Patents

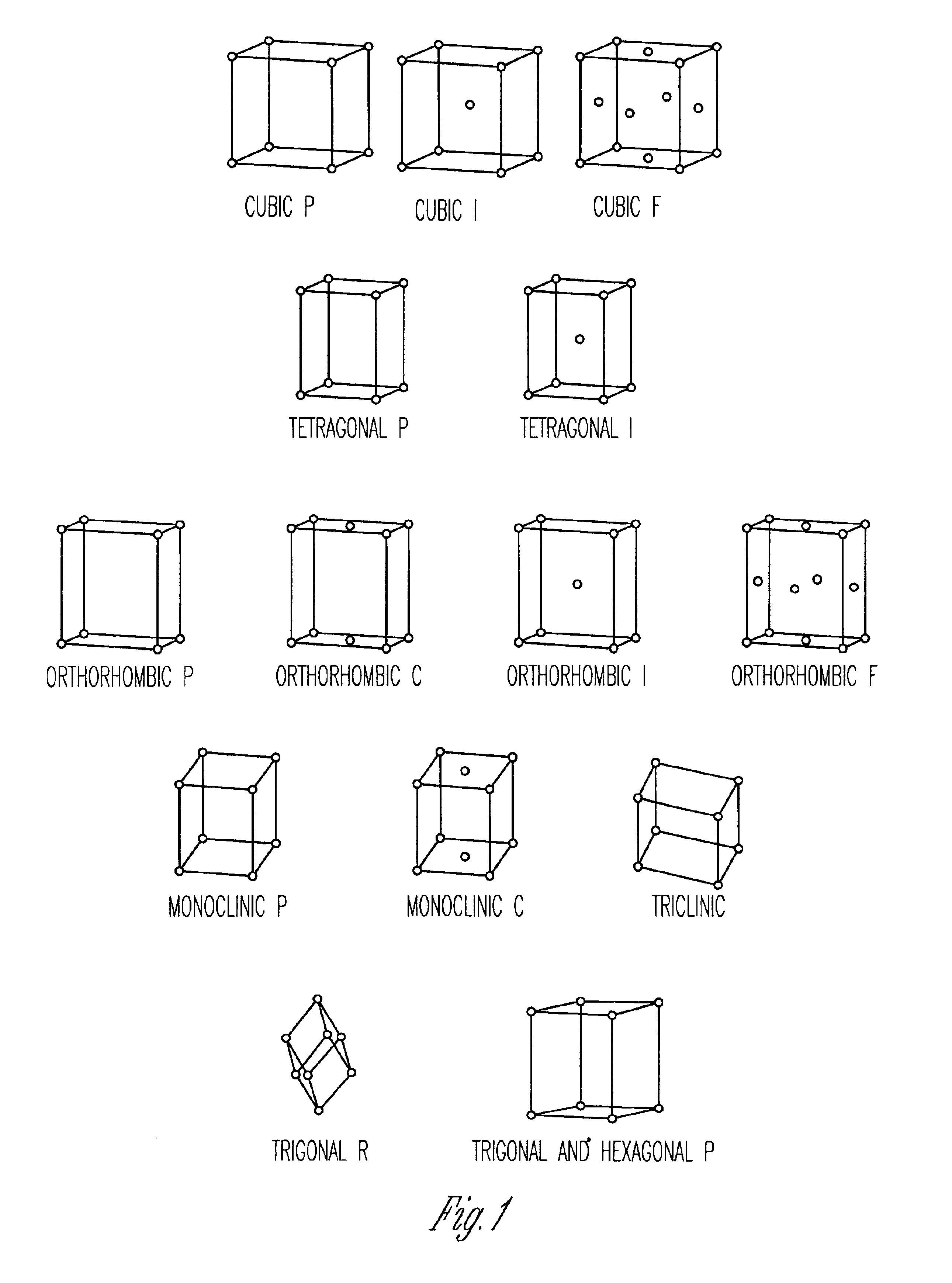

Literature

37 results about "Surface transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

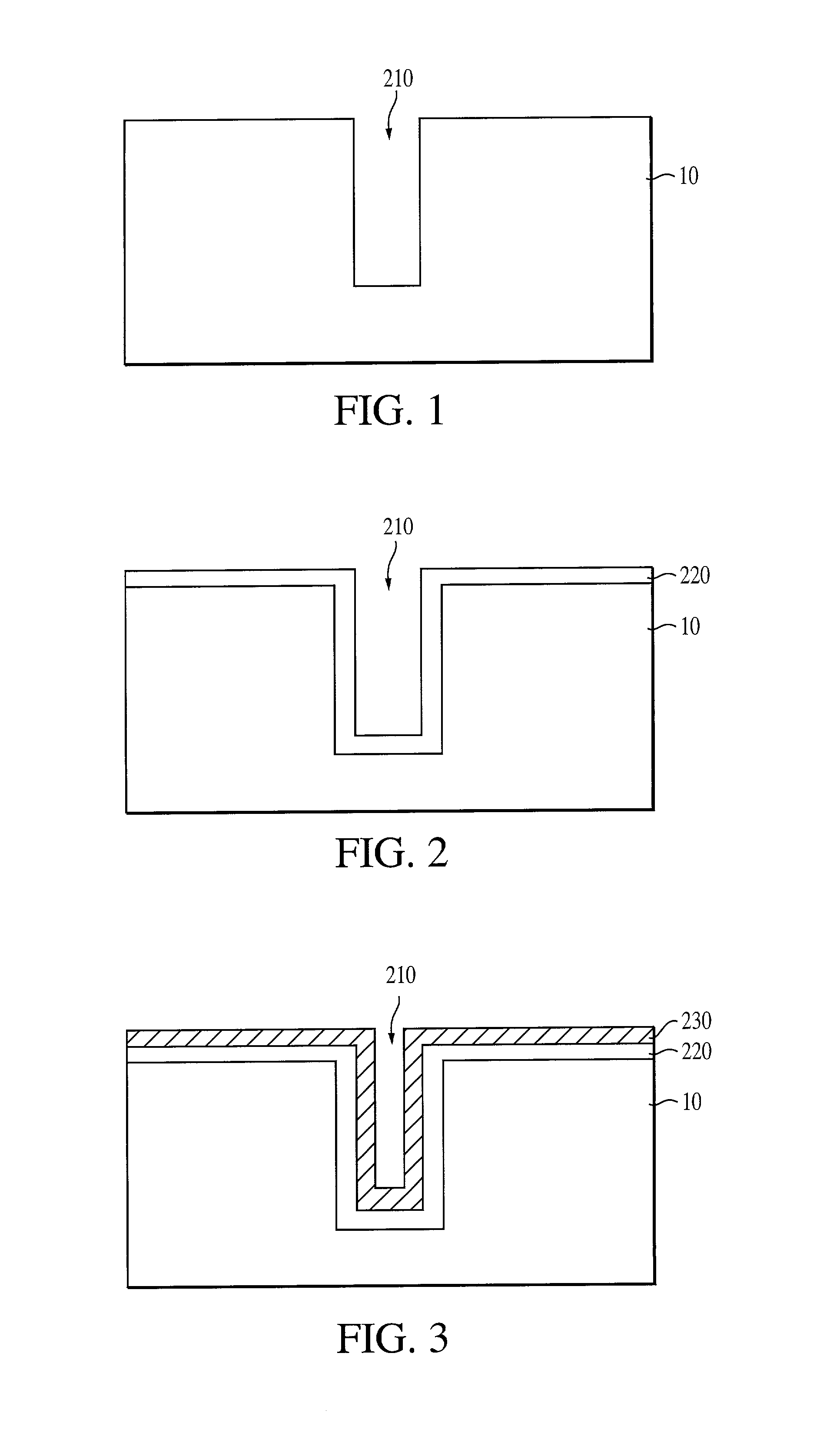

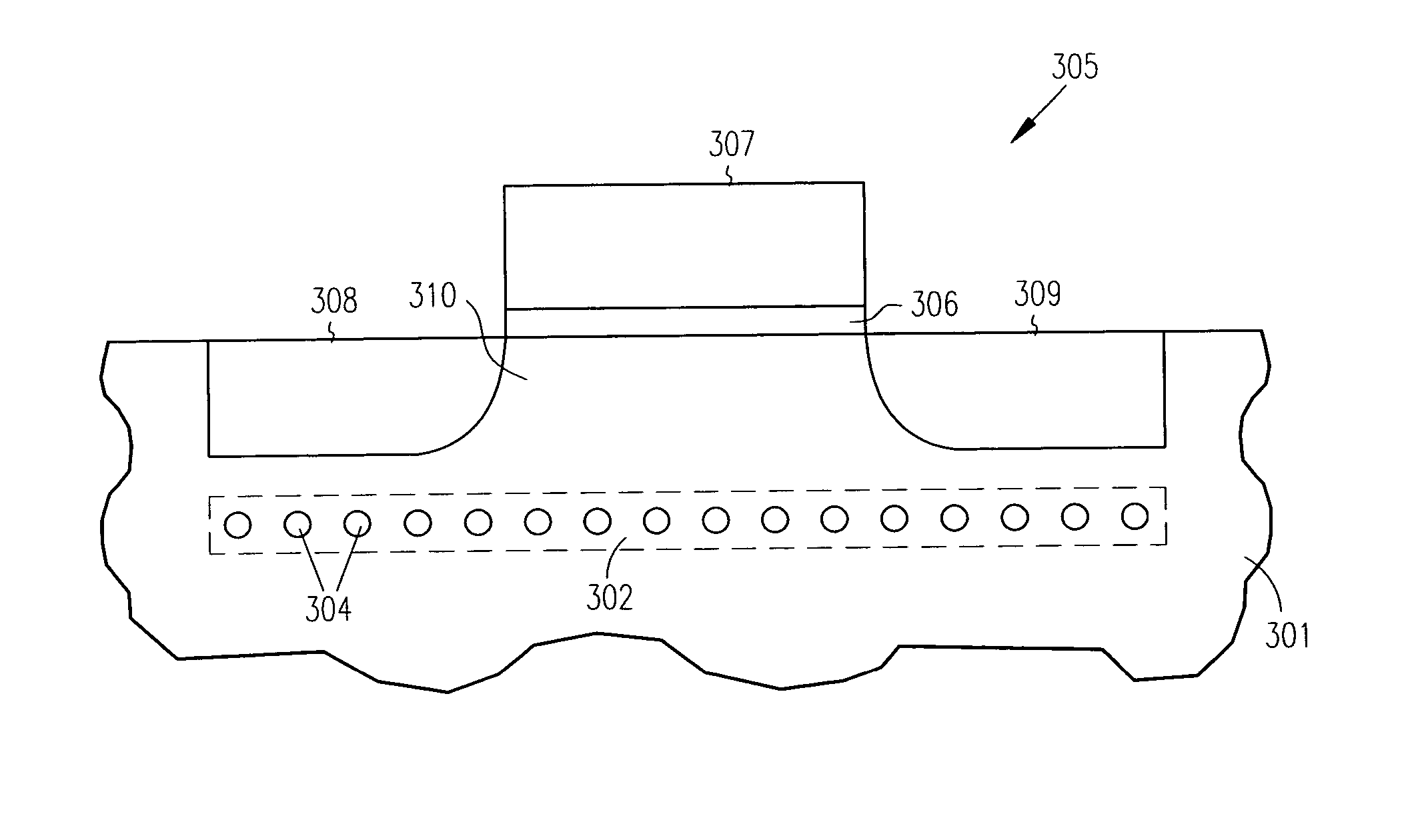

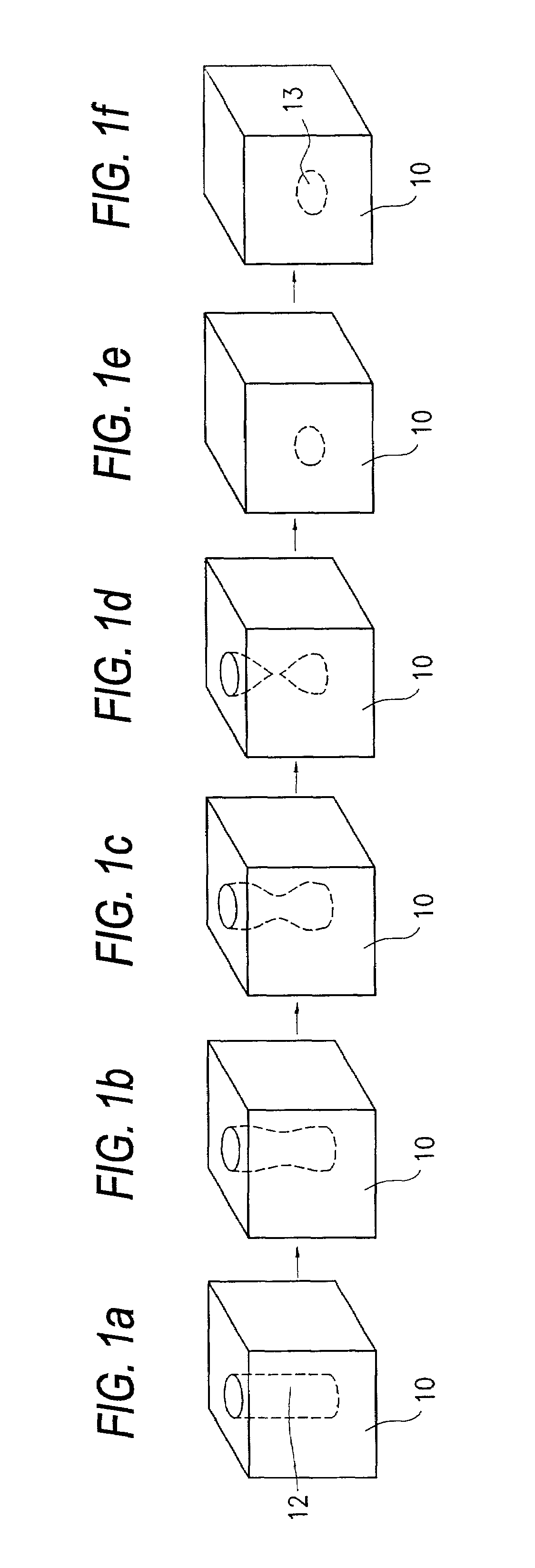

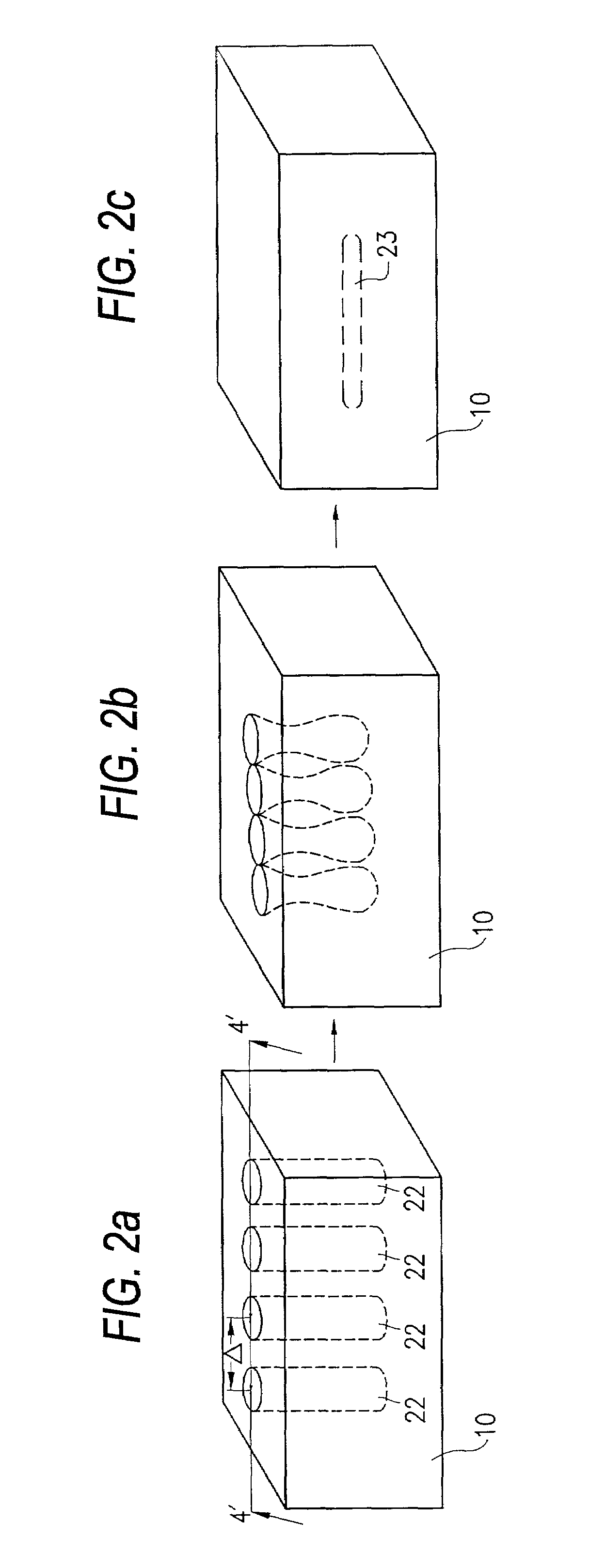

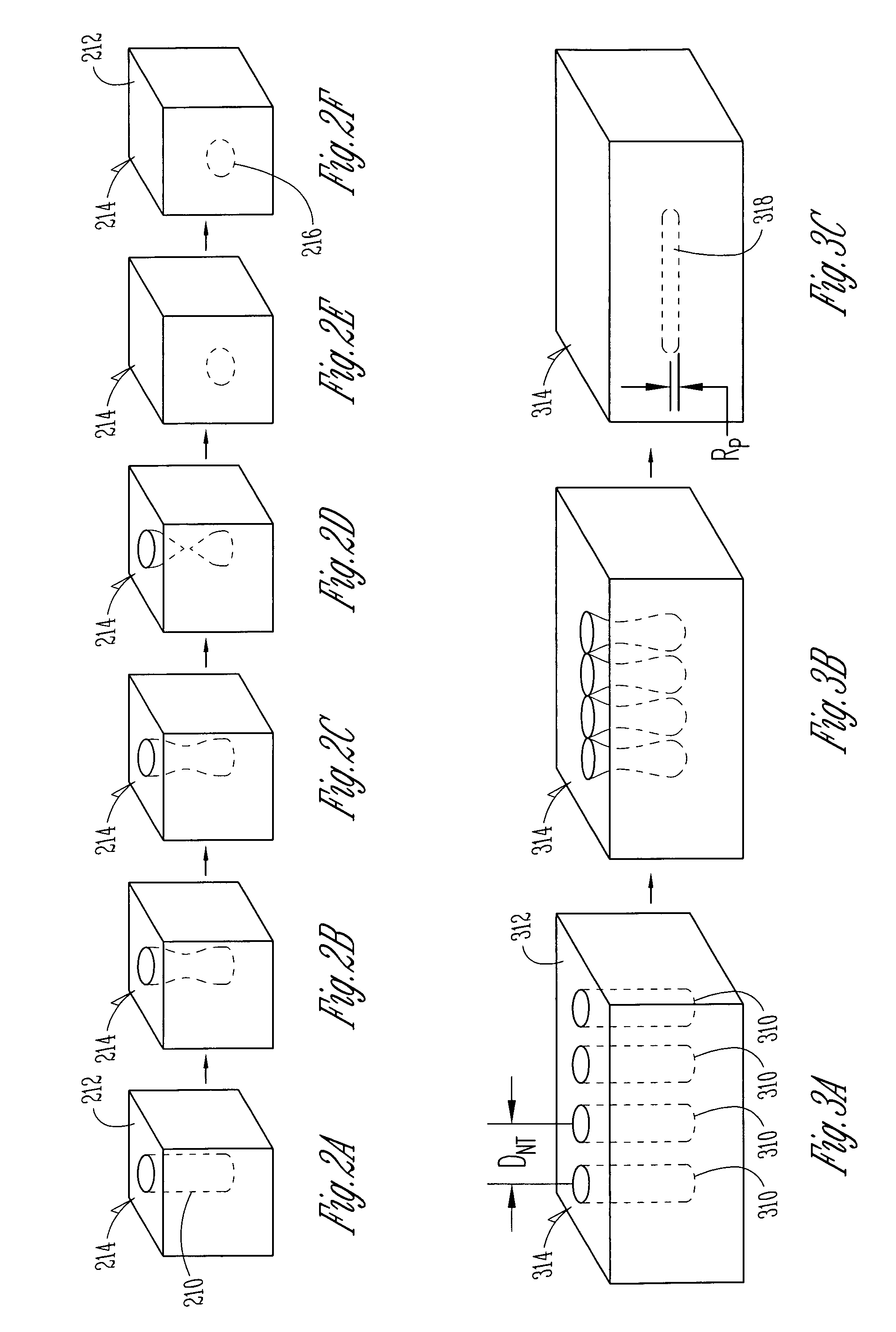

Gettering using voids formed by surface transformation

InactiveUS20050017273A1Increase inhalationIncrease the areaTransistorSolid-state devicesEngineeringSemiconductor

