Patents

Literature

53 results about "Studio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A studio is an artist or worker's workroom. This can be for the purpose of acting, architecture, painting, pottery (ceramics), sculpture, origami, woodworking, scrapbooking, photography, graphic design, filmmaking, animation, industrial design, radio or television production broadcasting or the making of music. The term is also used for the workroom of dancers, often specified to dance studio.

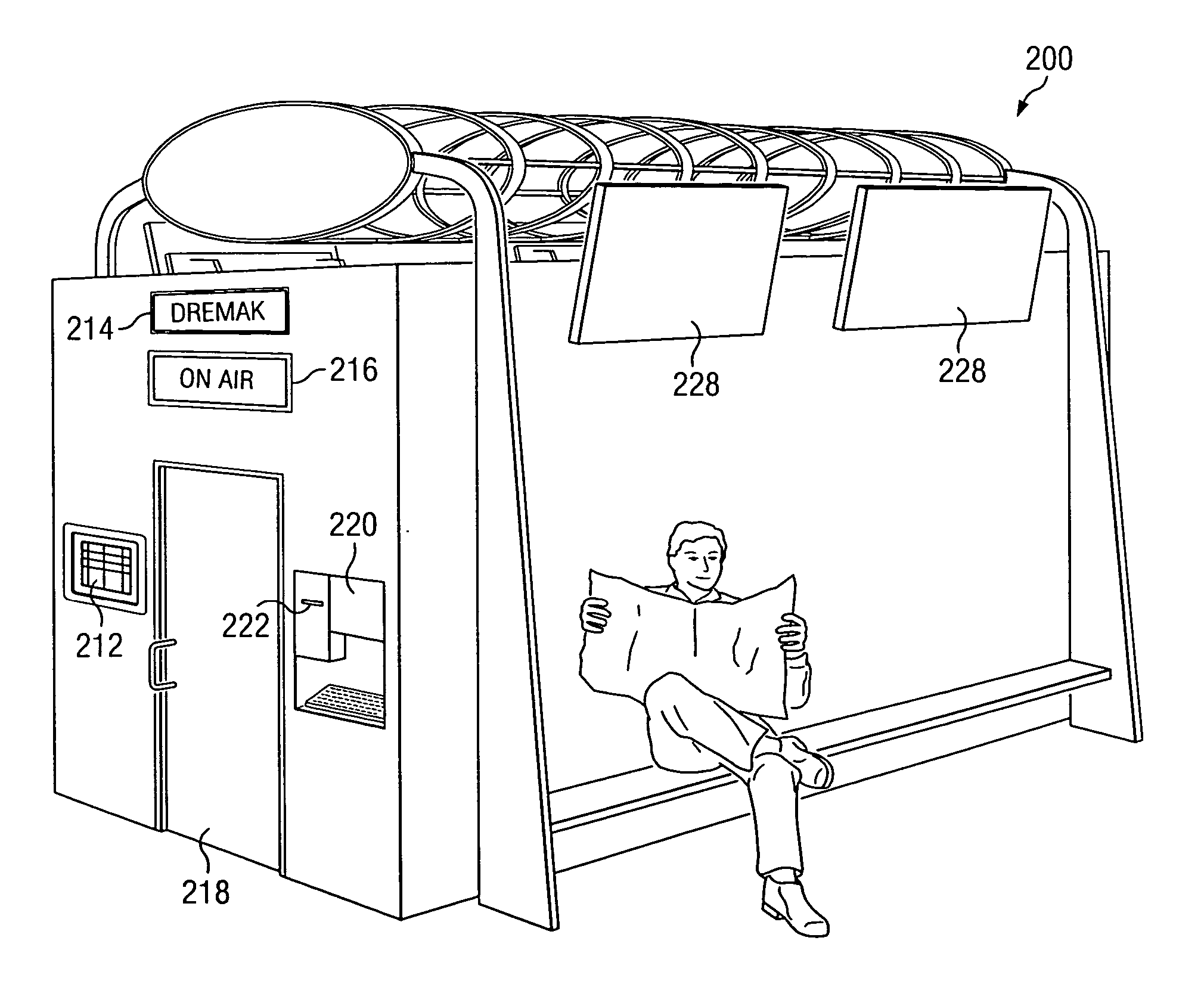

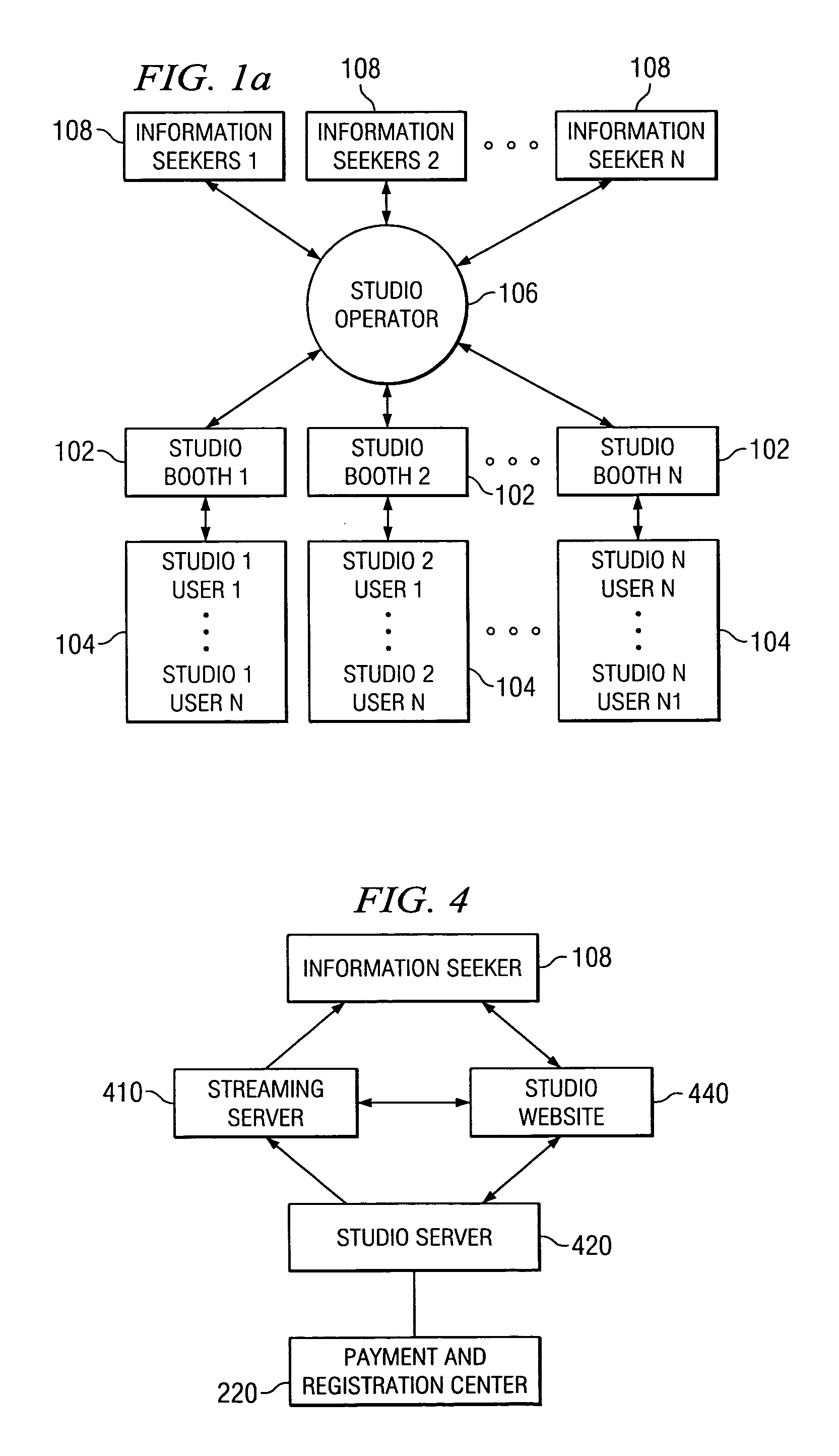

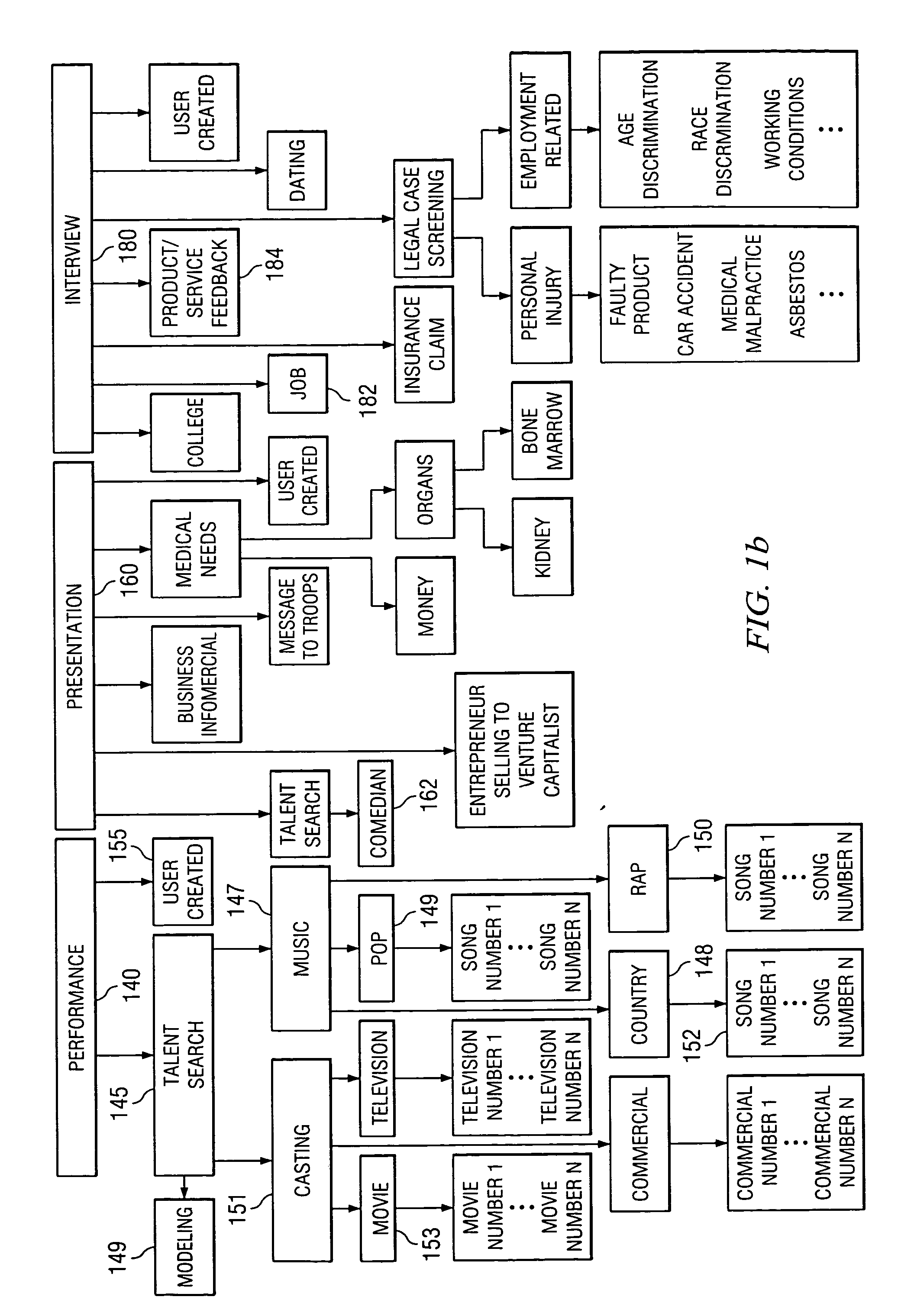

Interactive personal service provider

InactiveUS20050097613A1Precise positioningMinimal costTelevision system detailsTelevision conference systemsPublic placeThe Internet

The proposed invention is an apparatus and method that enables video communication through a studio that is placed in a public location whereby a studio user records a performance, presentation, or an interview. In one embodiment, information seekers with special interests may view interviews or presentations recorded by studio users pertaining to subject matter relevant to that special interest. In one embodiment, a performance is recorded and uploaded to the Internet where the general public locates and views the performance. In an alternative embodiment, the performance is rated.

Owner:ULATE ALBERTO JOSE RAGGIO +1

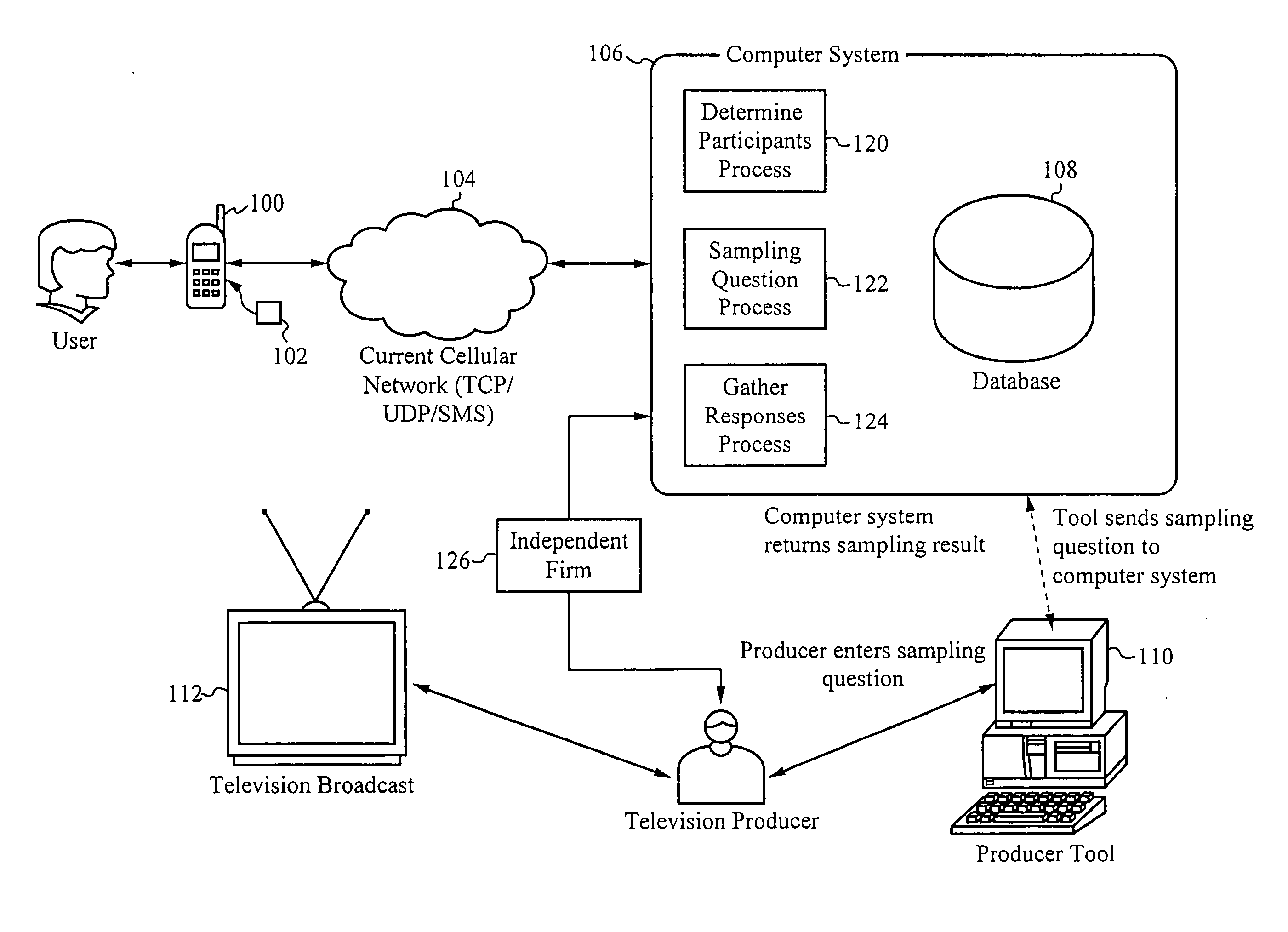

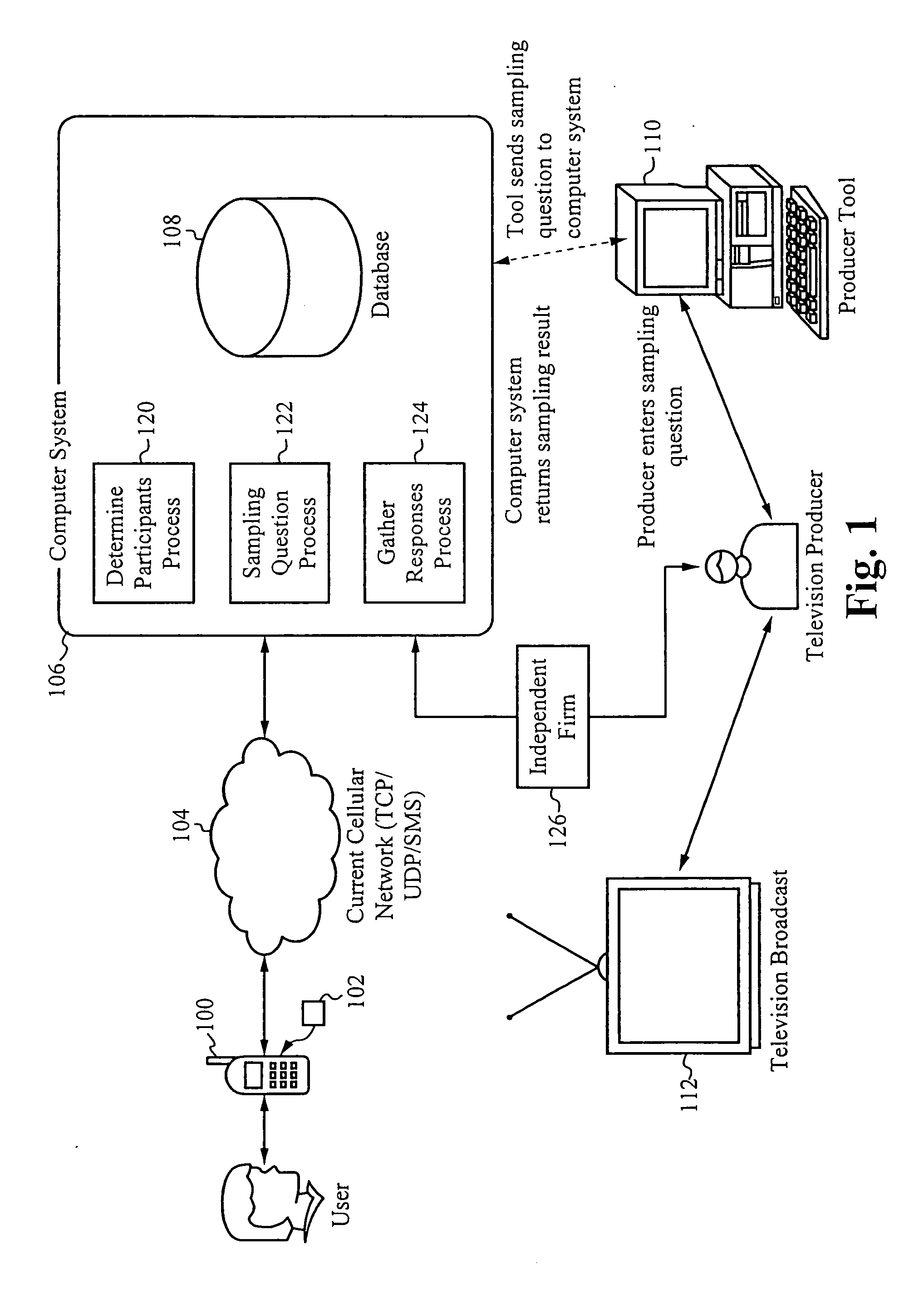

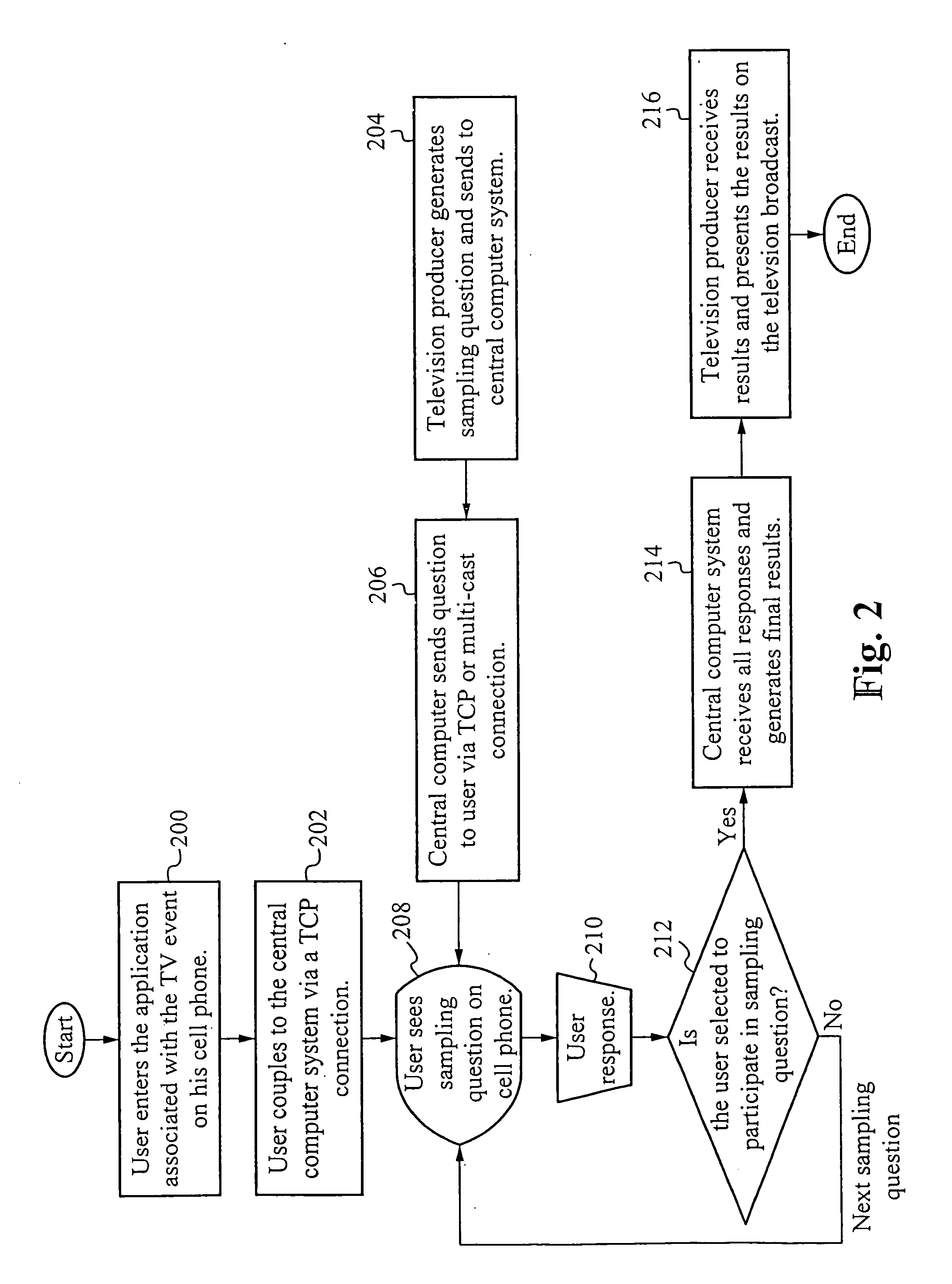

Live television show utilizing real-time input from a viewing audience

InactiveUS20070028272A1Analogue secracy/subscription systemsBroadcast information monitoringStudioLive feedback

A live television show utilizing real-time input from a viewing audience is described herein. Specifically, the viewing audience is at home or at least not in the studio, and they use their cellular phones to input responses or make selections. The audience input is transmitted in real-time so that the producers of the television show are able to incorporate the results of the responses into the show. To permit an audience of millions to participate in real-time, a large random sample is utilized to provide real-time feedback. For example, the audience is able to determine the winner of a talent contest, which door is opened by a contestant, the results of a poll and affect the future direction of the telecast.

Owner:WINVIEW

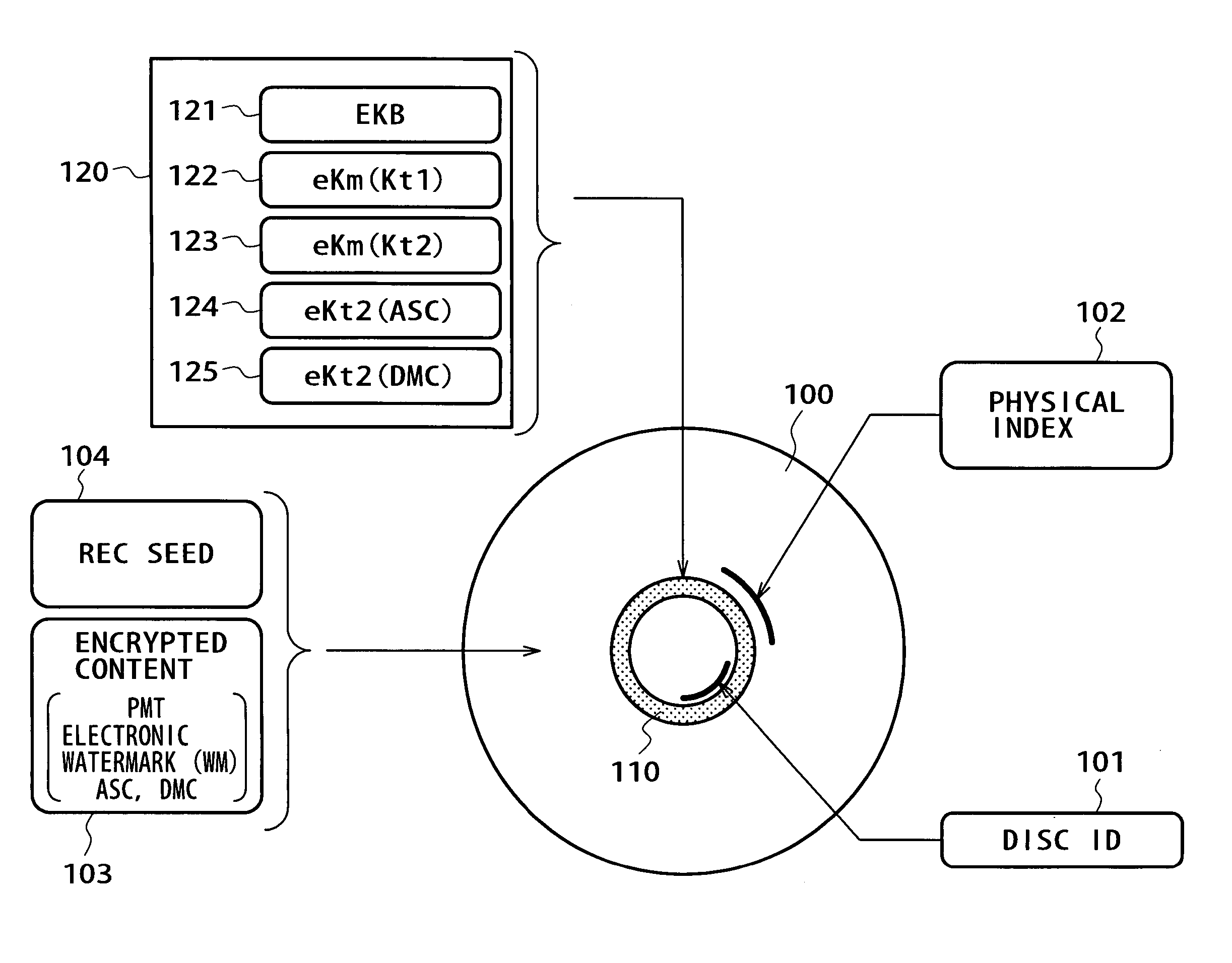

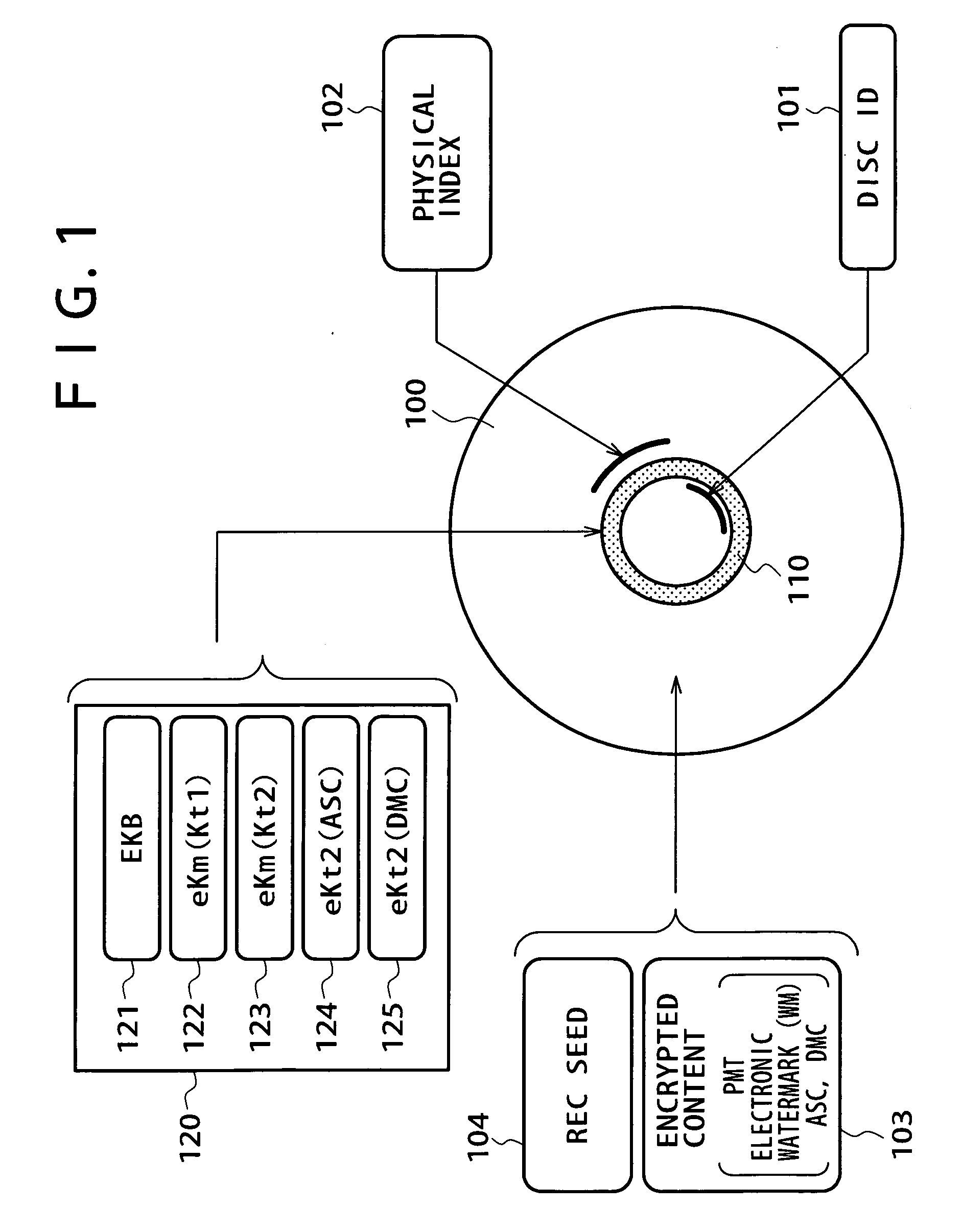

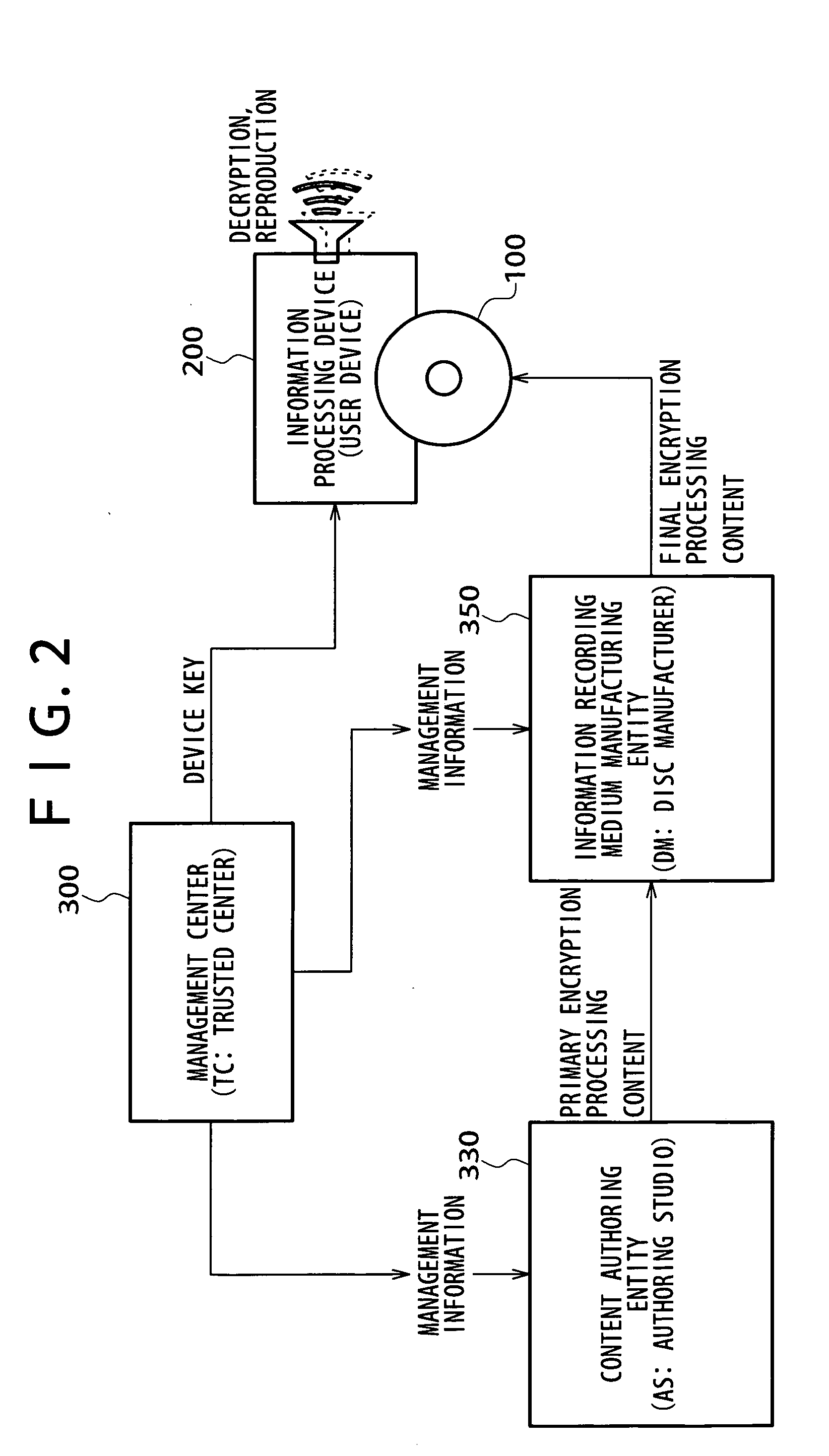

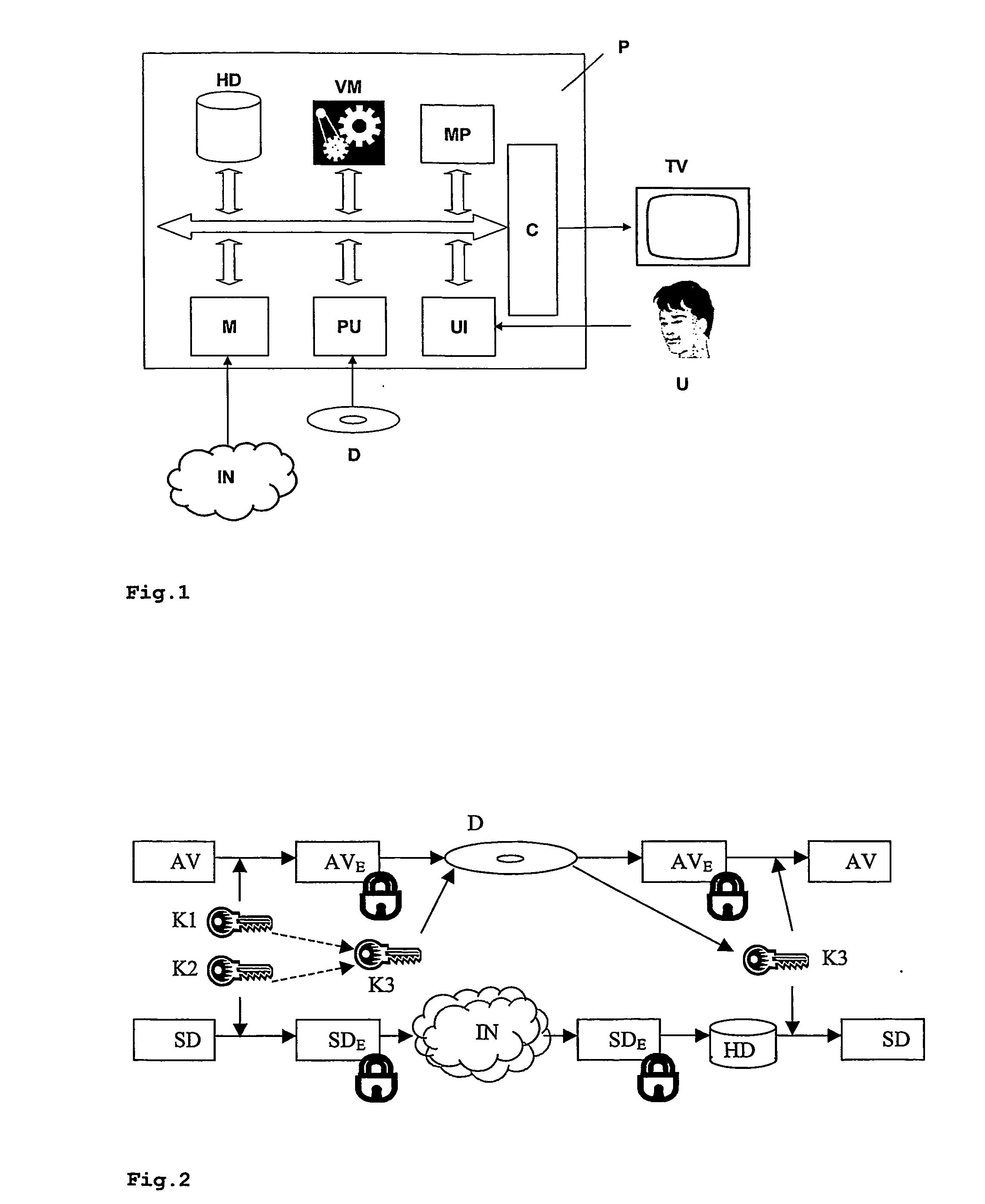

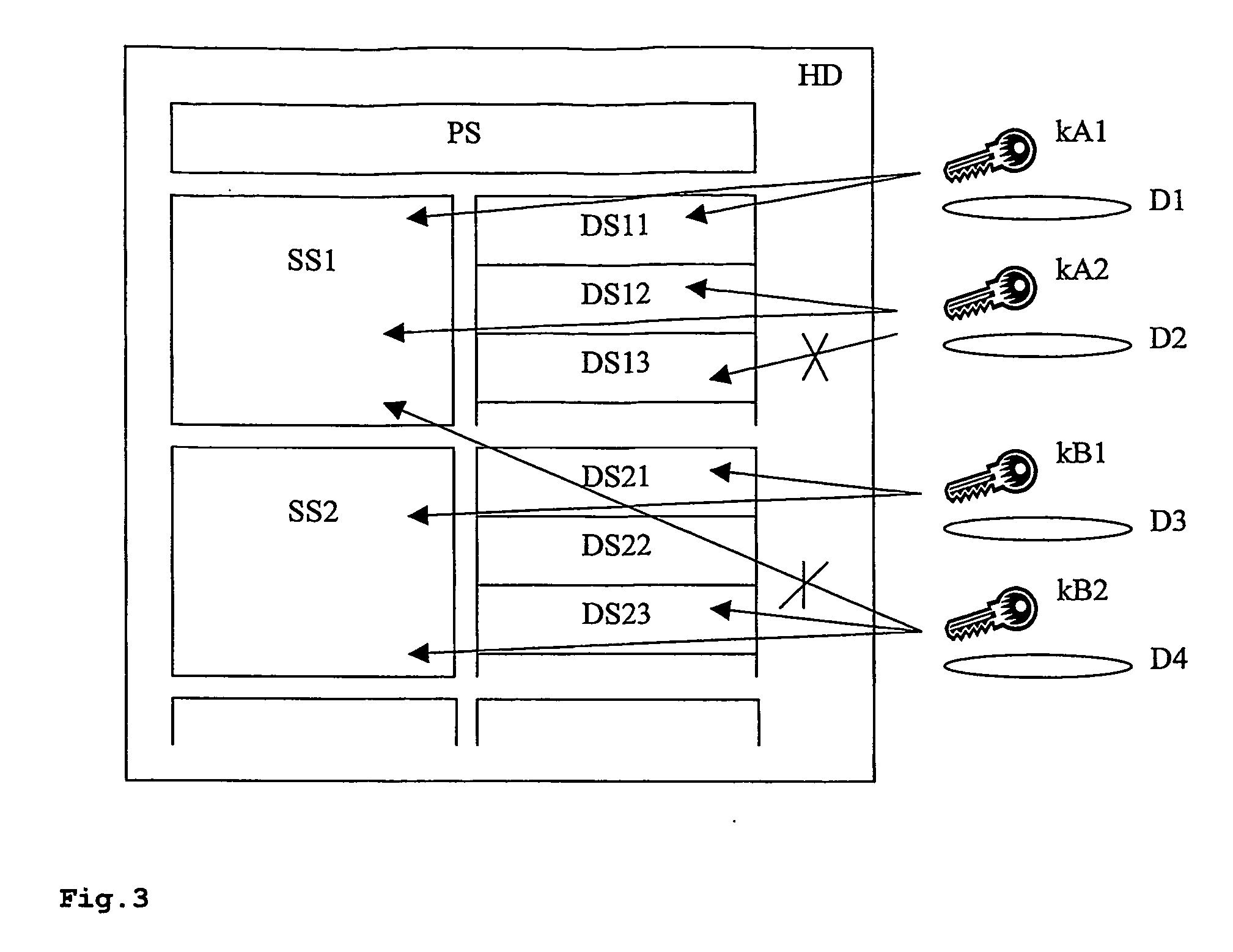

Information recording medium, data processing method, and computer program

InactiveUS20060150251A1Prevention of leakage of identification informationPrevent leakageKey distribution for secure communicationDigital data processing detailsData setManufacturer code

The present invention provides a configuration for preventing each entity code stored in information recording media from being leaked. Authoring studio code (ASC) and disc manufacturer code (DMC) are encrypted without failure and the encrypted codes are stored in information recording media. The data setting location in program map table (PMT) is controlled such that these entity codes will not overlap the seed area that provides key generating information, so that, if the packet storing the program map table storing authoring studio code (ASC) and disc manufacturer code (DMC) is set to an arbitrary position in a content packet sequence, these entity codes will not overlap the seed area that is non-encrypted data, thereby preventing these entity codes from being leaked outside.

