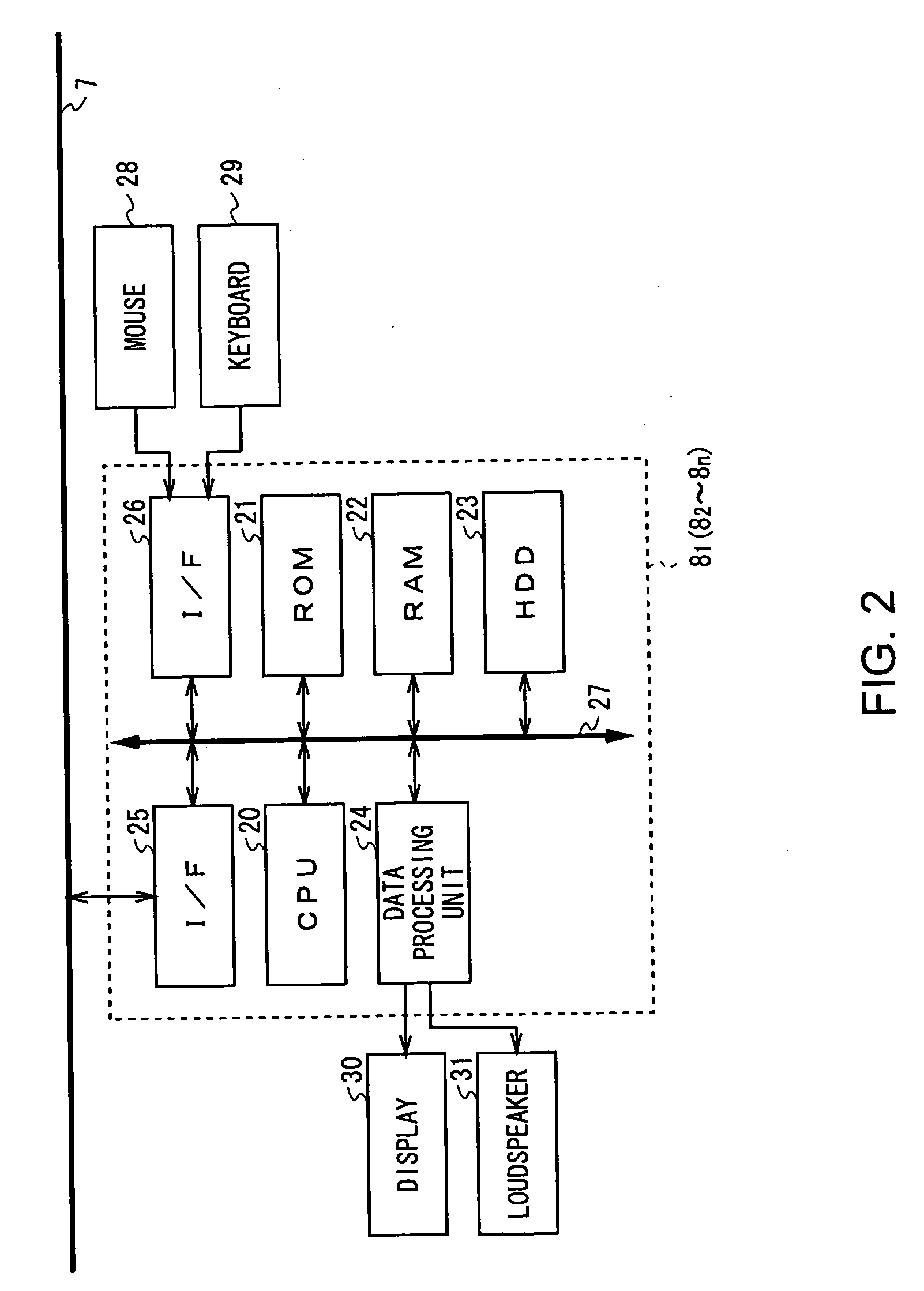

Remote radio operating system, and remote operating apparatus, mobile relay station and radio mobile working machine

InactiveUS6778097B1Improve reliabilityShort working hoursElectric signal transmission systemsDigital data processing detailsMobile relayRemote control

The present invention relates to remote radio control technology, and a remote radio control system includes a radio movable working machine (1), a remote control apparatus (6A), and a movable repeater station (7). First bidirectional communication means (31, 71) having a high radio wave directionality and first automatic tracking means (32, 71A) are provided between the working machine (1) and the repeater station (7), and second bidirectional communication means (63, 76) having a high radio wave directionality, second automatic tracking means (63A, 76A), and emergency spread spectrum bidirectional communication means (64, 87) for enabling bidirectional communication between the remote control apparatus (6A) and the repeater station (7) when communication by the second bidirectional communication means (63, 76) is impossible are provided between the remote control apparatus (6A) and the repeater station (7). Consequently, even if communication between the working machine (1) and the movable repeater station (7) is disabled, each of the working machine (1) and the repeater station (7) is permitted to perform a minimum necessary operation, and any other person than those skilled in actual controlling operation of the working machine (1) can perform remote control easily.

Owner:CATEPILLAR SARL

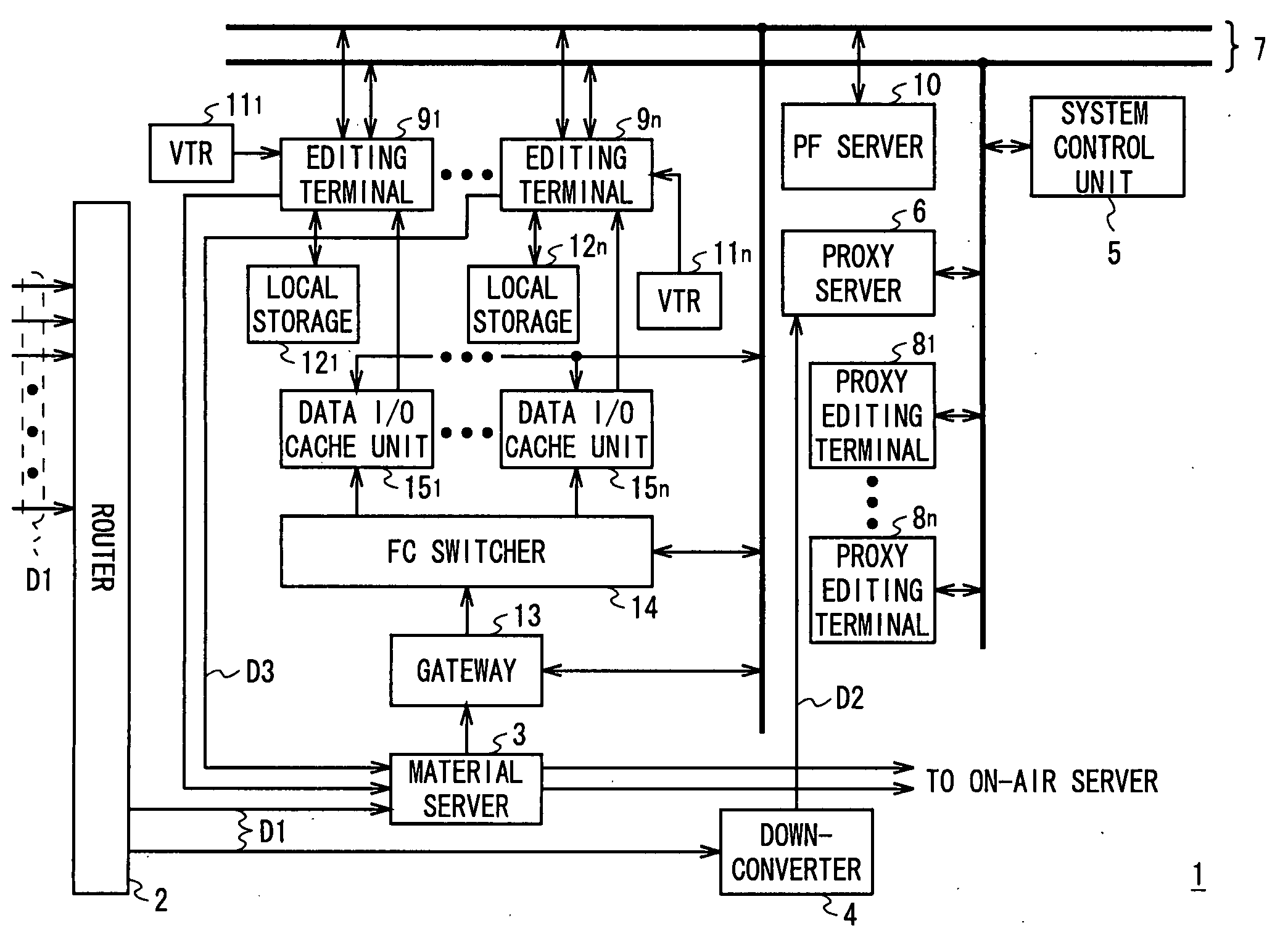

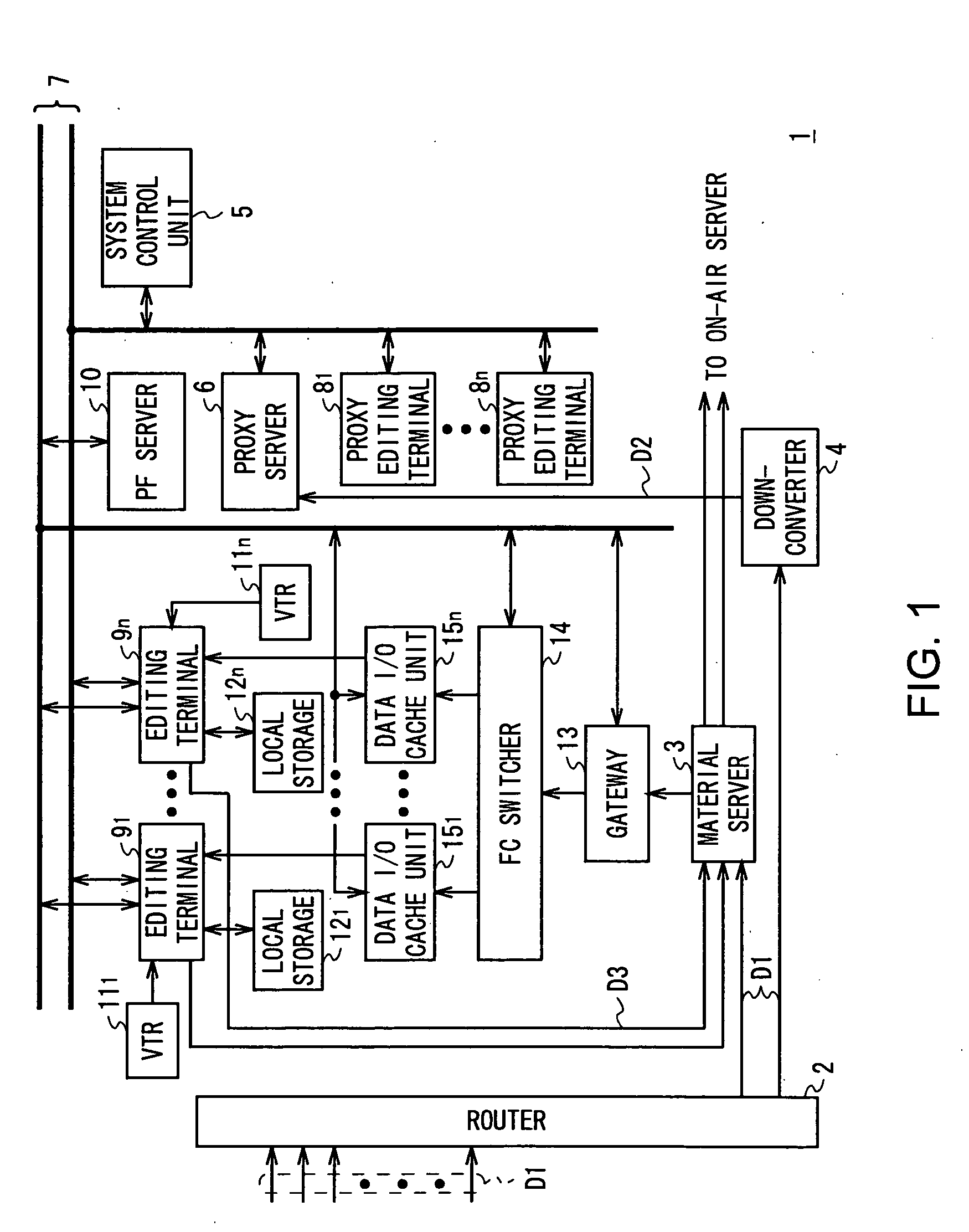

Editing system and control method thereof

ActiveUS20050025454A1Improve work efficiencyShorten the timeTelevision system detailsRedundant array of inexpensive disk systemsComputer graphics (images)Image resolution

This invention realizes an editing system and control method thereof capable of significantly improving working efficiency of editing work. A proxy editing terminal device creates an EDL with low-resolution video / audio data, resulting in reducing time to create the EDL. Further, the low-resolution video / audio data and high-resolution video / audio data having the same contents and different resolutions are previously stored, so that the creation of a final edit list with the high-resolution video / audio data based on the EDL can be started in a short time after the EDL is created with the low-resolution video / audio data. Thus working efficiency of the editing work can be significantly reduced with reducing time to create the EDL and the final edit list.