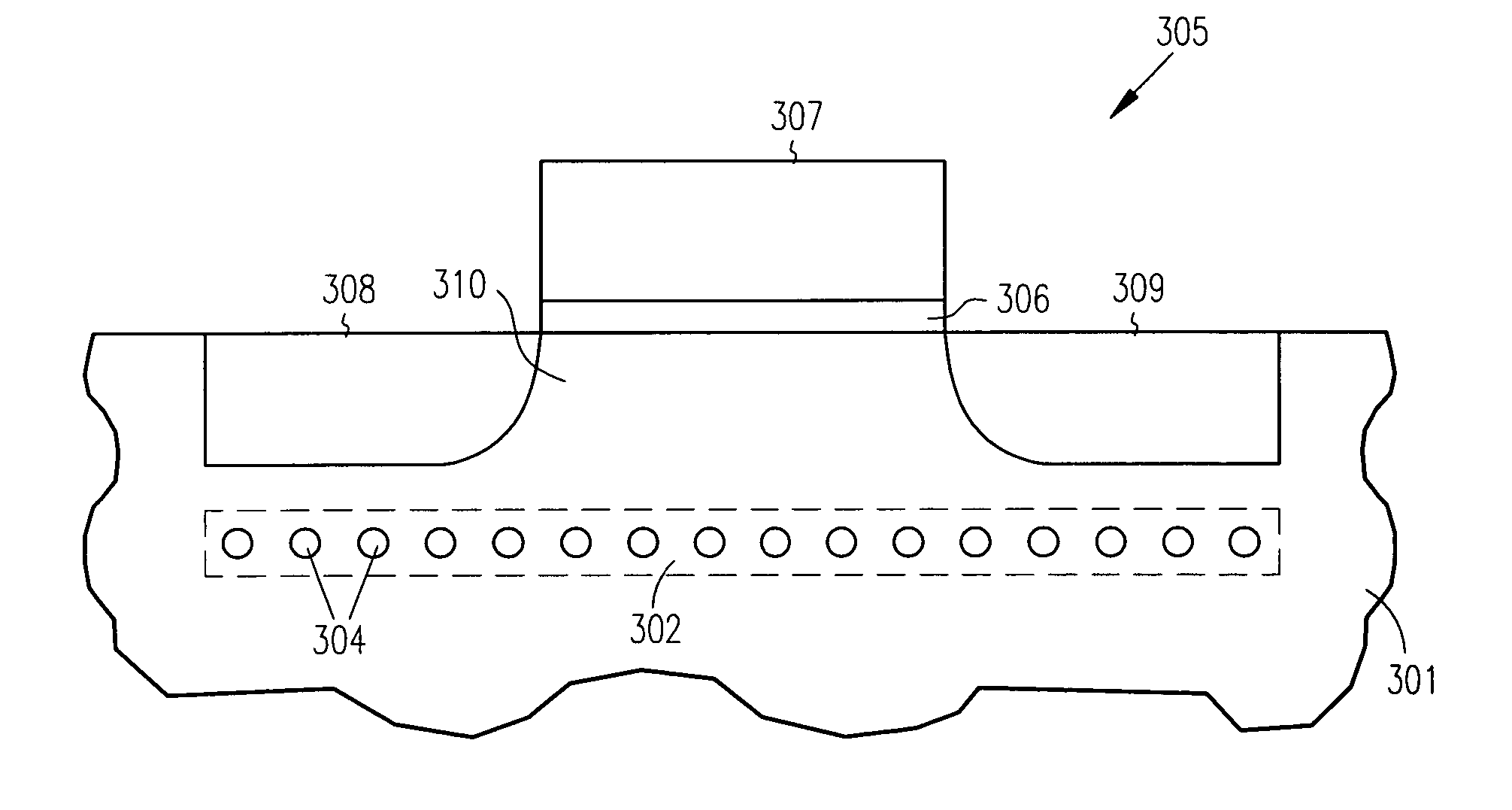

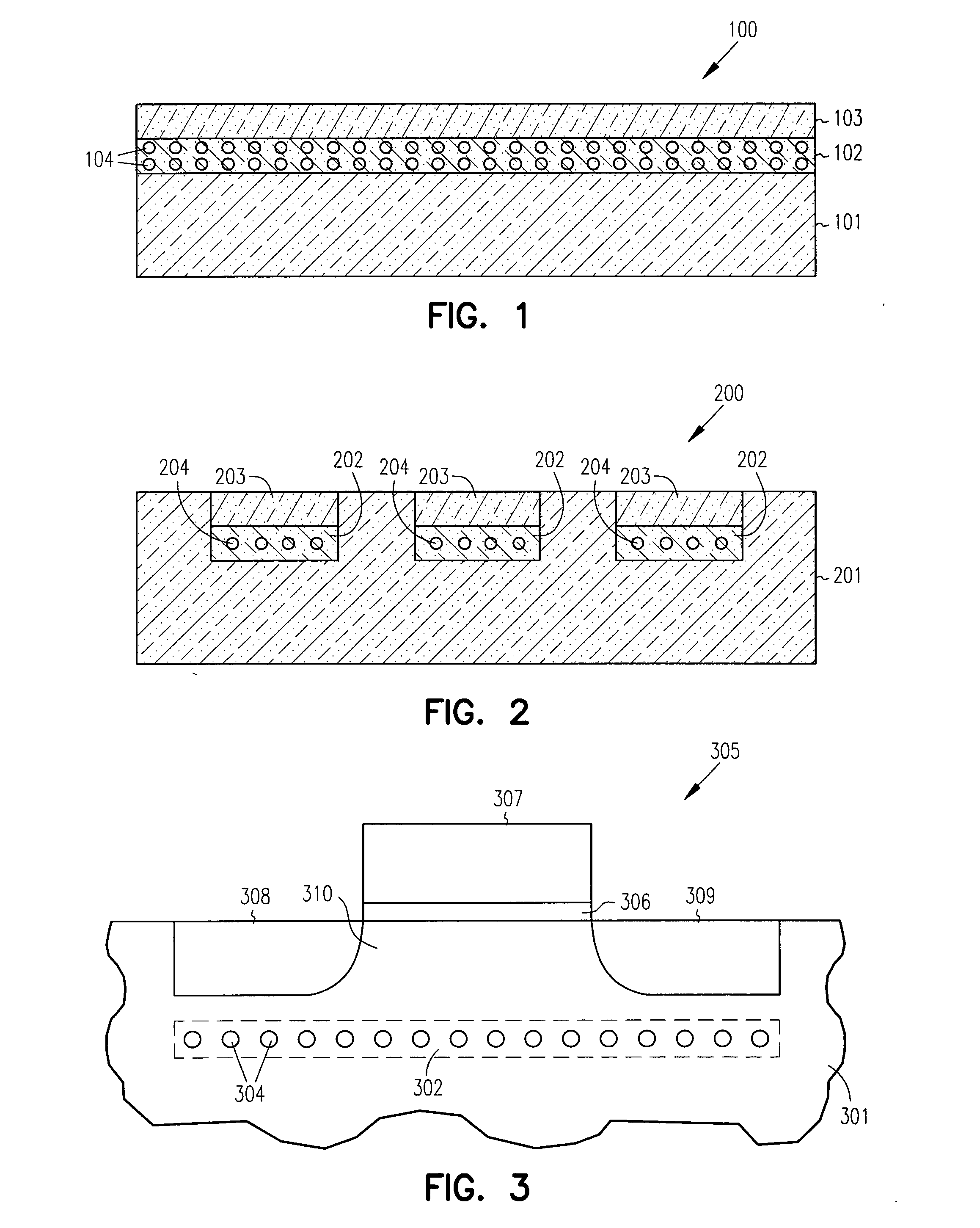

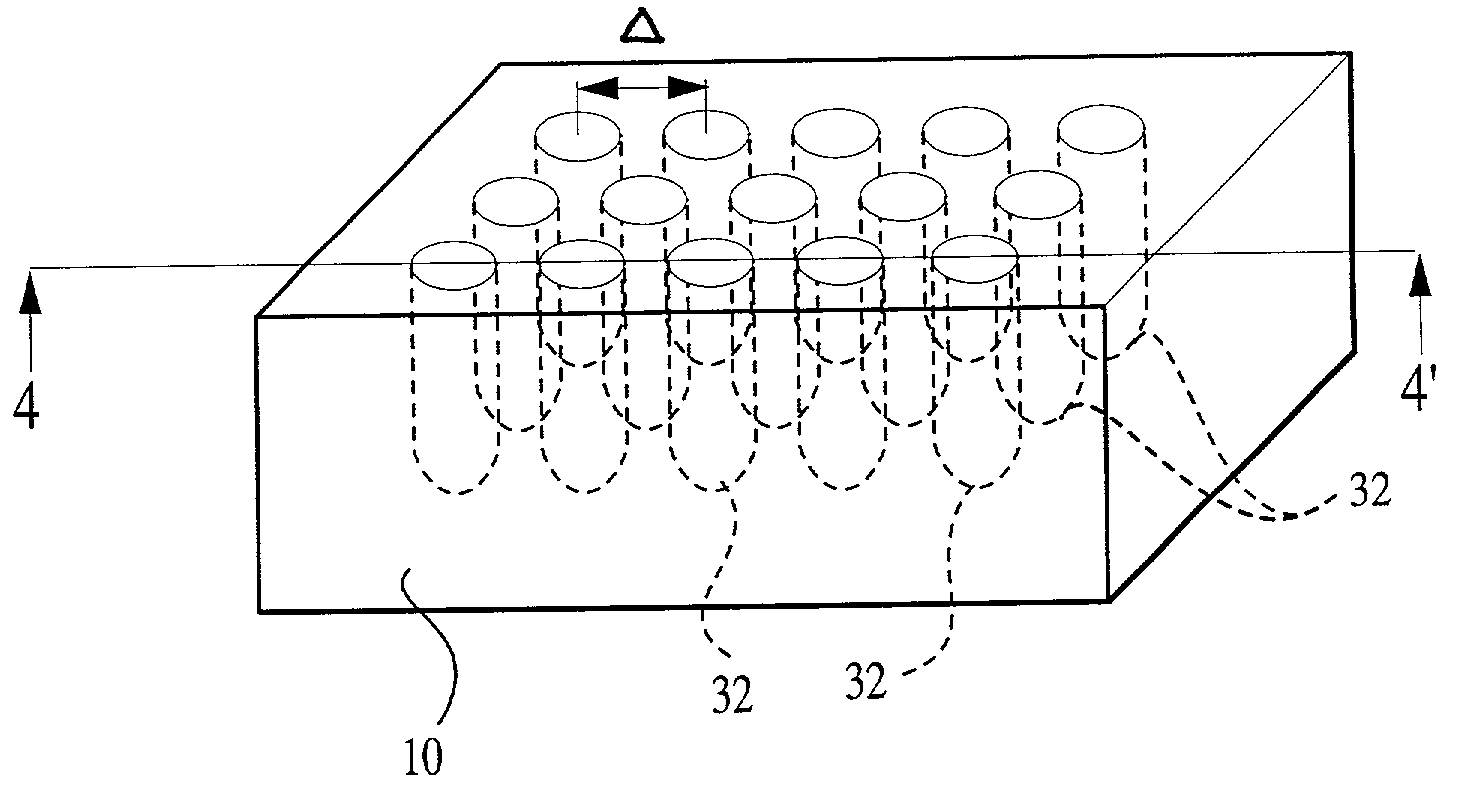

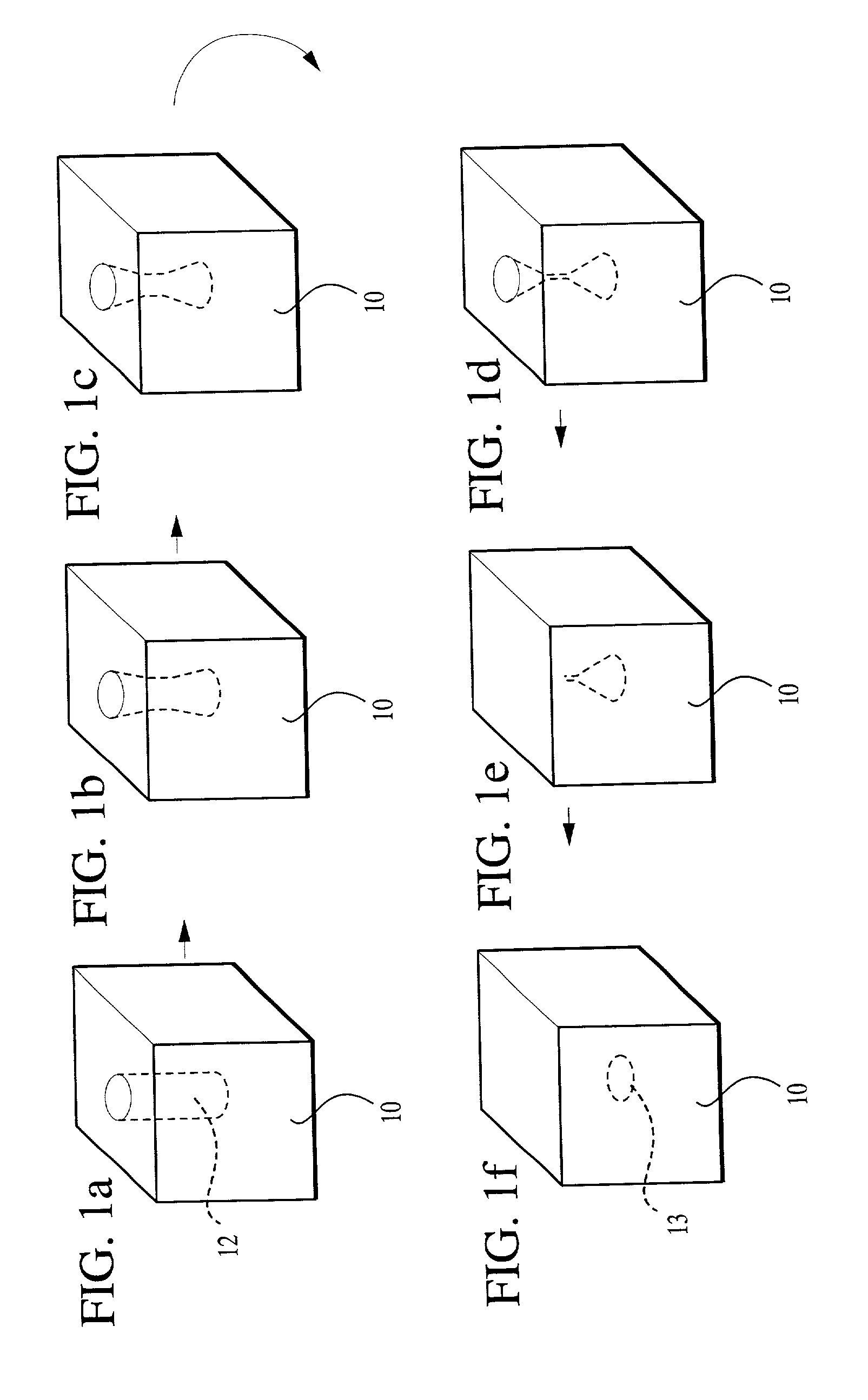

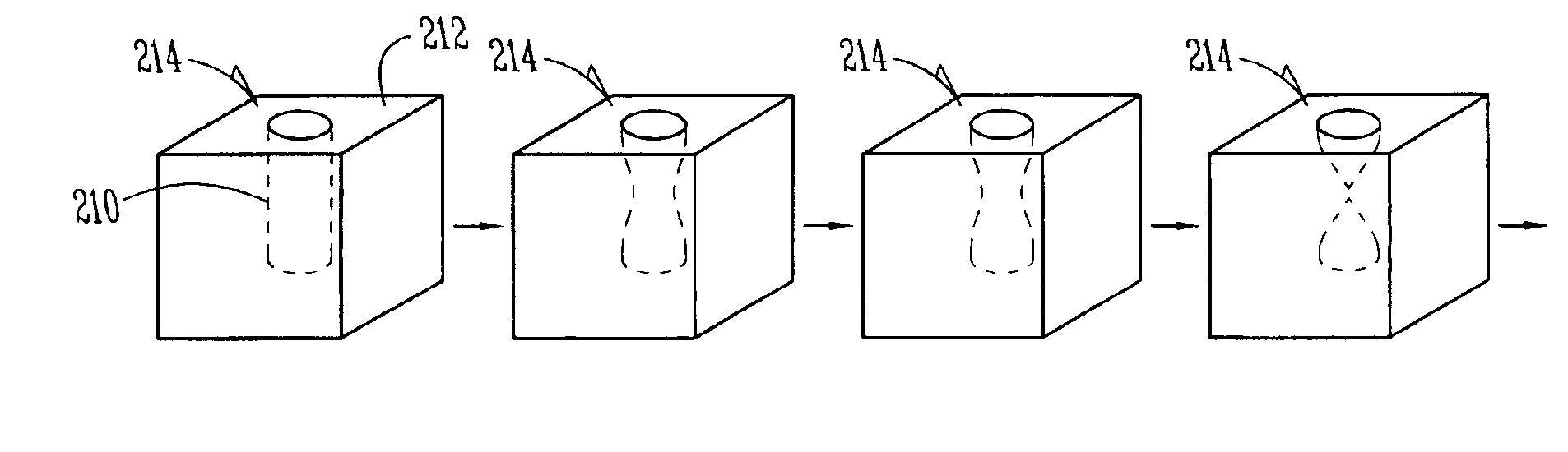

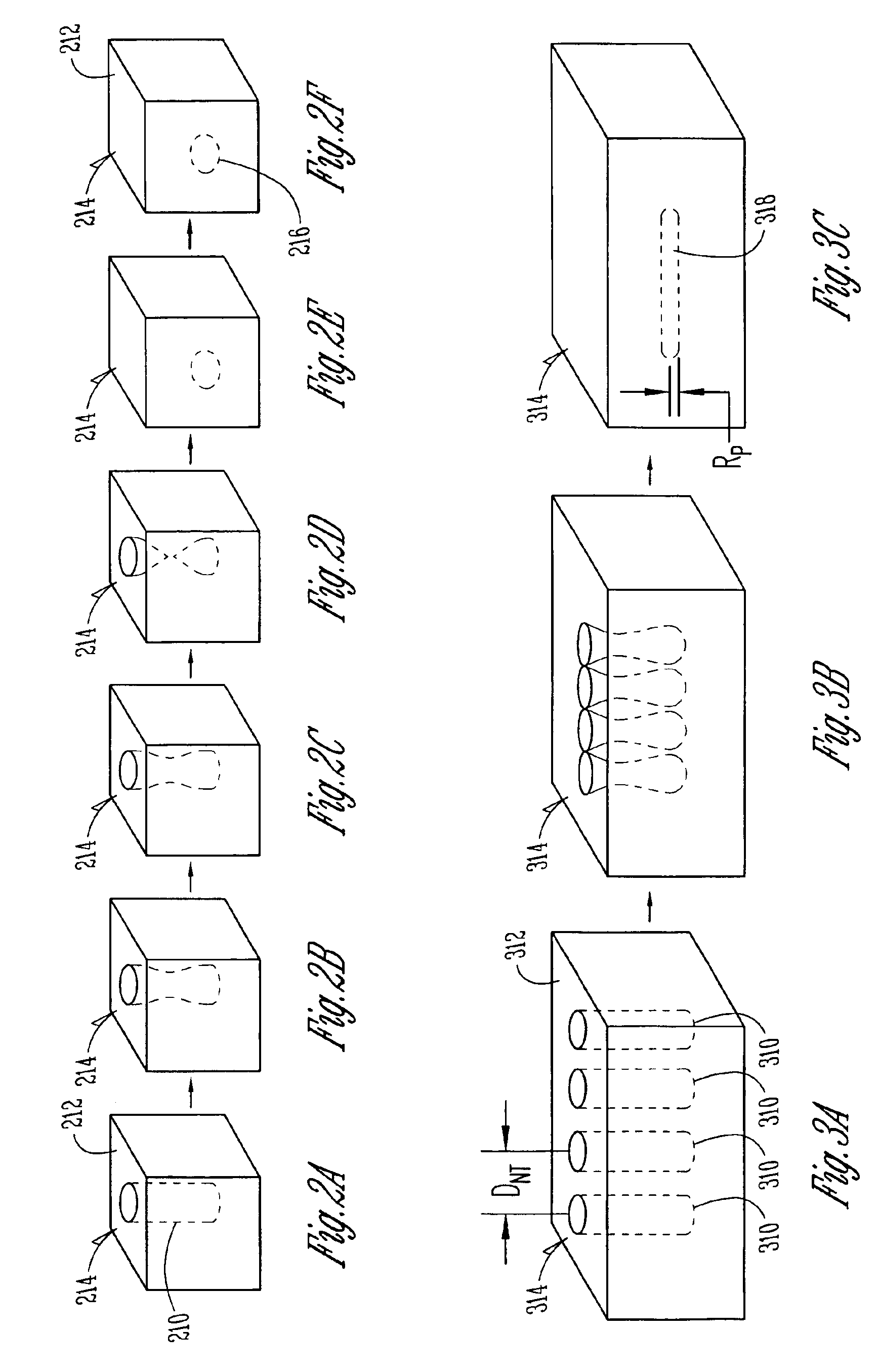

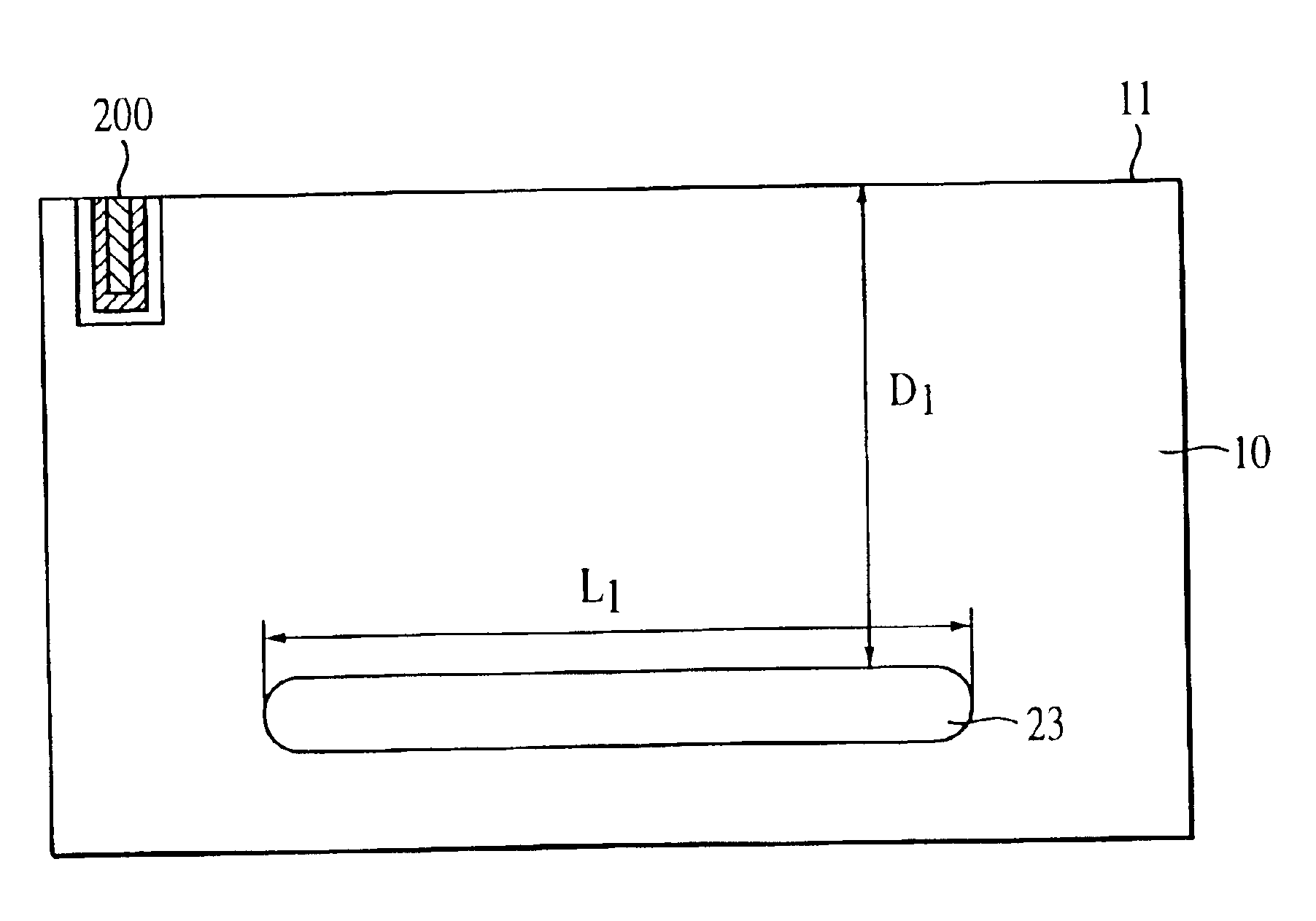

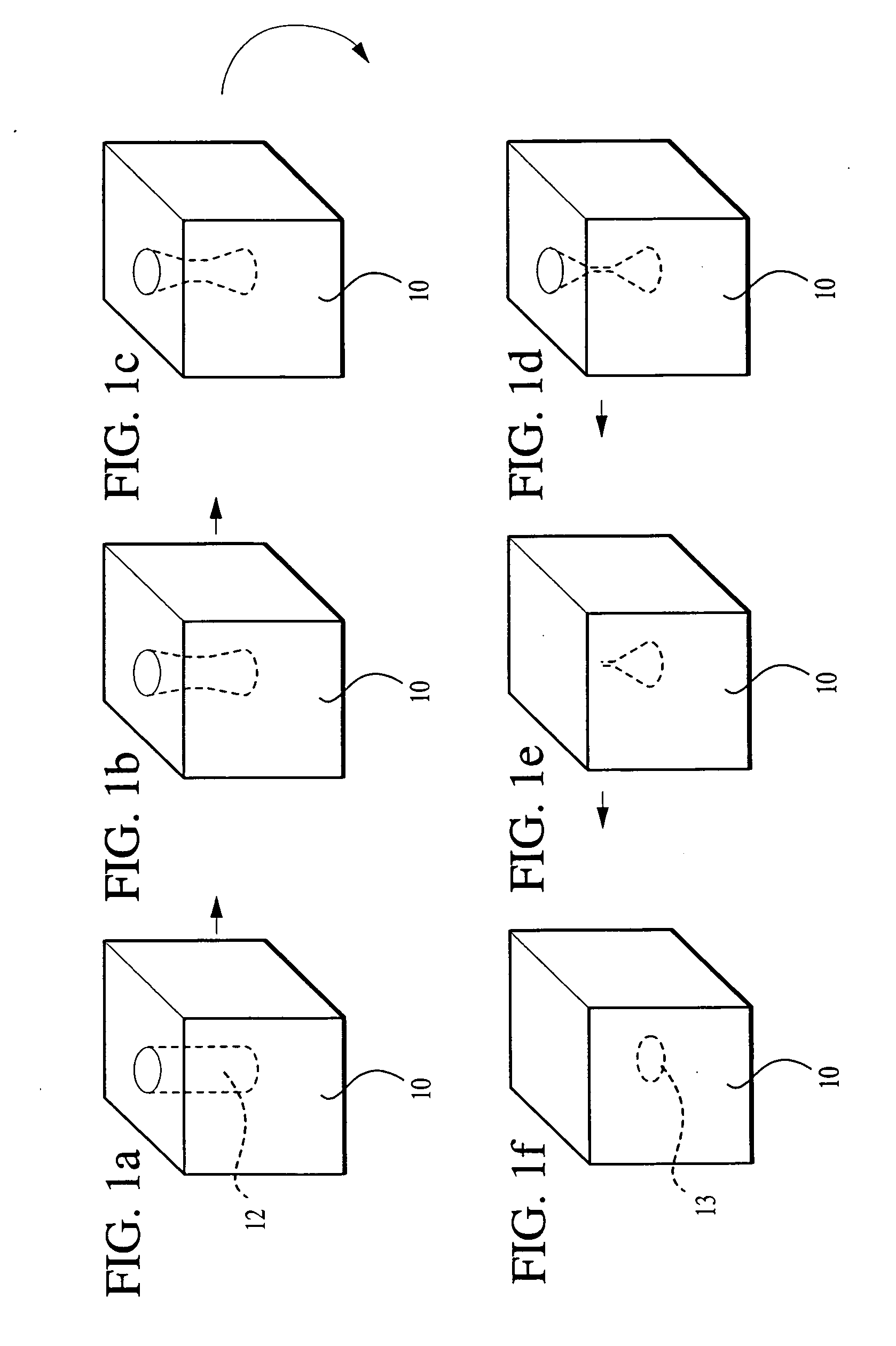

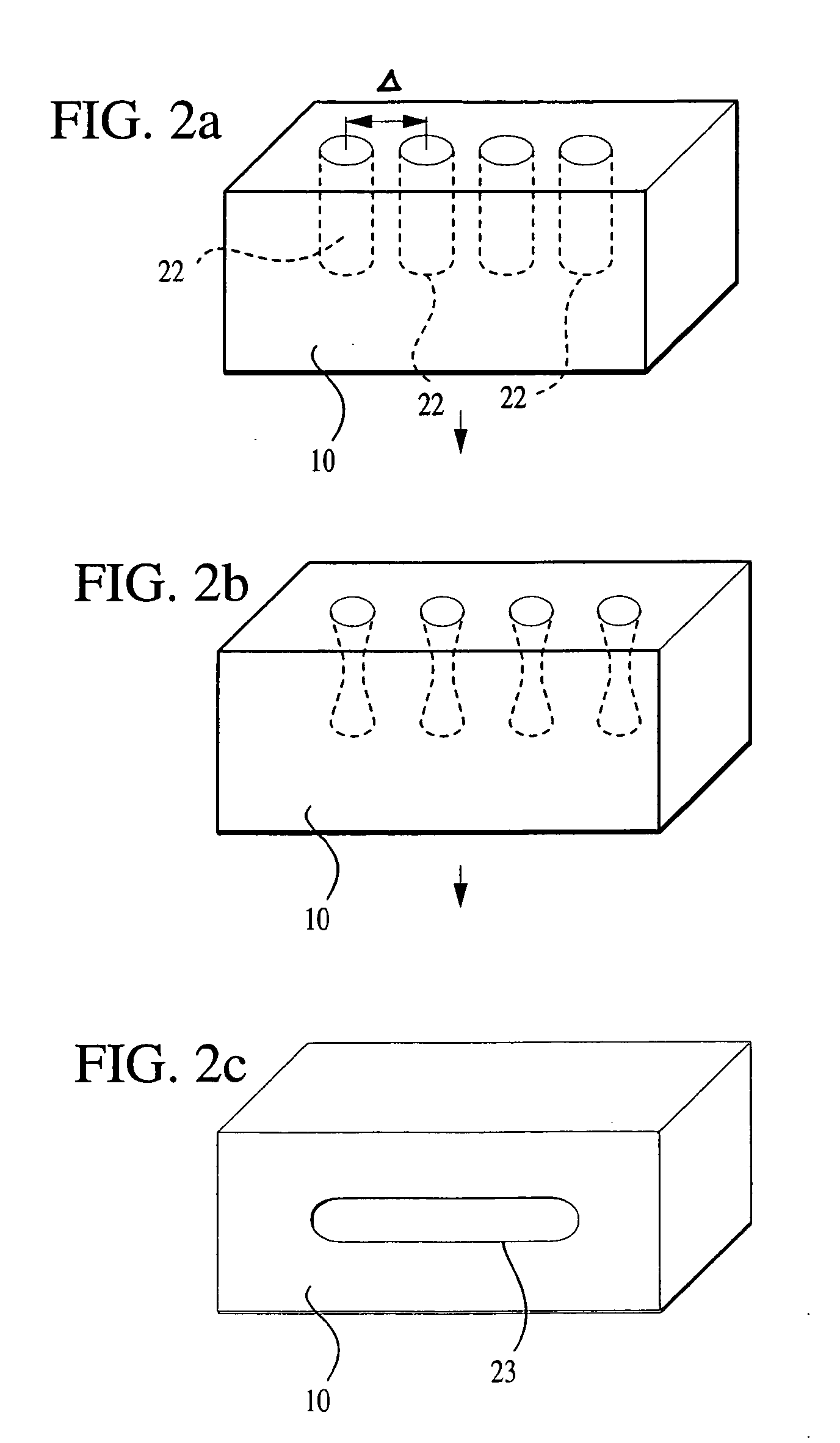

One aspect of this disclosure relates to a method for creating a gettering site in a semiconductor wafer. In various embodiments, a predetermined arrangement of a plurality of holes is formed in the semiconductor wafer through a surface of the wafer. The wafer is annealed such that the wafer undergoes a surface transformation to transform the arrangement of the plurality of holes into a predetermined arrangement of at least one empty space of a predetermined size within the wafer to form the gettering site. One aspect relates to a semiconductor wafer. In various embodiments, the wafer includes at least one device region, and at least one gettering region located proximate to the at least one device region. The gettering region includes a precisely-determined arrangement of a plurality of precisely-formed voids that are formed within the wafer using a surface transformation process. Other aspects and embodiments are provided herein.

