Patents

Literature

133results about How to "Convey accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

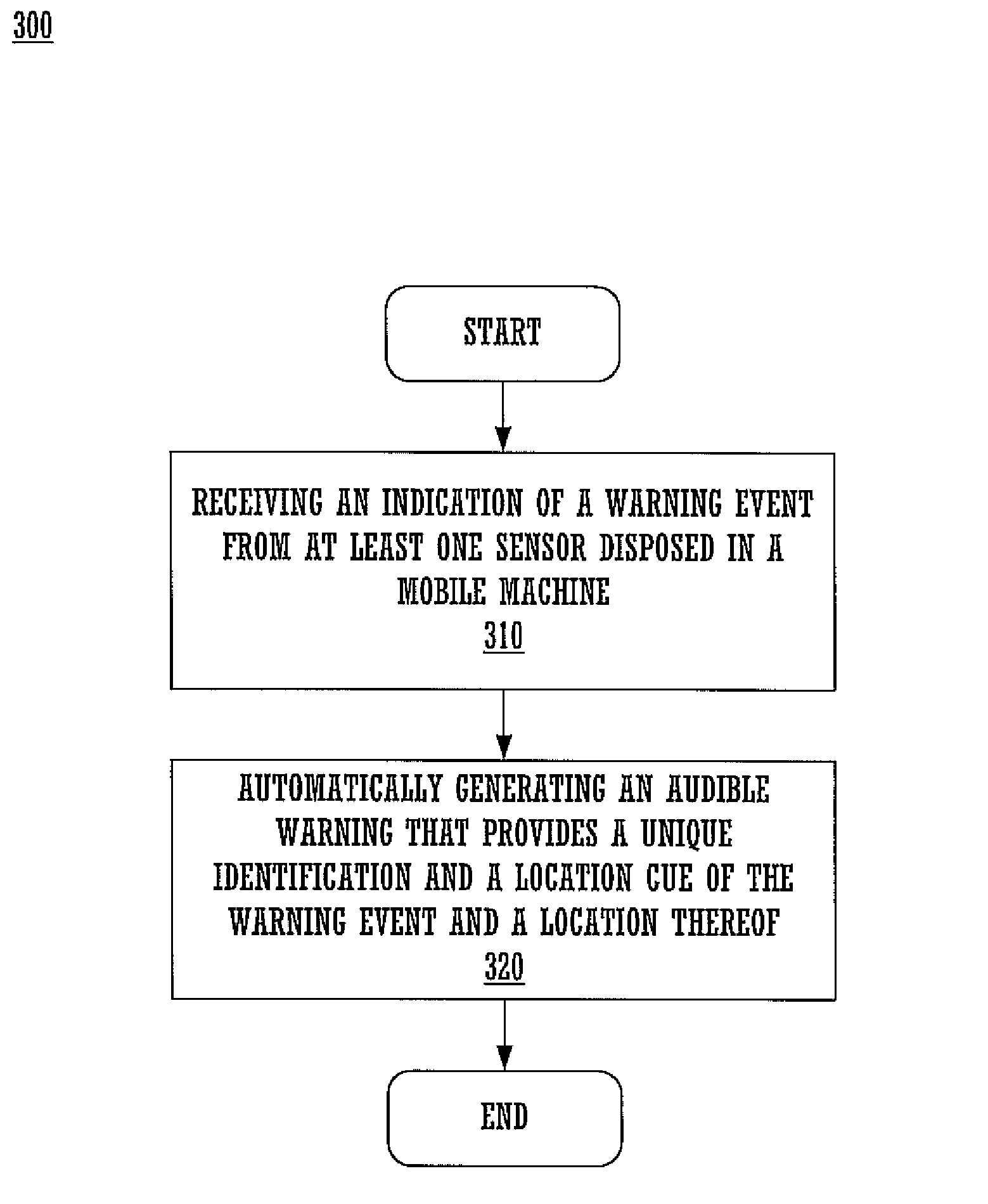

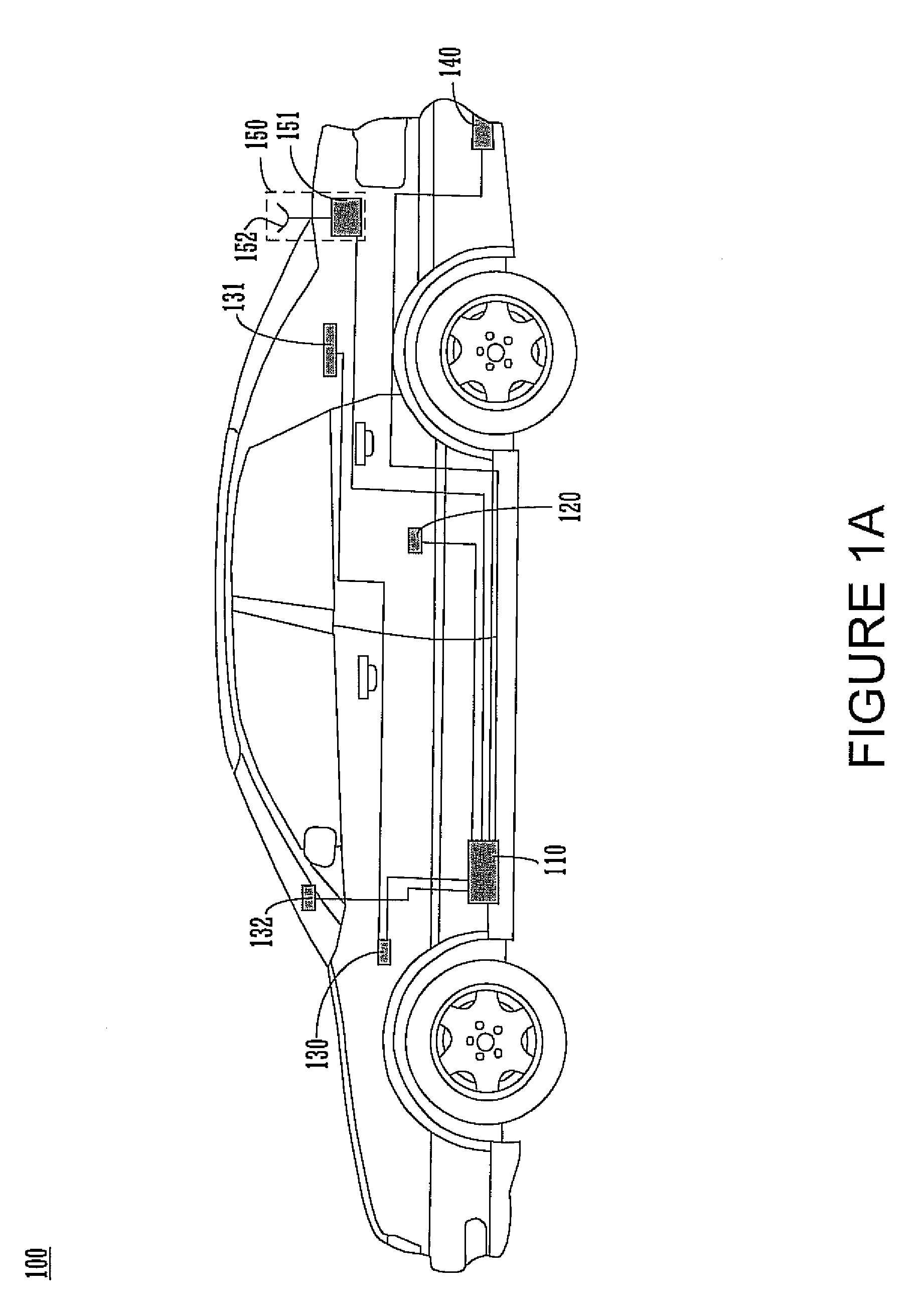

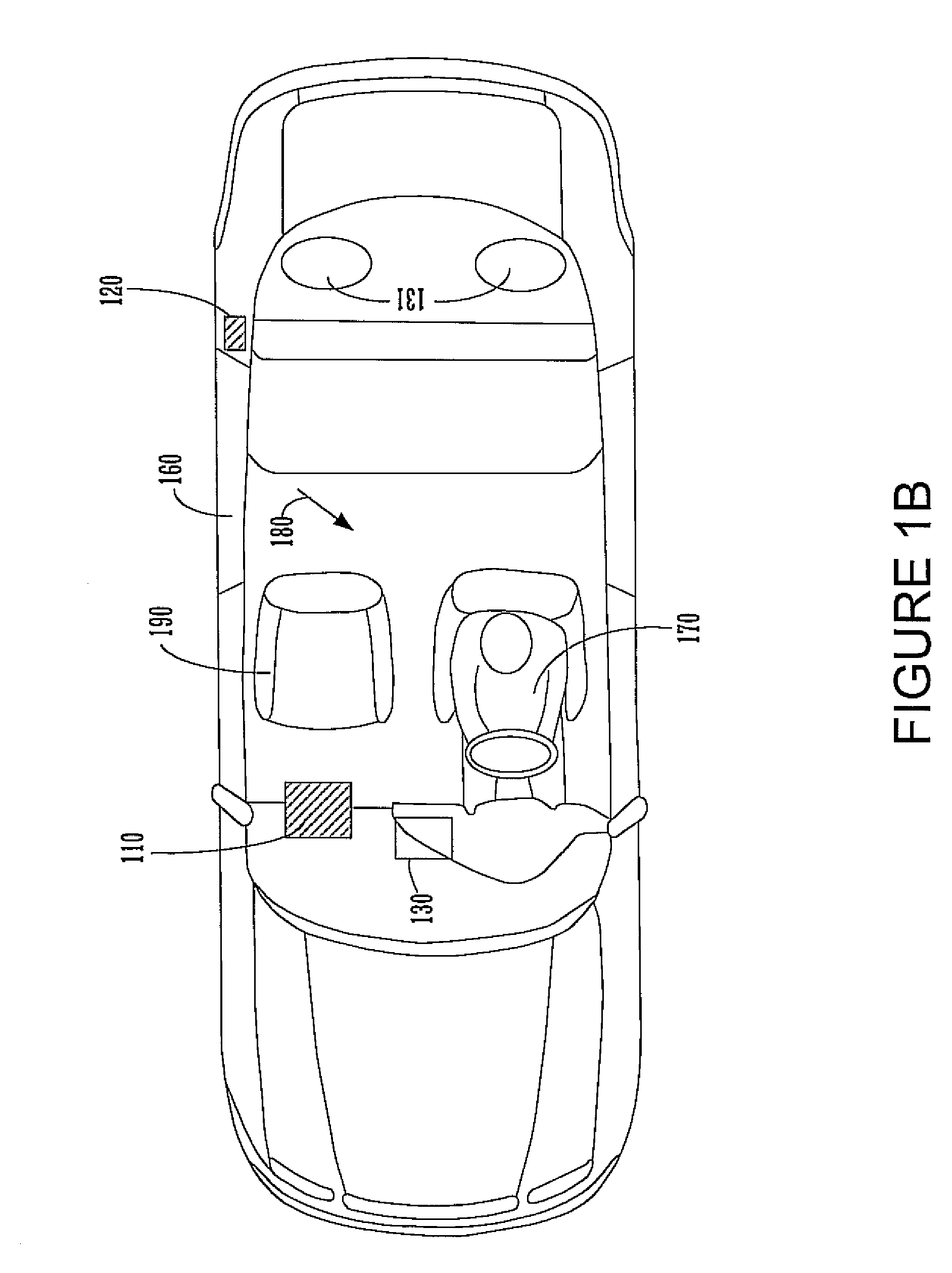

Positional audio cues for an vehicle indicator system

ActiveUS7649444B1Precise positioningConvey accuratelyAcoustic signal devicesNavigation instrumentsWrong directionVehicle detection

Embodiments of the present invention recite a method and system for providing positional audio cues for an vehicle warning system. In one embodiment, a sensor disposed in a vehicle detects a warning event and generates a corresponding signal. In response to receiving the signal, a controller uses a positional audio algorithm to generate an audible warning via an audio system associated with the vehicle. The audible warning uniquely identifies the warning event and provides a location cue indicating the location of the warning event. In embodiments of the present invention, a sensor coupled with the controller may detect the proximity of and external object with reference to the vehicle and generate a corresponding signal. In embodiments of the present invention, the audible warnings may comprise steering cues indicating a desired direction, or a wrong direction, to a destination in response to input from a vehicle navigation system.

Owner:NVIDIA CORP

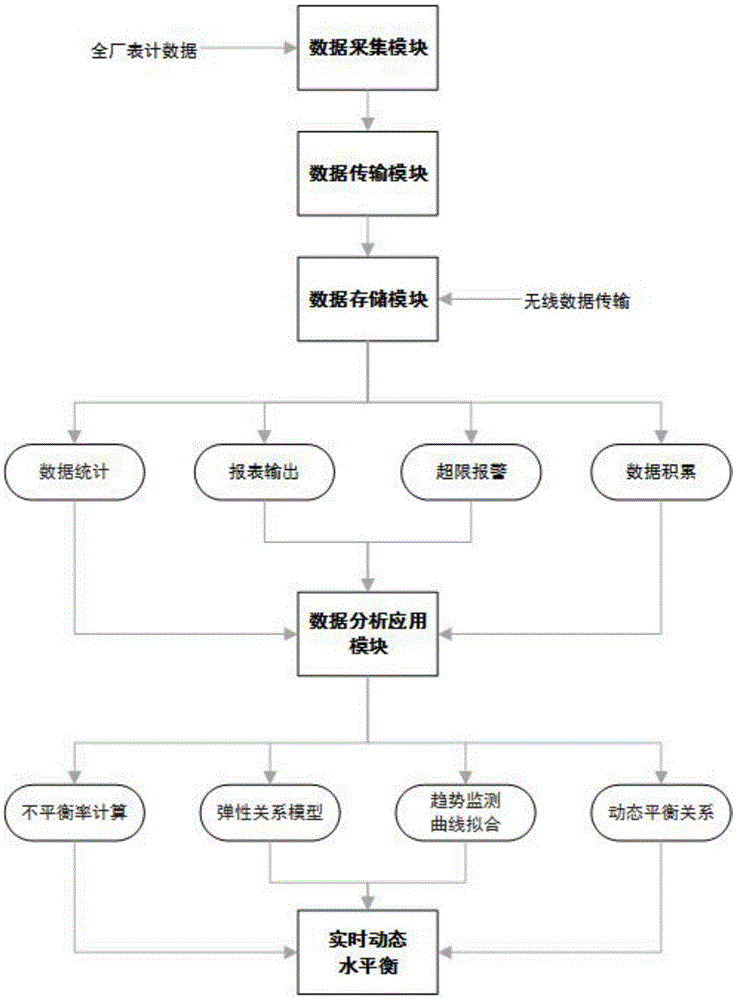

Real-time dynamic 3D water balance monitoring system of power plant and working method of system

InactiveCN105549557AEffective monitoringEfficient managementTotal factory controlProgramme total factory controlWater balanceApplication module

The invention relates to a real-time dynamic 3D water balance monitoring system of a power plant and a working method of the system. The system is characterized by comprising a data collection module, a data transmission module, a data storage module, a monitoring center and a data analysis and application module, wherein the data collection module collects flow data, and the data transmission module returns data collected by the data collection module in real time. Water volume data of different collection points is collected by the data collection module, transmitted to the data storage module by the data transmission module, and further transmitted to the data analysis and application module by the data storage module. The system and method have the advantages that the relation between water volume change and generating load is found via data analysis, the imbalance rate is calculated, and thus, scientific basis is provided for planning water-saving measures of the power plant.