Owner:SONY CORP

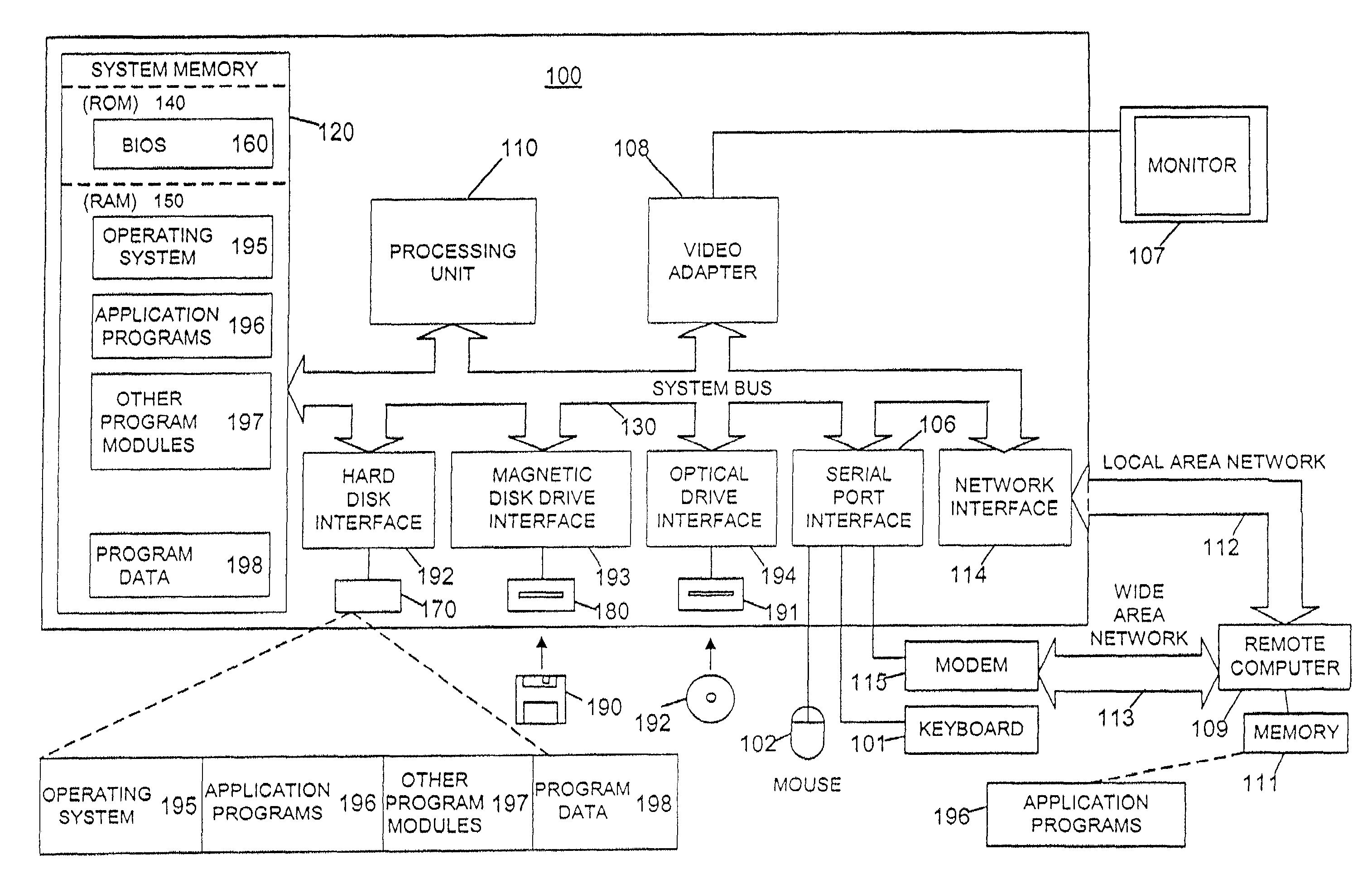

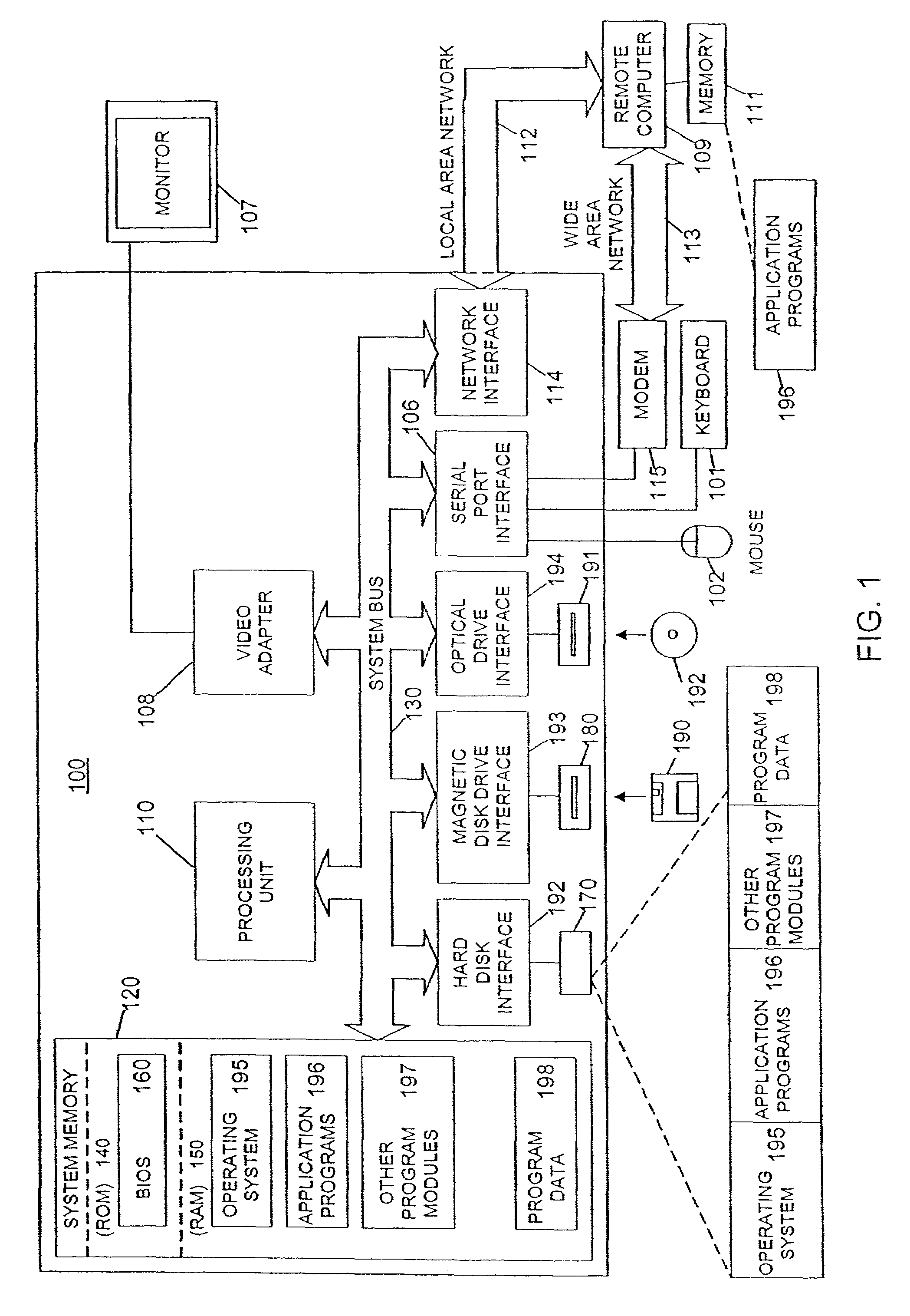

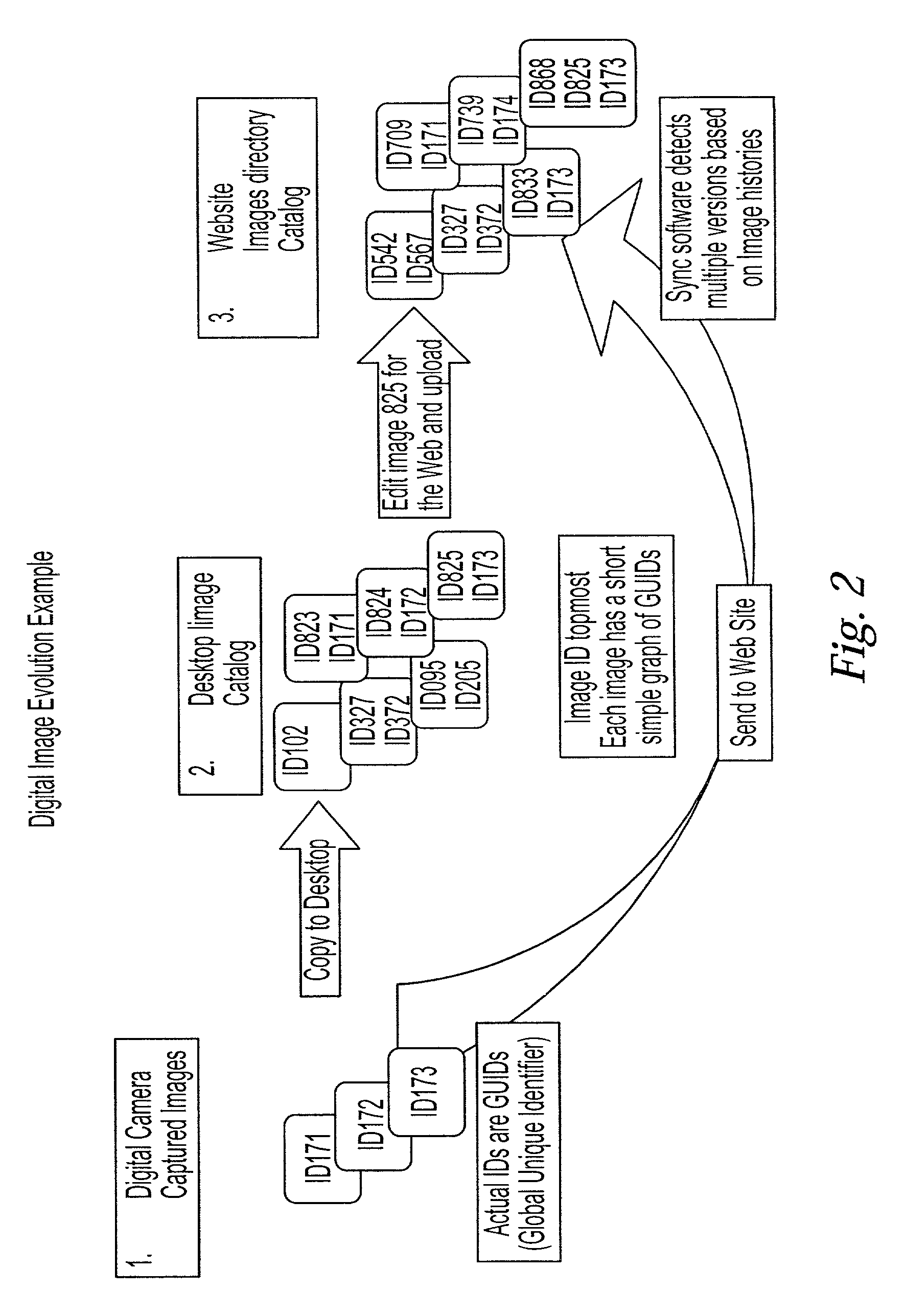

Method and apparatus for synchronizing multiple versions of digital data

InactiveUS7216289B2Reduce overheadGuaranteed to workData processing applicationsDigital data information retrievalDigital dataUnique identifier

A method and system for synchronizing multiple versions of multimedia objects is provided. Each multimedia object may be identified by a unique identifier. In addition, a history graph may be generated and maintained for each object, where the history graph includes nodes that store unique identifiers and whose vectors describe the relationship between the multimedia objects. Metadata may be used to describe the transformations of objects.

Owner:MICROSOFT TECH LICENSING LLC

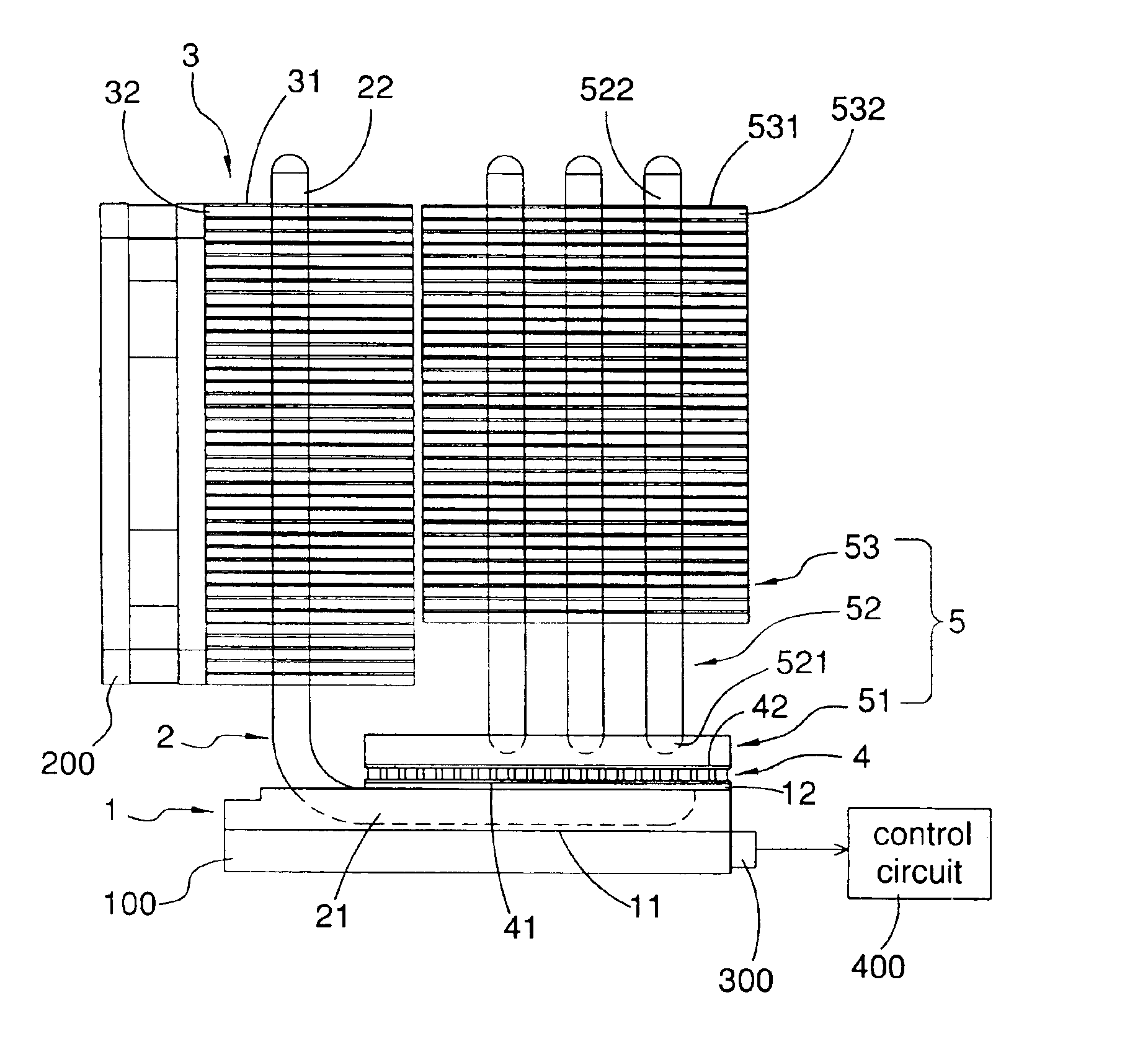

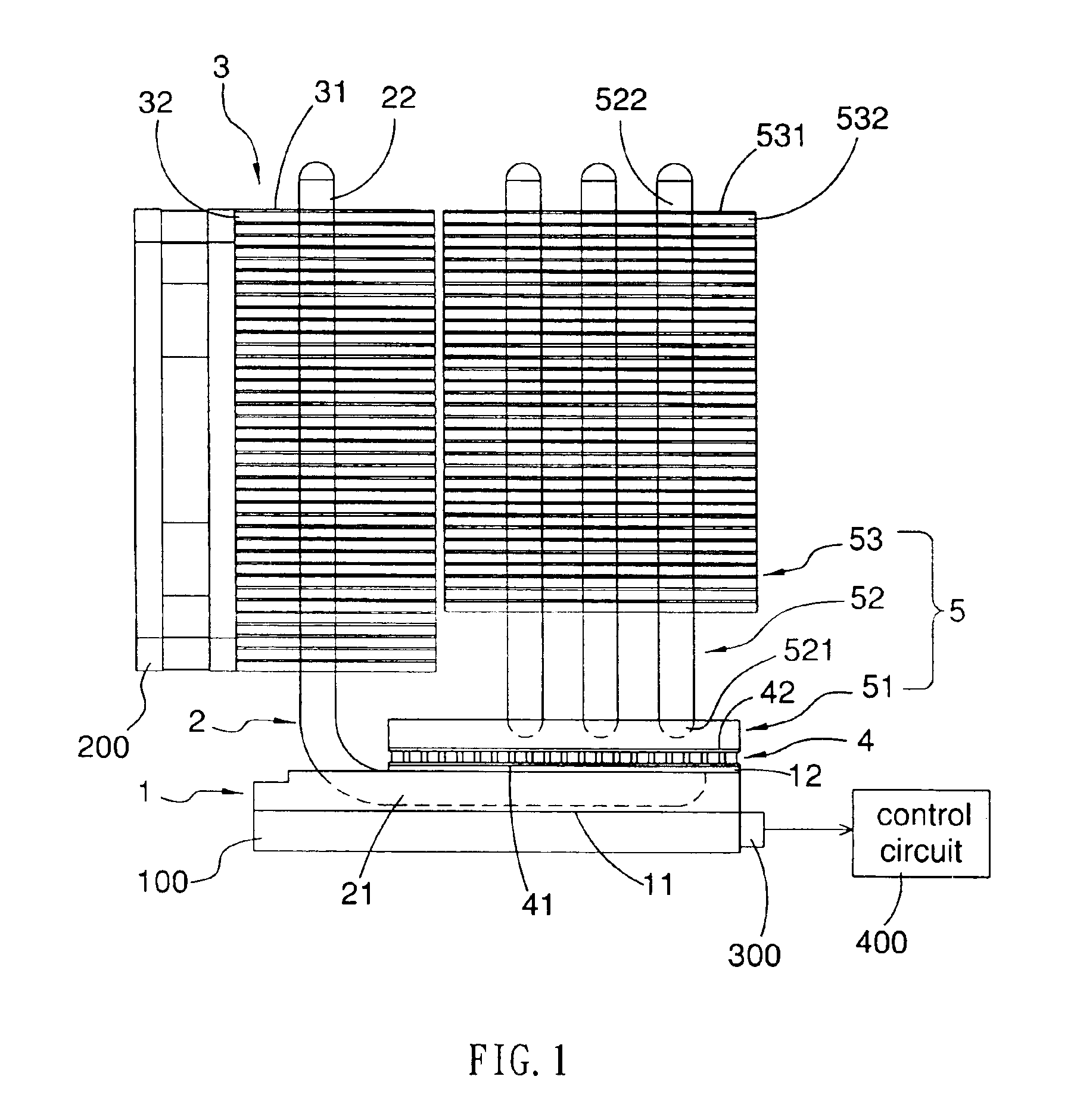

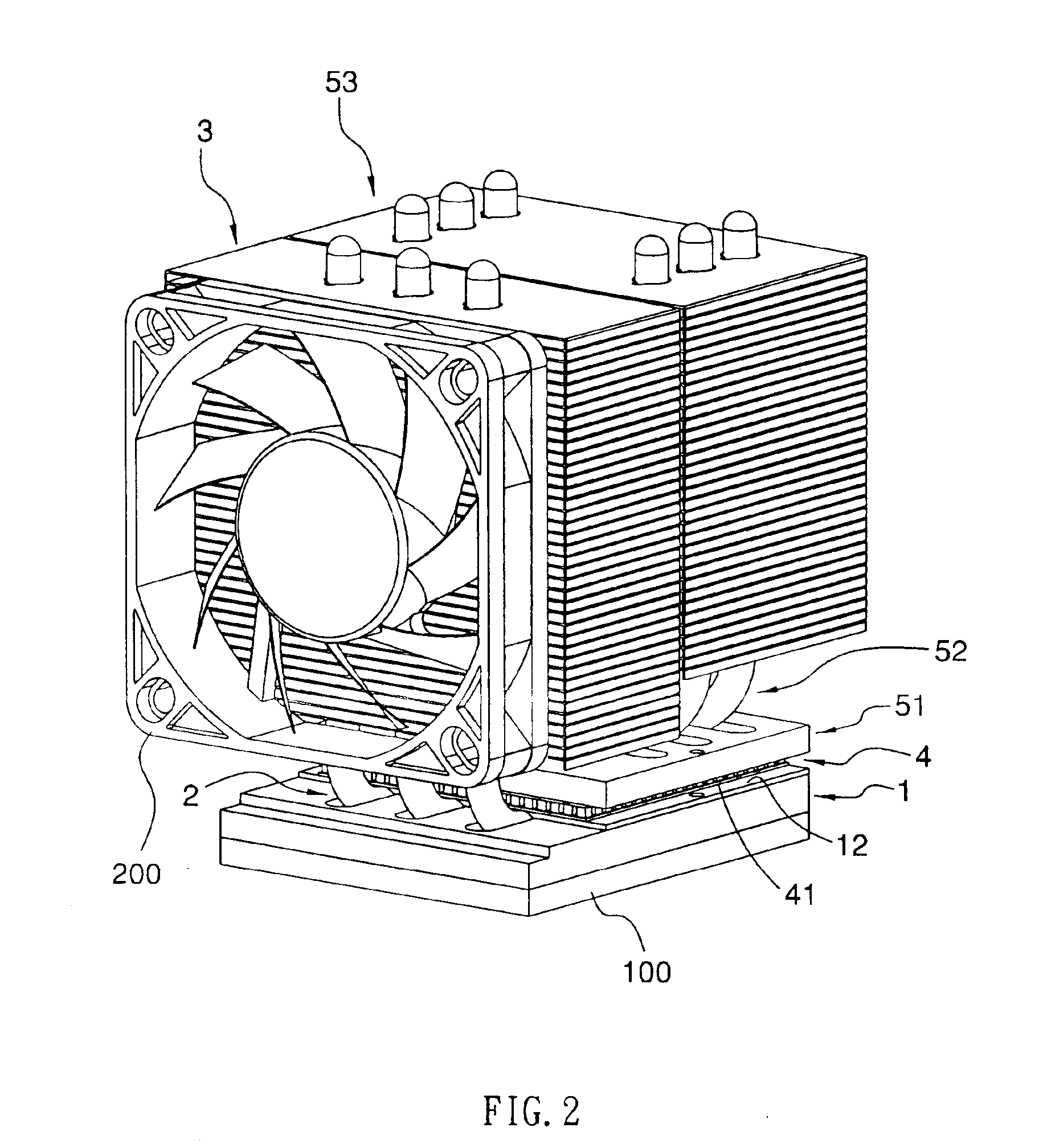

Two stage radiation thermoelectric cooling apparatus

ActiveUS6880346B1Guaranteed to workThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsSecondary stageEngineering

The present invention provides a thermoelectric cooling apparatus for cooling an electronic device such as a CPU, or a computer chip. The apparatus cools the electronic device by two stages. In the first stage, a heat absorbing block collects the heat produced by the electronic device and the apparatus pre-cools the electronic device by dissipating a portion of the collected heat in a distant location through a front heat conductive device and a front radiator. Thereby the heat of the electronic device is reduced to a degree that a TEC can efficiently handle. In the second stage, a TEC of the apparatus dissipate the residual of the heat produced by the electronic device through at least a back heat pipe and a back radiator.