Owner:MICRON TECH INC

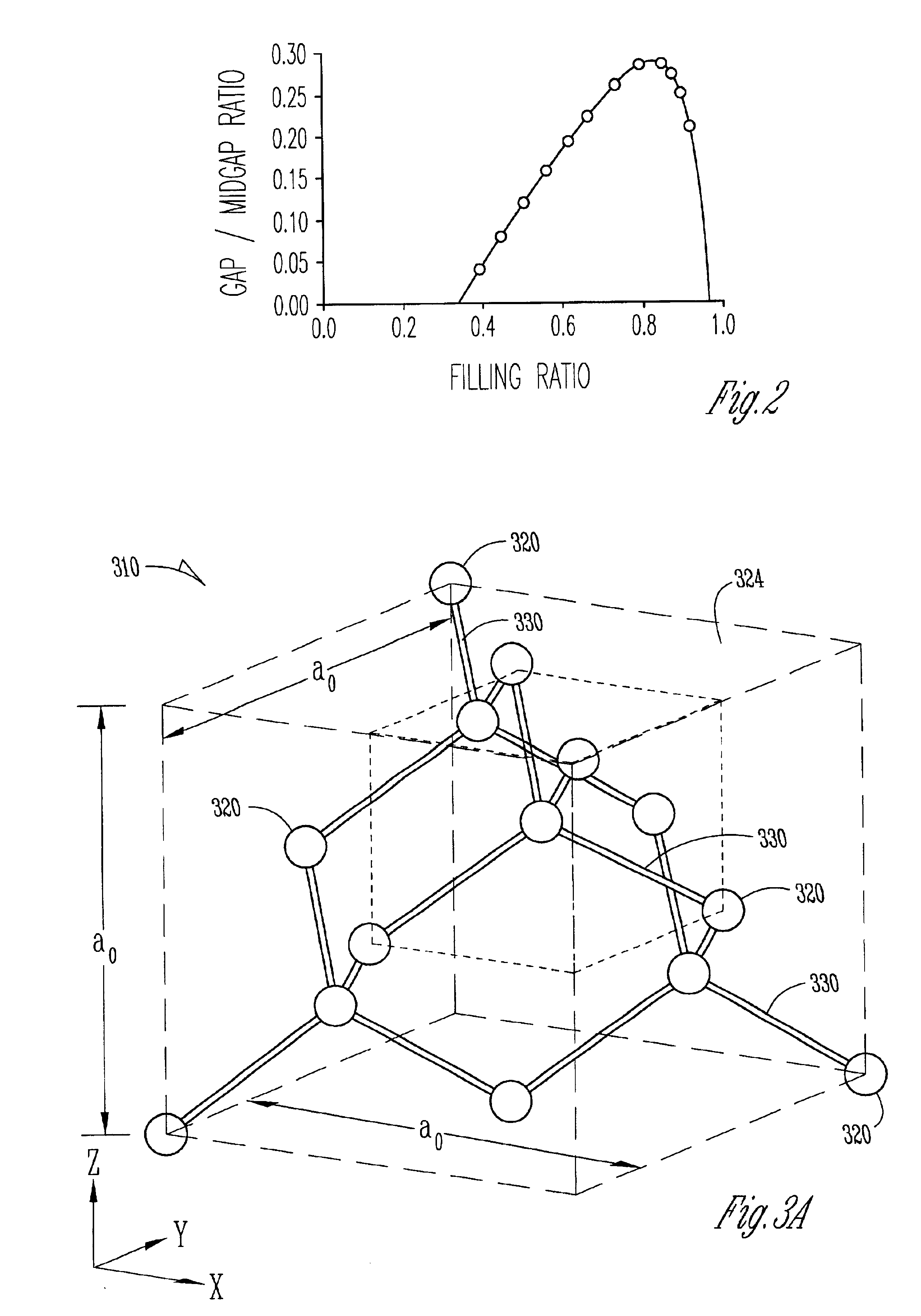

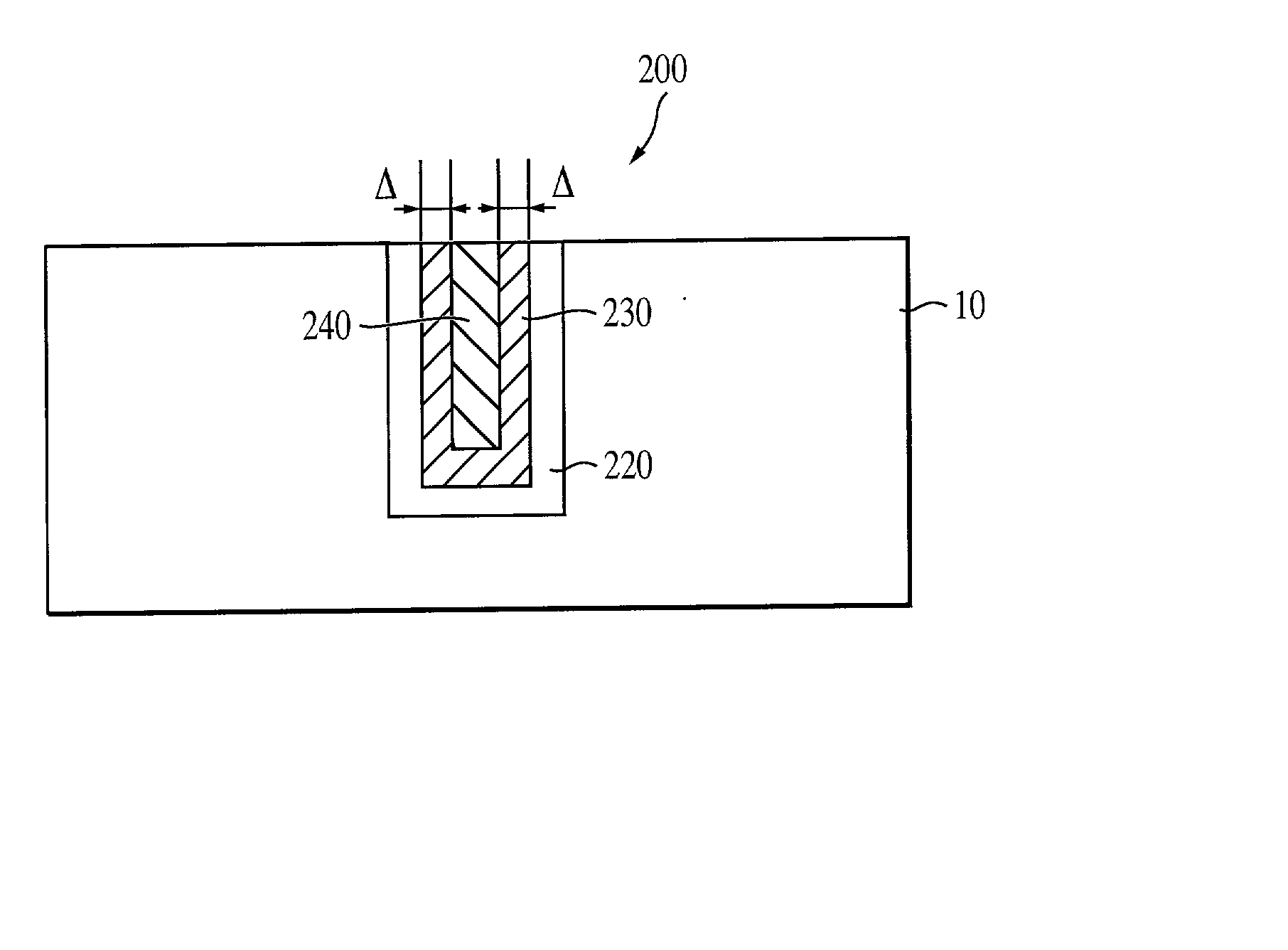

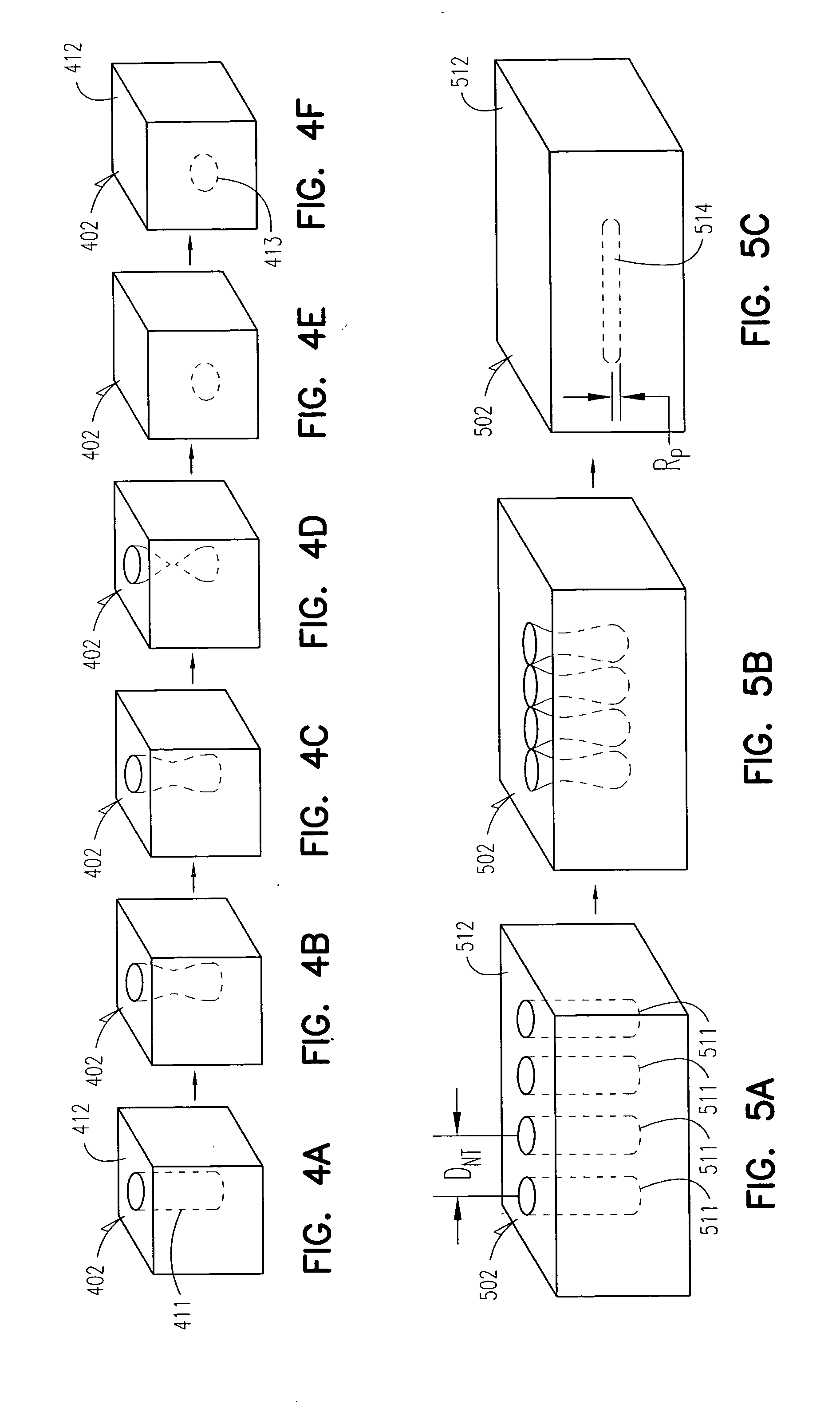

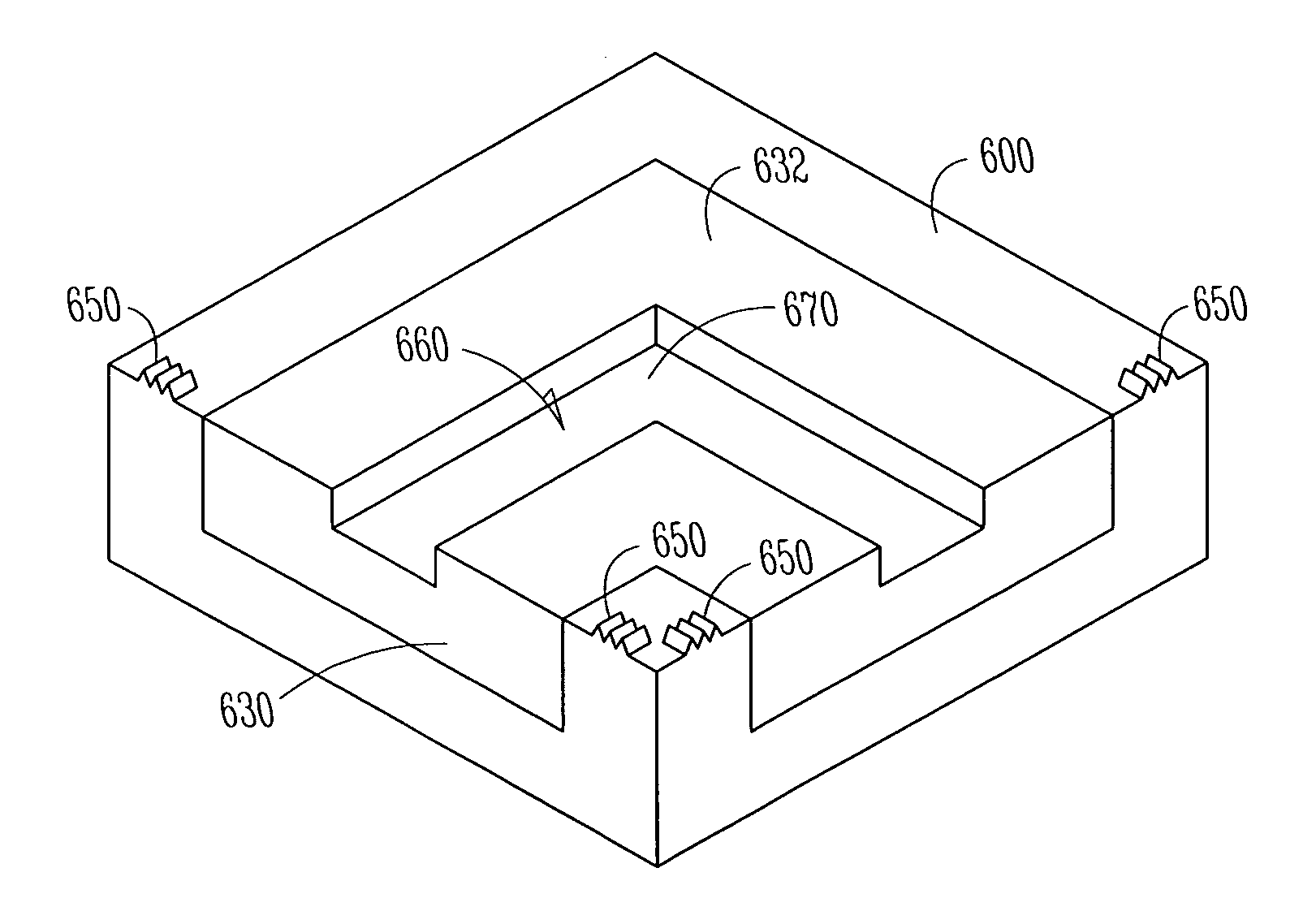

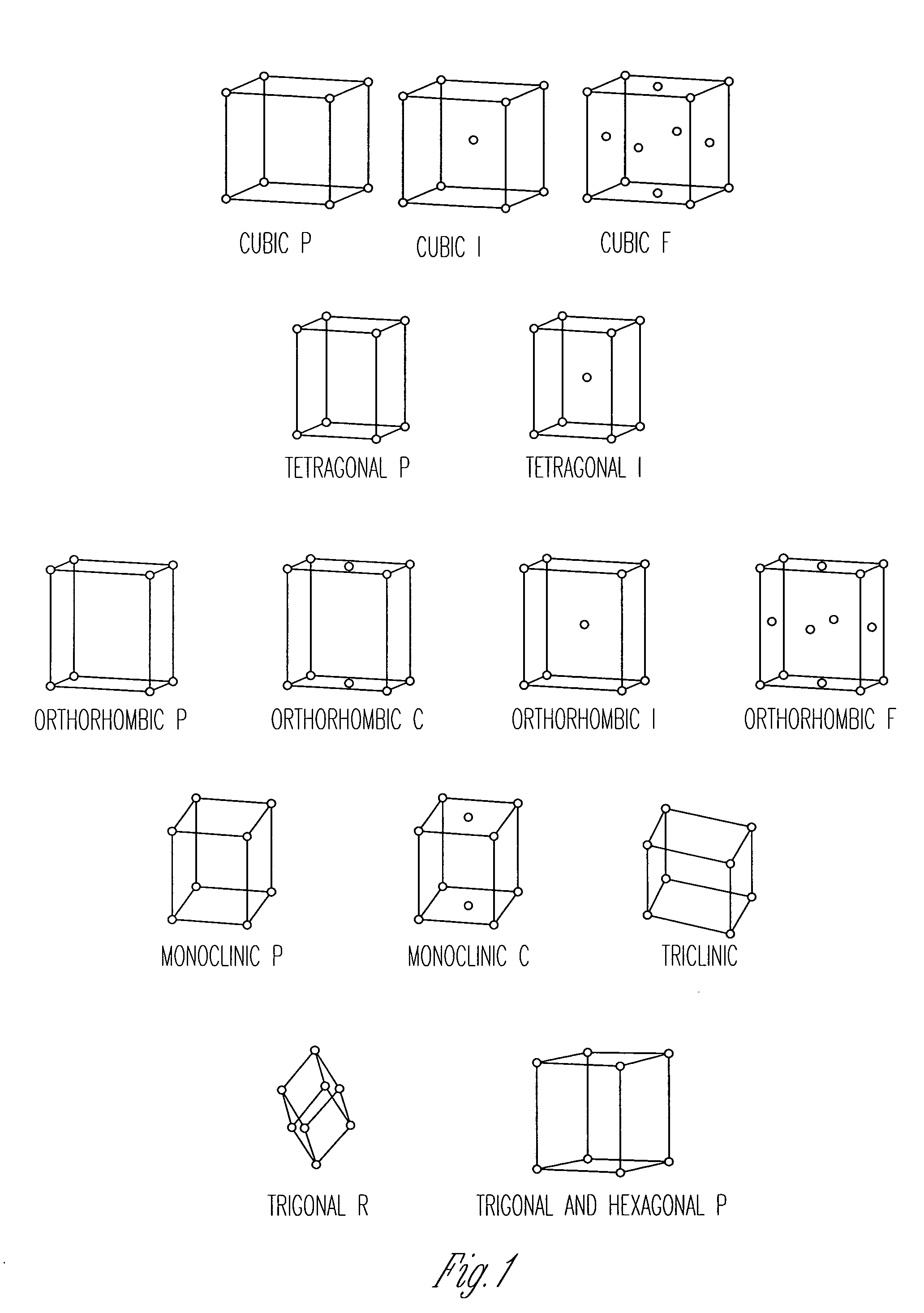

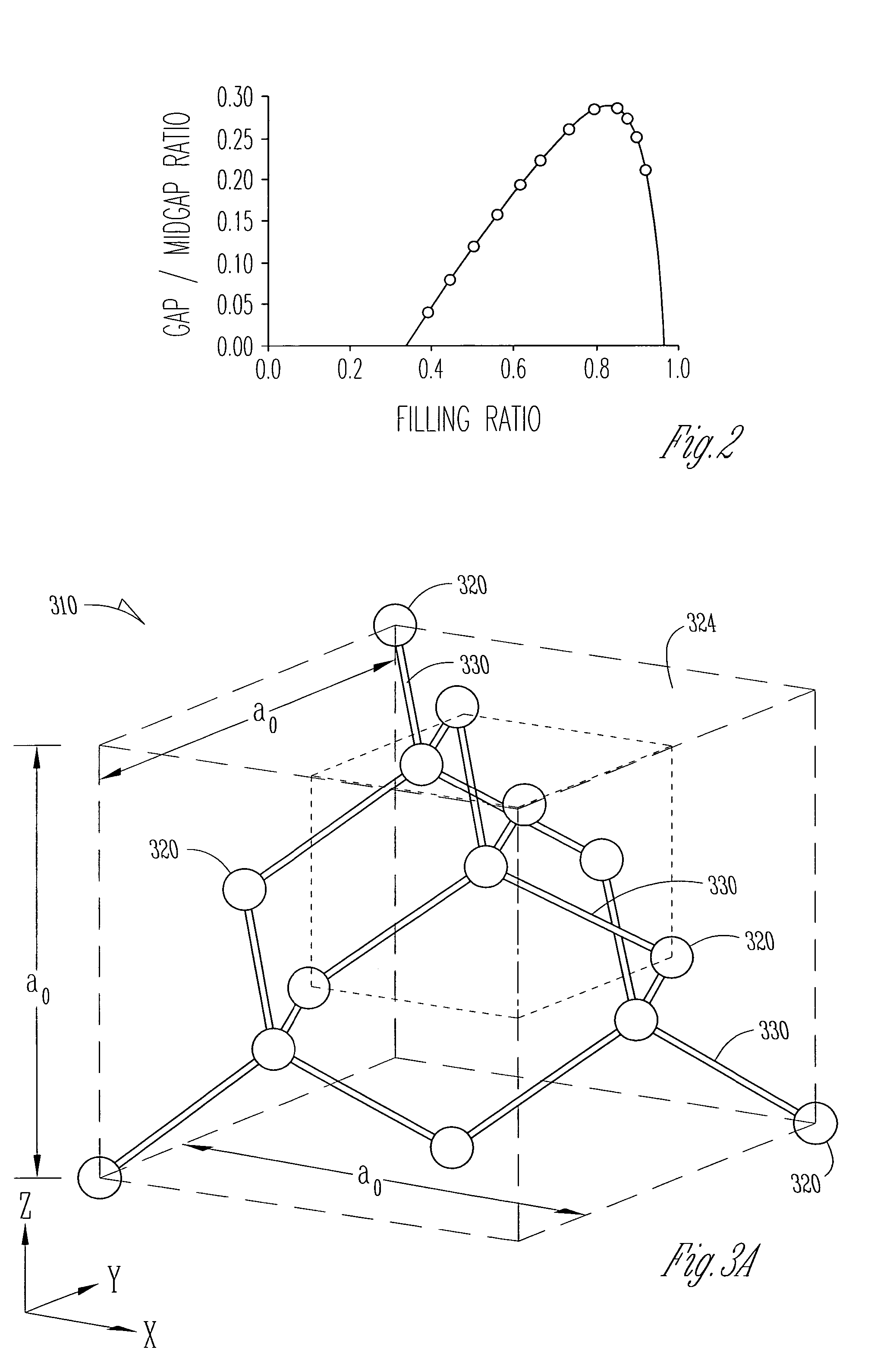

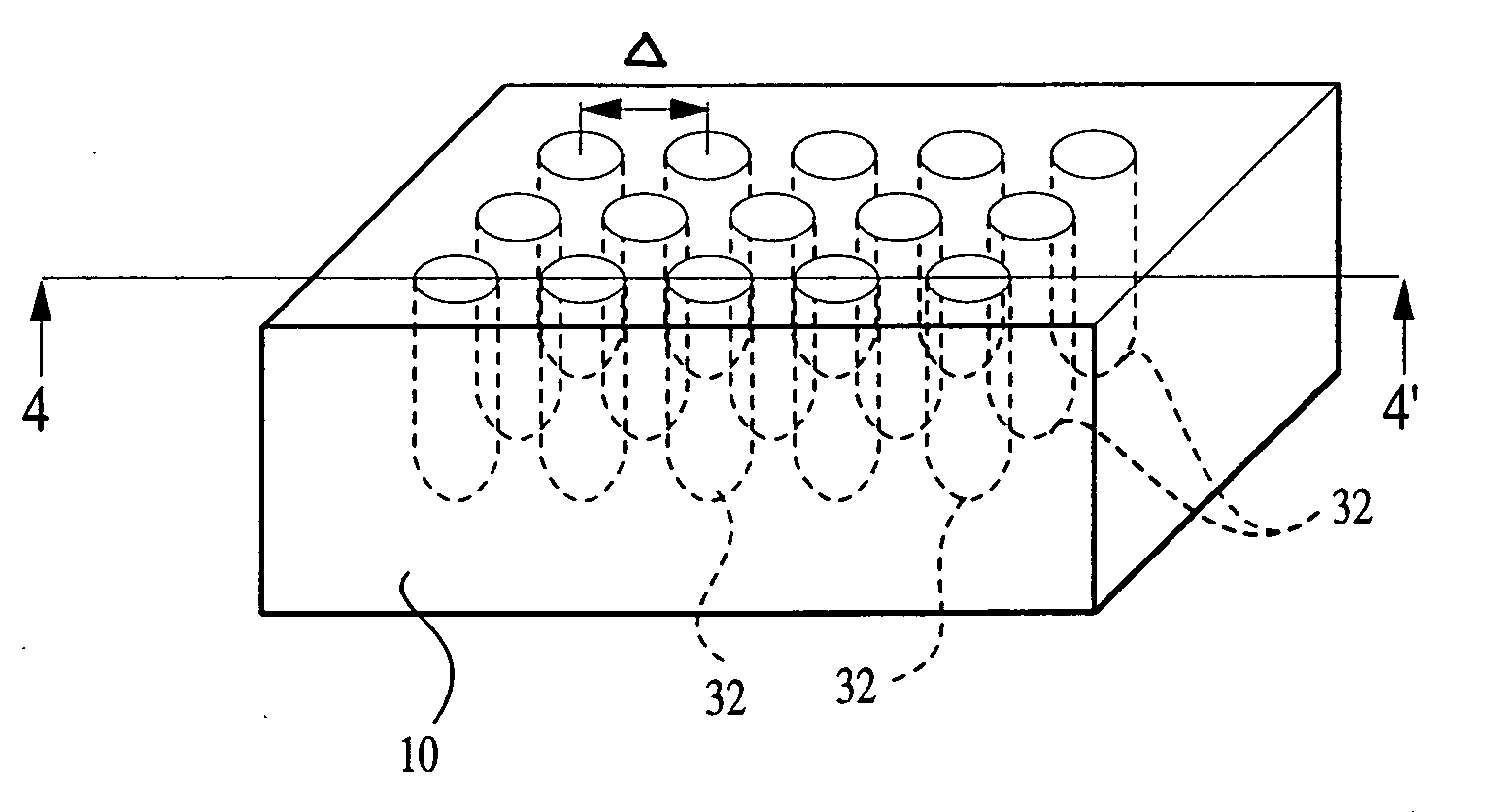

Three-dimensional photonic crystal waveguide structure and method

InactiveUS6898362B2Polycrystalline material growthLaser optical resonator constructionPhotonic bandgapSolid substrate

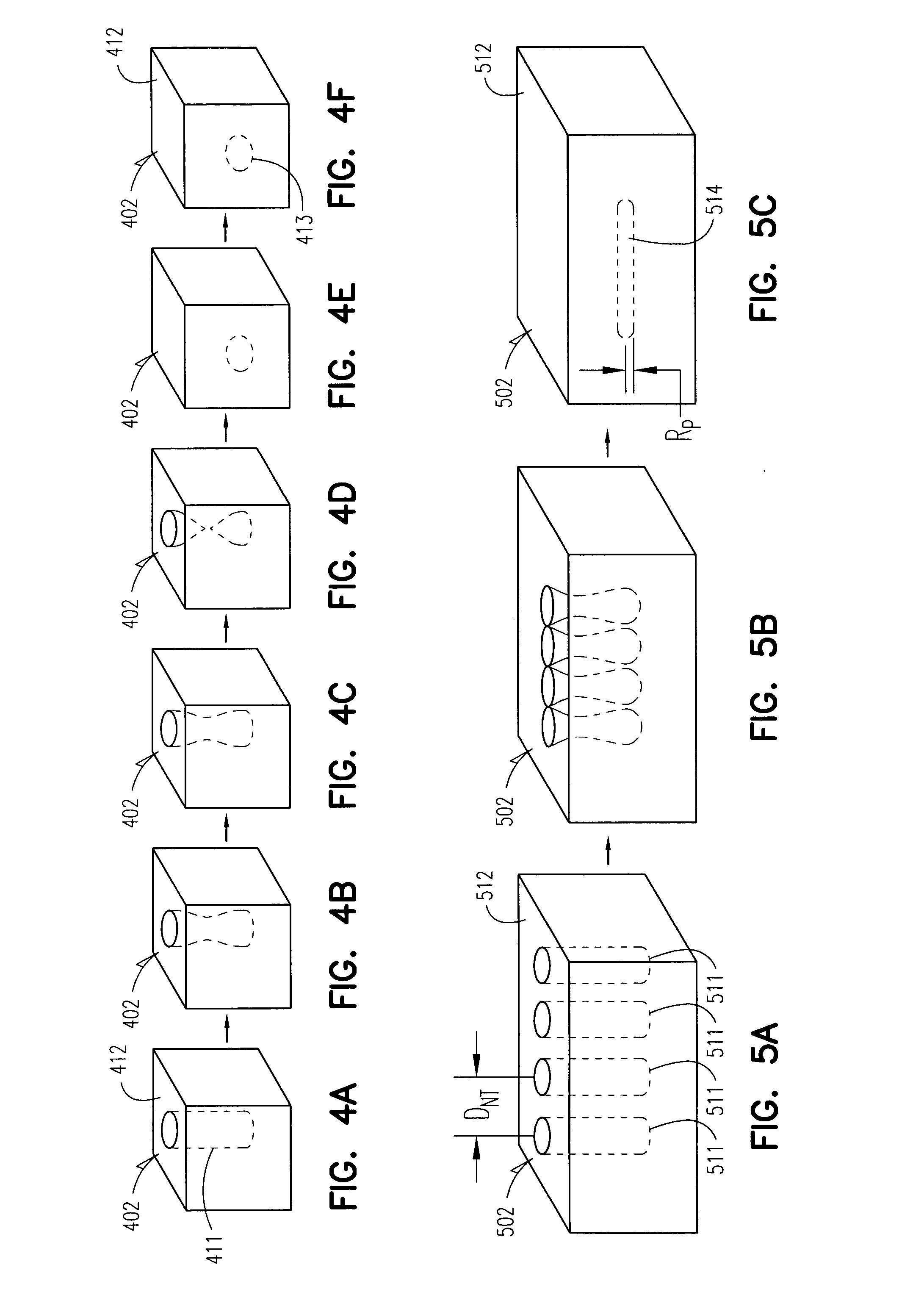

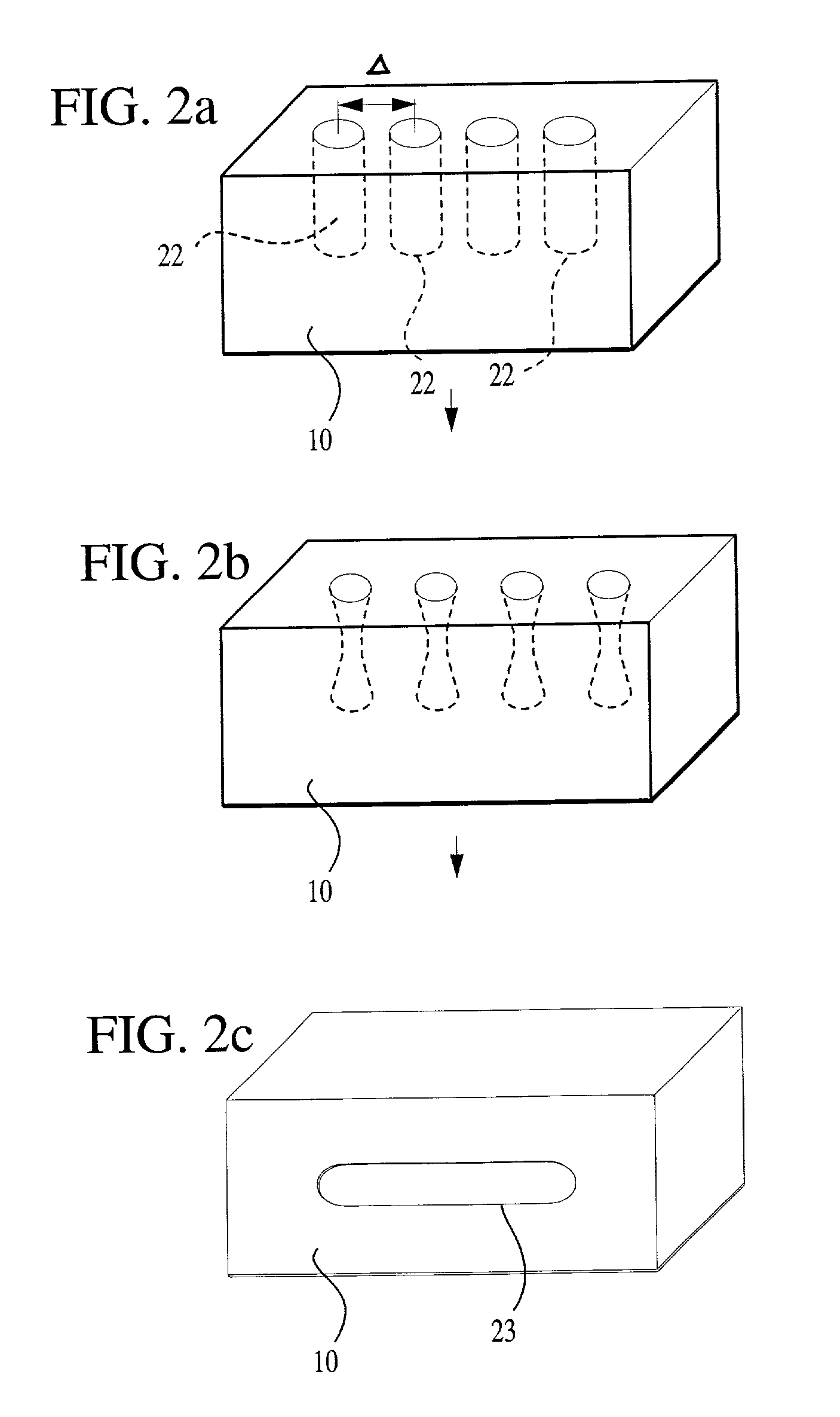

A waveguide structure formed with a three-dimensional (3D) photonic crystal is disclosed. The 3D photonic crystal comprises a periodic array of voids formed in a solid substrate. The voids are arranged to create a complete photonic bandgap. The voids may be formed using a technique called “surface transformation,” which involves forming holes in the substrate surface, and annealing the substrate to initiate migration of the substrate near the surface to form voids in the substrate. A channel capable of transmitting radiation corresponding to the complete bandgap is formed in the 3D photonic crystal, thus forming the waveguide. The waveguide may be formed by interfacing two 3D photonic crystal regions, with at least one of the regions having a channel formed therein. The bandgap wavelength can be chosen by arranging the periodic array of voids to have a lattice constant a fraction of the bandgap wavelength.

Owner:MICRON TECH INC

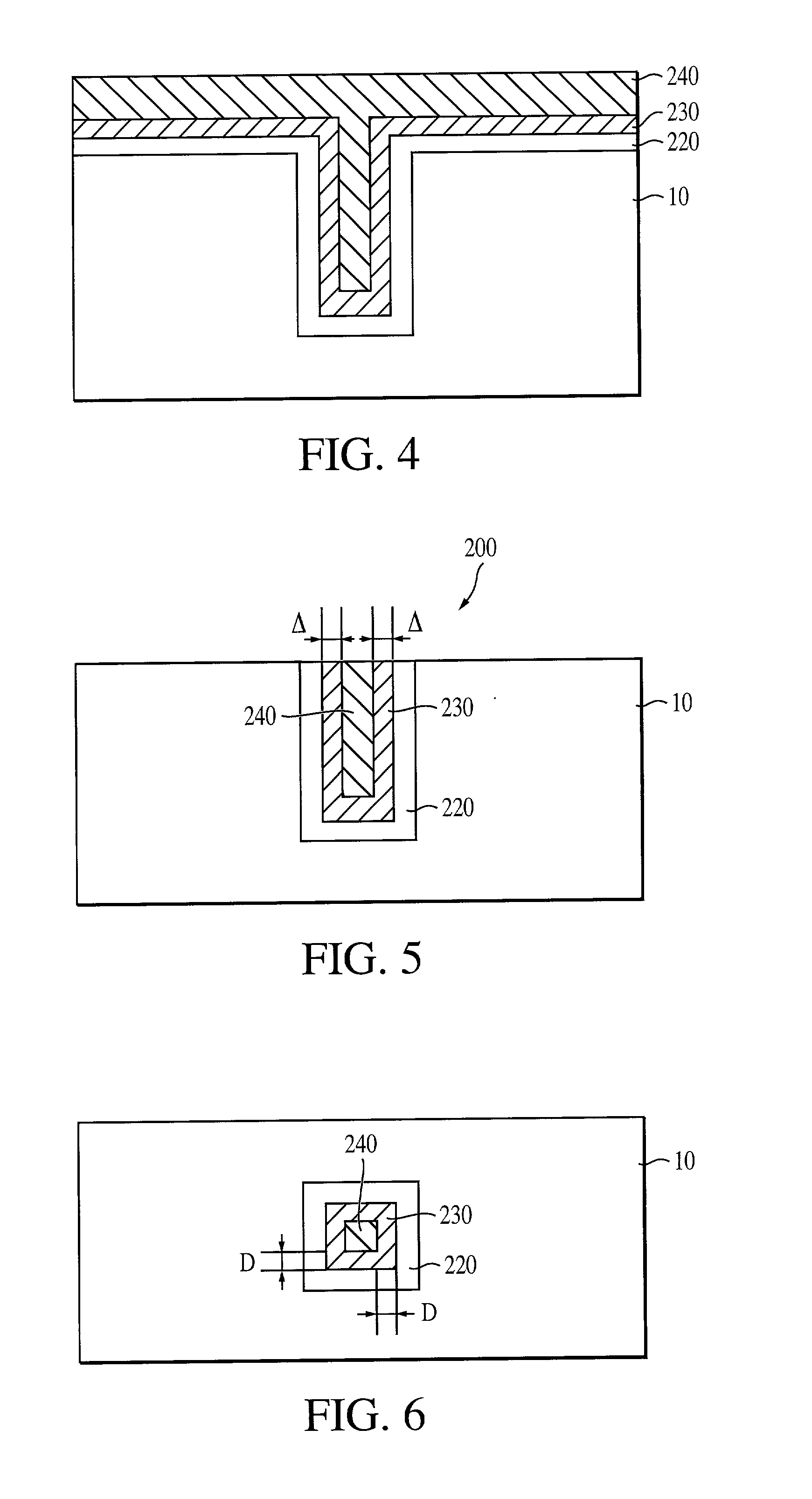

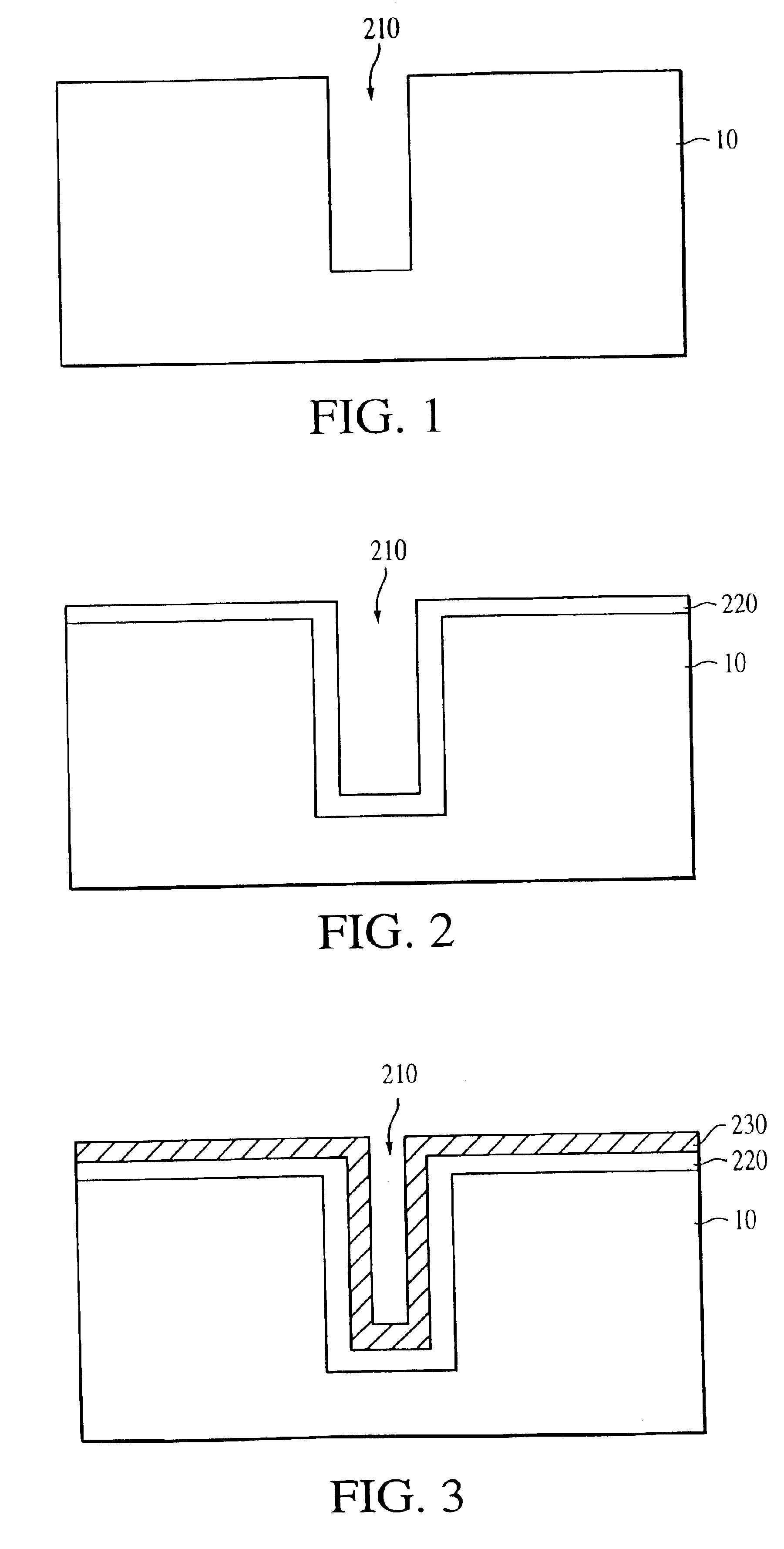

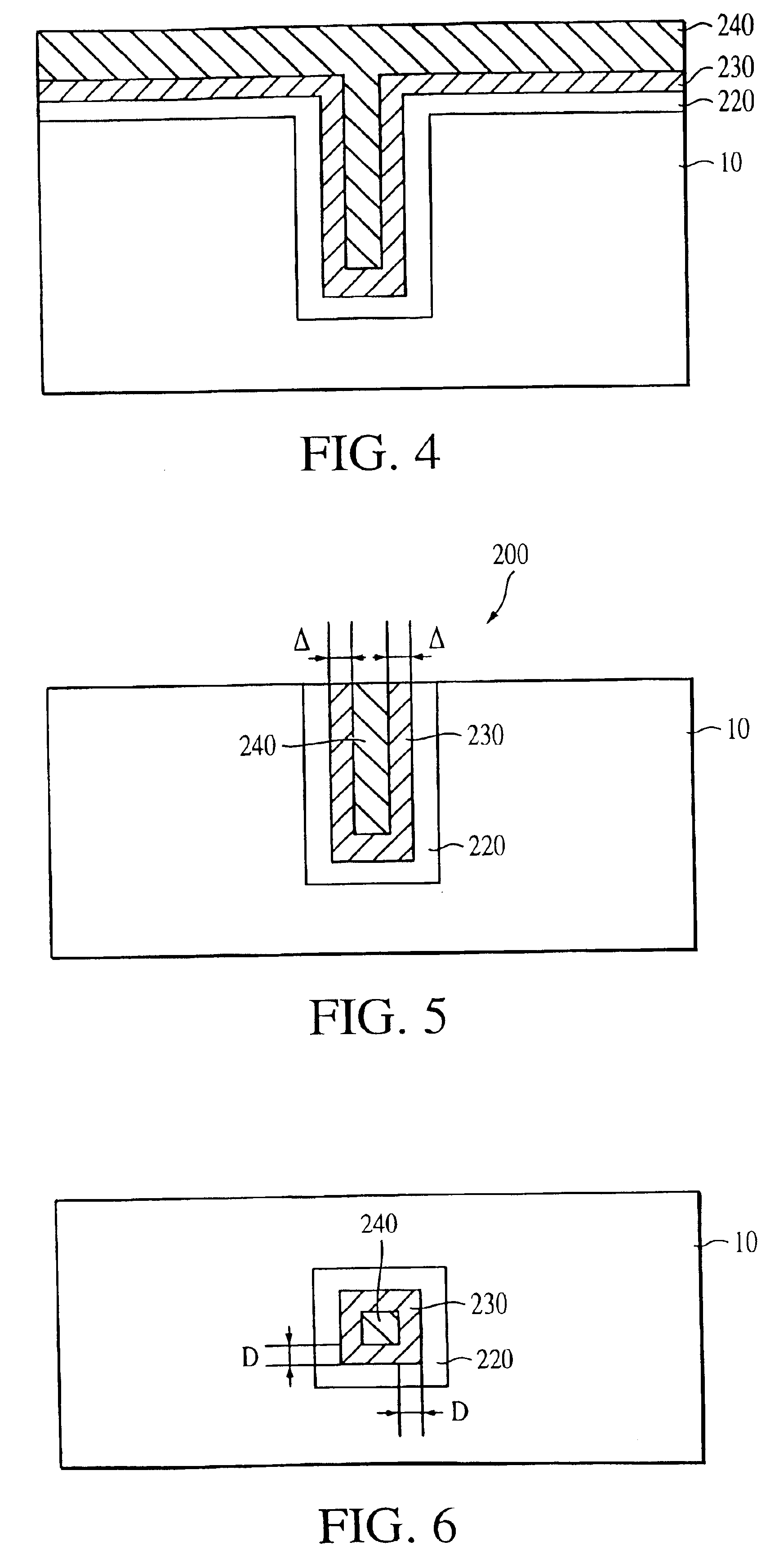

Method of alignment for buried structures formed by surface transformation of empty spaces in solid state materials

InactiveUS20020076896A1Precise alignmentSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDevice material

A method of aligning a plurality of empty-spaced buried patterns formed in semiconductor monocrystalline substrates is disclosed. In an exemplary embodiment, high-temperature metal marks are formed to include a conductive material having a melting temperature higher than an annealing temperature used to form such empty-spaced buried patterns. The high-temperature metal marks are formed prior to the formation of the empty-spaced buried patterns formed in a monocrystalline substrate, so that the empty-space buried patterns are aligned to the marks. Subsequent semiconductor structures that are formed as part of desired semiconductor devices can be also aligned to the marks.

Owner:MICRON TECH INC

Gettering using voids formed by surface transformation

One aspect of this disclosure relates to a method for creating a gettering site in a semiconductor wafer. In various embodiments, a predetermined arrangement of a plurality of holes is formed in the semiconductor wafer through a surface of the wafer. The wafer is annealed such that the wafer undergoes a surface transformation to transform the arrangement of the plurality of holes into a predetermined arrangement of at least one empty space of a predetermined size within the wafer to form the gettering site. One aspect relates to a semiconductor wafer. In various embodiments, the wafer includes at least one device region, and at least one gettering region located proximate to the at least one device region. The gettering region includes a precisely-determined arrangement of a plurality of precisely-formed voids that are formed within the wafer using a surface transformation process. Other aspects and embodiments are provided herein.

Owner:MICRON TECH INC

Method of forming mirrors by surface transformation of empty spaces in solid state materials

ActiveUS20050070036A1Easy to customizeSemiconductor/solid-state device manufacturingOptical resonator shape and constructionOptoelectronicsPhysics