Owner:TIANJIN AOLANG NEW ENERGY RESOURCES & TECH CORP

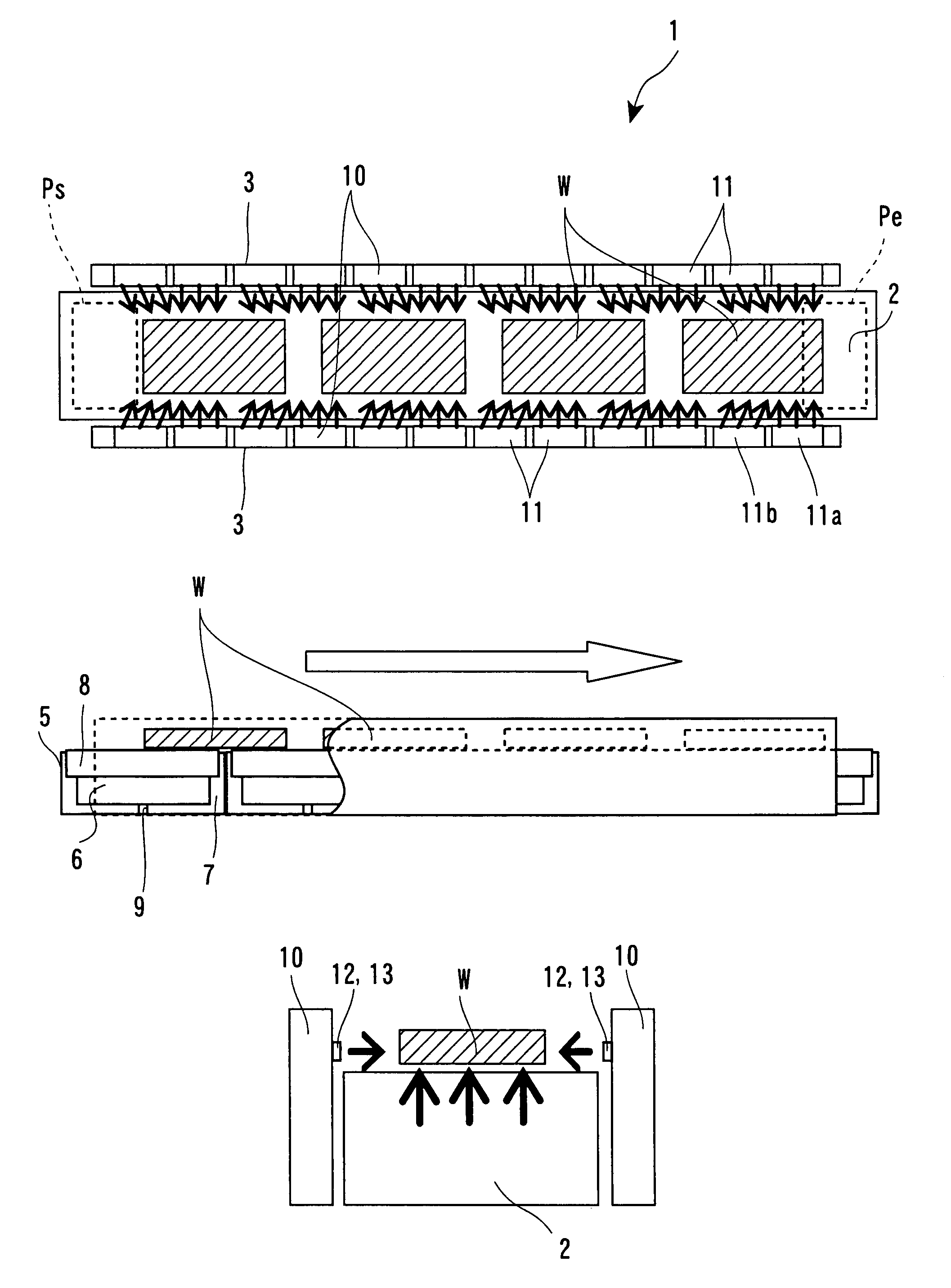

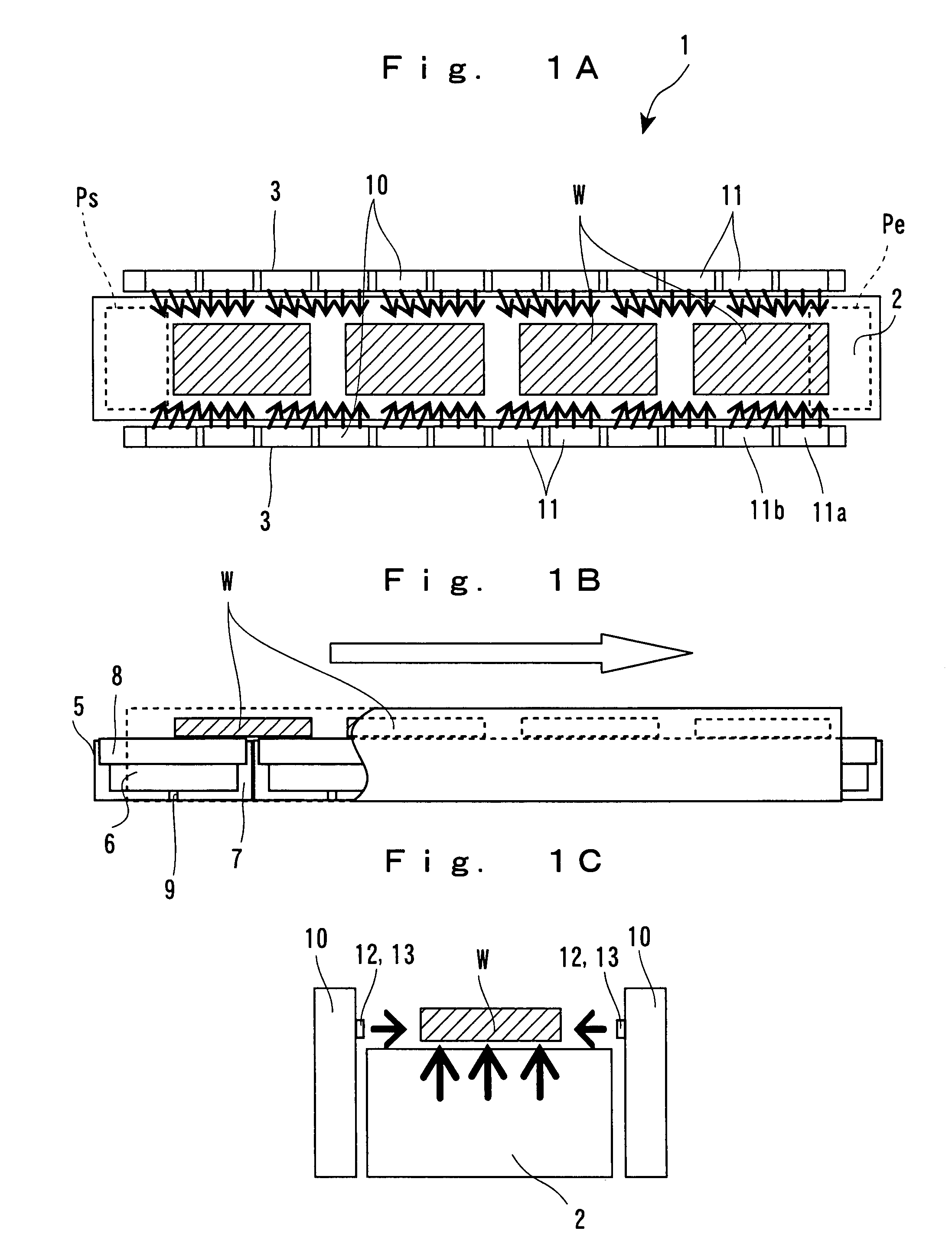

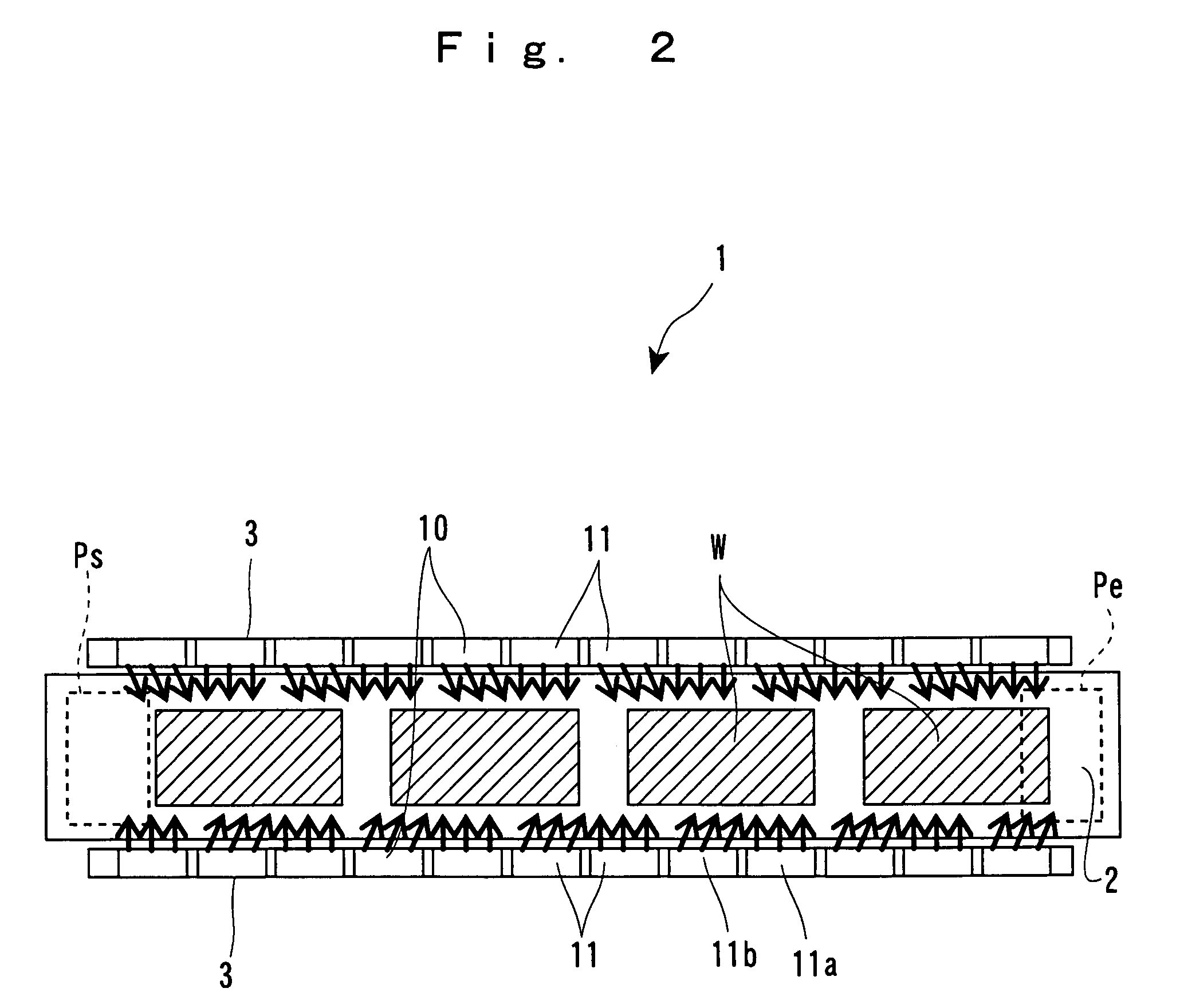

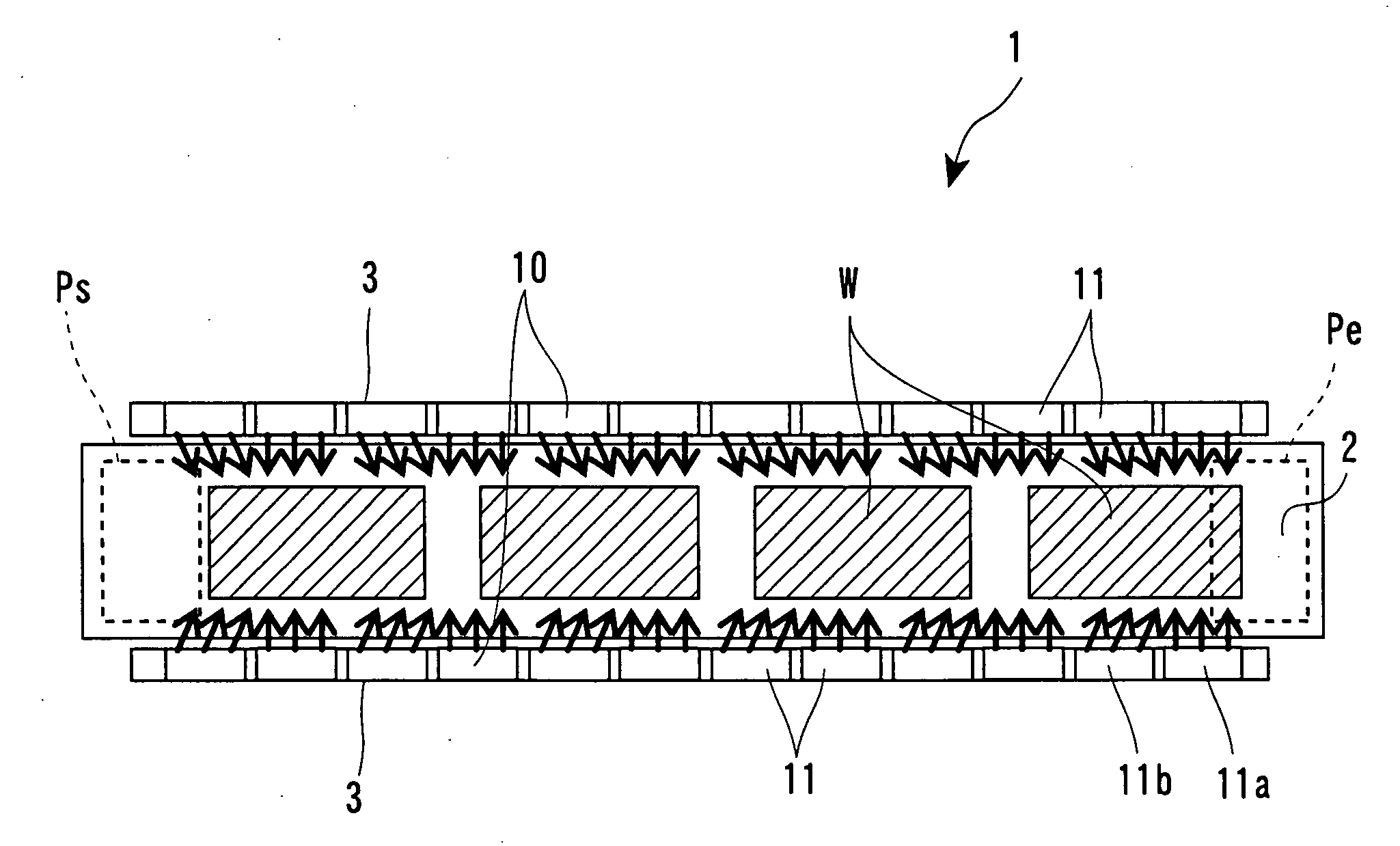

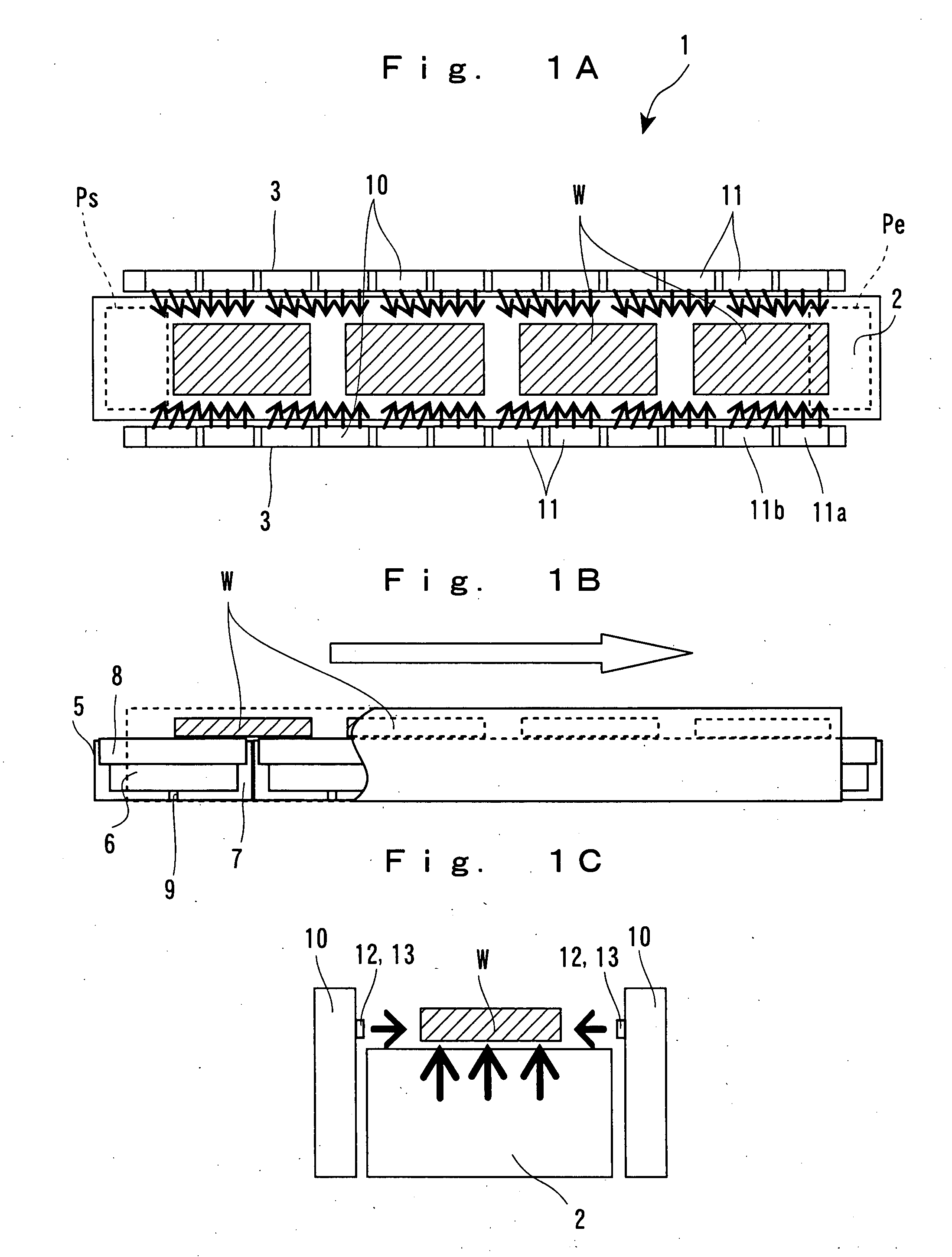

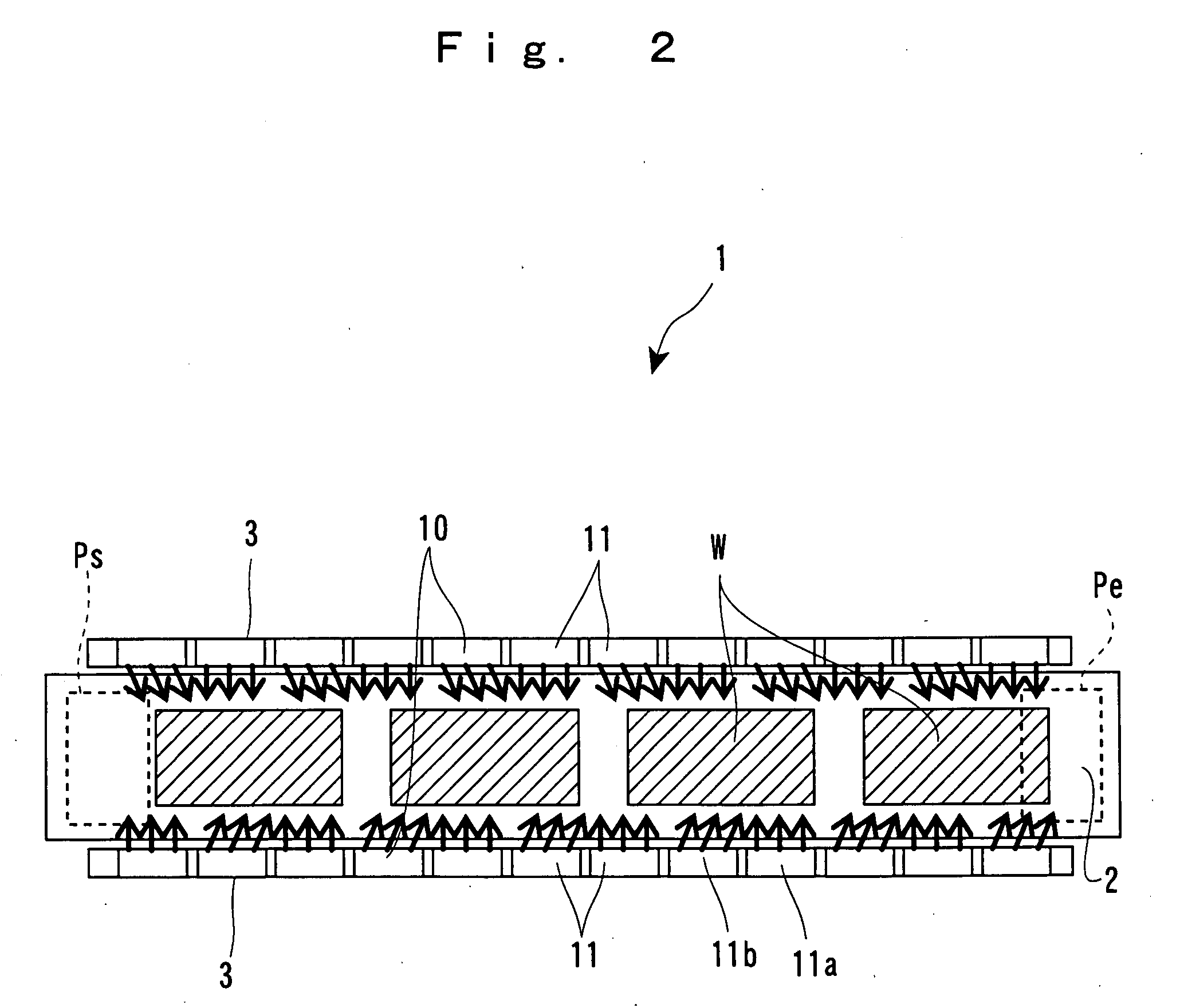

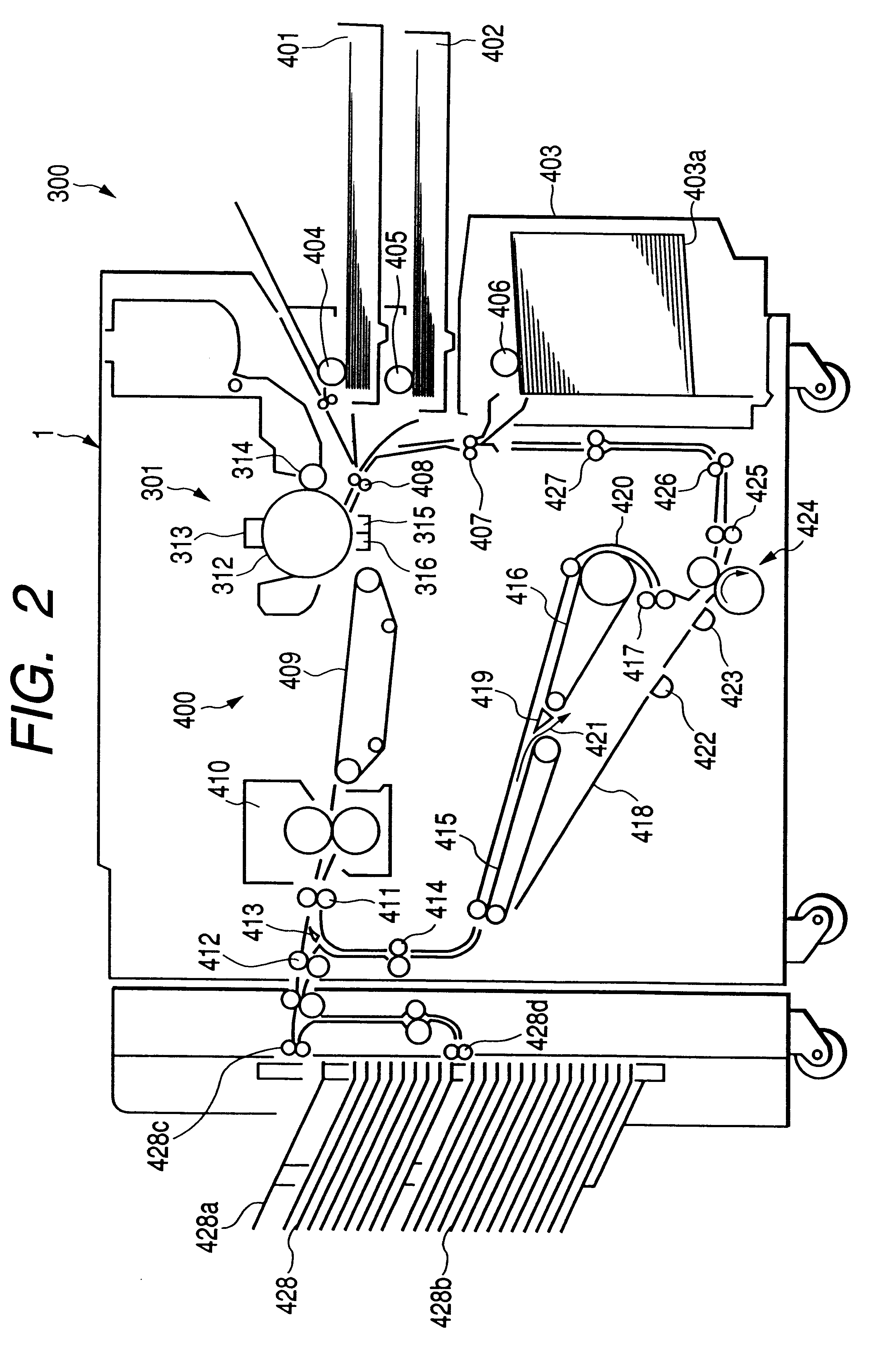

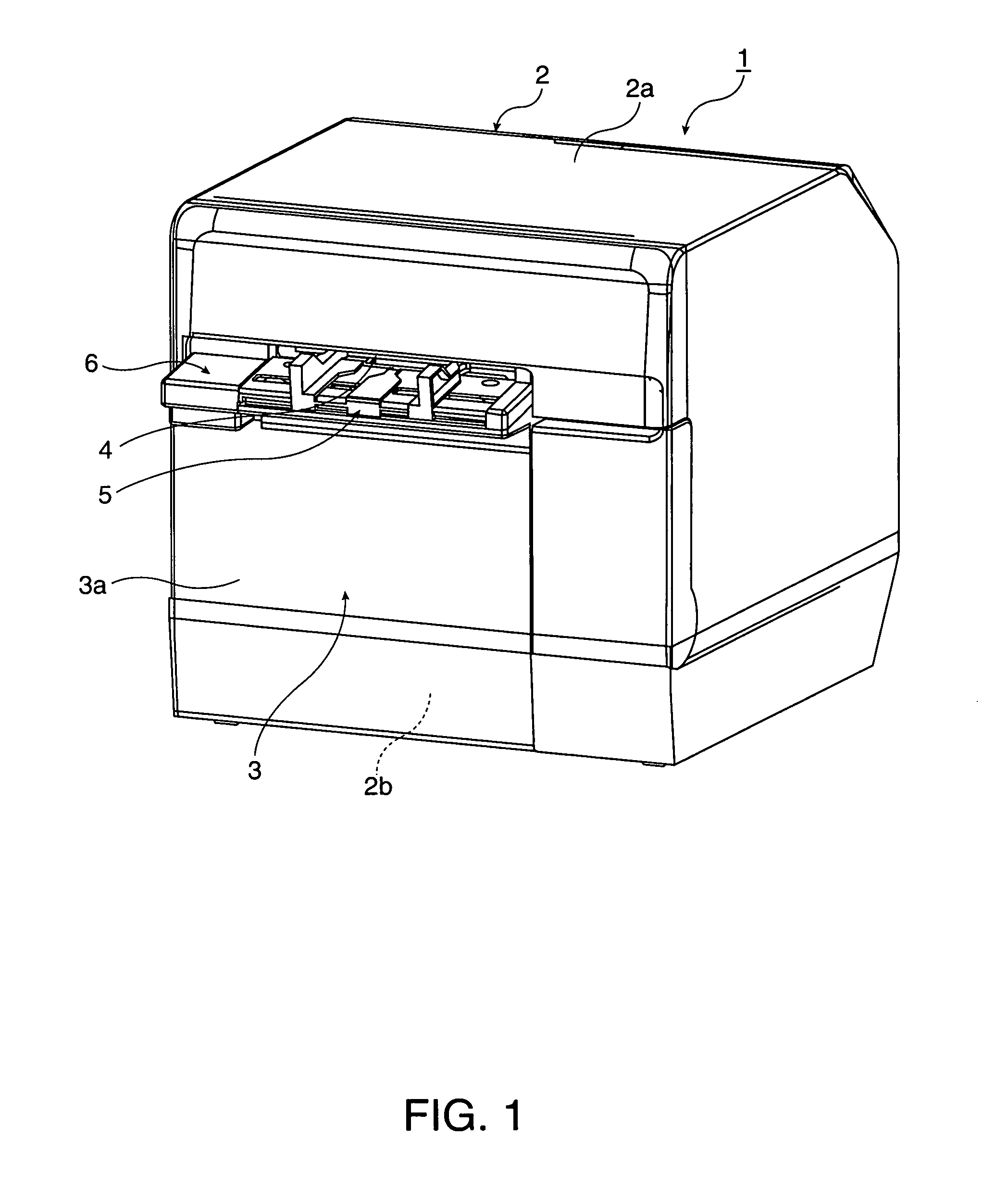

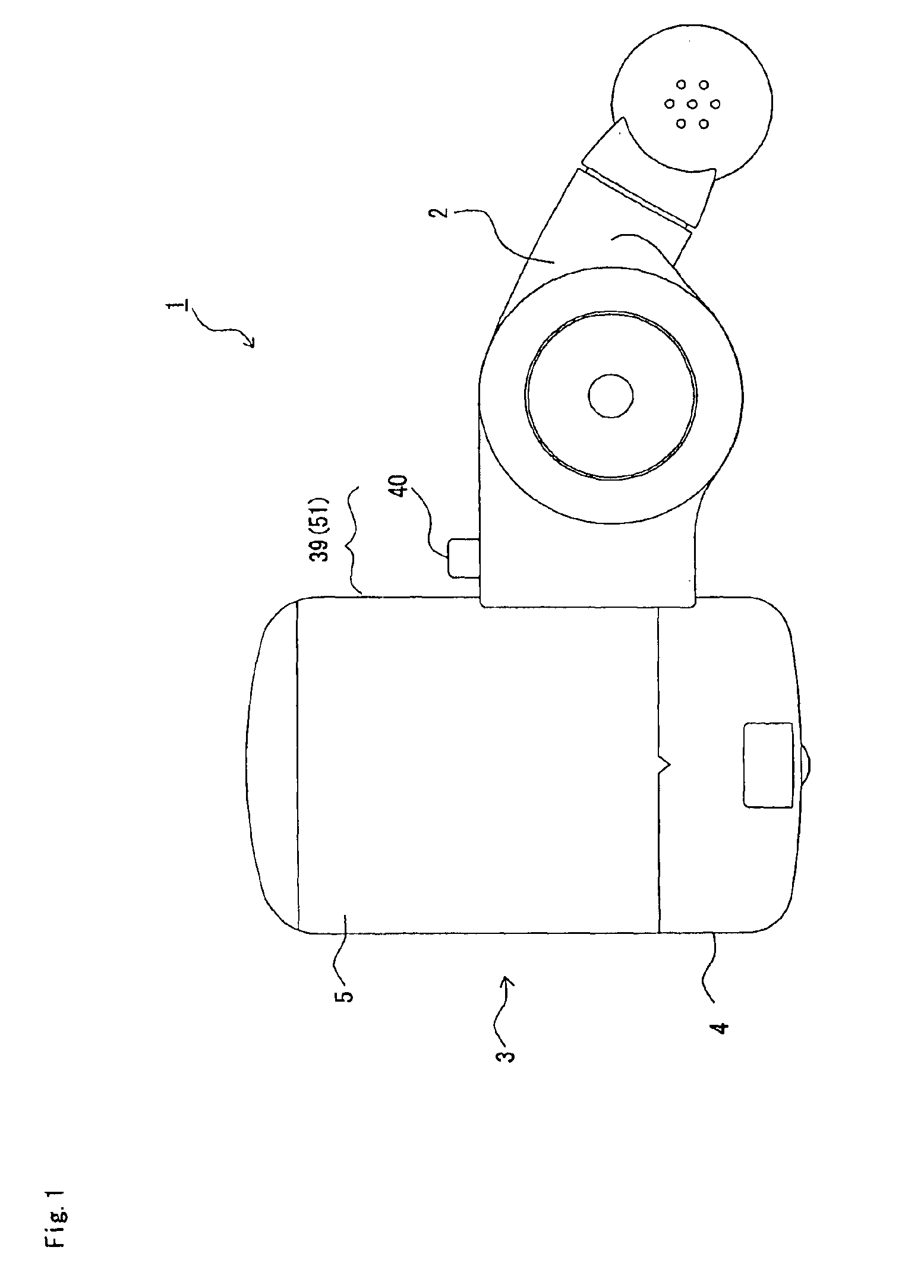

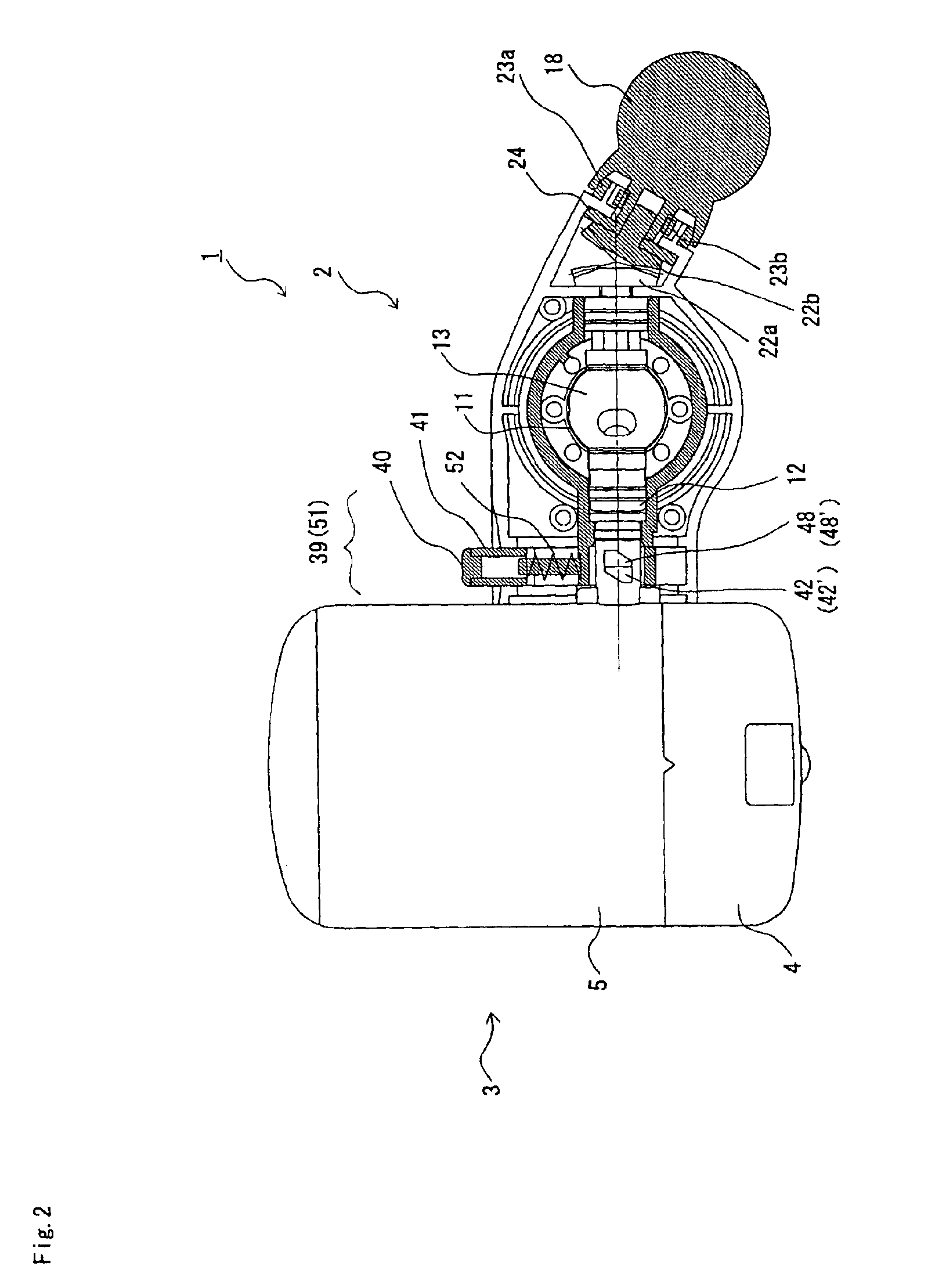

Workpiece conveyor and method of conveying workpiece

InactiveUS7513716B2Simple configurationSmall amount of airSemiconductor/solid-state device manufacturingBulk conveyorsEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

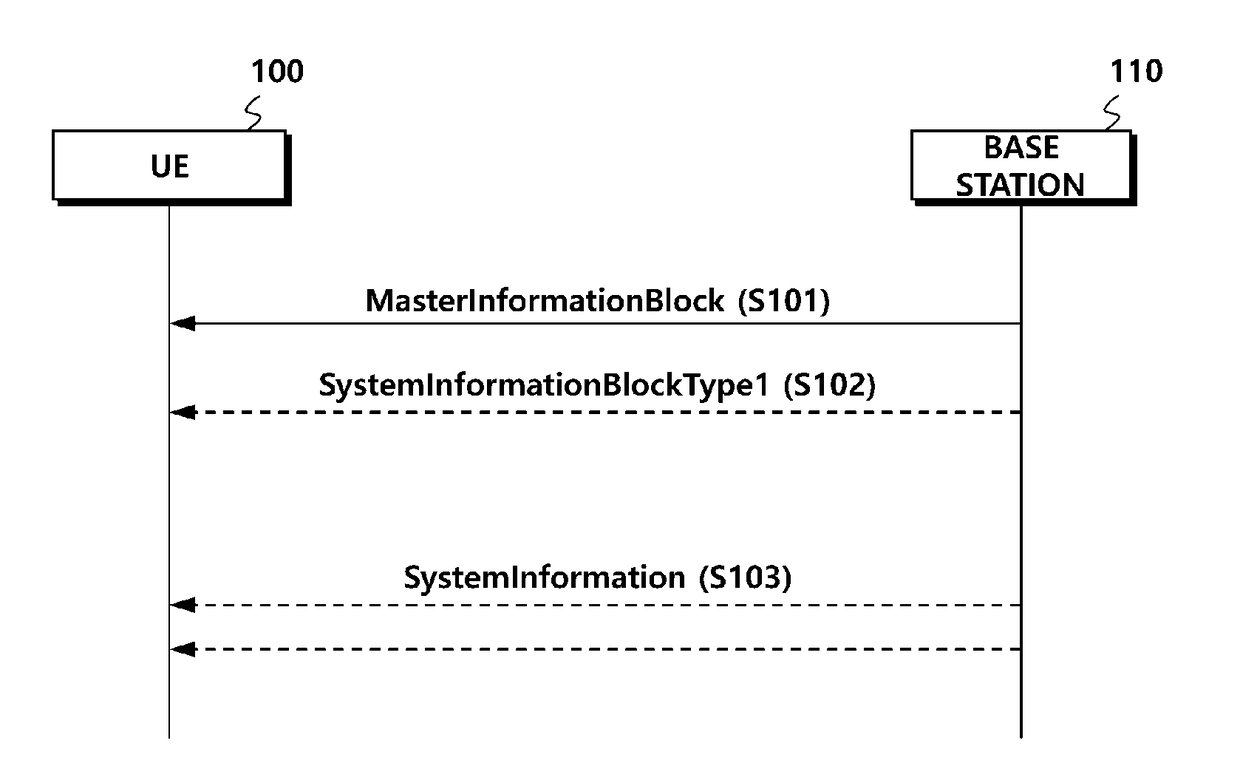

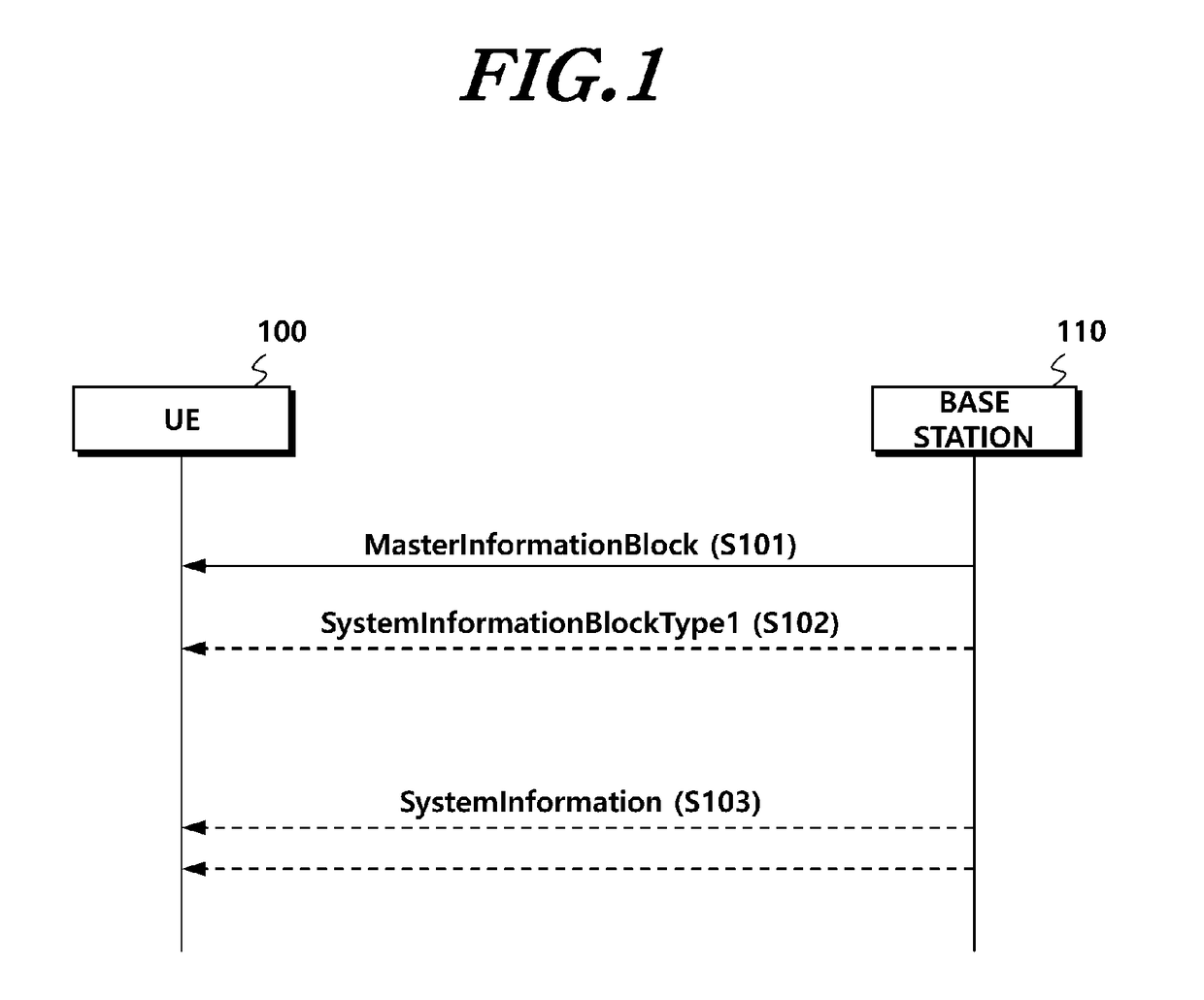

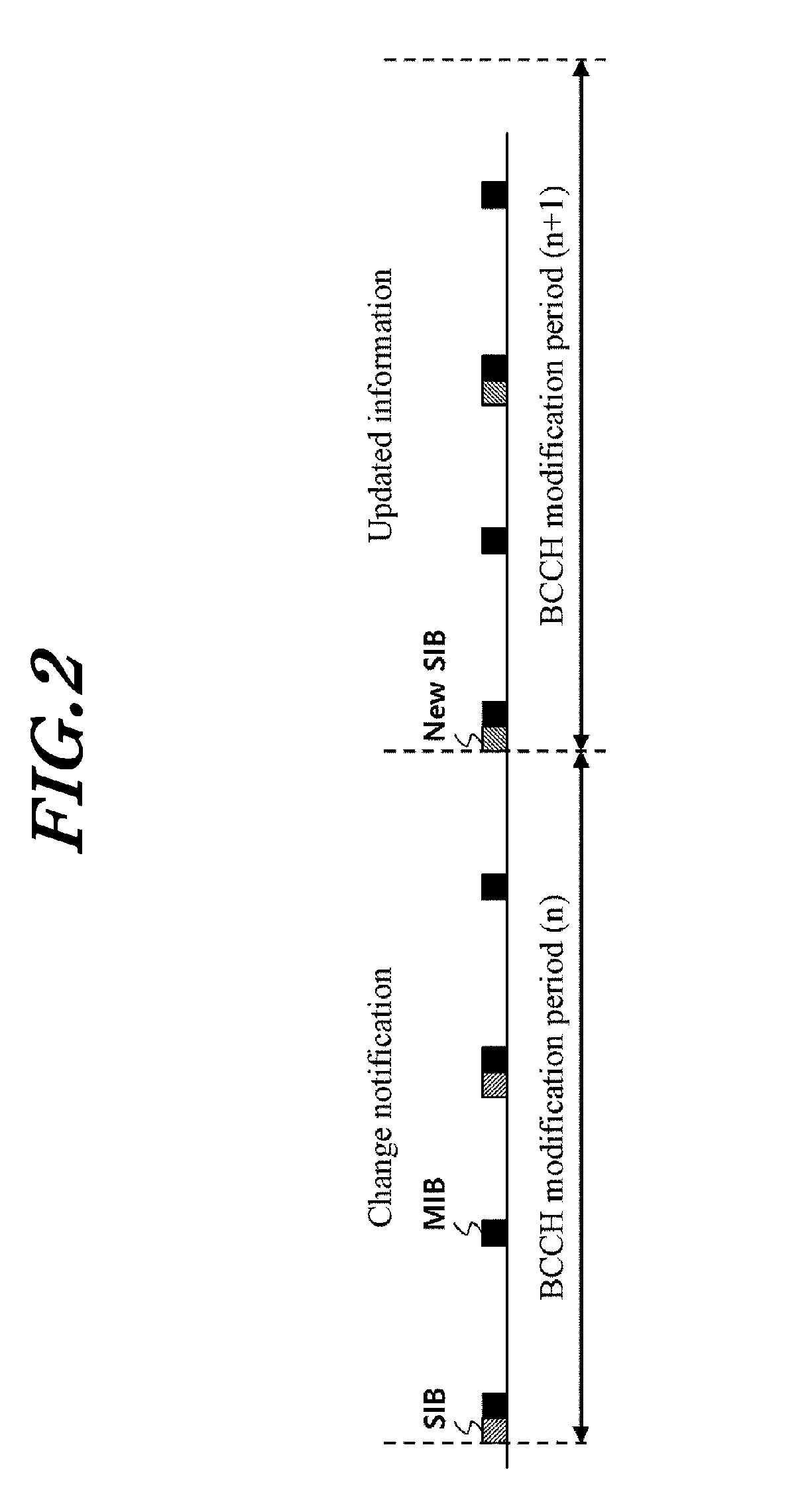

Method and apparatus for receiving random access response for mtc ue

ActiveUS20170094688A1Avoid mistakesConvey accuratelyAssess restrictionWireless commuication servicesRandom-access channelData transmission

The present disclosure relates to a downlink data transmission / reception technique for supporting a low-complexity UE category / type for a MTC operation. A method may be provided for an MTC UE to receive a random access response. The method may include: repeatedly transmitting a random access preamble to a base station through a Physical Random Access Channel (PRACH) of at least one subframe; determining a Random Access Radio Network Temporary Identifier (RA-RNTI) using first time index information, frequency index information, and second time index information on the PRACH; and receiving a random access response to the random access preamble using the RA-RNTI within a random access response window.

Owner:KT CORP

Workpiece conveyor and method of conveying workpiece

InactiveUS20070212174A1Simple configurationSmall amount of airSemiconductor/solid-state device manufacturingBulk conveyorsEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

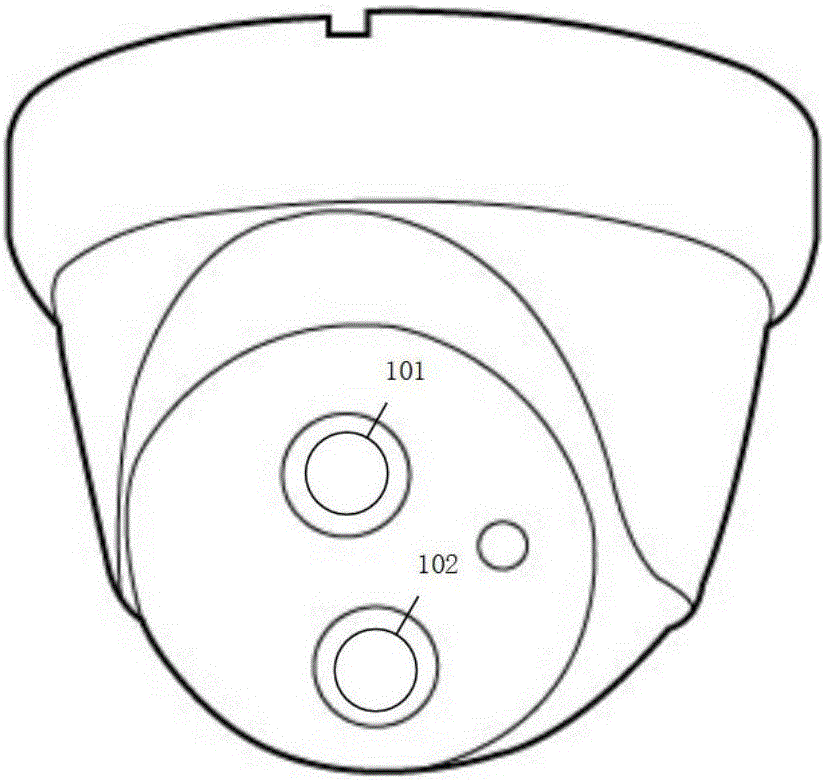

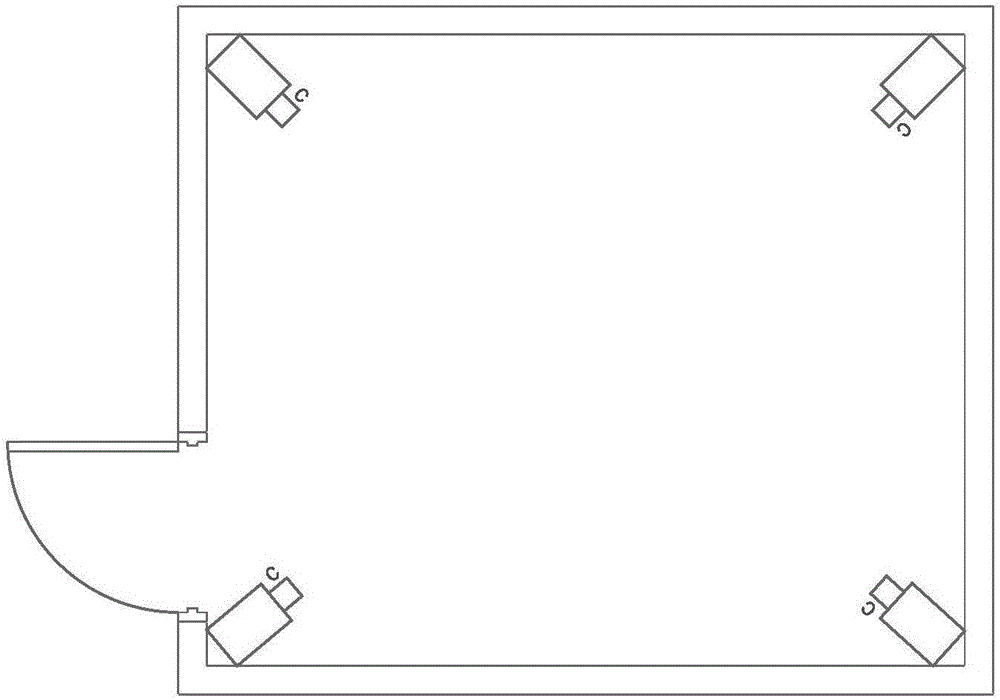

Smart home old age support video monitoring abnormal behavior system and method

ActiveCN106027978AAccurate identificationFully describeClosed circuit television systemsAcquiring/recognising facial featuresVideo monitoringMonitoring system

The invention discloses a smart home old age support video monitoring abnormal behavior system and method, and belongs to the technical field of mode identification and computer vision. The monitoring system provided by the invention comprises a double-lens monitoring camera, a video processing node and a communication center. According to the system, the indoor activity condition can be monitored in real time through the double-lens monitoring camera; an abnormal behavior is processed through the video processing node; whether there is an abnormal behavior activity or not is detected by taking face expressions as auxiliary identification; and abnormal behavior alarm information is sent to a user through the communication center. According to the system and the method, the body activity state can be monitored in real time, and alarm is generated when there is the abnormal condition. The system and the method have the advantages of wide application range, high security and stable and reliable identification.

Owner:NANJING UNIV OF TECH

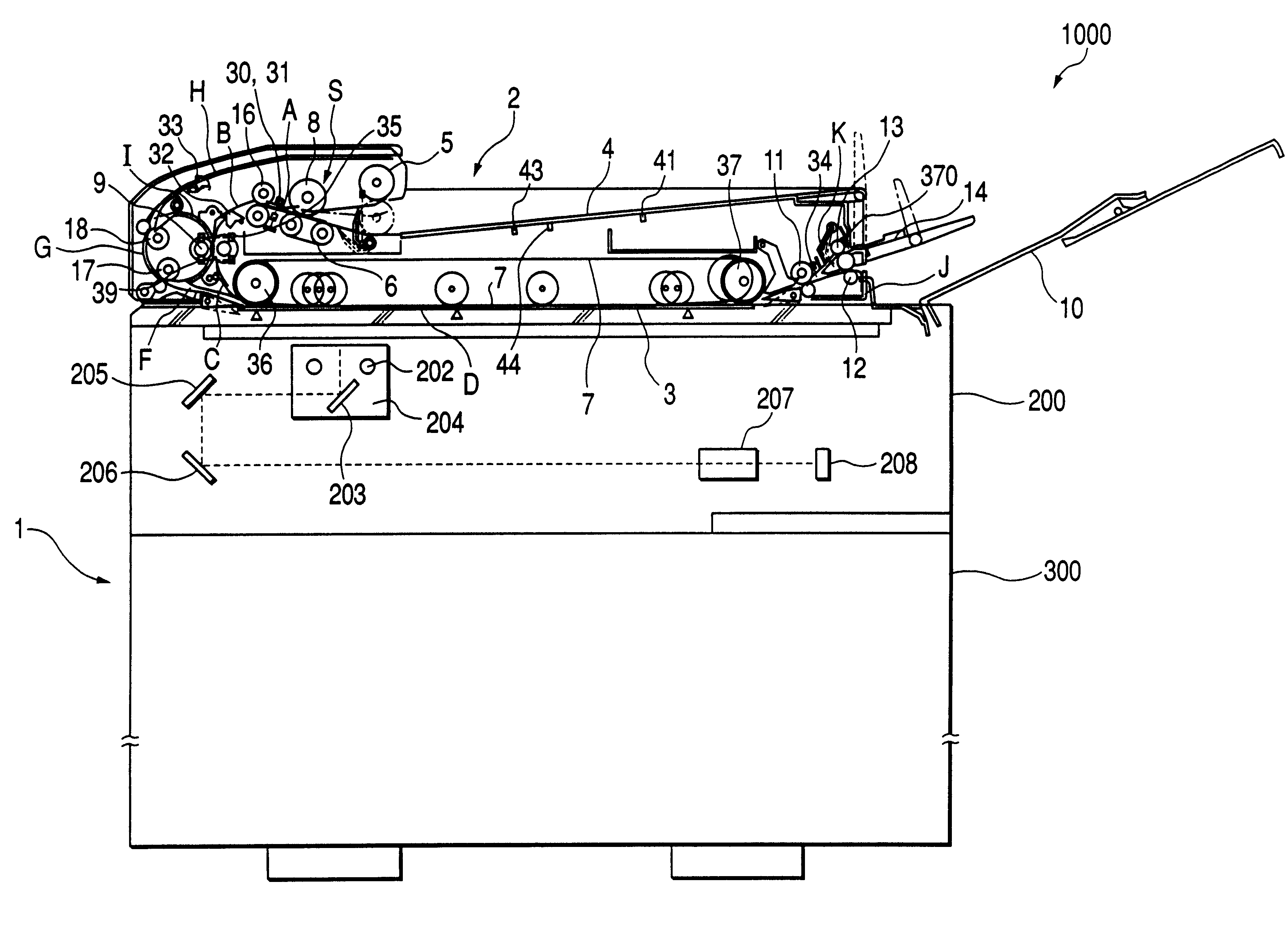

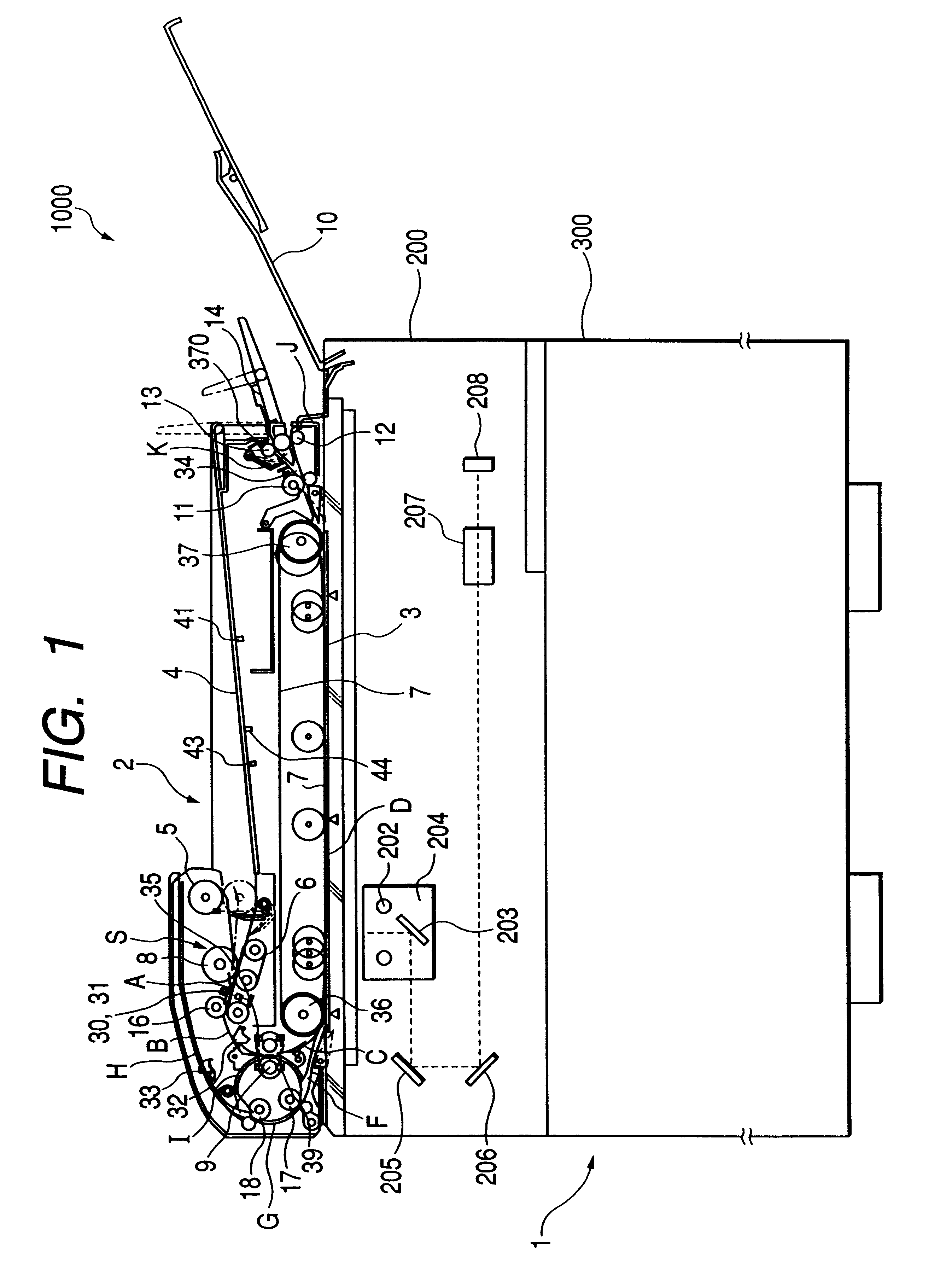

Sheet conveying apparatus and image forming apparatus therewith

InactiveUS6493113B1Convey accuratelyElectrographic process apparatusArticle feedersStackerEngineering

An original conveying apparatus including an original stacker, a conveying roller for conveying originals on the original stacker one by one, a first rotary member for further conveying the original to a reading position, a second rotary member for conveying the original conveyed by the first rotary member to read the original, a reading device, a sensor disposed in the vicinity of the first rotary member for detecting passage of the original, and a control device for controlling an original conveying amount of the second rotary member by the action of the sensor to convey a leading end of the original to a predetermined position on the reading position, and wherein the control device controls the original conveying amount in consideration of a length of the original based on a timing when a trailing end of the original passes by the sensor when the original has a fixed size and controls the original conveying amount based on a timing when a leading end of the original passes by the sensor when the original has a non-fixed size.