Owner:GIGA BYTE TECH CO LTD

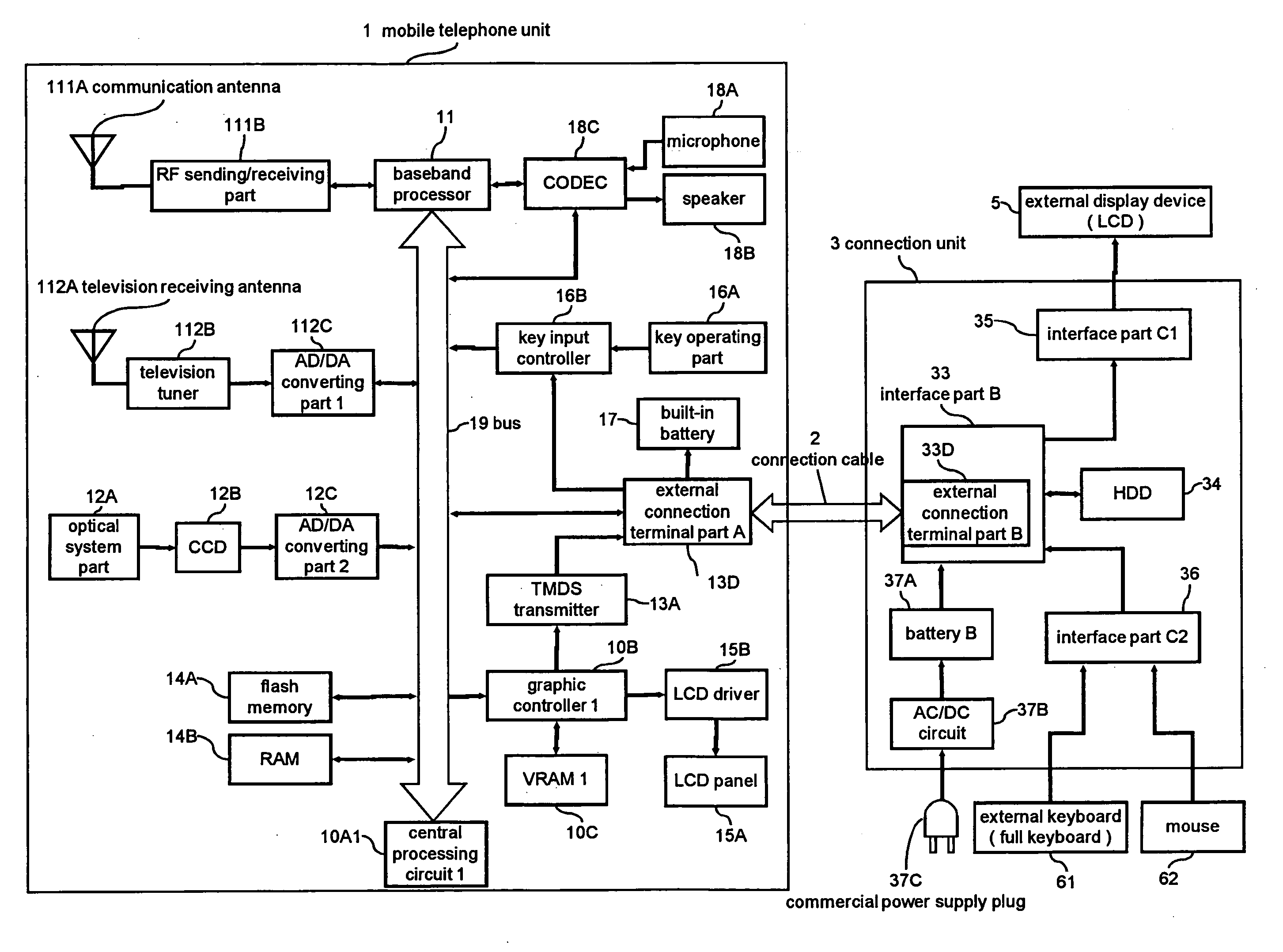

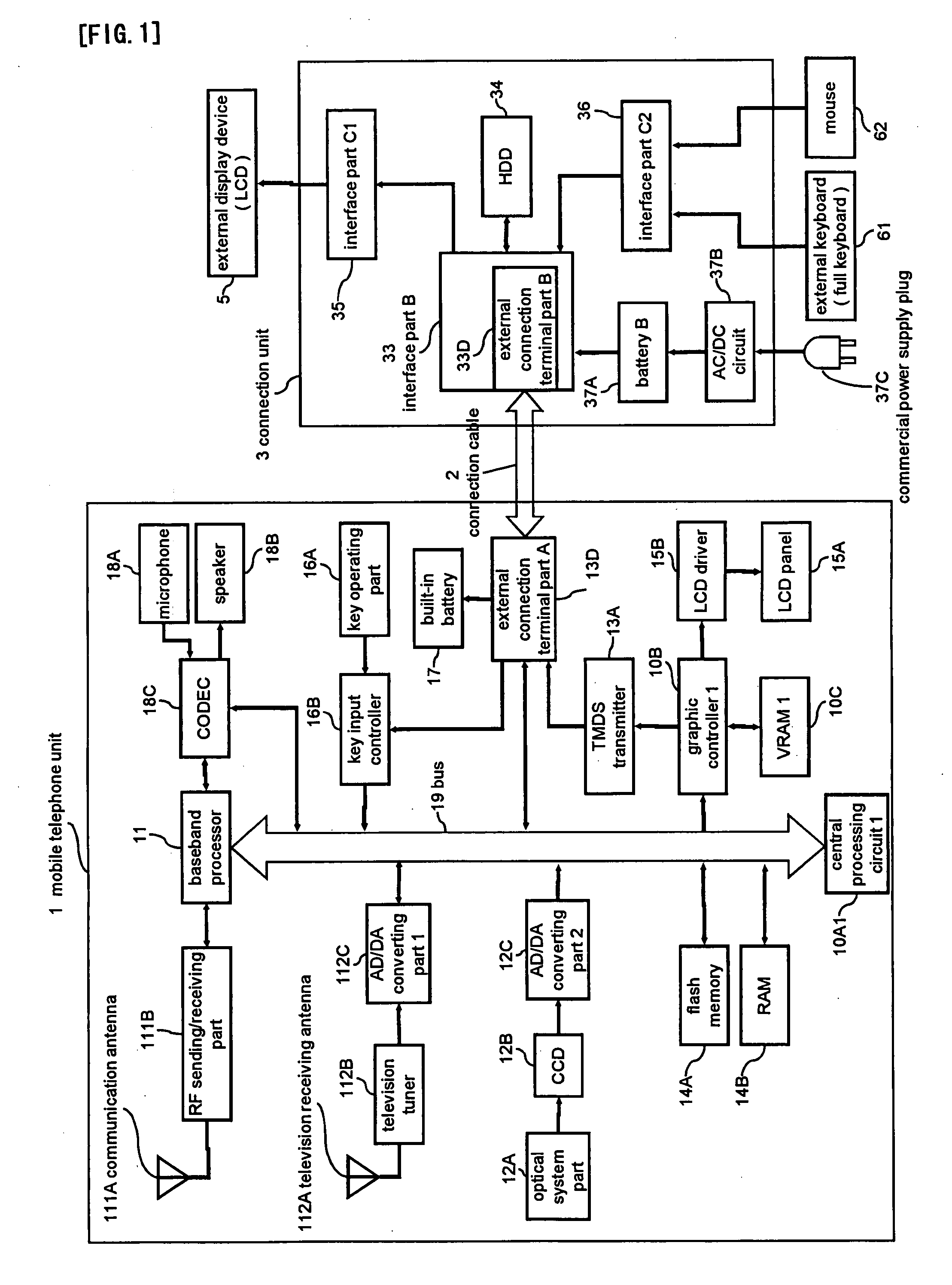

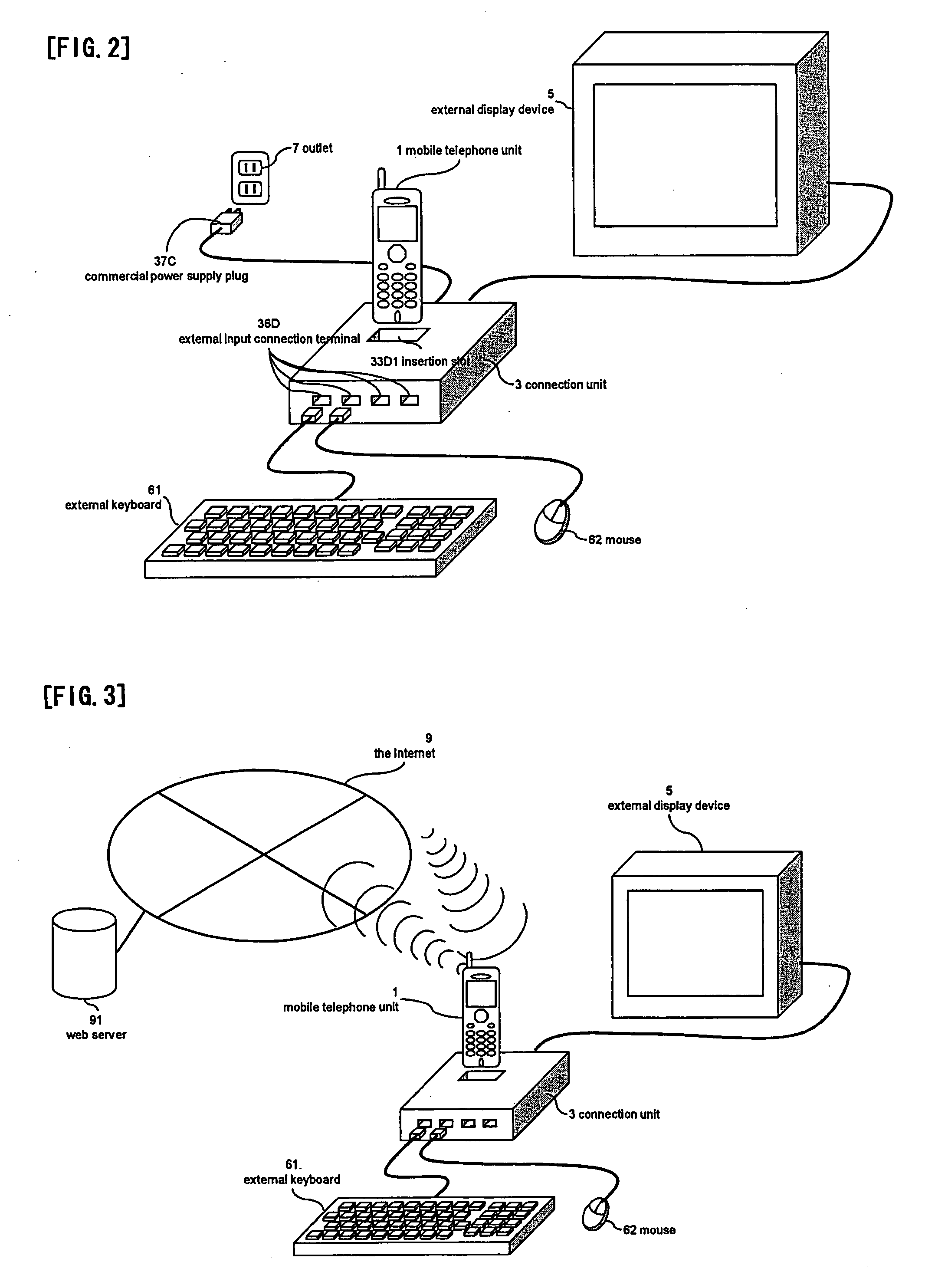

Mobile Information Communication Apparatus, Connection Unit for Mobile Information Communication Apparatus, and External Input/Output Unit for Mobile Information Communication Apparatus

ActiveUS20080140886A1Smoothly continue his workReduce wasteCordless telephonesCathode-ray tube indicatorsImage resolutionCommunication device

[PROBLEMS] To display, on an external display device, an image with a higher resolution than a screen's resolution of a display belonging to a mobile information communication apparatus. This is achieved only by additionally providing an interface means between the external display device and the mobile information communication apparatus and further additionally providing some functions to a display data generating means originally belonging to the mobile information communication apparatus.[MEANS FOR SOLVING PROBLEMS] A mobile information communication apparatus comprising a data processing means for sending plotting command / data to a display control means that controls the pixels of a display panel belonging to the mobile information communication apparatus; wherein an interface means is provided which receives the plotting command / data generated by the data processing means and sends, based on plotting command / data, an external display signal to the external display device; and wherein the data processing means and the interface means are configured to send, from the interface means, a higher-resolution external display signal.

Owner:DAP REALIZE

Patient activity monitor

ActiveUS7336187B2Increasing quality and levelLow costFrequency-division multiplex detailsSurgeryGraphicsGraphical user interface

A patient activity monitoring system that allows caregivers of multiple patients to work more efficiently and with reduced cost, while increasing the quality and level of patient care. The system includes a plurality of remote monitoring subsystems, a plurality of user notification units, and a central monitoring unit with a Graphical User Interface (GUI) communicably coupled between the remote monitoring and user notification units. Each remote monitoring subsystem includes a remote monitoring unit, and a sensor device associated with a respective patient that detects one or more activity and / or physiological parameters of the patient. A simplified user interface including the GUI and the user notification units provides indications of the type and level of assistance required by one or more patients to caregivers at centralized and remote locations.