Owner:SONY CORP

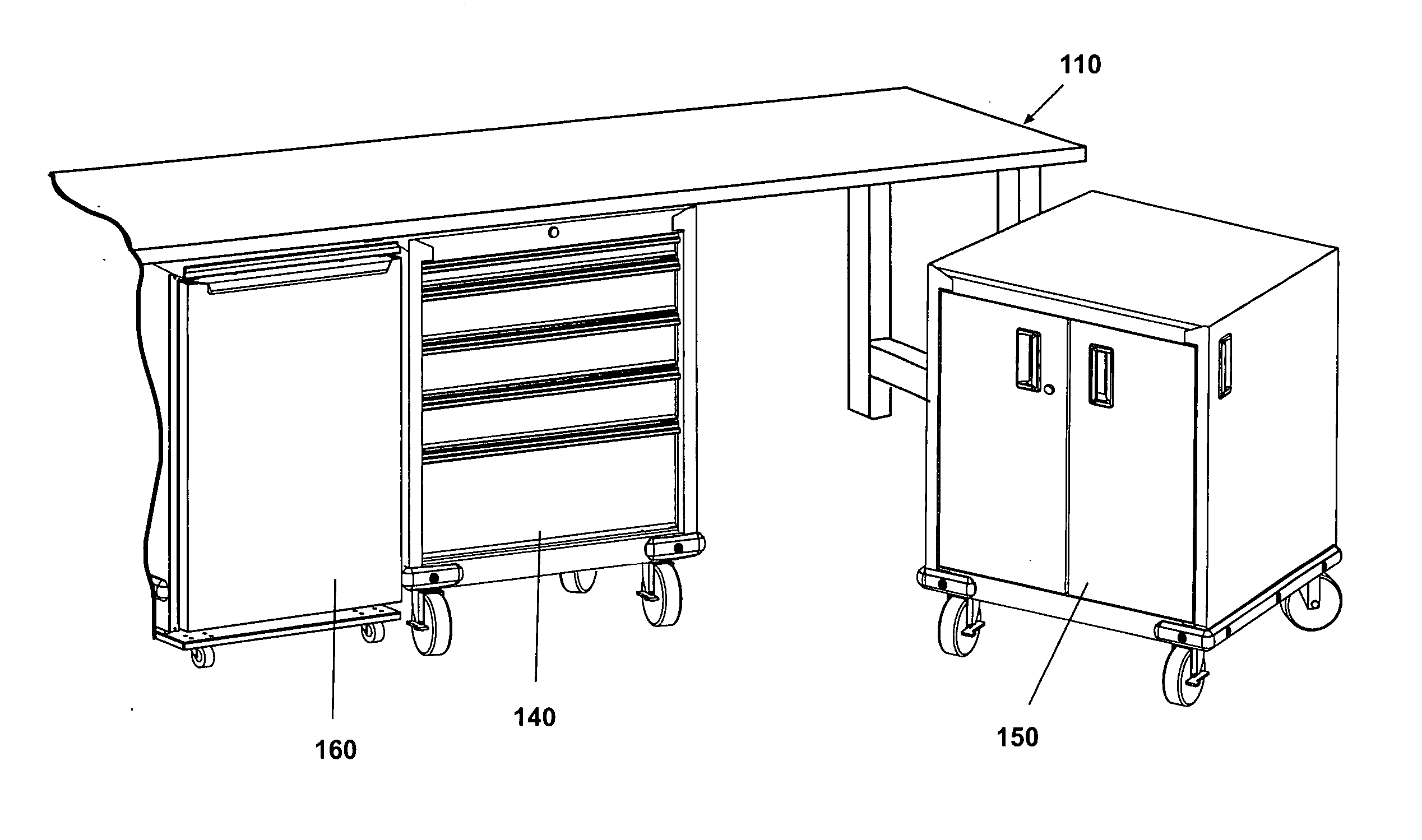

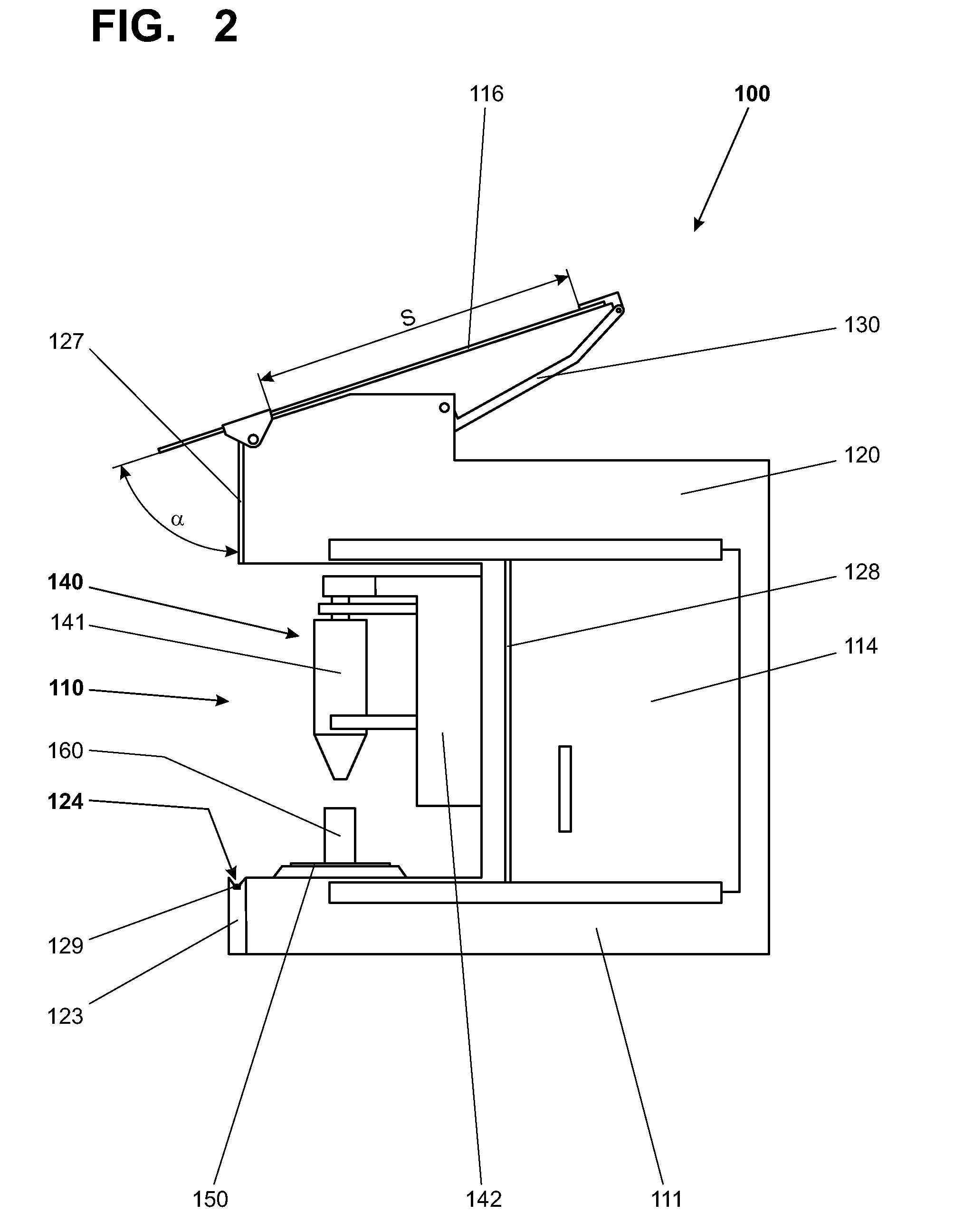

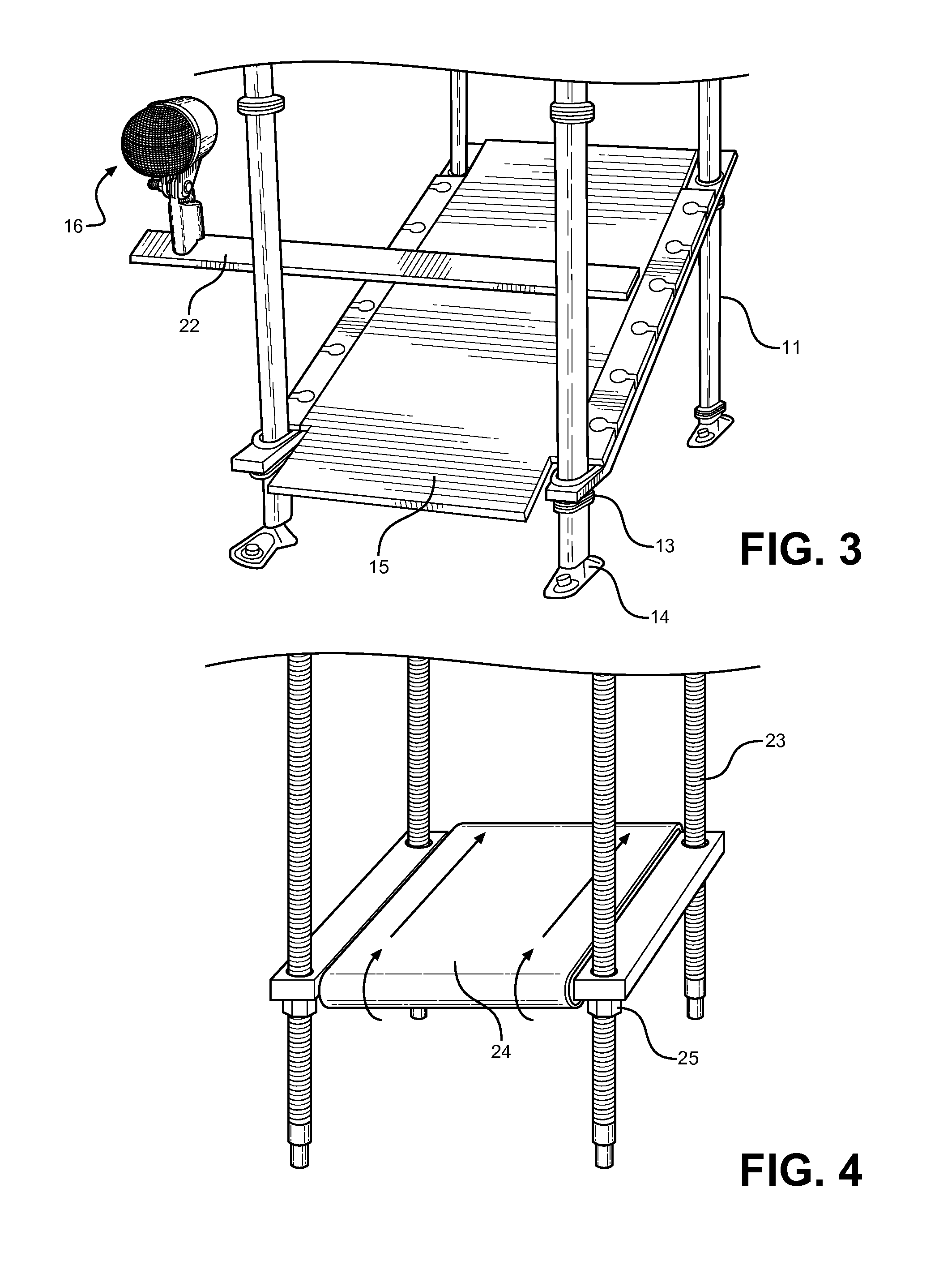

Workroom storage system

InactiveUS20040251227A1Easy to moveEasy to relocateCandle holdersLighting support devicesEngineeringWorkbench

A space-efficient workroom organization system comprising a slotwall panel and / or slot track storage system with at least one repositionable slotwall or slot track mounted storage cabinet, and a workbench system comprising a workbench having a work surface and defining a storage recess beneath the work surface, with at least one mobile storage cabinet.

Owner:WHIRLPOOL CORP

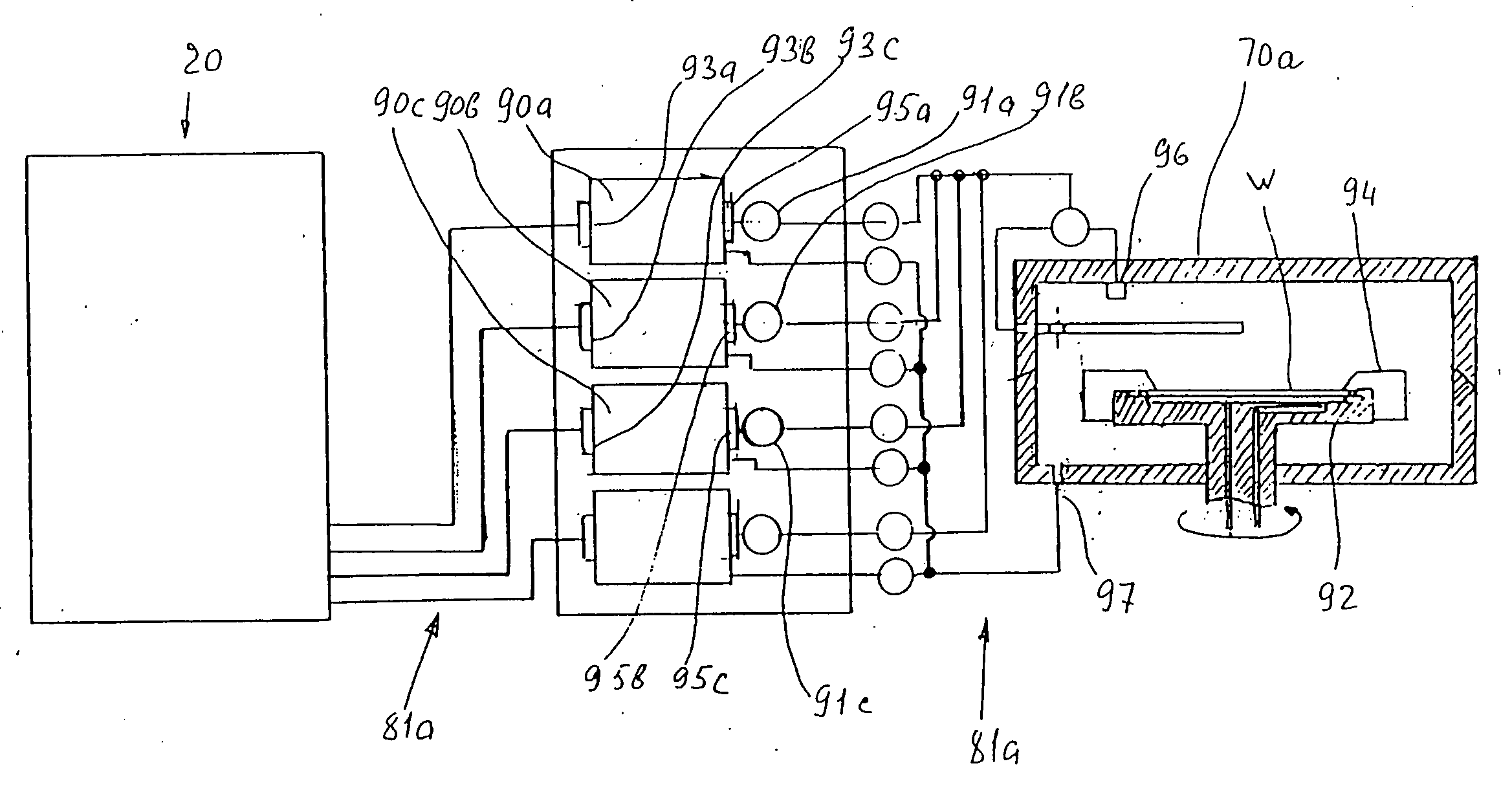

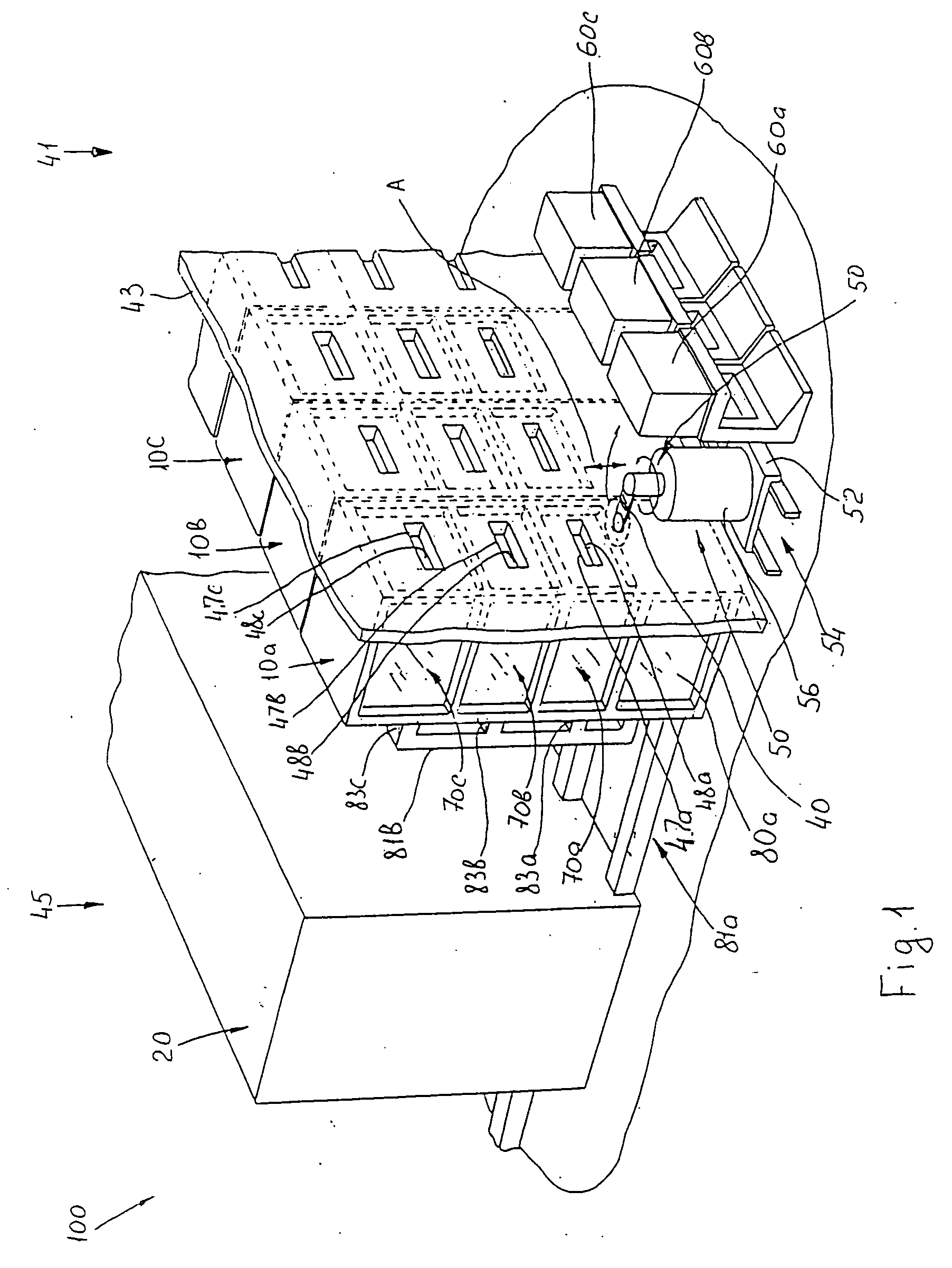

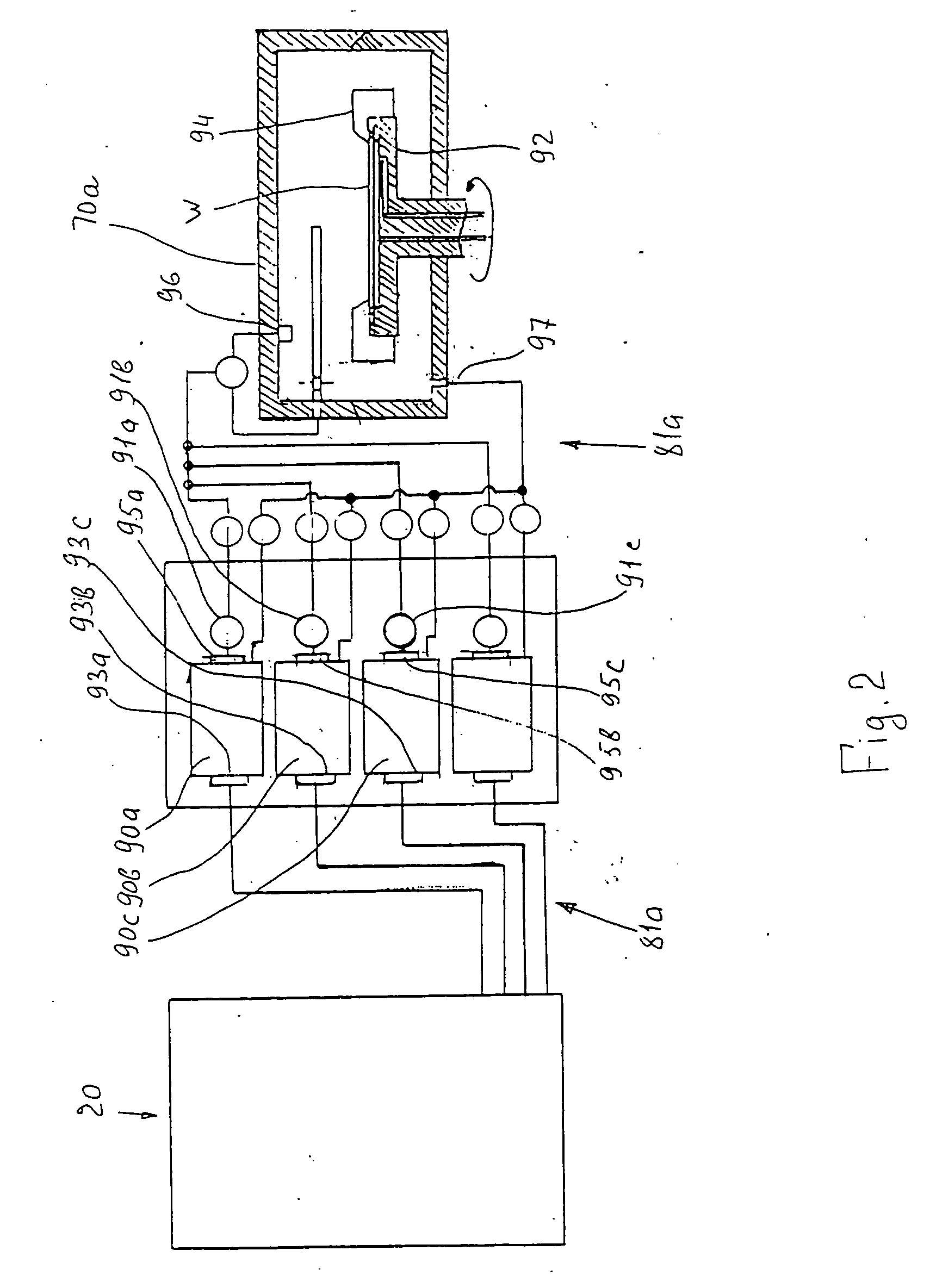

Spatially-arranged chemical processing station

InactiveUS20070051306A1Improve interconnect densityEfficient productionLiquid surface applicatorsMovable spraying apparatusChemical treatmentElectricity

The present invention discloses a station, e.g., for IC fabrication with a flexible configuration. It consists of an array of processing chambers, which are grouped into processing modules and arranged in a two-dimensional fashion, in vertical levels and horizontal rows, and is capable of operating independent of each other. Each processing chamber can perform electroless deposition and other related processing steps sequentially on a wafer with more than one processing fluid without having to remove it from the chamber. The system is served by a single common industrial robot, which may have a random to access to all the working chambers and cells of the storage unit for transporting wafers between the wafer cassettes and inlet / outlets ports of any of the chemical processing chambers. The station occupies a service-room floor space and a clean-room floor space. The processing modules and the main chemical management unit connected to the local chemical supply unit occupy a service-room floor space, while the robot and the wafer storage cassettes are located in a clean room. Thus, in distinction to the known cluster-tool machines, the station of the invention makes it possible to transfer part of the units from the expensive clean-room area to less-expensive service area.

Owner:LAM RES CORP

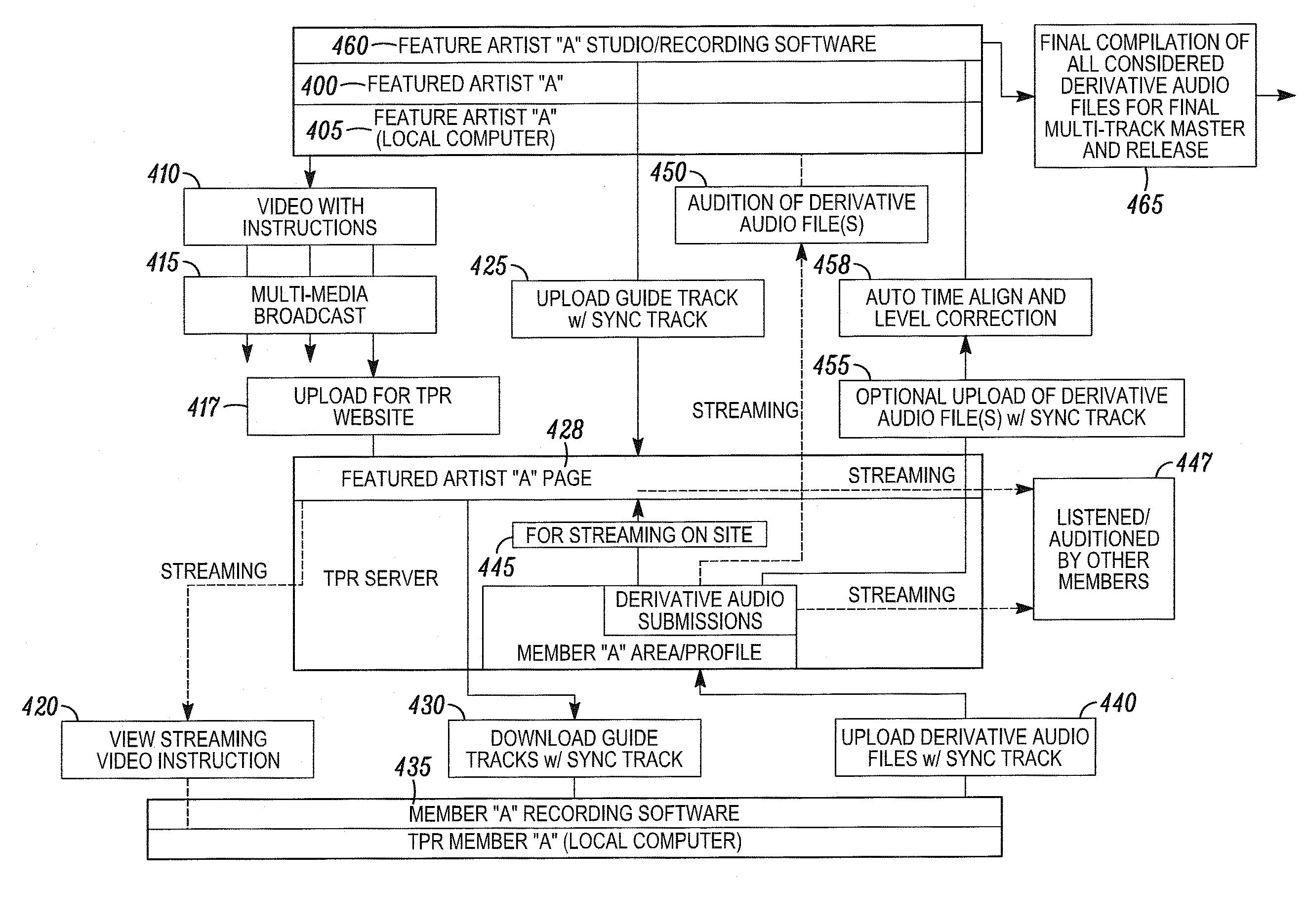

Virtual studio for identifying and developing public talent

InactiveUS20120047077A1Data processing applicationsDigital data information retrievalPublic placeEngineering

The teachings generally relate to a method of creating a derivative artistic work that includes a select, virtual submission from the public obtained from a set of random, virtual submissions submitted, for example, through a network or public venue. The teachings are directed a virtual studio, a method of creating a derivative, multi-track musical work that includes a virtual performance from the public.

Owner:THE PUBLIC RECORD

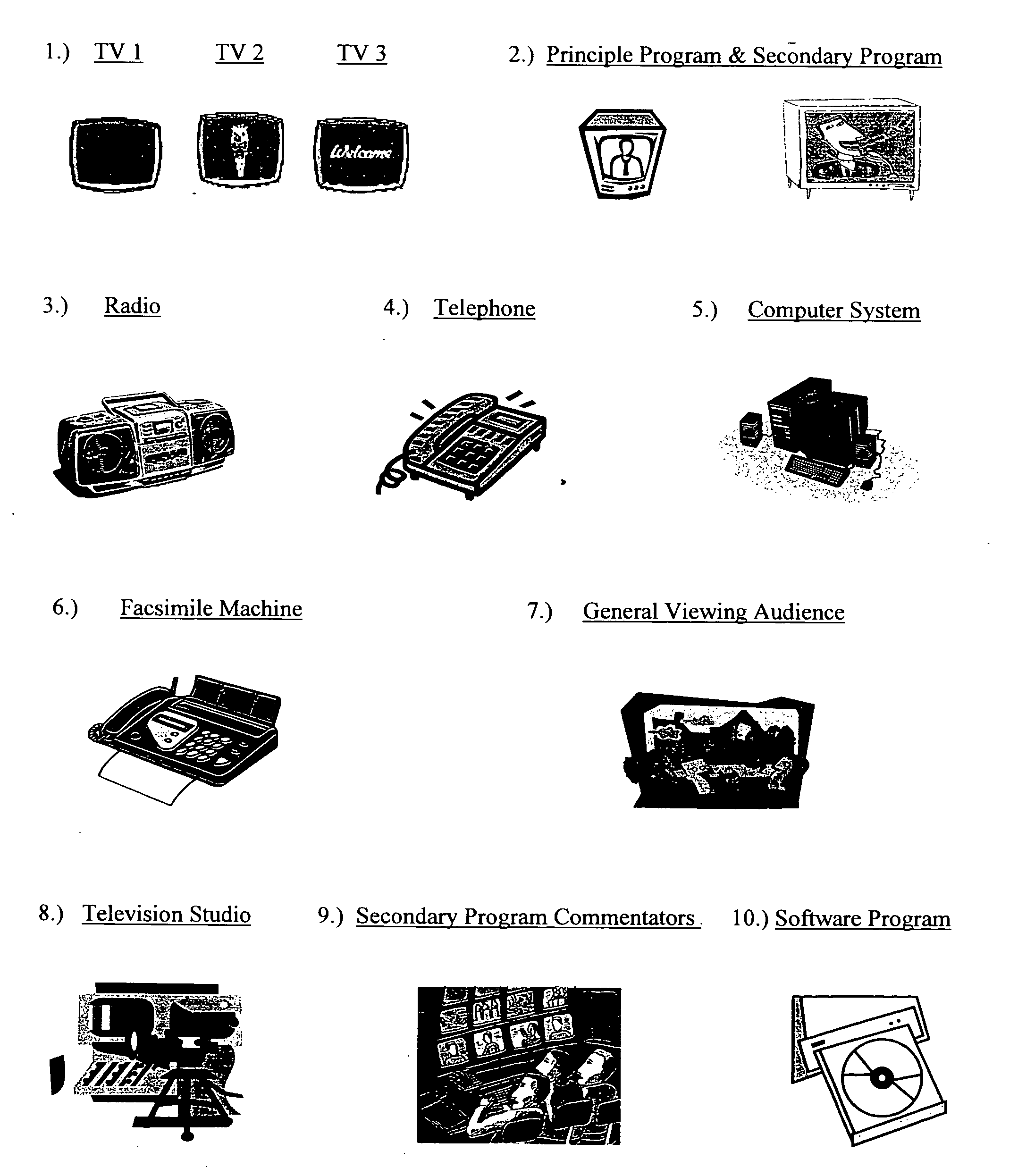

Television viewer/studio interactive commentary

InactiveUS20050125843A1Picture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningTv viewerWalkie-talkie

Televisions, computers, computer devices, facsimile machines, radios, telephones, walkie-talkies, are used to view, listen to and communicate with individuals in the television studio who, as the secondary program, are watching a primary program (sports, news, commercials, awards, etc.) and discussing those events along with any other topic they choose to. The listening / viewing audience is able to enjoy the primary and secondary programs with two televisions, or one television with picture in picture capability, or a television and a computer. The secondary program commentators and viewing / listening audience may use phones, walkie-talkies, computers, computer devices, and facsimile machines to communicate with each other concerning the primary programming, which could consist of any life event or topic they choose.

