Patents

Literature

1200results about How to "Forming accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

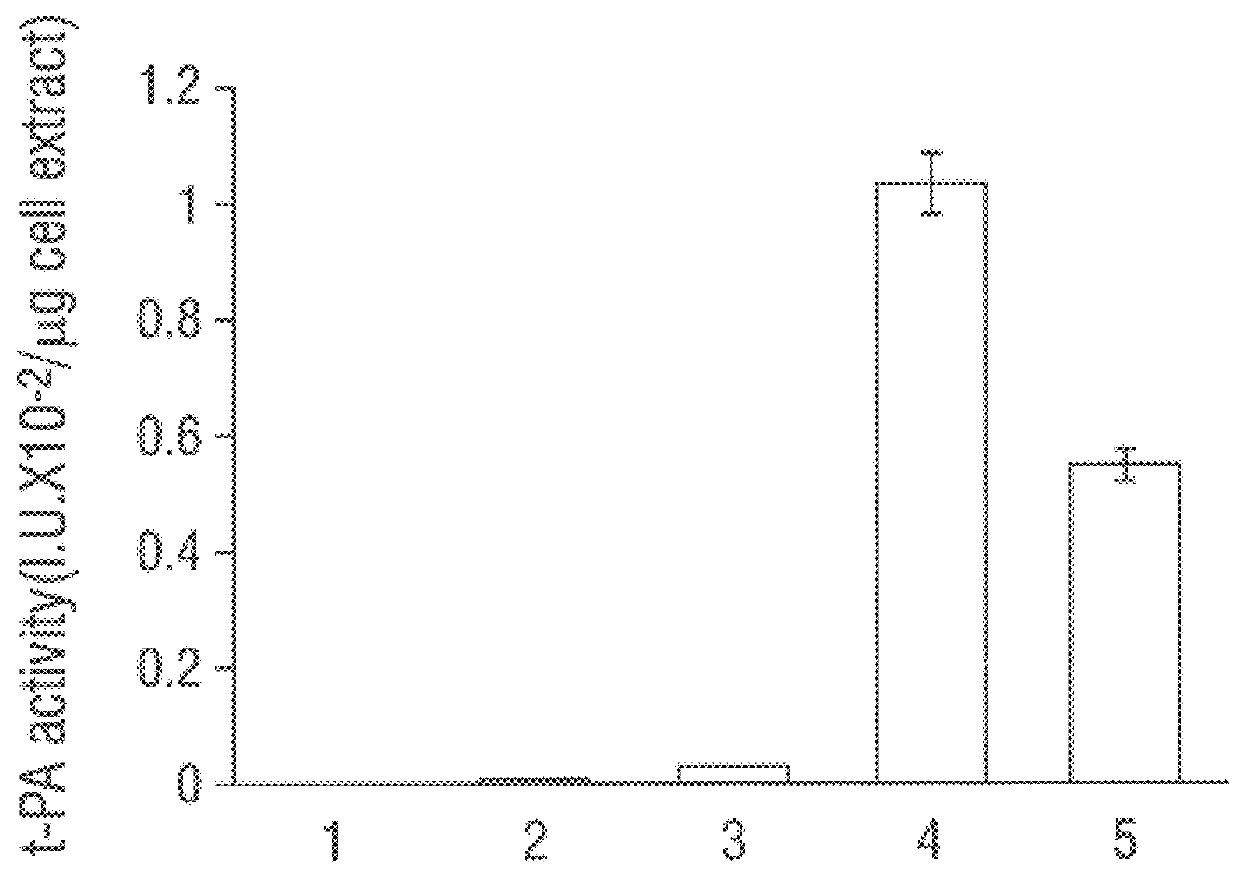

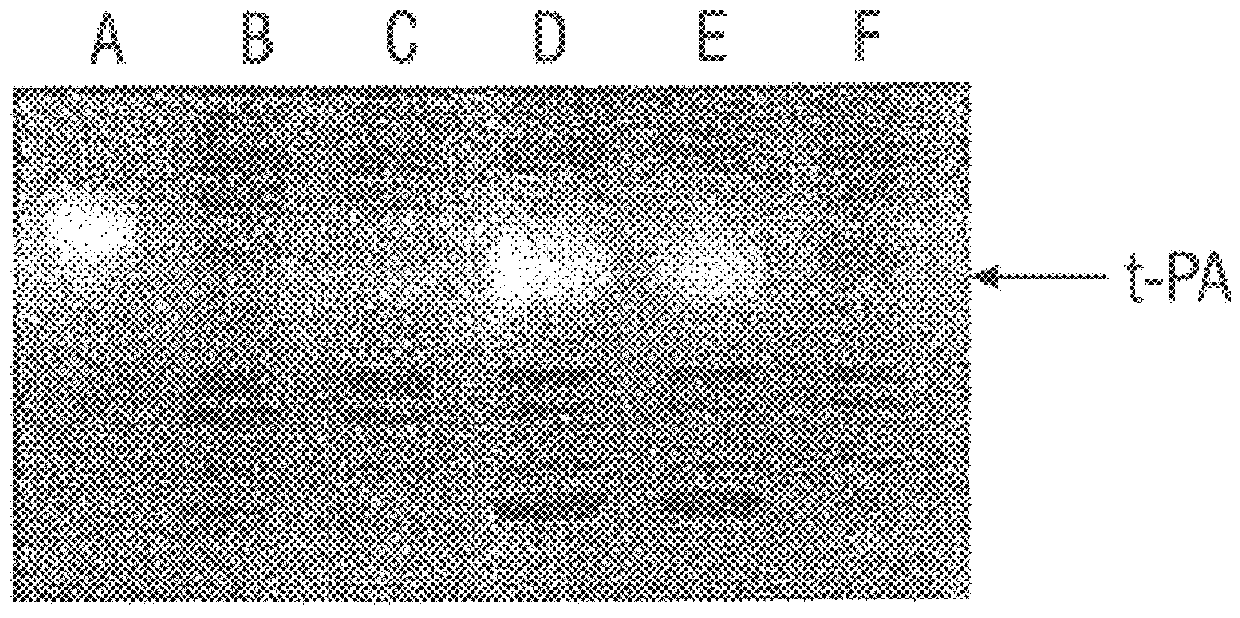

Methods for producing heterologous disulfide bond-containing polypeptides in bacterial cells

InactiveUS6083715AEfficient productionFold preciselyBacteriaUnicellular algaeMolecular biologyDisulfide bond

Disclosed are methods and compositions for producing heterologous disulfide bond containing polypeptides in bacterial cells. In preferred embodiments the methods involve co-expression of a prokaryotic disulfide isomerase, such as DsbC or DsbG and a gene encoding a recombinant eukaryotic polypeptide. Exemplary polypeptides disclosed include tissue plasminogen activator.

Owner:GENENTECH INC +1

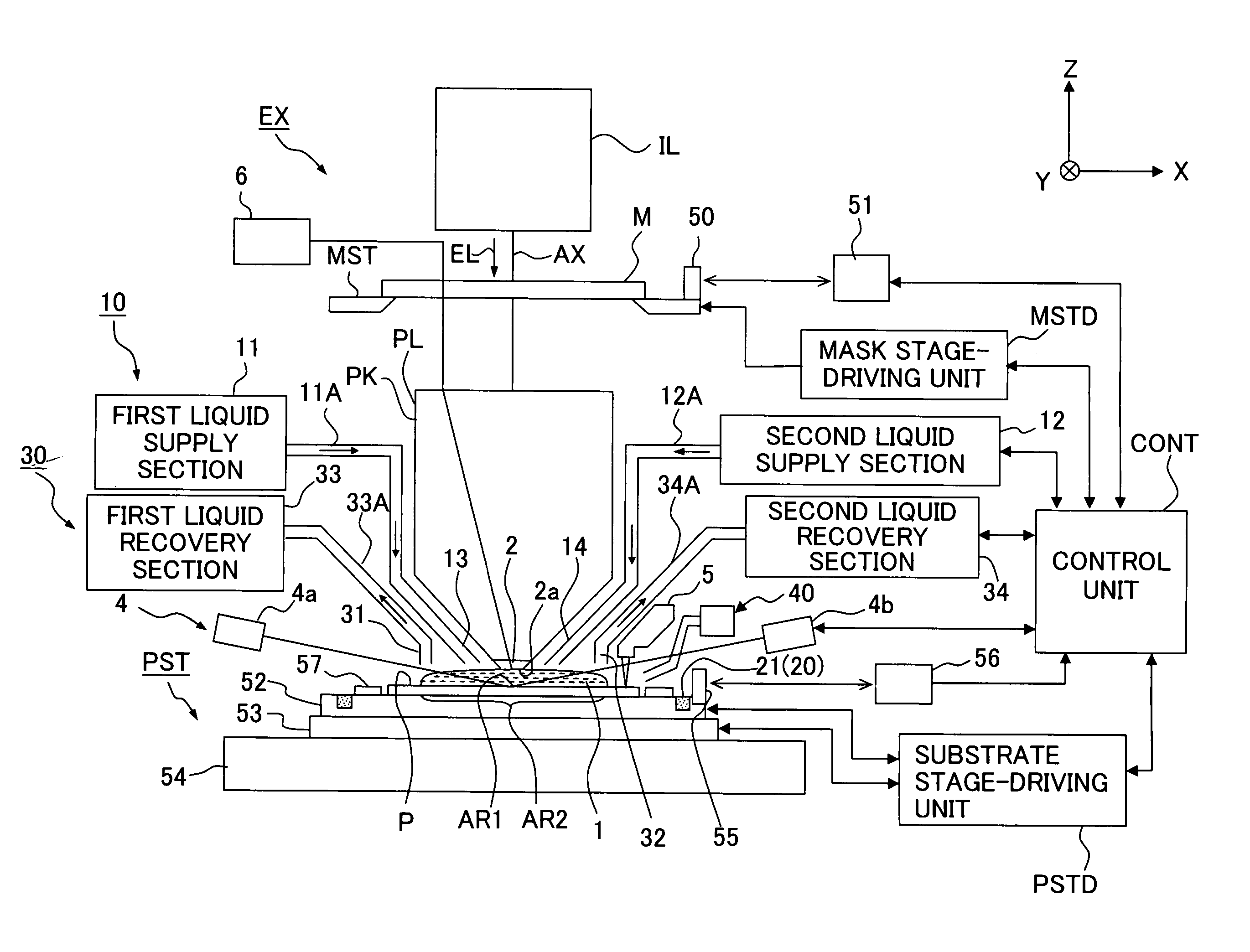

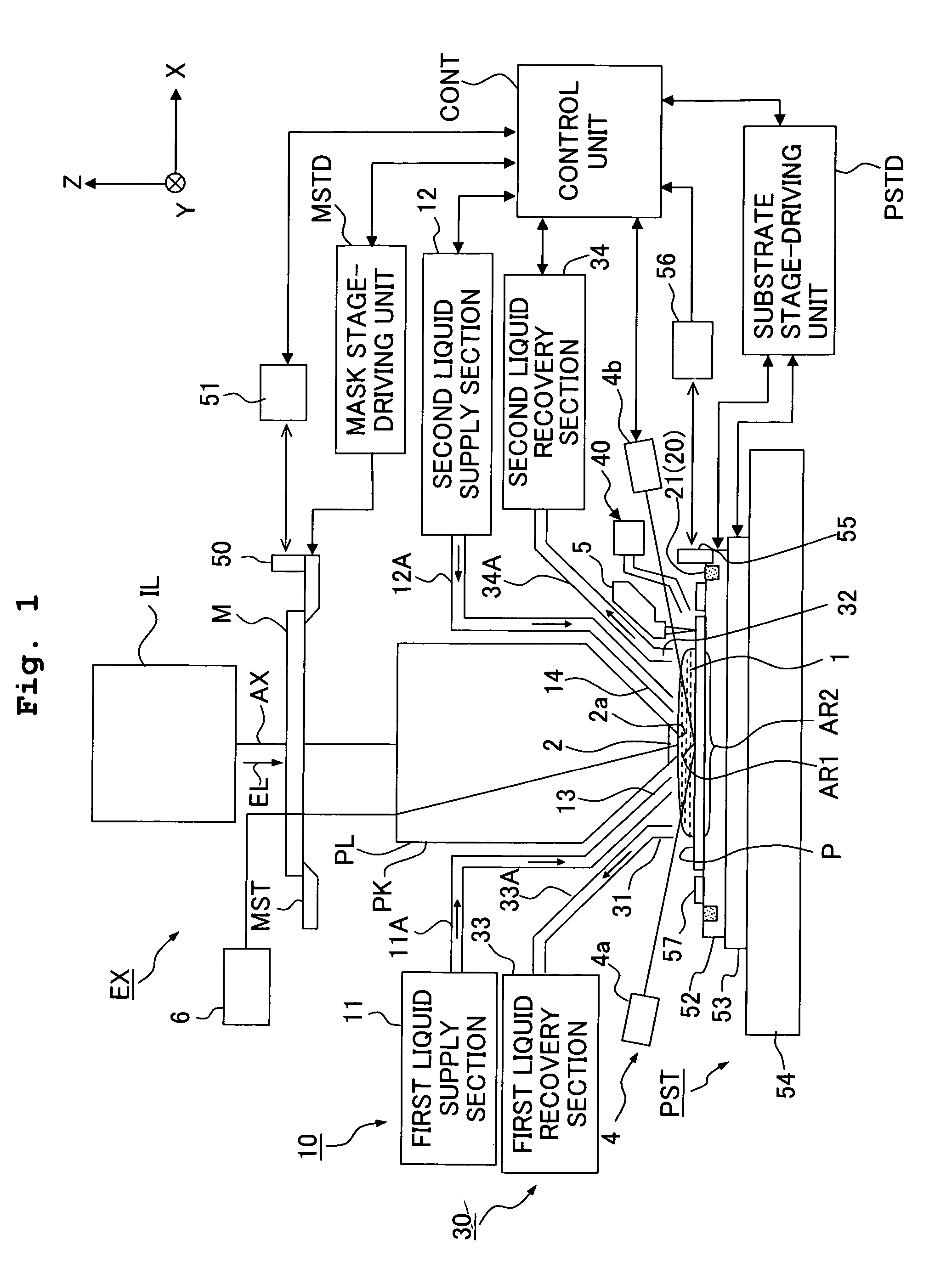

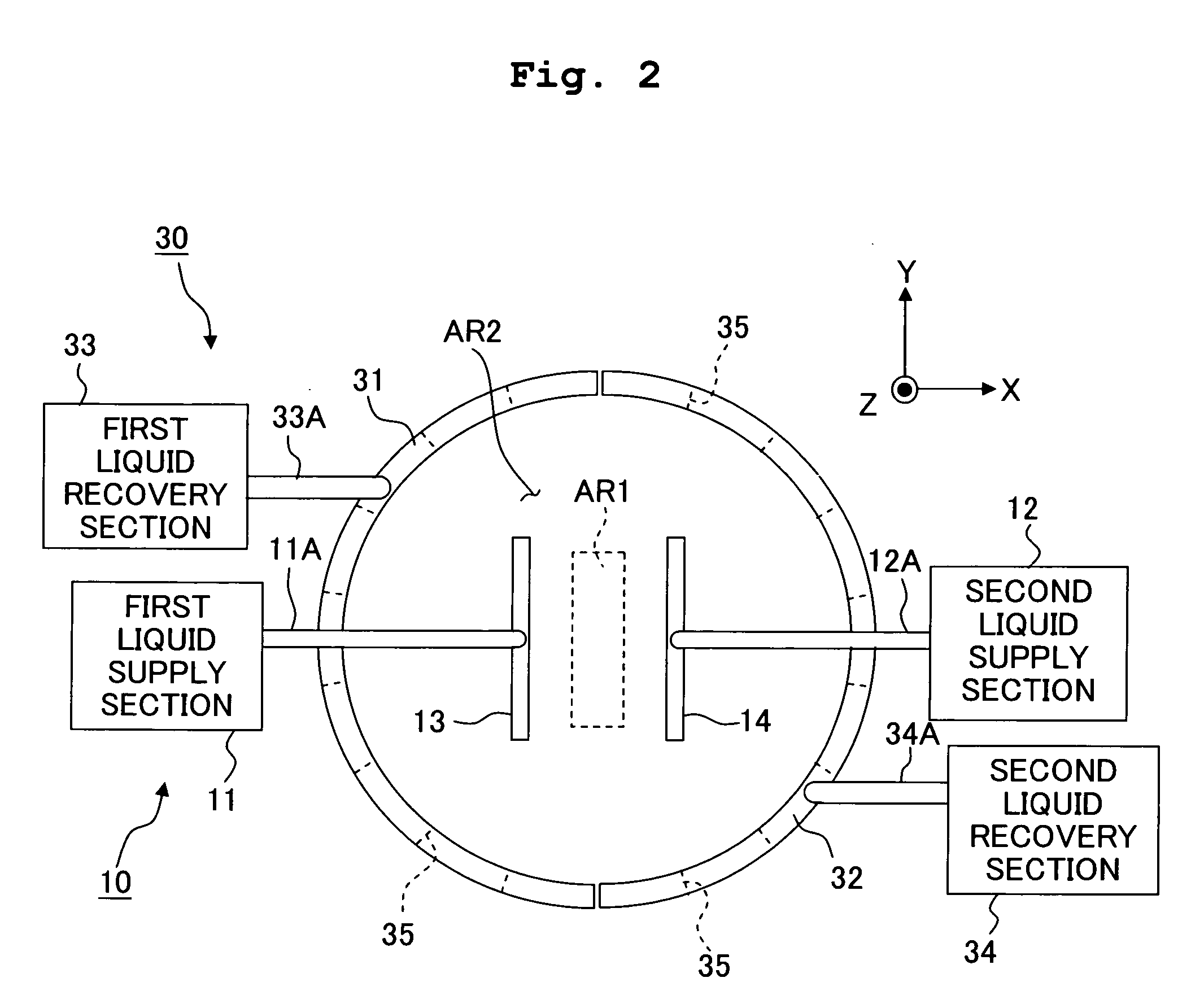

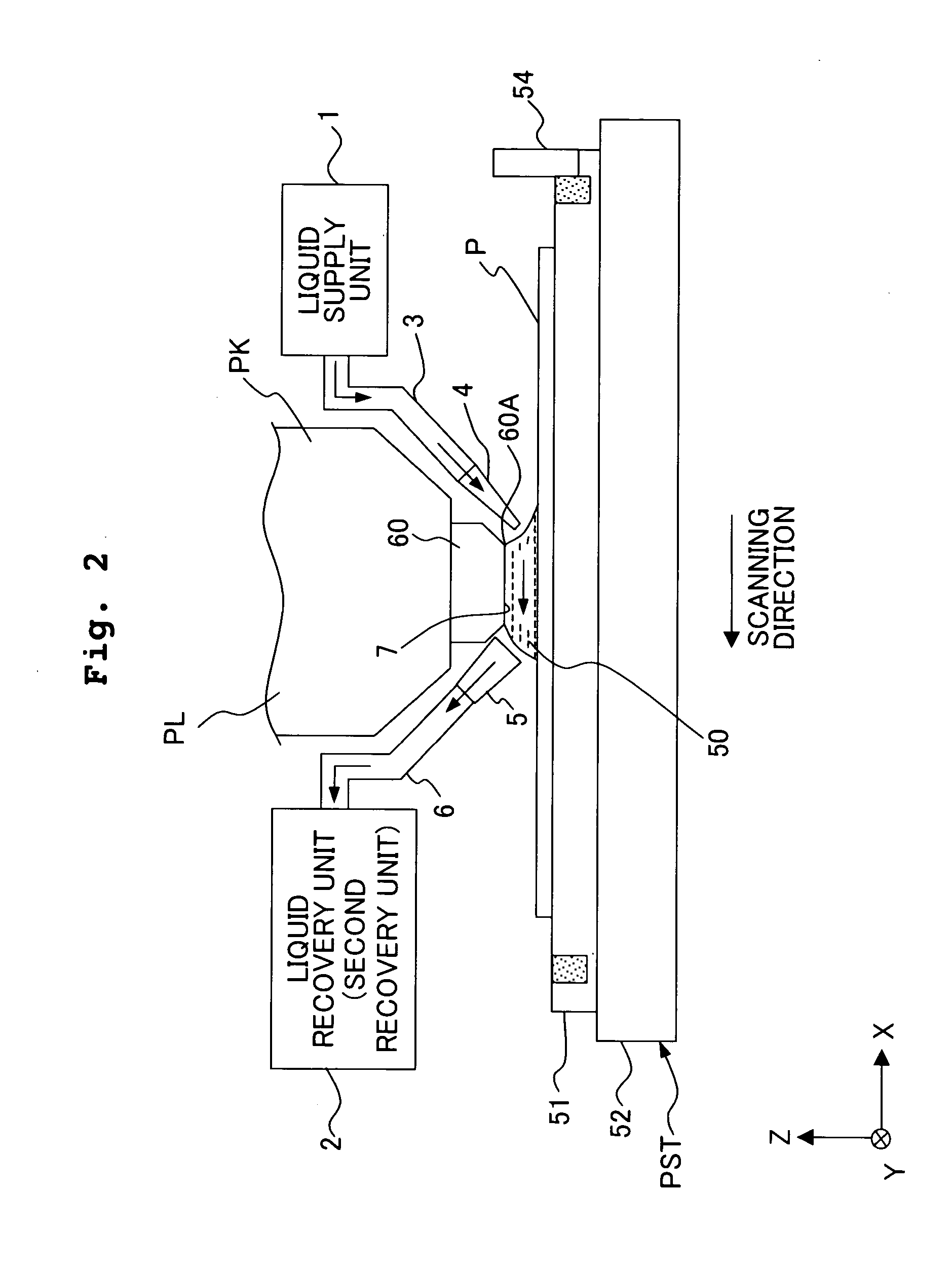

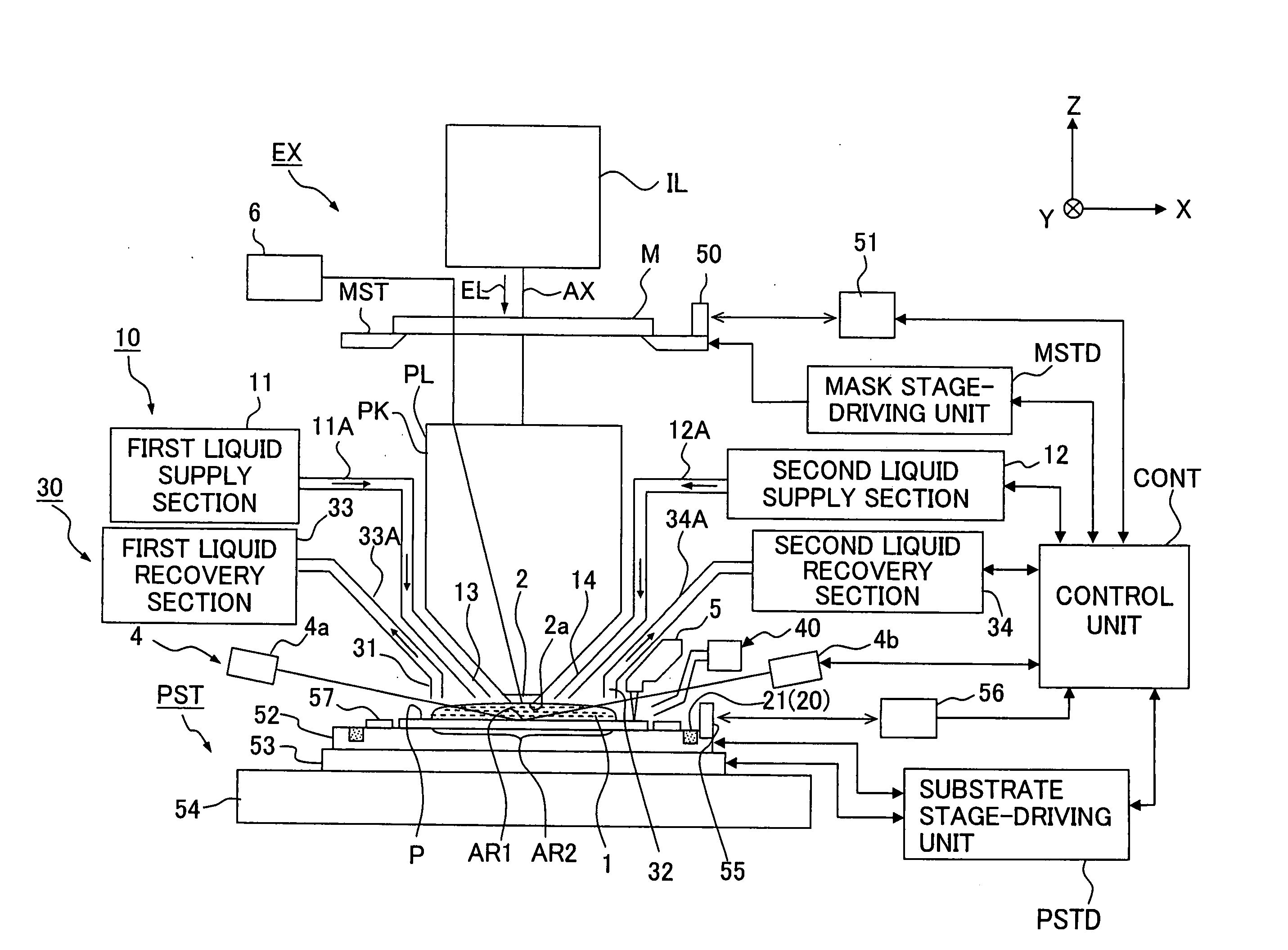

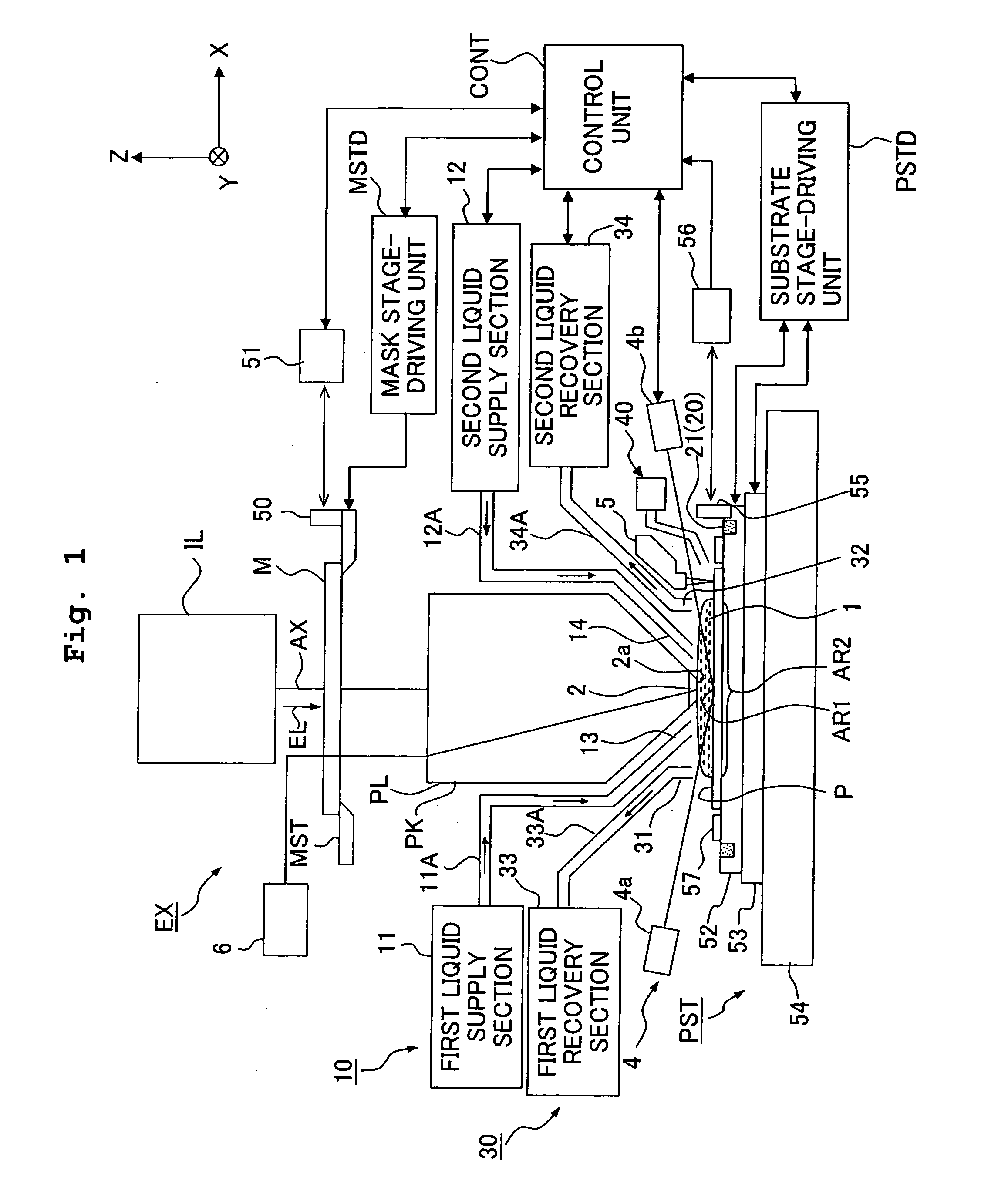

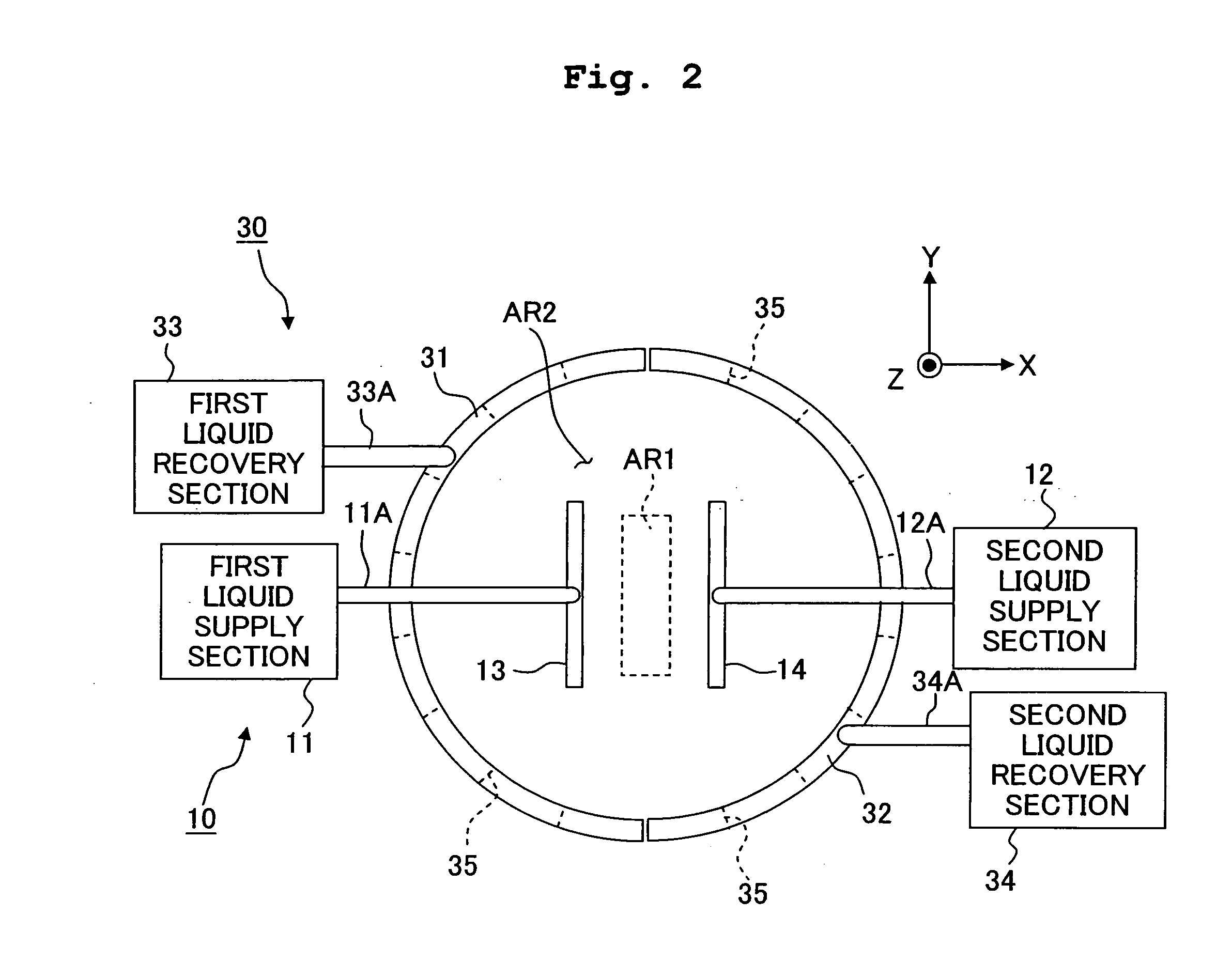

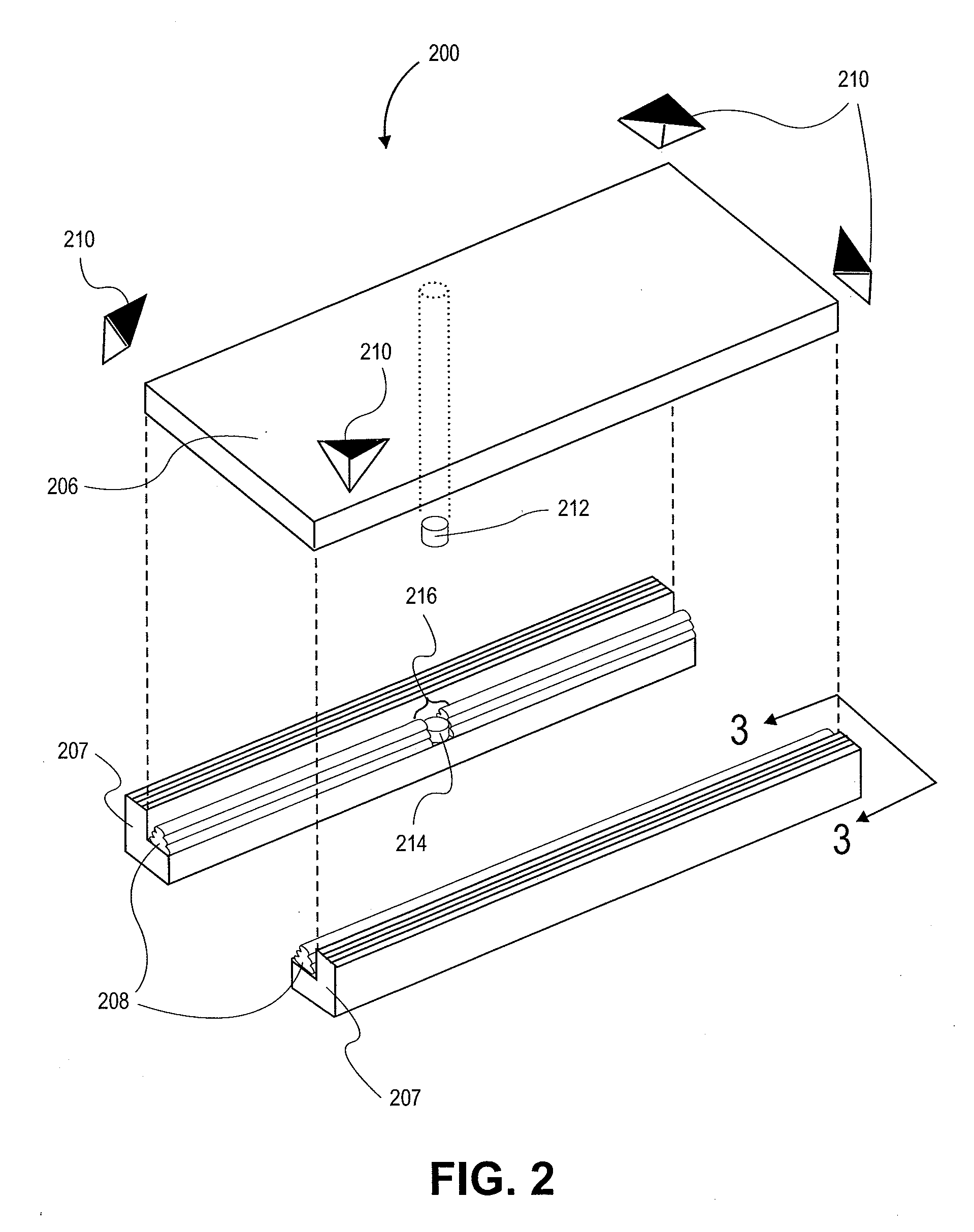

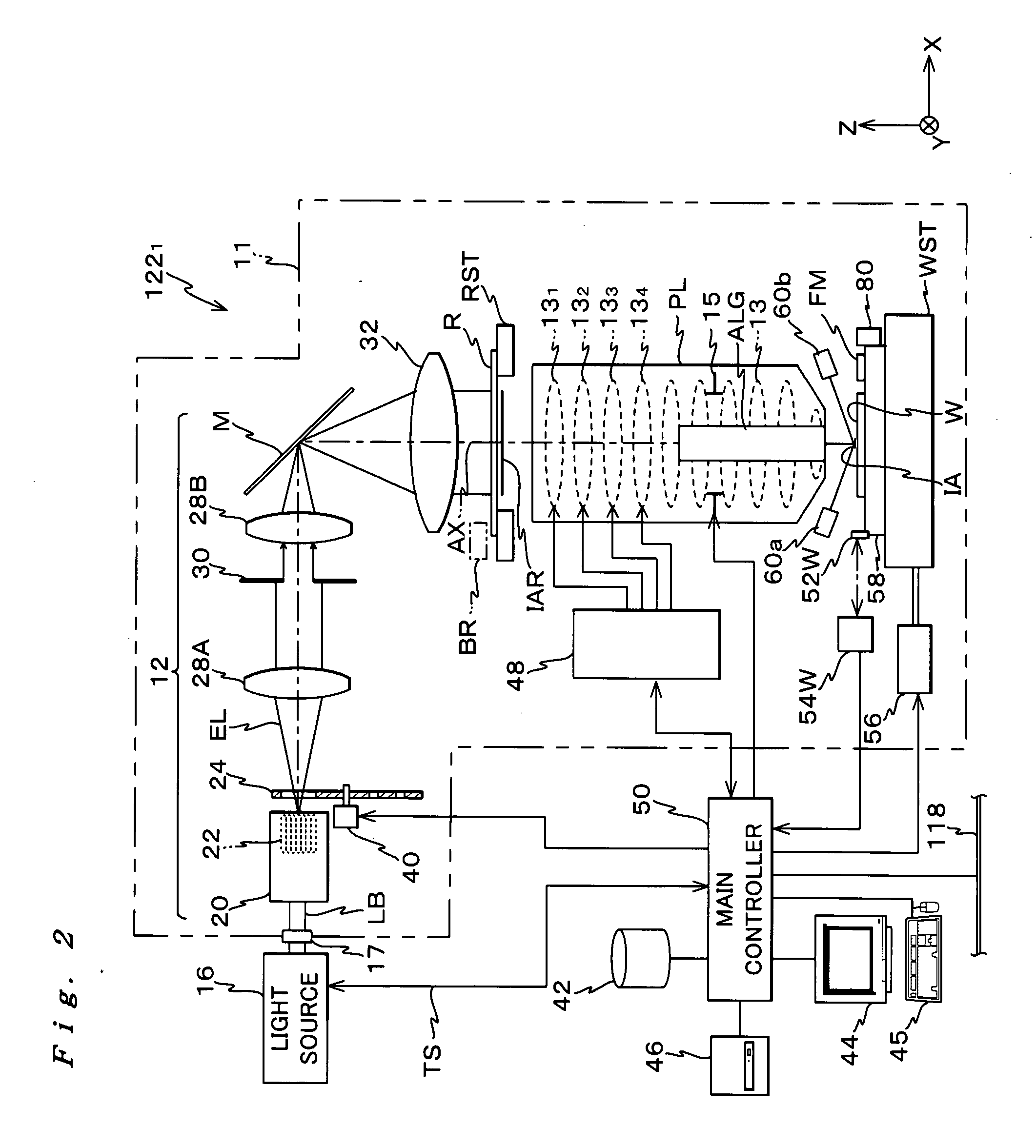

Exposure apparatus and method for producing device

InactiveUS20060077367A1Forming accuratelySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

There is provided an exposure apparatus capable of forming a desirable device pattern by removing unnecessary liquid when performing exposure by projecting a pattern onto the substrate via a projection optical system and the liquid. The exposure device projects an image of the pattern onto the substrate P via the projection optical system and the liquid so as to expose the substrate P. The exposure device includes a liquid removing mechanism 40 which removes the liquid remaining on a part 7 arranged in the vicinity of the image plane of the projection optical system.