Owner:CANON KK

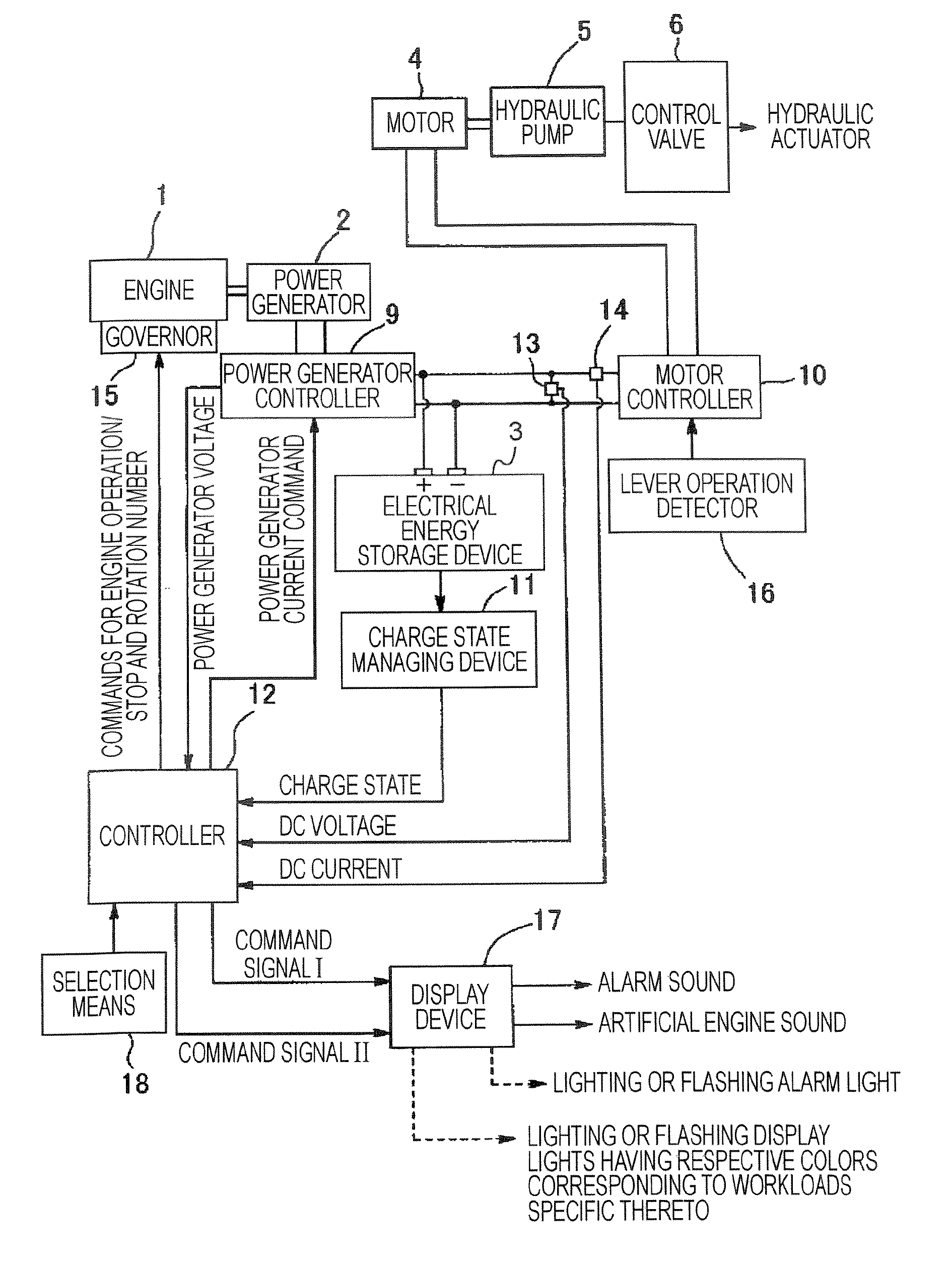

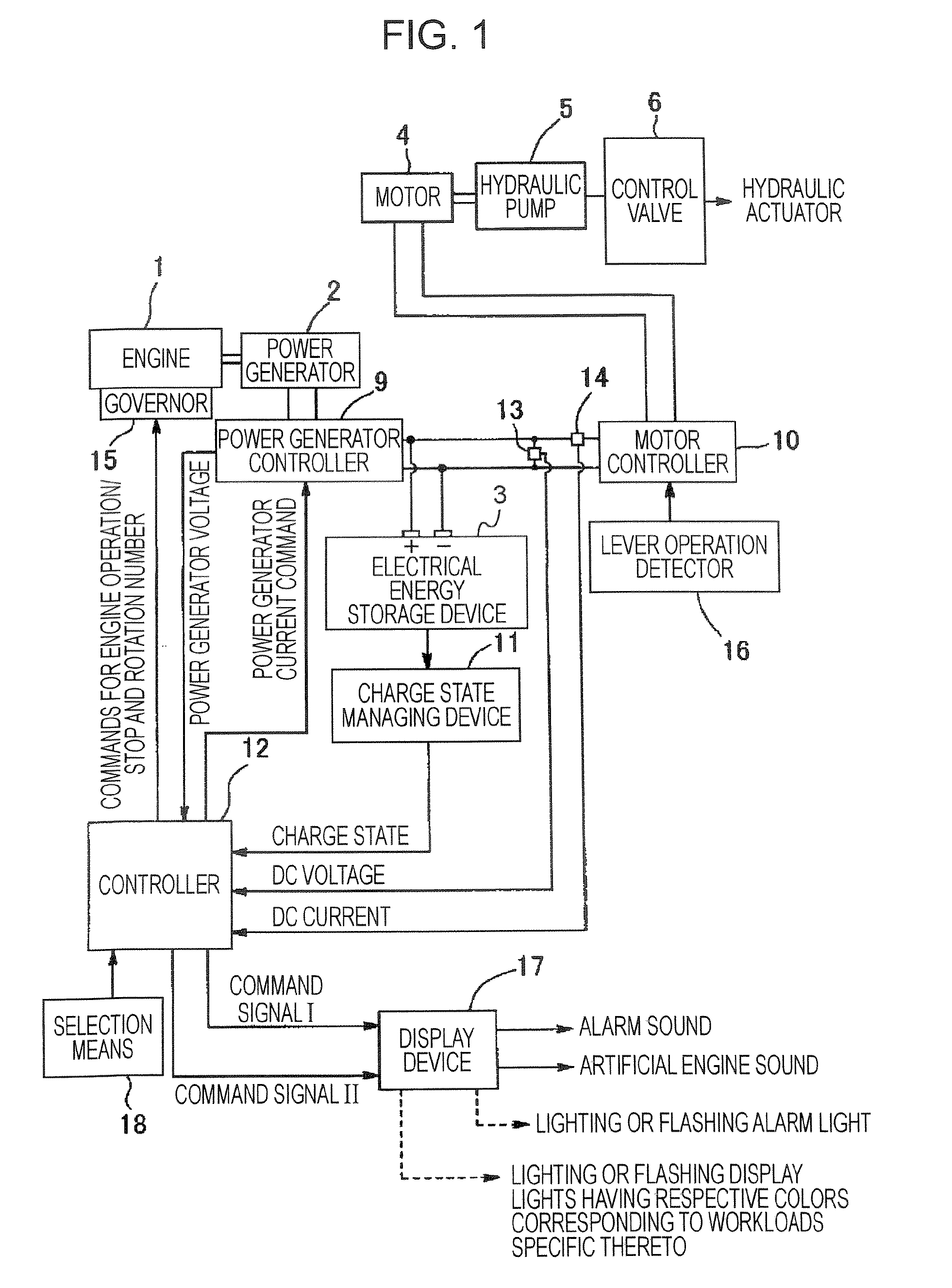

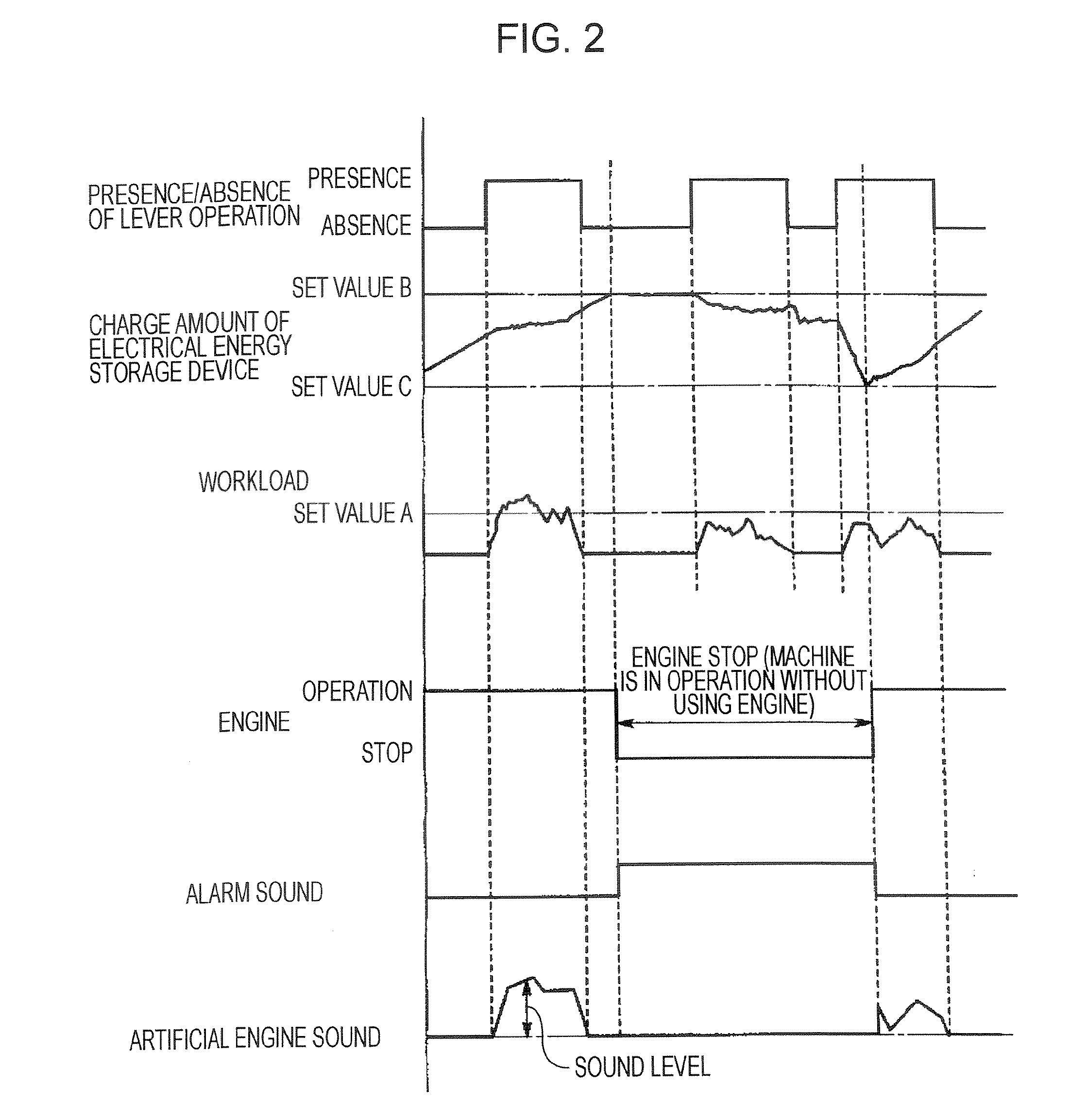

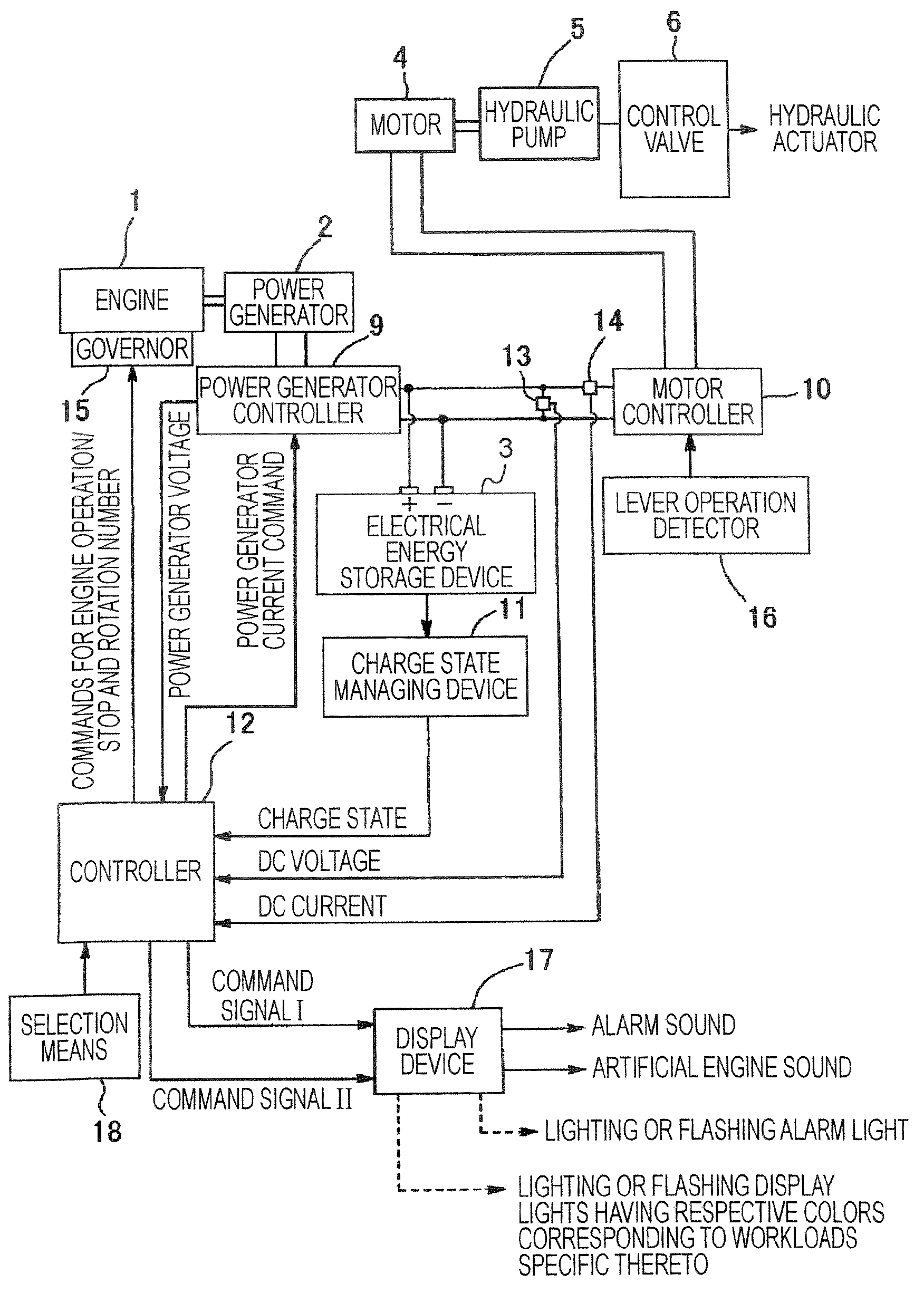

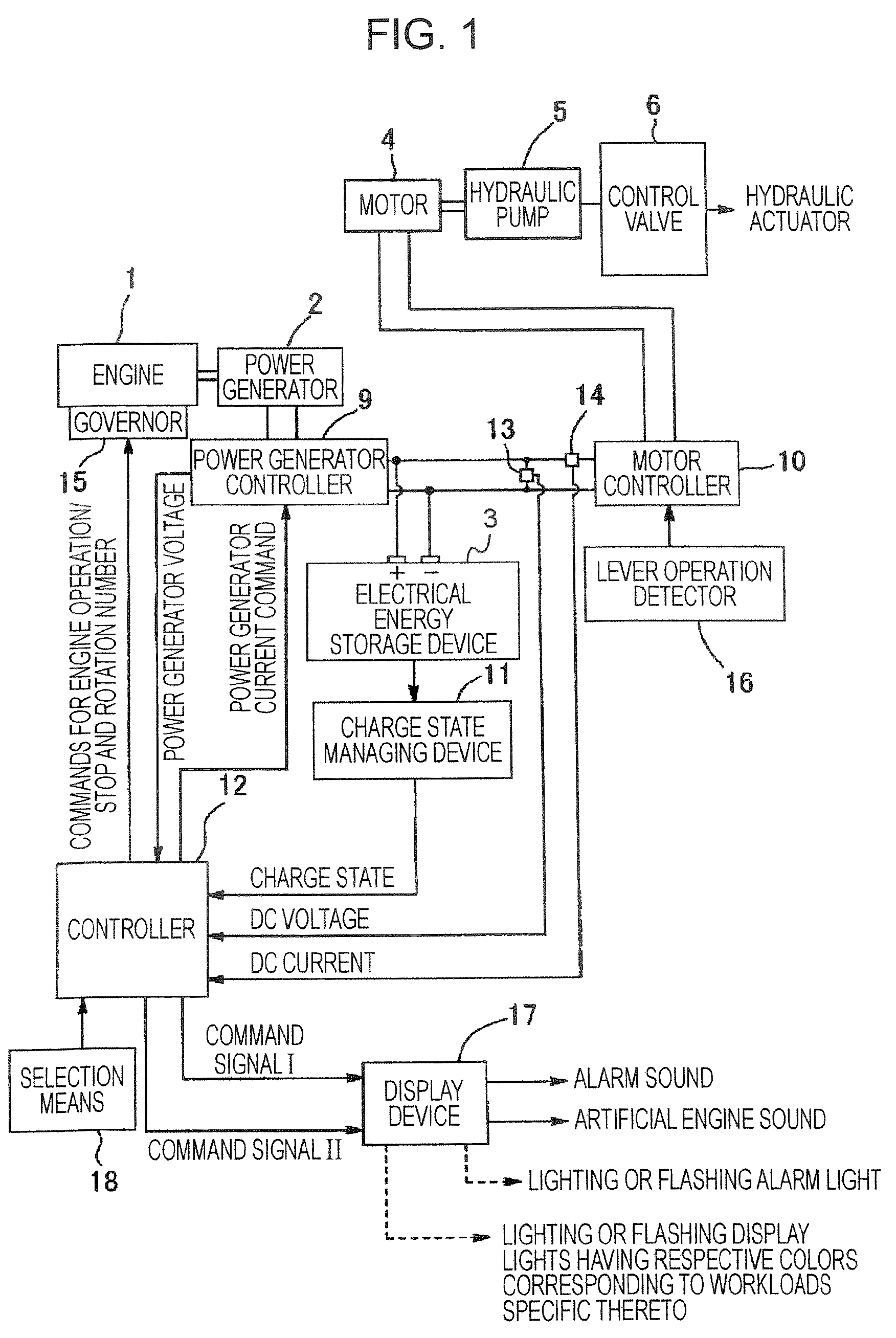

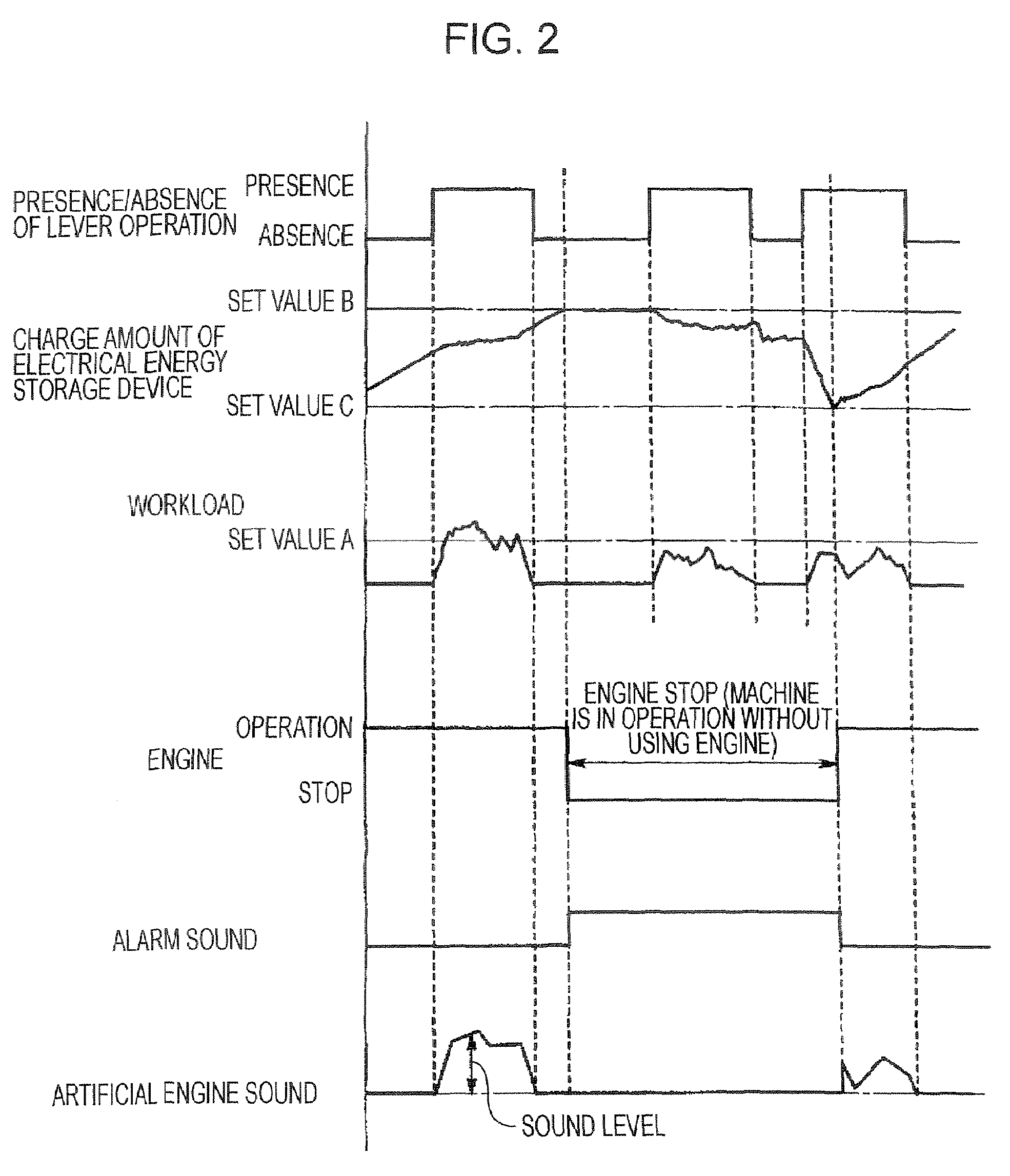

Construction machine

InactiveUS20070096667A1Convey accuratelyEnsure safetyAnalogue computers for vehiclesAnalogue computers for trafficDisplay deviceWorkload

In a hybrid construction machine, its display device displays, toward an operator, an artificial engine sound serving as load information according to a magnitude of a workload, instead of an engine sound. Furthermore, the display device issues an alarm sound to surrounding workers when performing an operation by only stored electrical power of an electrical energy storage device without using an engine. In this hybrid construction machine, in addition to the issuing of alarm from the display device during the operation without using the engine, the display device issues an advance notice sound for engine restart when at least one value out of the workload and a charge amount of the electrical energy storage device has become an advance notice set value close to a set value of engine restart.

Owner:KOBELCO CONSTR MASCH CO LTD

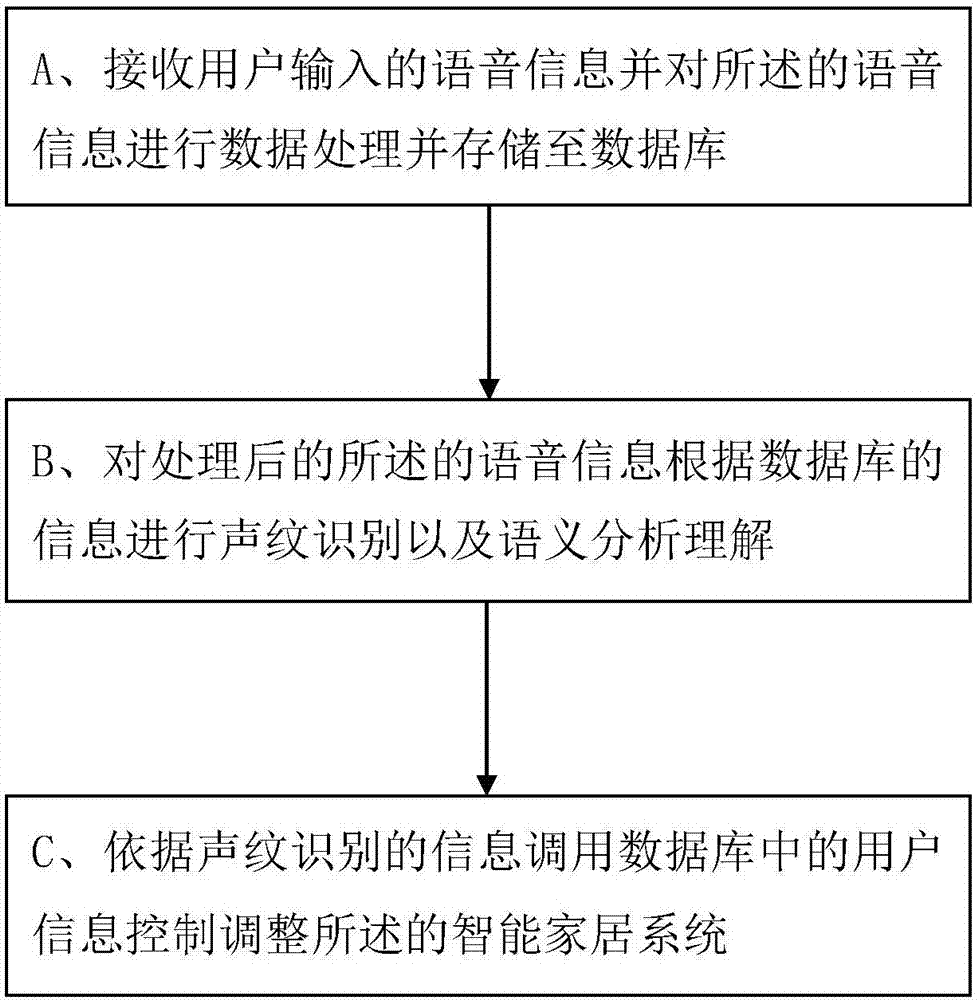

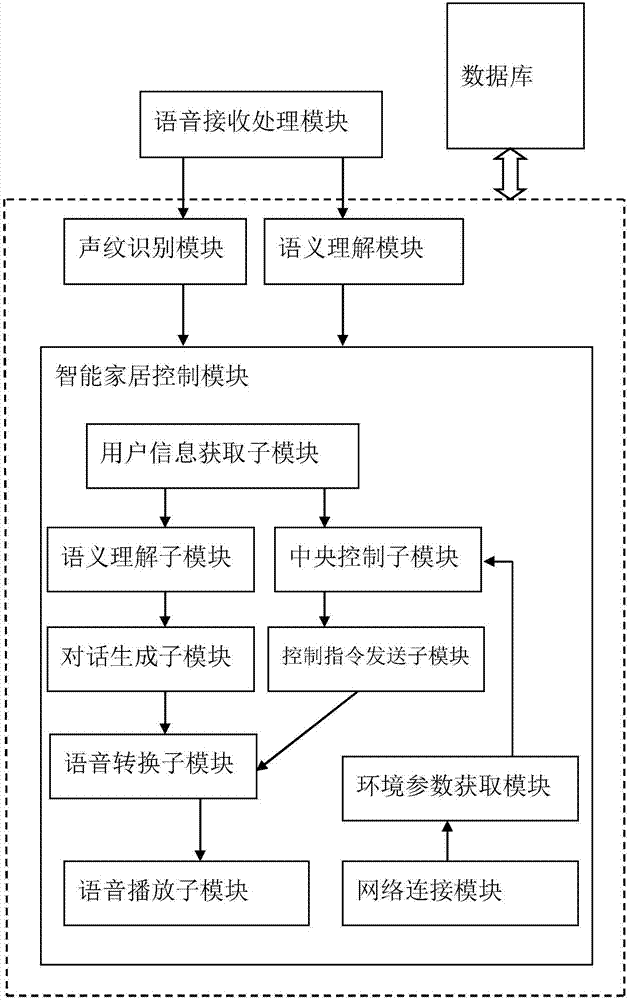

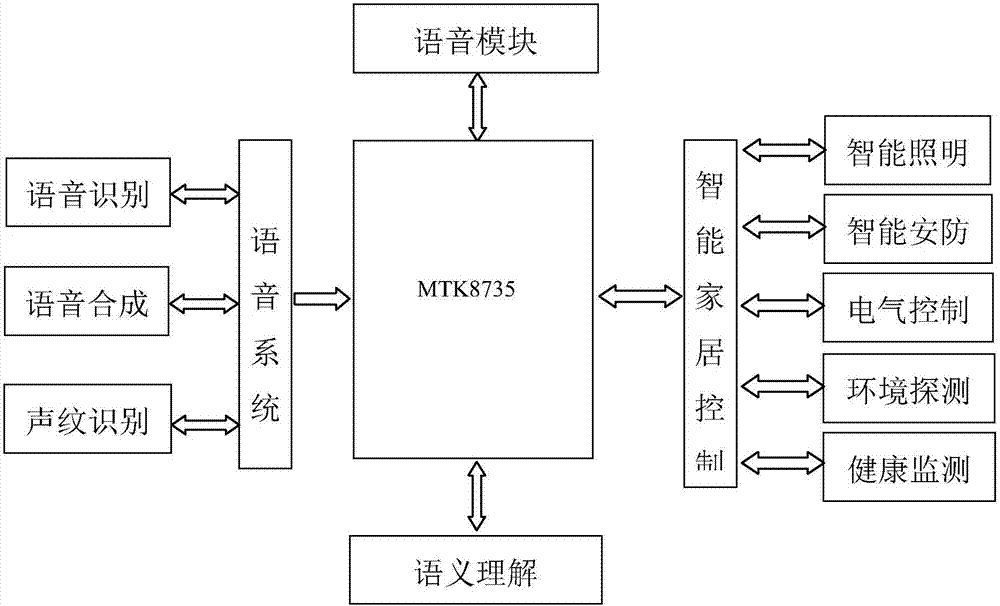

Smart home management method and robot device thereof

InactiveCN106886162AEnsure safetyAvoid misuseComputer controlTotal factory controlUser inputSemantics

The present invention discloses a robot device for smart home management. The device is used for managing various smart home systems. The device comprises a database for storing the management information. The device at least further comprises a voice receiving and processing module used for receiving the voice information input by a user, processing the data of the voice information, and storing the data of the voice information into the database; a voiceprint recognition module used for subjecting the converted voice information to voiceprint recognition and determining the identity information of the user; a semantic understanding module used for subjecting the converted voice information to speech understanding and determining the semantics of the voice information of the user; and a smart home control module used for controlling or adjusting a smart home system according to the information in the database, the identity information of the user determined by the voiceprint recognition module, and the semantics information determined by the semantic understanding module. Meanwhile, the invention also provides a smart home management method. According to the technical scheme of the invention, the home safety can be guaranteed. At the same time, various misoperations are prevented, so that the high safety performance is realized.