Owner:OKEZIE CHARLES E +1

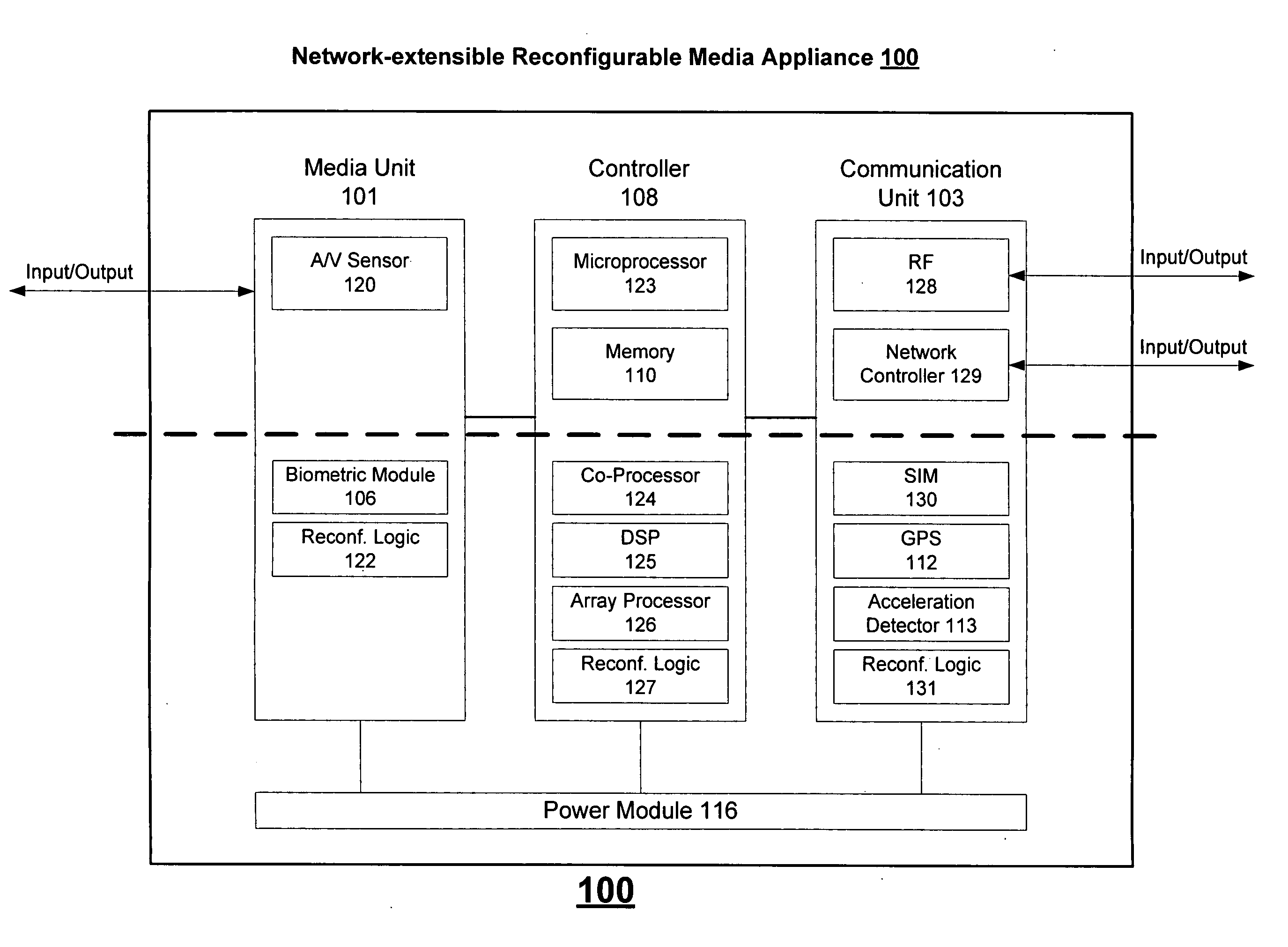

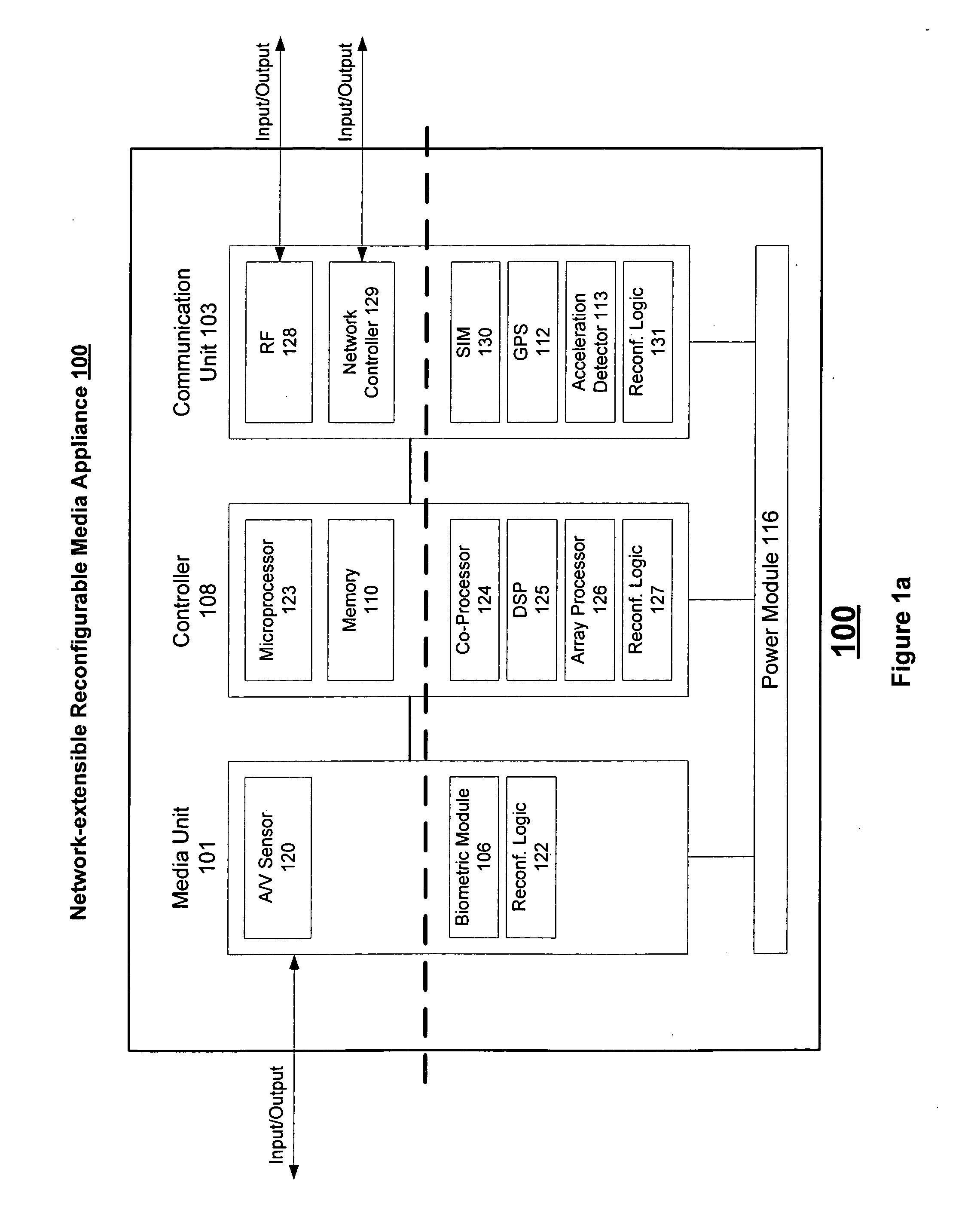

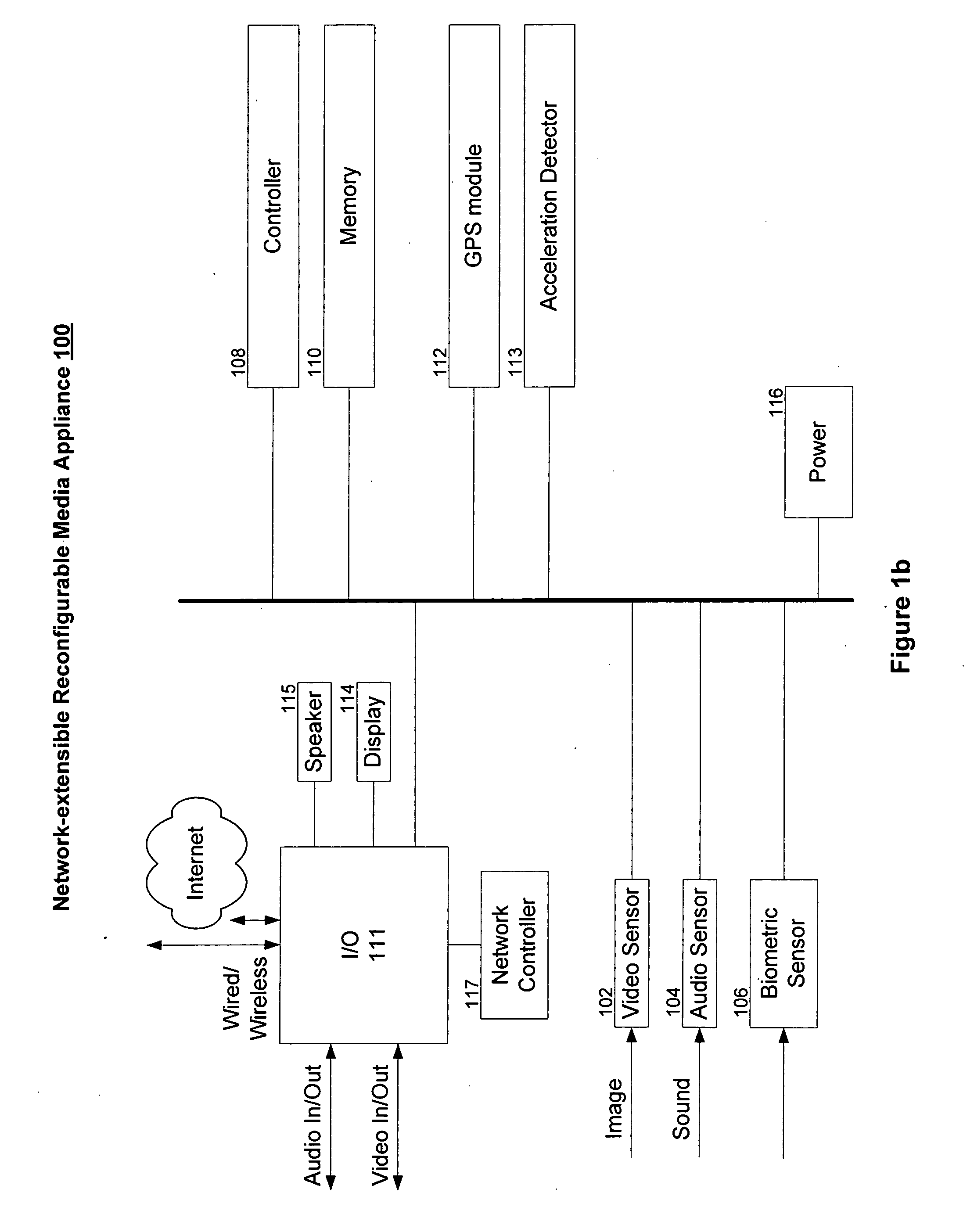

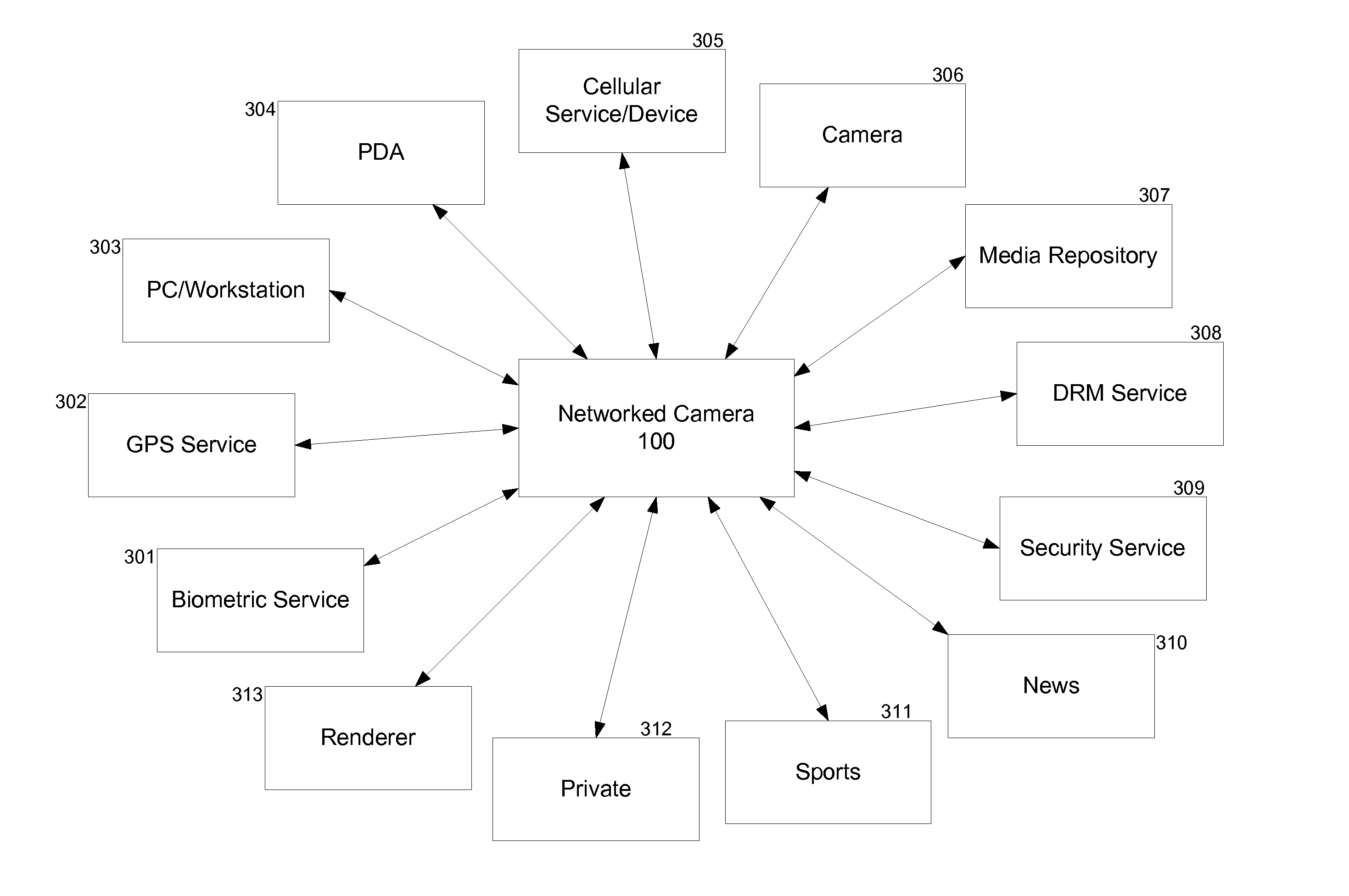

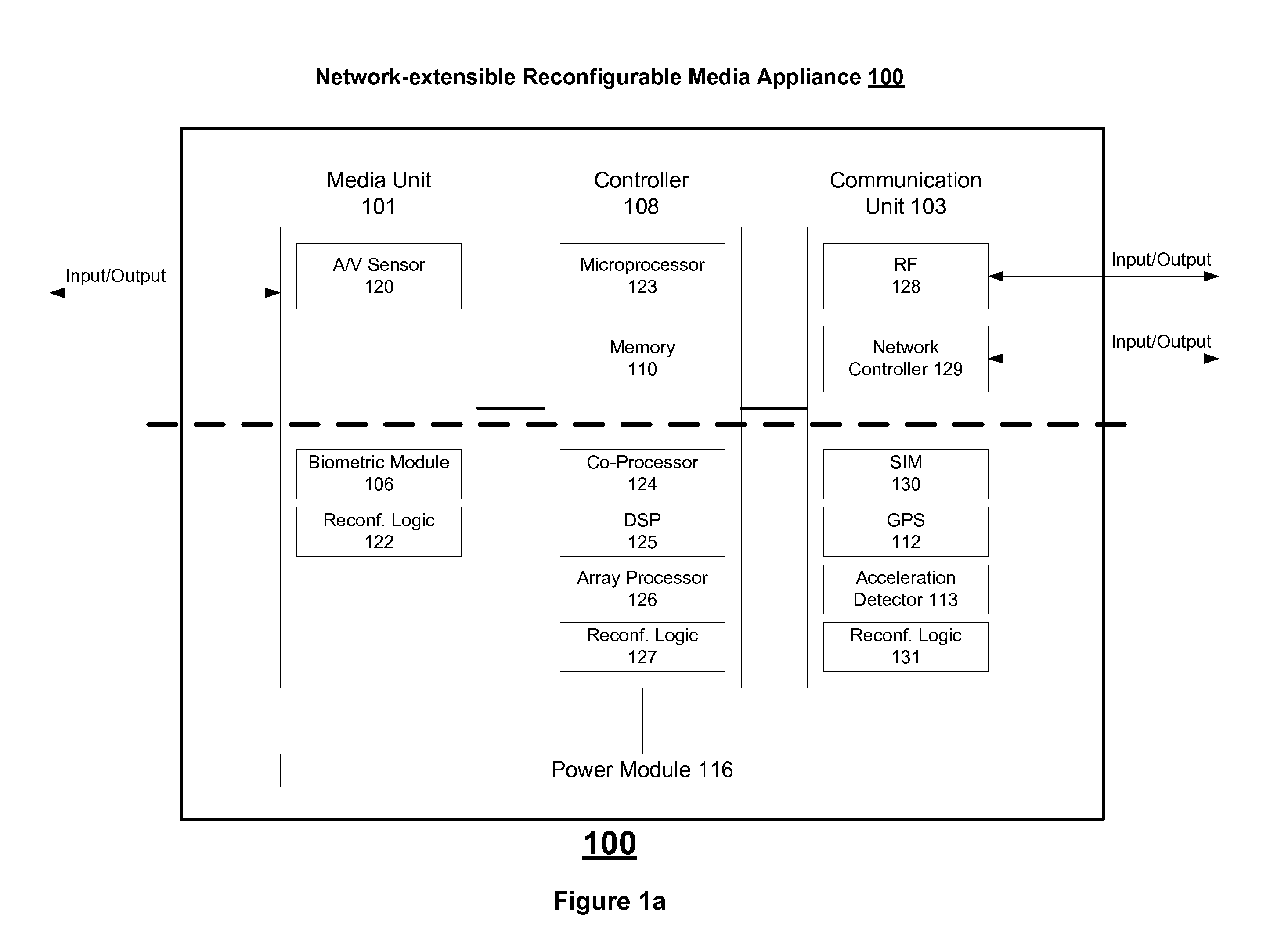

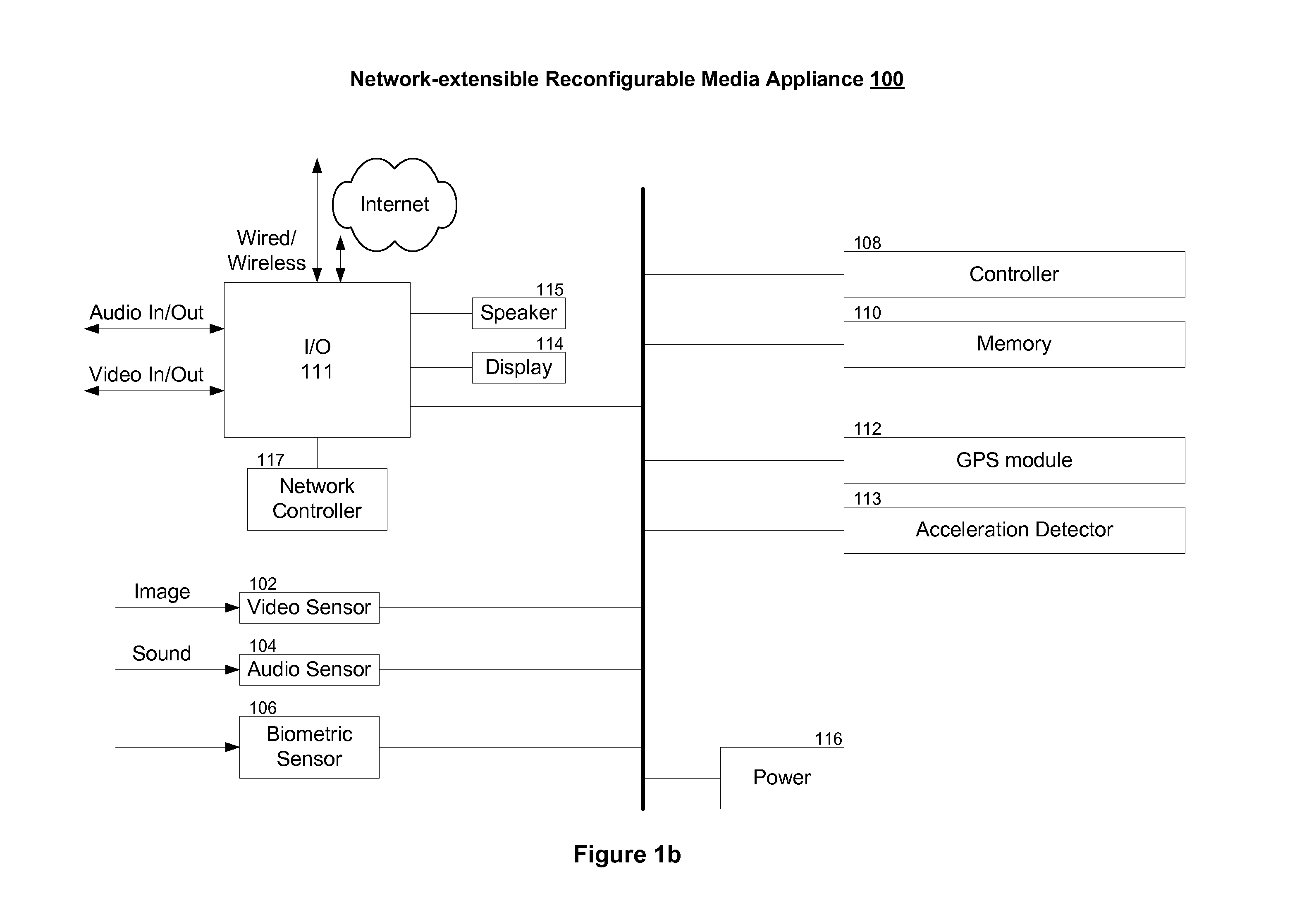

Network-extensible reconfigurable media appliance

ActiveUS20070150917A1Suitable for applicationTelevision system detailsUser identity/authority verificationVideo storageComputer graphics (images)

Extensible reconfigurable media appliance for security and entertainment captures images digitally for storage. Digital effects and filters are applied to incoming video stream on-the-fly or to video data stored in memory. Digital effects and filters are dynamically stored, modified, updated or deleted, providing extensible reconfigurable effects studio. Digital media appliance communicates wirelessly with other media appliances, computers, security systems, video storage, email, chat, cellular services or PDAs to provide seamless integration of captured video stream.

Owner:GOOGLE LLC

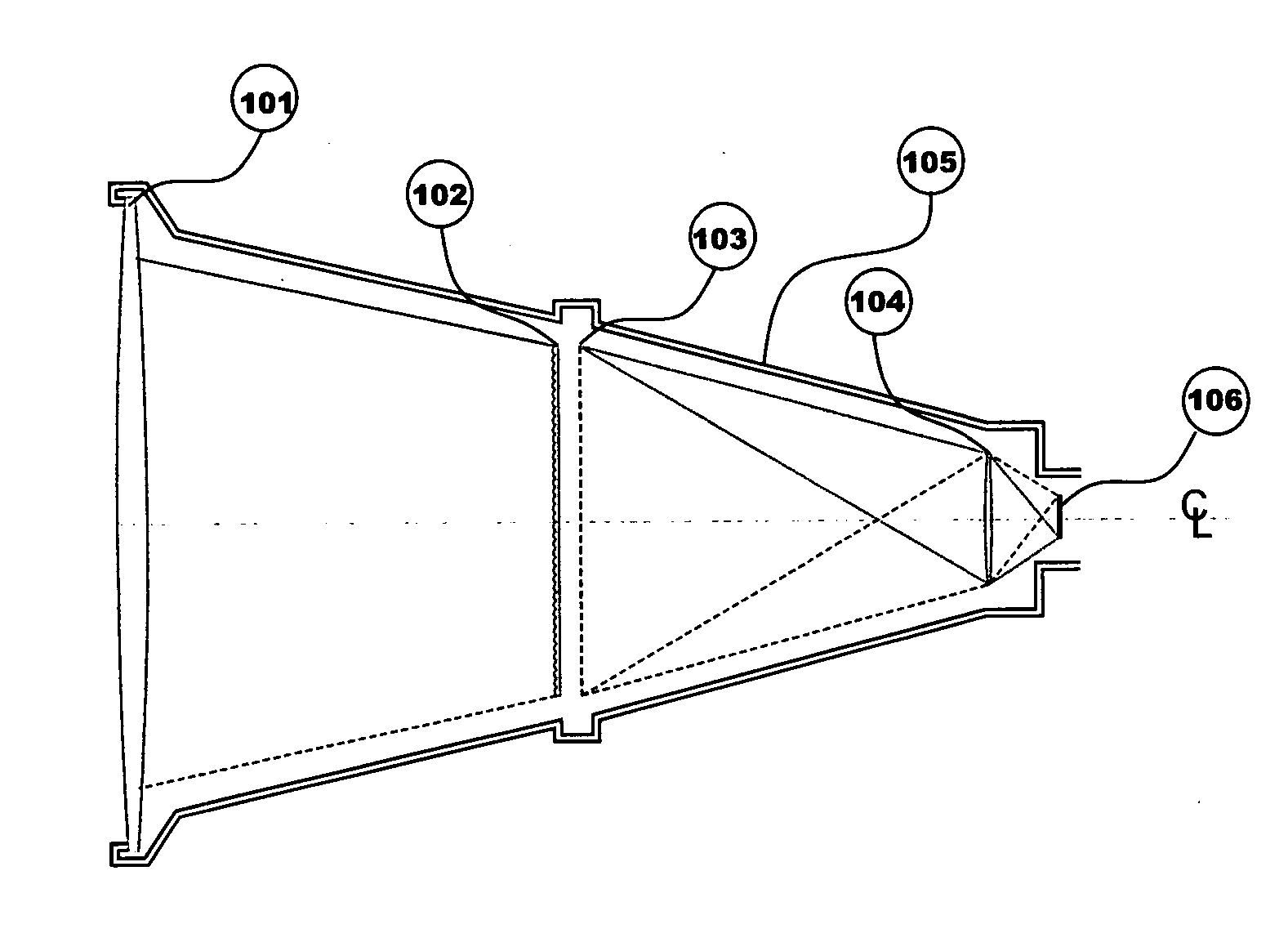

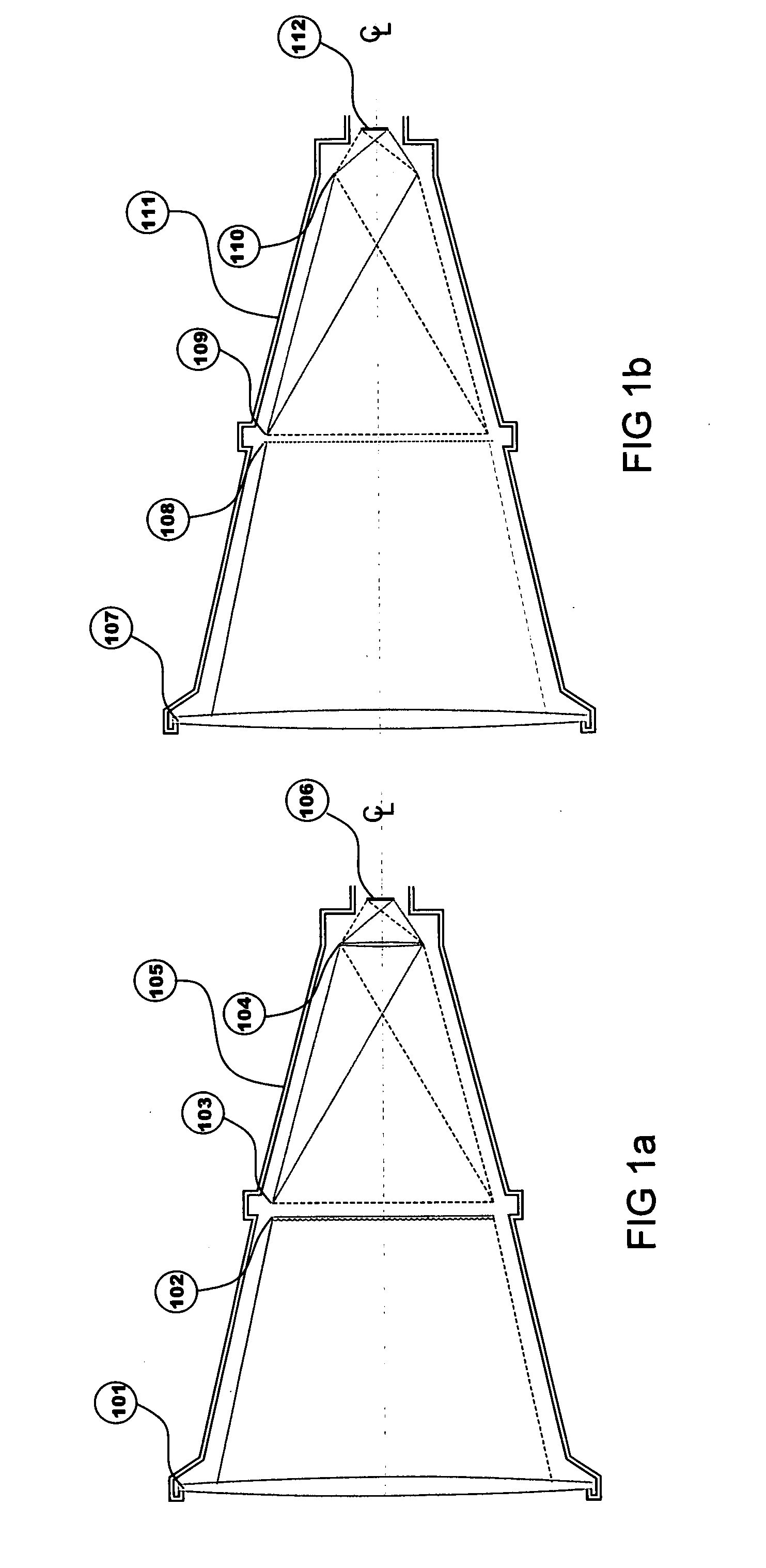

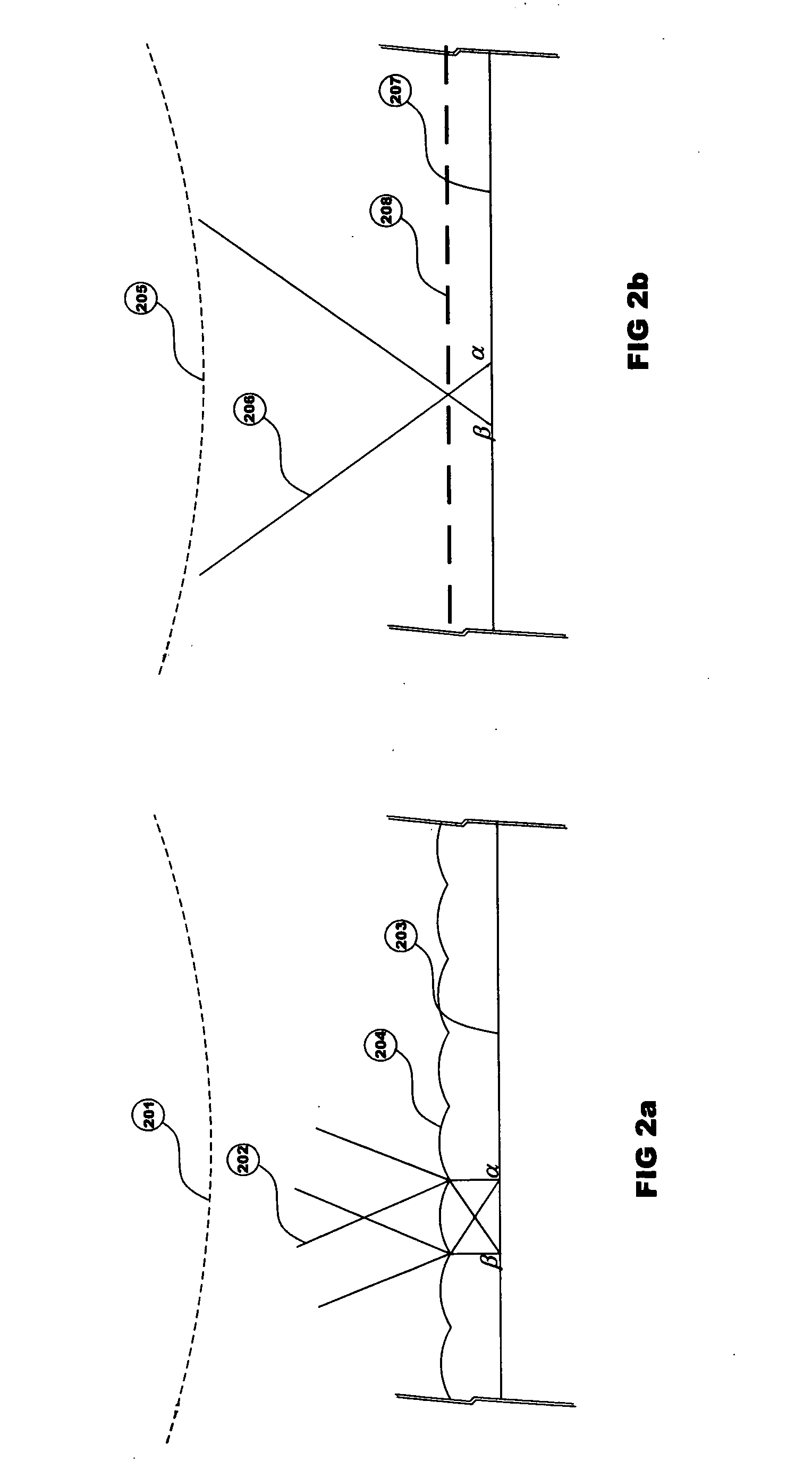

Autostereoscopic electronic camera

The Electronic Autostereoscopic Camera comprises a taking “lens” that gathers full scene information and encodes this information onto the camera electronic sensor such that the “Depth” of the scene constituents is thereby preserved. This camera may be of a monochrome, single sensor color, or multi-sensor color type and may utilize C.C.D., Analog, C.M.O.S., or other variety of photosensitive electronic sensor. The output information from the camera may be in any suitable format suitable for use in the C.C.T.V., Broadcast T.V., or A / V displays (Computer Generated). Post processing and recording of the data is handled in the same manner as the familiar Two-Dimensional content now utilized by such industries and users. The “lens” of this camera may be configured to function on other electronic cameras by fitting the scene “Depth Encoding” optical group to a particular camera as may be desired by the user. These cameras may include Simple Hand Held, Shoulder Mounted, Tripod Mounted, Laboratory, Studio, or Vehicle Mounted models of various design and manufacture.

Owner:MCKEE WILLIAM JAMES

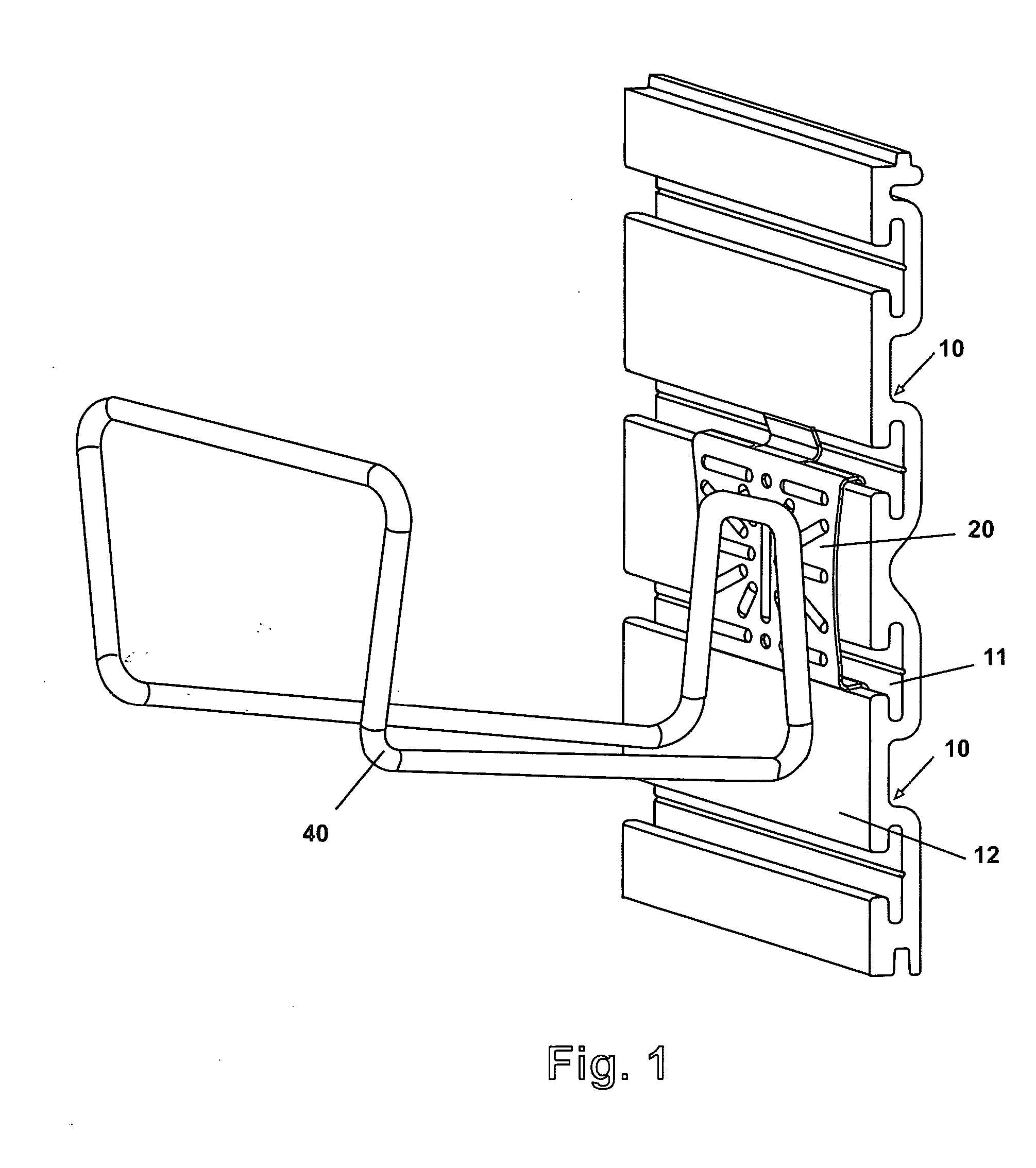

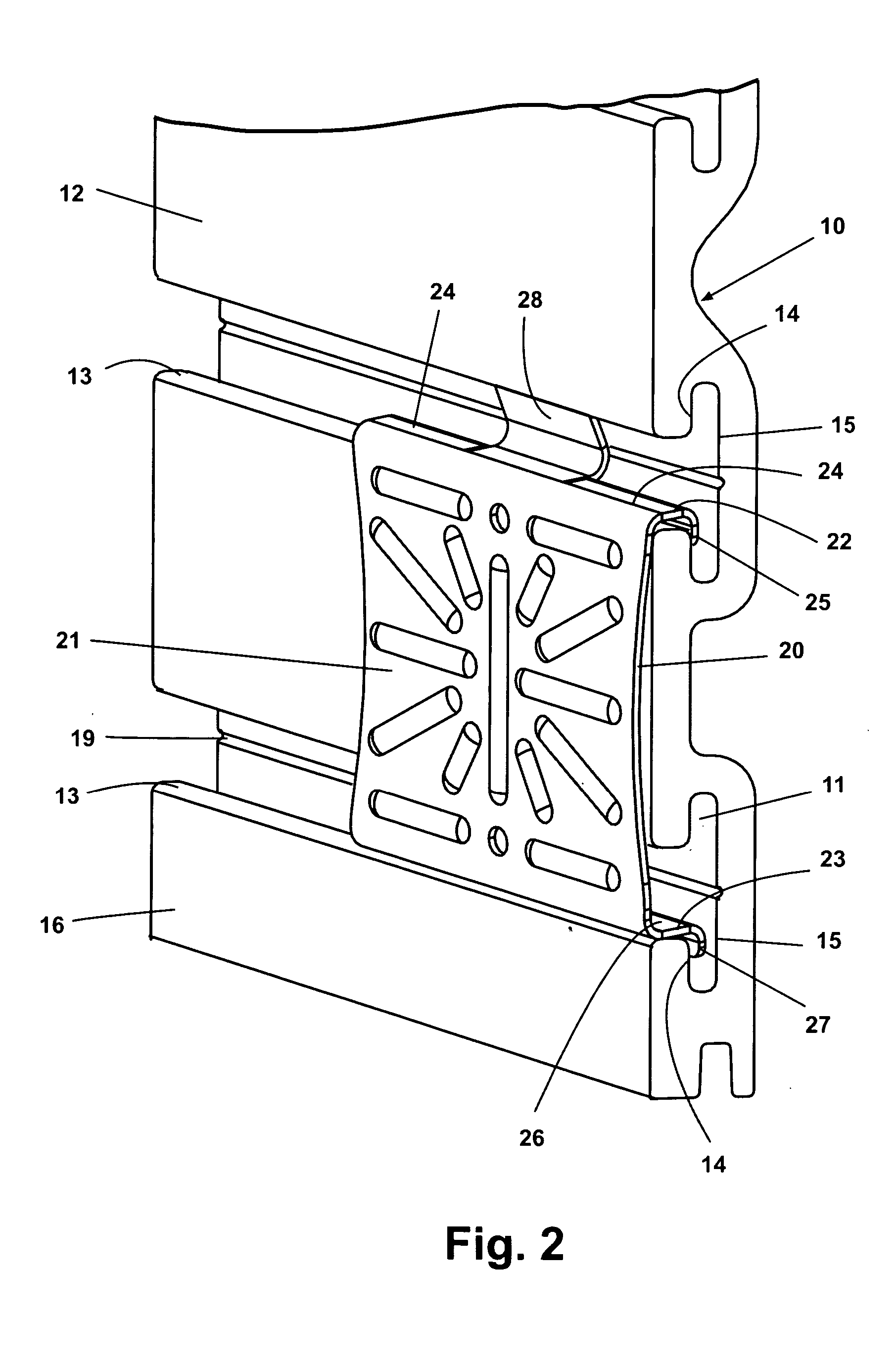

Laboratory instrument with a protected working compartment

ActiveUS20100276213A1Easy accessWork is requiredDoors/windowsWeighing apparatus detailsLinear motionEngineering

A laboratory instrument with a housing containing a weighing cell has a working compartment that is connected to the housing. The working compartment has a floor, a top cover, a rear wall, a front wall and two sidewalls. Arranged in the working compartment is a load receiver which is connected to the weighing cell. Also connected to the housing is at least one guiding device which serves to guide a linear movement and simultaneous swivel movement of individual portions of the front wall or the entire front wall.