Owner:NIKON CORP

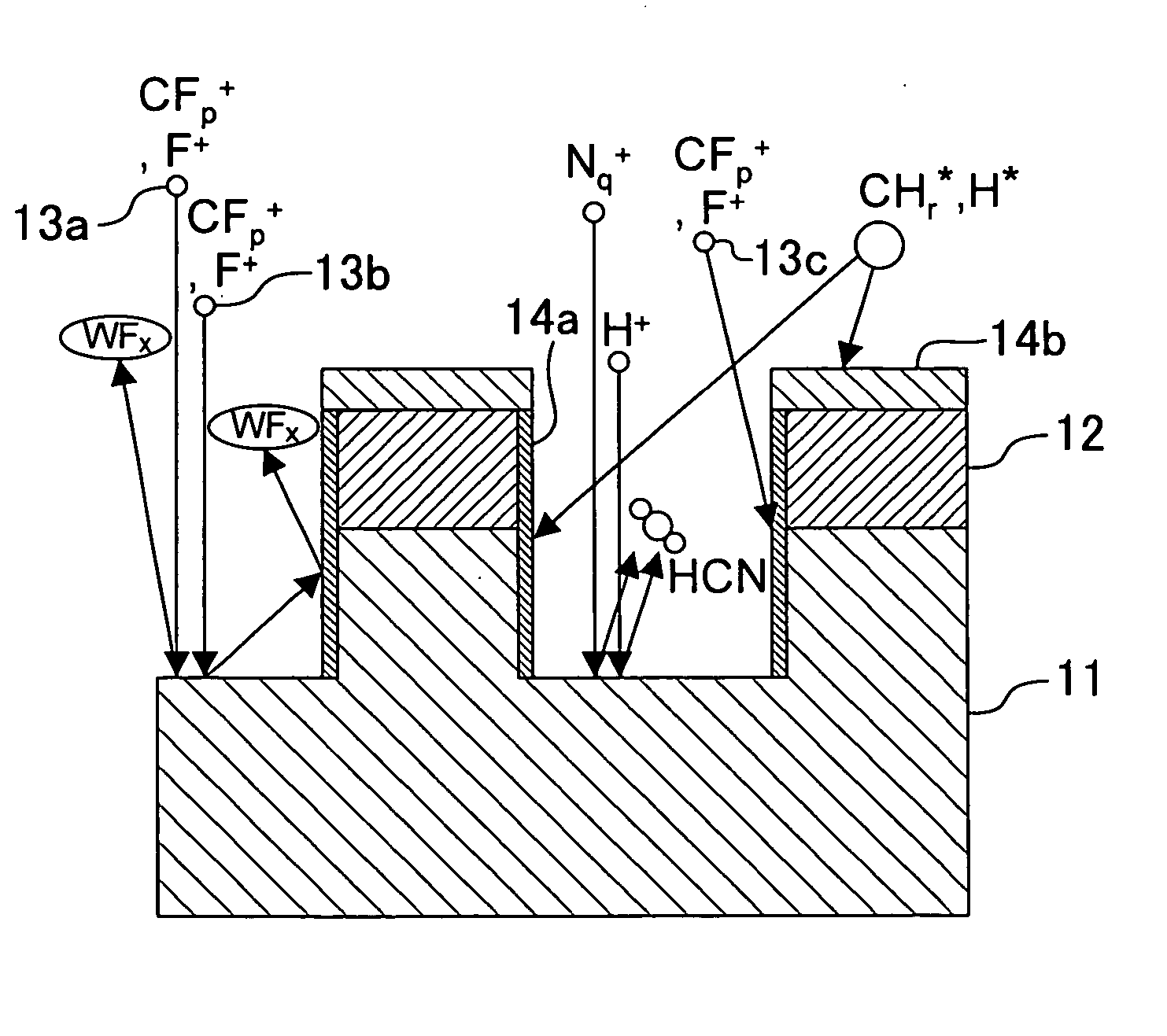

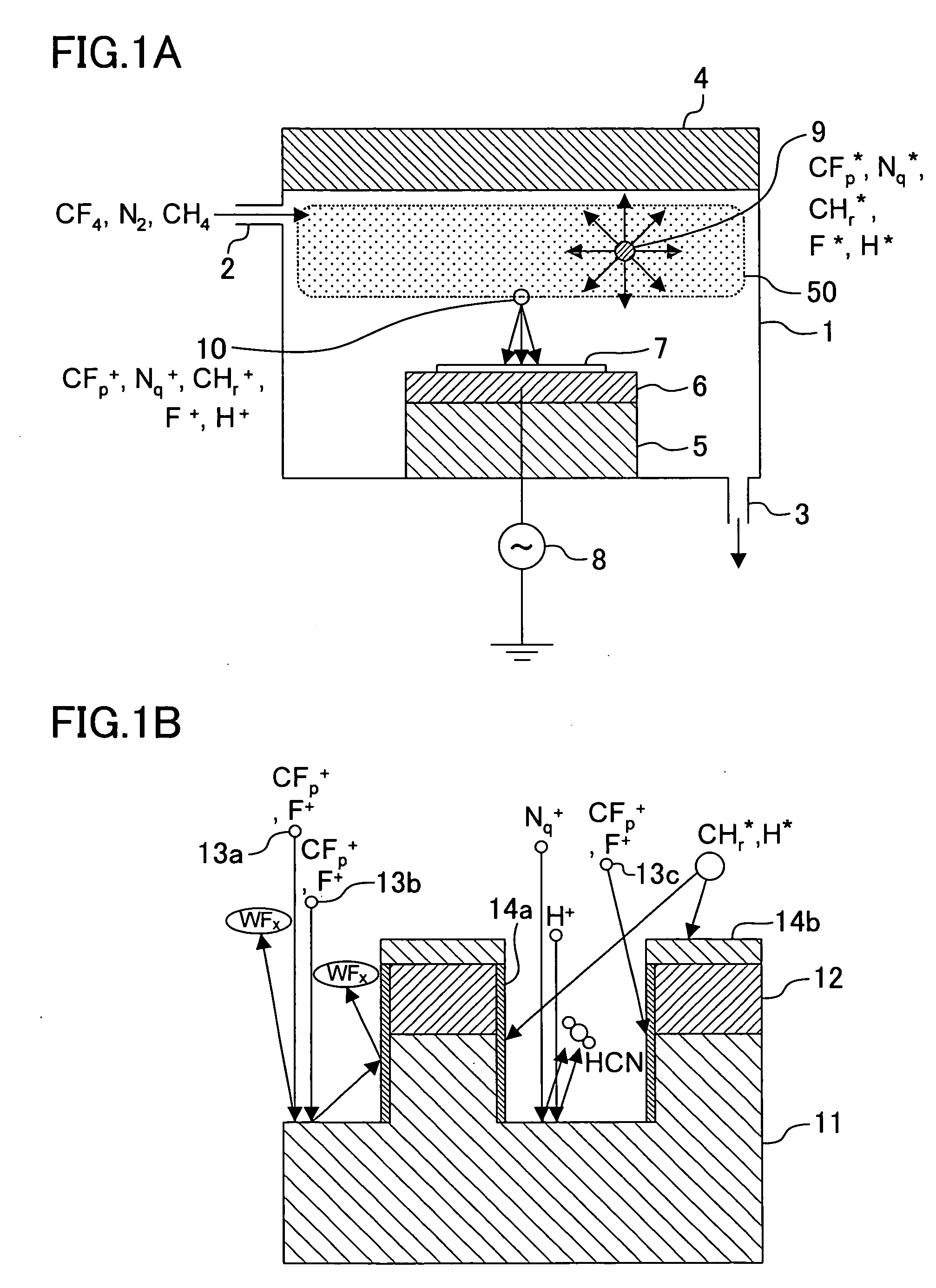

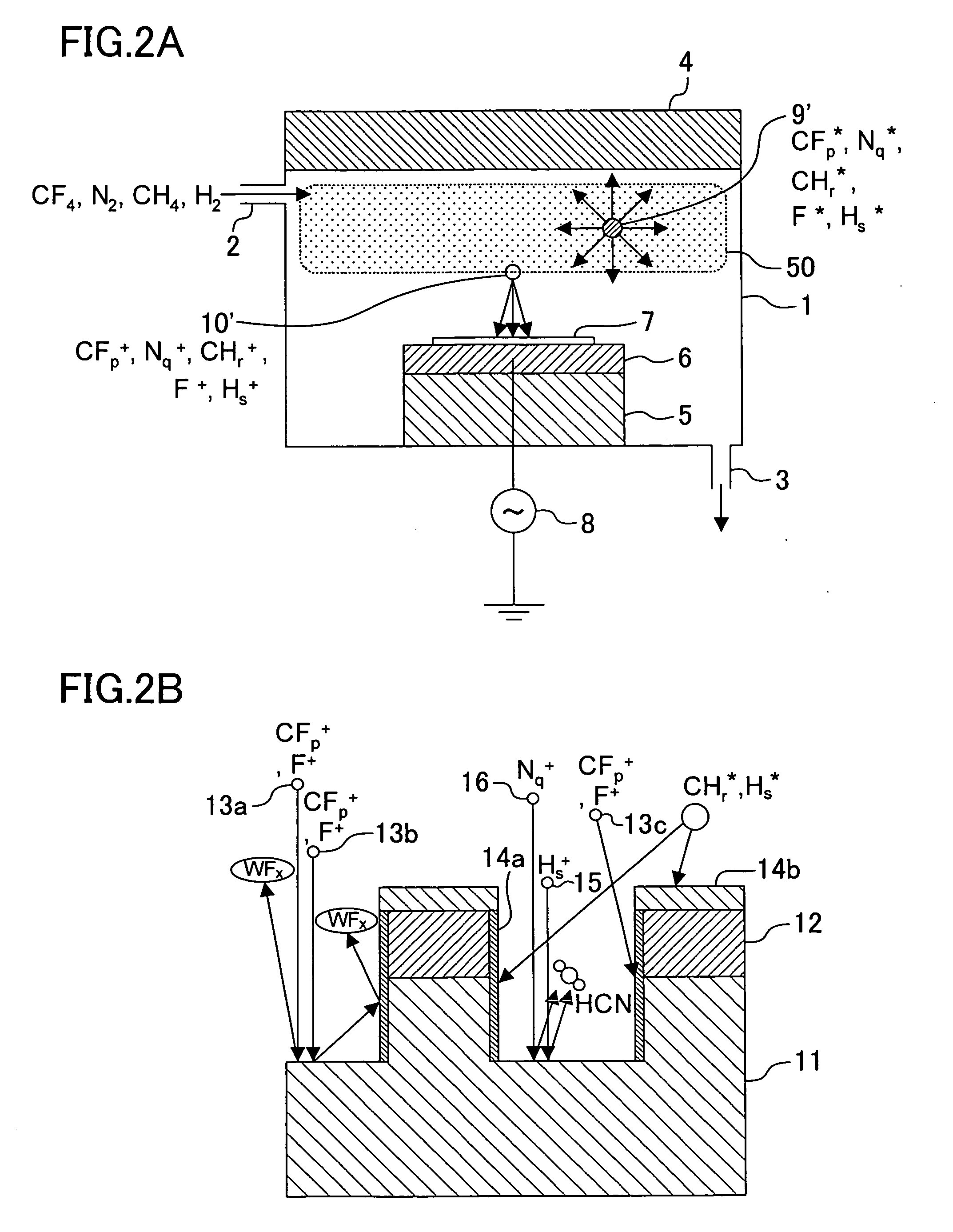

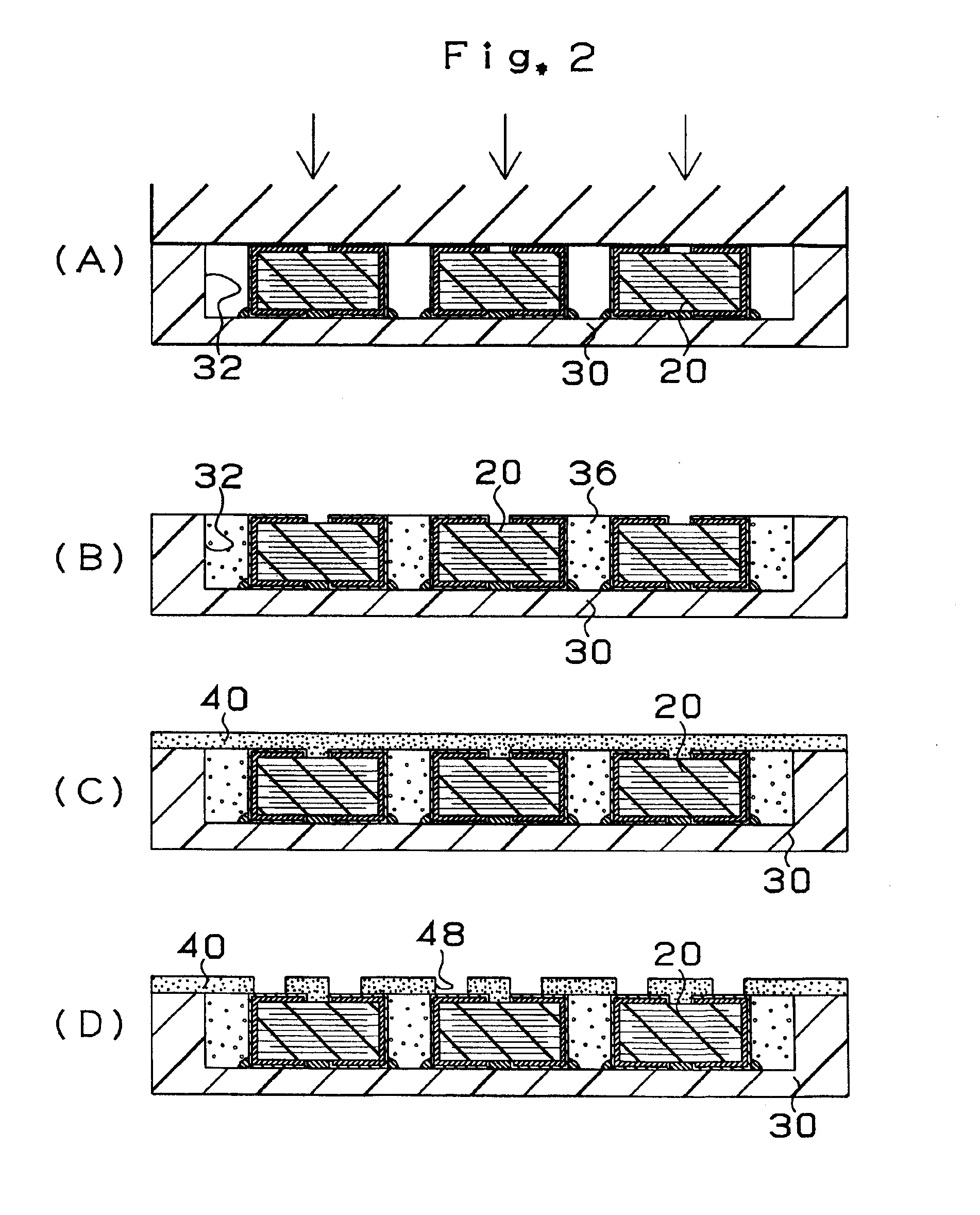

Dry etching method, fine structure formation method, mold and mold fabrication method

InactiveUS20070187362A1Increase preciseness and easinessAccurately formedDecorative surface effectsOptical light guidesNitrogen atomTungsten

Owner:PANASONIC CORP

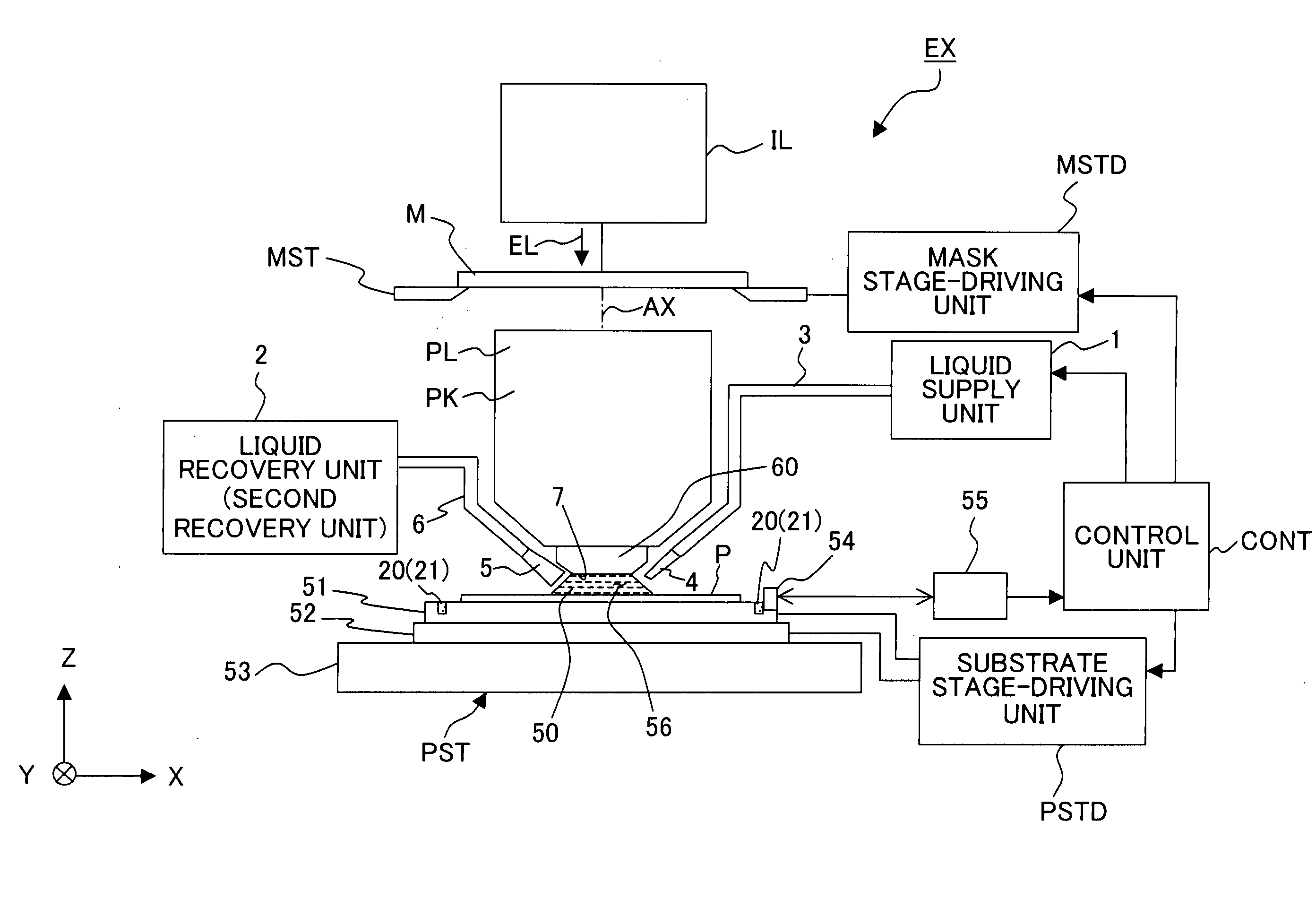

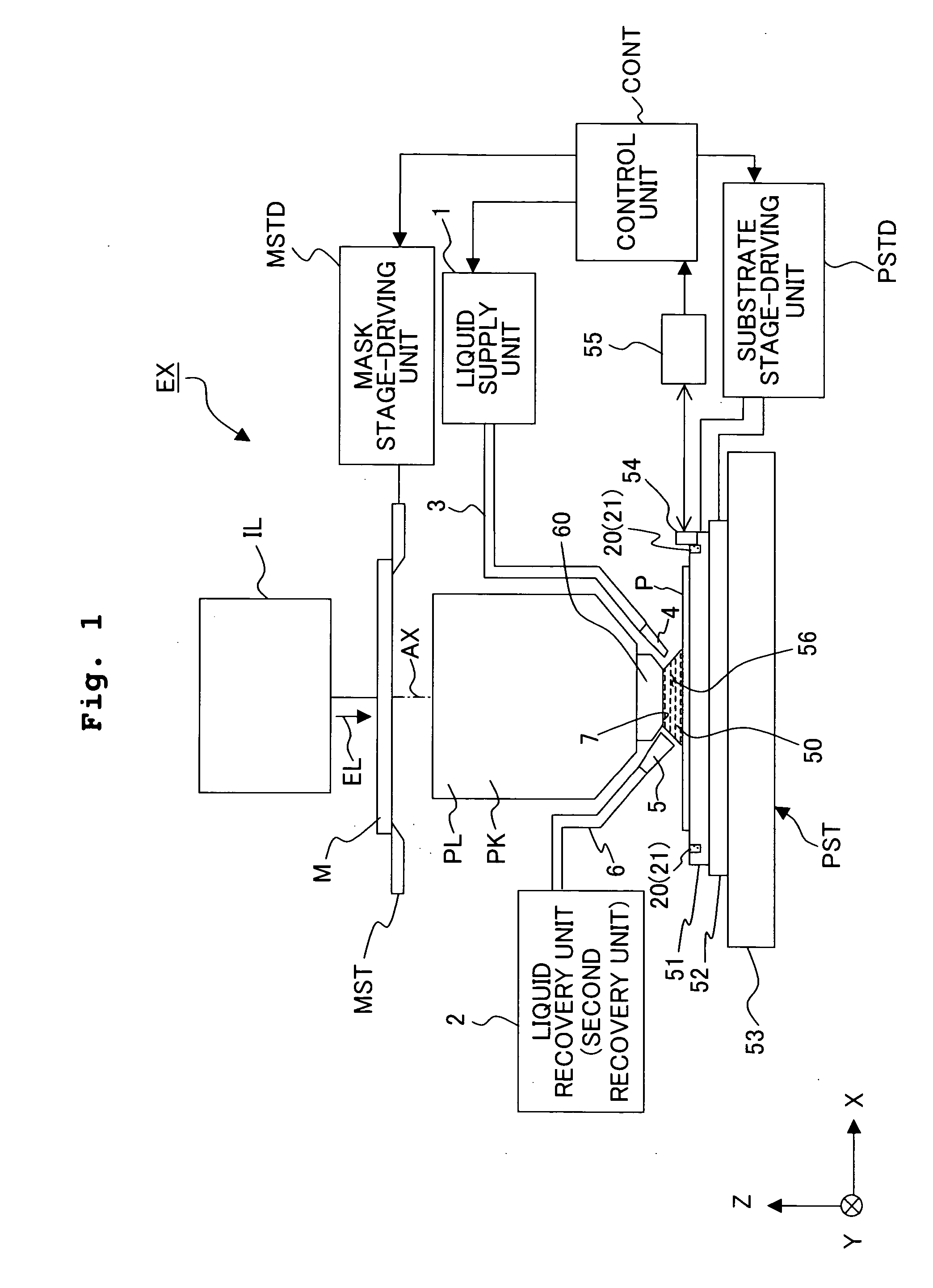

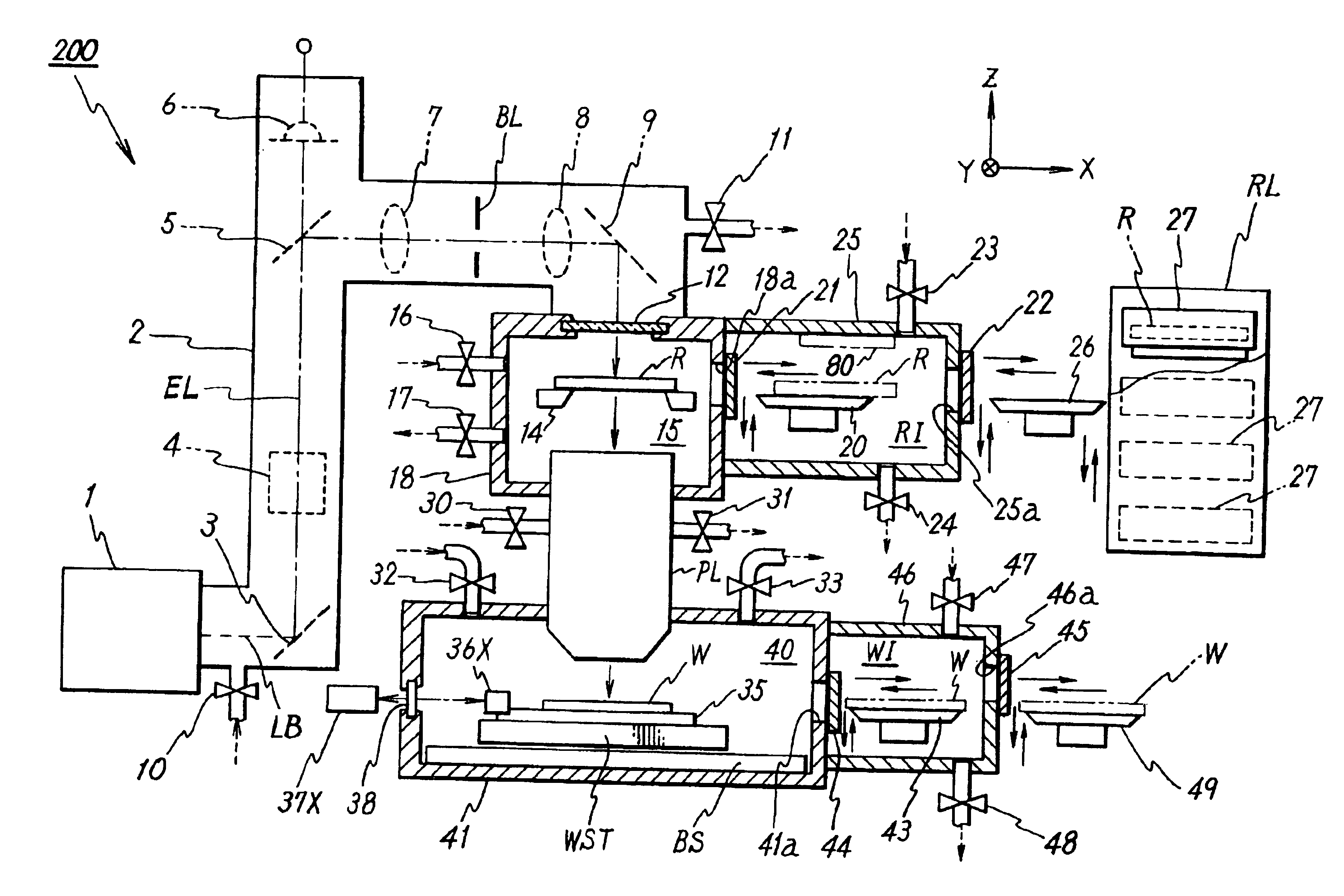

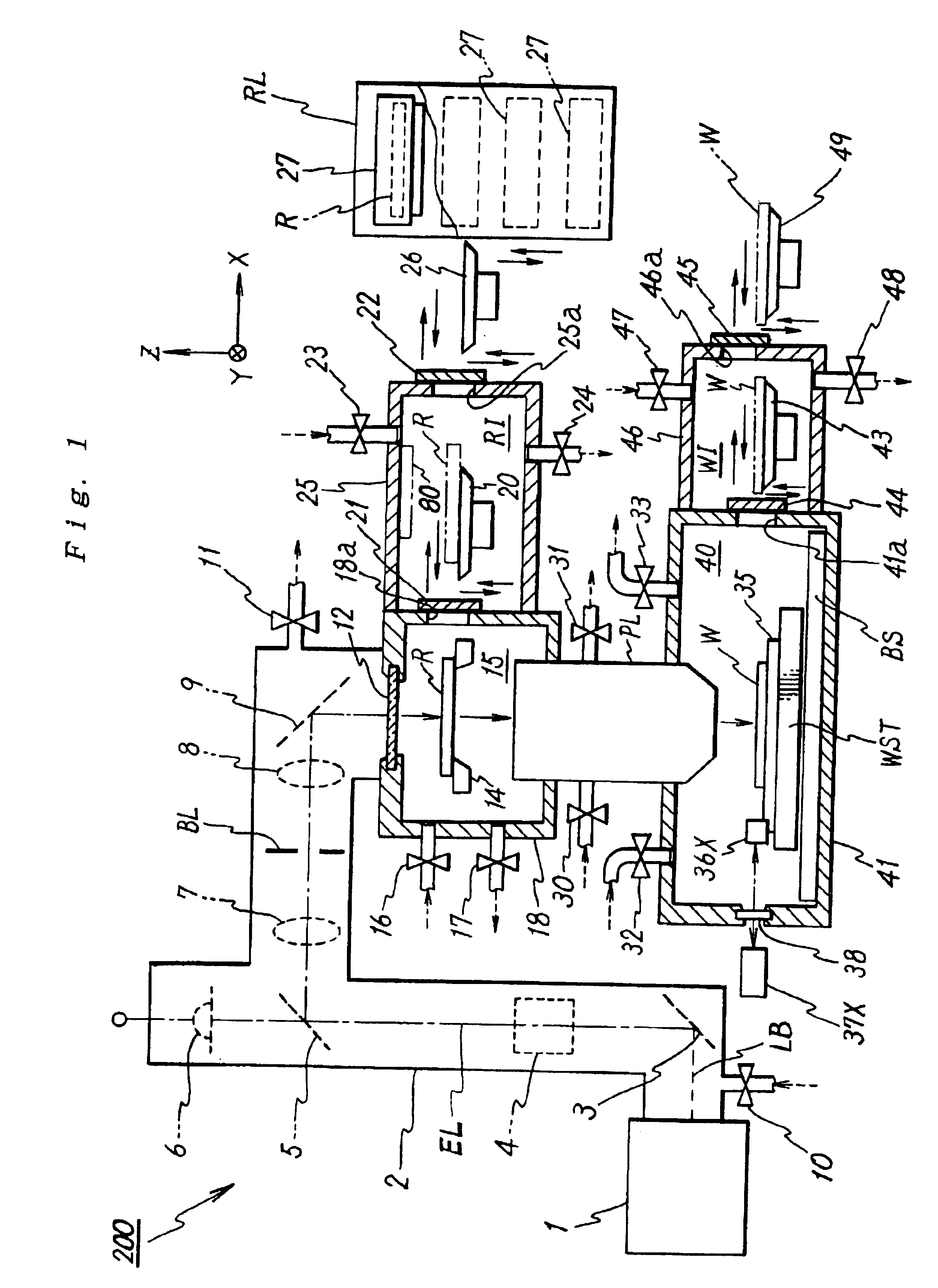

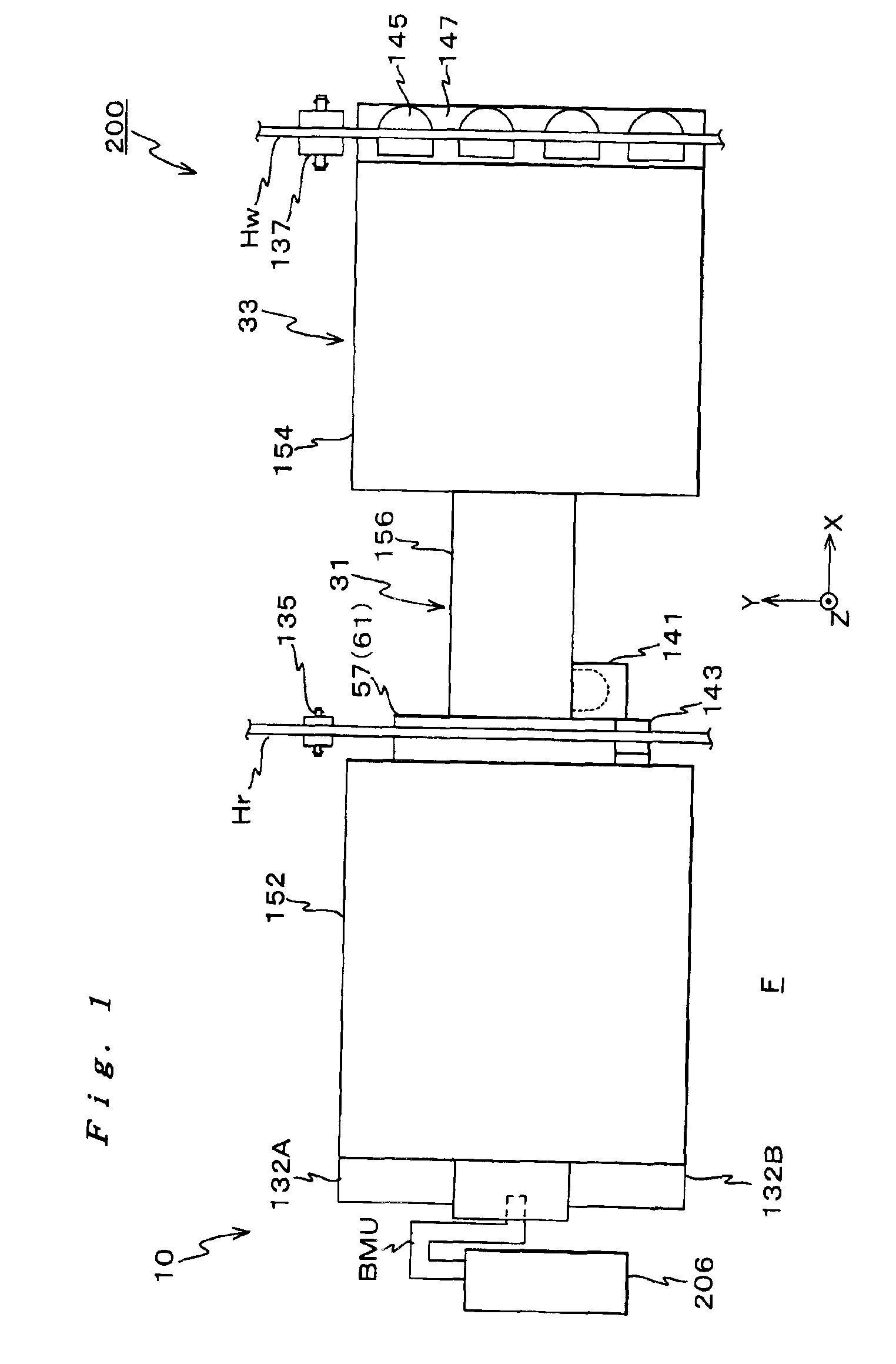

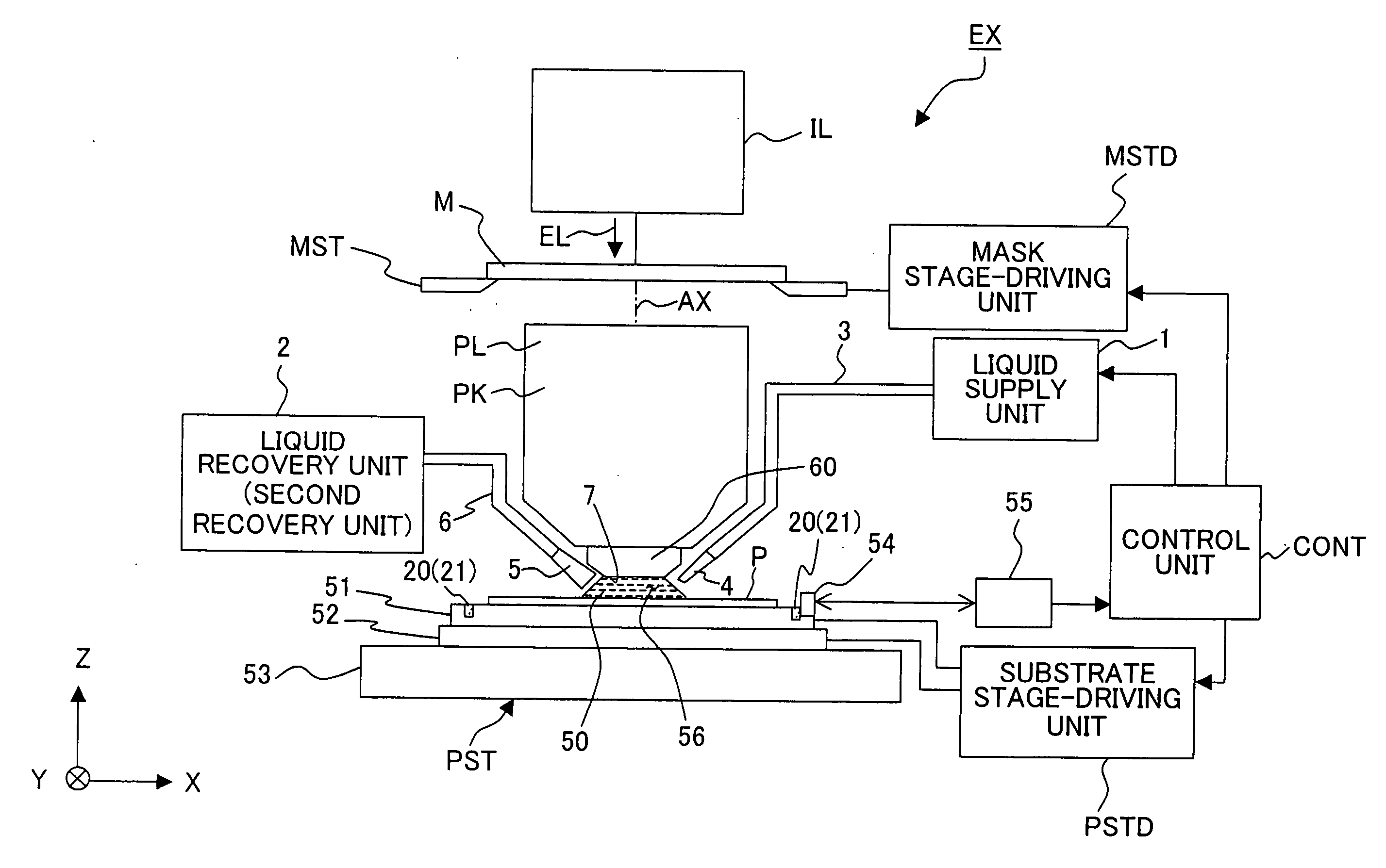

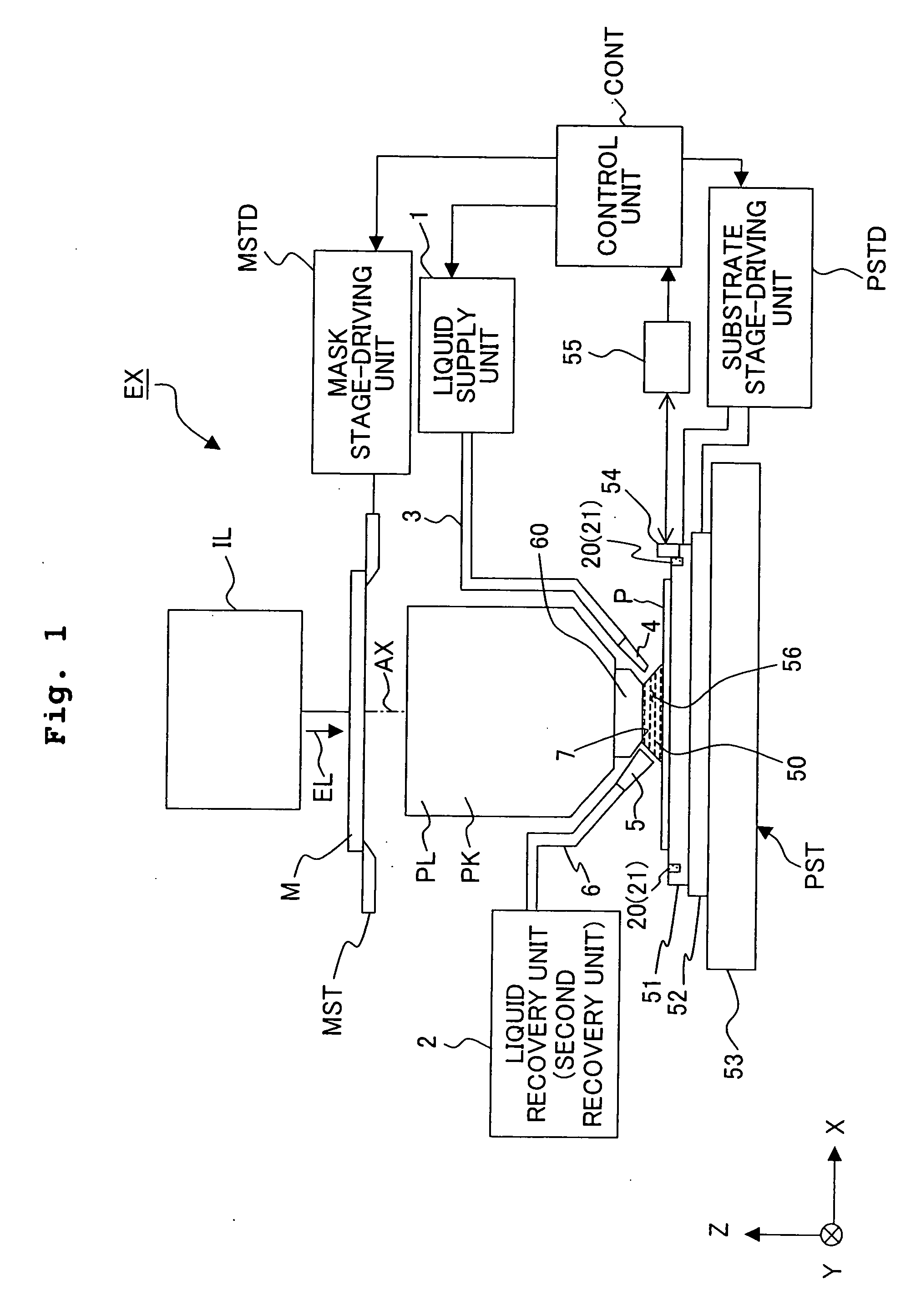

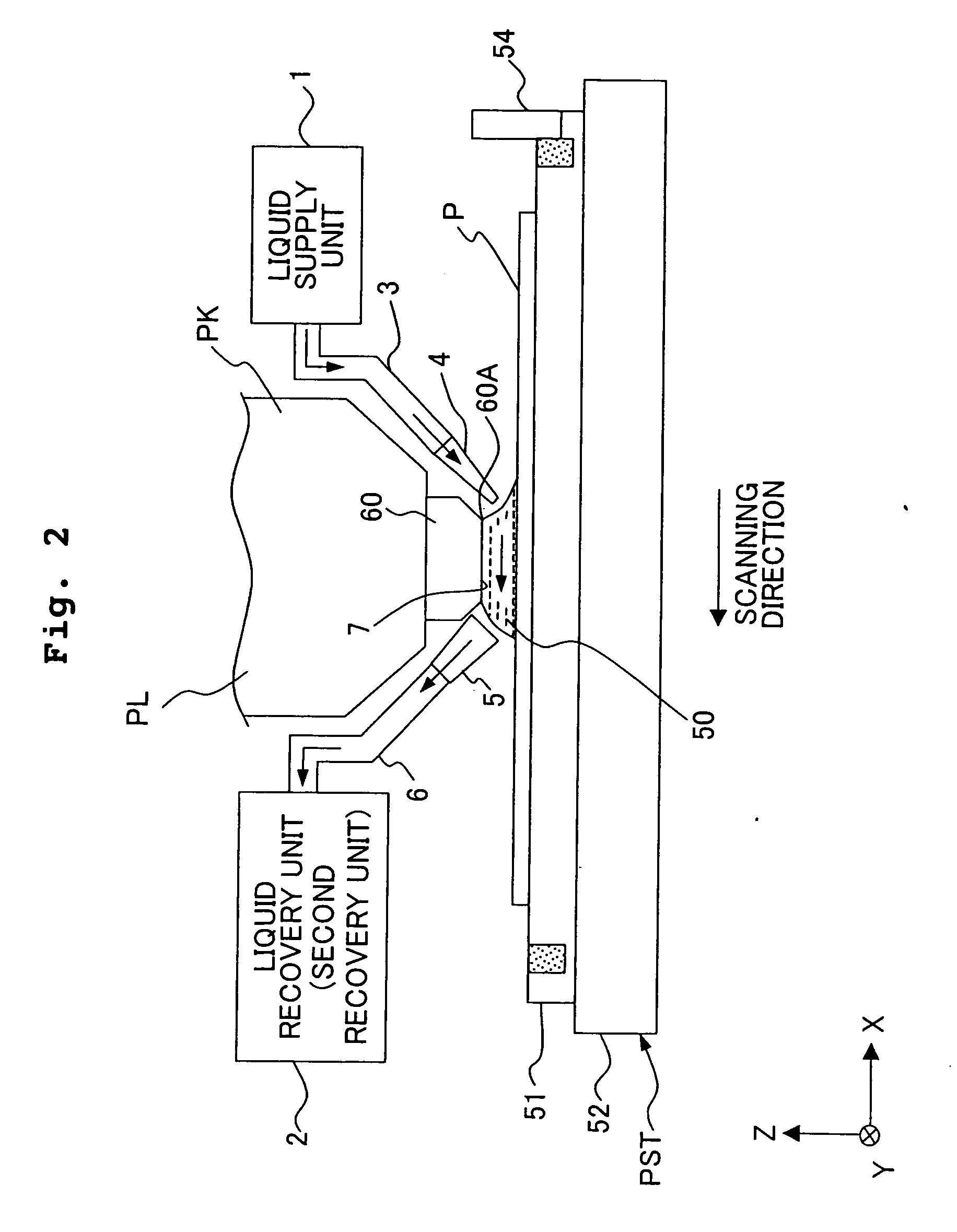

Exposure apparatus and method for producing device

InactiveUS20050219488A1Accurate transferHigh pattern accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

An exposure apparatus exposes a substrate P by locally filling a side of an image plane of a projection optical system PL with a liquid 50 and projecting an image of a pattern onto the substrate P through the liquid 50 and the projection optical system PL. The exposure apparatus includes a recovery unit 20 which recovers the liquid 50 outflowed to the outside of the substrate P. When the exposure process is performed in accordance with the liquid immersion method, the pattern can be transferred accurately while suppressing any environmental change even when the liquid outflows to the outside of the substrate.