Owner:SHENZHEN QIANHAI YYD ROBOT CO LTD

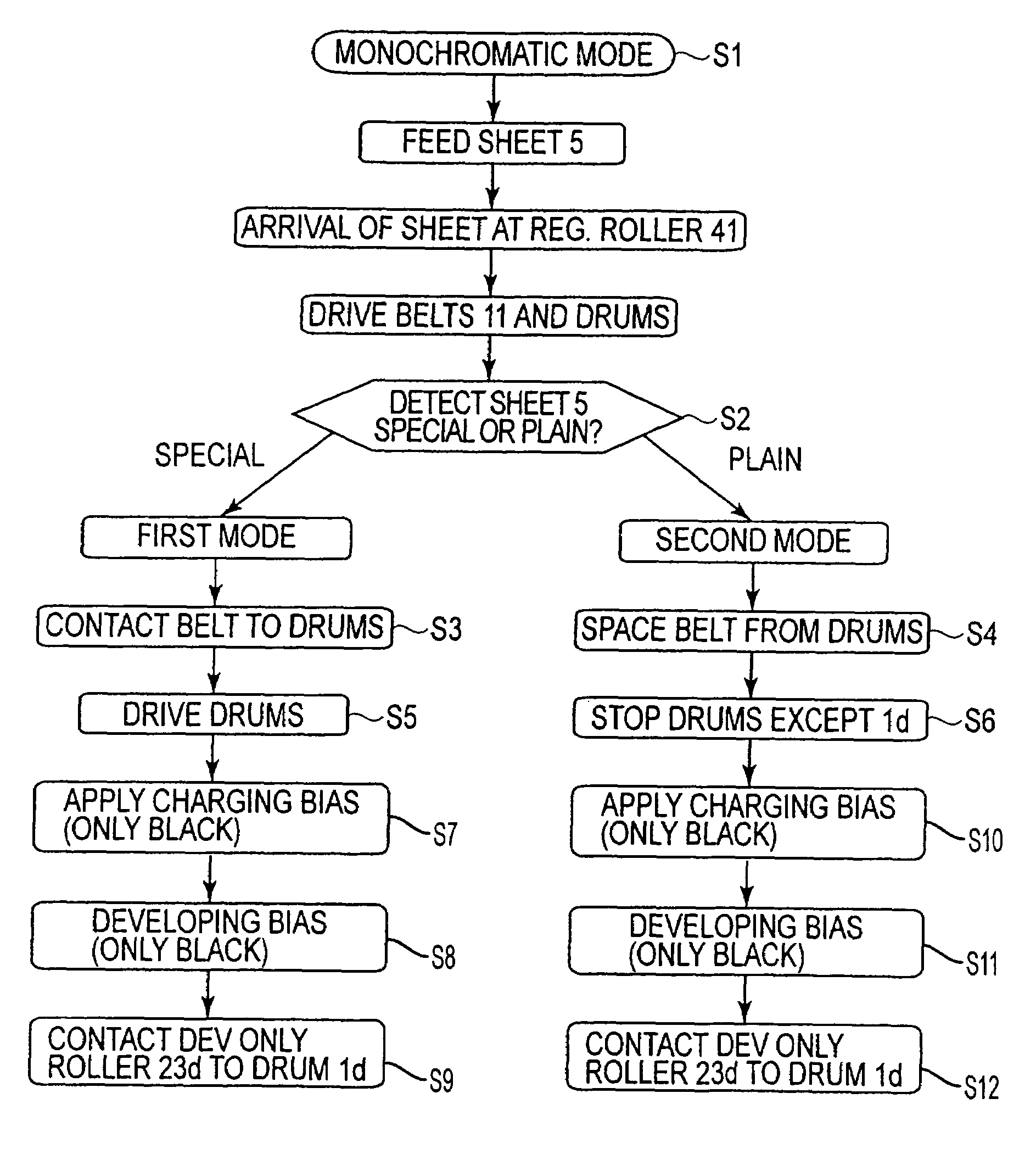

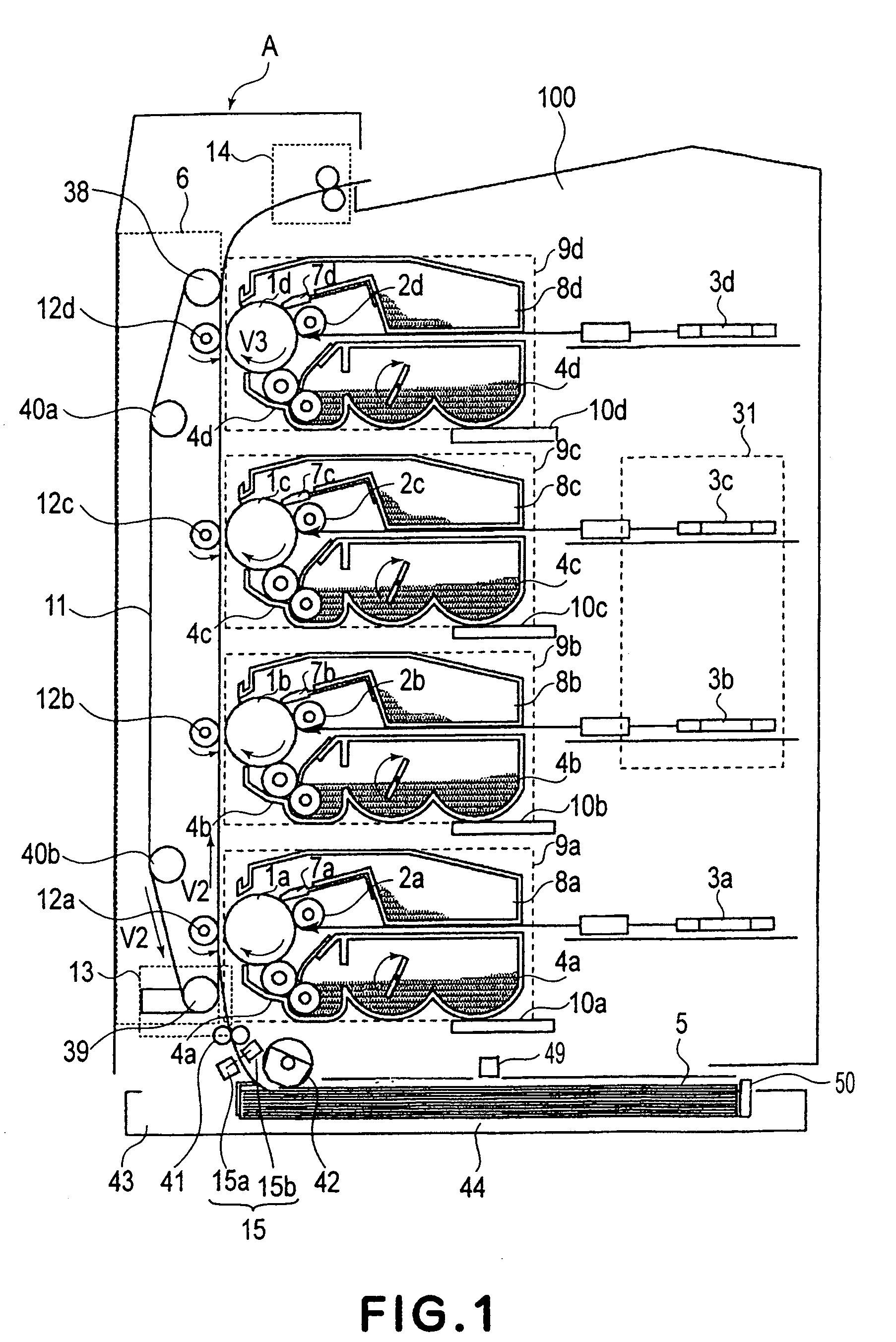

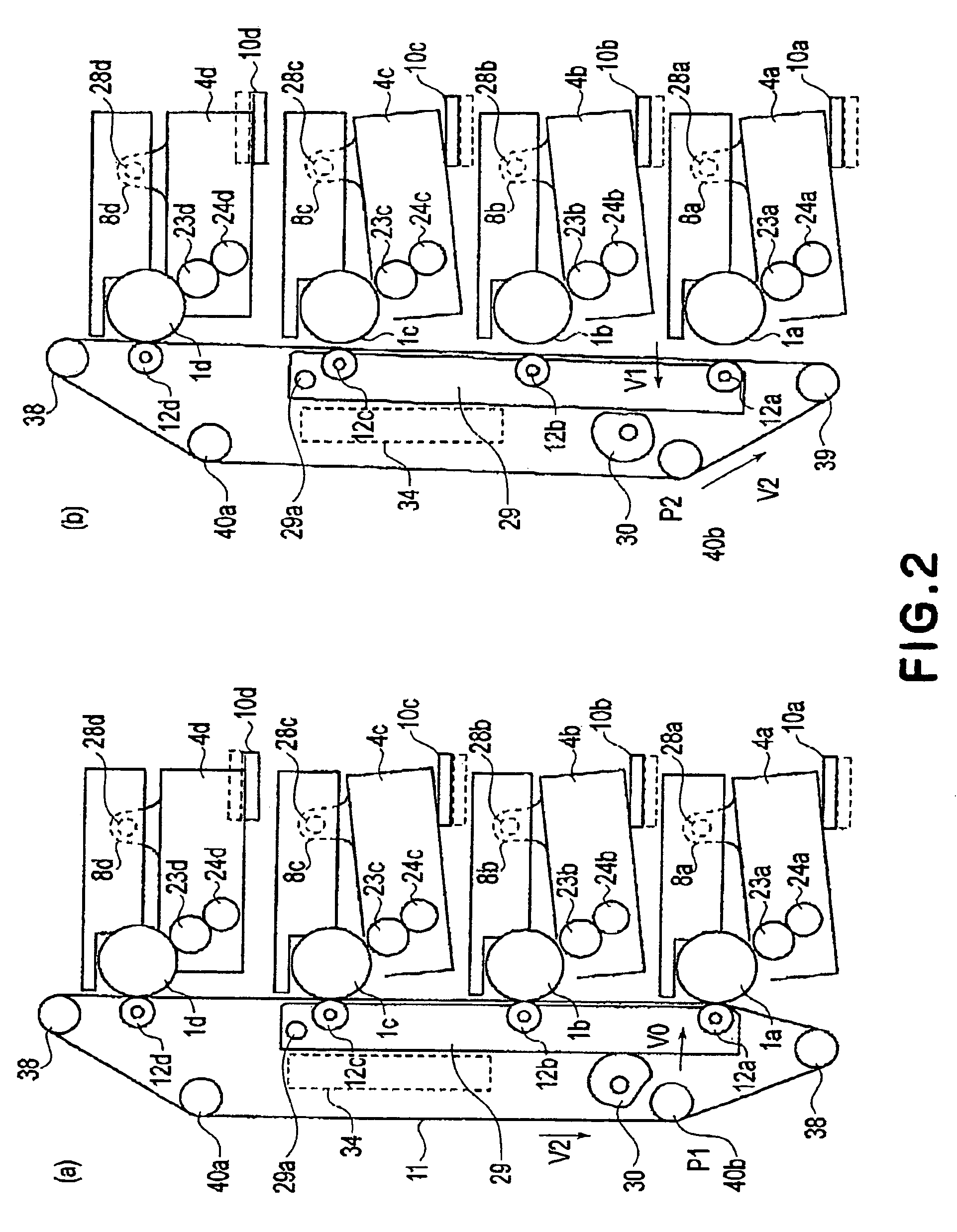

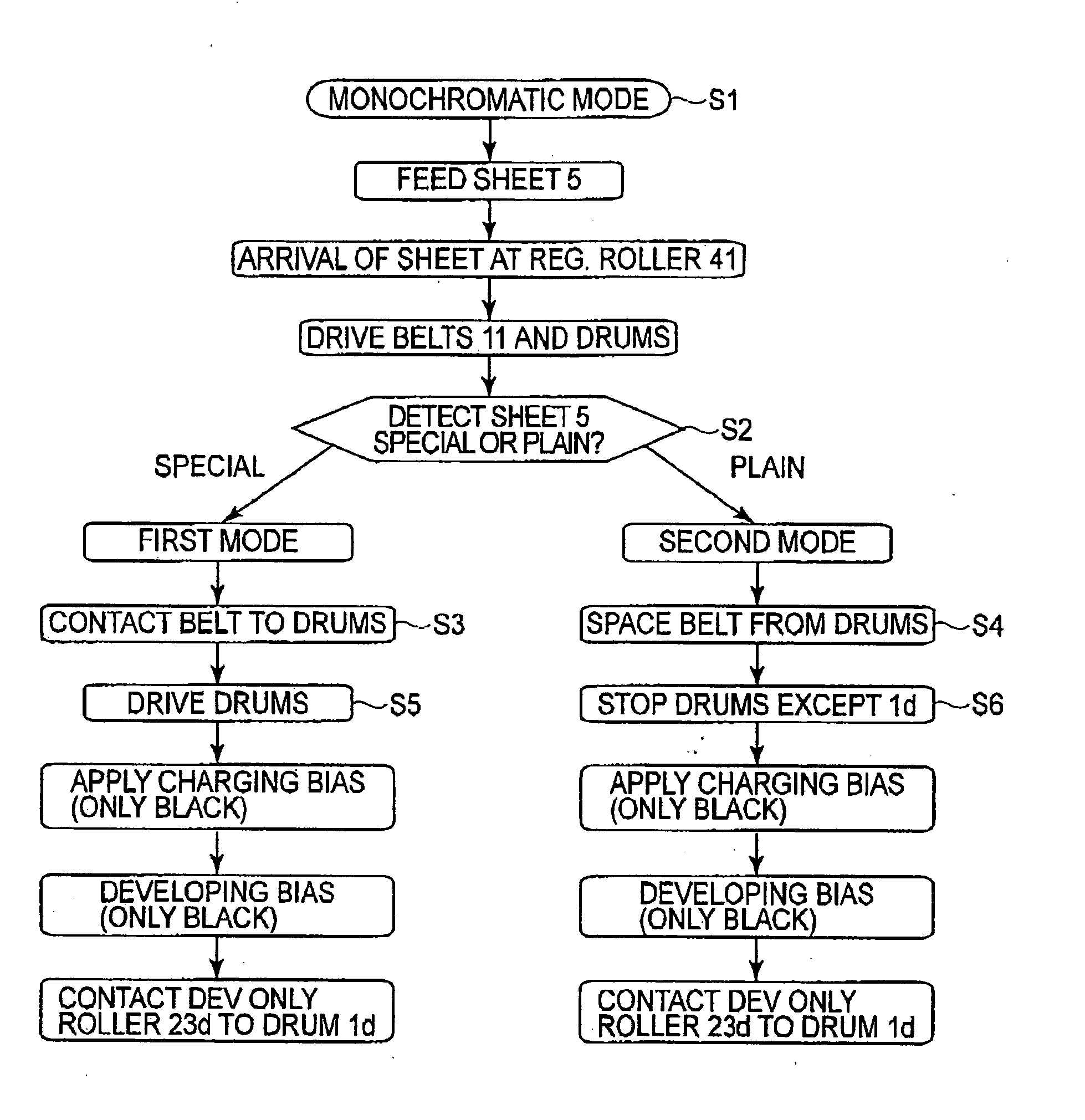

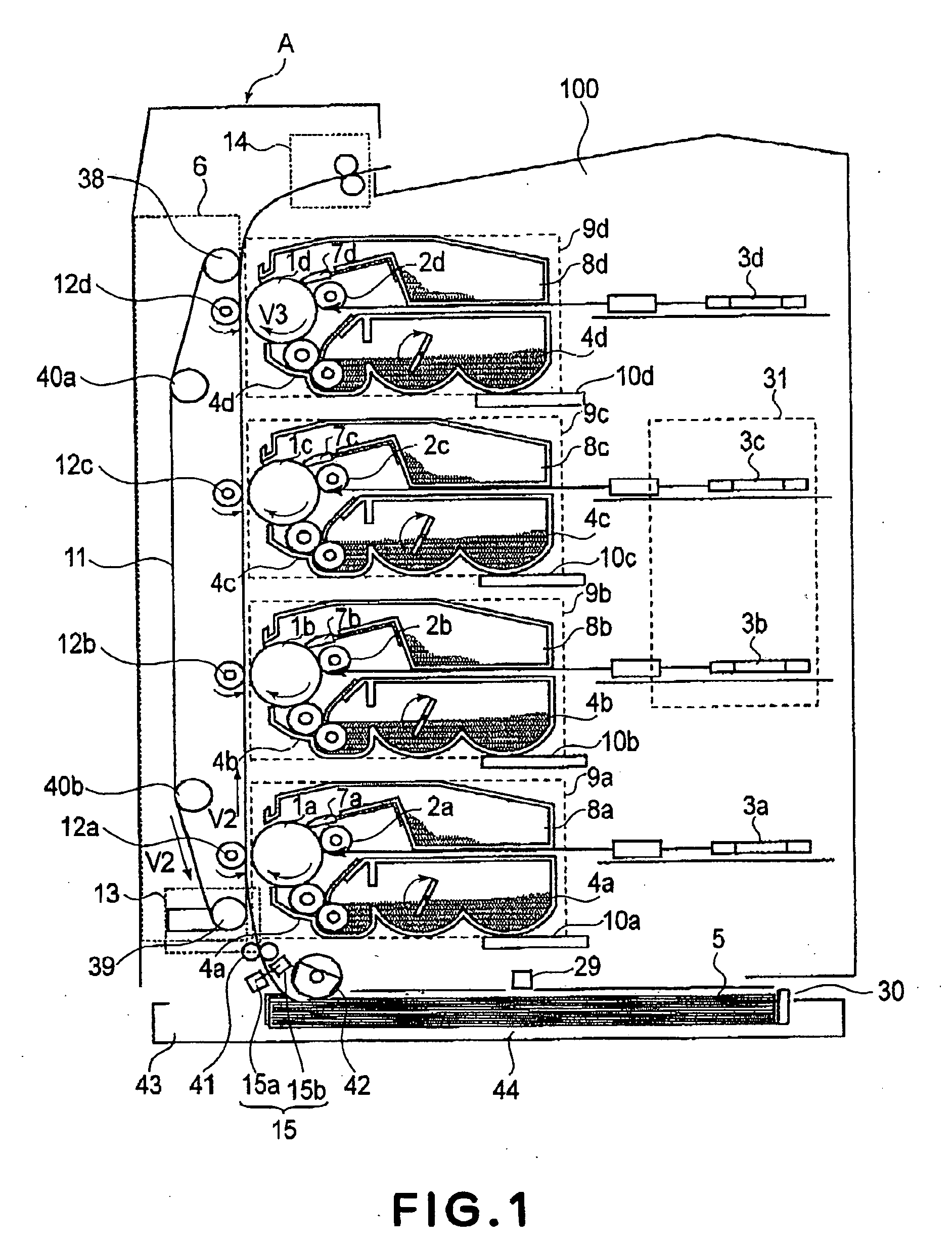

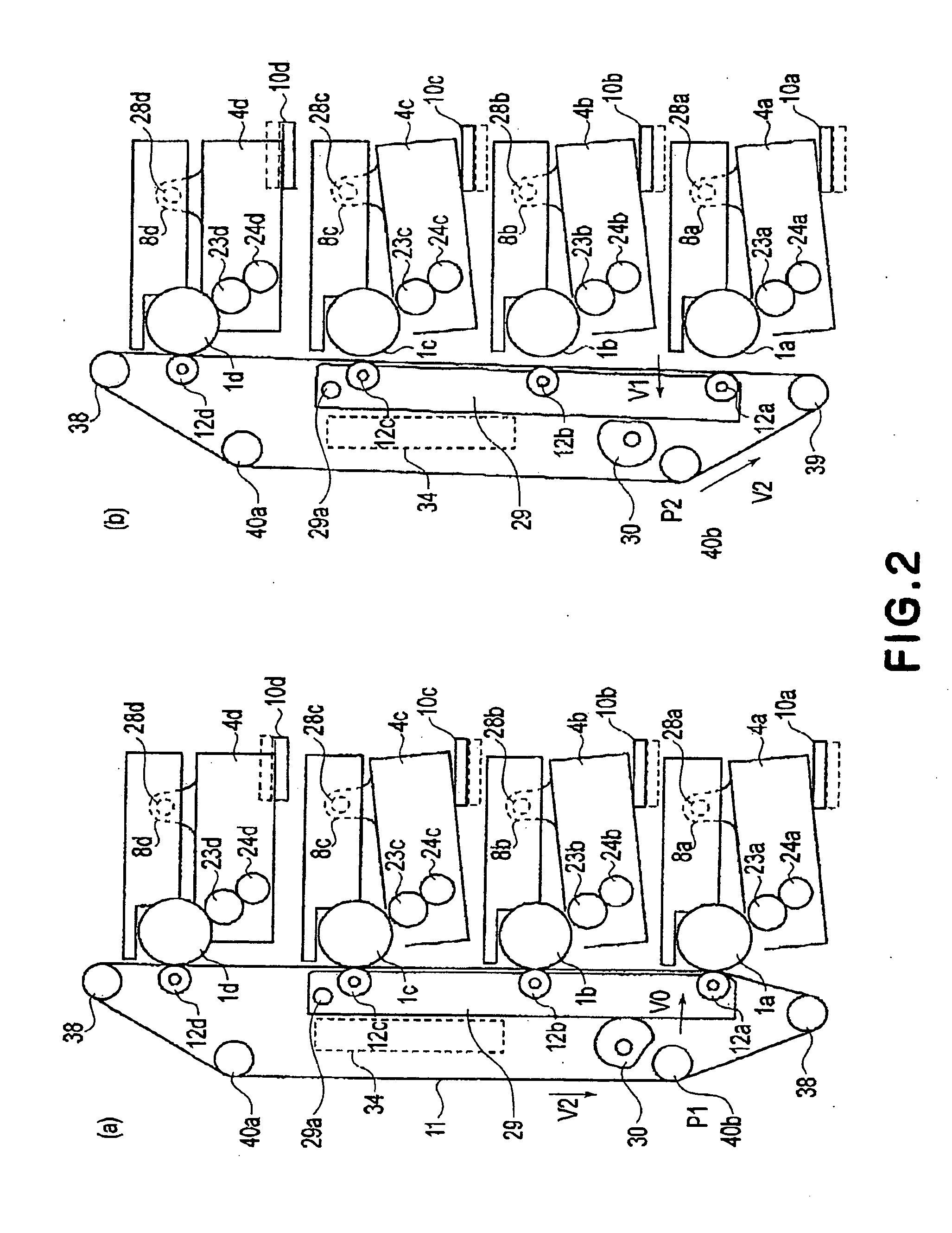

Image forming apparatus switching developing rollers of mounted process cartridges between contact and spaced states and switching the contact position of a feeding belt contactable to drums of the mounted cartridges

InactiveUS7200350B2Convey accuratelyAccurate transferElectrographic process apparatusPrintingLatent imageImage formation

A color electrophotographic image forming apparatus for forming an image on a recording material, includes (i) a mounting portion for detachably mounting process cartridges developing images with different colors and each including an electrophotographic photosensitive drum and a developing roller for developing an latent image formed on the drum, wherein roller is movable between a contact state contacting the drum and a spaced state spaced from the drum; (ii) a switching device switching the rollers between the contact and spacing states; (iii) a feeding belt for feeding the recording material along all of the drums; (iv) a controller for switching between a first monochrome mode in which the belt contacts all of the drums and a second monochrome mode in which the belt contacts only the drum of the cartridge which develops the latent image for image formation.

Owner:CANON KK

Image forming apparatus

InactiveUS20050152716A1Convey accuratelyForming accuratelyElectrographic process apparatusPrintingLatent imageTransmission belt

A color electrophotographic image forming apparatus for forming an image on a recording material, includes (i) a mounting portion for detachably mounting a plurality of process cartridges each including an electrophotographic photosensitive drum and a developing roller for developing an latent image formed on the drum, wherein developing roller is movable between a contact state where the developing roller is contacted to the drum and a spaced state where the developing roller is spaced from the drum, wherein the cartridges develop the latent images with colors different from each other; (ii) switching means for switching the developing rollers between the contact state and the spacing state when the cartridges are set in the mounting portions; (iii) a feeding belt for feeding the recording material along all of the drums of the cartridges set in the mounting portion; (iv) control means for switching, in accordance with a kind of the recording material in a monochromatic mode operation, between a first mode in which the feeding belt is placed at a first position for contacting to all of the drums of the cartridges and a second mode in which the feeding belt is placed at a second position position wherein the feeding belt contacts only the drum of the cartridge which develops the latent image for image formation, wherein in the monochromatic modes the image is formed on the recording material through development only one of the cartridges, and wherein in a cartridge in which no development is performed in the monochromatic mode, the switching means is in the spaced state.

Owner:CANON KK

Construction machine

InactiveUS7487023B2Convey accuratelyEnsure safetyAnalogue computers for vehiclesAnalogue computers for trafficDisplay deviceEngineering

In a hybrid construction machine, its display device displays, toward an operator, an artificial engine sound serving as load information according to a magnitude of a workload, instead of an engine sound. Furthermore, the display device issues an alarm sound to surrounding workers when performing an operation by only stored electrical power of an electrical energy storage device without using an engine. In this hybrid construction machine, in addition to the issuing of alarm from the display device during the operation without using the engine, the display device issues an advance notice sound for engine restart when at least one value out of the workload and a charge amount of the electrical energy storage device has become an advance notice set value close to a set value of engine restart.

Owner:KOBELCO CONSTR MASCH CO LTD

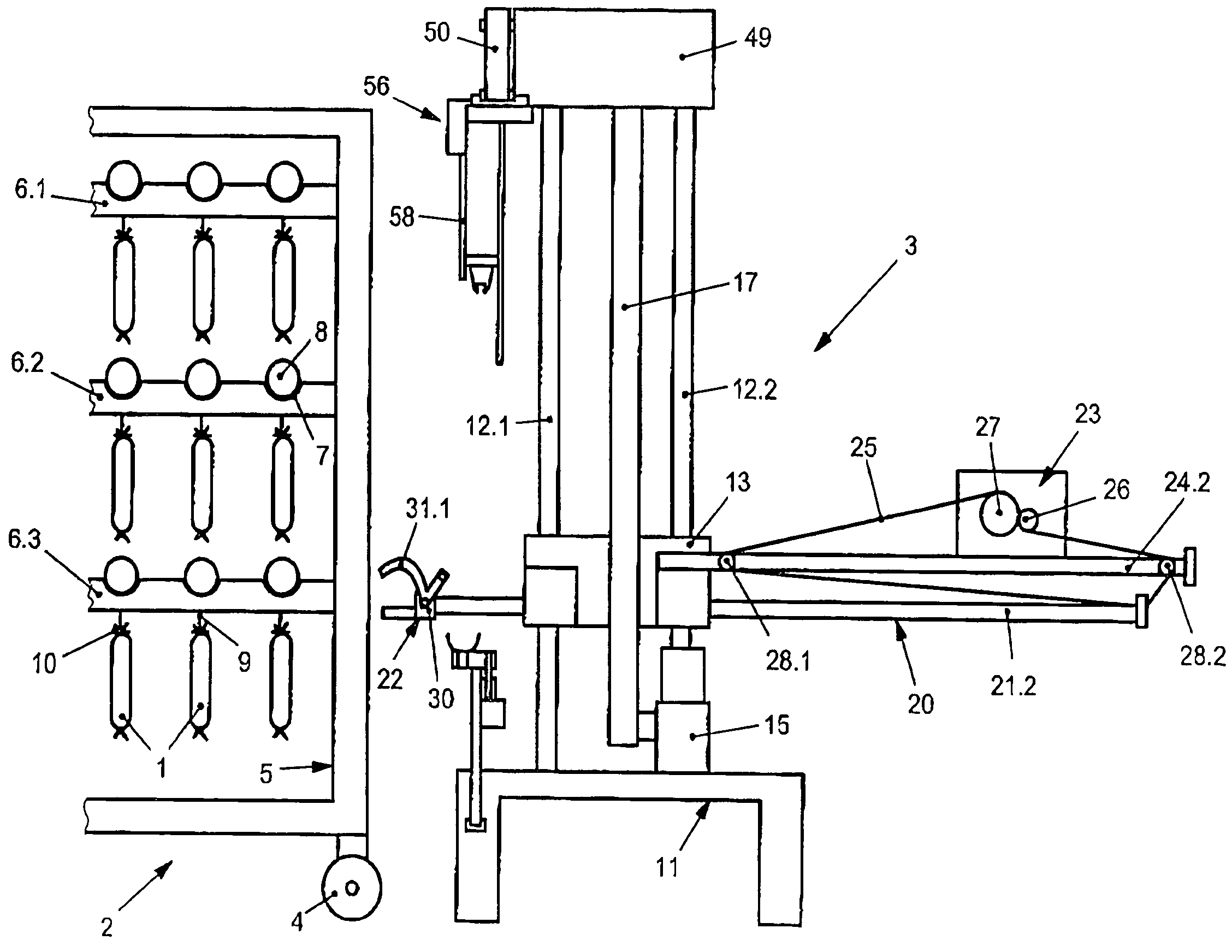

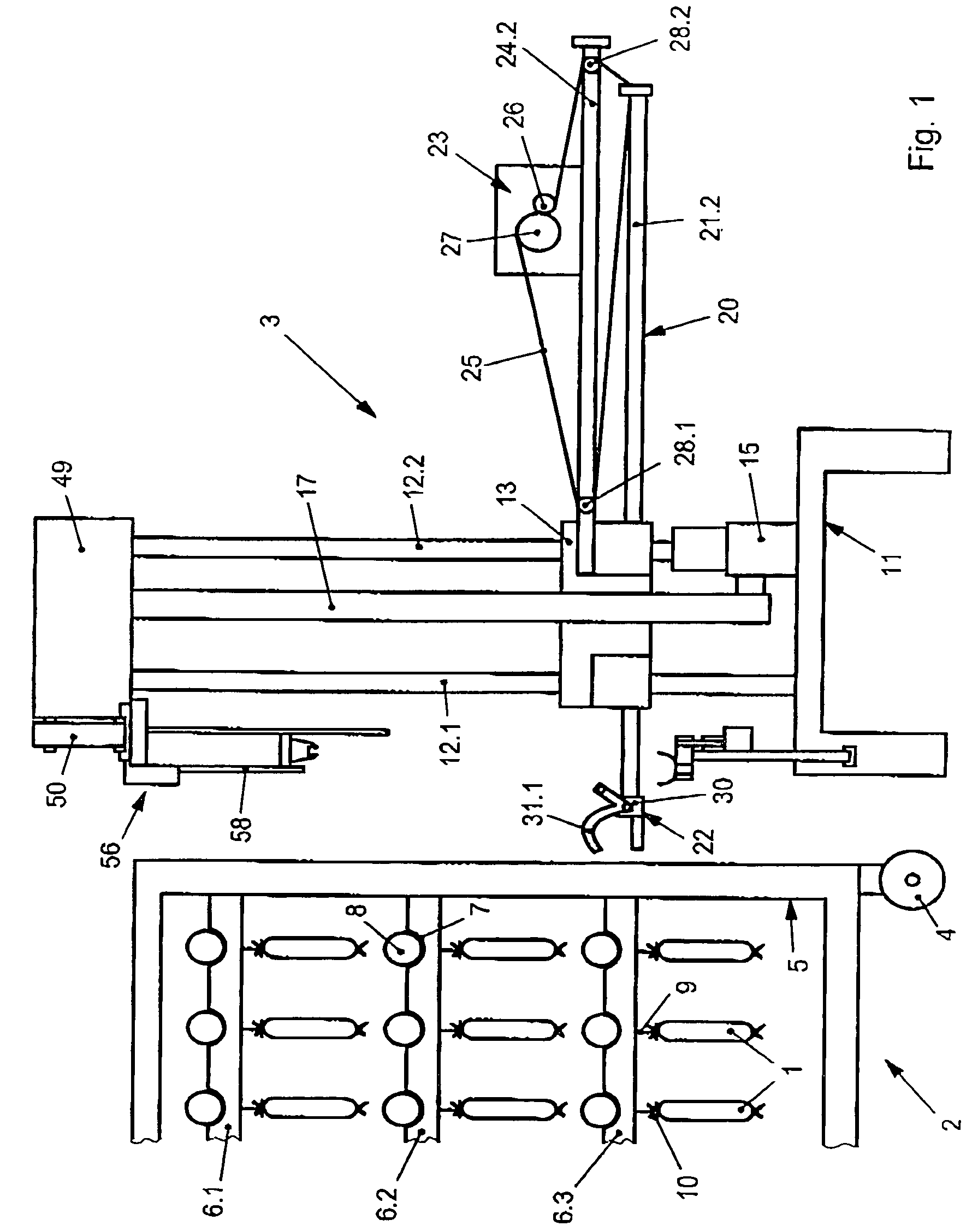

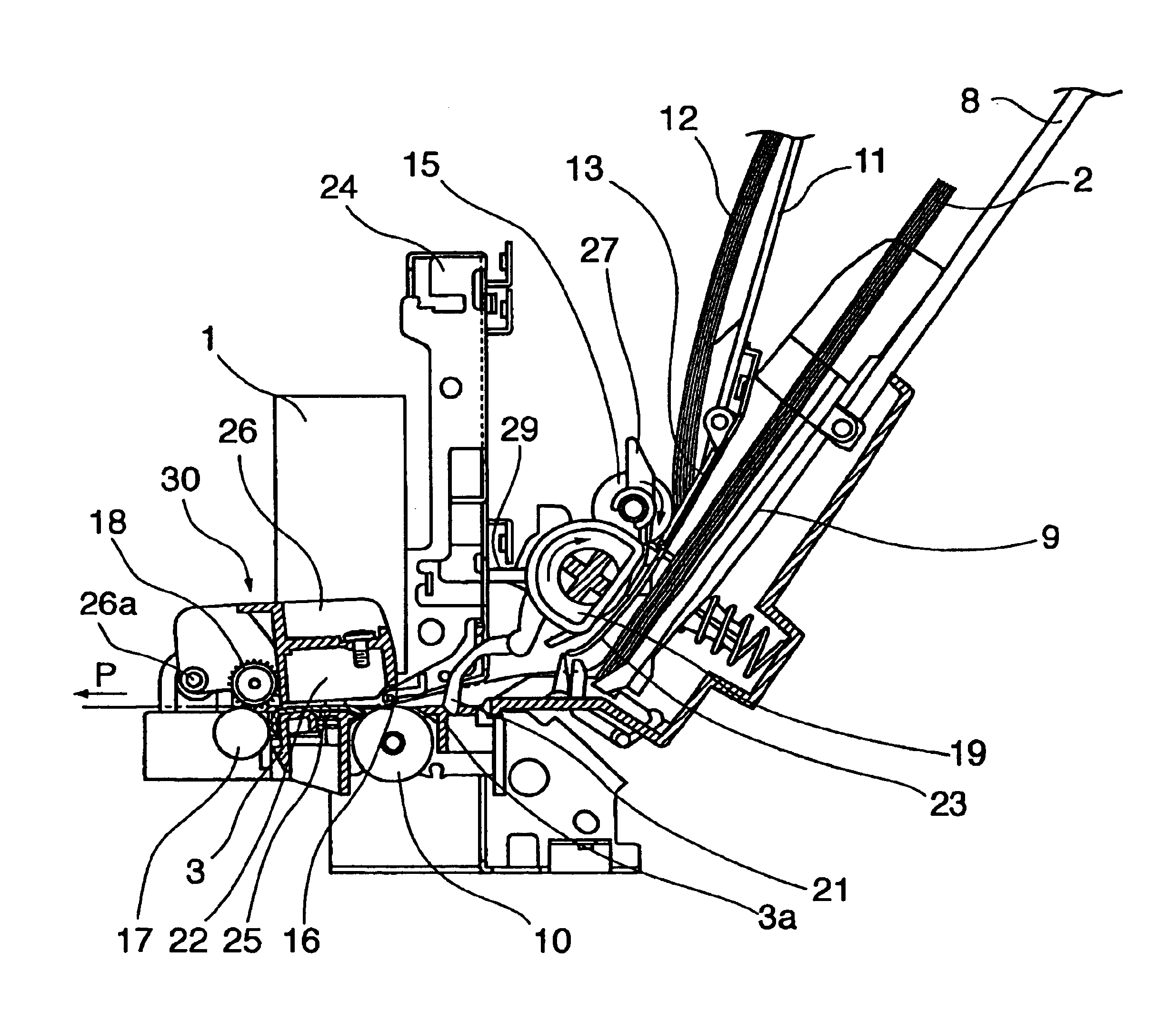

Handling system for sausages

A handling system for sausages (1) wherein sausages are suspended on strings (9), on carriers in a supporting frame for handling sausages (1) on smoke sticks (8), wherein the supporting frame (2) includes a handling device (3) with a gripping device for removing the carriers from and / or inserting the carriers into the supporting frame (2).

Owner:STIMPFL CHRISTOF

Paper supply mechanism and roll paper printer

ActiveUS20090114758A1Easily moved widthwiseIncrease loadProjector film strip handlingCamera film strip handlingRolling paperLocking mechanism