Owner:SOTERA WIRELESS

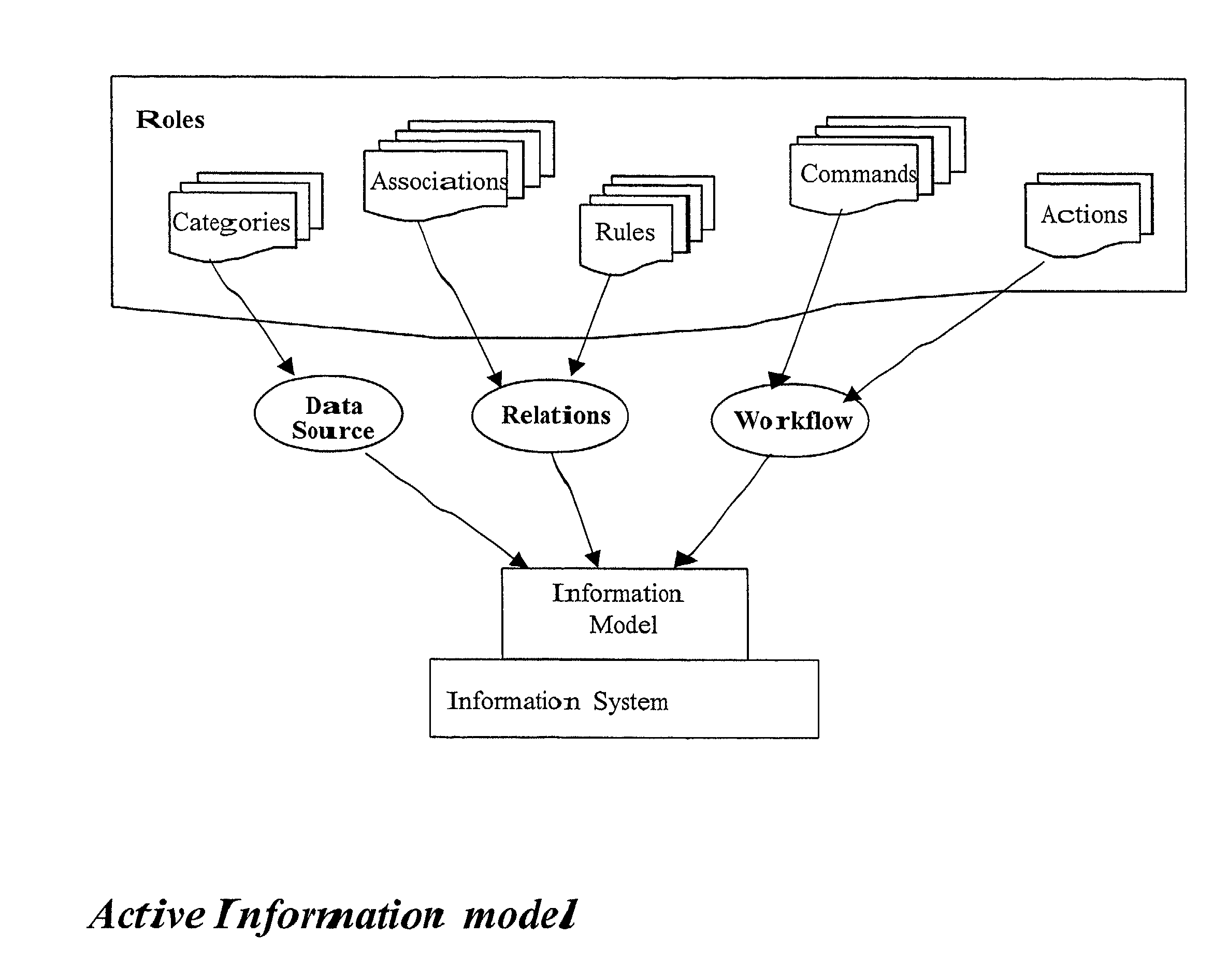

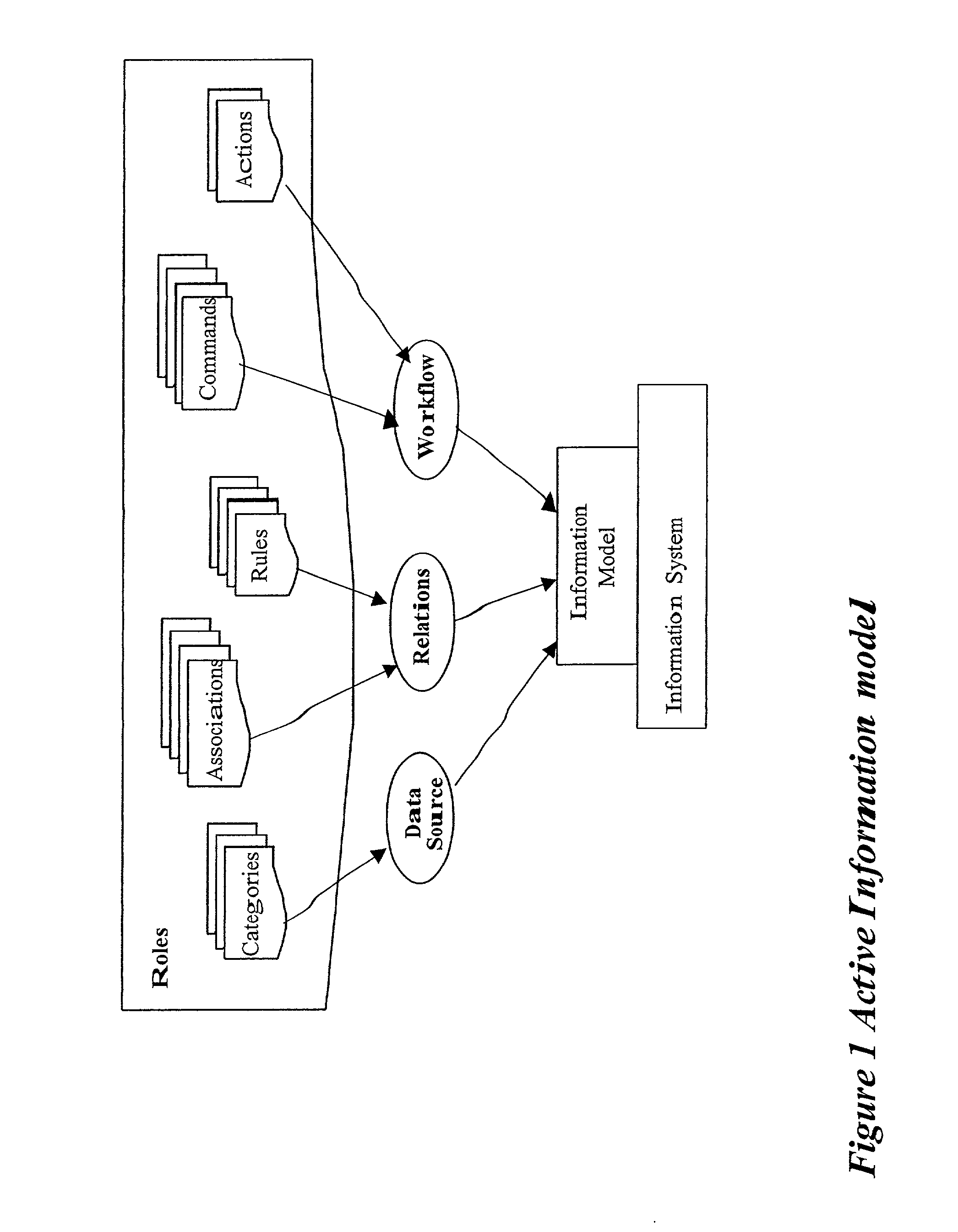

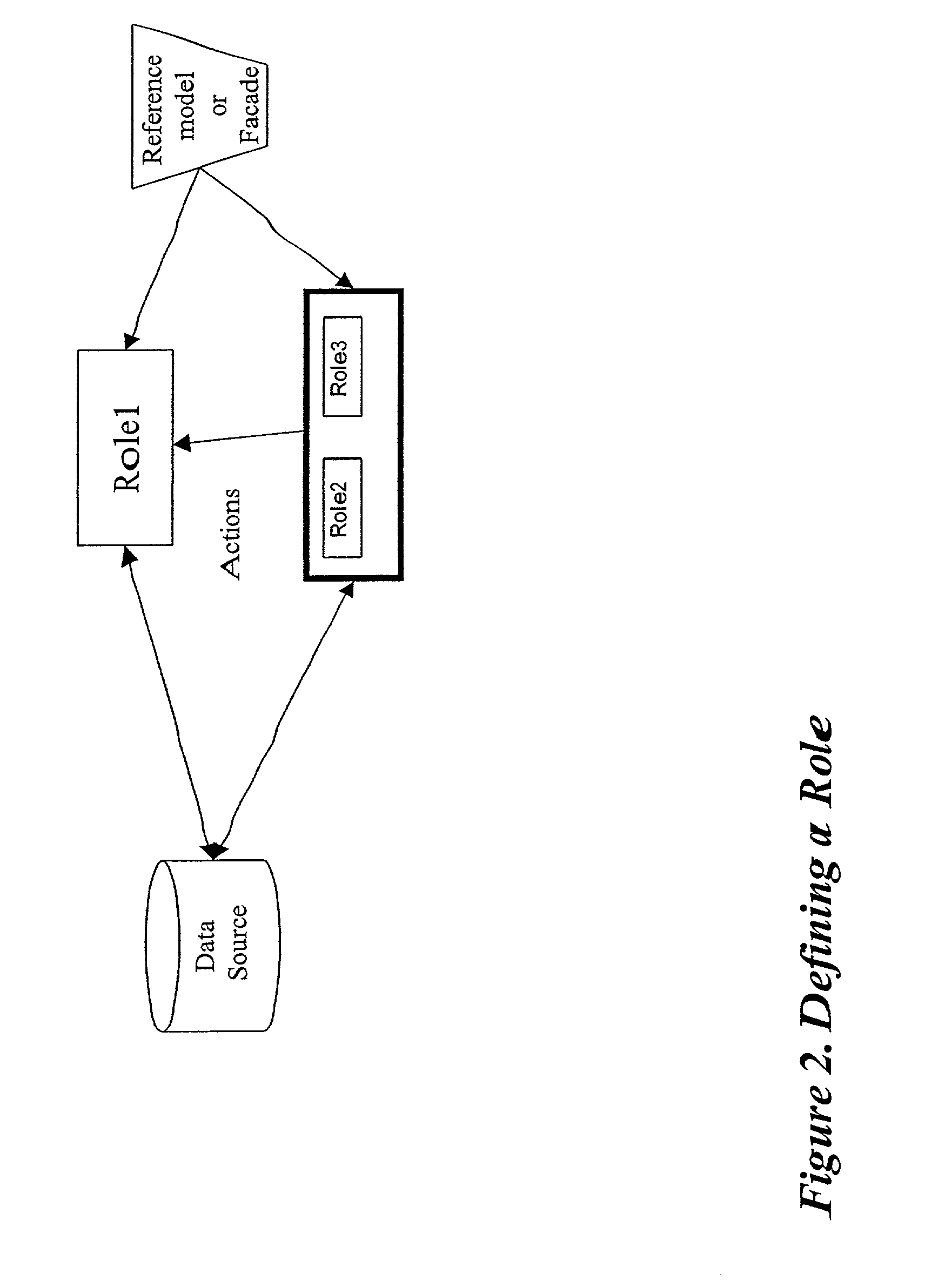

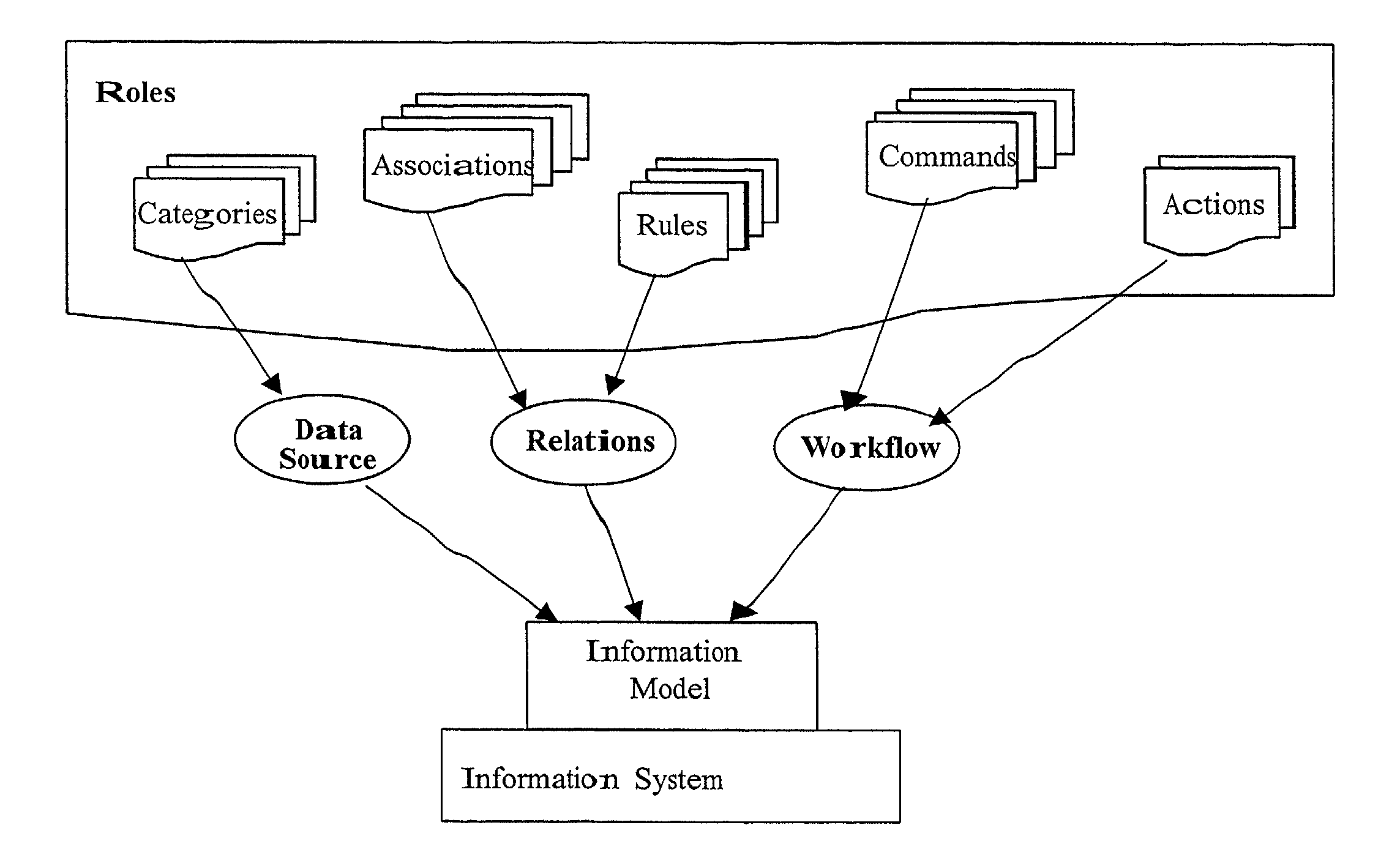

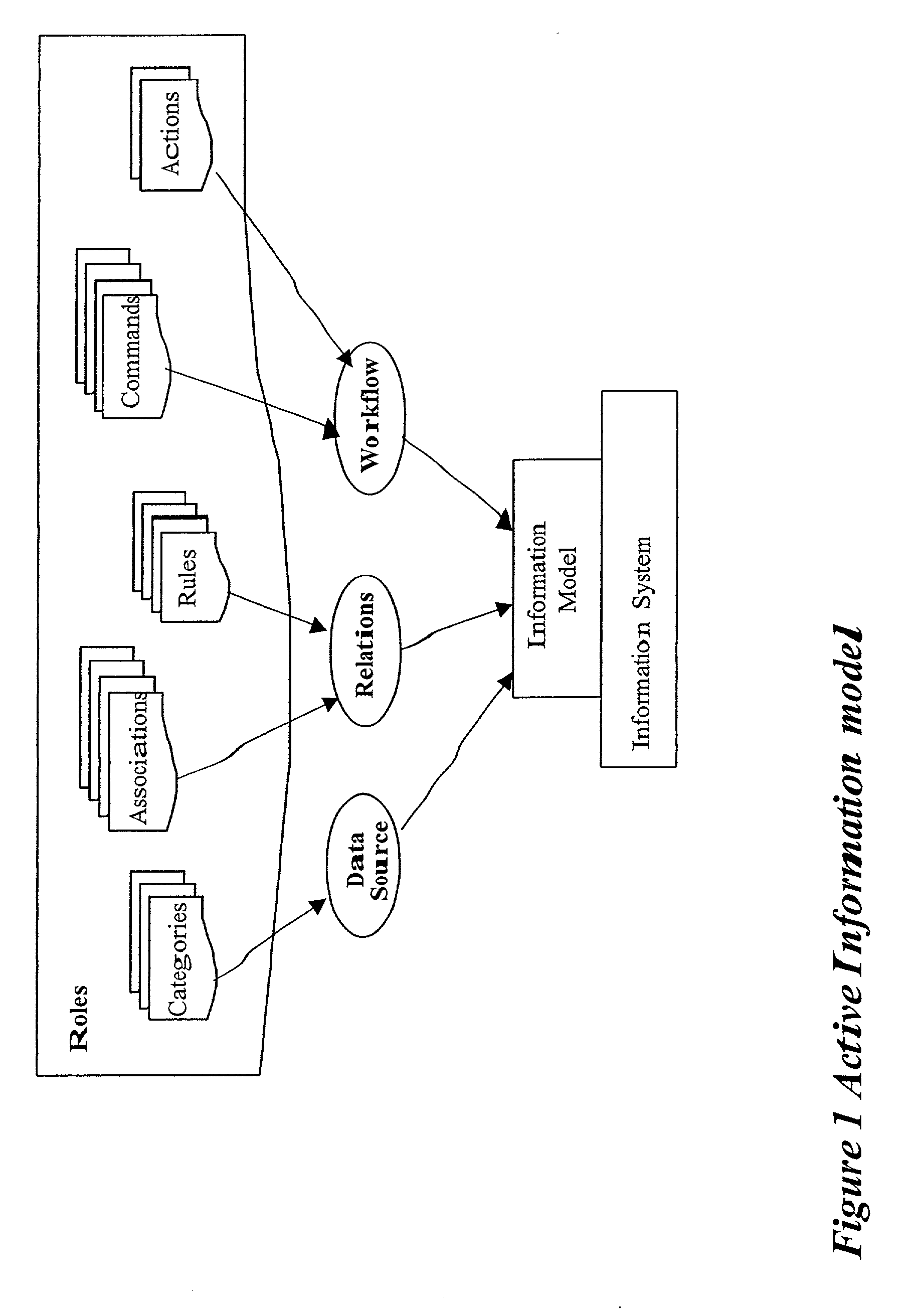

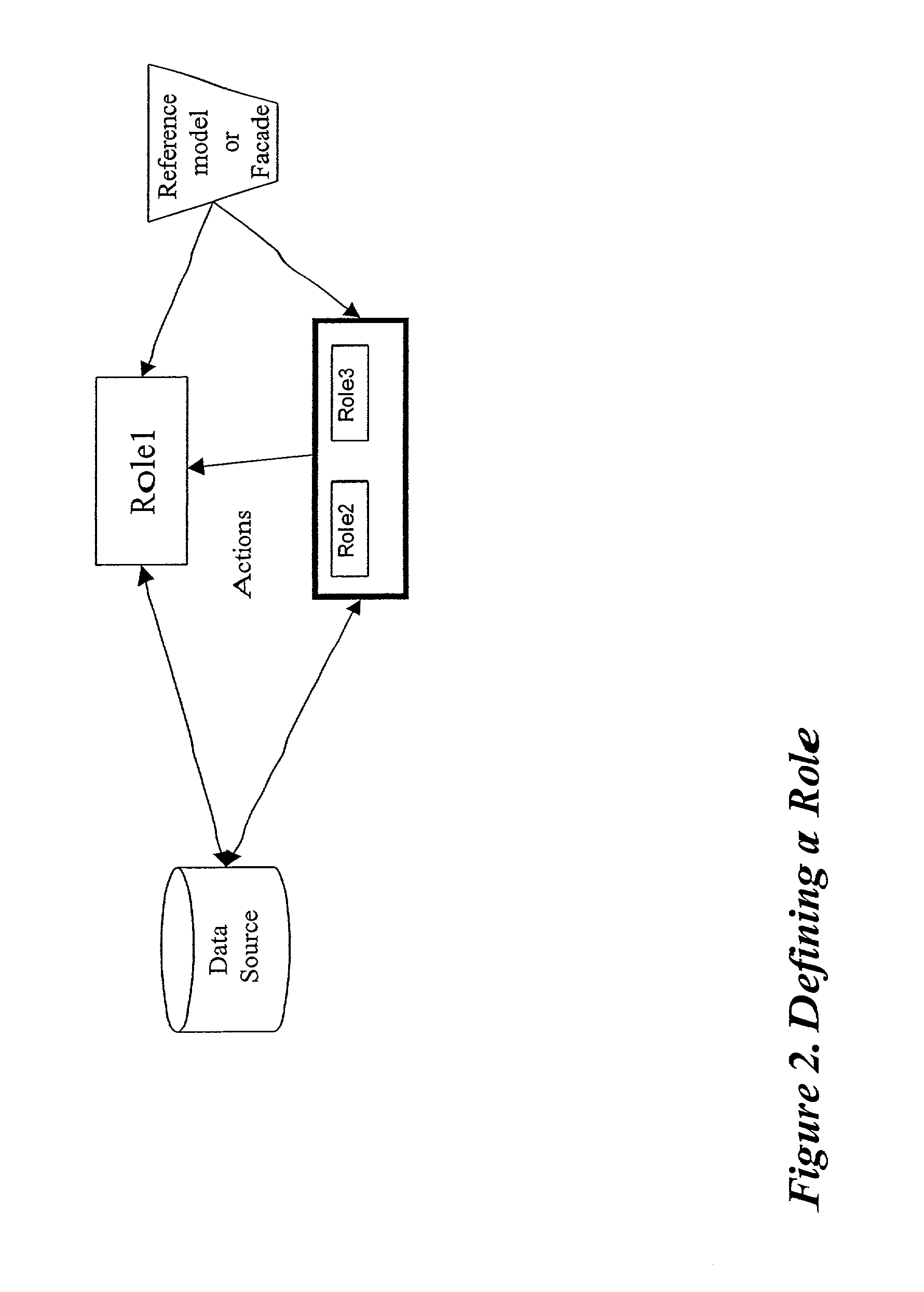

Method and apparatus for implementing an active information model

InactiveUS7328233B2Guaranteed to workMultiple digital computer combinationsOffice automationService provisionActive agent

An active information model constructed from an aggregation of personal information portals containing an active agent. In a preferred embodiment, the system of this invention can be offered as a network service providing for information access and exchange according to the individual users' preferences.

Owner:CORYBANT

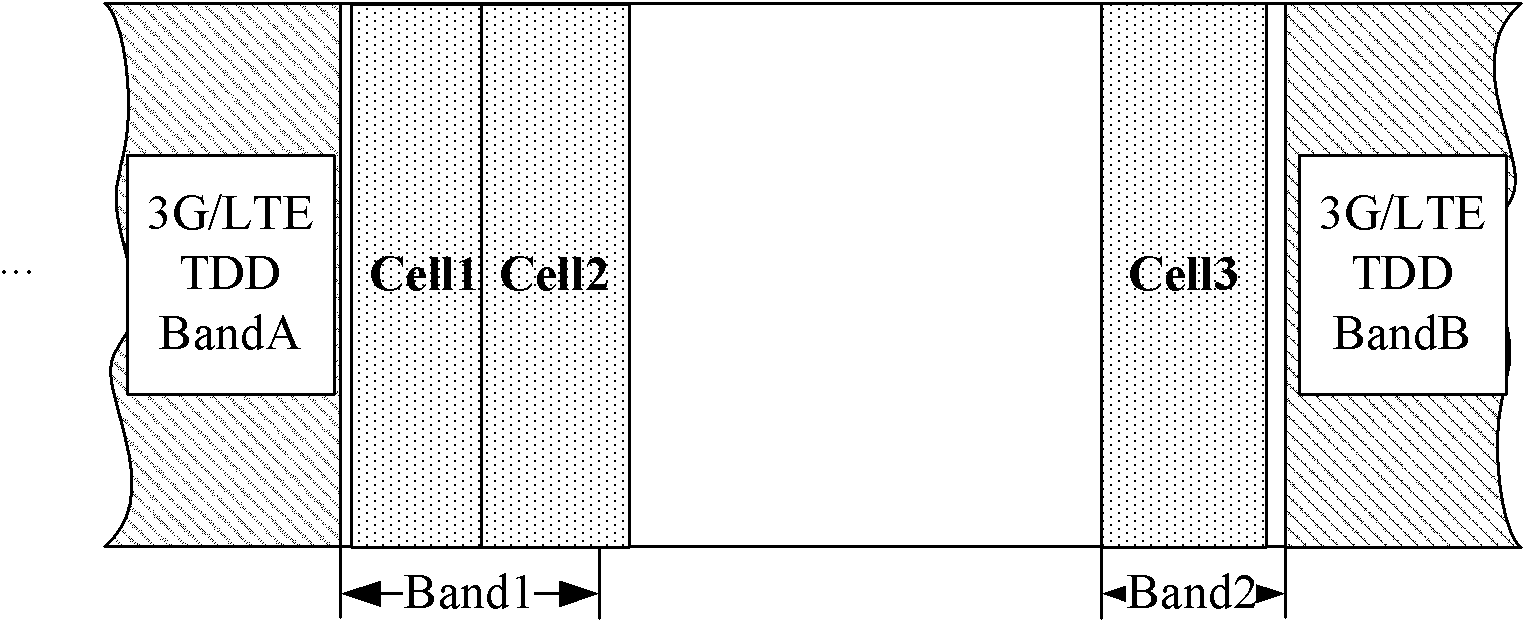

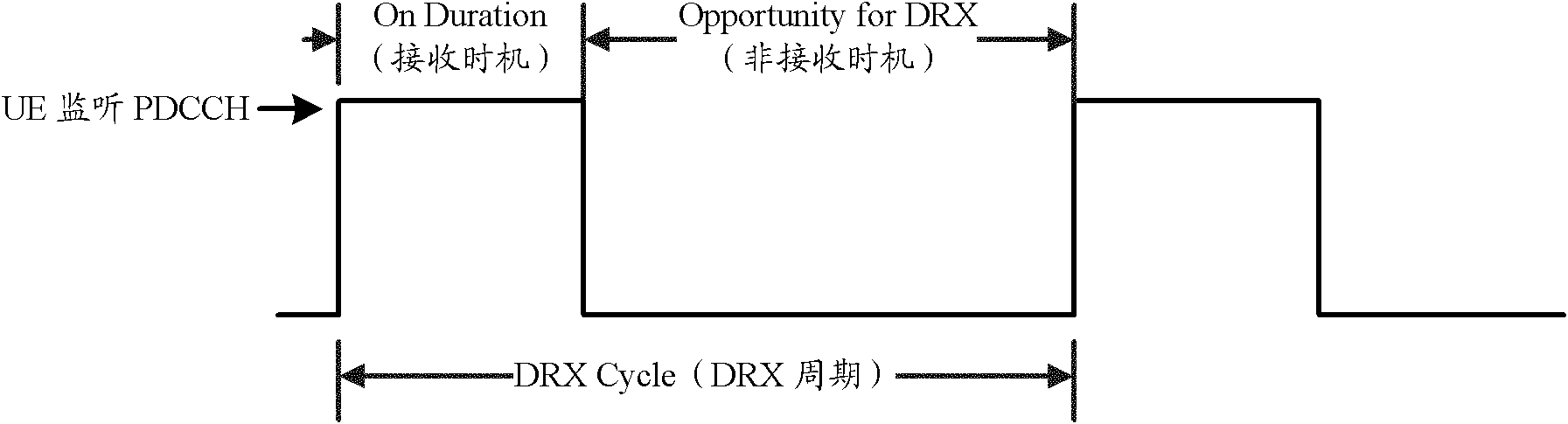

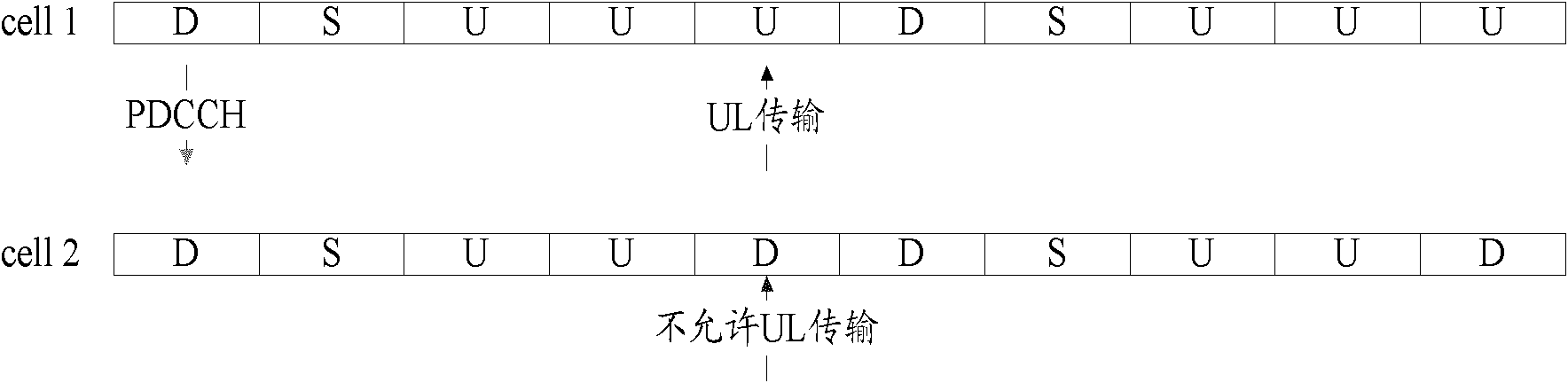

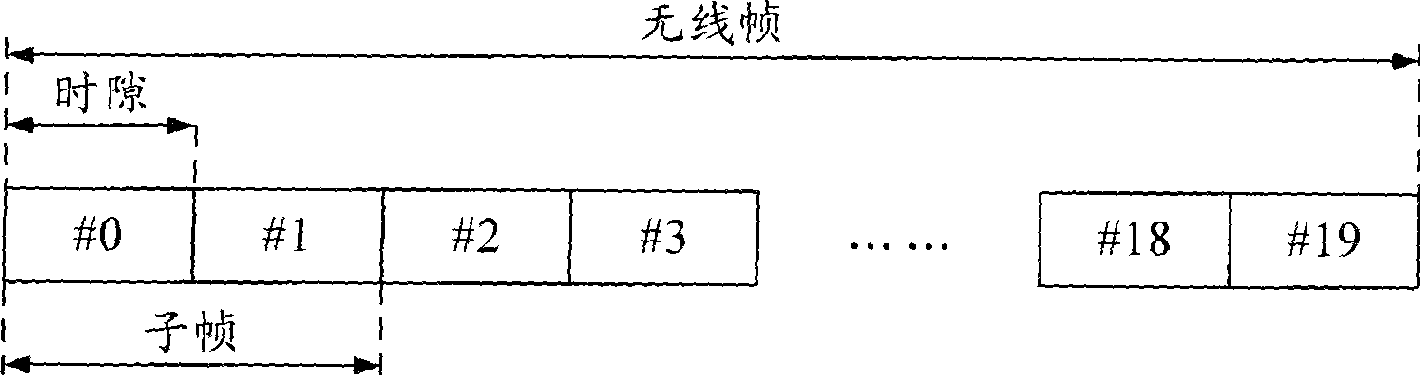

Carrier aggregation (CA) technology-based data transmission method and device

ActiveCN102075949AGuaranteed to workGuaranteed uptimeError prevention/detection by using return channelTransmission path divisionPrimary cellData transmission

The invention relates to the field of communication and discloses a CA technology-based data transmission method and a CA technology-based data transmission device, which are used for ensuring the normal operation of user terminals when a plurality of cells in which the user terminals supporting CA technology aggregate have different kinds of time division duplex uplink / downlink (TDD UL / DL) configuration. In the method, a TDD UL / DL configuration set concept is introduced, an especial cell (Ecell) concept is introduced for each TDD UL / DL configuration set, each TDD UL / DL configuration set may contain one or more cells and has one Ecell which may have all or part of functions of a primary cell (Pcell), the user terminals can perform data communication with the base station through TDD UL / DLconfiguration information and the corresponding Ecells, and thus, the method can ensure the user terminals operate normally when the plurality of cells in which the user terminals aggregate have different kinds of TDD UL / DL configuration and ensure the normal operation of the system.