Owner:NIKON CORP

Semiconductor device manufacturing method

InactiveUS20110039407A1Appropriately and efficiently manufacturingAppropriatelySemiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerDevice material

A semiconductor device manufacturing method, the method including: forming an insulation layer having a protruding portion, the insulation layer having a surface and a rising surface that protrudes upward from the surface, on a semiconductor substrate; forming a conductive layer to cover the insulation layer having the protruding portion; and removing a predetermined region of the conductive layer by patterning the predetermined region according to an etching process using microwave plasma, which uses a microwave as a plasma source, while applying bias power of 70 mW / cm2 or above on the semiconductor substrate, under a high pressure condition of 85 mTorr or above.

Owner:TOKYO ELECTRON LTD

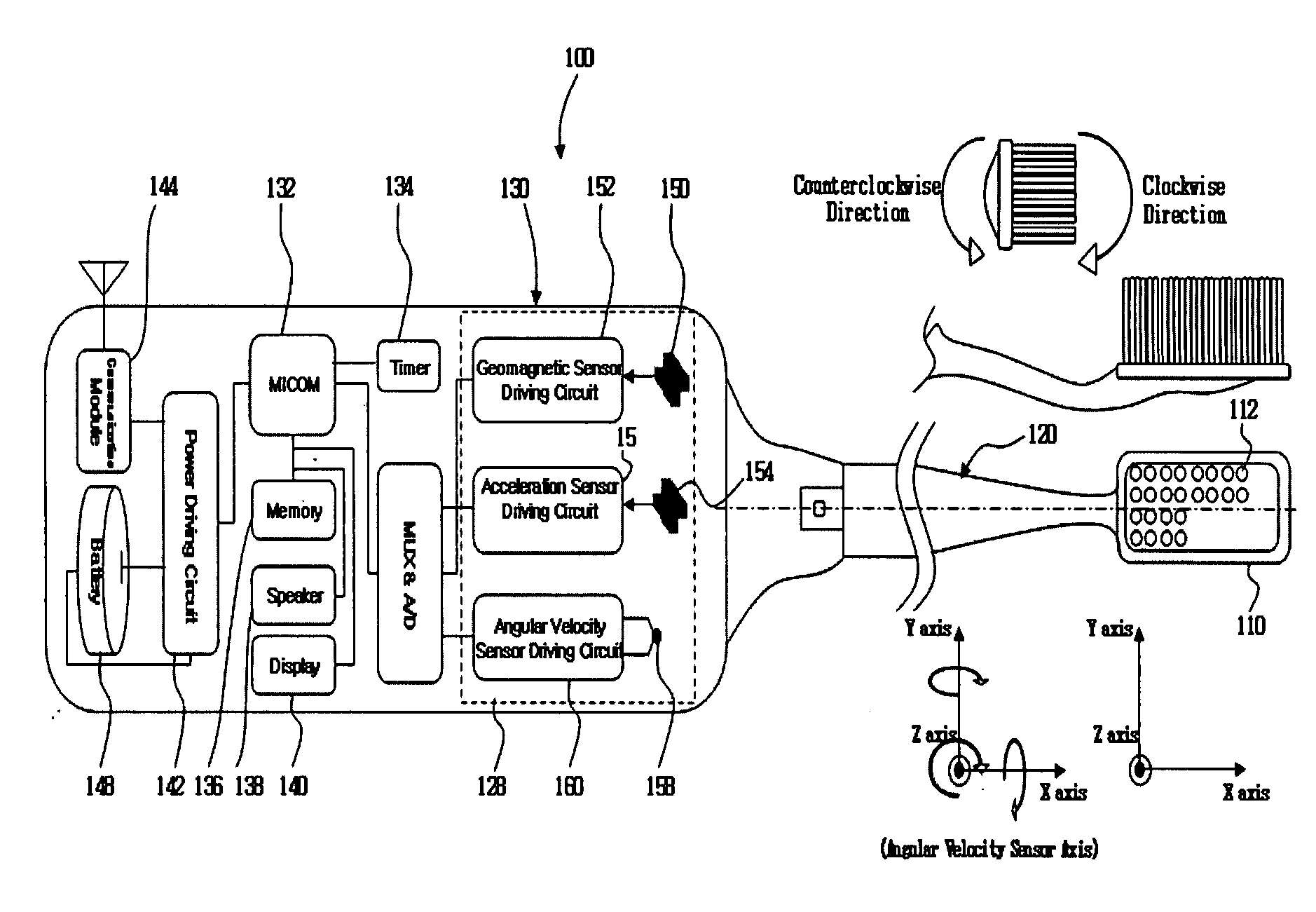

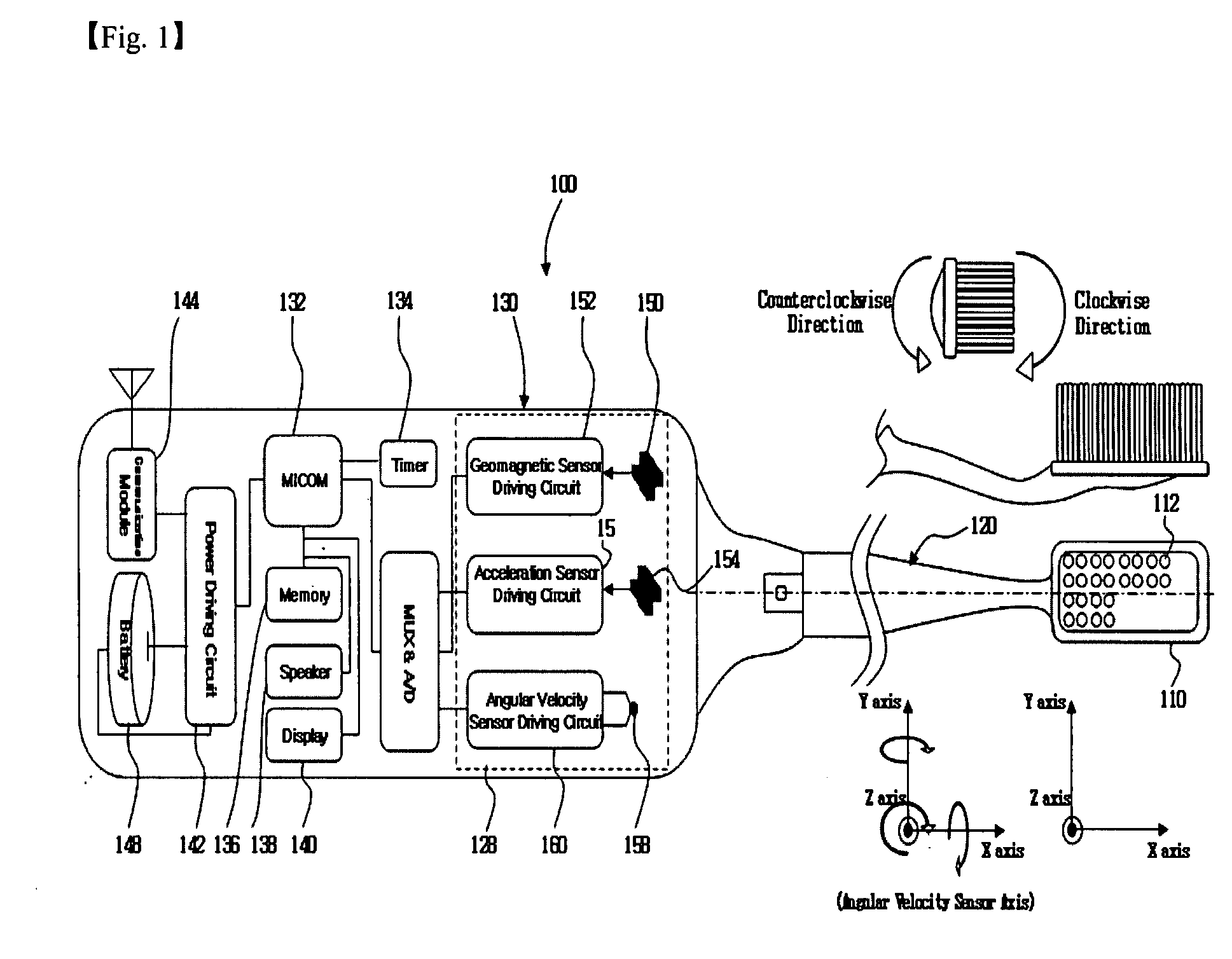

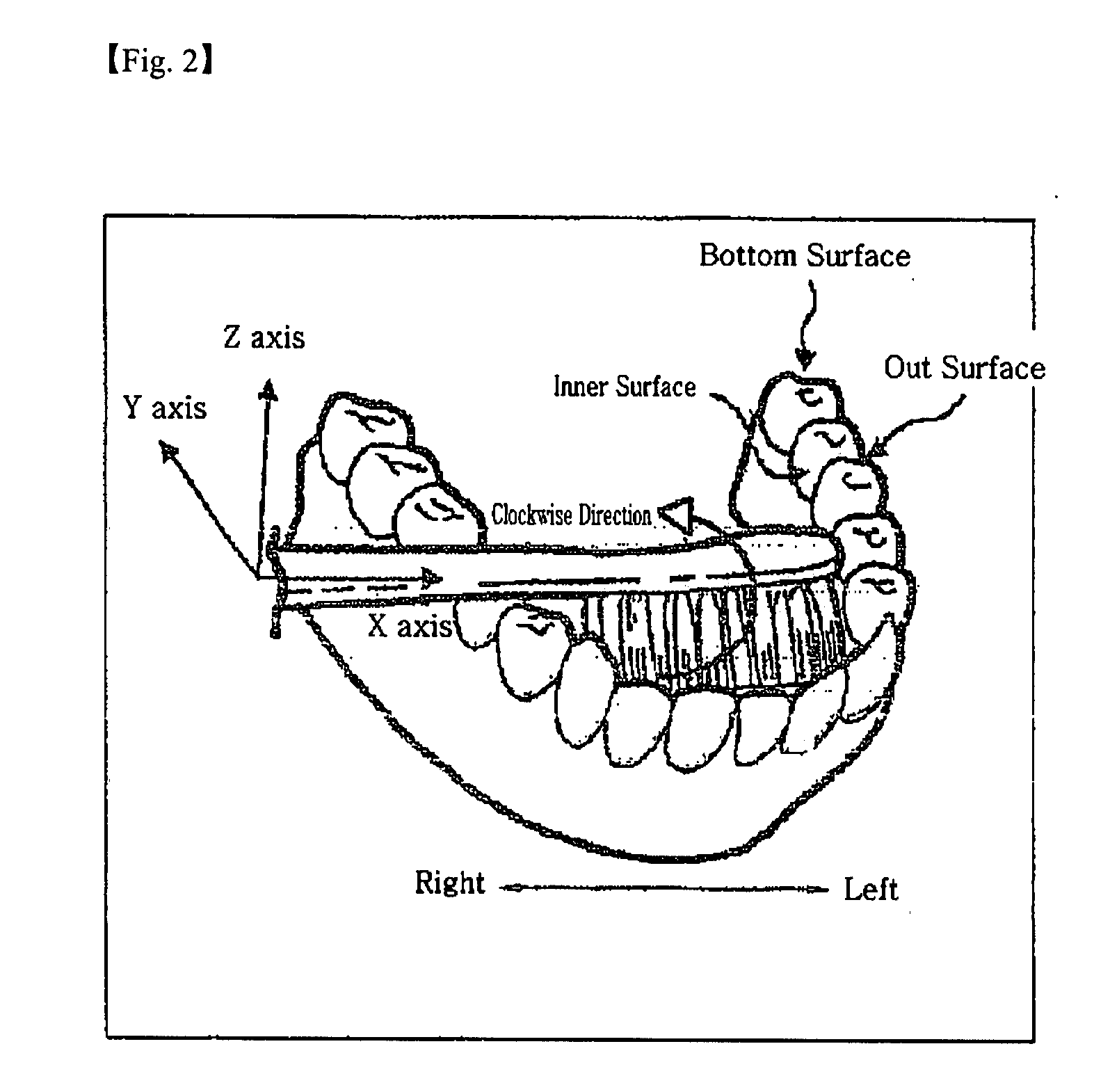

Tooth brushing pattern analyzing/modifying device, method and system for interactively modifying tooth brushing behavior

InactiveUS20090092955A1Good estimateEffective correctionMechanical/radiation/invasive therapiesFinanceEngineeringCorrection method

Disclosed are a toothbrushing pattern analyzing / correcting device, a toothbrushing pattern analyzing / correcting method, a method and a system for interactively correcting toothbrushing behavior. The toothbrushing pattern analyzing / correcting device of the present invention includes: a body part formed in the same direction as a toothbrush surface; a sensing unit having a sensor with at least one or more axes for sensing a user's toothbrushing motion and a sensor with one or more axes for sensing two or more toothbrushing positions; and a controller for operating signals input from the sensing unit to classify a user's toothbrushing motion into at least two or more patterns and at least two or more toothbrushing parts. Further, the toothbrushing pattern analyzing / correcting method includes the steps of: detecting the start of a user's toothbrushing; displaying a guiding screen in response to the start of a user's toothbrushing; detecting a user's toothbrushing pattern; analyzing the user's detected toothbrushing pattern; and providing a toothbrushing correction screen with the intention of increasing compliance in accordance with the analyzed result. Accordingly, toothbrushing behavior correction compliance can be further enhanced with a method of interactively correcting a user's toothbrushing behavior through multimedia image substances in real time, and more systematic management and health consultation are possible by building a database of information of the user's toothbrushing behavior.

Owner:XIU SOLUTIONS

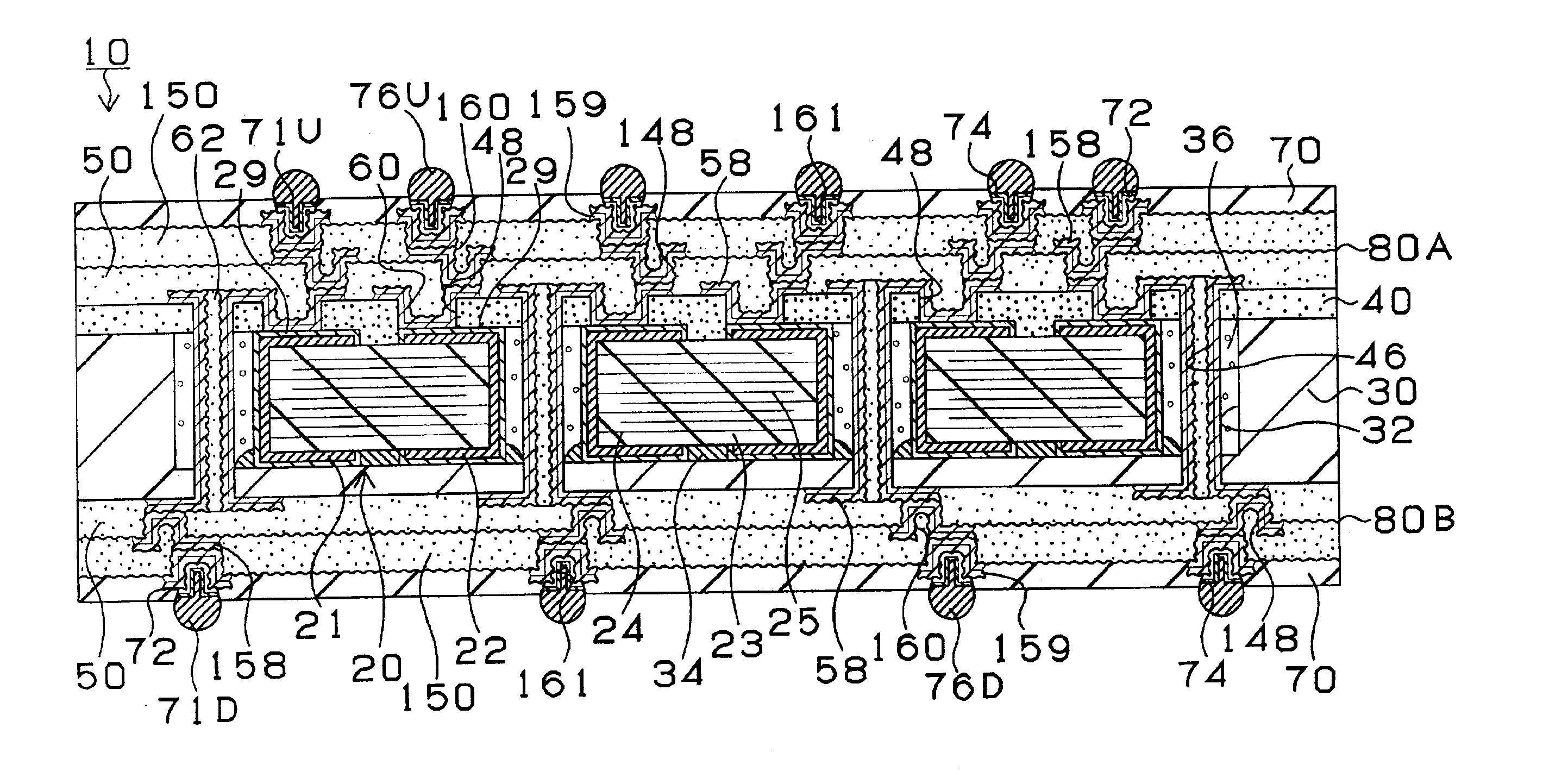

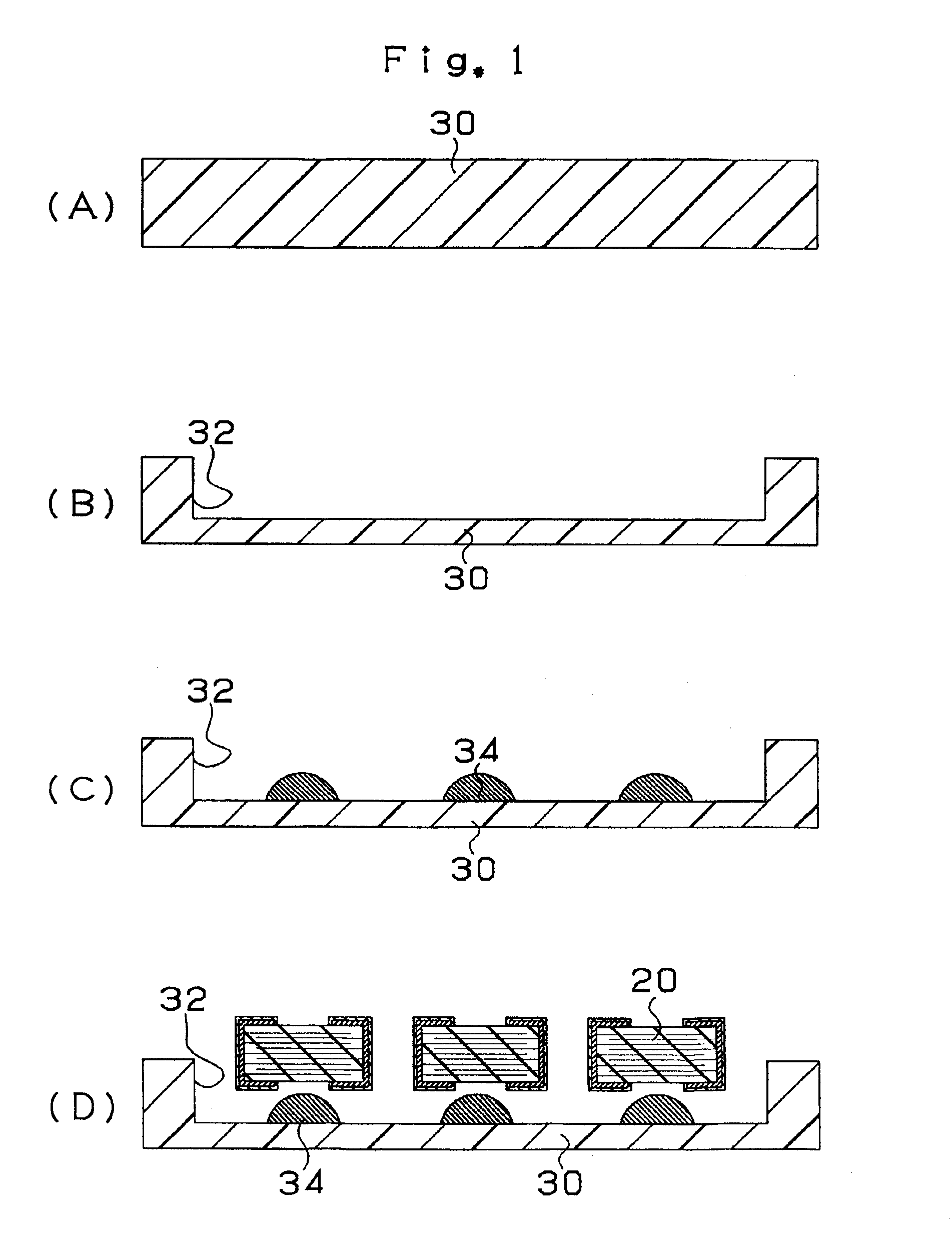

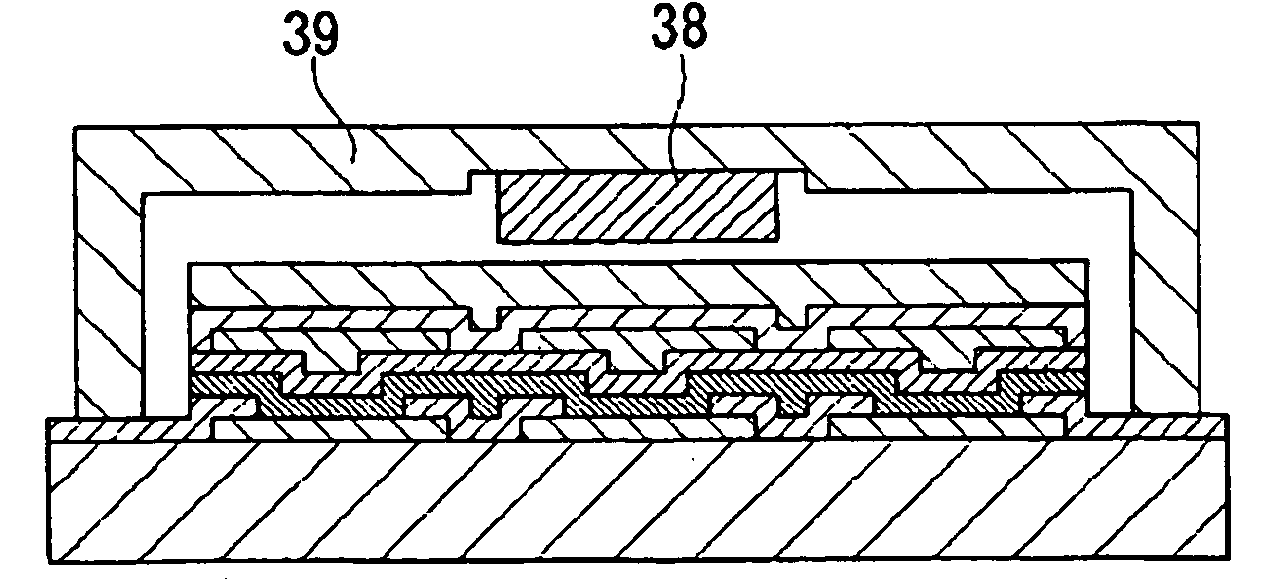

Printing wiring board and method of producing the same and capacitor to be contained in printed wiring board

InactiveUS6876554B1Improve reliabilityFlat surfaceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPrinted circuit board

Chip capacitors 20 are provided in a printed circuit board 10. In this manner, the distance between an IC chip 90 and each chip capacitor 20 is shortened, and the loop inductance is reduced. In addition, the chip capacitors 20 are accommodated in a core substrate 30 having a large thickness. Therefore, the thickness of the printed circuit board does not become large.

Owner:IBIDEN CO LTD

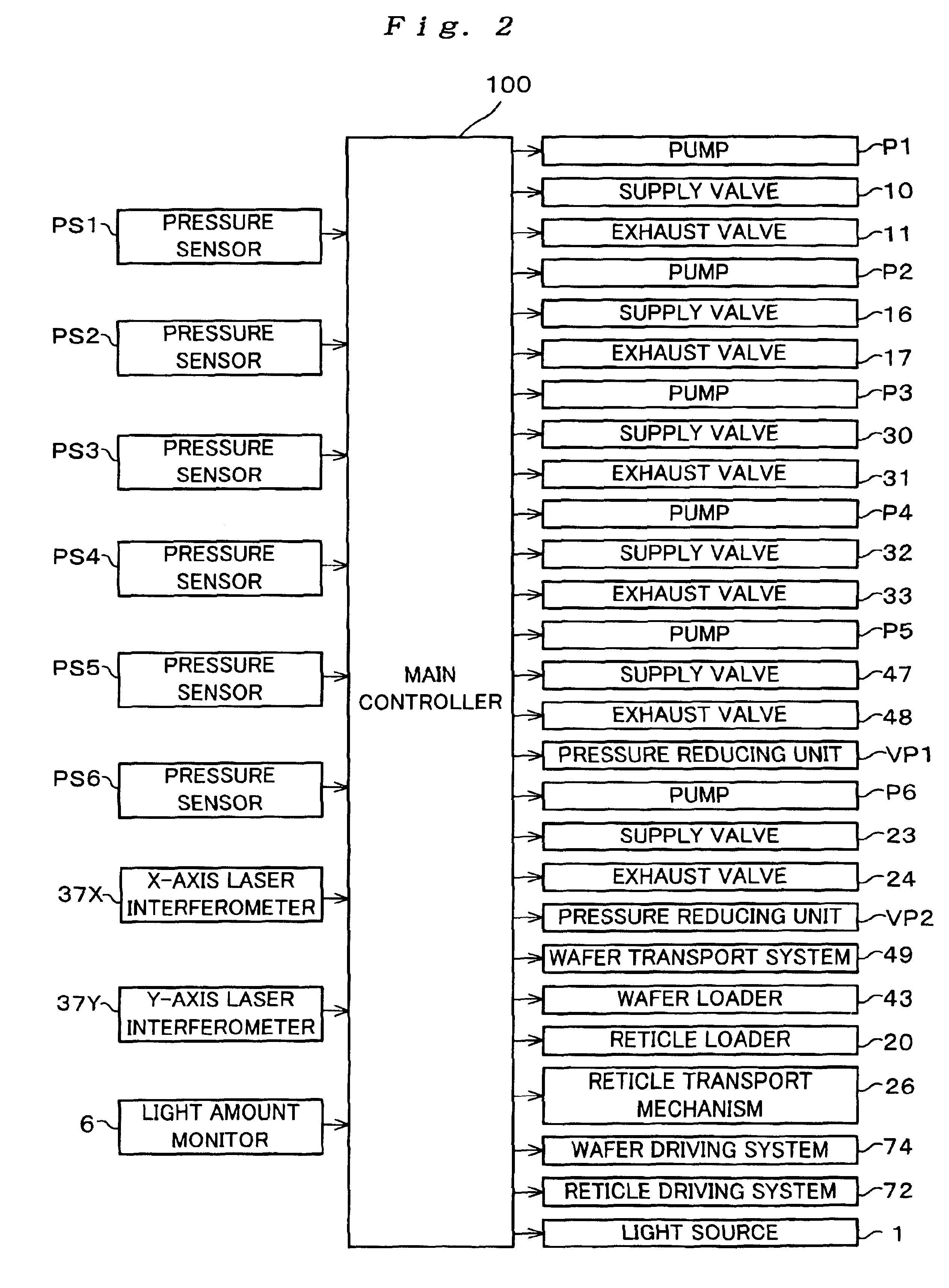

Exposure apparatus and exposure method, and device manufacturing method

InactiveUS6842221B1Stable exposure intensityForming accuratelyPhotomechanical exposure apparatusMicrolithography exposure apparatusMask ROMEngineering

After a mask is carried into a reserve room for temporarily storing before carrying into a mask room filled with specific gas that has an impurity concentration lower than a first concentration (e.g. 1 ppb) and that has a characteristic of absorbing little exposure light, gas-replacement mechanisms replace gas in the reserve room with specific gas having an oxygen concentration not lower than the first concentration. Therefore, when subsequently carrying the mask into the mask room, impurities from the outside (including absorbent gas) can be substantially prevented from getting into the optical path inside the mask room. When replacing a wafer, gas in a reserve room is also replaced in the same way as the above.

Owner:NIKON CORP

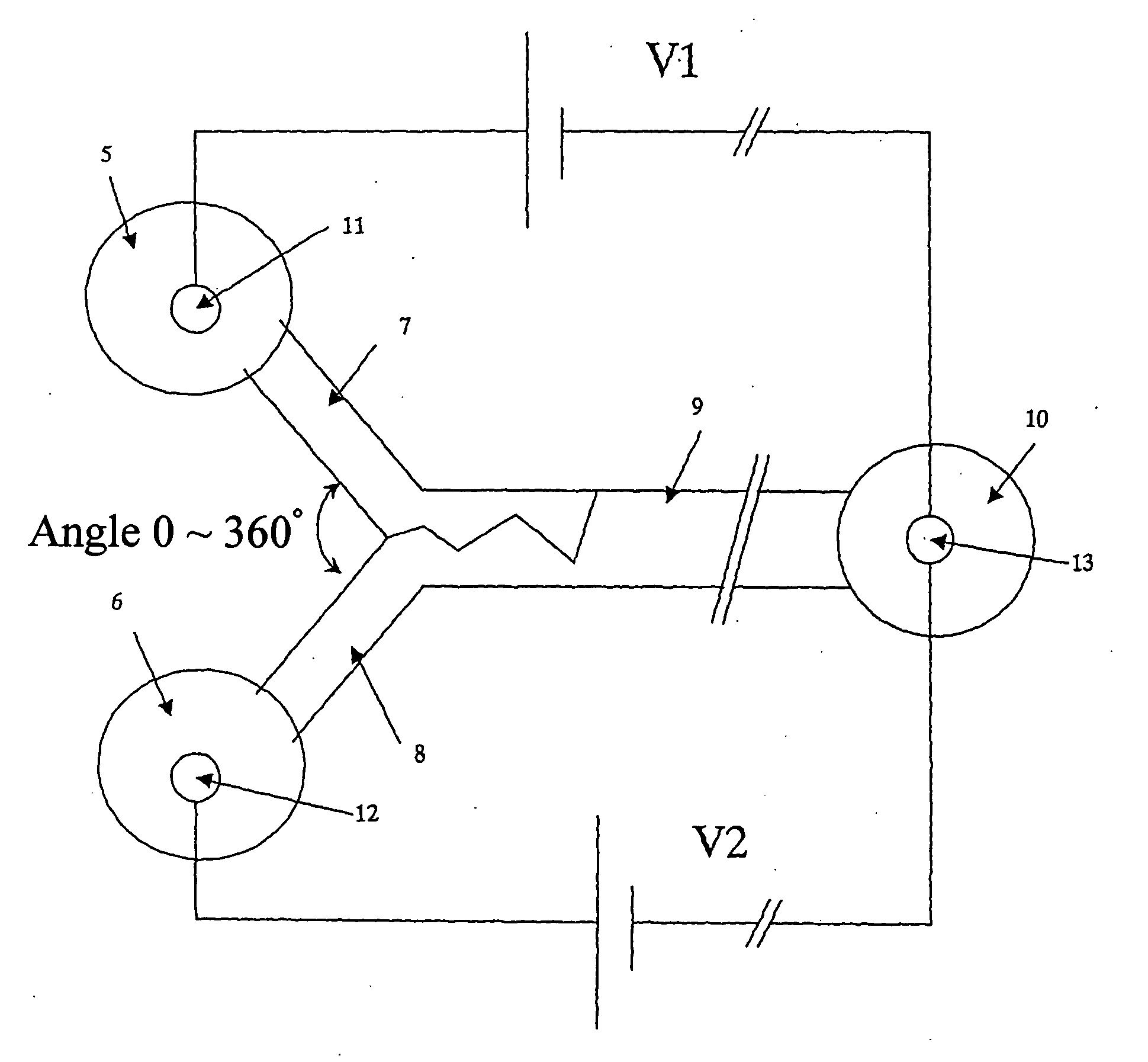

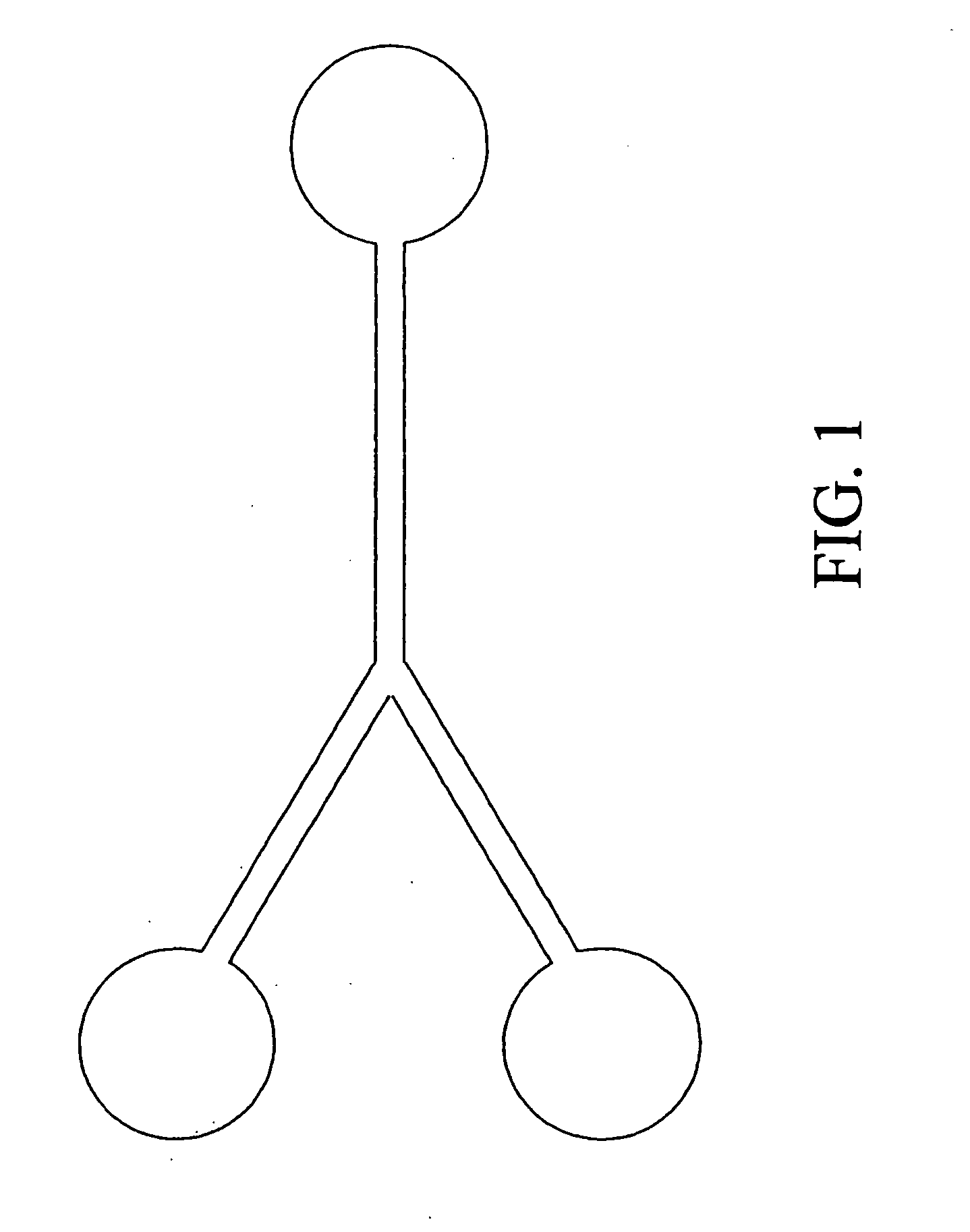

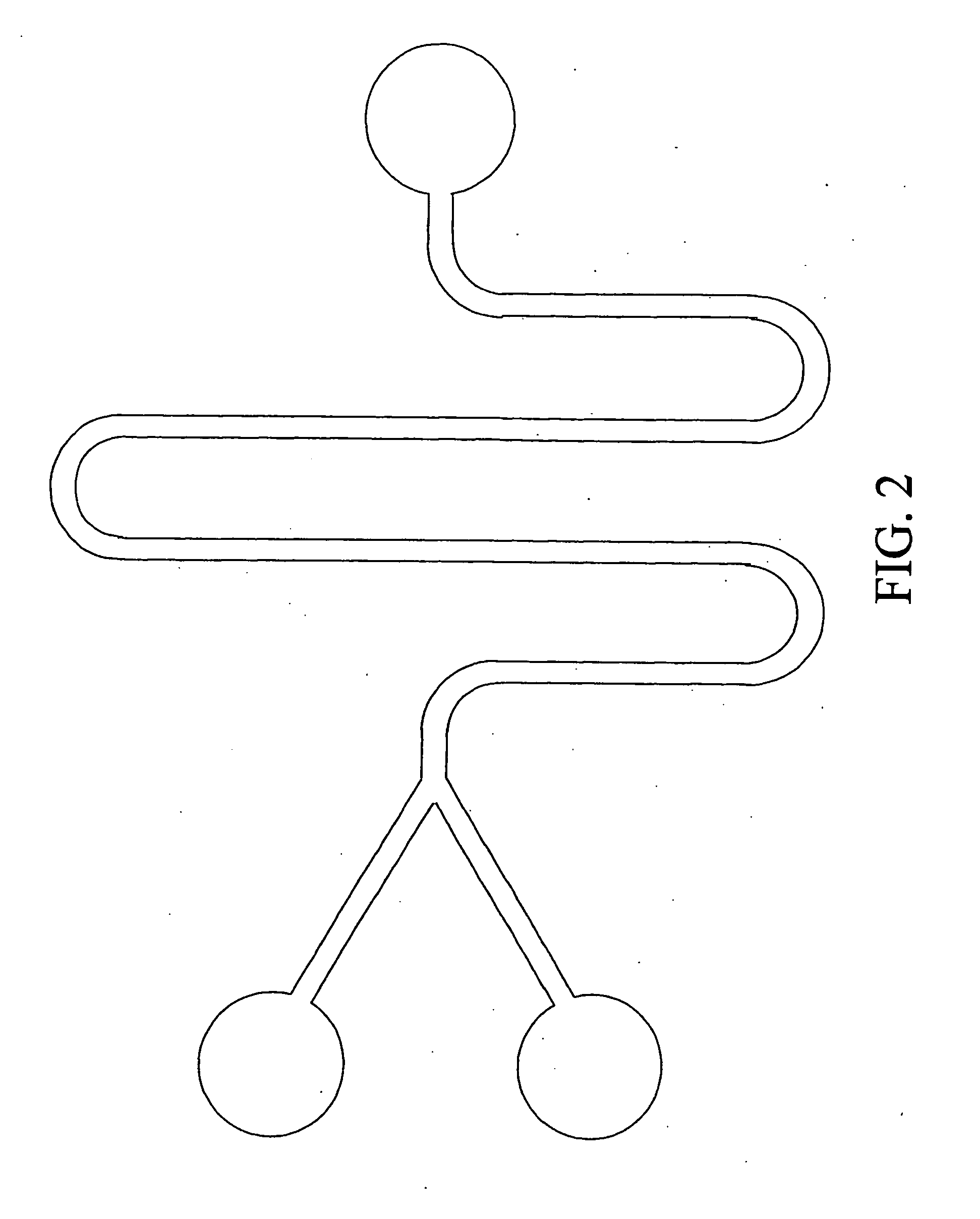

Microfluidic treatment method and device

InactiveUS20050161326A1Easily compiled into databaseAccurate gradientShaking/oscillating/vibrating mixersSludge treatmentGel electrophoresisMicrochip Electrophoresis

The present invention relates to a microchip apparatus using liquids. More specifically, the invention provides a liquid mixing apparatus comprising at least two microchannels for introducing liquids and a mixing microchannel that connects to the at least two liquid-introducing microchannels, wherein the liquids are transported from the respective liquid-introducing microchannels toward the mixing microchannel, the apparatus further comprising means for enhancing the mixing of the liquids that converge in the mixing microchannel. The invention also provides an electrophoretic apparatus and a microchip electrophoretic apparatus for denaturing gradient gel electrophoresis.