Owner:METTLER TOLEDO GMBH

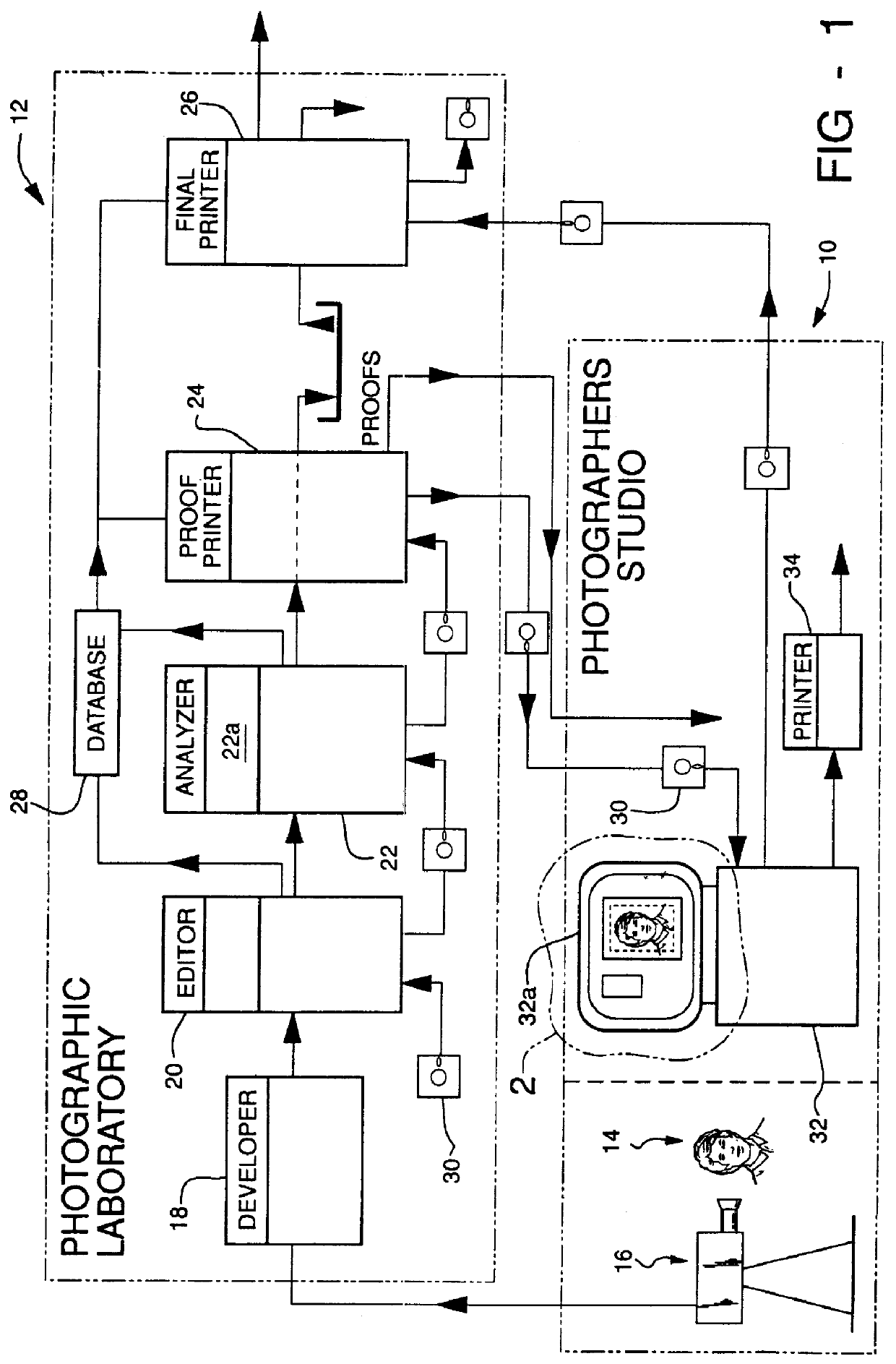

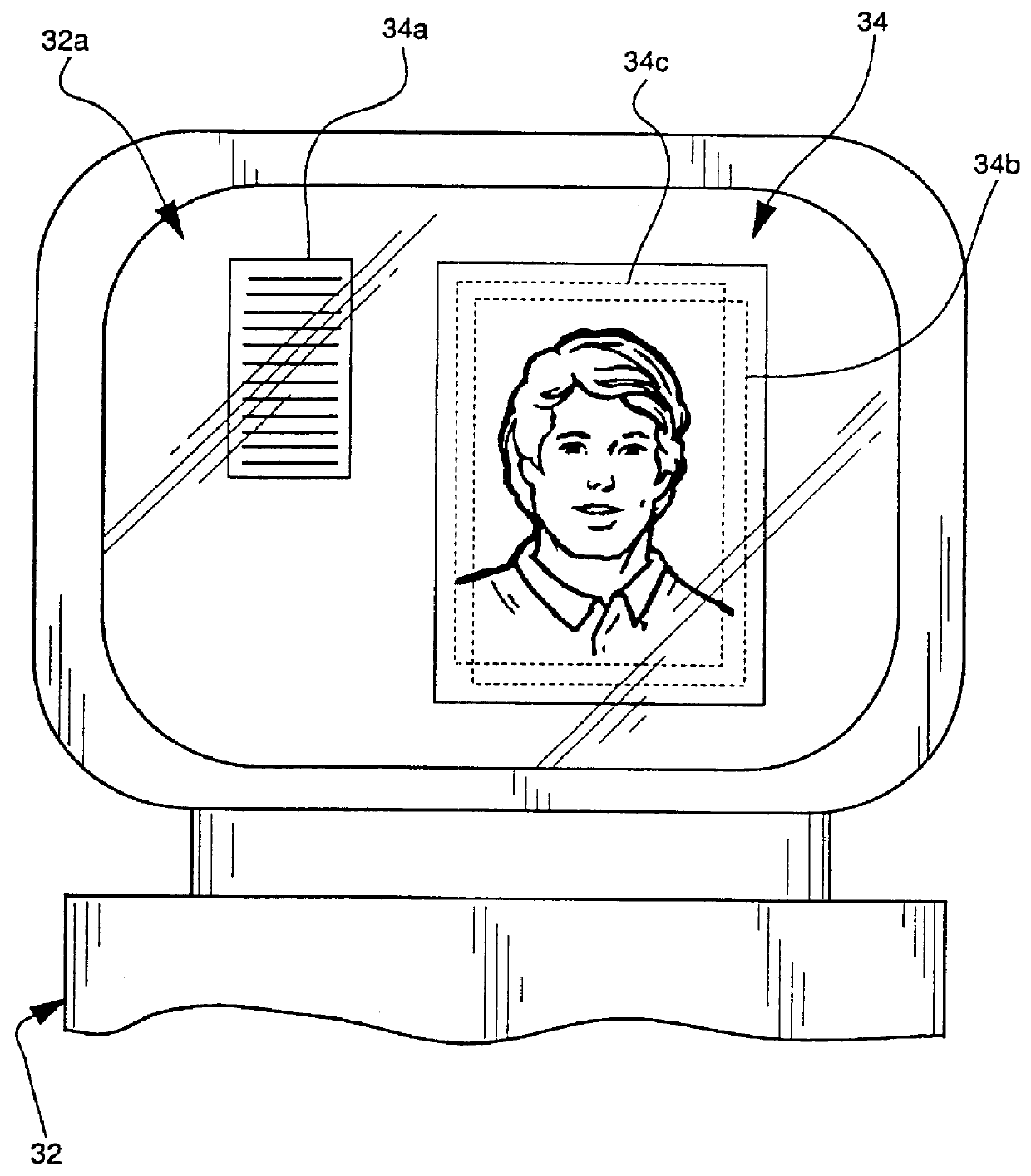

Method of producing photographic prints

InactiveUSRE36535E1Easy to manufactureConvey accuratelyPhotography auxillary processesPhotoprinting processesGraphicsComputer monitor

A methodology for handling photographic film in which a video image of each frame of film is acquired on a diskette as the frames are originally being processed in the photographic laboratory, the diskette is transmitted to the photographer's studio, along with the proof prints, for viewing by the photographer / subject, the photographer / subject makes further desired corrections or adjustments of each frame by viewing the video image of each frame on a computer monitor, the farther corrections or adjustments are recorded on the diskette for each frame, and the revised diskette is returned to the photographic laboratory where it is used in conjunction with the film to produce final photographic prints. The final photographic prints thus graphically and objectively reflect the precise desires of the photographer / subject.

Owner:KODAK ALARIS INC

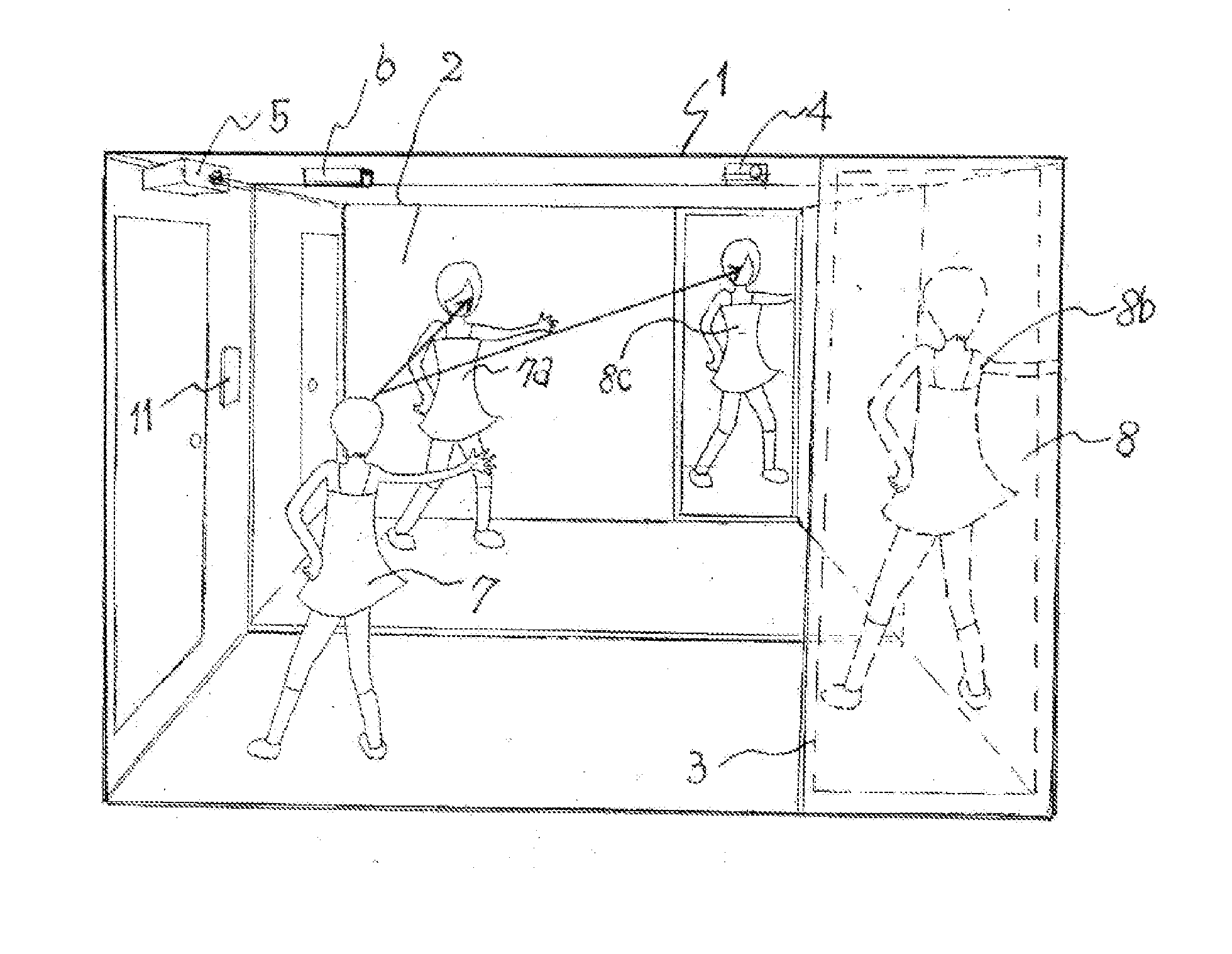

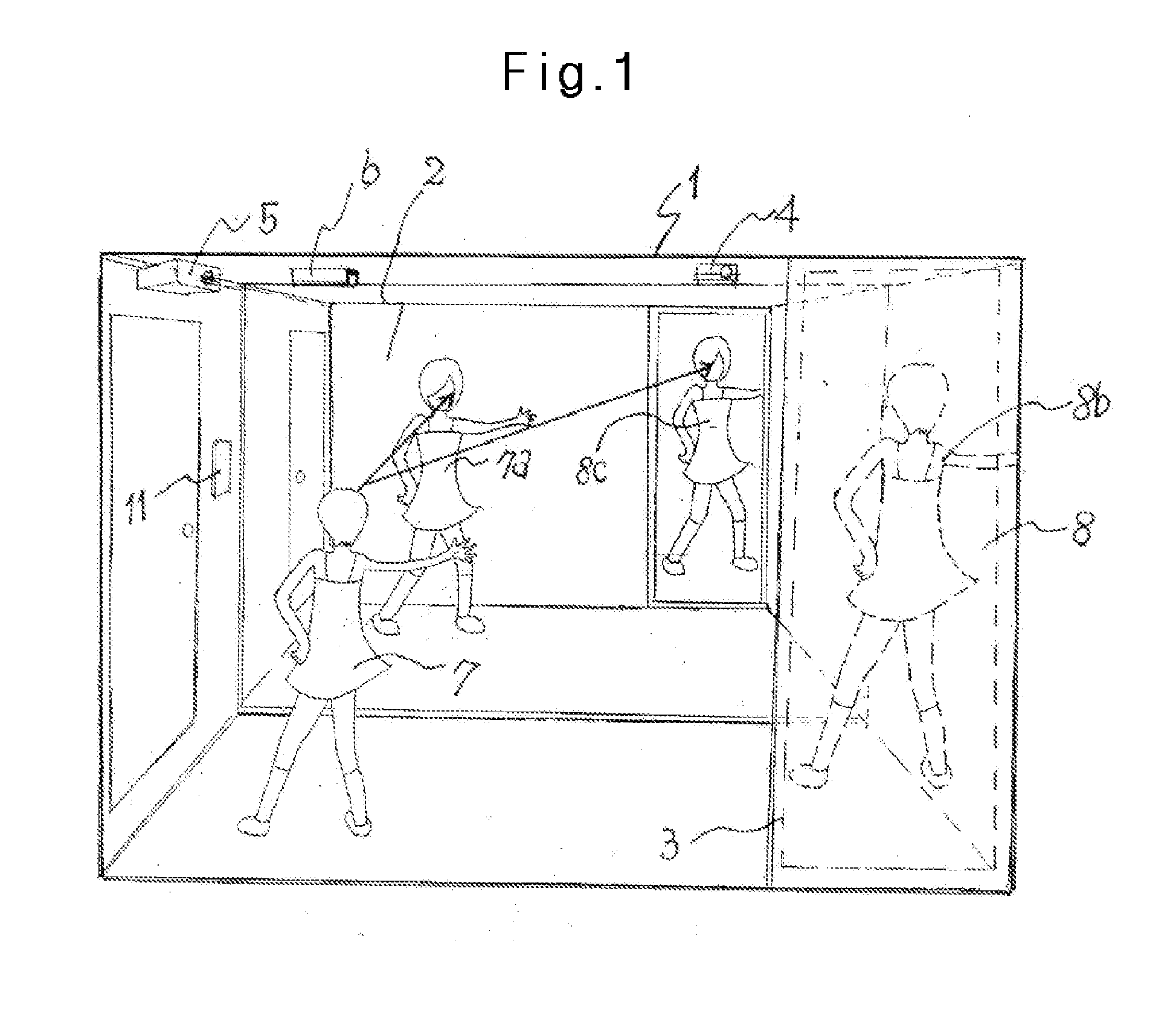

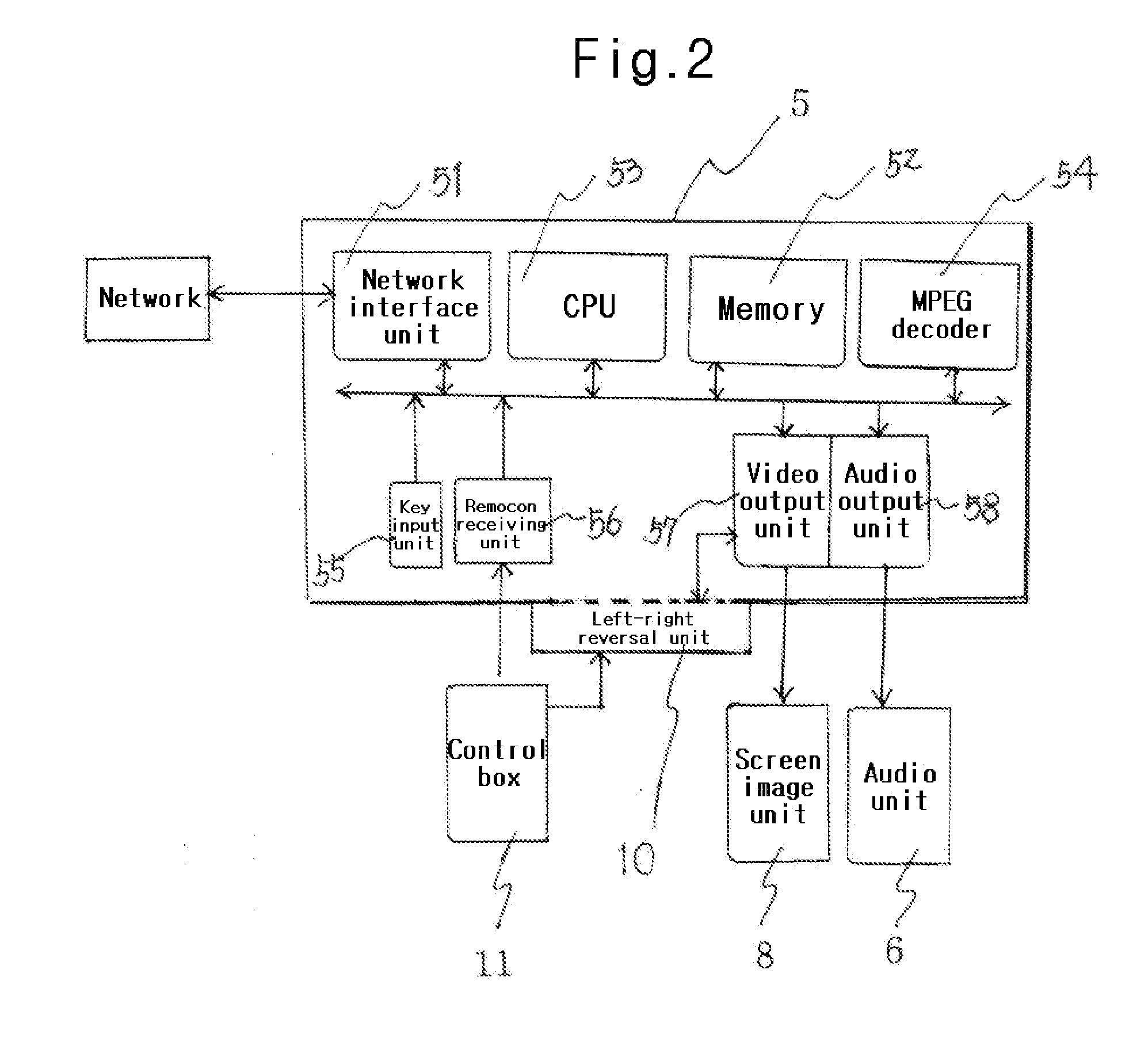

System for screen dance studio

InactiveUS20120079555A1Real experienceProjectorsAnalogue secracy/subscription systemsLarge screenImage storage

A system for an exercise screen dance studio includes an image storage unit, an audio unit, a controller, a large mirror, a projector, a screen image unit, and a left-right image reversal unit for reversing left-right sides of an image. In addition, a screen image unit is provided either behind a trainee dancer with a large mirror being provided in front of the trainee or the screen image unit can be integrated with the large mirror. A large screen image unit and a projector for proving audio and image may be provided, wherein the large mirror is arranged in front of the trainee and the screen image unit is placed on a rear side thereof or inside the mirror so that the trainee can see simultaneously his / her reflected exercising image and the projected dance exercising image through the mirror in the same orientation with regard to left-right sides or as a reversed image.

Owner:CHOI HAE YONG

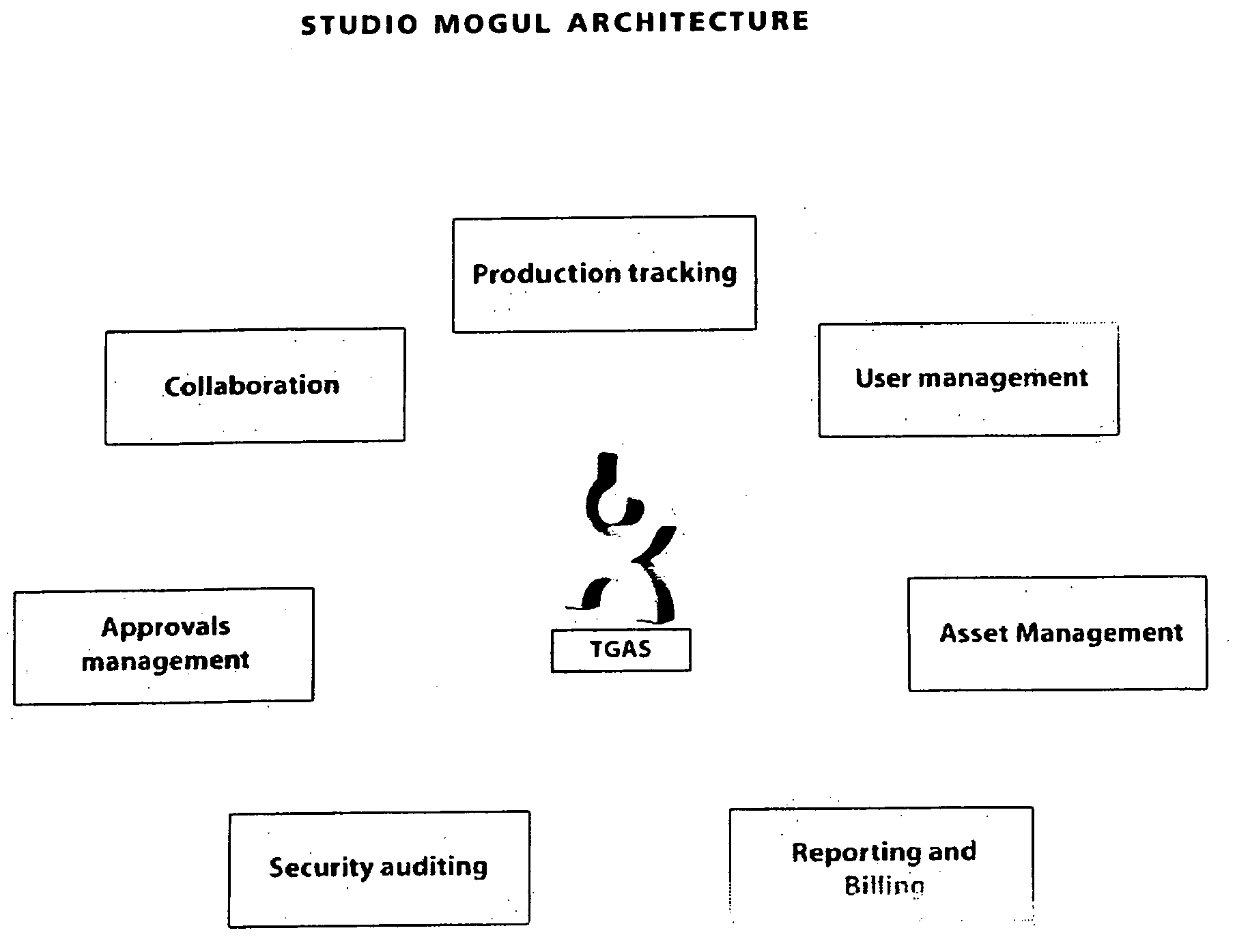

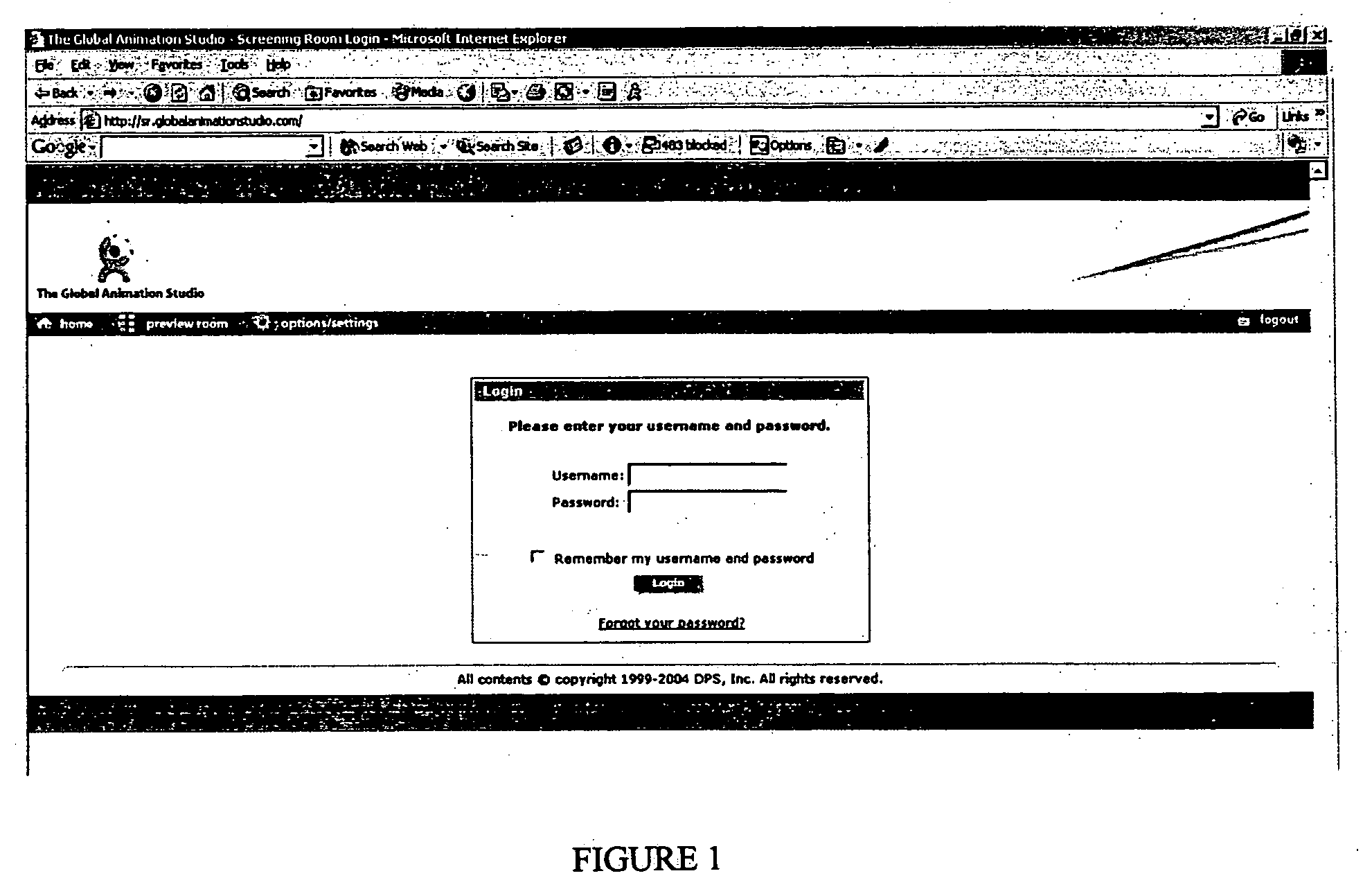

Global animation studio

InactiveUS20050187806A1Buying/selling/leasing transactionsSpecial data processing applicationsAnimationAnimation system

A global animation system includes: a pool of reusable characteristics for at least one character or feature; and a pool of available artists, wherein a member of the pool of available artists selects at least one reusable characteristic from the pool of reusable characteristics to create a character or feature. A method for managing an animation project includes: obtaining an animation project; disassembling the animation project into at least one individual task; assigning the at least one individual task to an artist, wherein the artist completes the at least one individual task using at least one characteristic stored in a pool of reusable characteristics.

Owner:STARZ DISTRIBUTION

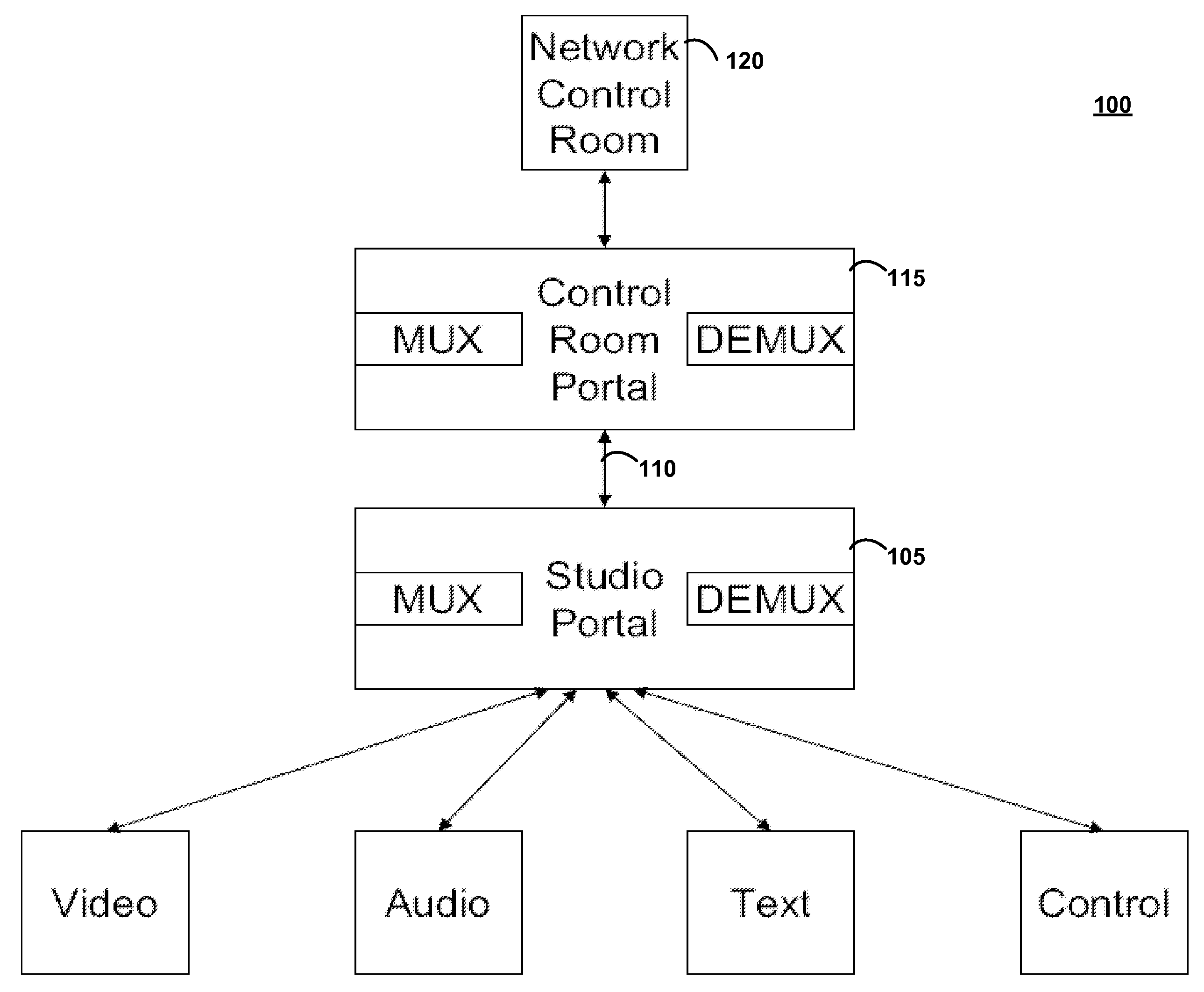

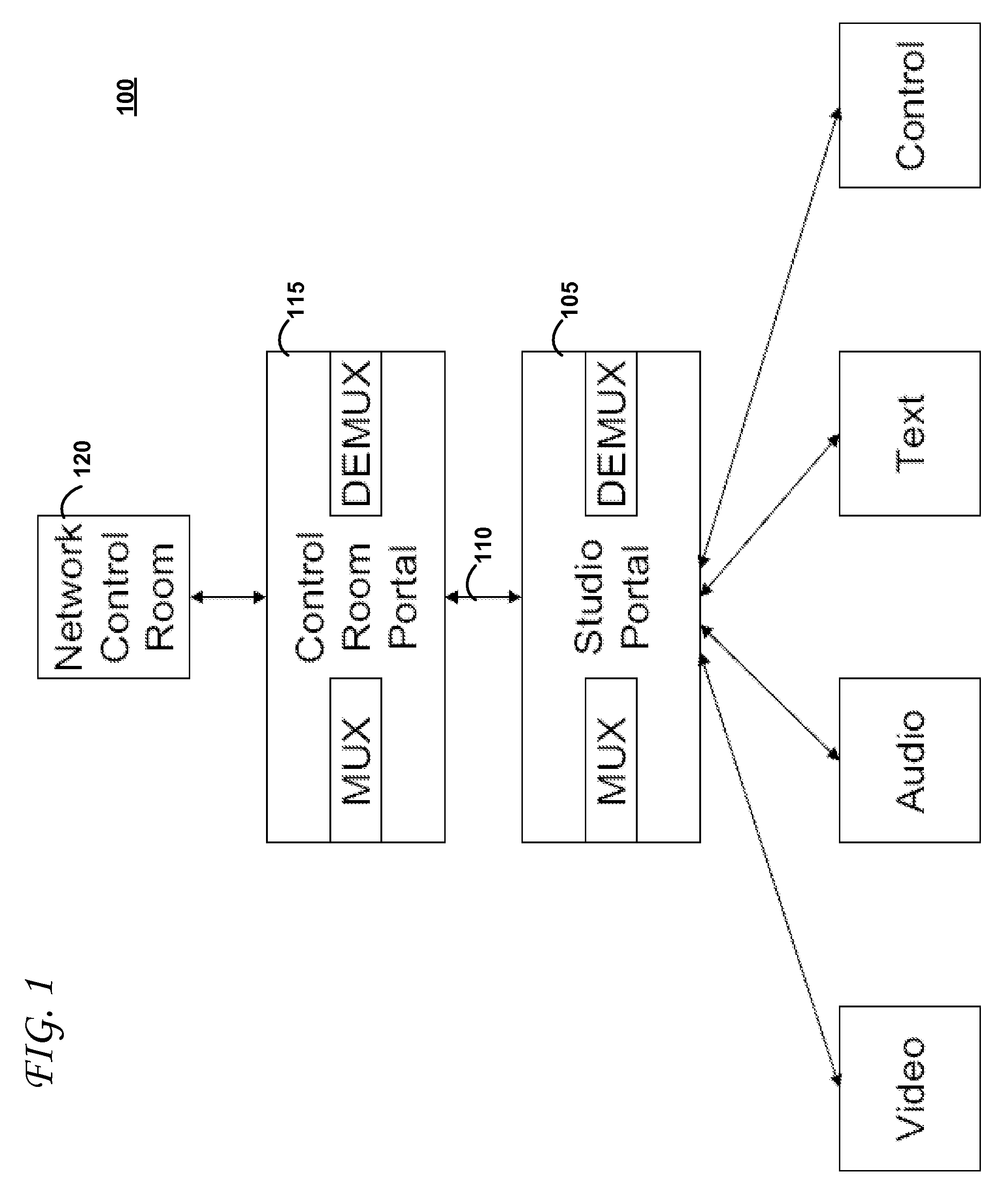

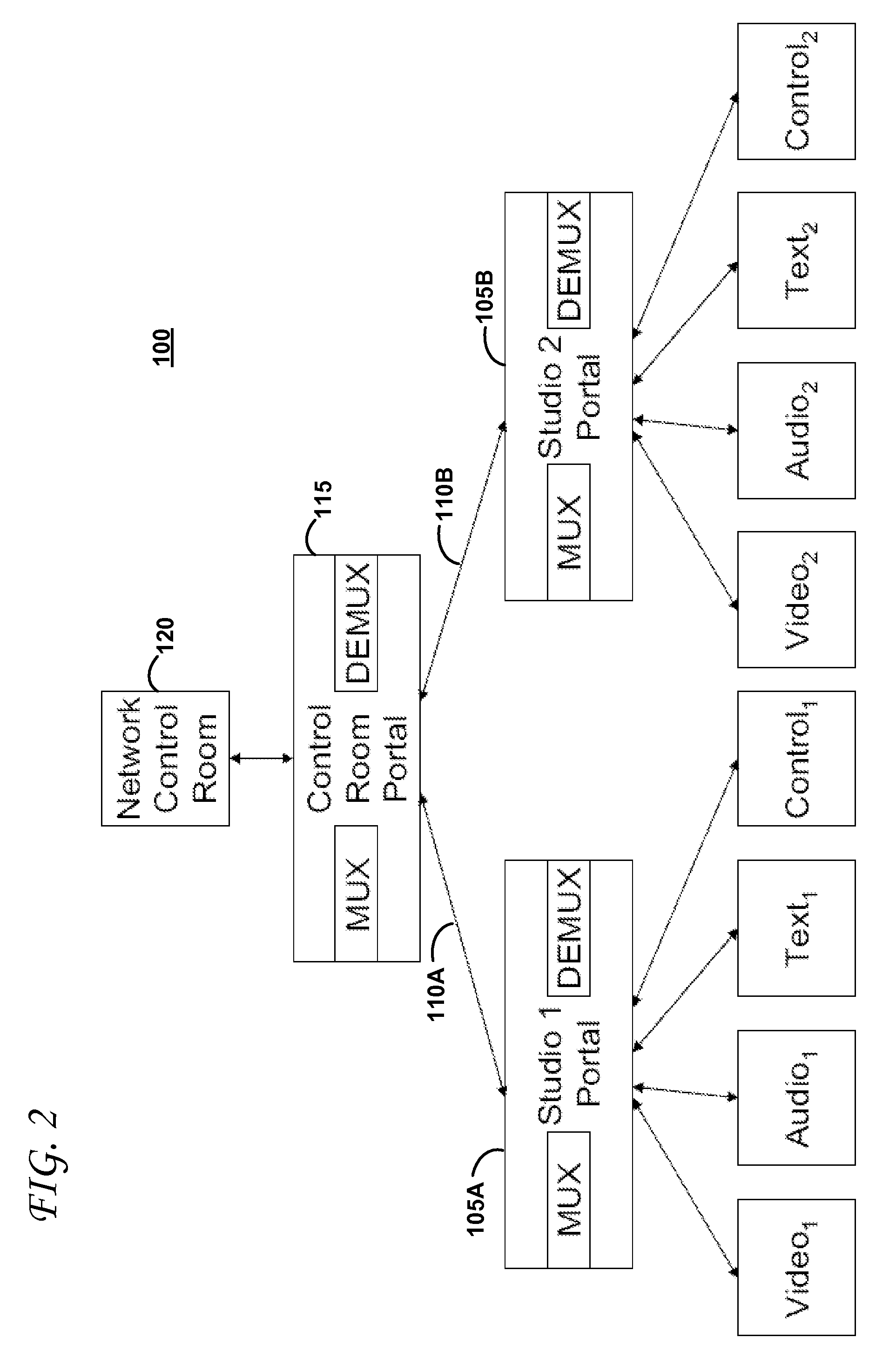

Systems and methods for remote video production

InactiveUS20090290070A1Quantity minimizationTelevision system detailsColor television detailsMultiplexerVideo production

The present invention describes systems and methods for remote video production. In an exemplary embodiment, the present invention provides a remote video production system including a first portal. The first portal includes a number of ports, the ports configured to receive taking place at a studio. Furthermore, the first portal includes a multiplexer configured to communication signals from equipment designed to capture a performance combine the communication signals into a transport stream. Additionally, the first portal includes at least one transmitter configured to transmit the transport stream to a location remote from the first portal.