Owner:SEIKO EPSON CORP

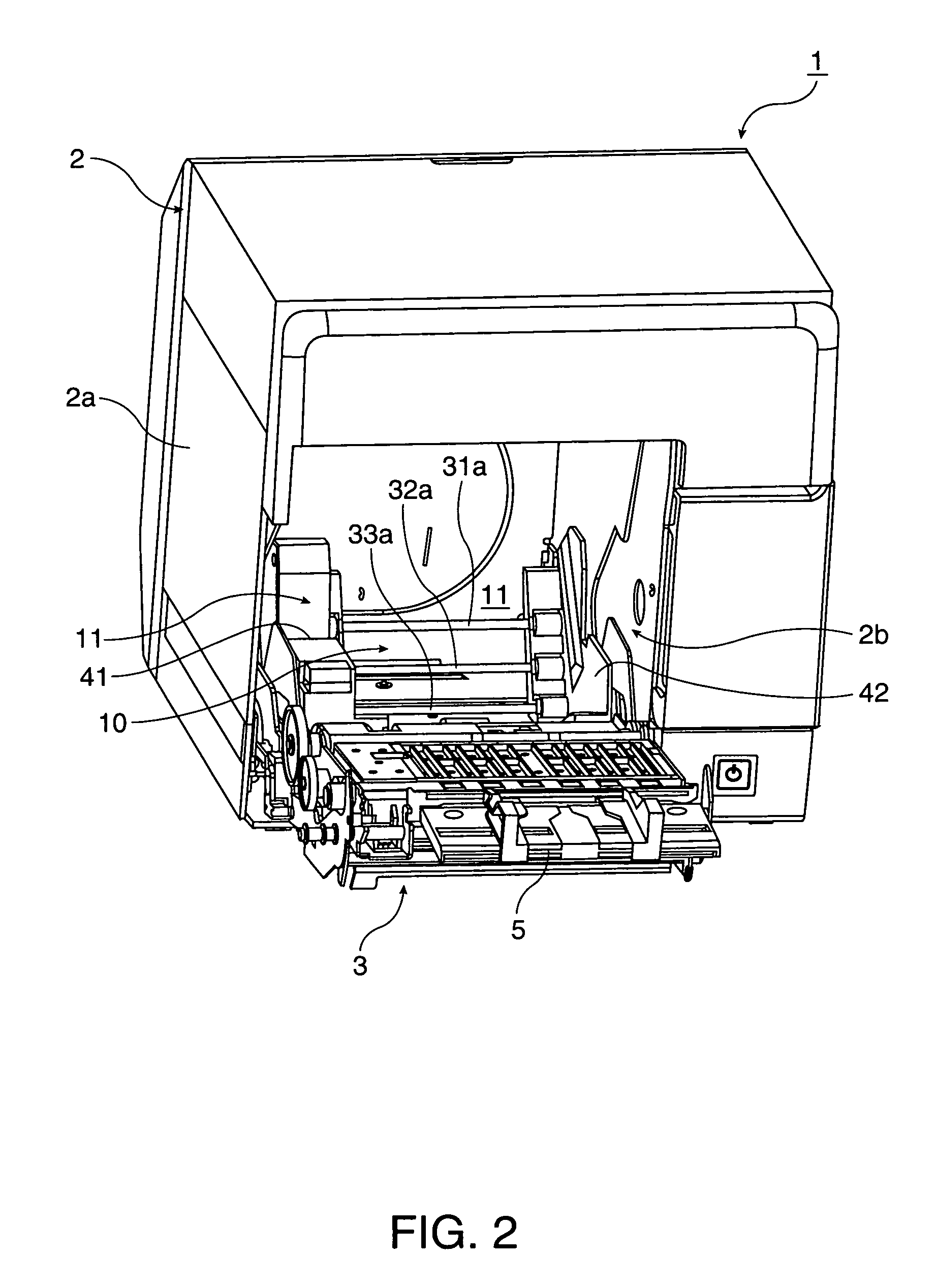

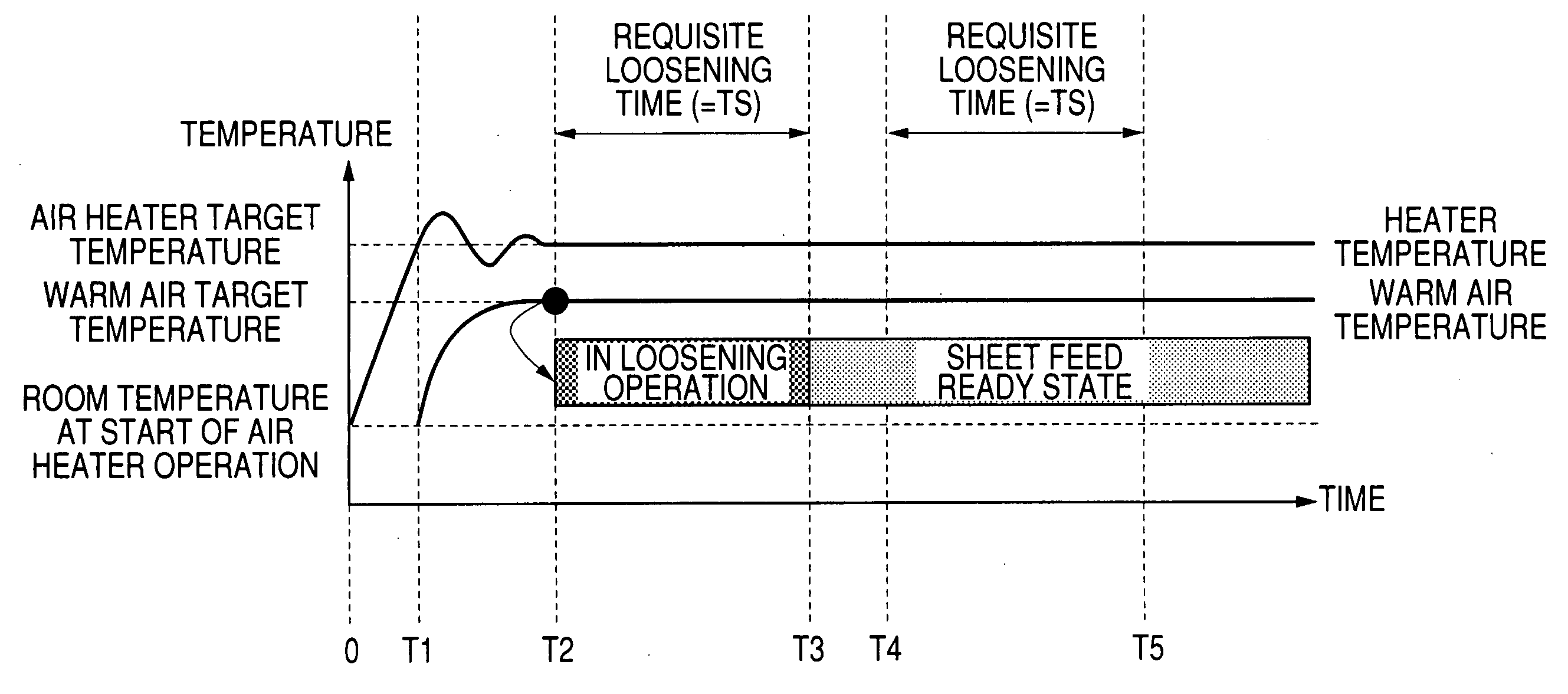

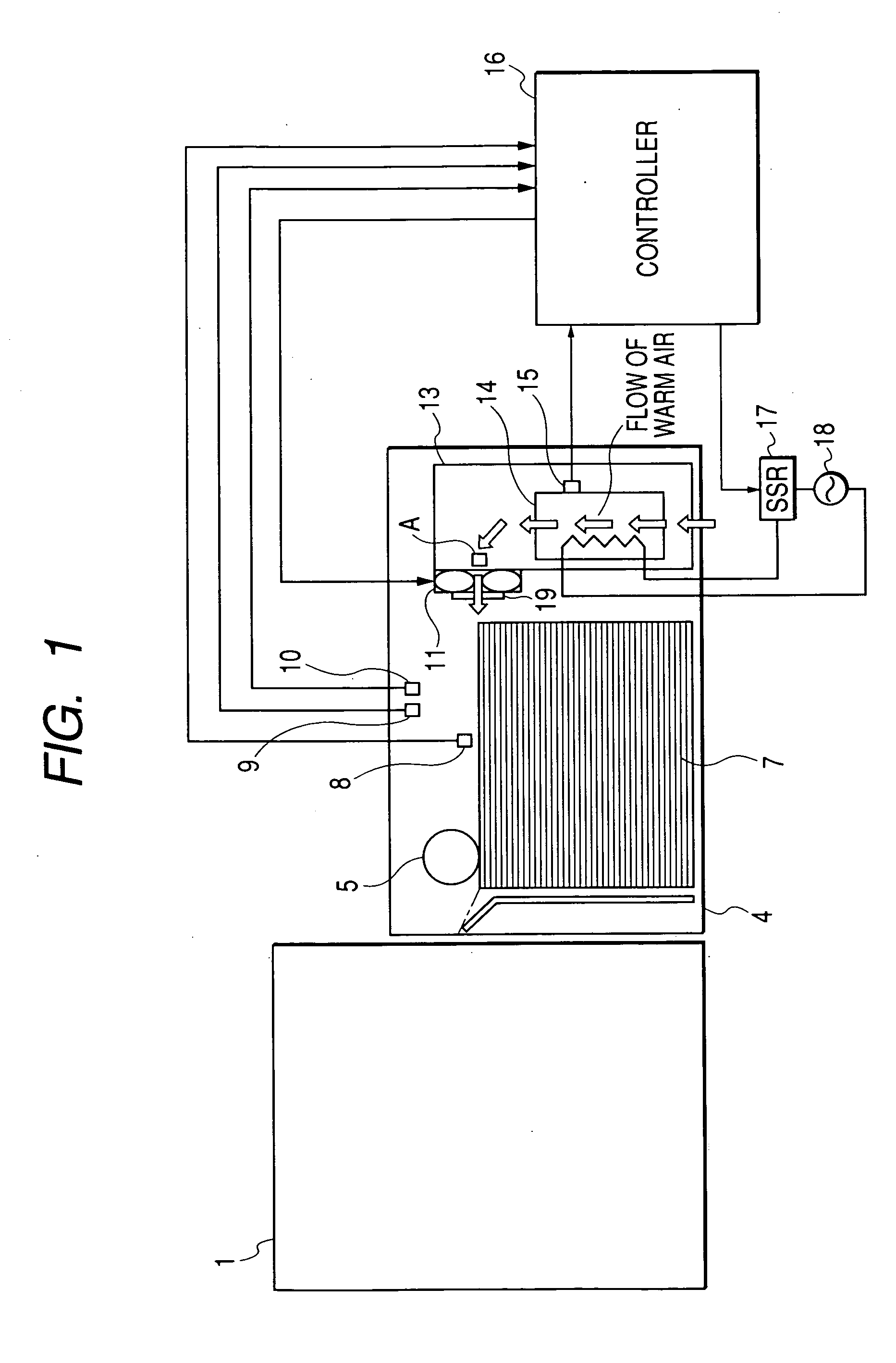

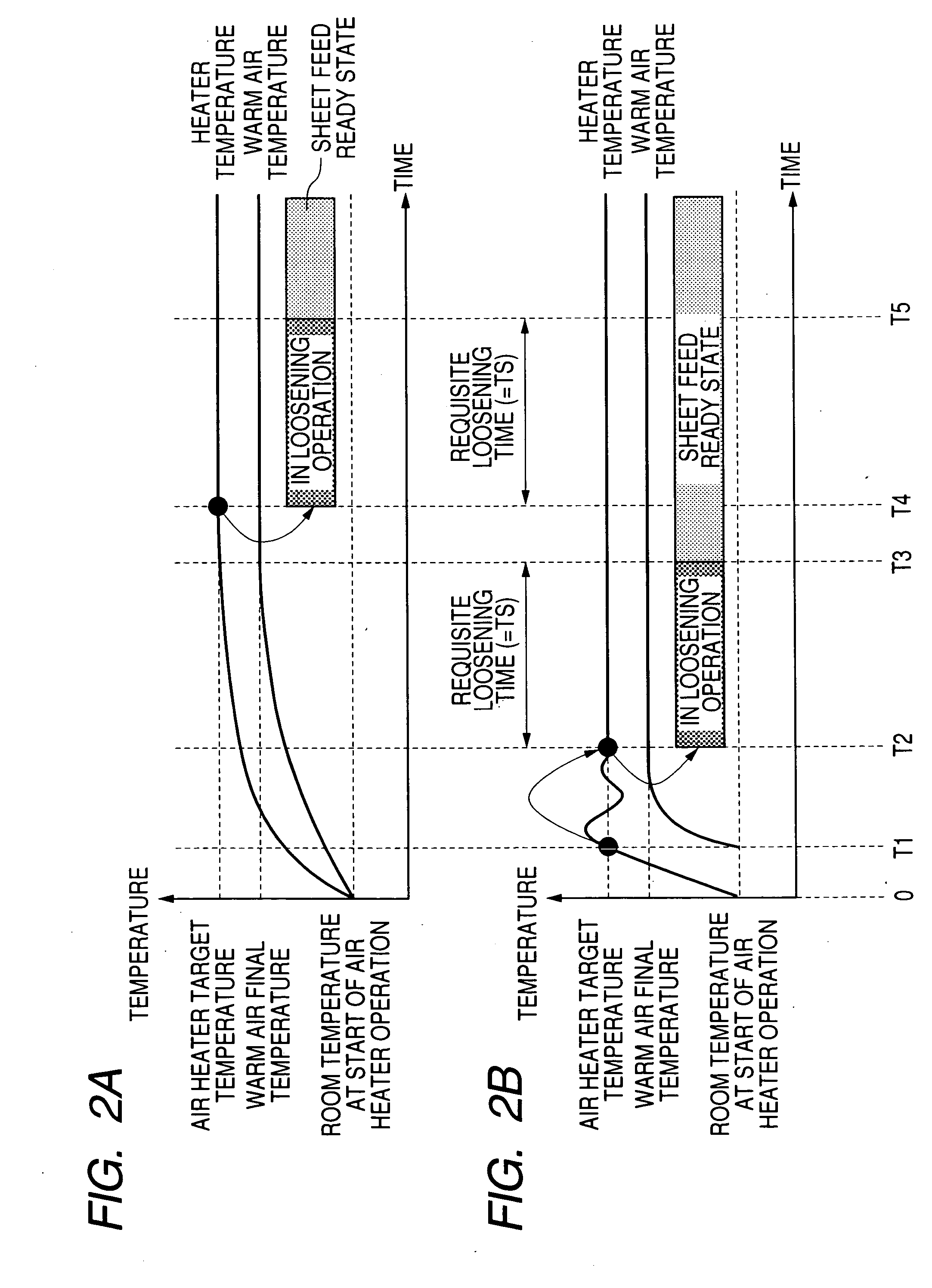

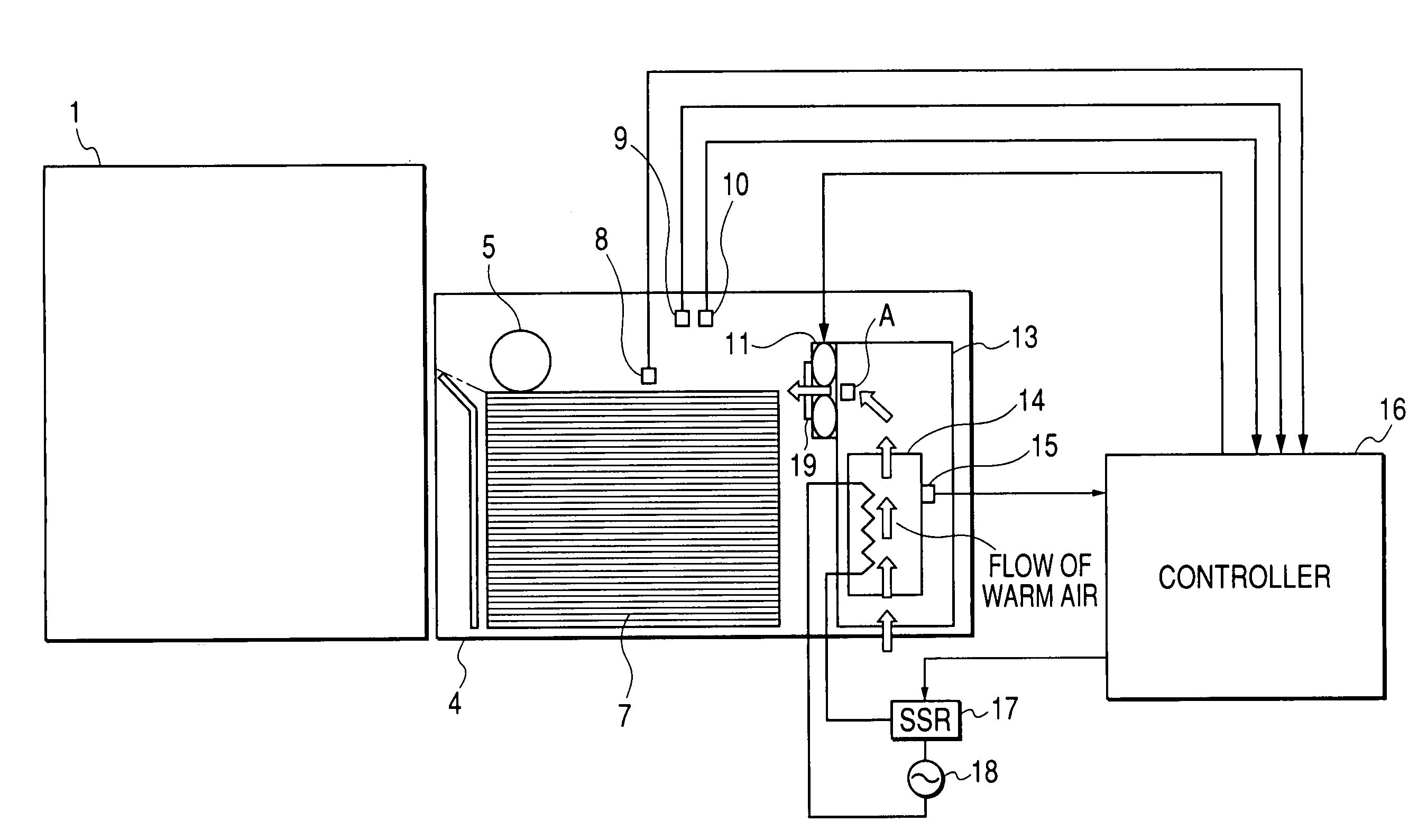

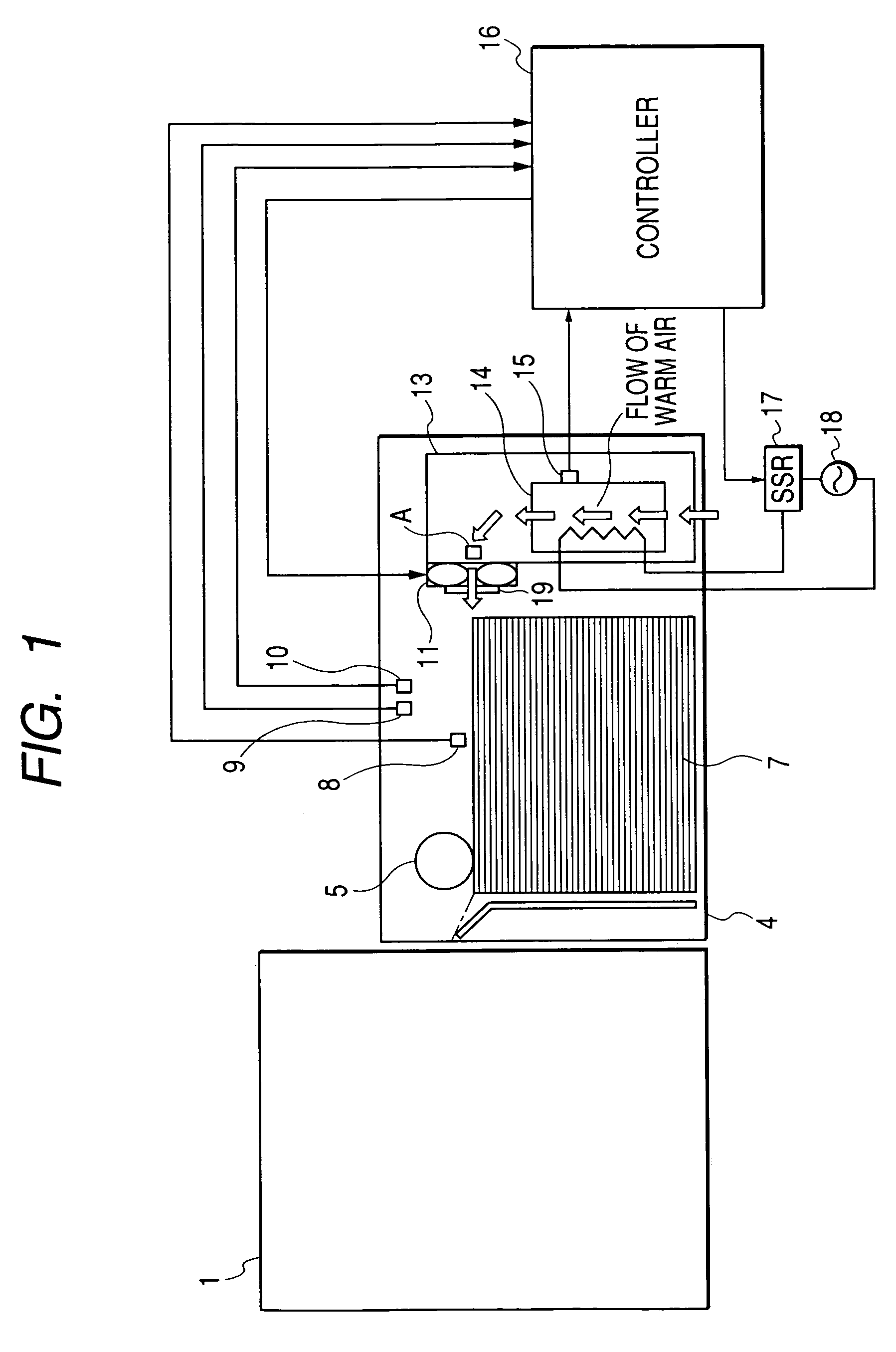

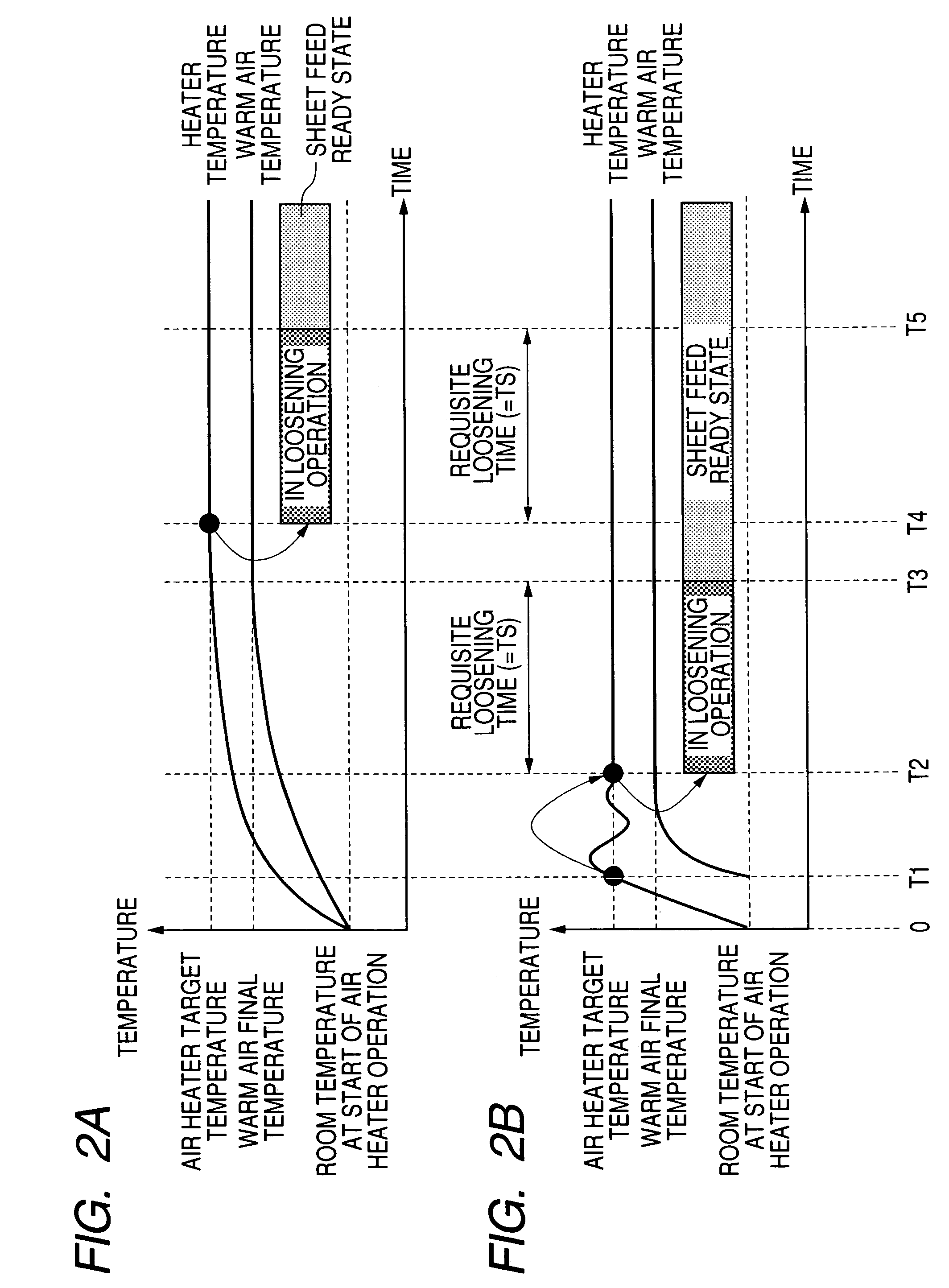

Sheet feeding apparatus

InactiveUS20050063023A1Eliminate inconvenienceQuickly and reliably effect loosening of sheetElectrographic process apparatusArticle feedersTemperature controlElectrical and Electronics engineering

A sheet feeding apparatus including a stacking portion for stacking a plurality of sheets thereon, a sheet feeding portion for feeding the sheets stacked on the stacking portion, a fan for sending air to the sheets to loosen the sheets stacked on the stacking portion, a heater for warming the air sent by the fan, a temperature detecting portion for detecting the temperature of the heater, and a control portion for starting the driving of the fan in conformity with the temperature detecting portion having detected a predetermined temperature after temperature control for adjusting the heater to a target temperature has been started.

Owner:CANON KK

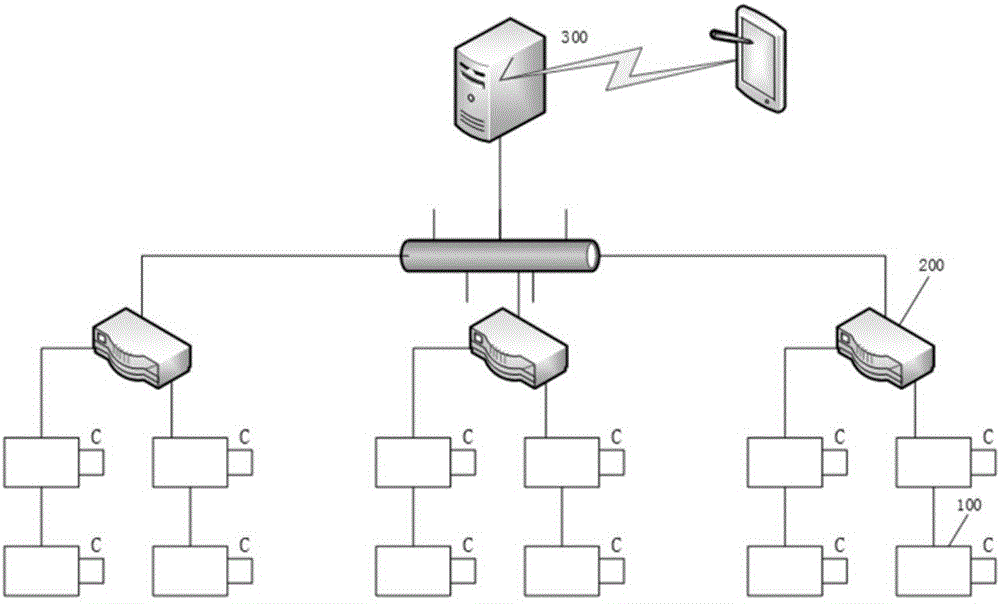

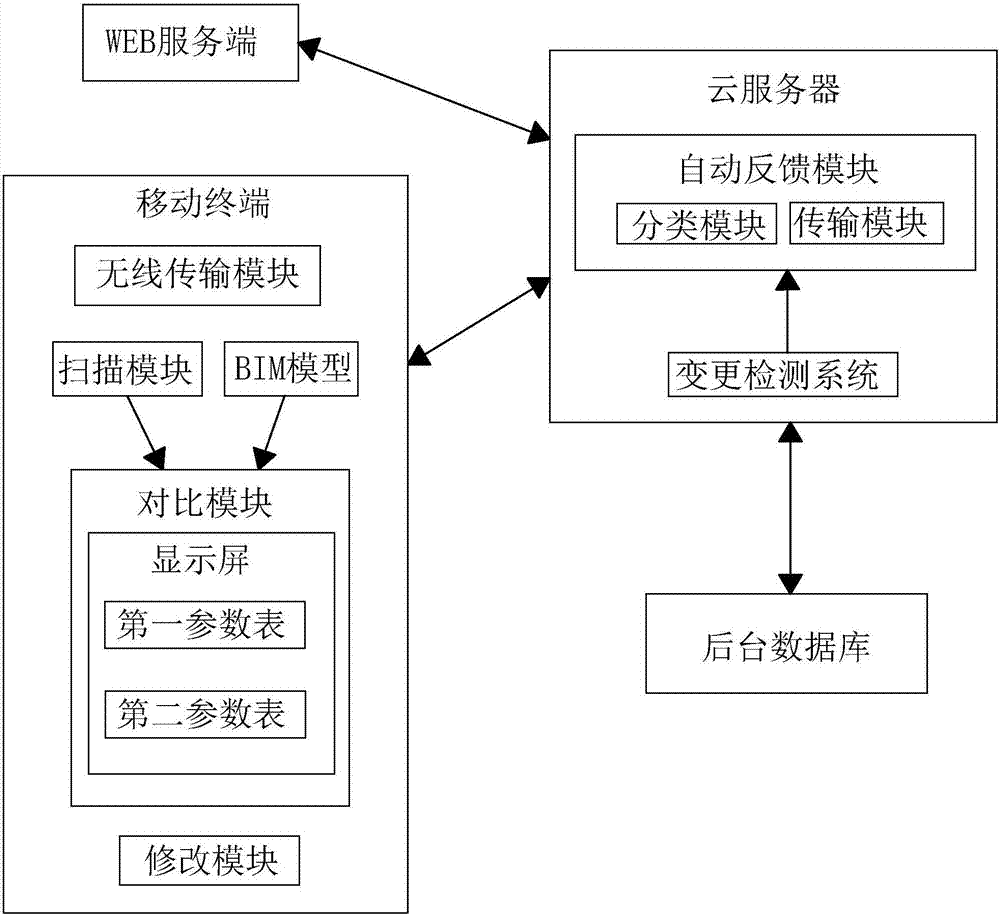

BIM based project supervision information management system

InactiveCN107516165AEasy to understandImprove communication efficiencyOffice automationResourcesWireless transmissionWeb service

The invention relates to a BIM based project supervision information management system. The system includes a background database, a cloud server, a WEB service terminal and a mobile terminal. The mobile terminal also includes a wireless transmission module, a scanning module and a comparison module. The comparison module is connected with the scanning module and the wireless transmission module and is used for determining difference between practical working conditions and a BIM model through comparison and transmitting the field working conditions to the cloud server through the wireless transmission module when the difference between the practical working conditions and the BIM model is greater than a preset numerical value. The system has beneficial effects that the field working conditions can be reflected at any time and in any place by a worker during a working process by utilizing a mobile terminal, so that information communication efficiency is improved and different departments can know dynamic information timely. At the same time, understanding is facilitated through combination of the field working conditions and the BIM model.

Owner:南通市交通建设咨询监理有限公司

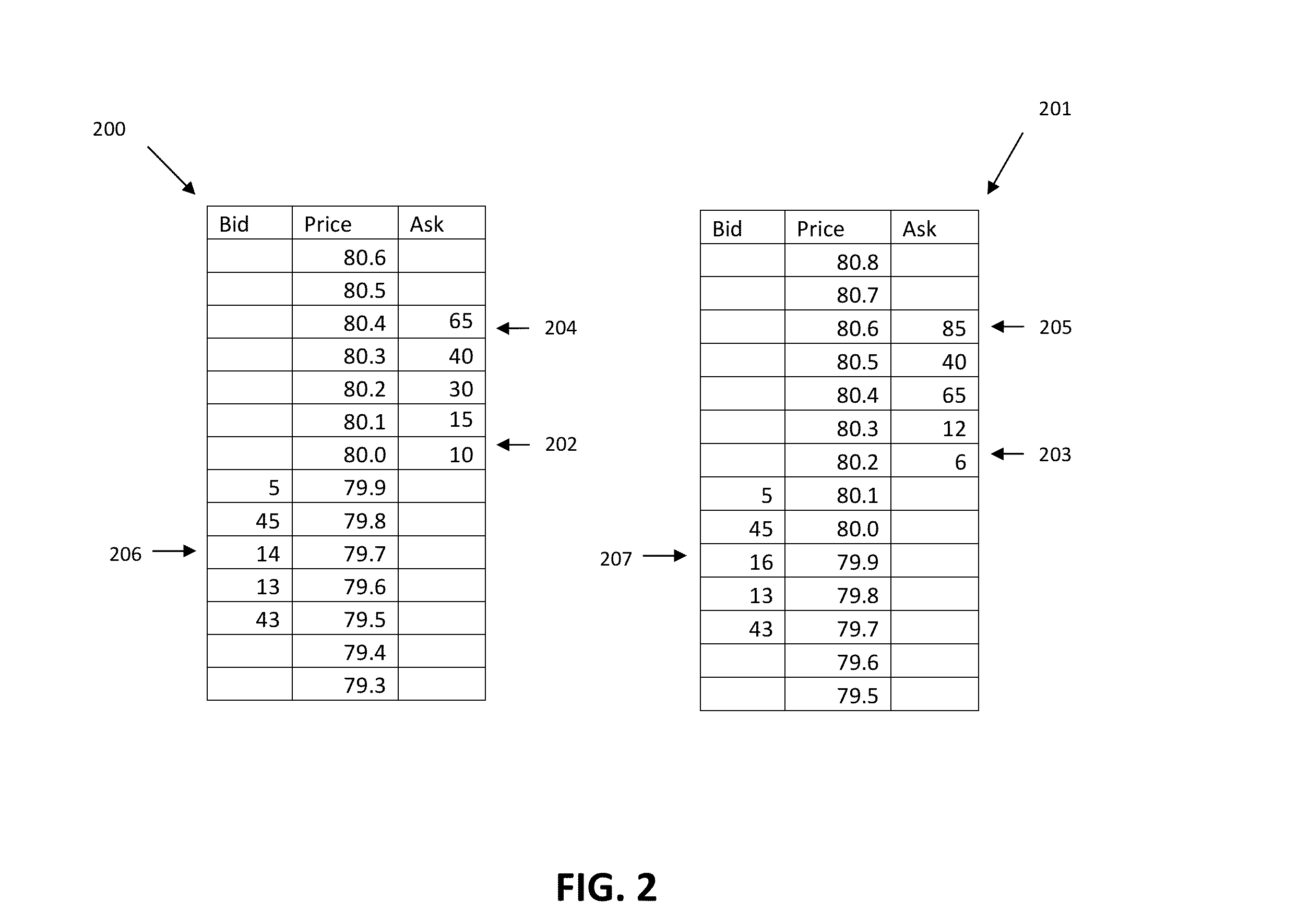

System and methods for analyzing, computing and displaying depth of market volume strength

InactiveUS20130066803A1Improve abilitiesConvey accuratelyFinanceData miningUltimate tensile strength

Owner:WORLIKAR MANISH PRAMOD

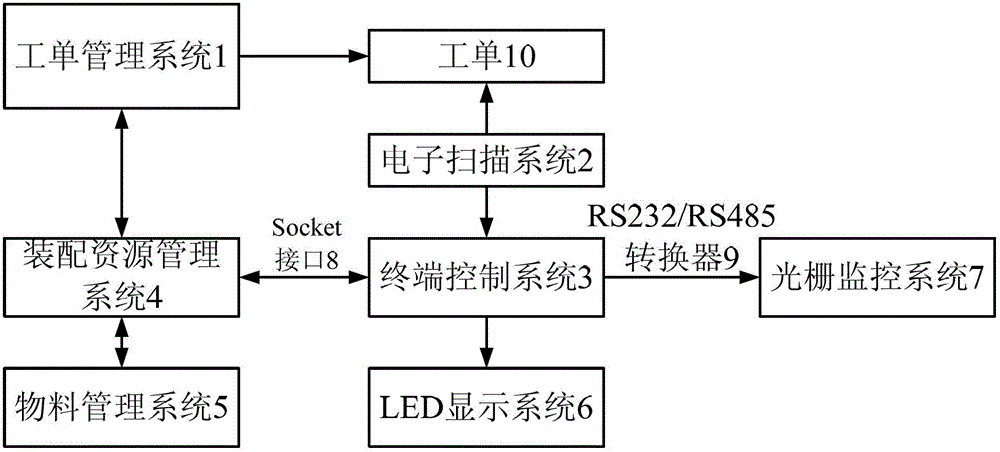

Misassembly preventive system for electrical product assembly

ActiveCN102723243AReduce the possibility of errorConvey accuratelyEmergency protective device manufactureGratingLED display

The invention discloses a misassembly preventive system for electrical product assembly. A work order management system generates and prints a work order according to an assembly plan, an electronic scanning system scans bar code information on the work order and transmits the bar code information to a terminal control system, the terminal control system transmits the bar code information to a material management system through an assembly resource management system, the material management system inquires all material information related to the work order and transmits the material information to the terminal control system through the assembly resource management system, the terminal control system enables material list information to be displayed on an LED display system and synchronously transmits the material list information to a grating monitoring system, and the grating monitoring system detects whether workers take materials from correct material cabinets or not, and if not, alarms and displays. Relationships between materials and assembly products are established by the work order management system, assembly workers learn materials needed for assembly by scanning the work order and monitor by utilizing gratings on material shelves, and accordingly problems of neglected assembly, misassembly of electrical products and the like are effectively solved.

Owner:SHANGHAI JIAO TONG UNIV

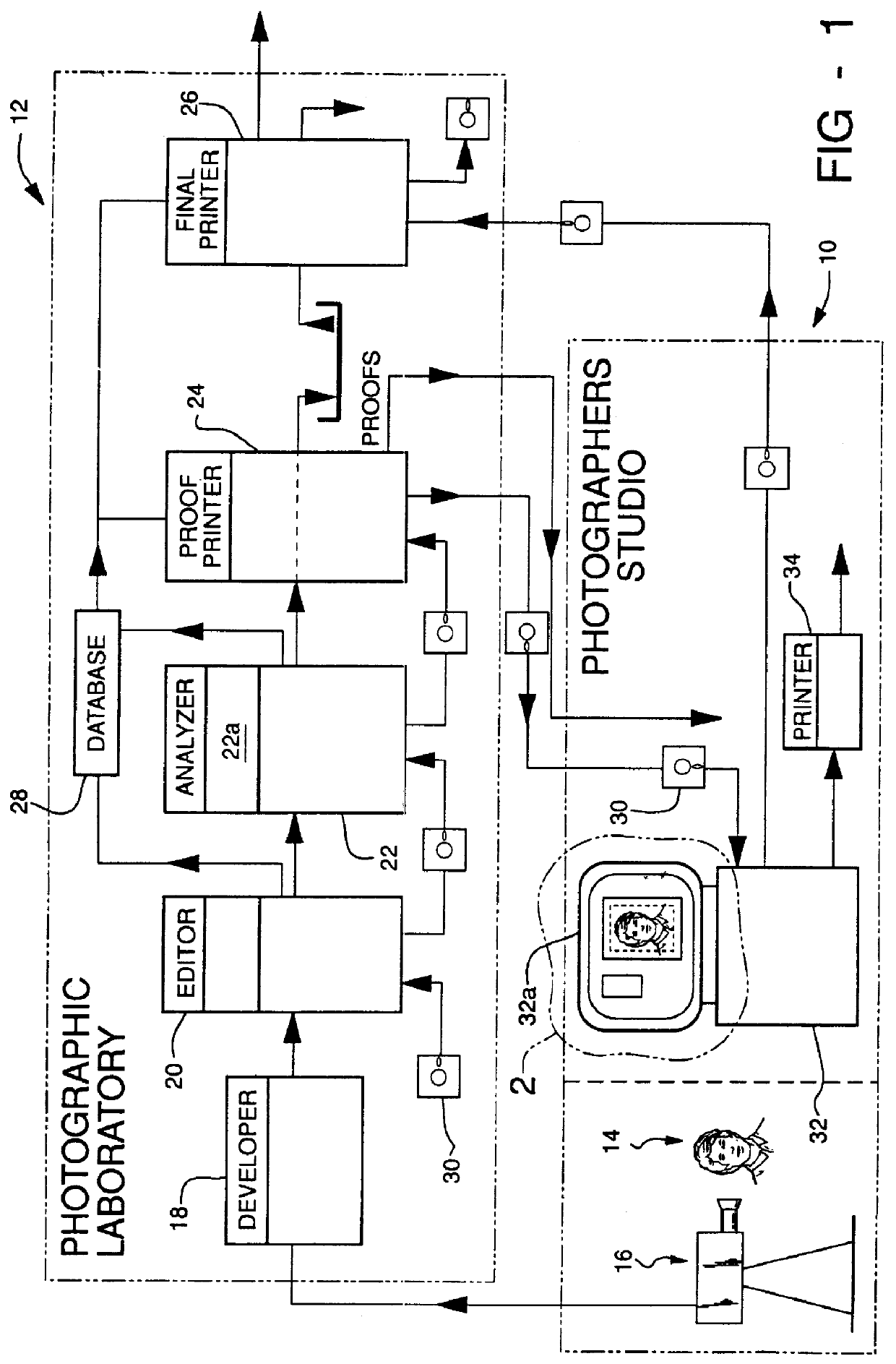

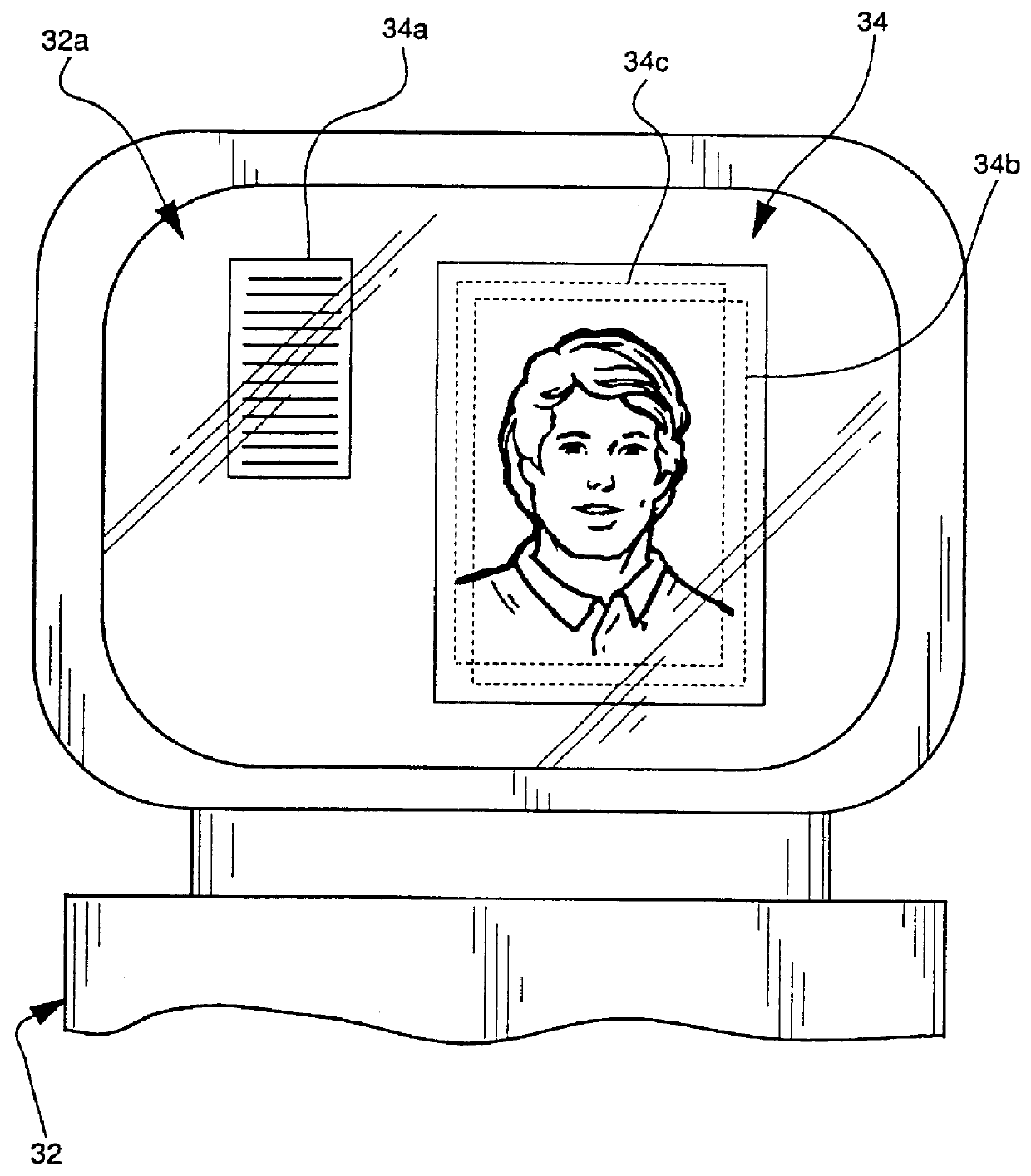

Method of producing photographic prints

InactiveUSRE36535E1Easy to manufactureConvey accuratelyPhotography auxillary processesPhotoprinting processesGraphicsComputer monitor

A methodology for handling photographic film in which a video image of each frame of film is acquired on a diskette as the frames are originally being processed in the photographic laboratory, the diskette is transmitted to the photographer's studio, along with the proof prints, for viewing by the photographer / subject, the photographer / subject makes further desired corrections or adjustments of each frame by viewing the video image of each frame on a computer monitor, the farther corrections or adjustments are recorded on the diskette for each frame, and the revised diskette is returned to the photographic laboratory where it is used in conjunction with the film to produce final photographic prints. The final photographic prints thus graphically and objectively reflect the precise desires of the photographer / subject.