Owner:EBARA CORP

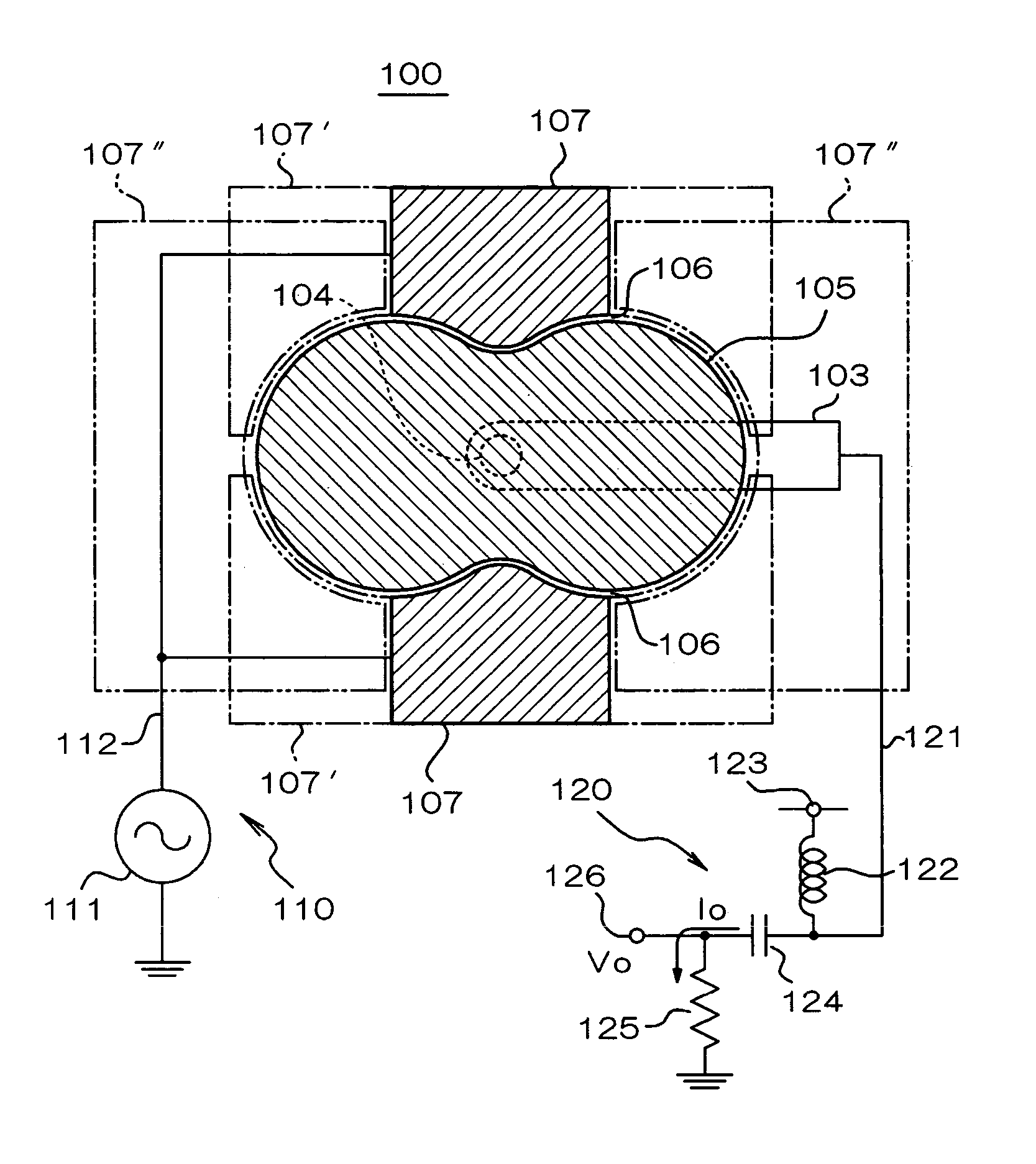

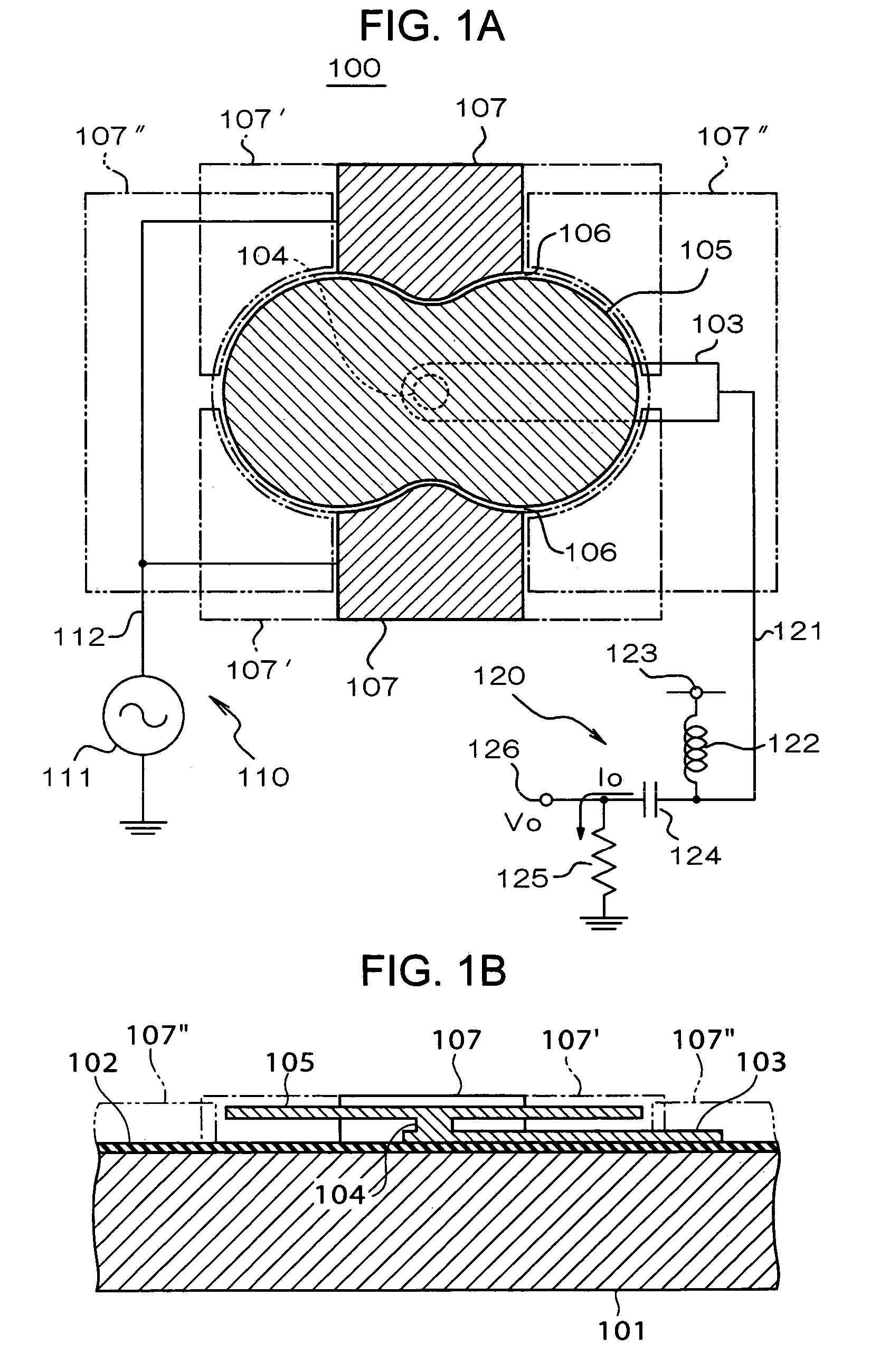

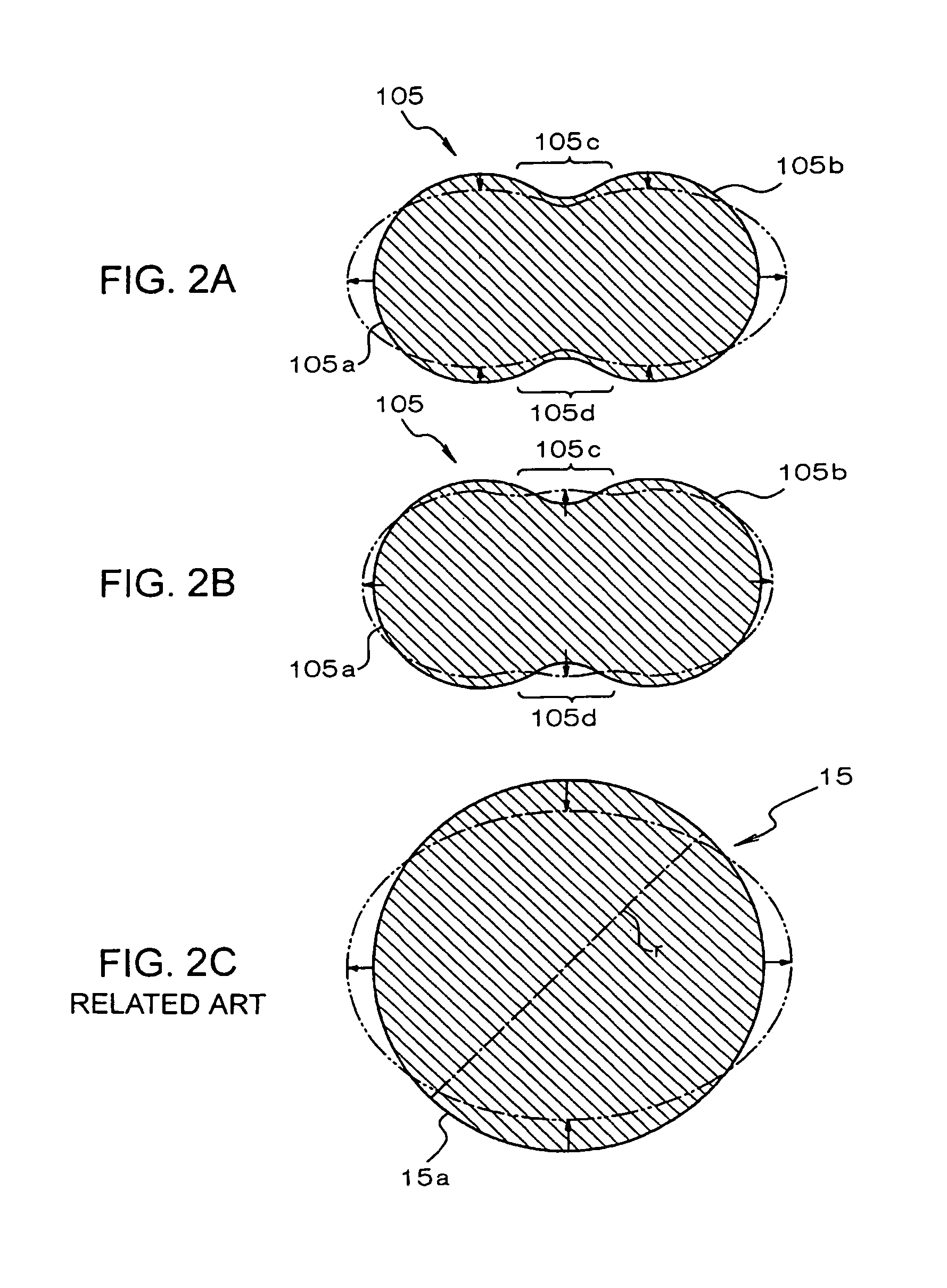

Micromechanical electrostatic resonator

InactiveUS7215061B2CapacitanceLarge capacitancePiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsCapacitanceAlternating current

Owner:SEIKO EPSON CORP

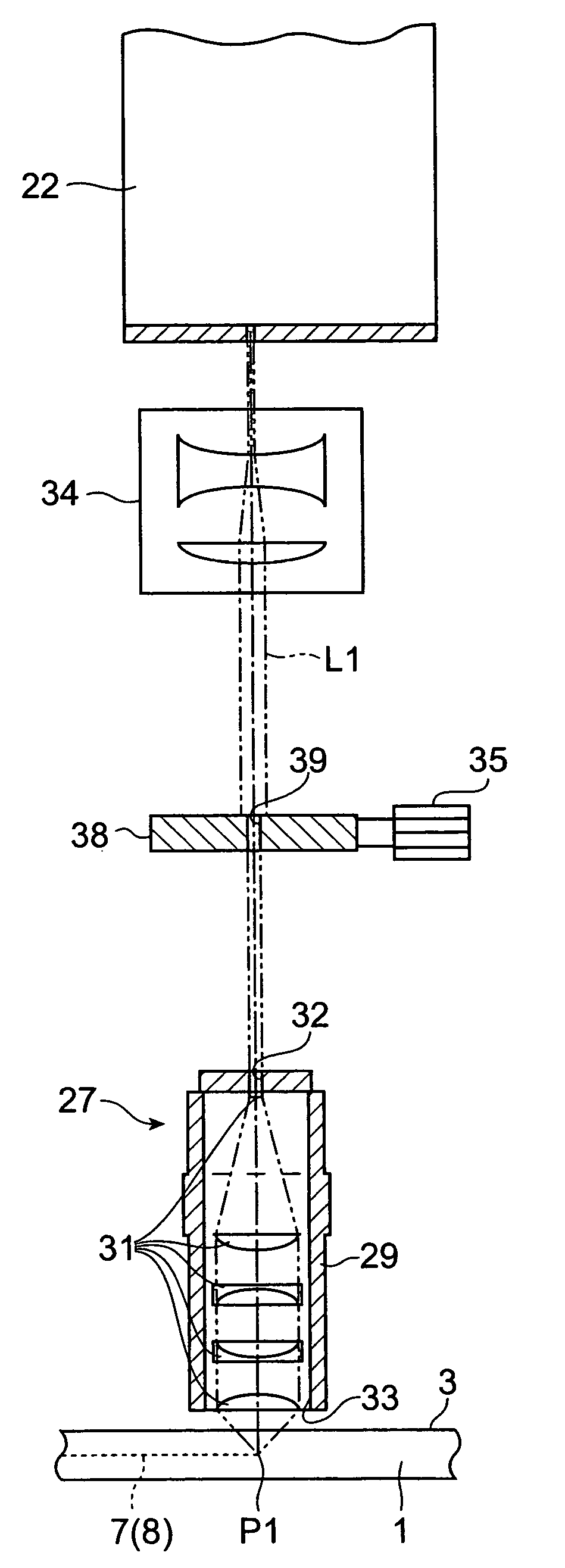

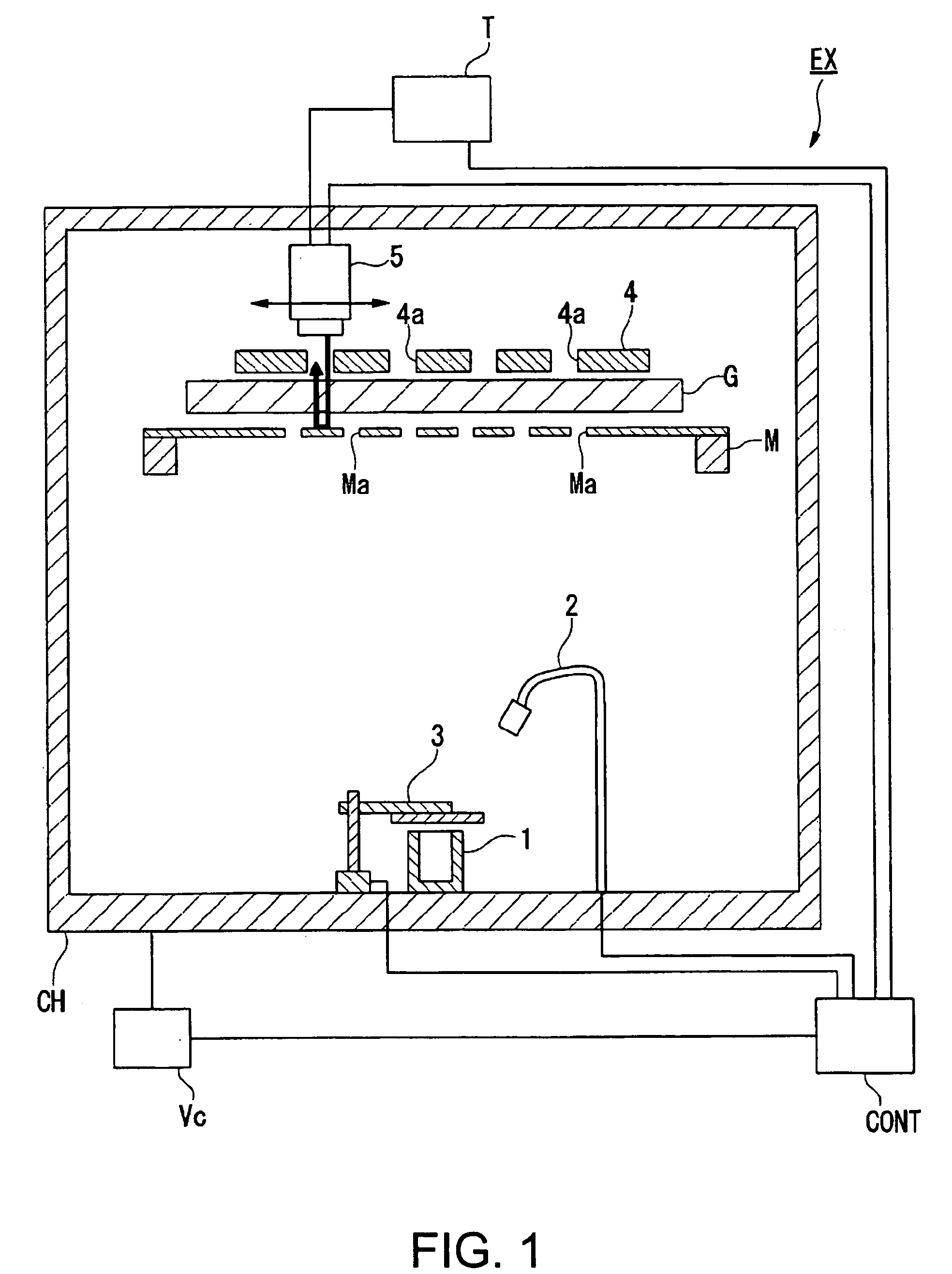

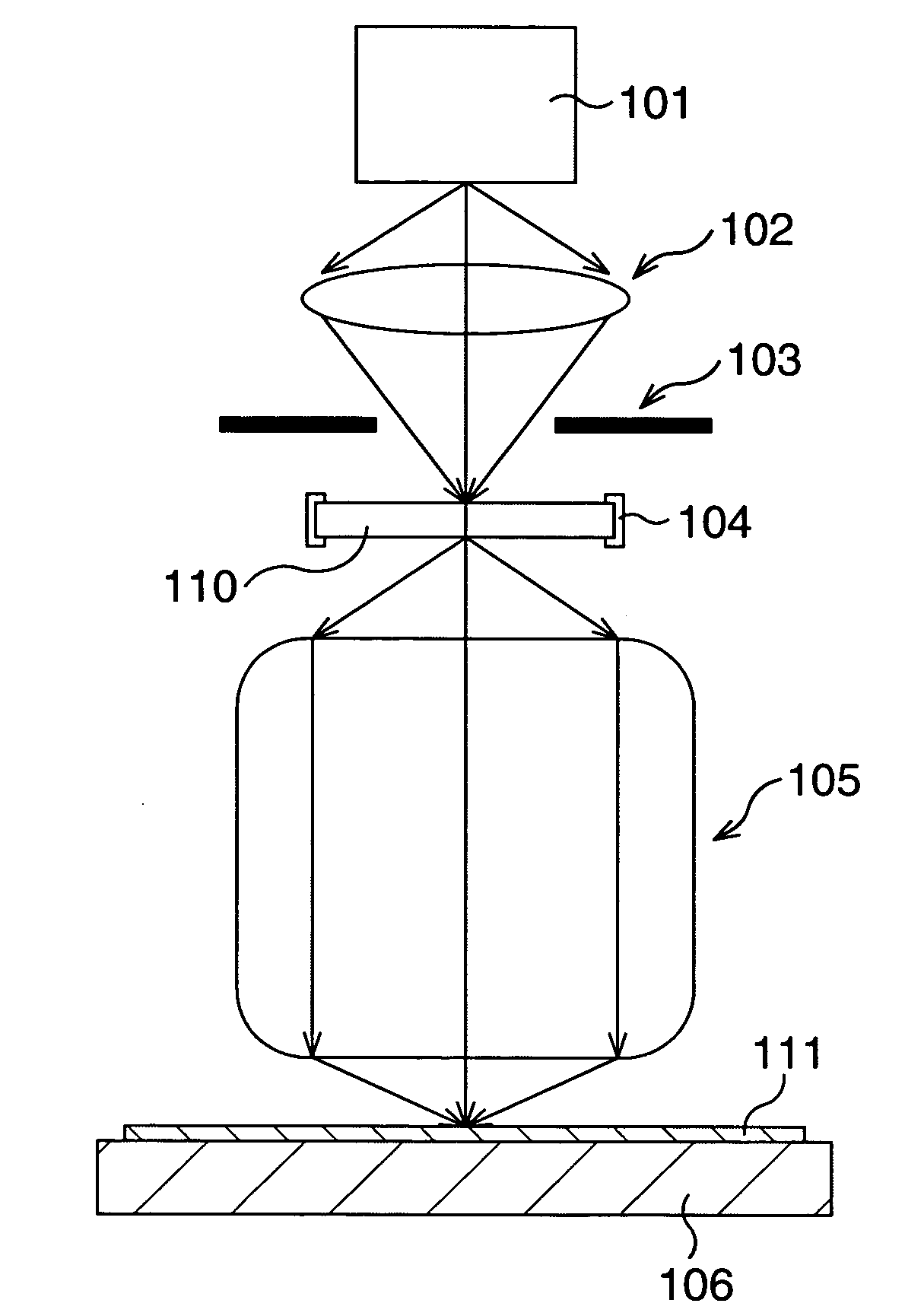

Laser processing device

ActiveUS7489454B2Suppress positional fluctuationReduce lightLaser detailsFine working devicesBeam expanderLaser processing

A laser processing apparatus which can suppress the positional fluctuation in light-converging point of laser light during laser processing is provided. On an optical path of laser light L1 connecting a beam expander 34 and a first light-transmitting hole 32 of a lens holder 29 to each other in a laser processing apparatus 20, a stop member 38 including a second light-transmitting hole 39 having the same diameter as that of the first light-transmitting hole 32 is disposed. Hence, the amount of laser light L1 cut by the surrounding part of the first light-transmitting hole 32 can substantially be eliminated, whereby the lens holder 29 can be prevented from being heated upon irradiation with the laser light L1. Also, even when the stop member 38 is heated by the laser light L1 cut by the surrounding part of the second light-transmitting hole 39, heat is prevented from being transmitted from the stop member 38 to the lens holder 29, since the stop member 38 is separated from the lens holder 29. Therefore, the positional fluctuation in light-converging point P1 of the laser light L1 during laser processing can be suppressed to a low level.

Owner:HAMAMATSU PHOTONICS KK

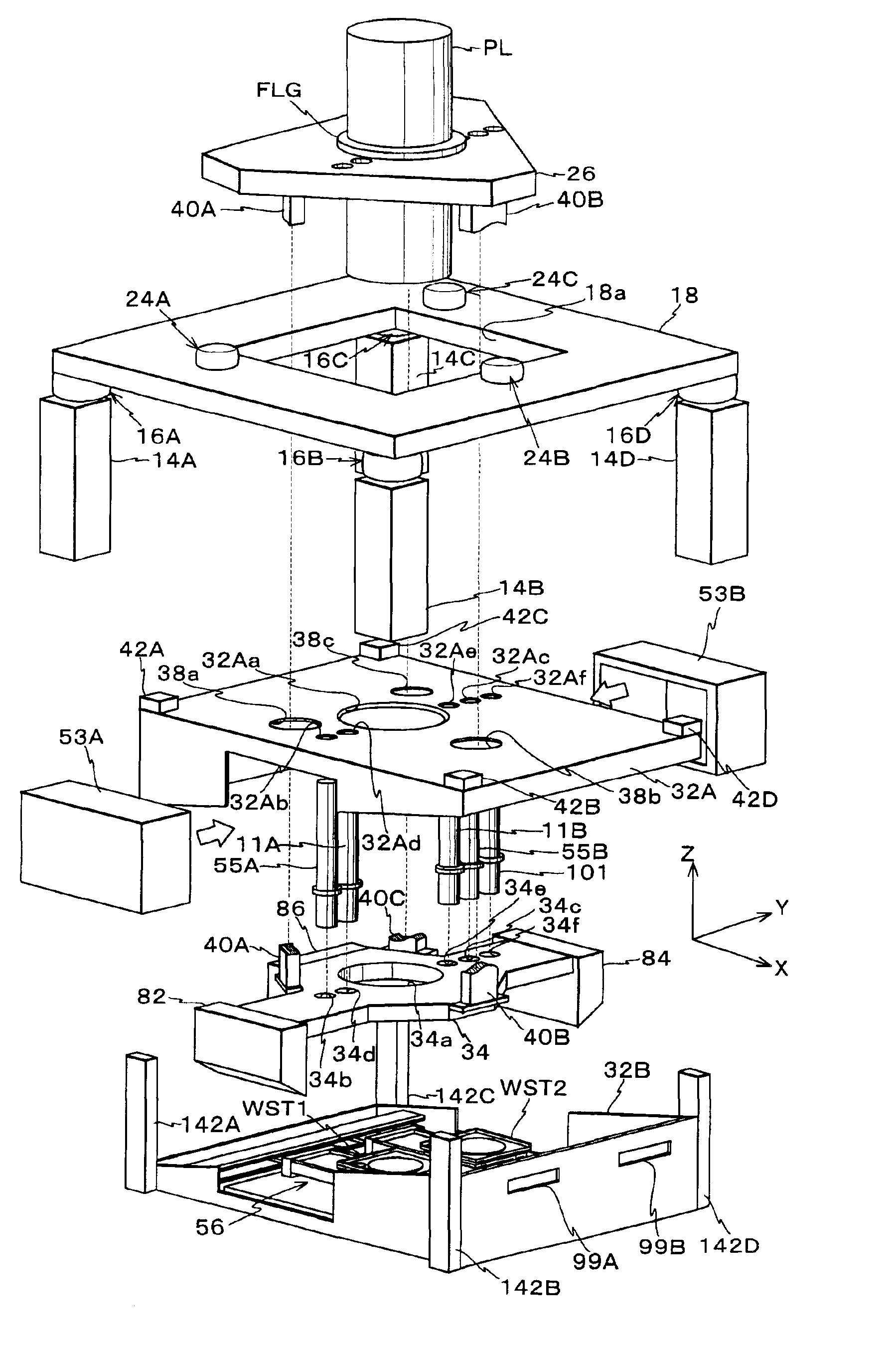

Exposure apparatus, substrate processing system, and device manufacturing method

InactiveUS6853443B2Improve productivityEasy to integrateLiquid surface applicatorsSemiconductor/solid-state device manufacturingProduction rateEngineering

A first main body unit for supporting a substrate stage is supported at four points by vibration isolators, and a second main body unit is supported on the first main body unit at three points by second vibration isolators. This allows the first main body unit and the substrate stage to be supported stably with high rigidity, and for example, allows maintenance on the stage portion from the back side of the apparatus, which is not possible with the first main body unit supported at three points. Further, the apparatus comprises vibration isolation units connected in series in two platforms, which has a great effect of suppressing background vibration from the floor surface. Accordingly, exposure with high precision can be performed which improves the yield of devices, and the reduced maintenance time can improve the operation rate, consequently leading to an improvement in productivity of devices as end products.

Owner:NIKON CORP

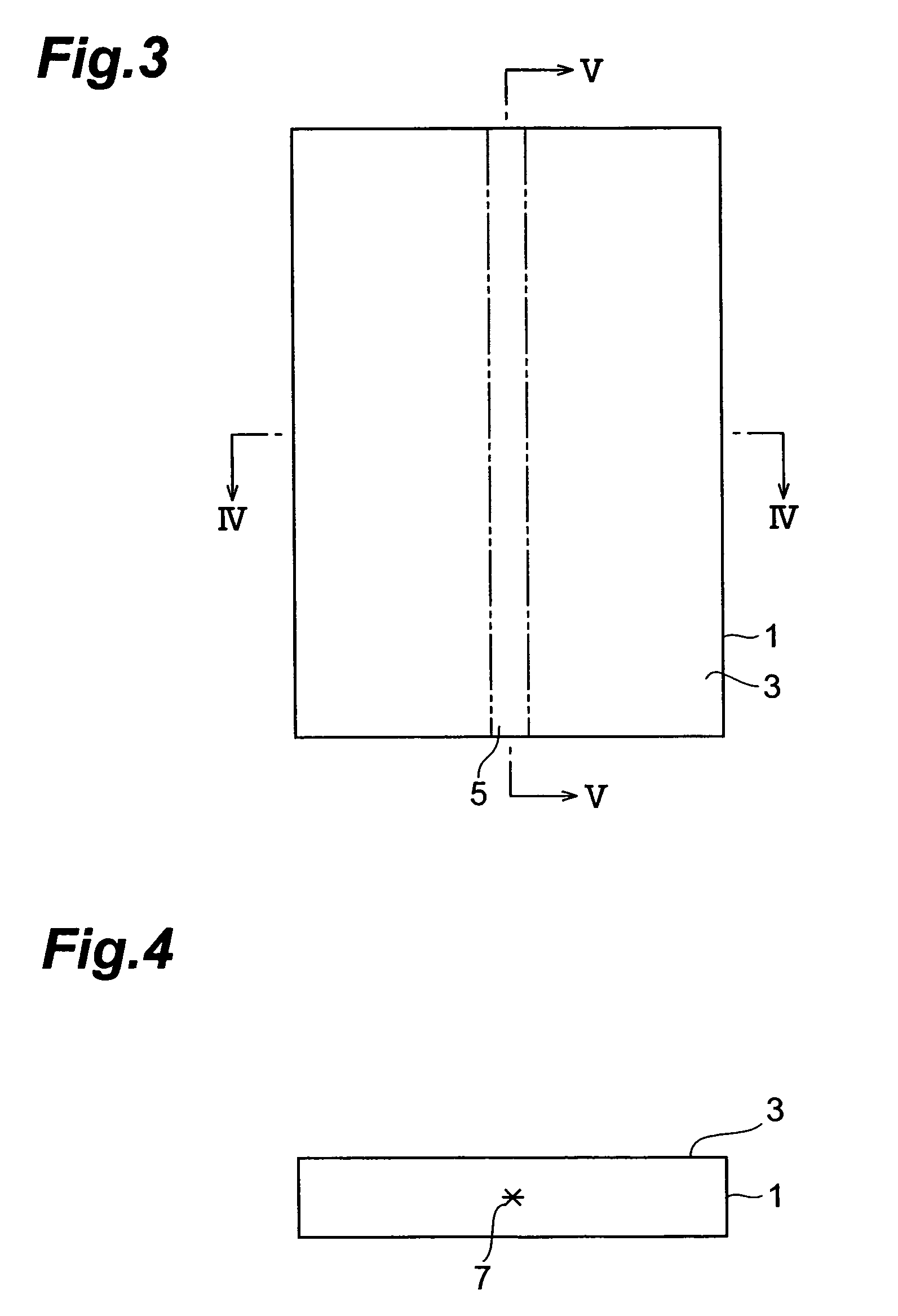

Exposure apparatus and method for producing device

InactiveUS20070064210A1Forming accuratelySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

There is provided an exposure apparatus capable of forming a desirable device pattern by removing unnecessary liquid when performing exposure by projecting a pattern onto the substrate via a projection optical system and the liquid. The exposure device projects an image of the pattern onto the substrate P via the projection optical system and the liquid so as to expose the substrate P. The exposure device includes a liquid removing mechanism 40 which removes the liquid remaining on a part 7 arranged in the vicinity of the image plane of the projection optical system.

Owner:NIKON CORP

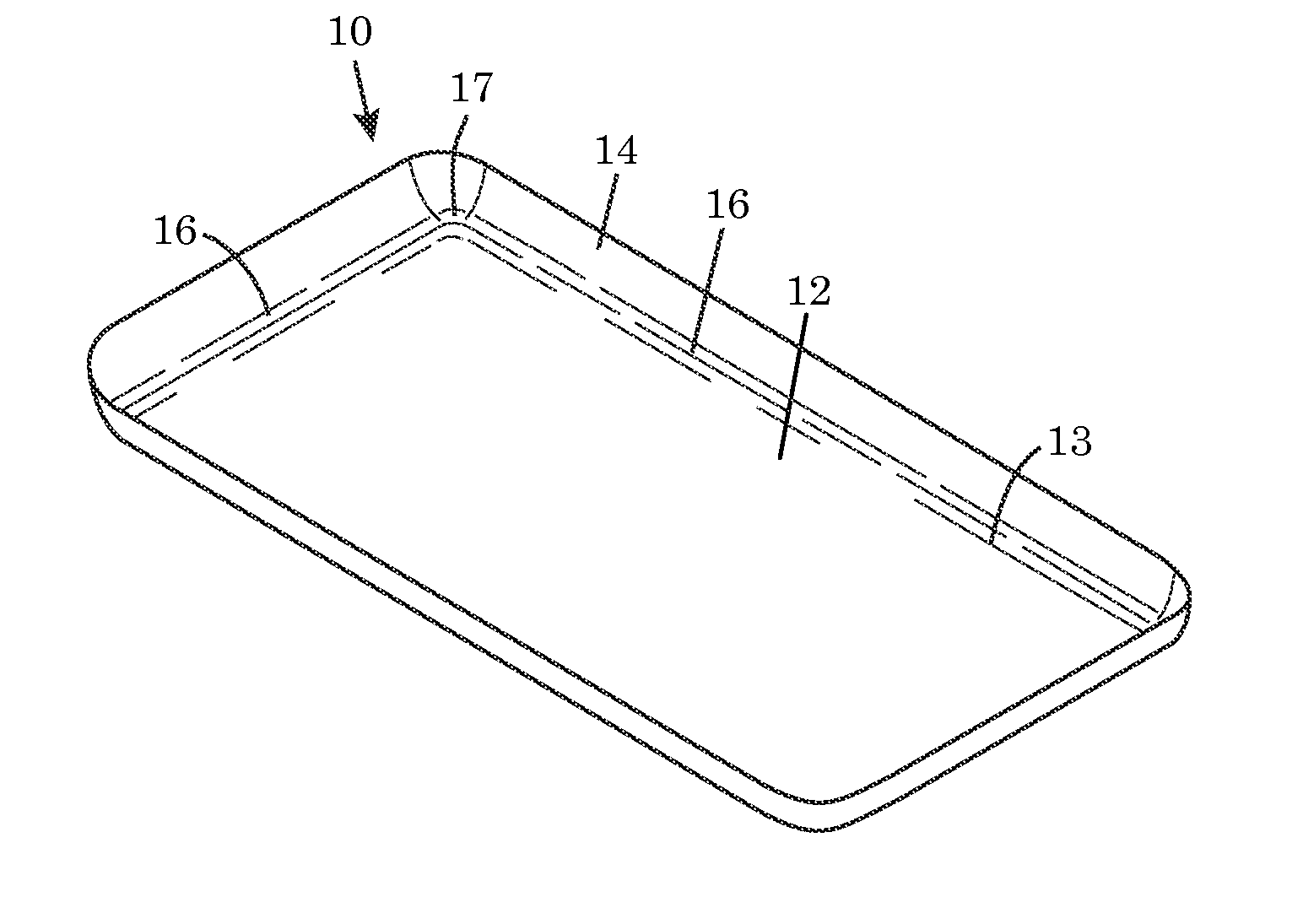

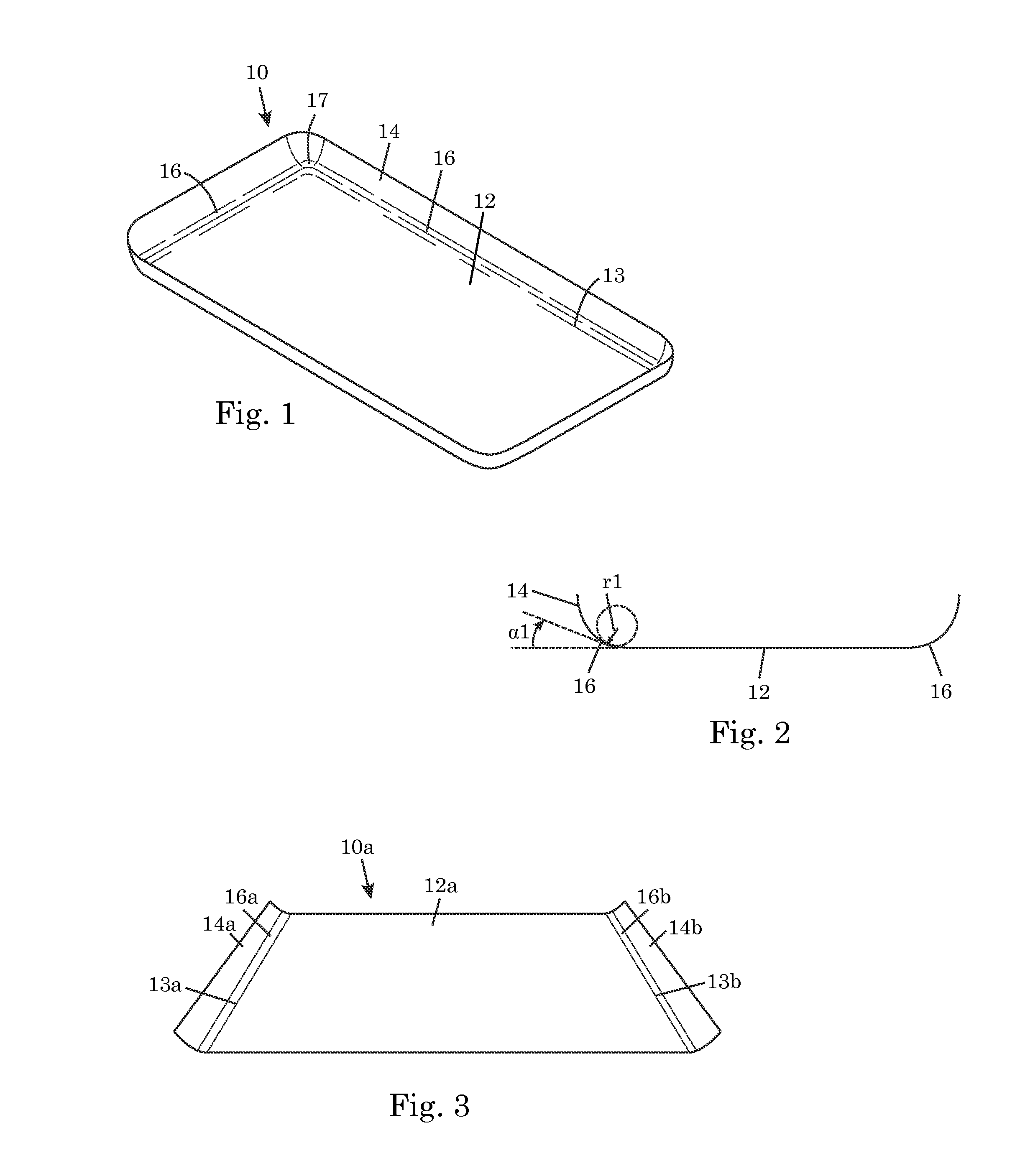

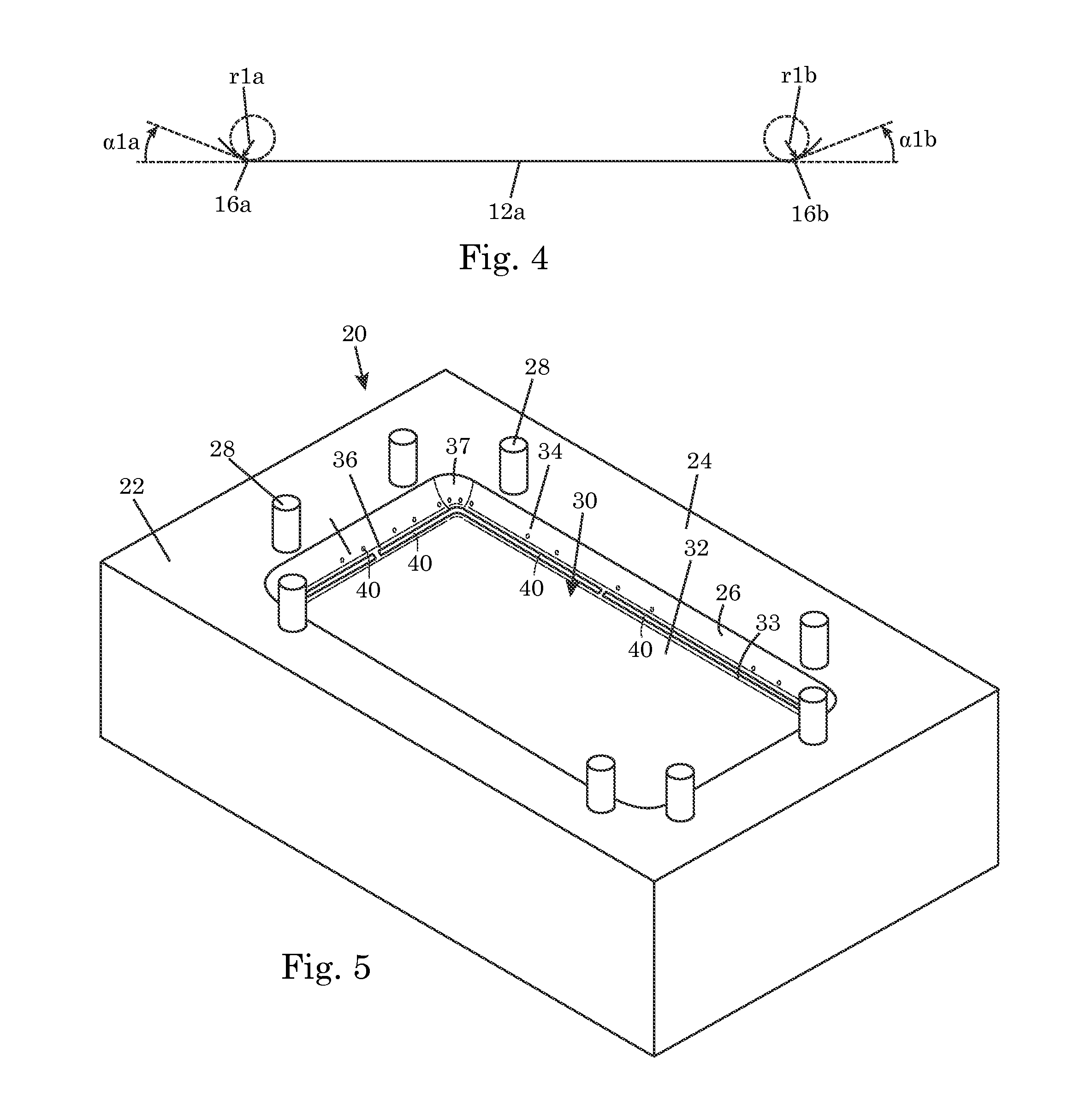

Method and system for forming shaped glass articles

ActiveUS20140234581A1Forming accuratelyLayered productsDigital data processing detailsPoiseGlass sheet

A method of forming a shaped glass article includes placing a glass sheet on a mold such that a first glass area of the glass sheet corresponds to a first mold surface area of the mold and a second glass area of the glass sheet corresponds to a second mold surface area of the mold. The first glass area and the second glass area are heated such that the viscosity of the second glass area is 8 poise or more lower than the viscosity of the first glass area. A force is applied to the glass sheet to conform the glass sheet to the mold surface. During the heating of the second glass area, the first mold surface area is locally cooled to induce a thermal gradient on the mold.