Owner:ALL MOBILE VIDEO

Digital workroom

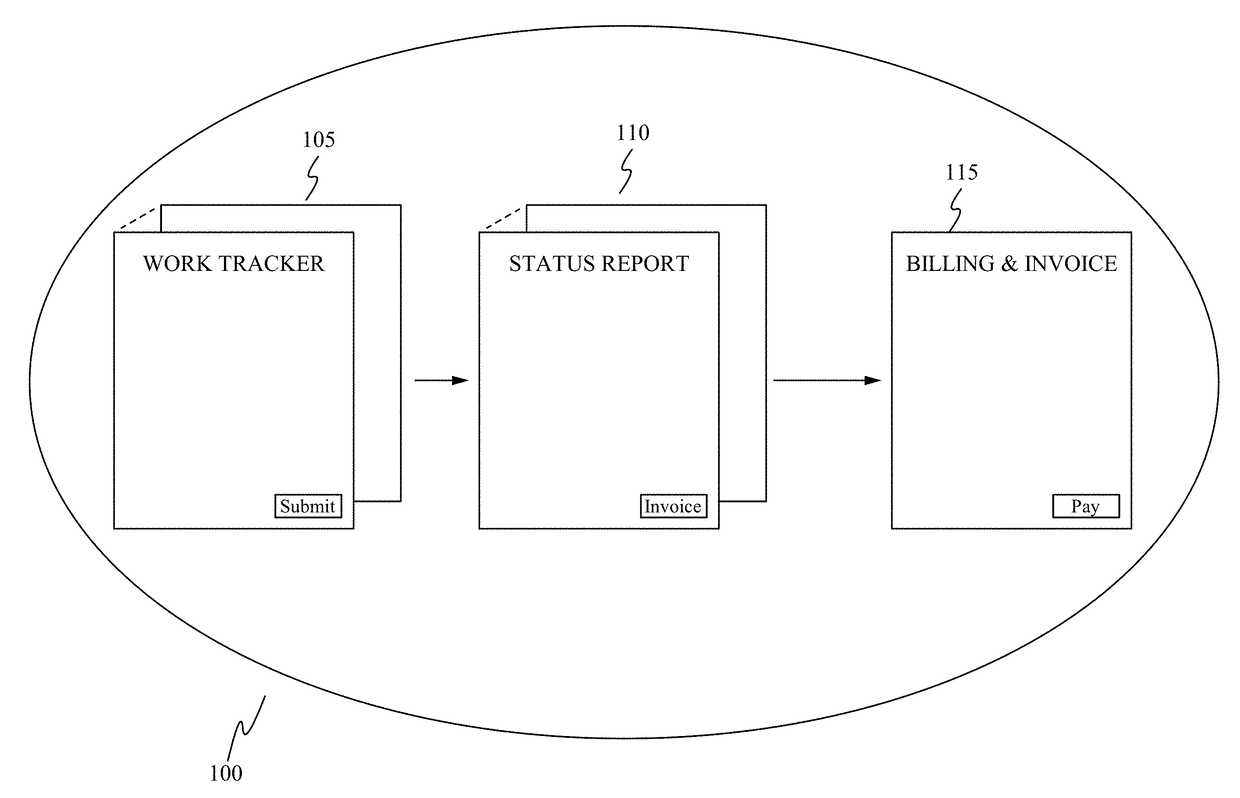

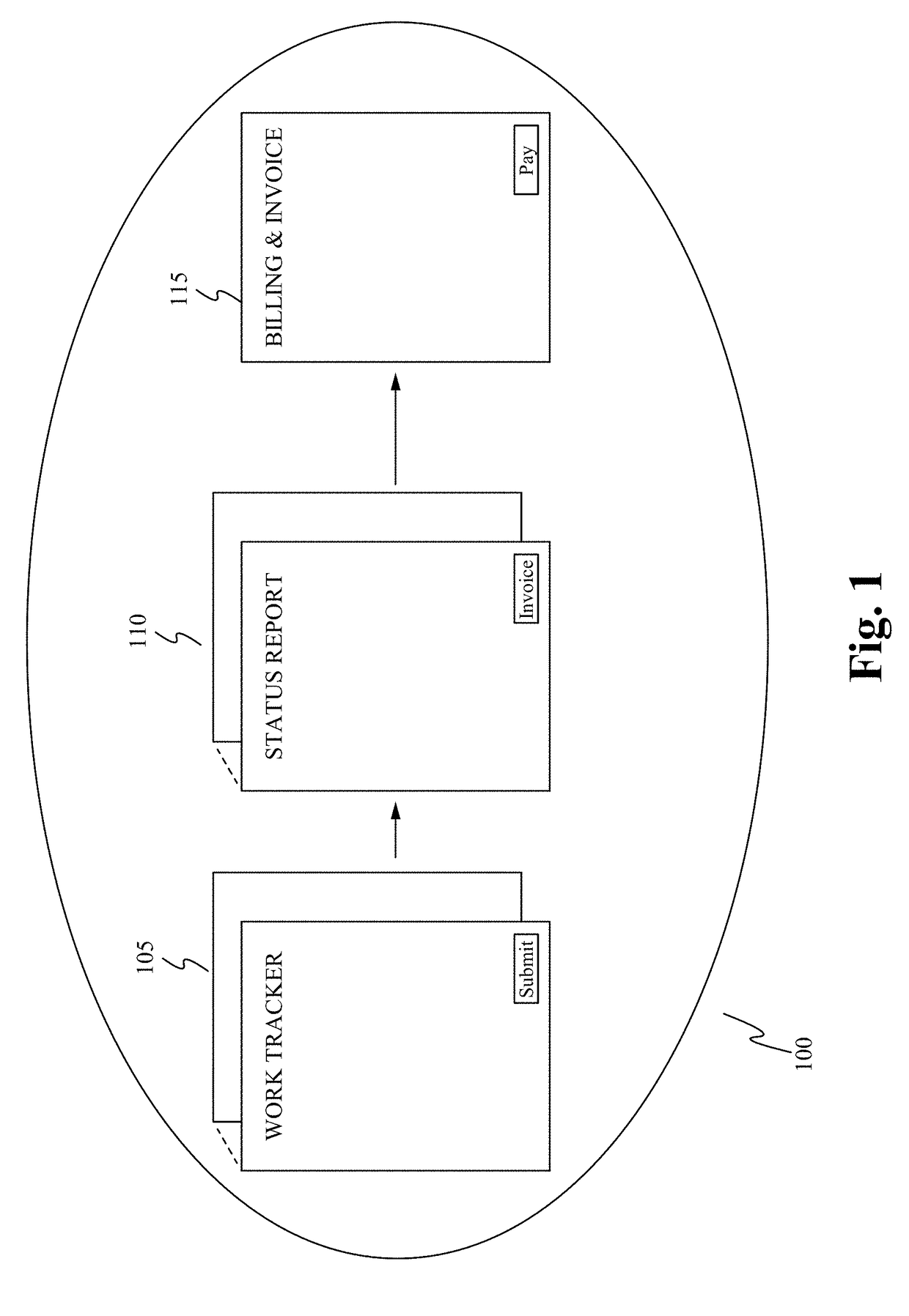

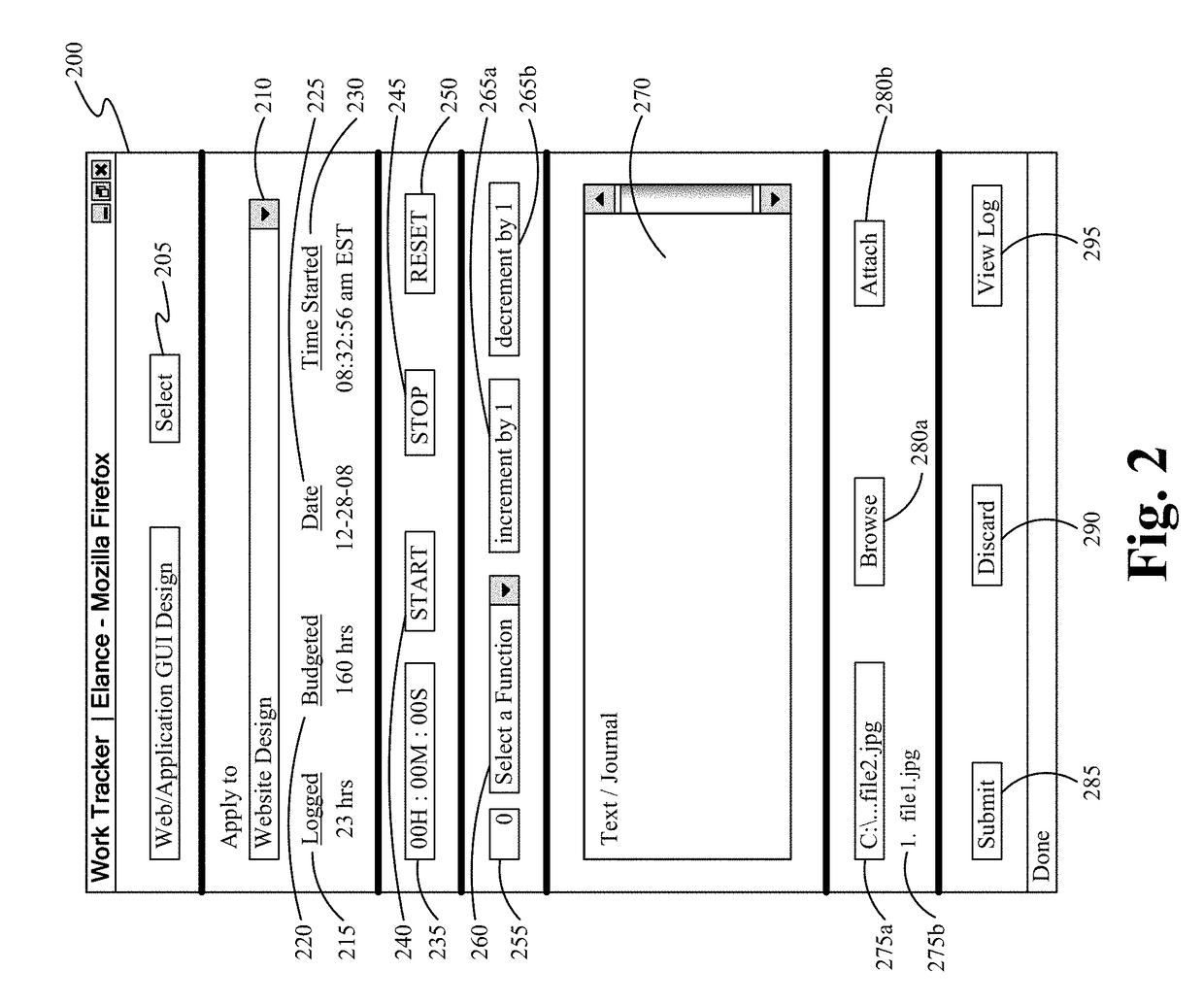

A workroom is automatically established for each job created and is associated with a unique email address. The workroom allows members to hold live meetings, communicate in real-time, including via email, upload / manage / share files, and automatically provide transcripts of communication. The workroom also allows team members to launch work trackers directly from the workroom. A work tracker collects work information and directly generates one or more status reports based on the work information collected. A status report includes a back-end version viewable and modifiable by a service provider and a front-end version viewable by a buyer. The status report directly generates an invoice based on the information from the status report. The invoice is submitted to the buyer and allows the buyer to directly pay the service provider.

Owner:ELANCE

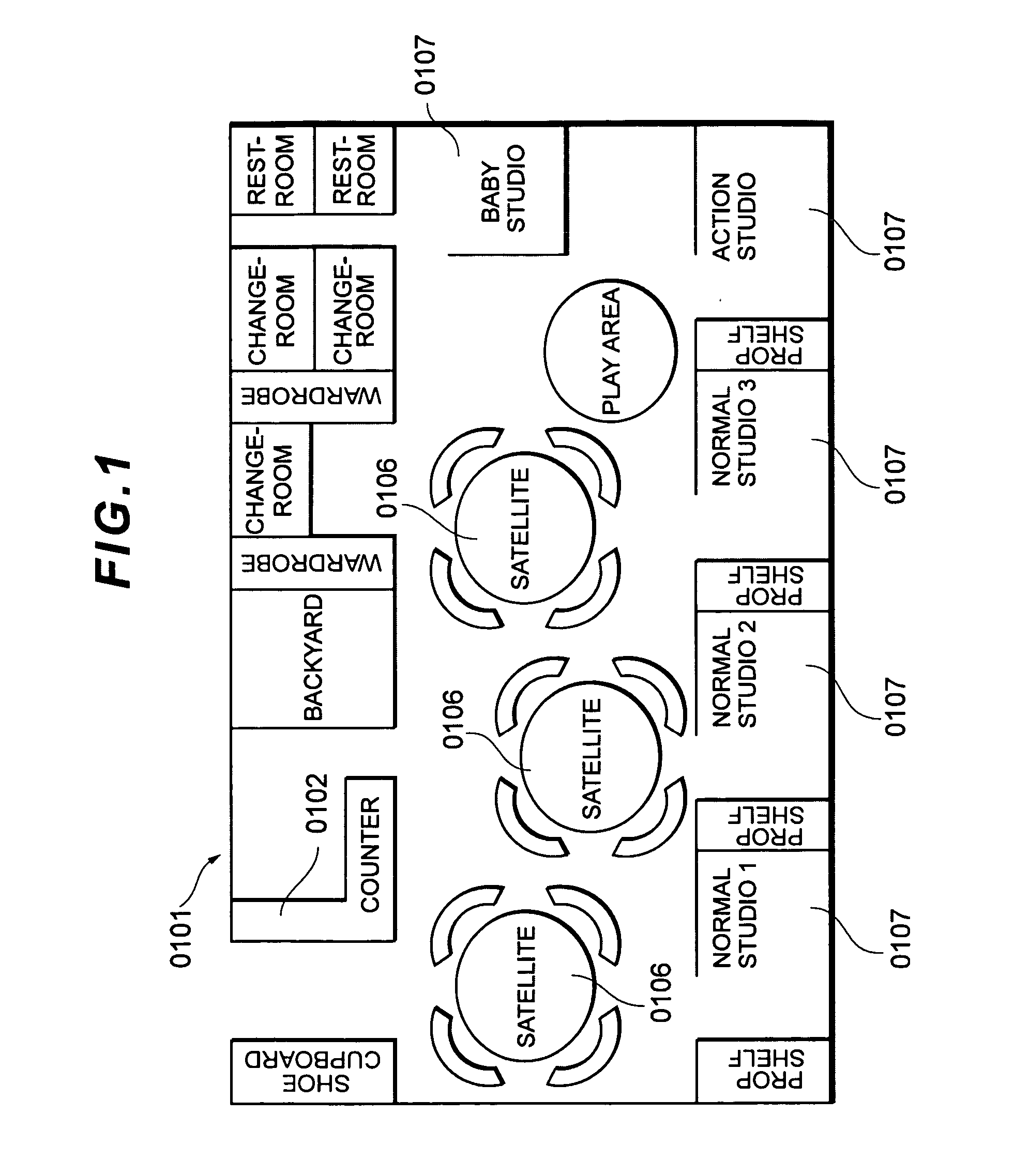

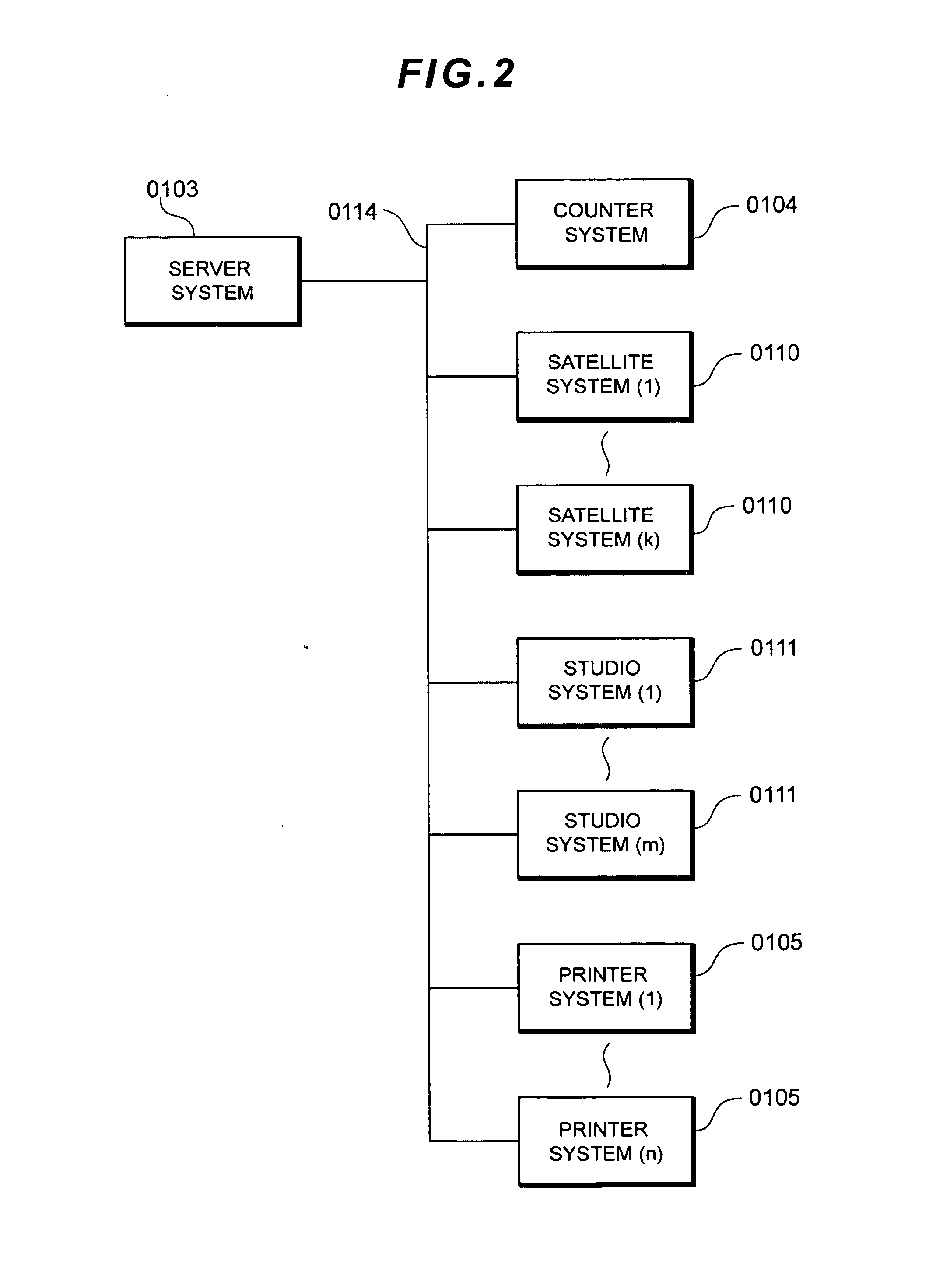

Automatic photo studio

InactiveUS20070014550A1Easy and inexpensiveTelevision system detailsPhotographyComputer printingComputer science

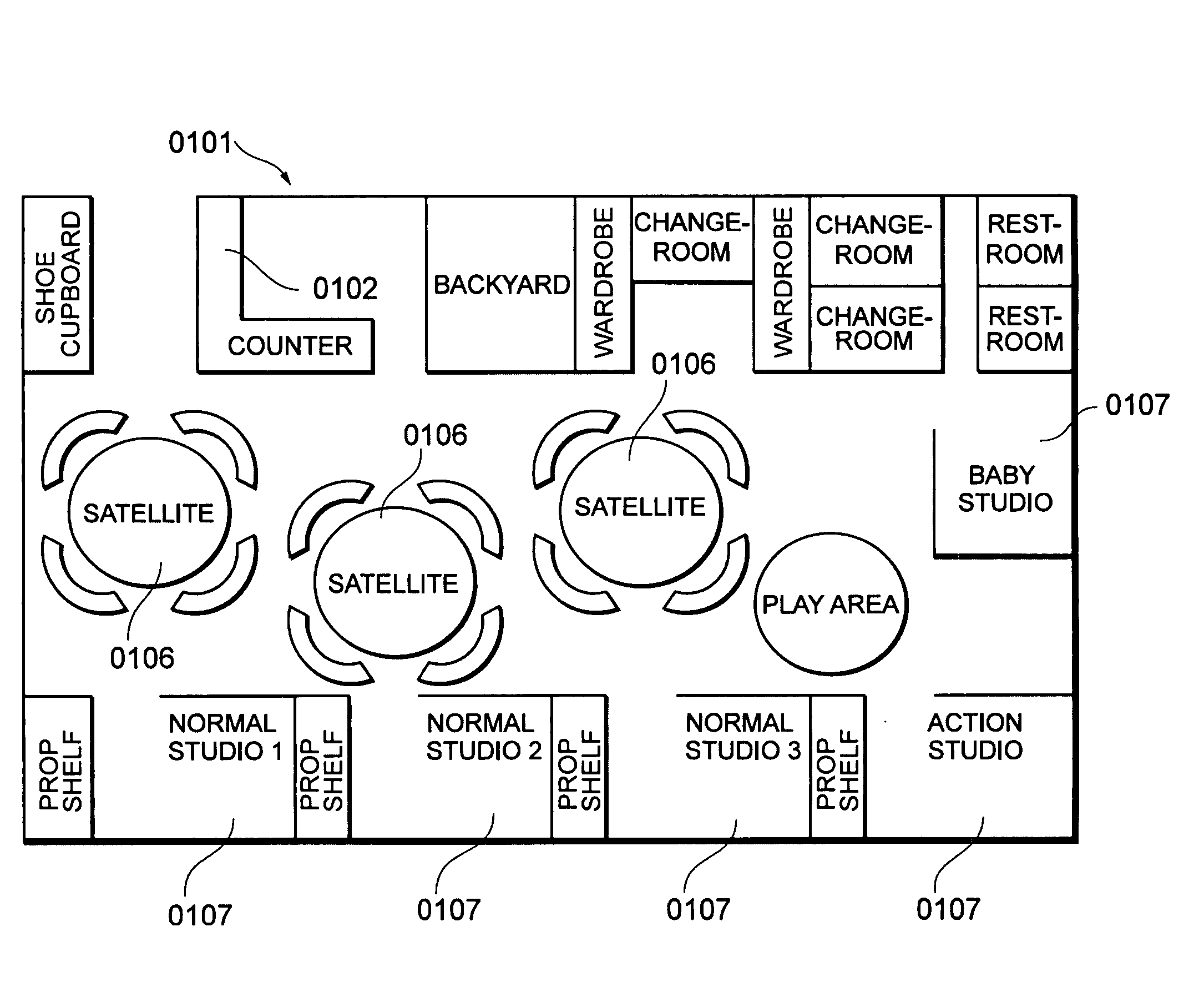

The present invention enables a user to photograph and edit a photograph suiting one's taste slowly and while having fun. The automatic photo studio of this invention has a counter for a person to receive a user, a plurality of satellites having a function of receiving operations of a user and a function of showing various displays to the user, and a plurality of studios for photographing a subject. The automatic photo studio further includes a counter system provided in the vicinity of the counter for performing visitor processing and checkout processing to the user, a printer system provided in the vicinity of the counter for printing images based on subject images photographed in the studio, a satellite system provided to the satellite for enabling the user to edit the subject images photographed in the studio, and a studio system provided to the studio for controlling the photo shooting conditions and photo shoot timing. The satellite system and the studio system determine whether the user is an authorized user based on information written in a player information storage medium as an information storage medium in the possession of the user, and permit the user to use the satellite or the studio when the user is an official user as the authorized user.

Owner:SEGA CORP

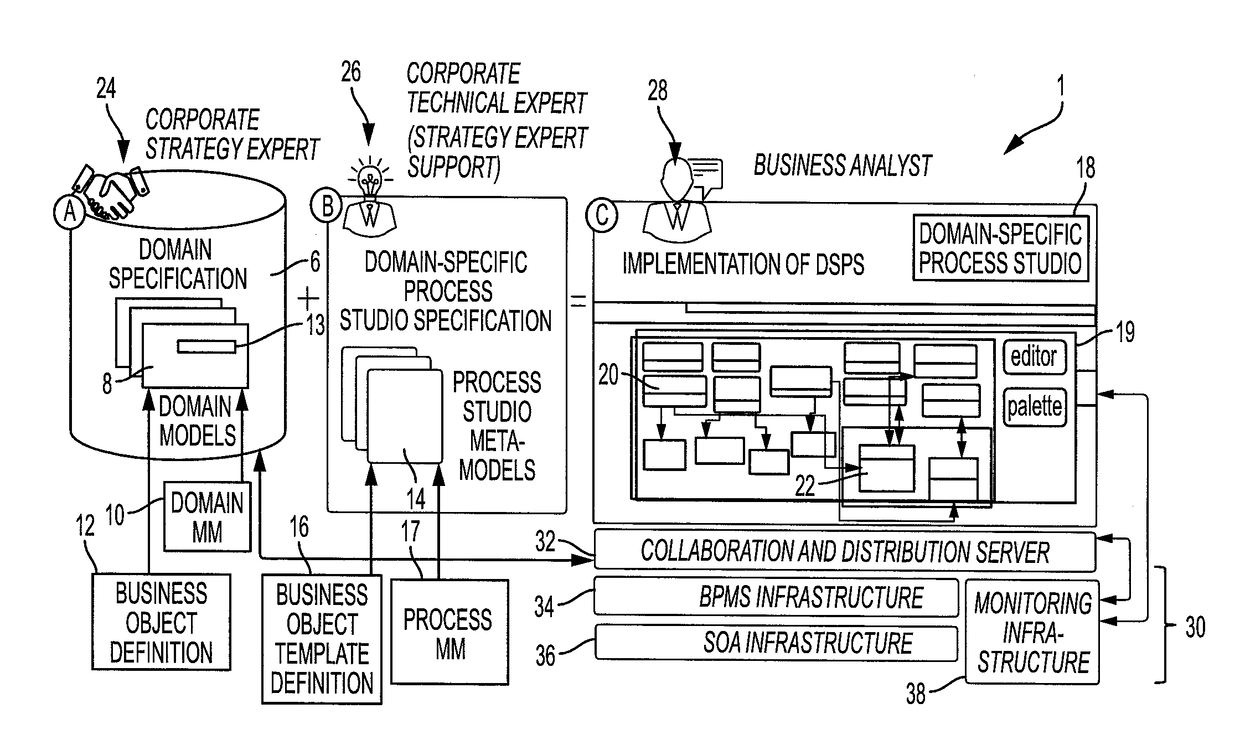

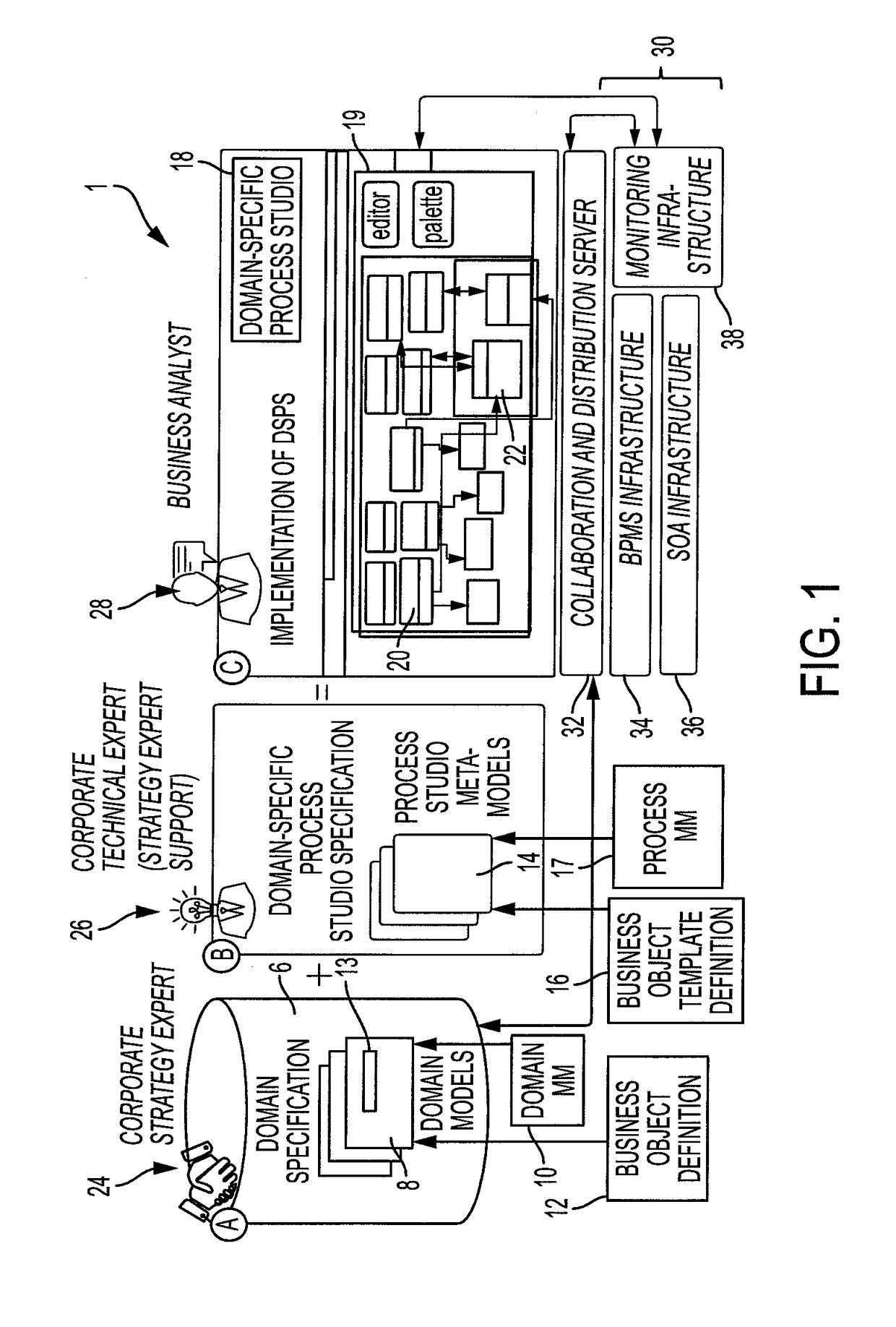

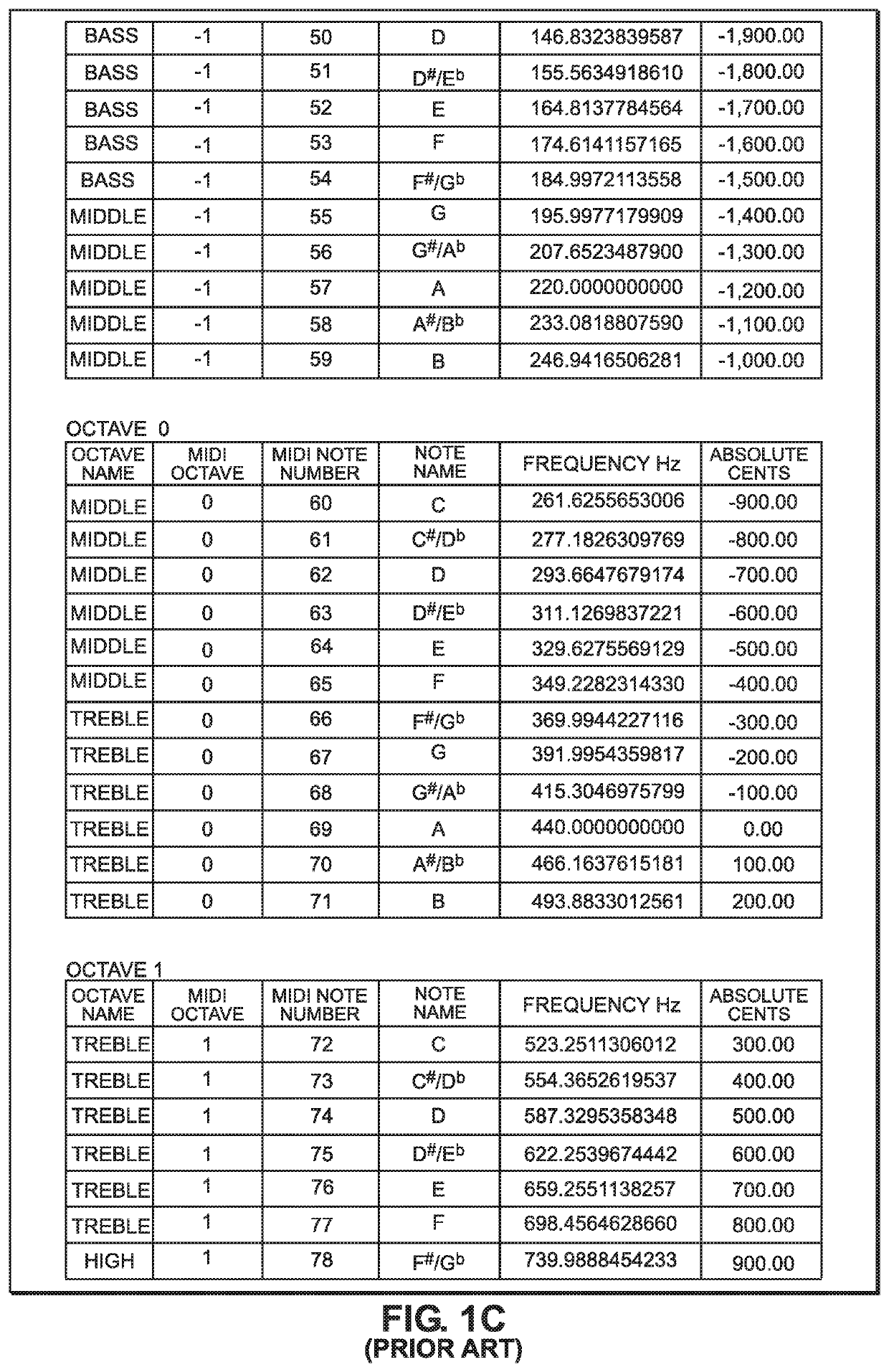

Domain-specific business objects for process design

A system and method provide for incorporating domain-specific business objects into process design. The method includes providing a domain meta-model, which links a set of elements, the elements including domain-specific business objects representing pieces of data, each of the domain-specific business objects being associated with a set of features, the set of features including an identifier feature. Business object definitions for types of domain-specific business objects are incorporated into the domain meta-model to generate a domain model including the defined domain-specific business objects. A domain-specific process studio is generated, based on the domain model, which enables a user to edit a representation of a business process that includes a sequence of process steps. The representation of the business process includes at least one process step that is linked to one of the domain-specific business objects in the domain model. One or more of the steps of the method may be performed with a processor.