Owner:MICRON TECH INC

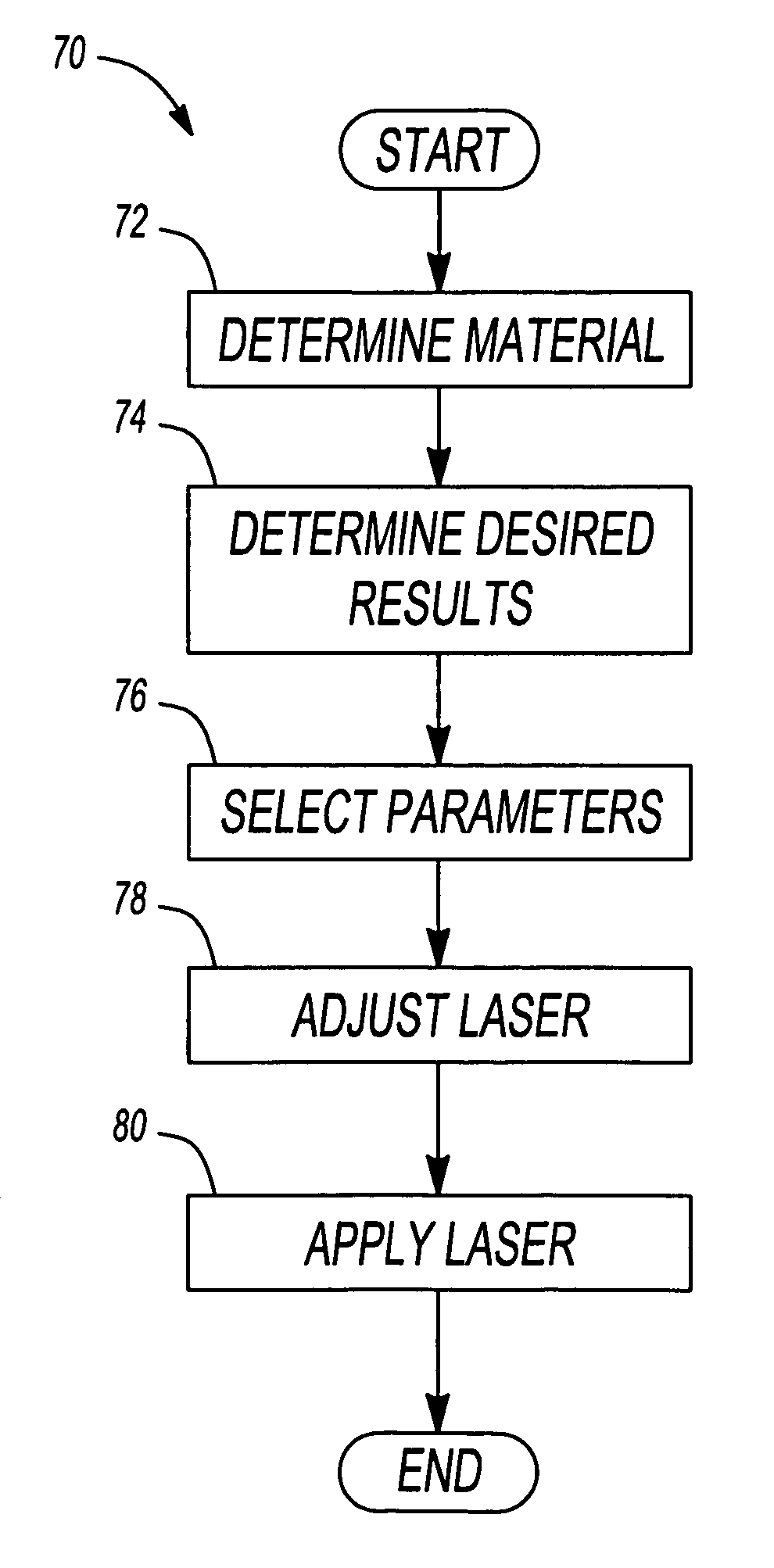

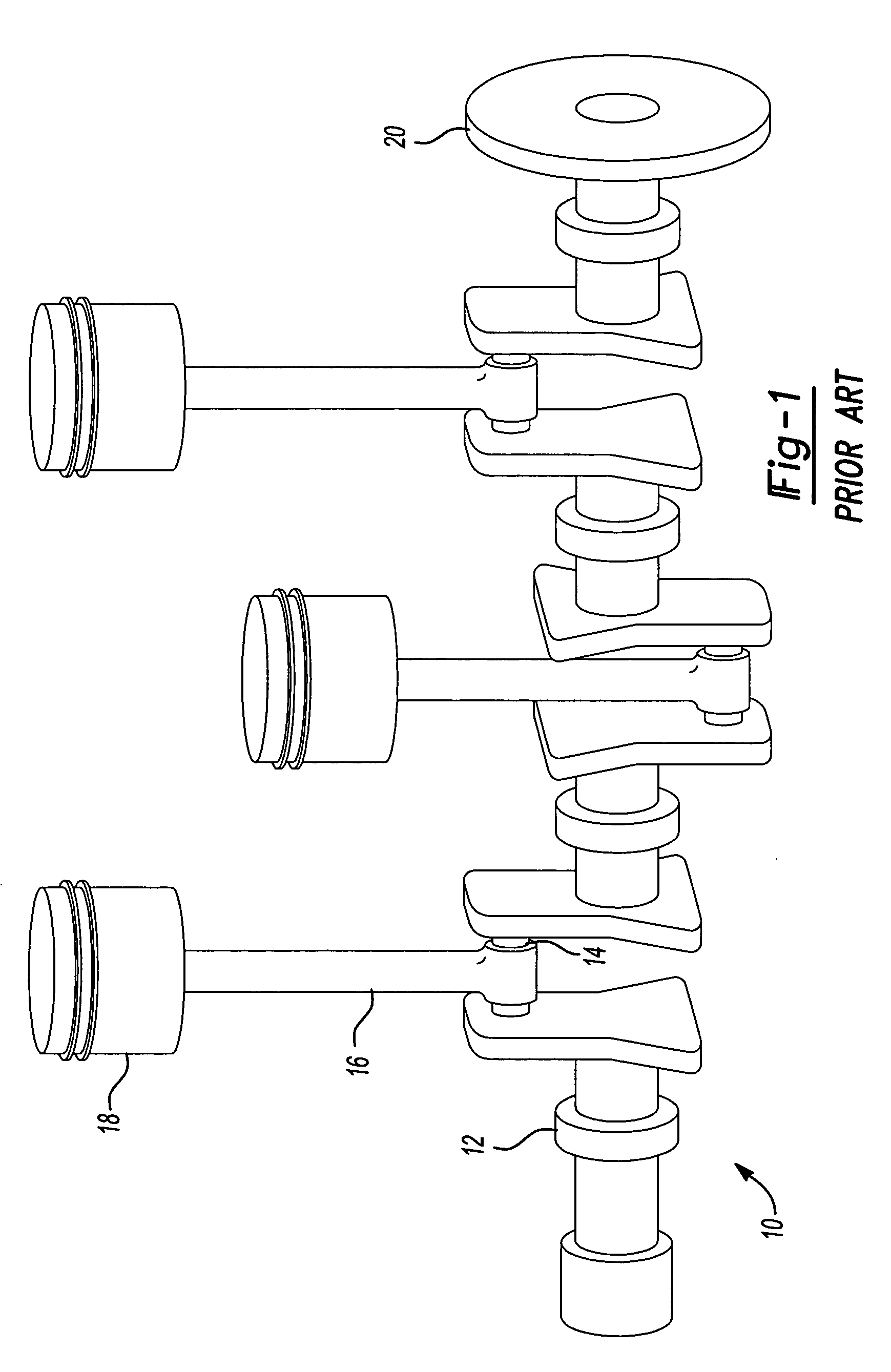

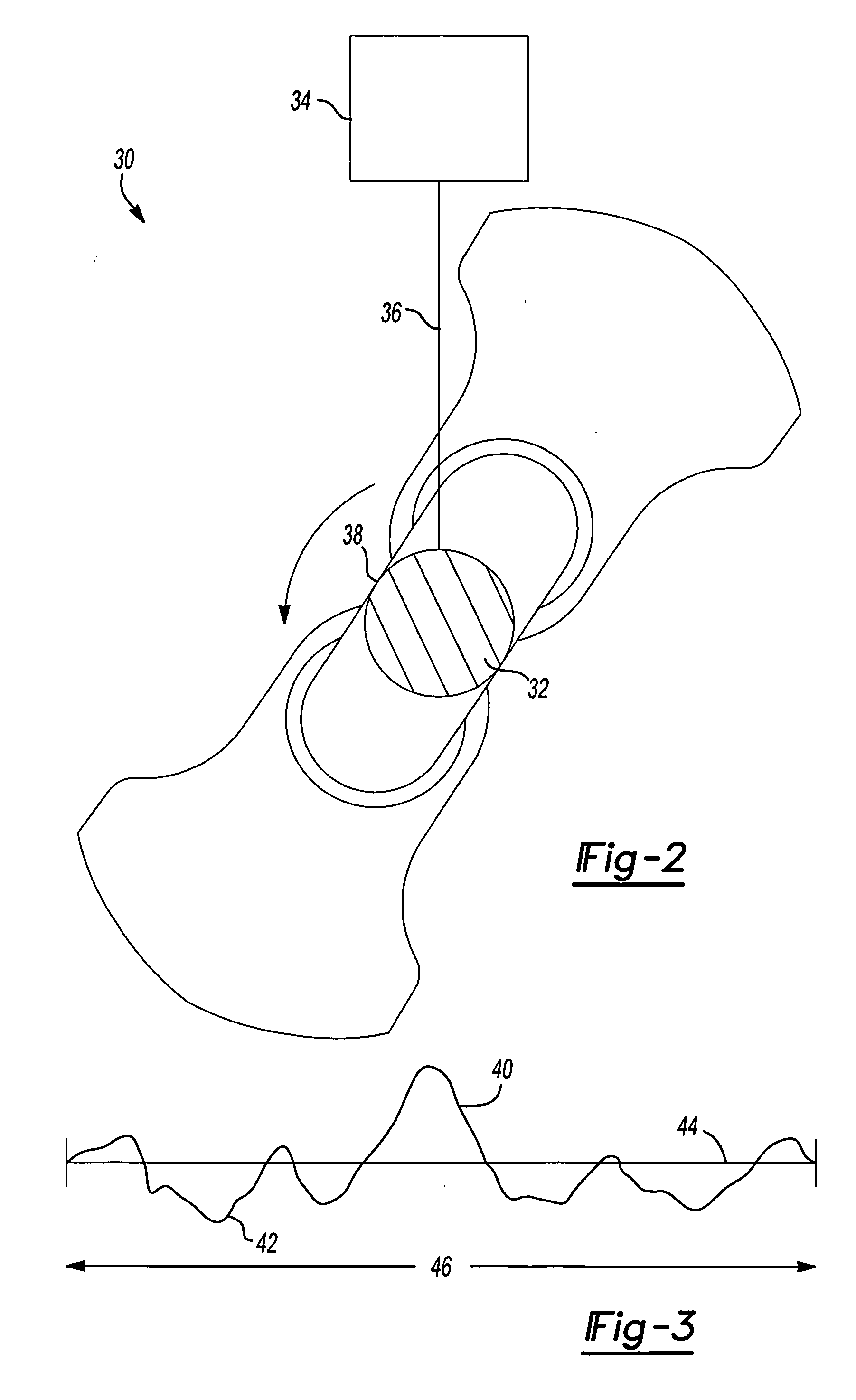

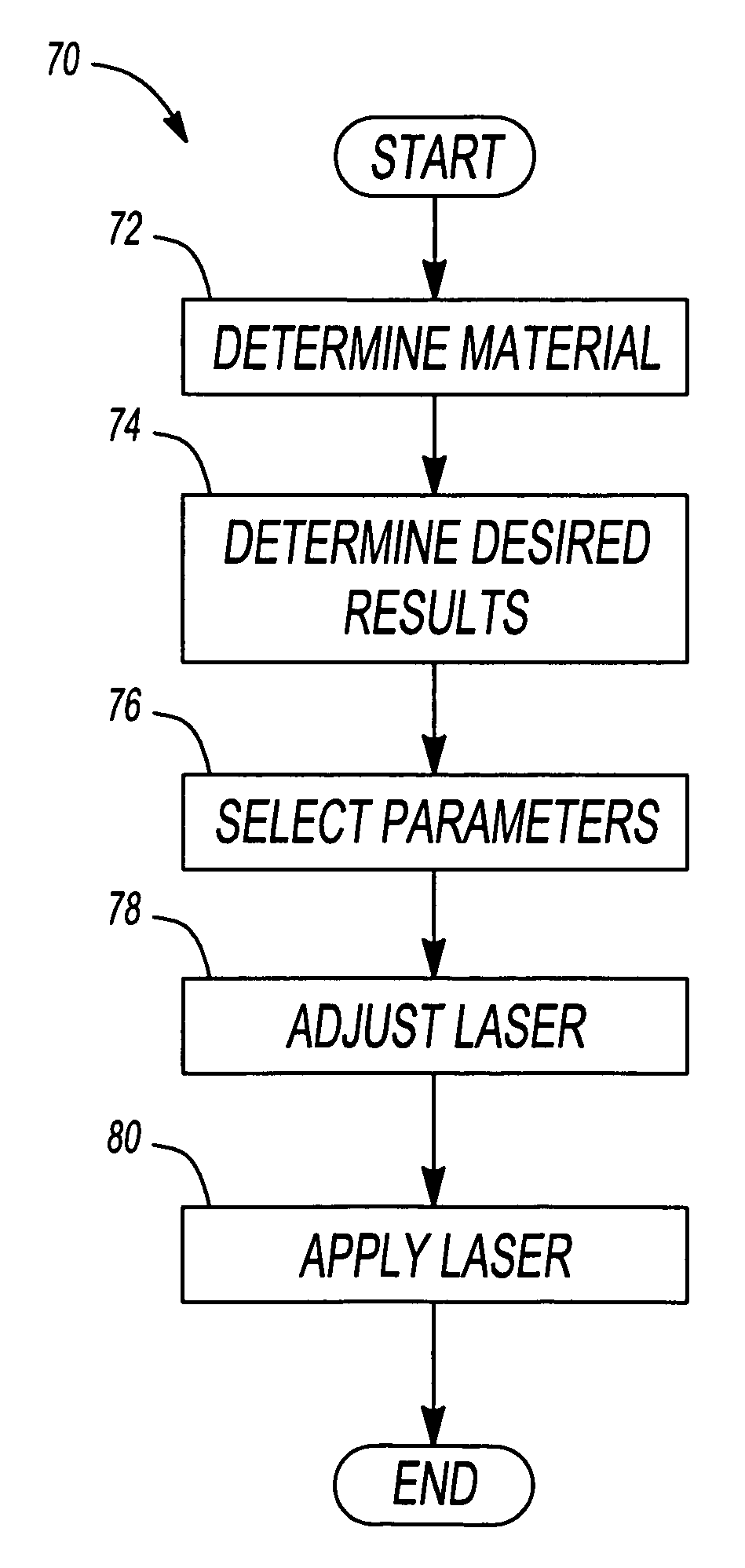

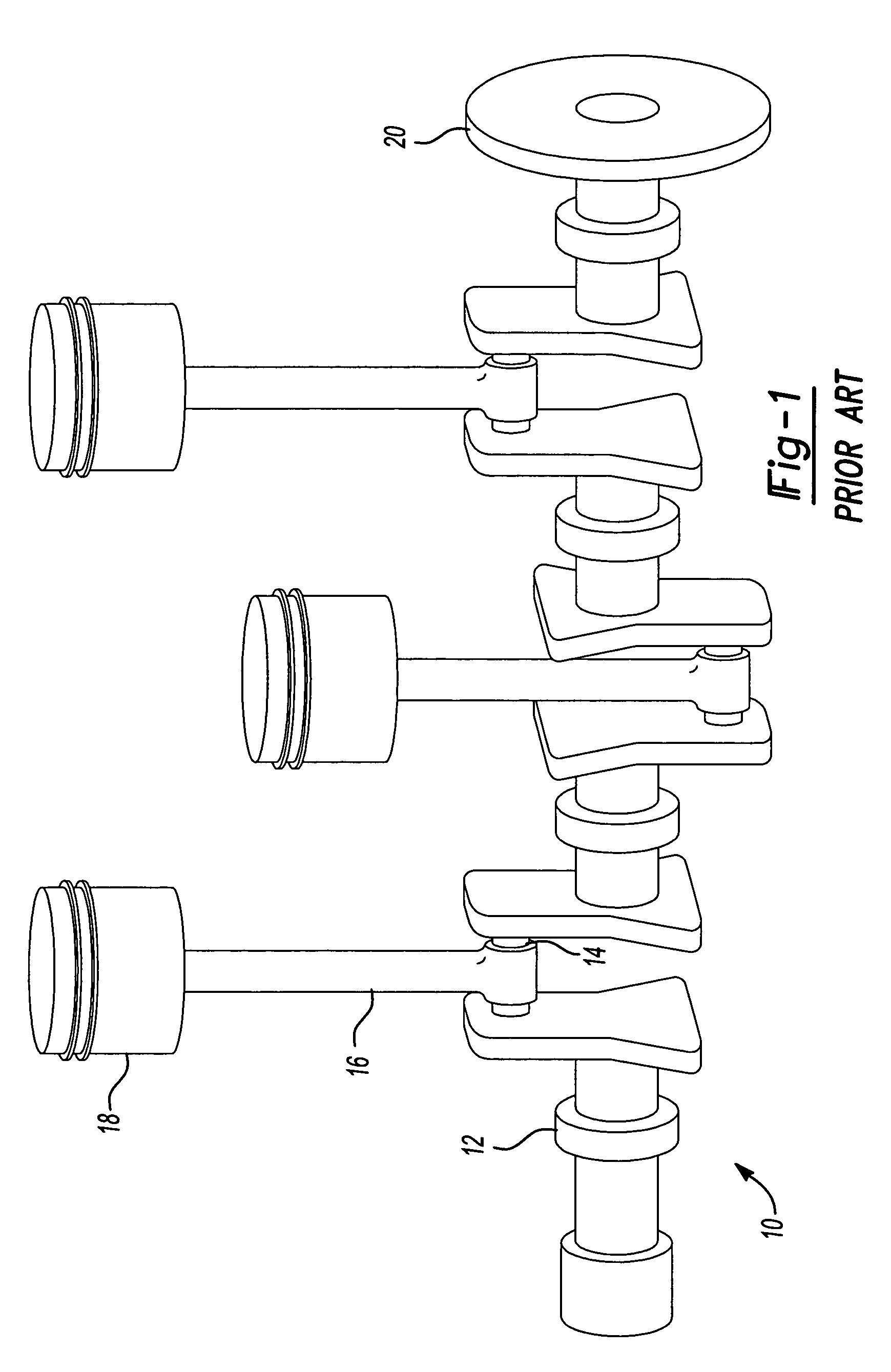

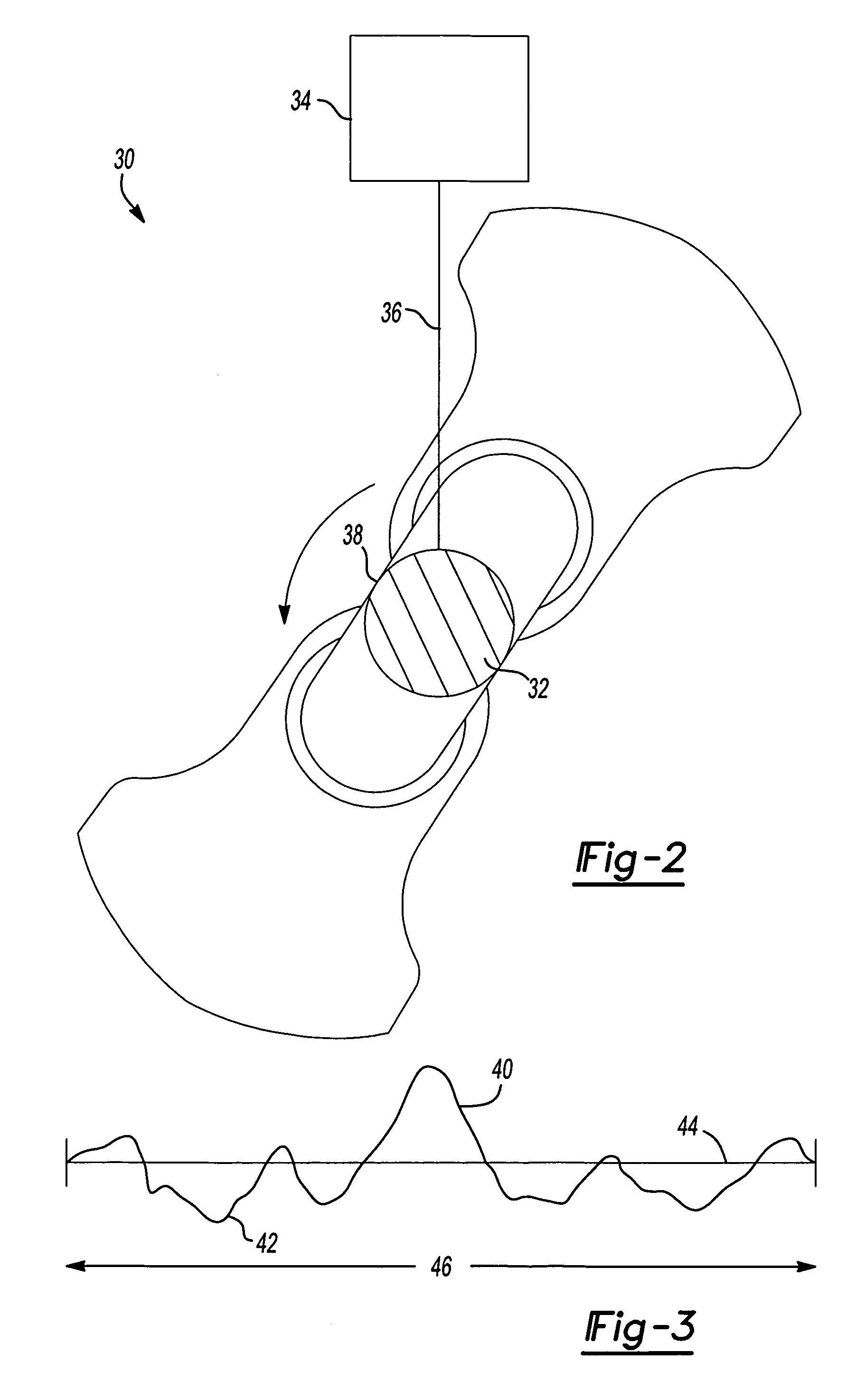

Manufacturing method that uses laser surface transformation to produce new and unique surface profiles for rotating bearings

ActiveUS20060138100A1Semiconductor/solid-state device manufacturingPhotosensitive material processingOil retentionEarth surface

A laser ablation method is used to polish a bearing surface of an automotive crankshaft. A laser ablation device generates a laser according to parameters such as wavelength, pulse duration, pulse repetition rate, and beam quality. The laser is applied to the surface of a rotating engine component, such as a crankshaft, as the component is rotated in order to polish the surface according to the parameters. The laser substantially improves tribological performance of the bearing surface by changing the waviness and form of the surface profile. Further, oil-retention reservoirs are formed in the surface. As a result, the friction coefficient of the crankshaft surface is reduced while the roughness of the crankshaft surface is maintained, reduced, or increased.

Owner:ADCOLE CORP +1

Three-dimensional photonic crystal waveguide structure and method

InactiveUS7054532B2Polycrystalline material growthLaser optical resonator constructionPhotonic bandgapSolid substrate

Owner:MICRON TECH INC

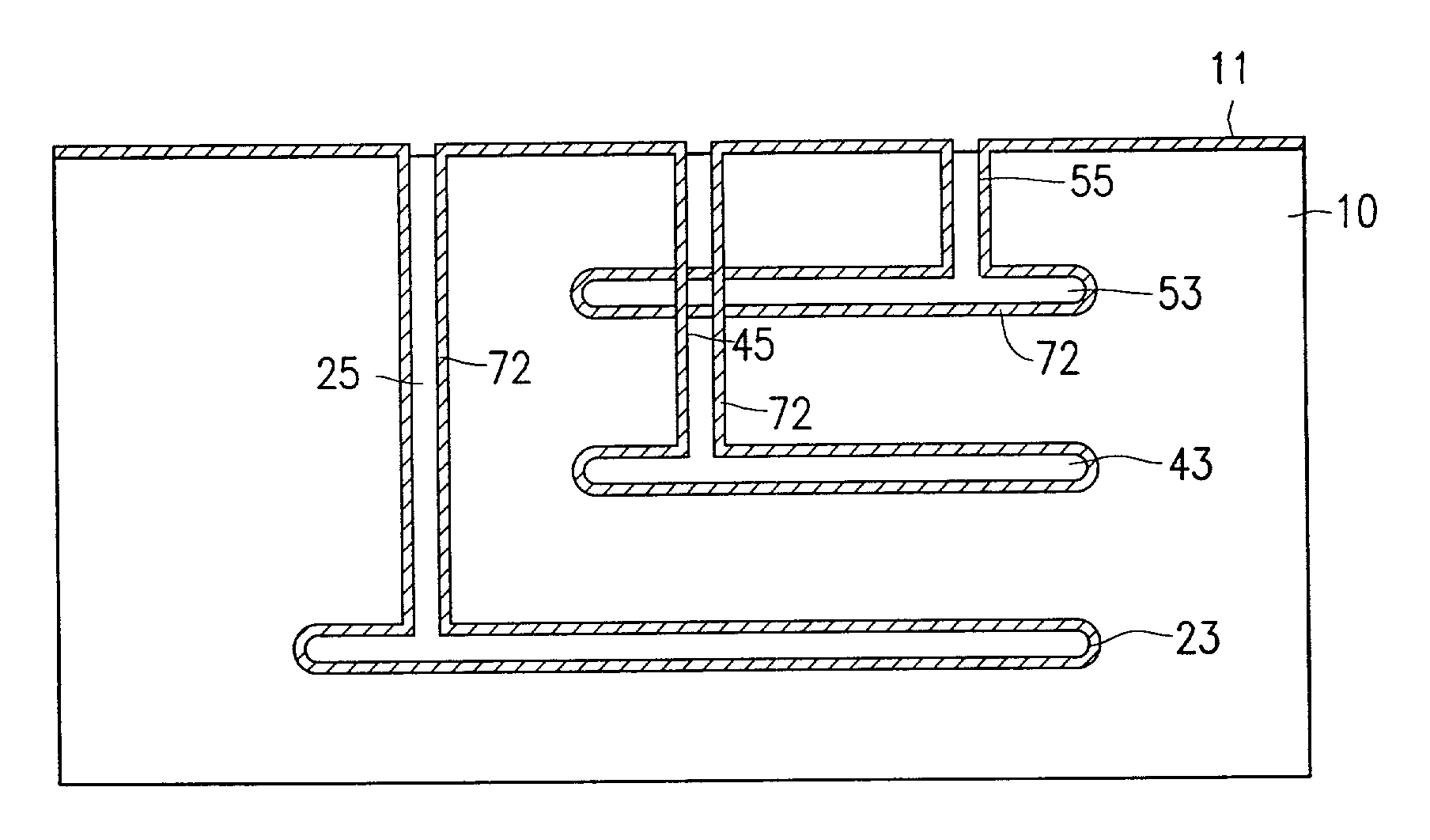

Buried conductor patterns formed by surface transformation of empty spaces in solid state materials

InactiveUS7164188B2Semiconductor/solid-state device detailsSolid-state devicesSingle crystalConductive materials

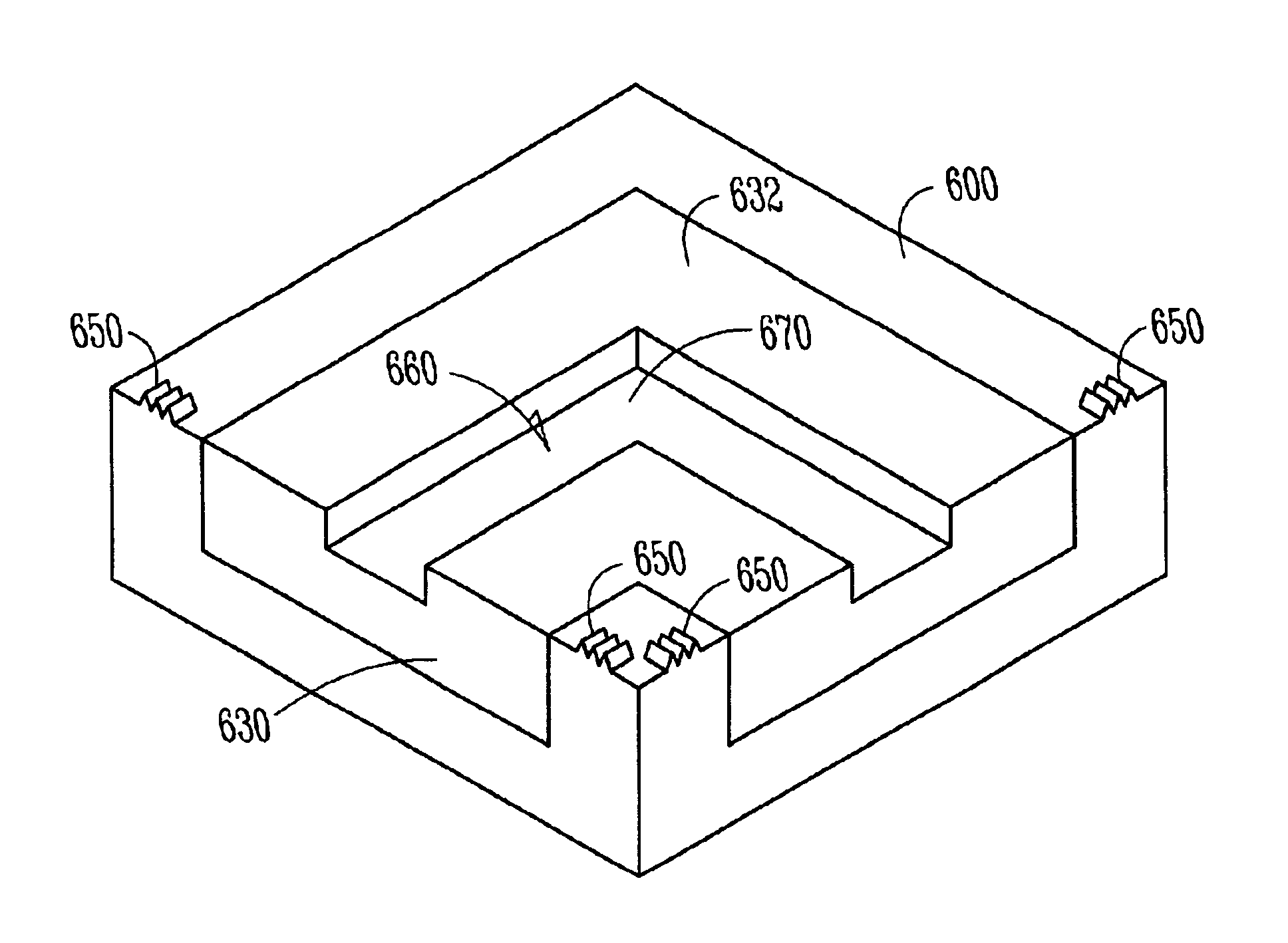

A plurality of buried conductors and / or buried plate patterns formed within a monocrystalline substrate is disclosed. A plurality of empty-spaced buried patterns are formed by drilling holes in the monocrystalline substrate and annealing the monocrystalline substrate to form empty-spaced patterns of various geometries. The empty-spaced patterns are then connected through vias with surfaces of the monocrystalline substrate. The empty-spaced patterns and their respective vias are subsequently filled with conductive materials.

Owner:MICRON TECH INC

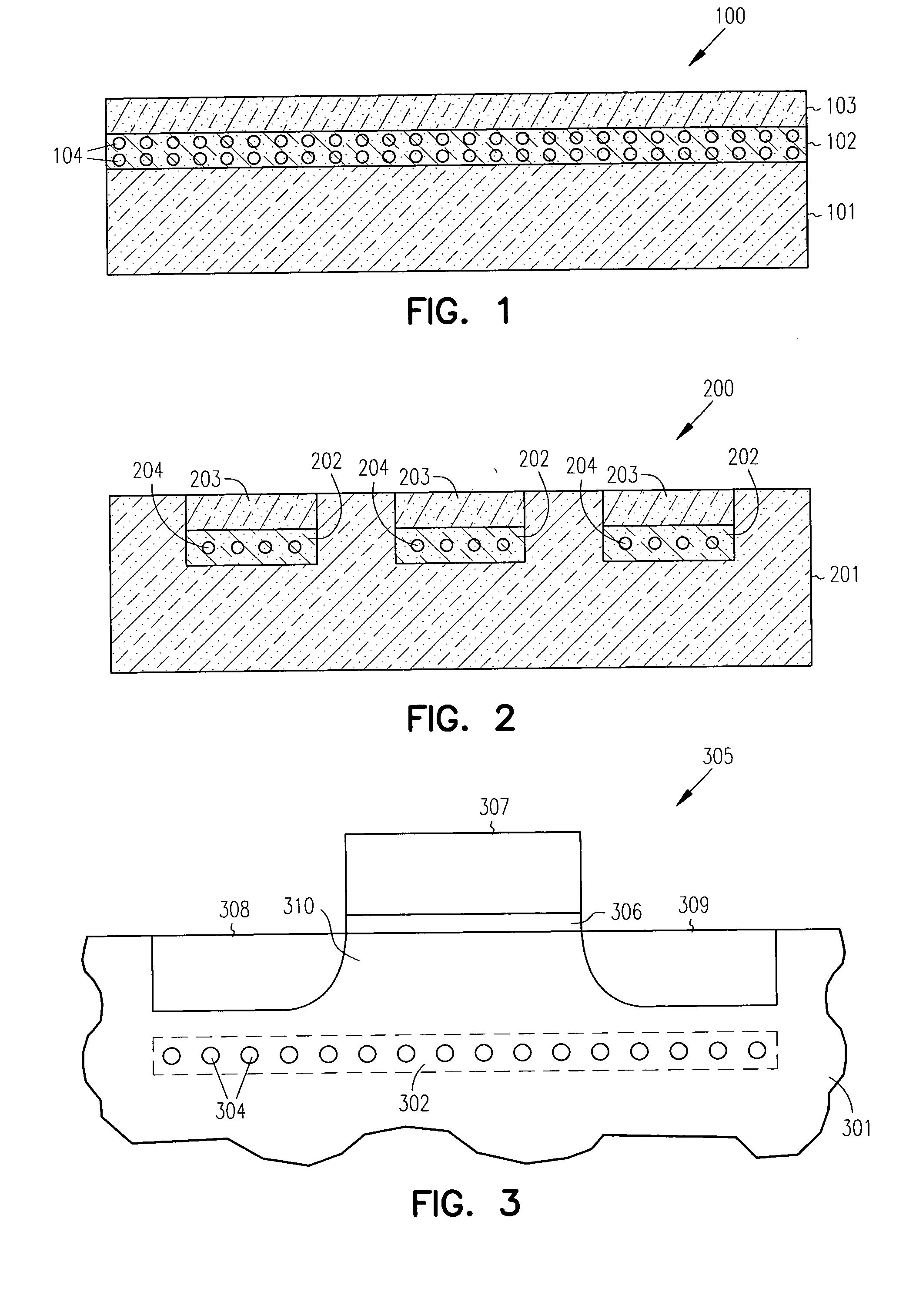

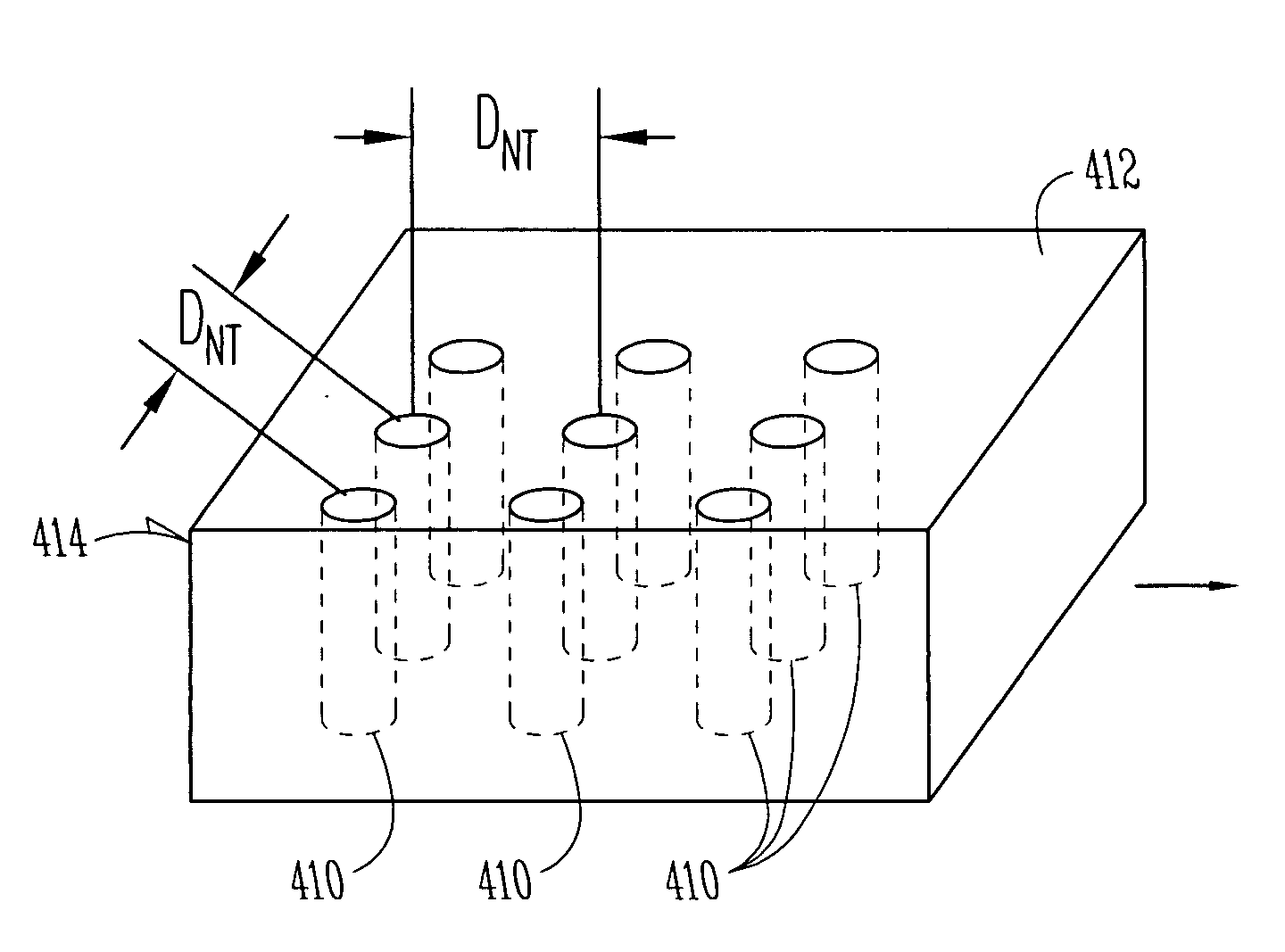

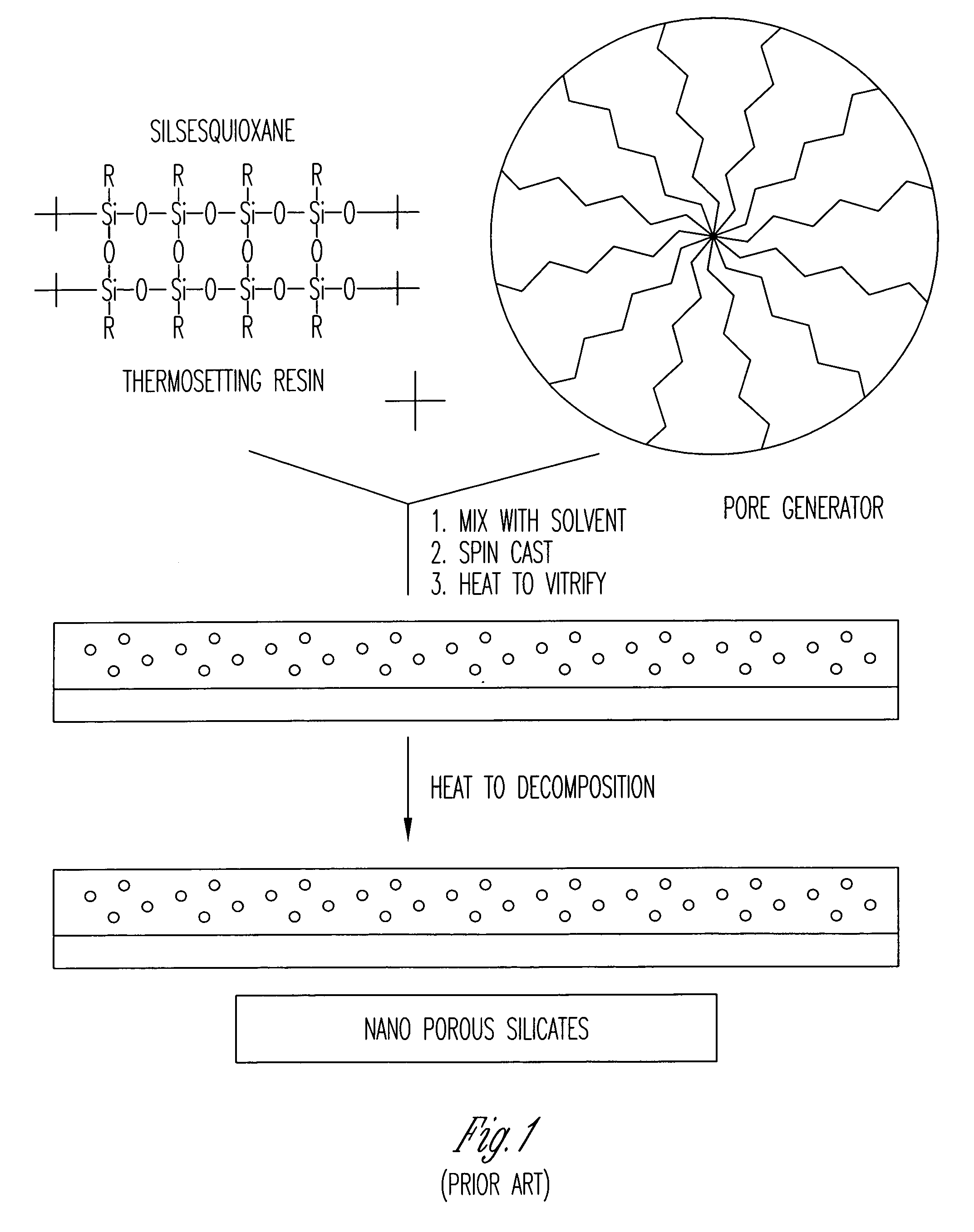

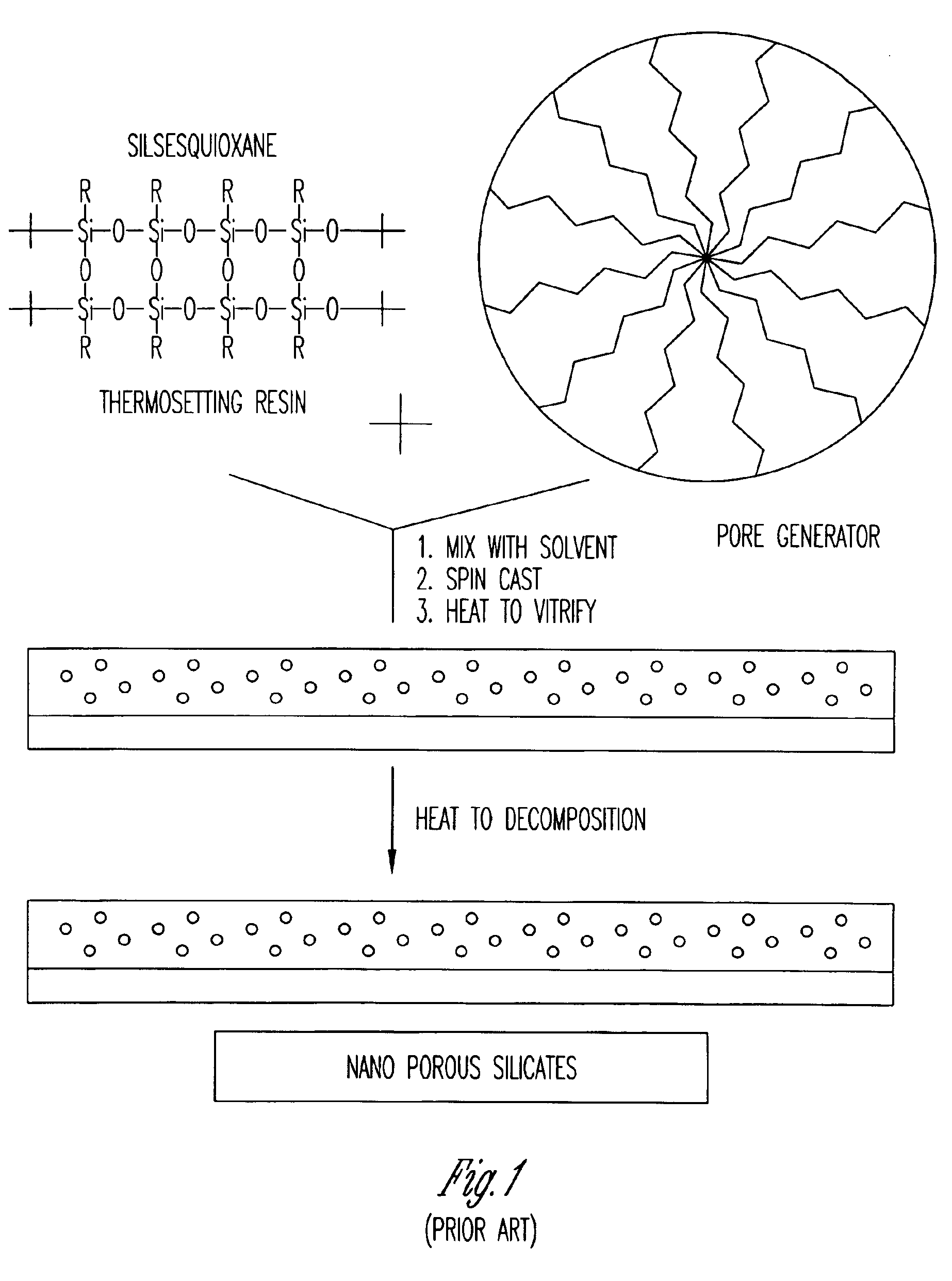

Low k interconnect dielectric using surface transformation

InactiveUS20050029501A1Easy to prepareImproves integrated circuit performanceSemiconductor/solid-state device detailsSolid-state devicesSolid structureEngineering

Systems, devices and methods are provided to improve performance of integrated circuits by providing a low-k insulator. One aspect is an integrated circuit insulator structure. One embodiment includes a solid structure of an insulator material, and a precisely determined arrangement of at least one void formed within the solid structure which lowers an effective dielectric constant of the insulator structure. One aspect is a method of forming a low-k insulator structure. In one embodiment, an insulator material is deposited, and a predetermined arrangement of at least one hole is formed in a surface of the insulator material. The insulator material is annealed such that the low-k dielectric material undergoes a surface transformation to transform the arrangement of at least one hole into predetermined arrangement of at least one empty space below the surface of the insulator material. Other aspects are provided herein.