Owner:CORNING INC

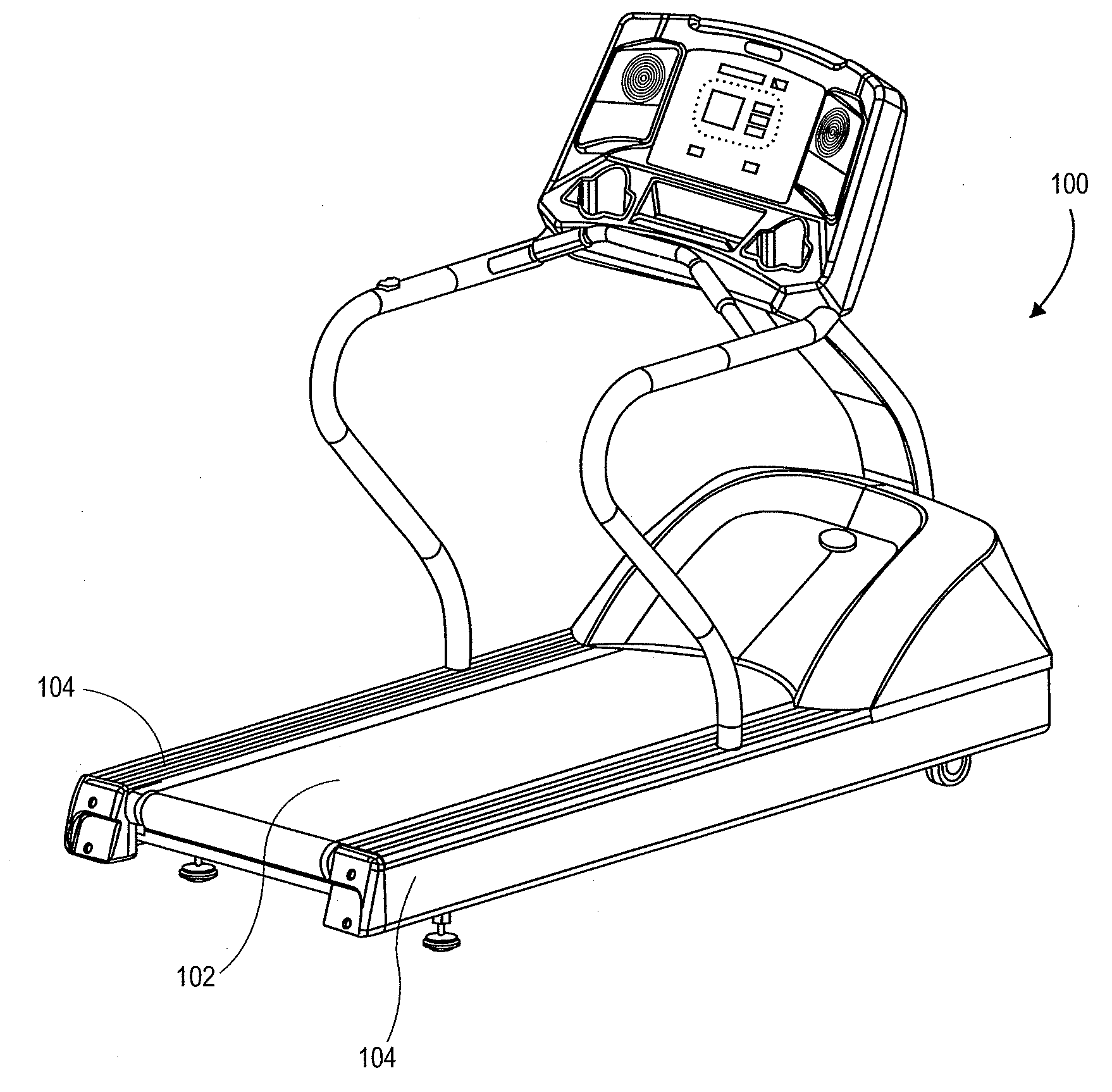

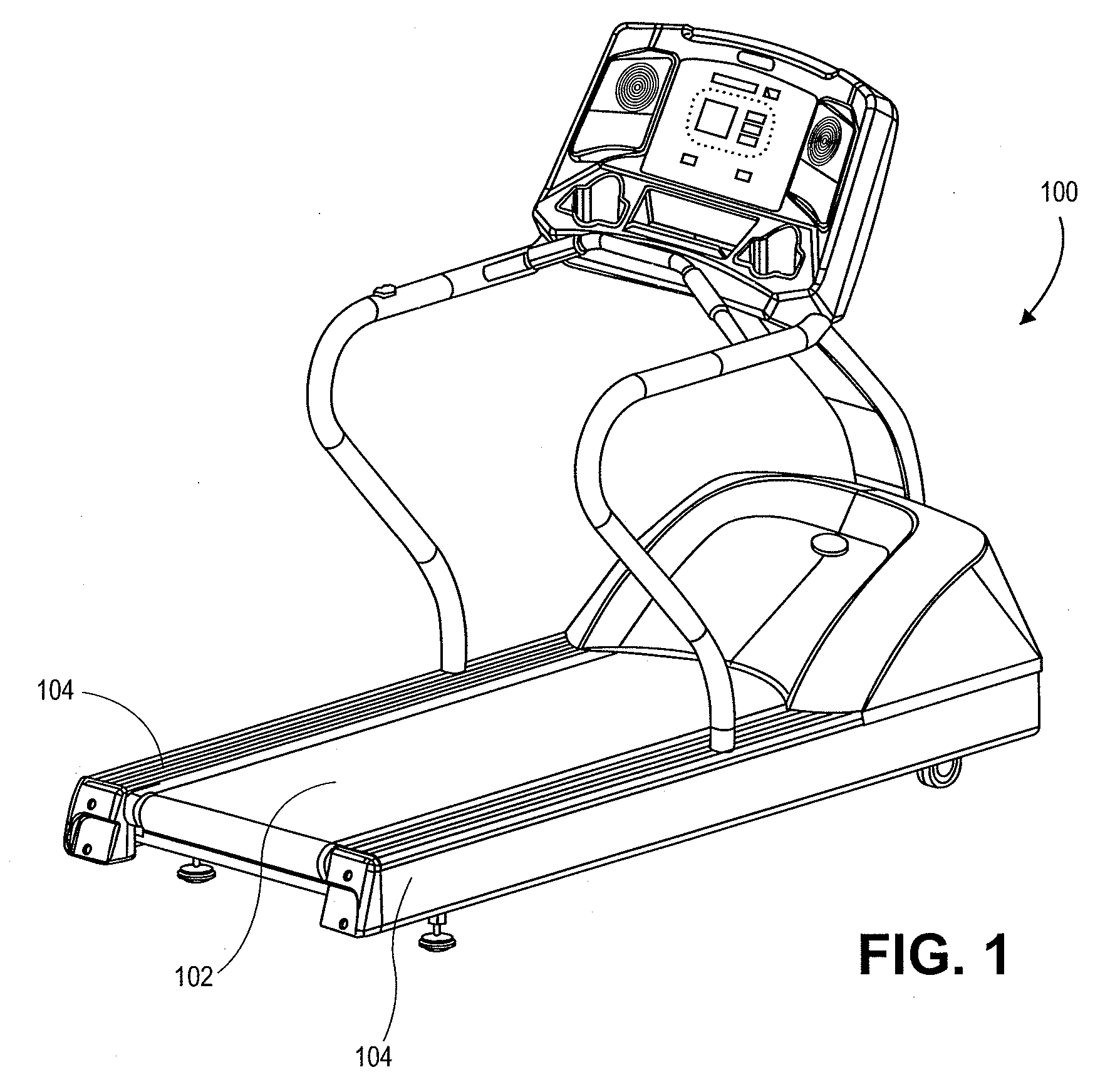

User detection for exercise equipment

InactiveUS20100160115A1Diagnose and correct runningDiagnose and correct and walking form issueMovement coordination devicesCardiovascular exercising devicesPhysical medicine and rehabilitationSimulation

Embodiments of the present disclosure include a user detection system for exercise equipment, such as a treadmill. In an embodiment, a sensor monitors displacement between a deck supporting a moveable treadmill belt and aspects of a treadmill frame. As users interact with the treadmill, a processor uses a sensor signal indicative of the displacement to determine whether a user has mounted the treadmill belt.

Owner:CORE INDS MICHIGAN

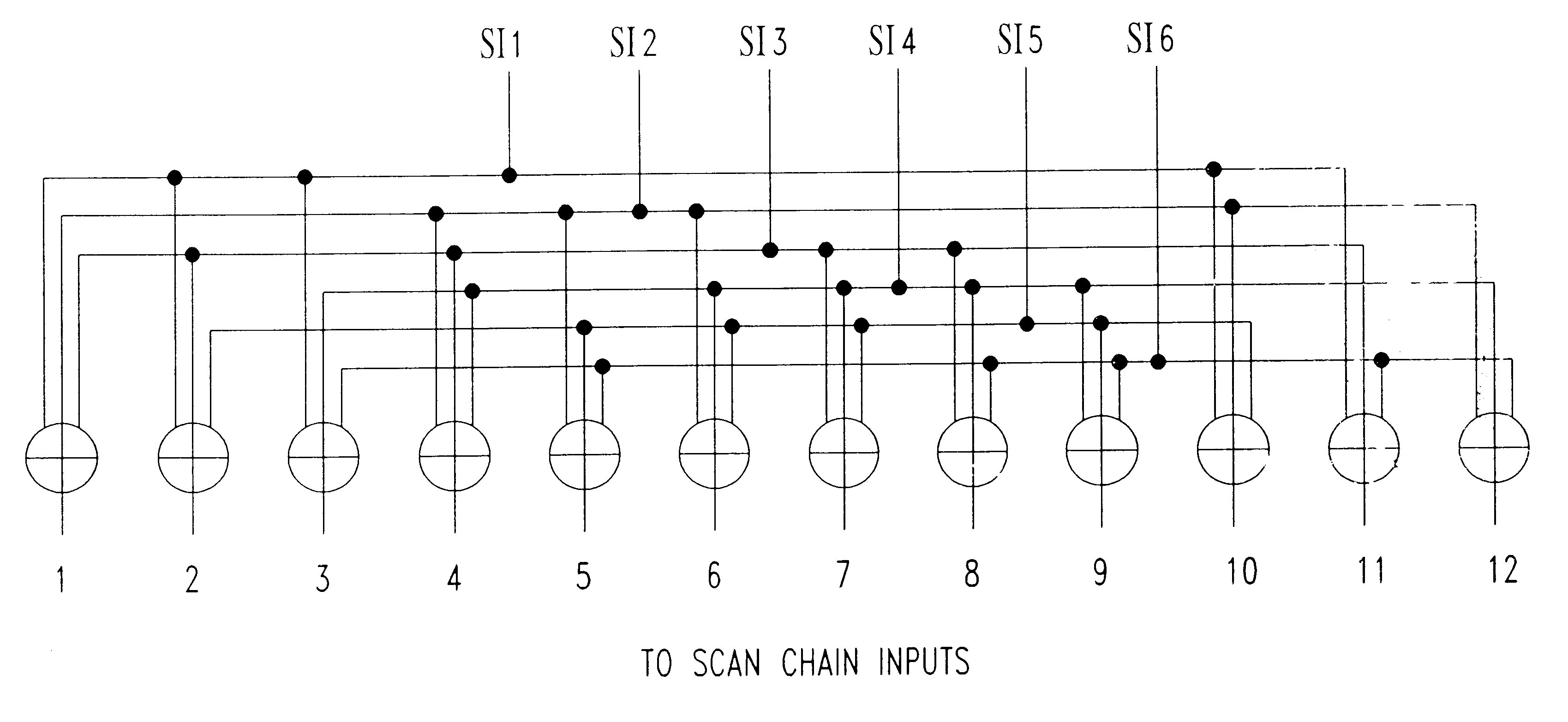

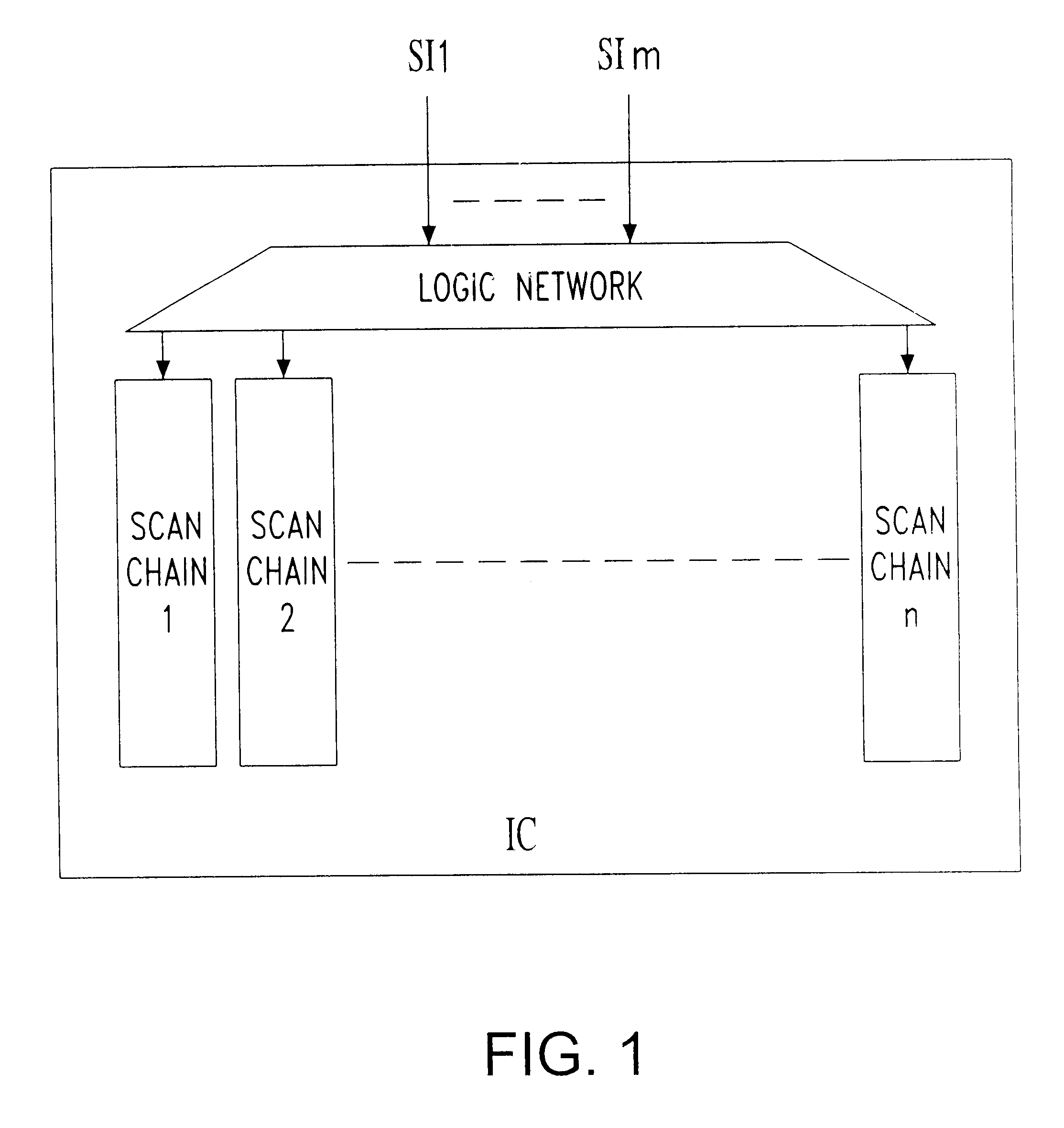

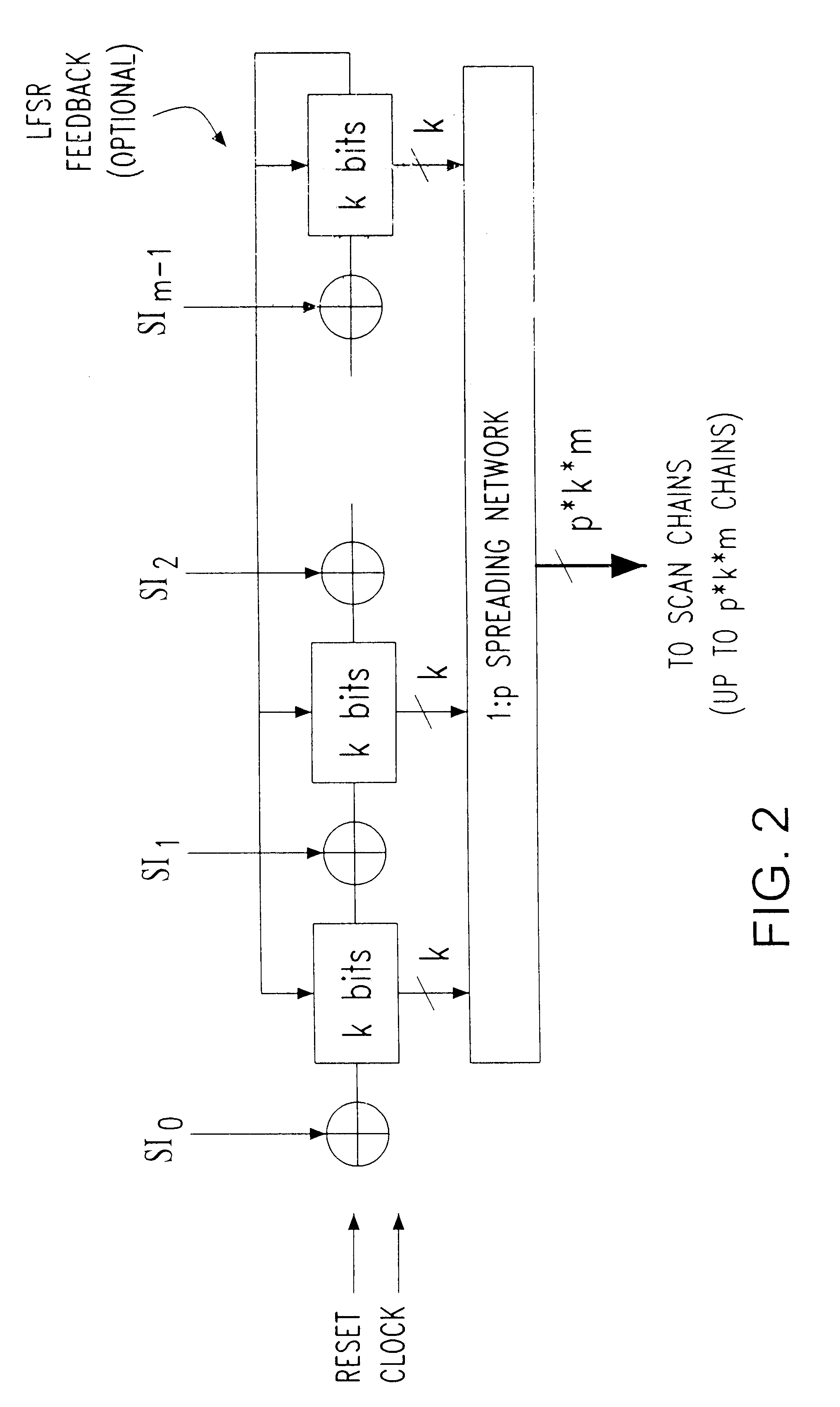

Real-time decoder for scan test patterns

InactiveUS6611933B1Cost-efficiently integratedForming accuratelyElectronic circuit testingError detection/correctionComputer hardwareTest efficiency

A method and apparatus for improving the efficiency of scan testing of integrated circuits is described. This efficiency is achieved by reducing the amount of required test stimulus source data and by increasing the effective bandwidth of the scan-load operation. The reduced test data volume and corresponding test time are achieved by integrating a real-time test data decoder or logic network into each integrated circuit chip. The apparatus, servicing a plurality of internal scan chains wherein the number of said internal scan chains exceeds the number of primary inputs available for loading data into the scan chains, includes: a) logic network positioned between the primary inputs and the inputs of the scan chains, the logic network expanding input data words having a width corresponding to the number of the primary inputs, and converting the input data words into expanded output data words having a width that corresponds to the number of the internal scan chains; and b) coupled to the internal scan chains, registers loaded with bit values provided by the expanded output data words while data previously loaded into the scan chains shifts forward within the scan chains by one bit position at a time; wherein a first plurality of the input data words supplied to the primary inputs produce a second plurality of expanded data words that are loaded into the internal scan chains to achieve an improved test coverage.

Owner:GOOGLE LLC

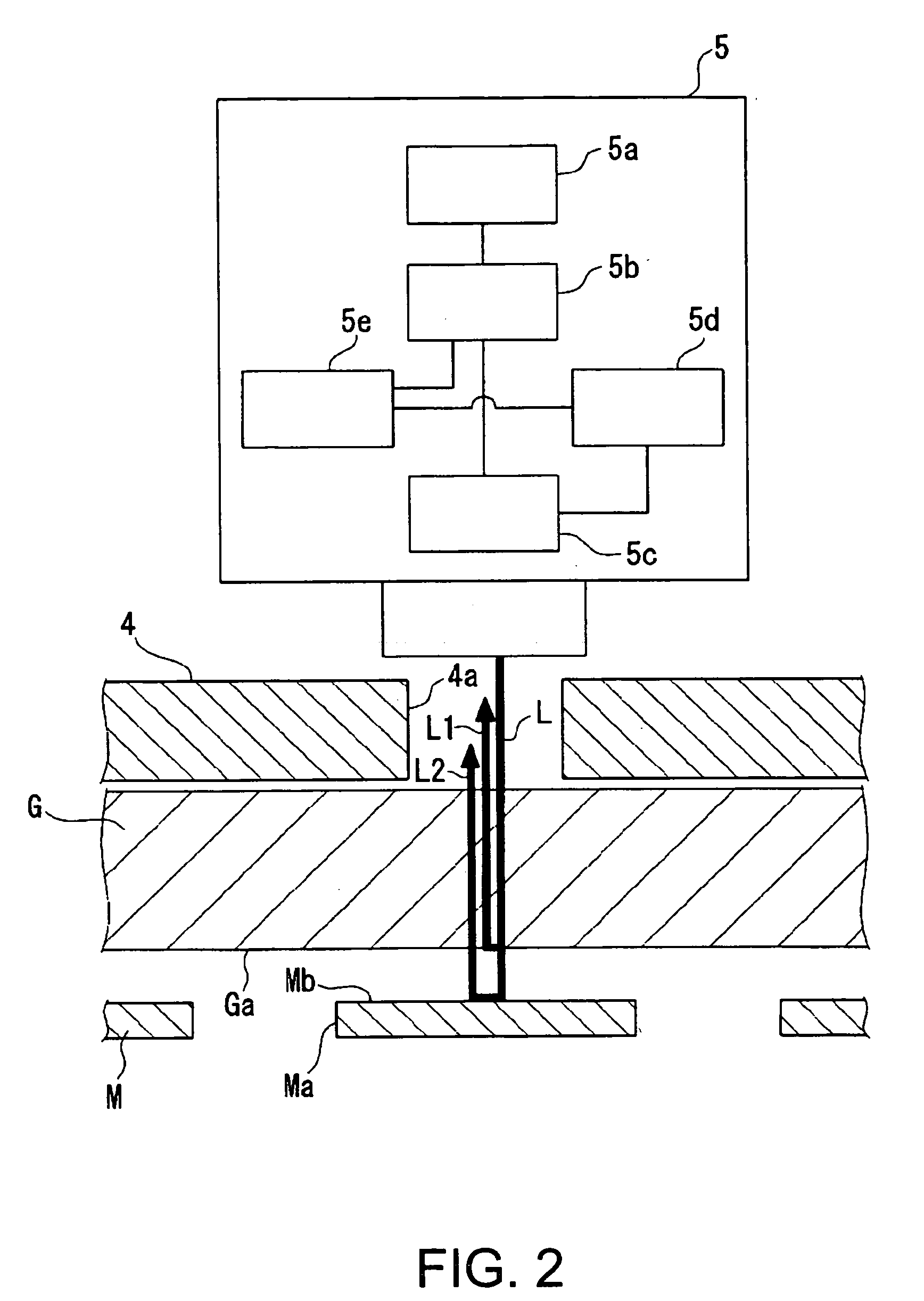

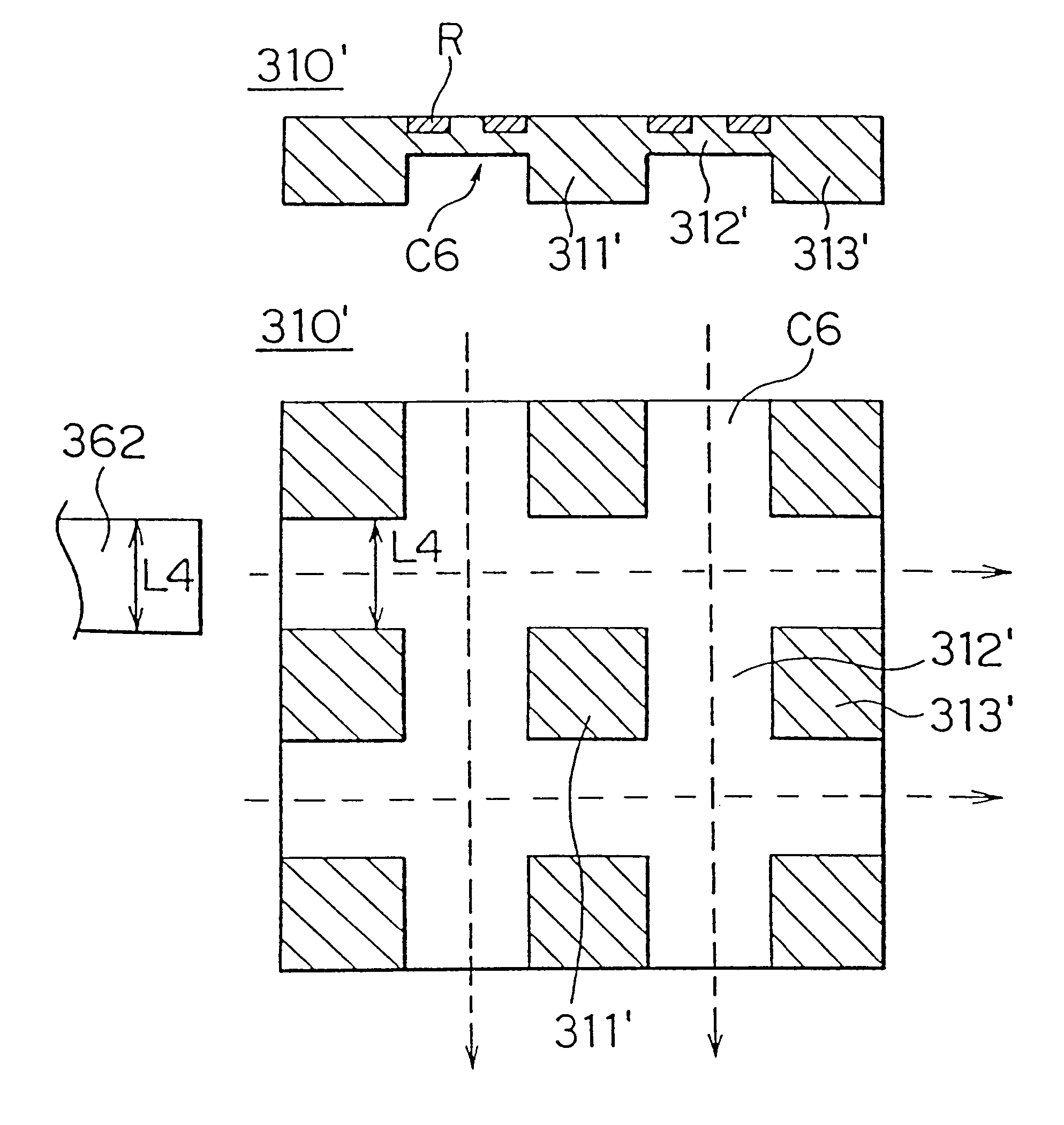

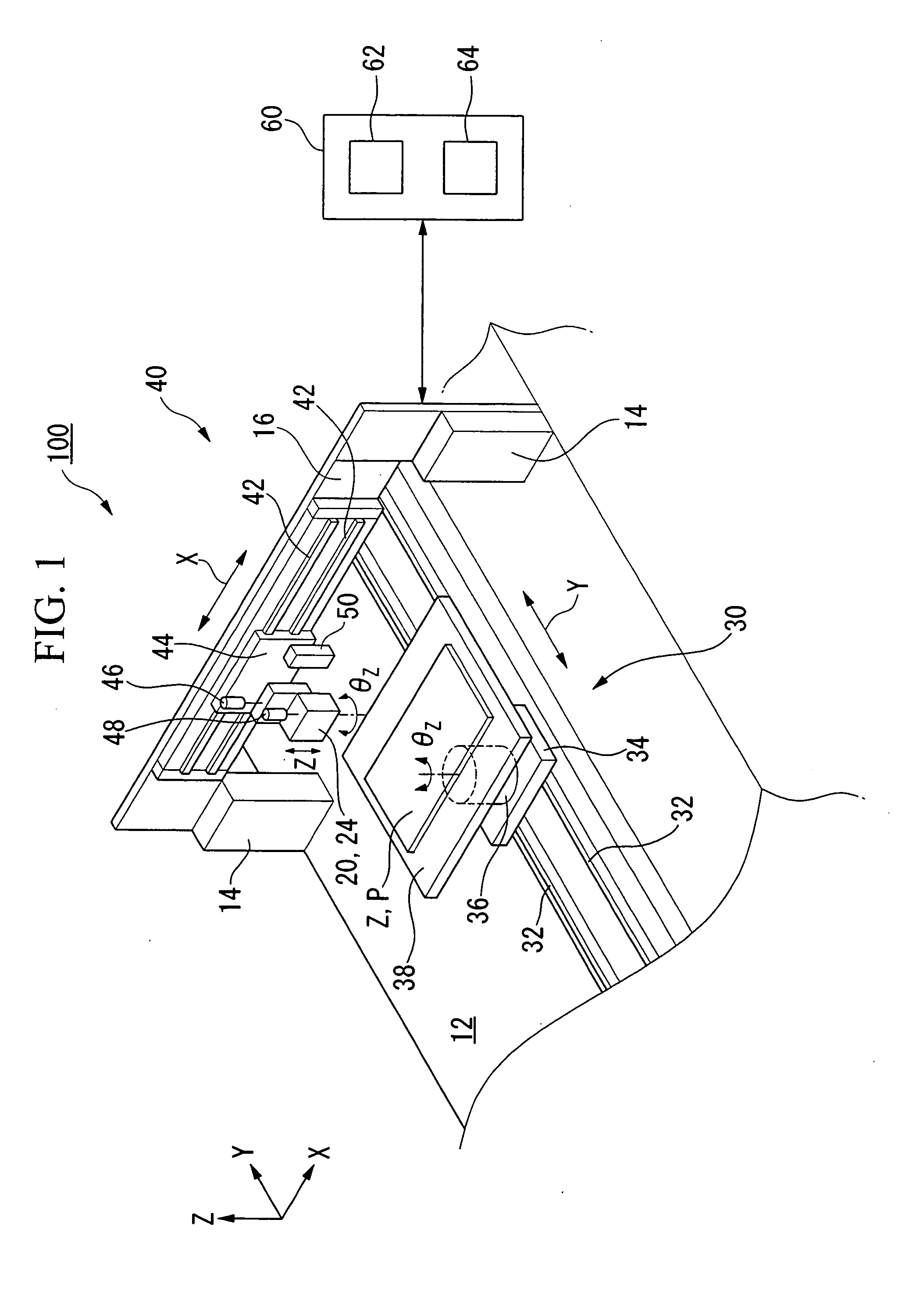

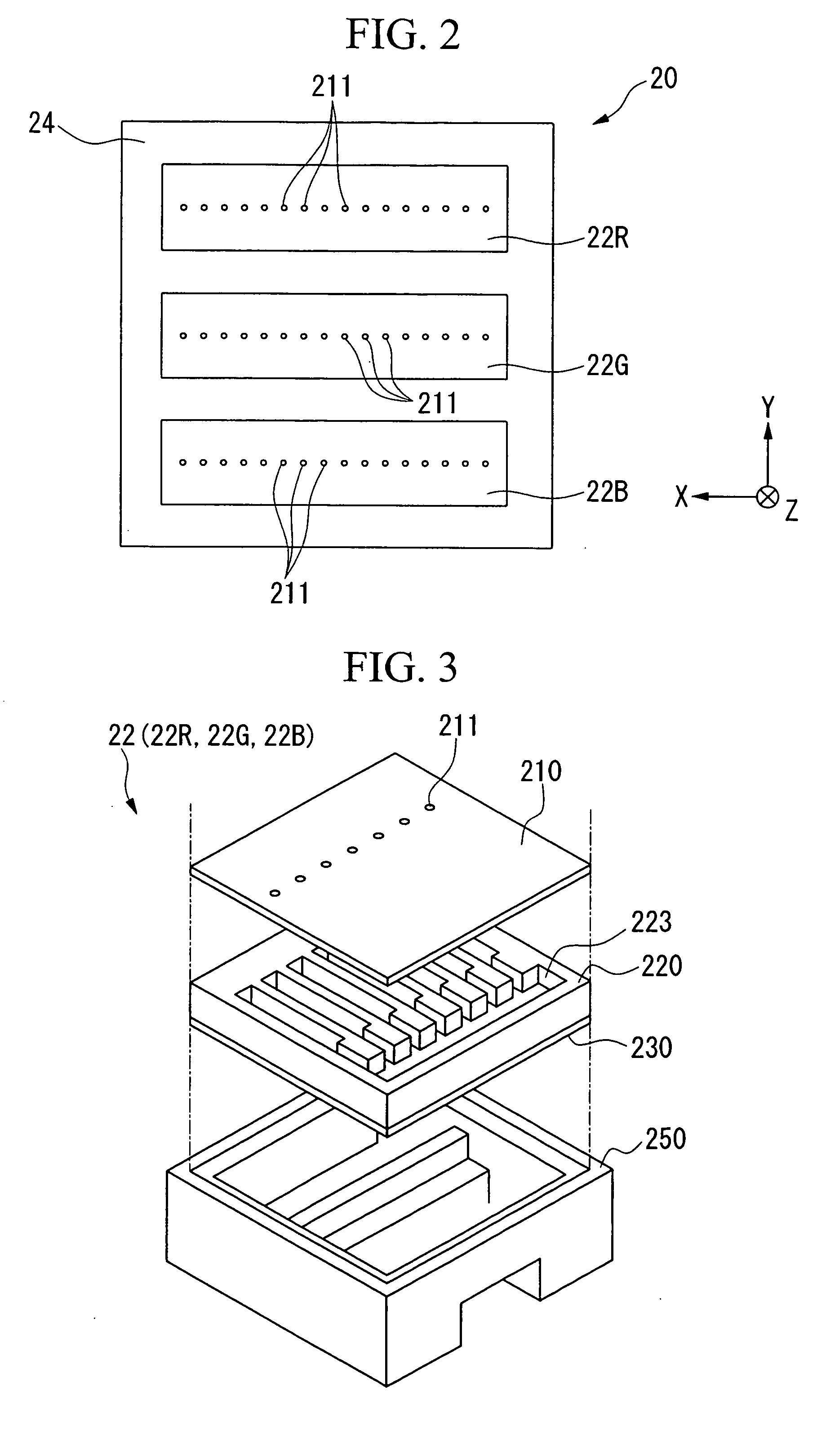

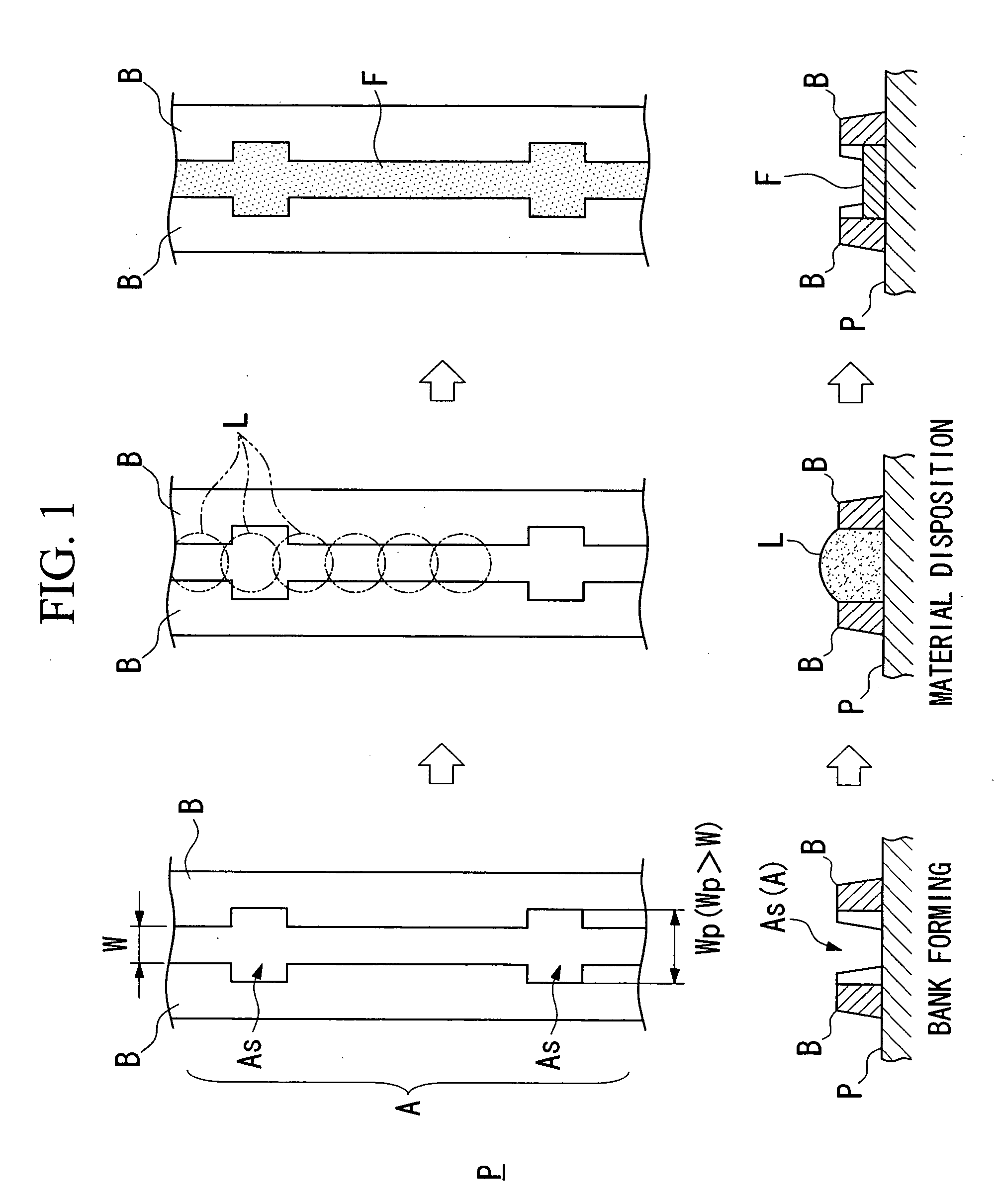

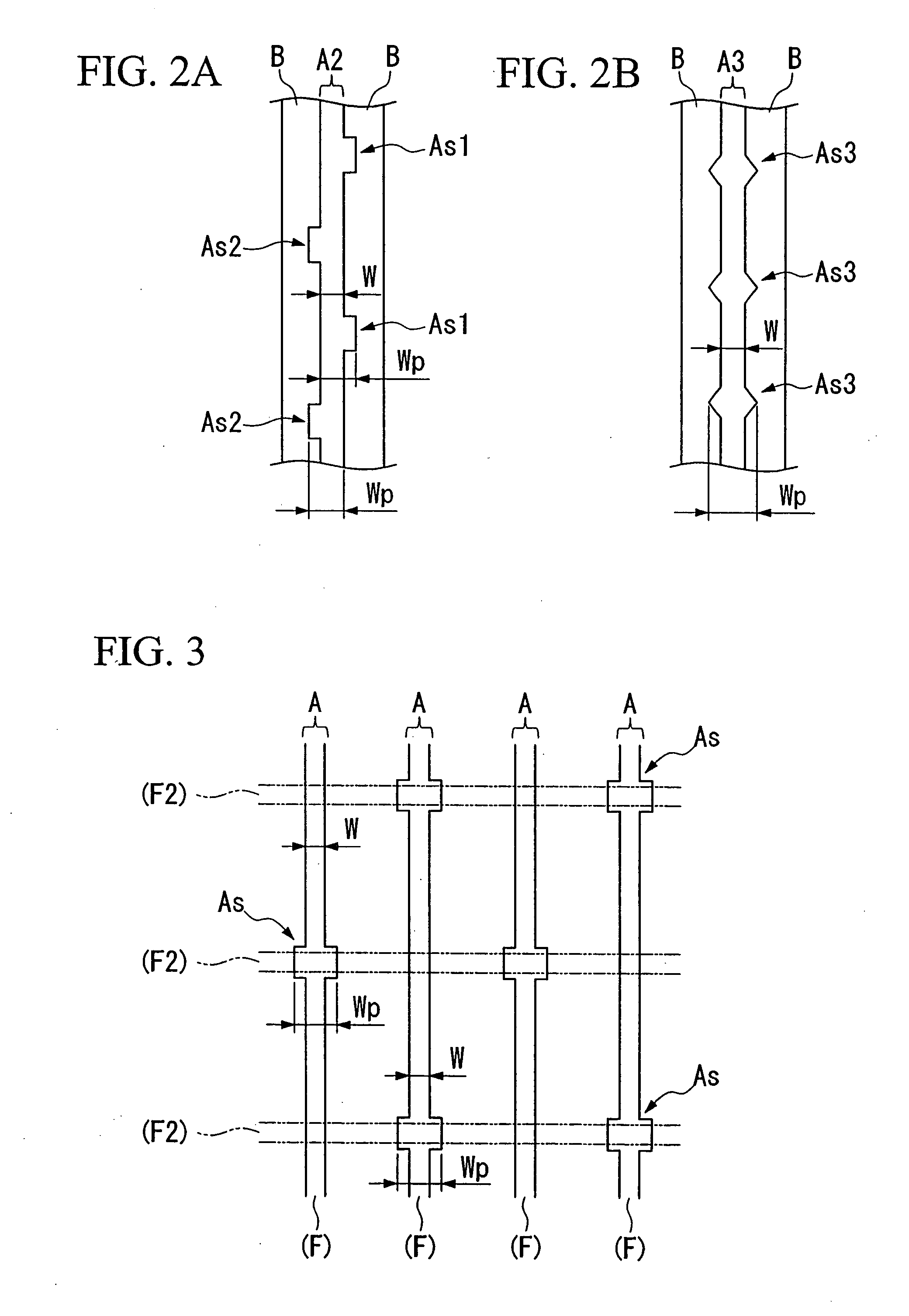

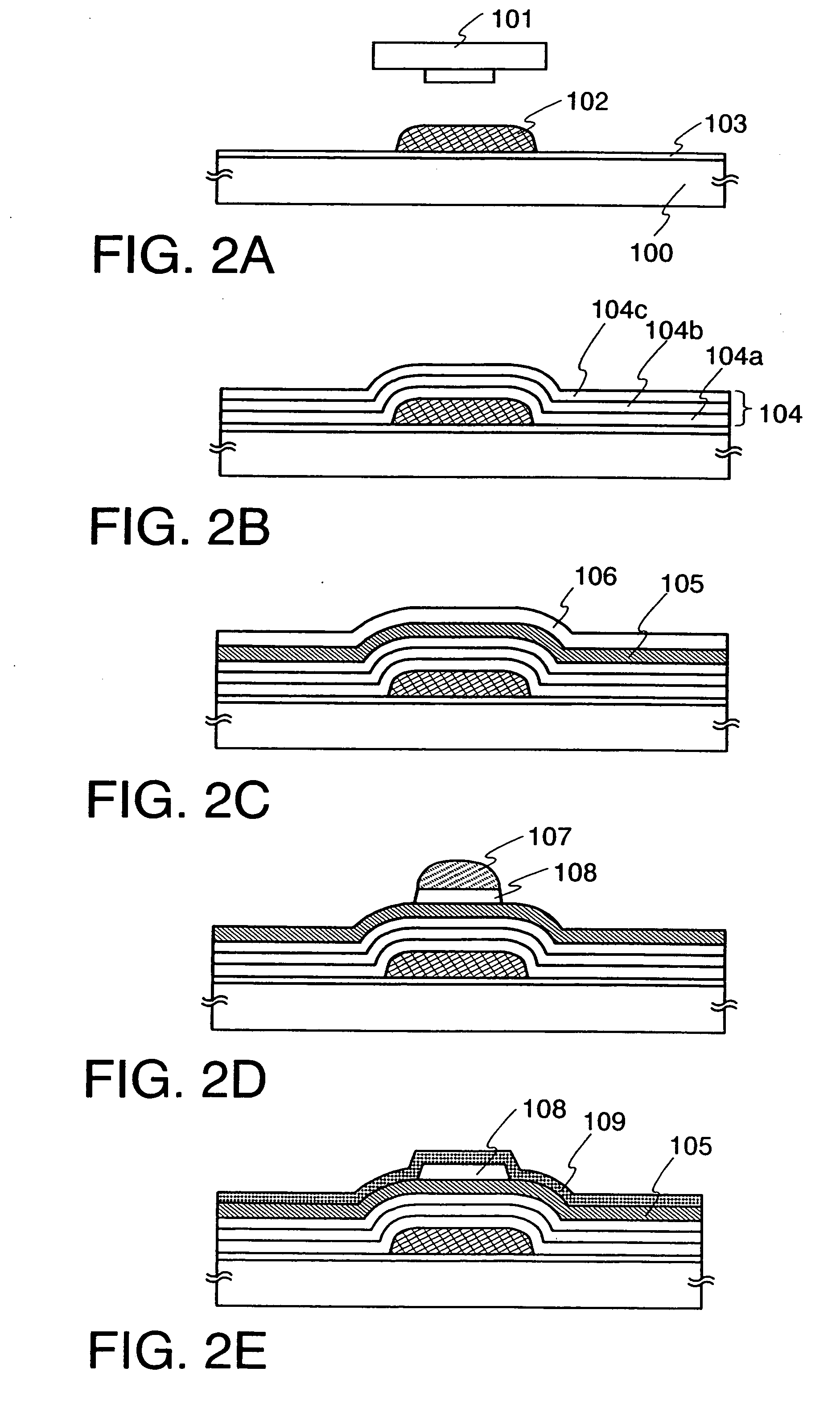

Thin film formation method, thin film formation equipment, method of manufacturing organic electroluminescence device, organic electroluminescence device, and electronic apparatus

InactiveUS20050153472A1Increase productionImprove accuracyMolten spray coatingSemiconductor/solid-state device testing/measurementOptoelectronicsOrganic electroluminescence

A thin film formation method is provided which can carry out various kinds of patterning deposition correctly and with high precision, and a thin film formation equipment. The thin film formation method arranges a mask between a substrate and a material source and forms the material of the material source as a thin film on the substrate. The method further includes: a substrate contacting process to contact the mask and the substrate; a gap measurement process to measure a gap between the mask and the substrate; and a thin film formation process to form the thin film according to the measurement result in the gap measurement process.