Owner:XEROX CORP

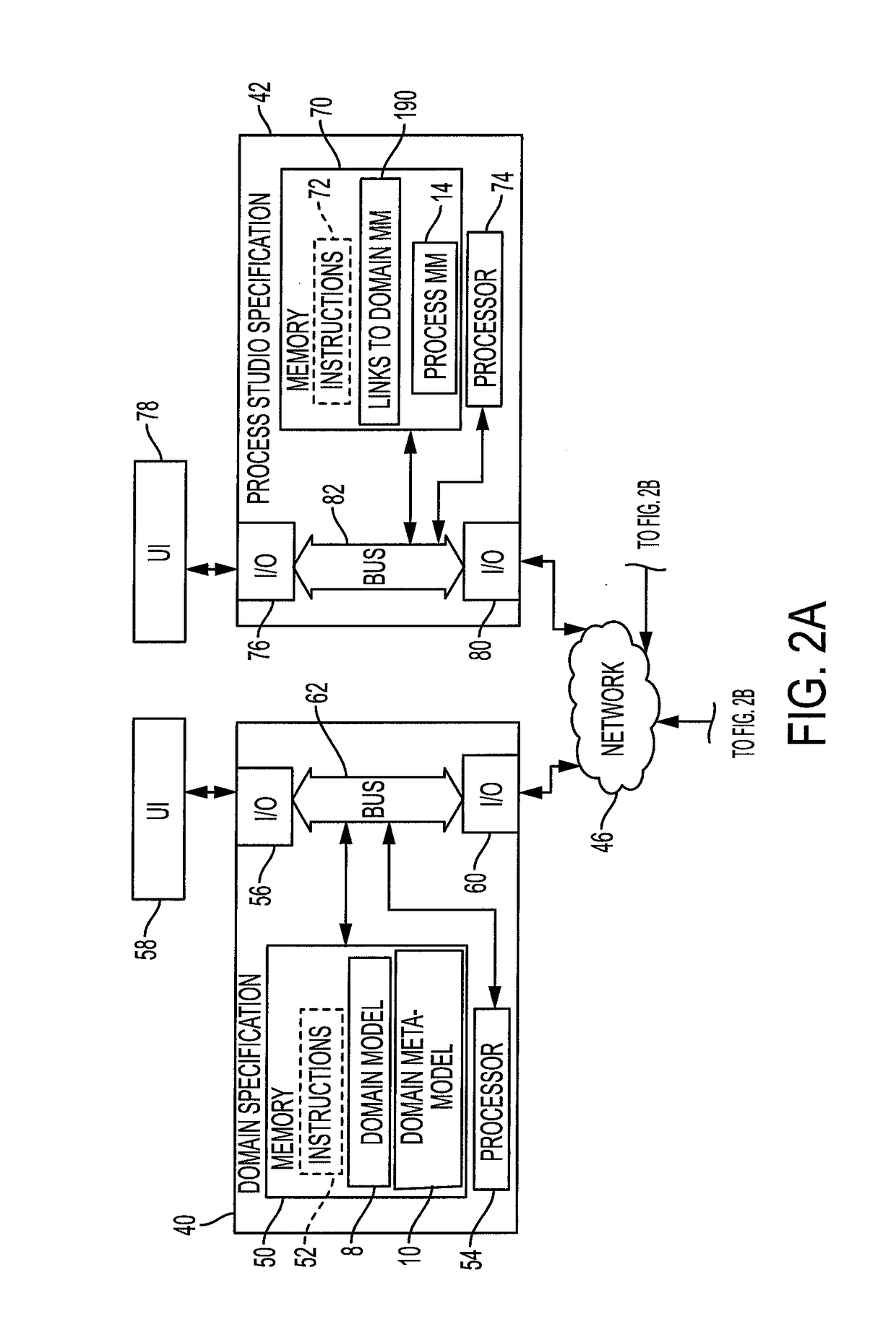

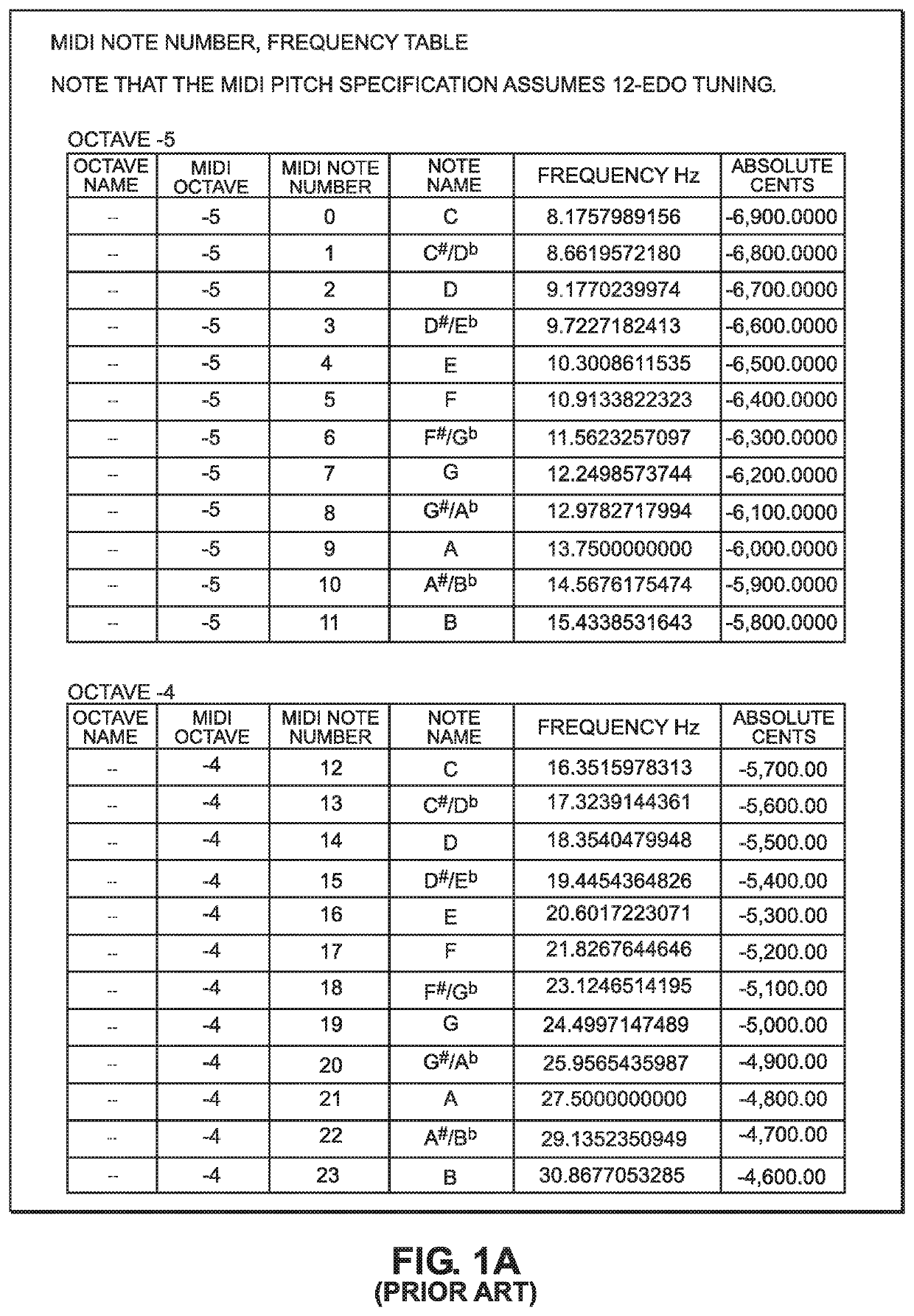

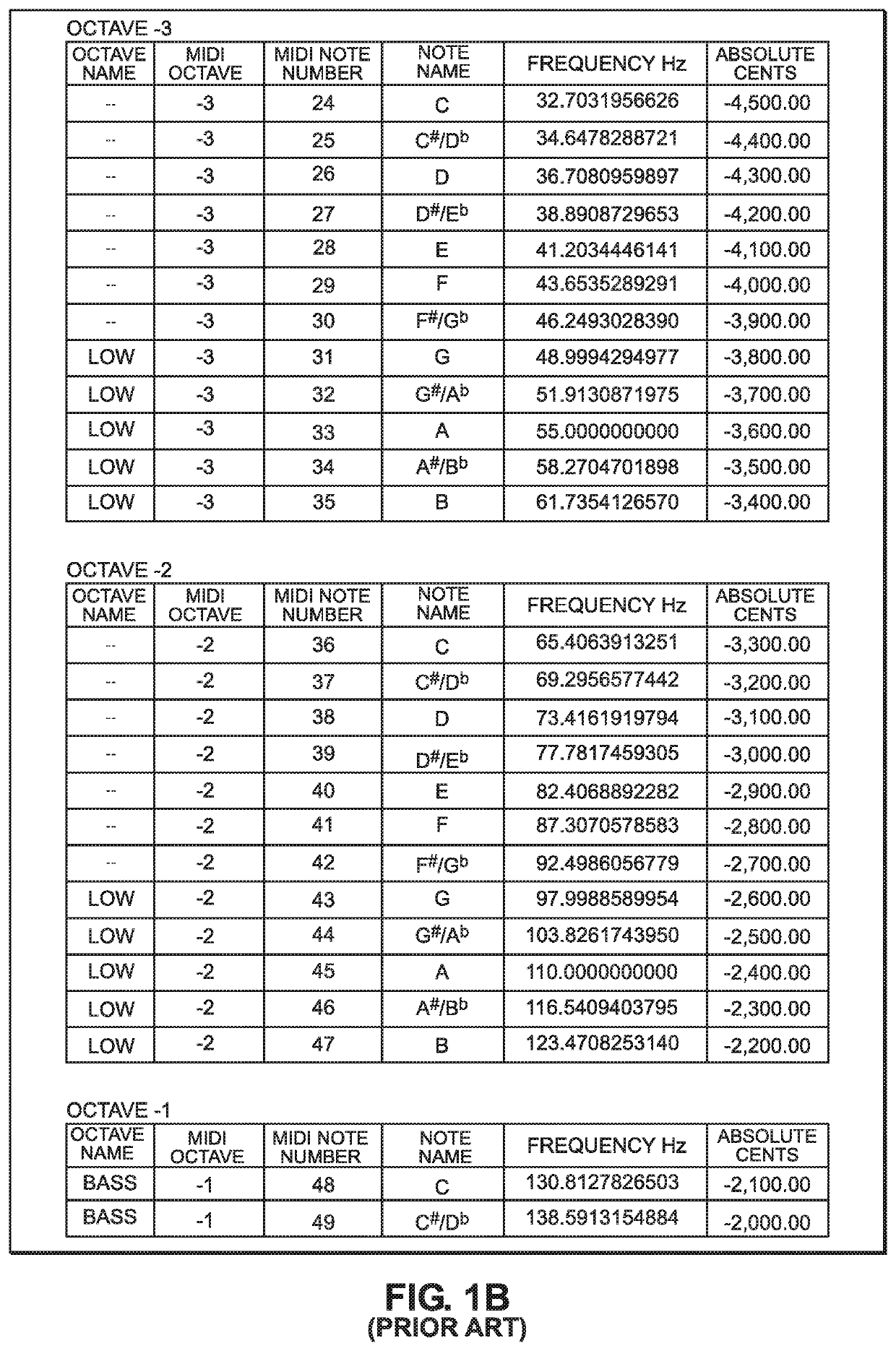

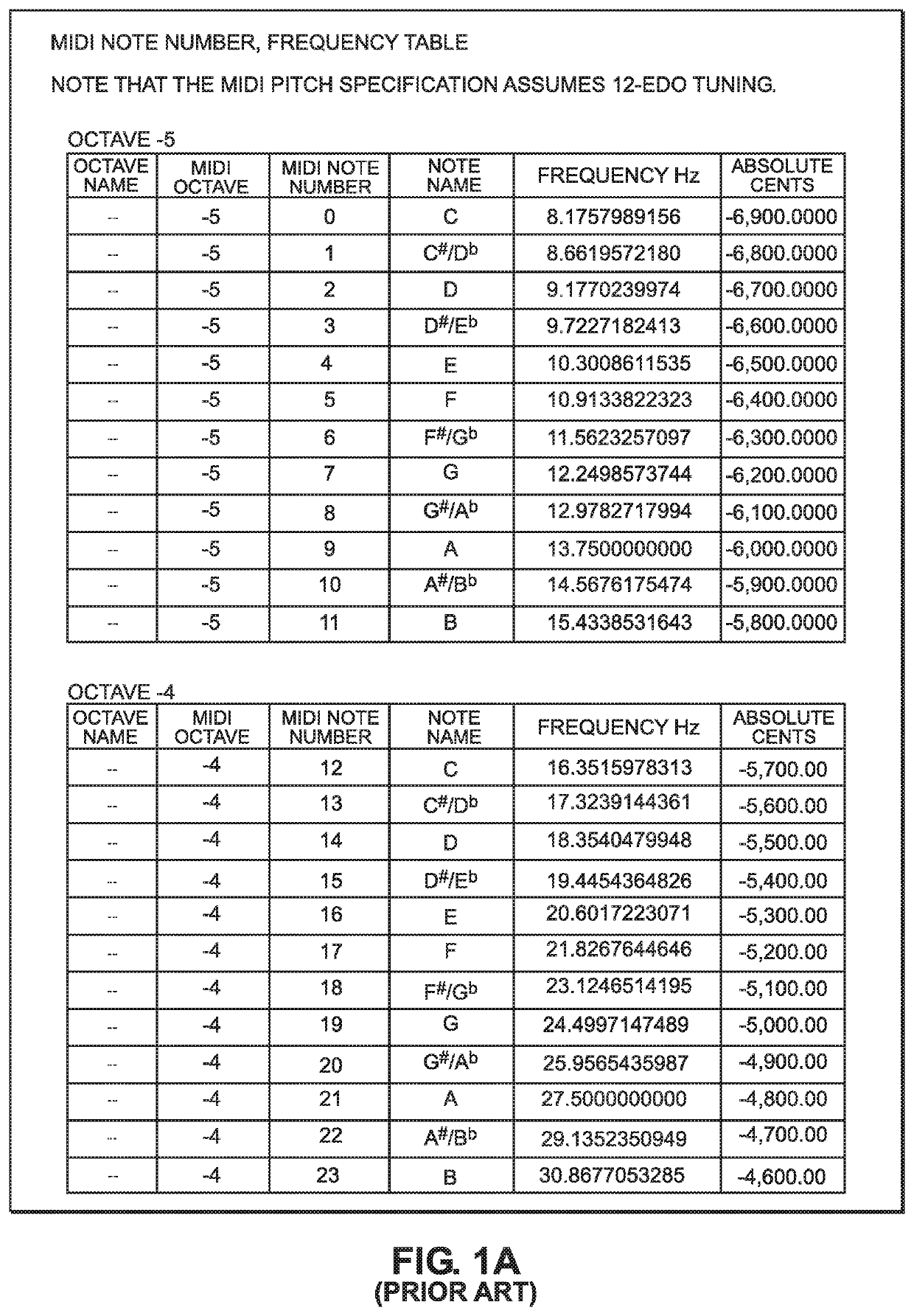

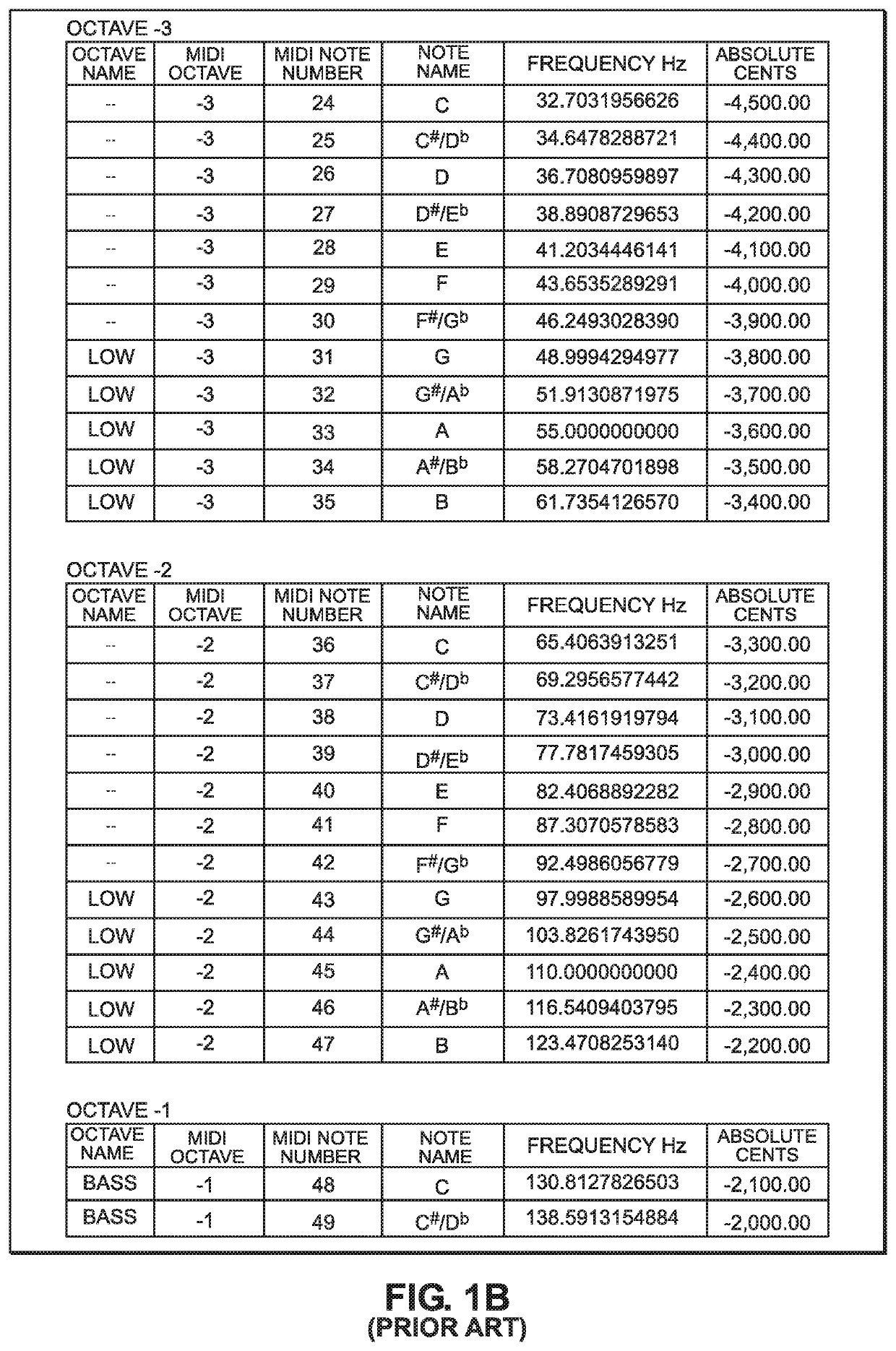

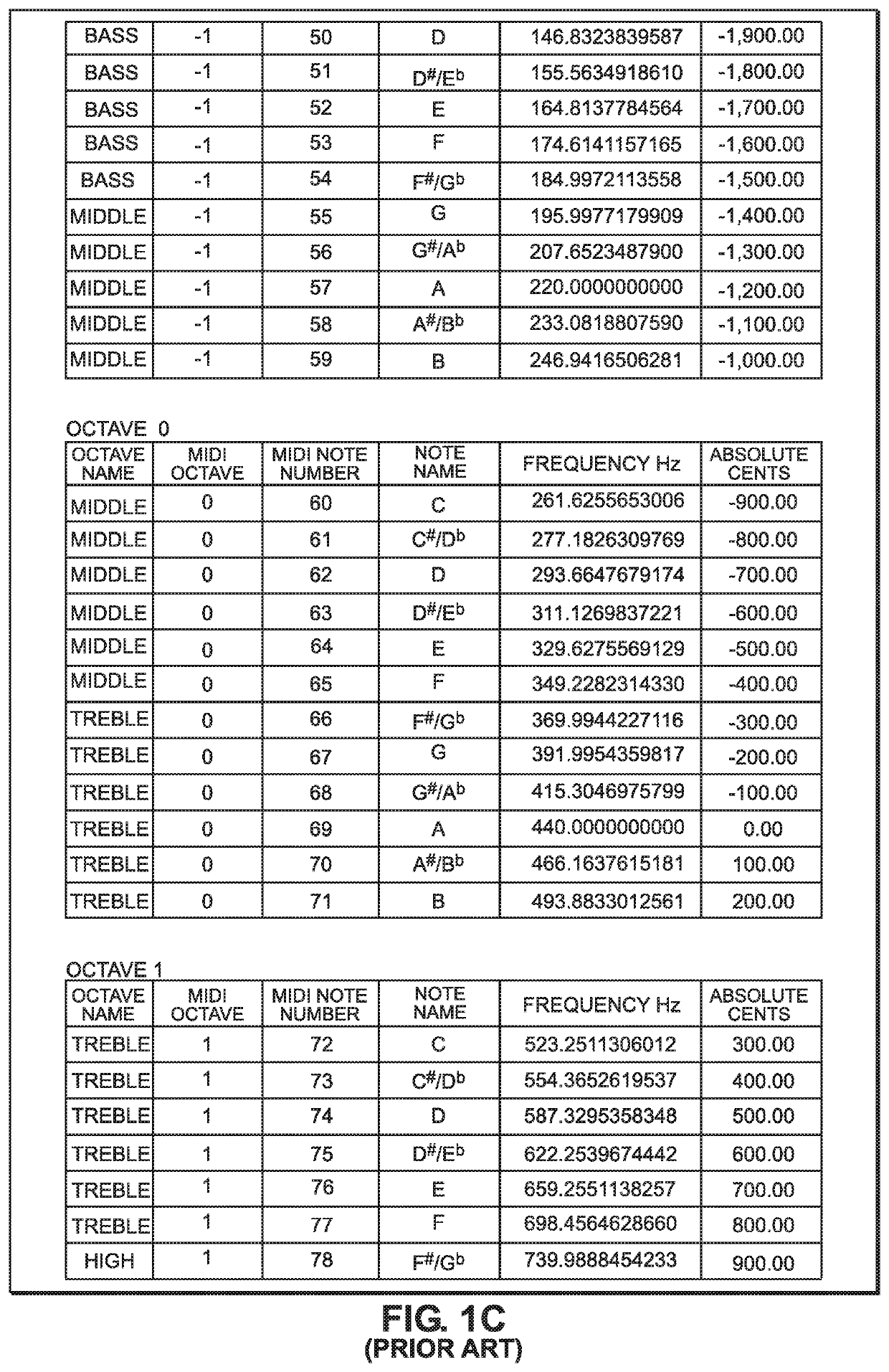

Method of digitally performing a music composition using virtual musical instruments having performance logic executing within a virtual musical instrument (VMI) library management system

ActiveUS20210110801A1Automated performanceRicher and flexible systemElectrophonic musical instrumentsEngineeringHuman–computer interaction

An automated music performance system that is driven by the music-theoretic state descriptors of any musical structure (e.g. a music composition or sound recording). The system can be used with next generation digital audio workstations (DAWs), virtual studio technology (VST) plugins, virtual music instrument libraries, and automated music composition and generation engines, systems and platforms. The automated music performance system generates unique digital performances of pieces of music, using virtual musical instruments created from sampled notes or sounds and / or synthesized notes or sounds. Each virtual music instrument has its own set of music-theoretic state responsive performance rules that are automatically triggered by the music theoretic state descriptors of the music composition or performance to be digitally performed. An automated virtual music instrument (VMI) library selection and performance subsystem is provided for managing the virtual musical instruments during the automated digital music performance process.

Owner:SHUTTERSTOCK

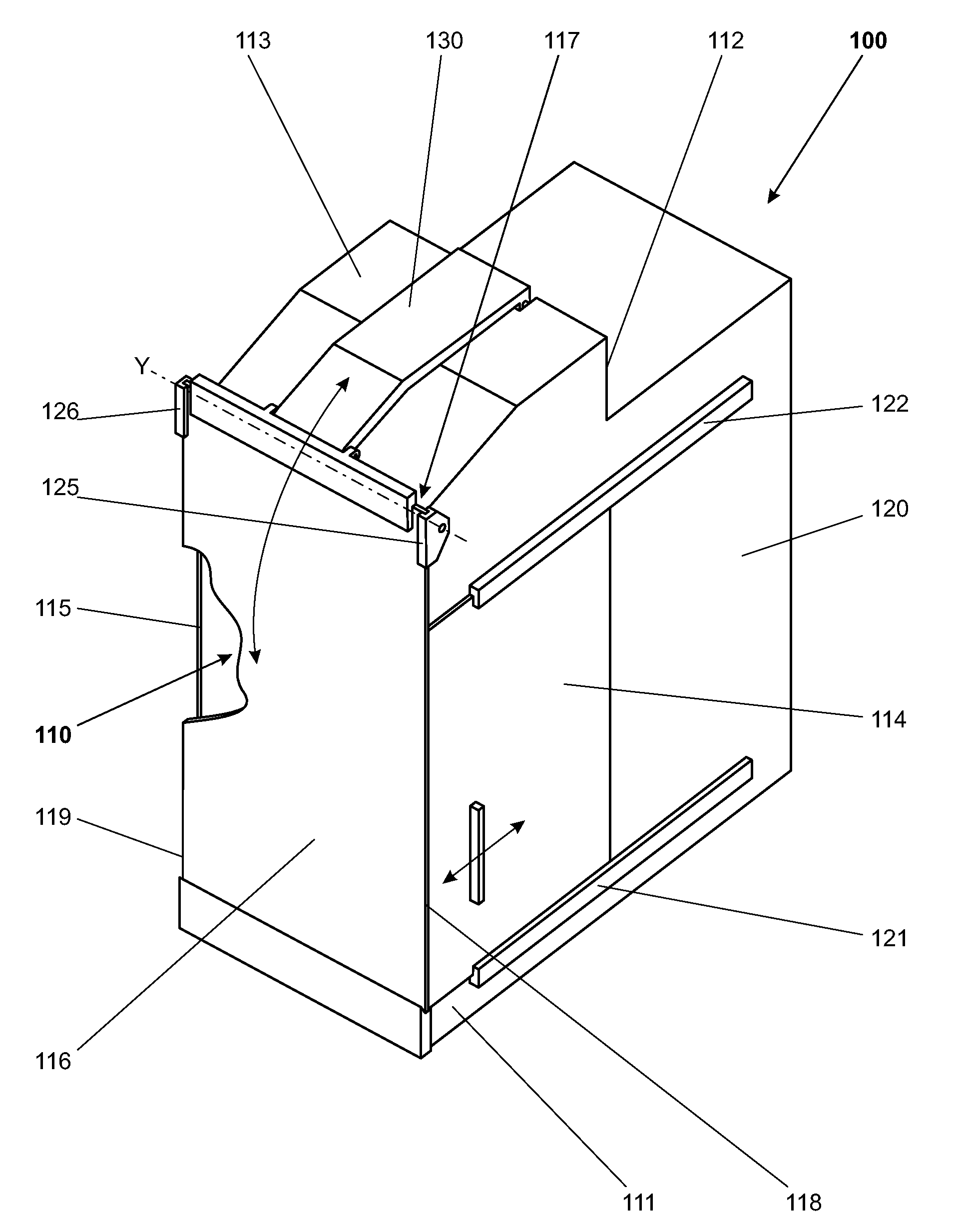

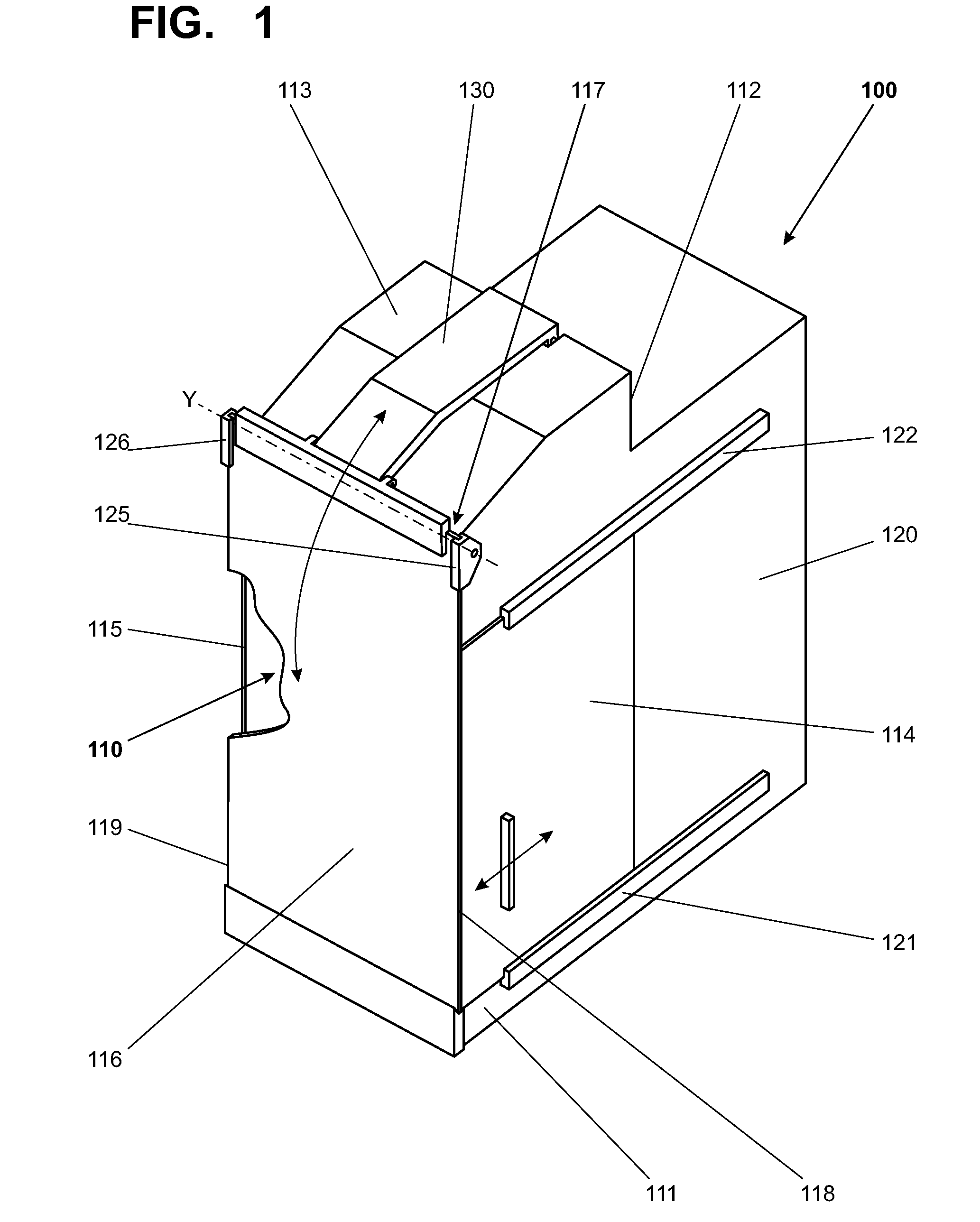

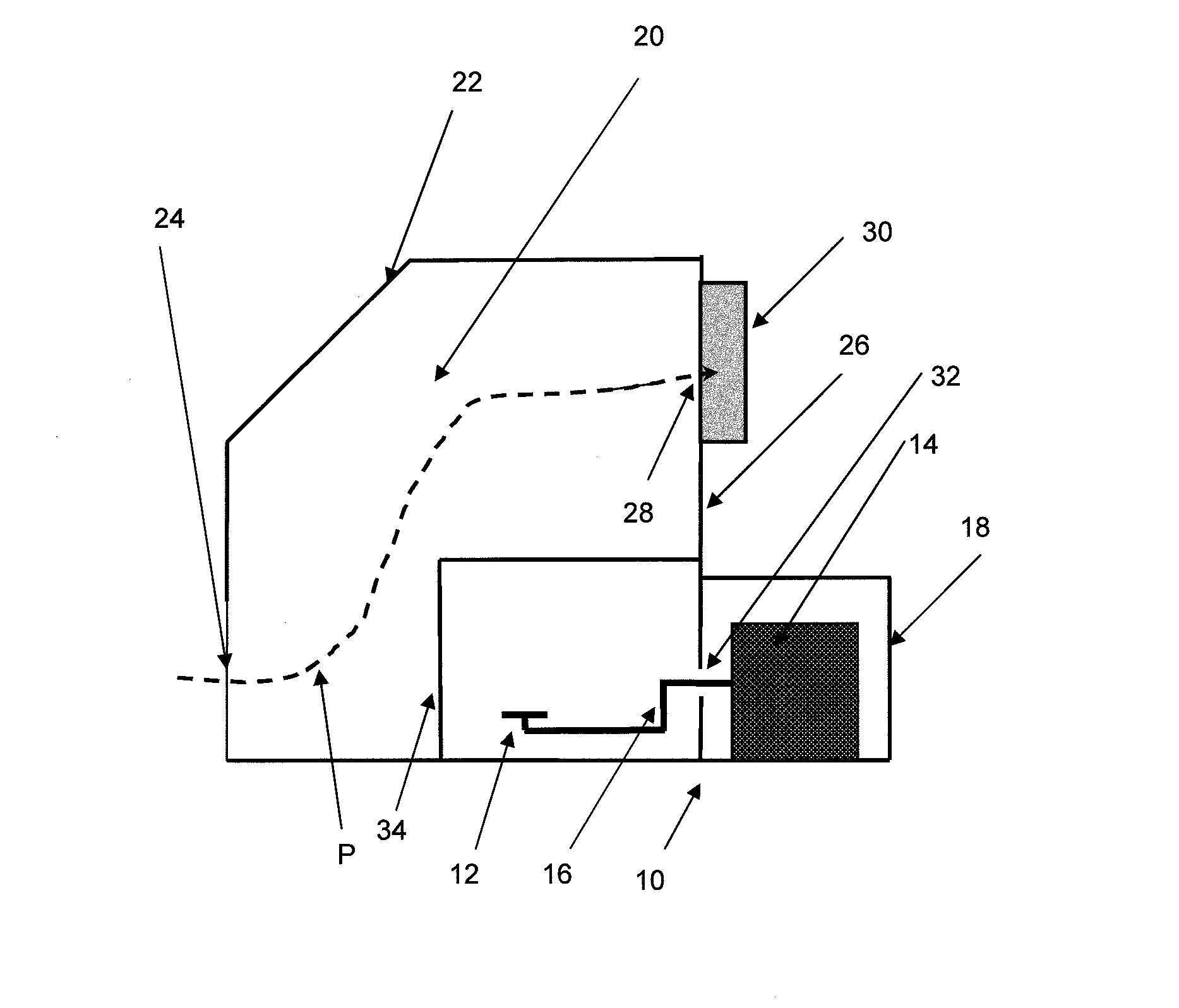

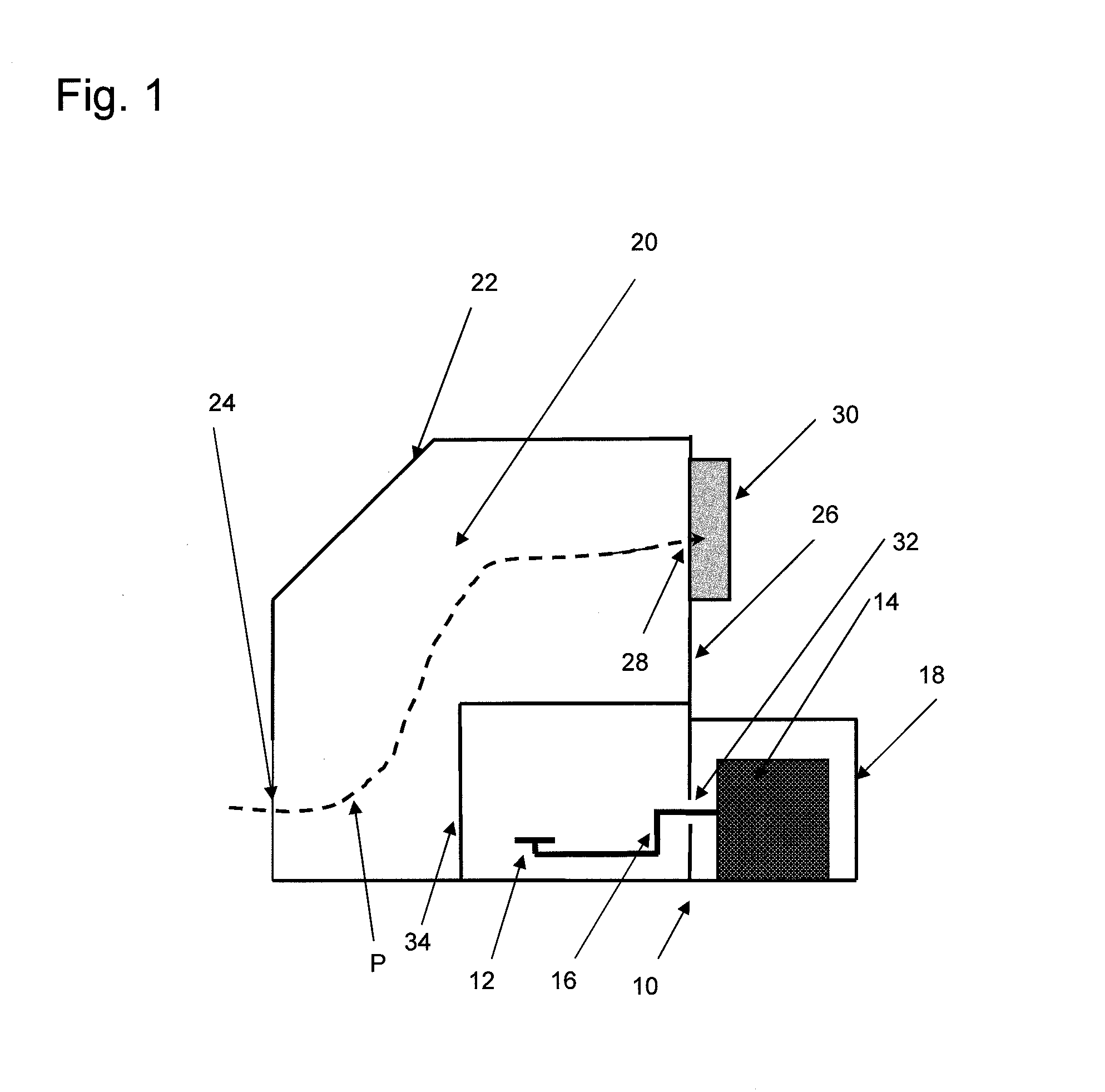

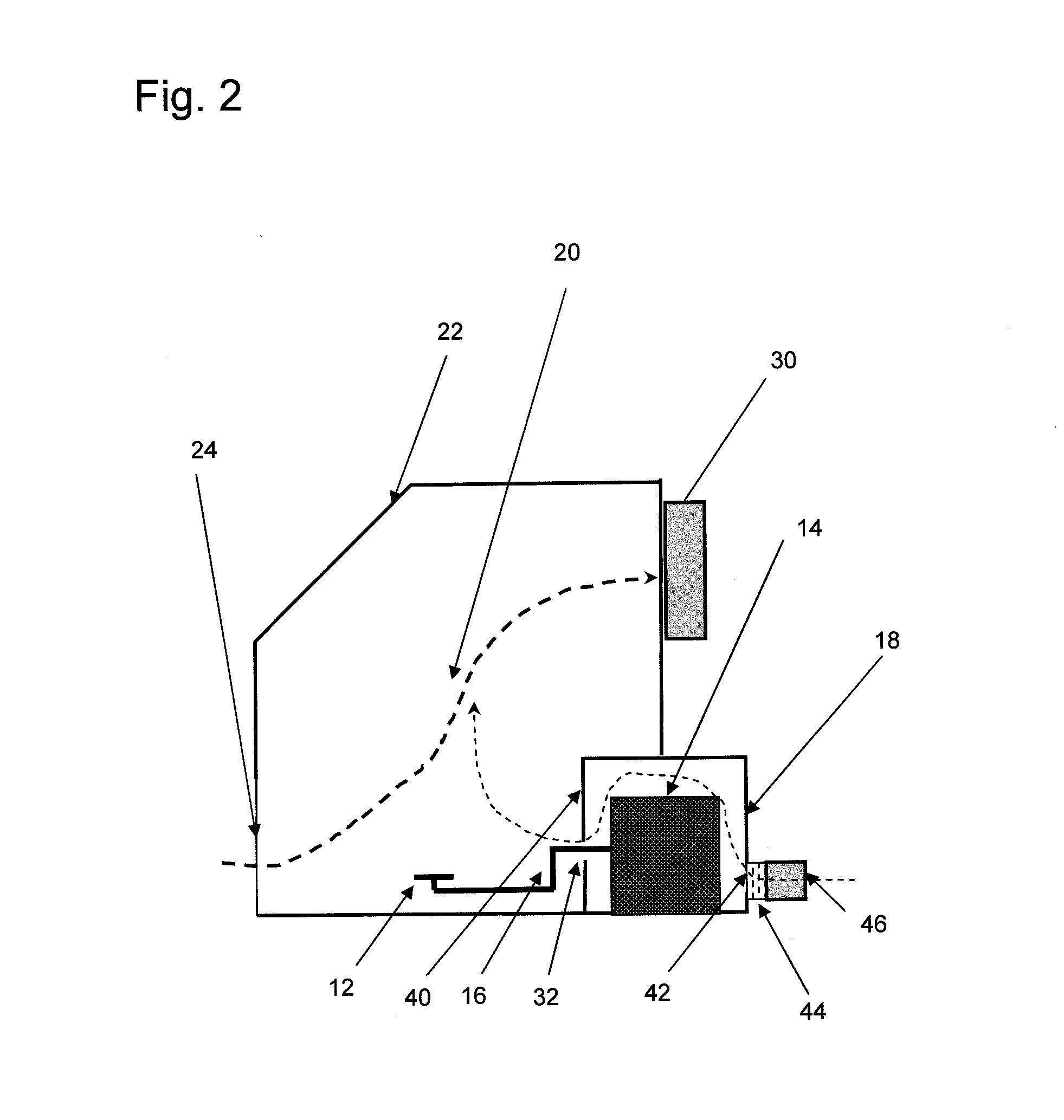

Work booth having an integrated scale

InactiveUS20130292193A1Improve protectionImprove matchDirt cleaningWeighing indication devicesCouplingStudio

A work booth (22) having a work chamber (20) and an integrated scale (10) that includes a load carrier (12) which is arranged in the work chamber (20) of the work booth (22), a weighing system (14) which is arranged outside the work chamber of the work booth (22), and a coupling element (16) which connects the load carrier (12) to the weighing system (14). The work chamber (20) of the work booth (22) has a ventilation opening (28), through which air can be extracted from the work chamber (20) of the work booth (22).

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Network-Extensible Reconfigurable Media Appliance

ActiveUS20070276783A1Television system detailsDigital data processing detailsVideo storageComputer graphics (images)

Extensible reconfigurable media appliance for security and entertainment captures images digitally for storage. Digital effects and filters are applied to incoming video stream on-the-fly or to video data stored in memory. Digital effects and filters are dynamically stored, modified, updated or deleted, providing extensible reconfigurable effects studio. Digital media appliance communicates wirelessly with other media appliances, computers, security systems, video storage, email, chat, cellular services or PDAs to provide seamless integration of captured video stream.

Owner:GOOGLE LLC

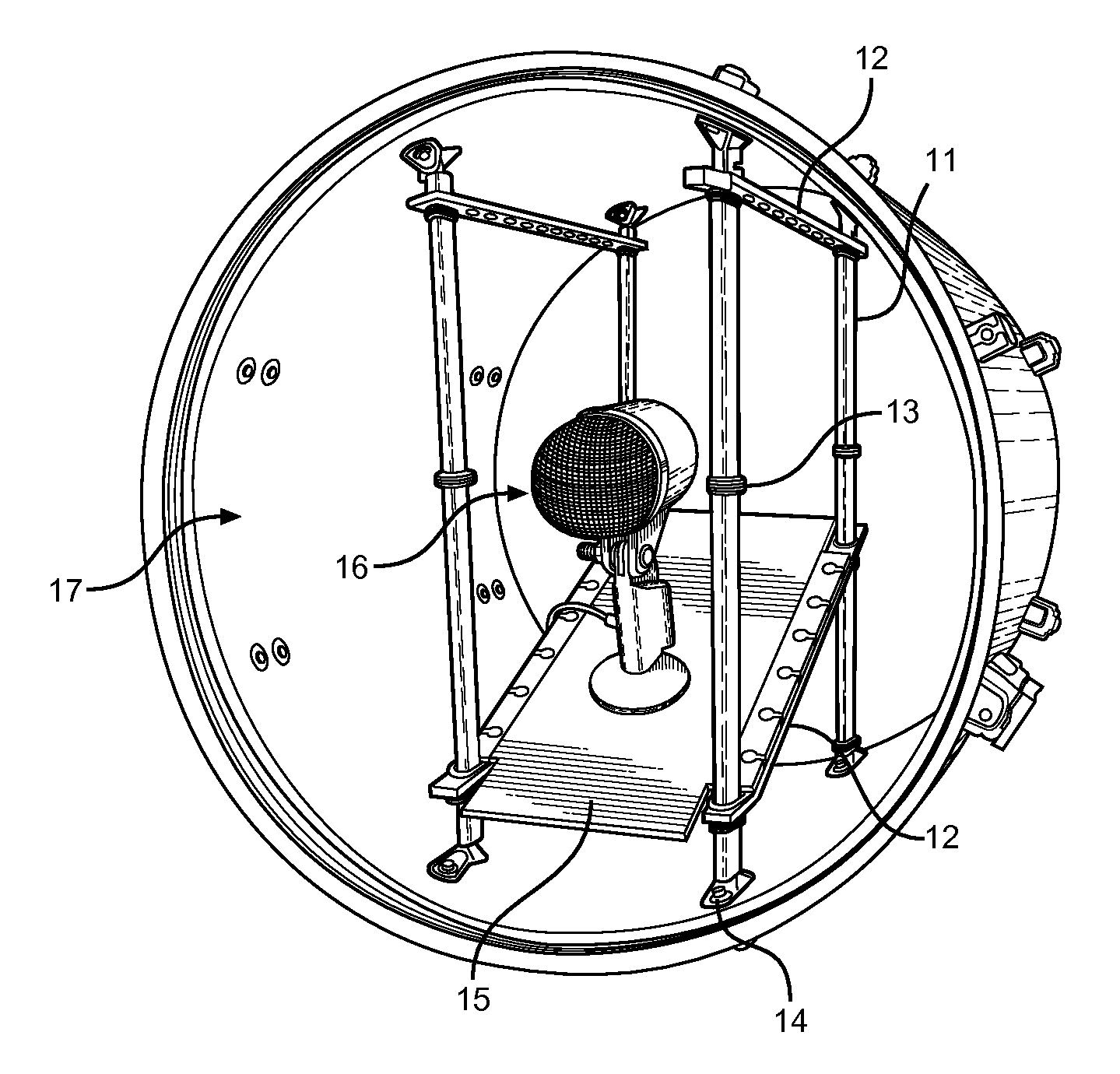

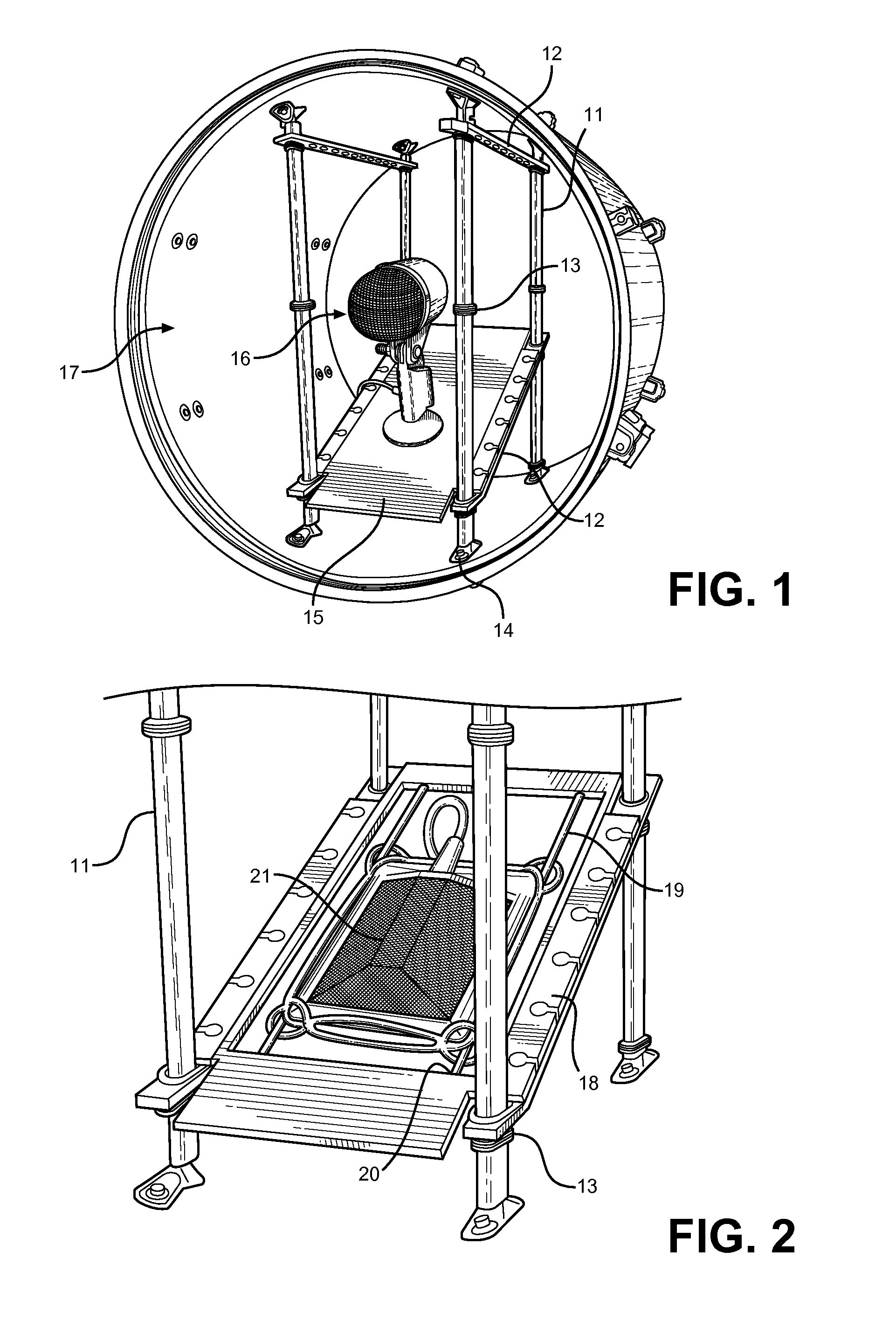

Internal Microphone Support System for Percussion Instruments

ActiveUS20110259175A1Achieve modularityPercussion musical instrumentsMouthpiece/microphone attachmentsSound qualityEngineering

An internal support device comprising horizontal and vertical straps and a plurality of mounting devices for positioning and isolating acoustic microphones interior to a percussion instrument. The vertical straps are rubber or similar shock absorbing material, arranged in a rectangular pattern and secured at their ends to a percussion instrument shell using a series of isolating lug attachments. Horizontal straps of similar material span opposing vertical straps to form two H-shaped frames for one or a plurality of microphone stand devices. Embodiments of the stand devices include a flat plane attached between the vertical straps, a modified flat plate with an internal wire harness for suspending a microphone, and a flat plane with microphone arm extensions therefrom. An alternate embodiment of the overall device includes a motorized adjustment means and a conveyor means for positioning and refining a microphone position within the drum interior without entering the drum cavity. The disclosed invention provides for modular placement and support for different types of microphones within a percussion instrument, as well as improved microphone isolation for better sound quality in a sound studio or recording environment.