Owner:MICRON TECH INC

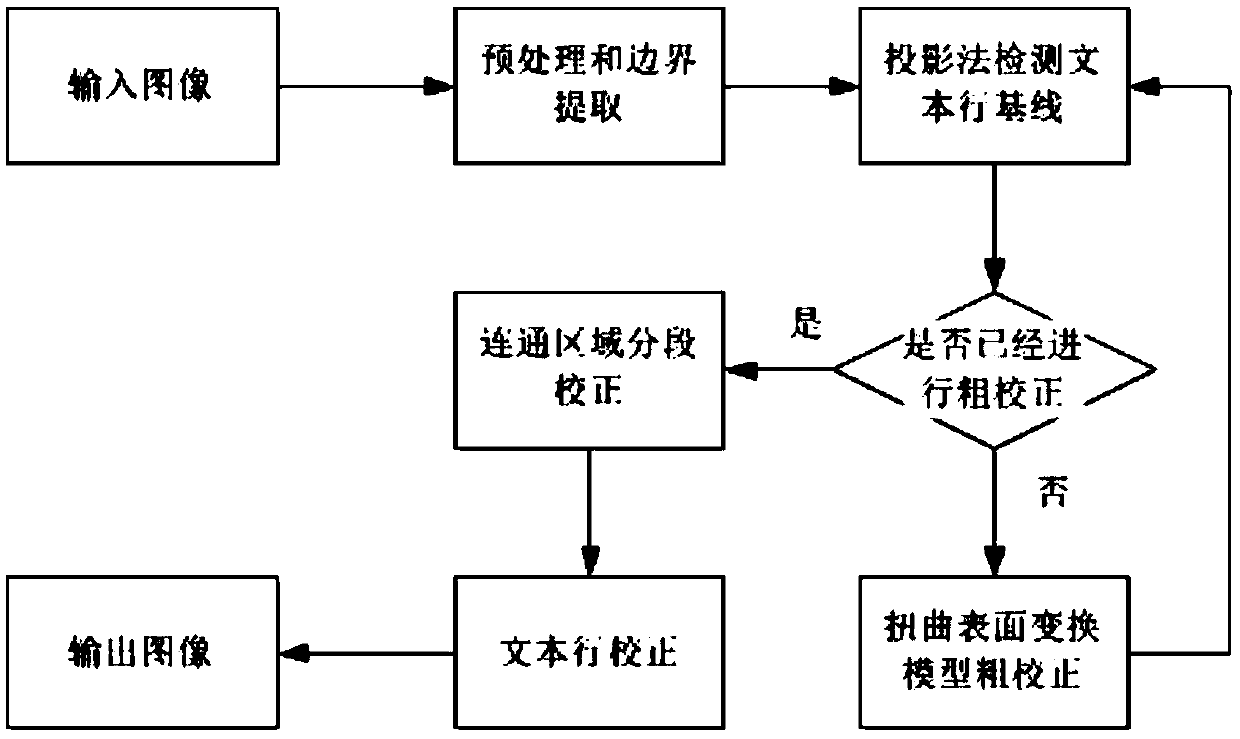

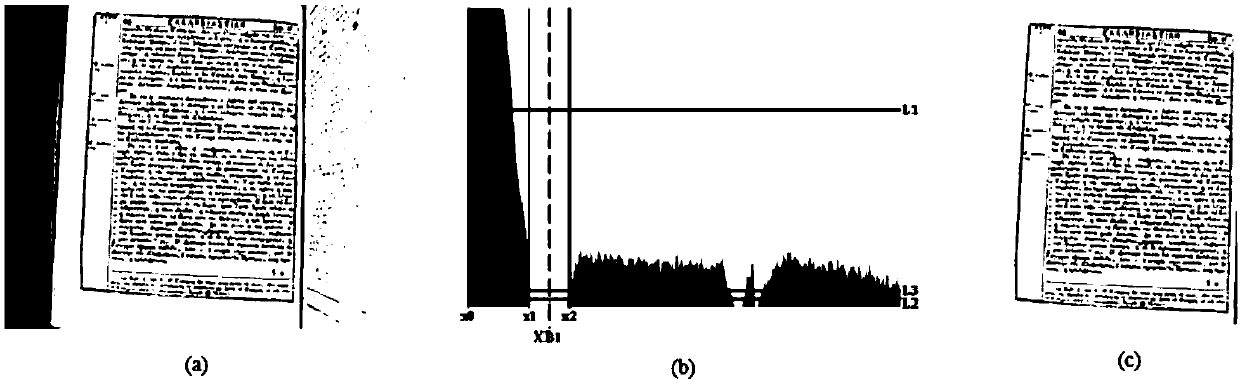

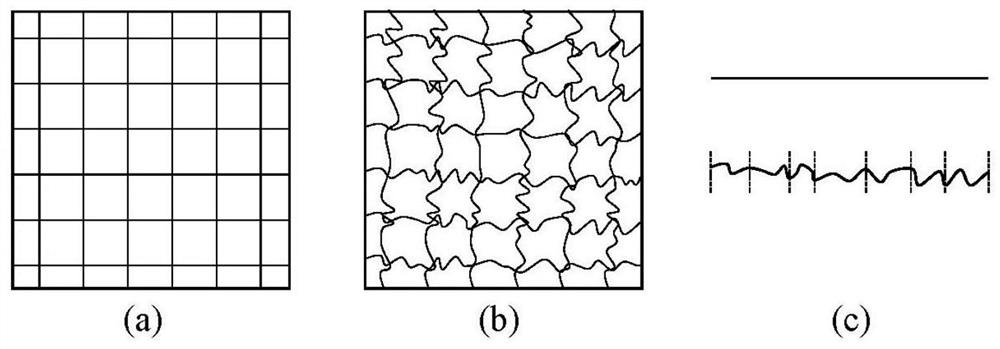

Two-stage document image nonlinear distortion correction method based on projection method

InactiveCN109063704AImprove recognition accuracyReduce distractionsCharacter recognitionNonlinear distortionImage correction

The invention discloses a two-stage document image non-linear distortion correction method based on a projection method. 1, binarizing the obtained document image, adaptively detecting and extractingthe boundary of an effective region by using a boundary detection and extraction algorithm, and obtaining a document image correction region; 2. For the preprocessed document image, the baseline of the text line being extracted based on the projection method, and then the base point is selected to construct the distorted surface transformation model for the first stage correction, which is calledrough correction. 3, after that coarse correction is carried out, the baseline of the text line being extracted from the image by the projection method again, and then the connected regions in the text lines being correct in a more detailed second stage according to the extracted baseline of the text lines in a text line unit of behavior, and the fine correction is called the fine correction. Theinvention can overcome the influence of a series of non-linear distortions such as perspective, tilt, distortion and the like in the document image on the OCR identification of the document image, andimproves the accuracy of the OCR identification.

Owner:XI AN JIAOTONG UNIV

Low k interconnect dielectric using surface transformation

InactiveUS7132348B2Relieve stressEasy to prepareSemiconductor/solid-state device detailsSolid-state devicesSolid structureEngineering

Systems, devices and methods are provided to improve performance of integrated circuits by providing a low-k insulator. One aspect is an integrated circuit insulator structure. One embodiment includes a solid structure of an insulator material, and a precisely determined arrangement of at least one void formed within the solid structure which lowers an effective dielectric constant of the insulator structure. One aspect is a method of forming a low-k insulator structure. In one embodiment, an insulator material is deposited, and a predetermined arrangement of at least one hole is formed in a surface of the insulator material. The insulator material is annealed such that the low-k dielectric material undergoes a surface transformation to transform the arrangement of at least one hole into predetermined arrangement of at least one empty space below the surface of the insulator material. Other aspects are provided herein.

Owner:MICRON TECH INC

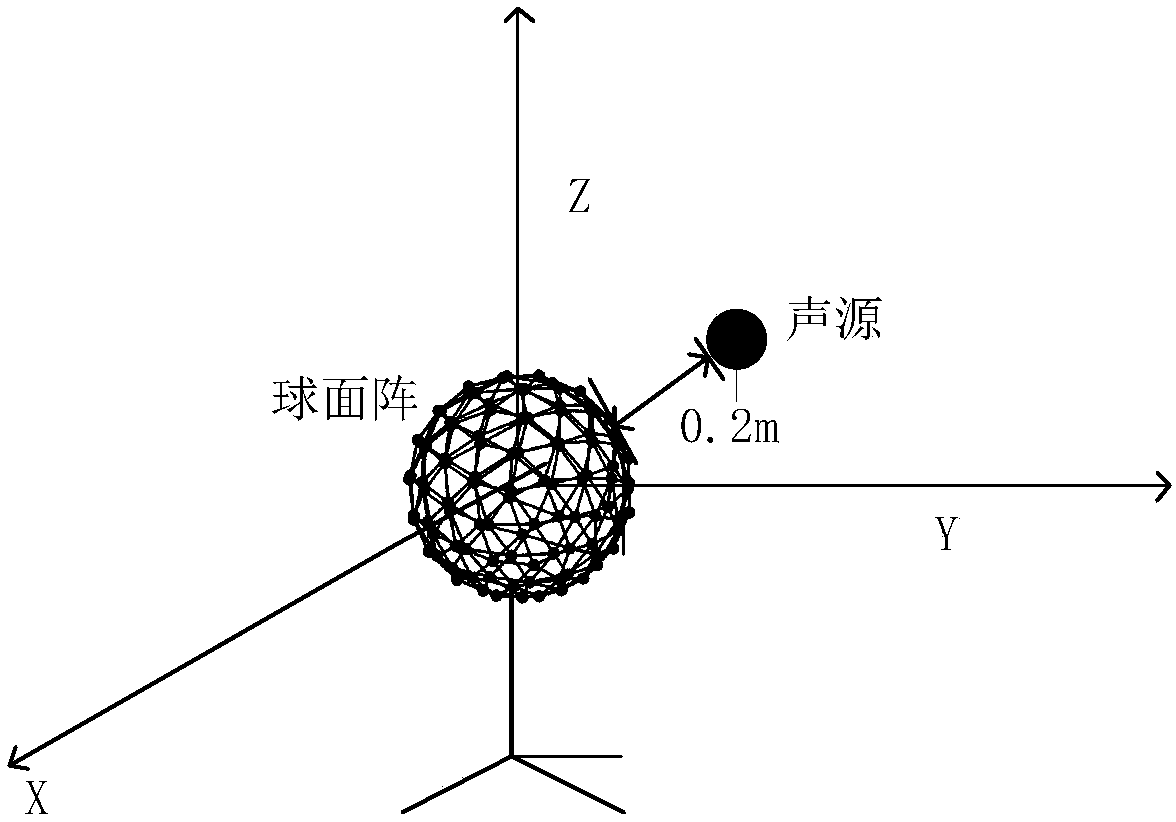

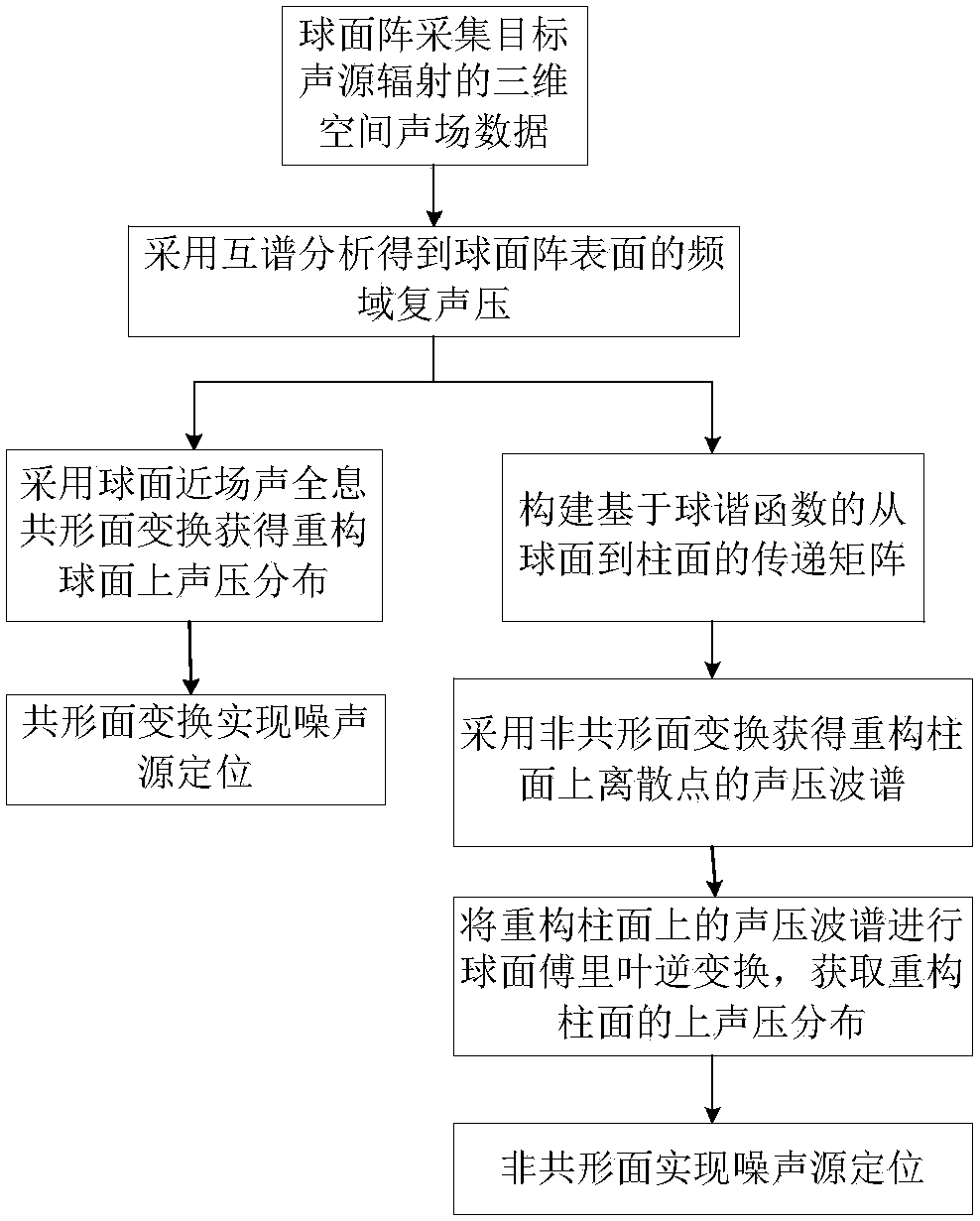

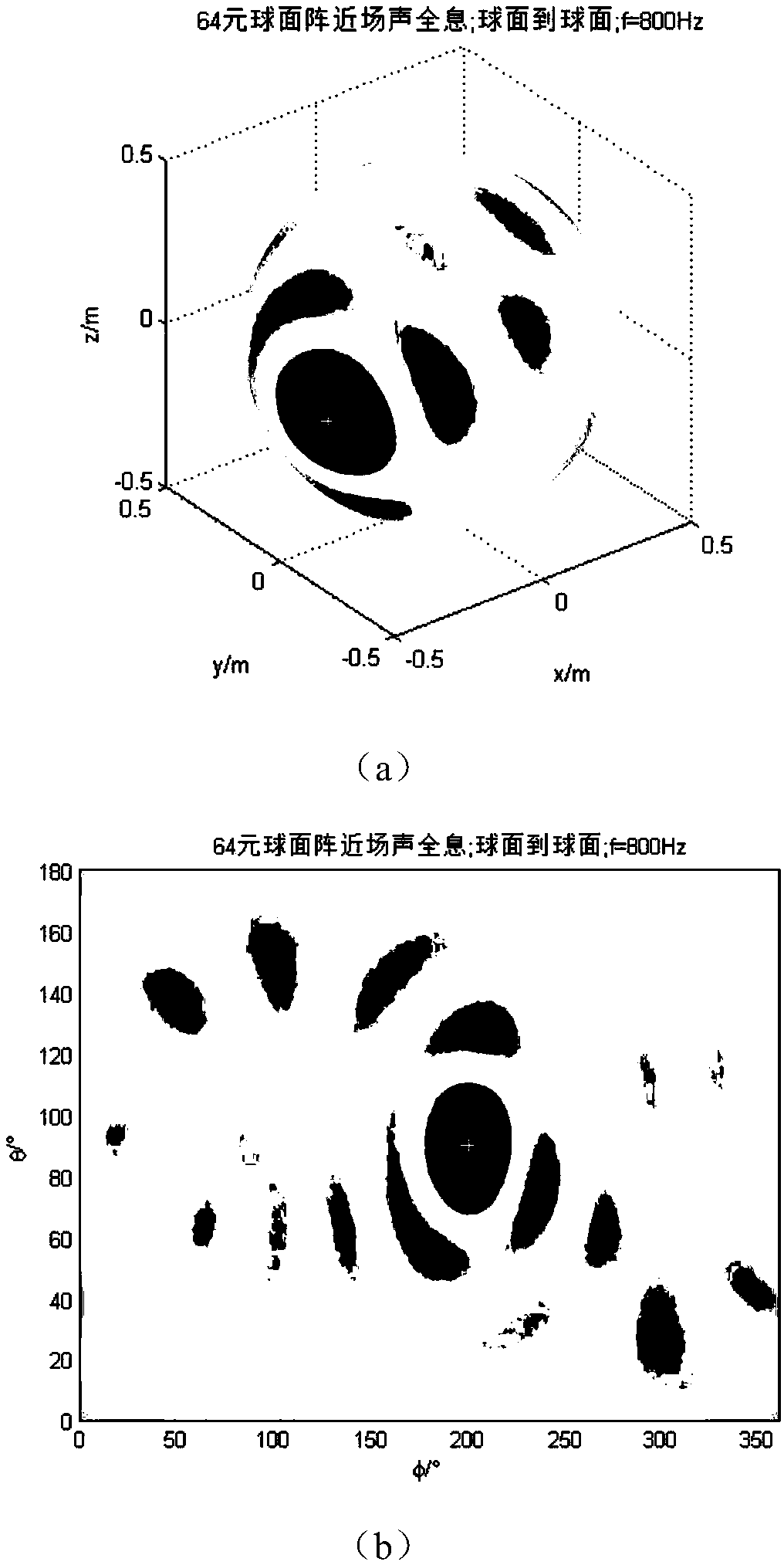

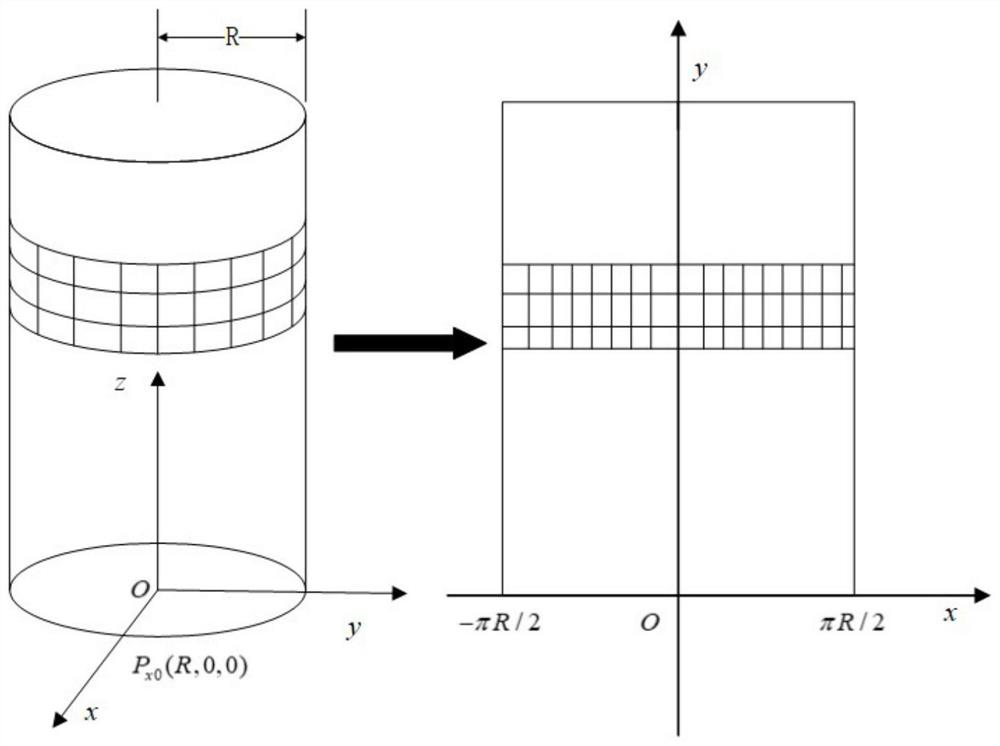

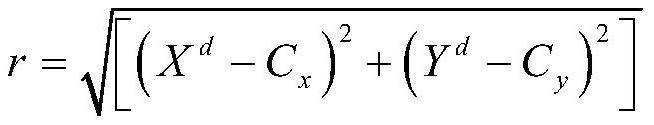

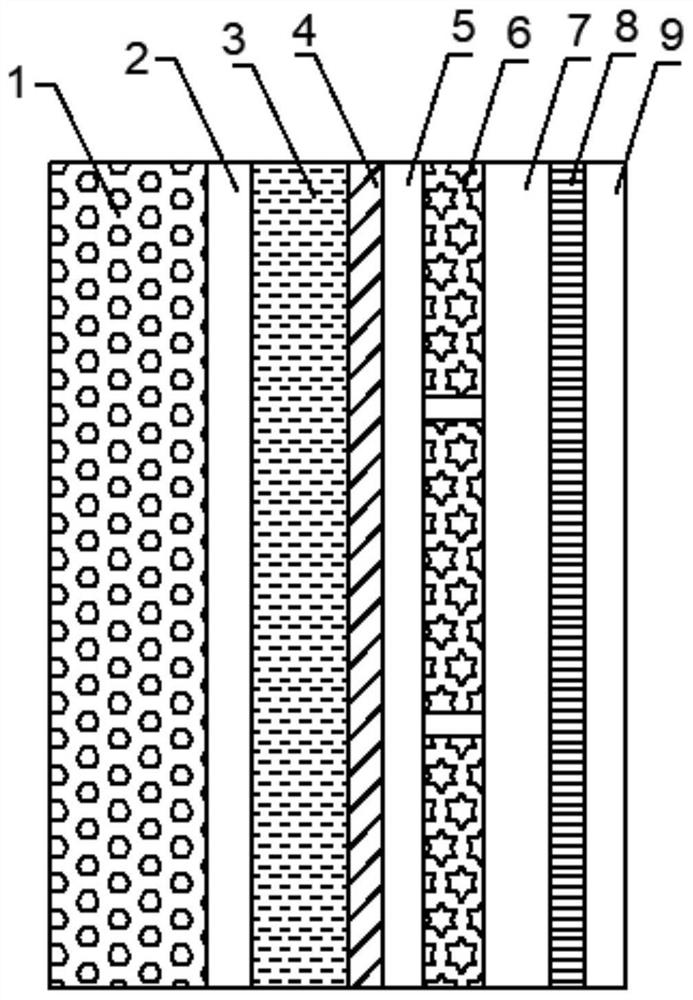

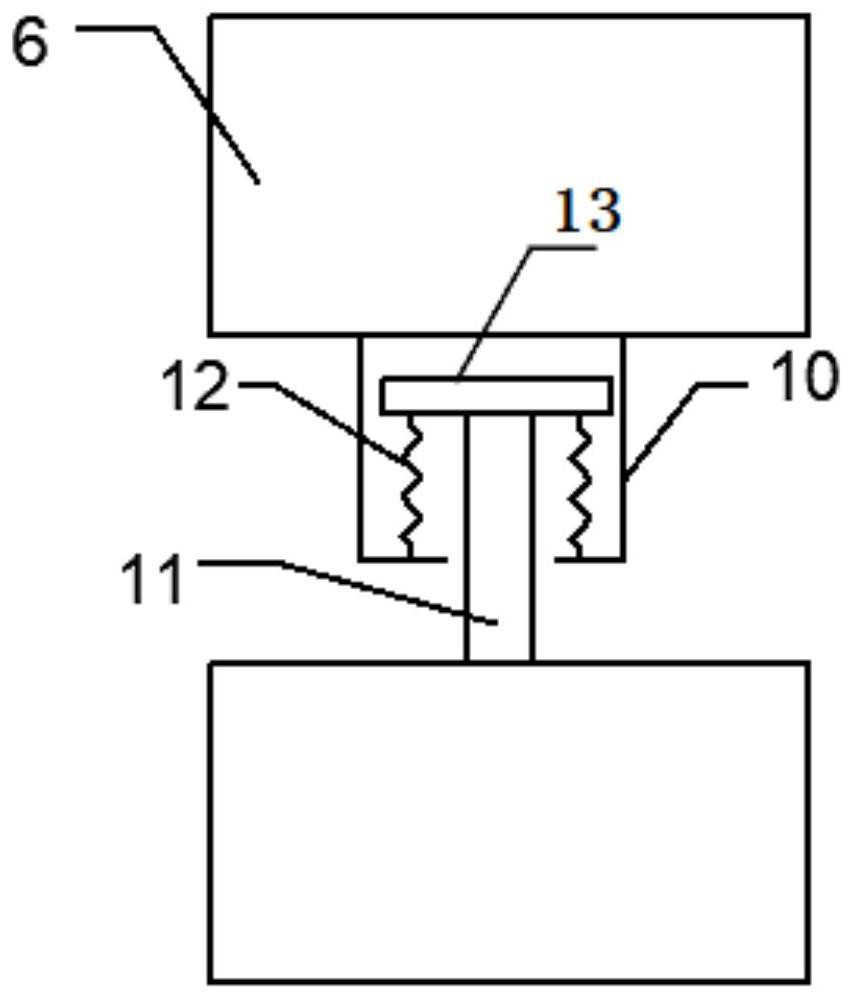

Positioning method of non-conformal surface transformation noise source based on spherical-harmonic function expansion

PendingCN108226866AAccurate and effective positioningAchieve positioningPosition fixationThree-dimensional spaceLongitude

The invention discloses a positioning method of a non-conformal surface transformation noise source based on spherical-harmonic function expansion. The positioning method comprises the following steps: constructing a transfer matrix from a spherical surface to a cylindrical surface by utilizing the spherical-harmonic function expansion and reconstructing spherical array measurement data to a cylindrical structure to accurately and effectively position the noise source in the cylindrical structure or the cylindrical noise source. Compared with the prior art, the positioning method disclosed bythe invention has the following advantages: 1) sound field information in all directions of a three-dimensional space can be measured at a time through the whole directivity and the three-dimensionalsymmetry of longitude and latitude angles of a spherical array; 2) the transfer matrix from the spherical surface to the cylindrical surface is constructed, the spherical array measurement data can bereconstructed to the cylindrical surface through a sound holographic algorithm, and the positioning problem of the cylindrical noise source or the noise source in the cylindrical structure is solved.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

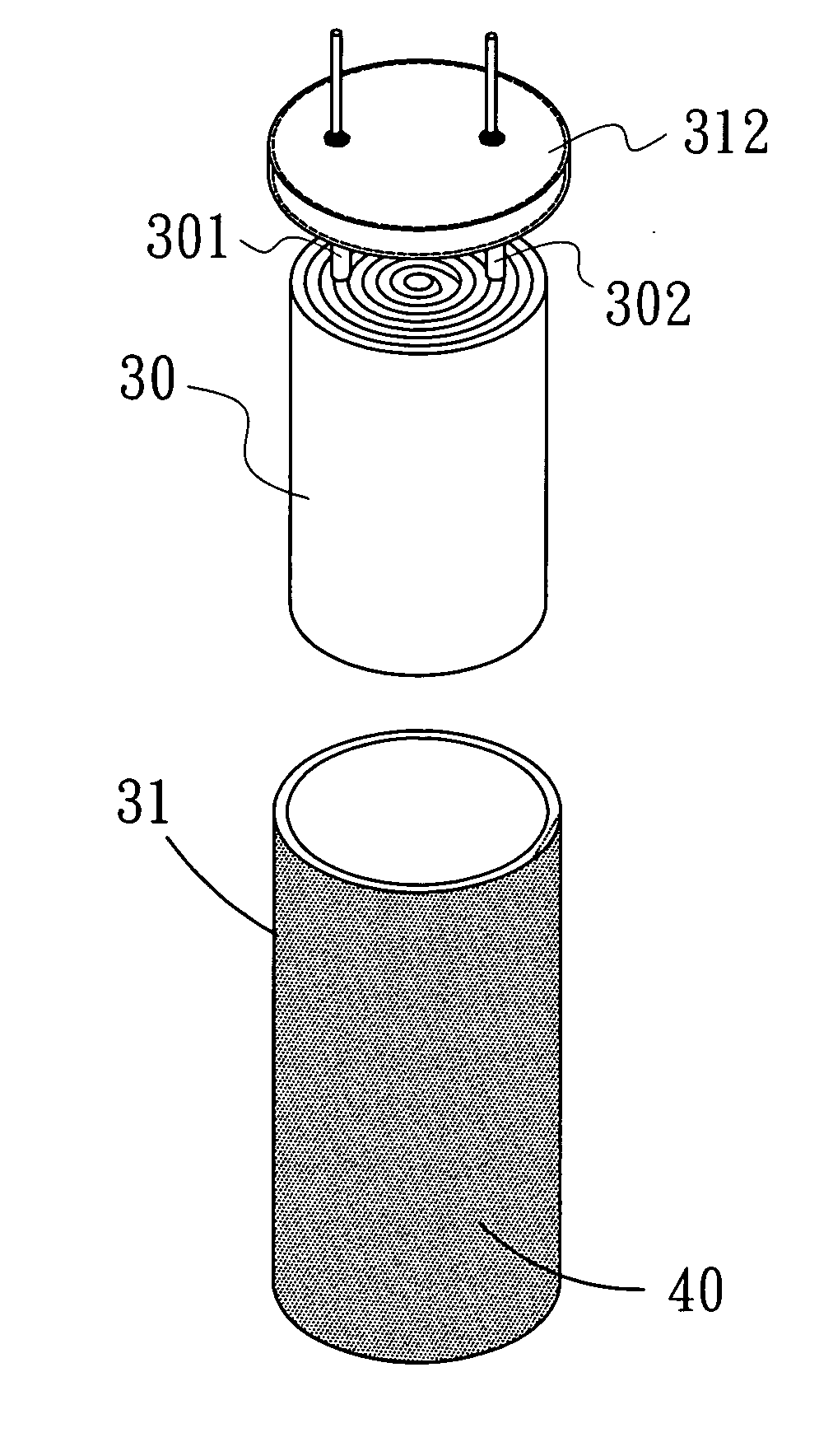

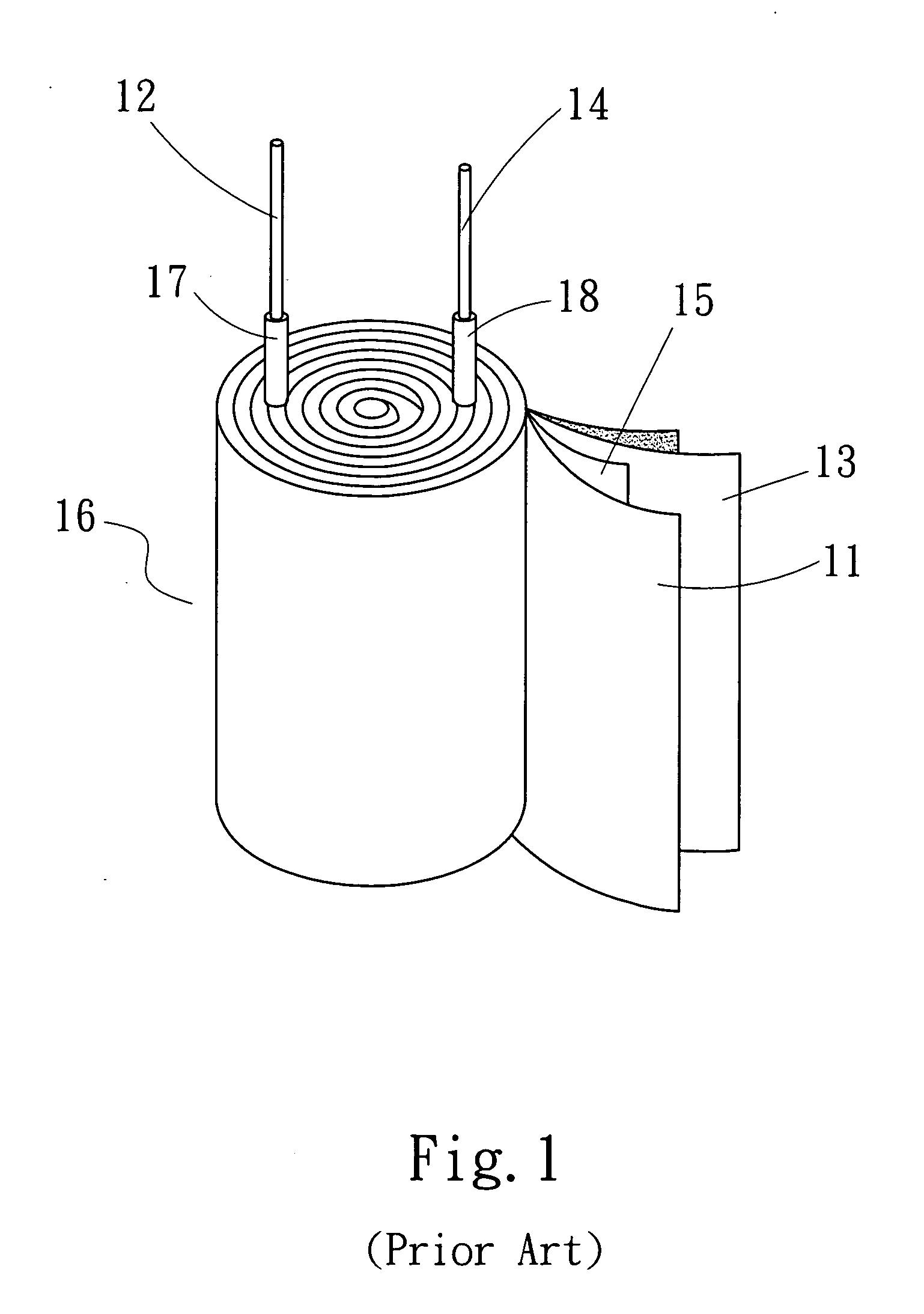

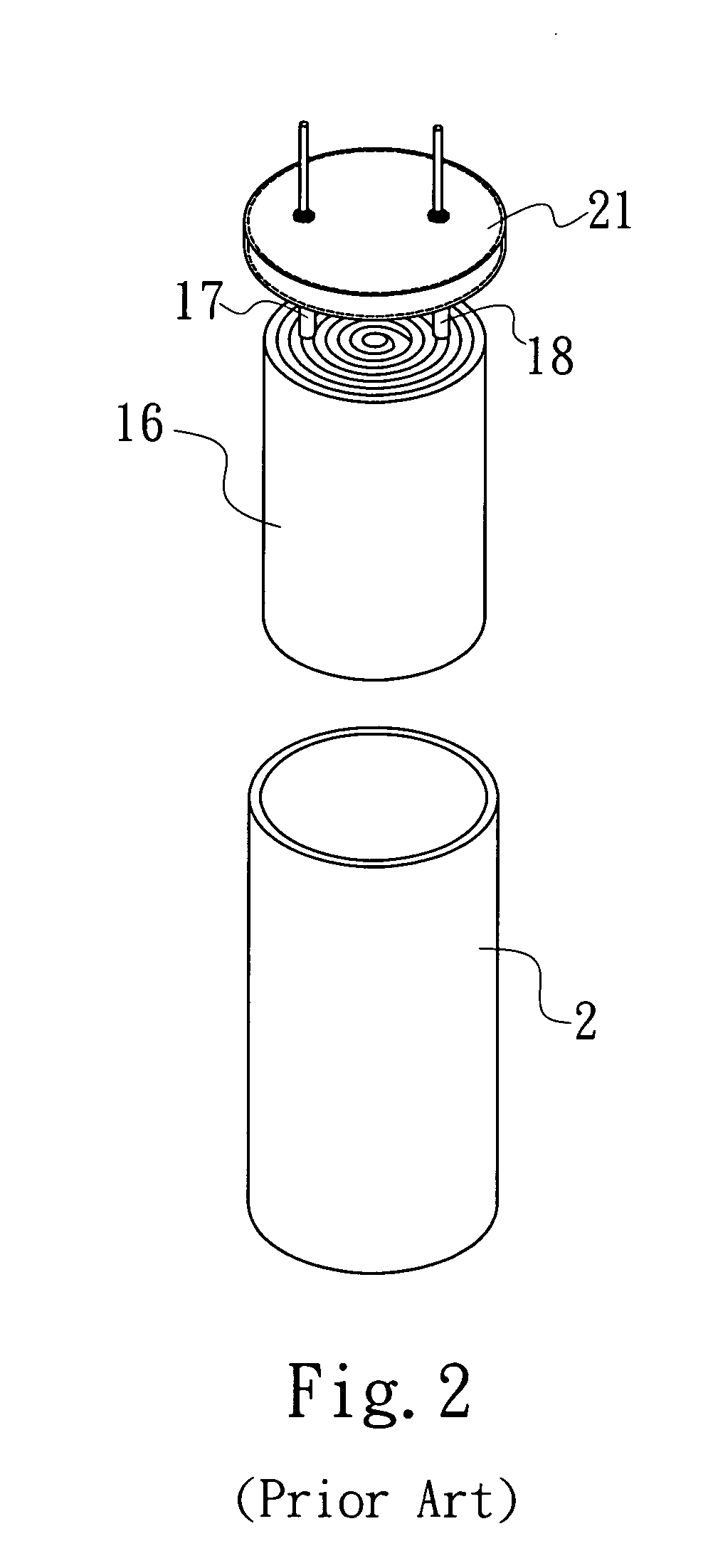

Capacitor having features of heat dissipation and of energy conservation

InactiveUS20100271747A1Improve cooling effectReduce environmental impactSolid electrolytic capacitorsLiquid electrolytic capacitorsPlastic filmAluminum metal