Owner:SEIKO EPSON CORP

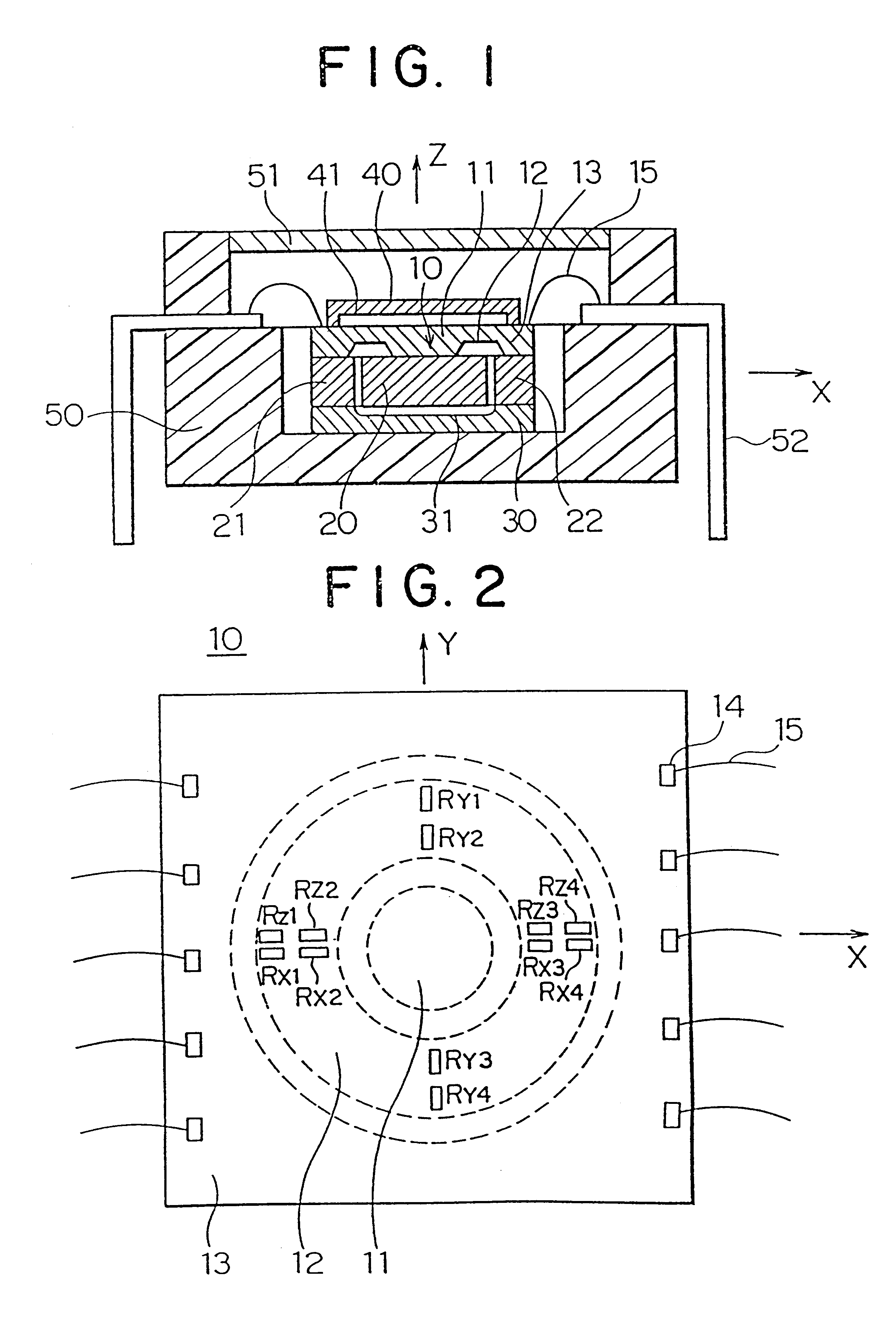

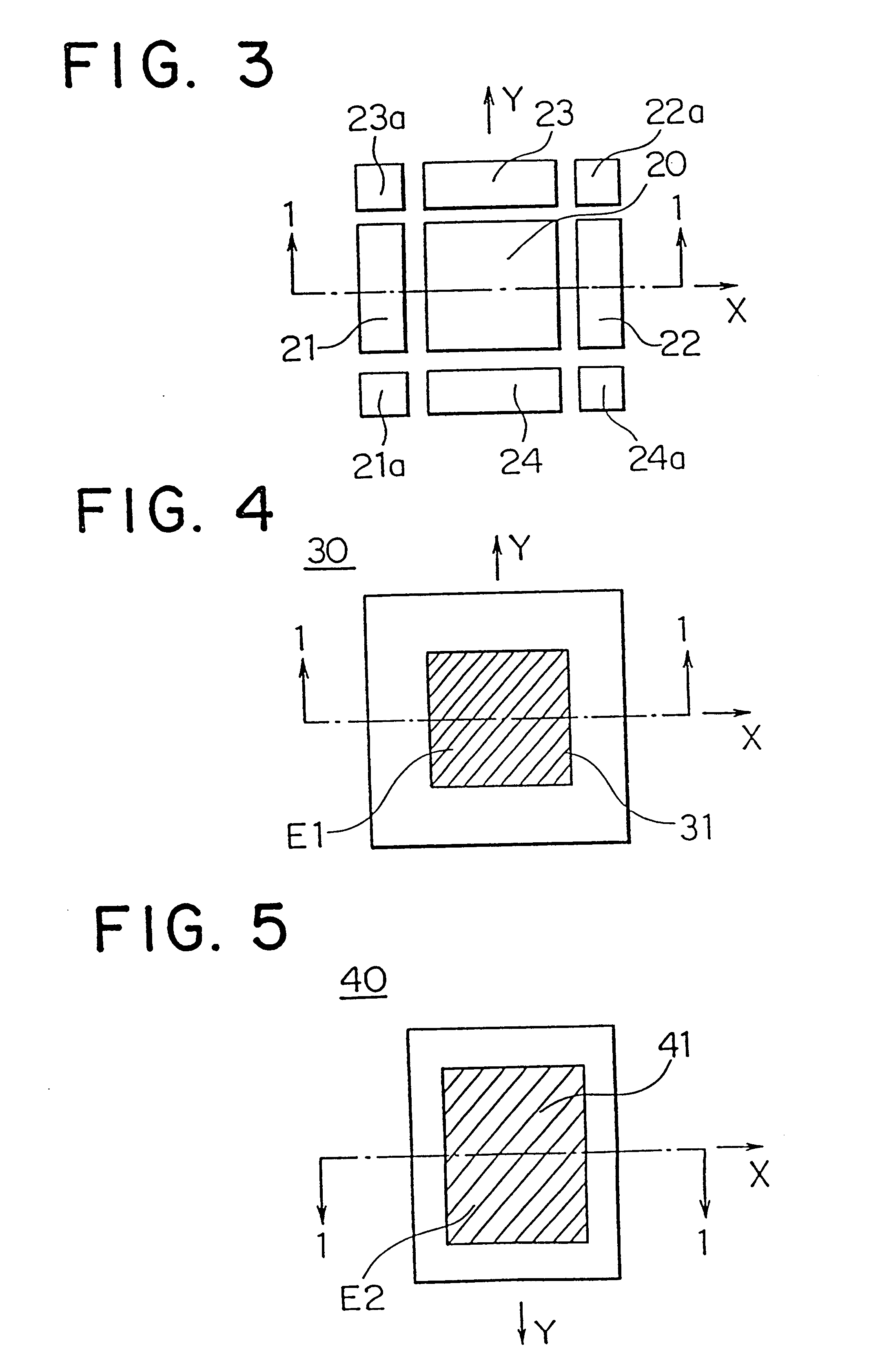

Method of manufacturing a sensor detecting a physical action as an applied force

InactiveUS6185814B1Low costSimple circuit configurationAcceleration measurement using interia forcesForce measurement using piezo-resistive materialsSignal processing circuitsSemiconductor chip

A sensor comprises a semiconductor pellet (10) including a working portion (11) adapted to undergo action of a force, a fixed portion (13) fixed on the sensor body, and a flexible portion (13) having flexibility formed therebetween, a working body (20) for transmitting an exterted force to the working portion, and detector means (60-63) for transforming a mechanical deformation produced in the semiconductor pellet to an electric signal to thereby detect a force exerted on the working body as an electric signal. A signal processing circuit is applied to the sensor. This circuit uses analog multipliers (101-109) and analog adders / subtracters (111-113), and has a function to cancel interference produced in different directions. Within the sensor, two portions (E3, E4-E8) located at positions opposite to each other and producing a displacement therebetween by action of a force are determined. By exerting a coulomb force between both the portions, the test of the sensor is carried out. Further, a pedestal (21, 22) is provided around the working body (20). The working body and the pedestal are located with a predetermined gap or spacing therebetween. A displacement of the working body is caused to limitatively fall within a predetermined range corresponding to the spacing. The working body and the pedestal are provided by cutting a same common substrate (350, 350')

Owner:OKADA KAZUHIRO

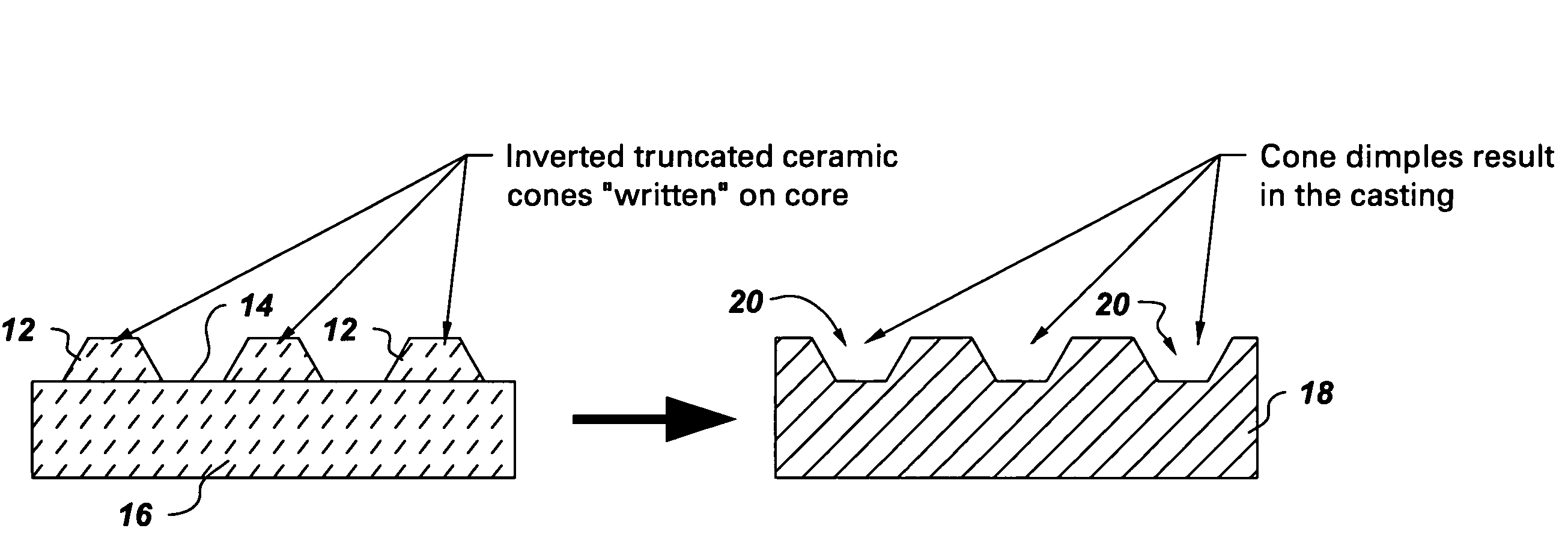

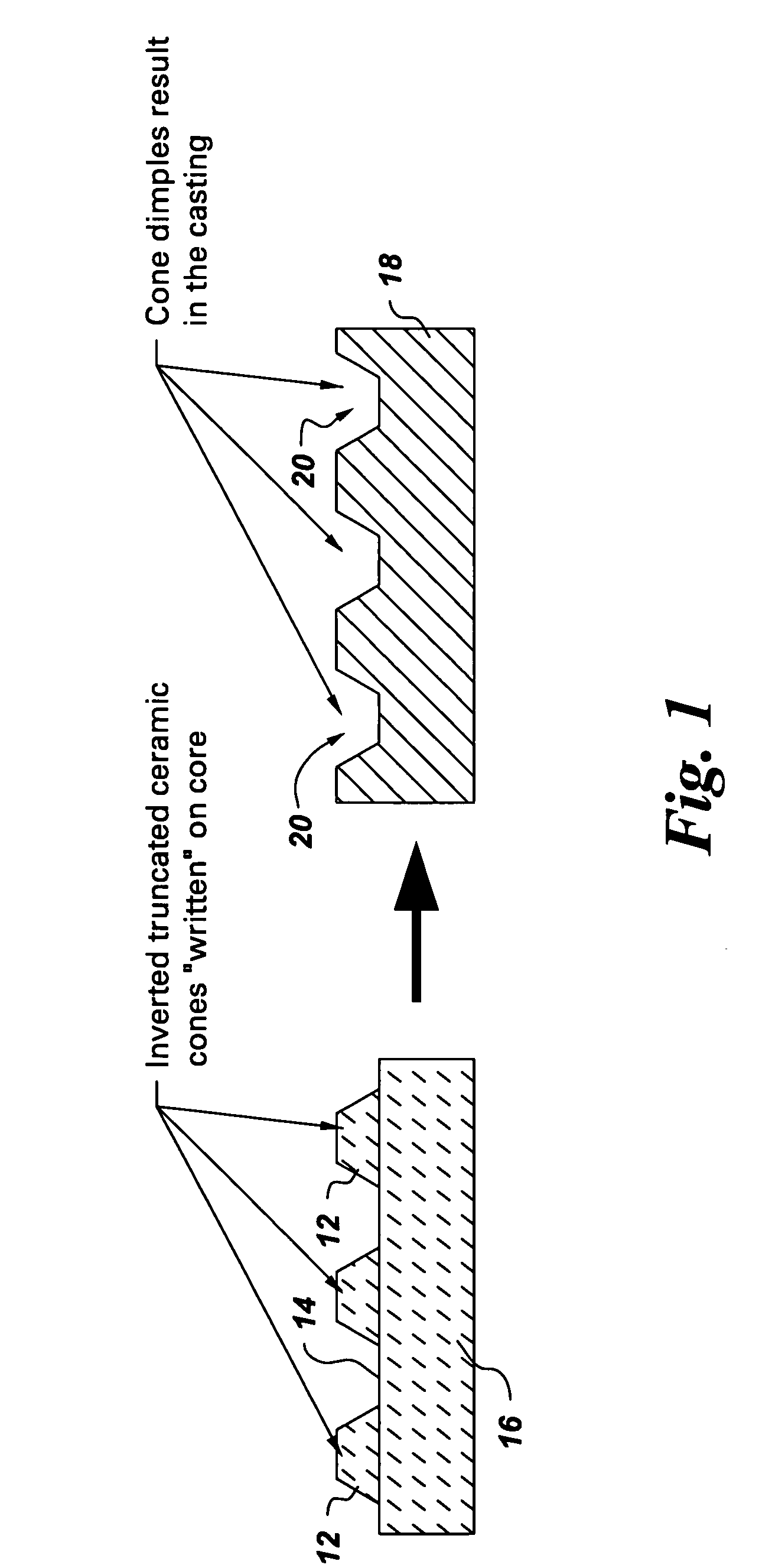

Method of forming concavities in the surface of a metal component, and related processes and articles

ActiveUS7302990B2Forming accuratelyAdditive manufacturing apparatusMolten spray coatingHeat treatedMetal

A method of forming at least one concavity of a selected size and shape within a surface of an internal passageway of a metallic component comprises: depositing a ceramic-based material by a direct-write technique onto a ceramic core which is suitable for forming the internal passageway during a casting process to form the metallic component, wherein the ceramic-based material is deposited as a positive feature; heat-treating the deposited ceramic-based material; forming the metallic component by a casting process in which the ceramic core is incorporated into the casting, in a position selected as a desired position for the internal passageway; and then removing the ceramic core from the metal component after the casting process is complete, thereby forming the internal passageway, with the concavity contained within the surface of the passageway, said concavity formed by removal of the positive feature of the ceramic-based material.

Owner:GE INFRASTRUCTURE TECH INT LLC

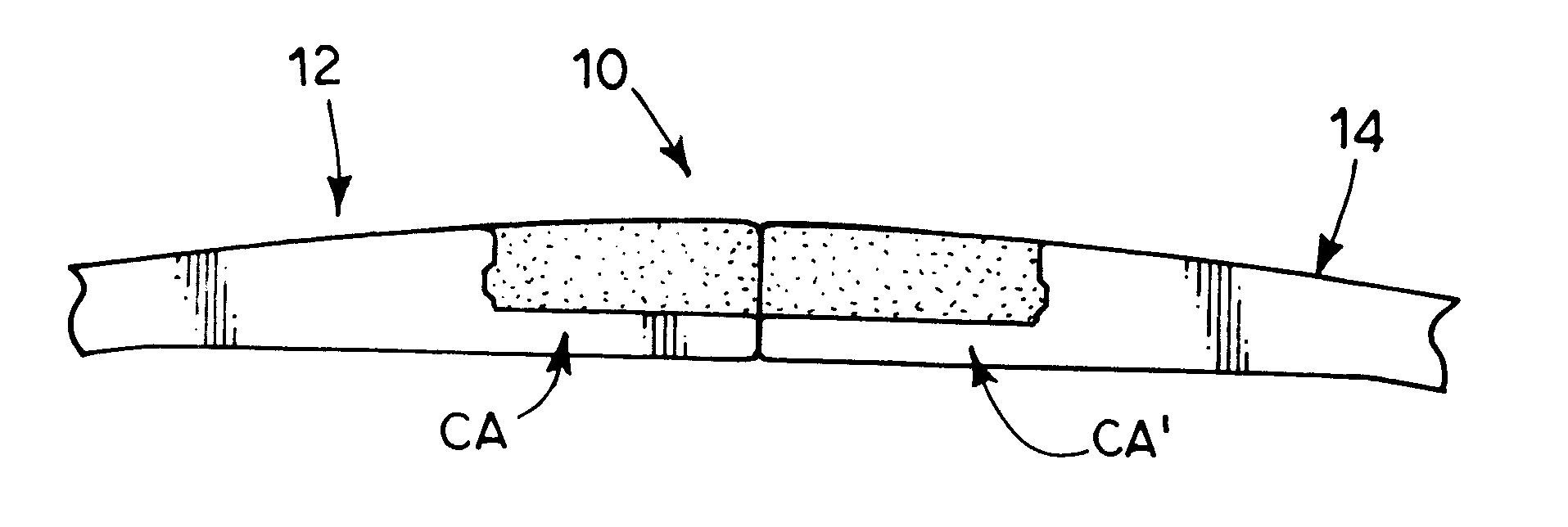

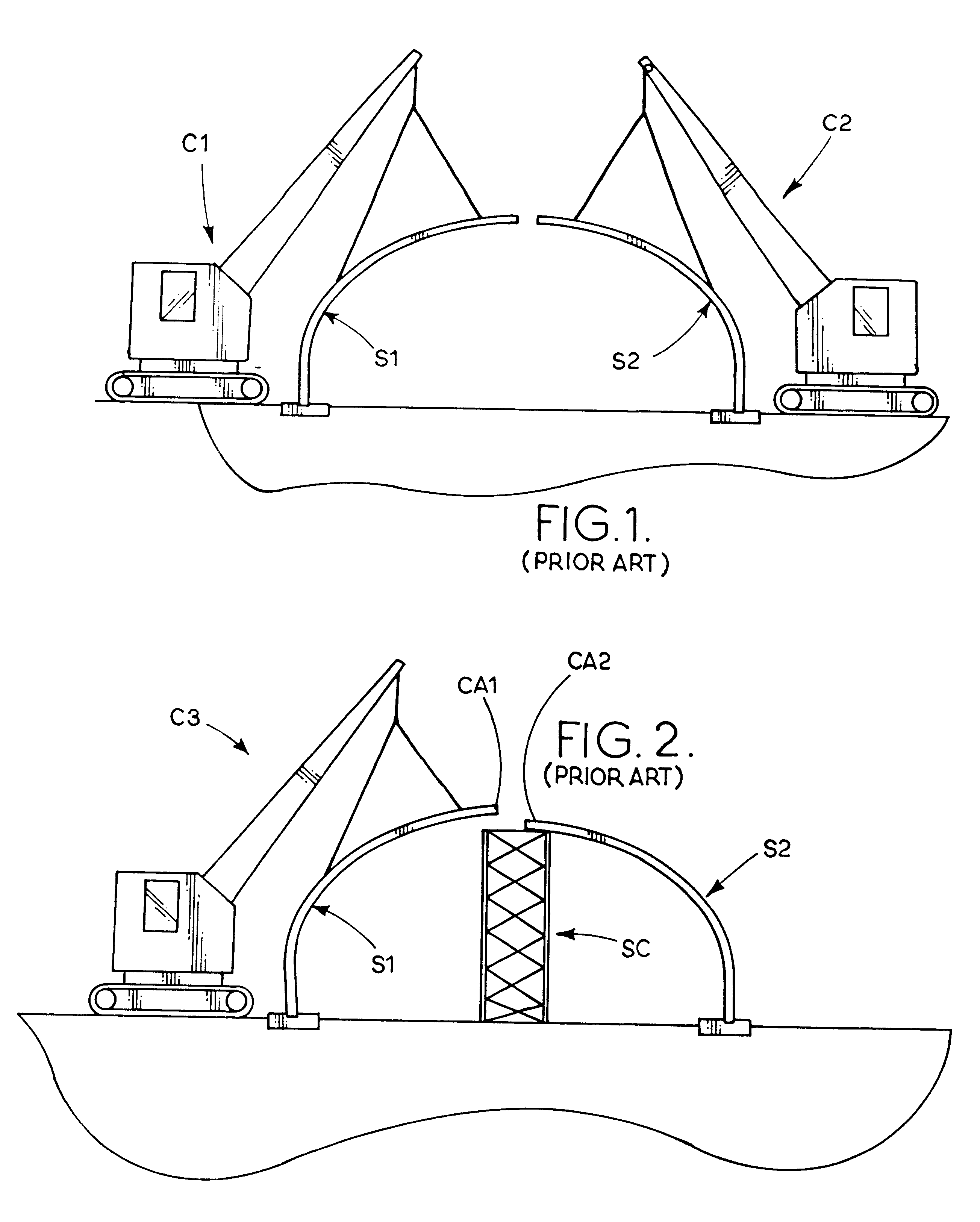

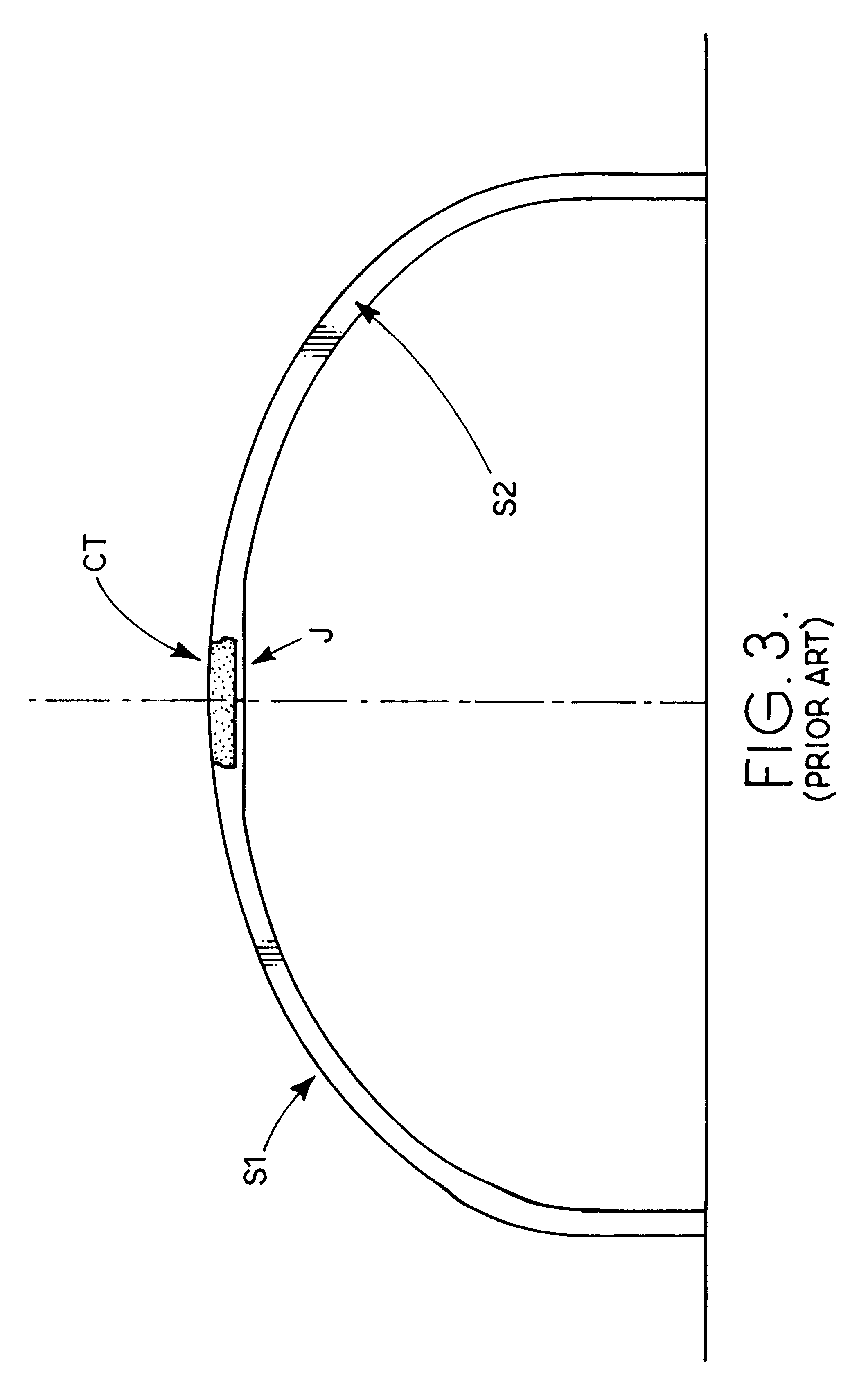

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

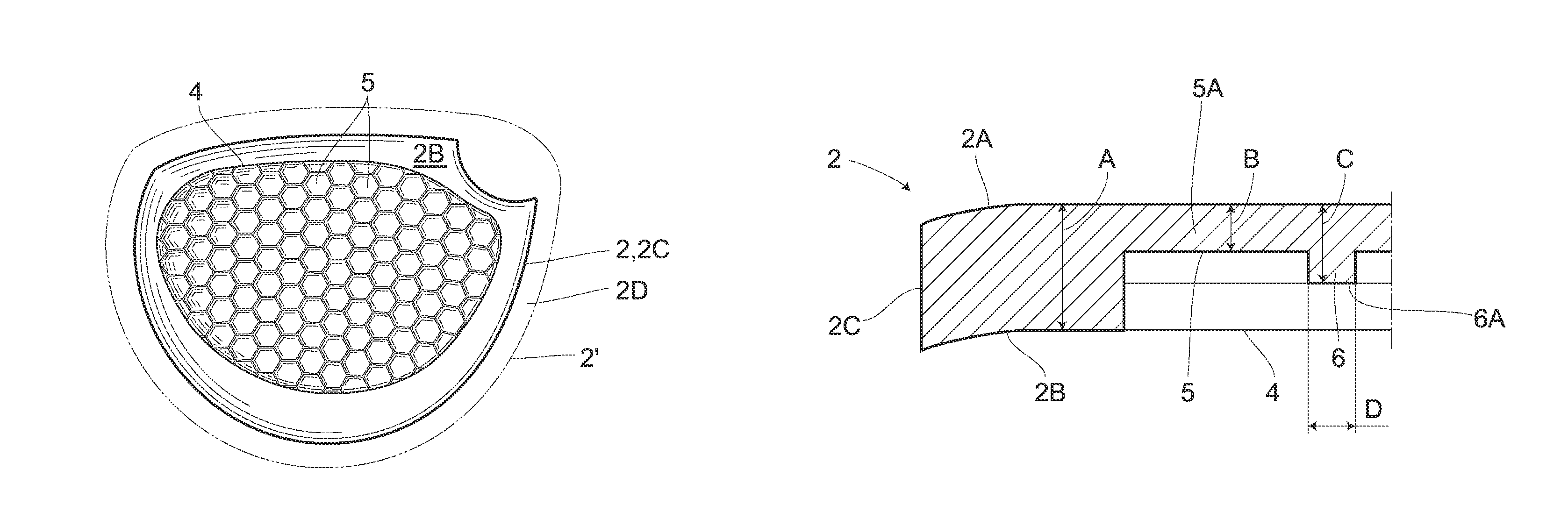

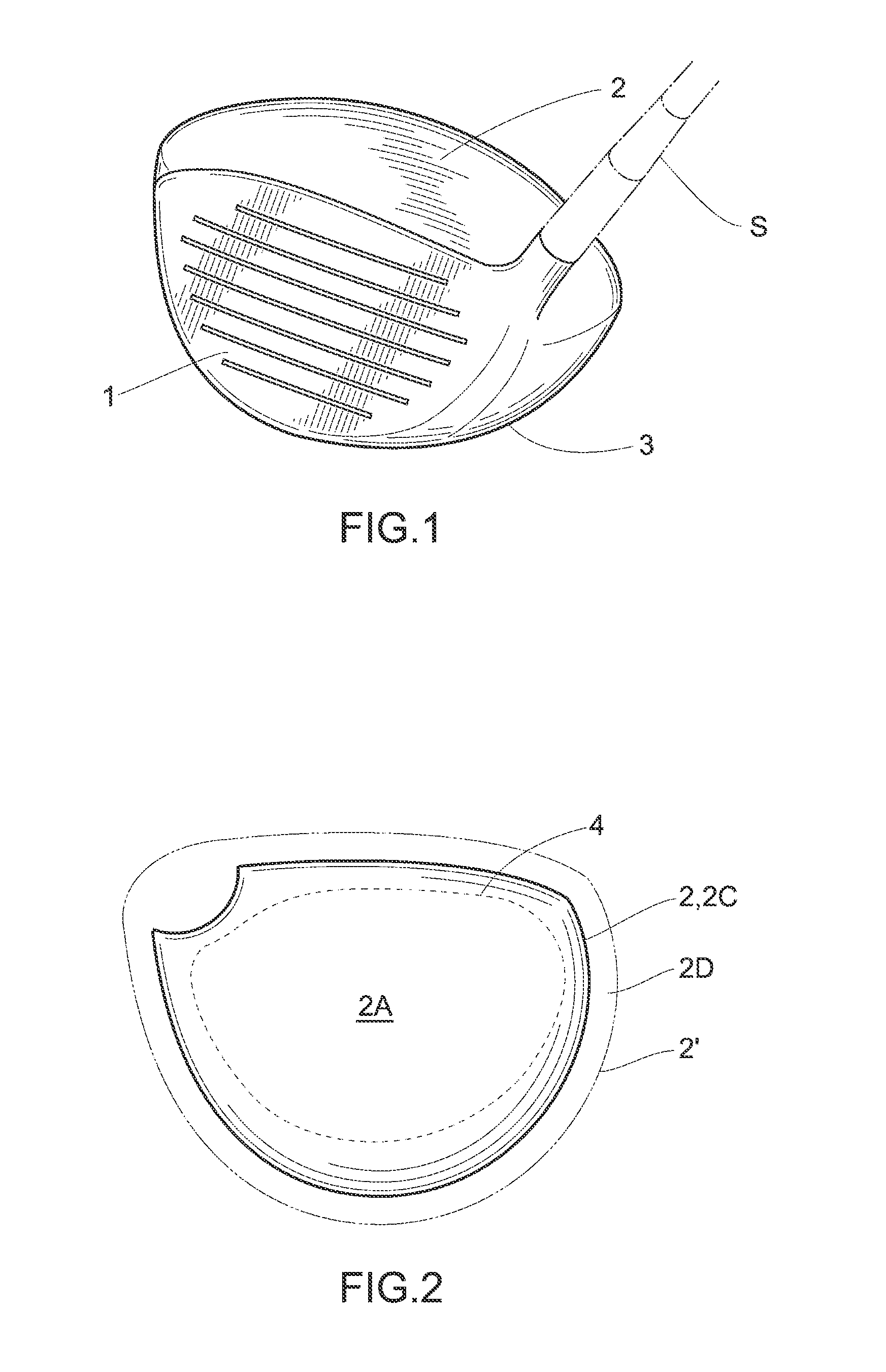

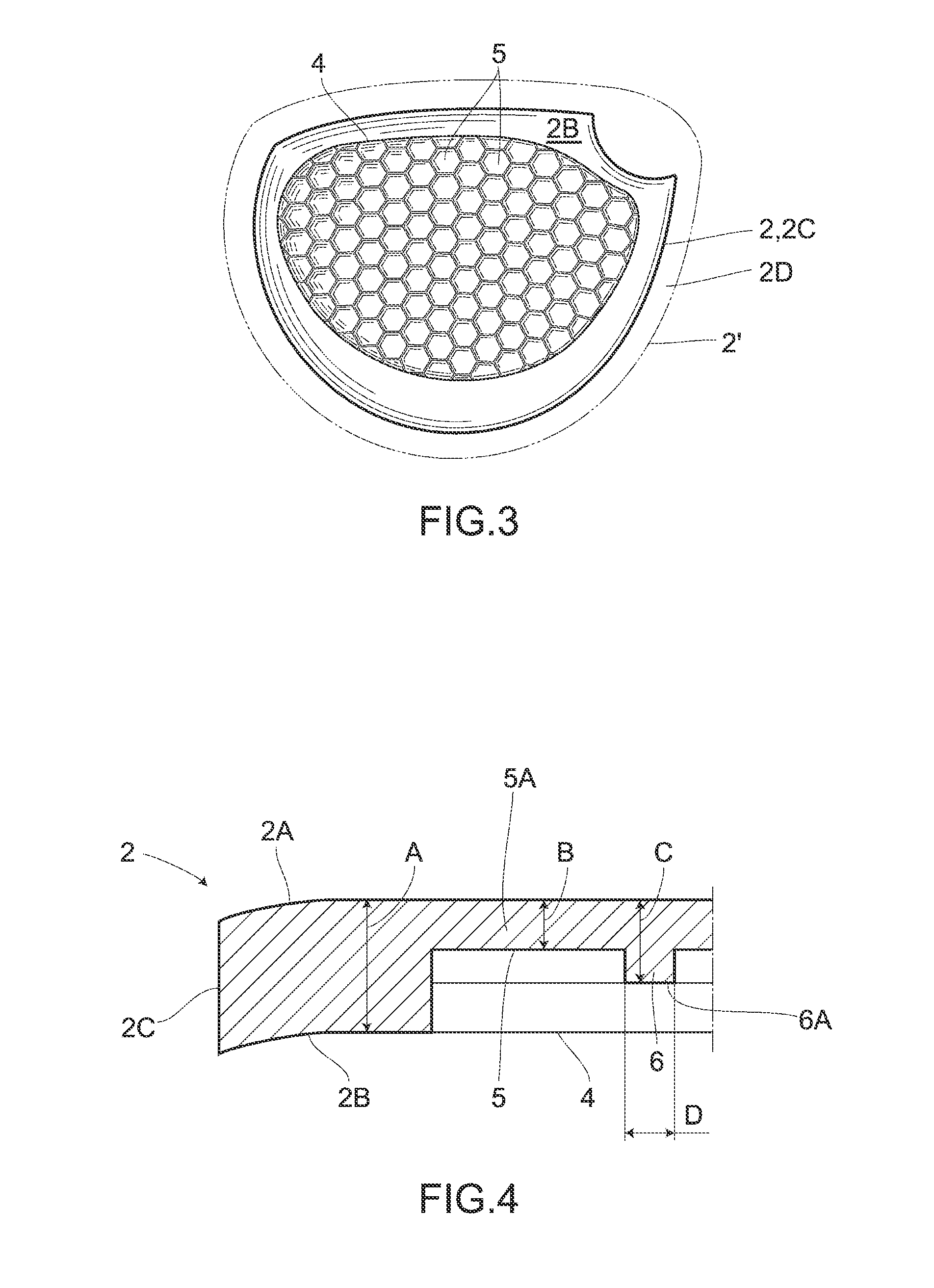

Hollow golf club head

InactiveUS8540590B2Improve performanceIncrease freedomGolf clubsStringed racketsRepulsion forceAlloy

There is provided a Ti alloy hollow club head which is more lightweight yet capable of realizing a better repulsion force by adjusting weight and thickness of a club head plate, with its strength ensured. Ribs are formed by chemically polishing the inner surface of a material of a crown plate to a 0.3 to 0.9 mm thickness, and a 0.3 to 4 mm width, and then first concave portions are formed to a 0.2 to 0.5 mm thickness. Thus, strength of the crown plate can be ensured by the ribs, while making the thickness thereof as thin as possible.