Owner:MOLLICK JONATHAN

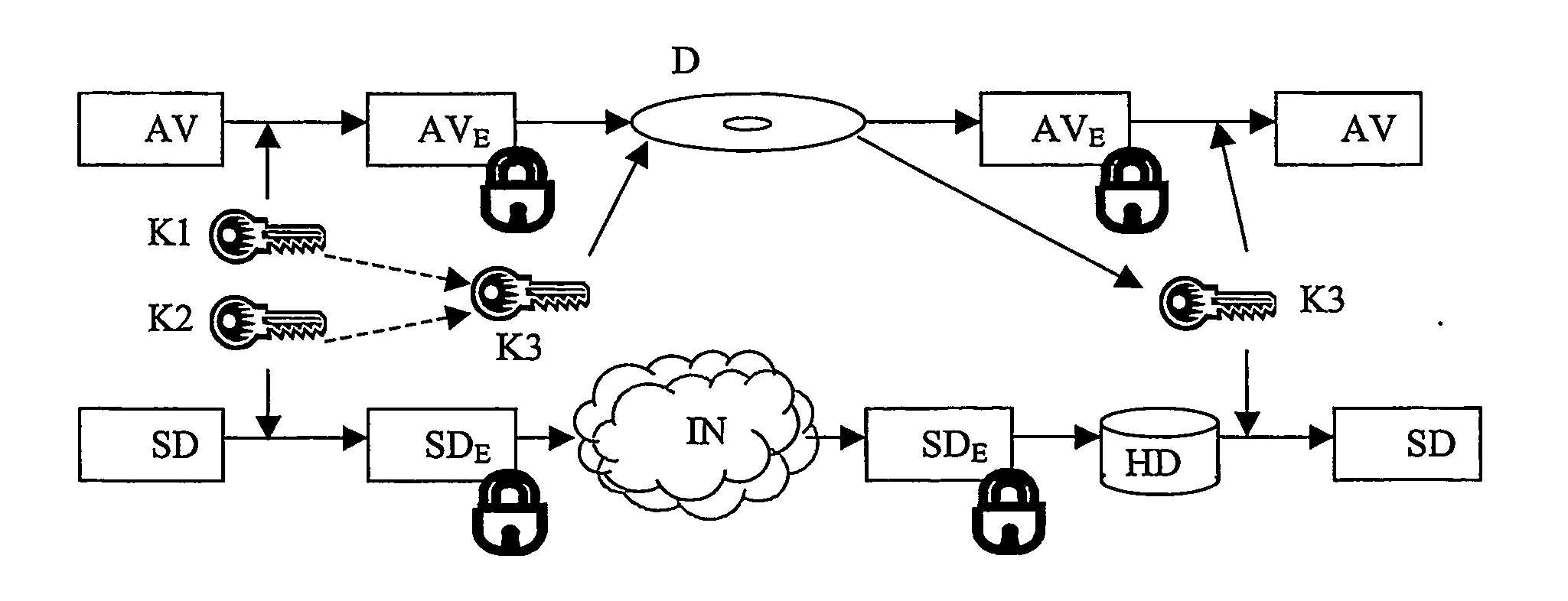

Method and apparatus for decrypting an encrypted supplementary data set

InactiveUS20070073620A1Easy to copyCheaply and easilyData processing applicationsRecord information storageData setRemovable media

Removable media such as optical discs may carry valuable audio-visual data representing movies or the like, which are sold by content providers or studios. To prevent pirate copies, data on these media are often encrypted for copy protection. This copy protection may use a disc specific electronic decryption key, which is stored on the disc itself. Supplementary data such as games, subtitle or audio streams that are regarded as being closely related to disc contents, but are not stored on the disc itself, are encrypted so that decryption is only possible with a decryption key retrieved from the disc, or in particular the same decryption key that is used for the disc contents. The method is particularly effective for copy protection or cross usage exclusion of supplementary data when the decryption key is prevented from being accessible to the user.

Owner:THOMSON LICENSING SA

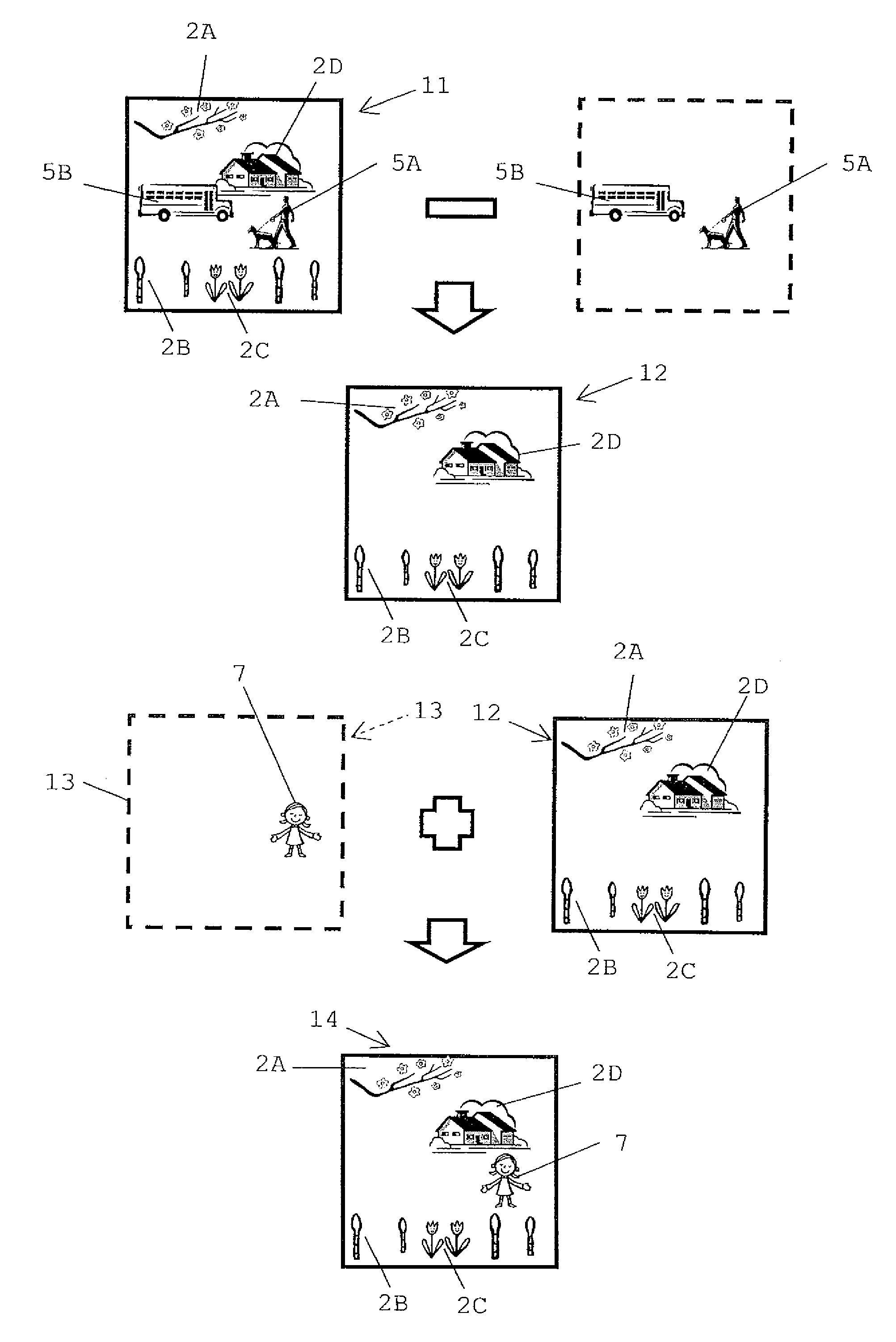

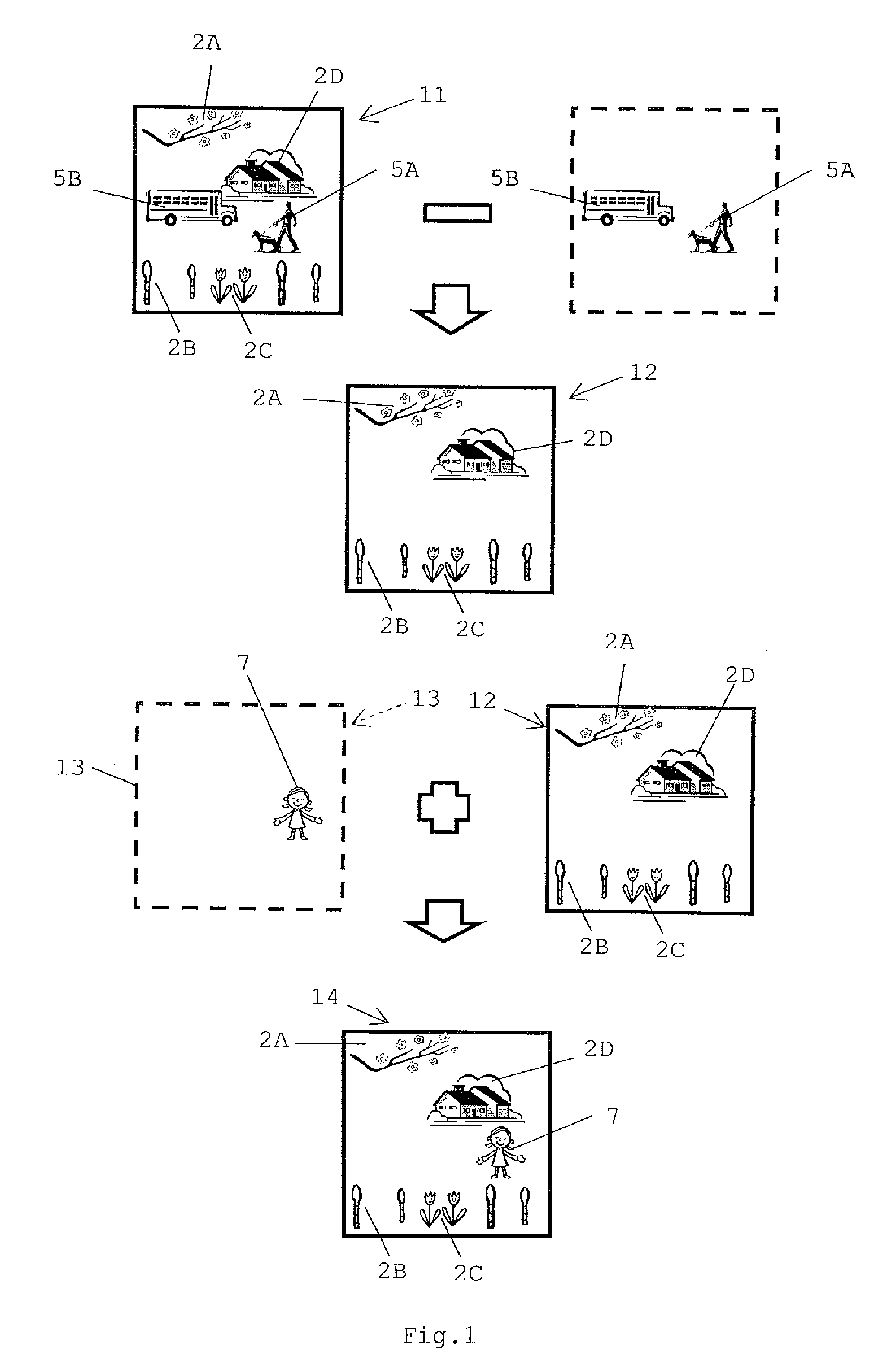

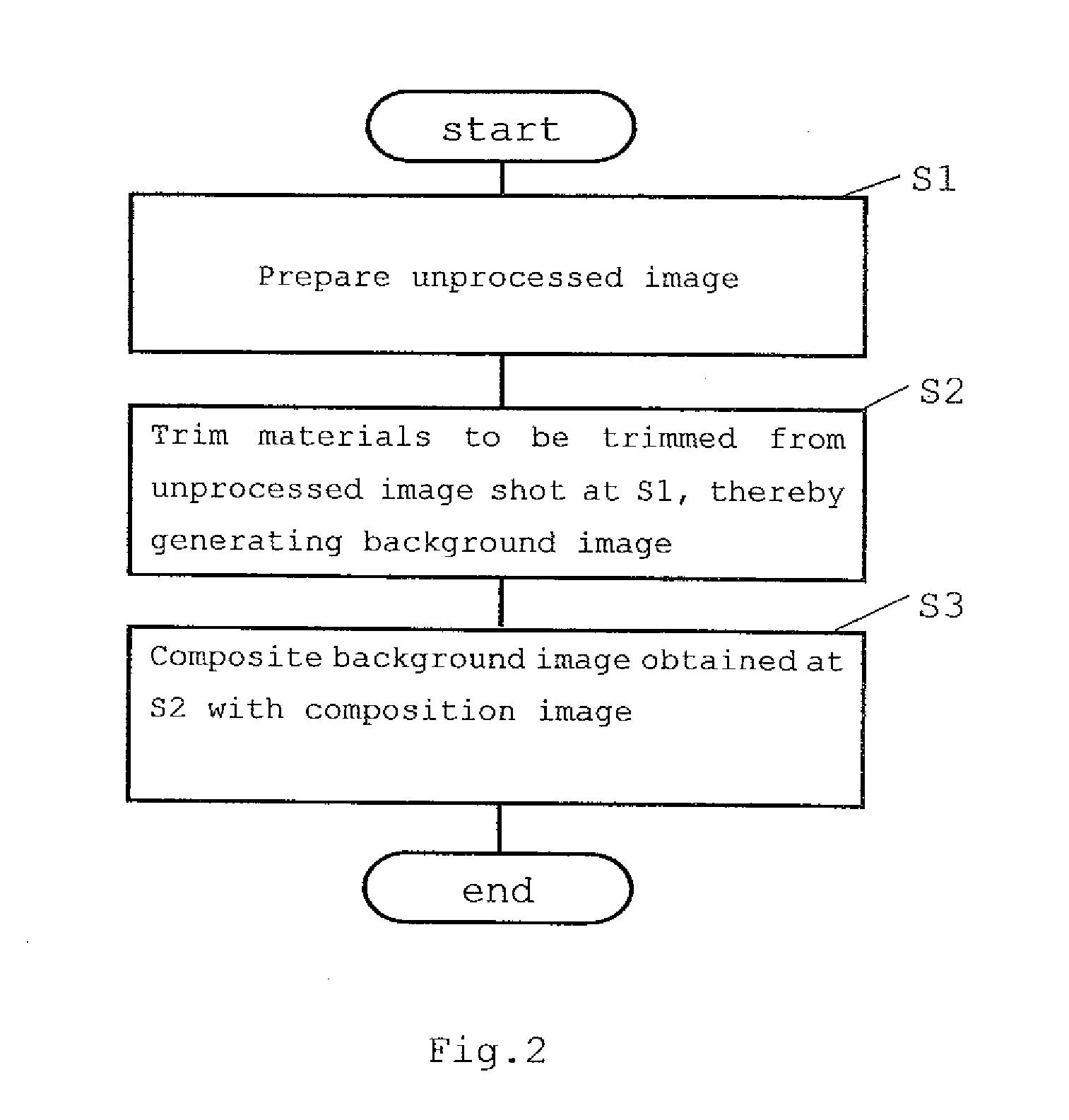

Method for generating background image and system for generating background image

InactiveUS20110176727A1Television system detailsColor signal processing circuitsBackground imageComputer science

An unprocessed image is prepared which is shot against an arbitrary background, including materials to be trimmed. Color values are collected from a plurality of frames of this unprocessed image in a collection point including one or more pixels, whereby a color information set is obtained. From the color information set, it is judged which color shows the background and which color shows the materials to be trimmed, thereby determining an optimum background-side color value. This process is applied to an area where to extract the background from, thereby obtaining a background image into which the background is extracted. This makes it possible to obtain background images from unprocessed images that are shot in busy locations, without traffic controls or dedicated studios.

Owner:M SOFT

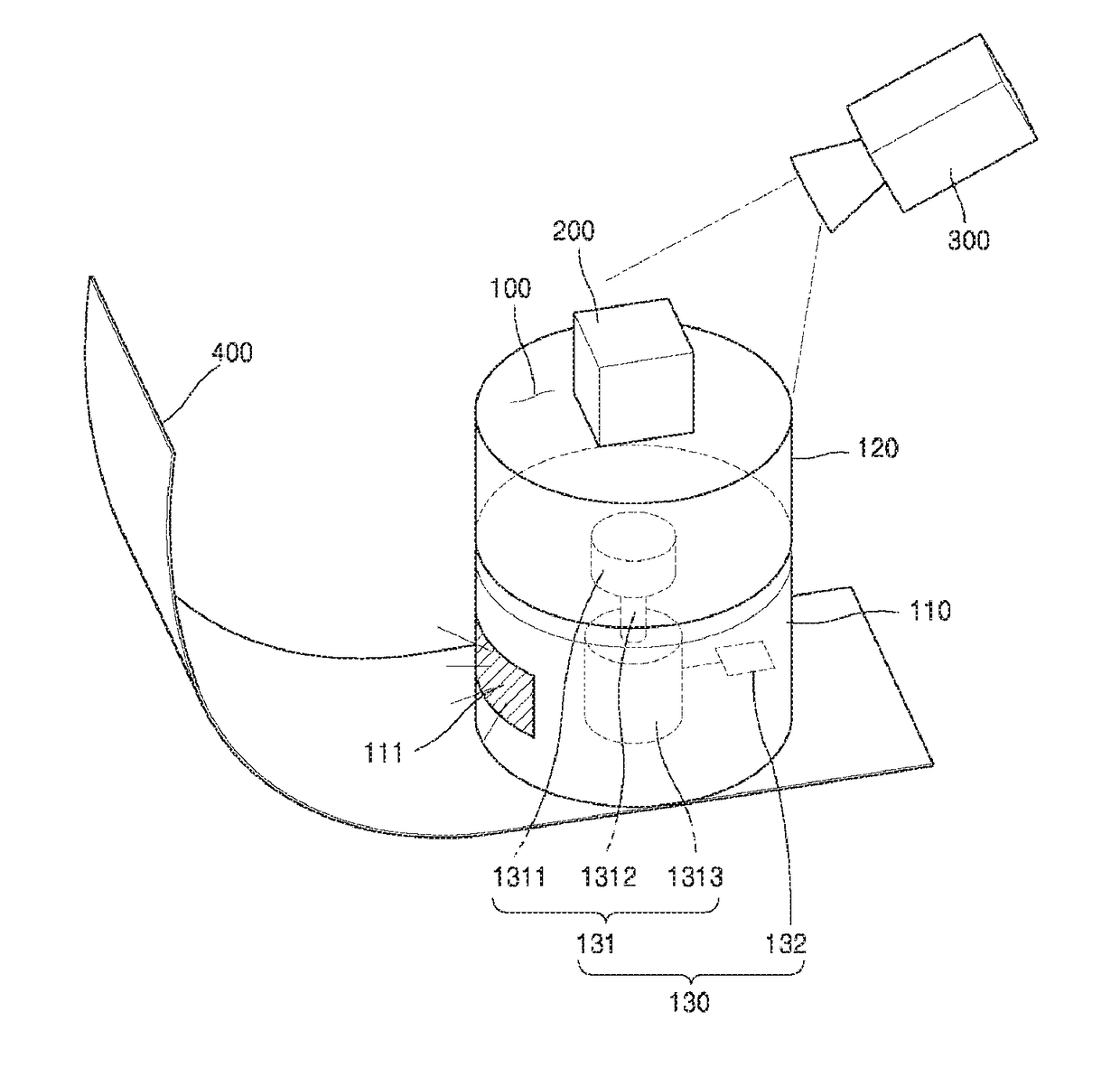

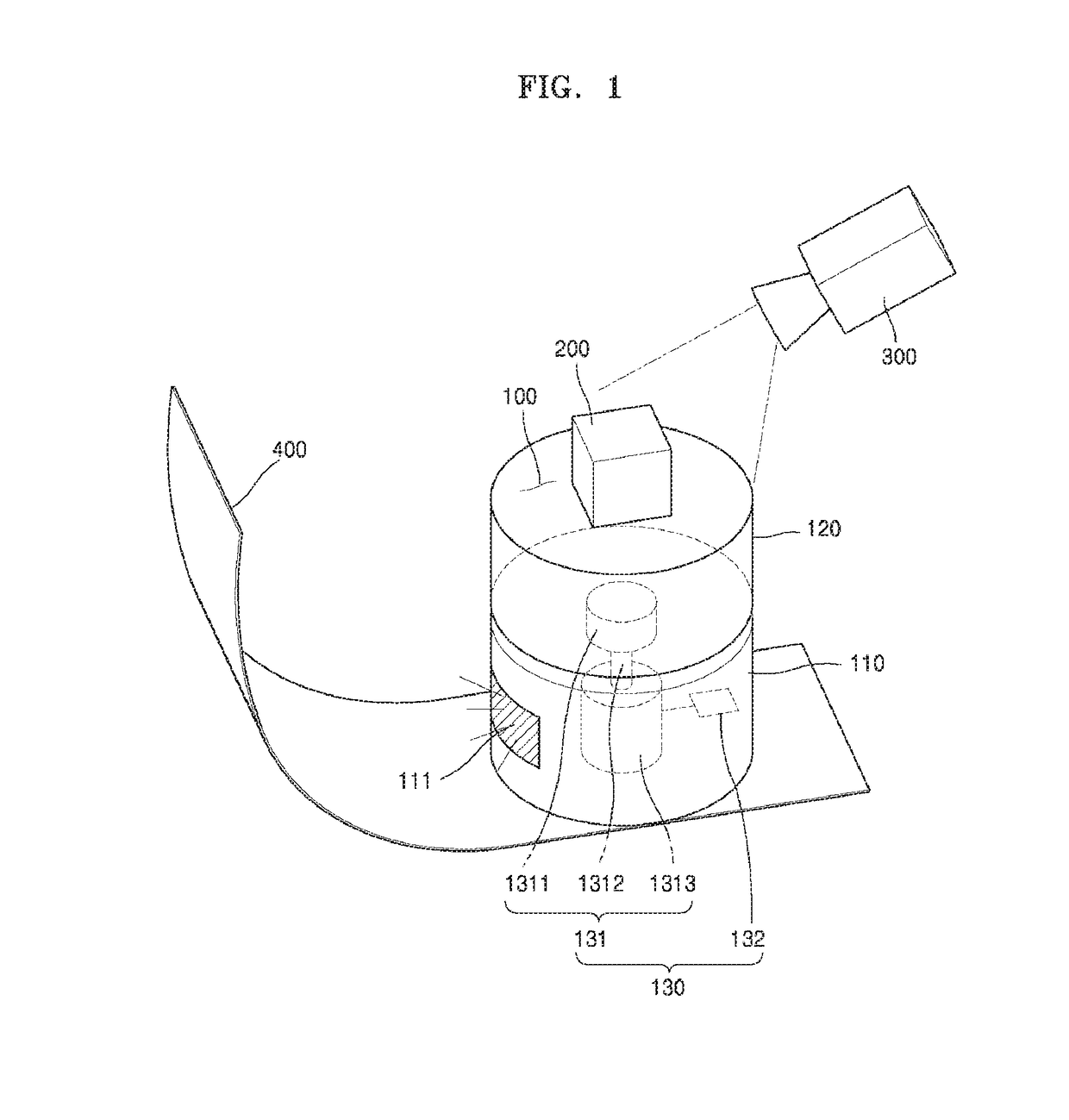

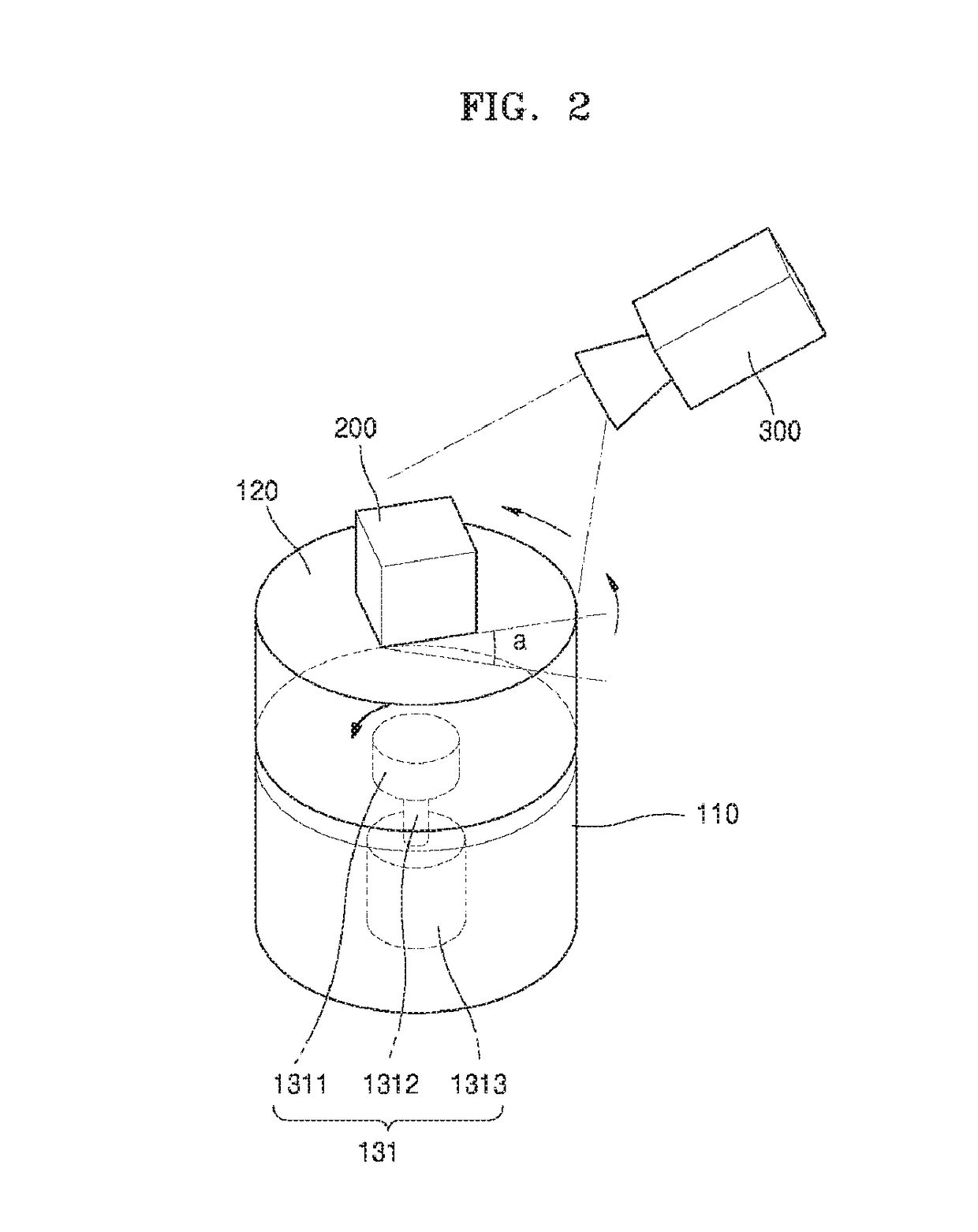

Turn Table for Photographing and Image Photgraphing System Using Same

ActiveUS20180309976A1Low costTelevision system detailsPanoramic photographyComputer graphics (images)Engineering

A technology is provided in which a user generates a 3-D image for a photographing target only by a simple device without the rent of a studio or the use of a professional product and easily controls the generation of the 3-D image. The photographing turn table is installed in one area of a studio device having one area in which a photographing target is located and having an open one surface to allow image photographing through the open one surface. The photographing turn table includes a lower body, which is fixedly located in the one area and provided at a part of one surface thereof located in an opposite direction to a direction of a photographing device to emit light from the outer surface toward an inner wall which is included in the one area to form a background of the studio device, an upper body coupled to a top surface of the lower body rotatably relatively to the lower body, and a rotation module which include a rotation unit to rotate the upper body relatively to the lower body, and a rotation control device including a communication function to receive a control command from an external device and to control driving of the rotation unit according to the control command.

Owner:ORANGEMONKIE KOREA INC

Method of and system for automated musical arrangement and musical instrument performance style transformation supported within an automated music performance system

ActiveUS11037538B2Automated performanceRicher and flexible systemElectrophonic musical instrumentsHuman–computer interactionDigital audio workstation

An automated music performance system that is driven by the music-theoretic state descriptors of any musical structure (e.g. a music composition or sound recording). The system can be used with next generation digital audio workstations (DAWs), virtual studio technology (VST) plugins, virtual music instrument libraries, and automated music composition and generation engines, systems and platforms. The automated music performance system generates unique digital performances of pieces of music, using virtual musical instruments created from sampled notes or sounds and / or synthesized notes or sounds. Each virtual music instrument has its own set of music-theoretic state responsive performance rules that are automatically triggered by the music theoretic state descriptors of the music composition or performance to be digitally performed. An automated virtual music instrument (VMI) library selection and performance subsystem is provided for managing the virtual musical instruments during the automated digital music performance process.

Owner:SHUTTERSTOCK

Digital file consumer information methods and devices

InactiveUS20060080275A1Increase desirability and instant gratificationImprove marketabilityBuying/selling/leasing transactionsSpecial data processing applicationsVideo playerReprogramming

A vending machine and vending method for audio, video, music, movie or other date file downloads is optimized for commercial viability and product placement. The vending machine offers standard connectors allowing users to access a library of download files and download those files to data players such as MP3 music download players, video players and so on. It further offers inexpensive data players to users in addition to offering downloads. Importantly, the device has hardware or software (video) softbuttons allowing remote reprogramming: in the product placement method of the invention, a commercial entity may pay to have the softbutton programmed to their desired data file source. Commercial entities buying placement on the vending machine may be artists, performers, studios, recording labels, on-line and other music libraries. The machine may accept coins, thus increasing saleability of the data products sold thereon.

Owner:CHRISTAL DEAN VEGAS

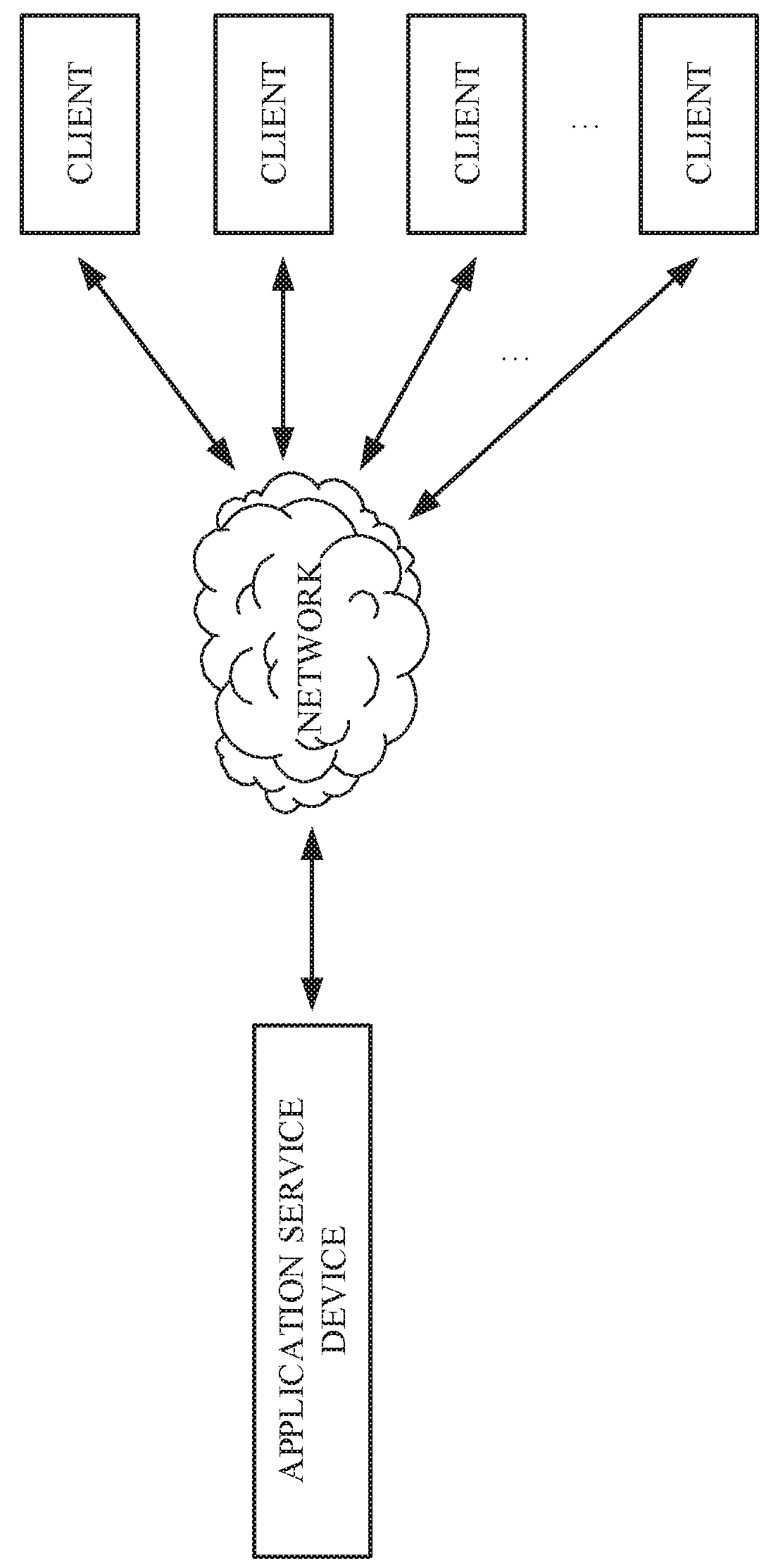

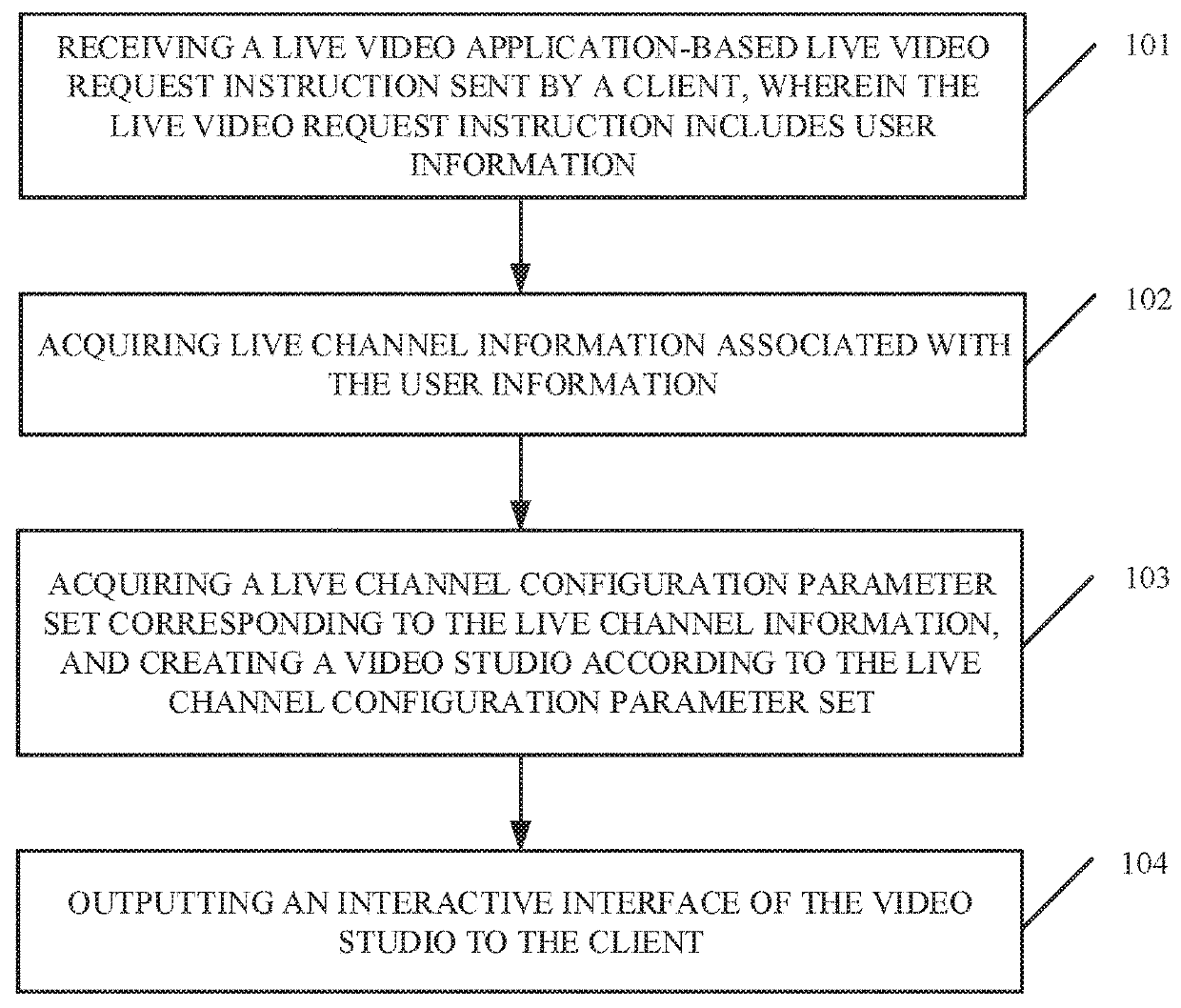

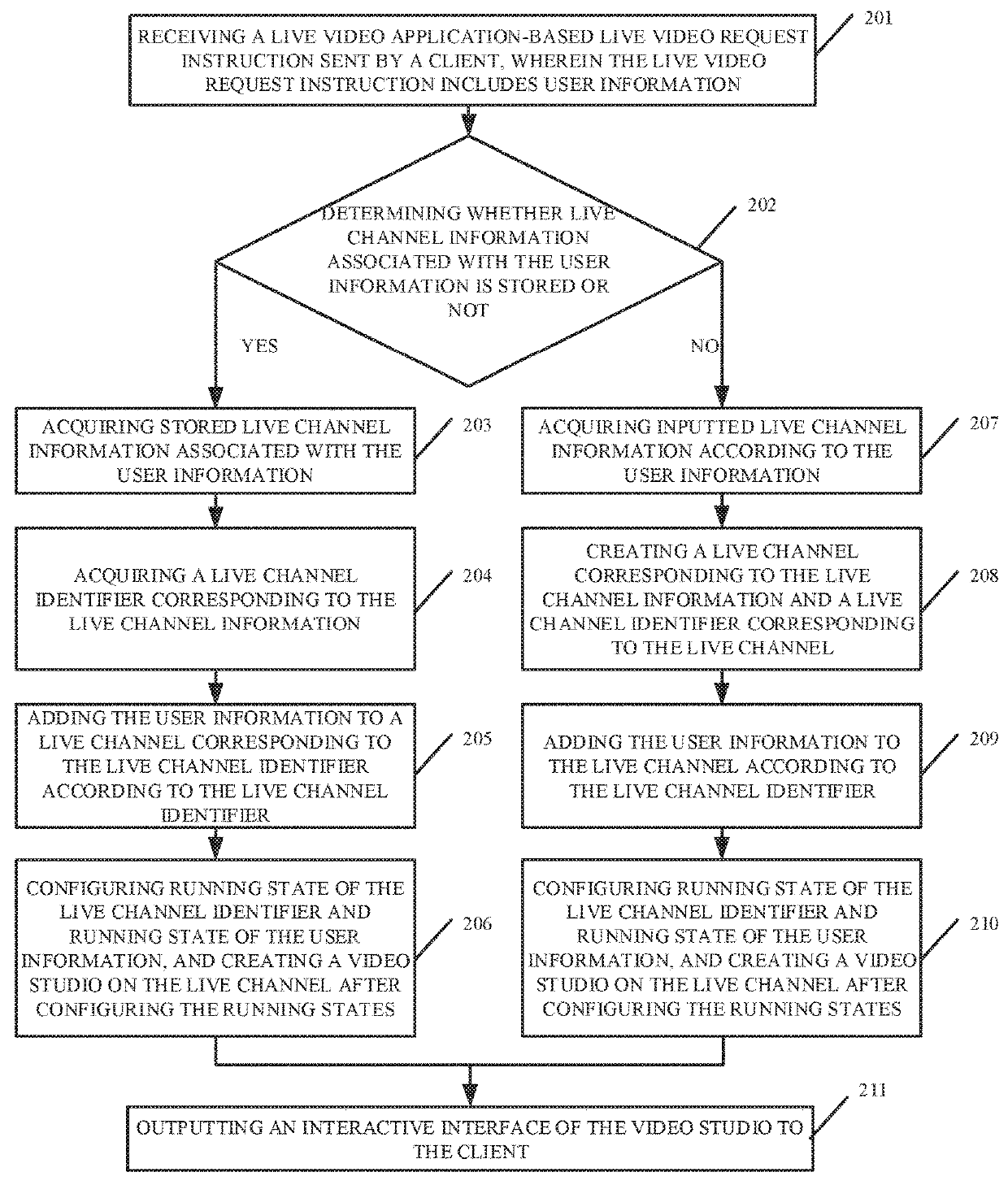

Video Studio Creating Method and Service Device

ActiveUS20180167689A1Simply and quickly performedImprove user efficiencySelective content distributionClient-sideLive video

Disclosed are a video studio creating method and a service device. The method includes: receiving a live video application-based live video request instruction sent by a client, in which the live video request instruction includes user information; acquiring live channel information associated with the user information; acquiring a live channel configuration parameter set corresponding to the live channel information, and creating a video studio according to the live channel configuration parameter set; and outputting an interactive interface of the video studio to the client.