Owner:DATANG MOBILE COMM EQUIP CO LTD

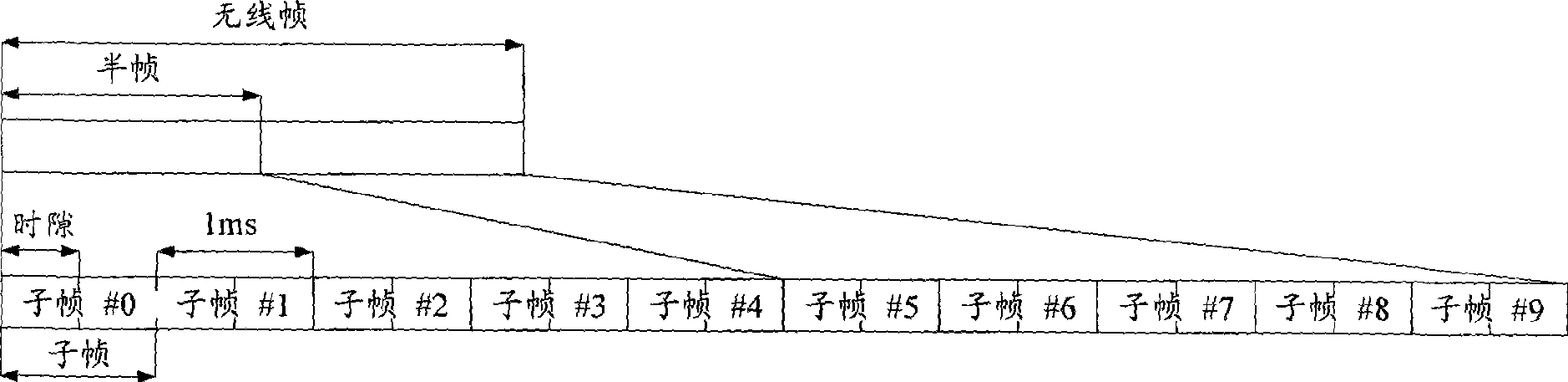

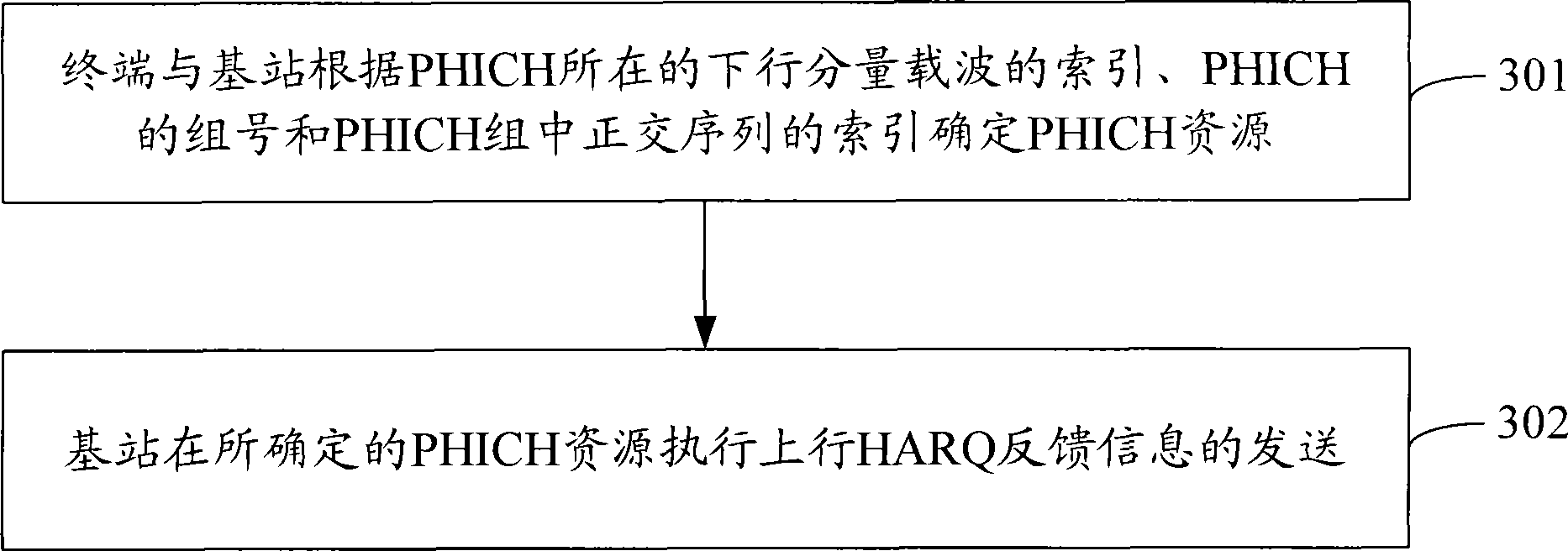

Method and device for sending upward HARQ feedback information

ActiveCN101465720ATroubleshoot sending issuesGuaranteed to workError prevention/detection by using return channelRadio transmission for post communicationFrequency spectrumCarrier signal

The invention discloses a method of sending uplink hybrid automatic retransmission request (HARQ) feedback information; the method includes that: a terminal and a base station determine PHICH resource according to the index of downlink component carrier of physical hybrid retransmission indication channel (PHICH), PHICH group number and the index of orthogonal sequence in PHICH group; the base station transmits uplink HARQ feedback information based on determined PHICH resource. The invention also discloses a device for transmitting uplink HARQ feedback information and solves the transmissionproblem of uplink HARQ feedback information in advanced long-term evolution system (LTE-Advanced), and ensures LTE-Advanced terminal to operate normally in spectrum aggregation mode and enables the LET-Advanced to be compatible with LTE Release-8, and facilitates improving the scheduling flexibility and throughput of system.

Owner:ZTE CORP

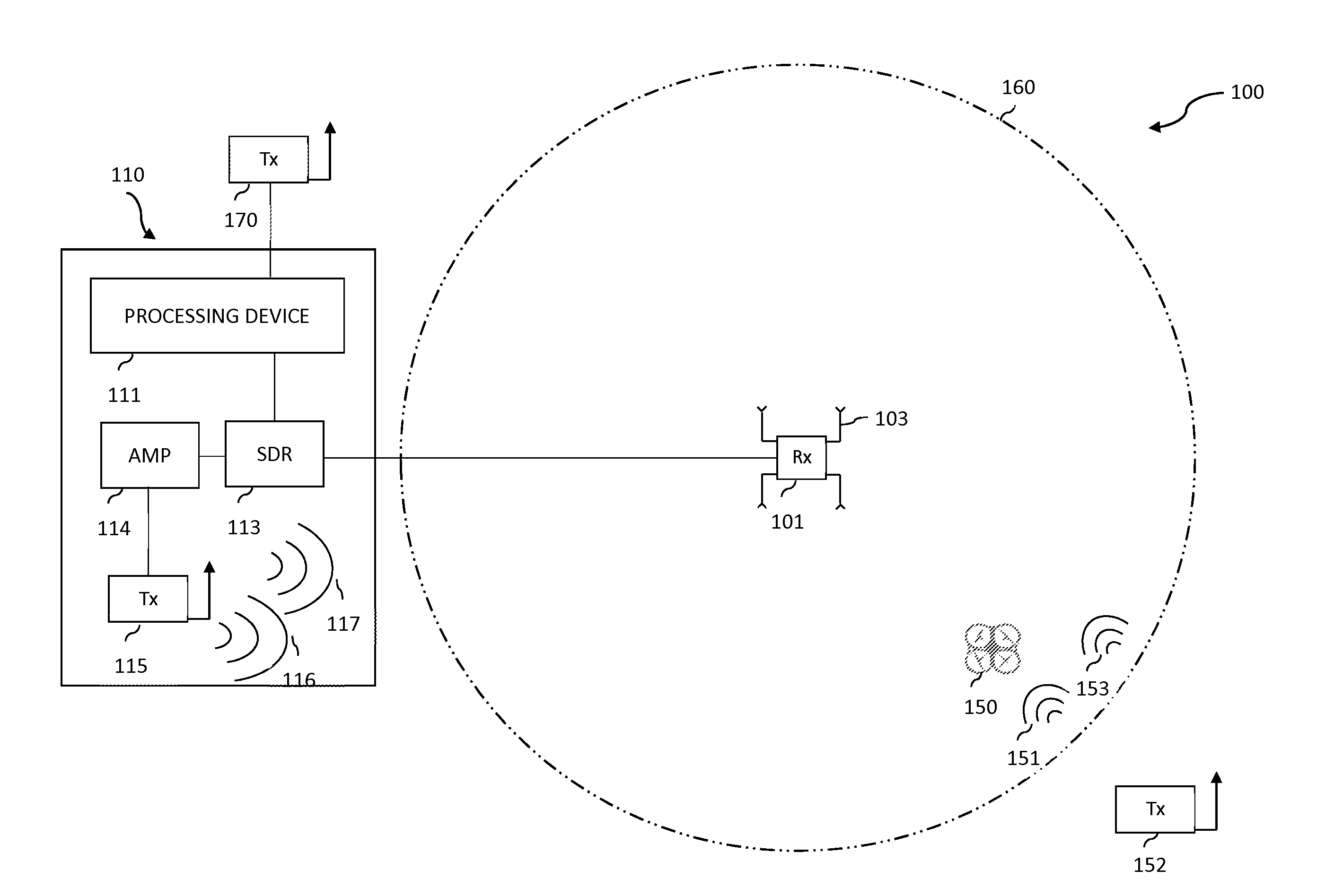

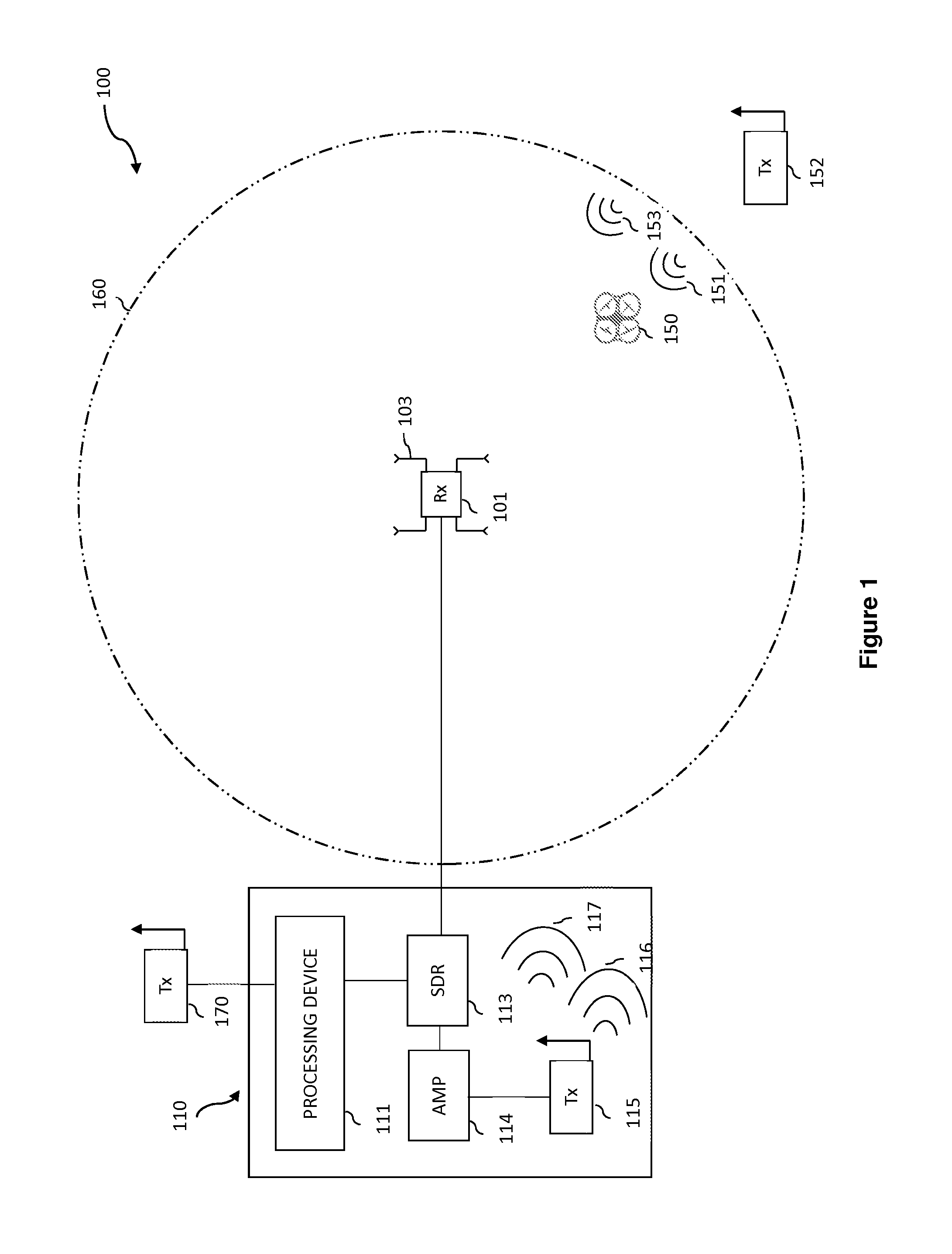

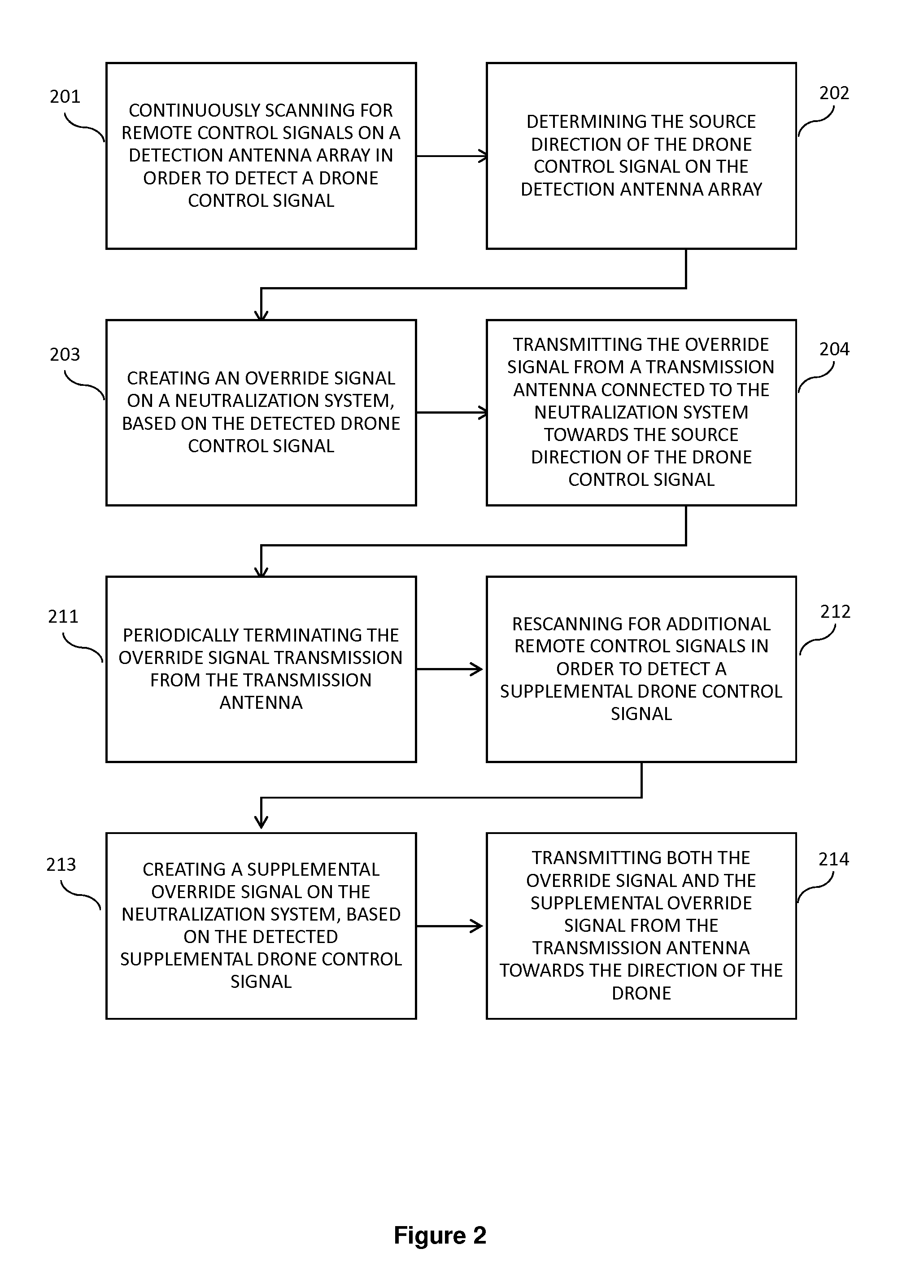

System and method for detecting and defeating a drone

ActiveUS9529360B1Process can be speededImprove energy conversion efficiencyUnmanned aerial vehiclesRemote controlled aircraftAudio power amplifierControl signal

The invention is directed to a system for detecting and defeating a drone. The system has a detection antenna array structured and configured to detect the drone and the drone control signal over a 360 degree field relative to the detection antenna array including detecting the directionality of the drone. The system also includes a neutralization system structured and configured in a communicating relation with the detection antenna array. The neutralization system has a transmission antenna structured to transmit an override signal aimed at the direction of the drone, an amplifier configured to boost the gain of the override signal to exceed the signal strength of the drone control signal, and a processing device configured to create and effect the transmission of the override signal. The invention is also directed to a method for detecting and defeating a drone.