Owner:KODAK ALARIS INC

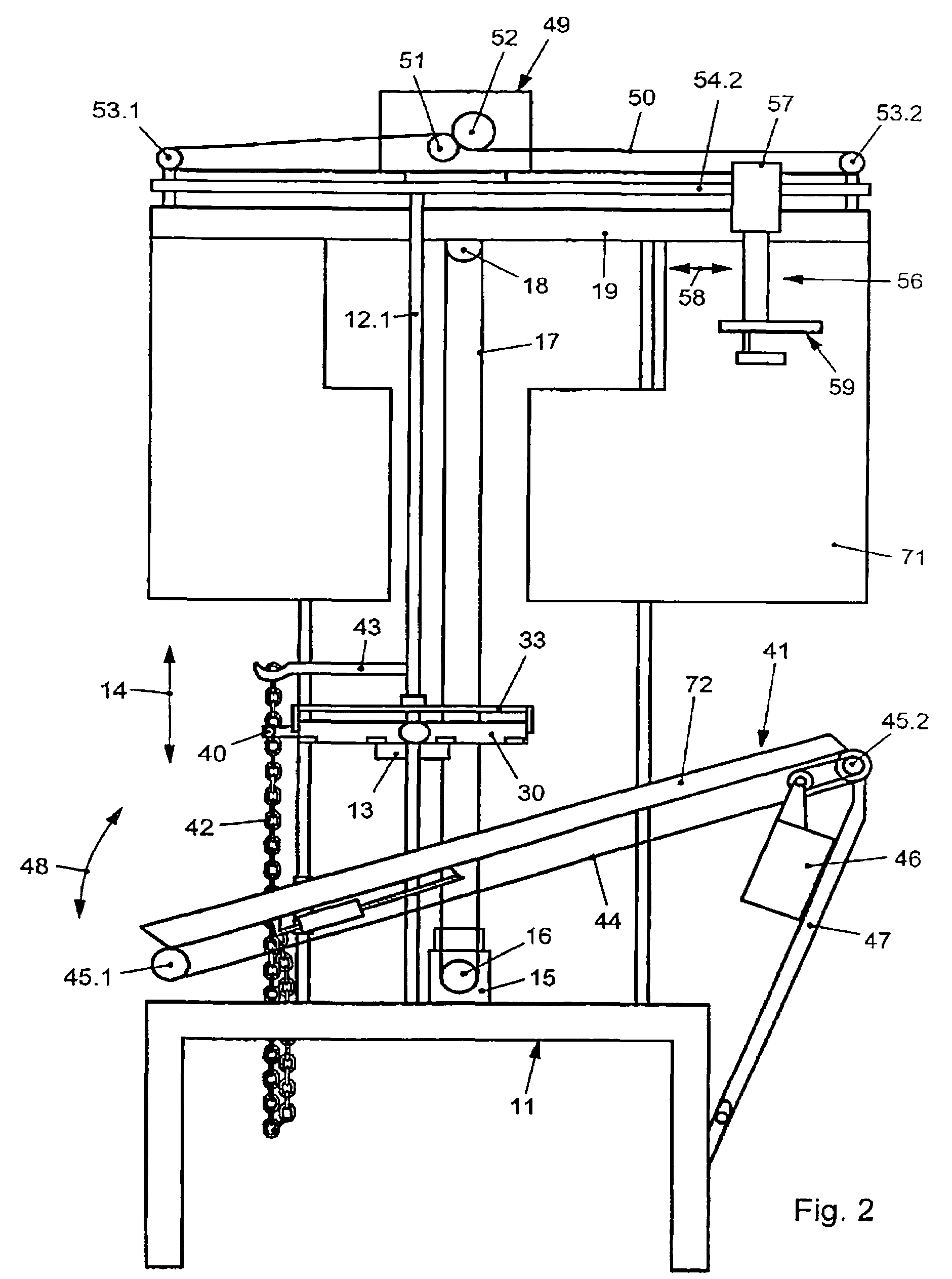

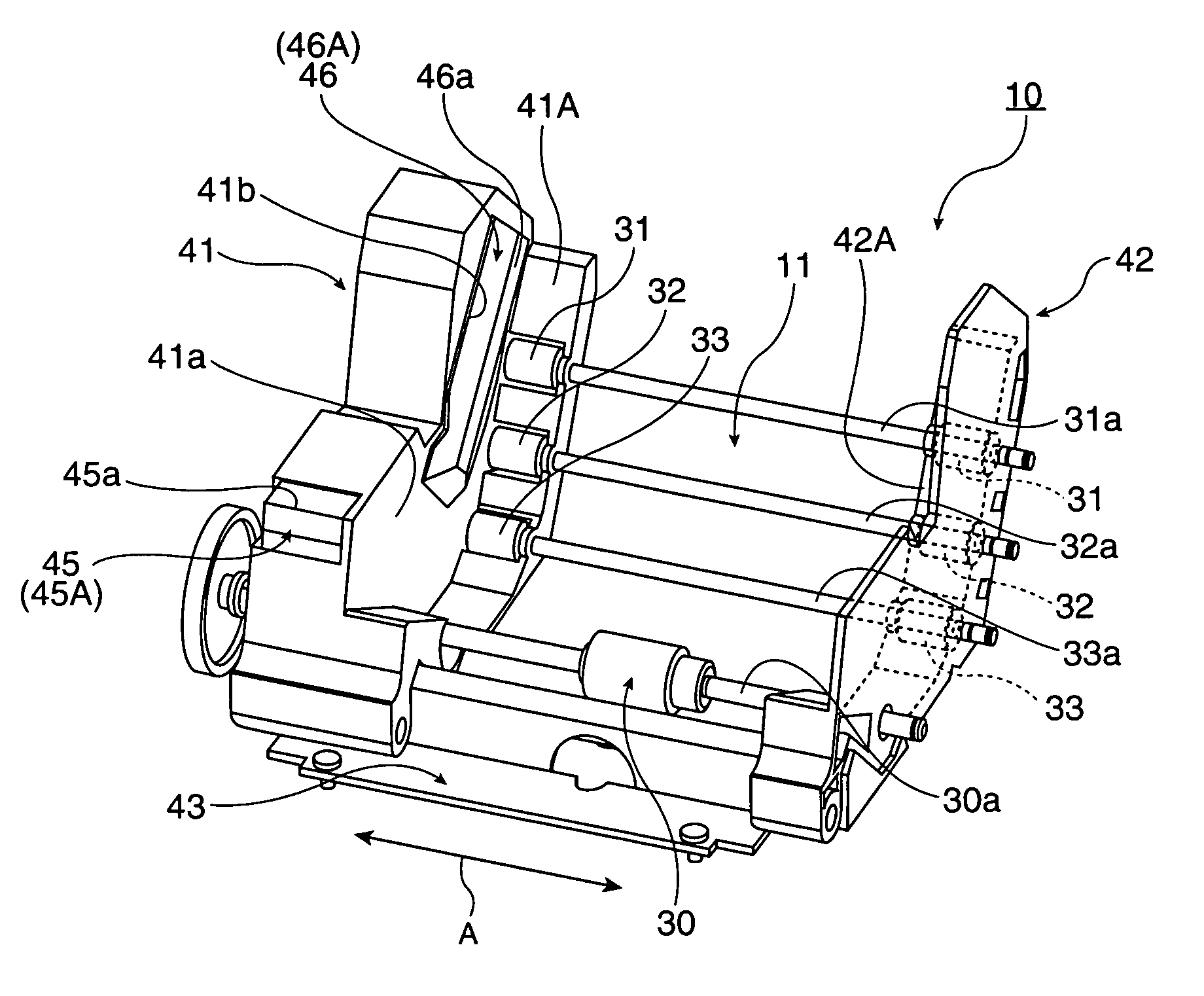

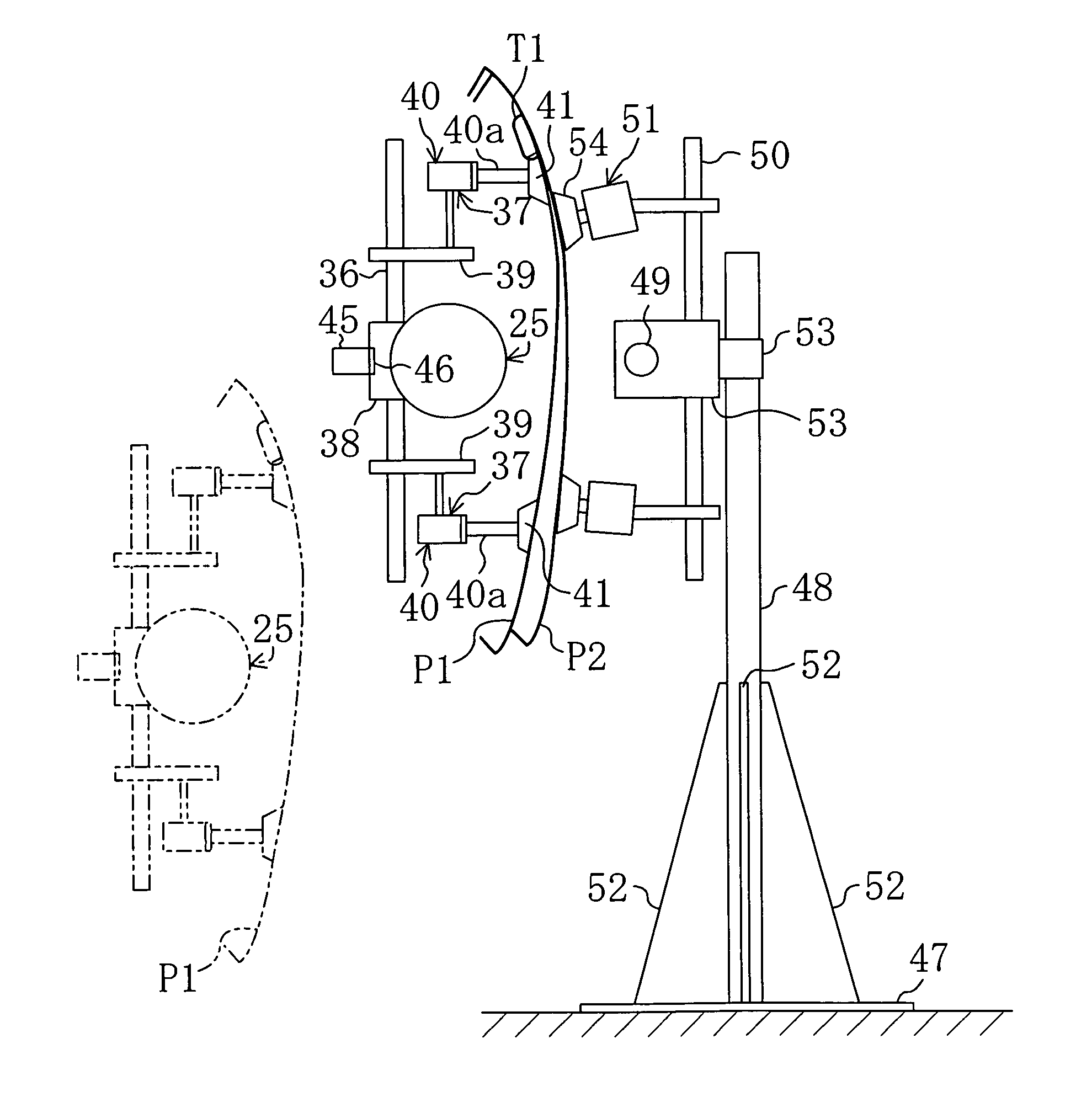

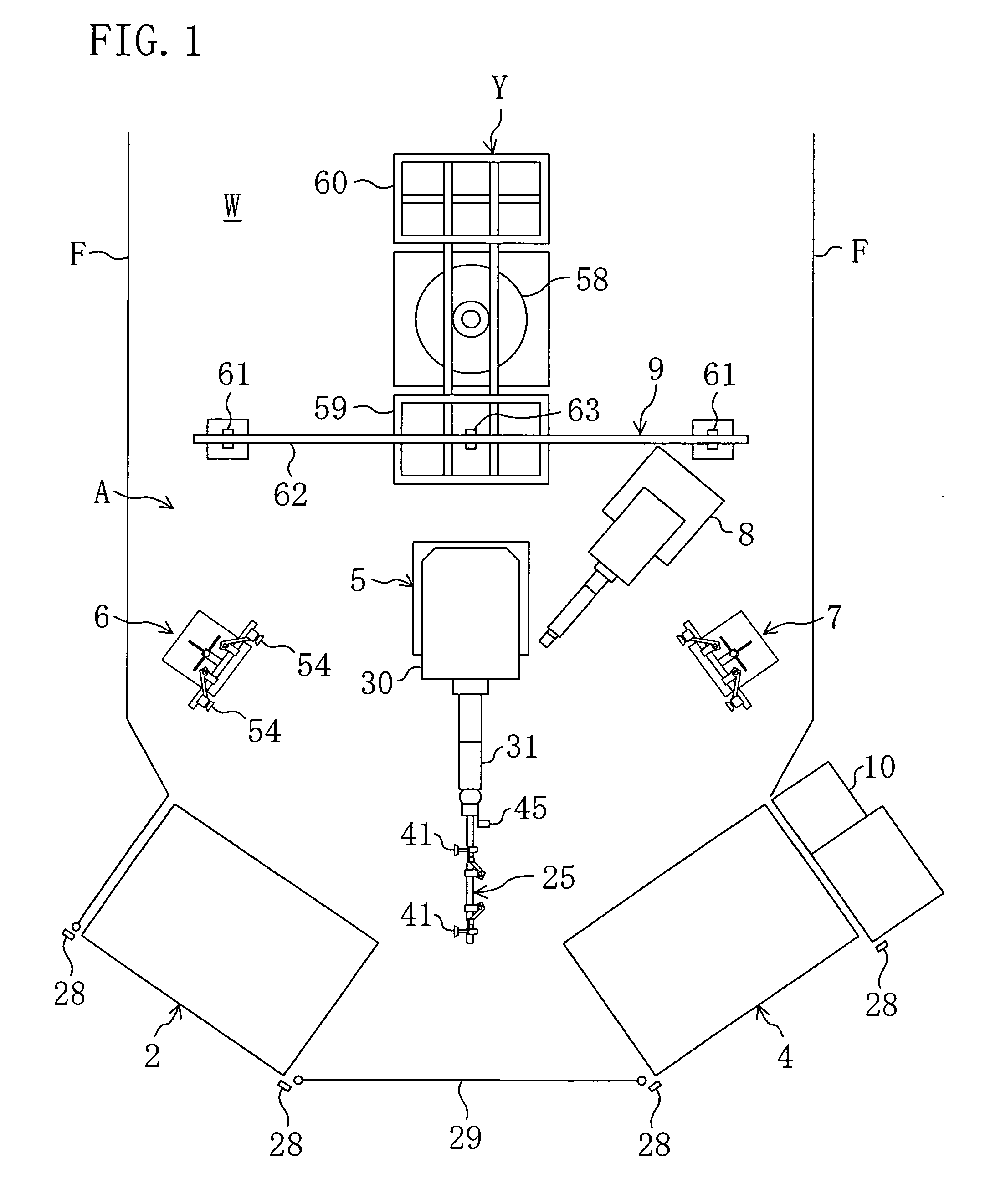

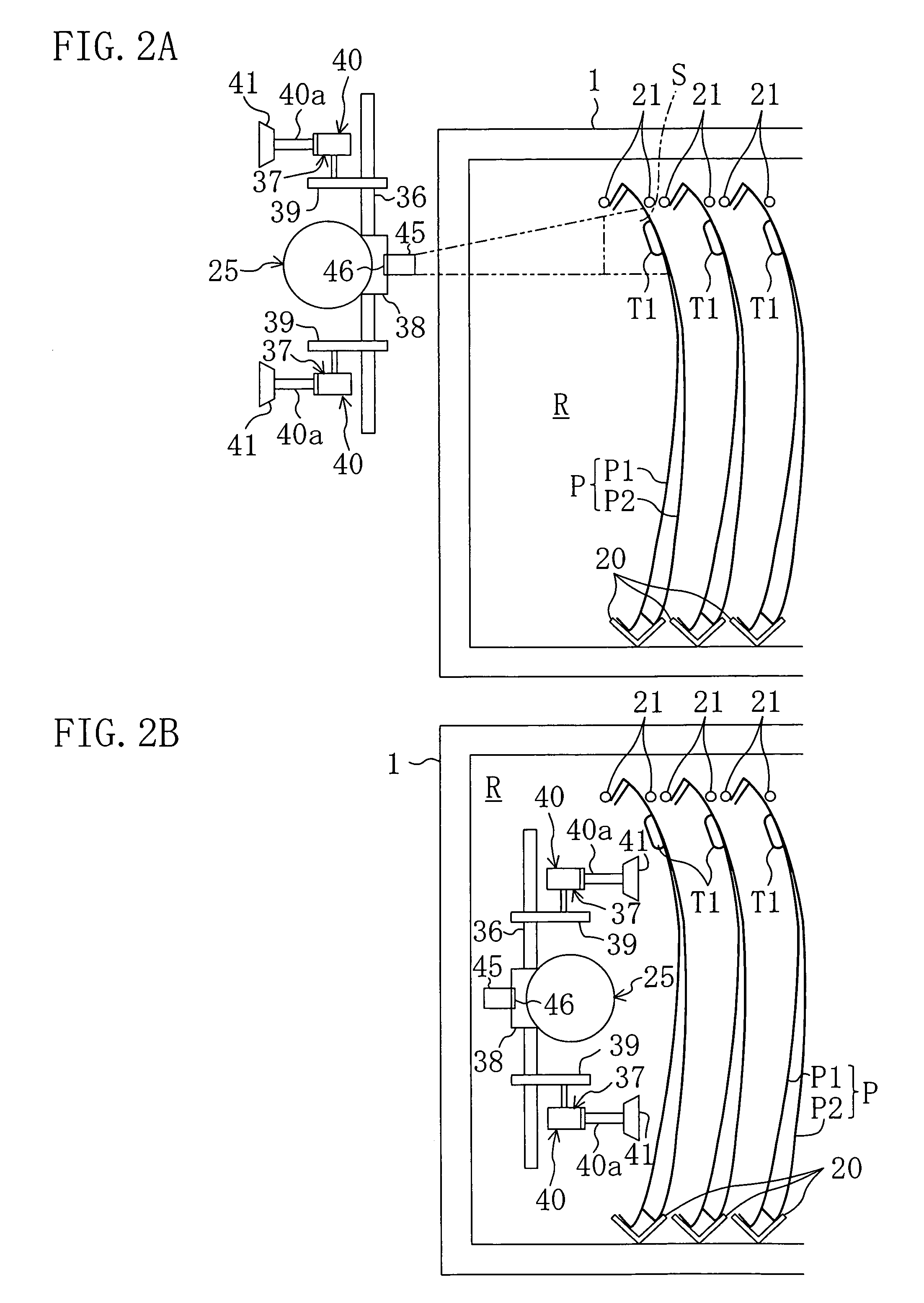

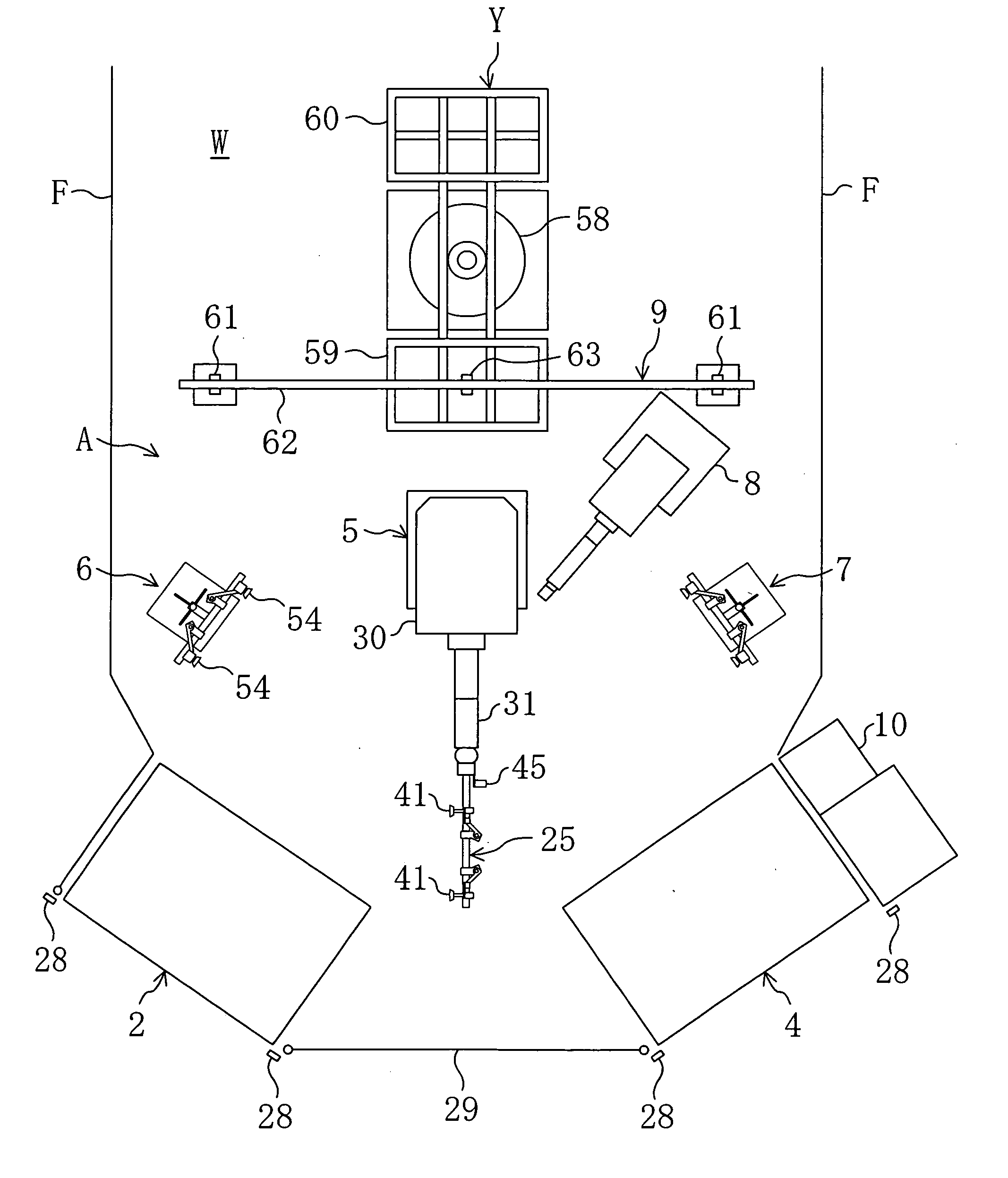

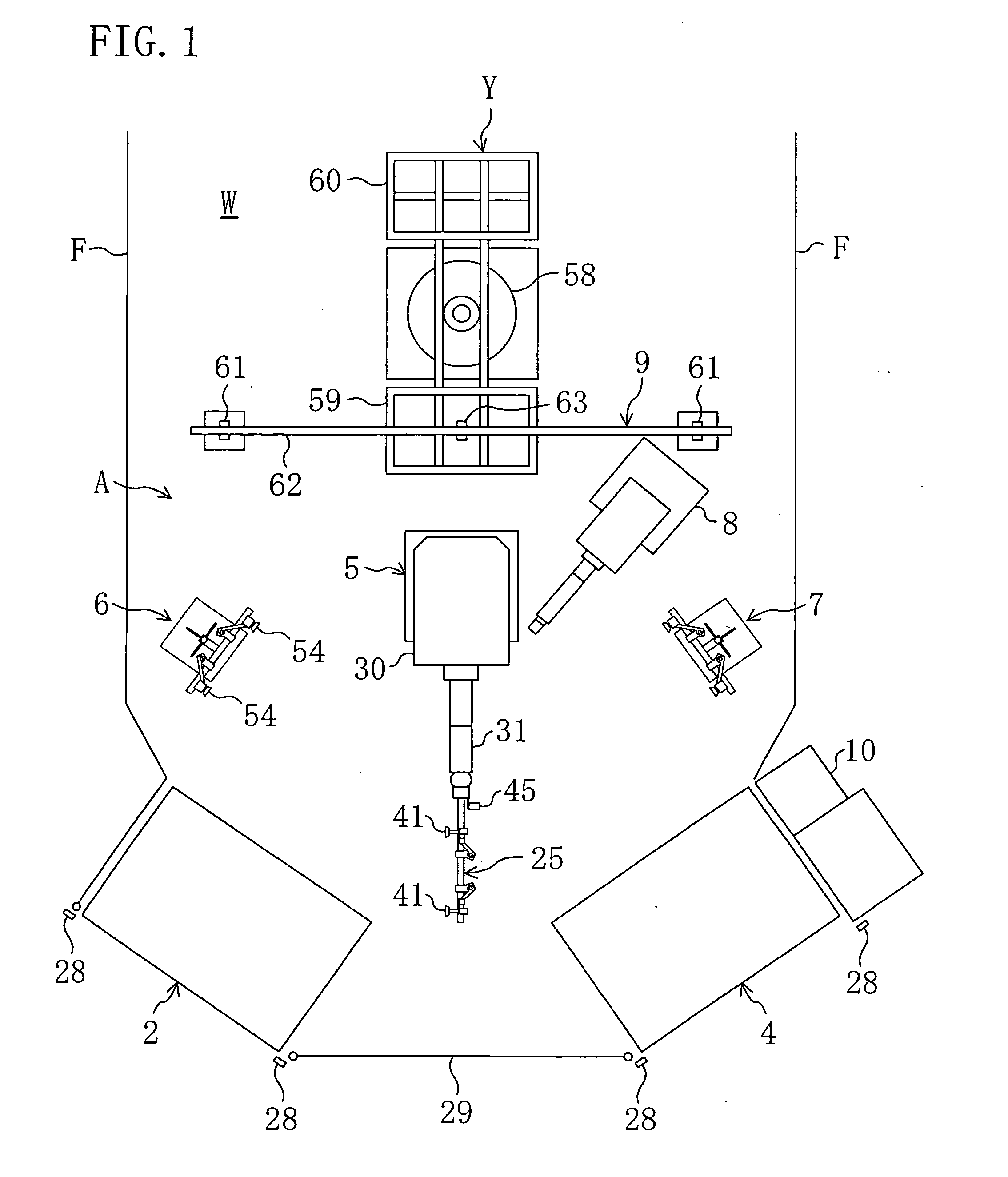

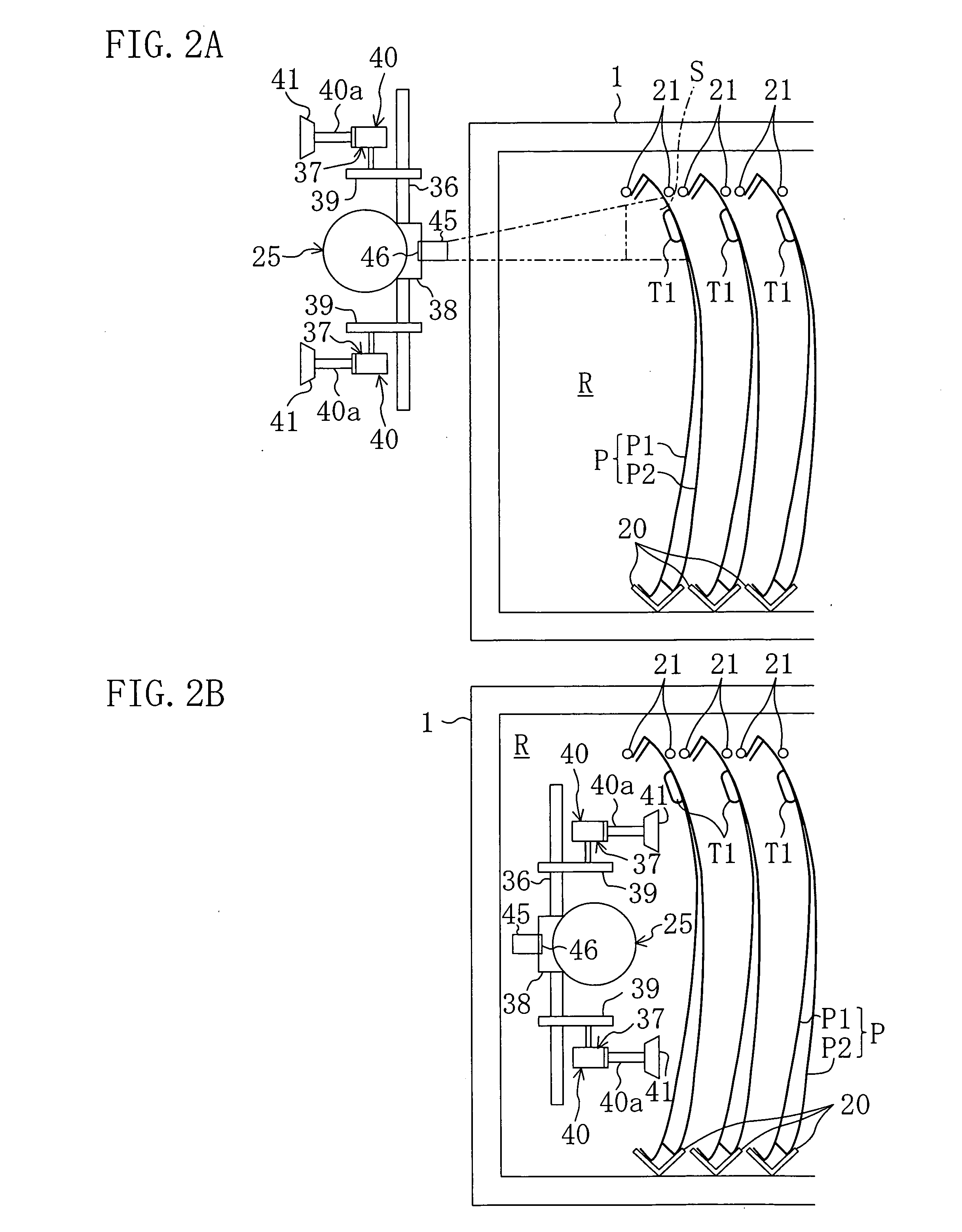

Work conveying method and conveying apparatus employing the conveying method

InactiveUS7575408B2Increase productivityShorten the timeGripping headsArticle unpackingIndustrial engineeringRobot

Plural wok pairs composed of a plurality of works are stored in work storing means. A movable sensor 45 fitted to a conveyance robot 5 detects the position of one of the work pairs in the work storing means, and the work gripping means 25 takes out a plurality of works at one time from the work storing means. One of the plurality of works is held temporally by temporal work holding means 6 or 7 while the other work is conveyed to a jig Y. In the course of conveyance, a fixed sensor 63 detects the relative positional relationship between the work and the work gripping means 25. If the relative positional relationship deviates from the regular positional relationship, the movement of a robot arm 31 is corrected.

Owner:HIROTEC CORP

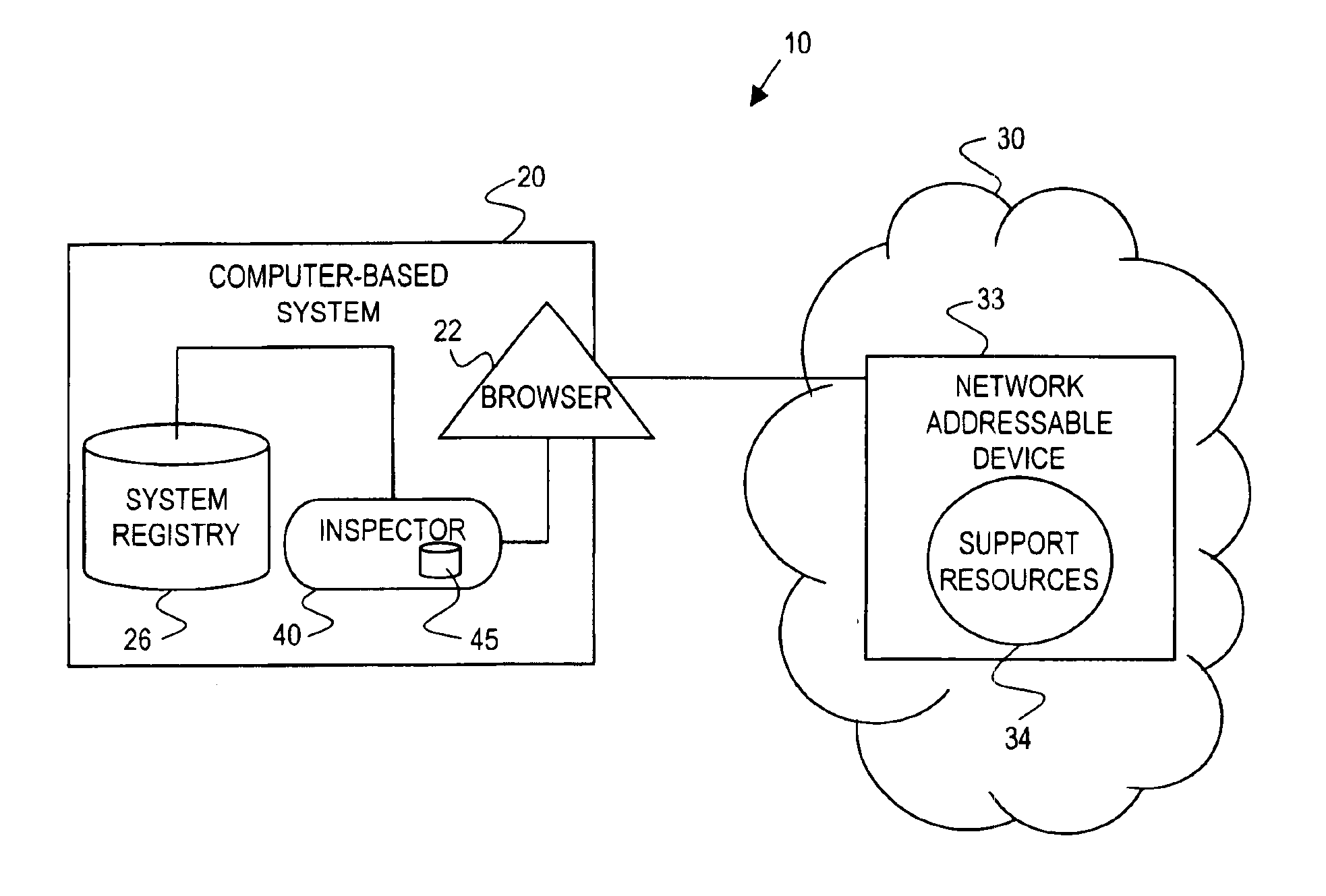

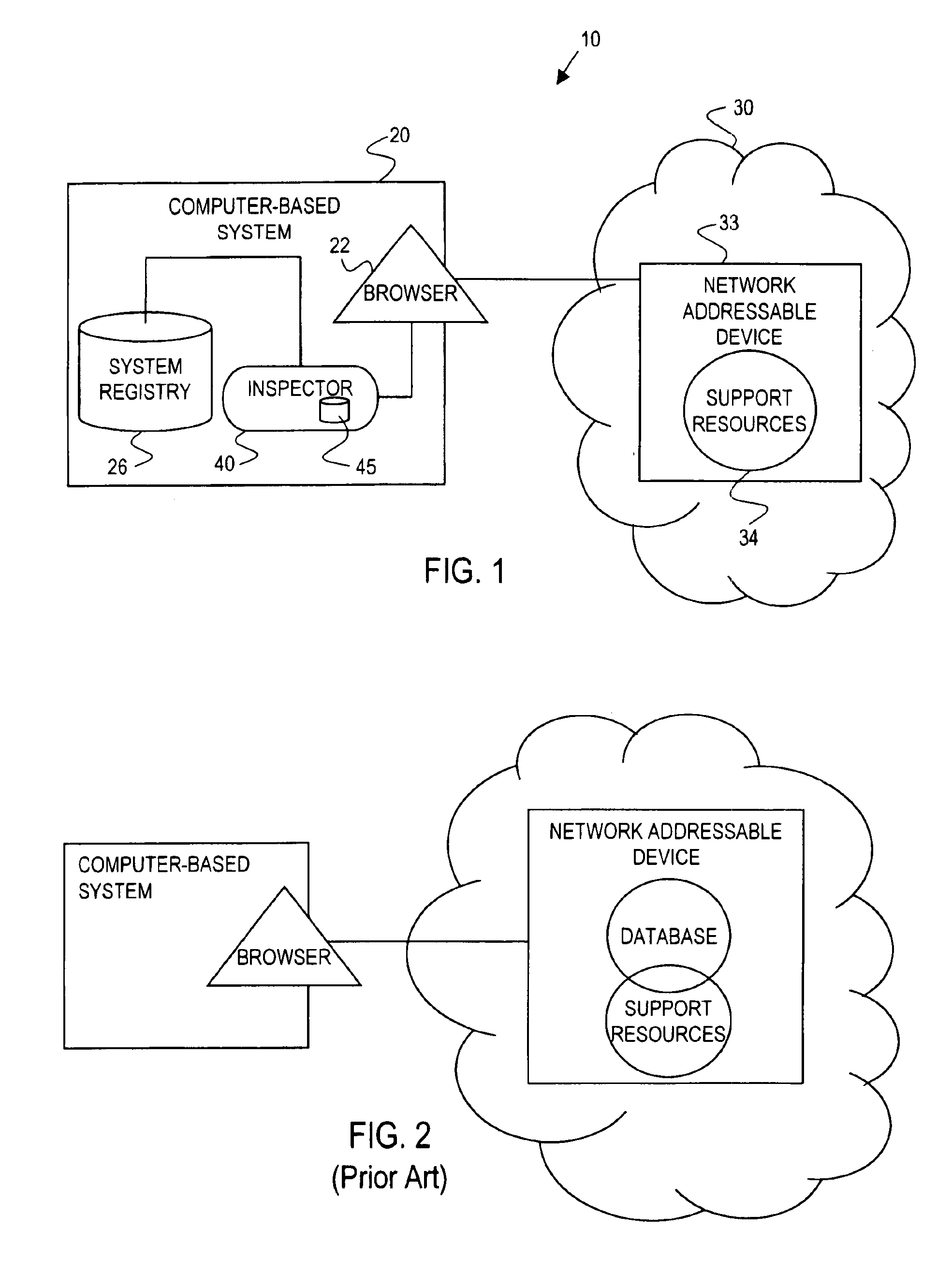

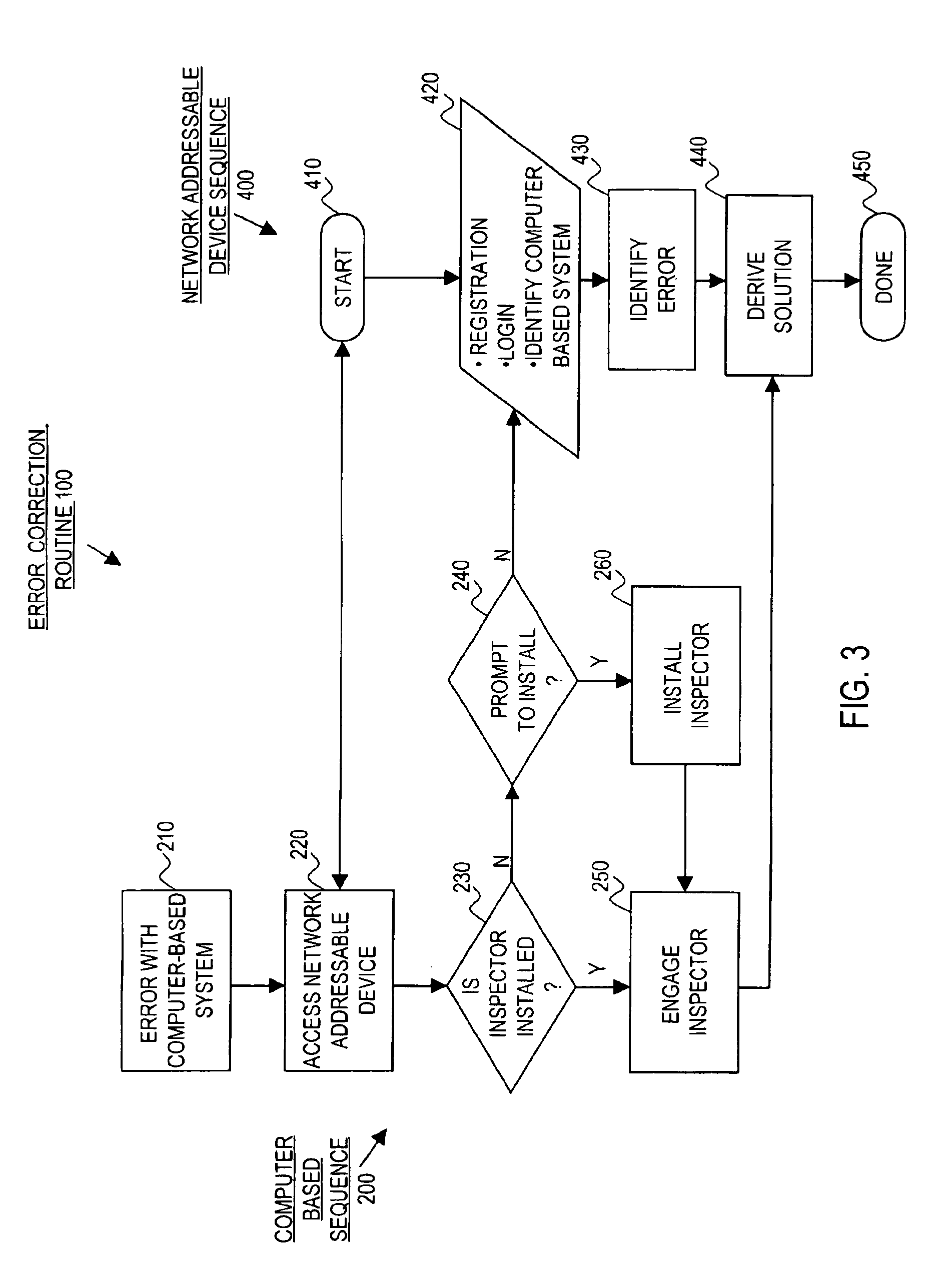

Enduser diagnostic system and method for computer-based error interpretation

InactiveUS6865696B2Convey accuratelyData processing applicationsDetecting faulty computer hardwareTime informationComputer hardware

An enduser diagnostic system or “system” (10) for computer-based error interpretation includes a network addressable device (33), a computer-based system (20), and an inspector (40). The network addressable device (33) provides solutions for error problems associated with the computer-based system (20). The computer-based system (20) includes a system registry (26) for storing information required for configuring software and hardware components that define the computer-based system (20). The inspector (40) is a software component linked with the system registry (26) and the network addressable device (33). The inspector (40) compiles examination data by accessing the computer-based system (20) including the system registry (26). By generating examination data, the inspector (40) quickly and accurately provides information, including real-time information, required for assisting the network addressable device (33) with supplying a solution to the error.