Owner:ENDO MFG COMPANY

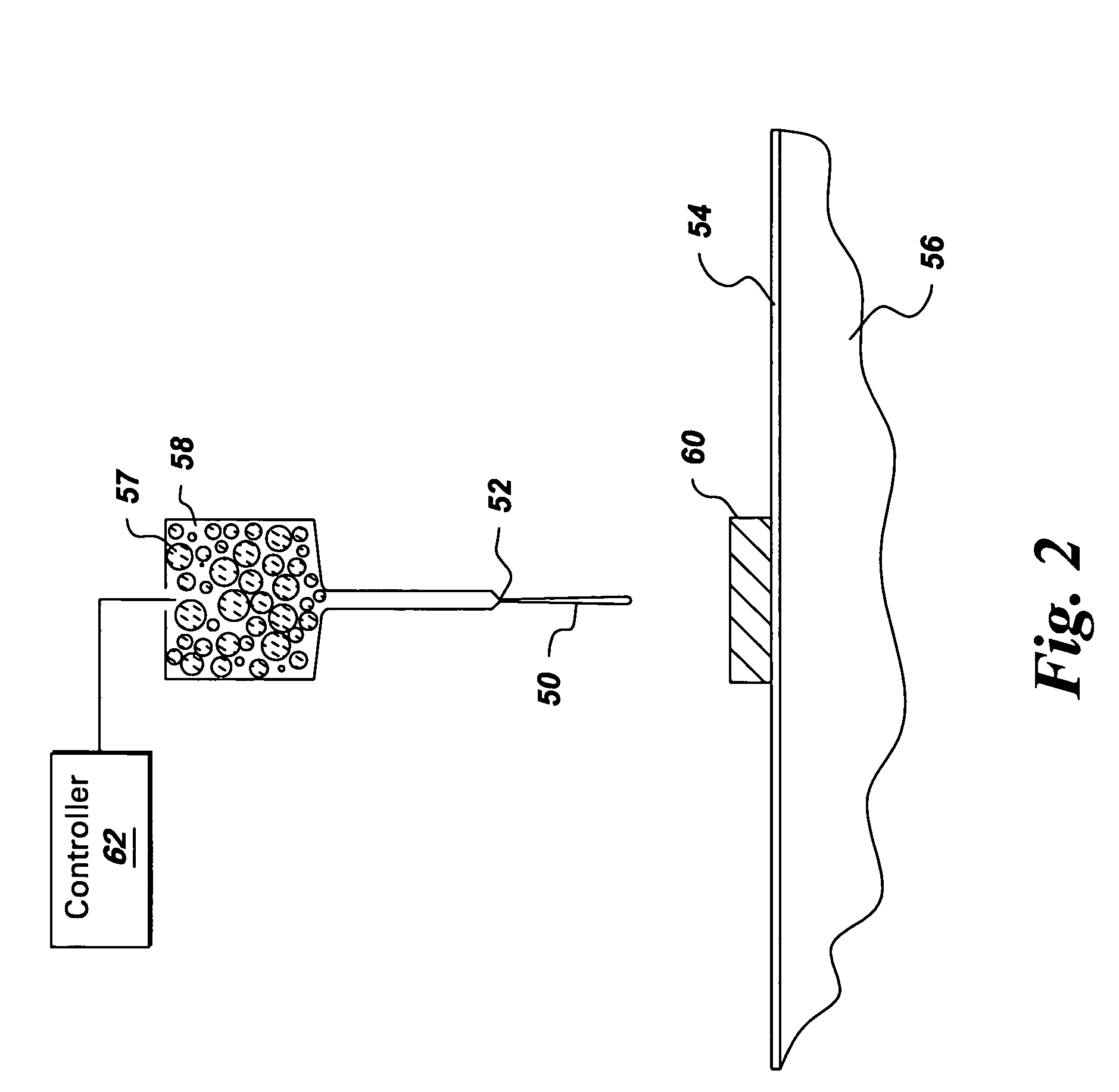

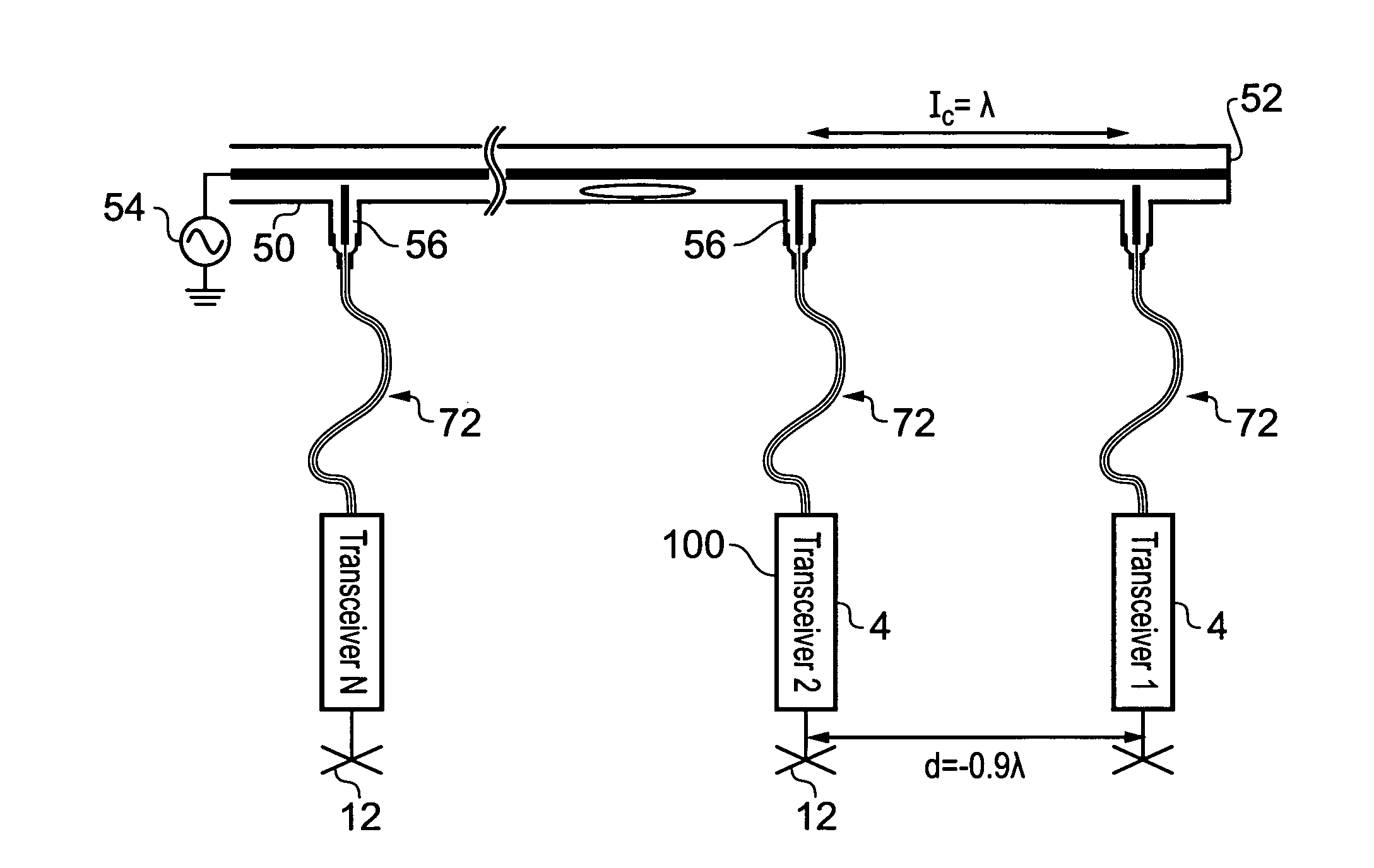

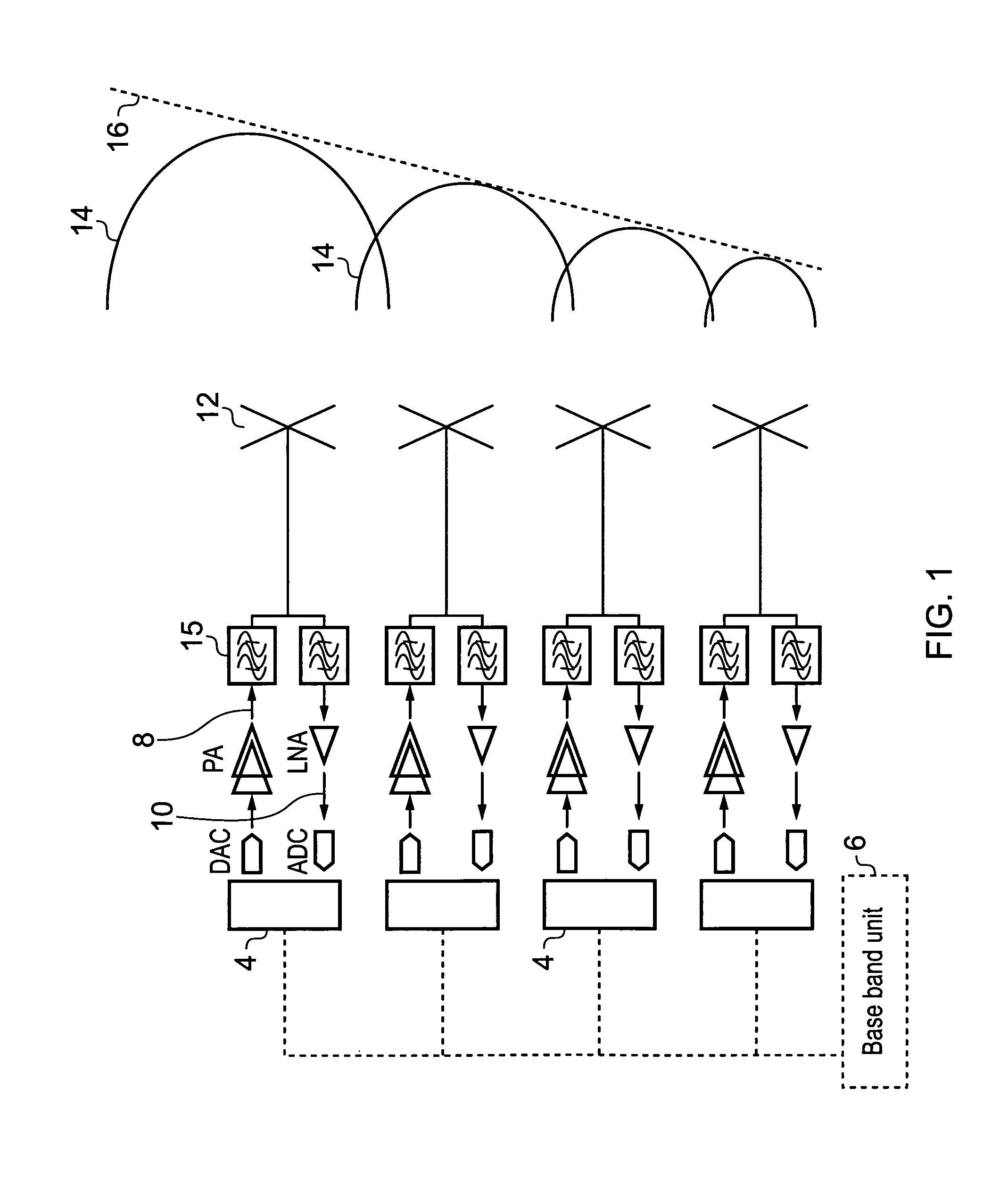

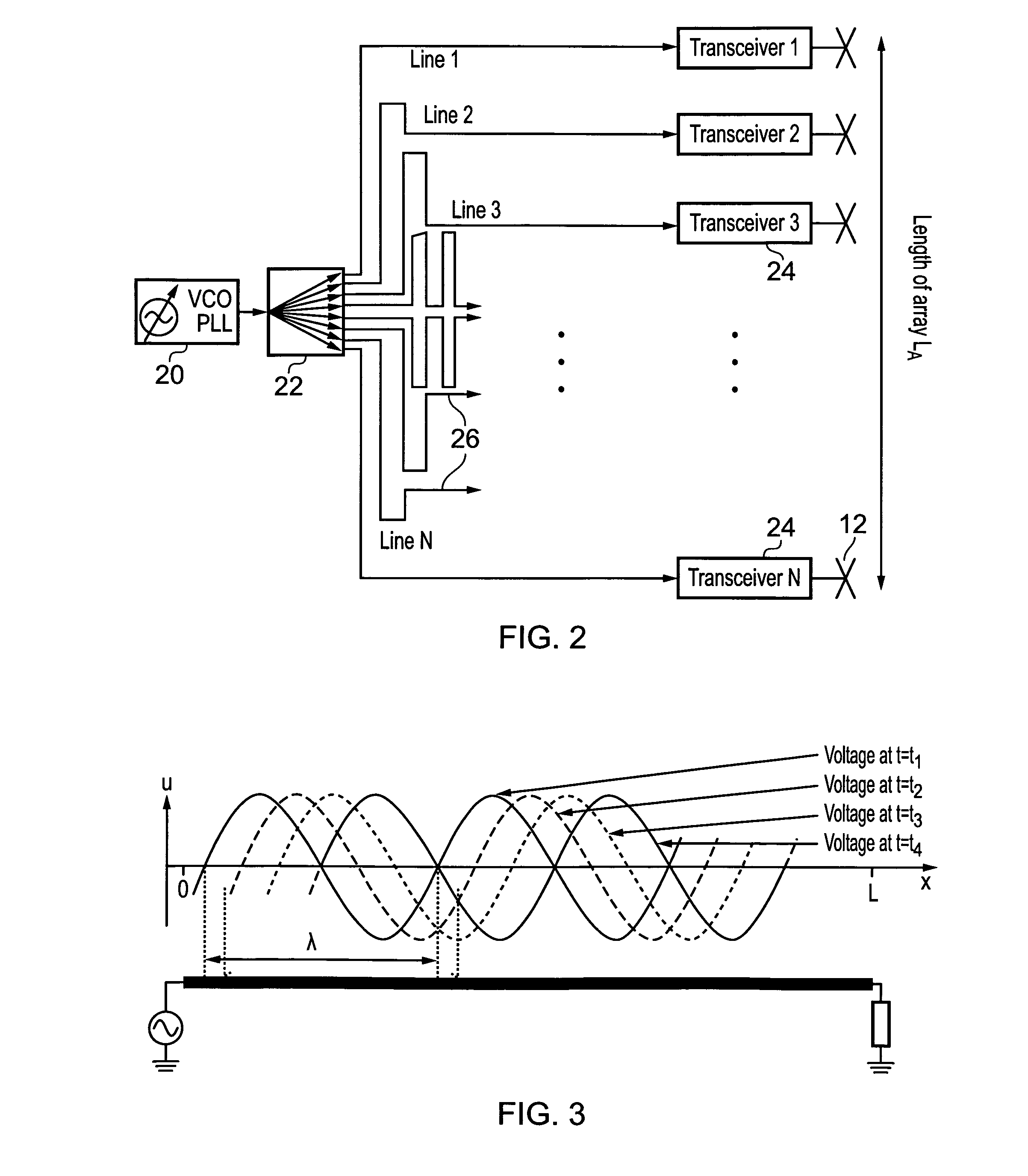

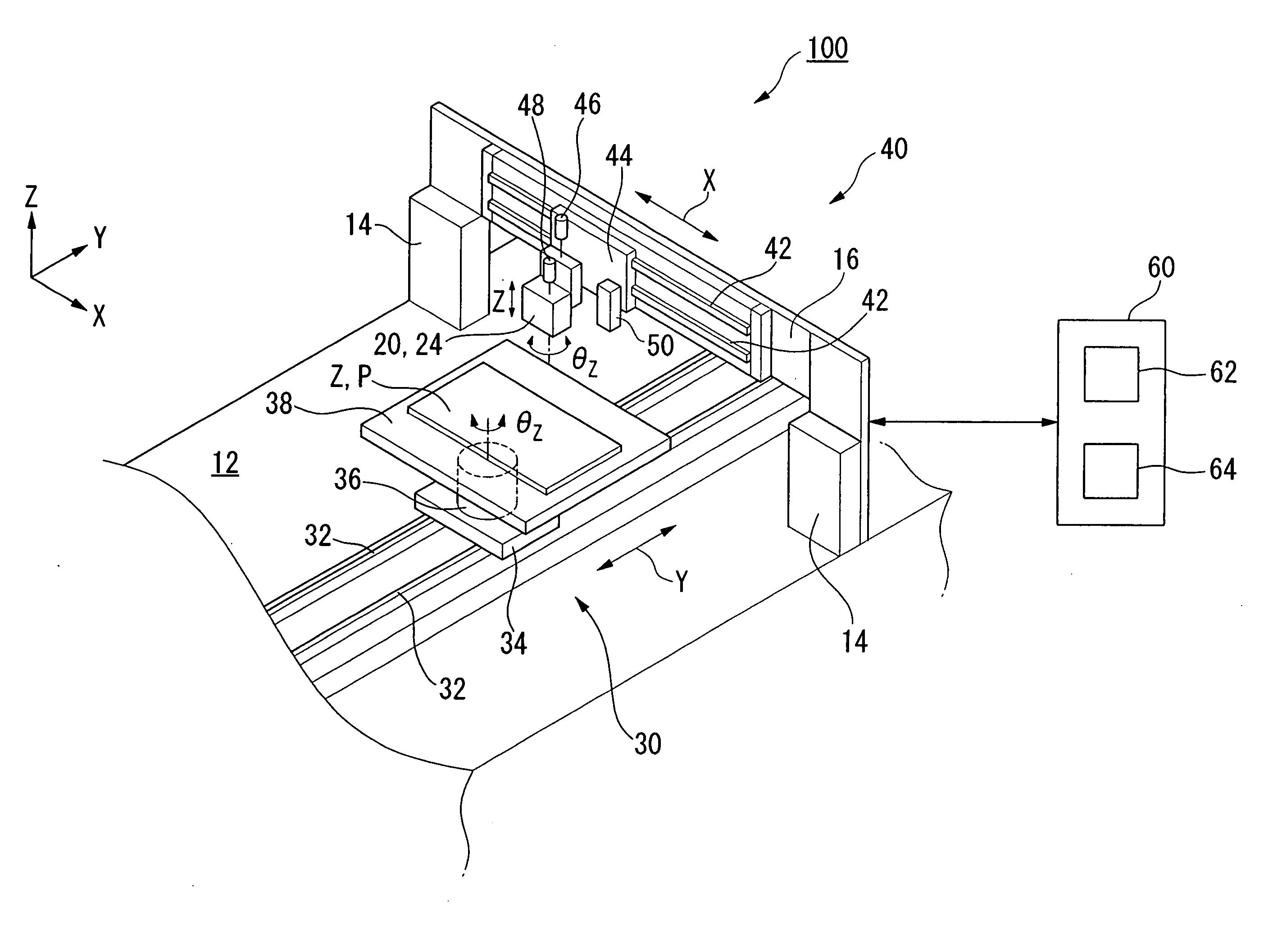

Calibration of active antenna arrays for mobile telecommunications

ActiveUS20130057447A1Limited mechanical accuracyForming accuratelyIndividually energised antenna arraysStanding waveVIT signals

In order to calibrate in amplitude and phase the individual transceiver elements (4) of an active antenna array for a mobile telecommunications network, each transceiver element including a transmit and a receive path (8, 10) coupled to an antenna element (12), each transceiver element includes a comparator (100) for comparing phase and amplitude of transmitted or received signals with reference signals in order to adjust the characteristics of the antenna beam. In order to provide an accurate means of reference signal distribution, a feed arrangement distributes the reference signals and includes a waveguide (50) of a predetermined length which is terminated at one end (52) in order to set up a standing wave system along its length, and a plurality of coupling points (56) at predetermined points along the length of the waveguide, which are each coupled to a comparator of a respective transceiver element.

Owner:ALCATEL LUCENT SAS

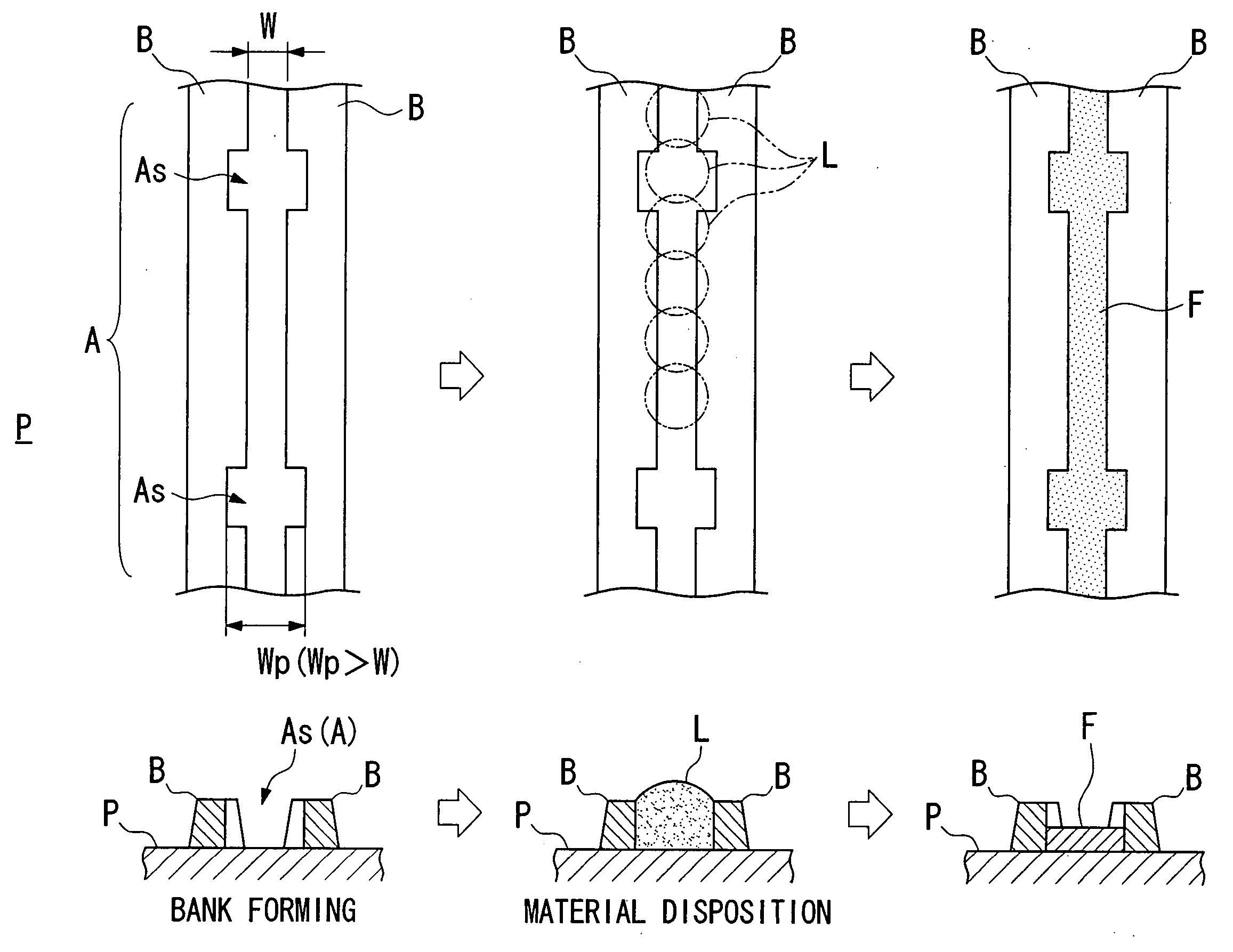

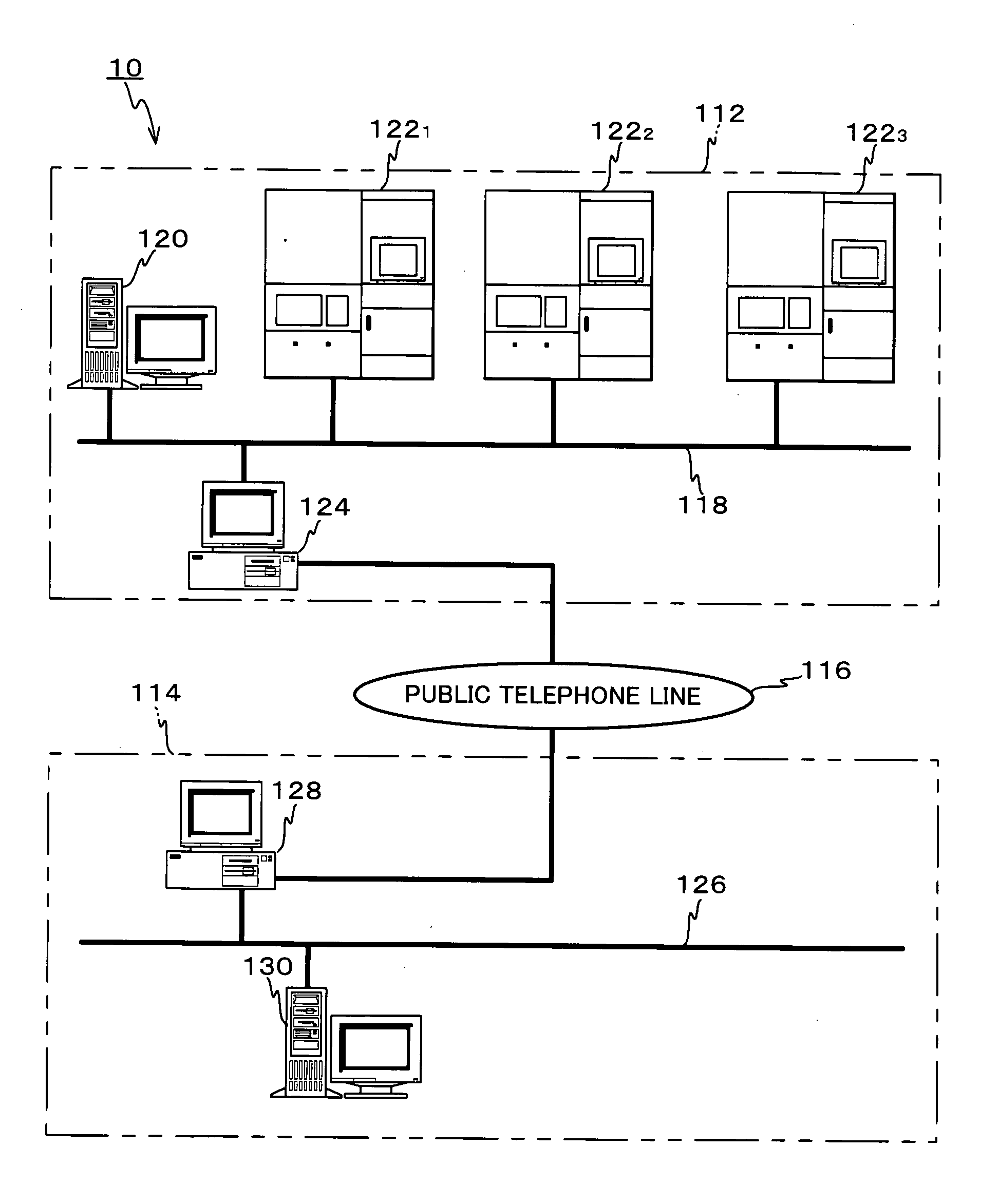

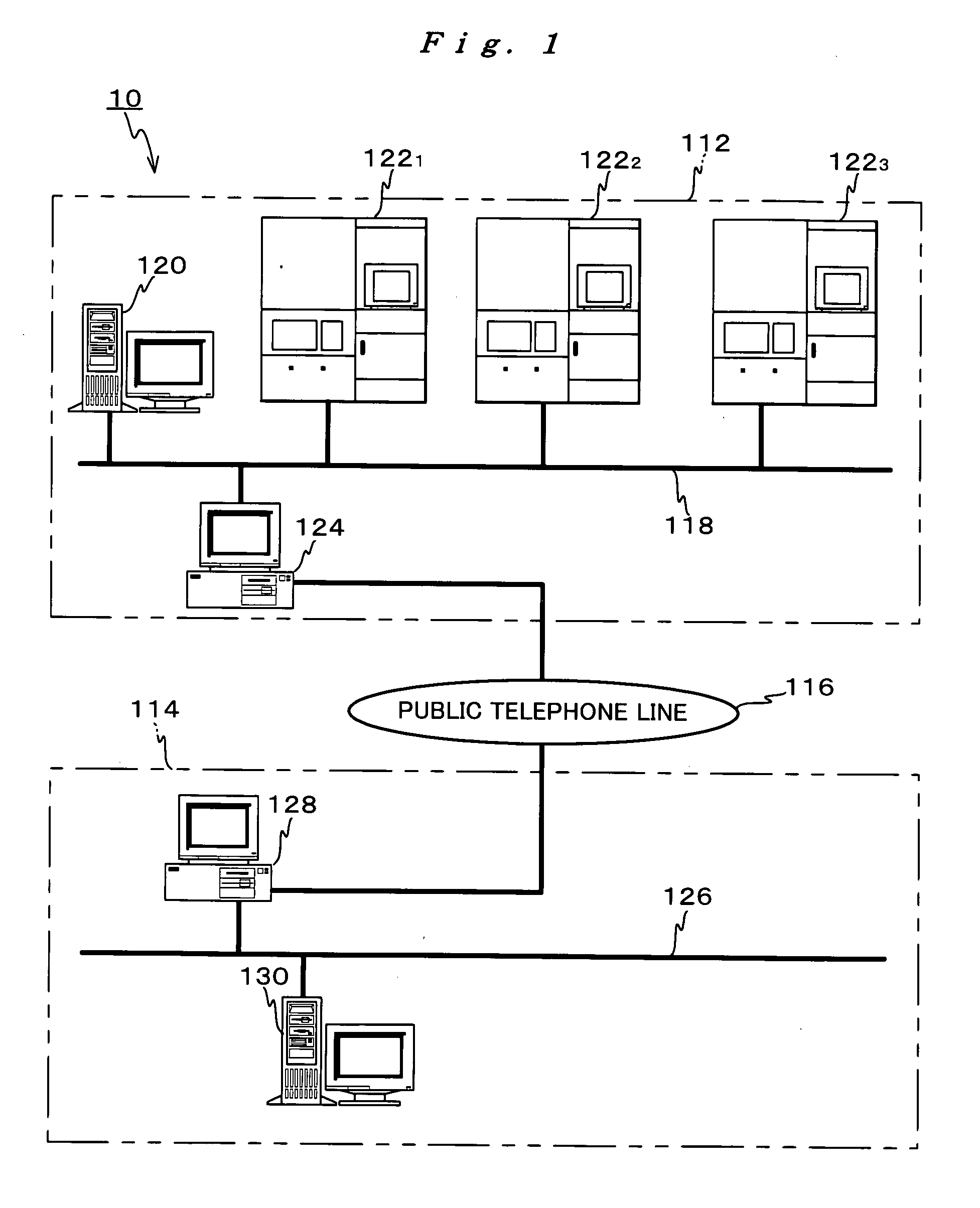

Method and apparatus for forming a pattern, device and electronic apparatus

ActiveUS20050177343A1Improve landing accuracyImprove accuracyElectric lighting sourcesSolid-state devicesEngineeringElectron

Owner:TOKYO ELECTRON LTD

Exposure apparatus and method for producing device

InactiveUS20060238730A1Accurate transferHigh pattern accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

An exposure apparatus exposes a substrate P by locally filling a side of an image plane of a projection optical system PL with a liquid 50 and projecting an image of a pattern onto the substrate P through the liquid 50 and the projection optical system PL. The exposure apparatus includes a recovery unit 20 which recovers the liquid 50 outflowed to the outside of the substrate P. When the exposure process is performed in accordance with the liquid immersion method, the pattern can be transferred accurately while suppressing any environmental change even when the liquid outflows to the outside of the substrate.