Owner:CELLANTENNA INT INC

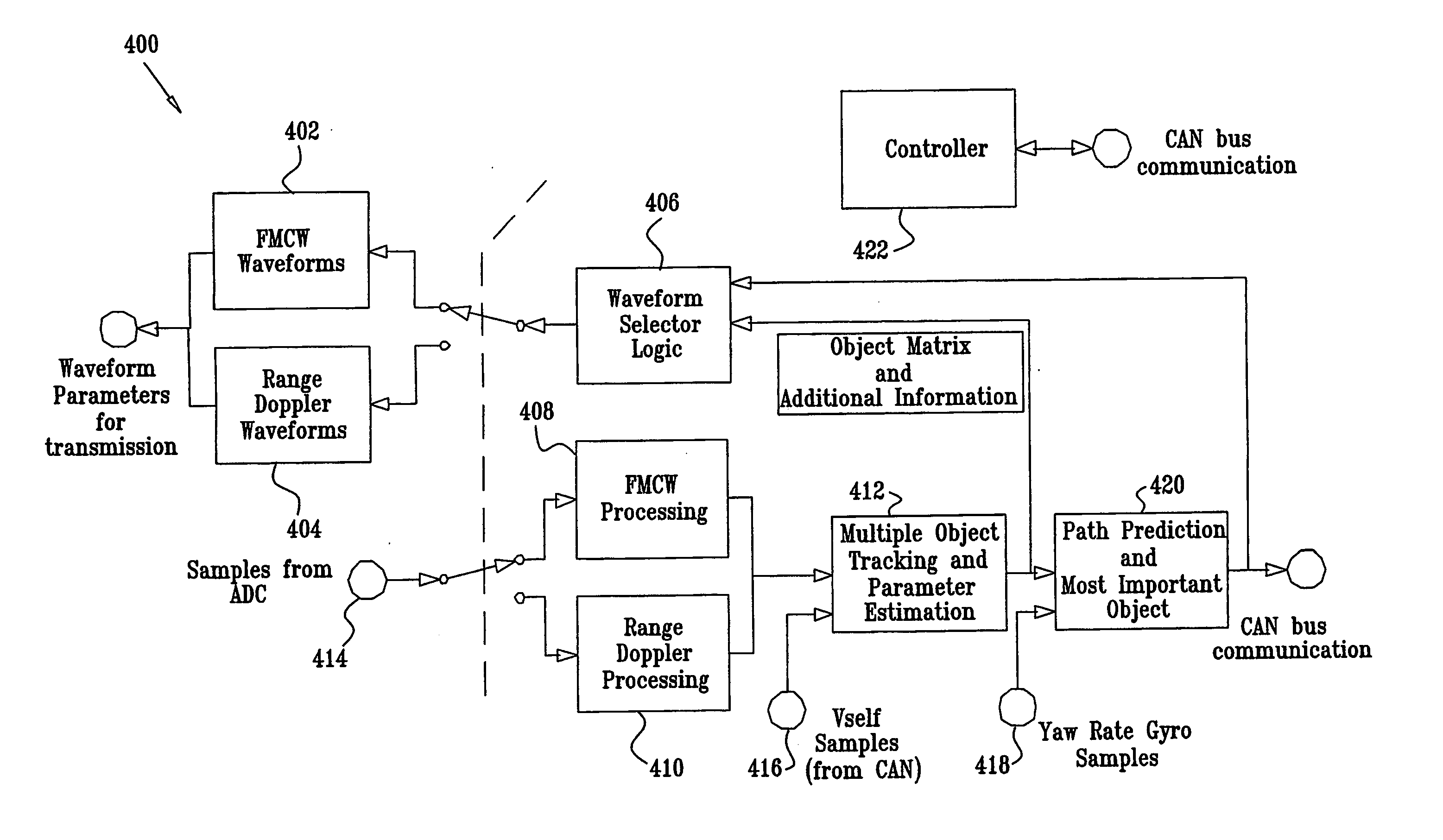

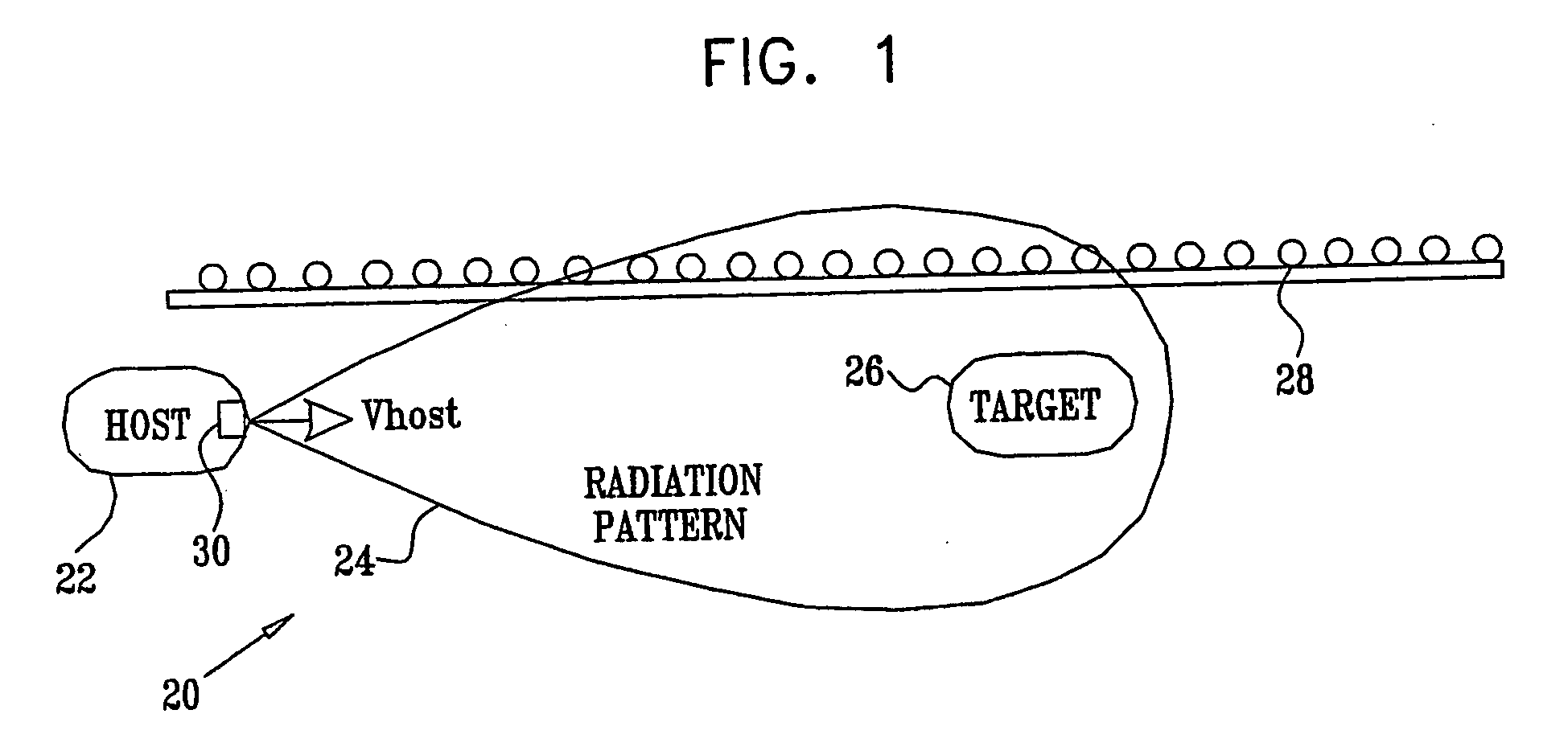

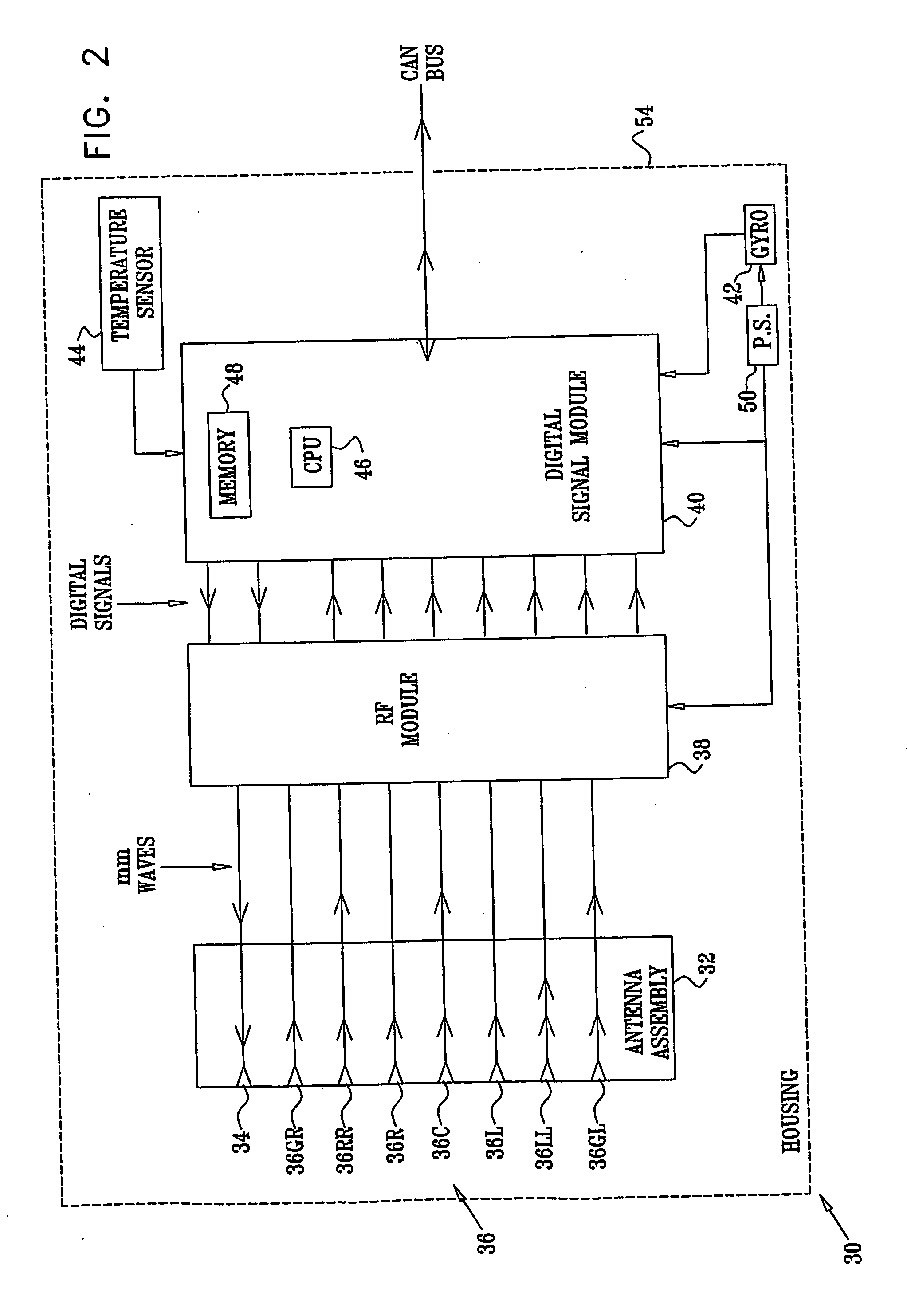

Forward-looking radar system

InactiveUS20050285773A1Improve discriminationPrecise maintenanceAntenna adaptation in movable bodiesRadio wave reradiation/reflectionElectricityRadar systems

An assembly for receiving and transmitting millimeter (mm) waves, including at least one mm wave reflector (84, 86, 88)and at least one mm transmission wave feed (72) configured in a transmission feed location (34) within the at least one mm wave reflector. The assembly also includes a plurality of receiving mm wave feeds (72) configured in respective receiving feed locations (36) within the at least one mm wave reflector; and a radio frequency (RF) module (38). The RF module is coupled to the at least one mm transmission wave feed and to the plurality of the receiving mm wave feeds, so as to drive the at least one mm transmission wave feed to transmit outgoing mm waves and to simultaneously receive incoming mm waves from all of the plurality of the receiving mm wave feeds.

Owner:GROENEVELD TRANSPORT EFFICIENCY

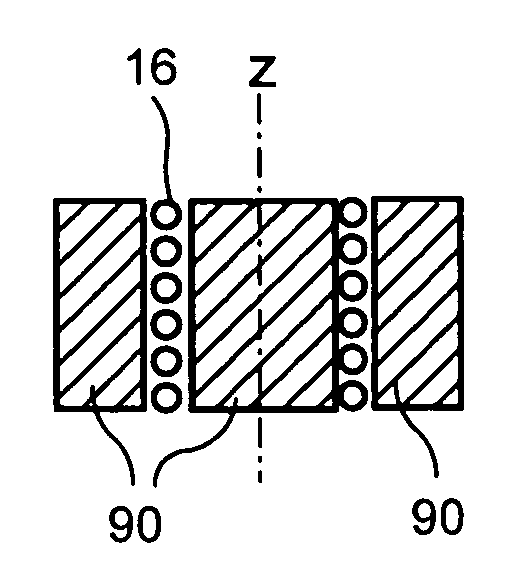

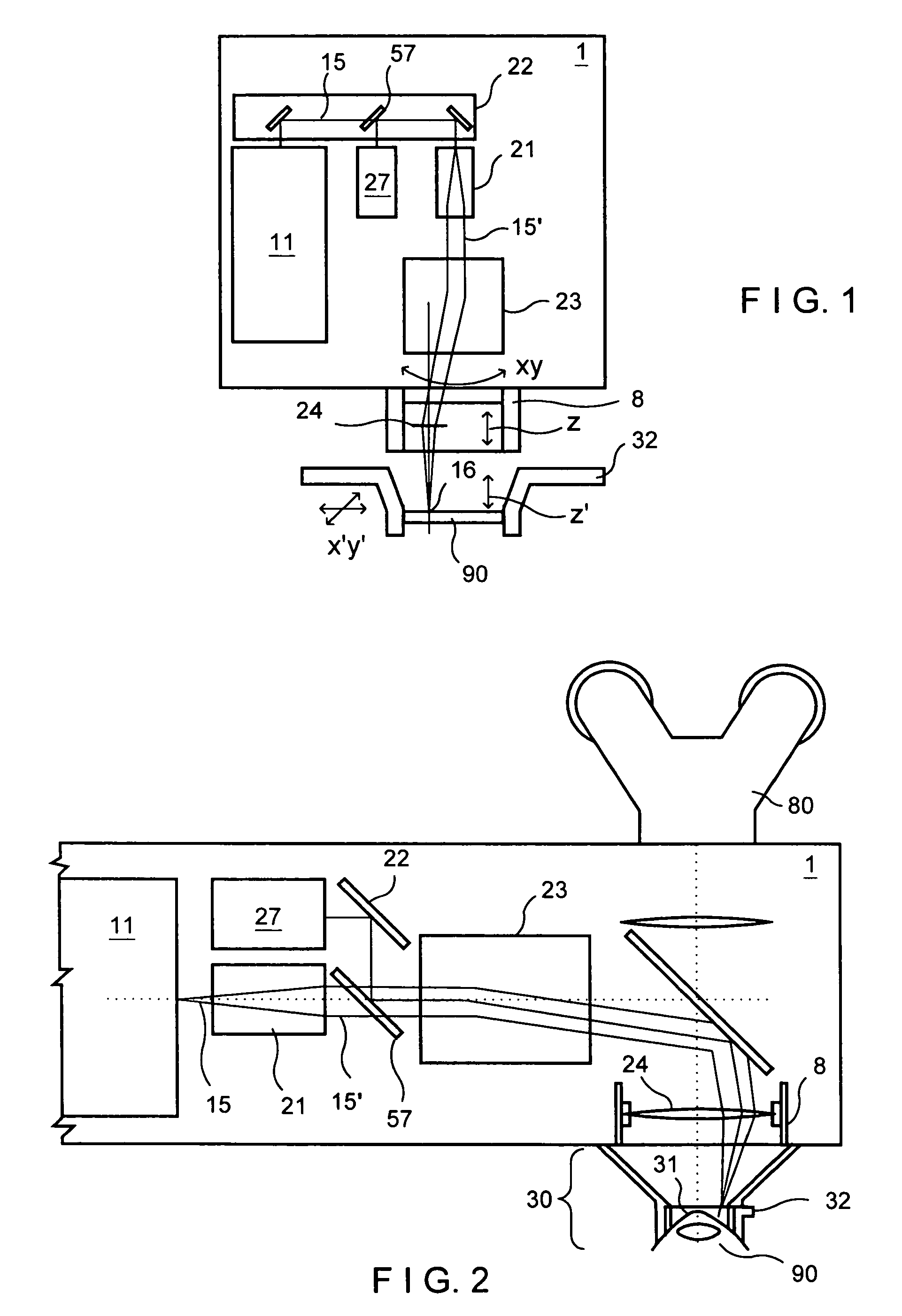

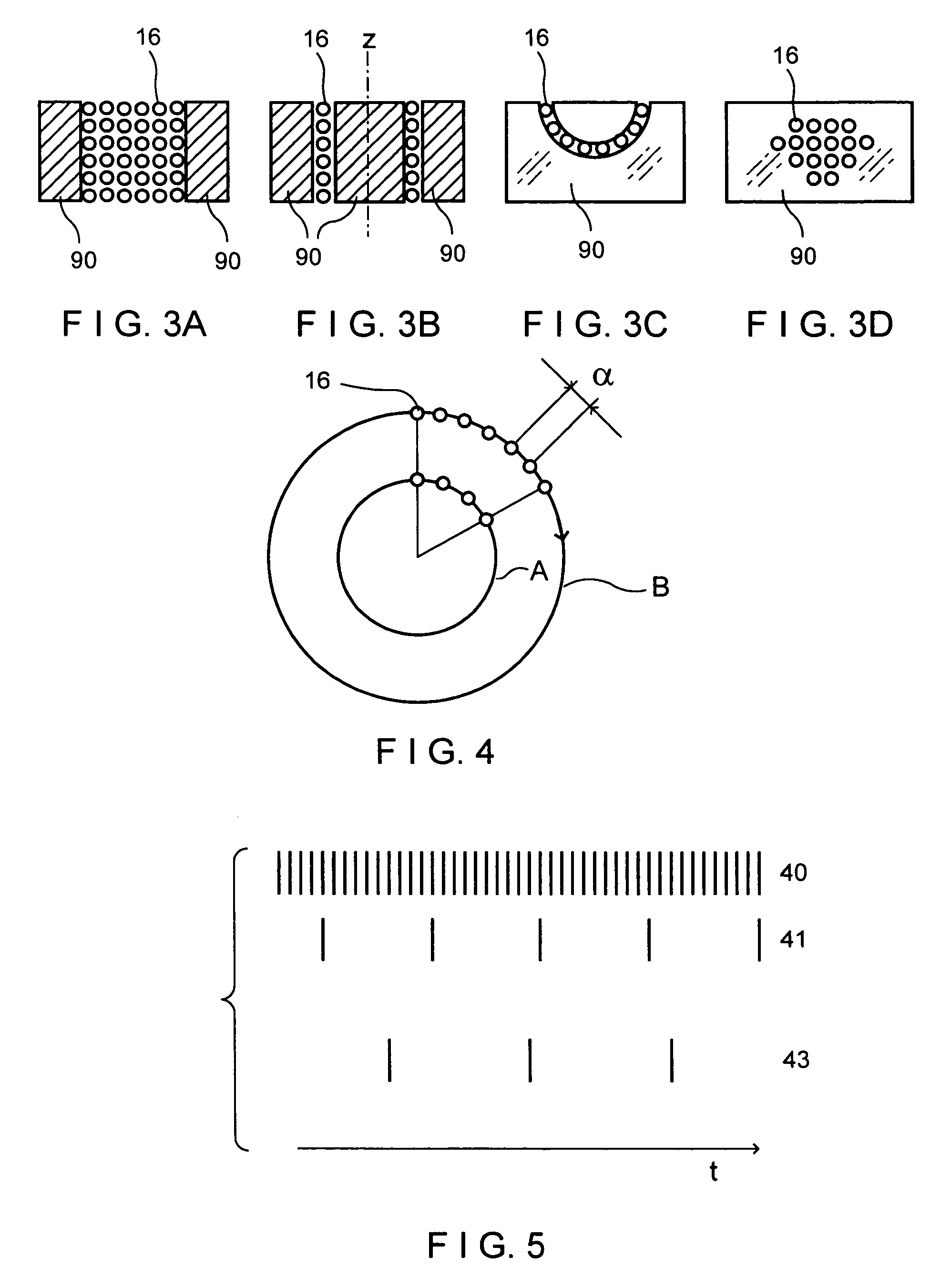

Method and apparatus for precision working of material

A method for precise working of material, particularly organic tissue, comprises the step of providing laser pulses with a pulse length between 50 fs and 1 ps and with a pulse frequency from 50 kHz to 1 MHz and with a wavelength between 600 and 2000 nm for acting on the material to be worked. Apparatus, in accordance with the invention, for precise working of material, particularly organic tissue comprising a pulsed laser, wherein the laser has a pulse length between 50 fs and 1 ps and with a pulse frequency of from 50 kHz to 1 MHz is also described.