Owner:HEWLETT PACKARD DEV CO LP

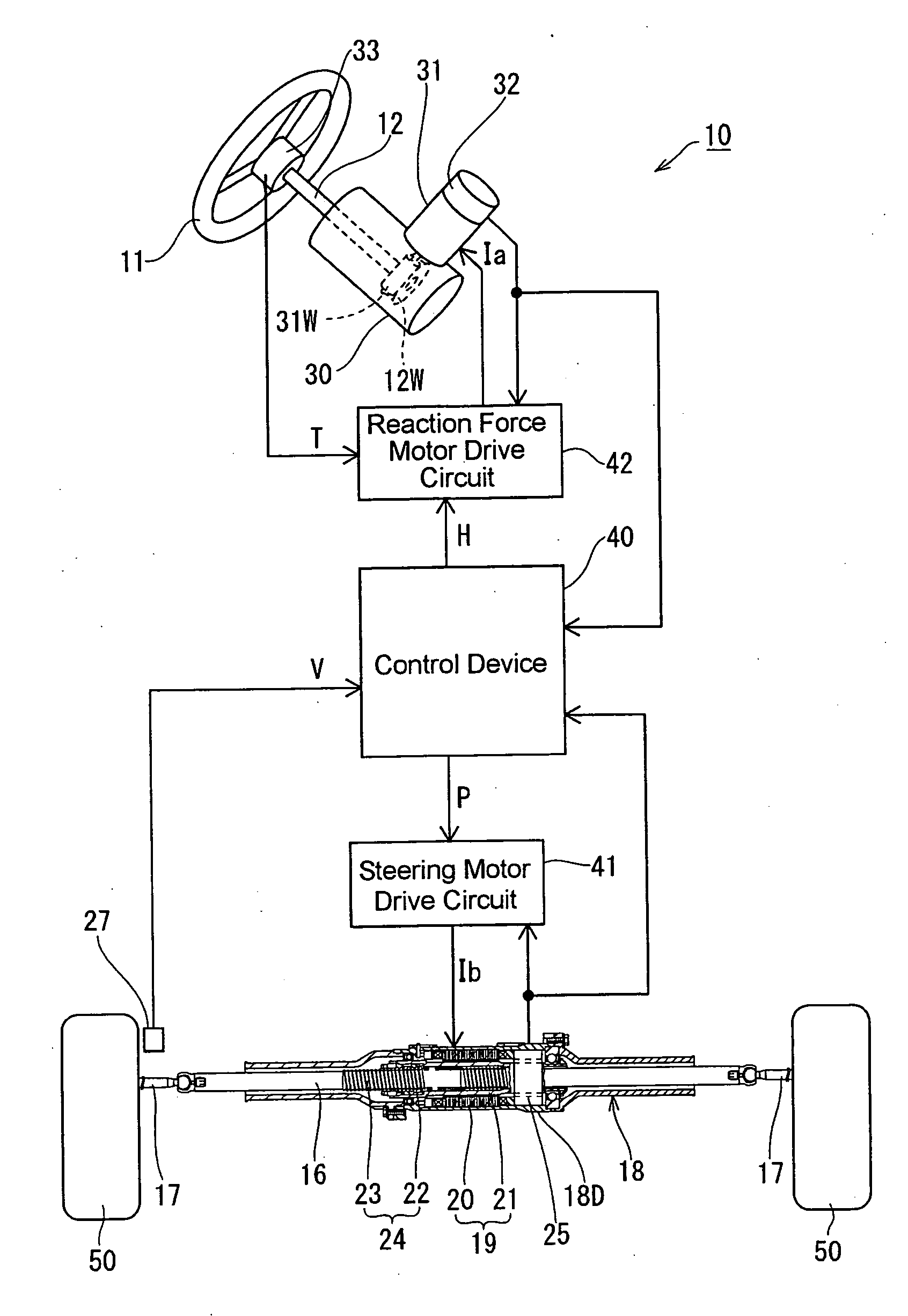

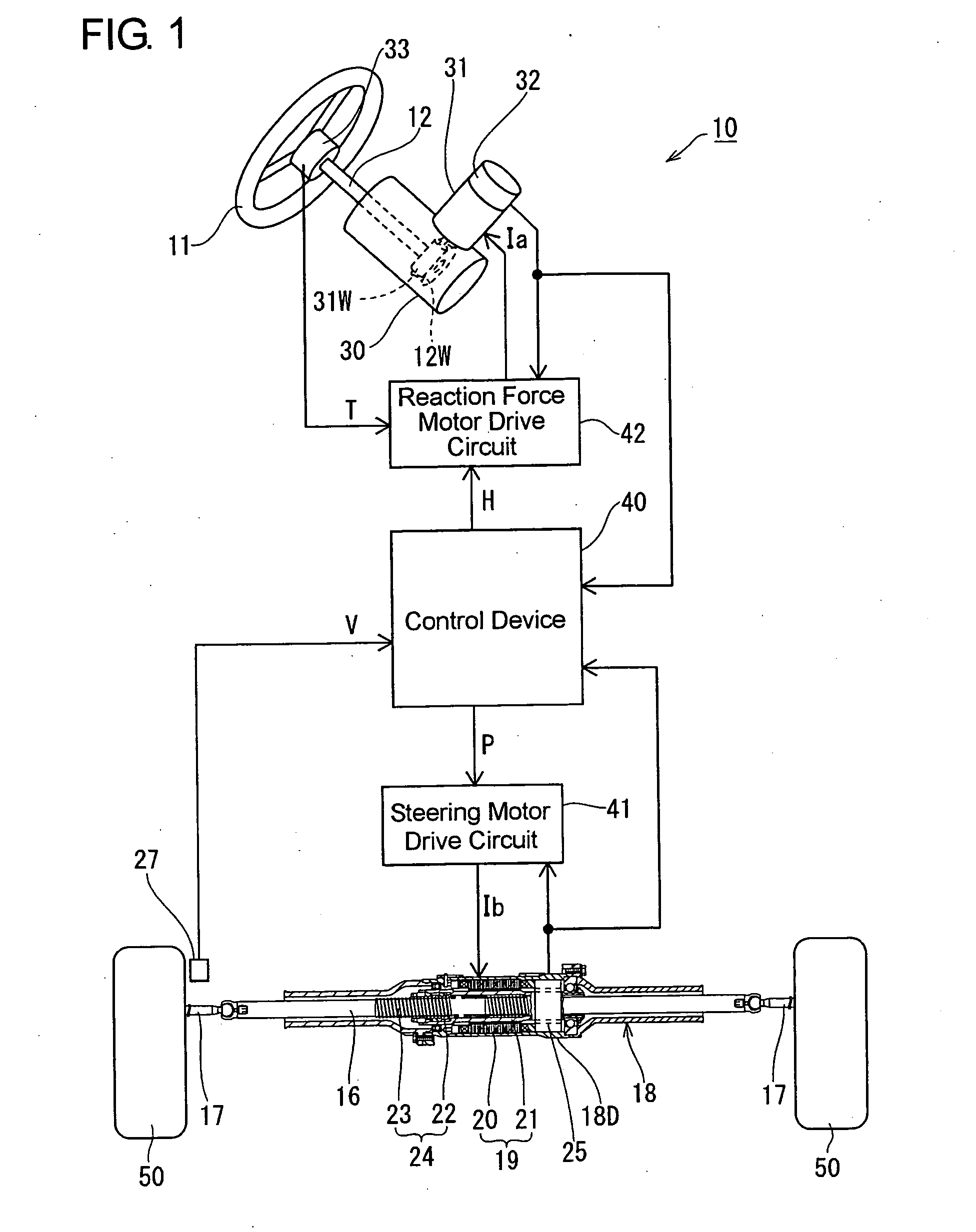

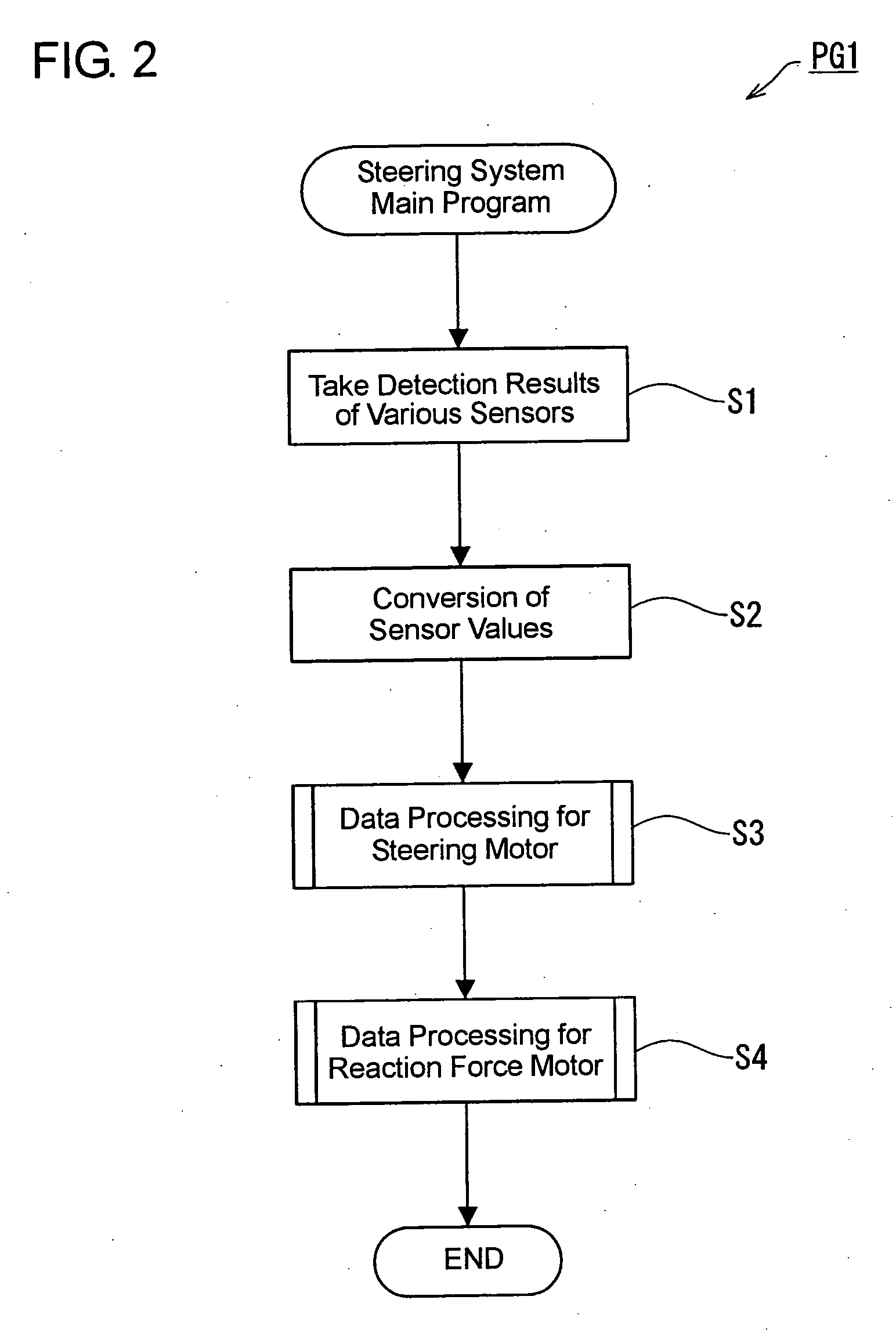

Steer-by-wire-system

InactiveUS20070169984A1Improve returnConvey accuratelySteering initiationsDigital data processing detailsSteering systemRoad surface

In a steer-by-wire system 10, a first steering reaction force made-up value (Hc1) is determined in dependence on a road reaction force (W), and a second steering reaction force made-up value (Hc2) is determined in dependence on a steering position (X) of a steering handle 11 or steerable wheels 50. A steering reaction force command value (H) is generated from both of the first steering reaction force made-up value (Hc1) and the second steering reaction force made-up value (Hc2) the weightings on which are adjusted by respective weighting gains (G1, G2), and the ratio of the weighting gains is properly altered in dependence on the state of a road surface. Thus, it can be realized to provide the steer-by-wire system 10 capable of adjusting the steering reaction force to be sensitive or insensitive to the state of the road surface.

Owner:JTEKT CORP

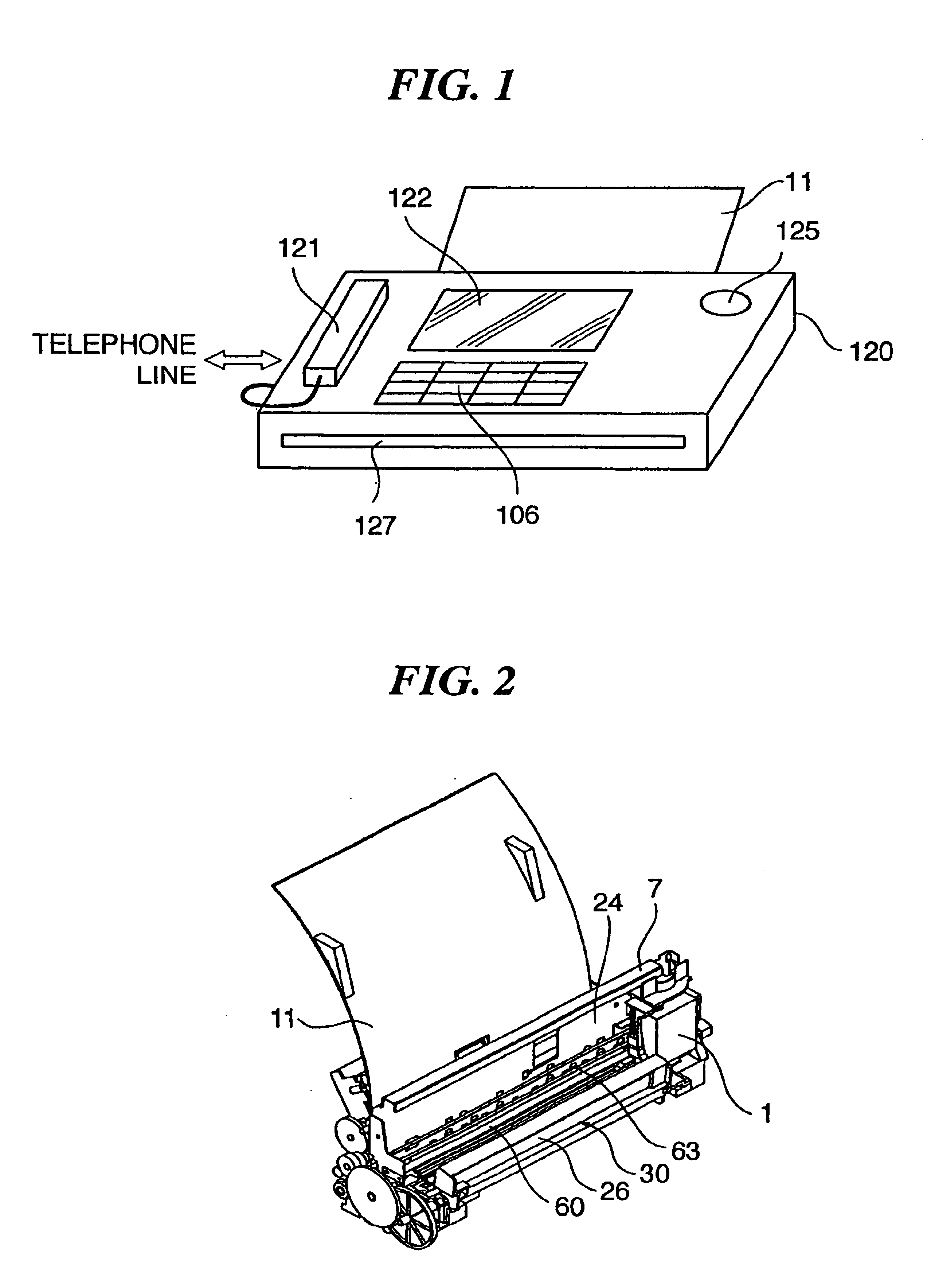

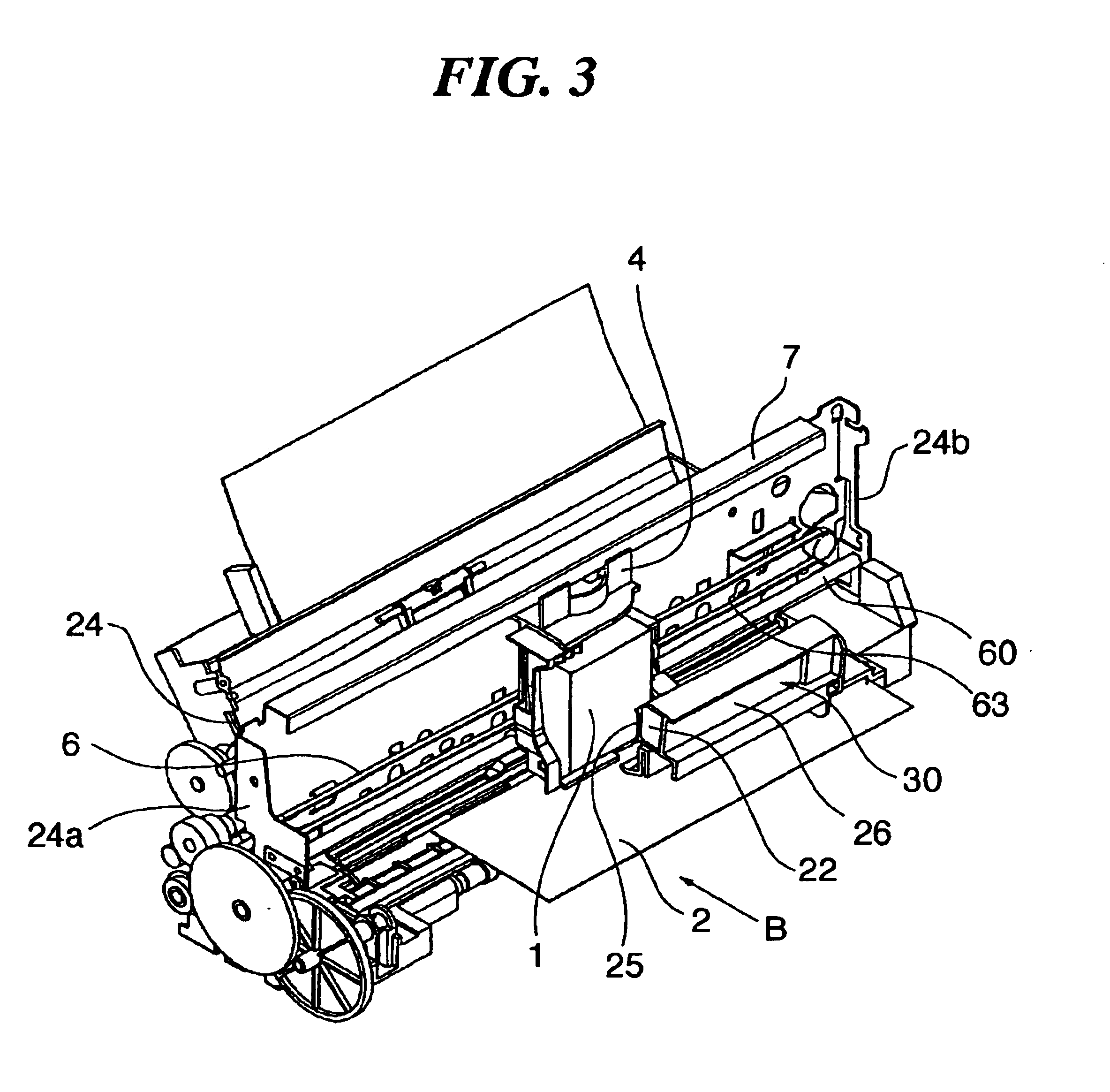

Reading/recording apparatus, reading control method, and program for implementing the method

ActiveUS6929414B2Avoid damageReduce stepsTypewritersElectrographic process apparatusComputer hardwareRecording media

Owner:CANON KK

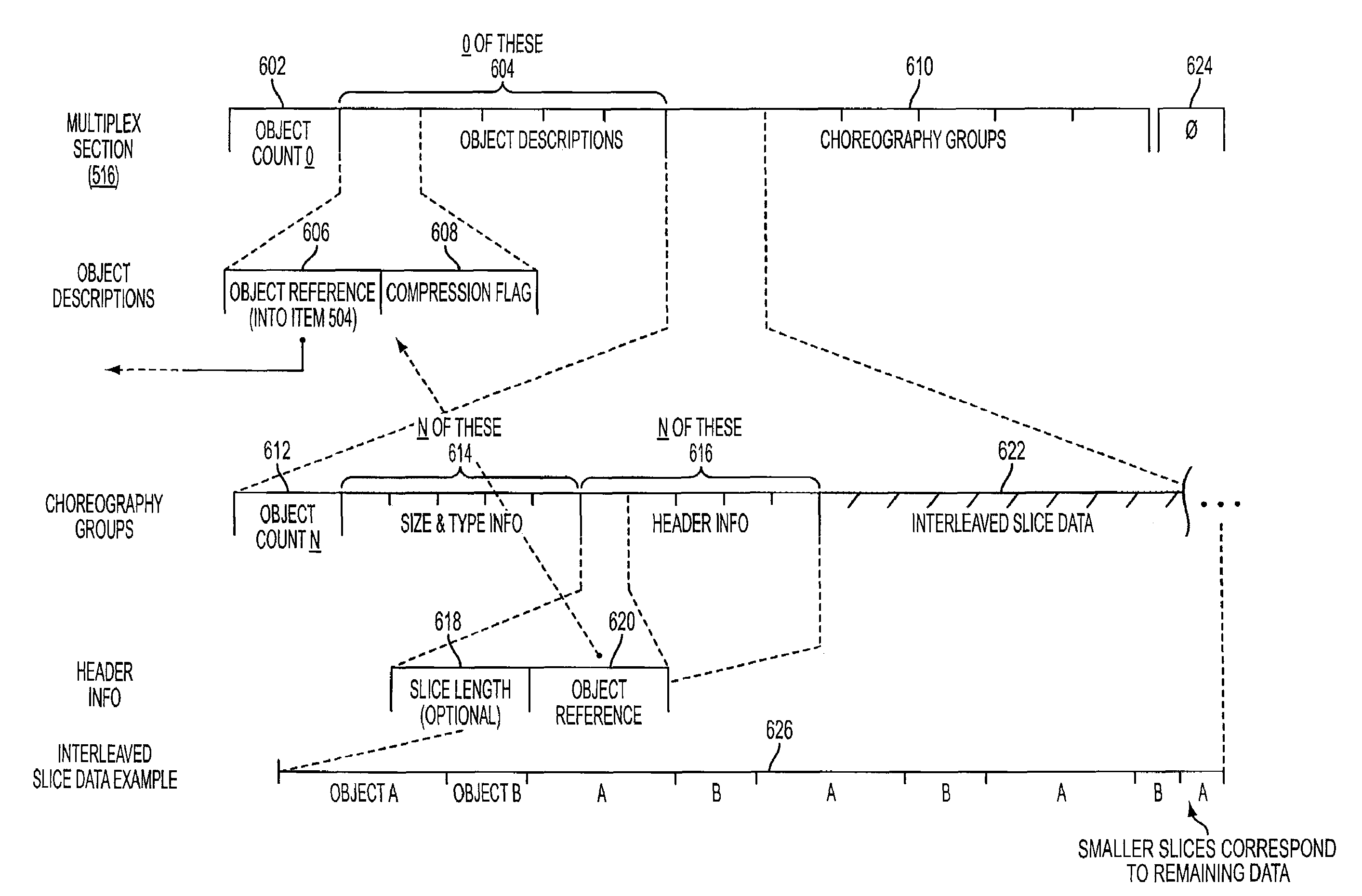

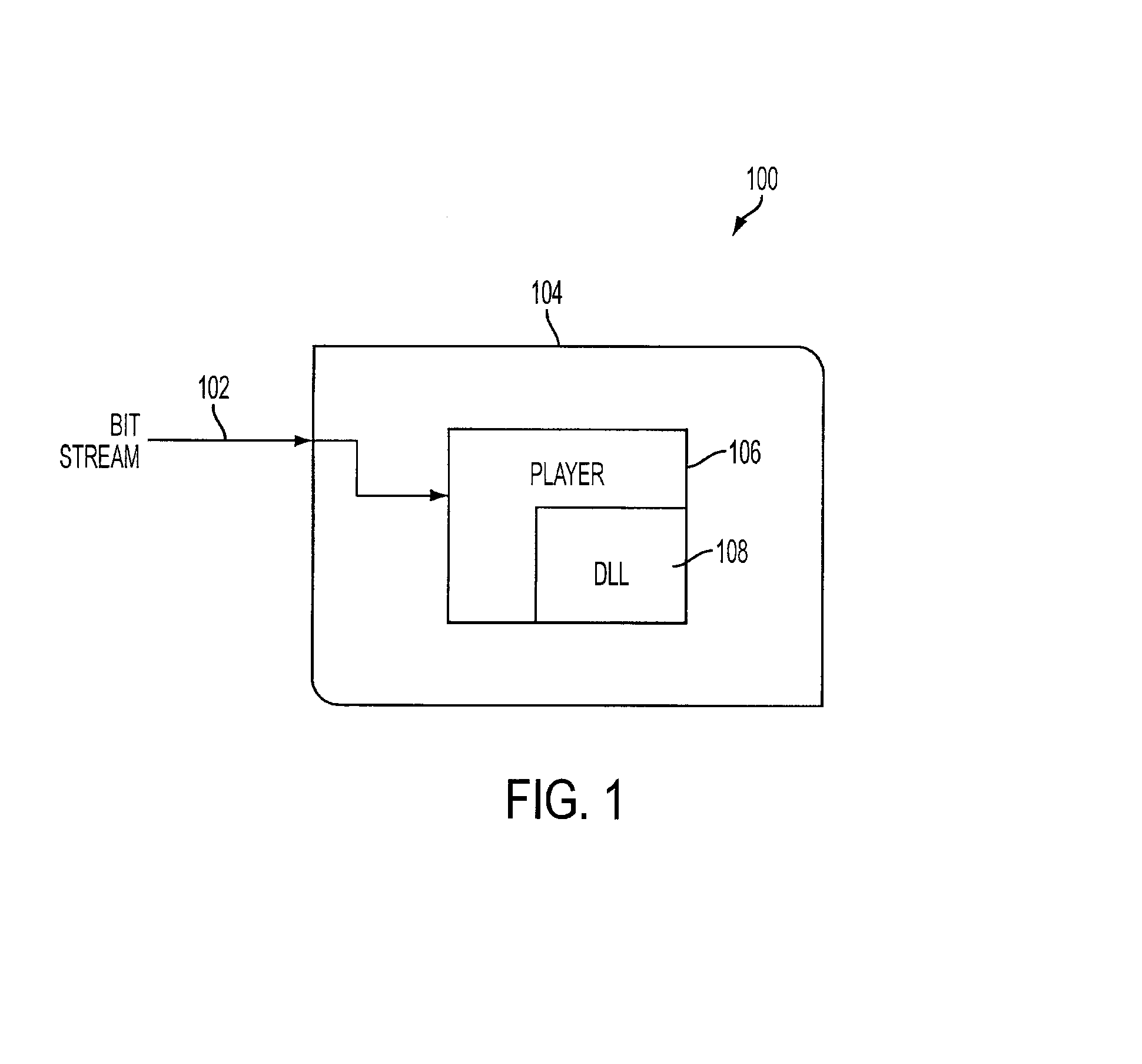

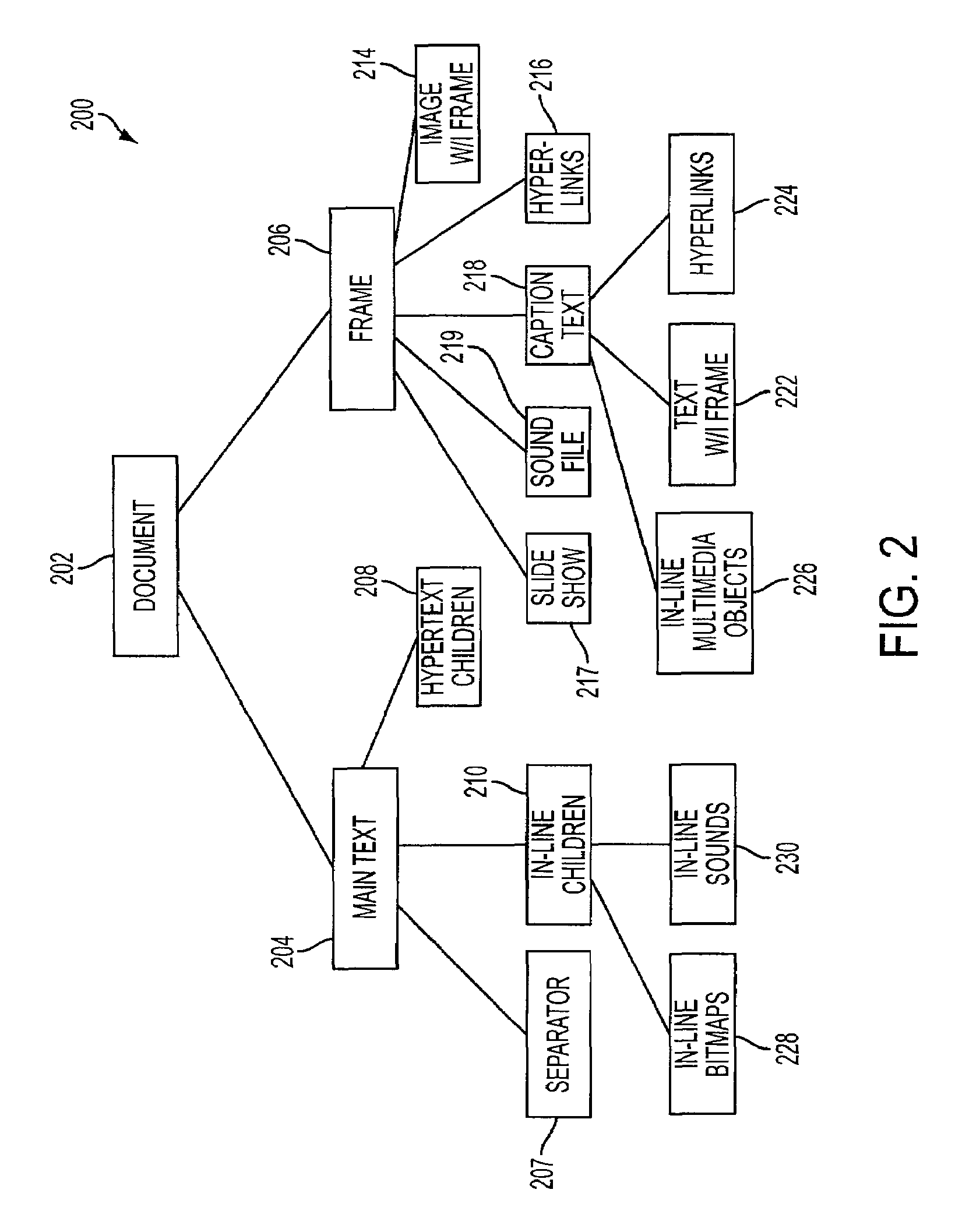

Encapsulated document and format system

InactiveUS7284187B1Easy to storeConvey accuratelyElectrophonic musical instrumentsDigital data information retrievalMultiplexingData file

Methods for producing and multiplexing a file format, as well as structures for a hierarchical file format and data file, are provided. The data file may include data that is divided in a hierarchical manner, including a highest level document portion that supports all lower level portions of the data file. The hierarchical data file forms a multimedia document that can be displayed on a computer display with accompanying audio. The multimedia document may include data in a variety of file formats, including image data, sound data, textual data, and video data. At least some of the data is preferably multiplexed in the data file, so that the multiplexed data can be progressively played and displayed as it is downloaded by a computer. Data that cannot be progressively played need not be multiplexed in the data file and can be located in an area of the data file separate from the multiplexed data.

Owner:META PLATFORMS INC

Water purifier filtration portion, water purifier main body, and water purifier including the both

InactiveUS6881333B2Promote sheddingReduce component countSettling tanks feed/dischargeLoose filtering material filtersCouplingFiltration

A water purifier is composed of a valve main body and a filtration portion, which are coupled to each other in an attachable and detachable manner at the main body side coupling portion and the filtration portion side coupling portion. Consequently, the water purifier filtration portion can be connected to the water purifier main body in a single step with ease in a secure manner, and at the same time, the water purifier filtration portion will not fall off easily even when water with a high water pressure flows in. Also, the water purifier is provided with a concave portion and a sensor packing formed as an integral portion of the concave portion and protruding toward an indicator portion on a wall surface of a cartridge. The indicator portion is provided with a conductive member at a position where it is brought into contact with a first input portion by a water pressure and thereby closes an electric circuit on a circuit board. Consequently, the service life (the rated service cycle) of a filter material (medium) can be notified to the user accurately, and a fluid-tight condition of the indicator portion and the cartridge portion can be ensured.