A capacitor that has the features of heat dissipation and energy conservation comprises a capacitor core, an aluminum shell surrounding the capacitor core, the aluminum shell is covered with rubber that completely covers the top of the capacitor core, then with the use of an extruding machine, the upper orifice of the aluminum shell is extruded and sealed up around the rubber completely; the outer surface of the aluminum is formed with an aluminum oxidized insulating layer after the aluminum shell is processed through an aluminum metal surface transformation treatment, since the aluminum shell is not covered with plastic film (or sleeve), heat dissipation is enhanced; in addition, since plastic film or sleeve is not used, no pollution is occurred, and hence more friendly to the environment; furthermore, since heat generation is low, energy is conserved.

Owner:APAQ TECH

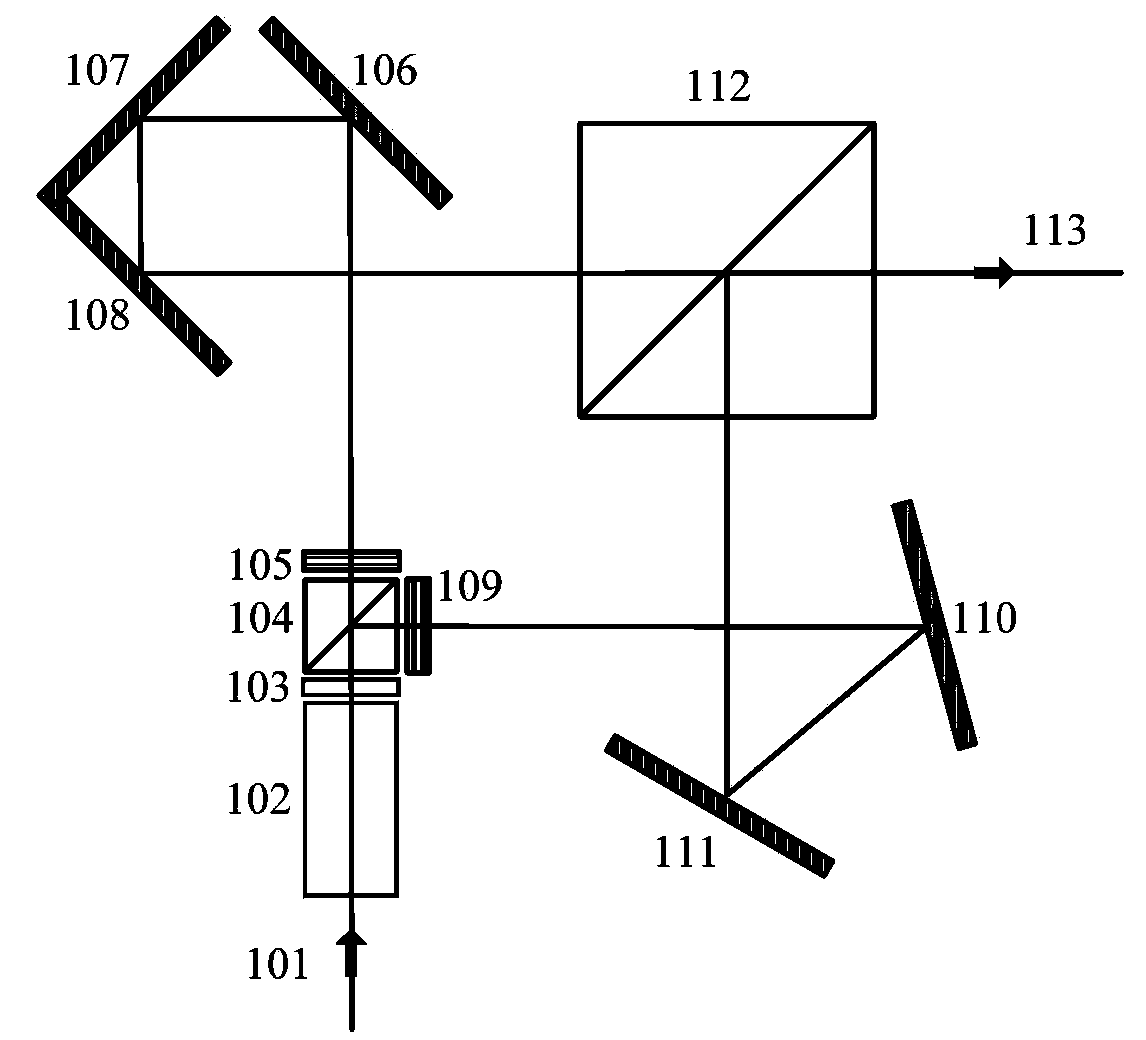

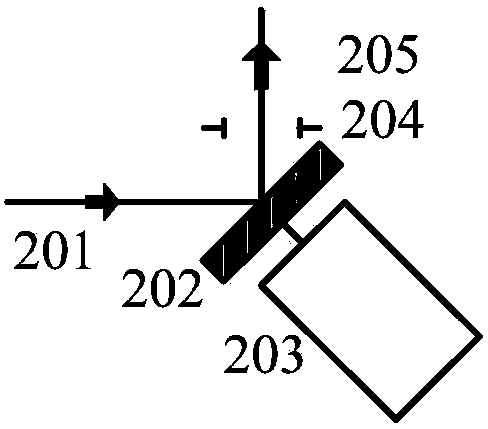

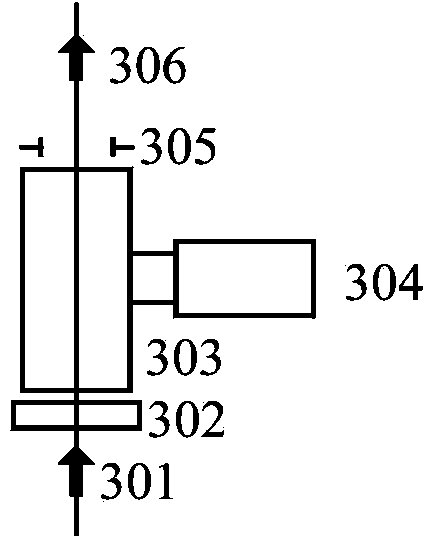

Linear scanning device for aplanatism wave surface transformation for orthophoria synthetic aperture laser imaging radar

InactiveCN103744071AAutomatic cancellation of wavefront aberrationEnsure precise synchronization accuracyElectromagnetic wave reradiationOptical elementsOptical pathlengthCross polarization

The invention discloses a linear scanning device for aplanatism wave surface transformation for an orthophoria synthetic aperture laser imaging radar. The linear scanning device for the aplanatism wave surface transformation for the orthophoria synthetic aperture laser imaging radar has the principle that a cross rail direction direct linear scanning structure adopts single reflecting mirror deflection movement linear scanning or single electro-optical crystal voltage linear driving scanning; a forward rail direction cross-polarization aplanatism wave surface transformation structure further decomposes a light beam into two space channels of a cross-polarization component; a forward rail direction cylindrical mirror is installed in each channel for wave surface transformation; a reflecting mirror is adopted for generating distance delay and wave surface inversion; two branches completely pass through the same device with completely equal optical paths; two scanning emission wave surfaces which are subjected to coaxial cross polarization are combined; finally, imaging is directly carried out on a target surface by an emission optical primary mirror. The linear scanning device for the aplantic wave surface transformation for the orthophoria synthetic aperture laser imaging radar has the advantages of simple and reliable structure and easiness in integration, two separation light paths have the completely equal optical paths and are singly driven, meanwhile, two wave surfaces carry out bidirectional scanning, single electro-optical crystal voltage driving scanning is adopted, no mechanical scanning speed is high, and the operation performance parameter of the radar can be conveniently changed by changing the reflecting mirror polarization range or the voltage modulation range.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Method of alignment for buried structures formed by surface transformation of empty spaces in solid state materials

InactiveUS6841408B2Semiconductor/solid-state device detailsSolid-state devicesSemiconductor structureSingle crystal

A method of aligning a plurality of empty-spaced buried patterns formed in semiconductor monocrystalline substrates is disclosed. In an exemplary embodiment, high-temperature metal marks are formed to include a conductive material having a melting temperature higher than an annealing temperature used to form such empty-spaced buried patterns. The high-temperature metal marks are formed prior to the formation of the empty-spaced buried patterns formed in a monocrystalline substrate, so that the empty-space buried patterns are aligned to the marks. Subsequent semiconductor structures that are formed as part of desired semiconductor devices can be also aligned to the marks.

Owner:MICRON TECH INC

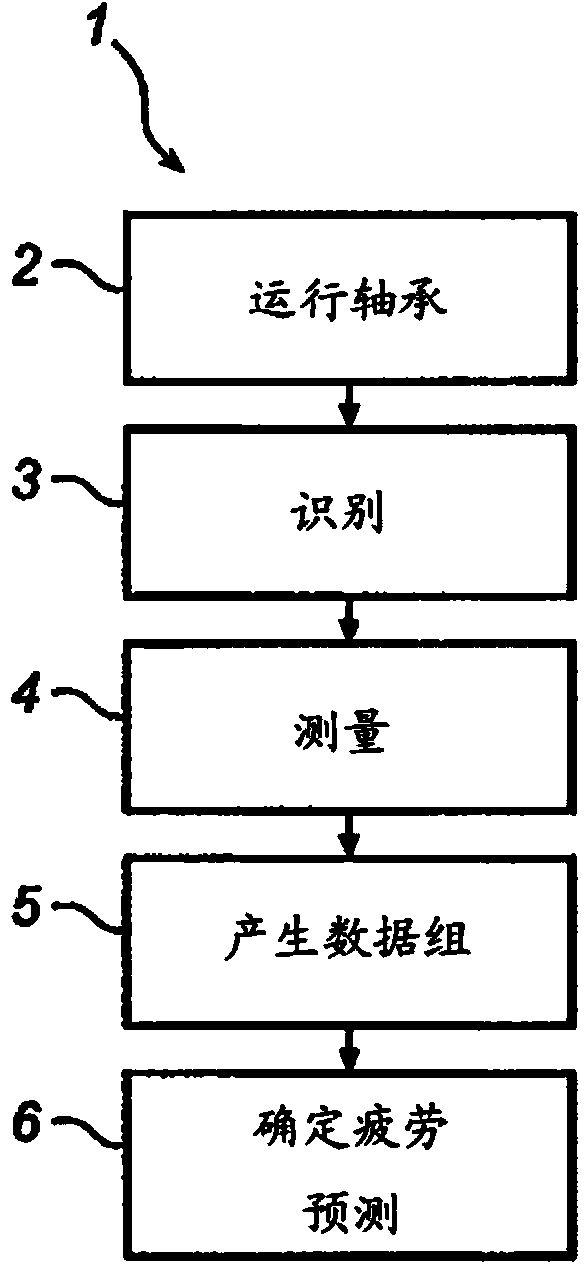

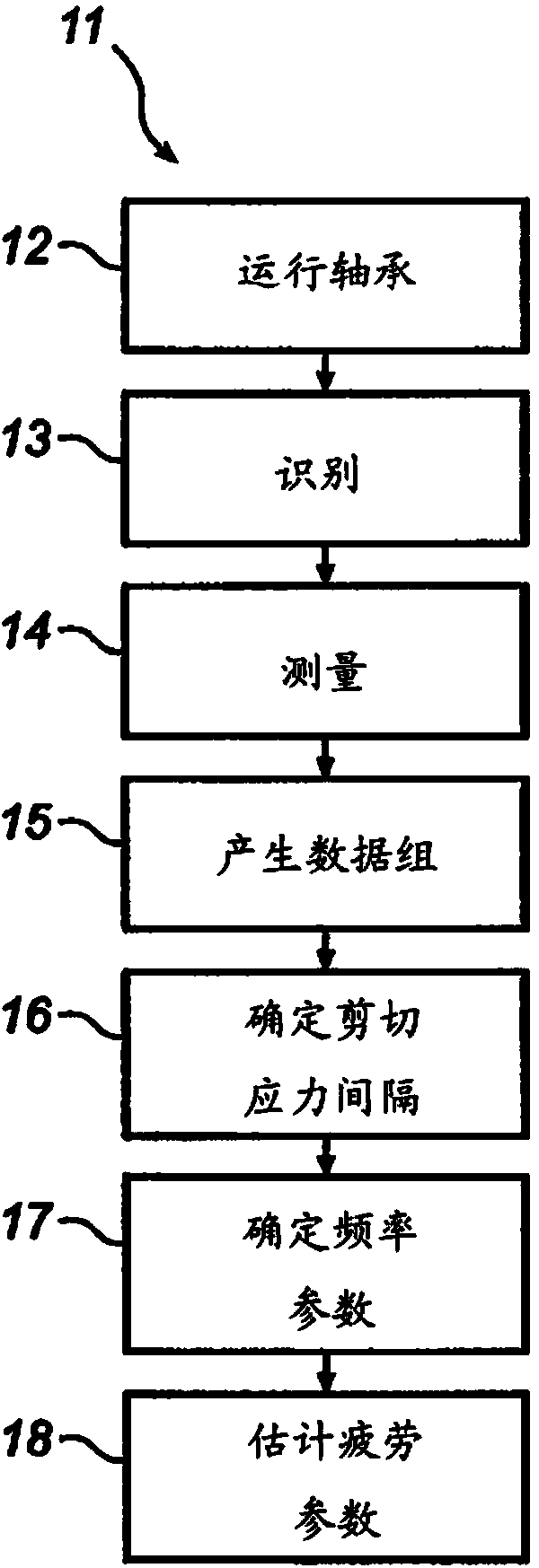

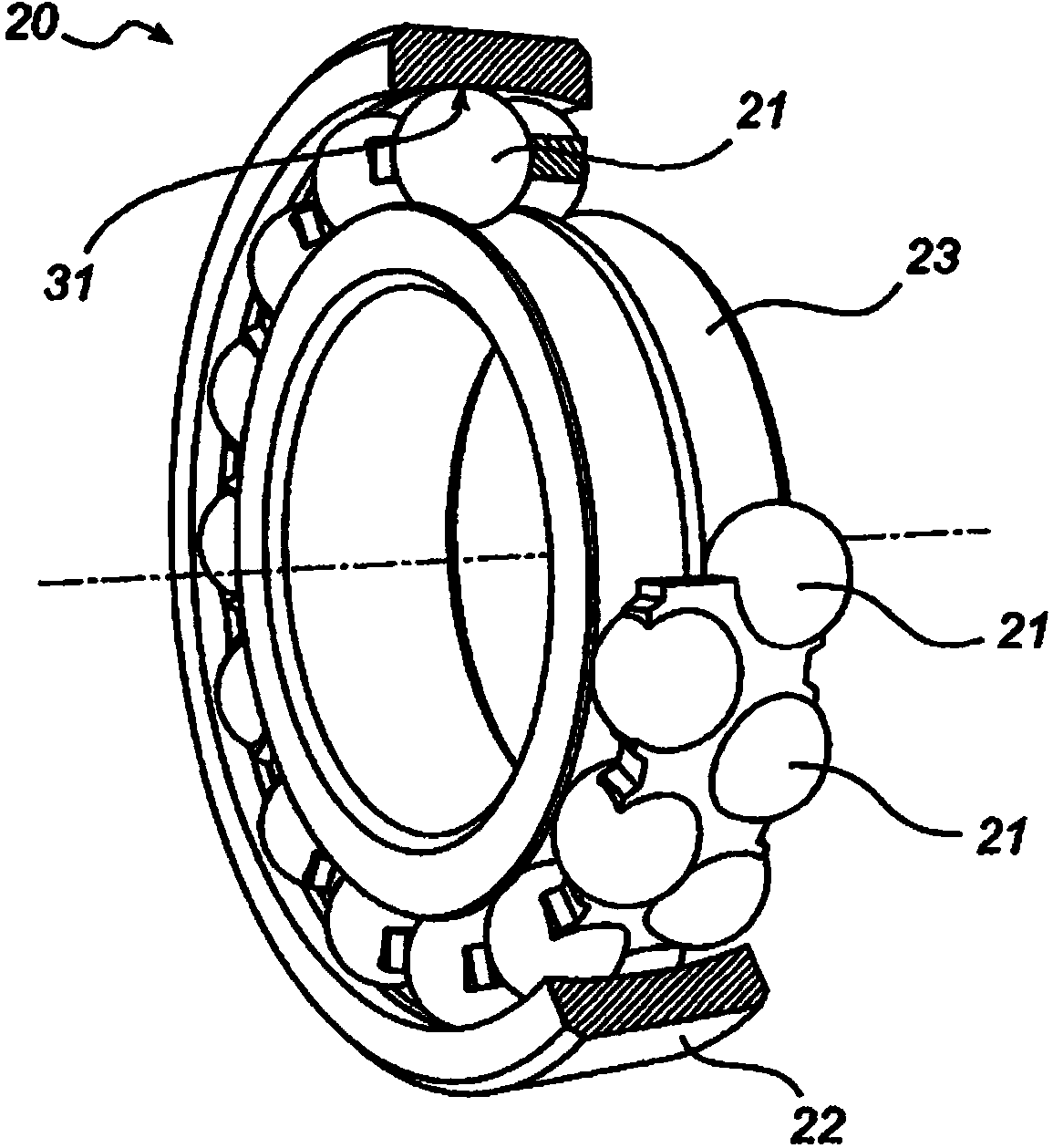

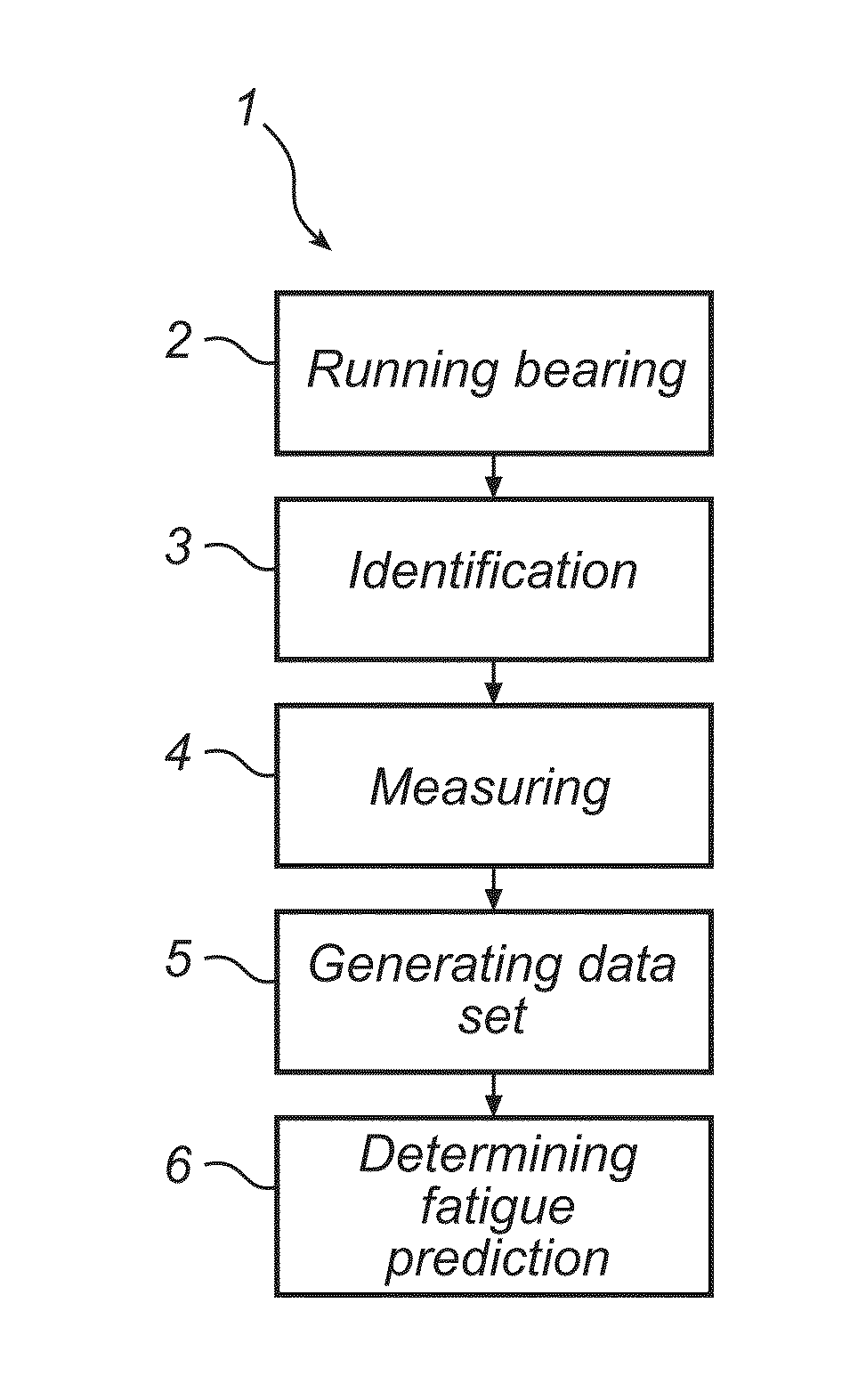

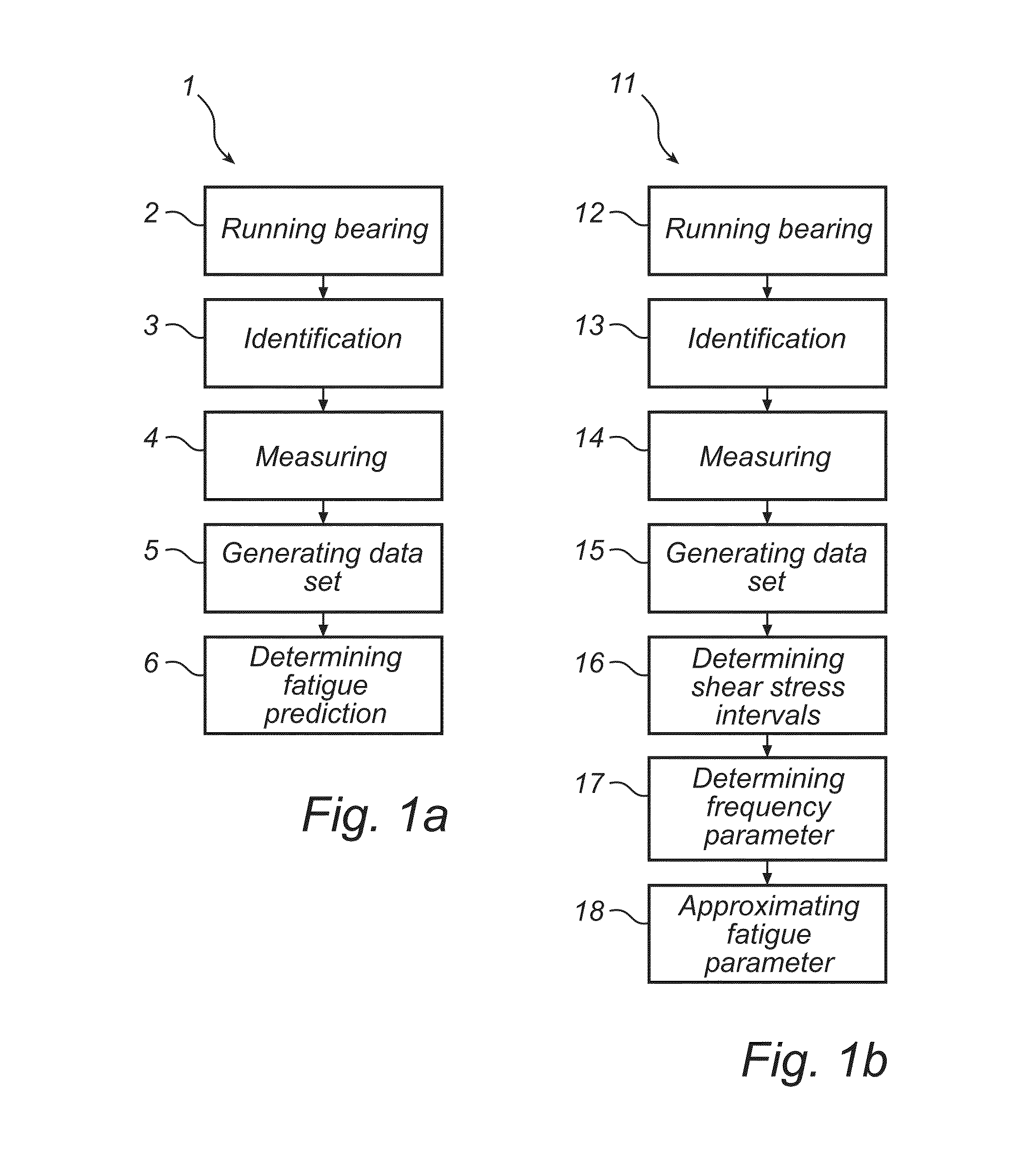

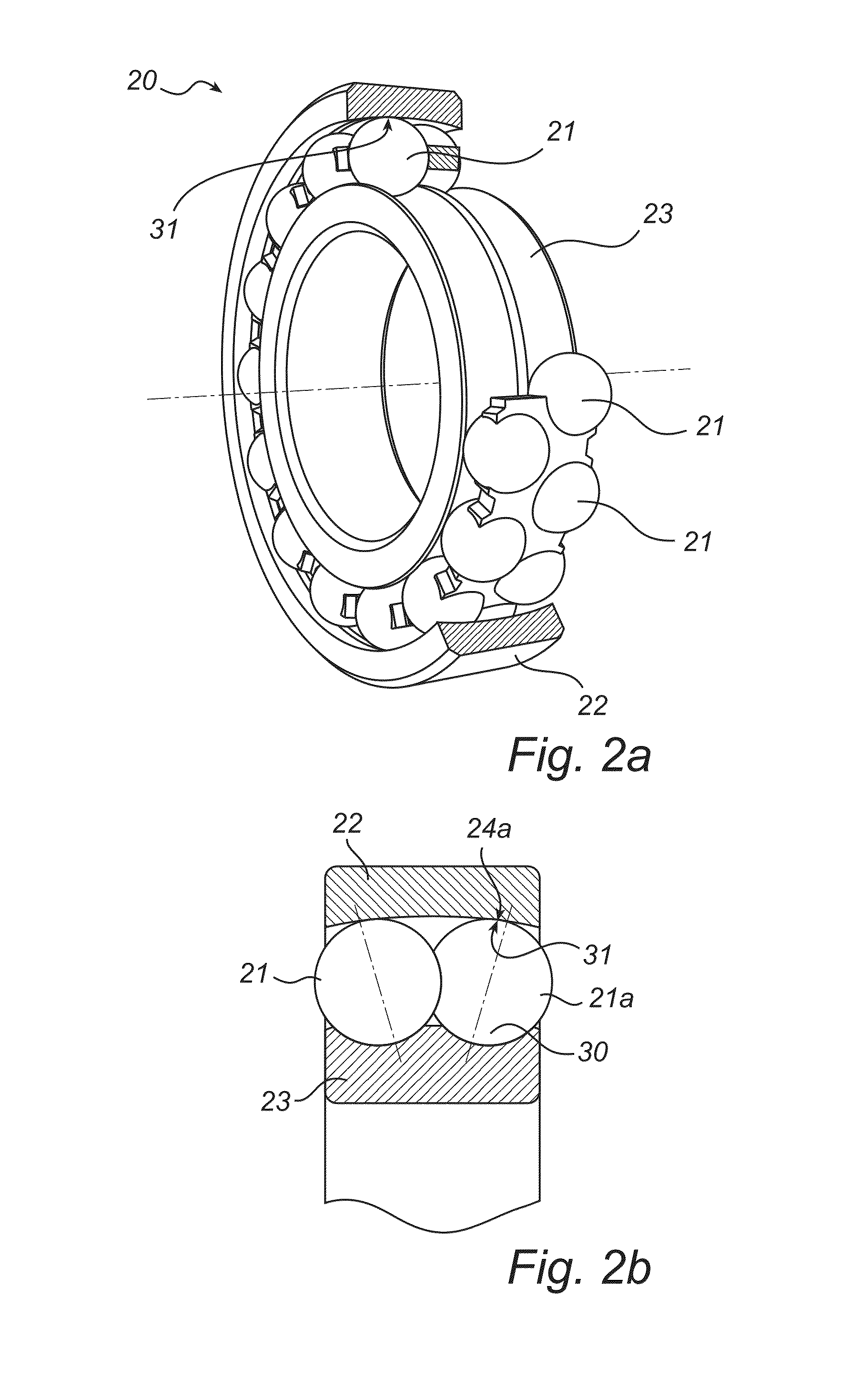

Method for fatigue assessment of rolling bearing

InactiveCN103748449AForecastRolling contact bearingsMachine bearings testingData setRolling-element bearing

The present invention relates to a method, and an apparatus arrangement, for determining a fatigue limit for rolling contact initiated fatigue of a rolling bearing. The method comprises running a rolling bearing while being exerted to a load which generates sub-surface transformations in a rolling element contact zone of the outer or inner ring. Furthermore a set of sub-surface transformations in the contact zone along a raceway portion of the rolling bearing is identified and measured and used for generation of a parameter data set, wherein a fatigue parameter value representative of a predicted fatigue limit for the rolling bearing is determined based on the generated data set of sub-surface transformations.