Owner:CARL ZEISS MEDITEC AG

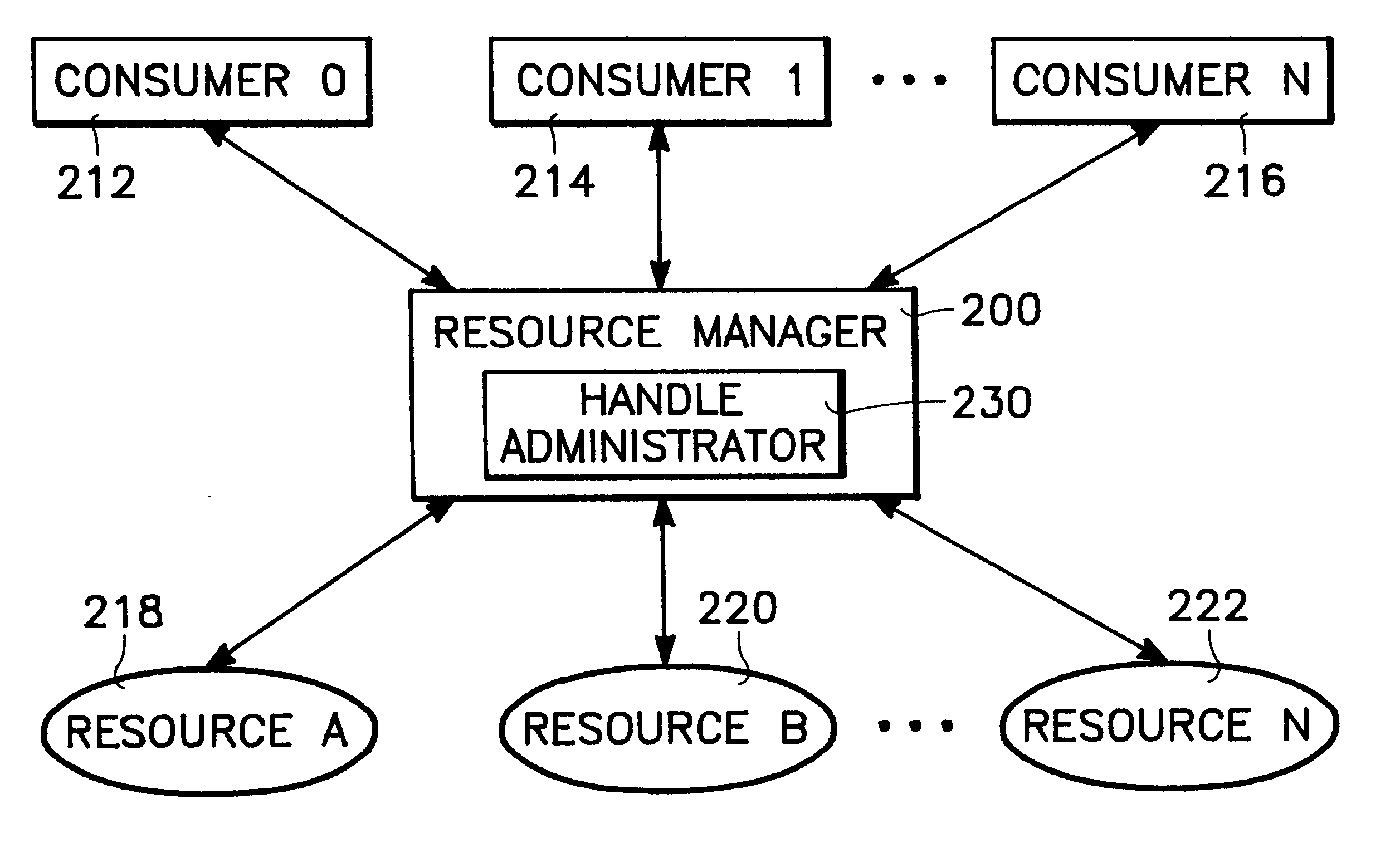

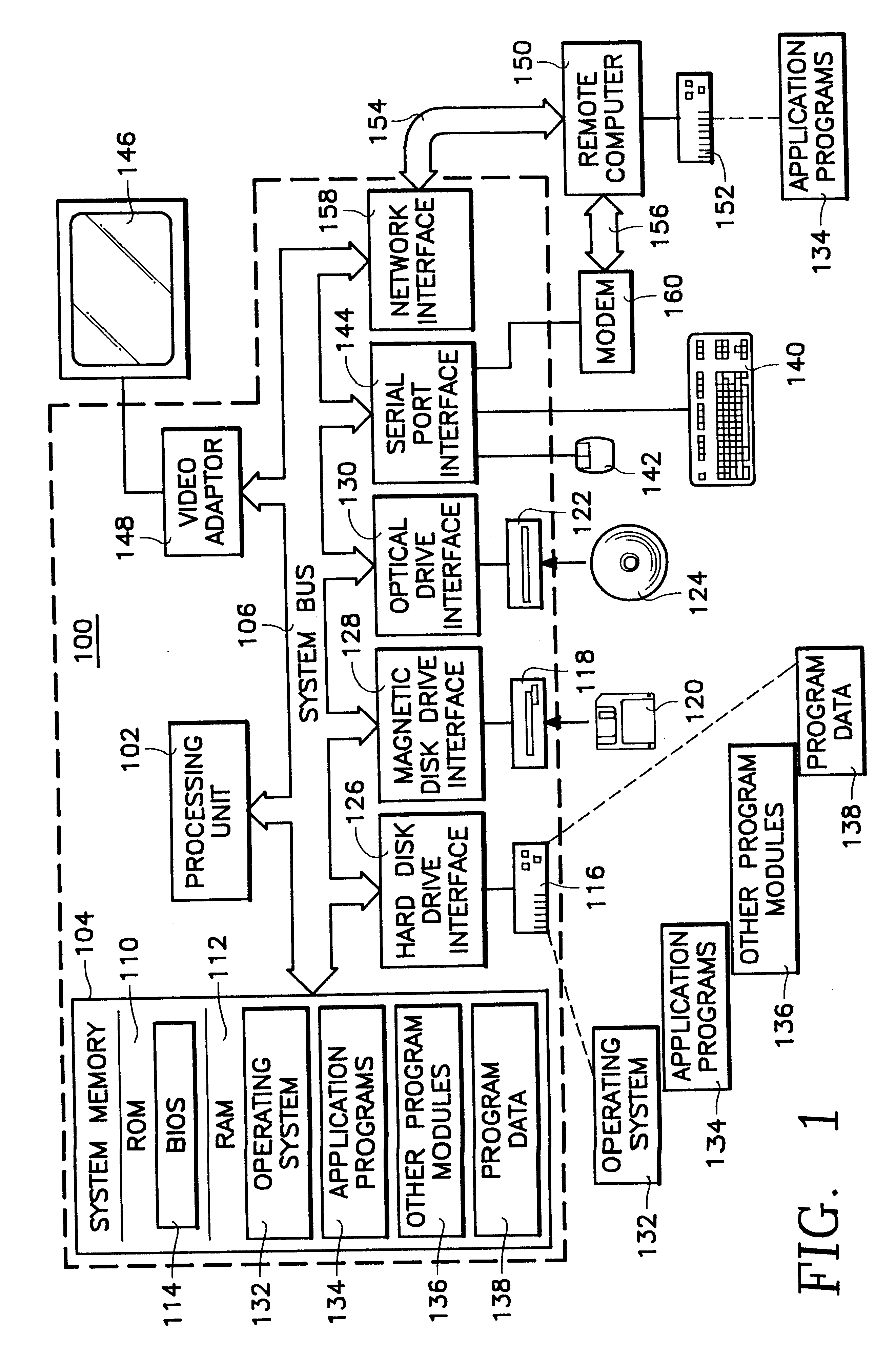

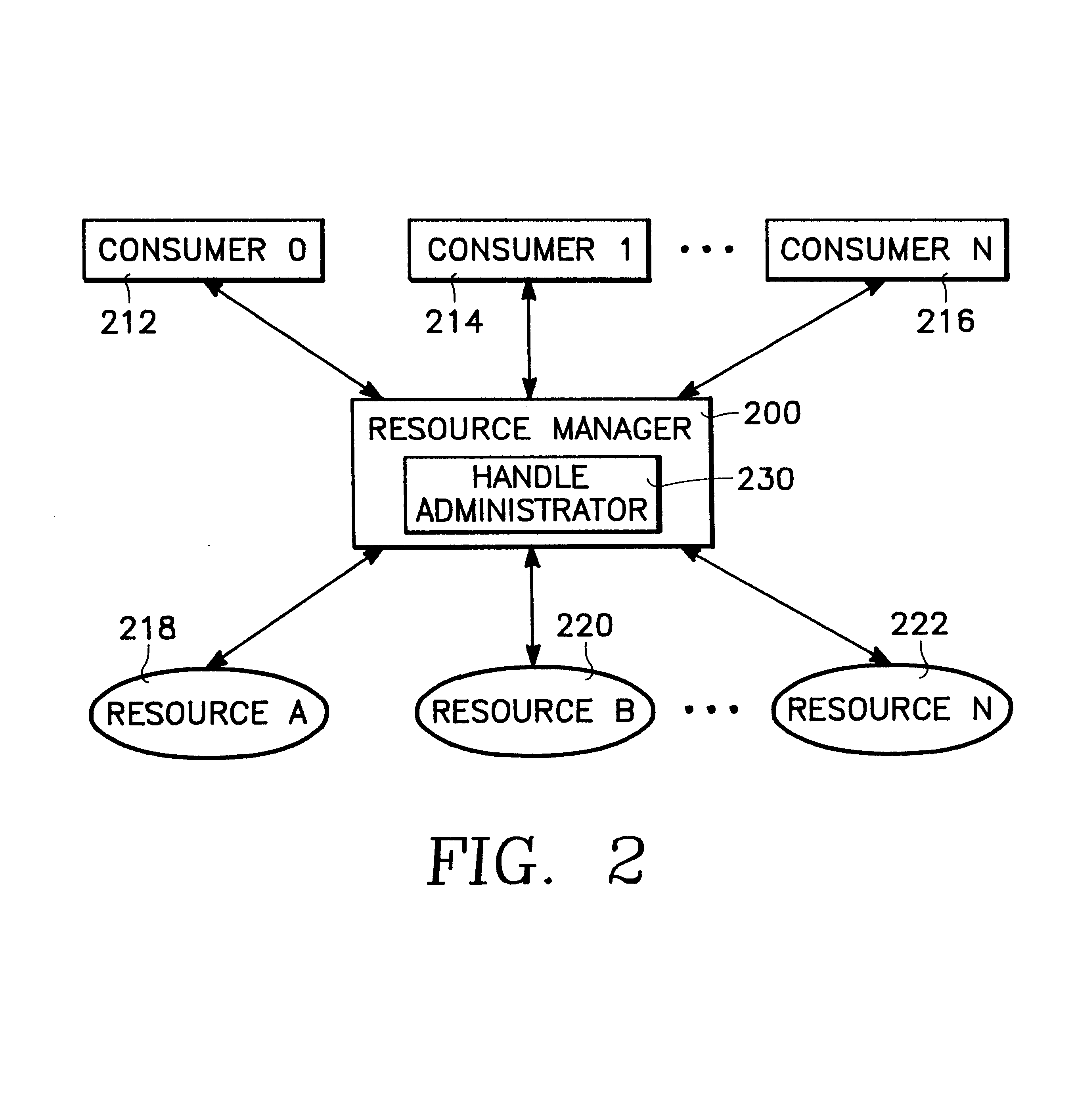

System and method for recycling numerical values in a computer system

InactiveUS6178423B1Efficient releaseGuaranteed to workData processing applicationsResource allocationHysteresisComputerized system

The present invention is embodied in a system and method for generating and validating reference handles for consumers requiring access to resources in a computer system. The system of the present invention includes a resource manager having a handle administrator, a plurality of consumers, and a plurality of resources. The handle administrator includes an assignment routine, a release routine, and a dereference routine. The assignment routine issues new handles, the release routine releases handles that are no longer required (thus rendering the handle invalid), and the dereference routine dereferences handles into a pointer to a resource, which entails verifying that the handle is valid. Also included is an auxiliary sub-routine for managing used and unused records, an expansion sub-routine for efficiently expanding the handle database, a handle recycling sub-routine for recycling handles, a contraction sub-routine for efficiently contracting the handle database, a hysteresis sub-routine for probabilistically contracting the handle database, and a memory allocation failure sub-routine to improve functionality in the event of memory allocation failure.

Owner:MICROSOFT TECH LICENSING LLC

Method and apparatus for implementing an active information model

InactiveUS20020035593A1Satisfies requirementGuaranteed to workMultiple digital computer combinationsOffice automationService provisionActive agent

An active information model constructed from an aggregation of personal information portals containing an active agent. In a preferred embodiment, the system of this invention can be offered as a network service providing for information access and exchange according to the individual users' preferences.

Owner:CORYBANT

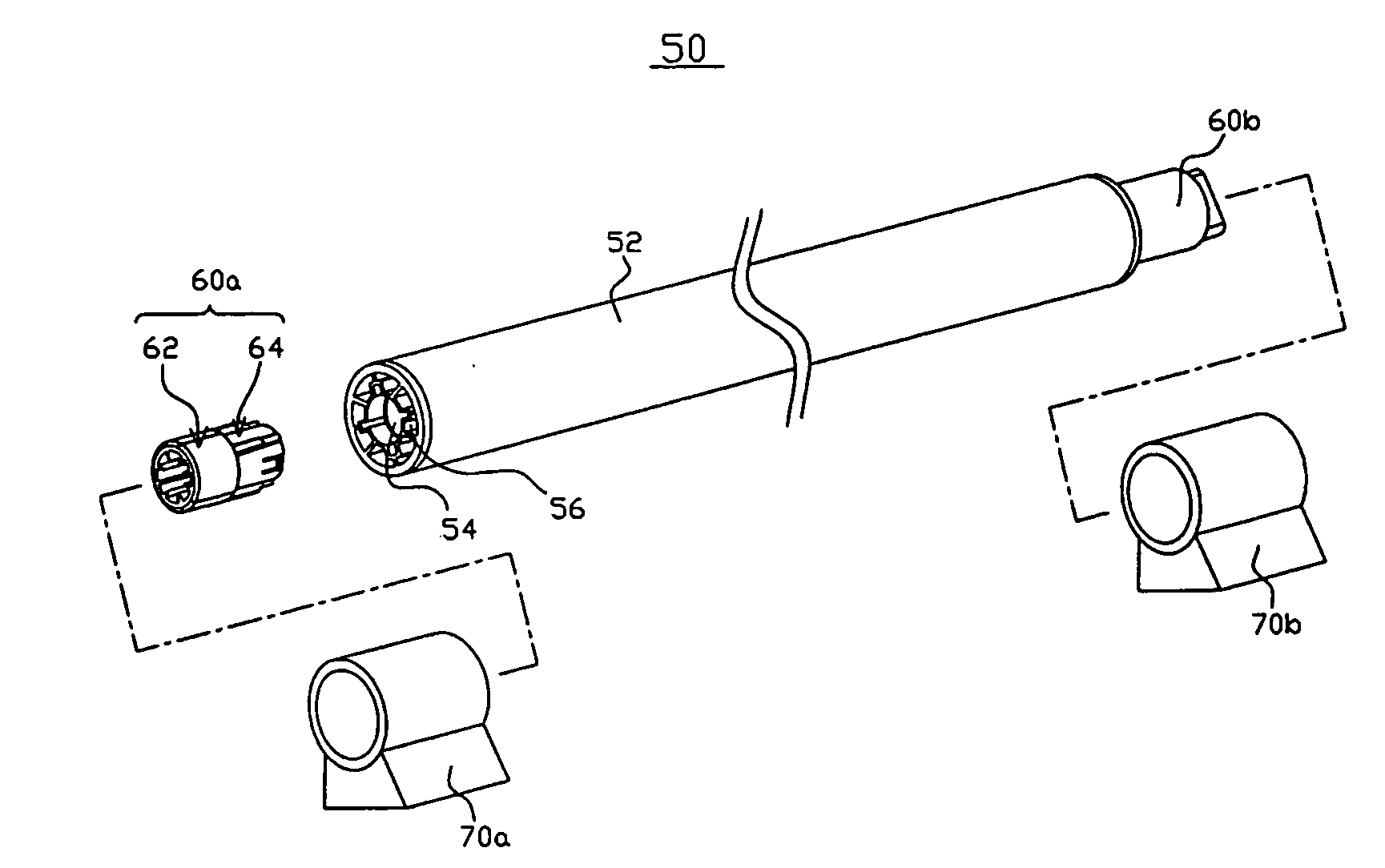

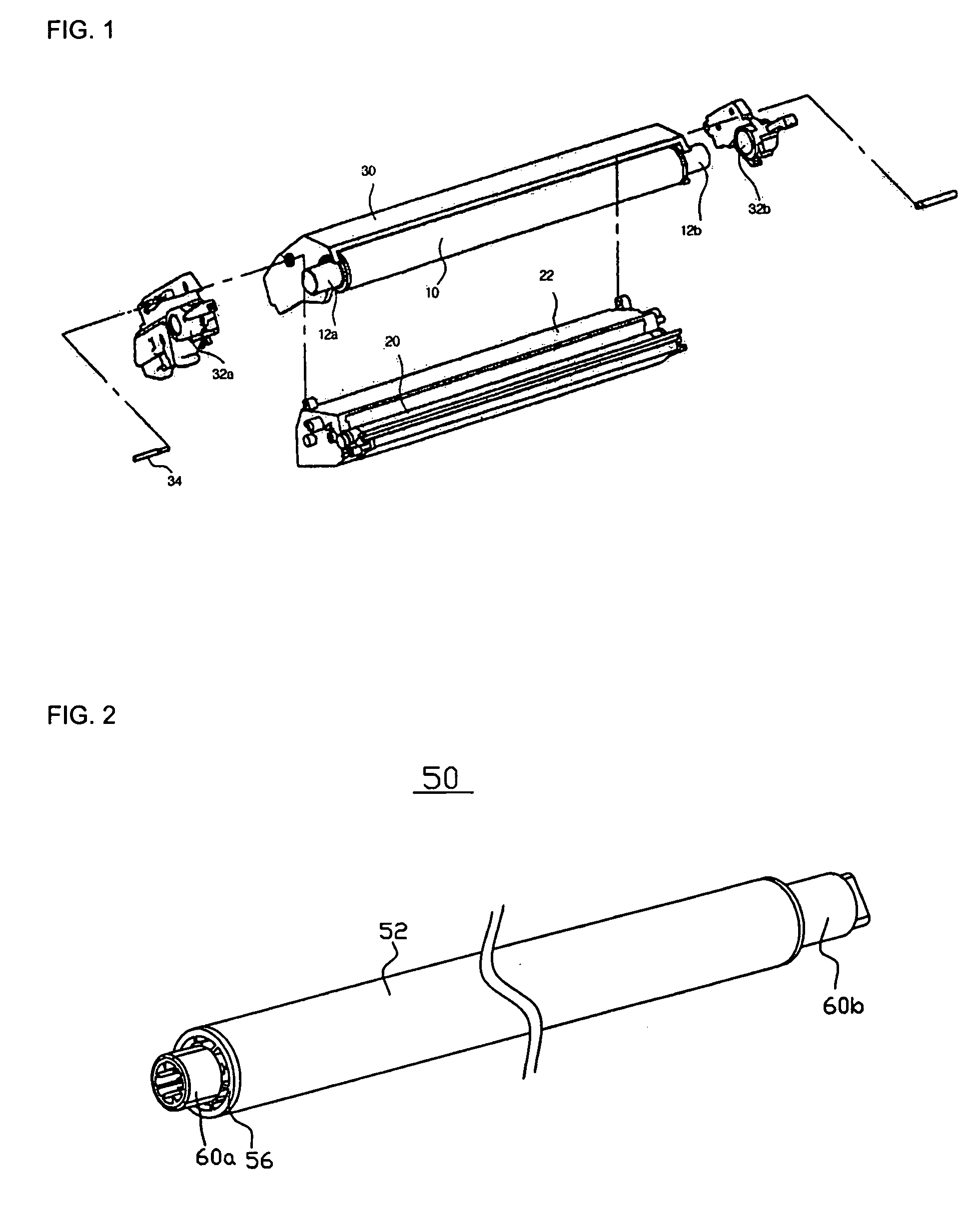

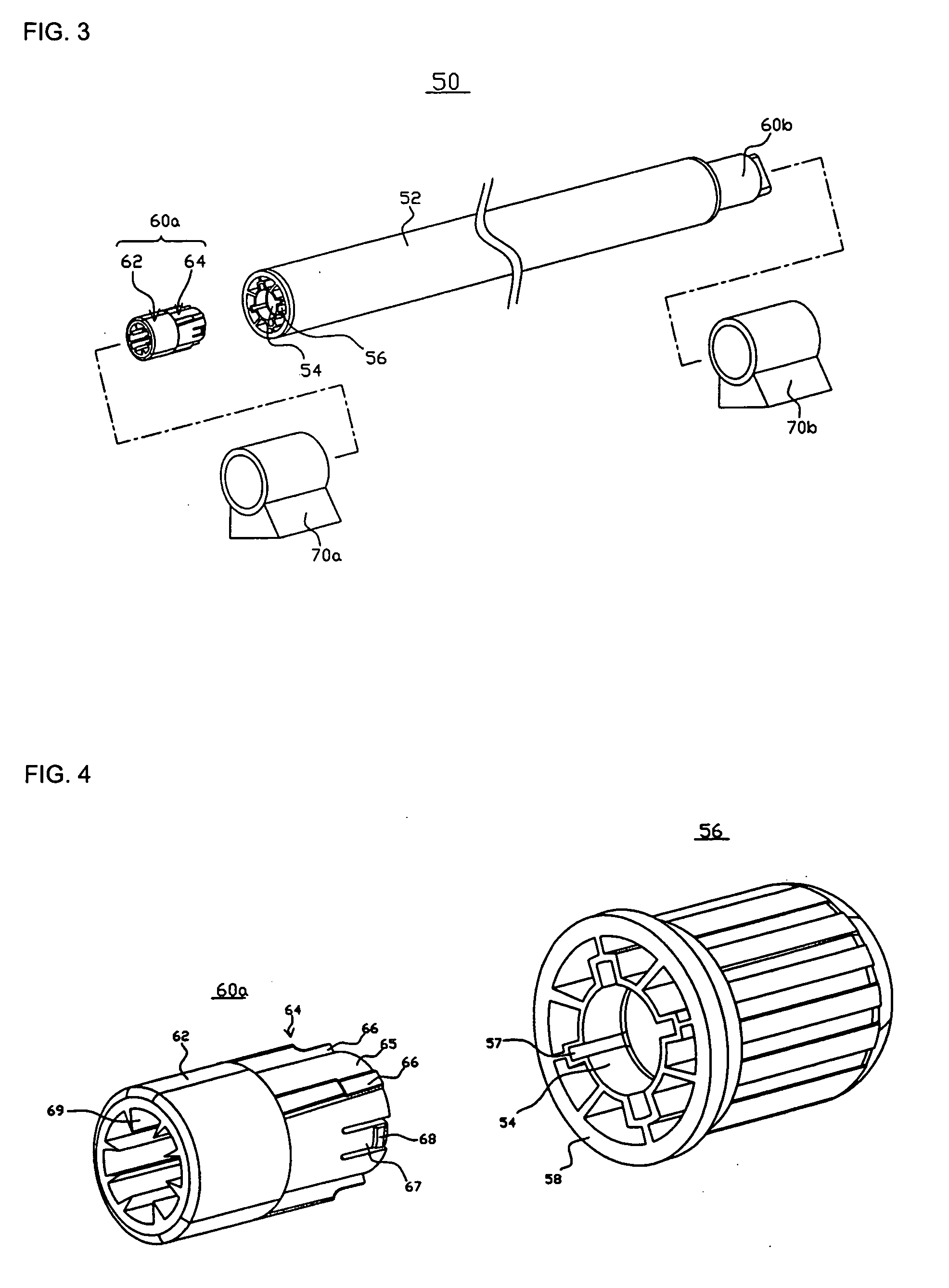

Photosensitive drum for printer cartridge and method for mounting the same

InactiveUS20070237545A1Guaranteed to workCouplings for rigid shaftsElectrographic process apparatusMechanical engineeringEngineering

A photosensitive drum for a printer cartridge, which can be easily mounted on a printer cartridge of which the positions of drum connectors are fixed, is disclosed. The photosensitive drum for a printer cartridge comprises a cylindrical drum having a photosensitive layer on a cylindrical surface thereof; and a pair of rotation shafts which is respectively mounted on the sides of the cylindrical drum for rotating and supporting the cylindrical drum, wherein at least one of the rotation shafts is insert-fitted to the side of the cylindrical drum.