Owner:GUANGZHOU HUADUO NETWORK TECH

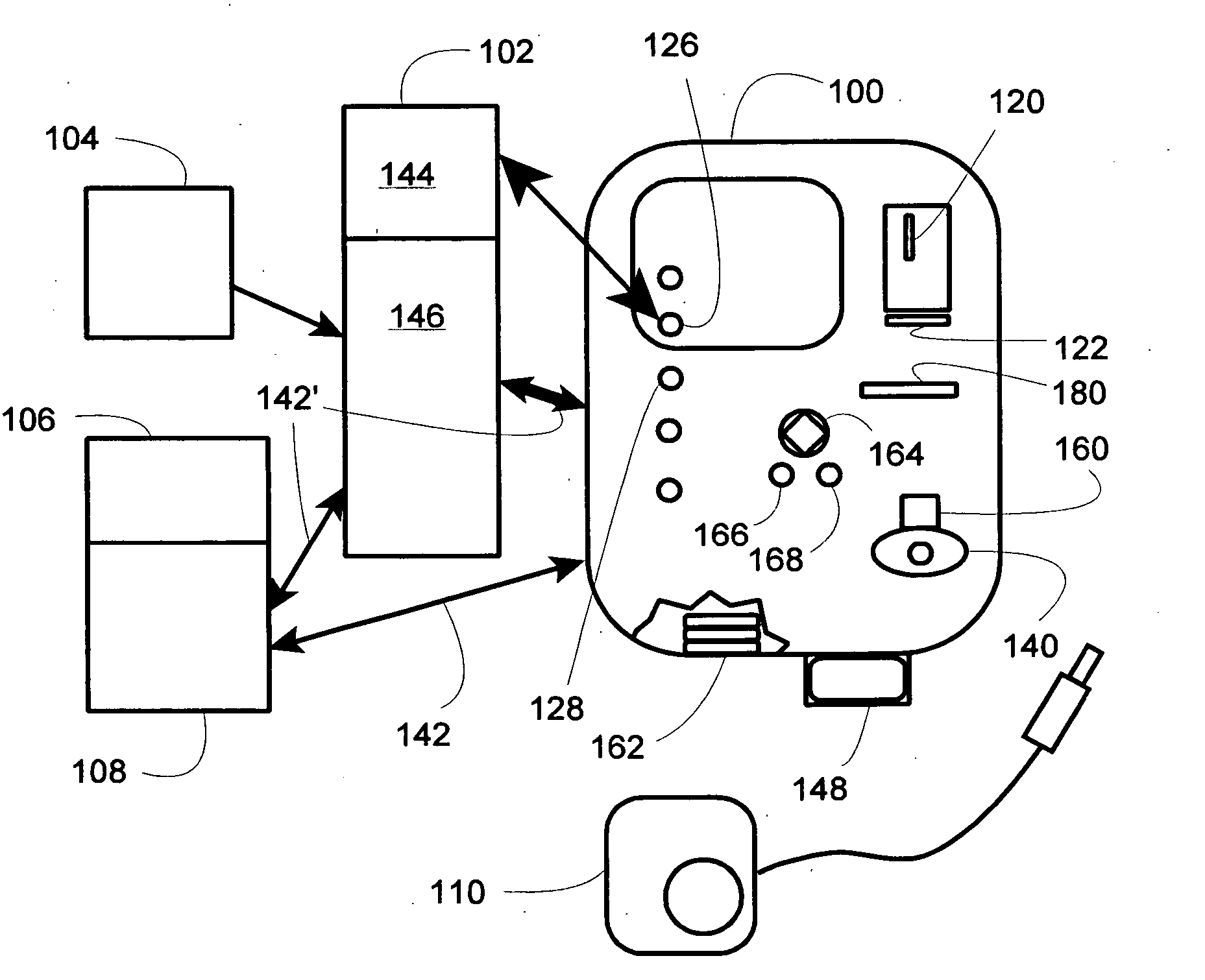

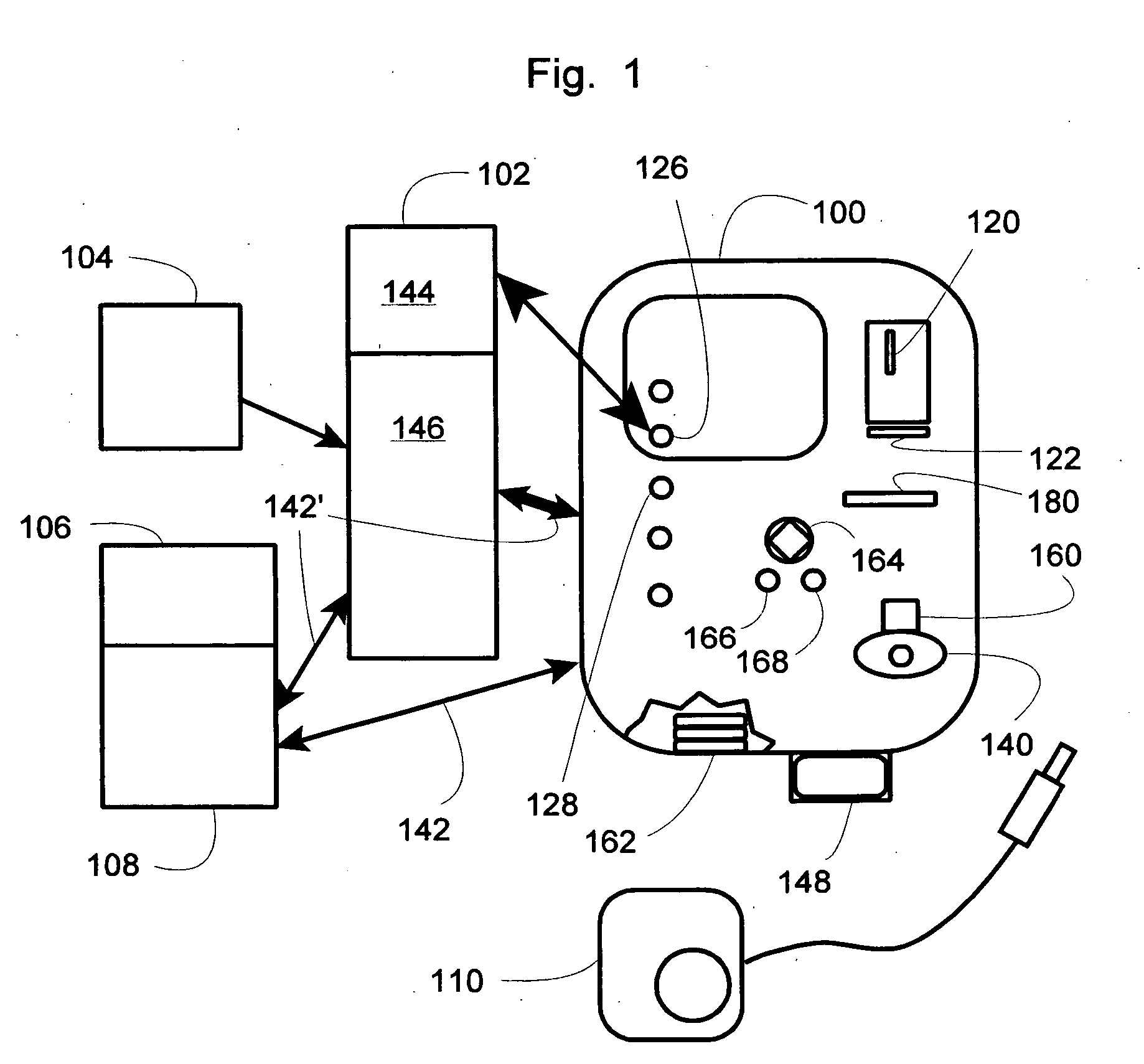

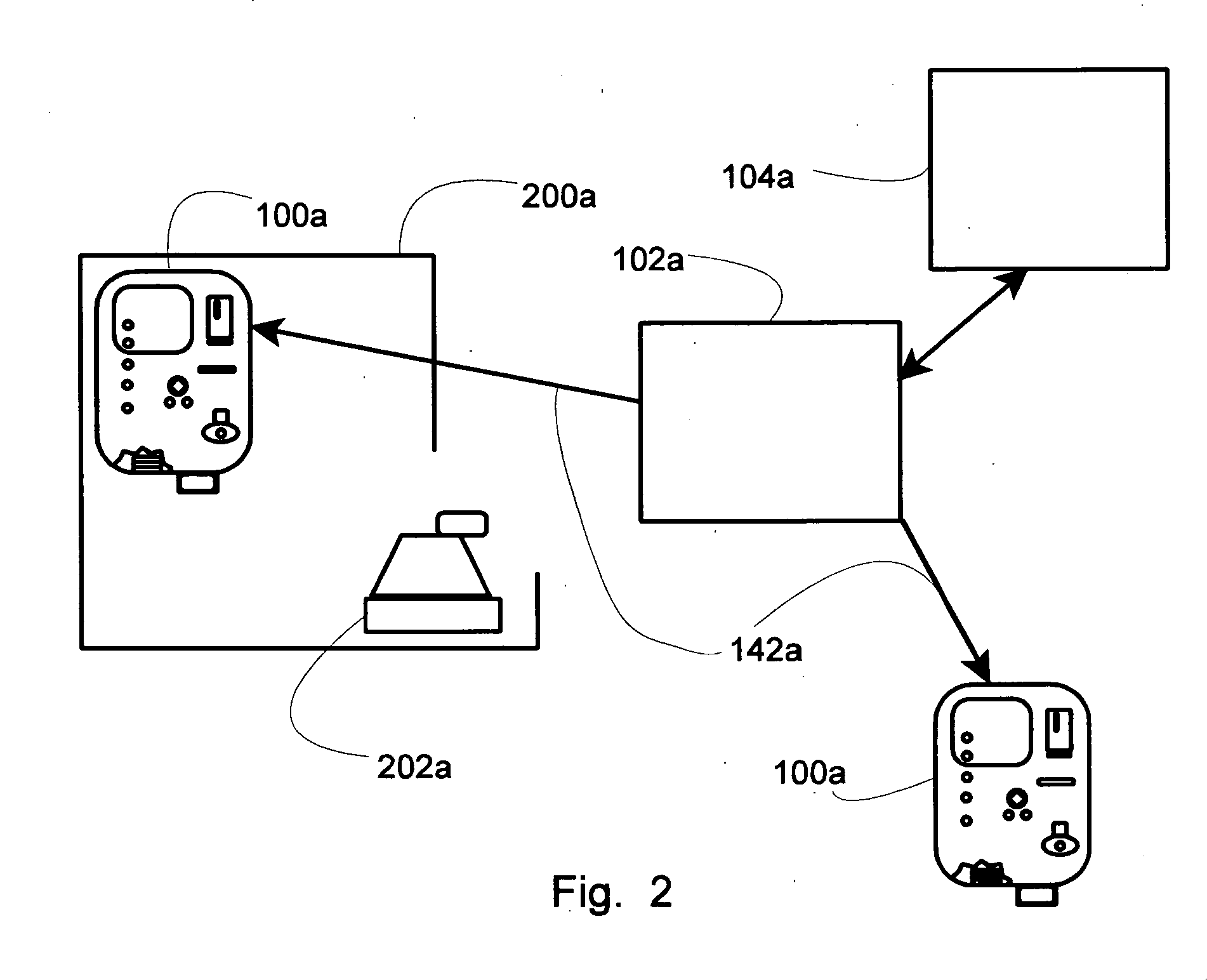

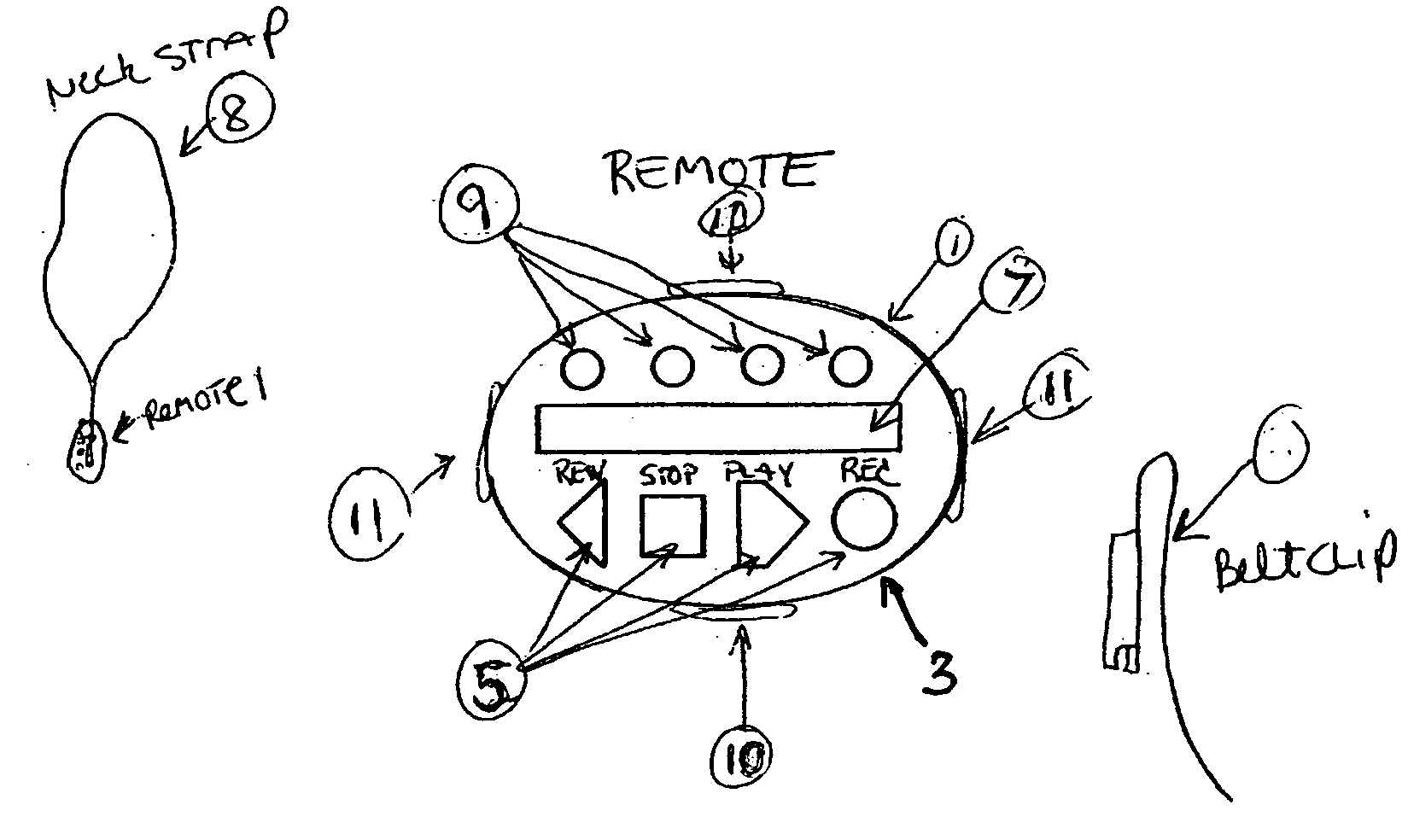

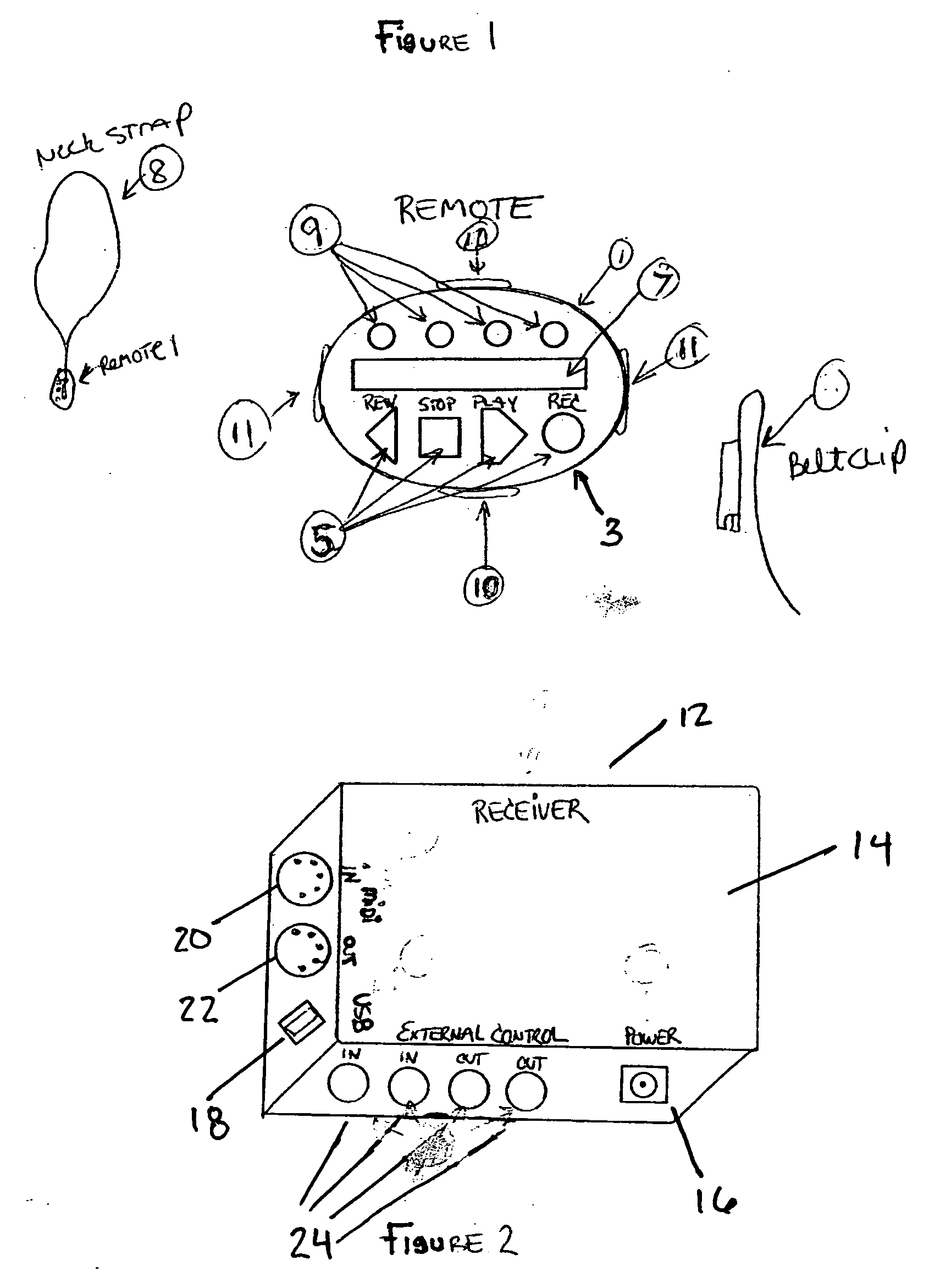

System and method for controlling a recording studio

InactiveUS20060126863A1Keep full controlNear-field transmissionTransmission systemsRemote controlWireless

A wireless remote control system for controlling an audio recording system in a recording studio is disclosed. This system incorporates a small wireless remote that can be mounted directly on the user's body that may include an arm, wrist, leg, belt, or any member. This remote controller may also be mounted directly on an instrument. The system will provide the user the freedom to walk around and control all aspects of a studio environment without being tied to one location.

Owner:INNOVATIVE TECH CORP

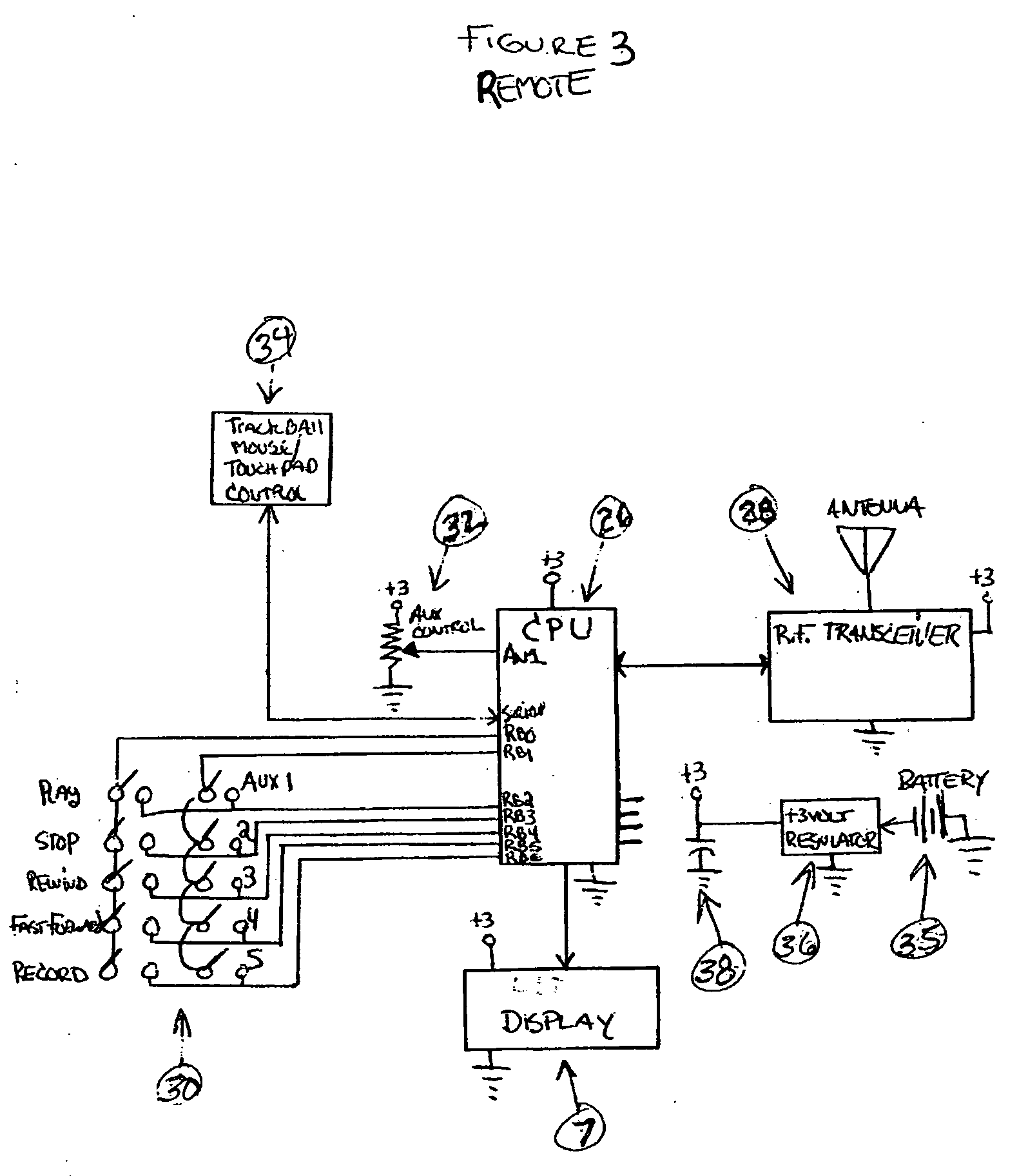

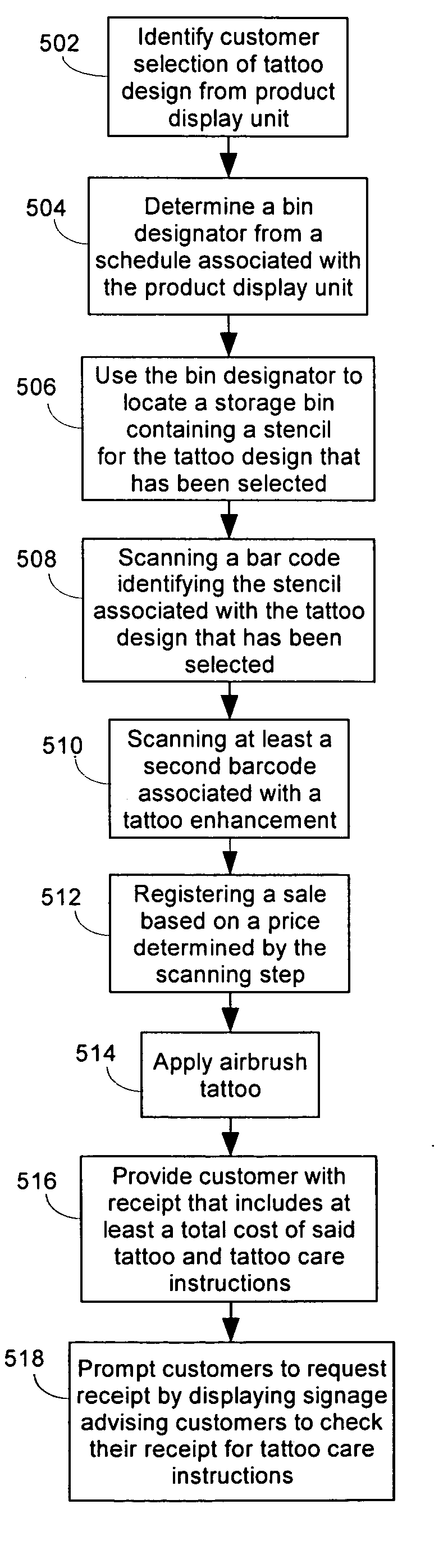

Inventory control system for body art studio

InactiveUS20050234751A1Hand manipulated computer devicesCharacter and pattern recognitionControl systemBarcode

A method for operating a tattoo studio includes identifying a customer selection of a tattoo design and a bin designator for a stencil for the tattoo design; locating a storage bin containing a stencil for the tattoo design; and scanning a bar code assigned to the stencil. The method can also include scanning at least a second barcode associated with a tattoo enhancement including a non-standard paint, an additional paint color, or a mixture of paint colors. Inventory control is verified using a match code and pre-packaged sets of numbered stencils.

Owner:BAKING ENTERTAINMENT

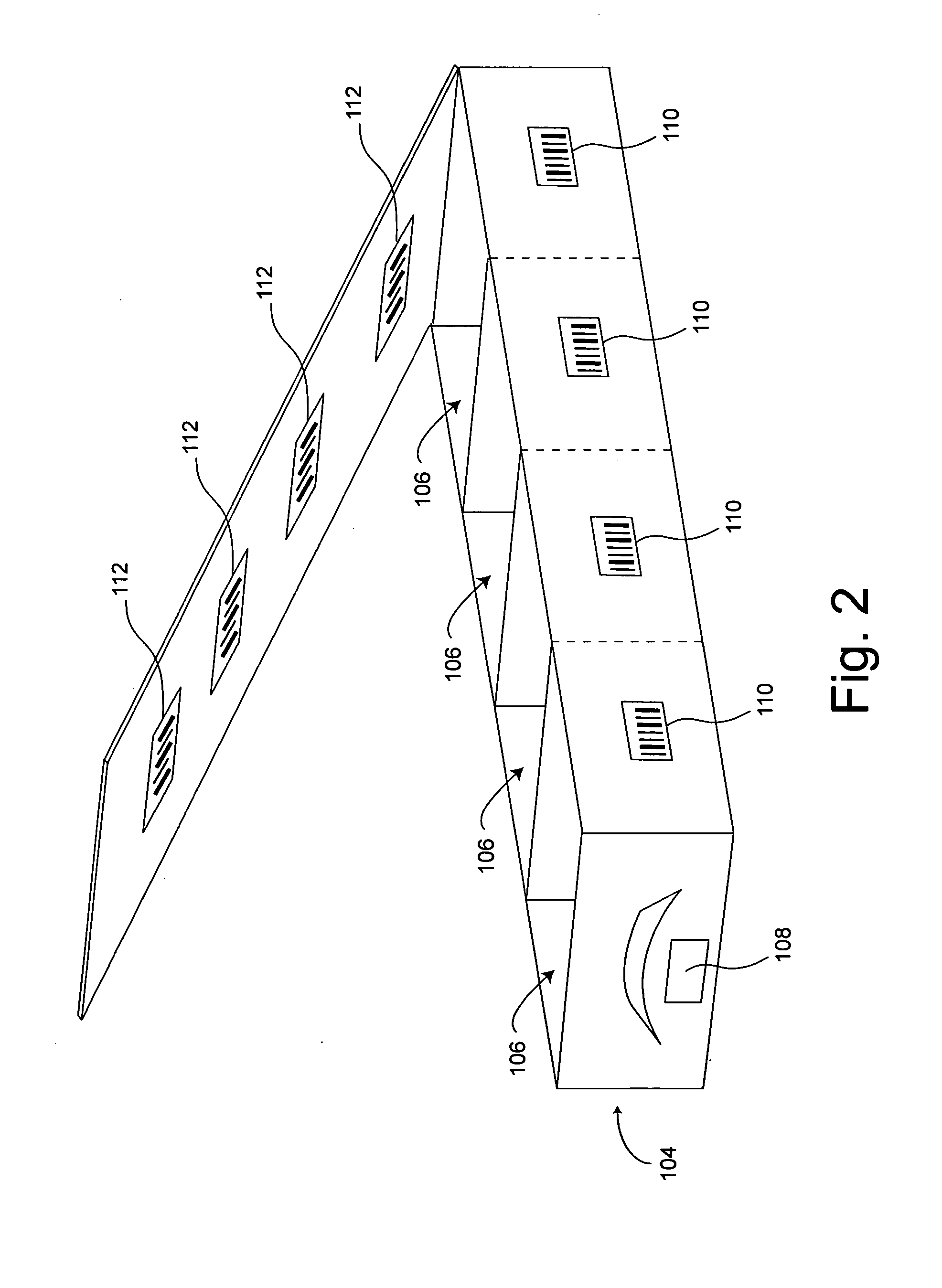

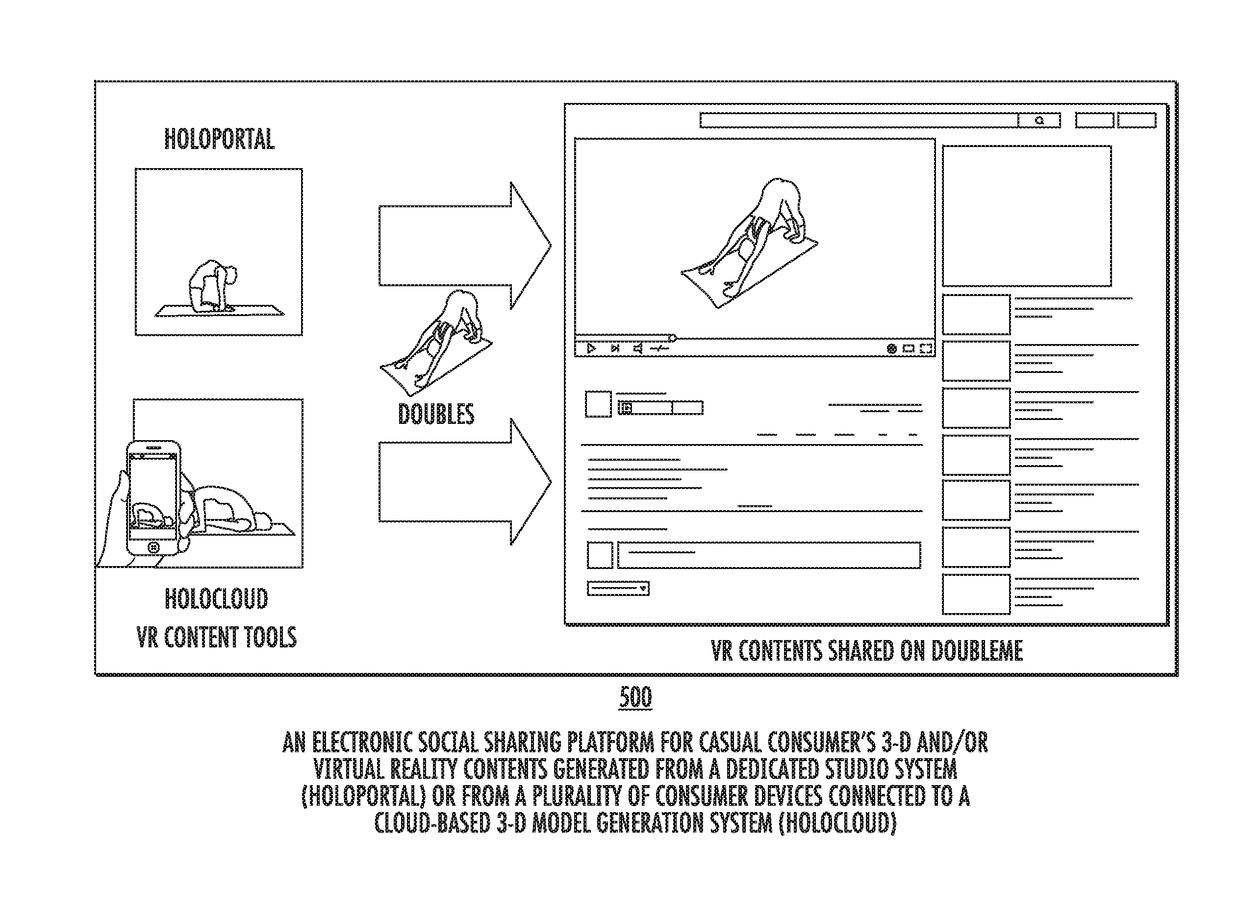

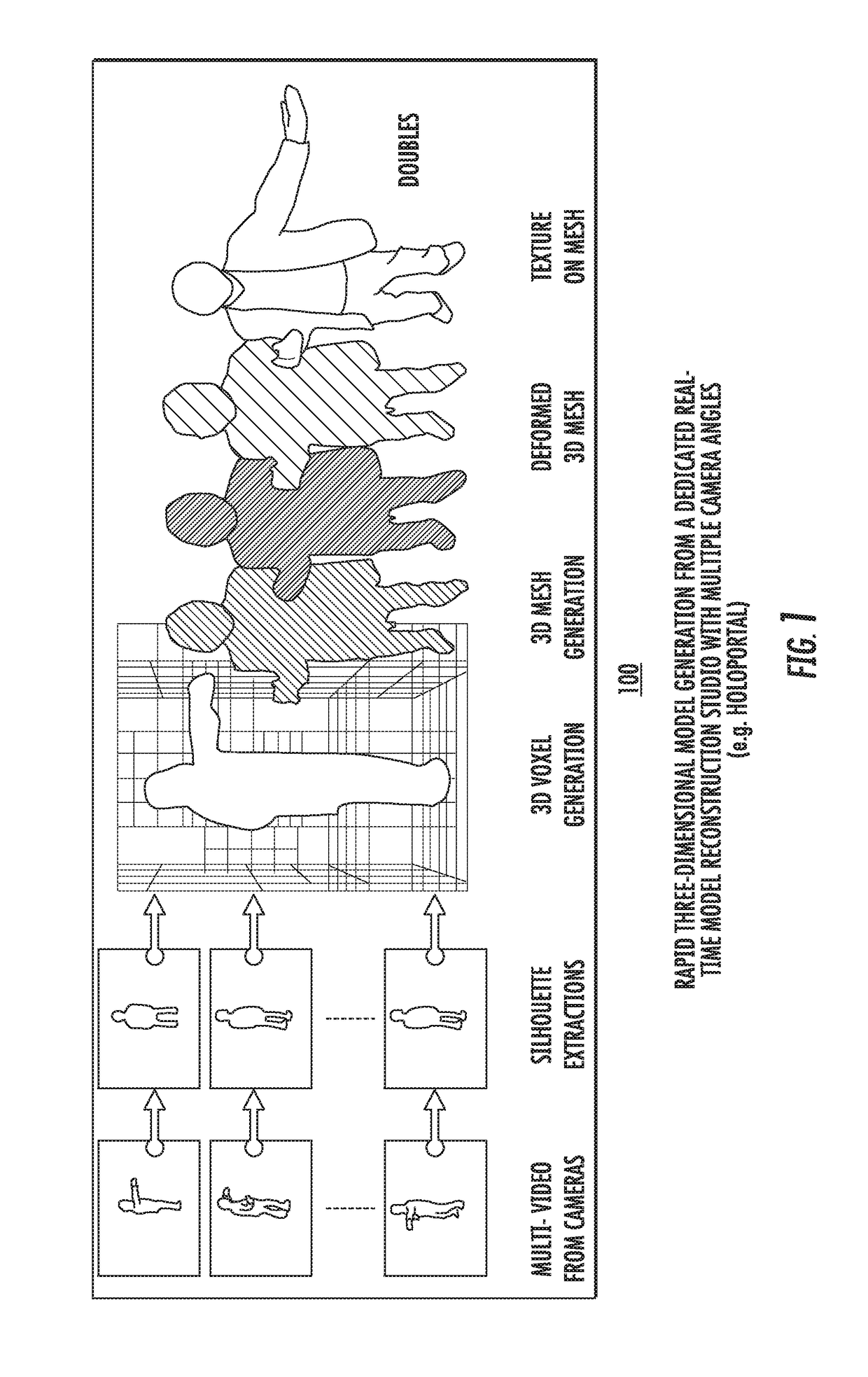

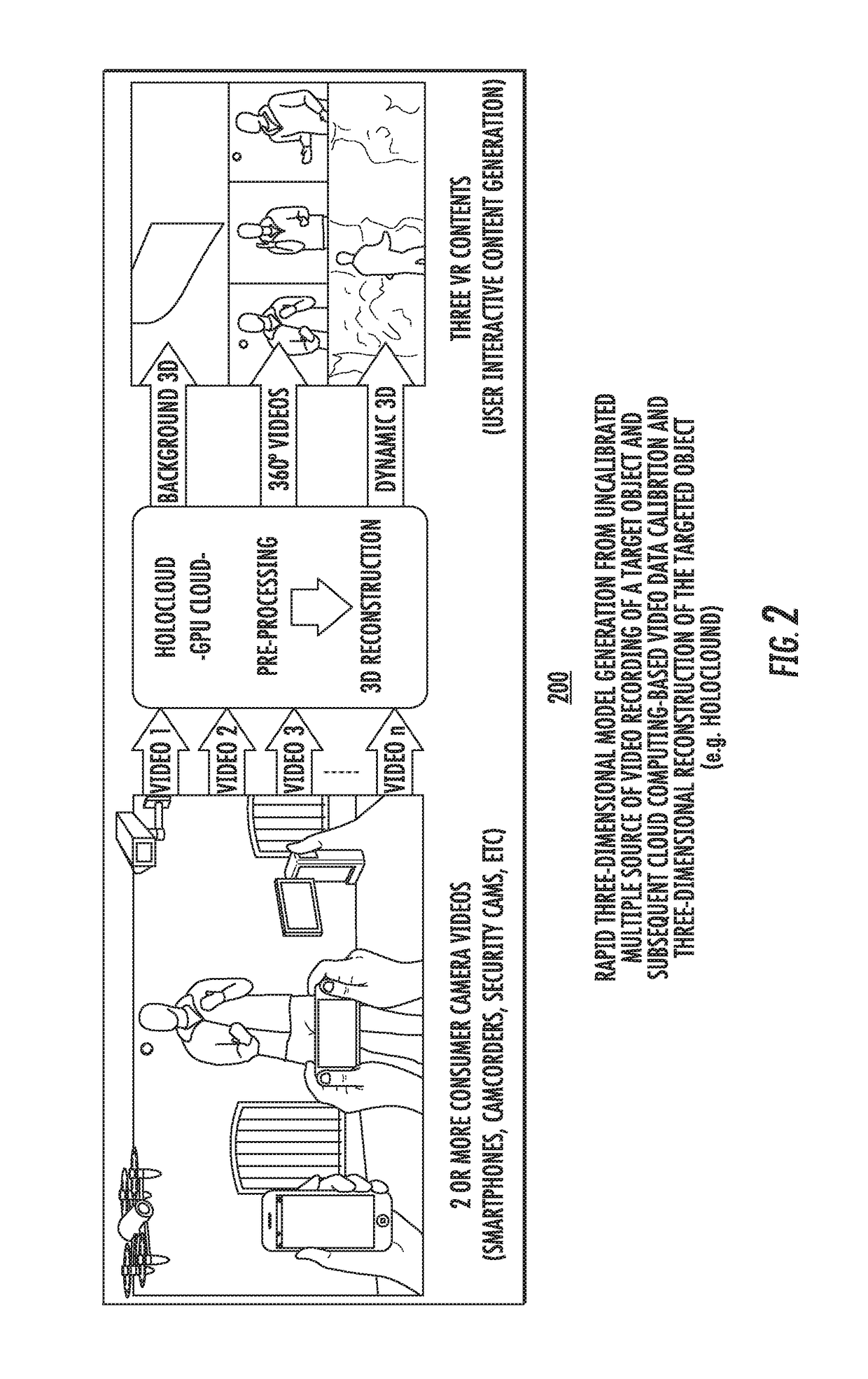

3D virtual reality model sharing and monetization electronic platform system

ActiveUS10116913B2Details involving 3D image dataProcessor architectures/configurationVideo recordingModel sharing

A novel electronic system provides fast three-dimensional model generation, social content sharing of dynamic three-dimensional models, and monetization of the dynamic three-dimensional models created by casual consumers. In one embodiment, a casual consumer utilizes a dedicated real-time 3D model reconstruction studio with multiple camera angles, and then rapidly create dynamic 3D models with novel computational methods performed in scalable graphics processing units. In another embodiment, uncalibrated multiple sources of video recording of a targeted object are provided by a plurality of commonly-available consumer video recording devices (e.g. a smart phone, a camcorder, a digital camera, etc.) located at different angles, after which the uncalibrated multiple sources of video recording are transmitted to a novel cloud computing system for real-time temporal, spatial, and photometrical calibration and 3D model reconstruction. The dynamic 3D models can be uploaded, listed, and shared among content creators and viewers in an electronic sharing platform.

Owner:DOUBLEME INC (OF KOREA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com