Owner:AB SKF

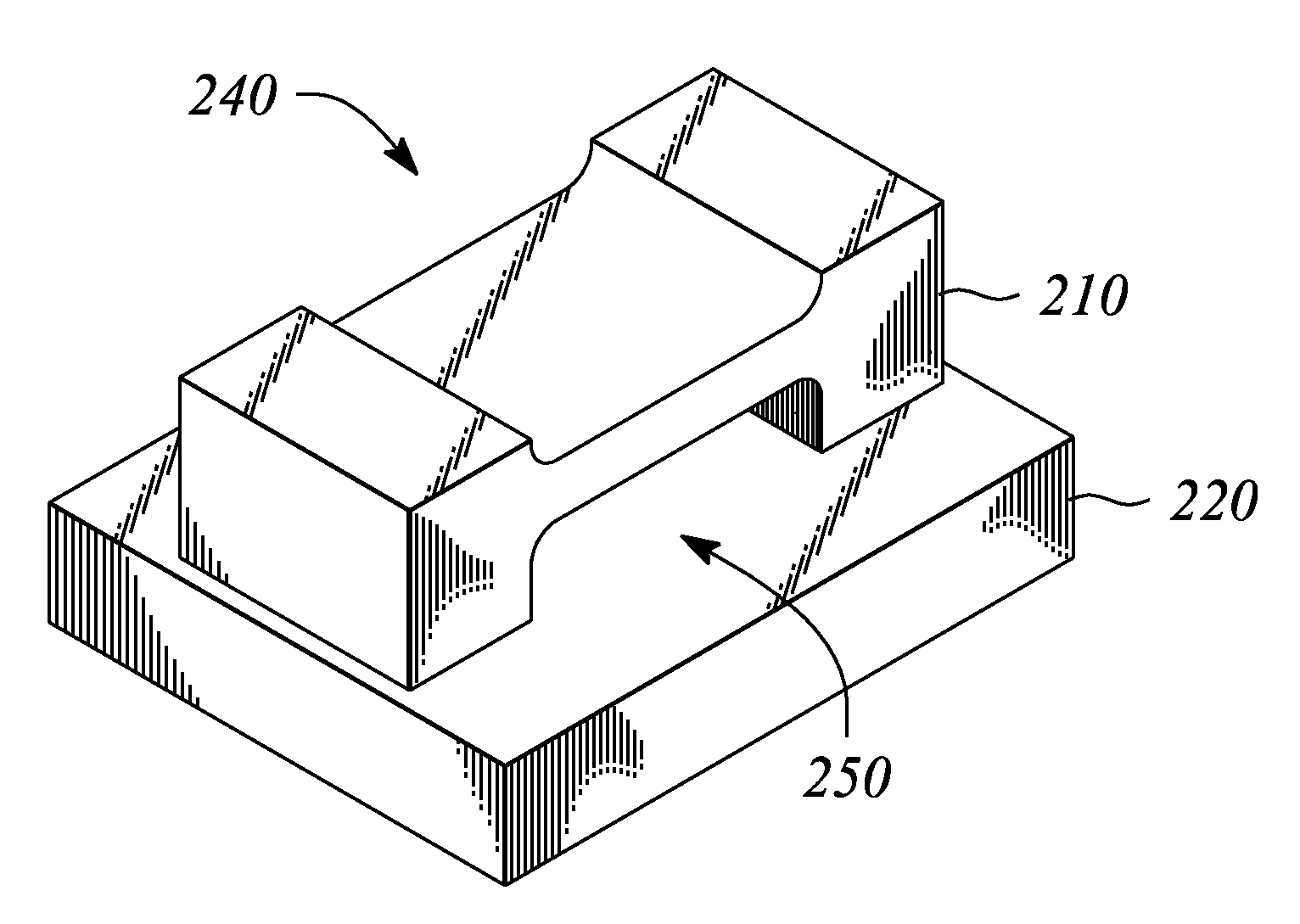

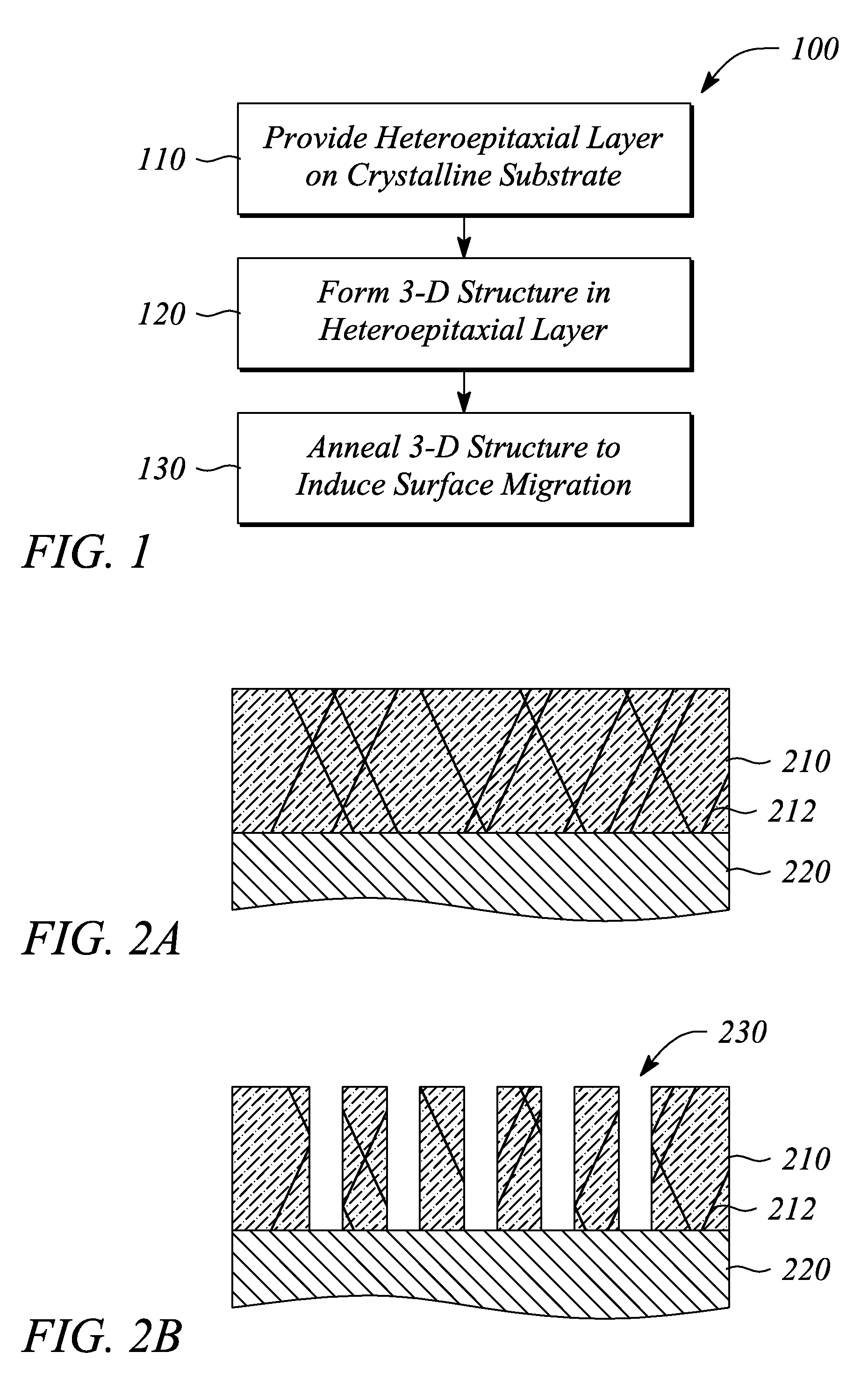

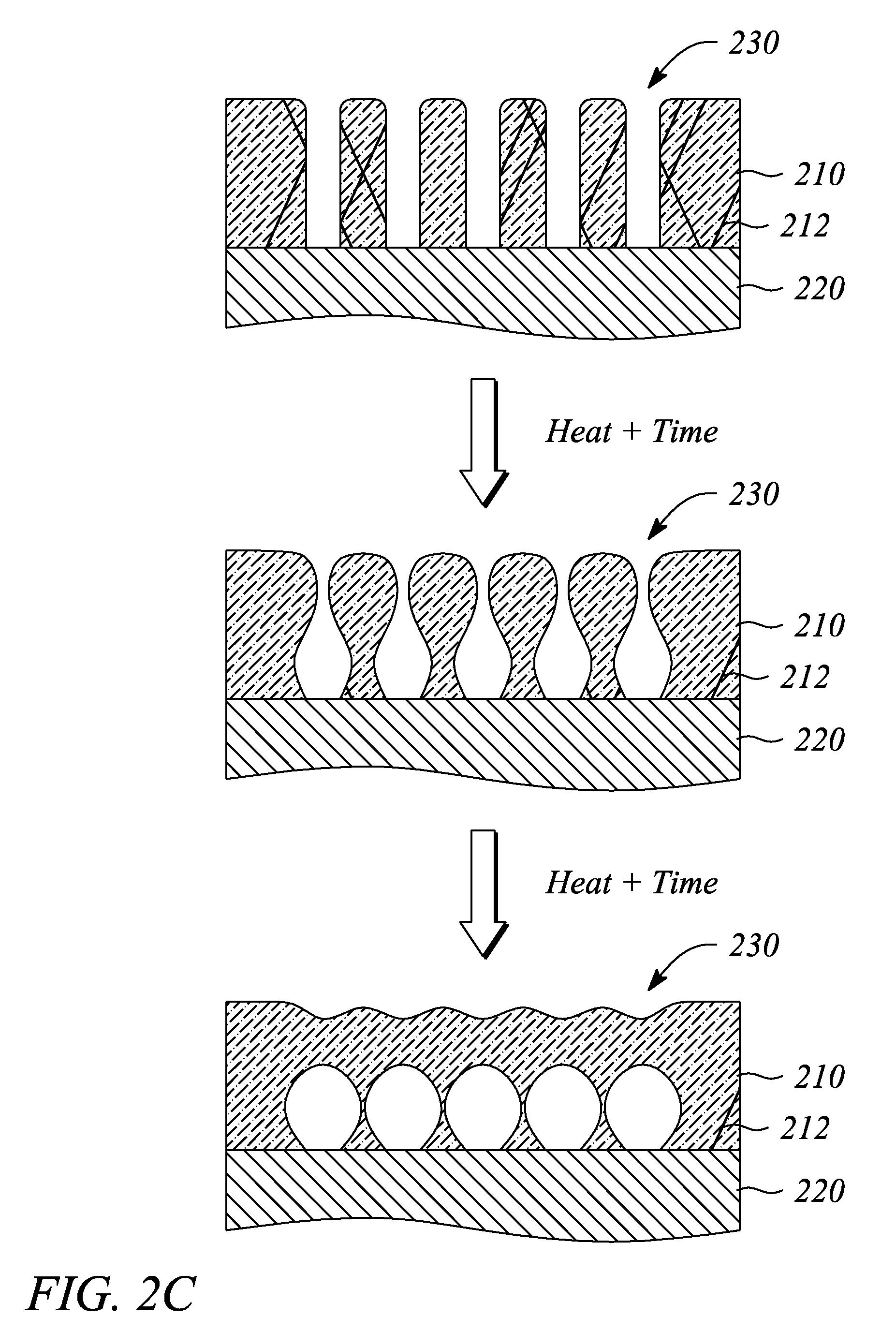

Suspended mono-crystalline structure and method of fabrication from a heteroepitaxial layer

InactiveUS20100187572A1Semiconductor/solid-state device manufacturingMicrostructural device manufactureSingle crystalOptoelectronics

Methods of fabricating a suspended mono-crystalline structure use annealing to induce surface migration and cause a surface transformation to produce the suspended mono-crystalline structure above a cavity from a heteroepitaxial layer provided on a crystalline substrate. The methods include forming a three dimensional (3-D) structure in the heteroepitaxial layer where the 3-D structure includes high aspect ratio elements. The 3-D structure is annealed at a temperature below a melting point of the heteroepitaxial layer. The suspended mono-crystalline structure may be a portion of a semiconductor-on-nothing (SON) substrate.

Owner:HEWLETT PACKARD DEV CO LP

Method for fatigue assessment of rolling bearing

InactiveUS20140026674A1Simple methodQuick forecastRolling contact bearingsMachine bearings testingData setRolling-element bearing

The present invention related to a method, and an apparatus arrangement, for determining a fatigue limit for rolling contact initiated fatigue of a rolling bearing. The method comprises running a rolling bearing while being exerted to a load which generates sub-surface transformations in a rolling element contact zone of the outer or inner ring. Furthermore a set of sub-surface transformations in the contact zone along a raceway portion of the rolling bearing is identified and measured and used for generation of a parameter data set, wherein a fatigue parameter value representative of a predicted fatigue limit for the rolling bearing is determined based on the generated data set of sub-surface transformations.

Owner:AB SKF

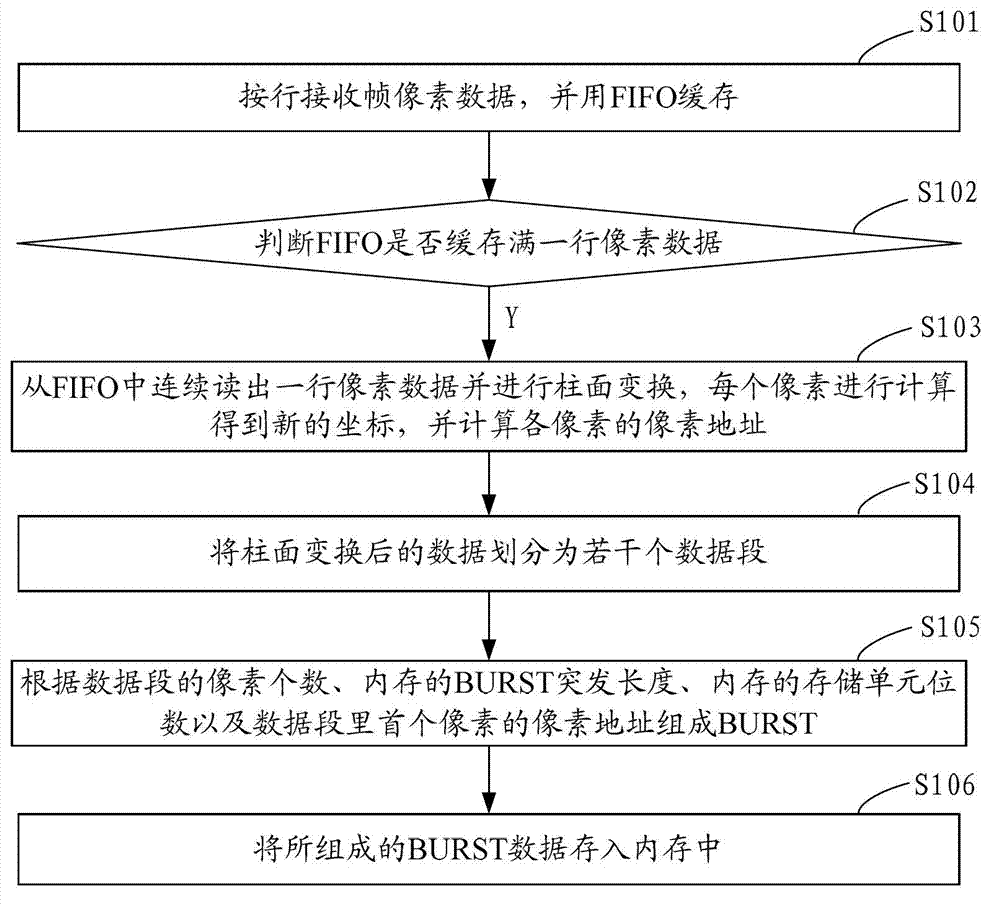

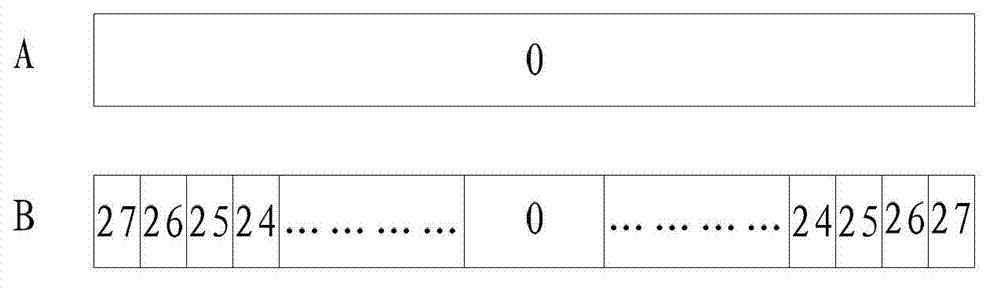

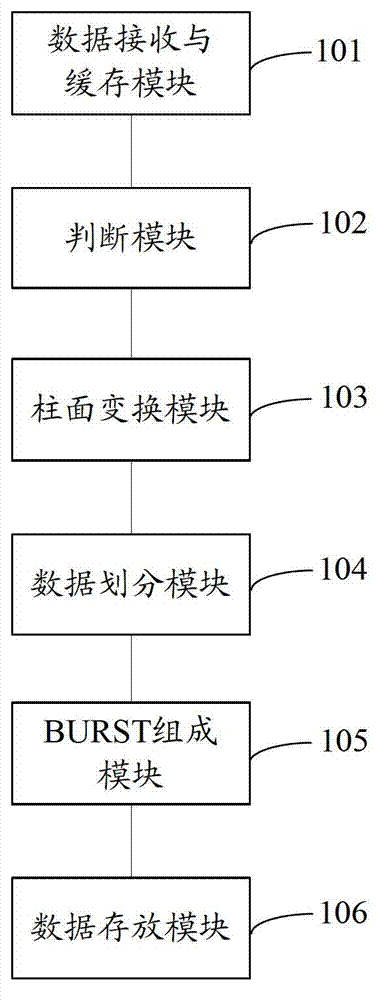

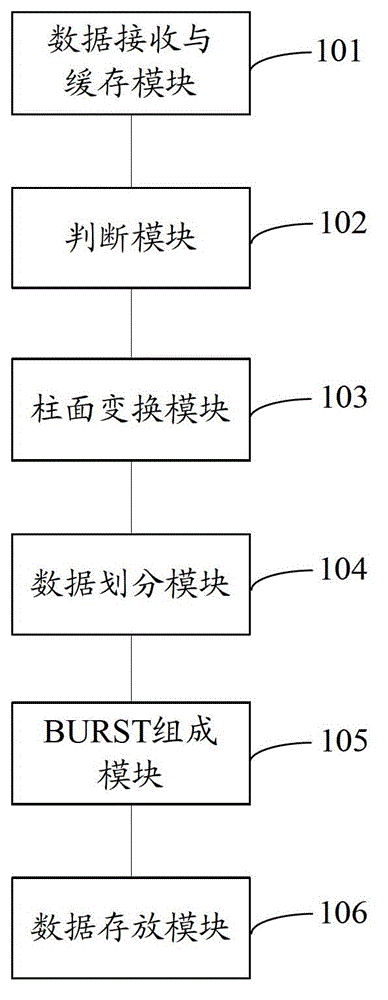

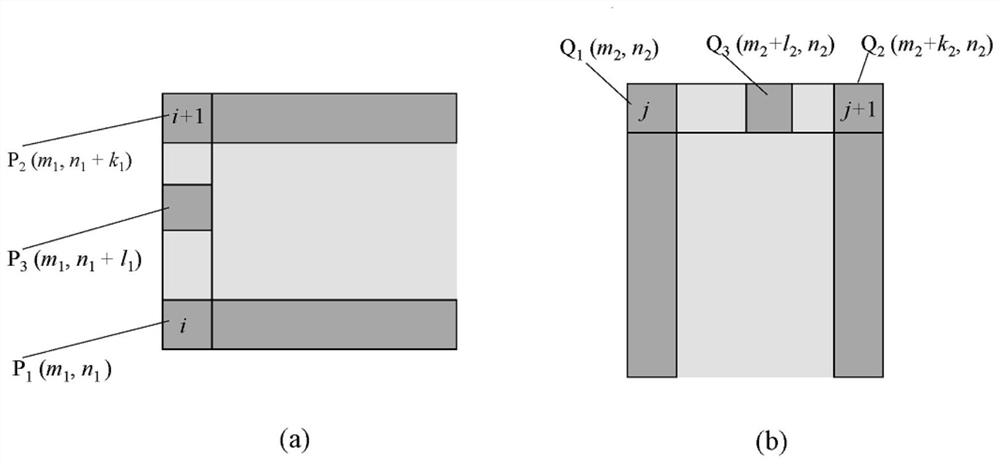

Full view video cylindrical surface image storage method and system

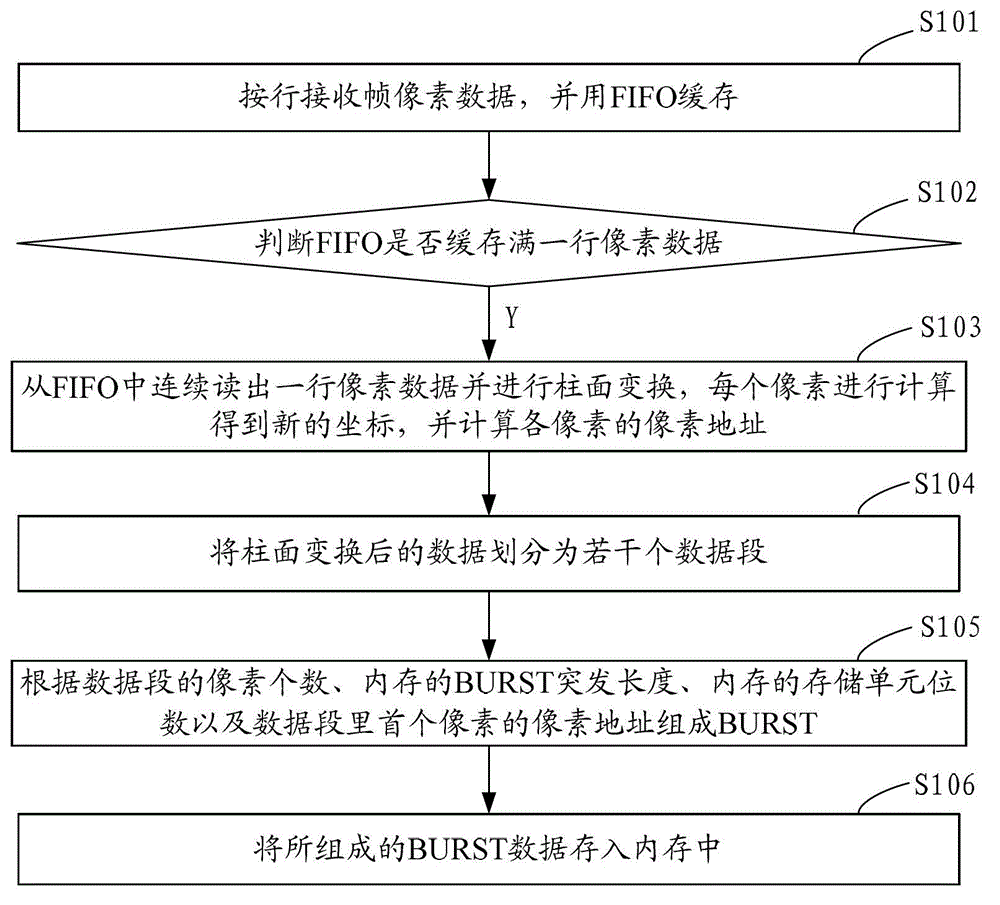

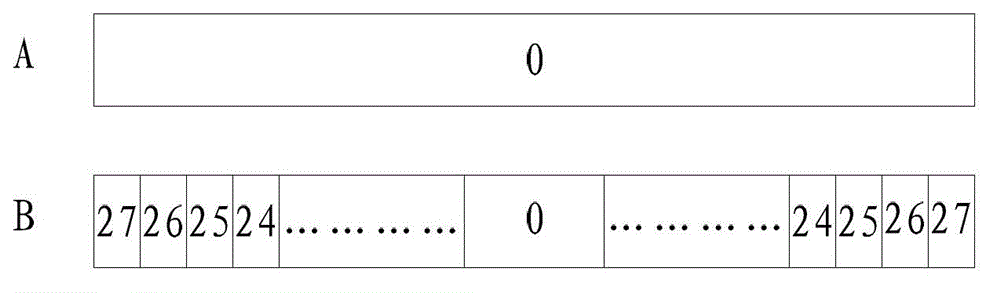

The invention provides a full view video cylindrical surface image storage method and a system. The method includes that pixel data is received by row and first in,first out (FIFO) is used for caching. Whether an FIFO is full of the caching pixel data or not is judged. If it is full, a row of pixel data is continuously read out from the FIFO and the cylindrical surface transformation is carried out. New coordinates are obtained by calculating each pixel and the pixel addresses of each pixel are calculated. Data after the transformation of the cylindrical surface is divided into a plurality of data sections, wherein, among the divided data sections, the pixel address in every data section is consecutive and the next data sections belong to different rows. BURST is formed by the pixel numbers in the data section, the BURST proruption length in the internal memory, the storage unit digit of the internal memory and the pixel address of the first pixel in the data sections. The composed BURST data is stored into the internal memory. The full view video cylindrical surface image storage method and the system achieve the transformation of the cylindrical surface of the video image as well as improve the bandwidth availability ratio.

Owner:GUANGDONG VTRON TECH CO LTD

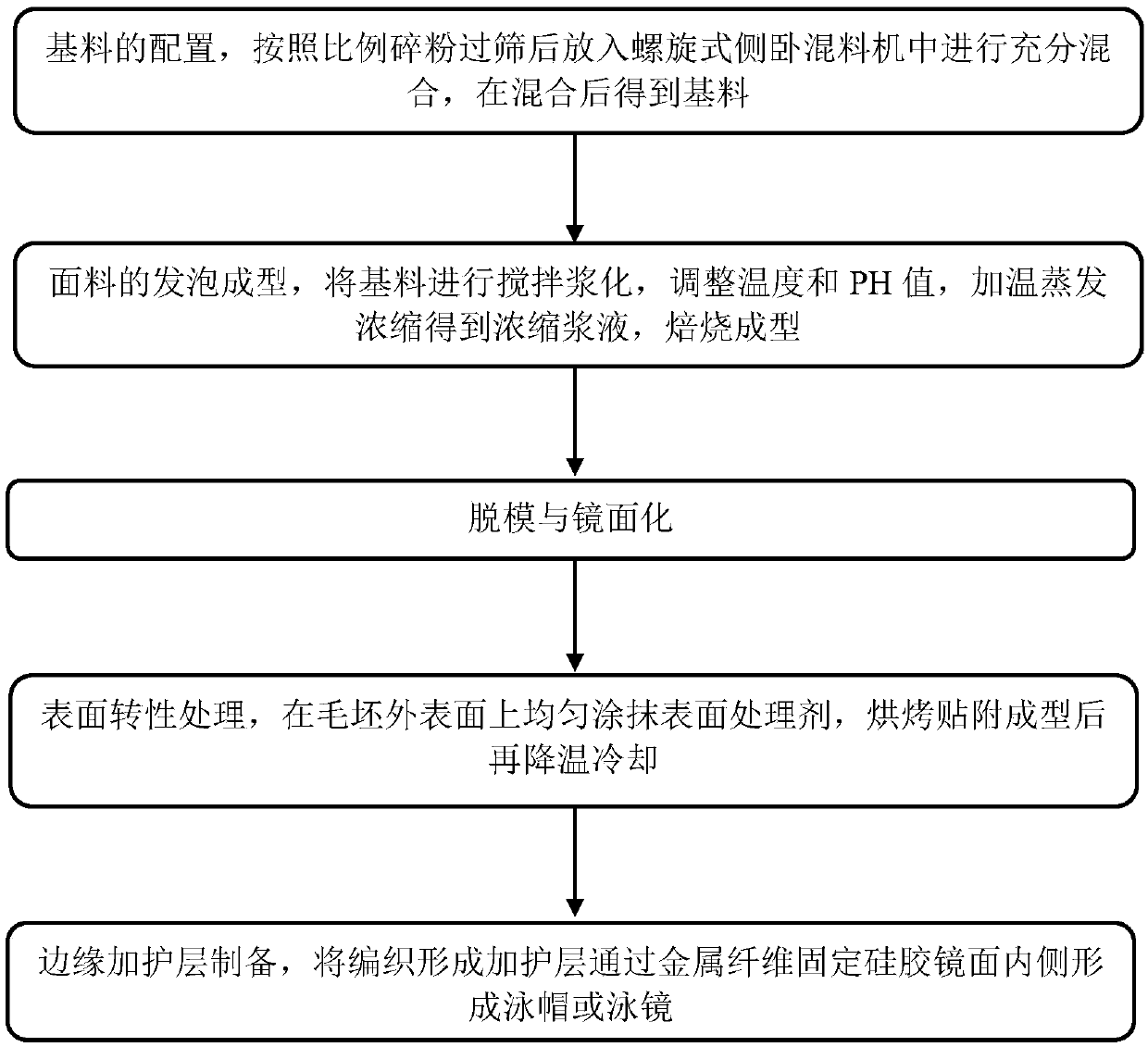

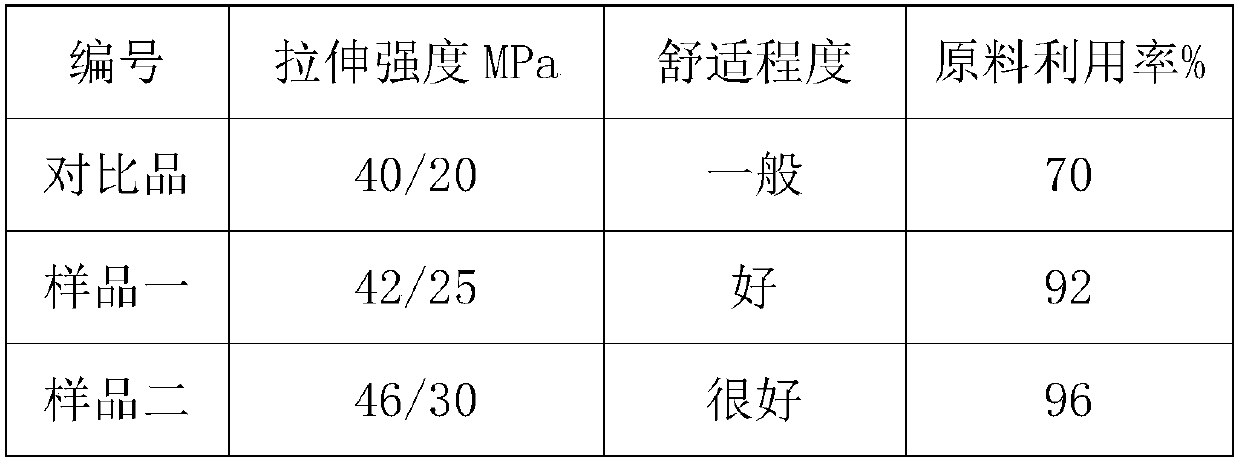

Formula and production process of antibacterial material applied to swimming goggles and swimming cap

The invention discloses a formula and production process of an antibacterial material applied to swimming goggles and a swimming cap. The antibacterial material consists of the following raw materialsin parts by weight: 40-60 parts of silica gel, 10-20 parts of bisphenol, 15-20 parts of polyethylene, 6-8 parts of nano silicon, 8-10 parts of an antibacterial agent, 10-15 parts of a foaming agent,4-5 parts of a lubricant, 2-3 parts of an antioxidant, 2-3 parts of an ultraviolet absorbent, 8-10 parts of spandex fibers, 6-8 parts of metal fibers and 10-12 parts of a waterproof coating. Through the preparation of a base material, and foaming and re-forming, and then through the mirror surface treatment and the surface transformation treatment, a protection layer is added for forming the swimming goggles or the swimming cap. With the adoption of the effect of the surface material mixing, in the forming process of the surface material, the material with an antibacterial effect is directly mixed into the silica gel, and the silica gel is directly molded again, so that a complete unified structure is achieved, the sterilization capability of the position at which bacteria breed due to long-time contact with human body is further improved, the antibacterial material has excellent comprehensive physical and chemical properties, the production efficiency is greatly improved, the performance is excellent, and the production process is convenient to operate.

Owner:共青城鑫航体育用品有限公司

Environmental-protective cleaning agent sued for lossless disassembly of equipment part

InactiveCN104327959AImprove dismantling efficiencyIncrease profitOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePolyethylene glycol

The invention discloses an environmental-protective cleaning agent used for lossless disassembly of equipment parts. The environmental-protective cleaning agent consists of following raw materials: 2-5% by weight of oxalic acid, 1-2% of OP-10 or / and dodecyl trimethyl amine bromide and polyethylene glycol, 0.05-0.1 g / L of hexamethylenetetramine or allylthiourea, 0.1-0.2% of hydroxymethyl cellulose and the balance water. The environmental-protective cleaning agent used for lossless disassembly of the equipment parts has a faintly acid property, a complexing property, a high permeability and a surface transformation effect, has a comprehensive effects including loosening, oil removing, rust removing and rust resistance, can increase disassembly efficiency and a reproducing utilization ratio of the parts. A particular use method of the environmental-protective cleaning agent includes a following step of coating joints of the parts by the cleaning agent for 1-2 hours.

Owner:PASSENGER CONTAINER BRANCH OF RIZHAO PORT GRP CO LTD +1

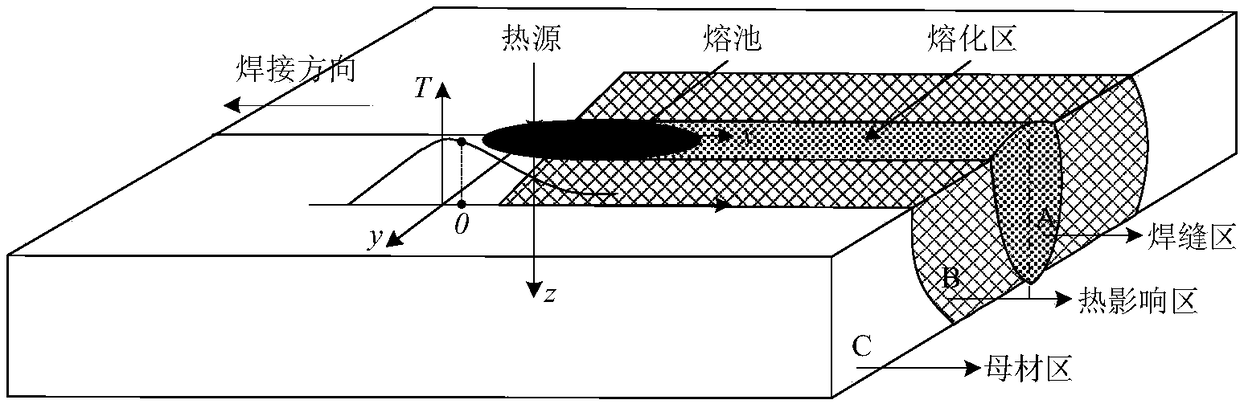

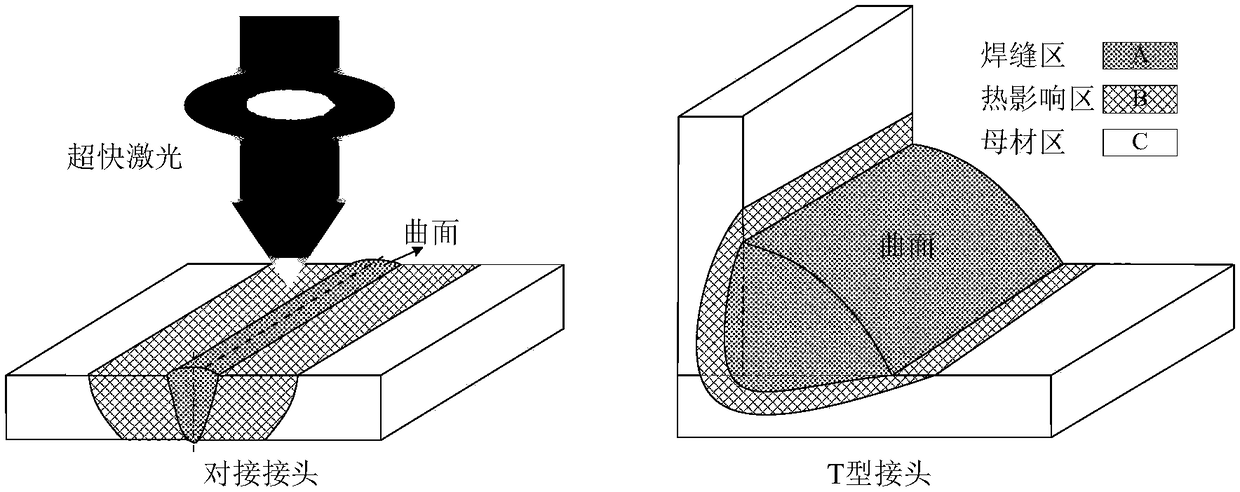

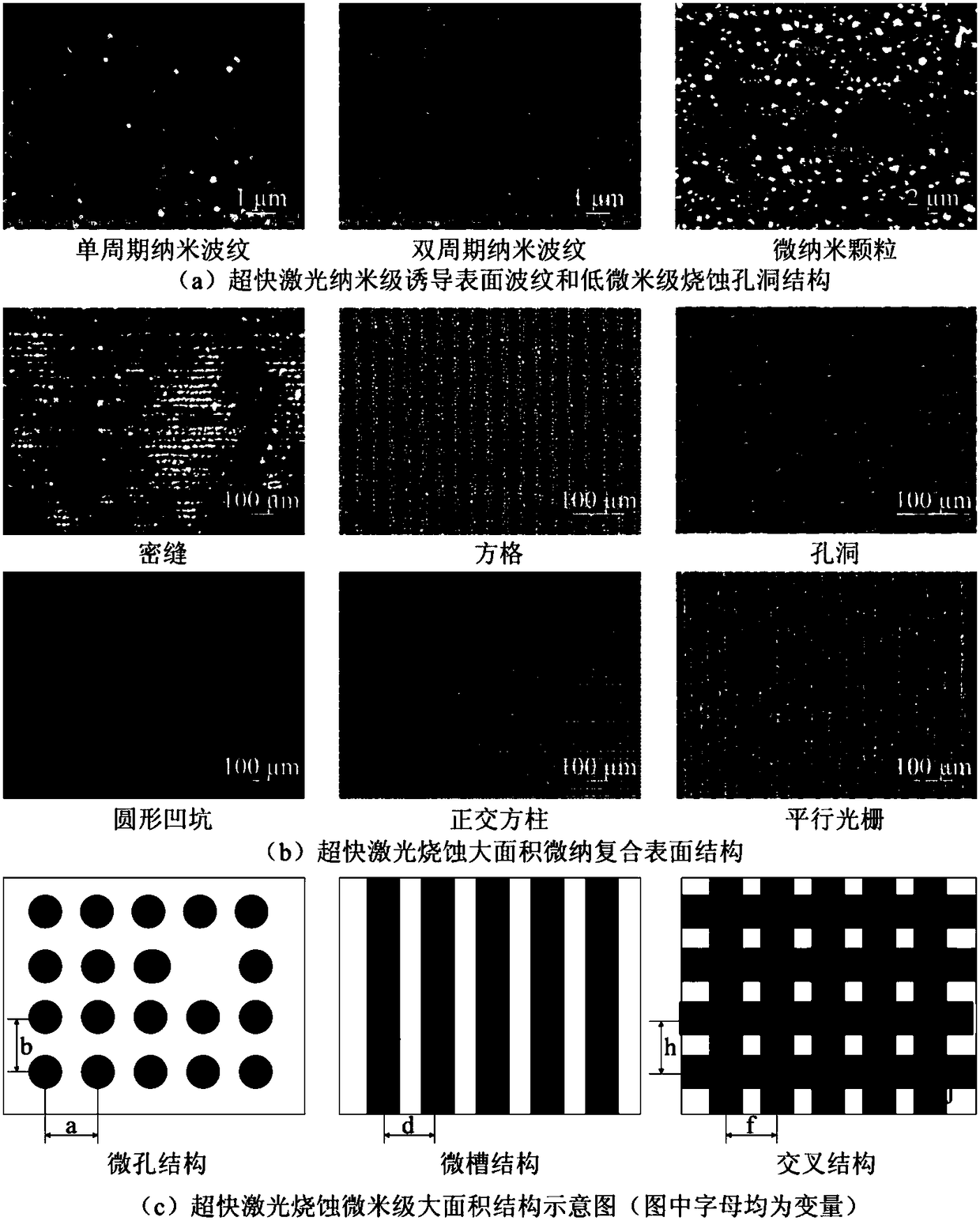

Ultrafast laser differential micro-nano texturing method for metal welding joint

ActiveCN108406093AAccelerated corrosionImprove wear resistanceLaser beam welding apparatusMicro nanoHeat-affected zone

The invention belongs to the technical field of laser micro processing and particularly relates to an ultrafast laser differential micro-nano texturing method for a metal welding joint. The ultrafastlaser differential micro-nano texturing method is a morphology-controllable differential functionalized micro-nano texturing technology based on ultrafast laser accurate zone selection. Targeted functionalized micro-nano texturing is conducted on differential phase components and microstructures of different zones (a weld zone, a heat affected zone and a base material zone) of the metal welding joint with an ultrafast laser as an energy source, thus surface transformation and modification are conducted on surface and end face zones of the joint, and the corrosion-resisting and abrasion-resisting properties of the surface and end zones of the metal welding joint are improved accordingly.