Owner:PARK&OPC

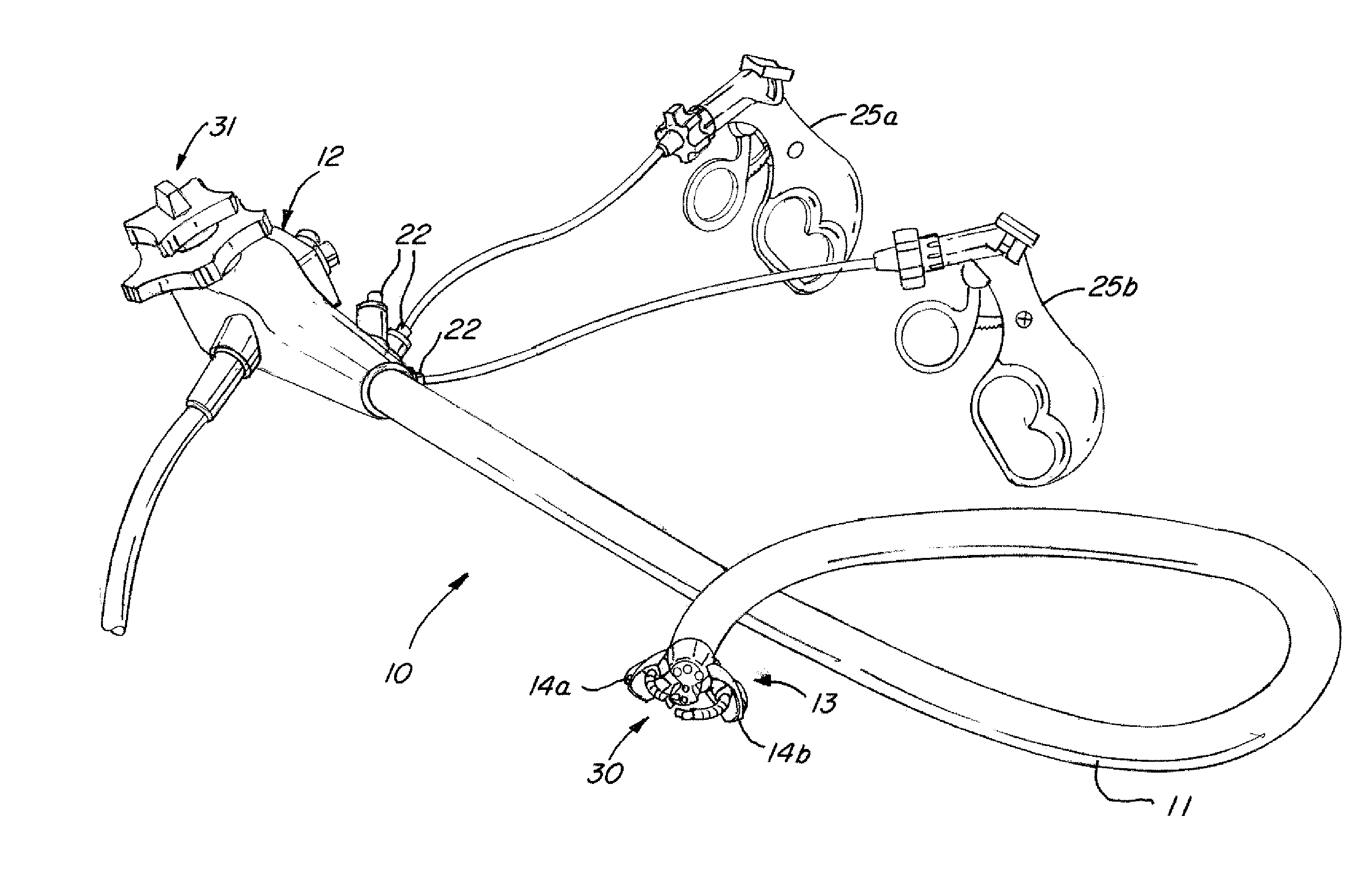

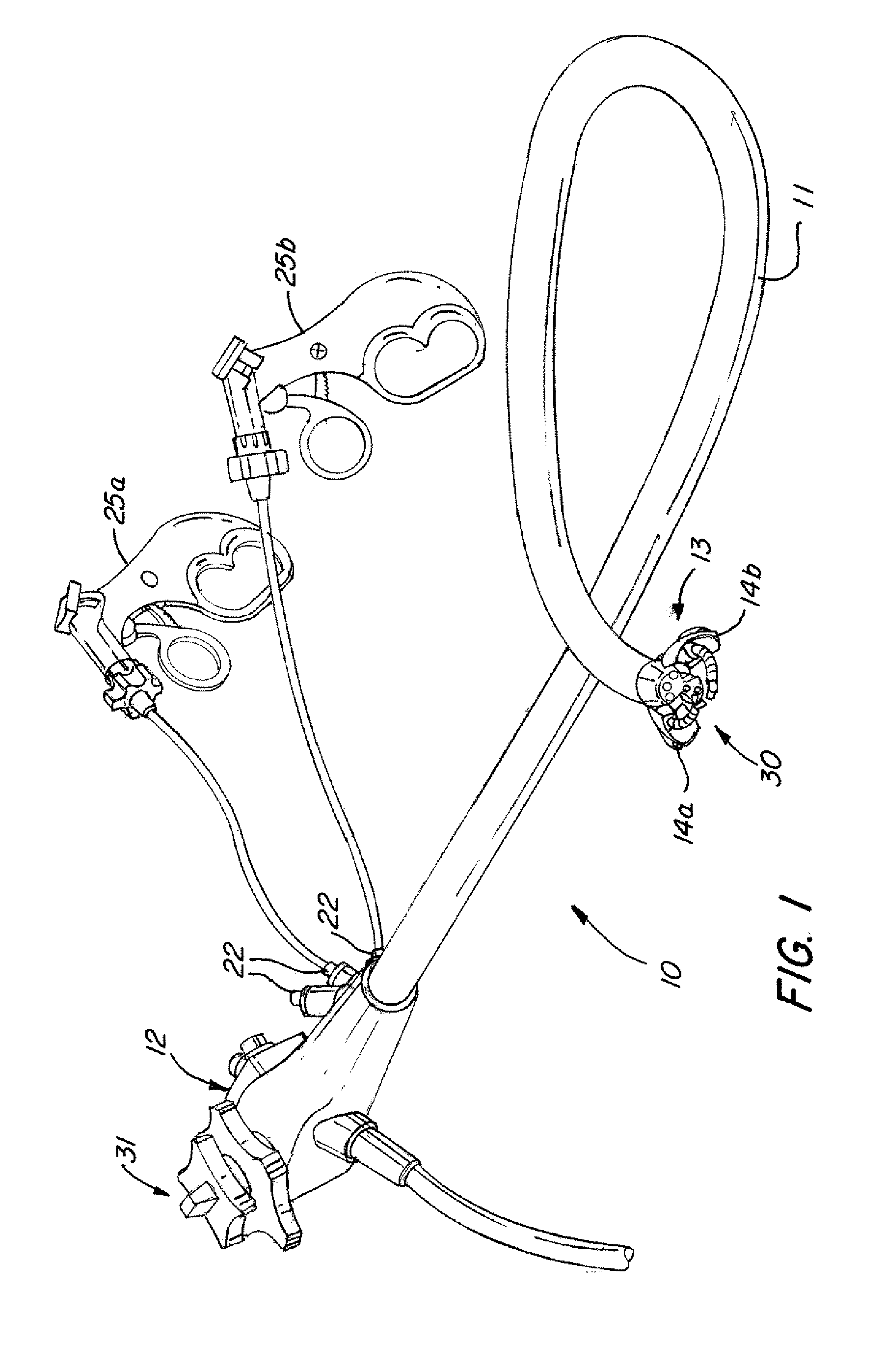

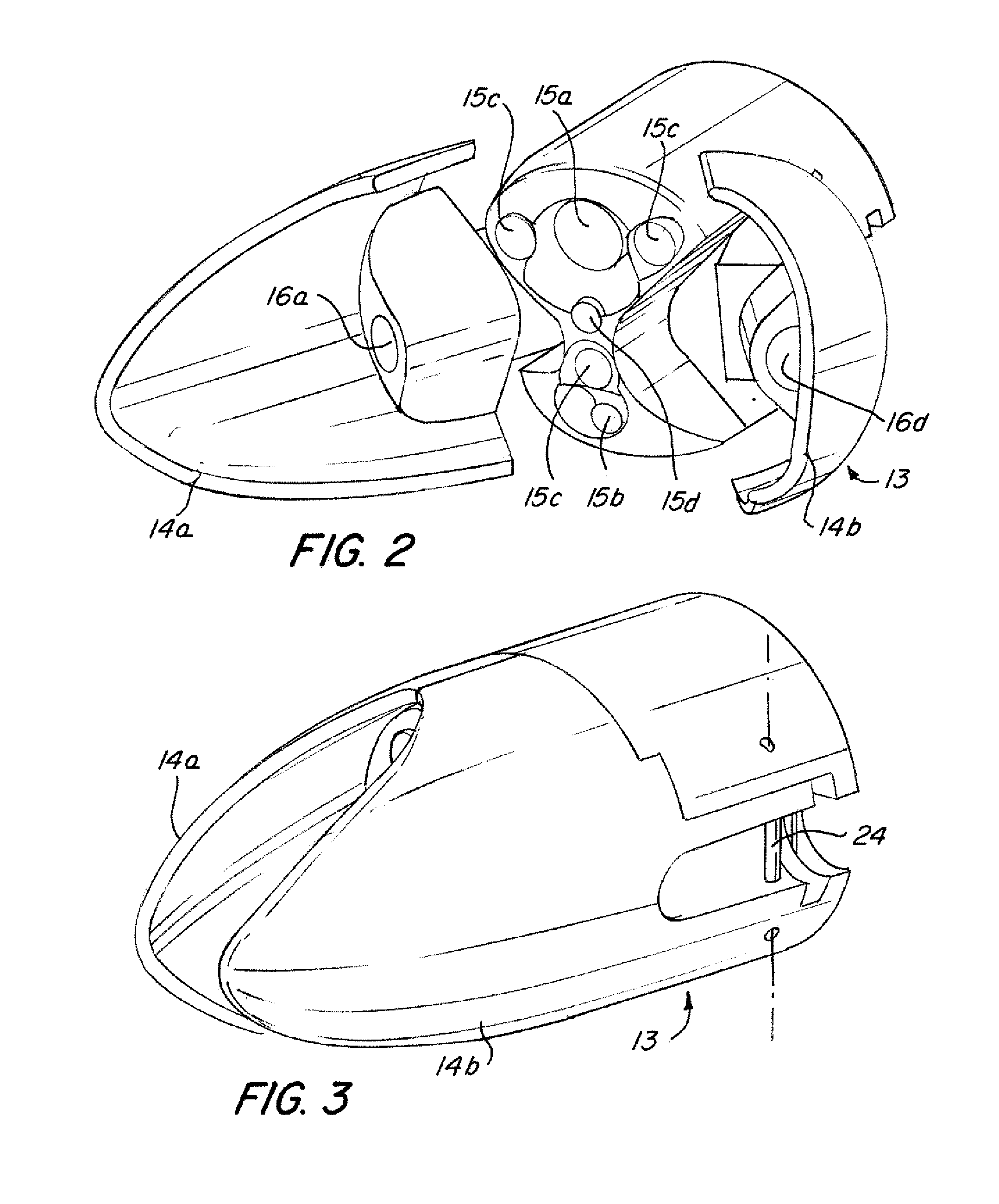

Endoscope system with pivotable arms

ActiveUS20080269562A1Pain minimizationMinimizes of recovery timeCannulasEndoscopesSurgical siteEndoscopic surgery

An endoscopic surgery apparatus is provided, including a tubular member, a handle located on a proximal end of the tubular member, and one or more pivotable arms detachably connected to a distal end of the tubular member. The tubular member has channels along its longitudinal axis, wherein at least one of the channels is an optical channel and at least one other channel is an illumination channel. The arms have guiding channels adapted to receive surgical tools, which direct the surgical tools. The arms are interchangeable with other arms of different configurations. Also, said arms have an open and a closed position, such that when the arms are in the closed position an opening is defined allowing viewing of a surgical site via the optical channel.

Owner:KARL STORZ ENDOVISION INC

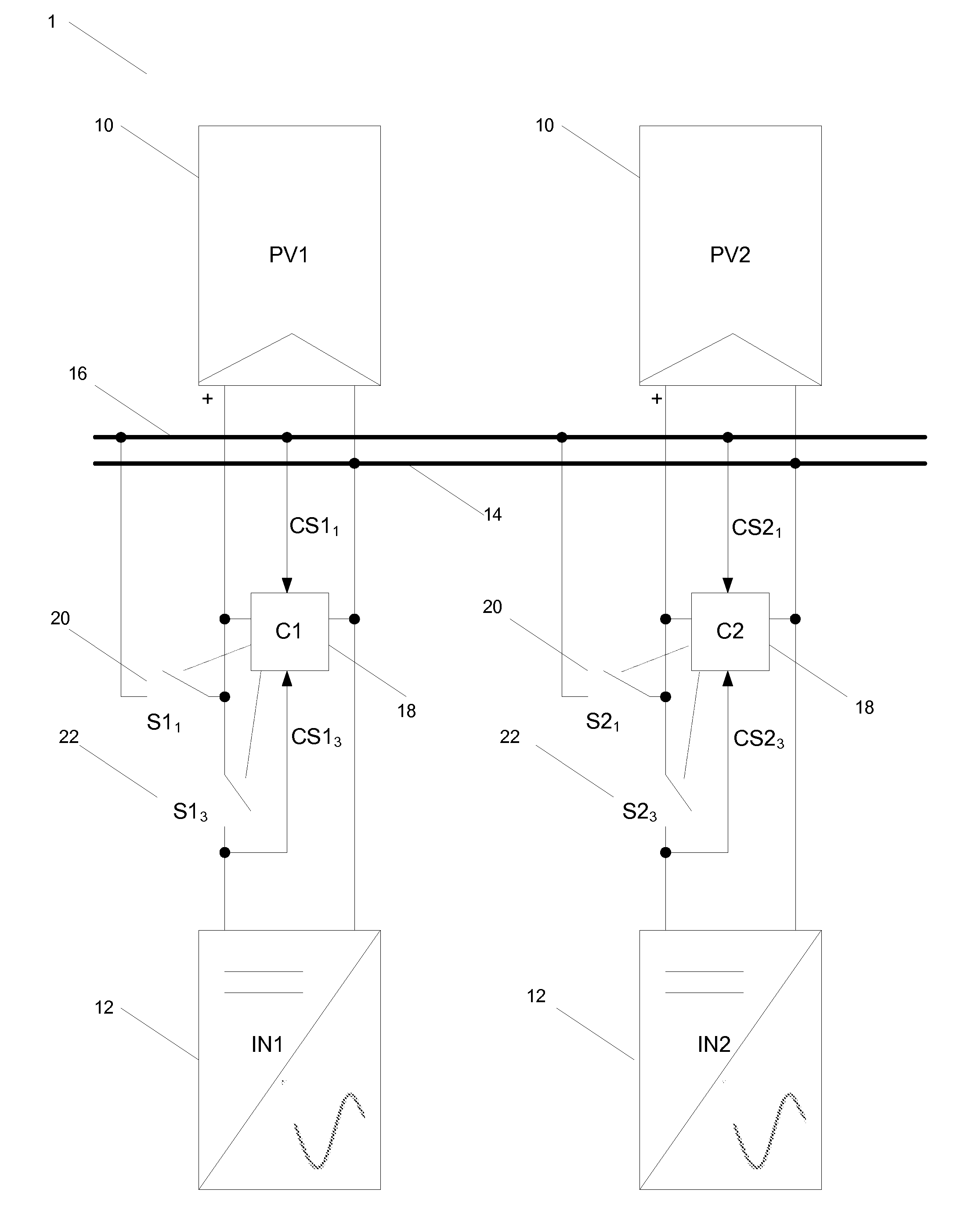

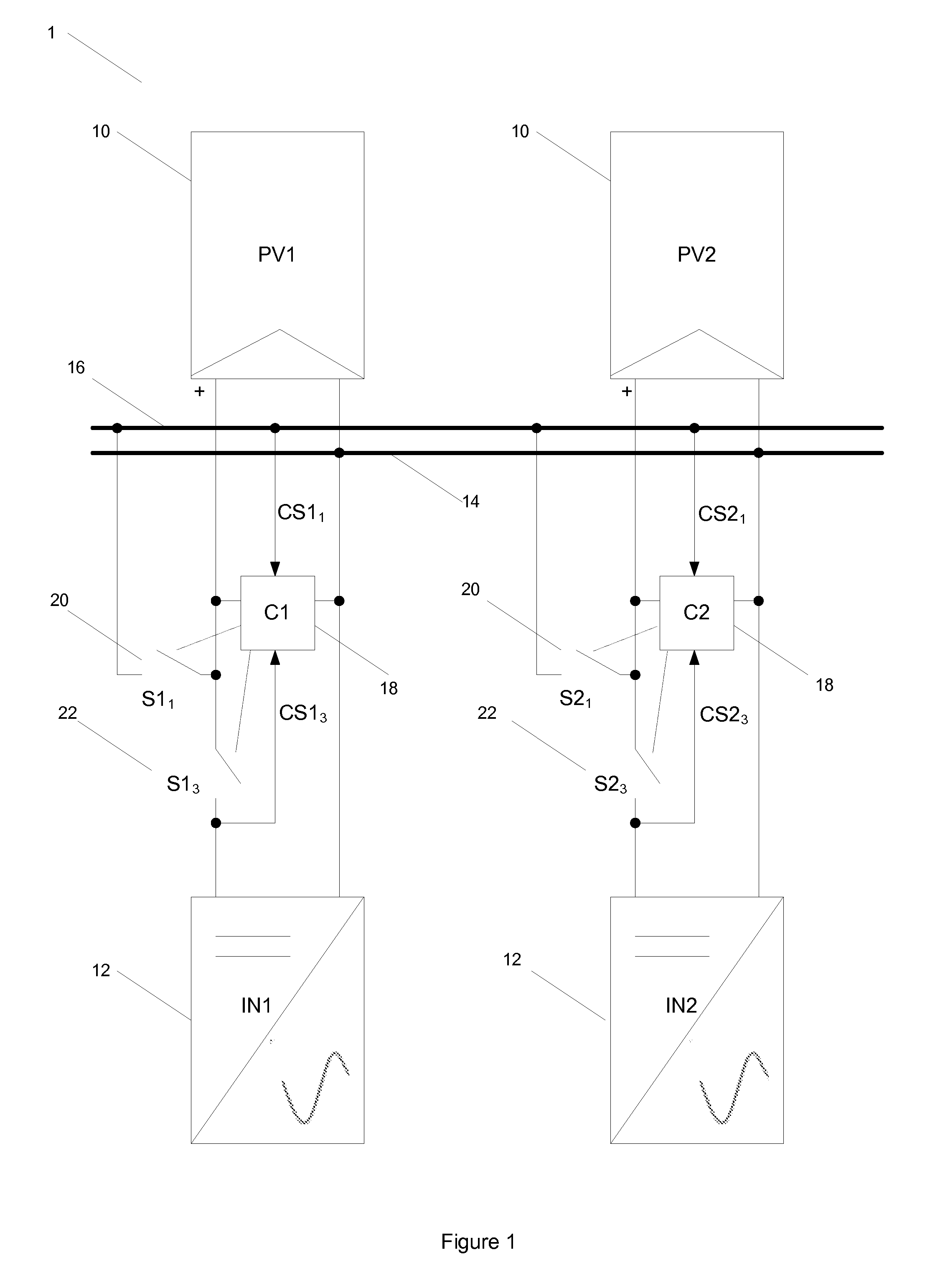

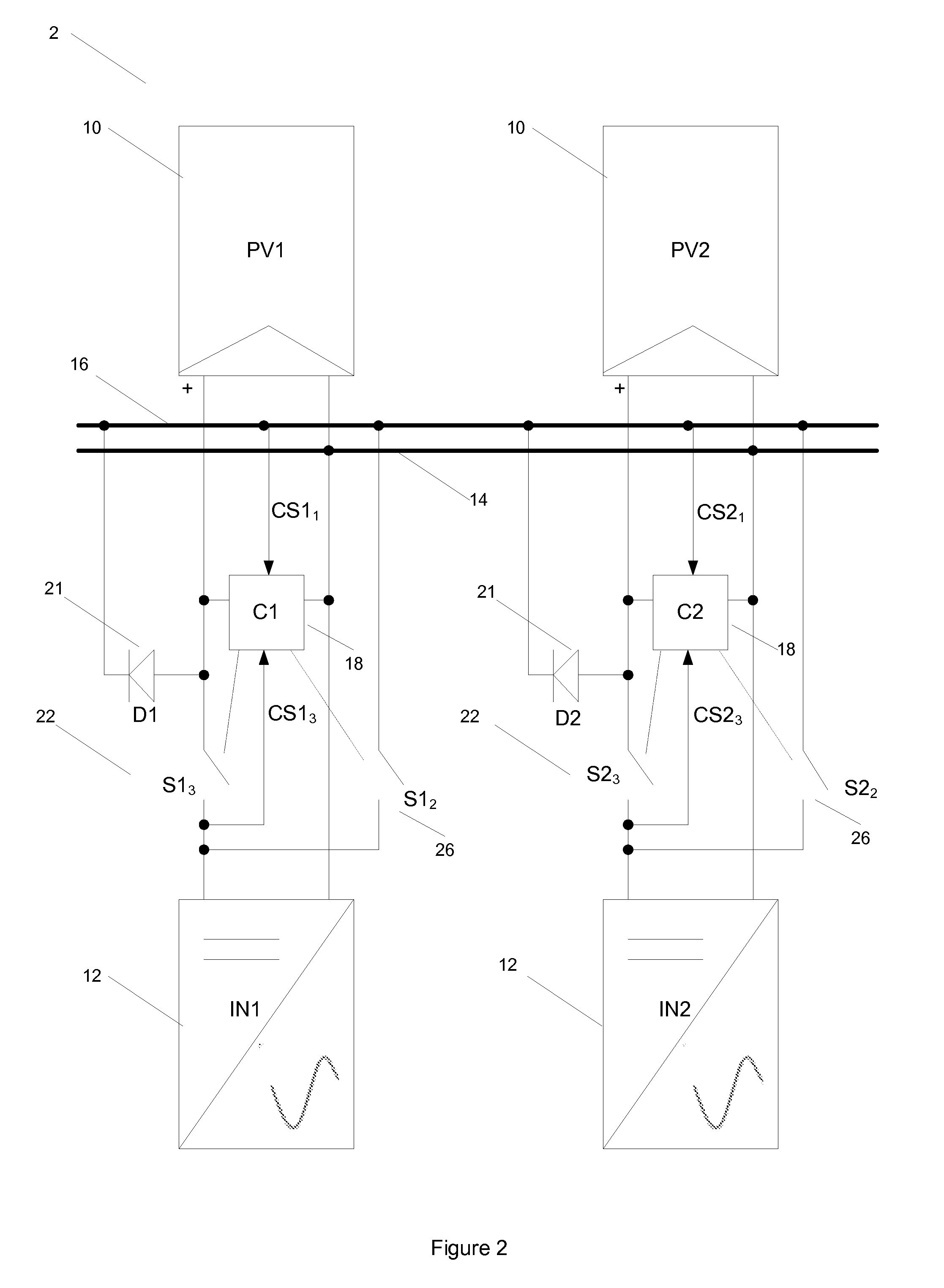

Solar Photovoltaic Systems

ActiveUS20120161528A1Avoid influenceModularity can be lostDc network circuit arrangementsEmergency protective circuit arrangementsPhotovoltaic power stationEngineering

Improved techniques for photovoltaic power generation are described. Inverter failure is can be a significant problem in solar photovoltaic systems as it can lead to loss of opportunity to harvest energy. A solar photovoltaic (PV) power generation system is described comprising solar PV panels and power conditioning units. A dc power distribution bus is coupled to the solar PV panels and the power conditioning units to switchably share dc power from the solar PV panels between the power conditioning units. Power distribution controllers detect a faulty power conditioning unit and reroute power from a solar PV panel coupled to the faulty power conditioning unit to other power conditioning units via the dc distribution bus.

Owner:TESLA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com