Owner:NIKON CORP

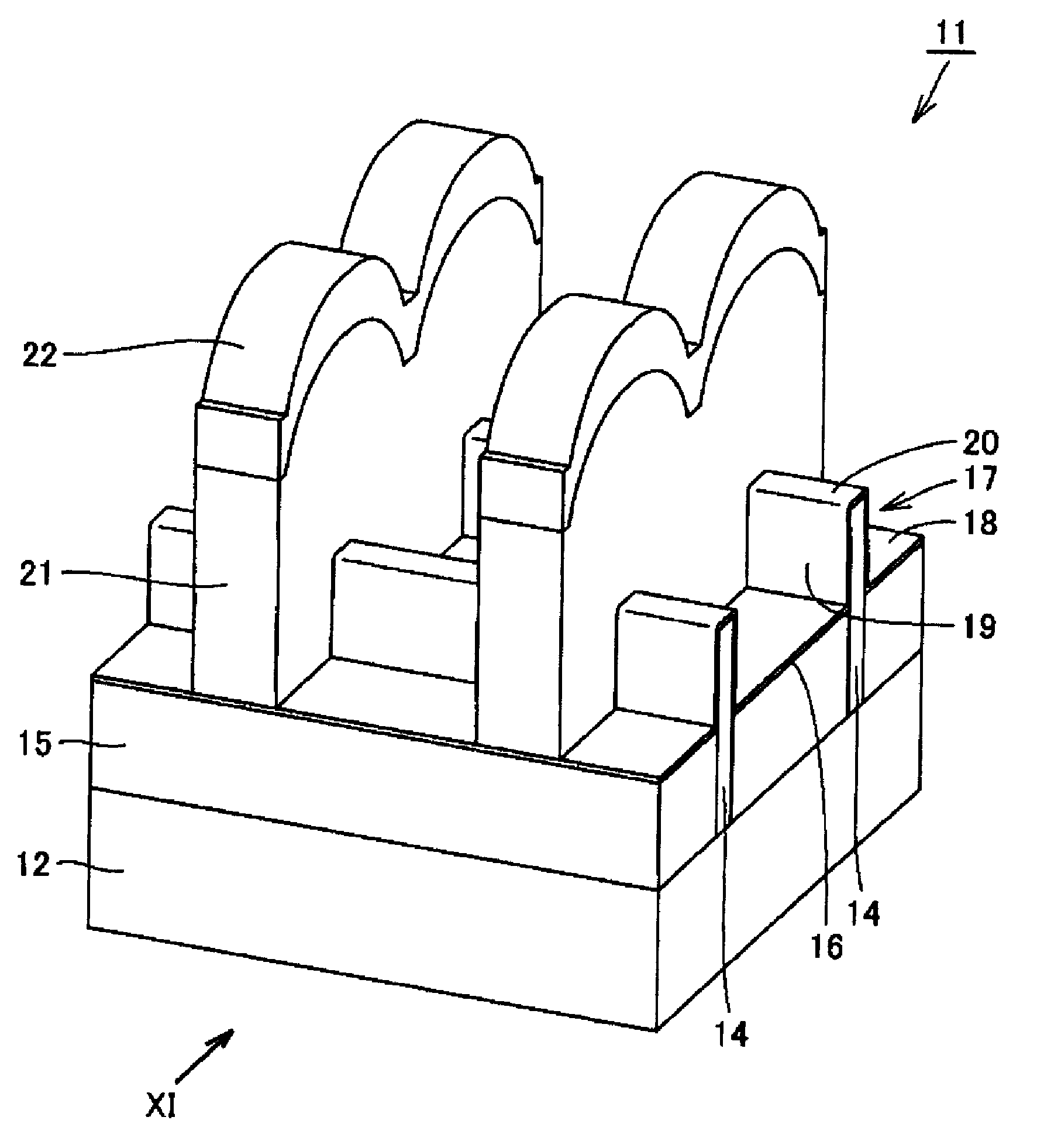

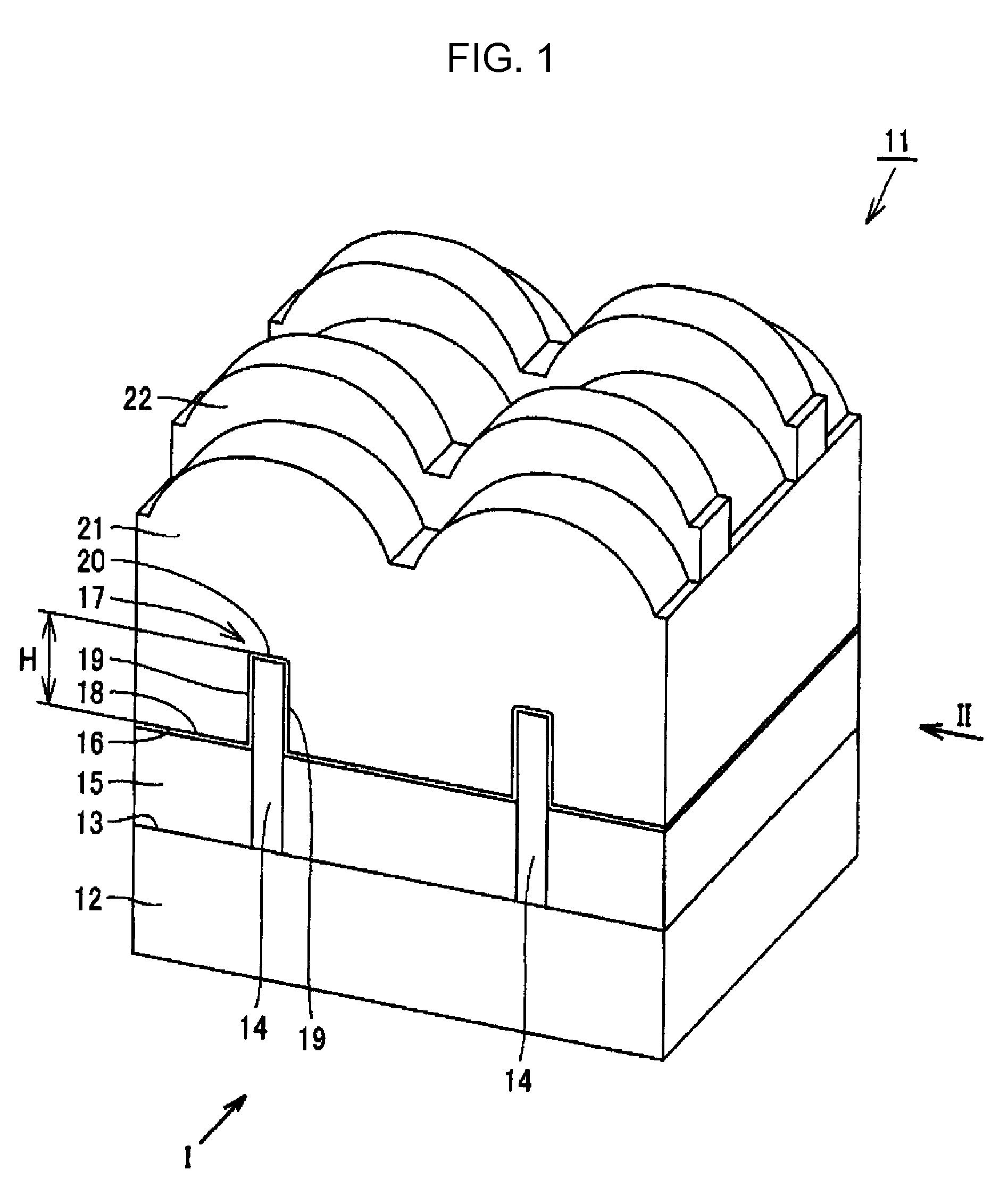

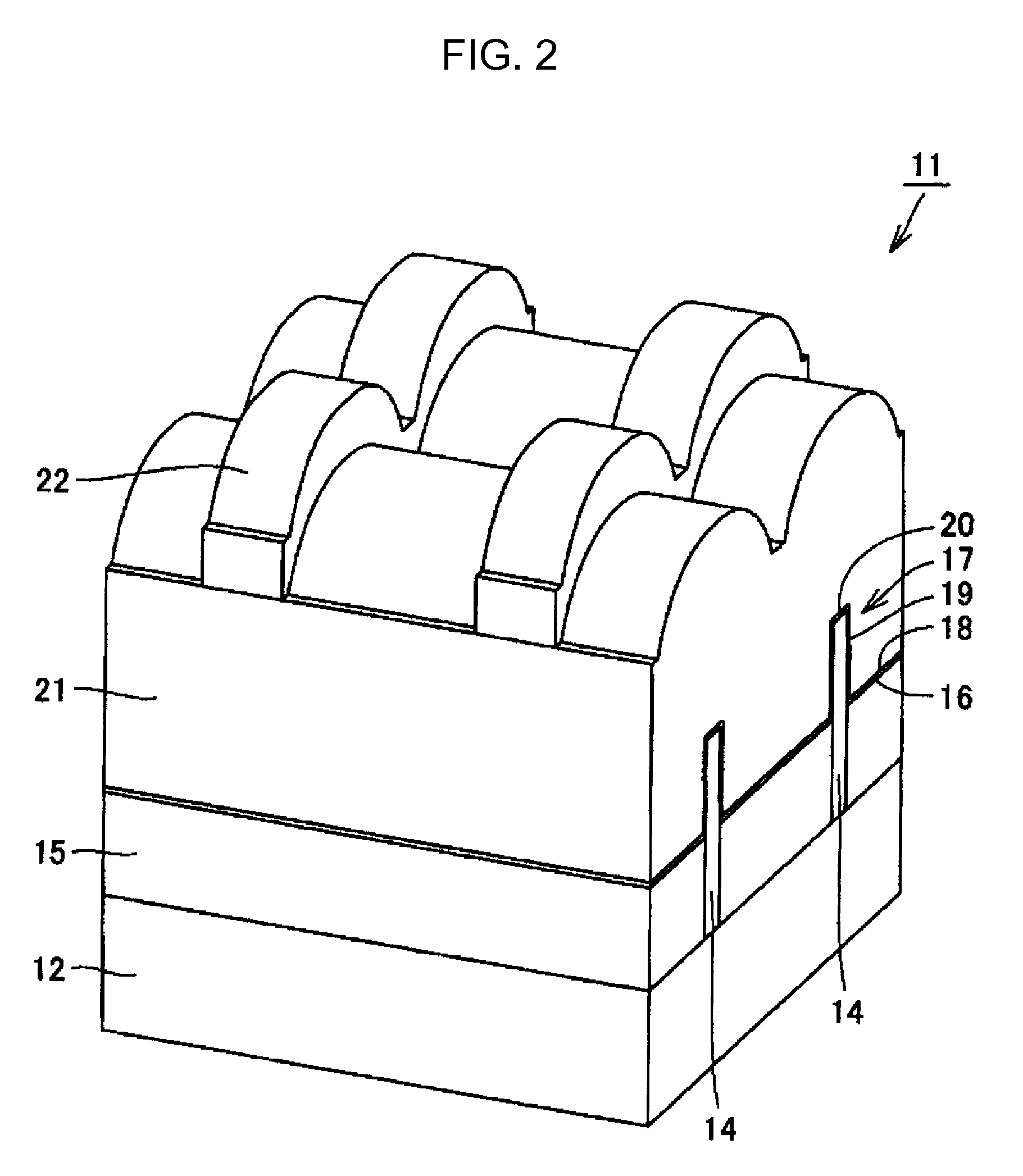

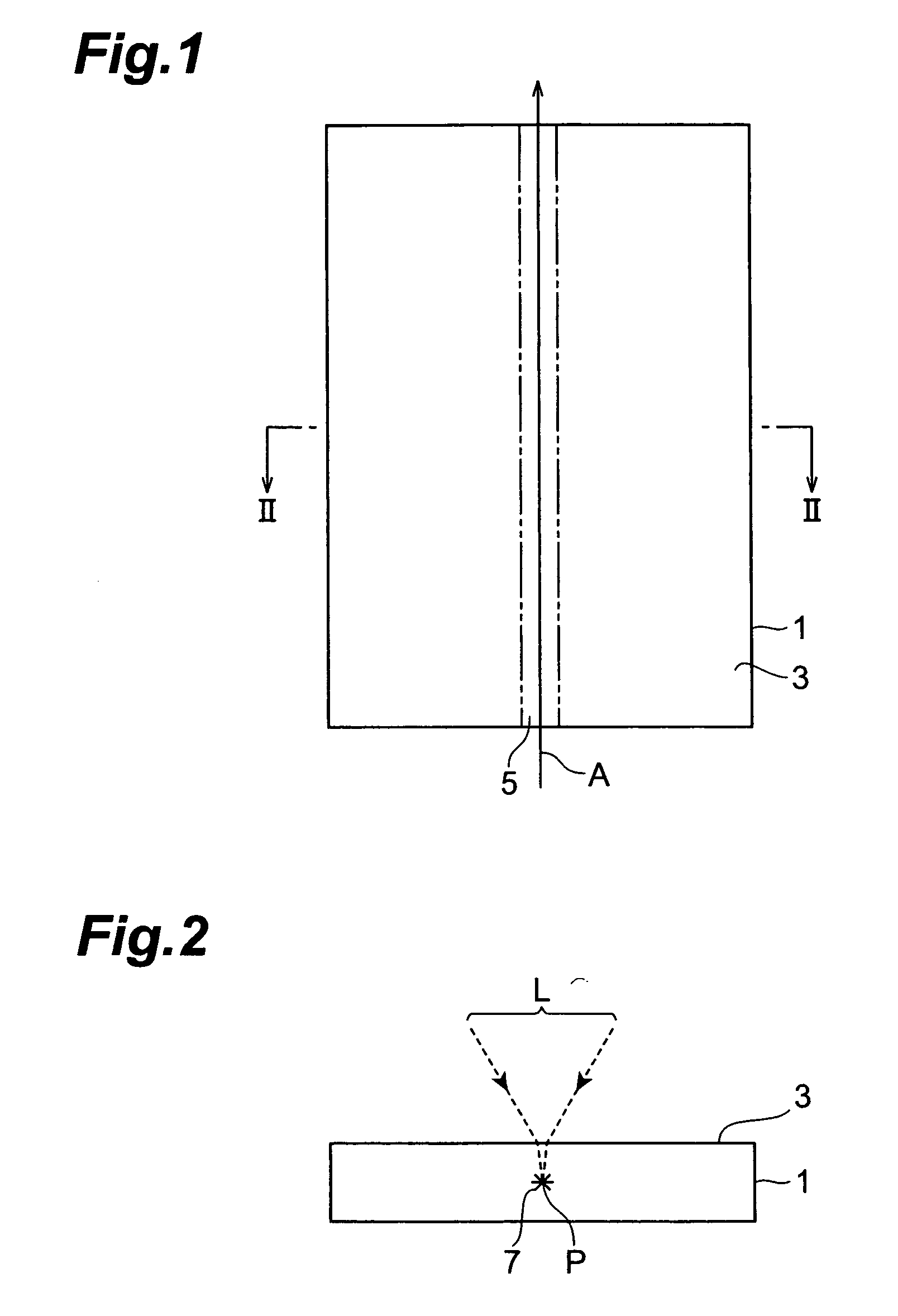

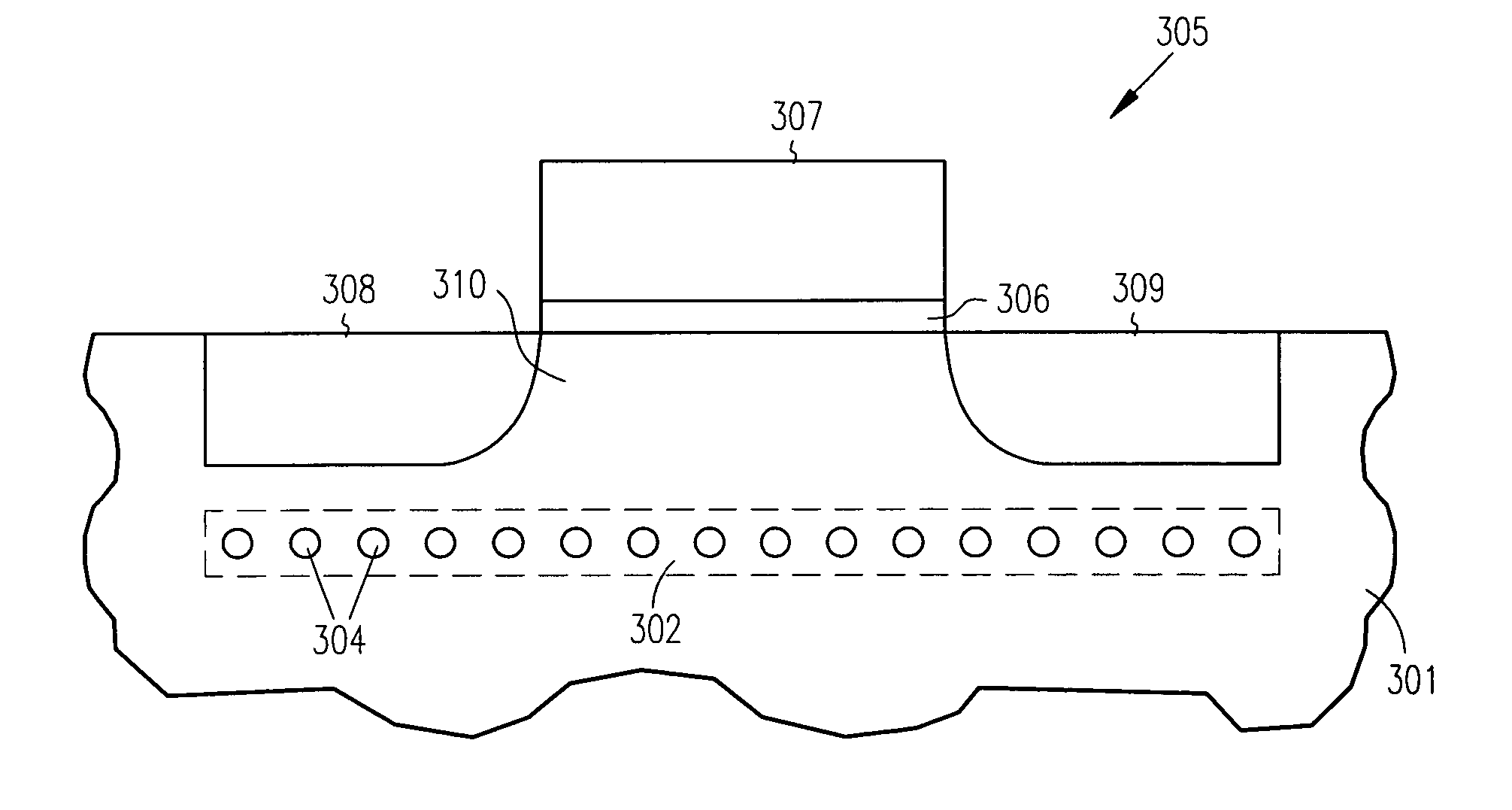

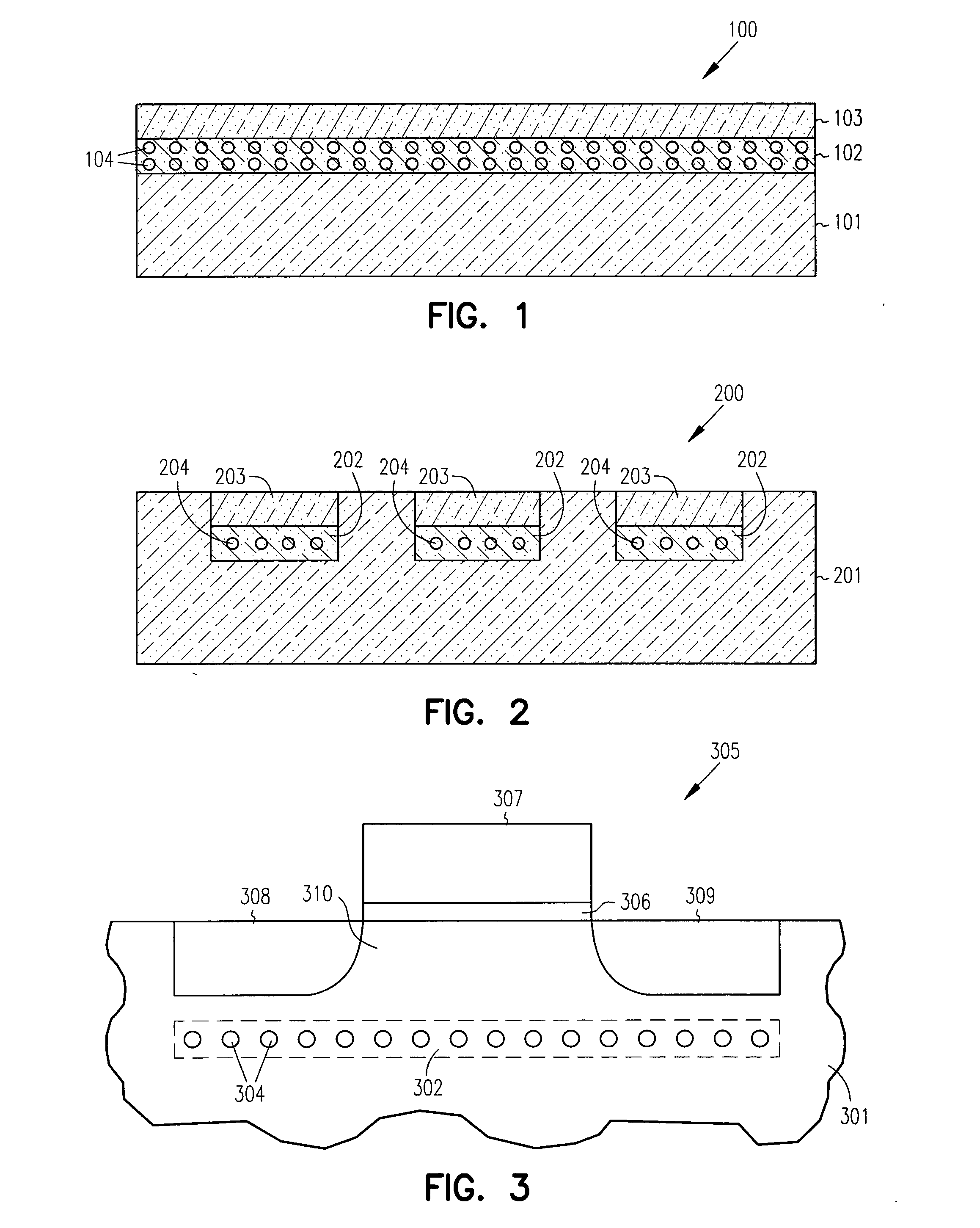

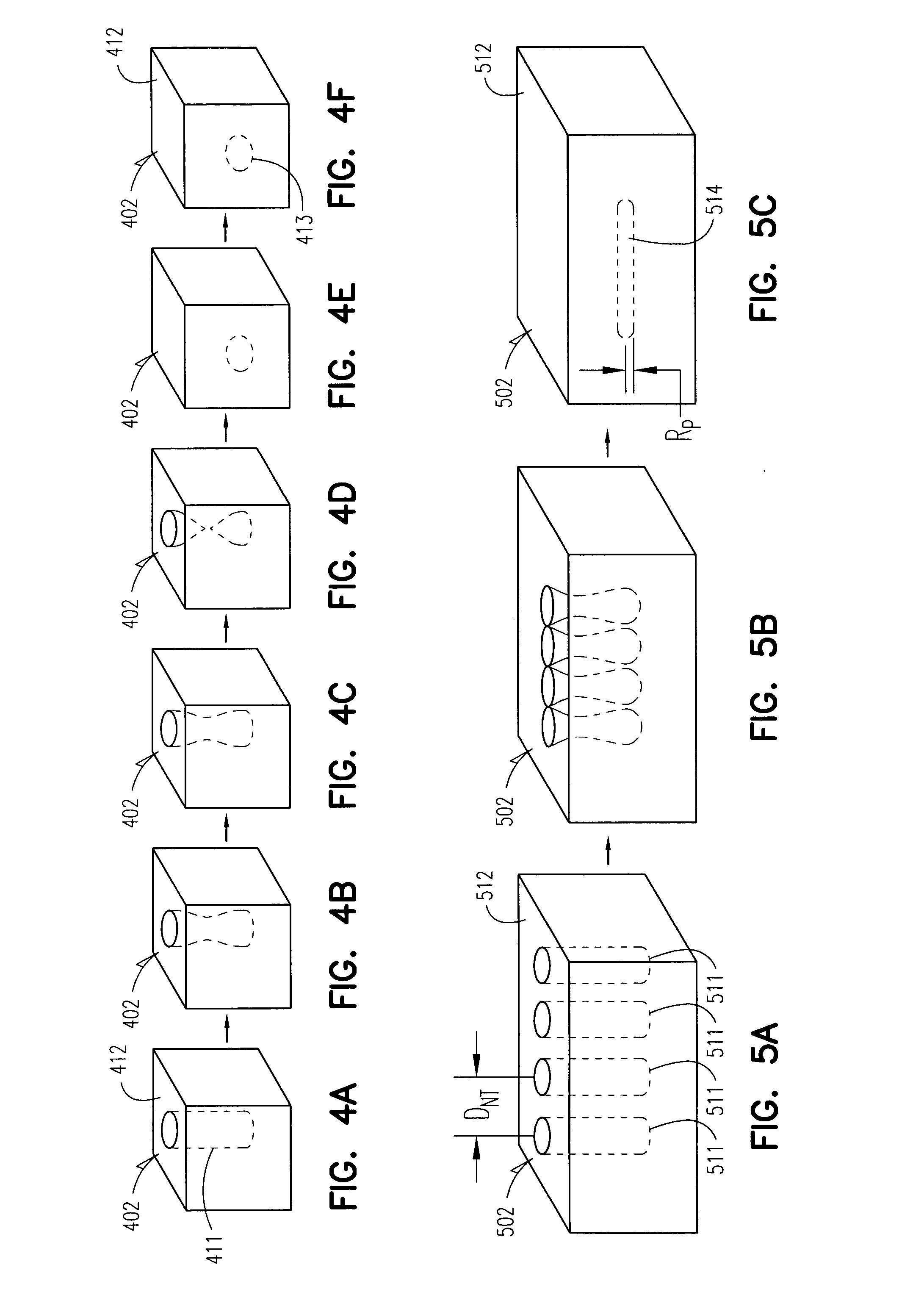

Gettering using voids formed by surface transformation

InactiveUS20050017273A1Increase inhalationIncrease the areaTransistorSolid-state devicesEngineeringSemiconductor

One aspect of this disclosure relates to a method for creating a gettering site in a semiconductor wafer. In various embodiments, a predetermined arrangement of a plurality of holes is formed in the semiconductor wafer through a surface of the wafer. The wafer is annealed such that the wafer undergoes a surface transformation to transform the arrangement of the plurality of holes into a predetermined arrangement of at least one empty space of a predetermined size within the wafer to form the gettering site. One aspect relates to a semiconductor wafer. In various embodiments, the wafer includes at least one device region, and at least one gettering region located proximate to the at least one device region. The gettering region includes a precisely-determined arrangement of a plurality of precisely-formed voids that are formed within the wafer using a surface transformation process. Other aspects and embodiments are provided herein.

Owner:MICRON TECH INC

Pattern forming method, device, method of manufacture thereof, electro-optical apparatus, and electronic apparatus

Owner:138 EAST LCD ADVANCEMENTS LTD

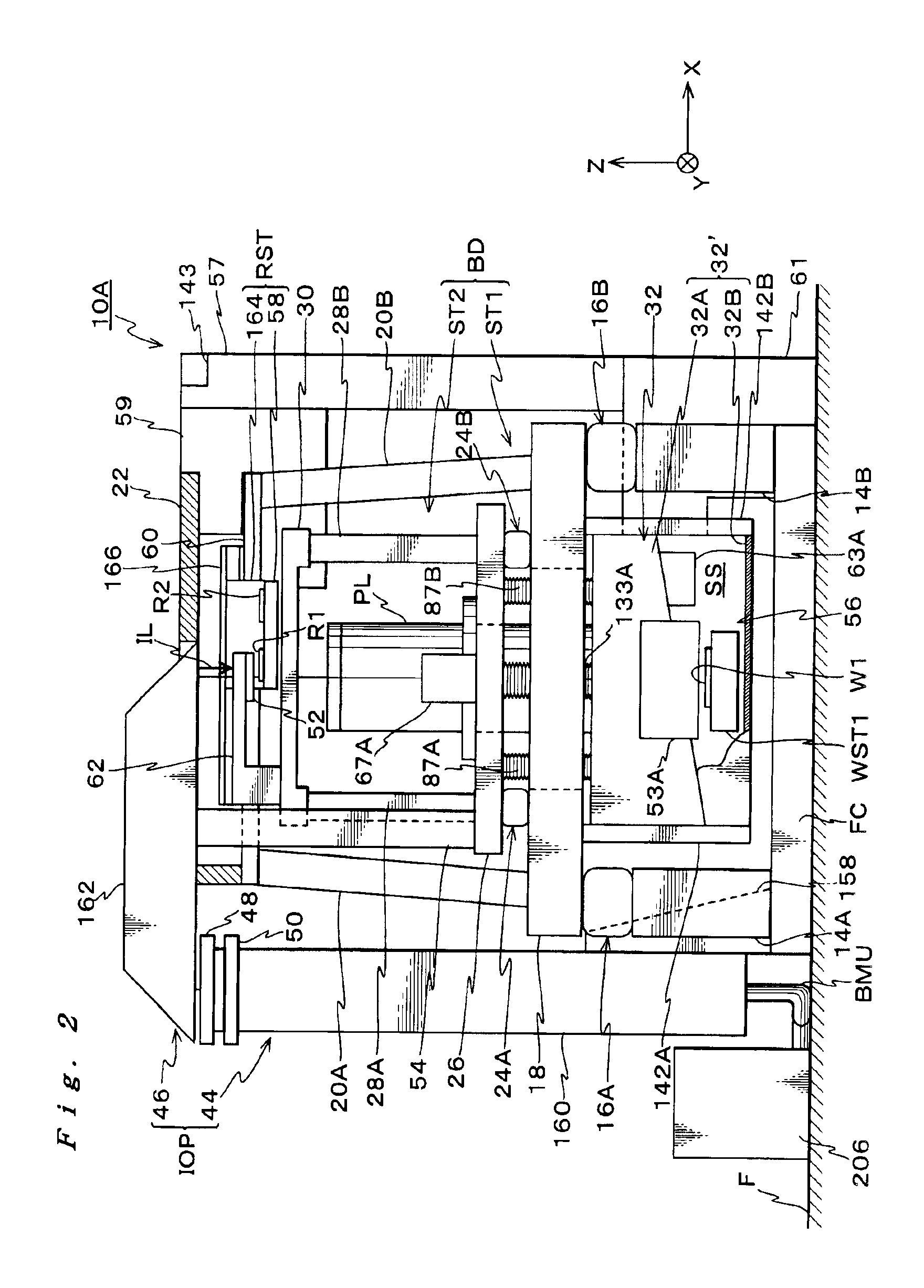

Exposure apparatus and exposure method, and device manufacturing method

InactiveUS20060285100A1Forming accuratelyEasy to integratePhotomechanical apparatusPhotographic printingOptic systemLeast squares

An exposure apparatus comprises: a movable body that is arranged on an image plane side with respect to a projection optical system; a wavefront measuring unit at least a part of which is arranged on the movable body and that measures wavefront information of the projection optical system; an adjusting unit that adjusts an imaging state of a projected pattern generated on an object via the projection optical system; and a controller that determines adjustment information of the projection optical system using the least-squares method based on the wavefront information and Zernike Sensitivity corresponding to exposure conditions of the object, and controls the adjusting unit based on the adjustment information. The controller determines a coefficient in a predetermined term of a Zernike polynomial from the wavefront information, and determines an adjustment amount of an optical element of the projection optical system as the adjustment information, based on data regarding a relation between an adjustment amount of the optical element of the projection optical system and variation of the determined coefficient in a predetermined term of a Zernike polynomial.

Owner:NIKON CORP

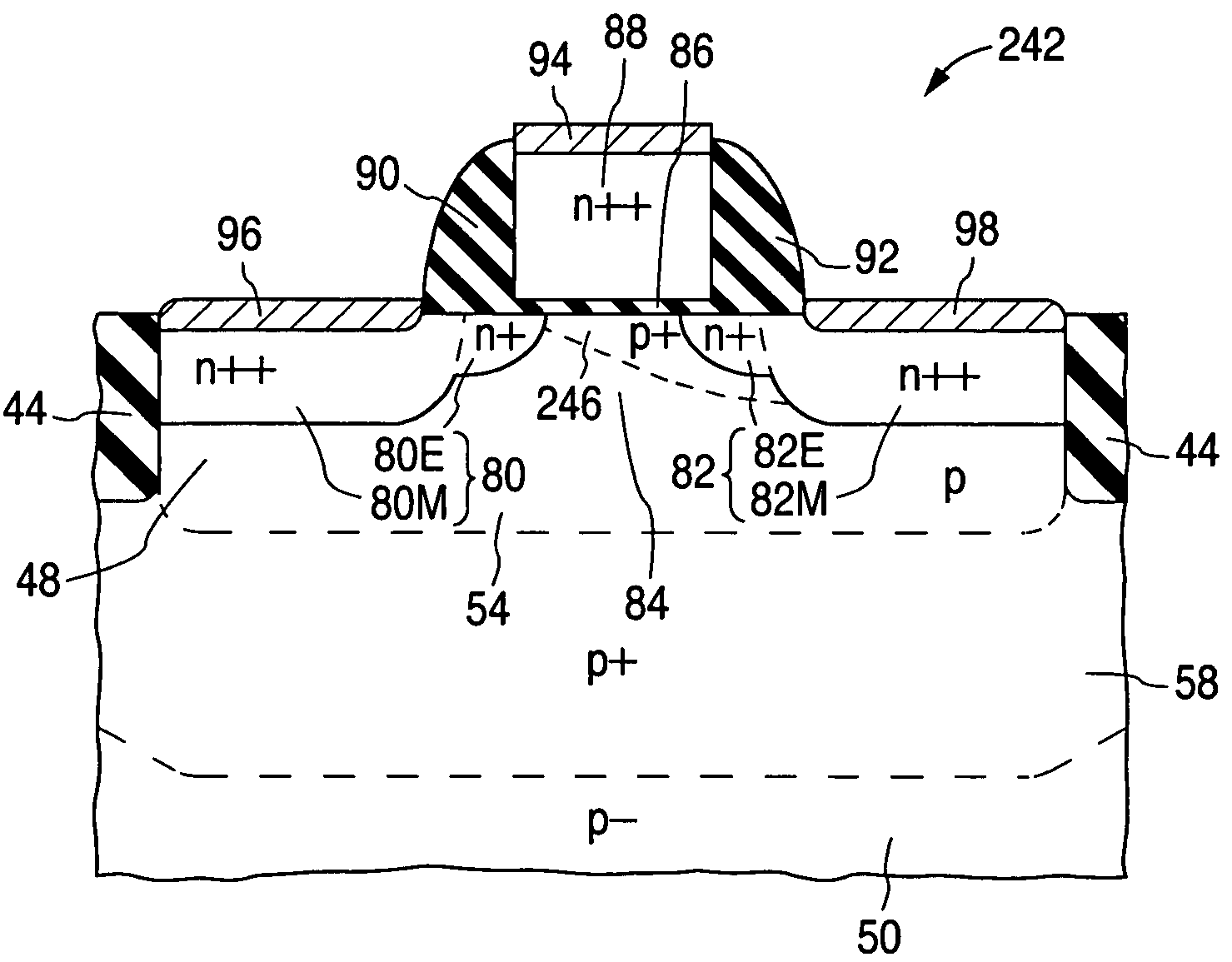

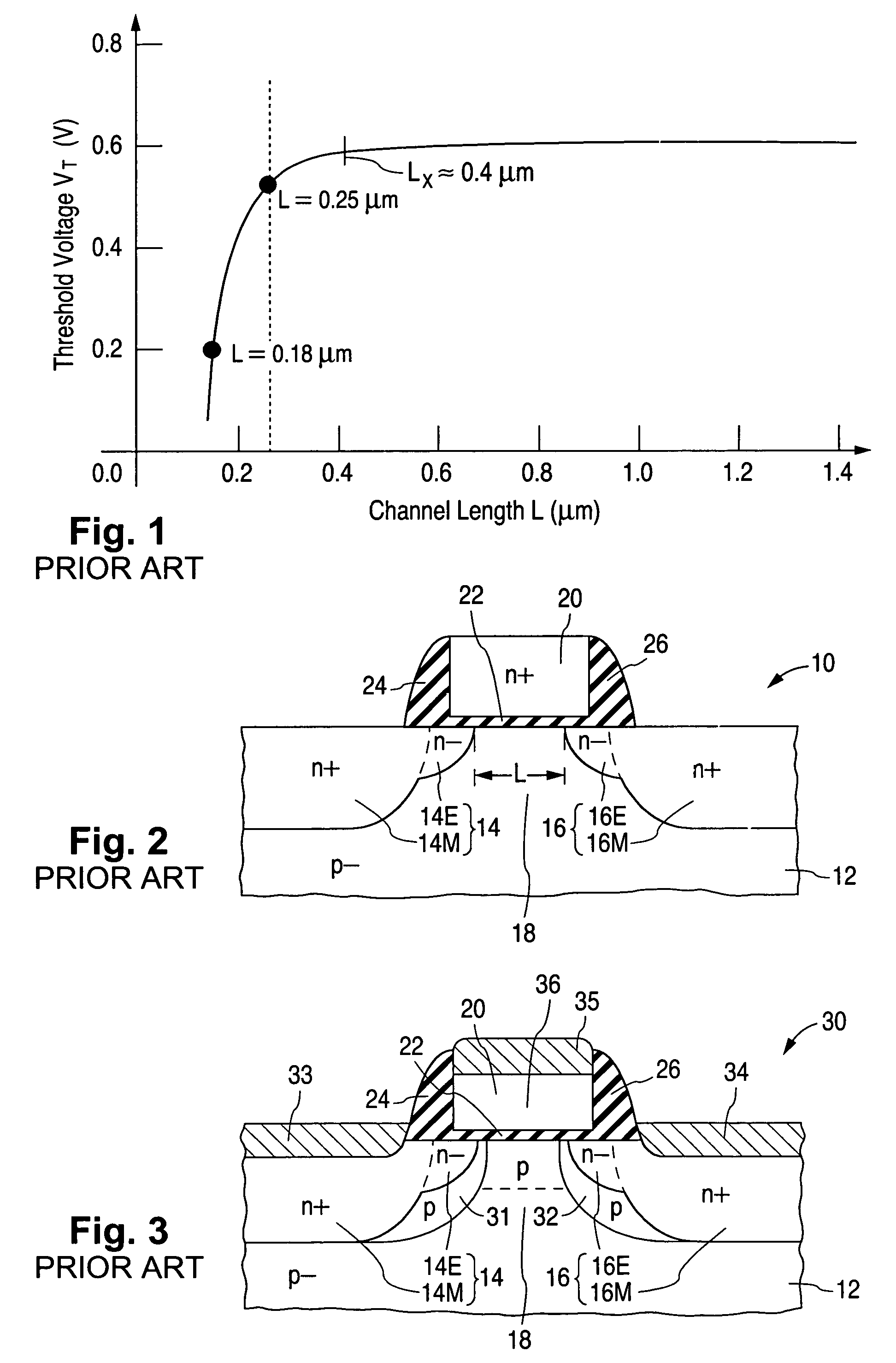

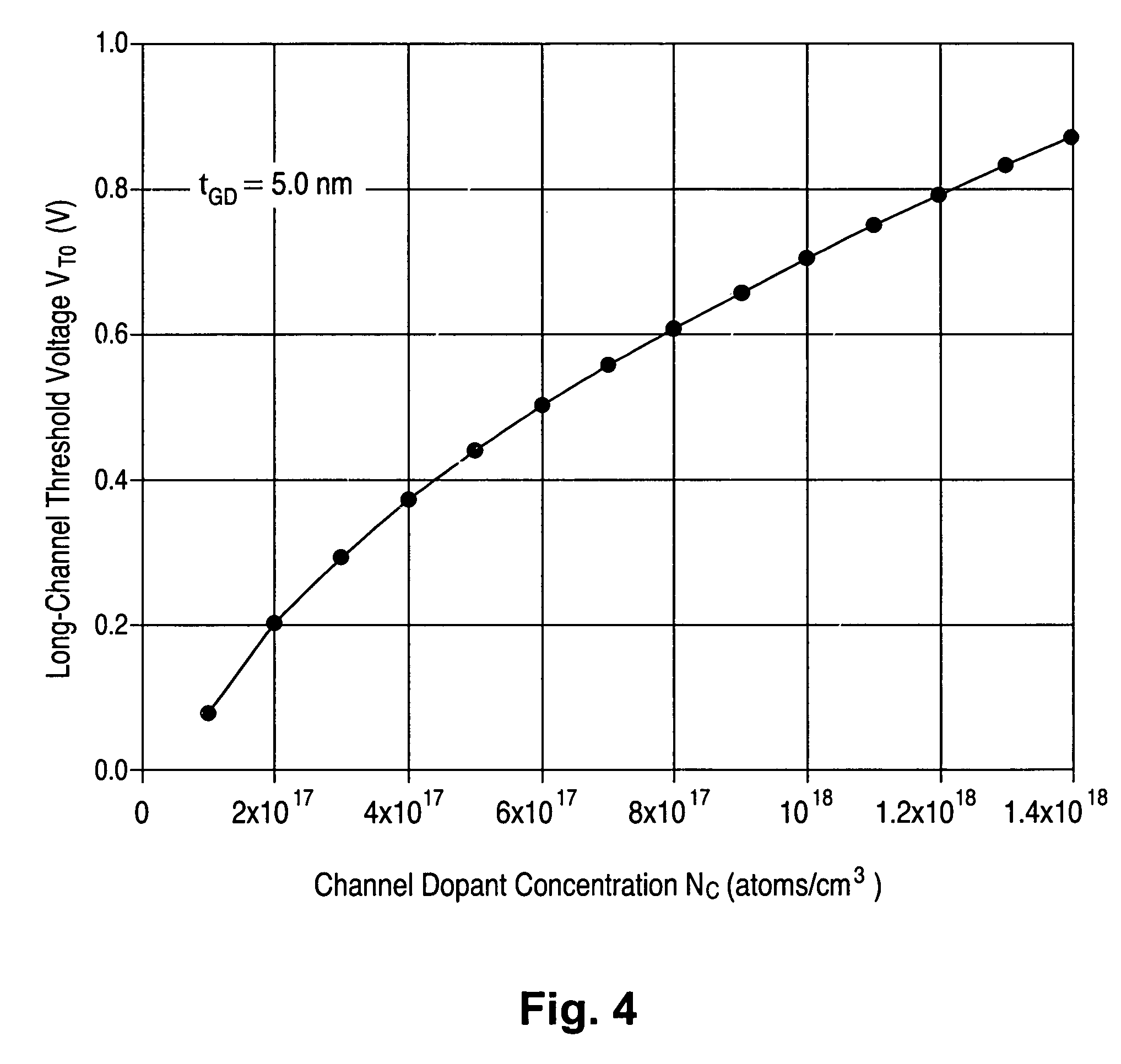

P-channel field-effect transistor with reduced junction capacitance

InactiveUS7145191B1Lower junction capacitanceIncrease in IGFET switching speedSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

The source / drain zones (140 and 142 or 160 and 162) of a p-channel IGFET (120 or 122) are provided with graded-junction characteristics to reduce junction capacitance, thereby increasing switching speed. Each source / drain zone contains a main portion (140M, 142M, 160M, or 162M) and a more lightly doped lower portion (140L, 142L, 160L, or 162L) underlying, and vertically continuous with, the main portion.

Owner:NAT SEMICON CORP

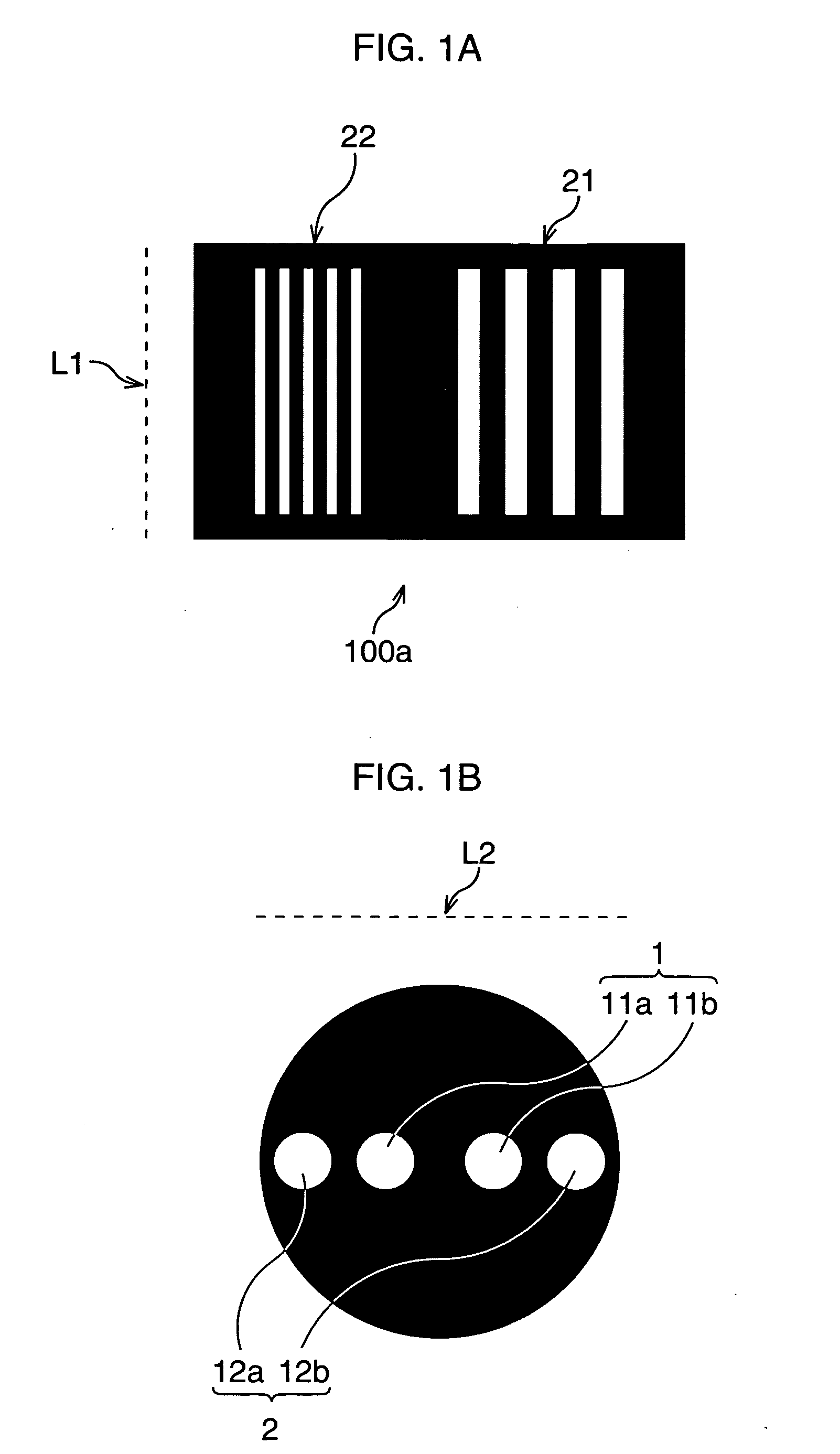

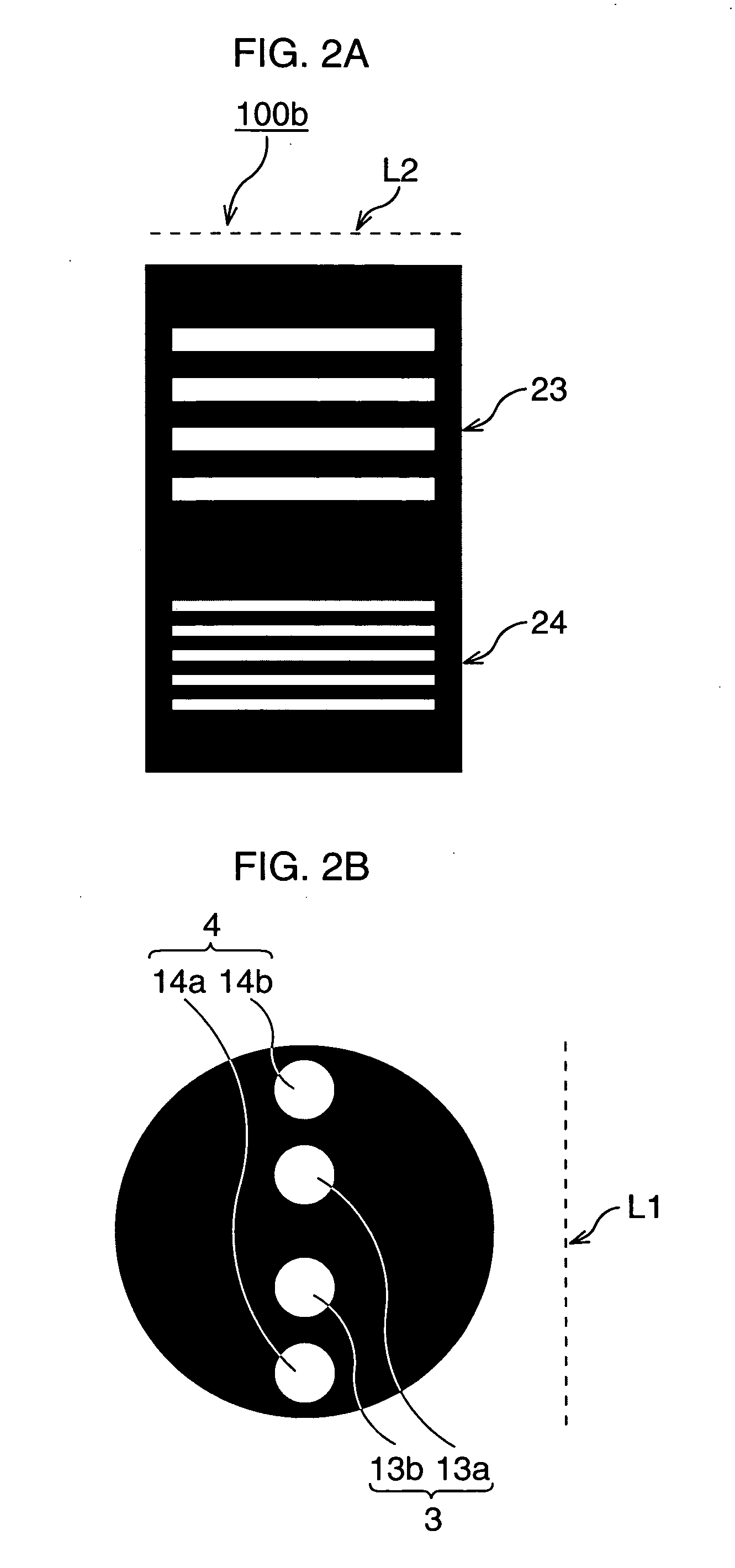

Illumination optical system, exposure method and designing method

InactiveUS20080030706A1Improve reliabilityForming accuratelyPhotographic printingPhysicsOptoelectronics

Exposure for performing patterning in which micropatterns differing in pitch exist in close vicinity to one another is handled, and micropatterns are formed with high accuracy with sufficient manufacture process margins without using a photomask complicated in manufacturing process at high manufacture cost like an alternating phase shift mask. A light intensity distribution of irradiation light constituted of double pole illuminations is formed to correspond to L&S patterns. The double pole illumination is constituted of a pair of illumination modes, and the double pole illumination is constituted of a pair of illumination modes.

Owner:FUJITSU SEMICON LTD

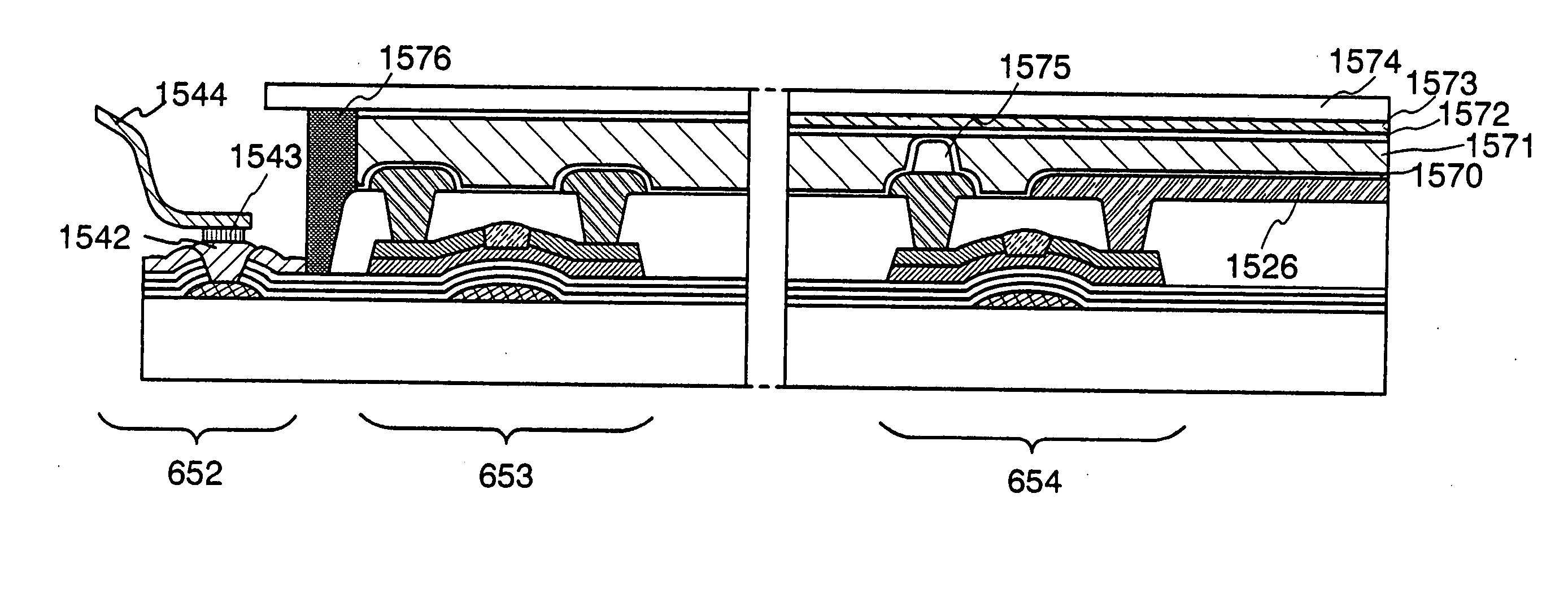

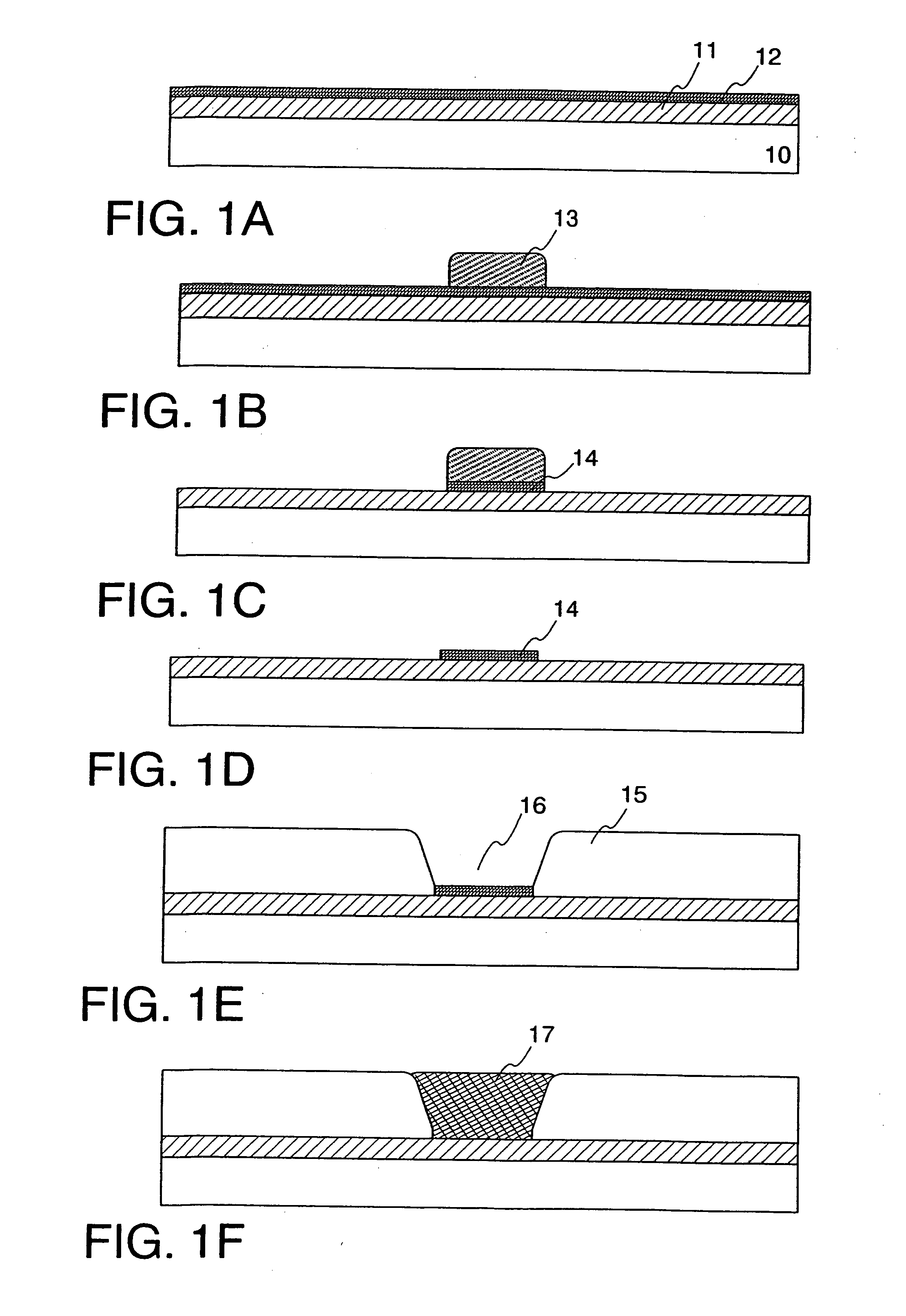

Forming method of contact hole, and manufacturing method of semicondutor device, liquid crystal display device and EL display device

When forming a contact hole by a conventional manufacturing step of a semiconductor device, a resist is required to be formed on almost entire surface of a substrate so as to be applied on a film other than an area in which a contact hole is to be formed, leading to drastically reduced throughput. According to a forming method of a contact hole and a manufacturing method of a semiconductor device, an EL display device and a liquid crystal display device of the invention, an island shape organic film is selectively formed over a semiconductor layer, a conductive layer or an insulating layer, and an insulating film is formed around the island shape organic film to form a contact hole. Therefore, a conventional patterning using a resist is not required, and high throughput and low cost can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com