Owner:SHANGHAI UNIV OF ENG SCI

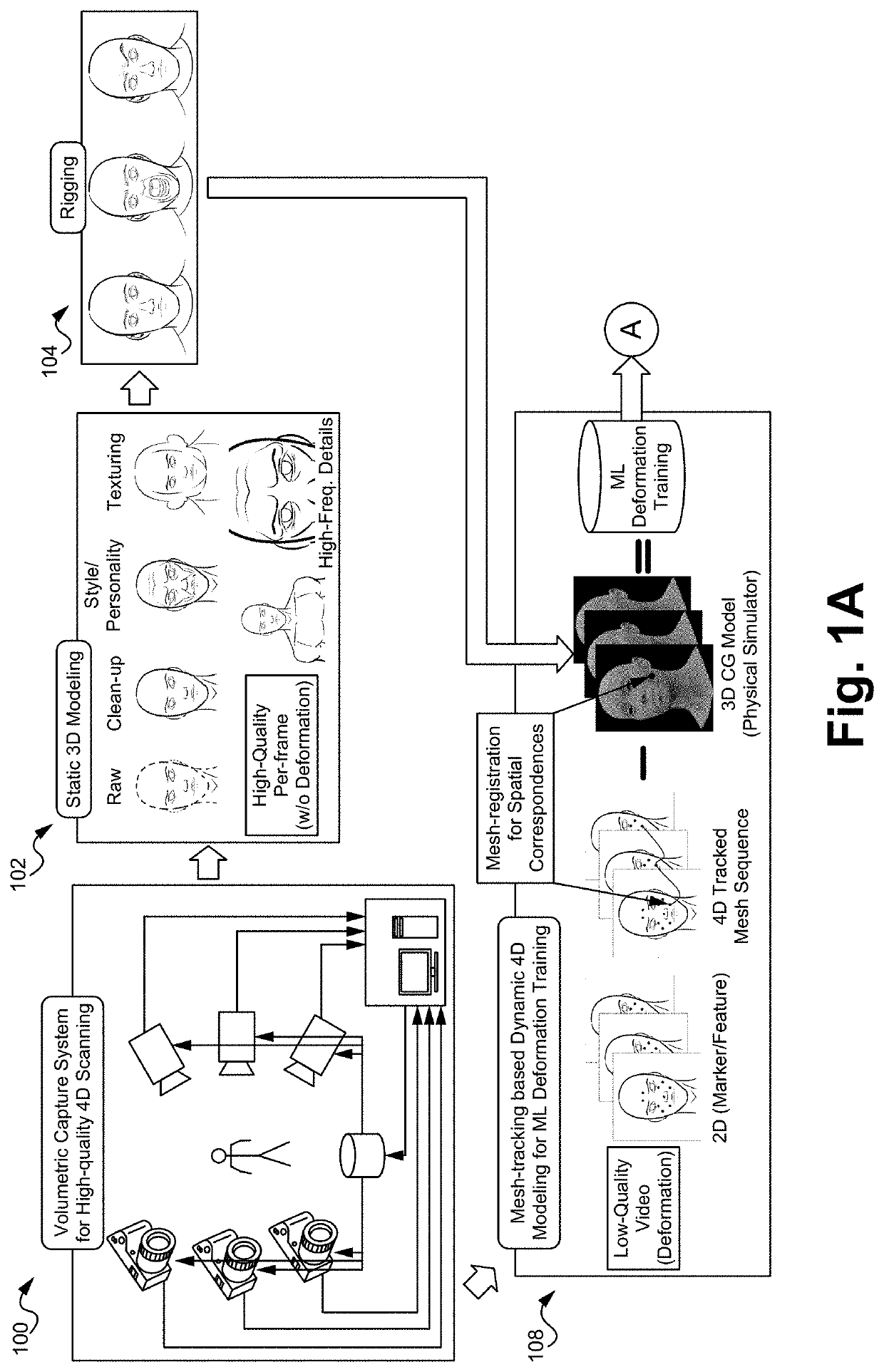

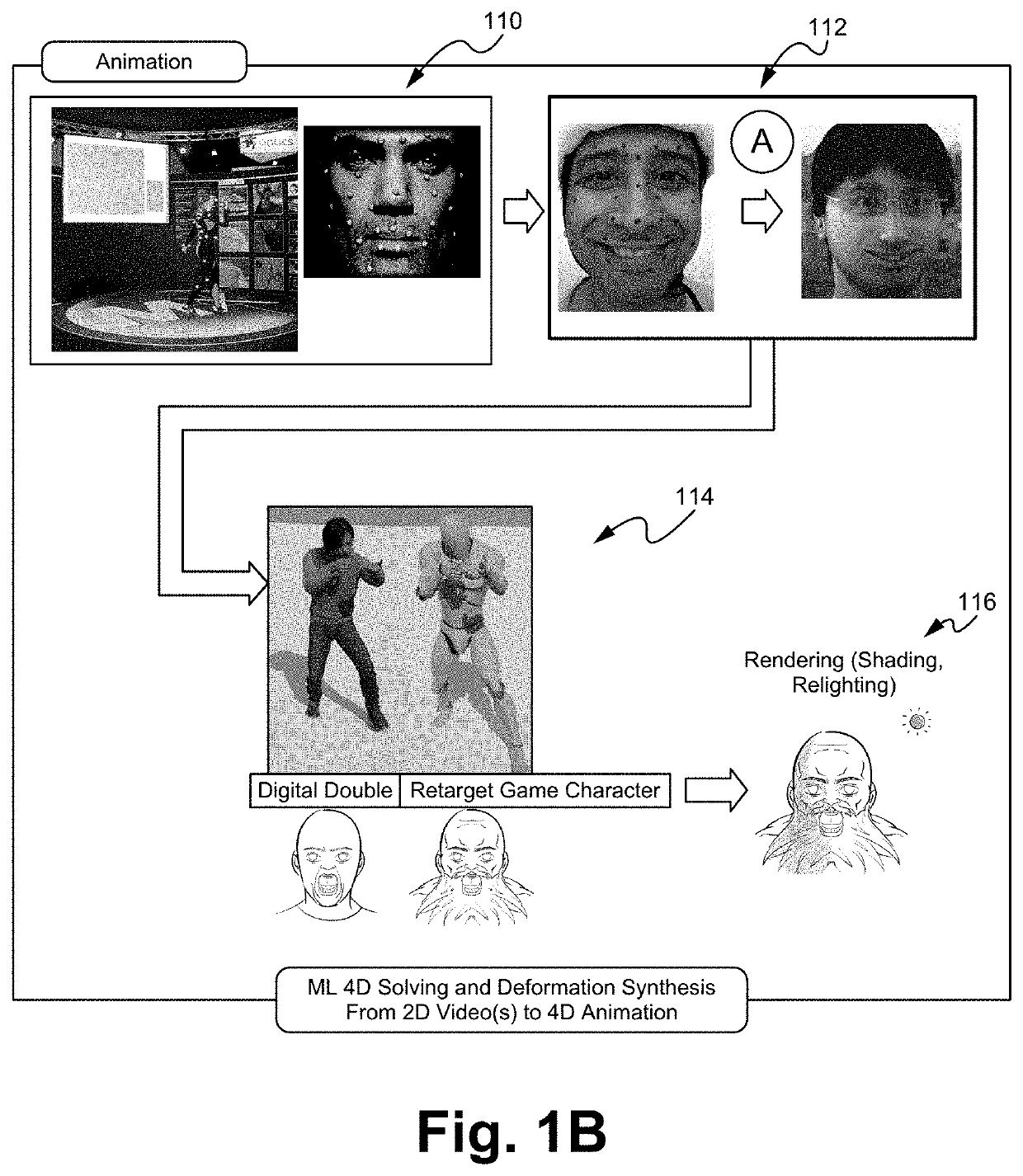

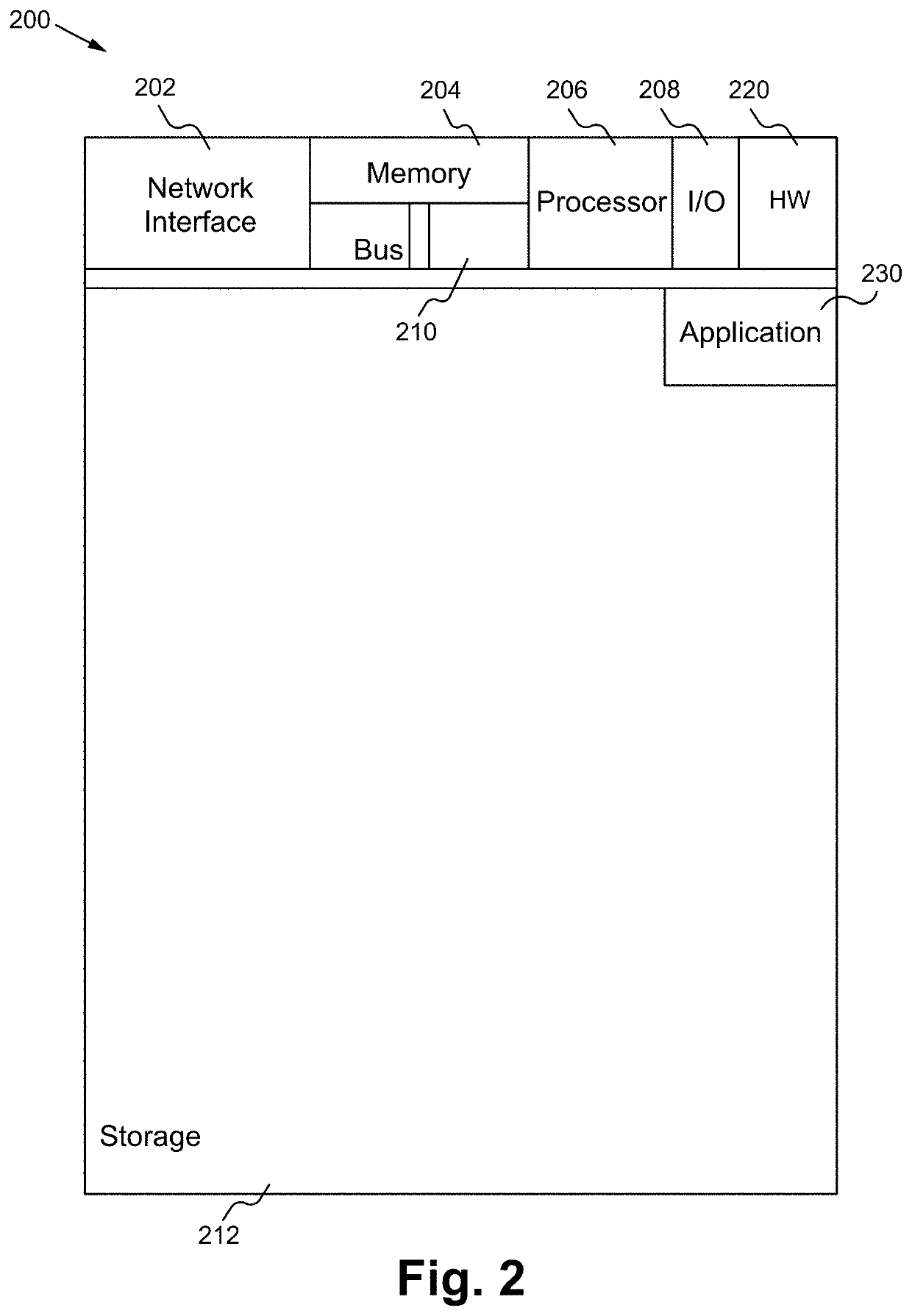

Volumetric capture and mesh-tracking based machine learning 4d face/body deformation training

Mesh-tracking based dynamic 4D modeling for machine learning deformation training includes: using a volumetric capture system for high-quality 4D scanning, using mesh-tracking to establish temporal correspondences across a 4D scanned human face and full-body mesh sequence, using mesh registration to establish spatial correspondences between a 4D scanned human face and full-body mesh and a 3D CG physical simulator, and training surface deformation as a delta from the physical simulator using machine learning. The deformation for natural animation is able to be predicted and synthesized using the standard MoCAP animation workflow. Machine learning based deformation synthesis and animation using standard MoCAP animation workflow includes using single-view or multi-view 2D videos of MoCAP actors as input, solving 3D model parameters (3D solving) for animation (deformation not included), and given 3D model parameters solved by 3D solving, predicting 4D surface deformation from ML training.

Owner:SONY CORP

Active metal cutting chip breaking method and active metal cutting chip breaking device for unmanned workshop

InactiveCN111390205AStable chip breaking effectAvoid personal injuryAuxillary equipmentHigh energy laser beamHigh energy laser

The invention relates to an active metal cutting chip breaking method and an active metal cutting chip breaking device for an unmanned workshop. The core concept of the active chip breaking method lies in that surface transformation and modification pretreatment is carried out in a special position of the surface of a workpiece before a tool is fed to cut every time. When the tool cuts to a pretreatment position, thickness or material characteristics of newly born chips on the surface of a workpiece changes suddenly, so that breakage is achieved. The principle of the active chip breaking device lies in that a material of the workpiece is gasified by applying a high energy laser beam to form a trench, and meanwhile, the characteristics of the material of the workpiece is changed by means ofthe heat effect of the laser beam, so that a heat influence area of a certain depth is formed. The device is provided with a high energy laser module, and a high energy laser output end is fixed to ahorizontal guide rail, so that the device has a translational function in the x-axis direction of a lathe. The horizontal guide rail is fixed to a knife rest. According to the structure, the focusingposition of the laser beam can change along with diameter change of the workpiece. Matched with movement of the knife rest in the z-axis direction of the knife rest, surface transformation and modification pretreatment on the surface of the workpiece is achieved. Compared with a chip breaking slot of the tool, the method and device are more stable and reliable in effect. Compared with high pressure water / gas jet chip breaking, the method and device are lower in energy consumption and cost and are further more environment-friendly.

Owner:NANJING UNIV OF TECH

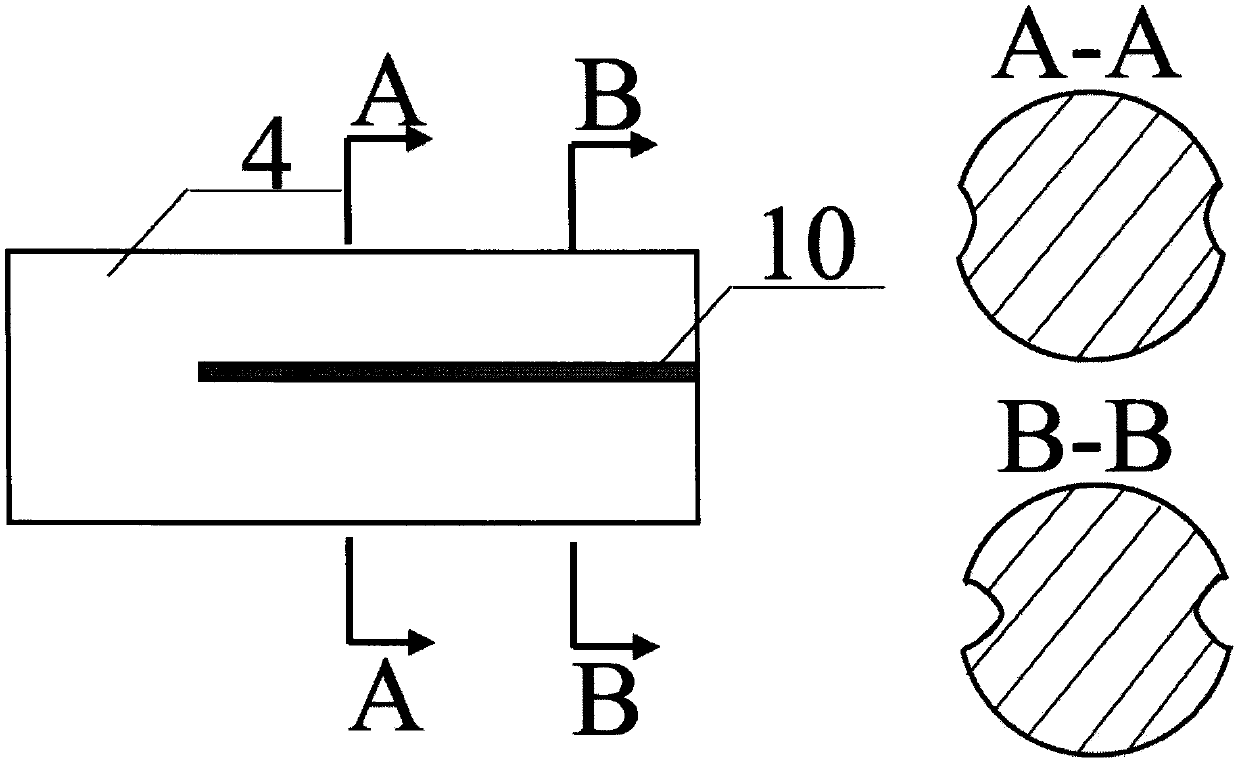

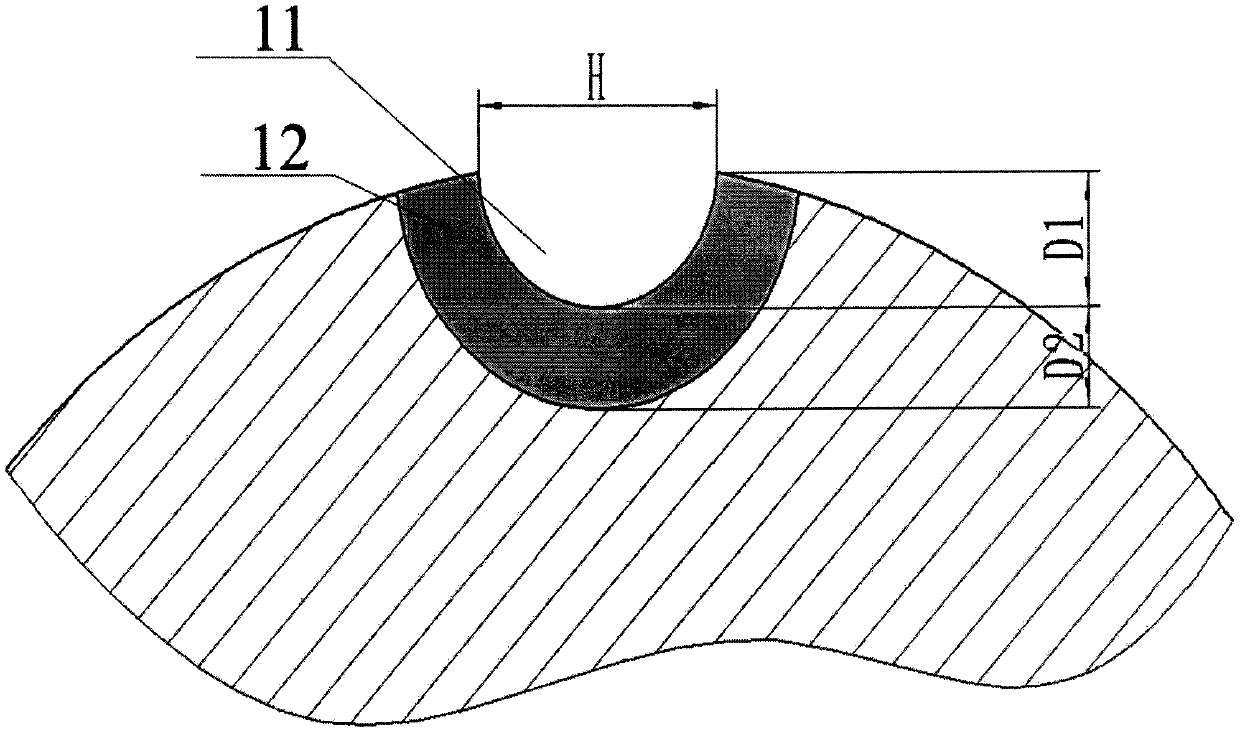

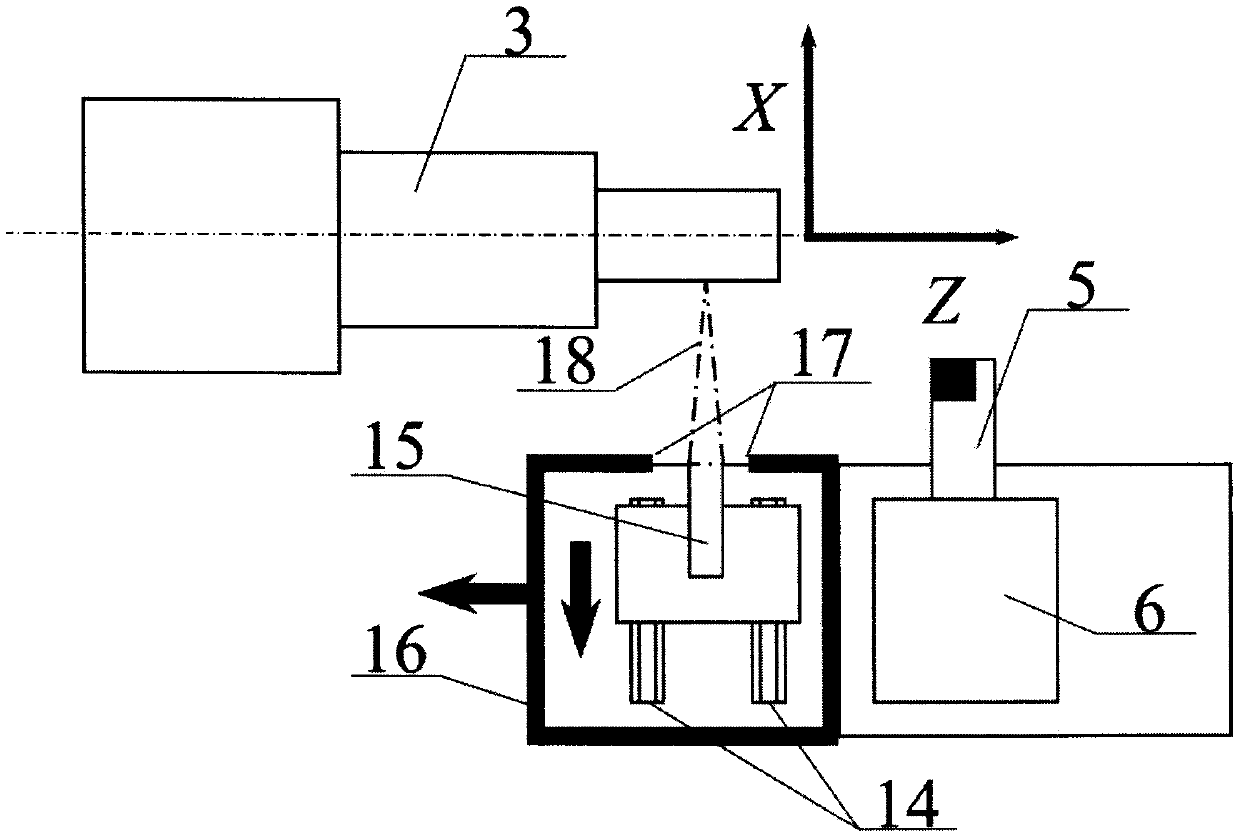

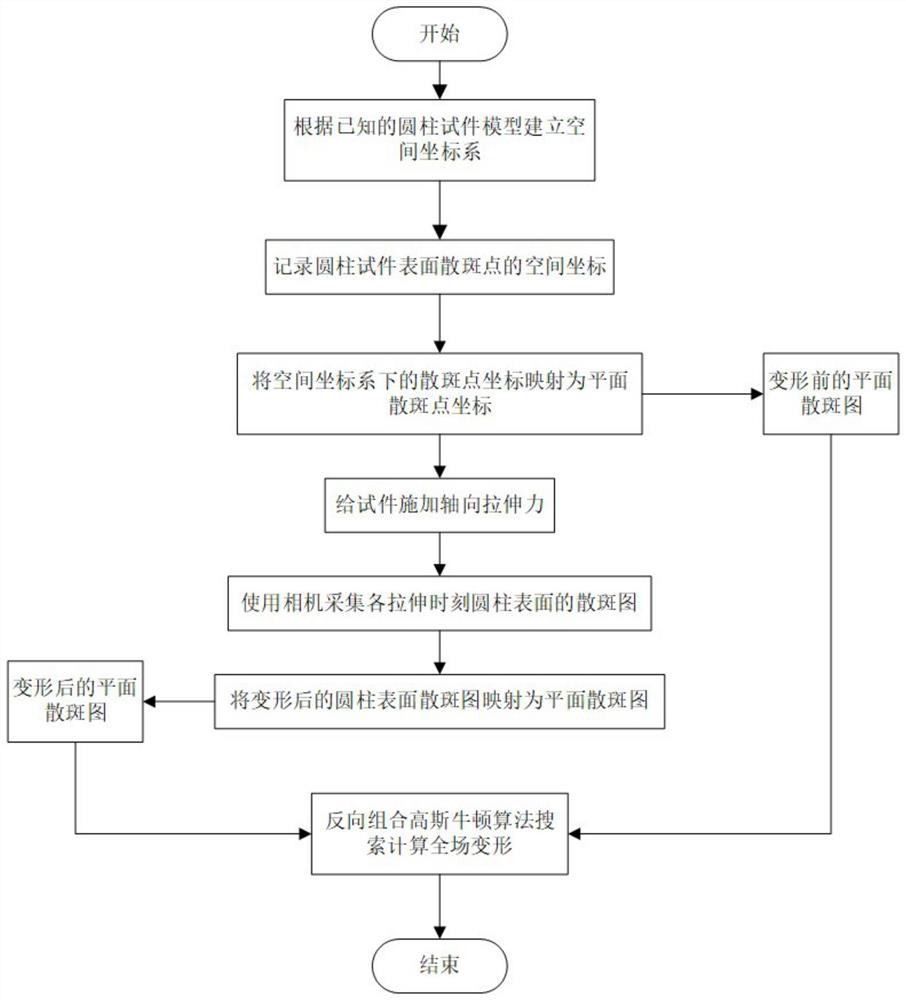

Testpiece quality detection method based on two-dimensional digital image correlation method

ActiveCN113012143AAvoid the impact of accuracy lossReduce cost of measurementImage enhancementImage analysisComputational physicsOptical measurements

The invention belongs to the field of optical measurement mechanics, and particularly relates to a test piece quality detection method based on a two-dimensional digital image correlation method.The method comprises the steps of obtaining the speckle spots of a test piece to be tested, establishing a space coordinate system with the center point of the test piece as the origin of coordinates; mapping the spatial speckles on the surface of the test piece into planar speckles; applying an axial tensile force to the test piece to be tested, and collecting a surface speckle pattern of the test piece after deformation; mapping each spatial speckle spot in the surface speckle pattern of the deformed test piece into a planar speckle spot; processing the mapping plane speckles before the deformation of the test piece and the mapping plane speckles after the deformation of the test piece by adopting a reverse combination Gaussian Newton algorithm to obtain a test piece surface deformation measurement result; according to the method for mapping the space coordinate points to the plane coordinate points, the one-to-one correspondence mapping relation between the original coordinate system and the new coordinate system is guaranteed, the calculation amount is small, and programming is easy to achieve.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Outer wall surface transformation method without removing original outer wall surface

ActiveCN113833298AReduce the risk of fallingSafety protection pressure is reducedCovering/liningsBuilding repairsAdhesiveCement mortar

The invention discloses an outer wall surface transformation method without removing an original outer wall surface. The outer wall surface transformation method comprises the following steps that a first layer of interface agent is brushed on a structural base layer of the original outer wall surface after an aged outer wall surface is removed; cement mortar continues to be smeared on the surface of the first layer of interface agent till an original ceramic tile surface / original plaster layer is leveled; the surface of the cement mortar is continuously coated with a second layer of interface agent and an adhesive in sequence, an extruded sheet is anchored into the surface of the adhesive, and the extruded sheet is fixed to the structural base layer of the original outer wall surface after the aged outer wall surface is removed through anchor bolts; and the surface of the extruded sheet is sequentially coated with a layer of anti-crack mortar, putty powder and exterior wall paint. According to the outer wall surface transformation method, the risk of falling of construction waste is reduced, the safety protection pressure is reduced, collection and transfer of the construction waste are reduced, manpower and material resources are saved, and the construction period is shortened.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

Manufacturing method that uses laser surface transformation to produce new and unique surface profiles for rotating bearings

ActiveUS7612314B2Semiconductor/solid-state device manufacturingPhotosensitive material processingOil retentionEngineering

A laser ablation method is used to polish a bearing surface of an automotive crankshaft. A laser ablation device generates a laser according to parameters such as wavelength, pulse duration, pulse repetition rate, and beam quality. The laser is applied to the surface of a rotating engine component, such as a crankshaft, as the component is rotated in order to polish the surface according to the parameters. The laser substantially improves tribological performance of the bearing surface by changing the waviness and form of the surface profile. Further, oil-retention reservoirs are formed in the surface. As a result, the friction coefficient of the crankshaft surface is reduced while the roughness of the crankshaft surface is maintained, reduced, or increased.

Owner:ADCOLE CORP +1

Method of forming mirrors by surface transformation of empty spaces in solid state materials

InactiveUS20050175058A1Easy to customizeSemiconductor/solid-state device manufacturingOptical resonator shape and constructionOptoelectronicsDrill hole

Owner:MICRON TECH INC

Panoramic video cylindrical image storage method and system

InactiveCN103093485BEasy to readSave resourcesMemory adressing/allocation/relocationInternal memoryData segment

The invention provides a full view video cylindrical surface image storage method and a system. The method includes that pixel data is received by row and first in,first out (FIFO) is used for caching. Whether an FIFO is full of the caching pixel data or not is judged. If it is full, a row of pixel data is continuously read out from the FIFO and the cylindrical surface transformation is carried out. New coordinates are obtained by calculating each pixel and the pixel addresses of each pixel are calculated. Data after the transformation of the cylindrical surface is divided into a plurality of data sections, wherein, among the divided data sections, the pixel address in every data section is consecutive and the next data sections belong to different rows. BURST is formed by the pixel numbers in the data section, the BURST proruption length in the internal memory, the storage unit digit of the internal memory and the pixel address of the first pixel in the data sections. The composed BURST data is stored into the internal memory. The full view video cylindrical surface image storage method and the system achieve the transformation of the cylindrical surface of the video image as well as improve the bandwidth availability ratio.

Owner:GUANGDONG VTRON TECH CO LTD

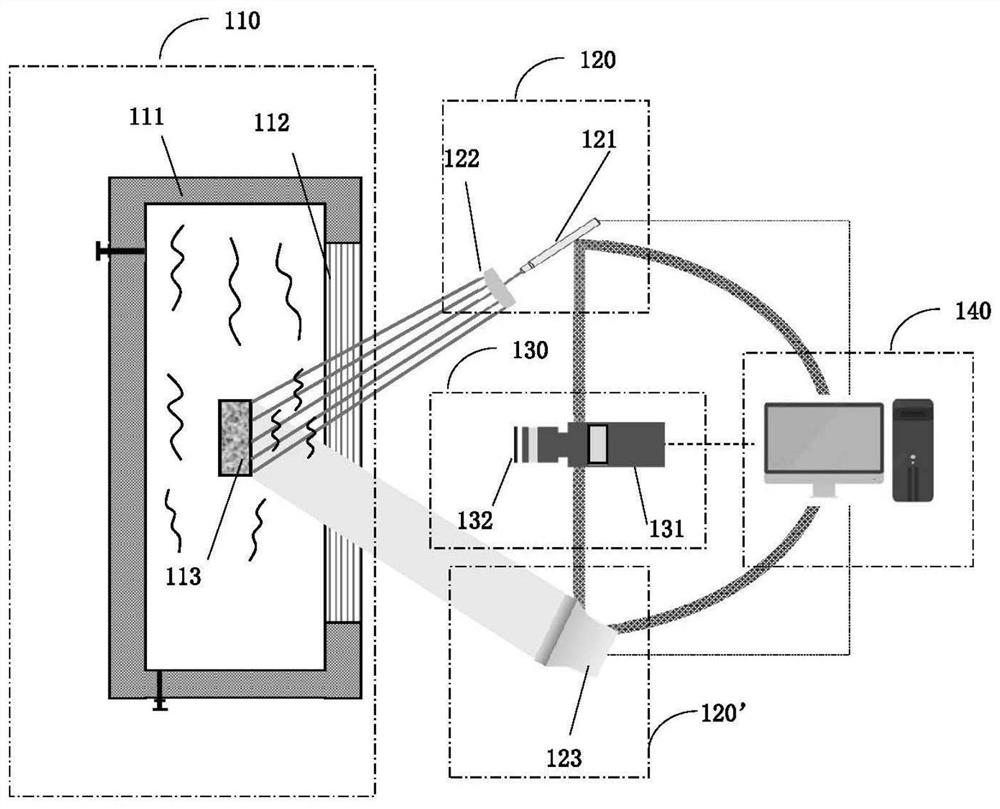

High temperature test image heat flow disturbance correction device and method

ActiveCN113012078BHigh precisionImprove calculation accuracyImage enhancementImage analysisBeam expanderLaser transmitter

The present disclosure relates to a device and method for correcting heat flow disturbance of a high-temperature test image. The device includes: a heating component, used for heating the test piece; a light emitting component, including a laser emitter, a grid beam expander and a compensation light source; an image acquisition component, used for collecting the first image of the test piece at room temperature and the The second image in the heating state; and the processing component, which is connected with the image acquisition component, and is used to process the image, so as to correct the error caused by heat flow disturbance when obtaining the surface deformation field of the test piece. The embodiments of the present disclosure can improve the calculation accuracy of the deformation field on the surface of the test piece by correcting the heat flow disturbance error of the deformation field on the surface of the test piece.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com