Owner:OSAKA GAS CHEM KK

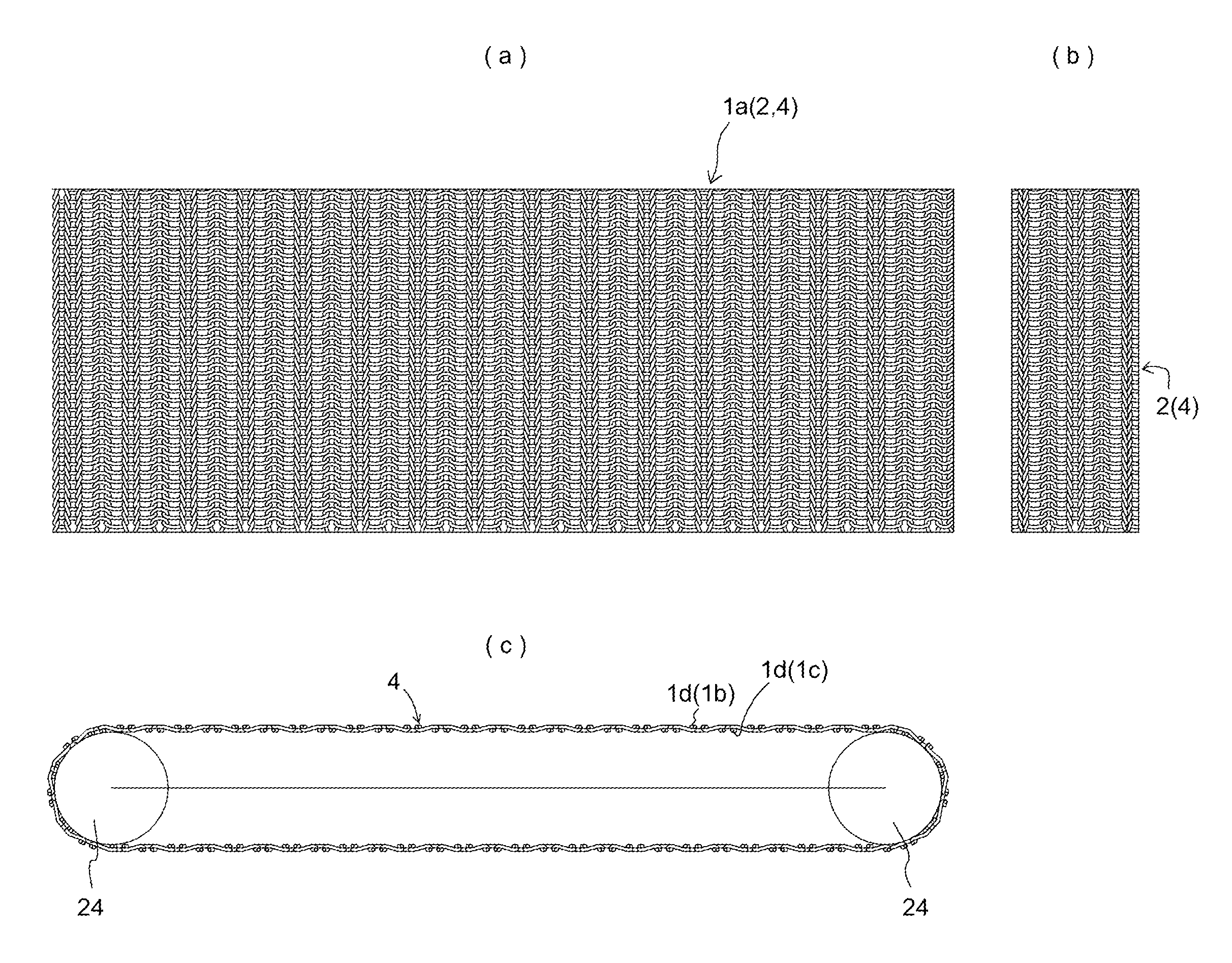

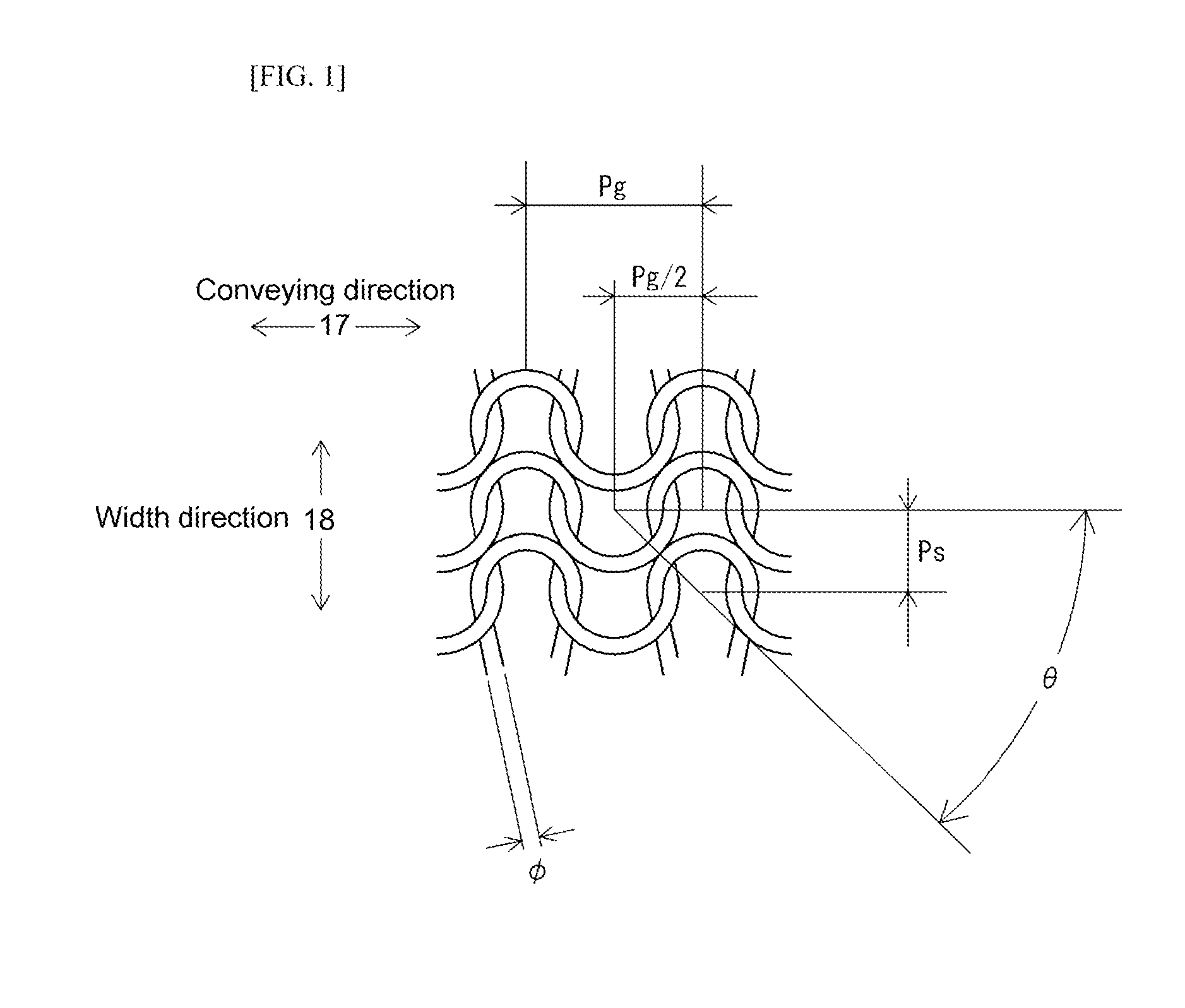

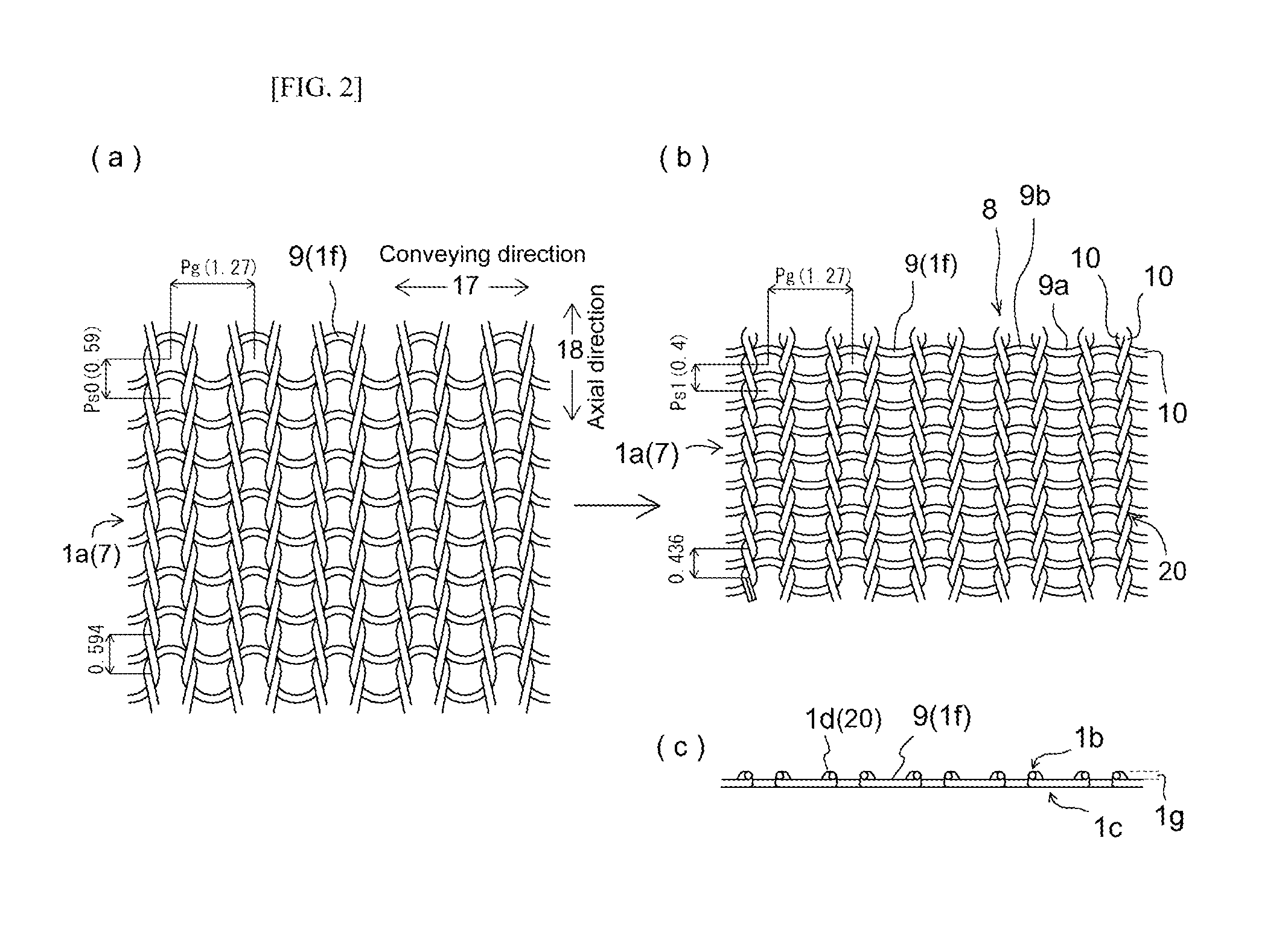

Conveyor belt and drive belt comprising knitted belt, and conveyor device using conveyor belt

(PROBLEM) To provide a seamless conveyor belt comprising knit fabric.(SOLUTION MEANS) A seamless conveyor belt employing monofilament made up of continuous fiber at filament constituting core yarn; being made up of weft-knit or warp-knit in which there is mutual intertwining of filament; flexural stress and heat causing monofilament at core yarn to undergo plastic deformation at locations of entanglement; being a seamless knit belt (1a) comprising a knit pattern (8) which is weft-knit or warp-knit; being a knit pattern (8) in which pitch (Ps) of stitch loops in a width direction (18) is smaller than pitch (Pg) of stitch loops in a conveying direction (17) of the seamless knit belt; mutually contacting loops (9) and filament undergoing deformation; entangled regions of filament being maintained; fraying at side ends of the knit belt (1a) during conveyance by the conveyor belt being prevented; spacing of pitch (Ps) of stitch loops in the width direction (18) being small; and strength being improved.

Owner:SANWA TECHNO +1

Sheet feeding apparatus

InactiveUS7249759B2Eliminate inconvenienceQuickly and reliably effect loosening of sheetElectrographic process apparatusPictoral communicationTemperature controlEngineering

A sheet feeding apparatus including a stacking portion for stacking a plurality of sheets thereon, a sheet feeding portion for feeding the sheets stacked on the stacking portion, a fan for sending air to the sheets to loosen the sheets stacked on the stacking portion, a heater for warming the air sent by the fan, a temperature detecting portion for detecting the temperature of the heater, and a control portion for starting the driving of the fan in conformity with the temperature detecting portion having detected a predetermined temperature after temperature control for adjusting the heater to a target temperature has been started.

Owner:CANON KK

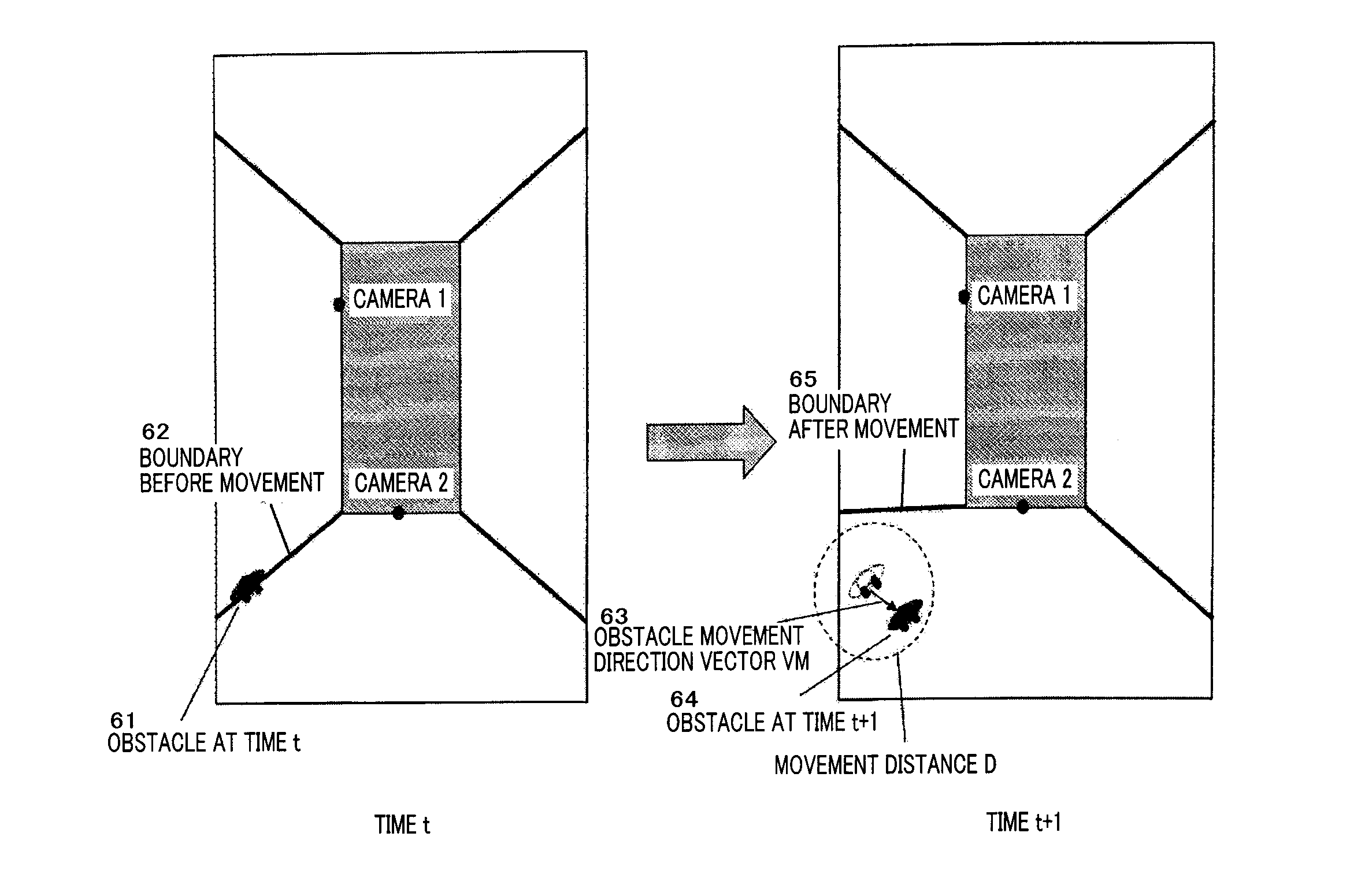

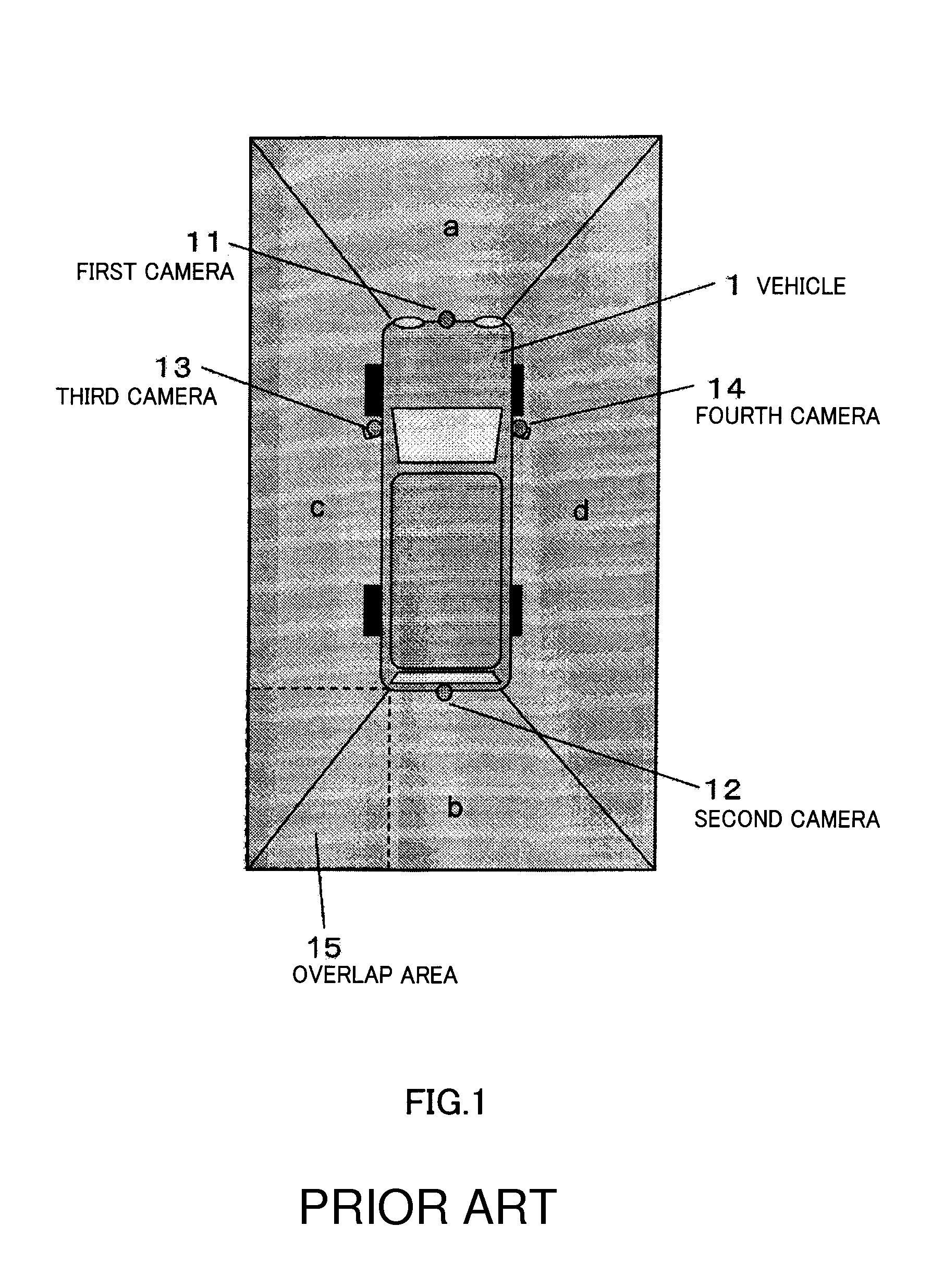

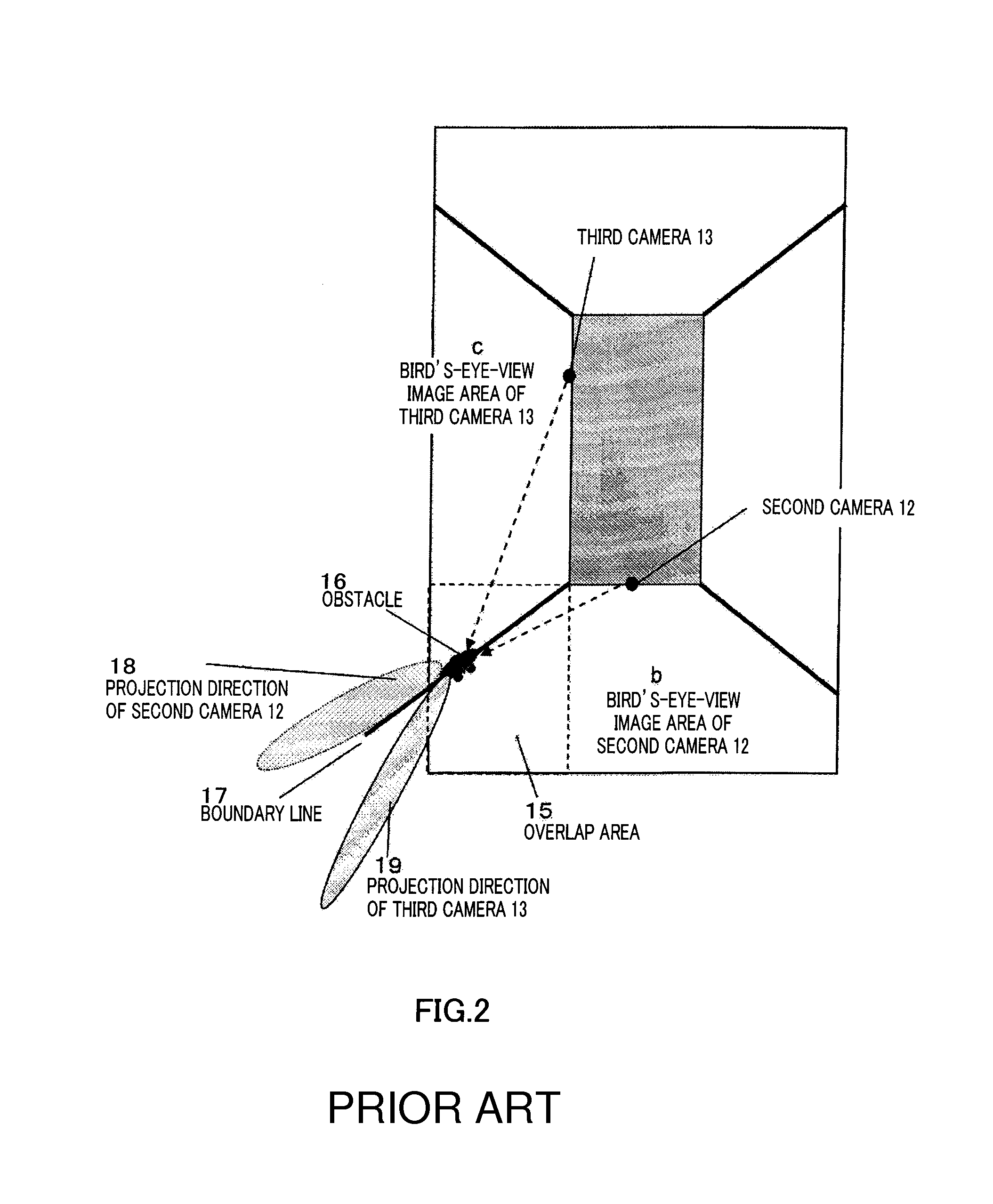

Driving support display device

ActiveUS8655019B2Driving safetyConvey accuratelyImage enhancementImage analysisDisplay deviceImage synthesis

Disclosed is a driving support display device that composites and displays images acquired from a plurality of cameras, whereby images which are easy for the user to understand and which are accurate in the areas near the borders of partial images are provided. An image composition unit (41) formulates a bird's eye perspective image on the basis of a mapping table reference unit (45) using images of the area around the vehicle acquired from a plurality of cameras (31). An obstacle detection unit (42) detects obstacles in the images acquired by the plurality of cameras (31). On the basis of the obstacle information detected by the obstacle detection unit (42), an obstacle trajectory prediction unit (43) predicts the trajectory of the obstacle and determines the borders so that the borders of the obstacle and the composite image from the plurality of cameras (31) do not overlap. The image composition unit (41) acquires necessary information from the mapping table reference unit (45) and creates a bird's eye perspective image in which the borders of the obstacle and the images from the plurality of cameras do not overlap.

Owner:PANASONIC CORP

Work conveying method and conveying apparatus employing the conveying method

InactiveUS20080163403A1Reduce timeSuppress damage and deformationGripping headsAmmunition loadingEngineeringIndustrial engineering

Plural wok pairs composed of a plurality of works are stored in work storing means. A movable sensor 45 fitted to a conveyance robot 5 detects the position of one of the work pairs in the work storing means, and the work gripping means 25 takes out a plurality of works at one time from the work storing means. One of the plurality of works is held temporally by temporal work holding means 6 or 7 while the other work is conveyed to a jig Y. In the course of conveyance, a fixed sensor 63 detects the relative positional relationship between the work and the work gripping means 25. If the relative positional relationship deviates from the regular positional relationship, the movement of a robot arm 31 is corrected.

Owner:HIROTEC CORP

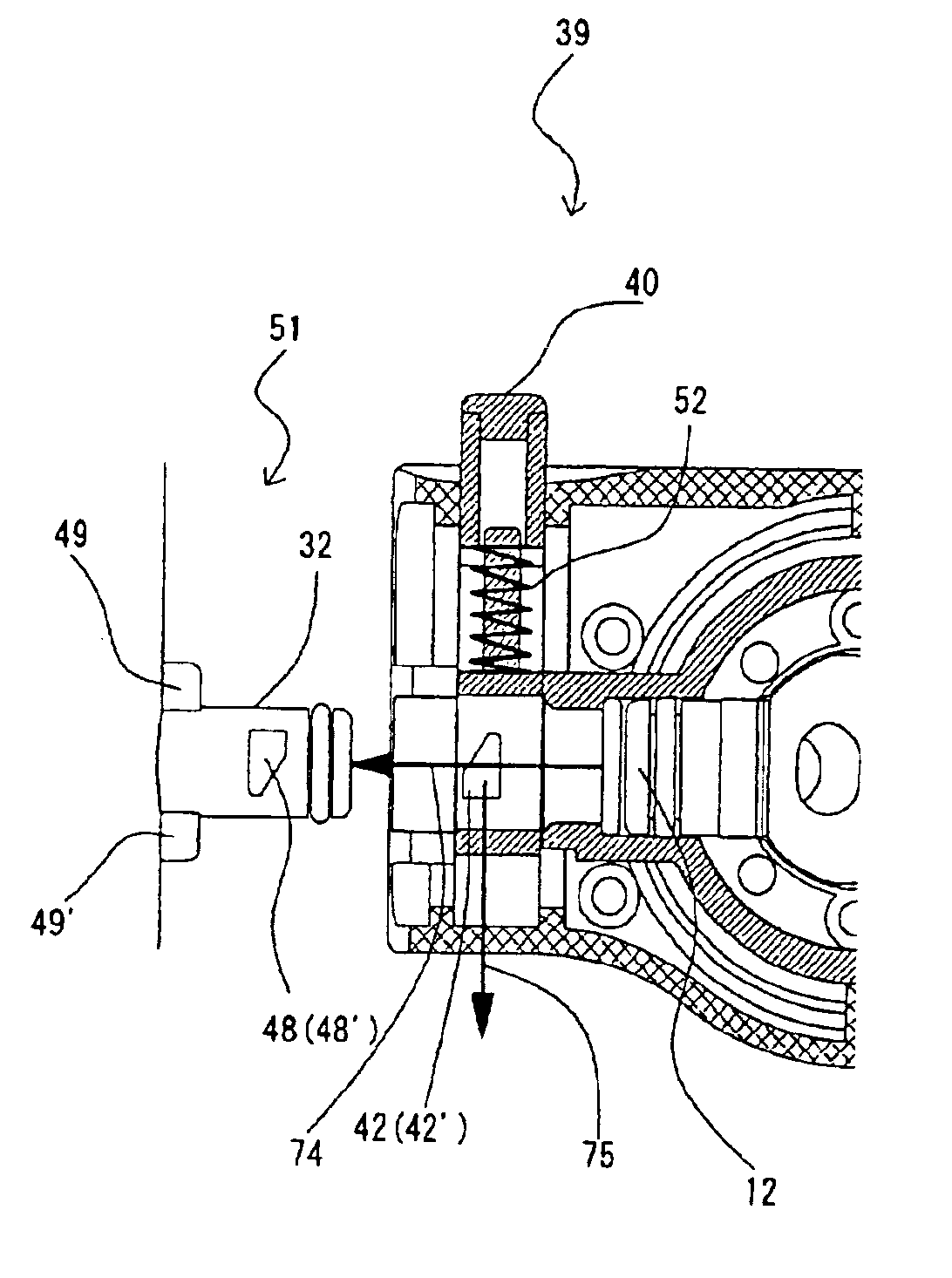

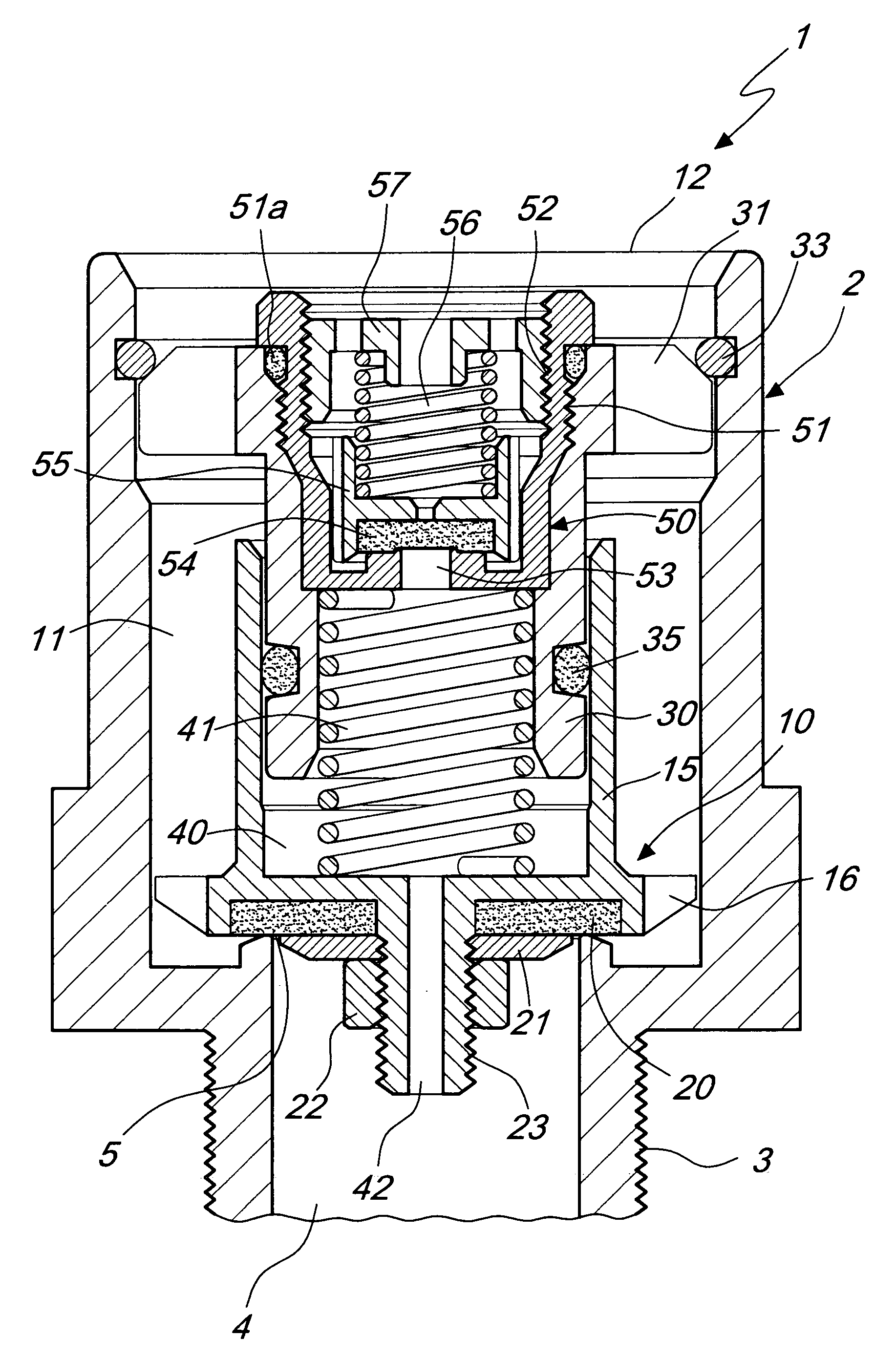

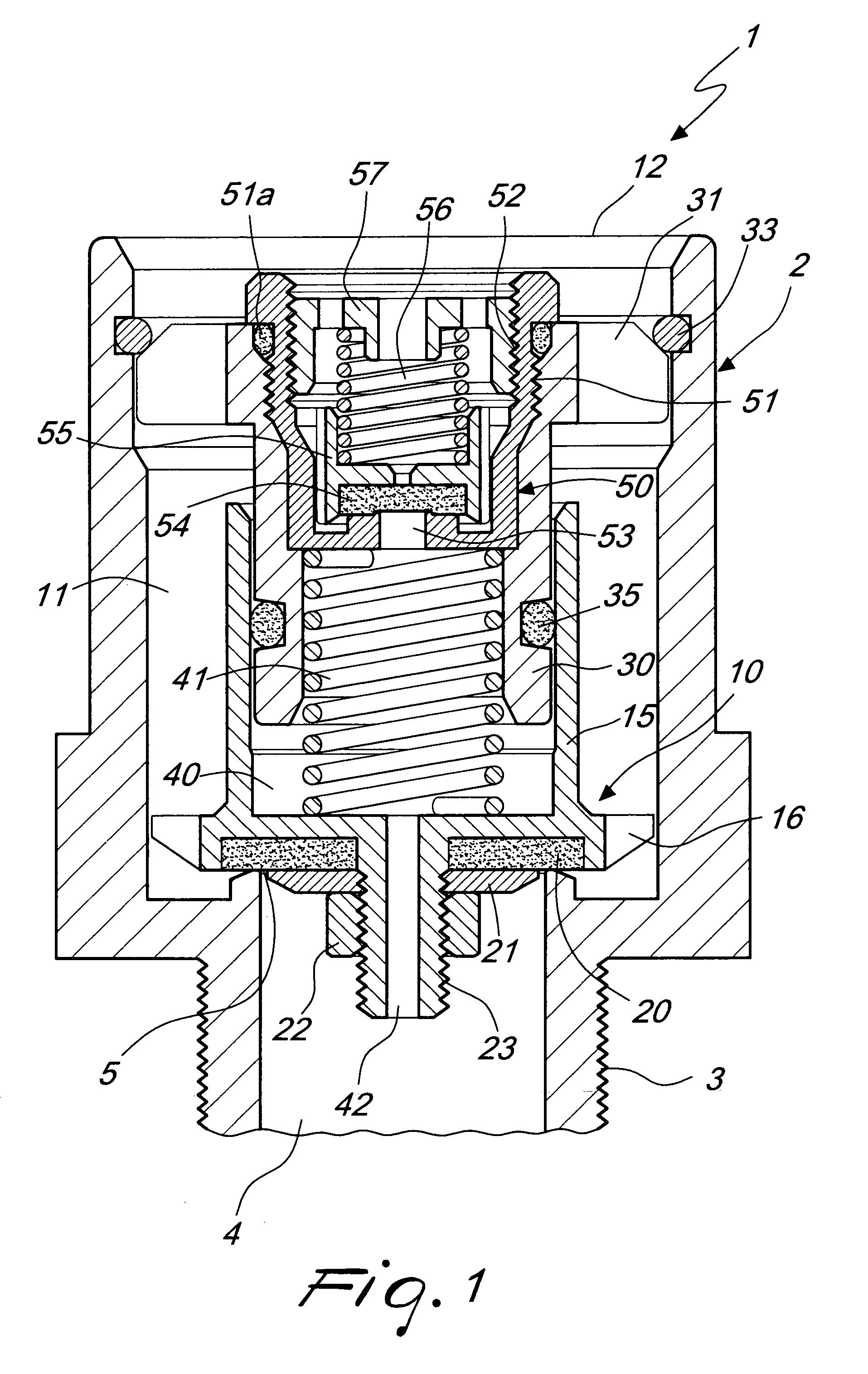

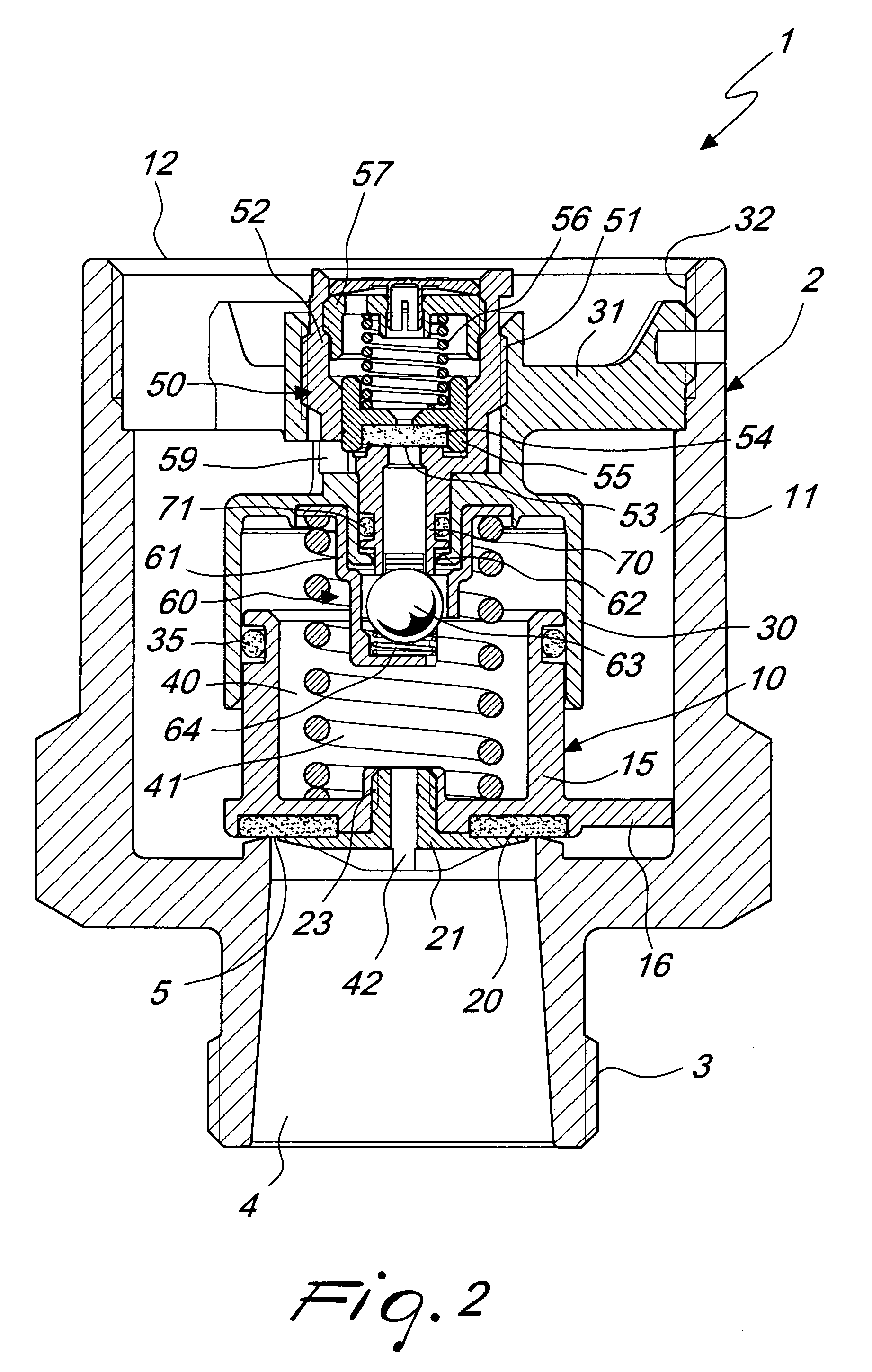

Spring-loaded pressure relief valve, particularly for containers of pressurized fluids

ActiveUS7077157B2Convey accuratelyEasy to getOperating means/releasing devices for valvesCheck valvesEngineeringVALVE PORT

A spring-loaded pressure relief valve, particularly for containers of pressurized fluids, comprising a valve body that is associable with a container and forms a discharge port that is controlled by a main piston; an auxiliary valve is further provided, which controls a venting port and drives the intervention of the main piston, such main piston being accommodated in a cavity that is formed in the valve body and is open in an axial direction on the opposite side with respect to the venting port.

Owner:CAVAGNA GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com